Patents

Literature

3320 results about "Frictional resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frictional resistance is the net fore-and-aft forces upon the ship due to tangential fluid forces. Frictional resistance accounts for nearly 80 percent of total resistance in slow-speed ships like oil tankers and as much as 50 percent in high-speed ships like container vessels.

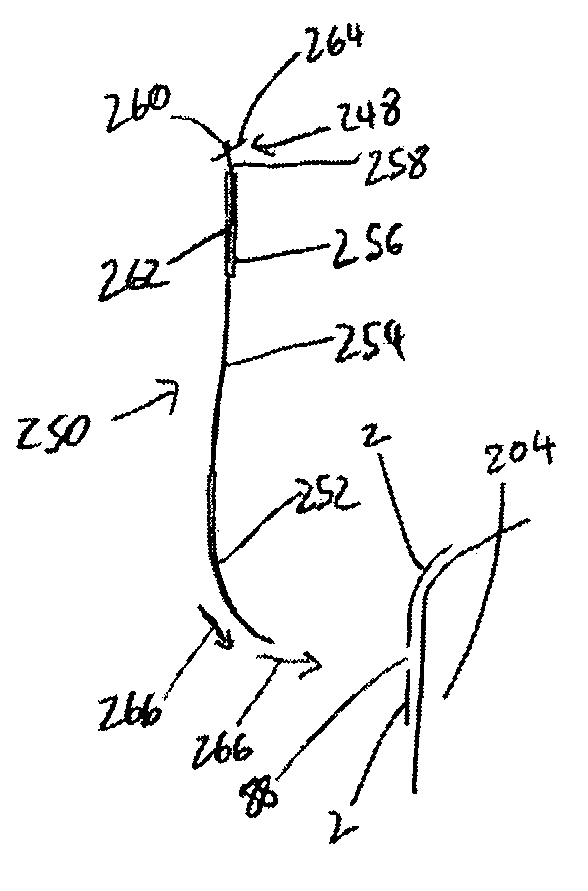

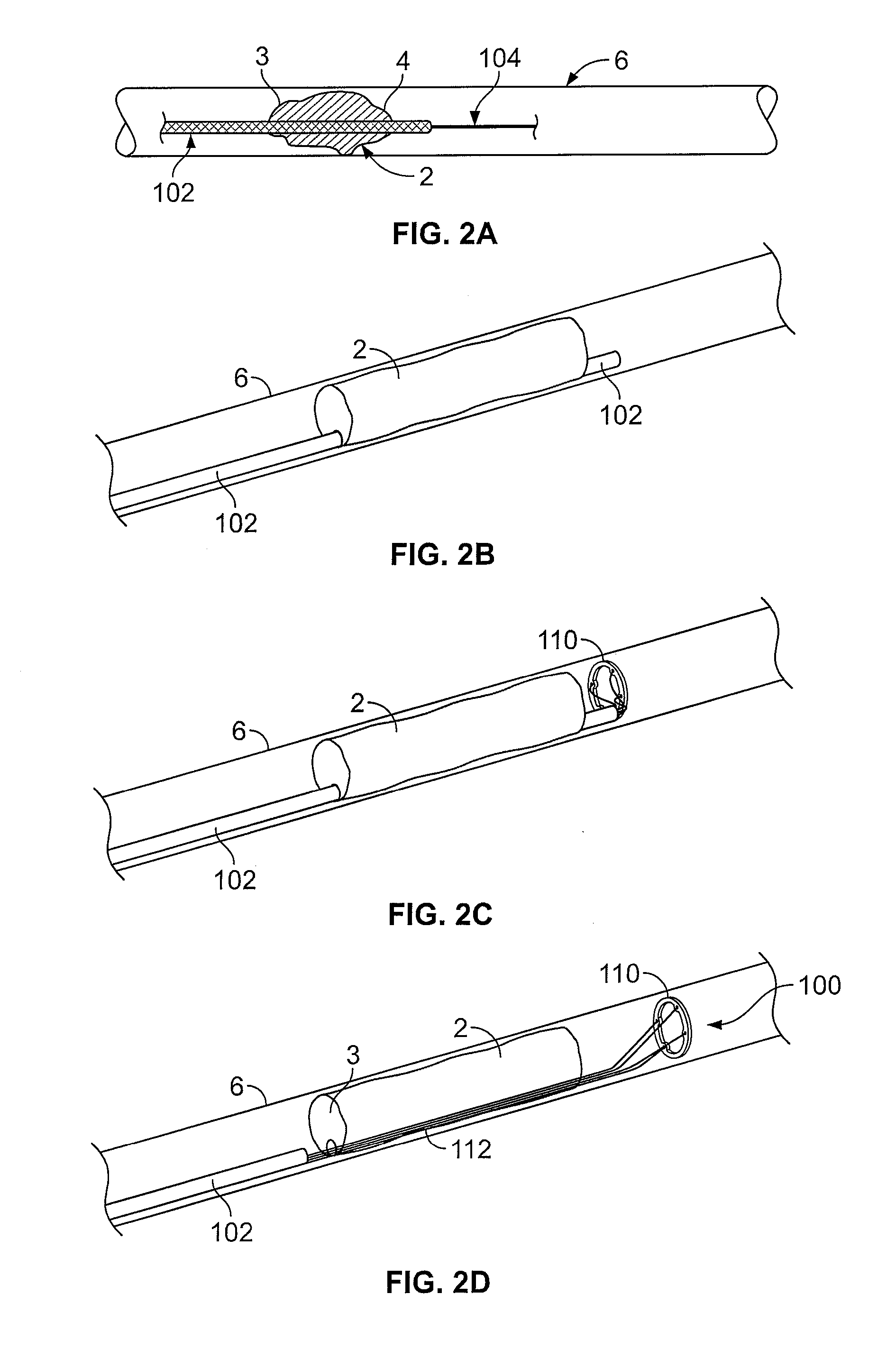

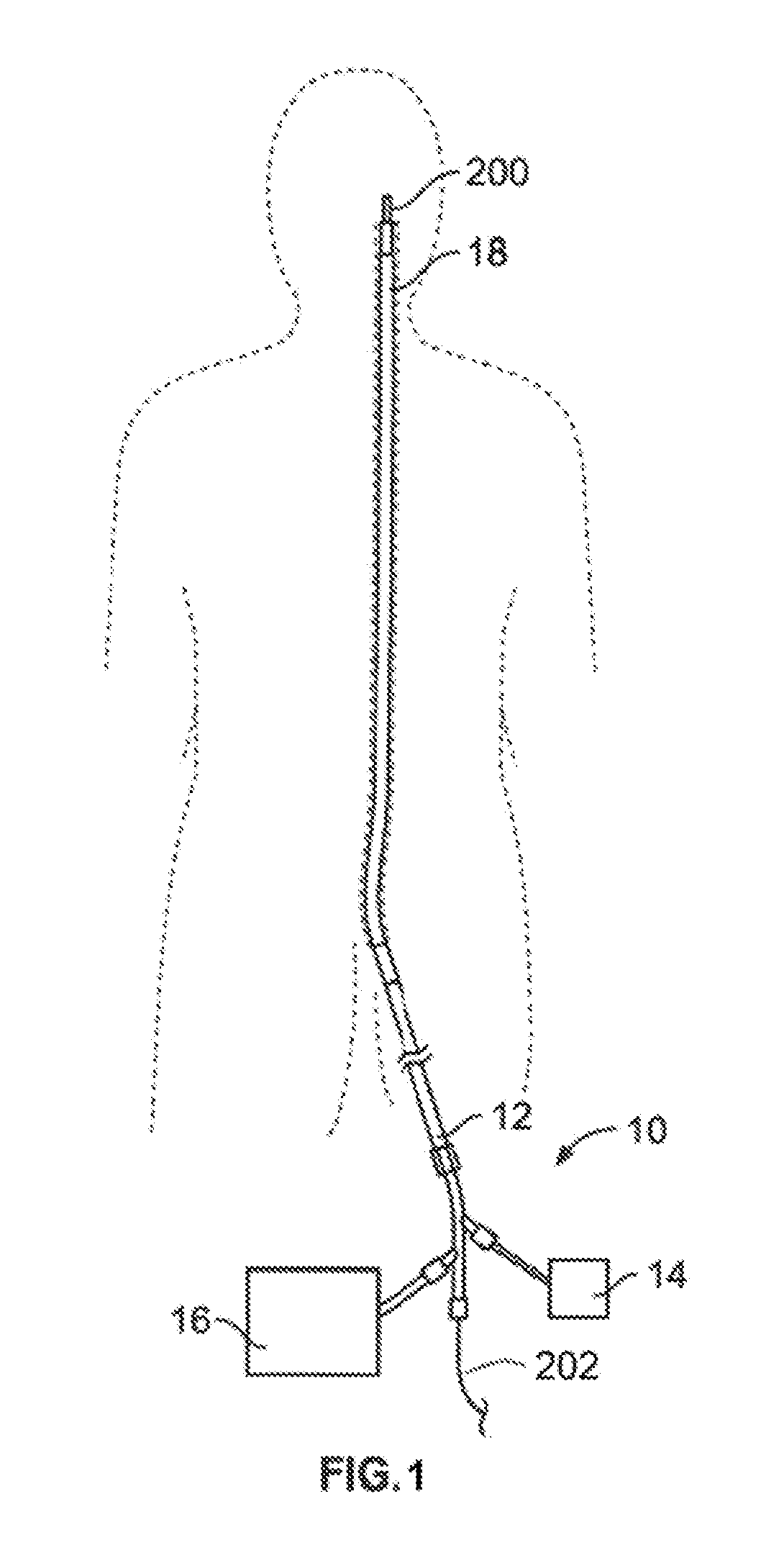

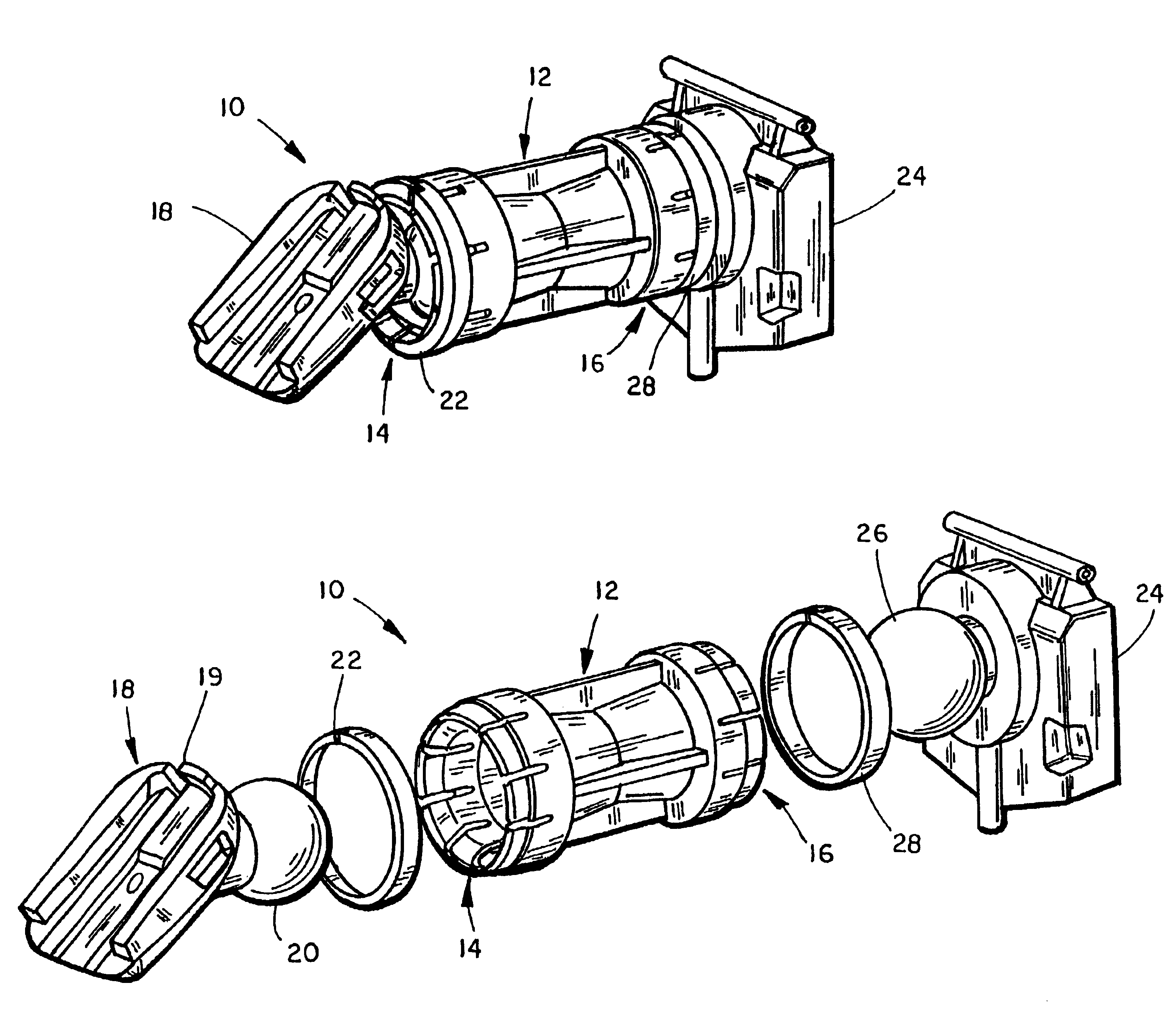

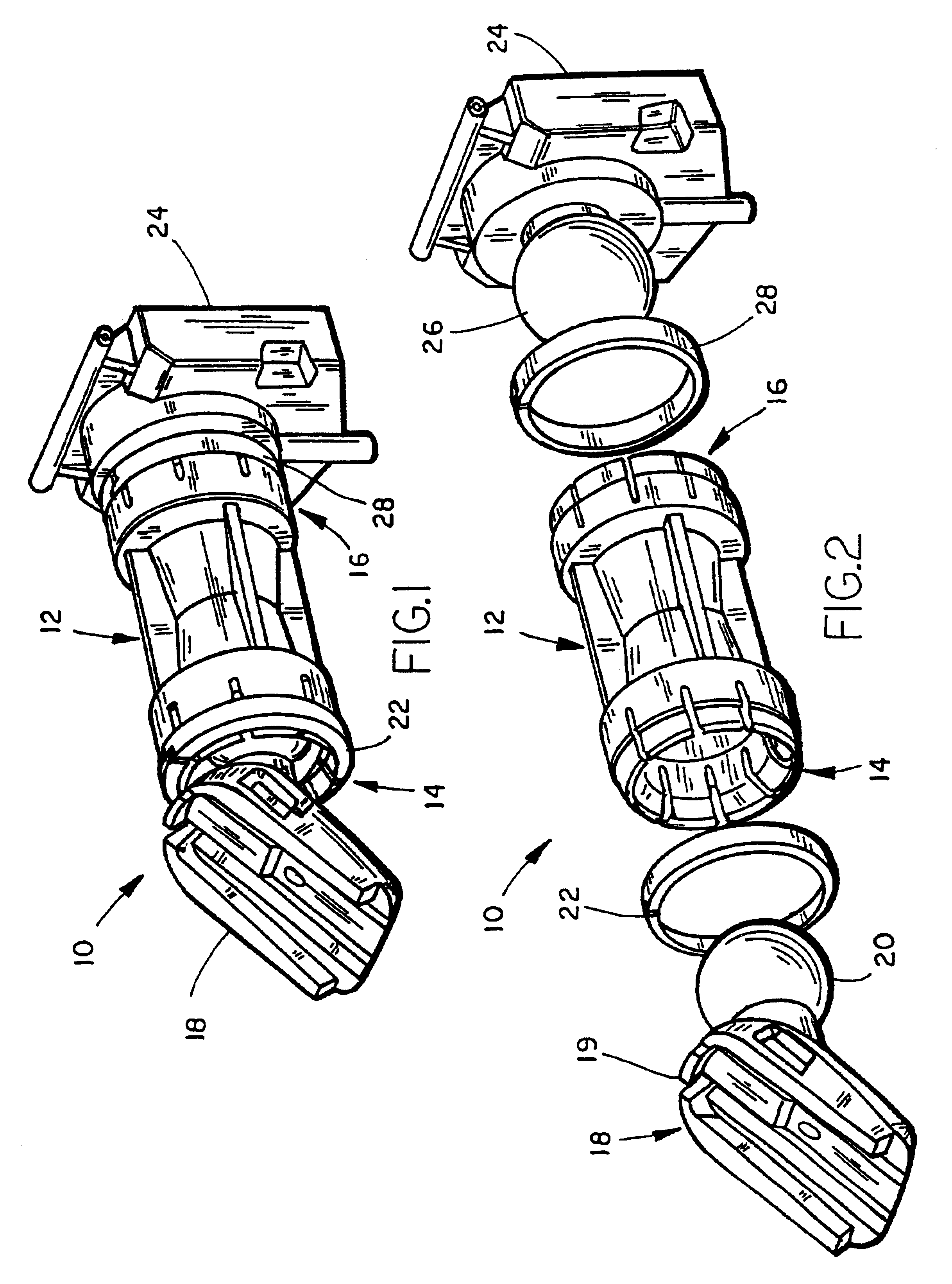

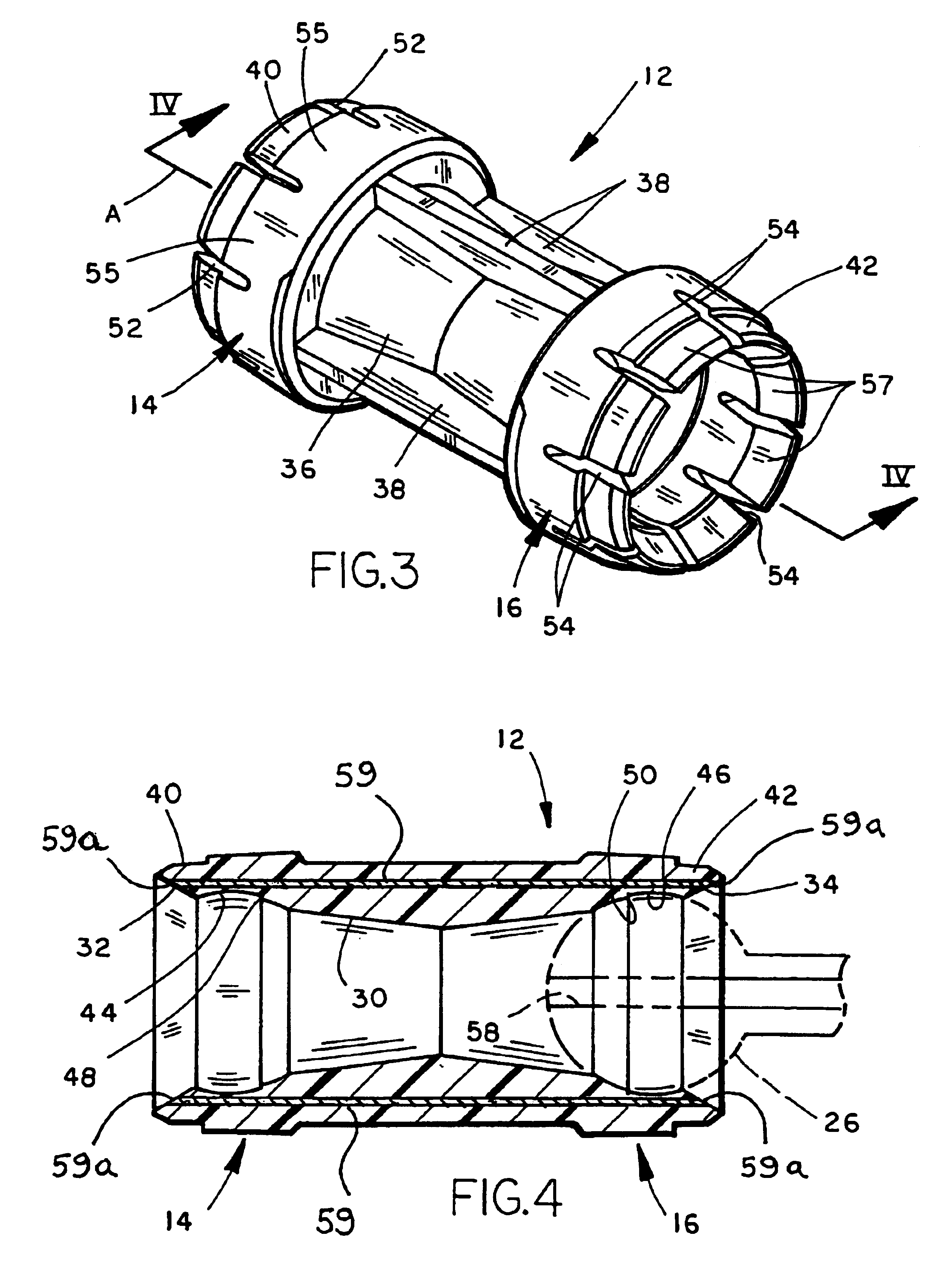

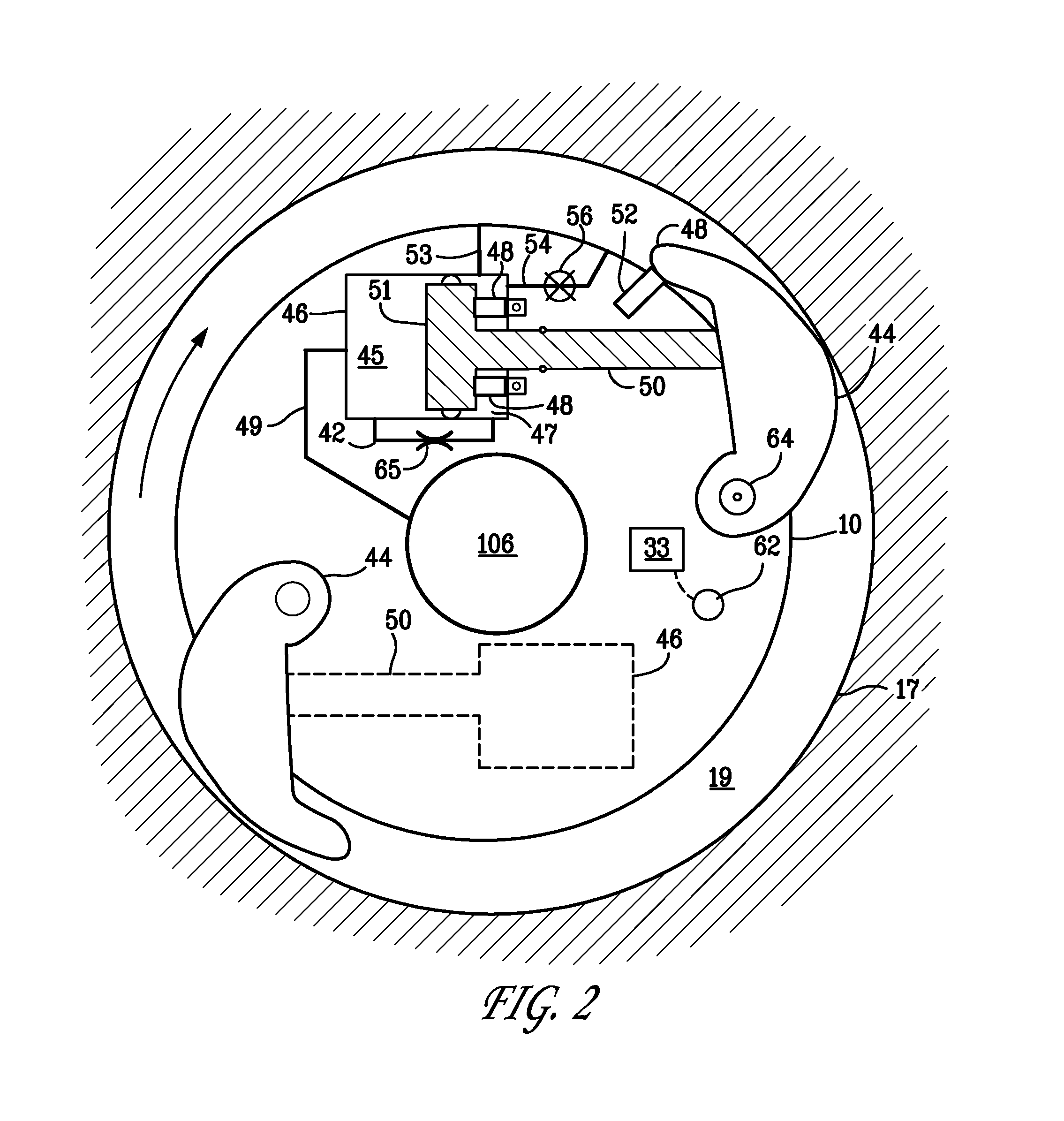

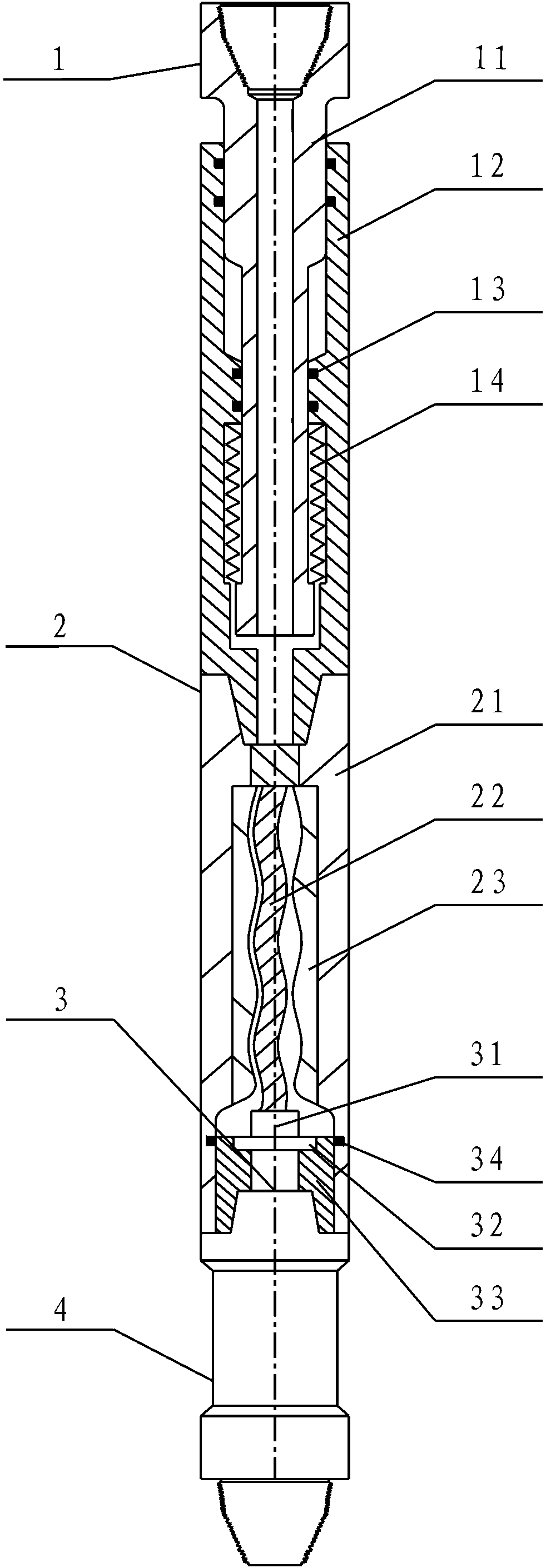

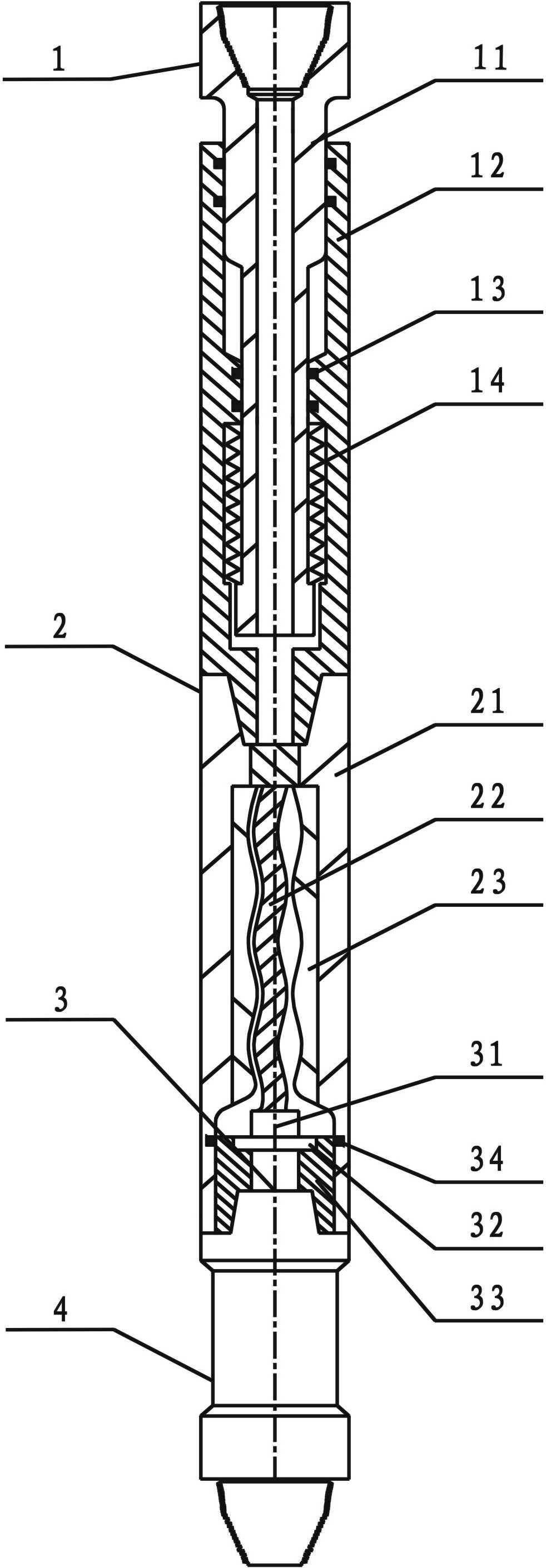

Fixturing assembly

A fixturing assembly is provided that includes a needle and a fixturing device. The needle includes a first sharpened end and a second end including a can. The fixturing device includes an elongate filament having first and second ends, and an enlarged fixturing device on the first end of the filament. The second end of the filament is held by the can by frictional resistance, the second end of the filament being removable from the can when a tensile force is applied between the needle and the second end of the filament that exceeds the frictional resistance. For example, the can may include a coil, corrugations, or a roughened inner surface to removably hold the end of the fixturing device.

