Patents

Literature

368 results about "Axial rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rigidity is the term used to define the stiffness of an object. And Axial Rigidity is used to define the stiffness of the object(say spring) in an particular axis. Practically Every object in the world is not 100 percent rigid. They are somewhat flexible.

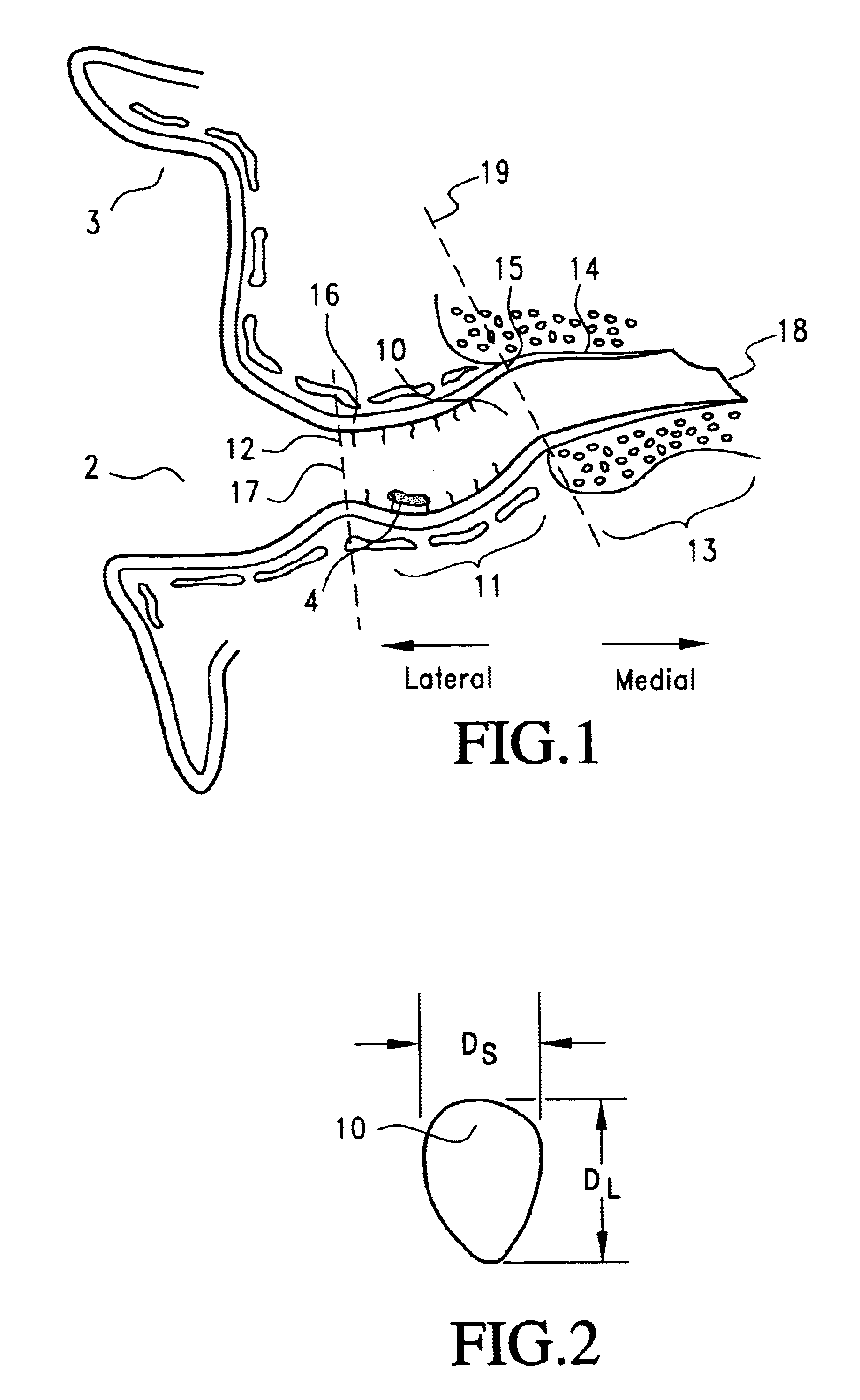

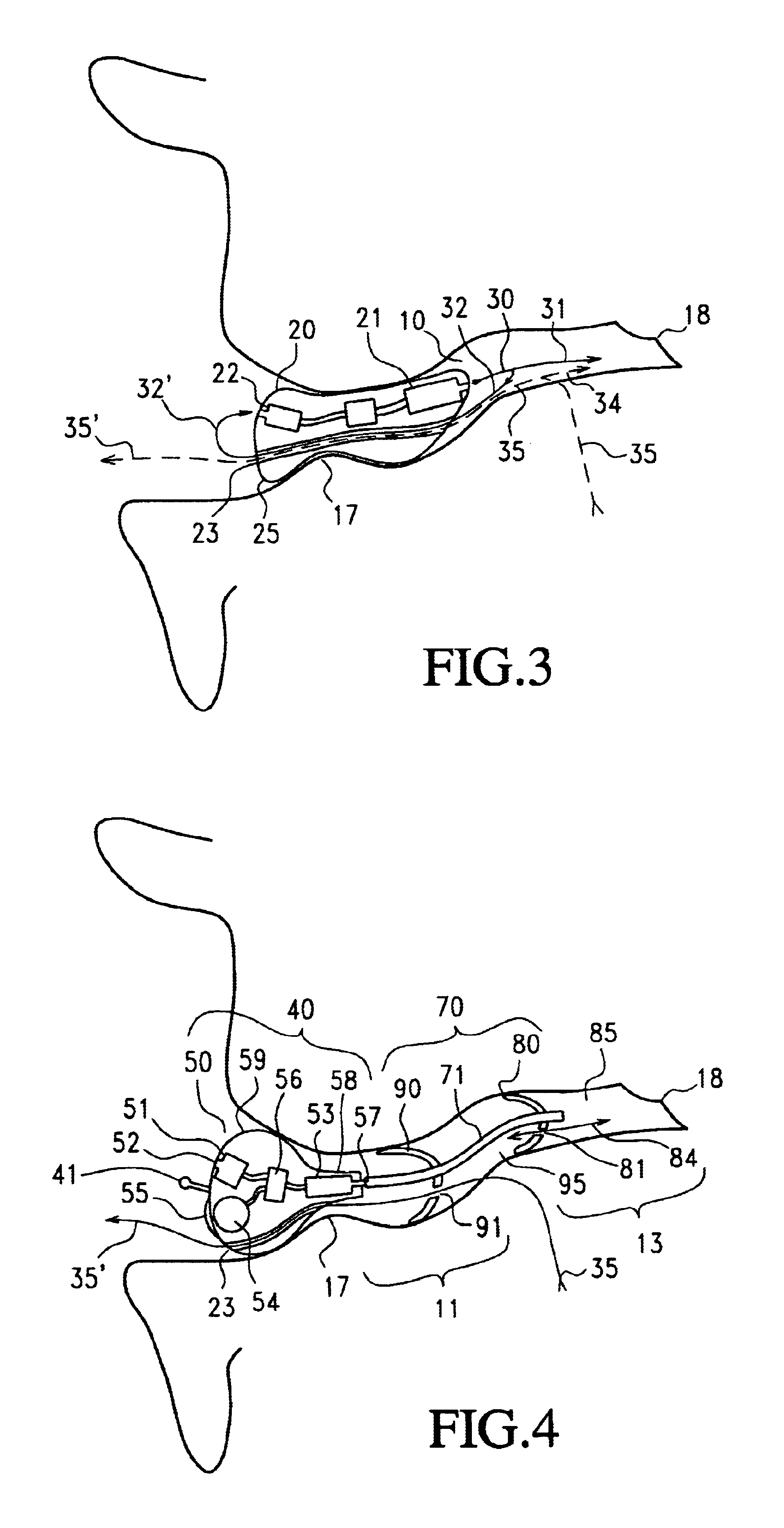

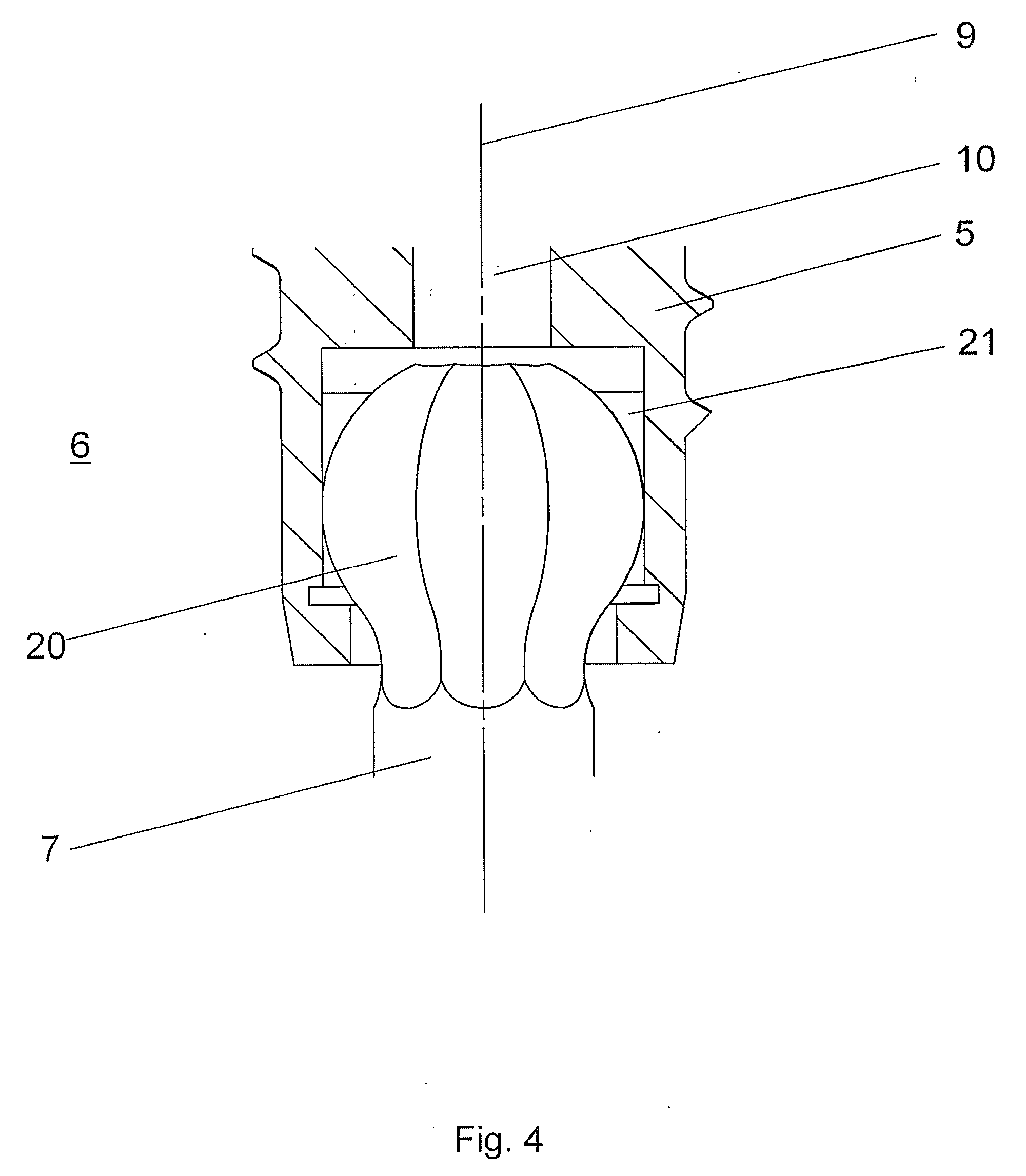

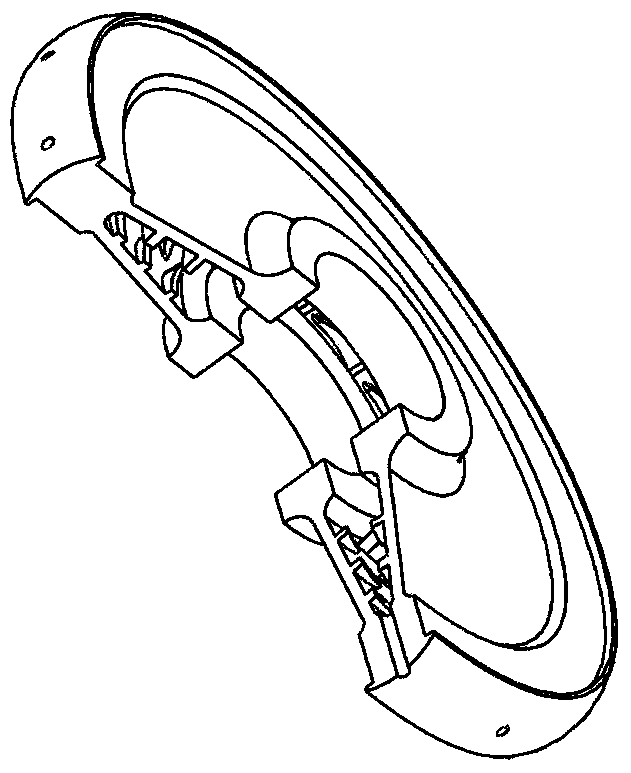

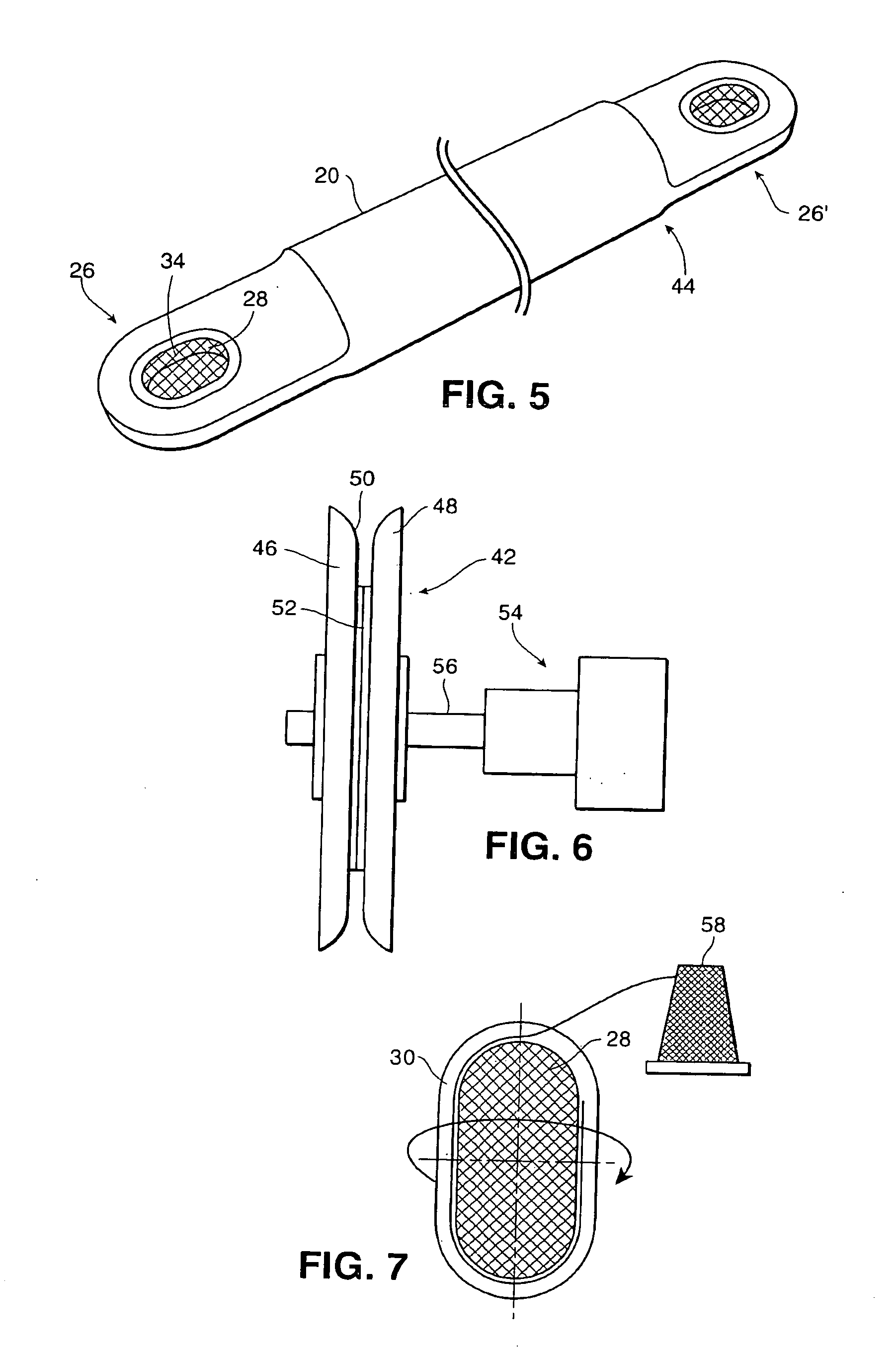

Canal hearing device with tubular insert

InactiveUS6724902B1Alleviate the social stigmaImprove high frequency responseElectrotherapyHearing aid ventsOcclusion effectCatheter

A canal hearing device with a dual acoustic seal system for preventing feedback while minimizing occlusion effects. The two-part device comprises a main module and an elongated tubular insert for conducting sound to the tympanic membrane and sealing within the bony region of the ear canal. The main module is positioned in the cartilaginous portion of the ear canal. The tubular insert comprises a sound conduction tube and a cylindrically hollow primary seal medially positioned in the bony region. The device also comprises a secondary seal laterally positioned in the cartilaginous region. The secondary seal, although providing additional acoustic sealing for the prevention of feedback, is sufficiently vented to provide a path of least acoustic resistance for occlusion sounds within the ear canal. In a preferred embodiment, the tubular insert comprises a coiled skeletal frame to provide high radial flexibility while maintaining sufficient axial rigidity for comfortable, kink-resistant, and consistent placement within the ear canal.

Owner:INSOUND MEDICAL INC

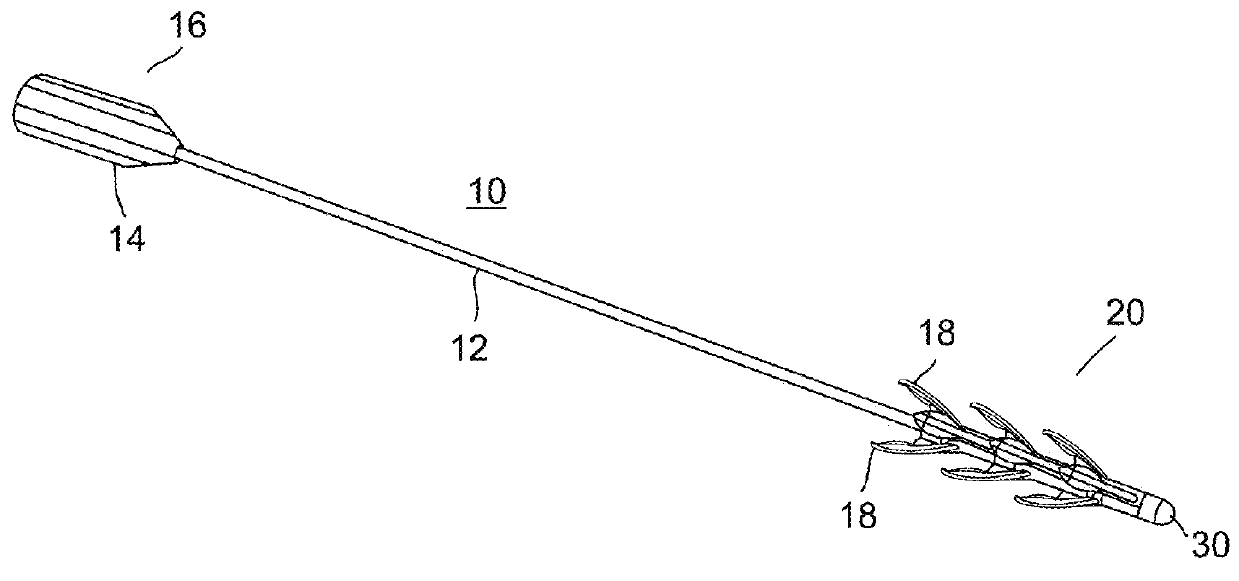

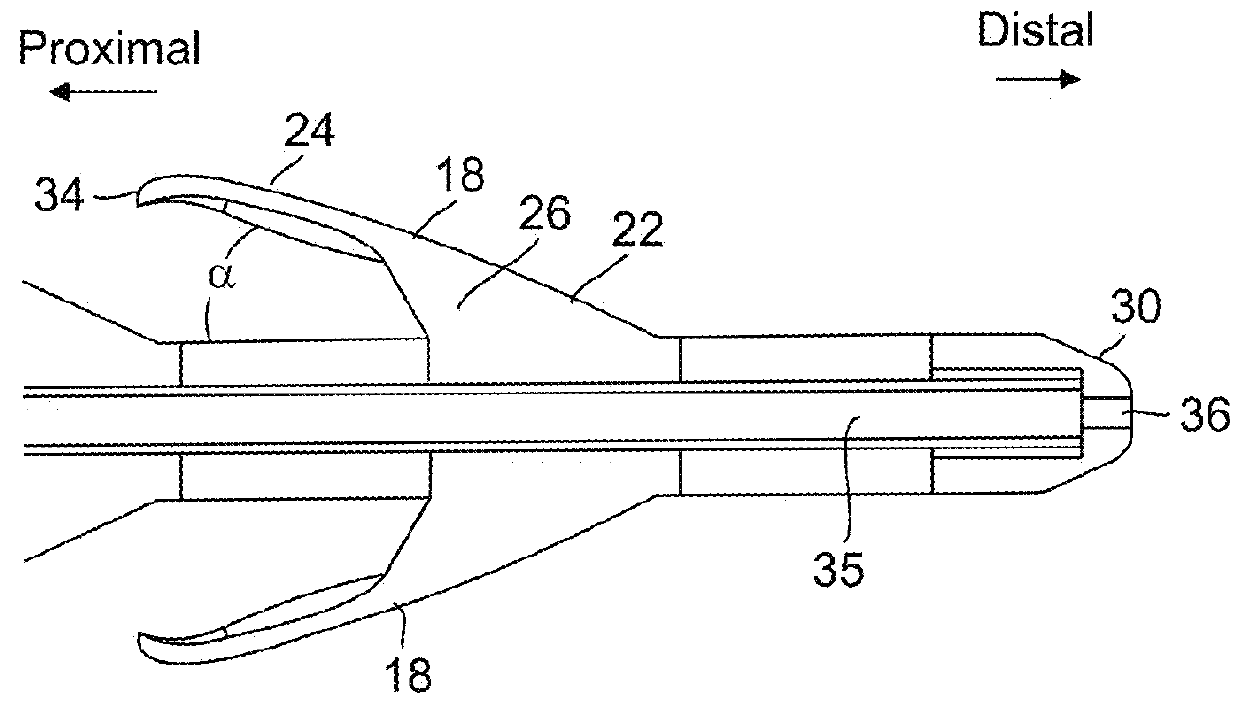

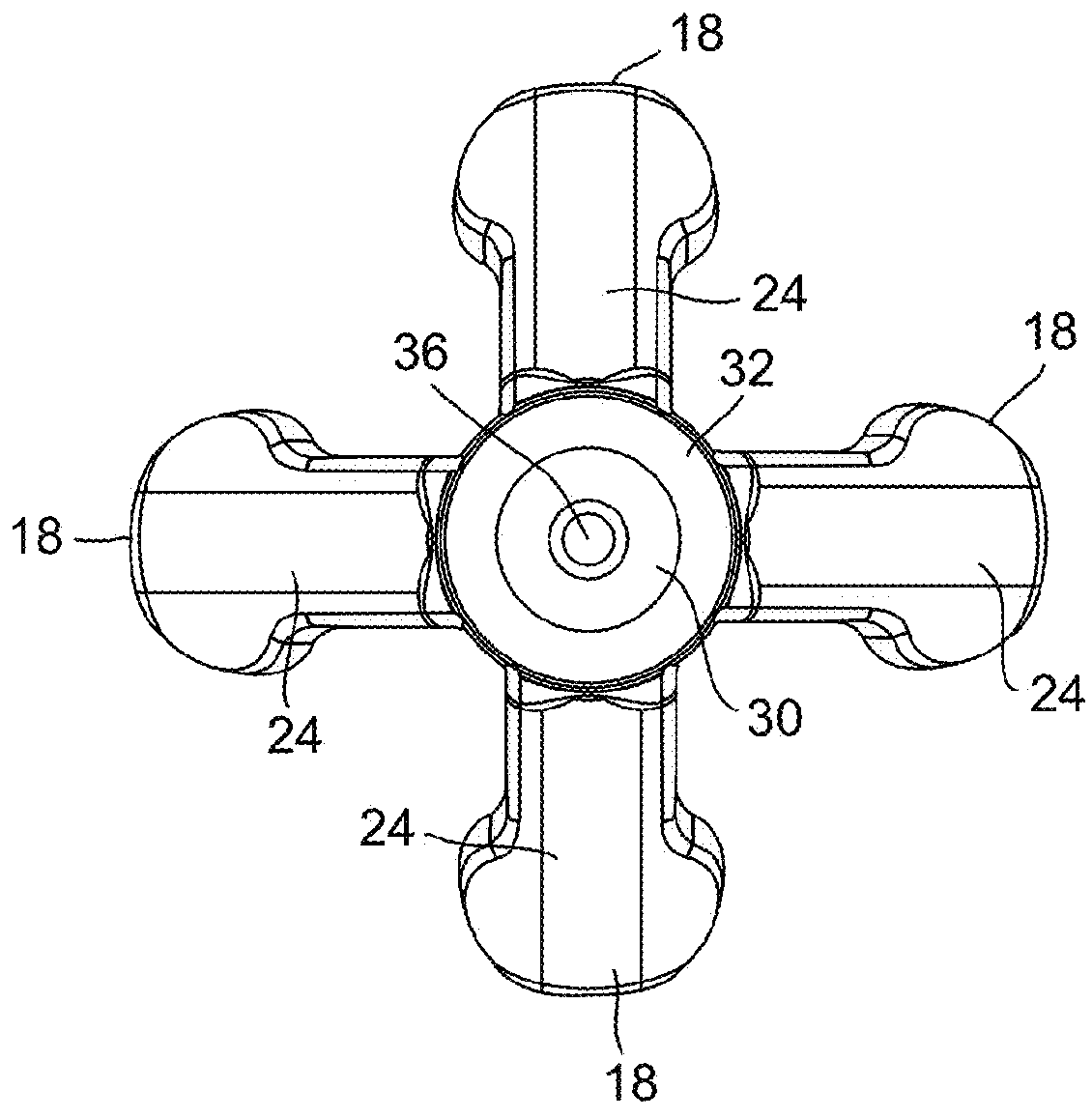

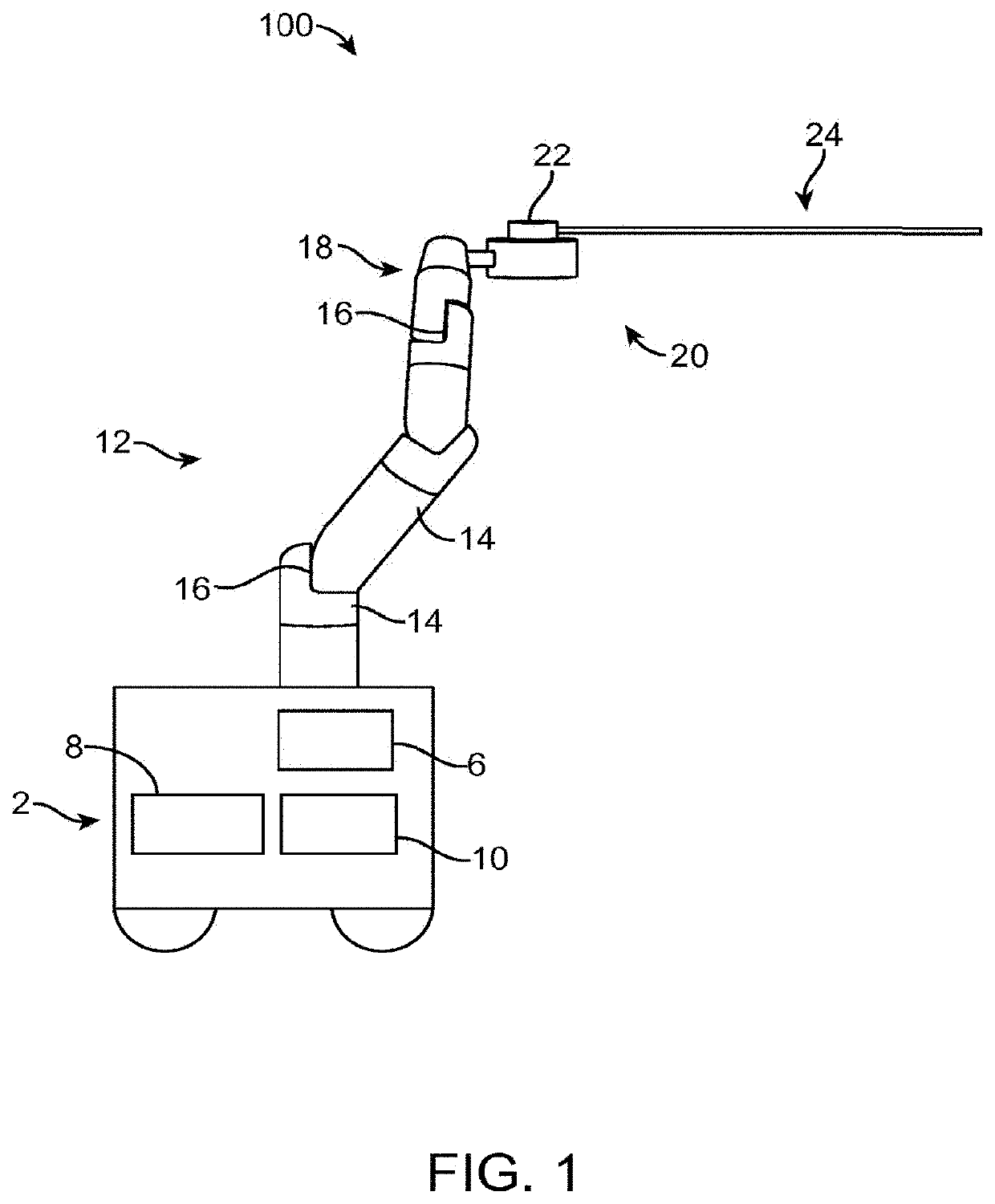

Device and method for removing occlusions in a biological vessel

ActiveUS20140309657A1Effectively and non-traumatically clearing occlusionImprove axial rigiditySurgeryDistal portionSurgery

A device for use within an occluded biological vessel and a method of using same to remove occlusion material from a vessel are provided. The device includes an elongated body configured for delivering projections arranged around a distal portion thereof into the biological vessel. Each of the projections includes a leaf-like structure connected to a stem portion having a higher axial rigidity than the leaf-like structure.

Owner:TRITICUM

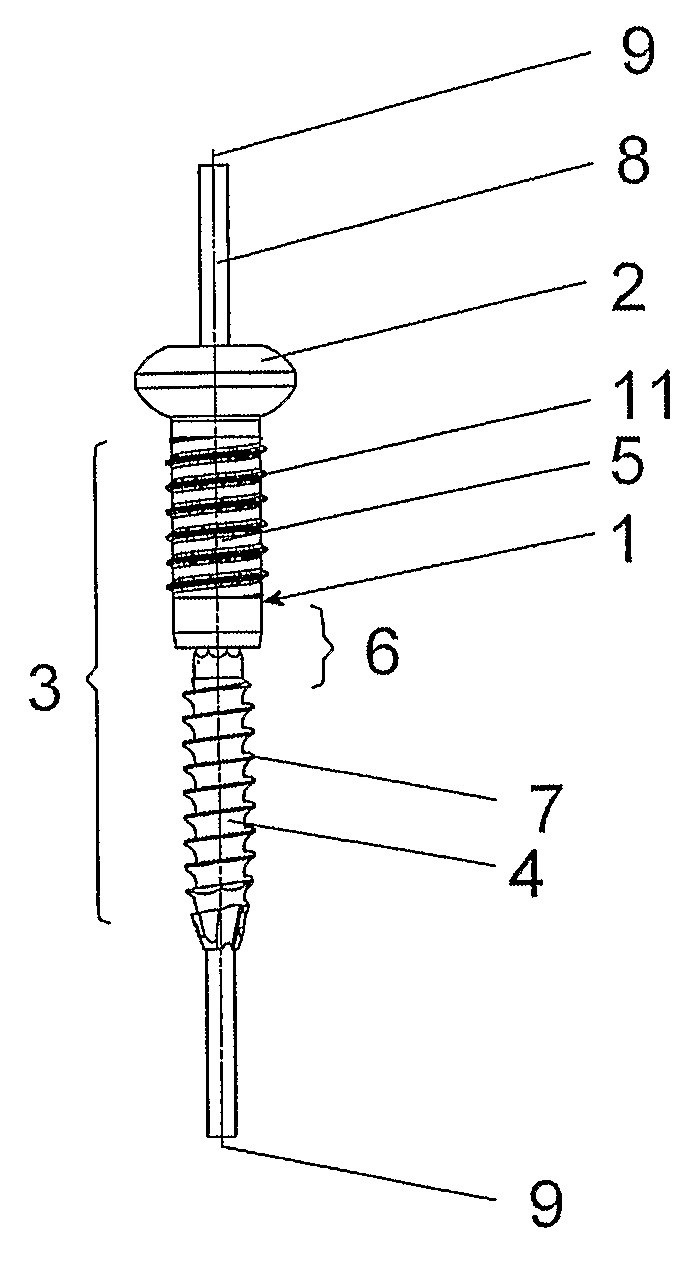

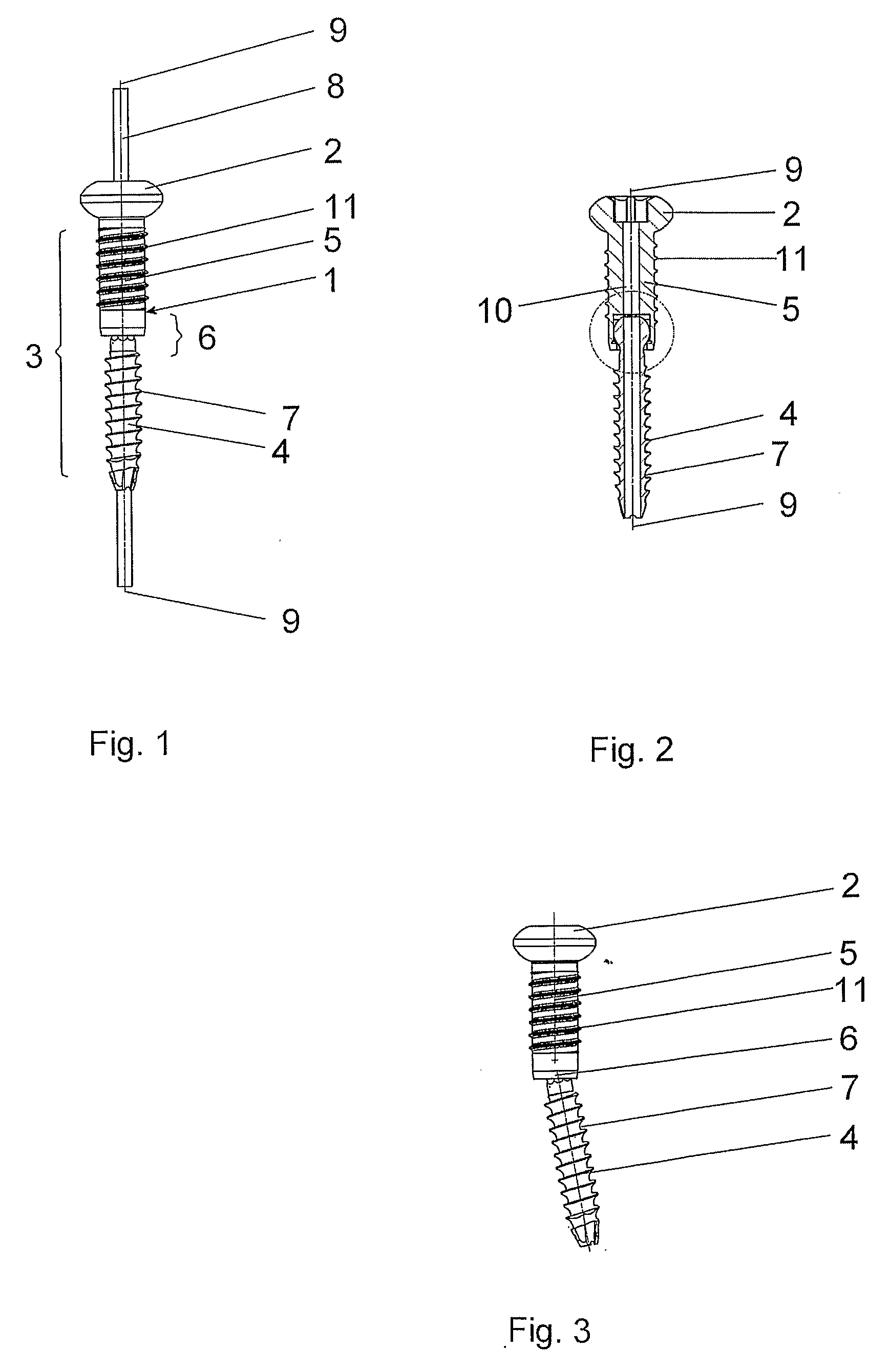

Articulated Bone Screw

InactiveUS20070282342A1Simple structure designSimple designInternal osteosythesisJoint implantsIliac screwBiomedical engineering

The bone screw has a head, a shaft and a longitudinal axis. The shaft comprises a proximal section adjacent to the head and a distal section secured to the proximal section by a cardan or cardan-like joint, the distal section being suitable for introduction into the bone and being provided with an outer thread. The bone screw can be bent in all directions relative to its longitudinal axis, while retaining its axial rigidity and fully transmitting a couple without the need for additional means.

