Patents

Literature

2865results about "Tractor-trailer combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

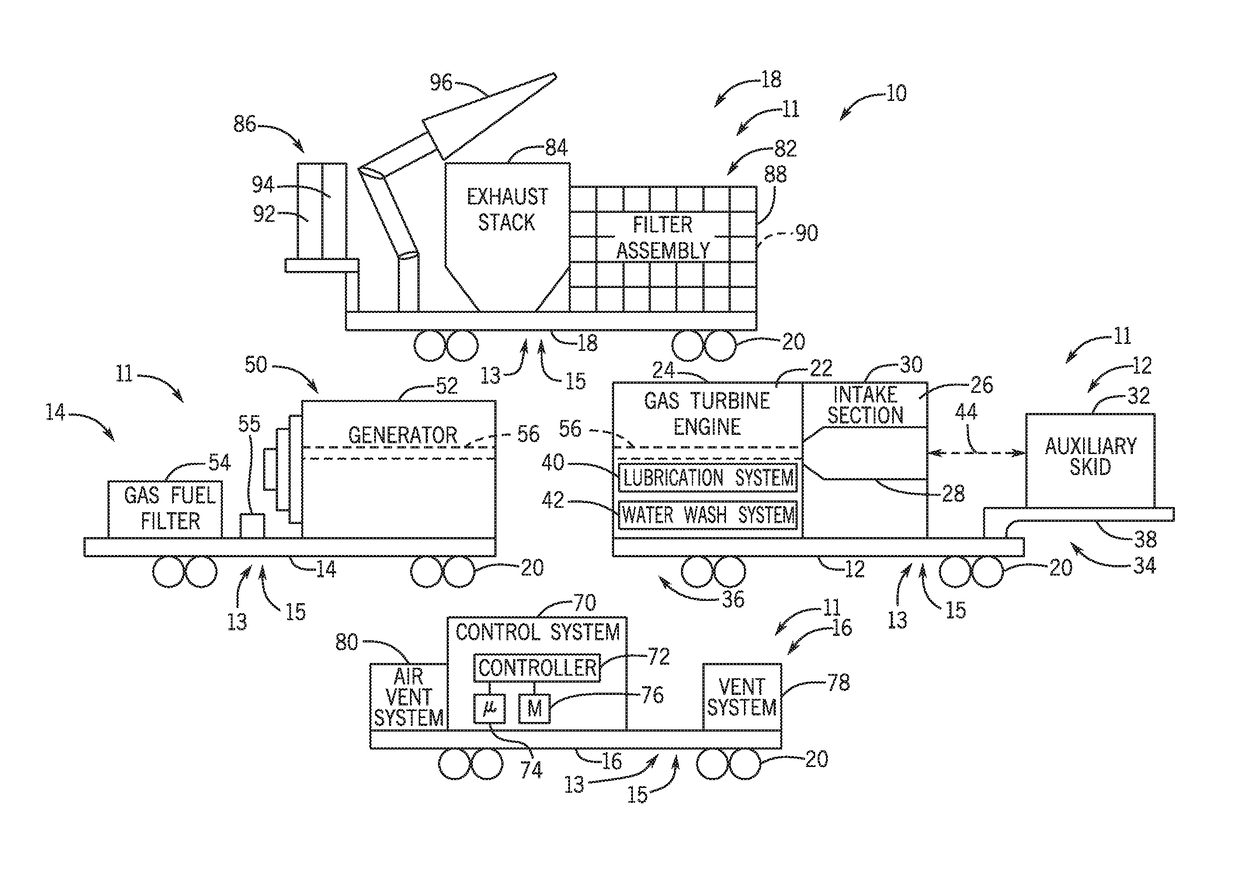

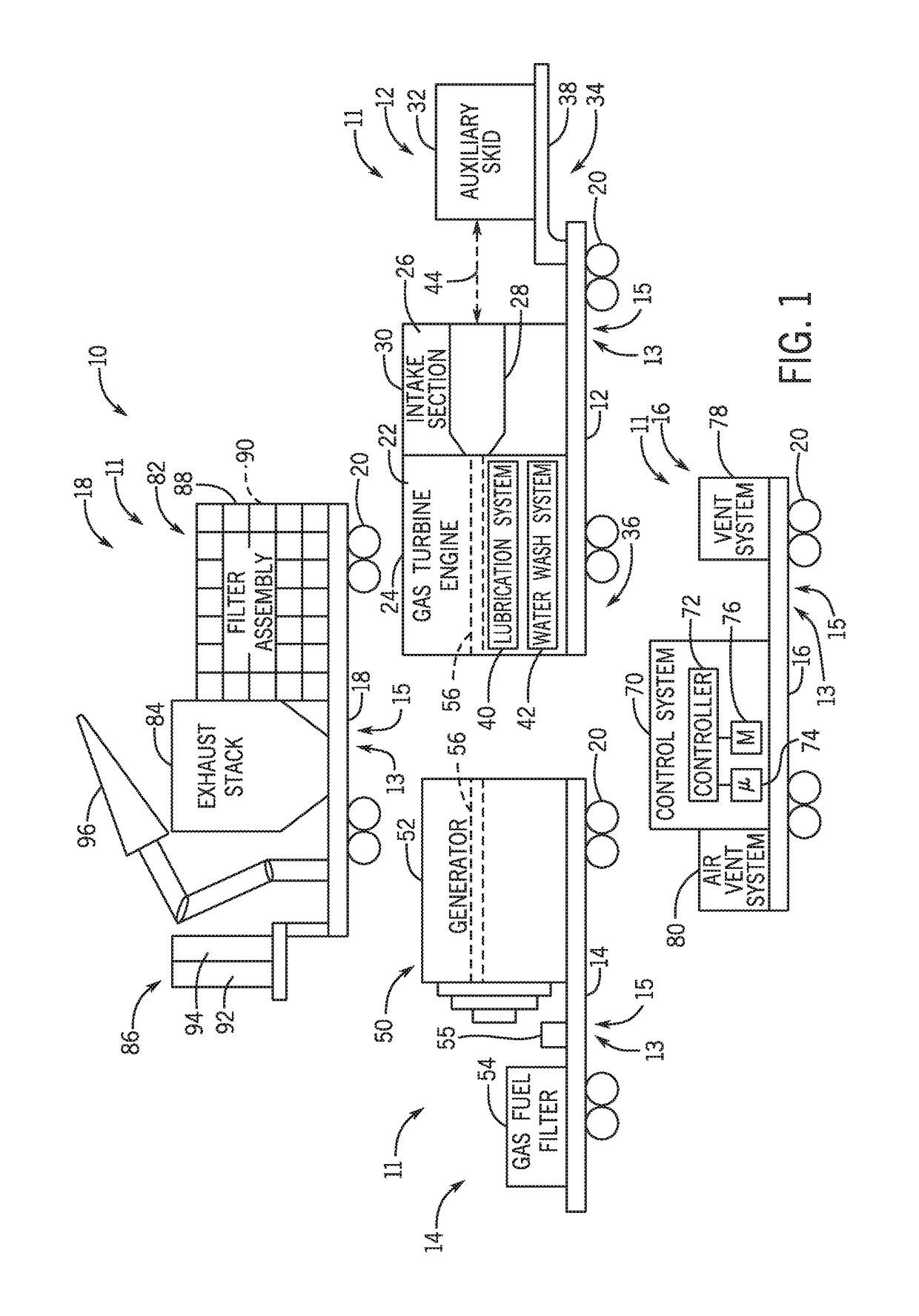

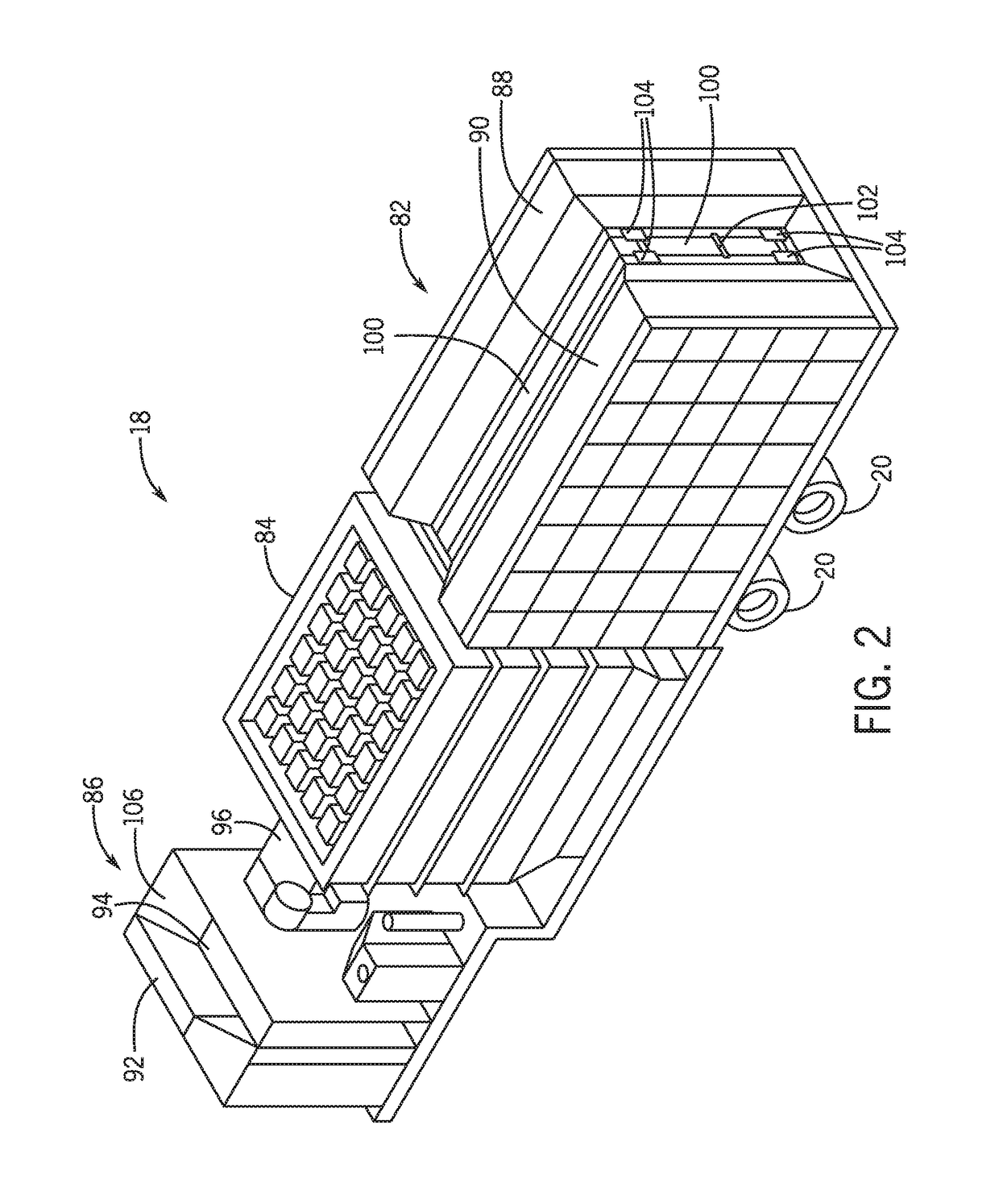

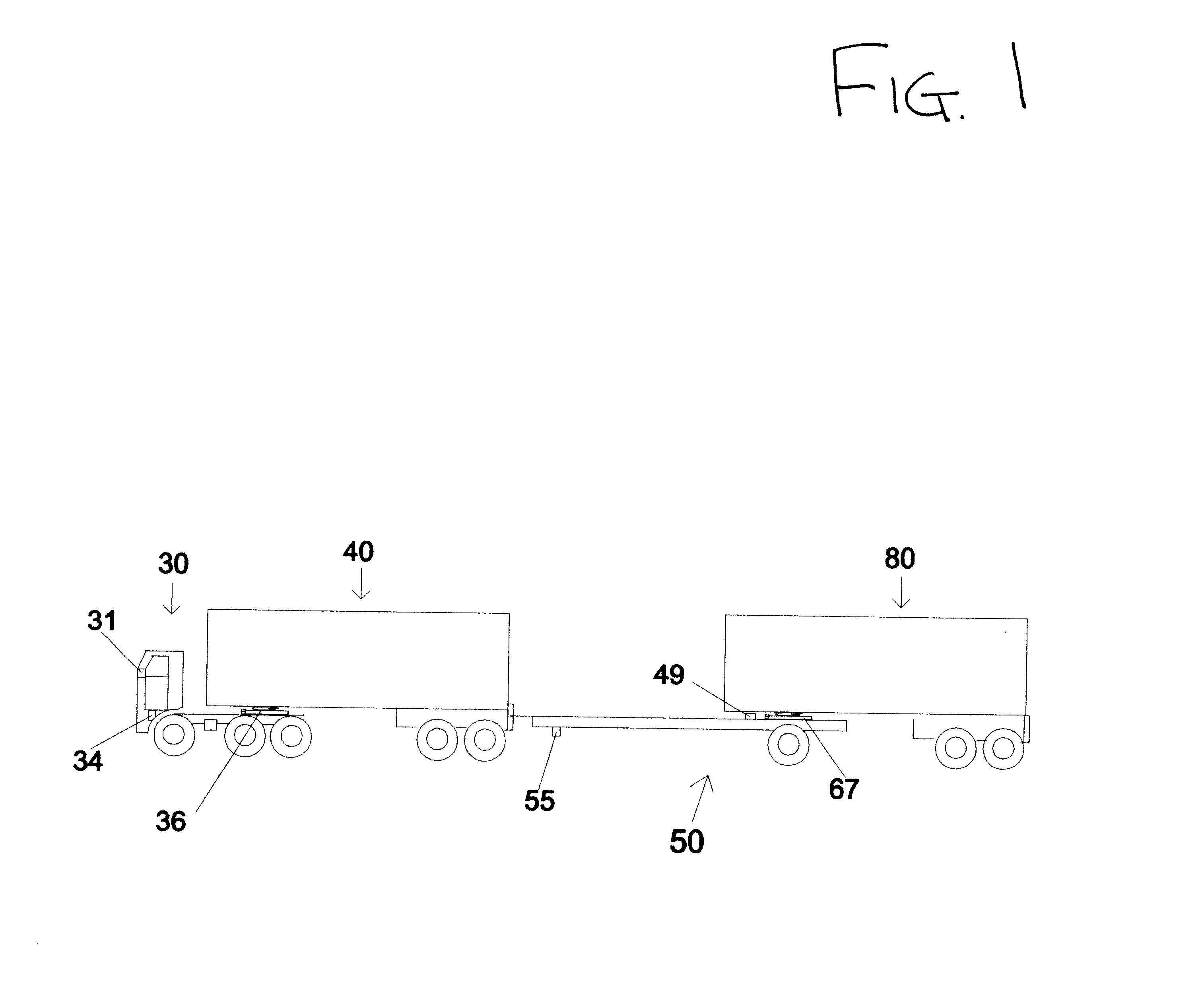

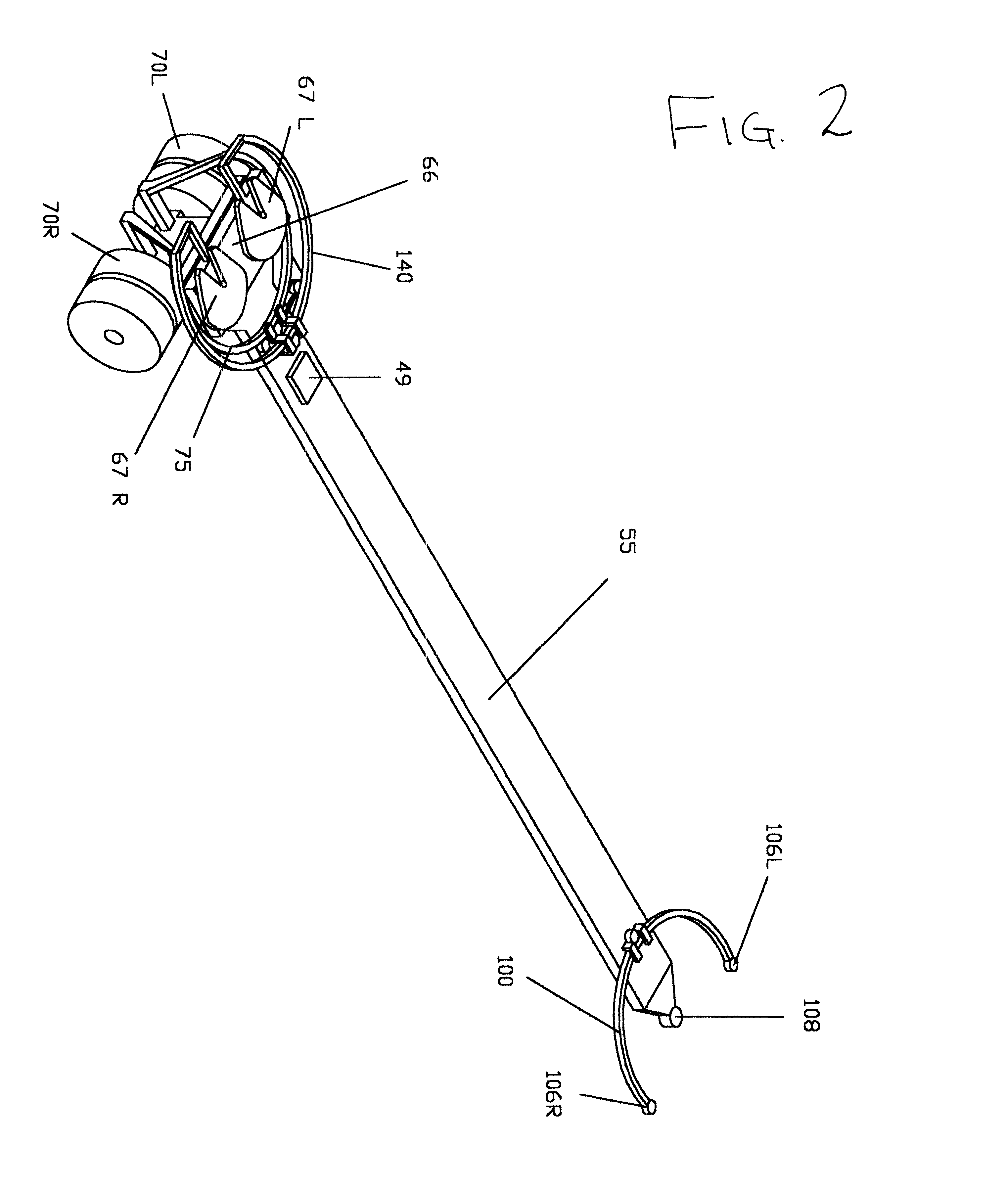

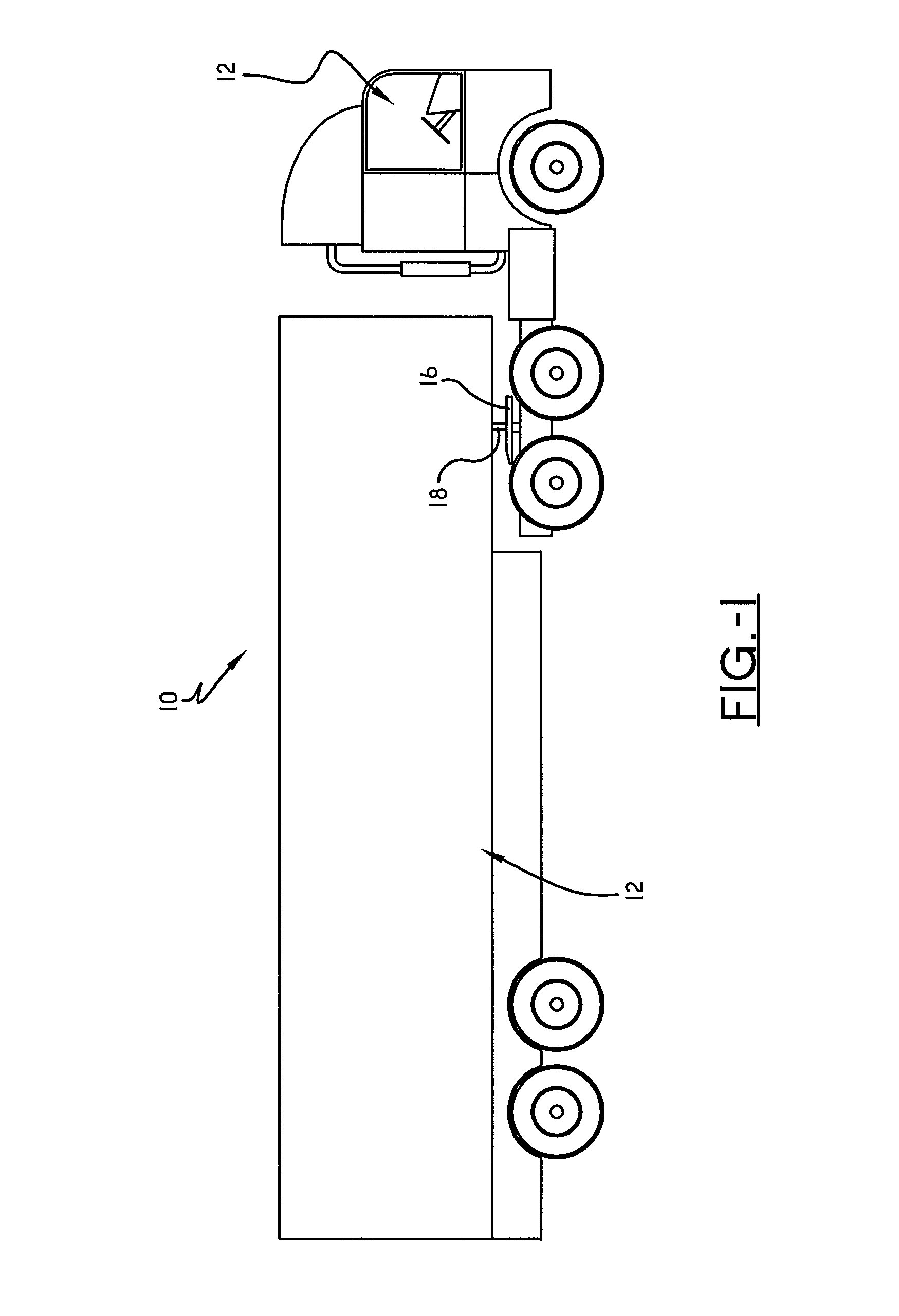

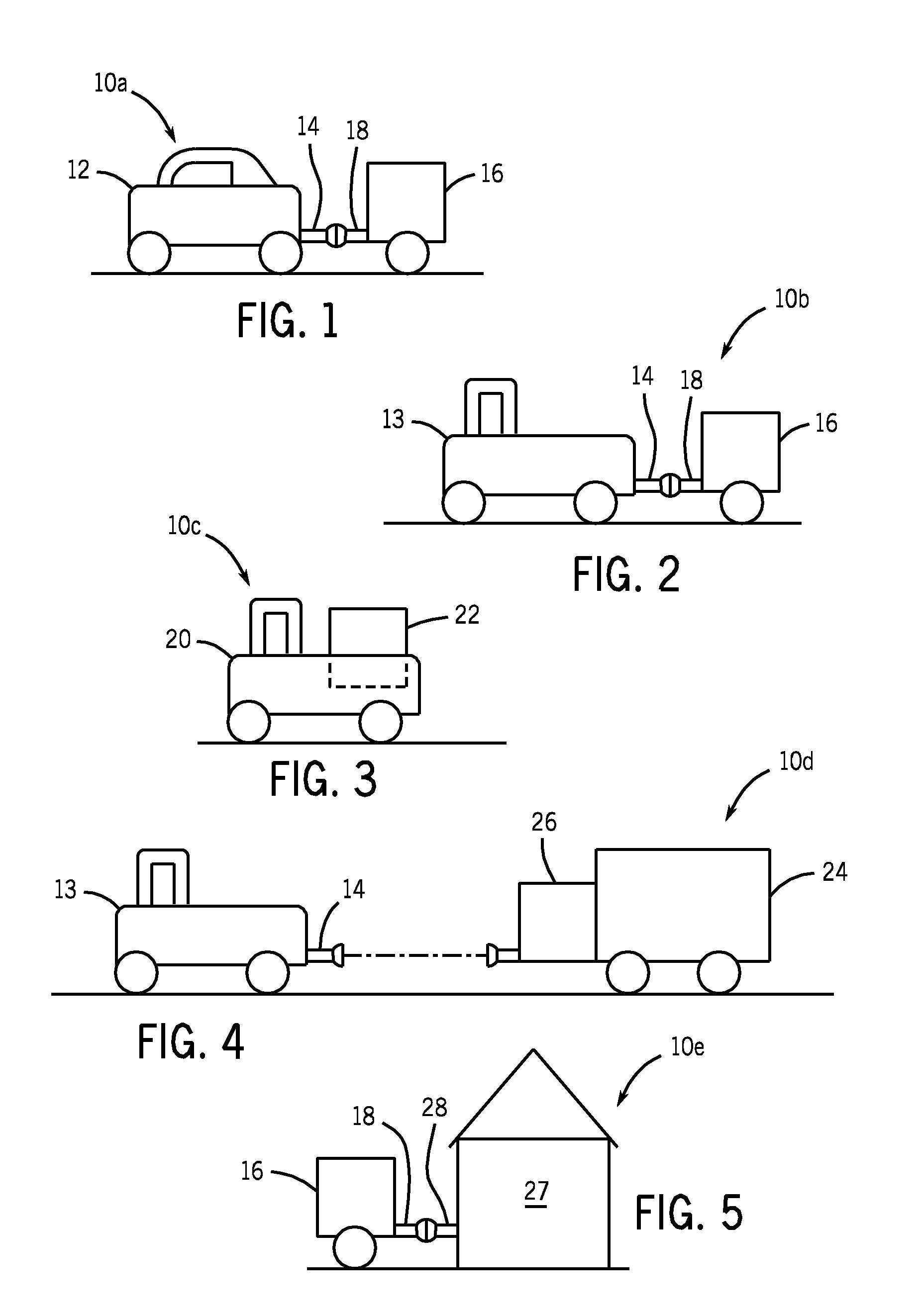

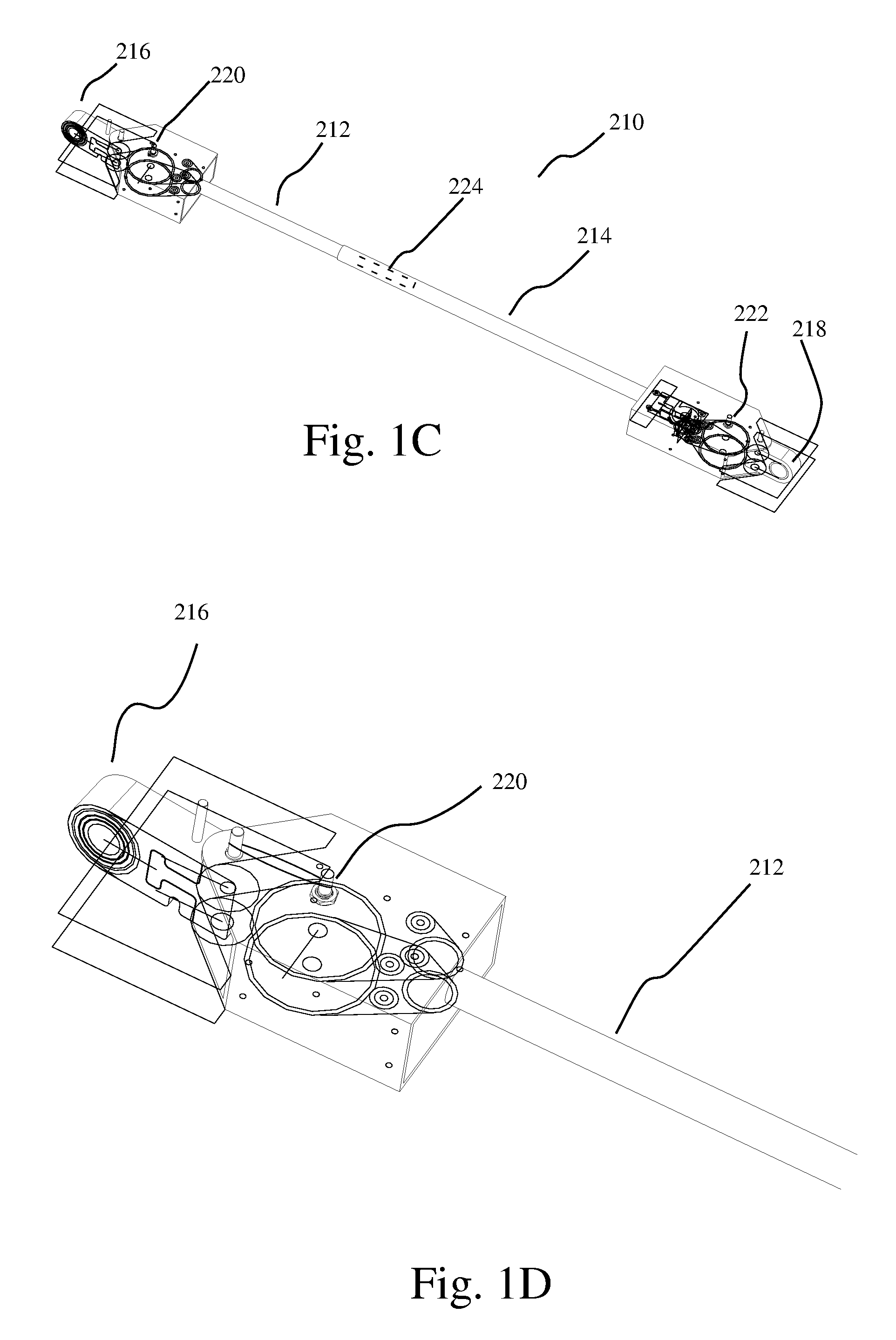

Systems and methods for a mobile power plant with improved mobility and reduced trailer count

A system a first mobile body configured to support a turbine engine and an auxiliary skid communicatively and fluidly coupled to the turbine engine. The auxiliary skid includes one or more interconnects configured to support a turbine engine component. The system also includes a second mobile body configured to support a generator. The first and second mobile bodies are configured to align a removable coupling between the turbine engine and the generator.

Owner:GE INFRASTRUCTURE TECH INT LLC

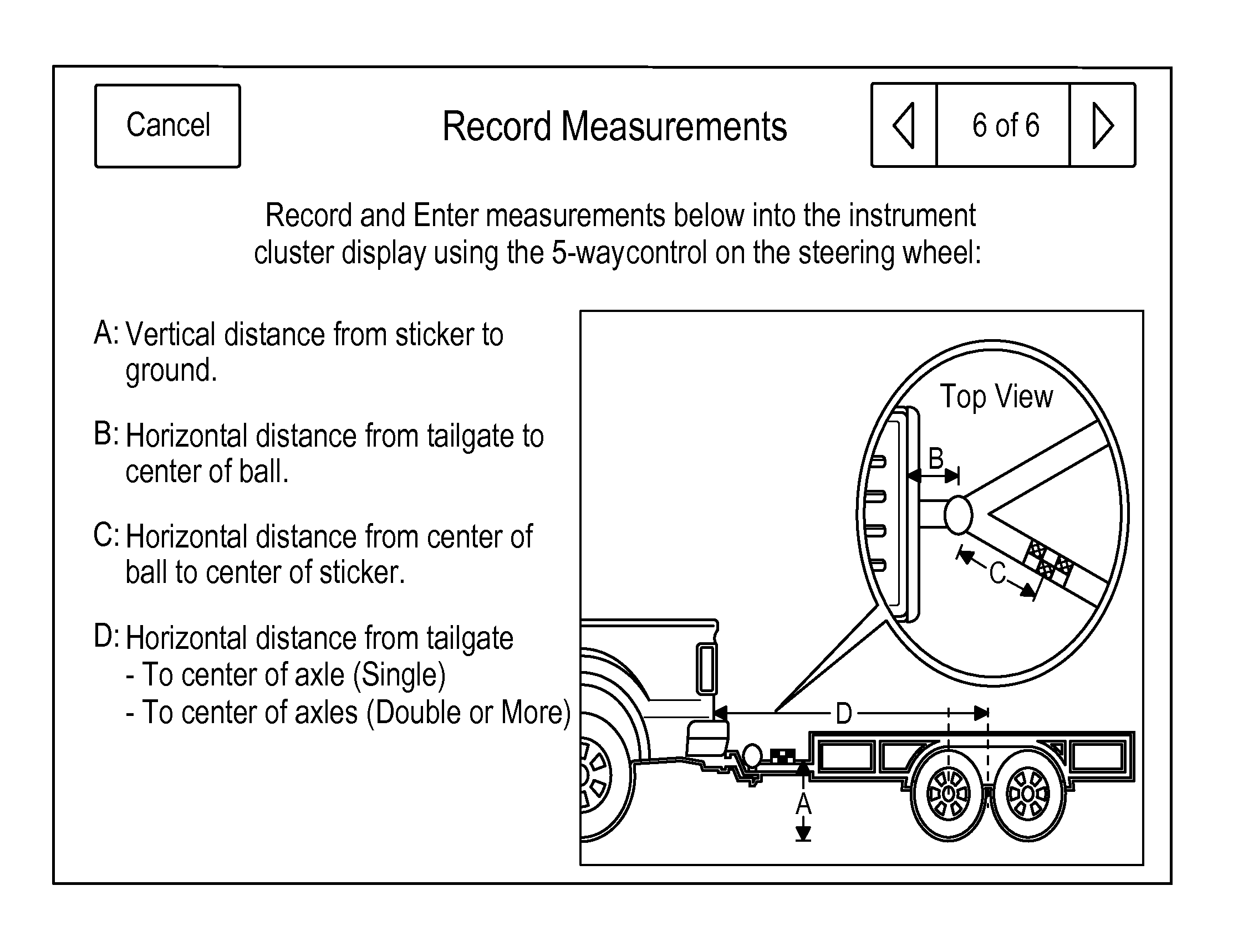

System and method for calculating a horizontal camera to target distance

ActiveUS20140218506A1Using electrical meansColor television detailsComputer graphics (images)On board

A system and method for calculating a horizontal camera to target distance is provided. A camera on board a vehicle is configured to image a target on a trailer that is aligned with the vehicle. A controller is in communication with the camera and is supplied a user-obtained measurement. The controller is configured to calculate a first horizontal distance and a second horizontal distance, and to sum the first and second horizontal distances to calculate a horizontal camera to target distance.