Owner:MEDTRONIC INC

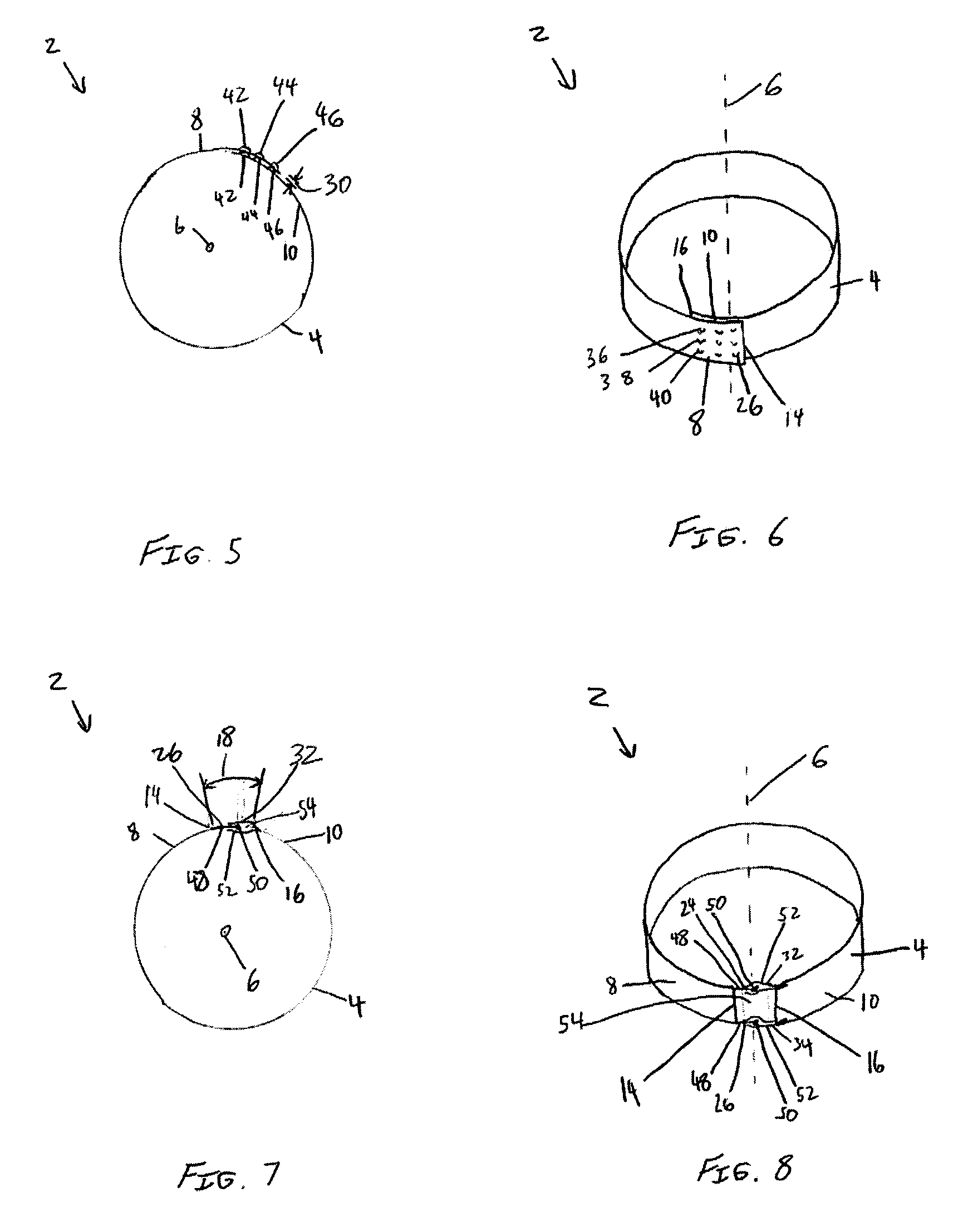

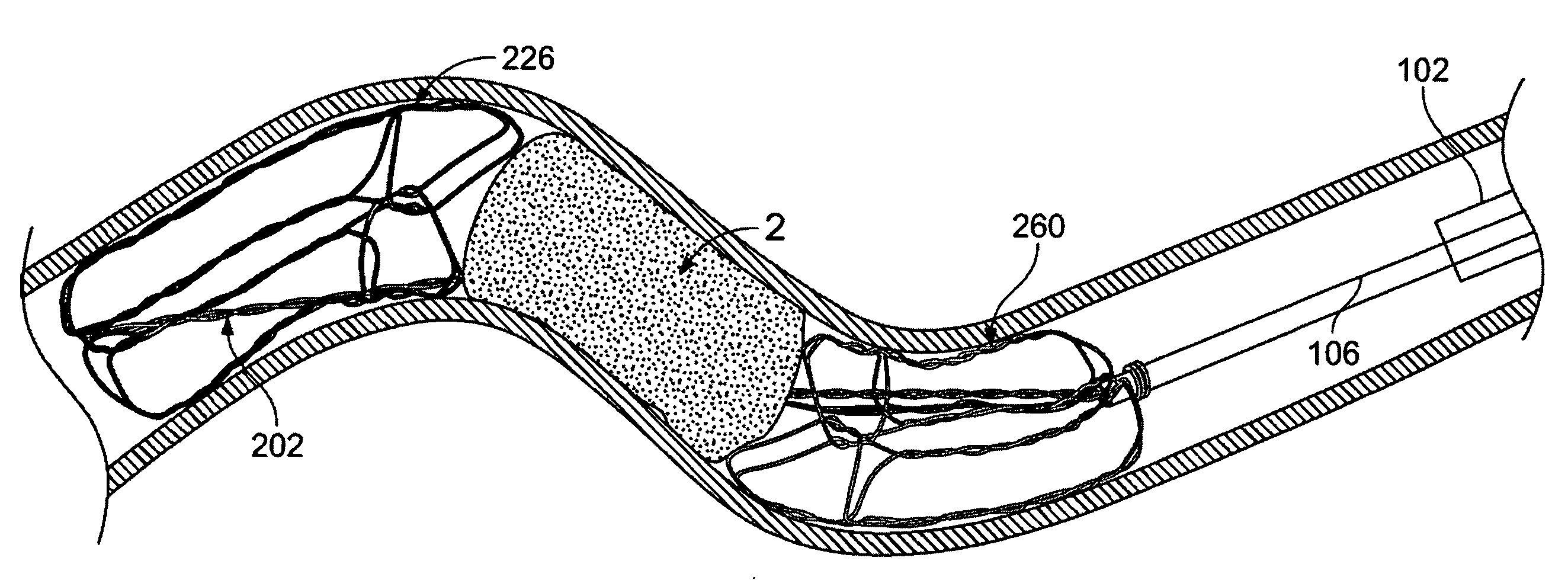

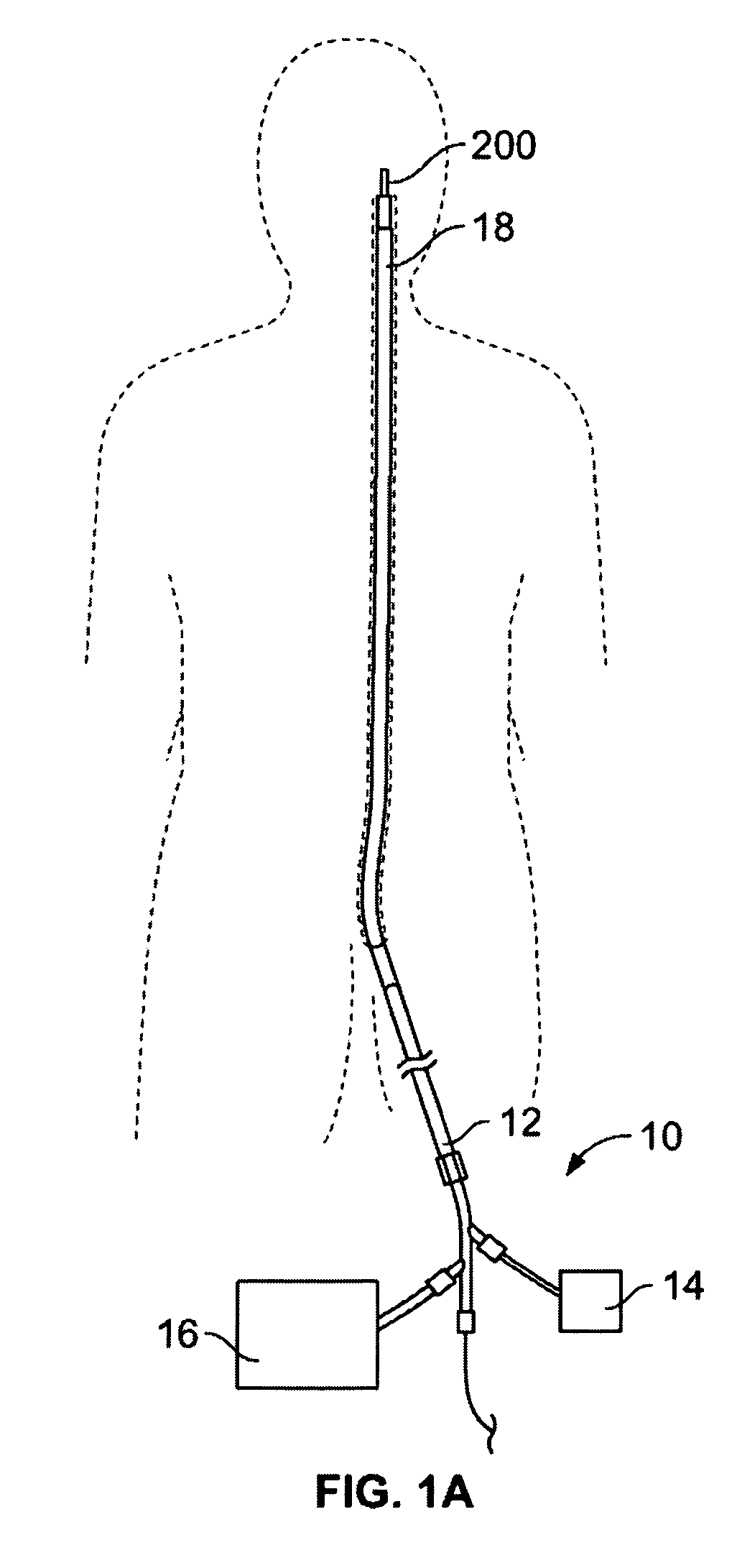

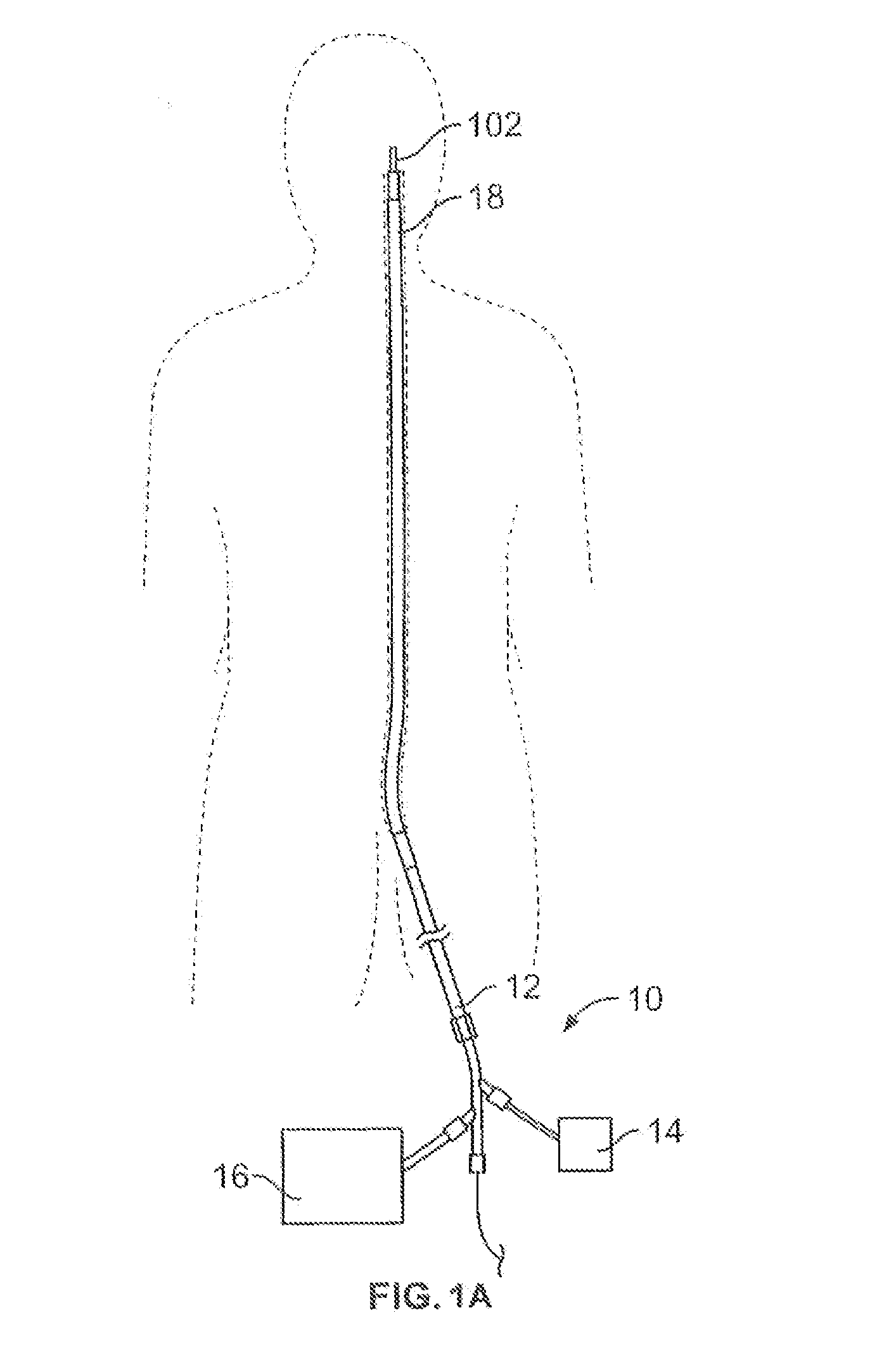

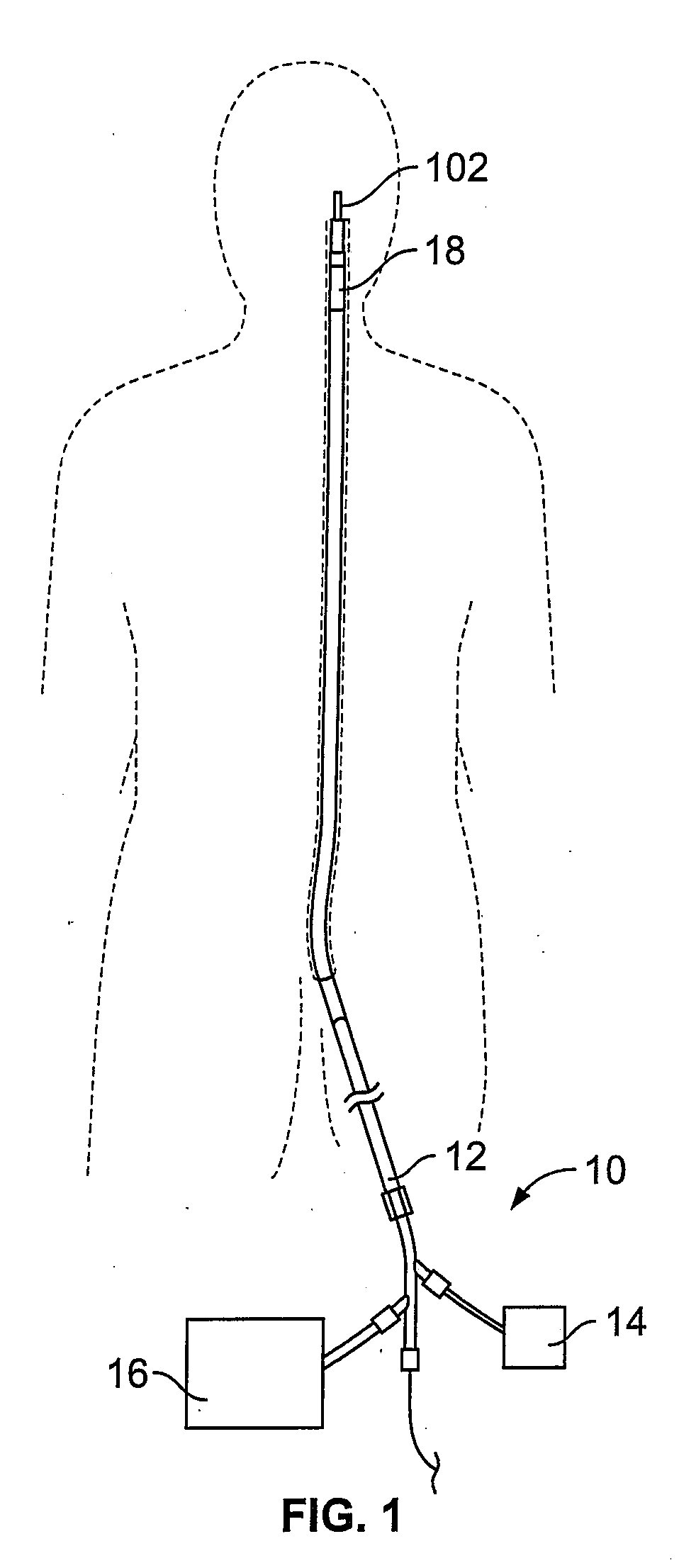

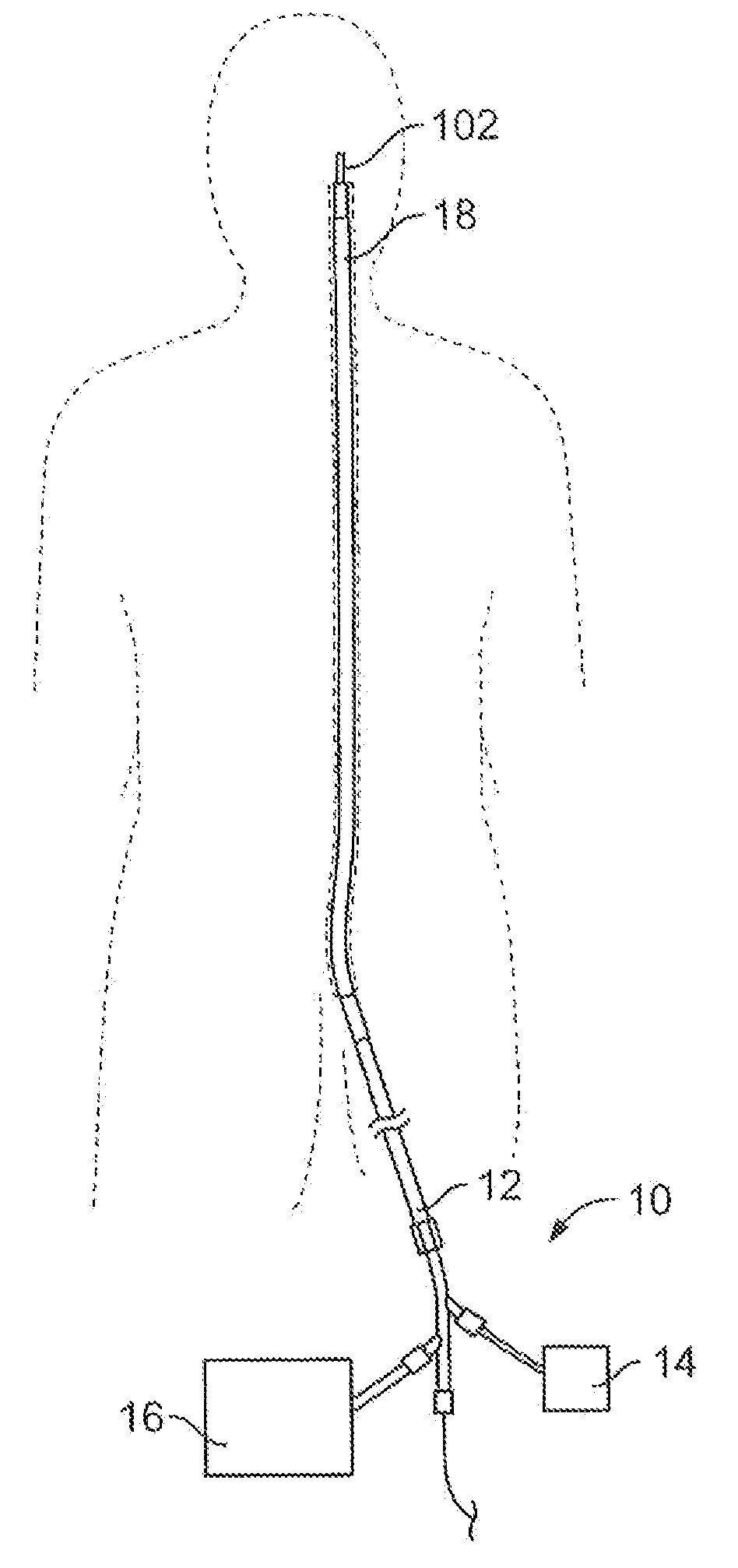

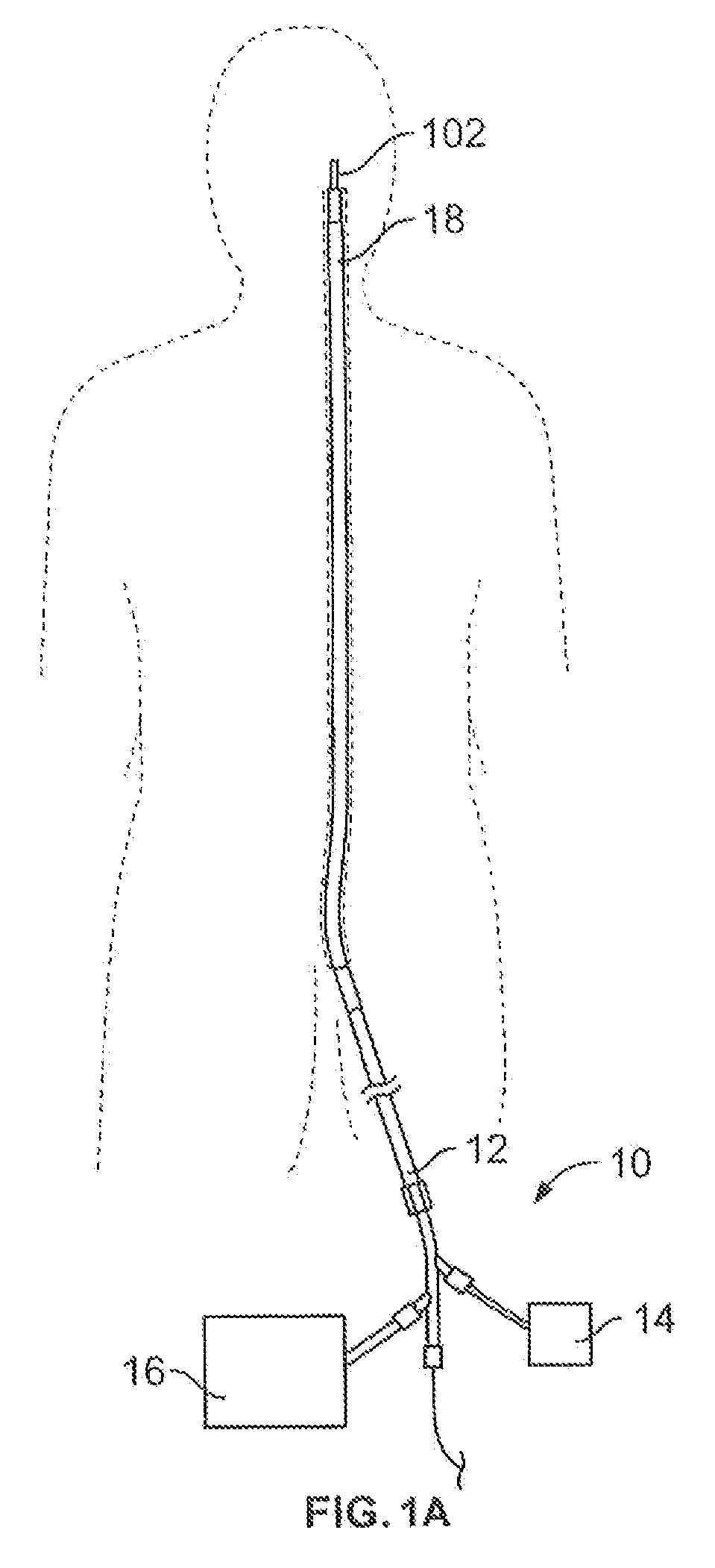

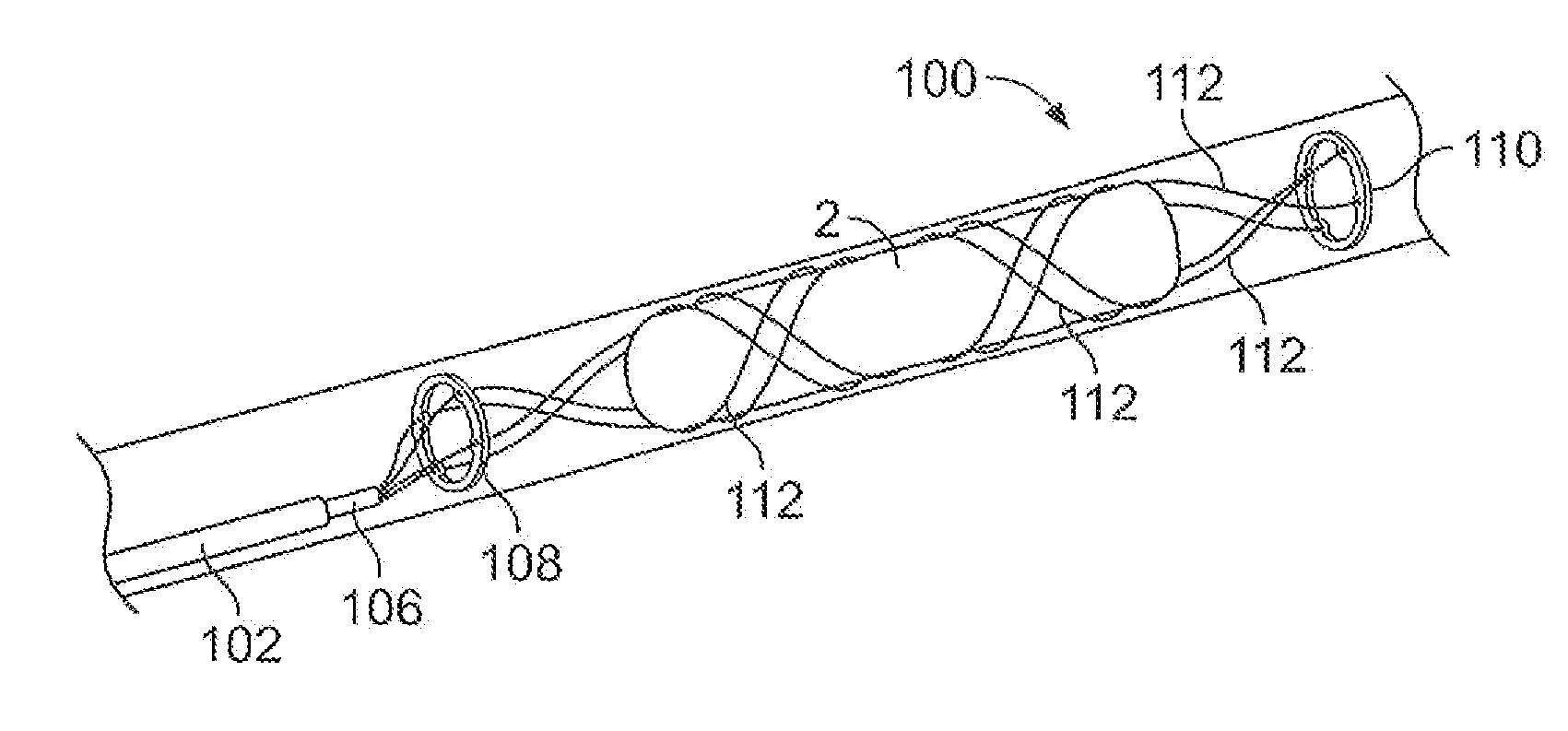

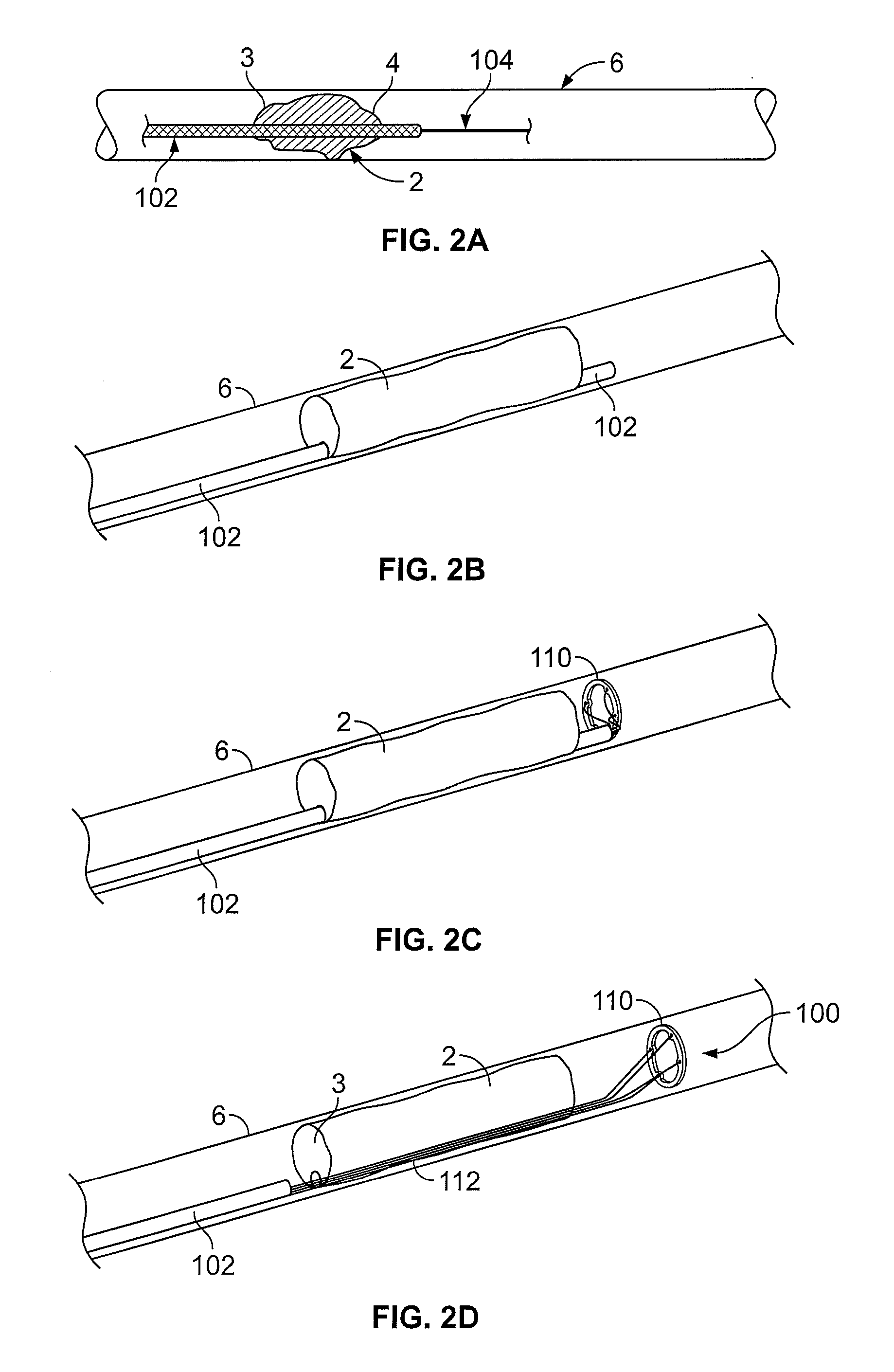

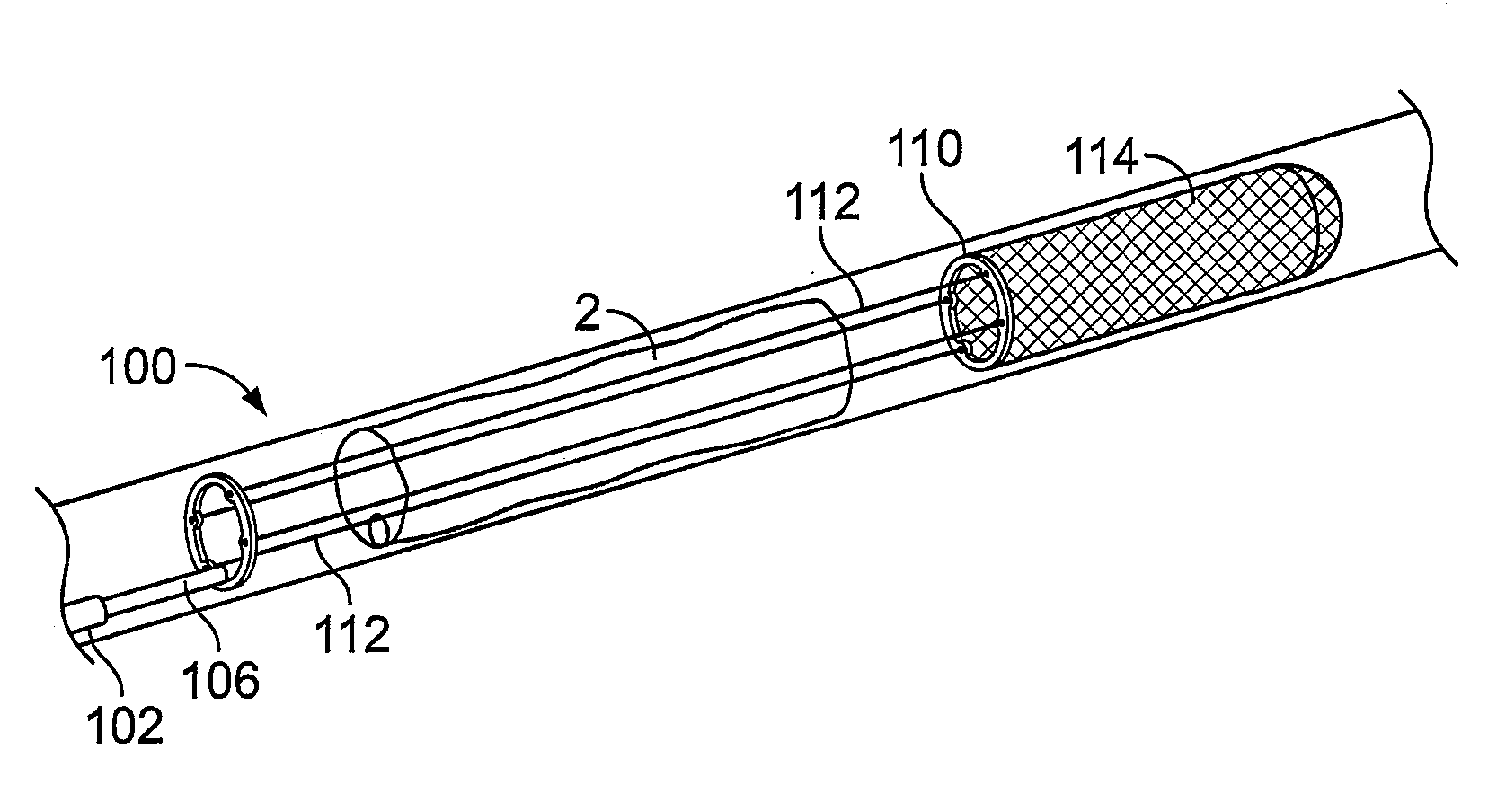

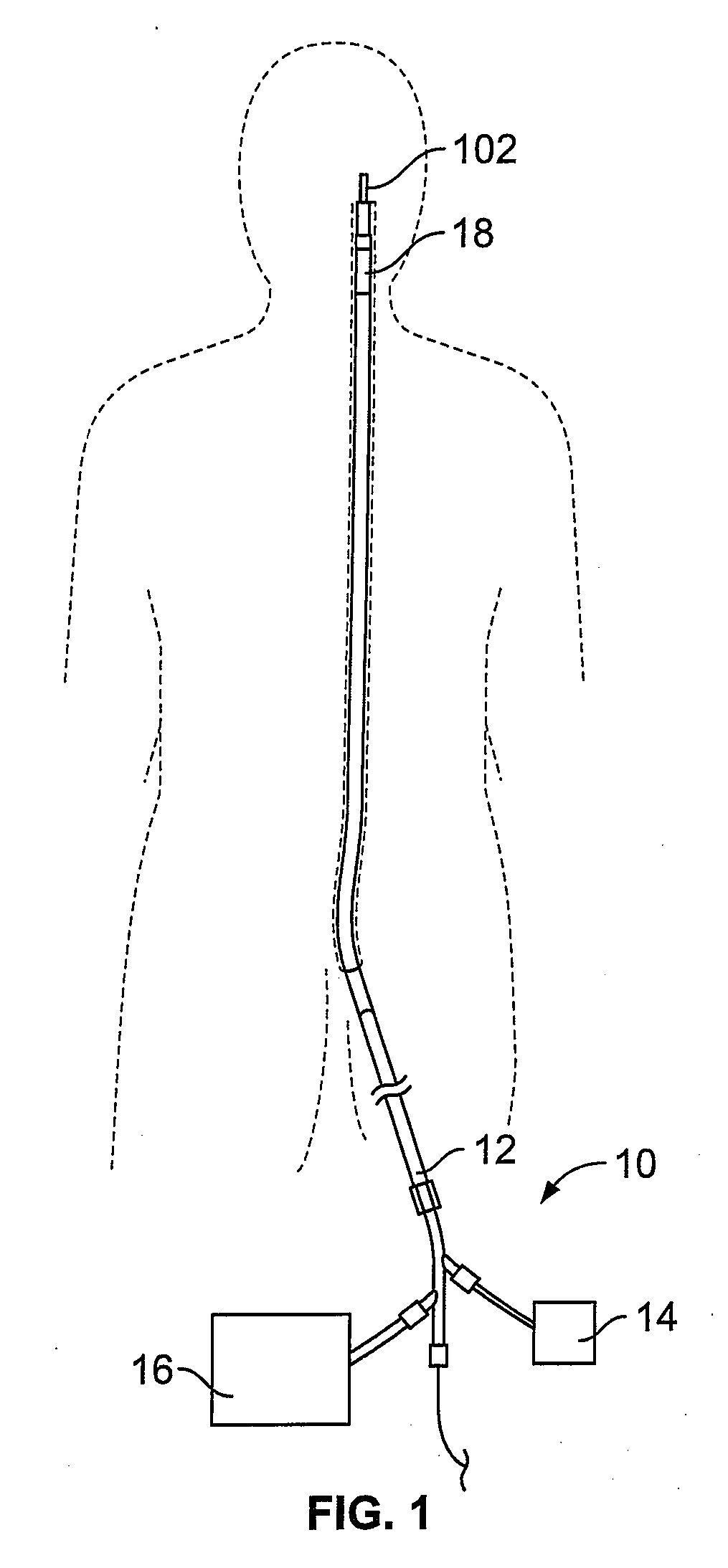

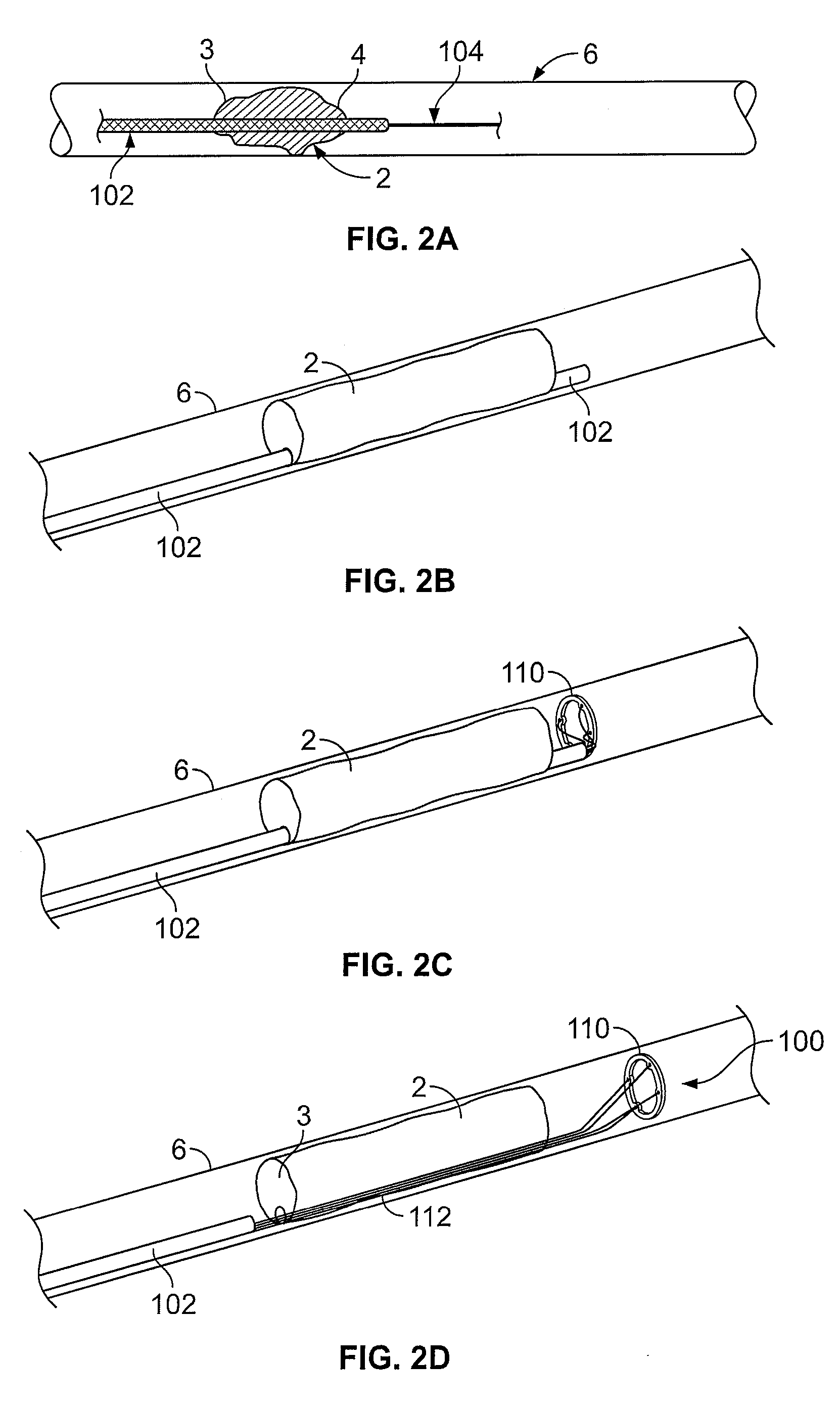

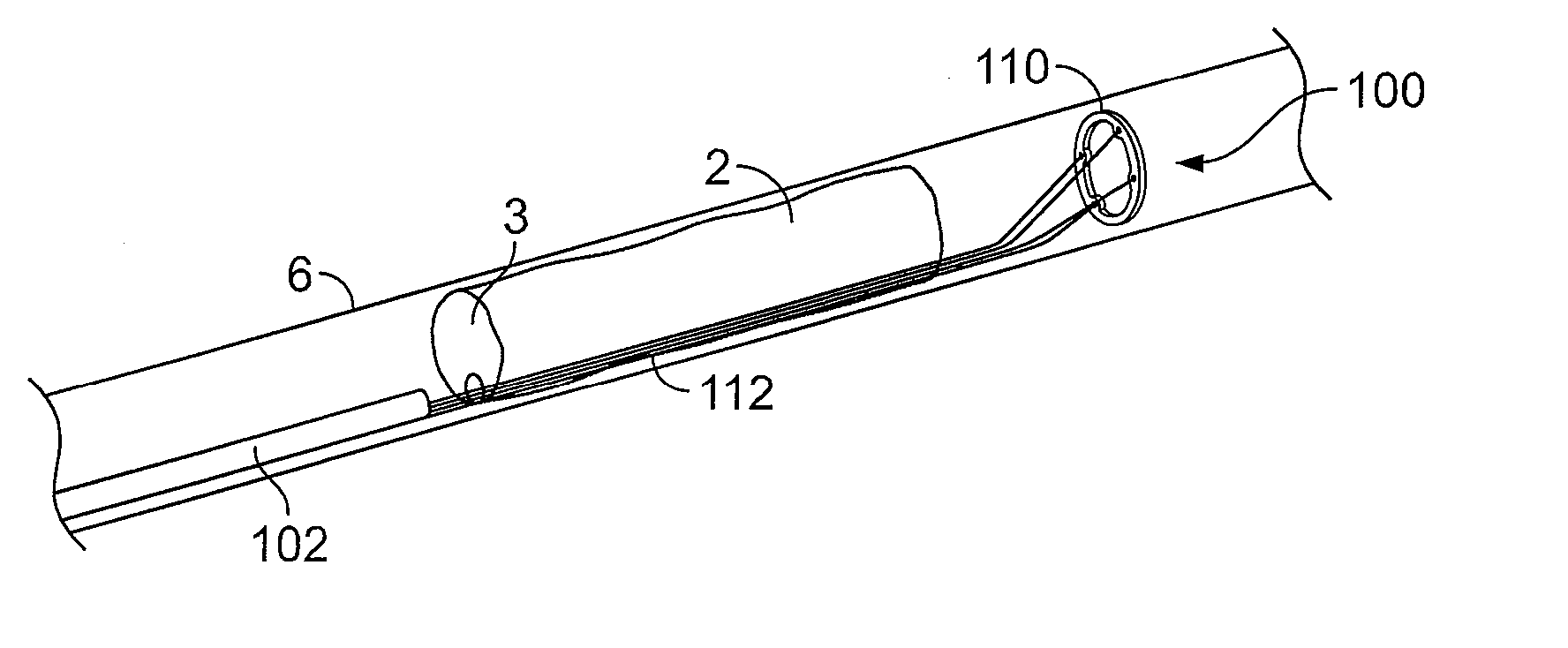

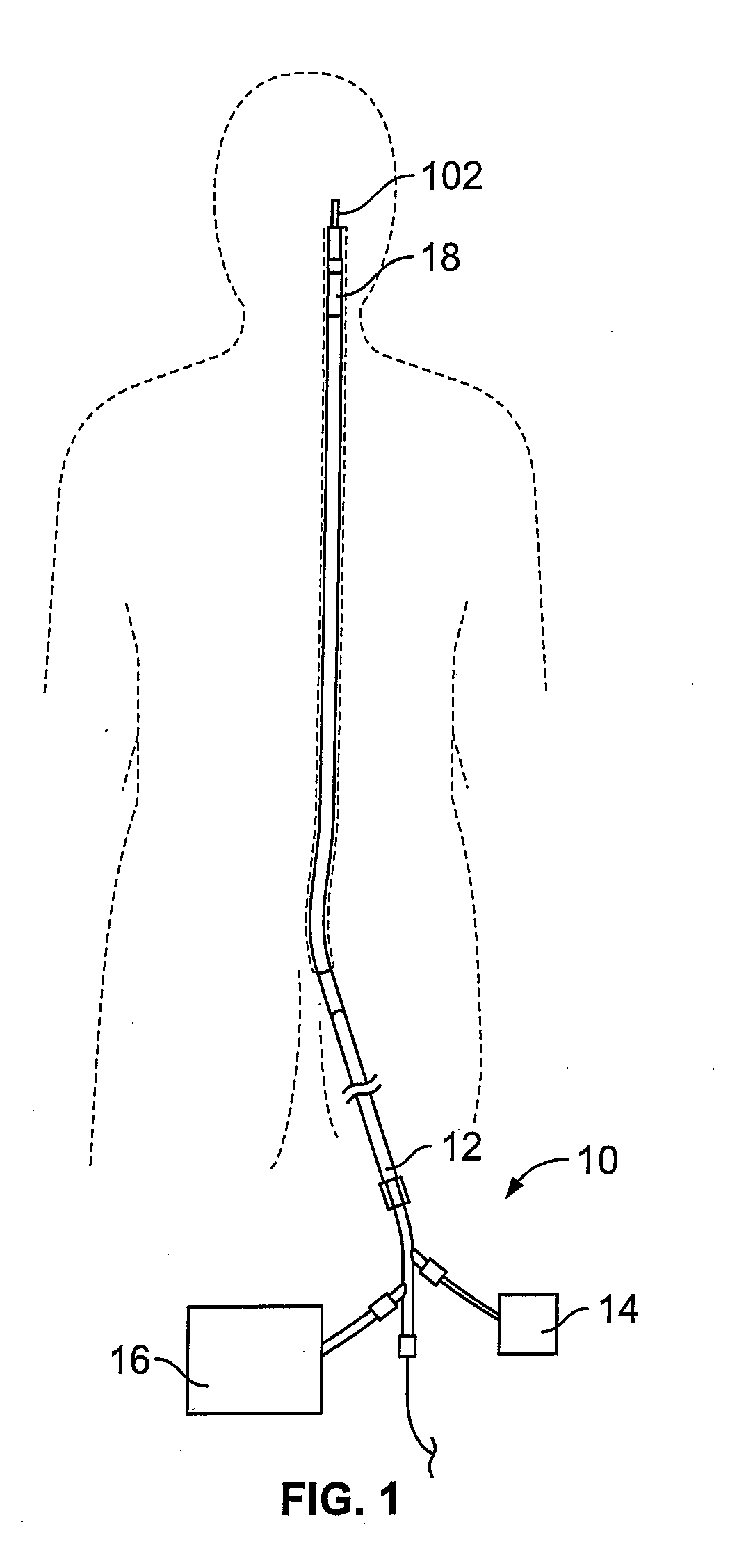

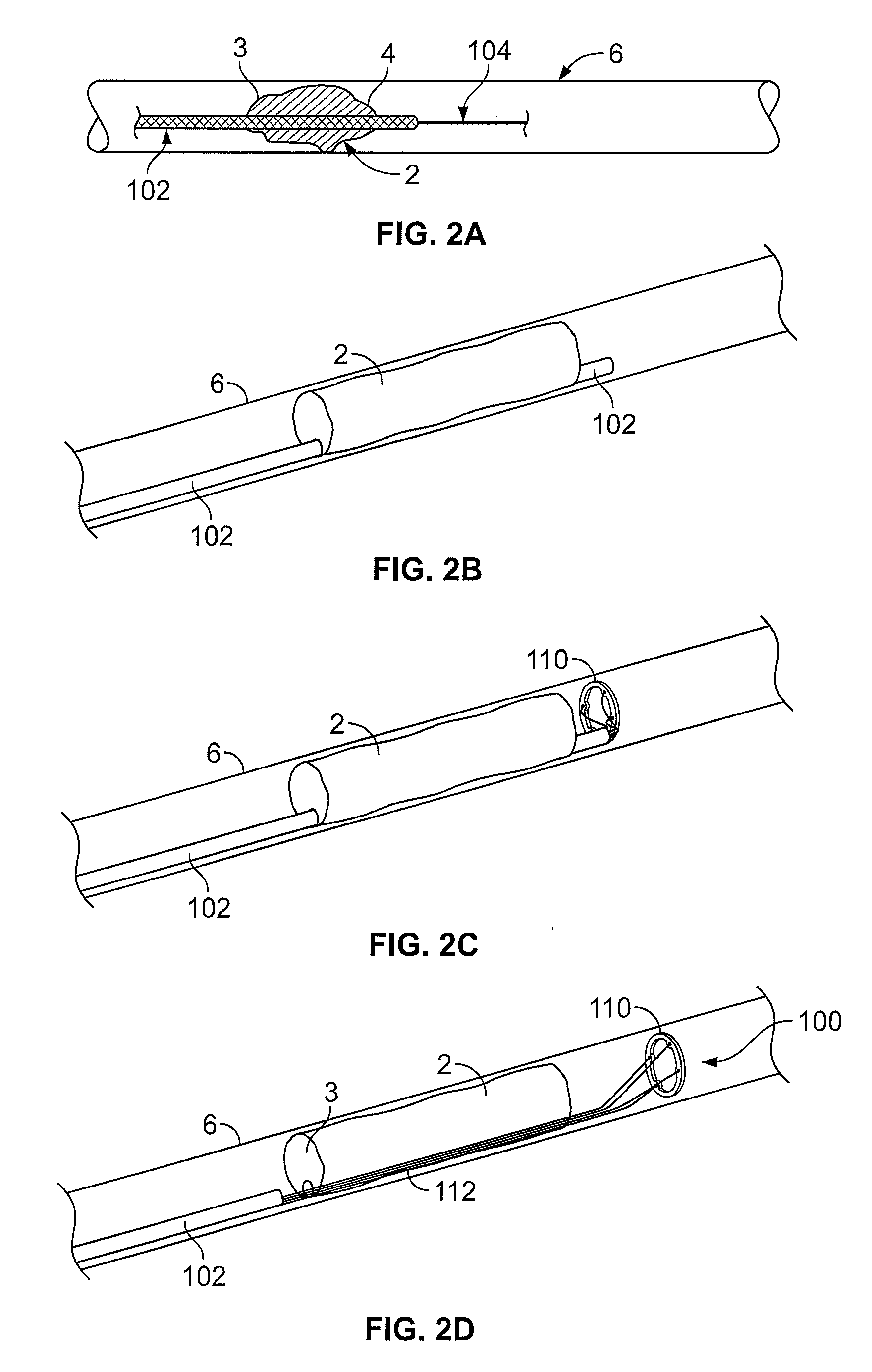

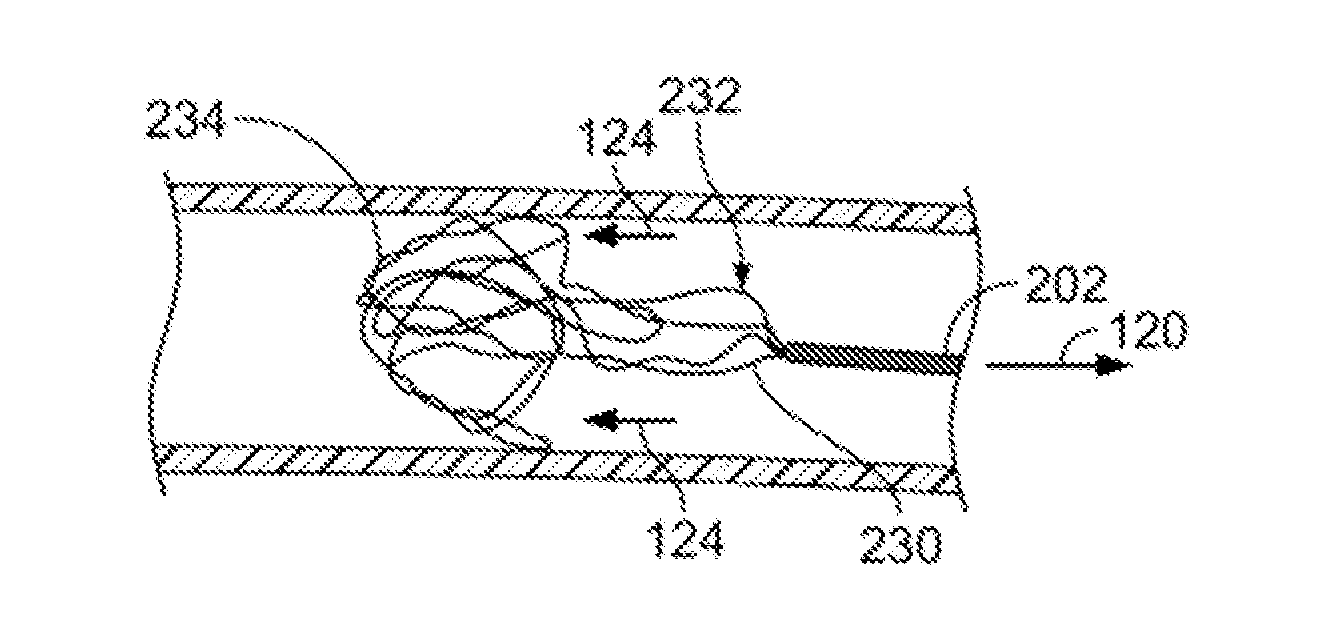