Owner:DEPUY SYNTHES PROD INC

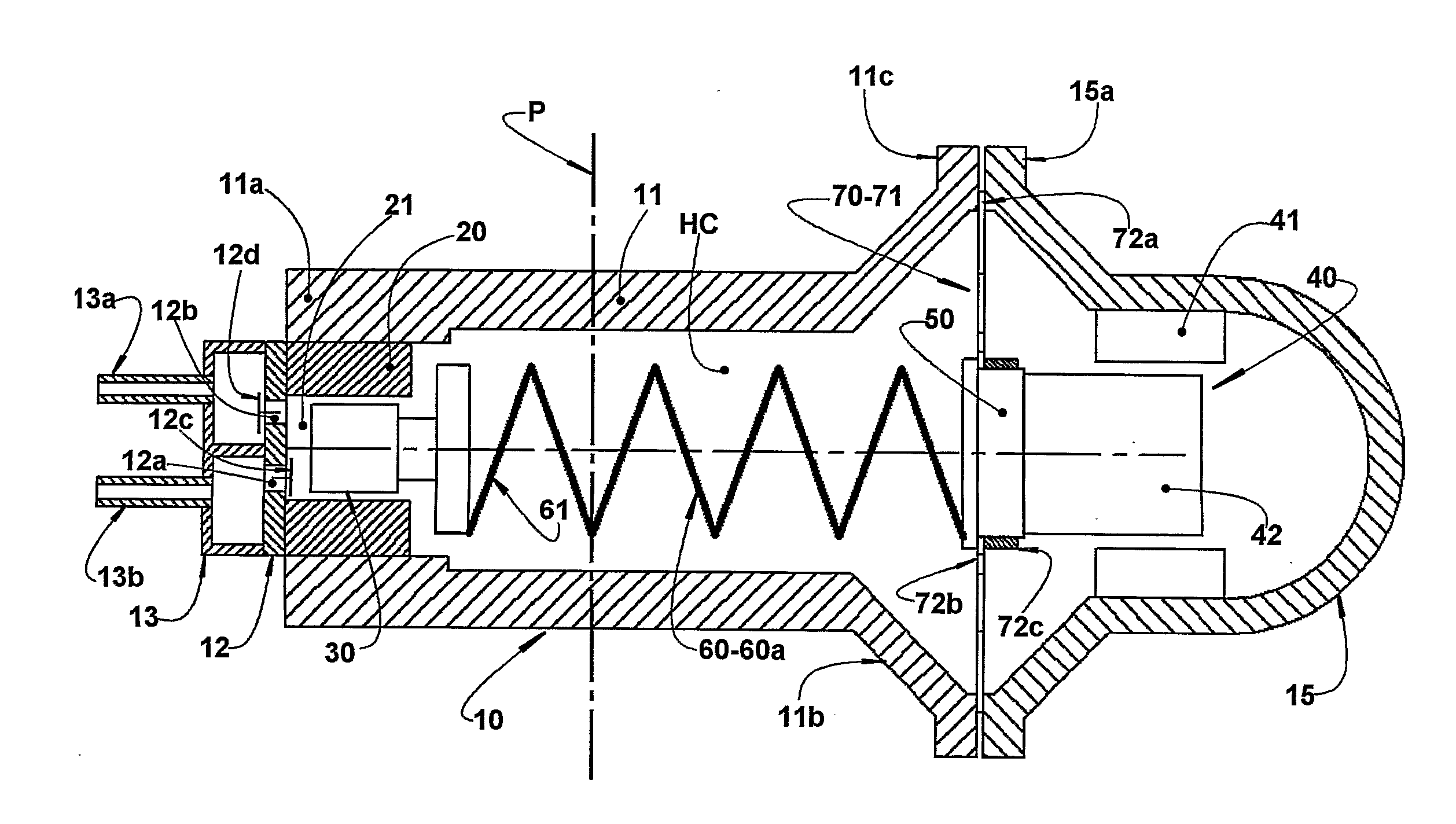

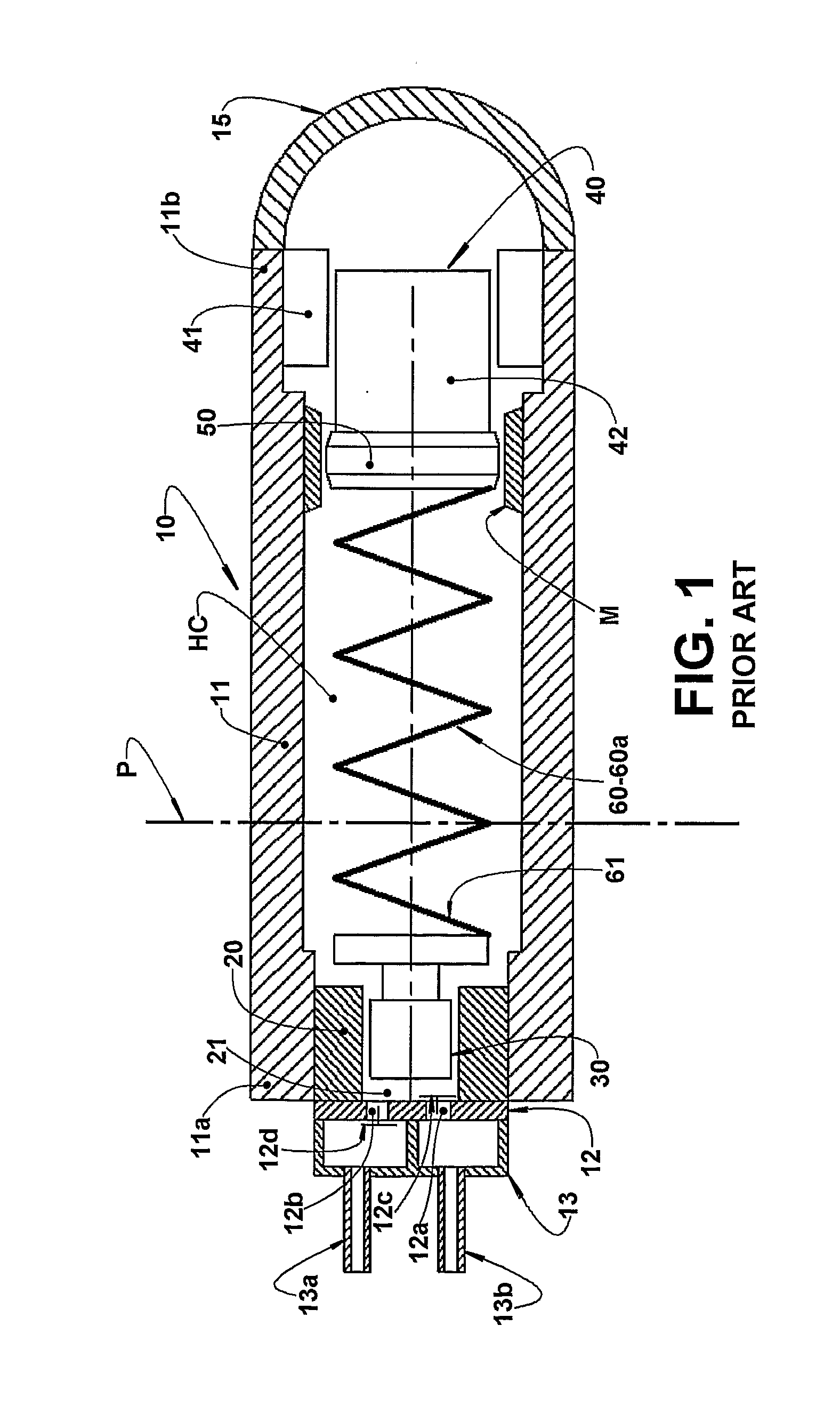

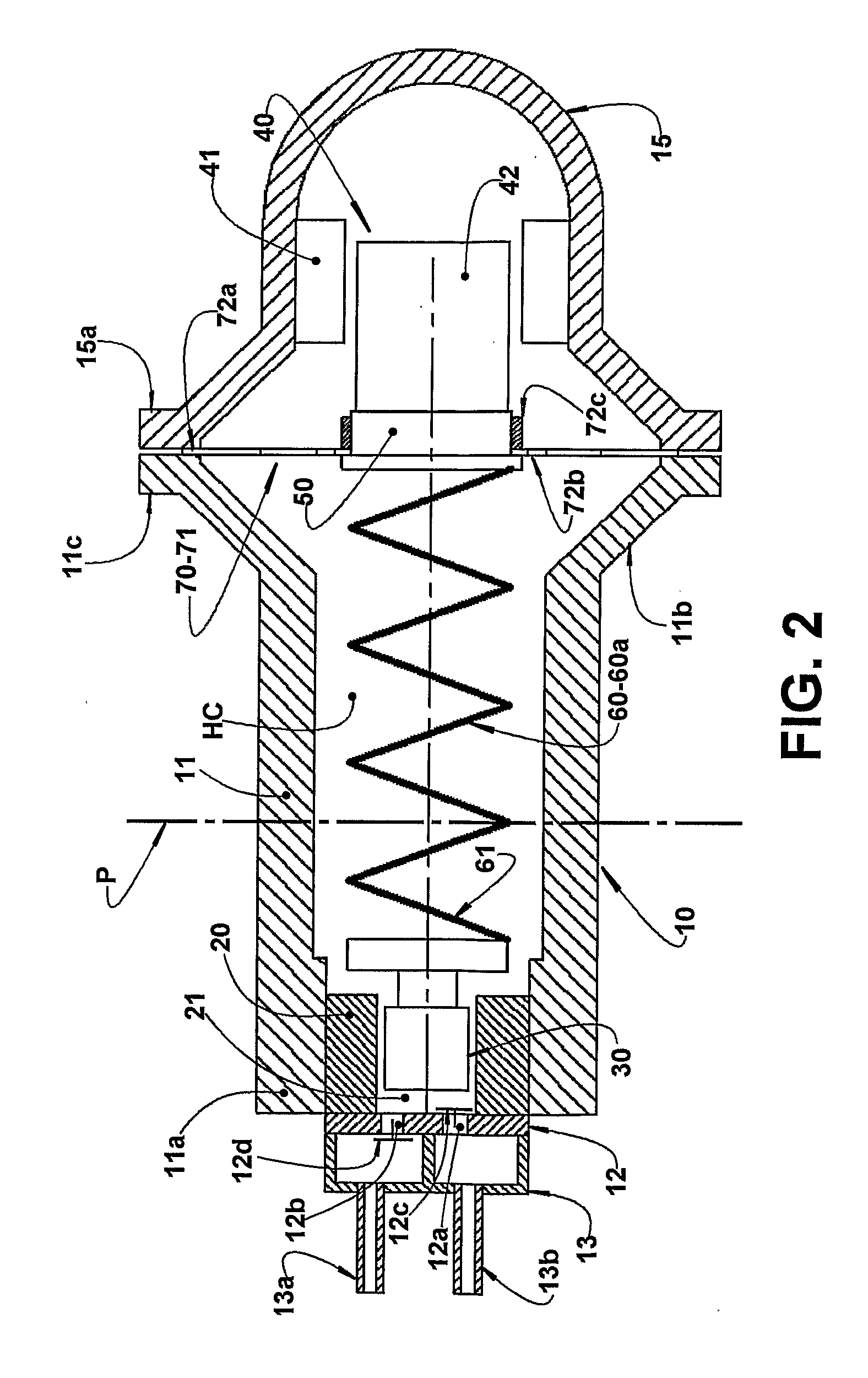

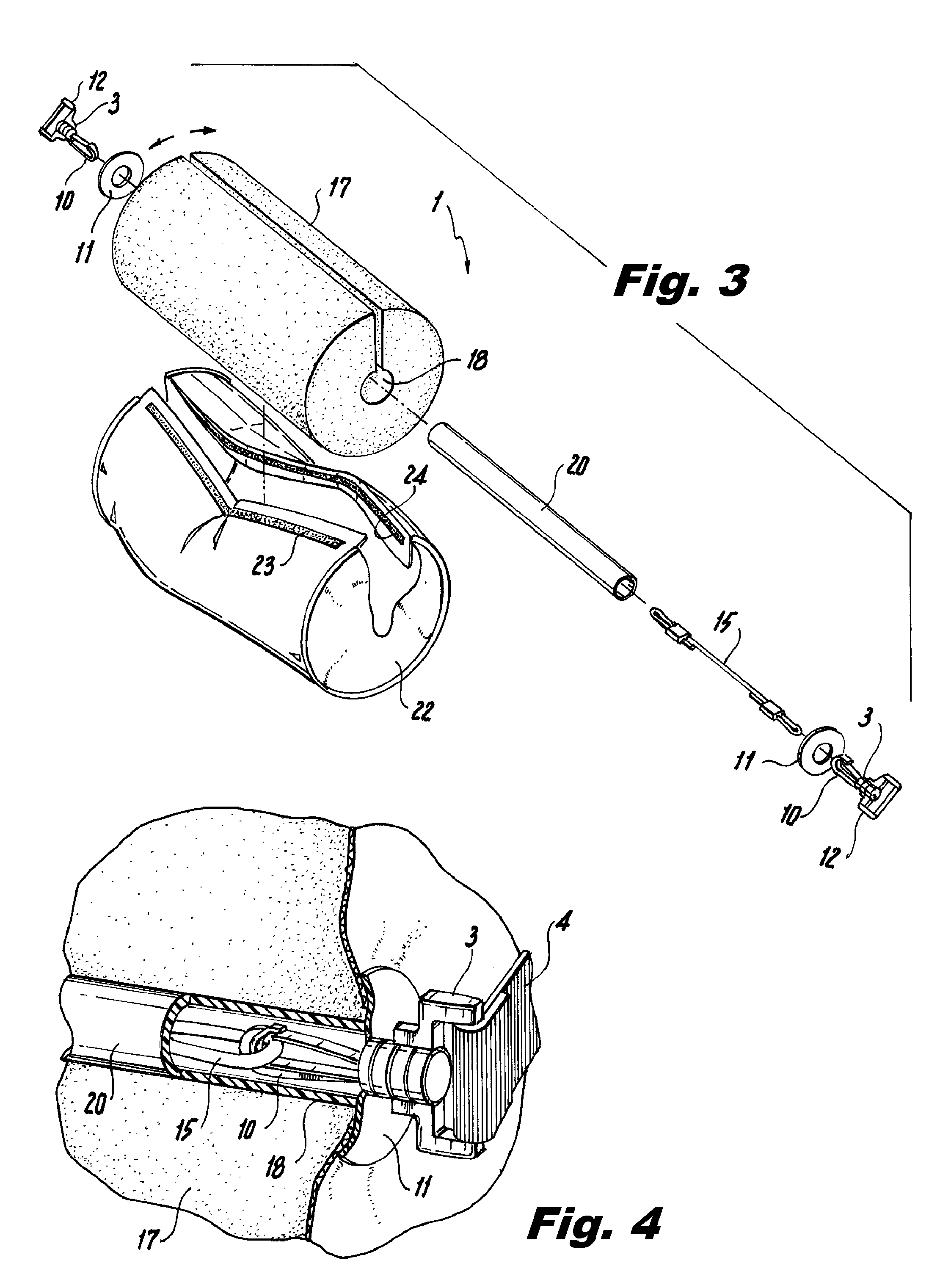

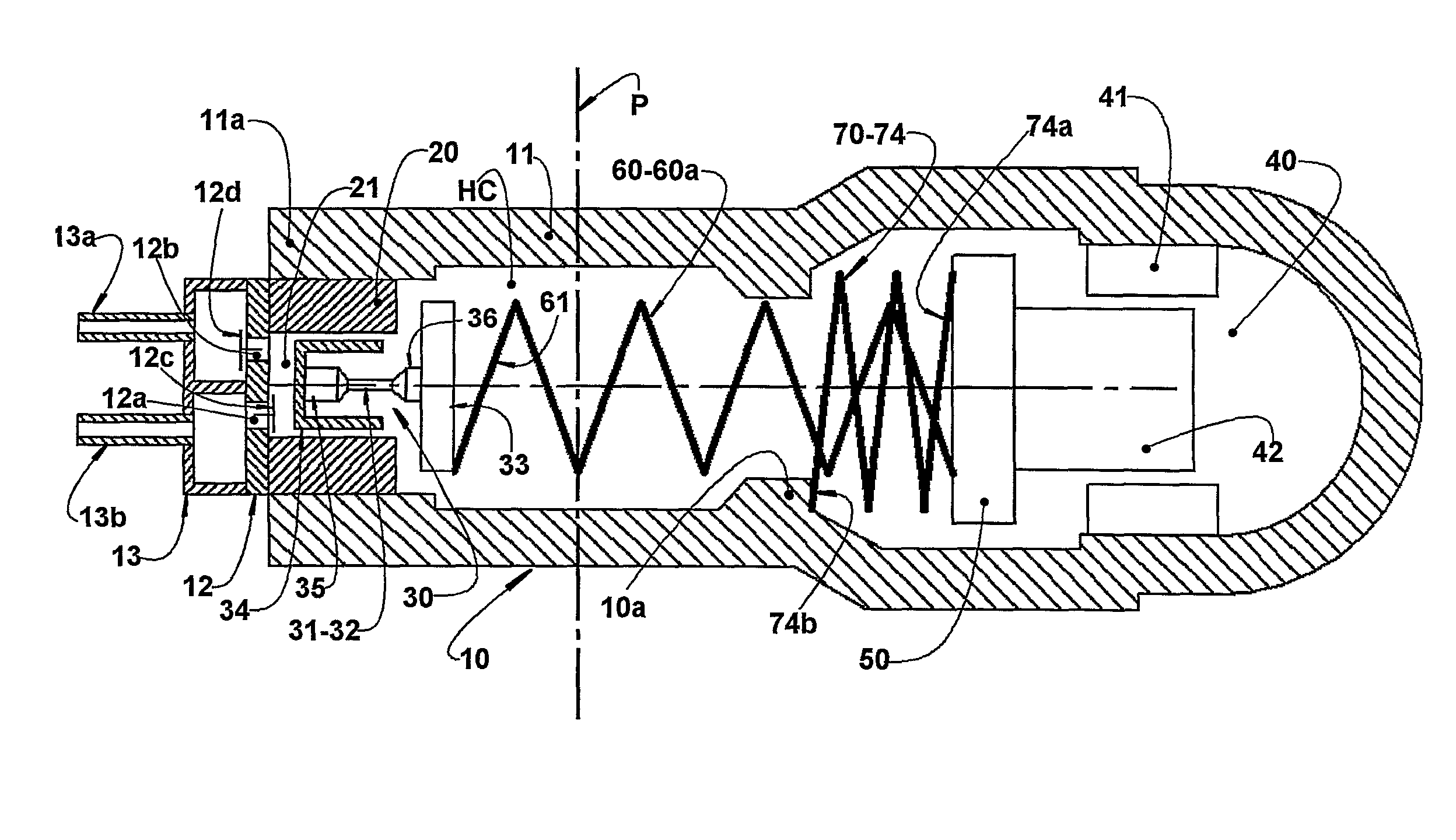

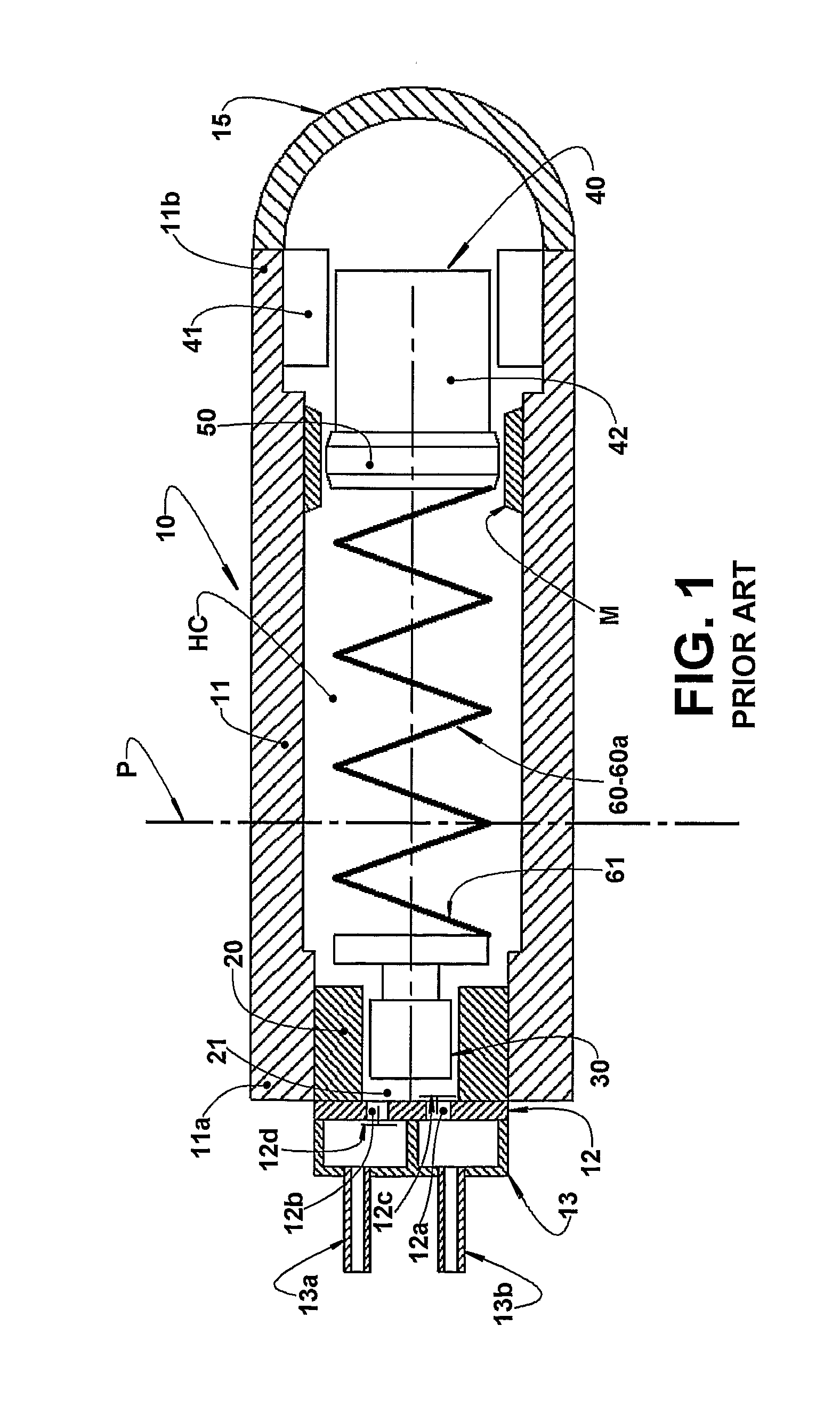

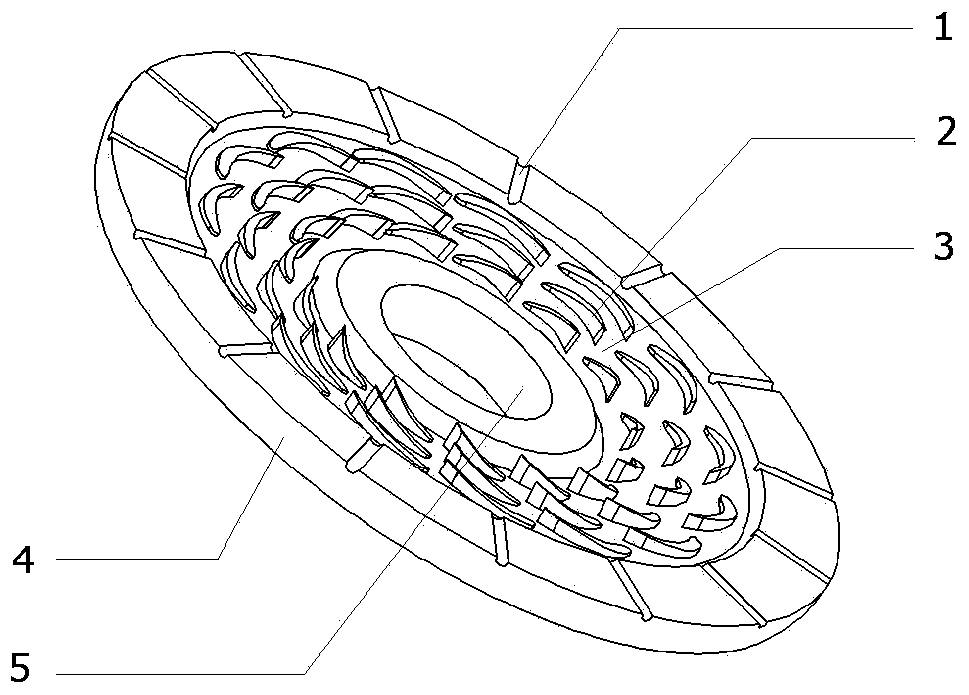

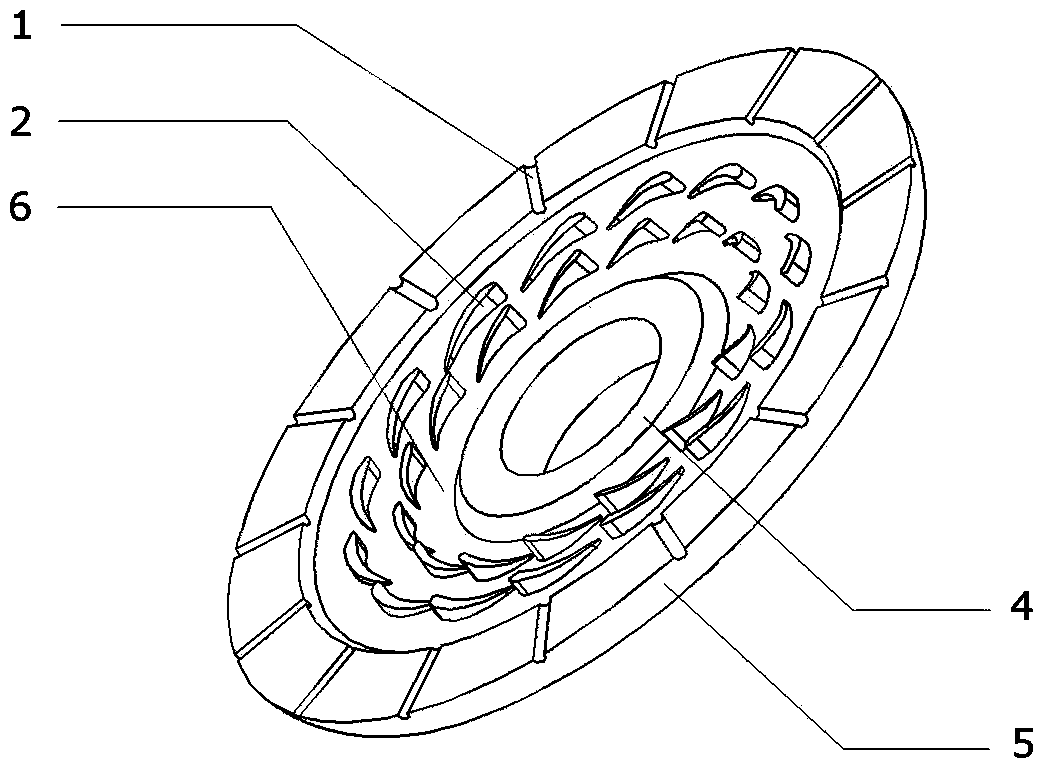

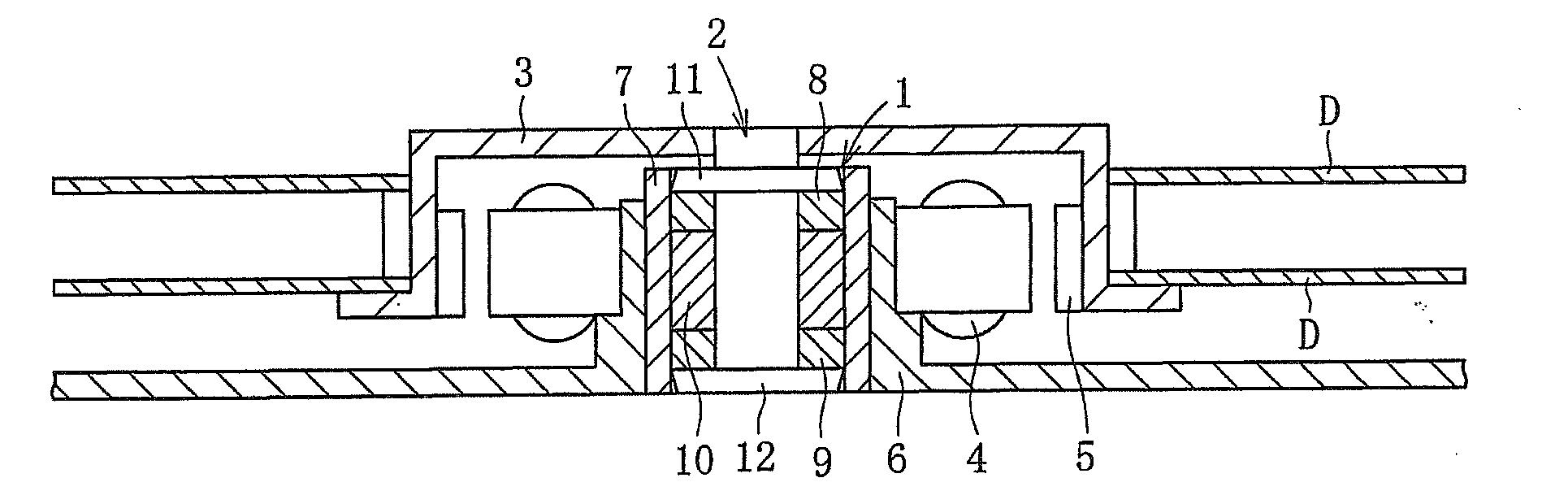

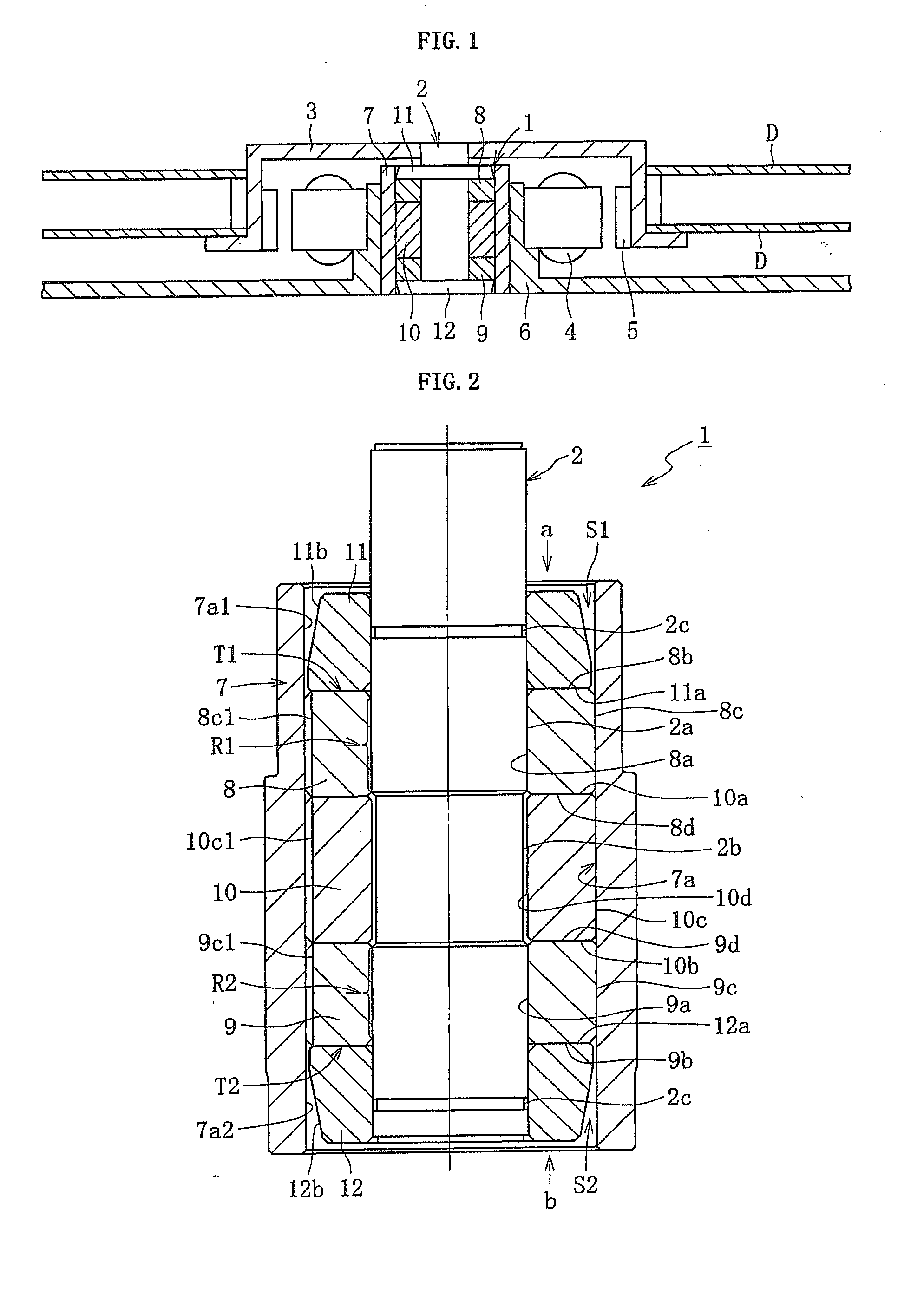

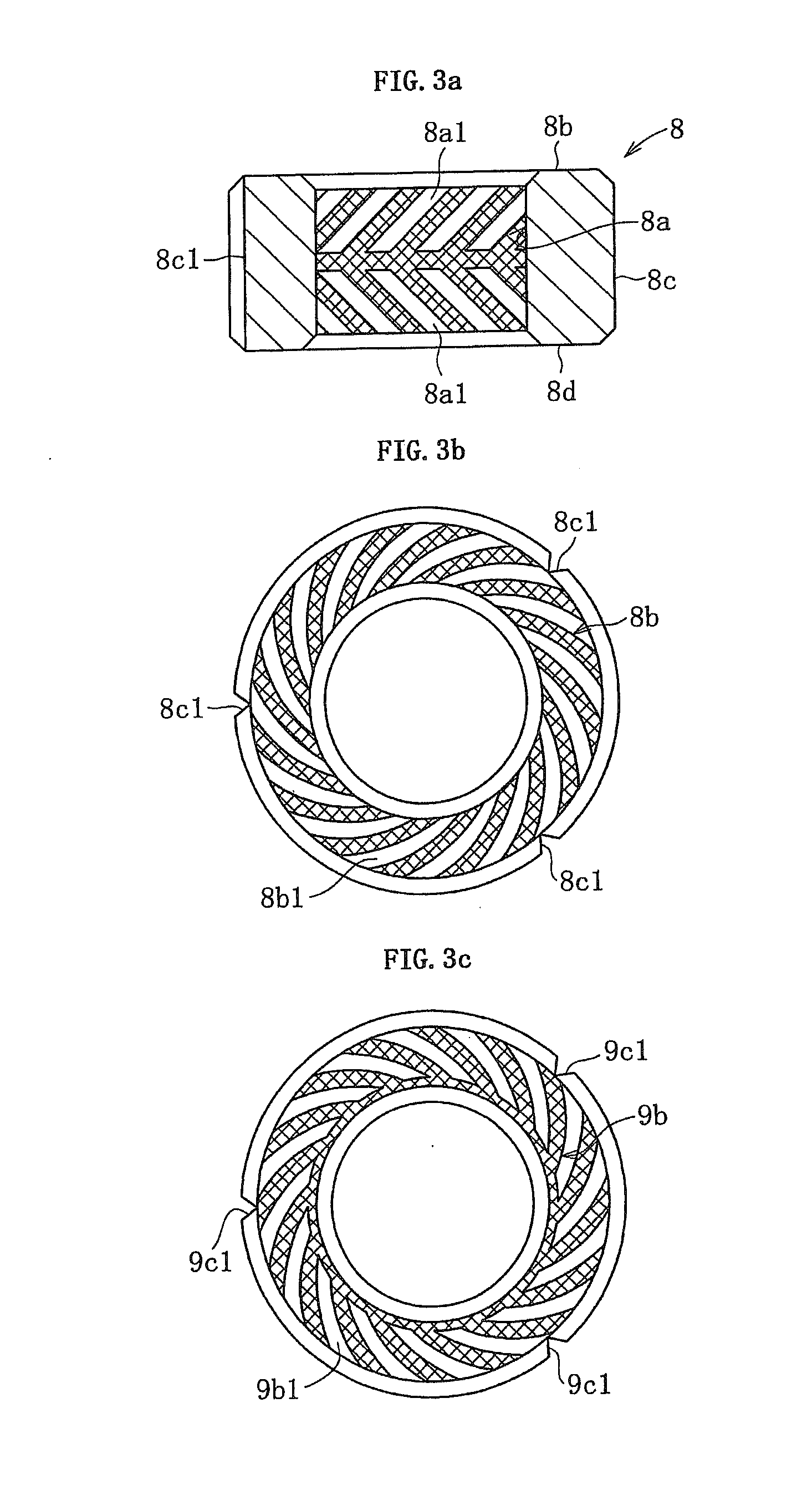

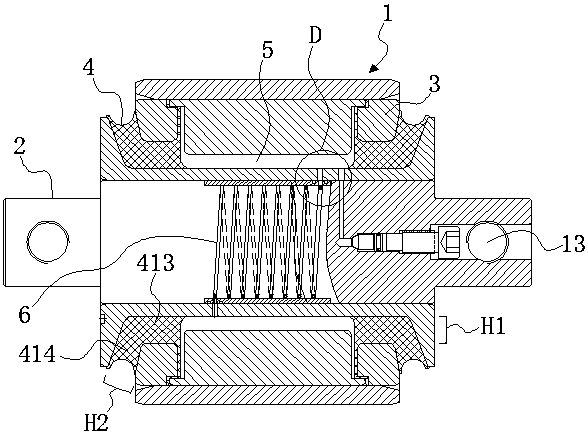

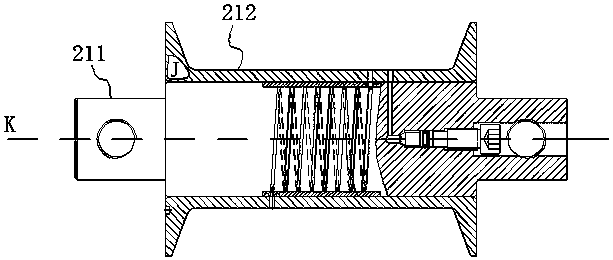

Linear compressor

ActiveUS20120177513A1Positive displacement pump componentsEngine fuctionsLinear compressorReciprocating motion

The linear compressor comprises a shell (10) which affixes a cylinder (20) defining a compression chamber (21) housing a piston (30); a linear electric motor (40) having a fixed part (41) affixed to the shell (10) and a reciprocating movable part (42); an actuating means (50) driven by the movable part (42); an elastic means (60a) coupling the actuating means (50) to the piston (30), so that they are reciprocated in phase opposition. A supporting elastic means (70) connects the actuating means (50) to the shell (10) and presents a radial rigidity for supporting the lateral loads actuating on said movable part (42) and actuating means (50), and for minimizing the axial misalignments between the movable part (42) and the fixed part (41) of the linear electric motor (40), the supporting elastic means (70) presenting a minimum axial rigidity for allowing the displacement of both the piston (30) and the actuating means (50).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

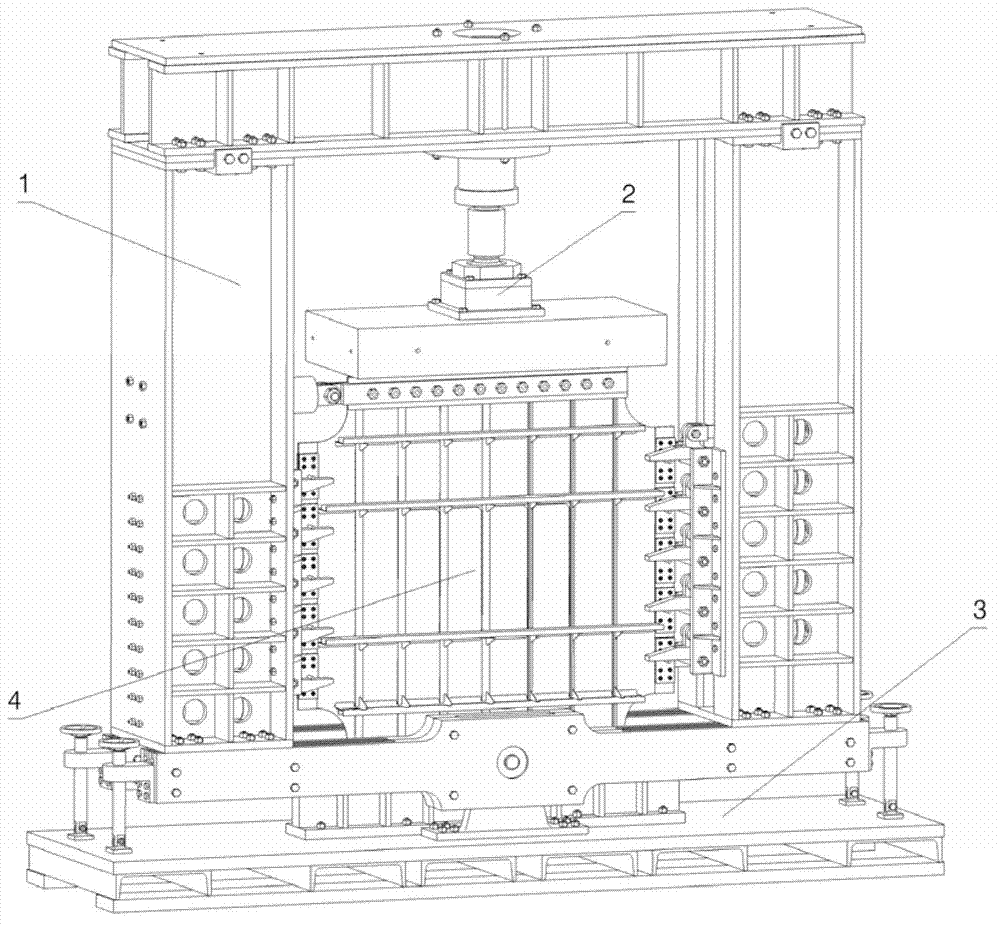

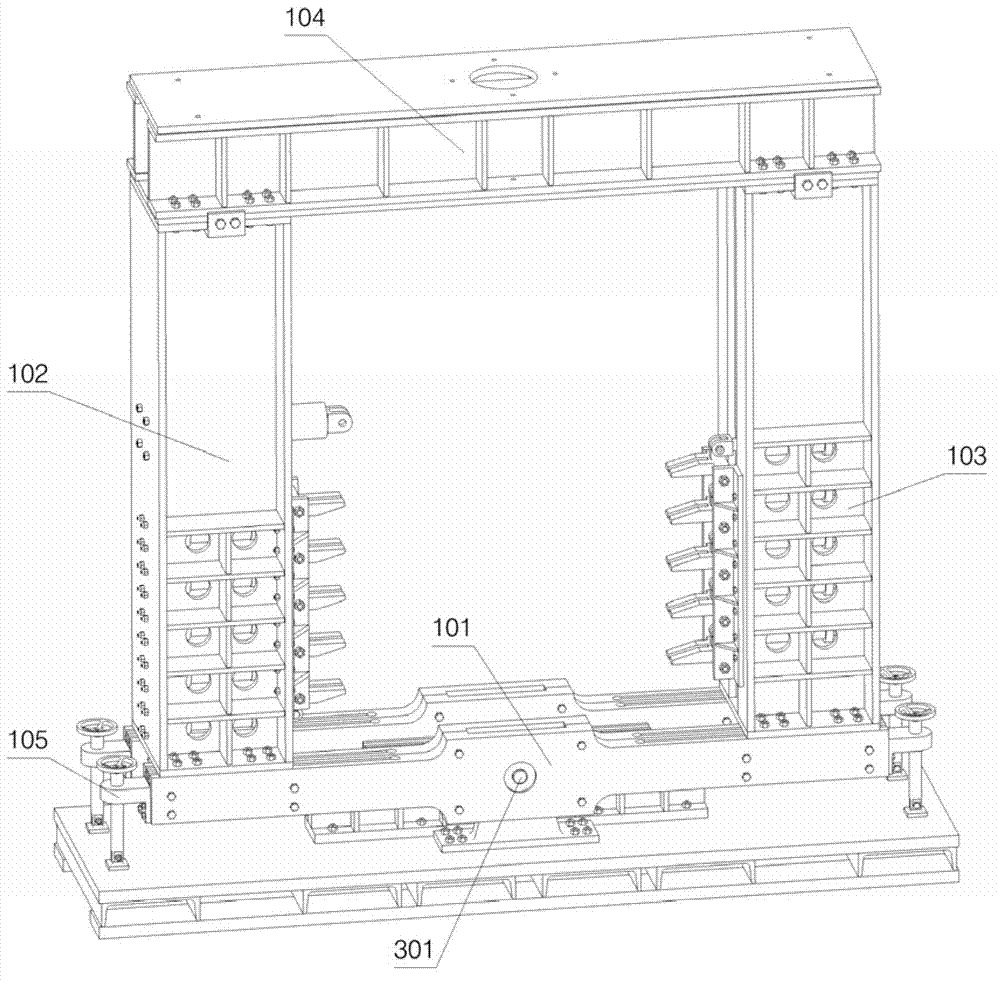

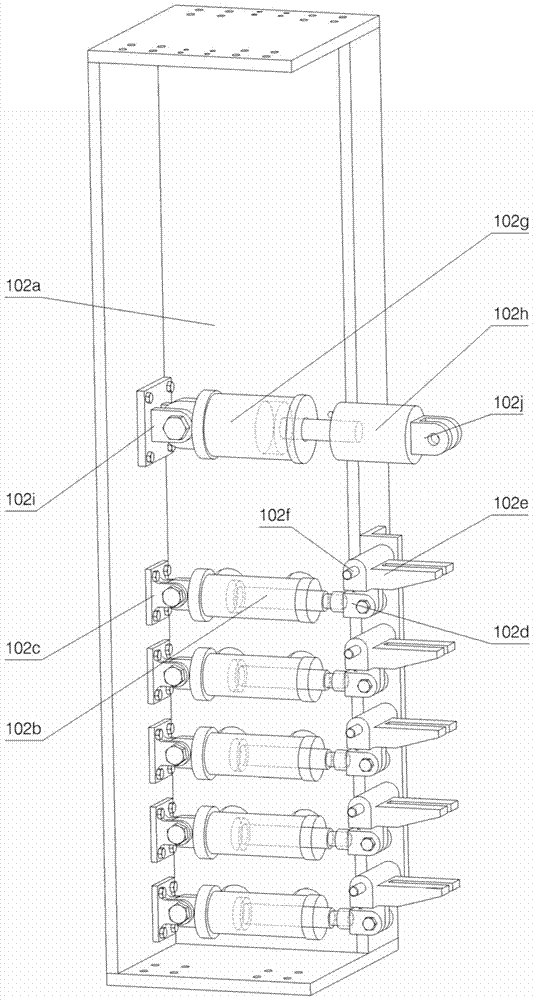

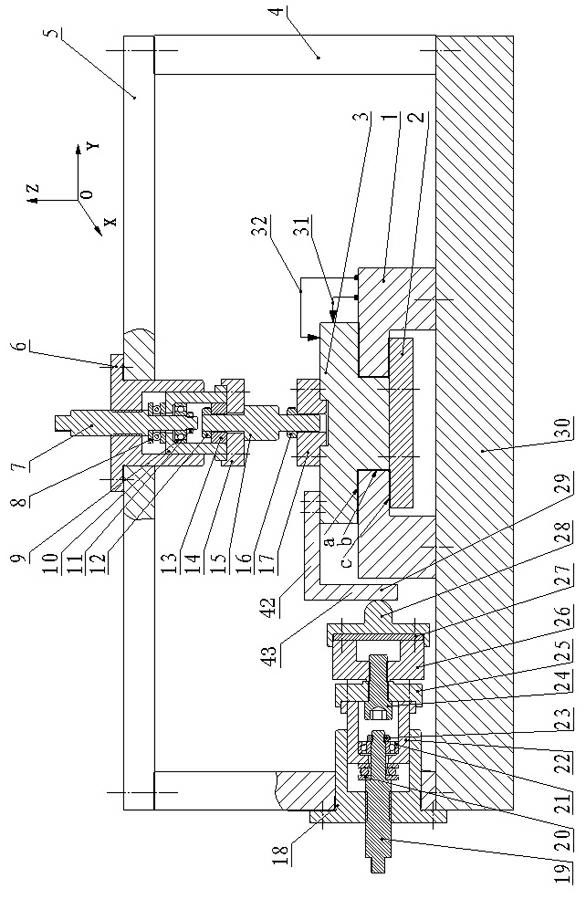

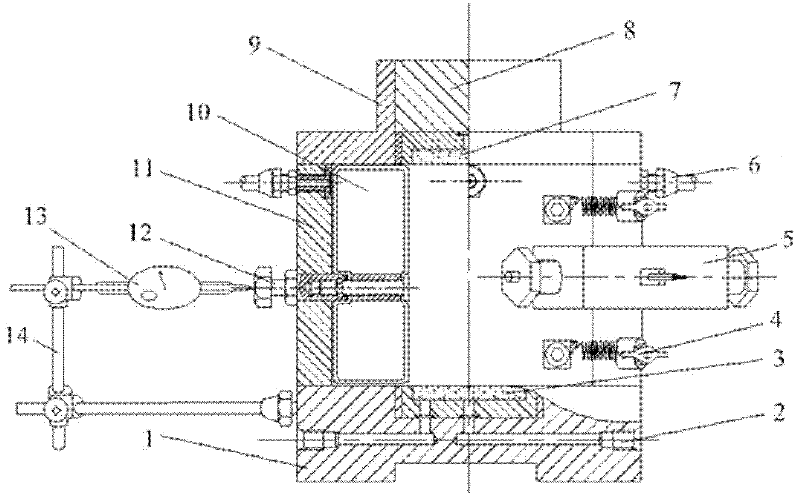

