Patents

Literature

132 results about "Composite joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite joint (compound joint) a type of synovial joint in which more than two bones are involved. condylar joint ( condyloid joint ) one in which an ovoid head of one bone moves in an elliptical cavity of another, permitting all movements except axial rotation; this type is found at the wrist, connecting the radius and carpal bones, and at ...

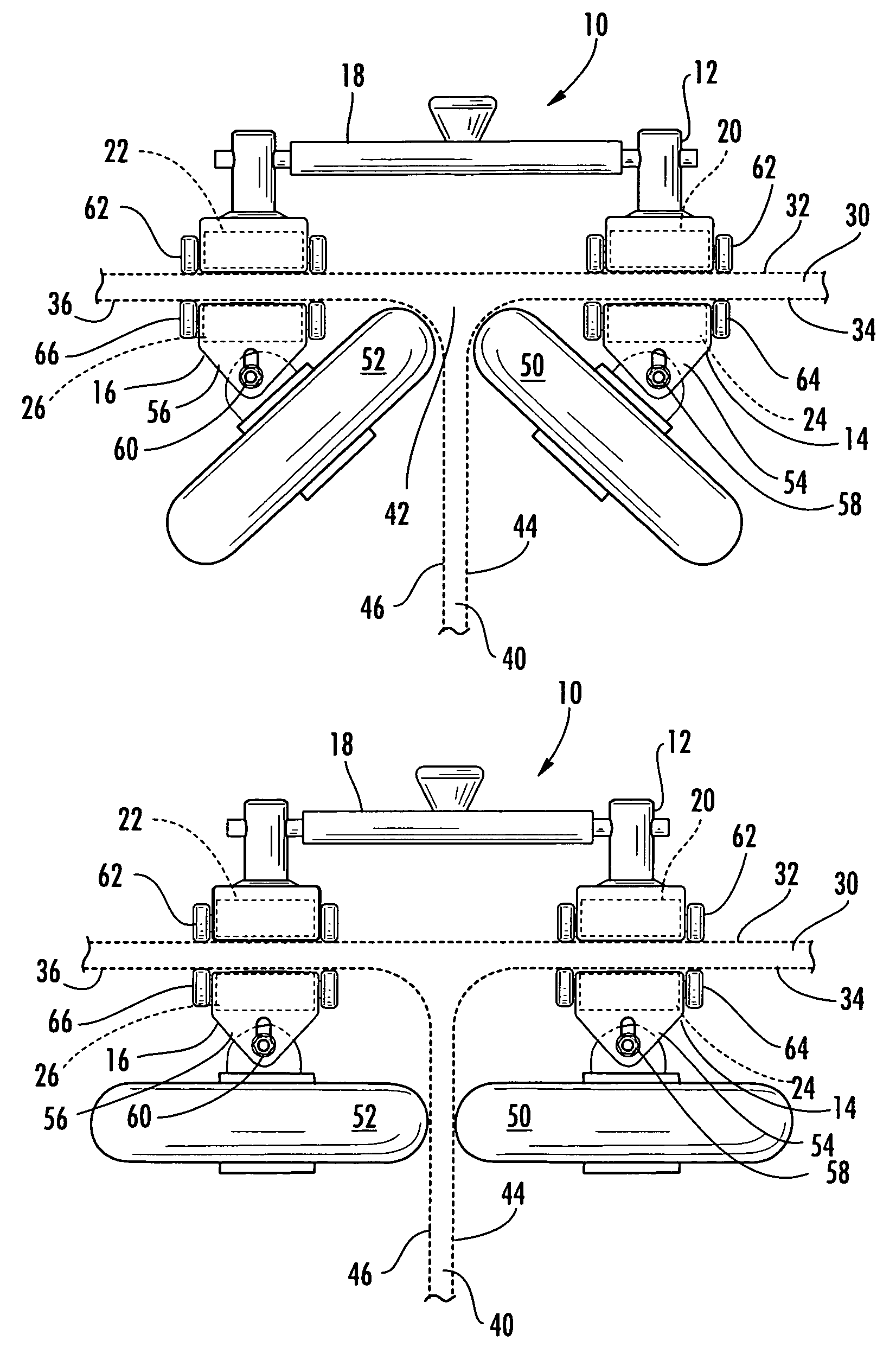

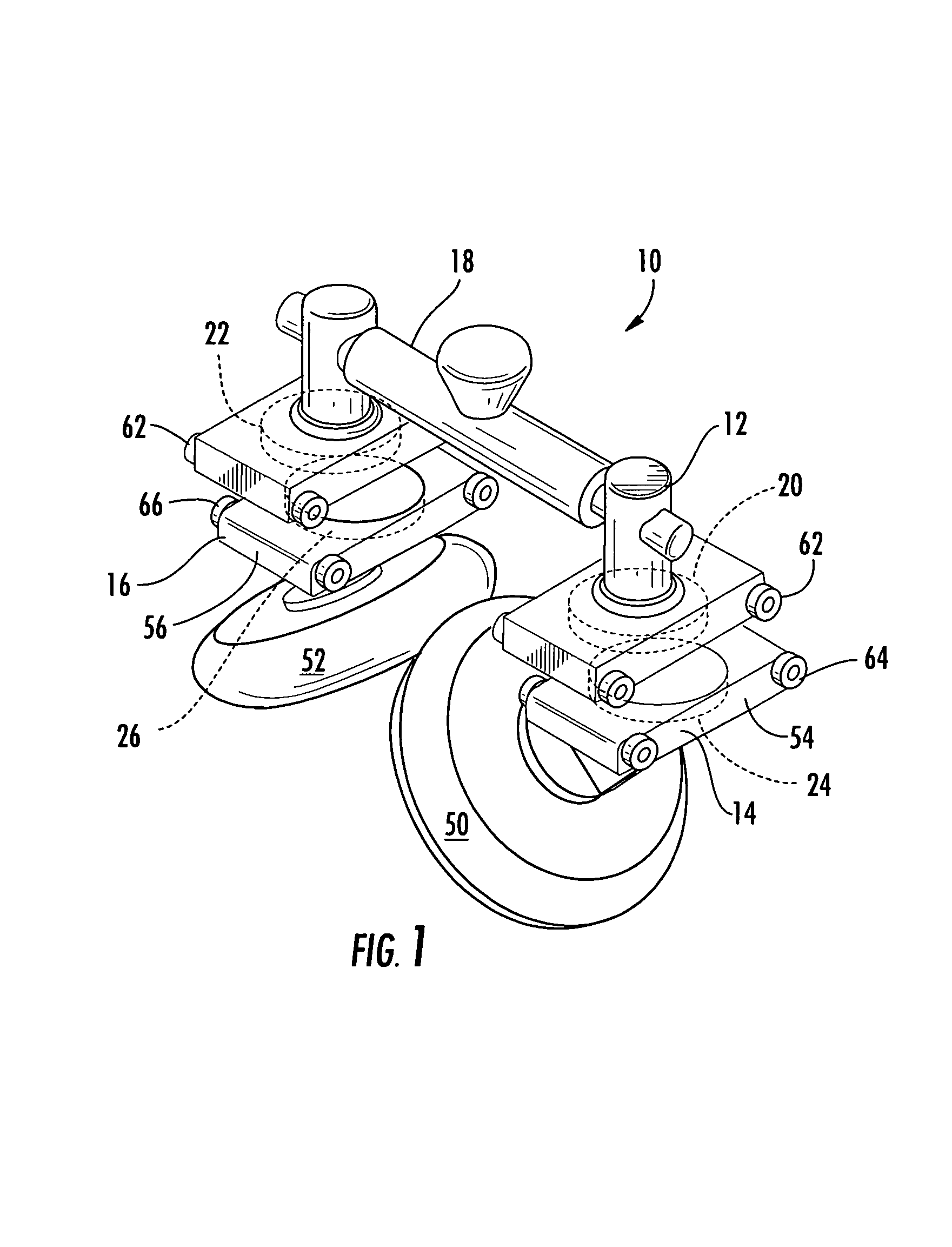

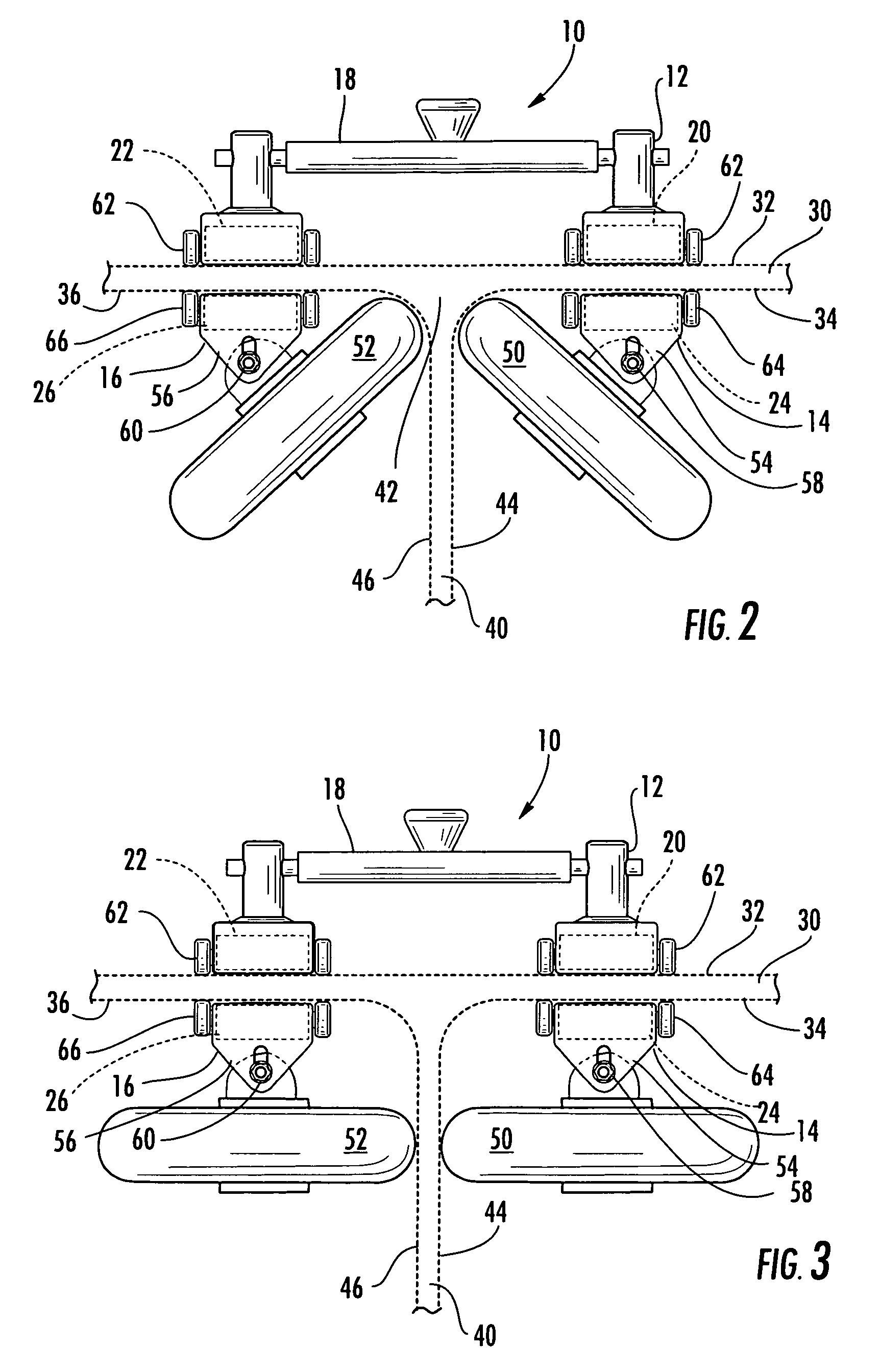

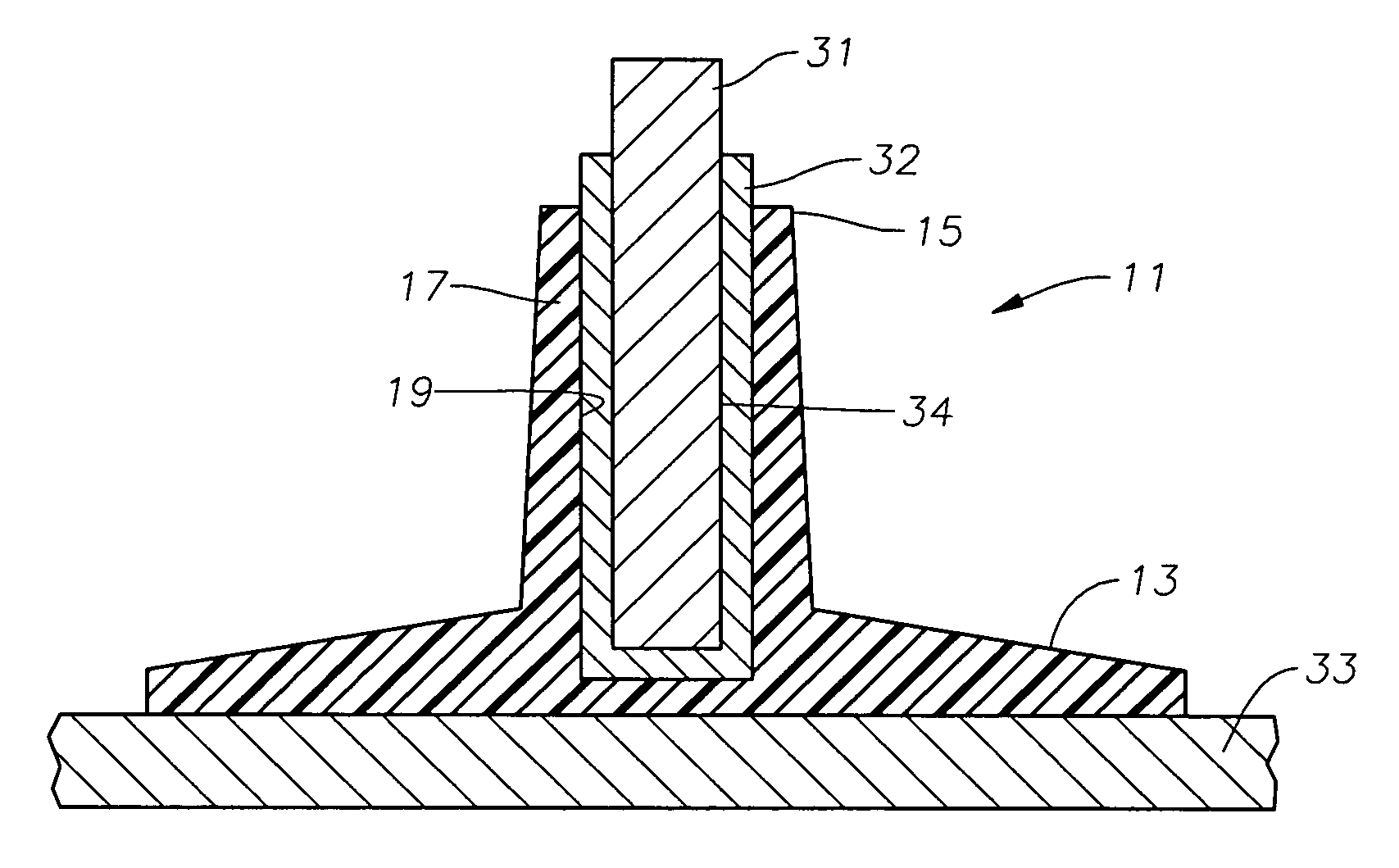

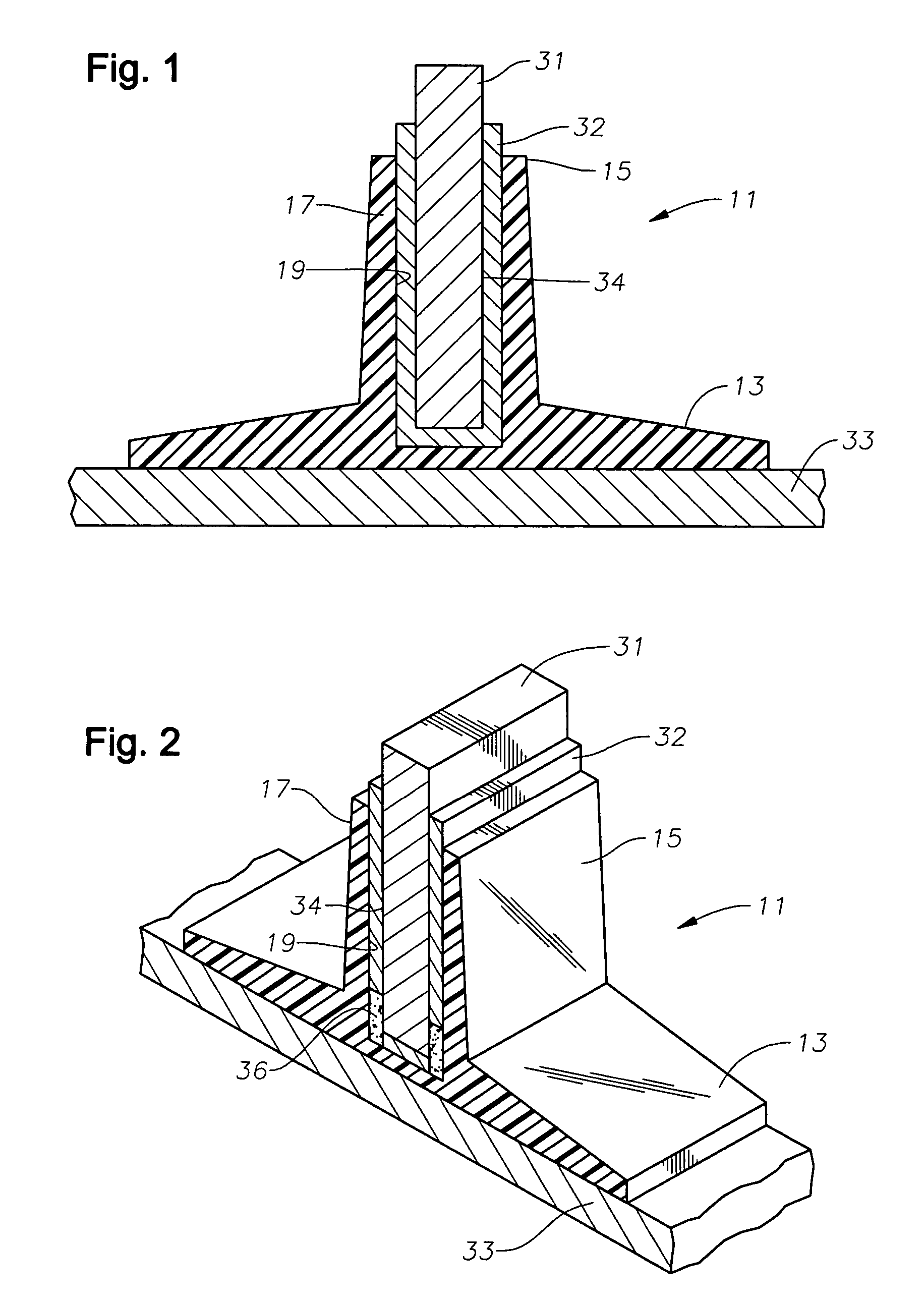

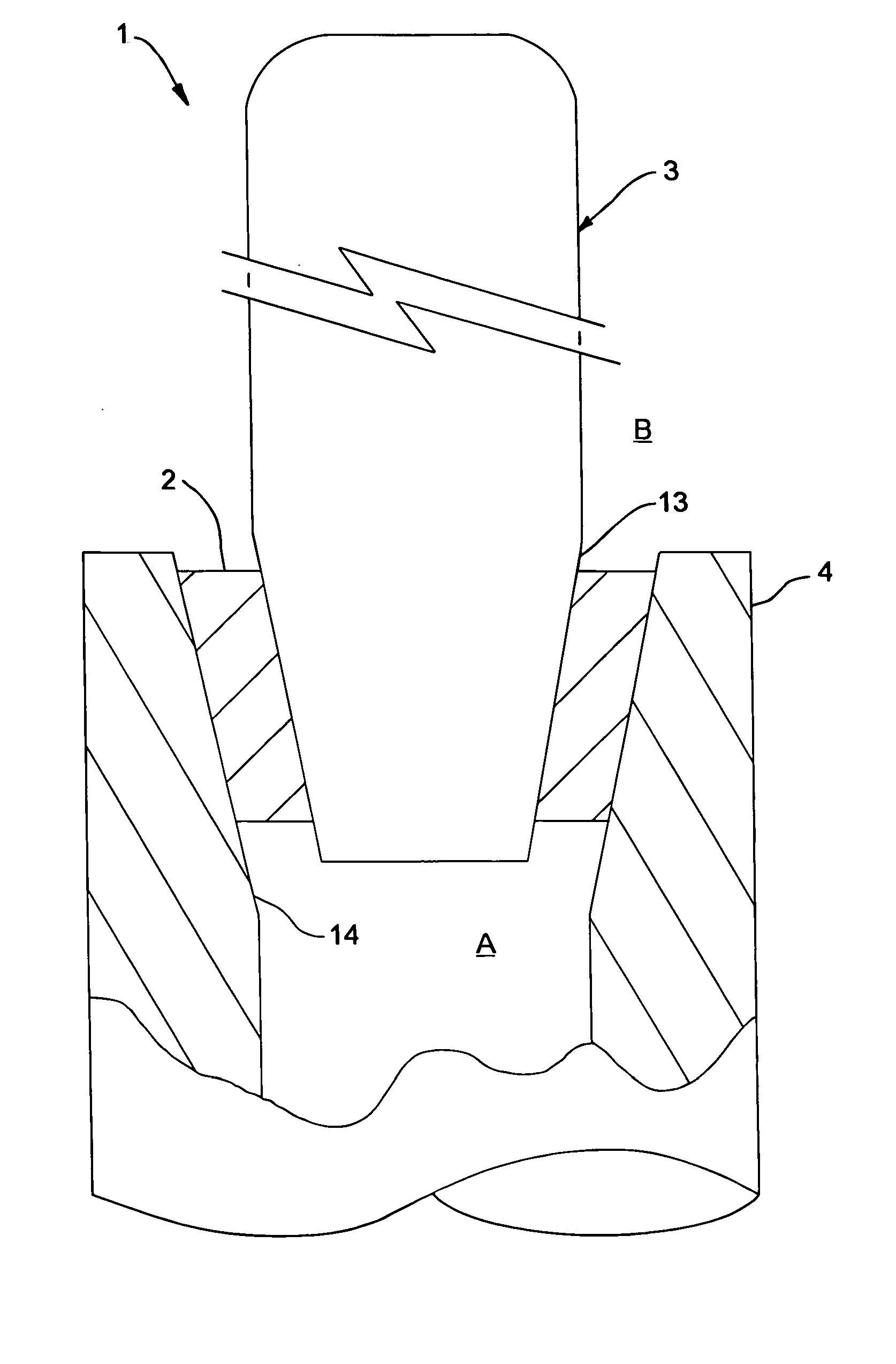

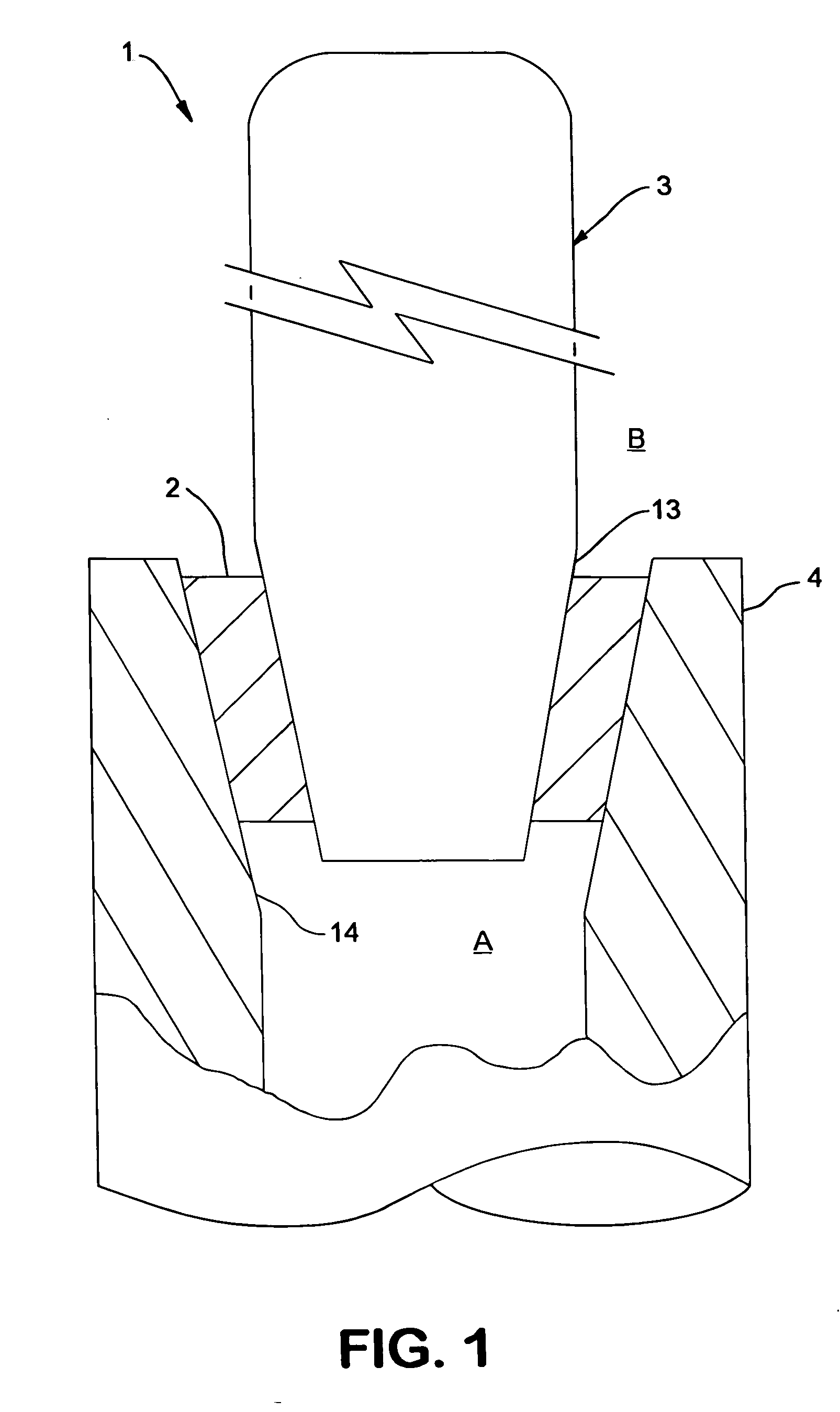

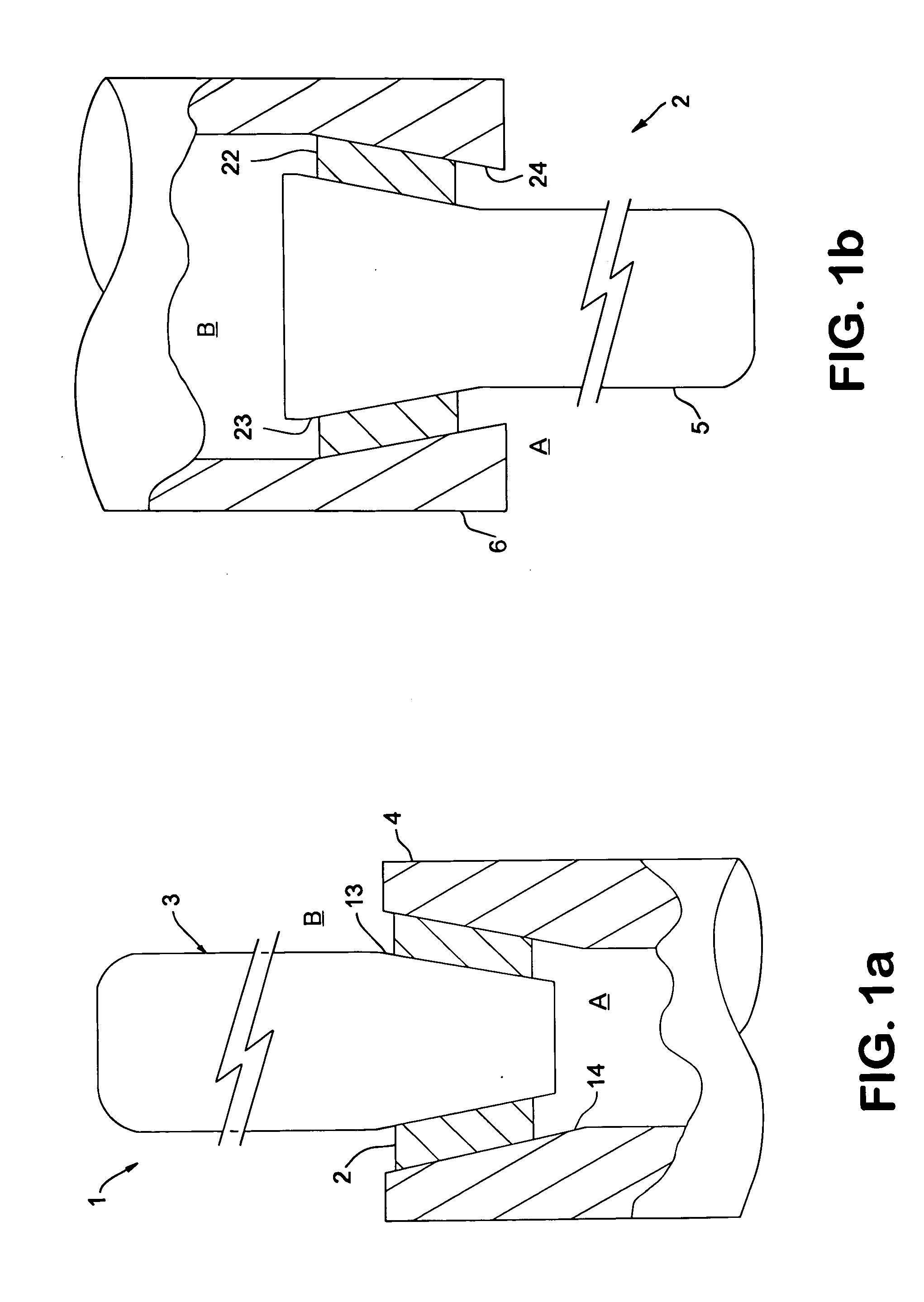

Composite joint implant

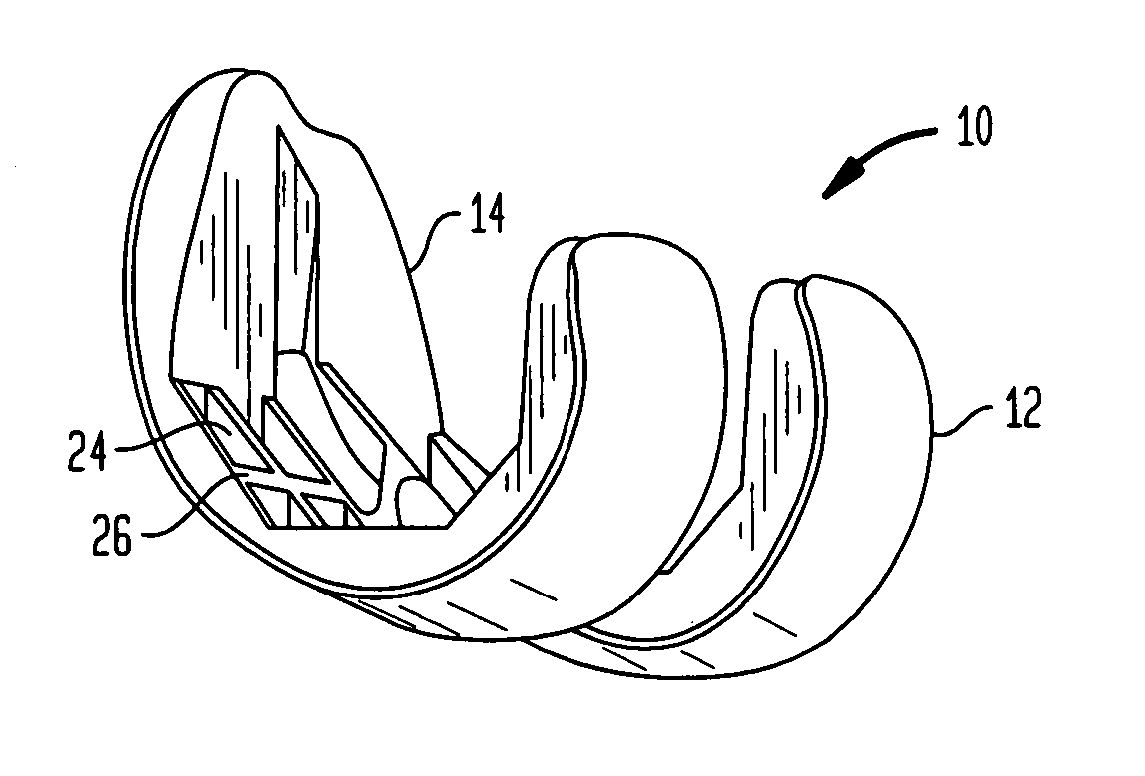

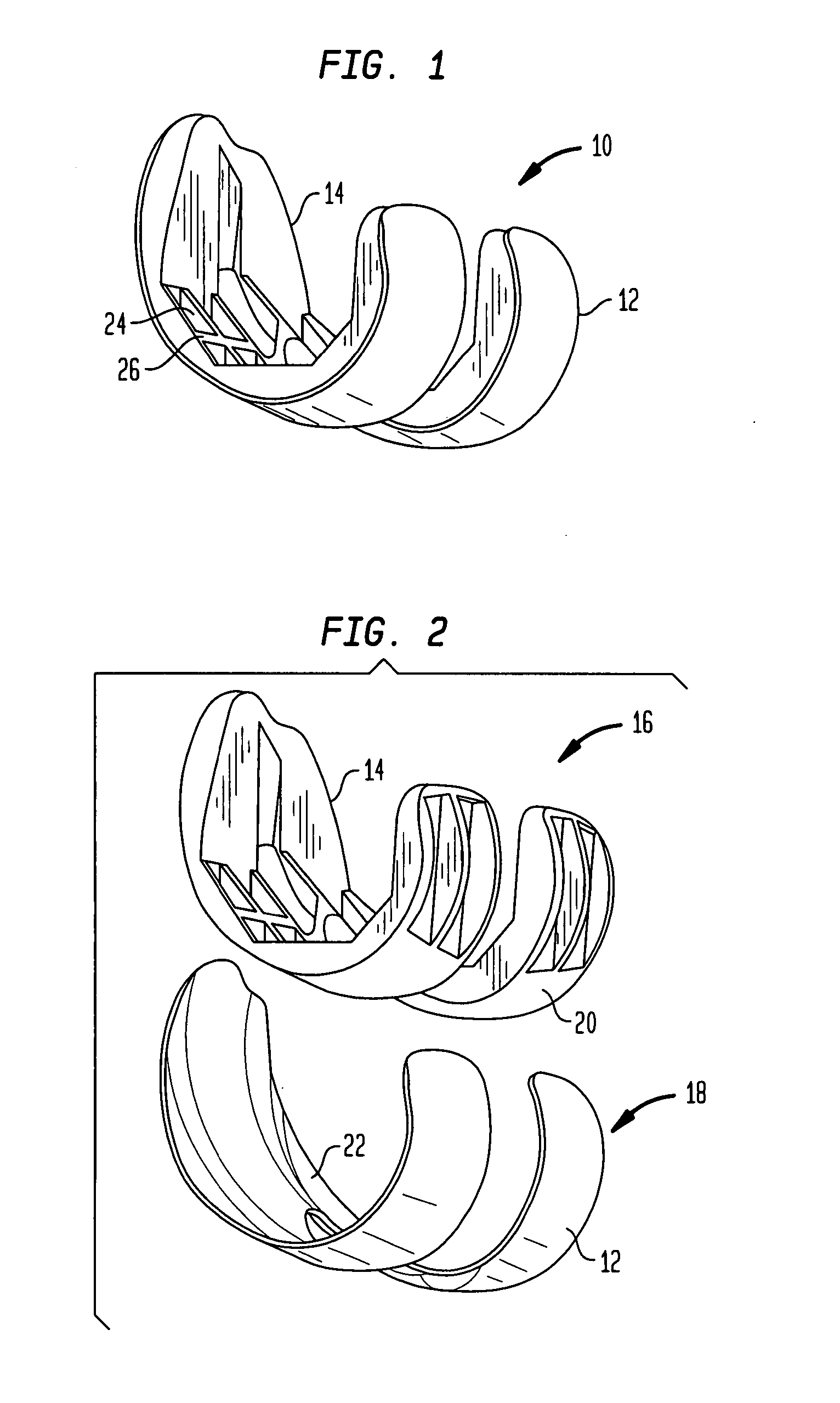

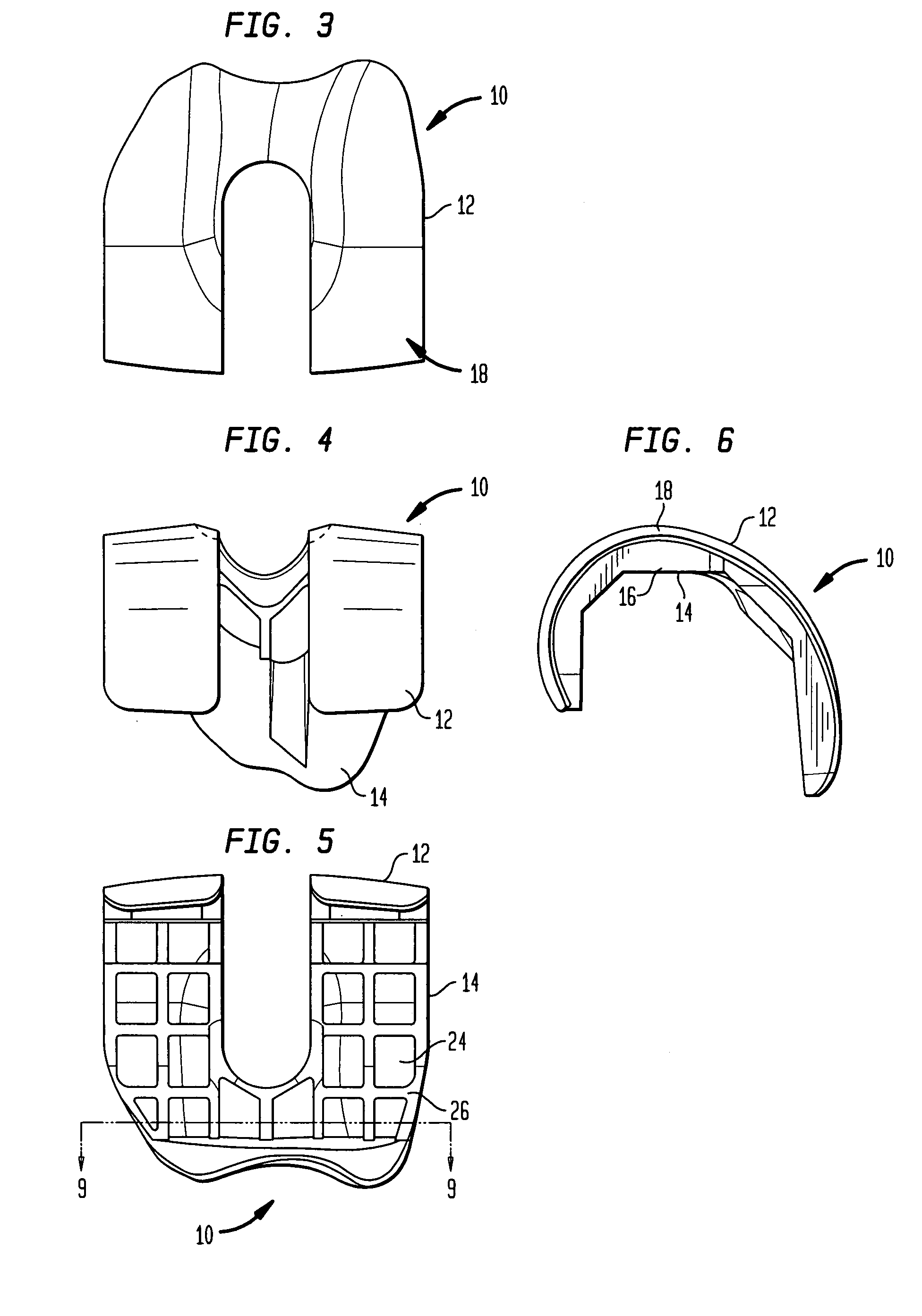

The present invention relates to a femoral component for use in connection with knee anthroplasty. The implant includes a support having a contoured inner bone engaging surface, and a shell affixed to the support. The shell has an outer surface spaced so as to provide an articulation surface for engaging the tibia that substantially replicates the shape of a femoral condyle, and an inner surface for receiving an outer surface of the support. The support bone engaging surface is structured to mate with a prepared surface of the distal femur and the support spaces the shell outer surface at a predetermined distance from the prepared surface.