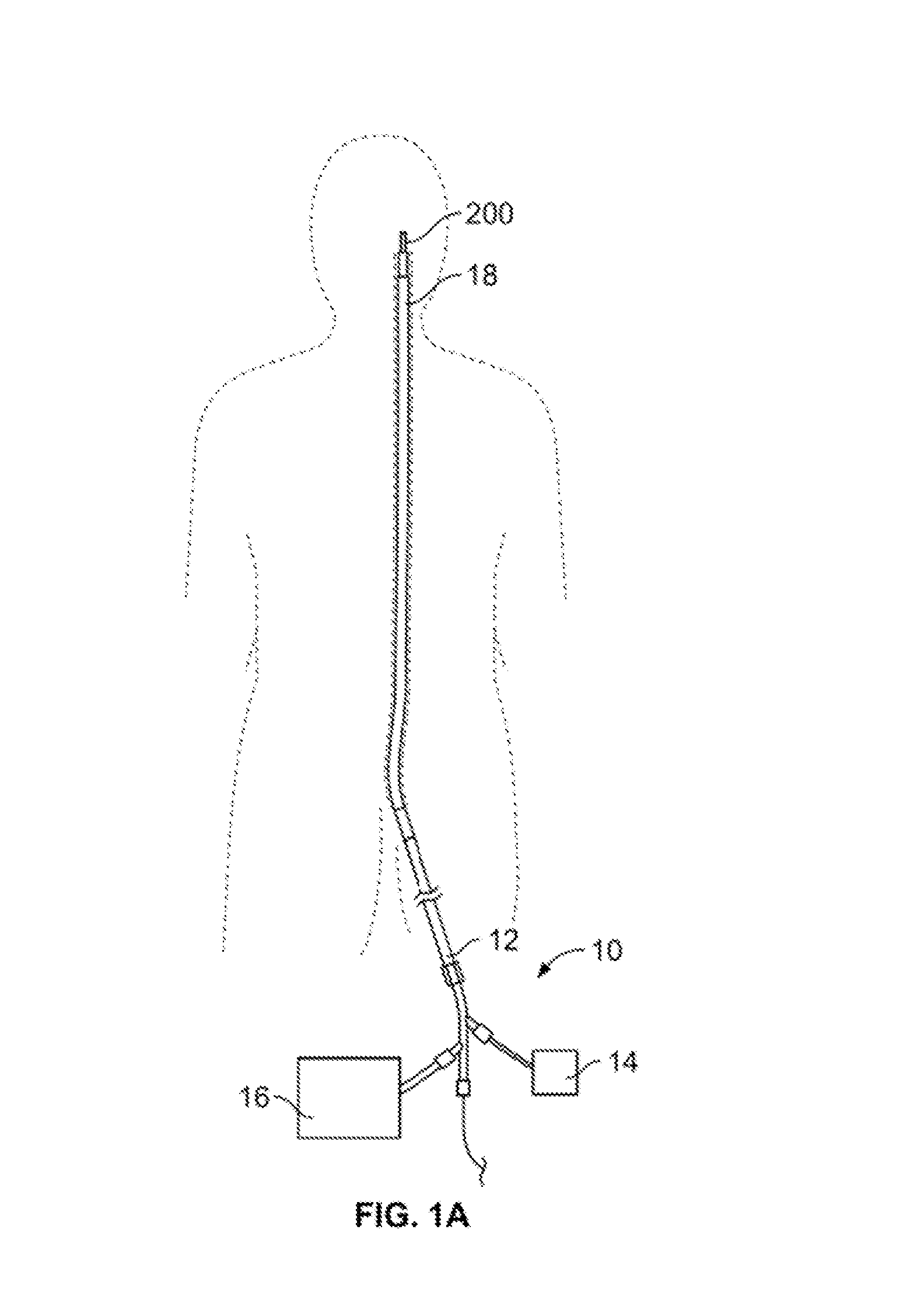

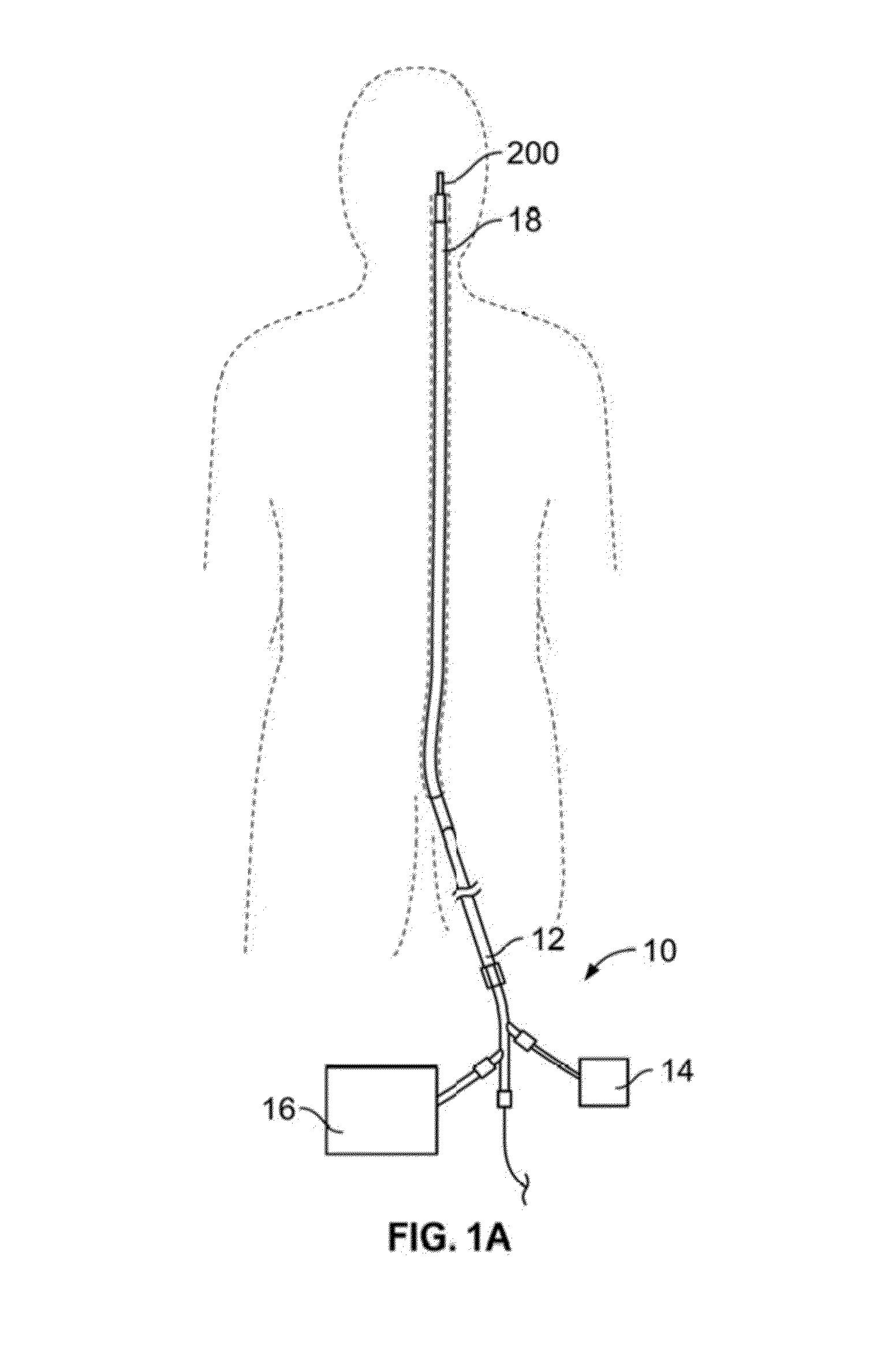

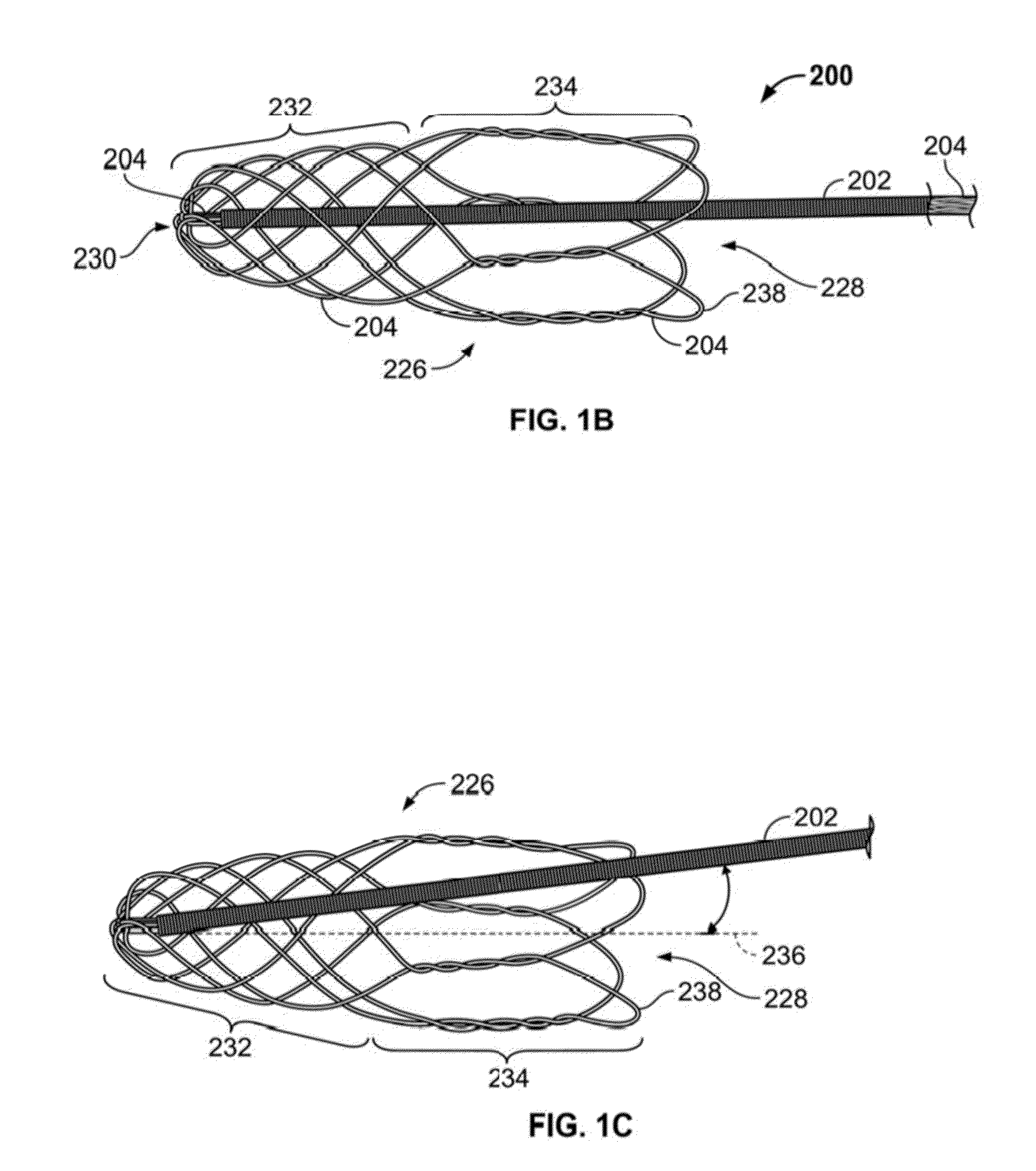

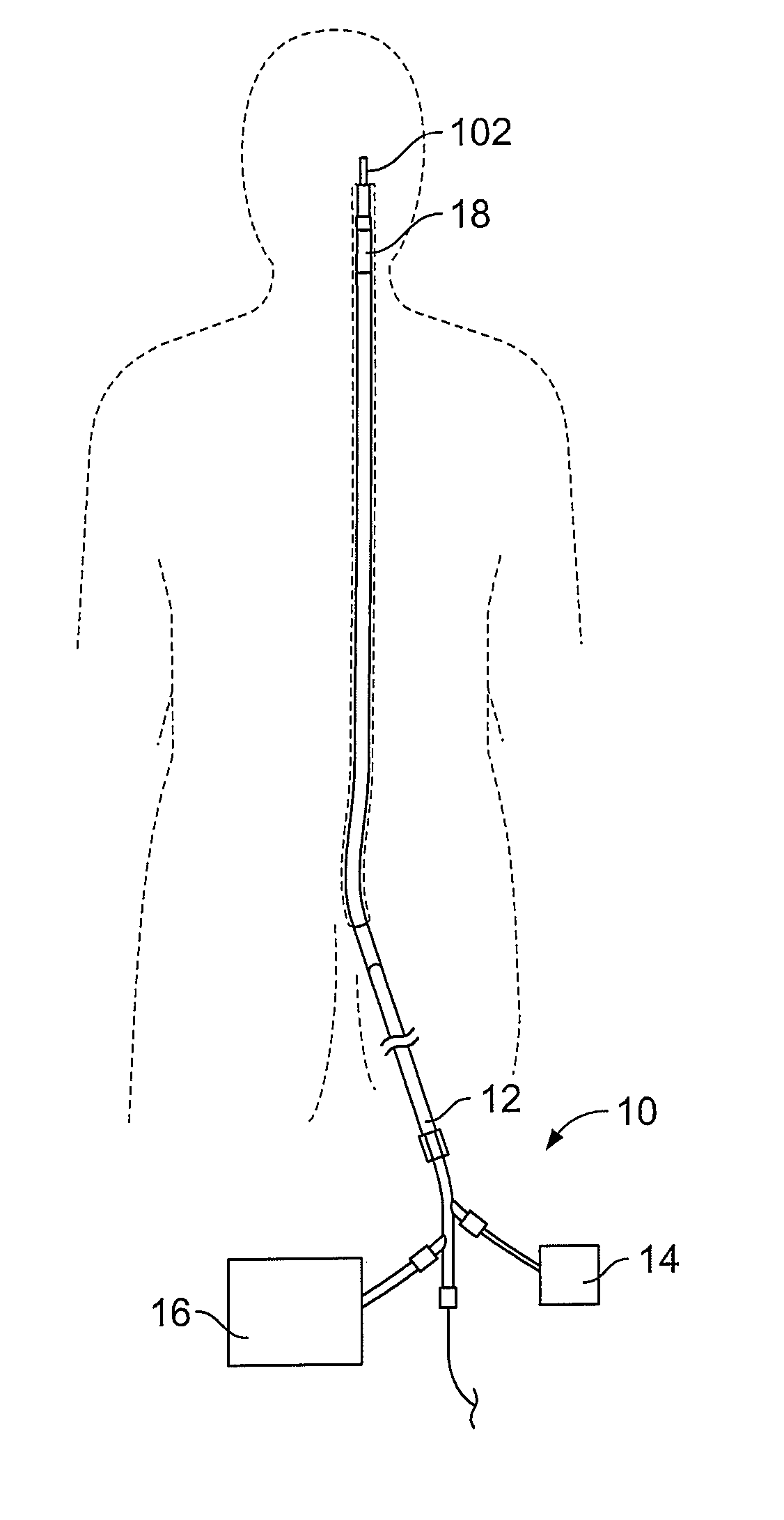

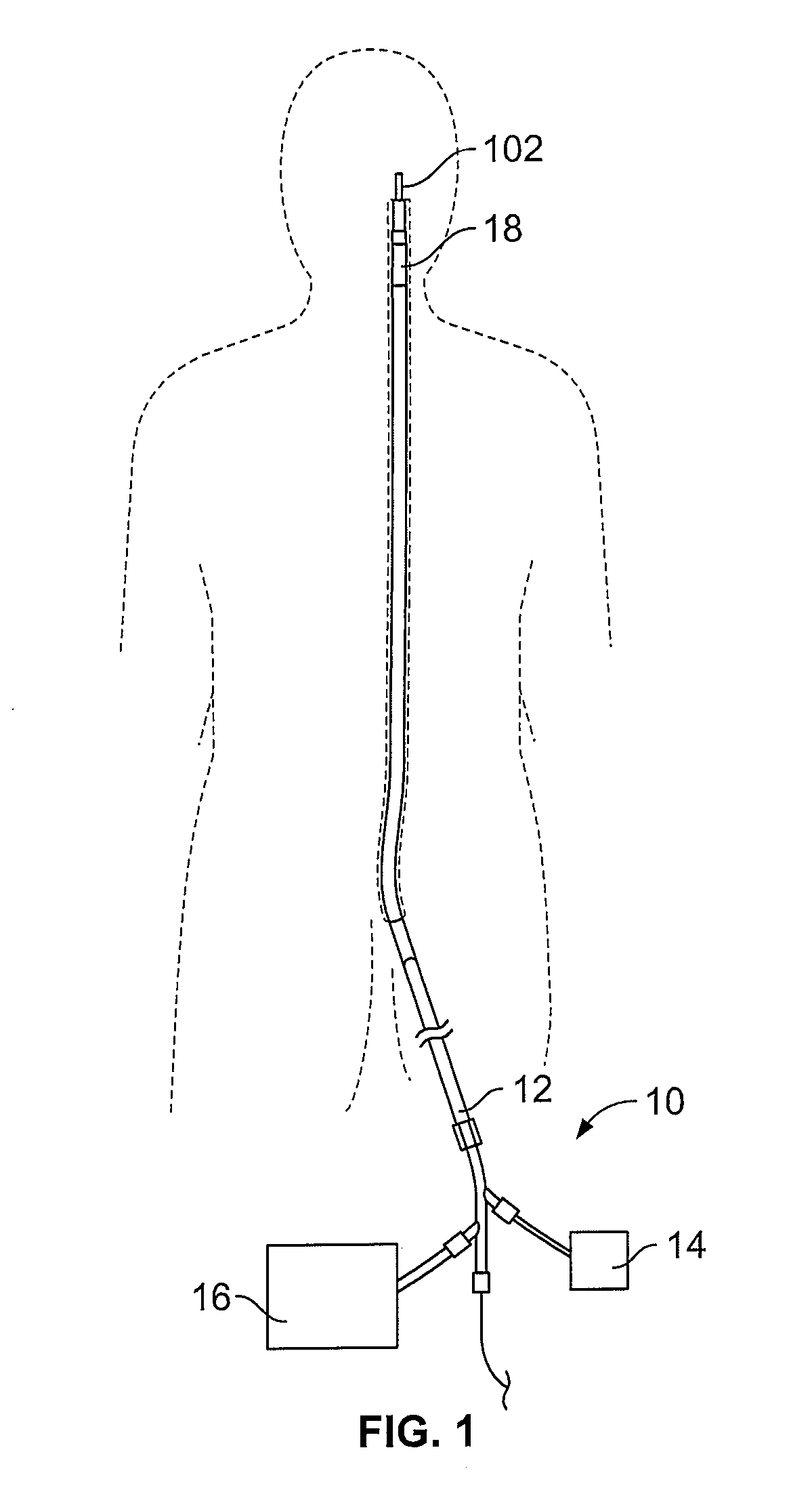

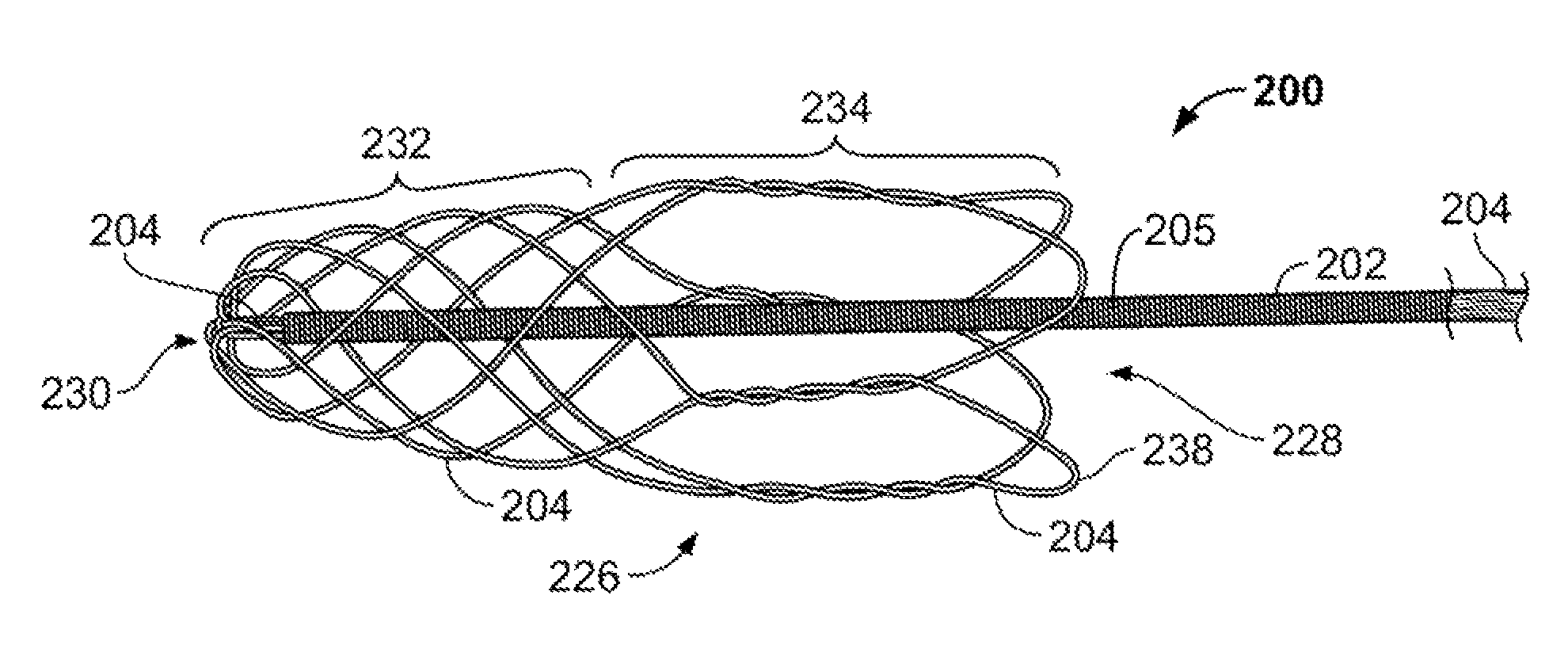

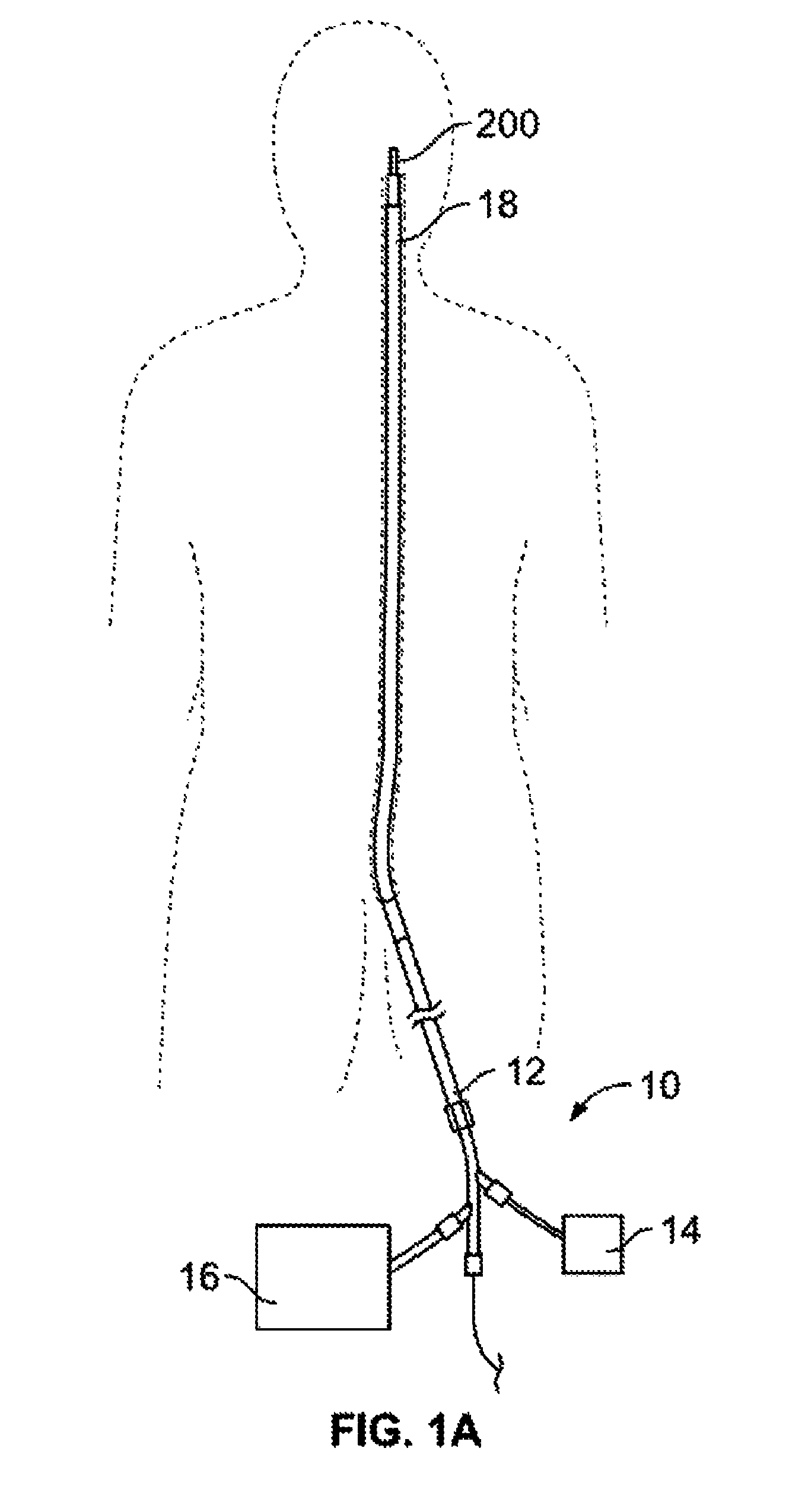

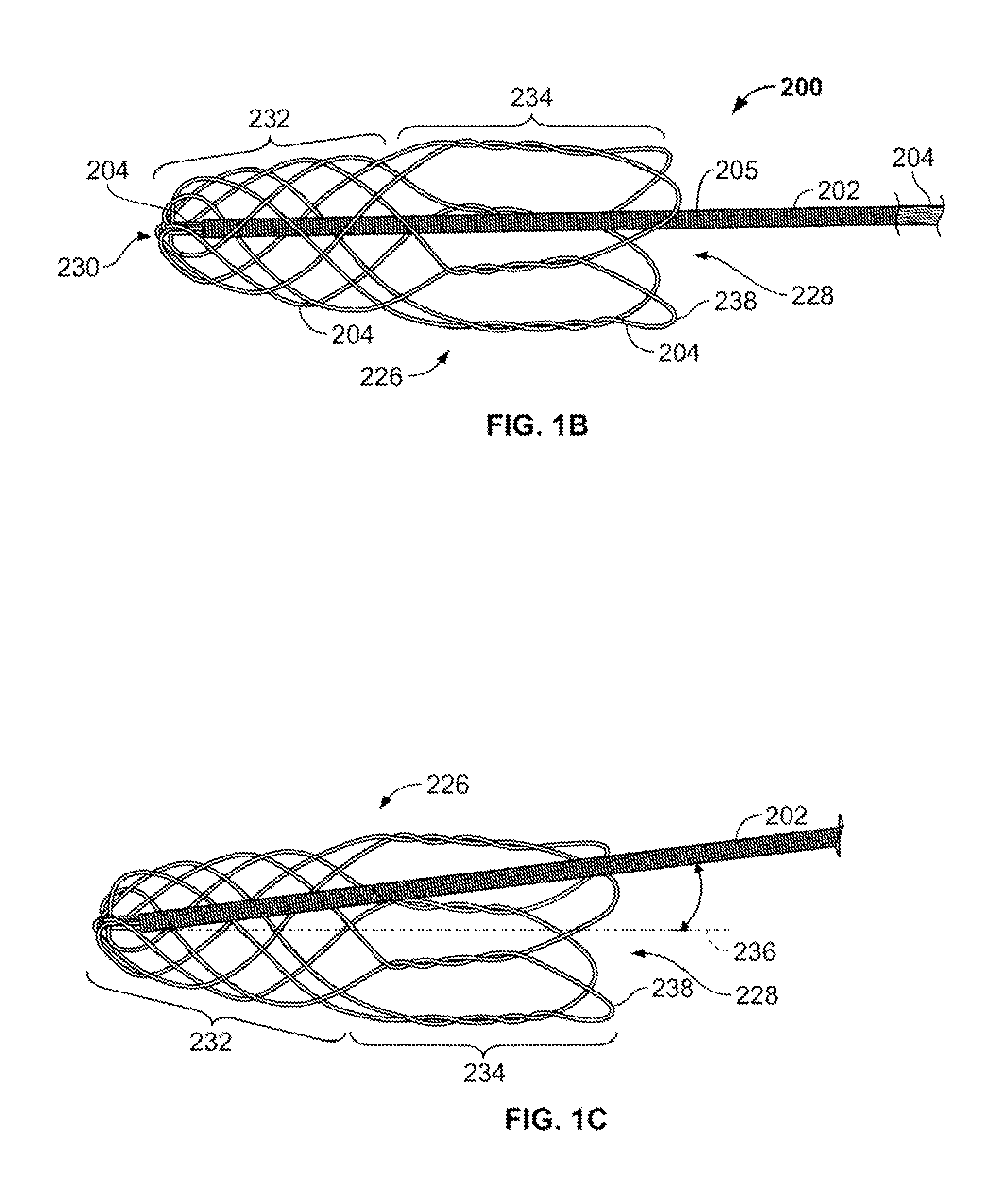

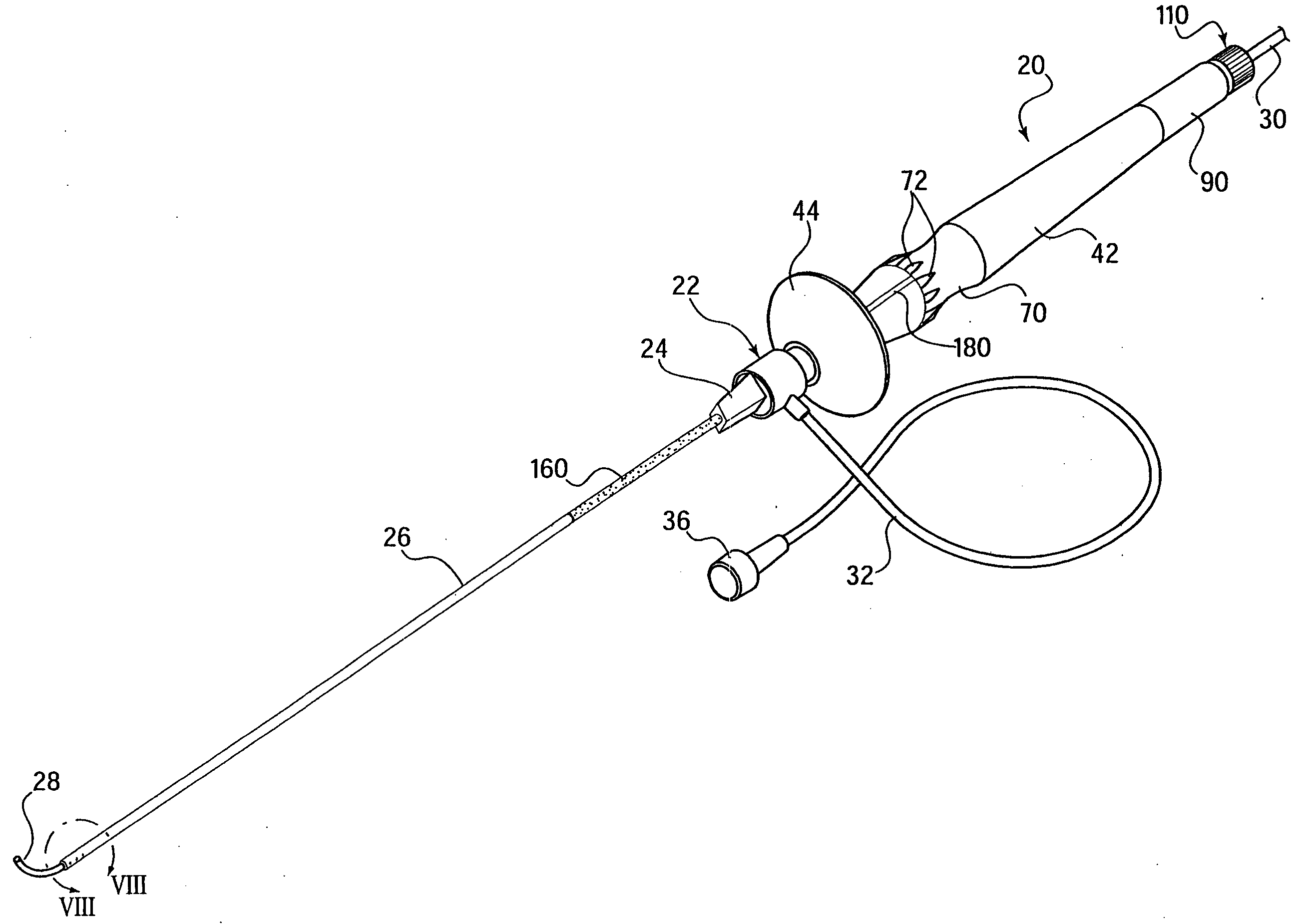

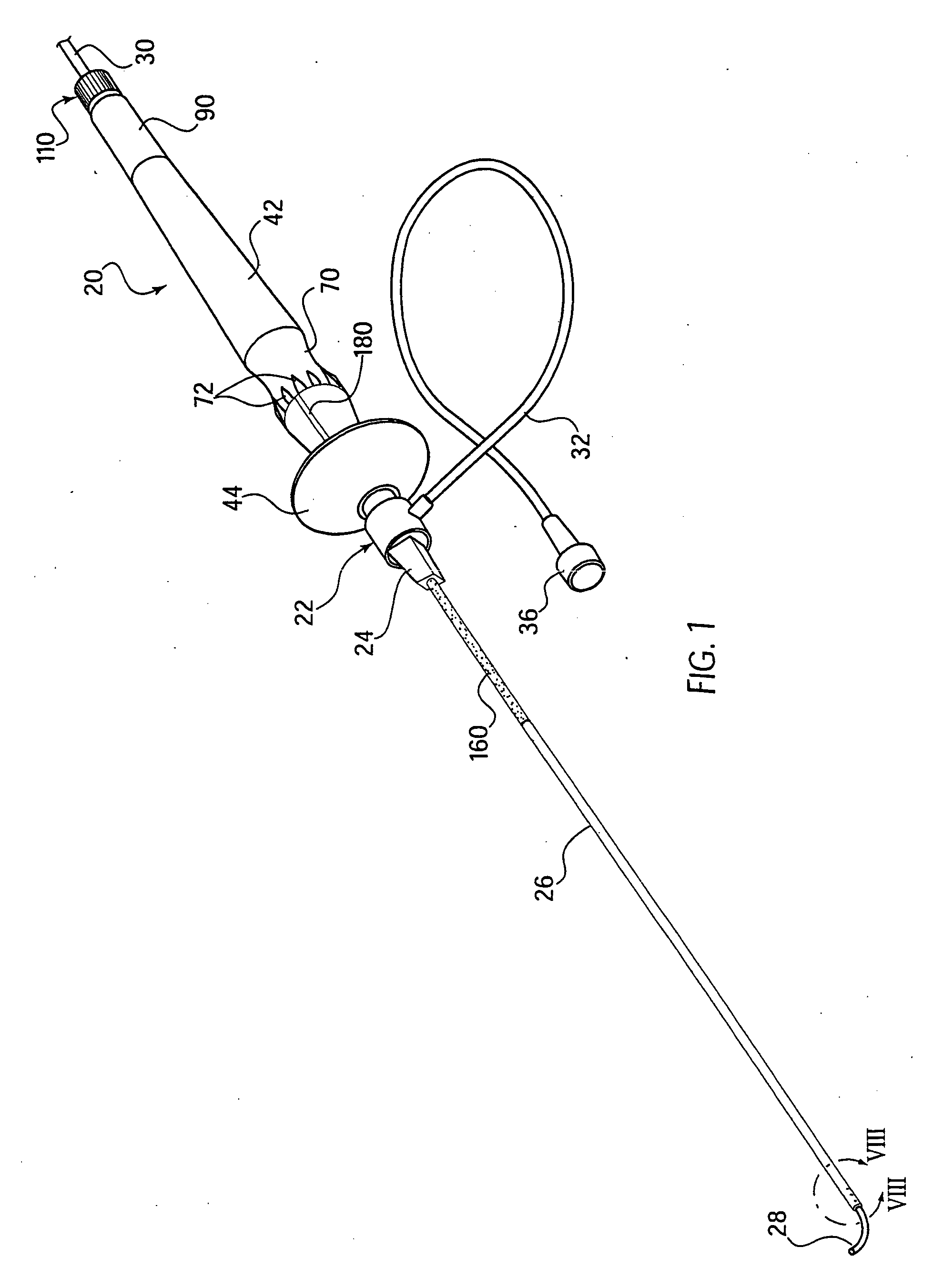

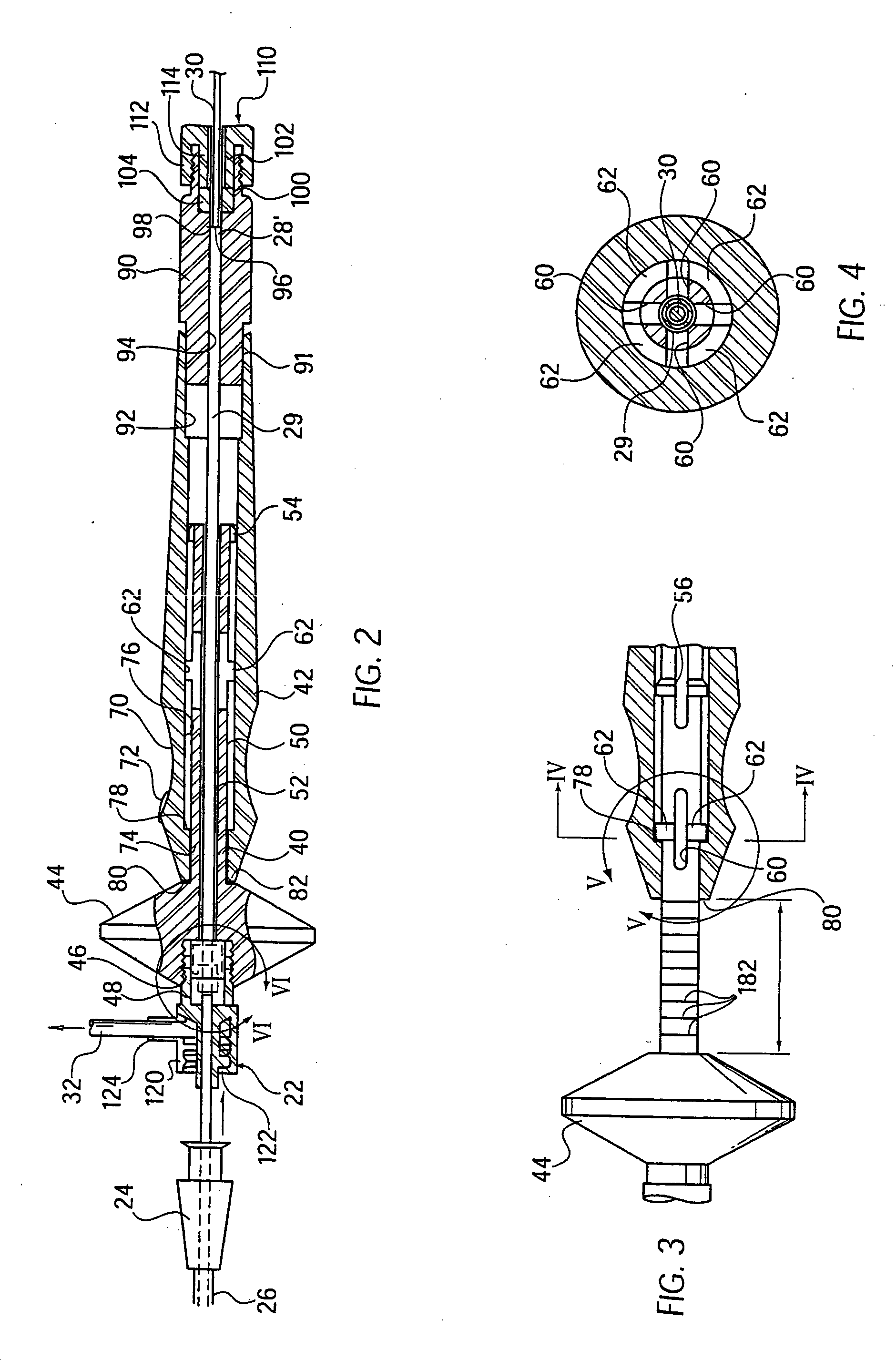

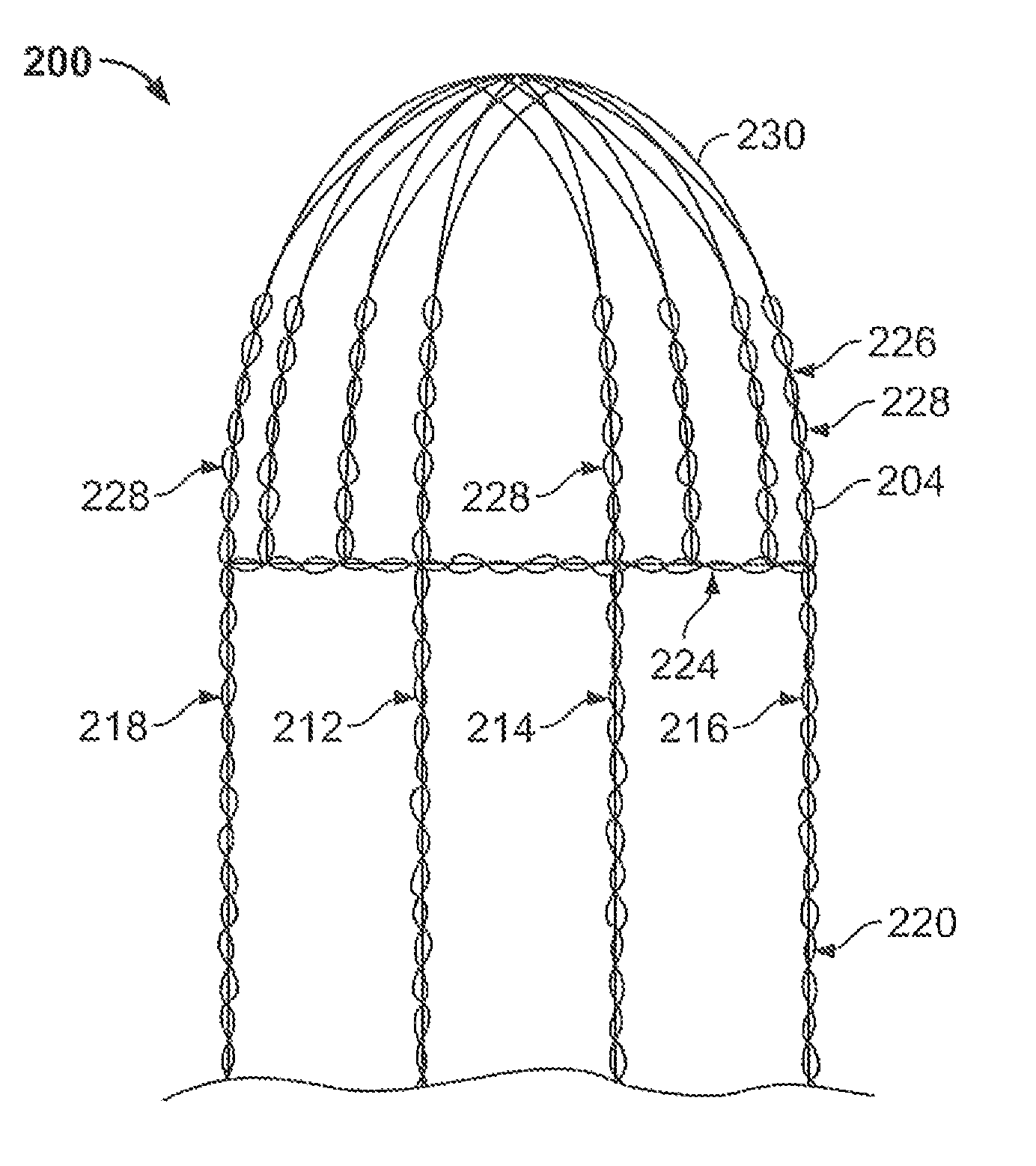

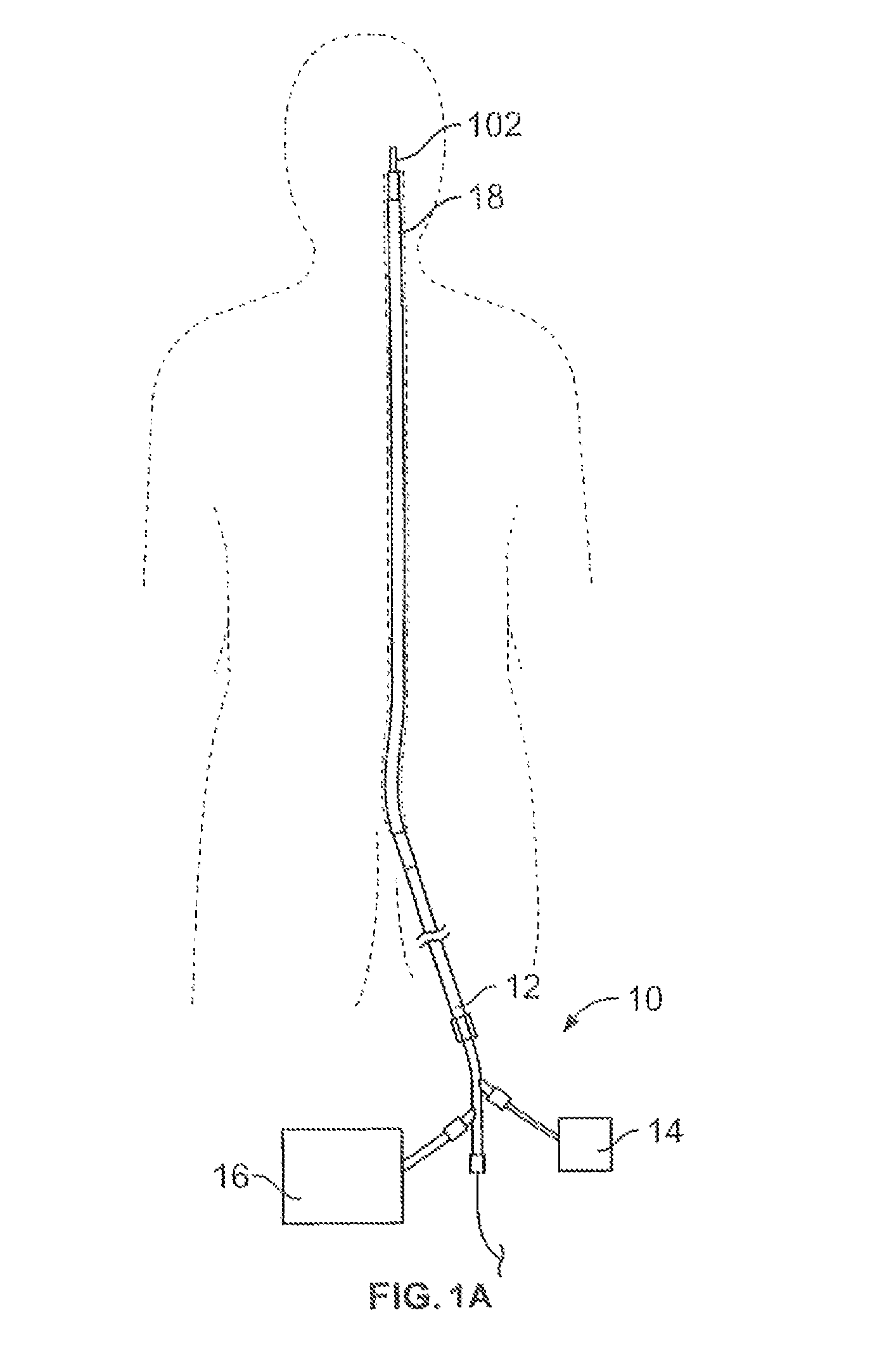

Articulating retrieval devices

ActiveUS20090069828A1Inhibit migrationImprove efficiencyCannulasSurgical veterinaryBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the body, including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