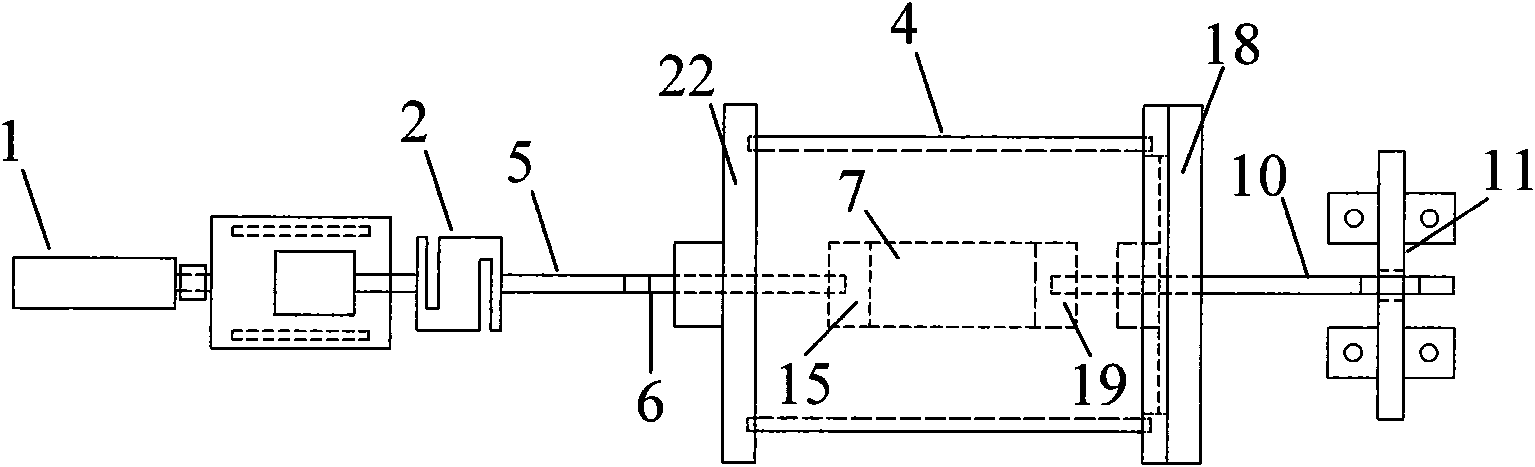

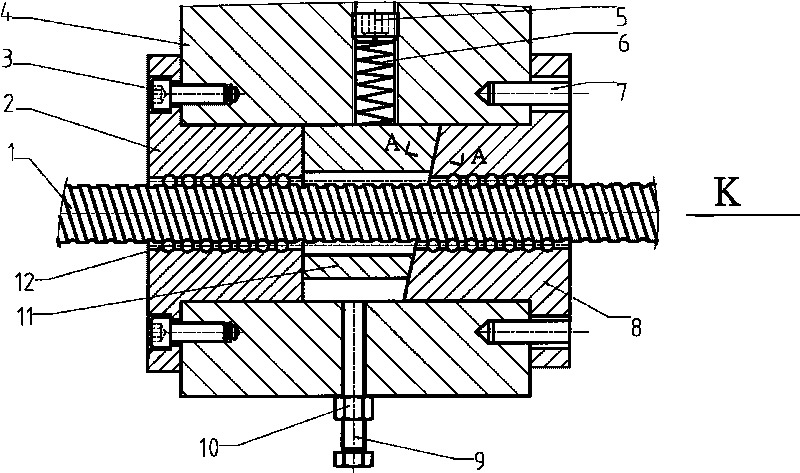

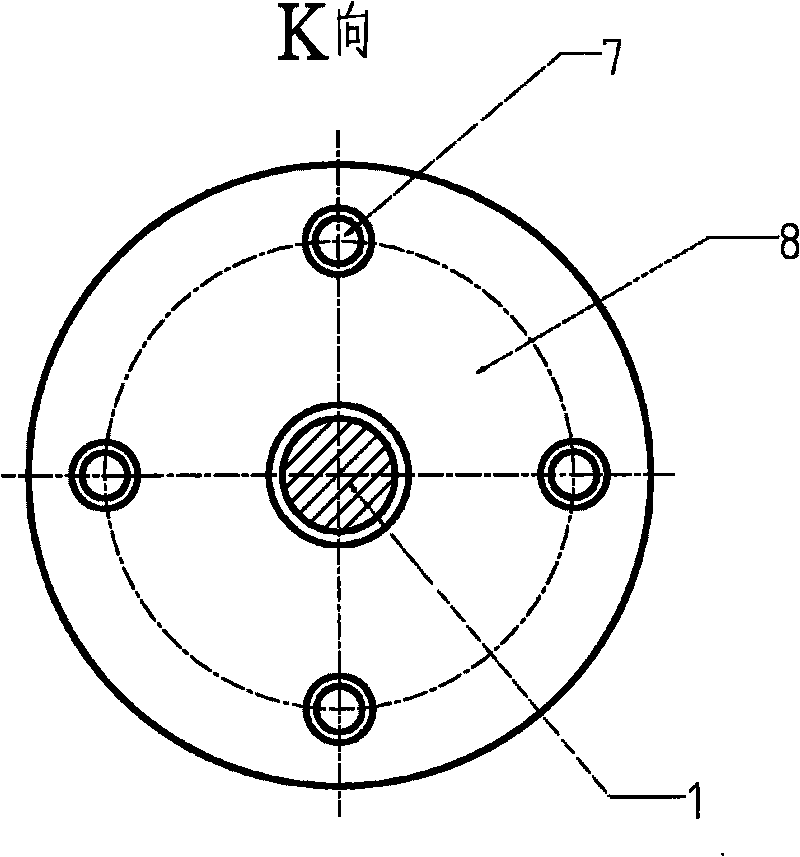

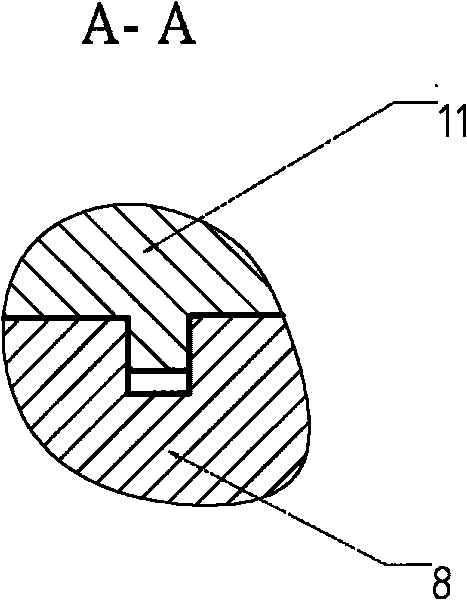

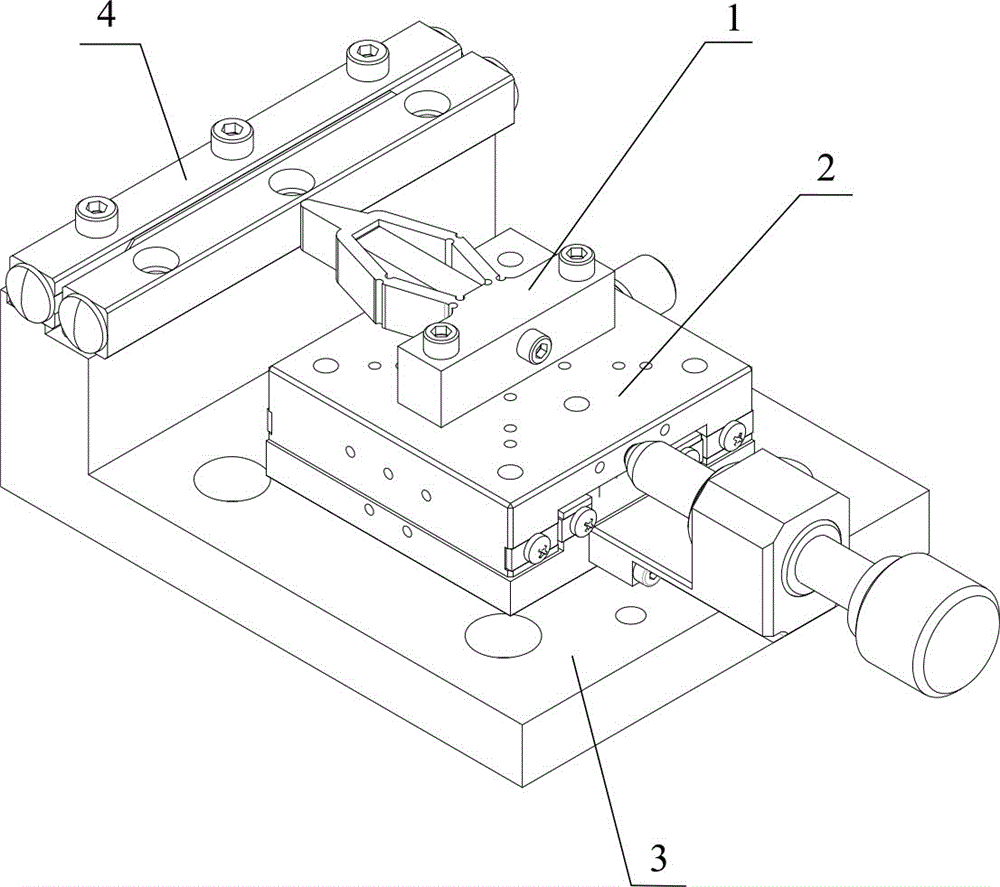

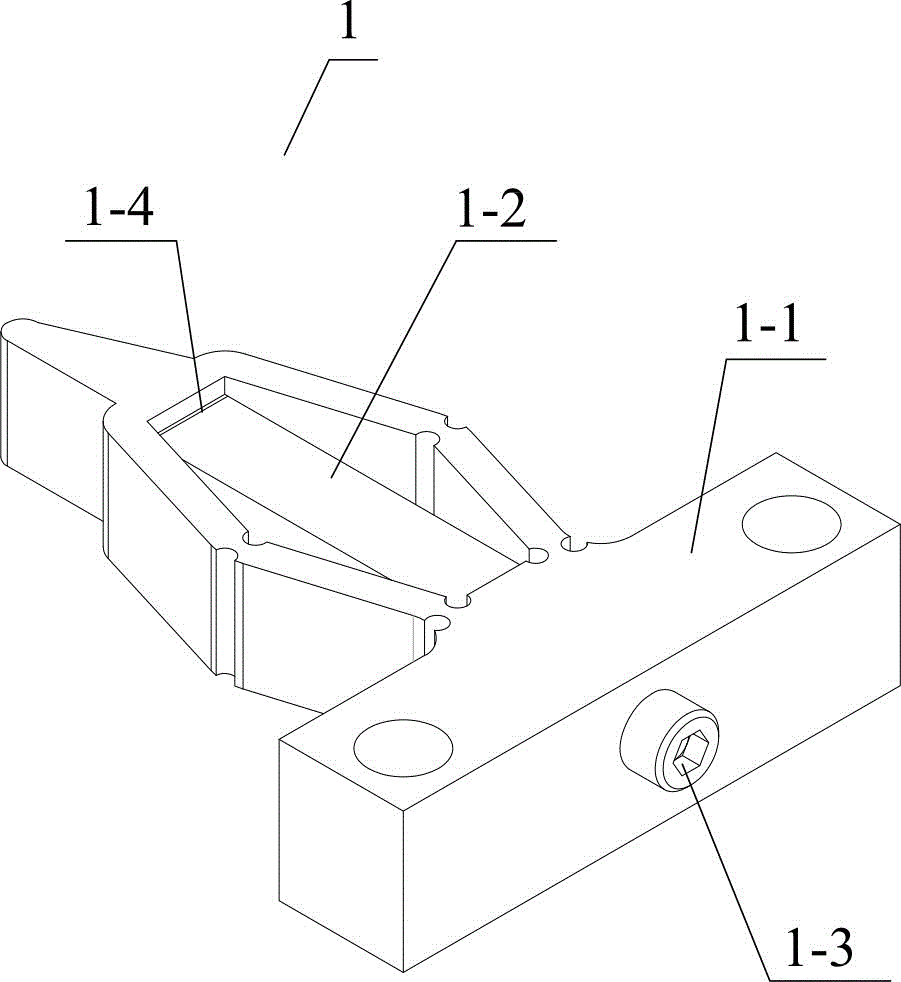

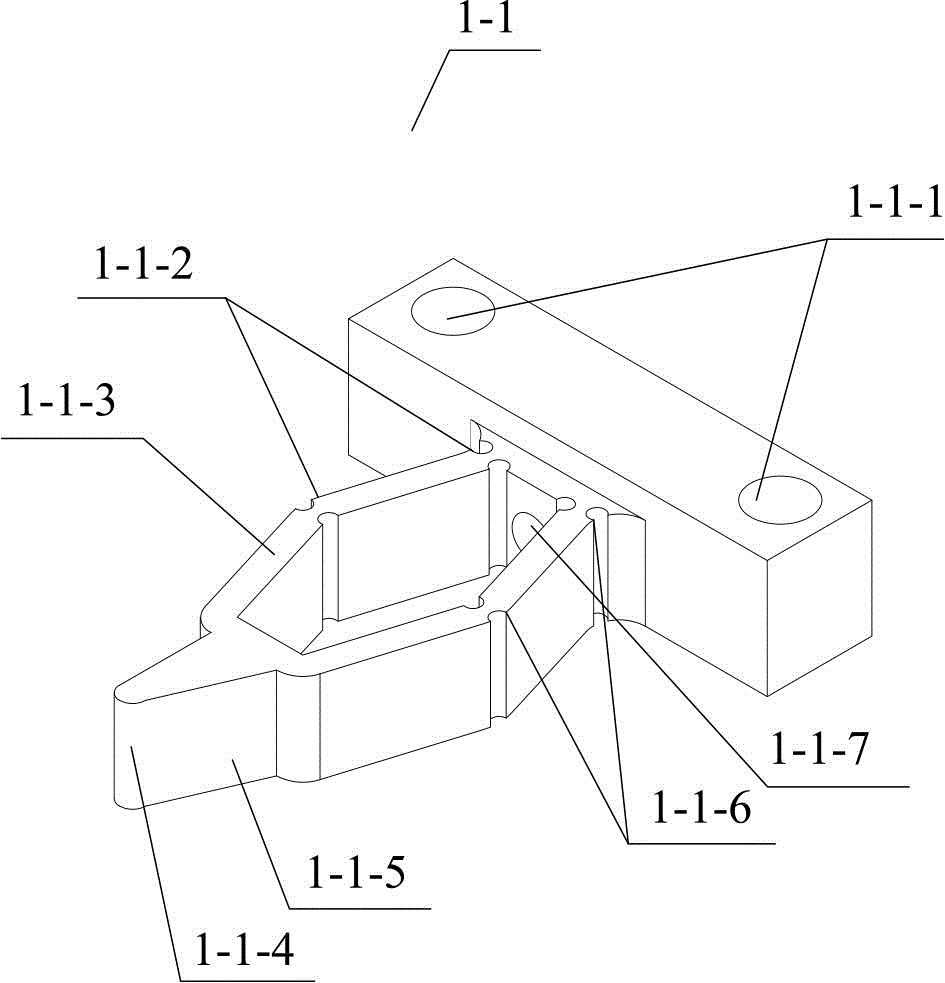

Test device capable of evenly applying axial compression load and shearing load

ActiveCN103033418AApply evenlyDoes not affect applied effectsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesAviationAxial compression

The invention belongs to the technical field of strength tests in aviation, and particularly relates to a test device capable of evenly applying an axial compression load and a shearing load. The test device comprises a shearing load applying component 1, an axial compression load applying component 2, a lower platform component 3 and a rib-adding flat plate component 4. According to the technology for independently loading the compression load and the shearing load, adopted by the device, the device not only is suitable for the flat plate, but also is suitable for a rib-adding flat plate. Furthermore, the test debugging of the single axial compression load and the single shearing load under the condition that the rib-adding flat plate is invariable in an installing posture can be realized, so that the reference can be provided for the analysis of the stress state of a lower wall plate under the joint action of the compression load and the shearing load. The device applies shearing force by the self-balance principle of a whole frame and a 'load balancer', so that the shearing force can be evenly applied, the axial rigidity of the rib-adding flat plate can not be enhanced due to an adopted segmental shearing reinforcement block, a compression load applying effect can not be influenced, and a 'side frame effect' can be avoided.

