Method for extracting various active ingredients from dendrobium officinale

A technology of Dendrobium candidum and active ingredients, which is applied in the field of extraction and separation of active ingredients of Chinese herbal medicines, can solve the problems of effective utilization of unfavorable raw materials, low extraction efficiency, long extraction time, etc., so as to improve effective extraction efficiency, comprehensive utilization rate, and high extraction efficiency , the effect of short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

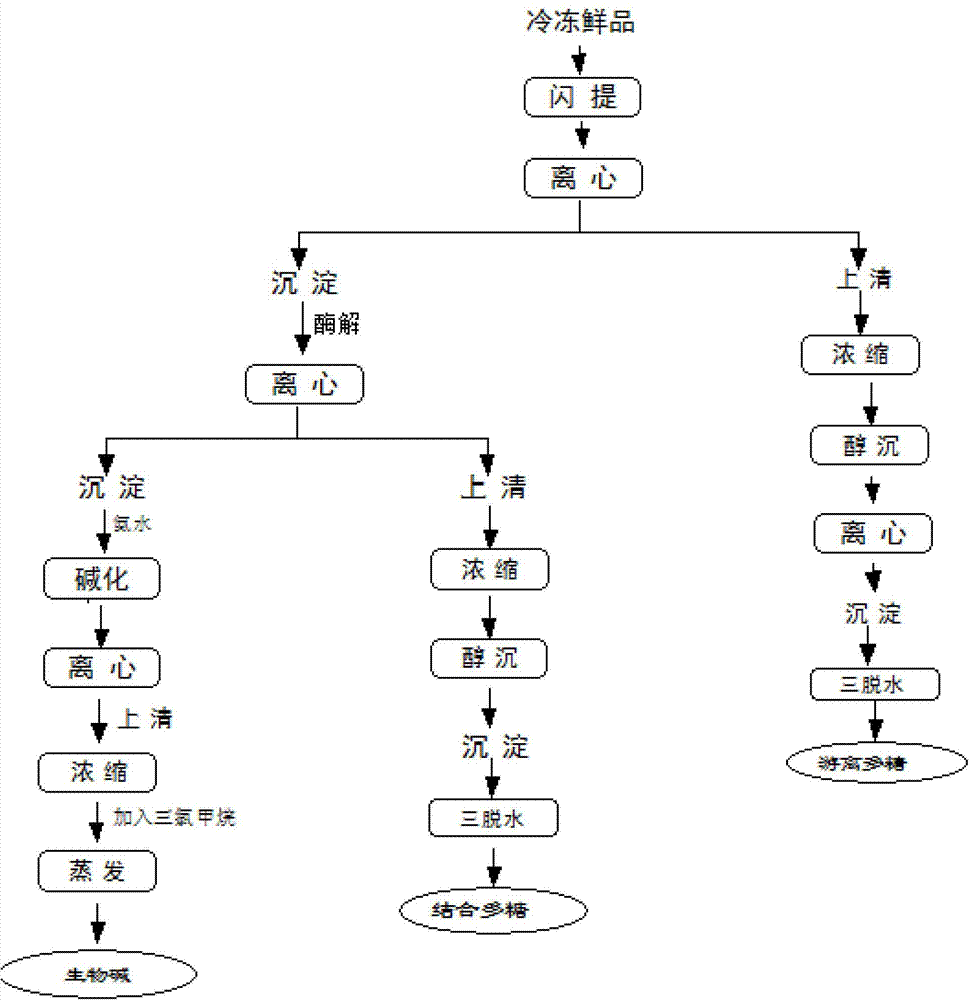

Image

Examples

Embodiment 1

[0054] A method for extracting active ingredient free polysaccharides from Dendrobium officinale, specifically comprising the following steps:

[0055] The first step: material pretreatment:

[0056] Weigh 80g of fresh Dendrobium candidum stored at -20℃, crush it, and add 1200ml of ultrapure water (solid-to-liquid ratio 1:15) for later use.

[0057] The second step: the crushed Dendrobium candidum is subjected to flash extraction:

[0058] According to the conditions of flash extraction time 2min (1min / time) and flash extraction rotation speed 4000rpm, the crude extract of Dendrobium candidum was obtained.

[0059] Step 3: Centrifuge the crude extract:

[0060] Centrifuge the crude extract after flash extraction, using a normal temperature centrifuge with a rotation speed of 5000rpm, and centrifuge for 15min. The water-soluble free polysaccharide exists in the centrifuged supernatant A, and the centrifuged precipitate A is retained. At this time, the polysaccharide exists i...

Embodiment 2

[0068] The difference between this example and Example 1 is that it includes the process of preparing the conjugated polysaccharide, specifically:

[0069] Add pure water (solid-to-liquid mass ratio: 1:3) to the precipitate A obtained by centrifugation in the third step, stir well to make it uniform, add cellulase (dry basis) according to the mass of precipitate A at 0.6%, and add cellulase according to the mass of precipitate A Add papain at 1.5%, adjust to PH = 5, place in a water bath at a temperature of 50°C, stir with a stirrer, and react for 1.5h. After completion, the reacted solution was heated to boiling and kept boiling for 3 minutes to remove excess protein. Then centrifuge at 5000 rpm for 15 minutes, the bound polysaccharide exists in the supernatant B after centrifugation, and the precipitate B after centrifugation is preserved. Take the supernatant B and add ethanol until the volume concentration of ethanol in the final solution reaches 80%, place it for 1.5h, u...

Embodiment 3

[0071] The difference between this embodiment and embodiment 2 is: it also includes the step of extracting alkaloids, specifically:

[0072] Add ammonia water to the precipitate B obtained in the step of Example 2 for alkalization. After alkalization, add ethanol with a purity of 90%, and centrifuge to get the supernatant C. After the supernatant C was concentrated, chloroform was added, and the chloroform volatilized to obtain a solidified alkaloid, and the mass of the alkaloid was weighed to be 0.15 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com