Owner:HOWMEDICA OSTEONICS CORP

Energy absorbent laminate

InactiveUS7087296B2Tensile modulusImprove toughnessAutomatic/semiautomatic turning machinesSynthetic resin layered productsFiberFlexural modulus

Owner:SAINT GOBAIN TECHN FABRICS CANADA +1

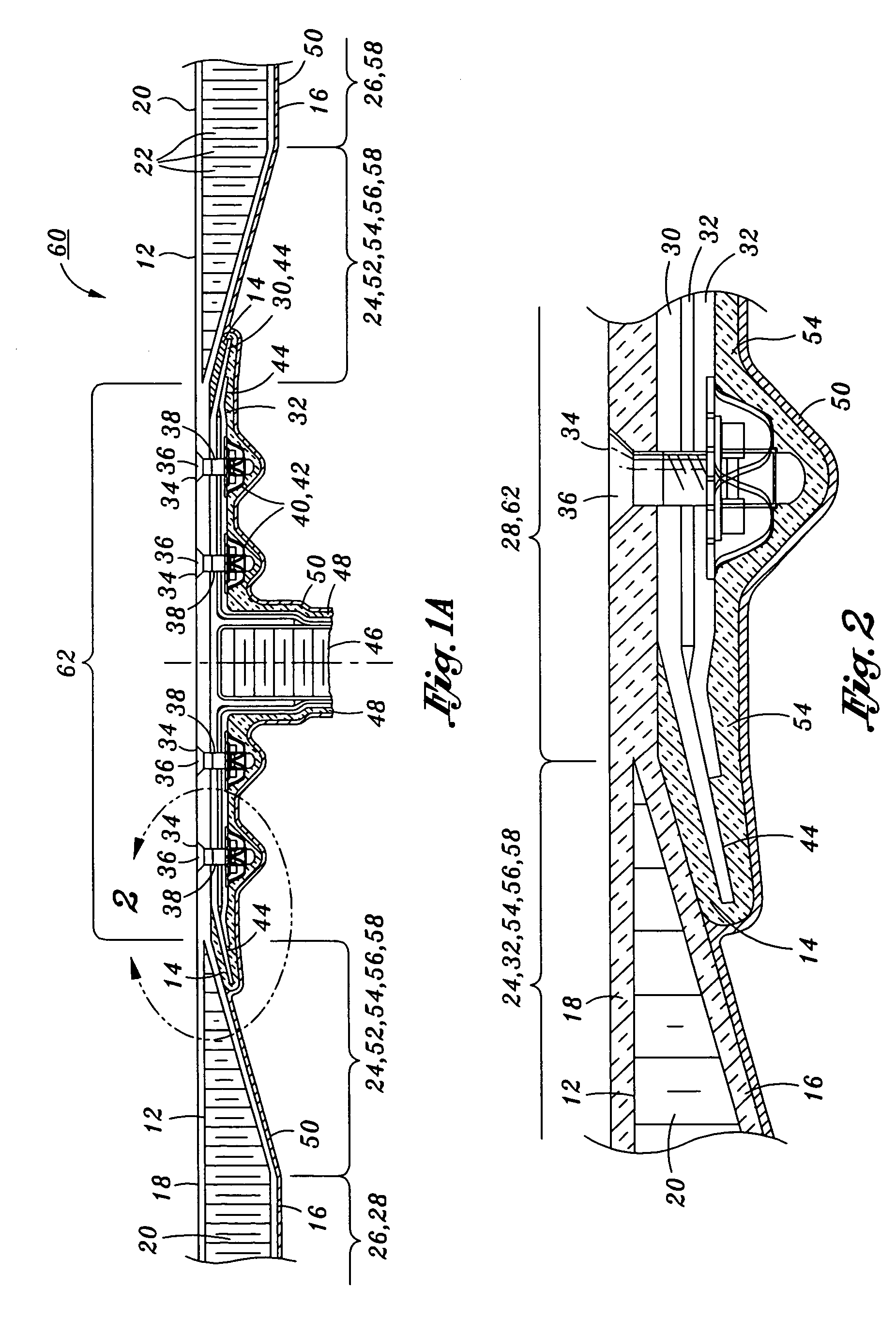

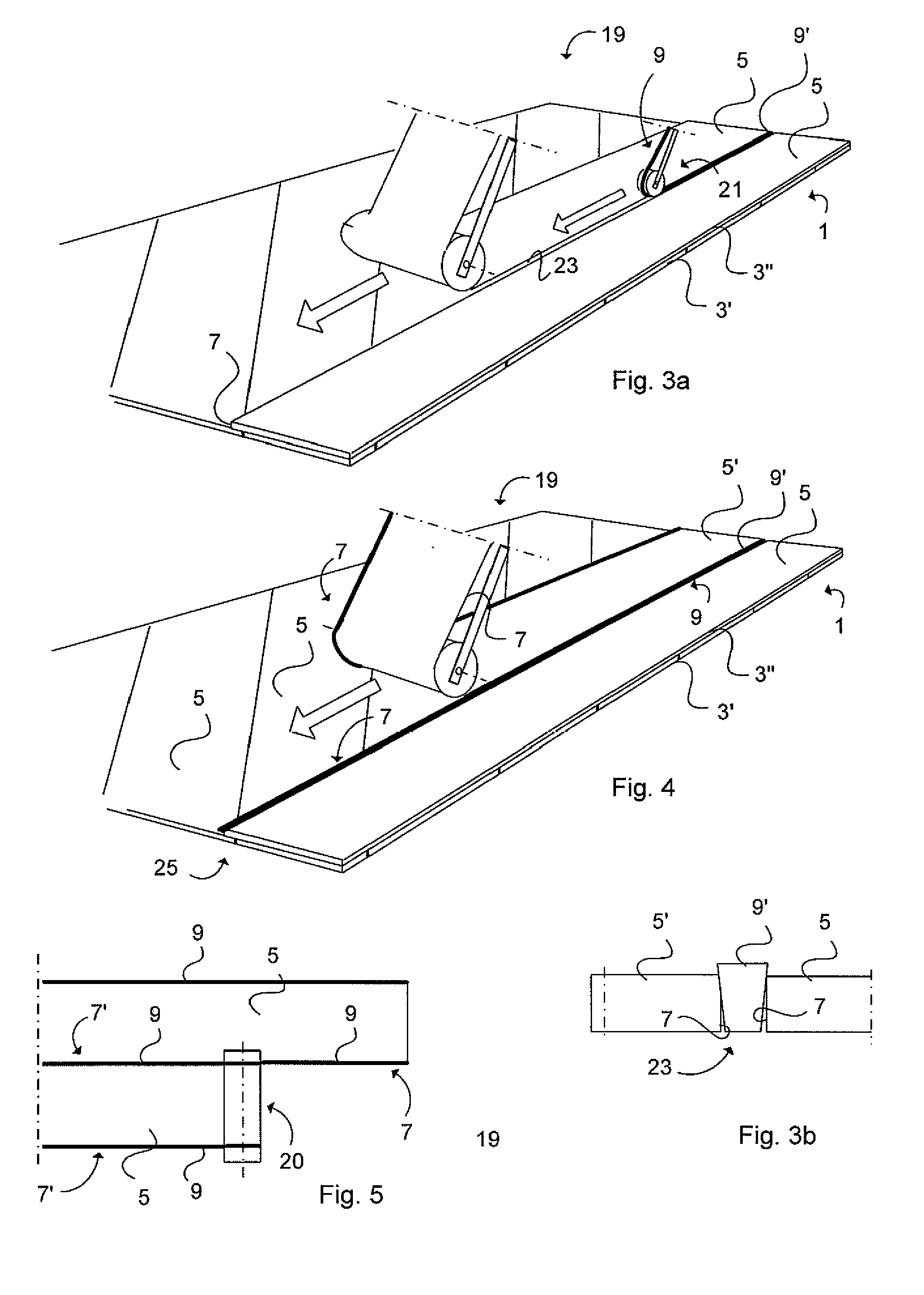

Thermally insulated structure - tapered joint concept

InactiveUS20060248854A1Increasing the thicknessThermal resistanceSynthetic resin layered productsWingsComposite jointFilling materials

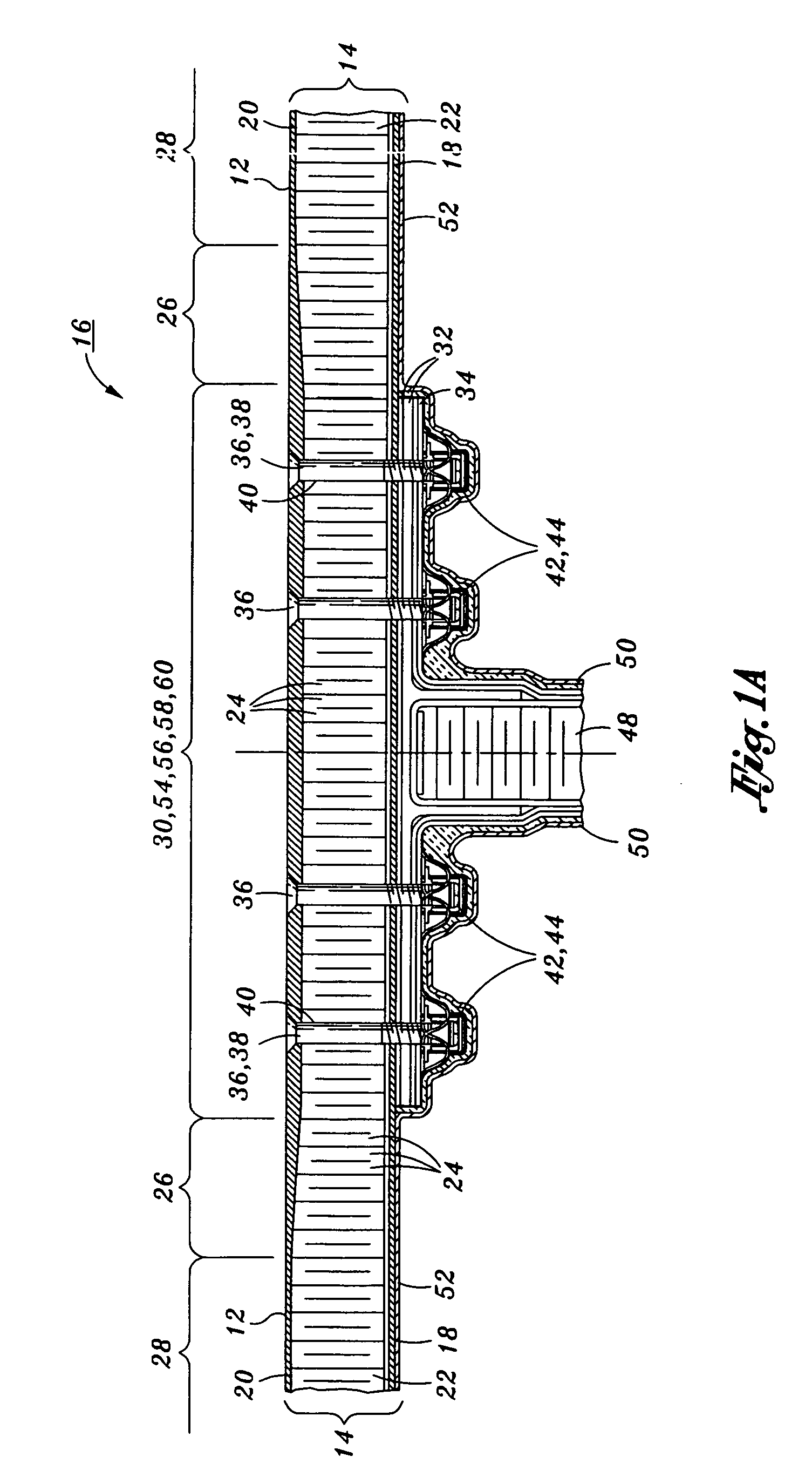

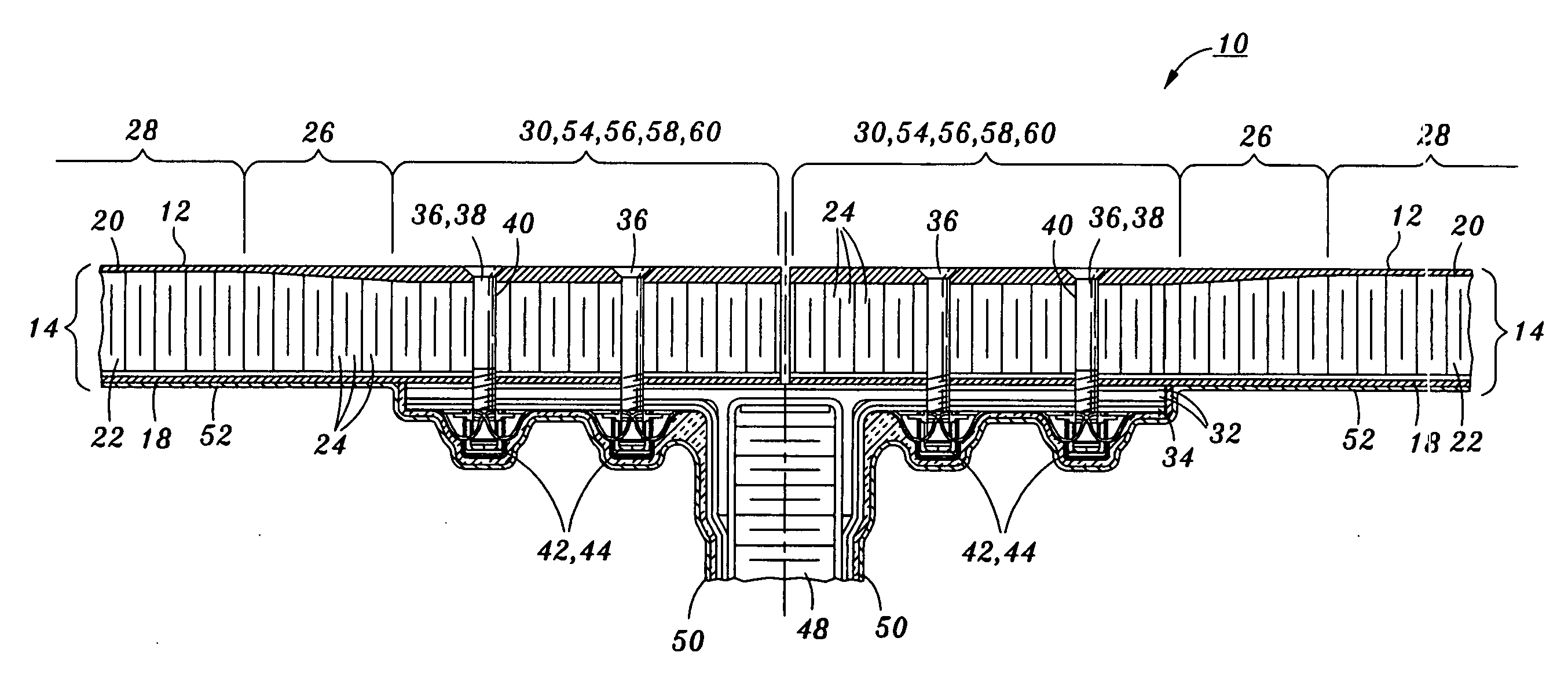

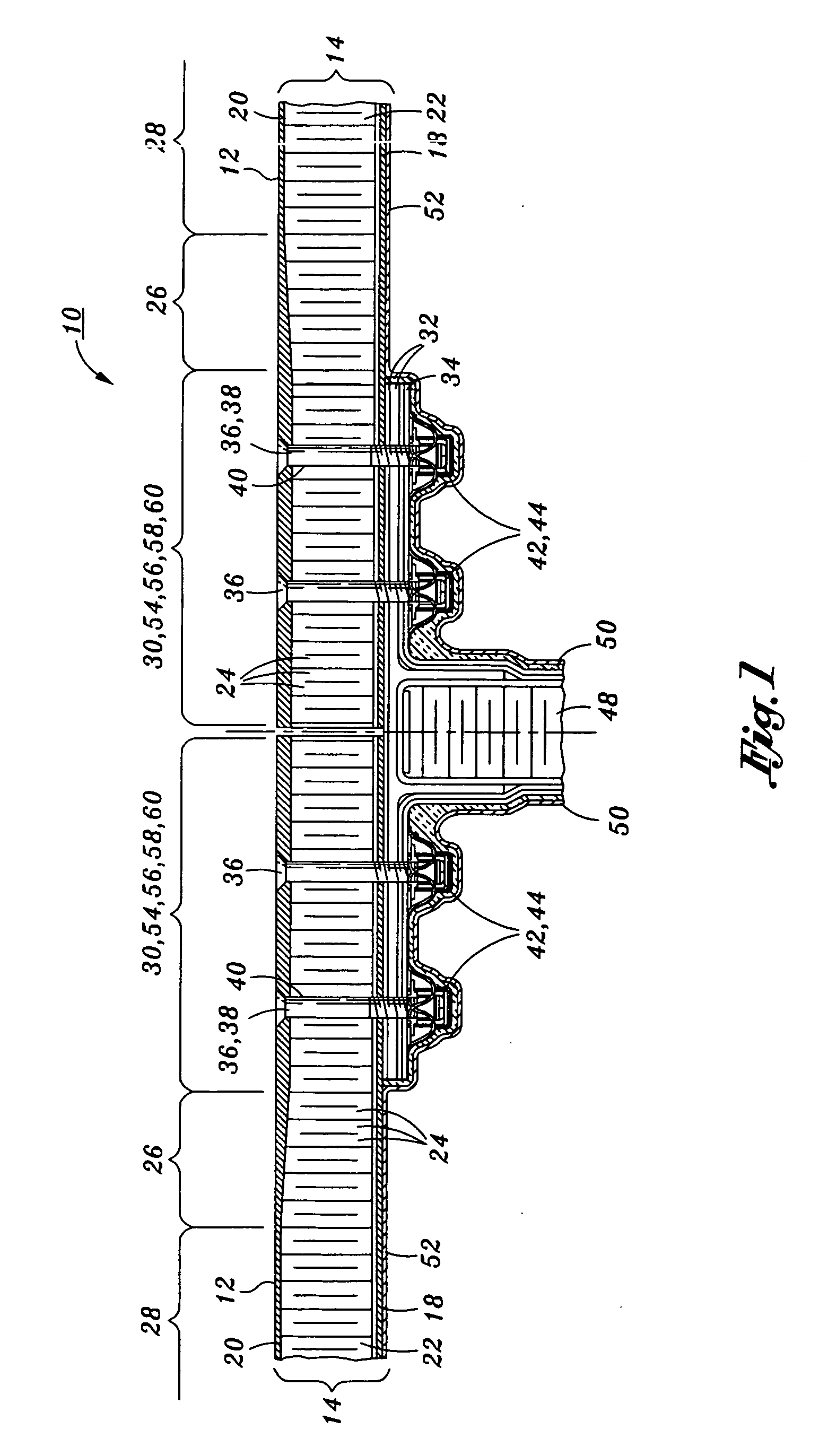

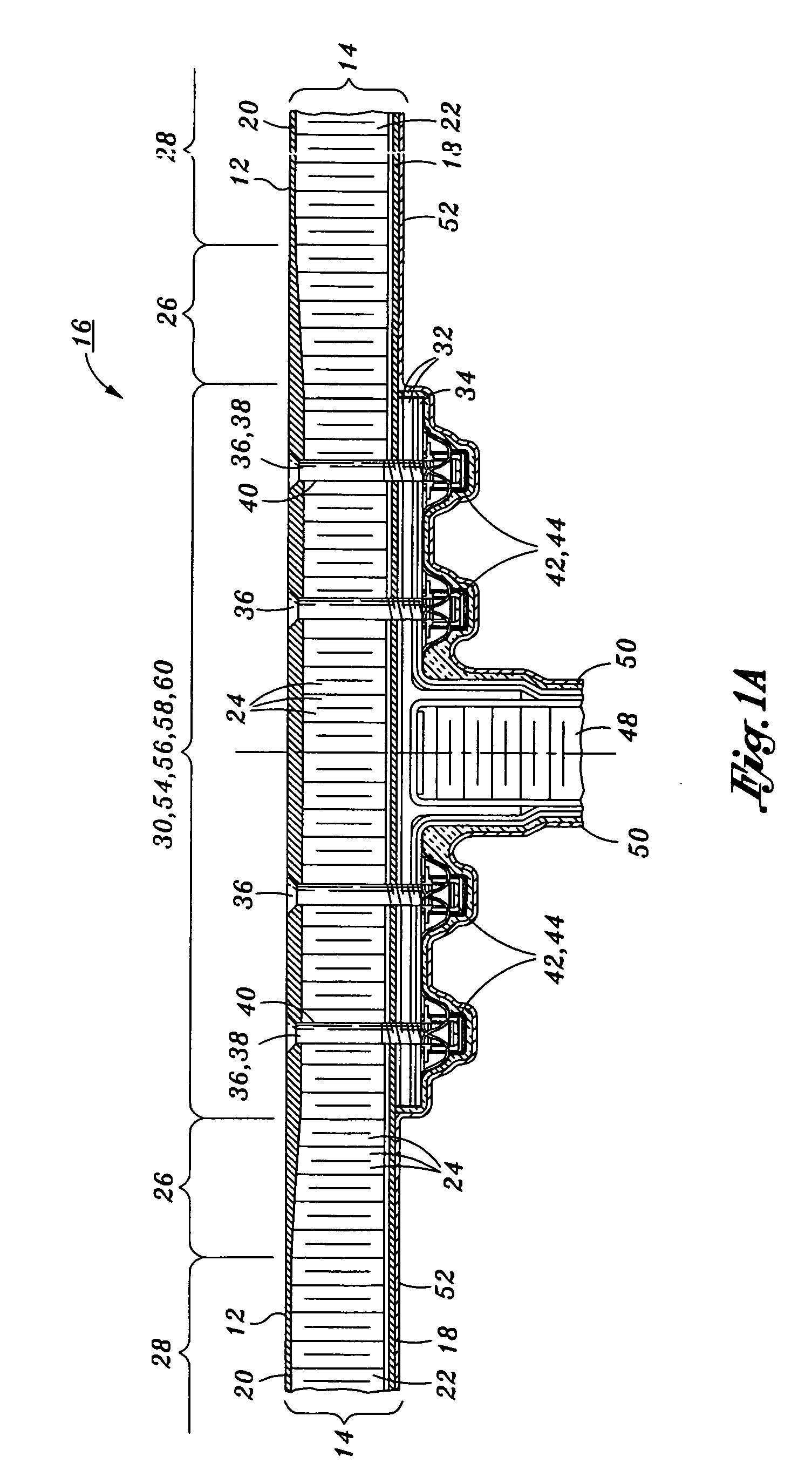

Provided is a composite joint comprising a pair of adjoining composite panels disposed in side-by-side arrangement and being generally aligned with one another. Each one of the composite panels has opposing inner and outer face sheets sandwiching a core panel therebetween and includes a ramp portion wherein the composite panel transitions into a reduced thickness solid laminate edge portion. The core panel includes a plurality of cells extending between the inner and outer face sheets. The cells within the ramp portions are substantially filled with a filler material. The cells adjacent to the ramp portions are substantially filled with aerogel. The composite joint further comprises a primary splice plate extending across the solid laminate edge portions of the adjoining composite panels with mechanical fasteners extending through the solid laminate edge portions and passing through the primary splice plate. A layer of thermal barrier compound covers the primary splice plate.

Owner:NORTHROP GRUMAN CORP

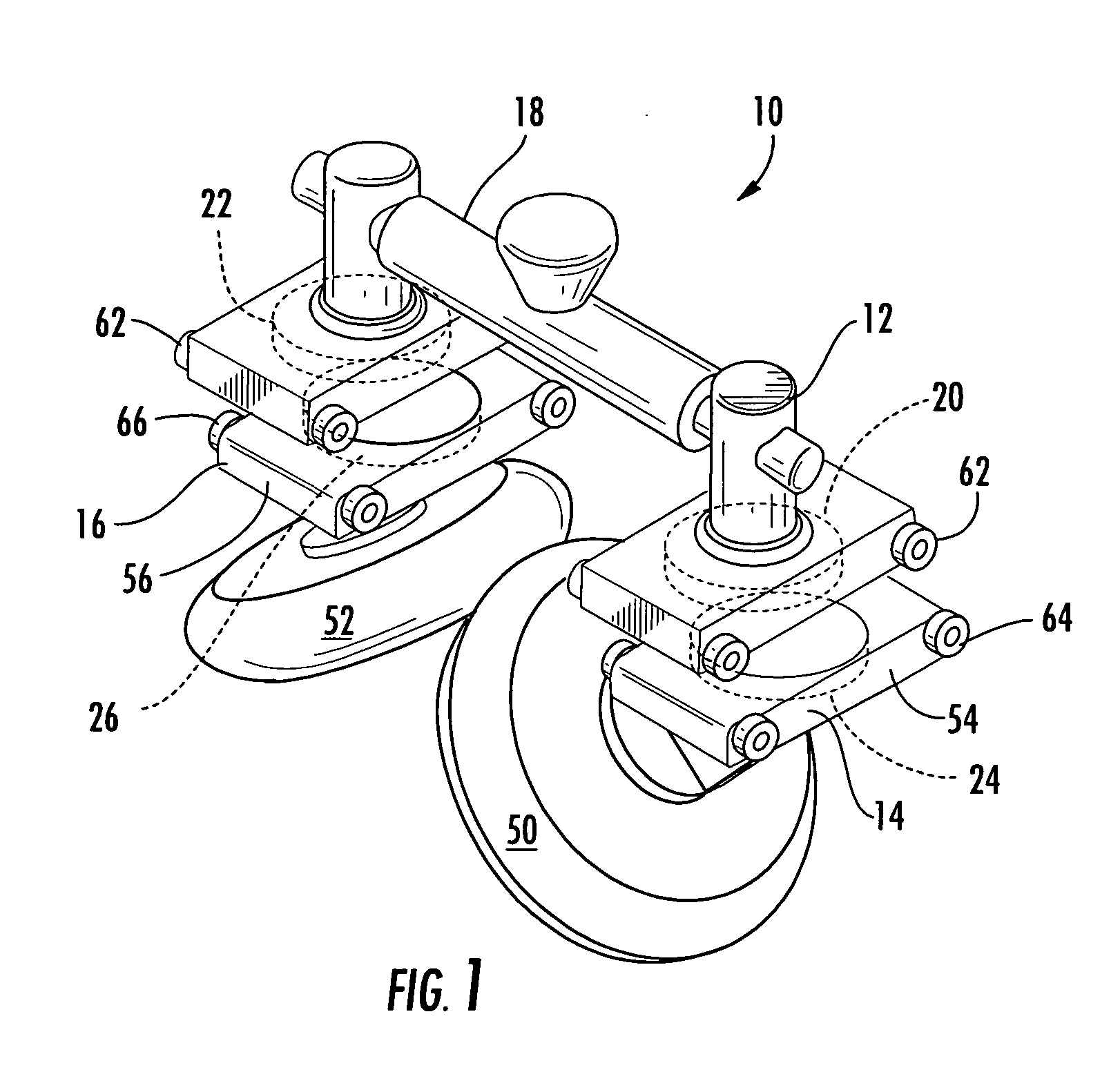

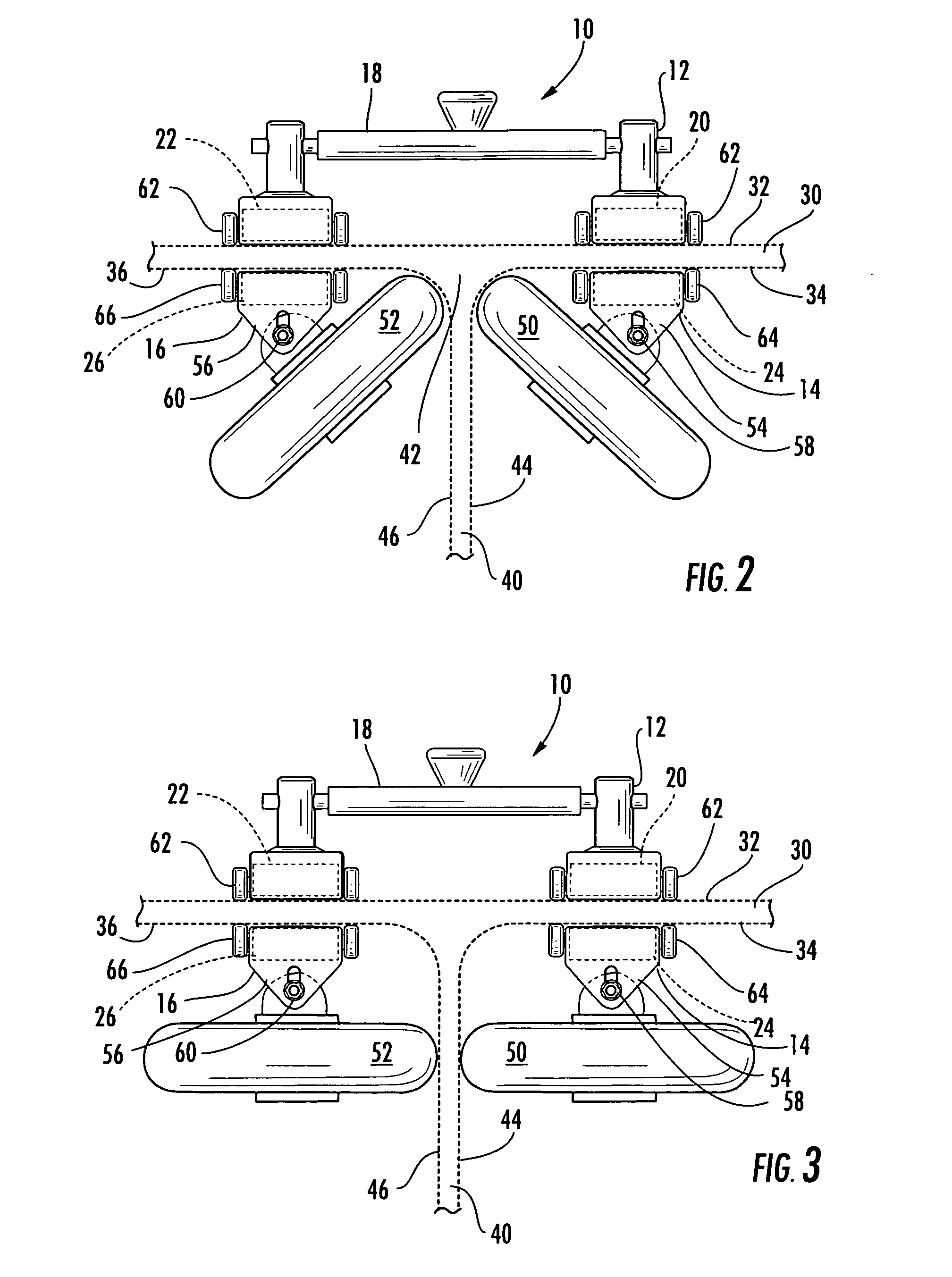

Remote radius inspection tool for composite joints

InactiveUS20060042391A1Convenient and reliable inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesThermometers using physical/chemical changesNon destructiveLimited access

