Patents

Literature

53results about How to "Less assembly work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

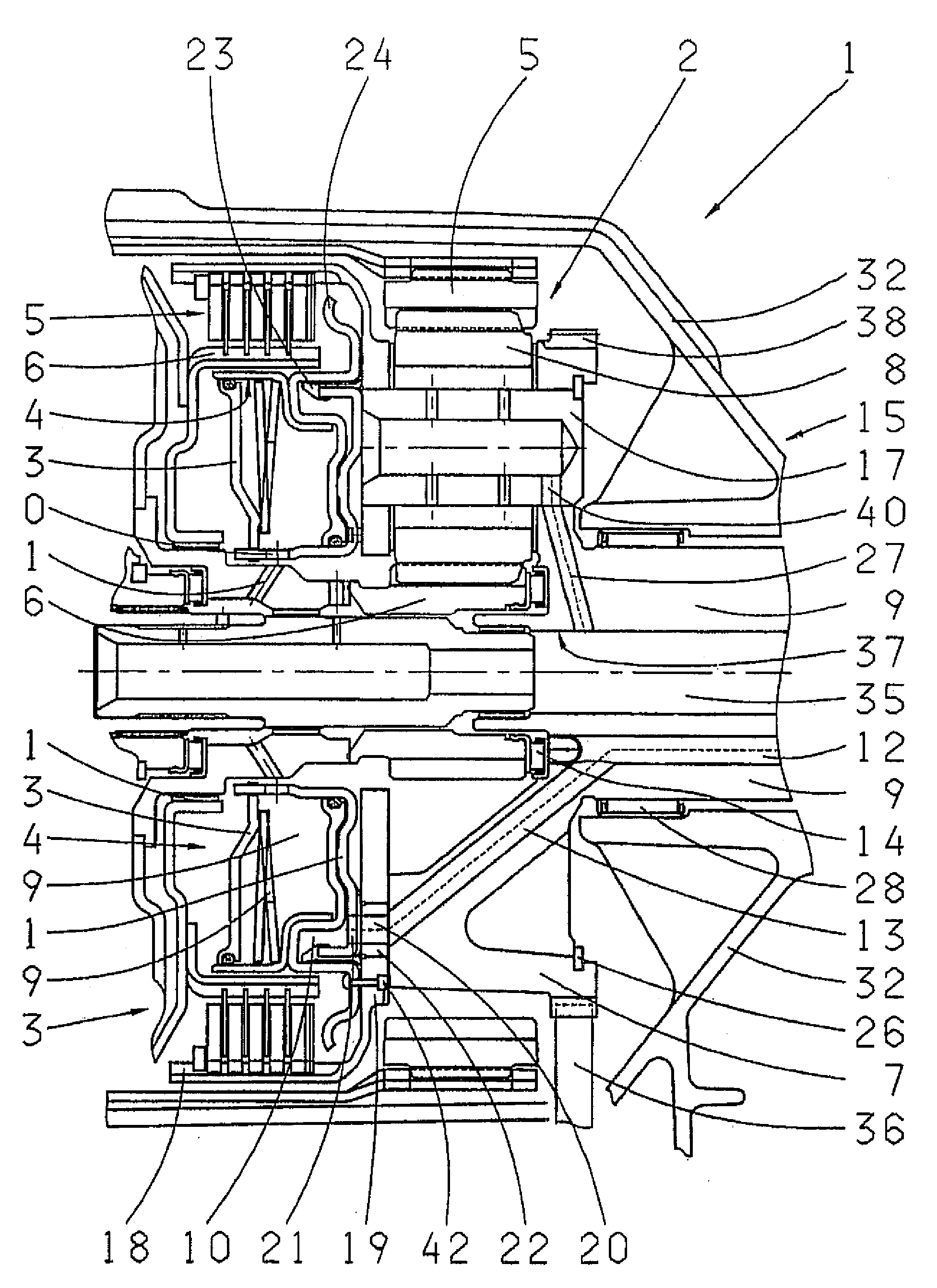

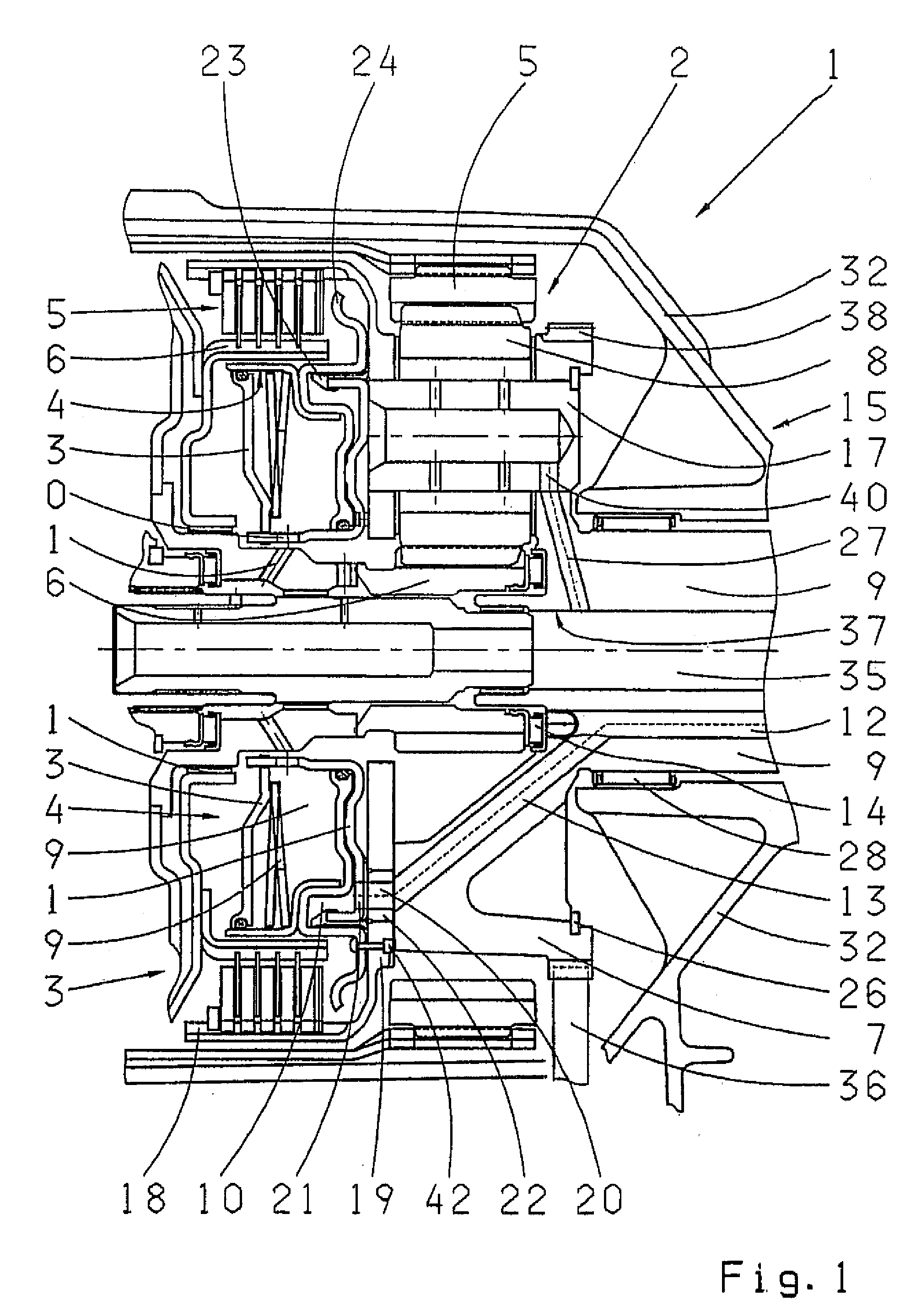

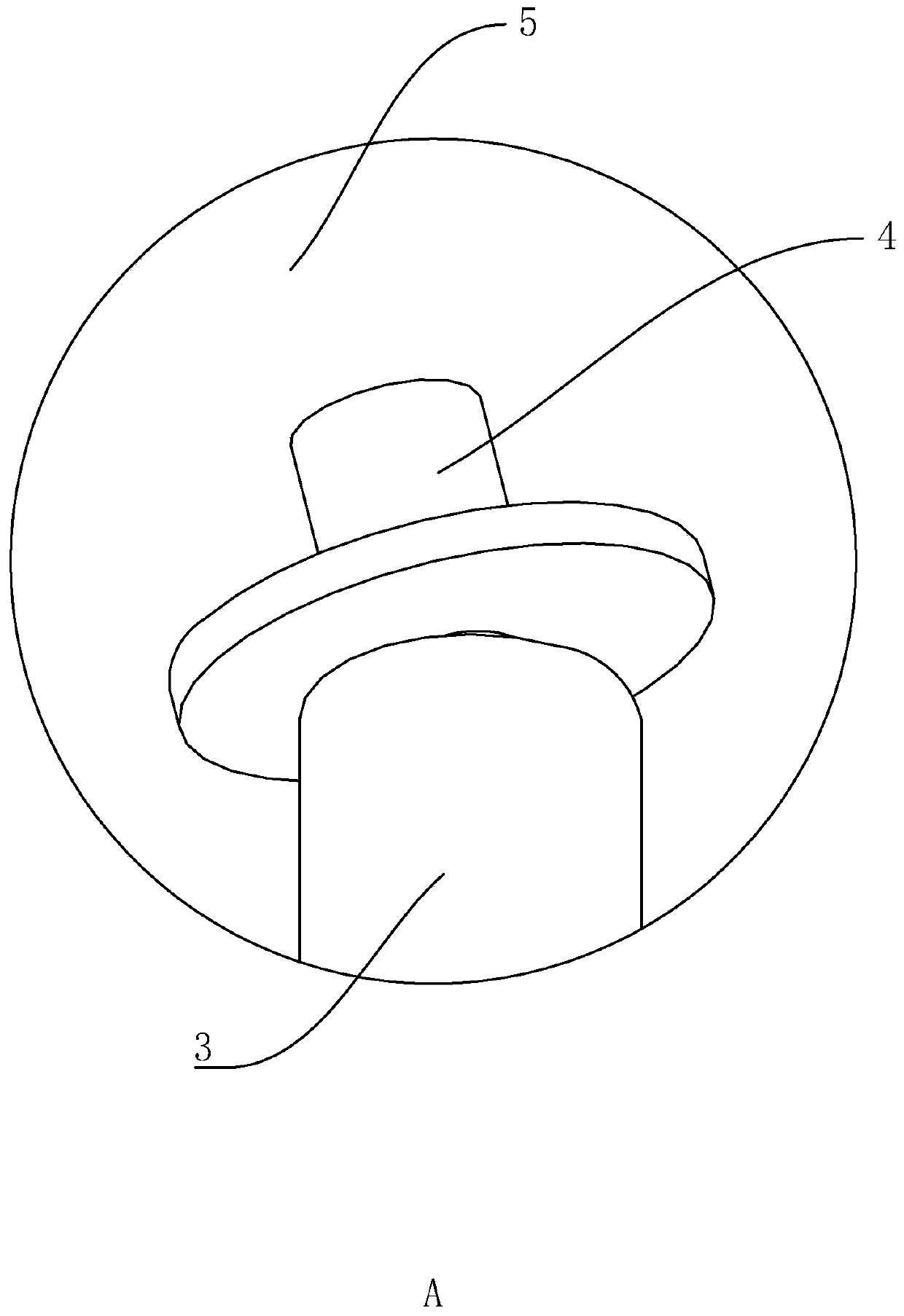

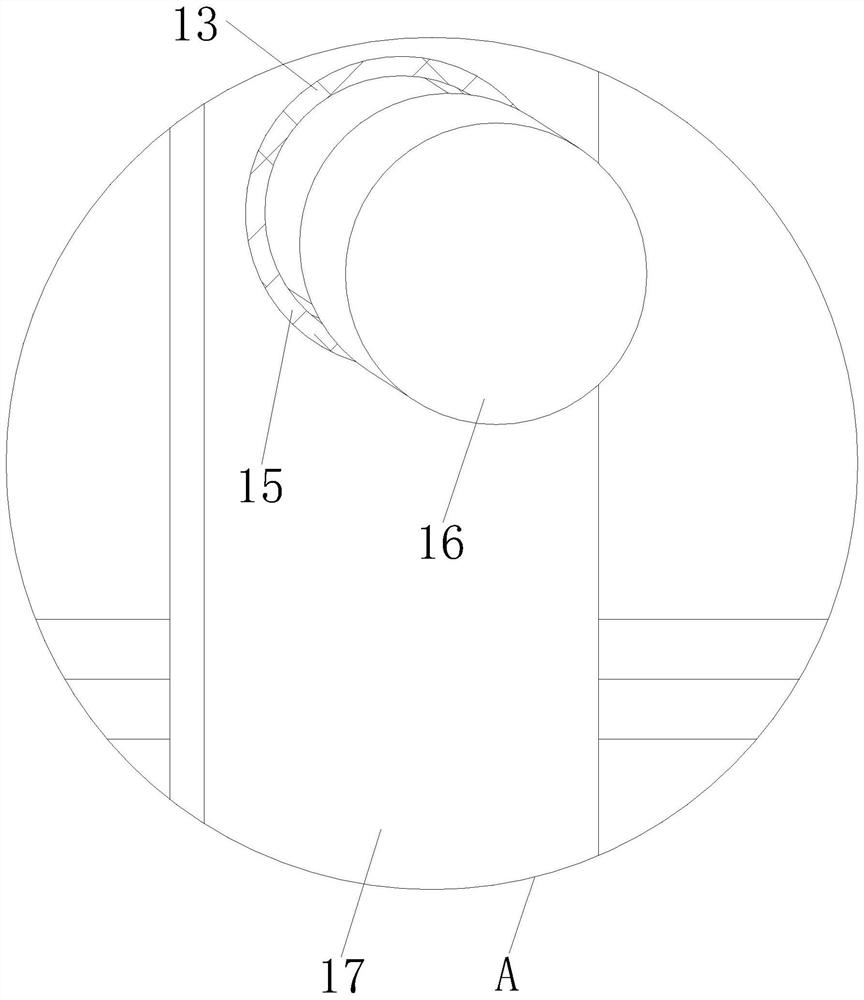

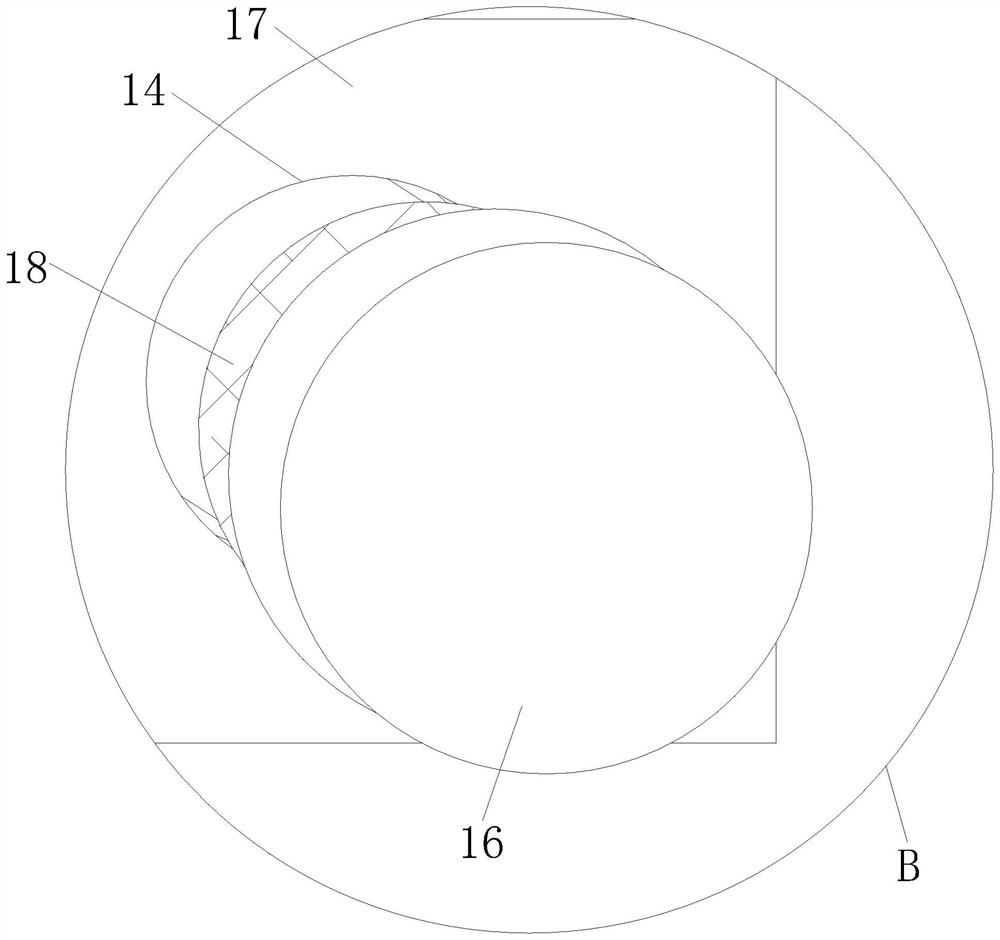

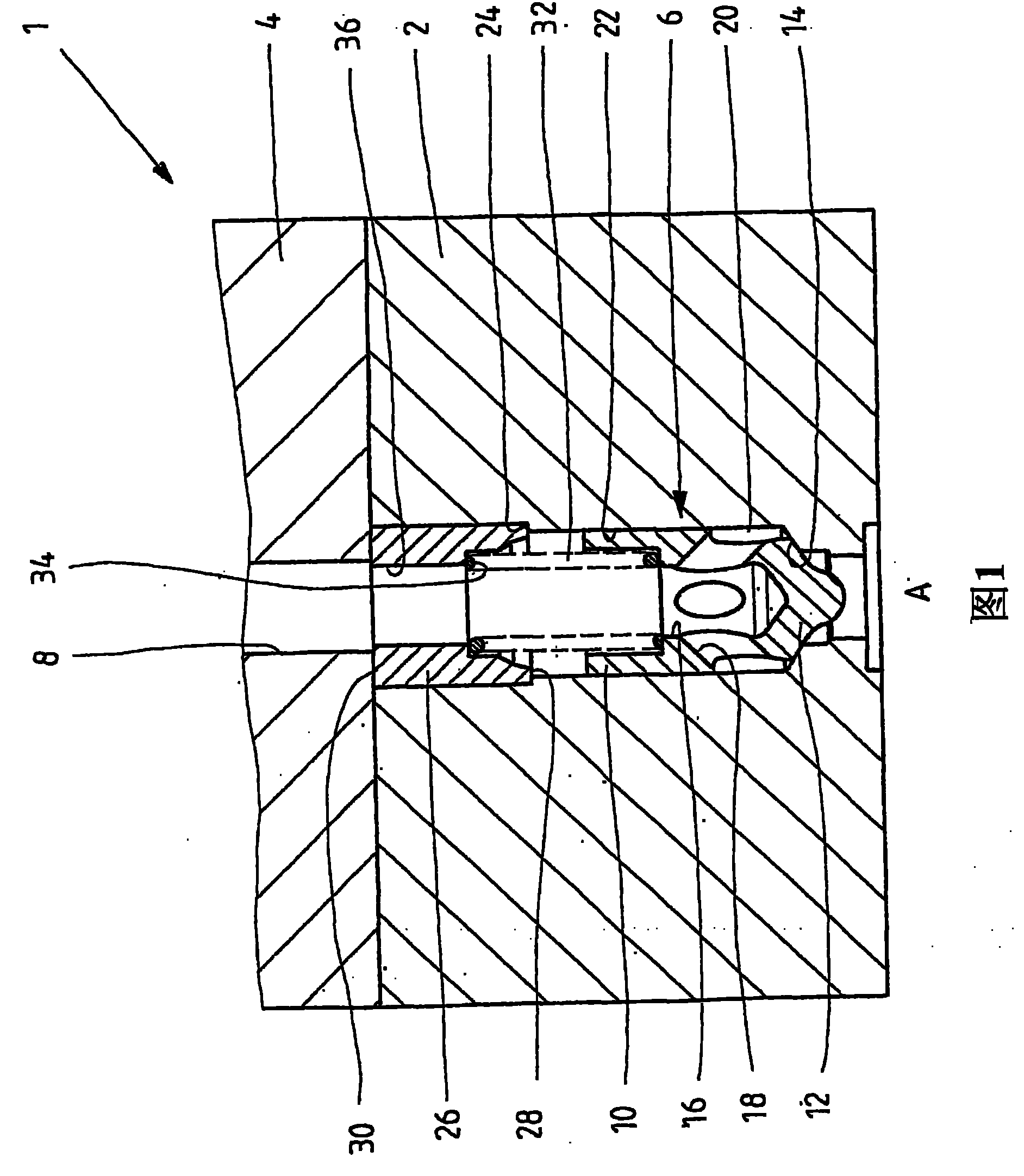

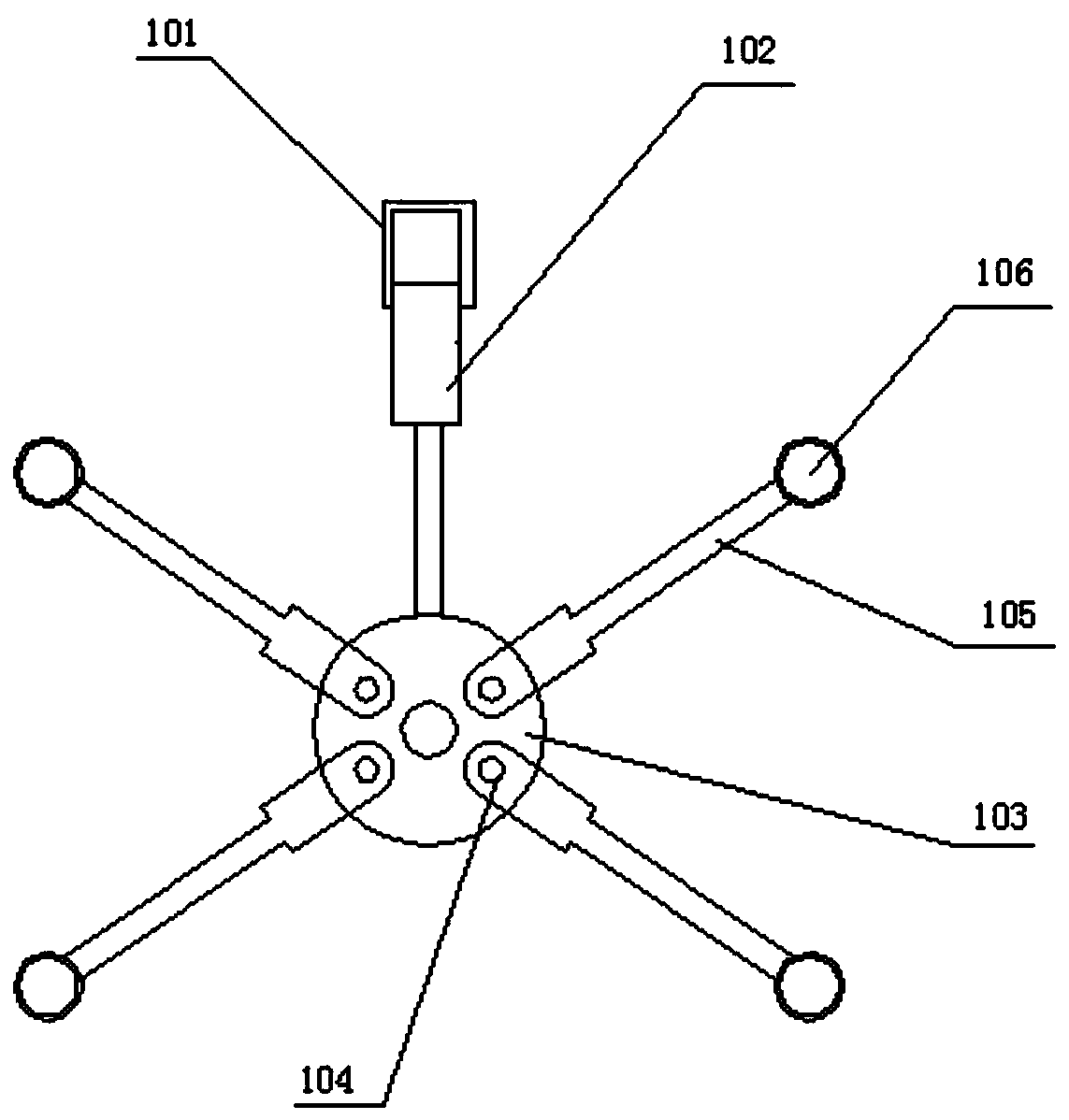

Trailer hitch for a motor vehicle

InactiveUS7159890B2Less assembly workReduce effortAutomatic initiationsTractor-trailer combinationsEngineeringMechanical engineering

