Patents

Literature

88 results about "Thermal Destructions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

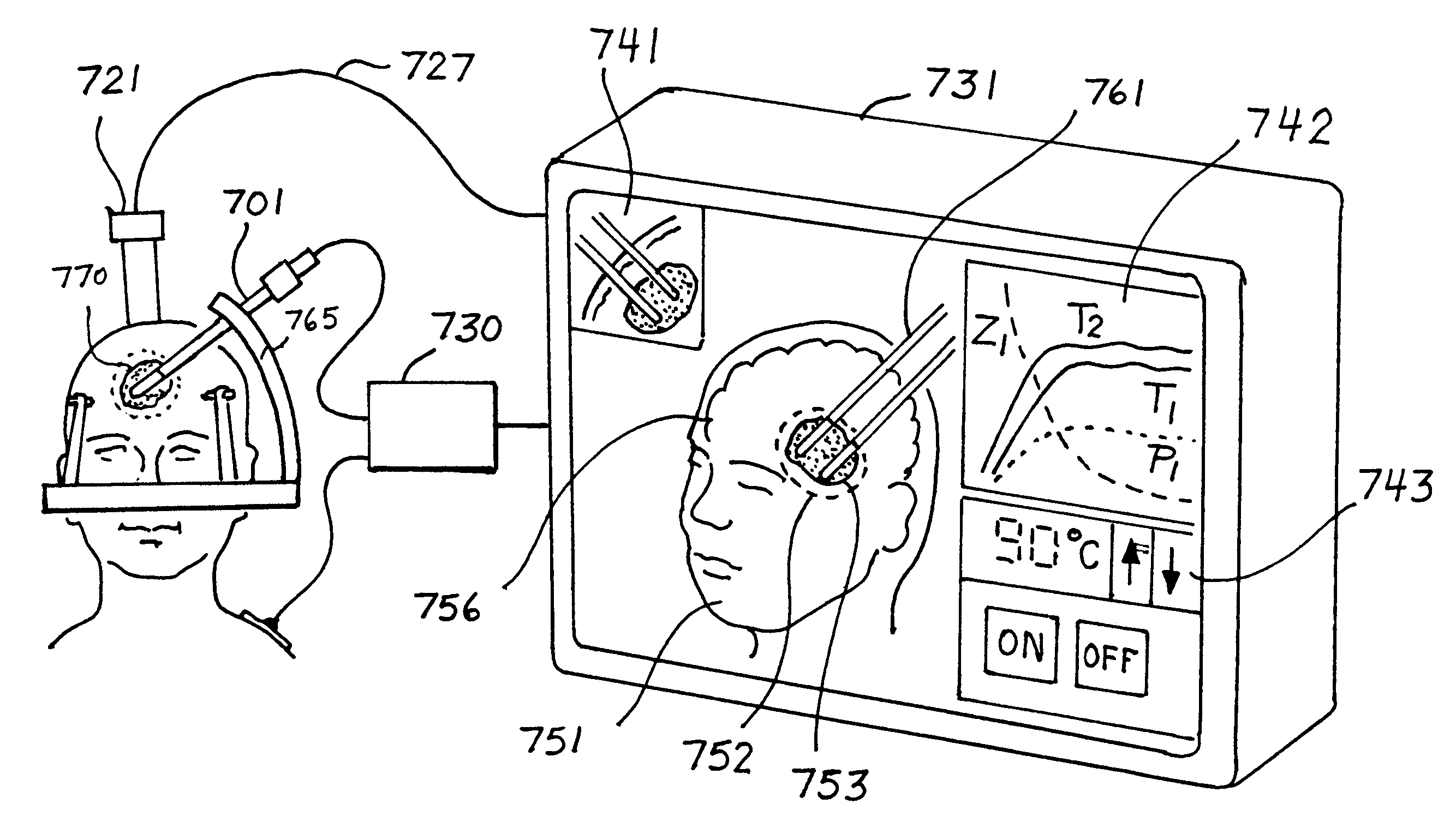

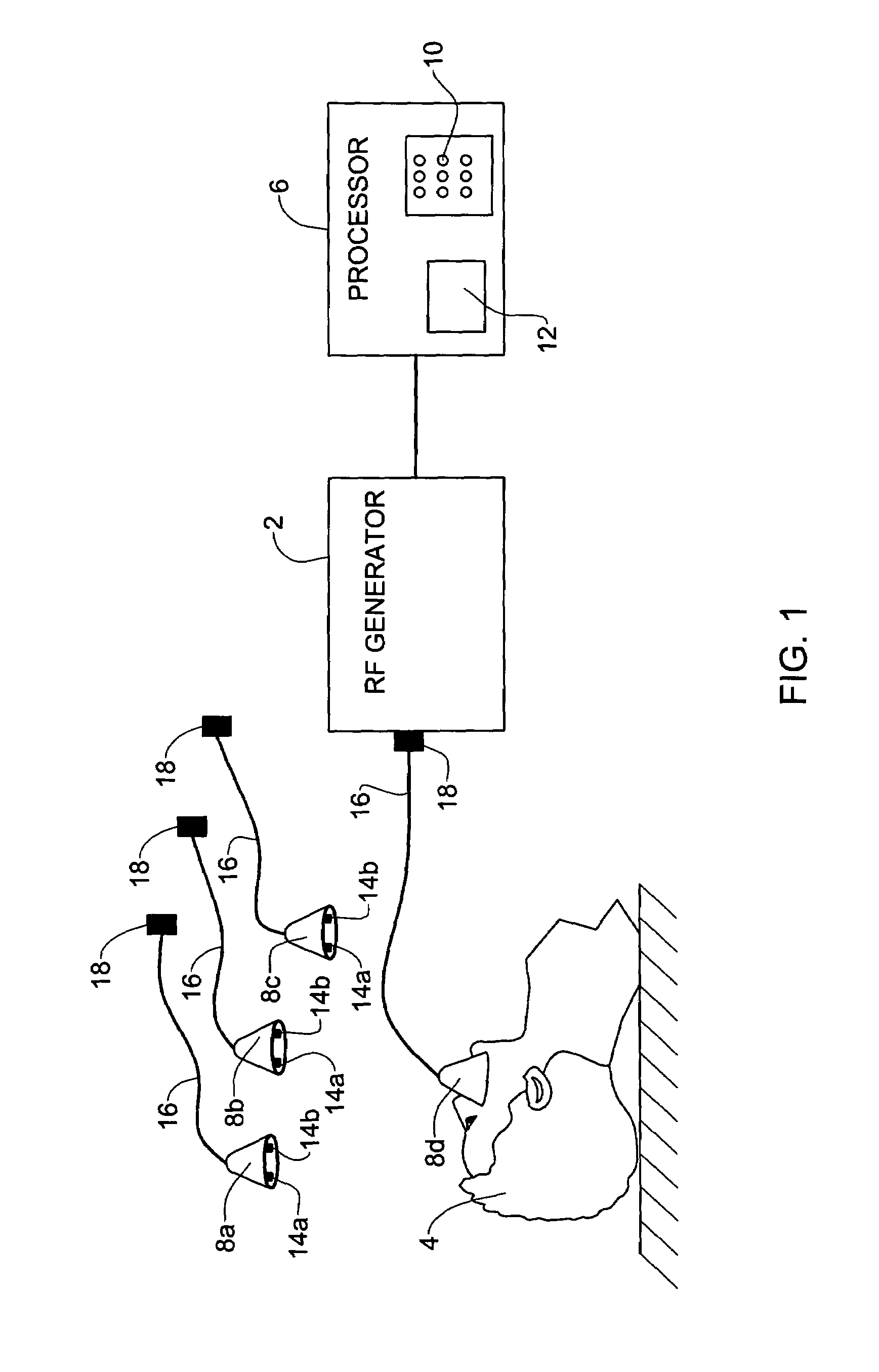

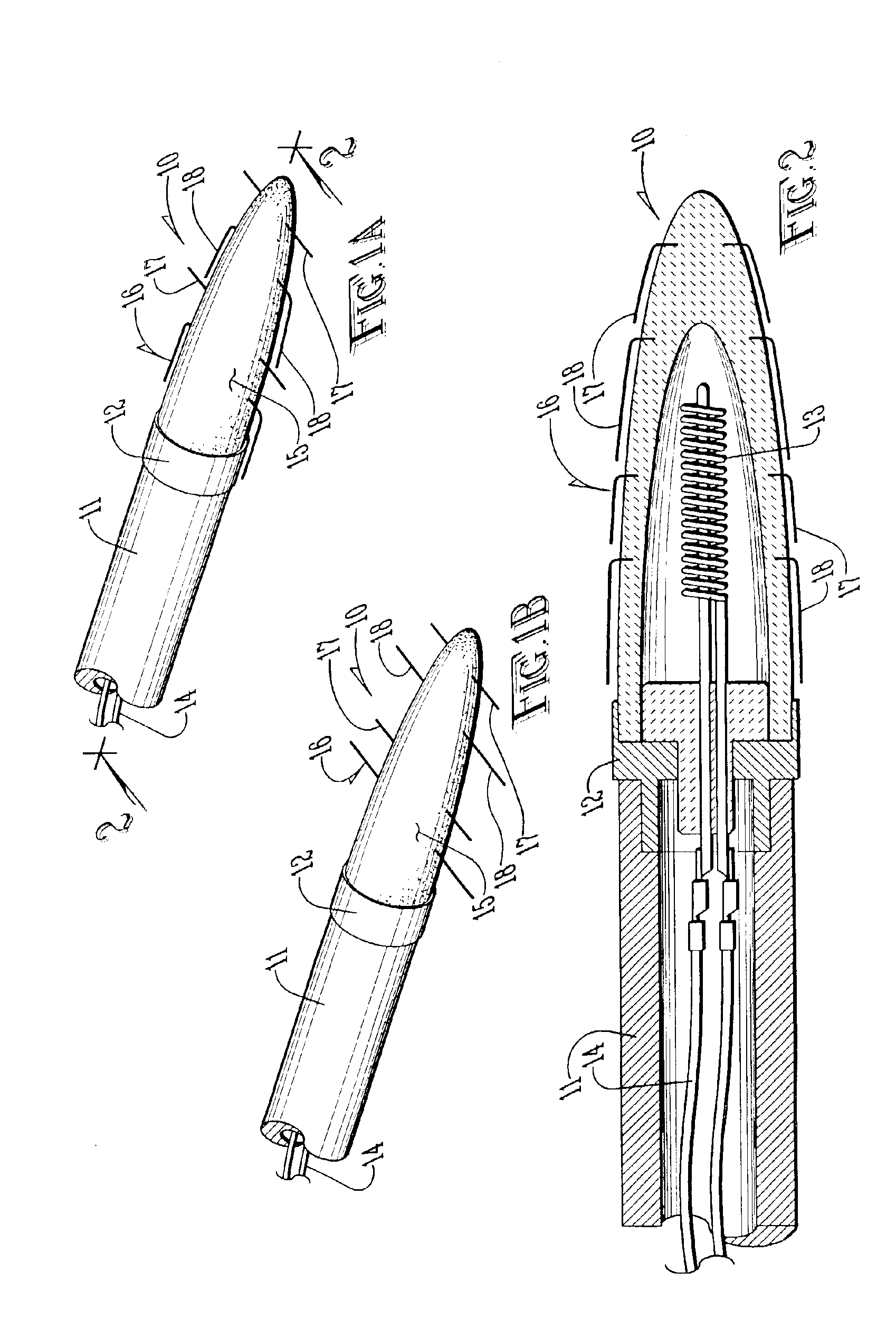

High frequency thermal ablation of cancerous tumors and functional targets with image data assistance

InactiveUS6241725B1Ultrasonic/sonic/infrasonic diagnosticsSurgical needlesAbnormal tissue growthTumour volume

This invention relates to the destruction of pathological volumes or target structures such as cancerous tumors or aberrant functional target tissue volumes by direct thermal destruction. In the case of a tumor, the destruction is implemented in one embodiment of the invention by percutaneous insertion of one or more radiofrequency probes into the tumor and raising the temperature of the tumor volume by connection of these probes to a radiofrequency generator outside of the body so that the isotherm of tissue destruction enshrouds the tumor. The ablation isotherm may be predetermined and graded by proper choice of electrode geometry and radiofrequency (rf) power applied to the electrode with or without temperature monitoring of the ablation process. Preplanning of the rf electrode insertion can be done by imaging of the tumor by various imaging modalities and selecting the appropriate electrode tip size and temperature to satisfactorily destroy the tumor volume. Computation of the correct three-dimensional position of the electrode may be done as part of the method, and the planning and control of the process may be done using graphic displays of the imaging data and the rf ablation parameters. Specific electrode geometries with adjustable tip lengths are included in the invention to optimize the electrodes to the predetermined image tumor size.

Owner:COVIDIEN AG

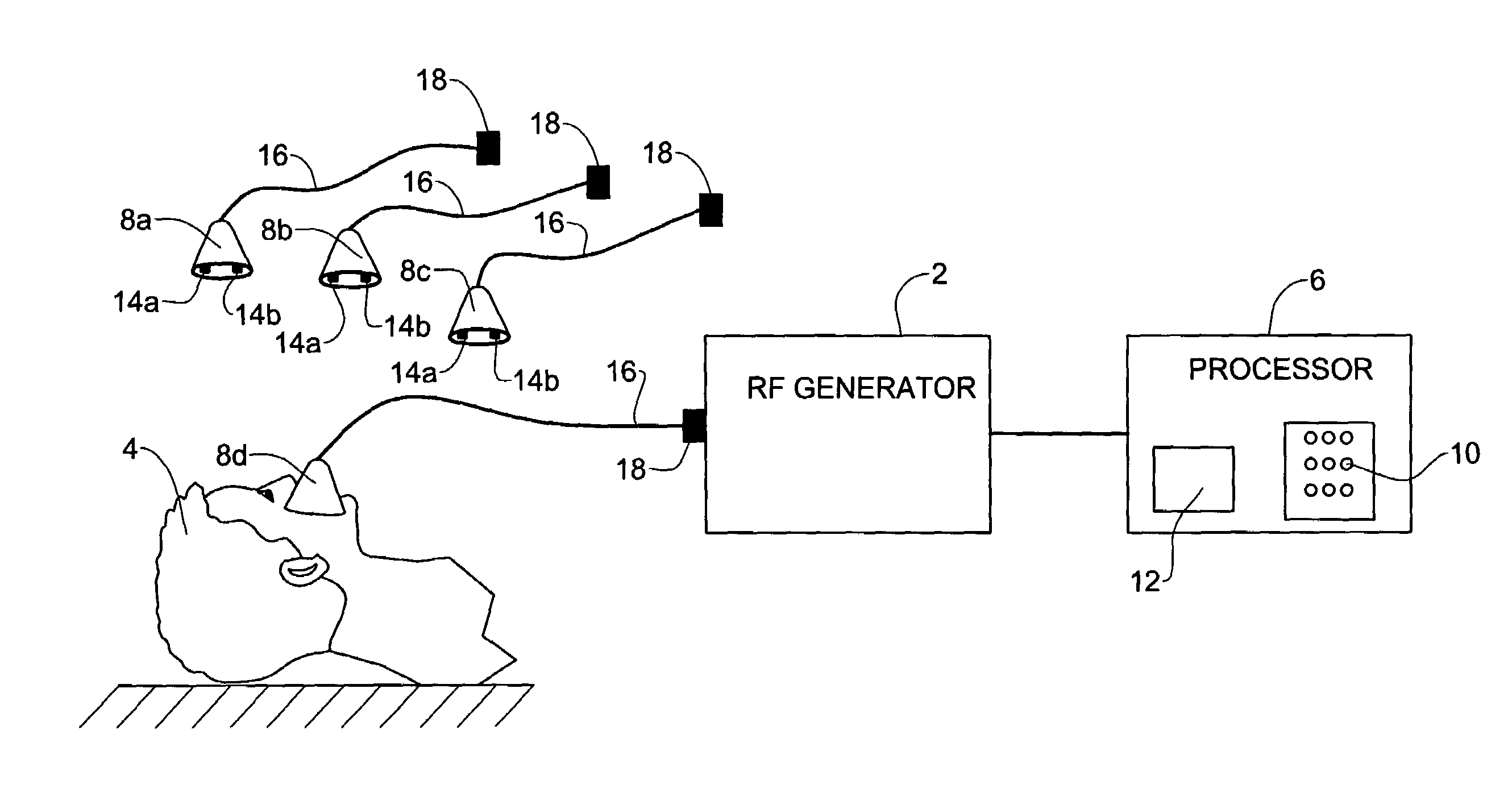

Method and system for selective electro-thermolysis of skin targets

A method for non-invasive selective thermal destruction of a skin target by RF current. One or more characteristics of an RF current and a bipolar RF electrode system are determined based upon one or more features of the target in order to create in the target an average energy density exceeding 5 Joules / cm3 but lower than a skin coagulation level. The determined electrode system is then applied to the skin and an average energy density exceeding 5 Joules / cm3 but lower than a skin coagulation level is generated in the target.

Owner:SYNERON MEDICAL LTD

Method and devices for creating a multiplicity of holes in workpieces

InactiveUS20130209731A1Quality improvementReduce material strengthLayered productsGlass reforming apparatusThermal DestructionsLaser beams

Methods and apparatuses for producing a multiplicity of holes in thin workpieces made of glass or glass-like materials and semiconductors are provided. The method includes directing multiple laser beams onto predetermined perforation points of the workpiece in a wavelength range between 1600 and 200 nm and with a radiation intensity that causes local non-thermal destruction of the workpiece material along respective filamentary channels. Subsequently, the filamentary channels are widened to the desired diameter of the holes.