Owner:FORD GLOBAL TECH LLC

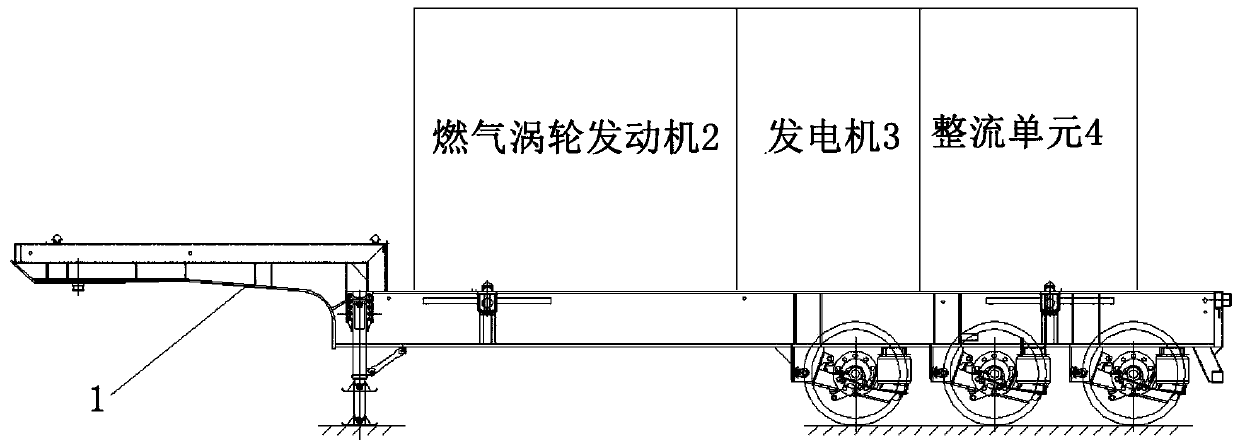

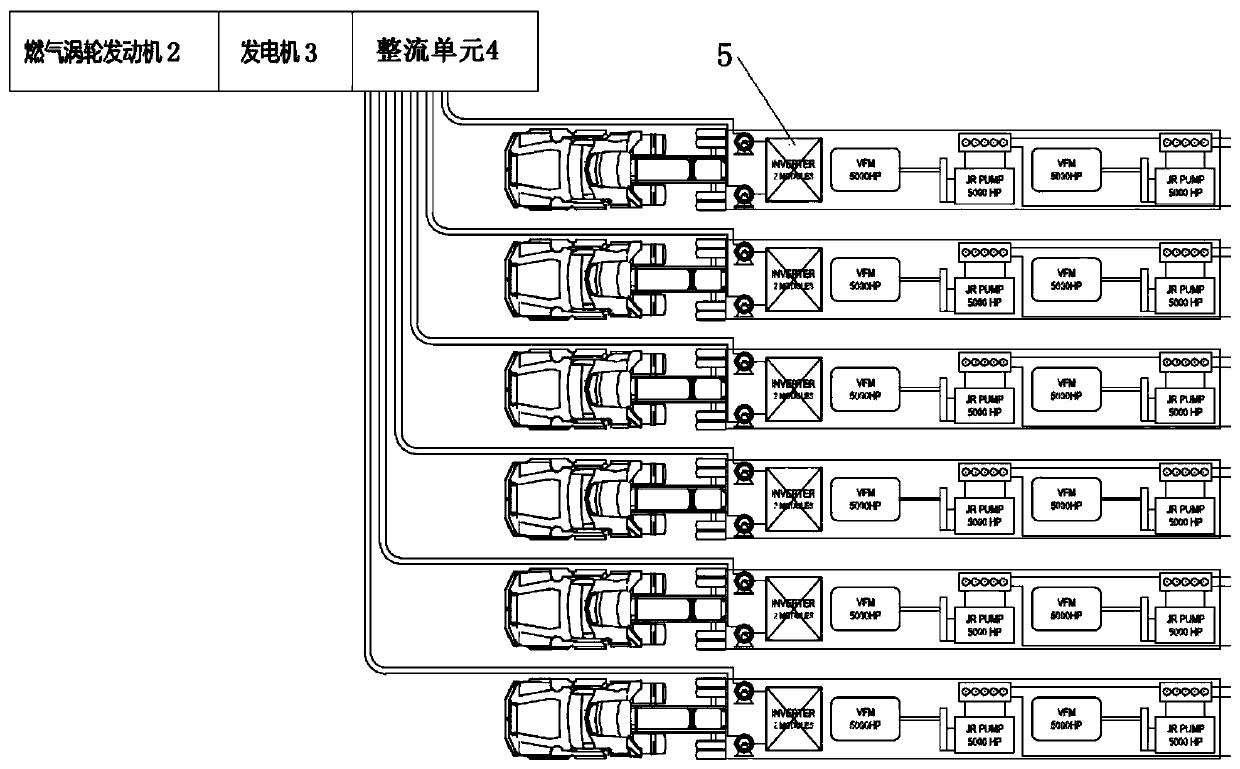

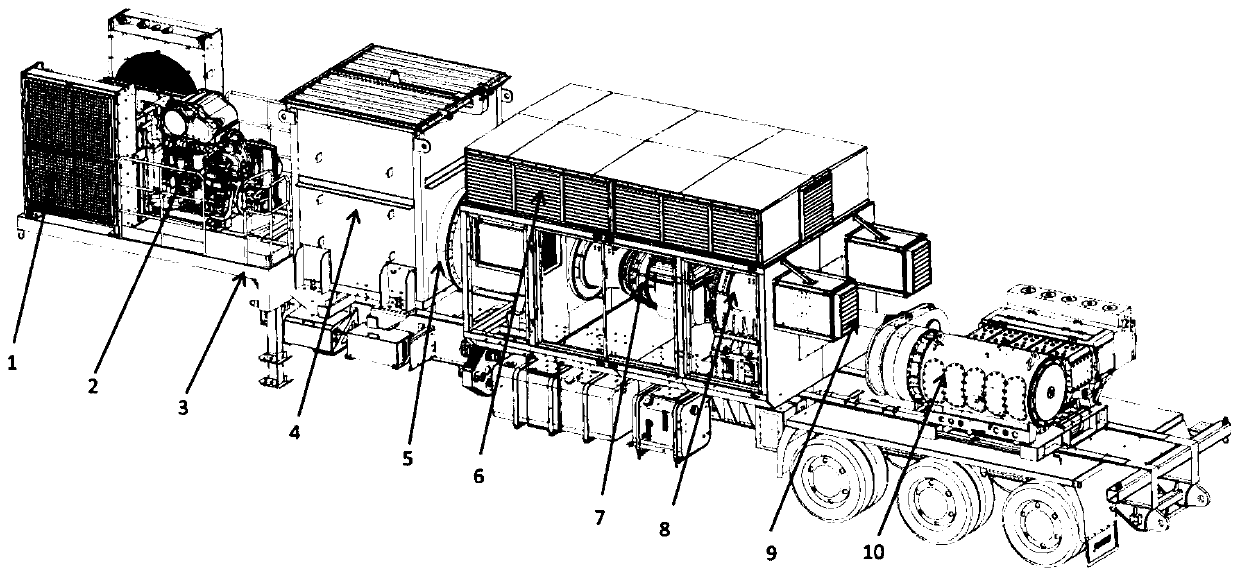

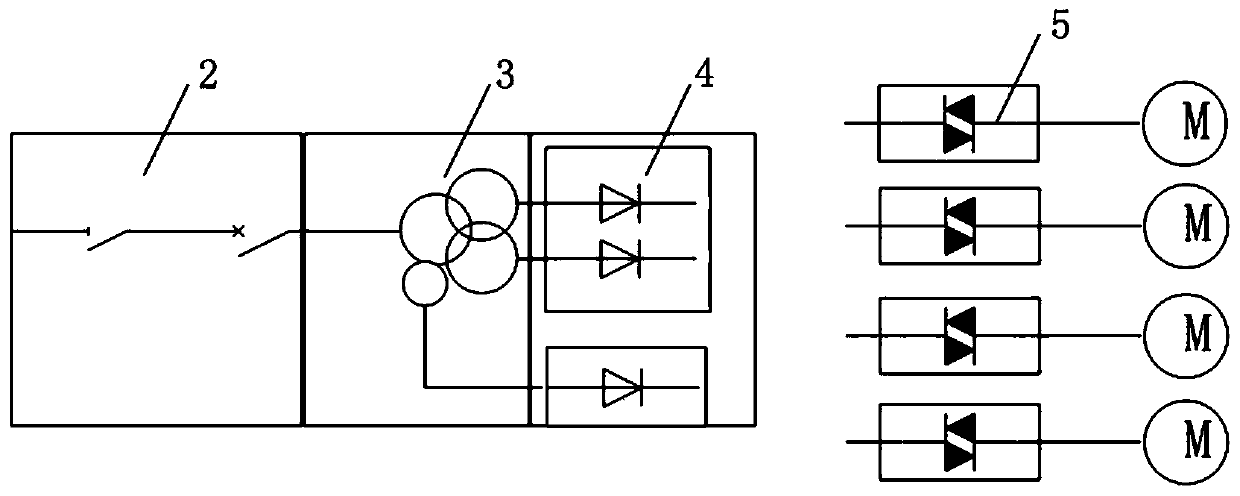

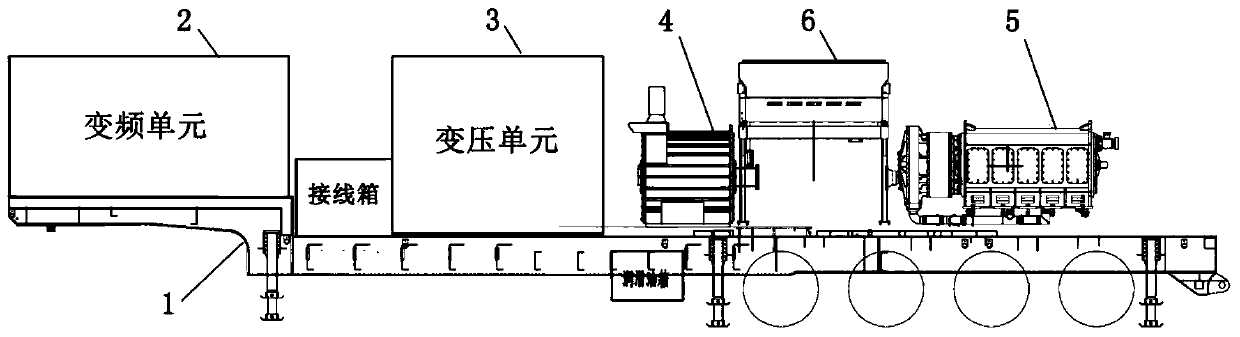

Power supply semi-trailer of electric drive fracturing equipment

PendingCN110118127AReduce wiringOptimize space layoutAssociation with control/drive circuitsGas turbine plantsElectricityTransformer

The invention discloses a power supply semi-trailer of electric drive fracturing equipment. The combination manner of a gas turbine engine, a power generator and a rectification unit is adopted, the power generator directly transmits the winding form and voltages needed by a rectification unit, conventional rectification transformer equipment is omitted, the rectification unit is connected with inversion units through common direct current buses, the common direct current buses can drive the multiple inversion units separately, and wiring of power supply circuits is reduced. The high-voltage inversion units are arranged on a gooseneck of the electric drive semi-trailer, and the space arrangement of the equipment is optimized. The whole power supply equipment is more compact in structure, small in occupied area and simple in wiring.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

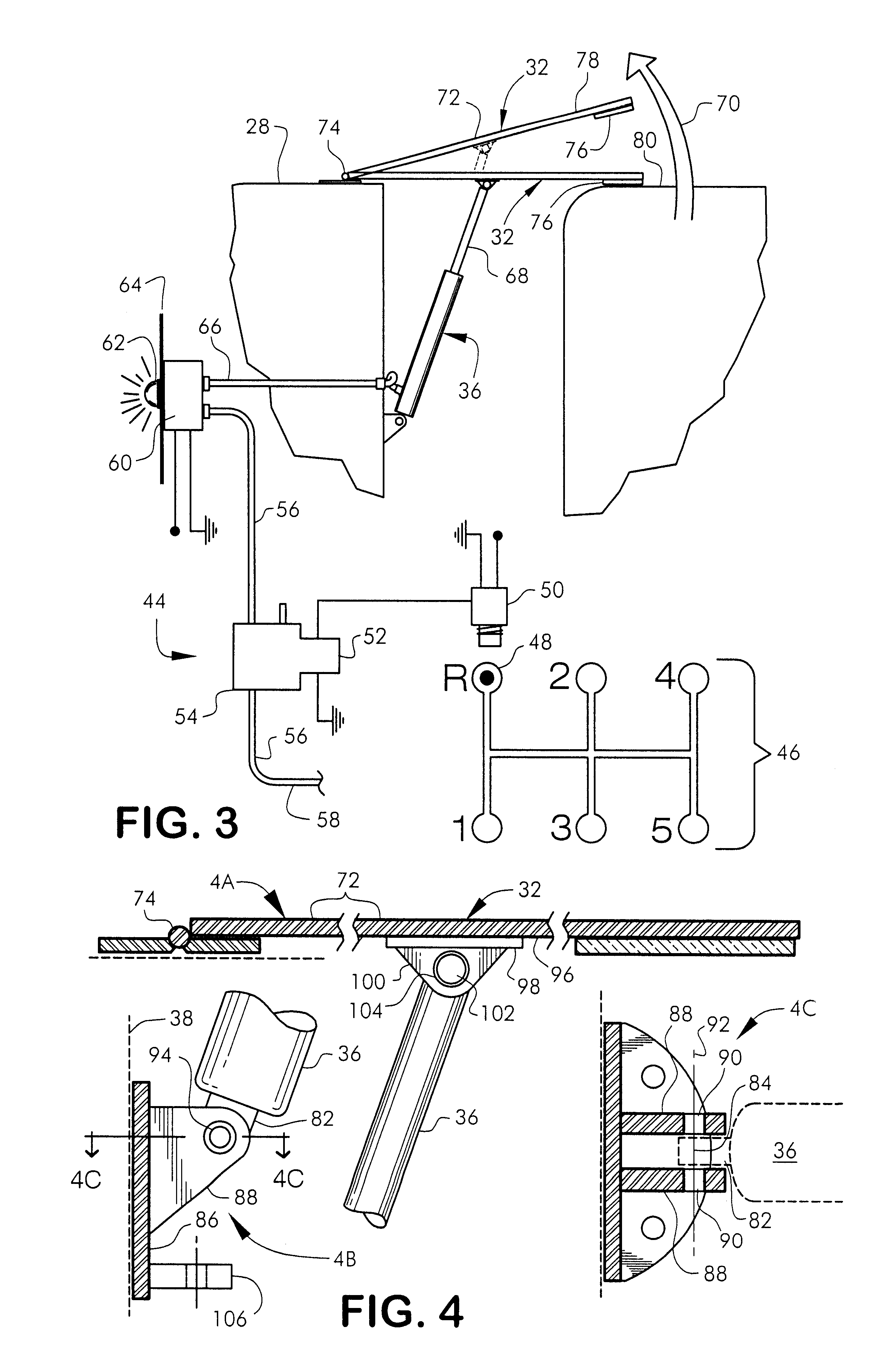

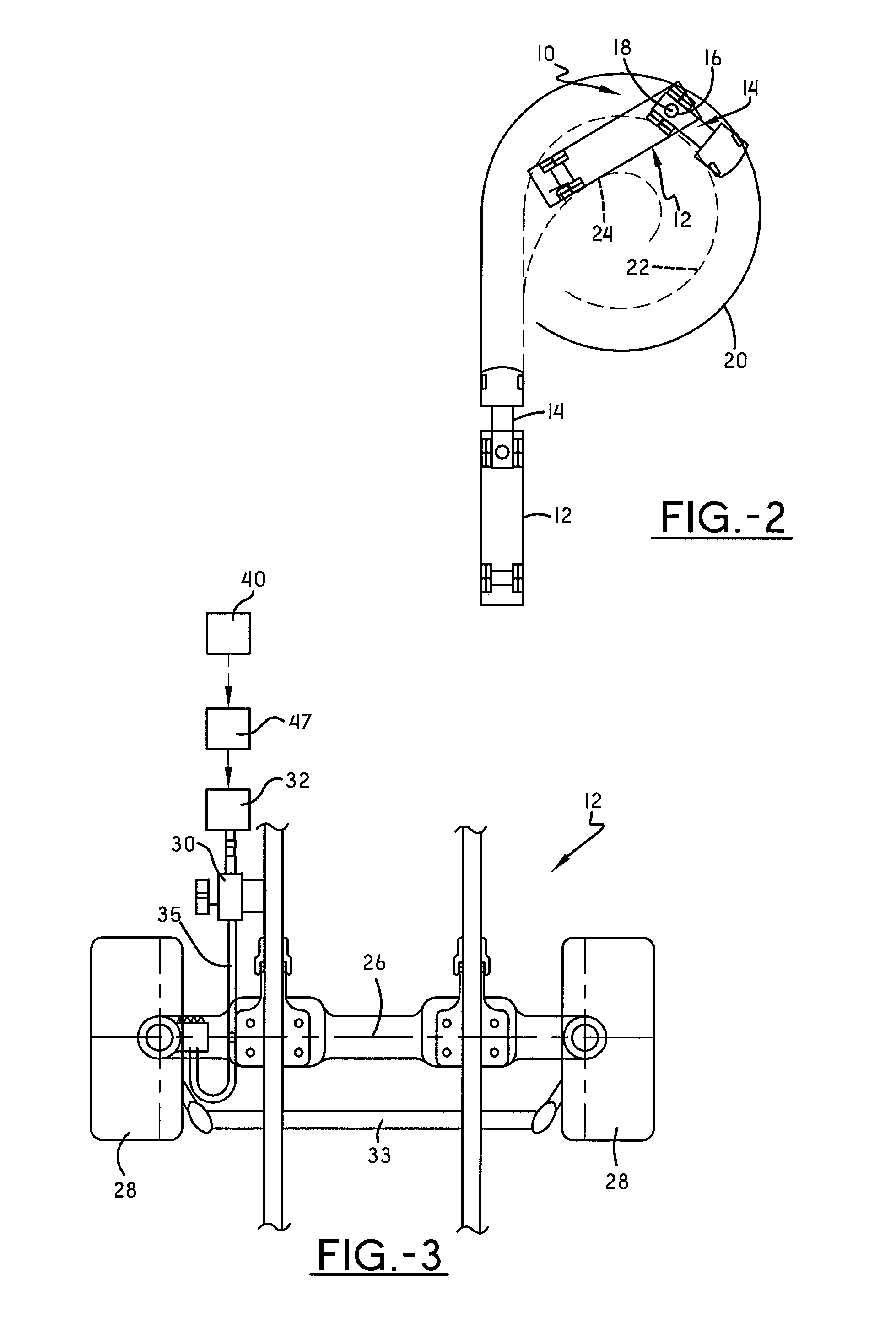

Trailer backing up device and method

ActiveUS7715953B2Easy to operateEfficient use ofDigital data processing detailsTractor-trailer combinationsDriver/operatorInstability

The present invention helps a driver steer a vehicle while backing up a trailer. A trailer being pushed wants to turn around and be pulled (i.e., to jackknife). To compensate for this instability, the driver must skillfully control his steering to cause the trailer to alternately move to be pulled from the opposite side thereby repeatedly crossing the centerline of the pushing vehicle. The moment when the trailer crosses this centerline is the moment of greatest instability and the position in which the driver would most desire to have the trailer travel. A pointer indicates in what direction the trailer is presently being directed; to backup the trailer, the driver turns the vehicle's wheel such that the pointer is kept pointing in the direction of the intended trailer destination. The present invention can be adapted to most vehicle and trailer combinations with minimal cost and complexity.

Owner:SHEPARD BRITTA MRS +1

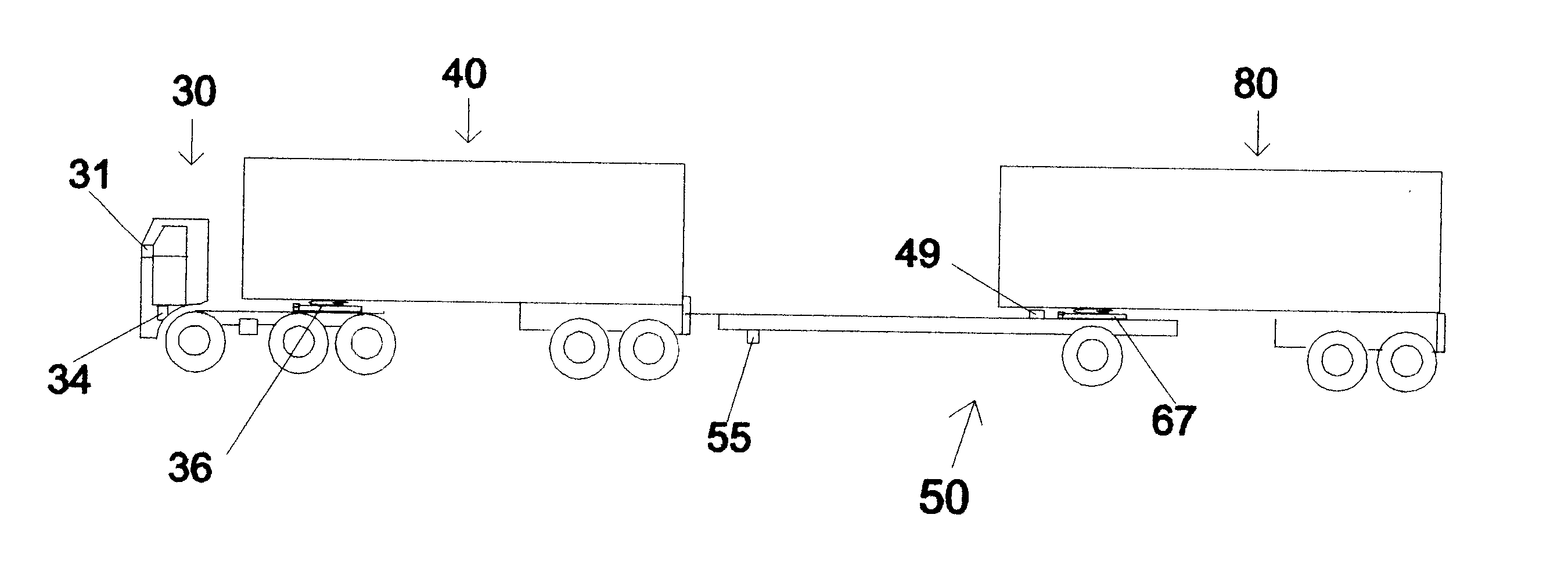

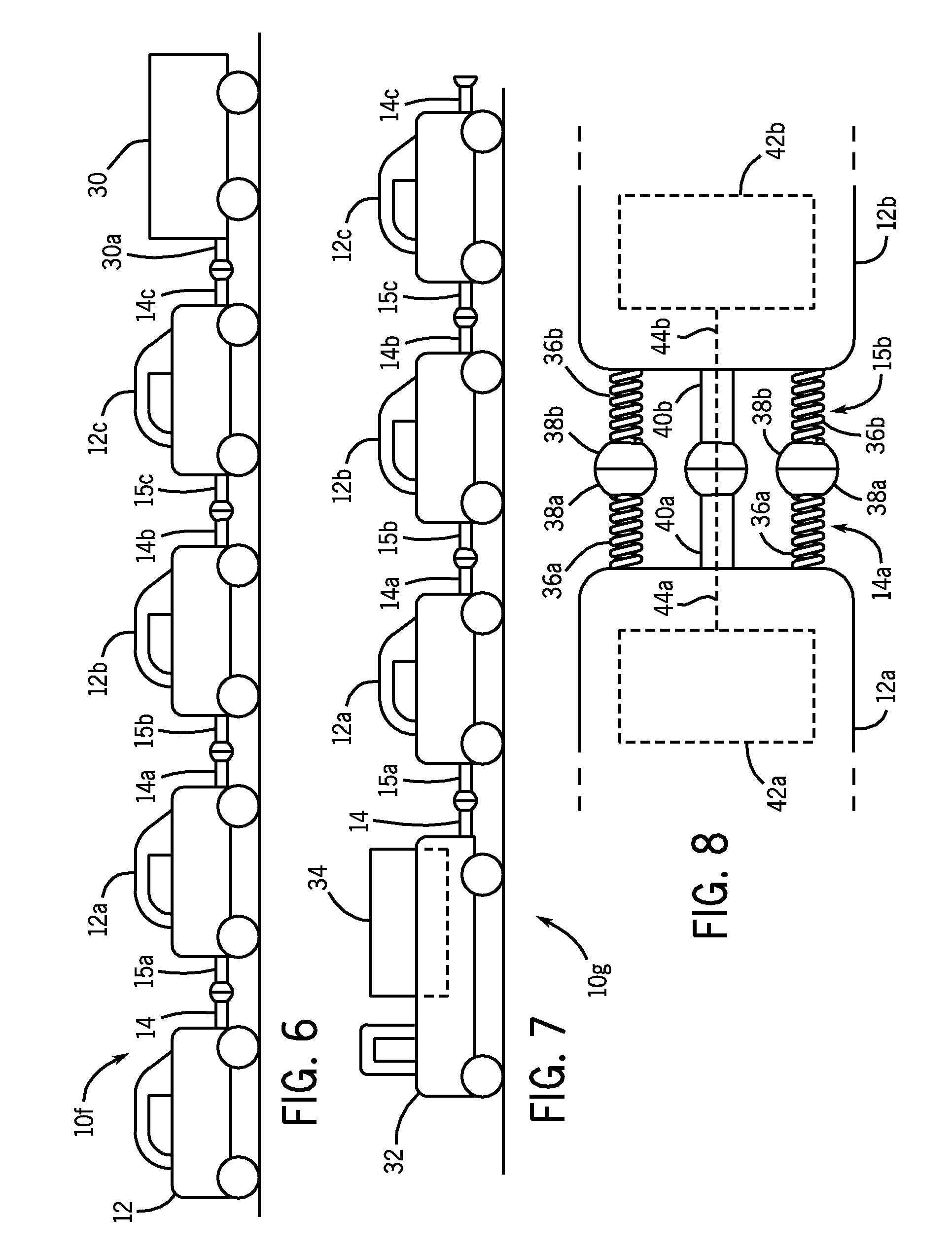

Robotic vehicle that tracks the path of a lead vehicle

A method and apparatus for controlling the steering of a trailing section of a multi-sectioned vehicle is described. The trailing section follows the path of the first section. Data is acquired by a controller from sensors on the various sections. The controller then processes this data, generating a configuration needed for the controller-steered wheels to follow a path approximately equivalent to the path taken by the first steered section. Power is then applied by some means to steer these controller-steered wheels, forcing them into the desired configuration. The complexity of the control system can be varied with different algorithms providing alternative steering patterns as desired. This system can be extended with more trailing sections without necessitating more than minor changes to the control algorithms.

Owner:MASTERS NATHAN EUGENE +2

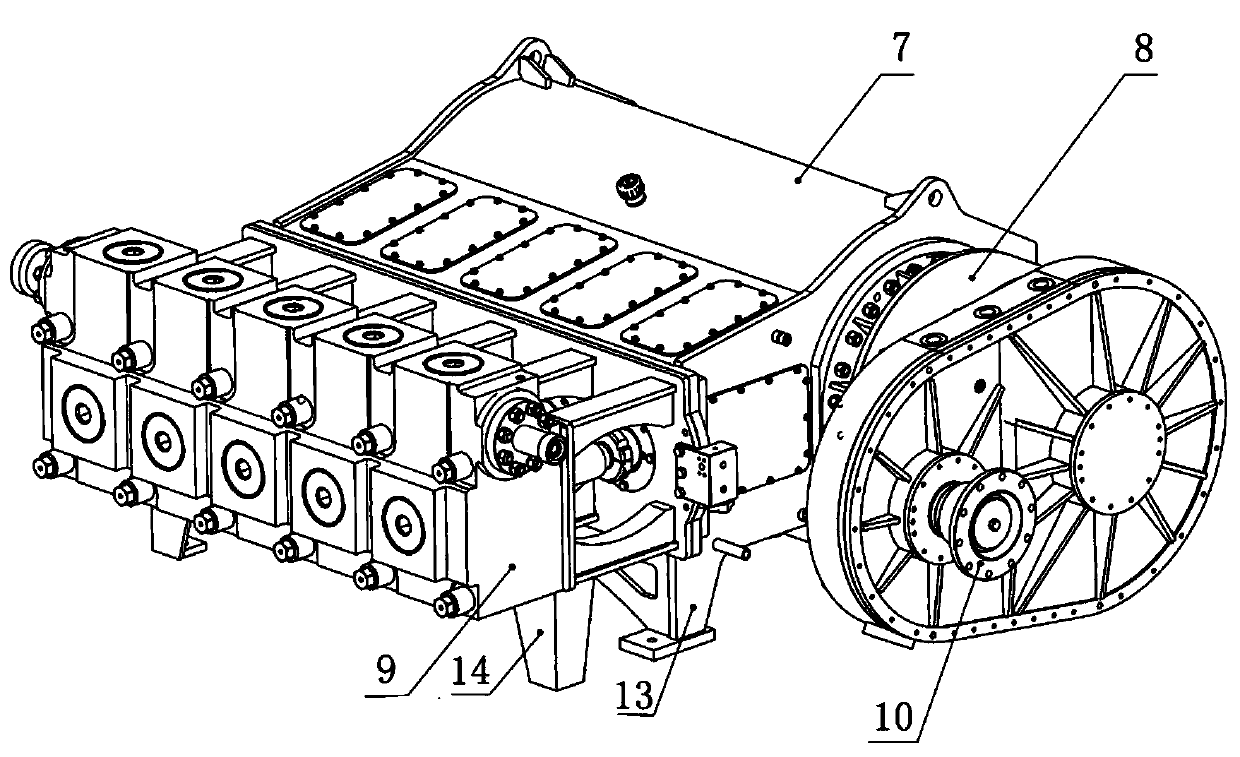

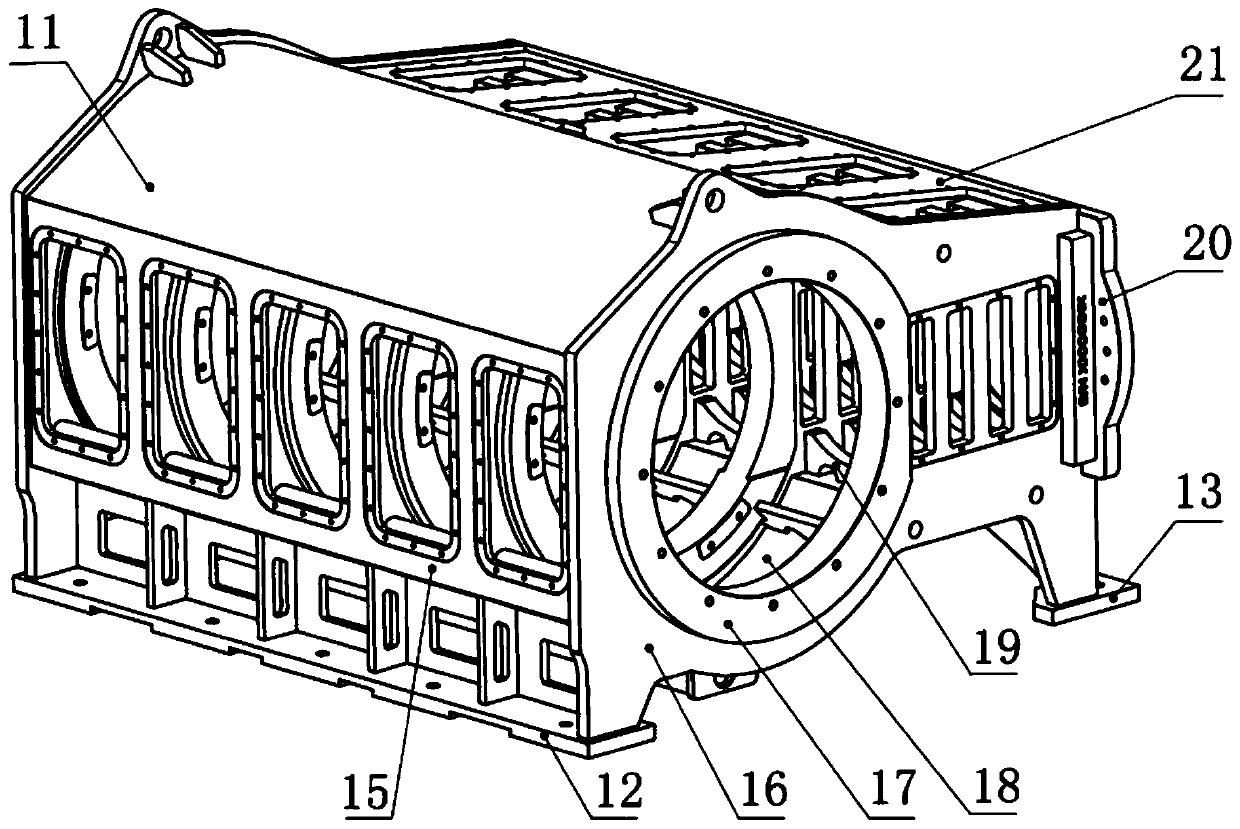

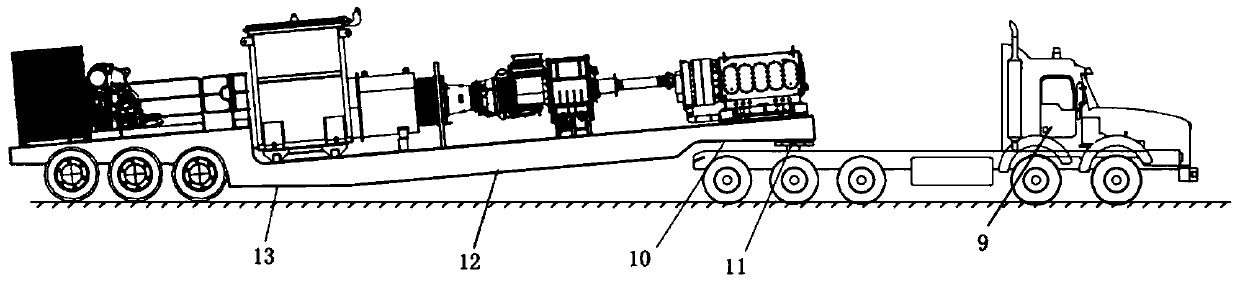

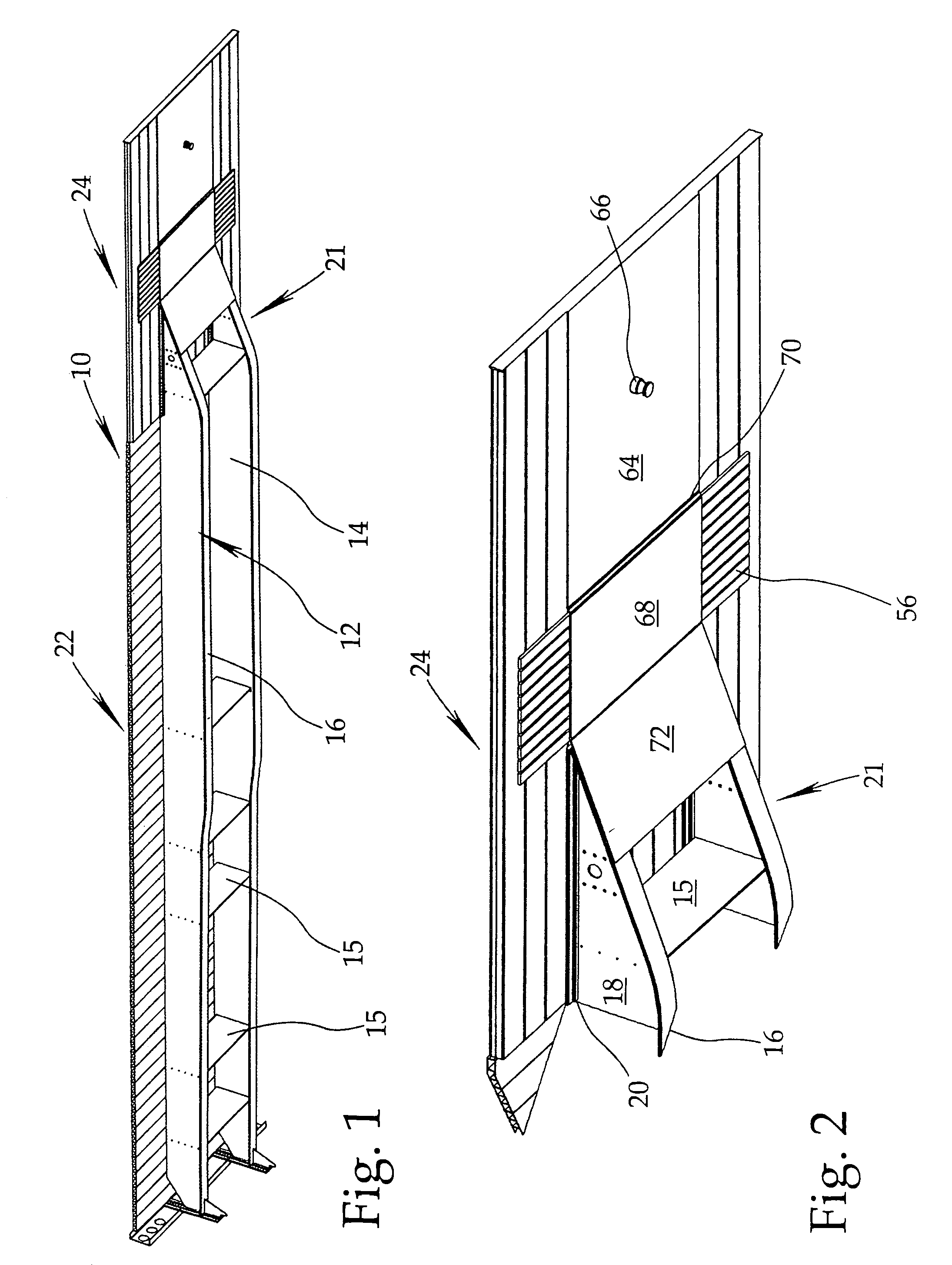

Turbine fracturing semitrailer

PendingCN110485983AReduce volumeReduce weightEngine manufactureEngine fuctionsTransmission lossFailure risk