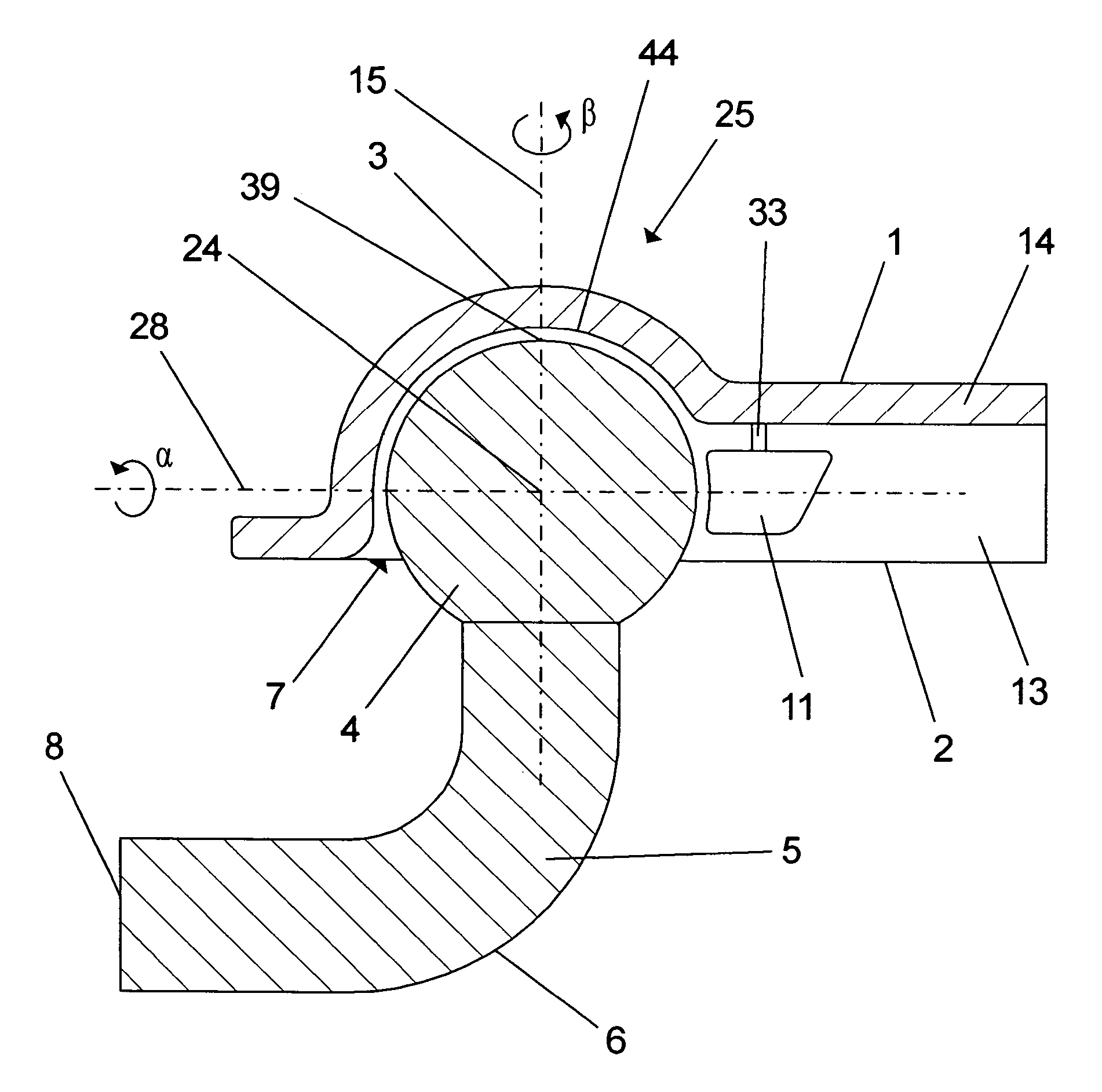

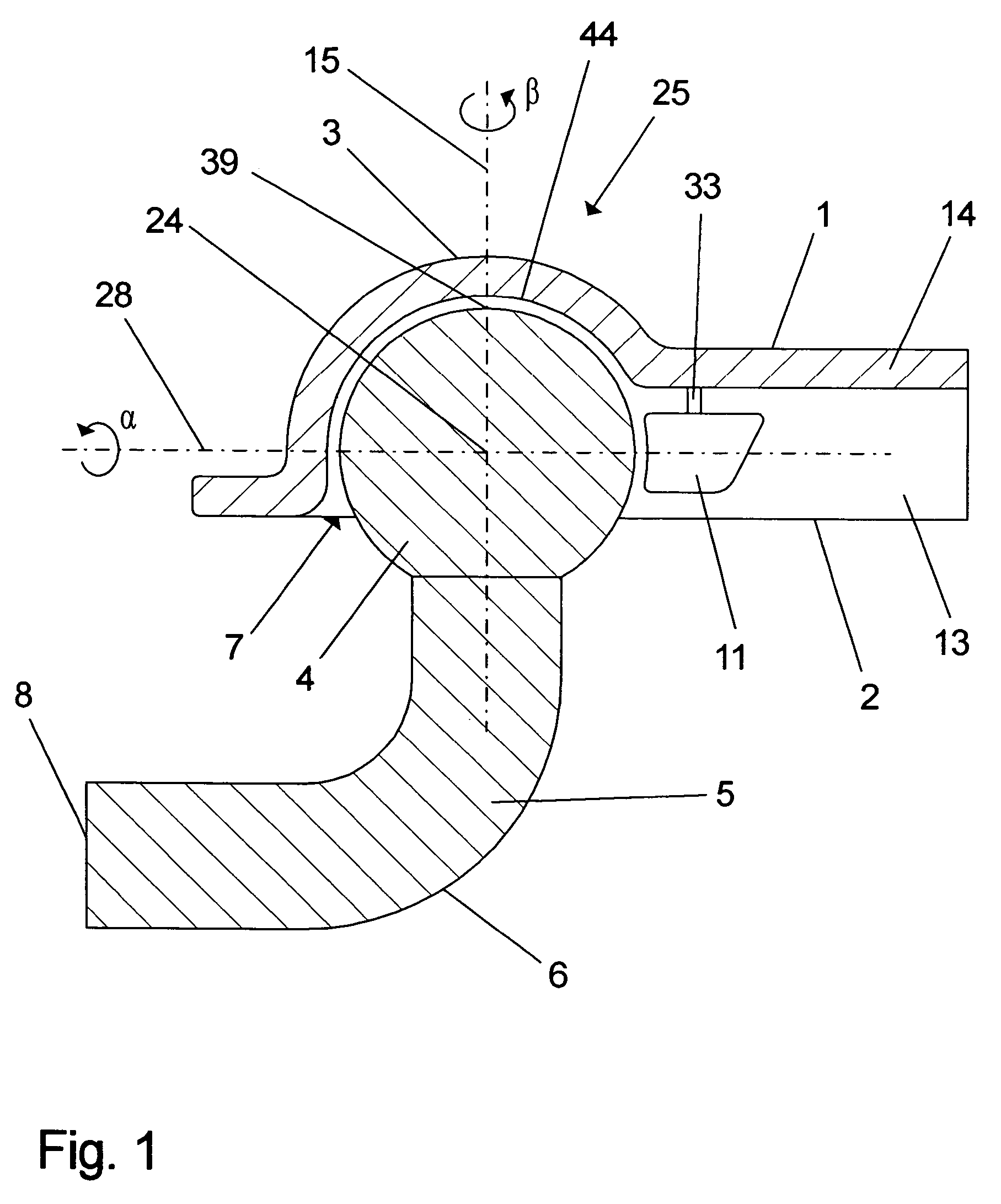

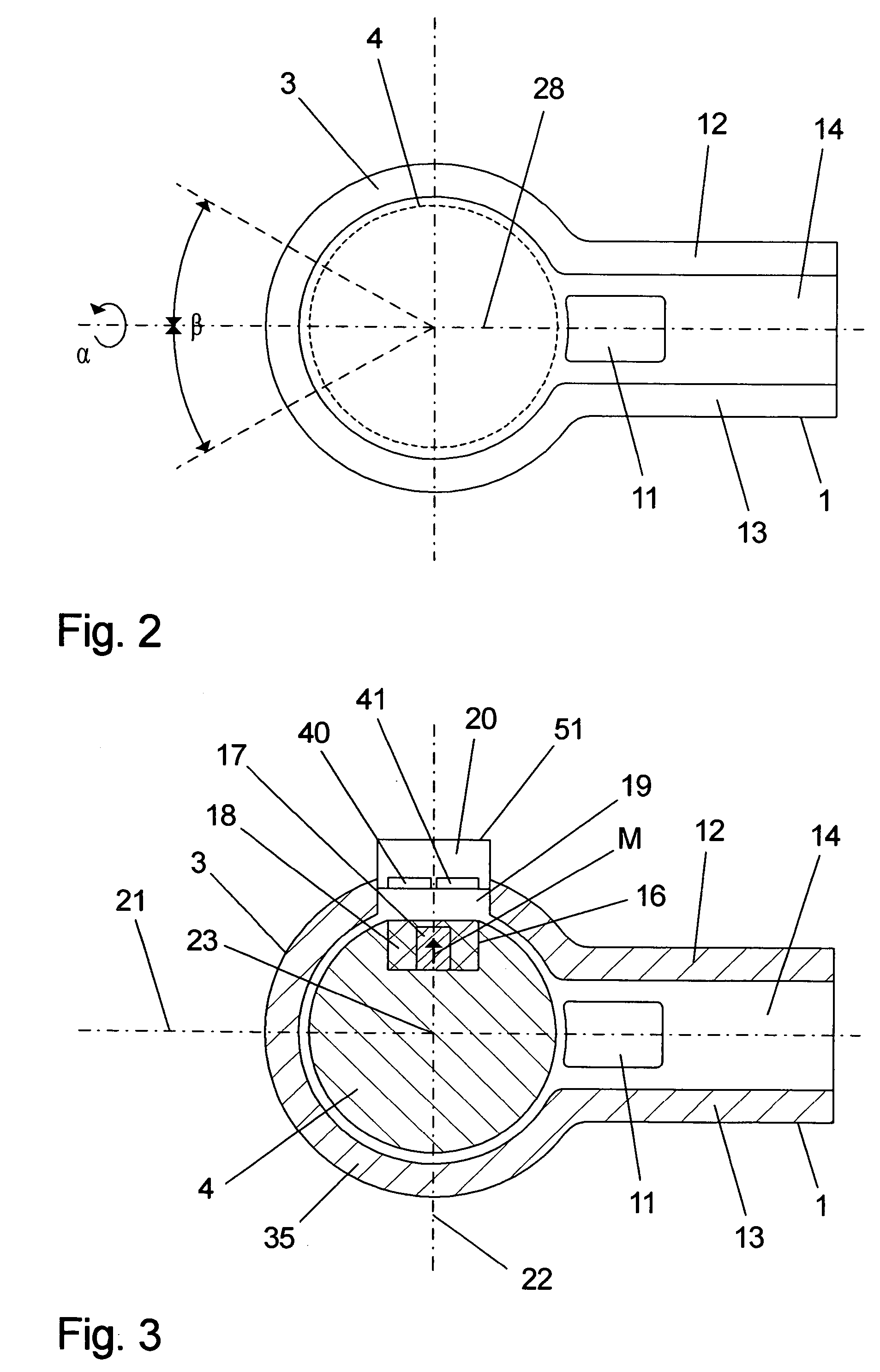

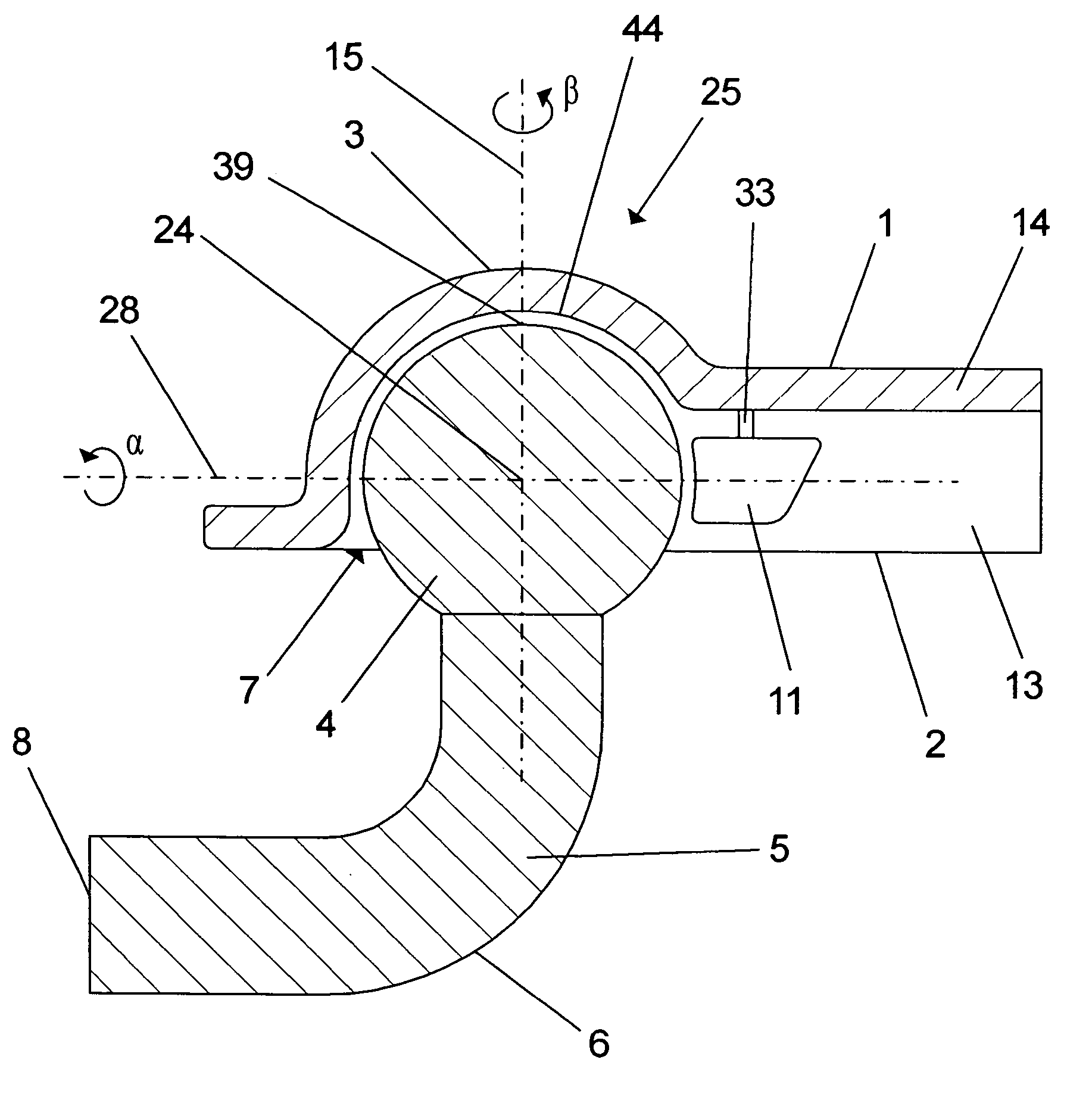

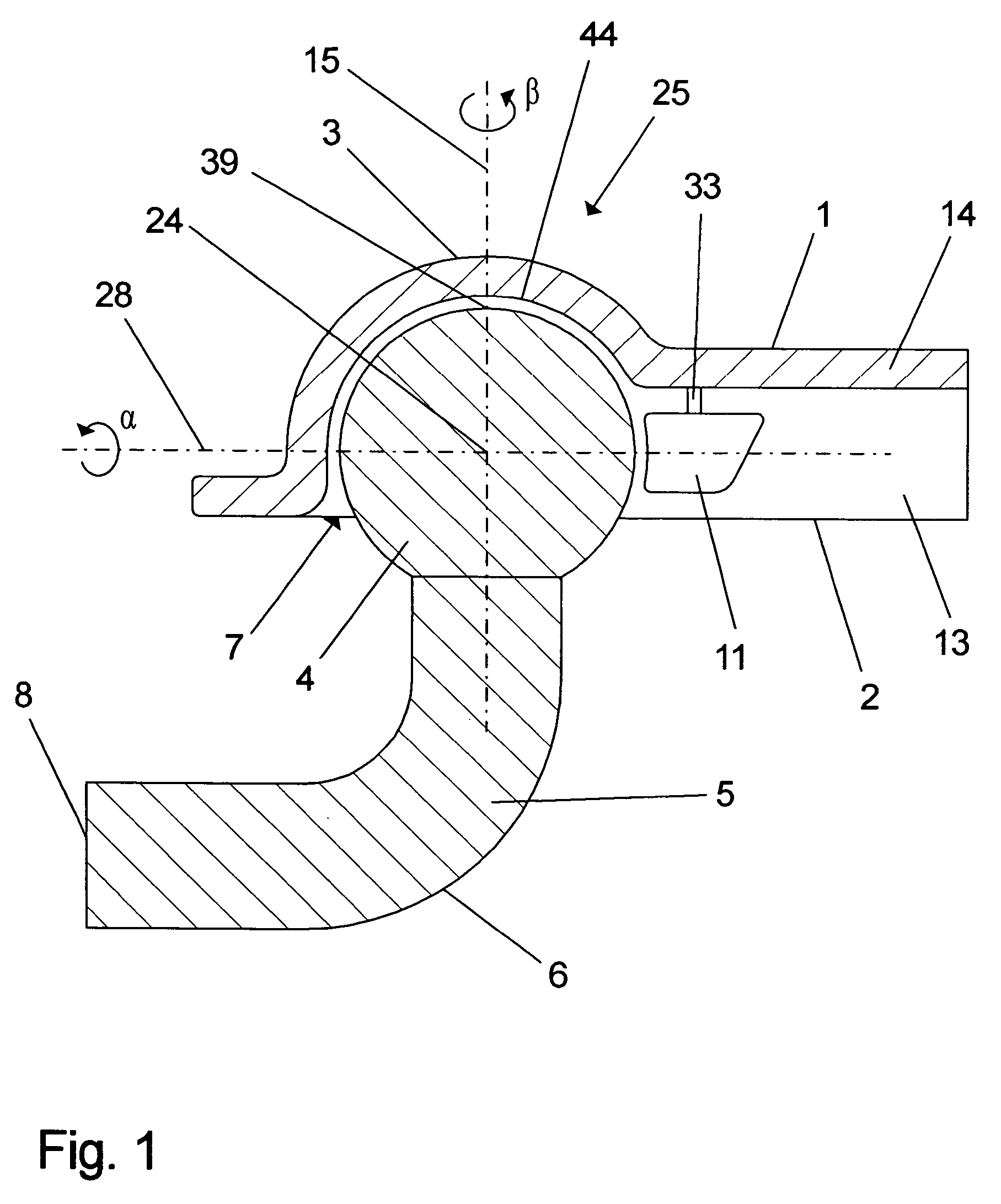

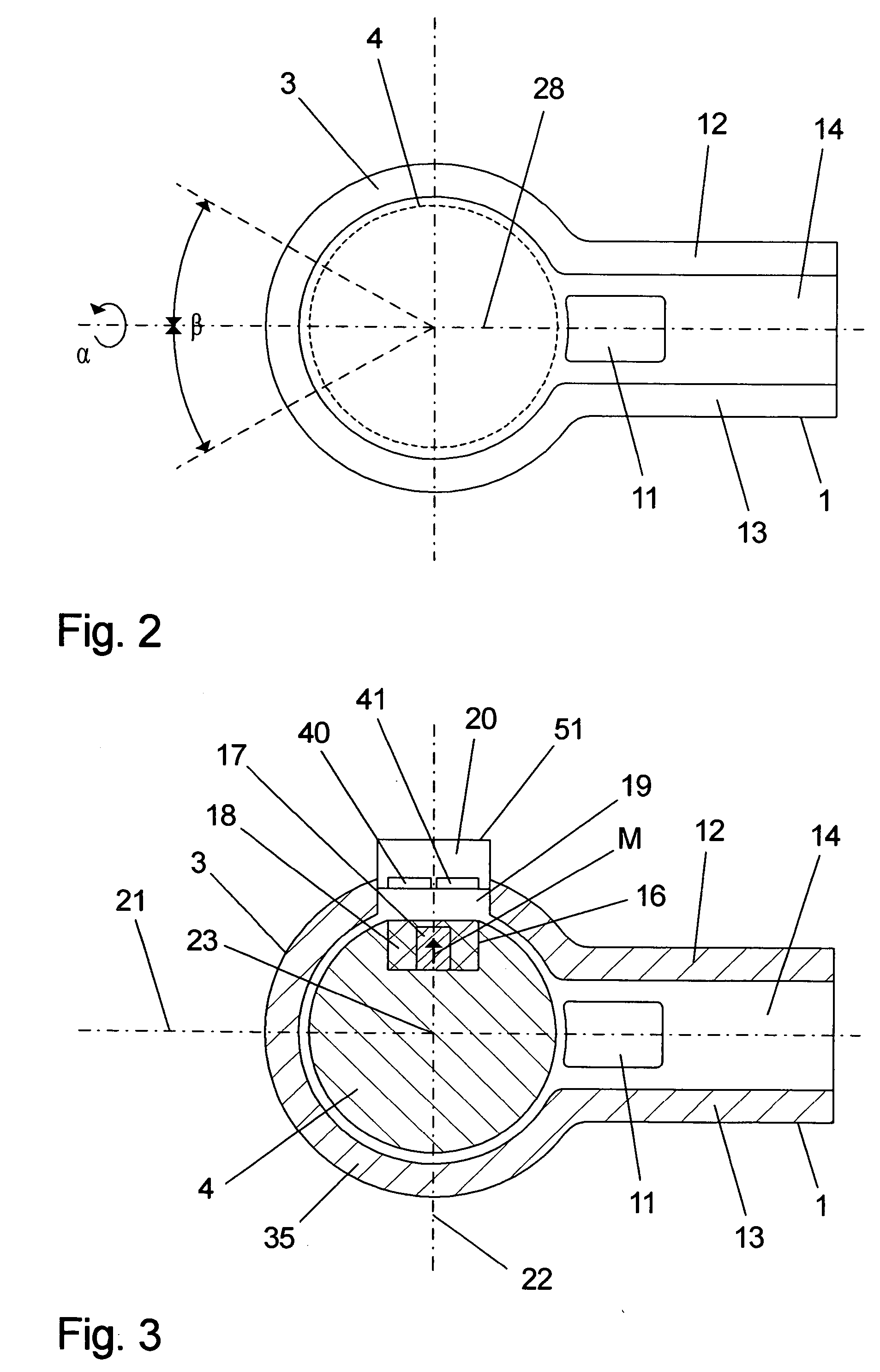

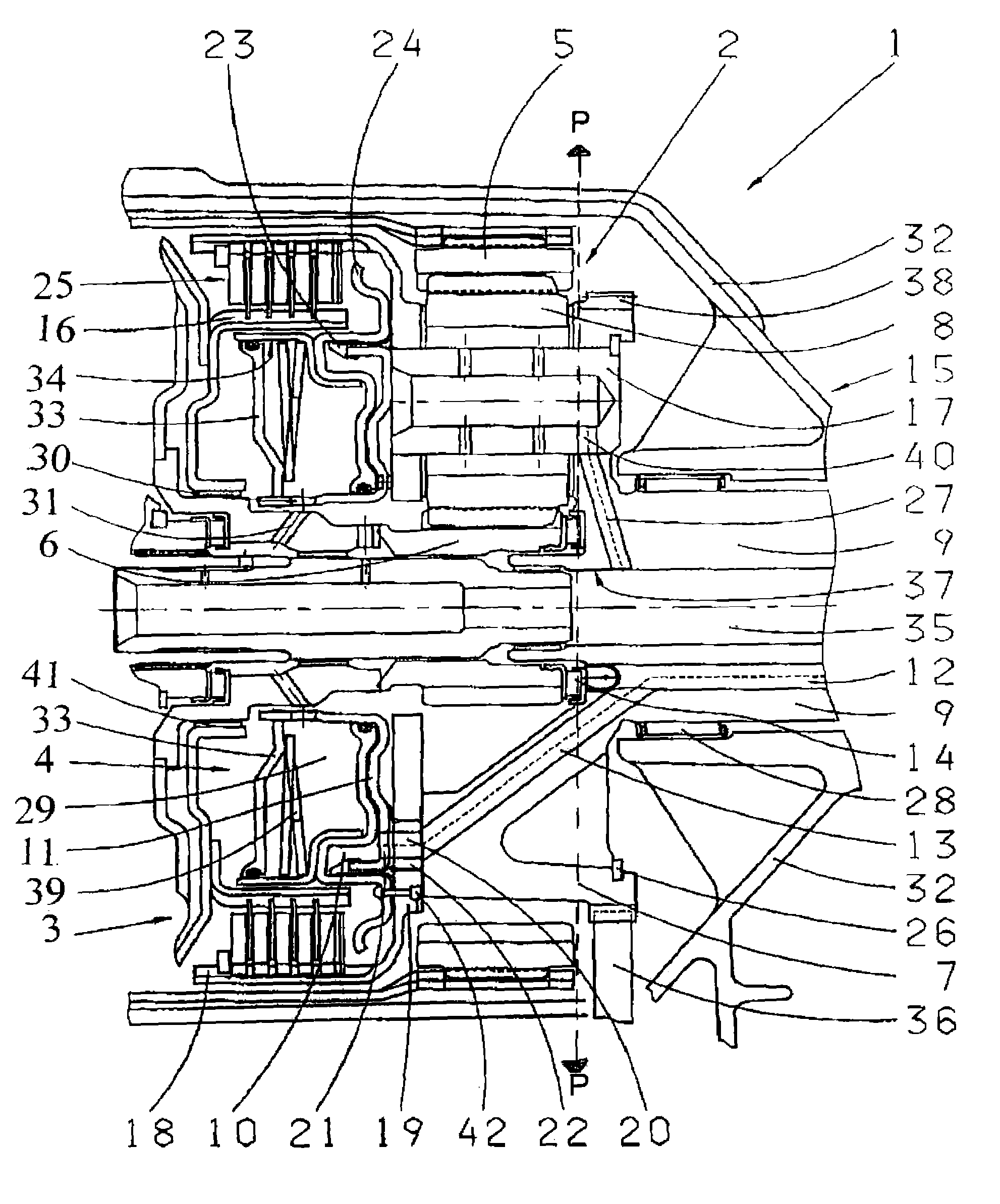

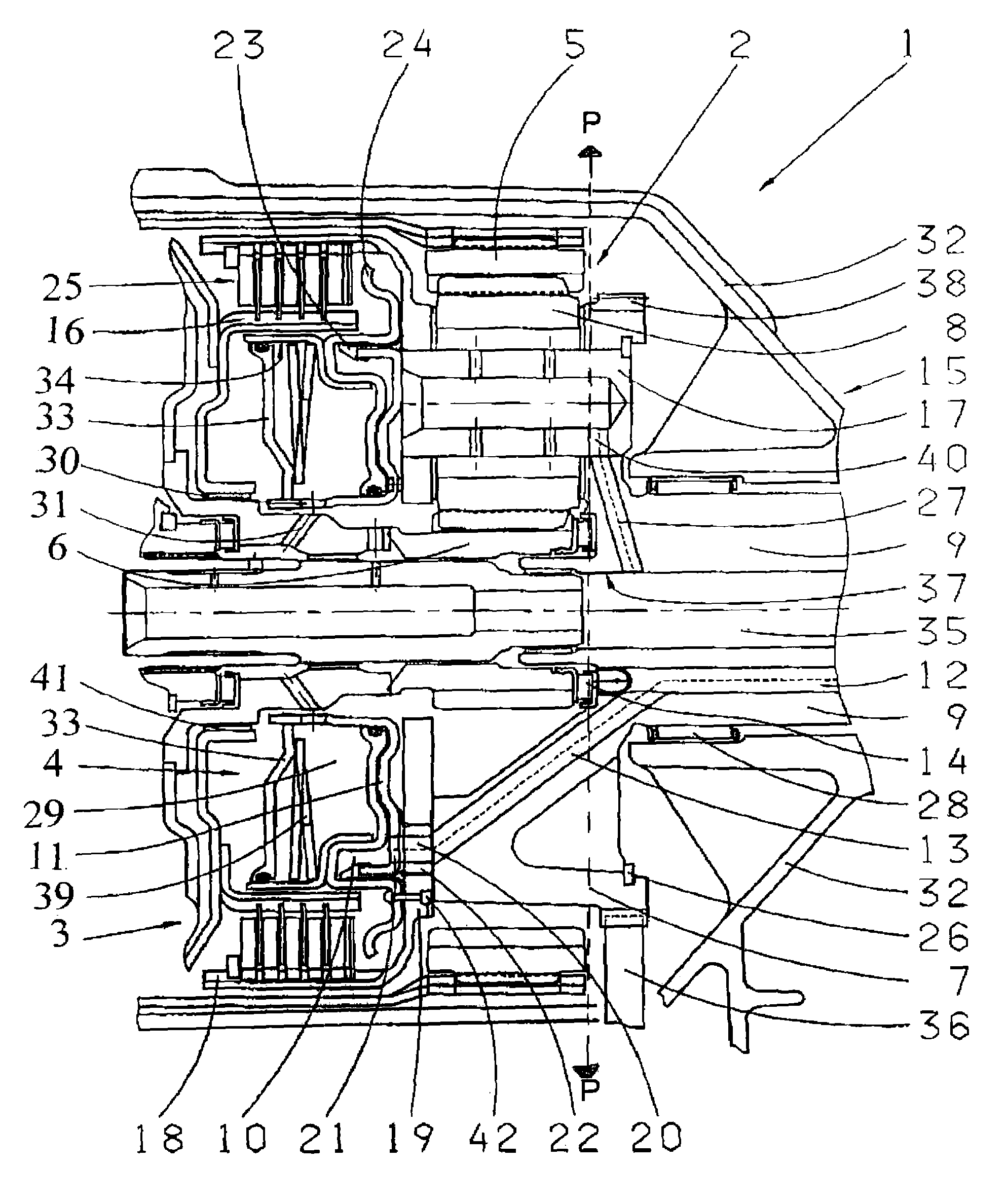

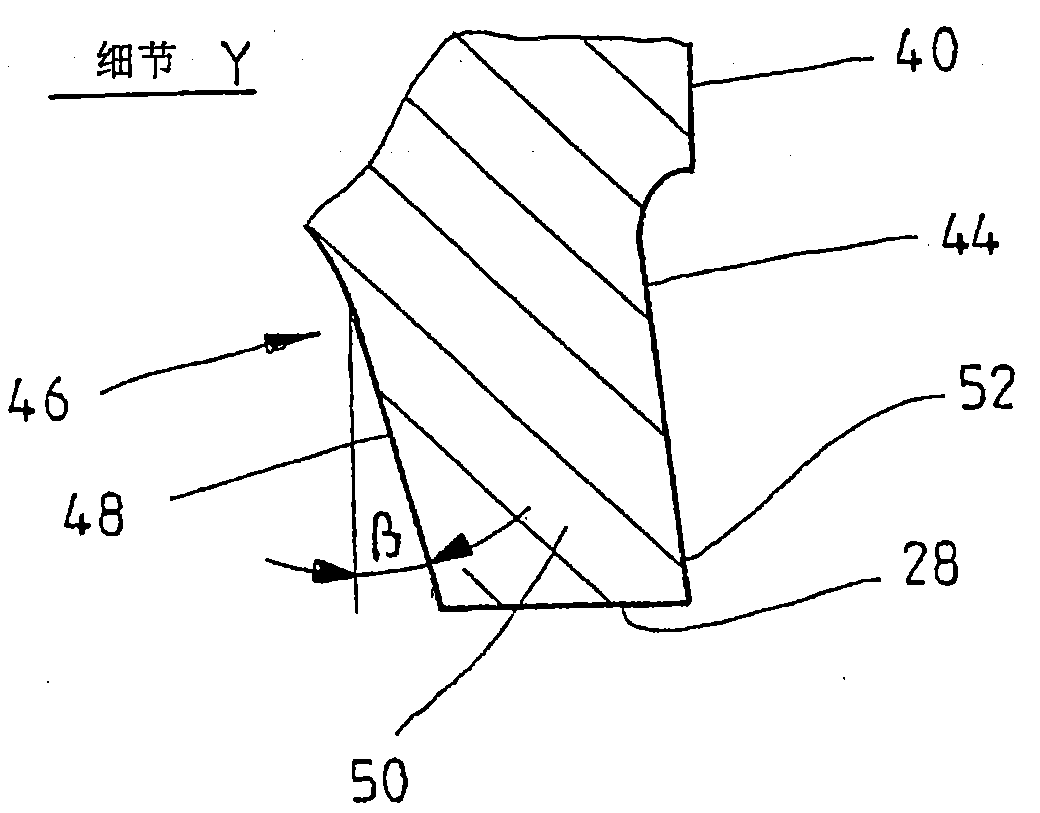

A trailer hitch for a motor vehicle includes a towbar (2) having an arm (1) and a ball cup (3) provided with an opening and with a ball pivot (6). The ball pivot (6) has a ball head (4) and a pivot (5) and is mounted with the ball head (4) rotatably and pivotably in the ball cup (3) and passes through an opening (7) and juts out of the ball cup (3). An angle-measuring device having a signal transmitter (17) and two sensors (40, 41) is arranged in the joint unit formed from the ball cup (3) and the ball head (4).

Owner:ZF FRIEDRICHSHAFEN AG

Trailer hitch for a motor vehicle

InactiveUS20060071448A1Less assembly workReduce effortAutomatic initiationsTractor-trailer combinationsEngineeringHead parts

A trailer hitch for a motor vehicle includes a towbar (2) having an arm (1) and a ball cup (3) provided with an opening and with a ball pivot (6). The ball pivot (6) has a ball head (4) and a pivot (5) and is mounted with the ball head (4) rotatably and pivotably in the ball cup (3) and passes through an opening (7) and juts out of the ball cup (3). An angle-measuring device having a signal transmitter (17) and two sensors (40, 41) is arranged in the joint unit formed from the ball cup (3) and the ball head (4).

Owner:ZF FRIEDRICHSHAFEN AG

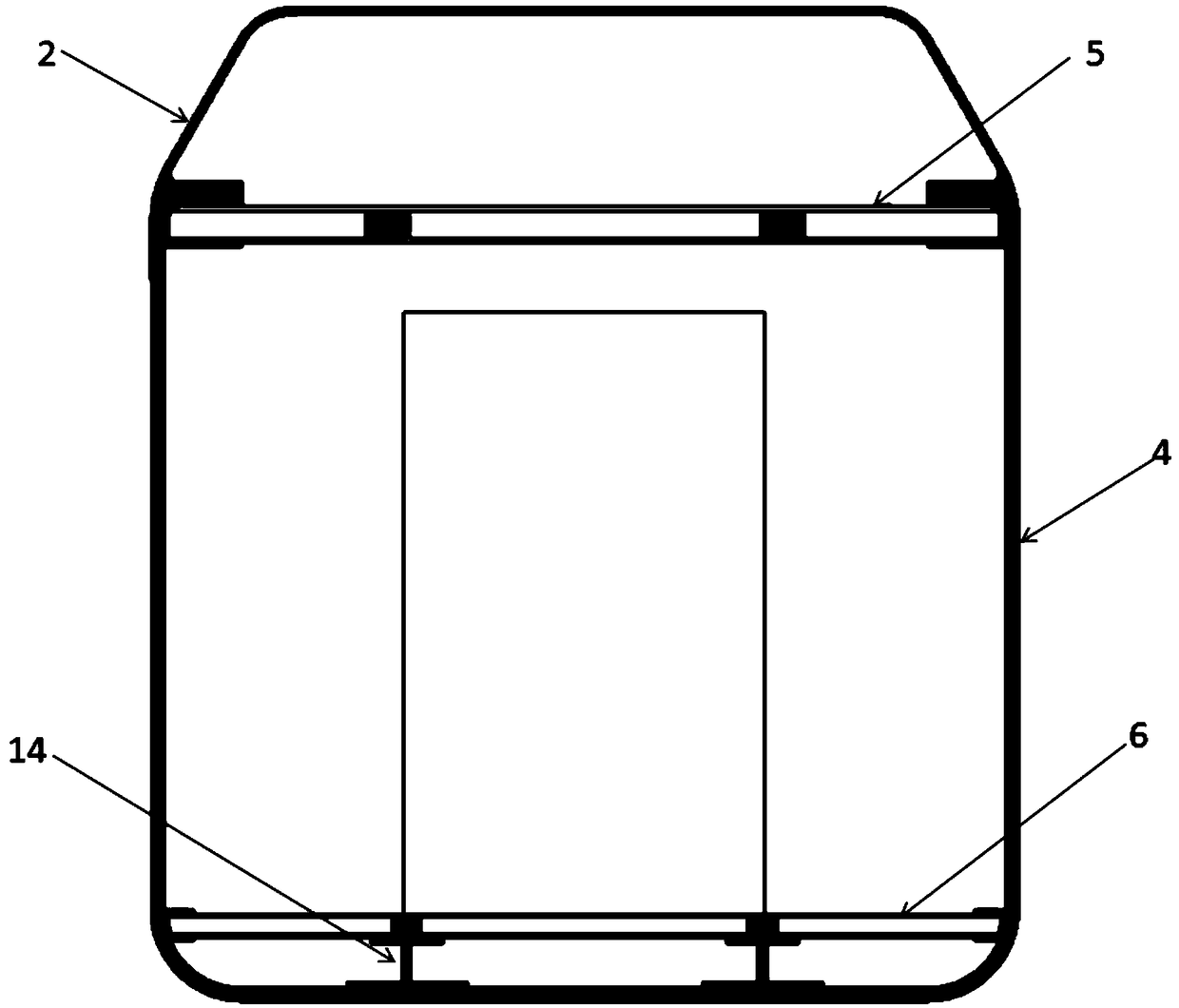

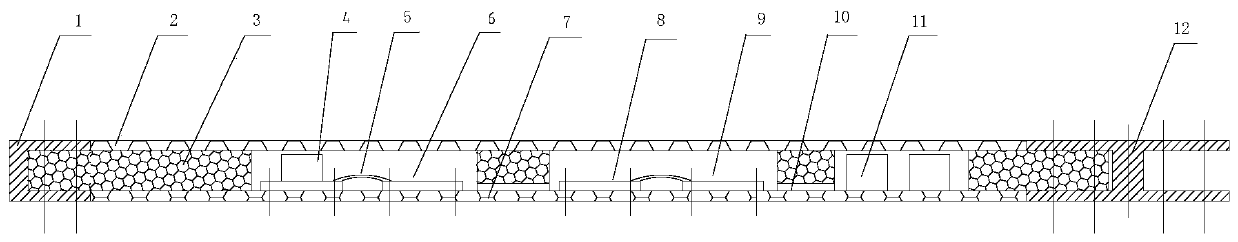

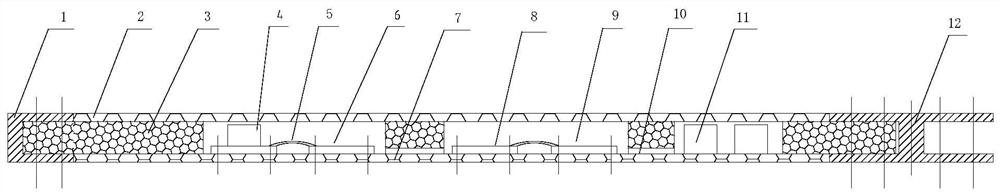

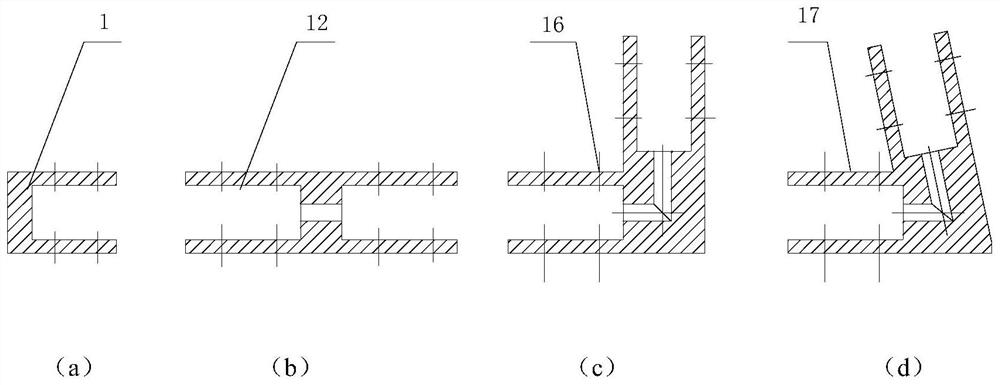

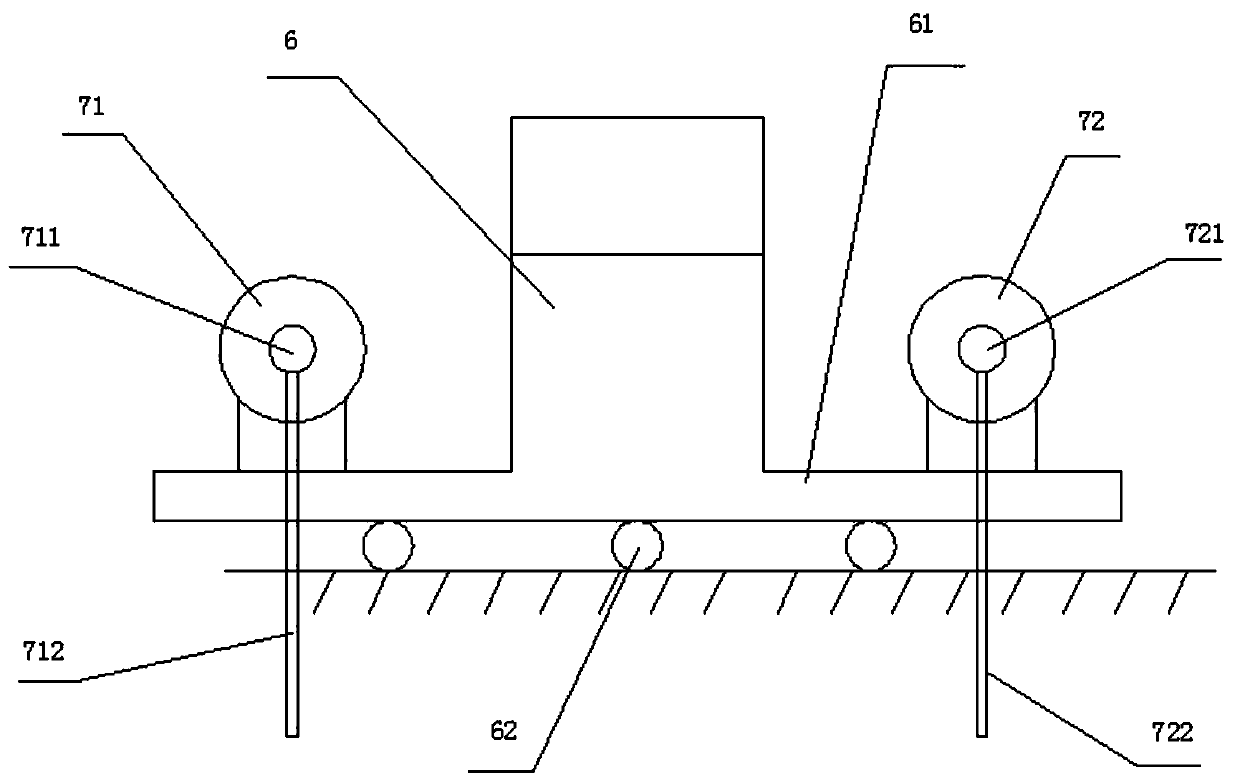

Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

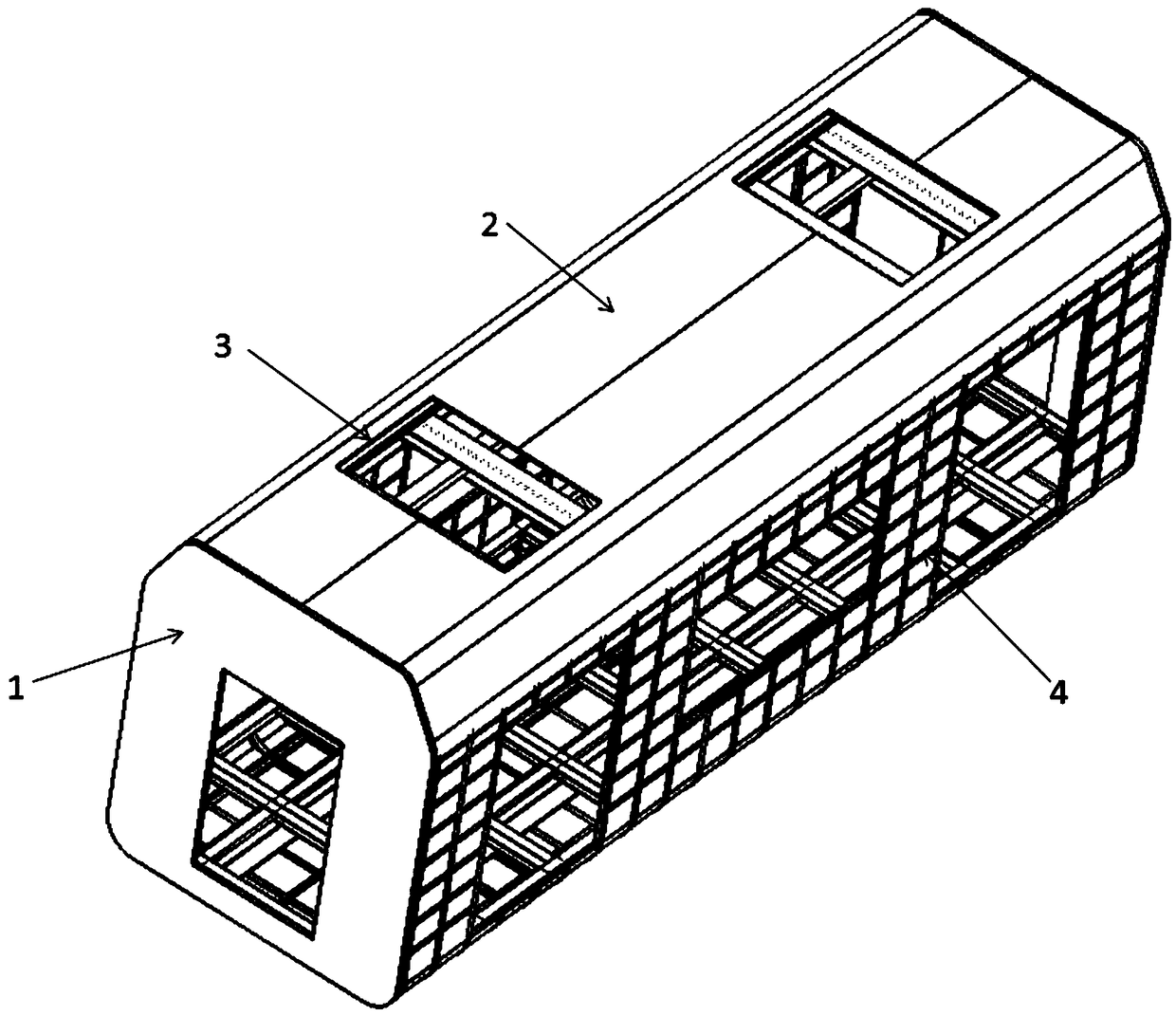

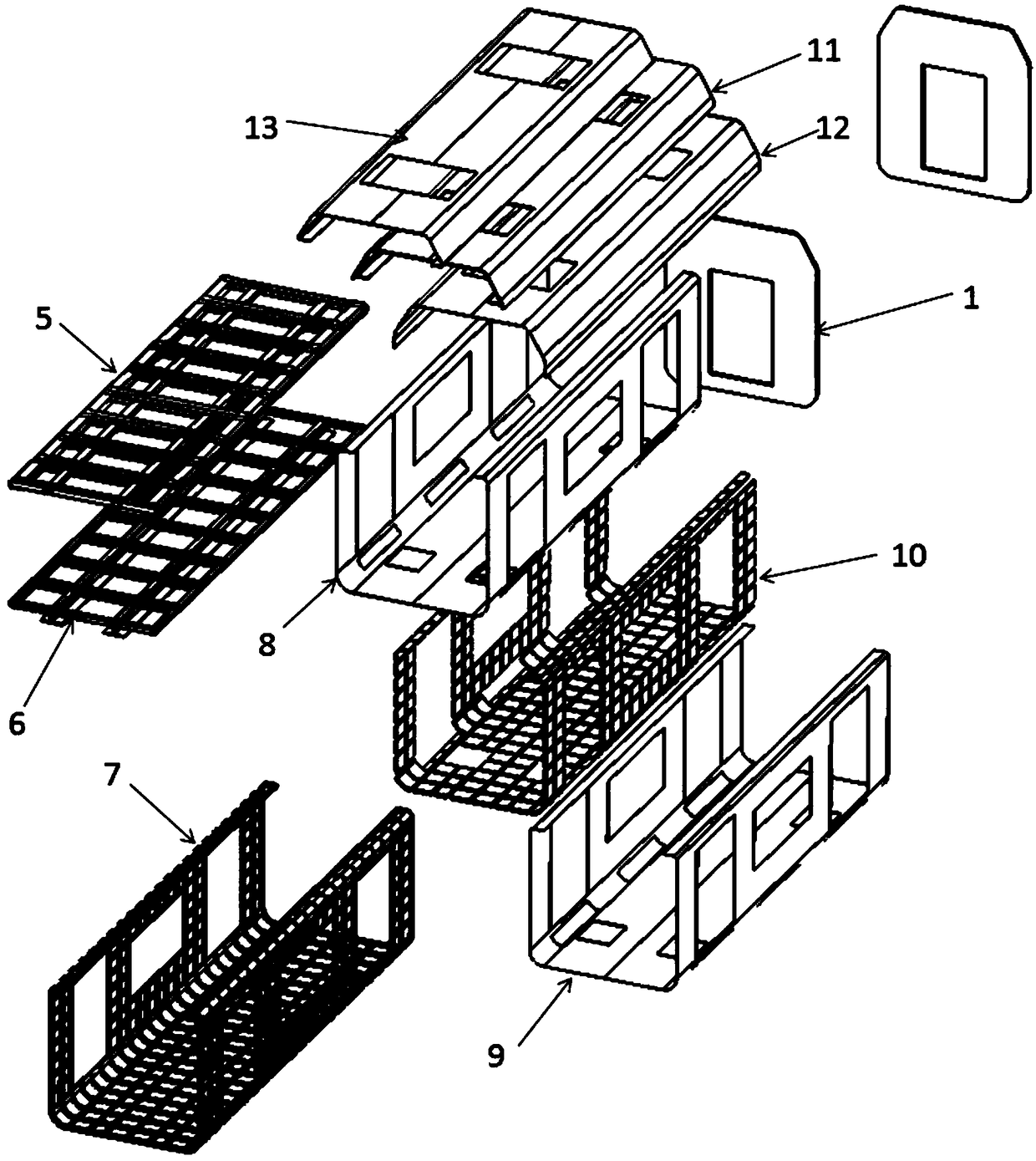

ActiveCN108622123AAchieve lightweightIncrease stiffnessRailway roofsAxle-box lubricationBogieEngineering

