Patents

Literature

303results about How to "Improve axial stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

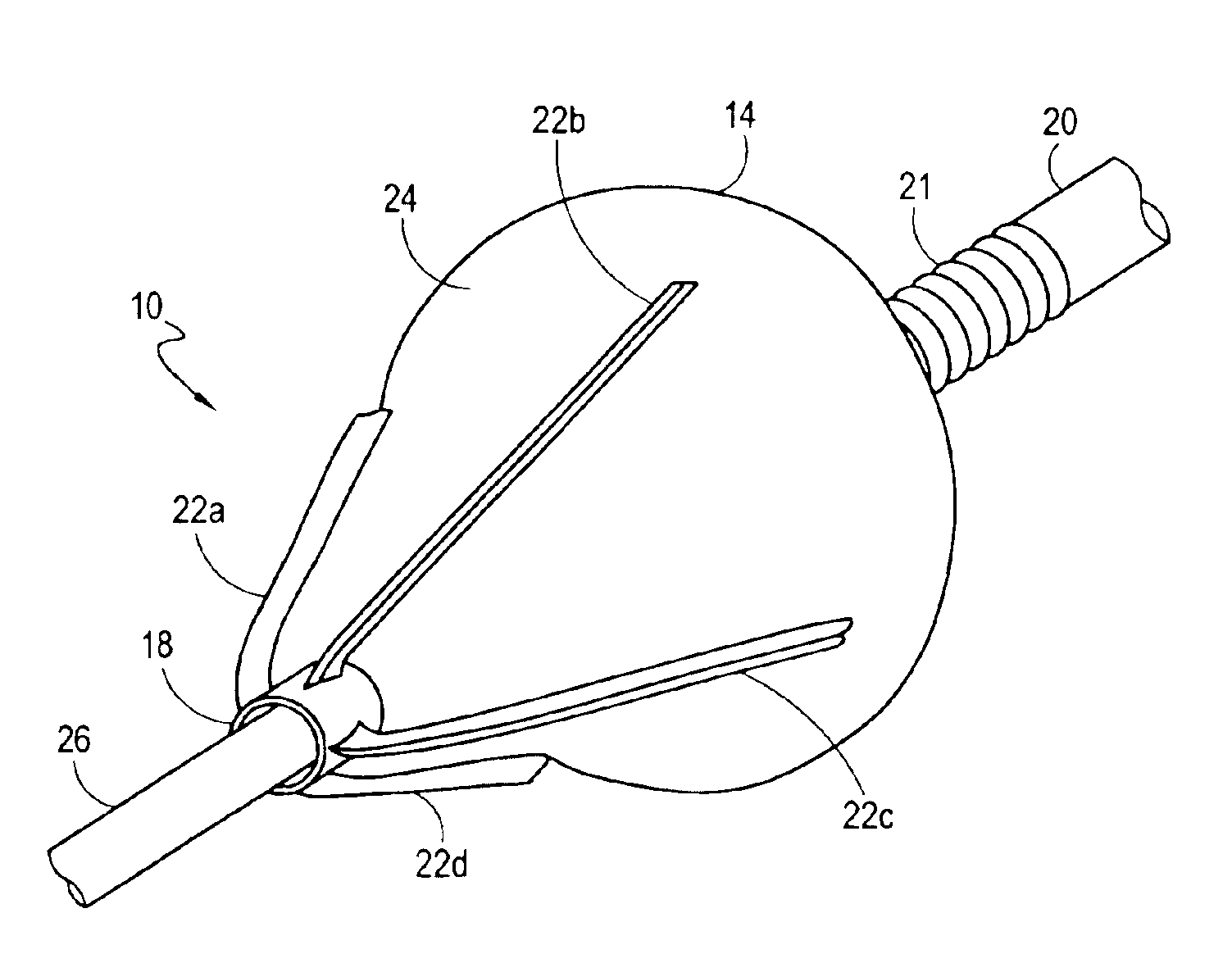

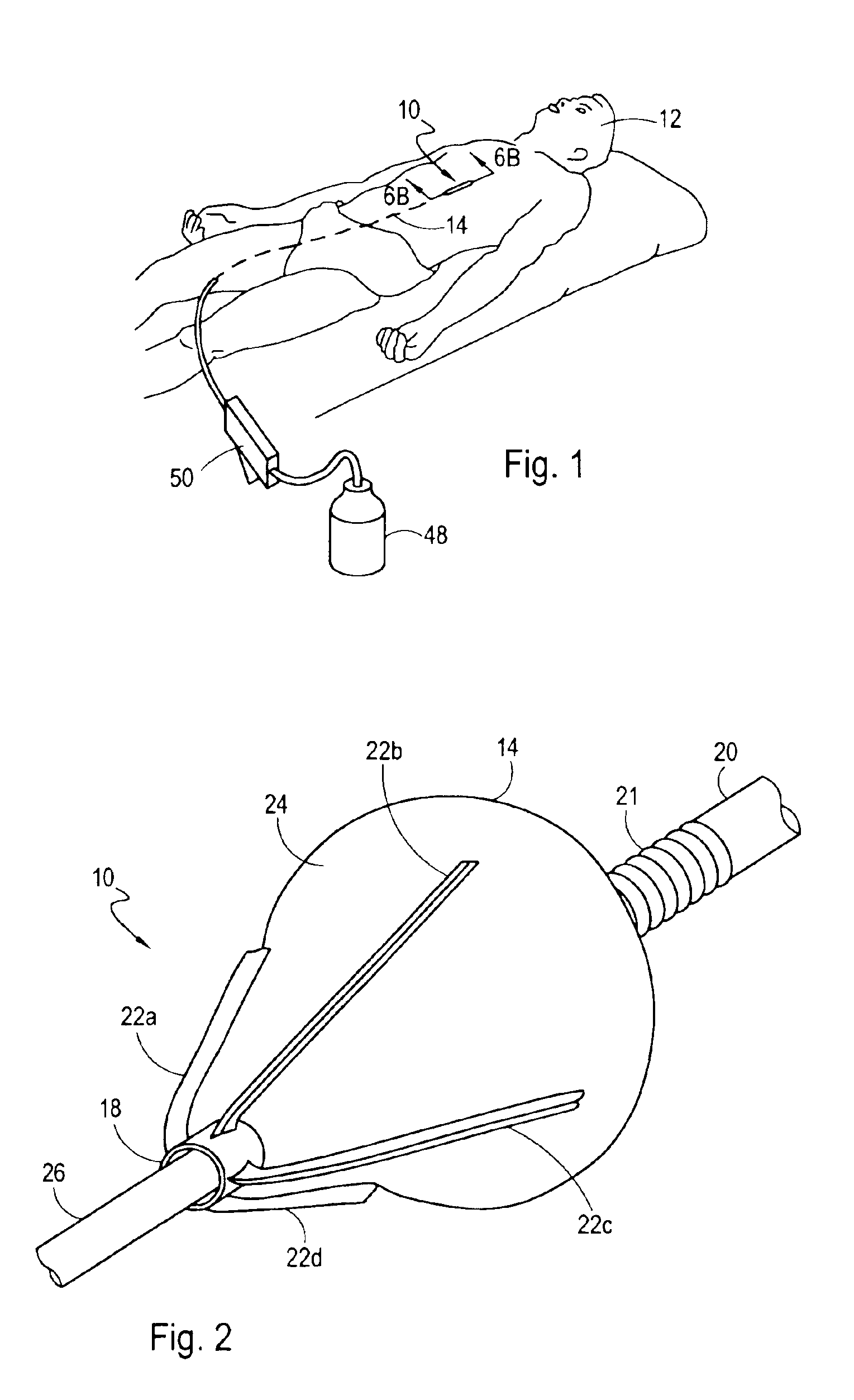

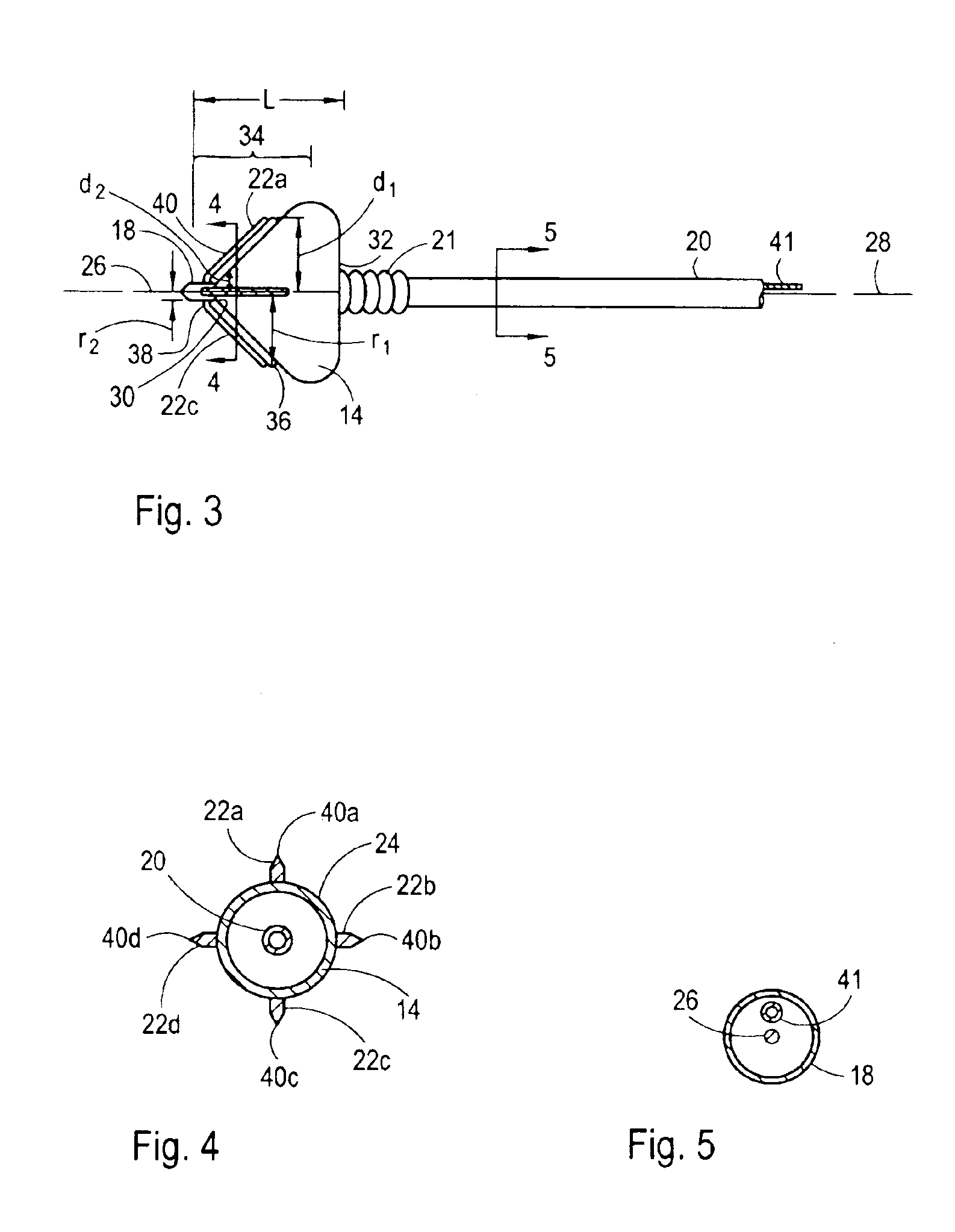

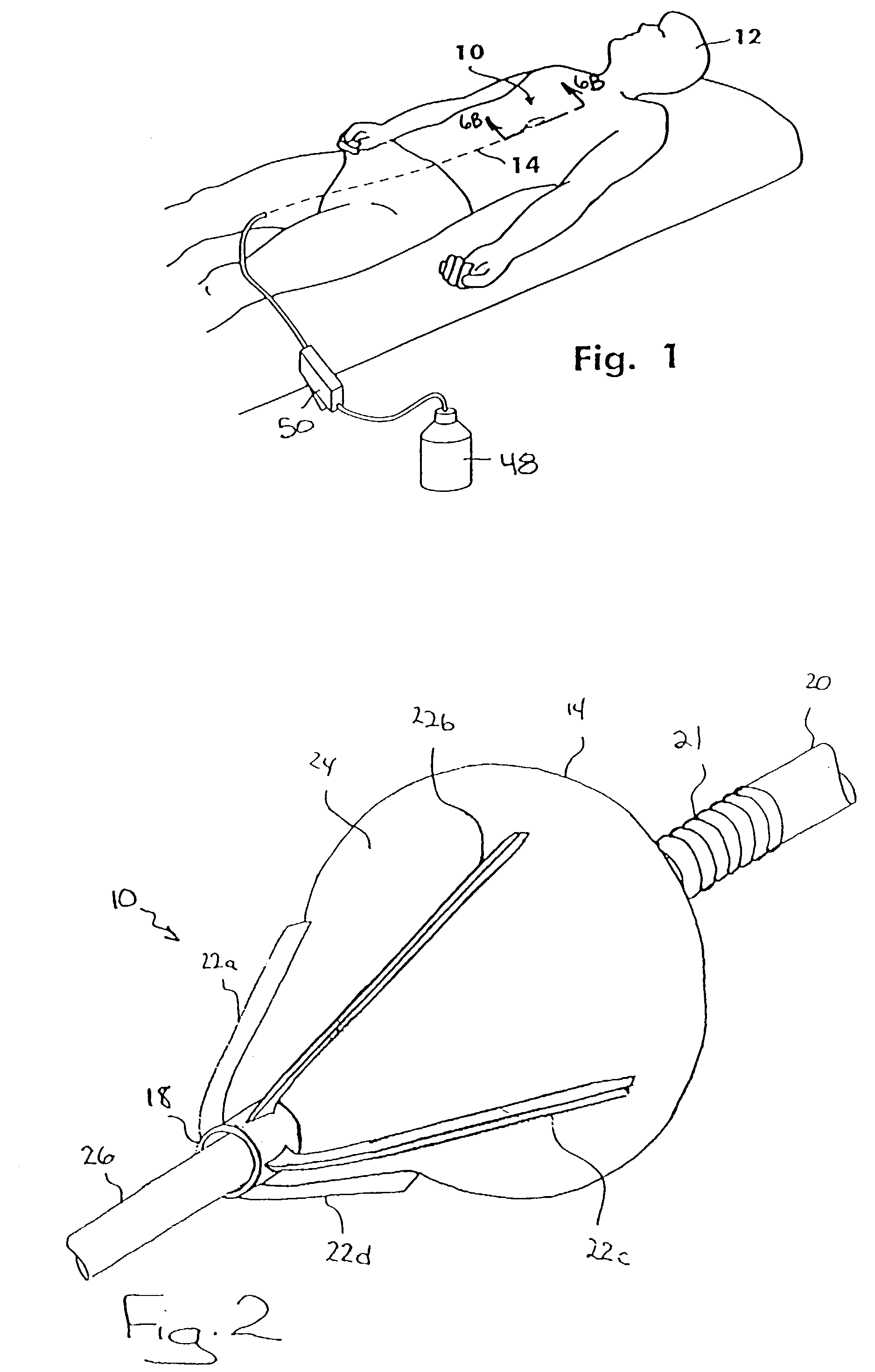

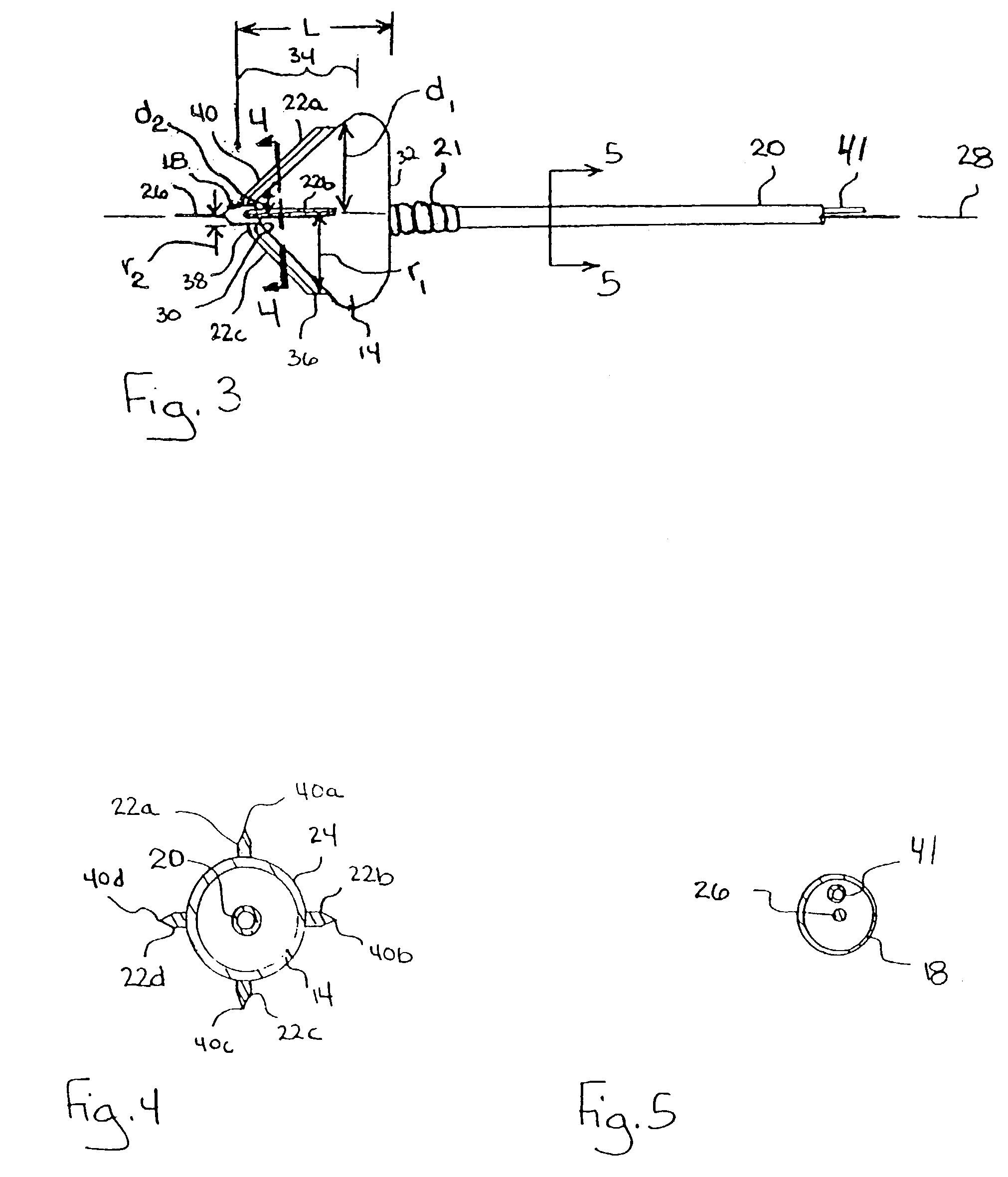

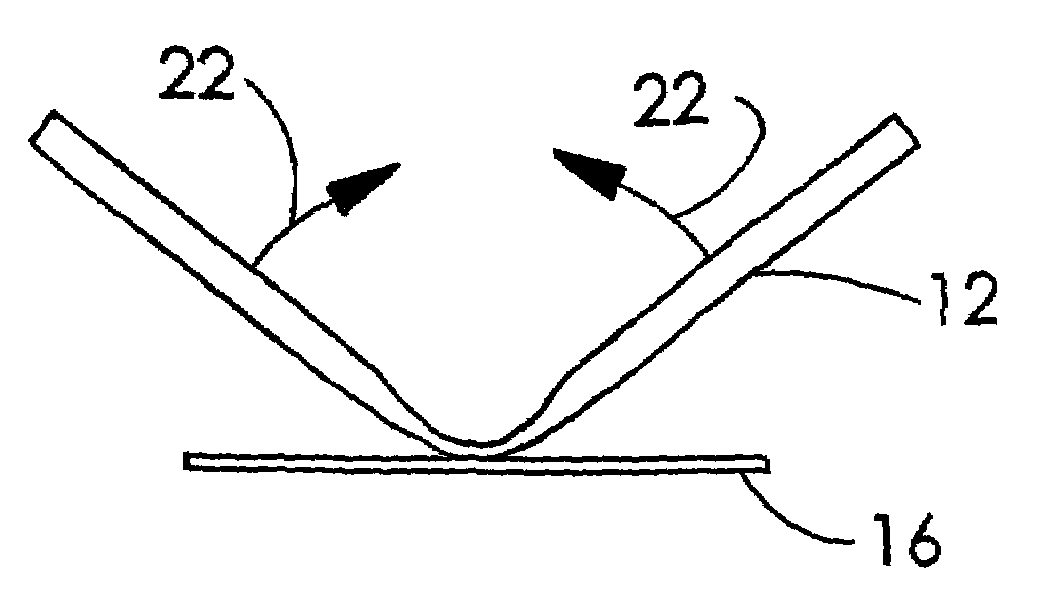

Reciprocating cutting and dilating balloon

Owner:LARY RES & DEV

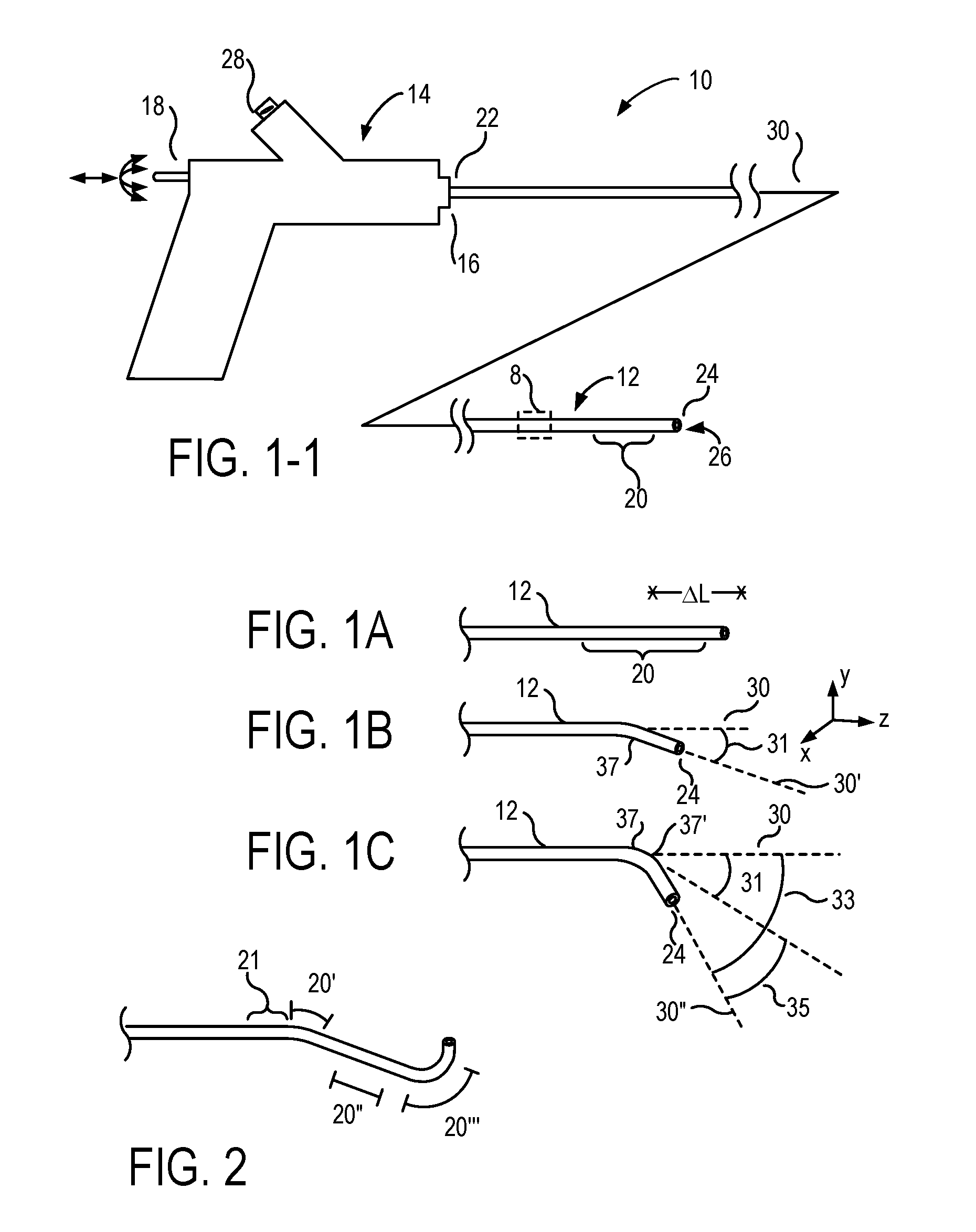

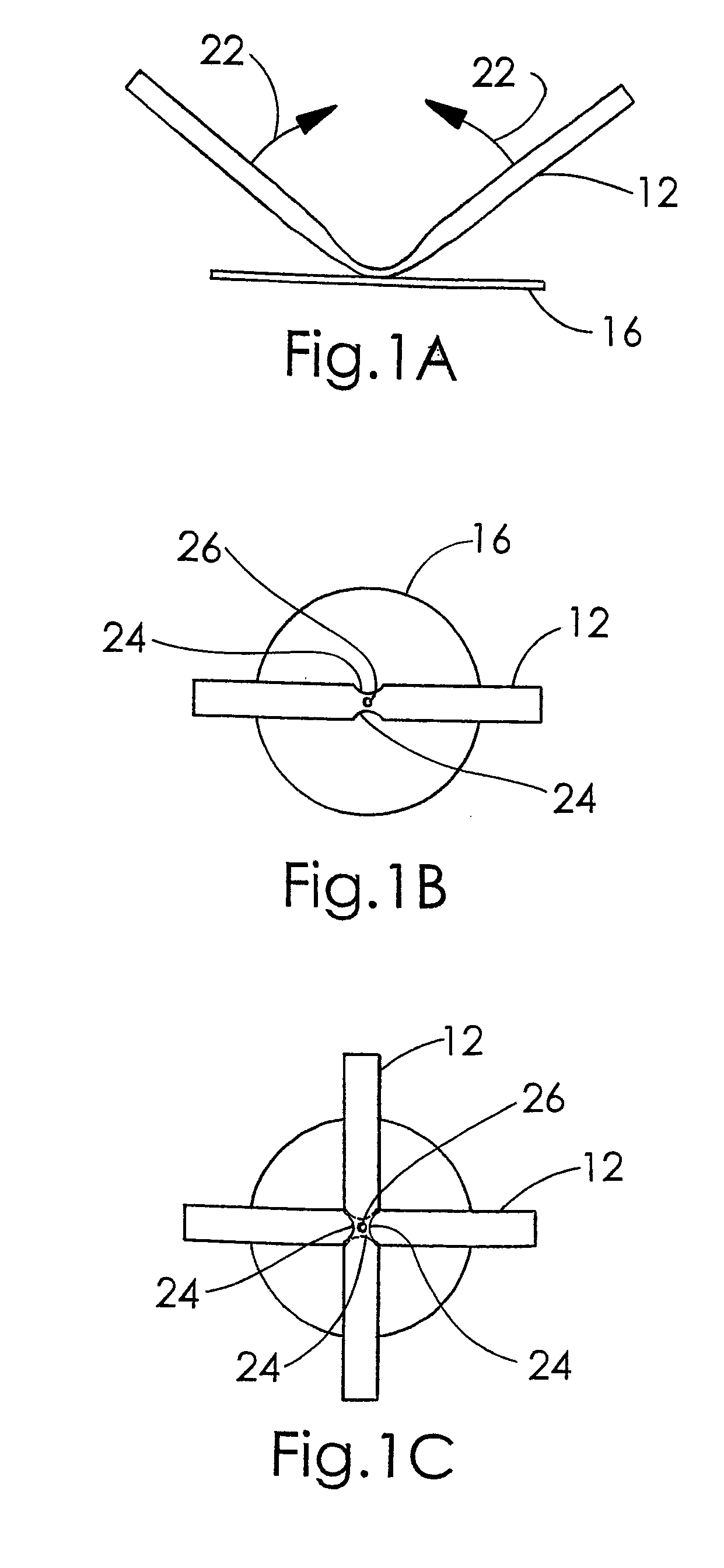

Reciprocating cutting and dilating balloon

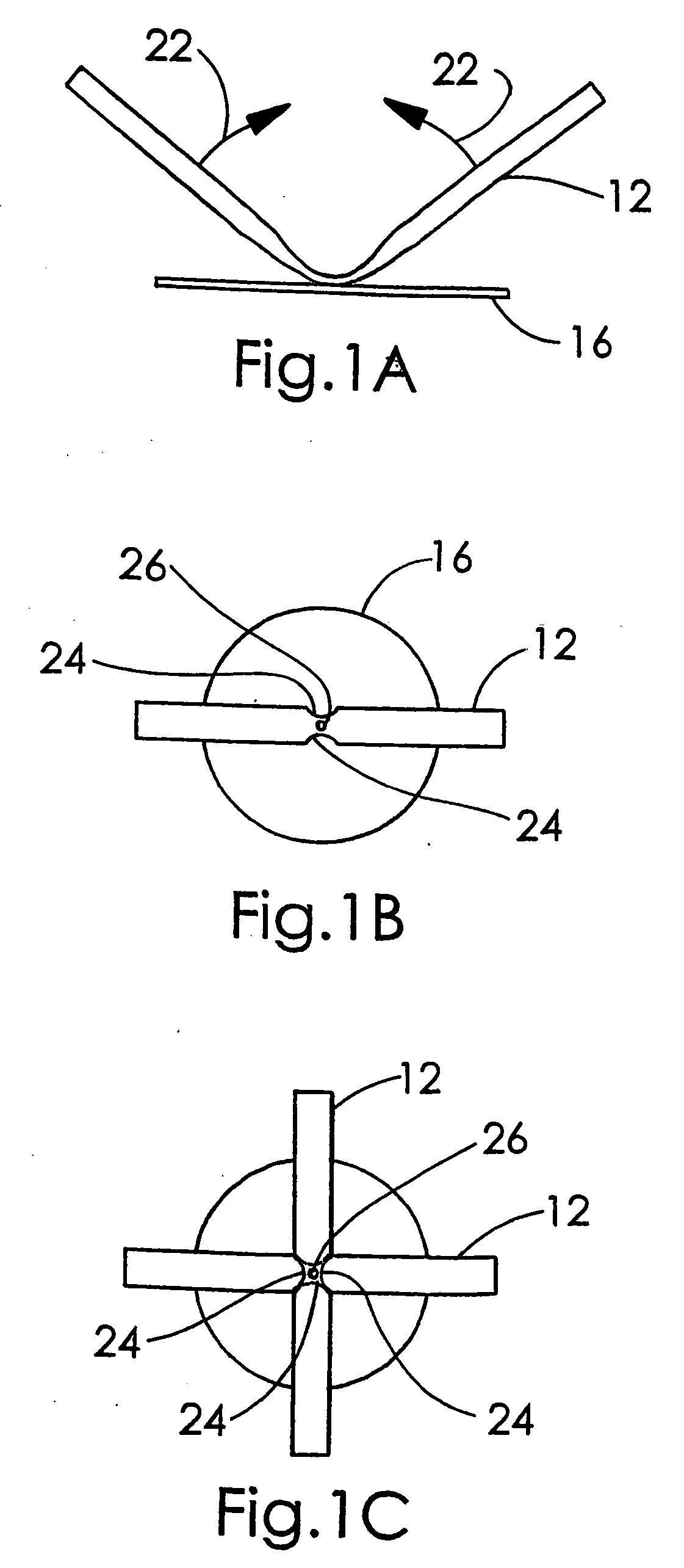

InactiveUS20030144677A1Easy to browseImprove axial stiffnessStentsCannulasTubular stenosisBlood vessel

An apparatus for incising a stenosis within a vascular conduit of a patient includes an inflatable balloon attached to an elongated catheter that defines a longitudinal axis. The distal end of the balloon includes a tapered section and at least one incising blade is attached to the tapered section. Each incising blade is oriented on the tapered section with the proximal end of the blade radially distanced from the longitudinal axis at a distance r.sub.1 and the distal end of the incising blade radially distanced from the longitudinal axis at a distance r.sub.2. After the balloon has been inflated, each incising blade is oriented with r.sub.1>r.sub.2 to position the incising blades at an angle relative to the axis. This cooperation of structure allows the incising blades to cut an incision into a stenosis during axial advancement of the inflated balloon.

