Patents

Literature

815 results about "Axial vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

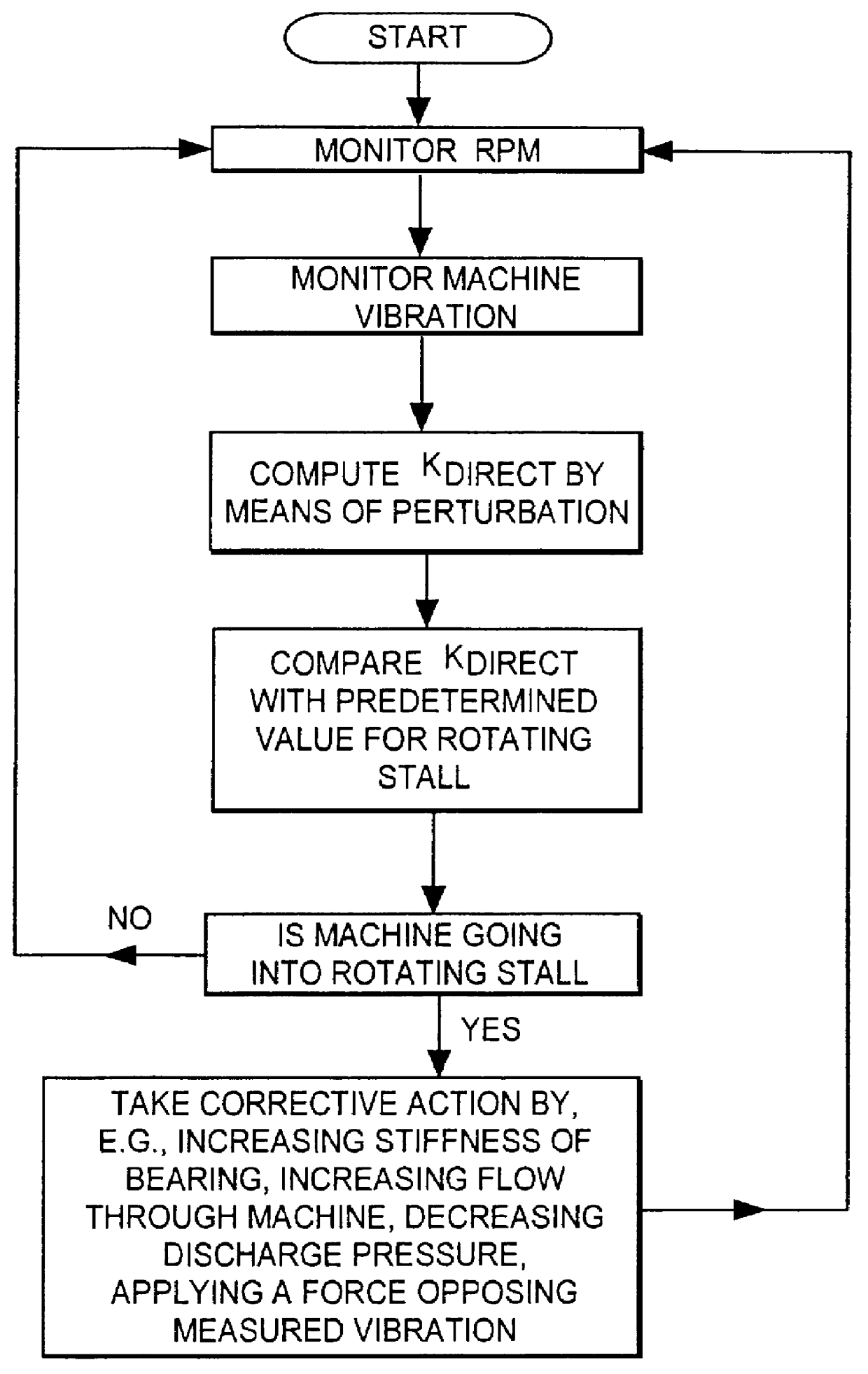

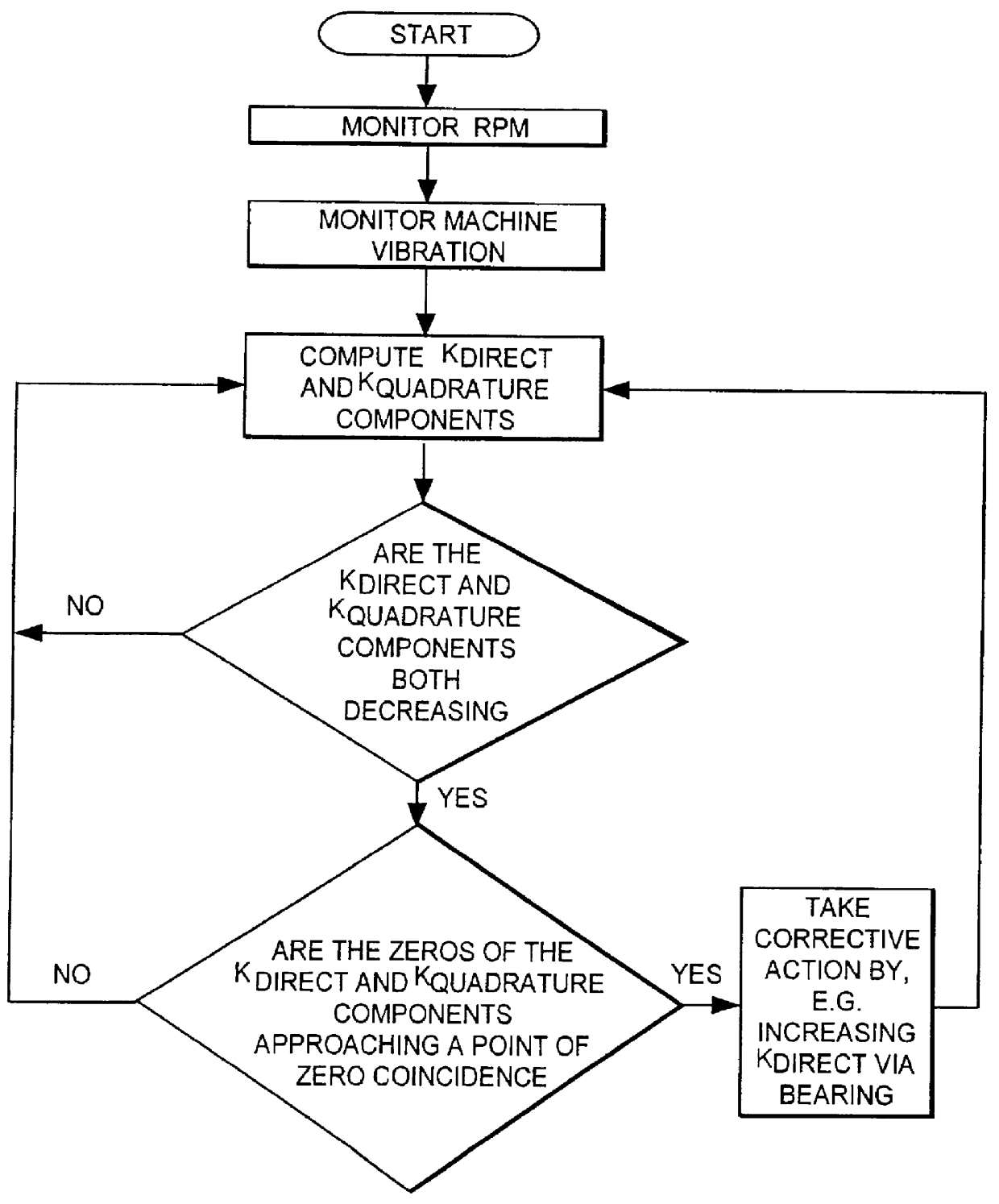

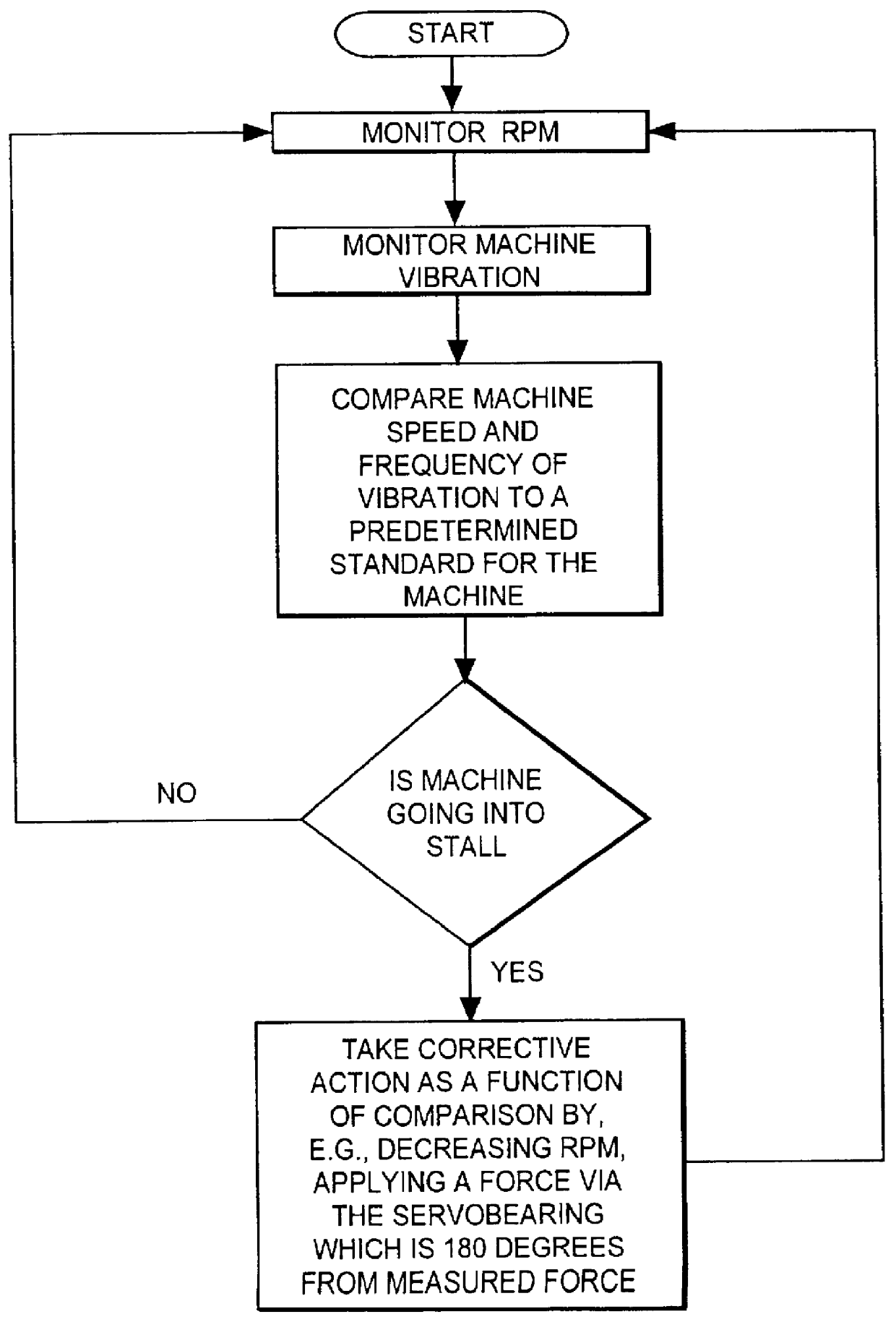

Method and apparatus for diagnosing and controlling rotating stall and surge in rotating machinery

InactiveUS6092029AProtection from damageMachine bearings testingFlow propertiesDynamic stiffnessPrecession

A method and apparatus is provided for diagnosing and correcting rotating stall and surge in rotating machines by monitoring dynamic shaft precession and comparing this precession with a standard and altering the precession as the machine approaches a destabilizing condition when indicated by the comparison step. Axial vibration monitoring means is also provided for monitoring and comparing a dynamic axial vibration of the machine with a standard and altering the axial vibration as the machine approaches a destabilizing condition. Furthermore, the instant invention measures the complex dynamic stiffness of the machine and computes the direct dynamic stiffness and the quadrature dynamic stiffness for use as a destabilizing warning device by monitoring for a drop in direct dynamic stiffness and / or a coincidence of zero crossing of both the direct dynamic stiffness and the quadrature dynamic stiffness components. One embodiment for altering the rotating stall and / or surge is by a controlled active servobearing.

Owner:BENTLY NEVADA CORP

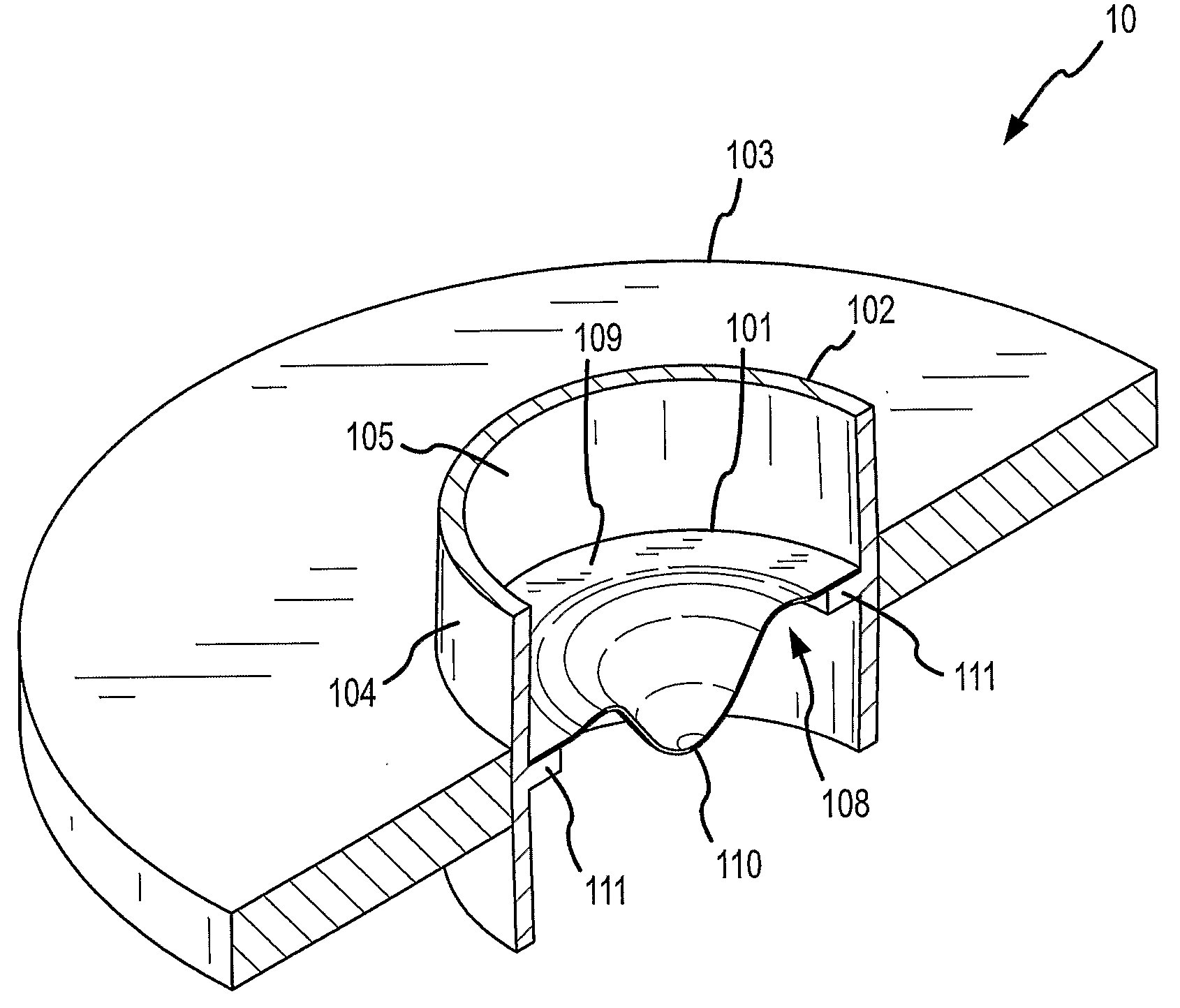

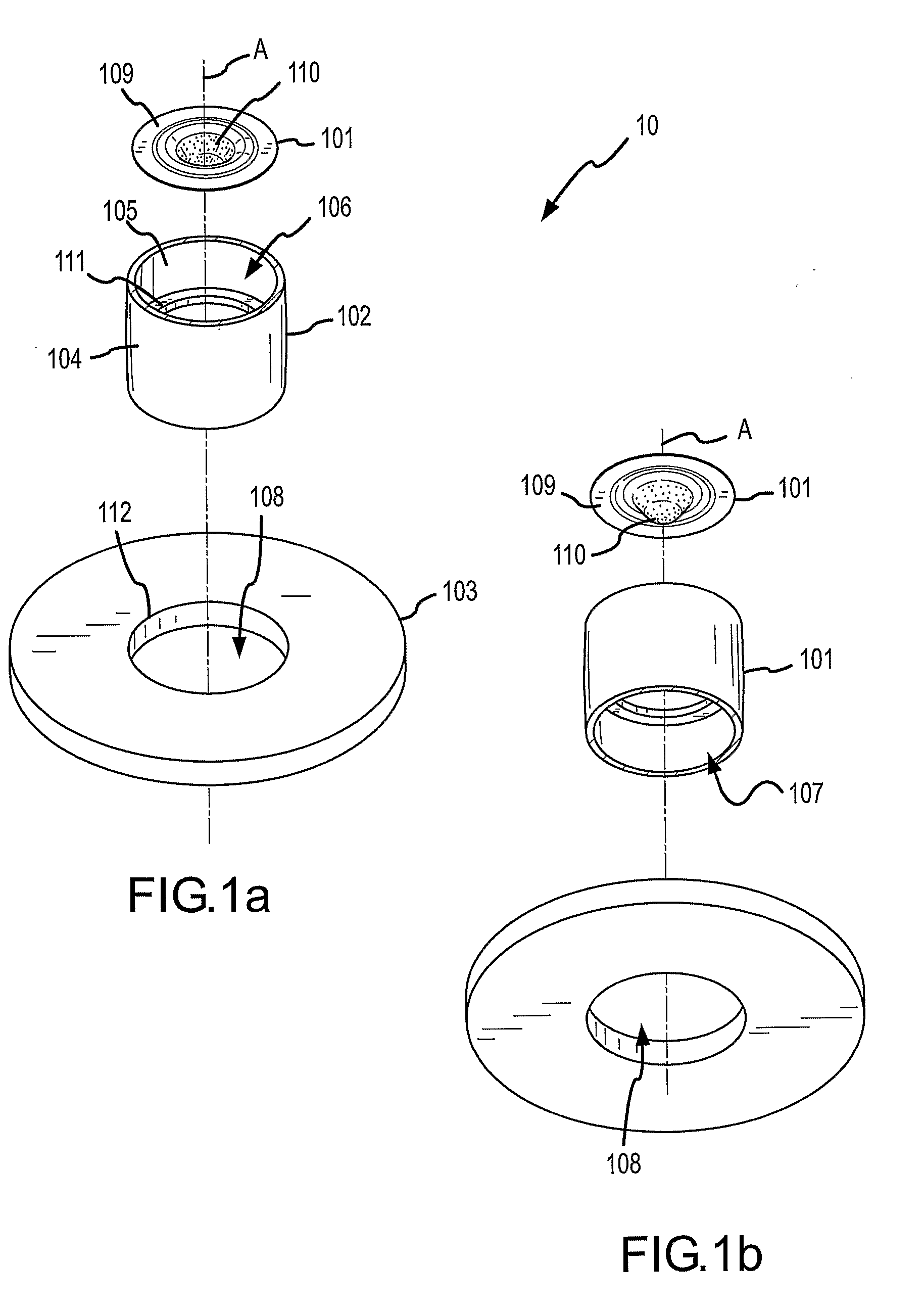

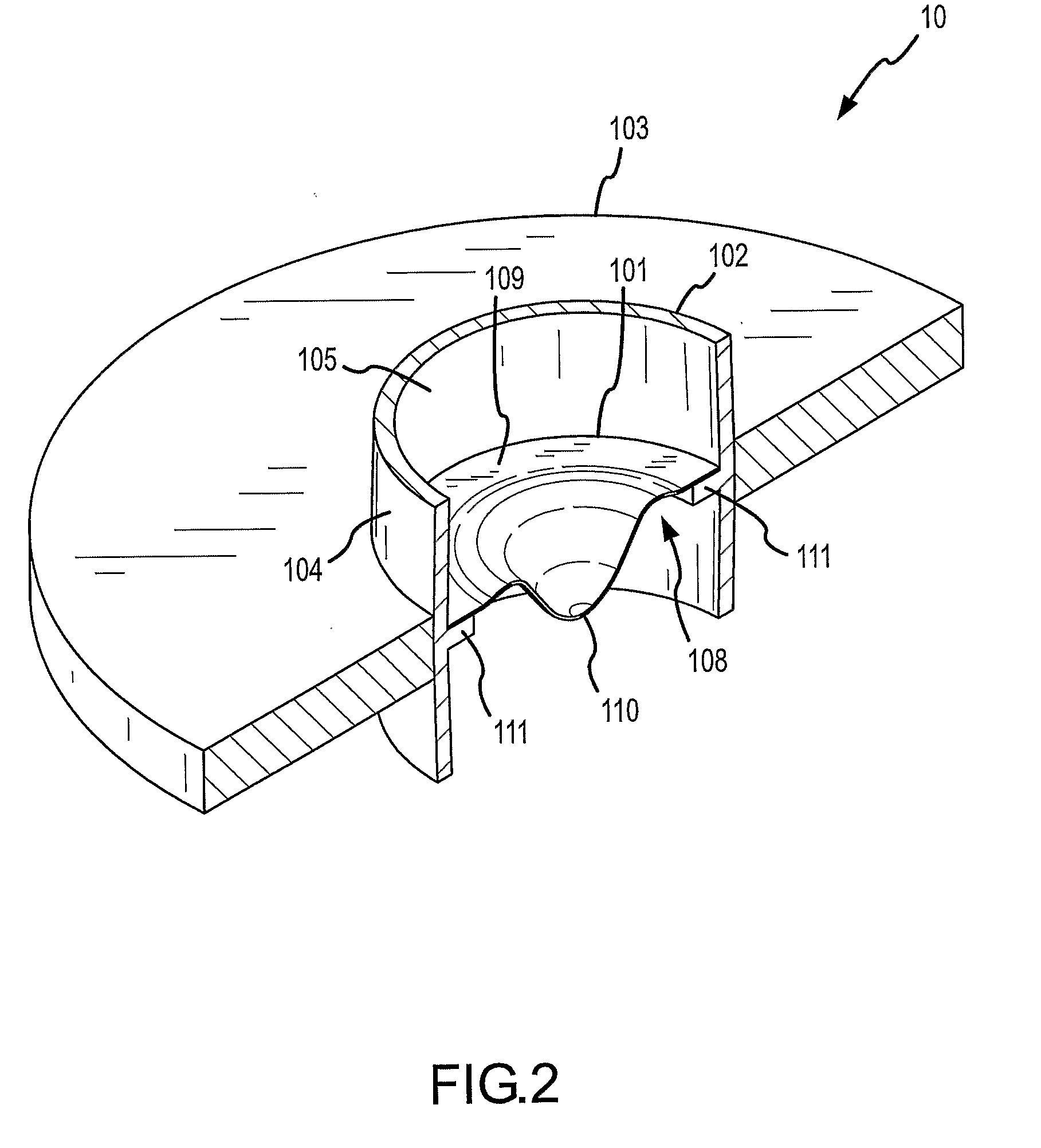

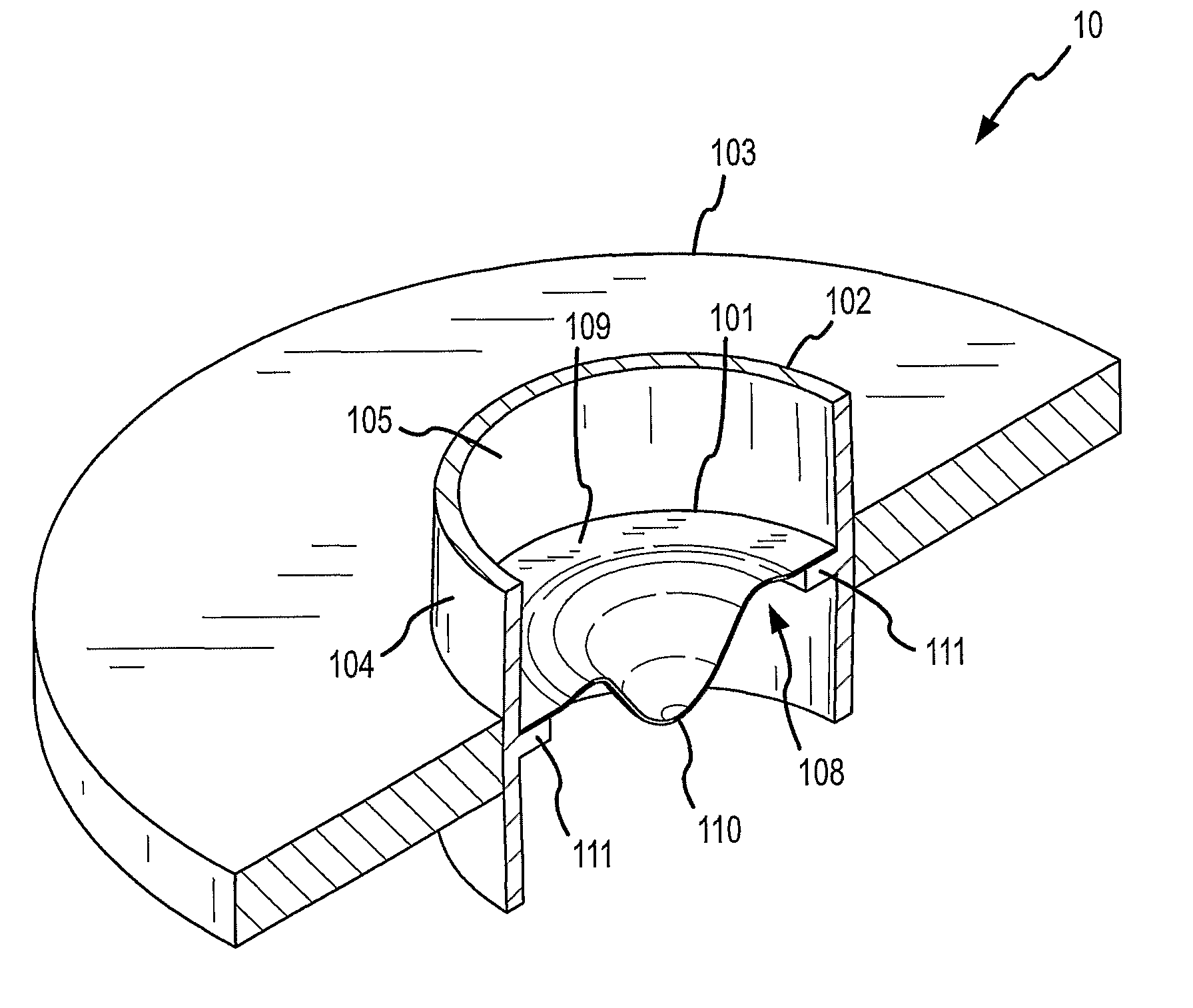

Vibration Systems and Methods

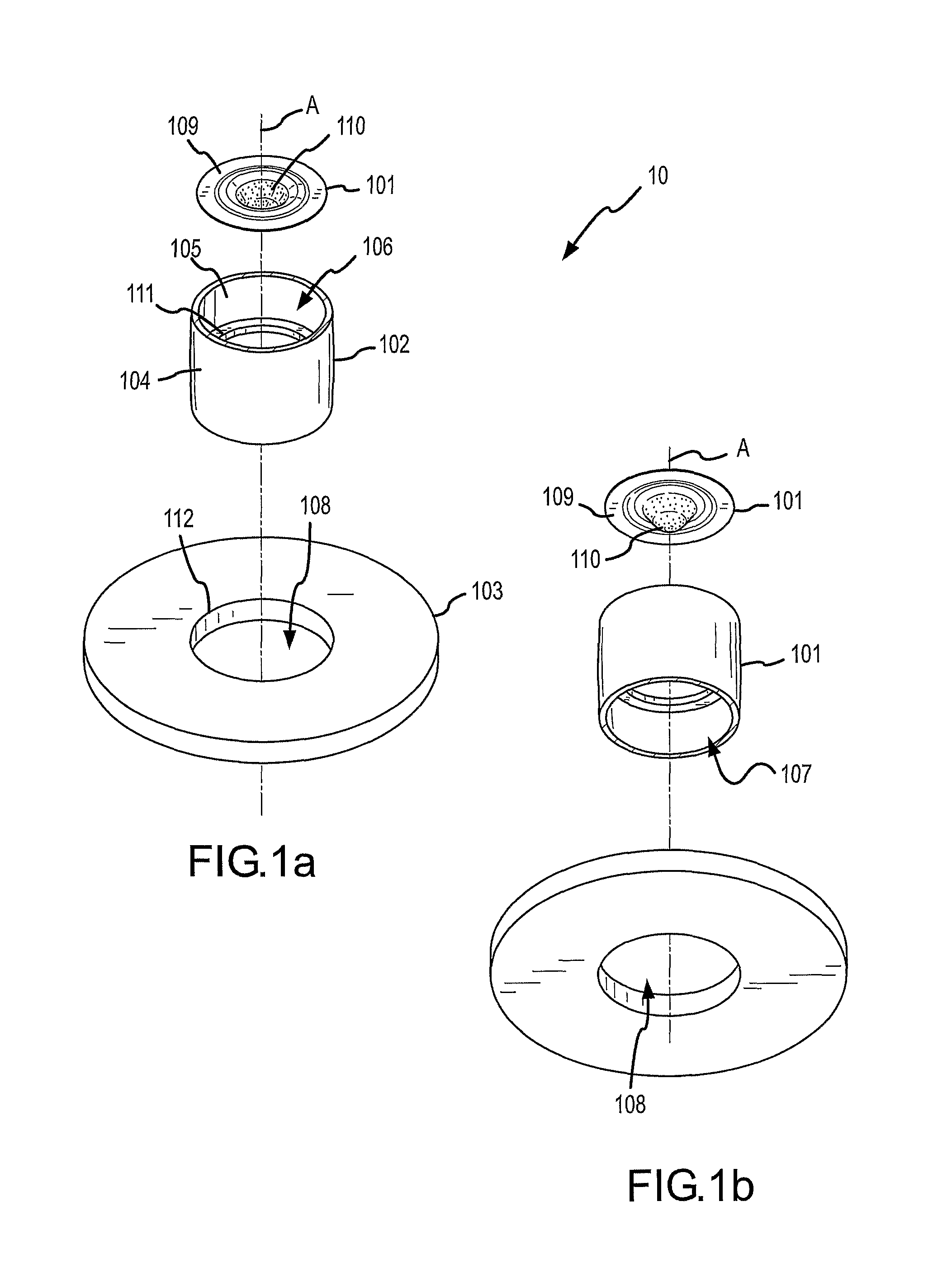

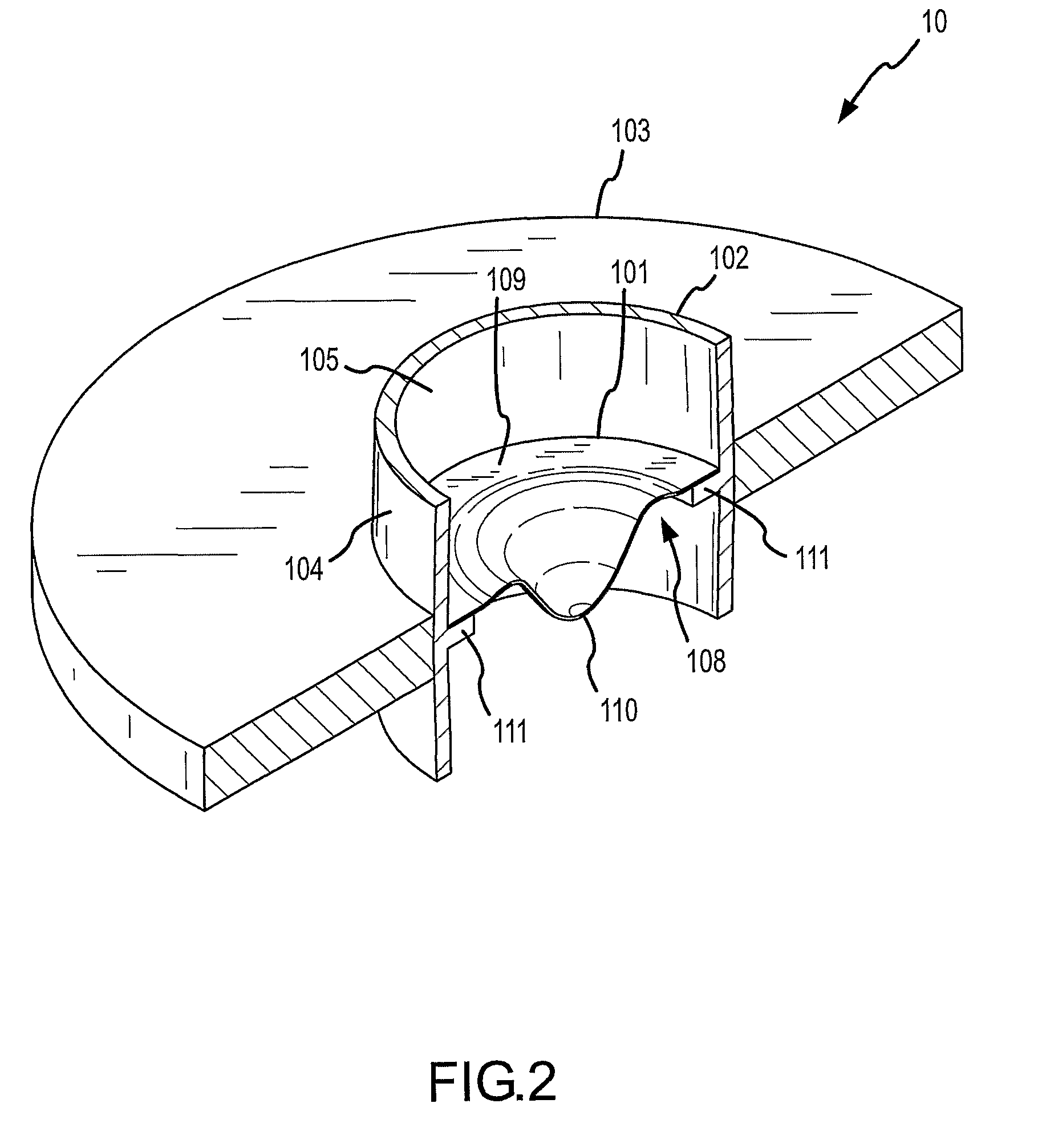

ActiveUS20090134235A1Simple and inexpensive to manufactureEfficient transferPiezoelectric/electrostrictive device manufacture/assemblyMovable spraying apparatusEngineeringAxial vibration