Owner:THE BOEING CO

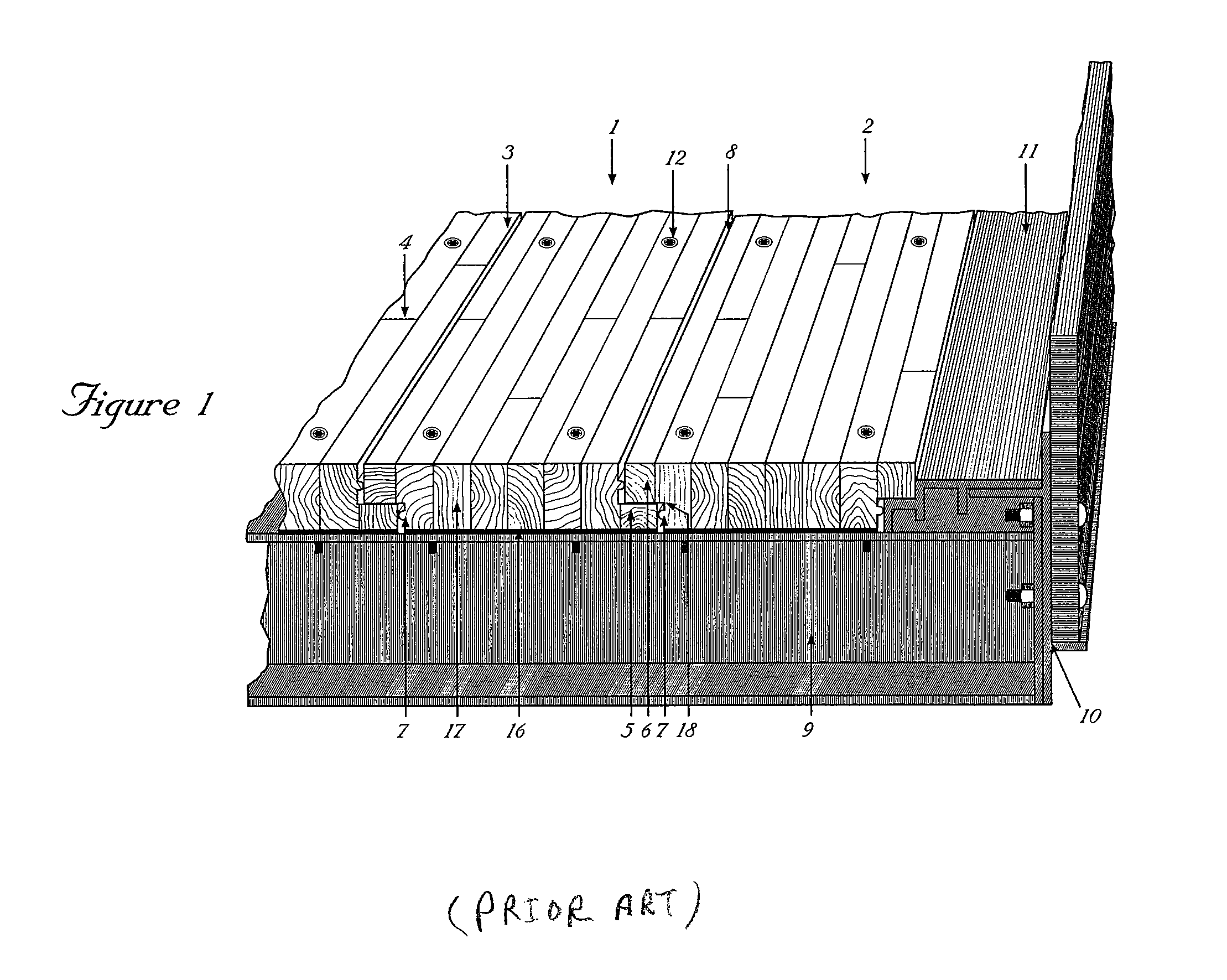

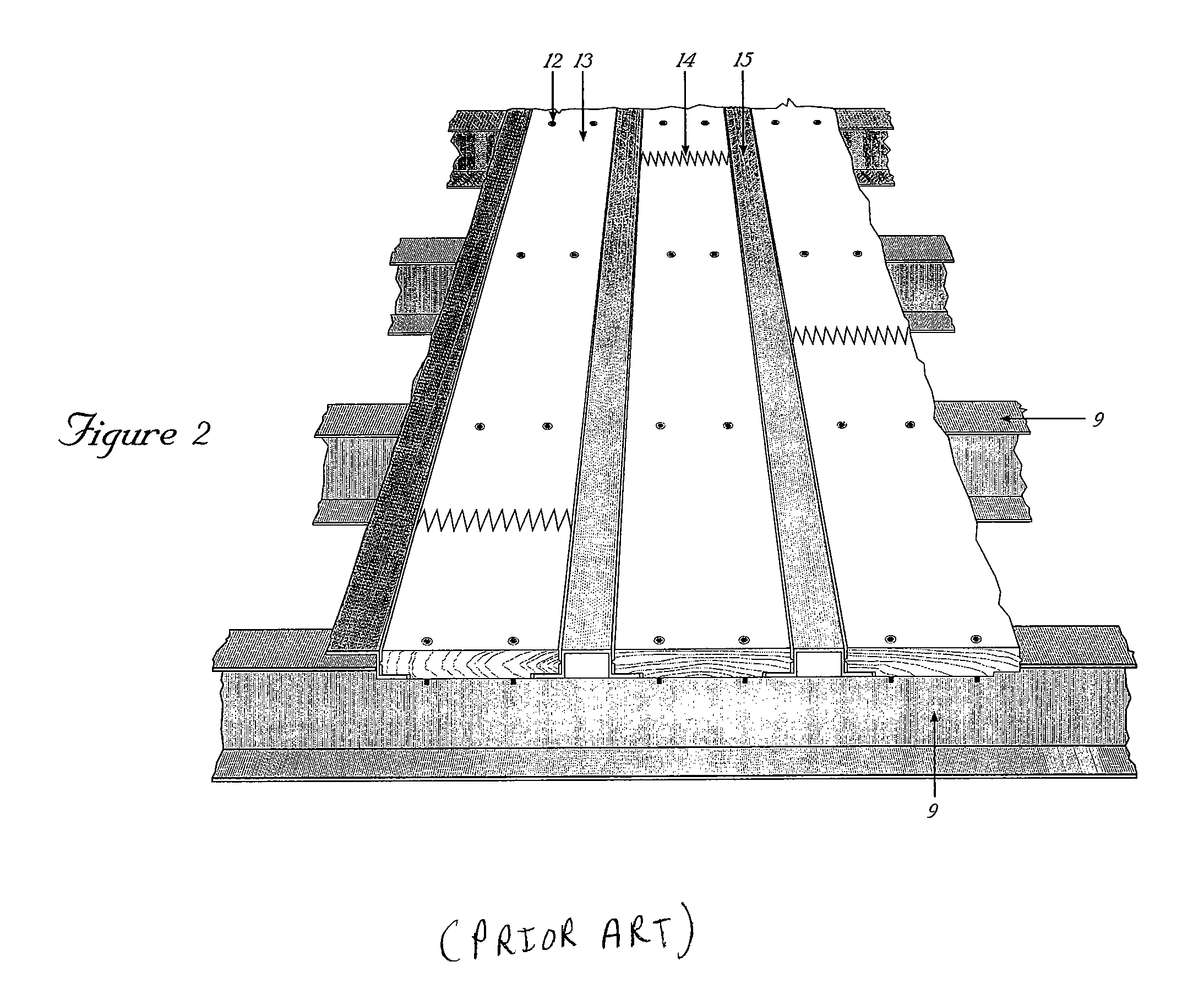

Flexible composite lap joint for trailer flooring

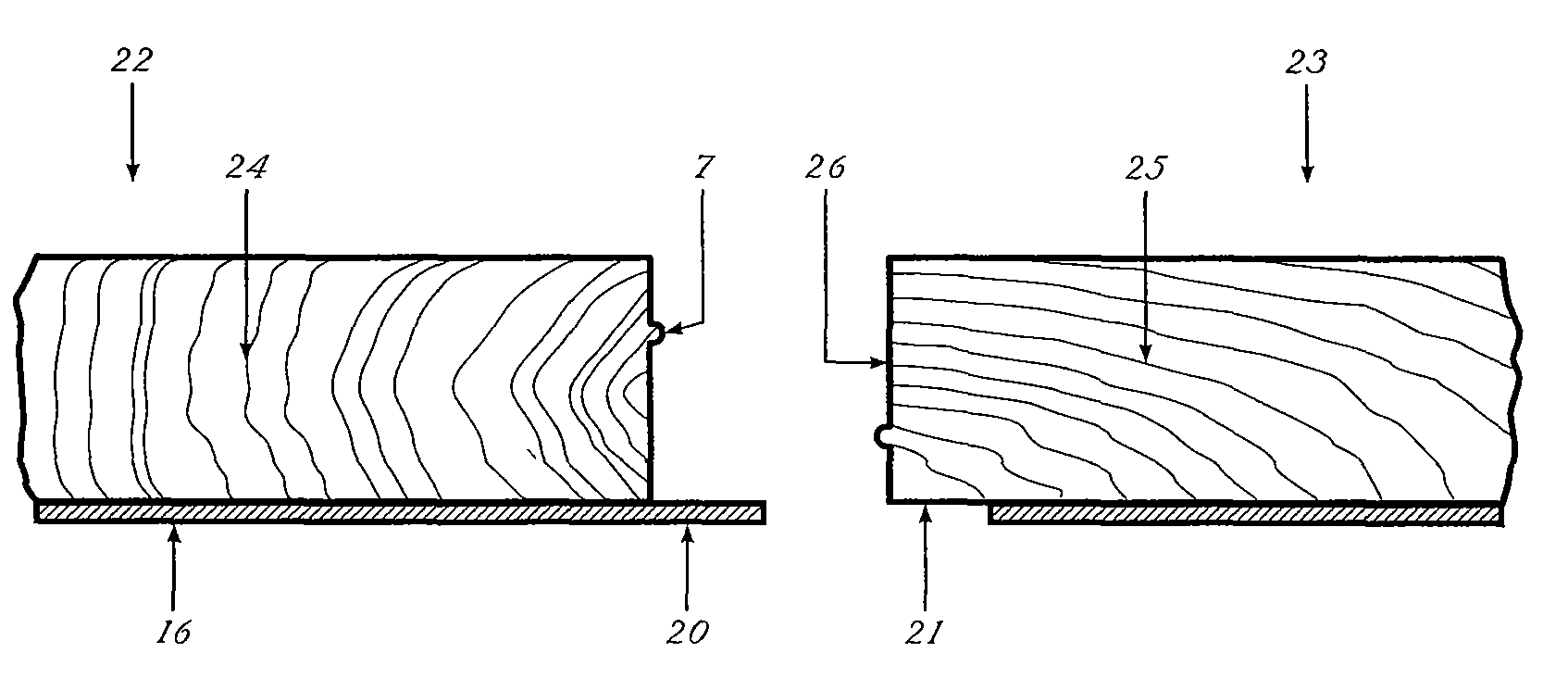

A composite lap joint for the assembly of a first and a second floor board from a plurality of boards, used to make the floor for a vehicular trailer, each board composed of a layer of wood at the top side and a layer of fiber reinforced composite at the bottom side, wherein the composite layer is at least partly bonded to the wood layer; the composite layer of a first board forming a lip, wherein the lip is a lateral extension of the composite layer and the lip is disposed under the bottom side recess of an adjacent second board to form a composite joint, whereby the joint provides improved flexibility, moisture sealing ability at the seam of the joint and higher strength to the edges of the boards.

Owner:HAVCO WOOD PRODS

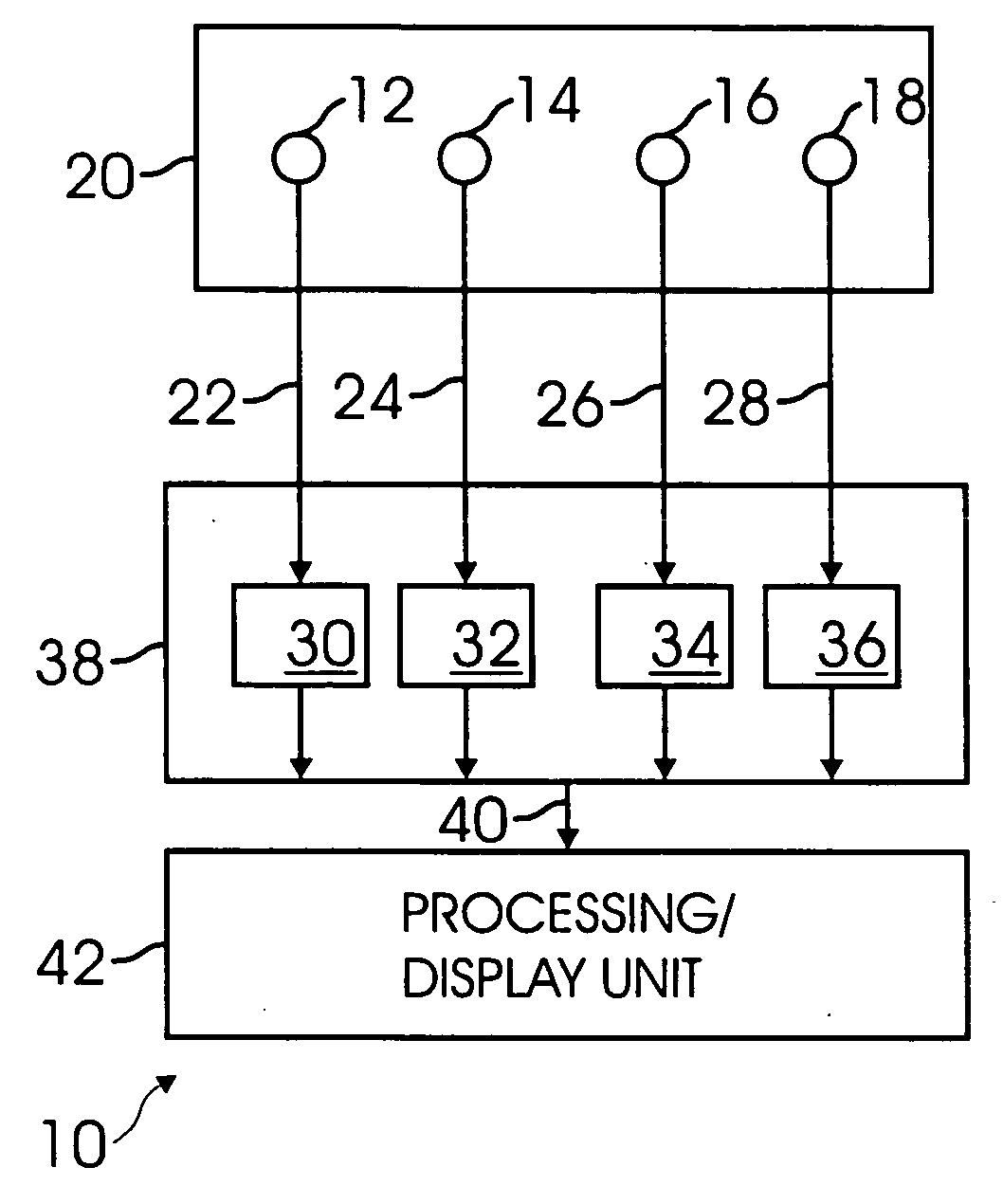

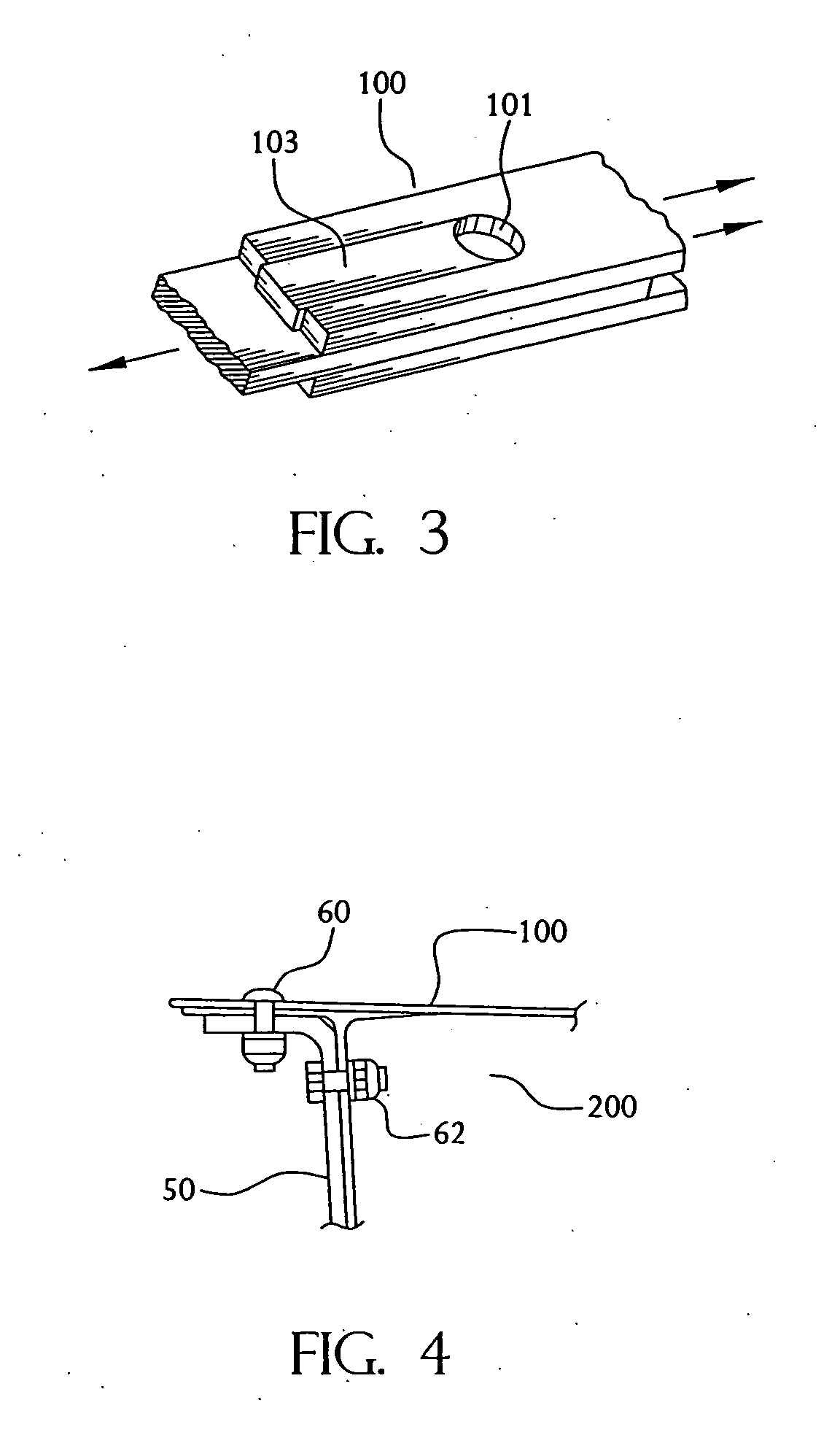

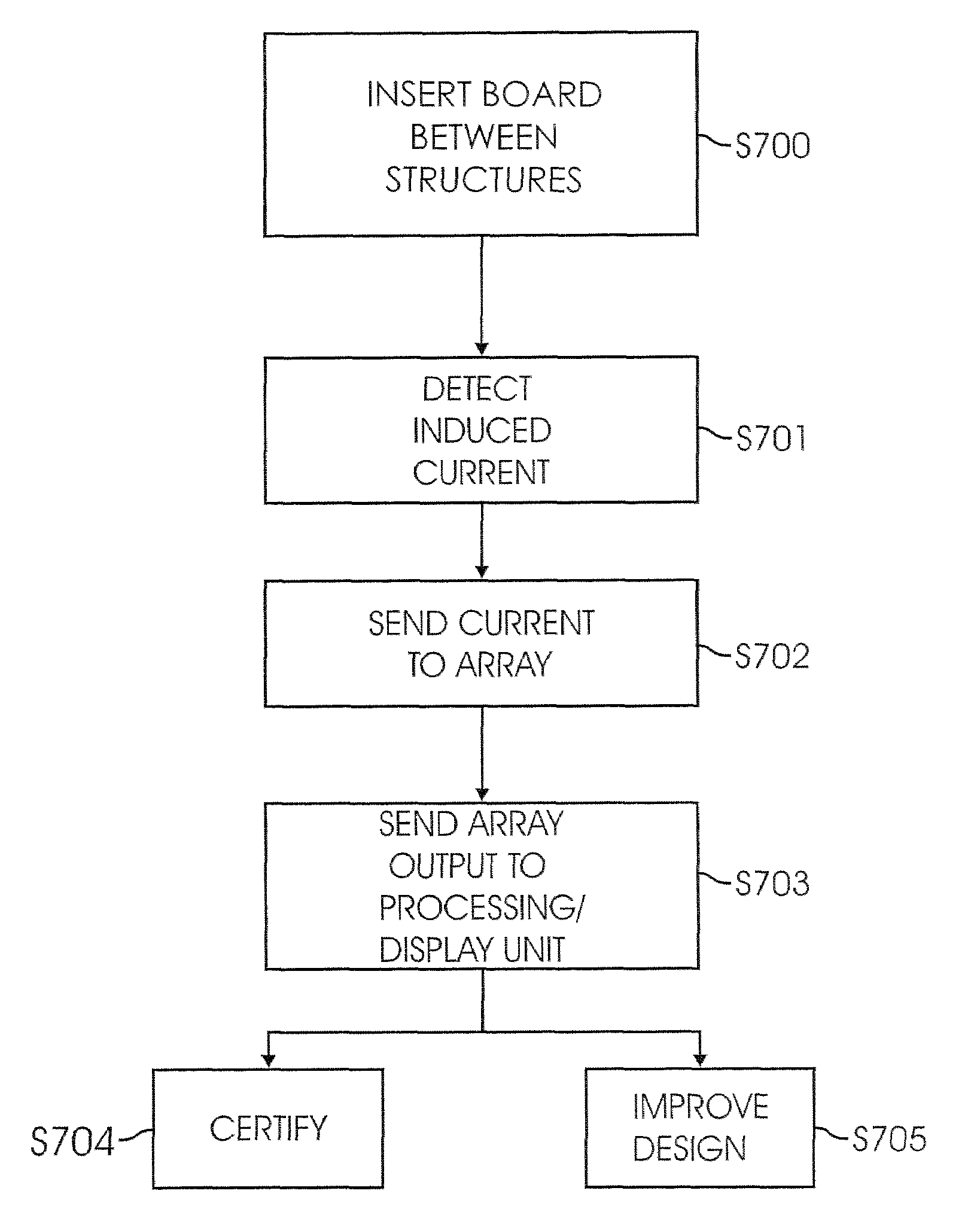

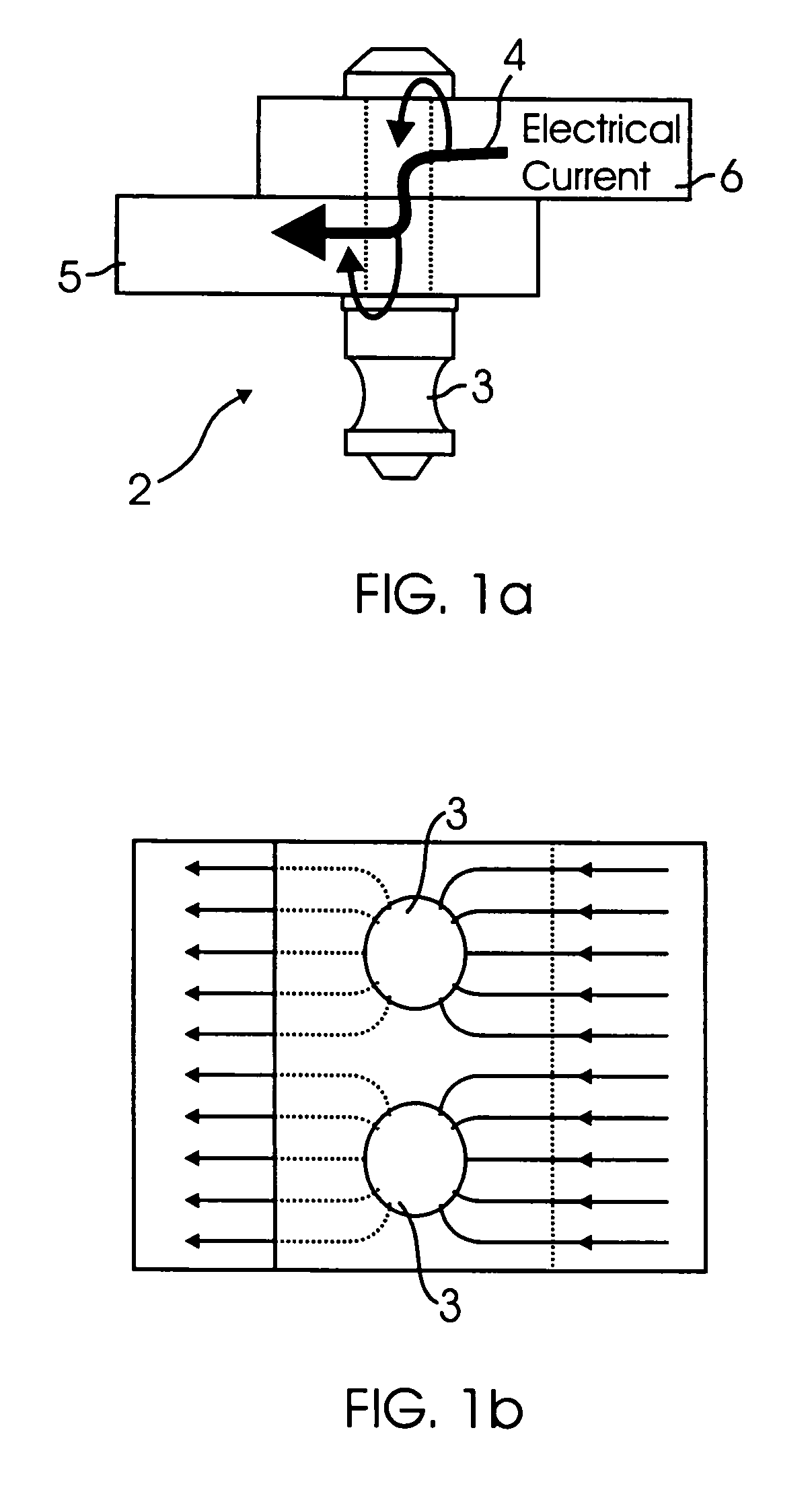

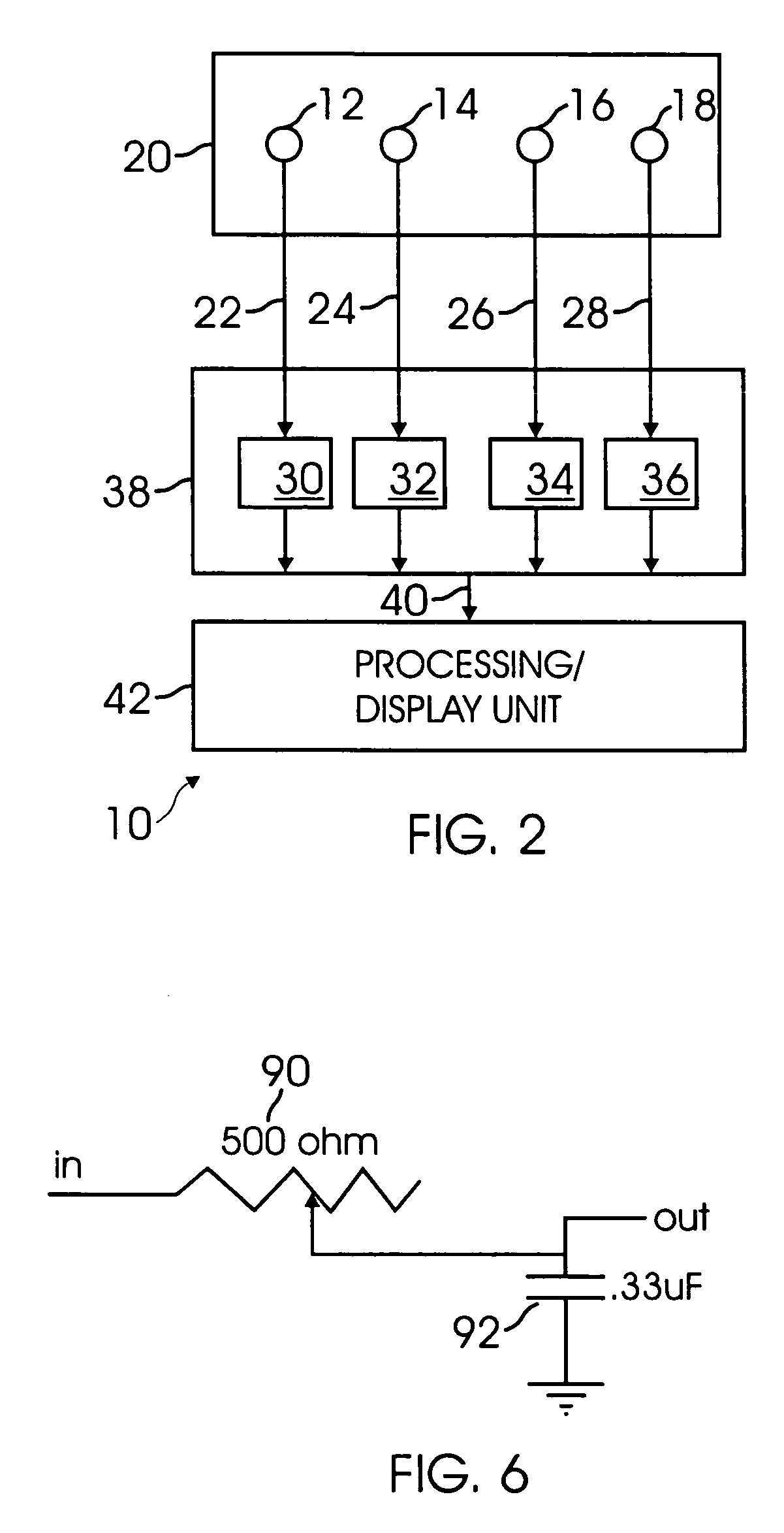

Method and system for measurement of current flows in fastener arrays

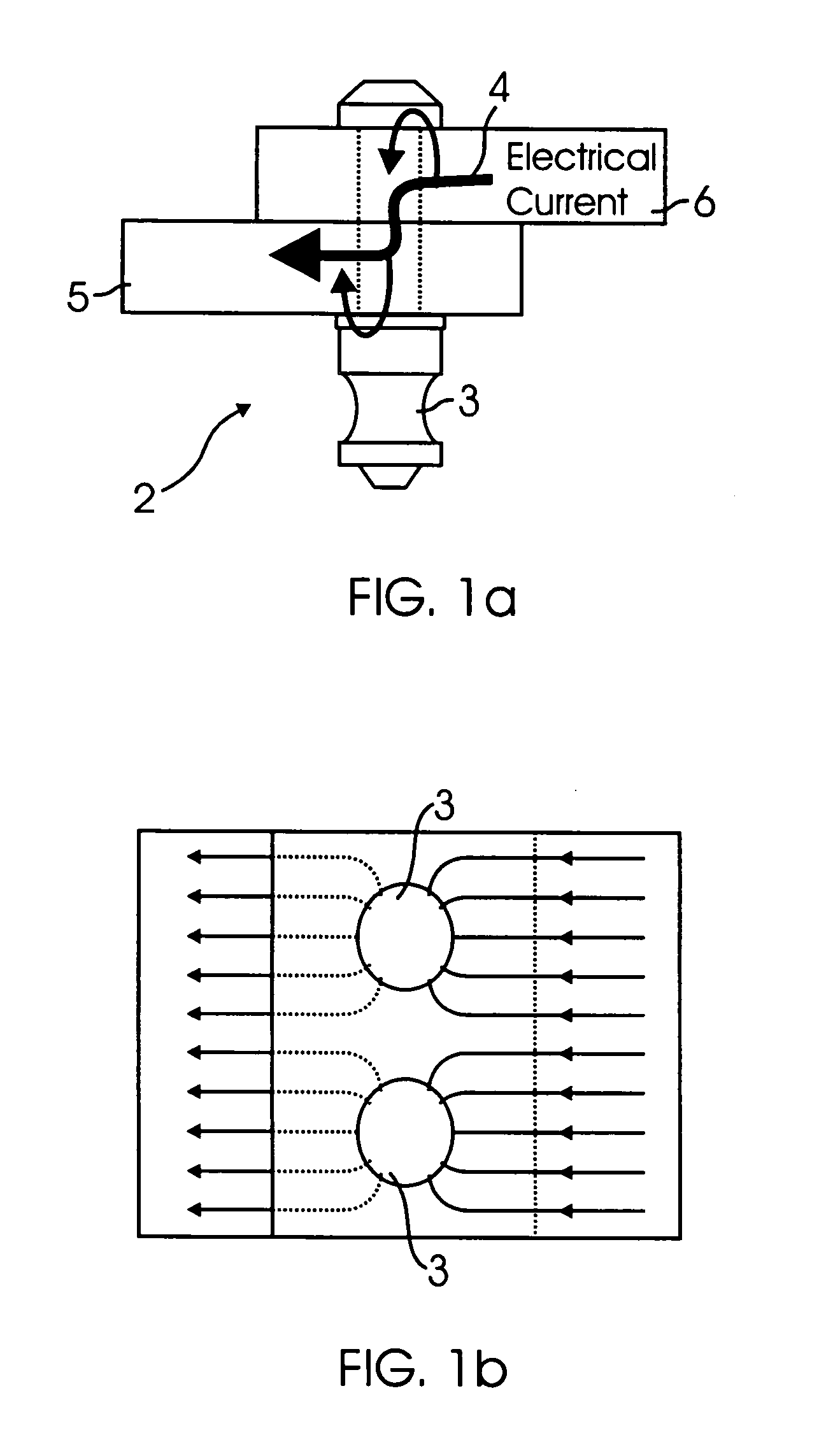

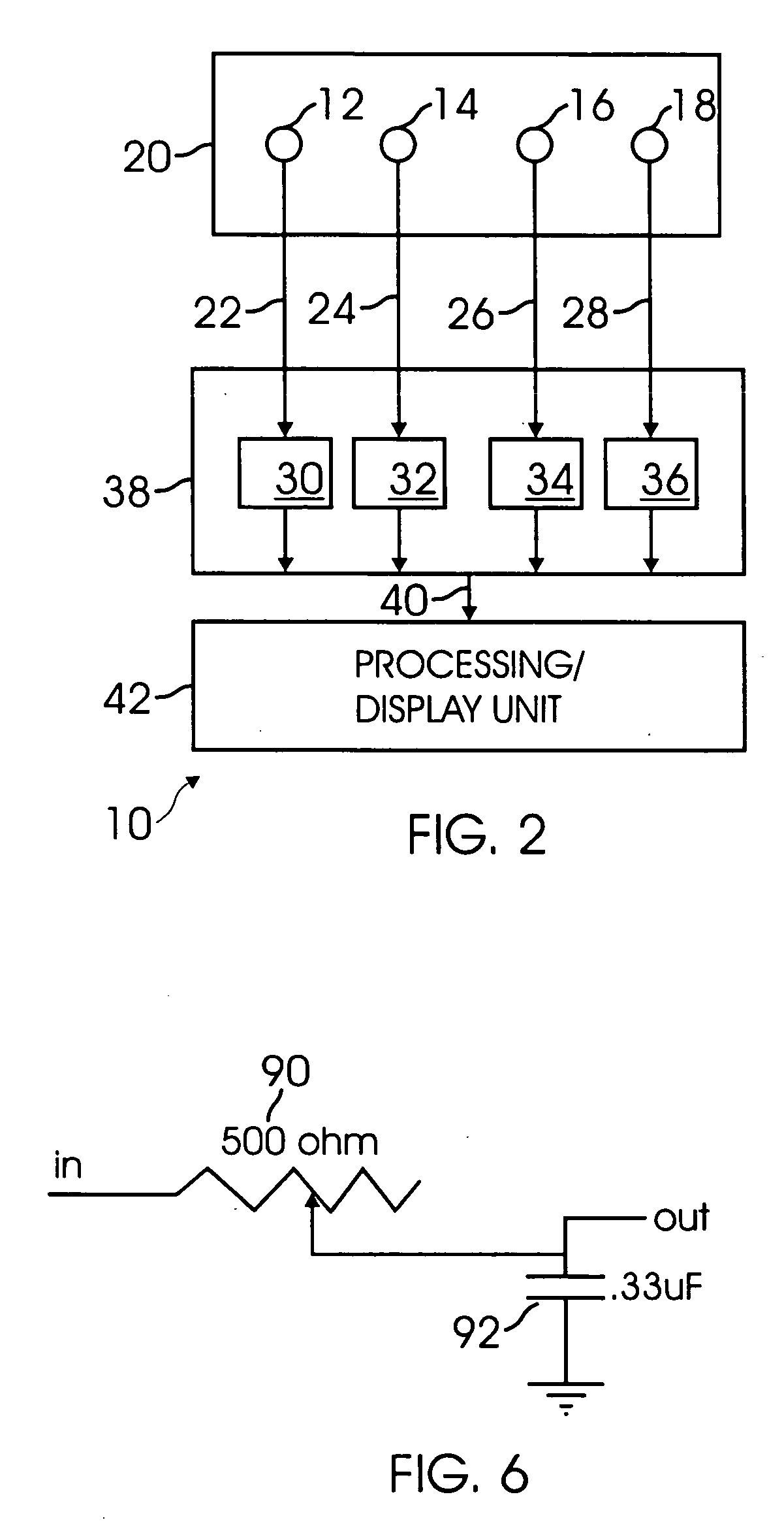

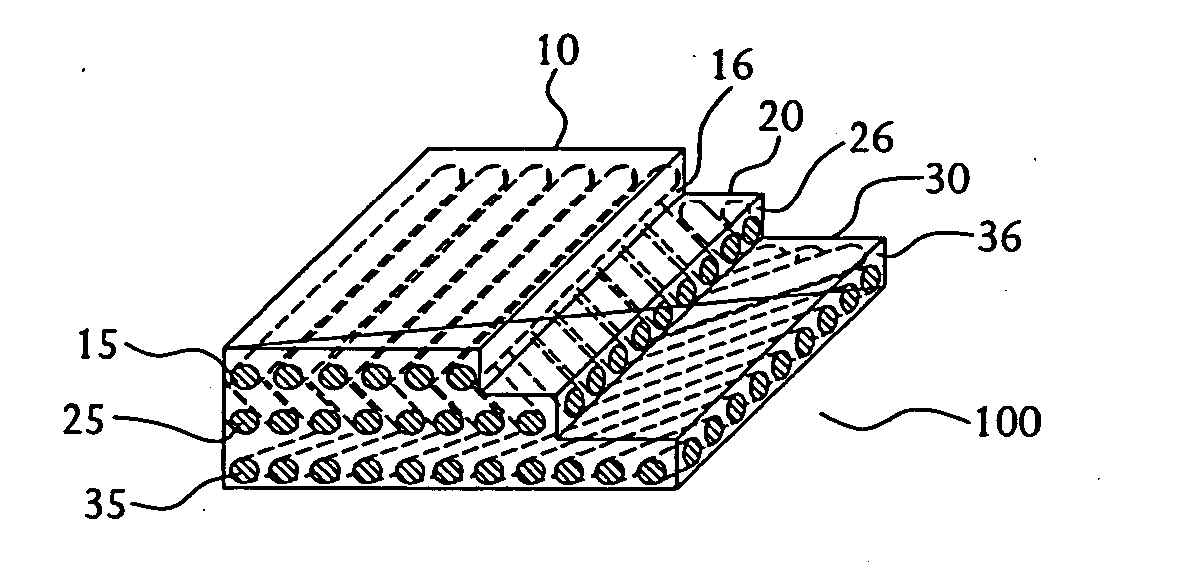

A method and apparatus for simultaneously measuring current flows through individual structures in a multi-structure composite joint is provided. The method comprising inserting a printed circuit board, etched with Rogowski coil sensory circuits, inside the joint between at least two structures with the at least two structures extending through the Rogowski coil sensory circuits in the printed circuit board; detecting induced current in the at least two fasteners; transmitting the induced current to a passive integrator array for capturing transient pulses from the printed circuit board and integrating the pulses into an array output; transmitting the array output to a processing unit.