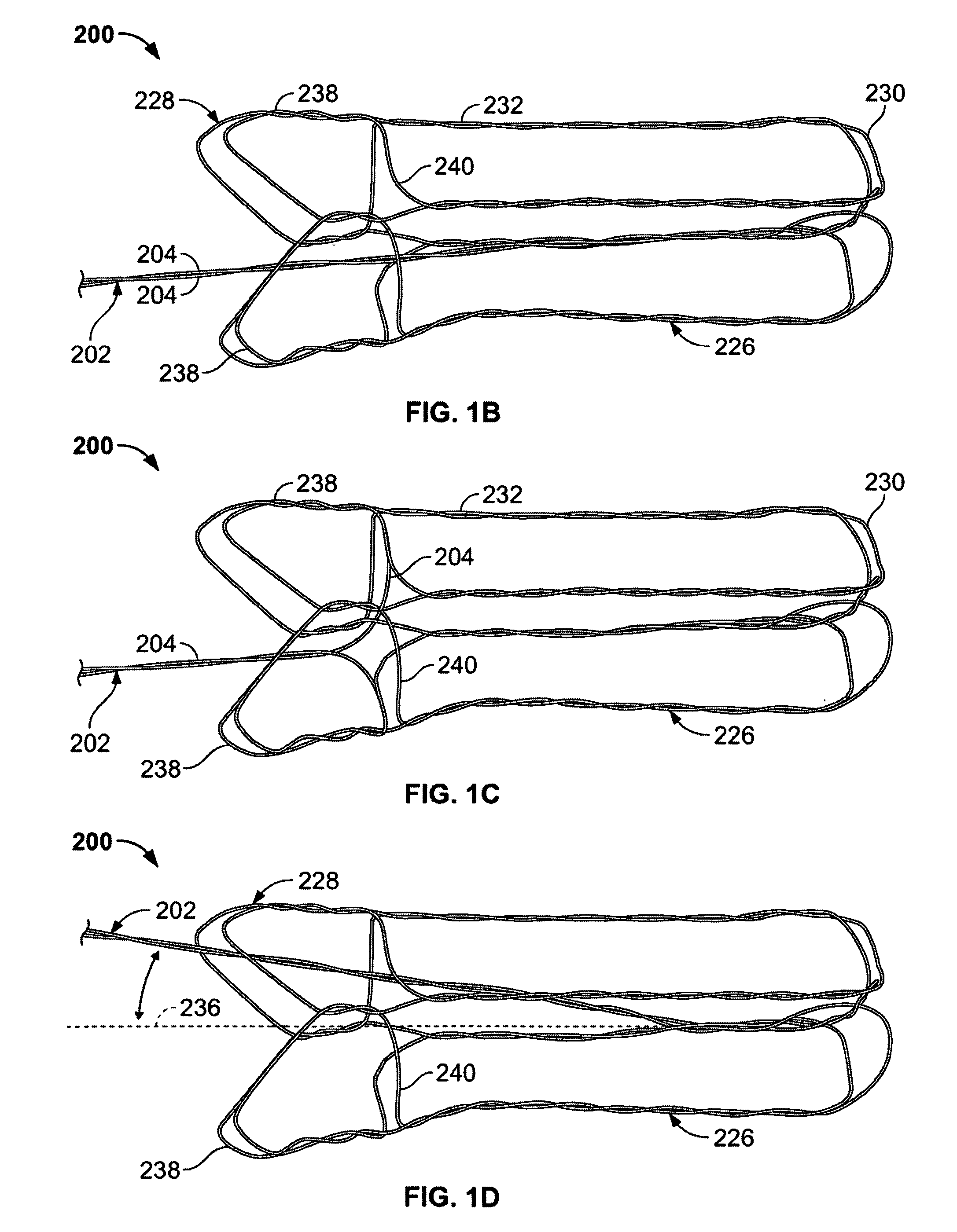

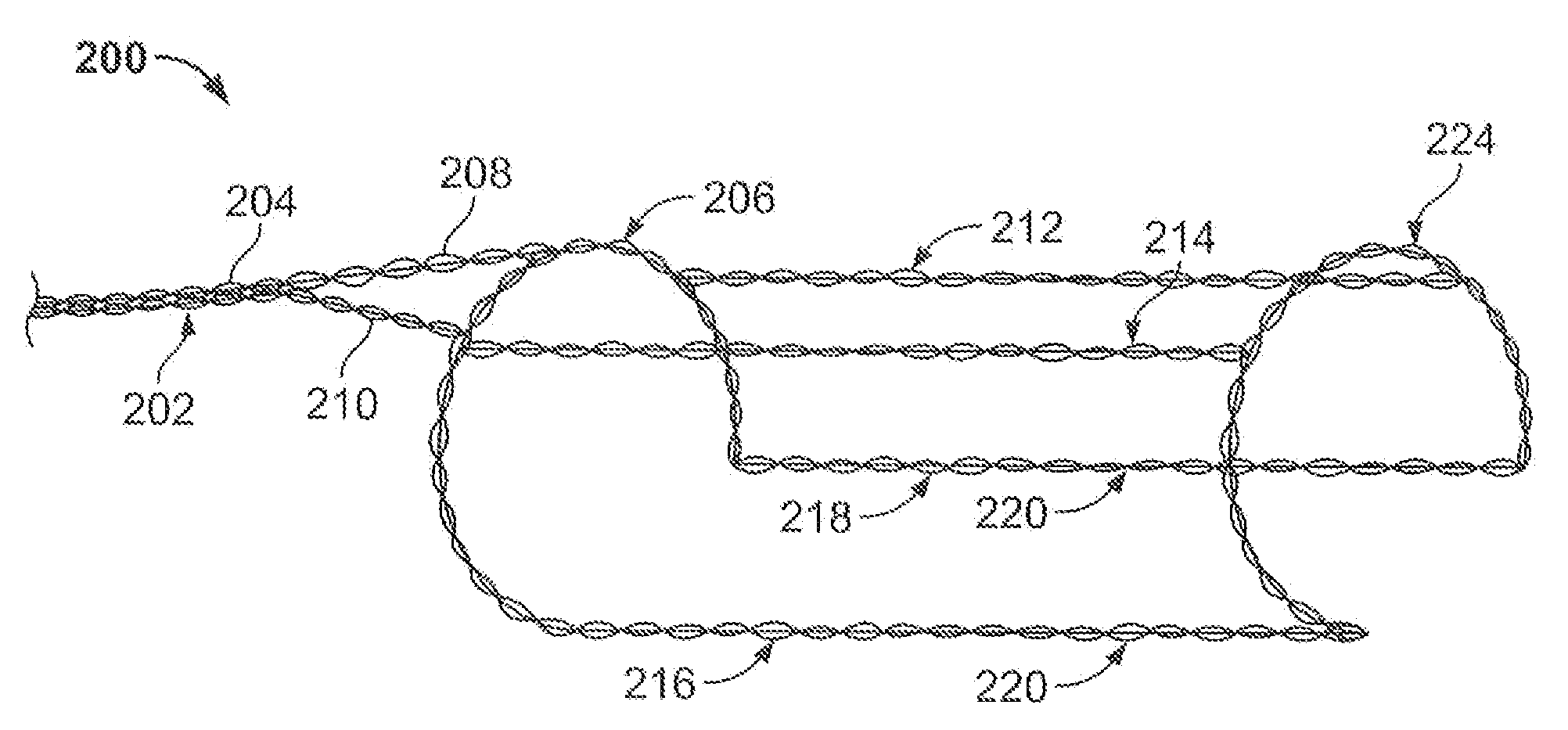

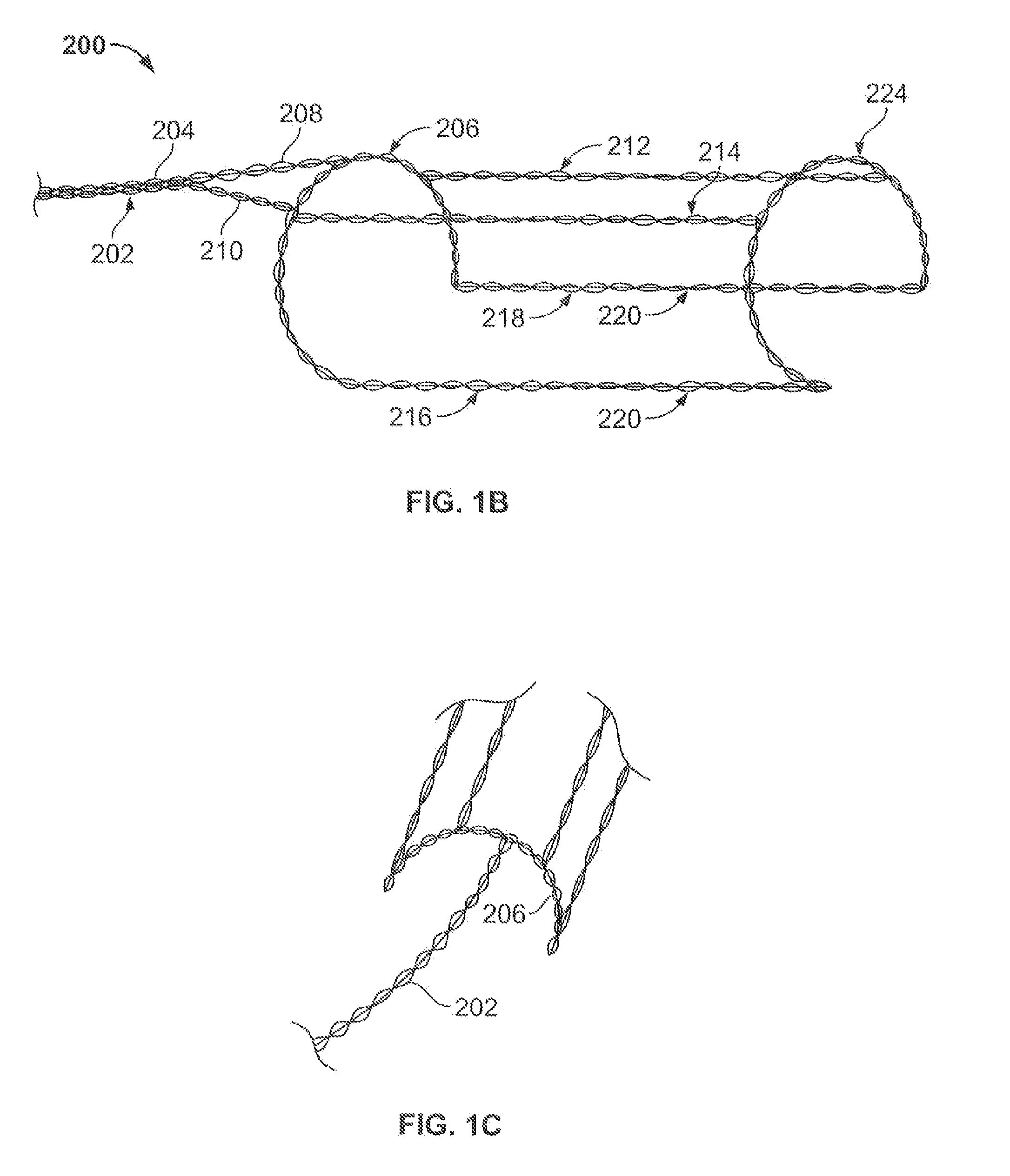

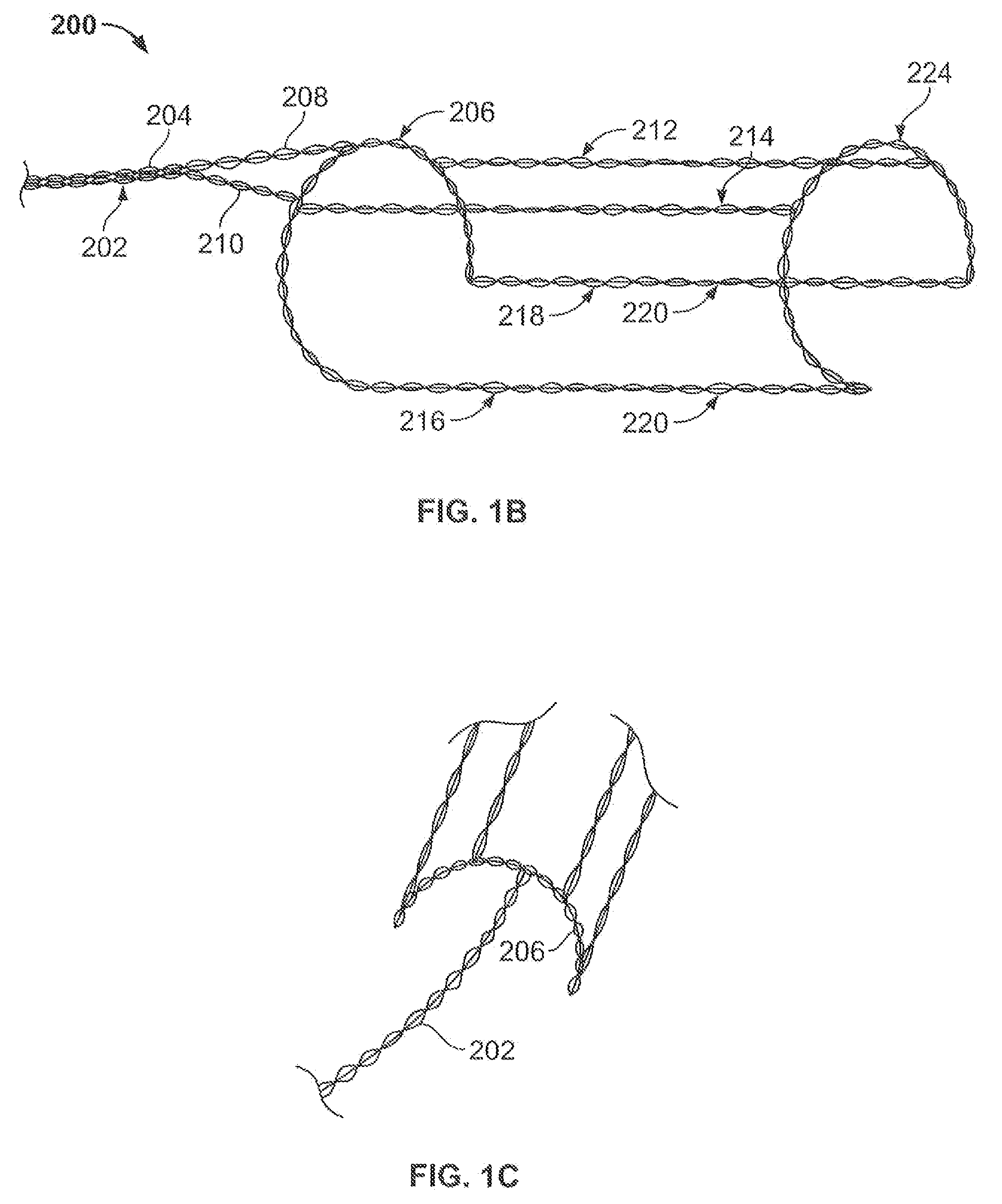

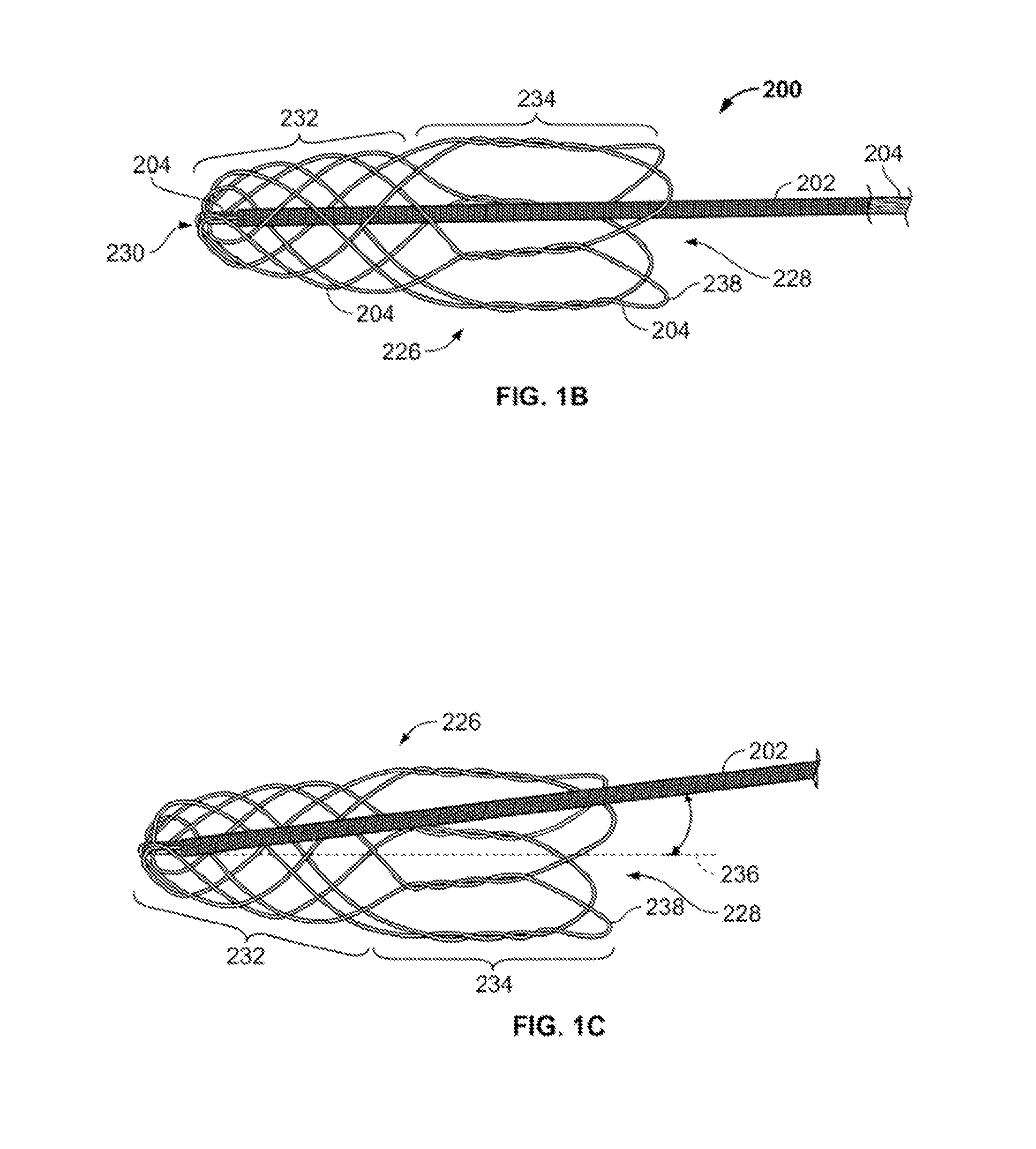

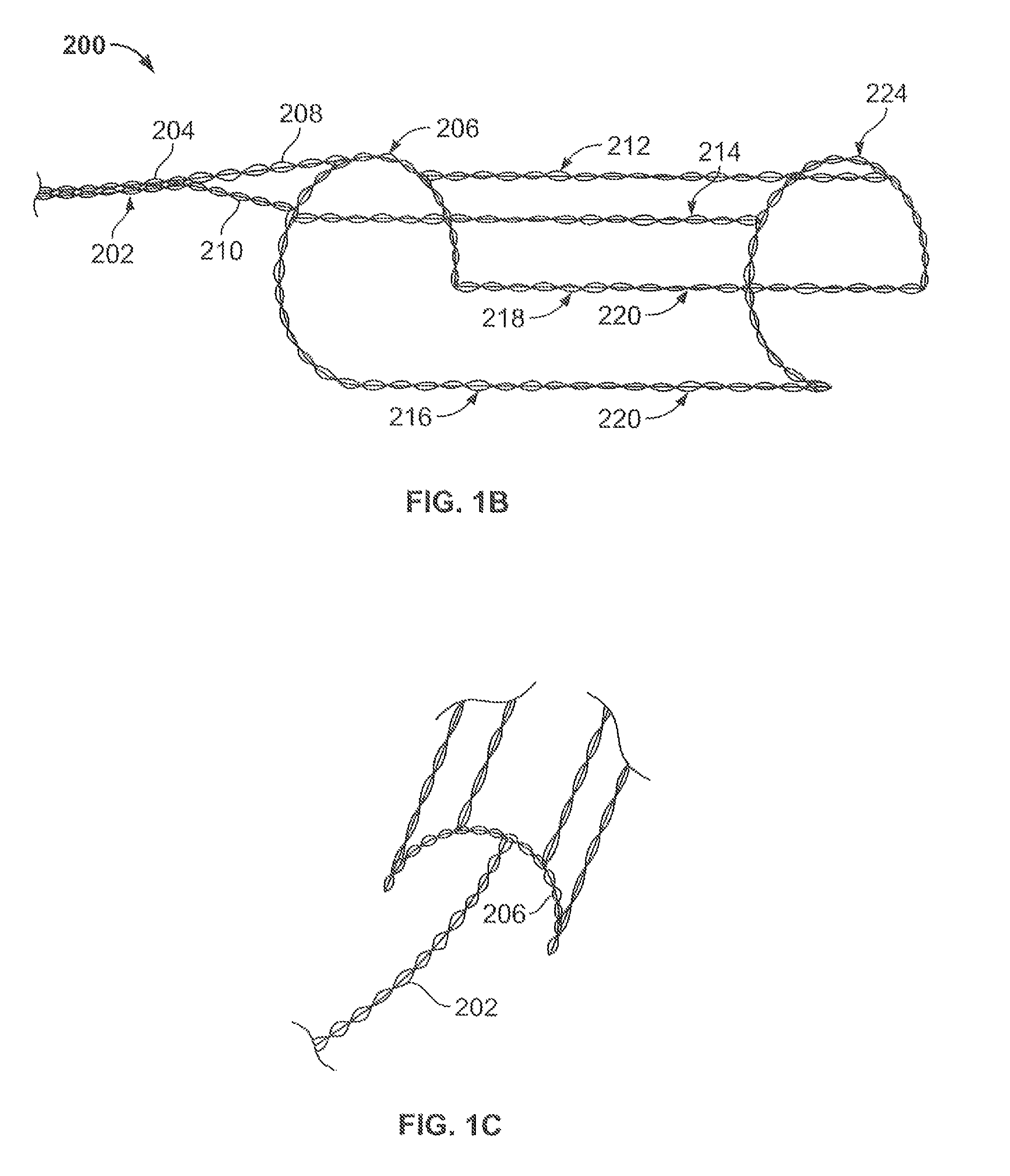

Complex wire formed devices

InactiveUS20080262532A1Shorten the lengthAvoid insufficient lengthDilatorsExcision instrumentsFrictional resistanceMedicine

The devices and methods described herein relate to jointless construction of complex structures. Such devices have applicability in through-out the body, including clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