Owner:LARY RES & DEV

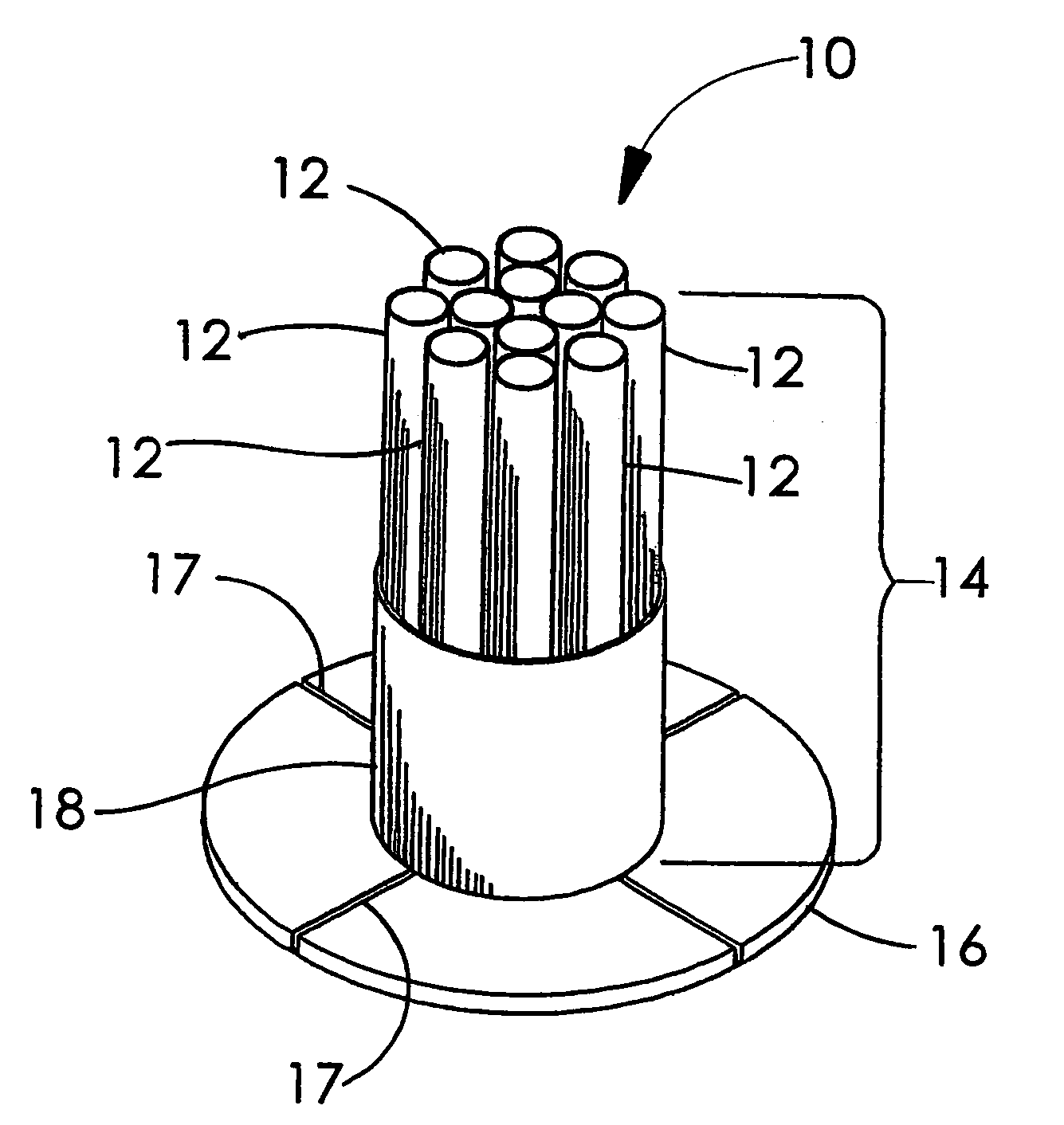

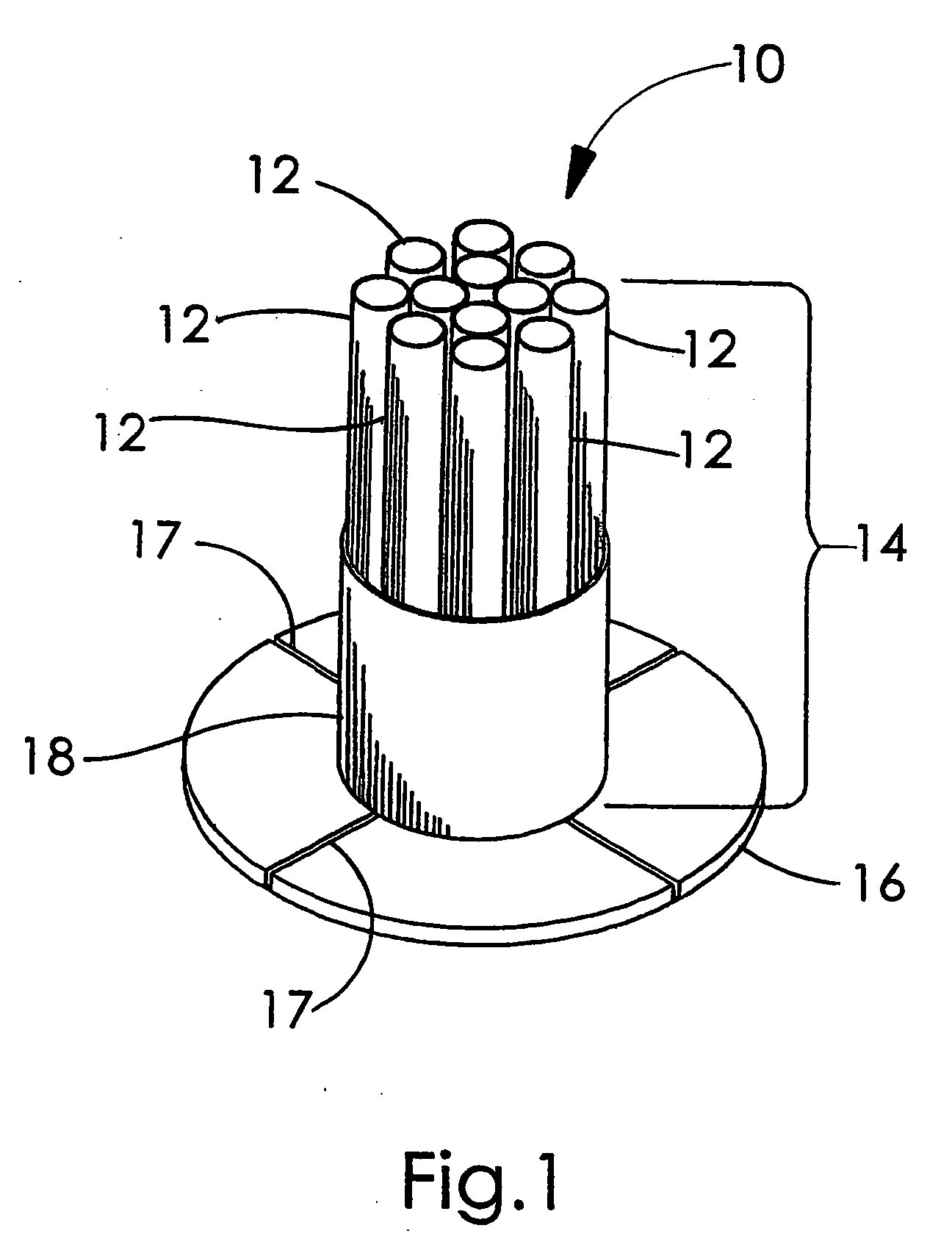

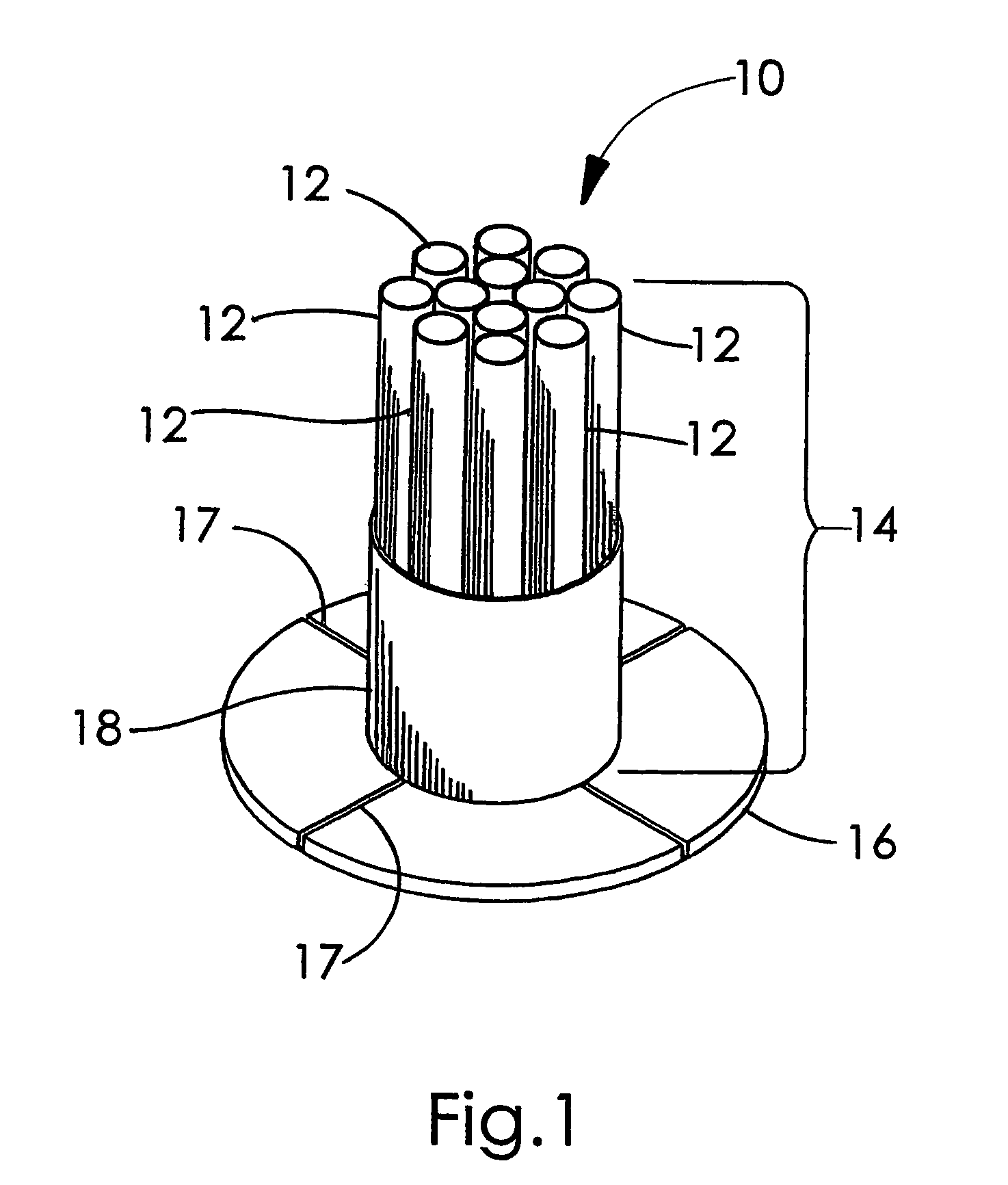

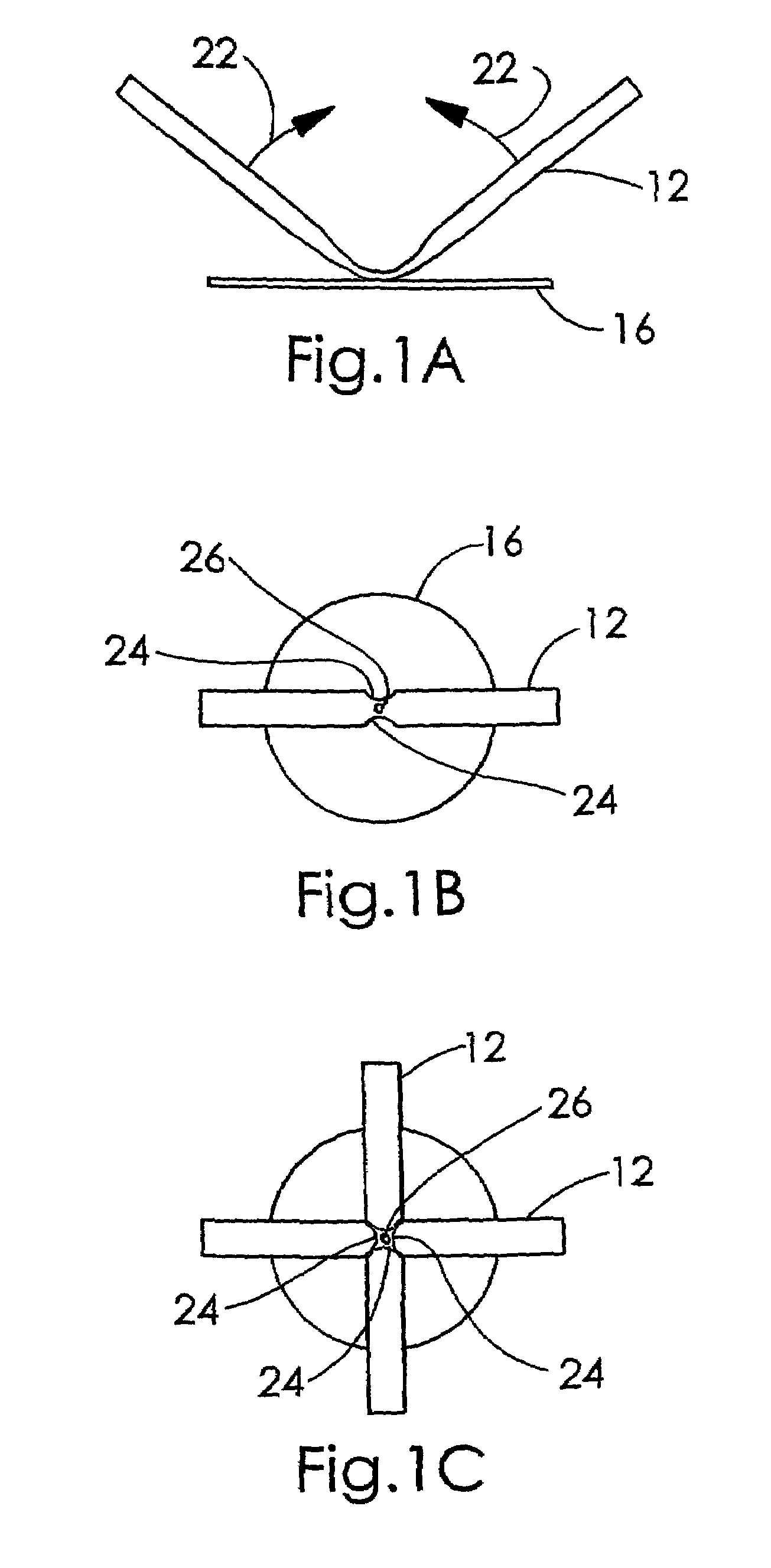

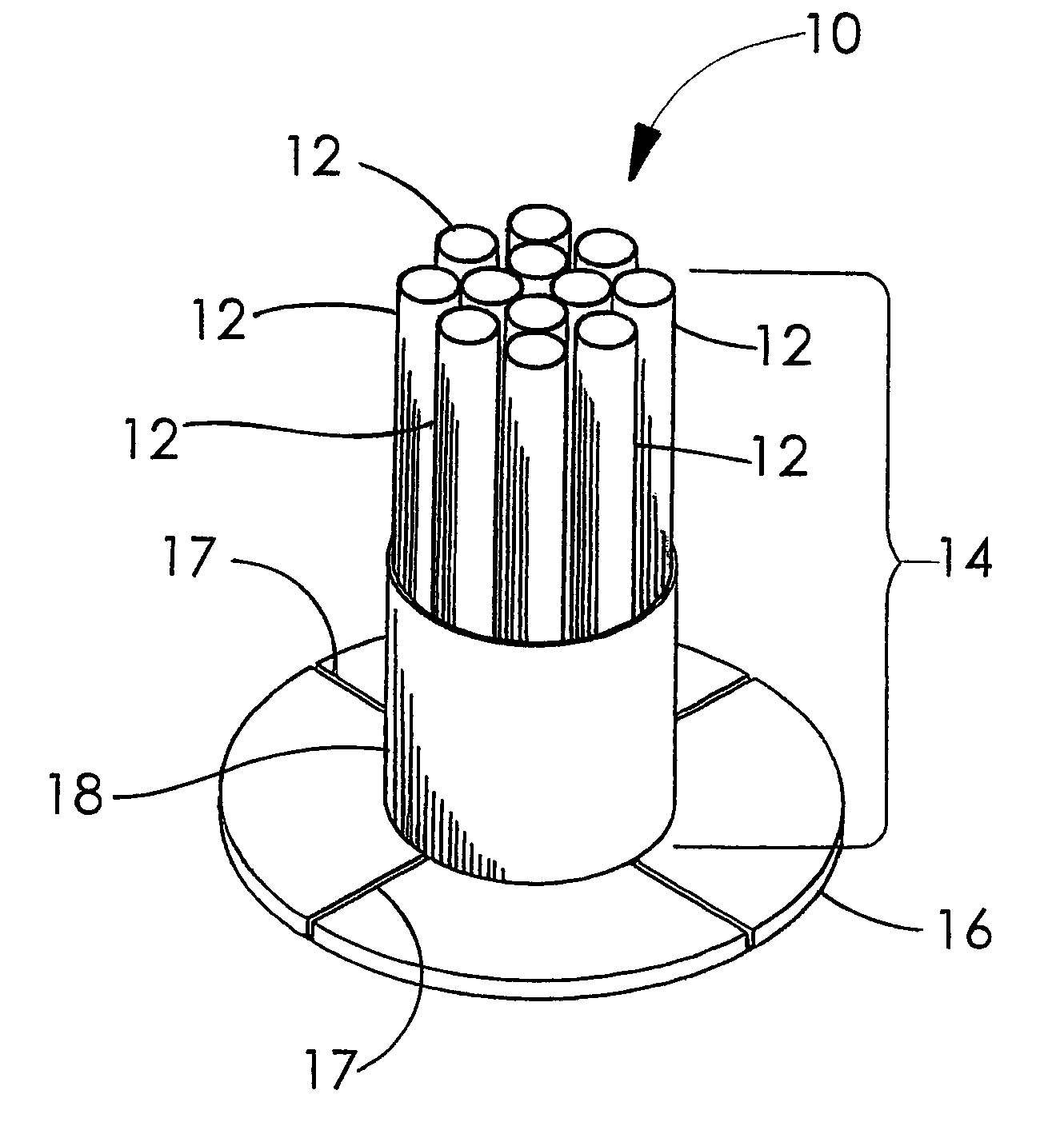

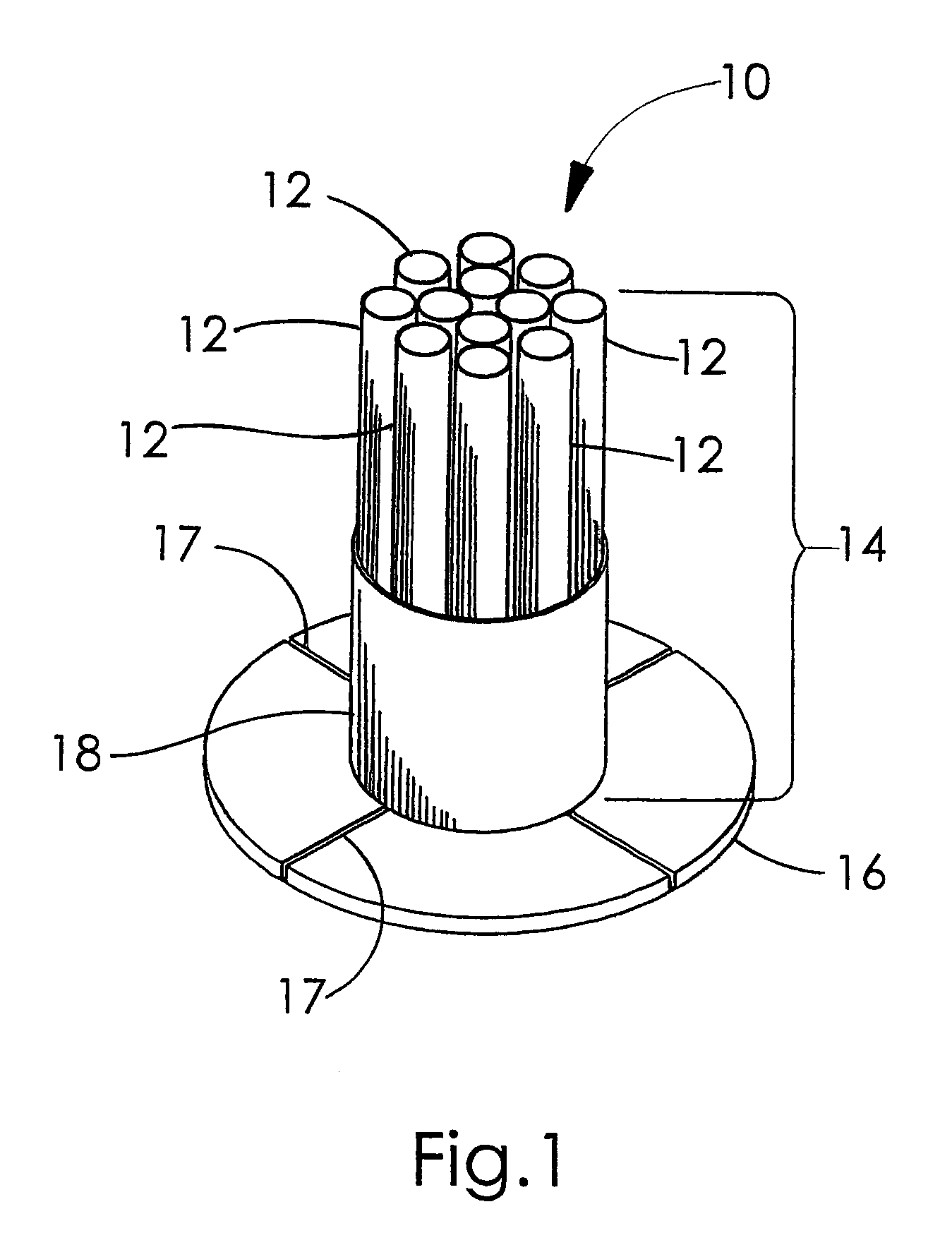

Soft tissue defect repair device

ActiveUS20050165447A1Shorten the lengthImprove axial stiffnessSuture equipmentsLigamentsDefect repairInguinal hernia

An inguinal hernia repair device in the form of an implantable plug that is affixed at one end to the center region of a sheet of implantable material. The plug takes the form of a plurality of hollow members, arranged so as to be in substantially parallel relationship when implanted into a defect. The hollow members are preferably tubular members and are preferably bundled together by various means, such as bonding or wrapping a band or strand about the plurality of hollow members to maintain them in adjacent and contacting relationship during insertion into a defect. The device is provided with a base member for anchorage made of a composite material having a non-bioabsorable component and a bioabsorbable component.

Owner:WL GORE & ASSOC INC

Axial flux brushless permanent magnet electrical machine rotor

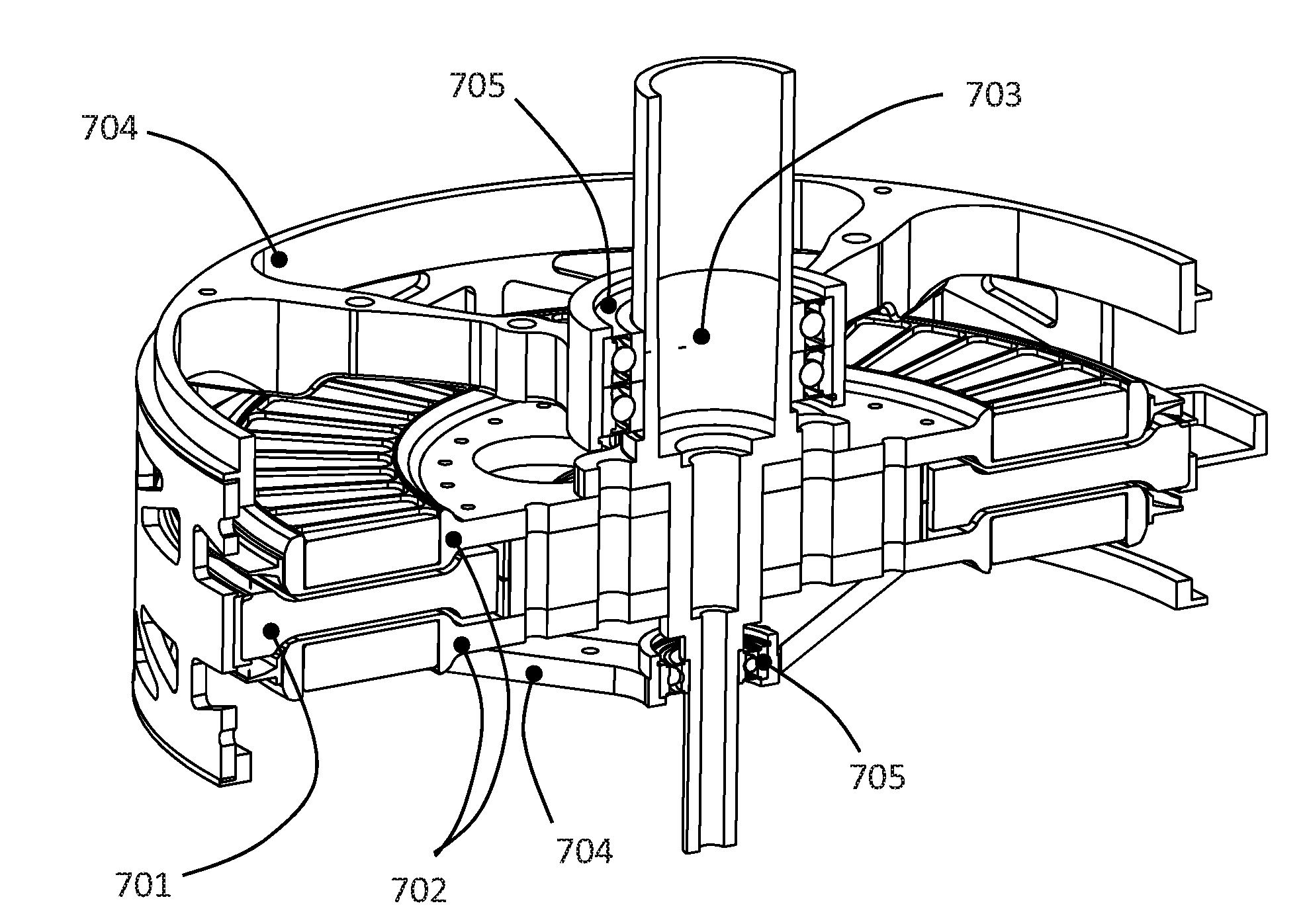

ActiveUS20160329795A1Maximize rotor strengthMinimizing structural massMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRotor magnetsAxial flux

An axial flux brushless permanent magnet electrical machine having a stator and at least one rotor. The rotor includes a Halbach array of magnets with at least four magnets per magnetic cycle. The rotor magnets are contained within pockets in the rotor. The pockets are formed with magnet pocket walls being radial walls, active surface walls, and / or inactive surface walls where the walls retain the magnets within the pockets.