Owner:SCHOTT AG

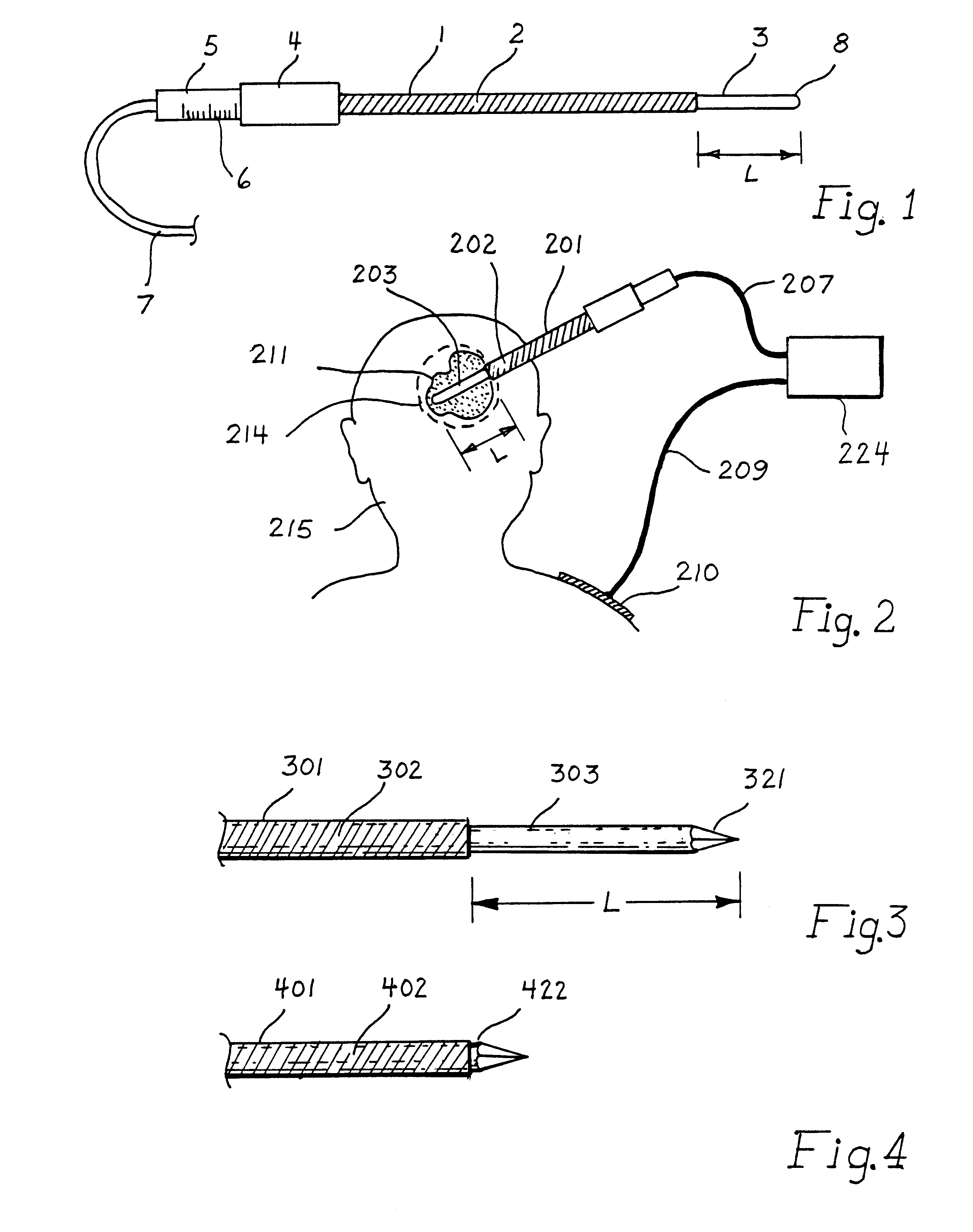

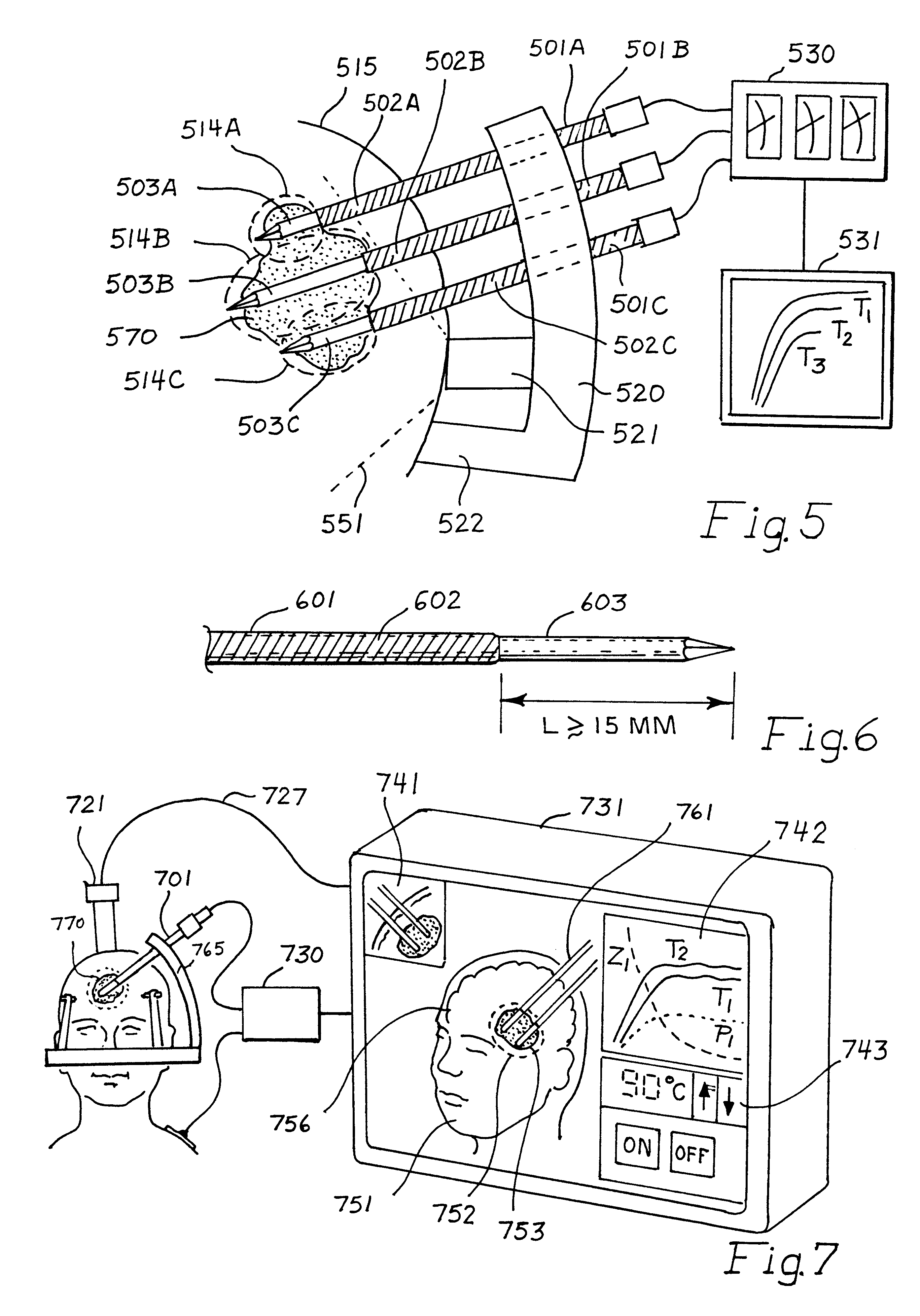

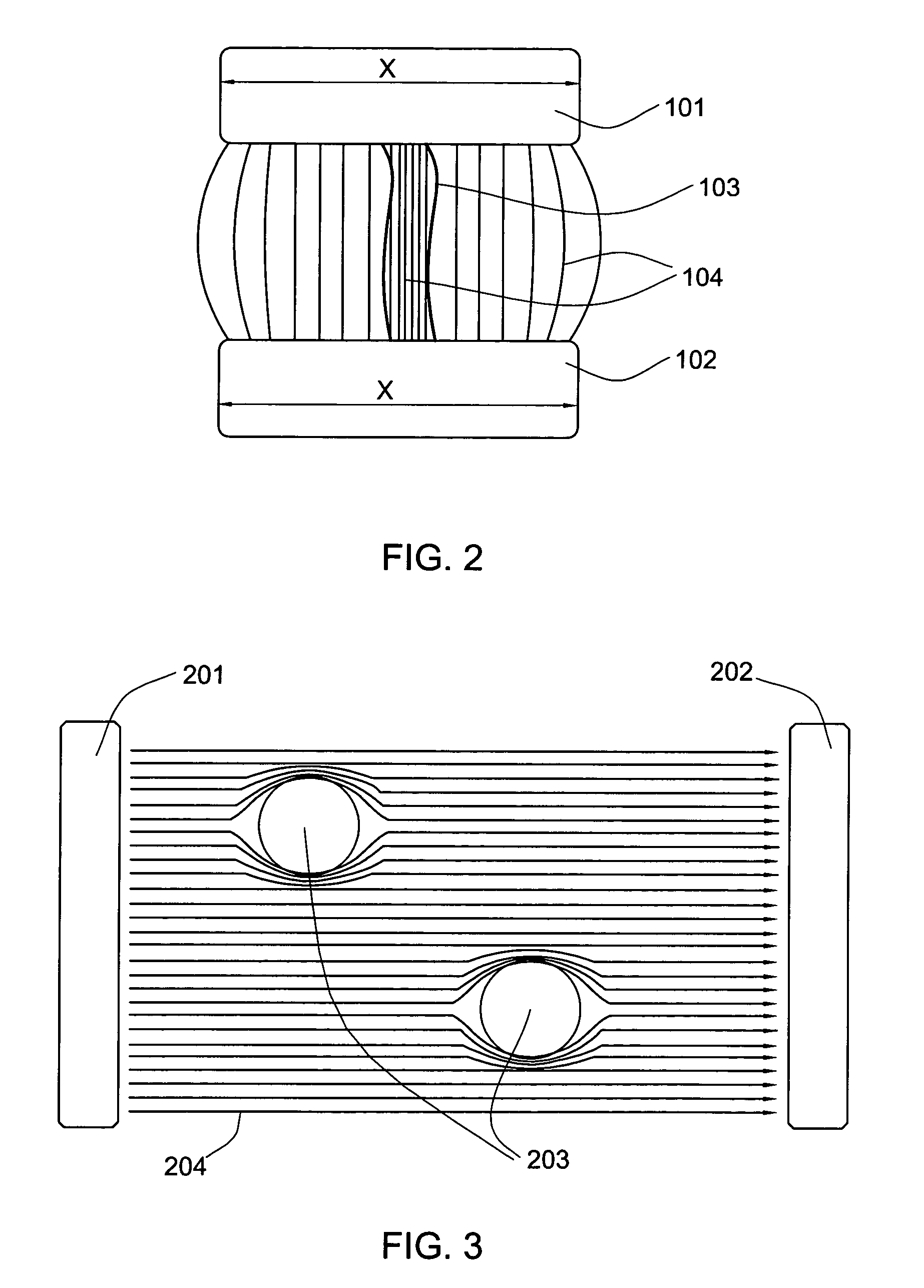

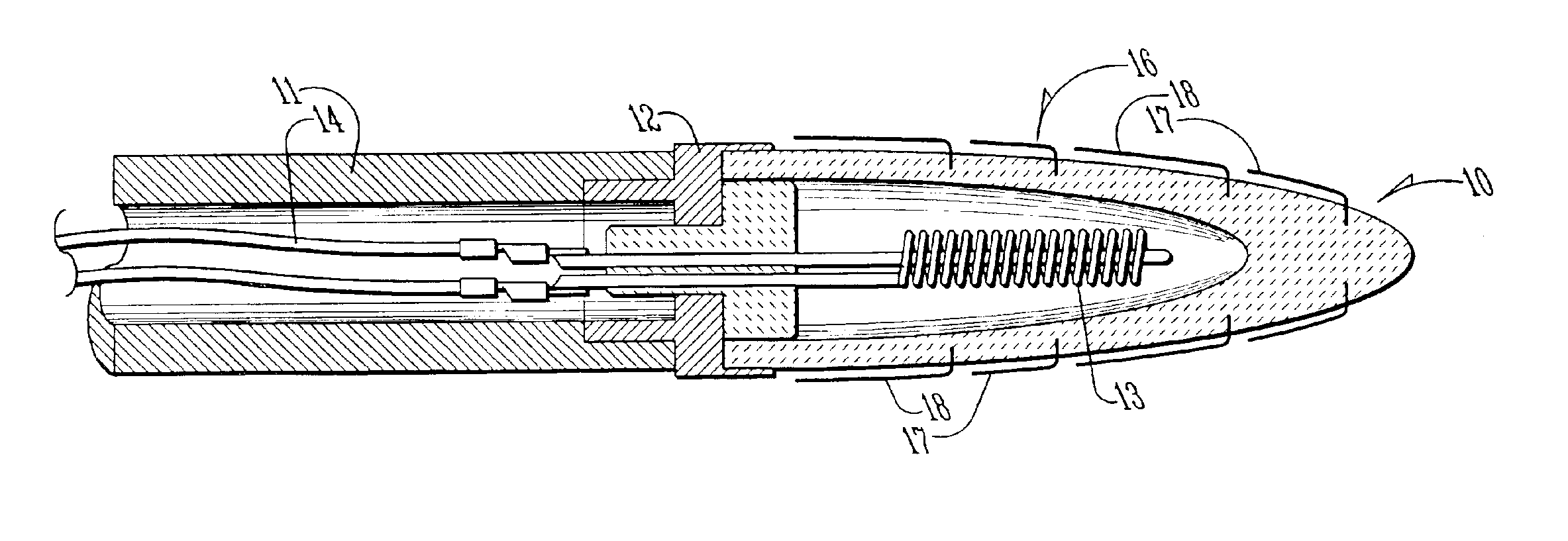

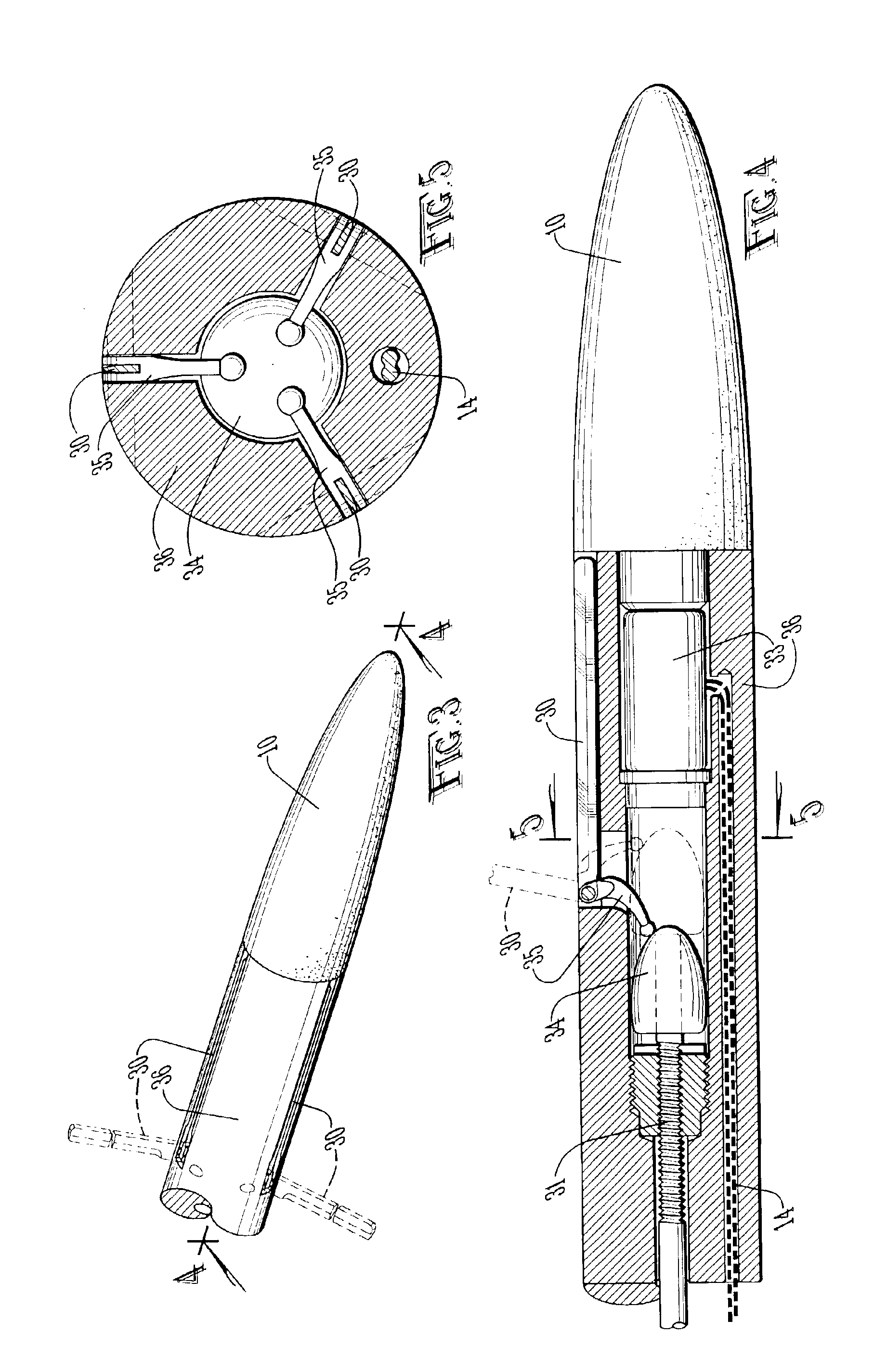

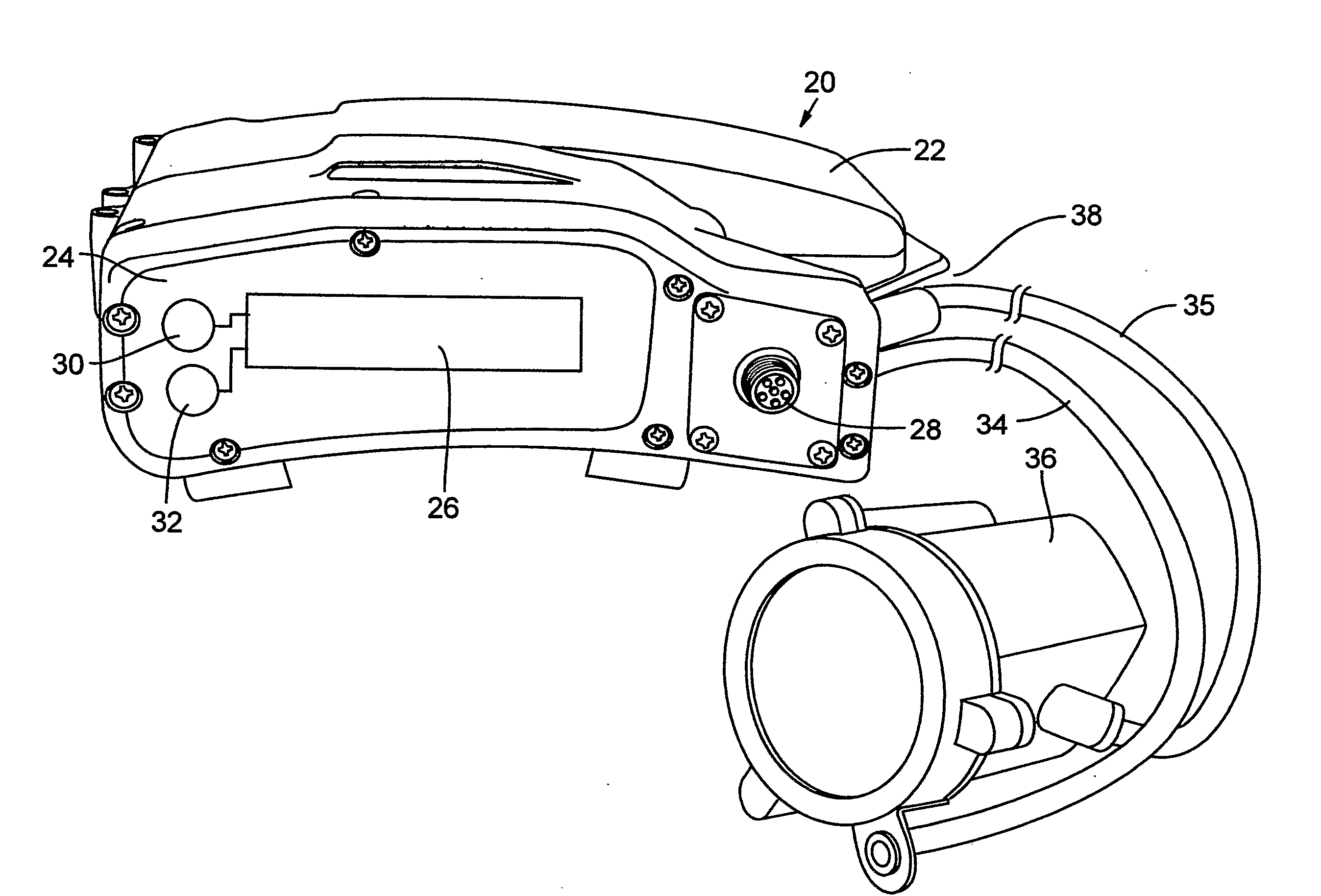

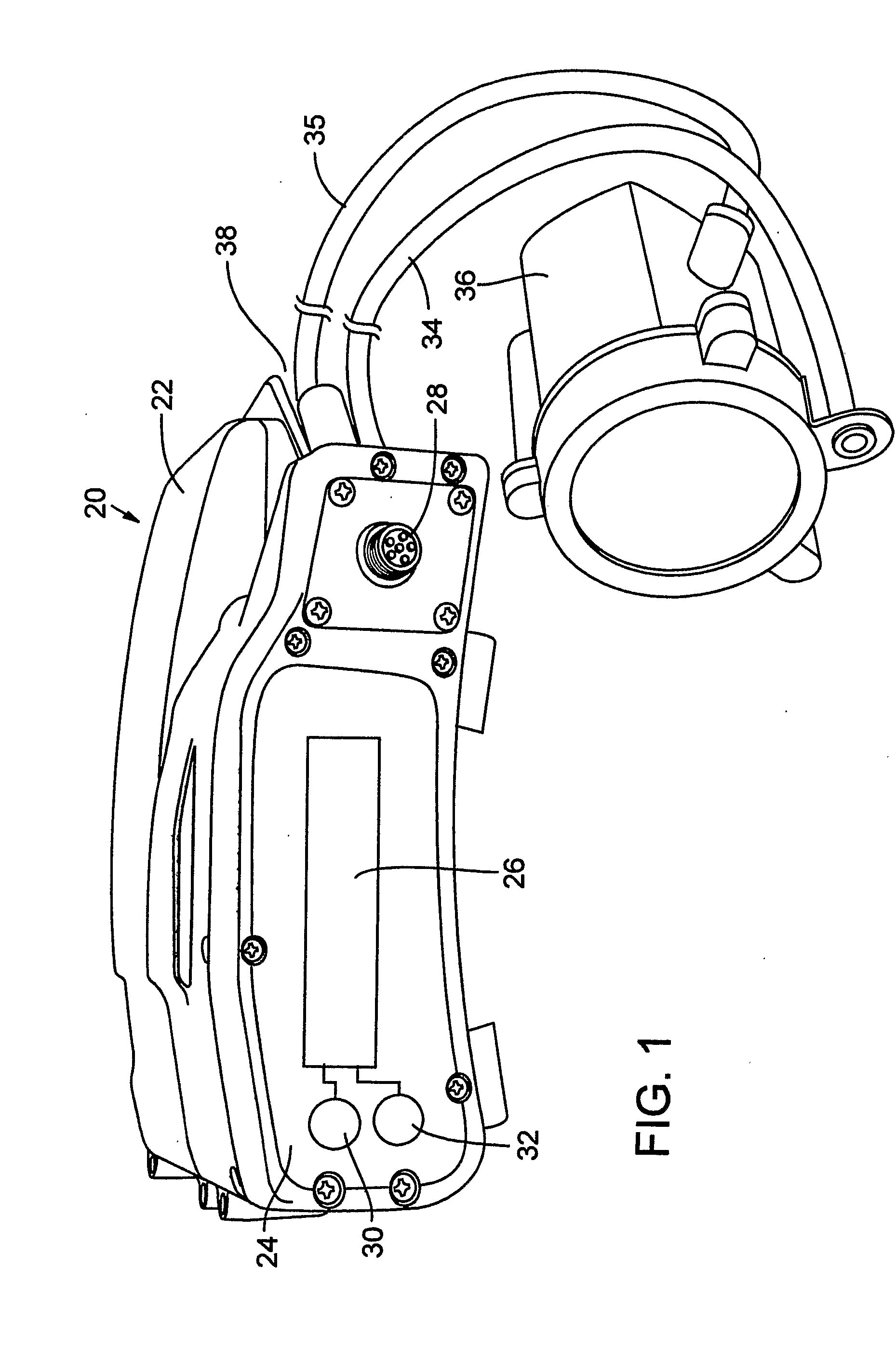

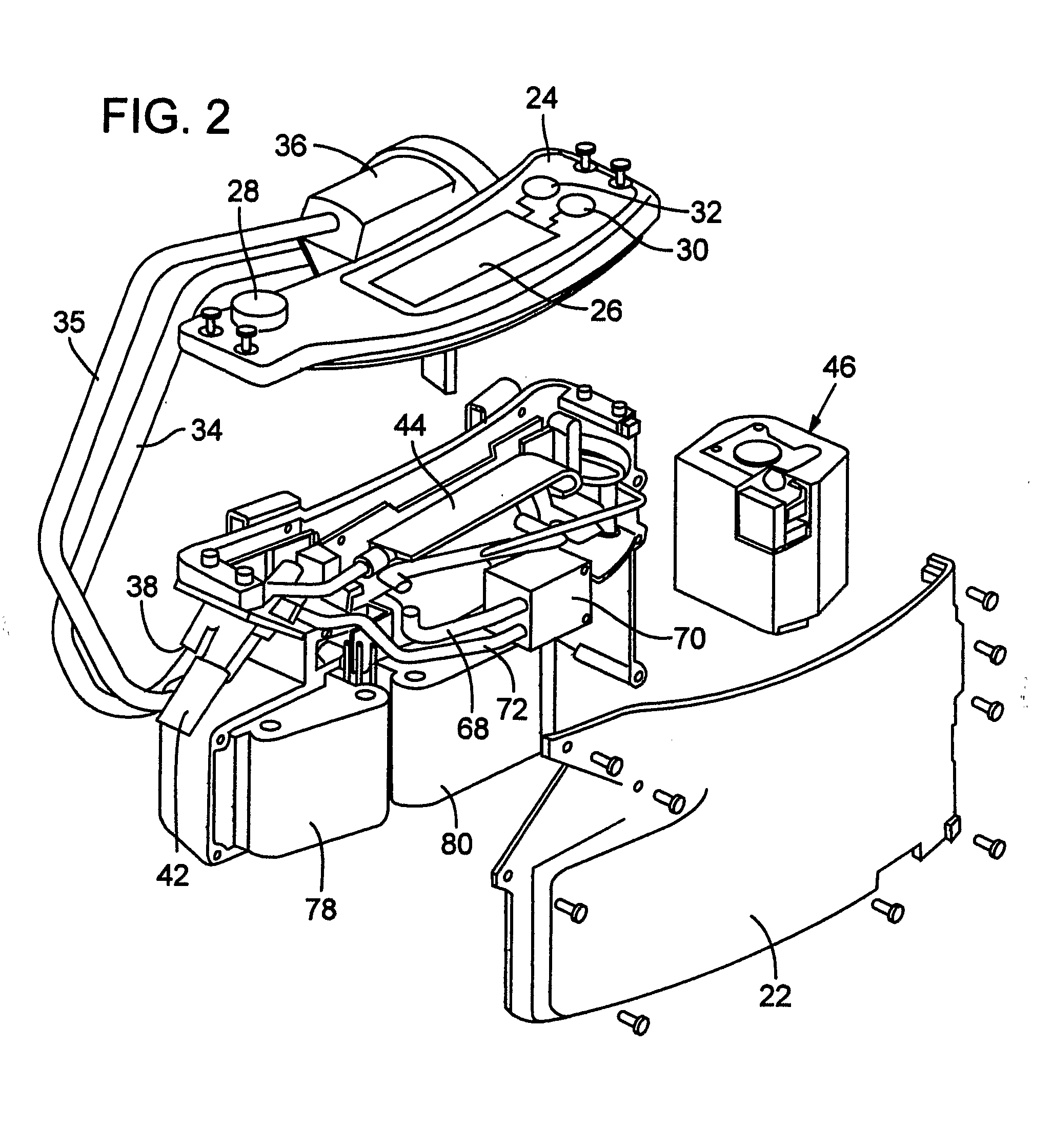

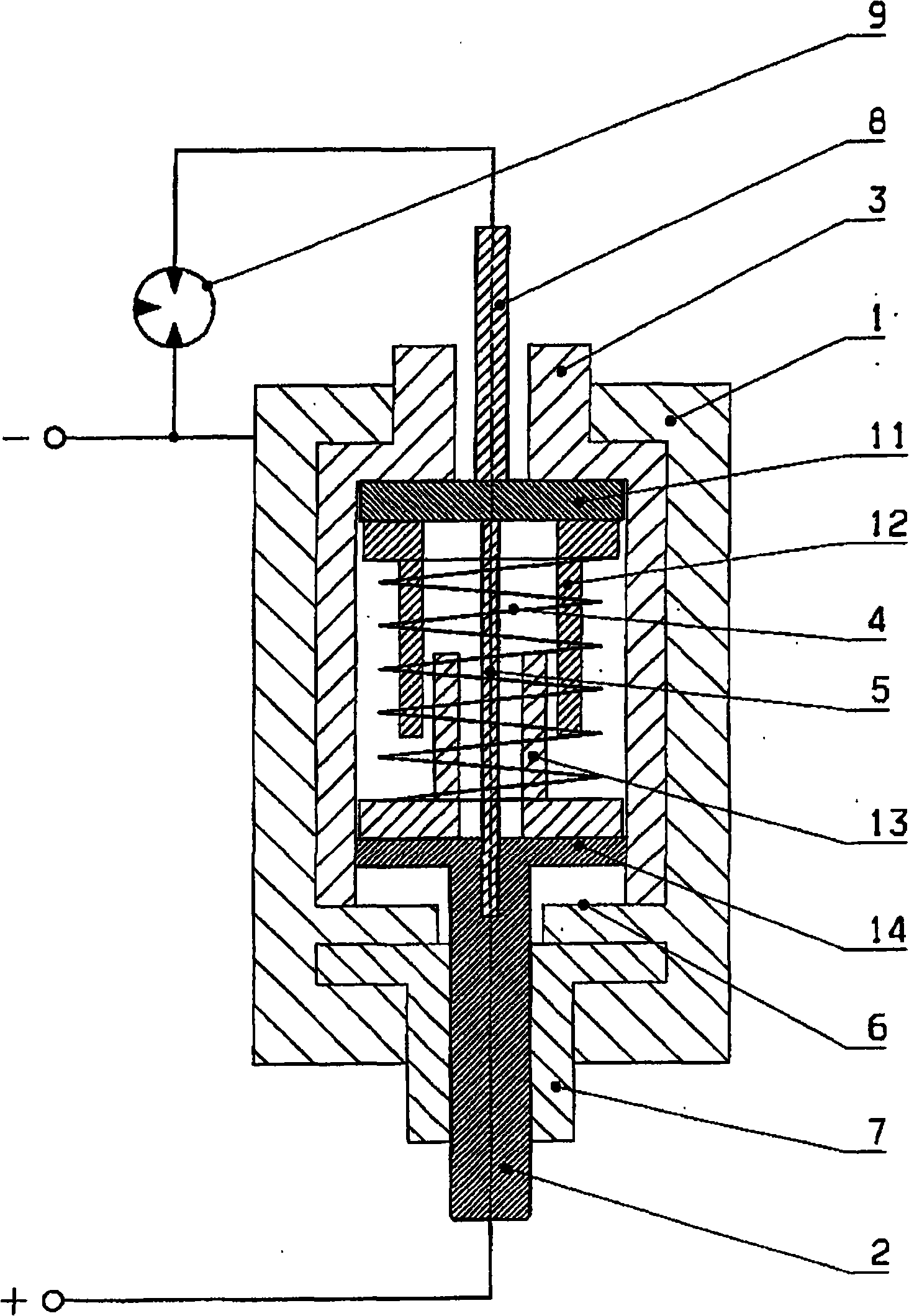

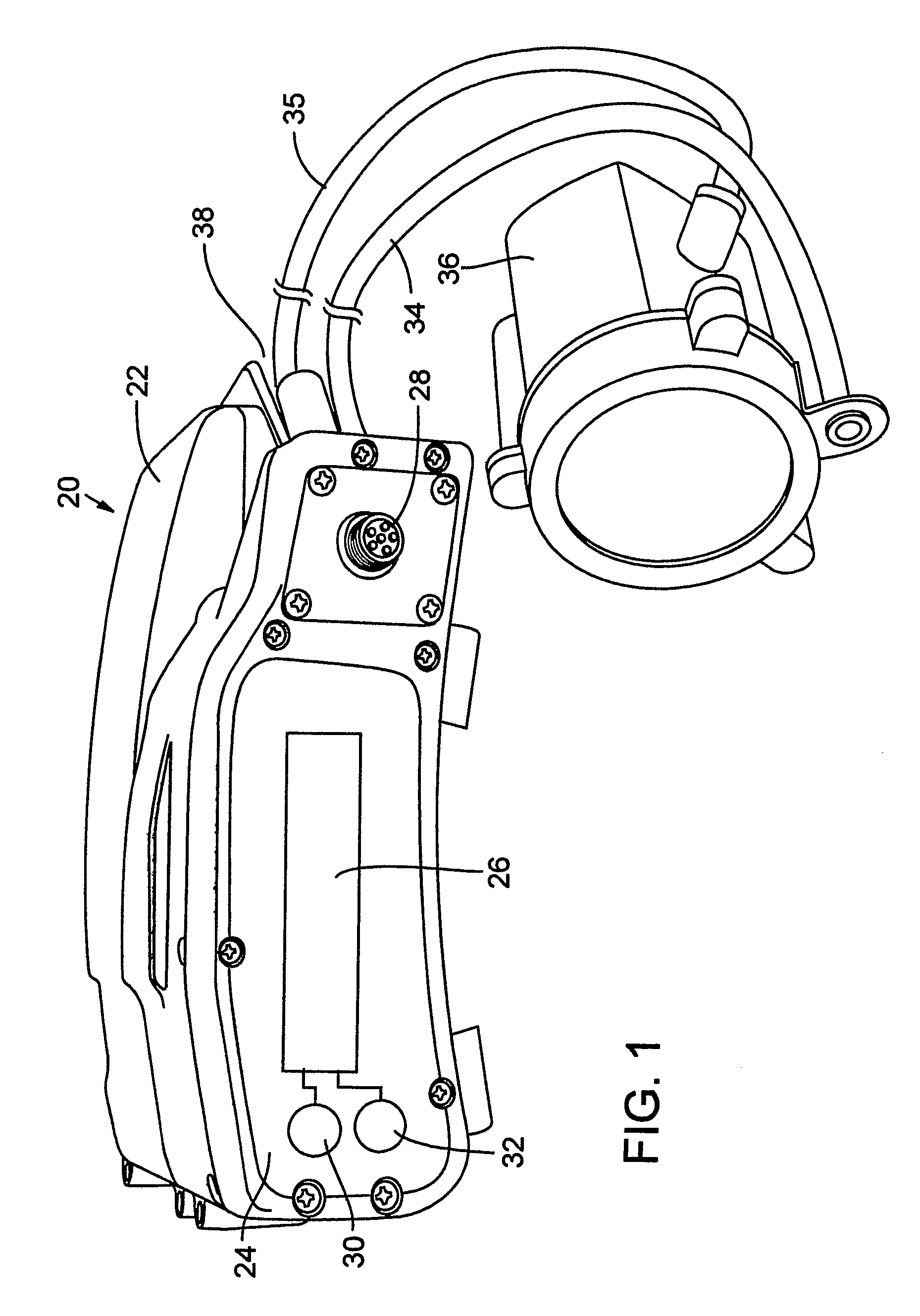

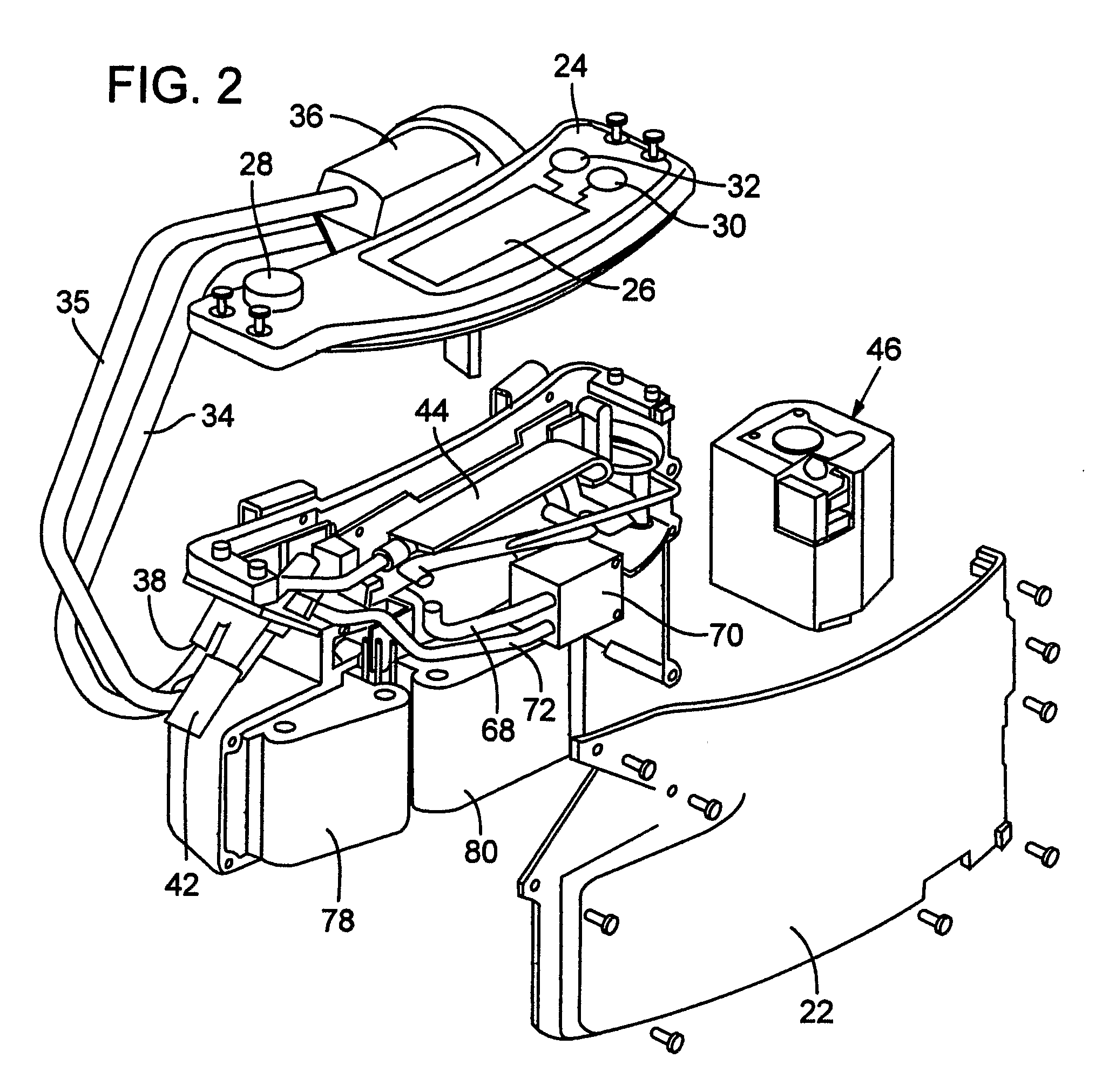

Conductive interstitial thermal therapy device

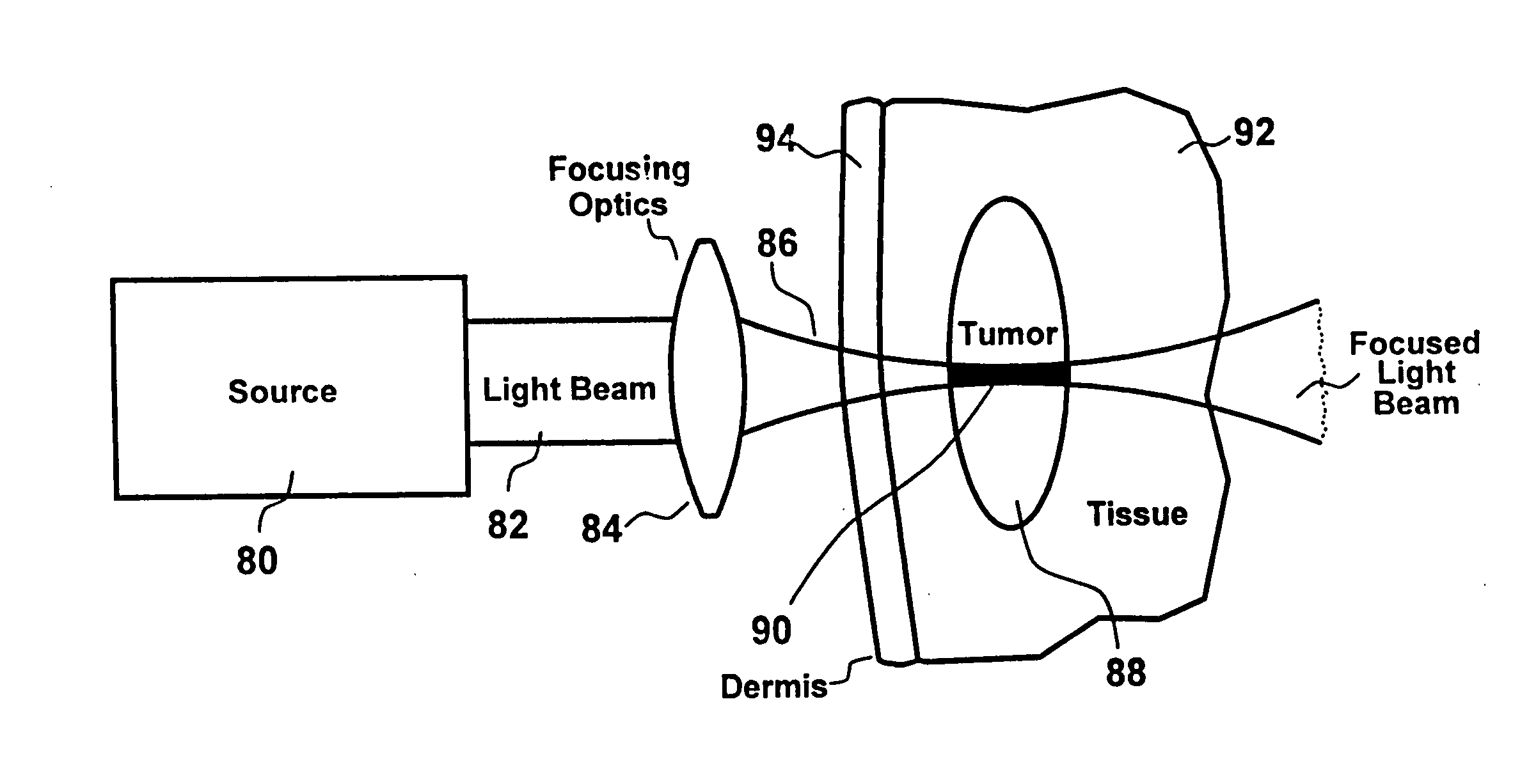

InactiveUS6872203B2Highly predictable temperature distributionLimit on maximum temperatureSurgical instruments for heatingThermal probeFiber