Owner:THE BOEING CO

Energy absorbent laminate

InactiveUS20060135022A1Tensile modulusImprove toughnessSynthetic resin layered productsPrinted circuit aspectsFiberFlexural modulus

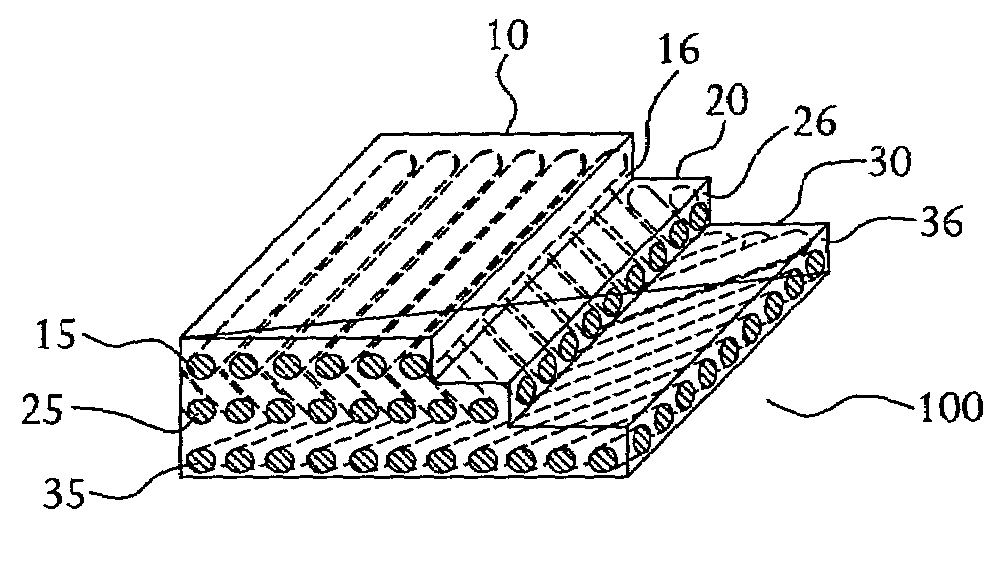

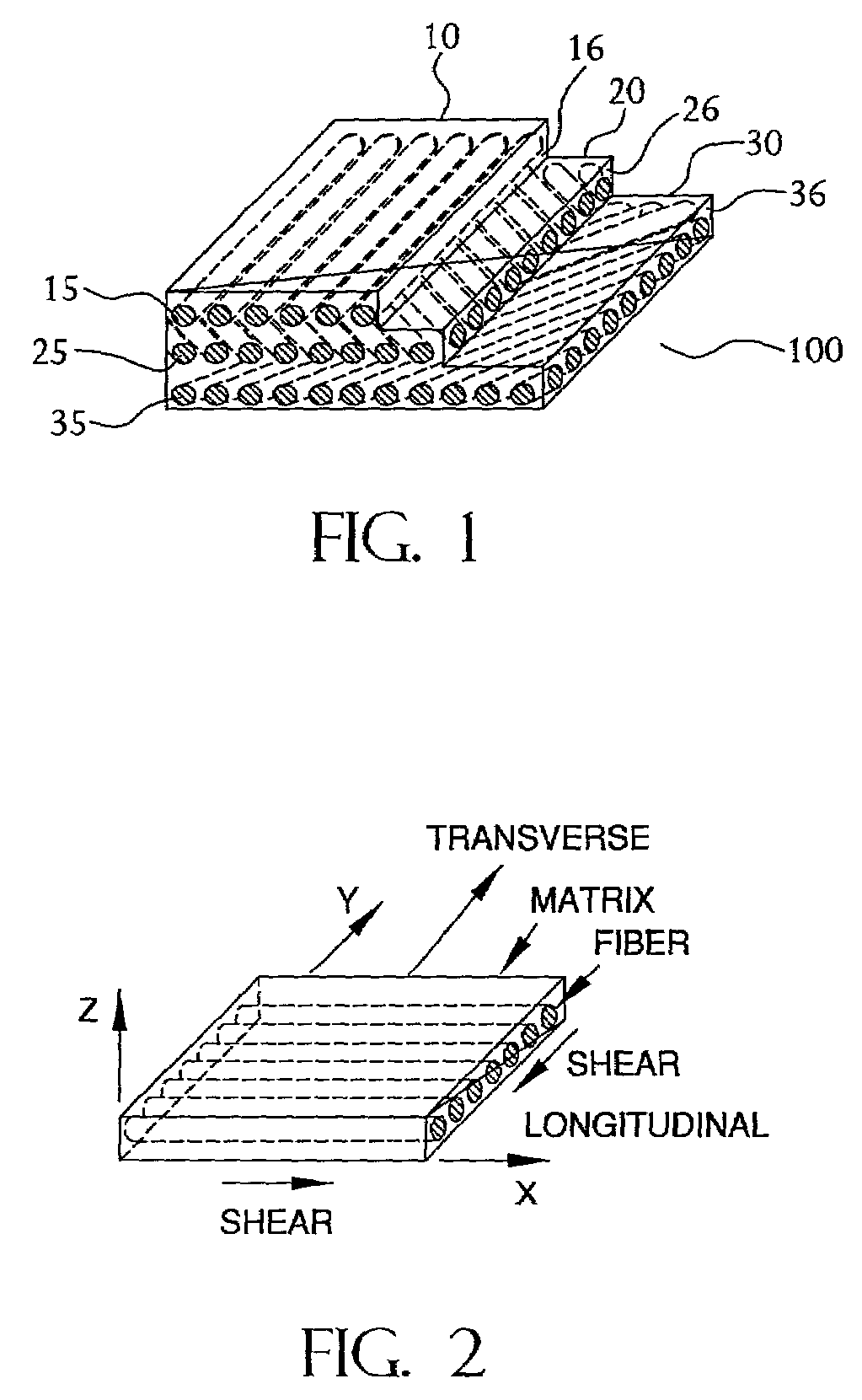

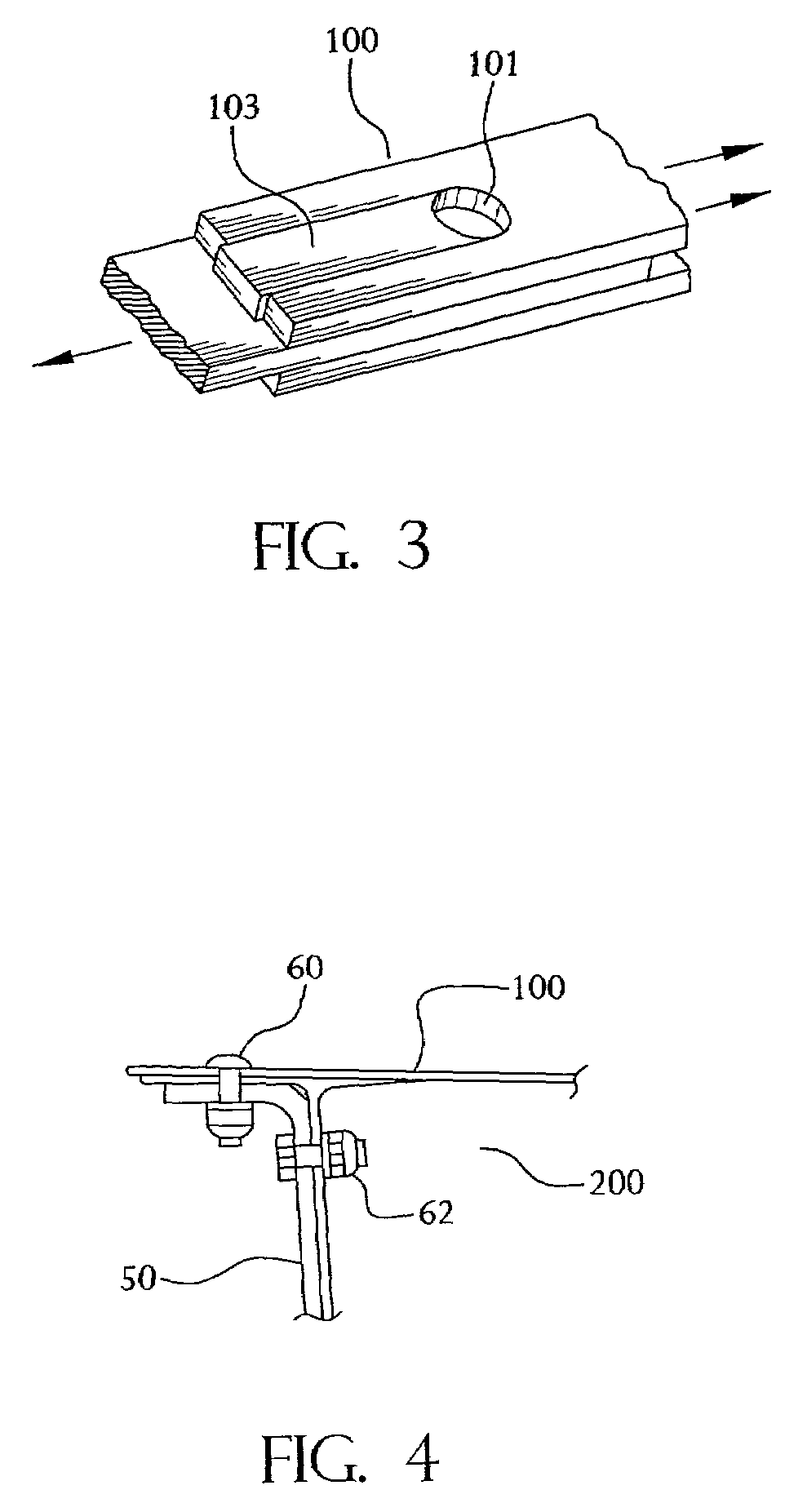

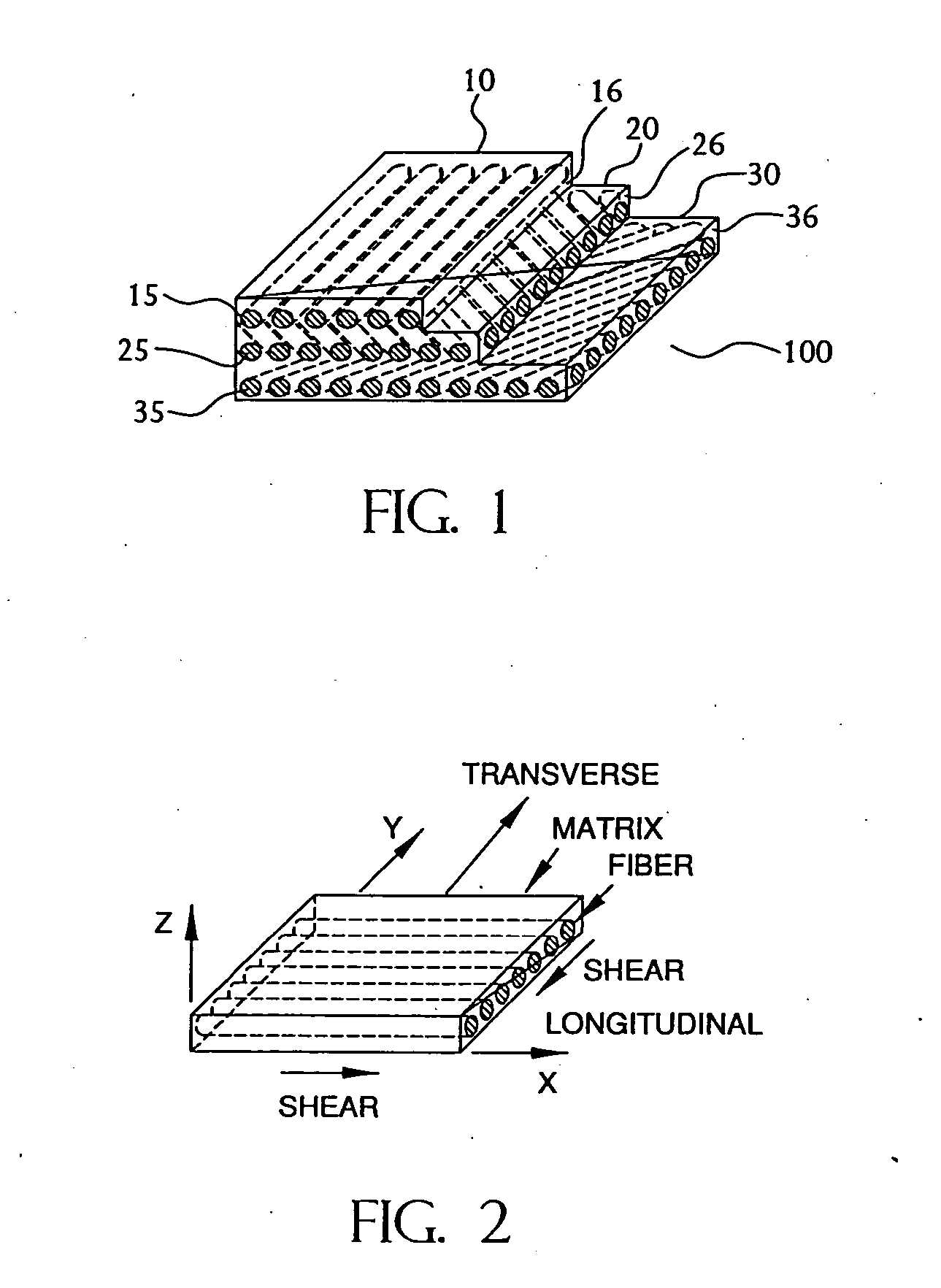

This invention provides multi-layered composites, laminates and composite joints in which at least one resin-impregnated, fiber-containing layer is joined or laminated to a core layer having a lower flexural modulus or higher elongation at break, higher toughness, or a combination of all or some of these properties. The multi-layer composite produced by laminating or joining these materials together has improved shearout, impact and cutting resistance, since stresses caused by outside forces can be more widely distributed throughout the composite.

Owner:SAINT GOBAIN BRUNSWICK TECH

Method and system for measurement of current flows in fastener arrays

ActiveUS7532000B2Measurement using dc-ac conversionMagnetic measurementsPassive integrator circuitPrinted circuit board

Owner:THE BOEING CO

Remote radius inspection tool for composite joints

InactiveUS7484413B2Convenient and reliable inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesThermometers using physical/chemical changesNon destructiveLimited access

Owner:THE BOEING CO

Composite joint implant

Owner:HOWMEDICA OSTEONICS CORP

Process for improving strength of friction stir welding (FSM) joint for discontinuously reinforced aluminum (DRA) matrix composites

ActiveCN102107327AAchieve weldingExpanded range of welding parametersNon-electric welding apparatusMechanical propertyQuenching

The invention relates to aluminum matrix composites and the field of welding, specially provides a process for improving the strength of a friction stir welding (FSM) joint for discontinuously reinforced aluminum (DRA) matrix composites, which is suitable for DRA matrix composites capable of being subjected to reinforced heat treatment. The process comprises the following steps: carrying out solution treatment on aluminum matrix composites which can be subjected to reinforced heat treatment; after the quenching operation is performed, carrying out friction stir welding on the obtained object within four hours; and carrying out natural ageing or artificial aging on the obtained weld assembly in the air according to the application demands, or carrying out reinforced heat treatment again onthe weld assembly by using a commonly-used industrial process. By using the welding process provided by the invention, the weldability of DRA matrix composites can be improved obviously, the tool wear can be reduced, and the mechanical property of a composite joint can be improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermally insulated structure-full depth sandwich joint concept

ActiveUS7291373B2Minimize heat conductionAvoid heat buildupFuselage framesLayered productsFilling materialsEngineering

Provided is a composite joint comprising a pair of composite panels each defining a composite panel thickness and having an inner face sheet and an outer face sheet sandwiching a core panel therebetween. The core panel defines a constant thickness portion and a ramp portion along which the core panel tapers to a reduced thickness portion. The outer face sheet is thickened in the area of the reduced thickness portion. The core panel includes a plurality of cells extending between the inner and outer face sheets. The cells within the reduced thickness portions are filled with a filler material. The cells within the ramp portions and constant thickness portions are filled with aerogel. A primary splice plate extends across the reduced thickness portions. Mechanical fasteners extend through the outer face sheet and into the primary and secondary splice plates. A themal barrier compound covers the primary splice plate.

Owner:NORTHROP GRUMMAN SYST CORP

Disbond resistant composite joint and method of forming

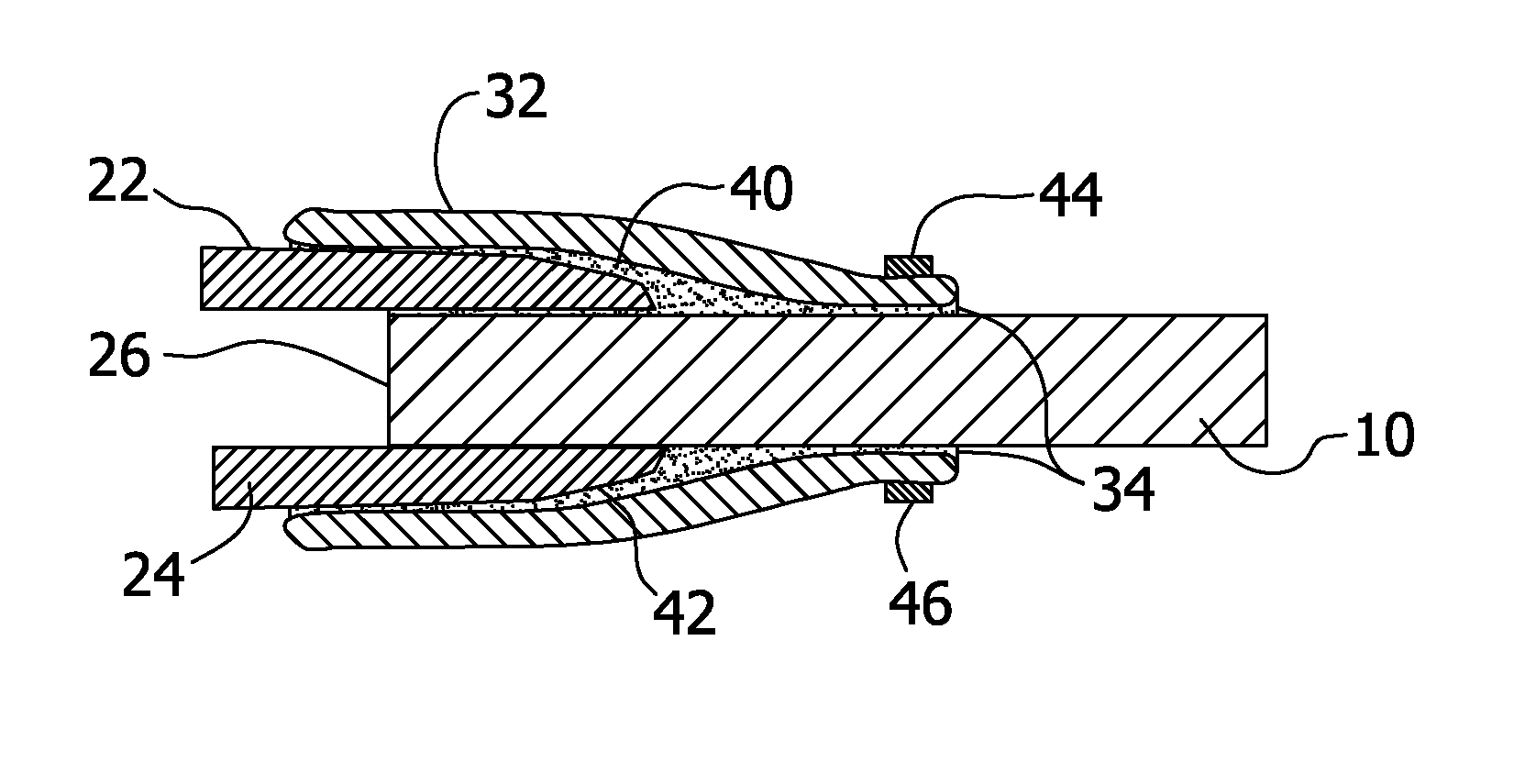

A disbond resistant multi-laminate composite product is provided having, a first member; a second member of composite material bonded to the first member; a third member of composite material bonded to at least the second member and being so positioned and arranged such that when the second and third members are stressed at least a portion of the third member will have higher stress than the adjacent second member. The third member preferably has a terminal portion adjacent the second member in which terminal portion the strain energy release rate is higher than in the adjacent second member when the second and third members are stressed. The second and third members are preferably so positioned and arranged such that the third member initiates delamination from the second member before the second member initiates delamination from the first member when the first, second and third members are under stress. A stress level indicator is preferably associated with the third member to measure the stress levels in the third member.

Owner:THE BOEING CO

Thermally insulated structure - full depth sandwich joint concept

ActiveUS20060248853A1Minimize heat conductionAvoid heat buildupFuselage framesLayered productsFilling materialsEngineering

Provided is a composite joint comprising a pair of composite panels each defining a composite panel thickness and having an inner face sheet and an outer face sheet sandwiching a core panel therebetween. The core panel defines a constant thickness portion and a ramp portion along which the core panel tapers to a reduced thickness portion. The outer face sheet is thickened in the area of the reduced thickness portion. The core panel includes a plurality of cells extending between the inner and outer face sheets. The cells within the reduced thickness portions are filled with a filler material. The cells within the ramp portions and constant thickness portions are filled with aerogel. A primary splice plate extends across the reduced thickness portions. Mechanical fasteners extend through the outer face sheet and into the primary and secondary splice plates. A themal barrier compound covers the primary splice plate.

Owner:NORTHROP GRUMMAN SYST CORP

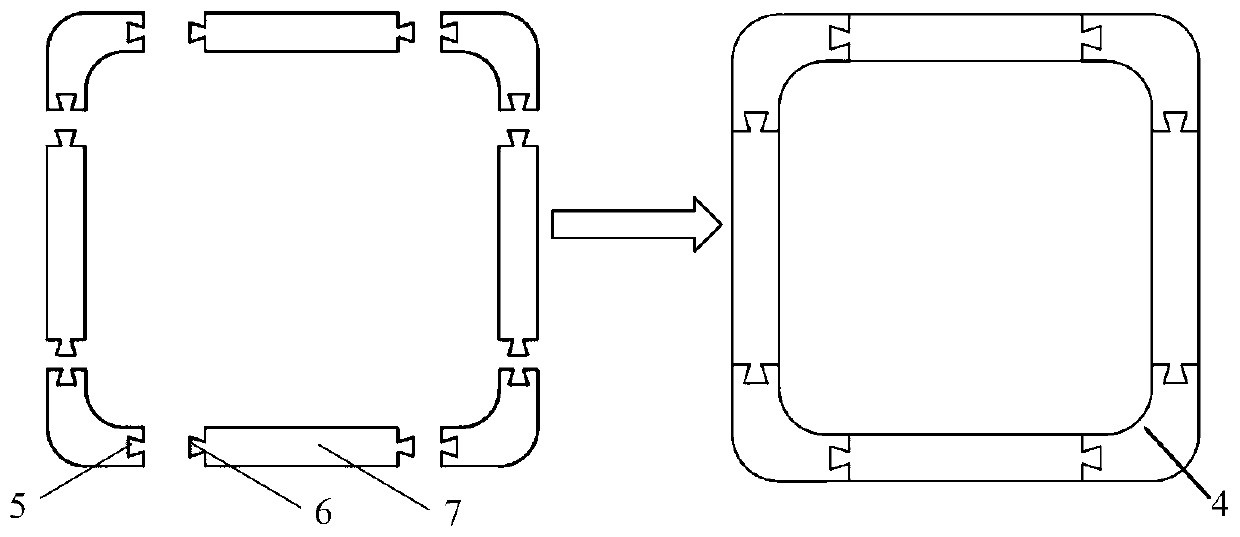

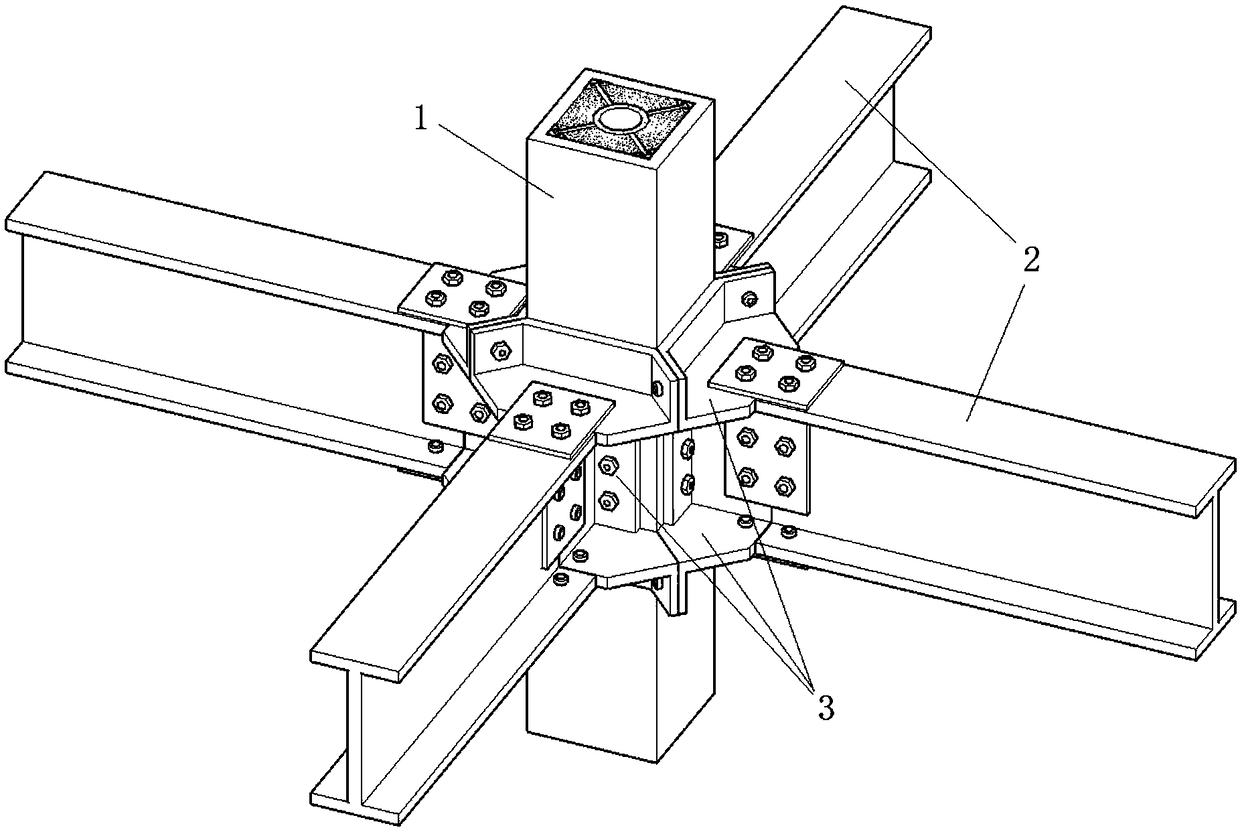

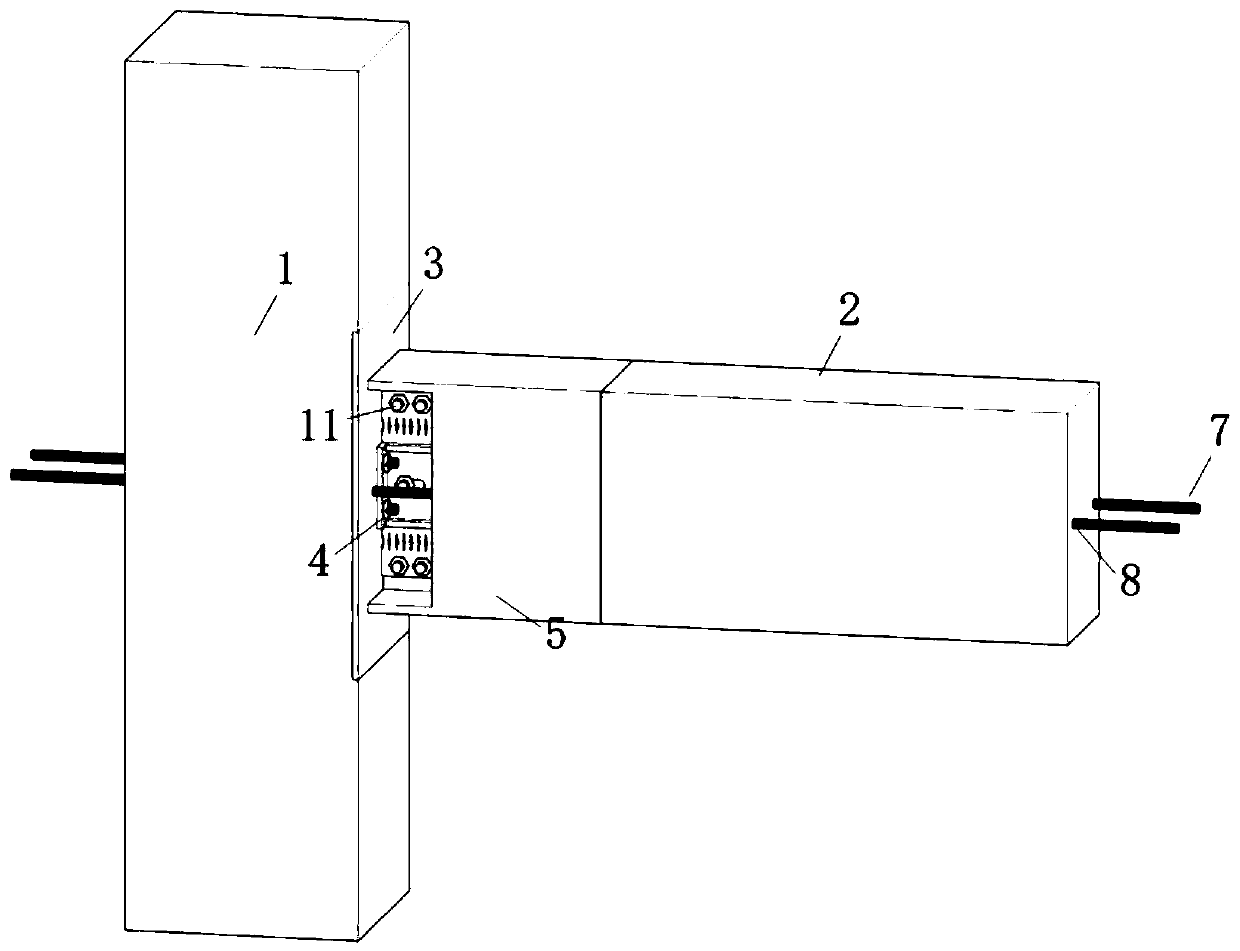

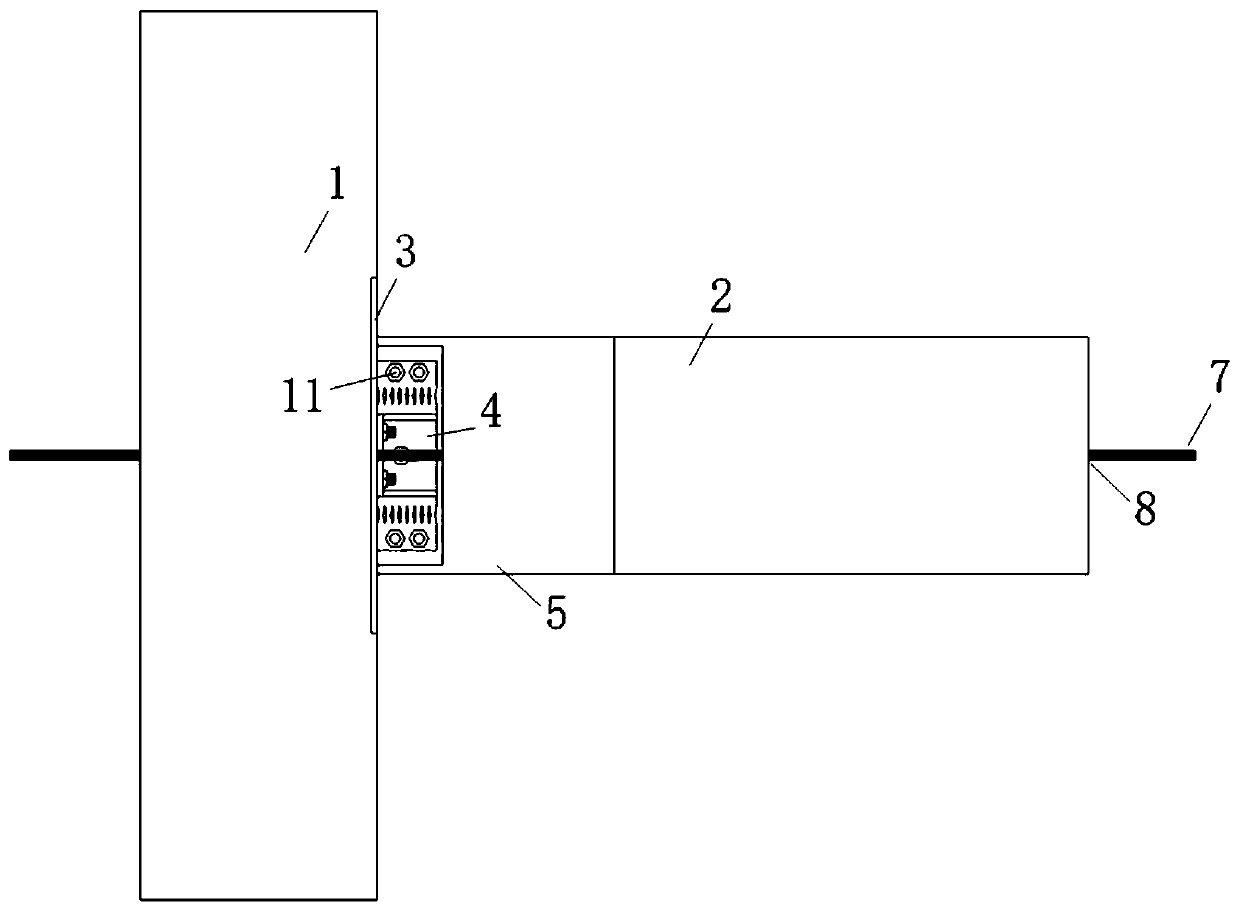

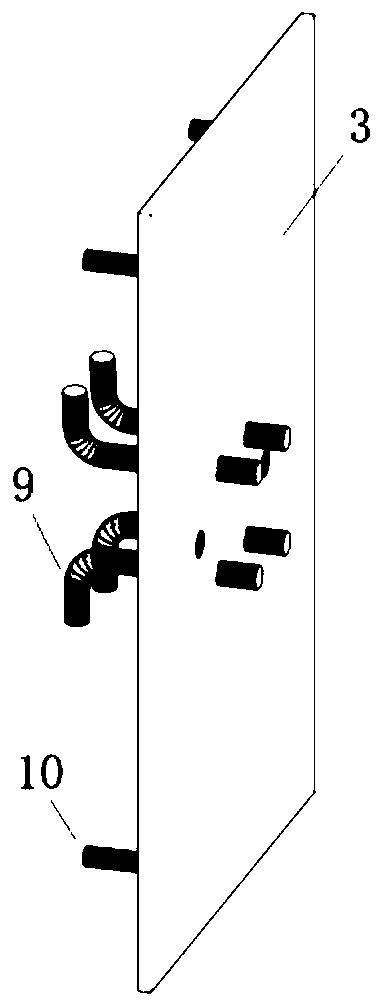

Fabricated steel-wood composite joint

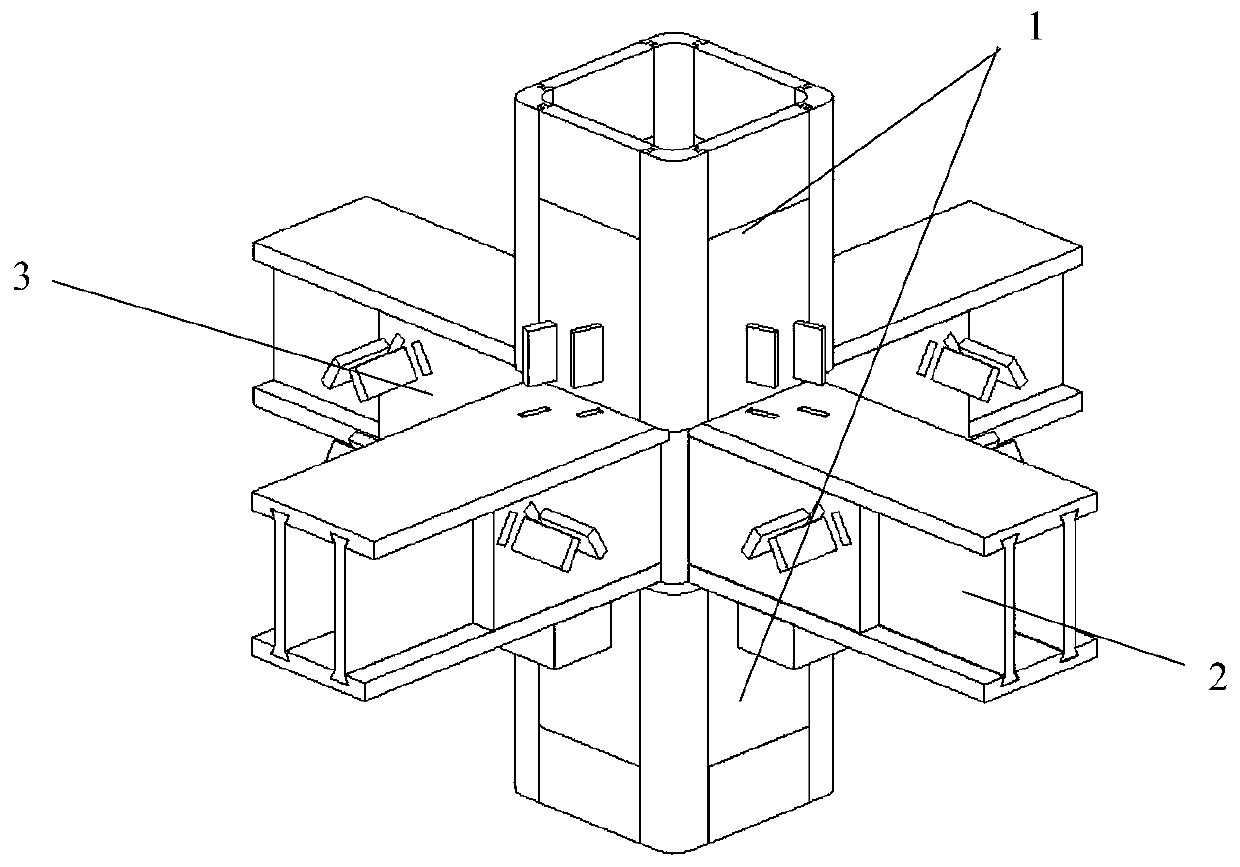

ActiveCN109853739AAchieve utilizationAvoid quality problemsStrutsGirdersEngineeringUltimate tensile strength