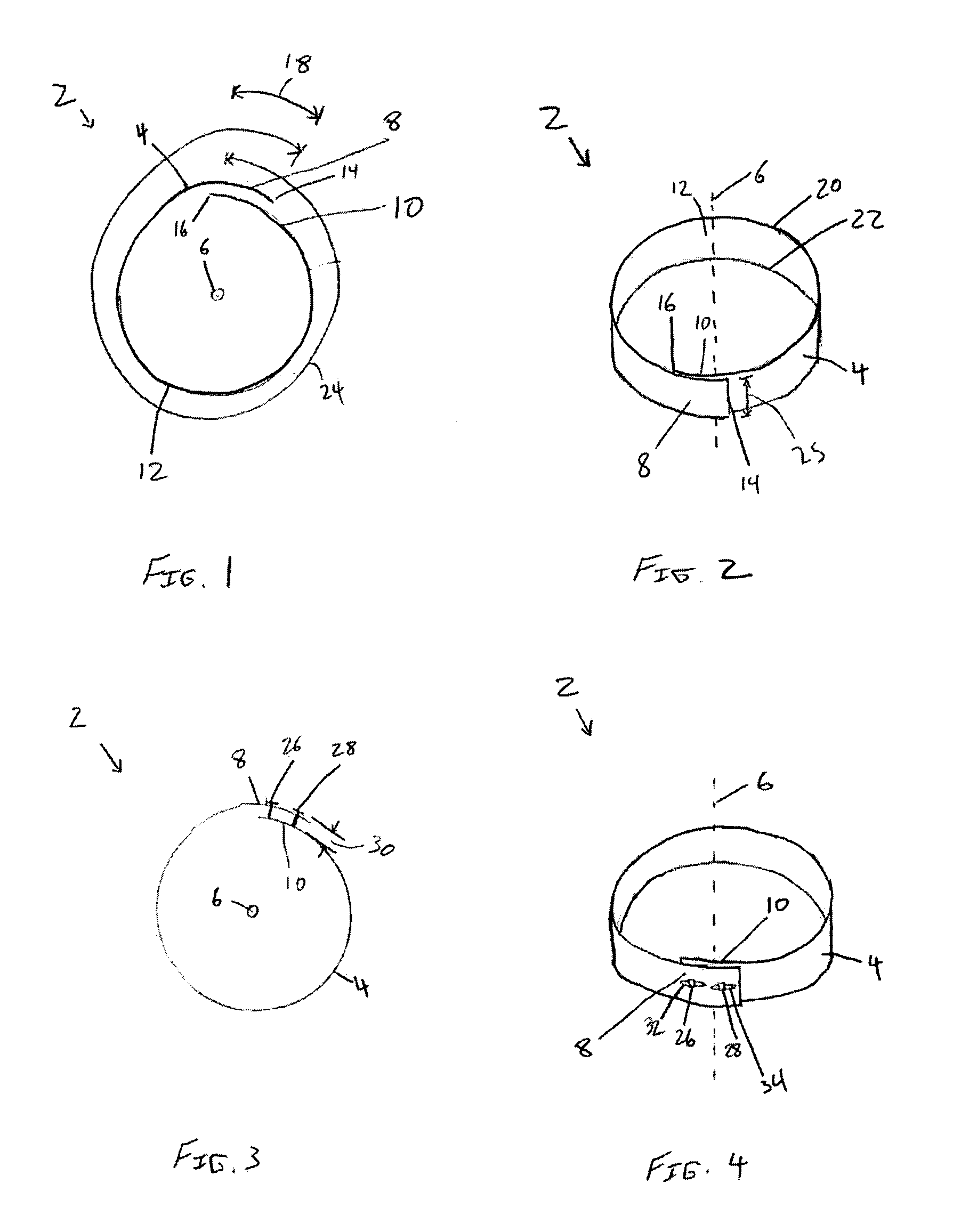

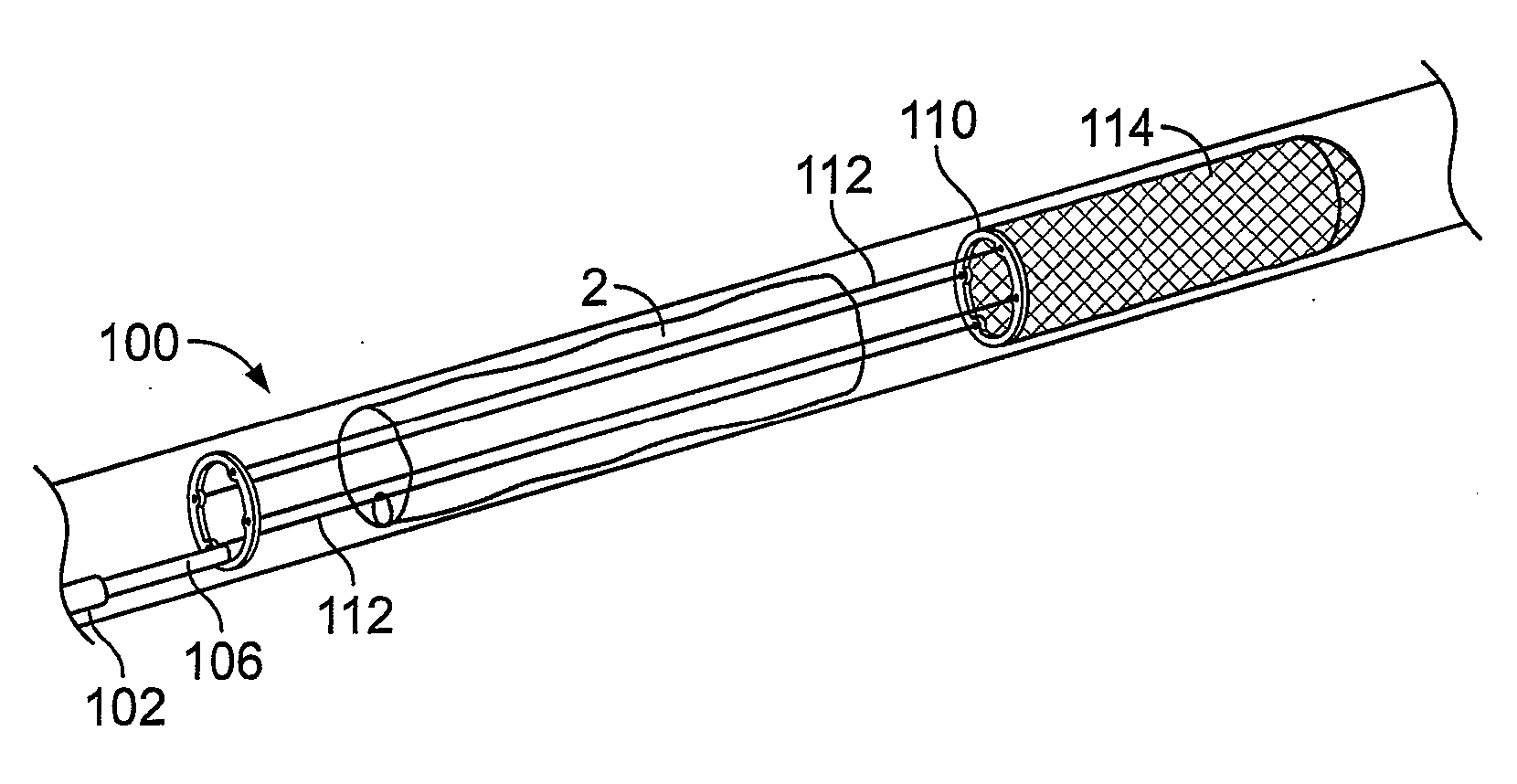

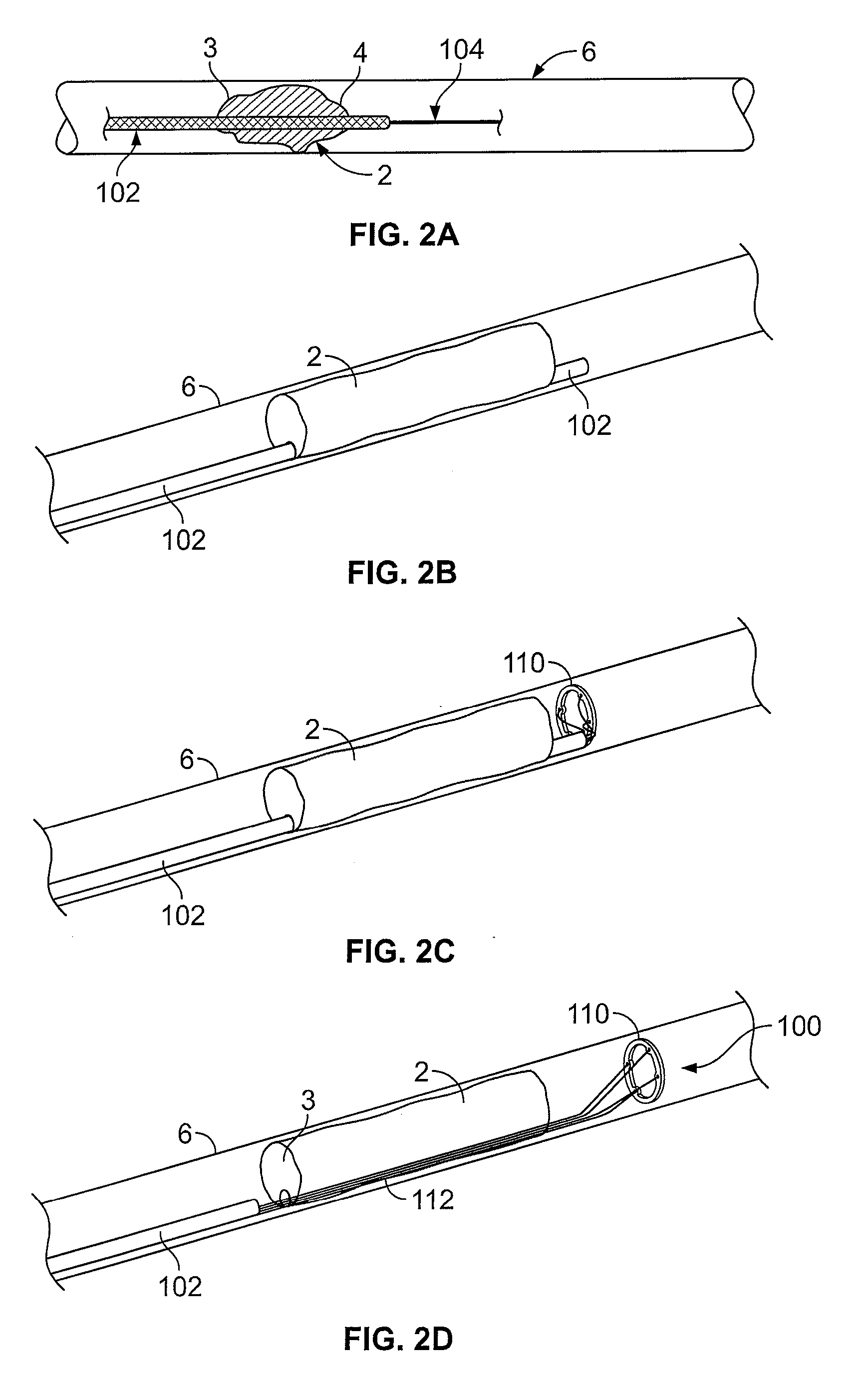

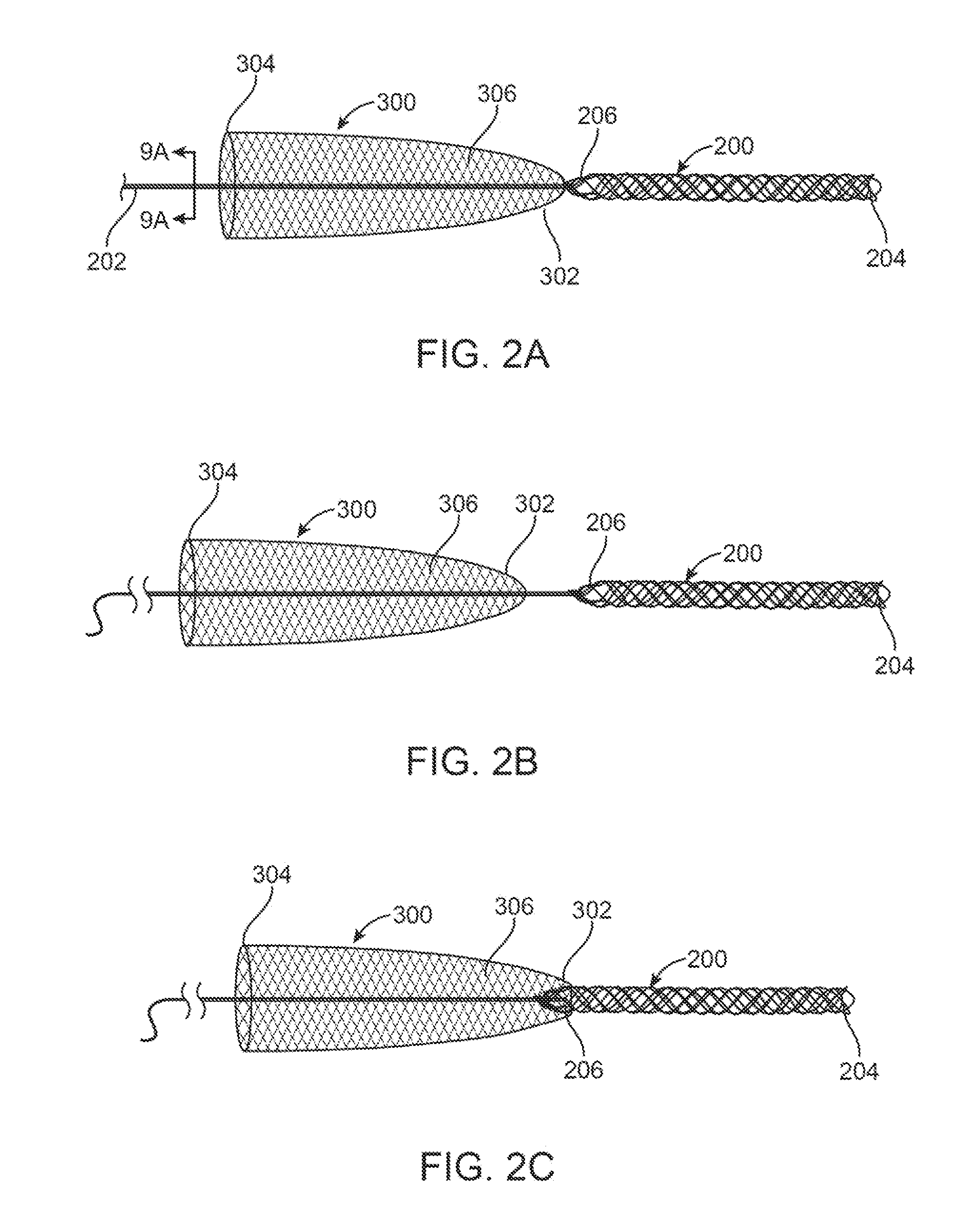

Devices for restoring blood flow within blocked vasculature

InactiveUS20070185501A1Increase frictionIncrease surface areaDilatorsExcision instrumentsBlood flowBiomedical engineering

The devices and methods described herein relate to clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:LAZARUS EFFECT

Complex wire formed devices

InactiveUS20080262528A1Shorten the lengthAvoid insufficient lengthDilatorsExcision instrumentsMedicineFrictional resistance

The devices and methods described herein relate to jointless construction of complex structures. Such devices have applicability in through-out the body, including clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

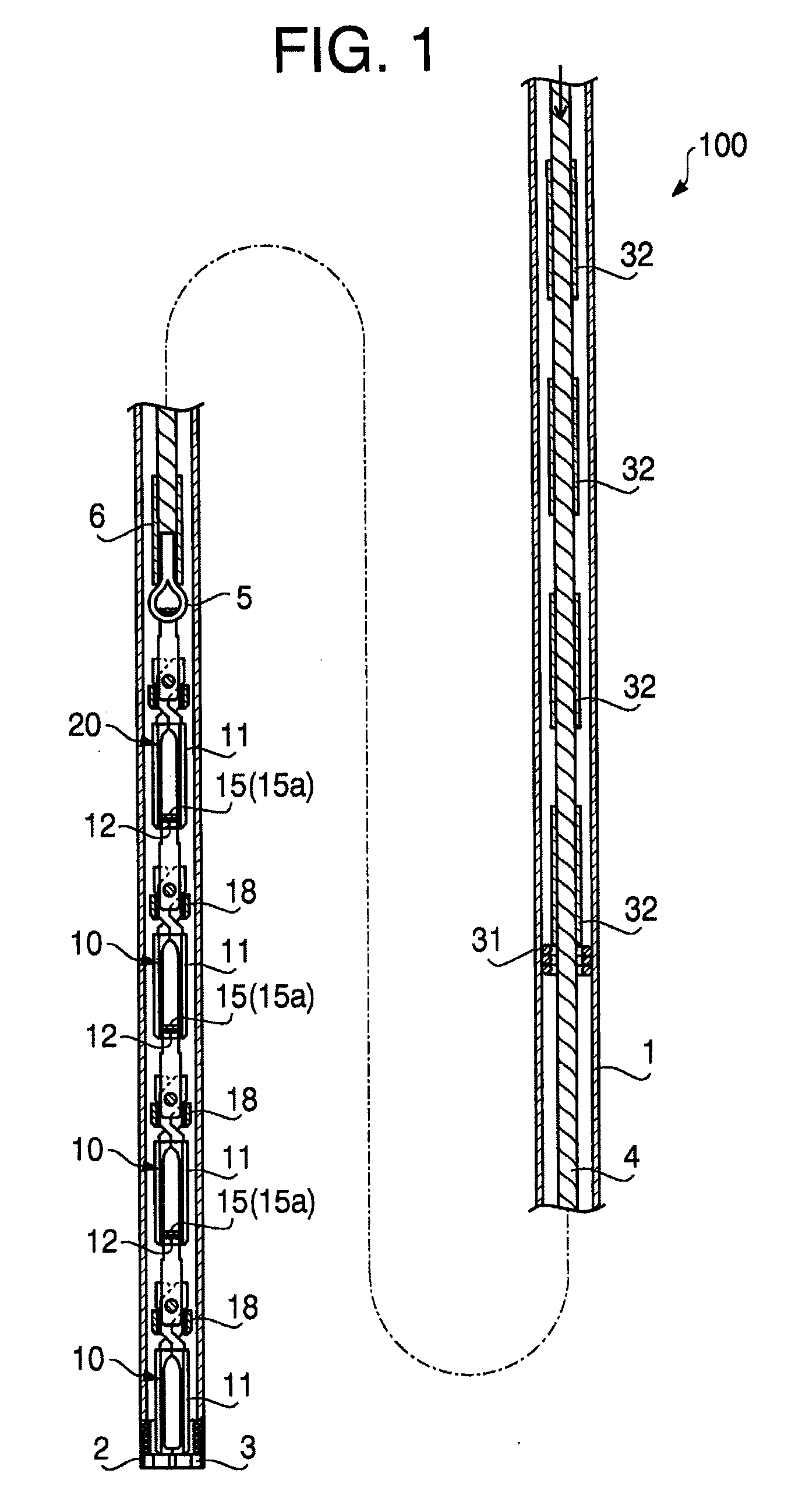

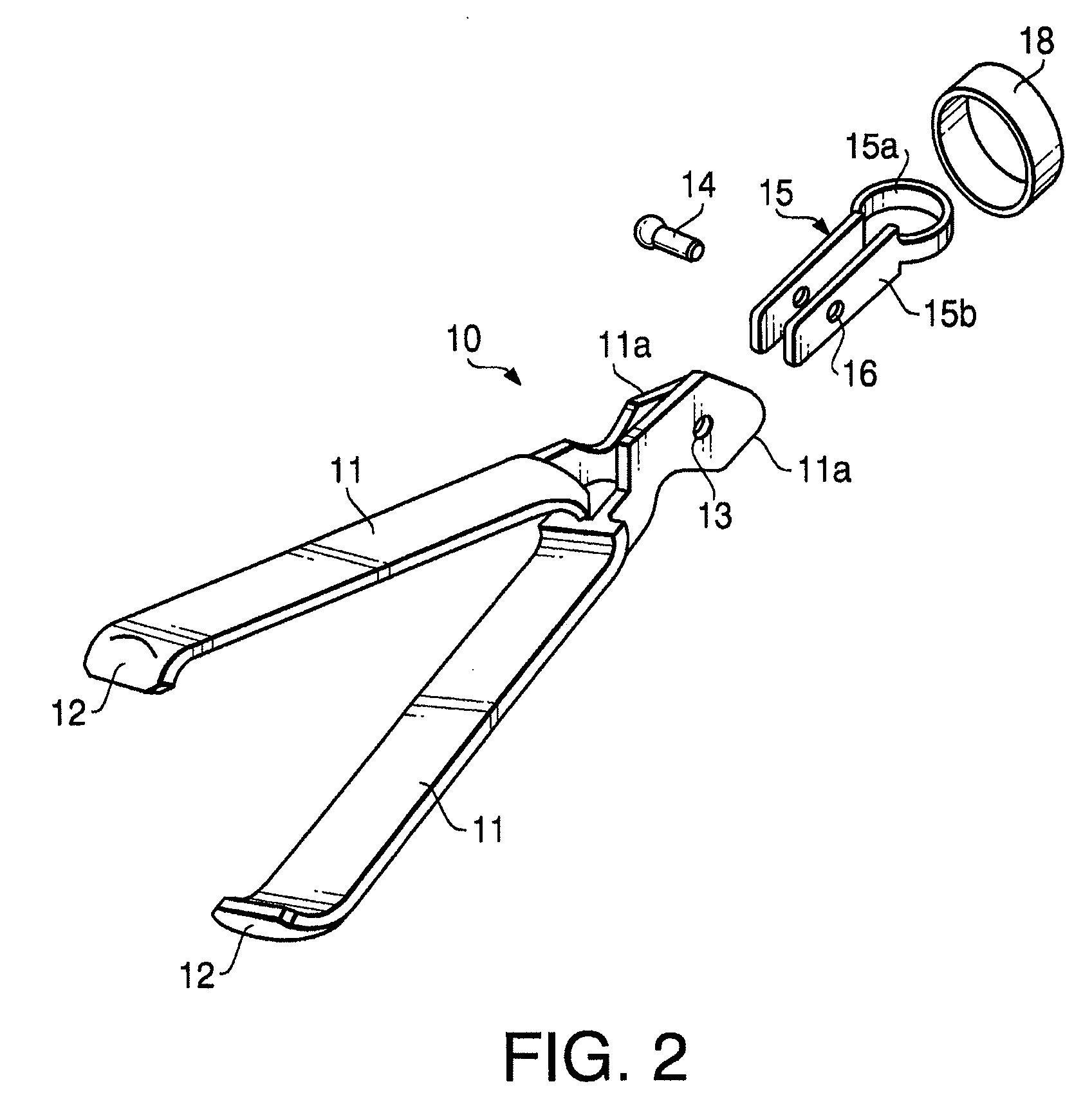

Clipping instrument for an endoscopic surgical device

A clipping instrument for an endoscope is provided. The clipping instrument includes a flexible sheath, an operation wire, which can be forwarded and retracted in an axial direction of the flexible sheath, at least one detachable clip assembly, including a pair of openable and closable clipping arms which can be projected forward to open outside the flexible sheath and to be closed to clip onto a treatment object outside the flexible sheath according to forwarding and retracting movements of the operation wire, and frictional members, which can generate frictional resistance between each other inside the flexible sheath. The frictional resistance is generated while the clipping arms of the clip assembly are forwarded by the forwarding movement of the operation wire to project out of the flexible sheath to be fully opened.

Owner:HOYA CORP

Methods for restoring blood flow within blocked vasculature

InactiveUS20070198030A1Increase frictionIncrease surface areaExcision instrumentsBlood flowBiomedical engineering

The devices and methods described herein relate to clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:LAZARUS EFFECT

Devices for restoring blood flow within blocked vasculature

InactiveUS20070185500A1Increase their ability to adhereStrong pullExcision instrumentsBlood flowBiomedical engineering

The devices and methods described herein relate to clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:LAZARUS EFFECT

Methods for restoring blood flow within blocked vasculature

InactiveUS20070198029A1Increase frictionIncrease surface areaExcision instrumentsBlood flowBiomedical engineering

The devices and methods described herein relate to clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:LAZARUS EFFECT

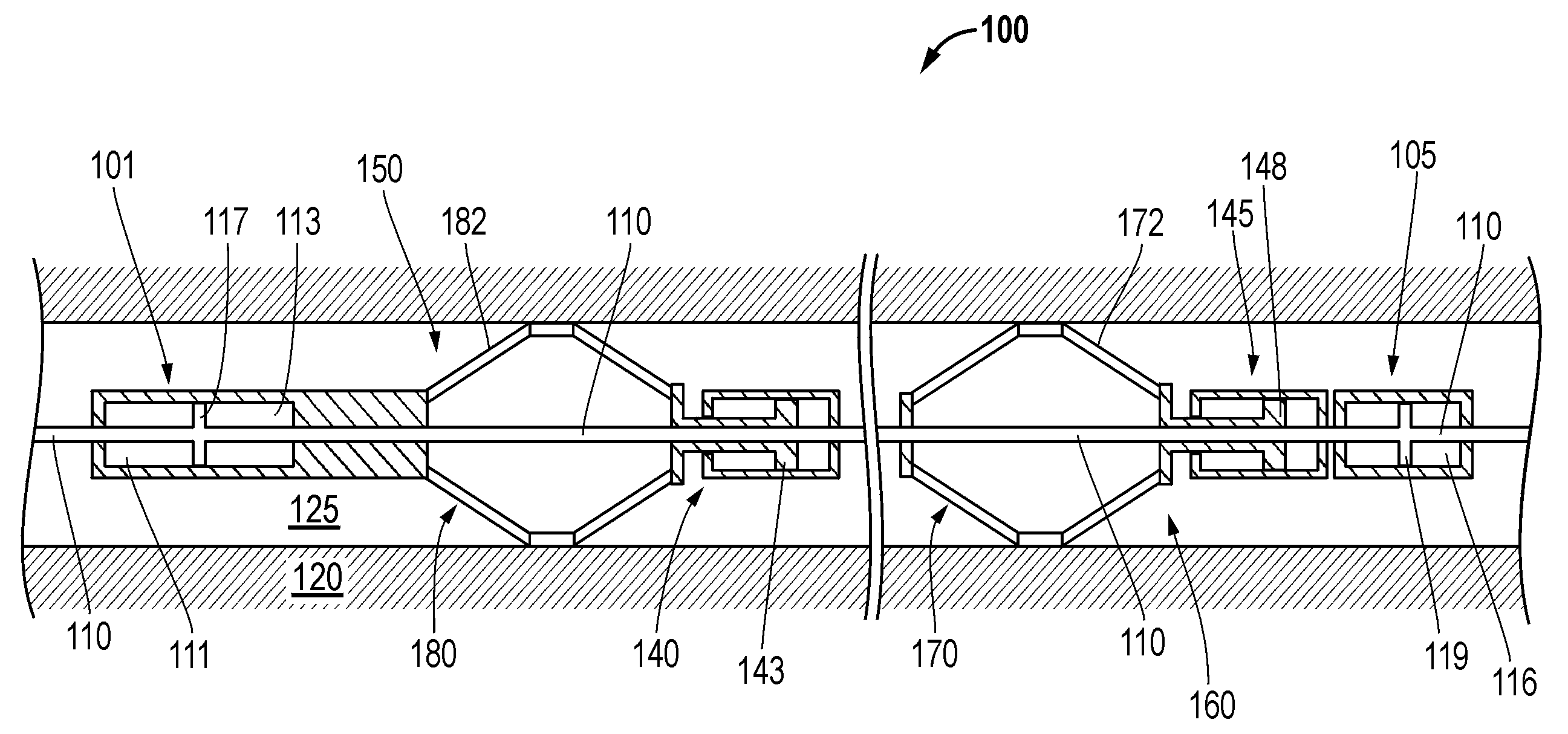

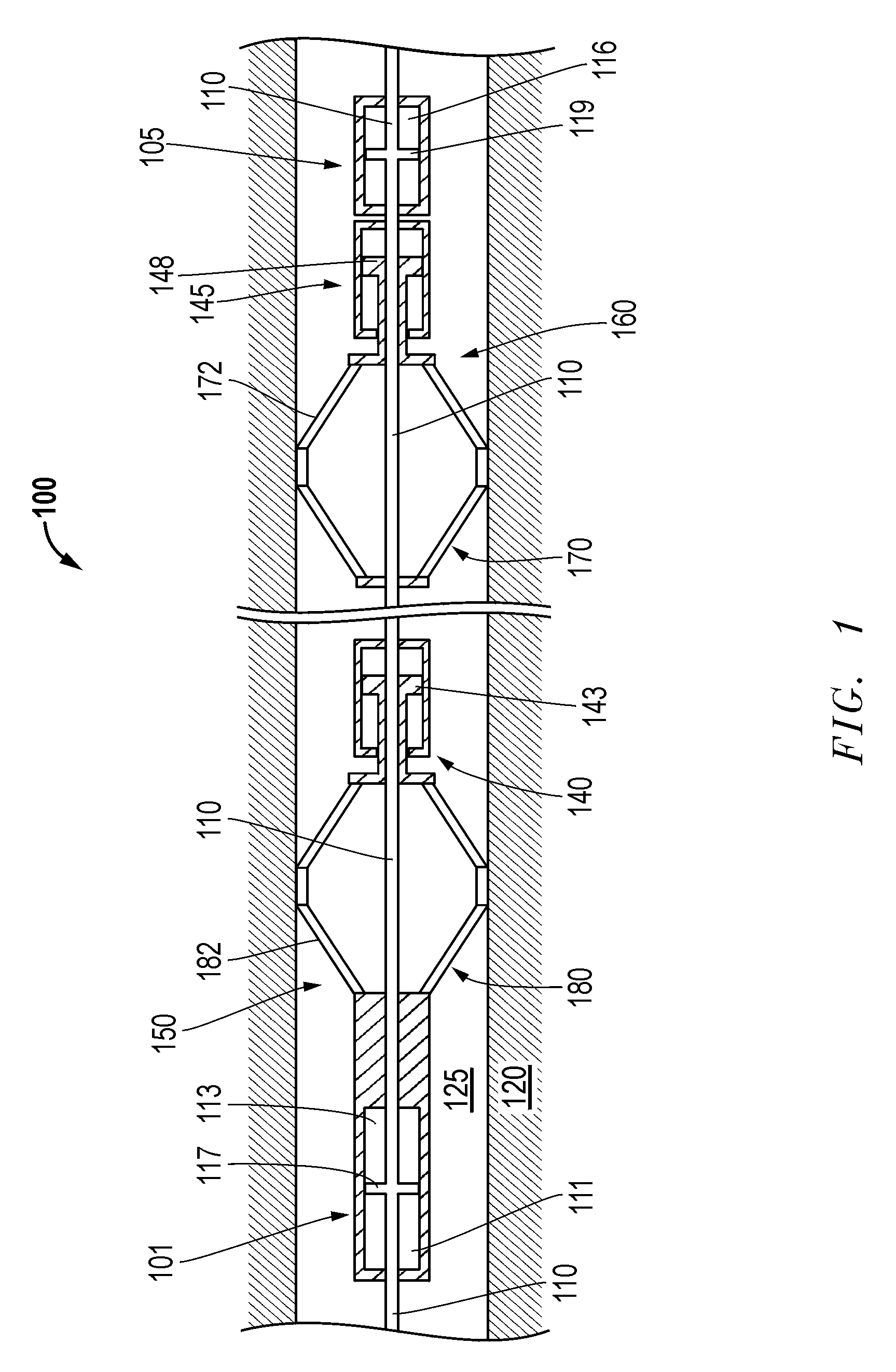

Retrieval systems and methods for use thereof

ActiveUS20110288572A1Inhibit migrationImprove efficiencyCannulasDilatorsBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the body, including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

Retrieval systems and methods for use thereof

ActiveUS20140005712A1Improves strength and flexibilityImprove abilitiesDilatorsExcision instrumentsBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the ho including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:TYCO HEALTHCARE GRP LP

Devices for restoring blood flow within blocked vasculature

InactiveUS20070197103A1Increase frictionIncrease surface areaExcision instrumentsTwo-part coupling devicesMedicineBlood flow

The devices and methods described herein relate to clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:LAZARUS EFFECT

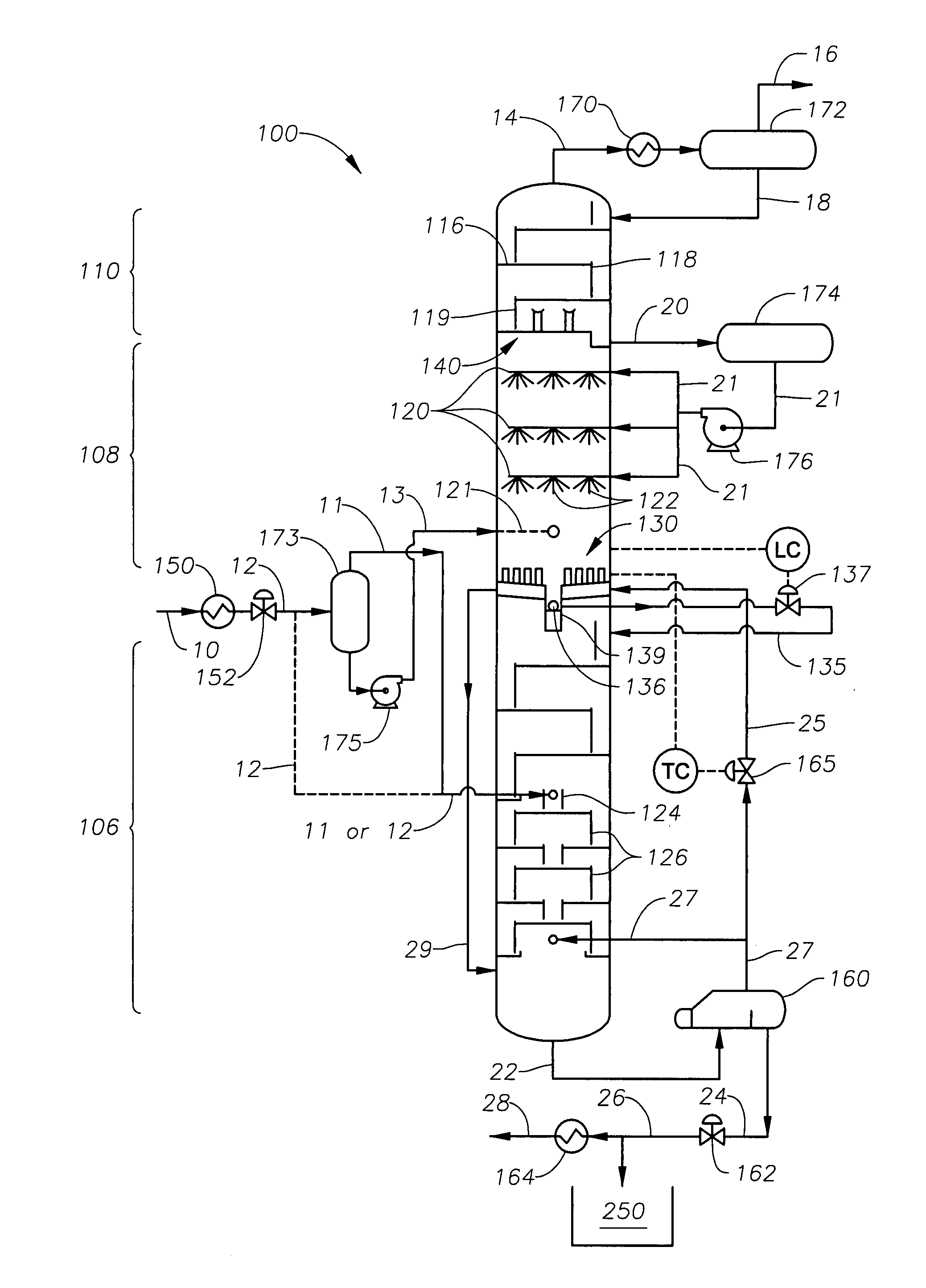

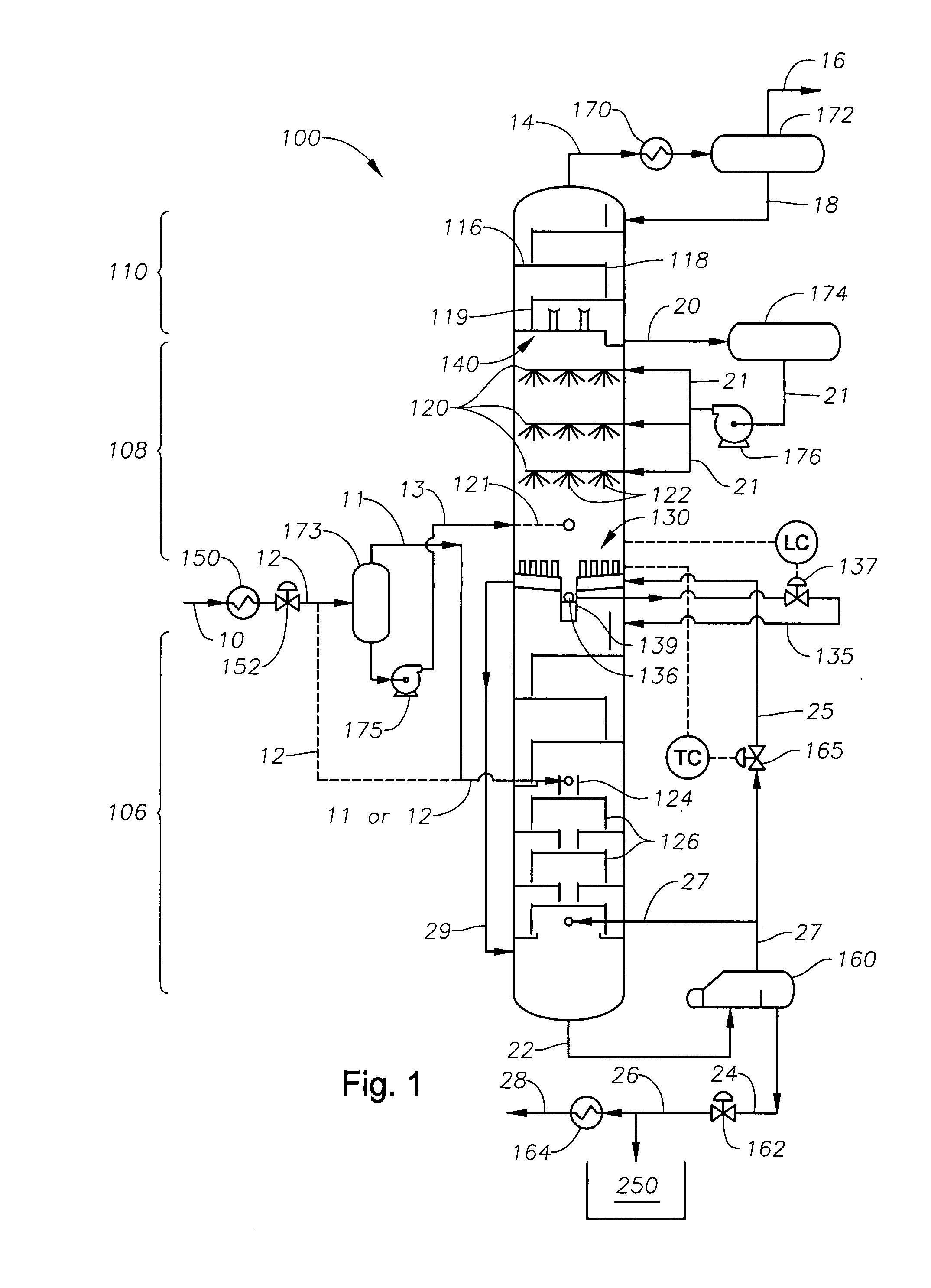

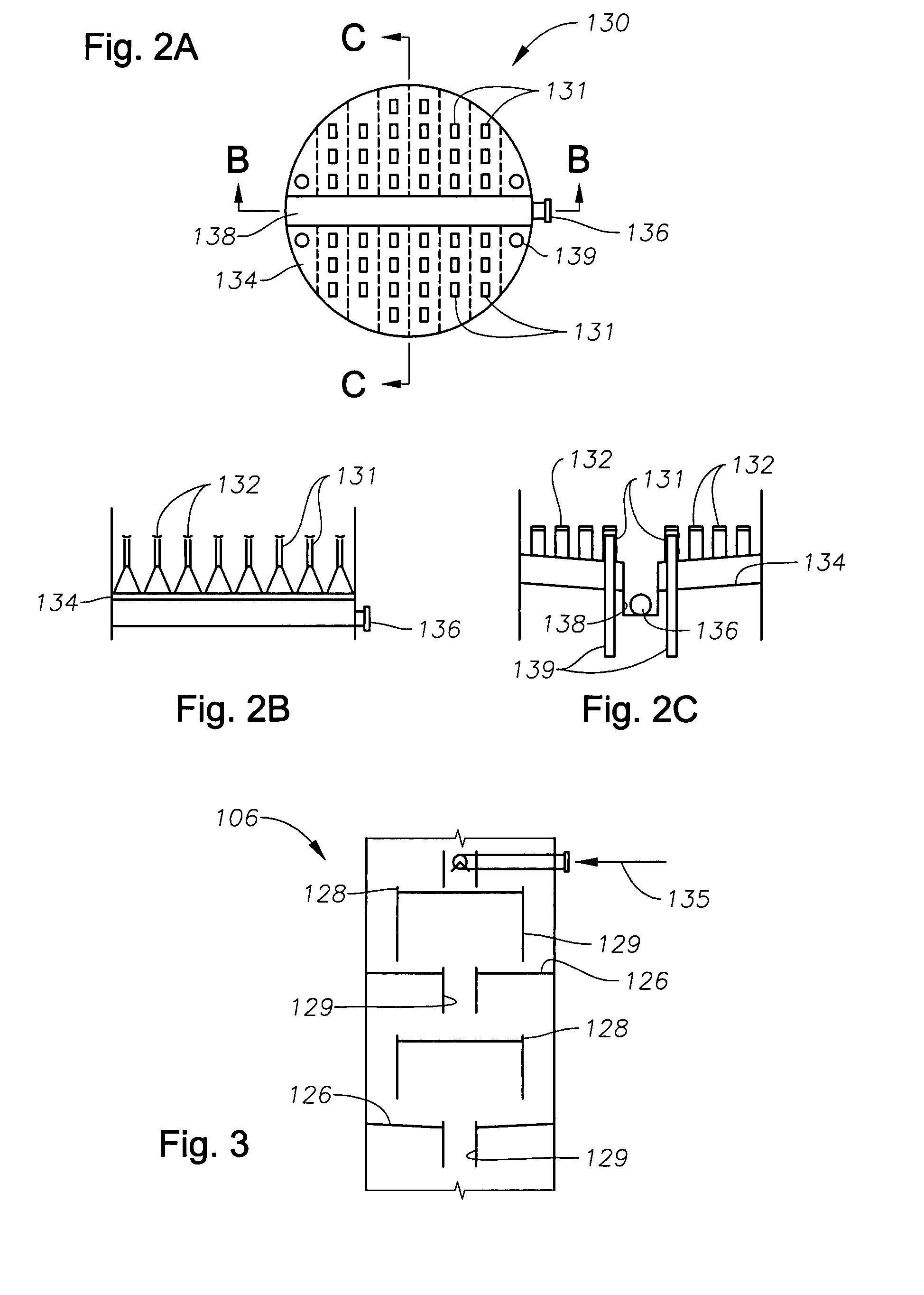

Controlled Freeze Zone Tower

A cryogenic distillation tower is provided for the separation of a fluid stream containing at least methane and carbon dioxide. The cryogenic distillation tower has a lower stripping section, an upper rectification section, and an intermediate spray section. The intermediate spray section includes a plurality of spray nozzles that inject a liquid freeze zone stream. The nozzles are configured such that substantial liquid coverage is provided across the inner diameter of the intermediate spray section. The liquid freeze zone stream generally includes methane at a temperature and pressure whereby both solid carbon dioxide particles and a methane-enriched vapor stream are formed. The tower may further include one or more baffles below the nozzles to create frictional resistance to the gravitational flow of the liquid freeze zone stream. This aids in the breakout and recovery of methane gas. Additional internal components are provided to improve heat transfer and to facilitate the breakout of methane gas.