An apparatus and method for thermally destroying tumors in which heat is generated by electrical resistance heating conducted to the target tissue. Computerized scanning is used to optimize the geometry of a thermal probe. The probe has a metal tip heated by a remote laser. The metal tip is mounted on the end of a wave guide fiber for transmitting the laser radiation to the metal tip. The tip is coated with a thin layer of biocompatible ceramic to avoid coagulated tissue sticking to the tip. The tip has one or more thin, thermally-conductive elements which deploy in stages to coagulate the tumor. The conductive elements may be thin wires or blades. On one embodiment, the conductive elements are composed of a shape memory material that is folded against the tip at lower temperatures and deploys at selected higher temperatures. In another embodiment, the conductive elements are blades that are deployed mechanically. The tip may be provided with a miniature thermocouple to provide temperature feedback information.

Owner:ARKANSAS CHILDRENS HOSPITAL RES INST +1

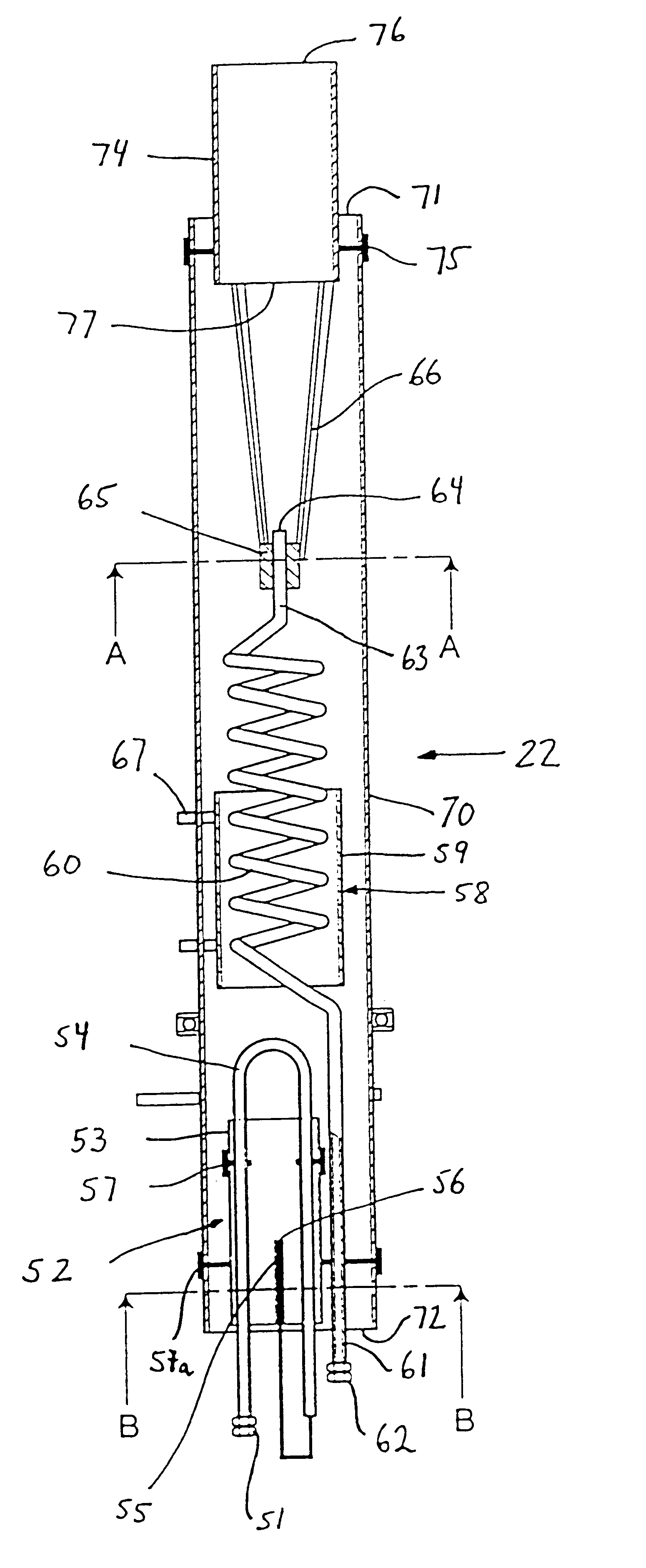

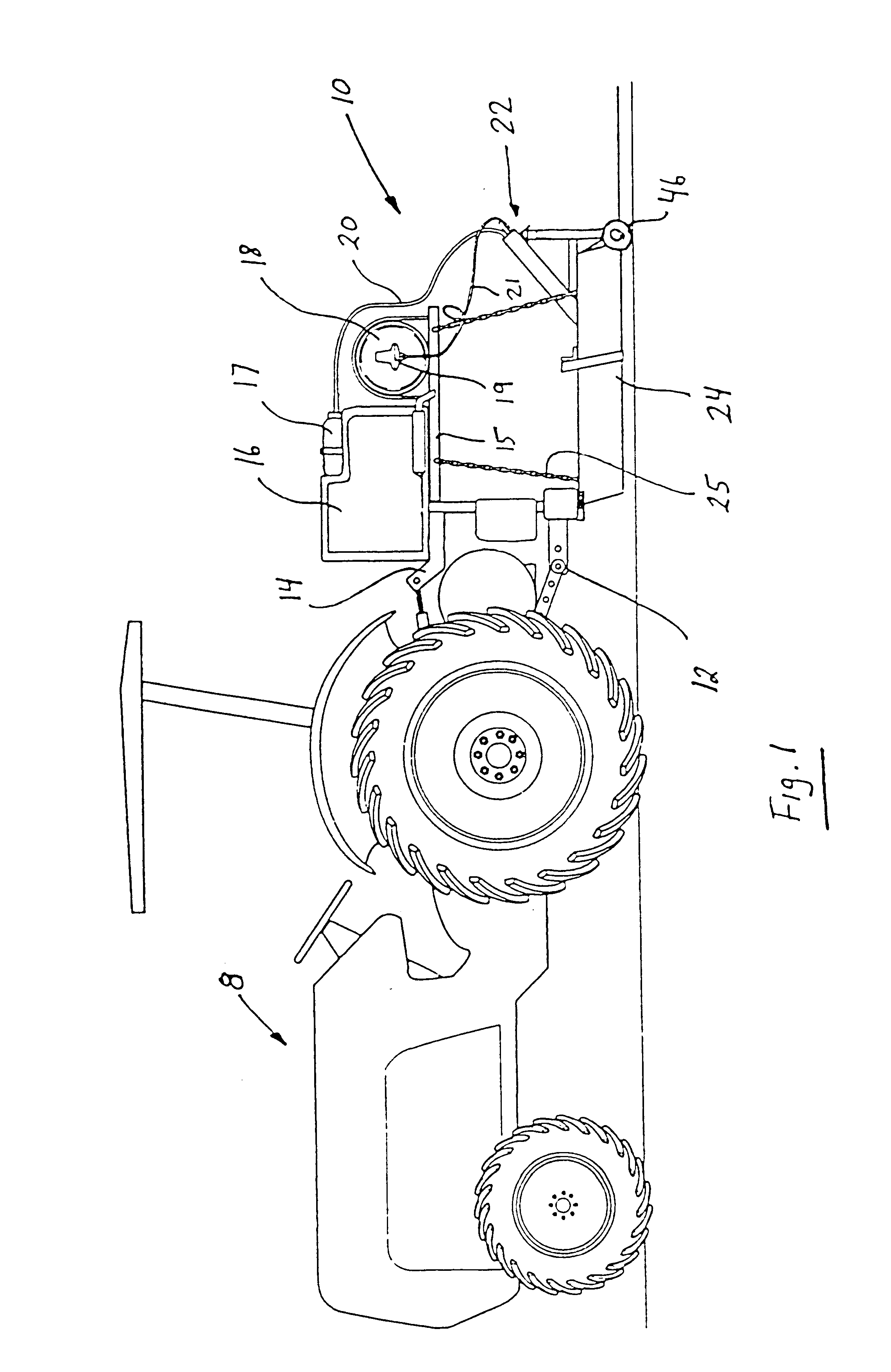

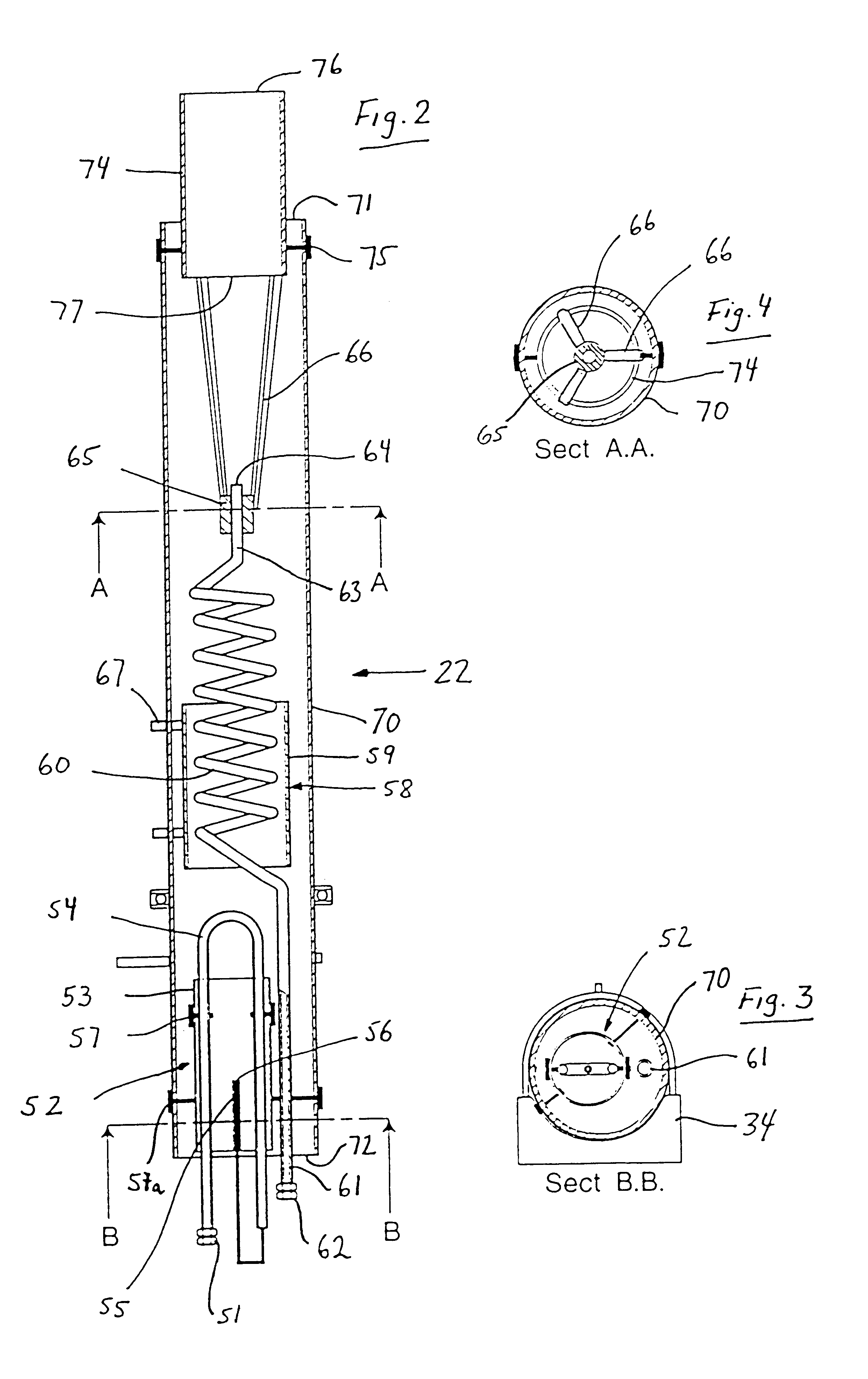

Weed and plant pests control apparatus and method

InactiveUS6505437B1Increase the ambient temperatureIncrease heatWeed killersFlame throwersVegetationCombustion

A method of destroying or controlling unwanted vegetation and agricultural pests is disclosed. The method produces a jet stream of treatment fluid, being mixed combustion gas and superheated or dry steam for application to thermally destroy unwanted vegetation and posts. The method involves the use of a hydrocarbon burner and a water source.