The invention discloses a turbine fracturing semitrailer. The turbine fracturing semitrailer comprises a semitrailer body, a turbine engine, a reduction gearbox, a transmission mechanism and a plungerpump; the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump are arranged on the semitrailer body, the output end of the turbine engine is connected with the reduction gearbox, and the reduction gearbox is connected with the plunger pump through the transmission mechanism in a transmission mode. The turbine fracturing semitrailer has the beneficial effects thatthrough linear connection of the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump in the power-transmission direction, excessive transmission loss can be avoided, and efficient transmission performance is guaranteed; and the whole semitrailer is small in size, light in weight, low in the use cost, and low in failure risks.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

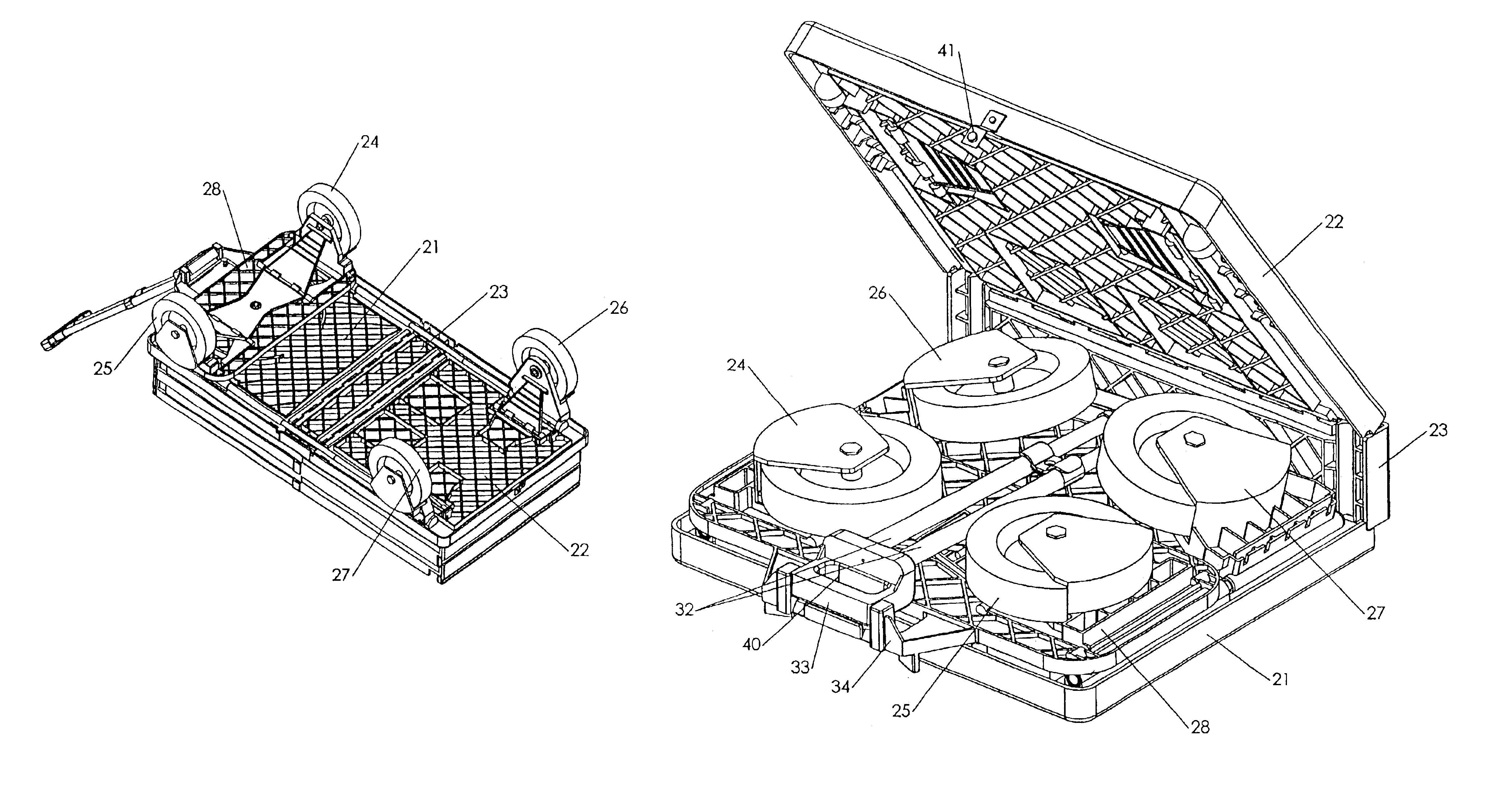

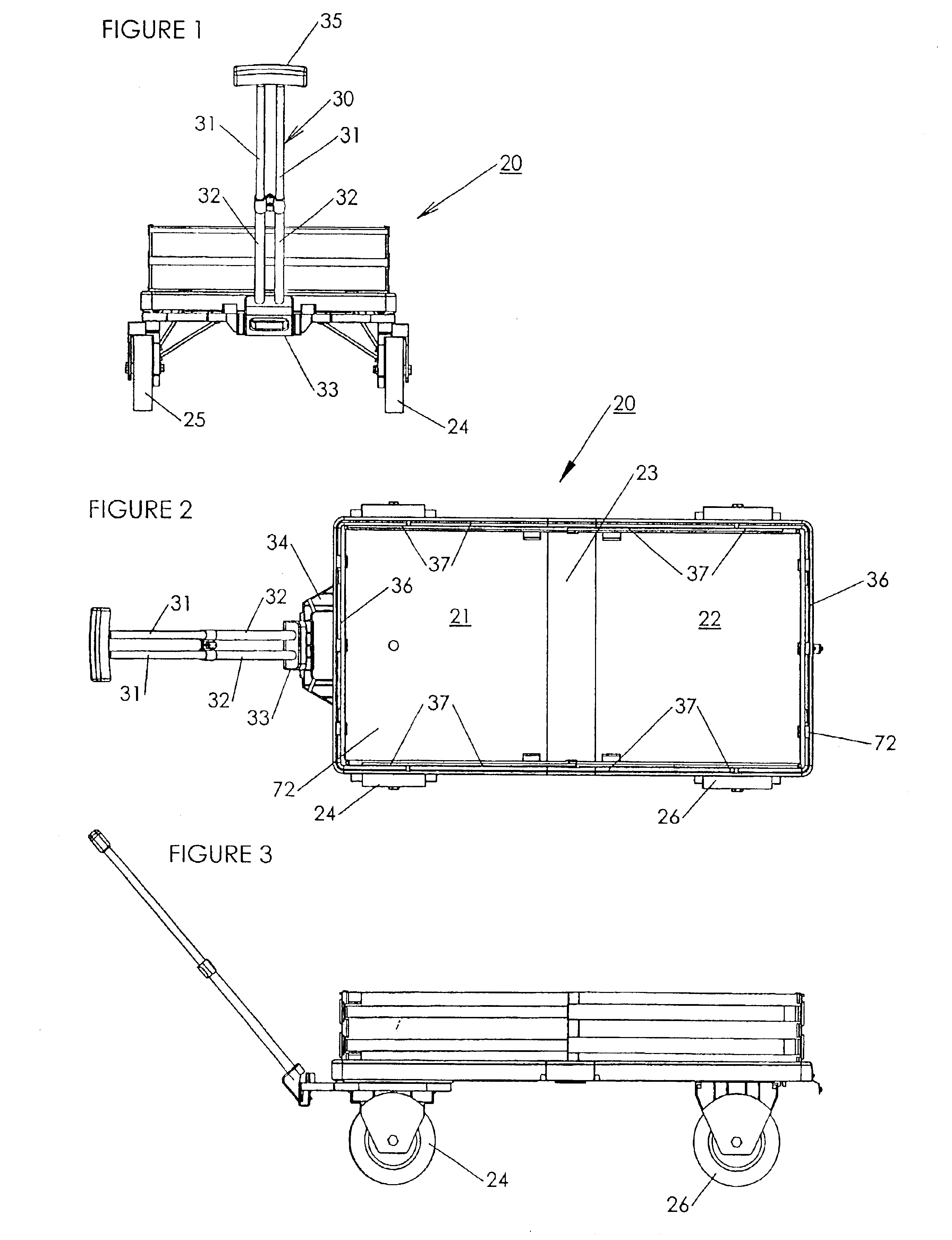

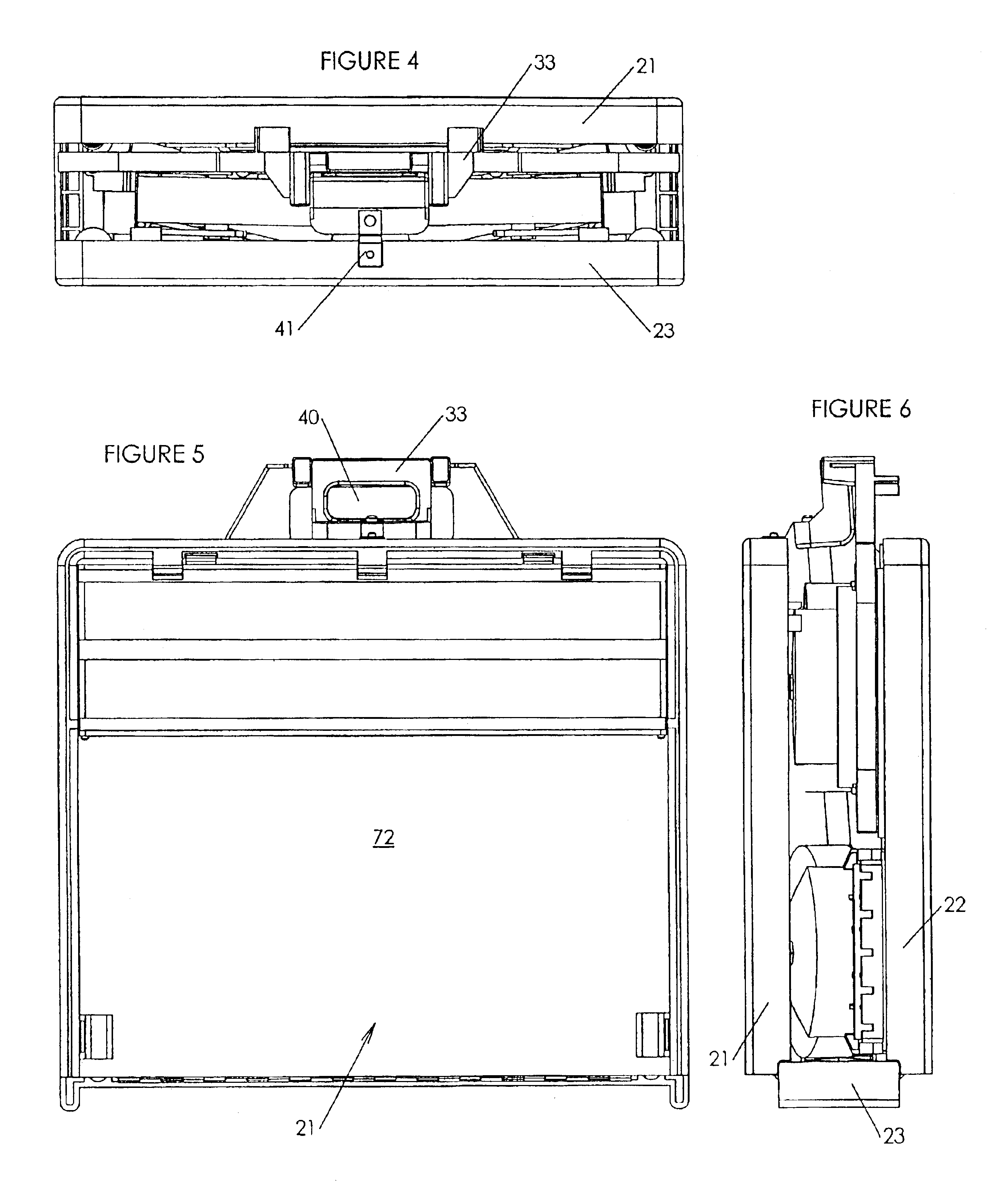

Folding wagon/cart

InactiveUS6845991B1Improve portabilityEasy to assembleCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineeringTruck

By providing a plurality of cooperating, foldable panel members in combination with a plurality of foldable wheel assemblies, a unique wagon or cart construction is attained which is capable of being folded into a small, compact area, whenever desired, and then quickly and easily deployed into a fully erected and operational position, which enables virtually any desired object to be easily transported. In addition, in the preferred construction of this invention, an automatically deployed structural supporting member is incorporated into the wagon / cart for providing inherent strength and rigidity to the wagon / cart when fully erected. In this way, heavy objects previously incapable of being transported are capable of being accommodated with ease.

Owner:RITUCCI LOUIS N +2

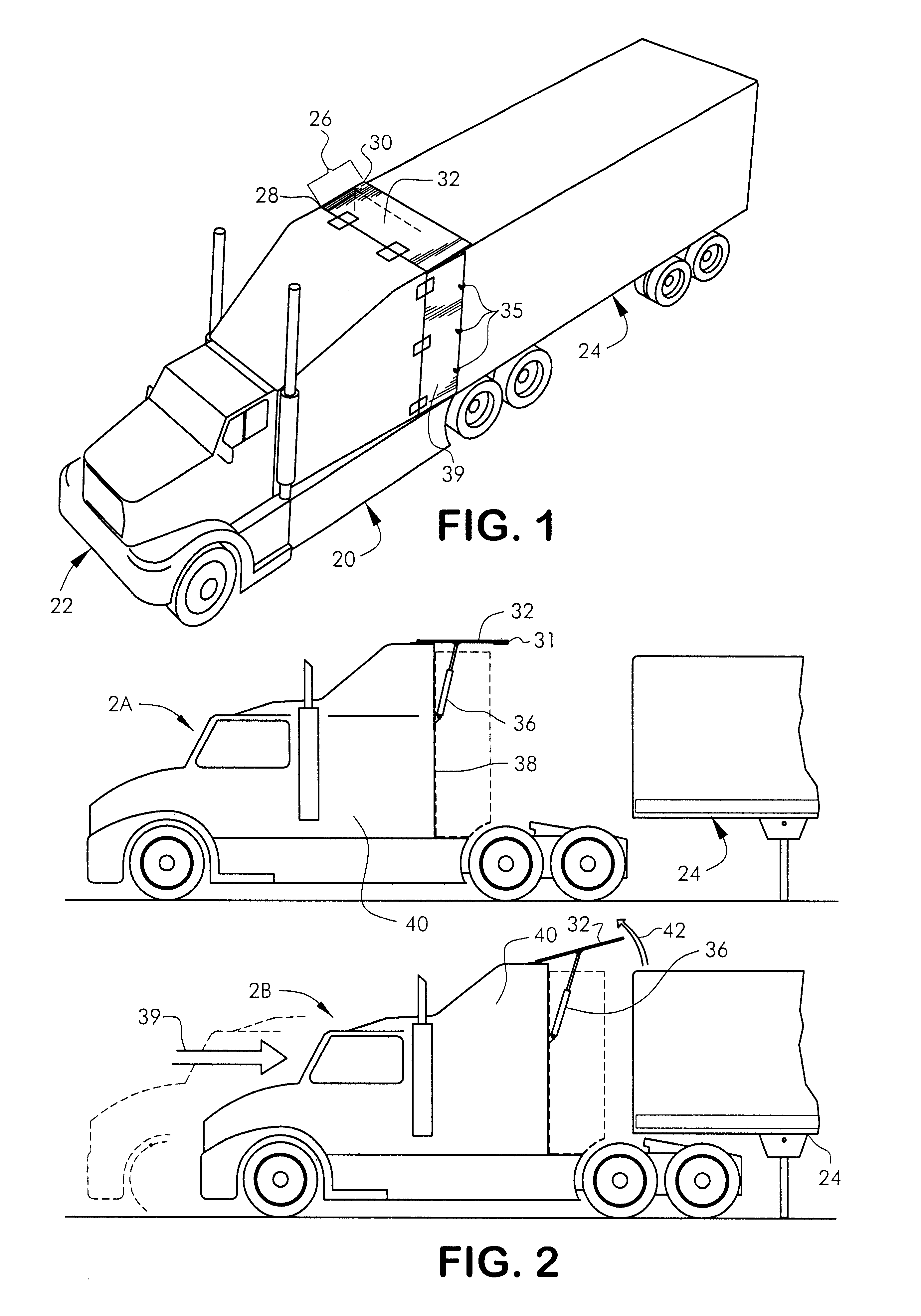

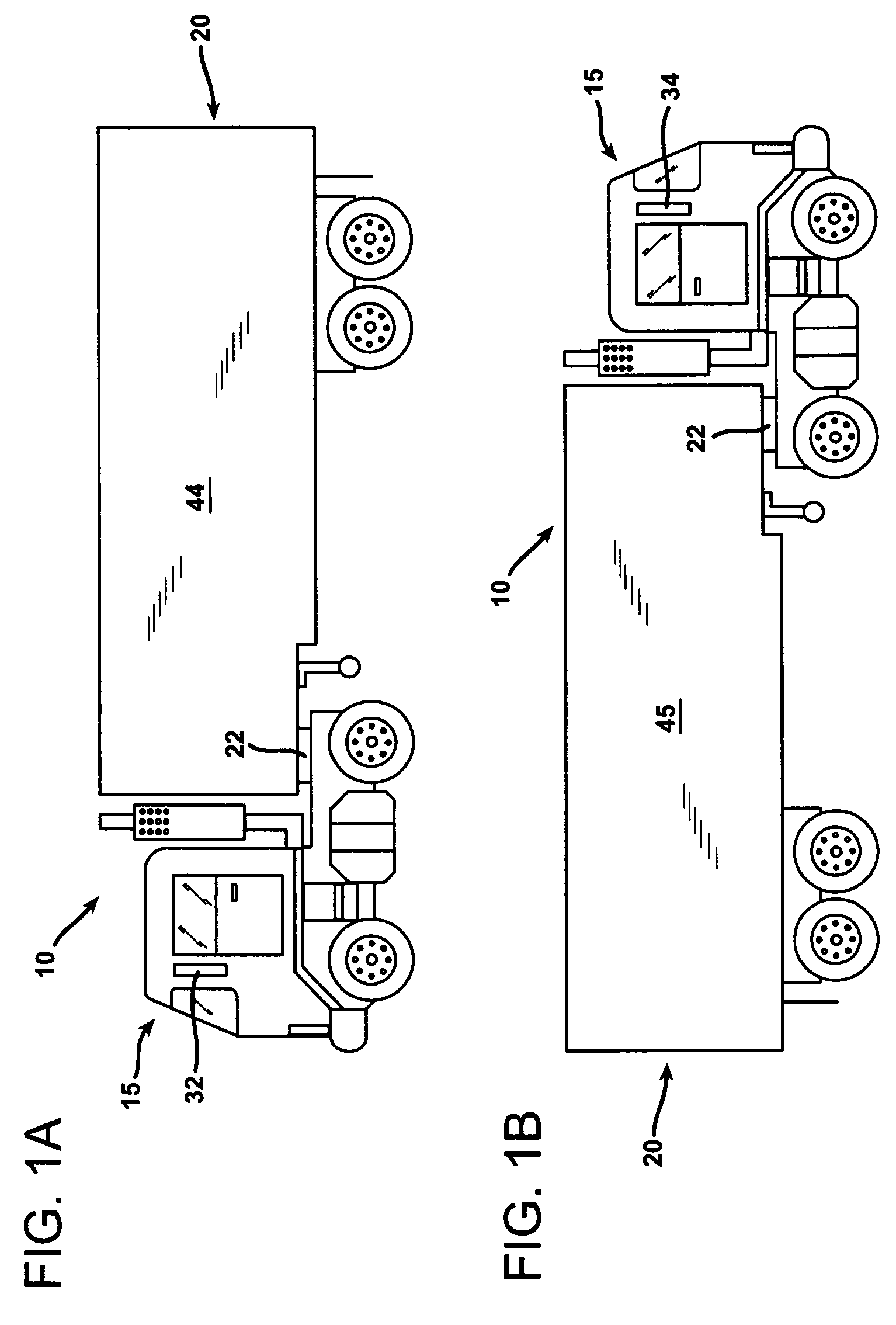

Fuel-efficient tractor-trailer system

A fuel-efficient tractor-trailer system for improving the fuel mileage of a tractor-trailer combination by improving the air resistance that occurs in the area between the rear of the tractor and the front of the semi-trailer. The fuel-efficient tractor-trailer system provides an improved roof extension, which automatically raises when the tractor is put into reverse gear and an improved wheel mechanism for assisting the side extensions to slide around the semi-trailer ends when the tractor-trailer is turning. The fuel-efficient tractor-trailer system requires only modification to the tractor and not the trailer.

Owner:GENERAL DYNAMICS C4 SYSTEMS

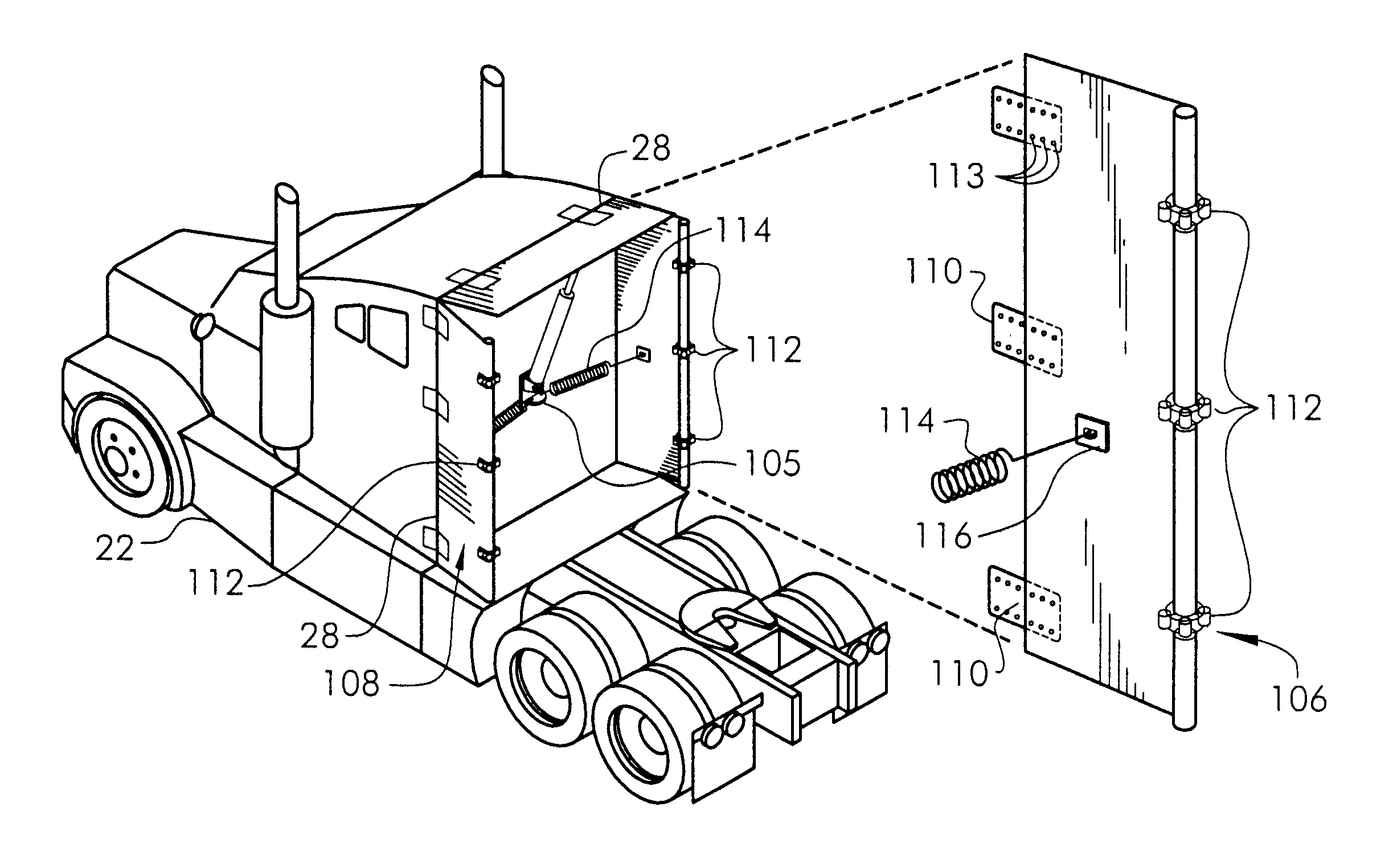

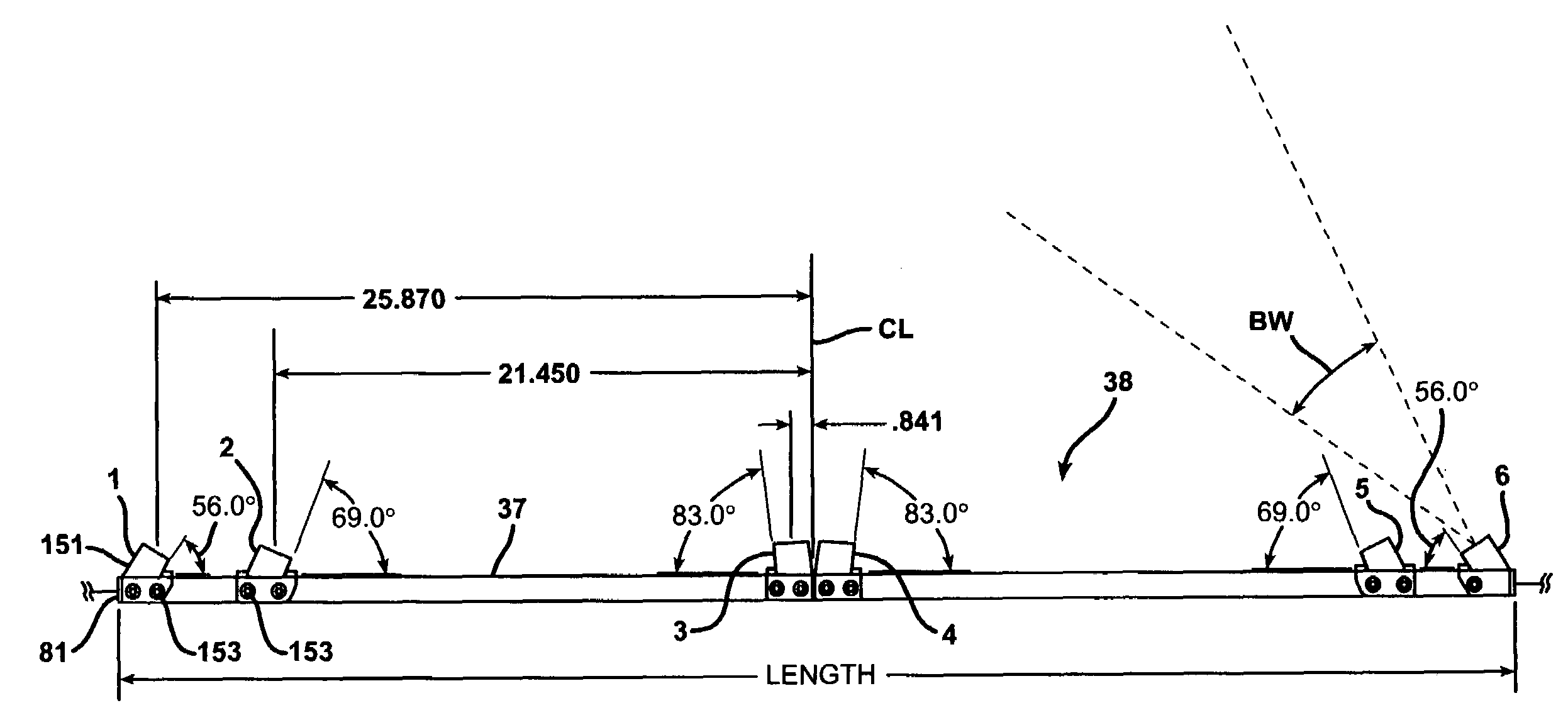

Vehicle safety system having methods and apparatus configurable for various vehicle geometries

Methods and apparatus for automatically adjusting the angle of a rotatable side view mirror of an articulated tractor and trailer includes transducers attached to the tractor for transmitting signals toward the trailer and for receiving signals reflected by the trailer. The transducers have a substantially symmetrical arrangement about a centerline of a linear transducer bar attached to the tractor and each has an angular orientation substantially dissimilar to adjacent transducers on a same side of the centerline. A control circuit sequentially activates ones of the transducers such that only a single transducer transmits signals at any given time. Thereafter, the control circuit only processes reflected signals received by the emitting transducer. The control circuit calculates an angle between the tractor and trailer and causes the mirrors to rotate. Transducer calibration and mirror adjustment relative to a zero position set by a driver are also contemplated.