Owner:CHINA AIRPLANT STRENGTH RES INST

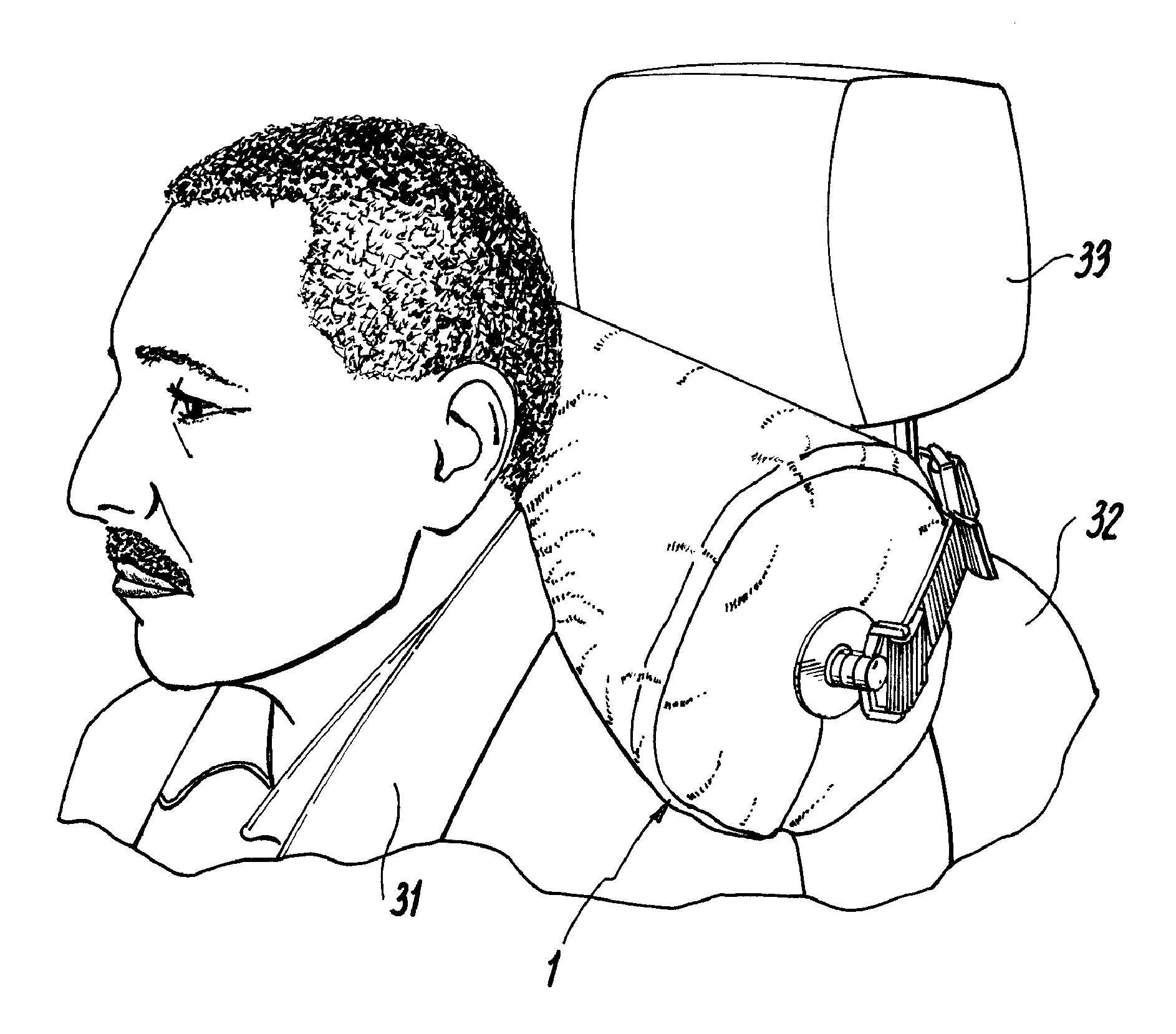

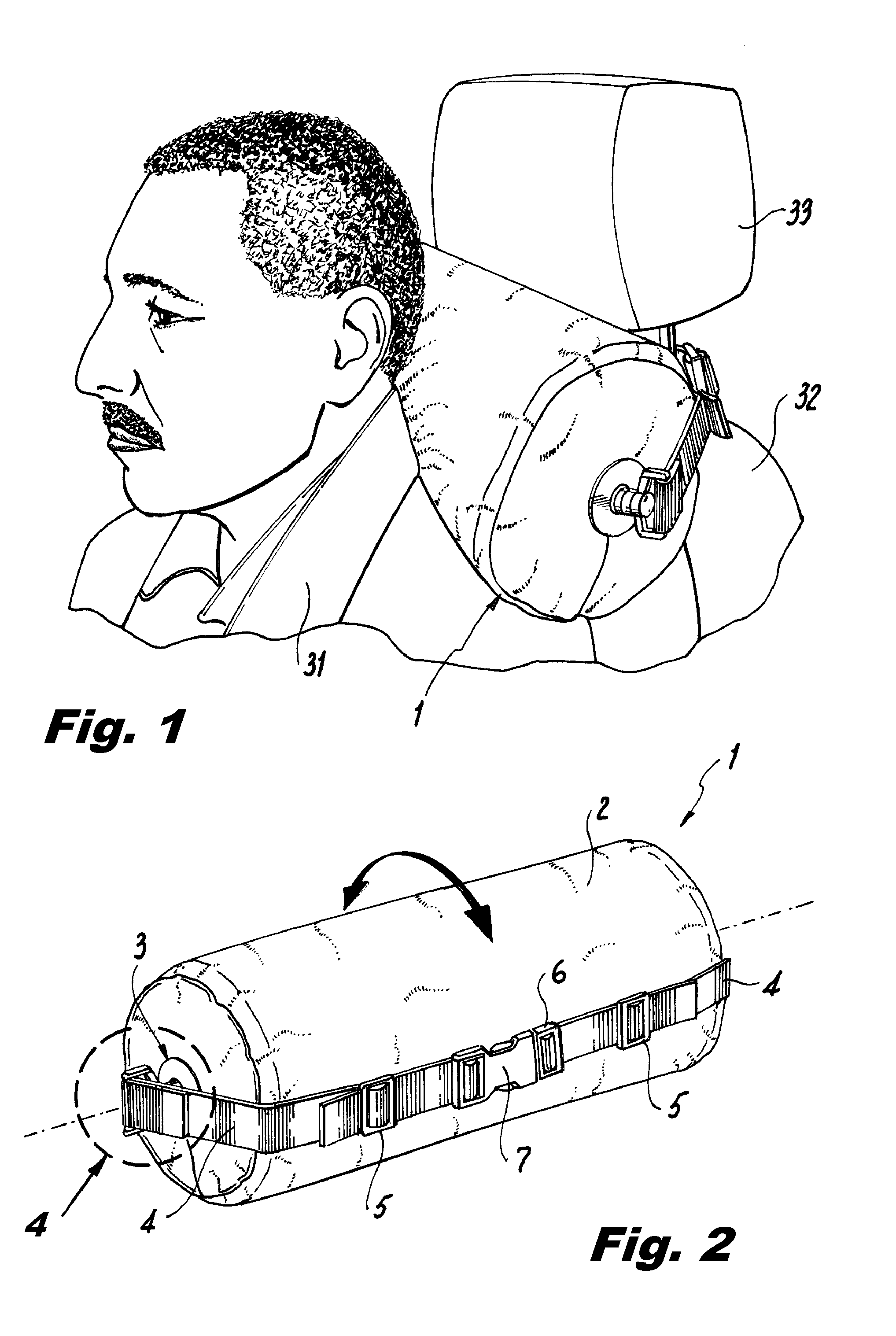

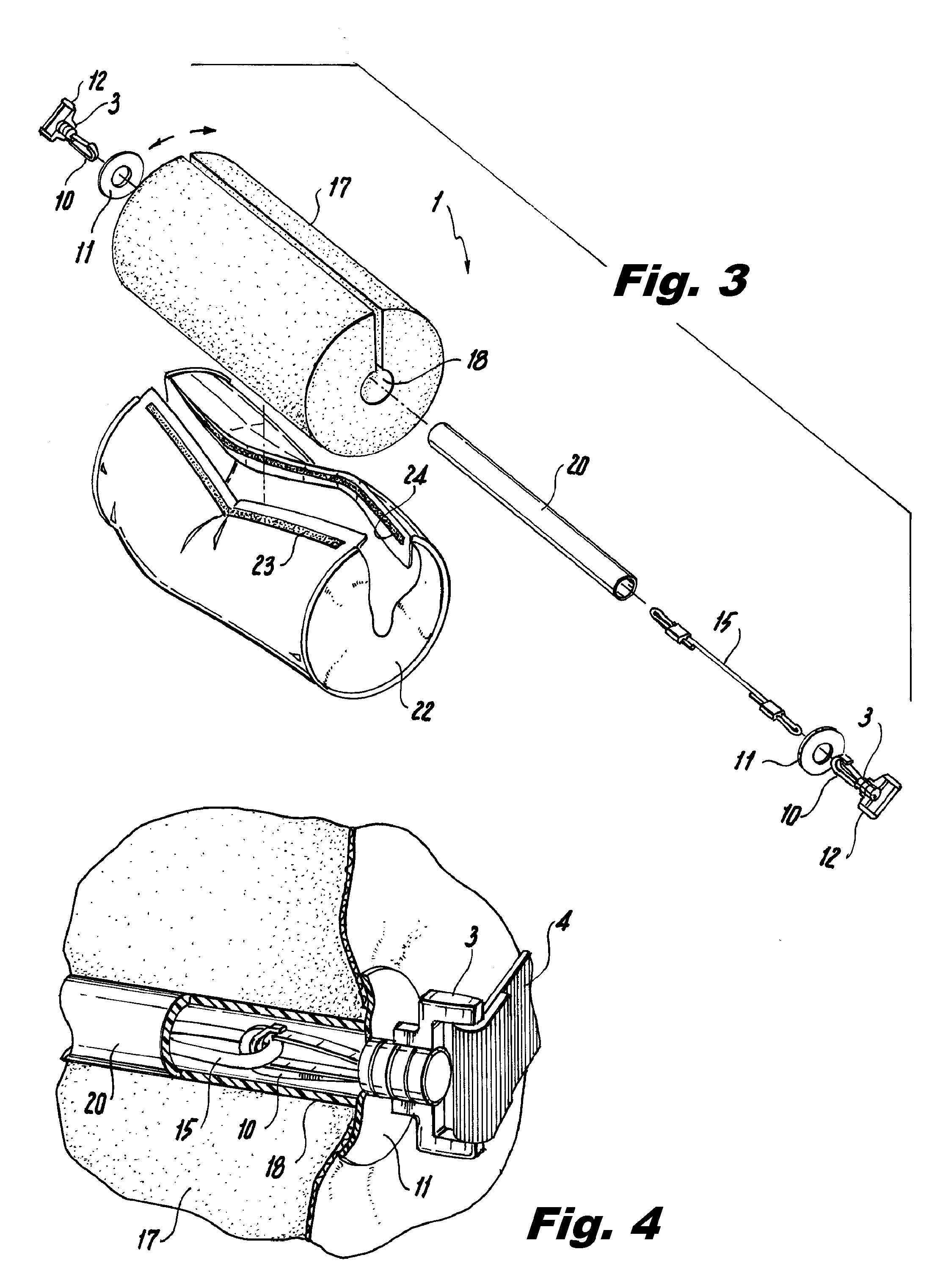

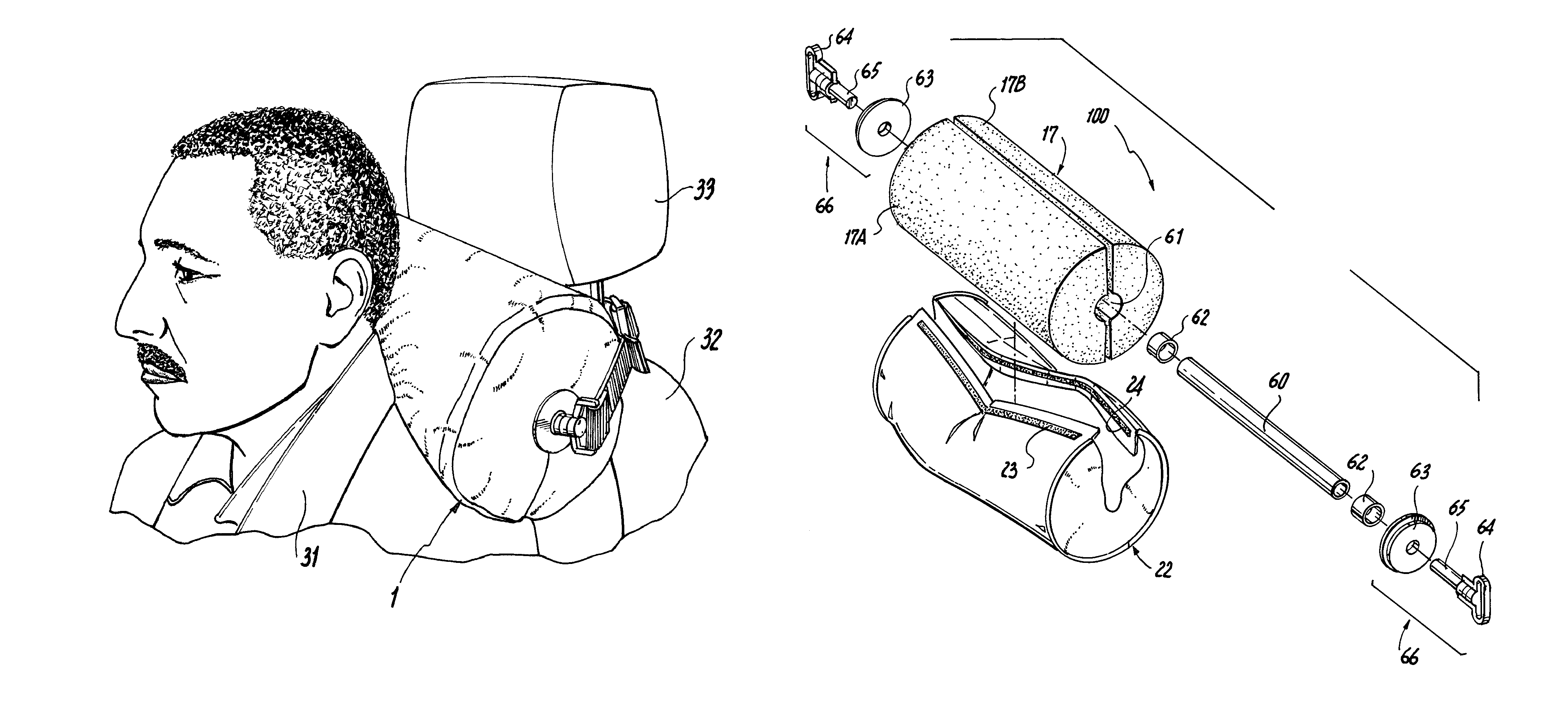

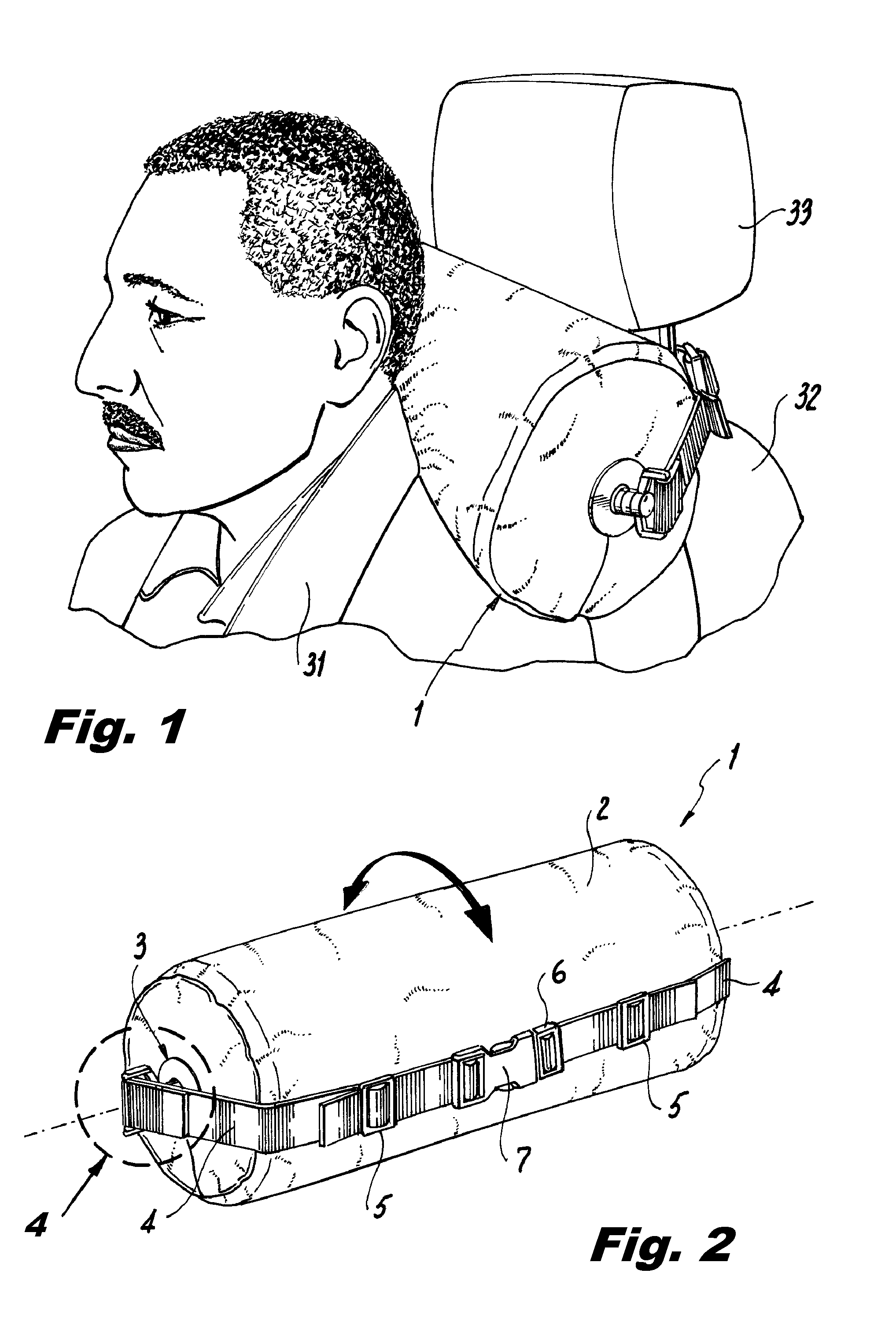

Rotatable cervical pillow for heavy equipment and other vehicles

InactiveUS20130119716A1Easy to disassembleSmooth rotationVehicle seatsOperating chairsHigh densityCervical pillows

A rotatable circular crossection cervical pillow is manually rotated in a continuous fashion as desired by a person whenever a fresh clean contact spot is sought, or a contact spot of variable support is sought, while the pillow is still attached to a seat back. The rotatable pillow is a cylinder of medium and / or firm high density polyurethane foam. An axial through-hole in the center permits the snug insertion of a rigid length of tubing to give the pillow axial rigidity. Swivel fixtures are attached at each end of the pillow by virtue of the central tube. A fabric cover with an opening closure covers the entire polyurethane cylinder snugly. Optionally the cover may carry therapeutic imparting elements therein. Straps with adjustable buckles are attached to each swivel fixture. Therefore, the cervical pillow rotates easily while still strap-attached to the seat back.

