Fabricated steel-wood composite joint

A steel-wood combination and assembly technology, applied in truss structures, protective buildings/shelters, beams, etc., can solve problems such as lack of fire and moisture resistance, heat and fire resistance of steel structures, and poor corrosion resistance, and avoid Quality problems, improve construction efficiency, and achieve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

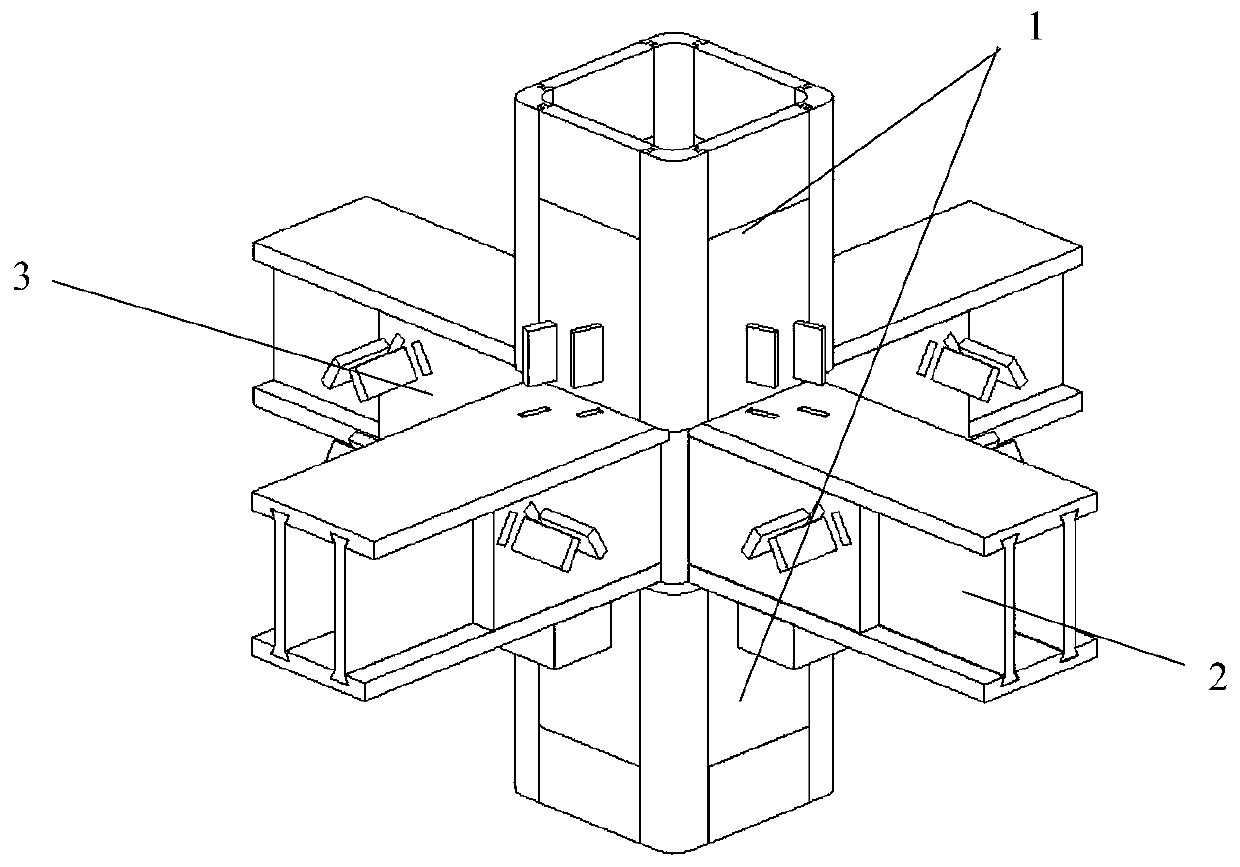

[0035] Embodiment 1, an assembled steel-wood composite node, such as figure 1 with Figure 10 As shown, it includes a square pipe column 1, a steel-wood composite beam 2, and a beam-column connection assembly 3 connecting the square pipe column 1 and the steel-wood composite beam 2;