Owner:CLEAR VIEW MIRROR LLC

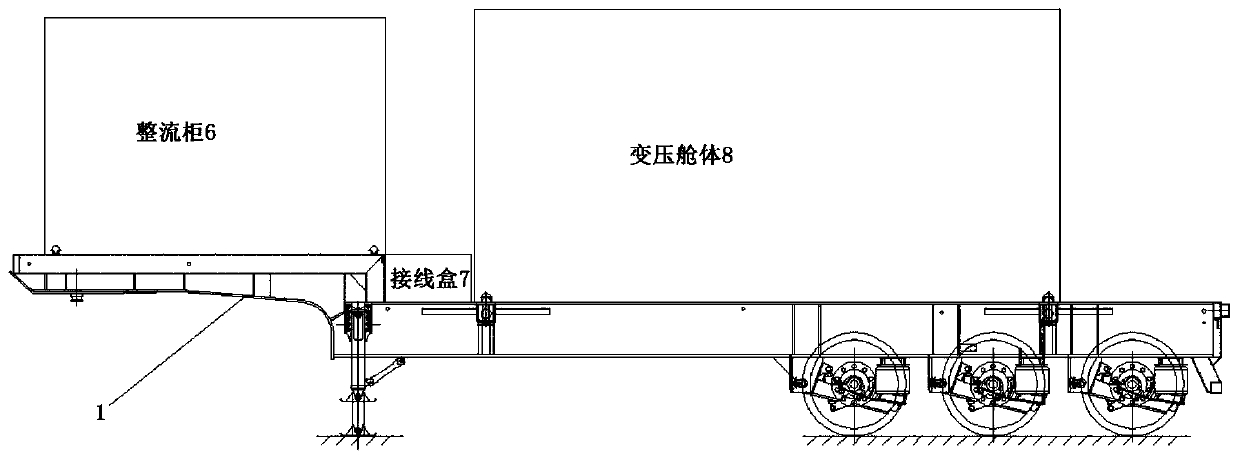

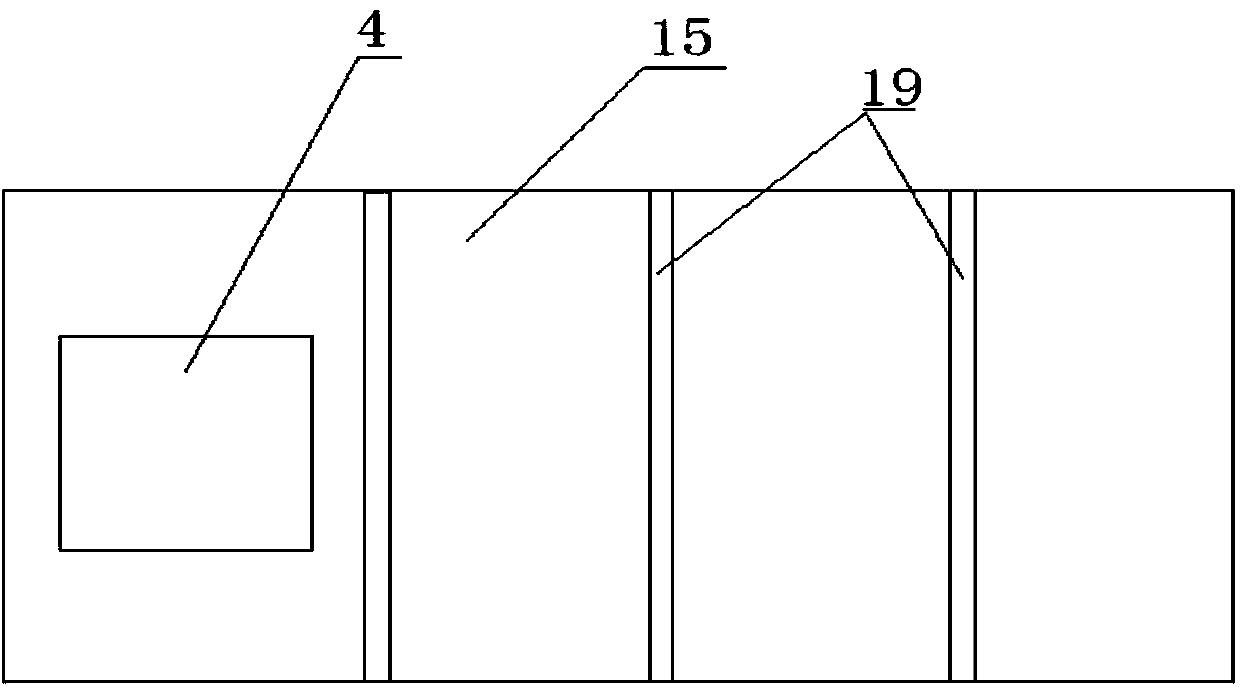

Electric driving fracturing type power supplying semitrailer

PendingCN110155193AReduce volumeCompact layoutAc-dc conversion without reversalSubstation/switching arrangement detailsTransformerLow voltage

The invention discloses an electric driving fracturing type power supplying semitrailer. The electric driving fracturing type power supplying semitrailer is characterized in that a high-voltage switch, a transformer and two rectifying unit sets are adopted to correspondingly drive a plurality of high-voltage converting units and a plurality of low-voltage converting units through common DC buses.The whole electric driving fracturing type power supplying semitrailer is small in size, compact in arrangement, and economic; the common high-voltage switch, the transformer and the rectifying unitsare adopted, so that the wiring of power supplying circuits can be reduced; the equipment quantity and investment output power can be decreased; and the use demand can be met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

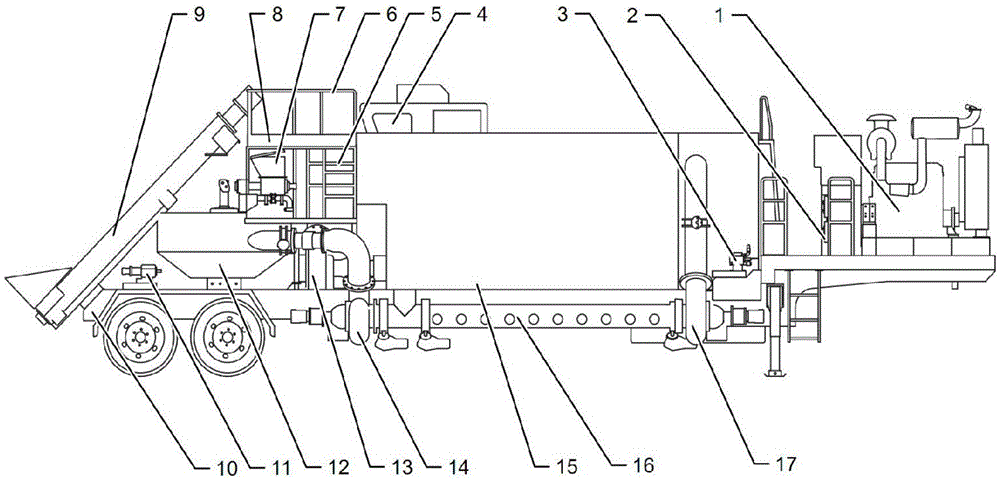

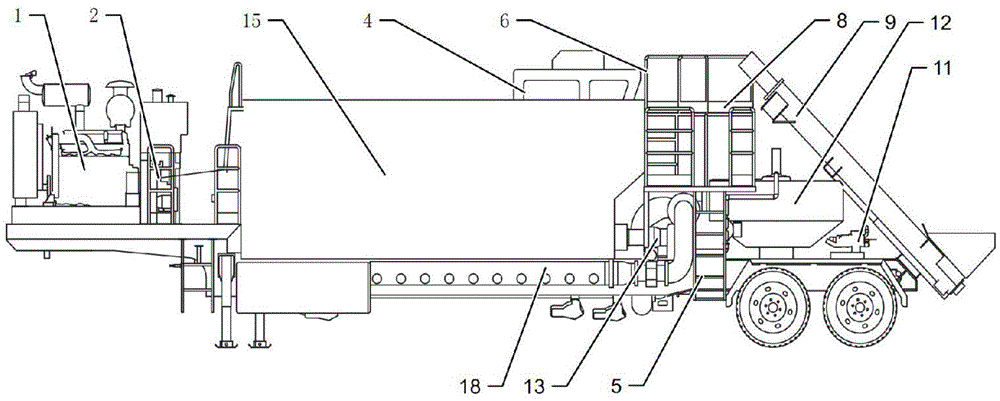

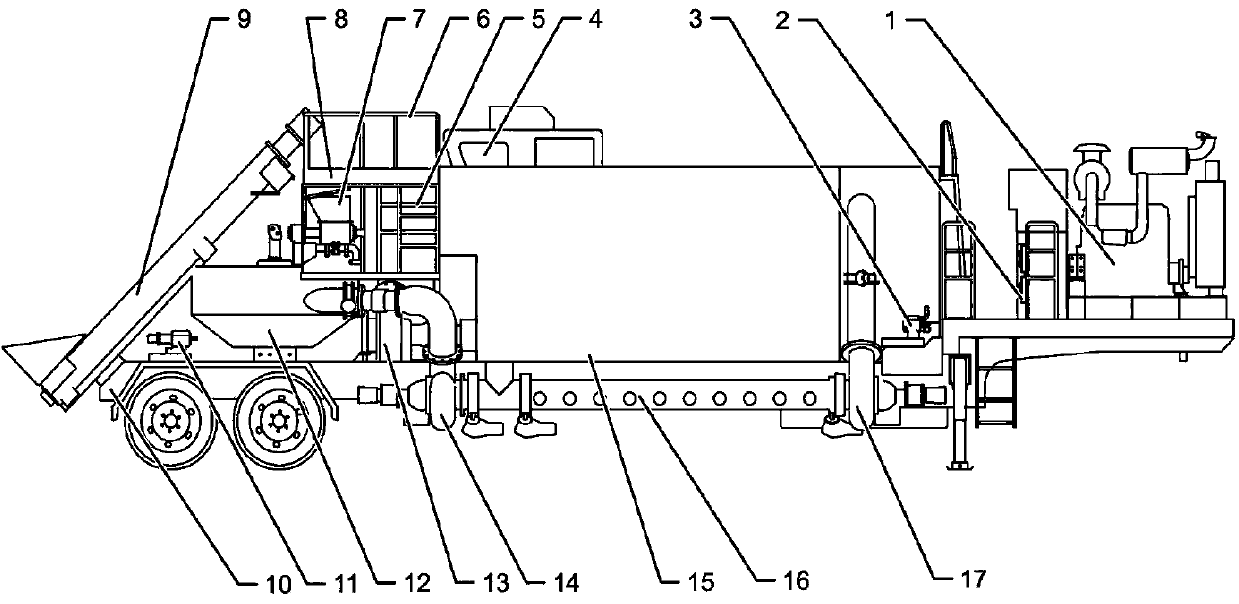

A fracturing fluid mixing sand mixing semi-trailer

ActiveCN103993869BReduce workloadLess supporting equipmentFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

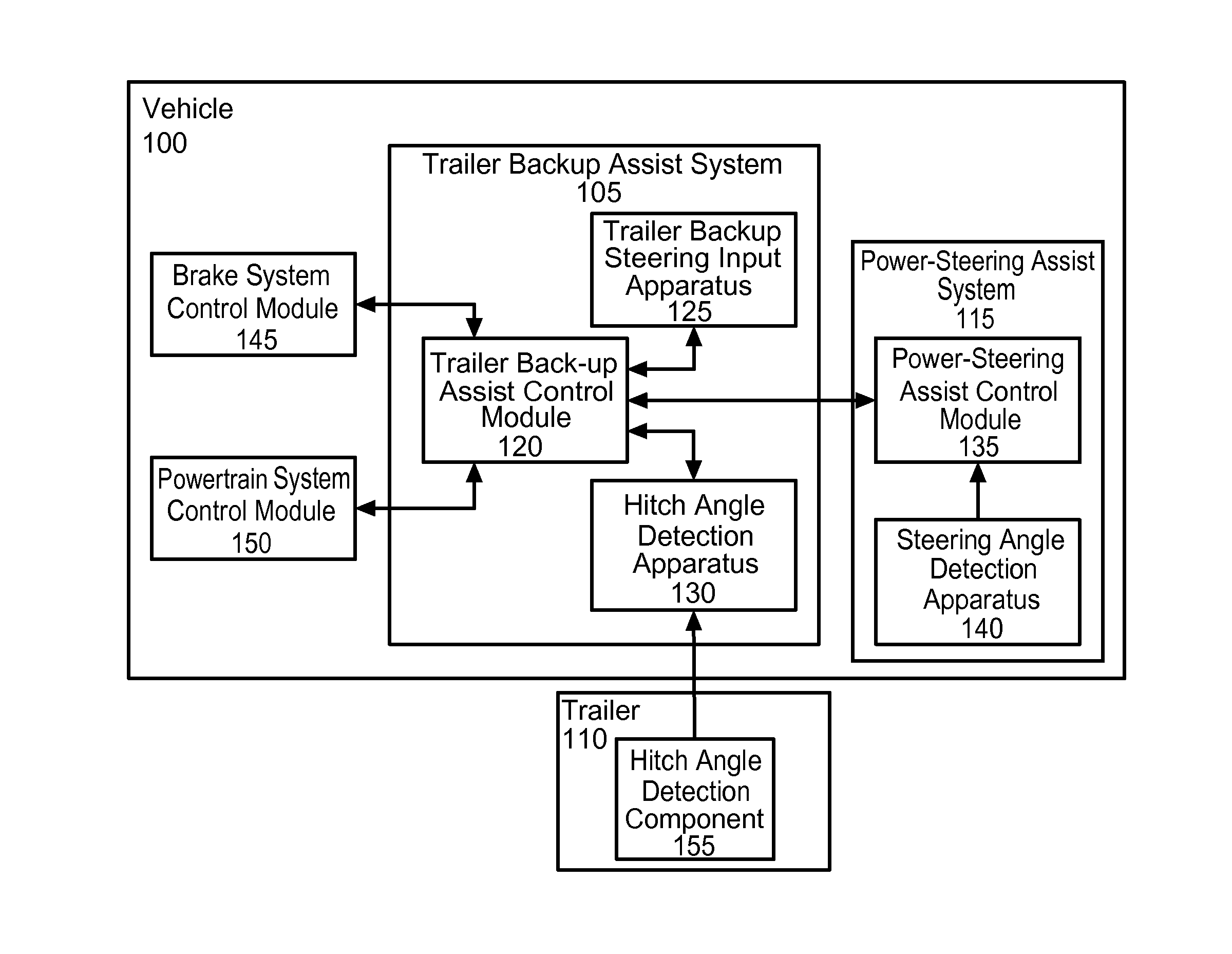

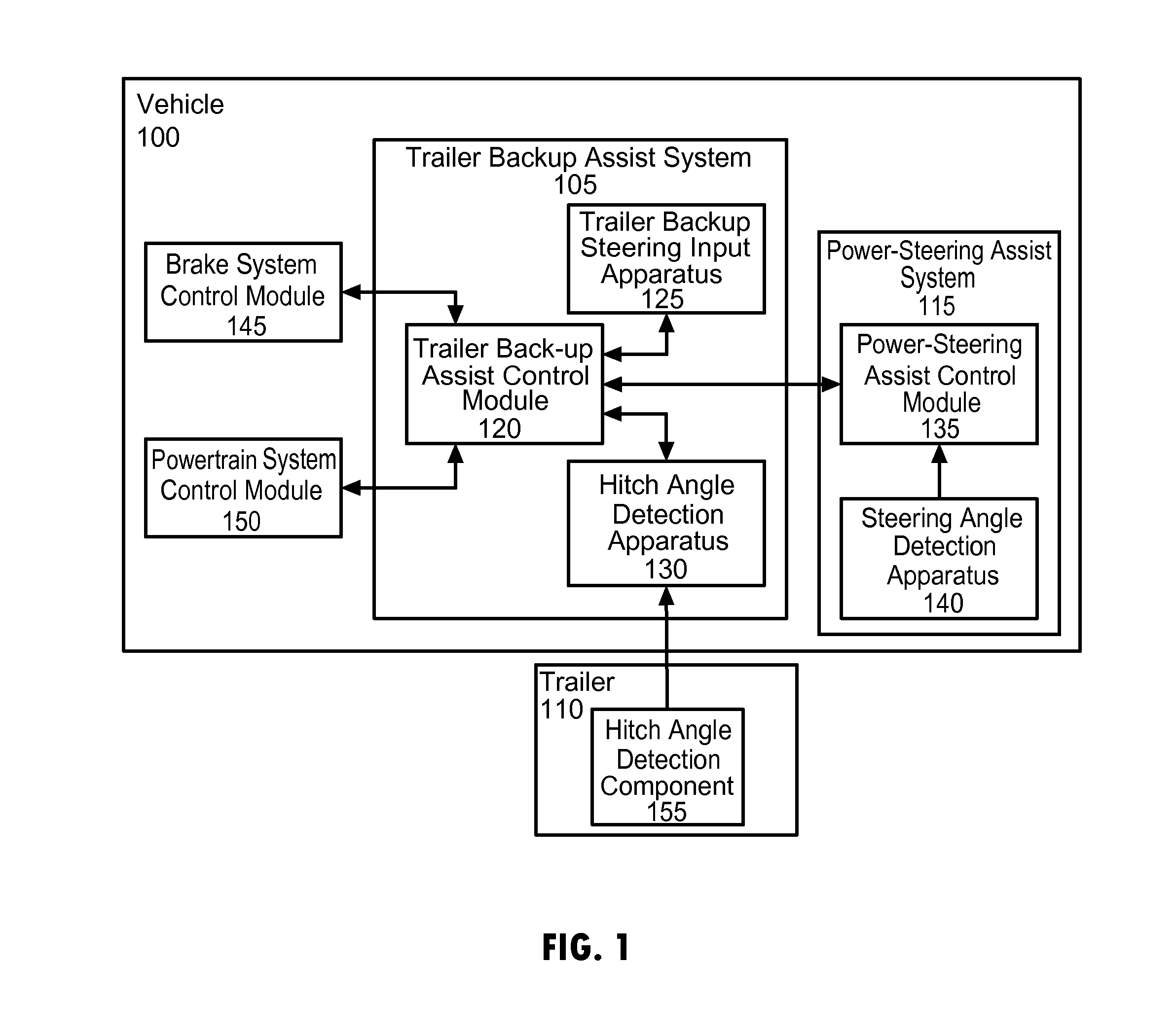

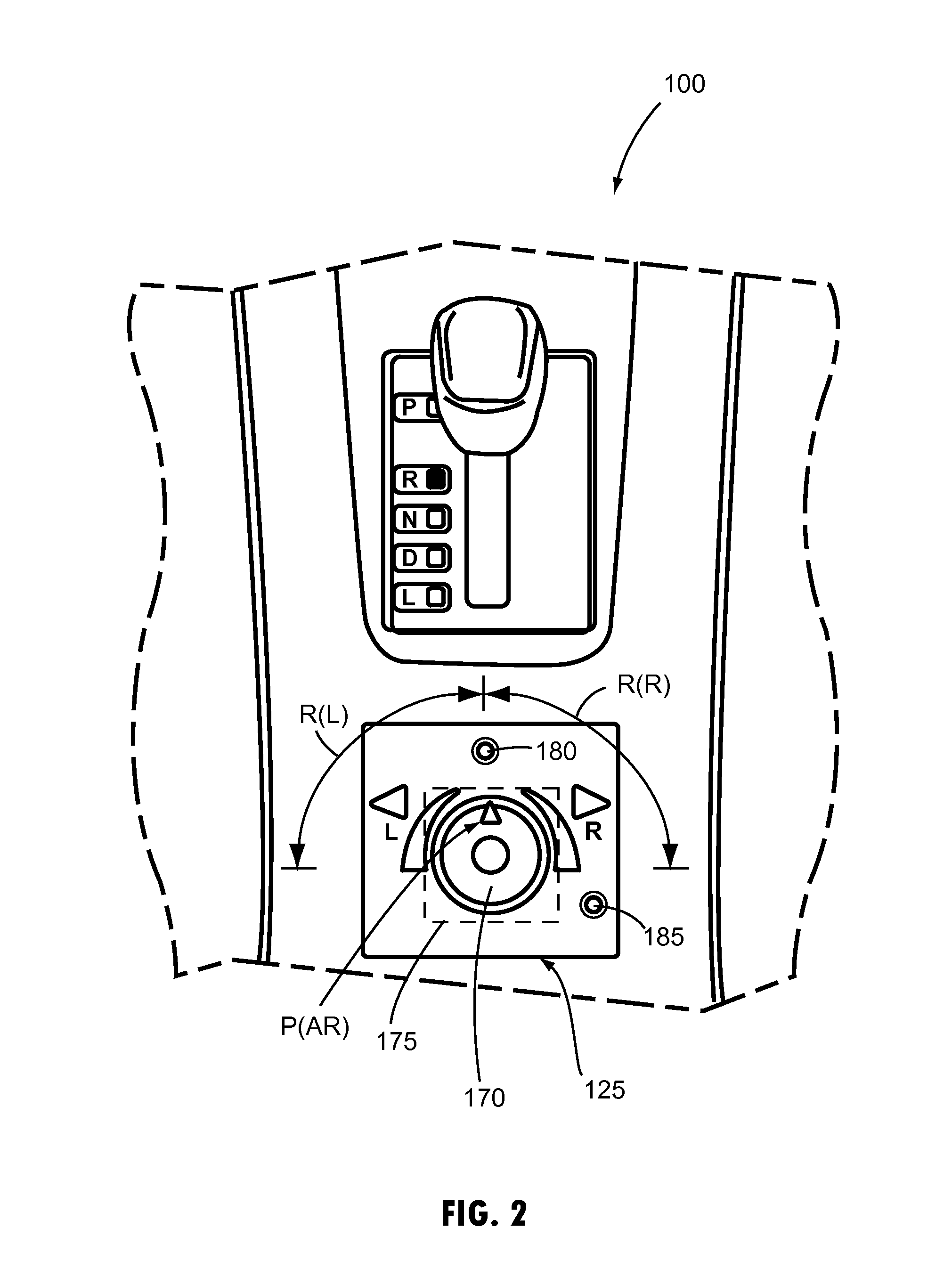

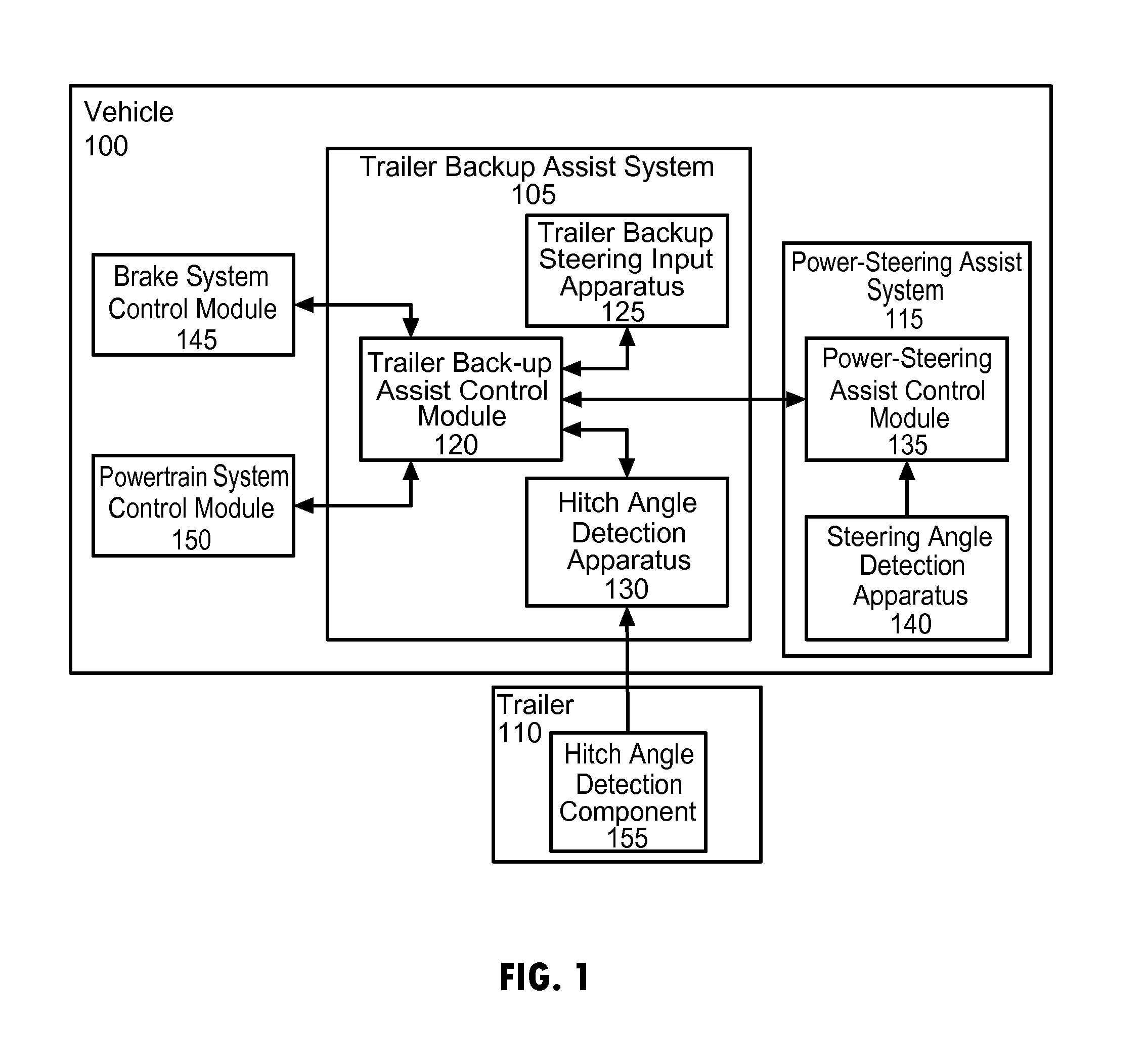

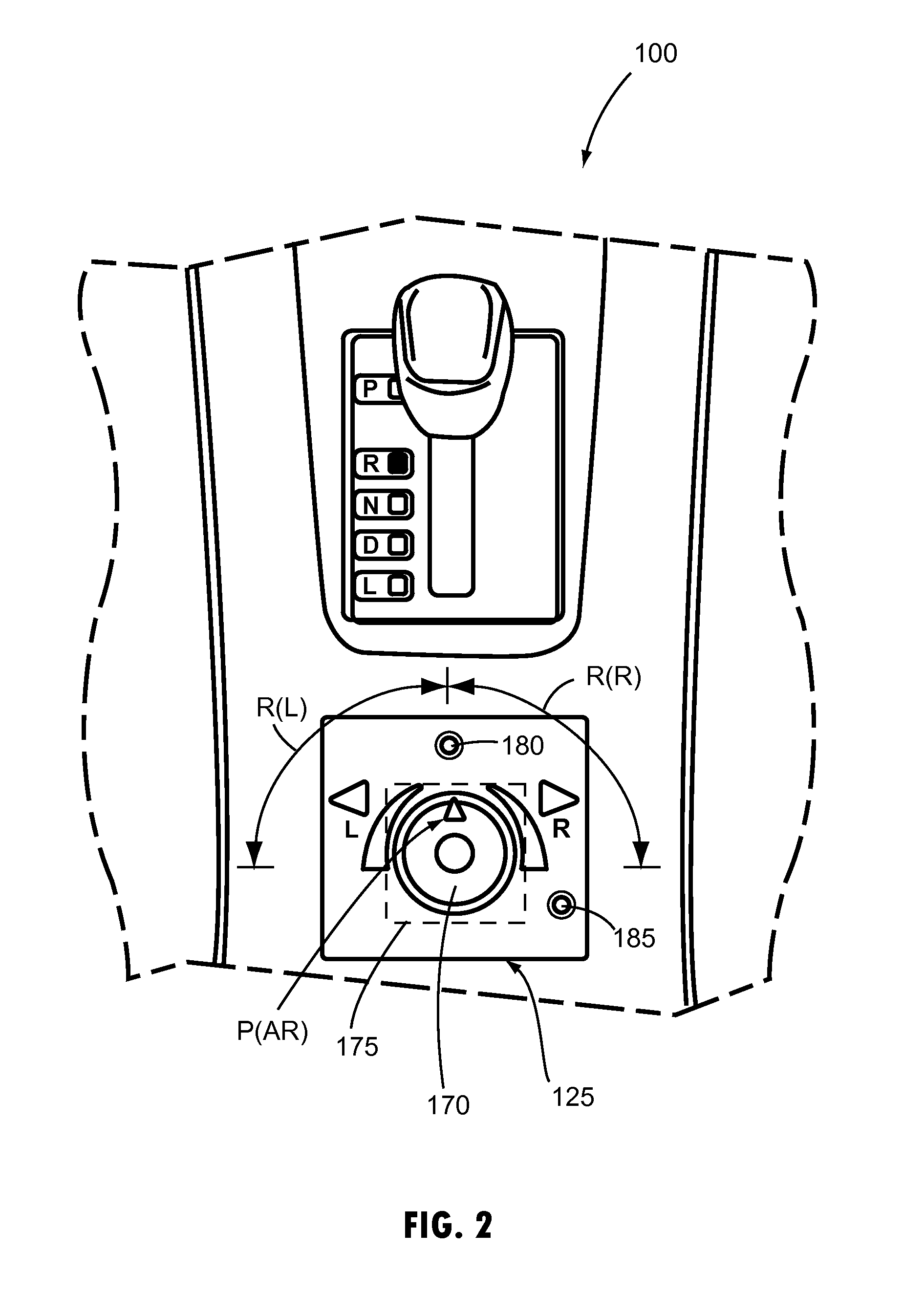

System and method for determining a hitch angle offset

ActiveUS20140188346A1Steering initiationsDigital data processing detailsSteering angleSteering linkage

A system and a method are provided for estimating an actual hitch angle between a vehicle and a trailer. A hitch sensor on the vehicle continuously senses a measured hitch angle and a steering sensor continuously senses a steering angle of steered wheels of the vehicle. A controller determines an offset between the measured hitch angle and the actual hitch angle when the measured hitch angle and the steering angle are substantially constant while the vehicle and trailer are reversing.

Owner:FORD GLOBAL TECH LLC

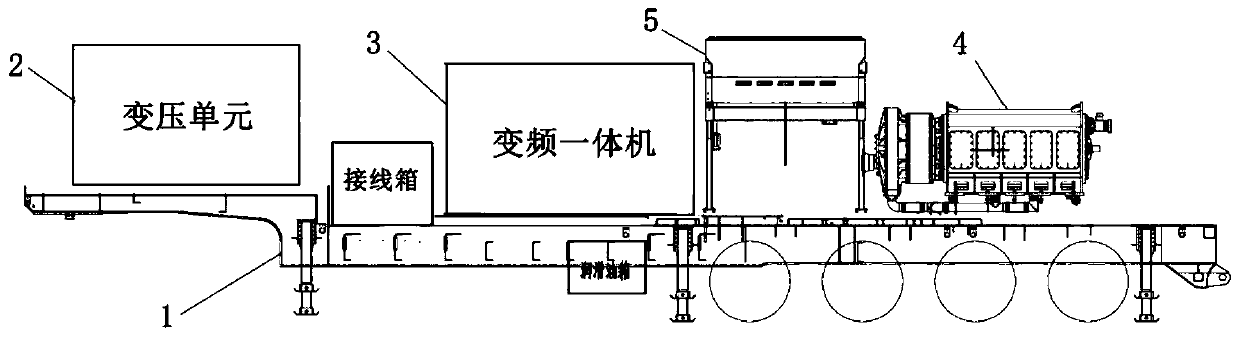

Electric drive fracturing semi-trailer of frequency conversion integrated machine

PendingCN110608030AOptimize layoutNo emission pollutionPositive displacement pump componentsFluid removalFrequency changerEngineering

The invention discloses an electric drive fracturing semi-trailer of a frequency conversion integrated machine. The optimization and integration of the traditional power supply semi-trailer and the fracturing semi-trailer realize the functions of power supply and fracturing of one semi-trailer without using the complete set of the power supply semi-trailer and the fracturing semi-trailer, the electric drive fracturing semi-trailer is more flexible in actual use, and the well field layout of oil and gas fields is greatly optimized; the transportation is convenient; only a set of high-voltage cables can be connected with the high-voltage power supply to reach a working state, and the wiring installation is faster; compared with diesel-driven fracturing, and the noise of the electric drive fracturing is low without exhaust emission pollution; the driving source is power, which has lower cost than the diesel; the electric drive fracturing semi-trailer adopts an integrated design of a motorand a frequency converter (namely, the frequency conversion integrated machine), the space occupied by the electric motor and the inverter in the prior art is reduced effectively, so the installing part of the electric drive fracturing semi-trailer has smaller volume and the transportation is more convenient, and can also provide space guarantee for installing other equipment on the semi-trailerbody.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Fracturing fluid mixing and sand mixing semitrailer

ActiveCN103993869ALess supporting equipmentReduce workloadFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

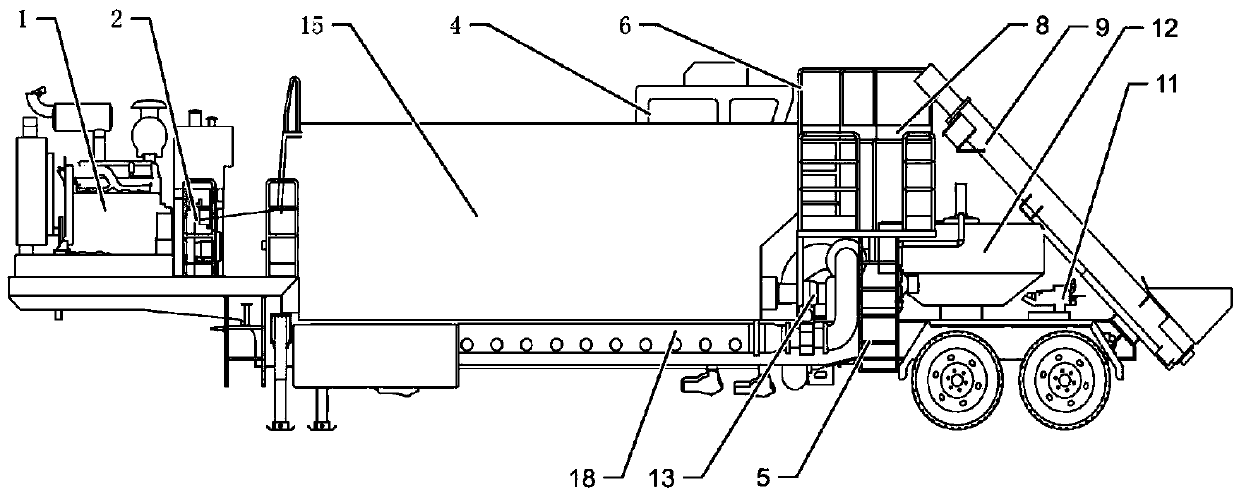

Single-machine single-pump electric drive fracturing semitrailer

PendingCN110656919AOptimize layoutNo emission pollutionPositive displacement pump componentsFluid removalExhaust gas emissionsElectric drive

The invention discloses a single-machine single-pump electric drive fracturing semitrailer. A traditional power supply semitrailer and a fracturing semitrailer are integrated in an optimized manner torealize a semitrailer simultaneously having power supply and fracturing functions; the power supply semitrailer and the fracturing semitrailer do not need to be used in a matched manner so that the single-machine single-pump electric drive fracturing semitrailer is more flexible in actual use and the oil and gas field well site layout is greatly optimized; the transportation is convenient; a working state can be reached only by using one group of high voltage cables to be connected with high voltage power supply so that the wiring mounting is faster; compared with diesel oil drive fracturing,electric drive fracturing has the advantages of small noise and no waste gas exhaust pollution; and as a driving source is electric power, compared with the diesel oil, the electric power has the advantage of lower use cost.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

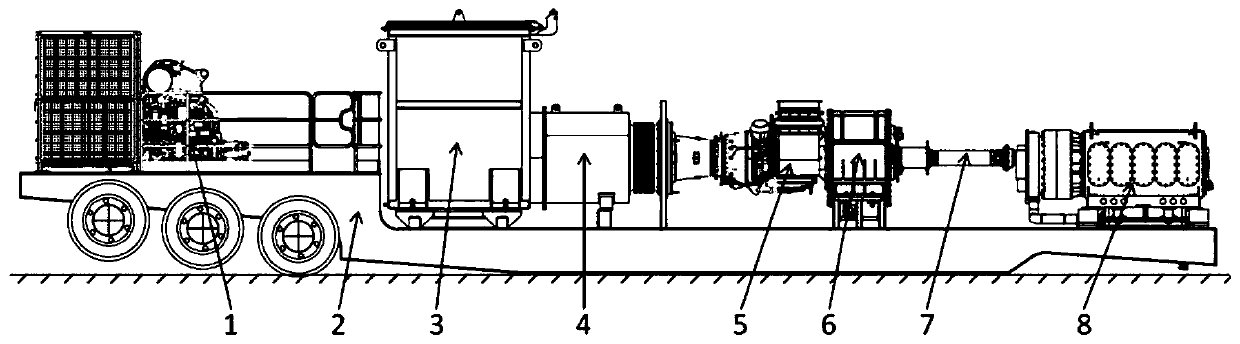

Turbine fracturing equipment

PendingCN110485982AReduce volumeReduce weightPositive displacement pump componentsTurbine/propulsion engine coolingOperational costsGravity center

The invention discloses turbine fracturing equipment. The turbine fracturing equipment comprises a transporting device, a turbine engine, a reduction gearbox, a transmission mechanism and a fracturingpump, wherein the output end of the turbine engine is connected with one end of the reduction gearbox; the other end of the reduction gearbox is in transmission connection with the fracturing pump; the transportation device is used for bearing the turbine engine, the reduction gearbox, the transmission mechanism and the fracturing pump and comprises a chassis; the chassis is provided with a transporting section, a bearing section and a lapping section which are connected in sequence; when the turbine fracturing equipment is in a working state, the bearing section can be contacted with the ground; and when the turbine fracturing equipment is in a transporting state, the bearing section does not make contact with the ground. The turbine fracturing equipment has the beneficial effects that the equipment adopts the design of linear connection and a special chassis, so that the gravity center of the turbine fracturing equipment is doubly reduced, and the stability and the safety are well ensured; the structure is simpler, and the investment cost and the operation cost are reduced; the collapse risk of the whole fracturing site is reduced; and the turbine fracturing equipment is good intransmission property and is suitable for long-time and bulky load continuous operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