In one or more embodiments, a vibration system comprises a vibratable plate, a support member surrounding the vibratable plate, and a vibration-inducing member surrounding the support member, wherein the vibration-inducing member is configured to radially expand and contract against the support member so as to produce axial vibration of the vibratable plate. In one embodiment, the vibratable plate has an outer circumference; a tubular member is concentrically disposed about the outer circumference of the plate, and an annular vibration-inducing member is concentrically disposed about the outer circumference of the tubular member. The vibration-inducing member is preferably a piezoelectric ring that is radially expandable and contractable against the wall of the tubular member to cause the plate to vibrate in the axial direction. In another embodiment, an aerosol generating system comprises an piezoelectric ring that is radially expandable and contractable upon actuation thereof; a tubular member disposed within the center hole of the piezoelectric ring, and a circular vibratable aperture plate disposed across the internal lumen of the tubular member. The piezoelectric ring is radially expandable and contractable against the tubular member to cause the aperture plate to vibrate in the axial direction, and a reservoir of liquid is coupled to the tubular member so as to supply the liquid to the vibratable aperture plate and produce an aerosol upon vibration thereof.

Owner:STAMFORD DEVICES LTD

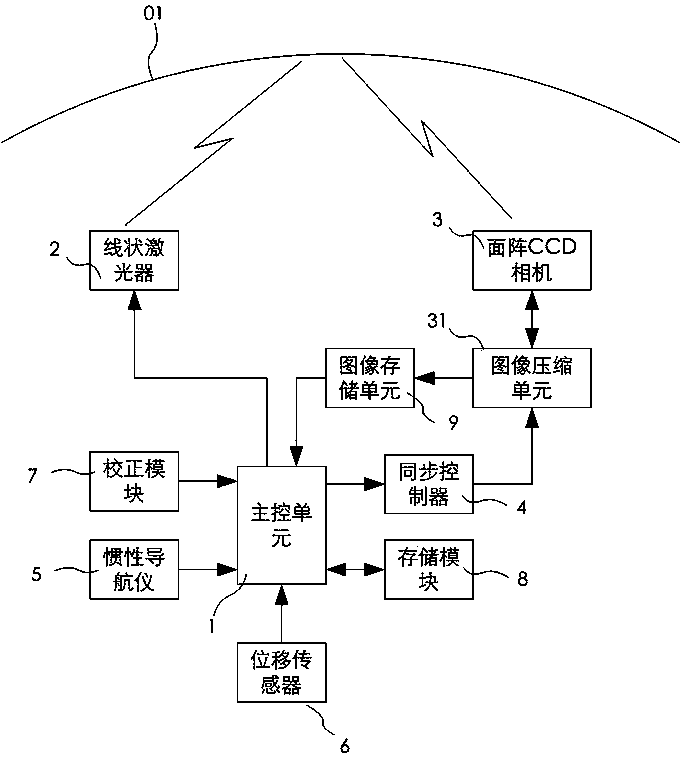

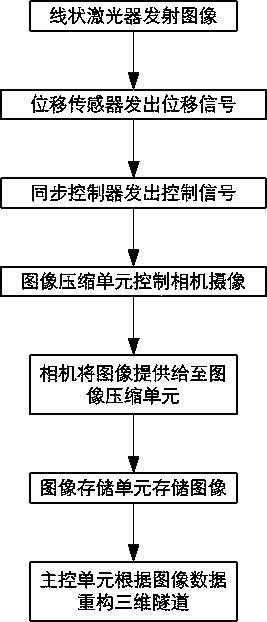

High-speed detection system and method of tunnel defects

ActiveCN104048970AMeasuring fast dynamicsHigh precisionOptically investigating flaws/contaminationUsing optical meansObservational errorImage compression

The invention provides a high-speed detection system and method of tunnel defects. The system comprises a master control unit, a linear laser, an area array charge coupled device (CCD) camera, an image compression unit, a displacement sensor, a synchronous controller, an image storage unit, a storage module, a correction module and an inertial navigator. A special measurement locomotive serves as a mobile monitoring platform for the design and is particularly suitable for subway tunnel monitoring, and subway and other tunnel space structures can be effectively, rapidly and dynamically measured; the actually measured data is compared with actual real distance, errors are analyzed, the parameter setting is adjusted, and the measurement accuracy is greatly improved; moreover, the XYZ axial vibration of the mobile monitoring platform is subjected to error correction through the inertial navigator, and a measurement error is prevented from being introduced into mobile measurement.

Owner:樊晓东

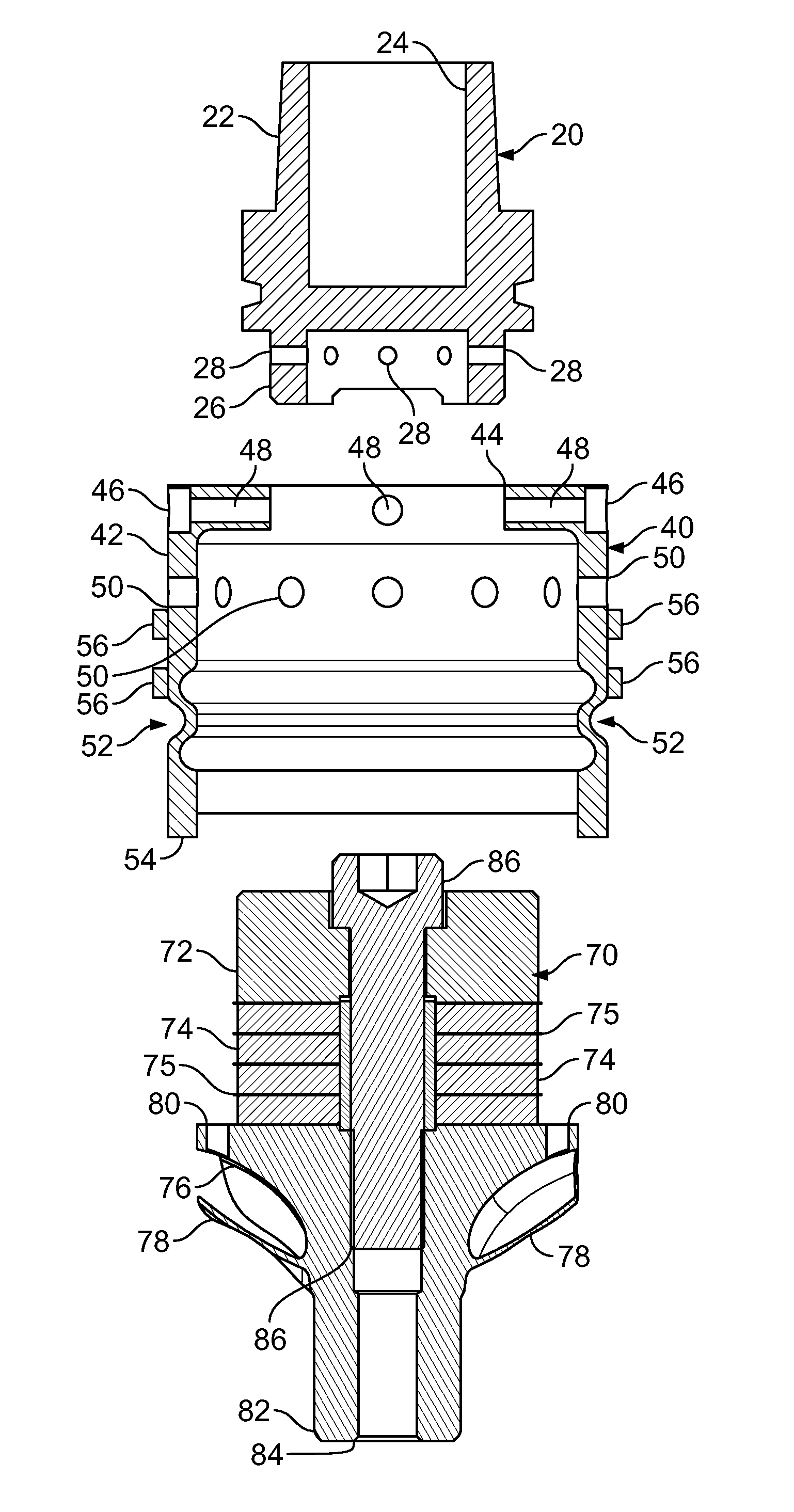

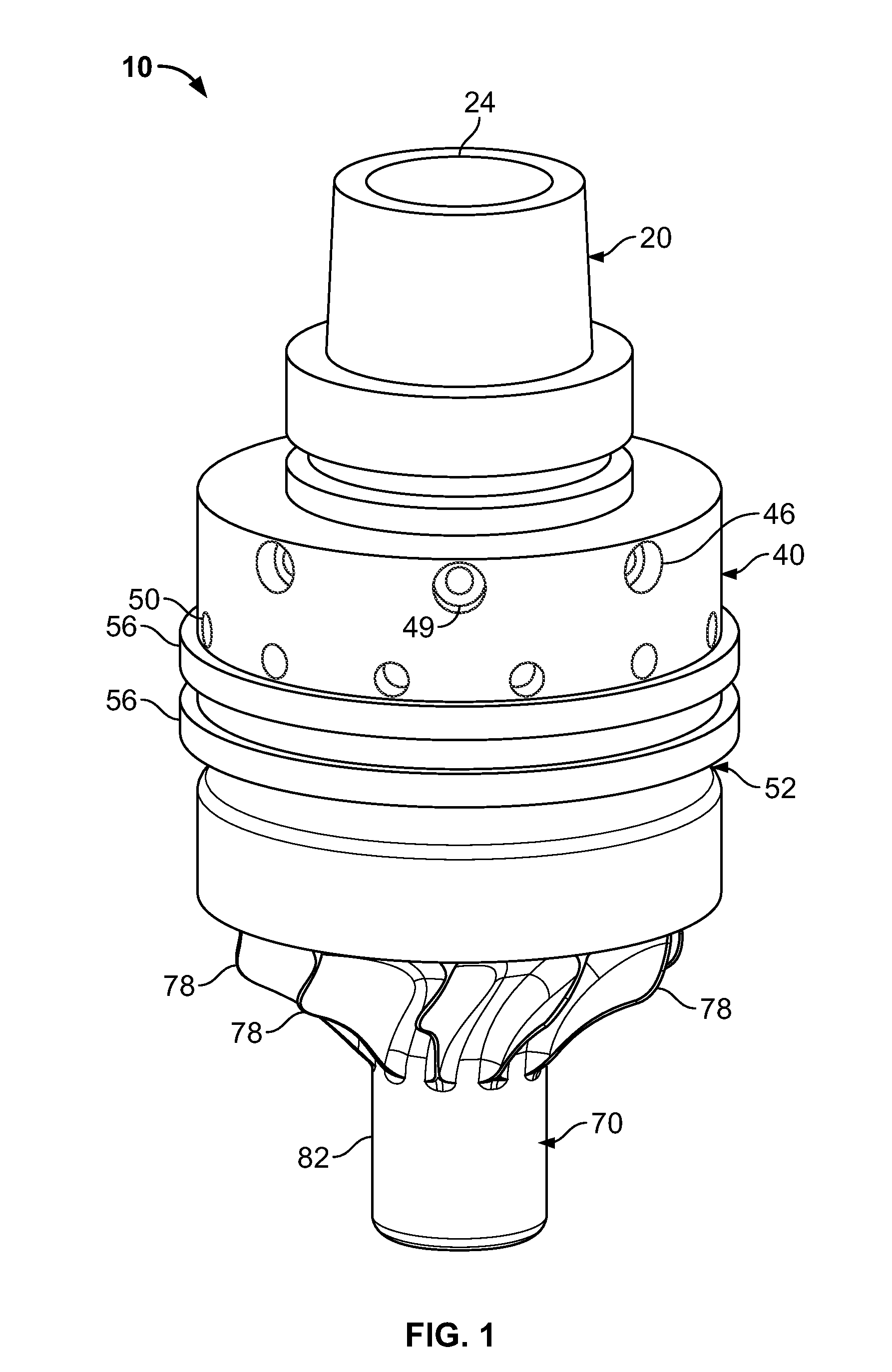

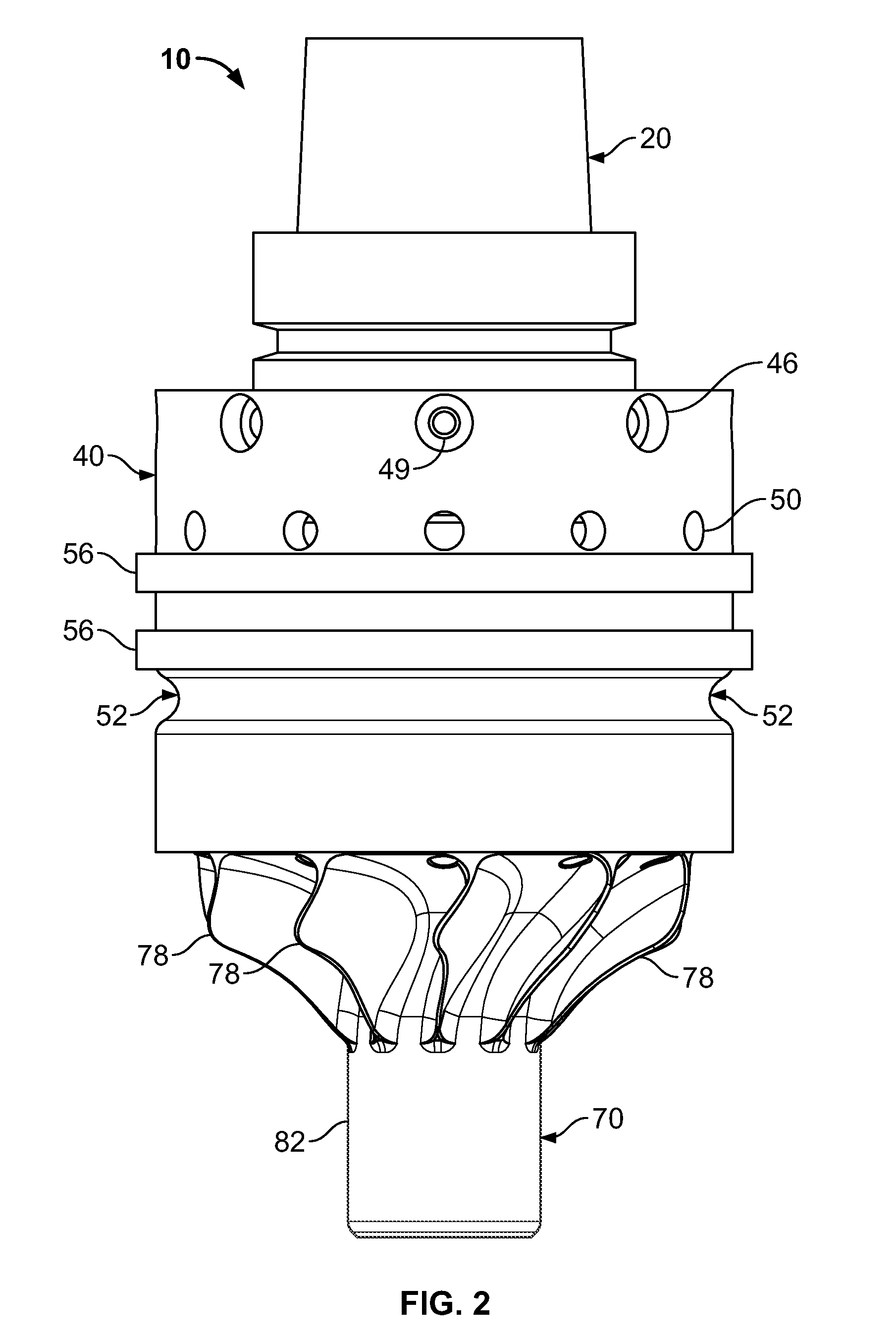

Ultrasonic machining module

A device for use in a machining system, including an ultrasonic transducer, wherein the ultrasonic transducer is adapted to receive a tool bit; a housing adapted to be both compatible with the machining system and to receive the ultrasonic transducer, wherein the housing is operative to isolate all radial and other vibrations generated by the ultrasonic transducer except the axial vibrations transmitted to the tool bit; and a tool holder, wherein the tool holder and the top portion of the housing are mechanically coupled to one another.

Owner:EDISON IND INNOVATION

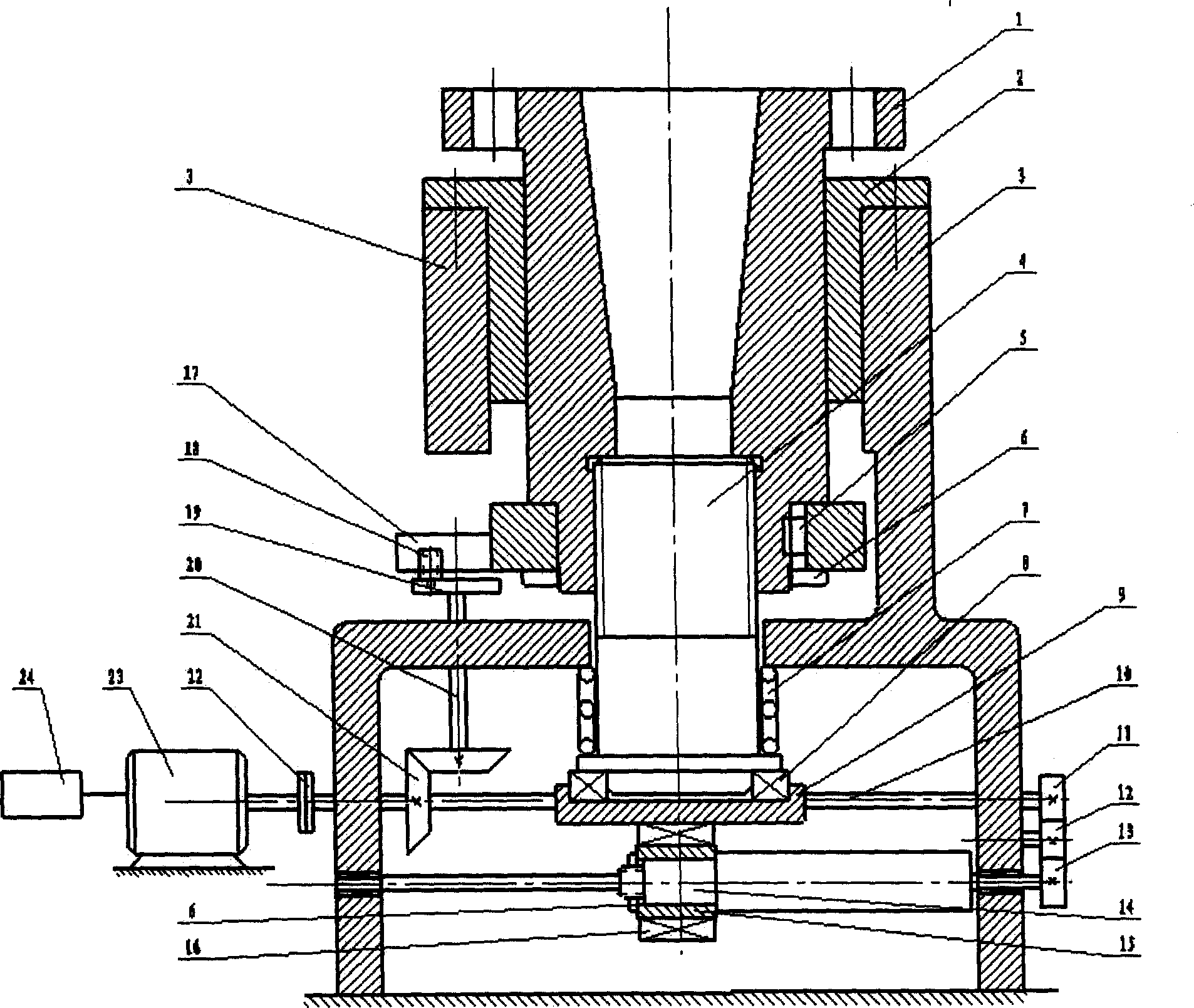

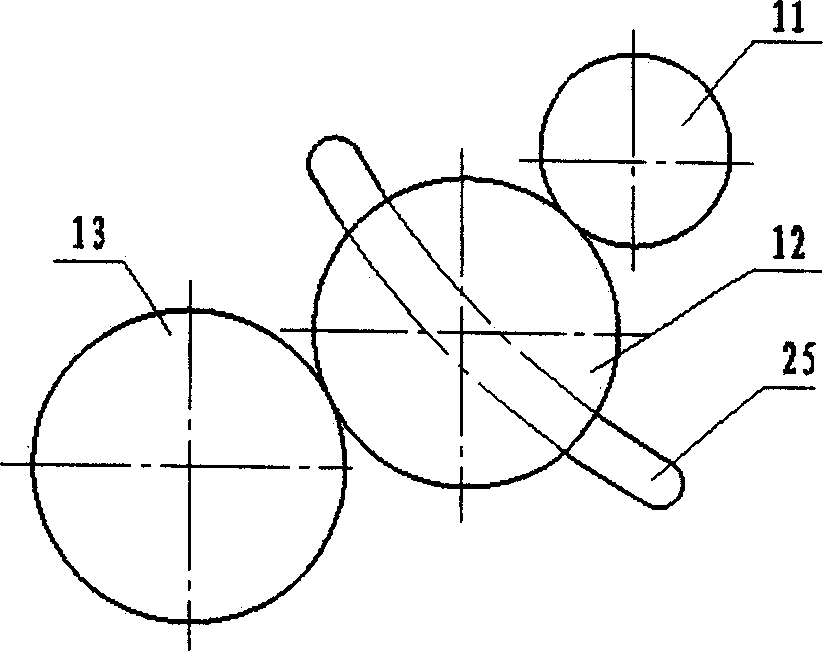

Compound vibration drilling device

InactiveCN105499626AStrong structural versatilityWide adaptabilityBoring/drilling machinesEngineeringAxial vibration

The invention relates to a compound vibration drilling device which is applied to various drilling machines and the drilling procedure of a processing center. The compound vibration drilling device mainly consists of three parts, namely a machine body, an ultrasonic torsion vibration system and a low-frequency axial vibration system, wherein the machine body plays a role of connecting and fixing the other two parts on the basis of the original processing function. The compound vibration drilling device realizes required ultrasonic torsion vibration by enabling the ultrasonic torsion vibration system to drive a drilling bit; the low-frequency axial vibration system drives a workpiece to realize low-frequency axial vibration; proper rotating speed and feeding amount can be selected by a drilling parameter setting system of the machine to perform compound vibration drilling processing. The compound vibration drilling device has the characteristics of high structural generality, high material applicability and the like, can develop respective advantages of different vibration drilling methods in ultrasonic, low frequency, torsion and axial direction, and is favorable for improving the drilling quality and realizing high-precision inner-hole drilling.