The invention relates to a fabricated steel-wood composite joint. The fabricated steel-wood composite joint comprises a square pipe column, a steel-wood composite beam and a beam-column connecting assembly connecting the square pipe column with the steel-wood composite beam; the square pipe column comprises a connecting corner column and a connecting side plate, the steel-wood composite beam comprises an upper flange, a lower flange and a wood web plate connecting the upper flange with the lower flange, and the beam-column connecting assembly comprises a central column connecting assembly anda corner column connecting assembly. Through special structural design, under the premise of welding and bolting connection, the beam and the column are effectively connected, certain toughness and good seismic performance are achieved, components of the fabricated steel-wood composite joint can be prefabricated in a factory, the component precision is high, on-site splicing is achieved, construction is easy and convenient, the processes are reduced, and the construction cycle is effectively shortened; and by adopting a steel-wood composite structure, the utilization rate of materials of different strength is increased, through ingenious connection and cooperation, the efficient and reasonable structure new form is achieved through combination and synergy of the steel-wood structure, and the rich diversity of architectural performance is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Disbond resistant composite joint and method of forming

ActiveUS20060204364A1Simple arrangementSimple structurePropellersPump componentsStress levelEngineering

A disbond resistant multi-laminate composite product is provided having, a first member; a second member of composite material bonded to the first member; a third member of composite material bonded to at least the second member and being so positioned and arranged such that when the second and third members are stressed at least a portion of the third member will have higher stress than the adjacent second member. The third member preferably has a terminal portion adjacent the second member in which terminal portion the strain energy release rate is higher than in the adjacent second member when the second and third members are stressed. The second and third members are preferably so positioned and arranged such that the third member initiates delamination from the second member before the second member initiates delamination from the first member when the first, second and third members are under stress. A stress level indicator is preferably associated with the third member to measure the stress levels in the third member.

Owner:THE BOEING CO

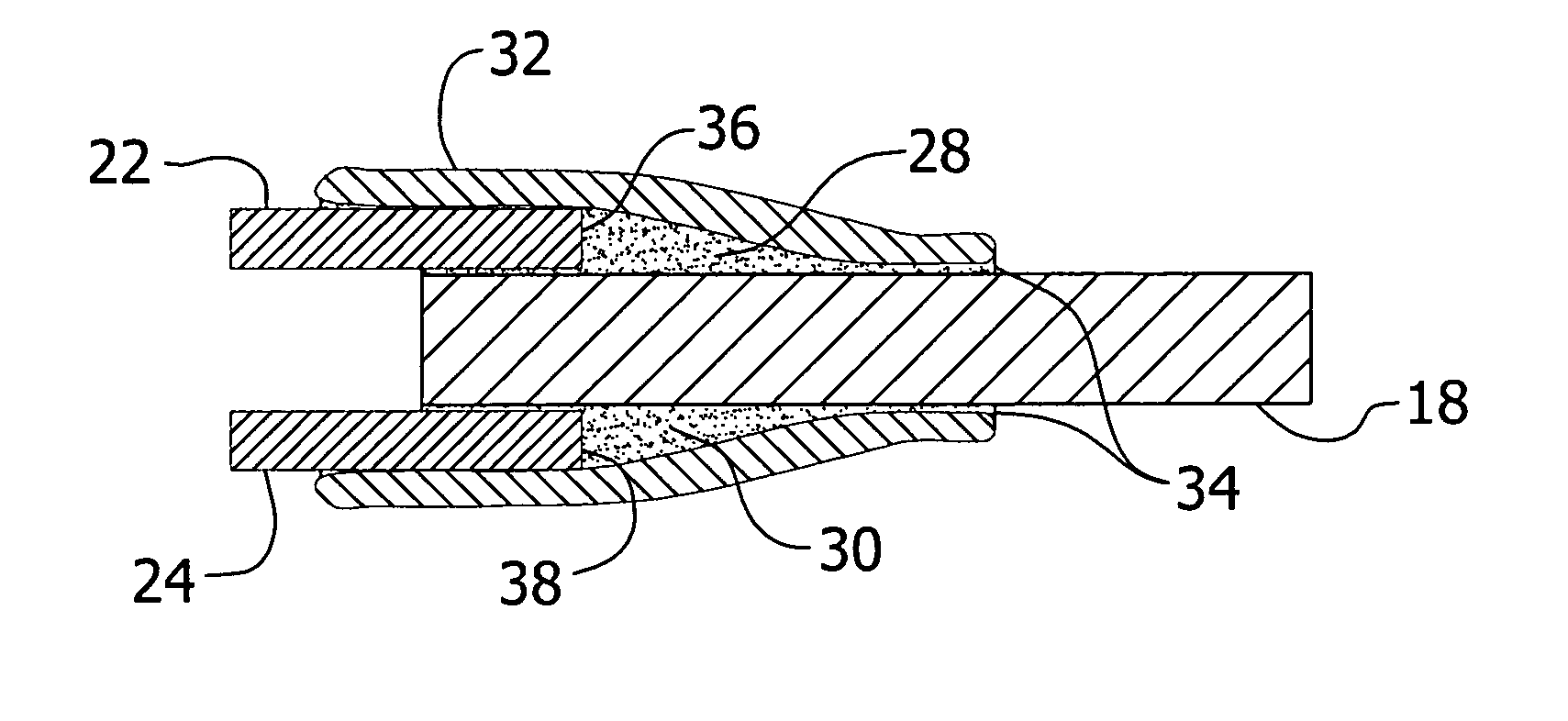

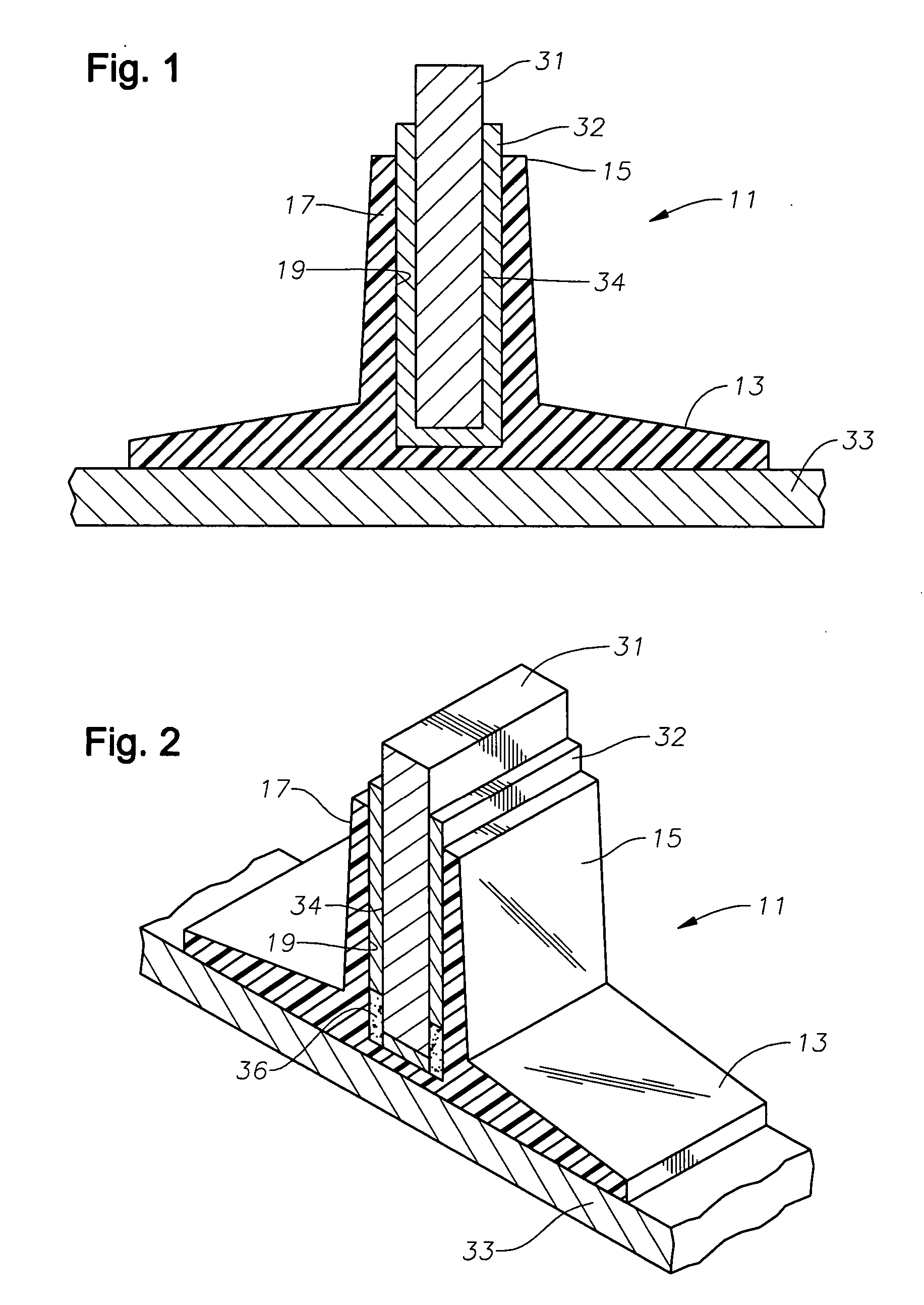

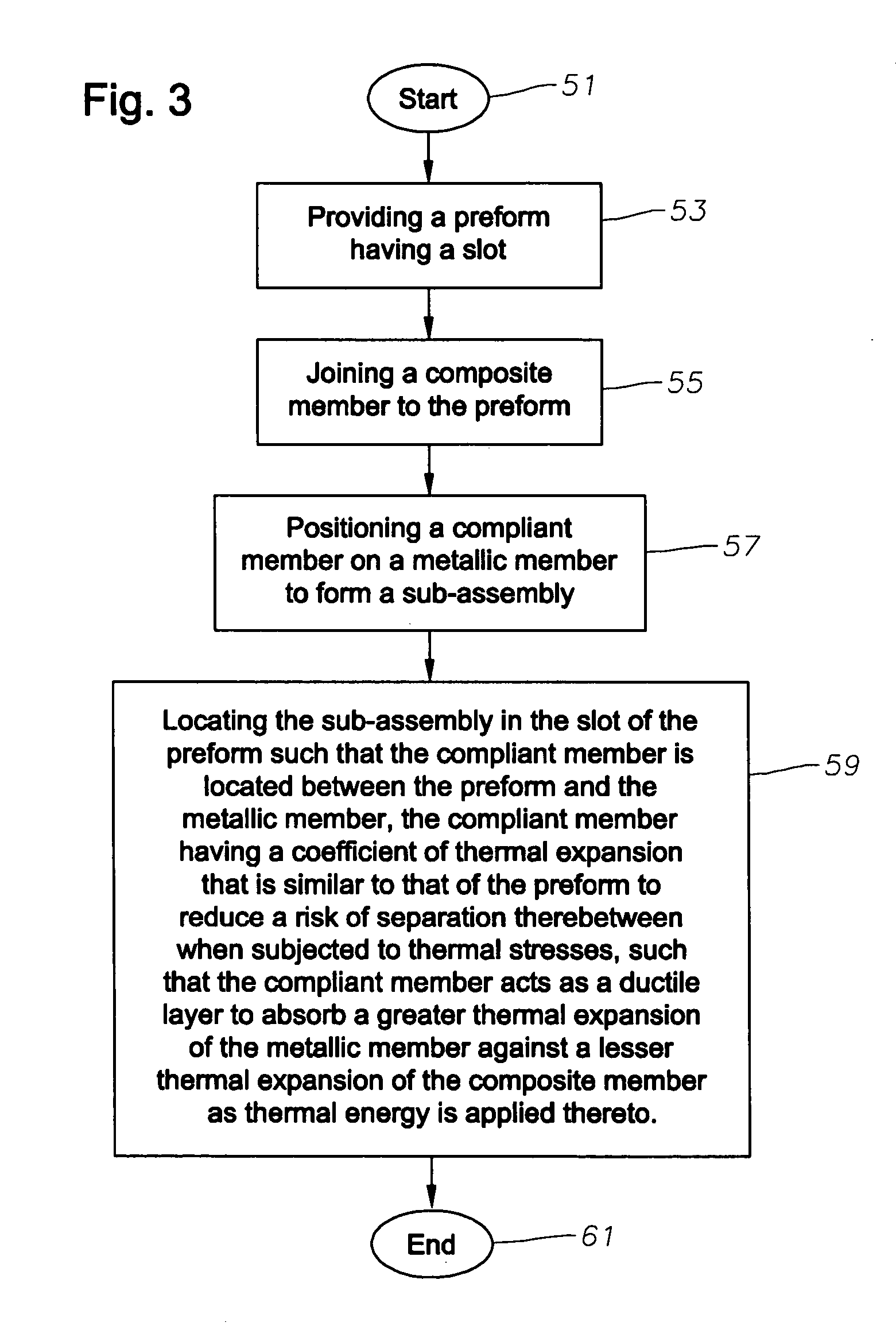

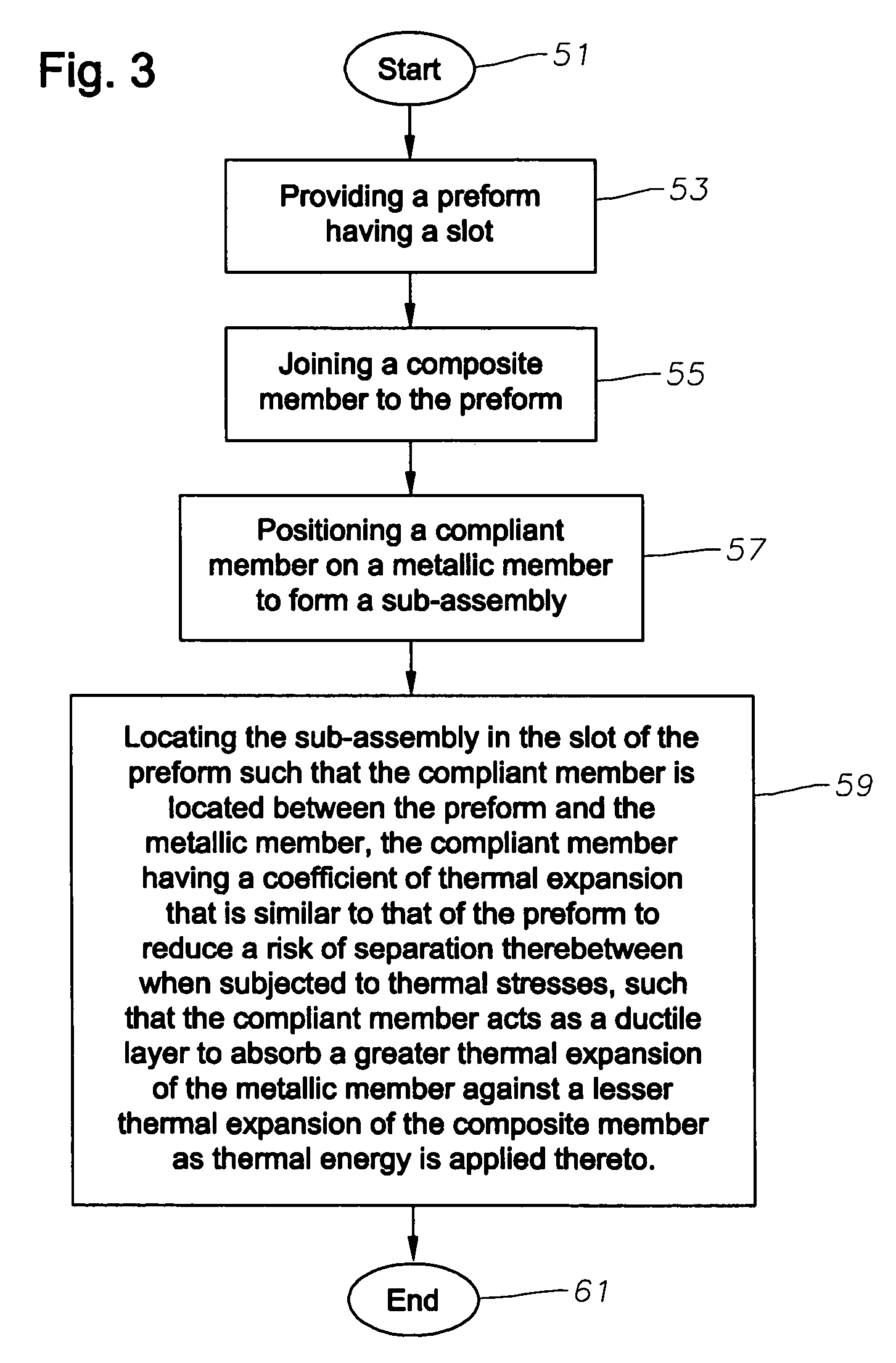

System, method, and apparatus for metallic-composite joint with compliant, non-corrosive interface

ActiveUS20070175966A1Reduce riskBarrier to galvanic corrosionAircraft stabilisationLayered productsFiberCarbon fibers

A metallic-composite joint is formed by inserting a metallic member into a slot of a pi-shaped composite preform. The preform is formed from woven carbon fiber in a binder of resin and may or may not be cured prior to assembly. An inert compliant layer is located between the legs of the preform and the metallic member. The resin binder or an adhesive is used to bond the compliant layer to the preform. The compliant layer has a coefficient of thermal expansion that more closely matches that of the preform. The properties of the compliant layer also avoid galvanic corrosion between the carbon in the preform and the metallic member.

Owner:LOCKHEED MARTIN CORP

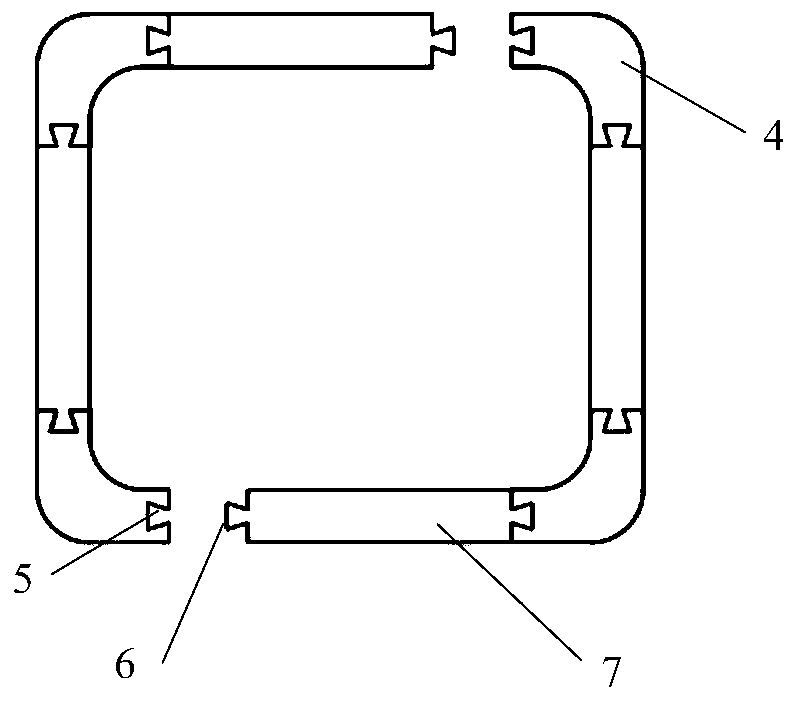

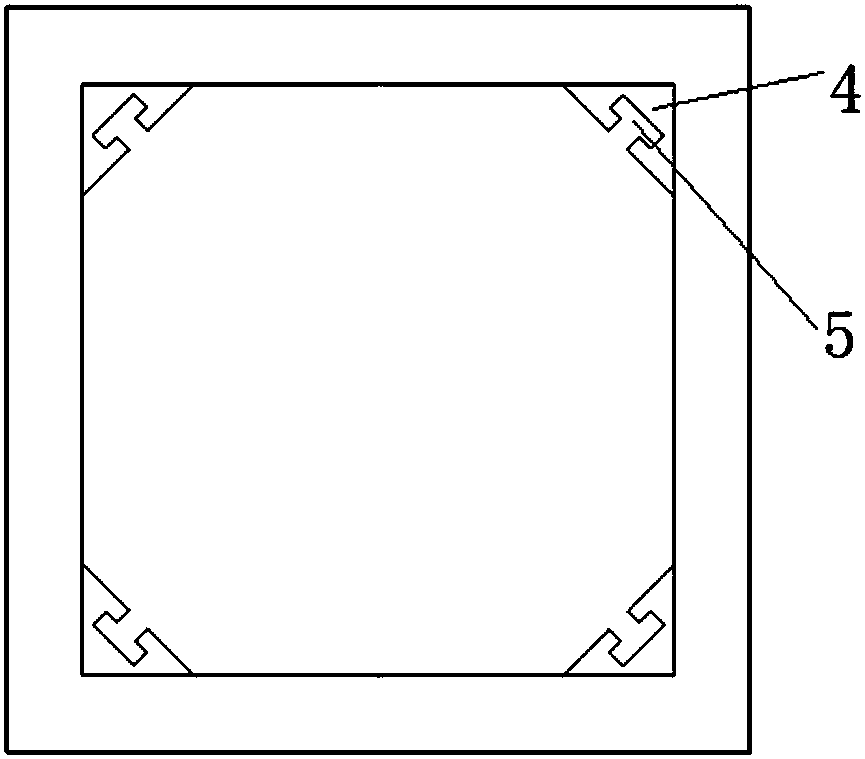

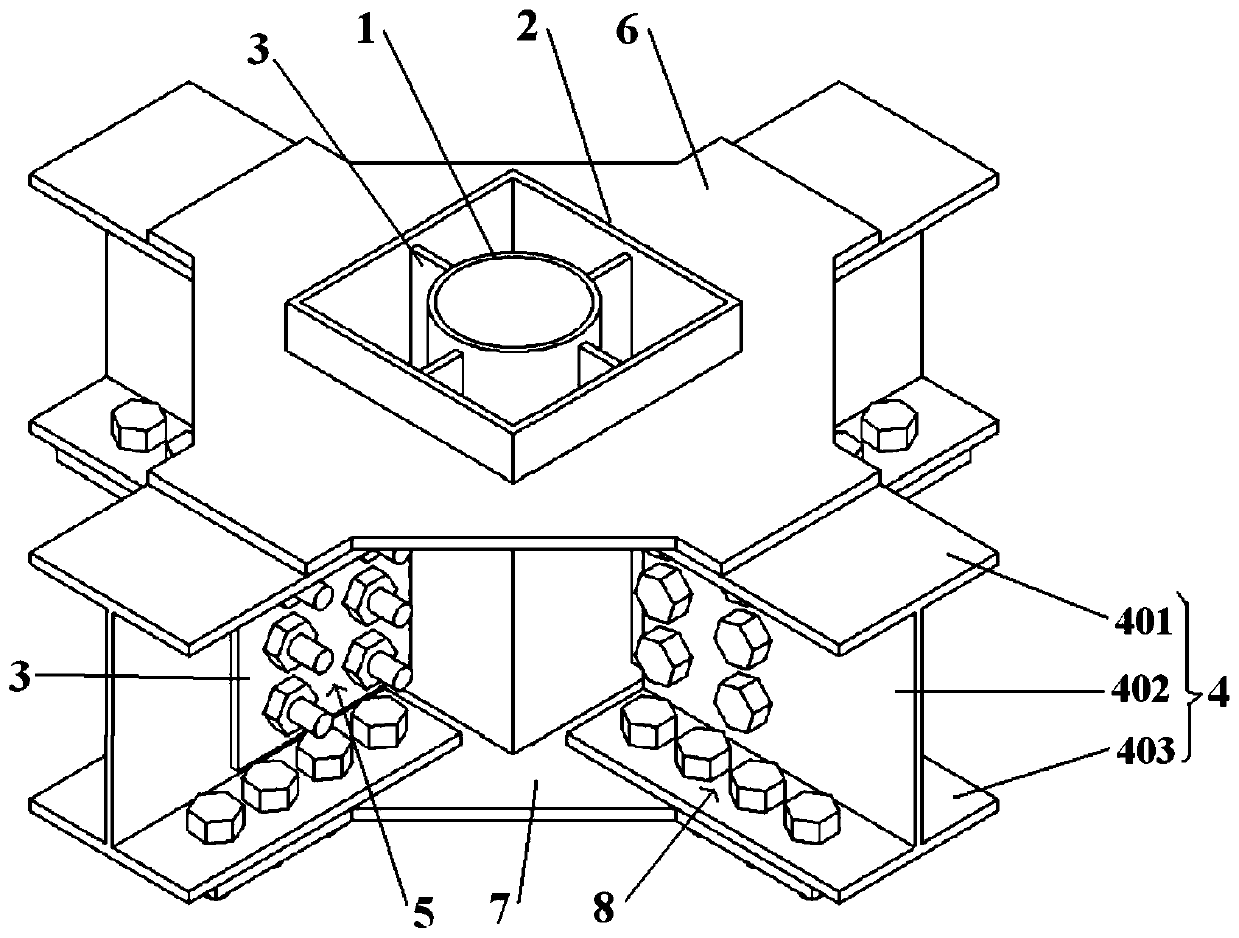

Ring plate splicing type hollow sandwich concrete-filled steel tube composite joint and installation method

ActiveCN108532759AGuaranteed carrying capacityImprove seismic performanceBuilding constructionsMaterials scienceBeam column

The invention relates to the technical field of connection of building structures, and discloses a ring plate splicing type hollow sandwich concrete-filled steel tube composite joint and an installation method. The composite joint comprises a square steel tube column, an I-shaped steel beam and beam-column connecting assemblies connecting the square steel tube column and the I-shaped steel beam, wherein the square steel tube column is connected with T-shaped connecting side plates of a round steel tube column through T-shaped holes in a matching manner; each beam-column connecting assembly comprises an upper group and a lower group of splicing plates which are symmetrically arranged and a T-shaped connecting piece which is arranged between the two groups of splicing plates and connects thetwo groups of splicing plates; each group of the splicing plates comprises four identical splicing plates, wherein each splicing plate comprises a horizontal part, a vertical part and a connecting lug, and the back surface of the horizontal part is provided with a T-shaped slider; each T-shaped connecting piece is provided with a T-shaped sliding groove matched with the T-shaped slider. The position of a central steel pipe column is fixed, connecting joints are spliced and connected by special outer ring plates, and a design concept of 'strong column and weak beam' is realized; the welding ofall components was completed in a factory and all the components are connected by bolts on site, and thus a complete assembly construction is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

System, method, and apparatus for metallic-composite joint with compliant, non-corrosive interface

ActiveUS7611595B2Reduce riskBarrier to galvanic corrosionWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingFiberCarbon fibers