Owner:LAUNCHPOINT ELECTRIC PROPULSION SYST INC

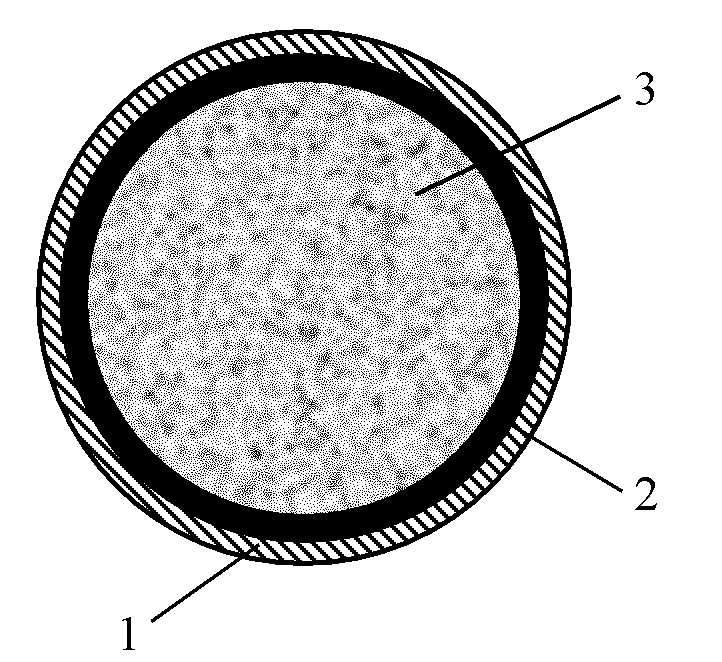

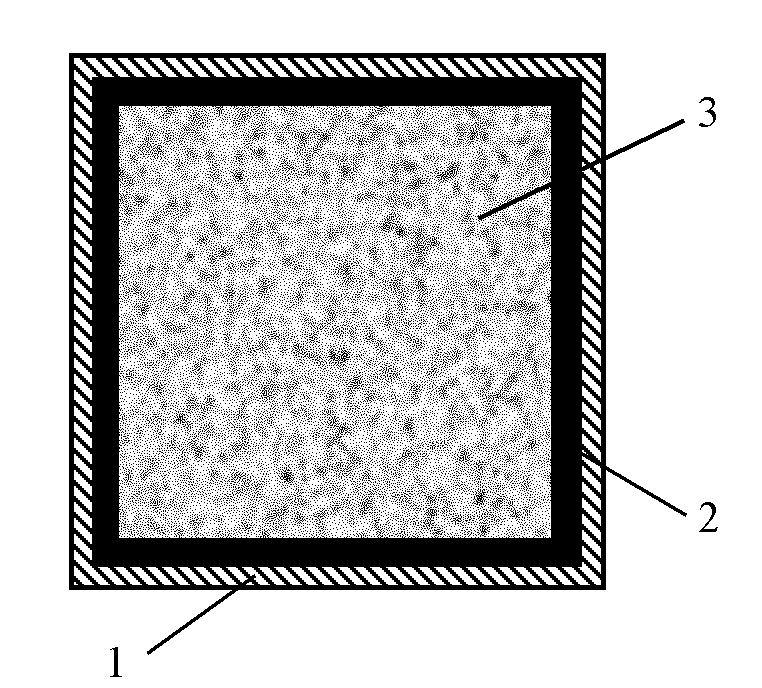

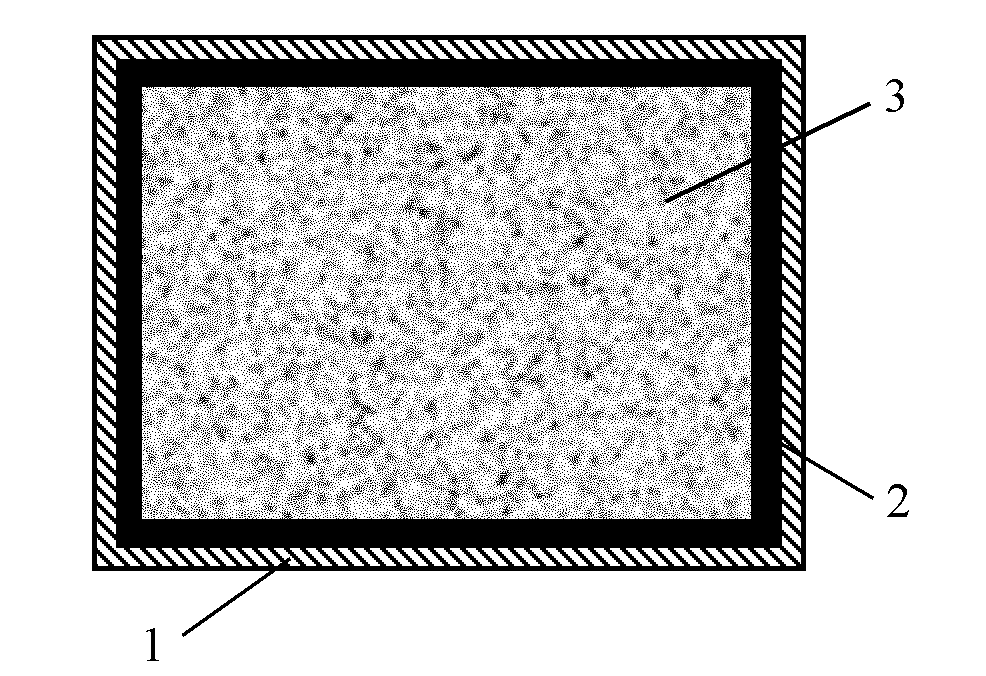

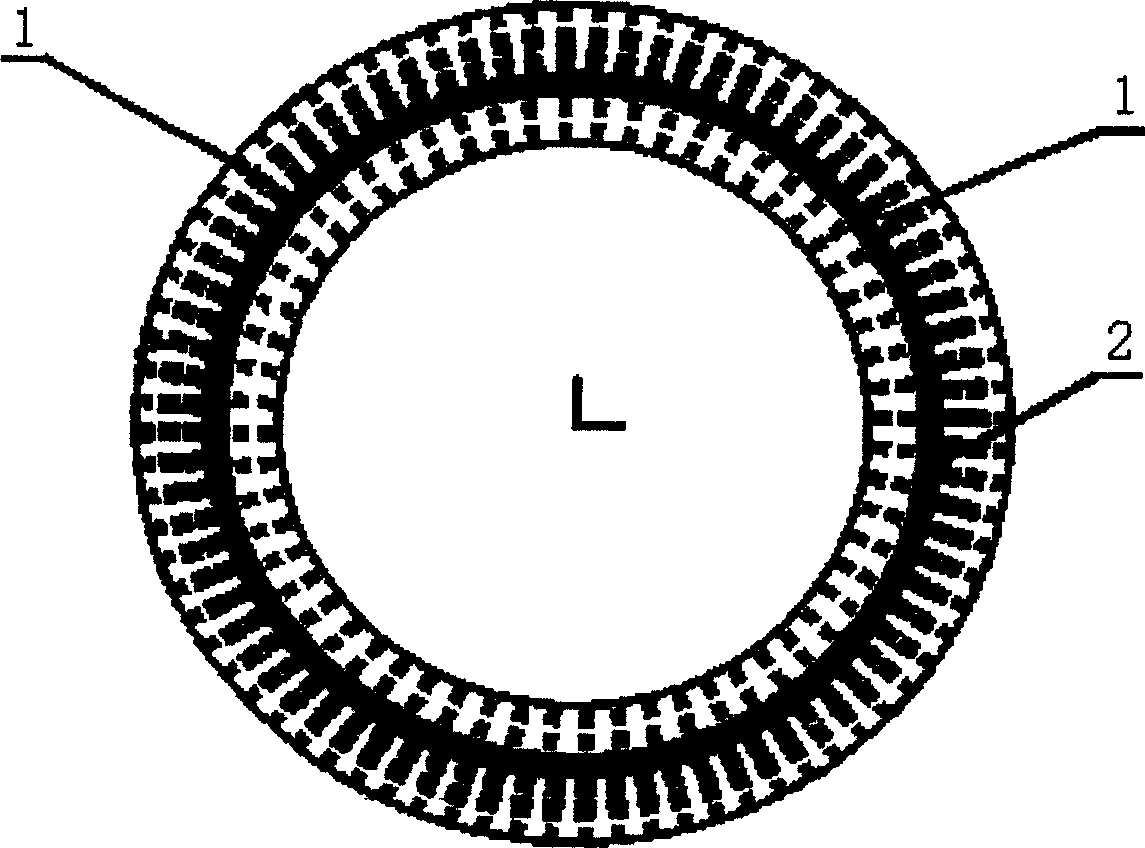

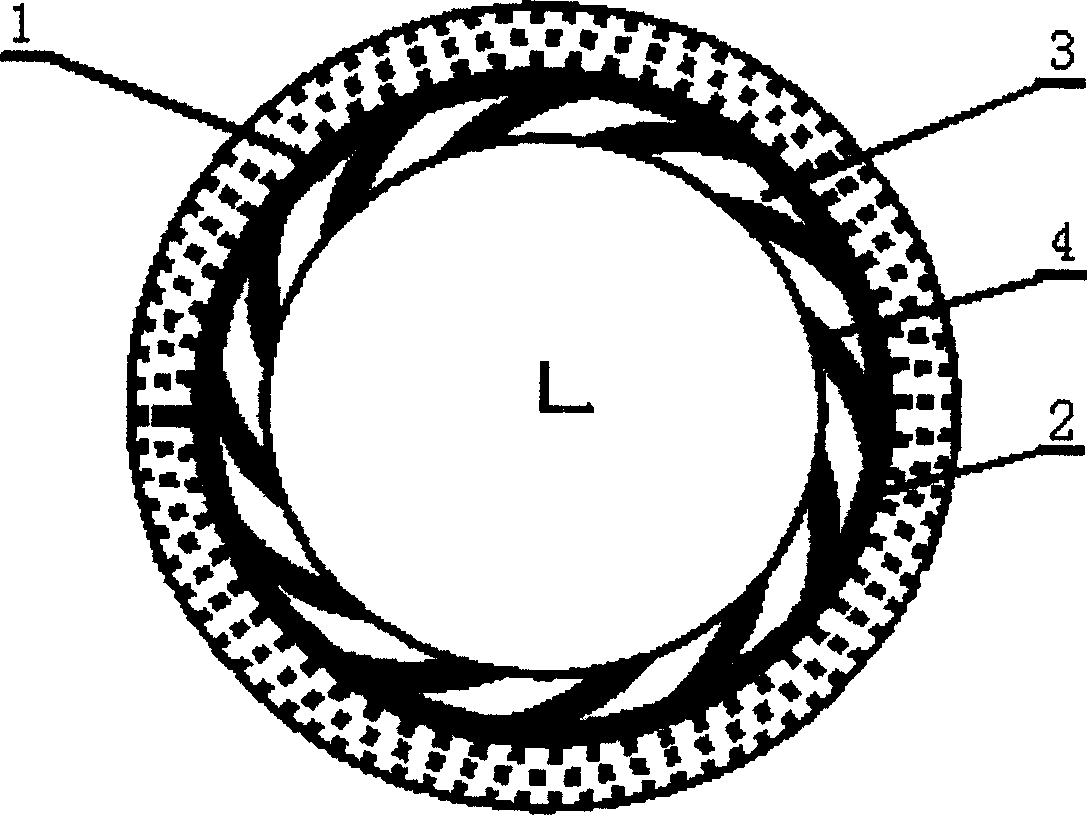

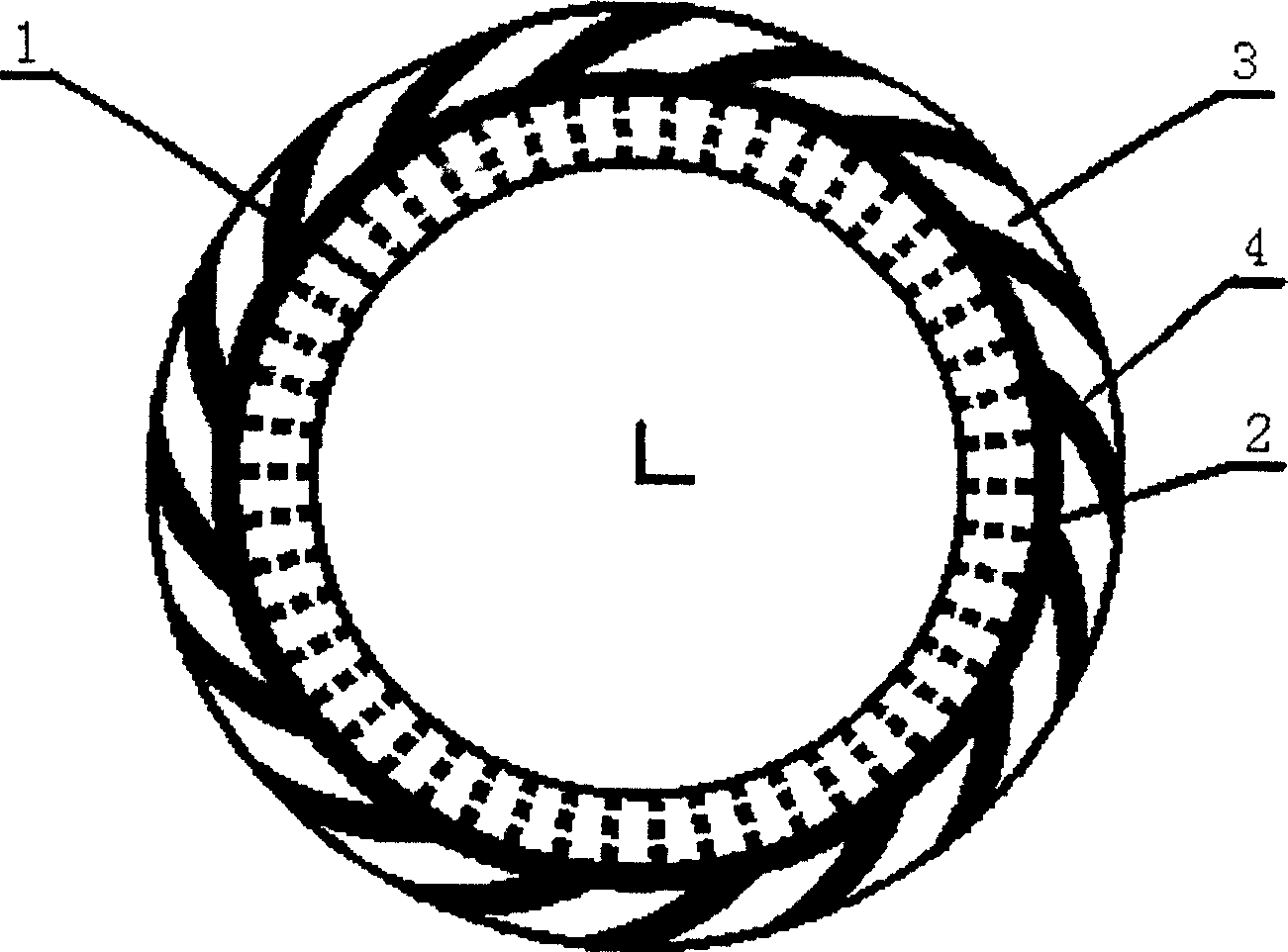

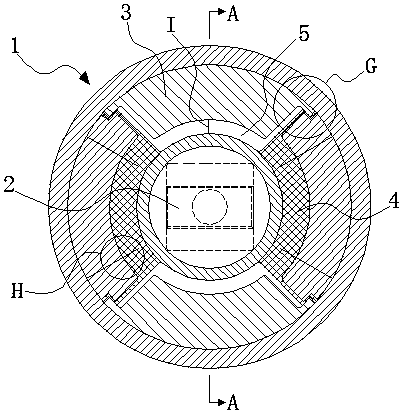

FRP (fiber reinforced plastic)-steel composite tube concrete column

InactiveCN101985851AGive full play to carrying capacityPersistent Circumferential ConstraintStrutsBridge structural detailsFiberYarn

The invention discloses an FRP (fiber reinforced plastic)-steel composite tube concrete column and relates to a civil engineering structural element, the composite tube concrete column consists of an FRP-steel composite tube and concrete filled therein and is characterized in that the FRP-steel composite tube is formed by compounding a steel tube as an inner wall with an FRP tube as an outer wall, the steel tube is formed by welding a steel plate, the FRP tube is prepared by winding continuous fiber yarn on the outer surface of the steel tube, and the solid concrete is poured in the composite tube. The FRP-steel composite tube concrete column can fully play the respective advantages of three composition materials of FRP, steel and concrete and has the characteristics of high bearing capacity, corrosion resistance, excellent aseismic performance and the like, thereby providing a new choice for civil engineering construction.

Owner:DALIAN UNIV OF TECH

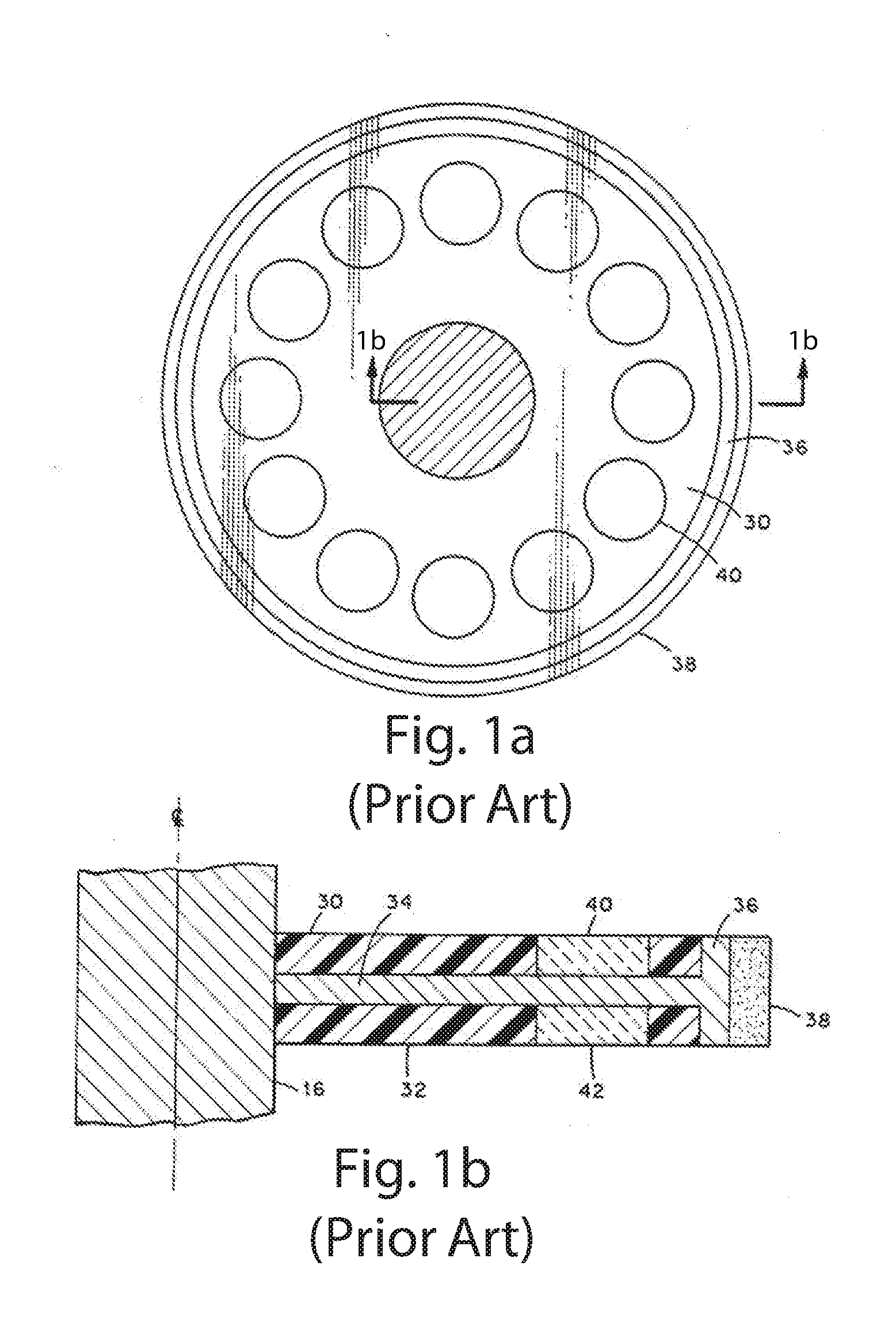

Soft tissue defect repair device

InactiveUS6991637B2Improve axial stiffnessImprove complianceProsthesisWound clampsDefect repairEngineering

An inguinal hernia repair device in the form of an implantable plug that is affixed at one end to the center region of a sheet of implantable material. The plug takes the form of a plurality of hollow members, arranged so as to be in substantially parallel relationship when implanted into a defect. The hollow members are preferably tubular members and are preferably bundled together by various means, such as bonding or wrapping a band or strand about the plurality of hollow members to maintain them in adjacent and contacting relationship during insertion into a defect.

Owner:WL GORE & ASSOC INC

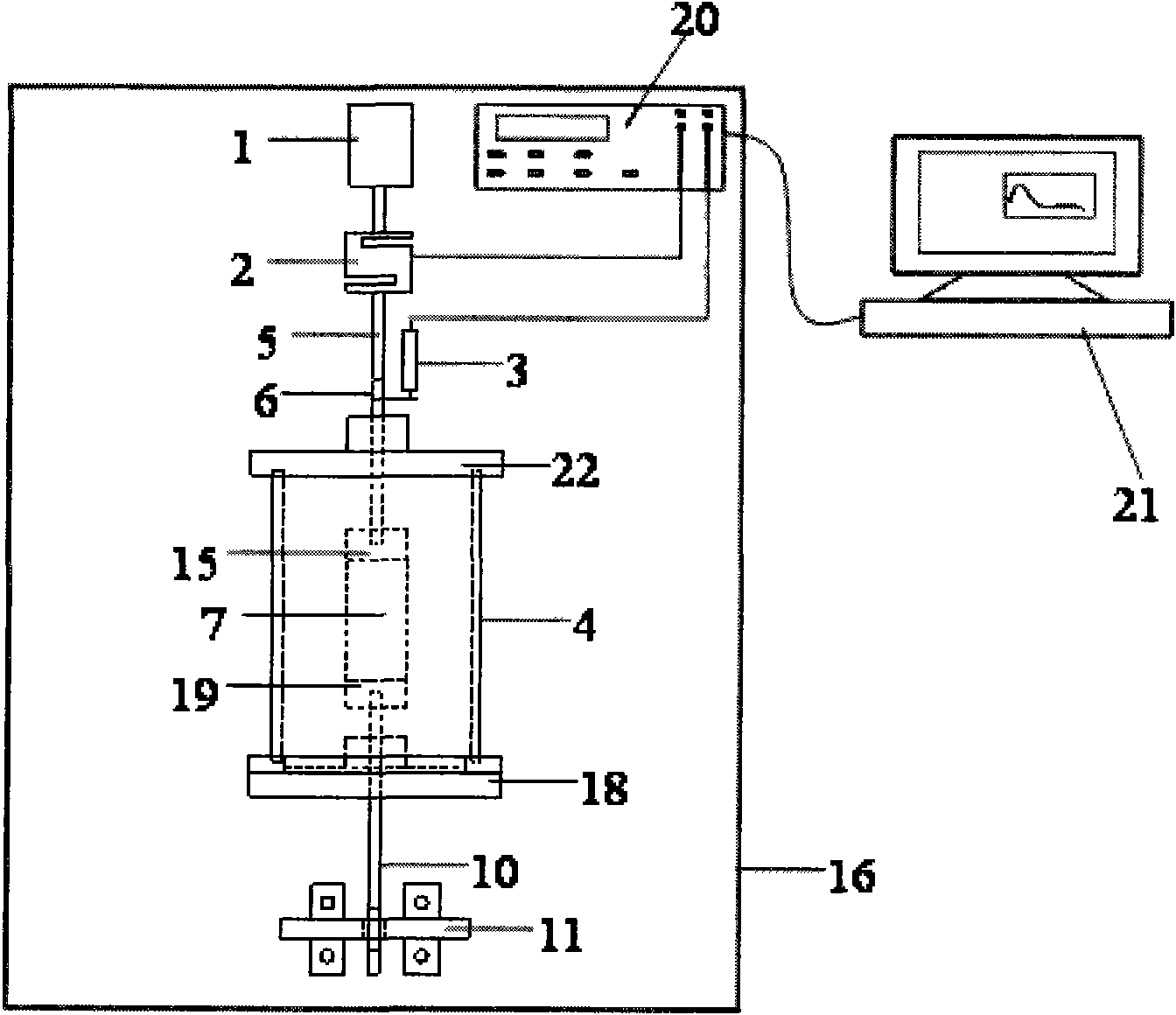

A differential type graphene resonant beam acceleration sensor

InactiveCN107015025AEliminate the effects of movementIncrease sensitivityAcceleration measurementMicroelectromechanical systemsAxial displacementGraphene

The invention discloses a differential type graphene resonant beam acceleration sensor comprising a substrate (1), a sensitive mass plate (2), a first insulating layer (3), a second insulating layer (4), a first excitation electrode pair (1), a first graphene resonant beam (6), a second graphene resonant beam (7), a third insulating layer (8), a second excitation electrode pair (1) and a vacuum cap (10). The differential type graphene resonant beam acceleration sensor of the invention adopts a direct sensitive acceleration mode: a sensitive mass block directly senses the measured accelerated speed, transforms the measured accelerated speed into a concentrated force to cause the axial displacement of the sensitive mass block and cause the change of the axial stress of the graphene resonator beams, thereby causing the changes of the resonant frequency of the beams. Through detection of the resonant frequency of the beams, measurement of the accelerated speed can be realized. The two graphene resonant beams positioned in the axial direction of the sensitive mass block work in a differential mode in the detected acceleration direction so as to enhance detection signals, raise the sensitivity and the measurement accuracy and suppress conjugate interferences.