Owner:HENAN INST OF SCI & TECH

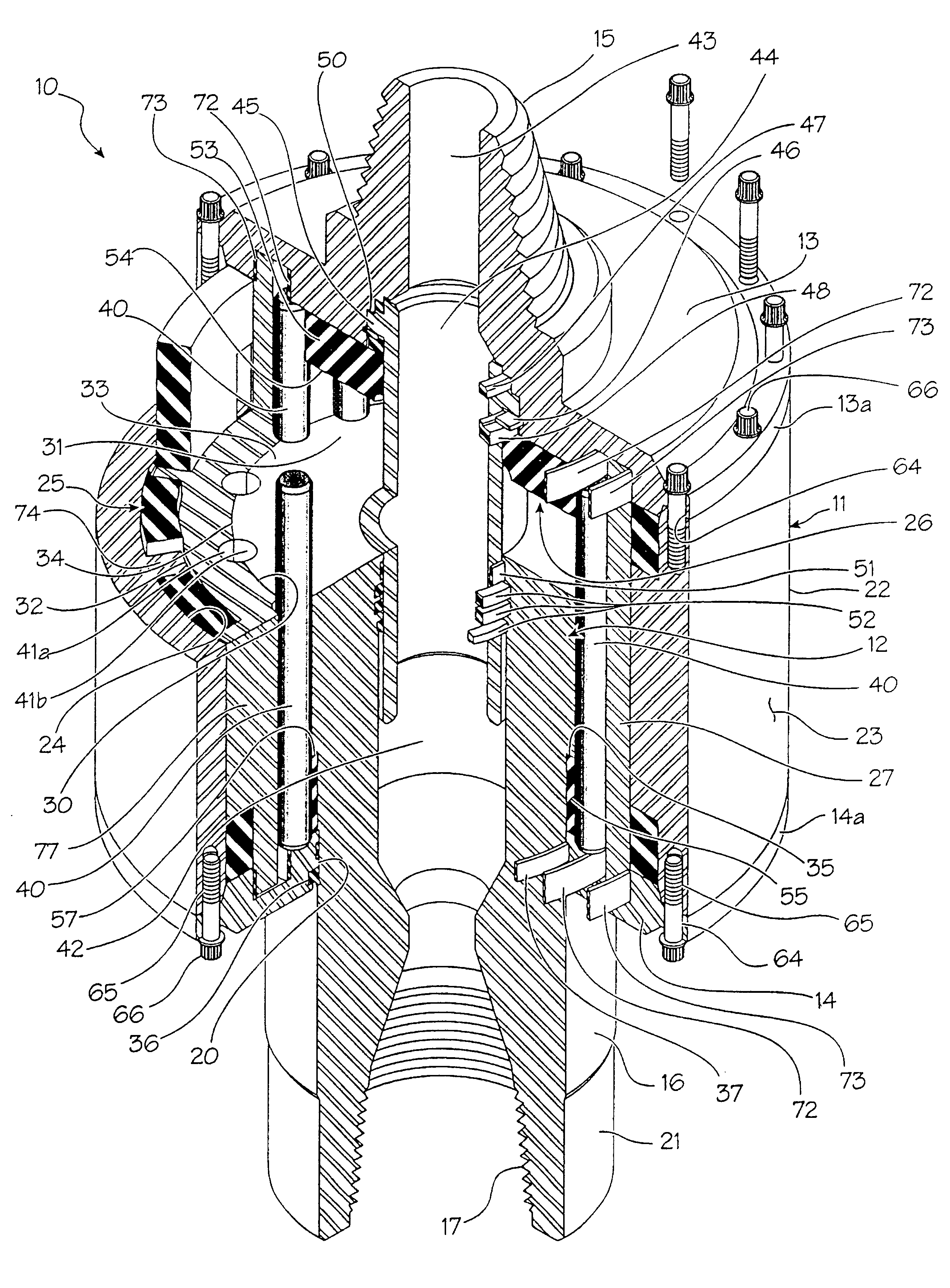

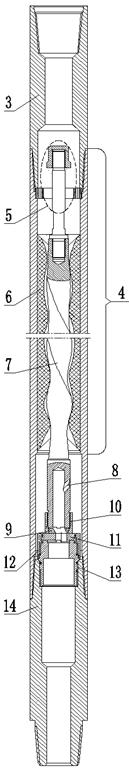

Floating cushion sub

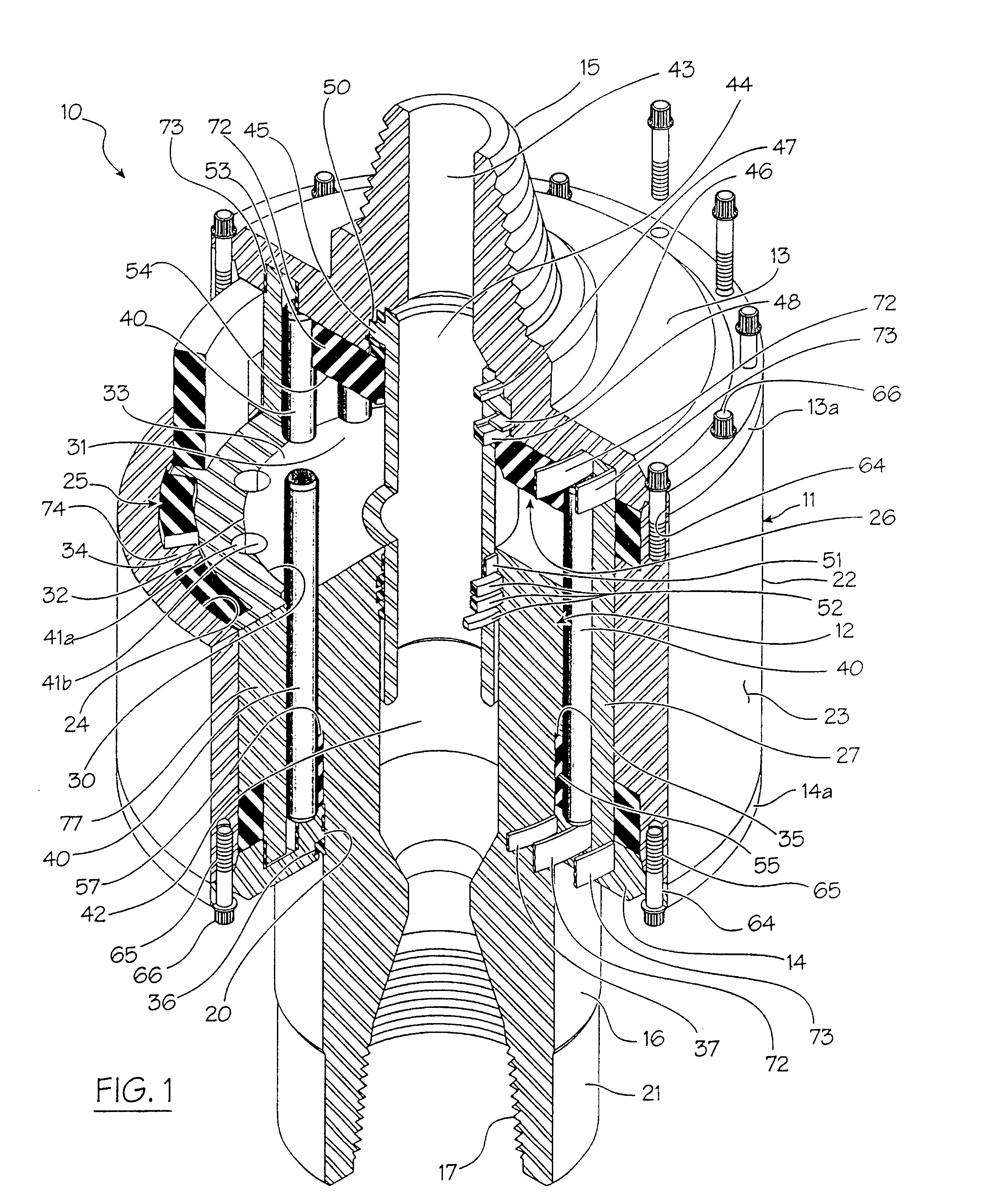

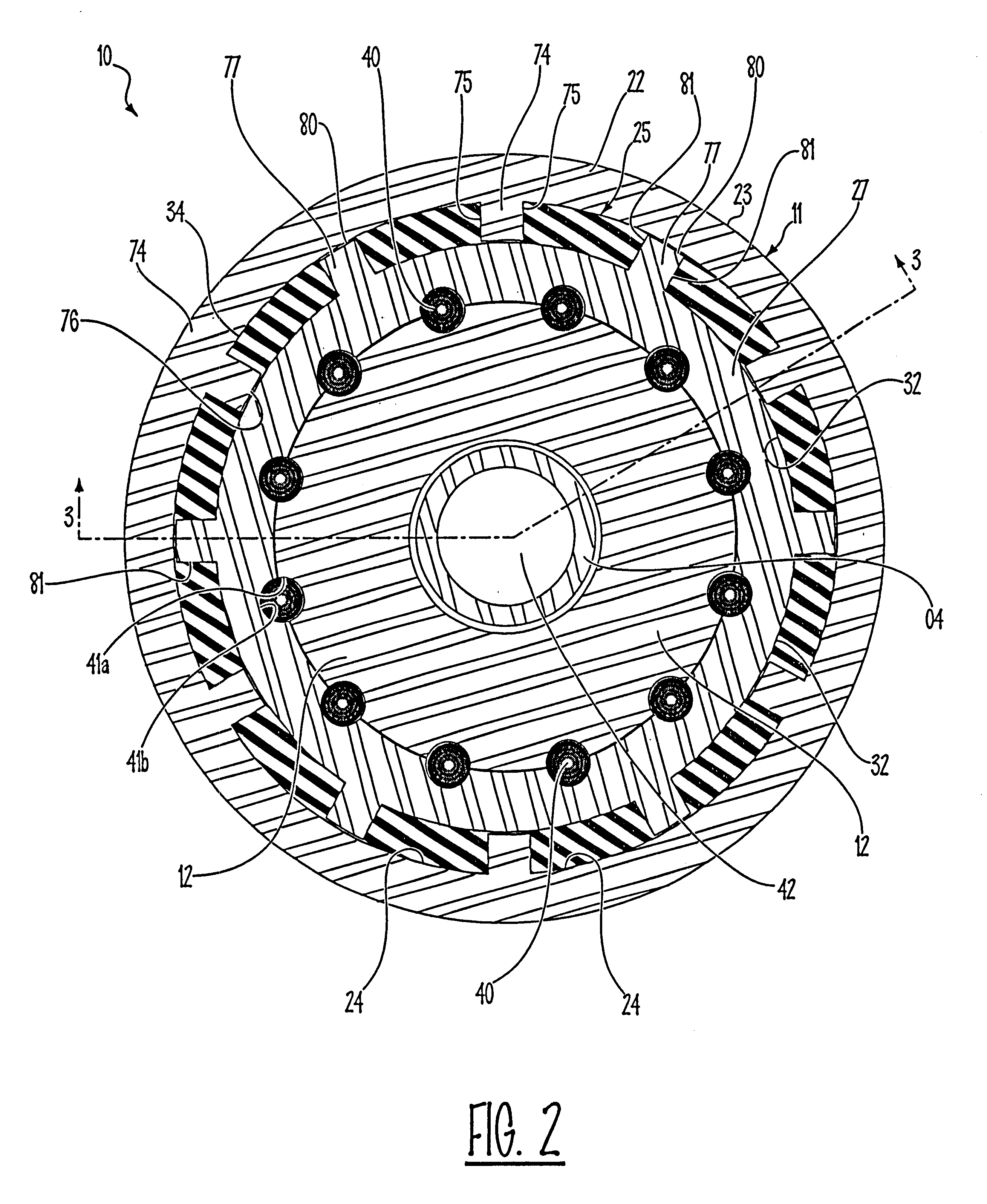

InactiveUS6332841B1Easy to handleEffective absorptionYielding couplingDrilling rodsTorsional vibrationAxial vibration

A cushion sub for absorbing both axial and torsional vibration in a drill string and including an outer casing connectable at one end to a section of a drill string, and an inner piston reciprocally mounted in a cylinder within the casing, the piston having a shaft projecting from the other end of the casing connectable to another section of the drill string. The cylinder includes a first cushion device at opposite ends thereof for engagement by the piston to absorb axial vibrations. A spline type connection prevents relative rotation between the piston and the cylinder. The cylinder is mounted for arcuate turning in a chamber within the casing, but the cylinder has vanes which are interposed between vanes fixed to the casing, and elastomeric material between the vanes of the cylinder and the vanes of the casing absorbs torsional vibrations being transmitted between the cylinder and the casing. The elastomeric material is preferably formed in situ as an integral mass in the chamber of the casing by pouring the elastomeric material in a fluid state into the chamber.

Owner:FOREMOST INDS

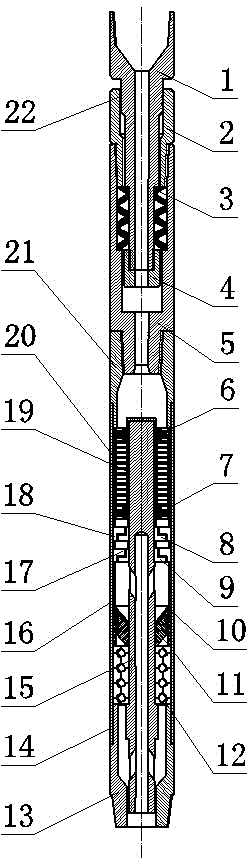

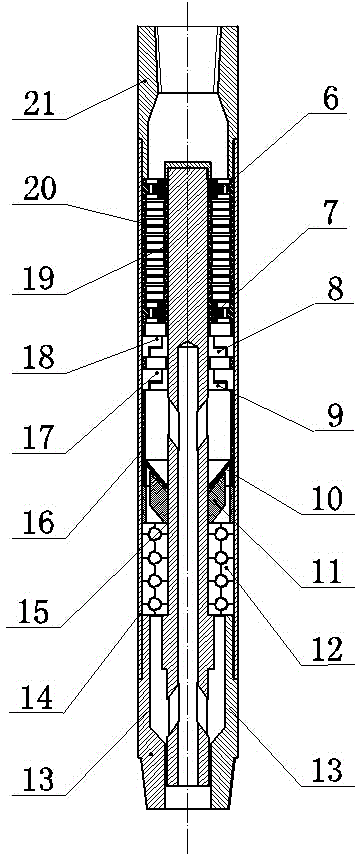

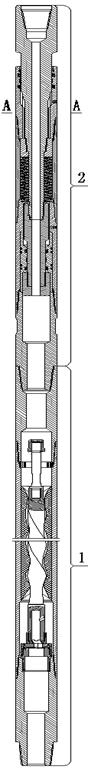

Dual-pulse hydraulic oscillator for well drilling

InactiveCN104405287AReduce frictional resistanceExtended service lifeVibration drillingWell drillingThrust bearing

The invention relates to a dual-pulse hydraulic oscillator for well drilling, and belongs to the technical fields of petroleum and natural gas exploration and well drilling tools. The dual-pulse hydraulic oscillator consists of an oscillation short section assembly and a power short section assembly, and is characterized in that the oscillation short section assembly consists of a spline mandrel, a connection sleeve, a pressure converter, an oscillation shell and the like; the power short section assembly comprises a pressing sleeve and a turbine shaft; a sealing piece is mounted between the spline mandrel and the connection sleeve; the connection sleeve is connected with the oscillation shell; the lower end of the turbine shaft is connected with the power short section assembly; the pressing sleeve at the upper end of the power short section assembly is connected with the oscillation shell; the lower end of the pressing sleeve is connected with a power shell; the turbine shaft is mounted at the center of the power shell; a straightening bearing, a turbine stator, a turbine rotor, two groups of movable valves and fixed valves, a sleeve, a flow division ring, a flow division sleeve and a thrust bearing are mounted on the turbine shaft in sequence from top to bottom. Radial swinging is avoided; under low flow, higher axial vibration with higher frequency can be realized; the friction resistance is low, so that effective drilling pressure is increased, and the mechanical drilling speed is increased.

Owner:YANGTZE UNIVERSITY

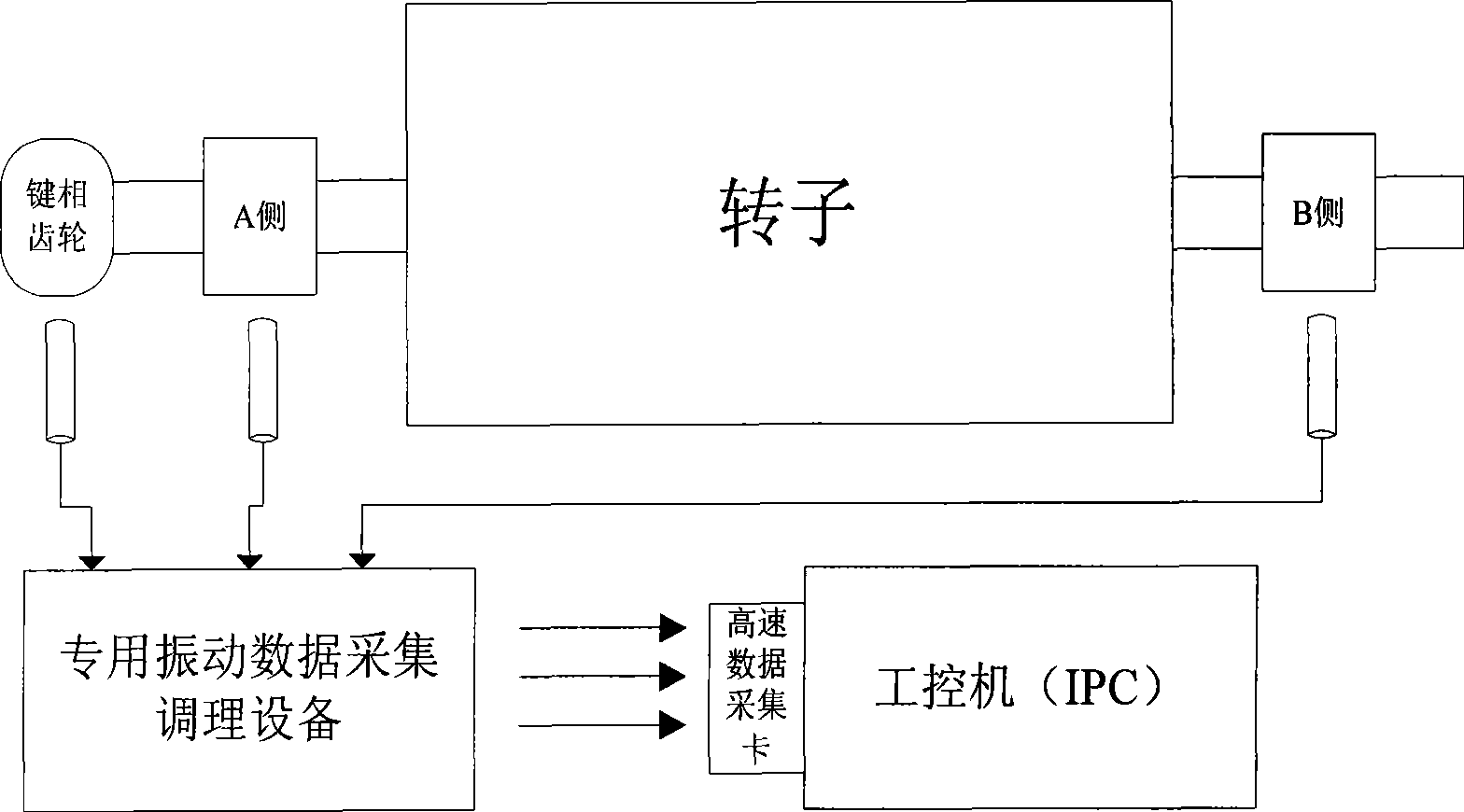

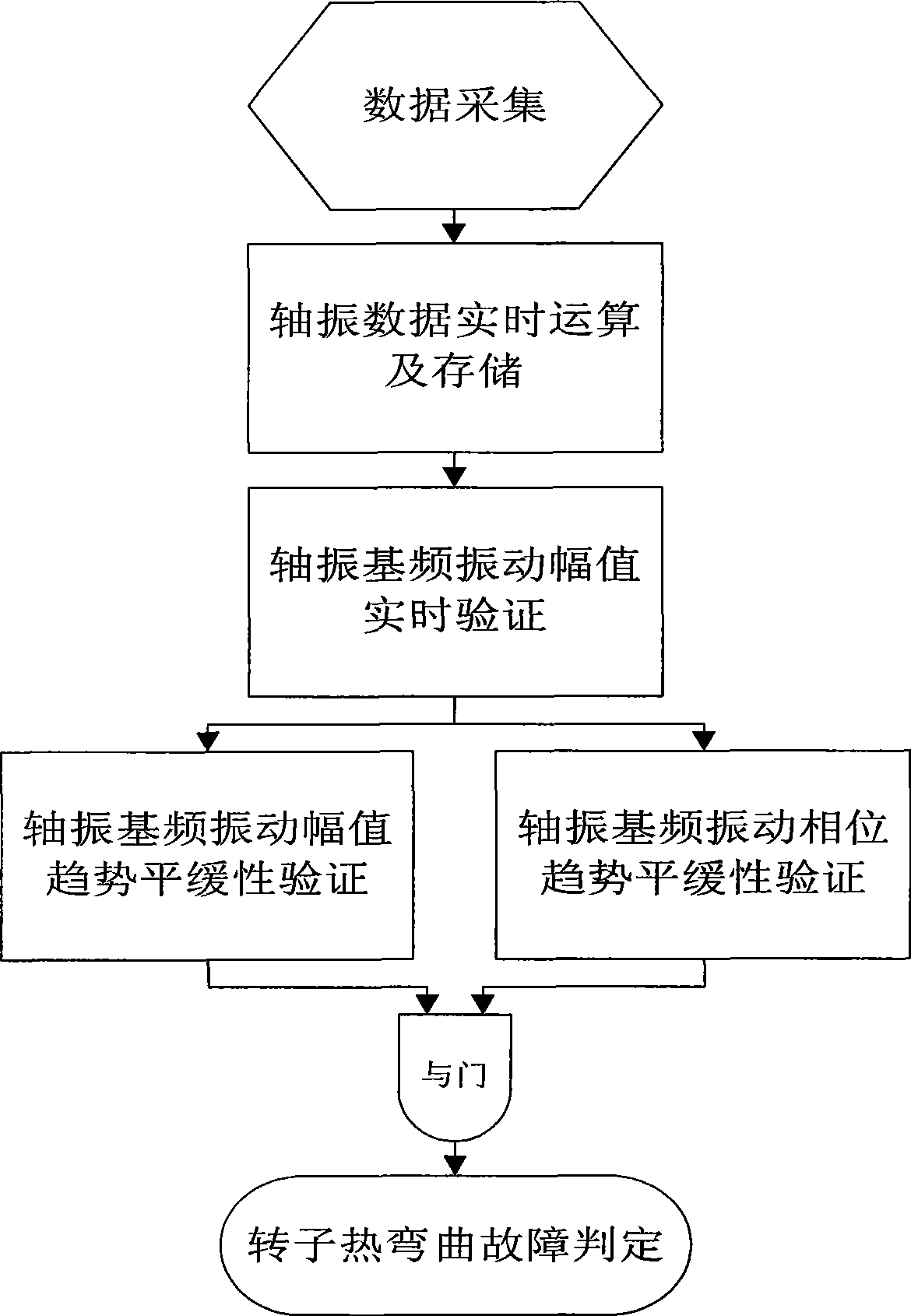

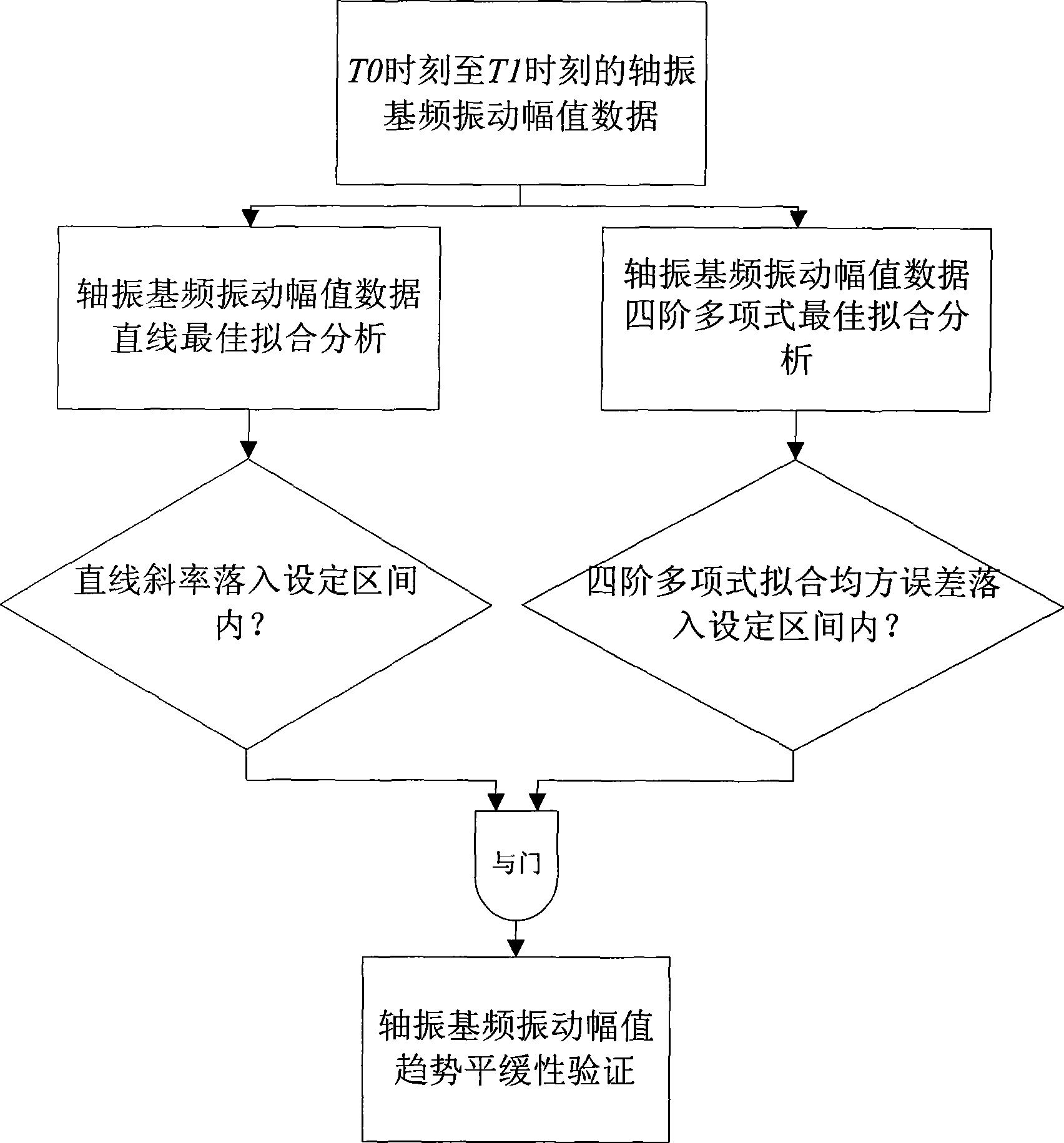

Steam-electric generating set rotor thermal bending unbalance fault real time diagnostic method

InactiveCN101451898AMethod scienceConclusion scienceStatic/dynamic balance measurementVibration amplitudeAxial vibration

The invention discloses a real time diagnosing method for turbo unit rotor thermal bending malfunctions. The method processes the calculation, analysis and judgments for the vibrating data via collecting the rotor vibrating signals of the turbo unit; and the method processes the real-time calculation of storage on both sides of the rotor shaft relative vibration frequency of vibration amplitude and phase values, and real-time axis vibration frequency of vibration amplitude in real-time authentication, determine any side of the rotor shaft vibration amplitude of the vibration frequency is greater than the vibration amplitude threshold. Then the method is combined with least square method, based on the axial vibration frequency of vibration data axis vibration frequency of the vibration amplitude of the trend of flat-based authentication and shaft vibration frequency vibration phase of verification, such as the trend of moderate real-time quantitative calculation and analysis. Calculated in real-time quantitative analysis based on the combined results of the verification, automatic real-time diagnosis of whether units imbalance rotor thermal bending failure. The invention has the advantages of scientific method; reliable conclusions can automatically real-time online monitoring, fault diagnosis and so on.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