Owner:STRONCONI CHARLES J

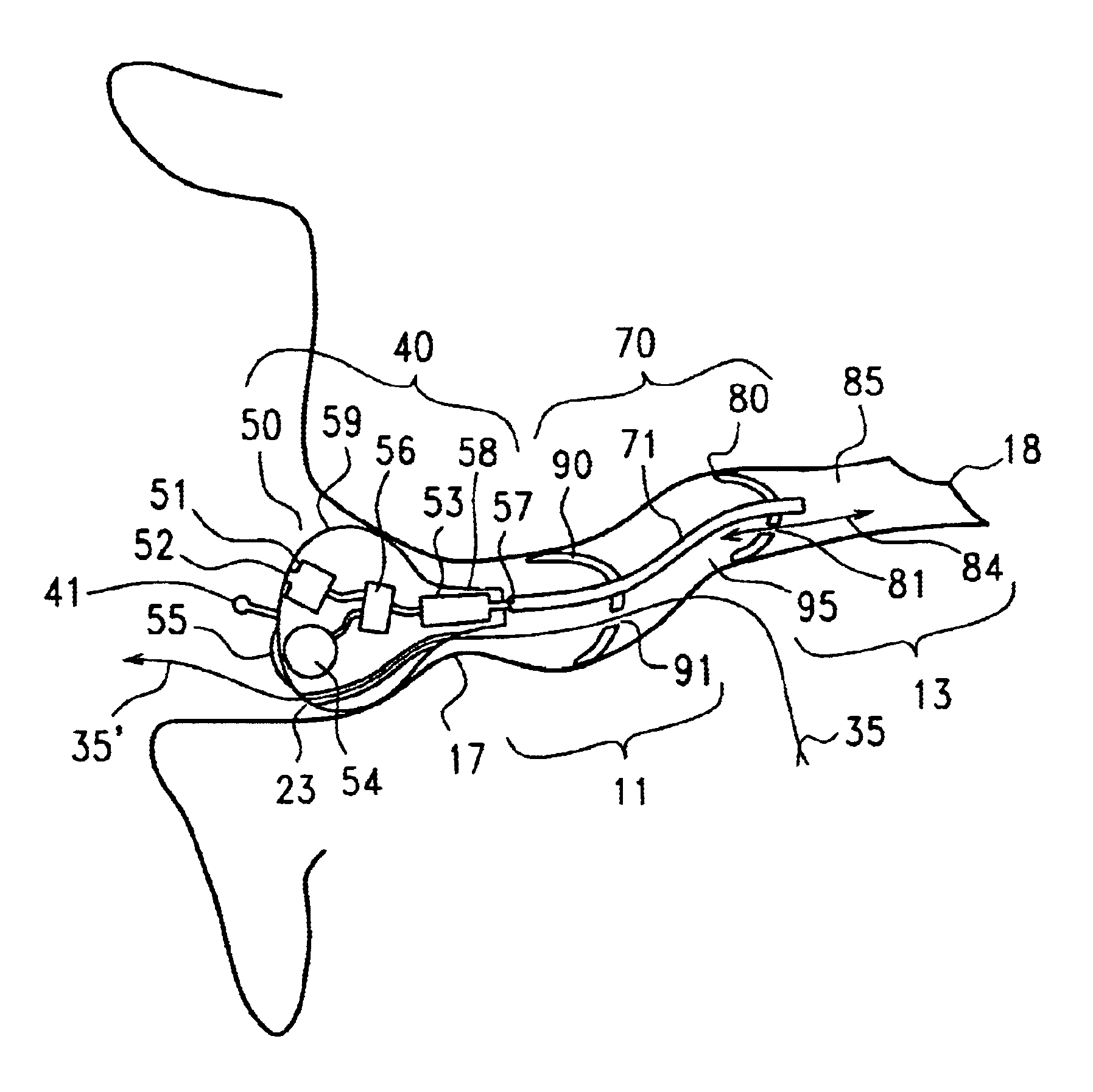

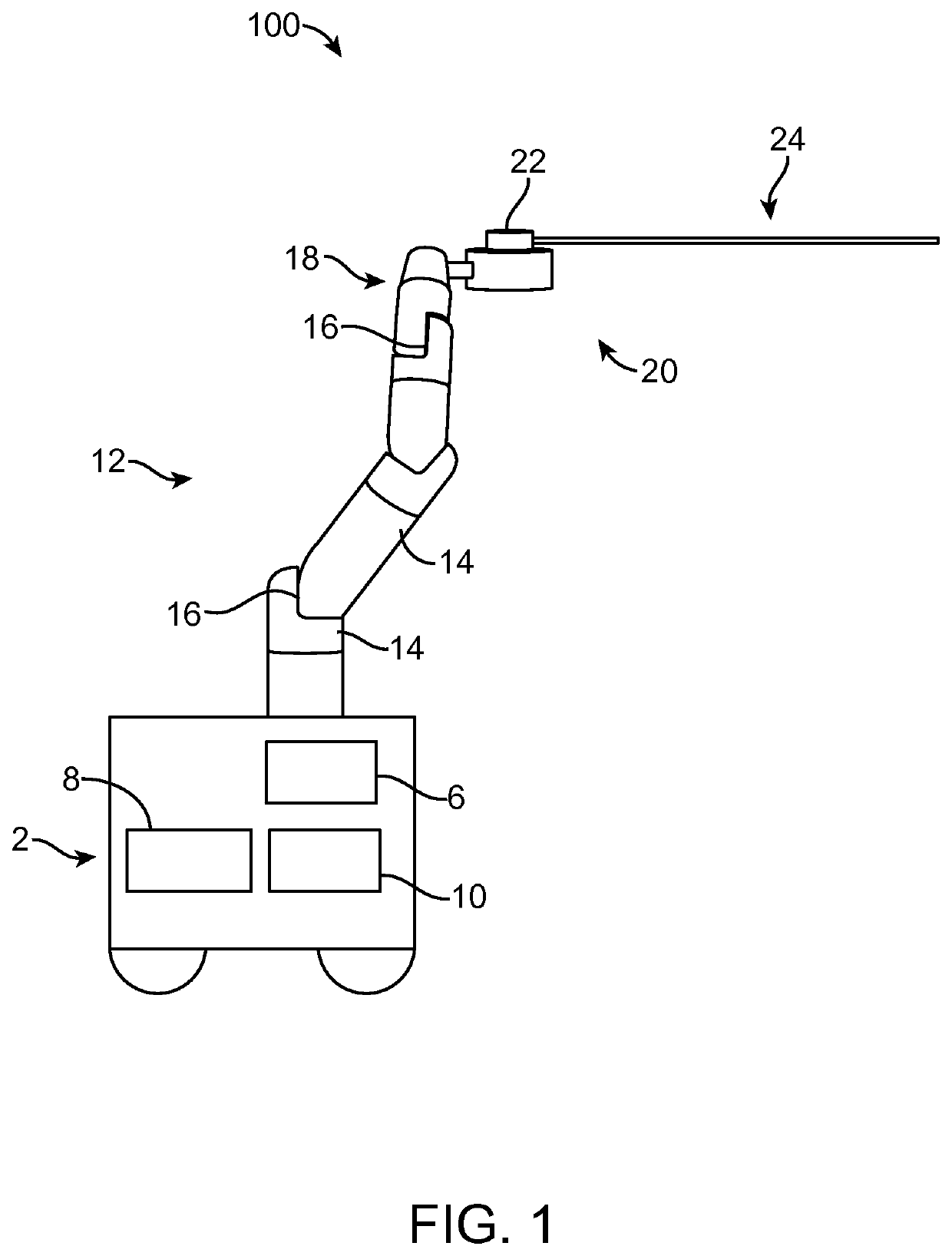

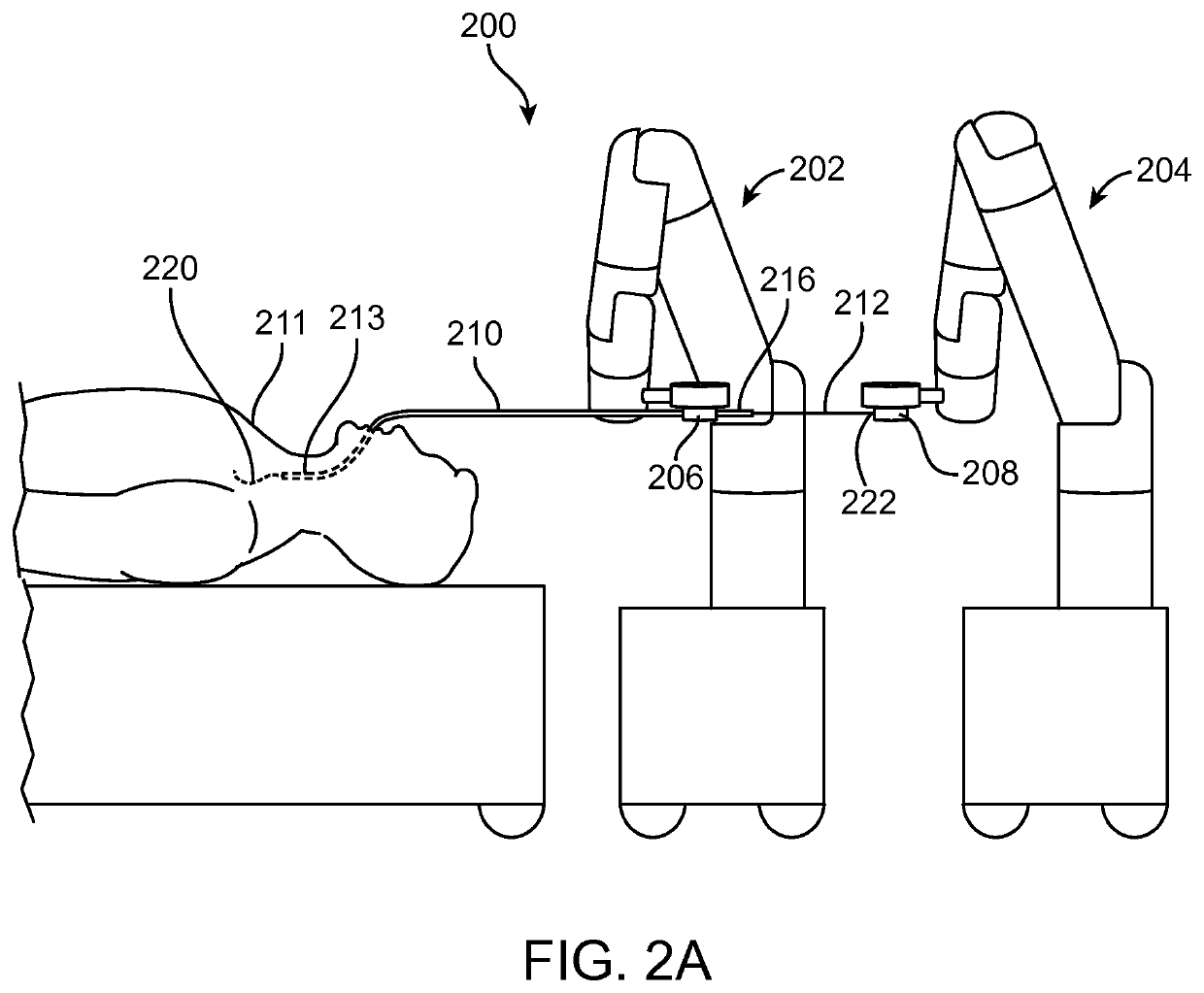

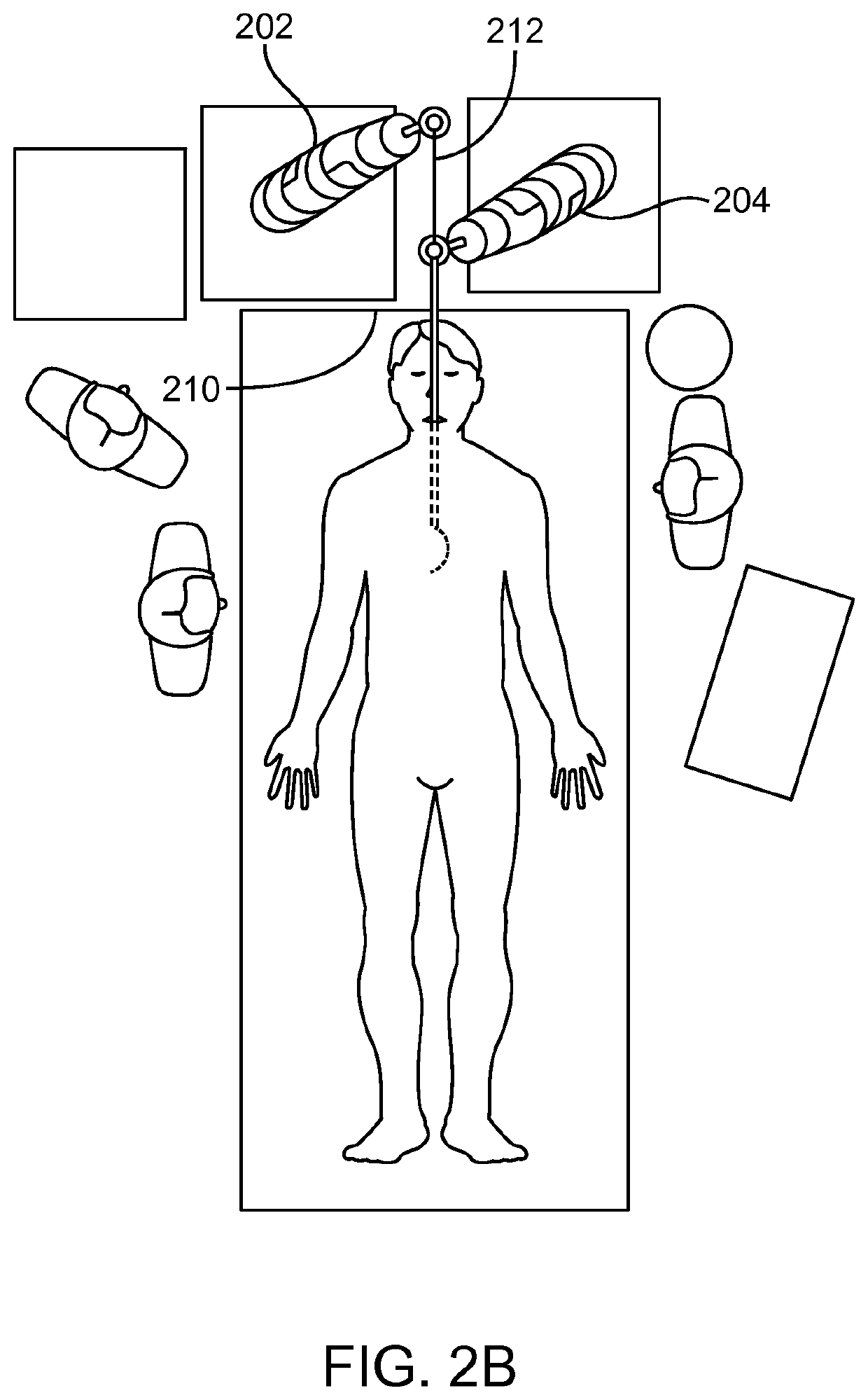

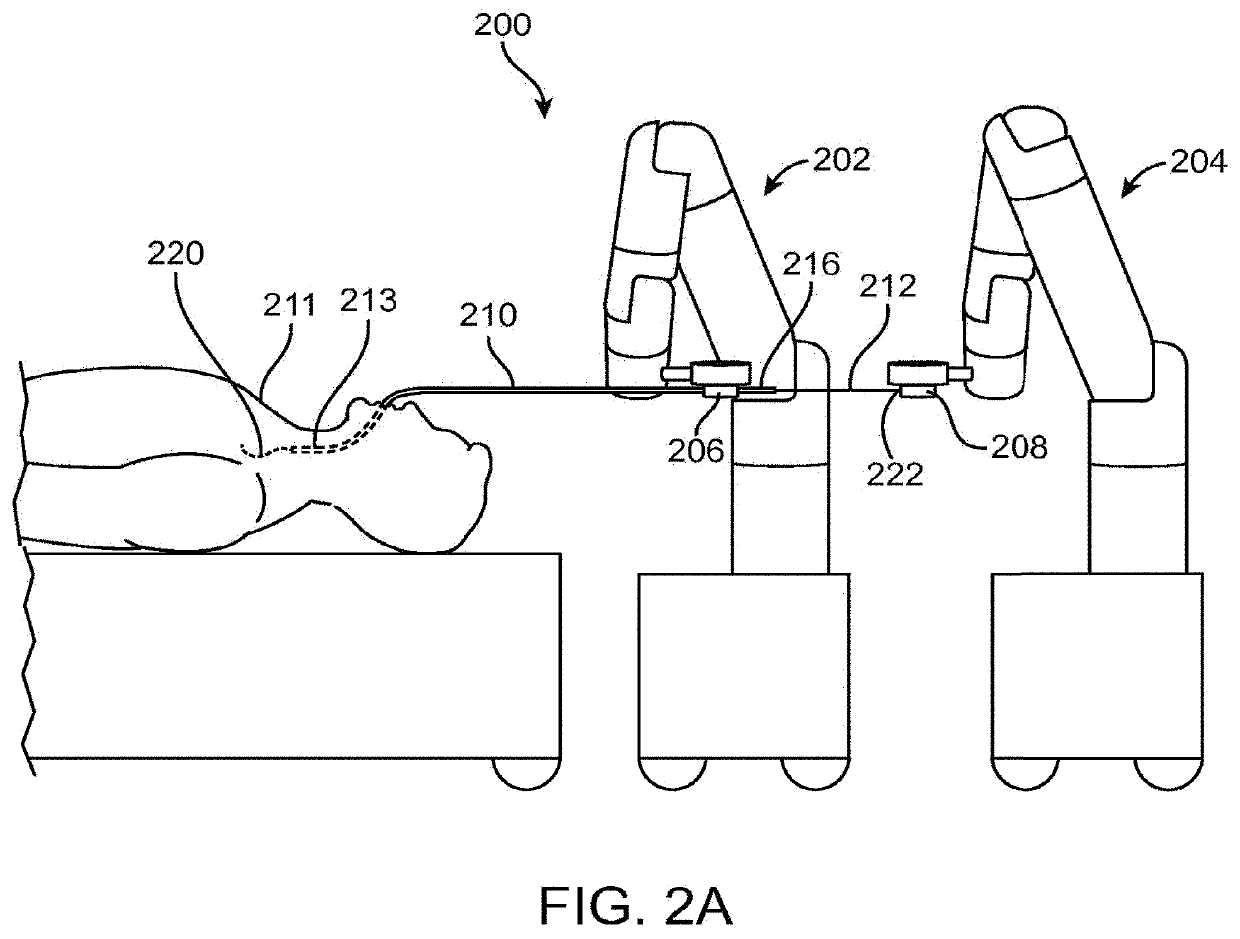

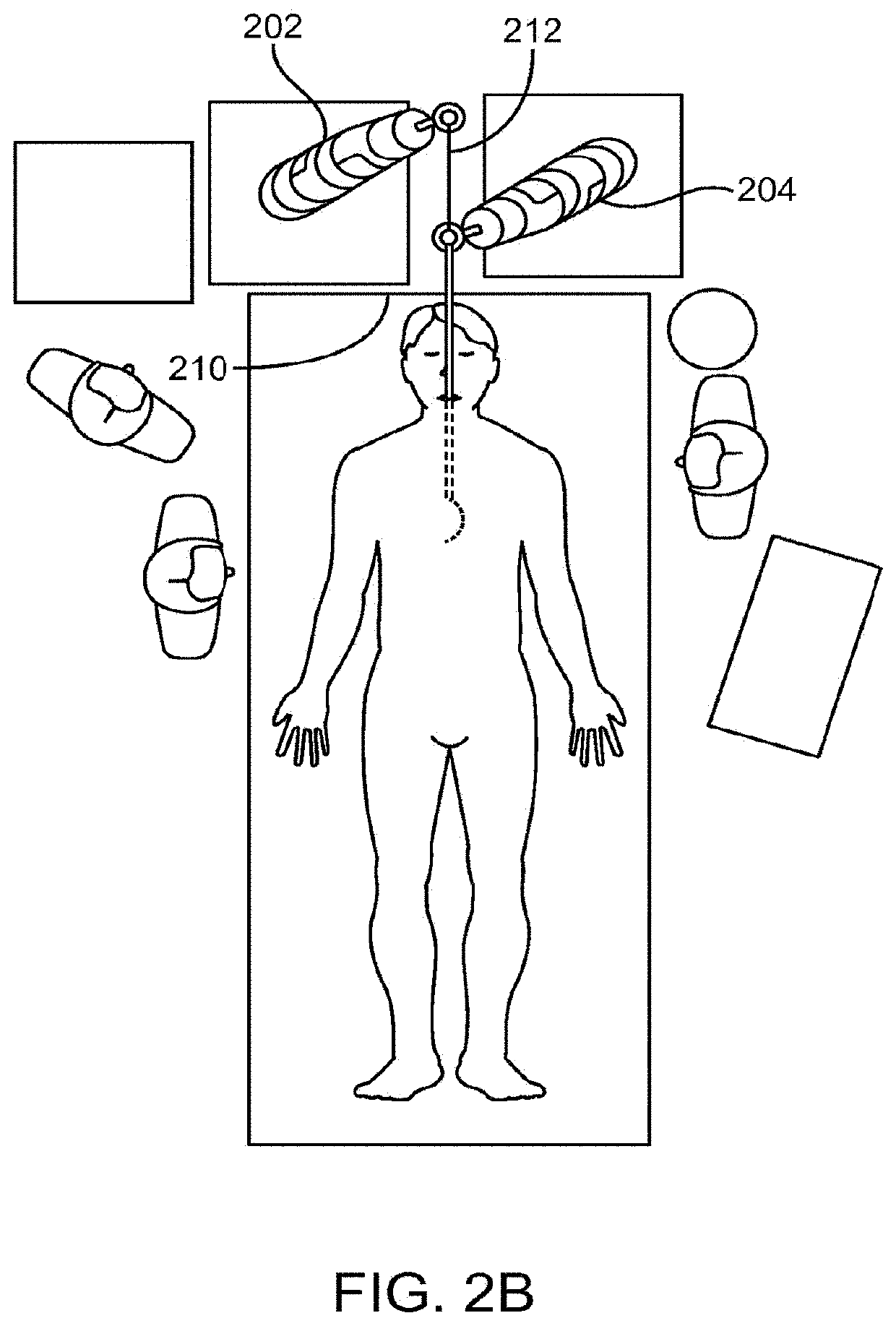

Tool and method for using surgical endoscope with spiral lumens

An embodiment of the present invention provides for an elongated medical device with a hypotube backbone running through the device, and a spiral lumen spiraled around the backbone along the length of the backbone. The backbone may be formed from a nitinol alloy for increased bendability without compromising axial stiffness. The device may also incorporate a jacket around the hypotube and spiral lumen formed using either melting, molding, bonding, or casting. The spiral lumen may be configured to accommodate a variety of uses, including actuation members (e.g., pull wires), tools, and means for aspiration, irrigation, image capture, and illumination. Additionally, the present invention provides a method for constructing an elongated medical device with a hypotube backbone running through the device, and a spiral lumen spiraled around the backbone along the length of the backbone.

Owner:AURIS HEALTH INC

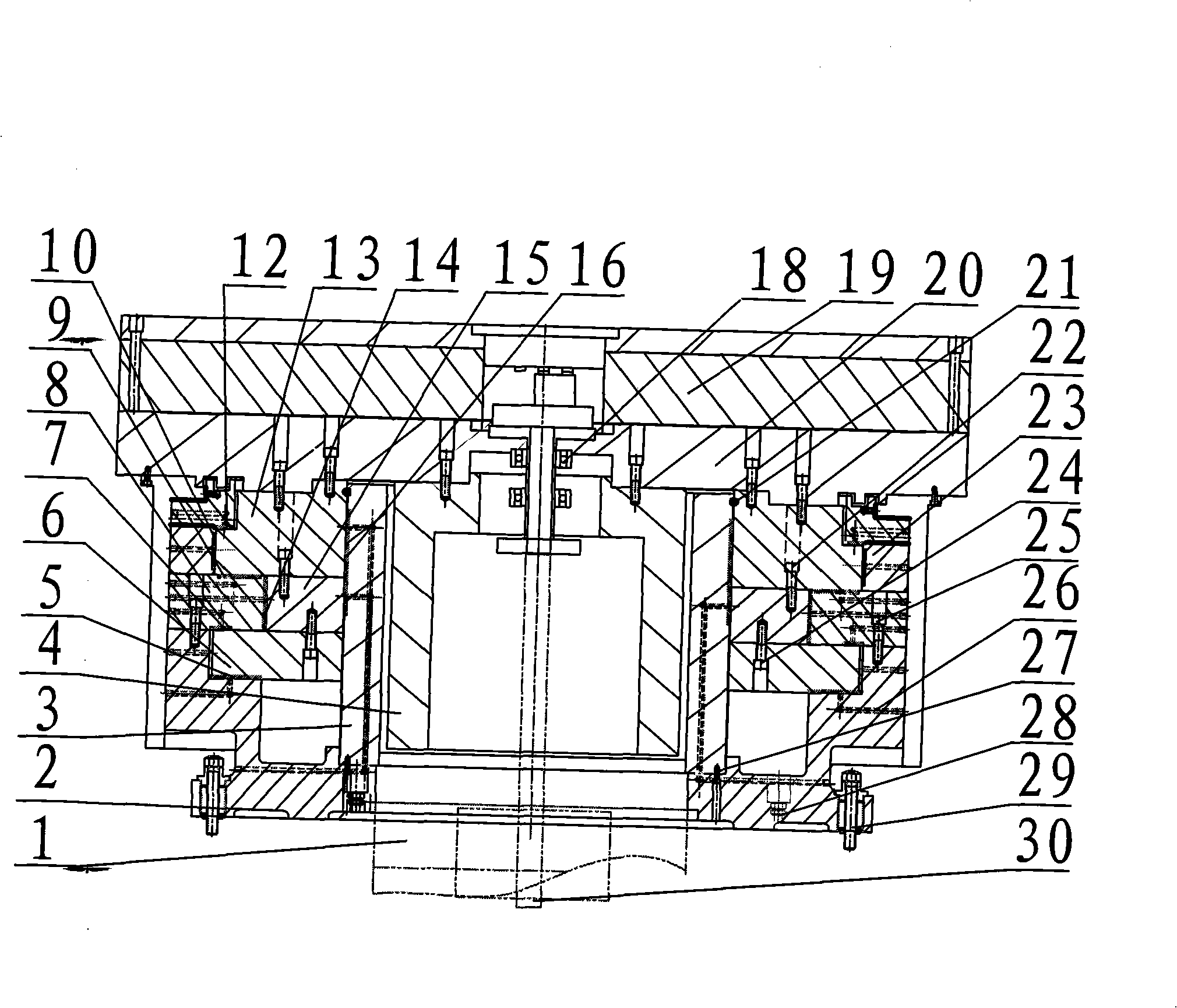

High precision high rigidity closed type fluid static pressure / dynamic-static pressure rotary table

ActiveCN101407024AImprove carrying capacityReduce volumeShaftsLarge fixed membersBall bearingKinematic pair

The invention provides a closed fluid static pressure / dynamic static pressure revolving worktable with high precision and rigidity, and relates to the field of automatic equipment of precision machinery. A plurality of axial bearings and radial bearings arranged along the axial direction are fixed by a plurality of slewing rings and bearing guide rails; the revolving worktable is provided with a balanced bearing to balance; kinematic pairs of a plurality of bearings rotate synchronously and are connected; fixed pairs of the bearings are connected through a base of the worktable; and sliding pairs of the radial bearings and bearing pairs of the axial bearings move rigidly, integrally and synchronously; and a relatively still sliding surface of the sliding pair of each bearing is provided with an oil chamber. Under the conditions that fluid pressure of the revolving worktable is same and the volume is equal, the axial rigidity, the radial rigidity and the bearing capacity are multiply improved, and the improved multiple is in direct proportion to the number of the bearings. The revolving worktable has the advantages of convenient design, simple manufacture, low cost, high precision and no abrasion. The revolving worktable is a key part of a high-precision metal working machinery, in particular to a functional part of large and oversize heavy equipment by using the key technology, and has more remarkable advantages in manufacturing equipment in the fields of navigation, astronavigation, large aircraft, and the like.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

Tool and method for using surgical endoscope with spiral lumens

An embodiment of the present invention provides for an elongated medical device with a hypotube backbone running through the device, and a spiral lumen spiraled around the backbone along the length of the backbone. The backbone may be formed from a nitinol alloy for increased bendability without compromising axial stiffness. The device may also incorporate a jacket around the hypotube and spiral lumen formed using either melting, molding, bonding, or casting. The spiral lumen may be configured to accommodate a variety of uses, including actuation members (e.g., pull wires), tools, and means for aspiration, irrigation, image capture, and illumination. Additionally, the present invention provides a method for constructing an elongated medical device with a hypotube backbone running through the device, and a spiral lumen spiraled around the backbone along the length of the backbone.

Owner:AURIS HEALTH INC

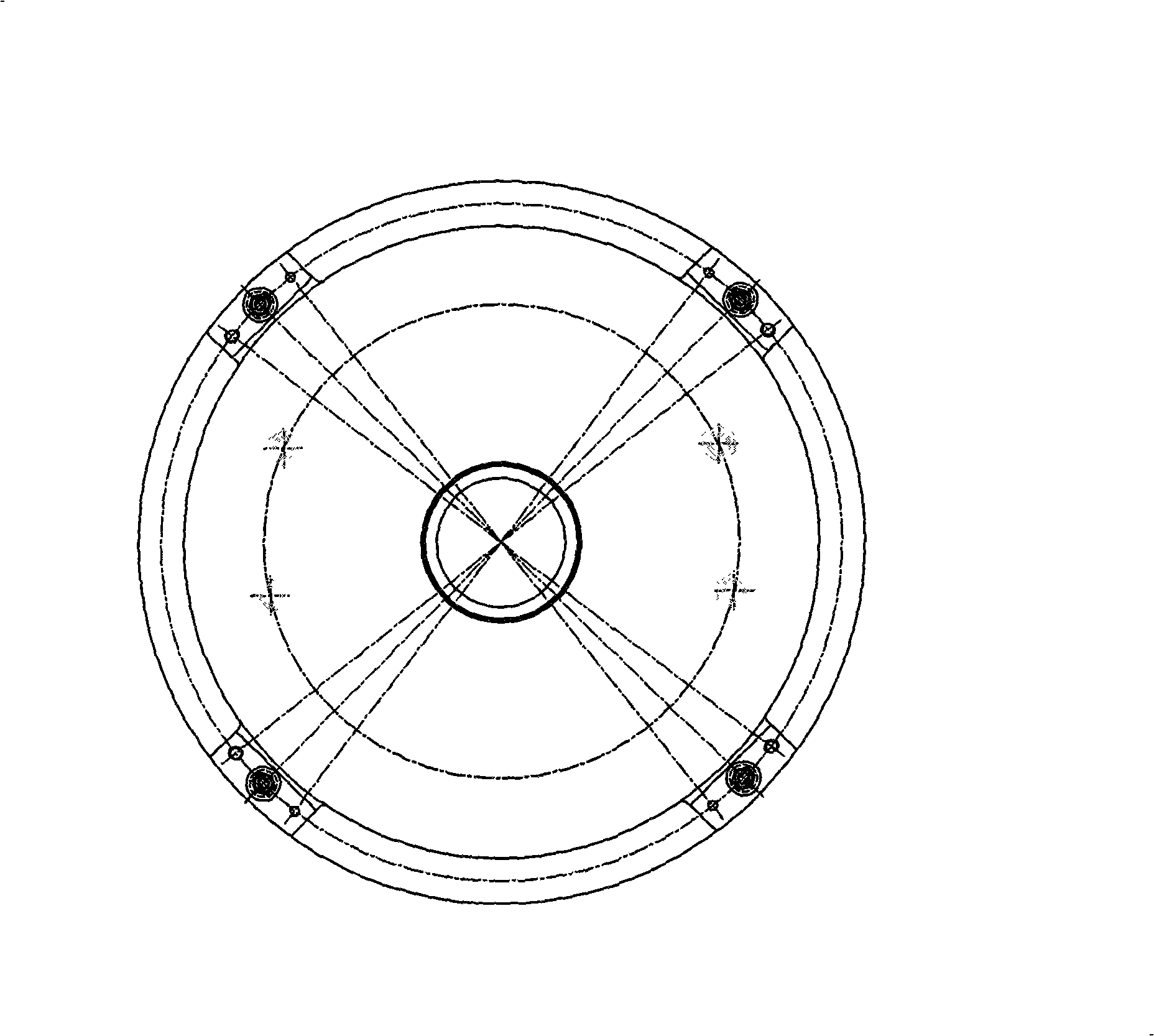

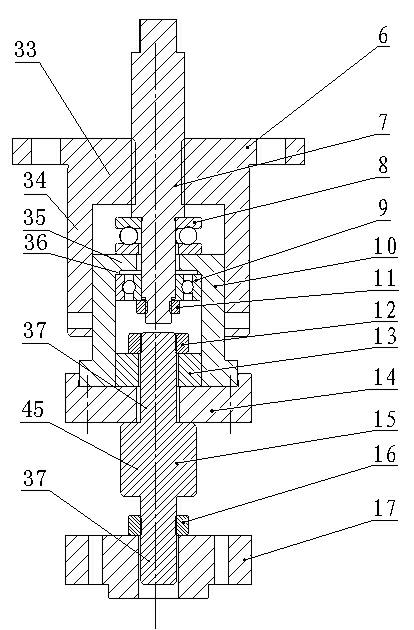

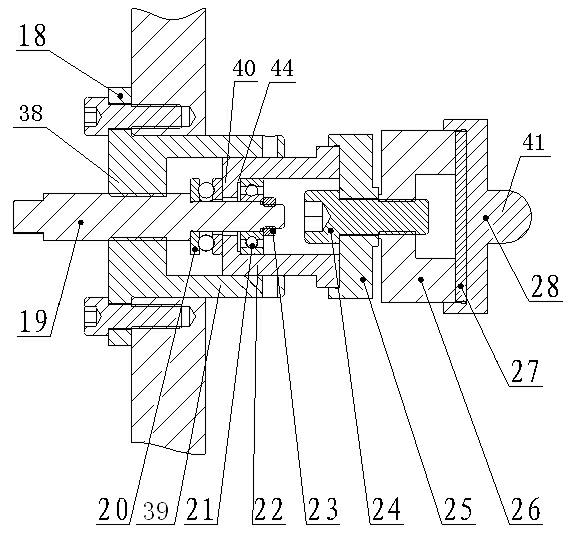

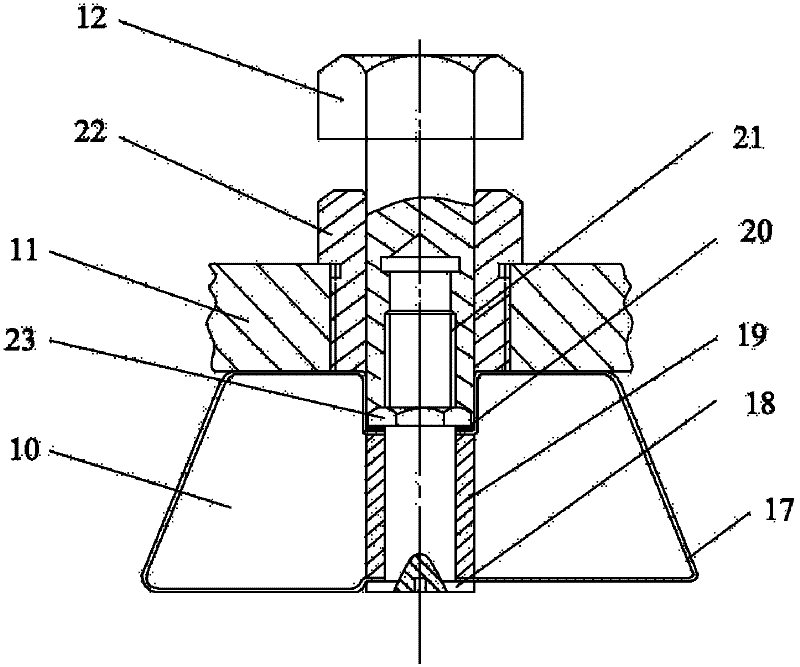

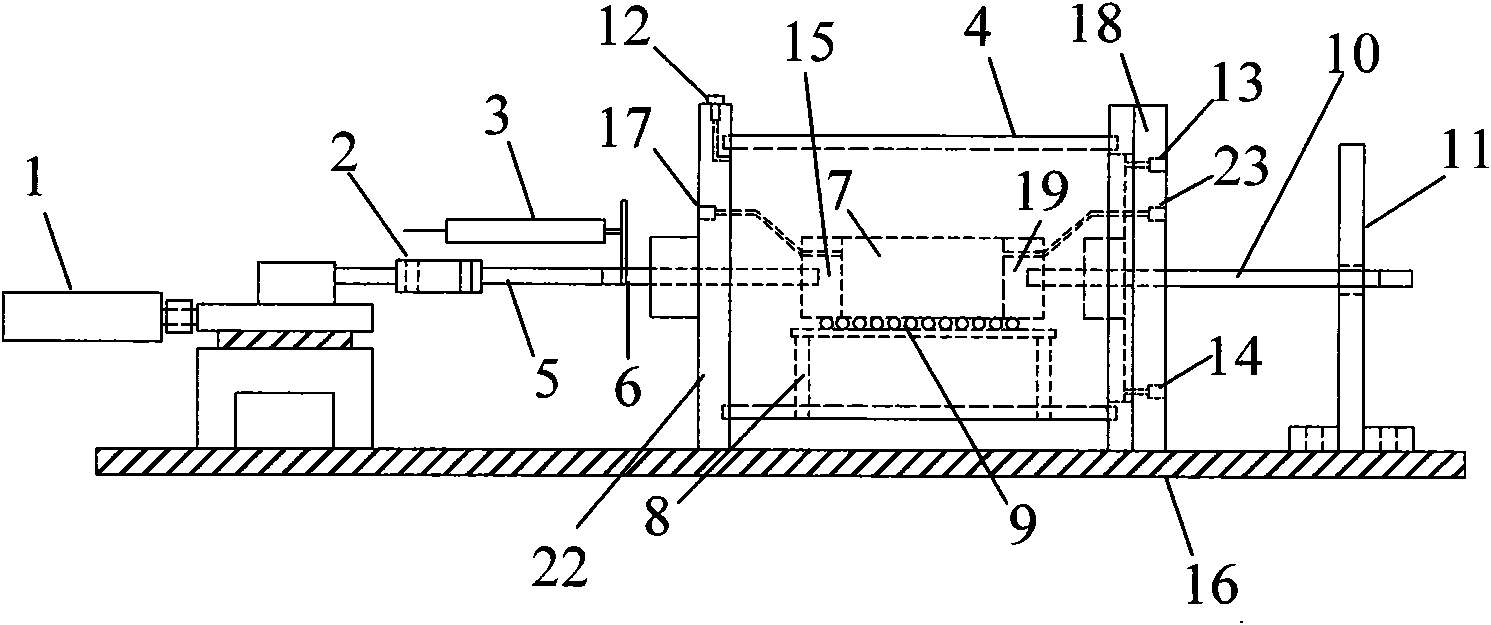

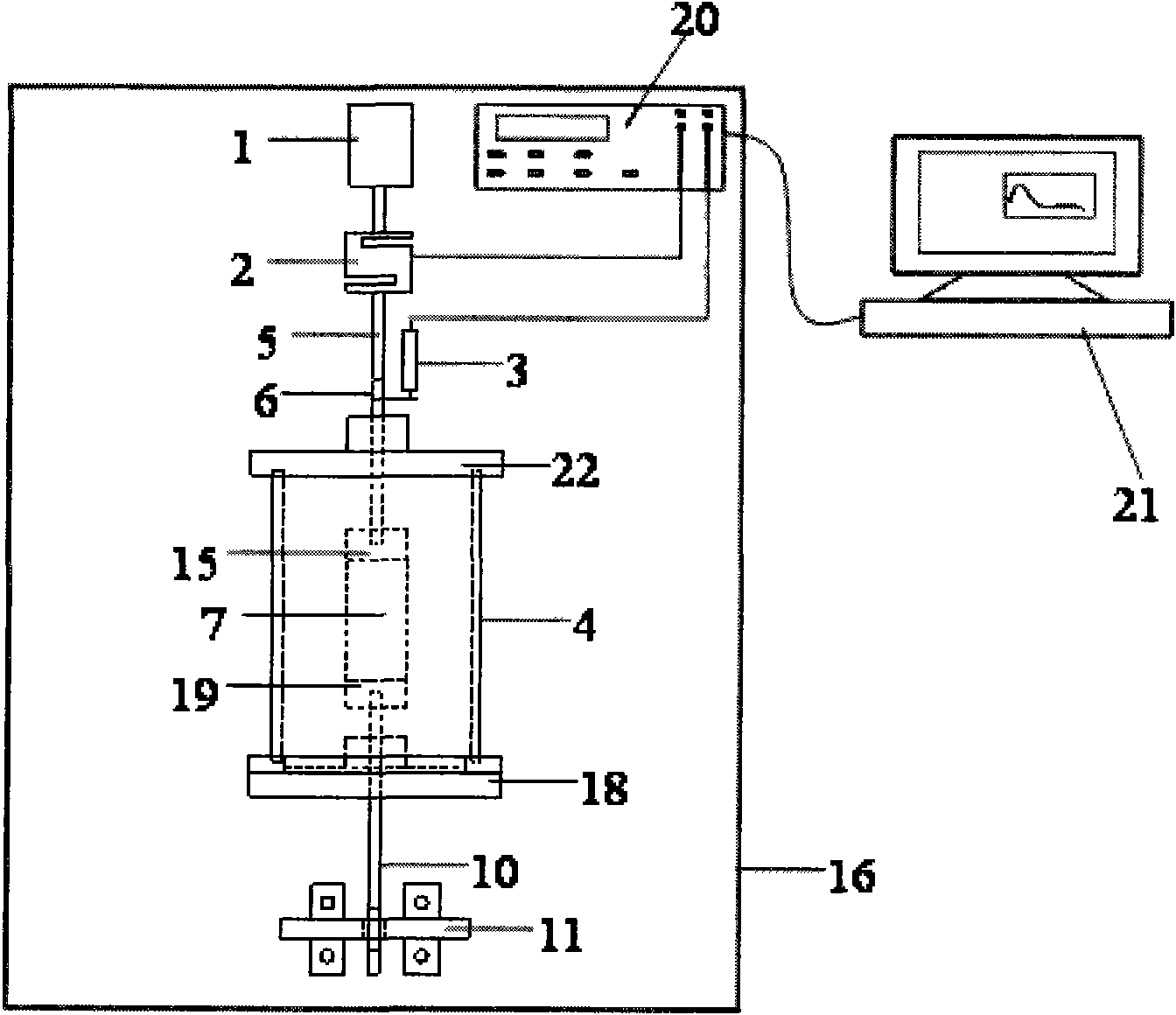

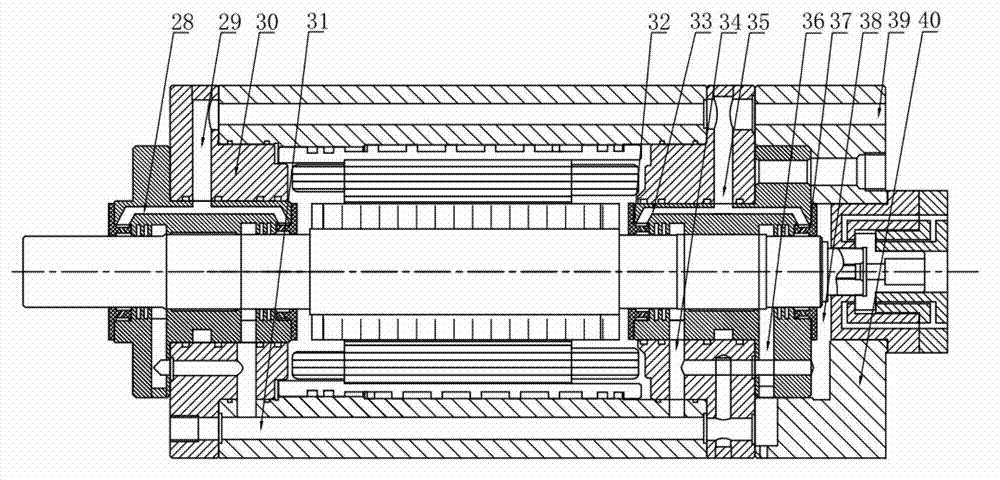

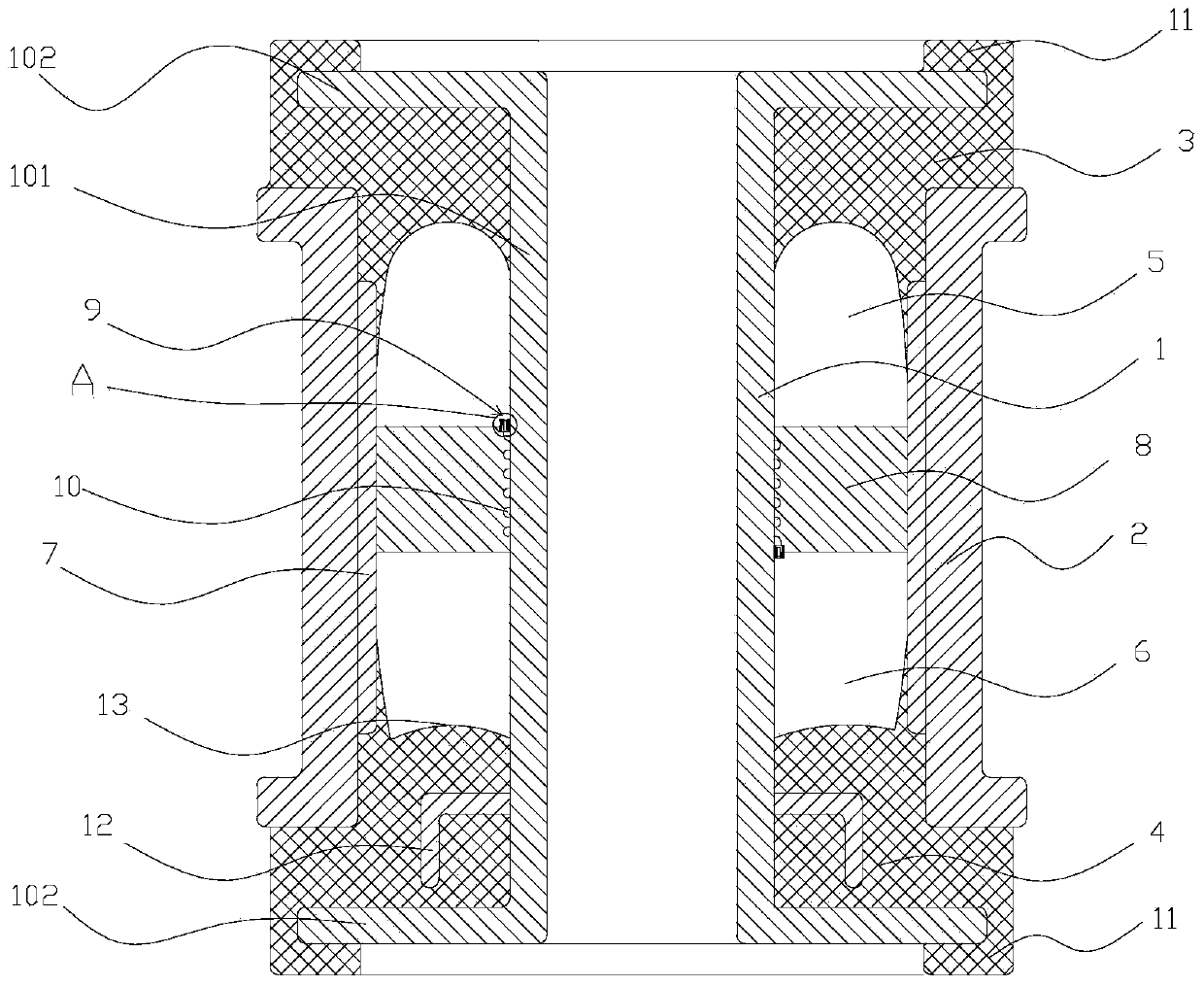

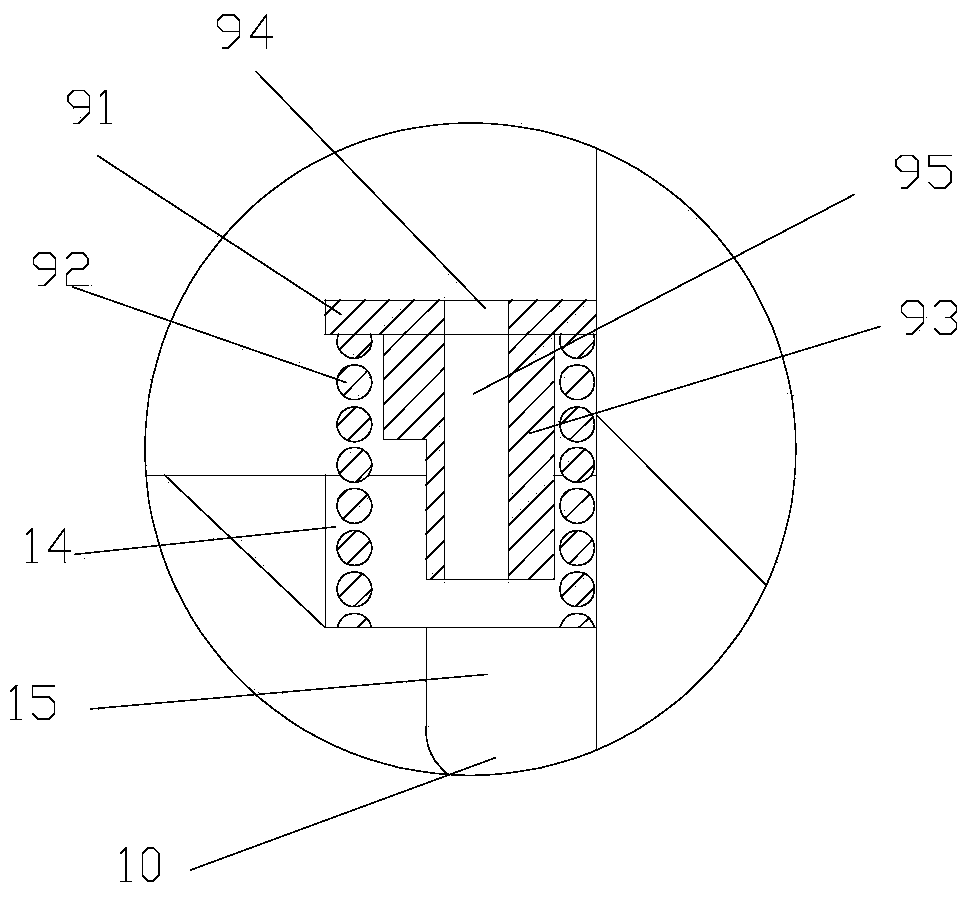

Method and device for testing axial rigidity and radial rigidity of rotary hydrostatic guide rail

The invention provides a method and device for testing axial rigidity and radial rigidity of a rotary hydrostatic guide rail. A rotary guide rail seat is fixed on a platform, a pressing plate and a rotary assembly are fixedly connected to form a rotary part, and the rotary part is used for guiding in a rotary motion way by depending on a hydrostatic guide rail pair; an axial load assembly comprises a flange sleeve, a screw rod, a thrust bearing, a radial bearing, a sleeve, a connecting piece, force sensors and a terminal pad which are vertically arranged; a radial load assembly comprises a flange sleeve, a screw rod, a thrust bearing, a radial bearing, a sleeve, a connecting piece, a force sensor, a loading piece and a connection bending plate which are horizontally arranged; and a mounting support of a displacement sensor assembly is fixed on the rotary guide rail seat, and a measuring head aligns to the rotary assembly. The method and device provided by the invention can be used for acquiring the axial and the radial rigidity data of the hydrostatic guide rail in a rotary motion and can also be used for an confirmatory experiment on a method for analyzing the rigidity of the hydrostatic guide rail in the rotary motion and the influence of oil film tangential adhesive force.