Owner:LOCKHEED MARTIN CORP

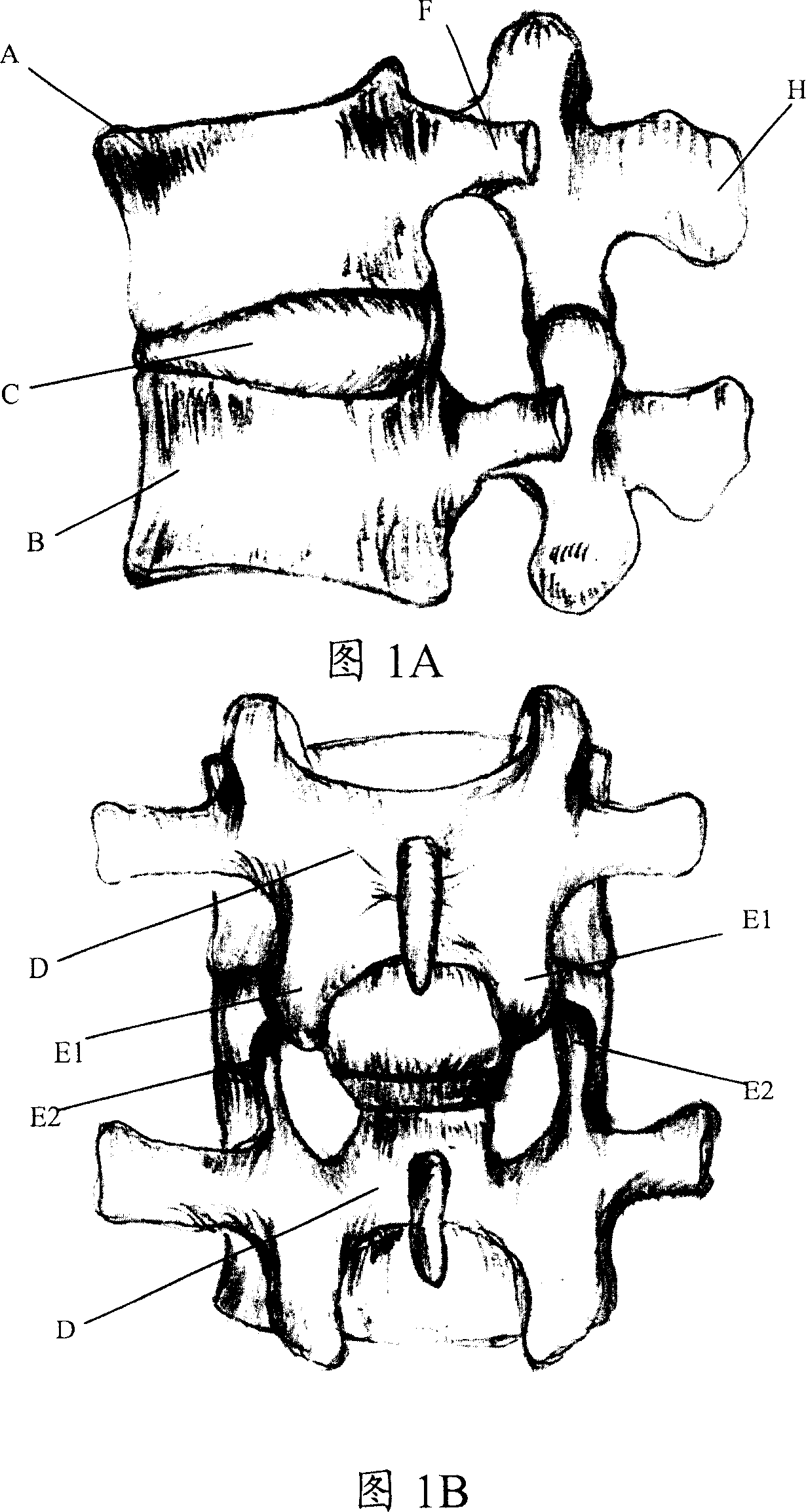

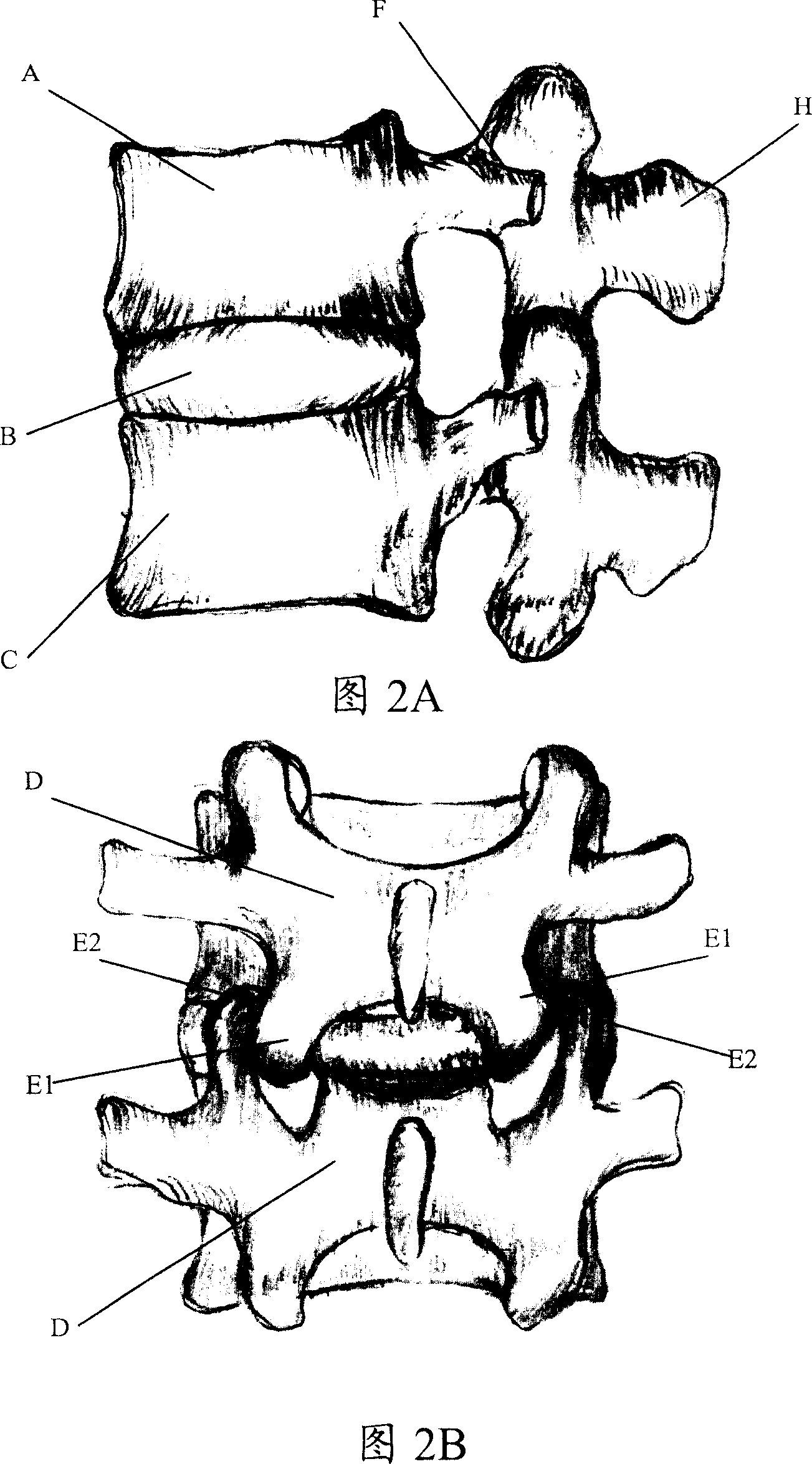

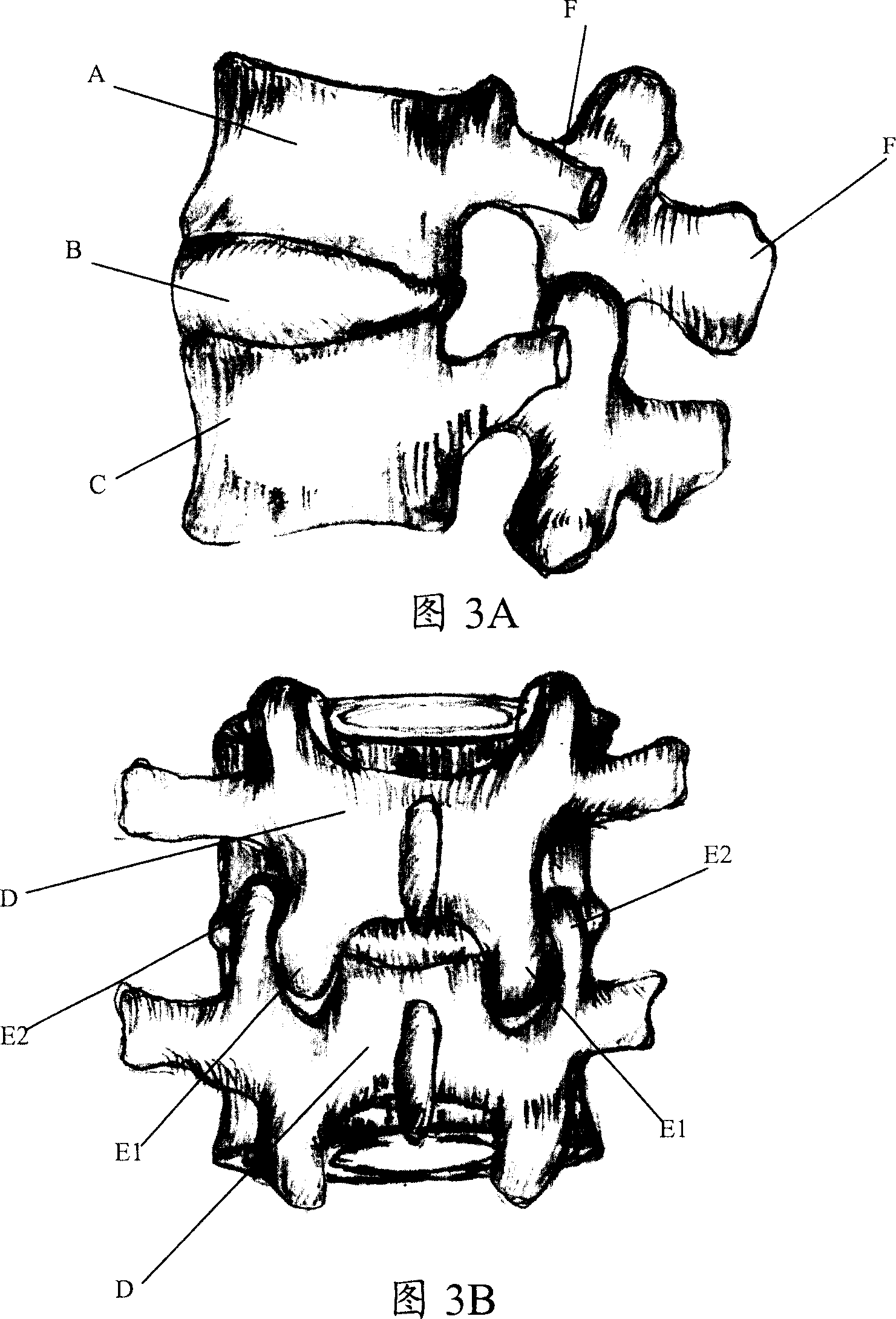

Coupling full intervertebral joints system

InactiveCN101015470ACause degradationCause hardeningInternal osteosythesisSpinal implantsLamina terminalisTreatment effect

The invention discloses a coupled full-intervertebral joint system, which possesses little oligodynamic joint between upper and lower intervertebral end-plate on the spine, wherein one little oligodynamic joint is set between each little joint position on two sides of upper and lower intervertebral or upper and lower crests; one end of little oligodynamic joint is fixed on the vertebral arch root or crest of upper vertebral bulk with the other end fixed on the vertebral arch root or crest of lower vertebral bulk; the joint system is composite joint system with intervertebral little oligodynamic joint and little oligodynamic joint, which replaces lateral joint to support vertebra to avoid joint from degenerating and hardening effectively.

Owner:博能华医疗器械(北京)有限公司

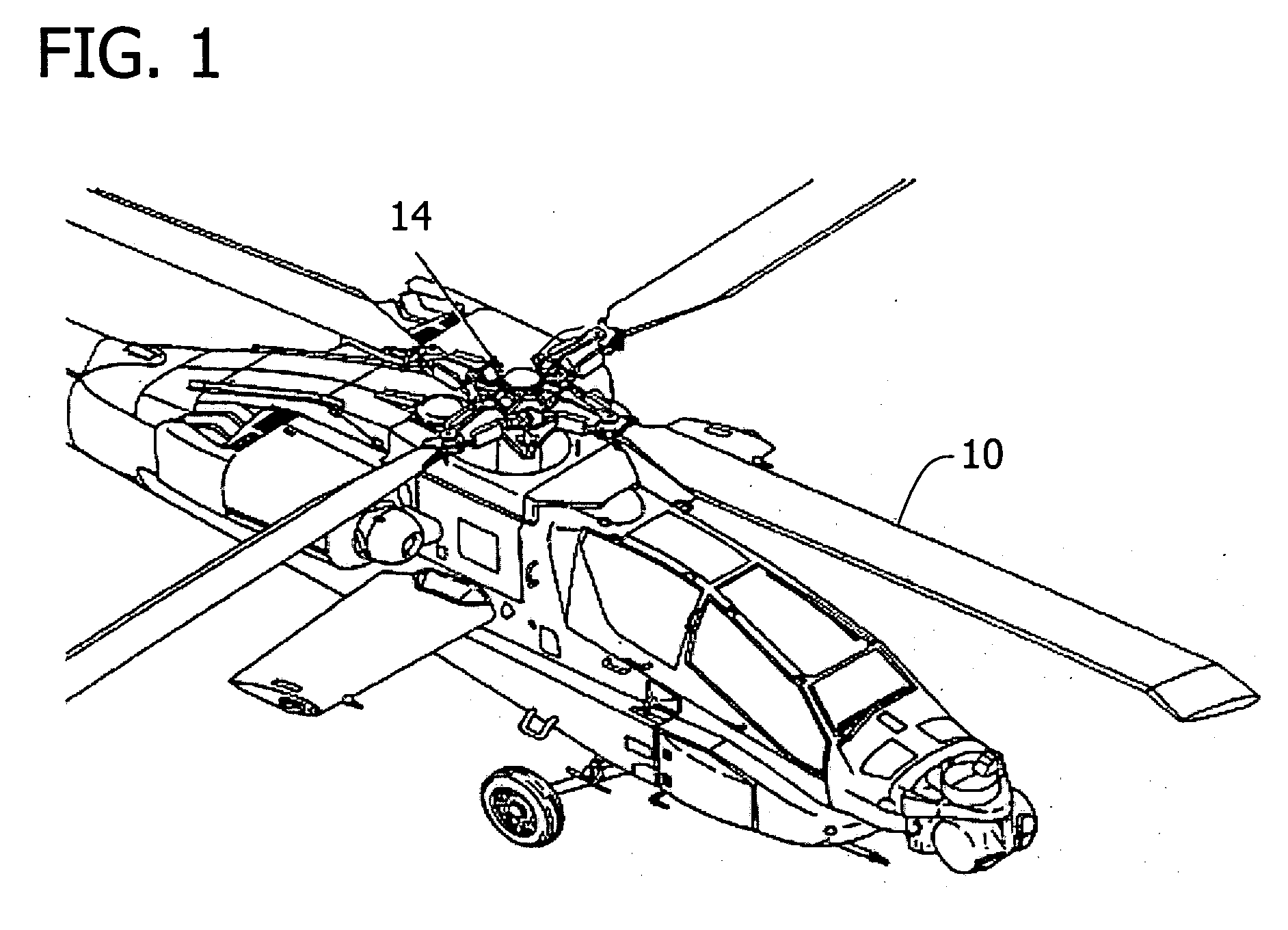

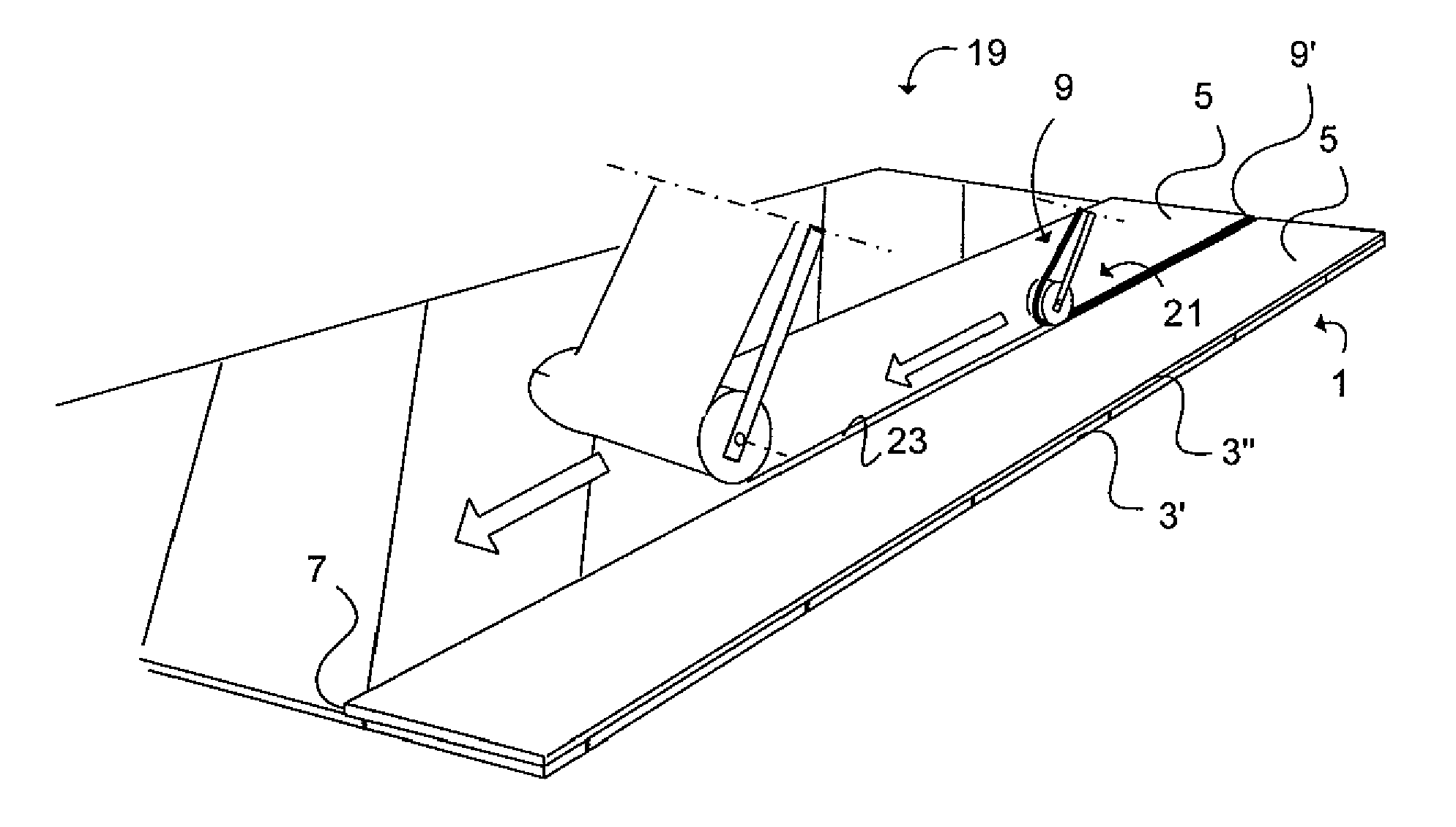

Structural longitudinal composite joint for aircraft structure

InactiveUS20120088056A1Reduced thermal linear expansionEasy to handleMaterial nanotechnologyLayered productsFiberNanostructure

A structural composite part made of pre-impregnated fiber plies. The edges of two adjacent fiber plies are connected via a longitudinal composite joint made structural by a nanostructure arranged within the composite joint. A method of producing a structural composite part made of pre-impregnated fiber plies. The edges of two adjacent fiber plies are connected via a longitudinal composite joint made structural by a nanostructure and an aircraft structure comprising such structural composite parts.

Owner:SAAB AB

High temperature joints for dissimilar materials

InactiveUS20050200124A1Improve the immunityHigh strengthPipe-jointsPipe connection arrangementsEngineeringThermal expansion

Composite joints for gas-tight members that exhibit different coefficients of thermal expansion are disclosed. Broadly, apparatus of the invention provides composite joints which include a girdle of a resilient material disposed between mating surfaces of a high strength metallic member and a nonmetallic member in an arrangement wherein a difference in fluid pressures across the joint provides compressive force upon the girdle through tapered mating surfaces thereby improving resistance to fluid leakage. Composite joints of the invention are particularly useful for joining a high strength weldable metallic conduit and a gas-tight ceramic member having a tubular structure, closed at one end, with a tapered mating surface at a distal end thereof contiguous with a portion of the girdle. Processes beneficially using joints in accordance with the invention include converting methane gas into value-added-products, for example, production of synthesis gas comprising carbon monoxide and molecular hydrogen. Advantageously, the synthesis gas is free of deleterious and / or inert gaseous diluents such as nitrogen.

Owner:BP CORP NORTH AMERICA INC

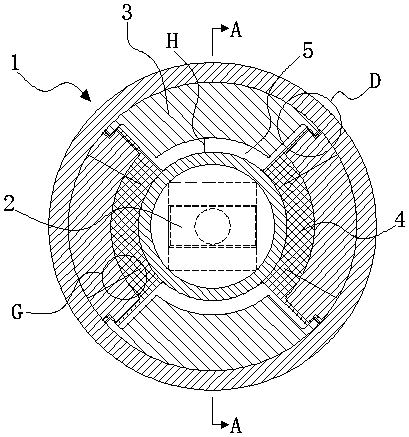

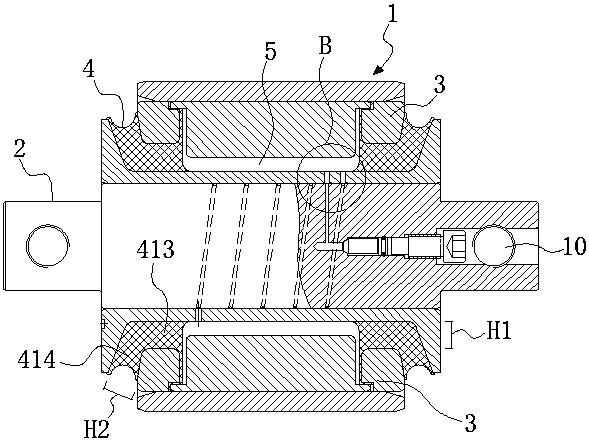

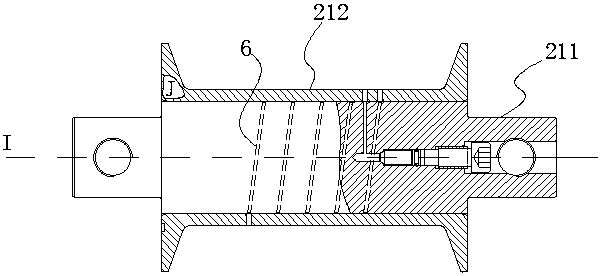

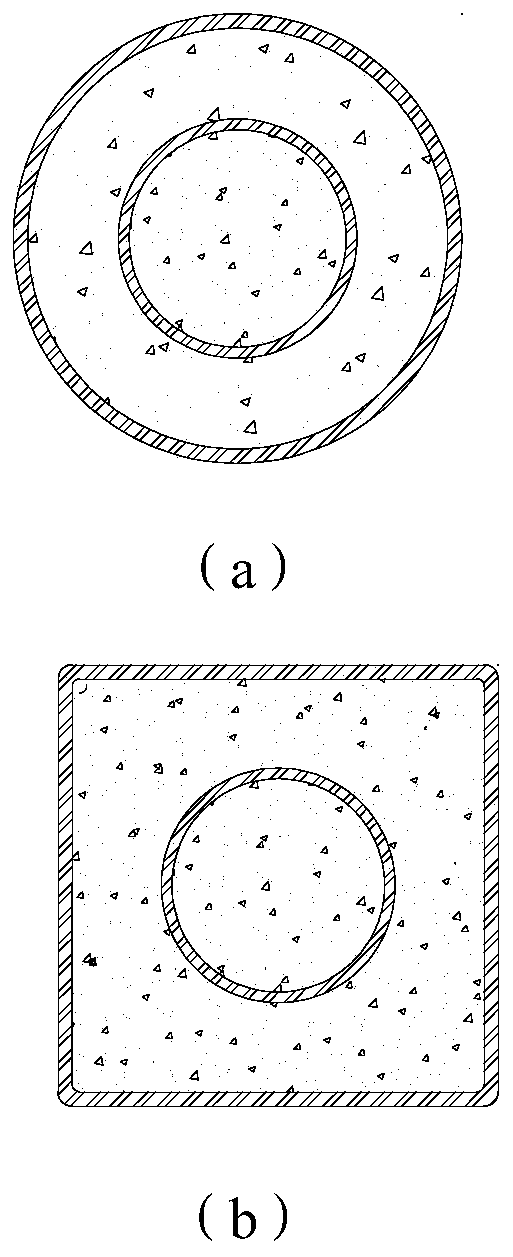

Forming method of liquid rubber composite joint with inner groove flow channel and joint

ActiveCN110425248AImprove performanceReduce radial stiffnessSpringsShock absorbersComposite jointEngineering

The invention discloses a forming method of a liquid rubber composite joint with an inner groove flow channel and the joint. The forming method comprises the steps that a middle spacing sleeve is additionally arranged between an outer sleeve and a core shaft, the middle spacing sleeve and the core shaft are pasted together through rubber vulcanization, and the middle spacing sleeve and the core shaft which are integrated are assembled into the outer sleeve; and the inner groove flow passage is arranged in the core shaft, the middle spacing sleeve is hollowed out to form a plurality of spaces,after vulcanization is carried out, rubber and the multiple spaces form a plurality of independent liquid cavities, liquid exists in the multiple liquid cavities, and the multiple liquid cavities arein communication with each other through the inner groove flow channel. By means of the forming method and the joint, small radial stiffness and large axial stiffness can be provided, a large dynamicand static ratio is achieved, and the product performance of the liquid rubber composite joint is optimized.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

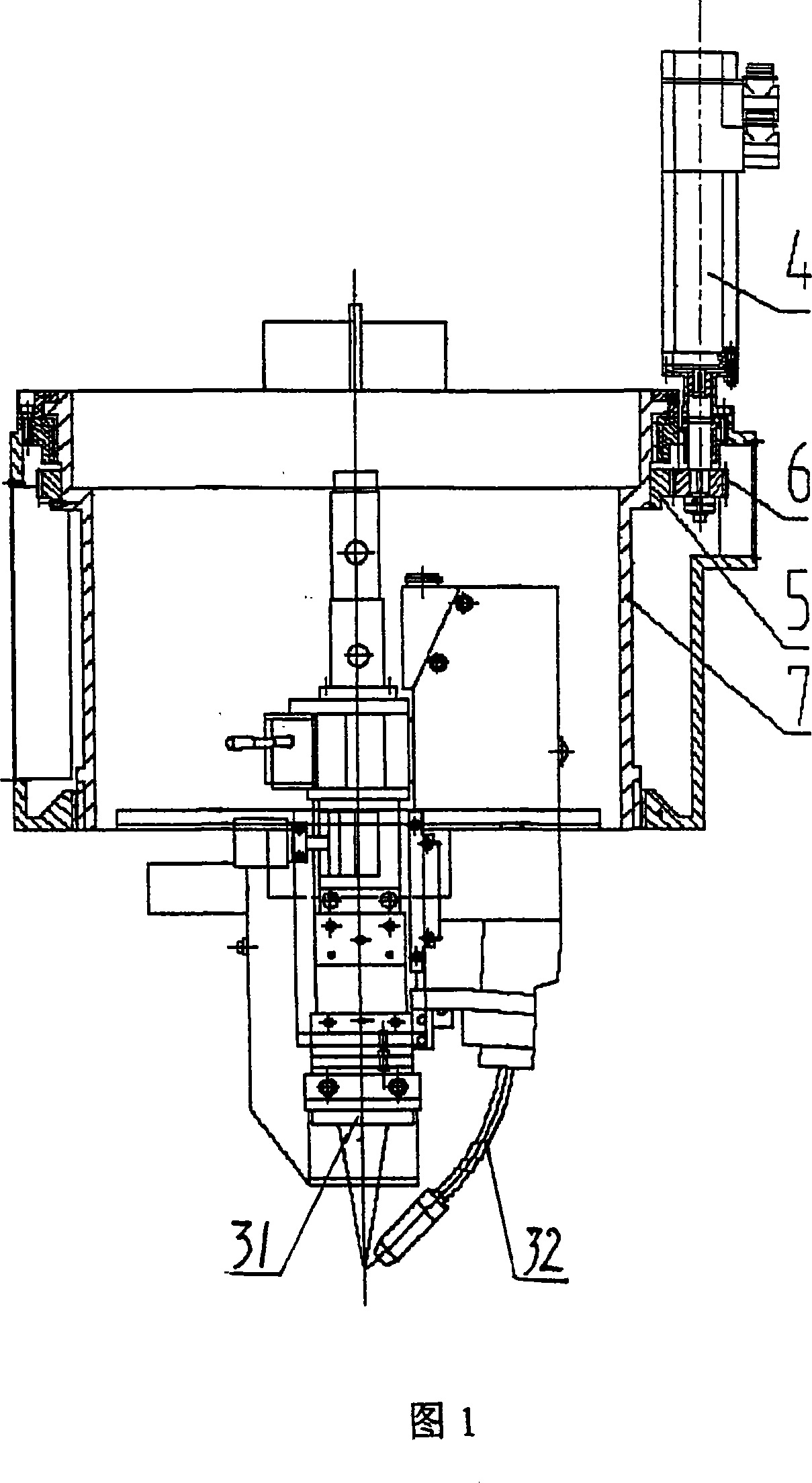

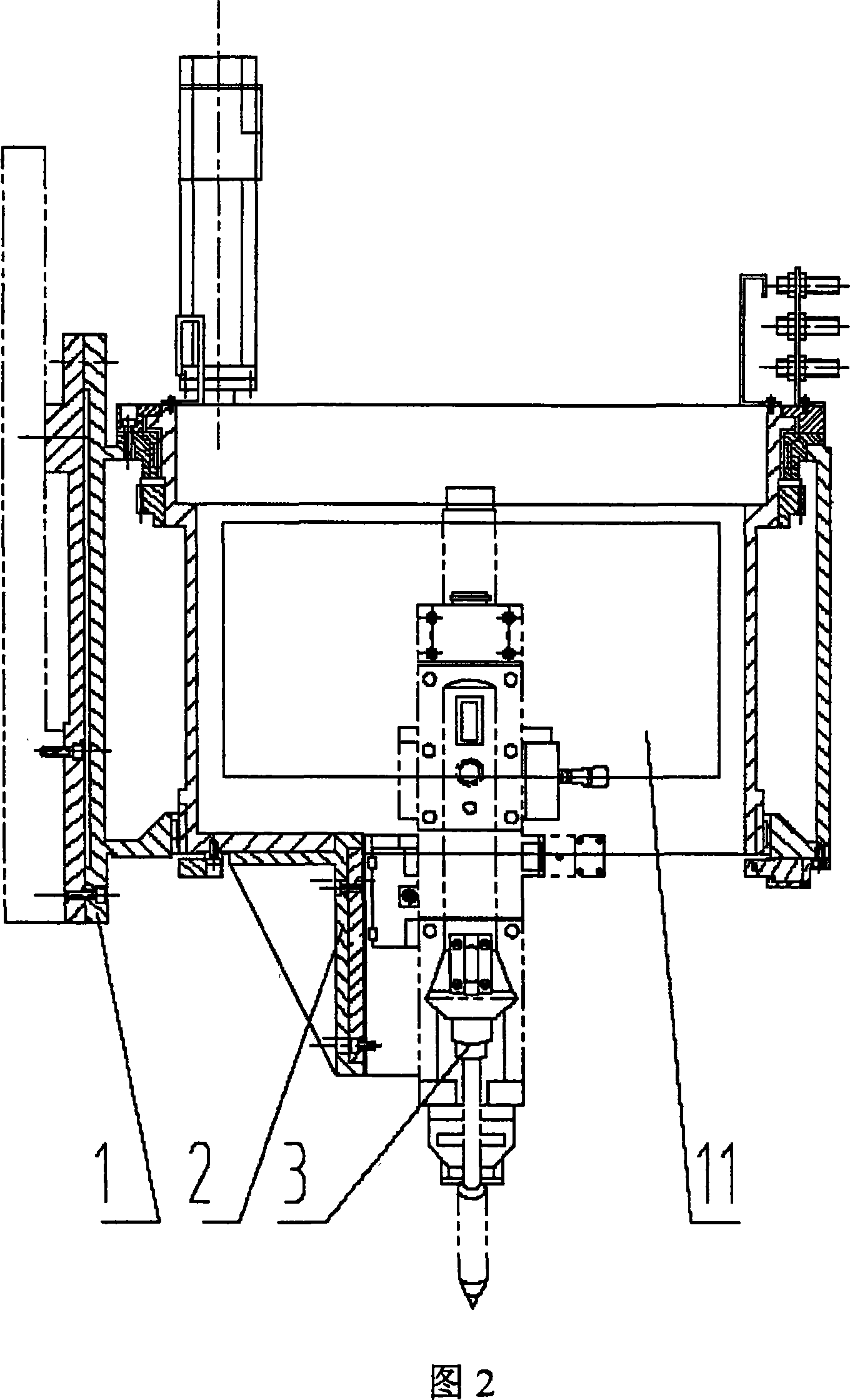

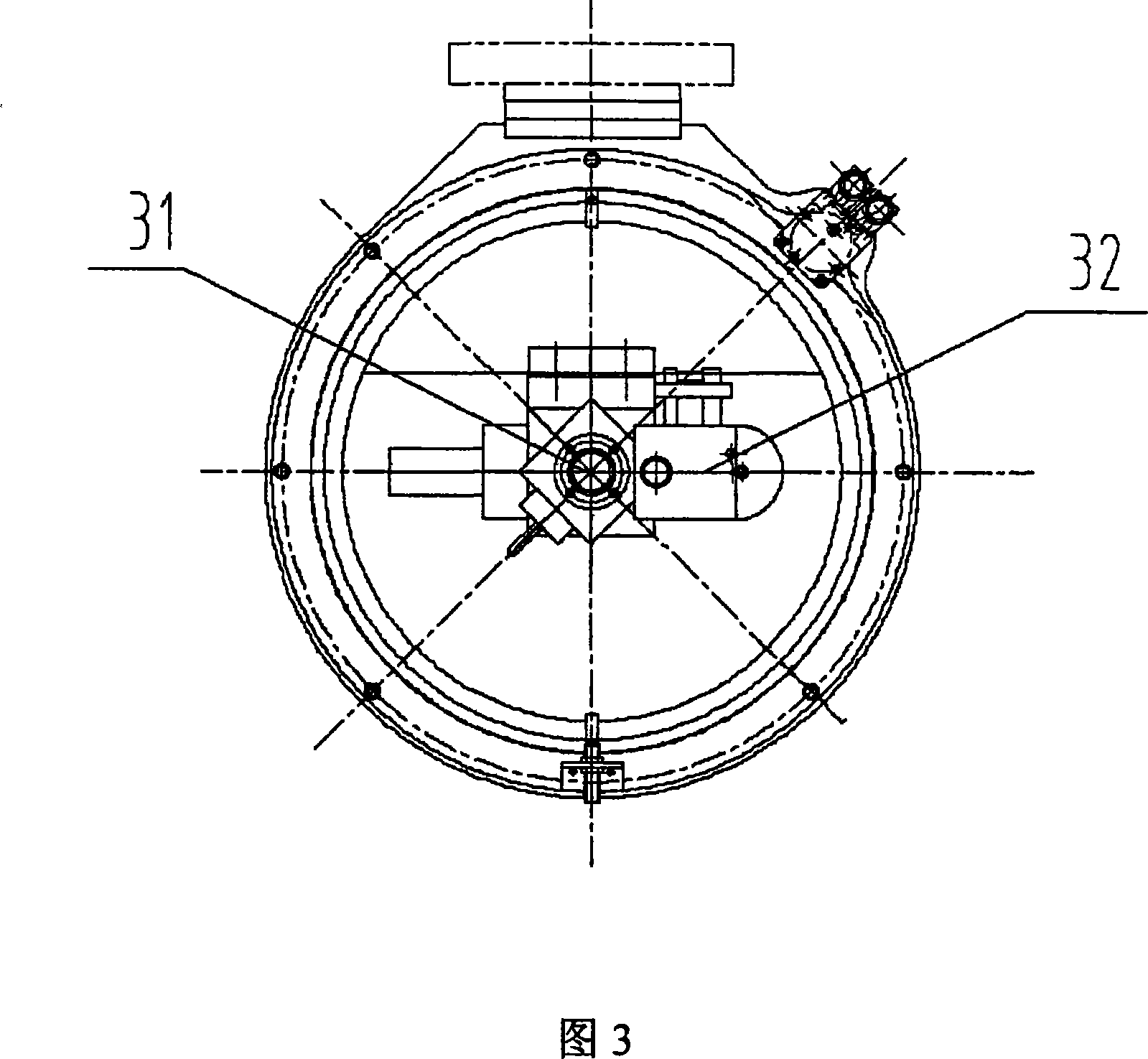

Laser compound welding tip device

ActiveCN101204759AControl speedControl rotation angleArc welding apparatusLaser beam welding apparatusGear wheelEngineering

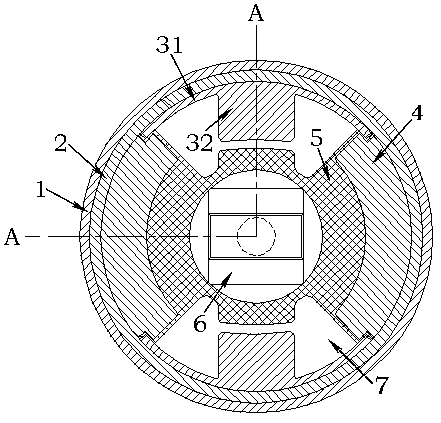

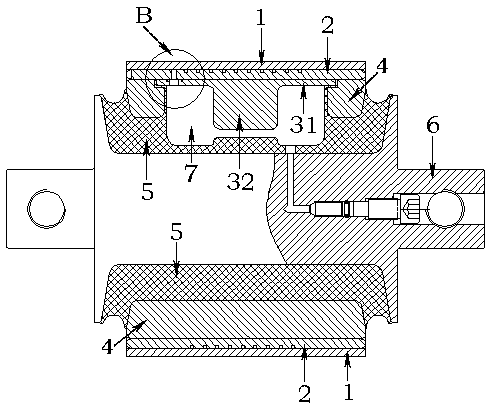

The invention relates to the technical field of a welding device, in particular to a laser composite welding joint device, which comprises a box body, a composite welding joint, a combined plate, a big gear ring, a sleeve, a small gear and an electric motor. The composite welding joint consists of a laser welding torch and an arc torch. The electric motor drives the big gear ring to rotate through the small gear and simultaneously the sleeve tightly fixed with the big gear ring concentrically rotates together. The combined plate is fixedly connected with the hollow sleeve. The laser welding torch and the arc torch are arranged on the combined plate. The laser welding torch is arranged on a central shaft of the sleeve; consequently during a rotating process, the arc torch enwinds rotates at a 360 degrees around the laser beam of the laser welding torch. The rotating speed and the rotating angle of the composite joint can be controlled through controlling the running of the electric motor to lead the composite joint to be able to adopt the welding on a curve welding line of different curvatures or curvature changes.

Owner:DG HUST MFG ENG RES INST +1

Fabricated self-resetting concrete frame soft steel energy dissipation composite joint

InactiveCN110258787AImprove energy consumptionReduce pollutionProtective buildings/sheltersShock proofingReinforced concrete columnEarthquake intensity

The invention discloses a fabricated self-resetting concrete frame soft steel energy dissipation composite joint. The fabricated self-resetting concrete frame soft steel energy dissipation composite joint includes a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, soft steel dampers, a pre-stressed steel strand, embedded high-strength bolts and anchored steel bars, wherein the prefabricated reinforced concrete beam is provided with a beam end embedded steel sleeve, and a column end embedded steel plate is arranged at the butt-joint position between the prefabricated reinforced concrete column and the beam end embedded steel sleeve; the pre-stressed steel strand penetrates through a pre-stressed steel strand hole channel of the prefabricated reinforced concrete column, a pre-stressed steel strand opening of the column end embedded steel plate, a pre-stressed steel strand opening of the beam end embedded steel sleeve and the pre-stressed steel strand channel of the prefabricated reinforced concrete beam in sequence, so that the prefabricated reinforced concrete column and the prefabricated reinforced concrete beam are spliced together; and the soft steel dampers are arranged on both sides of a web plate of the section steel part of the beam end embedded steel sleeve. The fabricated self-resetting concrete frame soft steel energy dissipation composite joint enables the prefabricated concrete frame structure to have excellent seismic performance and self-resetting ability under high earthquake intensity.