The invention discloses a structure and a manufacturing process of a low-cost carbon fiber composite material sky railway train body, and belongs to the technical field of application of composite materials on rail vehicles. The structure comprises a train body side wall, wherein end walls are assembled and connected to the both ends of the train body side wall; a top frame and a bottom frame arecorrespondingly assembled and connected to the inner top surface and the inner bottom surface of the train body side wall, a ceiling is assembled and connected to the outer top surface of the train body side wall, and a bogie mounting hole is formed in the ceiling; the train body side wall and the end walls both comprise reinforced rib frames, inner skins and outer skins, and grids of the reinforcing rib frames are filled with sandwich foam blocks; the ceiling comprises a sandwich panel, an upper skin and a lower skin, and the top frame, the bottom frame, the reinforcing rib frame, the inner skins, the outer skins, the upper skin and the lower skin are all integrally molded from carbon fiber composite materials; and the inner portions of the reinforcing rib frames are filled with sandwichfoam, and the purpose of satisfying the function and structure of the load bearing mode of a suspension-type train body on the premise of light weight of the train body is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

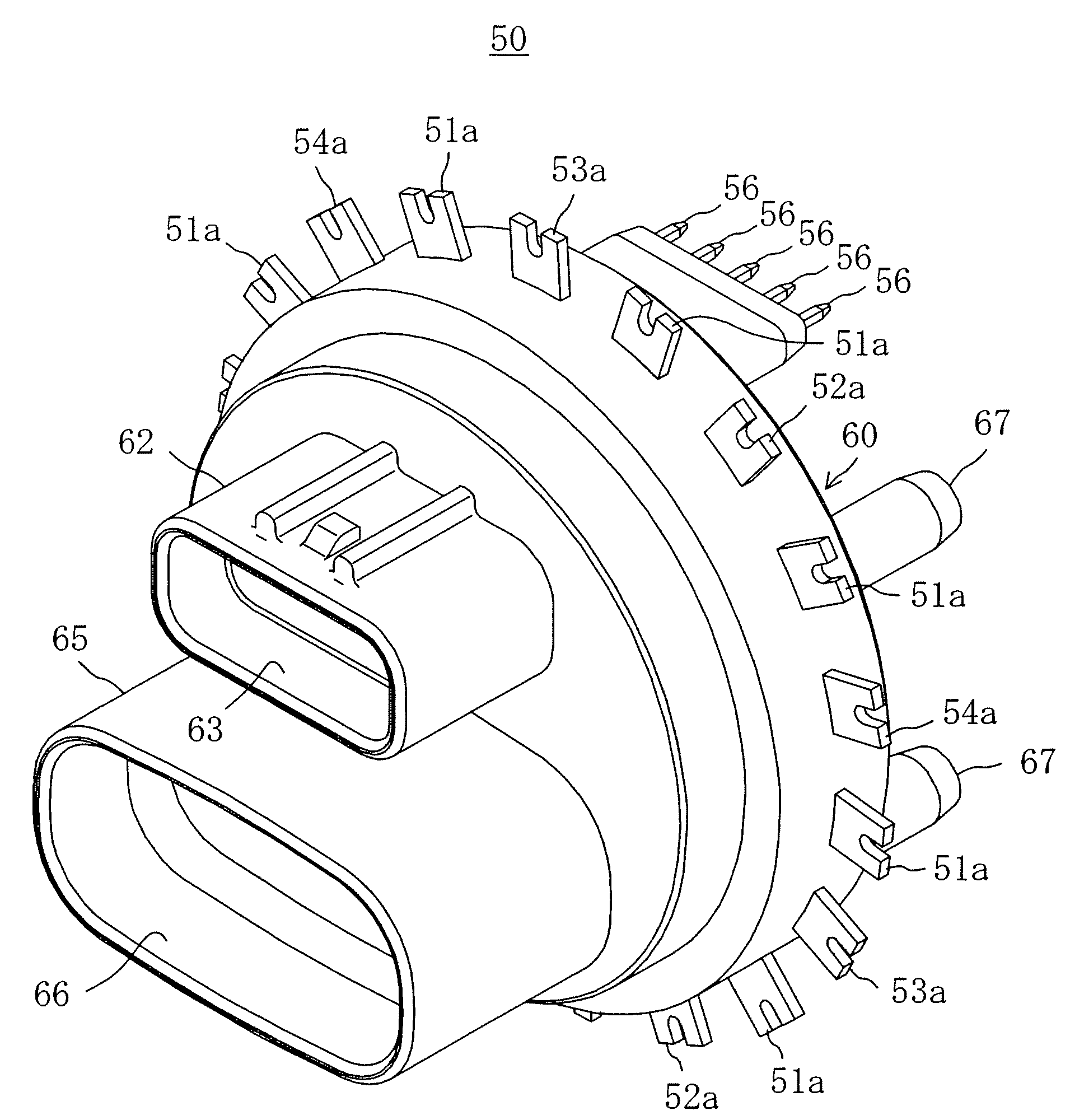

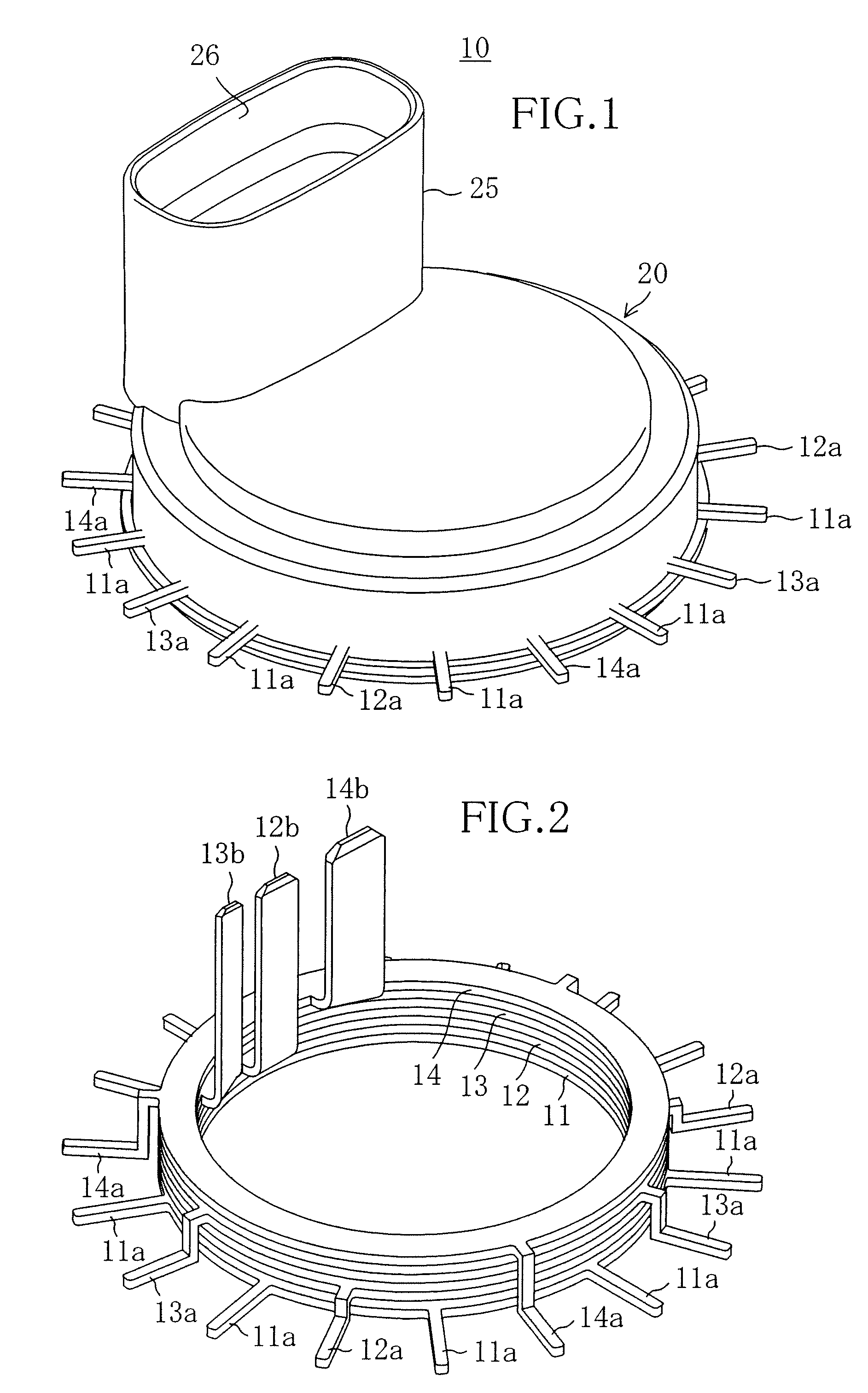

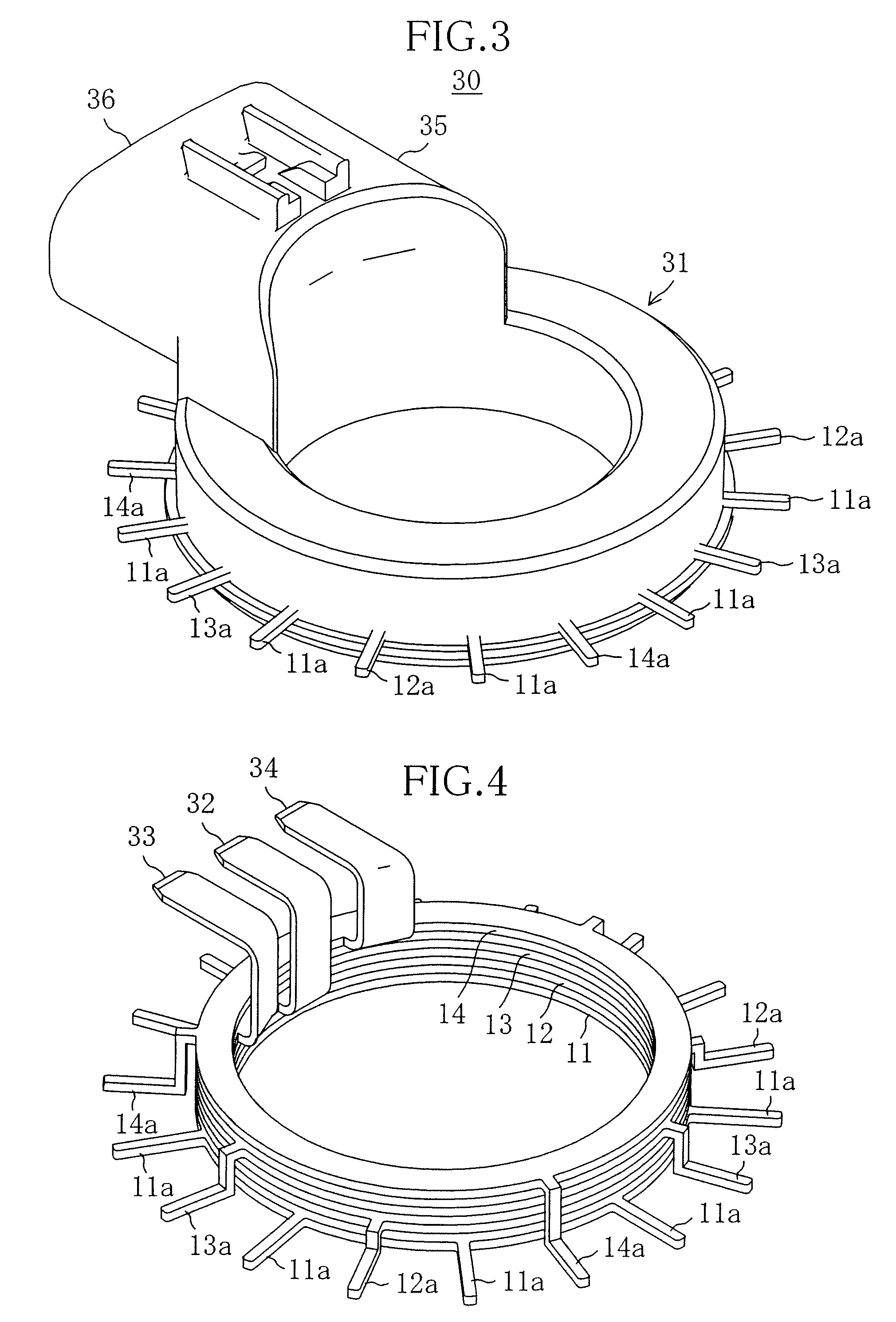

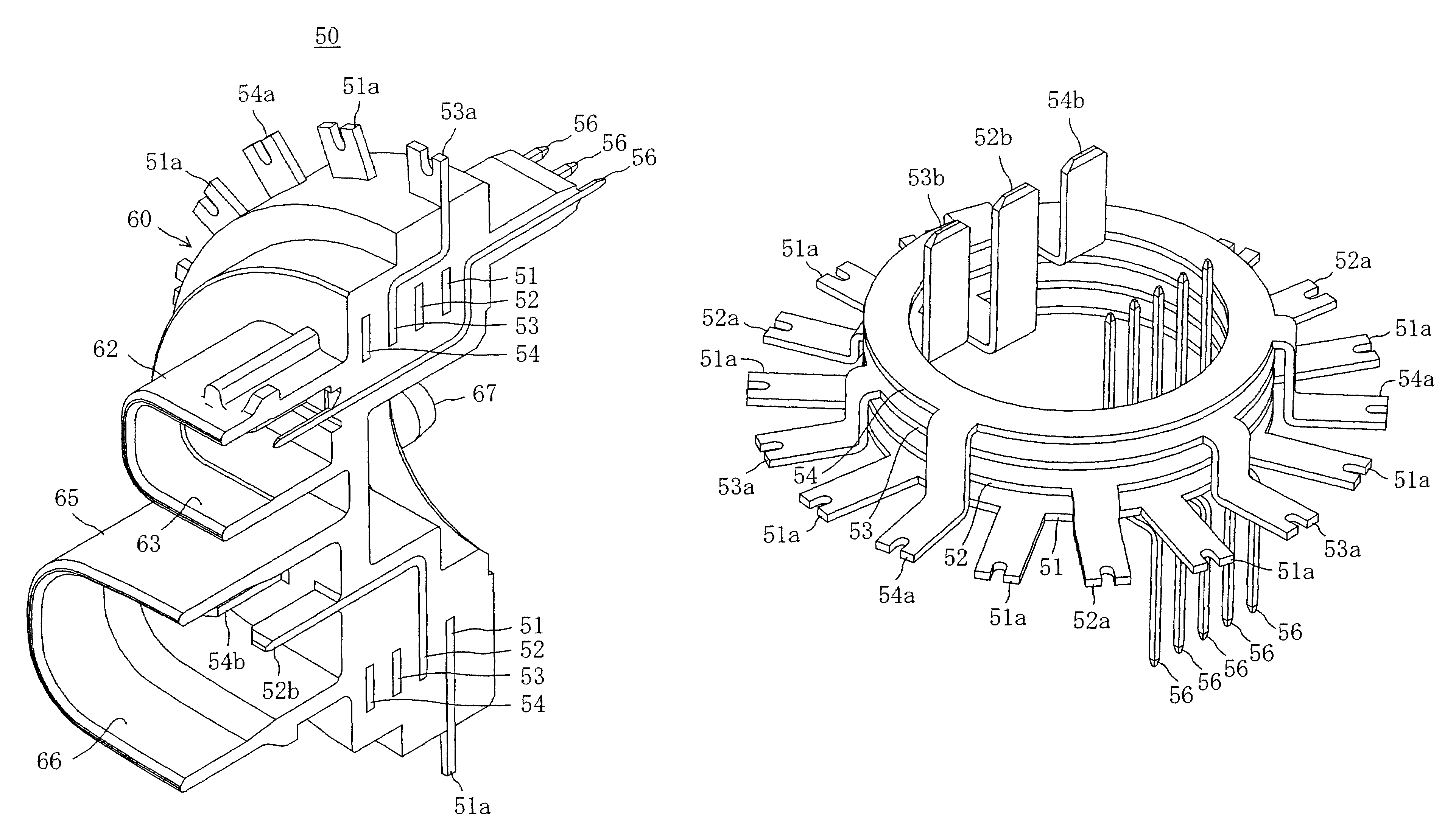

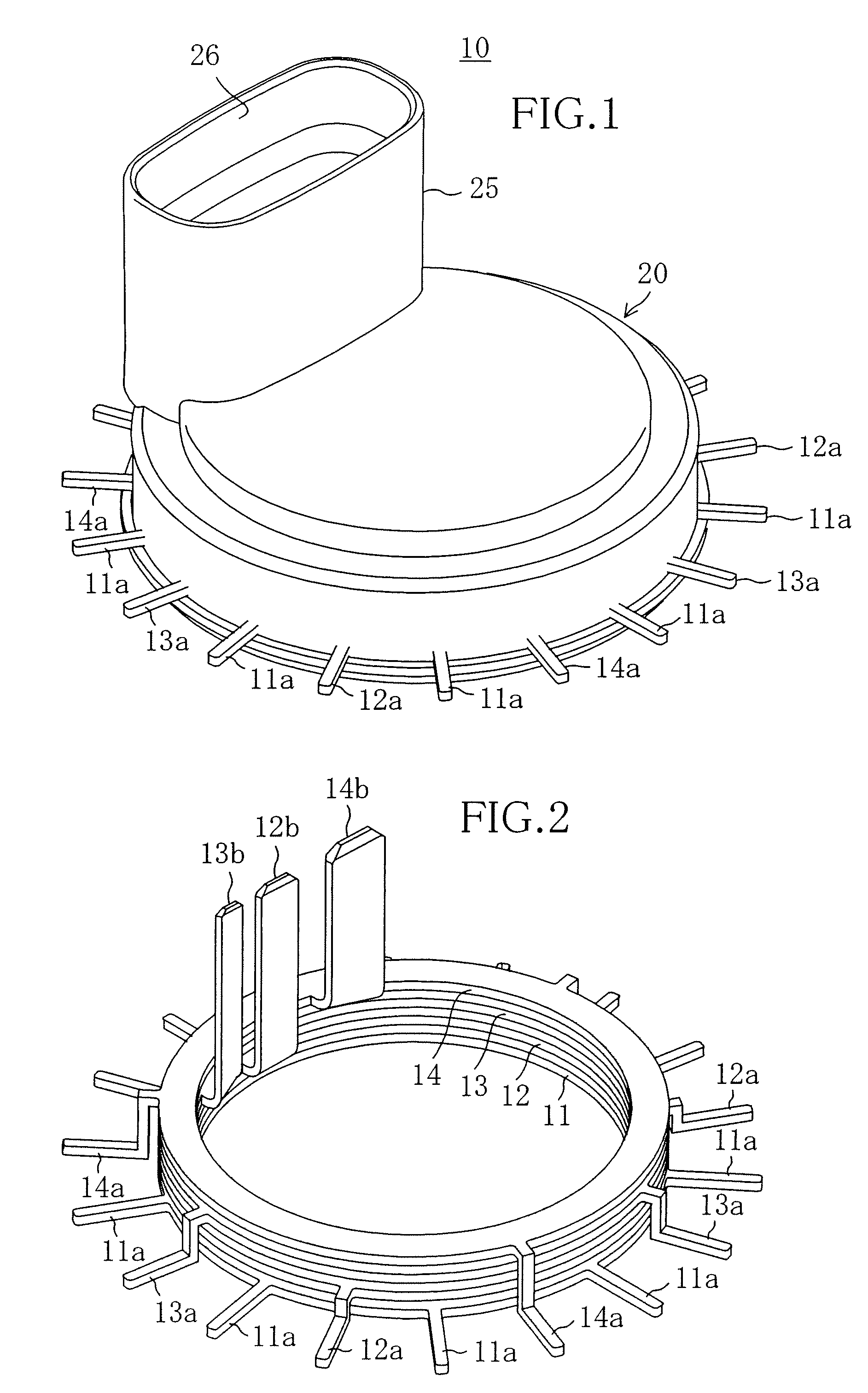

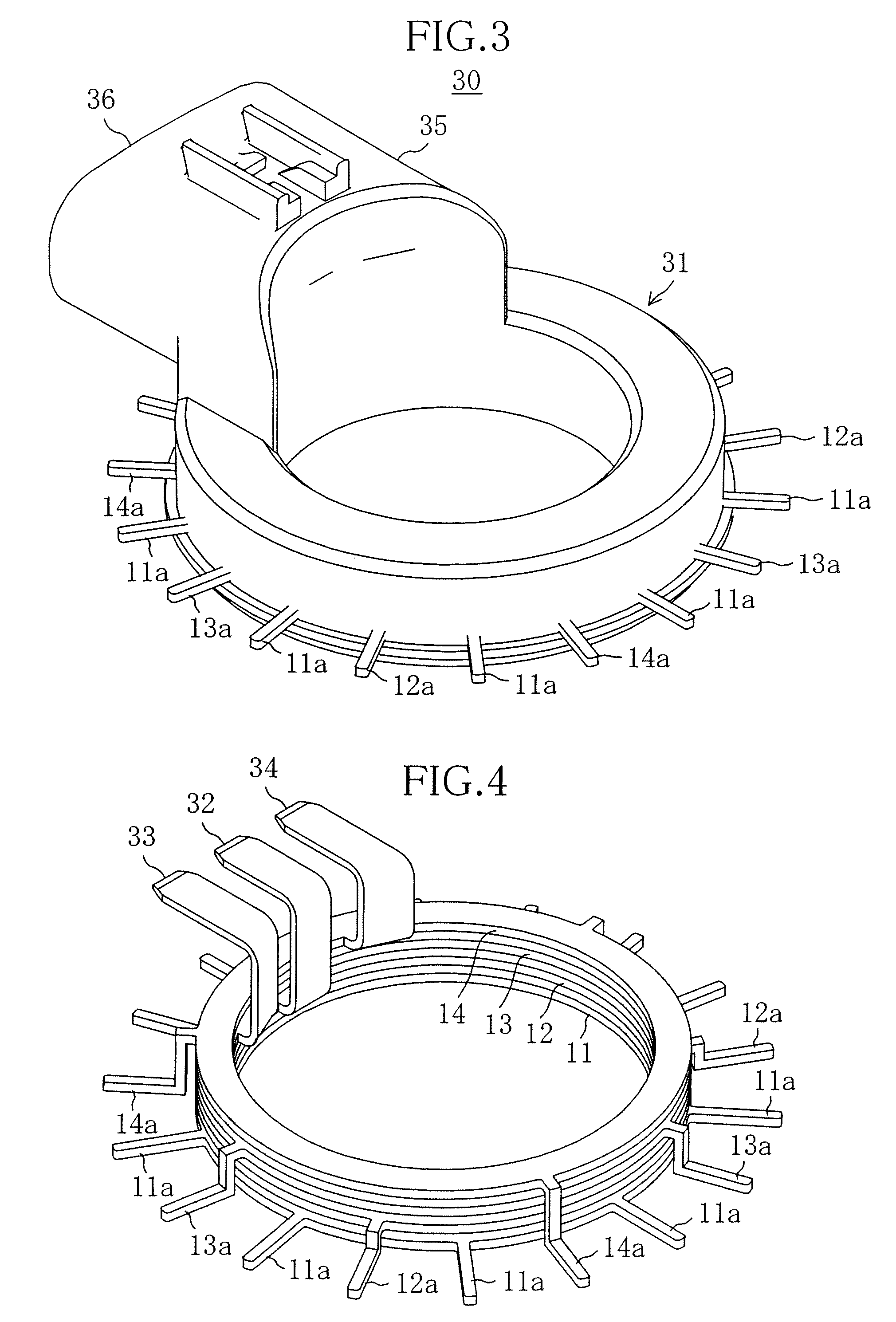

Insulating motor housing

ActiveUS20080150377A1Reduce the burden onIncrease supplyWindingsMagnetic circuit characterised by insulating materialsEngineeringElectrical and Electronics engineering