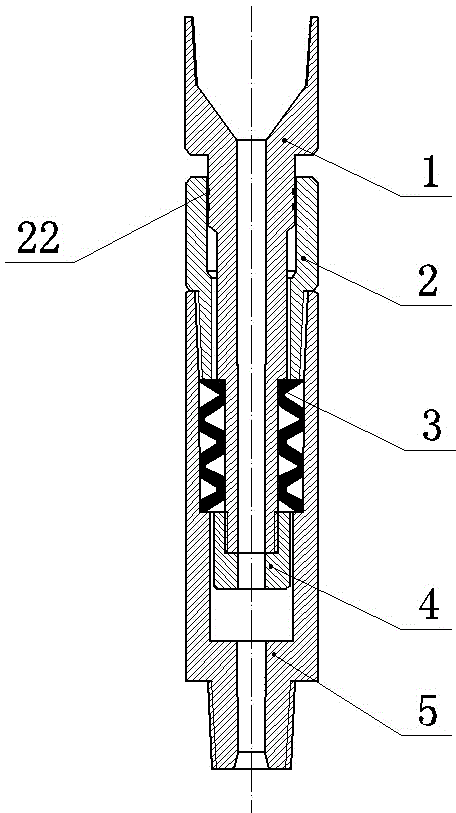

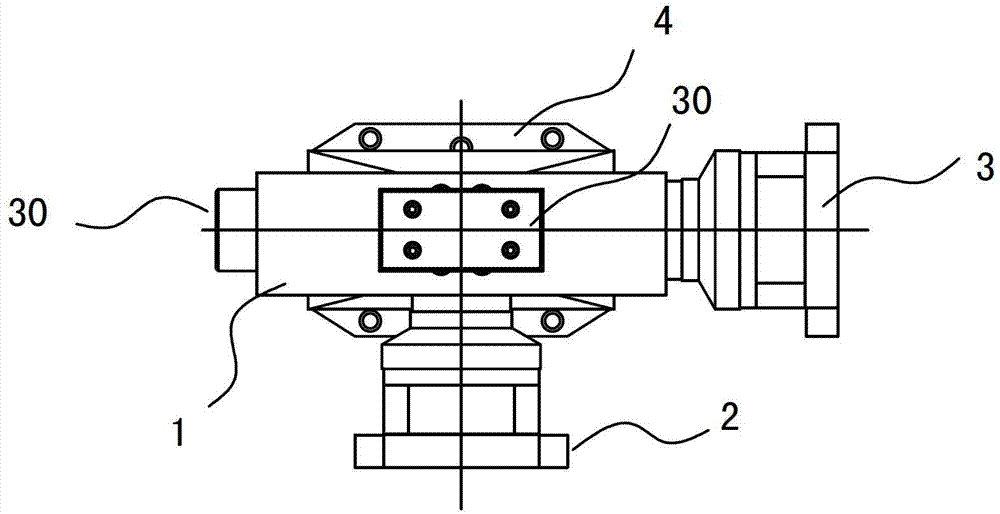

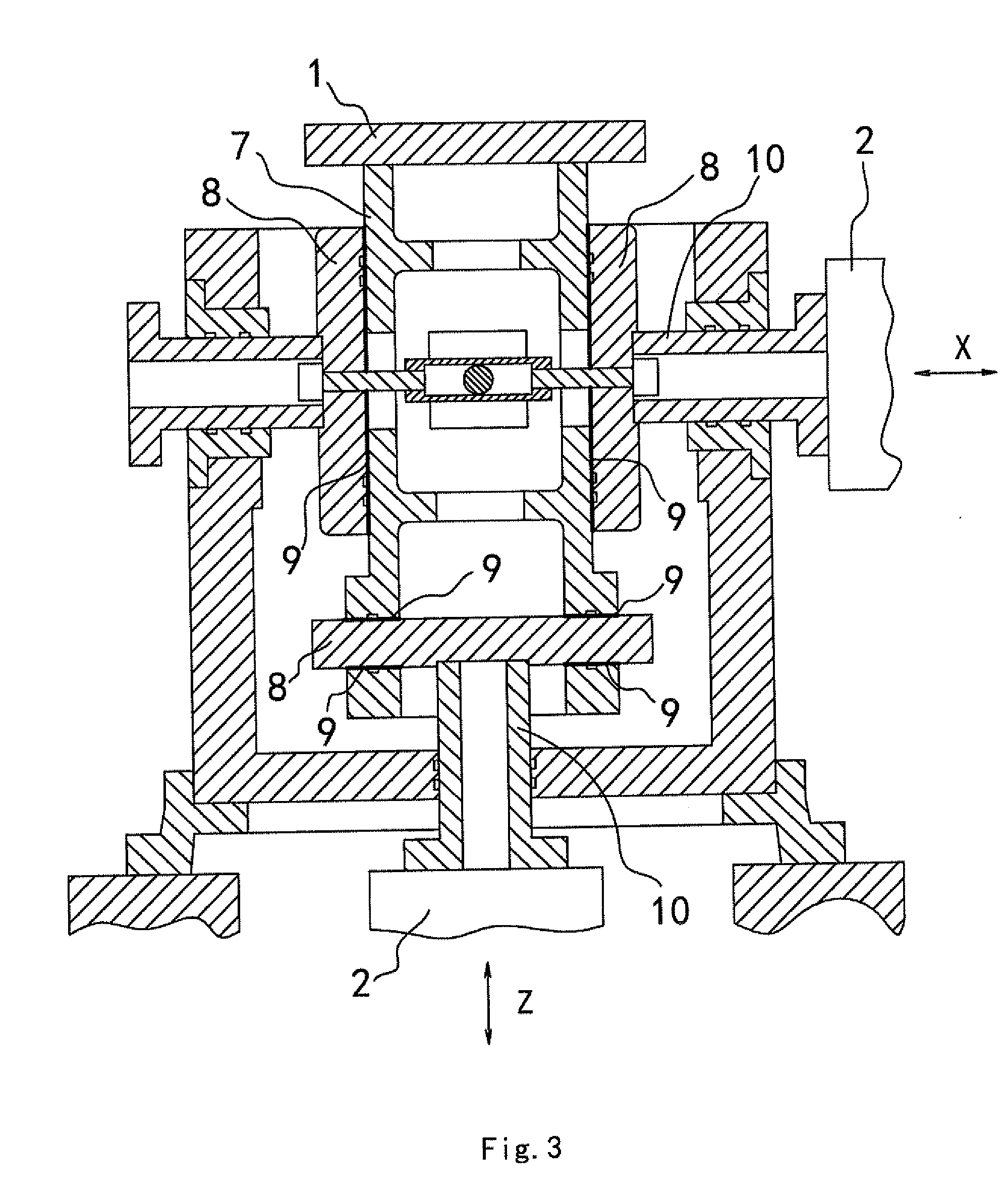

Drilling head with axial vibrations

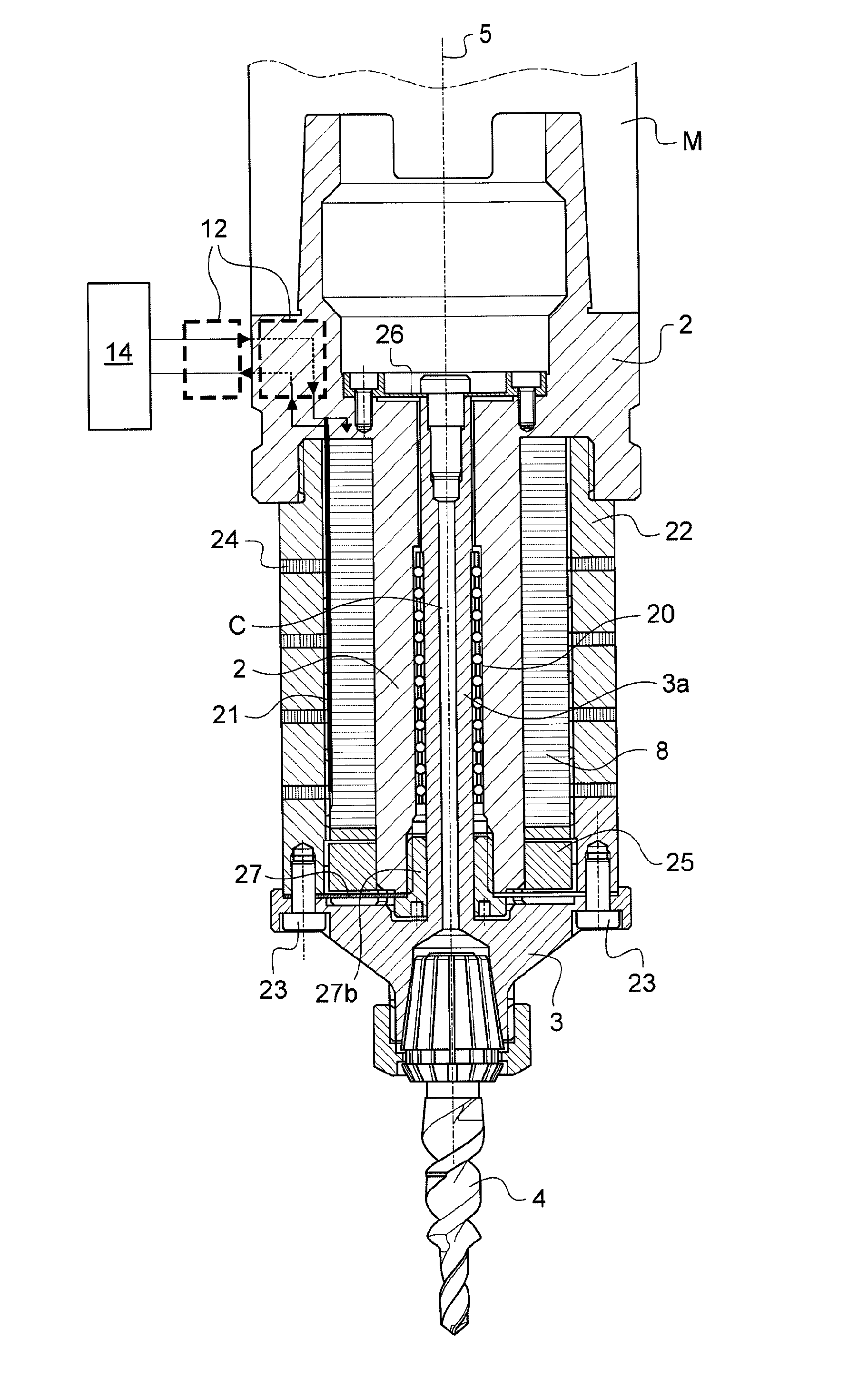

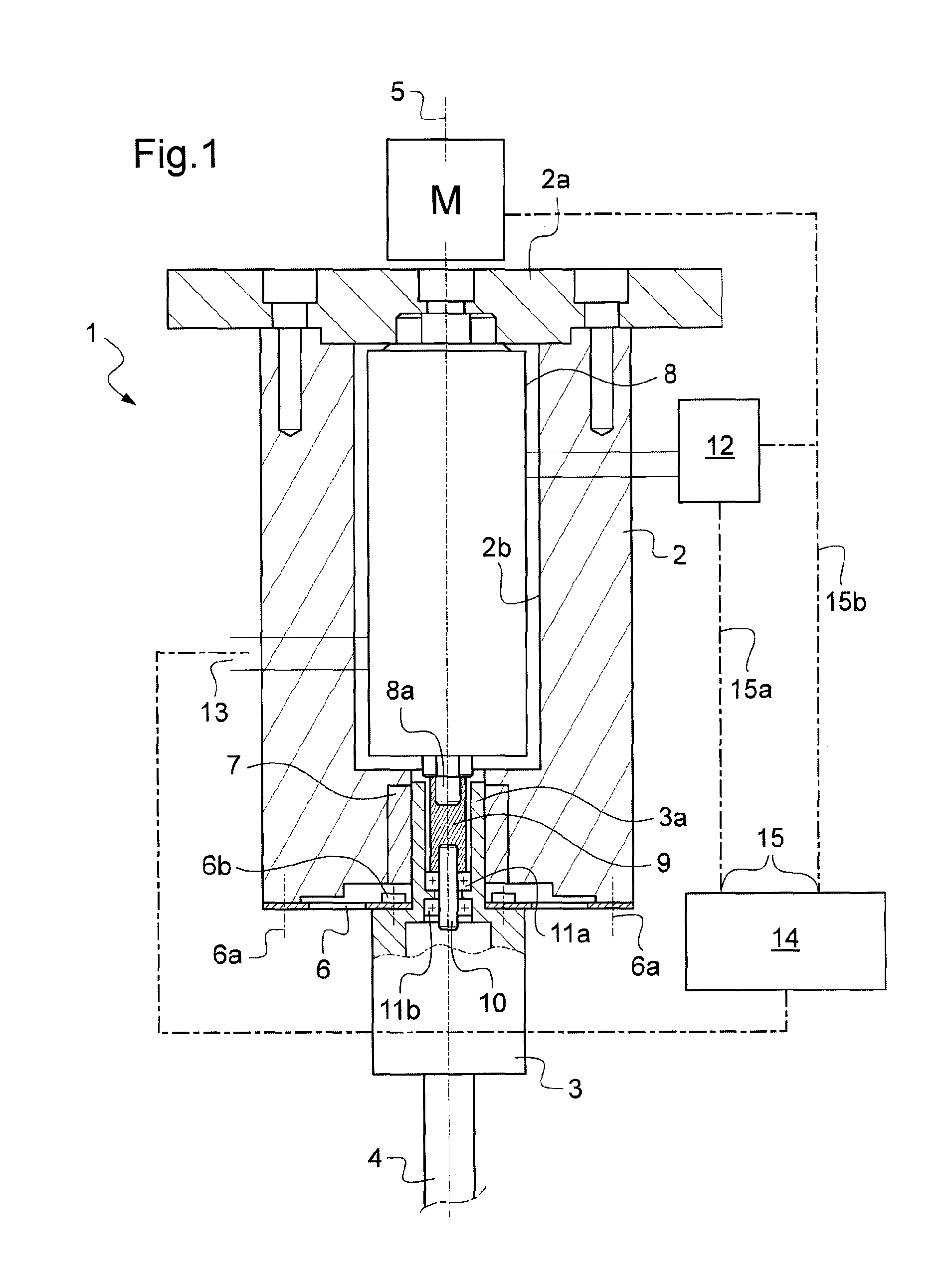

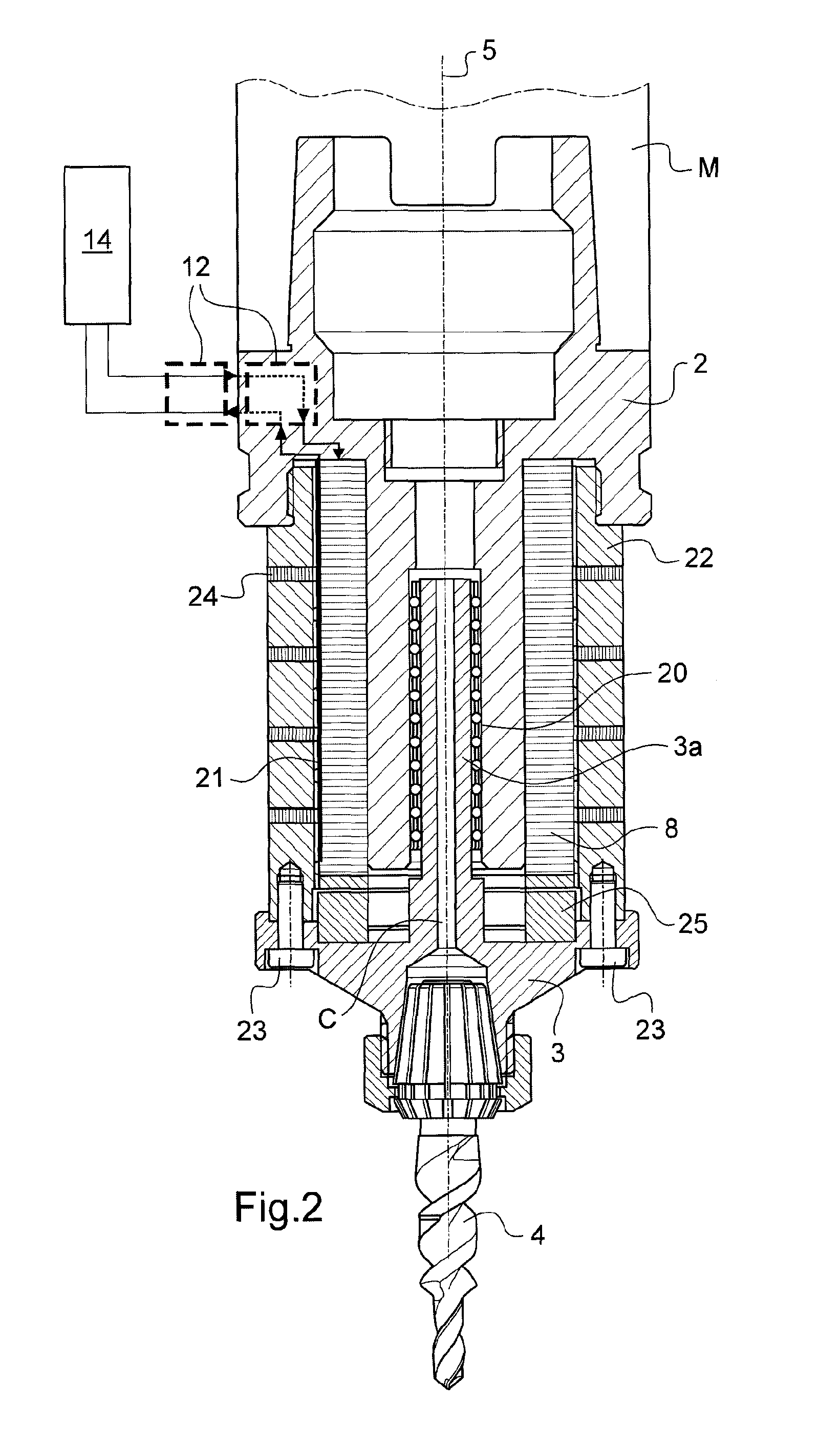

ActiveUS20120107062A1Relieve shimAdjustable preloadWorkpiecesTurning toolsCouplingReciprocating motion

A drilling head (1) with an axial oscillation generator, includes a mounting (2) for coupling the head to a motor for rotating the mounting about an axis, the mounting (2) having a longitudinal axis (5) coinciding with the axis of rotation of the motor, a tool holder (3), an elastically deformable element (6) for retaining the tool holder (3) in the mounting (2) and an element (7) for guiding the tool holder (3) in the mounting (2) along the longitudinal axis (5) of the mounting, wherein the mounting of the drilling head includes a controlled generator (8) of reciprocating movements in the direction of the aforementioned axis (5) positioned between the mounting (2) and the tool holder, the tool holder and the generator being connected by a longitudinal coupling member (9) suitable for damping the impacts withstood by the tool holder while enabling the transmission of the reciprocating movements.