Owner:XIAN UNIV OF TECH

Rotatable cervical pillow for heavy equipment and other vehicles

InactiveUS8708416B2Easy to disassembleSmooth rotationVehicle seatsOperating chairsHigh densityCervical pillows

A rotatable circular crossection cervical pillow is manually rotated in a continuous fashion as desired by a person whenever a fresh clean contact spot is sought, or a contact spot of variable support is sought, while the pillow is still attached to a seat back. The rotatable pillow is a cylinder of medium and / or firm high density polyurethane foam. An axial through-hole in the center permits the snug insertion of a rigid length of tubing to give the pillow axial rigidity. Swivel fixtures are attached at each end of the pillow by virtue of the central tube. A fabric cover with an opening closure covers the entire polyurethane cylinder snugly. Optionally the cover may carry therapeutic imparting elements therein. Straps with adjustable buckles are attached to each swivel fixture. Therefore, the cervical pillow rotates easily while still strap-attached to the seat back.

Owner:STRONCONI CHARLES J

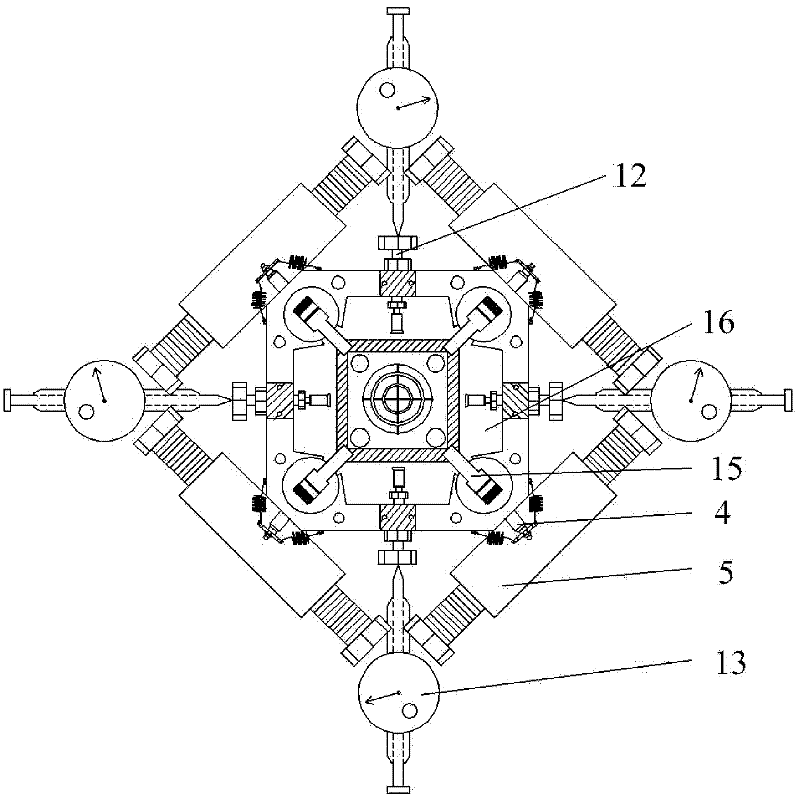

Measurement mechanism for lateral deformation of pressure chamber of true triaxial apparatus

InactiveCN102507334AStrong contrastReliable test resultsMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementEmulsionEngineering

The invention discloses a measurement mechanism for lateral deformation of a pressure chamber of a true triaxial apparatus. The pressure chamber of the true triaxial apparatus is formed by a pressure chamber base, pressure chamber lateral walls and a pressure chamber top cover. Four pressure cavities are symmetrically distributed in the pressure chamber, and an emulsion membrane is respectively arranged in the four pressure cavities, and four emulsion membranes are respectively connected with an external pressure source and respectively form flexible hydraulic capsules after being filled withliquid. Lateral displacement measurement guide rods are radially and horizontally arranged in the four pressure cavities in a penetrating mode. One ends of the lateral displacement measurement guide rods penetrate through the corresponding emulsion membranes to be fixedly provided with vertical inner end plates which are flushed with the outer surfaces of the flexible hydraulic capsules, the other ends of the lateral displacement measurement guide rods extend out of the pressure chamber to be respectively connected with an electronic dial indicator. The measurement mechanism for the lateral deformation of the pressure chamber of the true triaxial apparatus is suitable for the true triaxial apparatus with axial rigidity loading and lateral flexible loading, and accurate measurement on the lateral deformation through the true triaxial apparatus is achieved.

Owner:XIAN UNIV OF TECH

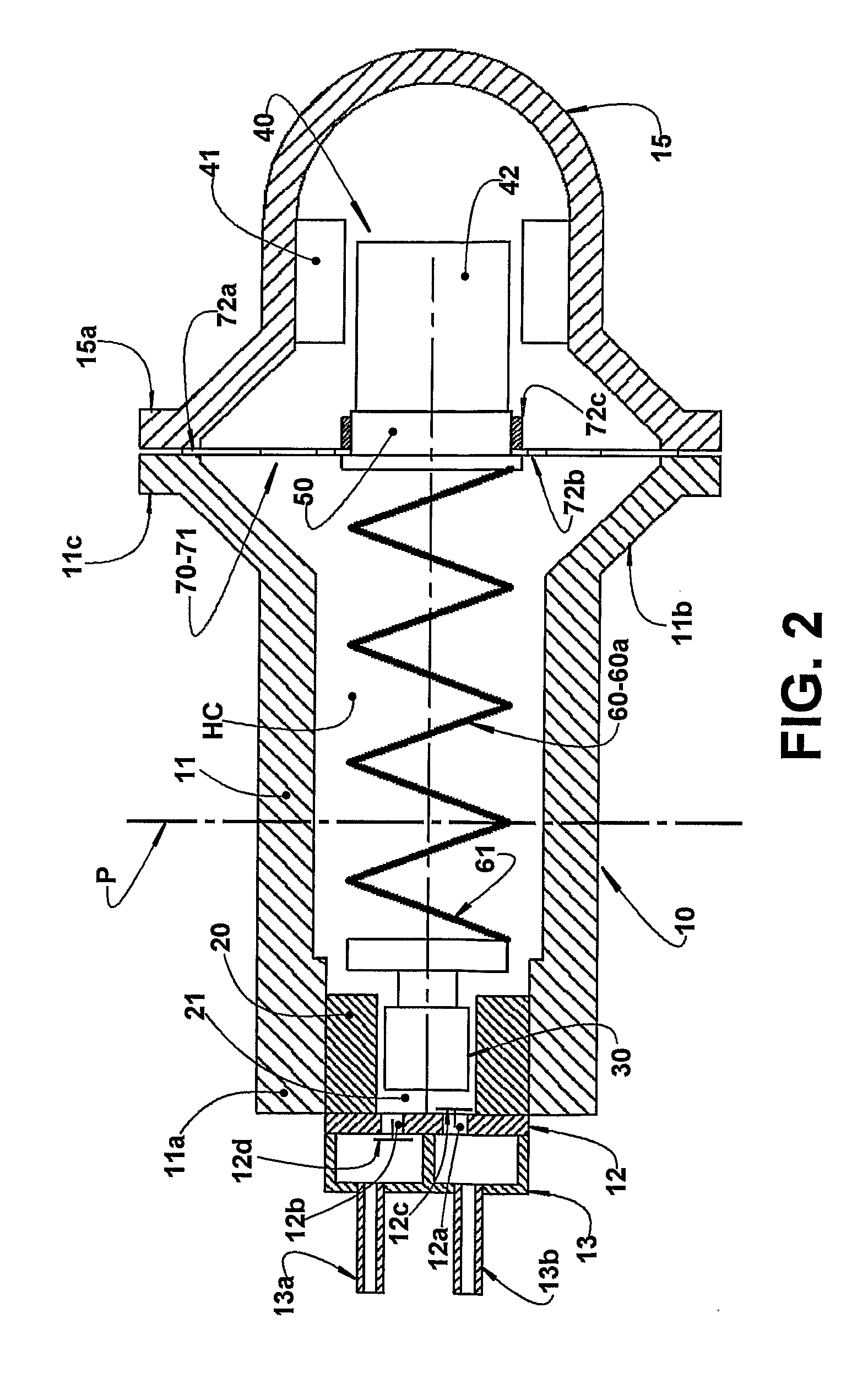

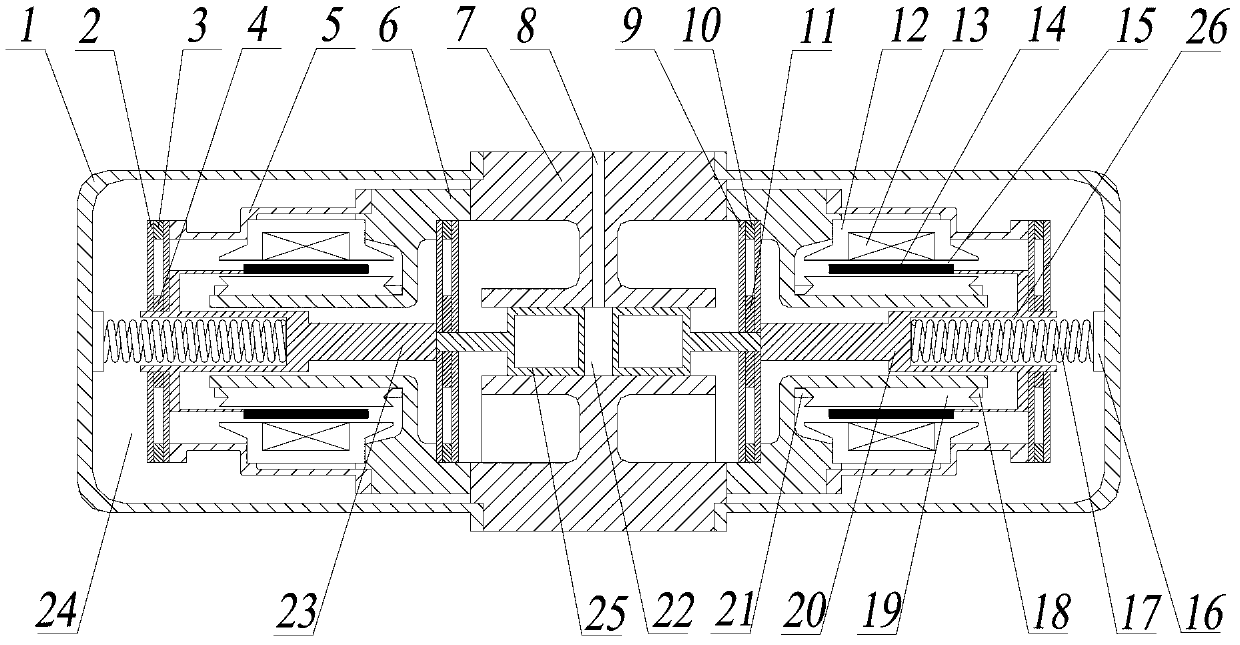

Linear compressor

ActiveUS8998589B2Positive displacement pump componentsEngine fuctionsReciprocating motionLinear compressor

The linear compressor comprises a shell (10) which affixes a cylinder (20) defining a compression chamber (21) housing a piston (30); a linear electric motor (40) having a fixed part (41) affixed to the shell (10) and a reciprocating movable part (42); an actuating means (50) driven by the movable part (42); an elastic means (60a) coupling the actuating means (50) to the piston (30), so that they are reciprocated in phase opposition. A supporting elastic means (70) connects the actuating means (50) to the shell (10) and presents a radial rigidity for supporting the lateral loads actuating on said movable part (42) and actuating means (50), and for minimizing the axial misalignments between the movable part (42) and the fixed part (41) of the linear electric motor (40), the supporting elastic means (70) presenting a minimum axial rigidity for allowing the displacement of both the piston (30) and the actuating means (50).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

Horizontal triaxial tension and compression tester

InactiveCN101614638AImprove integrityGuaranteed integrityMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention relates to a horizontal triaxial tension and compression tester comprising an AC machine arranged on a test platform. The power output end of the AV machine is connected with a rigid load bar on which a force sensor is arranged; the rigid load bar is connected with a front piston rod; the front piston rod is also provided with a displacement sensor; the force sensor, the displacement sensor and a data acquisition board are connected with a computer; the other end of the front piston rod is connected with a sample cap after passing through a front baffle board, and the sample cap is connected with an air exit hole on the front baffle board by a plastic soft tube; the other end of a rolling bearing on a horizontal stand is also provided with a sample cap which is connected with a rear piston rod; the rear piston rod is connected with a fixed baffle board after passing through a rear baffle board; the AC machine is started, and then an acquisition program carries out real-time acquisition and preserves output values of the force sensor and the displacement sensor; a drain hole is opened, and then a sample is removed after water is completely discharged; and subsequently, the width of a sample tension failure zone is measured. The invention has the characteristics of good integrity, high stability of loading and high axial rigidity.

Owner:TSINGHUA UNIV

Three-freedom-degree precision locating platform

InactiveCN103727364ACompact structureImprove axial stiffnessInstrumental componentsStands/trestlesElectricityMicro nano

The invention discloses a three-freedom-degree precision locating platform which comprises a base and a moving platform arranged in the base. The base and the moving platform are connected through three hinge expansion mechanisms evenly distributed in the peripheral direction of the platform and three plate-shaped flexible hinge mechanisms. One end of each hinge expansion mechanism is in flexible connection with the base, the other end of the hinge expansion mechanism is in flexible connection with the moving platform, the middle of the hinge expansion mechanism is provided with the input end, and the input end is connected with a piezoelectric ceramic driver. Each plate-shaped flexible hinge mechanism comprises an arc flexible plate and one to five radial flexible plates perpendicularly fixed to the arc flexible plate. The three-freedom-degree precision locating platform can achieve two horizontal movements and one rotation and is simple and compact in structure. Displacement expansion and force transmission are conducted by utilizing the hinge expansion mechanisms, so that the plate-shaped flexible hinge mechanisms have elastic deformation to drive the moving platform to move and achieve output of micro-nano displacement, the output displacement is large, and axial rigidity is high. The three-freedom-degree precision locating platform can serve as an auxiliary locating platform of a nano-micro operating system to achieve micro-feeding and precise locating.

Owner:TIANJIN UNIV

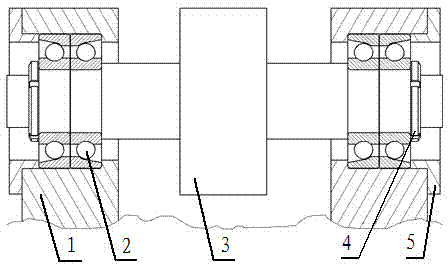

Dynamic measurement method for radial stiffness and axial stiffness of bearing

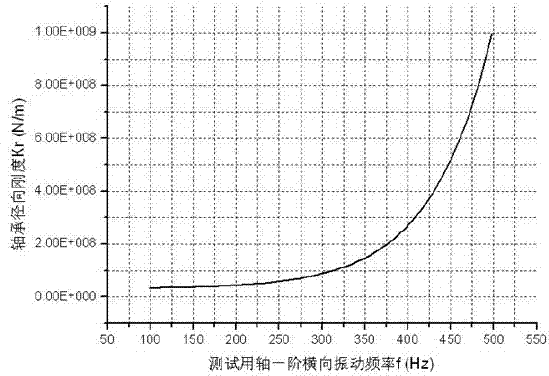

InactiveCN102889990AMeasuring Radial StiffnessMeasuring Axial StiffnessMachine bearings testingMeasurement testPhysical system

The invention belongs to the technical field of mechanical measurement and is applicable to measurement of radial stiffness and axial stiffness of bearings. The measurement principle is based on a relationship between the bearing stiffness and inherent vibration frequency of a shaft for test. The method comprises the following steps of: in the process of measuring the radial stiffness of the bearing, solving a function relationship between the radial stiffness of the bearing and the first-order transverse vibration frequency of a shaft for test, building a physical system among the shaft for test, a measured bearing and a rigid support, measuring the first-order radial vibration inherent frequency of the shaft for test, and finally, calculating the radial stiffness of the bearing according to a function relationship between the inherent vibration frequency and the radial stiffness of the bearing; and in the process of measuring the axial stiffness of the bearing, solving the mass of the shaft for test, building a physical system among the shaft for test, the measured bearing and the rigid support, measuring the first-order axial vibration inherent frequency of the shaft for test, and finally, calculating the axial stiffness of the bearing according to a relationship between the vibration inherent frequency and the axial stiffness of the bearing.

Owner:马会防

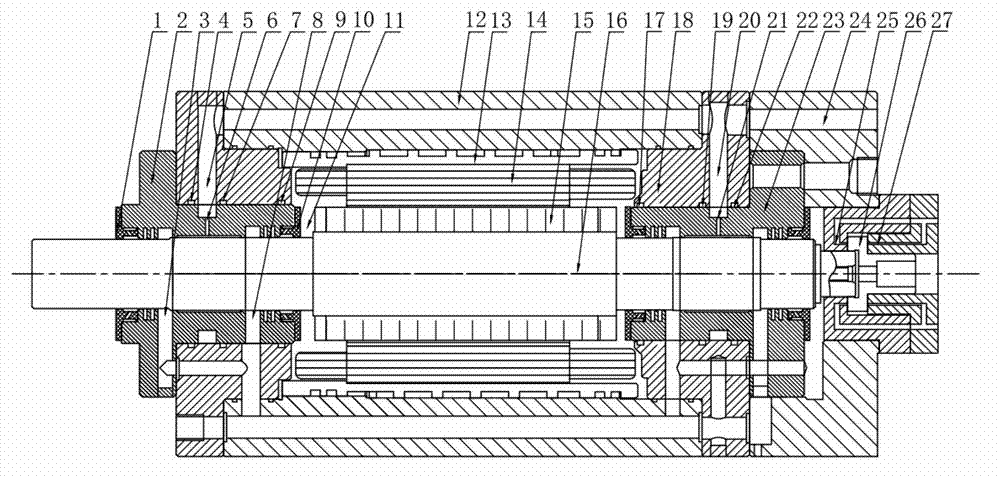

Motorized spindle device supported by high-speed hybrid bearings and lubricated by two phases of gas and liquid

InactiveCN103084588AReduce noiseControl axial displacementMetal-working apparatusElectricityAxial displacement

The invention discloses a motorized spindle device supported by high-speed hybrid bearings and lubricated by two phases of gas and liquid. The motorized spindle device comprises a shell, a cooling water jacket, a motorized spindle, a motor stator, a motor rotor, a front bearing, a rear bearing and a gas thrust bearing, wherein the cooling water jacket is fixed on the inner side of the shell, and the front and rear bearings support the two ends of the motorized spindle. Both of the front and rear bearings supporting the motorized spindle are hybrid sliding bearings and can promote the rigidity and the stability of the spindle and reduce temperature rise. Front and rear annular water return grooves are respectively formed in the two ends of each bearing, and lubricating medium liquid flows into the annular water return grooves and then flows out of the shell through a shell water outlet channel. Two gas seal devices are respectively arranged on two sides of each hybrid bearing and can prevent the lubricating medium liquid from flowing into the clearance between the motor stator and the motor rotor and flowing out of the shell along the axial direction of the motorized spindle. According to the gas thrust bearing, gas is used as the lubricating medium of the thrust bearing, and the gas thrust bearing provides the motorized spindle with axial rigidity and controls the axial displacement and the stability of the motorized spindle.

Owner:XI AN JIAOTONG UNIV

Device for automatically eliminating clearances of screw drive pair

InactiveCN101698284AAxial clearance automatically eliminatedNo reverse idle travelMetal working apparatusNumerical controlFeed drive

The invention relates to a device for automatically eliminating clearances of a screw drive pair, which comprises a leading screw, a main nut, a bolt, a machine tool sliding plate, an adjusting bolt, a spring, a guide post, a nut with an inclined plane, a bolt, a locking nut, a wedge block and a ball. The device is characterized in that the main nut and the nut with the inclined plane are connected with the leading screw respectively, the main nut is connected with the machine tool sliding plate through the bolt, and the flange of the nut with the inclined plane is provided with a through hole so that the nut with the inclined plane can move axially along the guide post. The wedge block with a self-locking function is supported between the main nut and the nut with the inclined plane; andone end of the spring is pressed on the wedge block with the self-locking function, while the other end is tightly pressed by the adjusting bolt. The incline plane of the nut with the inclined plane is provided with a guide groove. The device automatically eliminates axial clearances, has no reverse idle stroke, has adjustable pretightening force, good axial rigidity, smooth transmission, low cost, compact structure and high space utilization rate, is applied to feed drive systems of a metal cutting machine tool and a numerical control machine tool, and can greatly improve the processing accuracy.

Owner:李慎旺

Axial variable-damping hydraulic bushing for automotive suspension

ActiveCN104191927AGood elastic responseReduce the amplitudeResilient suspensionsRubber-like material springsAxial vibrationMechanical engineering

The invention discloses an axial variable-damping hydraulic bushing for an automotive suspension. The axial variable-damping hydraulic bushing comprises an inner tube, an outer tube and rubber bodies. The rubber bodies are arranged between the inner tube and the outer tube, are connected with each other and include an upper rubber body and a lower rubber body, the upper rubber body and the lower rubber body are of split structures, a hydraulic working cavity is formed among the upper rubber body, the lower rubber body, the inner tube and the outer tube, a cavity partition device is arranged in the hydraulic working cavity, and damping adjusting assemblies which are used for adaptively adjusting damping force are arranged at communicated ends of a damping channel, an upper working cavity and a lower working cavity. The axial variable-damping hydraulic bushing has the advantages that excellent axial damping effects can be realized when the bushing is vertically mounted along an automobile body, accordingly, the axial variable-damping hydraulic bushing is high in axial rigidity, axial vibration can be buffered, and noise can be reduced; the damping force can be adaptively adjusted according to different working conditions, so that service requirements under the different working conditions can be met.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