Owner:MITSUBISHI ELECTRIC CORP +2

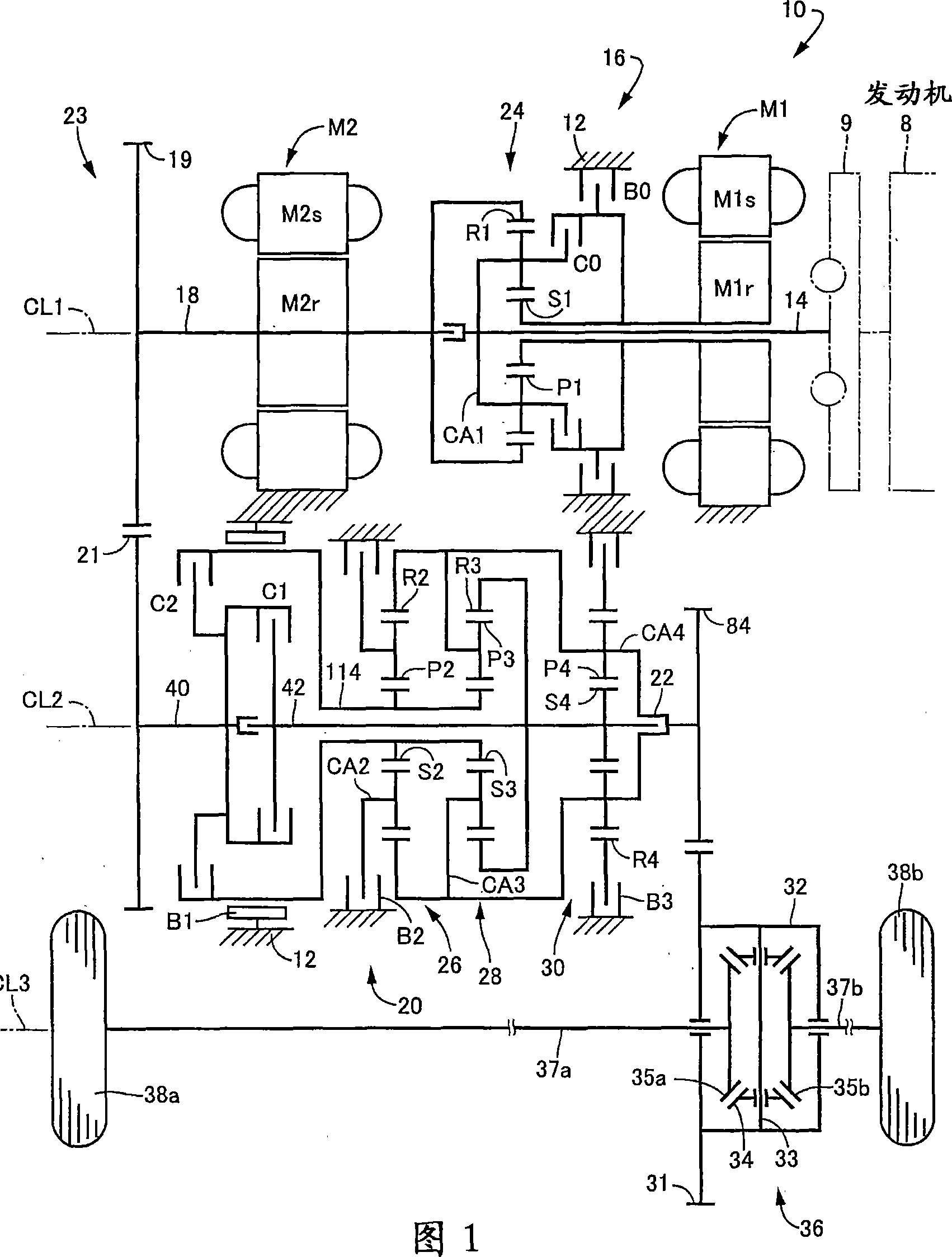

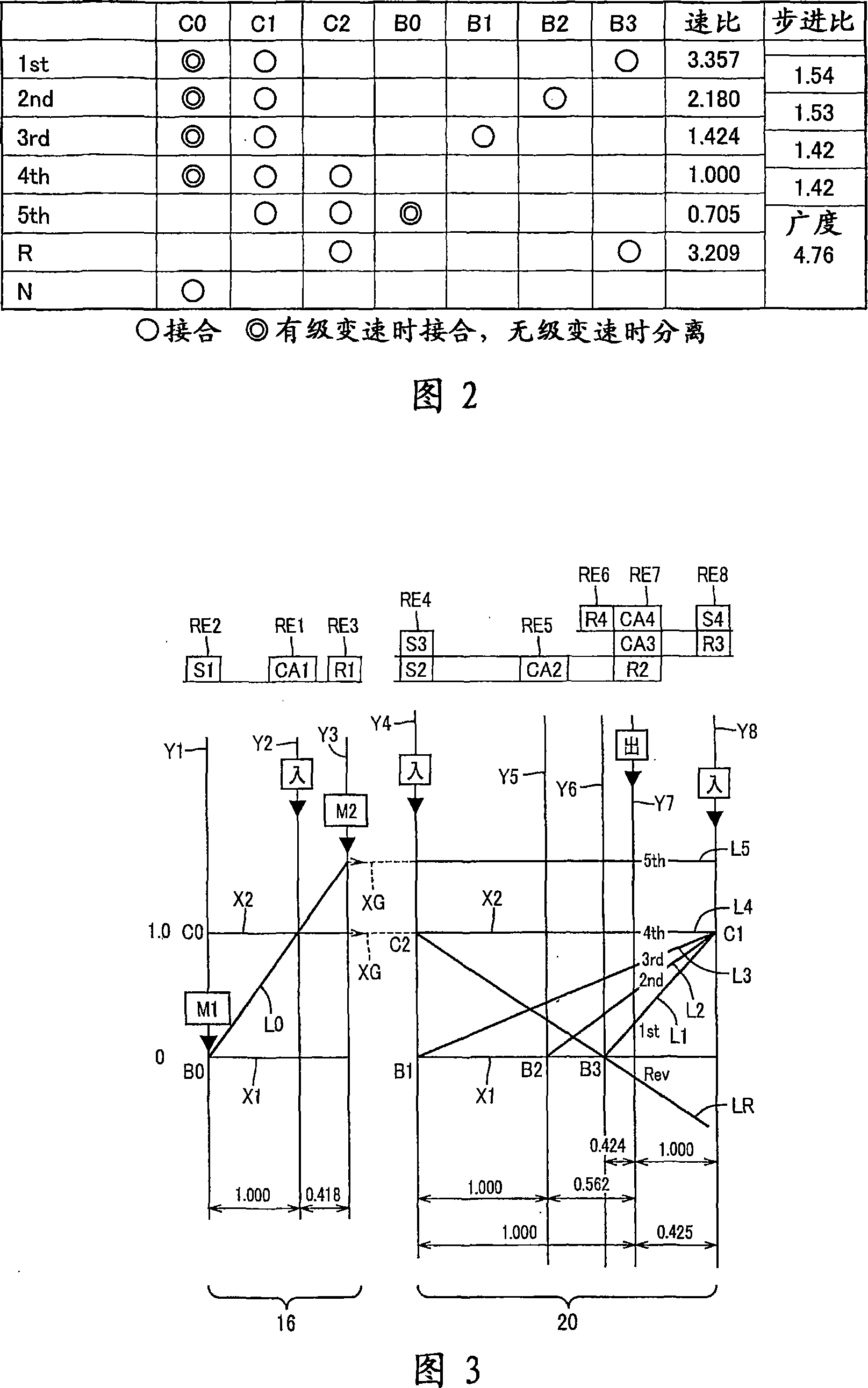

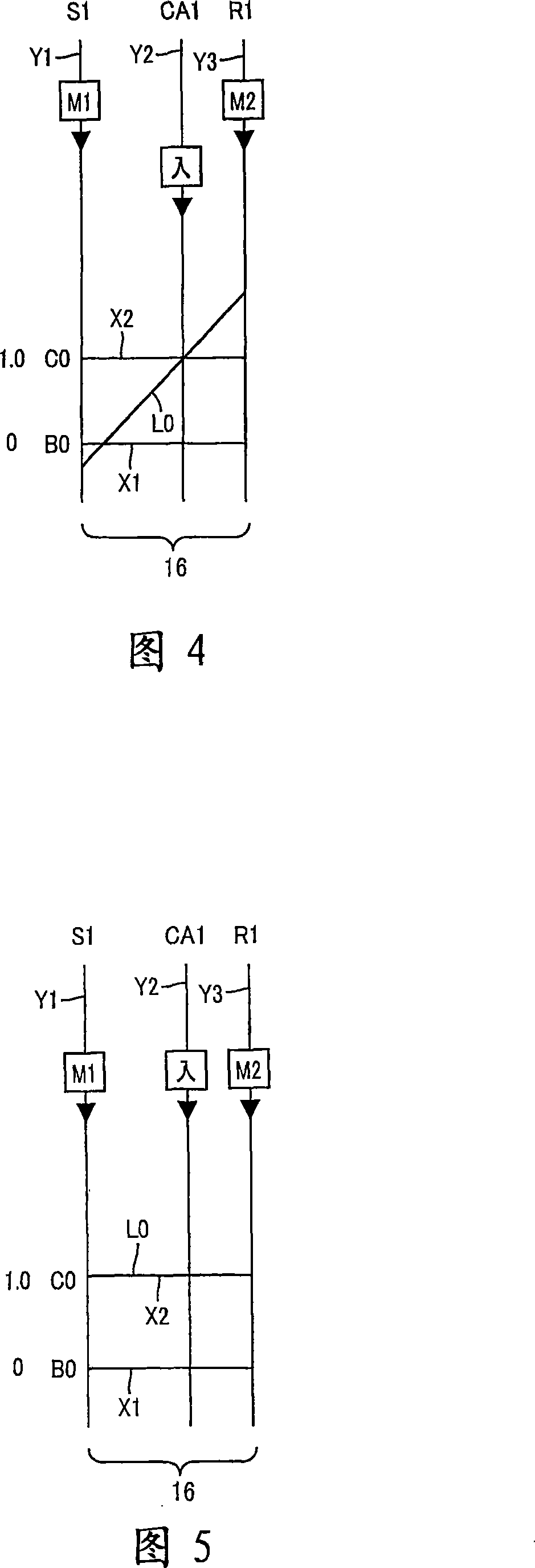

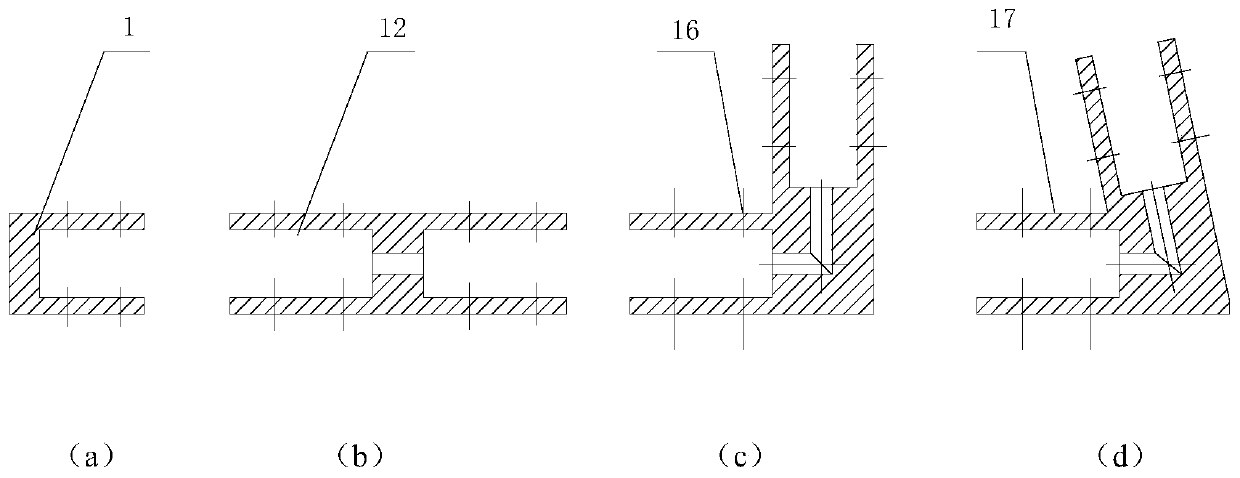

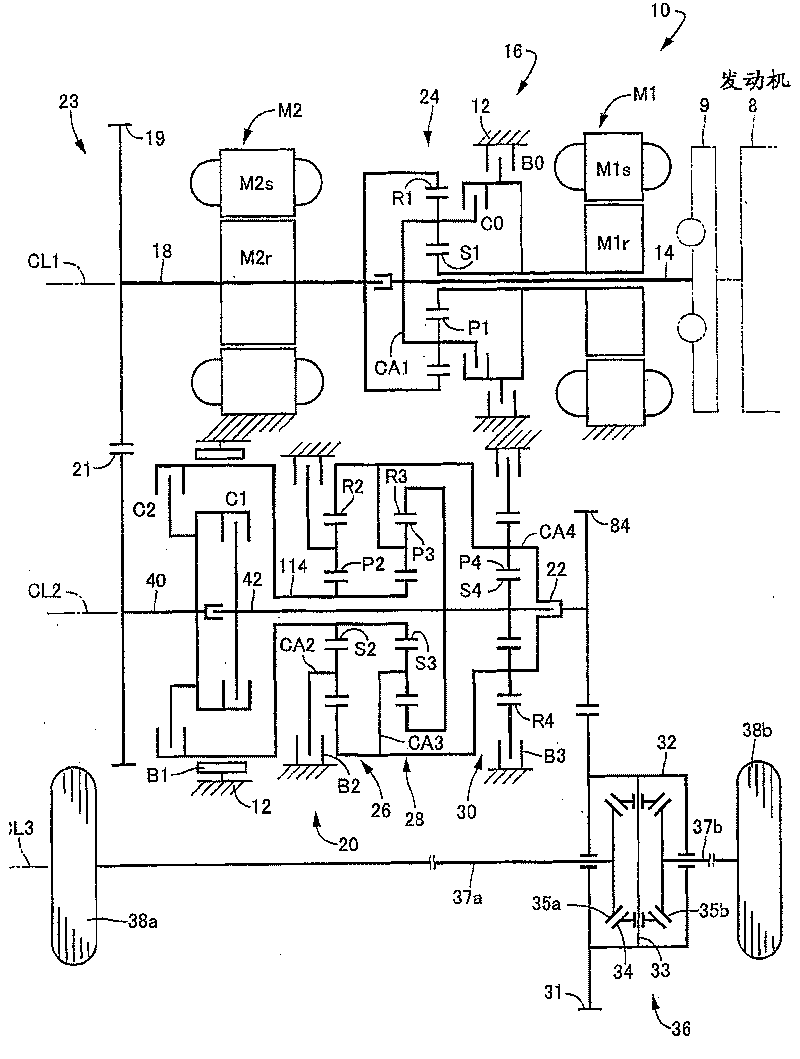

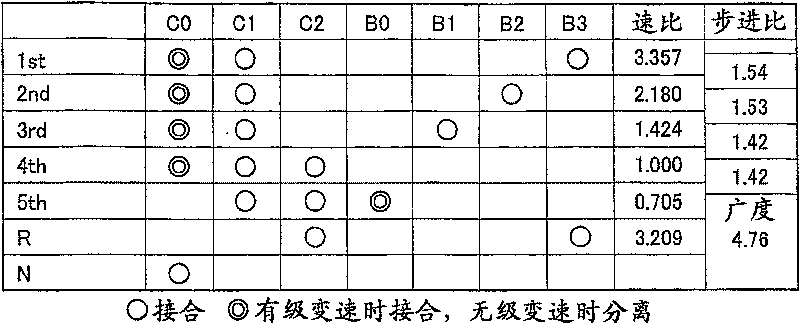

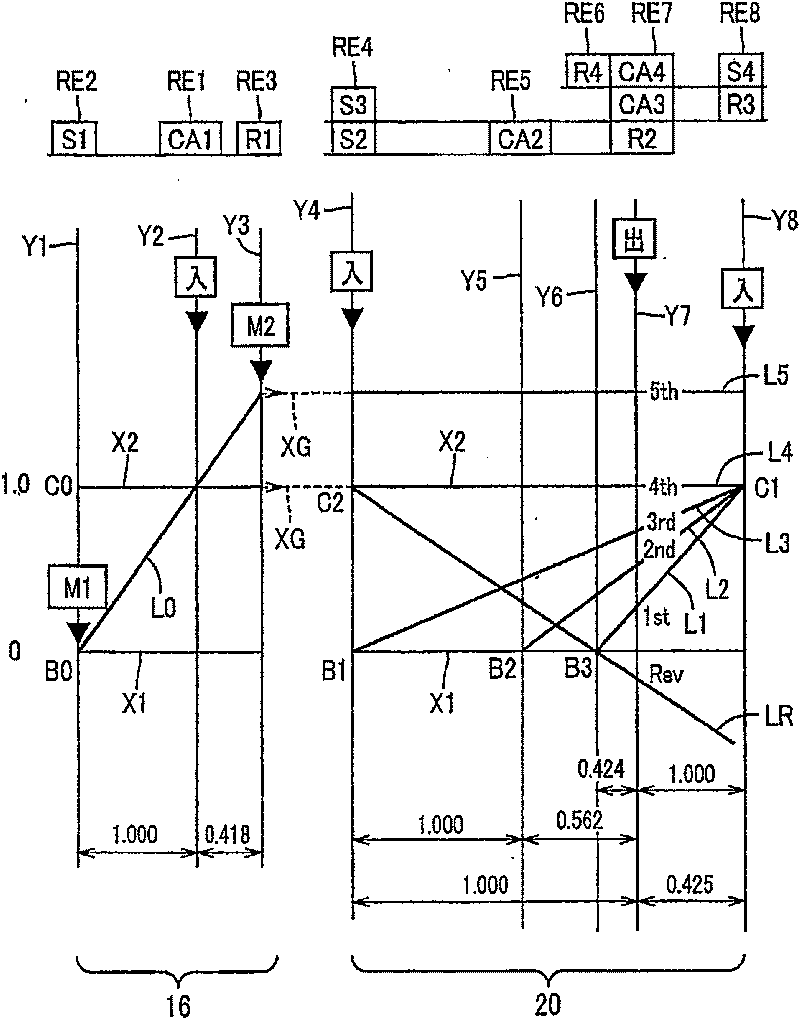

Drive device for vehicle and method of assembling the same

InactiveCN101203396AReduce axial sizeEasy to assembleGearboxesToothed gearingsAutomatic transmissionMedial axis

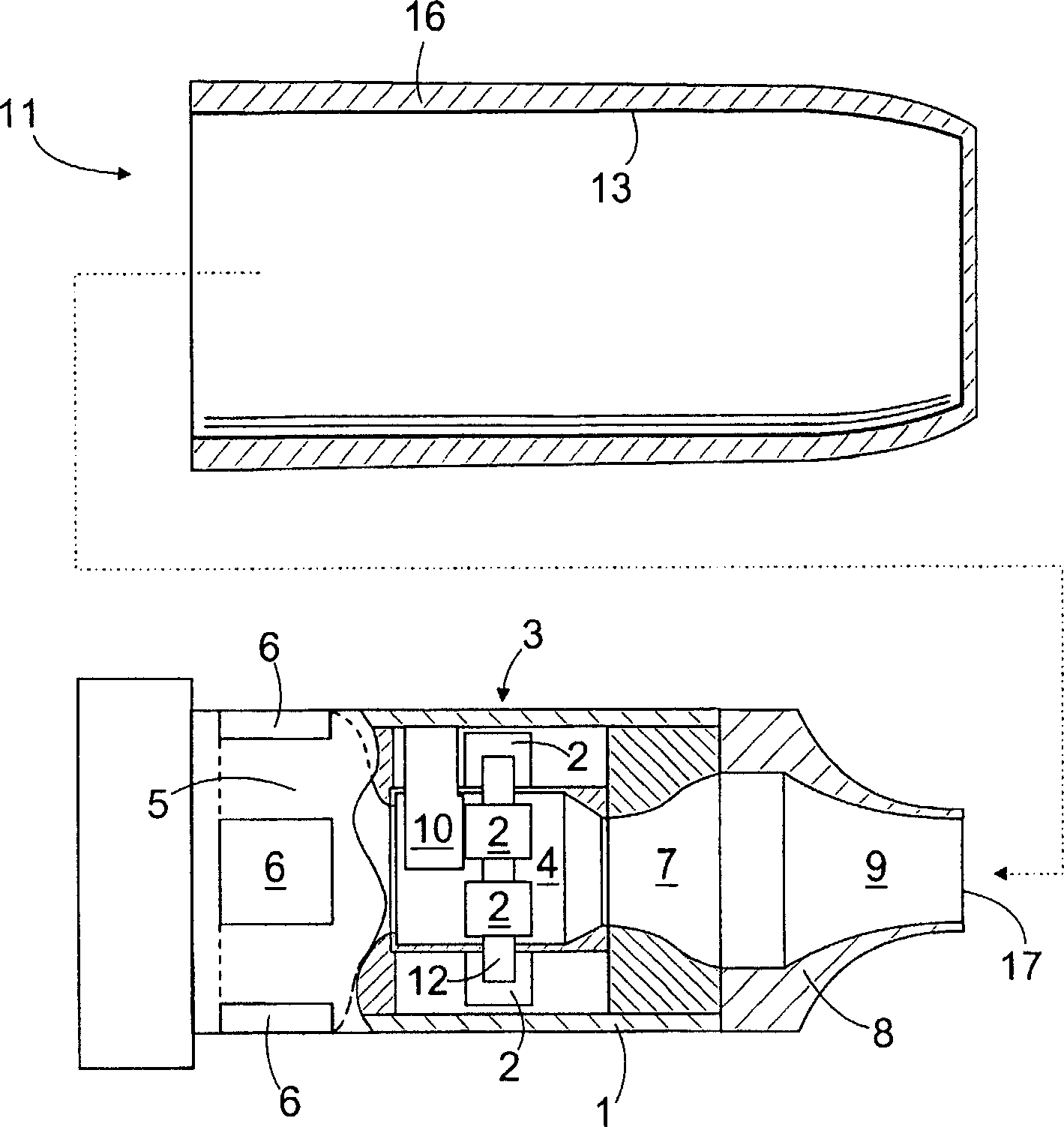

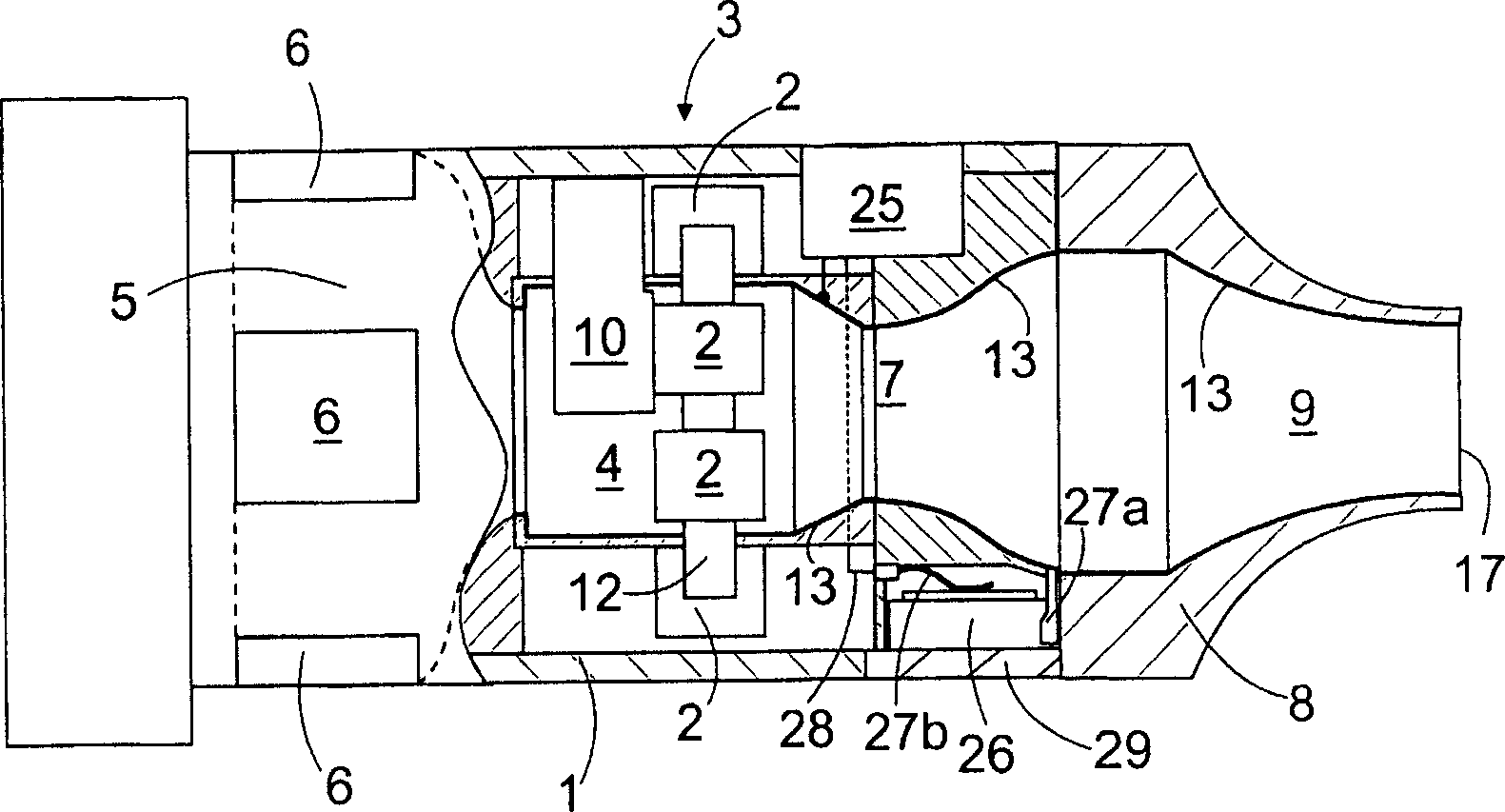

A drive device for a vehicle having excellent assemblability. A first motor (M1), a power distribution mechanism (16), and a second motor (M2) are disposed on a first axis CL1, and an automatic transmission part (20) is disposed on a second axis CL2 parallel with the first axis CL1. A transmission member (18) positioned on the first axis CL1 at the opposite side end of an input rotating member (14) is connected to a first countershaft (40) positioned on the second axis CL2 at the opposite side end of the input rotating member (14) through a connection device (23) so that a power can be transmitted to each other. Since the axial dimensions of the first motor (M1), the power distribution mechanism (16), and the second motor (M2) installed on the first axis CL1 are approximately equal to theaxial dimension of the automatic transmission part (20) installed on the second axis CL2, these axial dimensions can be suitably reduced. Since a housing (12) is divided into four parts, i.e., a firstcase part (12a), a second case part (12b), a third case part (12c), and a fourth case part (12d), the housing can be easily assembled.

Owner:TOYOTA JIDOSHA KK

Insulating motor housing

ActiveUS7579732B2Increase the number ofLow production costWindingsMagnetic circuit characterised by insulating materialsElectrical and Electronics engineeringEngineering

Owner:MITSUBISHI ELECTRIC CORP +2

Automatic gearbox

ActiveUS20100222173A1Relieve stressLess assembly workGear lubrication/coolingToothed gearingsAutomatic transmissionDrive shaft

The present invention relates to an automatic transmission (1) comprising at least one planetary stage (2) and at least one gear shifting element (3), wherein this gear shifting element (3) is disposed axially directly adjacent to the planetary stage (2), wherein a piston-cylinder arrangement (4) is provided for actuating the gear shifting element (3), wherein the planetary stage (2) comprises an internal gear (5), a sun gear (6) and a planet carrier (7), on which planet gears (8) are rotatably mounted, wherein the planet carrier (7) is connected non-rotatably to a transmission shaft (9), and wherein the pressure medium can be fed to the pressure chamber (10) of the cylinder (11) of the piston-cylinder arrangement (4) through a bore (12, 13) in the transmission shaft (9) and in the planet carrier (7).

Owner:ZF FRIEDRICHSHAFEN AG

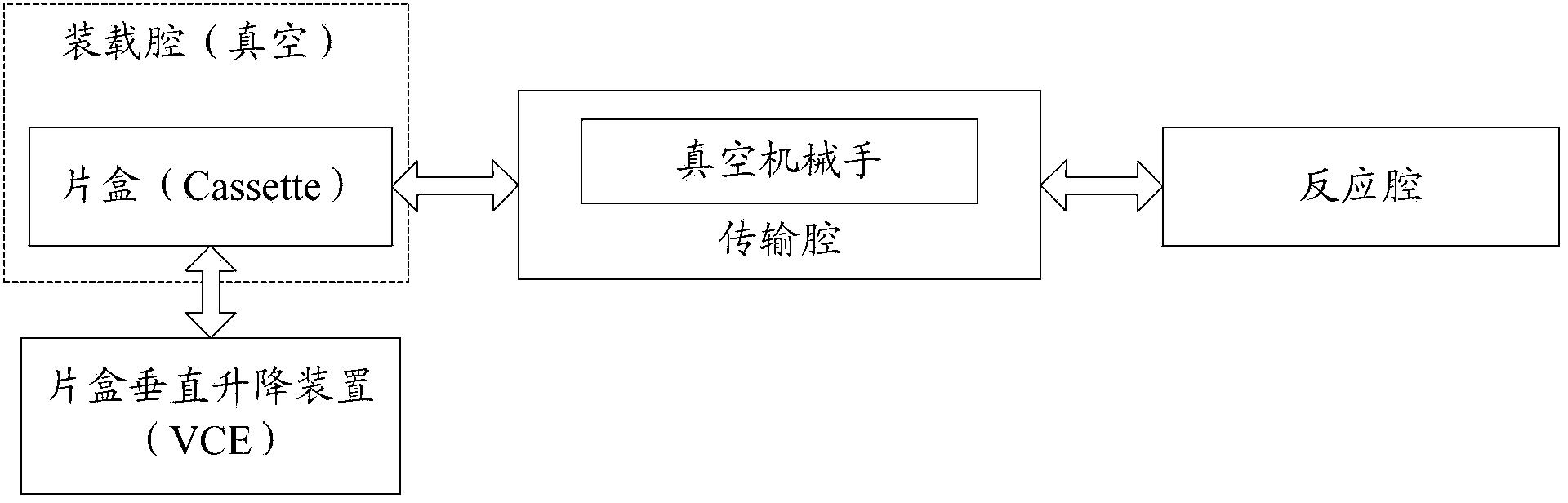

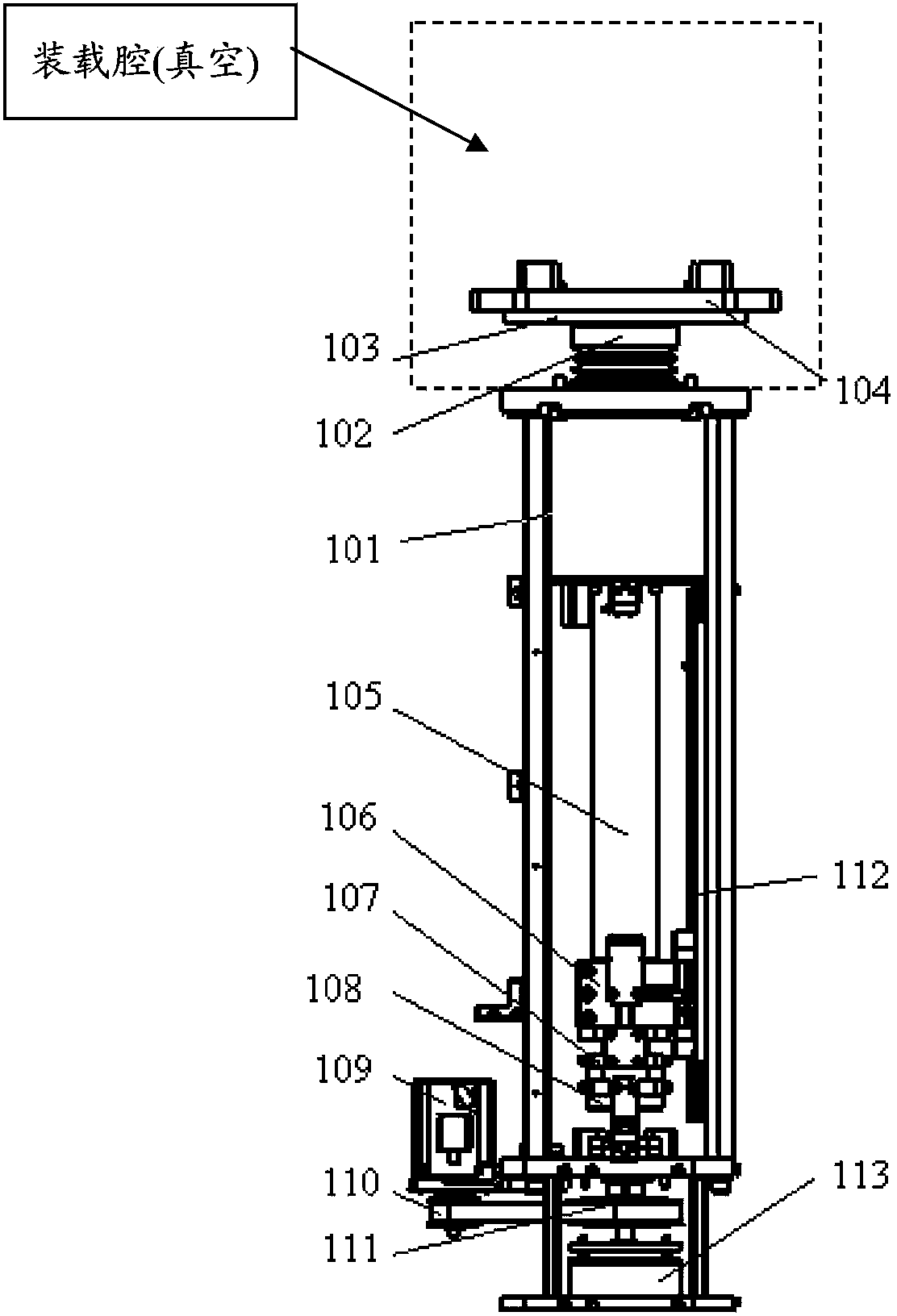

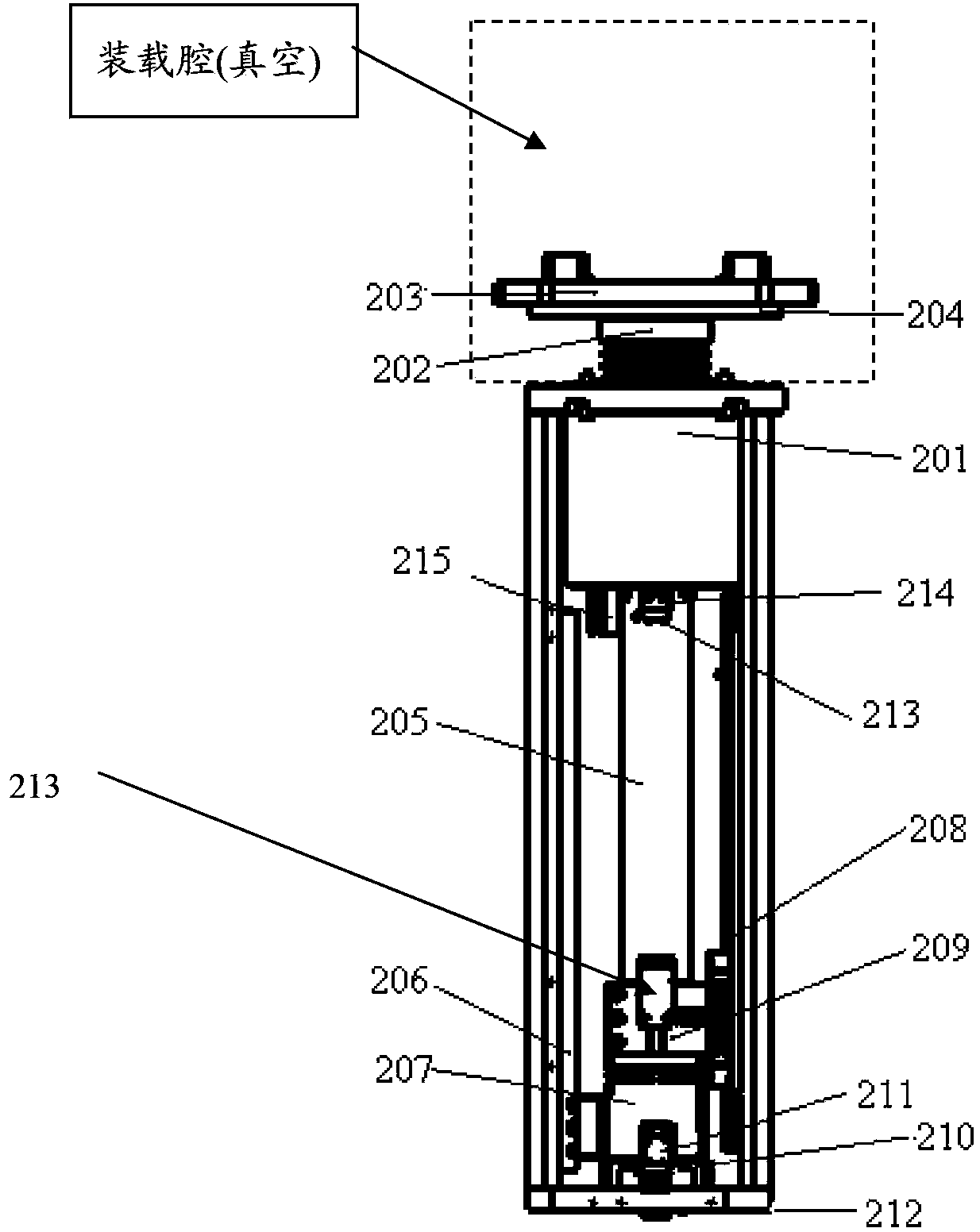

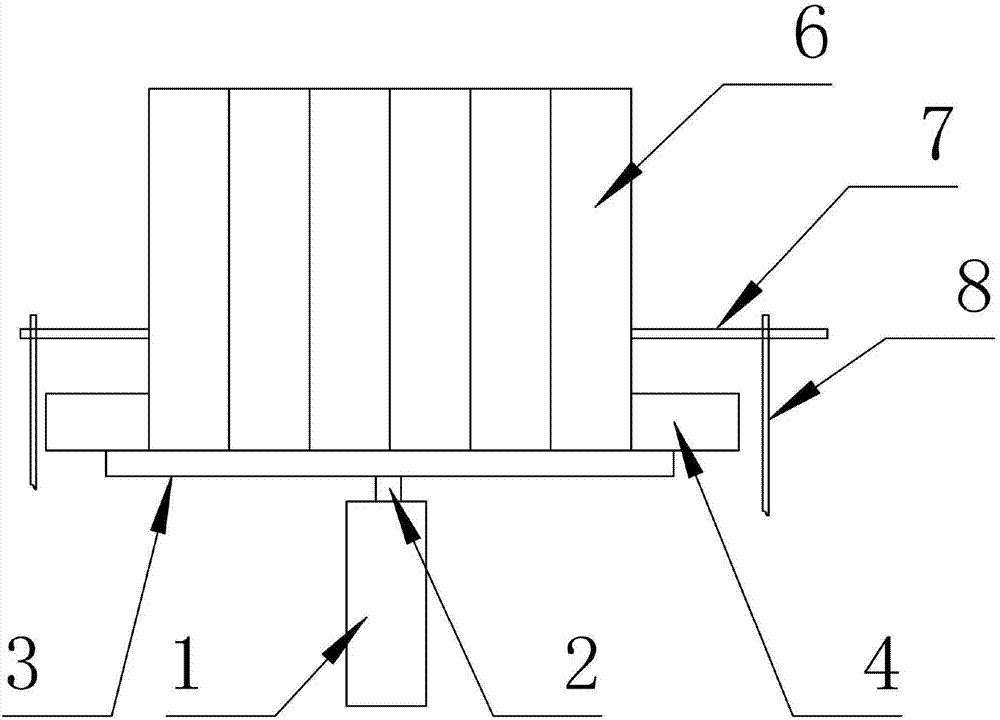

Vertical lifting device for cassette

InactiveCN104140062ASolution to short lifeSimple organizationLifting framesConveyor partsLinear motionEngineering

The invention provides a vertical lifting device for a cassette. The vertical lifting device for the cassette comprises an installation flange, a lifting corrugated tube, a lifting sleeve, a connecting element and a vertically-installed linear motor, wherein the upper end of the lifting corrugated tube is connected with the cassette, and the lower end of the lifting corrugated tube is connected with the installation flange; the upper end of the lifting sleeve is connected with the lifting corrugated tube, the lower end of the lifting sleeve is connected with the connecting element, and the linear motor is connected with the connecting element; the linear motor is used for driving the connecting element to carry out a linear motion along a vertical direction, the connecting element is used for pushing the lifting sleeve to drive the lifting corrugated tube to move, and then drive the cassette to ascend or descend along the vertical direction. On one hand, the vertical lifting device for the cassette provided by the invention is capable of simplifying the mechanism of the drive portion of the whole lifting device, and convenient to detach, install and maintain; on the other hand, the vertical lifting device for the cassette provided by the invention is capable of eliminating various location errors brought by intermediate links, and improving the location accuracy thereof.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Automatic gearbox

ActiveUS7931556B2Less assembly workGear lubrication/coolingToothed gearingsAutomatic transmissionMechanical engineering

The present invention relates to an automatic transmission (1) comprising at least one planetary stage (2) and at least one gear shifting element (3), wherein this gear shifting element (3) is disposed axially directly adjacent to the planetary stage (2), wherein a piston-cylinder arrangement (4) is provided for actuating the gear shifting element (3), wherein the planetary stage (2) comprises an internal gear (5), a sun gear (6) and a planet carrier (7), on which planet gears (8) are rotatably mounted, wherein the planet carrier (7) is connected non-rotatably to a transmission shaft (9), and wherein the pressure medium can be fed to the pressure chamber (10) of the cylinder (11) of the piston-cylinder arrangement (4) through a bore (12, 13) in the transmission shaft (9) and in the planet carrier (7).

Owner:ZF FRIEDRICHSHAFEN AG

Inhalator and method of manufacturing same

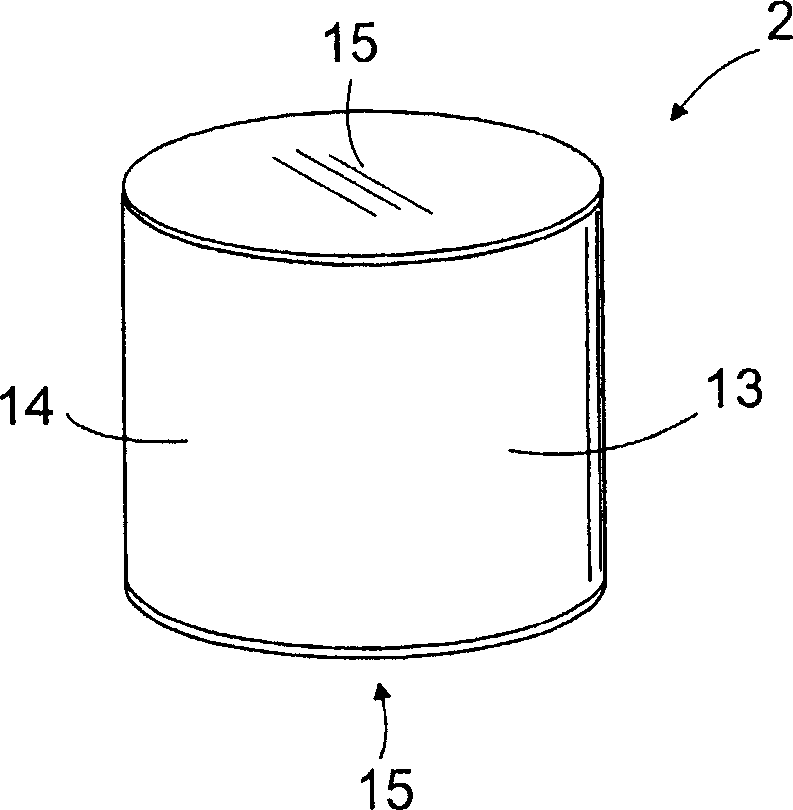

InactiveCN1662270AReduce penetrationReduce static chargeMedical devicesInhalatorsMoisture penetrationPolymer

An inhalator, an inhalator component and a method for manufacturing an inhalator component. The inhalator and inhalator component have at least one surface made of polymer material that comprises a coating layer (13). The coating layer (13) substantially reduces moisture penetration through said surface and lowers the specific electric resistance of said surface.