Owner:D J BATCHEN

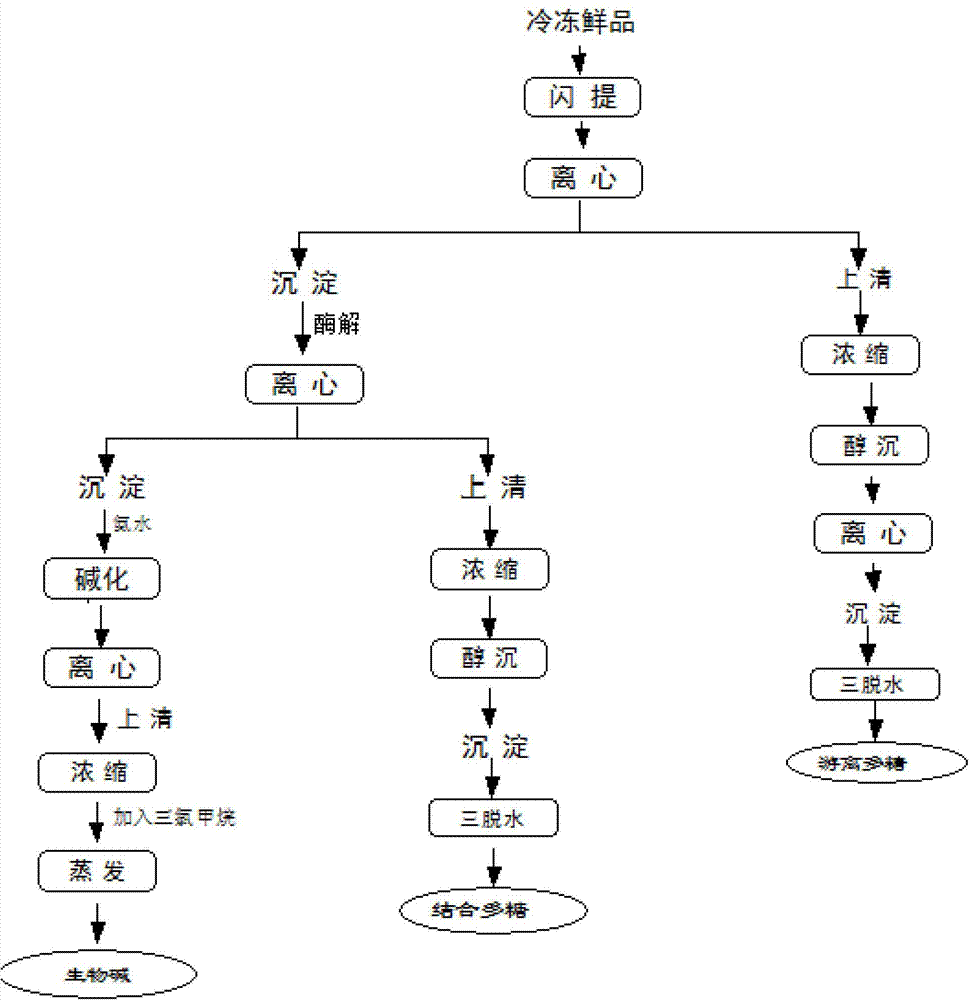

Method for extracting various active ingredients from dendrobium officinale

InactiveCN103113483AReduce dosageMild extraction conditionsAntipyreticAnalgesicsAlcoholThermal Destructions

The invention discloses a method for extracting various active ingredients from dendrobium officinale. The method comprises the following steps of: carrying out flash-extracting; centrifuging the flash-extracted crude extracting solution; carrying out alcohol precipitation and tertiary dehydration to the centrifuged liquid supernatant to obtain free polysaccharide; combining the centrifuged precipitates with polysaccharide and alkaloid extract; and extracting the various active ingredients from the dendrobium officinale, so that the comprehensive utilization of the dendrobium officinale resources is realized. The method disclosed by the invention is high in yield, capable of greatly shortening the extraction time during the extraction process, capable of avoiding the influences of thermal destruction to the products, capable of reducing the production cost and applicable to large-scale production.

Owner:BEIHANG UNIV

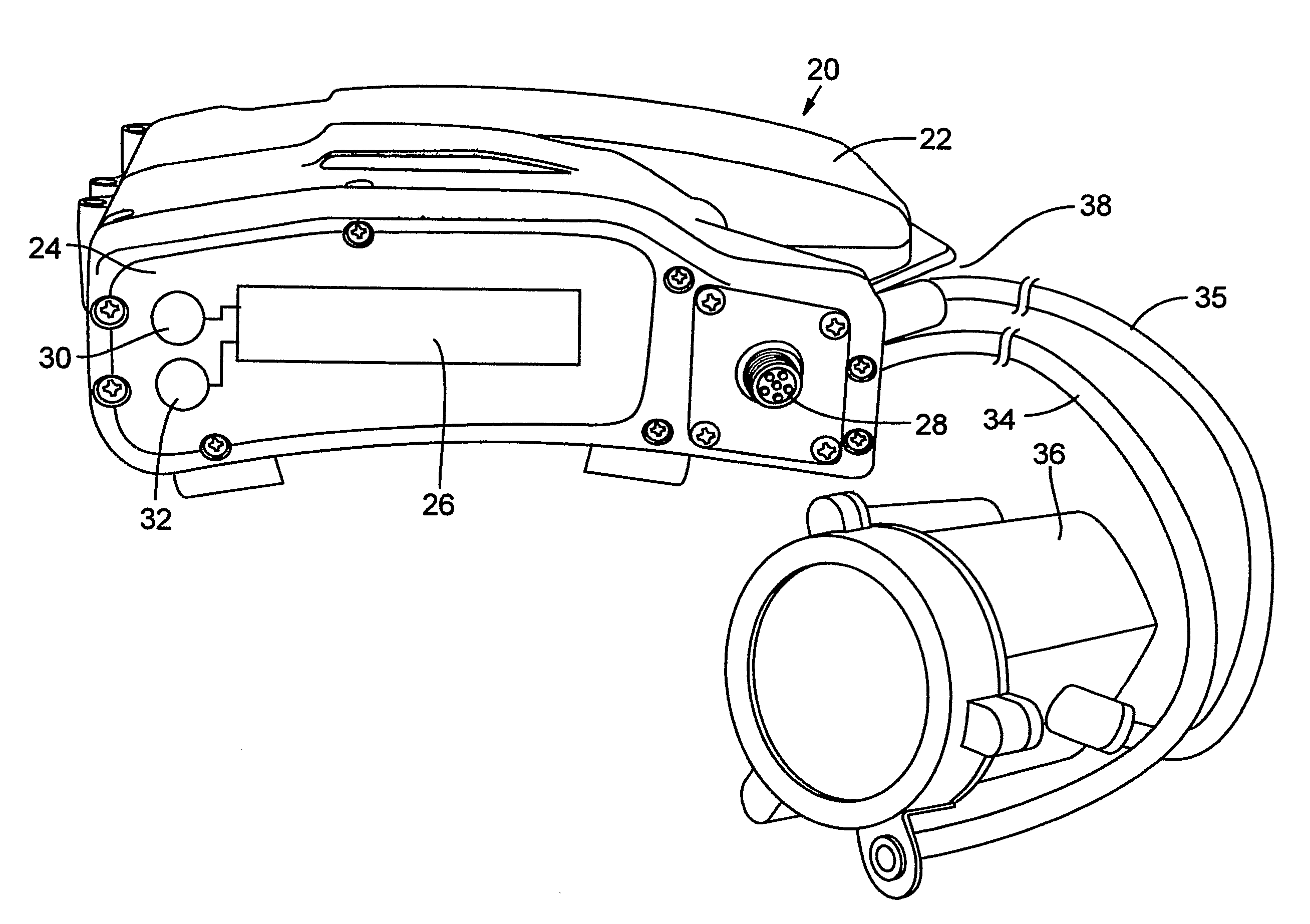

Monitor and methods for characterizing airborne particulates

InactiveUS20090081804A1Minimizes effortMinimize timeChemical analysis using combustionMaterial heat developmentParticulatesAnalyte

A dust monitor is disclosed that is suitably deployed in dusty environments and capable of providing near real-time indications of exposure to airborne particulates. The monitor includes a filter and filter assembly made of materials that do not interfere with subsequent instrumental (such as spectrometric) analysis for detecting and / or quantitating an analyte. In some disclosed embodiments, the filter is made of nylon or other material that is readily subjected to thermal destruction prior to spectrometric analysis. The dust monitor also includes a humidity correction feature that permits the filter to be made of ashable organic materials even if those materials are not highly hydrophobic. Transport devices are provided for shipment of the filter and / or filter assembly to an analytical laboratory which prevent loss of particulate matter and which facilitate an accurate analysis procedure.