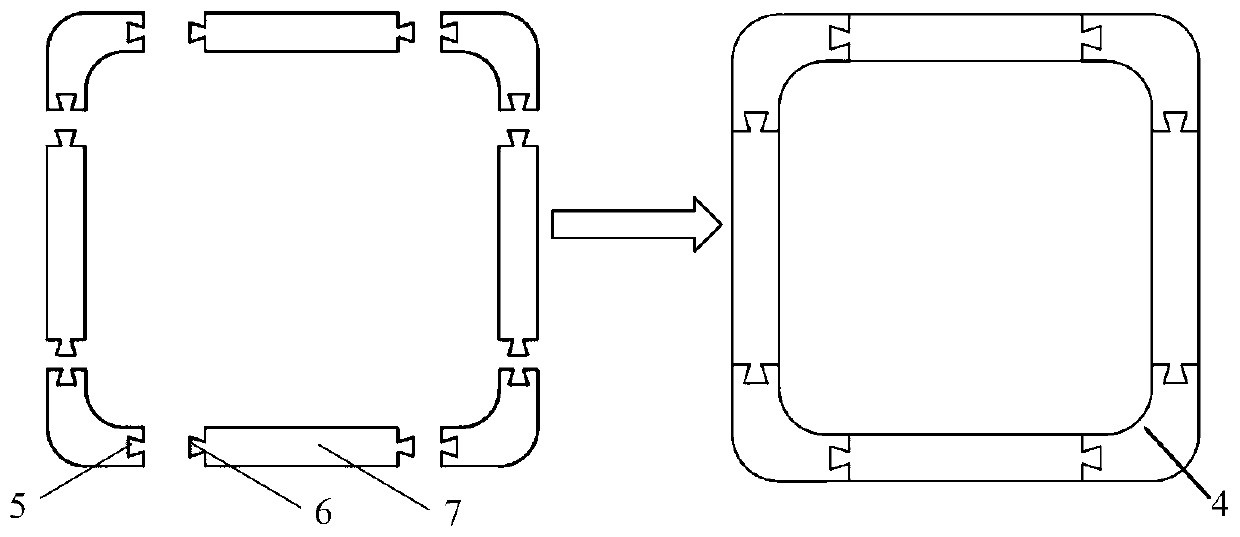

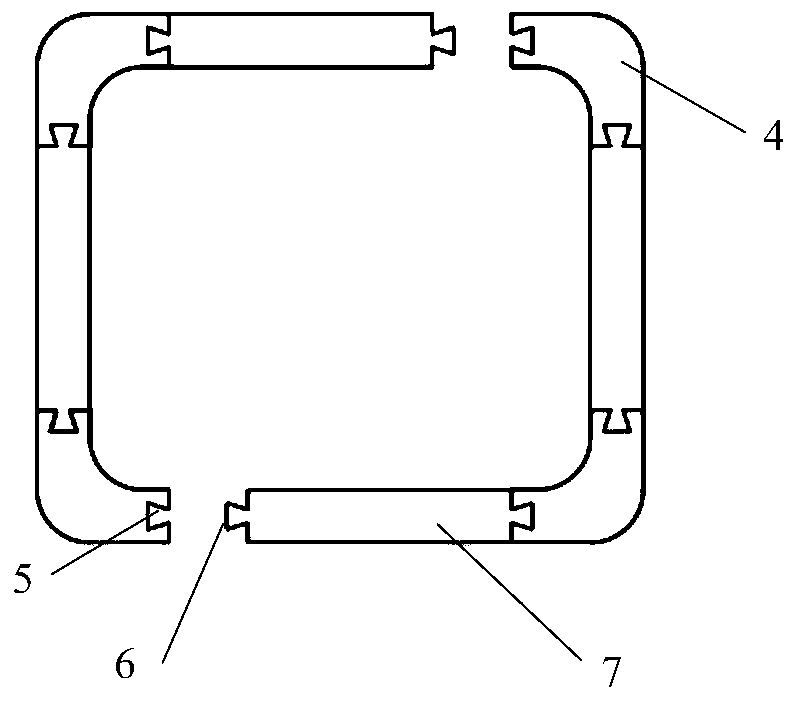

[0036] The square column 1 includes a connecting corner post 4 and a connecting side plate 7, such as figure 2 with image 3As shown, the square column 1 is composed of four connecting corner columns 4 and four connecting side panels 7 to form a hollow column structure, wherein the connecting corner columns 4 are column steel with high corrosion resistance, and the connecting side panels 7 are wooden boards . Compared with the pure steel structure, the steel-wood composite column has a higher bearing capacity per unit mass, which can reduce the weight of the overall structure to a certain extent and improve the overall life span. The cross-section of the connecting corner post 4 is a 90° arc...

Embodiment 2

[0047] The difference between Embodiment 2 and Embodiment 1 is that the center column beam-column connection assembly is replaced by the corner post connection assembly. For the corner post connection assembly, such as Figure 11 with 14 As shown, it adopts a similar design principle to the central column connection component, such as Figure 12 As shown, the shown corner post connection assembly also includes a square solid wooden post, two mutually perpendicular second square wooden beams ( 13 , 17 ) and two wooden bolts 26 . Respectively set I type chute 27 on both sides adjacent to the square solid wood column, the top of the I type chute 27 on one side runs through the whole solid wood column, the bottom of the I type chute on the other side runs through the whole solid wood column, the second The square wooden beam 13 and 17 is provided with the I type slide 29 that matches with the I type chute, and the I type slide 29 on the second square wooden beam 13 is arranged al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com