Owner:FIELER ELEANOR R +3

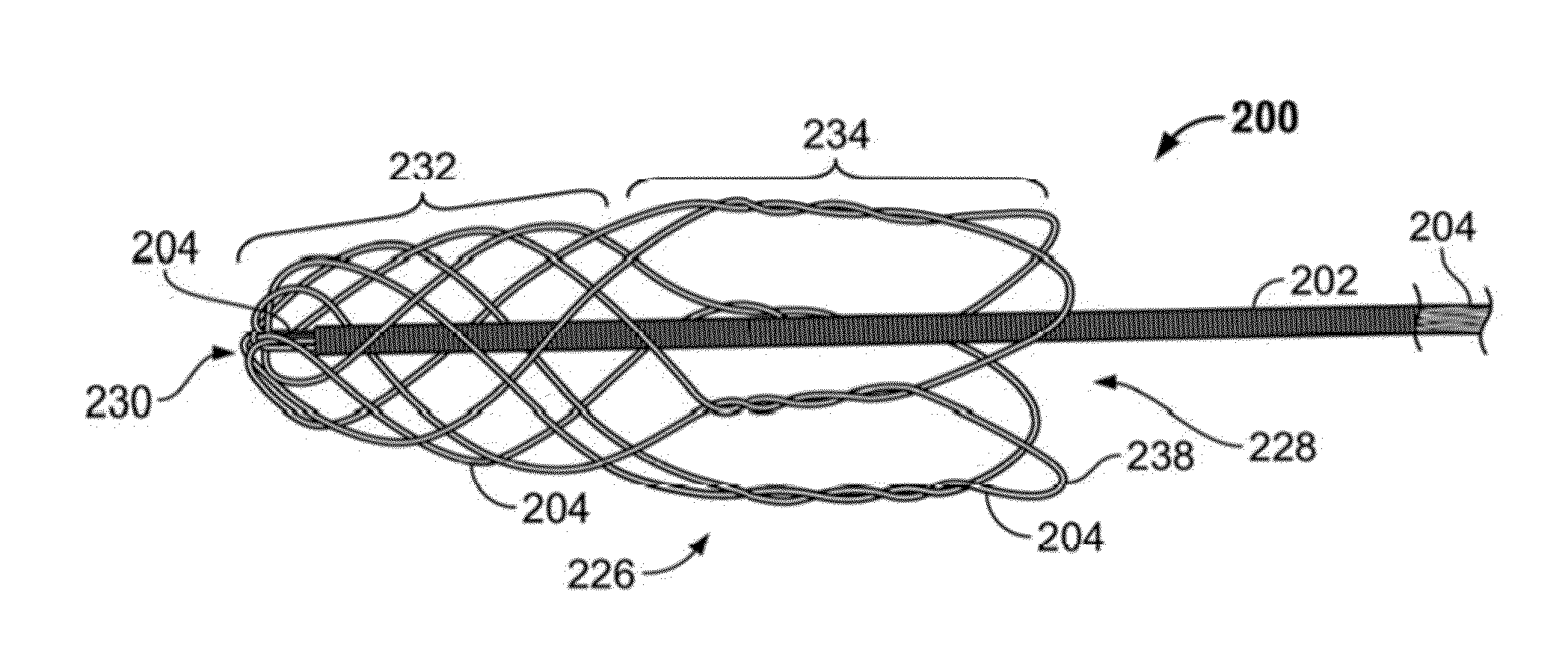

Retrieval systems and methods for use thereof

ActiveUS20130317589A1Little strengthReduce dislodging portionStentsCannulasBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the body, including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:TYCO HEALTHCARE GRP LP

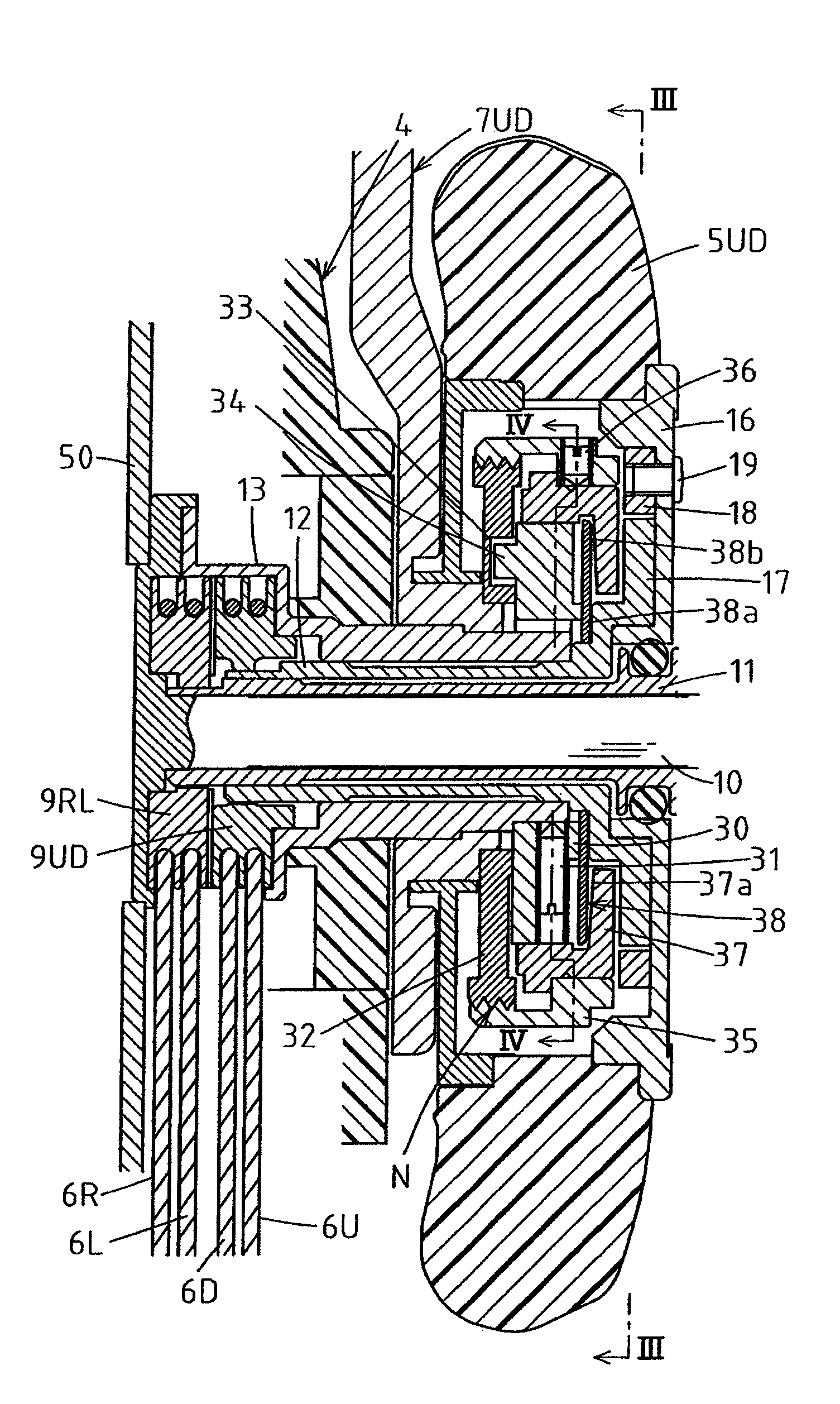

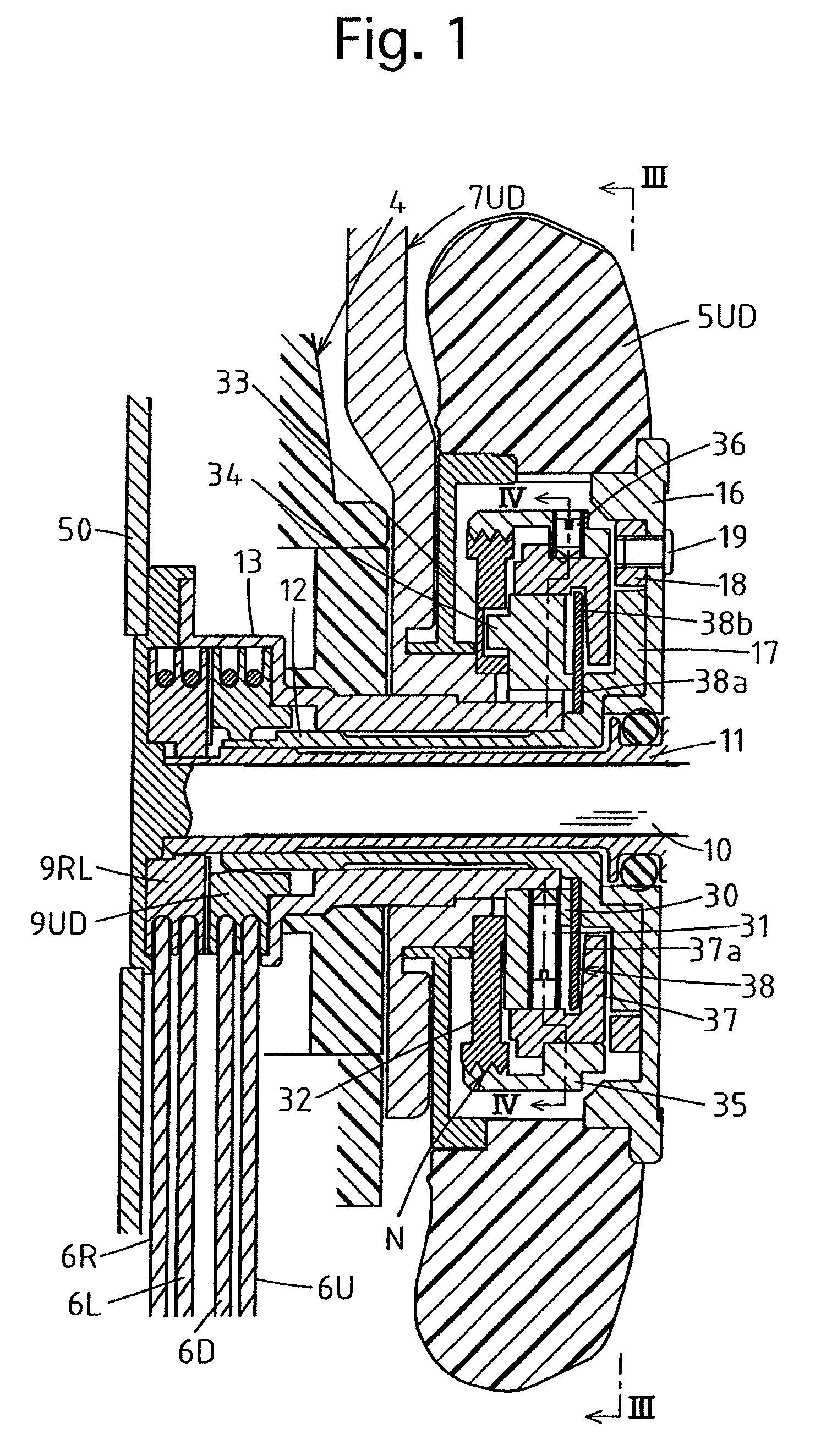

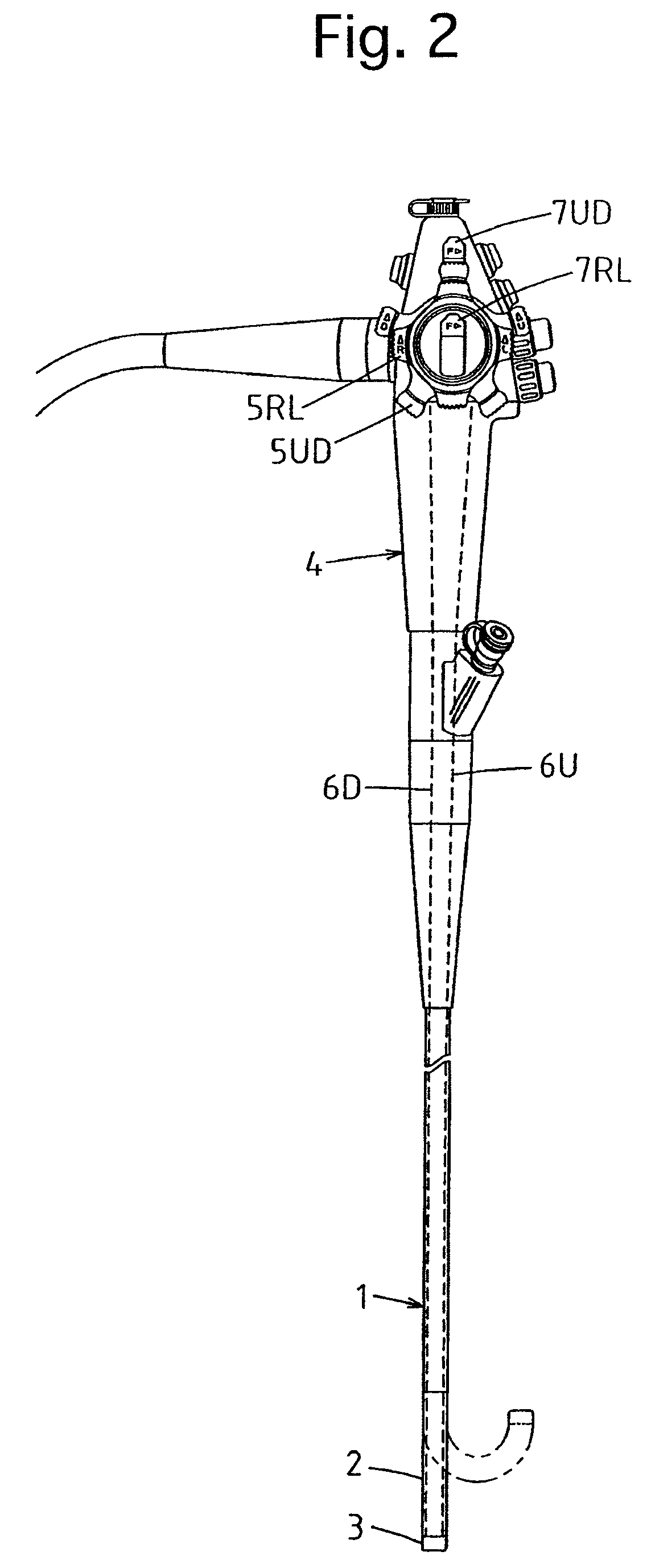

Bent state holding mechanism of an endoscope

A bent state holding mechanism for an endoscope which includes a control portion and an insertion portion extending therefrom, the insertion portion having a bendable portion at a distal end thereof, including a bendable portion control mechanism provided on the control portion, which is operated to bend the bendable portion, and at least two frictional resistance producing members which rotate relative to each other upon operation of the bendable portion control mechanism, to exert a frictional resistance for holding the bendable portion at any operated position. The two frictional resistance producing members include a radial plate spring made of resilient metal which includes a ring portion and a plurality of radial projections which project radially outwards from the ring portion; and an annular friction member having a pressure surface which is brought to be pressed obliquely against flat surfaces of the plurality of radial projections.

Owner:HOYA CORP

Interior rearview mirror assembly with polymeric components

InactiveUS6877709B2Manufacturing EasePerformance easePicture framesDomestic mirrorsElectrical conductorElectrical connection

An interior rearview mirror assembly for vehicles incorporates a rearview mirror mount, a rearview mirror, and a rearview mirror support. The support is pivotally attached to the mirror mount by a first pivot element, and to the rearview mirror by a second pivot element. The mirror mount, support, a rearview mirror housing, and the pivot elements are each formed by molding from polymeric material having a respective color. In various embodiments, the colors may all be substantially the same, such as black, gray, tan, brown, burgundy, green, or another color, or may be different. In one form, the rearview mirror housing includes at least one electrical accessory. Electrical conductors may extend through the pivot elements and mirror support to the rearview mirror housing to provide an electrical connection for the electrical accessory to the vehicle electrical system. The pivot elements preferably include ball pivot members and sockets on various of the mirror mount, support and rearview mirror housing, and may include surfaces for enhanced frictional resistance to pivotal movement. In one form, the rearview mirror mount preferably includes receiving members which release the assembly from a windshield attachment member when sufficient force is applied such as upon impact.

Owner:DONNELLY CORP

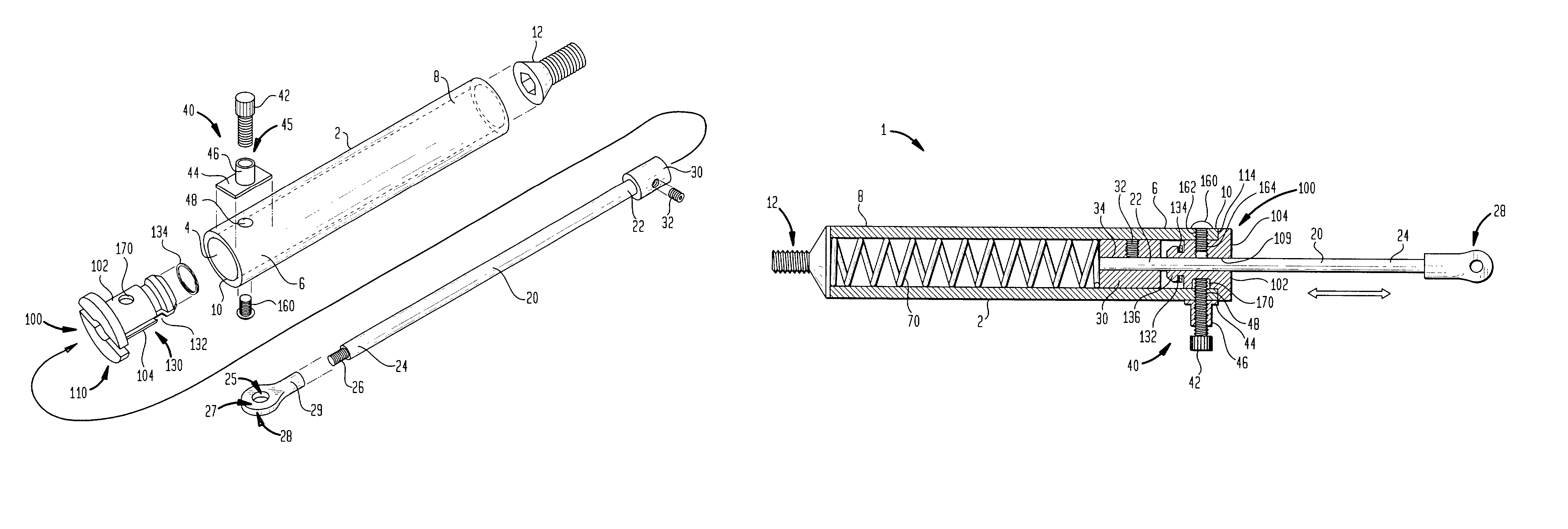

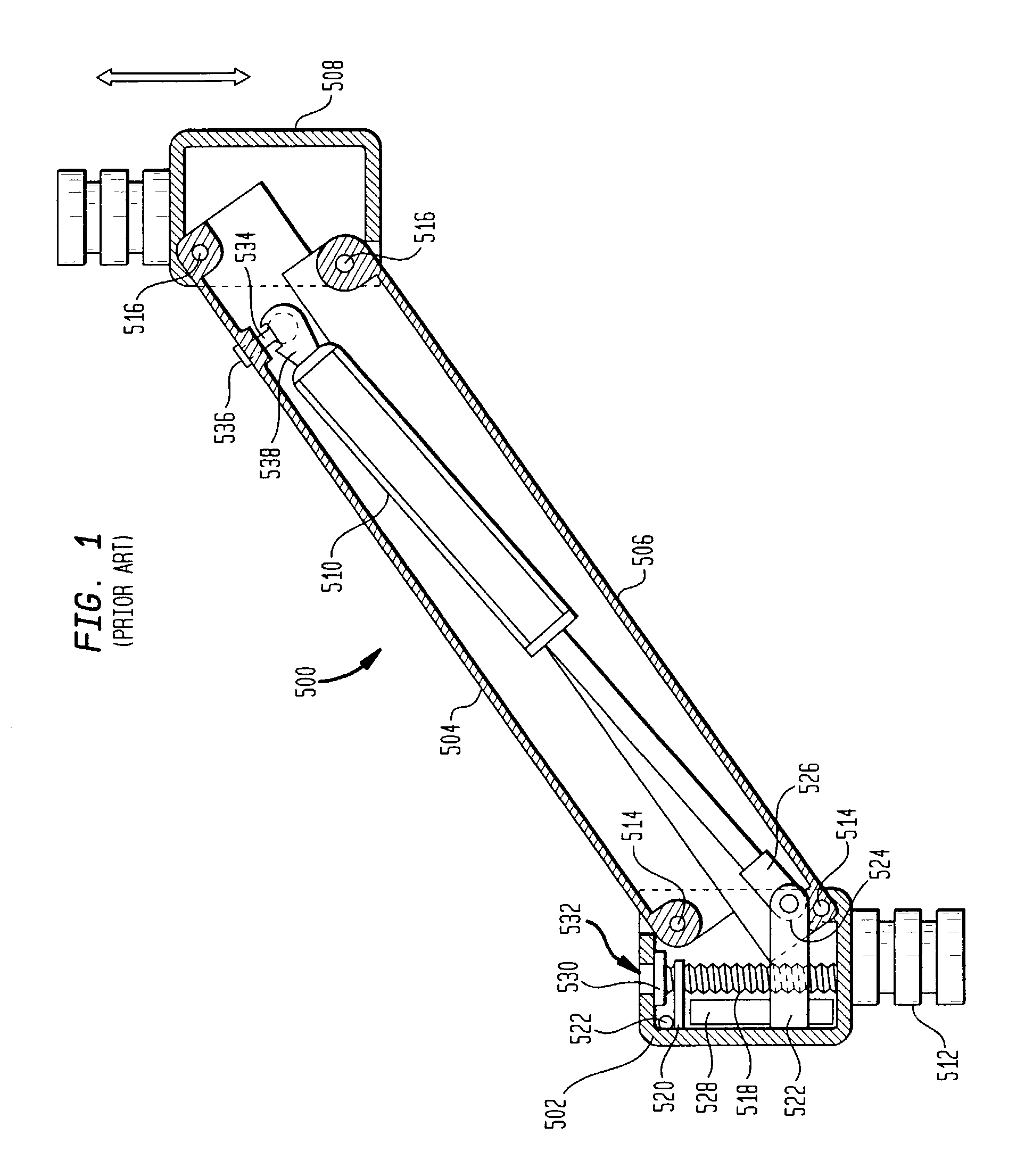

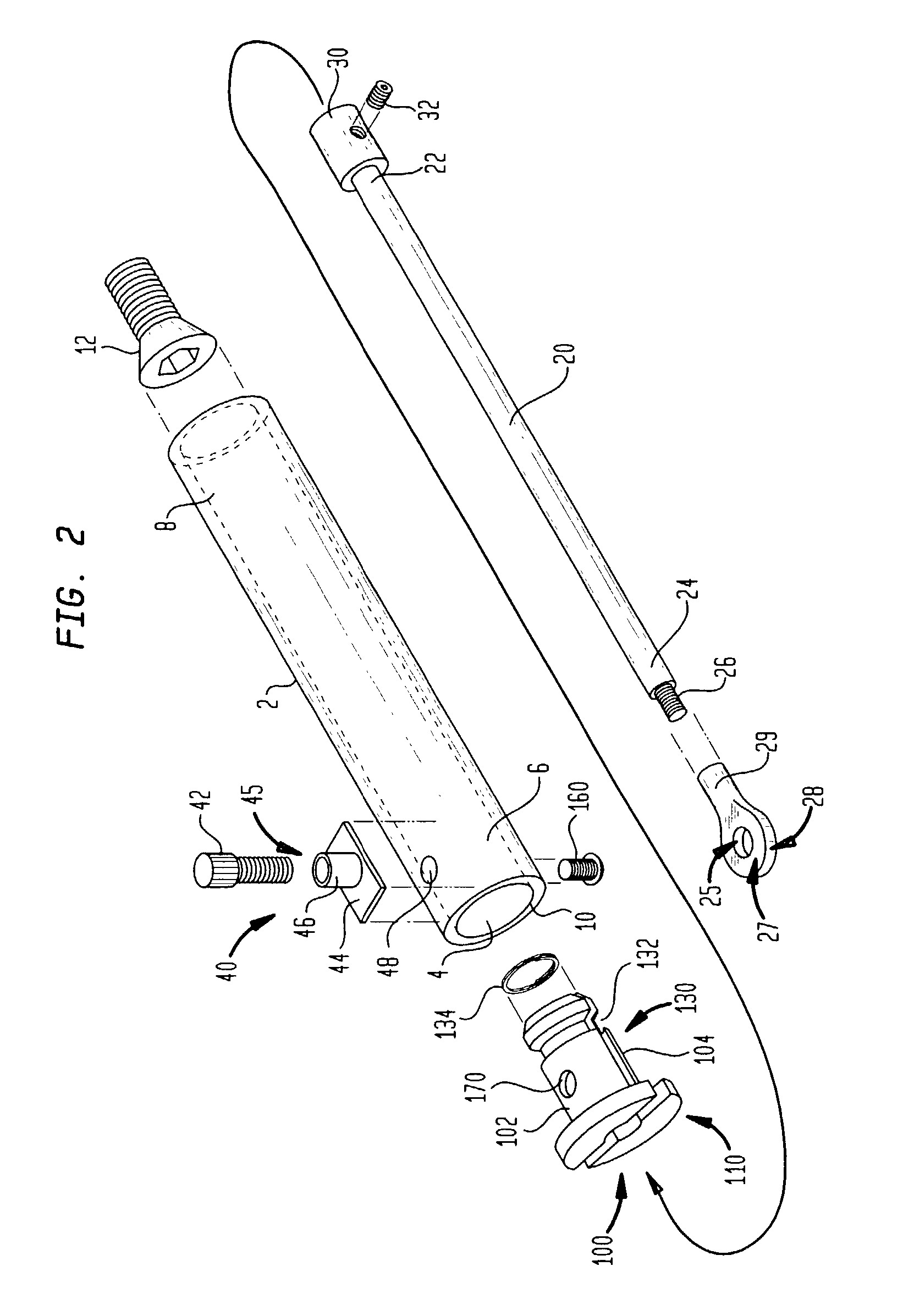

Friction cylinder for a support device

InactiveUS7014157B2Good for stable movementAvoid elevationPortable framesSpringsGas springEngineering

A positionable support device includes a friction cylinder as a counterbalance in place of conventional gas springs. The support device includes a support arm pivotally secured between two endcaps to allow for vertical movement, the first endcap being mounted to a support structure such as a wall or desktop, the second endcap adapted to engage a mounting element for a device such as an electronic device. A friction cylinder is pivotally attached at one end to the first endcap, and at the other to an outward portion of the support arm. The friction cylinder includes a tubular member open at one end for receiving a friction bushing and a shaft. The friction bushing is secured to the tubular member and has a central passage which allows the shaft to slide through the friction bushing, extending and retracting in relation to the tubular member. The friction bushing is adjusted to apply frictional resistance to movement of the shaft sufficient to support the weight of the support device and the electronic device, thereby allowing the device to be adjusted to a desired vertical position.

Owner:INNOVATIVE OFFICE PROD INC

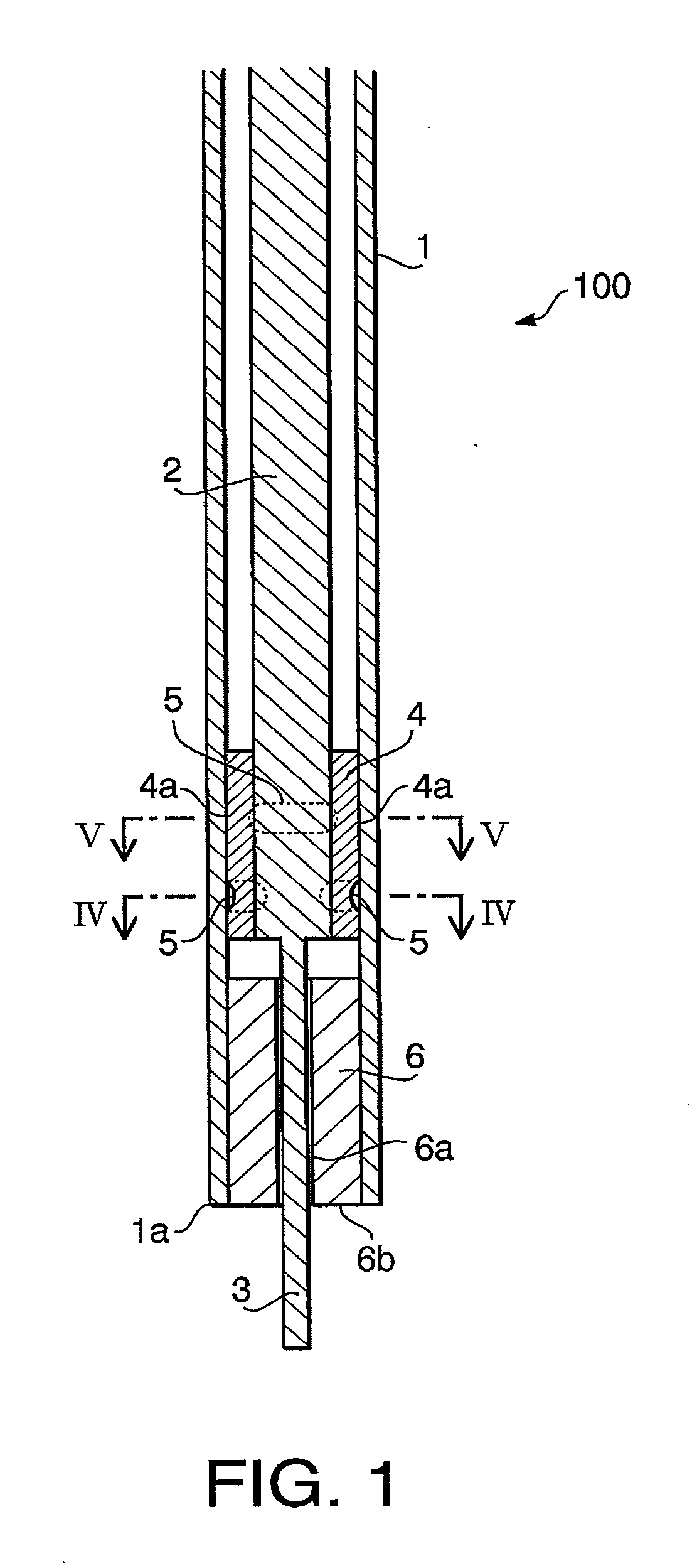

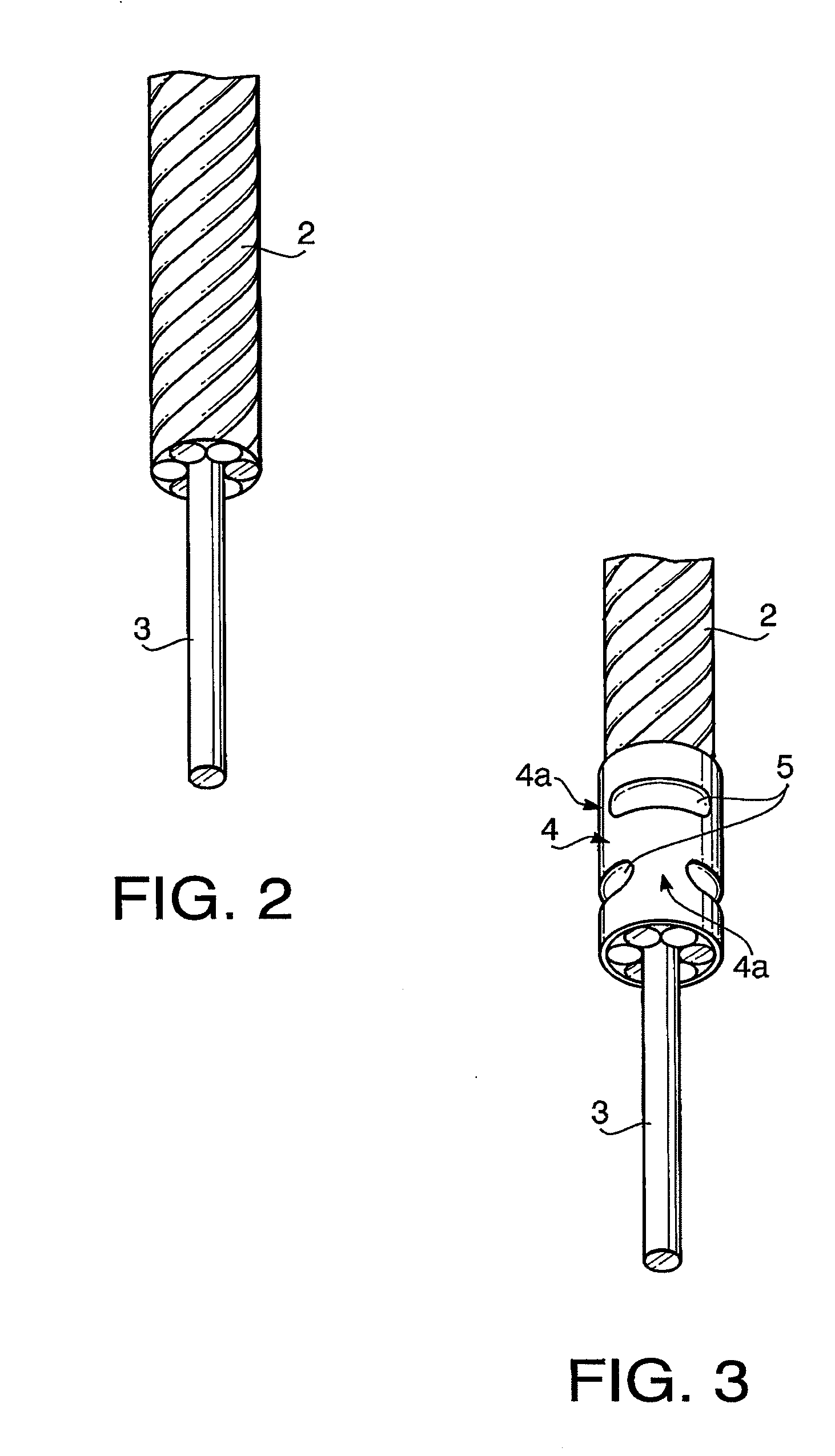

High-frequency treatment tool for endoscope

A high-frequency treatment tool for an endoscope, having an electrically insulating flexible tube, an operating wire, a high-frequency electrode, which is provided at a distal end of the operating wire and configured to be protrusible and retractable from a distal end of the flexible tube in the axial direction of the flexible tube, and a tubular member, is provided. The tubular member is fitted on the operation wire and immovably attached thereon by plastic deformation, which is caused as at least a part of the tubular member is deformed to interfere with an inner circumferential surface of the flexible tube so that the operating wire is halted with respect to the flexible tube at an arbitrary position in the flexible tube by frictional resistance caused between an interfering part of the tubular member and the inner circumferential surface of the flexible tube.