Owner:BEIHANG UNIV

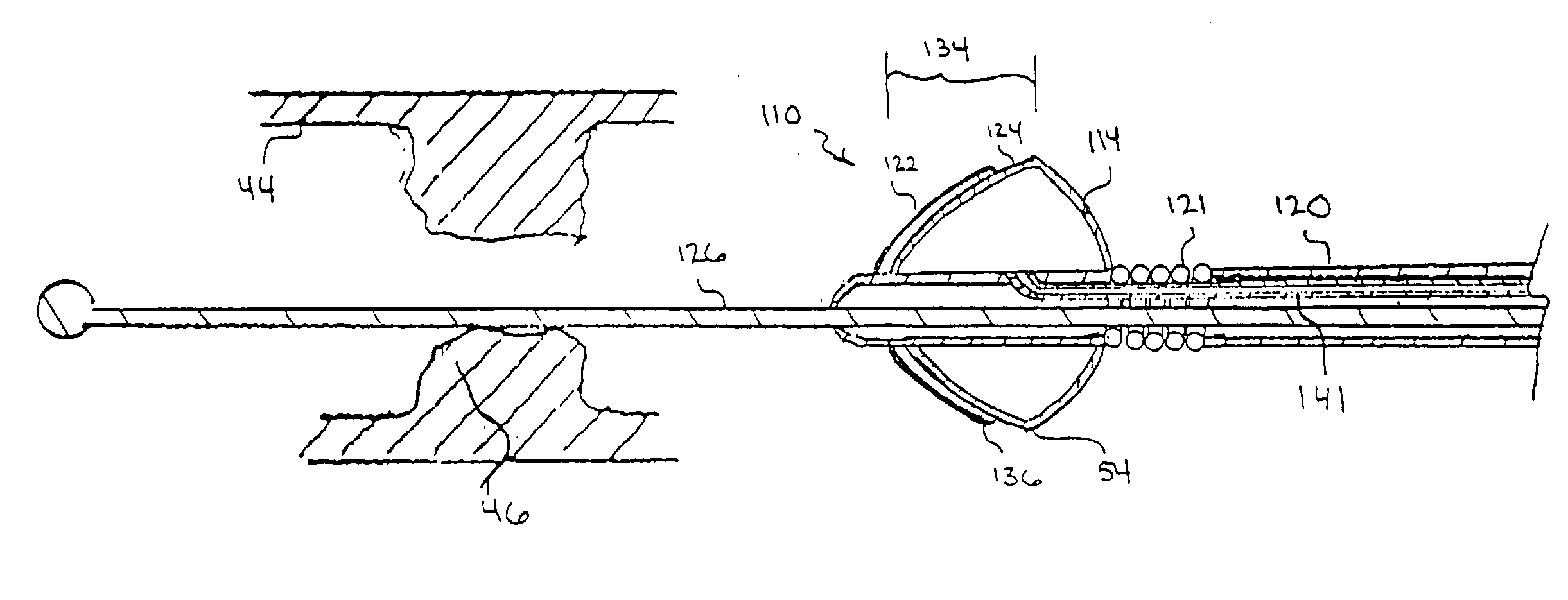

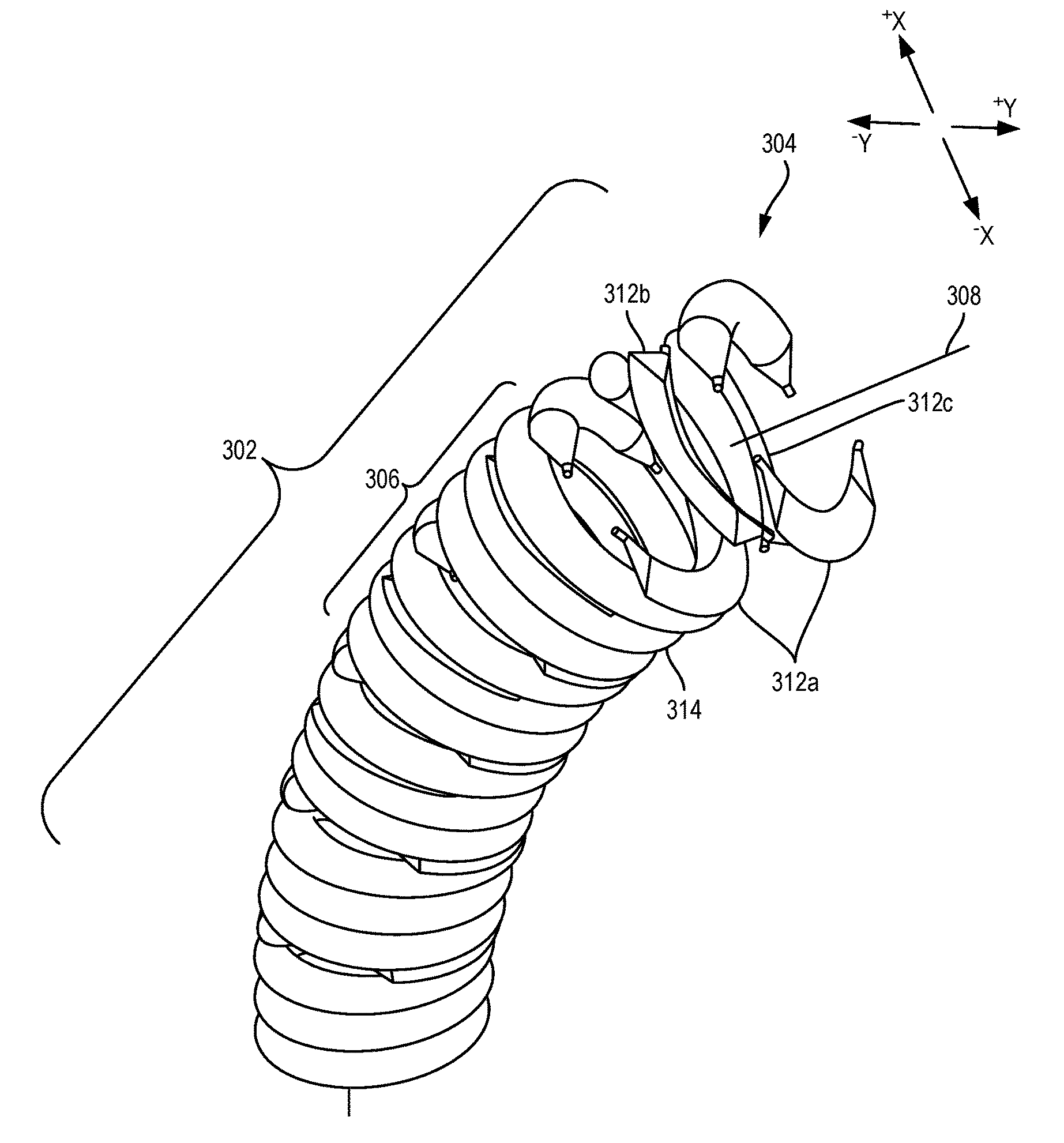

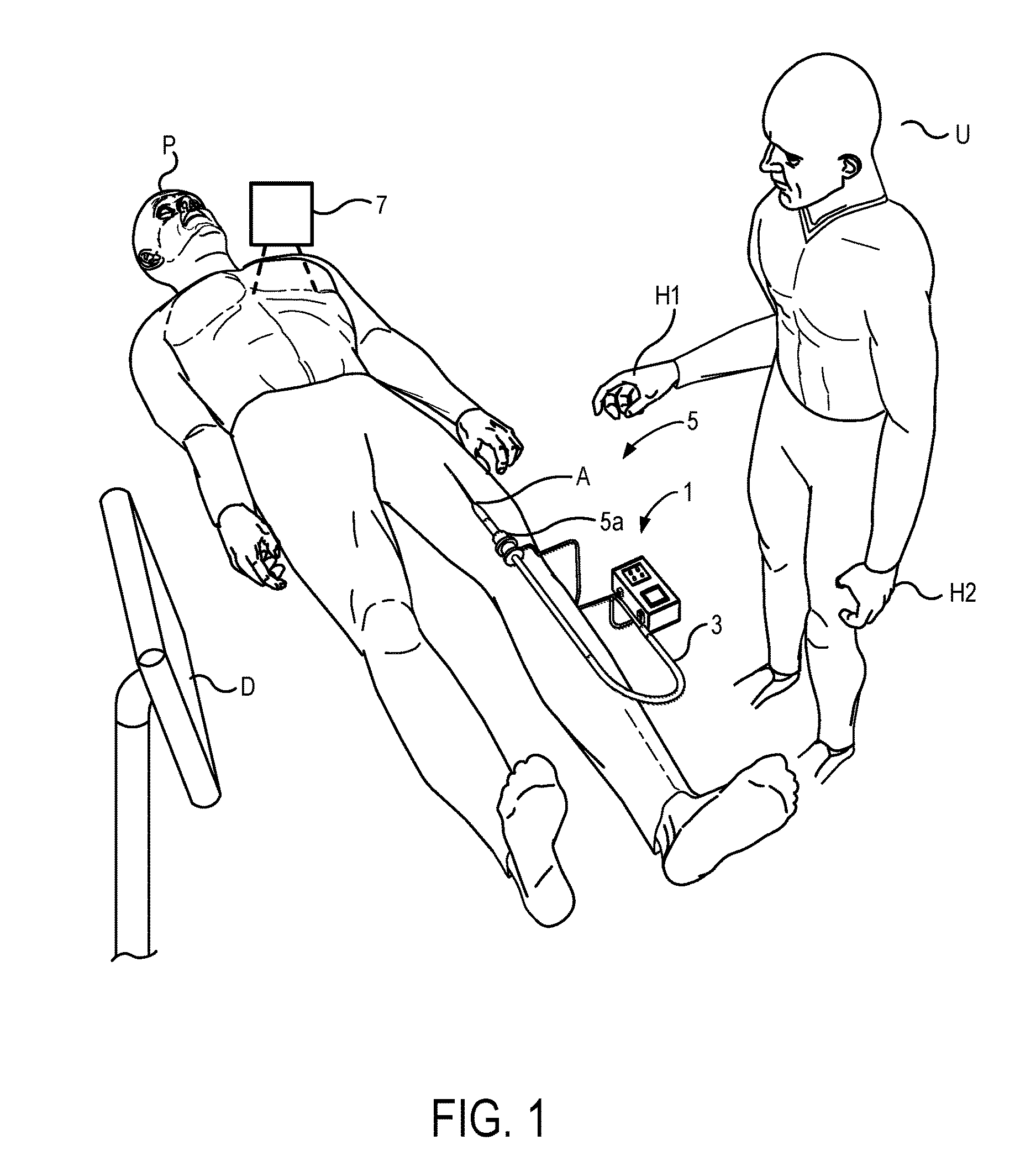

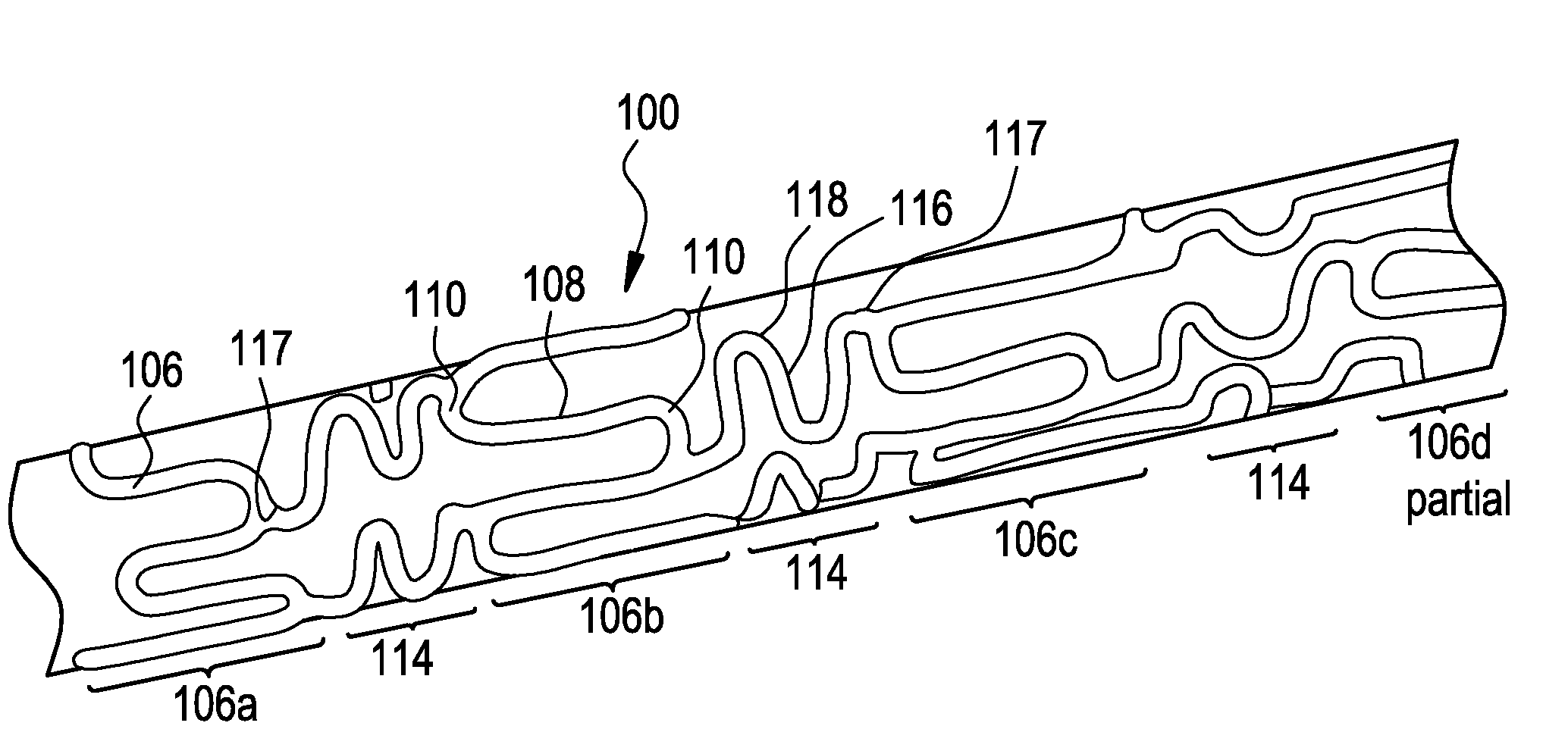

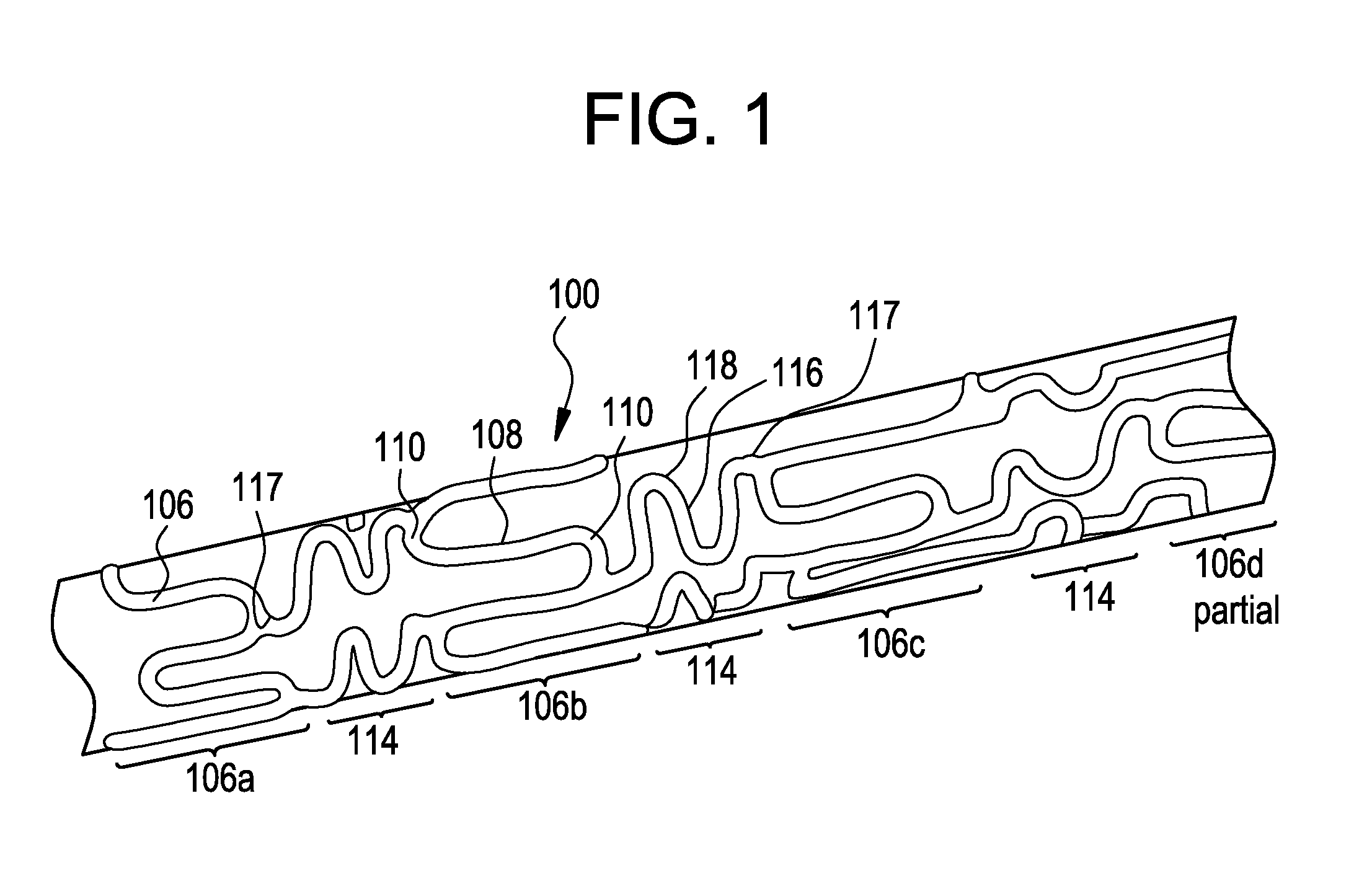

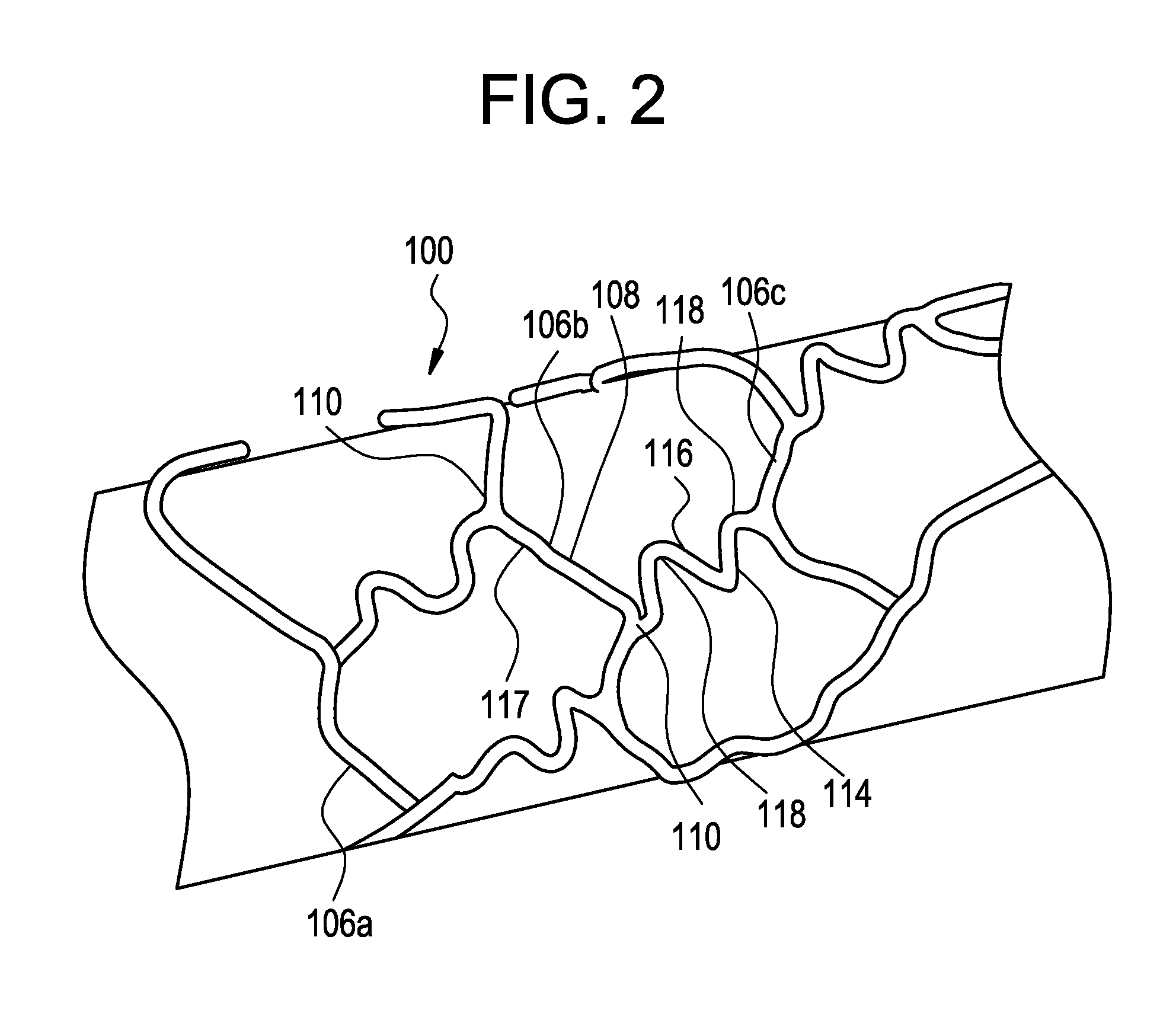

Fluid-Expandable Body Articulation of Catheters and Other Flexible Structures

ActiveUS20170021143A1Improve axial stiffnessEfficient modulationBalloon catheterSurgical navigation systemsHelical coilCatheter

Articulation devices, systems, methods for articulation, and methods for fabricating articulation structures will often include simple balloon arrays, with inflation of the balloons interacting with elongate skeletal support structures so as to locally alter articulation of the skeleton. The balloons can be mounted to a substrate of the array, with the substrate having channels that can direct inflation fluid to a subset of the balloons. The articulation array structure may be formed using simple planar 3-D printing, extrusion, and / or micromachining techniques. The skeleton may comprise a simple helical coil, and the array can be used to locally deflect or elongate an axis of the coil under control of a processor. Inflation fluid may be directed to the balloons from an inflation fluid reservoir of an inflation system, with the inflation system preferably including valves controlled by the processor. The articulation structures can be employed in minimally invasive medical catheter systems, and also for industrial robotics, for supporting imaging systems, for entertainment and consumer products, and the like.

Owner:PROJECT MORAY INC

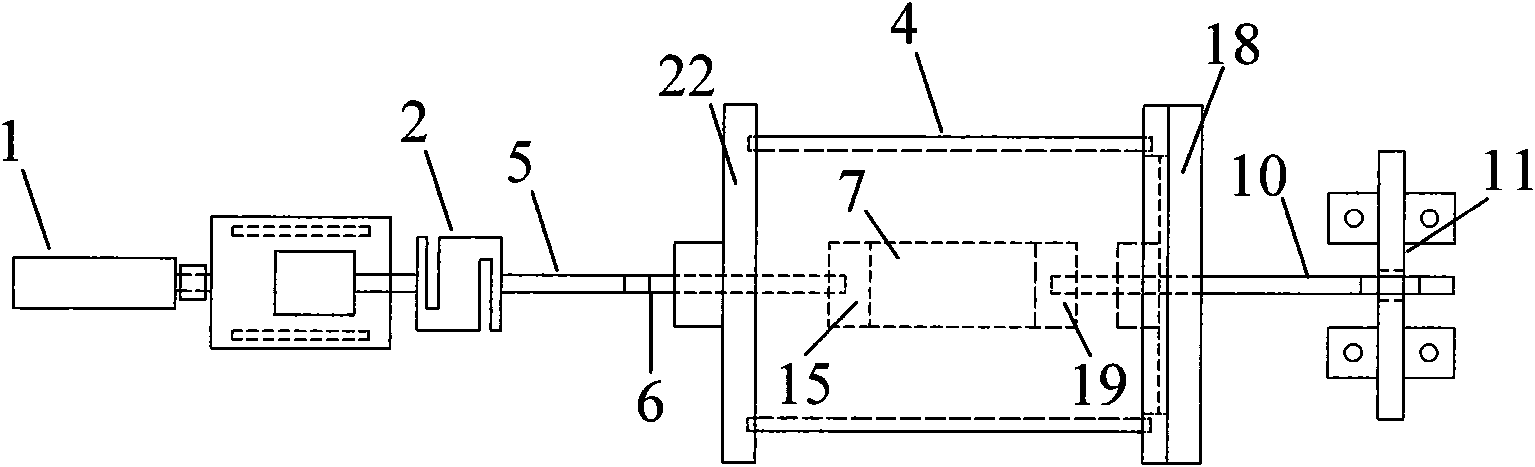

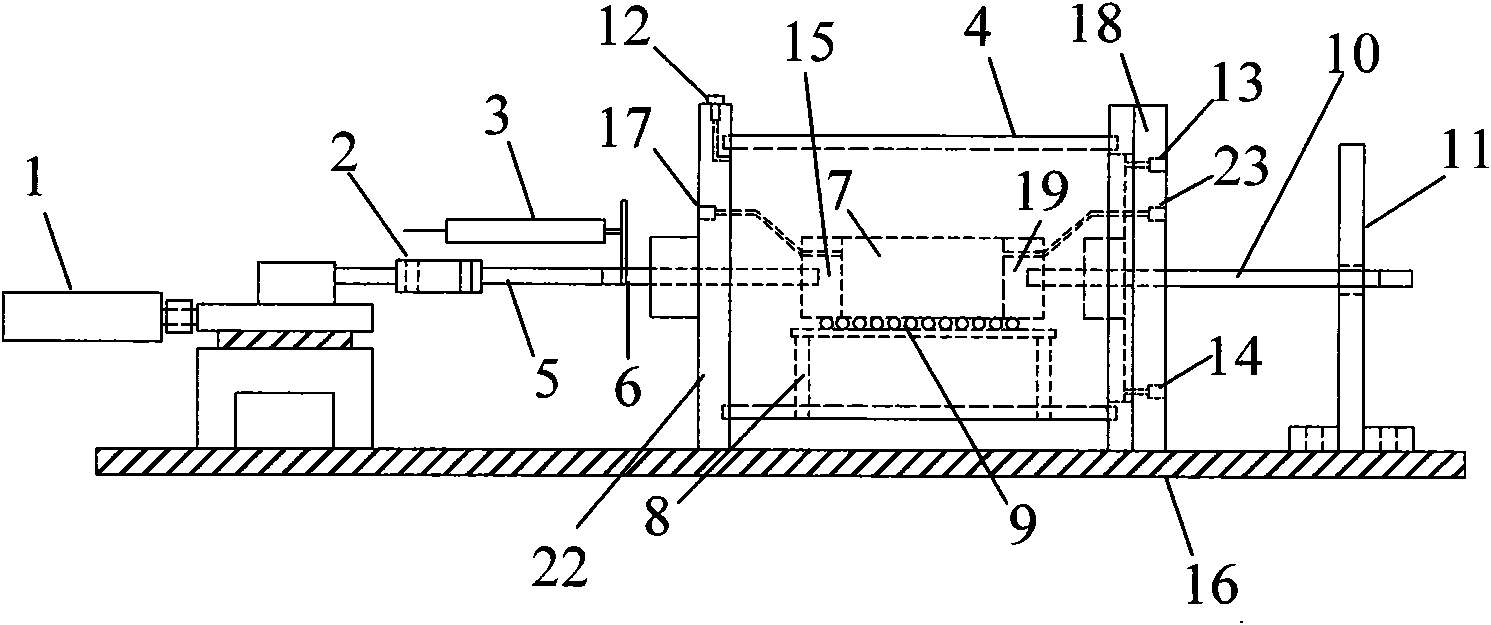

Horizontal triaxial tension and compression tester

InactiveCN101614638AImprove integrityGuaranteed integrityMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention relates to a horizontal triaxial tension and compression tester comprising an AC machine arranged on a test platform. The power output end of the AV machine is connected with a rigid load bar on which a force sensor is arranged; the rigid load bar is connected with a front piston rod; the front piston rod is also provided with a displacement sensor; the force sensor, the displacement sensor and a data acquisition board are connected with a computer; the other end of the front piston rod is connected with a sample cap after passing through a front baffle board, and the sample cap is connected with an air exit hole on the front baffle board by a plastic soft tube; the other end of a rolling bearing on a horizontal stand is also provided with a sample cap which is connected with a rear piston rod; the rear piston rod is connected with a fixed baffle board after passing through a rear baffle board; the AC machine is started, and then an acquisition program carries out real-time acquisition and preserves output values of the force sensor and the displacement sensor; a drain hole is opened, and then a sample is removed after water is completely discharged; and subsequently, the width of a sample tension failure zone is measured. The invention has the characteristics of good integrity, high stability of loading and high axial rigidity.