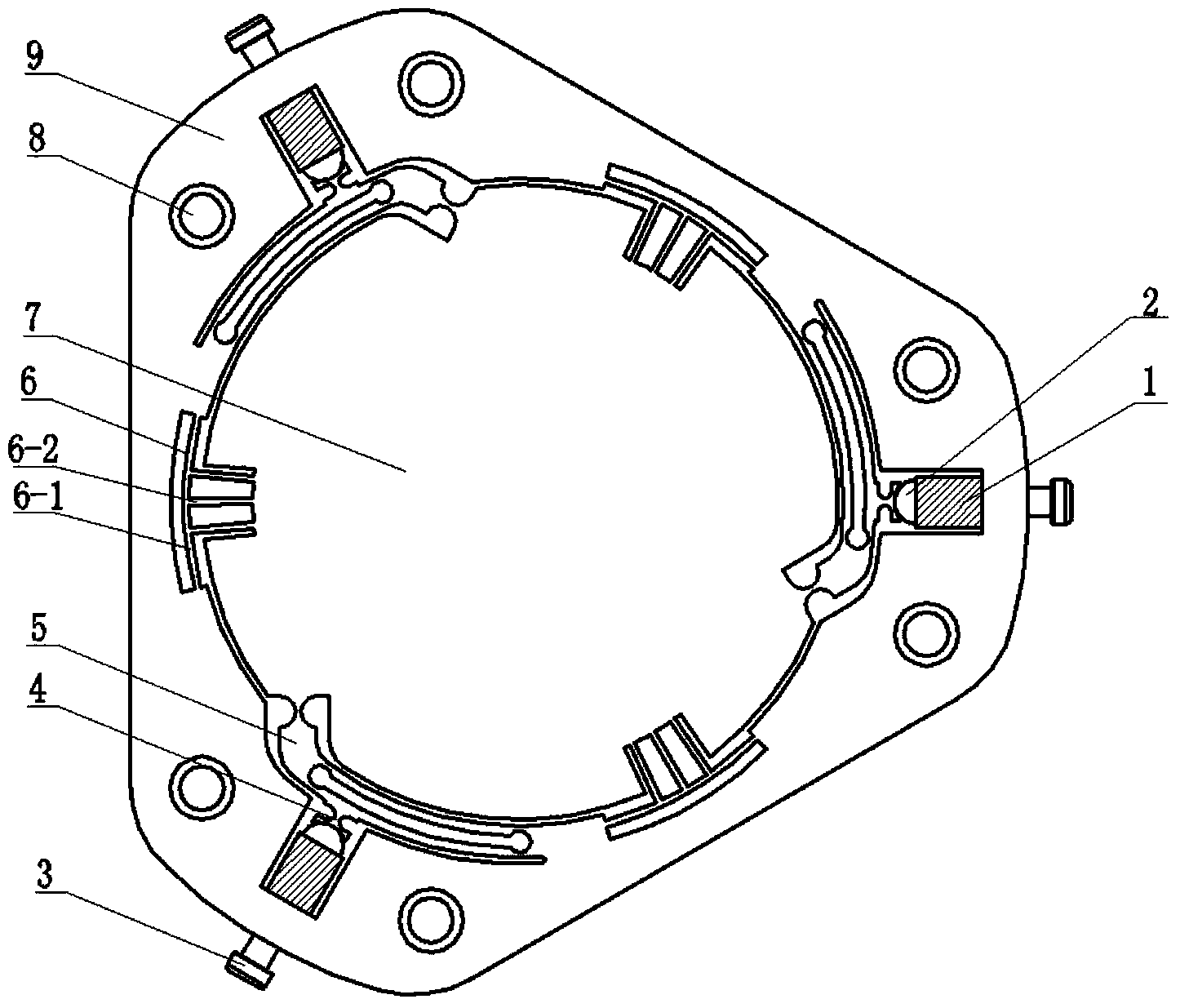

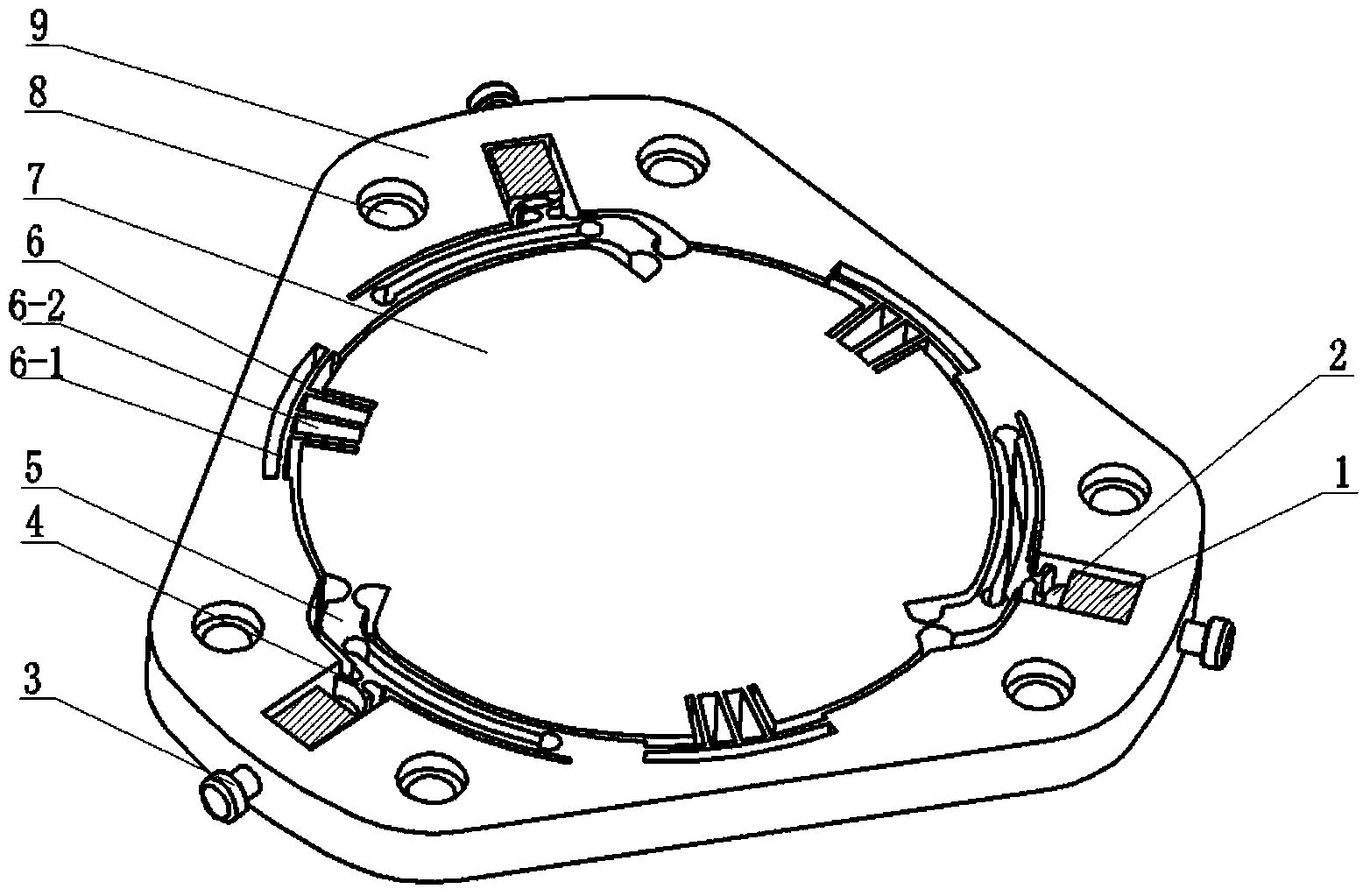

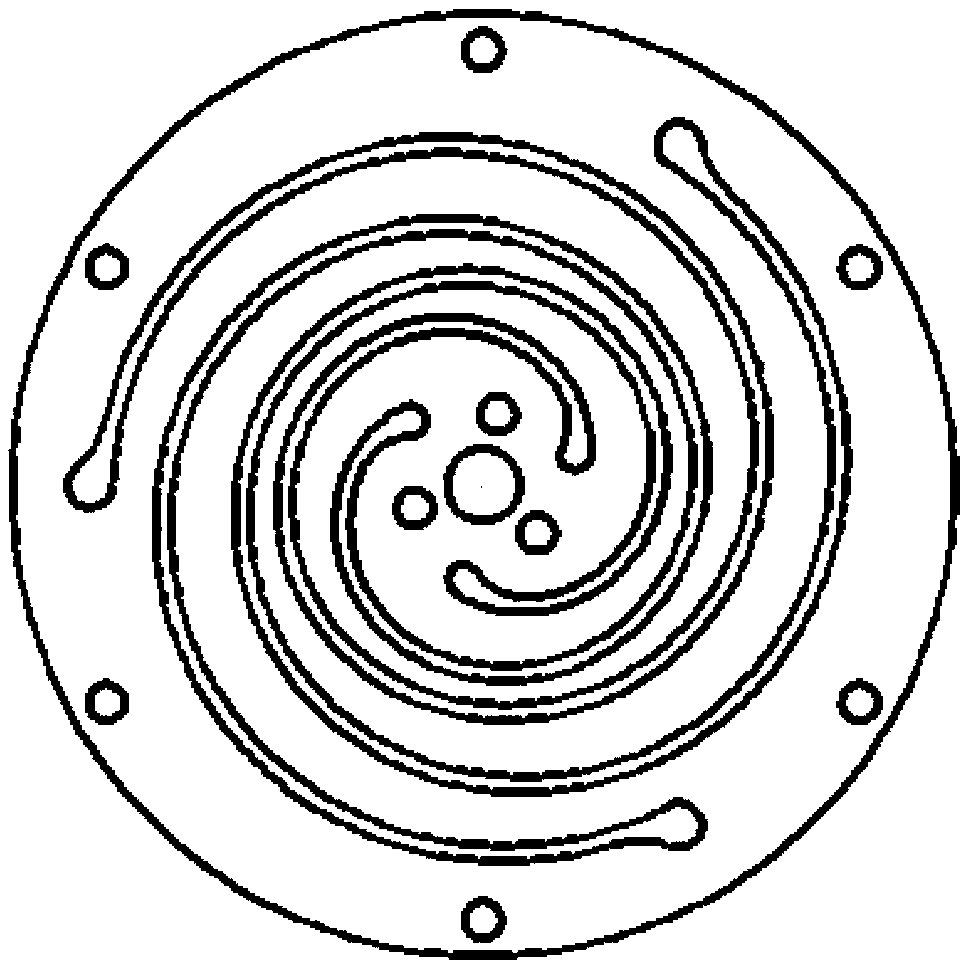

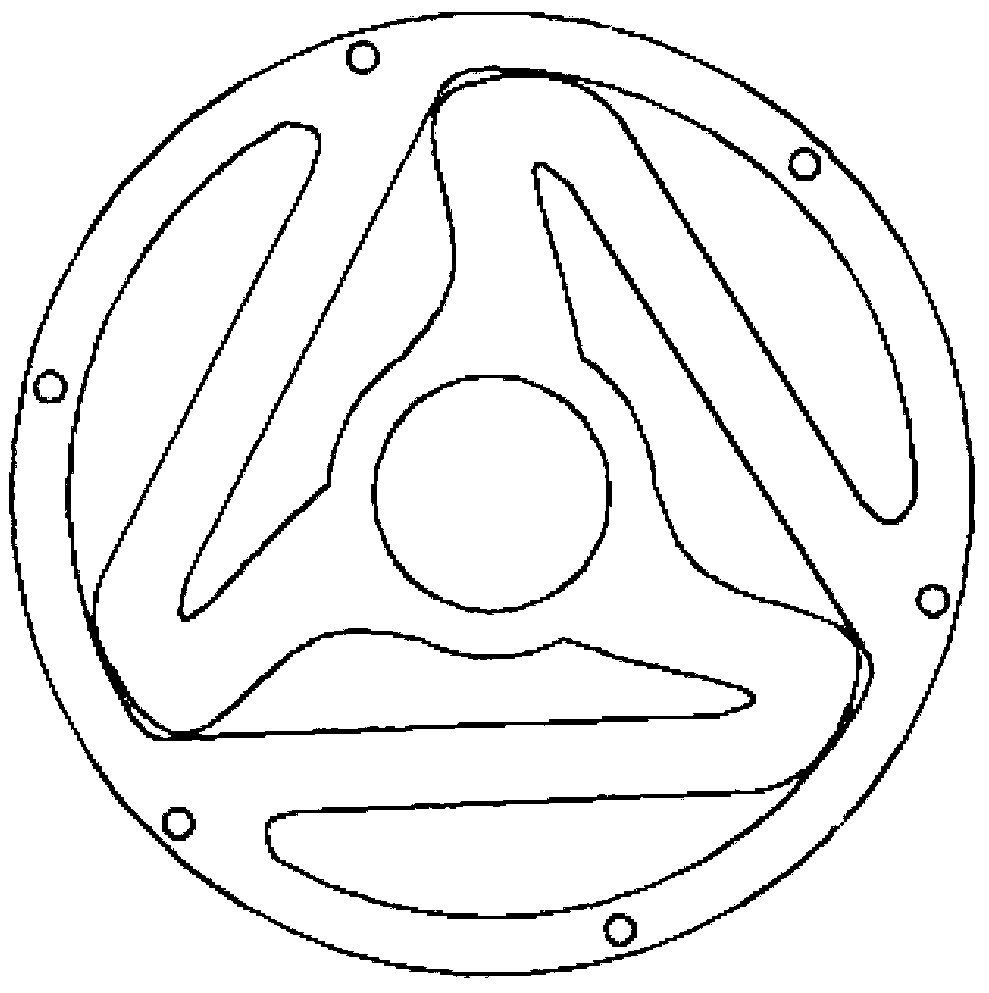

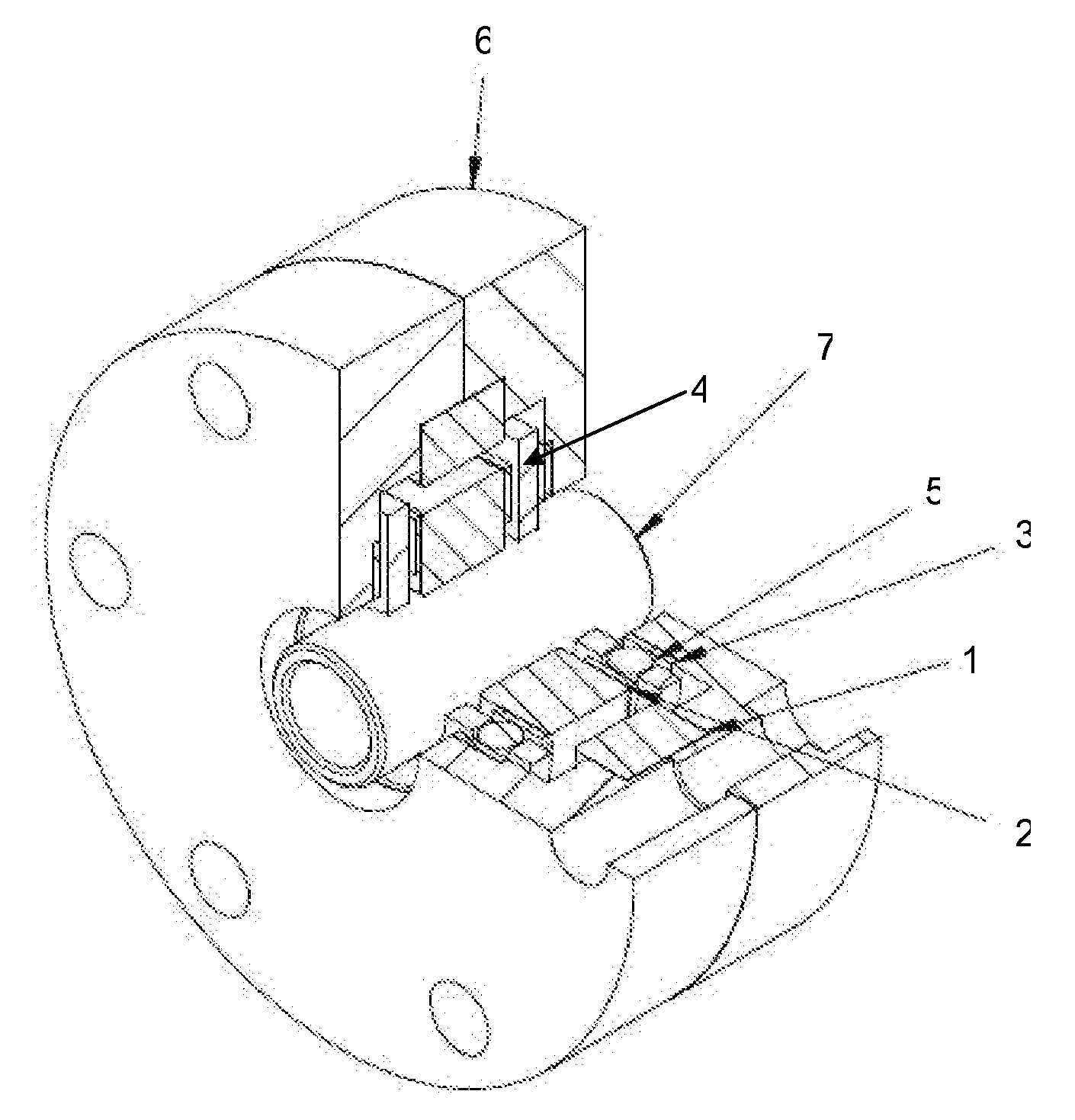

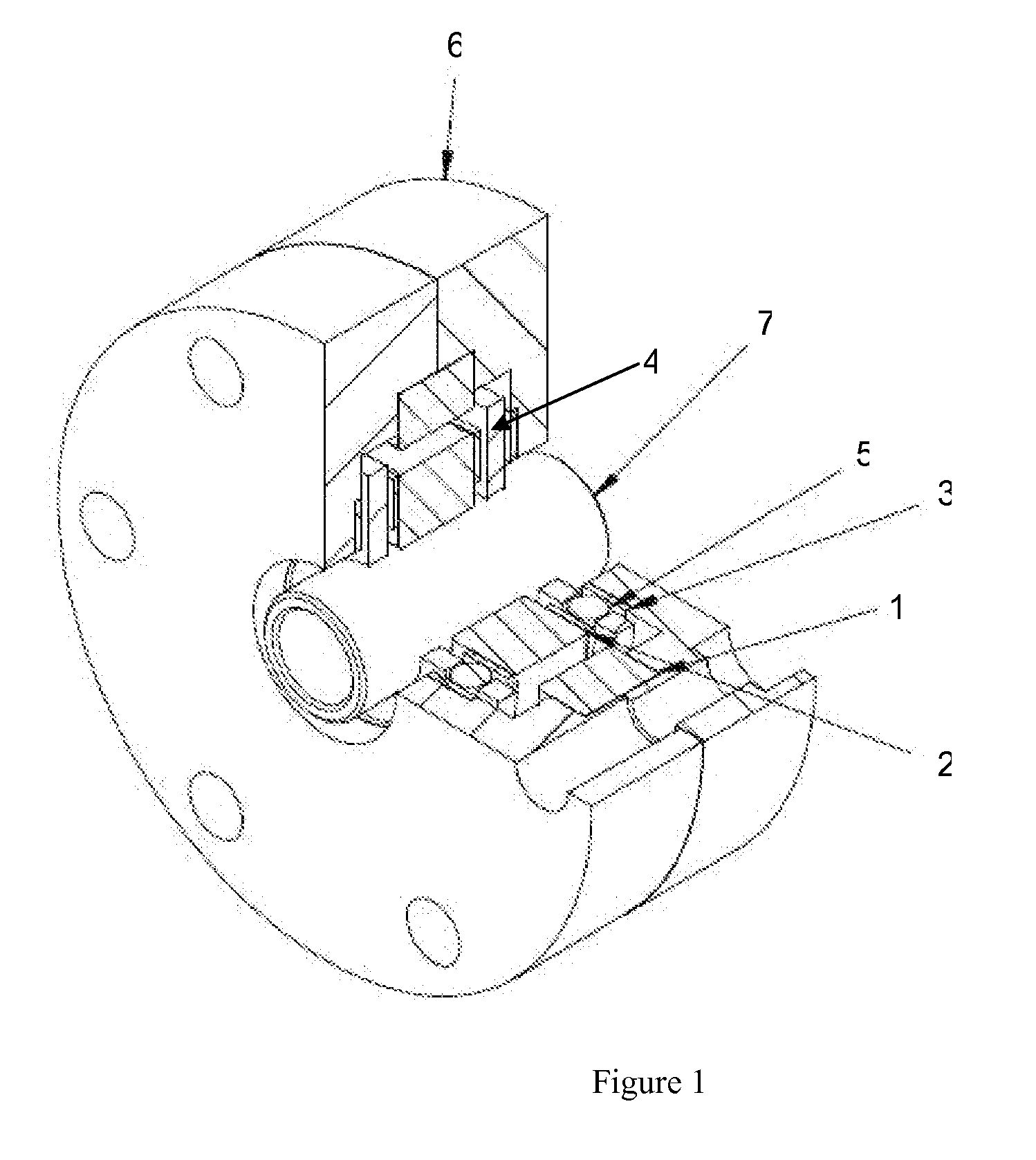

Linear compressor supported by three kinds of springs

InactiveCN103122837AEasy to fixImprove axial stiffnessPiston pumpsPositive-displacement liquid enginesReciprocating motionLinear compressor

The invention discloses a linear compressor supported by three kinds of springs. The linear compressor supported by the three kinds of springs comprises a support, a cylinder fixed with the support, two pistons in clearance fit with the inner wall of the cylinder, and two linear motors driving the two pistons to make coaxial and reciprocating motions, wherein the two linear motors are in transmission with the pistons correspondingly and respectively through piston shafts, two end portions of each piston shaft are fixed with the support respectively through a vortex arm plate spring assembly and a linear arm plate spring assembly, the vortex arm plate spring assemblies are close to the pistons, and a cylinder spiral spring used for providing axial elastic force is arranged between an end portion, far away from a corresponding piston, of each piston shaft and the support. Due to the fact that the linear compressor is supported by the three kinds of springs, clearance gap seal and oil-free lubrication technology are guaranteed, and axial rigidity of the springs is effectively improved. For a linear compressor with big rotor quality, high frequency resonance operation is achievable, operating efficiency is improved, and character match between the linear compressor and a cooling head of a low temperature refrigerator is achieved.

Owner:ZHEJIANG UNIV

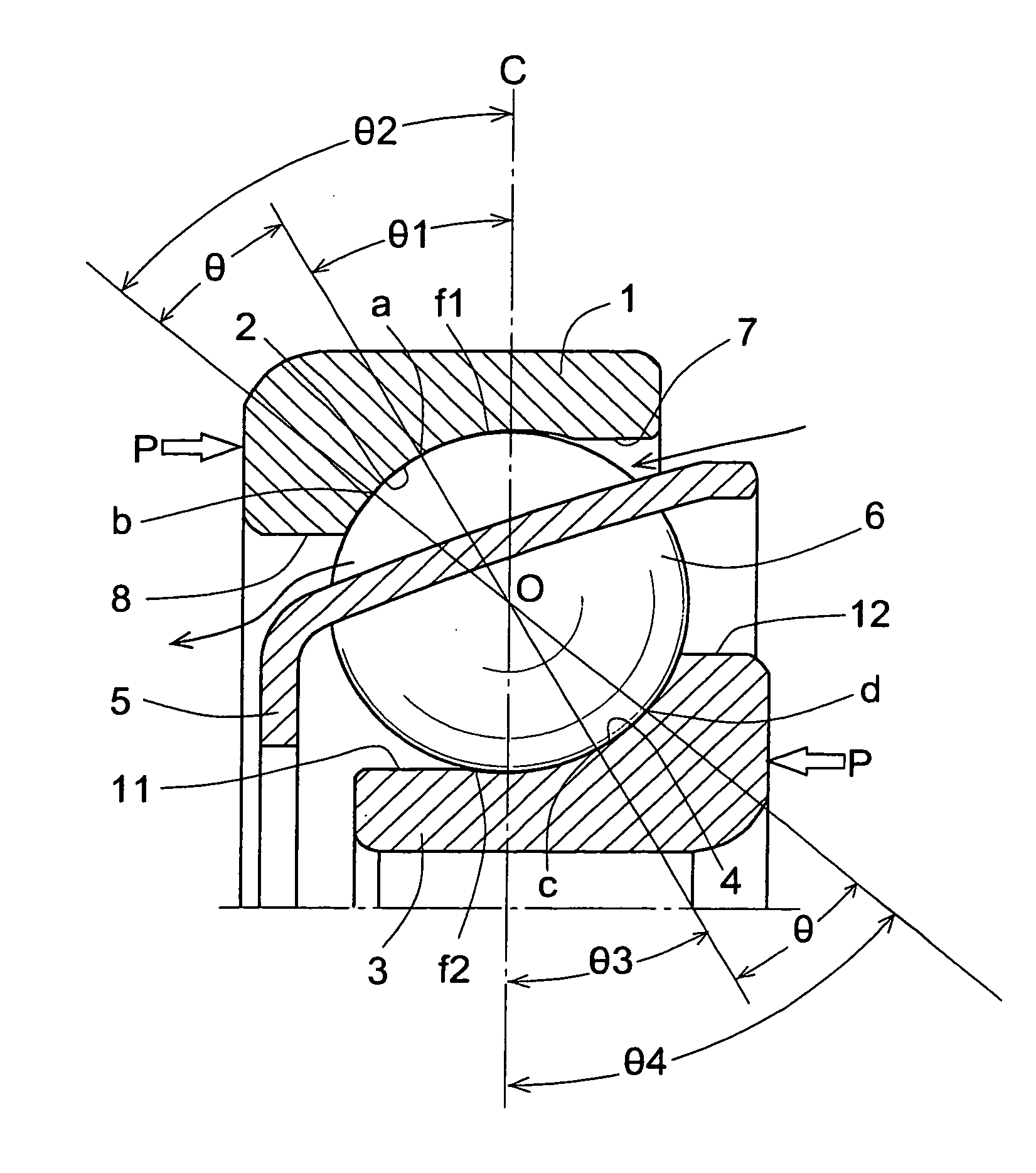

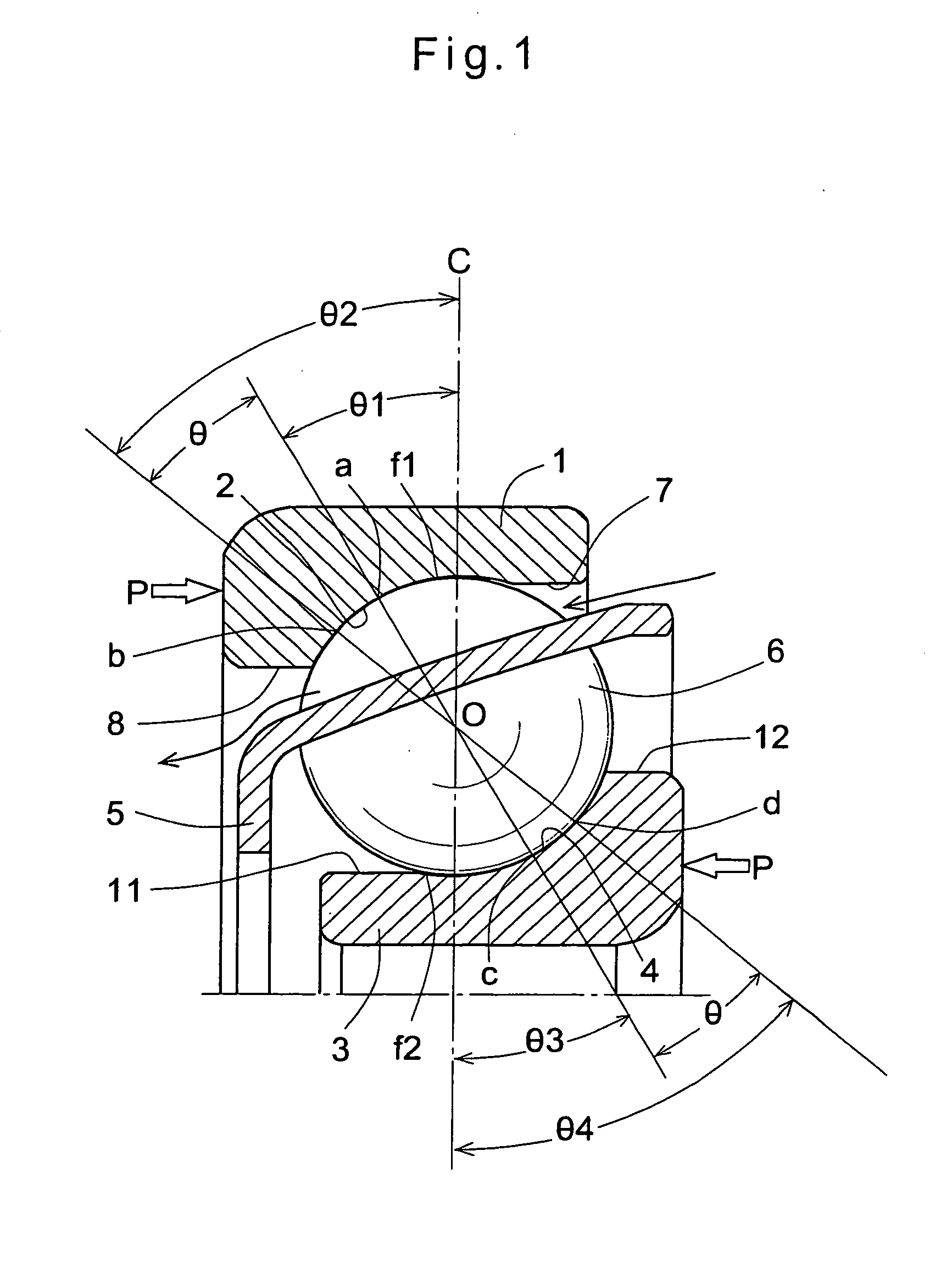

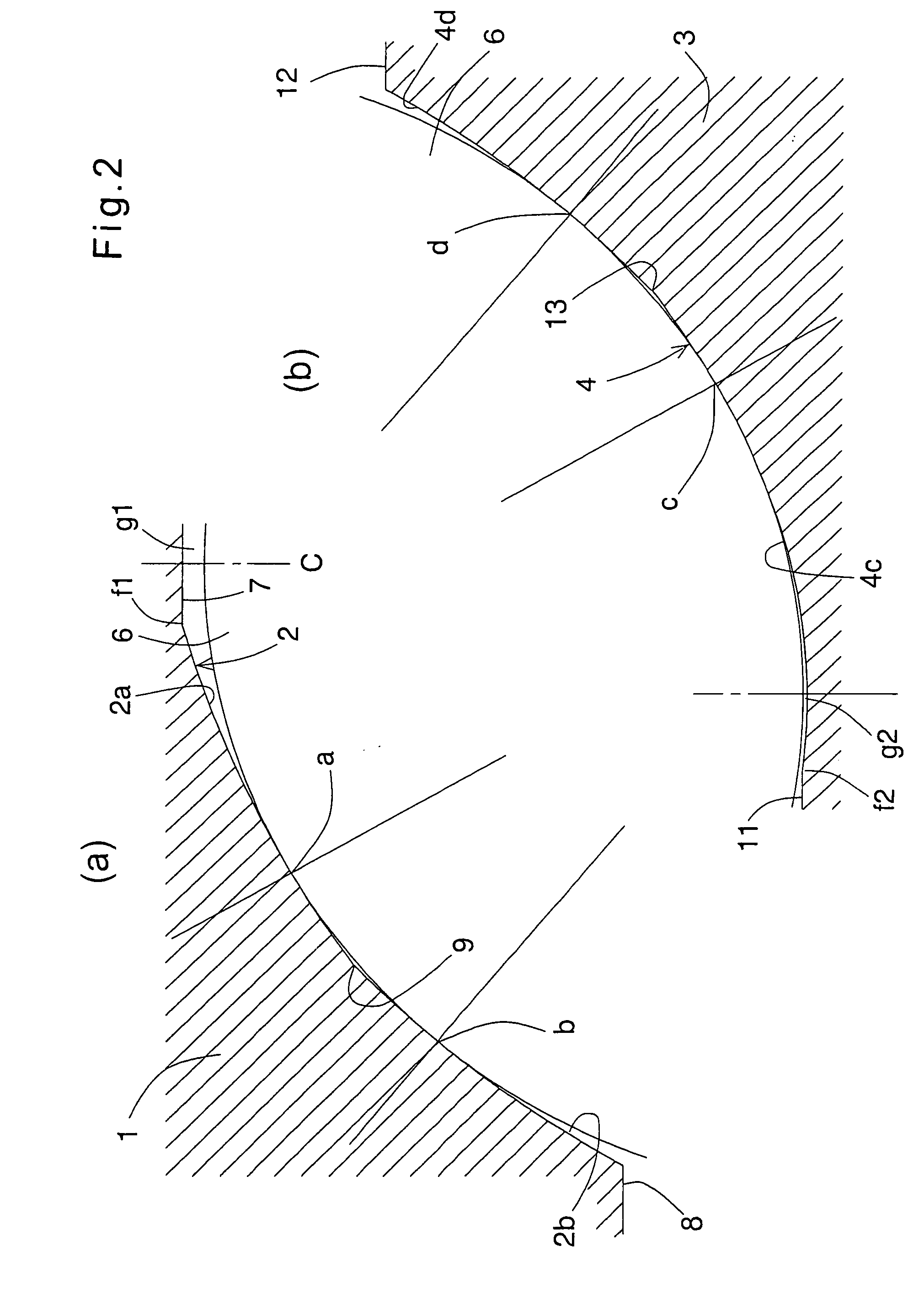

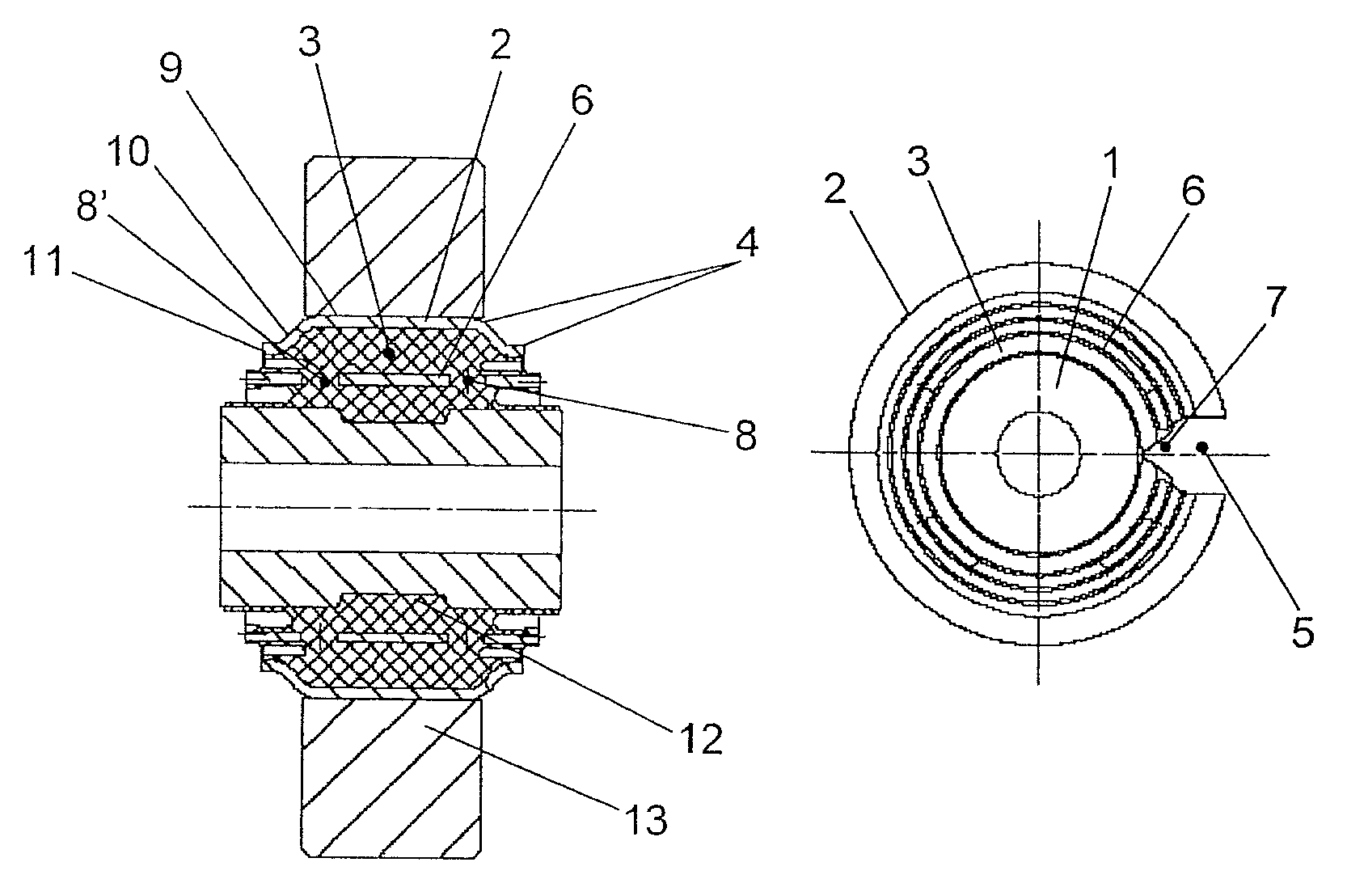

Angular Contact Ball Bearing and Joint Assembly for a Robotic Arm

It is aimed to increase the rigidity of an angular contact ball bearing of the type in which each ball contacts at least one of the raceways at two points, improve the lubricating environment of the balls, reduce the weight of the bearing while maintaining wear resistance and rigidity of the balls, reduce the weight of the bearing while maintaining wear resistance of the balls, improve the radial rigidity and axial rigidity of the bearing in a balanced manner, or to supply a sufficient amount of lubricating oil into an internal area between the two contact points between each ball and the raceway.A counter portion 7 is formed. With each ball 6 in contact with the raceway at two points, a gap is present between the portion of the bearing ring at the bearing centerline C and each ball 6. The balls 6 may be ceramic balls. A coating for improving wear resistance may be applied to the balls. The contact angle of the contact point close to the bearing center line is set at 15 to 25°, while the contact angle of the contact point remote from the centerline C is set at 40 to 50°.

Owner:NTN CORP

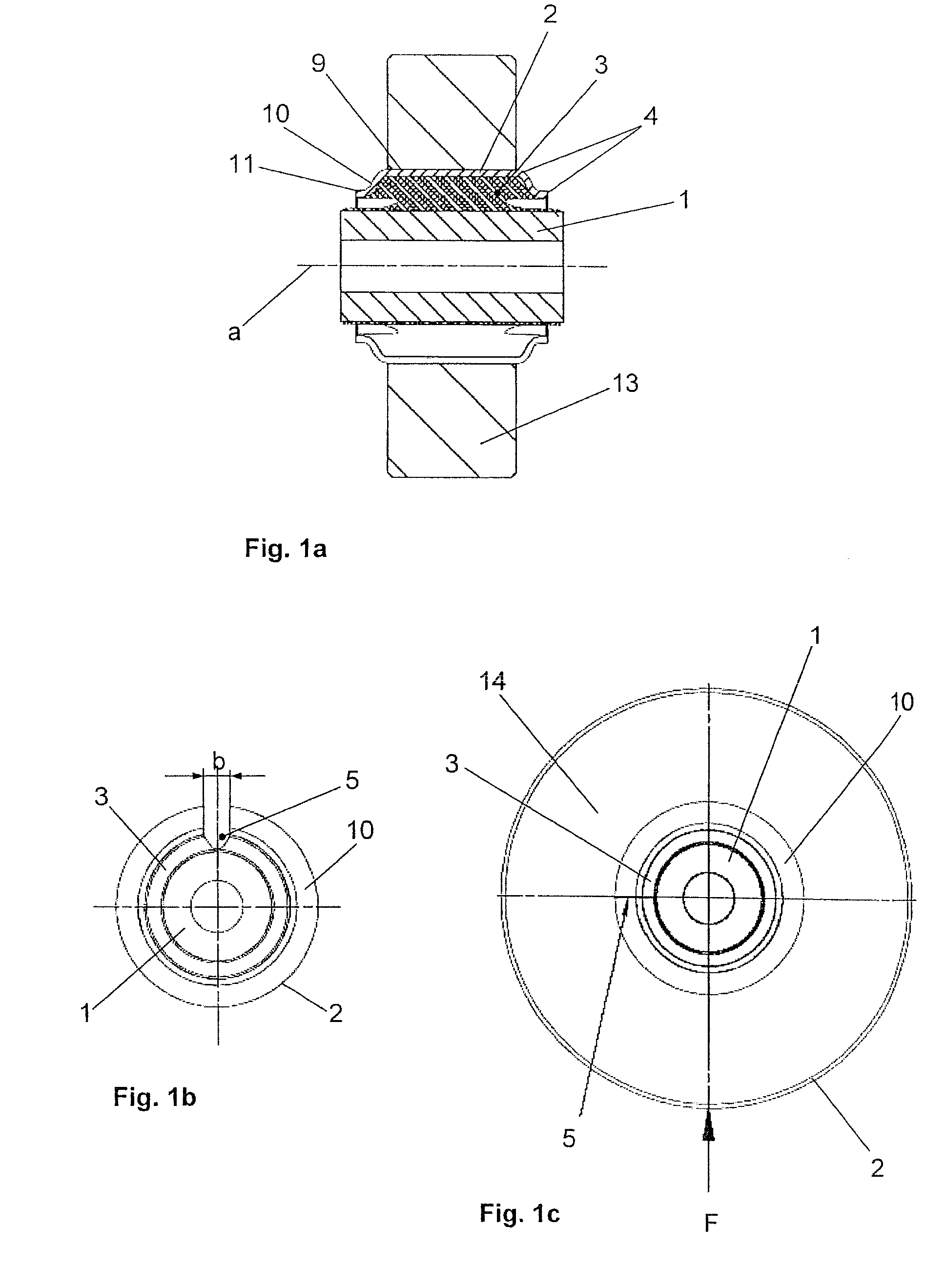

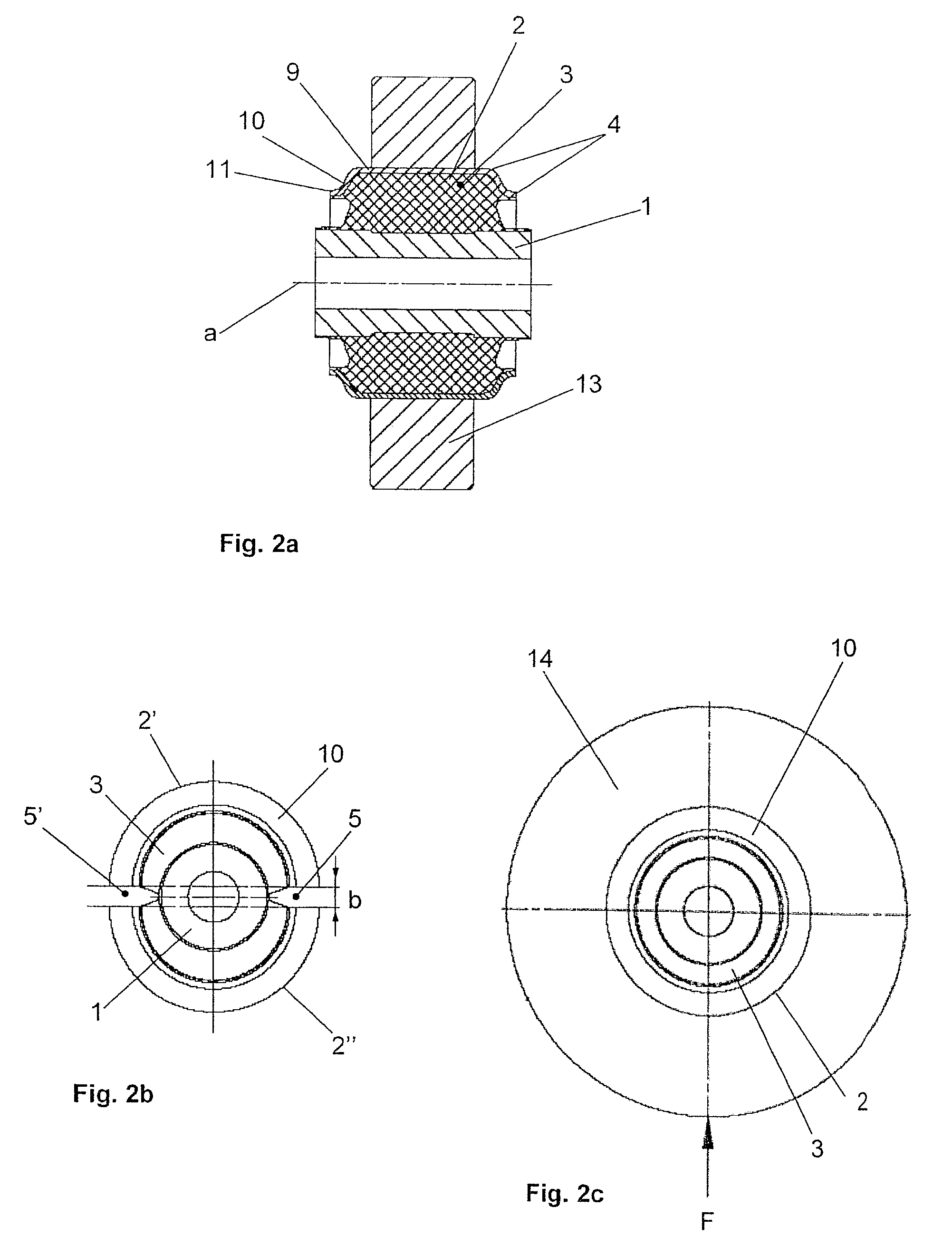

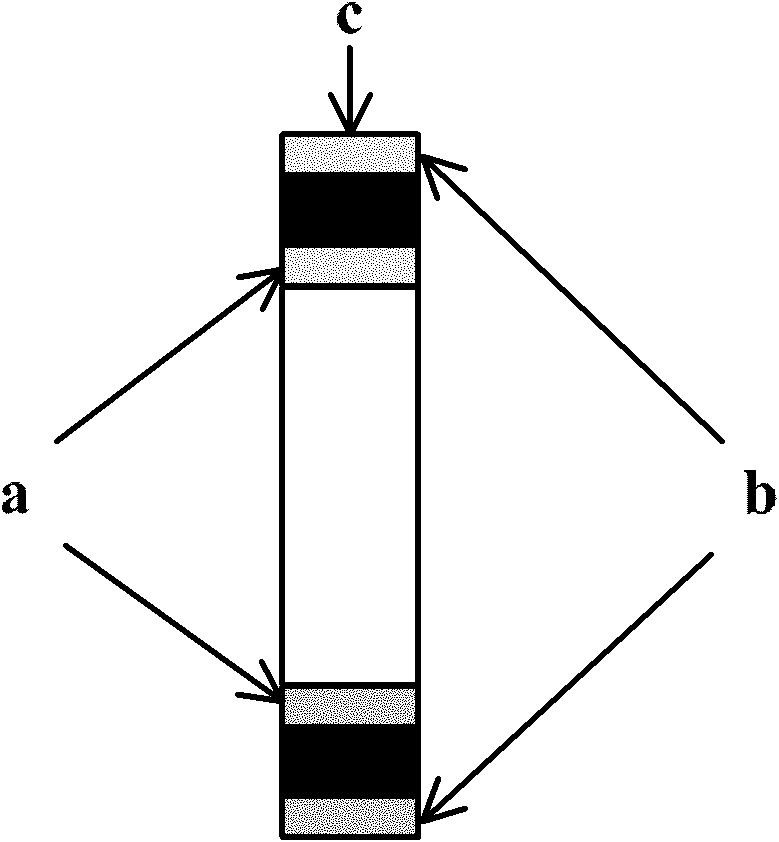

Elastomeric bush bearing and process for manufacturing same

InactiveUS7441759B2Improve radial stiffnessEvenly distributedSprings/dampers functional characteristicsResilient suspensionsElastomerGeometric design

An elastomeric bush bearing is designed as a slotted bush. To reach a high ratio of static radial stiffness to torsion spring rate along with a high axial stiffness at the same time, a beading is formed at least at one axial end but preferably at both axial ends of the slotted bush. In case of an especially advantageous embodiment, a slotted bush with additional intermediate parts inserted into the elastomeric bearing body, two encapsulated rubber packets are created by the simultaneous special geometric design of the inner part. The individual stiffnesses of the two rubber packets are thus compensated and thus there is a homogeneous increase in the overall stiffness of the bush. The beadings are prepared before the components of the bearing are assembled and vulcanized to the parts of the later outer sleeve.