Owner:UNITED STATES OF AMERICA

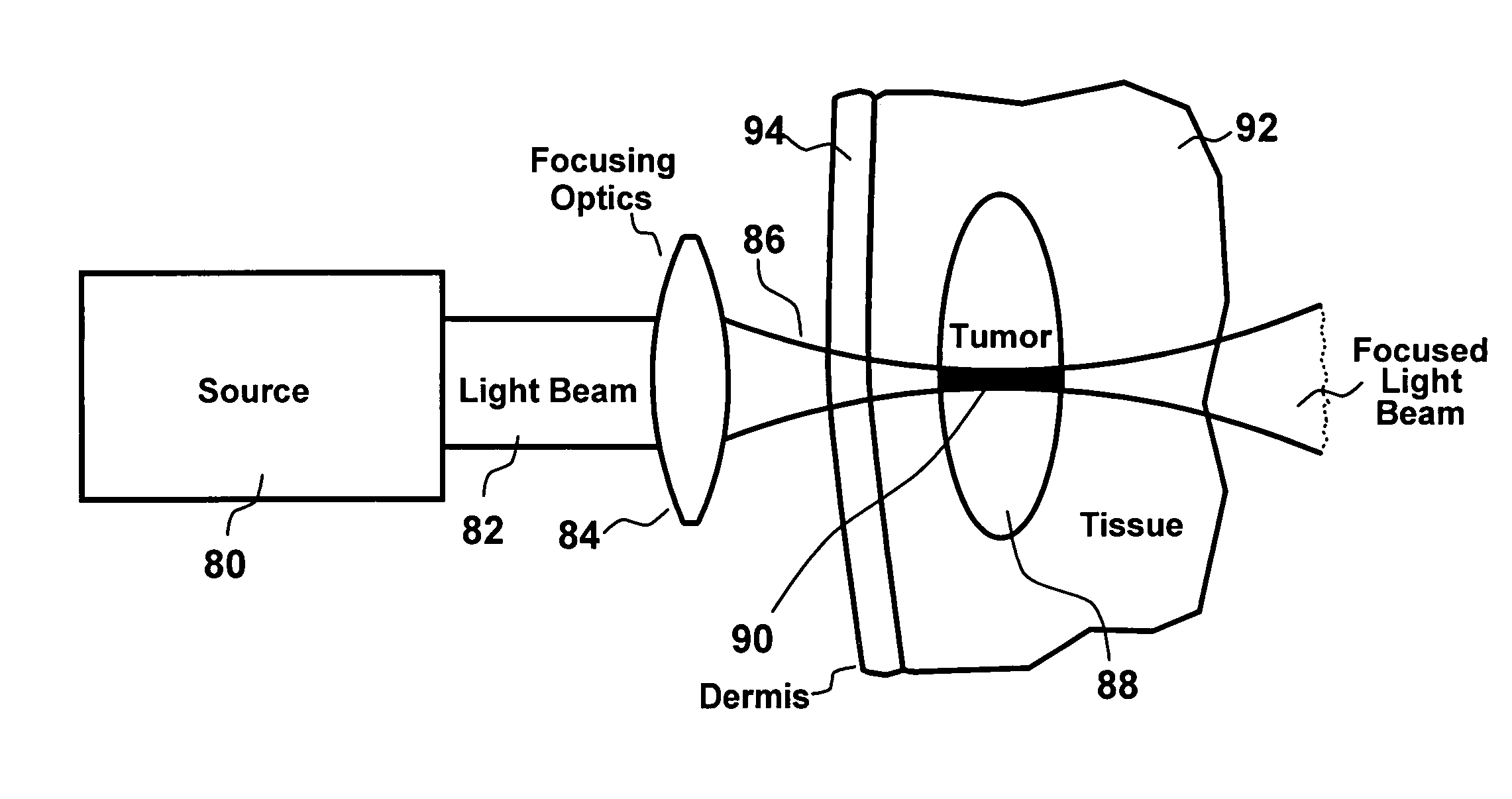

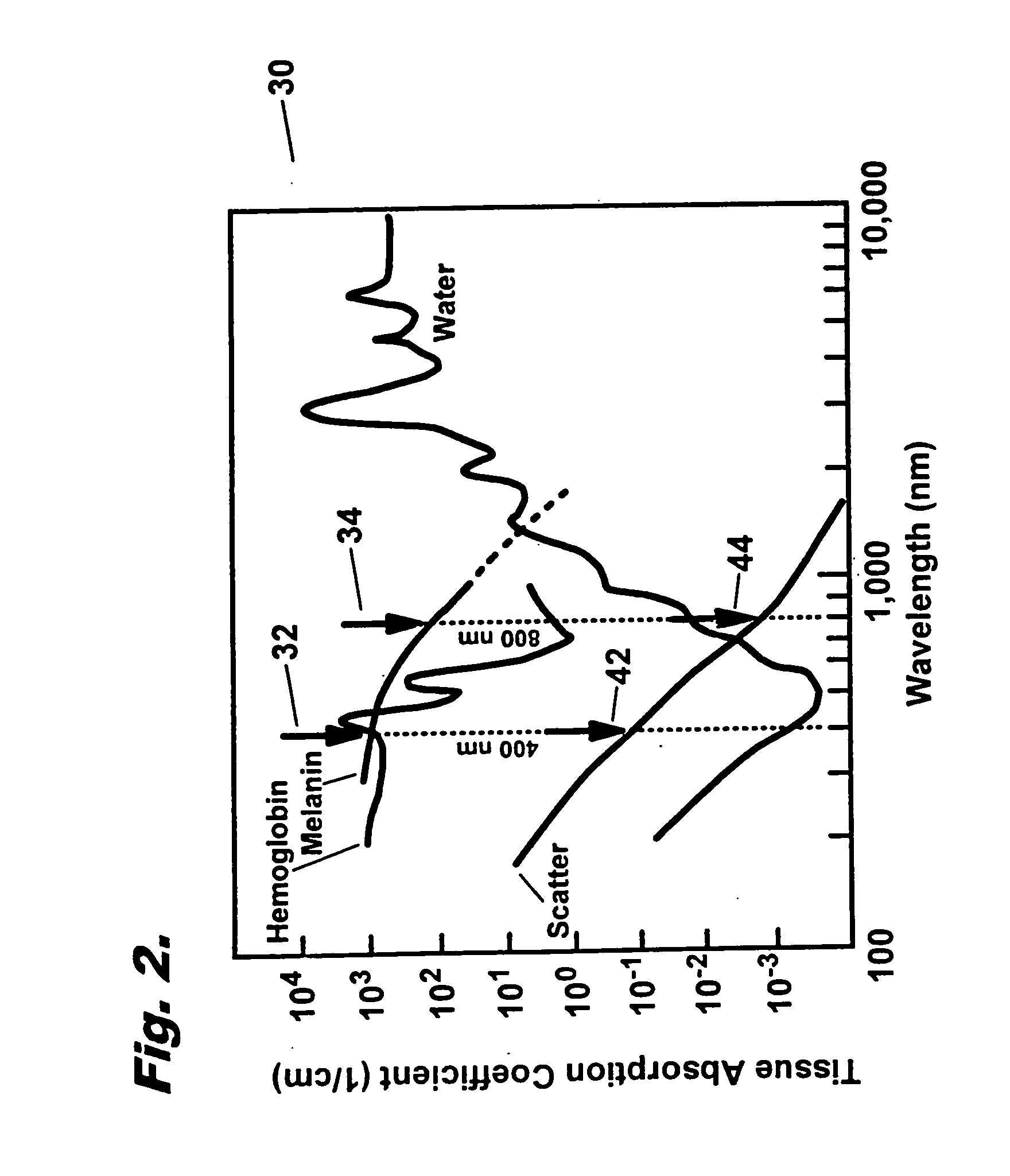

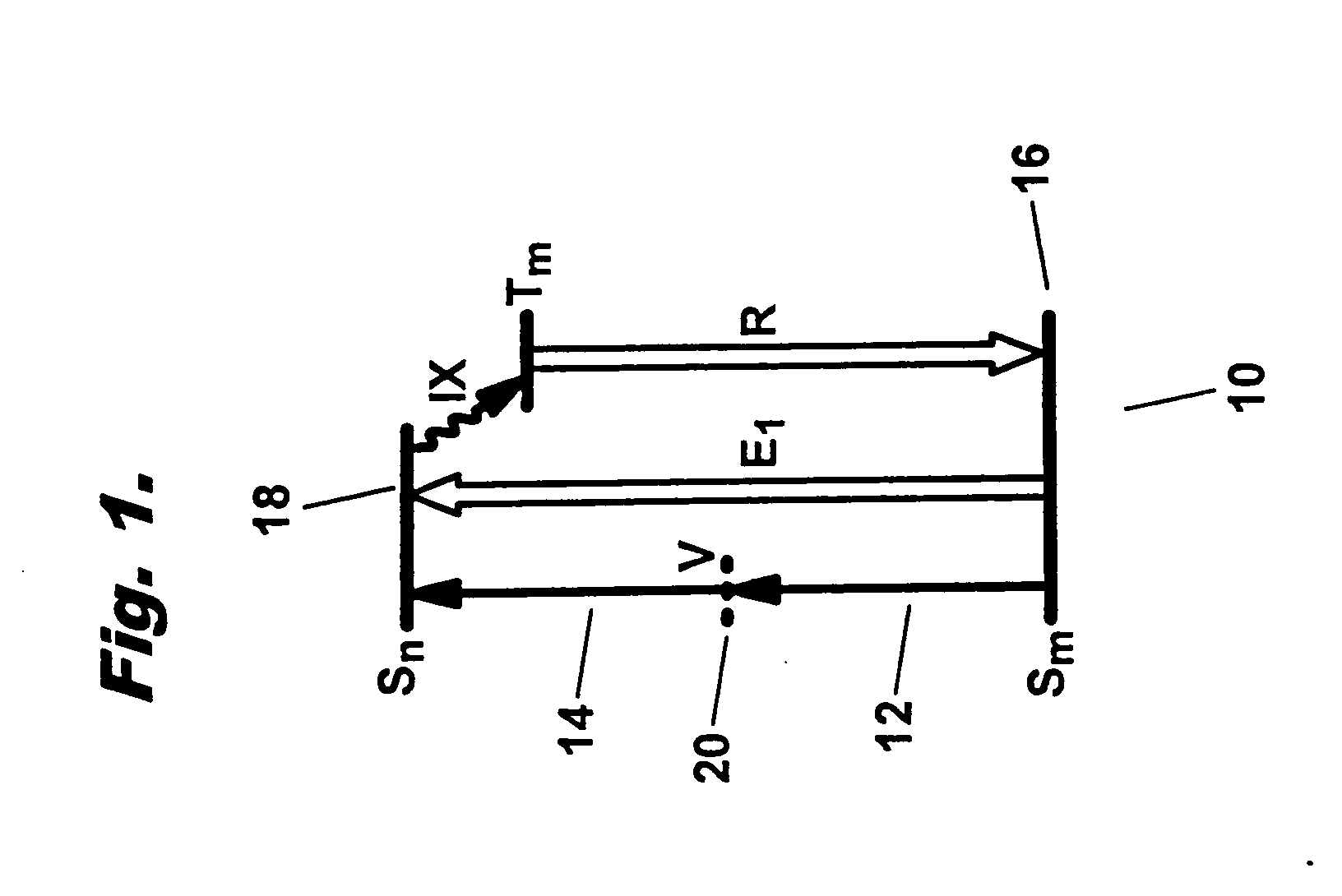

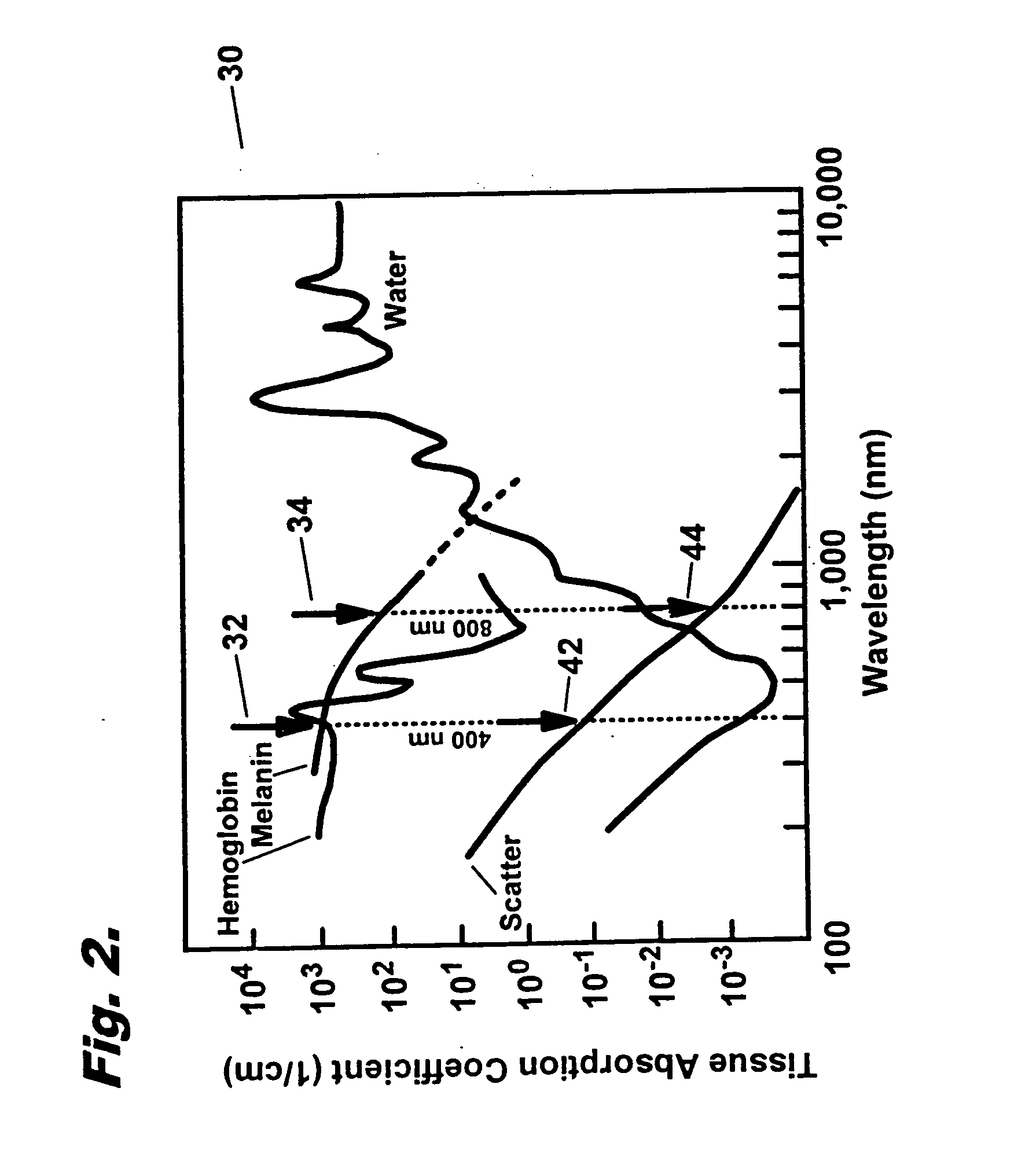

Treatment of pigmented tissues using optical energy

InactiveUS7036516B1Improve efficiencyElectrotherapyEnergy modified materialsThermal DestructionsOptical energy