Owner:ARTS +1

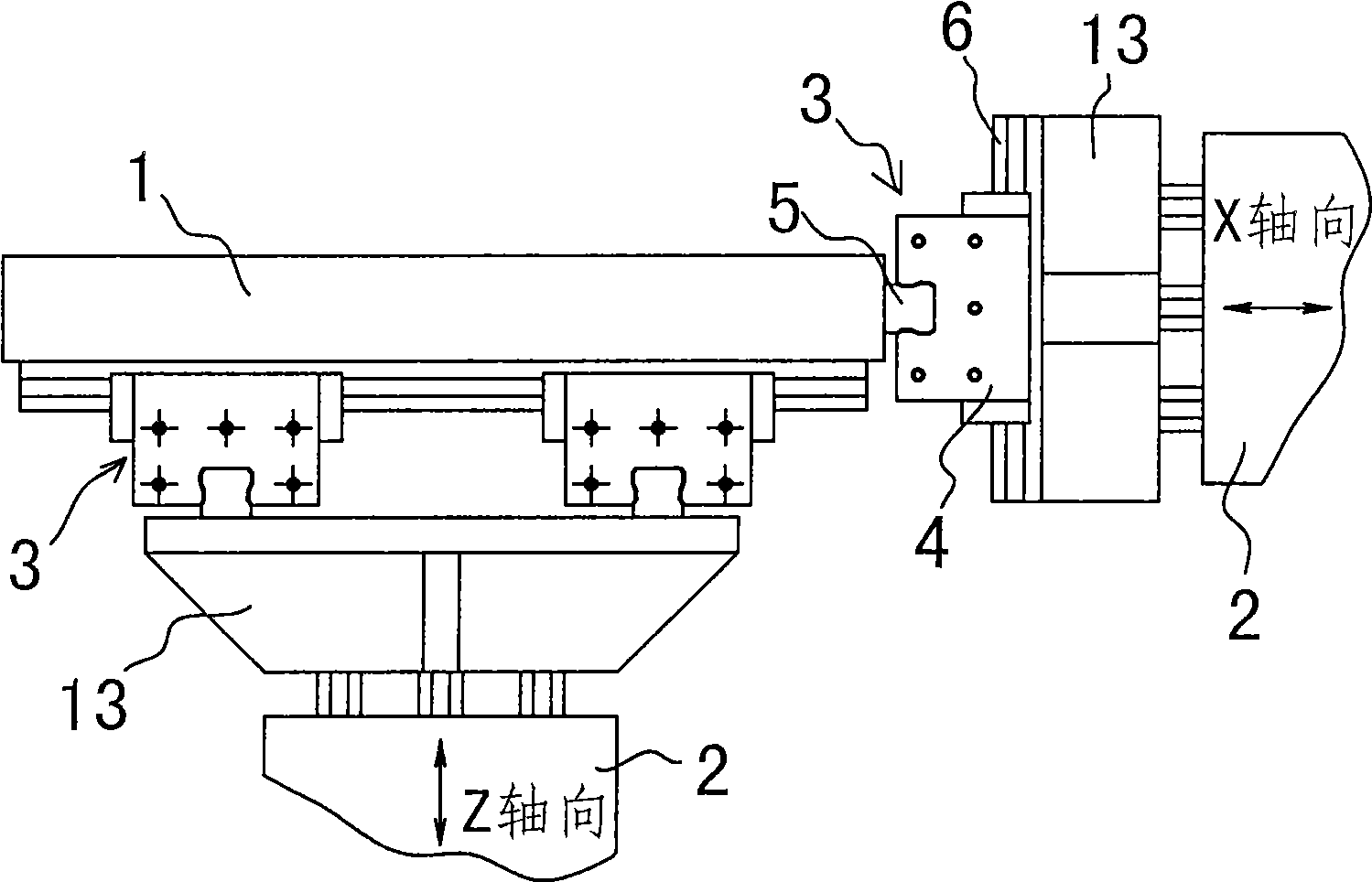

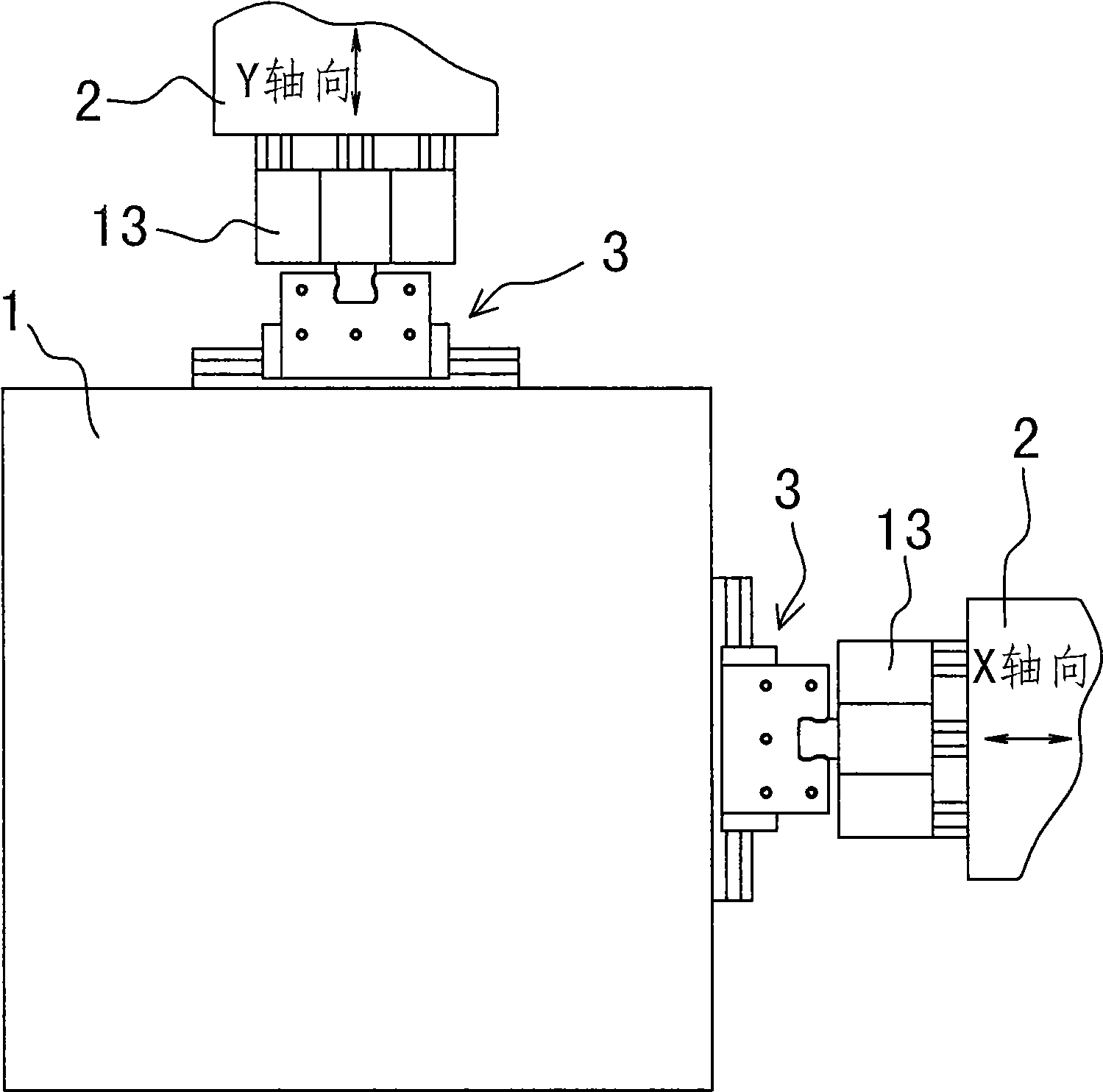

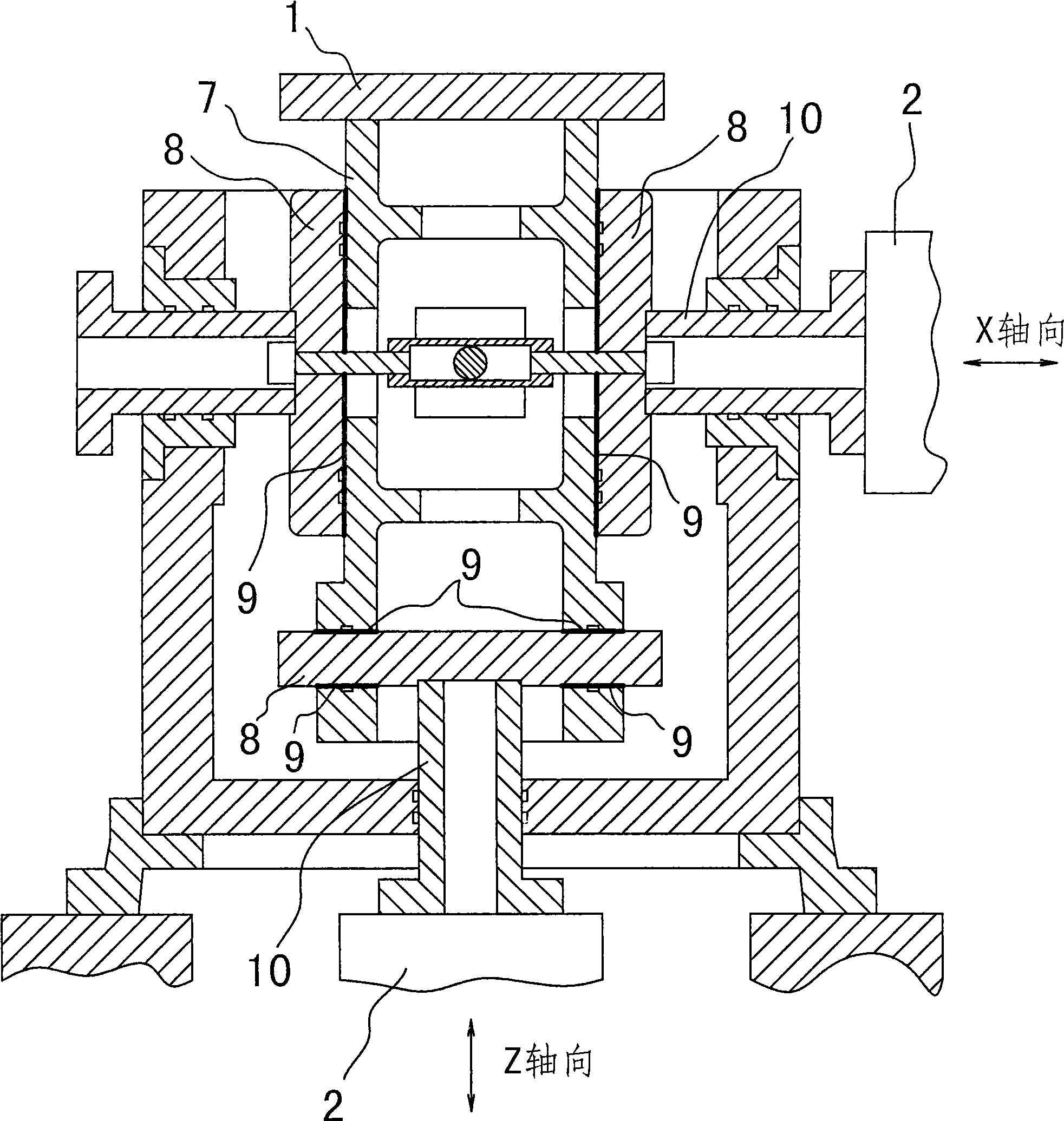

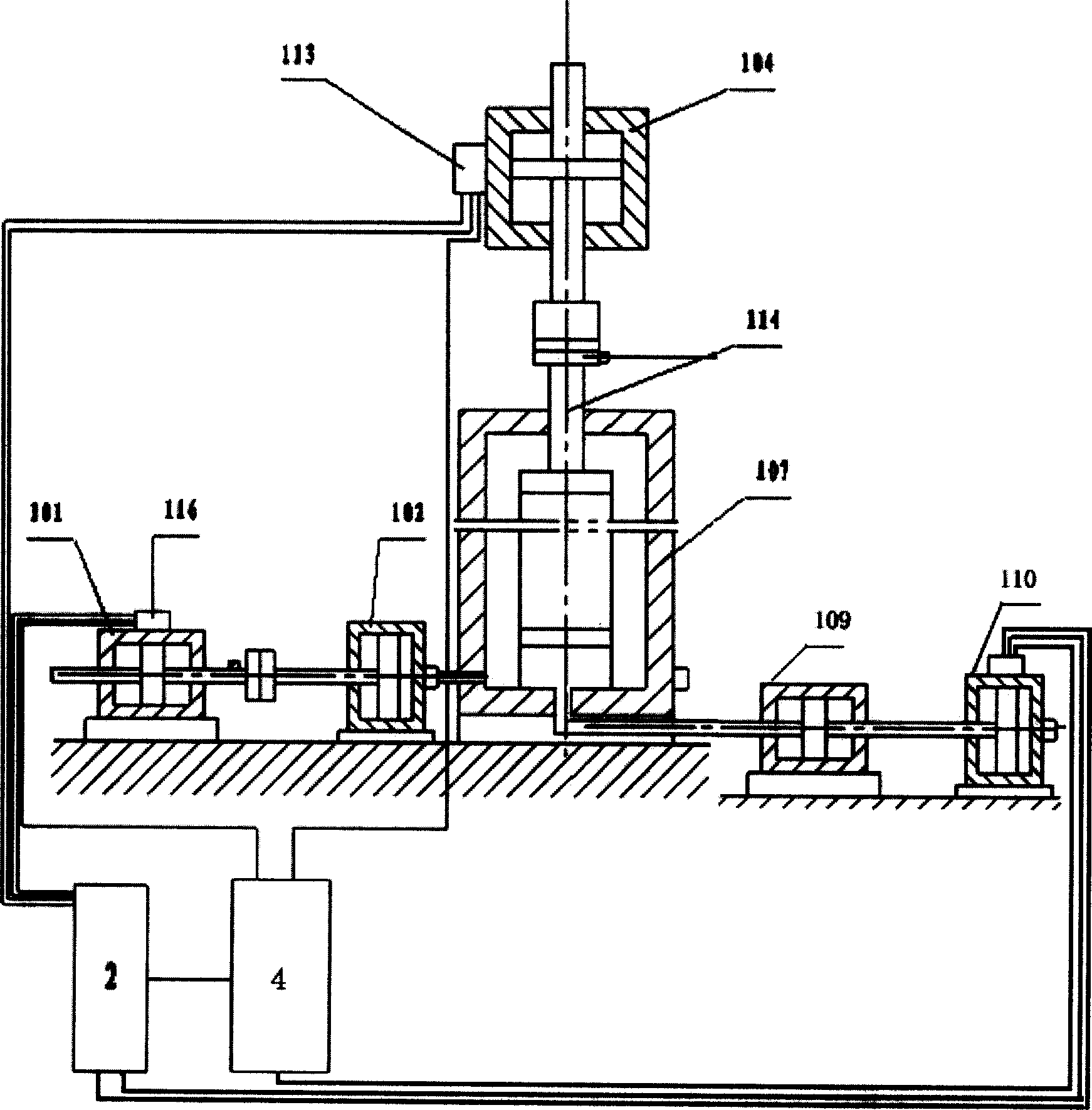

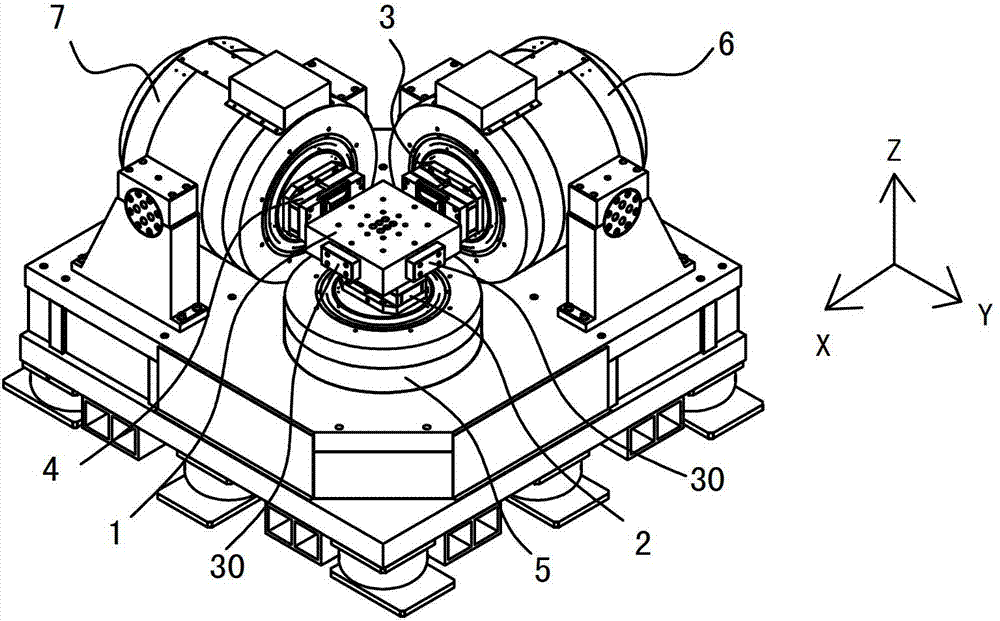

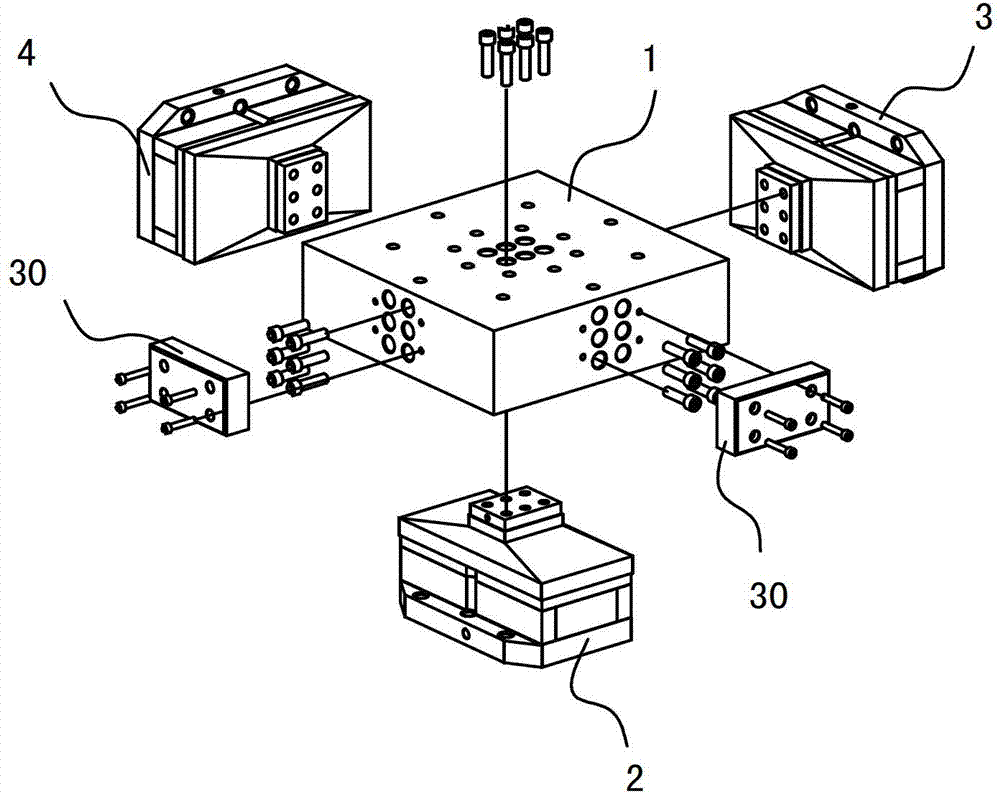

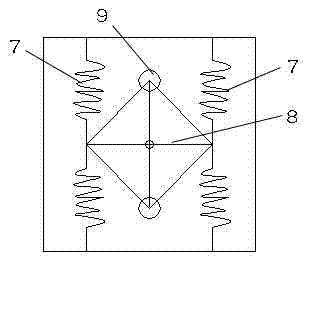

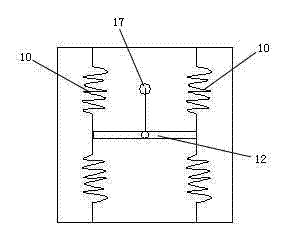

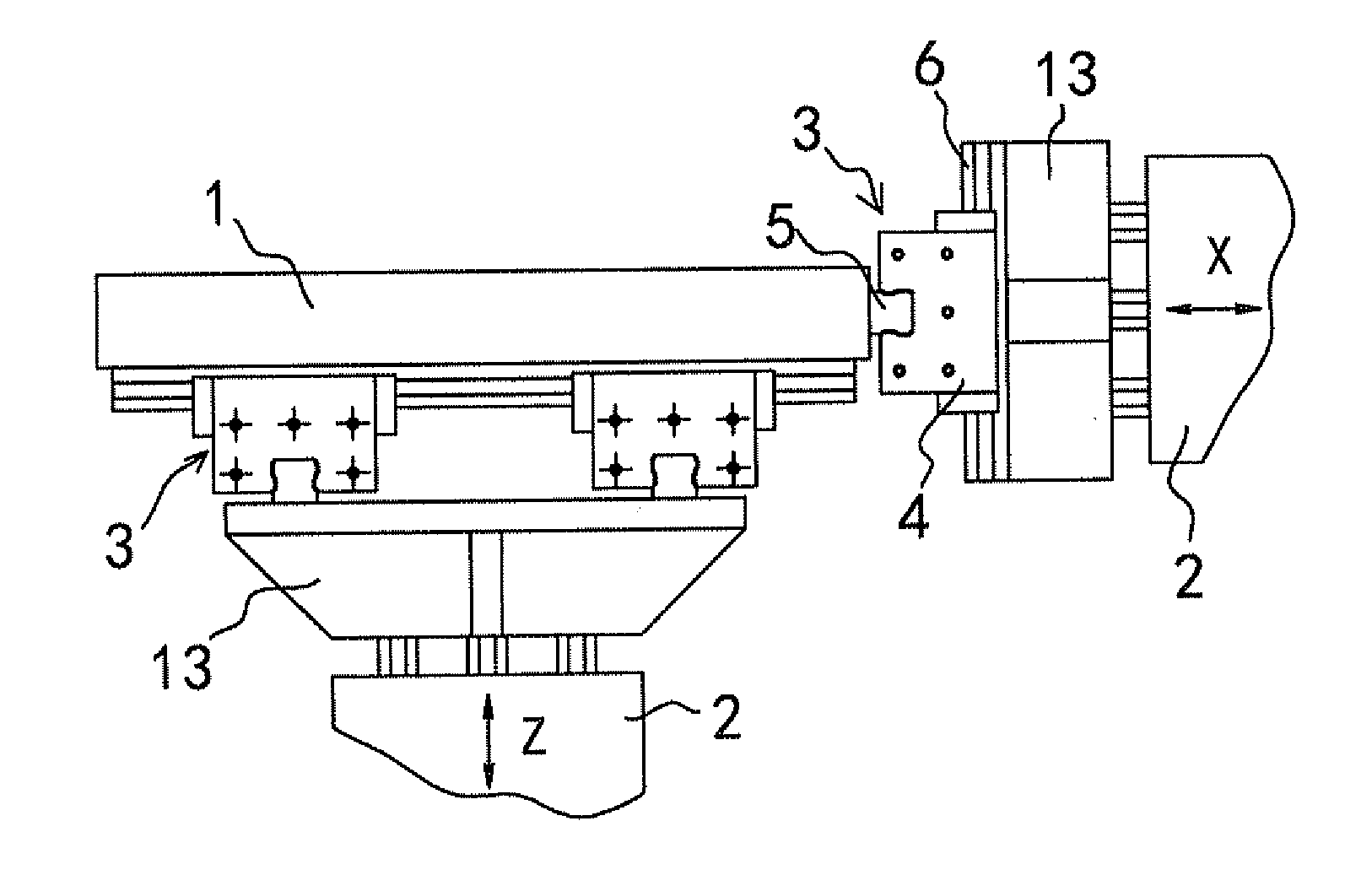

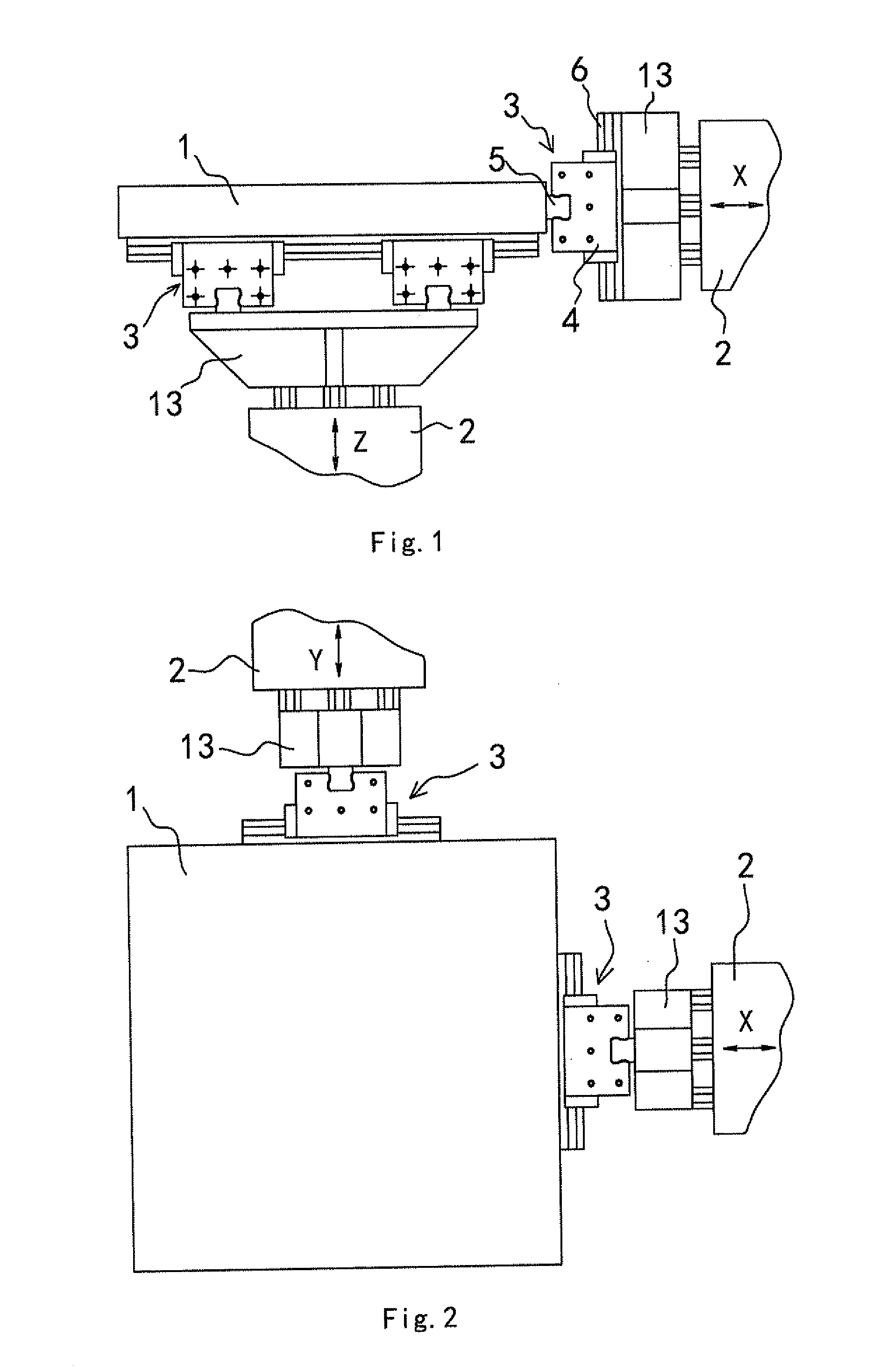

Three-axial vibration composite testing apparatus

A triaxial vibration composite testing device is provided with a worktable, and is characterized in that both a horizontal X-axis second axial transmission-vibration mechanism and a horizontal Y-axis third axial transmission-vibration mechanism are cross linear guide rail pairs, while a first axial transmission-vibration mechanism vertical to Z-axis comprises an upper clamp plate, a lower clamp plate and a central panel, wherein the upper clamp plate and the lower clamp plate are aligned vertically and arranged horizontally, the central panel is positioned between the upper clamp plate and the lower clamp plate, the upper clamp plate and the lower clamp plate oppositely clamp the central panel, the lower surface of the upper clamp plate and the upper surface of the central panel are in clearance fit to form an upper fit plane, the upper surface of the lower clamp plate and the lower surface of the central panel are in clearance fit to form a lower fit plane, and high-pressure oil is pumped into gaps of the upper fit plane and the lower fit plane to form static-pressure oil films so as to form a static-pressure plane bearing mechanism. The invention can further improve performance (working frequency in particular), improve capability of resisting capsizing moment, simplify structure, and lower manufacturing difficulty and cost.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

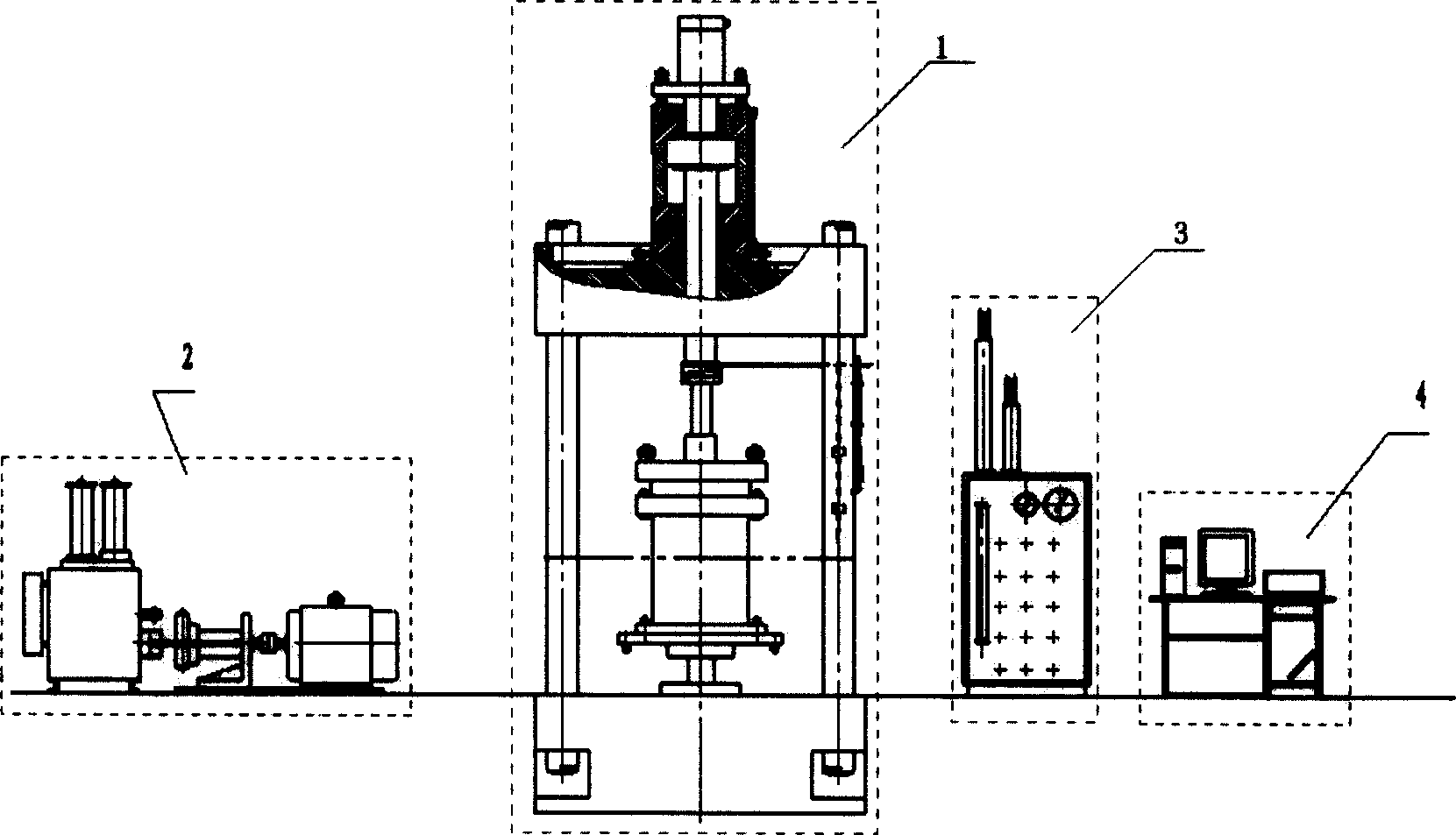

Large-sized multifunction material three-shaft static-dynamic test machine

InactiveCN1641350AIncrease profitHigh degree of automationEarth material testingStrength propertiesHydraulic cylinderMachine parts

The invention is a large-scale multifunctional material three-shaft static and dynamic tester, for providing a three-shaft static and dynamic tester for testing various materials, able to be adaptive to measure the mechanical performance of earth and stone and concrete materials, and also able to make separate seepage as well as seepage and stress coupling, and its characteristic: its main machine part includes side oil water exchange vat and serial water cylinder, side hydraulic cylinder driving the side oil water exchange cylinder,, seepage water cylinder, arranged at the bottom of the main machine and connected with the sample held in a three-shaft pressure room, and seepage hydraulic cylinder driving the seepage water cylinder, the serial water cylinder, is connected with the water path of the three-shaft pressure room through the side oil water exchange cylinder, the upper part of a piston rod driven by an axial vibration exciter is connected with the serial water cylinder and the lower part of the piston rod is connected with the sample held in the three-shaft pressure room. The tester of the invention has high rigidity, high measuring and control accuracy, multiple functions, and is extremely adaptive to material scientific research and engineering detection.

Owner:TSINGHUA UNIV +1

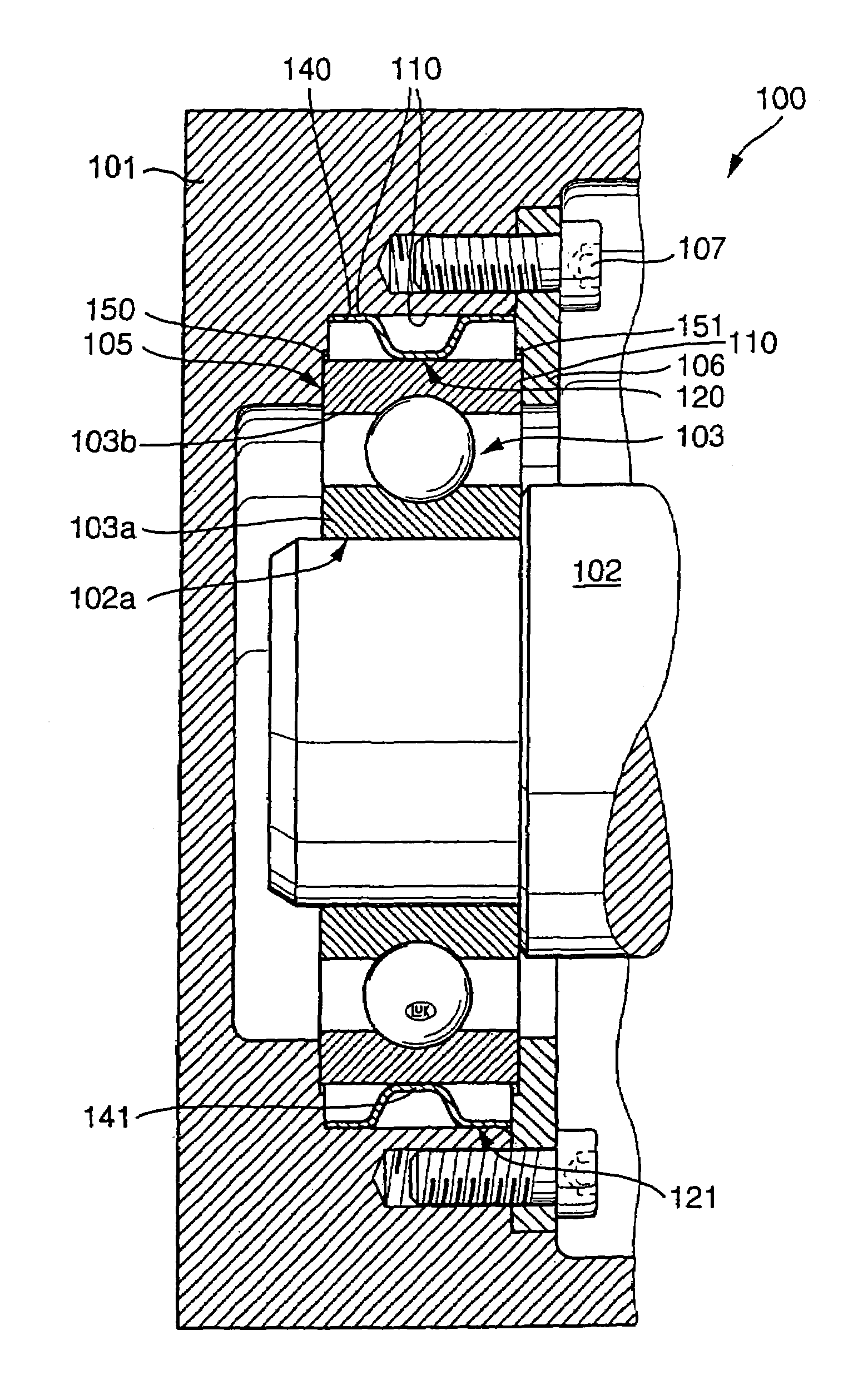

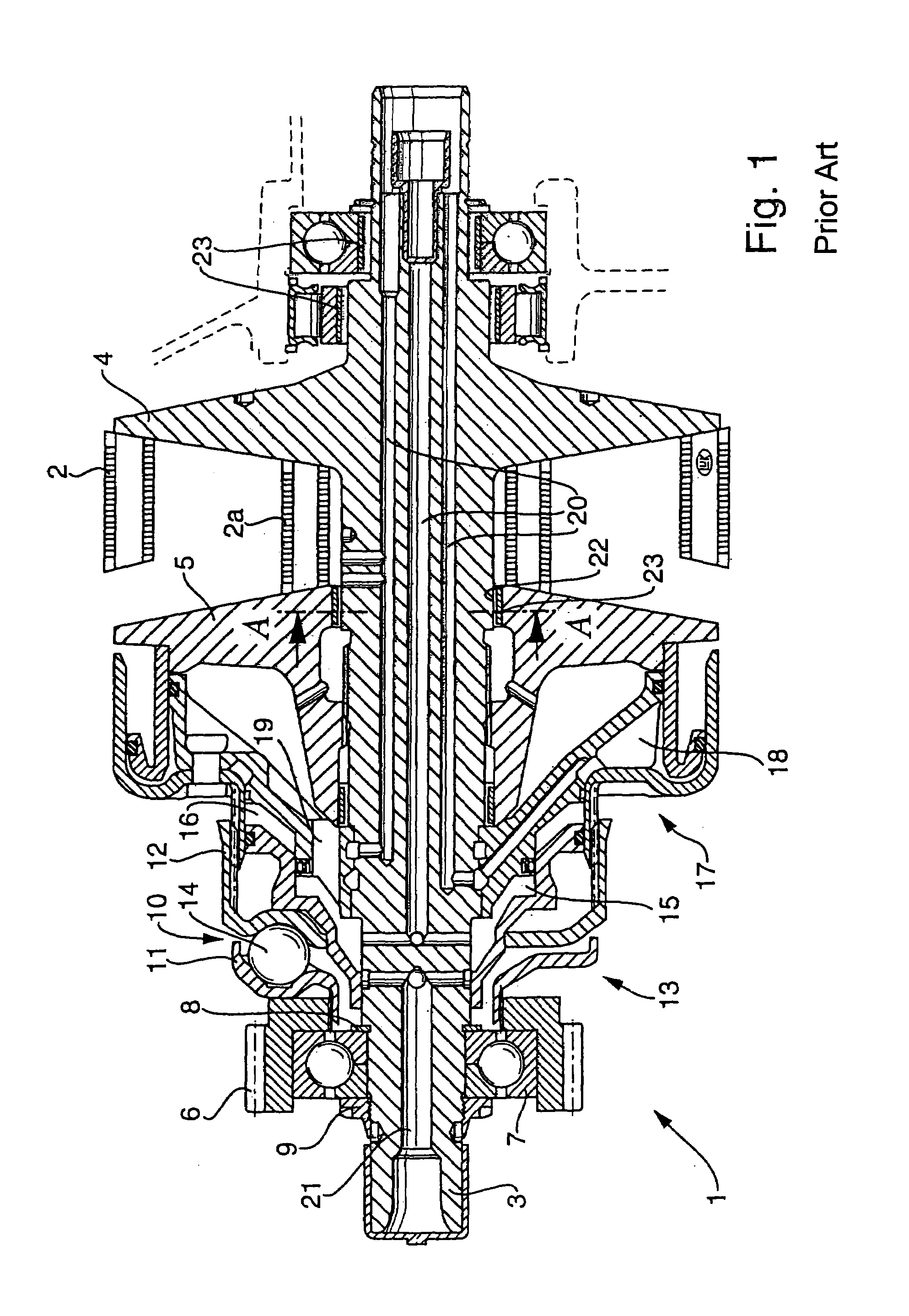

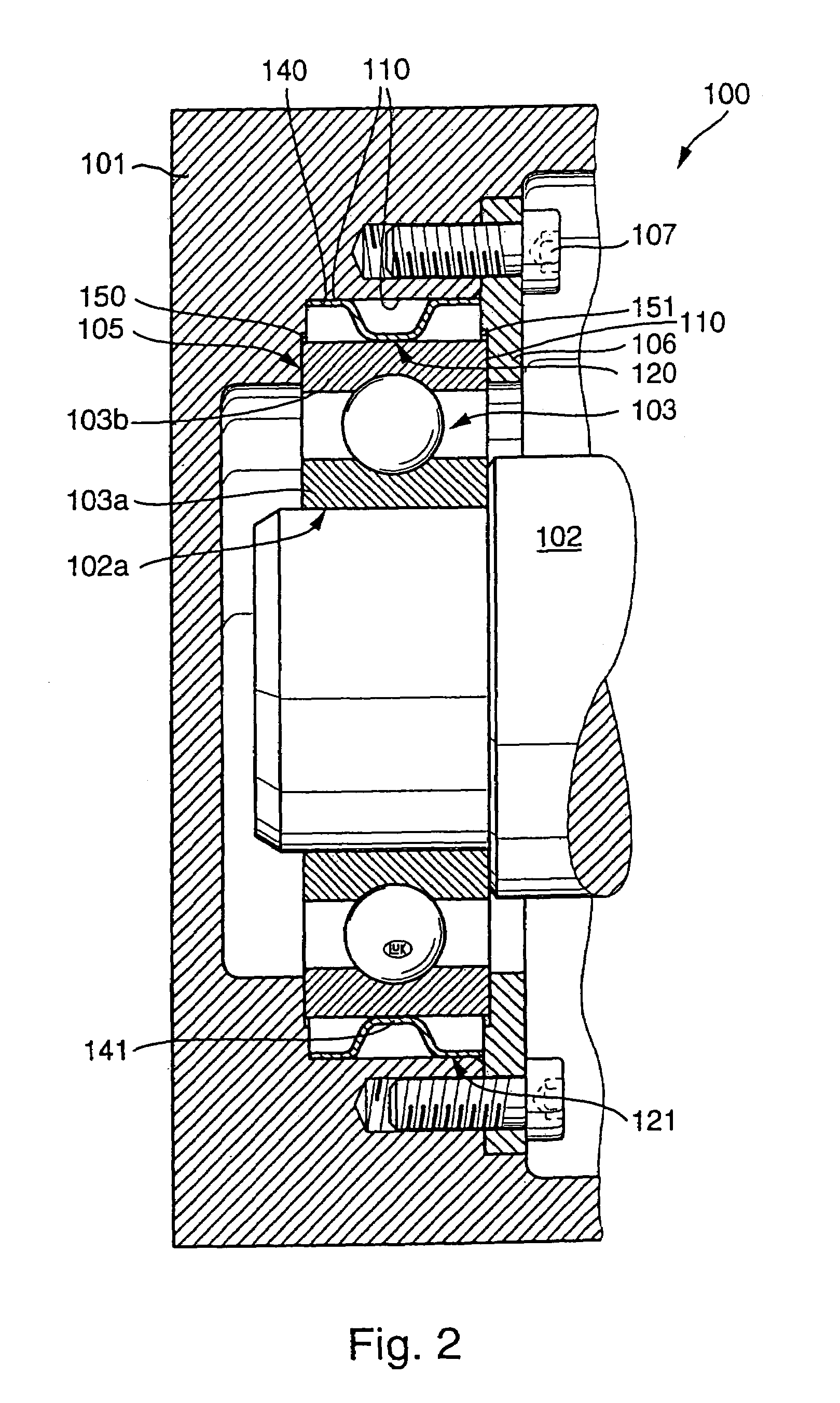

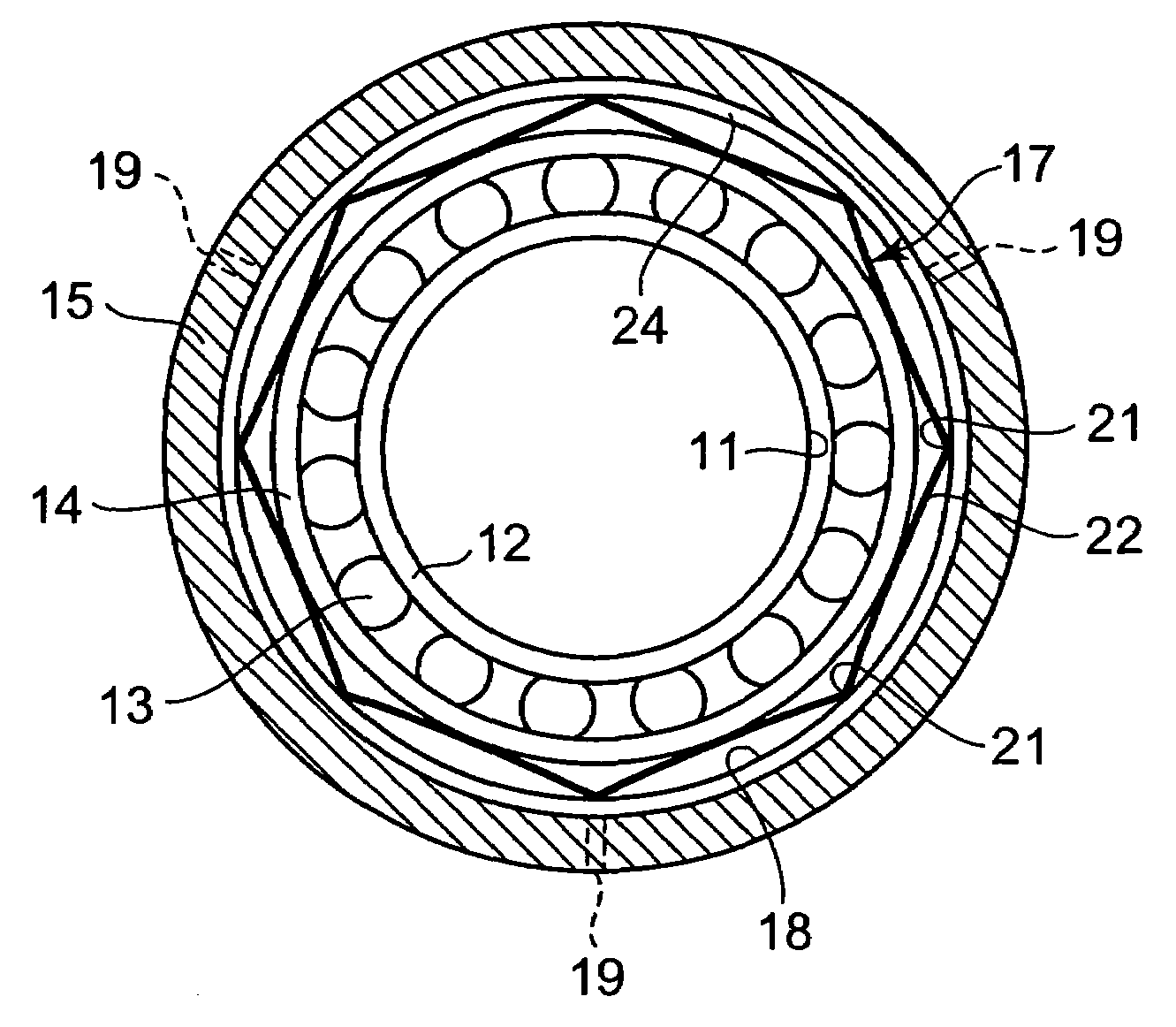

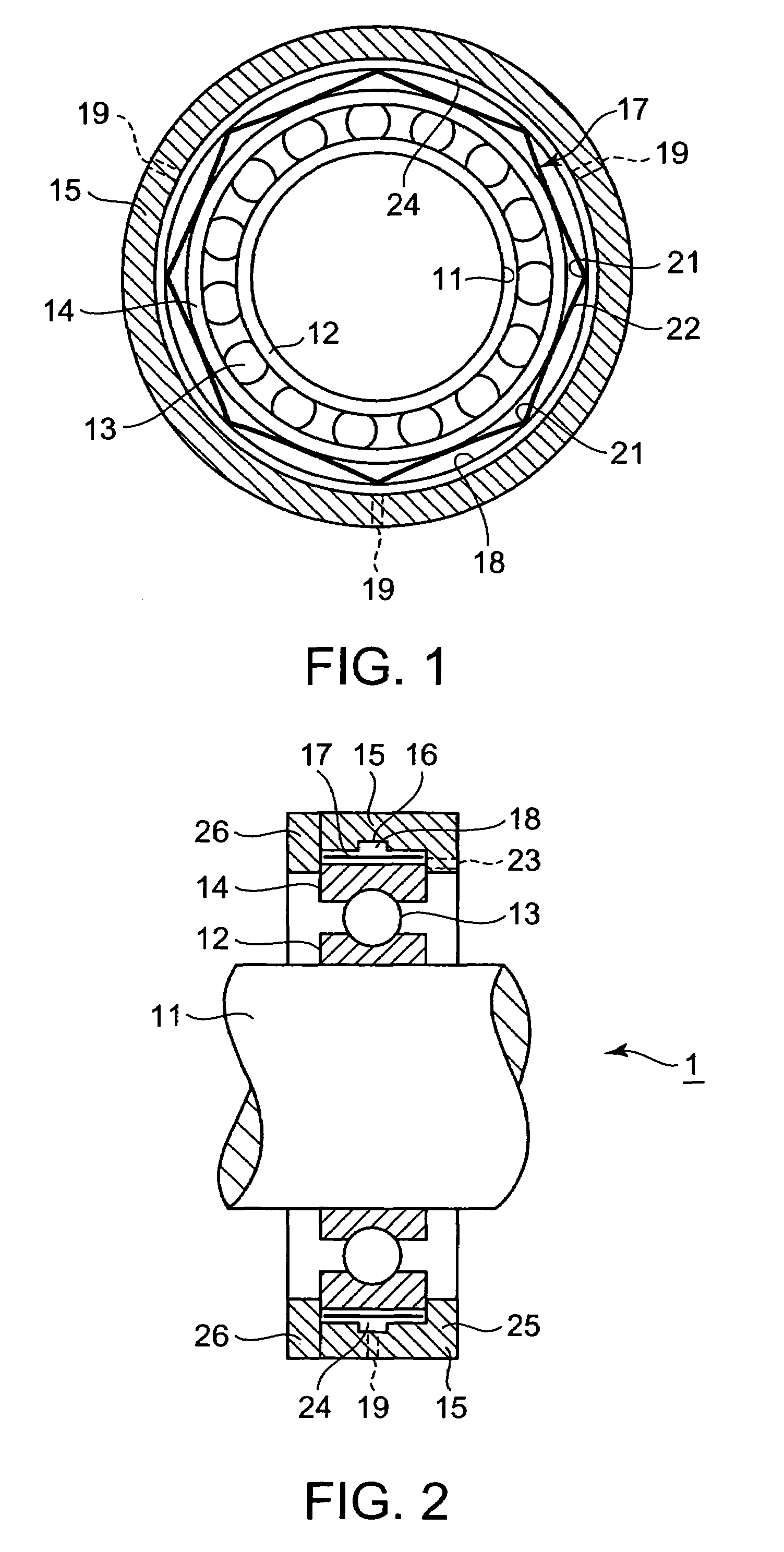

Bearing assembly

A bearing assembly including a bearing having an outer bearing ring and an inner bearing ring. The outer bearing ring is axially received in a bearing-receiving recess that includes a substantially cylindrical inner wall. An element that is radially flexible is located between at least one of the outer bearing ring and the inner wall of the recess, and the inner bearing ring and a rotatable member that is rotatably carried in the bearing assembly. The flexible element includes at least one annular element that is undulated in the radial direction, or is provided with projections. Flexible elements can also be disposed against a side surface of the bearing ring for damping axial vibrations.