Owner:MEDIFIQ HEALTHCARE

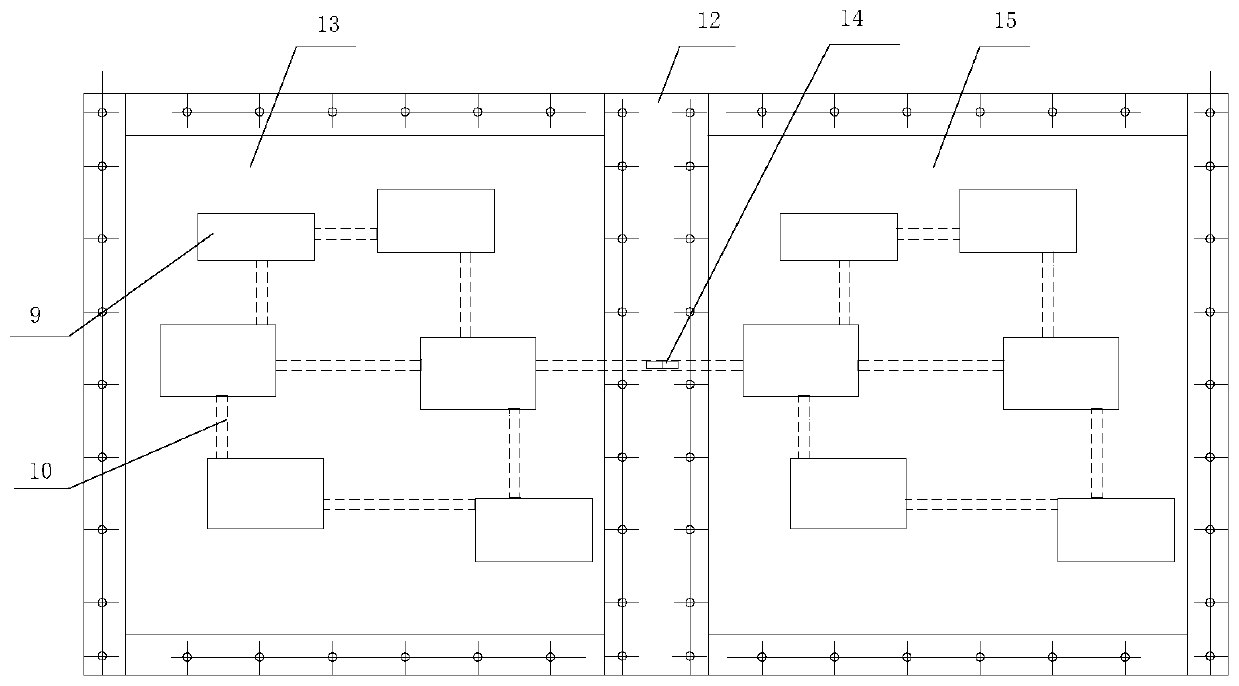

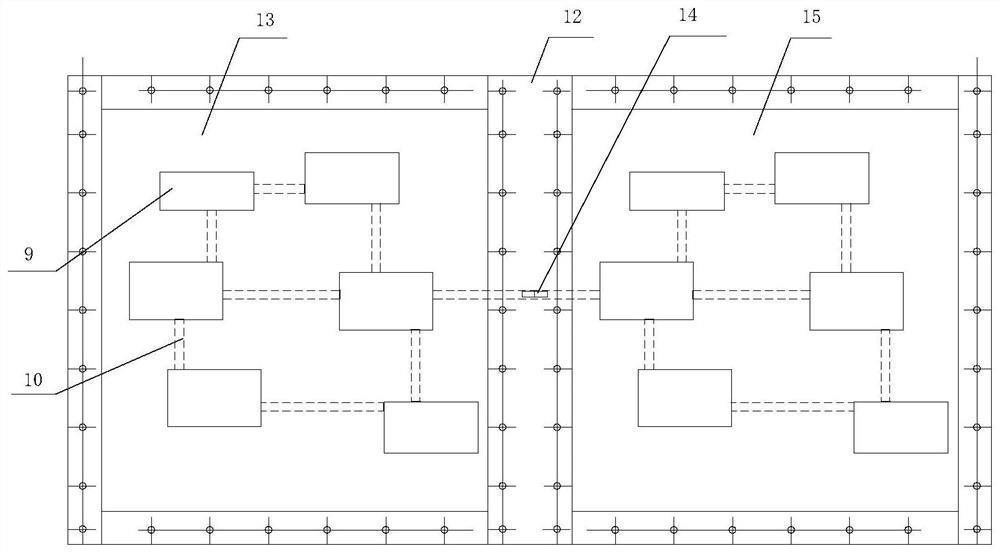

Electromechanical integrated intelligent backboard satellite framework

ActiveCN110187657AImprove stressLess assembly workProgramme controlComputer controlData transmissionSatellite

The invention discloses an electromechanical integrated intelligent backboard satellite framework. The electromechanical integrated intelligent backboard satellite framework comprises an intelligent backboard, wherein the intelligent backboard adopts a sandwich structure form and comprises an upper honeycomb board, a middle honeycomb board and a lower honeycomb board and the upper honeycomb board,the middle honeycomb board and the lower honeycomb board are connected together through backboard connecting pieces in different forms through bolts; electronic equipment in the board is arranged inmounting grooves arranged in the middle honeycomb board, wiring grooves are formed among the mounting grooves, and cables among the electronic equipment in the board are wired through the wiring grooves; the upper honeycomb board and the lower honeycomb board are connected with the middle honeycomb board in a glue joint mode; the electronic equipment in the board is made into an MCM multifunctional structure form or a single board PCB form, and all parts of the electronic equipment in the board are connected through power lines, cables and optical fibers. The electromechanical integrated intelligent backboard satellite framework eliminates a large-volume component, integrates subsystems such as data transmission and power distribution networks and the like, and embeds electronic equipmentinto a composite material to form the electromechanical integrated intelligent backboard. According to the invention, the satellite system is light in weight, simple to assemble and convenient and quick to test and debug.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

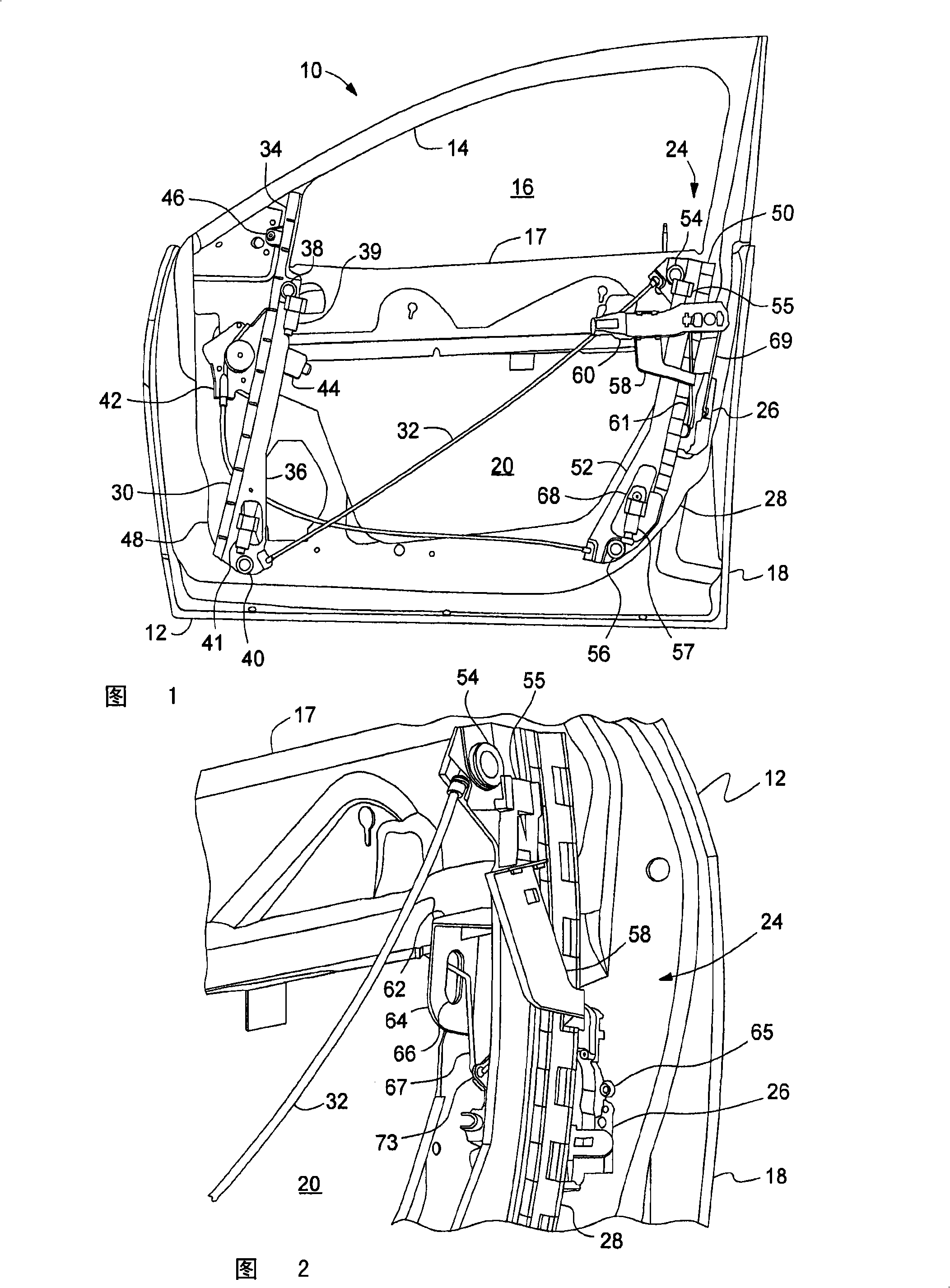

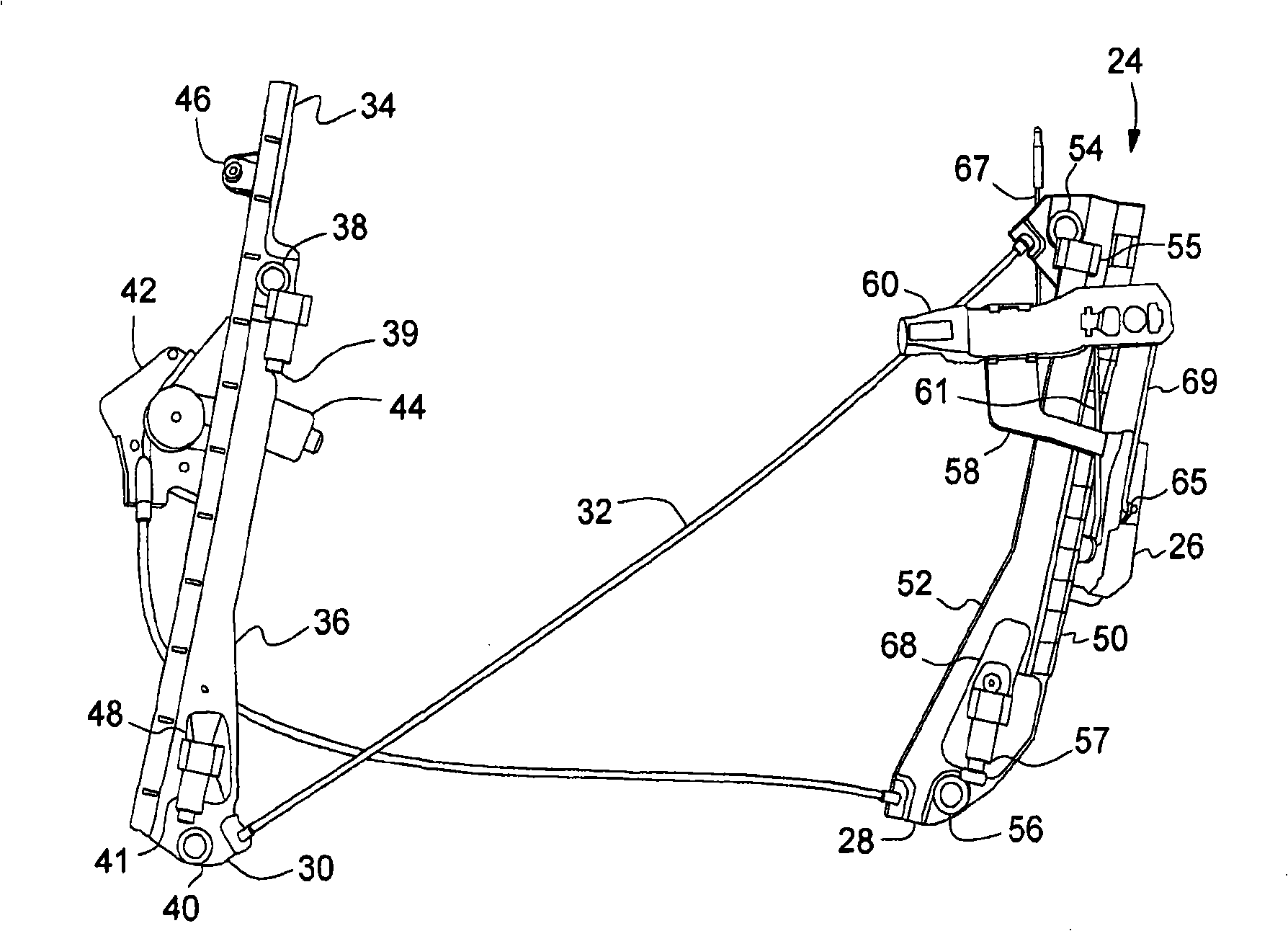

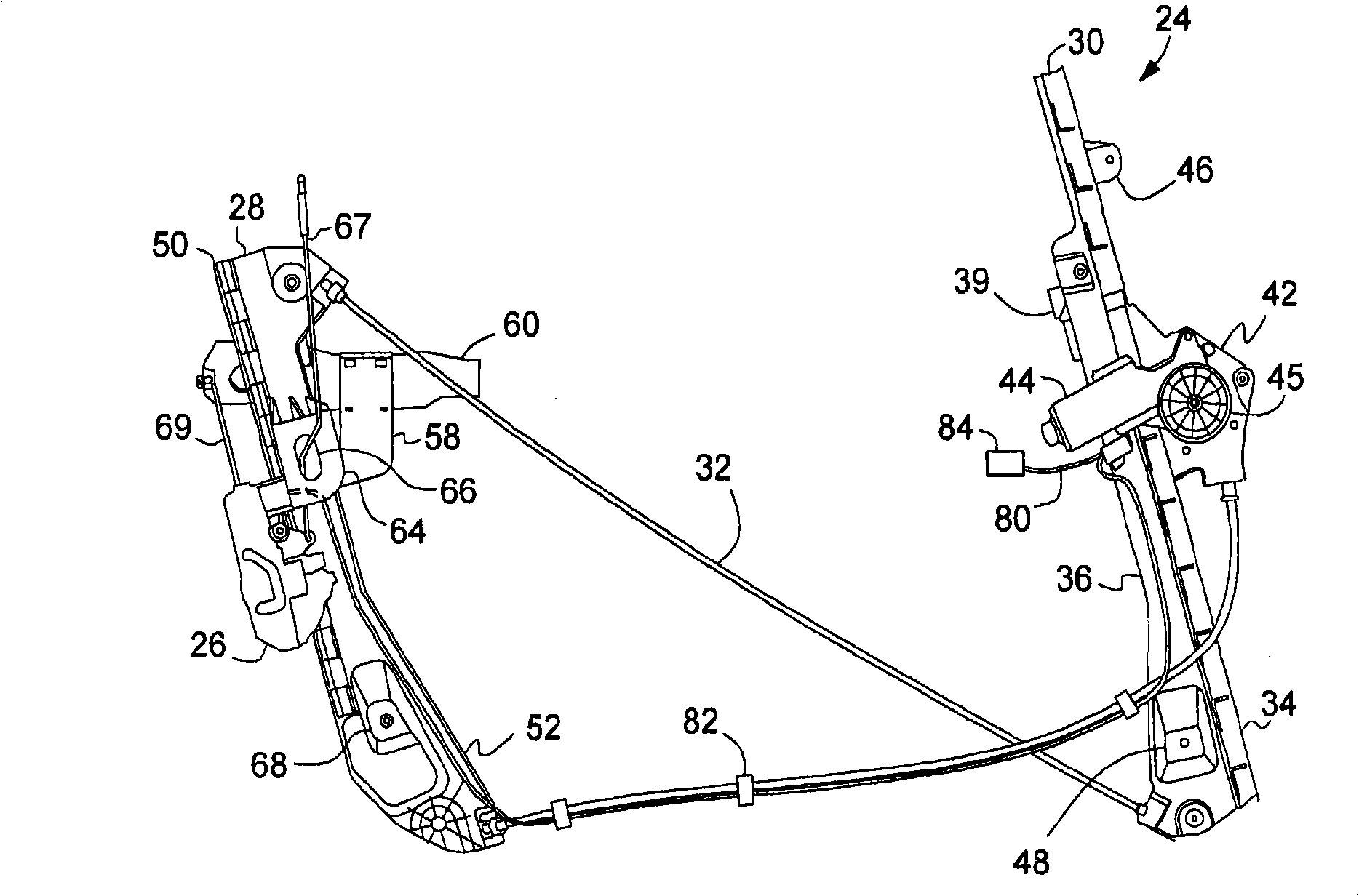

Integrated channel regulator for vehicle door

A vehicle door that may include a latch / window regulator module and rear and forward integrated channel / regulators, is disclosed. The rear integrated channel / regulator may include a glass run channel that is integral with a window regulator guide rail, and may also have a door latch assembly mounted to it. Other features may be integral with and extend from the rear integrated channel / regulator. The forward integrated channel / regulator may include a glass run channel that is integral with a window regulator guide rail, and may include an integral flange to which a cable drum and motor are mounted. The latch / window regulator module may be pre-assembled before being assembled into the vehicle door.

Owner:GM GLOBAL TECH OPERATIONS LLC

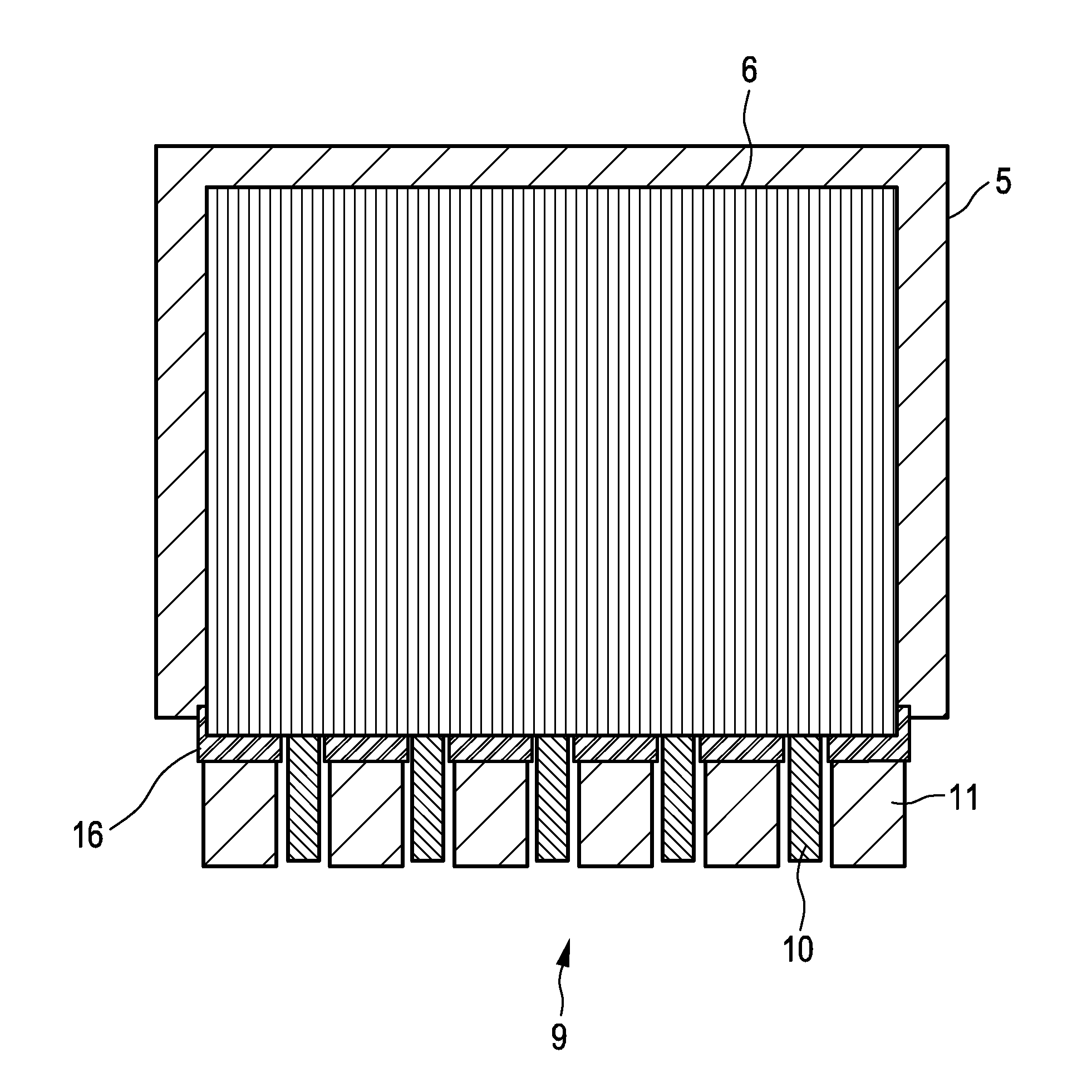

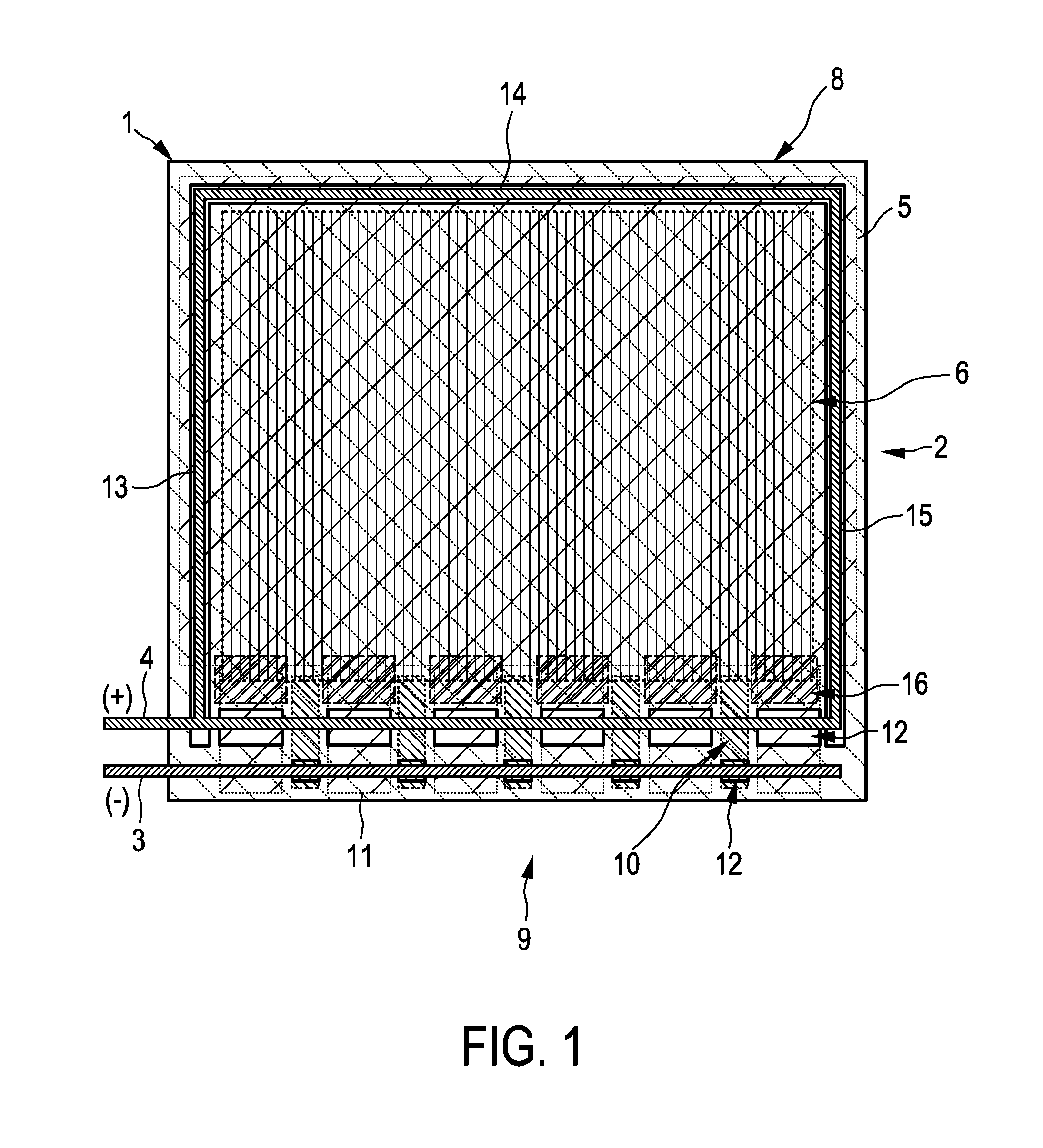

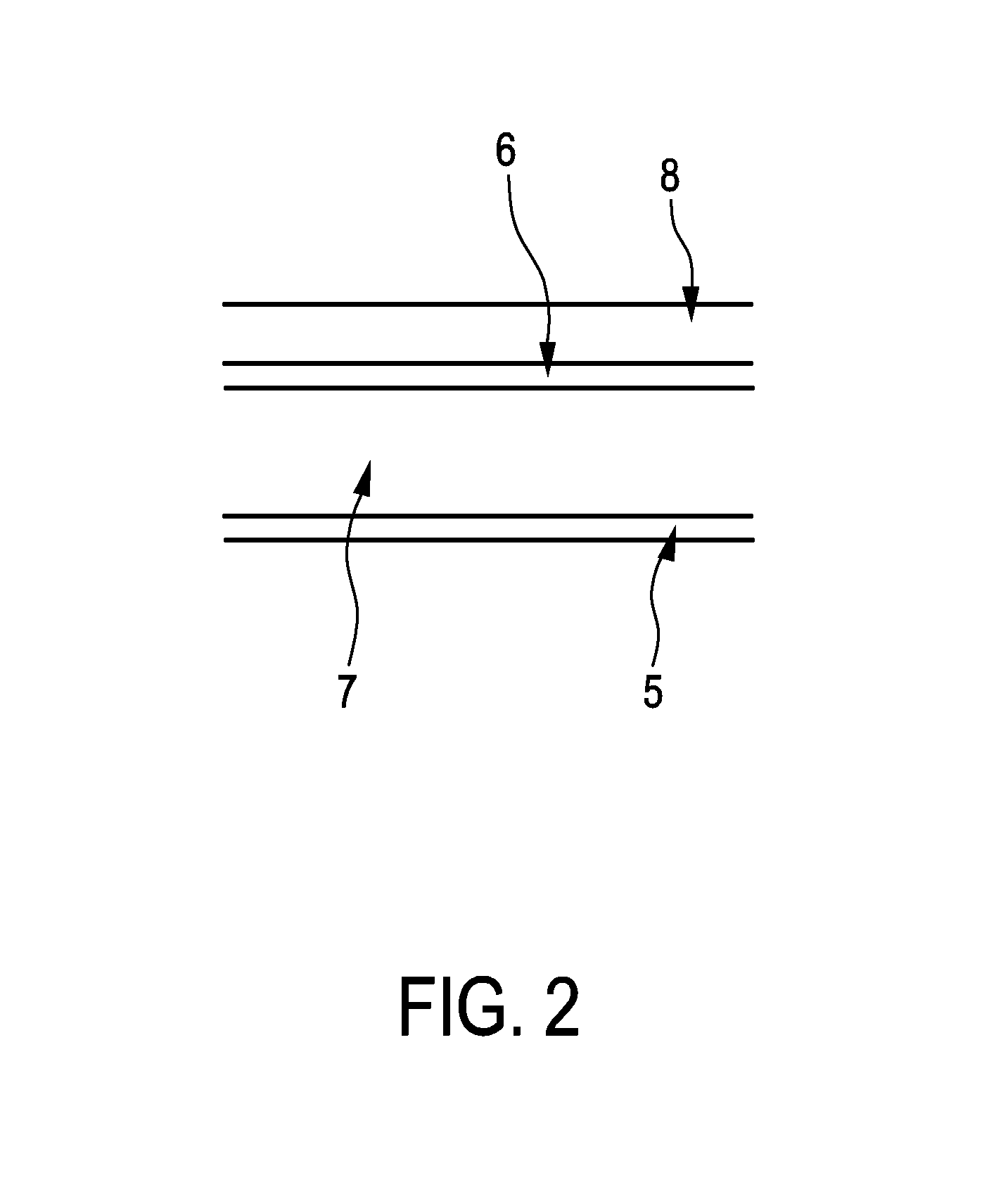

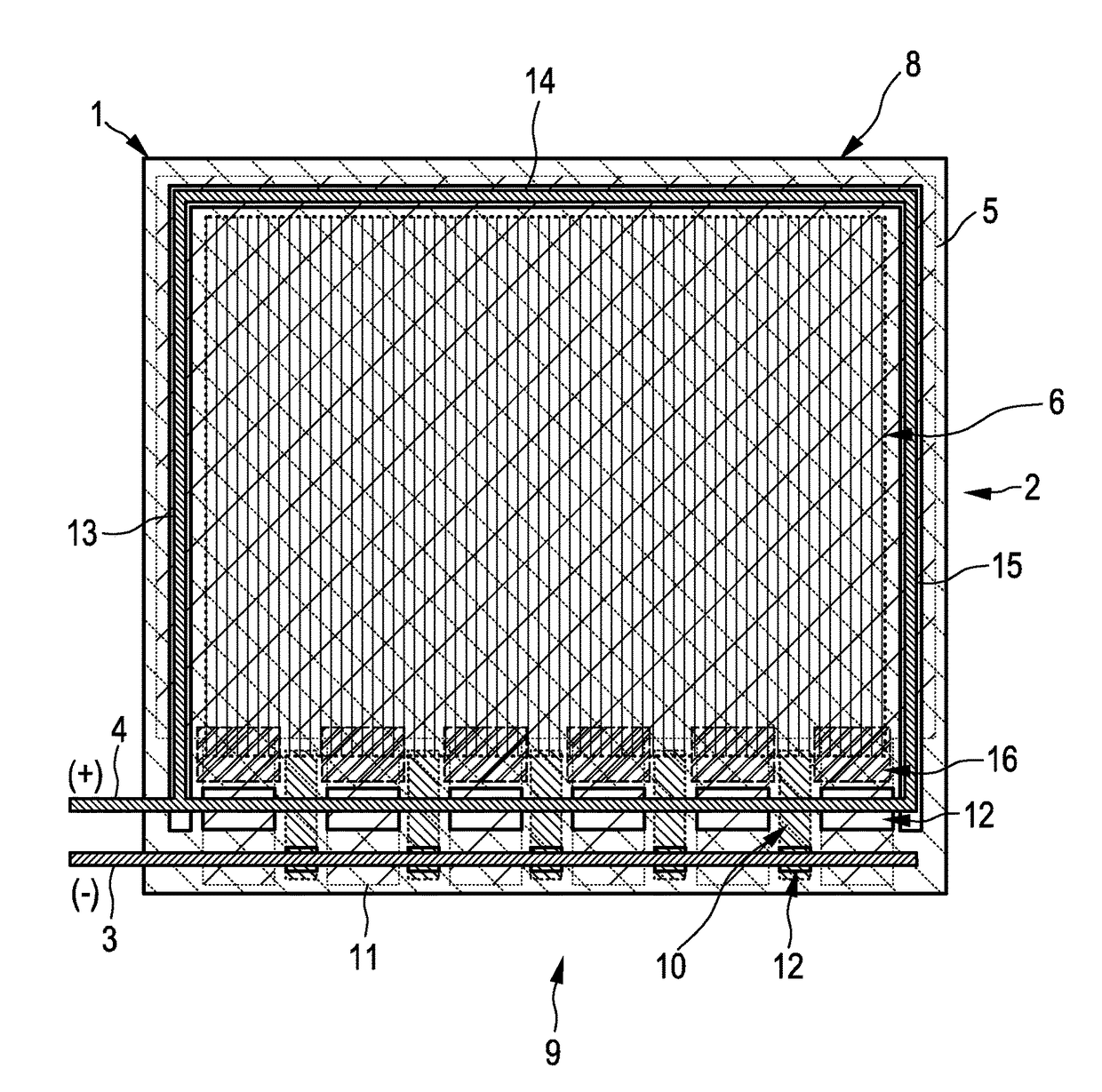

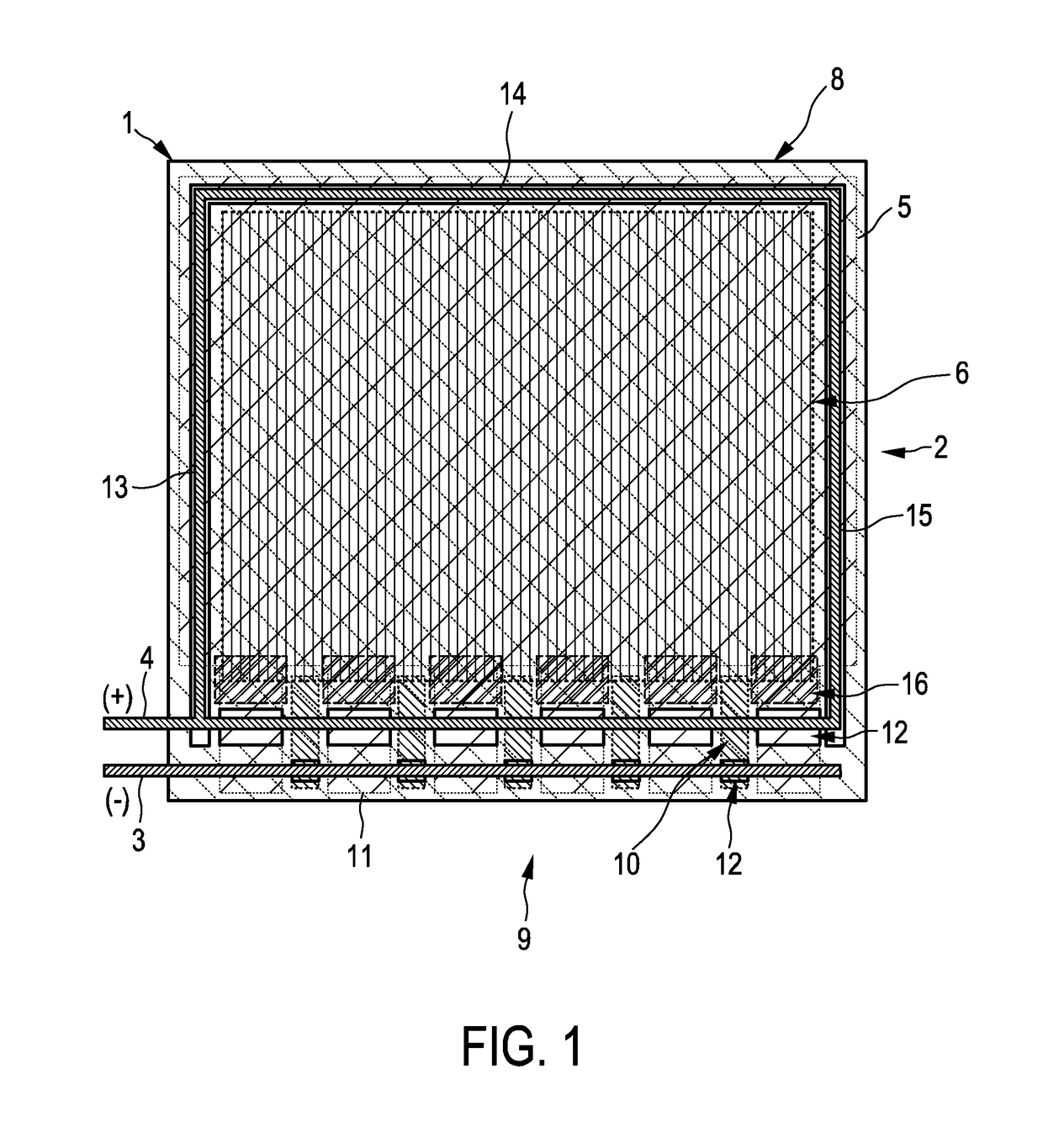

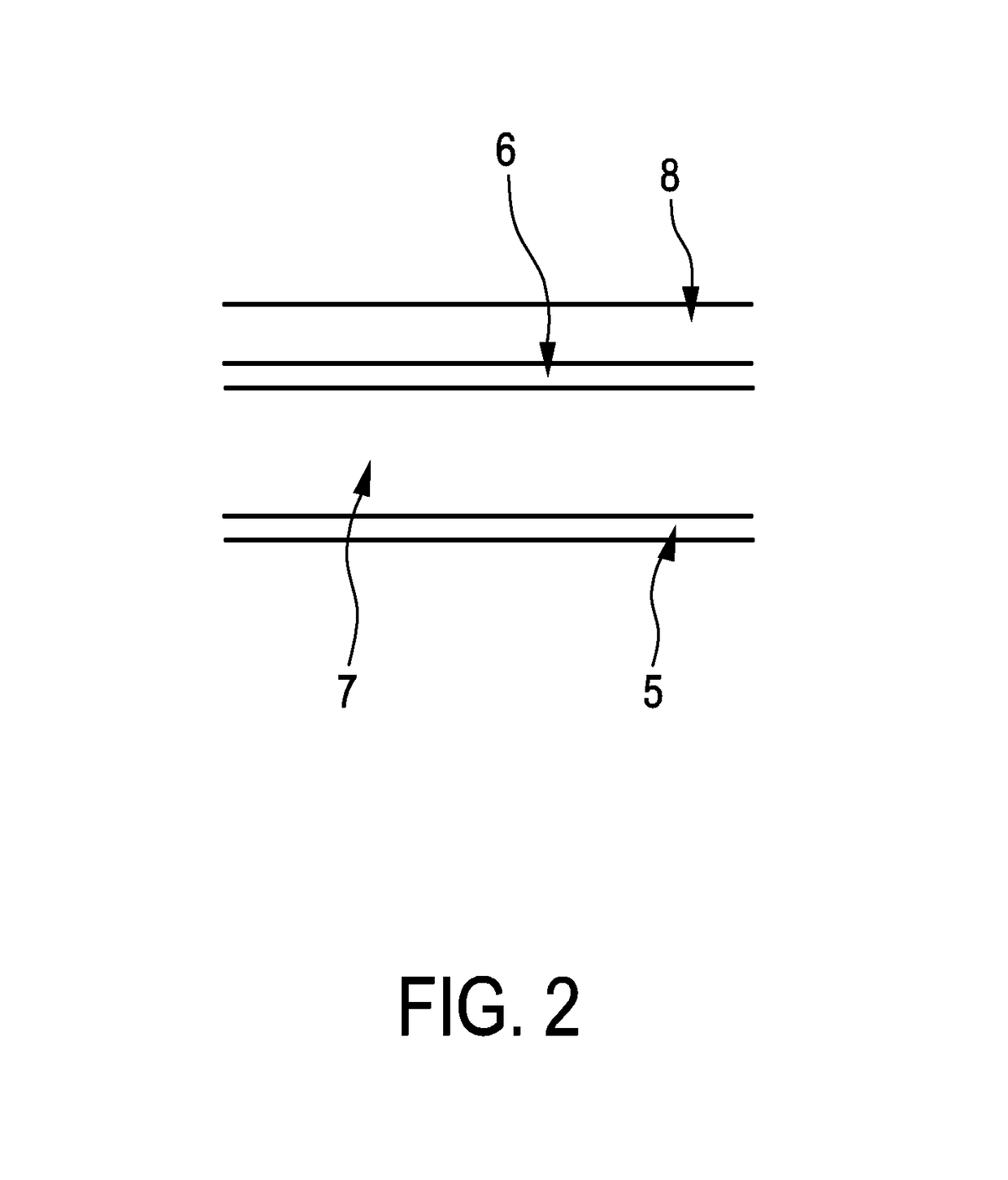

Light-emitting device with alternating arrangement of anode pads and cathode pads

ActiveUS20160133868A1Improve homogeneityReduce effortSolid-state devicesSemiconductor/solid-state device manufacturingElectricityElectrical connector

The invention relates to a light-emitting device like an OLED comprising a light emission region between an anode (5) and a cathode (6). An alternating arrangement (9) of anode pads (11) for electrically connecting the anode and cathode pads (10) for electrically connecting the cathode and an encapsulation (8) are configured such that the anode and cathode pads are electrically connectable by straight anode and cathode electrical connectors (3, 4) through openings (12) of the encapsulation. The alternating arrangement of the anode and cathode pads can lead to a more homogenous electrical field between the anode and the cathode and therefore allows for an improved degree of homogeneity of light emission. More, since the alternating arrangement of the anode and cathode pads is connectable by corresponding straight connectors, the contacting of the pads can be performed technically relatively easily.