Owner:TSINGHUA UNIV

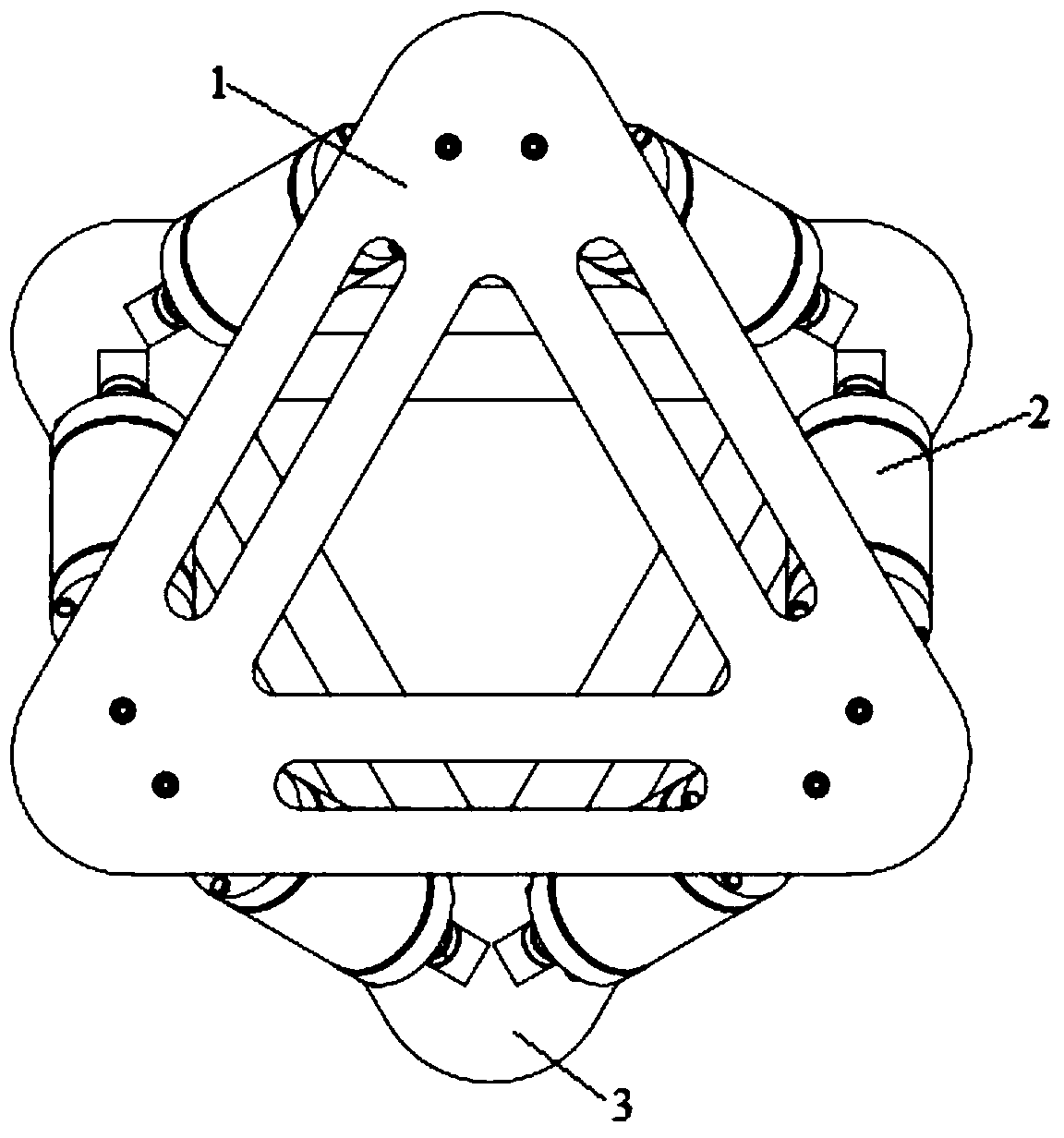

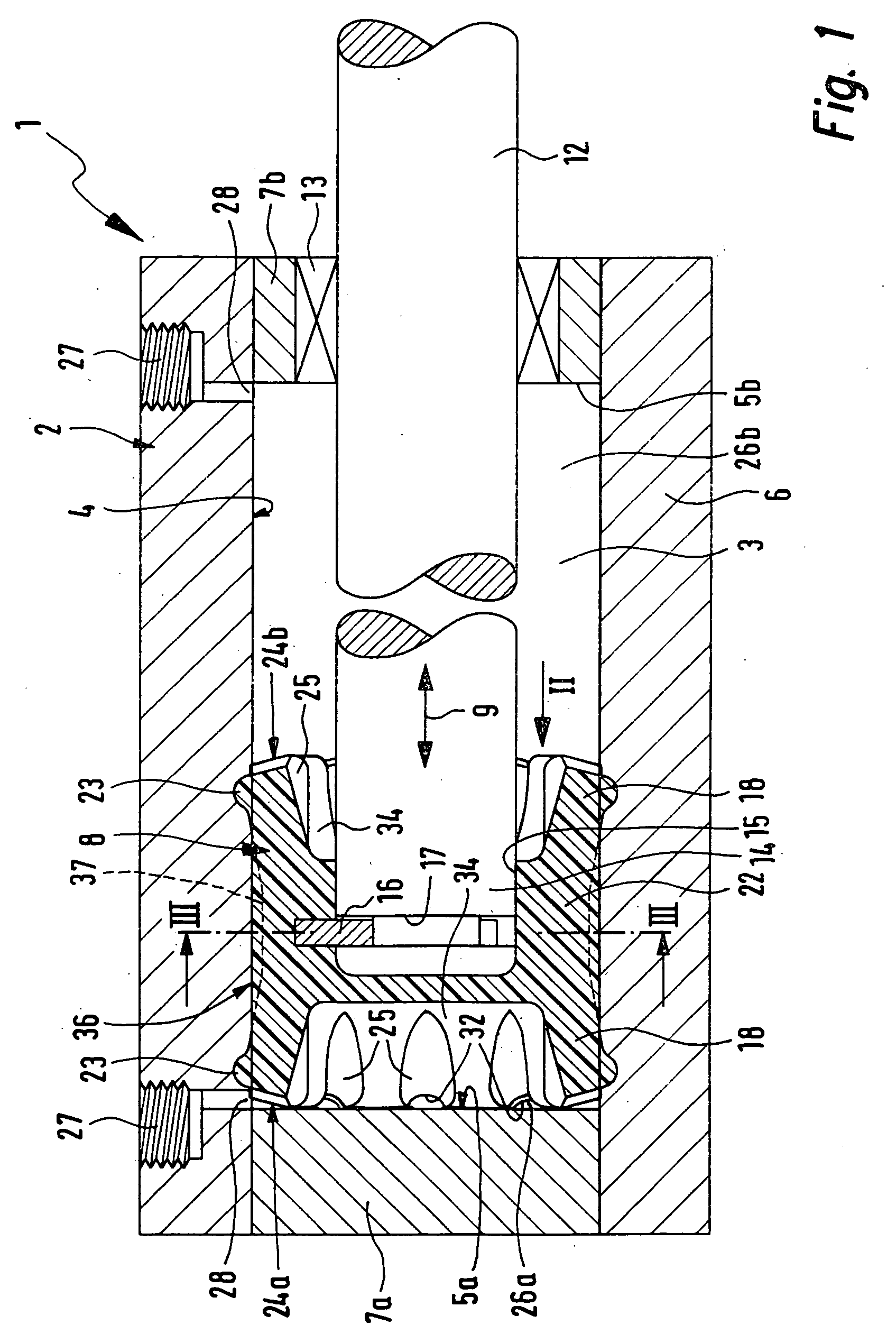

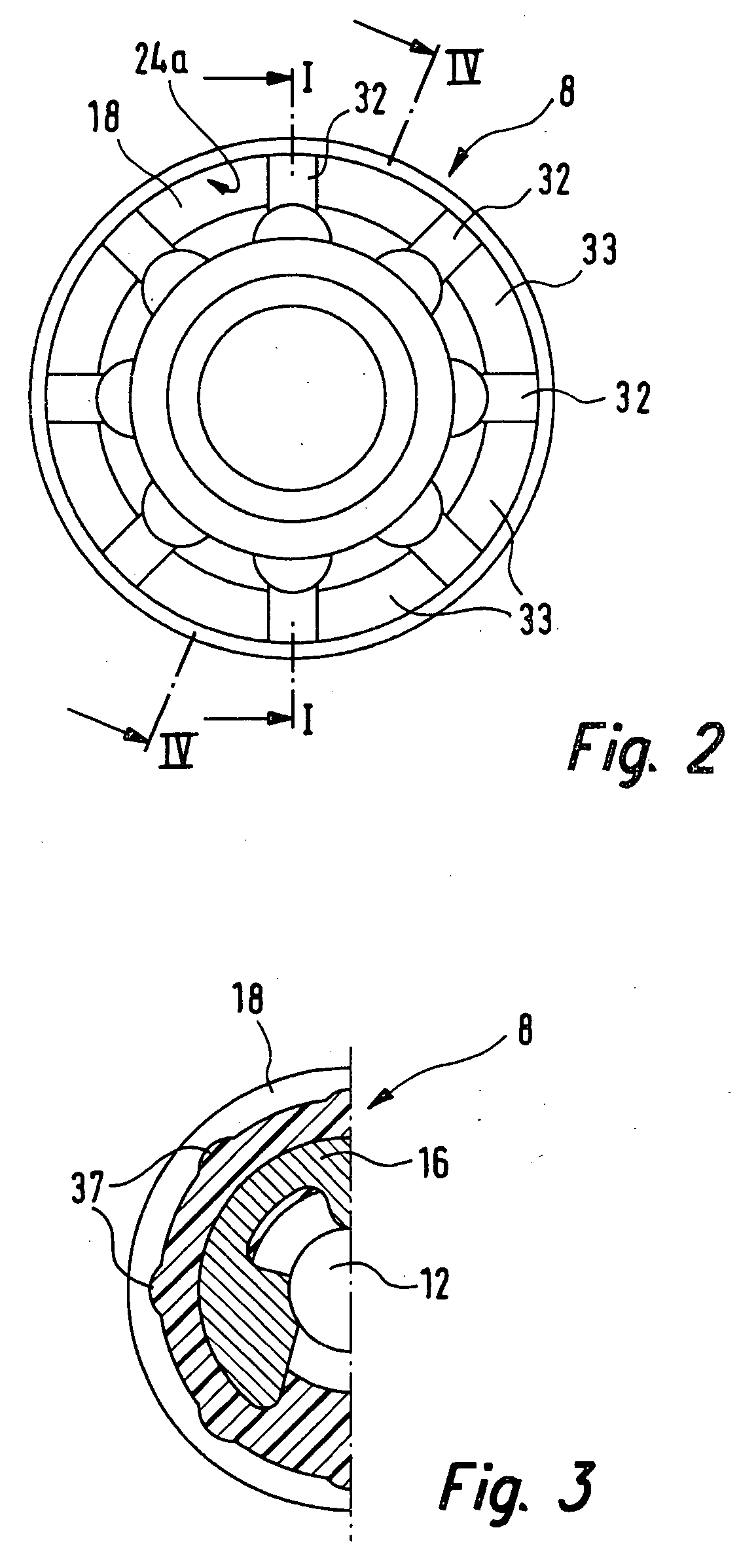

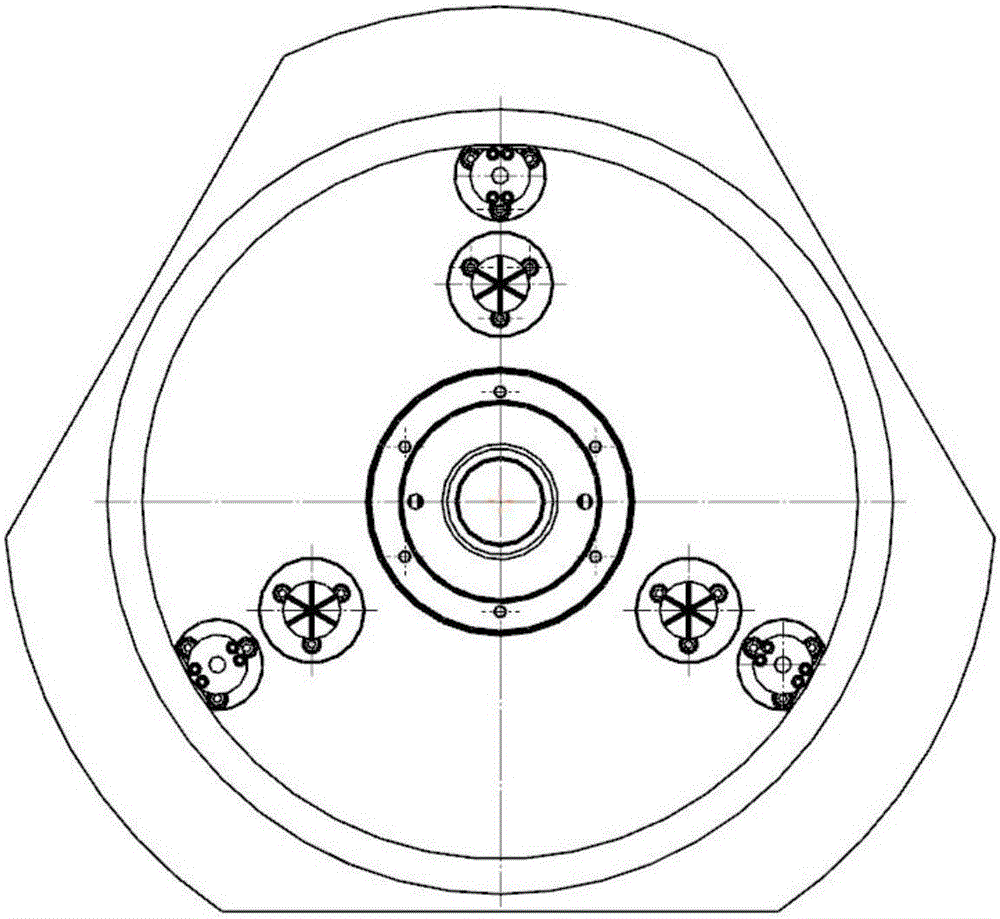

Three-freedom-degree precision locating platform

InactiveCN103727364ACompact structureImprove axial stiffnessInstrumental componentsStands/trestlesElectricityMicro nano

The invention discloses a three-freedom-degree precision locating platform which comprises a base and a moving platform arranged in the base. The base and the moving platform are connected through three hinge expansion mechanisms evenly distributed in the peripheral direction of the platform and three plate-shaped flexible hinge mechanisms. One end of each hinge expansion mechanism is in flexible connection with the base, the other end of the hinge expansion mechanism is in flexible connection with the moving platform, the middle of the hinge expansion mechanism is provided with the input end, and the input end is connected with a piezoelectric ceramic driver. Each plate-shaped flexible hinge mechanism comprises an arc flexible plate and one to five radial flexible plates perpendicularly fixed to the arc flexible plate. The three-freedom-degree precision locating platform can achieve two horizontal movements and one rotation and is simple and compact in structure. Displacement expansion and force transmission are conducted by utilizing the hinge expansion mechanisms, so that the plate-shaped flexible hinge mechanisms have elastic deformation to drive the moving platform to move and achieve output of micro-nano displacement, the output displacement is large, and axial rigidity is high. The three-freedom-degree precision locating platform can serve as an auxiliary locating platform of a nano-micro operating system to achieve micro-feeding and precise locating.

Owner:TIANJIN UNIV

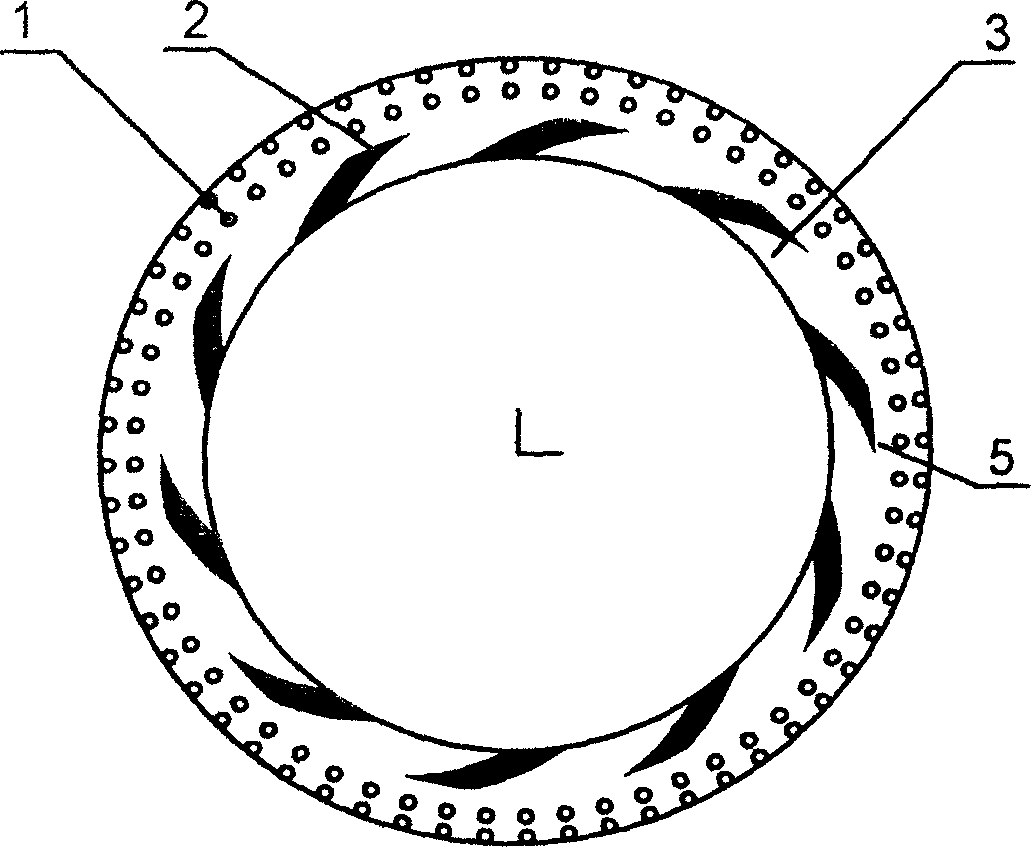

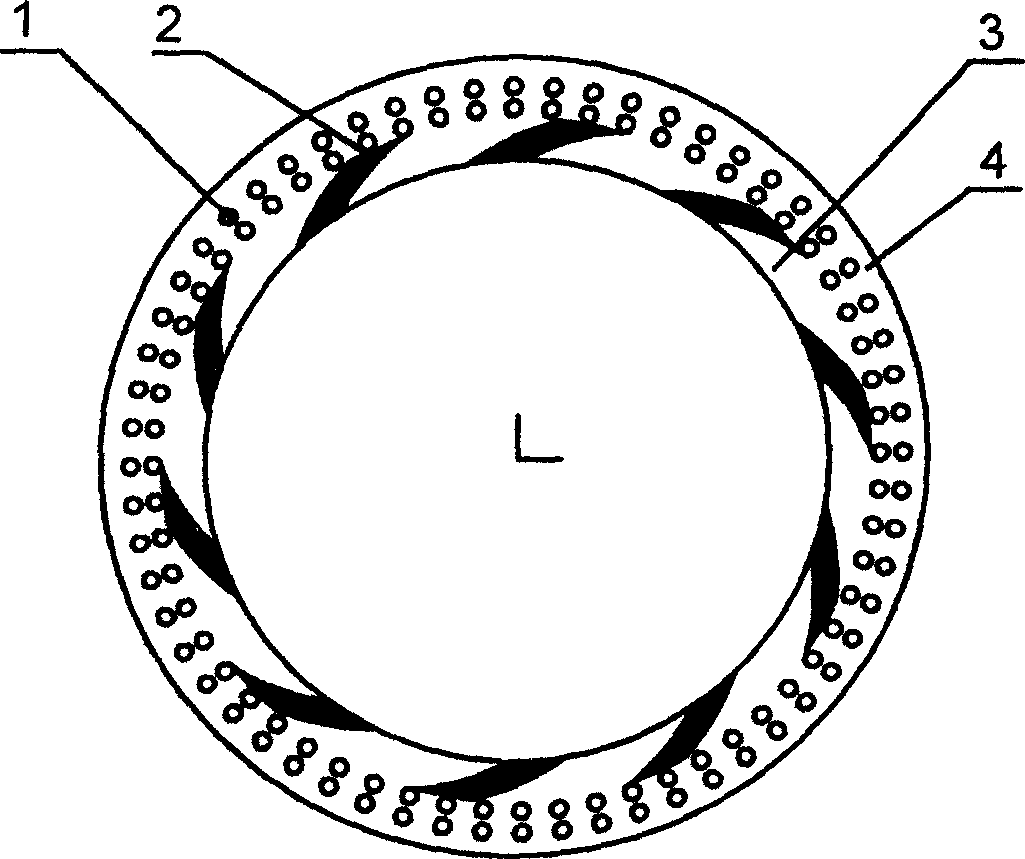

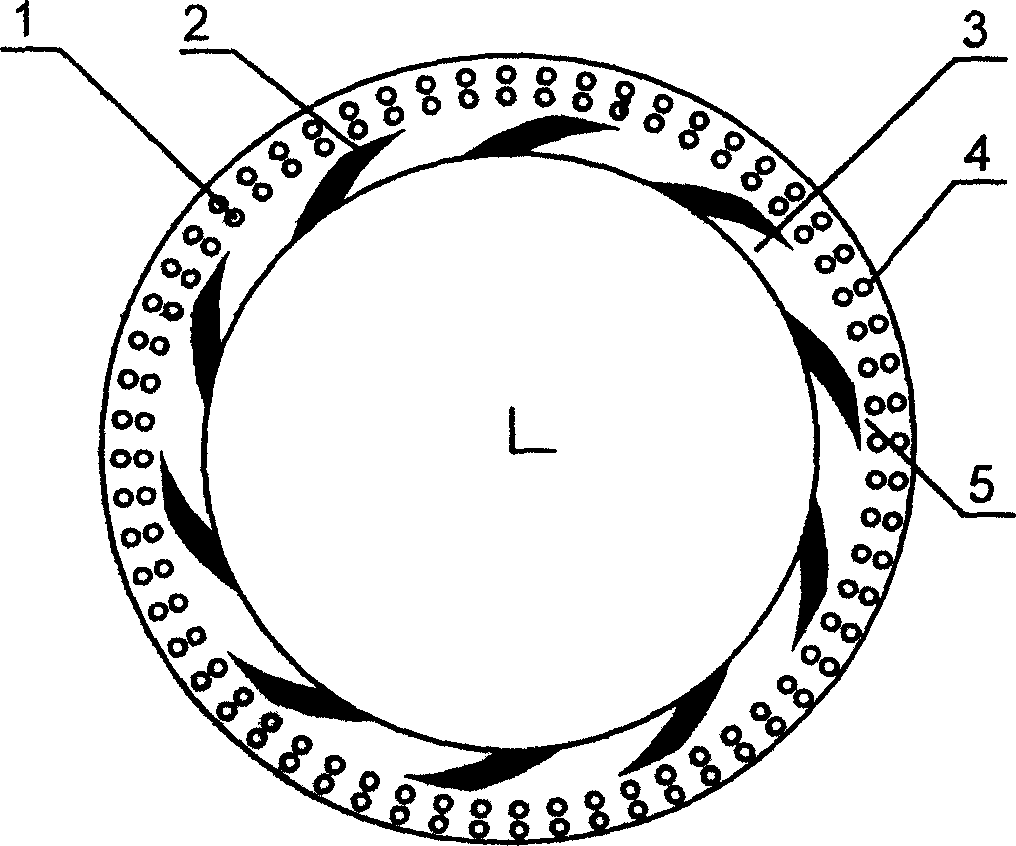

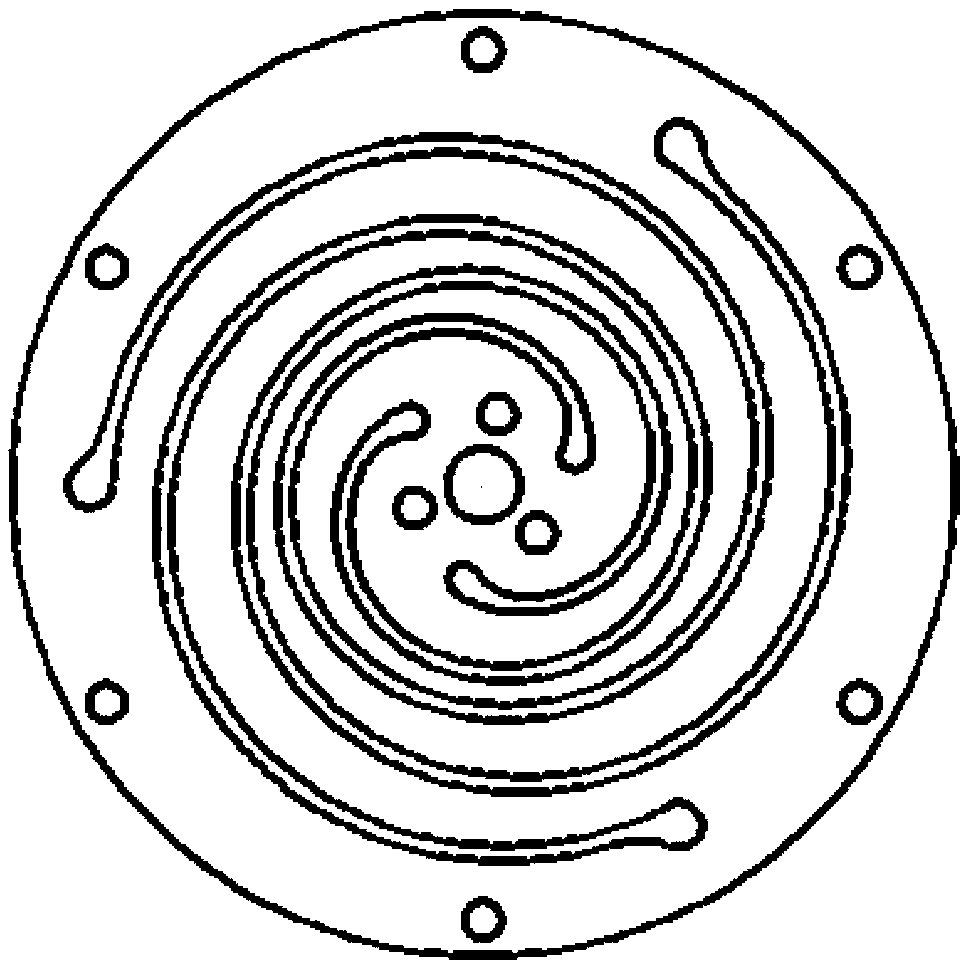

Non-contact mechanical end face sealing structure

InactiveCN1828098AImprove sealing abilityExtended service lifeEngine sealsCentre of rotationEngineering

The invention relates to a non-contact mechanical end surface sealing structure, which comprises mechanical sealed movable ring and stable ring. While the end surface of stable or movable ring has micro groove and porous zone that symmetry according to the rotational center. Wherein, said zone is at the ascending part of end surface and the micro groove is at the descending part, which has a circular sealing dam beside it. The invention can be used in variable mediums to increase the ability of solid particle, the static pressure property, fluid dynamic pressure property and the pump adsorption property, to attain better sealing effect, with long service life.

Owner:ZHEJIANG UNIV OF TECH

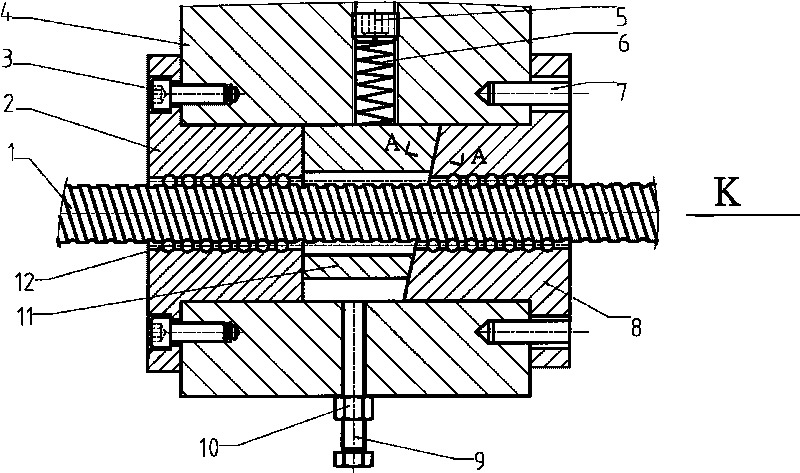

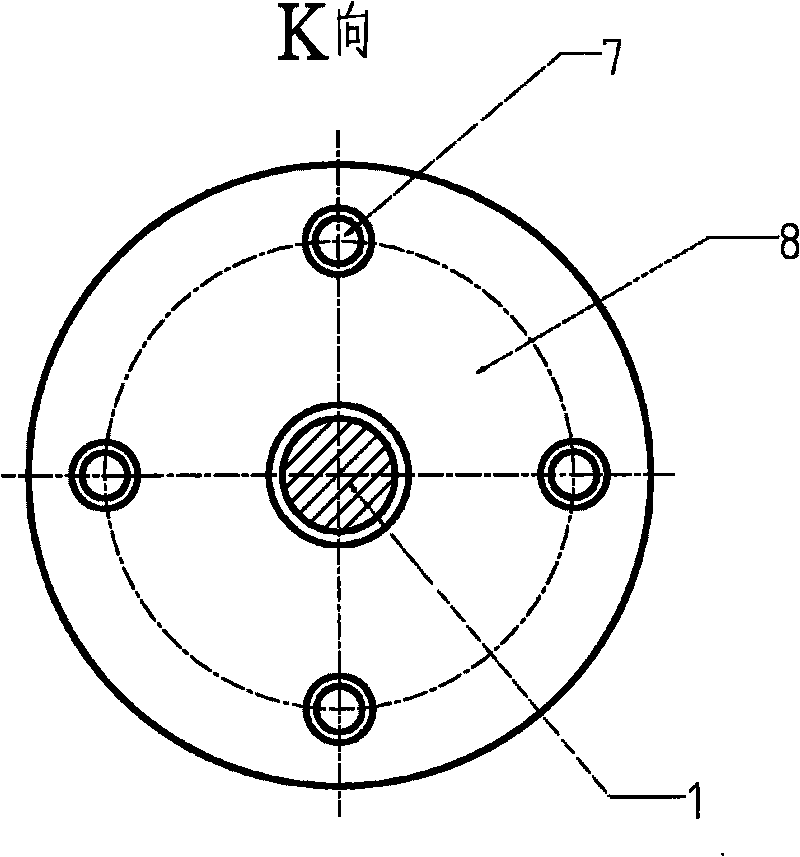

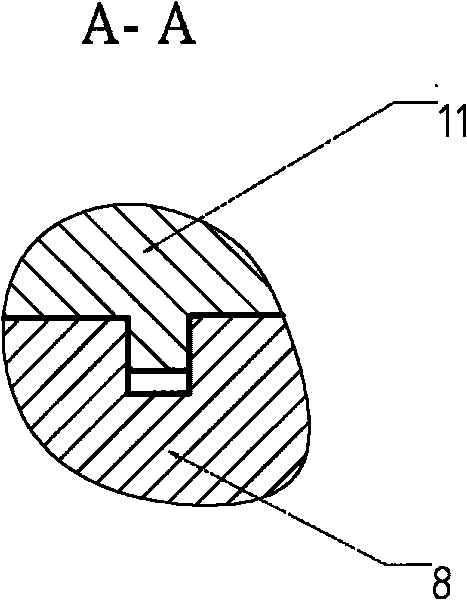

Device for automatically eliminating clearances of screw drive pair

InactiveCN101698284AAxial clearance automatically eliminatedNo reverse idle travelMetal working apparatusNumerical controlFeed drive

The invention relates to a device for automatically eliminating clearances of a screw drive pair, which comprises a leading screw, a main nut, a bolt, a machine tool sliding plate, an adjusting bolt, a spring, a guide post, a nut with an inclined plane, a bolt, a locking nut, a wedge block and a ball. The device is characterized in that the main nut and the nut with the inclined plane are connected with the leading screw respectively, the main nut is connected with the machine tool sliding plate through the bolt, and the flange of the nut with the inclined plane is provided with a through hole so that the nut with the inclined plane can move axially along the guide post. The wedge block with a self-locking function is supported between the main nut and the nut with the inclined plane; andone end of the spring is pressed on the wedge block with the self-locking function, while the other end is tightly pressed by the adjusting bolt. The incline plane of the nut with the inclined plane is provided with a guide groove. The device automatically eliminates axial clearances, has no reverse idle stroke, has adjustable pretightening force, good axial rigidity, smooth transmission, low cost, compact structure and high space utilization rate, is applied to feed drive systems of a metal cutting machine tool and a numerical control machine tool, and can greatly improve the processing accuracy.

Owner:李慎旺

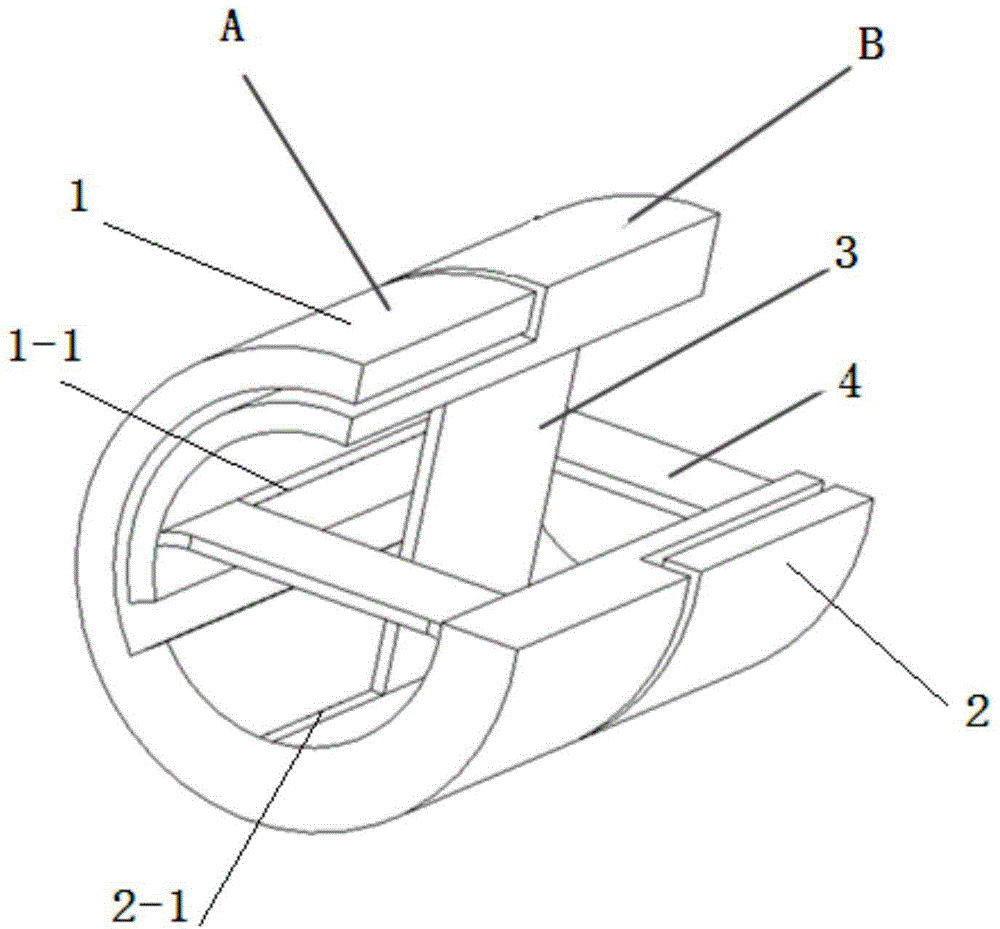

Double-reed large-turning angle flexible joint

InactiveCN104791377AImprove axial stiffnessImprove radial stiffnessPivotal connectionsKinematic pairEngineering

The invention discloses a double-reed large-turning angle flexible joint, relates to the technical field of mechanical kinematic pairs, and solves the problem that the conventional flexible hinge is small in motion range. The double-reed large-turning angle flexible joint is characterized in that a first shell is integrally formed by a 210-degree arc plate and a 90-degree arc plate; the side wall of the 210-degree arc plate and the side wall of the 90-degree arc plate are integrally connected, and the thickness of the 90-degree arc plate is smaller than that of the 210-degree arc plate; the 210-degree arc plate of the first shell is arranged outside a 90-degree arc plate of a second shell, the 90-degree arc plate of the first shell is arranged inside a 210-degree arc plate of the second shell, and a gap is formed between the first shell and the second shell; a first flexible plate is inserted into the first shell and the second shell through a first through groove and a second through groove; a second flexible plate is inserted into the first shell and the second shell through the remaining parts of the first through groove and the second through groove. The double-reed large-turning angle flexible joint is applied to the field of large-stroke precision transmission mechanisms and flexible transmission.