Owner:SCHAEFFLER TECH AG & CO KG

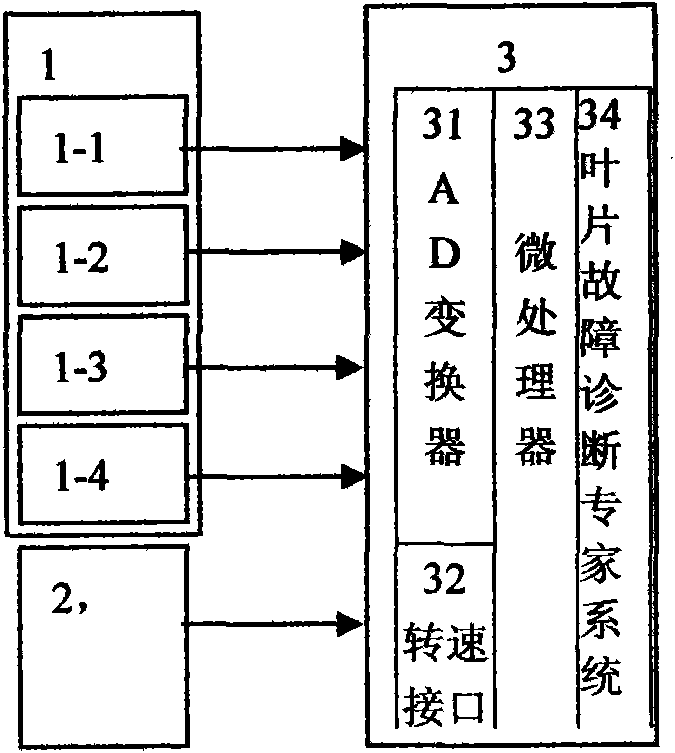

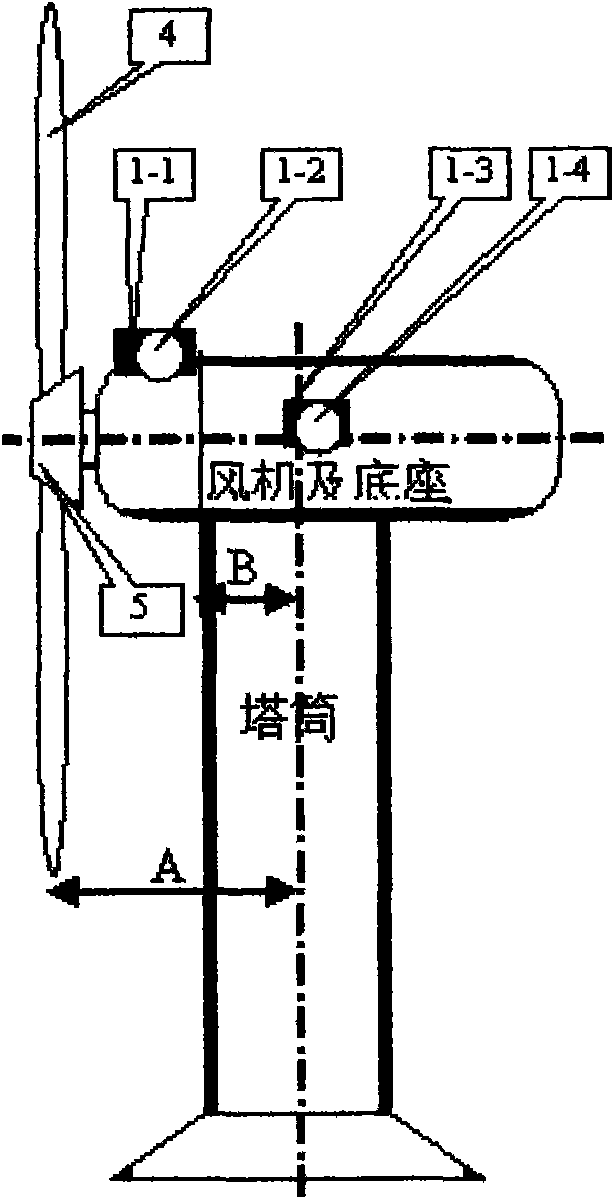

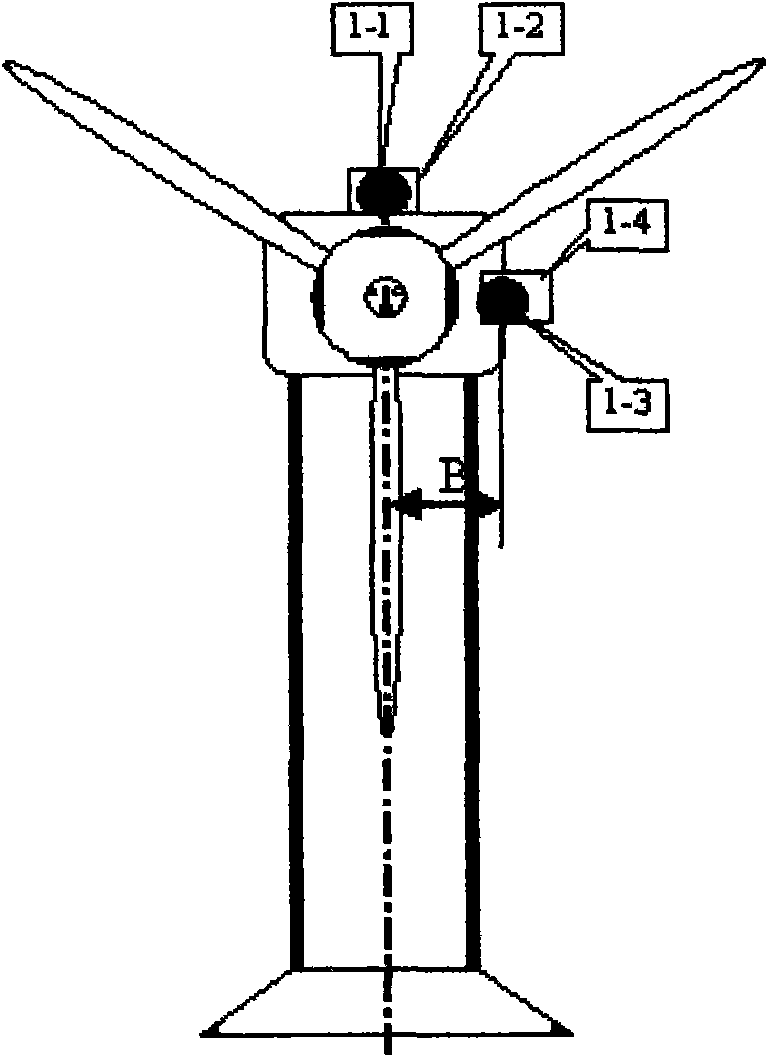

Fault indirect diagnosis technique of rotating blade

A fault indirect diagnosis technique of a rotating blade comprises a vibration impact sensor group which is installed on a static component of a blade machine, senses the vibration and impact caused by aerodynamic force and forcible touch and wear of rotor blades relative to static components and includes a rotational speed sensor for detecting operation frequency of the blade machine and a blade fault diagnosis device for analyzing signals reflecting blade fault information in the signals of the vibration sensor group relative to a signal rule of the rotational speed sensor, wherein the signals of the vibration impact sensor group including at least two vibration impact sensors and the signals of the rotational speed sensor with each rotator corresponding to one are connected to the blade fault diagnosis device, and blade fault diagnostician system software which is arranged in a microprocessor installed in the blade fault diagnosis device is used for diagnosing blade faults through vibration signals and rotational speed signals. The FFT analysis of the transverse vibration shock P of the blade machine in operation, the axial vibration shock Y of the blade machine and the torsional vibration NZ of a hanging or support device of the blade machine, and the analysis of the rotational speed frequency FN of the rotor are performed for recognizing blade faults by combining a computer technique with an electric sensor and the fault diagnostician system software. Various defects of prior art can be overcome.

Owner:北京唐智科技发展有限公司

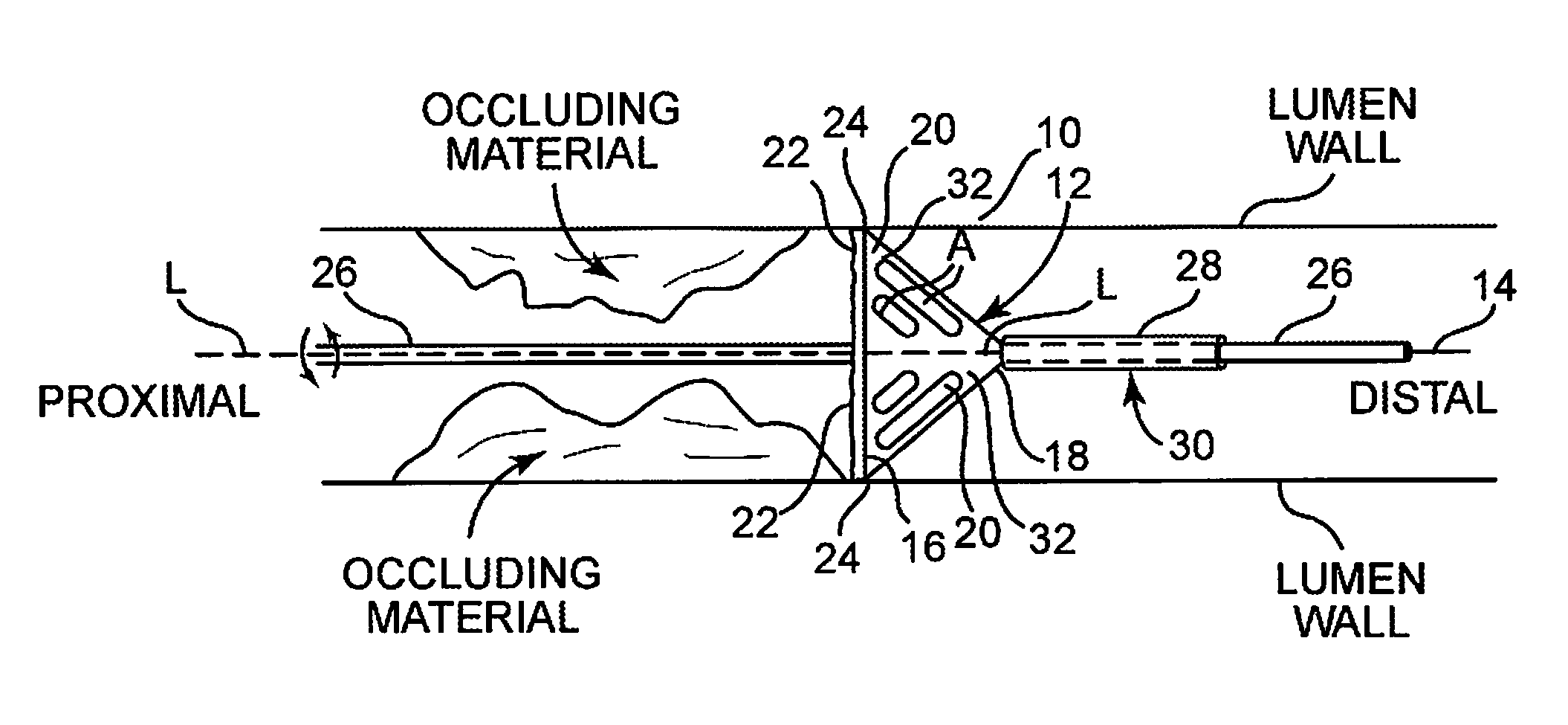

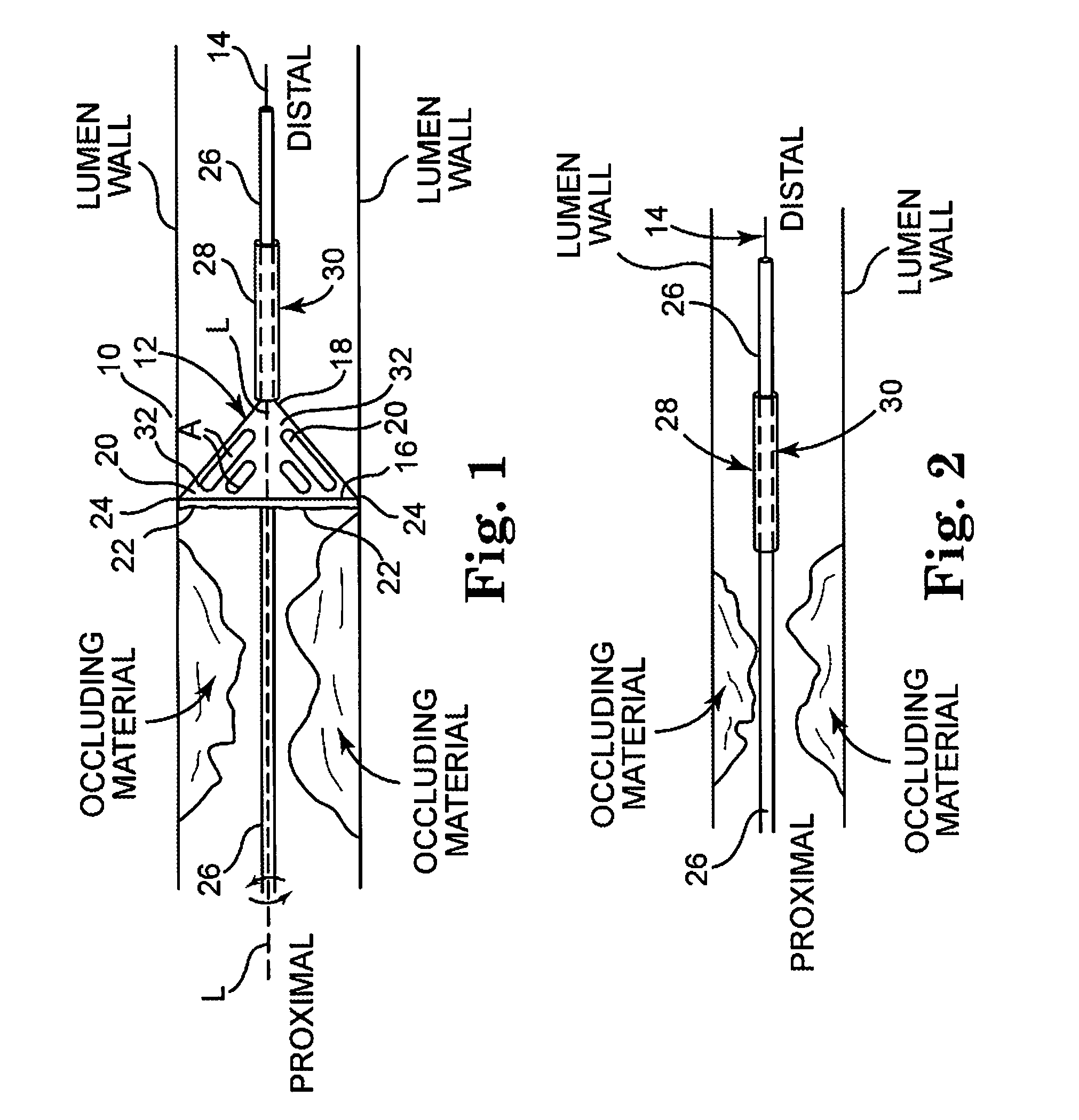

Cutting and coring atherectomy device and method

Owner:CARDIOVASCULAR SYST INC

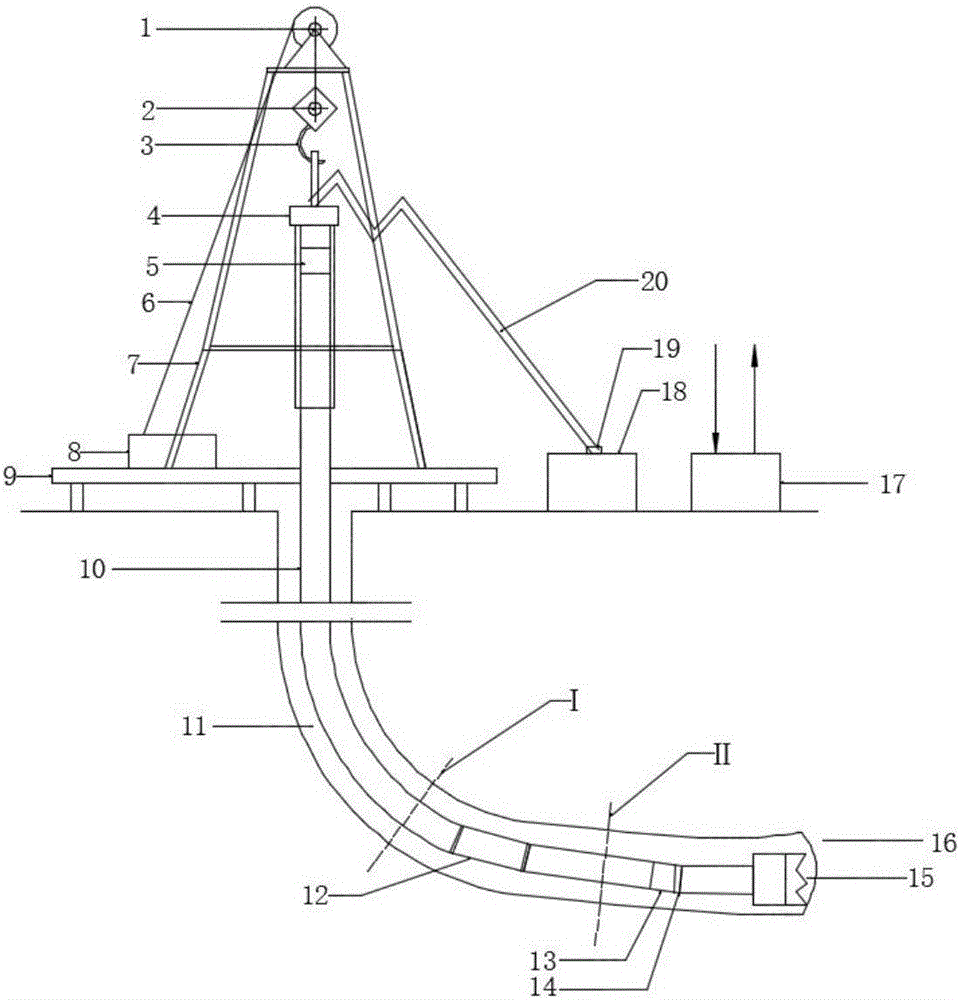

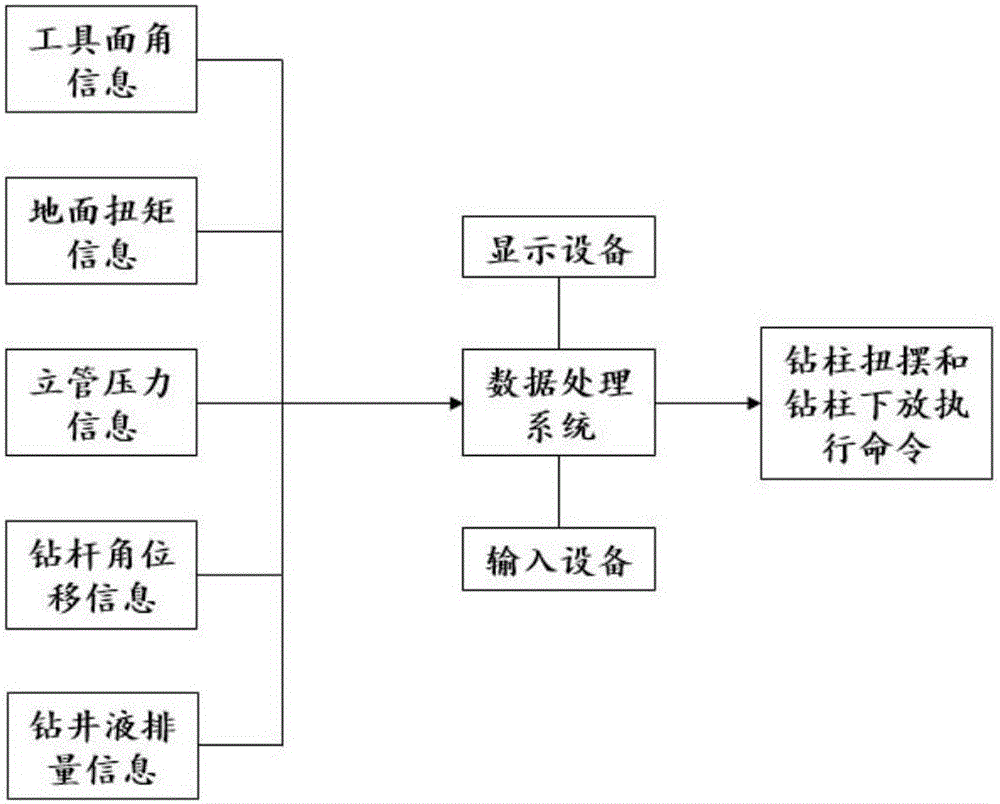

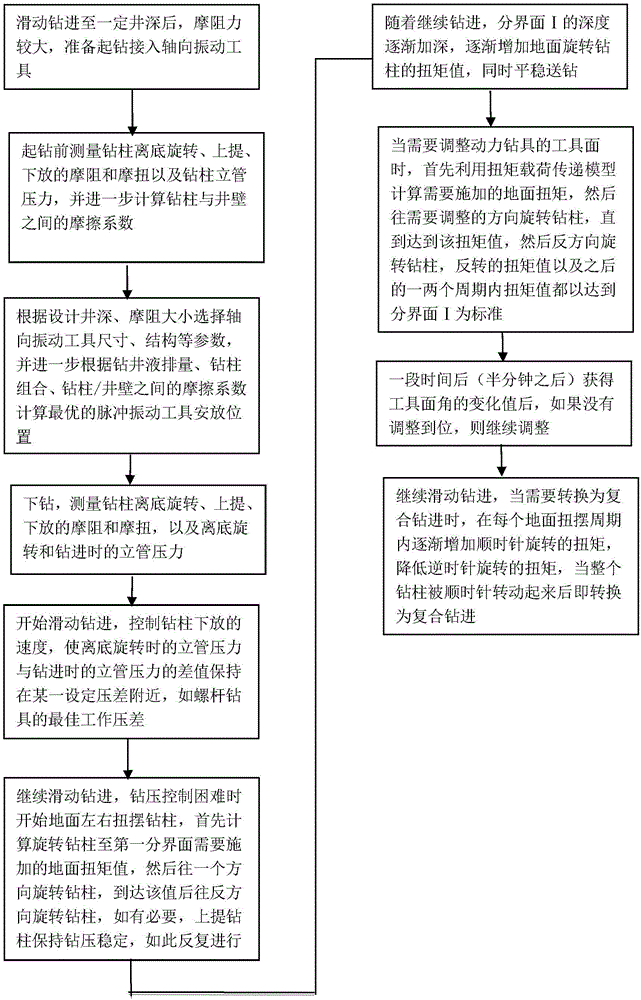

Complex structural well friction resistance reduction and power drill tool face adjusting method

InactiveCN106437513AReduce frictional resistanceReduce resistanceDrilling rodsDirectional drillingTop driveWell drilling

The invention belongs to the technical field of well drilling, and relates to a complex structural well friction resistance reduction and power drill tool face adjusting method. A whole originally pure sliding drilling string is divided into three portions, the upper portion of the drilling string rotates in a reciprocating manner under the action of torque applied by a surface well drilling top drive, the middle of the drilling string axially vibrates / creeps under the action of an axial vibration resistance reduction tool, and static friction between the drilling string and a well wall is transformed into dynamic friction, so that axial feeding resistance of the drilling string is reduced. A drill bit on the lower portion of the drilling string can axially vibrates, so that bit pressure fluctuates, rock breaking torque and reaction torque fluctuate, the fluctuating reaction torque acts on the lower portion of the drilling string close to the drill bit, the lower portion of the drilling string rotates in a reciprocating manner, and friction resistance can be reduced. The method is convenient in operation and scientific in principle, power drill tool face adjusting time can be saved, drilling is continued while a tool face is adjusted, the drilling efficiency of a complex structural well, particularly the complex structural well with long horizontal displacement is improved, and well drilling cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Bearing vibration damping mechanism

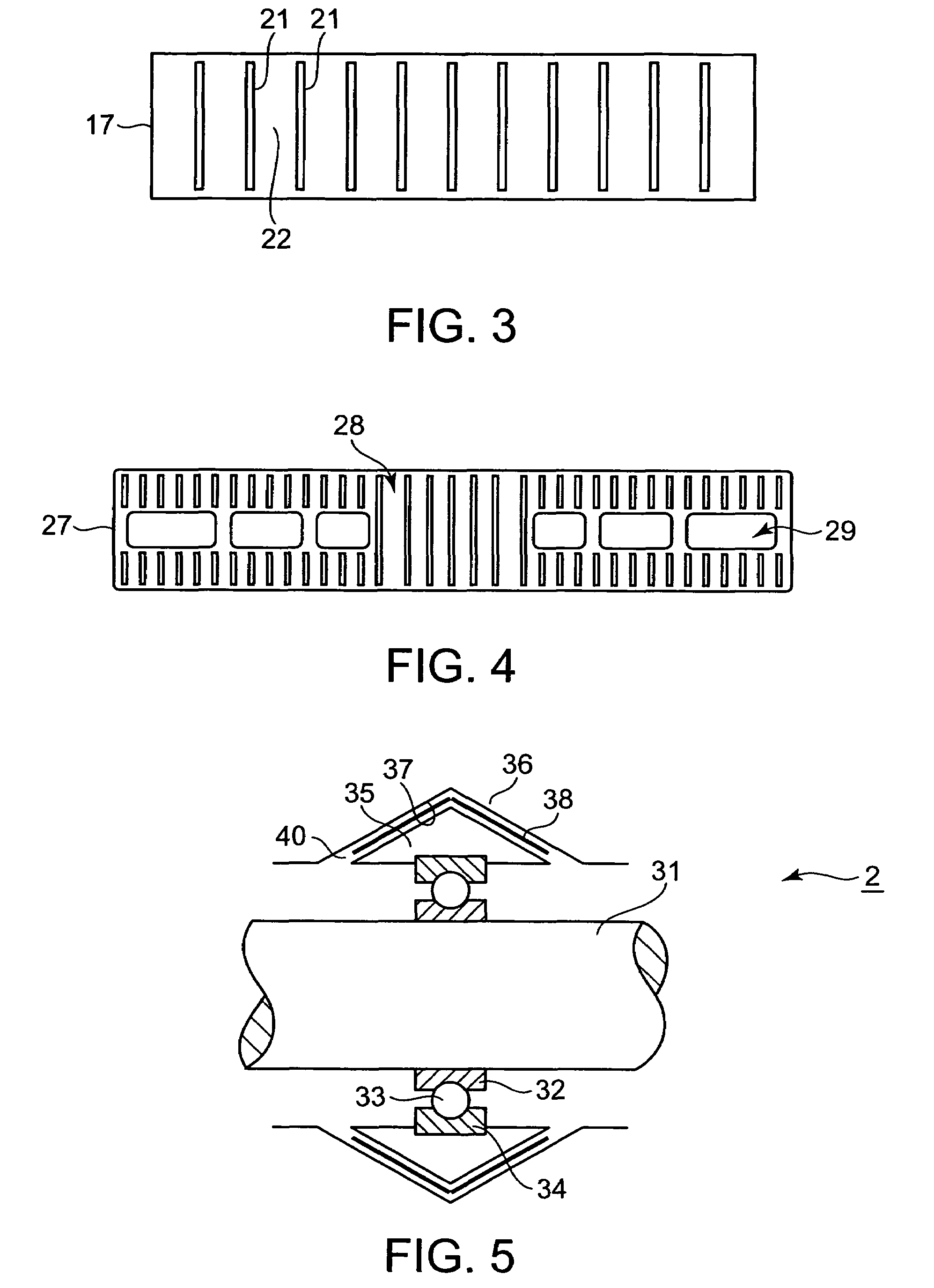

ActiveUS7628542B2Easy to produceReduce vibrationLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

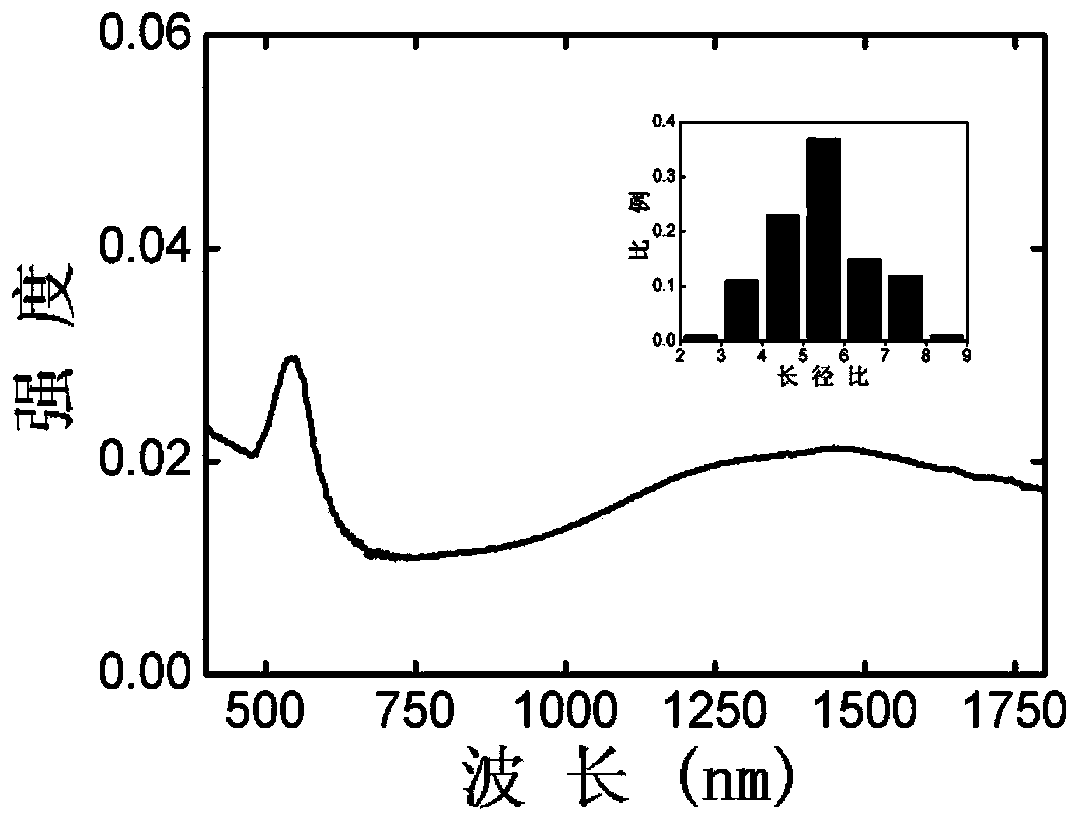

Saturable absorber based on plasmon axial vibration mode

The invention relates to a saturable absorber based on a plasmon axial vibration mode and belongs to the technical field of pulse laser. The invention particularly relates to a novel saturable absorber which consists of gold nanorods and film forming agent and can be used for mode-locked fiber lasers. The saturable absorber based on the gold nanorods can be prepared by adopting the method which comprises the steps of mixing the gold nanorod water dispersion and film forming agent water solution according to a molar ratio of (8-133):1, and performing ultrasonic dispersion for 2-5hours; and finally spin-coating the mixed solution on surfaces of flat silicon wafers and naturally drying the silicon wafers in a vacuum closed container till films are formed. The output of pulse laser at a near-infrared band is realized by using the unique longitudinal surface plasma resonance absorption characteristic of the gold nanorods. The saturable absorber based on the plasmon axial vibration mode enables the types of saturable absorbers to be expanded and can be widely used for mode locking of lasers at a visible-near infrared band.