Owner:HOYA CORP

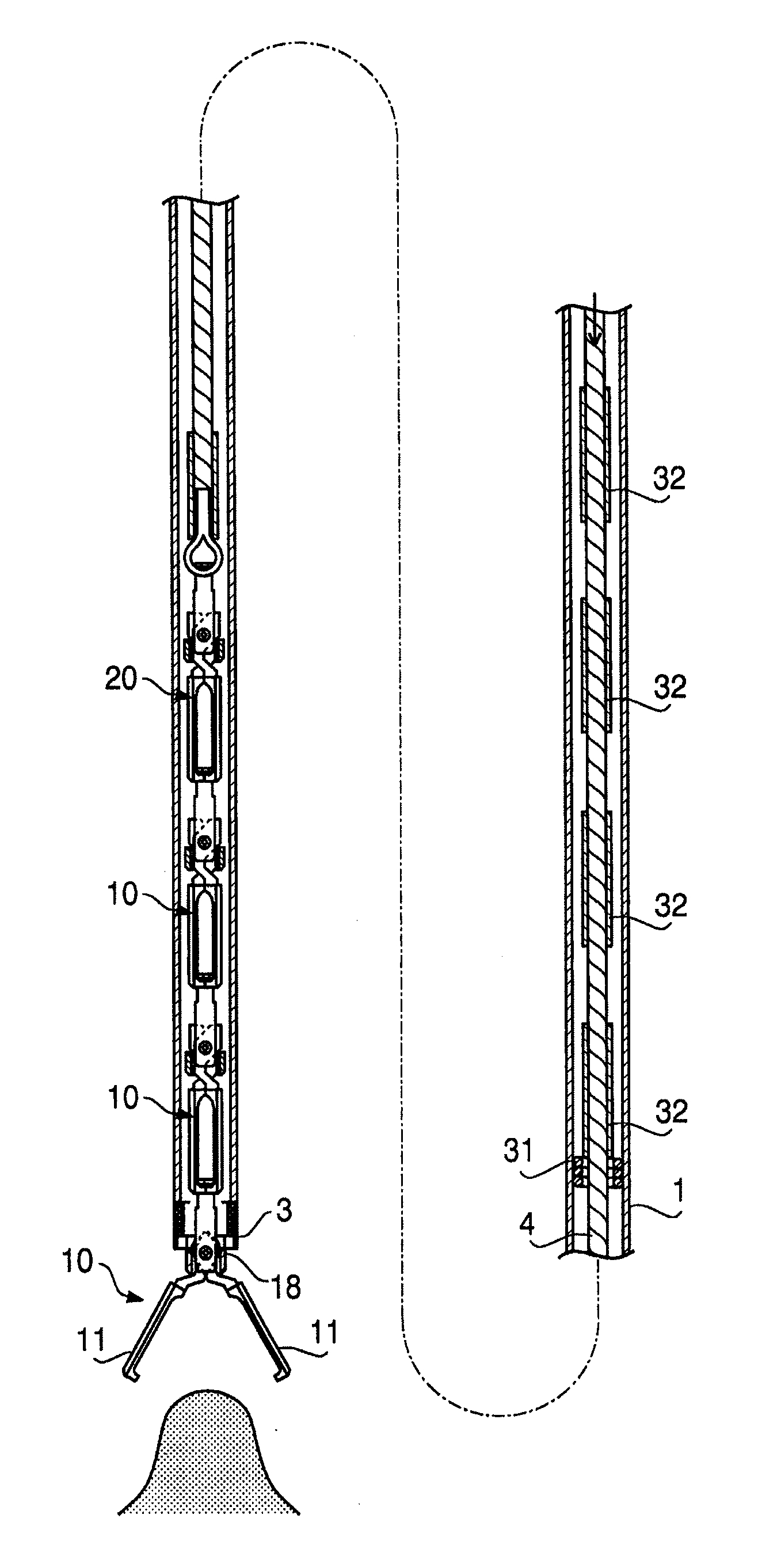

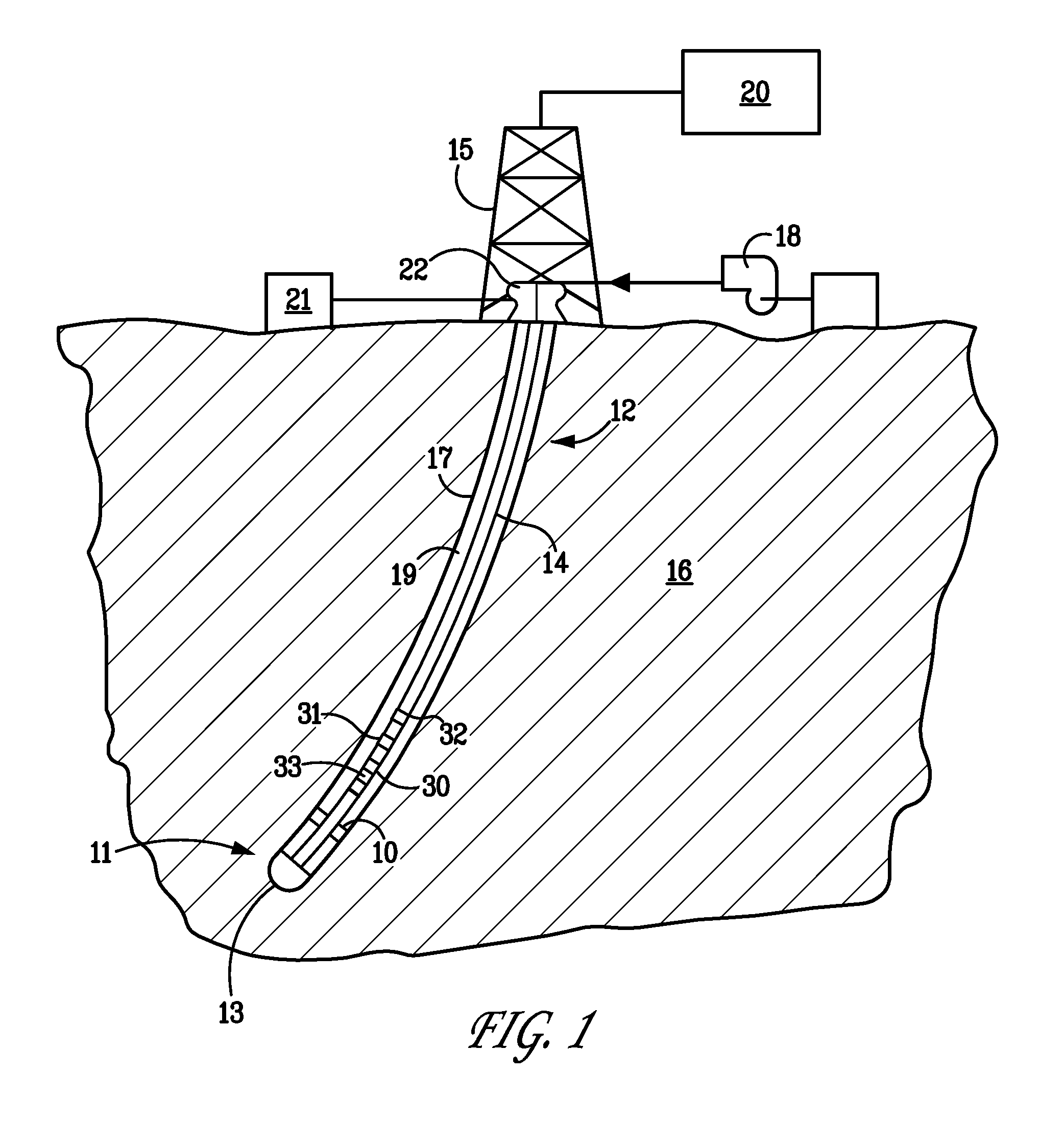

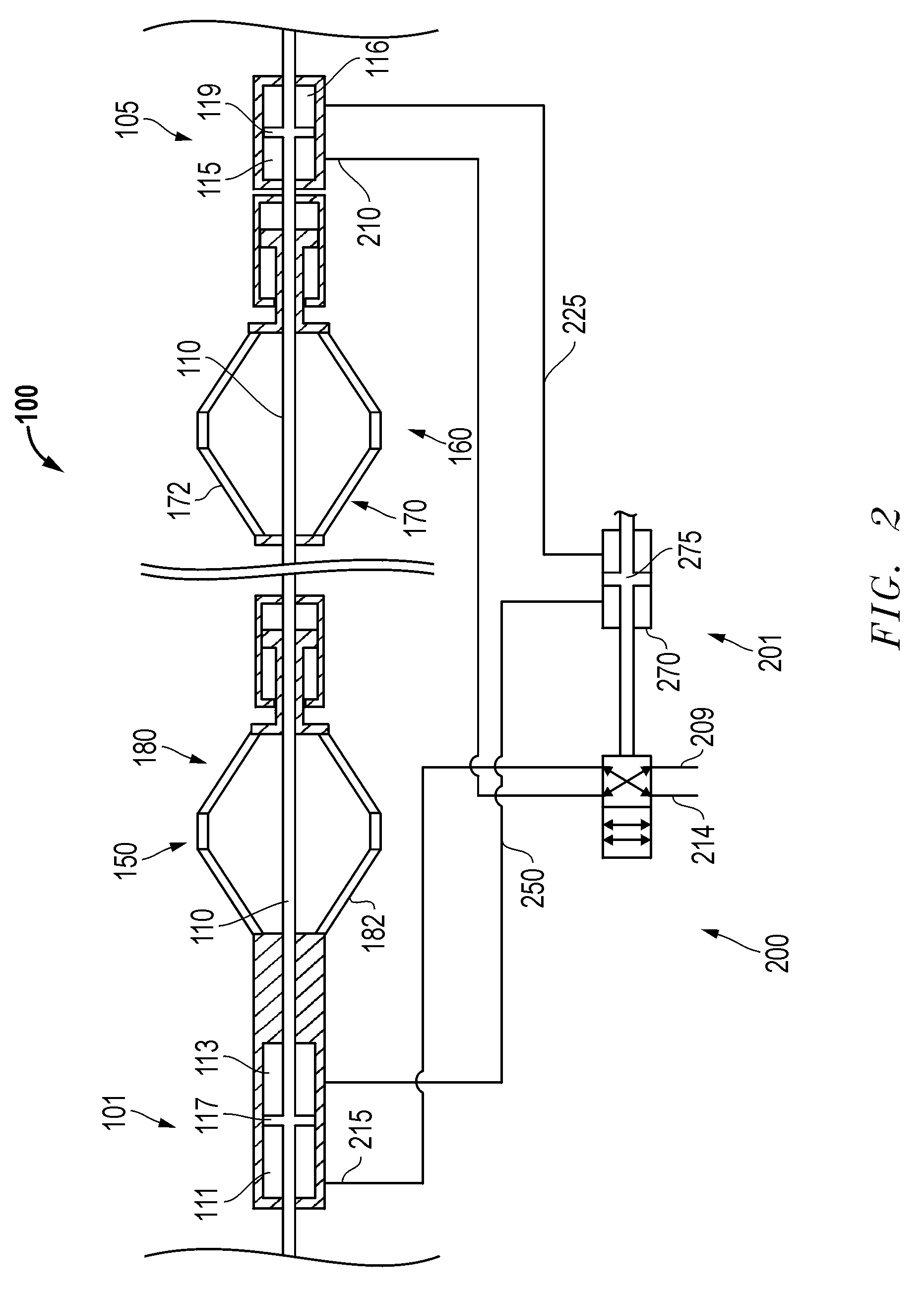

Apparatus And Method For Damping Vibration In A Drill String

ActiveUS20120228028A1Reducing drill string torsional vibrationLimiting maximum angular velocityDrilling rodsDirectional drillingMagnetorheological fluidAngular velocity

An apparatus and method for damping vibration, especially torsional vibration due to stick-slip, in a drill string, Sensors measure the instantaneous angular velocity of the drill string at one or more locations along the length of the drill string. One or more vibration damping modules are also spaced along the length of the drill string. When torsional vibration above a threshold is detected, the damping module imposes a reverse torque on the drill that dampens the torsional vibration. The reverse torque can be created by imparting a frictional resistance to the rotation of the drill string. The frictional resistance can be created externally, by extending friction pads from the damping module so that they contact the bore hole wall and drag along the bore hole as the drill string rotates, or internally by anchoring a housing mounted on the drill string to the wall of the bore hole and then imposing frictional resistance on a fluid, such as a magnetorheological fluid, flowing within the drill string.

Owner:APS TECH

Retrieval systems and methods for use thereof

InactiveUS8545526B2Improves strength and flexibilityImprove abilitiesCannulasDilatorsBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the body, including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen.

Owner:TYCO HEALTHCARE GRP LP

Hydro-oscillator for well drilling

InactiveCN102704842AIncrease frictional resistanceIncrease drilling speedVibration devicesVibration drillingWell drillingHarmonic vibration

The invention relates to a hydro-oscillator for well drilling. The hydro-oscillator consists of a hydraulic driving assembly, a fixed valve assembly, a bottom assembly and a vibrating pipe nipple, wherein the vibrating pipe nipple is connected with the hydraulic driving assembly; a rotor is connected with a vibrating valve; the fixed valve assembly is arranged on the bottom assembly; and a power shell is connected with the bottom assembly. A drilling fluid is used for driving the rotor to rotate, and the rotor is used for driving the vibrating valve to vibrate, so that flow holes of the vibrating valve and a fixed valve are staggered with each other, and simple harmonic pressure waves are modulated and are upwardly transmitted to a disc spring for driving the vibrating shell to perform continuous simple harmonic vibration in the axial direction, so that the friction resistance between a drilling column and a well wall is improved effectively, and the drilling speed is increased; and meanwhile, pressure waves are downwardly transmitted to drill bit jet flow, so that periodic change of rock breaking pressure is facilitated, and rocks are crushed effectively. The hydro-oscillator has the characteristics of simple structure, convenience for operating, safety, reliability, low pressure drop, high adaptability, no influence on the drilling tool structure and the like, and plays an important role in increasing the drilling speed and reducing cost.

Owner:CHINA PETROCHEMICAL CORP +1

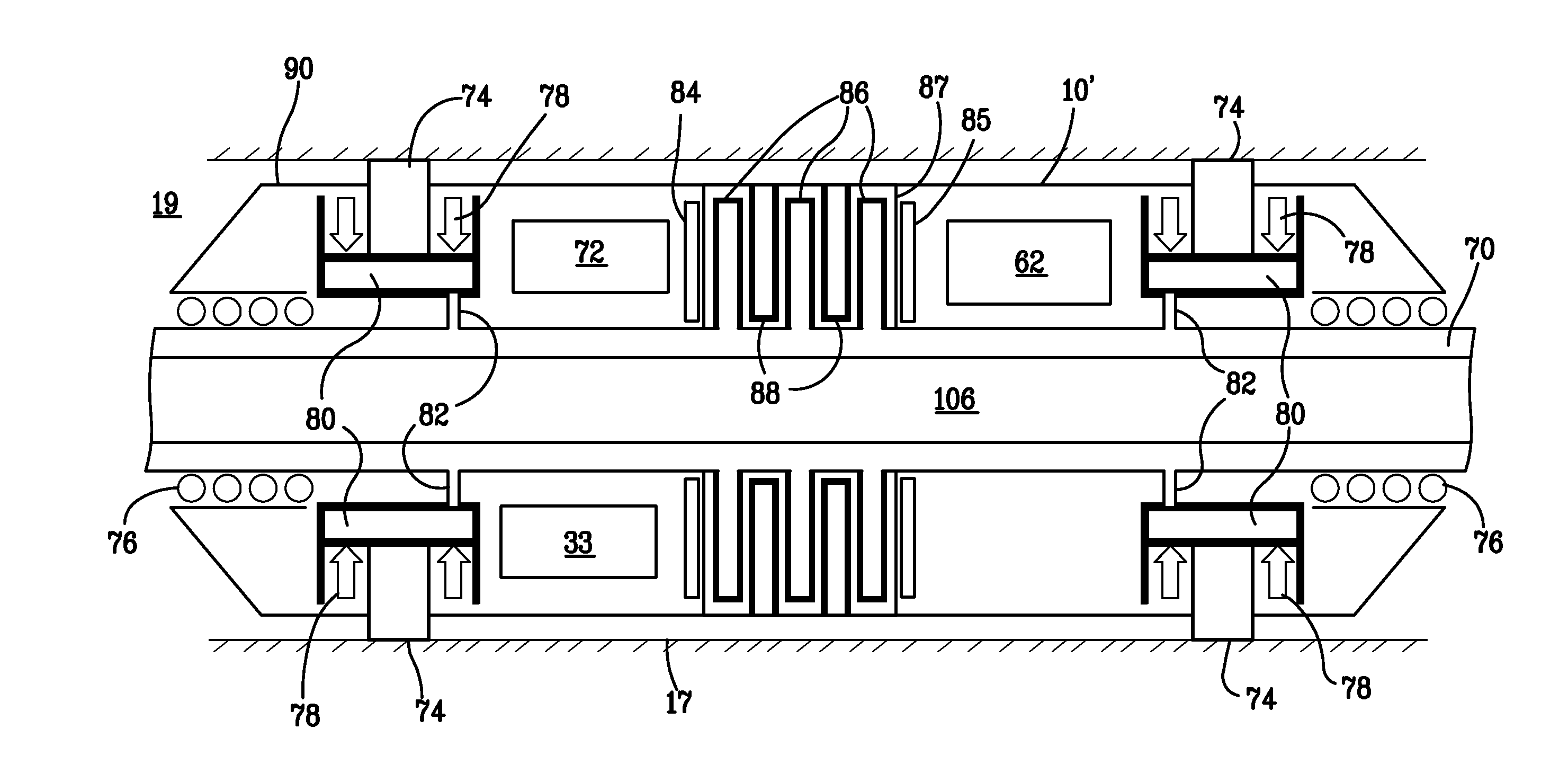

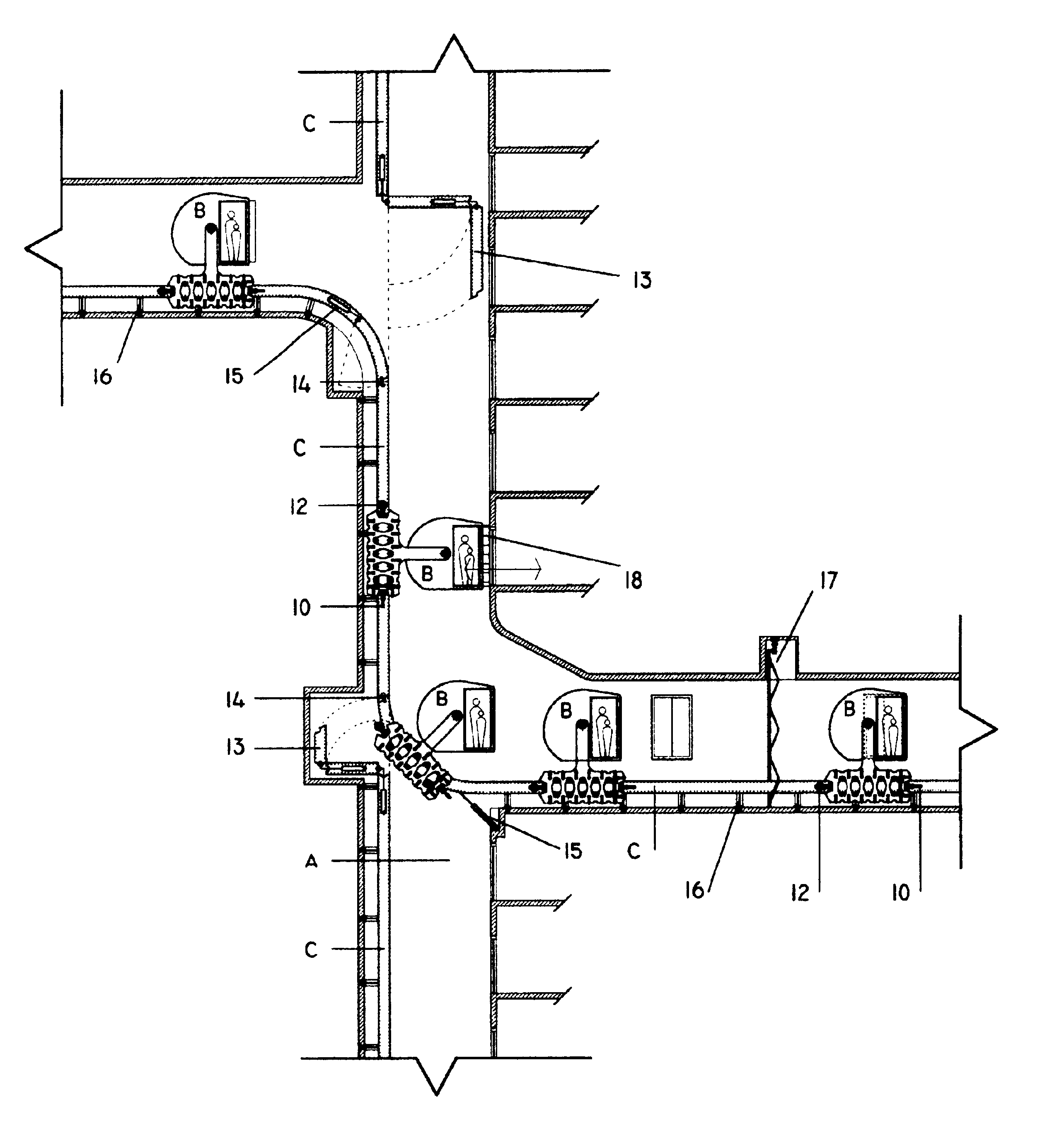

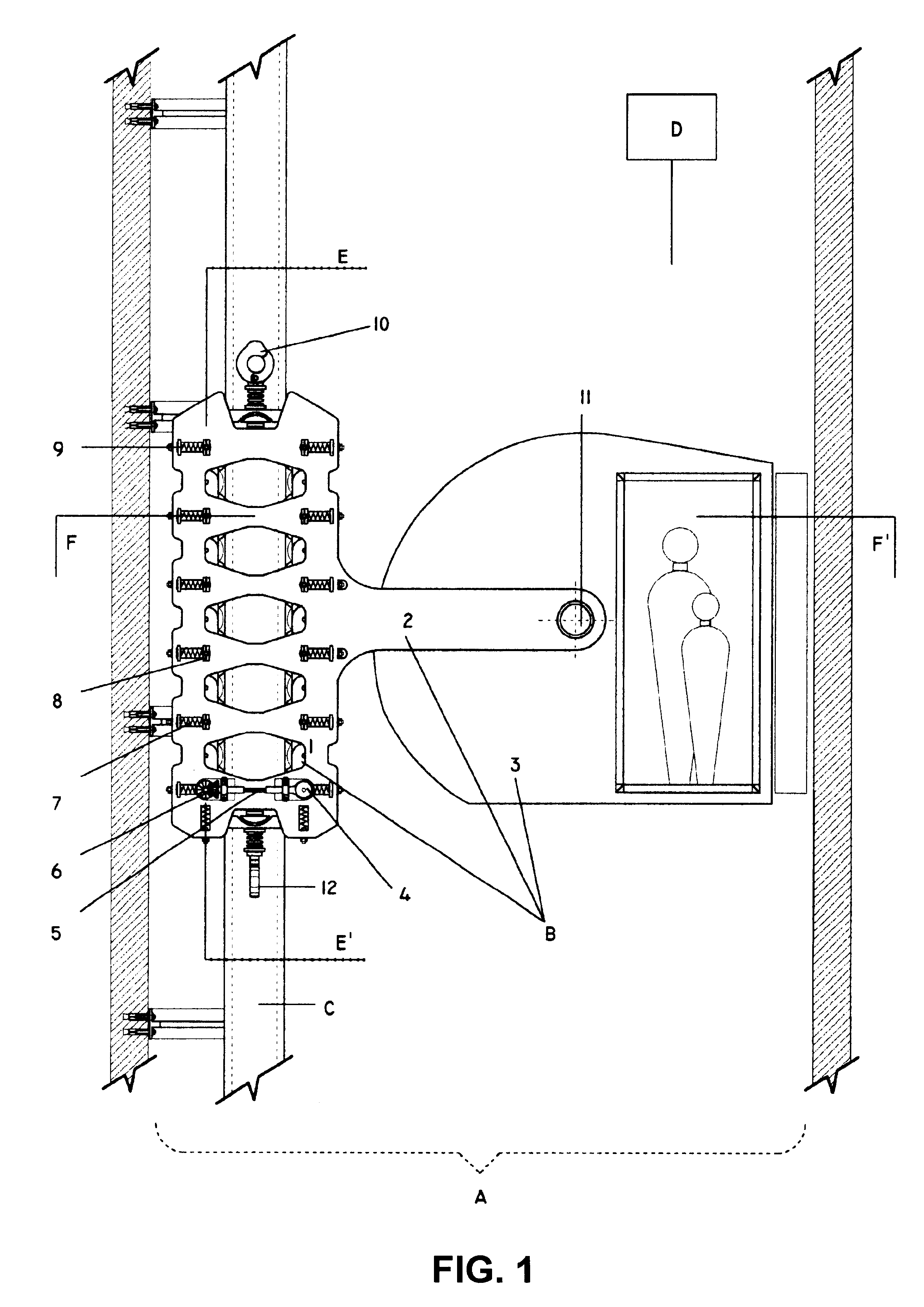

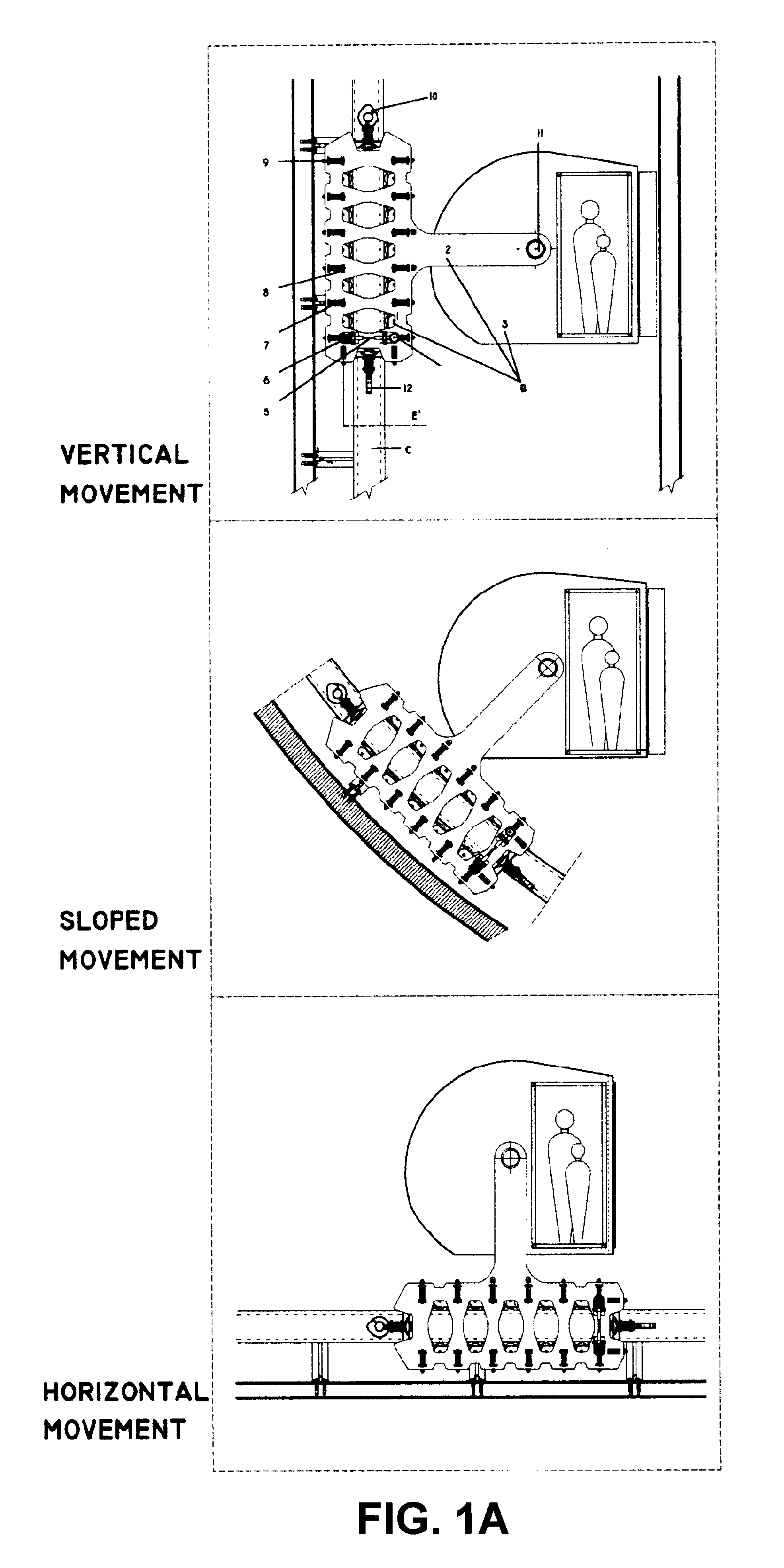

Autonomous transport system

An autonomous transport system is disclosed, formed by four main subsystems: a channel subsystem; a vehicle subsystem; a wheel guide subsystem and central control station subsystem. The system is designed for the transportation of people or goods, to be used in tall buildings and in small and large scale urban environments. It comprises unitary vehicles that may move in different directions: horizontal, steeply sloped and also vertical tracks, thanks to novel traction wheel assemblies that roll on carefully designed wheel tracks. The system's cabin maintains the horizontal level / position regardless of the changes of track direction or slanting thanks to pendulum based automatic level control and may rotate up to 180° under normal conditions and even a full 360° turn respect to the wheel assembly in space restricted positions. The cabin is mounted on a cantilever, thereby displacing its center of gravity respect of the wheel guides. Thus, a lever action is established, which presses the wheels against the wheel tracks and therefore enough frictional resistance is obtained so as to avoid wheel slippage on the wheel tracks. The vehicles are moved by non-polluting, electric drives that move and stop them with high energy savings. The vehicle runways are designed taking in account safety features against fire hazards. Several vehicles may be used at the same time and on the same track and may run individually or in groups, conforming a train. The system allows for vehicles to be parked in bypassed positions or else they may be disengaged from the convoy to be used individually.

Owner:SERRANO JORGE

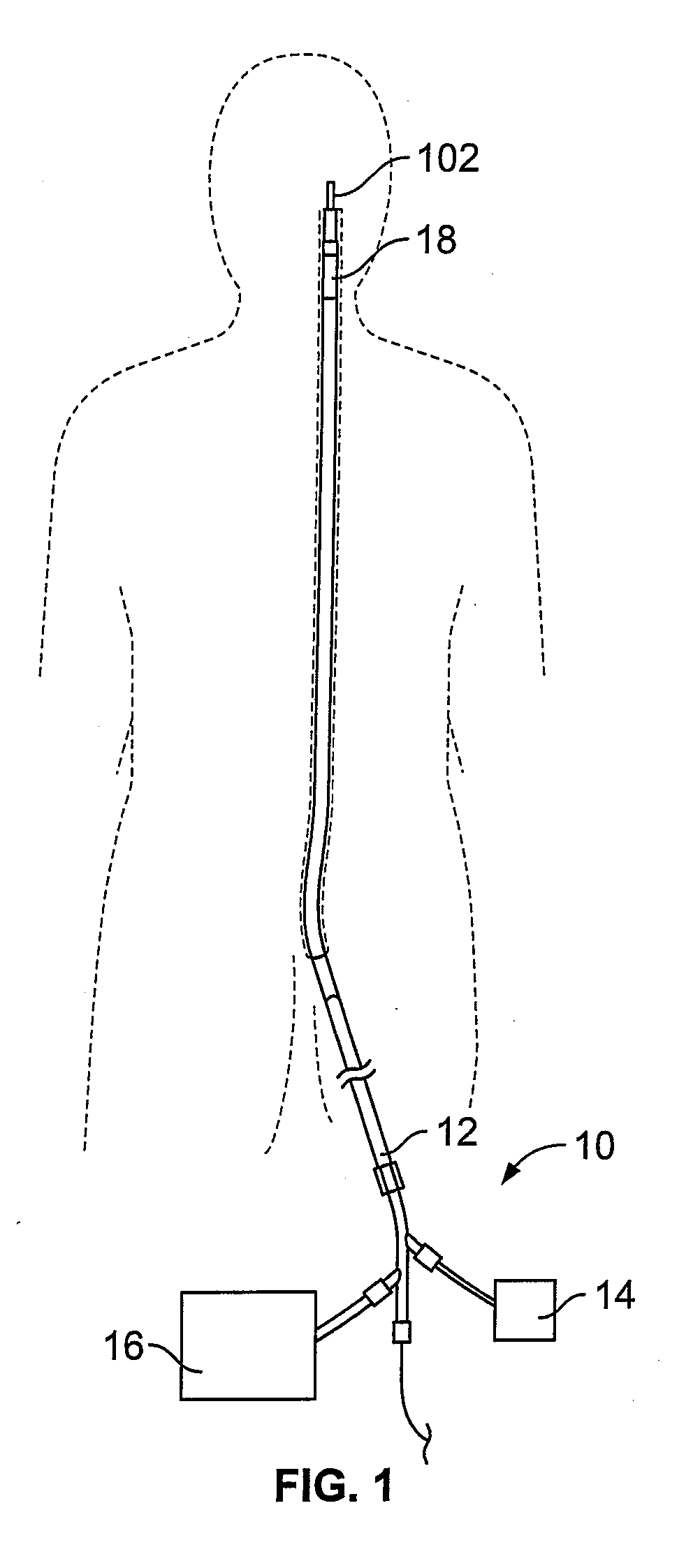

Apparatus and method for using a steerable catheter device

InactiveUS20050038412A1Great sensitivity and tactile feelHigh sensitivityGuide needlesGuide wiresMedicineWater irrigation

A handle includes a body portion and a handle portion which is slidably and rotatably mounted on the body portion. Shoulders on the body portion and the handle portion limit relative sliding movement of the body portion and handle portion. A catheter open at both ends has one end fixed to the handle portion for movement therewith, the opposite end of the catheter having a shape memory tip. A fitting is threadedly connected to an enlarged part of the body portion. A sheath is threadedly connected to the fitting and the catheter is slidable and rotatable within the sheath. An annular channel is provided between the sheath and the catheter, this channel being in fluid communication with a bore in the fitting. The outer end of the sheath has holes therethrough in fluid communication with the channel. An irrigation inflow and aspiration outflow tube is also in fluid communication with the bore in the fitting. A first lock is provided adjacent the fitting for controlling the amount of frictional resistance to lengthwise movement of the catheter relative to the sheath and to lock the catheter in position. A medical device such as an endoscope may be received within the catheter for movement relative thereto. A second lock is supported by the handle portion for locking a medical device in position relative to the catheter.

Owner:CYBERSONICS

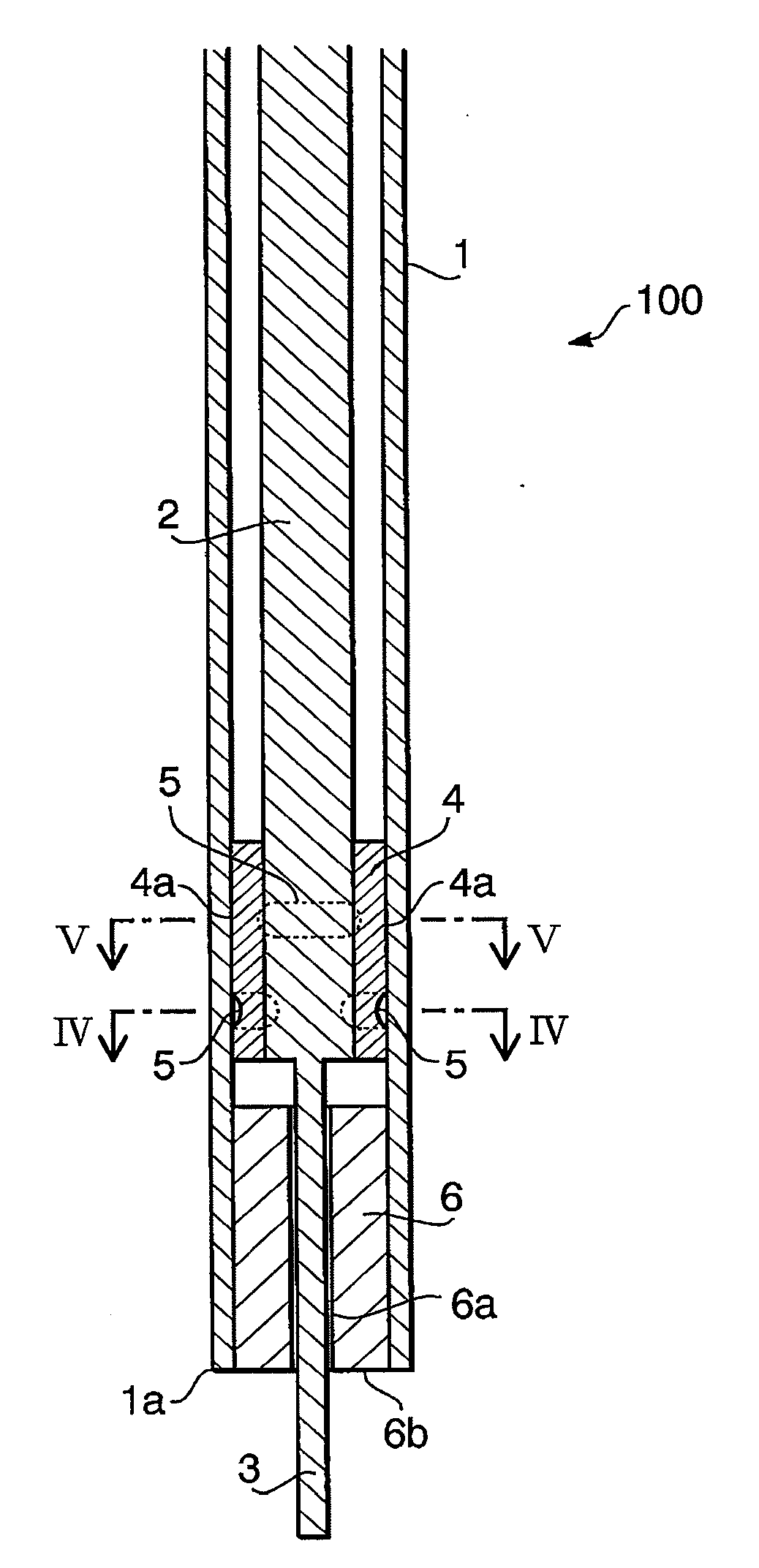

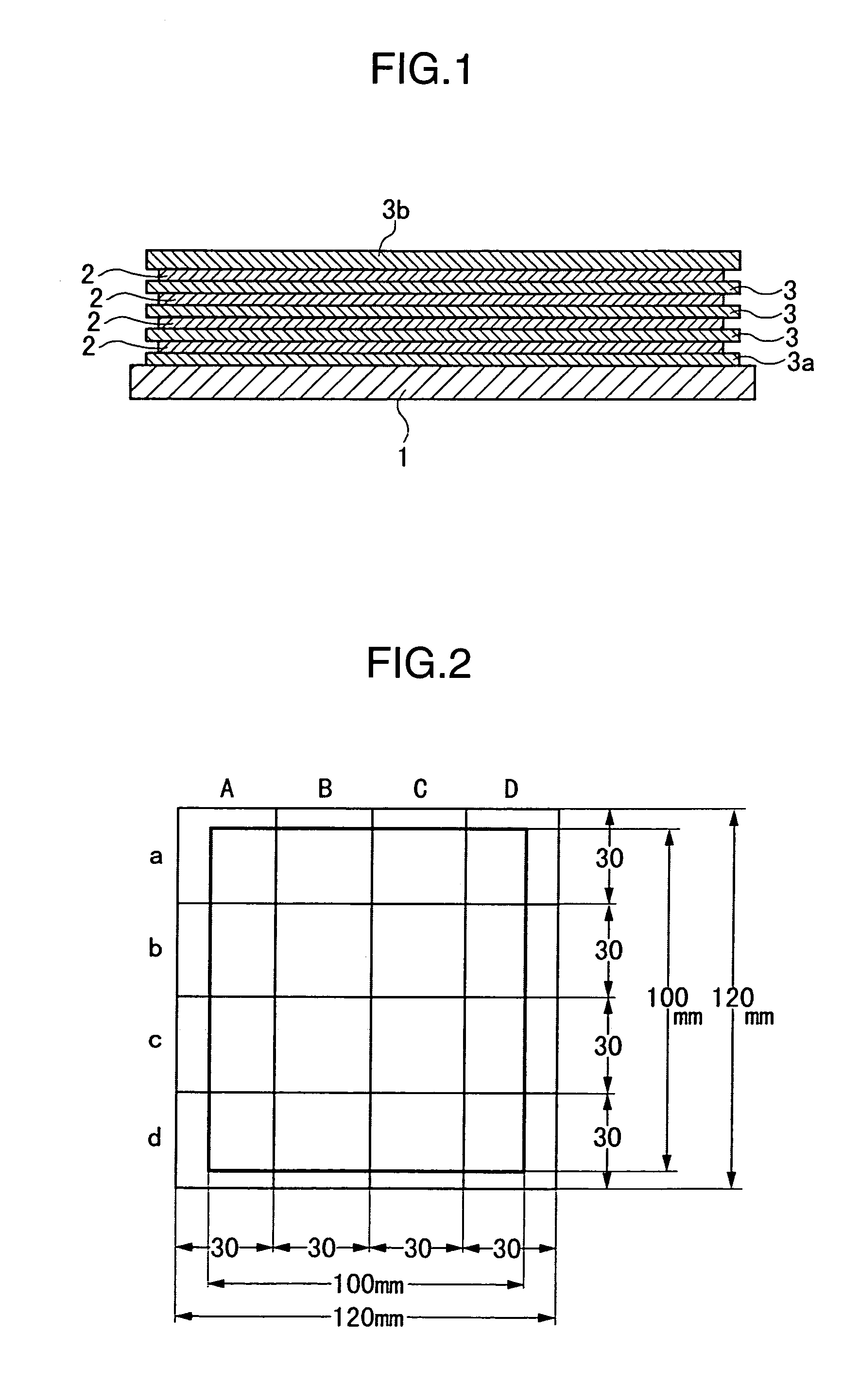

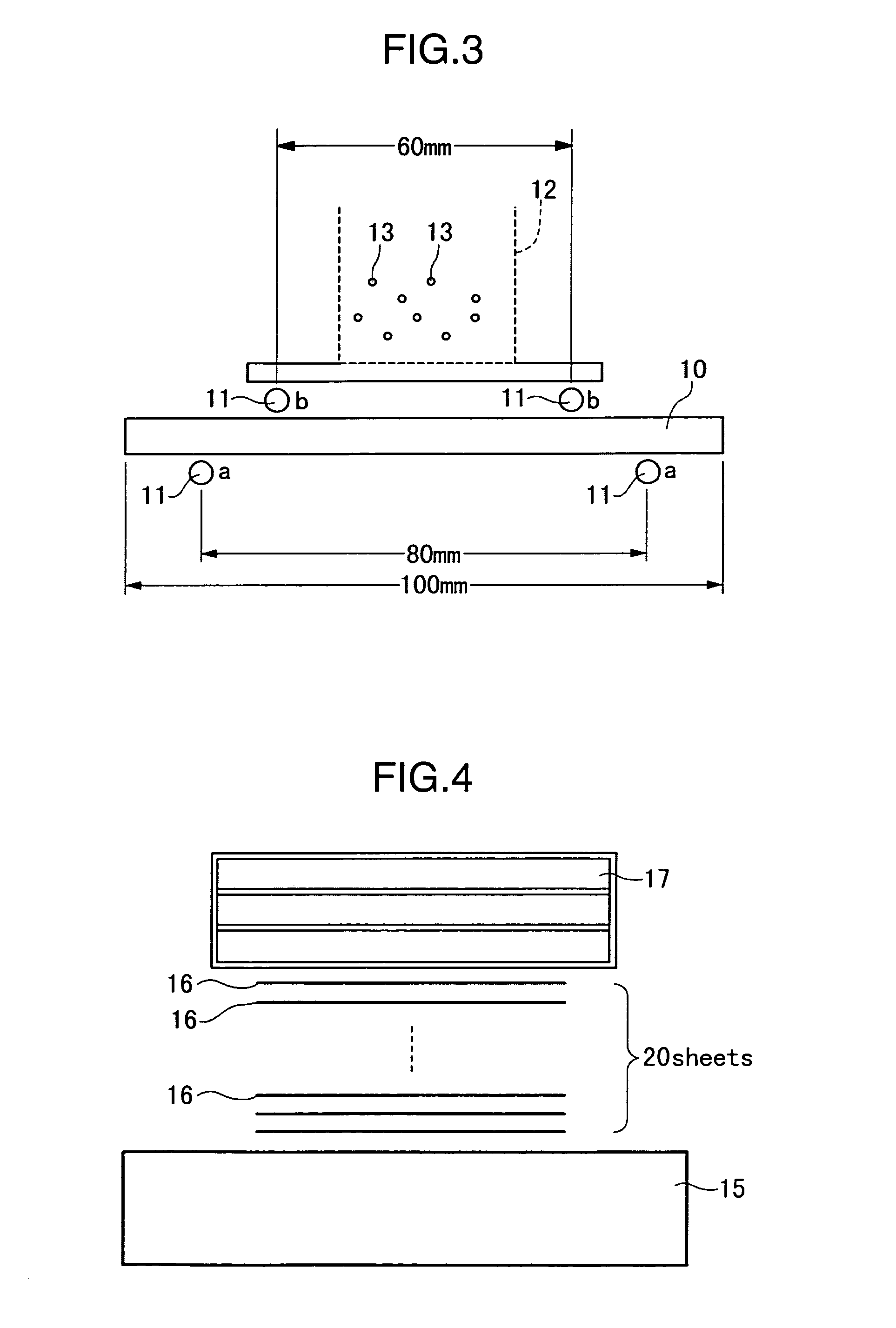

Ceramic sheet and method of producing ceramic sheet

InactiveUS7108827B1Suppress blemishesReduce frictional resistanceSynthetic resin layered productsRecord information storageForeign matterMetallurgy

The present invention relates to a ceramic sheet having uniform quality over its entire surface with a decreased number of defects such as foreign matters and flaws. When the ceramic sheet was divided into sections of 30 mm square or smaller, each divided section has 5 or less defects detected based on an image obtained with a charge coupled device (CCD) camera. The present invention also relates to a method of producing the ceramic sheet. In this method, a green sheet or a calcined sheet mainly including spherical ceramic particles having an average particle diameter of 0.1 to less than 5 μm was used as a spacer. By using this spacer, the green sheet for ceramic sheet slides smoothly on the spacer surface when it shrinks in baking, and the friction resistance between the green sheet for ceramic sheet and the spacer is lowered. In this manner, the method of the present invention can mass-produce the above-described high quality ceramic sheets.