Owner:HARBIN INST OF TECH

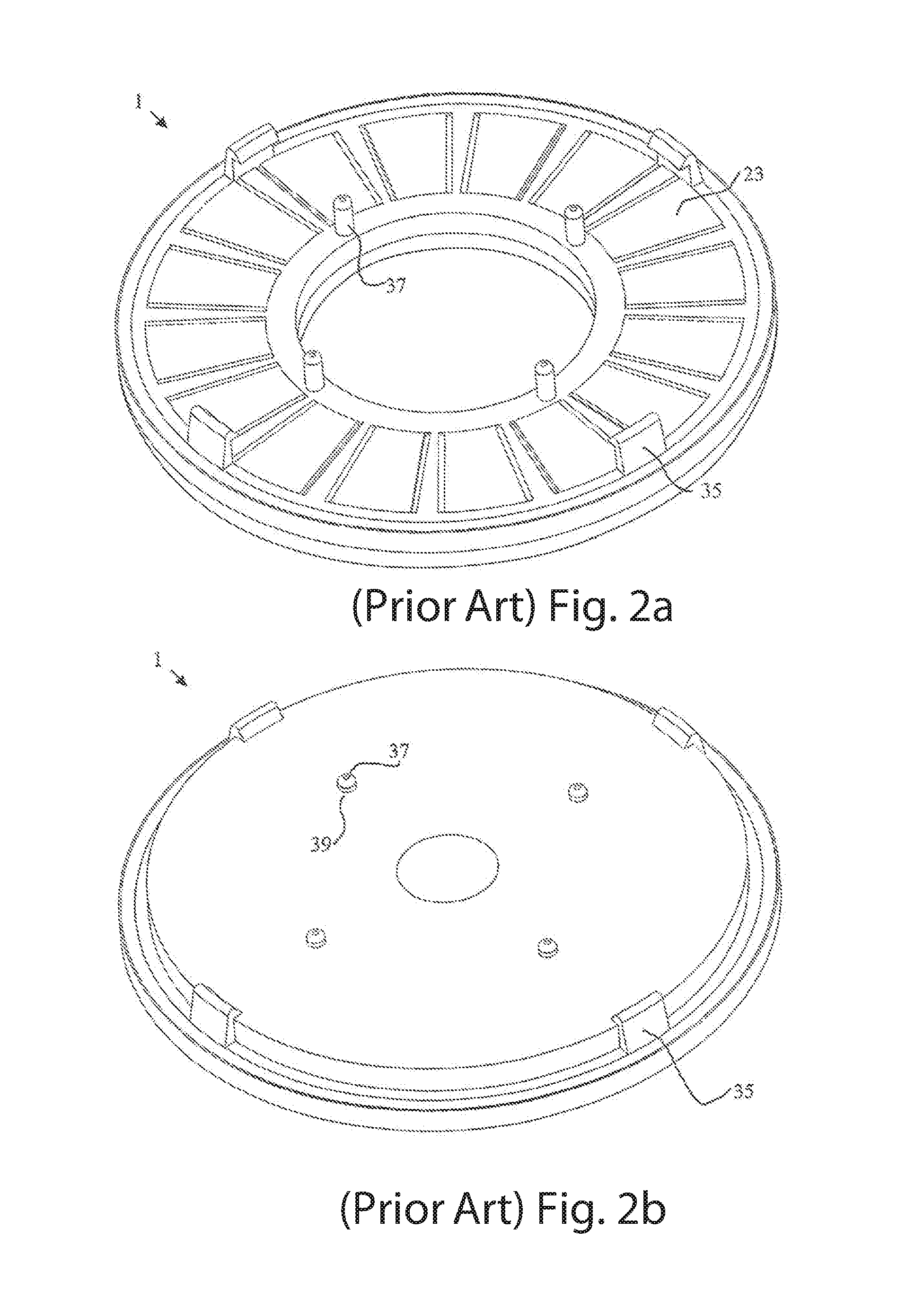

Soft tissue defect repair device

InactiveUS20050288787A1Heal fastShorten the lengthProsthesisWound clampsDefect repairInguinal hernia

An inguinal hernia repair device in the form of an implantable plug that is affixed at one end to the center region of a sheet of implantable material. The plug takes the form of a plurality of hollow members, arranged so as to be in substantially parallel relationship when implanted into a defect. The hollow members are preferably tubular members and are preferably bundled together by various means, such as bonding or wrapping a band or strand about the plurality of hollow members to maintain them in adjacent and contacting relationship during insertion into a defect.

Owner:LOREAL SA +1

Forming method for latticed composite material bearing cylinder applicable to satellite

ActiveCN104589663AAchieve continuous windingAngle deviation is smallNumerical controlWinding machine

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

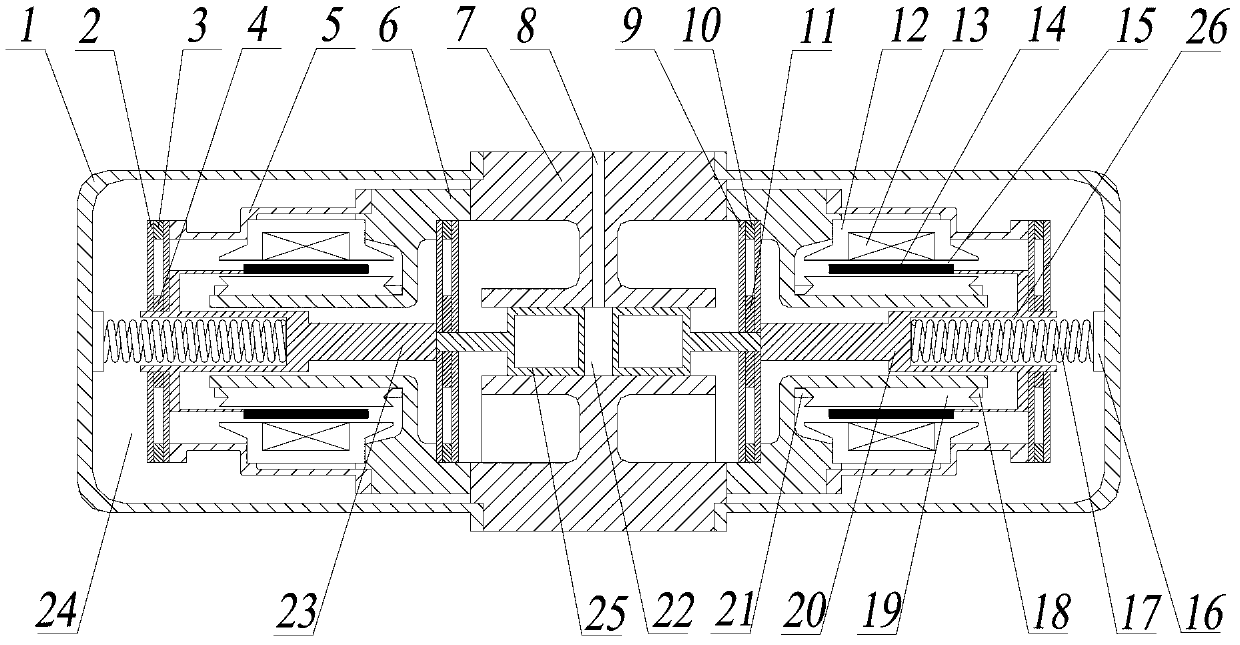

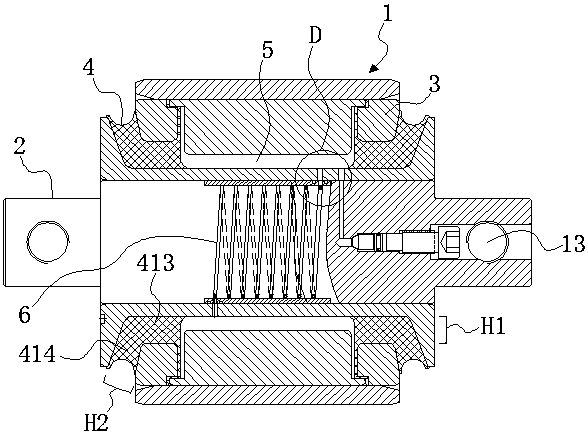

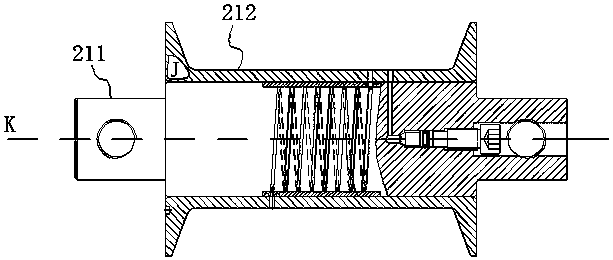

Linear compressor supported by three kinds of springs

InactiveCN103122837AEasy to fixImprove axial stiffnessPiston pumpsPositive-displacement liquid enginesReciprocating motionLinear compressor

The invention discloses a linear compressor supported by three kinds of springs. The linear compressor supported by the three kinds of springs comprises a support, a cylinder fixed with the support, two pistons in clearance fit with the inner wall of the cylinder, and two linear motors driving the two pistons to make coaxial and reciprocating motions, wherein the two linear motors are in transmission with the pistons correspondingly and respectively through piston shafts, two end portions of each piston shaft are fixed with the support respectively through a vortex arm plate spring assembly and a linear arm plate spring assembly, the vortex arm plate spring assemblies are close to the pistons, and a cylinder spiral spring used for providing axial elastic force is arranged between an end portion, far away from a corresponding piston, of each piston shaft and the support. Due to the fact that the linear compressor is supported by the three kinds of springs, clearance gap seal and oil-free lubrication technology are guaranteed, and axial rigidity of the springs is effectively improved. For a linear compressor with big rotor quality, high frequency resonance operation is achievable, operating efficiency is improved, and character match between the linear compressor and a cooling head of a low temperature refrigerator is achieved.

Owner:ZHEJIANG UNIV

Intraluminal medical device having variable axial flexibility about the circumference of the device

ActiveUS20080167707A1Facilitates device orientationEasy to passStentsBlood vesselsMedical deviceBiomedical engineering

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Wear-resistant mechanical sealing structure on end face

ActiveCN1818434AExtended service lifeStrong hydrodynamic effectEngine sealsWear resistantEngineering

A wear-proof mechanical end face sealing structure comprises mechanical sealing movable and fixed rings, on the end faces of which are machined microlugs arranged a girdle according to the centre of the end face. Beside the girdle is disposed a ring sealing dam with a smooth surface symmetrically about the centre of the end face and there is at least one ring sealing dam on the end face. The parametric range of the microlug structure is that, the aspect ratio or the breadth depth ratio is 0.5~30, the height is 2~500 mu m, the area density is 0.1~0.7 and the distance between the section axile wires of the adjacent microlugs is 0.05~1.0 mm.

Owner:ZHEJIANG UNIV OF TECH

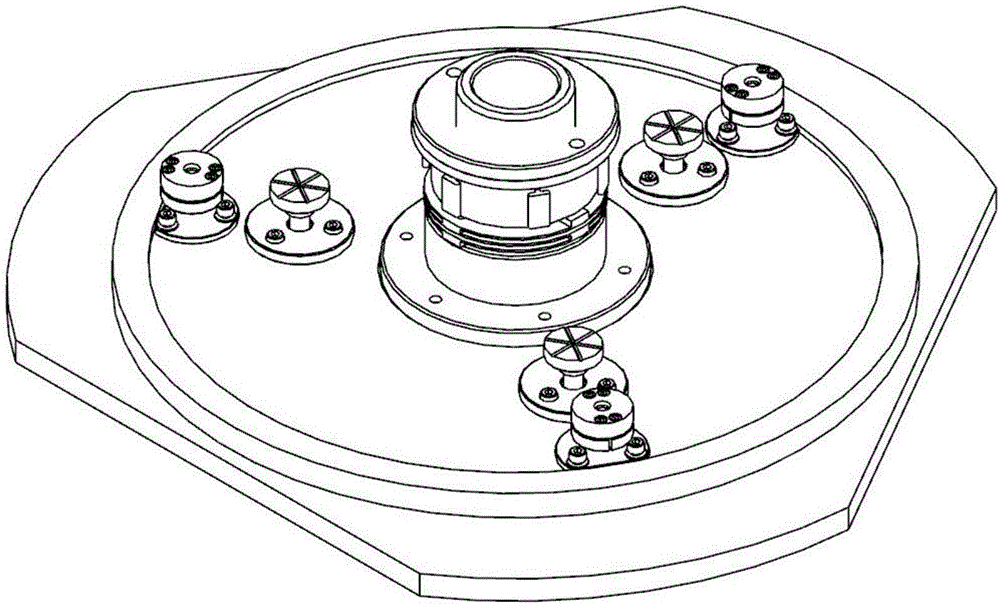

Large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table

ActiveCN103111855AImprove machining accuracyHigh axial accuracy and high rotational accuracyShaftsRotary machine partsEngineeringLarge aperture

The invention discloses a large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table, belongs to the technical field of ultra-precision manufacturing equipment, and meets the requirements of a large-size ultra-precision lathe used for machining high-precision large-aperture non-spherical optical parts. An upper floating throttler and a lower floating throttler are respectively installed on an upper floating thrust plate and a lower floating thrust plate, the upper floating thrust plate is fixedly connected with a base seat of the rotary table, the lower floating thrust plate is fixedly connected with the base seat of the rotary table through an inner isolation ring and is arranged in an annular groove of the upper floating thrust plate, a radial bearing bush is fixedly connected with the base seat of the rotary table through the lower floating thrust plate and the inner isolation ring, a main shaft is fixedly connected with an upper floating plate, and hydraulic oil is throttled through the throttlers and forms an upper floating liquid hydrostatic pressure thrust oil film between the upper floating plate and the upper floating thrust plate, a lower floating liquid hydrostatic pressure thrust oil film between a lower floating plate and the lower floating thrust plate, and a radial hydrostatic pressure support oil film between the radial bearing bush and the main shaft, so that an axial sealed-type liquid hydrostatic pressure plane round ring thrust bearing and a radial liquid hydrostatic pressure cylindrical bearing are formed. The large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table is applied to the large-size ultra-precision lathe used for machining the high-precision large-aperture non-spherical optical parts.

Owner:HARBIN INST OF TECH

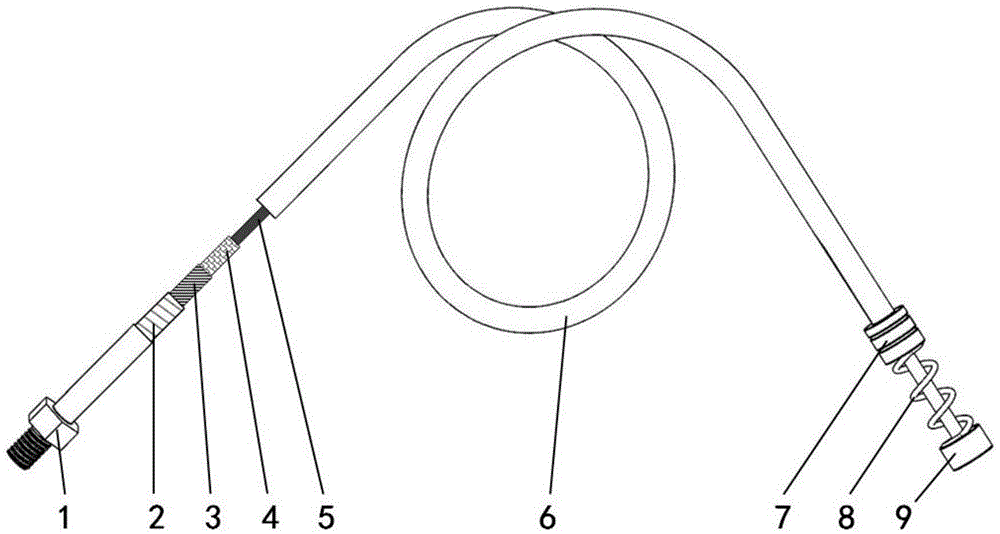

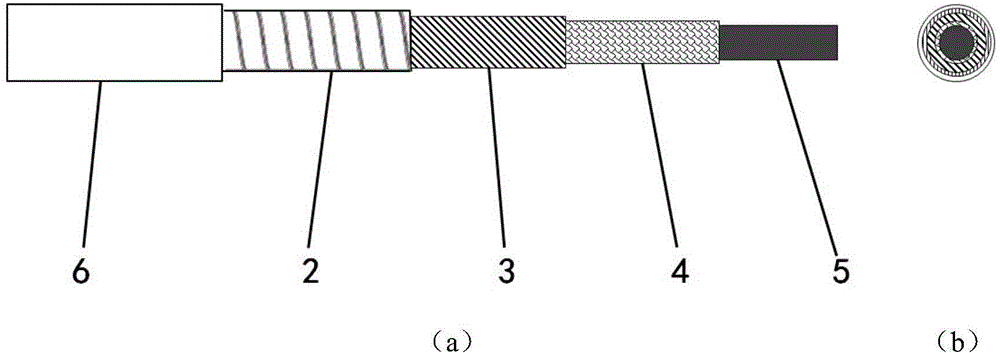

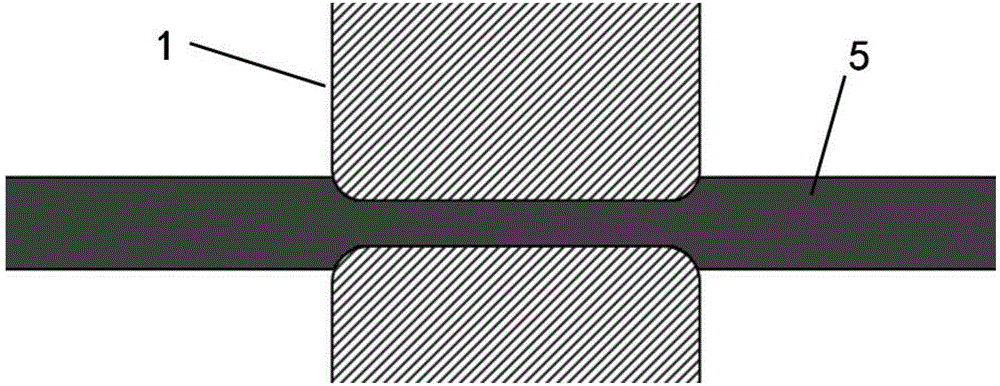

Brake cable type shape memory alloy driver

ActiveCN104454415ASimple structureEasy to installMachines/enginesMechanical power devicesShape-memory alloyAlloy

The invention provides a brake cable type shape memory alloy driver. An inner core is a shape memory alloy wire; a molybdenum disulfide coating coats the surface of the shape memory alloy wire; a polytetrafluoroethylene tube and a metal spiral hose sequentially wrap the molybdenum disulfide coating from inside to outside; a protecting layer of an outermost side of the shape memory alloy wire is a rubber tube; one end of the shape memory alloy wire is fixed on a mounting base; the other end of the shape memory alloy wire is connected with an actuating contact; two ends of the driver are fixed through the mounting base and a clamping seat; a bias spring is arranged between the clamping seat and the actuating contact; the shape memory alloy wire is lengthened for a certain distance before being mounted; after the driver is electrified and heated, the shape memory alloy wire generates a restoring force and restoring displacement owing to phase change; the restoring force acting on the actuating contact is greater than elasticity of the bias spring, and the actuating contact is driven to move; and after actuation is finished, current is switched off, the shape memory alloy wire is lengthened again under the effect of the elasticity of the bias spring, and repeated actuation of the driver is realized. The brake cable type shape memory alloy driver is simple in structure and high in actuation speed, is convenient during driving and can be used for triggering devices or driving devices in various fields.

Owner:BEIHANG UNIV

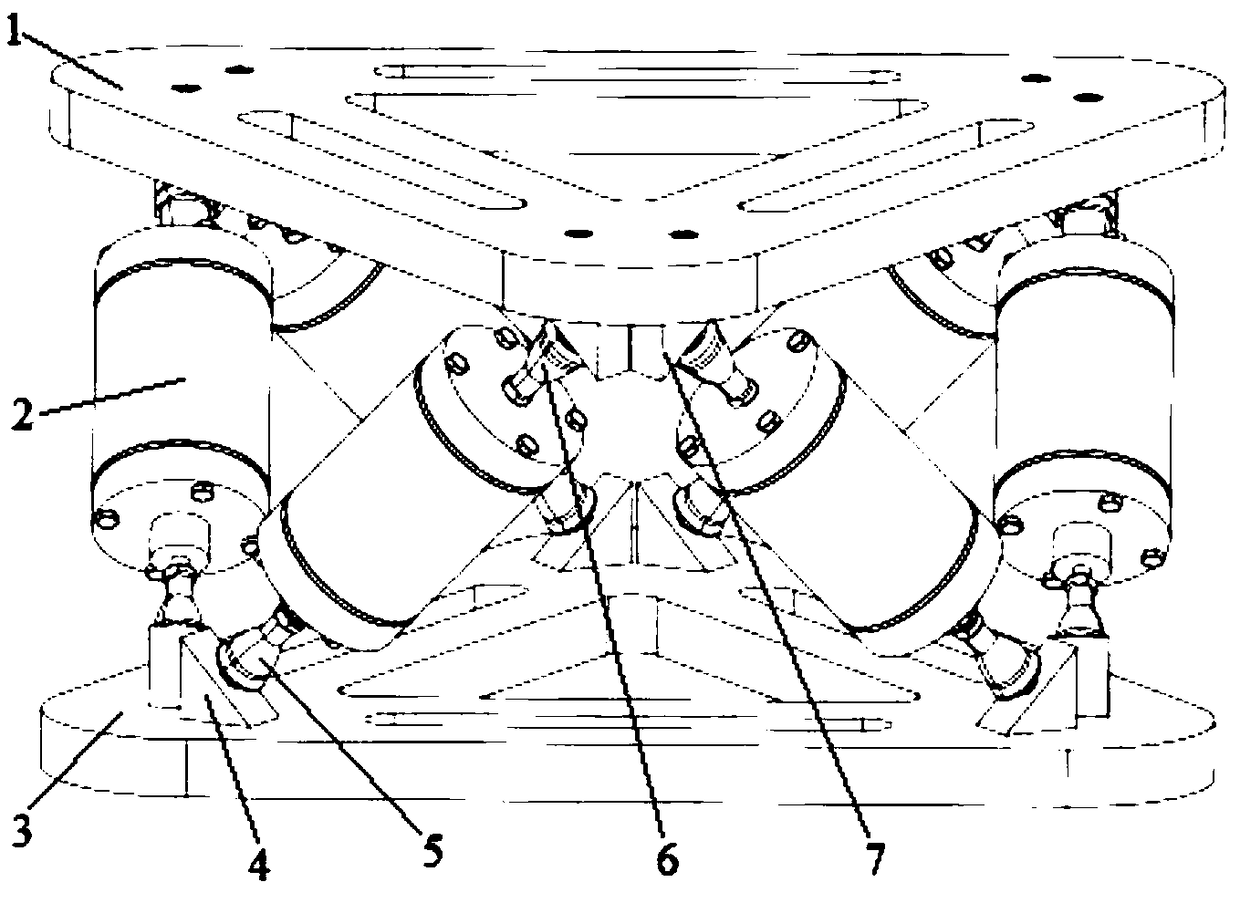

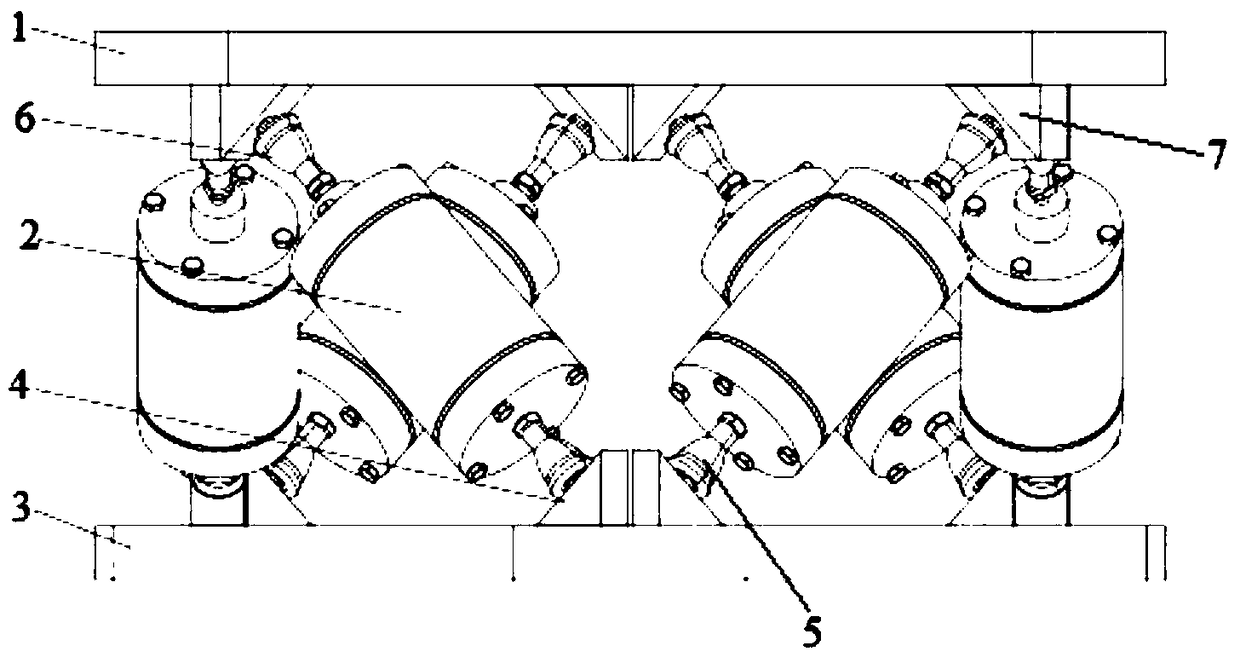

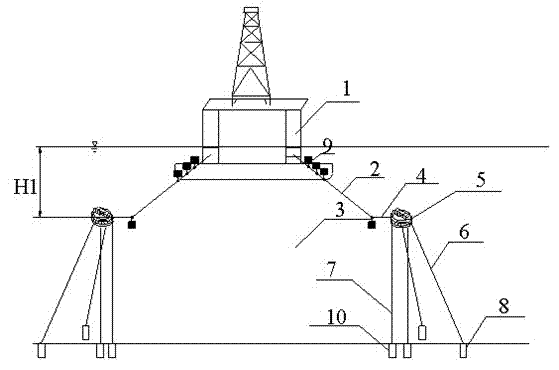

Hybrid shock absorber based on Stewart structure

ActiveCN109027088AReduce radial stiffnessAvoid damageMagnetic springsShock absorbersEngineeringEddy current

The invention discloses a hybrid shock absorber based on a Stewart structure. The hybrid shock absorber comprises an upper top plate, a lower bottom plate and six shock absorption units obliquely arranged between the upper top plate and the lower bottom plate in the circumferential direction. The upper end of each shock absorption unit is connected with the upper top plate through an upper rod endjoint bearing, and the lower end of each shock absorption unit is connected with the lower bottom plate through a lower rod end joint bearing. Every two adjacent shock absorption units are mutually symmetrical, and the included angles between the shock absorption units and the upper top plate and the included angles between the shock absorption units and the lower bottom plate are all equal. Theshock absorption units comprise upper end covers, lower end covers, upper diaphragm springs, magnetic eddy current dampers and lower diaphragm springs, wherein the upper diaphragm springs, the magnetic eddy current dampers and the lower diaphragm springs are sequentially connected from top to bottom. The upper end covers and the upper diaphragm springs are fixed to the upper sides of the magneticeddy current dampers from top to bottom, and the lower diaphragm springs and the lower end covers are fixed to the lower sides of the magnetic eddy current dampers from top to bottom. Through matchedusing of the diaphragm springs and the eddy current dampers, the shock absorption effect is greatly enhanced, the whole hybrid shock absorber is a simple in structure, and six-degree-of-freedom shockabsorption can be achieved.