Owner:OLEDWORKS GMBH

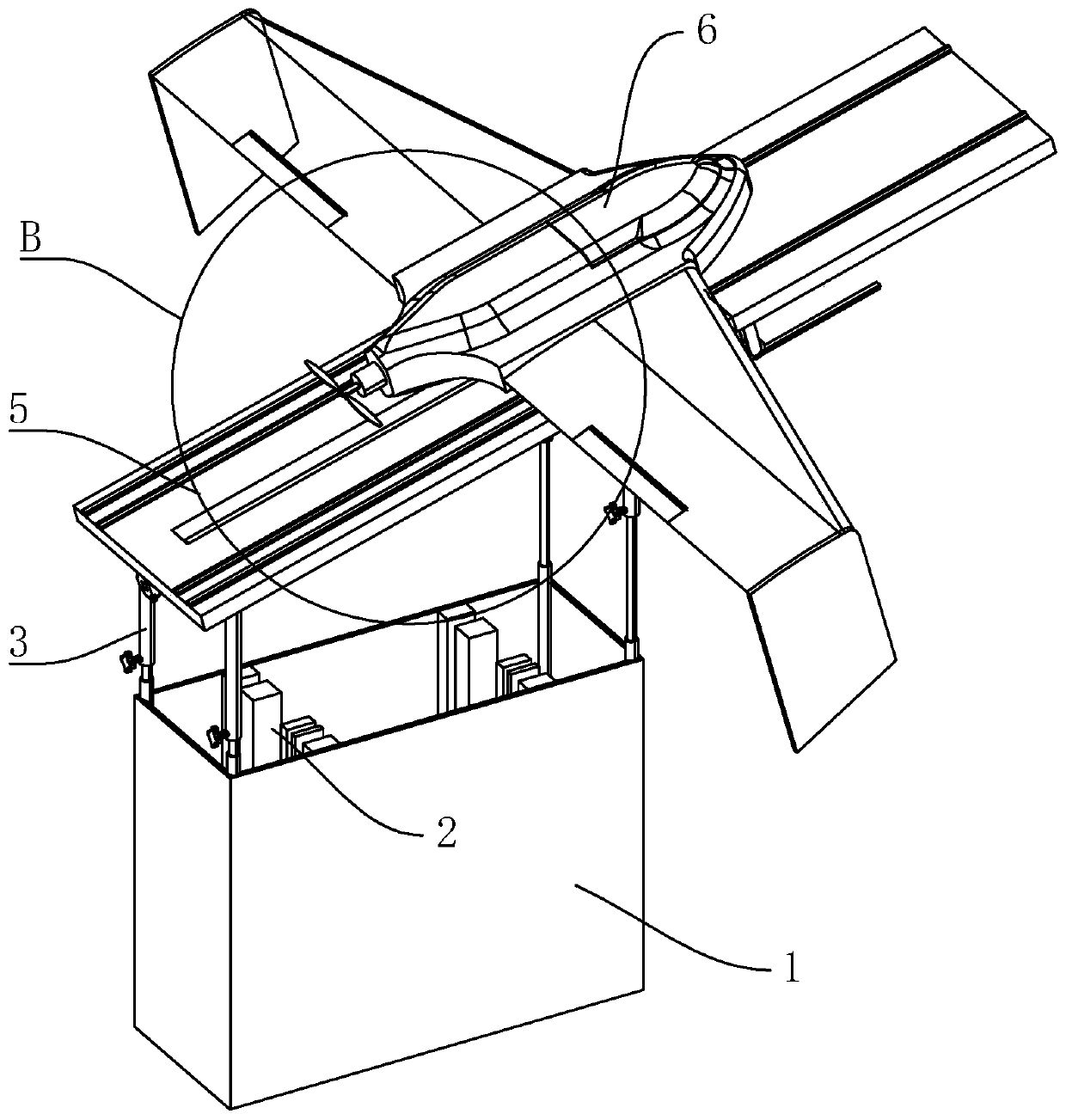

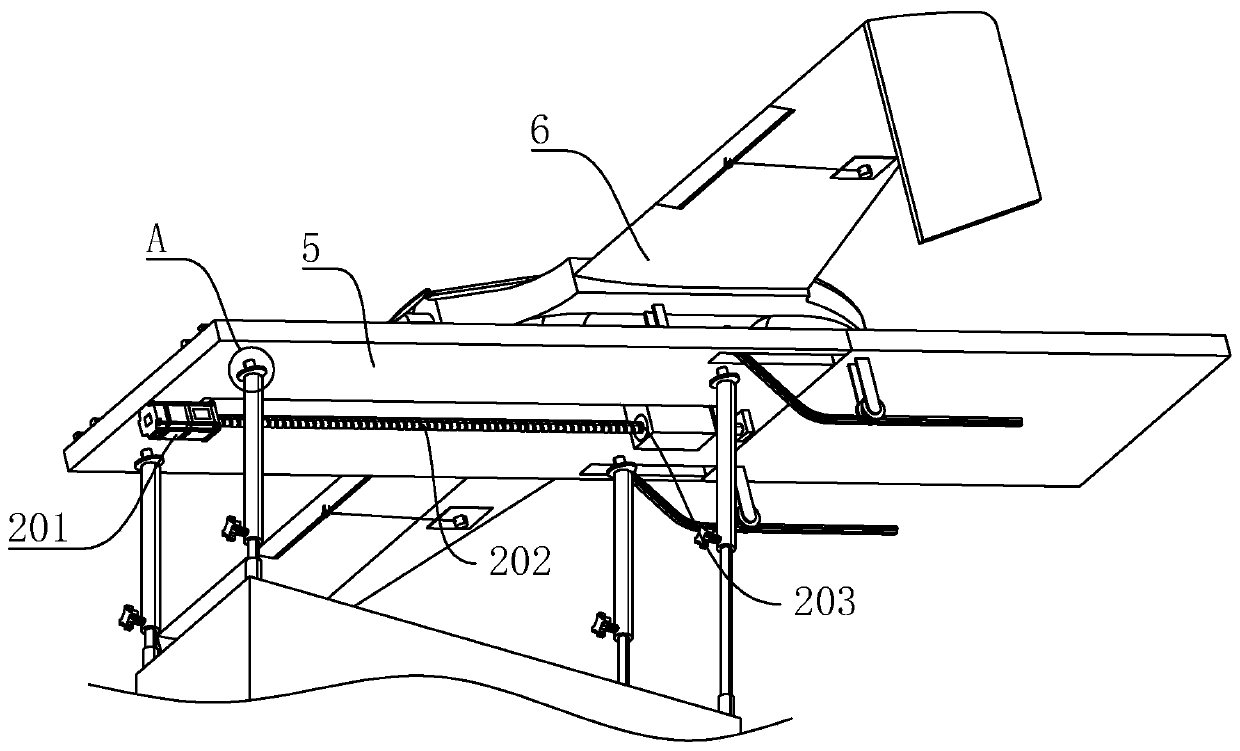

Unmanned aerial vehicle for aerial mapping and use method thereof

ActiveCN110733661AAchieve flightLess assembly workLaunching/towing gearElastic stringAerospace engineering

Owner:苏州华瑞测绘有限公司

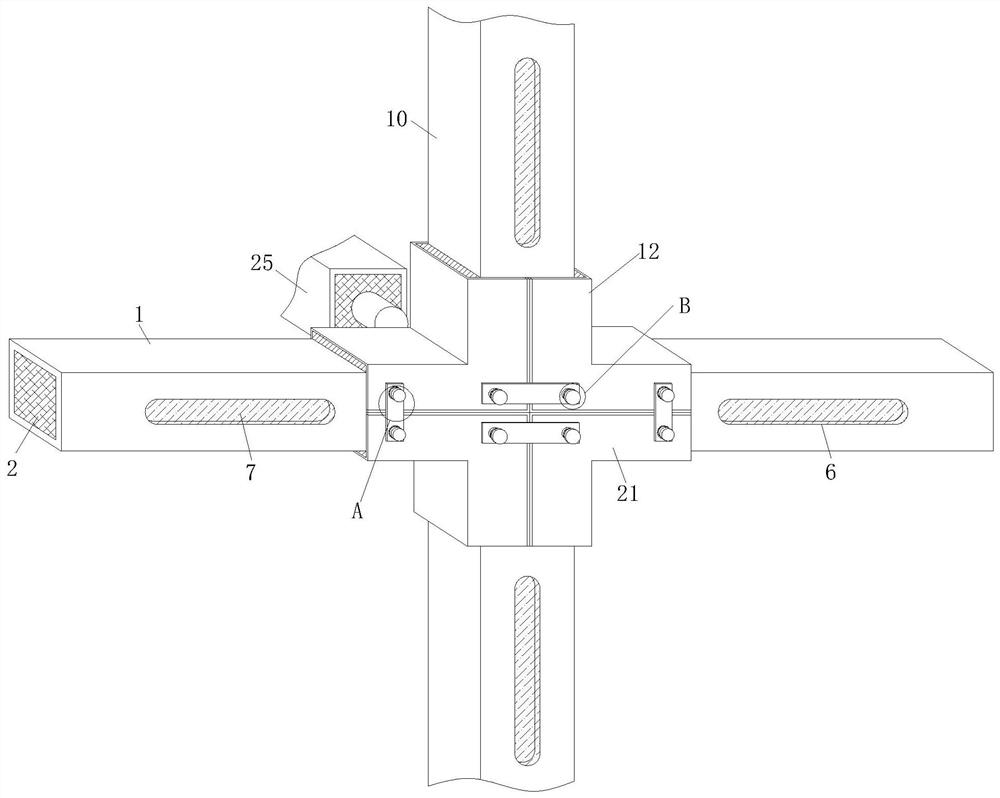

Connecting structure for steel structure house module

PendingCN112627334AImprove stabilityImprove seismic performanceProtective buildings/sheltersShock proofingEngineeringShock resistance

The invention discloses a connecting structure for a steel structure house module, and relates to the technical field of steel structure house modules. The connecting structure comprises a cross beam, supporting blocks are fixedly arranged on the inner wall of the cross beam, connecting frames are fixedly arranged on one sides of the supporting blocks, buffer holes are formed in the tops of the connecting frames, springs are movably arranged on the inner walls of the buffer holes, anti-seismic holes are formed in the front face of the cross beam, rubber damping pieces are fixedly arranged on the inner walls of the anti-seismic holes, and connecting blocks are fixedly arranged on one side of the cross beam. The fixing capacity of the connecting structure is enhanced by arranging rubber pads, the shock resistance of the structure can be improved, the connecting structure can bear larger weight, the fixing capacity of the steel structure house module is improved, the shock-resistant holes and the rubber damping pieces which are matched in shape and size can conduct damping and buffering on the whole structure, therefore, the structure cannot be broken when the weight is loaded, the safety performance of the structure is enhanced, the load capacity of the structure is improved, and the stability of the steel structure house module is improved.

Owner:湖南鸿云钢模科技有限公司

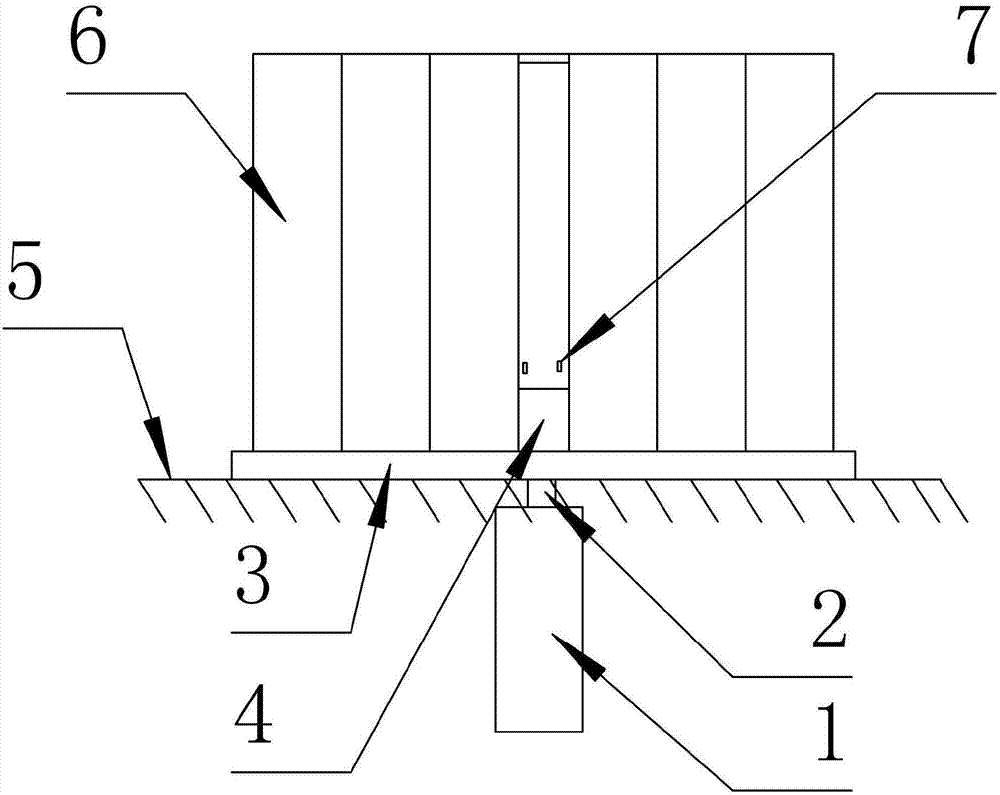

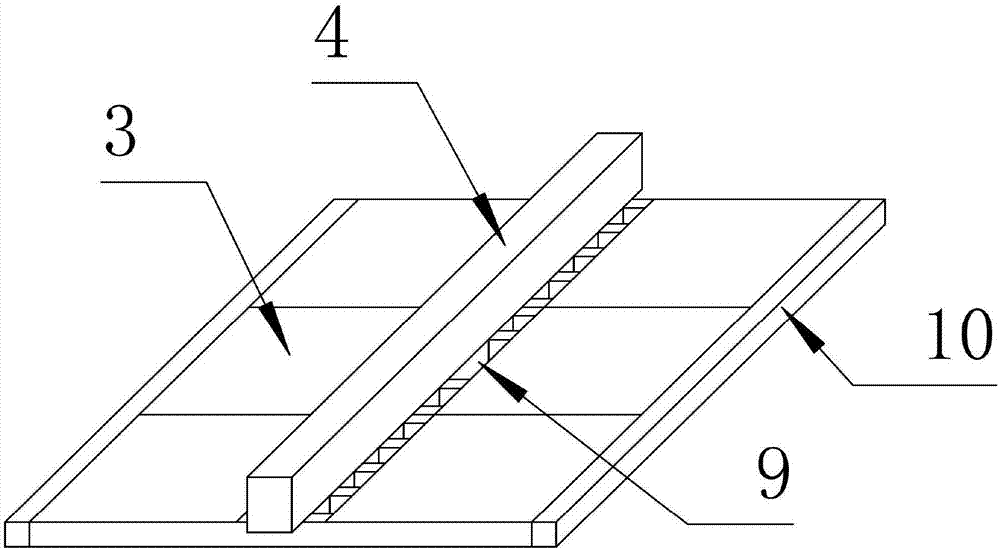

Overall type steel-based platform static load test load piling method for civil engineering

PendingCN107975077AAvoid collapse accidentsSave time and costFoundation testingTest requirementsEnergy conservation

The invention relates to an overall type steel-based platform static load test load piling method for civil engineering. The overall type steel-based platform static load test load piling method for civil engineering is characterized in that the method is performed according to the following steps that, a steel-based platform is selected, a jack is installed at the center of test points, a main beam is installed on the steel-based platform, a jack cylinder body and the main beam are effectively connected, and the steel-based platform and the main beam are effectively connected; a reference beam is installed, and loads are piled; after the weight of the piled loads reaches a regulated weight and a test instrument meets the test requirement according to check, test loading can be performed;after a test ends, parts of the loads are unloaded; and the steel-based platform, the main beam and part of the loads are transferred to a next test point, the above steps are repeated till detectionof the test points of the whole program ends. By means of the load piling method, the large tonnage load piling potential safety hazards can be eliminated, the detection time and the detection cost are saved, a large tonnage static load experiment can be safely and conveniently implemented, integrity is good, self moving can be achieved, speed is high, cost is low, and energy conservation and environmental protection are achieved.

Owner:张宗毅

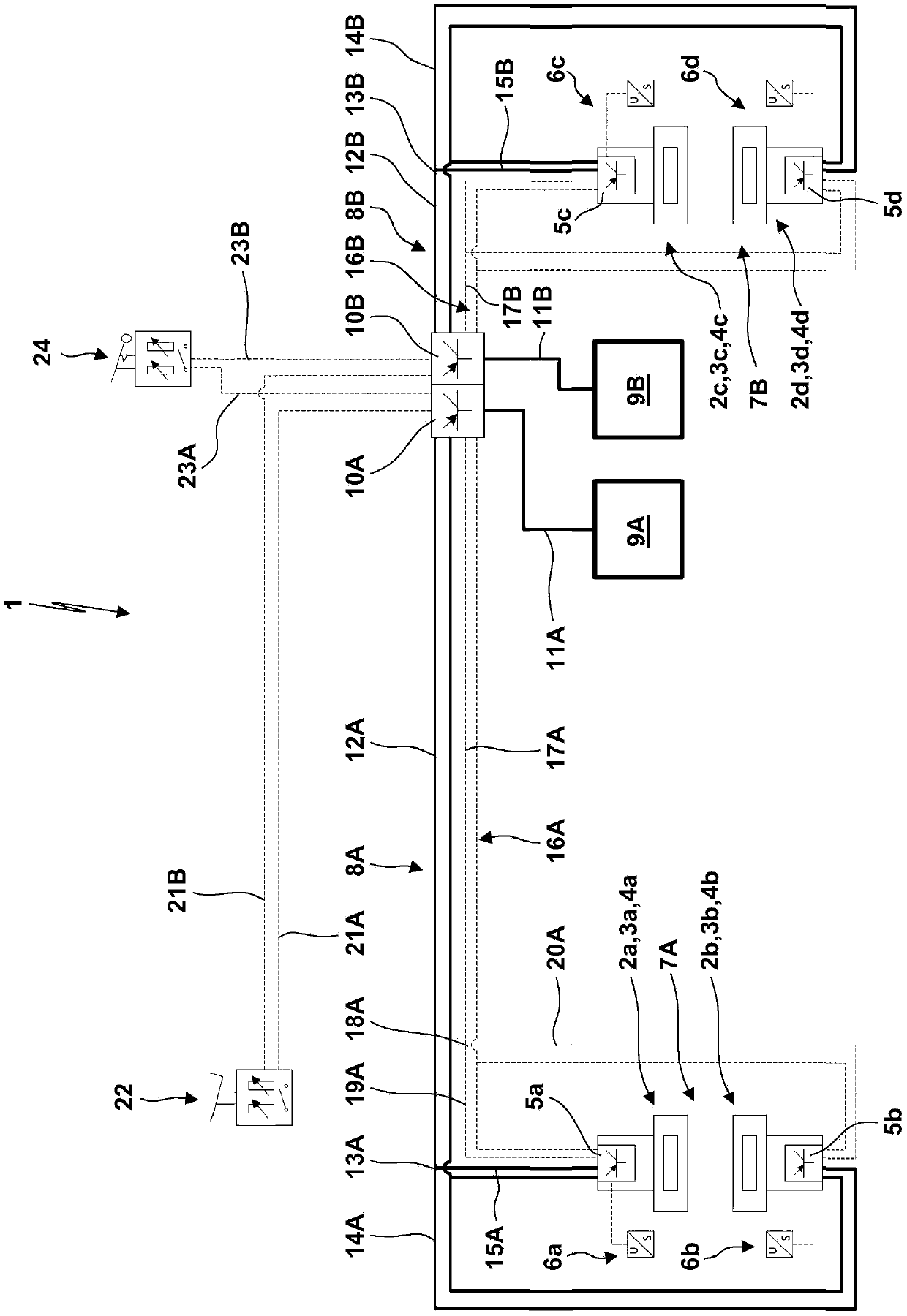

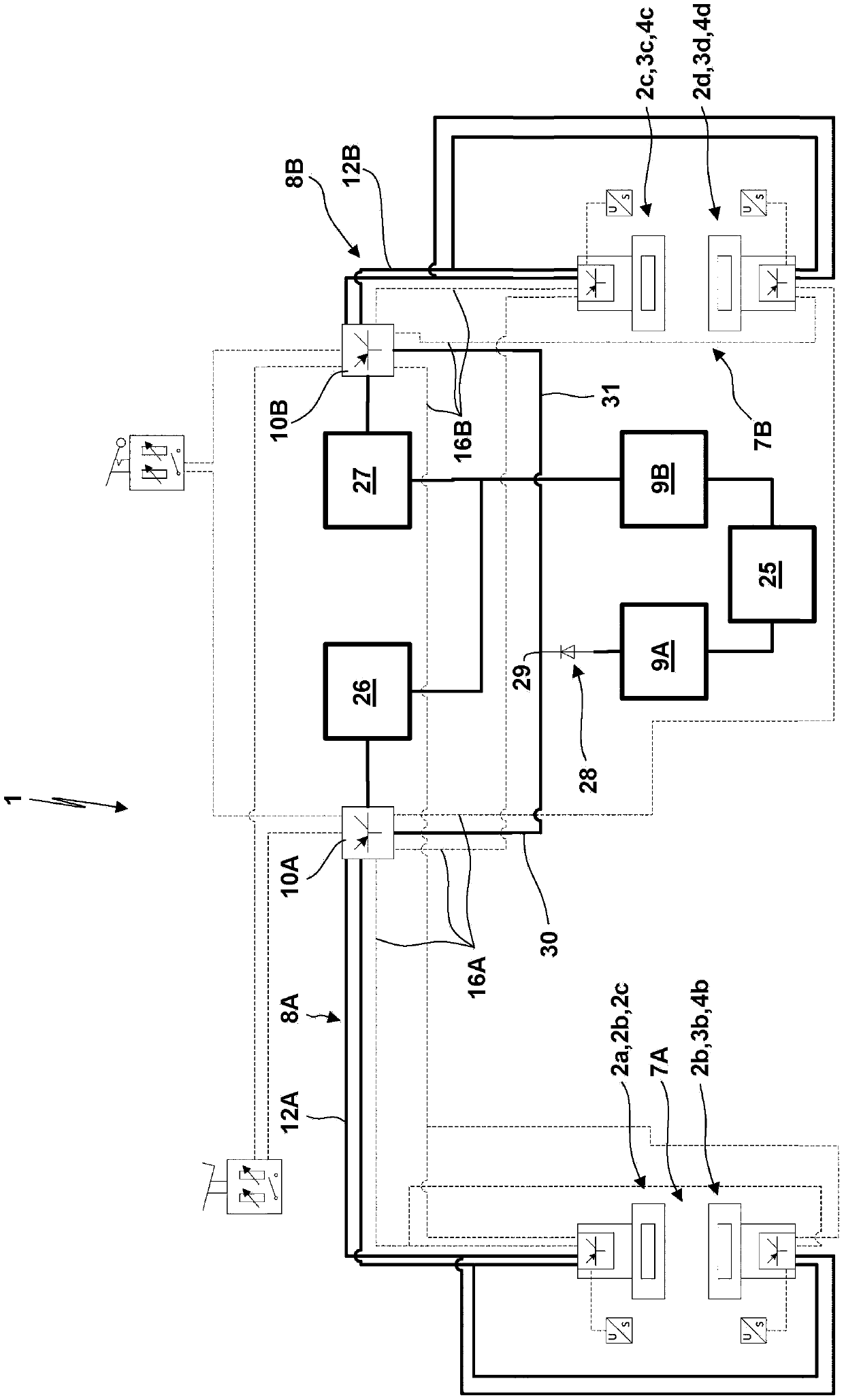

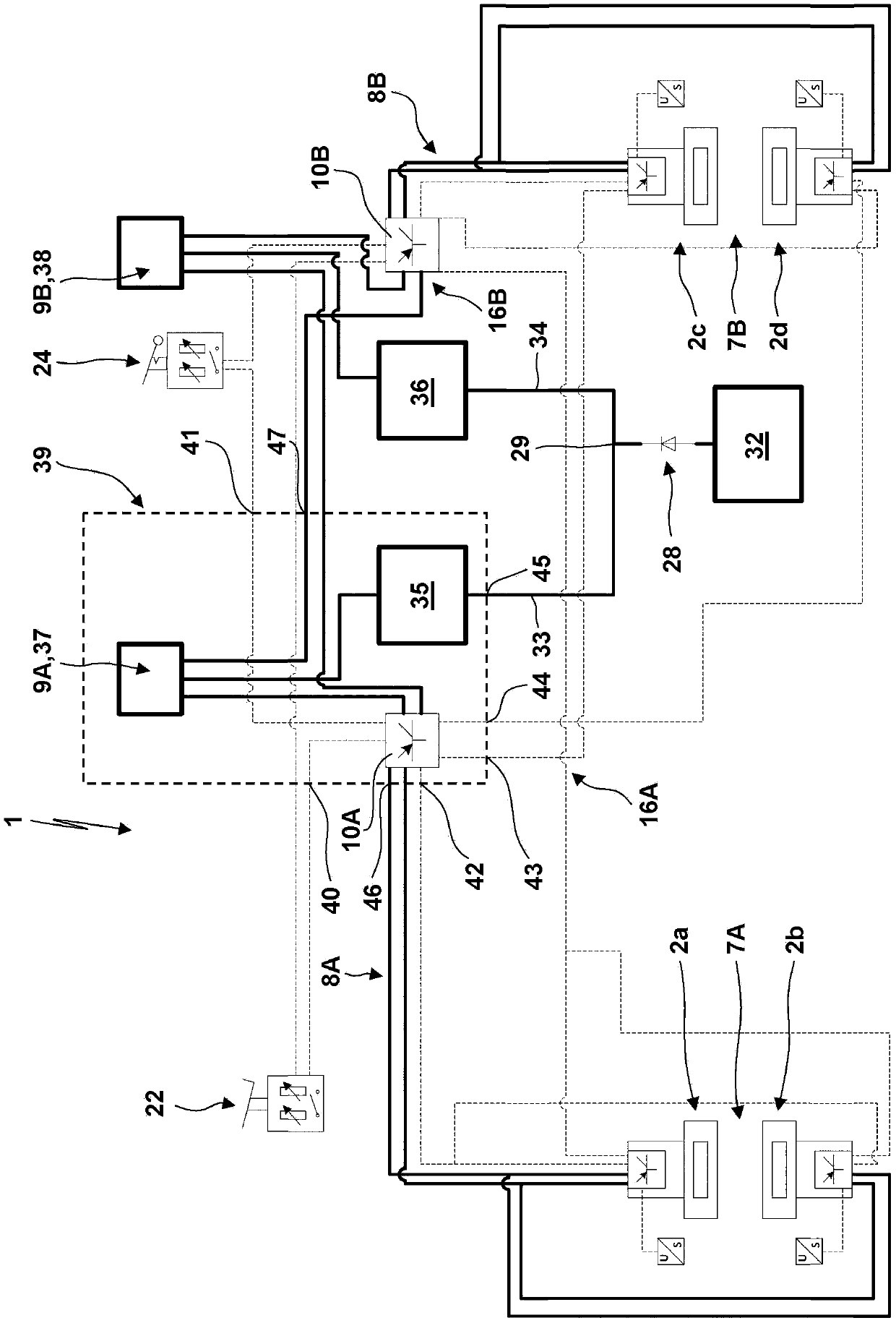

Electric brake system for a vehicle

ActiveCN110461669ARaise priorityLess assembly workHybrid vehiclesBatteries circuit arrangementsControl theoryControl circuit

Owner:HALDEX VIE (SHANGHAI) ELECTROMECHANICAL BRAKE SYST CO LTD

Transfer lock for a tabletting plant

ActiveUS20060269637A1Less assembly workMaximum tightnessConfectionerySweetmeatsMechanical engineering

A transfer lock for a tabletting plant, which has a casing with side walls where at least one wall has an aperture which is adapted to be closed by a first flap which is pivotable inwardly into the interior of the casing and is adapted to be locked by a locking device operable from the interior of the casing, wherein the aperture is externally surrounded by a connection profile which is adapted to be sealingly brought together with a counter-profile of a lock channel and the flap externally has a driver profile which interacts with a counter-driver profile of a second flap mounted at the end of the lock channel when the counter-profile of the lock channel is connected to the connection profile, thus allowing to pivot the two flaps into the interior of the casing when the locking device is unlocked, which integrates the connection profile into the material of the casing wall.

Owner:FETTE

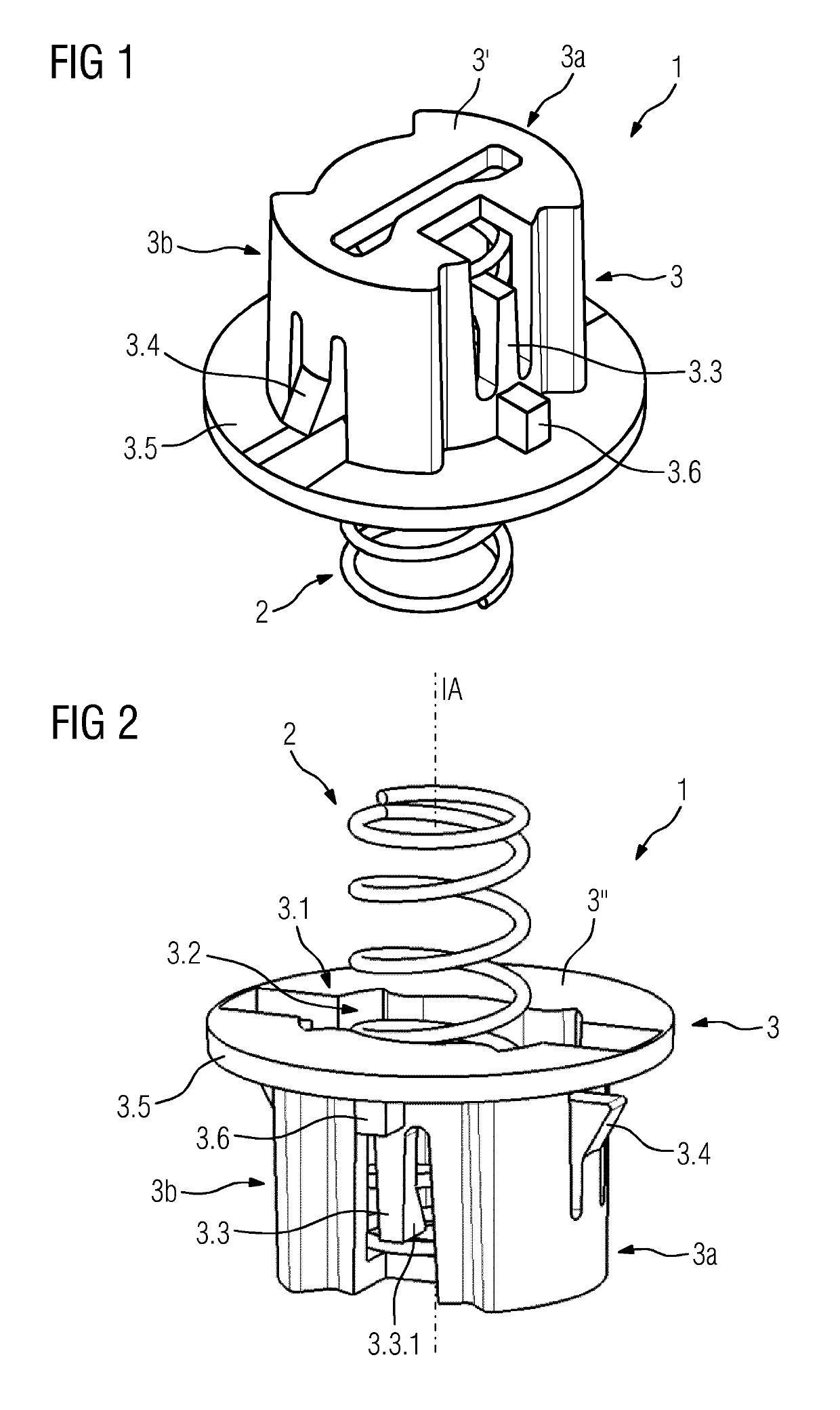

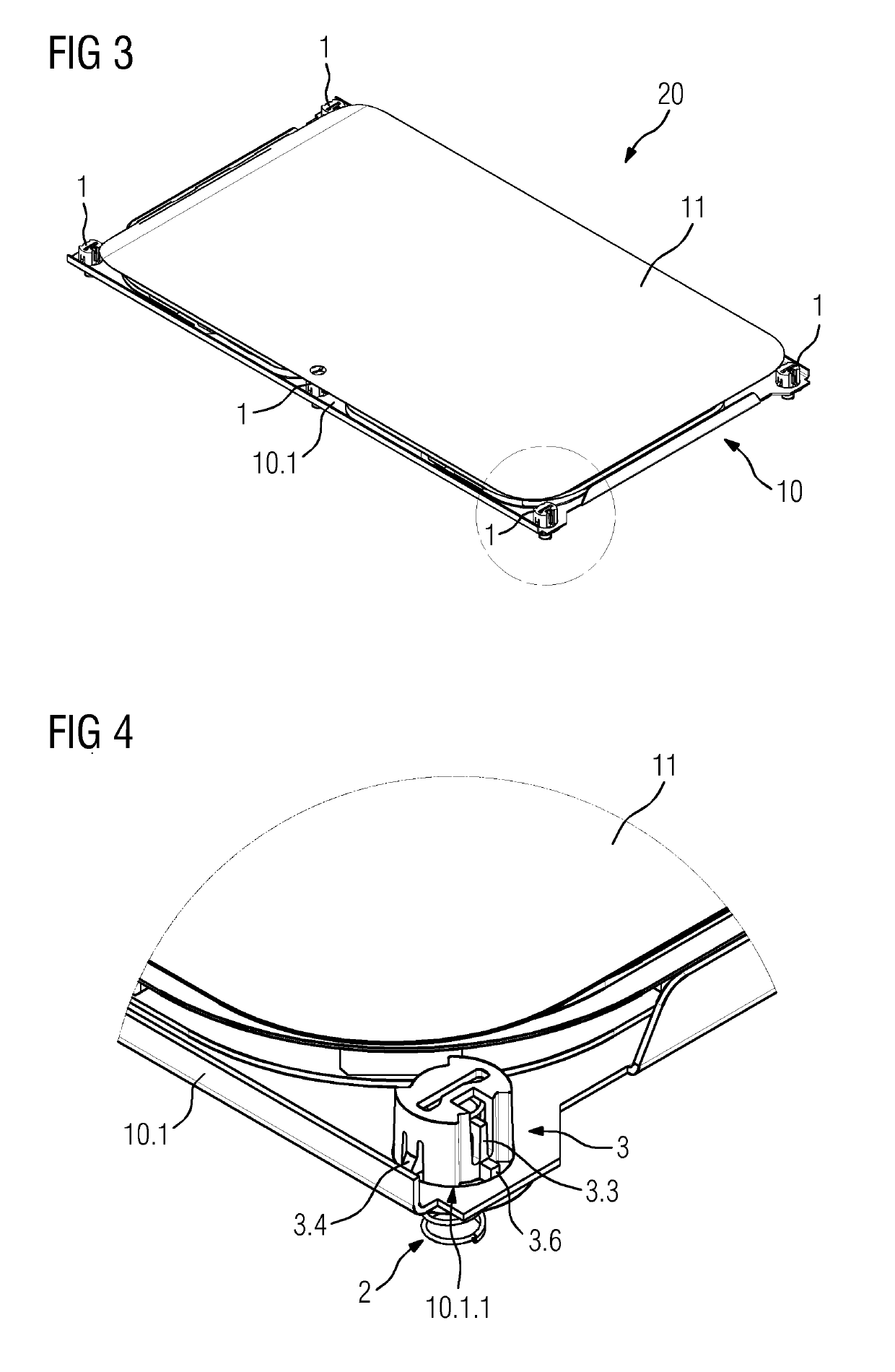

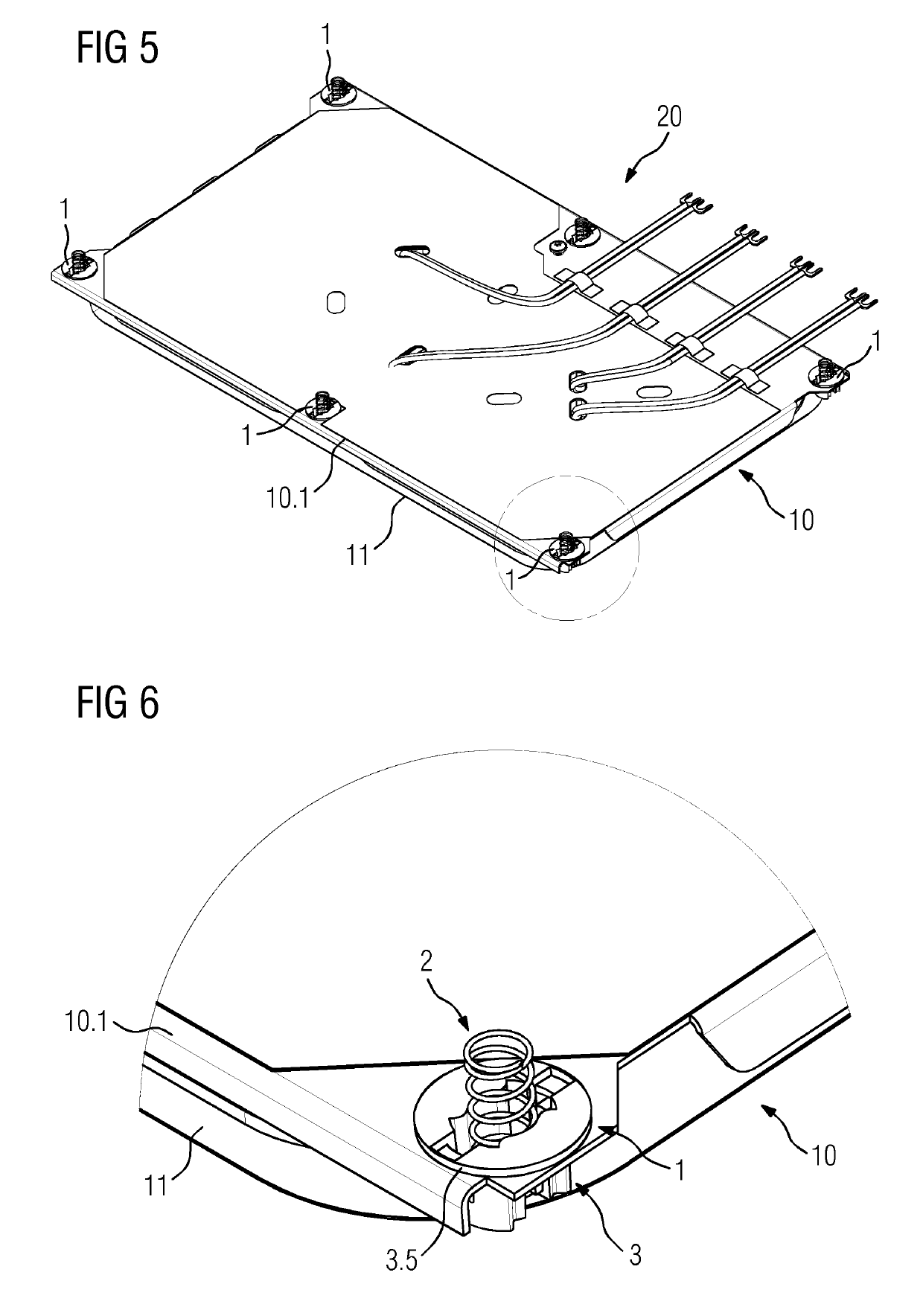

Pressing element and induction hob comprising a pressing element

PendingUS20190162419A1Simple structureLess assembly workDomestic stoves or rangesLighting and heating apparatusCouplingEngineering

The invention relates to a pressing entity (1) for pressing an induction heating unit (10) against a hob plate, the pressing entity (1) comprising: —a spring element (2); —a coupling element (3), said coupling element (3) being adapted to detachably couple the pressing entity (1) with the induction heating unit (10); wherein the coupling element (3) comprises a spring coupling portion (3.1) adapted to receive the spring element (2), said spring coupling portion (3) being adapted to receive the spring element (2) such that a portion of the spring element (2) protrudes out of the coupling element (3).