Owner:南京毕慕智能建筑科技有限公司

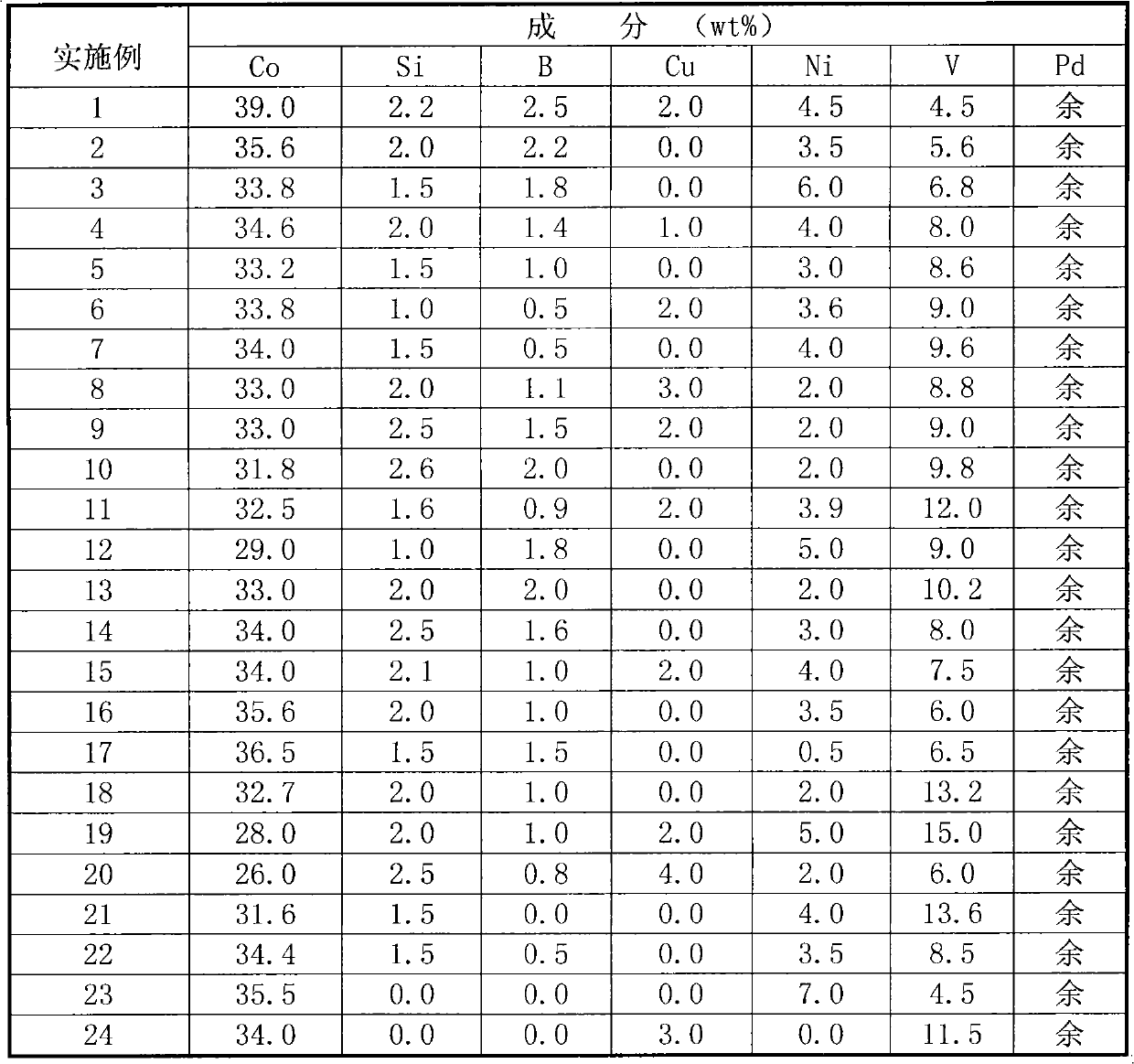

Palladium/cobalt-based high-temperature brazing filler for Cf/SiC composite material brazing

InactiveCN101920408AHigh strengthWelding/cutting media/materialsSoldering mediaFlexural strengthMetallic materials

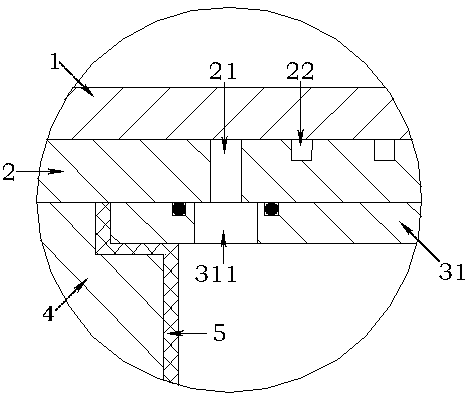

The invention relates to a palladium / cobalt-based high-temperature brazing filler for Cf / SiC composite material brazing, which comprises the following components in percentage by weight: 25.0-39.0% of Co, 0.0-4.0% of Cu, 0.0-7.0% of Ni, 4.5-15.0% of C, 0.0-2.6% of Si, 0.0-2.5% of B and the balance of Pd. The brazing filler can be used for obtaining Cf / SiC ceramic-based composite joint fittings at a brazing temperature of 1110-1250 DEG C, and the room-temperature three-point bending strength of the corresponding brazed fittings can be up to 110-170 MPa. The brazing filler is applicable to the brazing of Cf / SiC ceramic-based composite materials, SiC ceramics and SiCf / SiC ceramic-based composite materials, and is also applicable to the connection between these ceramics (or composite materials) and other ceramic materials (or composite) or metal combined fittings.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Radial rigidity adjusting method and structure for liquid rubber composite joints

The invention provides a radial rigidity adjusting method and structure for liquid rubber composite joints. Rubber bodies are vulcanized between middle spacer bushes and a mandrel; the two ends of a cover plate are closed on the middle spacer bushes in a covering manner, and the cover plate, the middle spacer bushes, the rubber bodies and the mandrel are together assembled into a flow channel outer sleeve; liquid cavities are formed between the cover plate and the rubber bodies, so that the liquid cavities are partitioned by the middle spacer bushes; the cover plate and the flow channel outersleeve are provided with liquid channels, and the liquid channels are enabled to communicate the partitioned liquid cavities with each other; and liquid is injected into the liquid cavities and the liquid channels. Due to the radial rigidity adjusting method and structure for the liquid rubber composite joints, by changing the shapes and the sizes of the liquid cavities and the liquid channels, the empty direction rigidity of the liquid rubber composite joints in the radial direction is adjusted, especially, the movable rigidity of the liquid rubber composite joints in the high-frequency stateand in the low-frequency state is adjusted, the critical speed and the through curve performance of vehicles are improved, and the abrasion is reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Composite joint filler seal material for joints in precast concrete structures

InactiveUS9034454B1Low creepCoastlines protectionPretreated surfacesPlastic materialsThermoplastic polyurethane

An apparatus for filling joints in precast concrete structures includes a core that has exceptionally low creep and conforms to ASTM D 1752 made of controlled particle size composites of recycled cellular rubber and plastic materials in the form of a rectangular slab. Holes are drilled through a central area and countersink recesses are formed around the holes. An outer coating of a thermoplastic polyurethane / polyurea elastomer system of a thickness of 0.075 inch covers the slab and countersink recesses. The coated core is abrasion and UV resistant while having the creep characteristics needed to make a dam expansion joint filler.

