Method for forming liquid rubber composite node with pipe body flow channel and node

A technology of liquid rubber and tube body, which is applied in the direction of hydraulic spring, shock absorber-spring combination, shock absorber, etc., can solve the problems that are difficult to realize, and achieve the effect of improving reliability, optimizing product performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

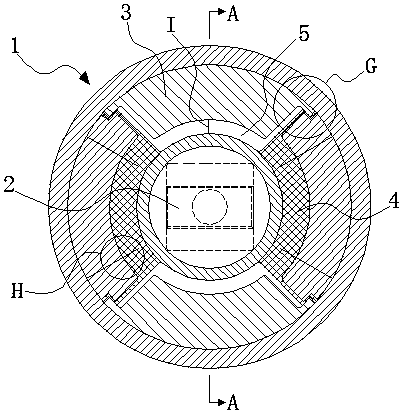

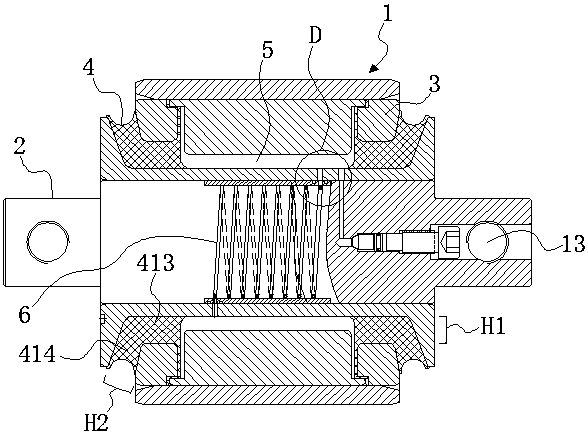

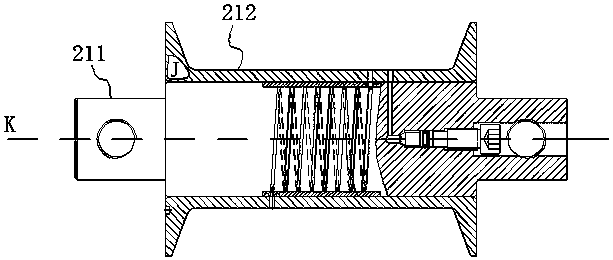

[0040] Embodiment 1: as figure 1 and figure 2 As shown, a method for forming a liquid rubber composite node with an inner groove flow path, which is to add an intermediate spacer 3 between the outer casing 1 and the mandrel 2, and bond the intermediate spacer 3 and the mandrel 2 through rubber 4 vulcanization. Connect together, and then assemble the integrated intermediate spacer and mandrel into the outer casing 1; set the pipe body flow channel in the mandrel 2, and hollow out multiple spaces on the middle spacer 3. After vulcanization, use The rubber 4 and the plurality of spaces form a plurality of liquid cavities 5 that are independent of each other. Liquids (not shown in the figure) are arranged in the plurality of liquid cavities 5, and the plurality of liquid cavities 5 pass through pipe flow channels. 6 phases are connected. The liquid rubber composite joint formed by the above method can provide smaller radial stiffness and greater axial stiffness, and achieve a l...

Embodiment 2

[0057] Embodiment 2: as Figure 11 As shown, compared with the embodiment 1, the difference of the present embodiment is that: the two ends of the coat 1 in the present embodiment adopt the cuff buckle design structure. One end of the intermediate spacer 3 is provided with a continuous step portion 14 and a step portion 2 15, the step portion 14 is located at the lower position (close to the mandrel), and the step portion 2 15 is located at the upper position (away from the mandrel) position), one end face of the jacket 1 is vertically flush with the lateral vertical surface of the step part 2 15, and an end sealing ring 16 is placed on the step part 2 15. When the flange is not crimped, the end sealing ring The height of 16 is higher than the height of step part 2 15, that is, the end sealing ring 16 is located between the step part 2 15 and the outer casing 1. A jacket flanging part 112 is extended on one end surface of the jacket 1. During the flanging operation, the end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com