Owner:ELECTROLUX APPLIANCES

A Mechatronic Smart Backplane Satellite Architecture

ActiveCN110187657BImprove stressHigh strengthProgramme controlComputer controlMonoboardMulti-function structure

The invention discloses a mechatronic intelligent backplane satellite structure, including an intelligent backplane, which adopts a sandwich structure, including an upper honeycomb panel, a middle honeycomb panel and a lower honeycomb panel, and adopts different forms of backplane connectors between them Connected together by bolts; the electronic equipment in the board is installed in the installation groove set in the middle honeycomb board, there is a wiring groove between the installation grooves, and the cables between the electronic equipment in the board are routed through the wiring groove; the upper and lower honeycomb The board and the middle honeycomb board are connected by glue; the electronic equipment in the board is made of MCM multifunctional structure or single-board PCB, and the parts of the electronic equipment in the board are connected by power lines, cables, and optical fibers. The invention eliminates large-volume components and integrates sub-systems such as data transmission and power distribution networks, and embeds electronic equipment into composite materials to form a mechatronic intelligent backplane. The satellite system is light in weight, simple in assembly, and convenient and fast in testing and debugging. .

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH +1

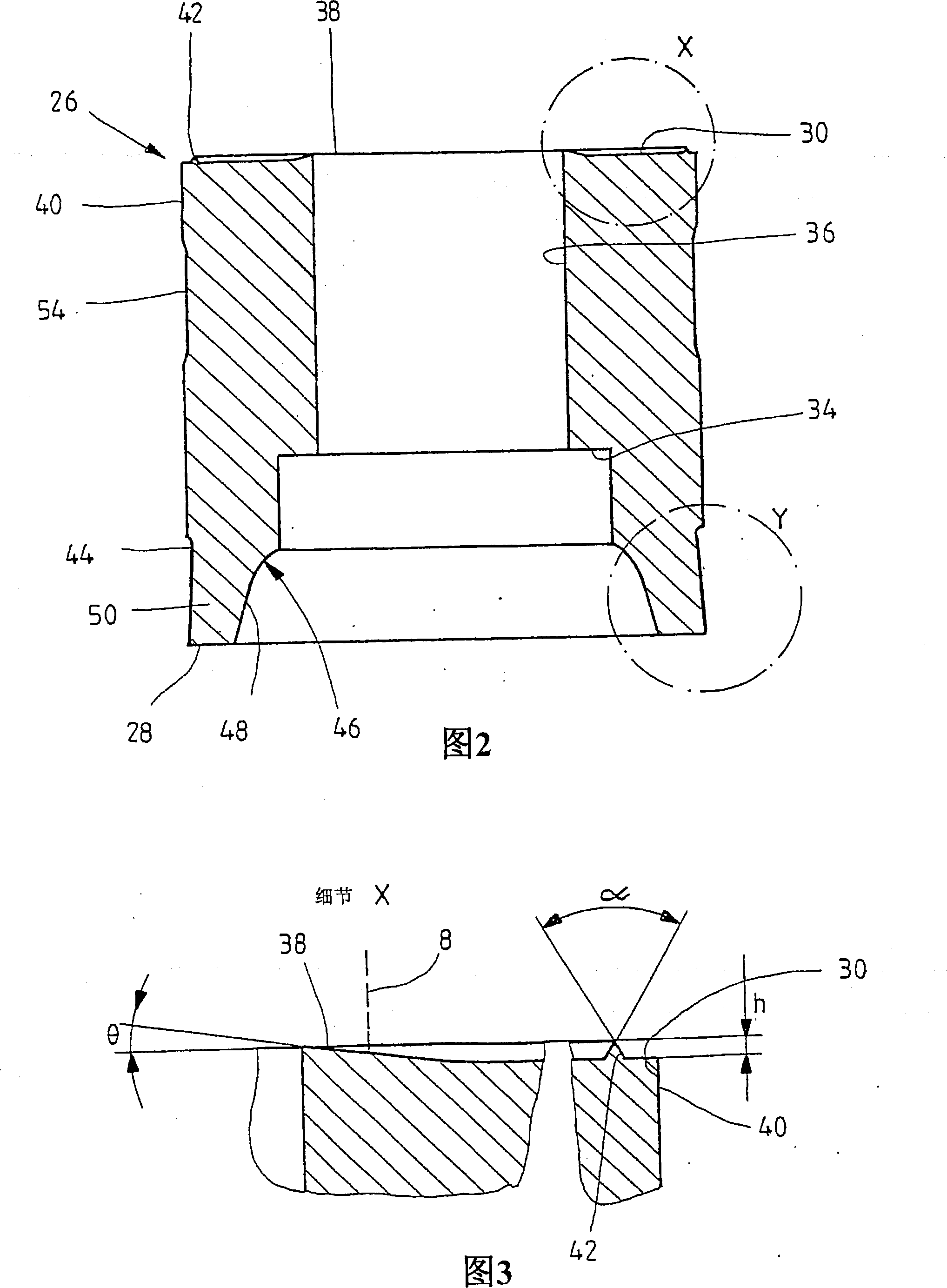

Sealing bush, hydraulic unit, and check valve

ActiveCN101031743BSimple and precise manufacturingLess assembly workCheck valvesLift valveEngineeringCheck valve

The invention disclosed bushing gasket (26), back valve and hydraulic device which is provided with the bushing gasket. the bushing gasket (26) is made up from plastics, and on the end-face (30) is provided with optimization taper shaped blow-up part (38) which can connect with the supporting shoulder hermetically.

Owner:BOSCH REXROTH AG

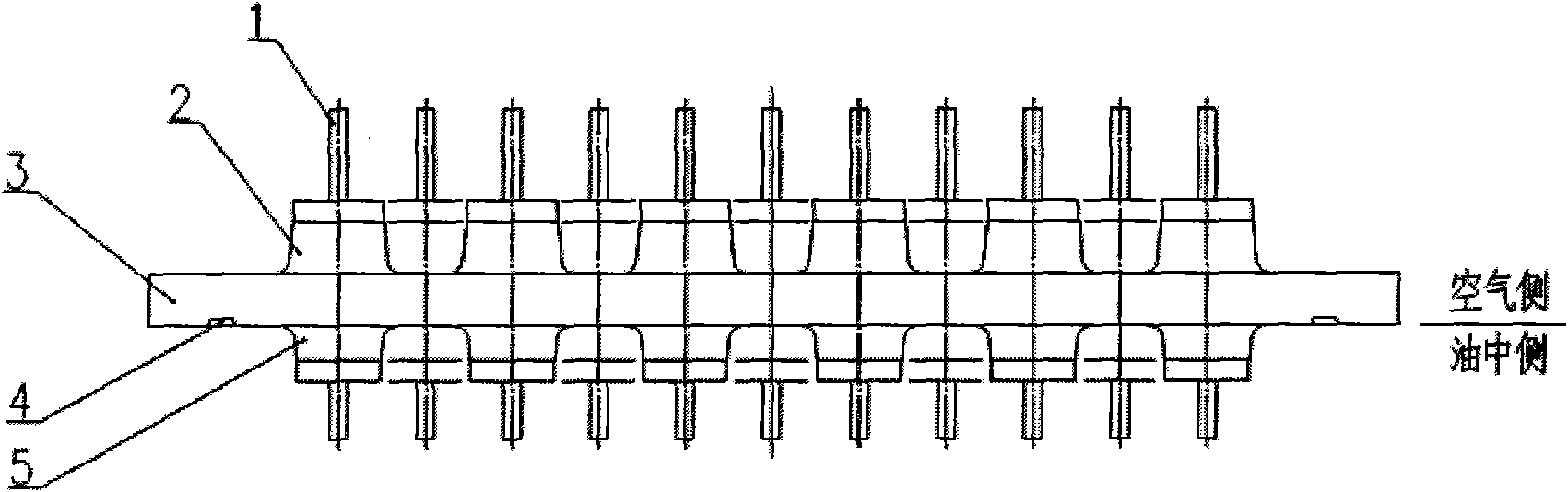

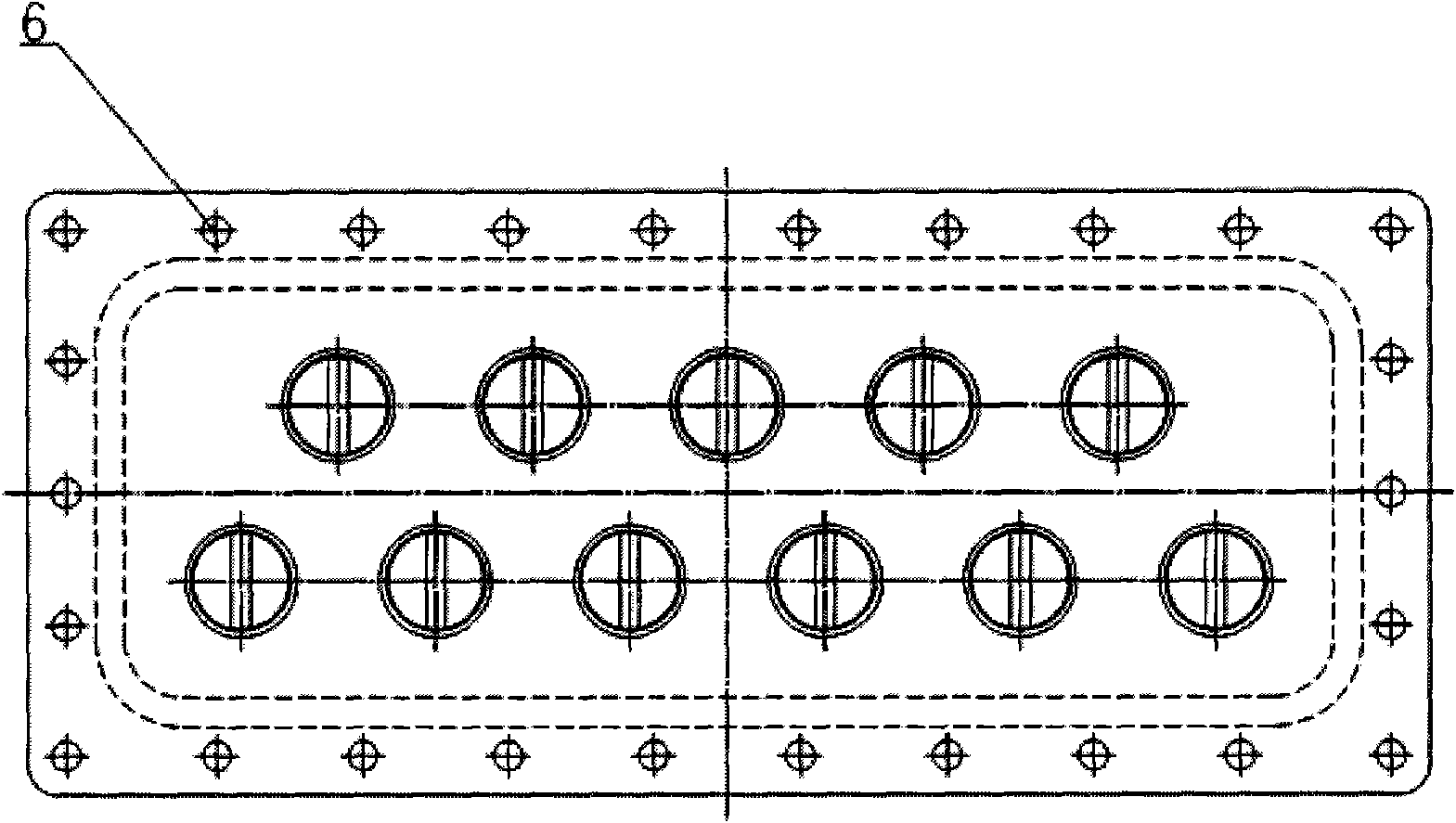

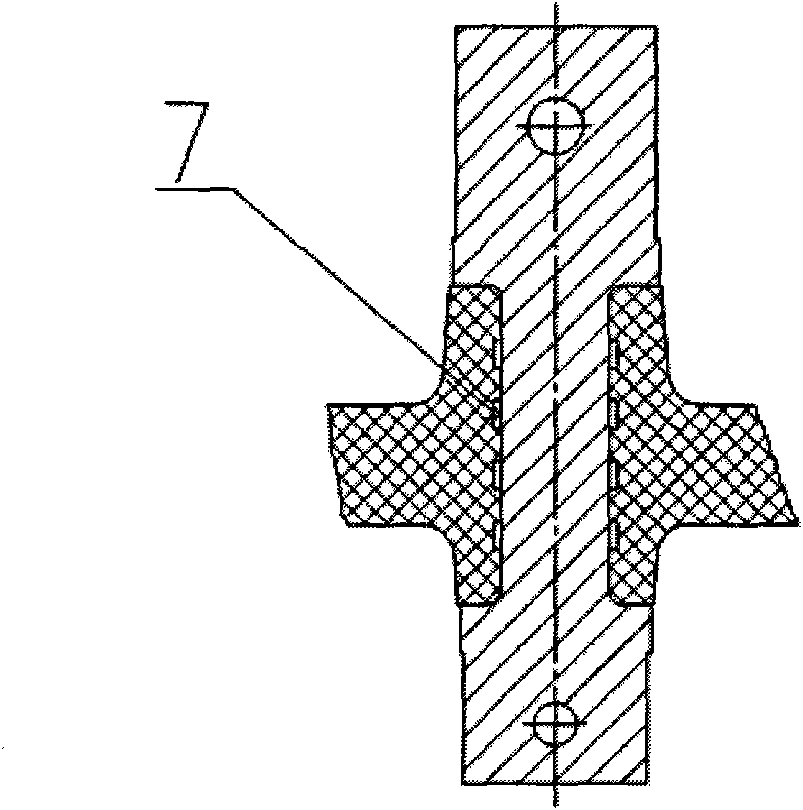

Terminal strip for electric locomotive hauling transformer

InactiveCN101667486AImprove insulation performanceHigh mechanical strengthTransformers/inductances coils/windings/connectionsEpoxyEngineering

The invention relates to a terminal strip for an electric locomotive hauling transformer, which consists of a connecting terminal, an air side insulated post, a mounting flange, a seal groove and an oil middle side insulated post; the air side insulated post, the mounting flange and the oil middle side insulated post have an integral structure formed by vacuum pouring of epoxy resin; the contacting surface of the connecting terminal and the epoxy resin is circularly provided with buffer circles; the air side insulated post and the oil middle side insulated post have a cone frustum shape, and joints of the roots of the two and the flange are provided with fillets; two ends of the connecting terminal are platy and the middle of the connecting terminal has a cylindrical structure; and the buffer circles are 4 to 6, made of elastic silicon rubber, and are circularly arranged on the contacting surface of the middle cylinder of the connecting terminal and the epoxy resin. The terminal striphas reliable insulation, strong mechanical strength, convenient operation, flexible installation, reliable seal, and long service life.

Owner:DALIAN NORTH INSTR TRANSFORMER GROUP

Drive device for vehicle and method of assembling the same

InactiveCN101203396BReduce axial sizeEasy to assembleGearboxesPropulsion using engine-driven generatorsAutomatic transmissionControl theory

A drive device for a vehicle having excellent assemblability. A first motor (M1), a power distribution mechanism (16), and a second motor (M2) are disposed on a first axis CL1, and an automatic transmission part (20) is disposed on a second axis CL2 parallel with the first axis CL1. A transmission member (18) positioned on the first axis CL1 at the opposite side end of an input rotating member (14) is connected to a first countershaft (40) positioned on the second axis CL2 at the opposite side end of the input rotating member (14) through a connection device (23) so that a power can be transmitted to each other. Since the axial dimensions of the first motor (M1), the power distribution mechanism (16), and the second motor (M2) installed on the first axis CL1 are approximately equal to theaxial dimension of the automatic transmission part (20) installed on the second axis CL2, these axial dimensions can be suitably reduced. Since a housing (12) is divided into four parts, i.e., a firstcase part (12a), a second case part (12b), a third case part (12c), and a fourth case part (12d), the housing can be easily assembled.

Owner:TOYOTA JIDOSHA KK

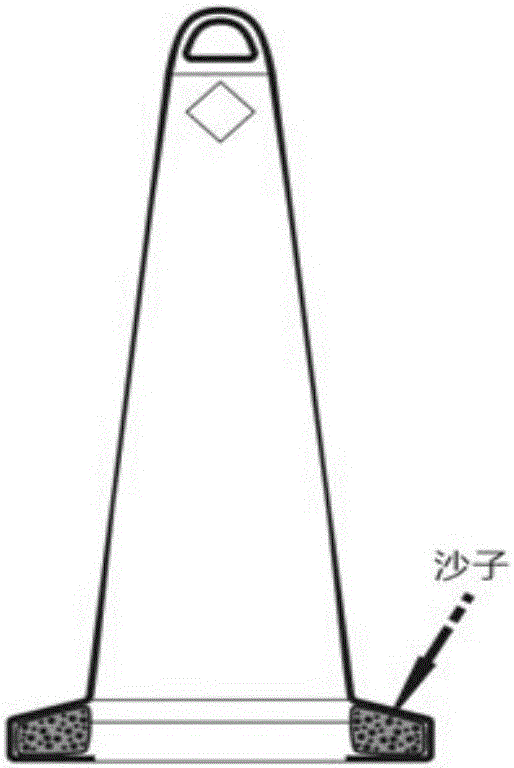

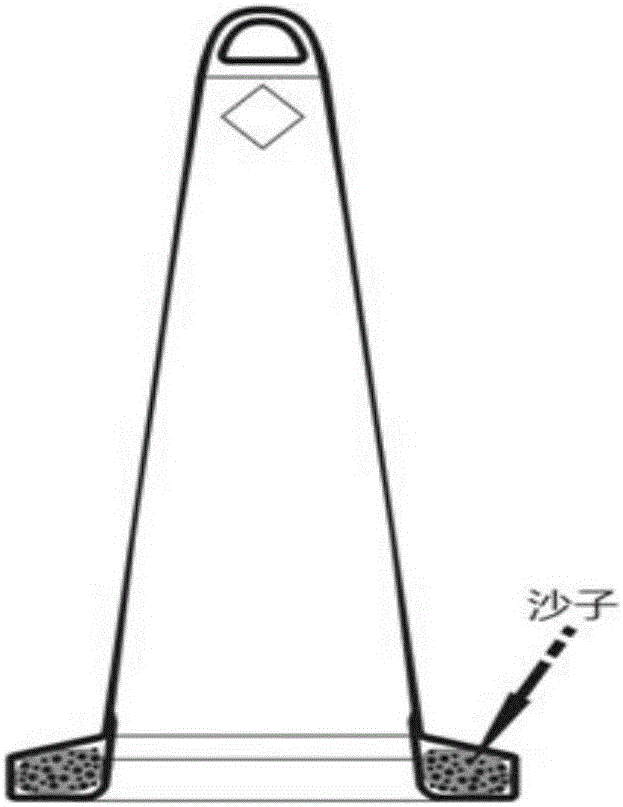

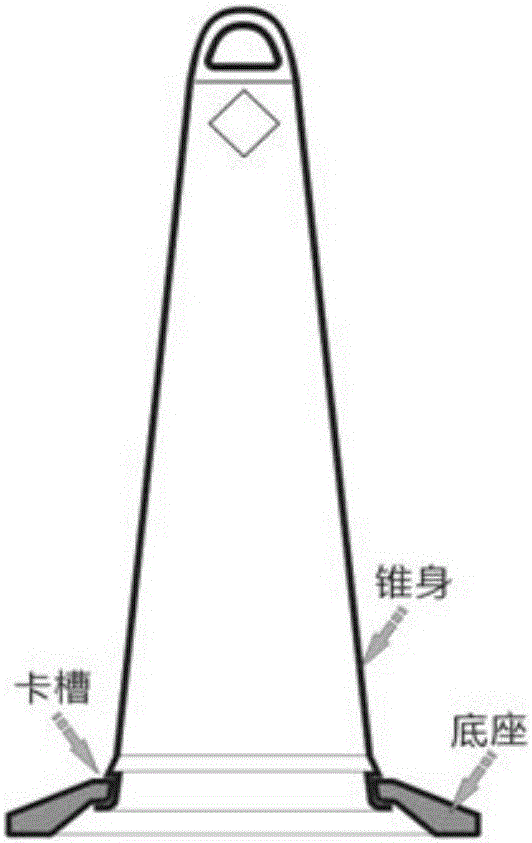

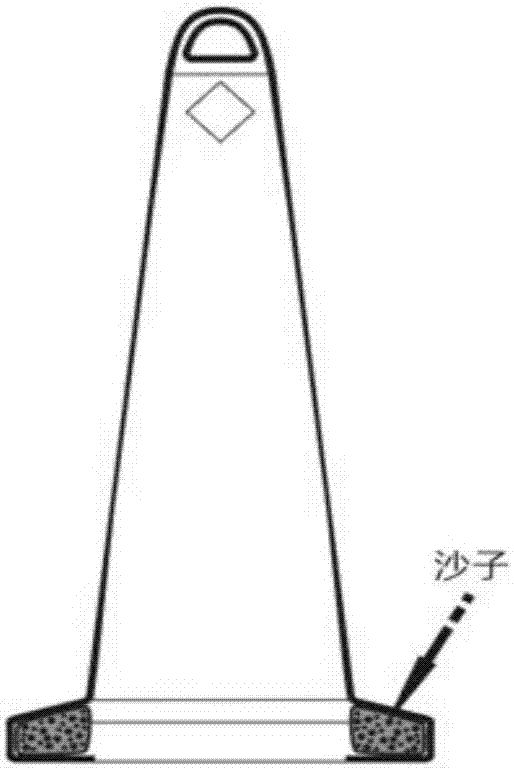

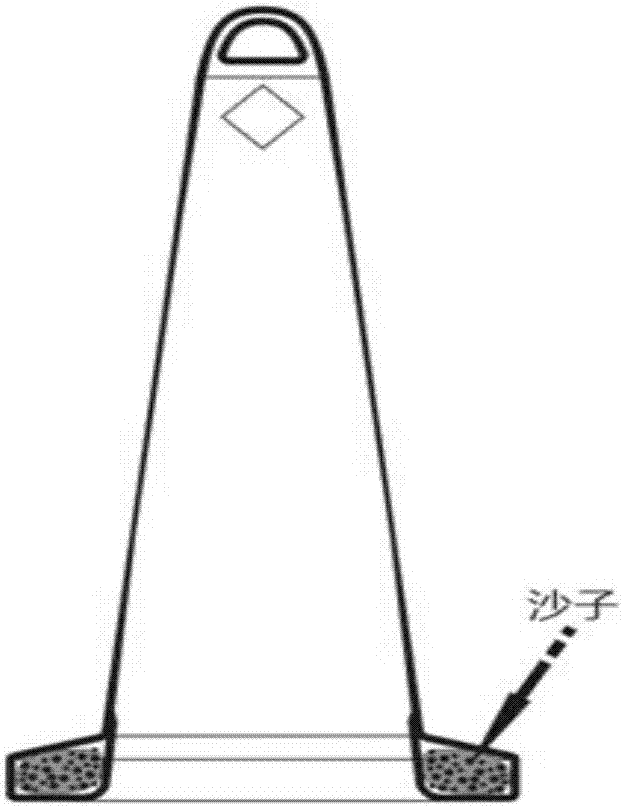

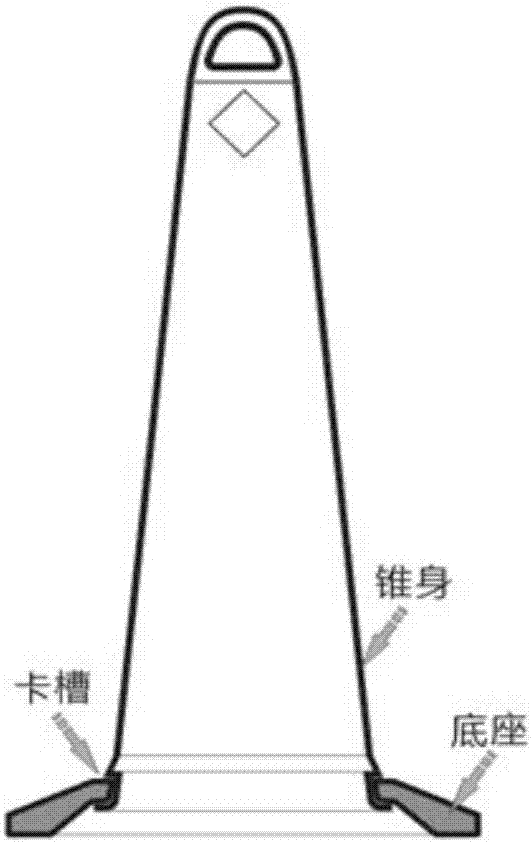

Disposable assembled formation processing method for split type traffic roadblock

ActiveCN105690744AMeet the needs of different product weightsLess assembly workTraffic signalsRoad signsBlow moldingEngineering

The invention discloses a disposable assembled formation processing method for a split type traffic roadblock. The disposable assembled formation processing method comprises the following steps: selecting raw materials, cleaning a die, pre-softening (drying the raw materials, heating and plastifying by an extruder and extruding a tube blank), closing the die, raising a lower die to form a sealed space between the lower die and a base, blow molding, backing off the lower die, then opening an upper die to obtain a product, and removing edge thorns from the product to finally obtain a finished product. According to the disposable assembled formation processing method, as pressure in a die cavity is utilized in the preparation method, a conical body material completely wraps the contact surface of the base and a conical body, and combination is firmer; and in addition, the conical body also has the natural phenomenon of cooling shrinkage to more tightly and firmly grasp the base, so that the phenomenon that the base is separated from the conical body becomes nearly impossible. The disposable assembled formation processing method also reduces assembly work in later period and can directly lower the production cost.

Owner:黄耿忠

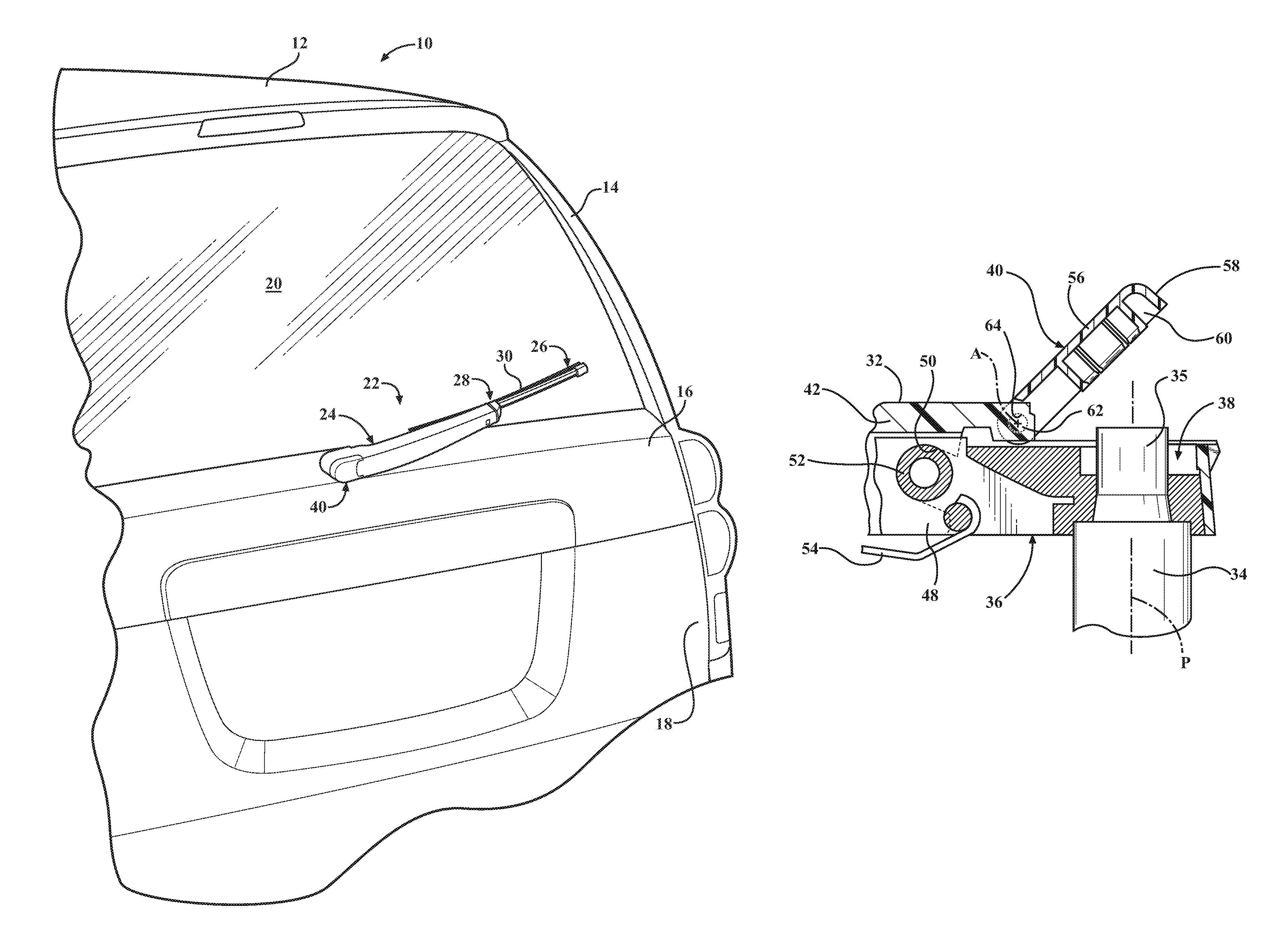

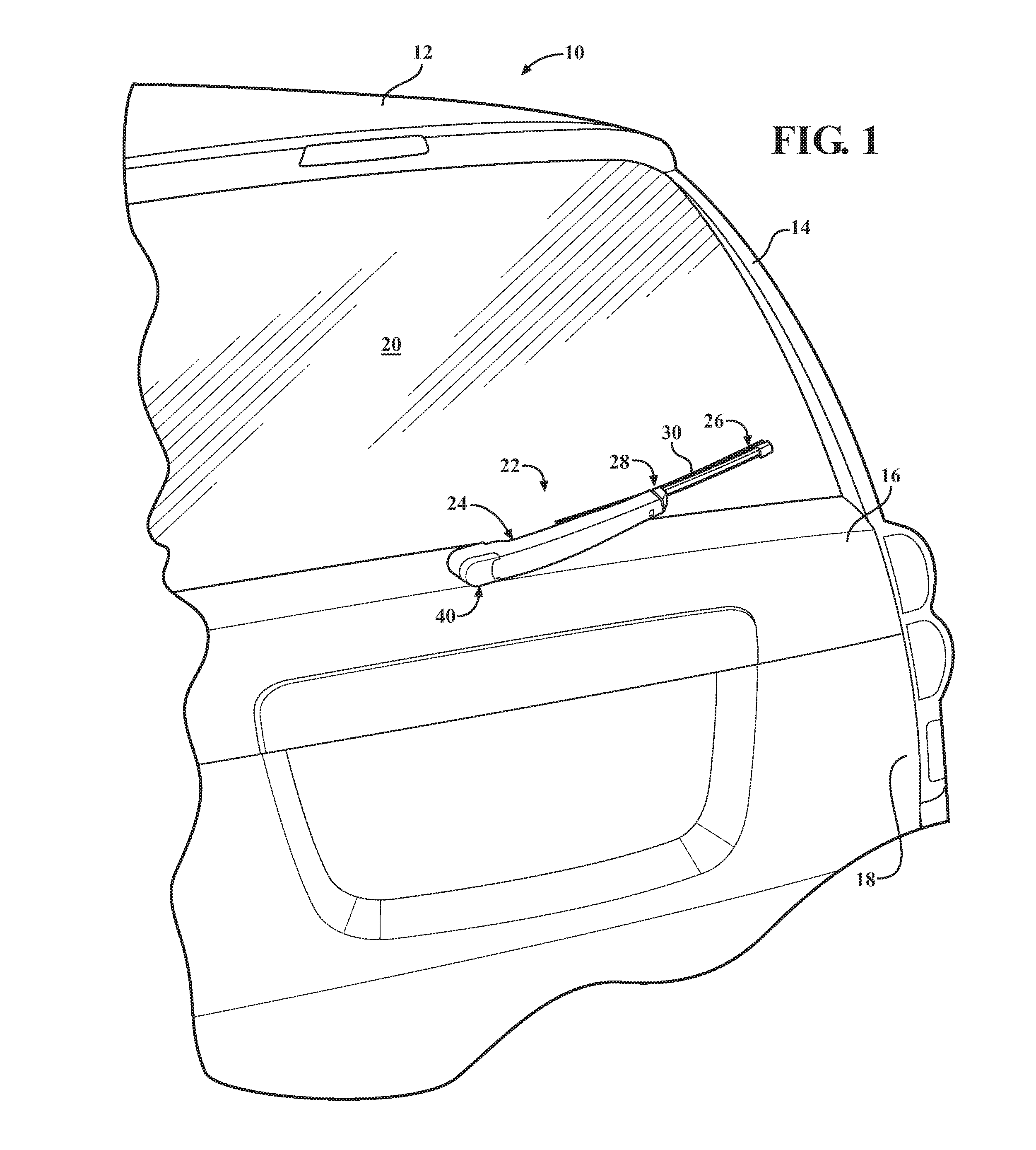

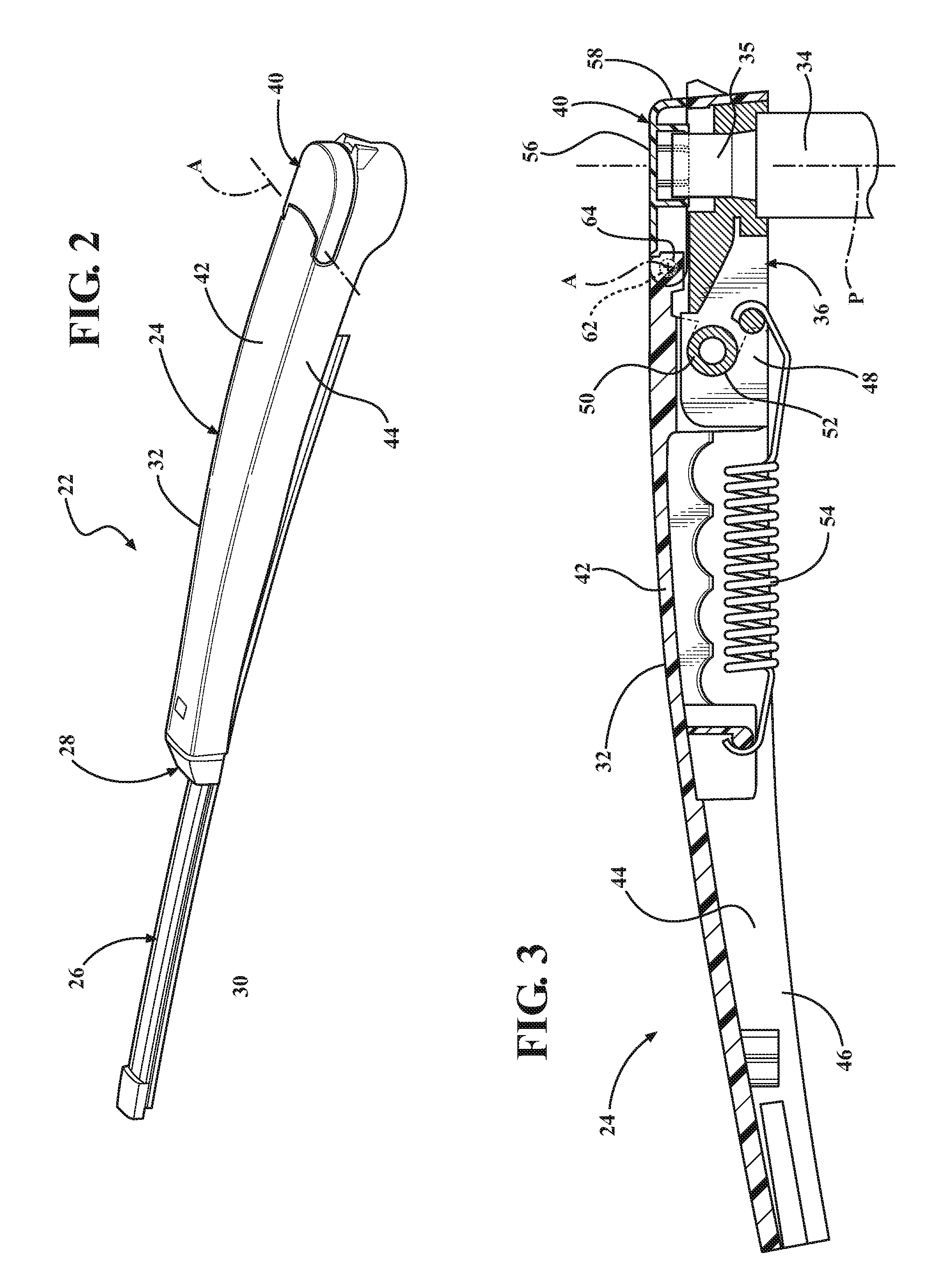

Wiper arm assembly having pivotal cover allowing access to pivot shaft

A wiper arm assembly is adapted to support a wiper blade as it moves across a surface to be wiped. The wiper arm assembly includes a body and a head supported by the body and adapted to be mounted to a pivot shaft that defines a pivot axis P and drives the wiper blade in an oscillating manner across the surface to be wiped. The body also includes an opening providing access to the head mounted to the pivot shaft. The wiper arm assembly includes a cover pivotally mounted to the body at the opening and is movable about an axis A substantially perpendicular to the pivot axis P from a first position closing the opening to a second position allowing access to the head. A locking mechanism on the cover locks the cover to a nut on the pivot shaft to retain the cover in the first position closing the opening.