Owner:SOUTHERN RUBBER COMPANY

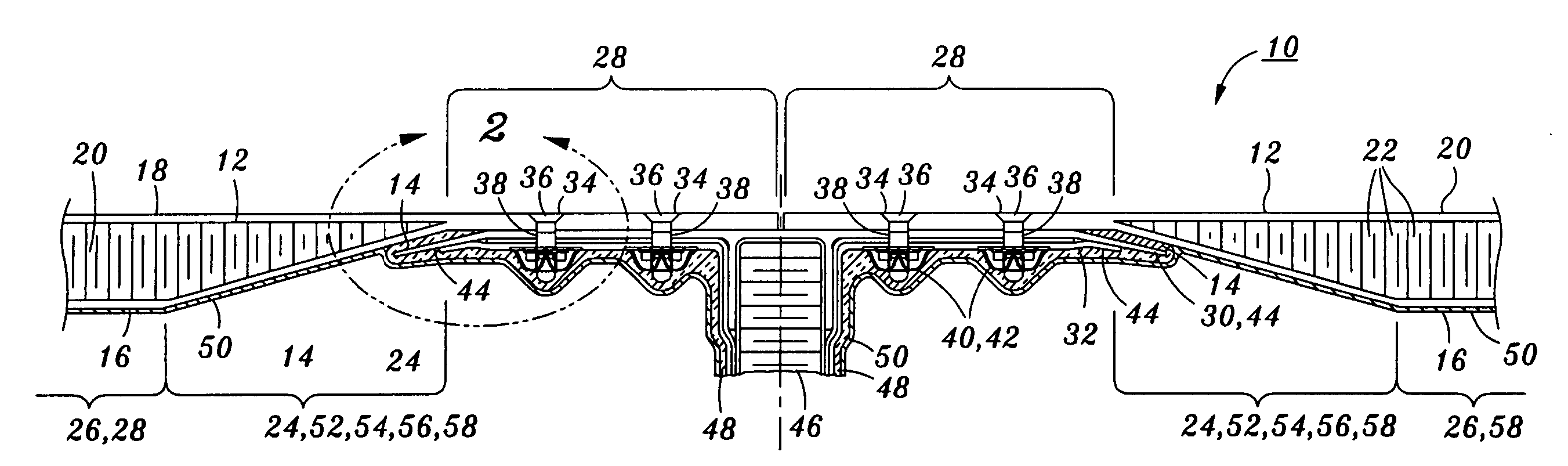

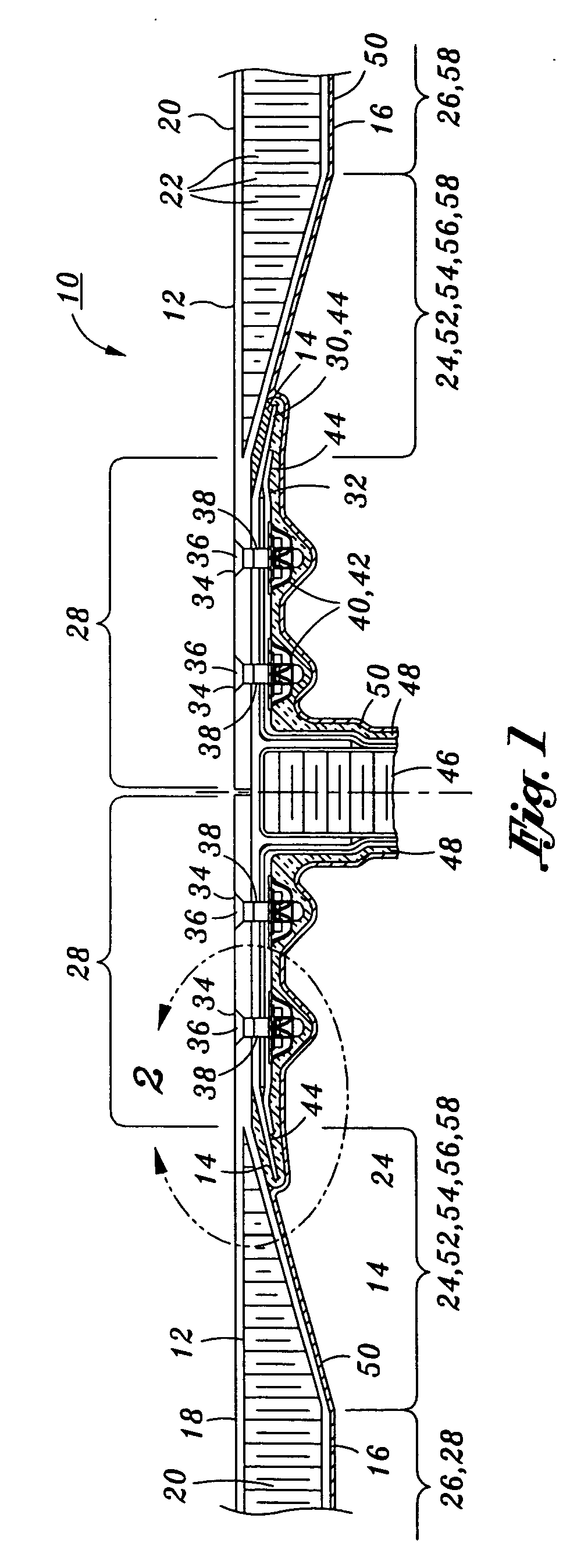

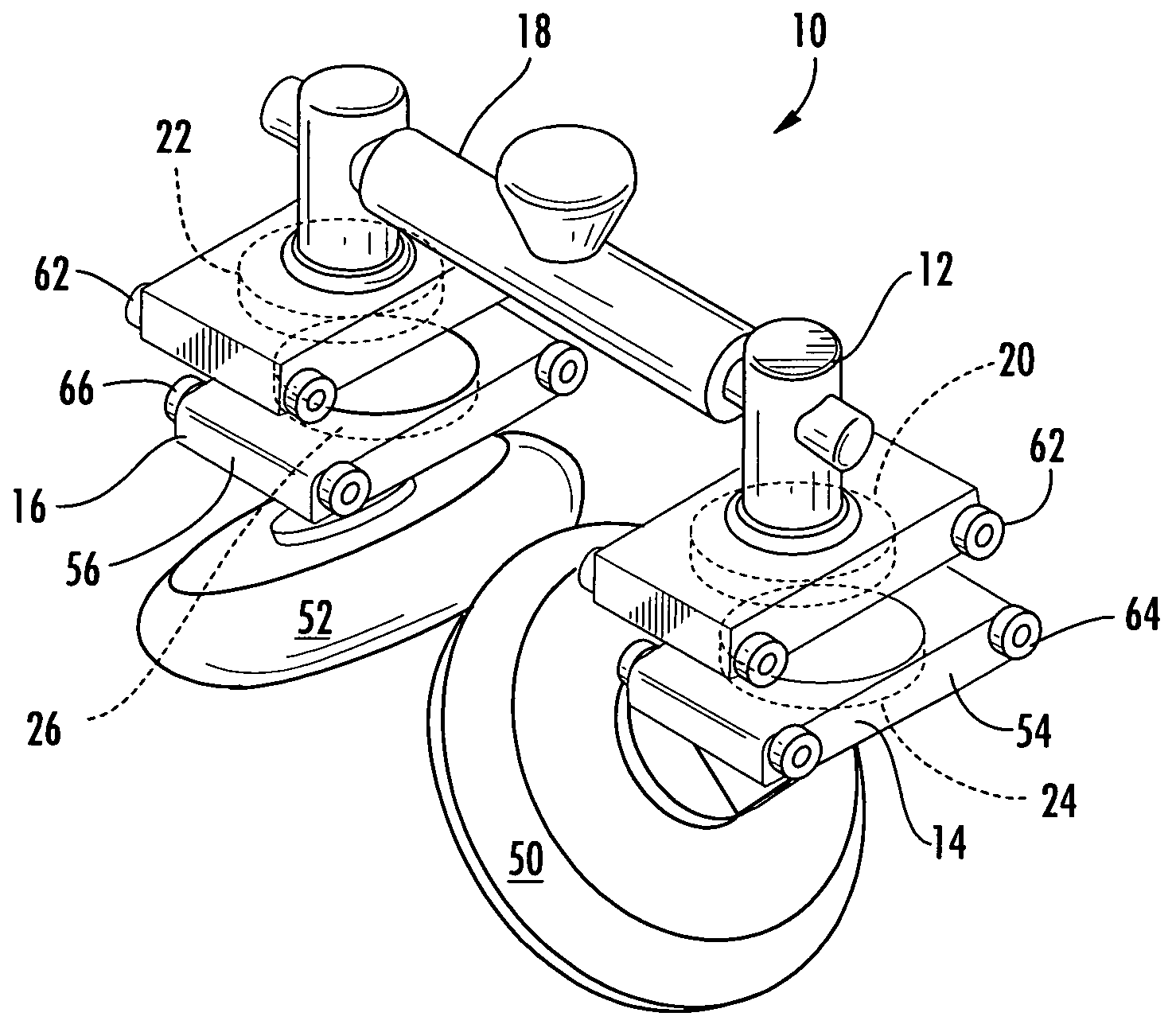

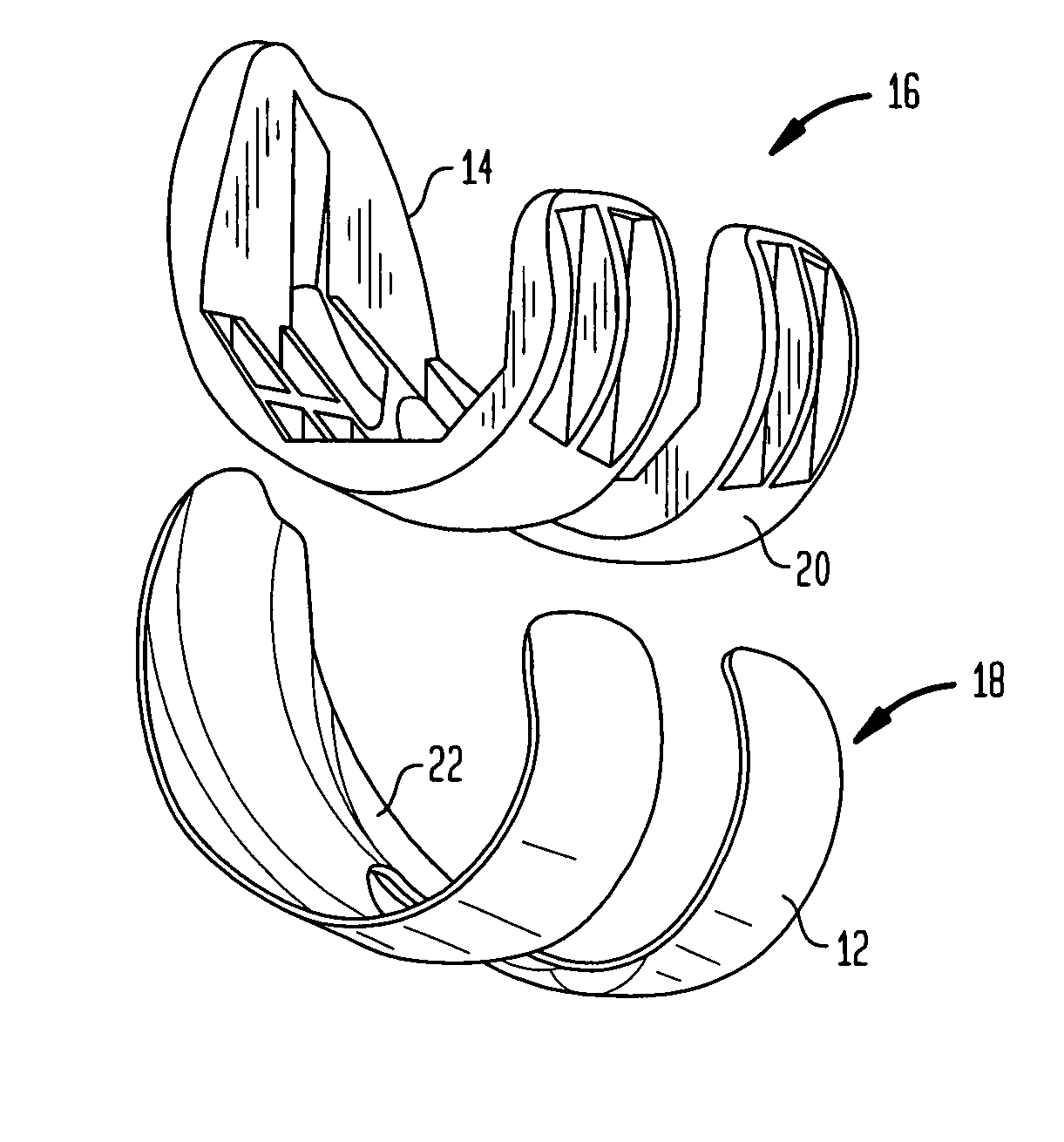

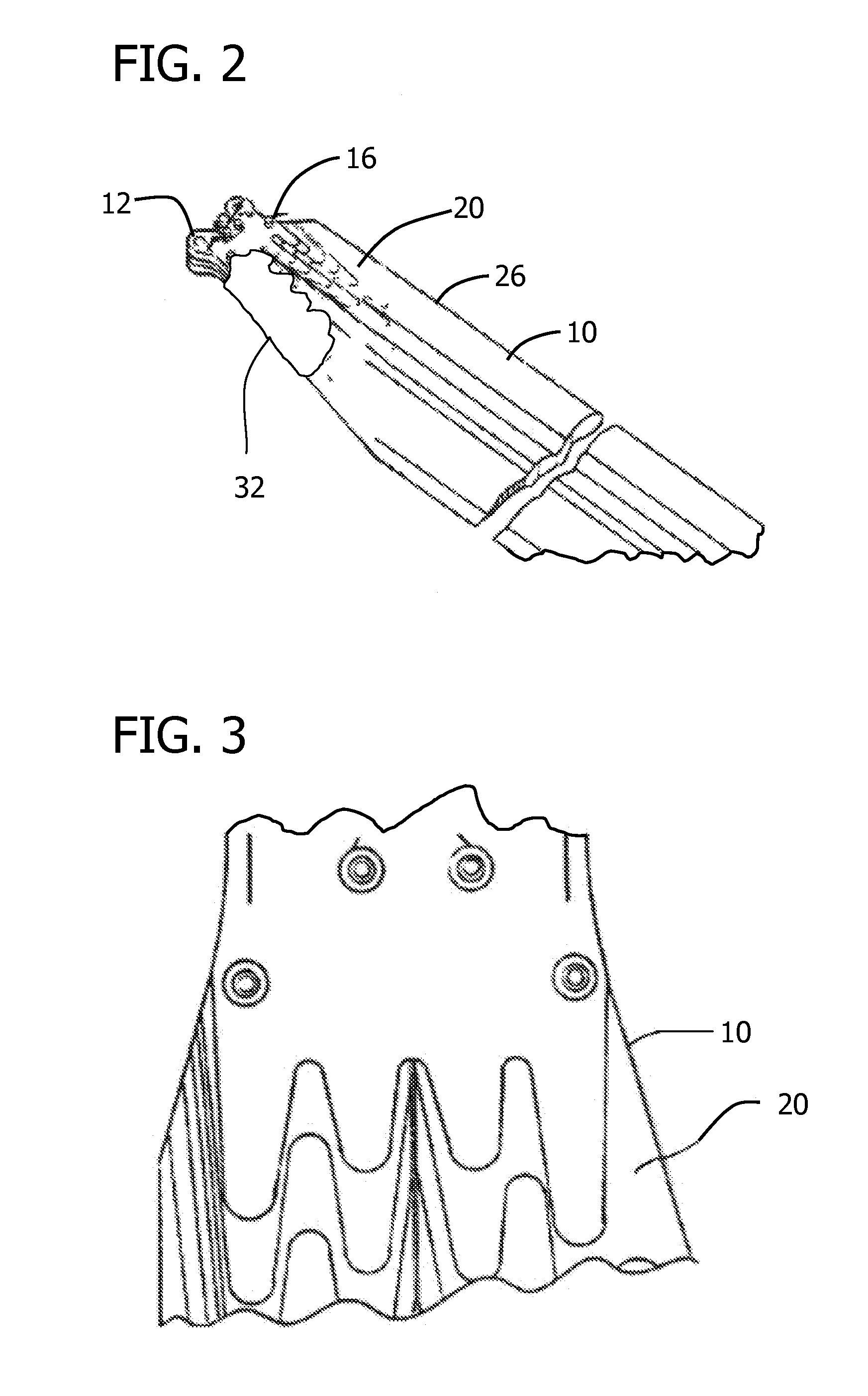

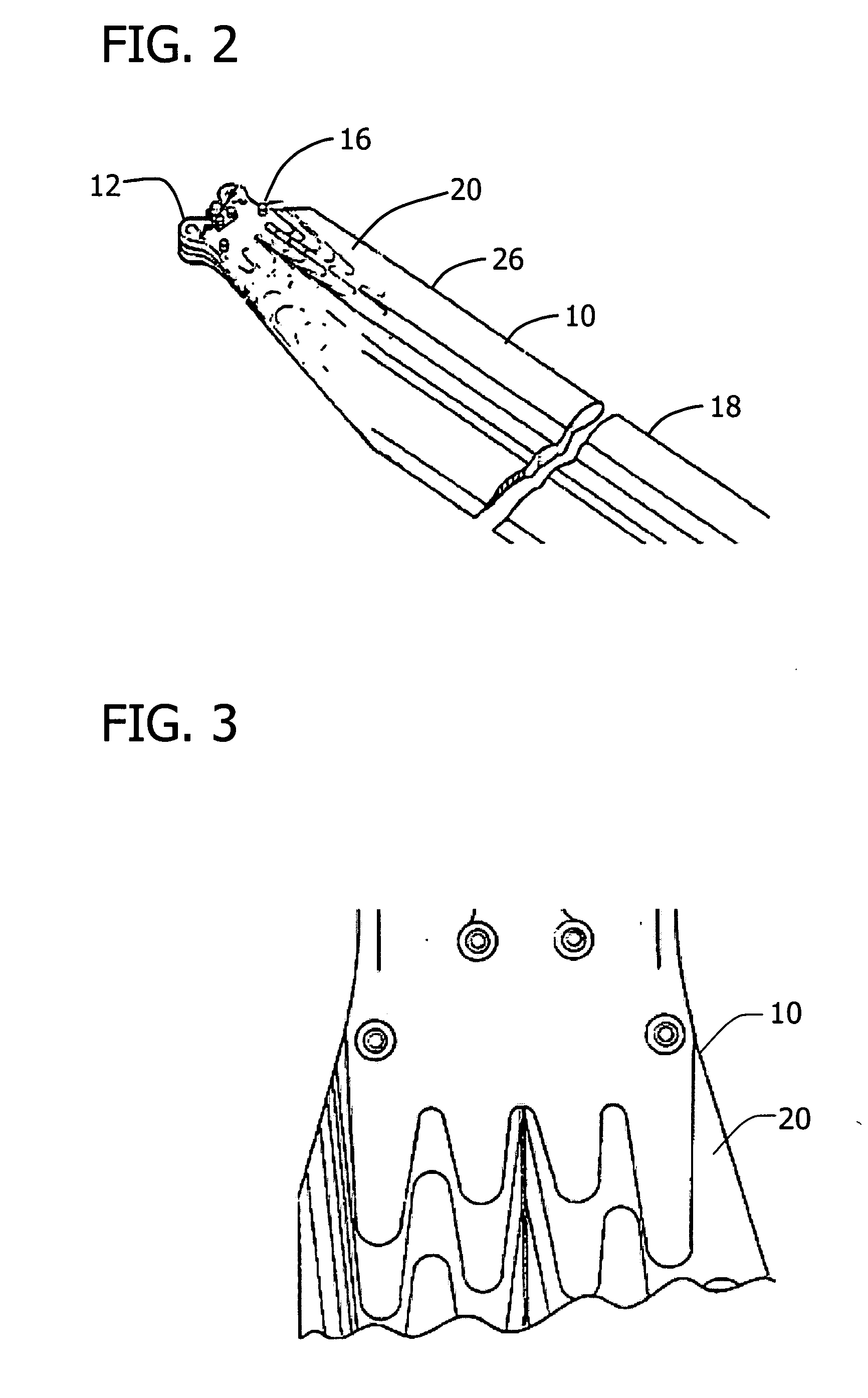

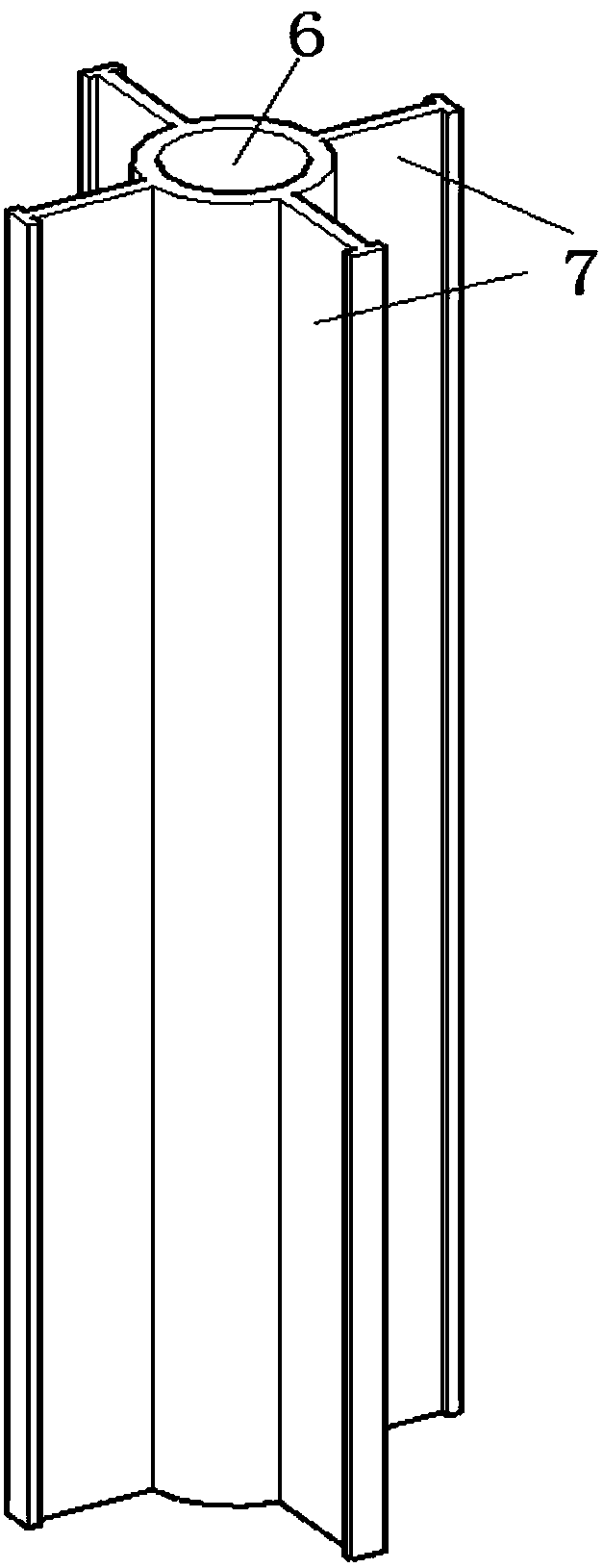

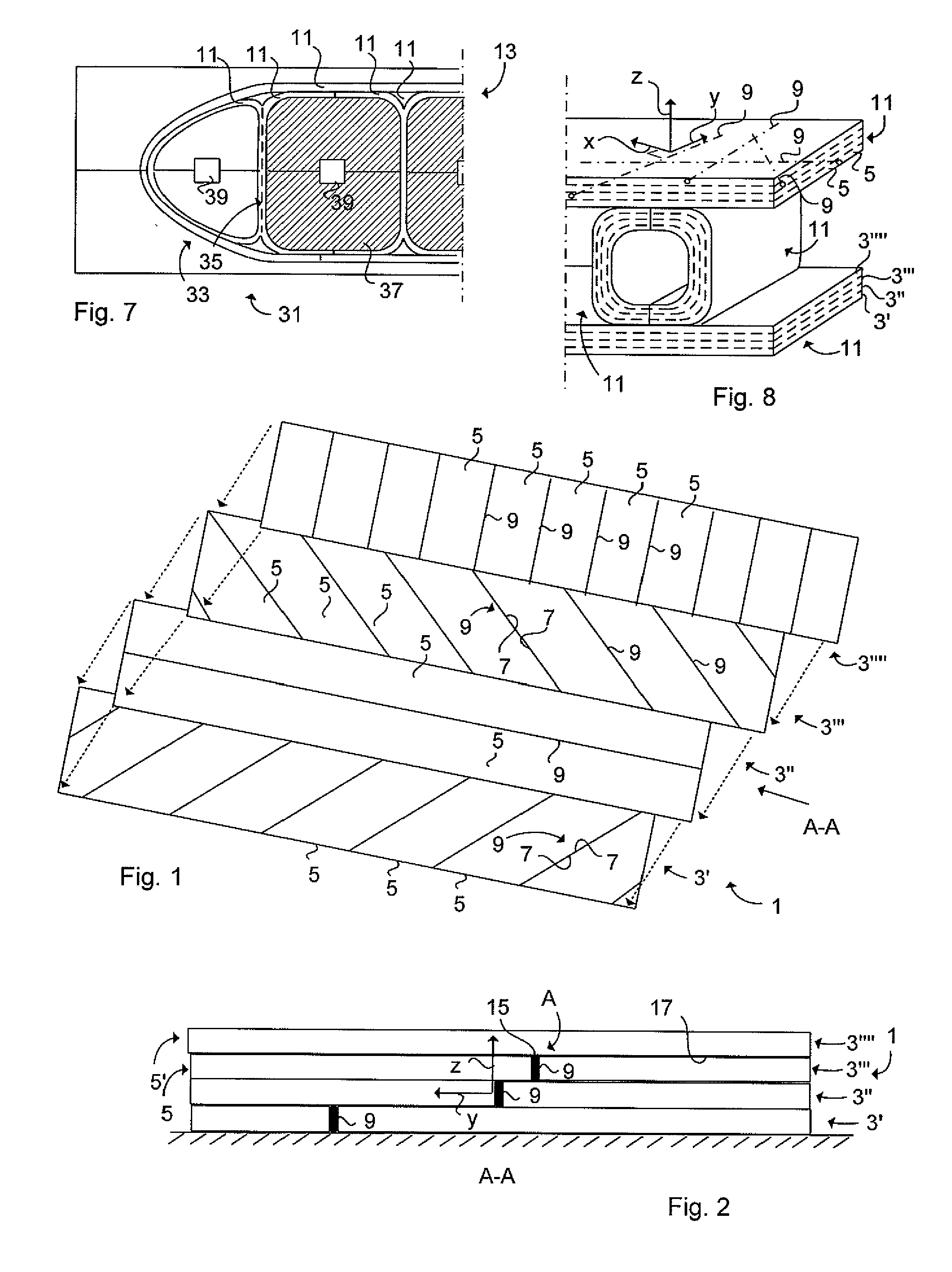

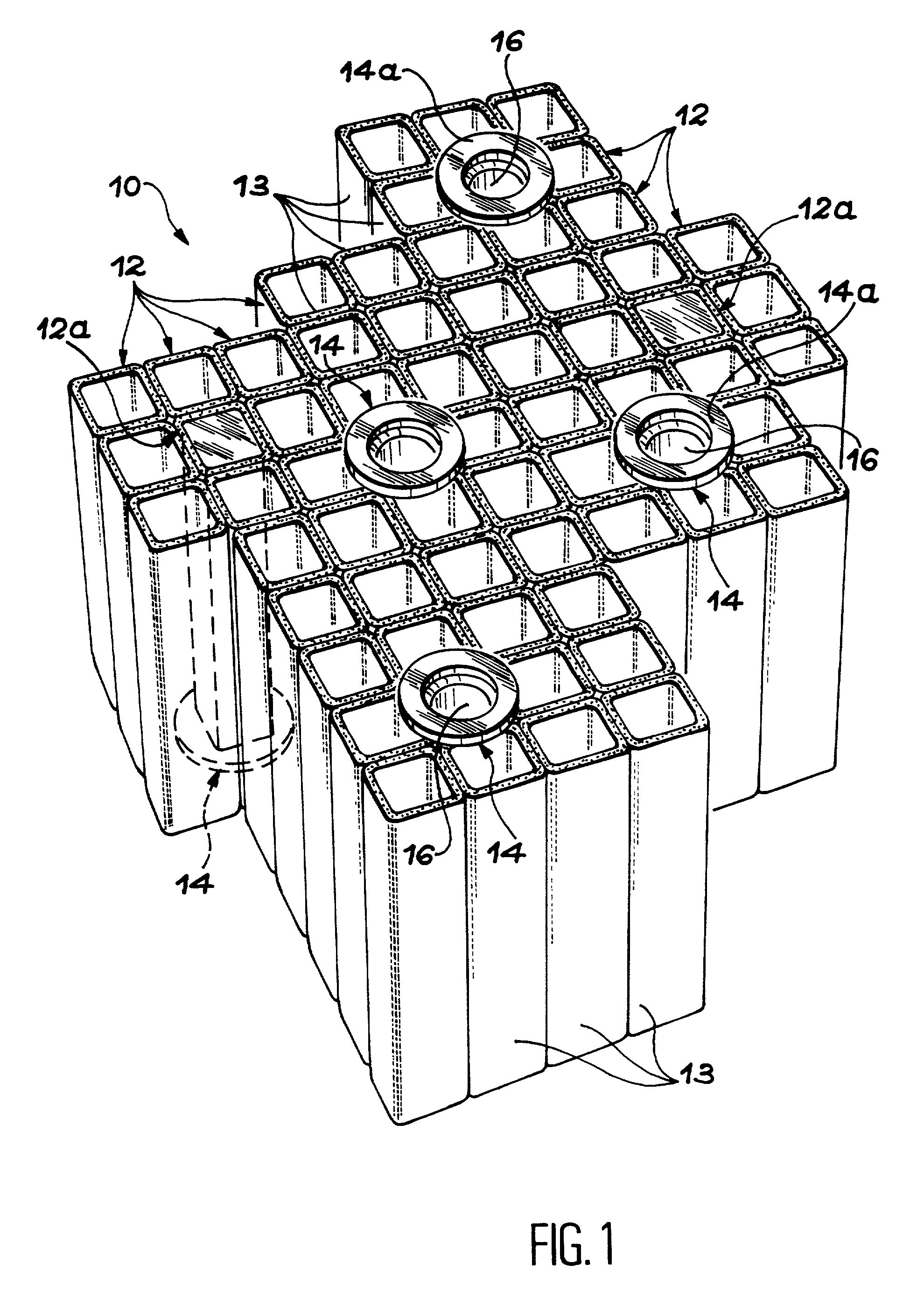

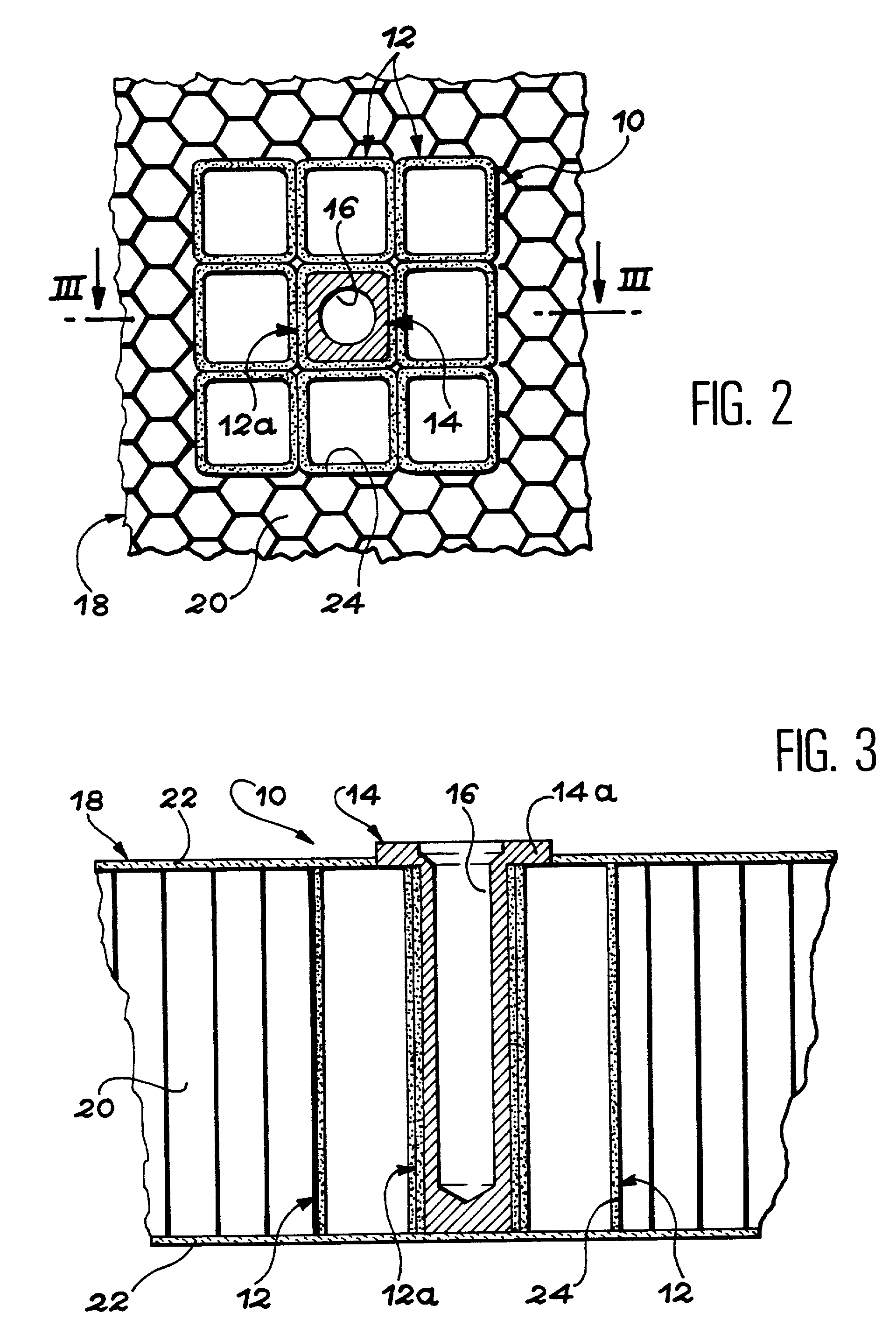

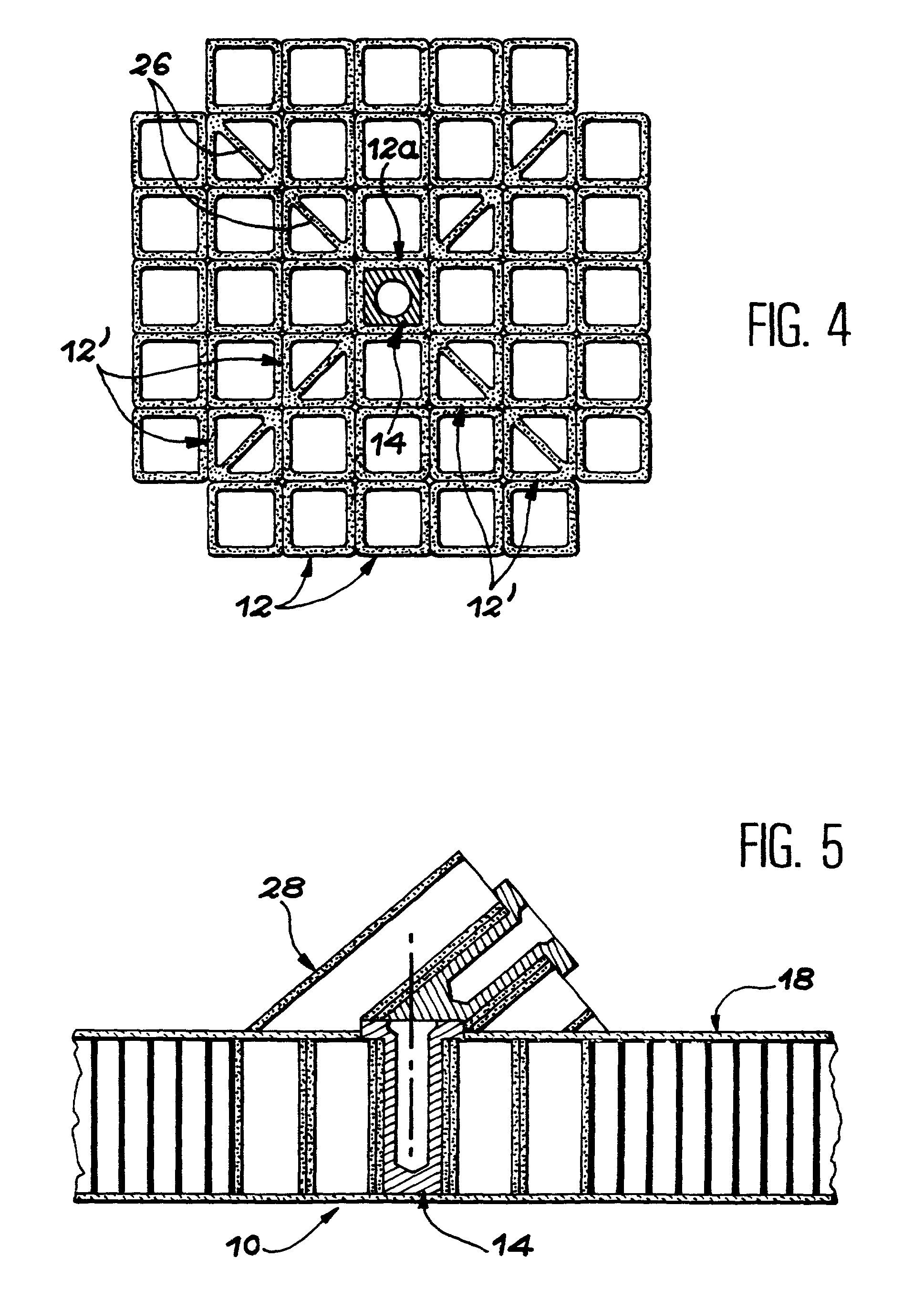

Composite joint for fitting at least one external member to a sandwich panel and panel integrating at least one such joint

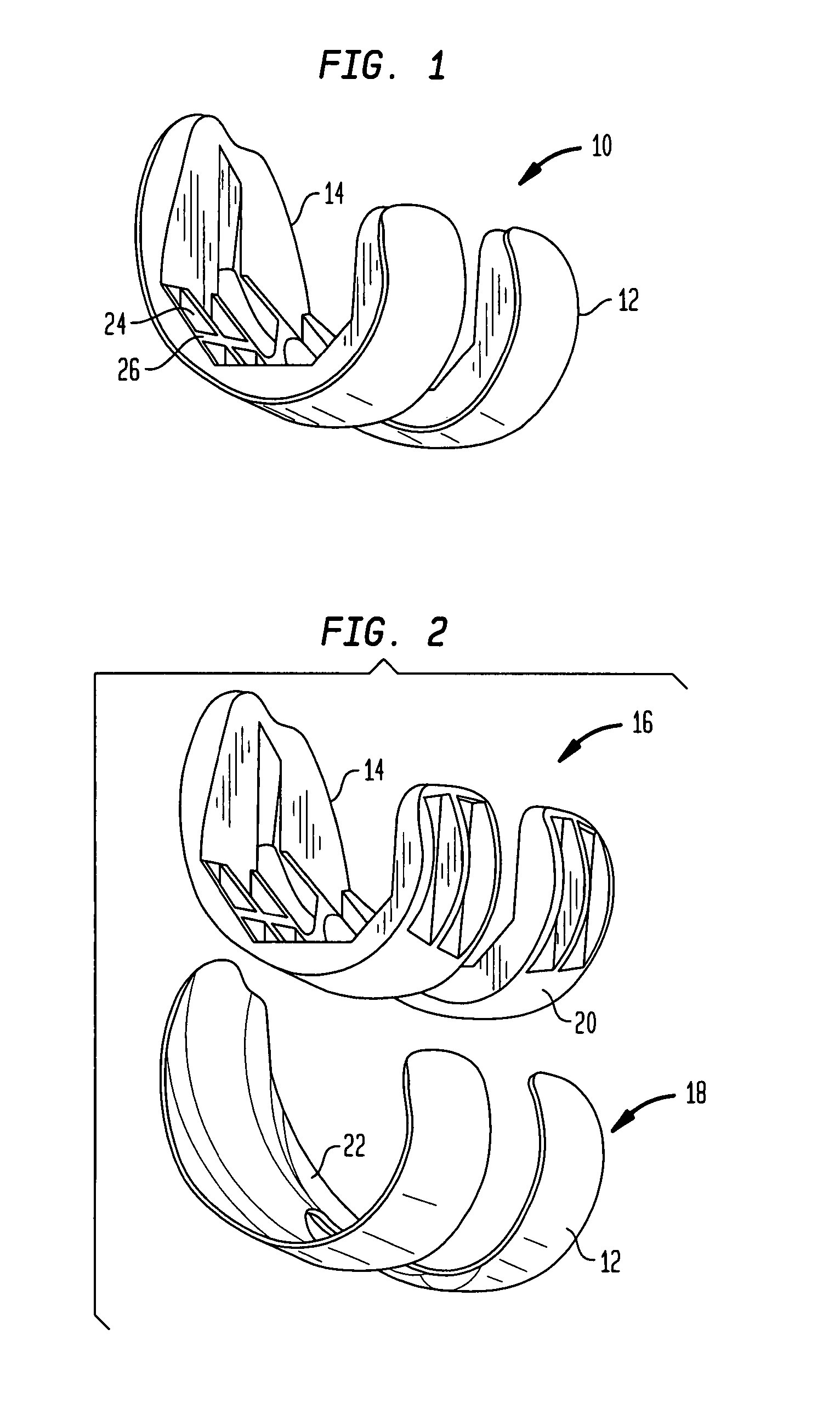

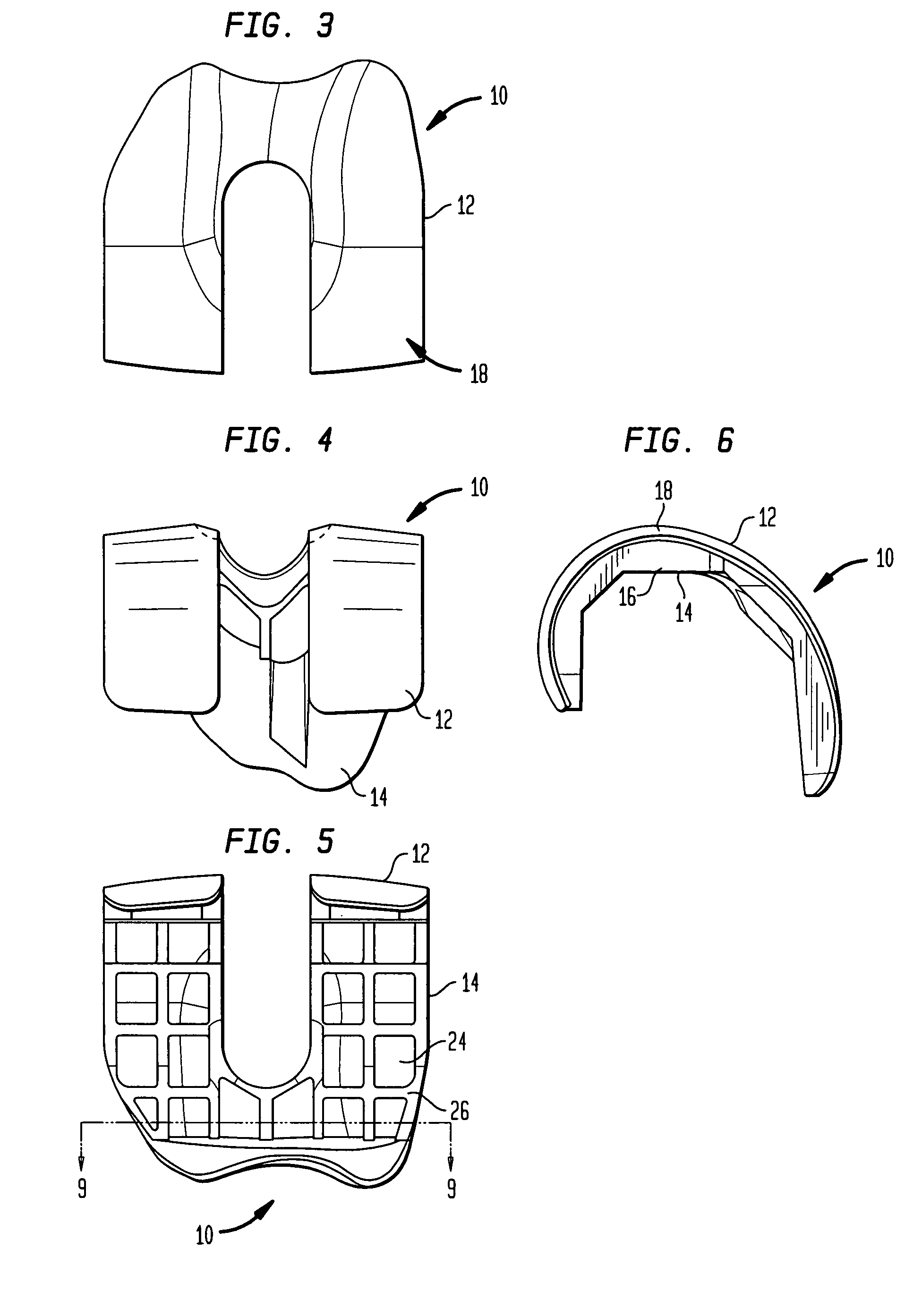

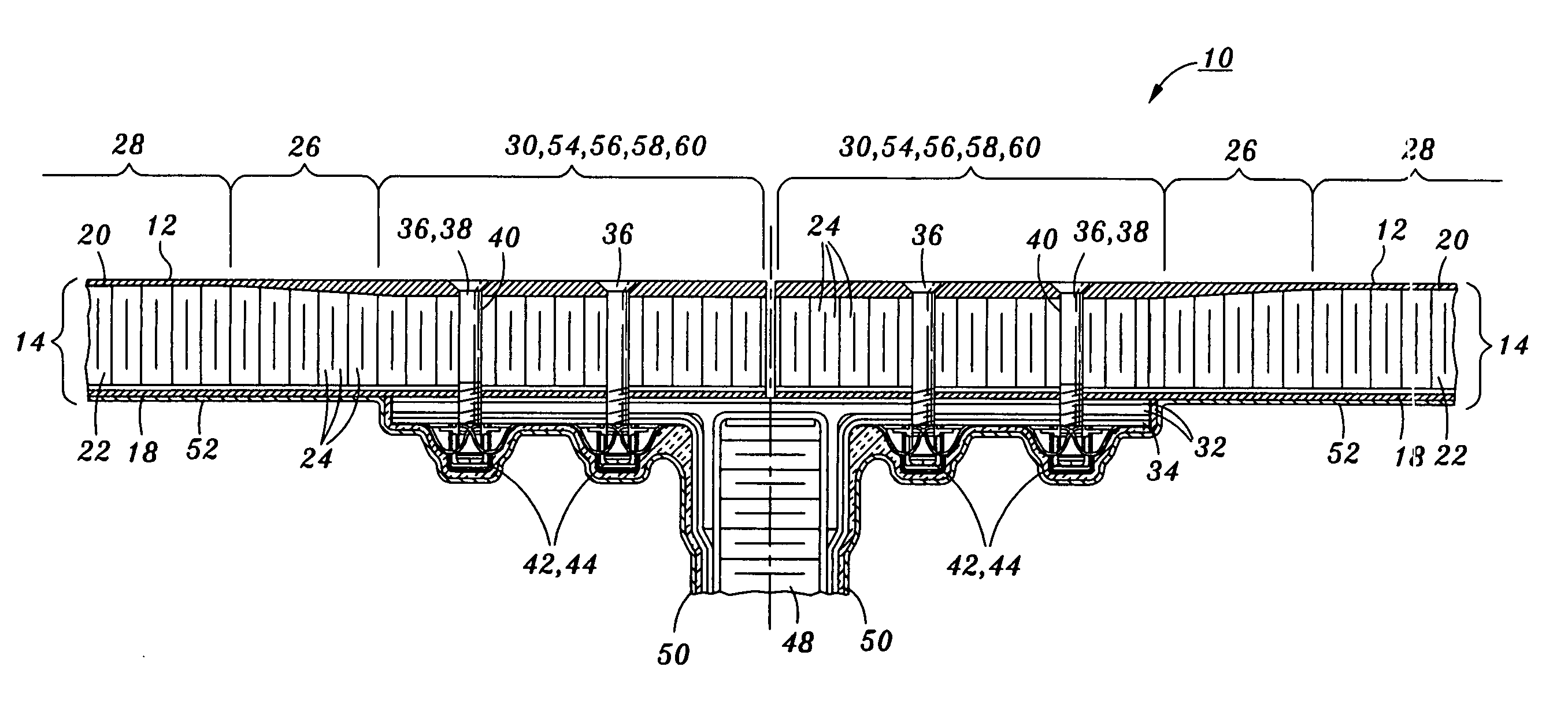

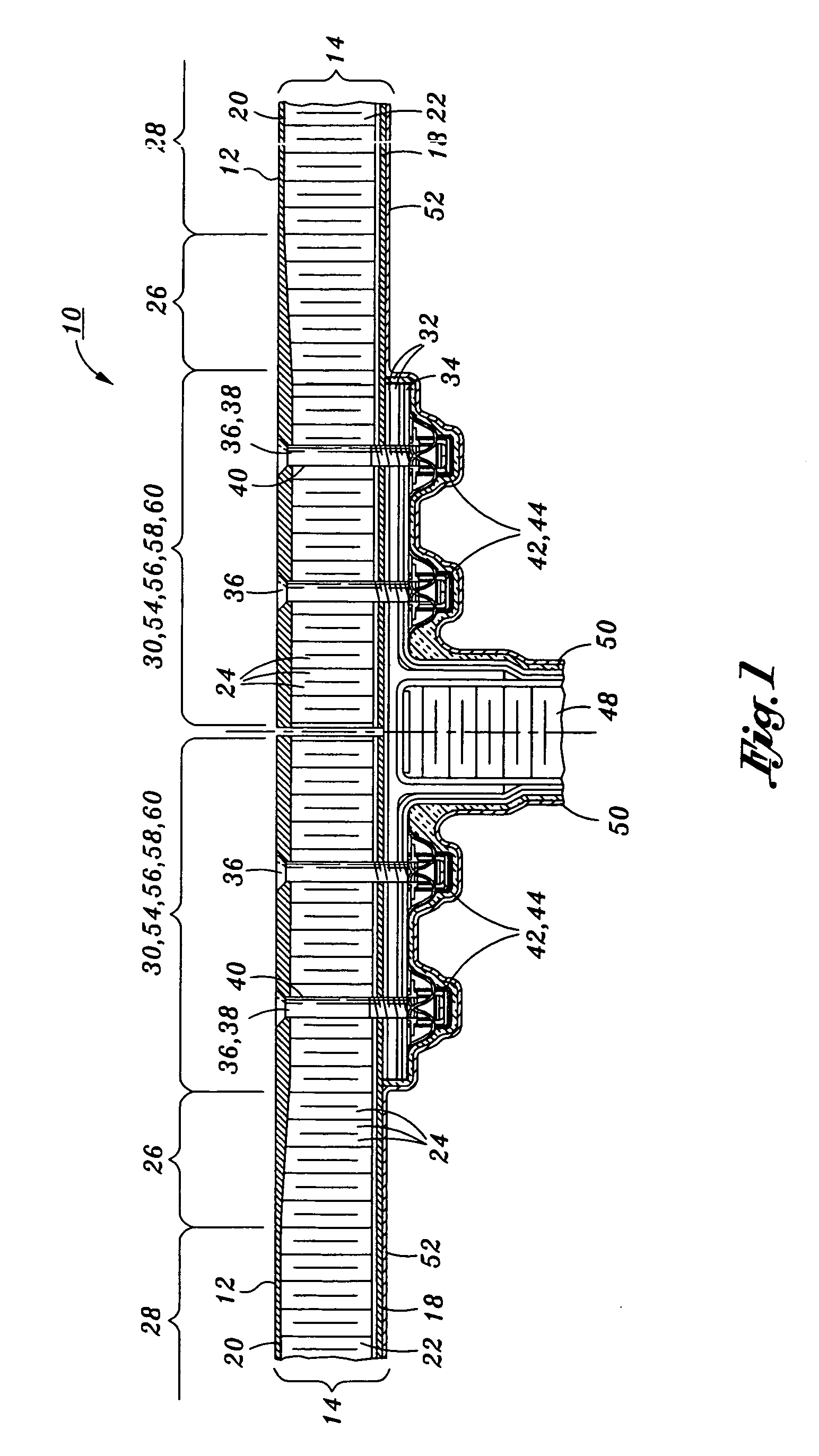

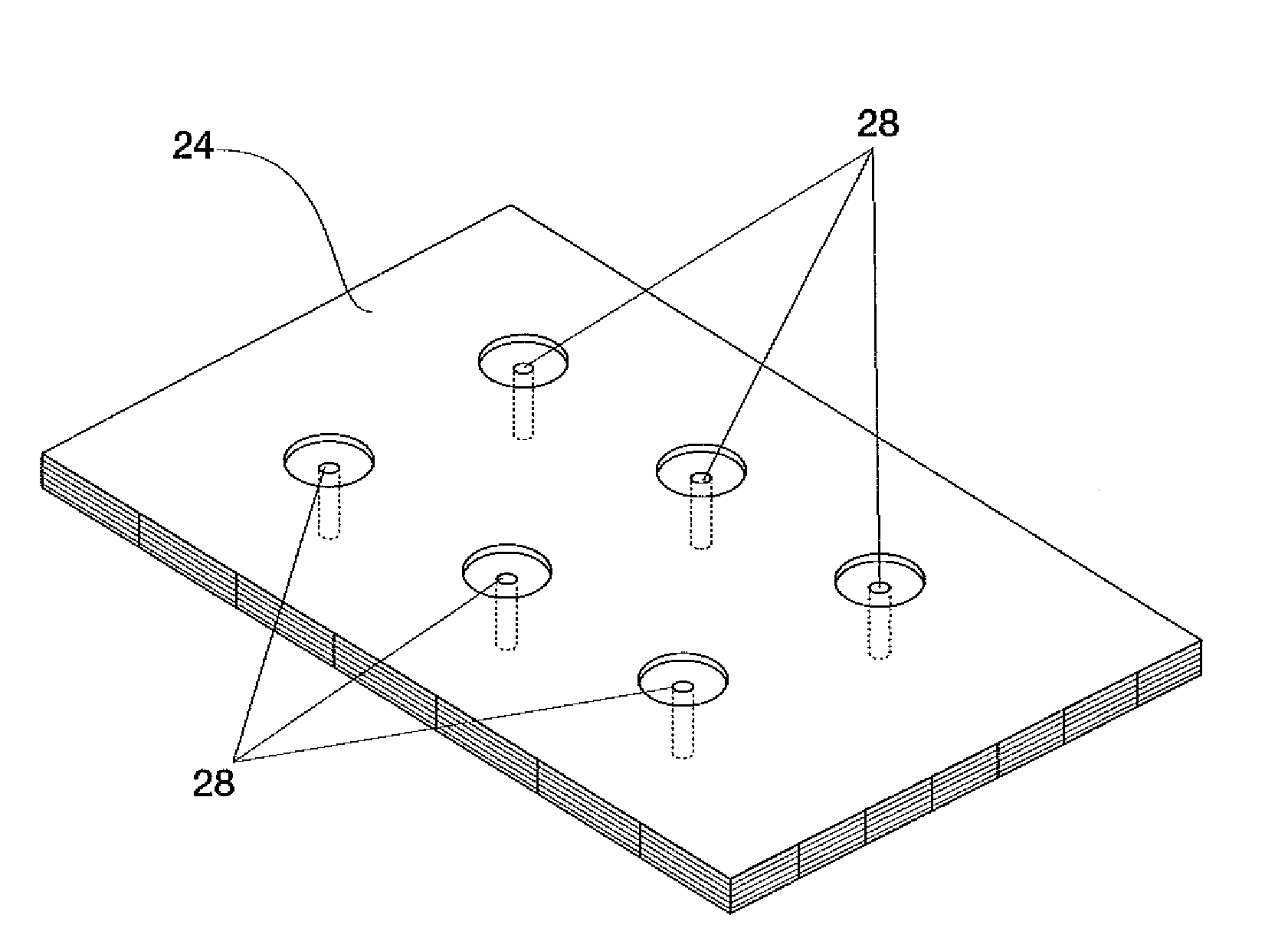

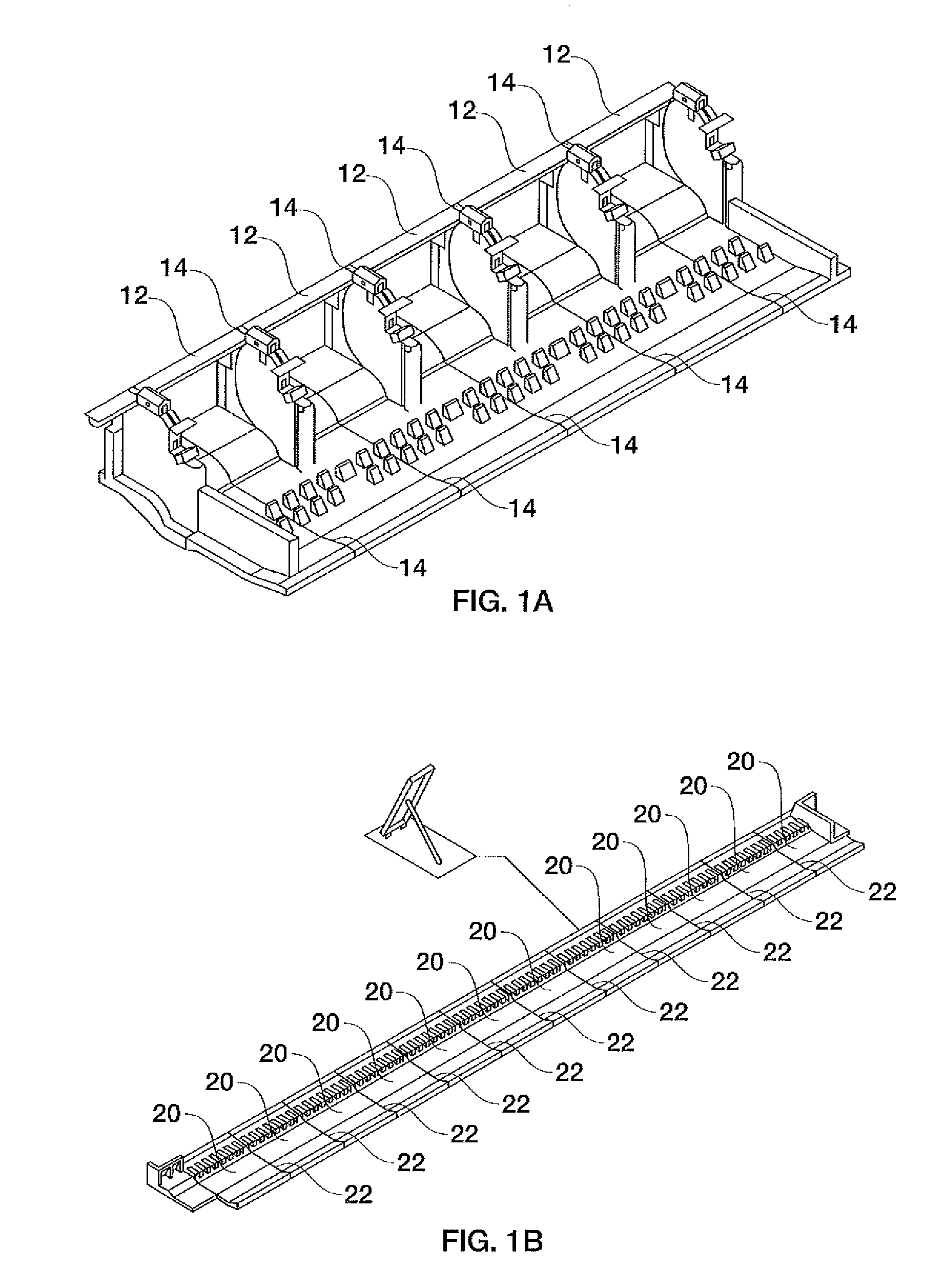

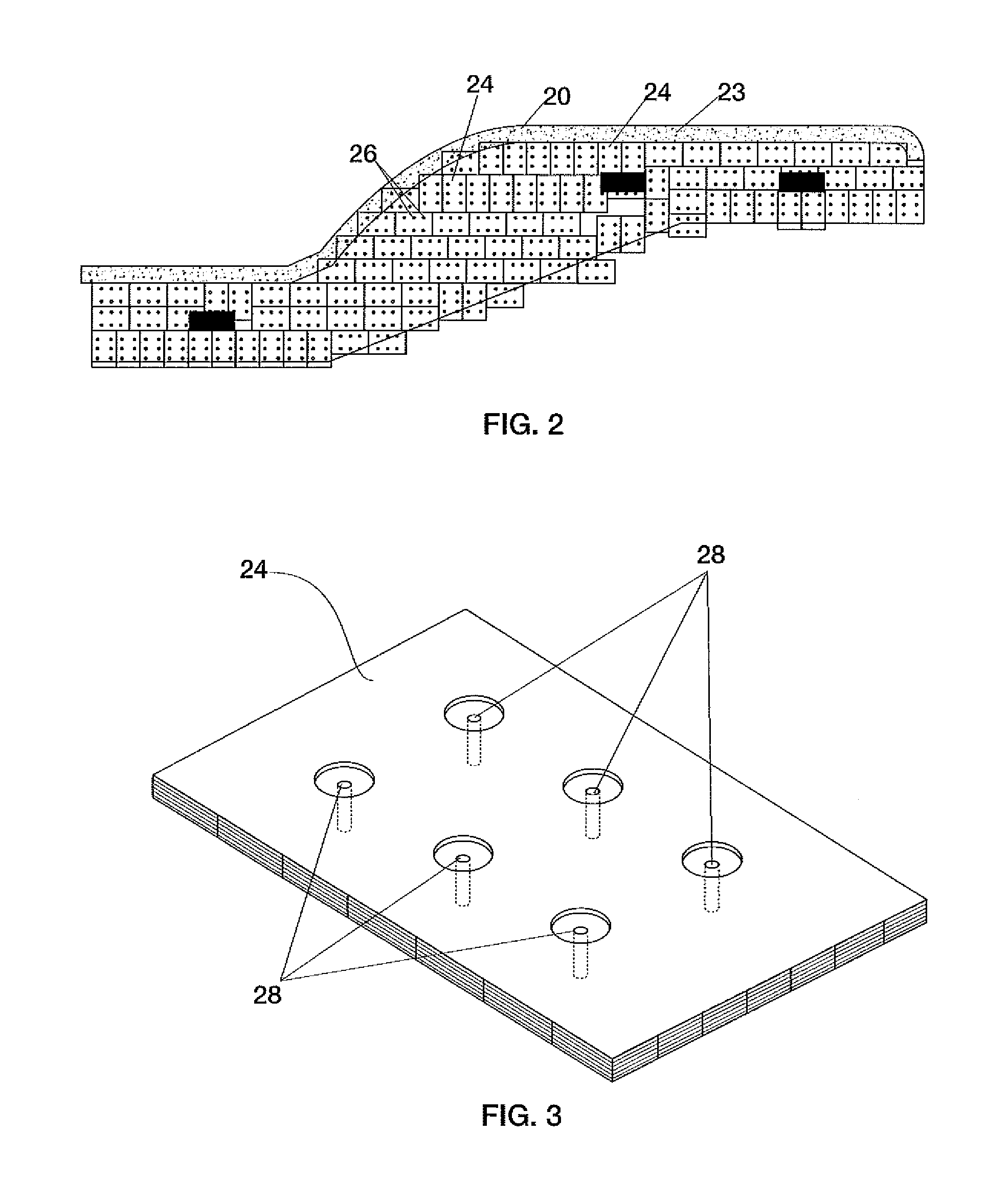

Composite joint for fitting at least one external member to a sandwich panel and panel integrating at least one such joint. To permit the transmission of static and / or dynamic stresses between at least one external member and a sandwich panel, into said panel is integrated at least one composite joint (10). Said joint comprises a plurality of juxtaposed, elementary, tubular cells (12), oriented in the panel thickness direction, as well as at least one stress introduction cell (12a), in which is fitted a rigid part (14) for fixing the external member. The tubular cells (12) comprise composite walls formed from braided fiber roves and resin.

Owner:SONACA

Multibarrel tube-confined concrete column and steel beam connection joint and manufacturing method thereof

InactiveCN110185160AGive full play to superior performanceImprove deformation abilityBuilding constructionsFloor slabReinforced concrete

The invention discloses a multibarrel tube-confined concrete column and steel beam connection joint and a manufacturing method thereof. The multibarrel tube-confined concrete column and steel beam connection joint comprises an inner steel tube, an outer steel tube, anchoring plates and steel beams, wherein the outer steel tube sleeves the inner steel tube, and steel beams are connected to the sidewall of the outer steel tube; the multiple anchoring plates are evenly arranged on the side wall of the inner steel tube, clamping grooves matched with the anchoring plates are formed in the outer steel tube, and the anchoring plates penetrate through the clamping grooves and extend out of the outer steel tube; and the extending ends of the anchoring plates and web plates of the steel beams are connected with first fixing mechanisms. The multibarrel tube-confined concrete column and steel beam connection joint is in an upper-welding and lower-bolting form, upper flanges of the steel beams andupper outer ring plates are connected through welding seams, and through reinforced concrete floor slabs, the connection welding beams can be effectively protected from being torn and damaged; and lower flanges of the steel beams and lower outer ring plates are connected through bolts, and thus the deformation capability of the composite joint under the effect of the earthquake load is enhanced.The manufacturing method of the multibarrel tube-confined concrete column and steel beam connection joint is simple and easy to operate and implement.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com