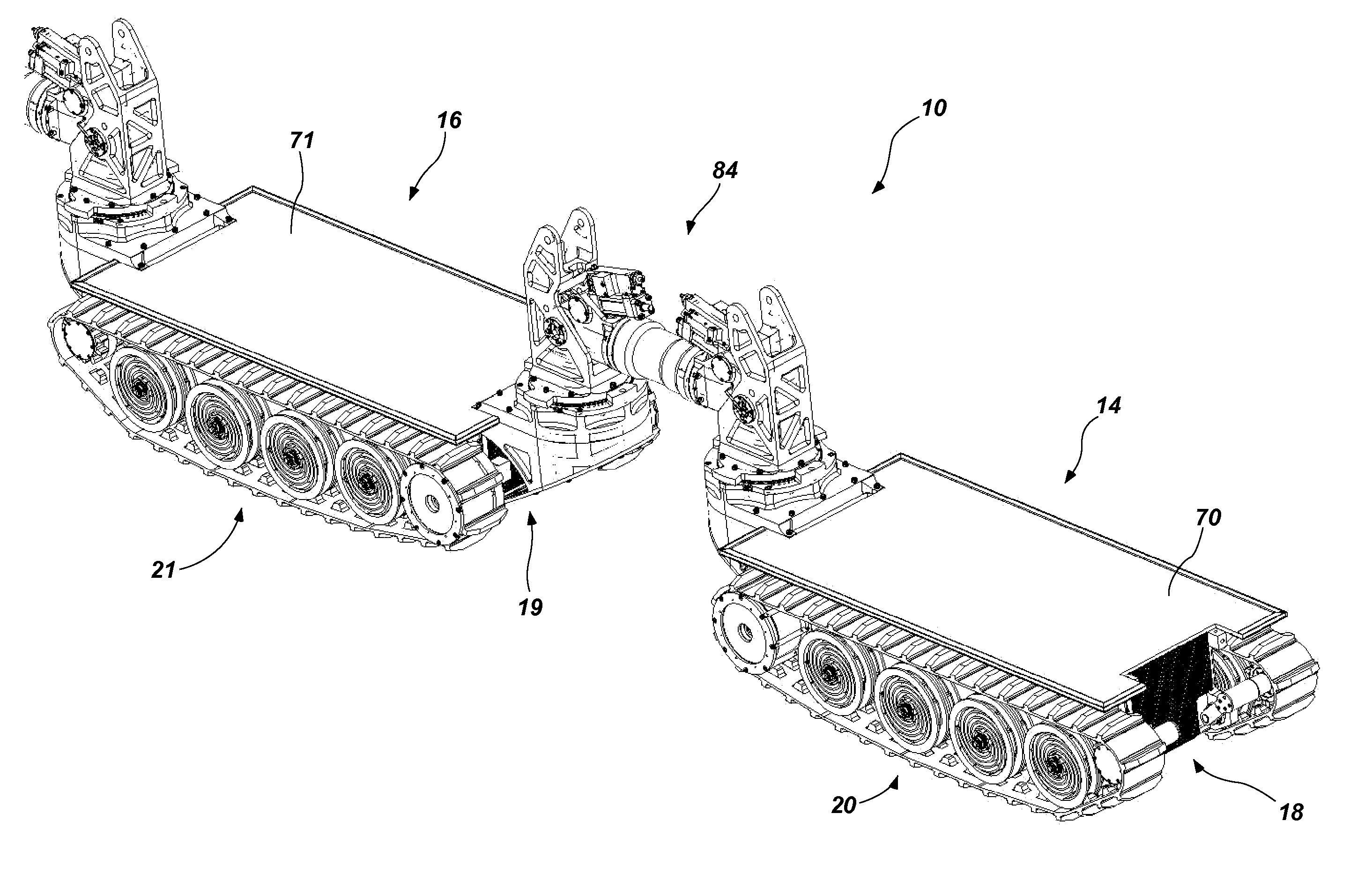

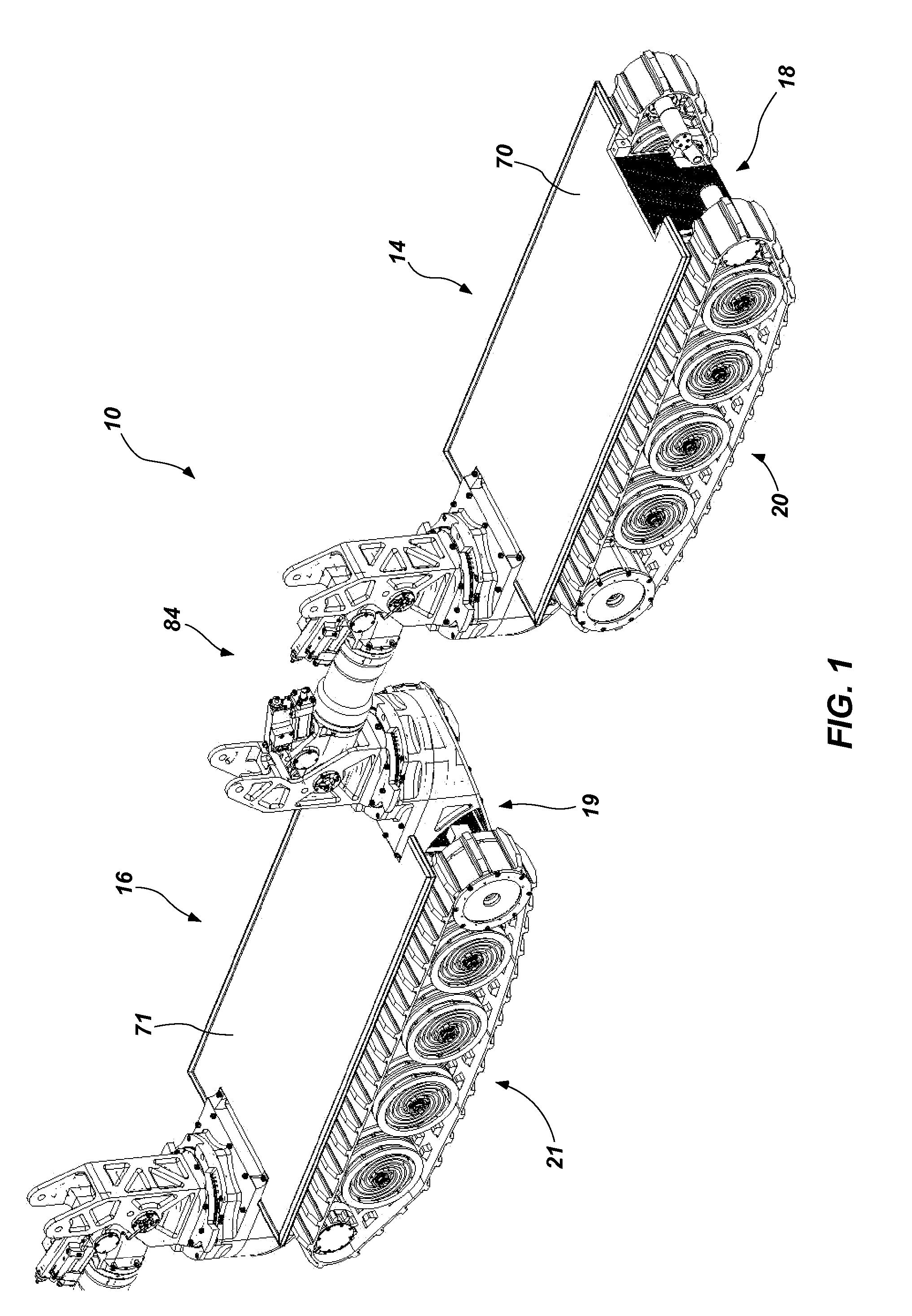

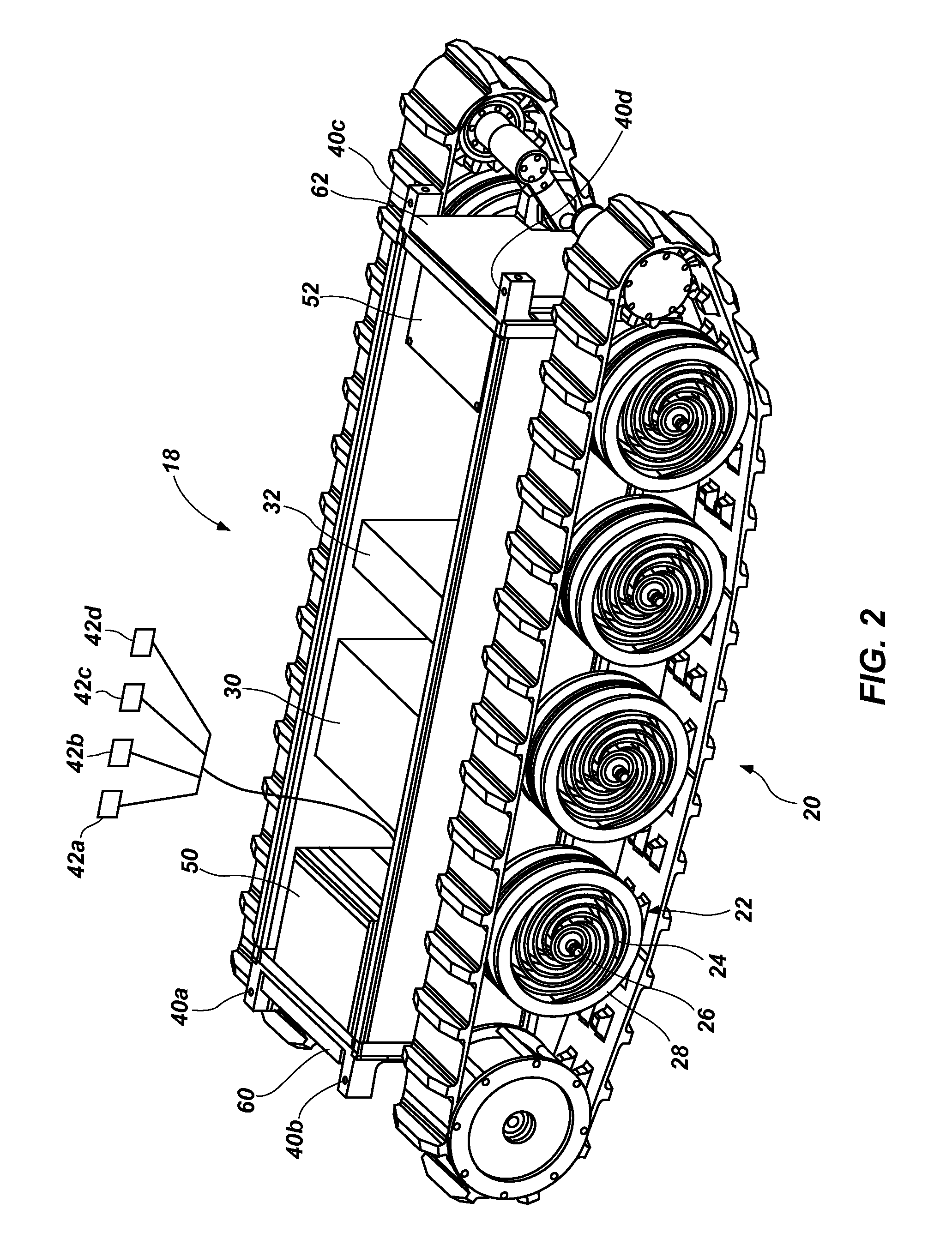

Robotic Mobile Low-Profile Transport Vehicle

ActiveUS20140246257A1Efficiently traverseImprove stabilityVehicle body stabilisationArmoured vehiclesTerrainControl system

A robotic mobile low-profile transport vehicle is disclosed. The vehicle can comprise a first transport module having a frame assembly, a mobility system, and a propulsion system and a second transport module having a frame assembly and a mobility system. A multi-degree of freedom coupling assemblage can join the first and second transport modules together. The vehicle can include a first platform supported about the frame assembly of the first transport module, and a second platform supported about the frame assembly of the second transport module. Each of the platforms can be configured to receive a load for transport. Additionally, the vehicle can include a control system that can operate to facilitate intra-module communication and coordination to provide a coordinated operating mode of the first and second transport modules and the coupling assemblage about a given terrain.