Owner:TRICO PROD CORP

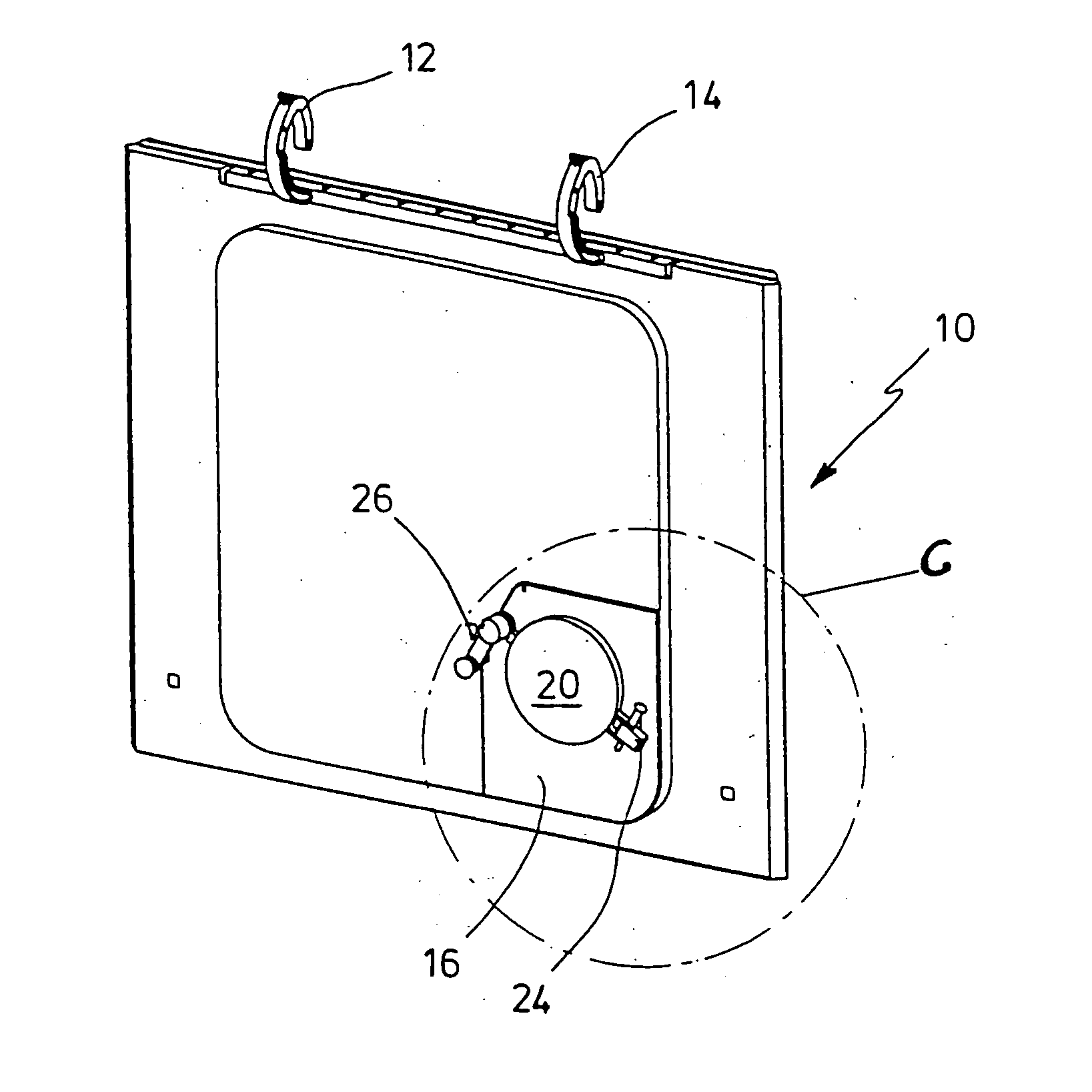

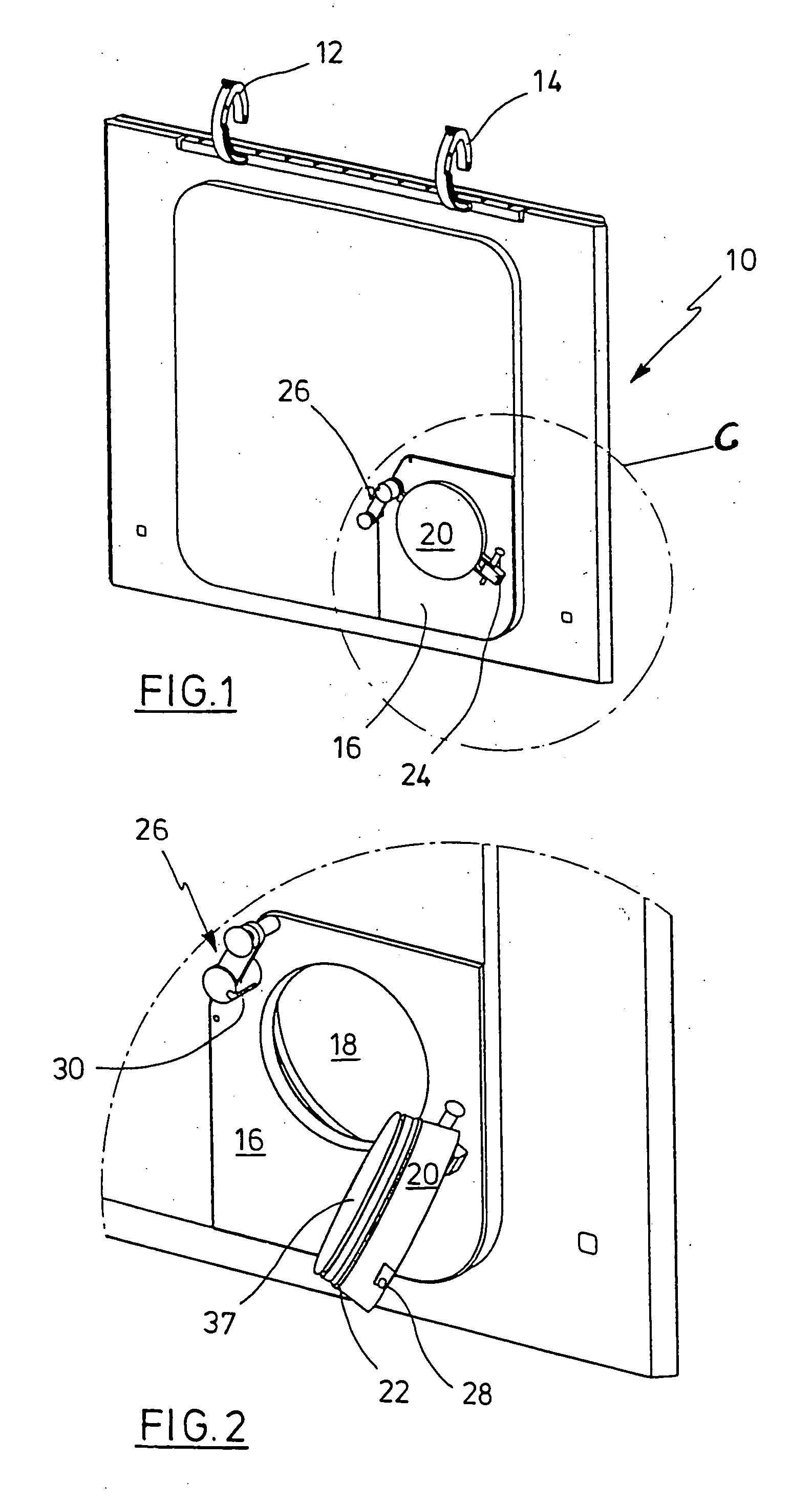

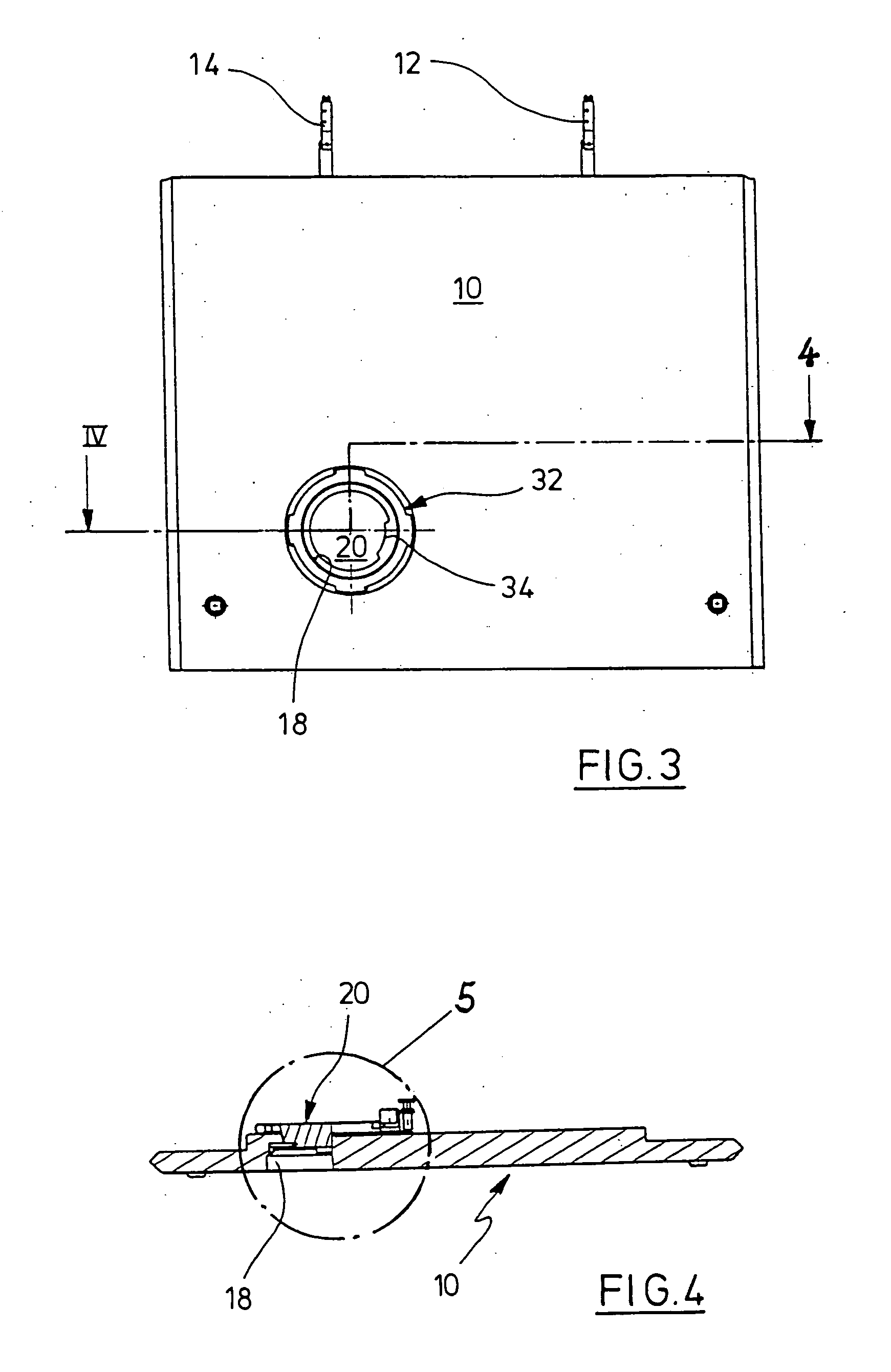

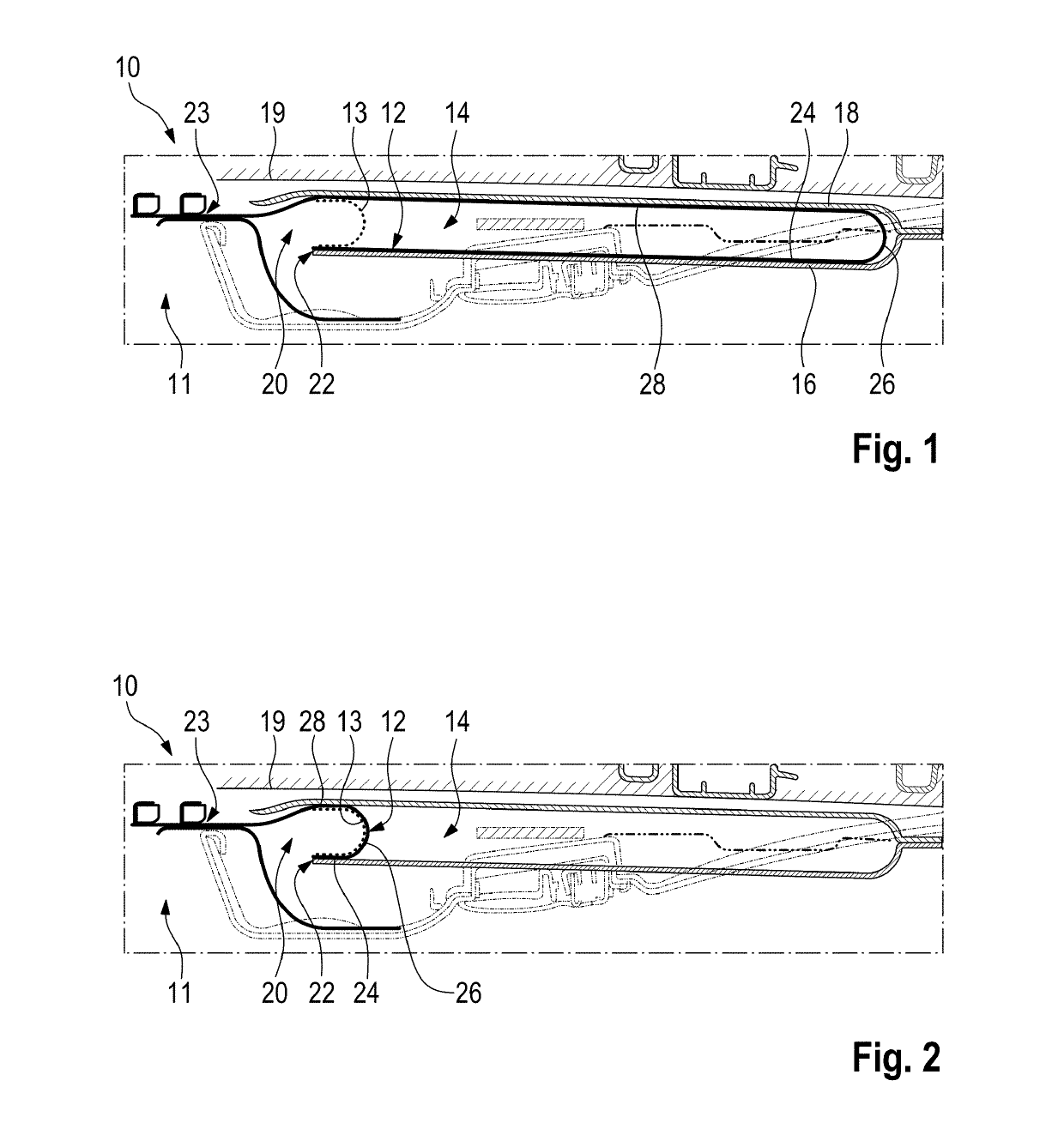

Shading blind for a roof window of a motor vehicle

A shading blind for a roof window of a motor vehicle is disclosed, having two guide rails, a roller blind element which has two lateral, flexible guide structures with which it is guided in the guide rails, and a receiving space for the roller blind element, the roller blind element being adjustable between an extended position in which it is largely located outside the receiving space, and a retracted position in which it is largely located in the receiving space, wherein the receiving space, measured in the adjustment direction of the roller blind element, has a length which is approximately half of the adjustment path between the extended and the retracted positions, the height of the receiving space, measured perpendicularly to the plane of the roller blind element located between the guide rails, is such that when the roller blind element is deflected in the receiving space by approximately 180°, the guide structures are only elastically deformed and a rear edge of the roller blind element is permanently attached in the receiving space.

Owner:ROOF SYST GERMANY

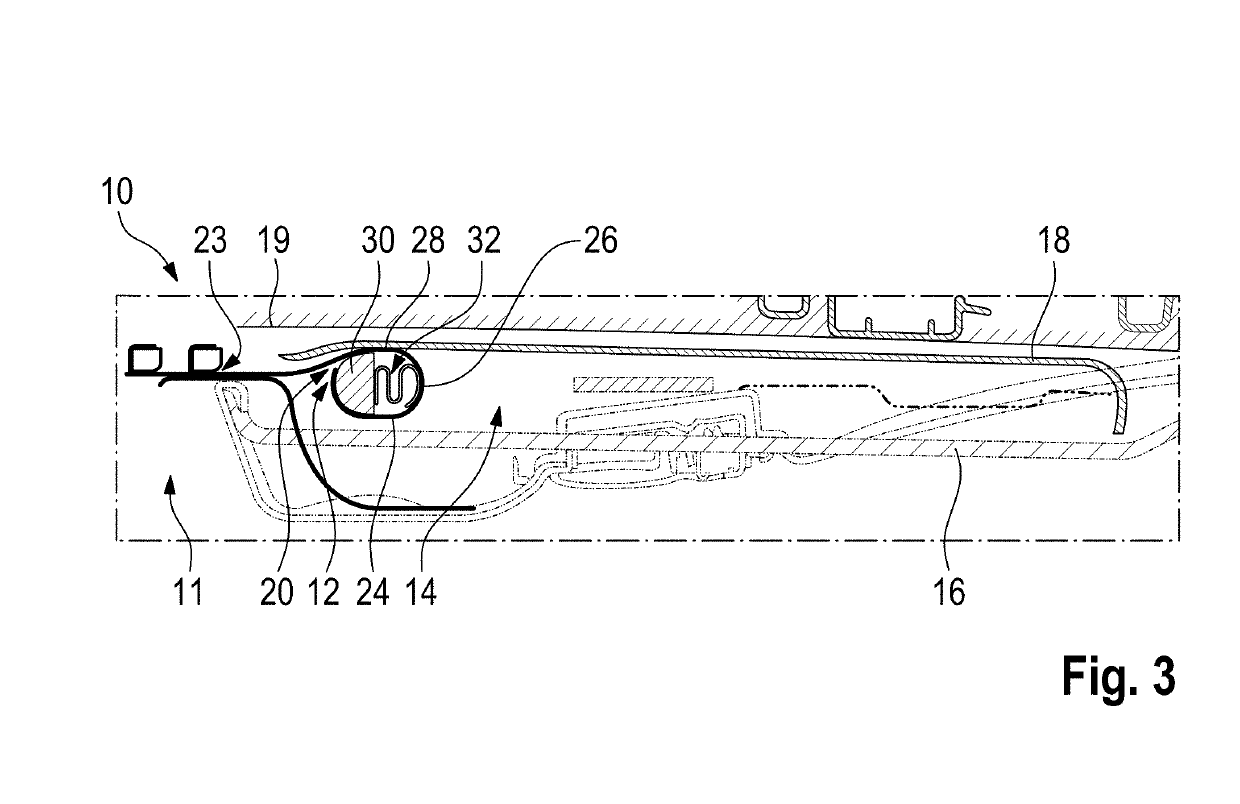

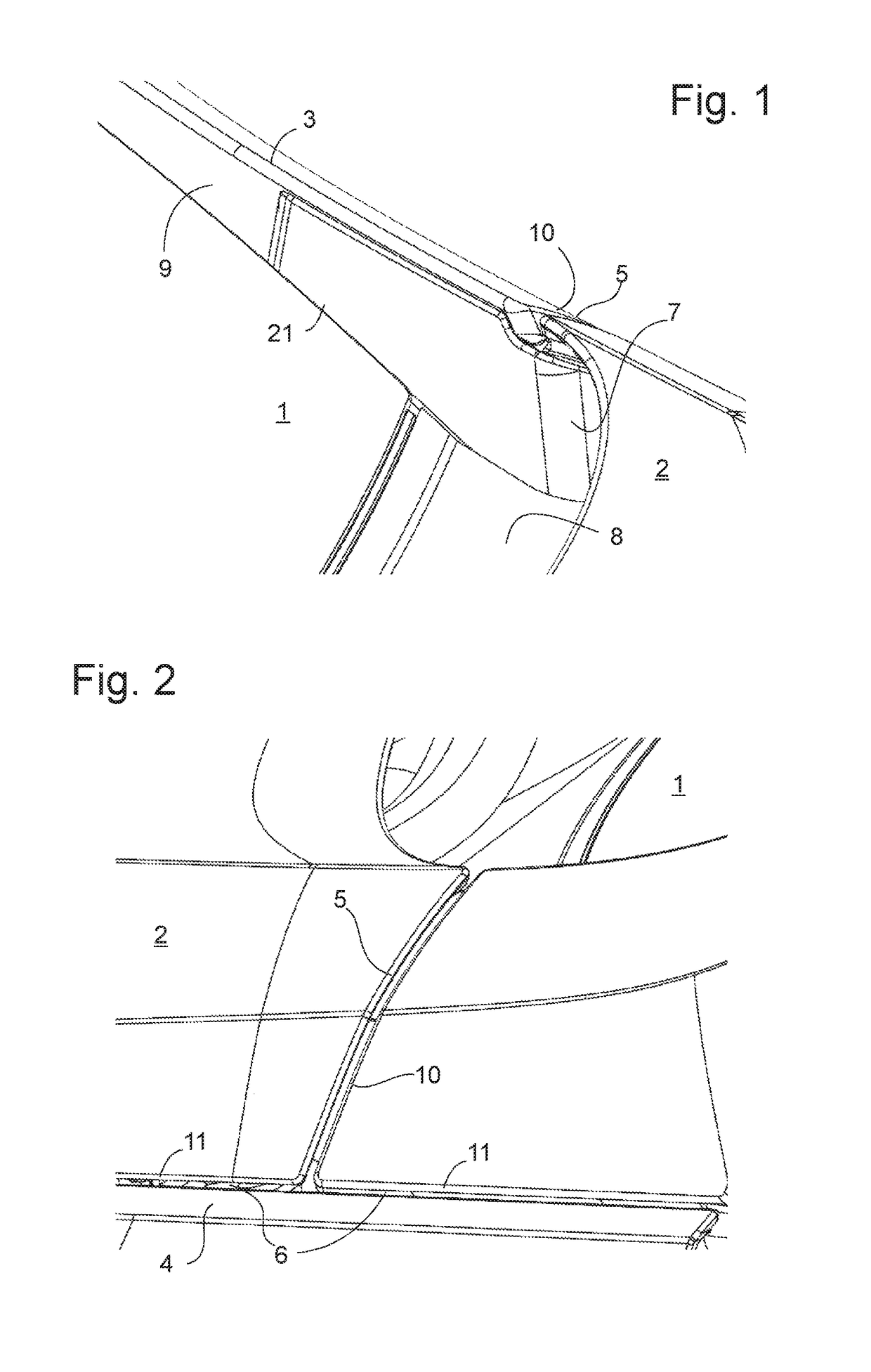

Motor vehicle body with filler piece

InactiveUS9821855B2Minimize impactThe implementation process is simpleSuperstructure subunitsRoofsElectrical and Electronics engineeringWindshield

A motor vehicle body includes an A-pillar panel, an outer skin body panel, which together with an edge of the A-pillar panel delimits a gap. A windshield is adjacent to a longitudinal edge of the A-pillar panel. A filler piece has a first portion which fills out the gap and a second portion which conceals a gap between the longitudinal edge of the A-pillar panel and the windshield.

Owner:GM GLOBAL TECH OPERATIONS LLC

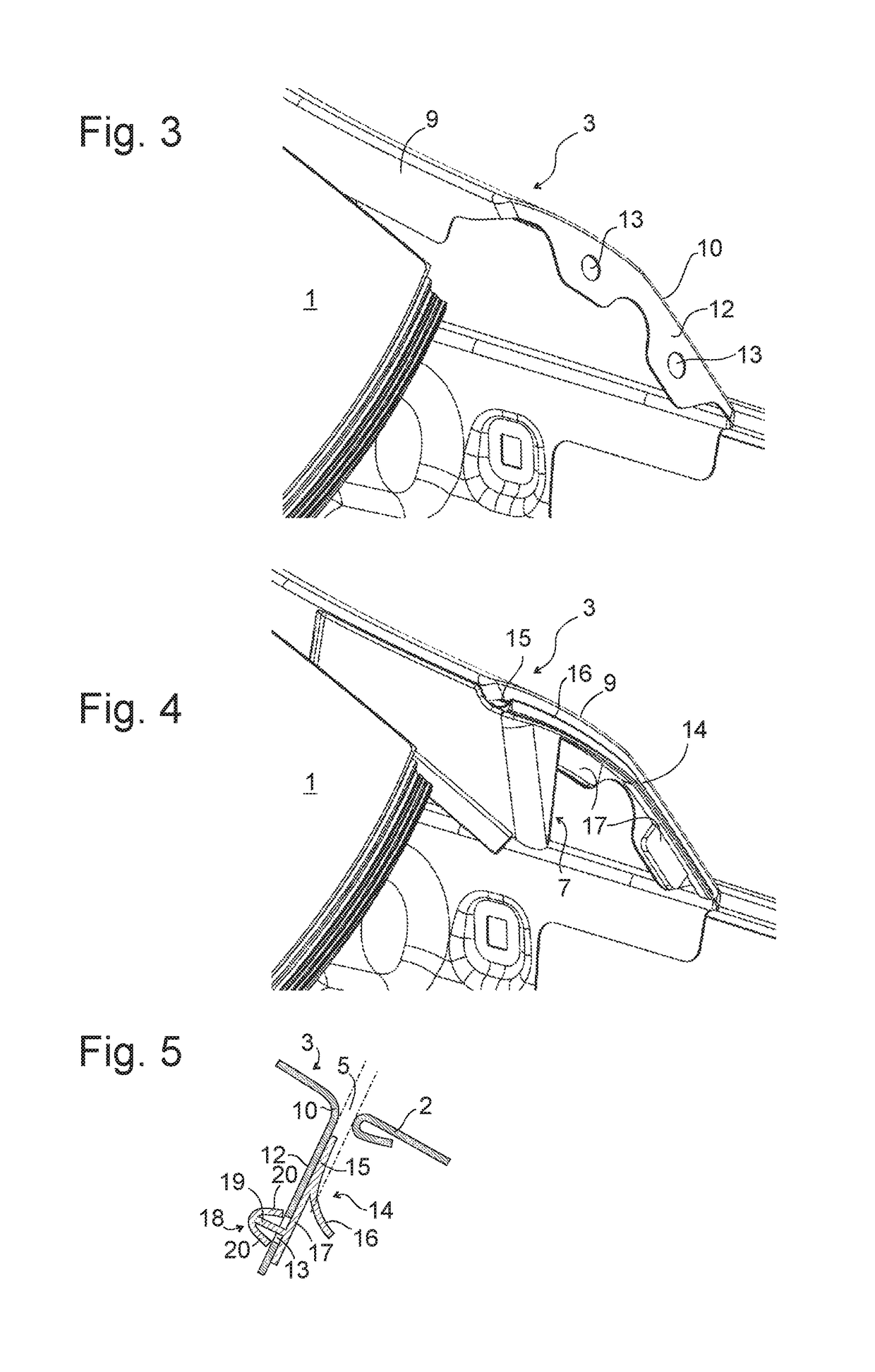

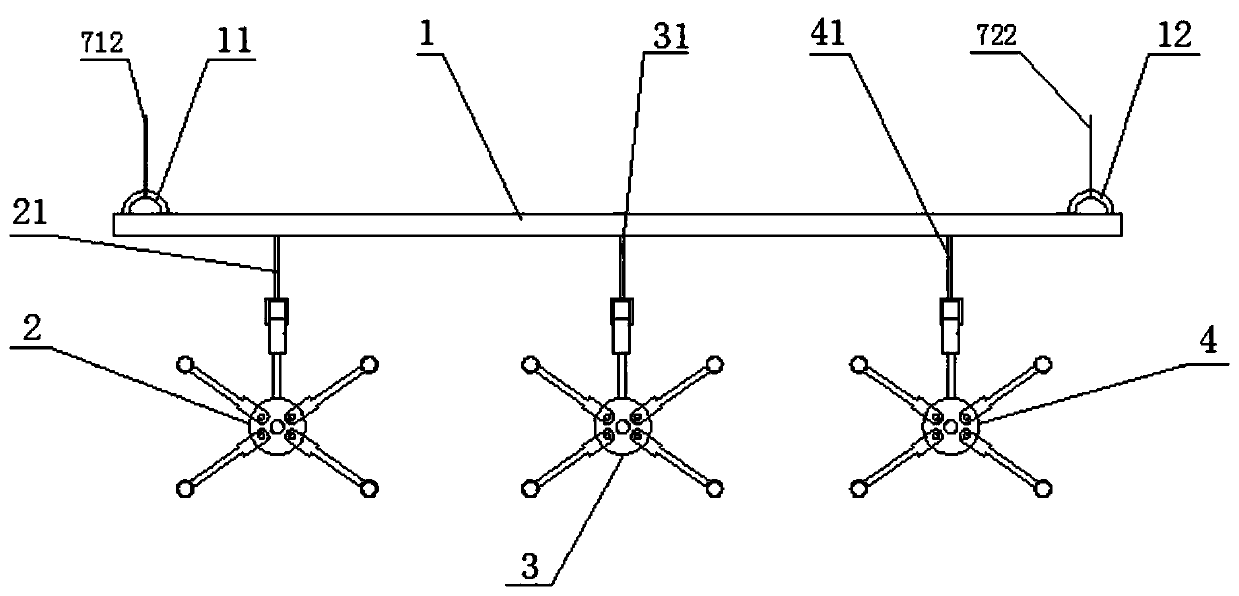

An integral hoisting device for building curtain wall glass and its working method

ActiveCN109052136BLess assembly workWork fasterLoad-engaging elementsSynchronous motorArchitectural engineering

The invention discloses an integral hoisting equipment for building curtain wall glasses and a working mode thereof. The equipment comprises a hoisting cross beam, a first sucker, a second sucker, a third sucker, curtain wall glasses, a hoisting truss and a synchronous motor. The first sucker, the second sucker and the third sucker are arranged below the hoisting cross beam side by side, the curtain wall glasses adsorb on the first sucker, the second sucker and the third sucker. The hoisting truss is arranged at a top end of the building, synchronous motors are mounted on two sides of a same side of the hoisting truss, and the hoisting cross beam is hoisted by the synchronous motors through cables. According to the integral hoisting equipment for the building curtain wall glass, the working difficulty of operators is reduced by splicing the curtain wall glasses on the ground, the flatness and stability of the spliced curtain wall glasses are well controlled, and the mounting operationspeed of the curtain wall glasses is accelerated.

Owner:湖北麻一建设有限公司

Light-emitting device with alternating arrangement of anode pads and cathode pads

ActiveUS9748511B2Improve homogeneityReduce effortSolid-state devicesSemiconductor/solid-state device manufacturingElectrical connectorLight emission

The invention relates to a light-emitting device like an OLED comprising a light emission region between an anode (5) and a cathode (6). An alternating arrangement (9) of anode pads (11) for electrically connecting the anode and cathode pads (10) for electrically connecting the cathode and an encapsulation (8) are configured such that the anode and cathode pads are electrically connectable by straight anode and cathode electrical connectors (3, 4) through openings (12) of the encapsulation. The alternating arrangement of the anode and cathode pads can lead to a more homogenous electrical field between the anode and the cathode and therefore allows for an improved degree of homogeneity of light emission. More, since the alternating arrangement of the anode and cathode pads is connectable by corresponding straight connectors, the contacting of the pads can be performed technically relatively easily.

Owner:OLEDWORKS GMBH

Disposable assembly molding processing method for split traffic barricade

ActiveCN105690744BEasy to holdImprove bindingTraffic signalsRoad signsBlow moldingAtmospheric pressure

The invention discloses a disposable assembled formation processing method for a split type traffic roadblock. The disposable assembled formation processing method comprises the following steps: selecting raw materials, cleaning a die, pre-softening (drying the raw materials, heating and plastifying by an extruder and extruding a tube blank), closing the die, raising a lower die to form a sealed space between the lower die and a base, blow molding, backing off the lower die, then opening an upper die to obtain a product, and removing edge thorns from the product to finally obtain a finished product. According to the disposable assembled formation processing method, as pressure in a die cavity is utilized in the preparation method, a conical body material completely wraps the contact surface of the base and a conical body, and combination is firmer; and in addition, the conical body also has the natural phenomenon of cooling shrinkage to more tightly and firmly grasp the base, so that the phenomenon that the base is separated from the conical body becomes nearly impossible. The disposable assembled formation processing method also reduces assembly work in later period and can directly lower the production cost.

Owner:黄耿忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com