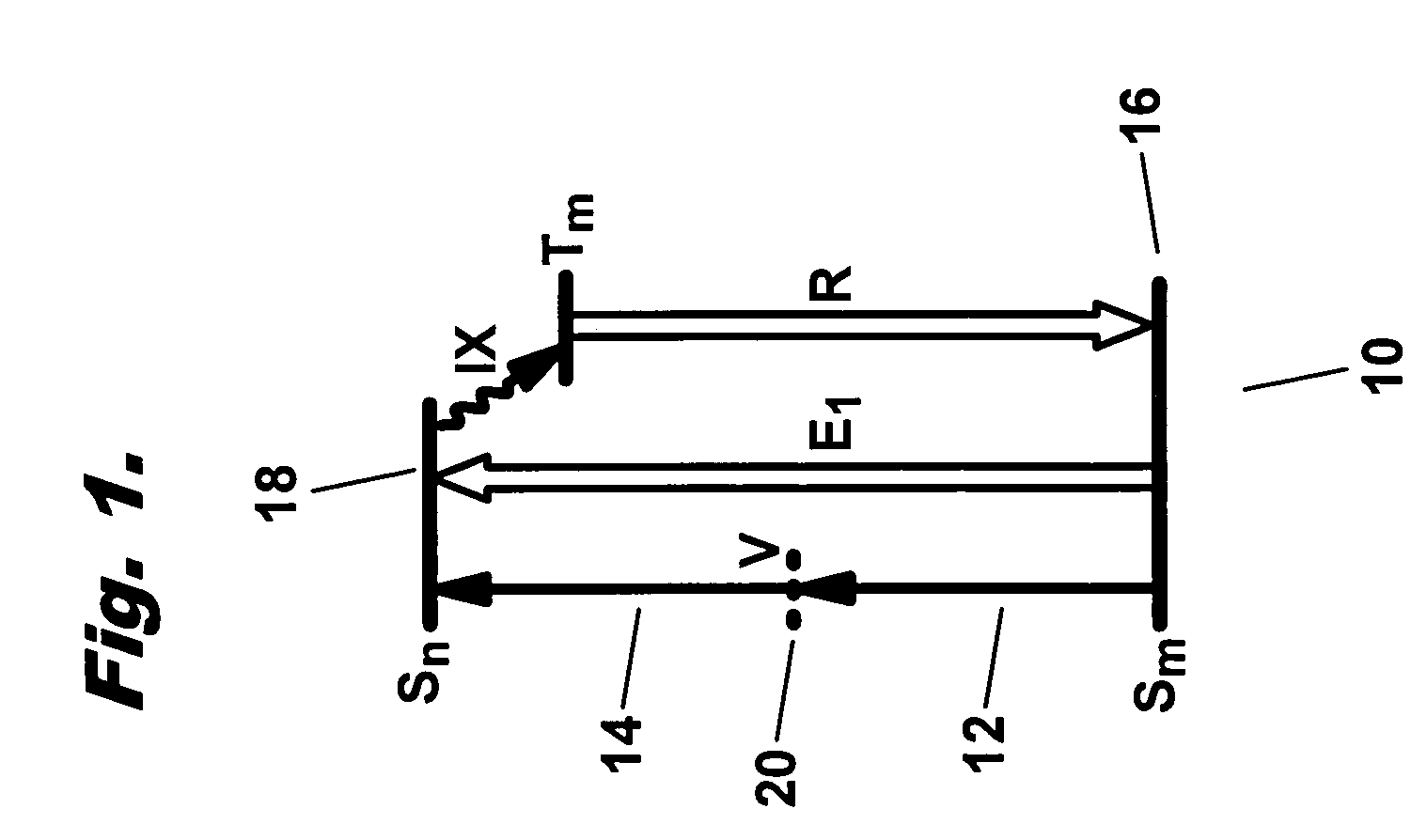

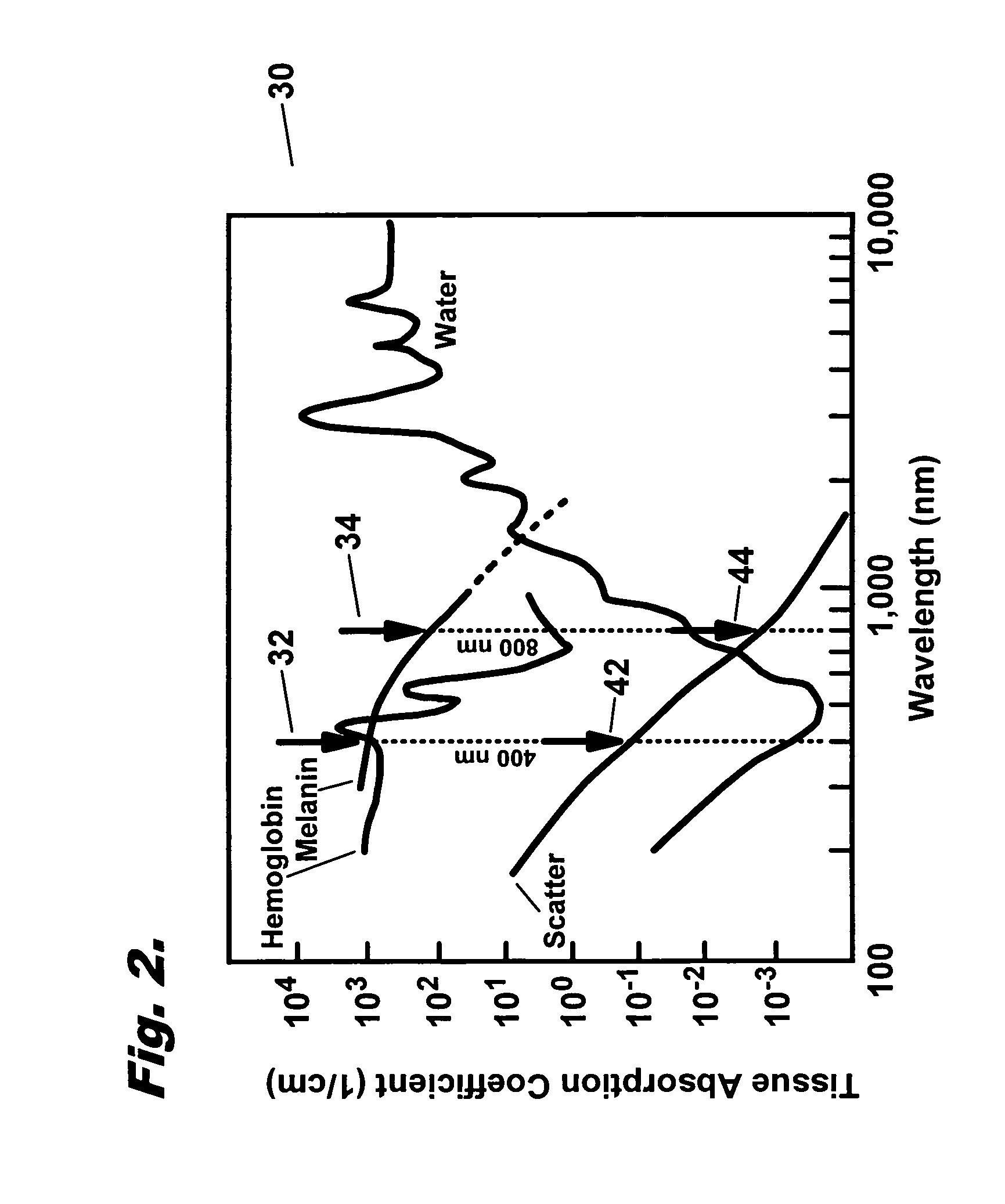

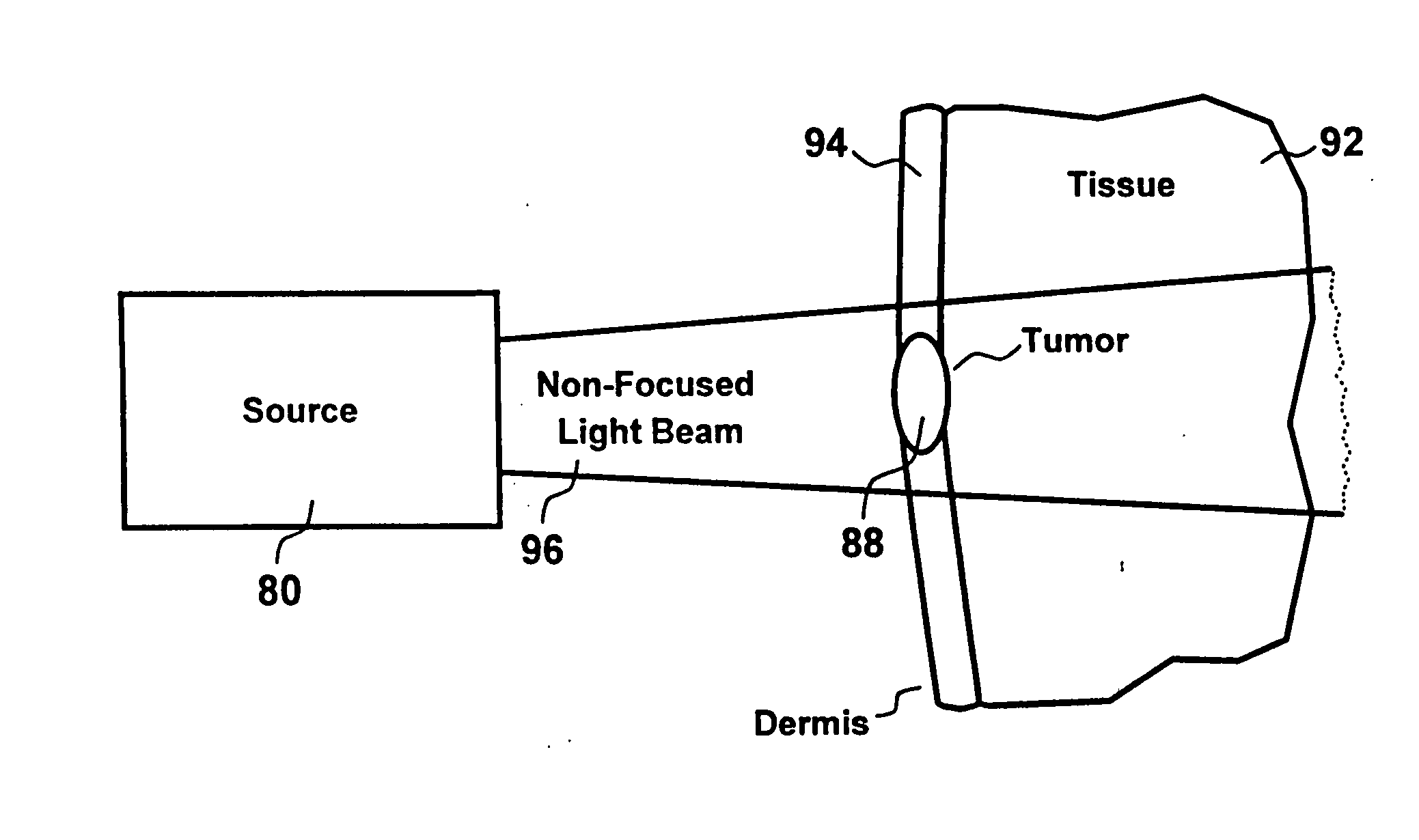

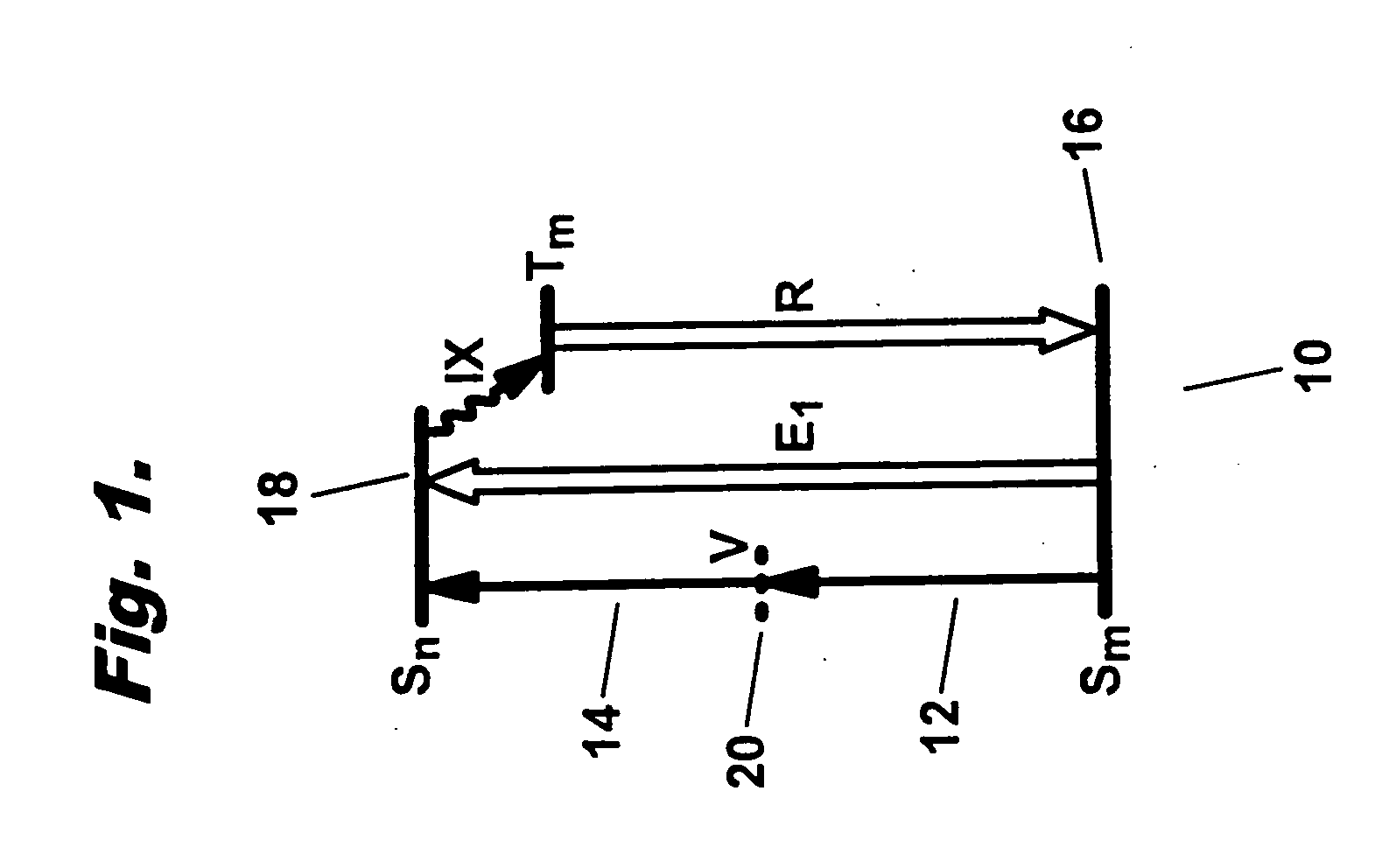

A method and apparatus for selectively photobleaching or killing pigmented tissues by photochemically converting pigments in the tissues using light and specifically two-photon excitation. Phototoxic products thereby produced then kill pigmented cells. Hyperthermia or an exogenous agent can also be added to augment efficacy. The present invention is also directed to selective thermal destruction of pigmented tissues using related optical means.

Owner:PROVECTUS DEVICETECH

Treatment of pigmented tissues using optical energy

InactiveUS20060095101A1Improve efficiencyEnergy modified materialsSurgical instrument detailsThermal DestructionsOptical energy

A method and apparatus for selectively photobleaching or killing pigmented tissues by photochemically converting pigments in the tissues using light and specifically two-photon excitation. Phototoxic products thereby produced then kill pigmented cells. Hyperthermia or an exogenous agent can also be added to augment efficacy. The present invention is also directed to selective thermal destruction of pigmented tissues using related optical means.

Owner:PROVECTUS DEVICETECH

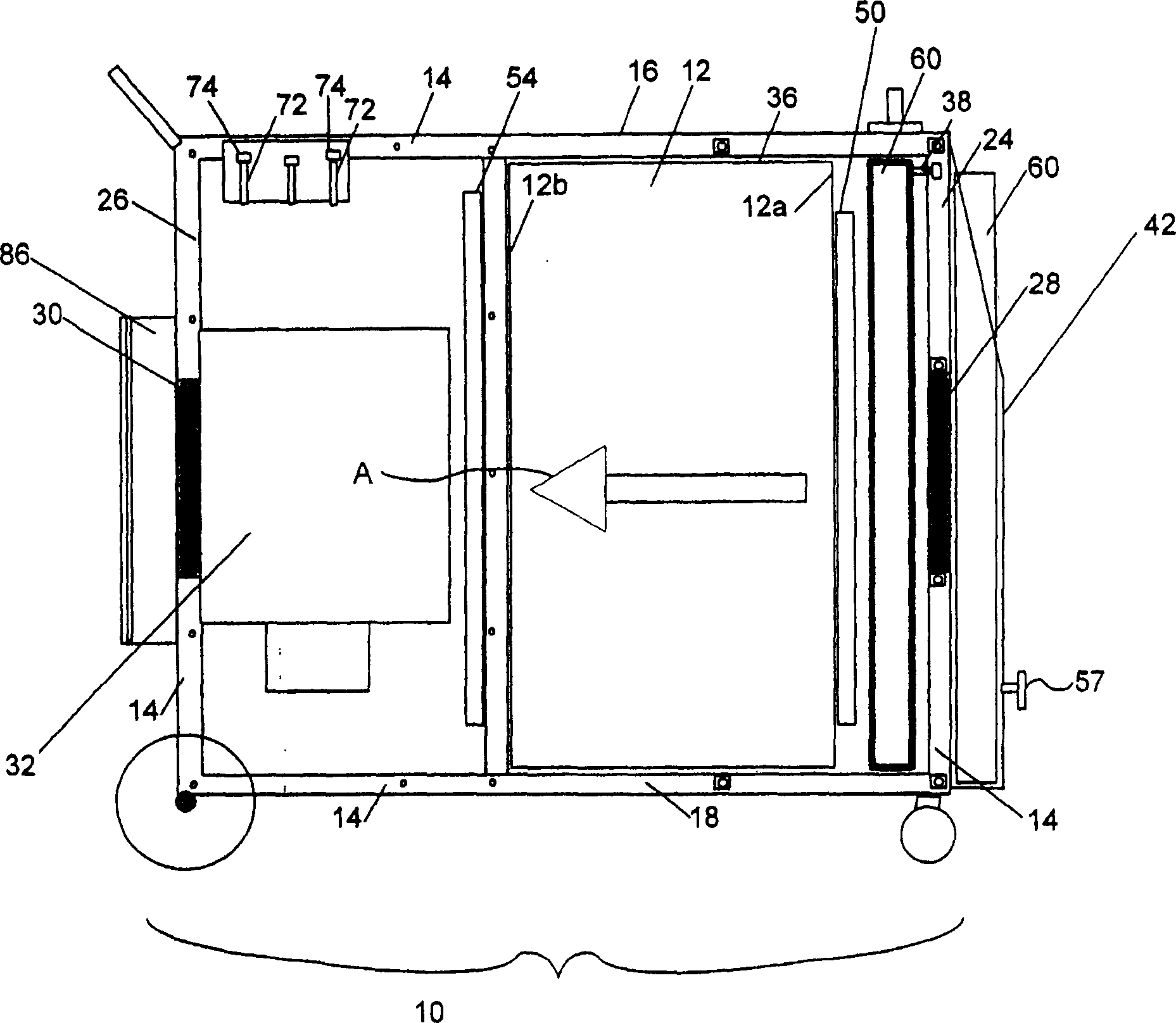

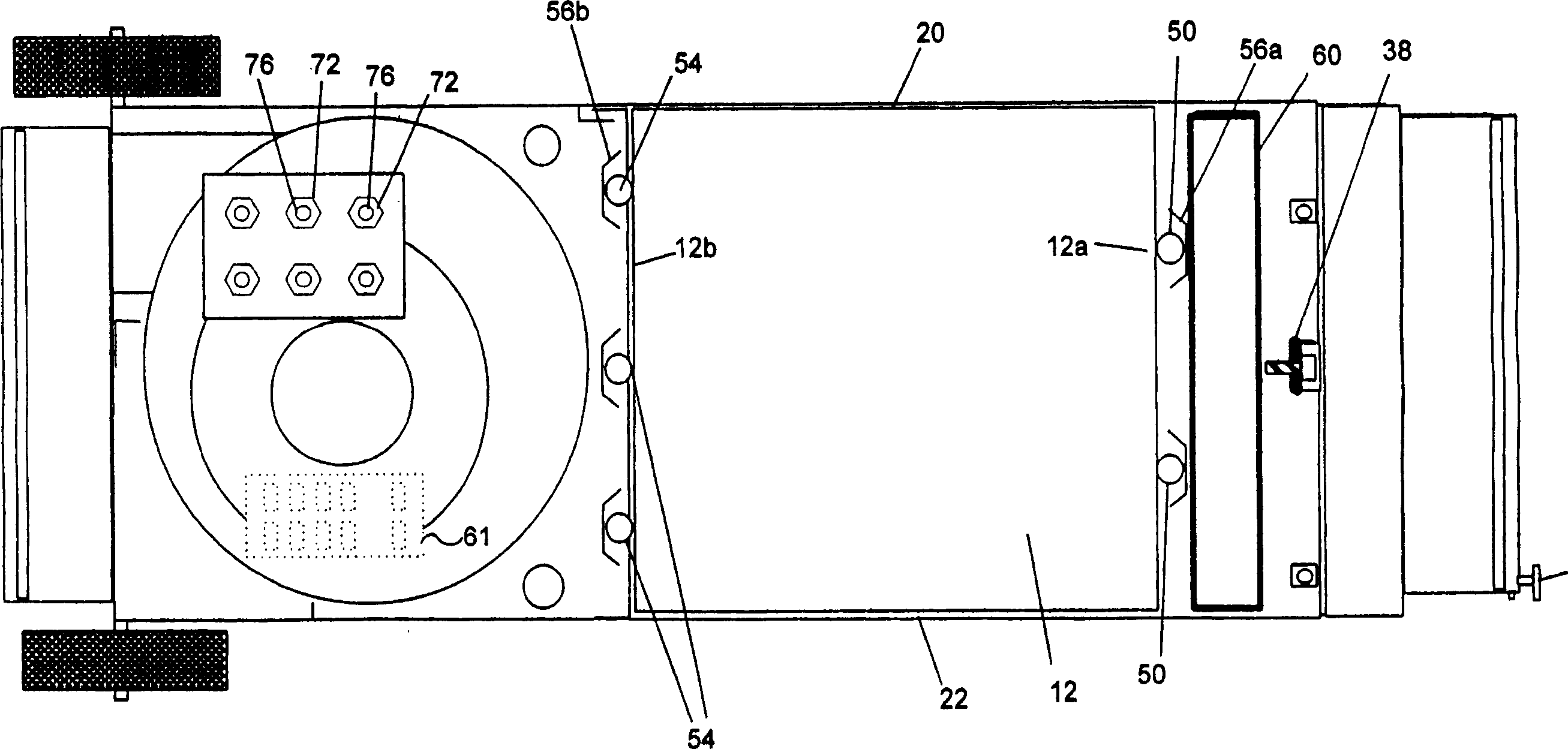

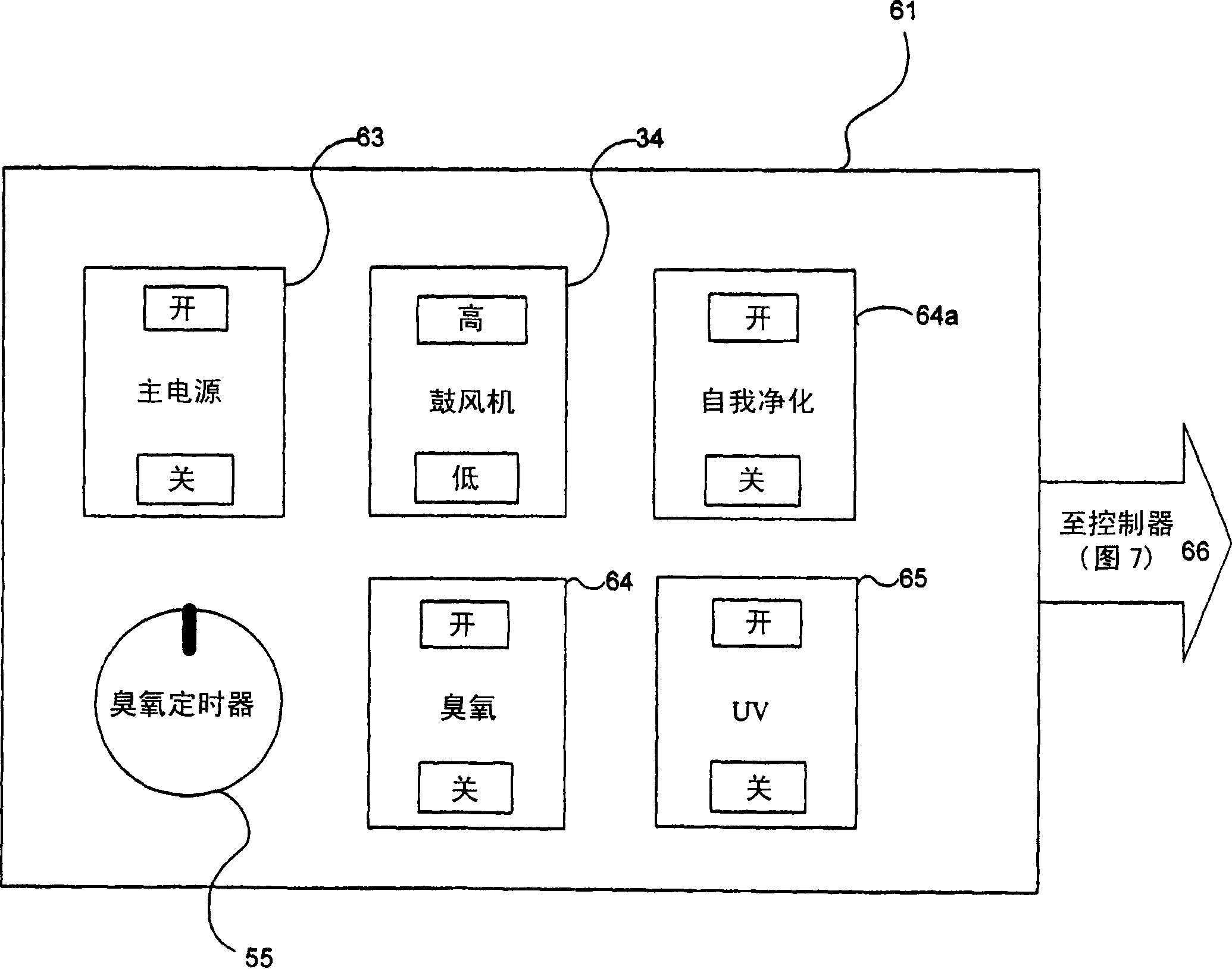

Air decontamination devices

Air decontamination method and device designed for bioterrorism, nerve gas, toxic mold, small pox, Ebola, anthrax and other agents require built in air sampling, rapid filter changes and the ability to use a mobile, transportable and connectable system in positive mode to push contaminates away or in negative mode to contain a toxin from spreading. This application combines features in respirators, industrial and hospital grade air filtration with the ability to provide air testing to guide the connection of the device with other treatment modules or existing HVAC and other equipment. With this new flexibility, ozone, UV, absorption, Thermal destruction, filters and liquid chemical neutralization can be manually or automatically adapted for emergency response to both daily airborne contamination and military grade terrorist threats of airborne contamination. The air decontamination units may be used to decontaminate the air after industrial and medical contaminations and terrorist biological, chemical and radiological attacks, for example. Mobile isolation units, and methods of decontaminating rooms, are disclosed, as well as Well as infection control and emergency response usage as an emergency clean air supply when connected to escape hoods, decon tents, or containment barriers to protect structures from homes to business from outside toxic agents. The unit can be powered by normal AC, 120 volts or 240 or be adapted to battery or field power supply units.