Owner:SARCOS LC

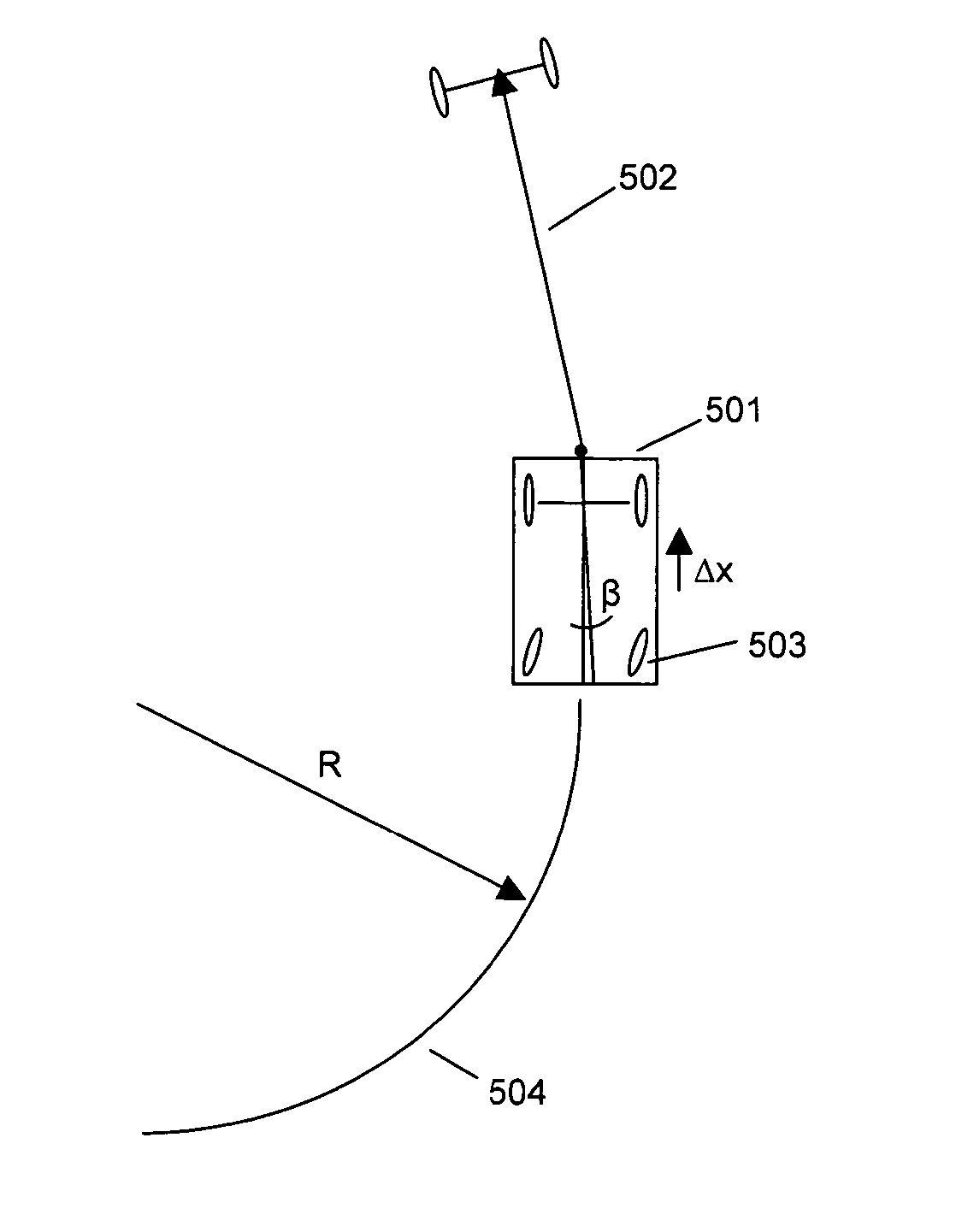

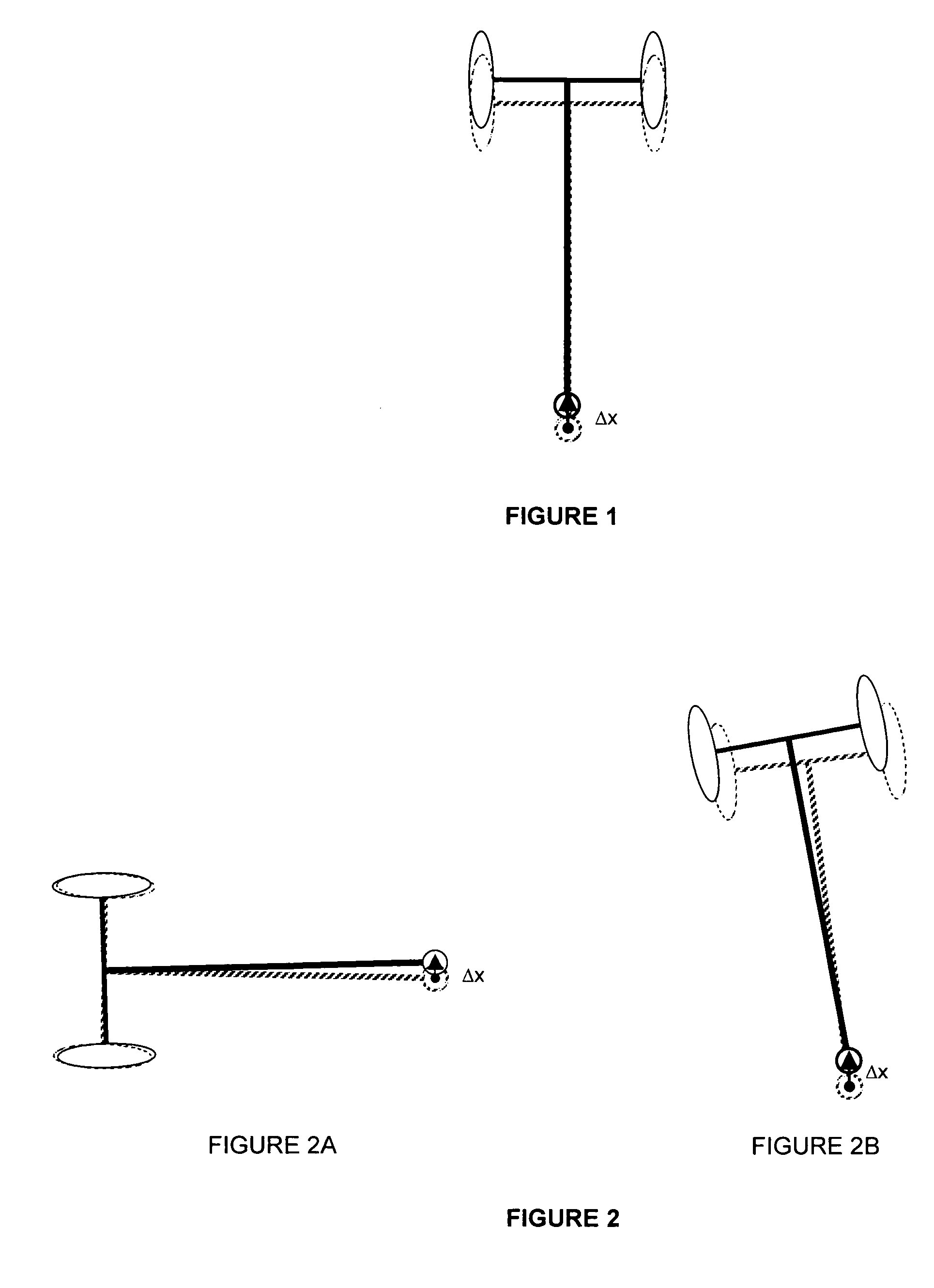

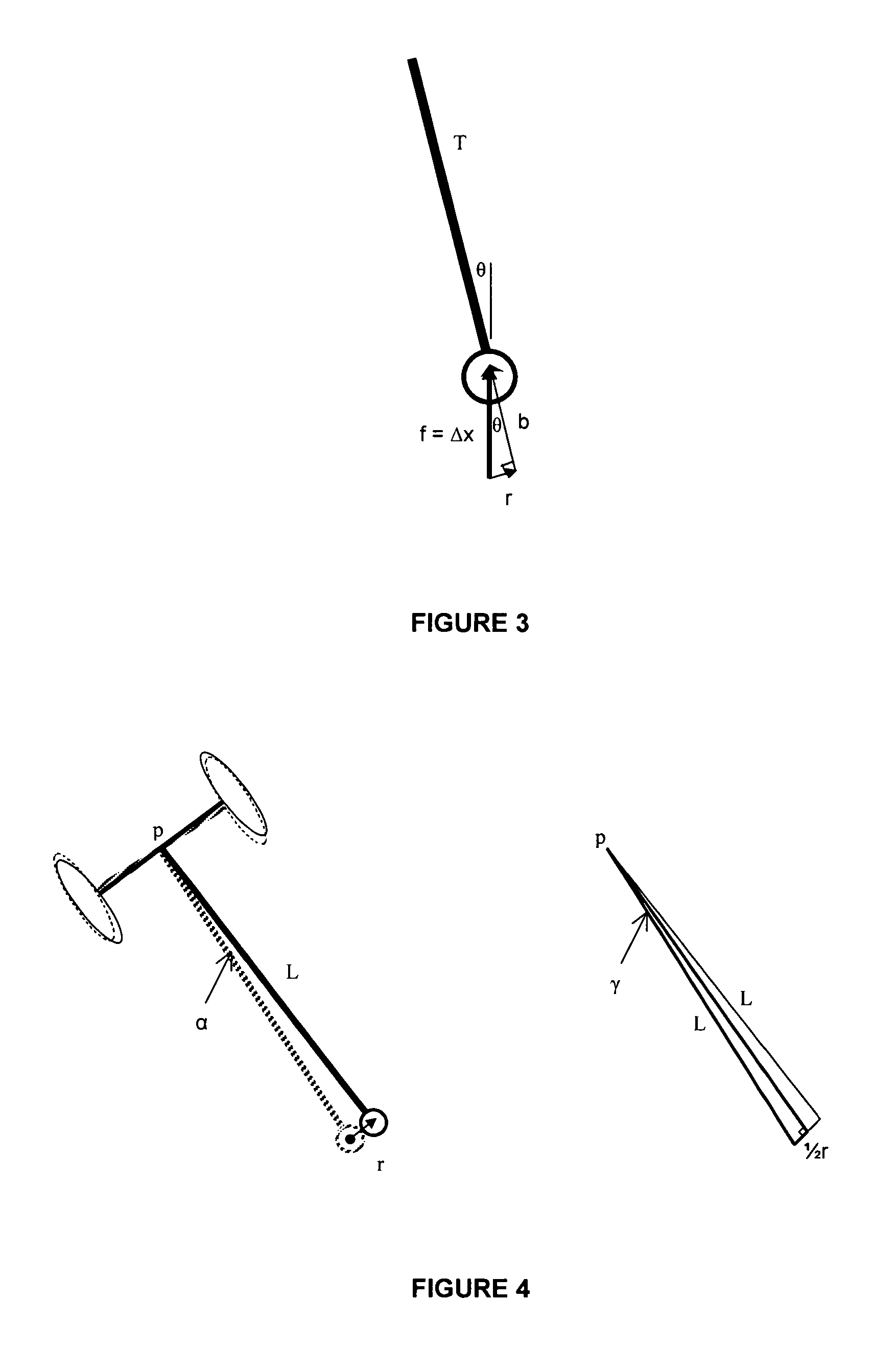

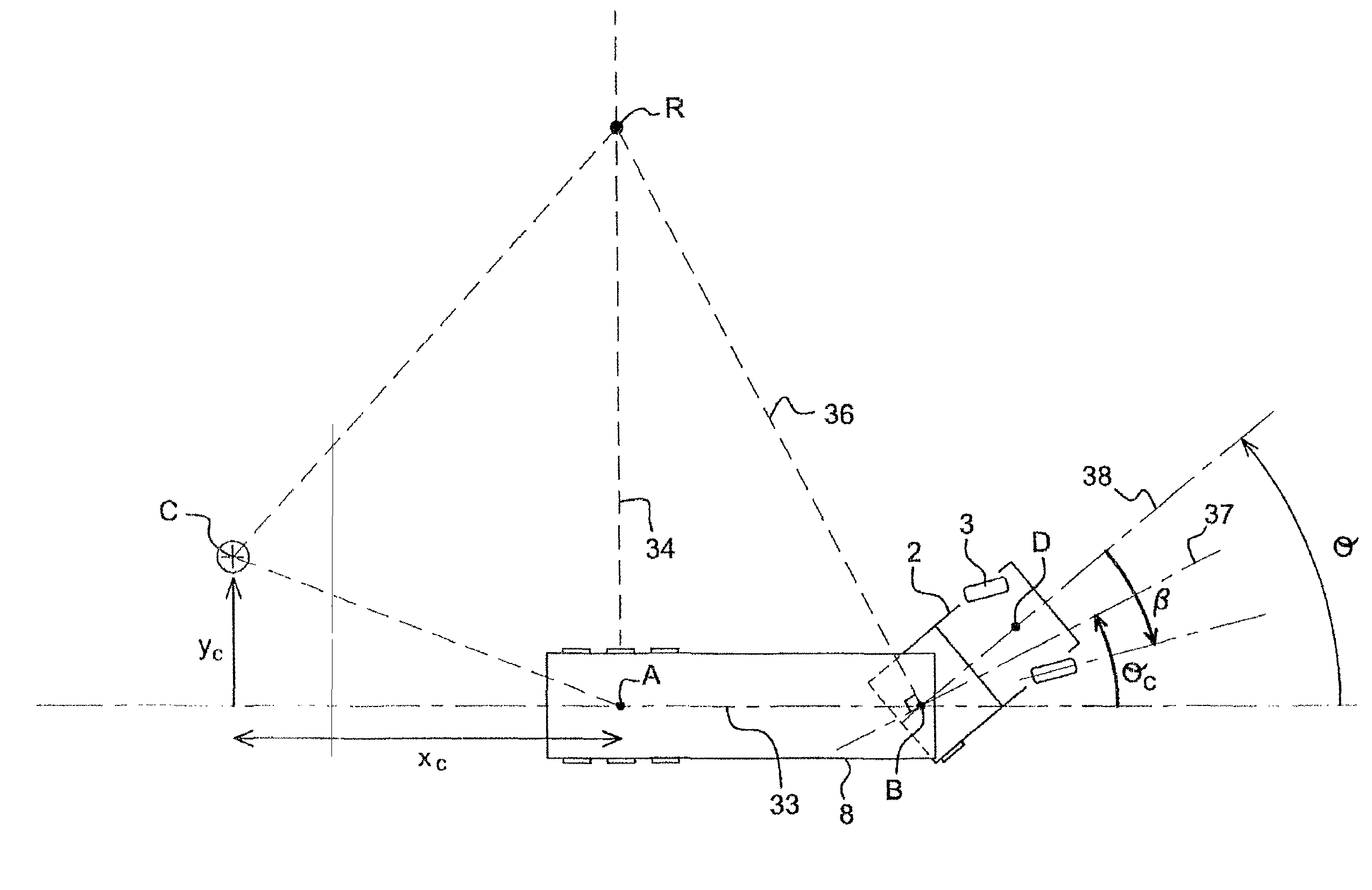

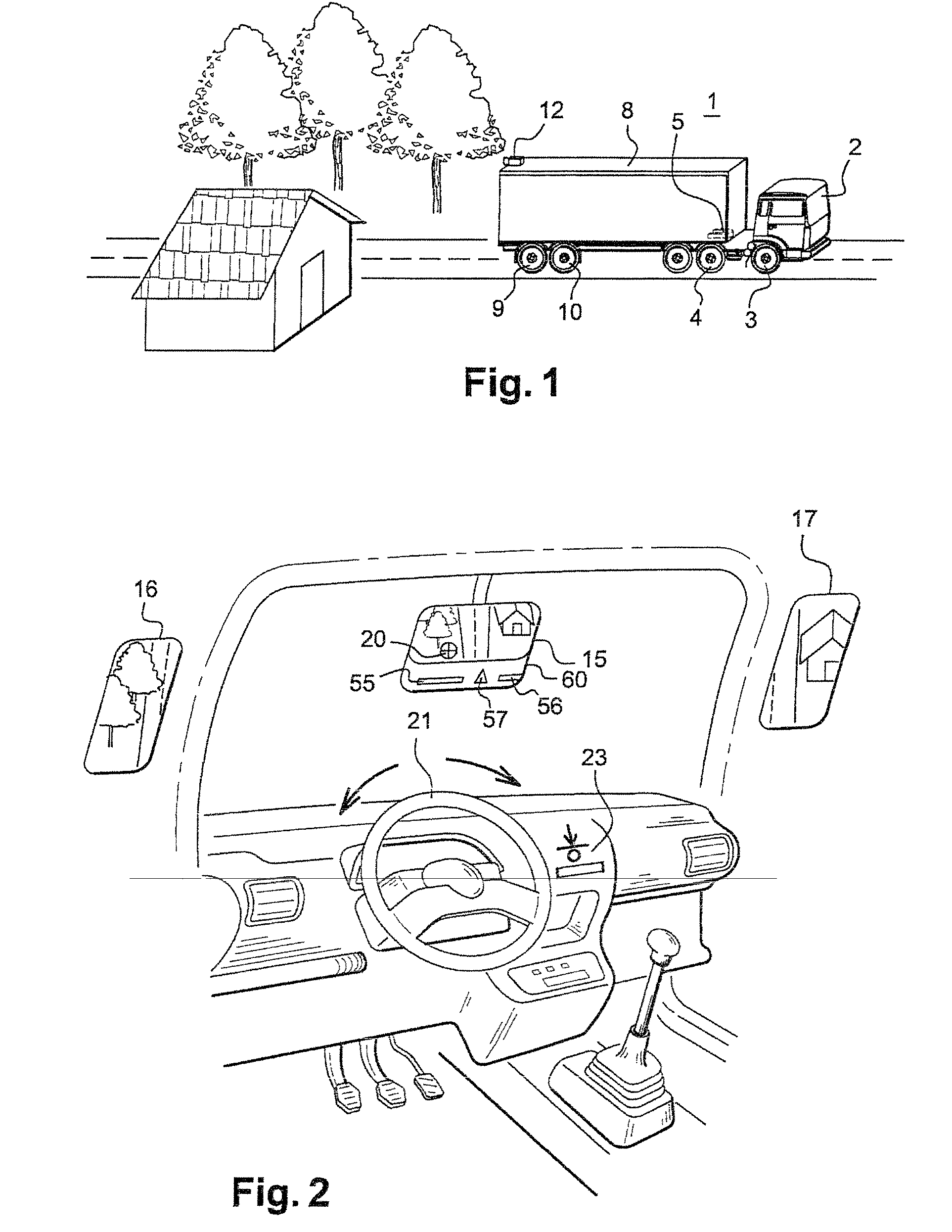

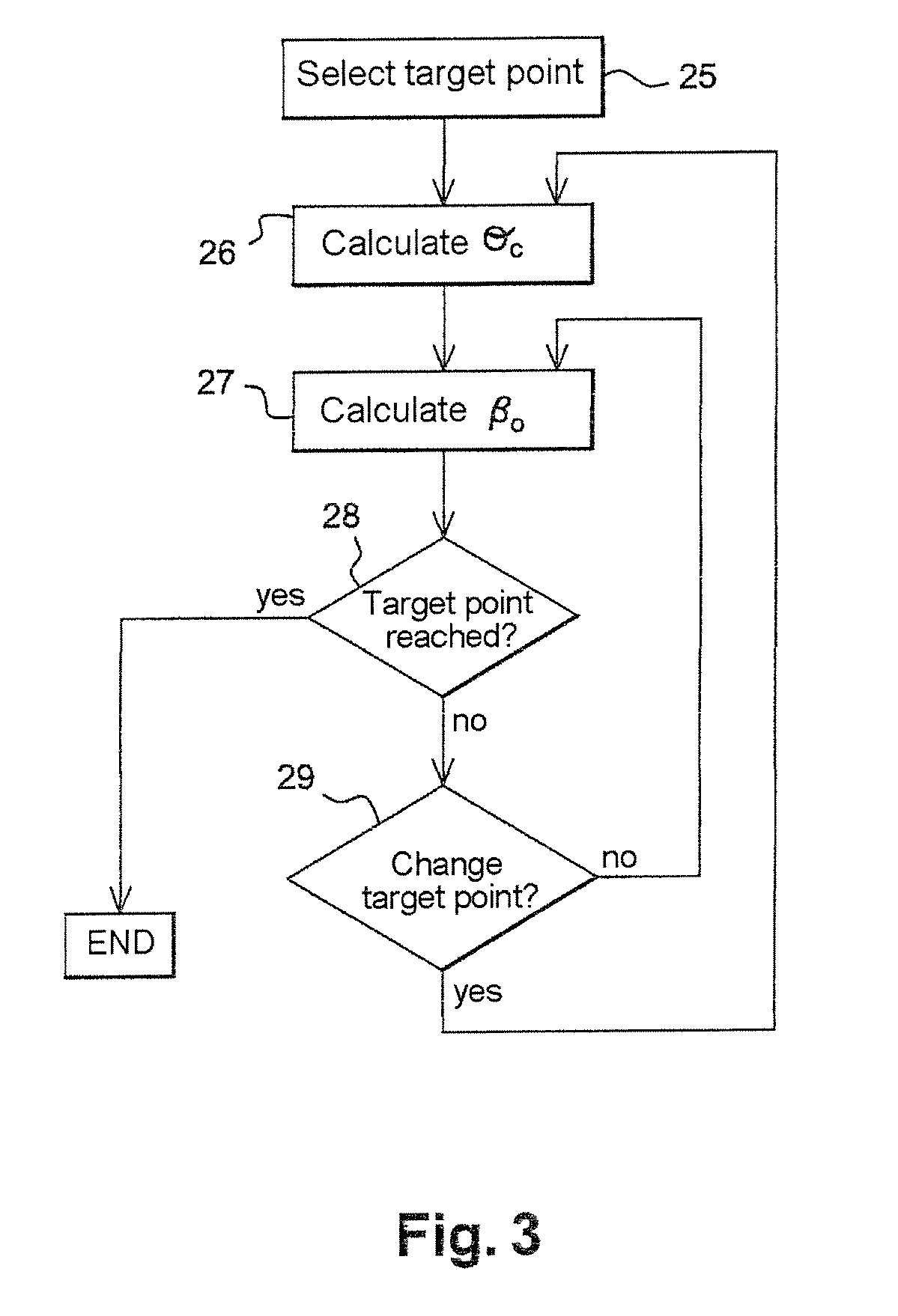

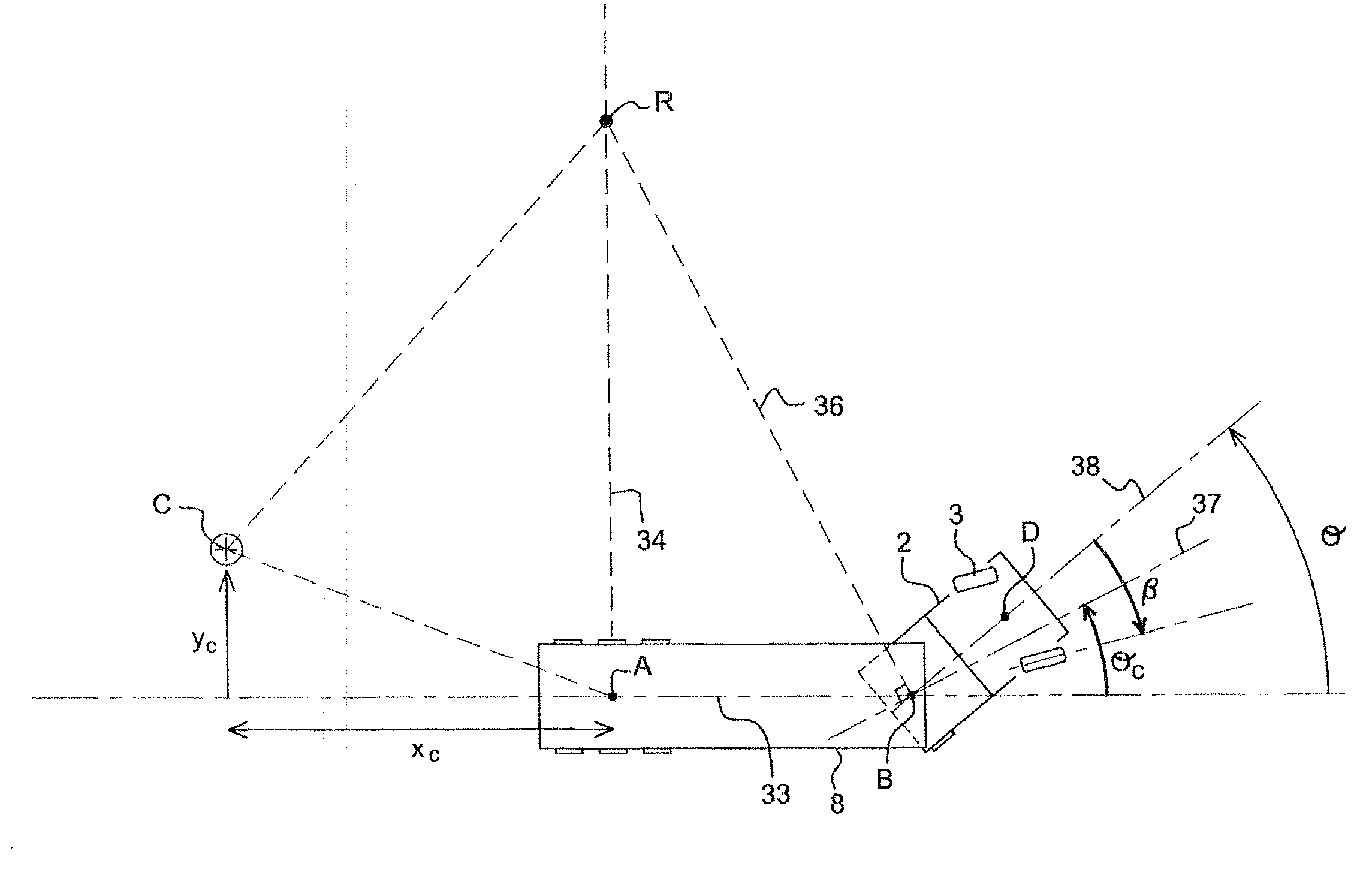

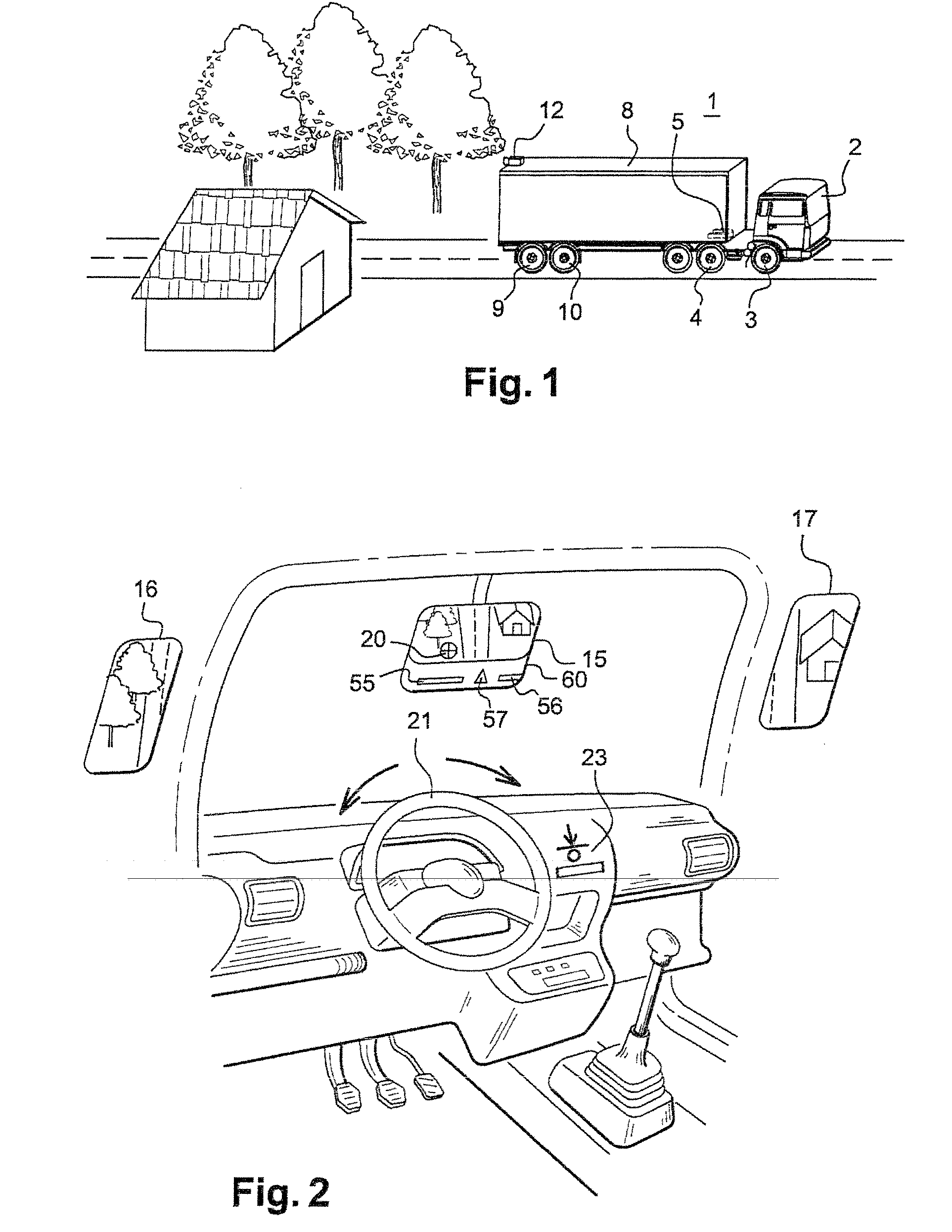

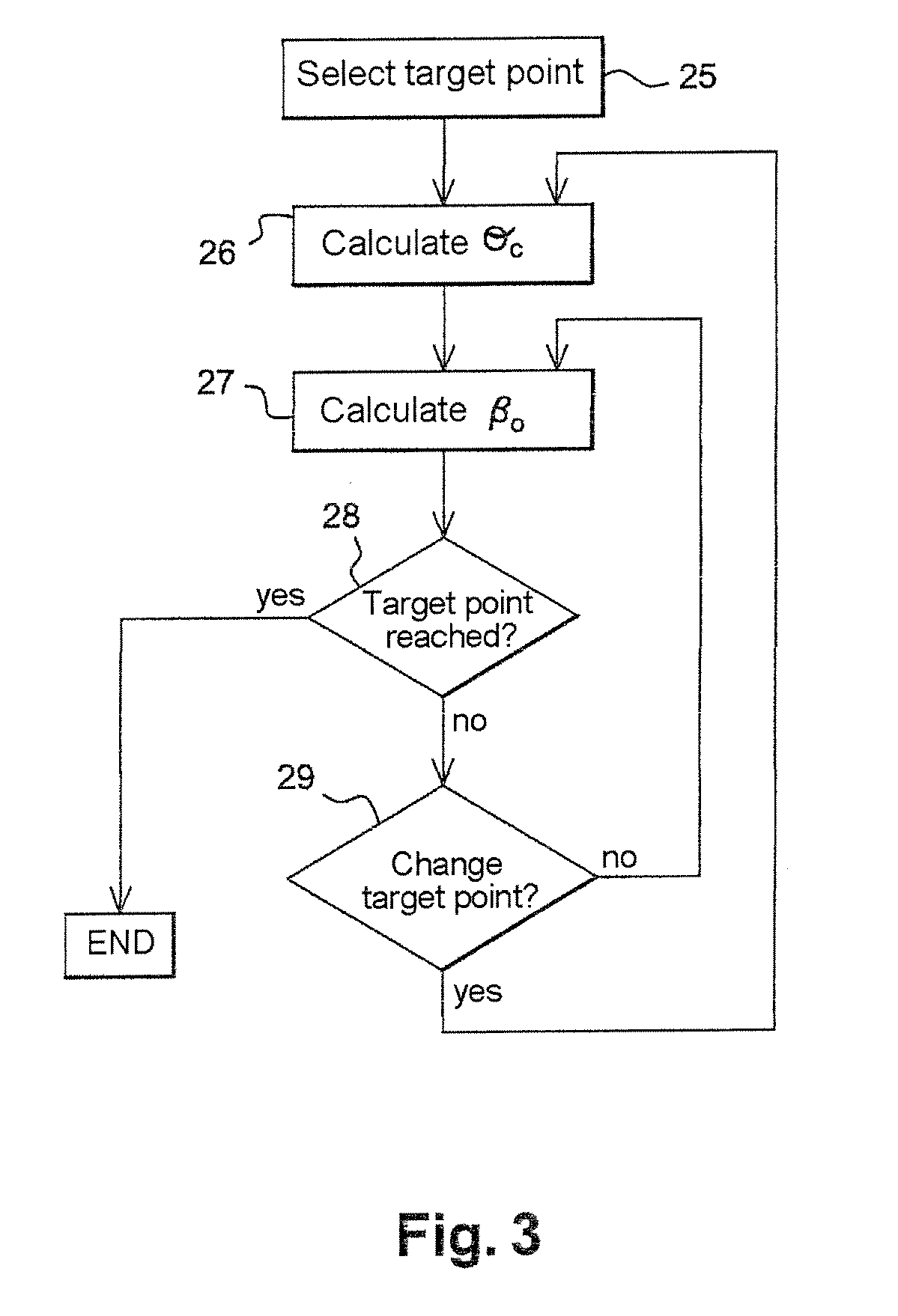

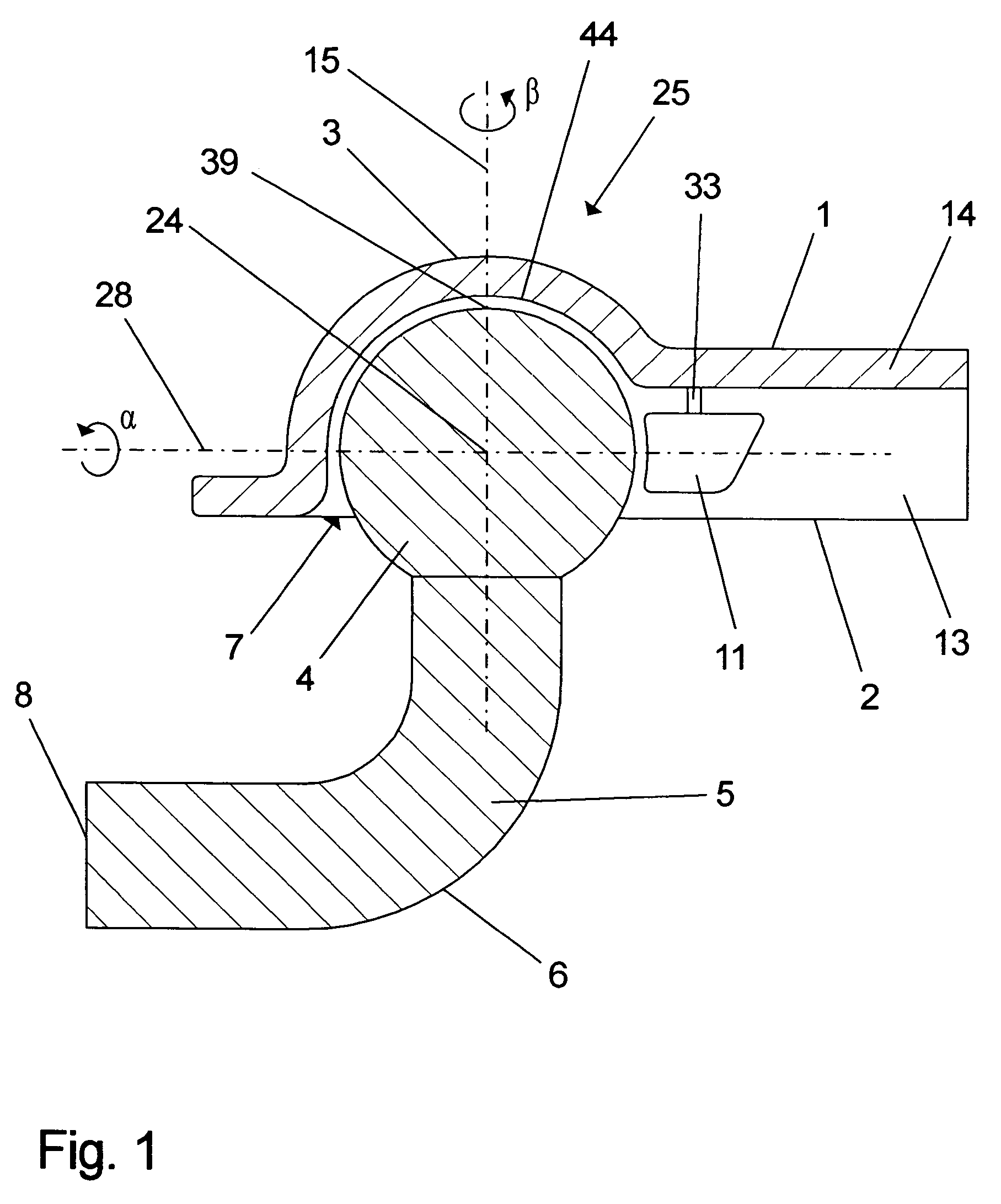

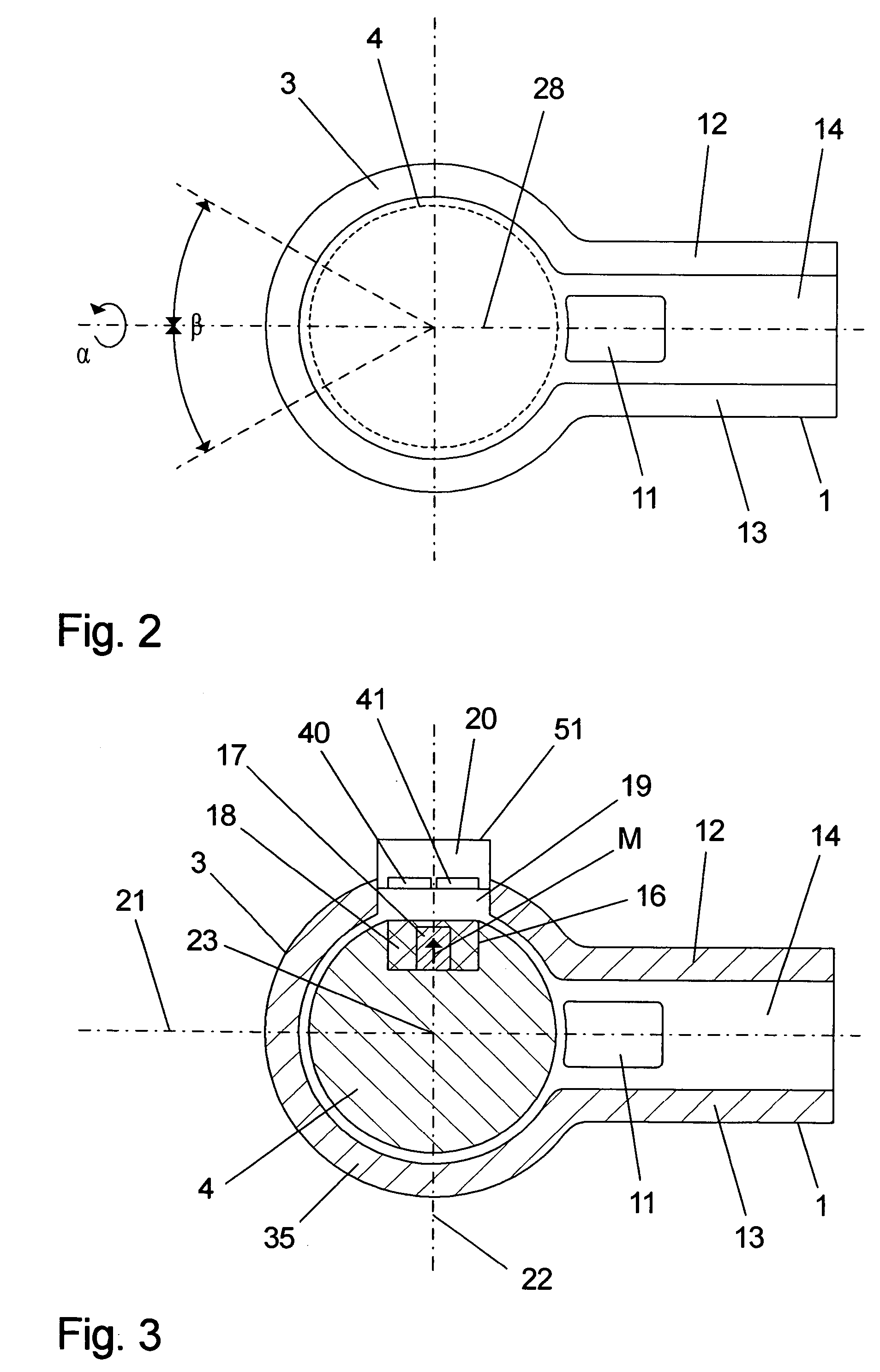

Method for determining a set steering angle of steered wheels of a vehicle

ActiveUS8036792B2Simple processEasy to operateSteering initiationsDigital data processing detailsSteering wheelSteering angle

The invention relates to a method for determining a set steering angle βo of steered wheels of a vehicle comprising a tractor and a trailer that is articulated with regard to the tractor. This method makes it possible to produce a set value that can be used for various purposes. This set value can thus be used for controlling an actuator acting upon the steering angle or for being communicated in order to inform the driver. According to the invention, during reversing maneuvers: based on a target point C via which the driver would like the path of the vehicle to pass, an angle set value ?c between the axes of the trailer and of the tractor is determined according to said target point C and to the dimensions of the vehicle, and; the set steering angle β of the steered wheels is determined according to a servo-system causing the measured angle ? between the axis of the trailer and the tractor to tend toward said angle set value ?c.

Owner:VOLVO TRUCK CORP

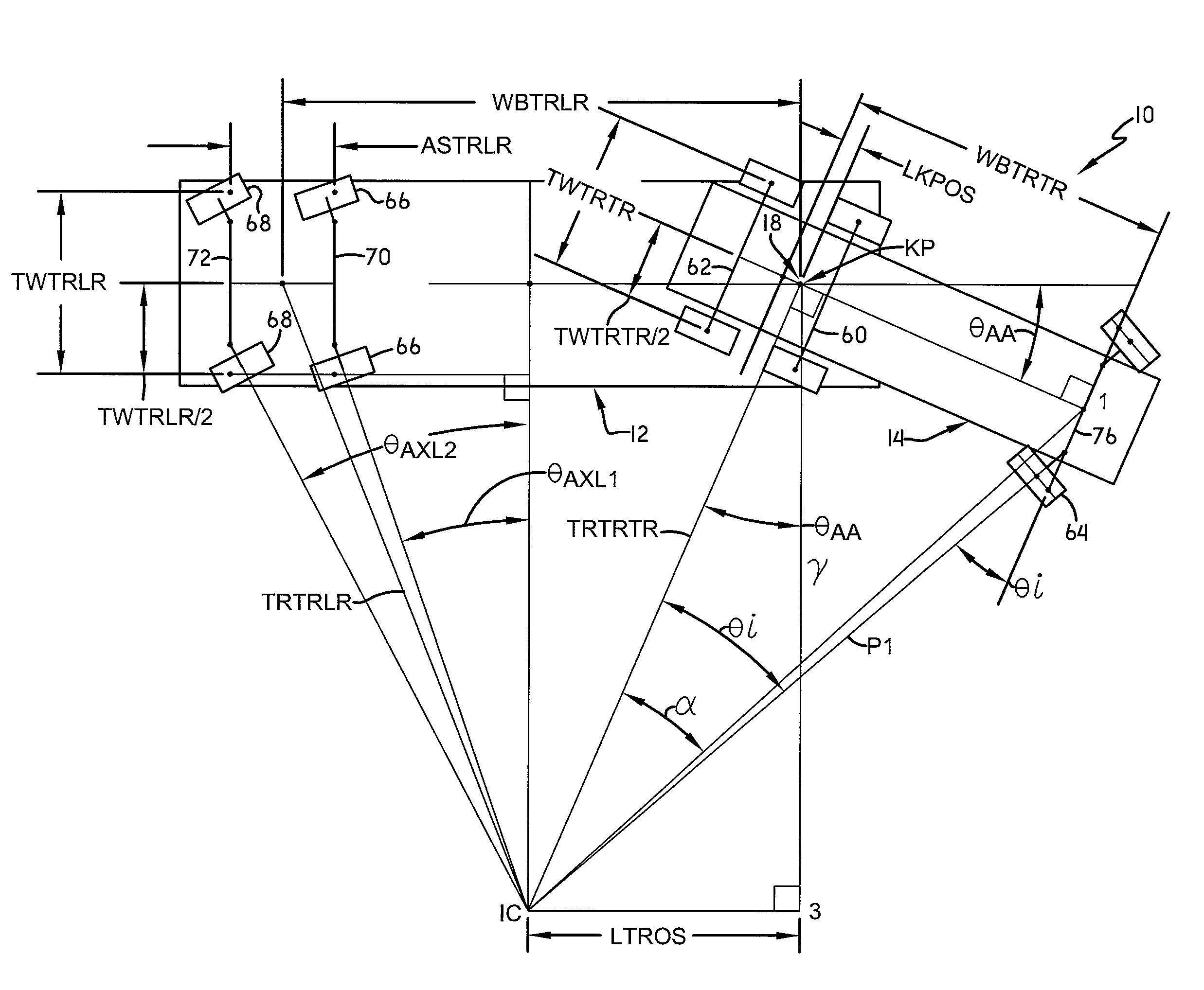

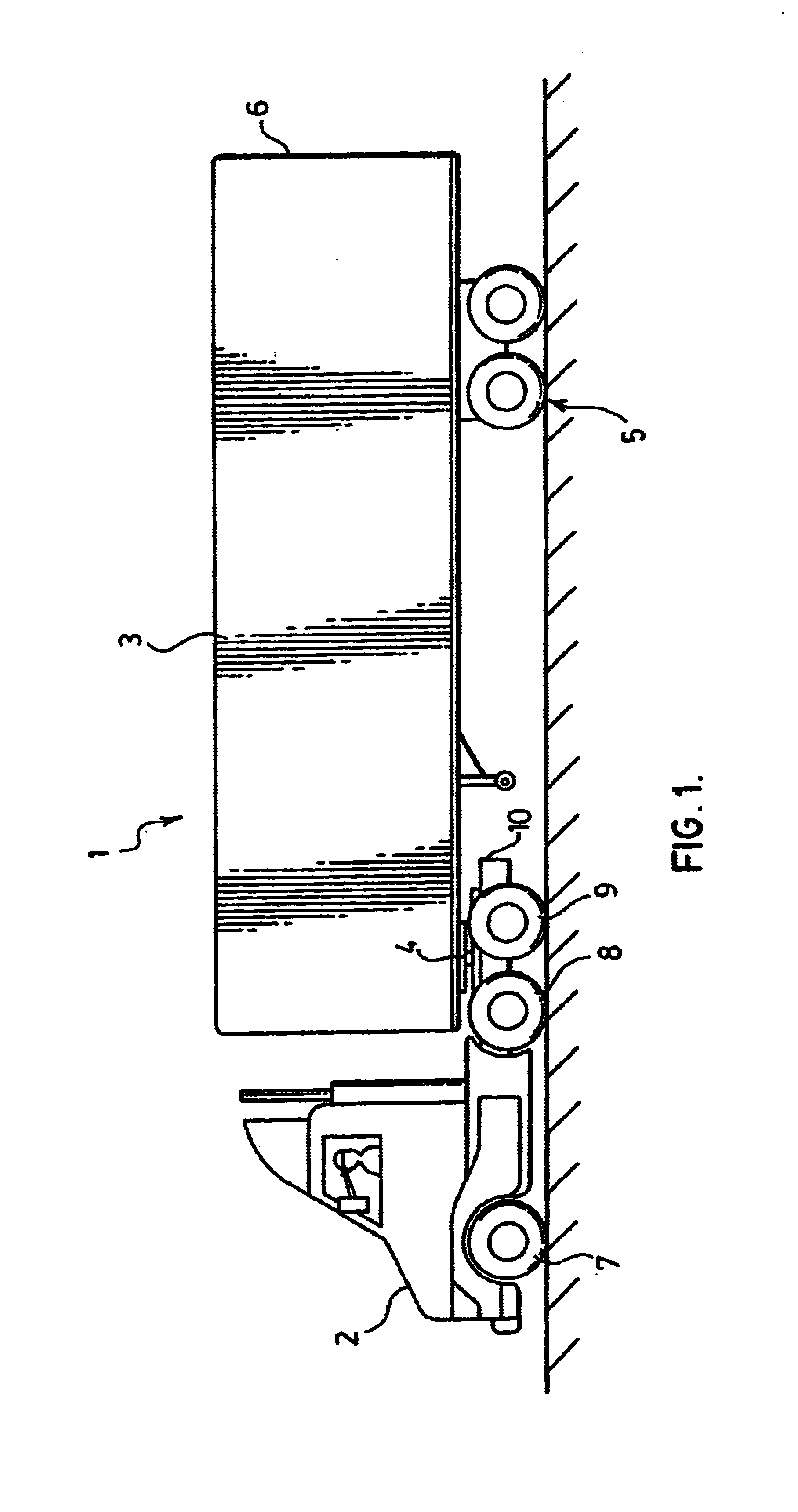

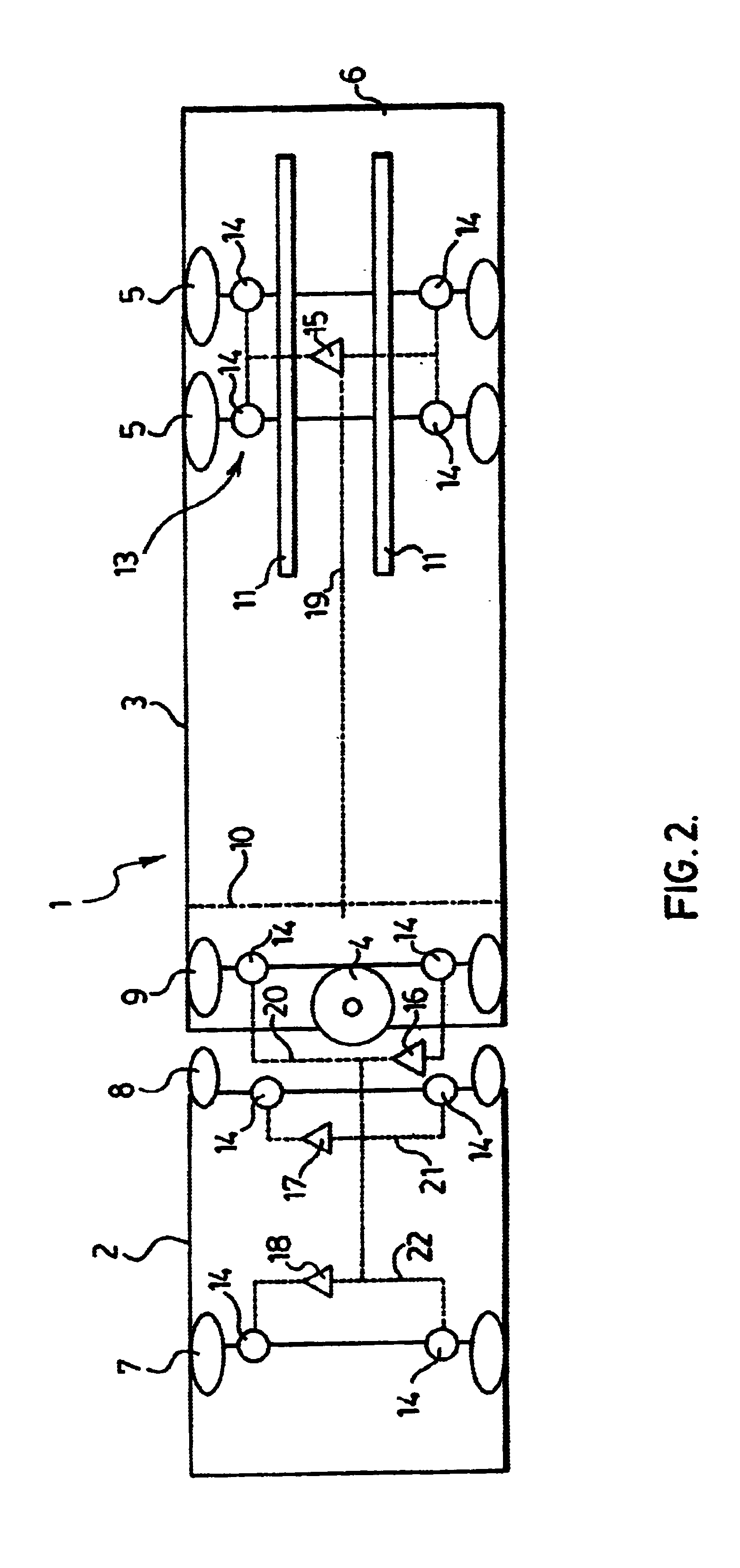

Trailer steering system for a tractor/trailer combination

A tractor / trailer combination wherein a trailer is connected to a tractor through the connection of a kingpin with a fifth wheel is provided with a trailer steering system. Using given dimensions of the tractor / trailer combination and a measured articulation angle between the tractor and trailer during a turn, the wheels of the rear axles of the trailer are turned so that they turn approximately about the instant center established for the tractor. In this way, the trailer turns around approximately the same point as does the tractor, thus significantly eliminating off tracking.

