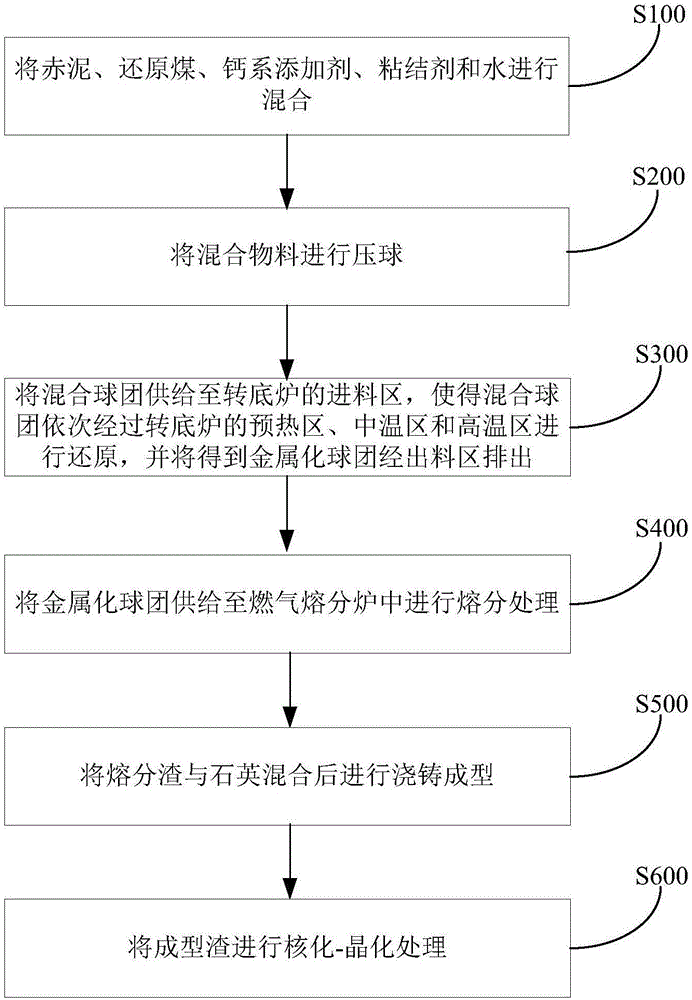

Method and system for processing red mud

A red mud and calcium-based technology, applied in the field of metallurgy, can solve problems such as poor corrosion resistance, retention, and secondary pollution, and achieve the effects of solving long-term storage, realizing comprehensive utilization, and improving metallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078]The composition of red mud is TFe23%. Put red mud, reduced coal, calcium carbonate, bentonite and water into the mixer according to the mass ratio of 100:15:4:2:14. The ball machine is used for briquetting, and the pressure of the briquetting machine is controlled at about 10MPa. The elliptical mixed pellets with a length of about 50mm and a thickness of 10-12mm can be obtained, and the pressed pellets are dried in a dryer at 200°C for 2 hours. Make sure that the dry ball moisture is less than 0.2%, and then distribute the dried pellets into the feed area of the rotary hearth furnace. The temperature is controlled at 1270°C±10°C, and the mixed pellets undergo reduction reactions in the preheating zone, medium temperature zone, and high temperature zone to obtain metallized pellets with a metallization rate greater than 85%, and the obtained metallized pellets pass through the discharge area Discharge, and then supply the obtained metallized pellets to a gas melting fur...

Embodiment 2

[0080] The red mud composition is TFe29%. Red mud, reduced coal, calcium carbonate, bentonite and water are added to the mixer according to the mass ratio of 100:23:8:4:18. After the materials are fully mixed and evenly passed through the roller press The ball machine is used for briquetting, and the pressure of the briquetting machine is controlled at about 10MPa. The elliptical mixed pellets with a length of about 50mm and a thickness of 10-12mm can be obtained, and the pressed pellets are dried in a dryer at 200°C for 2 hours. Make sure that the dry ball moisture is less than 0.2%, and then distribute the dried pellets into the feed area of the rotary hearth furnace. The temperature is controlled at 1270°C±10°C, and the mixed pellets undergo reduction reactions in the preheating zone, medium temperature zone, and high temperature zone to obtain metallized pellets with a metallization rate greater than 85%, and the obtained metallized pellets pass through the discharge area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com