Owner:NIPPON SHOKUBAI CO LTD

Graphene coating as well as preparation method and coating method thereof

The invention belongs to the technical field of materials and in particular relates to a graphene coating as well as a preparation method and a coating method thereof. The graphene coating is prepared from the components by weight: 5-95wt percent of less layer of grapheme, 5-95wt percent of adhesive, 0.01-50wt percent of dispersant and surfactant, 0.01-10wt percent of defoamer and the balance of solvent. With the adoption of the graphene coating, the thickness of an electricity and heat conductive coating can be controlled to be 100nm-20 microns; when the graphene coating is used on a plastic matrix, the volume resistivity can reach a range from 10<-2>ohm.cm to 10<-4>ohm.cm; while the graphene coating is used on a metal matrix, the volume resistivity can reach 10<-6>ohm.cm. The graphene coating can be applied to the metal surface so as to improve the cohesiveness, the electricity / heat conduction performance and the corrosion and oxidation resistance. When the graphene coating is coated on the plastic surface, the frictional resistance, the electricity and heat conduction performances and the static resistance can be lowered, and the graphene coating can be applied to the fields of printed circuits, electronic devices, radio frequency devices, touch screens, thin film solar energy, LEDs, magnetic shielding, radio frequency shielding and the like.

Owner:SUPERCDONGGUAN TECH

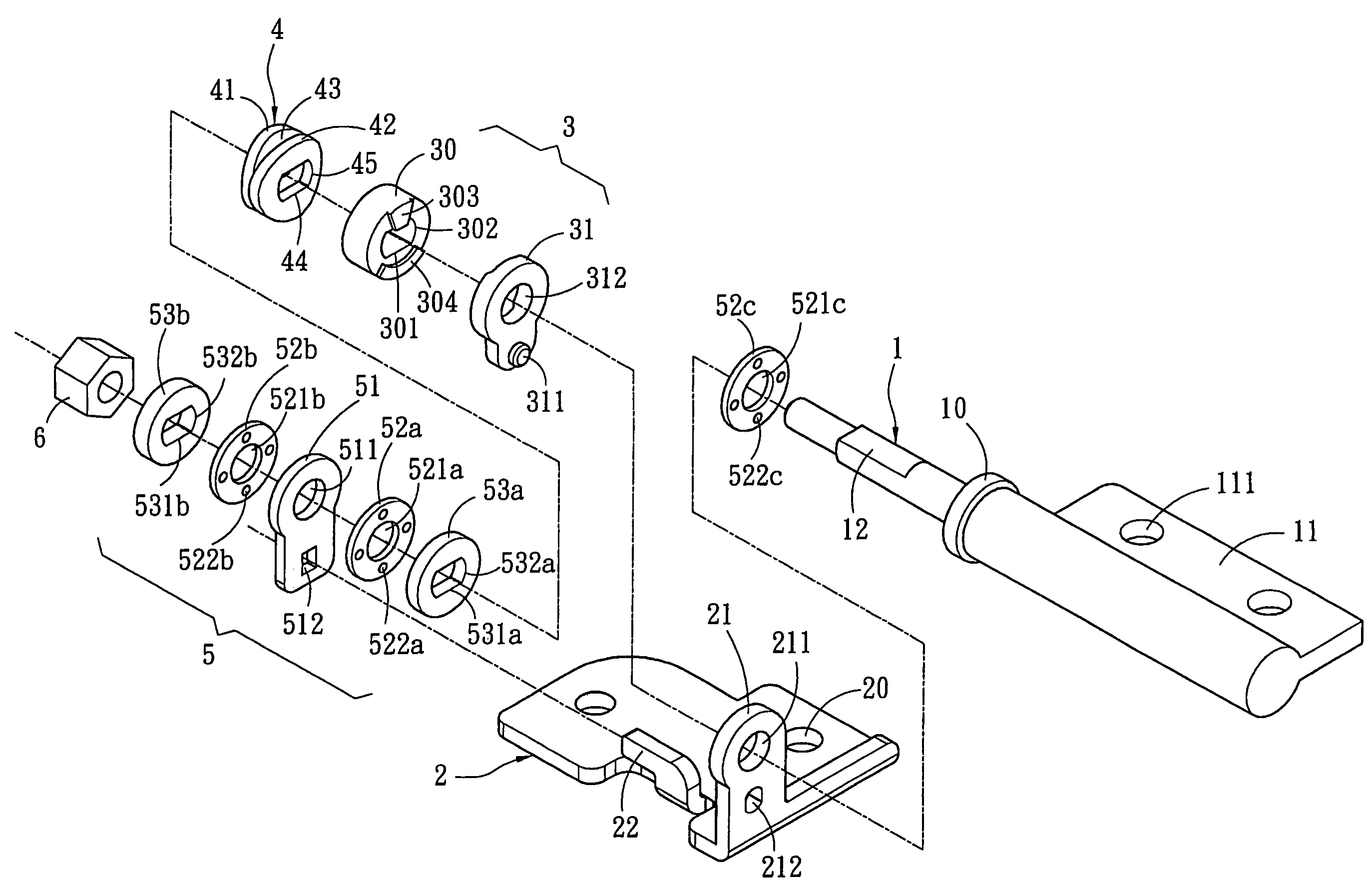

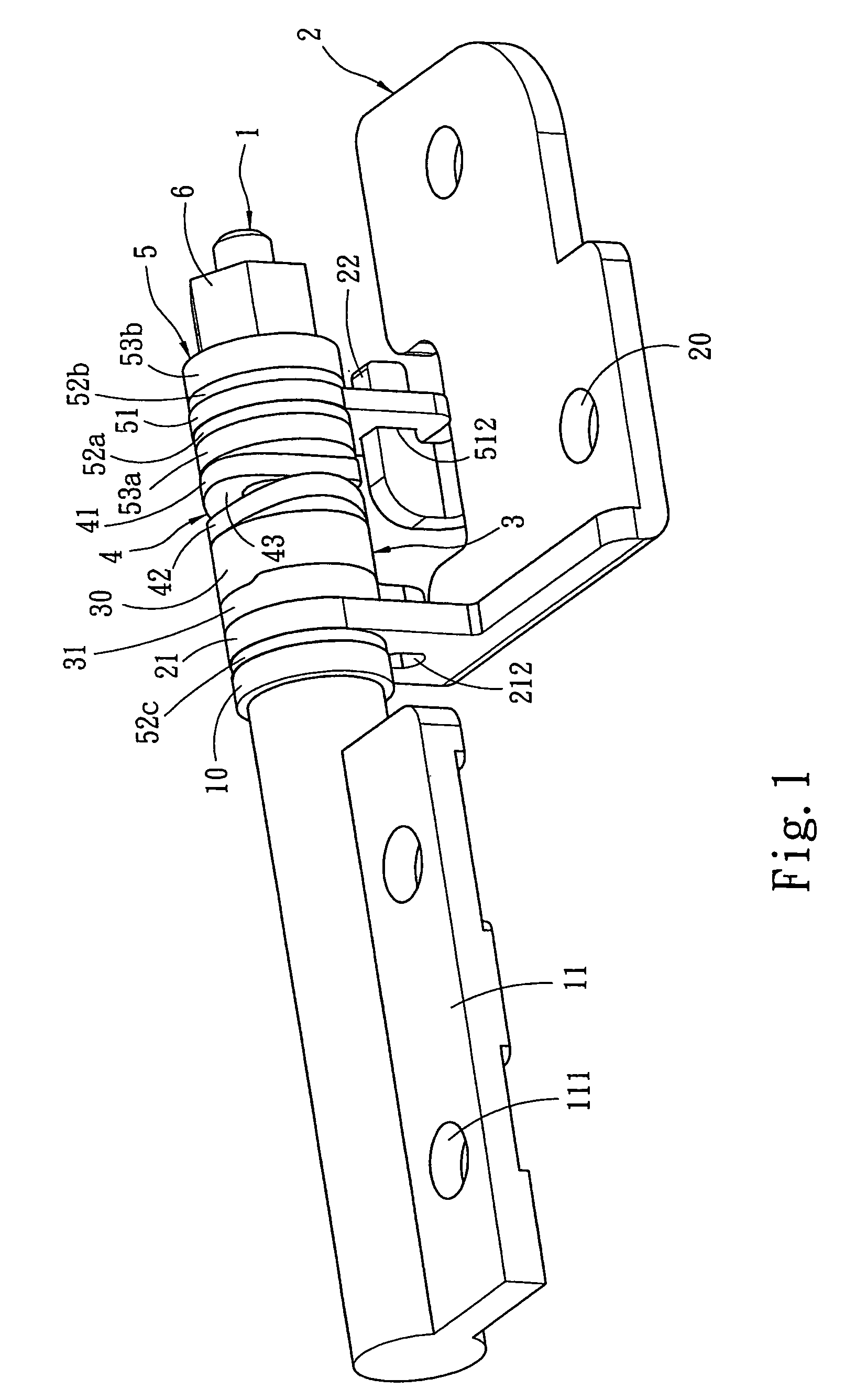

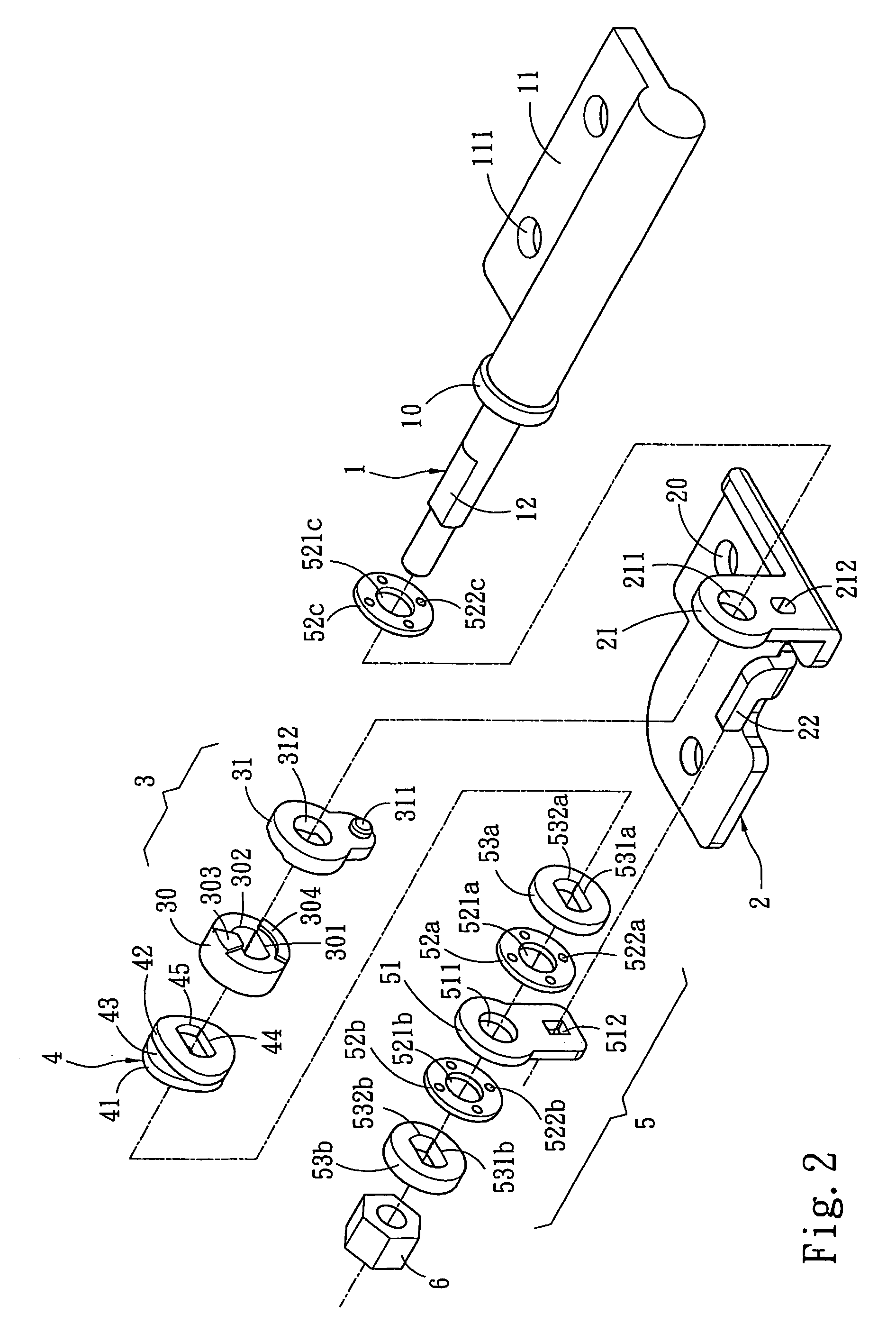

Hinge for anchoring and folding on a small pintle

ActiveUS7082642B2Increase frictional resistanceWing fastenersDetails for portable computersDisplay deviceEngineering

A hinge for anchoring and folding on a small pintle which has a diameter between 3 and 7.9 mm to form a stepless swiveling and anchoring by increasing the friction resistant force to counter the torque. It includes a maneuvering structure which has a rotary member and an anchor member that form a rotational displacement on the contact surfaces therebetween that can be swiveled and anchored in a stepless manner and latched on a fixed location for closing. A braking structure is provided that has braking elements and washers to increase the friction resistant forces so that the small pintle has adequate friction resistant forces to anchor a display device after unfolding. The maneuvering structure has anchor elements and retaining troughs of different sizes that cannot be coupled with each other when the display device is unfolded and swiveled to 180 degrees to maintain the original friction resistant forces so that the display device may be anchored at any angle after unfolded.

Owner:SINHER TECH INC

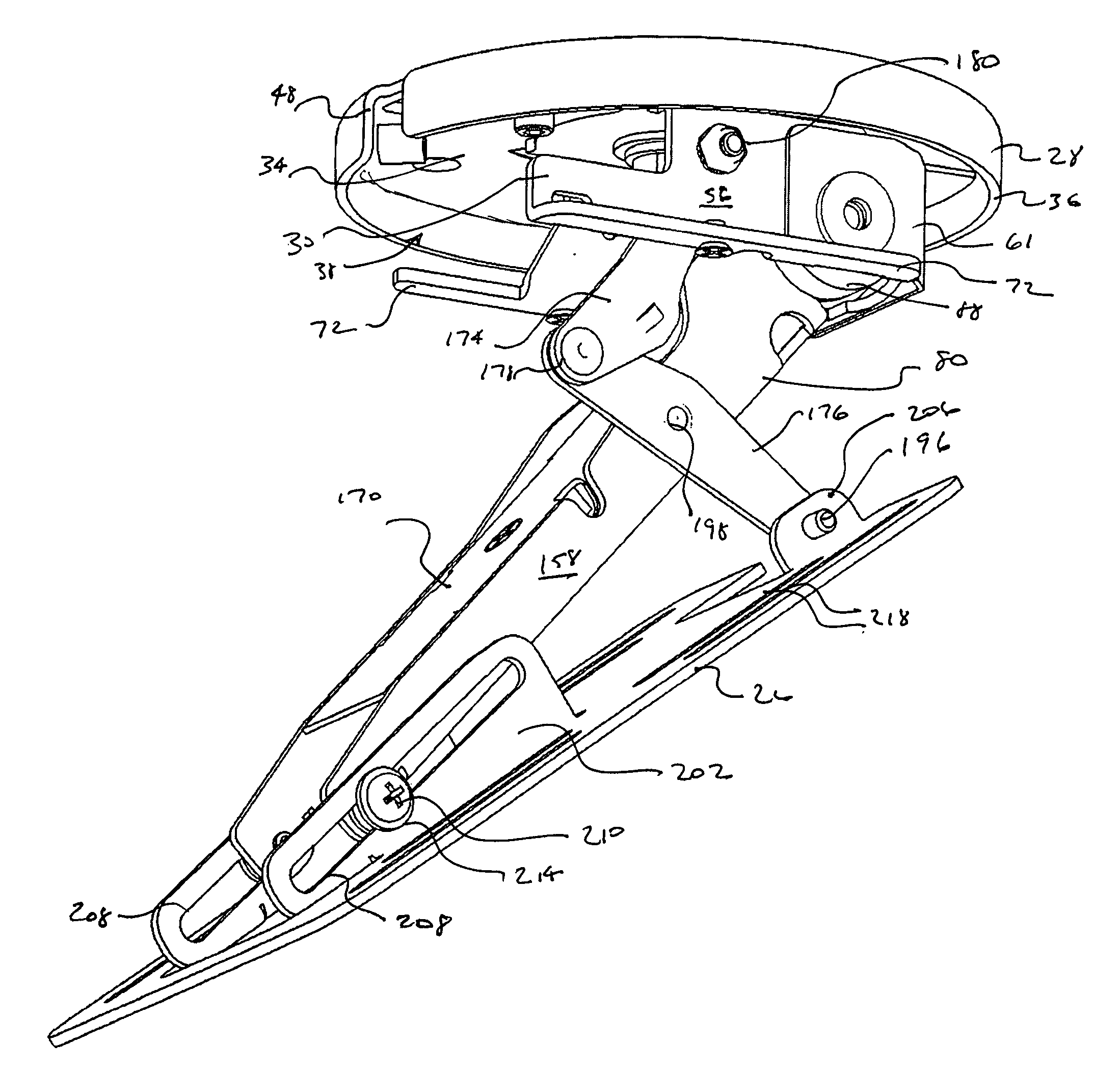

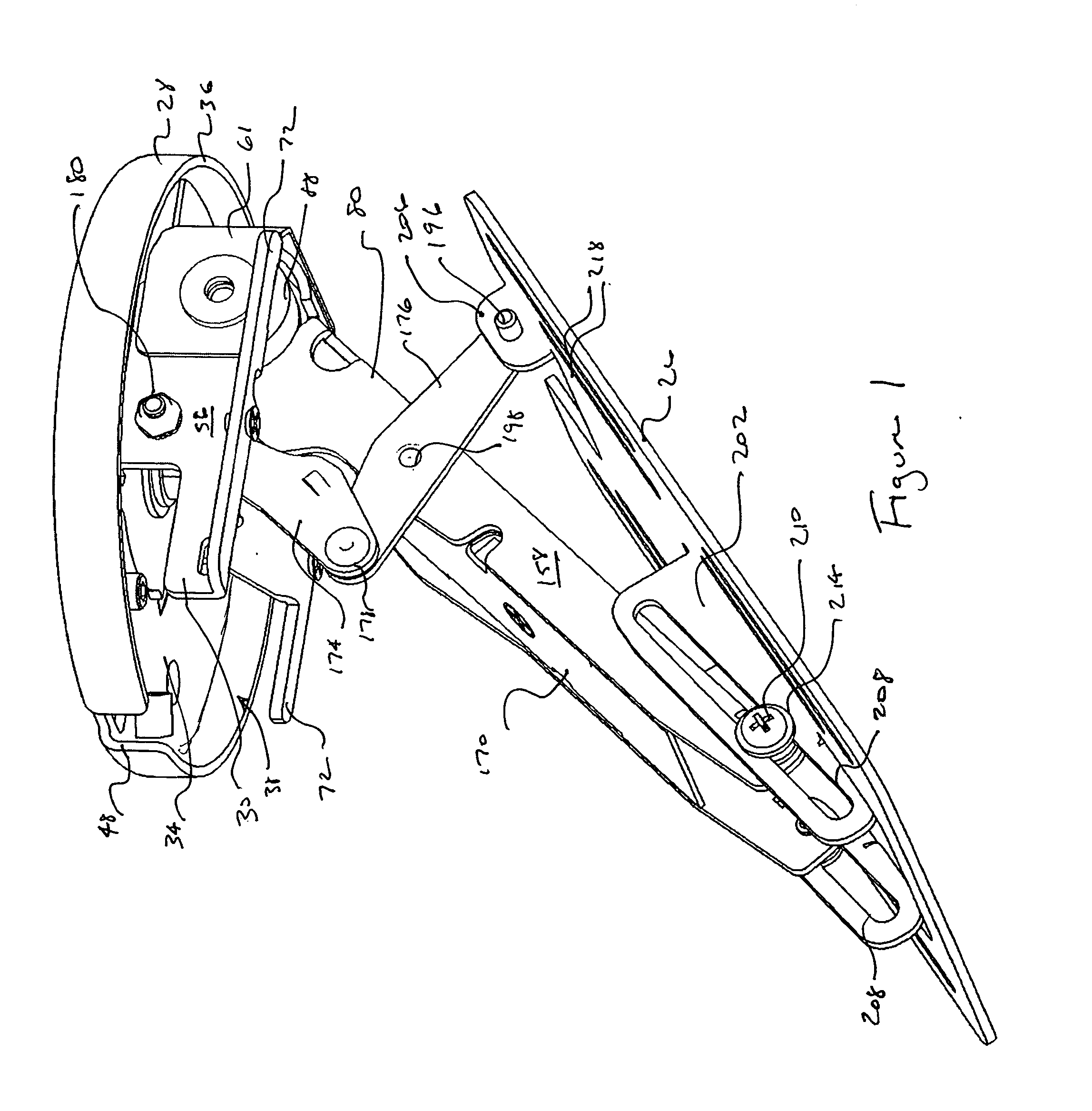

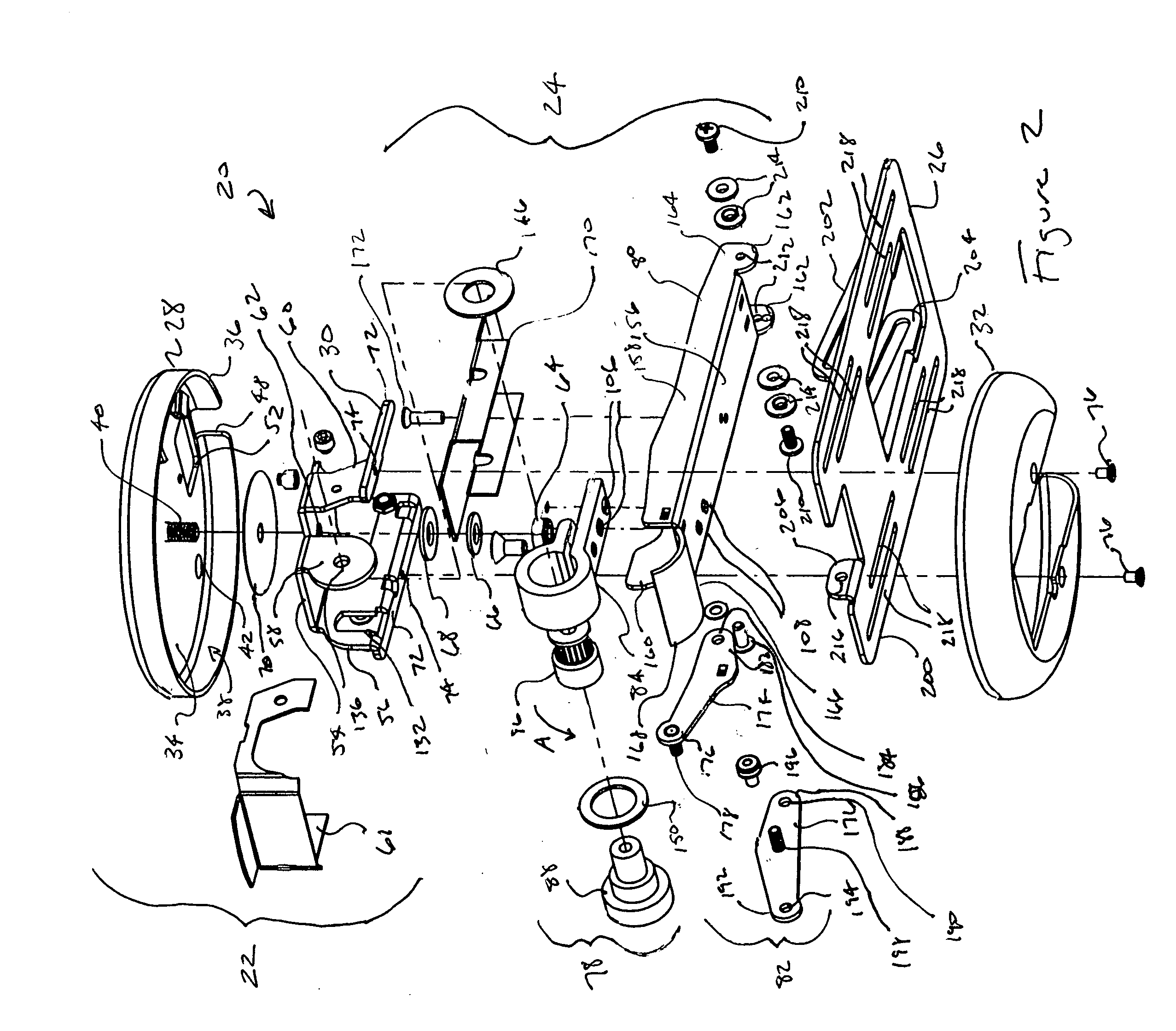

Under-cabinet mount for flat-panel displays

InactiveUS20050051688A1Easy to adjustEasy to operateDigital data processing detailsSpraying apparatusDisplay deviceEngineering

Owner:LEGRAND AV INC

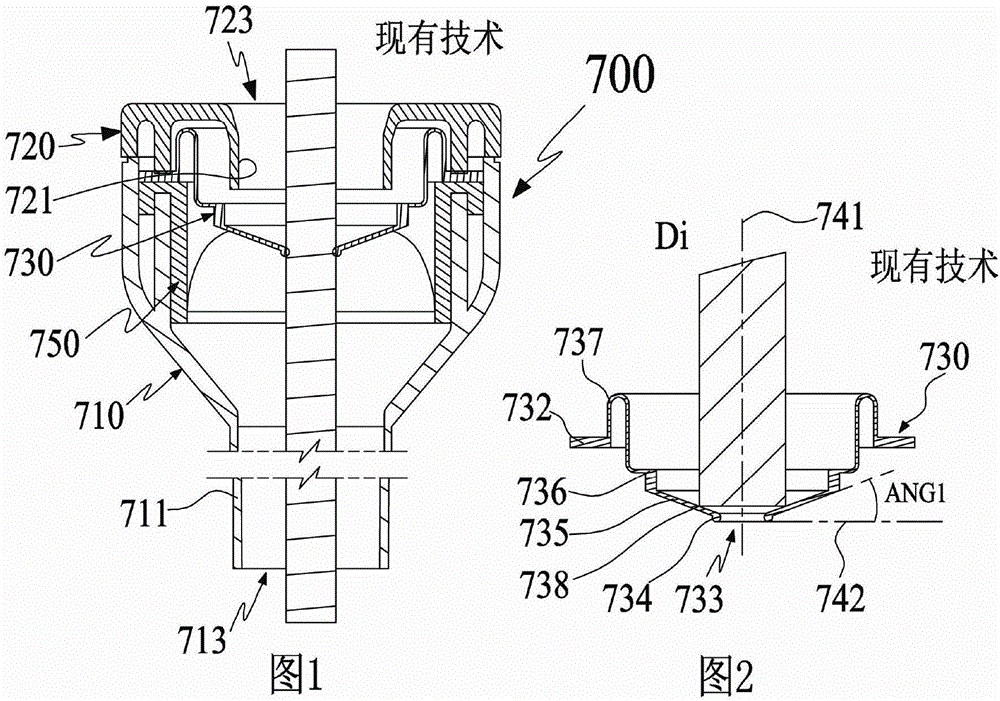

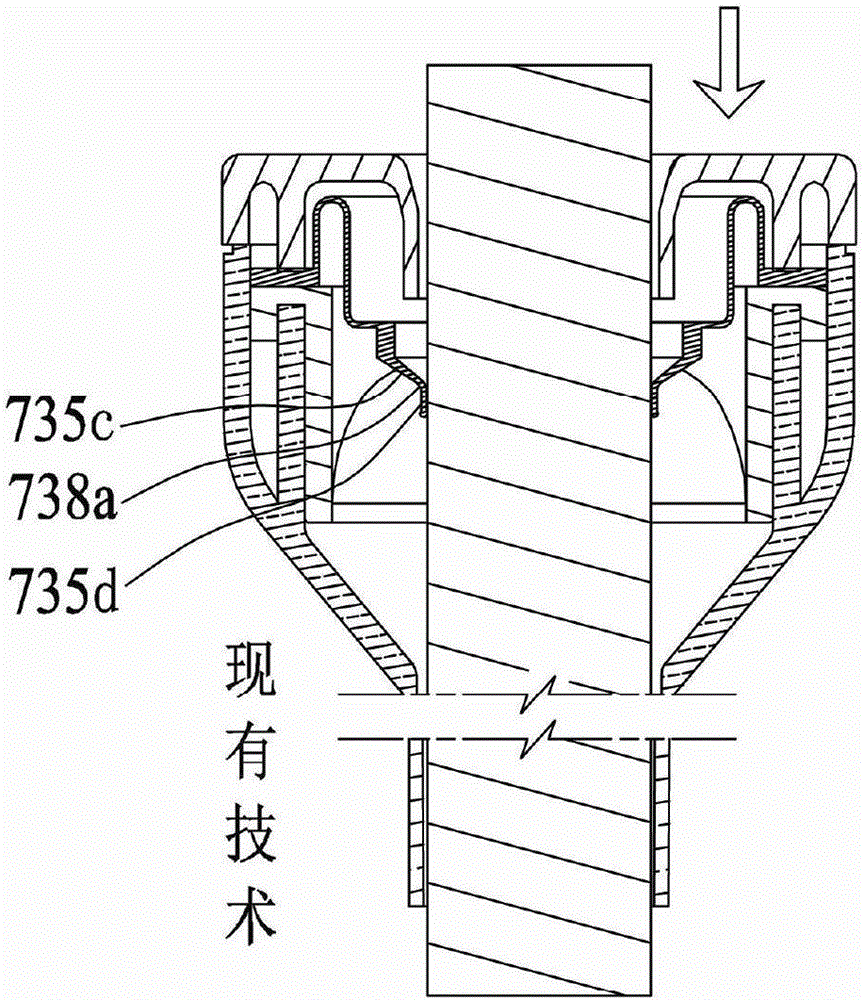

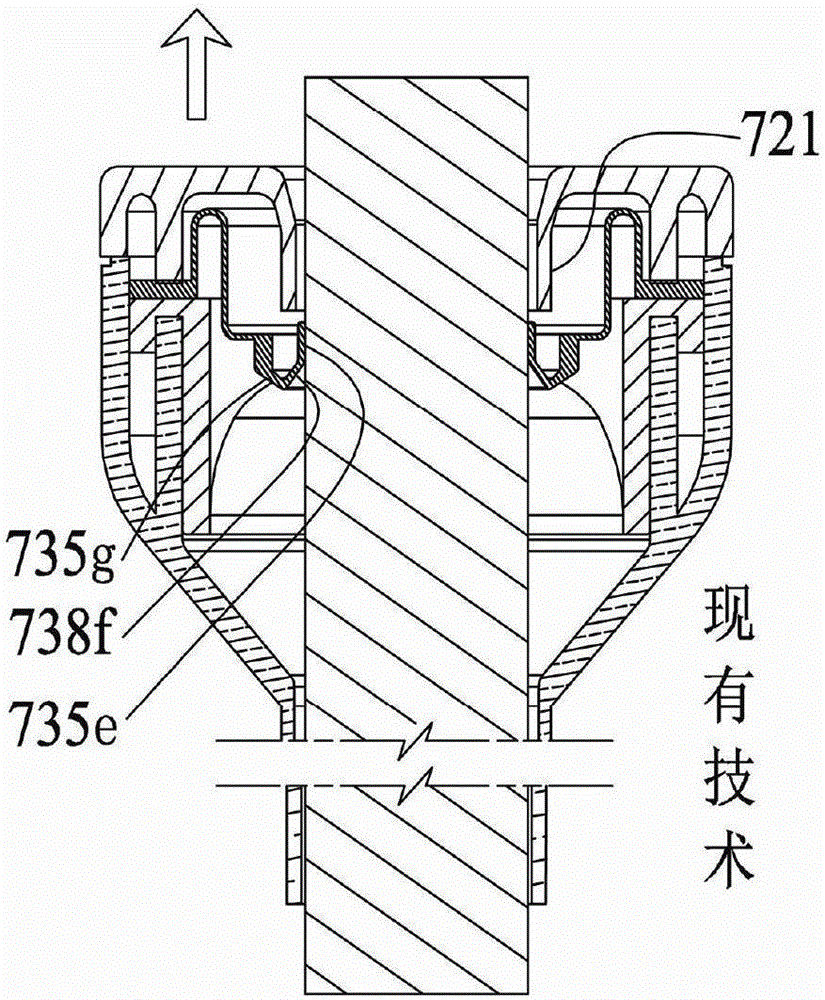

Fold-type puncture outfit sealing system

ActiveCN106175846AImprove sealingReduce frictional resistanceCannulasSurgical needlesFrictional resistance

The invention relates to a fold-type puncture outfit sealing system. The fold-type puncture outfit sealing system comprises a sealing membrane and a first protection device which are connected; the sealing membrane comprises a near-end opening, a far-end hole and sealing walls extending from the far-end hole to the near end, each sealing wall is provided with a near-end surface and a far-end surface, and the far-end hole is formed by a sealing lip; the first protection device comprises a near-end opening, a far-end opening and a protection wall extending from the far-end opening to the near end, each sealing wall comprises multiple folds which are externally tangent to the sealing lip and transversely and outwards extend, each fold comprises a fold peak, a fold valley and a fold wall extending from the fold peak to the fold valley, and the folds surround the sealing lip and are integrally arranged in a dish-shaped mode; the protection wall of the first protection device comprises folds of which the number is the same as that of the sealing walls and the shape and the size are matched with those of the sealing walls. According to the fold-type puncture outfit sealing system, bent stacking and winding of the protection device and the sealing membrane can be reduced, and then frictional resistance generated after inward turning is decreased.

Owner:5R MED TECH CHENGDU CO LTD

Complex wire formed devices

InactiveUS8512352B2Shorten the lengthAvoid insufficient lengthDilatorsExcision instrumentsEngineeringFrictional resistance

Owner:TYCO HEALTHCARE GRP LP

Hydraulically driven tractor

A large scale hydraulically driven downhole reciprocating tractor to display substantially continuous advancement. The tractor may be configured to pull coiled tubing downhole in a continuous manner so as to substantially avoid static frictional resistance to the pulling. As a result, the tractor and coiled tubing may achieve up to about twice the depth into the well otherwise attainable. Additionally, the tractor may include a fail safe mechanism whereby a plurality of pilot operated valves are employed to ensure that immobilization of at least one anchor of the tractor is present at all times during downhole advancement to thereby avoid the undesired effects of coiled tubing spring-back.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com