Owner:PADULA SANTO A

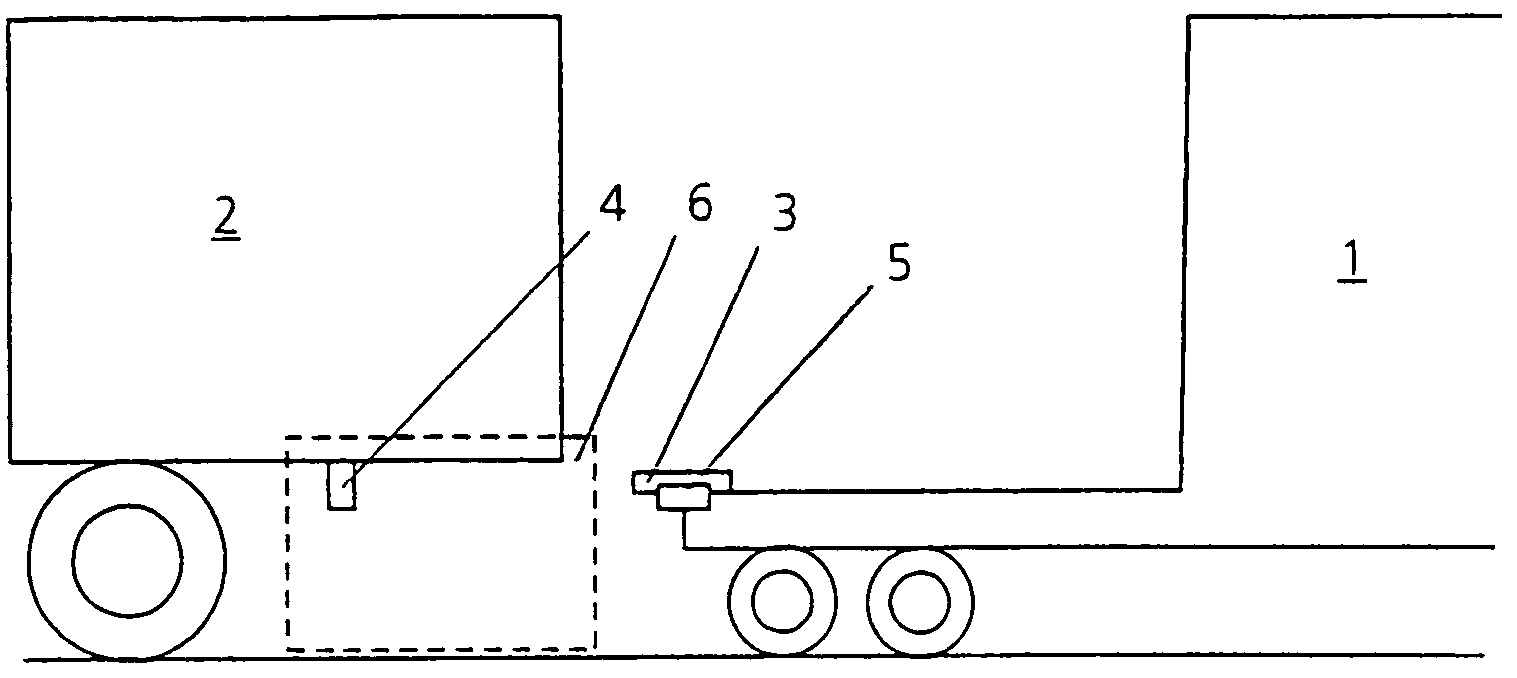

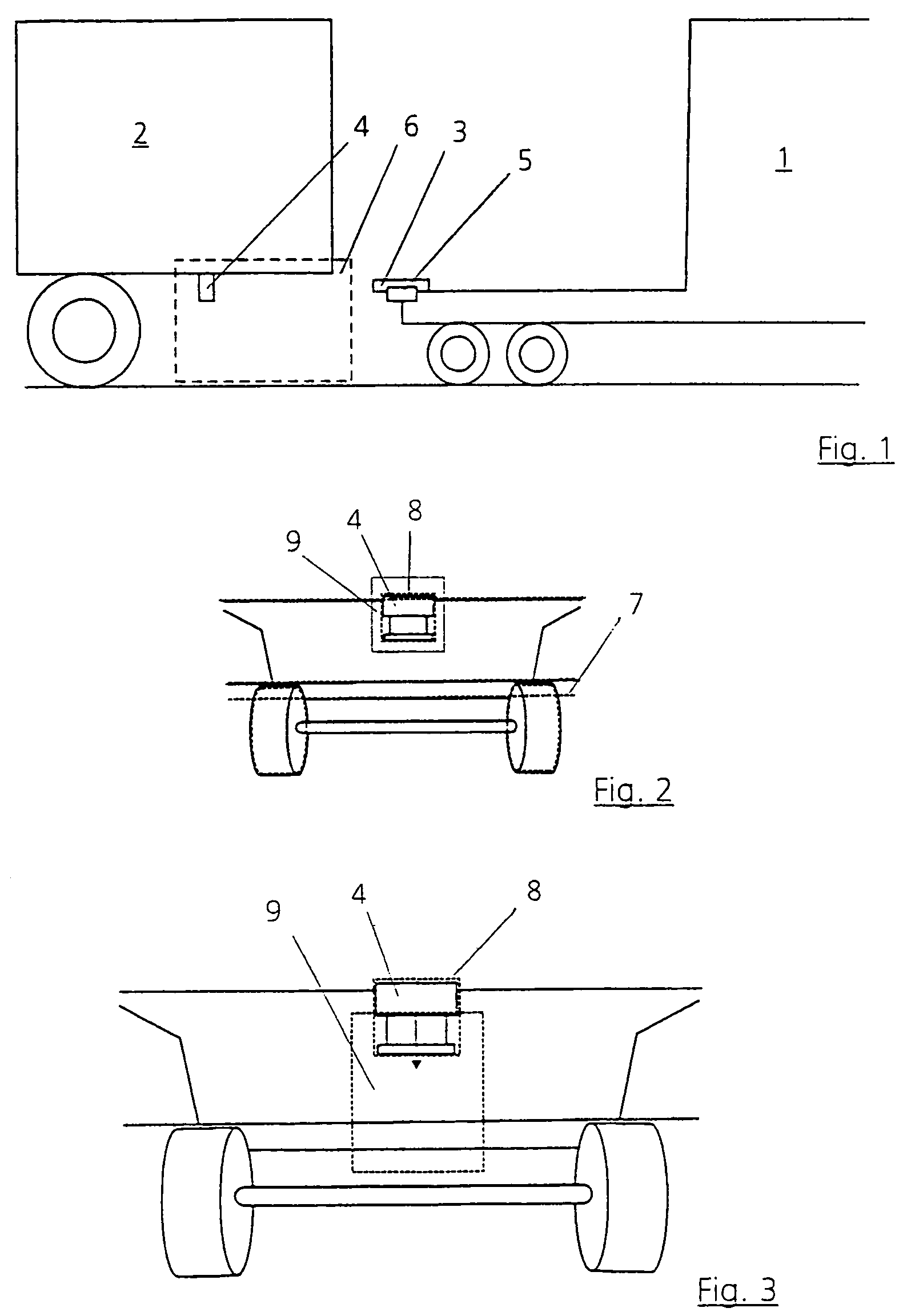

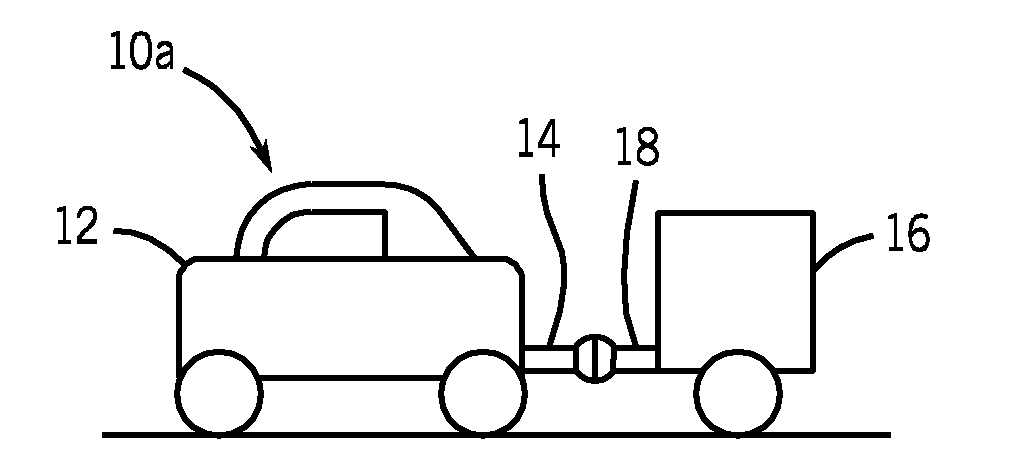

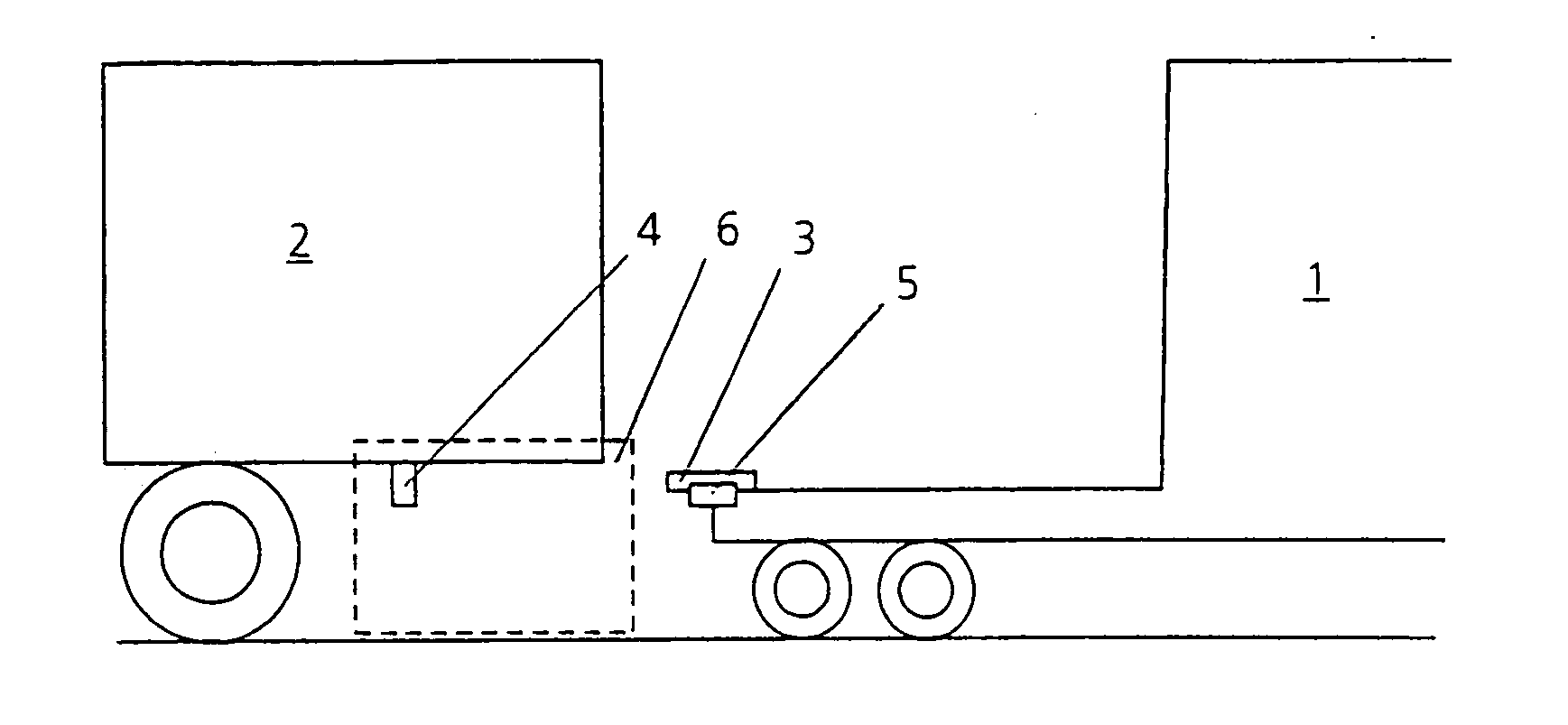

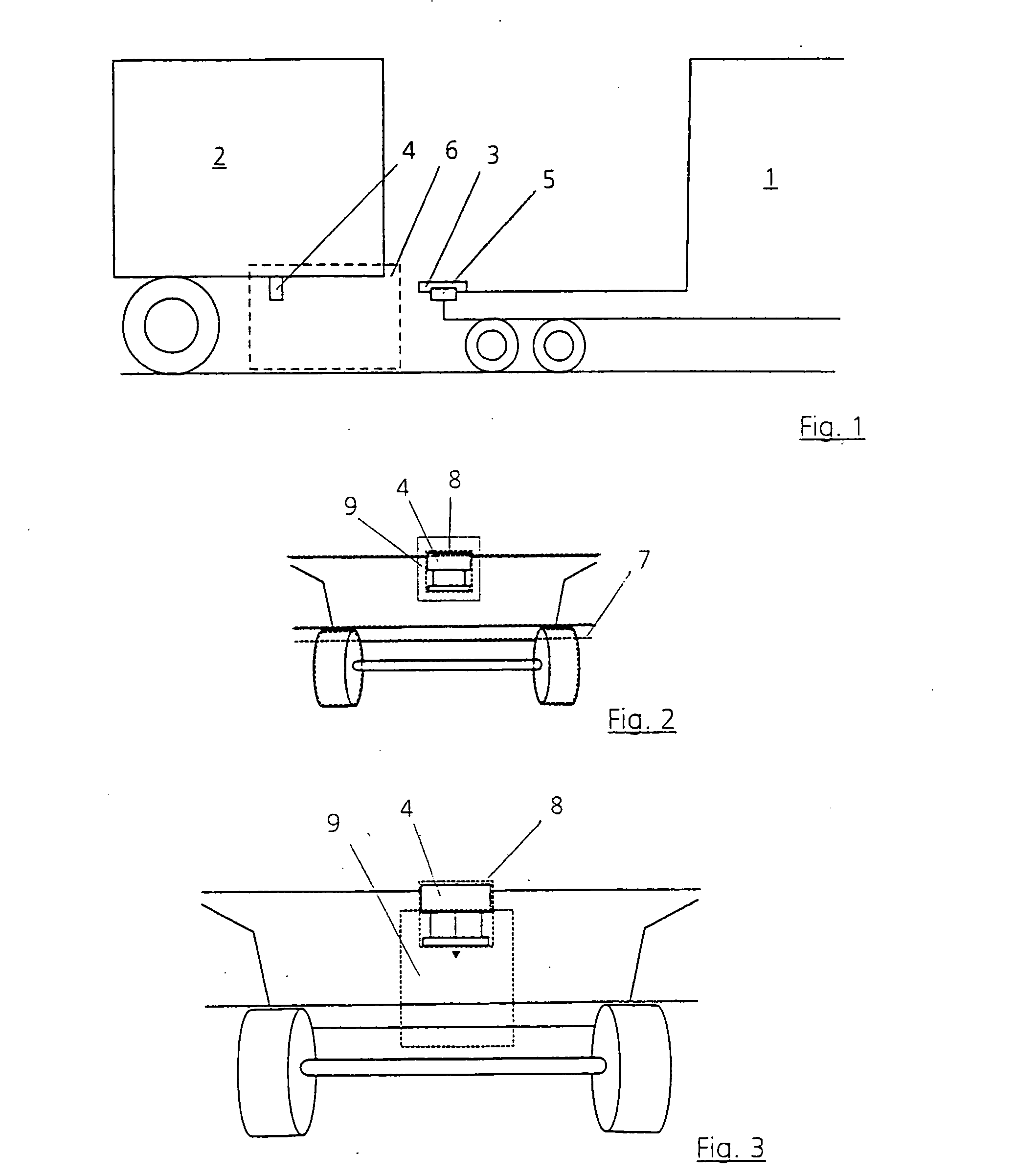

Process for coupling a trailer to a motor vehicle

InactiveUS7204504B2Easy to monitorEasy to controlPedestrian/occupant safety arrangementSteering linkagesMobile vehicleMotor vehicle part

In the case of a method for hitching a trailer (2) to a motor vehicle (1), in particular a semitrailer to a semitrailer towing machine, an image sensor (5) is provided which is arranged in a hitching region (6) in such a manner that image data of the hitching region (6) are recorded. During the approach of the motor vehicle (1) to the trailer (2), stored model data of the hitching region (6) of the trailer (2) are segmented in the image data recorded by the image sensor (5) and are in each case placed in the correct position in the image data. A target zone (9) for the hitching is determined therefrom. The arrangement of the target zone (9) in the image data is used as a measurement for a steering operation of the motor vehicle (1) during hitching.

Owner:DAIMLER AG

Method for determining a set steering angle of steered wheels of a vehicle

ActiveUS20090306854A1Simple processEasy to operateSteering initiationsDigital data processing detailsSteering angleSteering wheel

The invention relates to a method for determining a set steering angle β0 of steered wheels of a vehicle comprising a tractor and a trailer that is articulated with regard to the tractor. This method makes it possible to produce a set value that can be used for various purposes. This set value can thus be used for controlling an actuator acting upon the steering angle or for being communicated in order to inform the driver. According to the invention, during reversing maneuvers: based on a target point C via which the driver would like the path of the vehicle to pass, an angle set value ?c between the axes of the trailer and of the tractor is determined according to said target point C and to the dimensions of the vehicle, and; the set steering angle β of the steered wheels is determined according to a servo-system causing the measured angle ? between the axis of the trailer and the tractor to tend toward said angle set value ?c.

Owner:VOLVO LASTVAGNAR AB

Modular hybrid electric vehicle system

InactiveUS20110253463A1Tractor-trailer combinationsPropulsion by batteries/cellsModularityHybrid electrical vehicle

A modular hybrid electrical vehicle system may comprise an electric vehicle and a detachable power plant. The detachable power plant may be operable to externally attach to and provide power for the electric motor vehicle.

Owner:SMITH MARK ERIC

Process for coupling a trailer to a motor vehicle

InactiveUS20060071447A1Easy to monitorEasy to controlPedestrian/occupant safety arrangementSteering linkagesSemi-trailerControl theory

In the case of a method for hitching a trailer (2) to a motor vehicle (1), in particular a semitrailer to a semitrailer towing machine, an image sensor (5) is provided which is arranged in a hitching region (6) in such a manner that image data of the hitching region (6) are recorded. During the approach of the motor vehicle (1) to the trailer (2), stored model data of the hitching region (6) of the trailer (2) are segmented in the image data recorded by the image sensor (5) and are in each case placed in the correct position in the image data. A target zone (9) for the hitching is determined therefrom. The arrangement of the target zone (9) in the image data is used as a measurement for a steering operation of the motor vehicle (1) during hitching.

Owner:DAIMLER AG

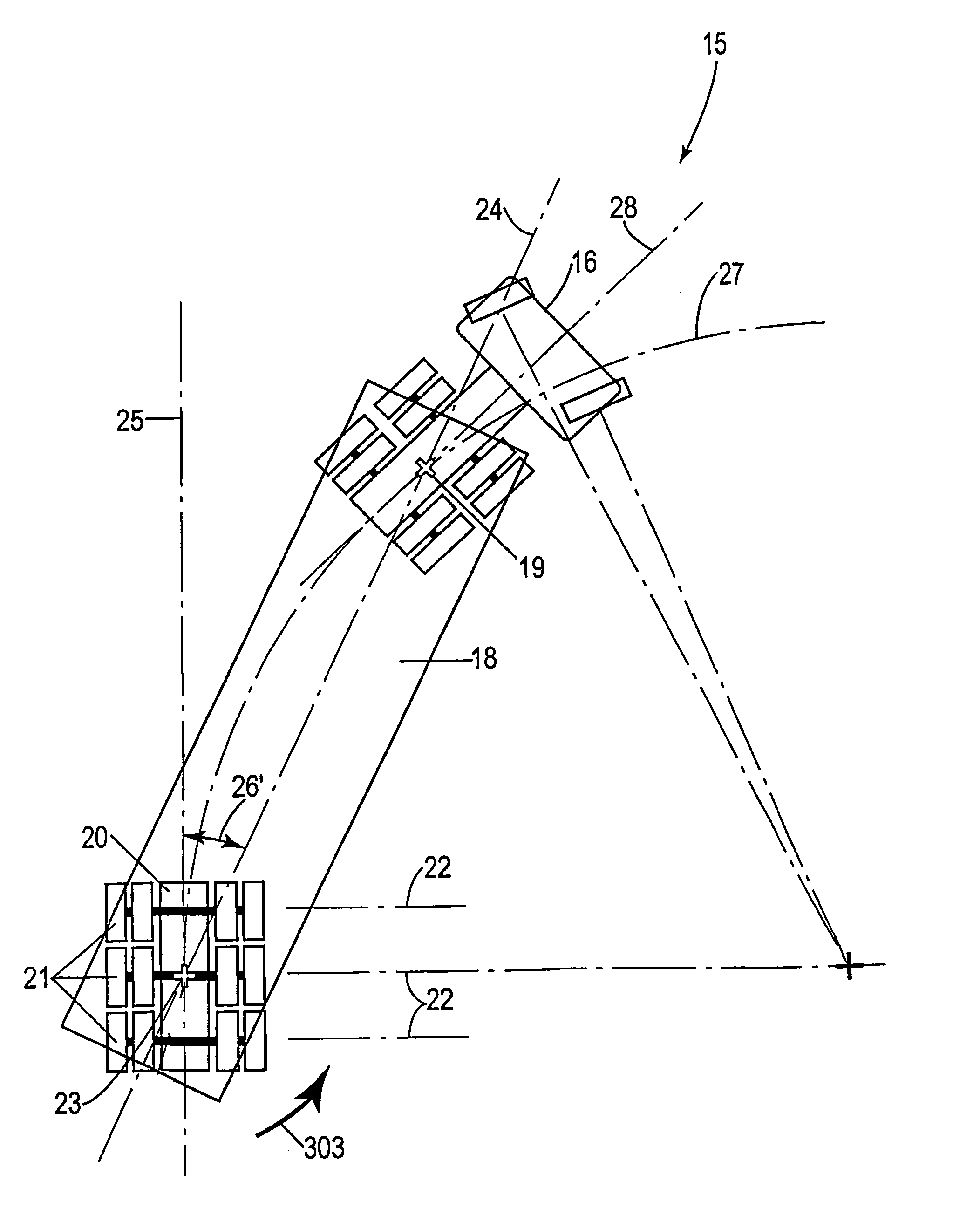

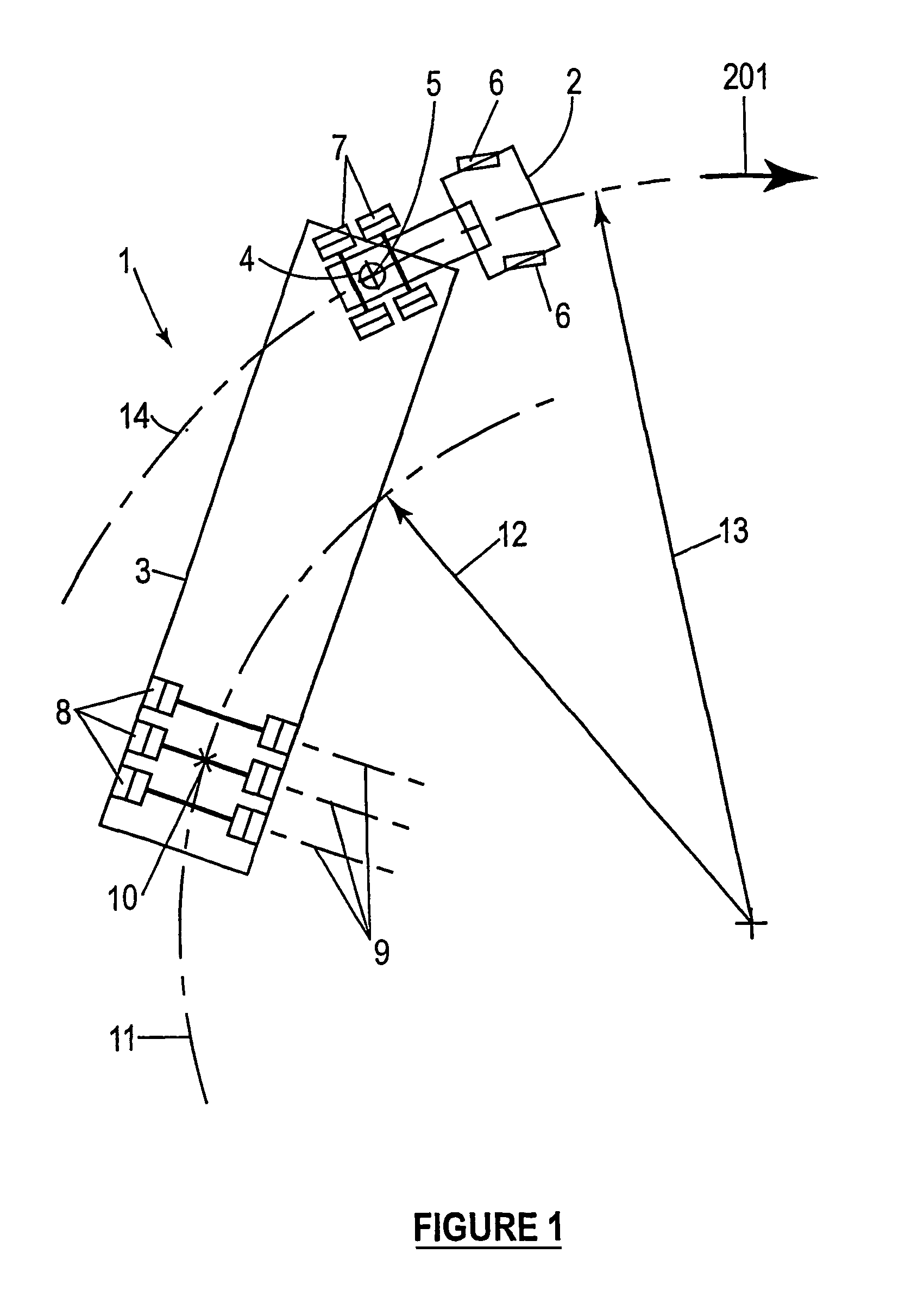

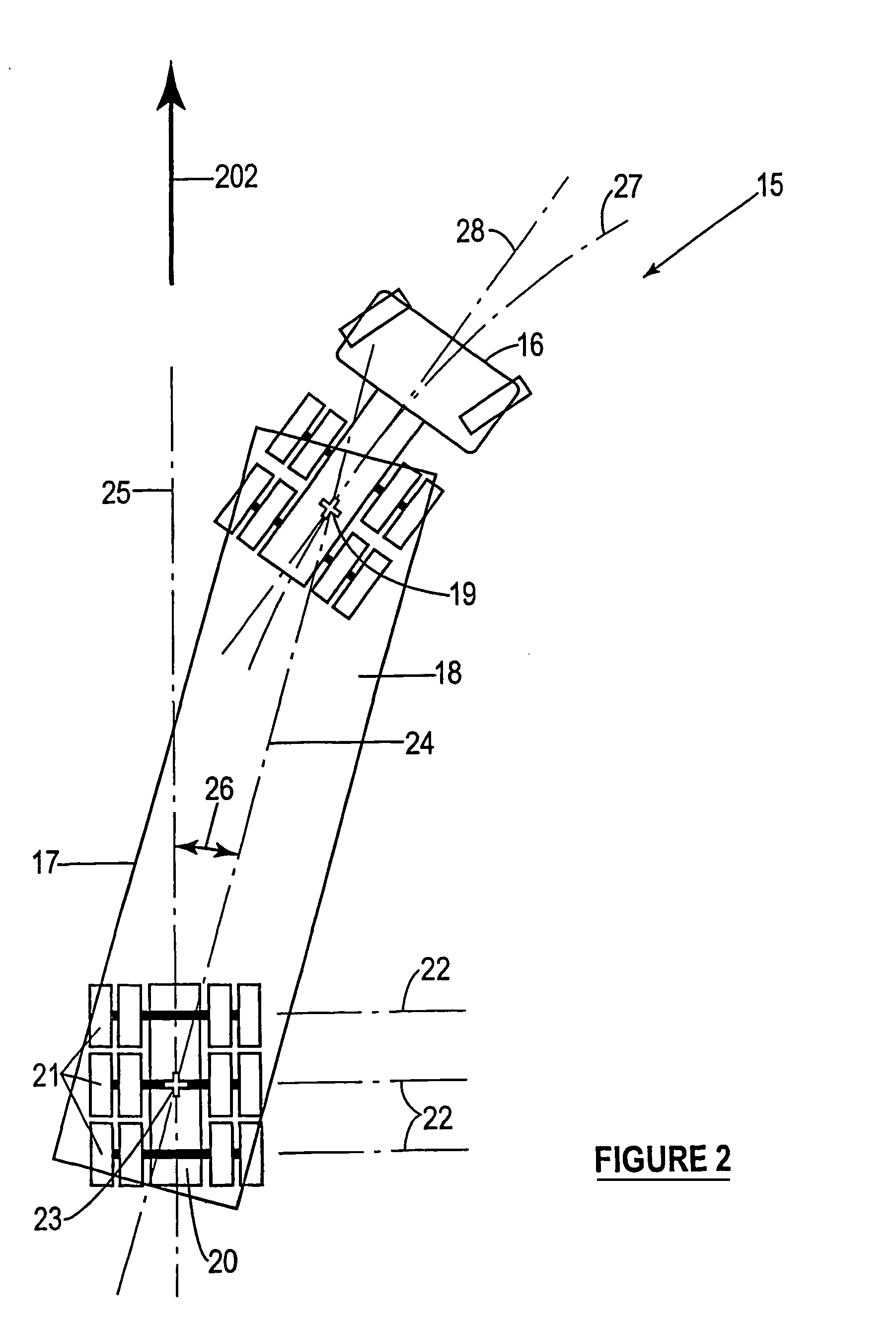

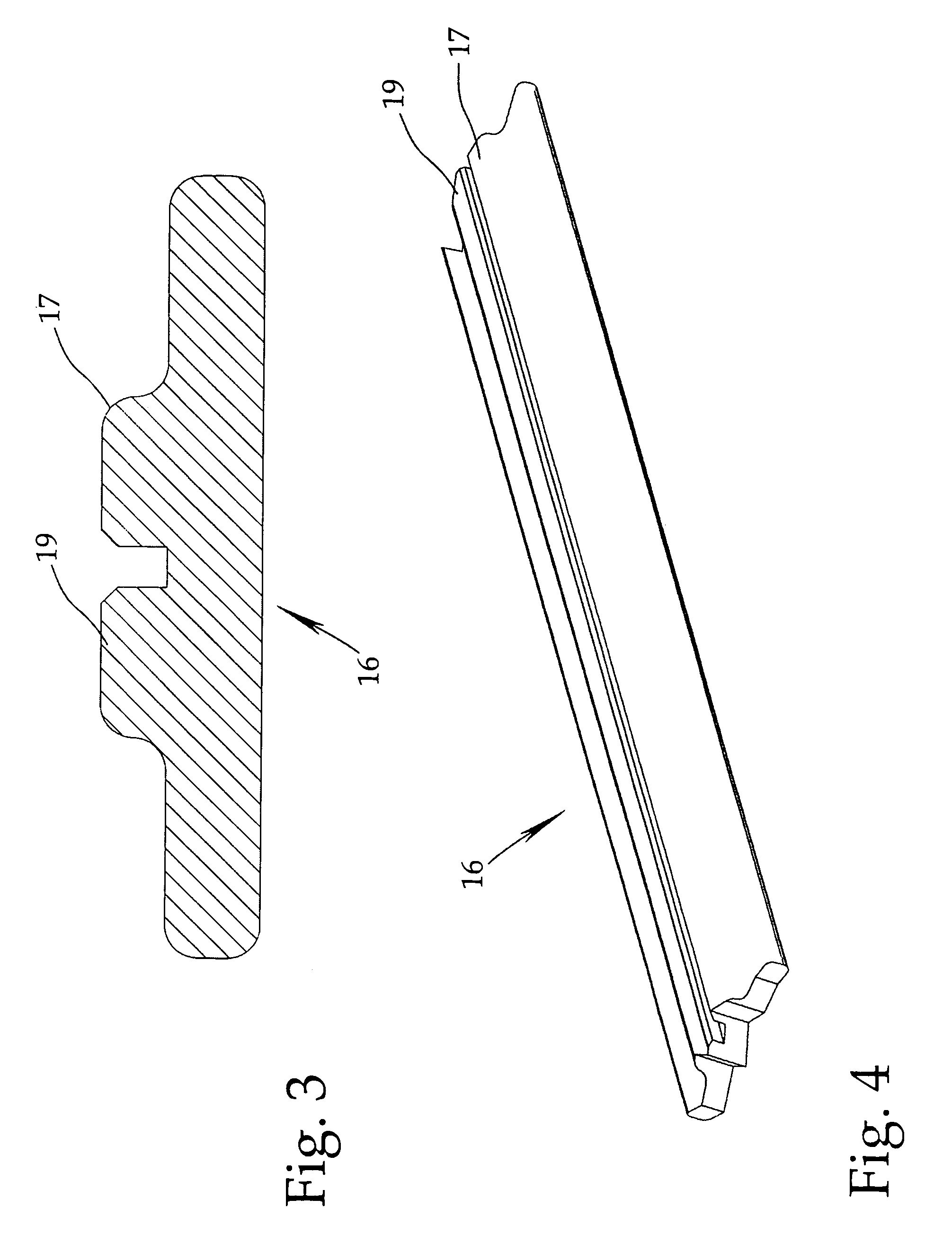

Articulated vehicle wheel tracking mechanism

InactiveUS7219913B2Reduce amount of scrubbingTractor-trailer combinationsTowing devicesArticulated vehicleChassis

The invention provides a trailer for use as part of an articulated vehicle (15) with improved cornering characteristics. The trailer includes: a main chassis (18) connectable to a wheeled section (16) of the vehicle immediately ahead of the trailer so that the trailer is rotatable relative to the wheeled section (16) about a substantially upright first axis (19) in the main chassis (18); a sub-chassis (20) having ground-engaging wheels (21) mounted thereto, the sub-chassis (20) being connected to the main chassis (18) and pivotable about a substantially upright second axis (23) in the main chassis (18); and stop means arranged for limiting rotation of the sub-chassis (20) about the second axis (23) and away from a position of a longitudinal alignment with the main chassis (18). The stop means is movable responsively to relative rotation of the wheeled section (16) and the main chassis (18) about the first axis (19). In a preferred arrangement, some wheels on the sub-chassis (20) are steerable responsively to rotation of the sub-chassis (20) about the second axis (23).

Owner:TRACKAXLE PTY LTD

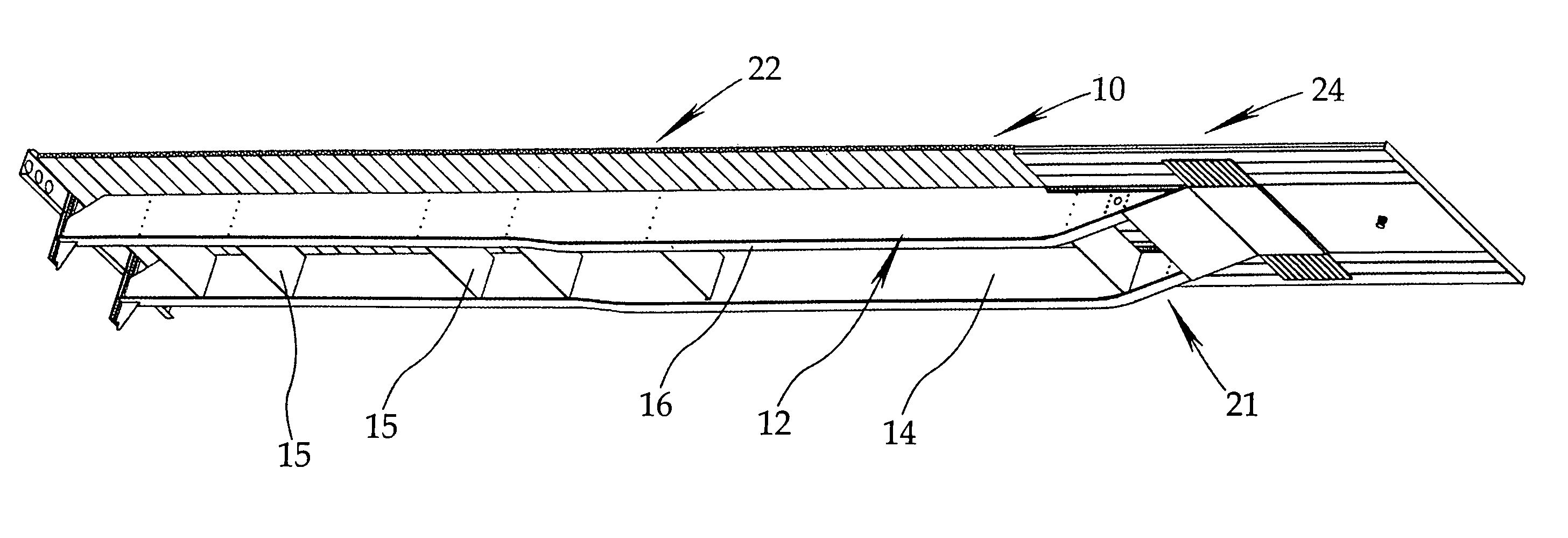

Trailer floor

InactiveUS7798558B2Reduce the overall heightImprove stabilityVehicle seatsSuperstructure subunitsMechanical engineering

Owner:MESSIER DONAT

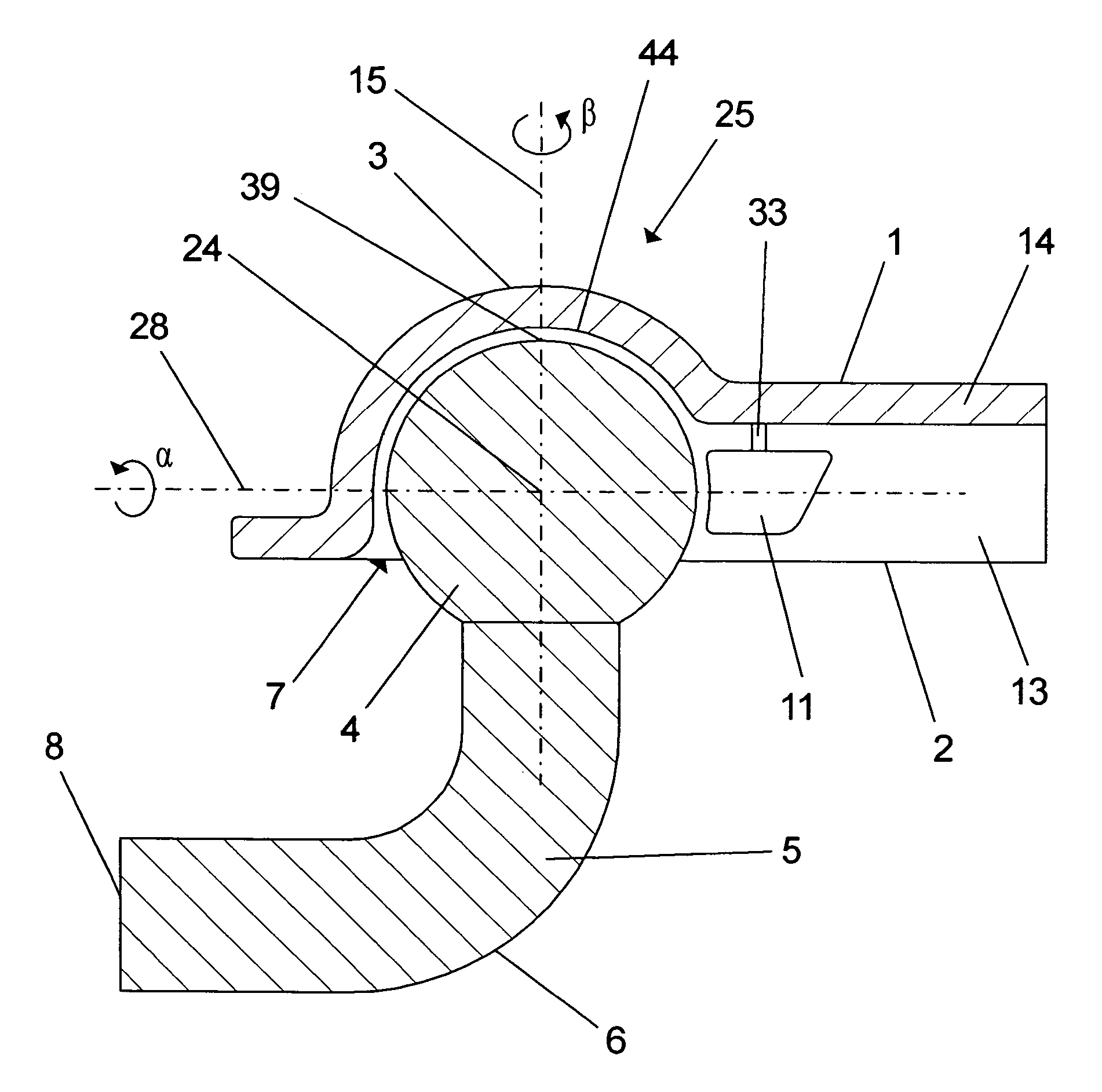

Trailer hitch for a motor vehicle

InactiveUS7159890B2Less assembly workReduce effortAutomatic initiationsTractor-trailer combinationsEngineeringMechanical engineering

A trailer hitch for a motor vehicle includes a towbar (2) having an arm (1) and a ball cup (3) provided with an opening and with a ball pivot (6). The ball pivot (6) has a ball head (4) and a pivot (5) and is mounted with the ball head (4) rotatably and pivotably in the ball cup (3) and passes through an opening (7) and juts out of the ball cup (3). An angle-measuring device having a signal transmitter (17) and two sensors (40, 41) is arranged in the joint unit formed from the ball cup (3) and the ball head (4).