Owner:JILIN UNIV

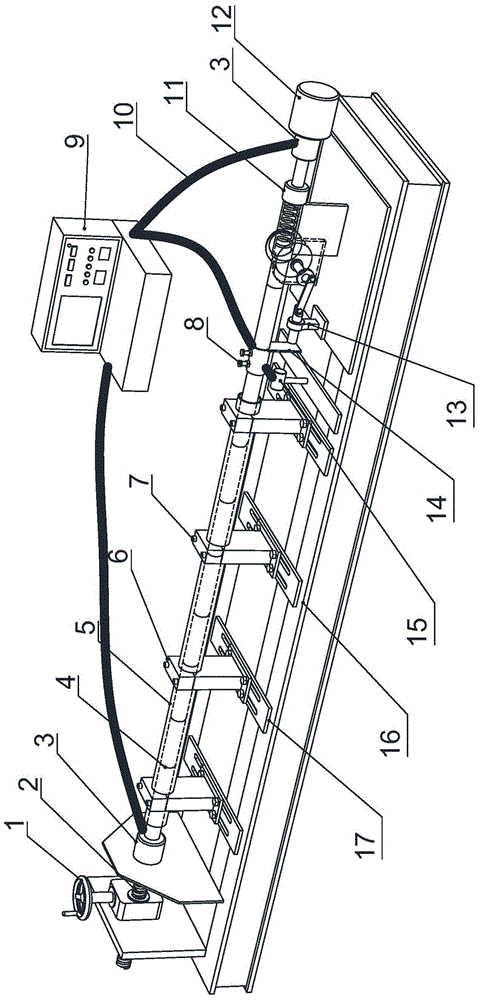

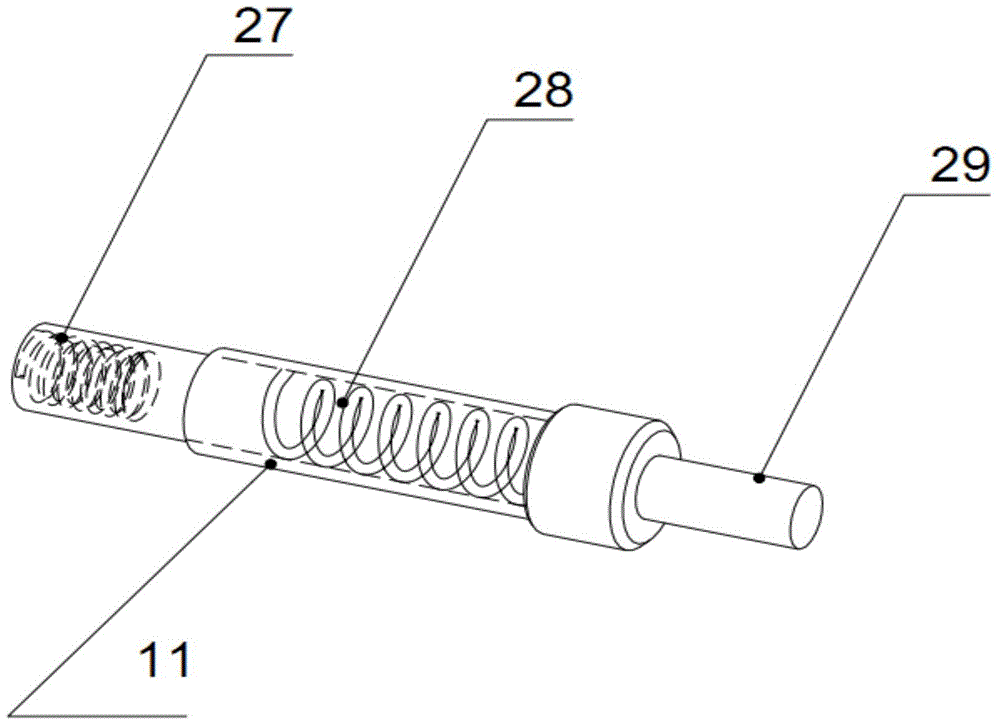

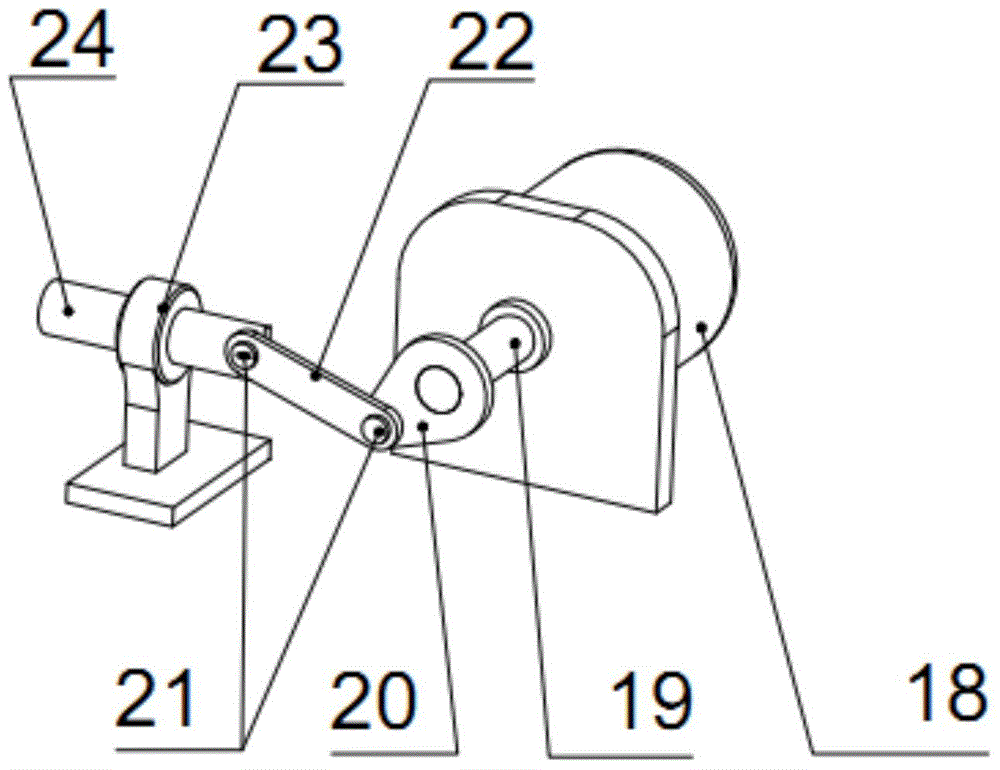

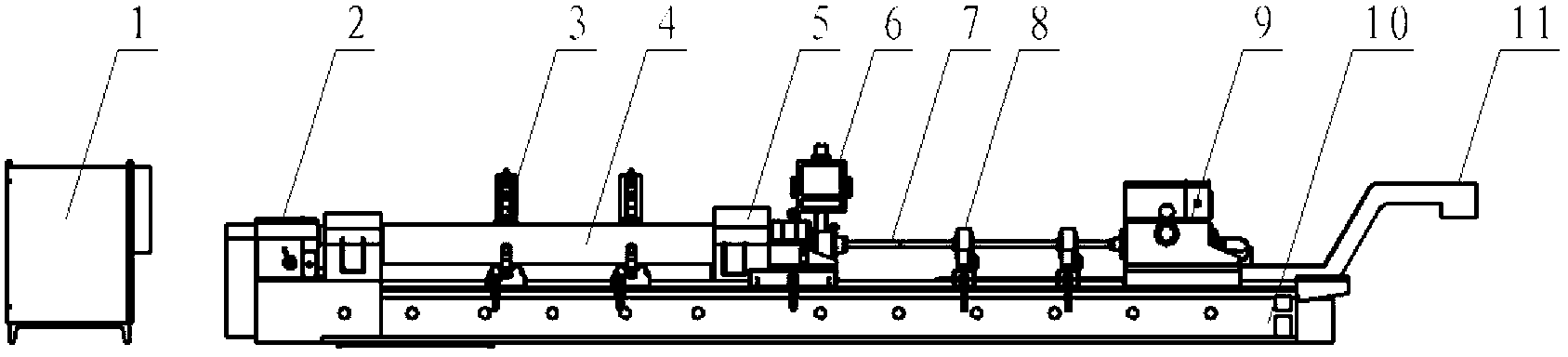

Indoor experimental device for antifriction resistance property of axial vibration of petroleum drilling pipe column

The invention discloses an indoor experimental device for antifriction resistance property of axial vibration of a petroleum drilling pipe column. The device comprises a simulated pipe column combination system, a loading system, a vibration system, a measurement system and a fixing system, wherein the simulated pipe column combination system comprises a simulated pipe column and a simulated shaft; the loading system comprises a loading hand wheel and a loading lead screw; the vibration system comprises a telescopic sleeve, a simulated vibration exciter and an impact baffle; the measurement system comprises pressure and displacement sensors, a data processing device, signal cables and a displacement sensor; the fixing system comprises a fixing bracket, fastening bolts, positioning bolts, a fixing piece, an experimental table and an open-groove bottom plate. The indoor experimental device can be used for researching the antifriction resistance property and mechanism of an axial vibration tool under the conditions of different wellbore curvatures, mounting positions, vibration amplitudes and frequencies, and provides a theoretical basis for design and field application of a special downhole tool for antifriction resistance of axial vibration.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

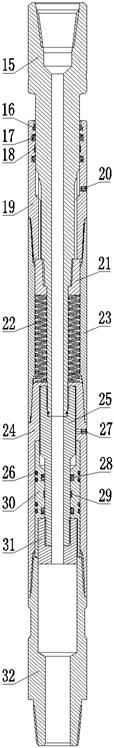

Pressure resistant tool for reducing frictional resistance of horizontal well section

ActiveCN102587832AStrong axial vibration capabilityEffective destructionDirectional drillingBorehole drivesUpper jointDrive shaft

The invention relates to a pressure resistant tool for reducing frictional resistance of a horizontal well section, which is used for reducing the frictional resistance of the horizontal well section and improving horizontal section extending and drilling capacity. The technical scheme includes: the pressure resistant tool for reducing the frictional resistance of a whole well consists of a pulse part and a vibration part. The pulse part mainly comprises an upper joint, a power part, an upper abrasion-resistant block, an upper fixing sleeve, a lower abrasion-resistant block, a lower fixing sleeve, a lower valve and a lower joint. The vibration part mainly comprises a spline transmission shaft, a spline righting tube, a locking nut, a disk spring, a supporting shell, a piston rod, a piston bush, a piston nut and a pulse pup joint. The vibration part is in threaded connection with the upper end of the pulse part. The overall overflowing area of a valve part driven by a motor rotor is gradually reduced, and fluid energy is converted into a series of pulse pressure to be transmitted to the vibration part. The pressure resistant tool has the advantages of high axial vibration capacity and simple structure, the frictional resistance between a drill stem and the well wall can be reduced, and the horizontal well and large-displacement well horizontal section extending and drilling capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Vibration systems and methods

ActiveUS9108211B2Simple and inexpensive to manufactureEfficient transferRespiratorsMovable spraying apparatusAxial vibrationMechanical engineering

In one arrangement, a vibration system includes a vibratable plate, a support member surrounding the vibratable plate, and a vibration-inducing member surrounding the support member. The vibration-inducing member is configured to radially expand and contract against the support member so as to produce axial vibration of the vibratable plate. In another arrangement, the vibratable plate has an outer circumference; a tubular member is concentrically disposed about the outer circumference of the plate, and an annular vibration-inducing member is concentrically disposed about the outer circumference of the tubular member. The vibration-inducing member is preferably a piezoelectric ring that is radially expandable and contractable against the wall of the tubular member to cause the plate to vibrate in the axial direction.

Owner:STAMFORD DEVICES LTD

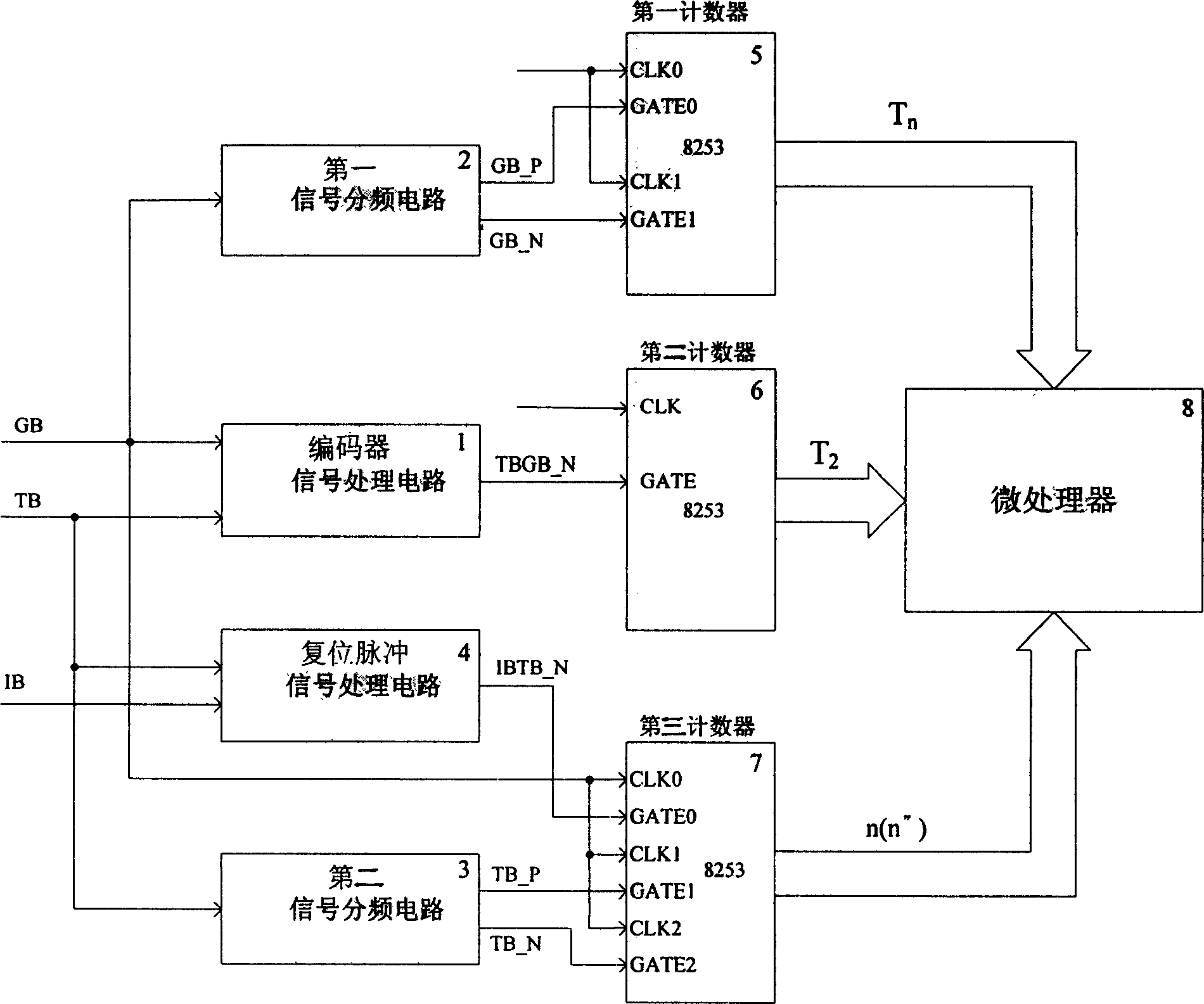

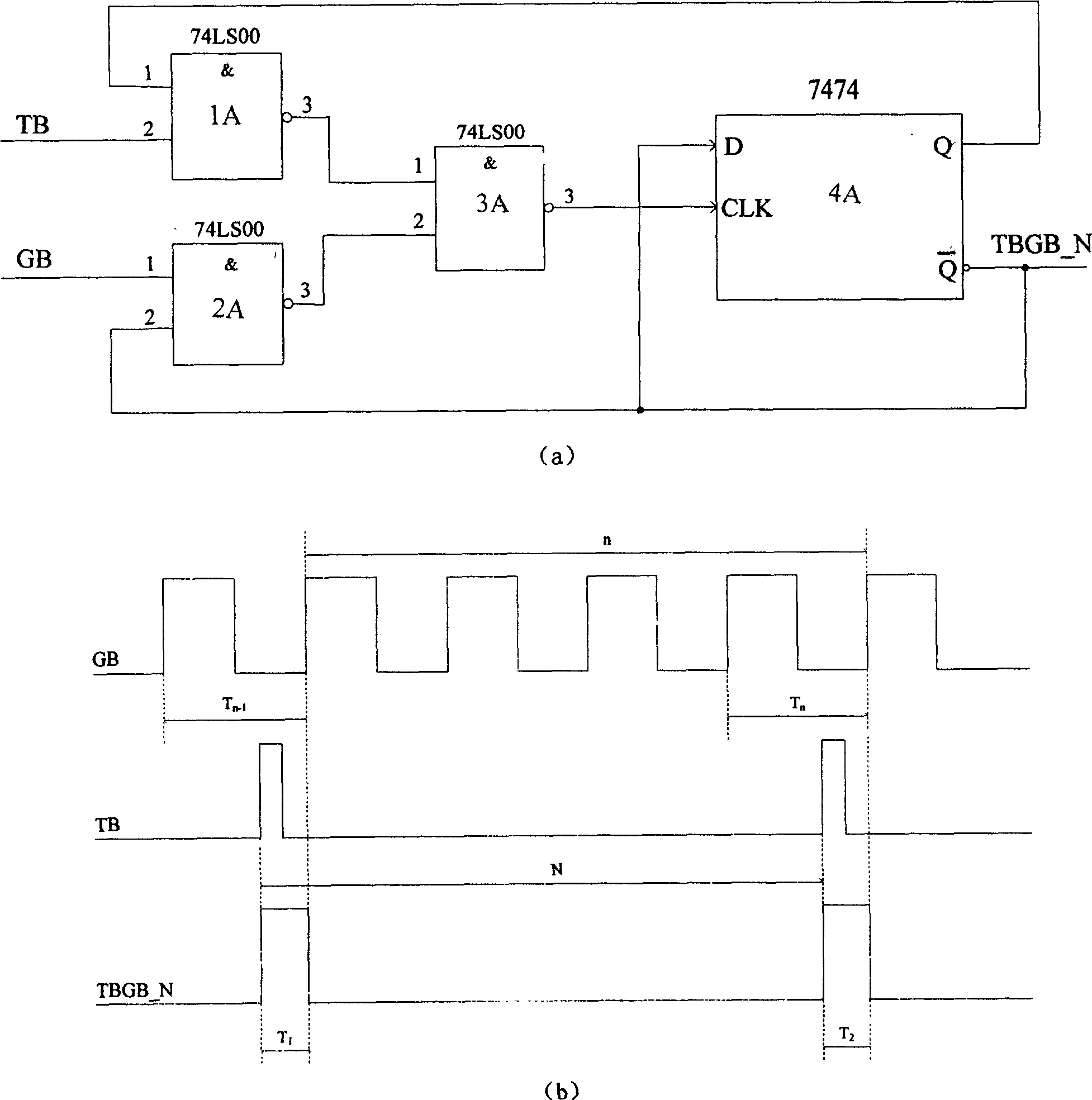

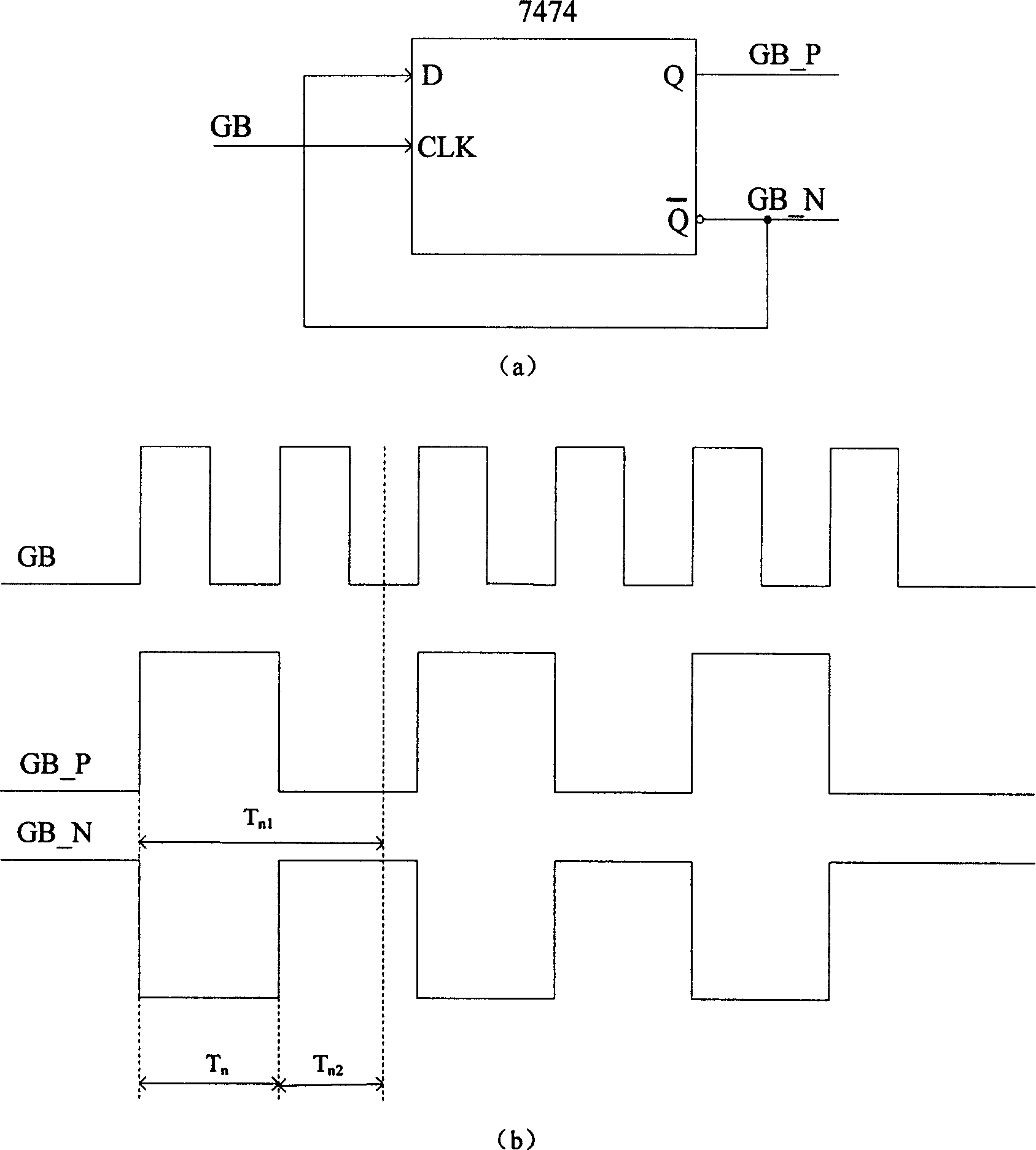

Comprehensive measuring method and circuit for electric motor rotating speed and rotor location

InactiveCN1645737AEliminate errorsHigh measurement accuracyDevices using electric/magnetic meansConverting sensor output electrically/magneticallyMeasurement deviceElectric machine

The method gets the periodic signal and compound signal of encoder through processing the pulse signal, reset signal from encoder and measurement period signal given by measuring man. By using the formula raised by the invention, the MPU can figure out the rotate speed of motor and the position of rotor. The invention can also remove the measuring error for motor caused by radial and axial vibration.

Owner:浙江大学三伊电气电子工程公司

Composite activator used for vibration-cutting

InactiveCN1861274AReduce and eliminate adverse effectsEasy to manufactureMechanical vibrations separationLarge fixed membersCouplingDrive shaft

A combined vibration exciter for vibration cutting is composed of casing, frequency varying unit, motor, shaft coupling, drive shaft, bevel gear set, vertical shaft, crank-slide block unit, dual-eccentric unit, vibration isolating unit, spring, central shaft, flat key and flange shaft. It can transform a rotation movement to an adjustable vibration consisting of a torsional vibration and an axial vibration.

