Overall type steel-based platform static load test load piling method for civil engineering

A technology for civil engineering and static load testing, applied in the testing of infrastructure, infrastructure engineering, construction, etc., can solve the problems of increasing detection auxiliary time, increasing detection cost, extending project construction period, etc., to reduce platform transfer work and save money. The effect of hoisting machinery and saving installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

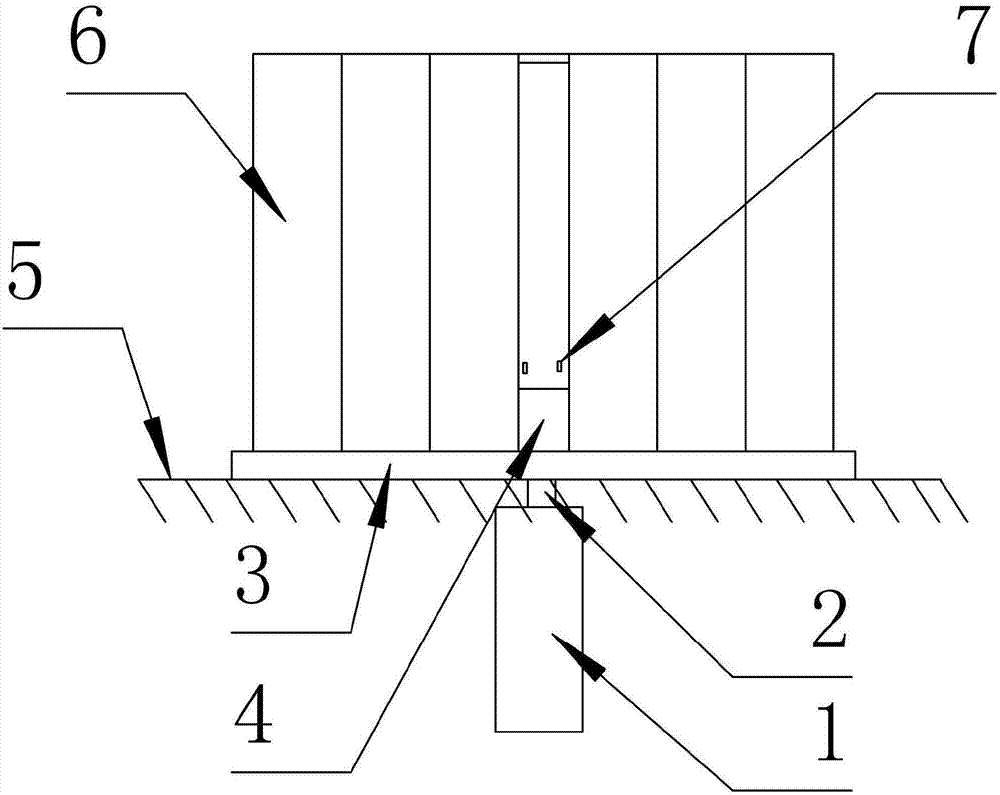

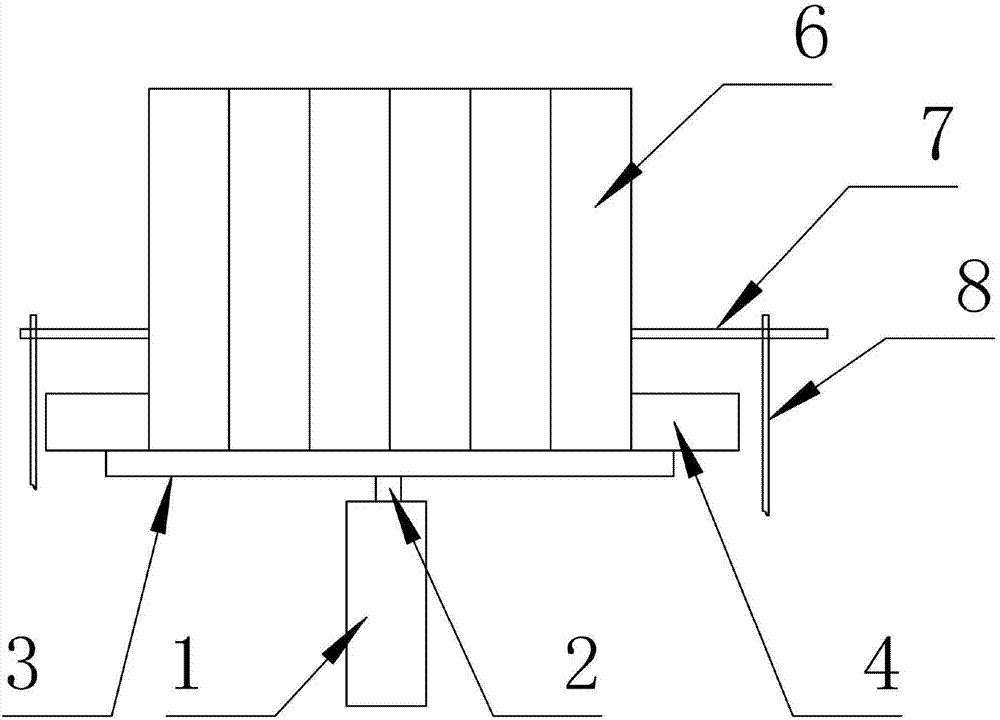

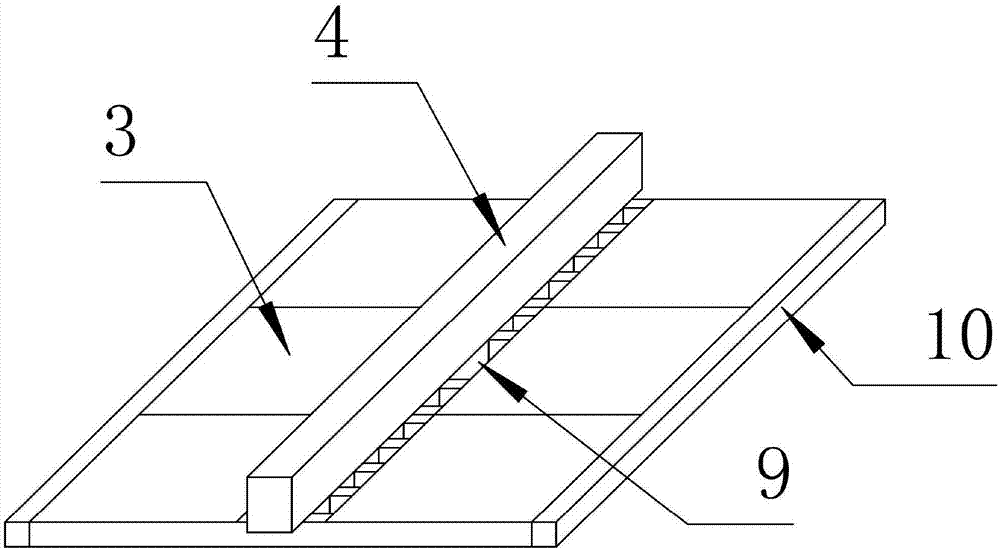

[0079] Such as Figure 1~3 As shown, a kind of static load test stacking method for civil engineering with integral steel-based platform described in this embodiment is characterized in that it is carried out according to the following steps:

[0080] a. Select the type and number of jacks according to the size of the test load;

[0081] b. Determine the ground elevation according to the height of the jack, the height of the main beam and the steel platform, and the elevation of the test point required by the design;

[0082] c. Level the site after determining the ground elevation, and the site under the steel-based platform is required to be level and uniform;

[0083] d. Lay out the line on the field with the test point as the center to determine the outer edge line of the steel-based platform so that the center of gravity of the platform coincides with the center of the test point;

[0084] e. Spread the medium-coarse sand on the test point and level it and place the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com