Owner:ZF FRIEDRICHSHAFEN AG

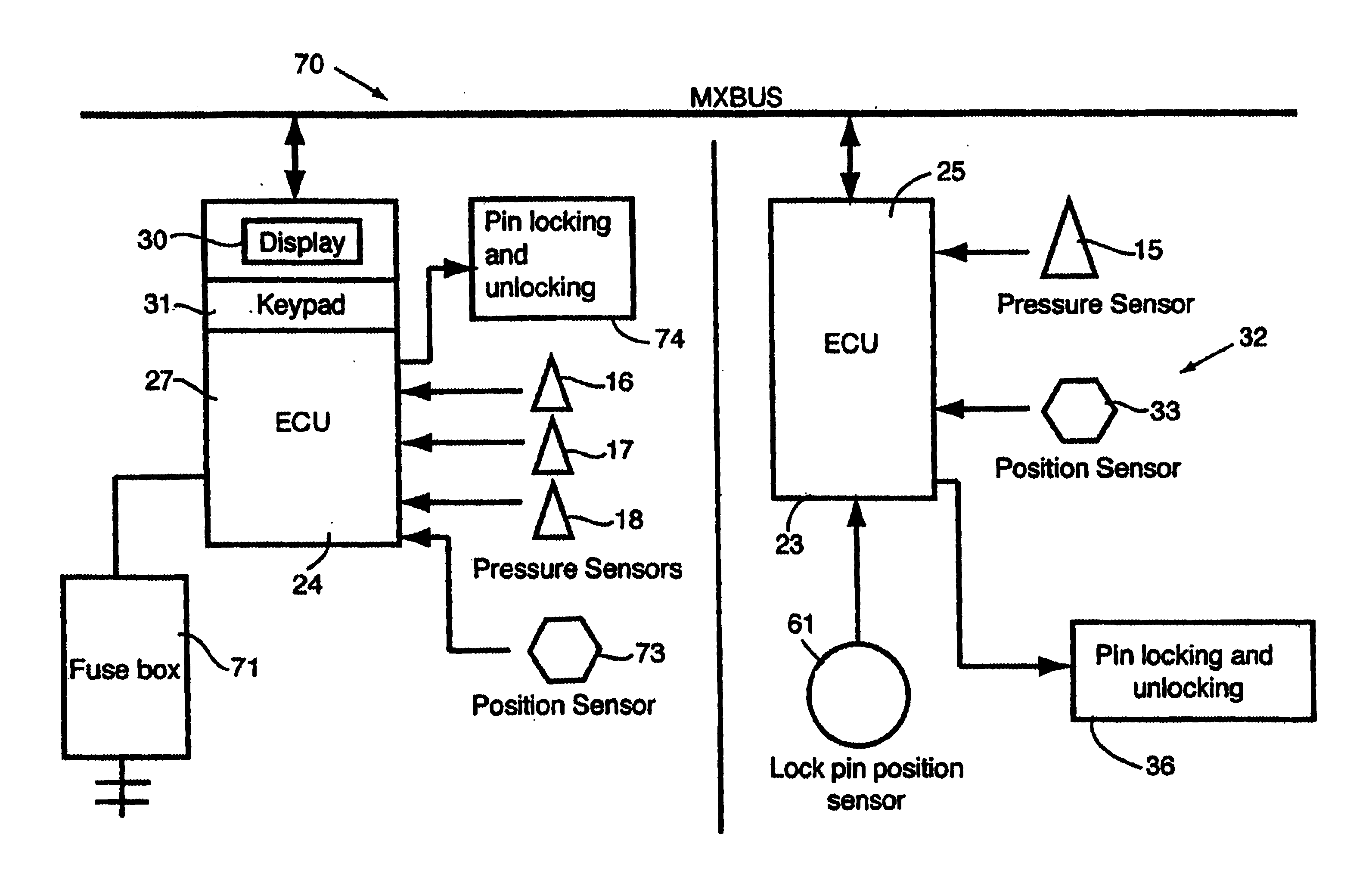

Axle weight distribution system

InactiveUS6921100B2Improve securityConvertible cyclesOptical signallingCommunication interfaceDisplay device

The present invention relates to a system for adjusting weight distribution throughout all axle groups of the truck and trailer. The trailer has at least one axle group mounted on a pair of rails attached to the frame of the trailer. These axle groups are locked in position on the rails by locking pins. The system for adjusting weight distribution according to the present invention measures the weight on every axle group on the truck and trailer. The measurement may be of weight directly by load cells etc. or indirectly, by taking measurements from the air suspension system to calculate weight. The measurements are delivered as an electrical signal to one or more microprocessors capable of receiving the electrical signals and calculating the optimum position of the axle group on the trailer. The position of the trailer axle groups relative to the rails is also determined and the position delivered to the microprocessor(s). The microprocessor(s) is programmed to calculate the weight on each axle group and determine any change in position of the trailer axle group(s) on the rails to optimize the weight distribution. The information is presented to the driver on a display located in the cab of the truck. The system further includes apparatus to lock and unlock the locking pins that lock the trailer axle group(s) in position on the rails. The system also includes a communication interface between the truck and the trailer.

Owner:WHEEL MONITOR

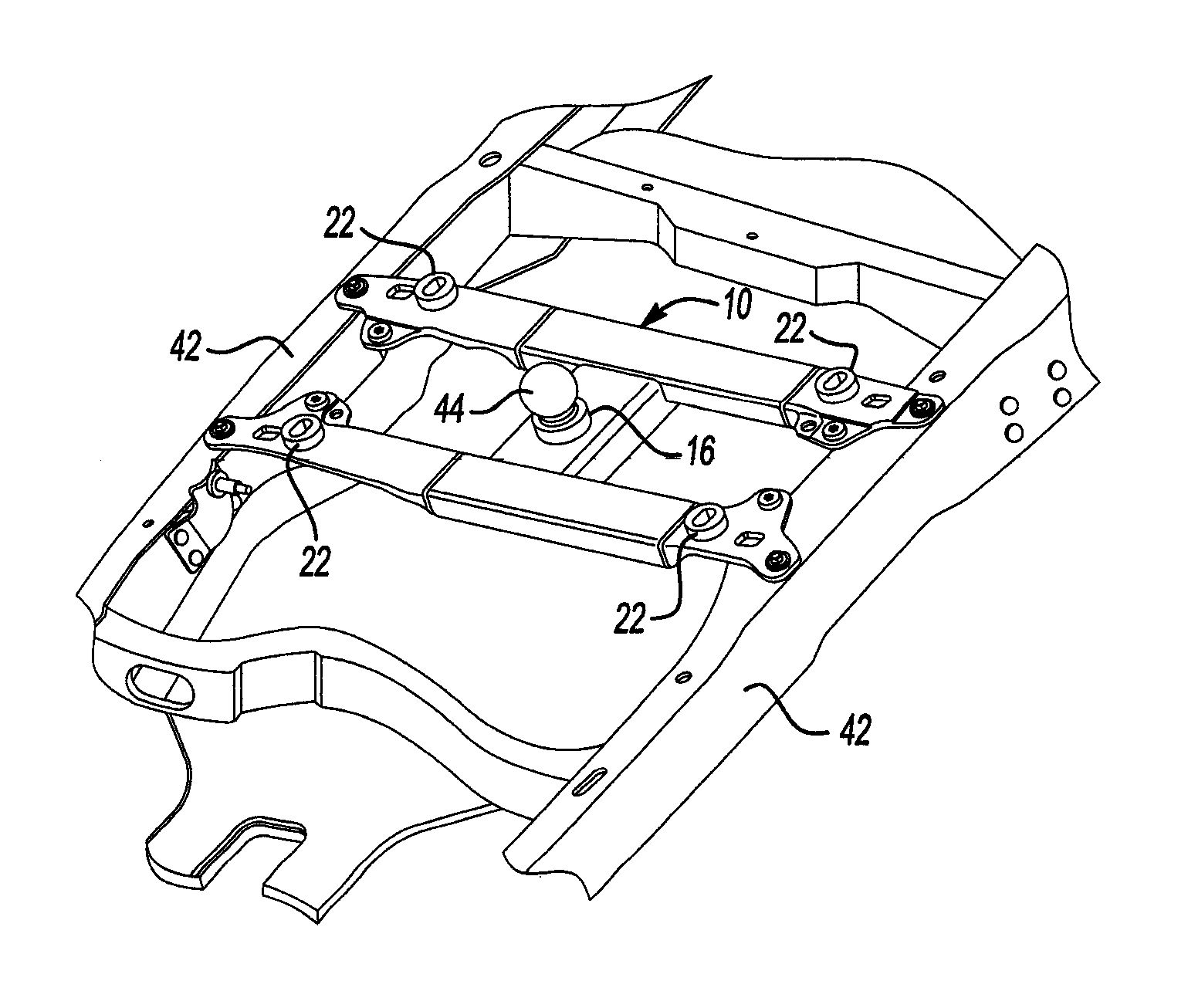

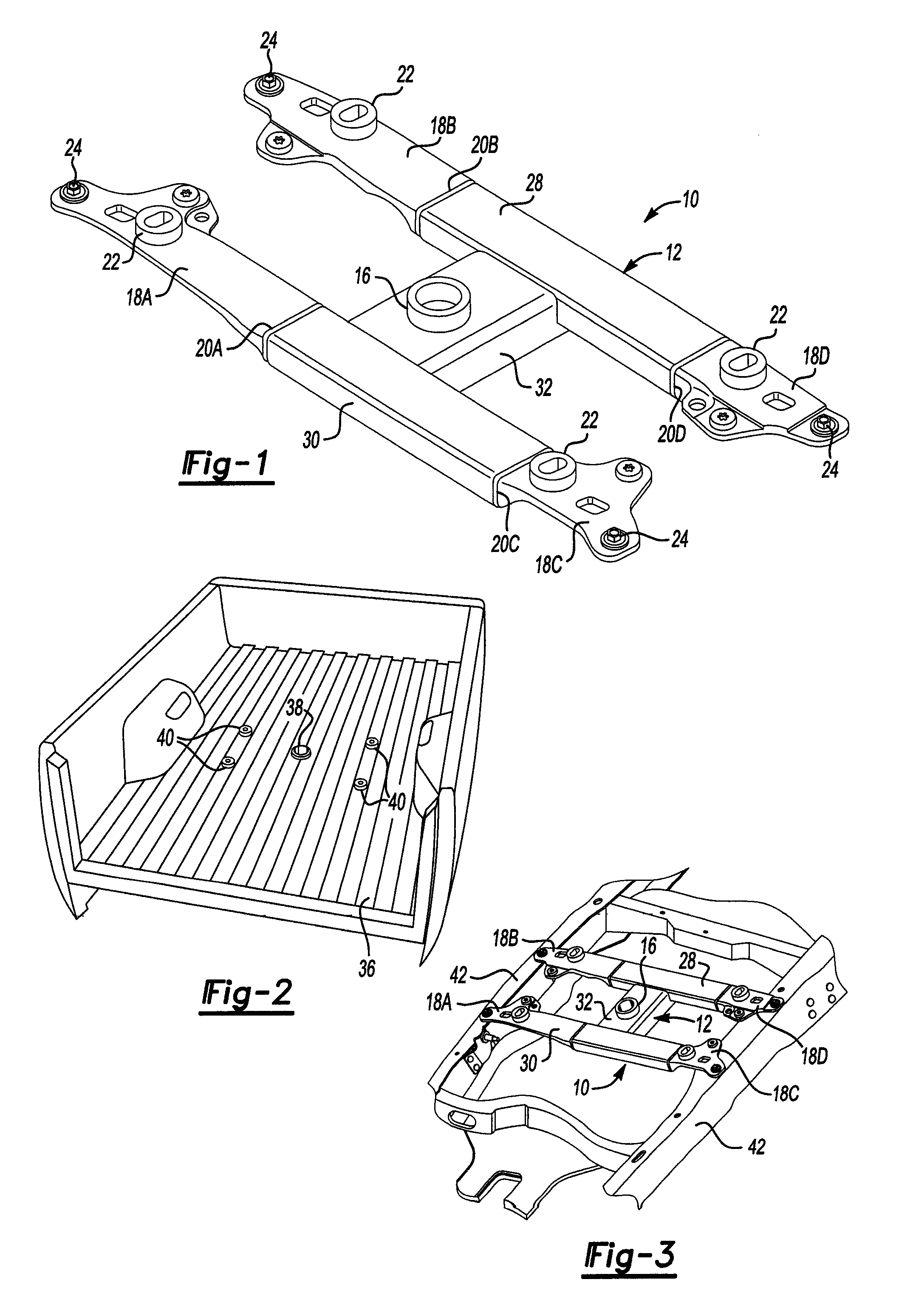

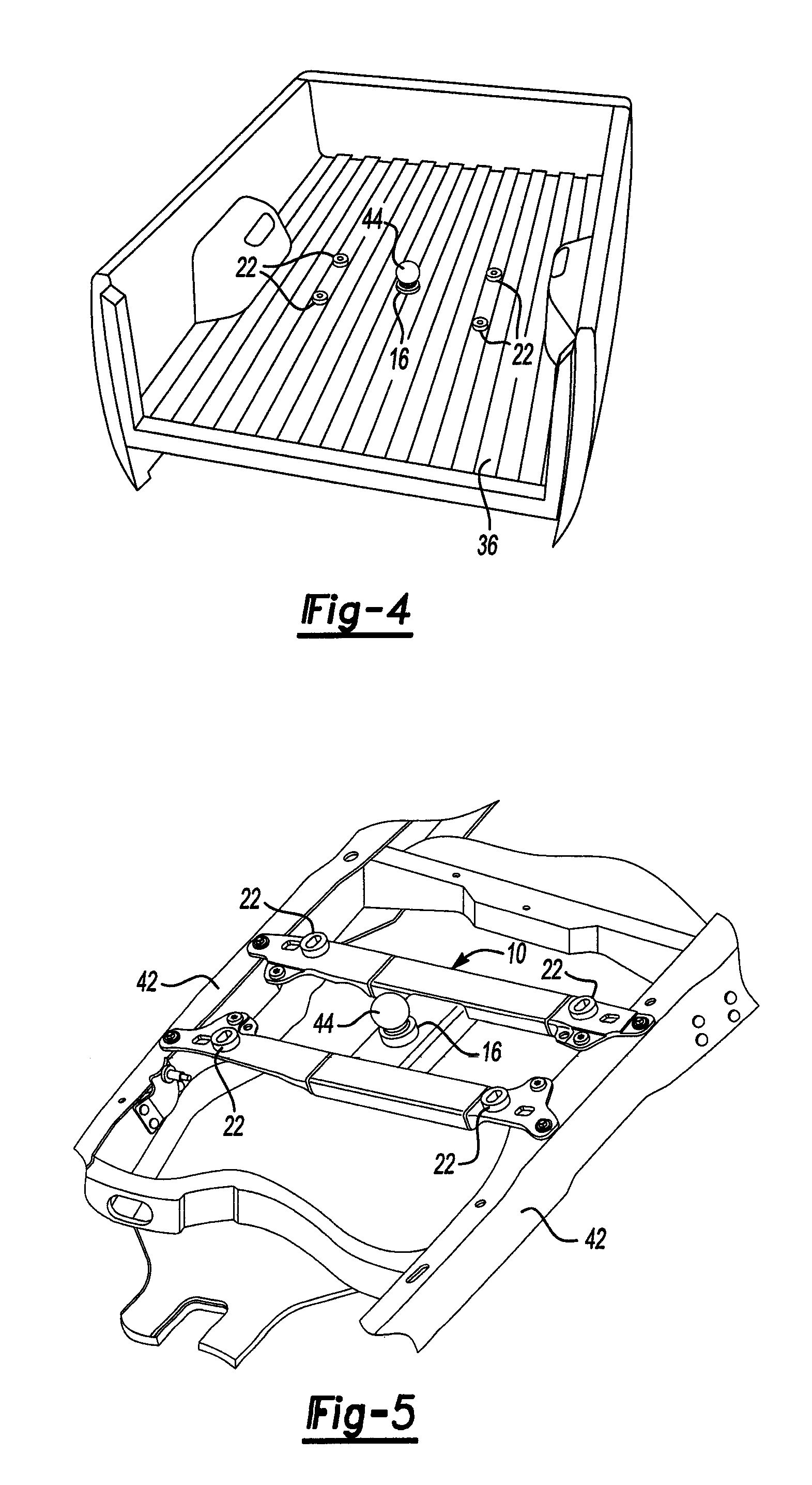

Integrated support structure for either a fifth wheel hitch or a gooseneck trailer hitch

An integrated support structure apparatus is provided for attaching either a fifth wheel trailer hitch or a gooseneck trailer hitch to a truck bed. The integrated support structure comprises an H-shaped body that is attached to at least one truck frame rail below the truck bed. A gooseneck ball receiver is attached to a central portion of the body and aligned with a gooseneck opening in the truck bed. A plurality of mounting pads are formed integrally as part of a plurality of end inserts that are assembled to the body.

Owner:FORD GLOBAL TECH LLC

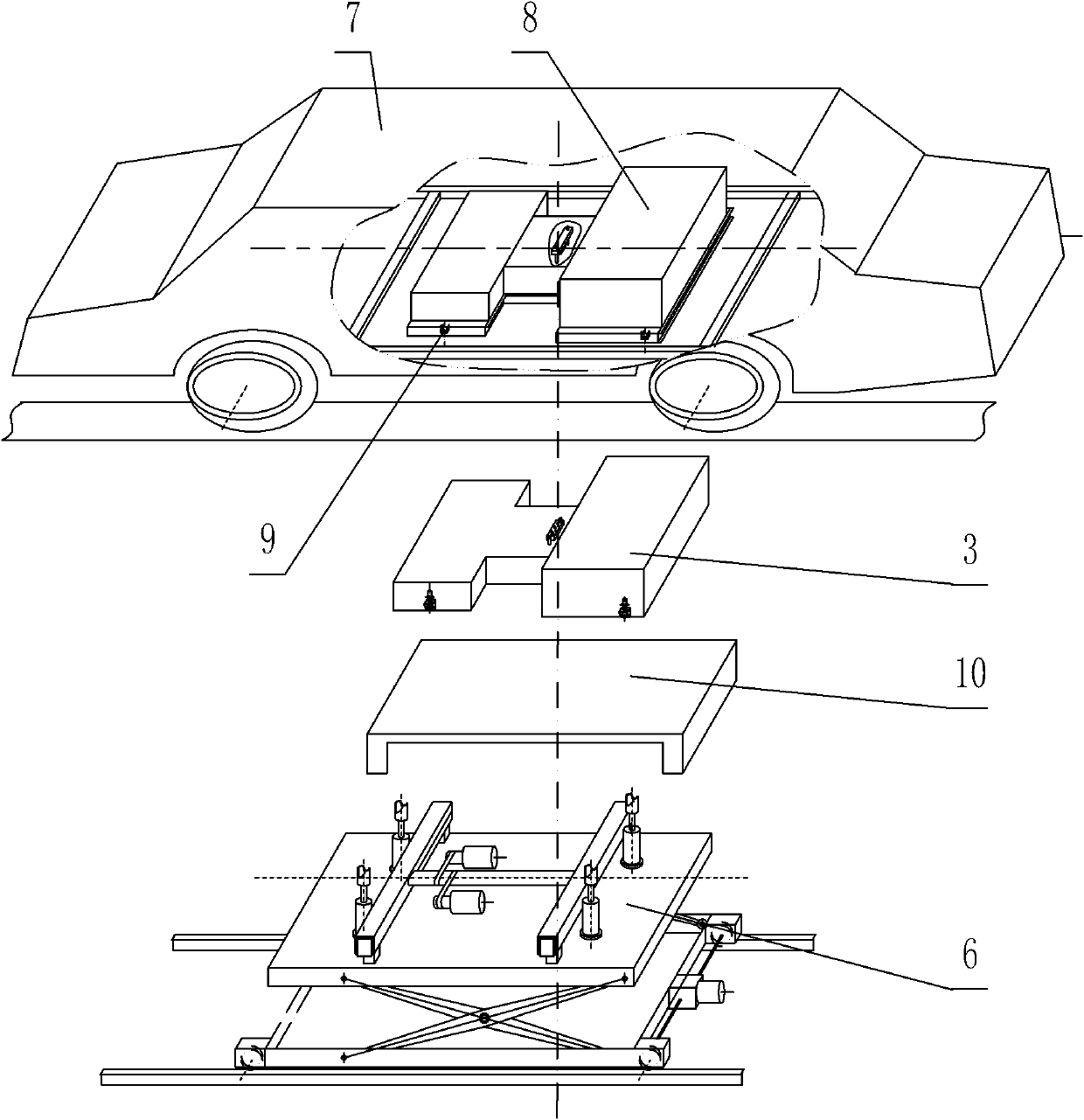

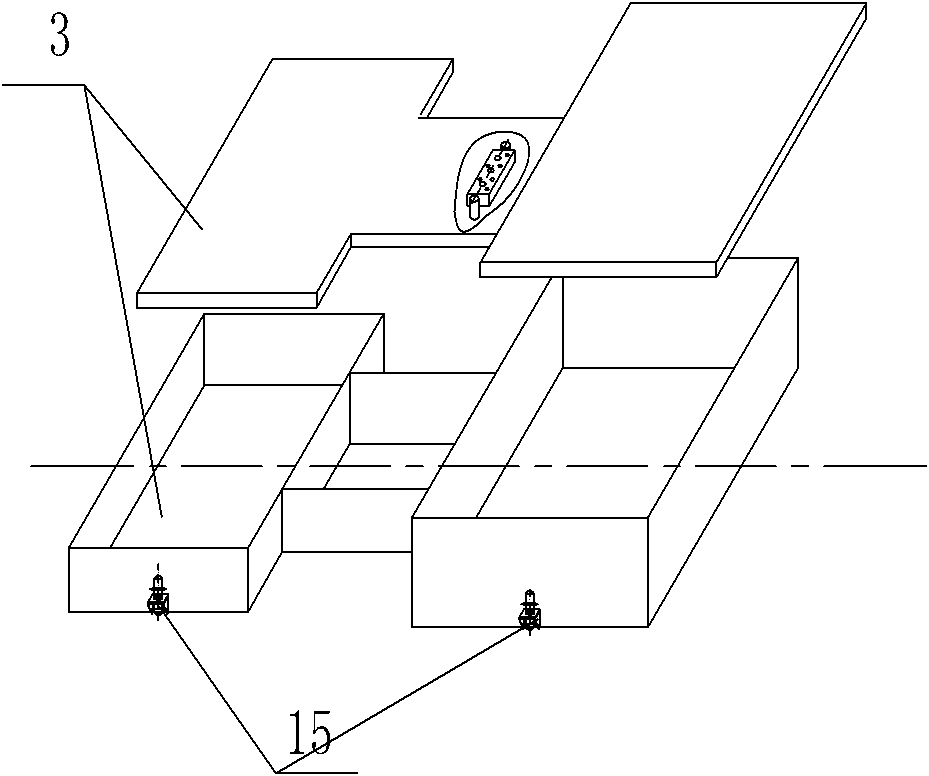

Automatic vehicle-mounted mobile power charging and exchanging station for electric vehicle and method for quickly exchanging battery

ActiveCN102180200ACompact structureLess investmentElectric propulsion mountingTractor-trailer combinationsElectricityAutomatic control

The invention discloses an automatic vehicle-mounted mobile power charging and exchanging station for an electric vehicle and a method for quickly exchanging a battery. The automatic vehicle-mounted mobile power charging and exchanging station comprises a tractor, a semitrailer and a battery box storage rack, a battery box, an automatic power exchanging device, a charging system, an electric quantity counting system, an automatic control unit and the like which are arranged on the semitrailer, wherein the storage rack can store a plurality of battery boxes three-dimensionally; the battery boxes are standard exchanging modules connected with a battery house on the lower part of a vehicle body by using a plurality of quick-opening locking bolts; the automatic power exchanging device comprises a lifting table, a transmigration machine, a shifting machine and a plurality of unlocking / locking bushings; the automatic power exchanging device can automatically transport and store the battery boxes, and lock or unlock the battery boxes and the battery house due to mutual matching of the lifting table, the unlocking / locking bushings and the quick-opening locking bolts, so automatic dismantling and exchange of the battery boxes can be realized; and the charging system is used for automatically charging the battery boxes. The station is complete in system, compact in structure, flexible in maneuvering, low in investment and short in construction period, so the automatic power charging / exchanging requirement of the battery of the electric vehicle can be met.

Owner:柳崇禧 +1

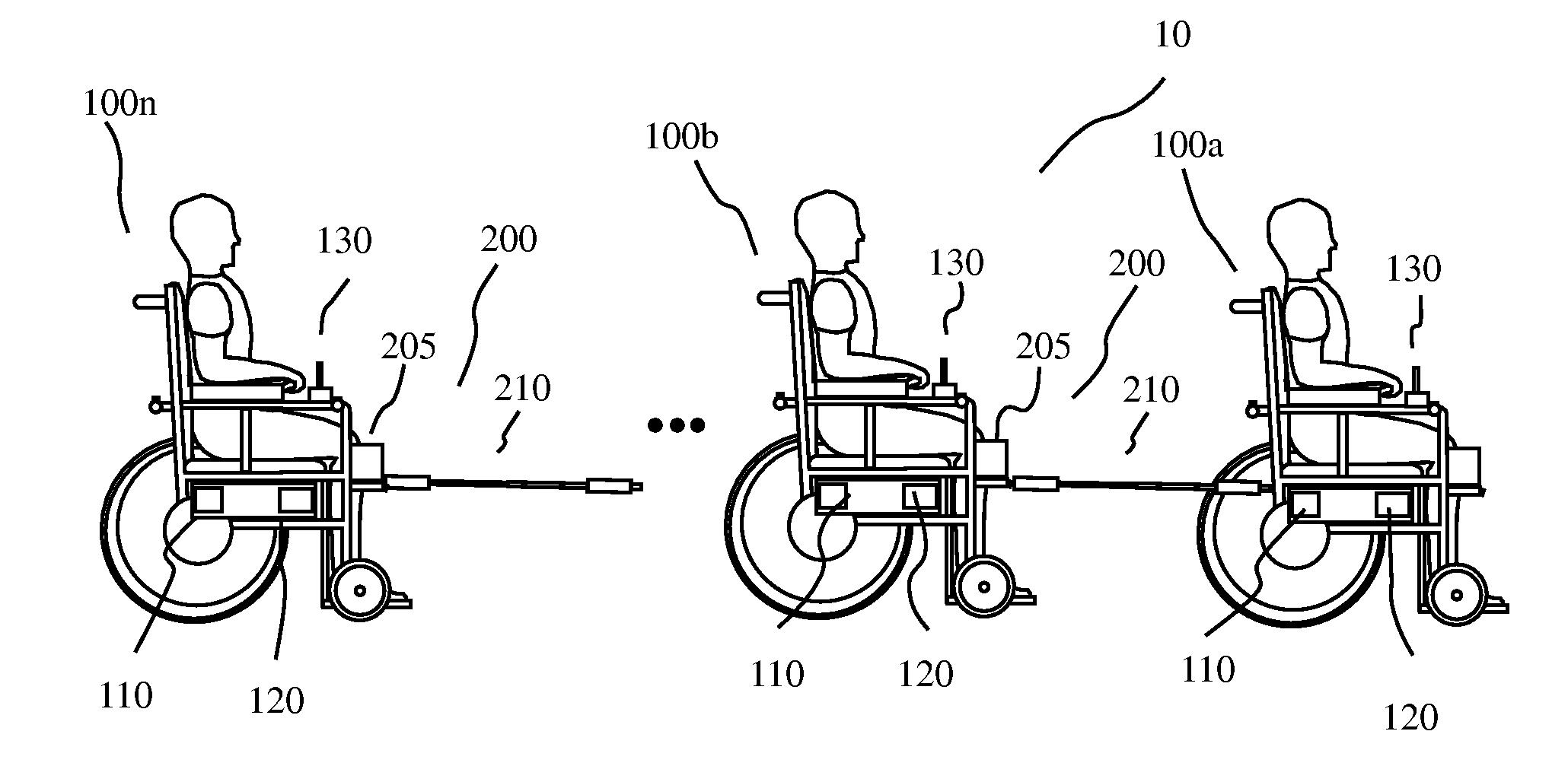

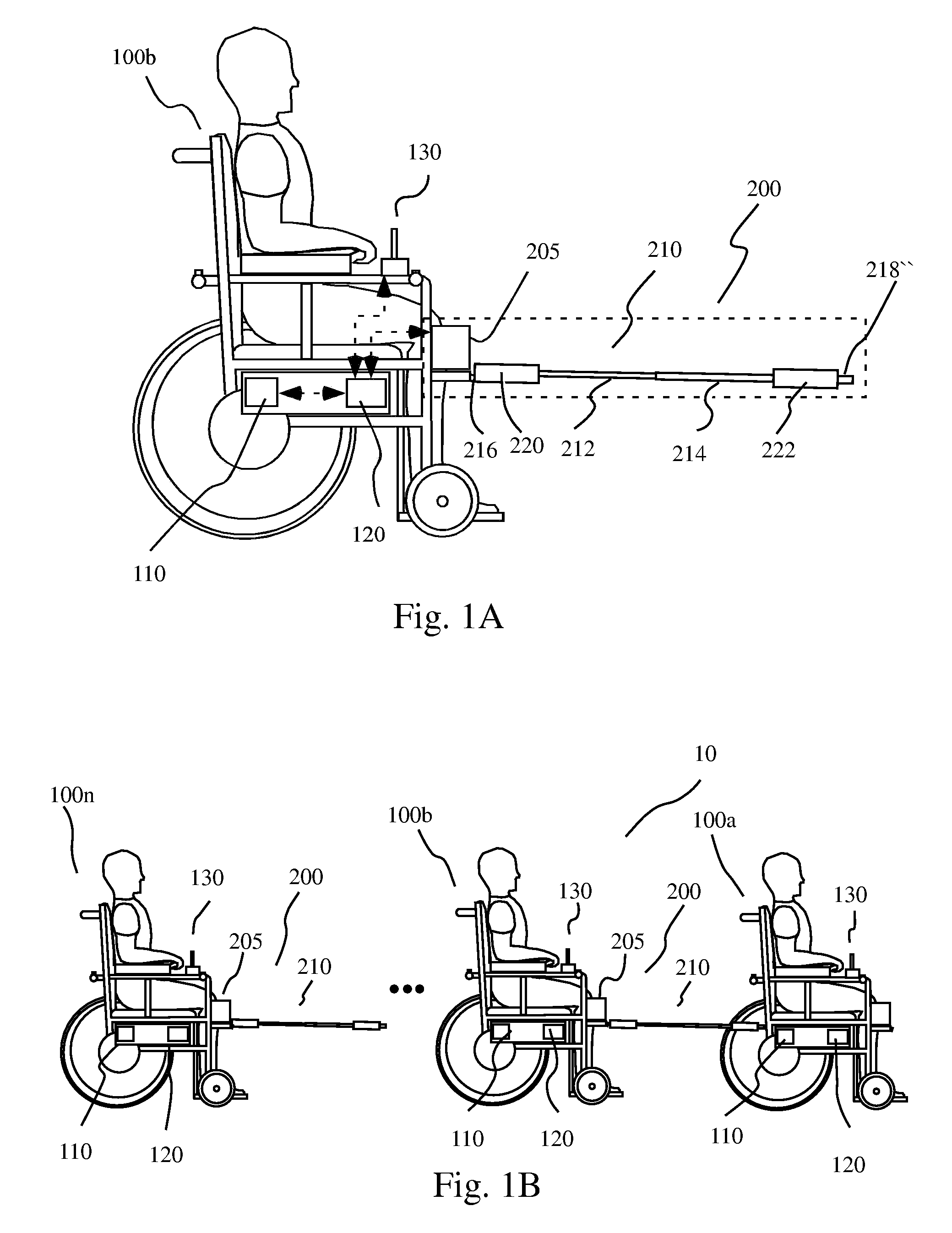

Powered vehicle convoying systems and methods of convoying powered vehicles

InactiveUS8326473B2Reduce and eliminate many problemQuickly assembly and disassemblyAgricultural machinesDigital data processing detailsEngineeringSelf-propelled wheelchair

Owner:UNIVERSITY OF PITTSBURGH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com