Hydro-oscillator for well drilling

A hydraulic oscillator and drilling technology, used in vibration drilling, earth-moving drilling, wellbore/well components, etc., can solve the problems of high requirements for supporting tools, poor continuous working ability, shortening the service life of drilling tools, etc. Production cost, improvement of frictional resistance, and effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

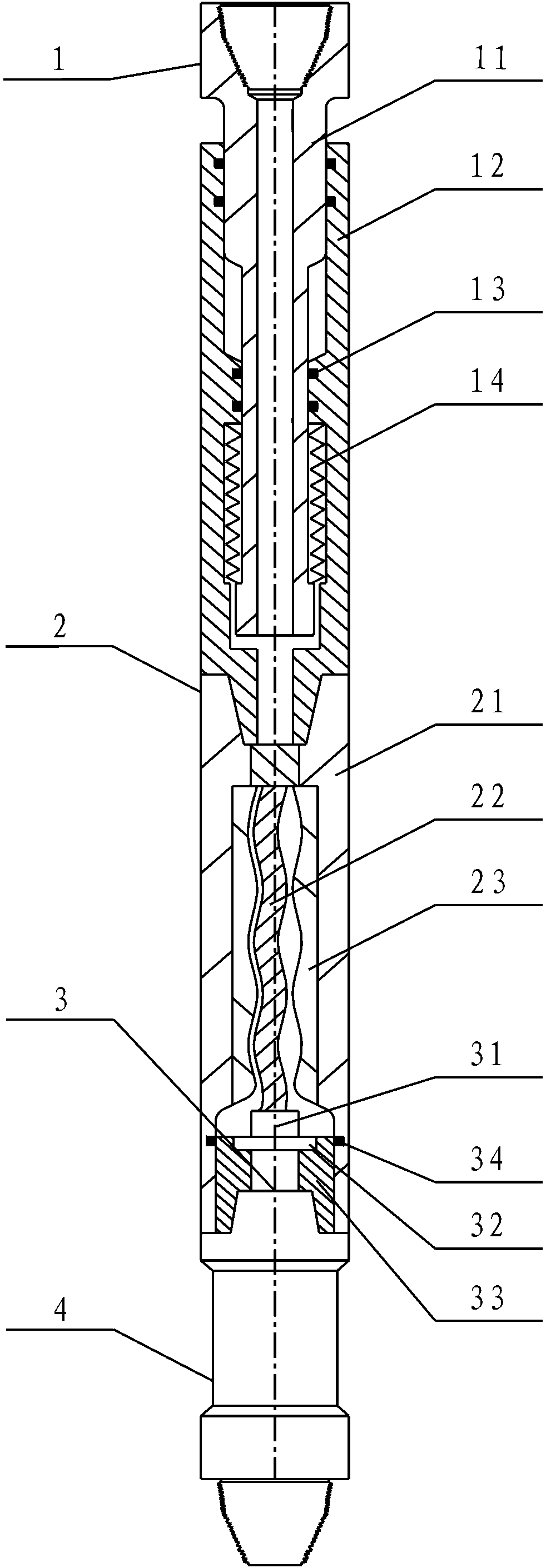

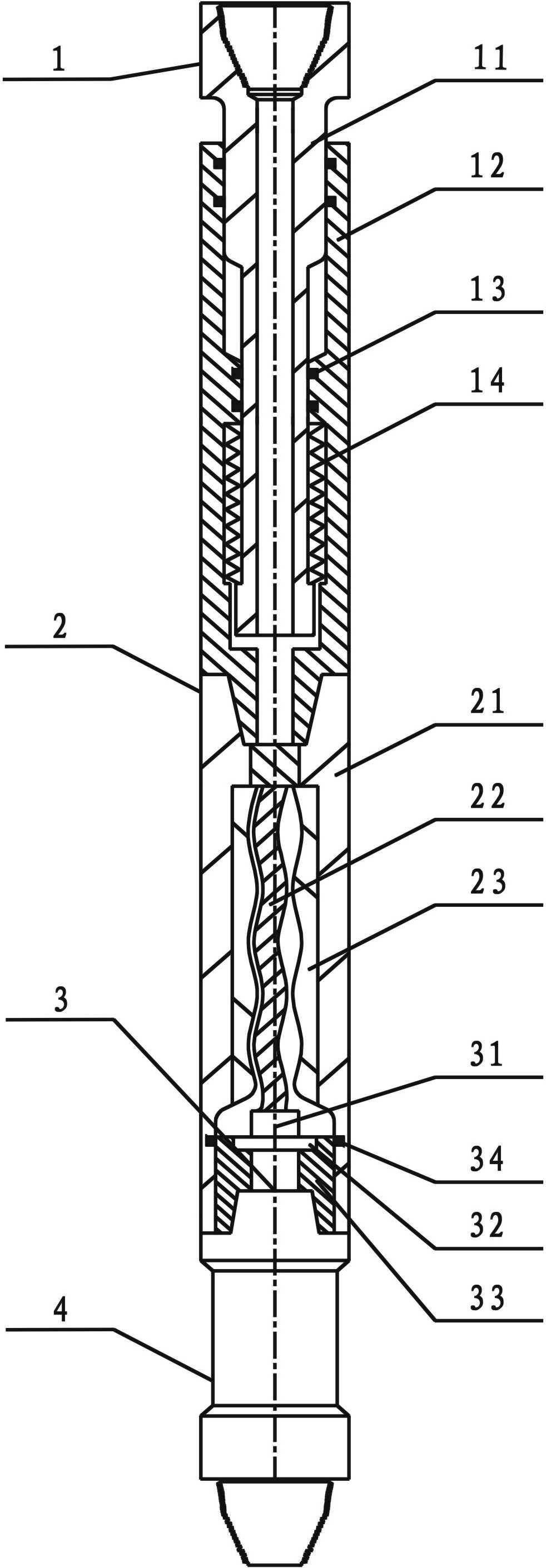

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] When the drilling hydraulic oscillator of the present invention is used to generate mechanical vibration, the vibration nipple 1 is connected with the hydraulic drive assembly 2, the rotor 22 is connected with the vibration valve 31, the fixed valve assembly 3 is installed on the bottom assembly 4, and the power casing The body 21 is connected to the bottom assembly 4 .

[0021] The vibrating short joint 1 mainly includes a vibrating shell 12, a disc spring 14, and a mandrel 11 with a flow channel processed in the center of the shaft. The mandrel 11 is loaded into the vibrating shell 12 and can slide up and down in the shell 12. The mandrel The space between the non-contact walls between 11 and the vibrating shell 12 is an annular space, the disc spring 14 is arranged in the annular space, and a seal is set between the wall contact surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com