Owner:SHANGHAI UNIV

Flexuose combined spherical hinge and producing/assembling method of the same

ActiveCN101109423AEasy to useImprove axial stiffnessRubber-like material springsPre compressionEngineering

A sawtooth modular ball hinge and making and assembling method for the ball hinge are provided. The ball hinge comprises a metallic casing, a core shaft and an elastic rubber element. Between the metallic casing and the elastic rubber element, a metallic partition bushing is provided, which is in 2-flap structure; the metallic partition bushing and the core shaft are in sawtooth shape; the sawteeth of them are mutually nested, engaged and vulcanized together. After the metallic partition bushing and the elastic rubber element are vulcanized, comparing with former diameter, along the radial direction a rubber-metal vulcanizate with a clearance in between is formed. The making of the ball hinge rubber elastic element is: the metallic partition bushing, the core shaft and the elastic rubber are vulcanized under high temperature and pressure into a rubber-metal vulcanizate, then the rubber-metal vulcanizate is pressed into a metallic casing, this forms a finished product. As the rubber-metal vulcanizate is of a 2-flap structure, and is certain distance apart in radial direction comparing with former diameter, when the vulcanizate is pressed into the metallic casing, the rubber is pre-compressed; the pre-compression volume can be adjusted for the rubber by adjusting the apart distance in radial direction of the 2-flap partition bushing.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

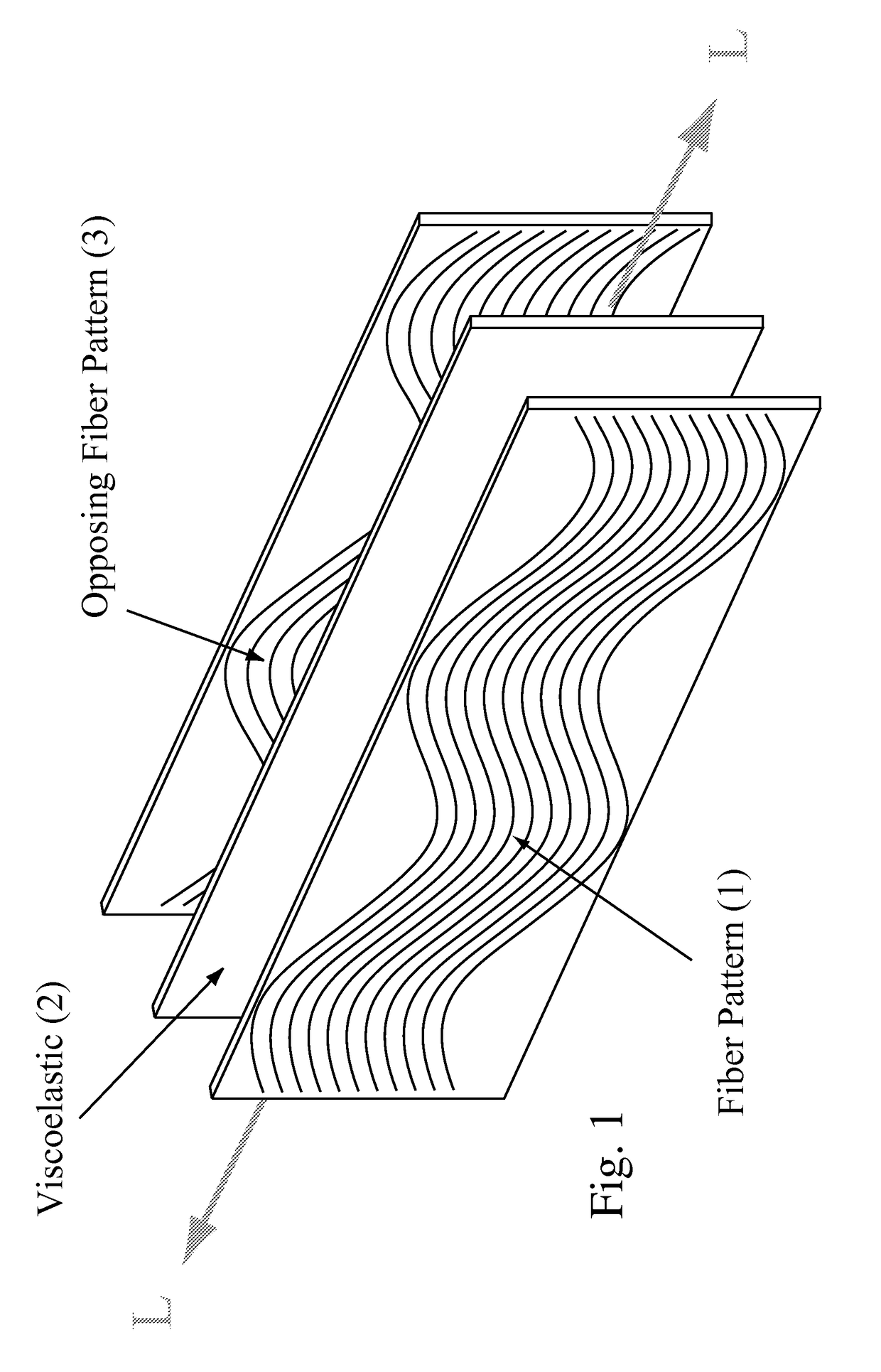

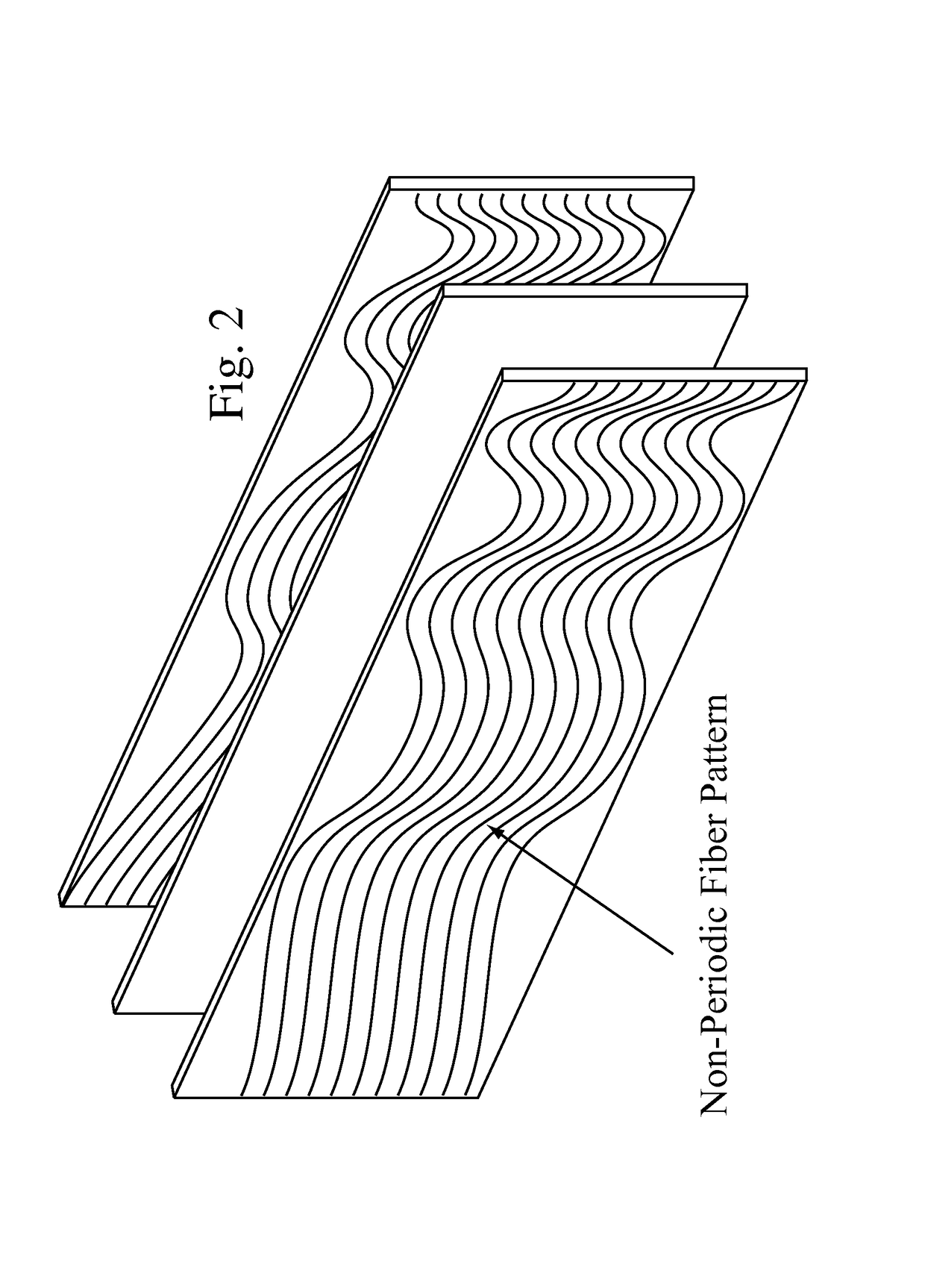

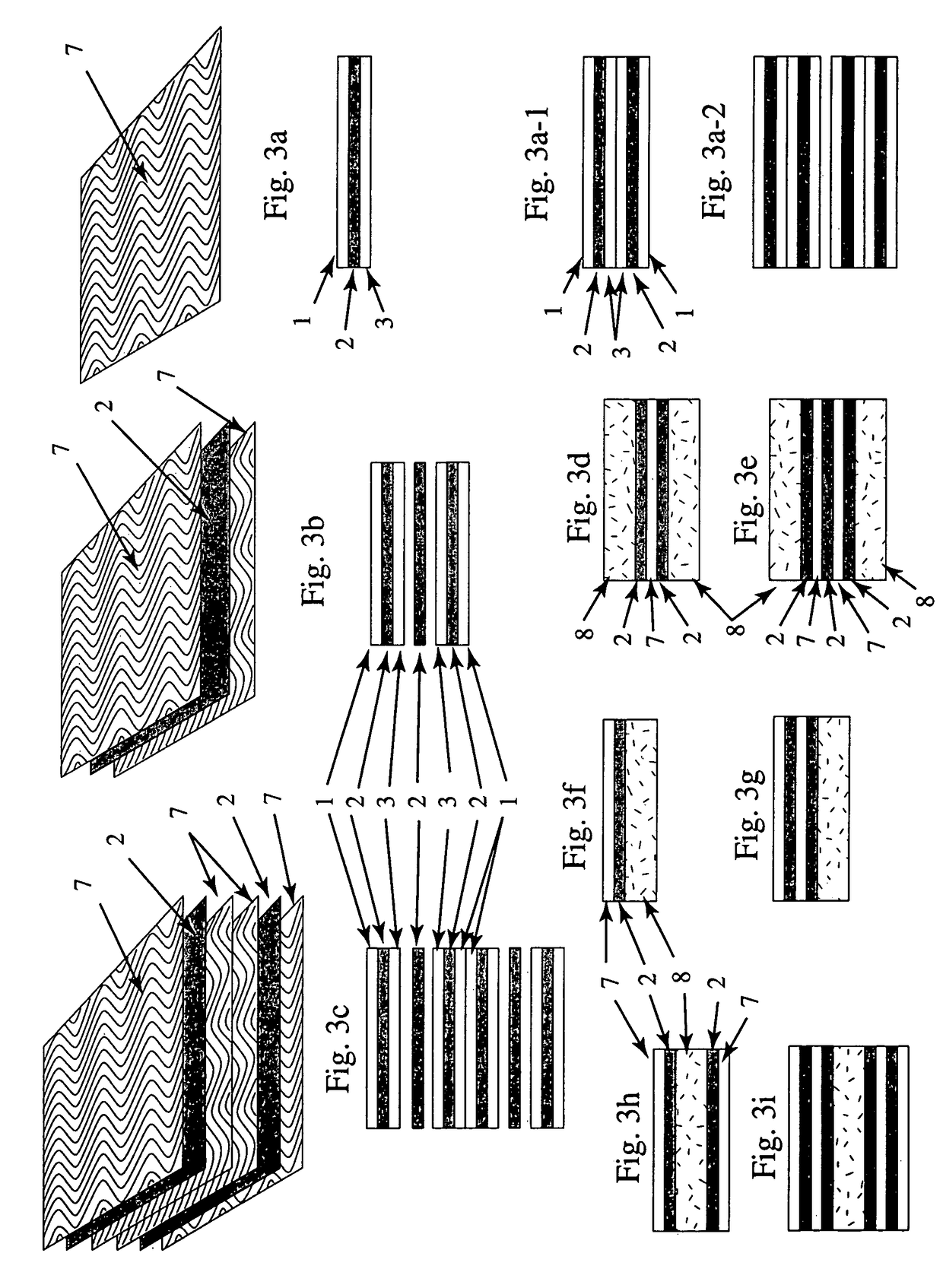

Wavy composite structures

InactiveUS7906191B2Improve suppression propertiesImprove axial stiffnessRotating vibration suppressionProtective buildings/sheltersFiberAngular orientation

Construction and advantages of improved wavy composite structures made from wavy composite, unidirectional composites, and damping materials is revealed. By combining wavy composite laminae in various waveforms, offsets, angular orientations and material combinations, it is possible to provide axial, torsion, or shear properties equivalent to unidirectional materials but without the limitations related to fiber discontinuity, labor costs for fabrication, and weakness at seams where laminates overlap. By combining wavy composite layers with unidirectional crossplies, or by using woven mats with various fill fiber levels where the warp fibers are sinuously arranged, improved strength and damping is possible. Several examples of both wavy crossply laminates and unidirectional crossply laminates are analyzed and compared.

Owner:PRATT WILLIAM F

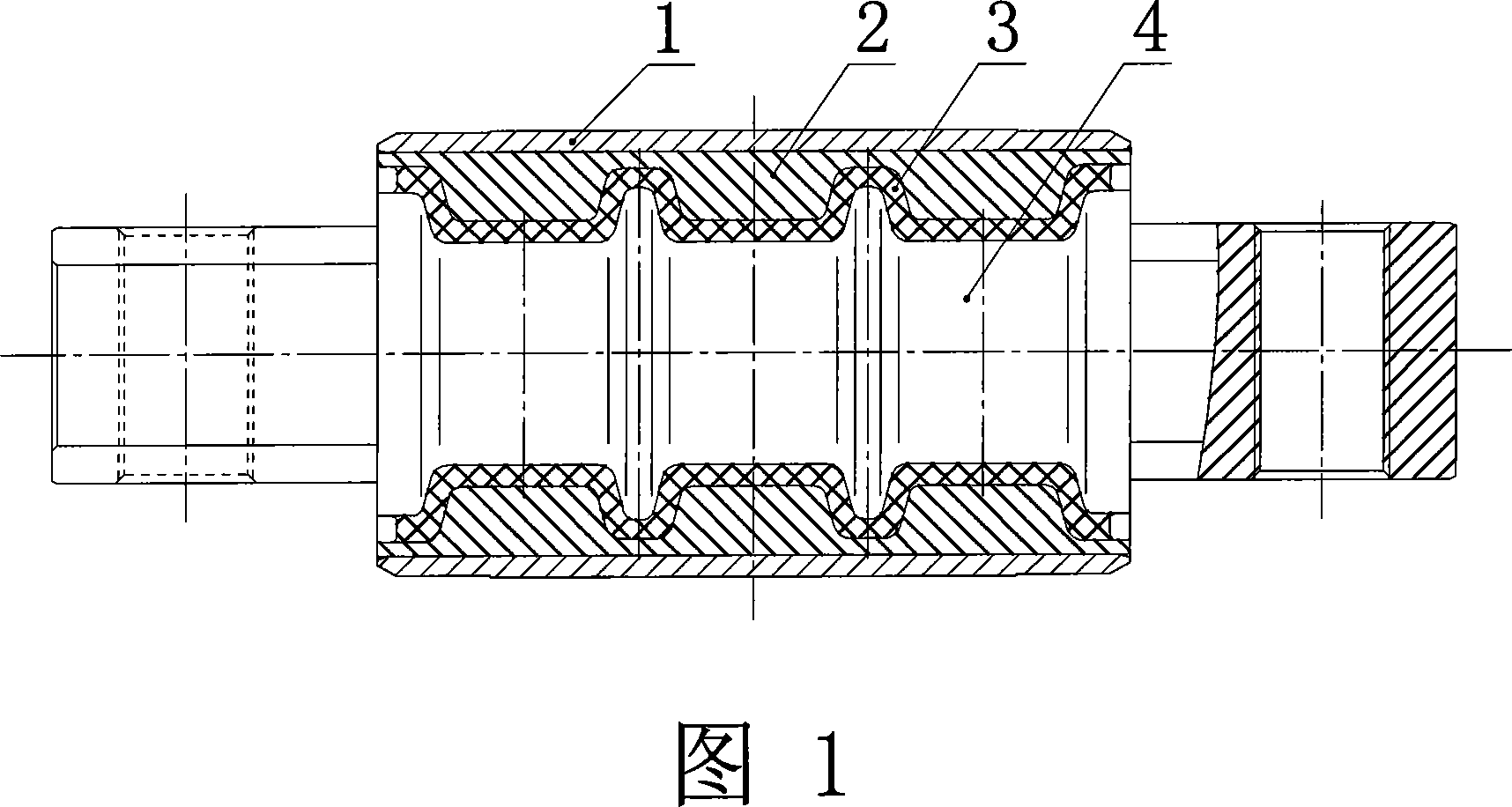

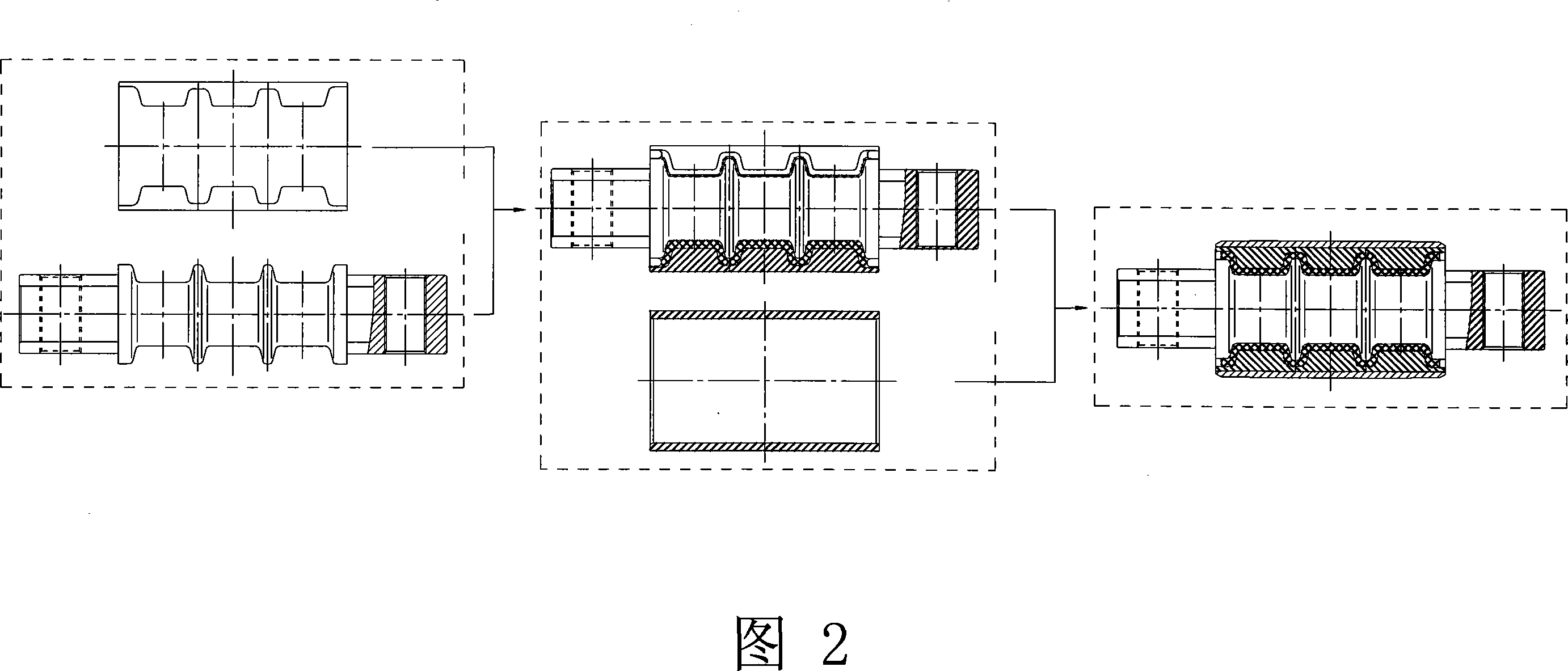

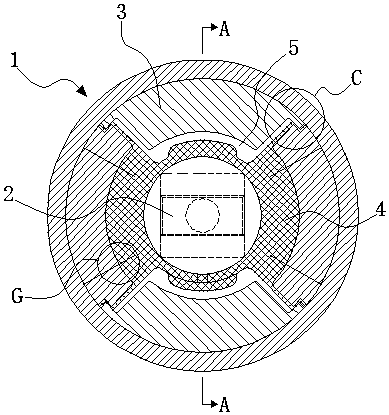

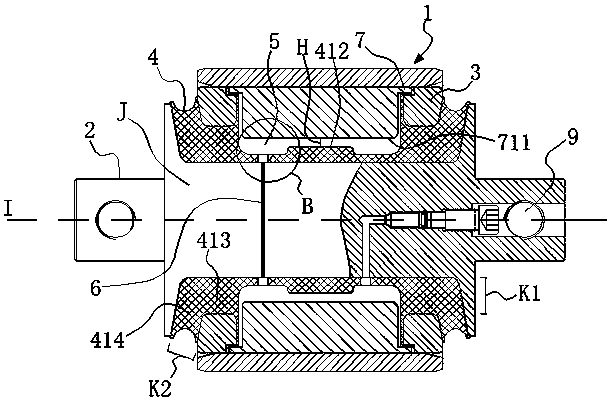

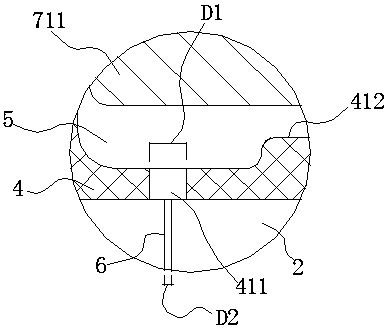

Method for forming liquid rubber composite node with pipe body flow channel and node

PendingCN110388401AExpand volume spaceImprove performanceLiquid springsVibration suppression adjustmentsVulcanizationEngineering

The invention discloses a method for forming a liquid rubber composite node with a pipe body flow passage and a node, wherein the forming method comprises the steps of additionally arranging a middlespacer sleeve between an outer sleeve and a core shaft, vulcanizing and bonding the middle spacer sleeve and the core shaft together through rubber, and assembling the middle spacer sleeve and the core shaft which are integrally formed into a whole into the outer sleeve; and arranging the pipe body flow passage in the core shaft, forming a plurality of spaces in the middle spacer sleeve by hollowing, after vulcanization, forming a plurality of liquid cavities independent of each other by the rubber and the plurality of spaces, arranging liquid in the plurality of liquid cavities, and the liquid cavities communicating with one another through the pipe body flow passage. The method for forming the liquid rubber composite node with the pipe body flow passage and the node can provide smaller radial rigidity and larger axial rigidity, and realize larger dynamic-static ratio, thereby optimizing the product performance of the liquid rubber composite node.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