Owner:JIANGSU UNIV

Plane static pressure type vibration transferring and decoupling device and tri-axial vibration composite experiment table

ActiveCN102865987AGood axial rigidityIncreased anti-overturning momentVibration testingHigh pressureAxial vibration

The invention relates to a tri-axial vibration composite experiment table and a plane static pressure type vibration transferring and decoupling device, wherein the experiment table comprises a working table top; and plane static pressure type vibration transferring and decoupling devices and vibration generators are connected in the direction of X, Y and X axes of the work table top. The plane static pressure type vibration transferring and decoupling device is characterized by consisting of a sliding block and a sliding seat via sliding connection; a sliding gap is arranged in a sliding surface; during the work, high-pressure oil is filled in the sliding gap through an oil filling channel to form a static pressure oil slick; as the static pressure oil slick has good rigidity under high pressure conditions, the sliding between the sliding block and the sliding seat is not obstructed. When a coaxial vibration generator generates high-frequency vibration and thrust, the vibration frequency and the thrust are transferred through a direction vertical to the static pressure oil slick; when a hetero-axial vibration generator generates high-frequency vibration and thrust, the decoupling is realized through the sliding between the sliding block and the sliding seat, so that the aim of combining the lossless transferring and the effective decoupling is realized to the greatest extent.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

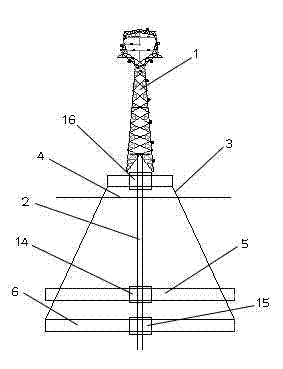

Swing aeroelastic model and shock-test wind tunnel test method thereby

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

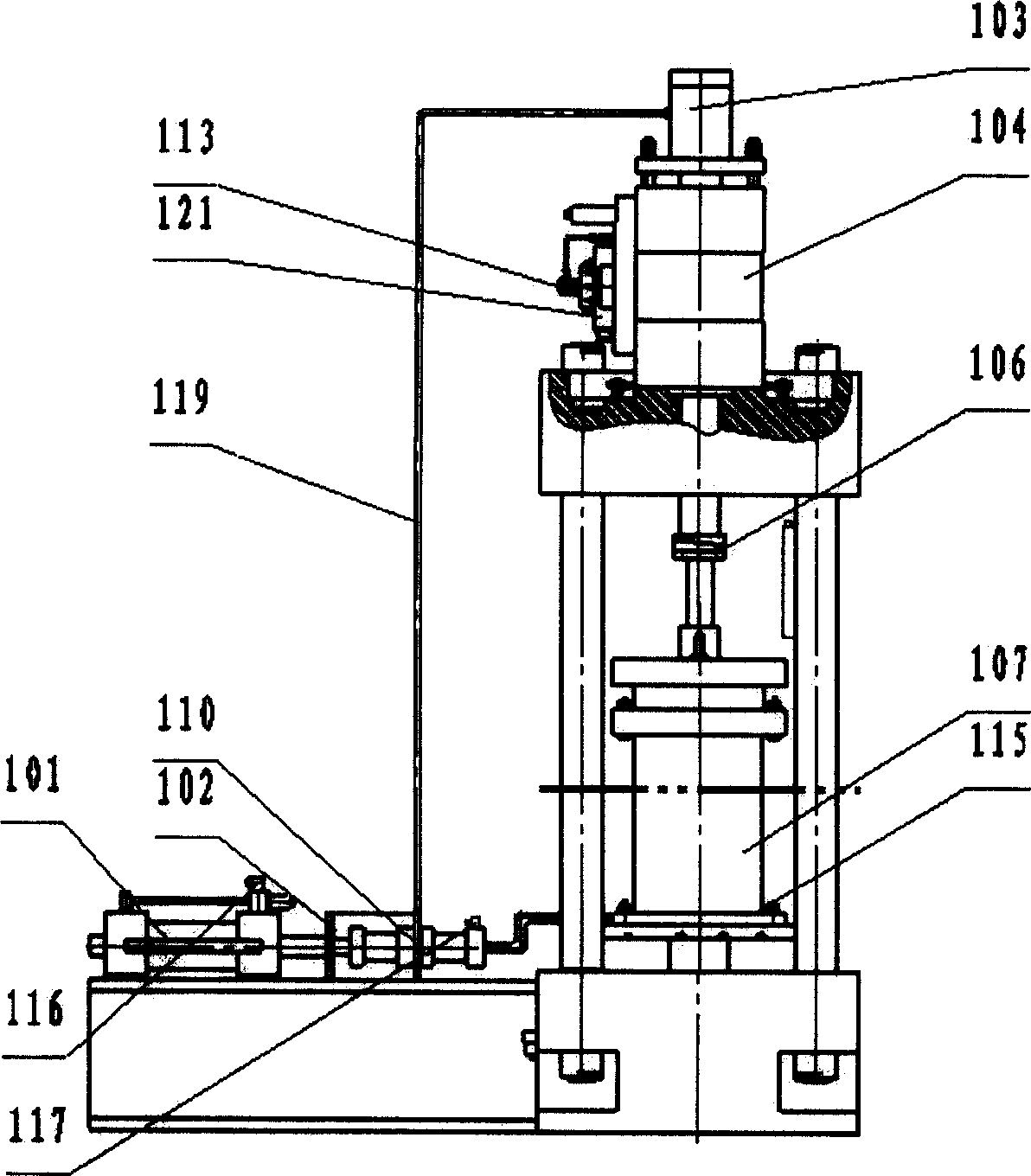

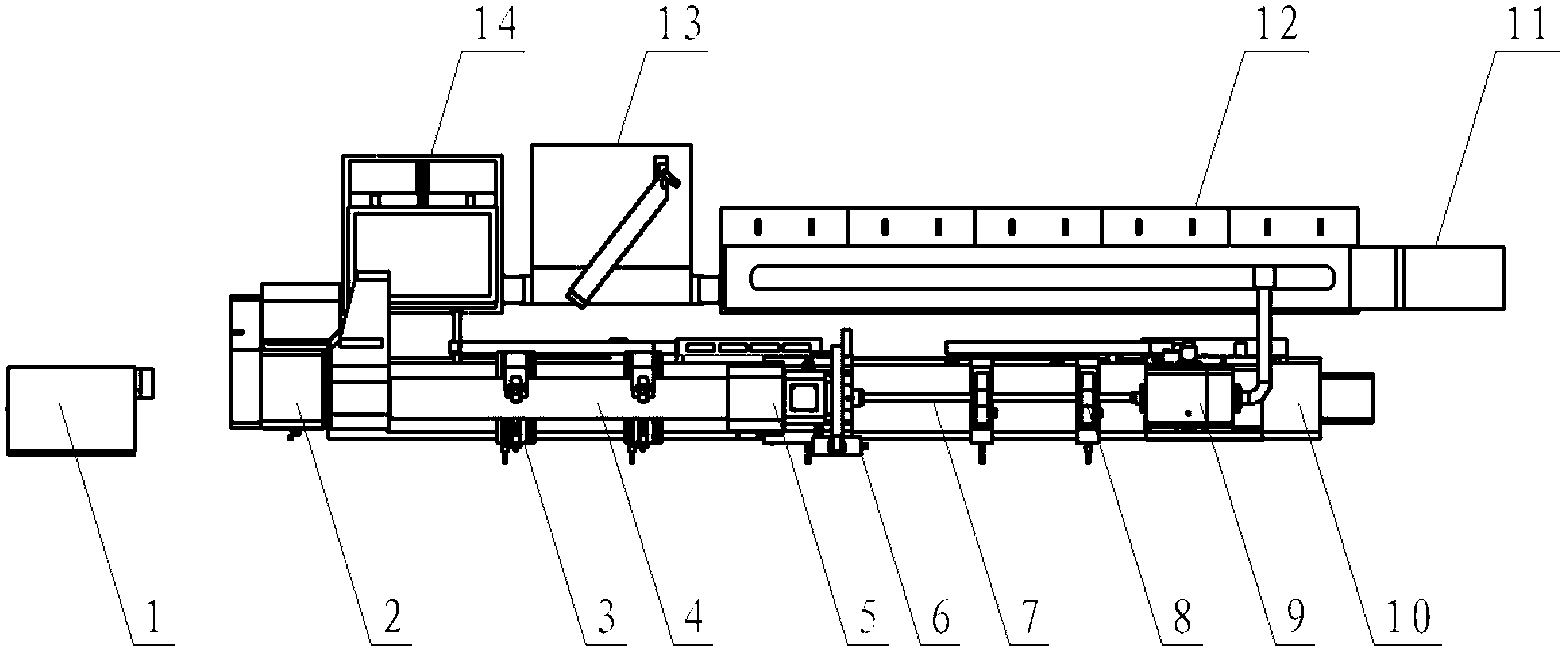

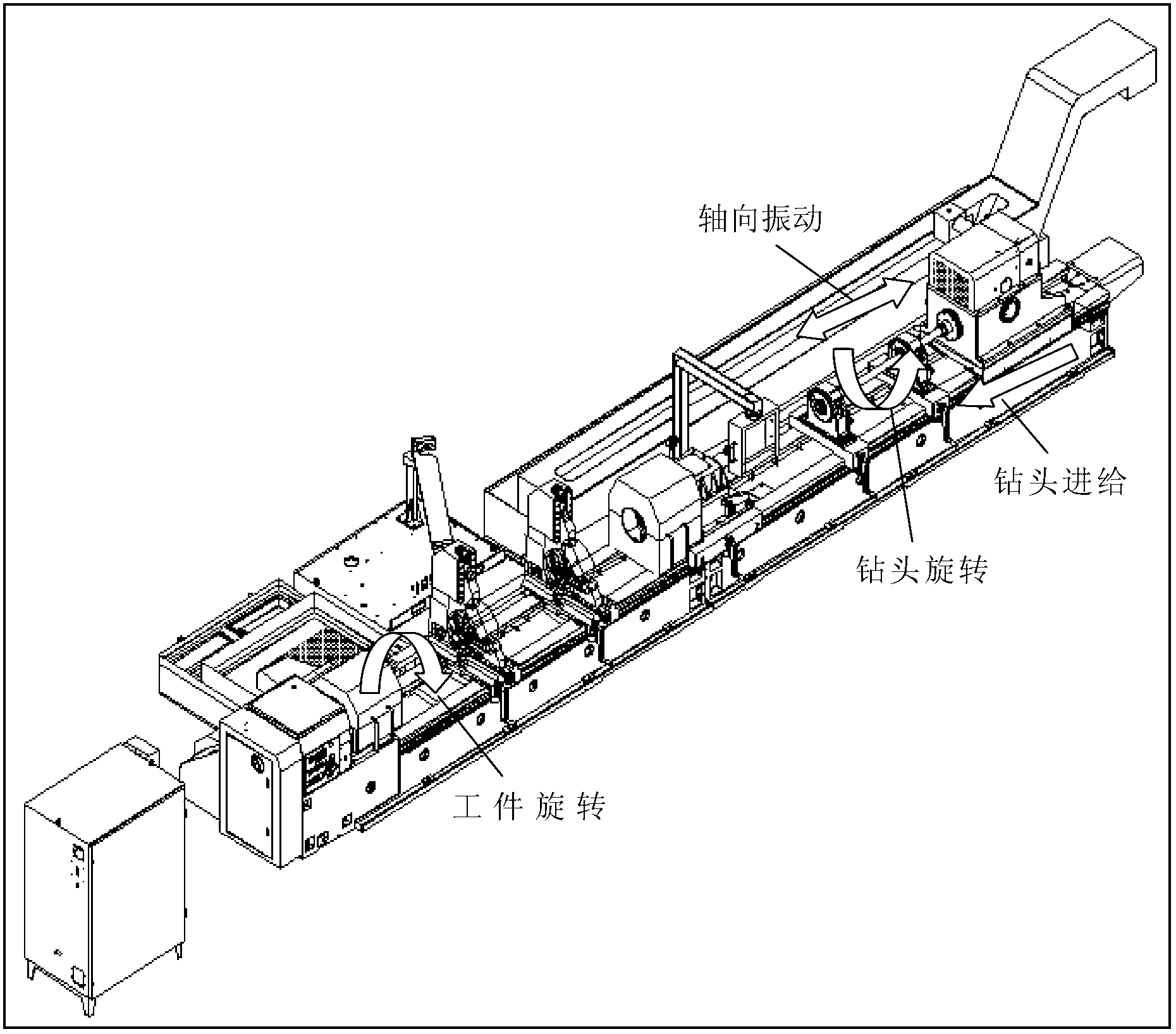

Numerical control vibration deep-hole drilling and boring machining equipment and method

InactiveCN102699375AImprove roundnessImprove straightnessBoring/drilling componentsMaintainance and safety accessoriesNumerical controlAxial vibration

The invention discloses numerical control vibration deep-hole drilling and boring machining equipment, which is characterized by comprising a workpiece arranged on a machine tool body, a drill bit and a drill stem, wherein the workpiece is driven by a main motor to rotate; and the drill bit is driven by the motor to rotate along with the drill stem and is simultaneously driven by a servo reducing motor and a vibration motor to make numerical control feed movement and axial reciprocating vibration. By the deep-hole drilling and boring equipment, the functions of rotating the workpiece and the drill bit in a bidirectional mode and axial vibration drilling can be realized, the severe working conditions and the lubricating effect of a cutting area of the drill bit are improved, the cuttings are automatically controlled, the process range of the equipment is greatly widened, the machining precision indexes of the holes such as roundness and straightness are improved, and the hole machining quality and efficiency are improved further; and moreover, the problem of chip breakage and removal in the prior art is solved, the cuttings can be automatically separated, collected and conveyed, automation of the drilling process is realized, and the equipment can be widely applied to the field of machining of rotary deep-hole parts.

Owner:XIAN UNIV OF TECH

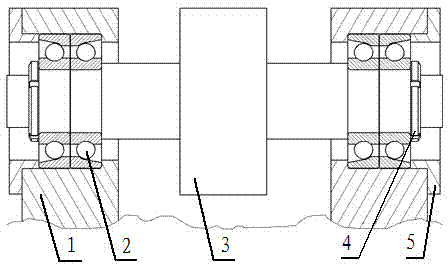

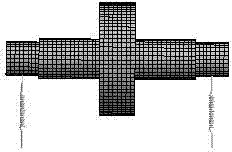

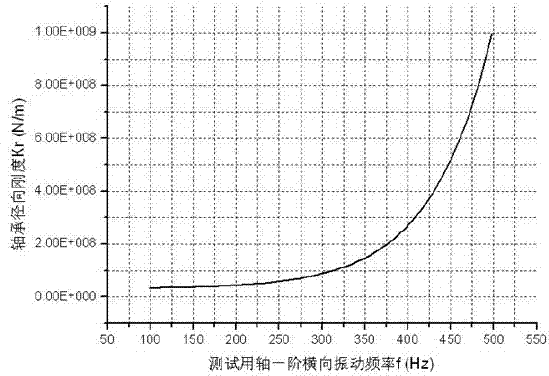

Dynamic measurement method for radial stiffness and axial stiffness of bearing

InactiveCN102889990AMeasuring Radial StiffnessMeasuring Axial StiffnessMachine bearings testingMeasurement testPhysical system

The invention belongs to the technical field of mechanical measurement and is applicable to measurement of radial stiffness and axial stiffness of bearings. The measurement principle is based on a relationship between the bearing stiffness and inherent vibration frequency of a shaft for test. The method comprises the following steps of: in the process of measuring the radial stiffness of the bearing, solving a function relationship between the radial stiffness of the bearing and the first-order transverse vibration frequency of a shaft for test, building a physical system among the shaft for test, a measured bearing and a rigid support, measuring the first-order radial vibration inherent frequency of the shaft for test, and finally, calculating the radial stiffness of the bearing according to a function relationship between the inherent vibration frequency and the radial stiffness of the bearing; and in the process of measuring the axial stiffness of the bearing, solving the mass of the shaft for test, building a physical system among the shaft for test, the measured bearing and the rigid support, measuring the first-order axial vibration inherent frequency of the shaft for test, and finally, calculating the axial stiffness of the bearing according to a relationship between the vibration inherent frequency and the axial stiffness of the bearing.

Owner:马会防

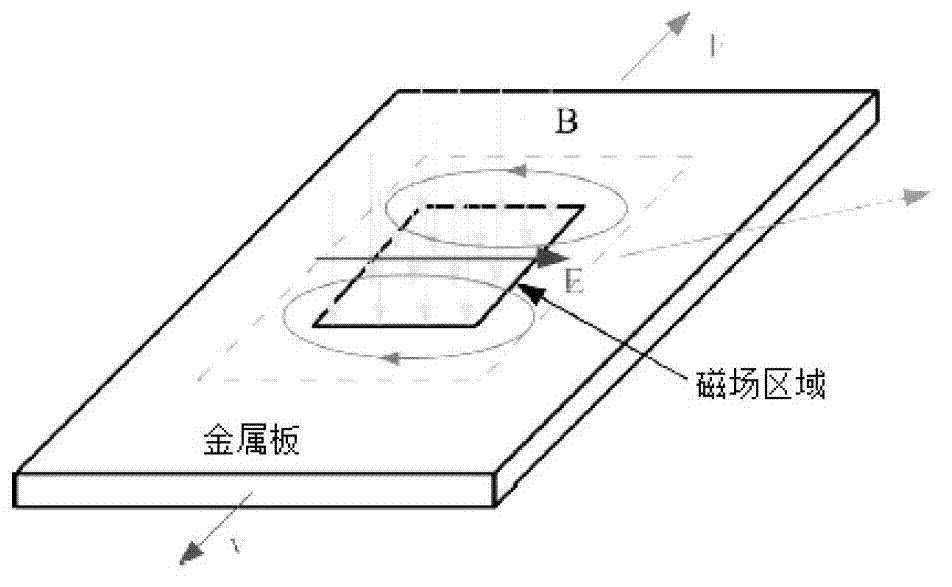

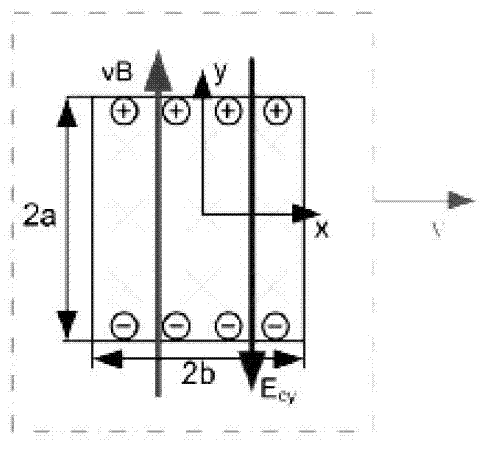

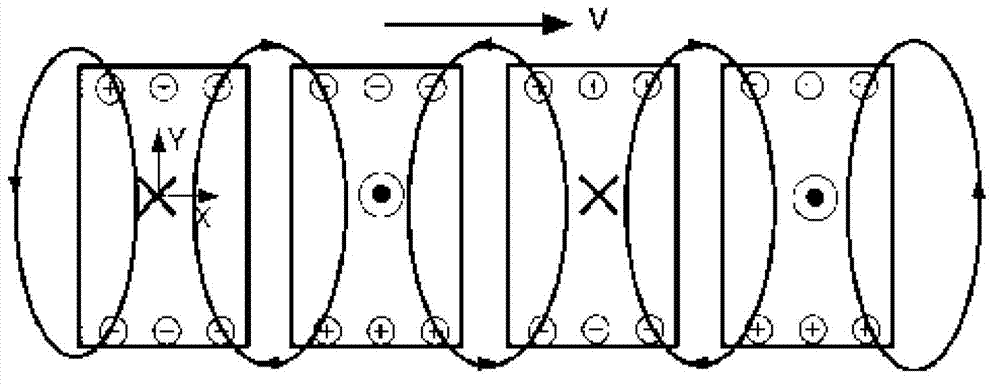

Eddy current energy consumption damper for suppressing axial vibration

InactiveCN102777525AGood vibration dampingGood time stabilityMagnetic springsShock proofingElectricityElectrical polarity

The invention discloses an eddy current energy consumption damper for suppressing axial vibration. The eddy current energy consumption damper consists of an eddy current energy consumption unit, a magnetic buffer unit, an electromagnetic shielding case and a connecting part, wherein the eddy current energy consumption unit and the magnetic buffer unit are respectively distributed at two ends of the damper; an eddy current barrel in the eddy current energy consumption unit is inserted into a magnetic field between inner and outer permanent magnets of the eddy current energy consumption unit, and the top end of the eddy current barrel is connected with one end of the connecting part and is used for connecting an external load; the other end of the eddy current barrel is connected with a movable permanent magnet in the magnetic buffer unit at the bottom; the bottom of the damper is provided with the magnetic buffer unit which consists of a movable permanent magnet and a fixed permanent magnet which have the opposite polarity directions; the movable permanent magnet on the upper part is fixedly connected with the tail end of the eddy current barrel and moves along with the eddy current barrel; and the other fixed permanent magnet is fixed at the bottom of the damper. The eddy current energy consumption damper has the characteristics of simple structure, no contact, long service life, high rigidity, controllable damping and the like, a working medium is not required, and the current energy consumption damper has high application value in the technical field of structural vibration control.

Owner:BEIHANG UNIV

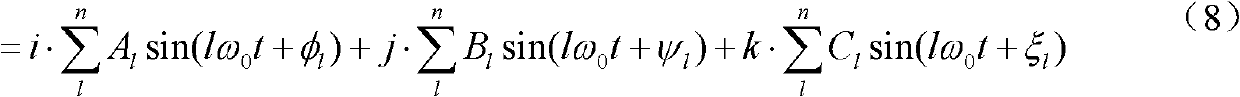

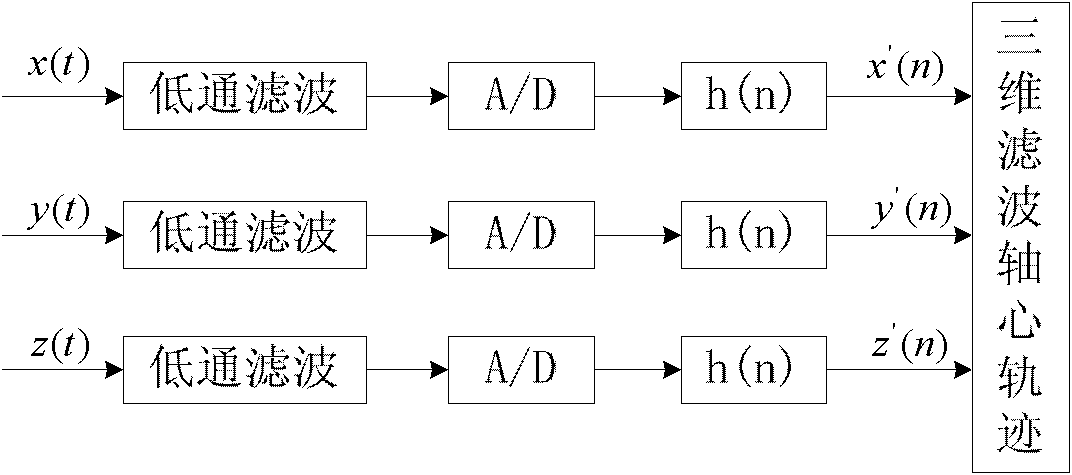

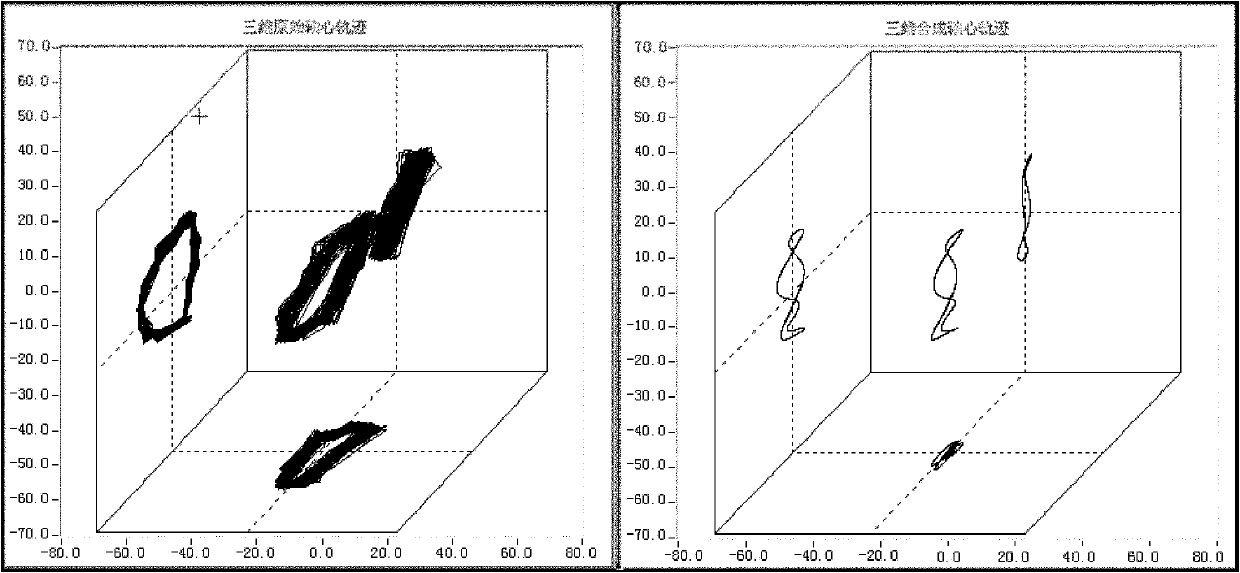

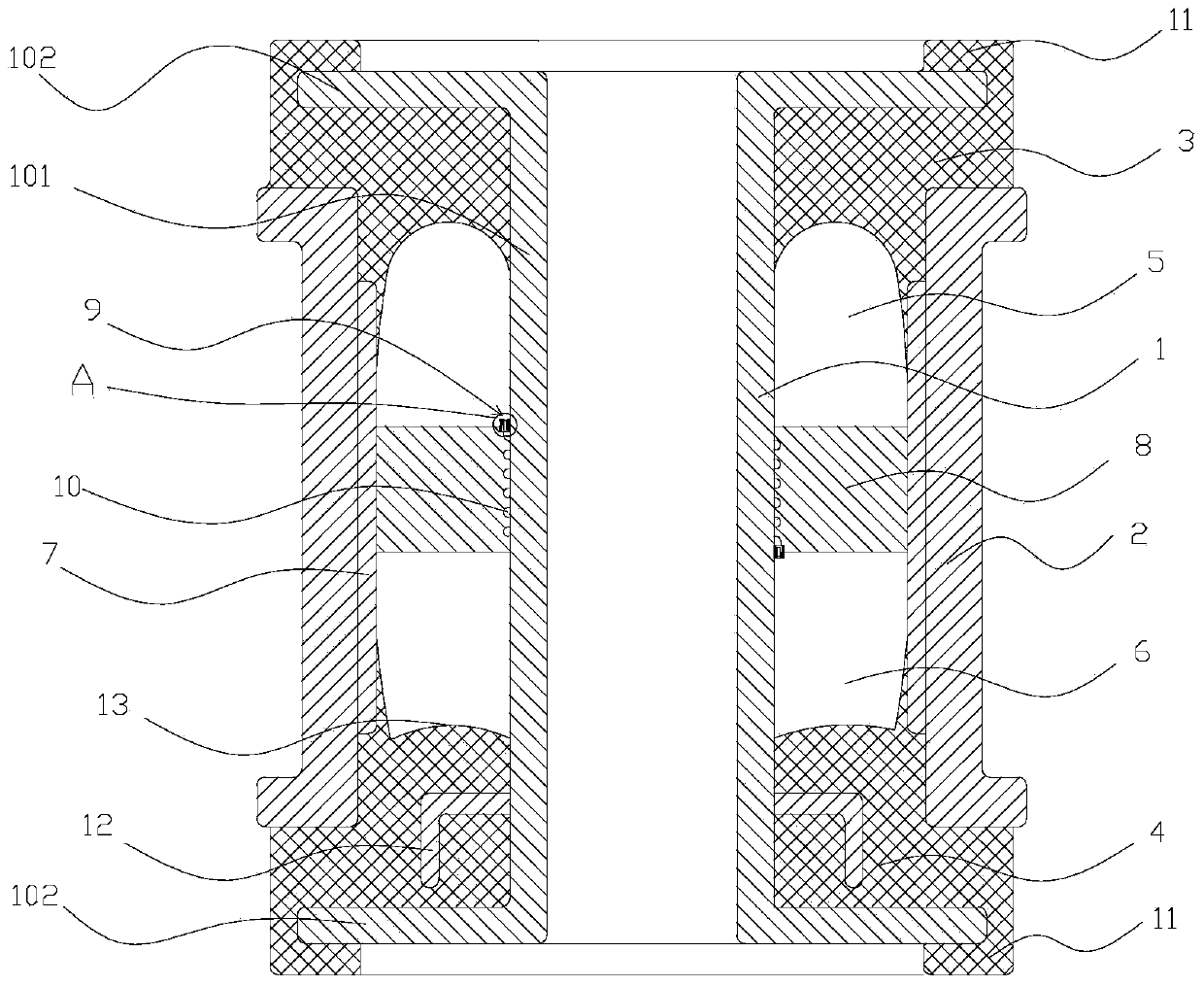

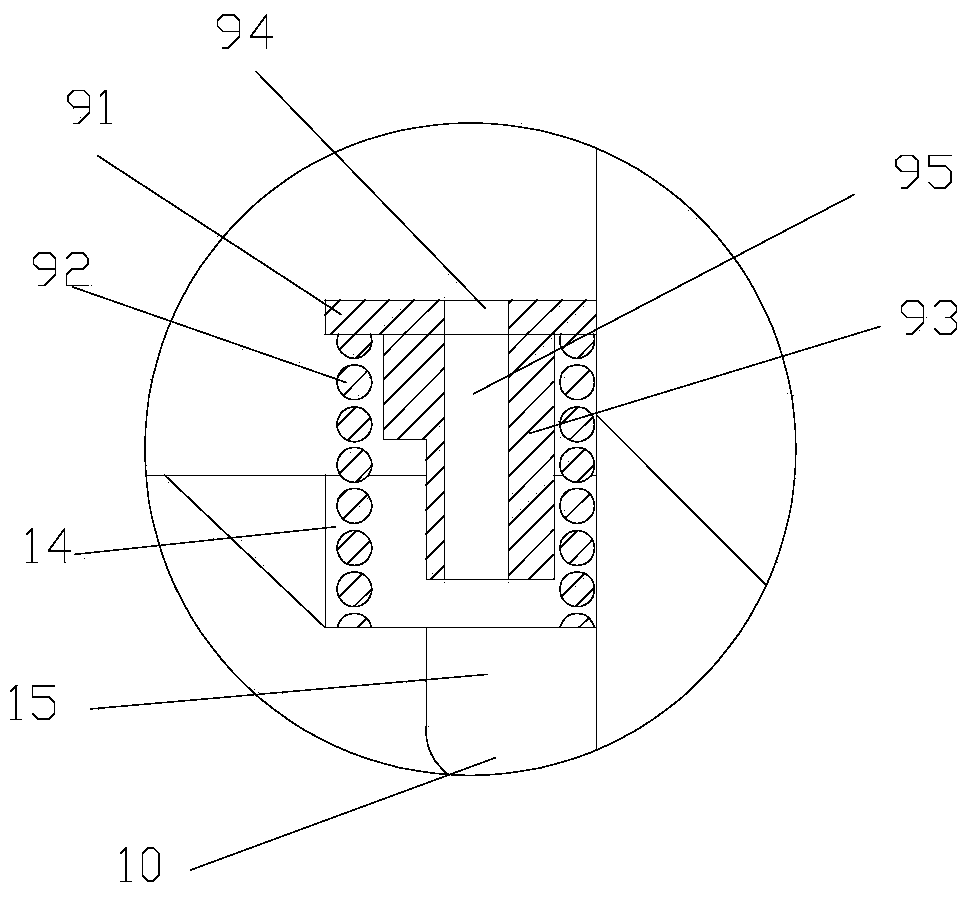

Fault diagnosis method of compressor shafting based on three-dimensional space axle center orbit

InactiveCN101907089AFully reflectReflect vividlyPump testingPositive-displacement liquid enginesTime domainFrequency spectrum

The invention discloses a fault diagnosis method of a compressor shafting based on a three-dimensional space axle center orbit, comprising the following steps: (1) detecting radial vibration signals x(t) and y(t) of a compressor rotor; (2) detecting an axial vibration signal z(t) of the compressor rotor; (3) carrying out low-pass filtering on the vibration signals to eliminate a high-frequency interference signal; (4) acquiring the three-dimensional axle center orbit w(t); (5) forming the three-dimensional axle center orbit; (6) respectively filtering the vibration signals x(t), y(t) and z(t) in three directions and then reconfiguring the vibration signals in a time domain to obtain the three-dimensional filter axle center orbit; and (7) synthesizing the vibration signals using a spectrum analysis principle to obtain the synthesized axle center orbit. The invention provides a three-dimensional vibration analysis method on the basis of a holo-spectrum technology, and the method comprises synthesized three-dimensional vibration analysis and filter three-dimensional vibration analysis, which can more clearly and vividly reflect running status and fault characteristics of equipment. Rotor vibration comprises horizontal, vertical and axial vibration, and the vibration signals in the three directions are synthesized to form the three-dimensional axle center orbit which comprises the three-dimensional filter axle center orbit and the three-dimensional synthesized axle center orbit. The method can really reflect motion situation of the axle center of the rotor and provide more complete information for the fault diagnosis.

Owner:XI AN JIAOTONG UNIV

Axial variable-damping hydraulic bushing for automotive suspension

ActiveCN104191927AGood elastic responseReduce the amplitudeResilient suspensionsRubber-like material springsAxial vibrationMechanical engineering

The invention discloses an axial variable-damping hydraulic bushing for an automotive suspension. The axial variable-damping hydraulic bushing comprises an inner tube, an outer tube and rubber bodies. The rubber bodies are arranged between the inner tube and the outer tube, are connected with each other and include an upper rubber body and a lower rubber body, the upper rubber body and the lower rubber body are of split structures, a hydraulic working cavity is formed among the upper rubber body, the lower rubber body, the inner tube and the outer tube, a cavity partition device is arranged in the hydraulic working cavity, and damping adjusting assemblies which are used for adaptively adjusting damping force are arranged at communicated ends of a damping channel, an upper working cavity and a lower working cavity. The axial variable-damping hydraulic bushing has the advantages that excellent axial damping effects can be realized when the bushing is vertically mounted along an automobile body, accordingly, the axial variable-damping hydraulic bushing is high in axial rigidity, axial vibration can be buffered, and noise can be reduced; the damping force can be adaptively adjusted according to different working conditions, so that service requirements under the different working conditions can be met.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

Triaxial vibration composite testing apparatus

ActiveUS20110239771A1Increase stiffnessReduce distanceMaterial analysis using sonic/ultrasonic/infrasonic wavesMechanical vibrations separationEngineeringHigh pressure

A triaxial vibration composite testing apparatus including a working tabletop, wherein the second axial vibration transmission mechanism in the horizontal X axial direction and the third axial vibration transmission mechanism in the horizontal Y axial direction are both cross linear guide pairs; the first axial vibration transmission mechanism in the perpendicular Z axial direction includes an upper and a lower clamps and a central panel, the upper and the lower clamps being horizontally opposite to each other up and down, the central panel being positioned between the upper and the lower clamps, the upper and the lower clamps oppositely clamping the central panel; a gap fit between the lower surface of the upper clamp and the upper surface of the central panel forms an upper fit plane, and a gap fit between the upper surface of the lower clamp and the lower surface of the central panel a lower fit plane; and the high pressure oil is pumped into the upper fit plane gap and the lower fit plane gap to form a hydrostatic oil film, thus constituting a hydrostatic plane bearing mechanism.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com