Owner:ZF FRIEDRICHSHAFEN AG

Rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor and composite excitation method thereof

ActiveCN105827143AIncrease frictionIncreased frictional driving forcePiezoelectric/electrostriction/magnetostriction machinesMicro nanoFriction force

The invention provides a rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor and a composite excitation method thereof to solve the problem that in an existing piezoelectric stick-slip linear motor, the mechanical output property is limited due to the fact that comprehensive regulation on friction force is difficult. The rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor is composed of an oblique-wedge stator, a preloading device, a mounting support and a rotor; the oblique-wedge stator adopts asymmetrical hinges of a wedged structure, lateral displacement is generated through an oblique-wedge rhombus motion converter and the ununiform axial rigidity distribution characteristic of a stator drive foot, the friction drive force is increased, and the friction resistance is decreased; meanwhile, friction regulation waves are overlapped into sawtooth drive waves in the rapid deformation stage of the stator, comprehensive regulation on the friction force is achieved, and the mechanical output characteristic of the piezoelectric stick-slip linear motor is significantly promoted. The rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor has the advantages of being simple in structure, high in precision, large in stroke and the like and has the good application prospect in the fields of micro-nano precise driving and positioning such as machining of precise medical instruments, optical precise instruments and semiconductors.

Owner:CHANGCHUN UNIV OF TECH

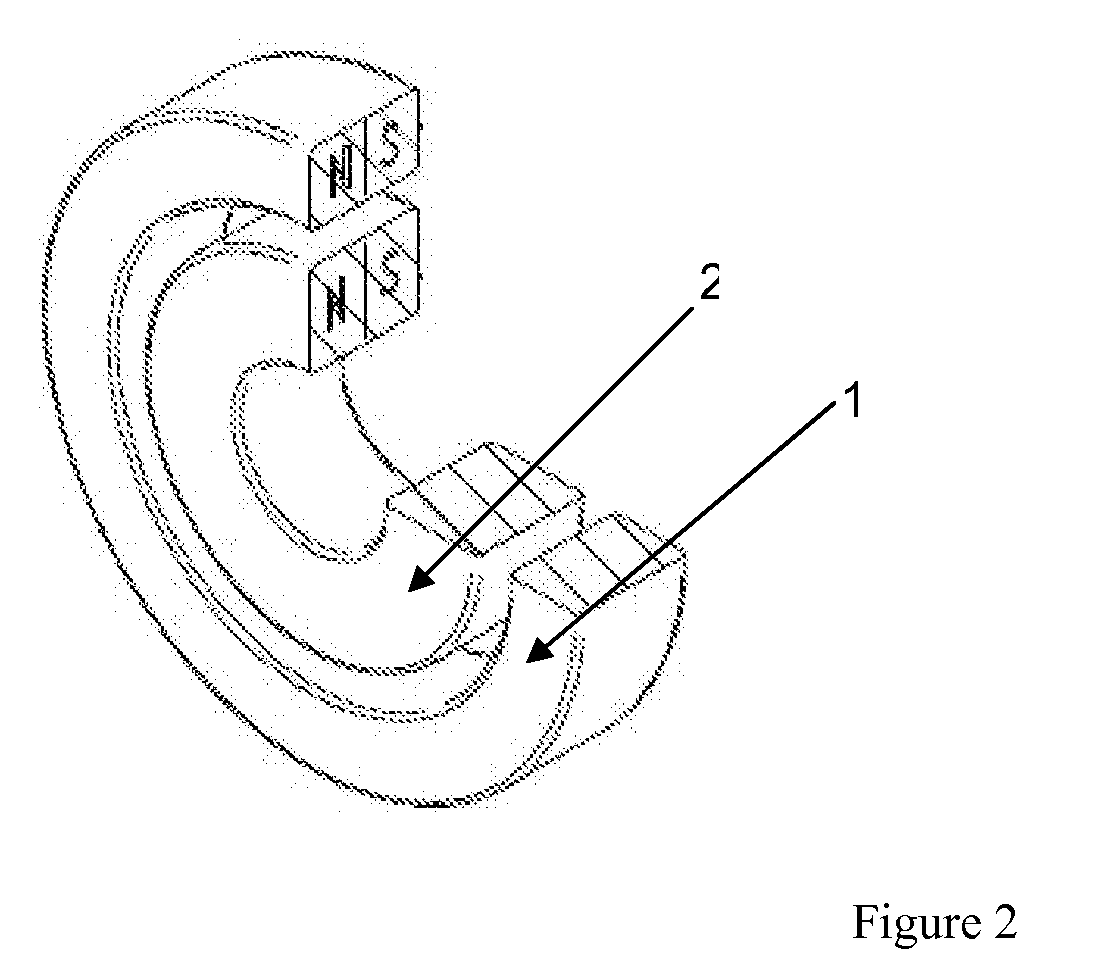

Passive magnetic bearing

InactiveUS20110001379A1MiniaturizationIncrease resistanceBall bearingsMechanical energy handlingMagnetic bearingEngineering

A passive magnetic bearing which has an exceptionally low friction couple. Radial and axial restraint is achieved through magnetic and mechanical means. The embodiment of the passive magnetic bearing has two axially magnetized rings, which each exhibit at least one pair of north and south poles. The magnetized rings are positioned in a manner where the poles are in a repulsive magnetic interaction such that the plane of symmetry which separates the like poles lies perpendicular to the axis of the rotation of a shaft and this radially constrains the movement of the shaft. Axial rigidity is added to the system by the use of ceramic bearings and related axial retaining mechanisms on one of the ring magnets thus maintaining the magnetic bearing in an otherwise unstable axial plane.

Owner:STEORN

Twin-web rotor disc provided with disc cavity flow-guide rib plates

ActiveCN104196572AImprove convective heat transfer efficiencyIncrease flow rateBlade accessoriesMachines/enginesEngineeringMechanical engineering

The invention discloses a twin-web rotor disc provided with disc cavity flow-guide rib plates. The plurality of flow-guide rib plates are arranged on two spoke plates of the twin-web rotor disc. Disc edge cool air channels are evenly distributed in the radial direction in the edge of the rotor disc along the circumference and cooling air enters cooling blades through the disc edge cool air channels from disc cavity of the twin-web rotor disc. An annular tongue plate is embedded between a front hub and a rear hub of the twin-web rotor disc, and a central channel of the tongue plate is communicated with an inner cavity of the rotor disc. The flow guide rib plates are distributed in a streamline layered mode in the rotating direction of the rotor disc and realizes a centrifugal supercharging effect when the rotor disc is rotating, so that flow speed and the pressure of the cooling air in the disc cavity are increased. The heat exchange area is increased, the convective heat exchange efficiency of the disc cavity is improved by using the flow guide rib plates, and the effect of enhancing heat exchange is achieved. The tongue plate structure is added between the front hub and the rear hub of the rotor disc, and the axial rigidity of an opening in the disc center is improved. By utilizing variable cross-section channels in the tongue plate and the disc edge, the pressure and the flow speed of the cooling air passing through the channels can be controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for stimulating fluid-solid-heat coupling value of machine tool spindle

ActiveCN102063549AAccurate estimateSolved the problem that the influence of coolant could not be accurately accounted forSpecial data processing applicationsCouplingEngineering

The invention discloses a method for stimulating a fluid-solid-heat coupling value of a machine tool spindle, which comprises the steps of: establishing a model of a spindle cooling liquid, replacing bearings in a spindle with equivalent rings with same sizes, simplifying the model; calculating relevant external boundary conditions of a spindle temperature field; guiding into grid division software ANSYS, ICEM and CFD for carrying out fluid and solid grid division; guiding into CFX software for carrying out fluid-solid-heat coupling calculation; guiding the simplified geometrical model into a stable temperature field module in a workbench, neglecting a cooling liquid model, re-dividing a grid; re-calculating a temperature field of the spindle according to the temperature field boundary condition; calculating radial and axial elastic modulus of the equivalent ring by using radial and axial rigidity of each bearing, and correcting the elastic modulus of each equivalent ring in the workbench; guiding the temperature obtained from the calculation of the stable temperature field into a stable static analyzing module in the workbench, and calculating the heat deformation.

Owner:XI AN JIAOTONG UNIV +1

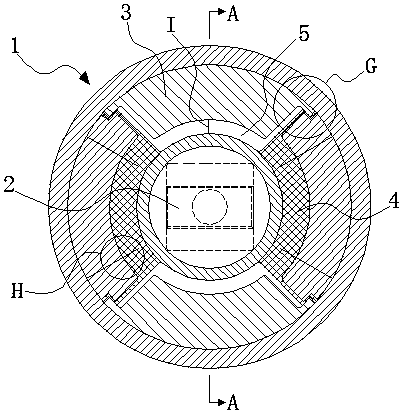

Fluid bearing device

InactiveUS20090297078A1Improve accuracyImprove rigiditySliding contact bearingsBearing unit rigid supportEngineeringFluid bearing

[Problems] Provided is a fluid bearing device in which bearing sleeves are positioned and fixed with respect to a housing with high accuracy.[Solving Means] To an inner periphery of a housing (7), a first bearing sleeve (8) and a second bearing sleeve (9) are fixed while being spaced apart in an axial direction. Between the bearing sleeves (8) and (9), a spacer (10) made of a resin is disposed. An axial rigidity of the spacer (10) is smaller than those of the first bearing sleeve (8) and the second bearing sleeve (9). Accordingly, in a state where the first bearing sleeve (8) and the second bearing sleeve (9) are positioned and fixed with respect to the housing (7), the spacer (10) is largely compressed in an axial direction compared to the bearing sleeves (8) and (9).

Owner:NTN CORP

Method for forming liquid rubber composite node with pipe body flow channel and node

PendingCN110388401AExpand volume spaceImprove performanceLiquid springsVibration suppression adjustmentsVulcanizationEngineering

The invention discloses a method for forming a liquid rubber composite node with a pipe body flow passage and a node, wherein the forming method comprises the steps of additionally arranging a middlespacer sleeve between an outer sleeve and a core shaft, vulcanizing and bonding the middle spacer sleeve and the core shaft together through rubber, and assembling the middle spacer sleeve and the core shaft which are integrally formed into a whole into the outer sleeve; and arranging the pipe body flow passage in the core shaft, forming a plurality of spaces in the middle spacer sleeve by hollowing, after vulcanization, forming a plurality of liquid cavities independent of each other by the rubber and the plurality of spaces, arranging liquid in the plurality of liquid cavities, and the liquid cavities communicating with one another through the pipe body flow passage. The method for forming the liquid rubber composite node with the pipe body flow passage and the node can provide smaller radial rigidity and larger axial rigidity, and realize larger dynamic-static ratio, thereby optimizing the product performance of the liquid rubber composite node.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

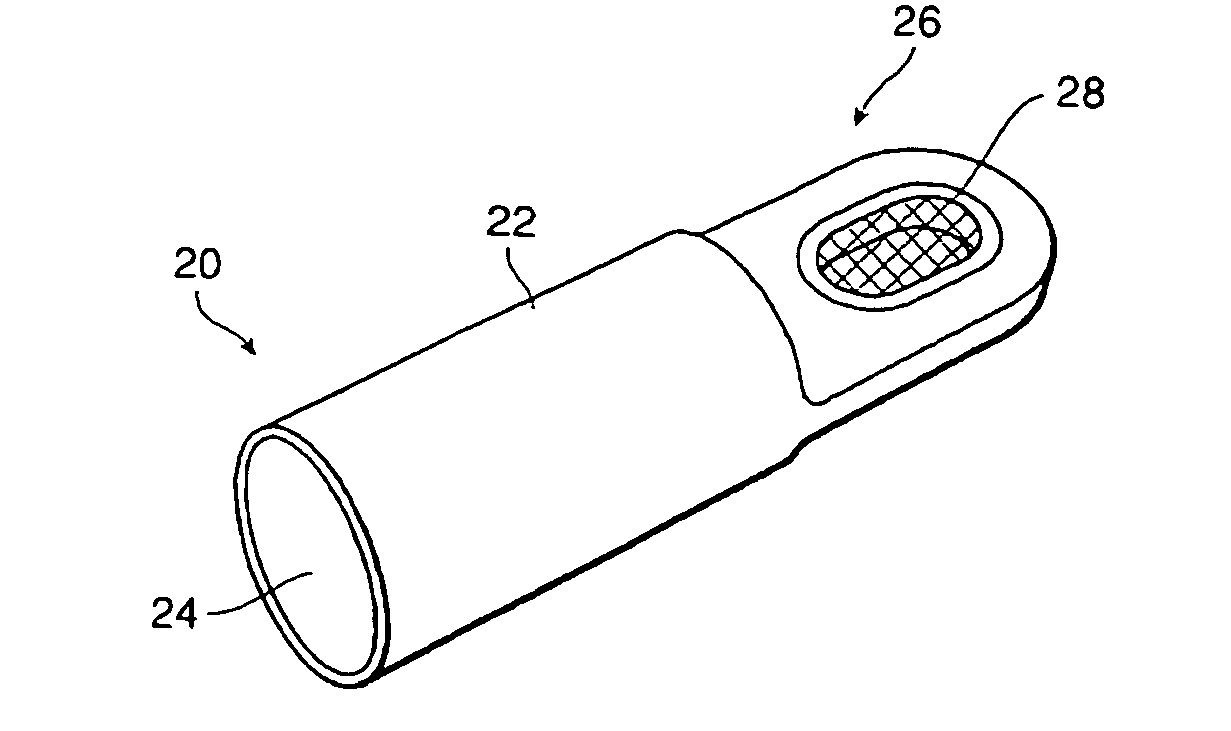

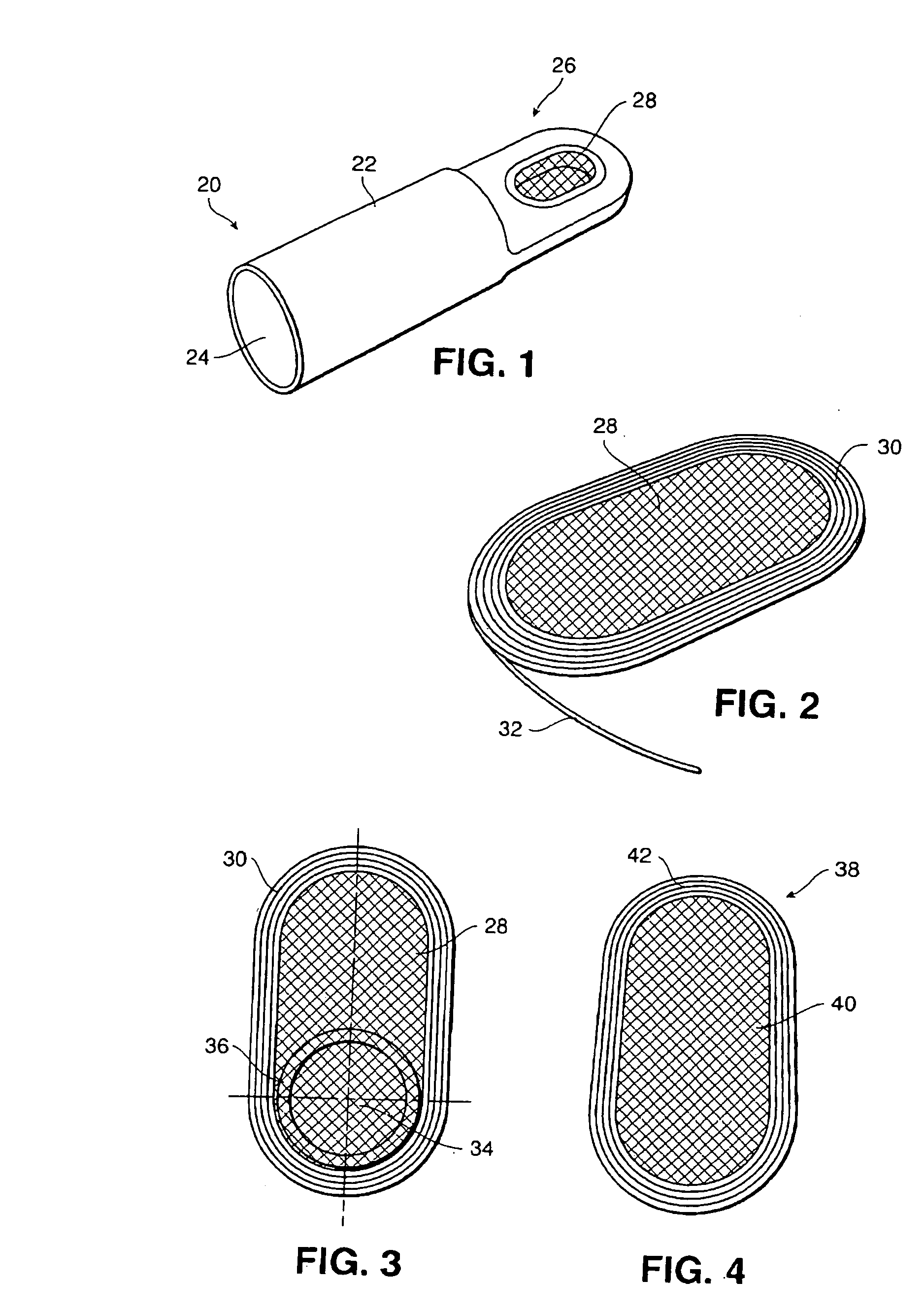

Filament wound strut and method of making same

InactiveUS20050056503A1Efficient responseEfficient loadingConnecting rodsSpringsUltimate tensile strengthConductor Coil

A filament wound strut as well as a method of making the strut. The filament wound strut has a cylindrical section merging into ends through tapered end sections and which ends may be forked or otherwise arranged to receive a lug fitting. The flat ends may be provided with a specially designed pre-form having a generally oval shape, and which is formed by filament reinforcement in a racetrack format surrounding a quasi-isotropic laminate. In accordance with this construction, the wound structure will react to tension loads and the inner laminate reacts to compression loads, while minimizing the load transfer through edge bearing and shear. A method of producing the strut is also provided in which filament materials are wound about a mandrel with proper winding pattern and sufficient thickness to produce the desired axial stiffness and the required strength in each of the end sections. Thereafter, the material may be consolidated and polymerized in an autoclave.

Owner:JONES BRIAN

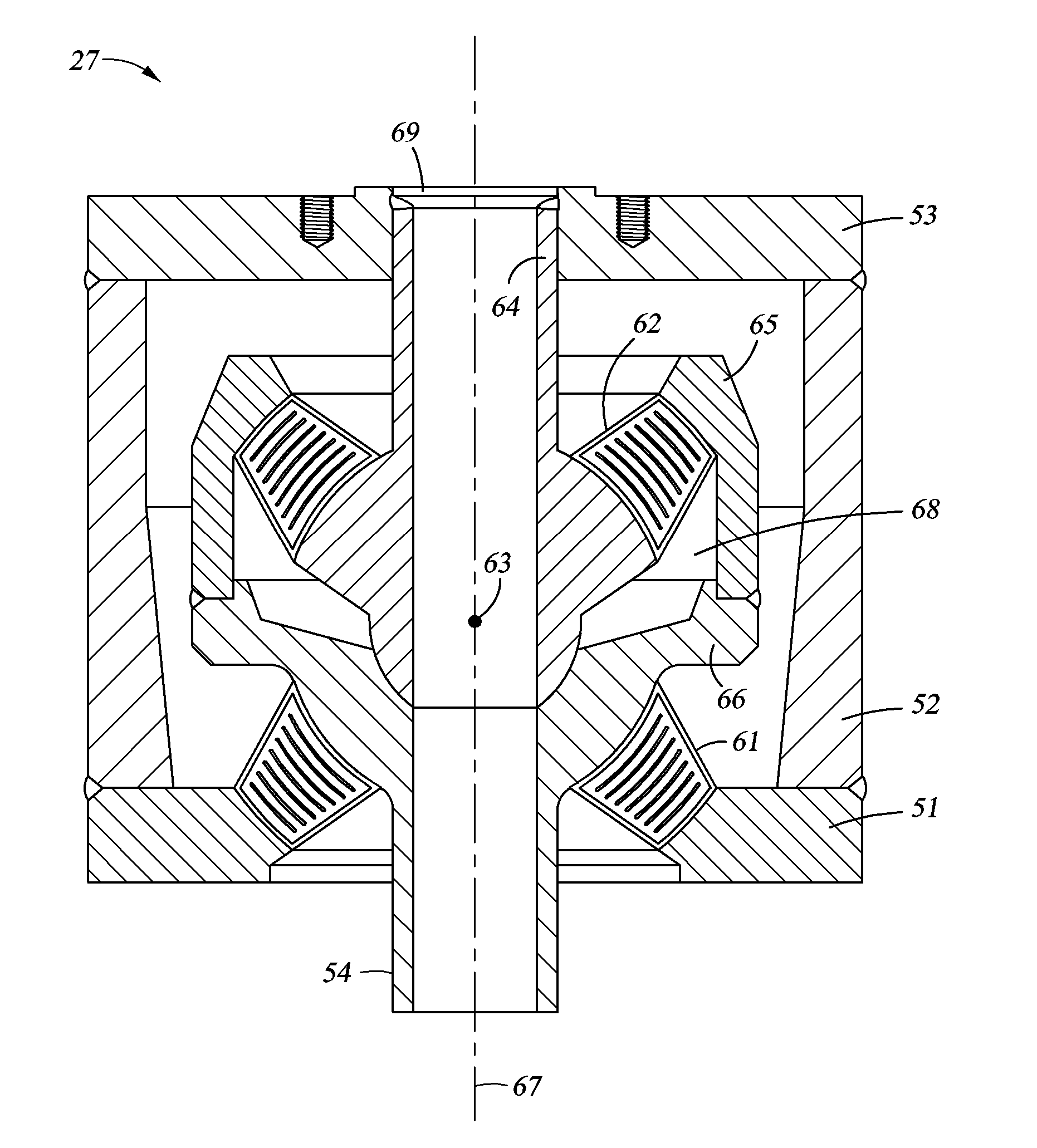

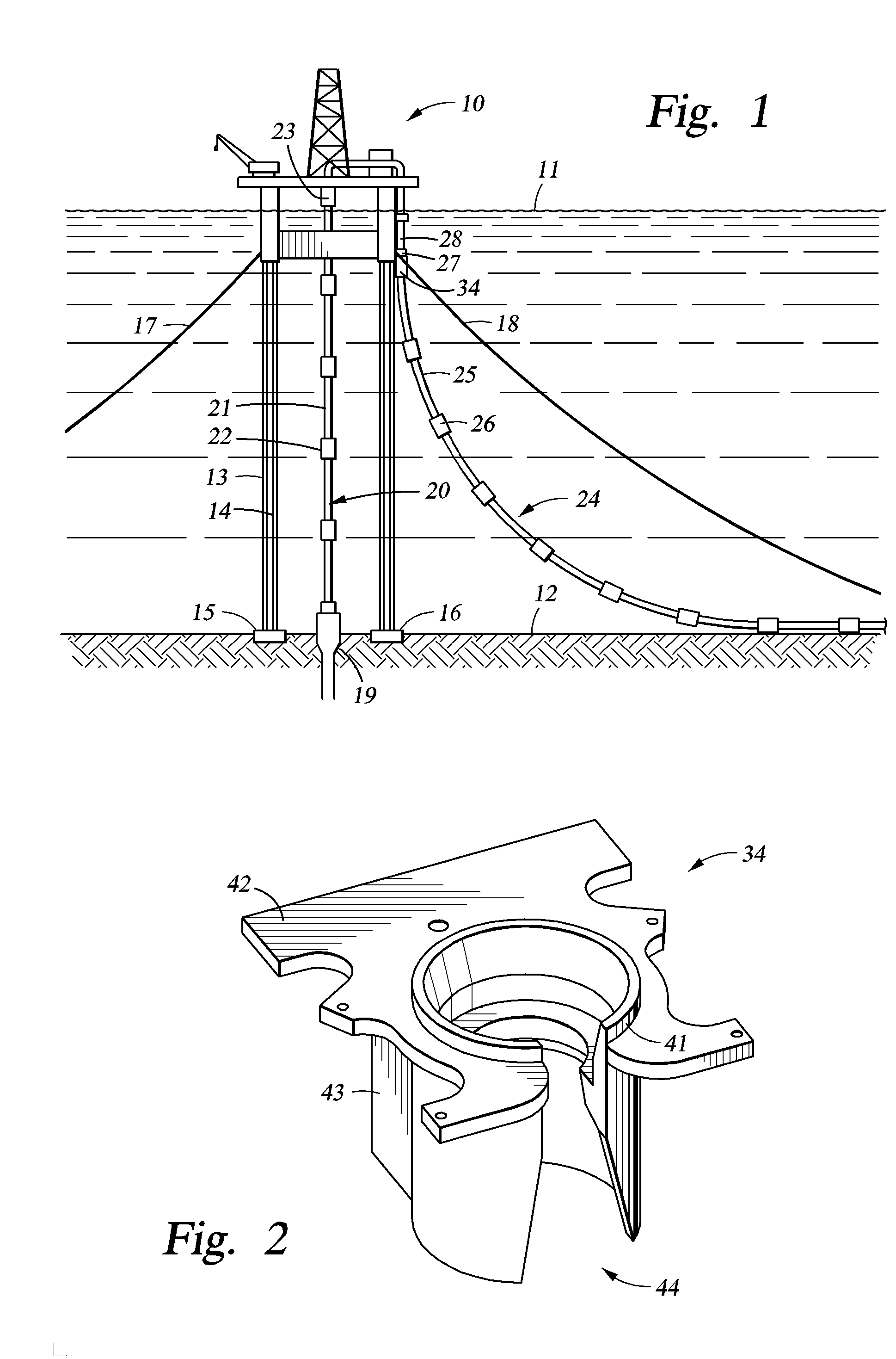

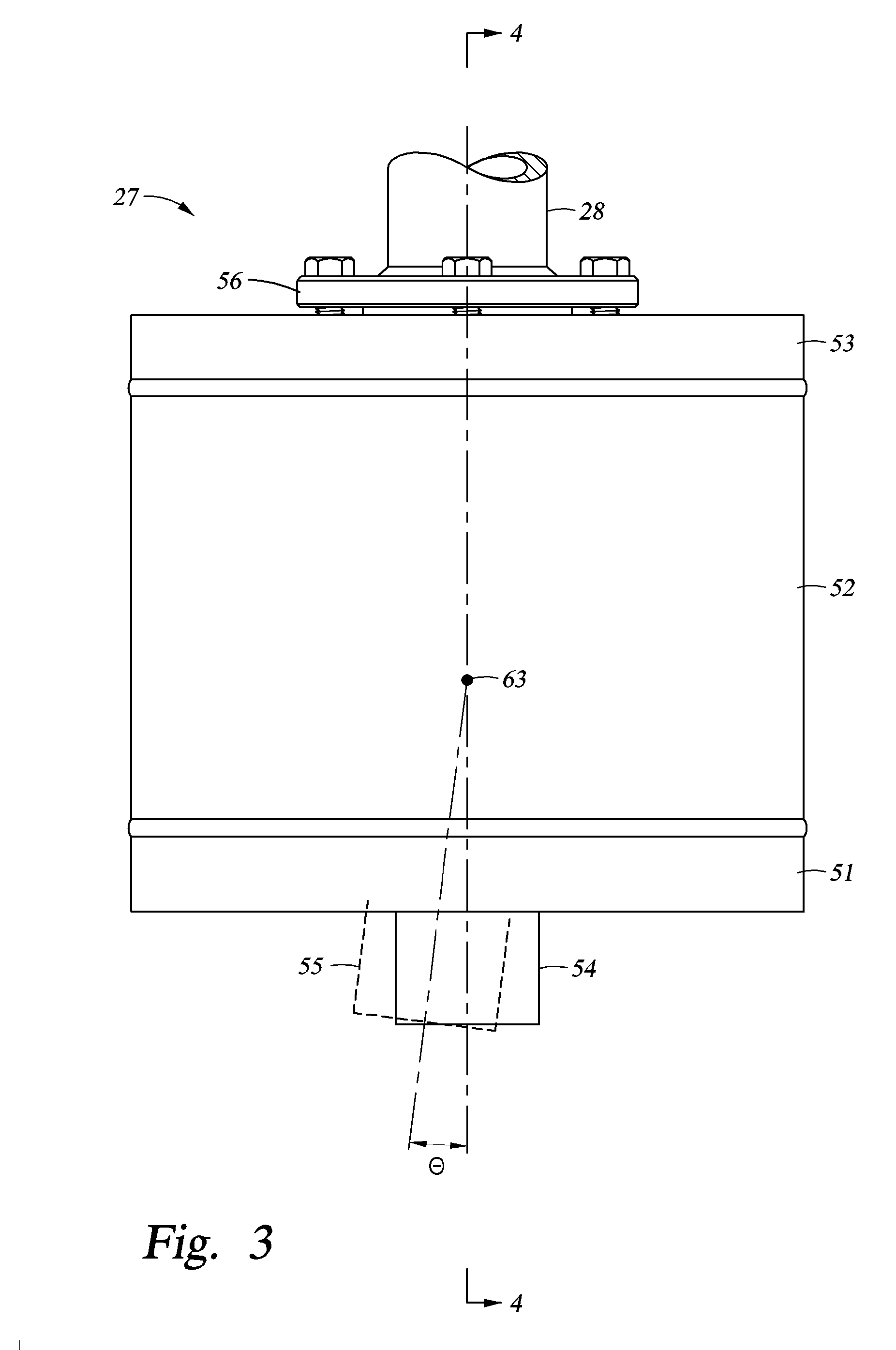

Two-element tandem flexible joint

ActiveUS20090212557A1Extended service lifeLoad capacity of the flexible joint is increasedDrilling rodsAdjustable jointsAxial displacementElastomer

A flexible joint has an extension mounted to a housing for relative angular displacement. Two or more annular elastomeric flex elements are stacked in a co-axial fashion and joined mechanically to mount the extension to the housing so that the flex elements react in parallel to angular and axial displacements of the extension with respect to the housing so that tensile load upon the extension places each of the flex elements in compression to split and share the tensile load among the flex elements in proportion to their relative axial stiffnesses. Therefore, for a given housing size or footprint, the overall load capacity is increased, and the lifetime of the flexible joint is increased for a given load capacity. The flex elements may have a common center of rotation, and the flex elements may be disposed either on the same side of the center of rotation or on opposite sides.

Owner:WELLS FARGO BANK NAT ASSOC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com