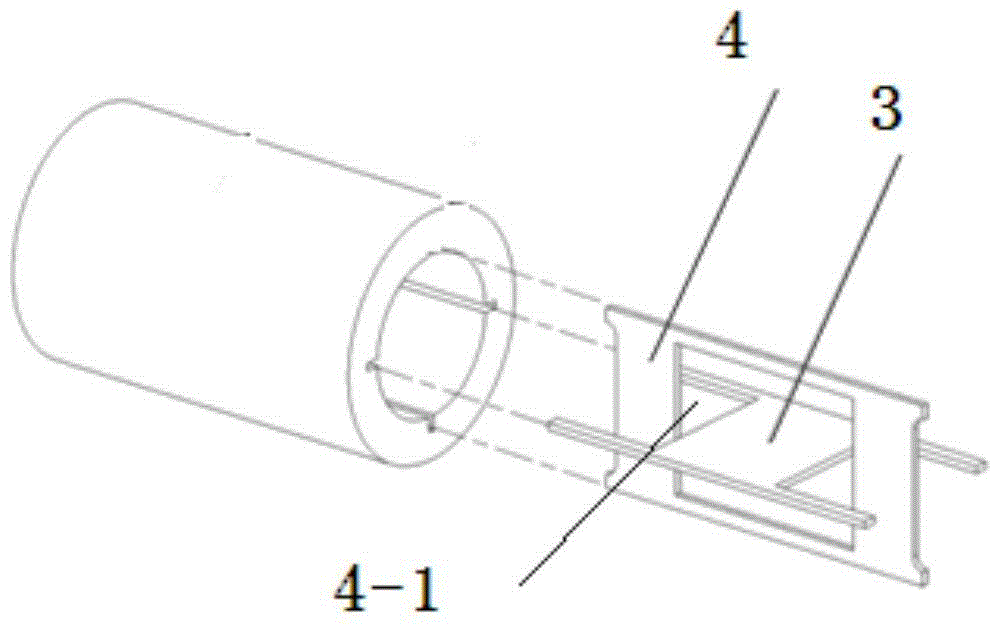

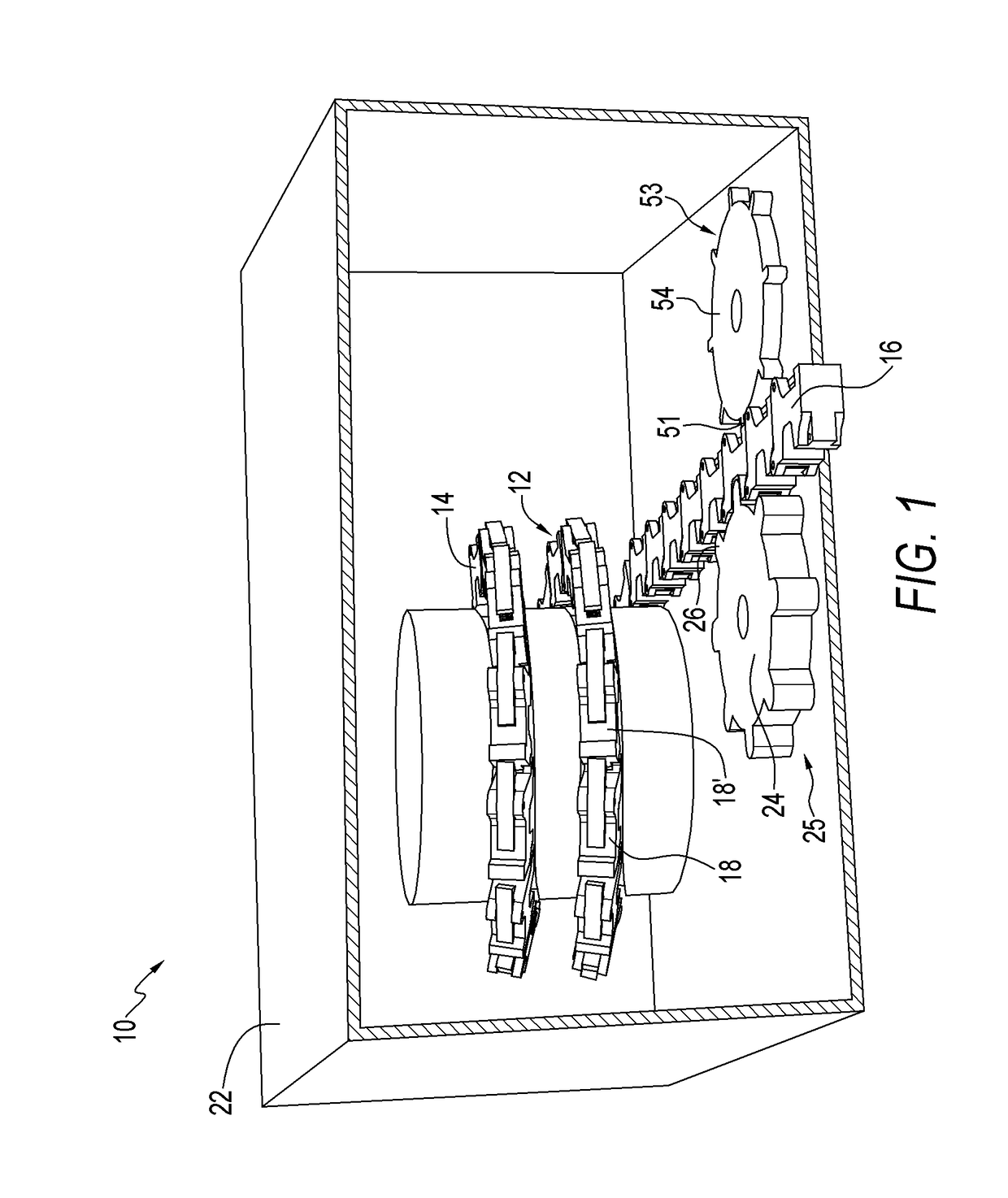

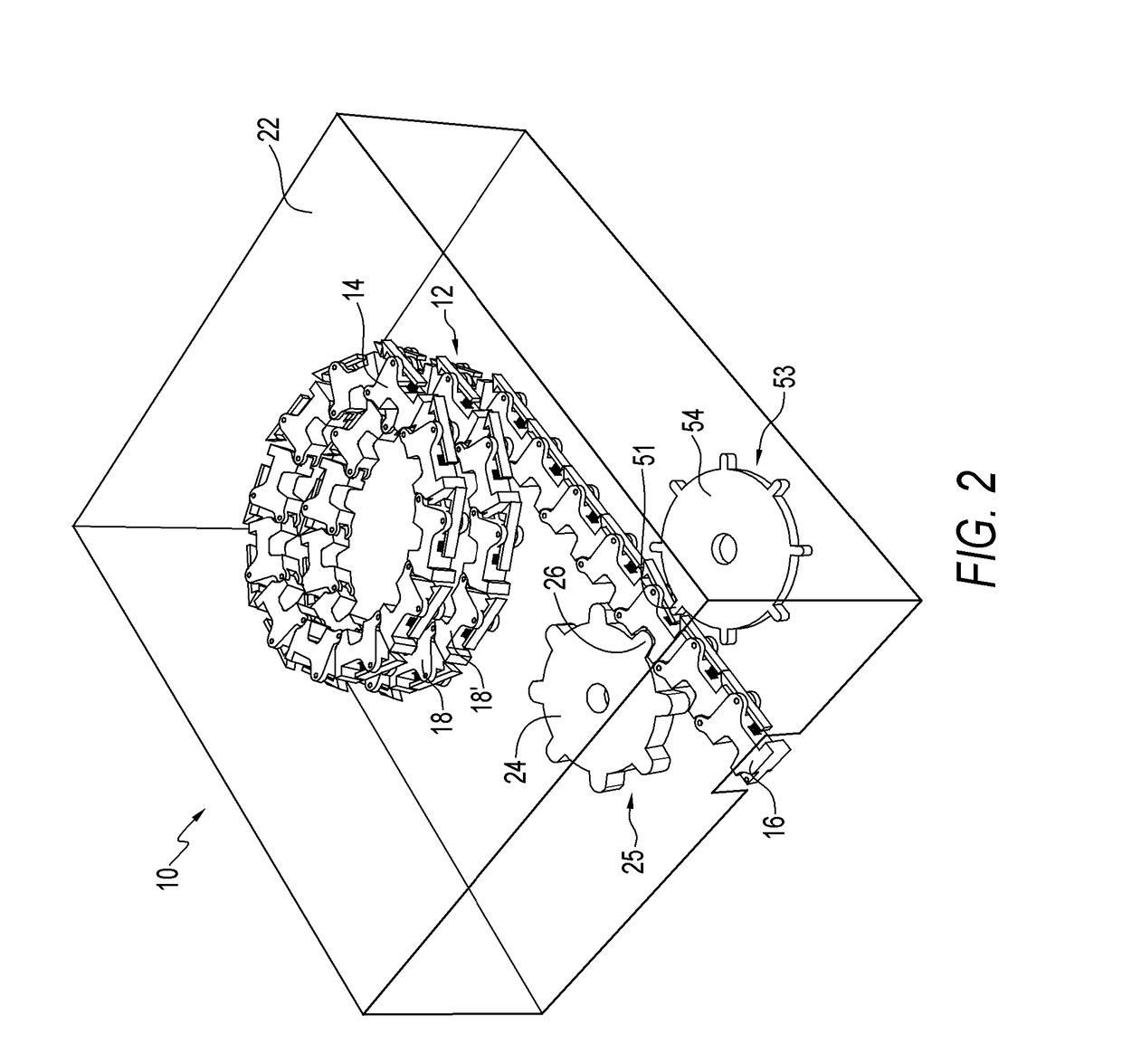

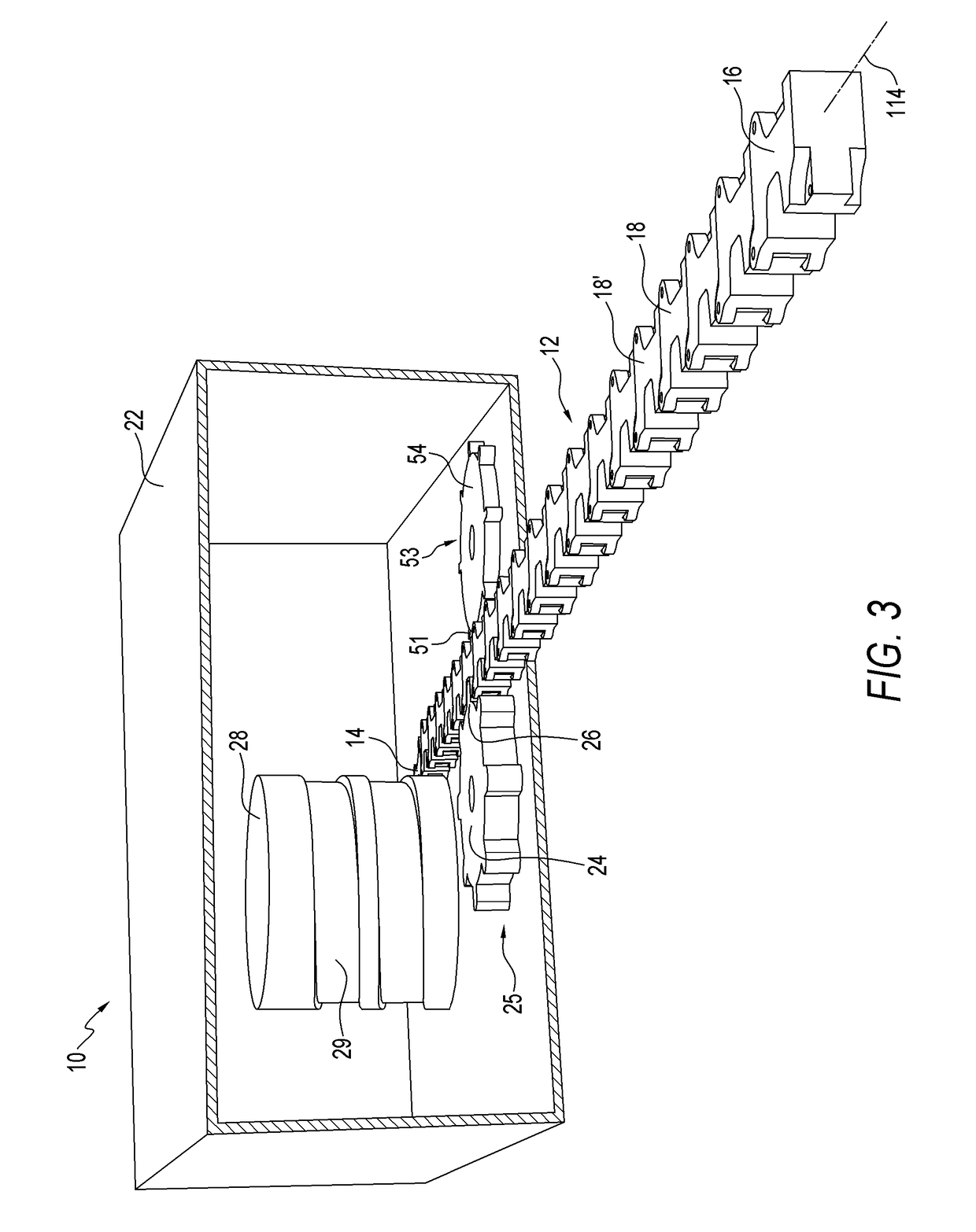

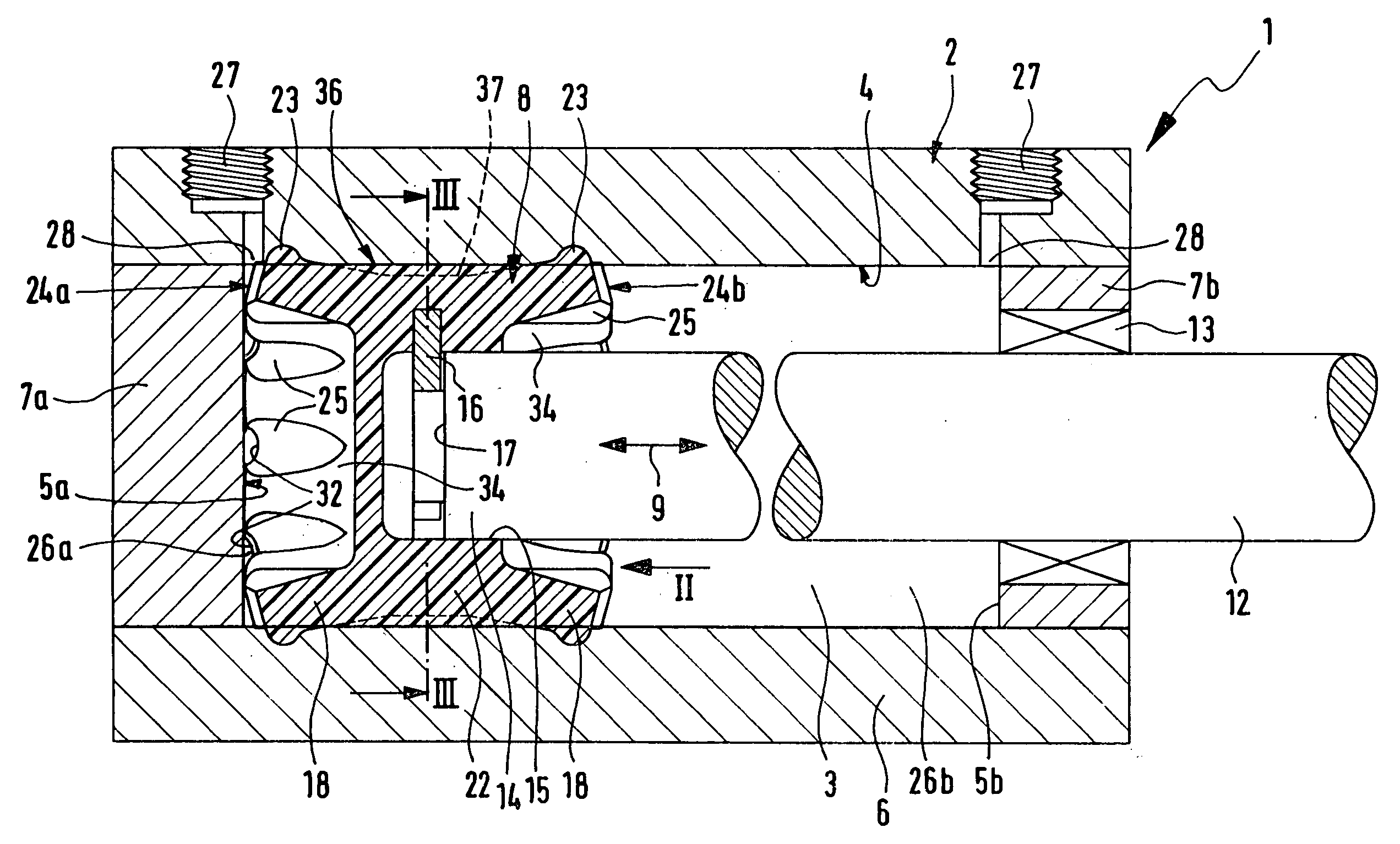

Single chain linear actuator

ActiveUS7905156B2Large extended lengthImprove axial stiffnessGearingChain elementsLocking mechanismEngineering

A linear actuator comprises a chain having adjacent first and second links. A pivotal connection pivotally connects the first link to the second link. The first link is pivotable about a pivot axis which is non-perpendicular to a longitudinal axis of the first link. A locking mechanism releasably locks the first link and the second link to prevent the first link from pivoting about the pivot axis. A releasing mechanism releases the locking mechanism to allow the first link to pivot about the pivot axis. A drive mechanism moves the chain between an extended position and a retracted position. At least a portion of the chain is helically wound when the chain is in the retracted position.

Owner:MARINE CANADA ACQUISITIONS INC

Method for forming liquid rubber composite node with damping through hole and node

ActiveCN110469623AExpand volume spaceImprove performanceSpringsSprings/dampers design characteristicsVulcanizationEngineering

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

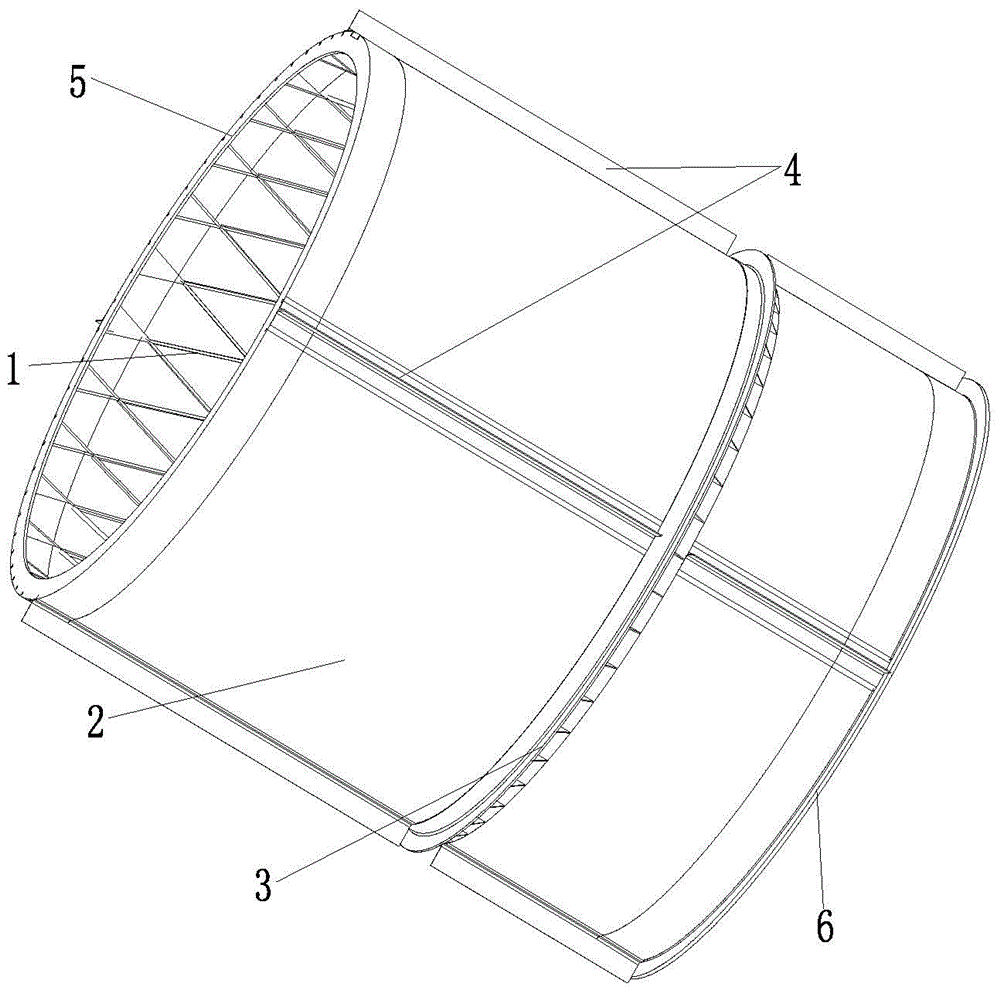

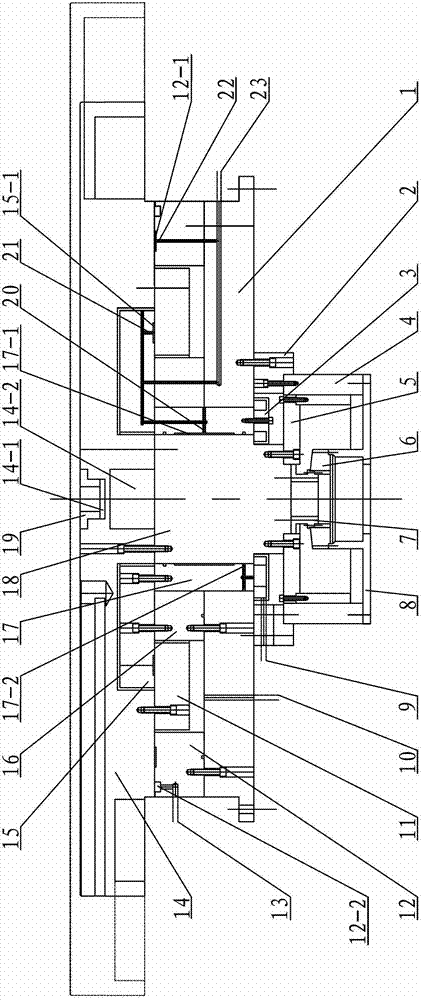

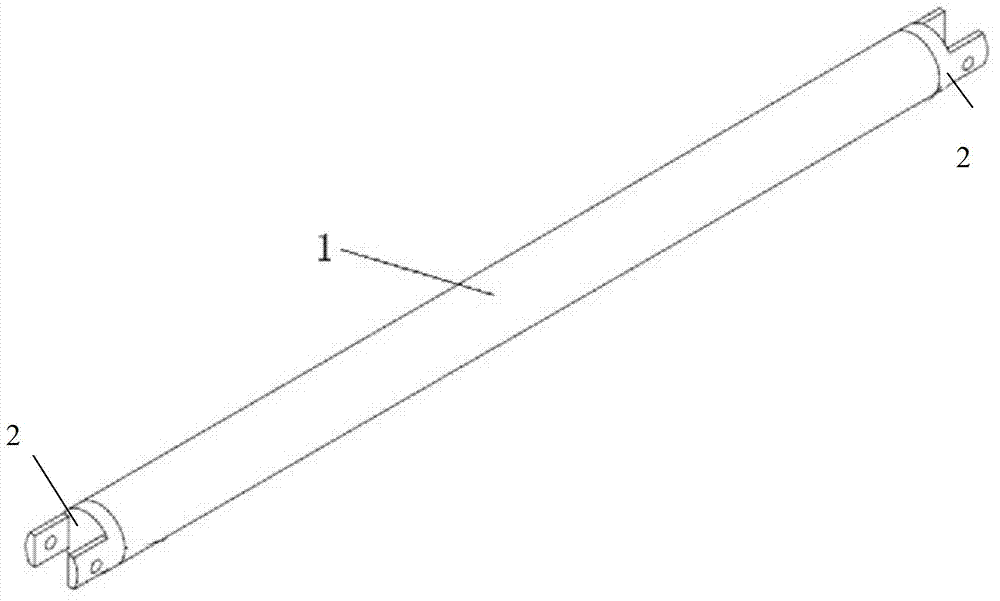

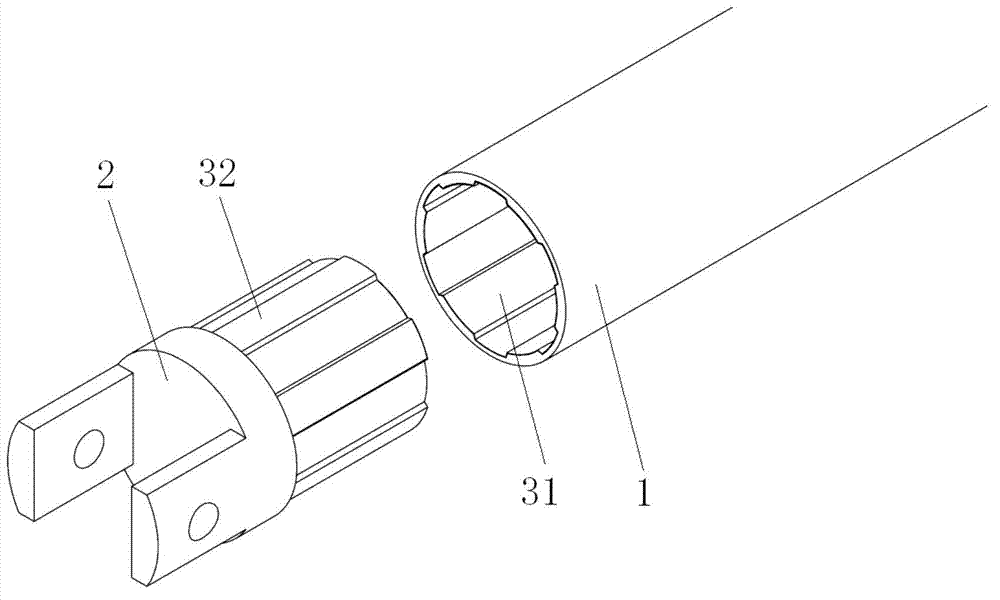

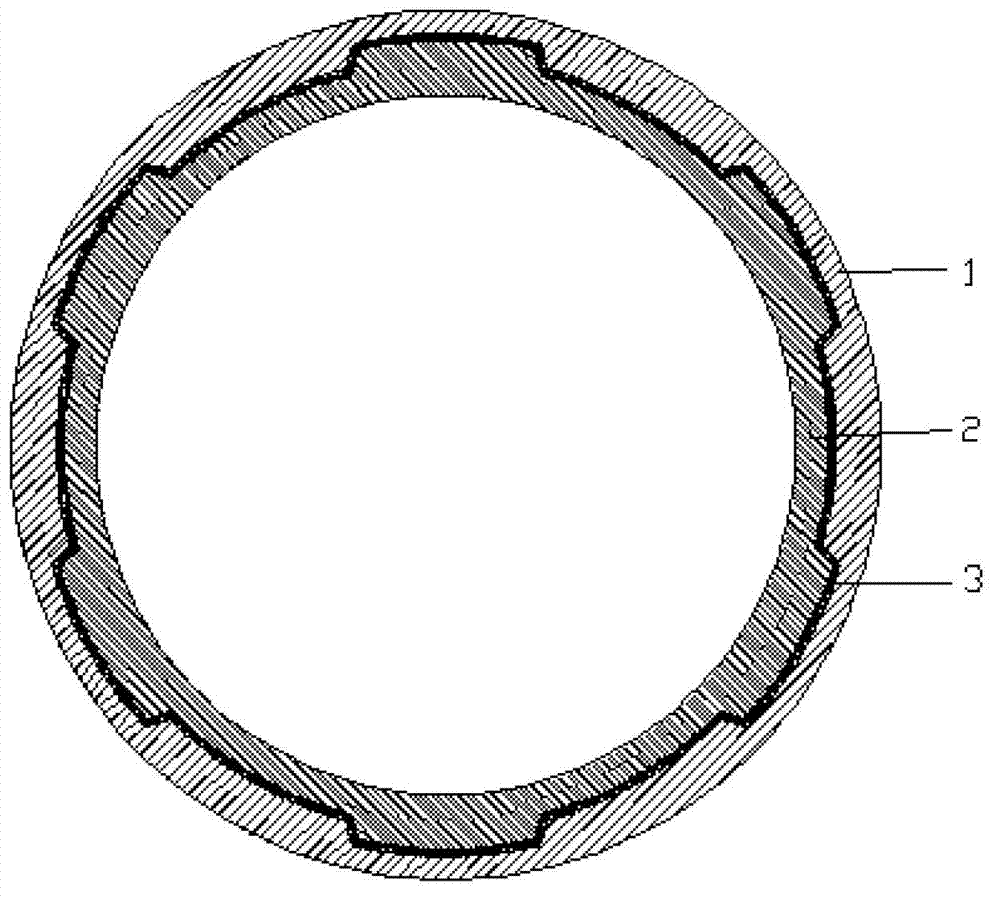

Composite-material automobile transmission shaft formed by pulling, squeezing and winding and preparation method thereof

ActiveCN102815210AEnsure efficient productionEnsure the consistency of finished product qualityControl devicesEngineeringMetal

The invention belongs to the field of a composite material, and relates to a composite-material automobile transmission shaft formed by pulling, squeezing and winding and a preparation method thereof. The composite-material automobile transmission shaft comprises a shaft pipe (1), metal connection pieces (2) and a glue layer (3), wherein the shaft pipe (1) sequentially comprises a pipe body (4), a lug boss (5) and a fabric reinforcing layer (6) from outside to inside; and the both ends of the shaft pipe (1) are connected with the metal connection pieces (2) through the glue layer (3) and the lug boss (5) in a spline connection and glued connection combined manner. The reasonable composite-material automobile transmission shaft is implemented according to a pulling, squeezing and winding process, the lug boss made of a composite material formed by pulling and squeezing is arranged on the inner side of the automobile transmission shaft along the axial direction of the entire shaft pipe, and at the connection part, the shaft pipe and each metal connection piece are connected with each other in the spline connection and glued connection combined manner, so that the connection strength is enhanced, and the automobile transmission shaft can be reliable for a long time.

Owner:上海鹏霄复合材料科技有限公司

Piston and a power cylinder fitted therewith

InactiveUS20060162551A1Effective dampingCompact dimensionsPiston ringsBraking action transmissionMechanical engineeringPiston

A piston for a fluid operated power cylinder has two mutually coaxial sealing lips axially extending away from each other and being able to radially yield, for sealing engagement with the piston running face of the power cylinder and adjacent to at least one piston end side an elastic buffer body serving for shock absorbing in the end of stroke position of the piston, said body having an impact face facing away from the piston. At least at one piston end face the sealing lip itself constitutes the buffer body and has the impact face at its end, groove-like recesses being formed on the inner periphery of the sealing lip with a distribution in the peripheral direction, such recesses opening toward said impact face.

Owner:FESTO AG & CO KG

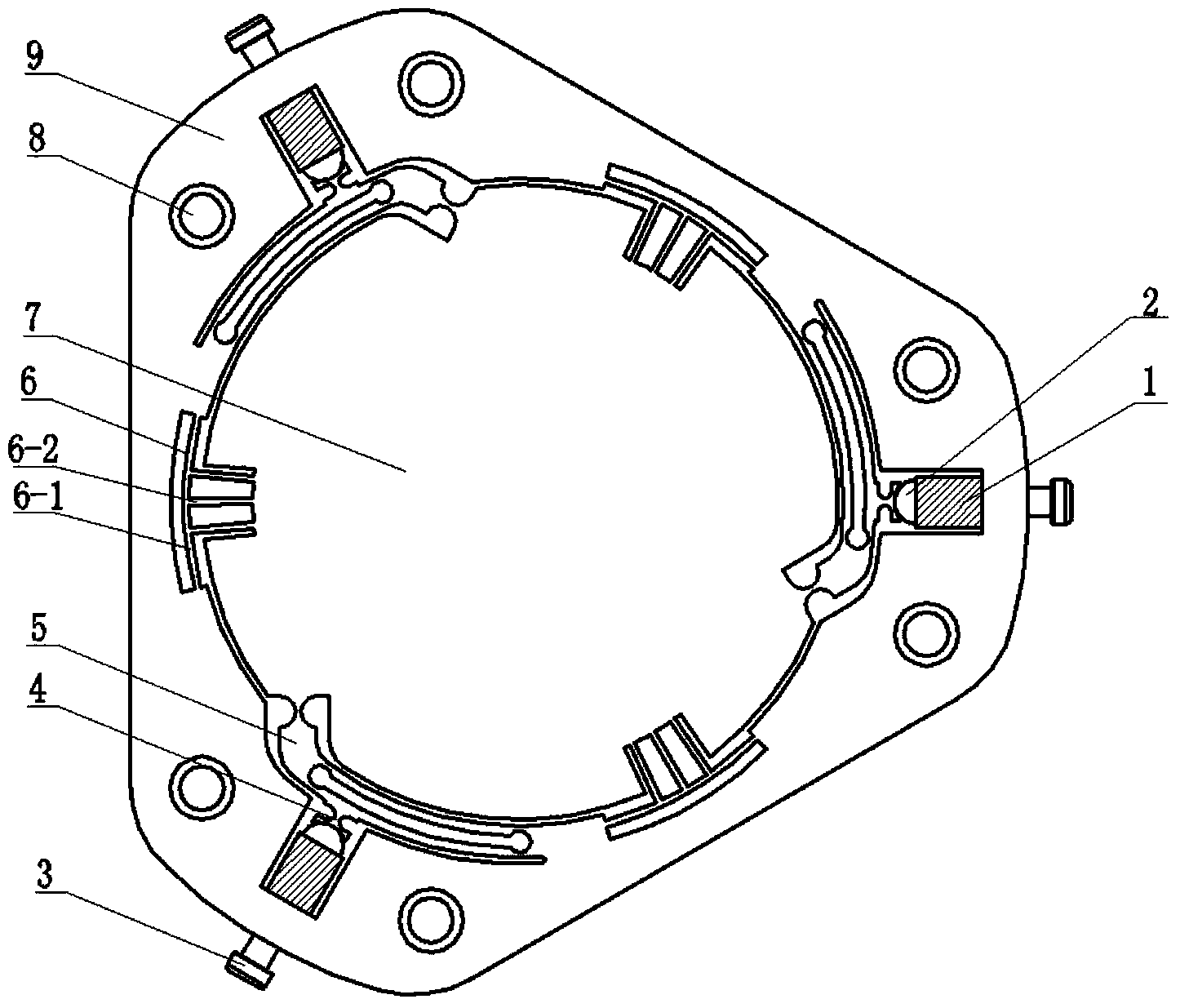

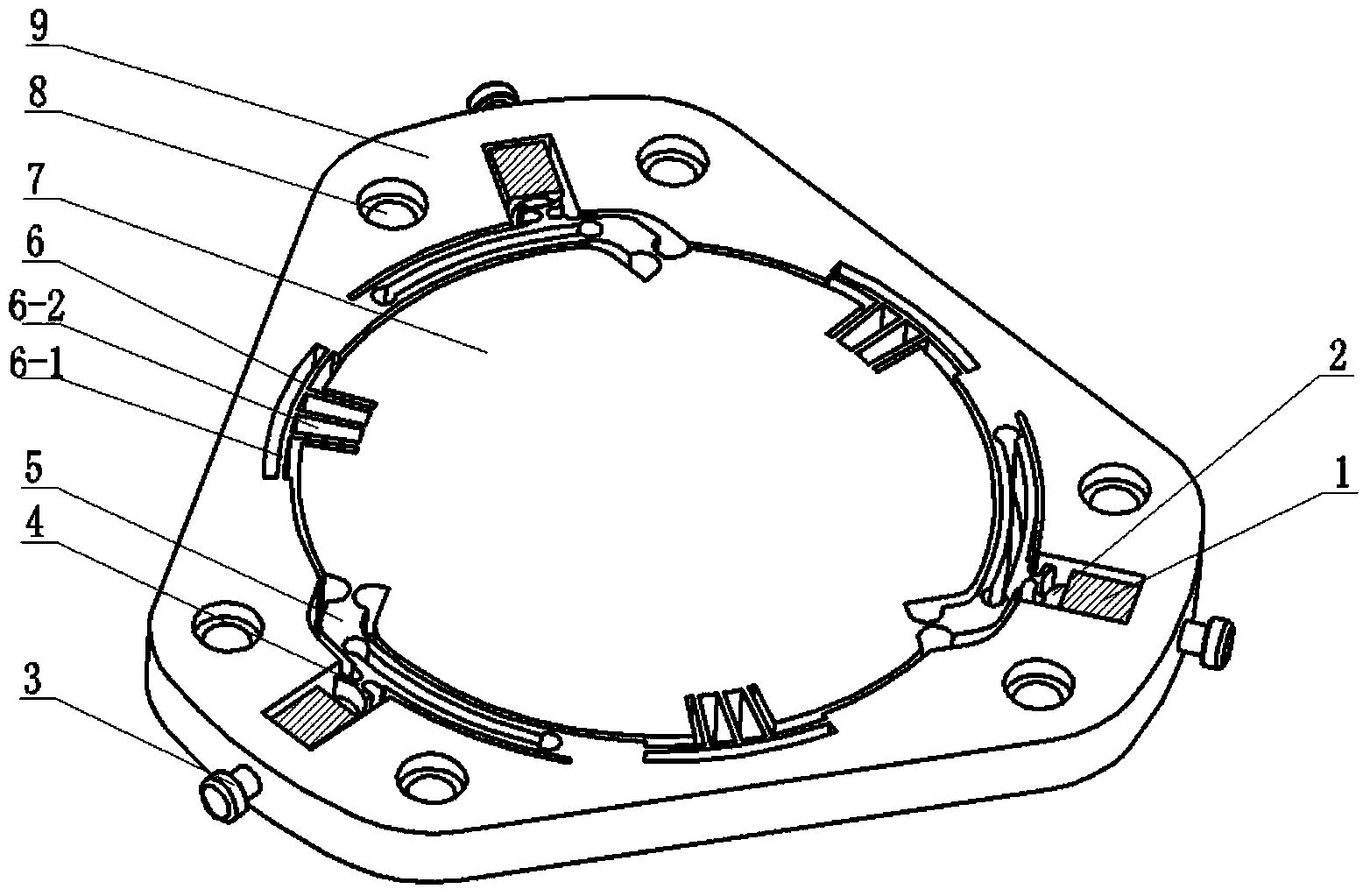

Primary mirror flexible support mechanism

ActiveCN106772917AGuaranteed Surface AccuracyAvoid interferenceMountingsRubber ringArchitectural engineering

A primary mirror flexible support mechanism relates to a primary mirror flexible support mechanism. The mechanism is provided to solve the problem of the existing primary mirror support mechanism, namely, the existing mechanism cannot isolate outside temperature change and has alignment error, the axial support component mechanism and the radial support mechanism interfere with each other as the pitch angle changes, and thus, the surface shape of the primary mirror is affected. The primary mirror flexible support mechanism comprises a support base, an axial support component supporting a primary mirror, a tensile component glued onto the back of the primary mirror, a radial support component glued to the center of the primary mirror, and a protective component. The radial support component comprises a flexible mandrel adhered into the center hole of the primary mirror, a center cylinder installed in the middle of the support base through spigot fitting, and a flexible diaphragm arranged between the center cylinder and the flexible mandrel. The protective component comprises an O-shaped rubber ring and a protective ring. The problem that the primary mirror may be broken due to overturn after failure of the axial support is prevented. The protective device ensures that the primary mirror can be protected under certain amplitude of vibration.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

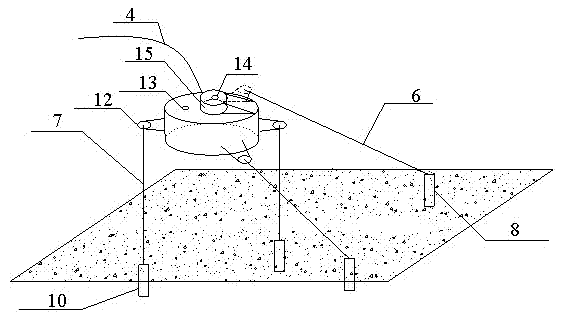

Self-adaption type deepwater mooring system

InactiveCN102815372AIncrease horizontal stiffnessIncrease vertical stiffnessAnchoring arrangementsBuoyMooring system

The invention discloses a self-adaption type deepwater mooring system which comprises a hanging buoy, a weight block, a mooring buoy, an anchor, a pile foundation, an upper tensioning cable, a connecting cable, a lower tensioning cable and a tension tendon, wherein the upper tensioning cable is used for connecting the hanging buoy with the weight block; the connecting cable is used for connecting the weight block with the mooring buoy; the lower tensioning cable is used for connecting the mooring buoy with the anchor; and the tension tendon is used for connecting the mooring buoy with the pile foundation. The self-adaption type deepwater mooring system has the advantages of high horizontal mooring rigidity, high vertical mooring rigidity and uniform tension distribution of a cable.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com