Owner:西奥多・A・M・阿尔茨

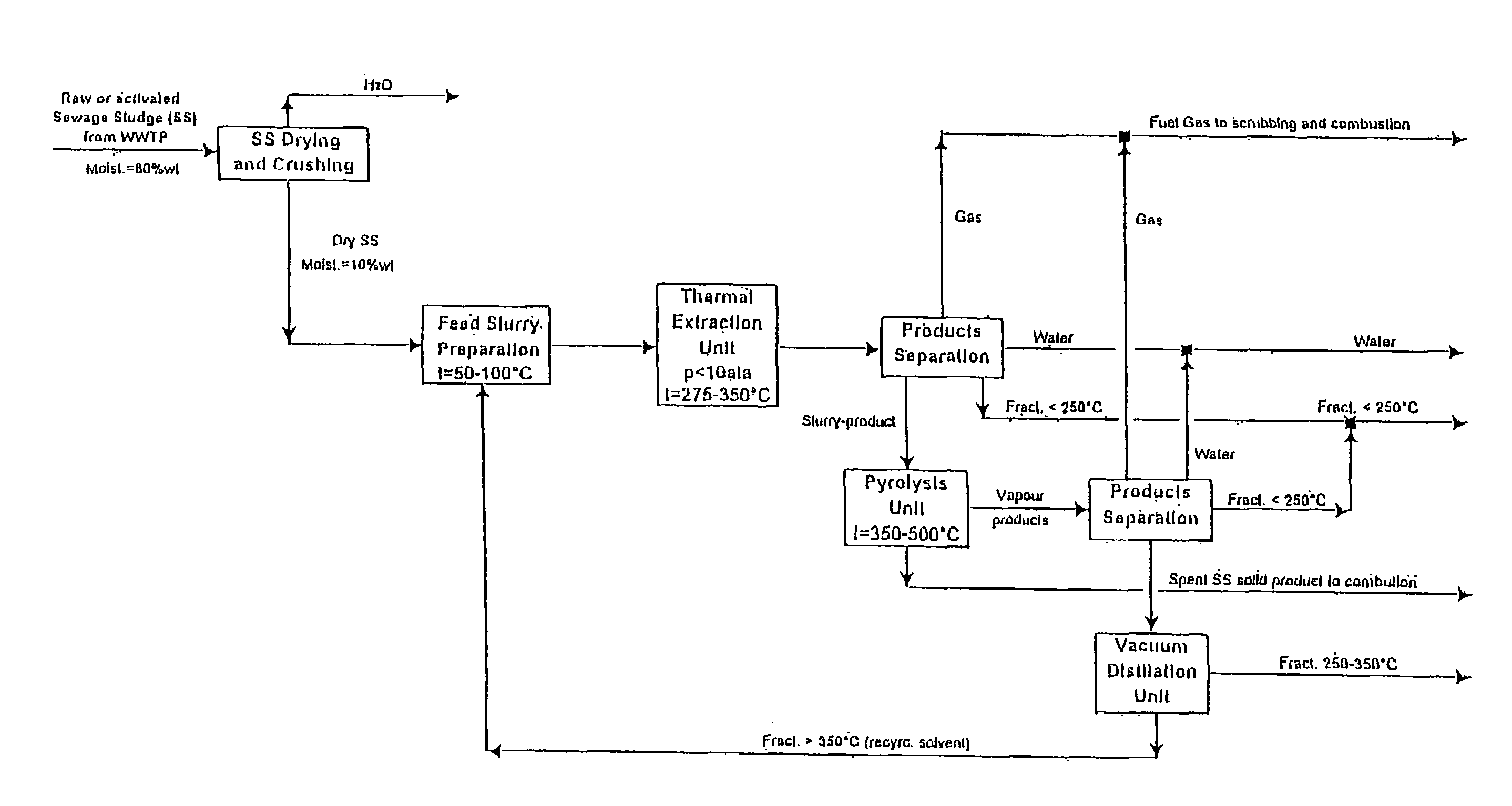

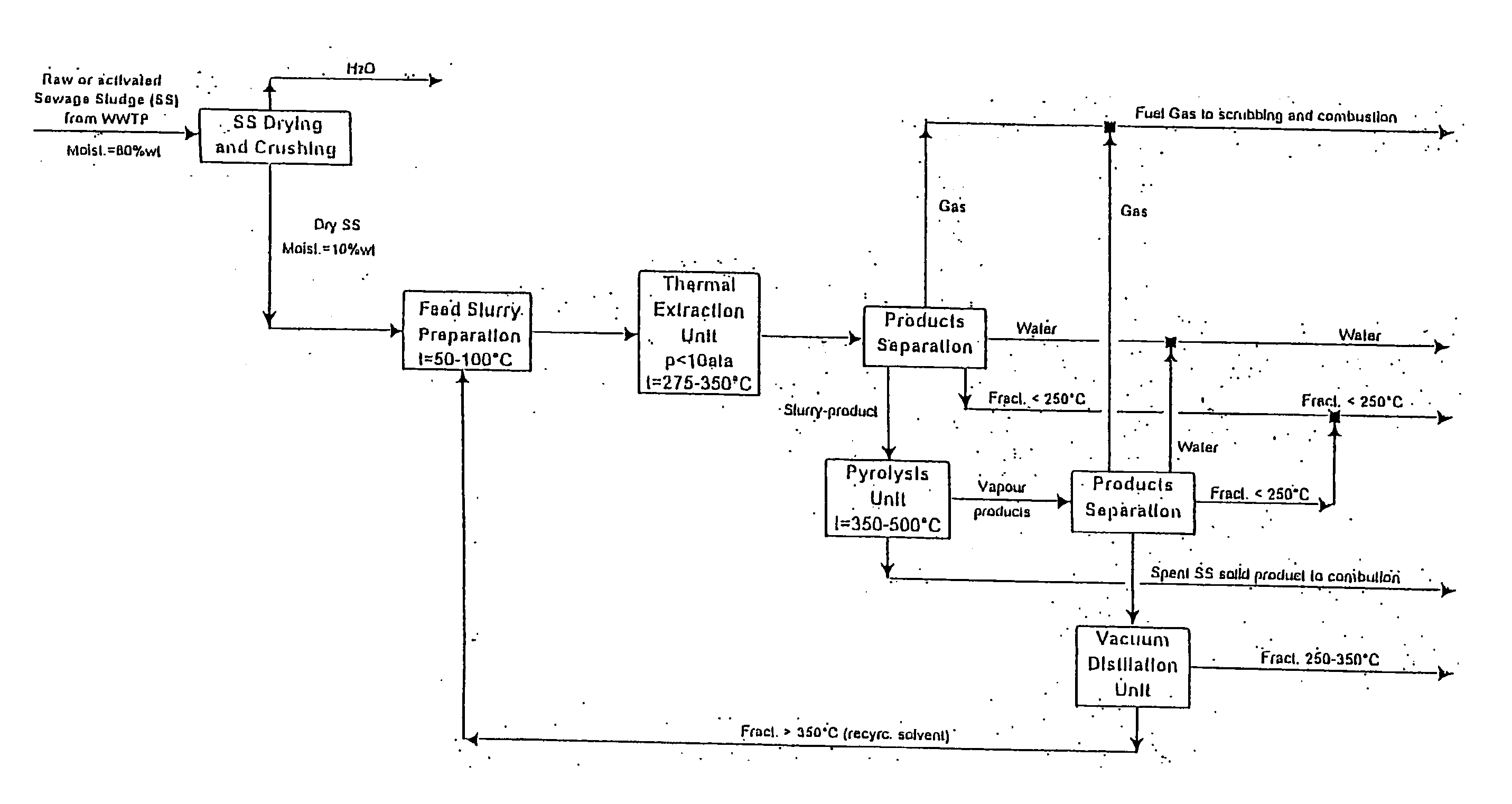

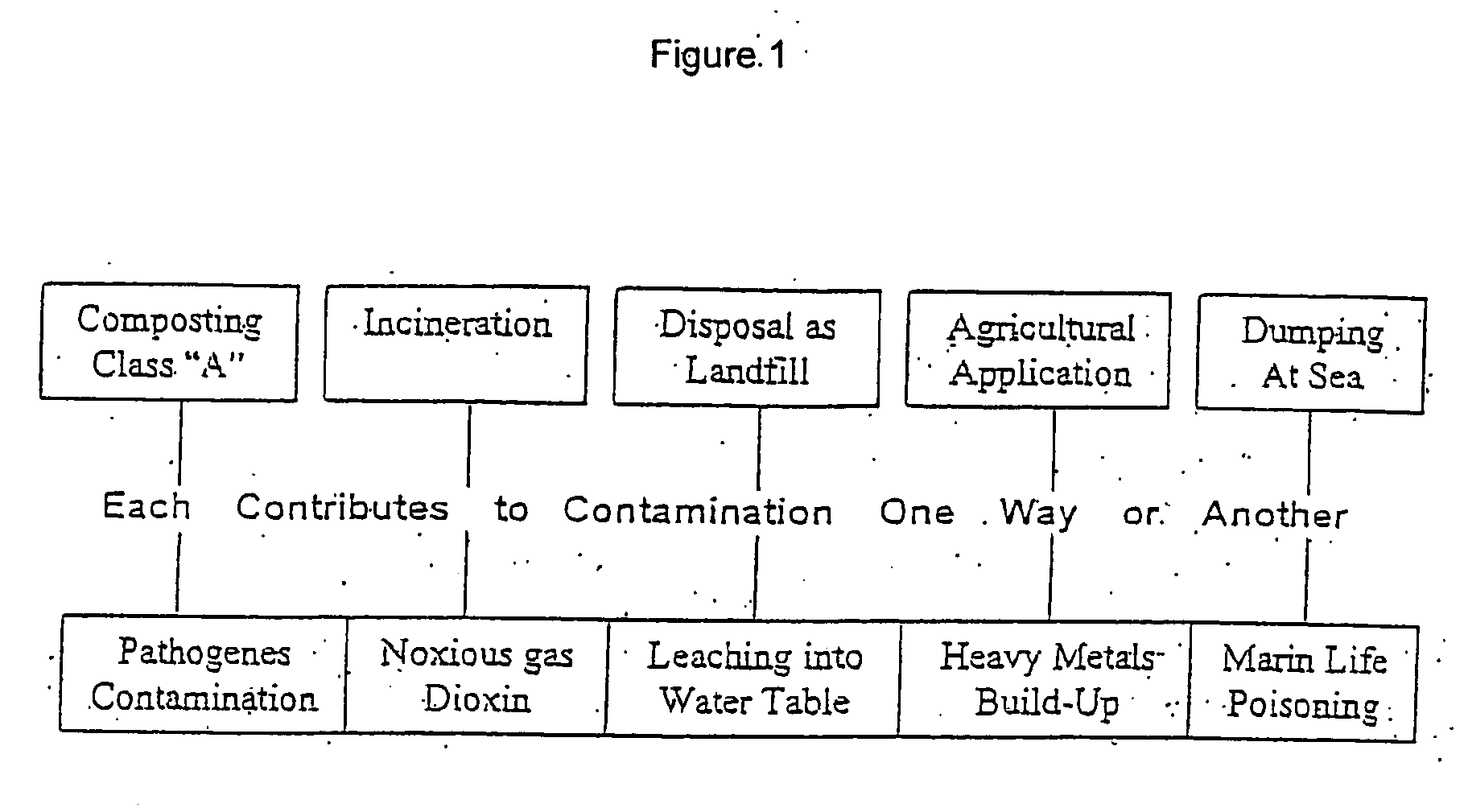

Process for treatment of organic waste

InactiveUS7276148B2Improve light outputIncrease productionCatalytic crackingMolecular sieve catalystsEvaporationSlurry

The invention provides a multi-stage process for the treatment of organic waste comprising drying said waste to reduce the water content to below 15%; subjecting said dried waste to a thermochemical liquefaction process in the presence of a recirculating solvent medium at a temperature of about 275° C. to 375° C. and a pressure of up to 10 atmospheres, thereby obtaining gaseous, liquid and solid products; separating the formed slurry product from condensable gas, water and other liquid fractions boiling out at up to 250° C.; transferring said slurry product obtained from thermal extraction from step c to a pyrolysis apparatus and treating the same at a temperature of about 350° C. to 500° C. to cause additional thermal destruction of unconvertible organic matter of feed material and heavy liquid fractions obtained is step c and their evaporation and removal from pyrolysis apparatus; separating vapor products from condensable oil products; vacuum distillation of oil products from step c for the removal of fractions having a boiling temperature of between 250° C. and 350° C.; and recirculating solvent medium for step b.

Owner:BIO GASOLINE

Process for treatment of organic waste

InactiveUS20060151357A1Improve light outputIncrease productionCatalytic crackingMolecular sieve catalystsEvaporationSlurry

The invention provides a multi-stage process for the treatment of organic waste comprising drying said waste to reduce the water content to below 15%; subjecting said dried waste to a thermochemical liquefaction process in the presence of a recirculating solvent medium at a temperature of about 275° C. to 375° C. and a pressure of up to 10 atmospheres, thereby obtaining gaseous, liquid and solid products; separating the formed slurry product from condensable gas, water and other liquid fractions boiling out at up to 250° C.; transferring said slurry product obtained from thermal extraction from step c to a pyrolysis apparatus and treating the same at a temperature of about 350° C. to 500° C. to cause additional thermal destruction of unconvertible organic matter of feed material and heavy liquid fractions obtained is step c and their evaporation and removal from pyrolysis apparatus; separating vapor products from condensable oil products; vacuum distillation of oil products from step c for the removal of fractions having a boiling temperature of between 250° C. and 350° C.; and recirculating solvent medium for step b.

Owner:BIO GASOLINE

Short-circuiting device for use in low-voltage and medium-voltage systems for the protection of parts and personnel

InactiveCN101278369ASpark gap detailsSpark gaps with auxillary triggeringLow voltageMetallic materials

The invention relates to a short-circuiting device for use in low-voltage and medium-voltage systems for the protection of parts and personnel, comprising a switching element, which can be actuated by the tripping signal of a fault detection device, two mutually opposite contact electrodes having power supply means, wherein contact can be made with said contact electrodes at a circuit having connections at different potentials, furthermore the contact electrodes, under mechanical prestress, carry out a relative movement in relation to one another in the event of a short-circuit assisted by spring force, and a further part short-circuits the contact electrodes in a relative movement with respect to said contact electrodes, a sacrificial element as the spacer between the contact electrodes and having an electrical connection between the sacrificial element and the switching element,; on the one hand, and one of the contact electrodes, on the other hand, in order to bring about thermal destruction of the sacrificial element in a targeted manner owing to current flow. In a first embodiment of the invention, the sacrificial element is a thin-walled hollow cylinder consisting of a high-melting metallic material. In a second embodiment of the invention, the sacrificial element is a wire or rod consisting of a conductive material having a low melting integral, wherein the sacrificial element is under mechanical prestress under tension in contrast to the first embodiment.

Owner:DEHN SOHNE GMBH CO KG

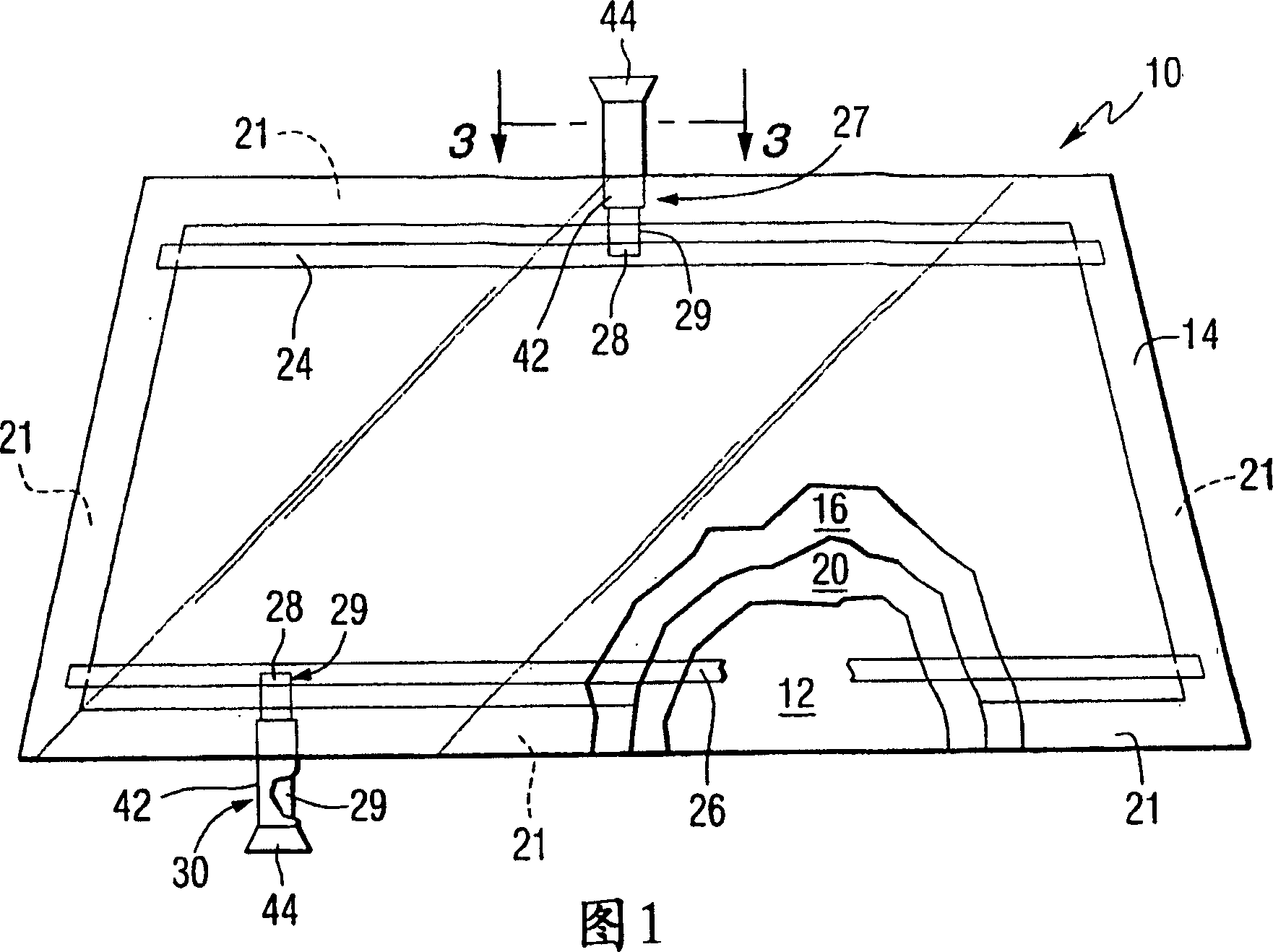

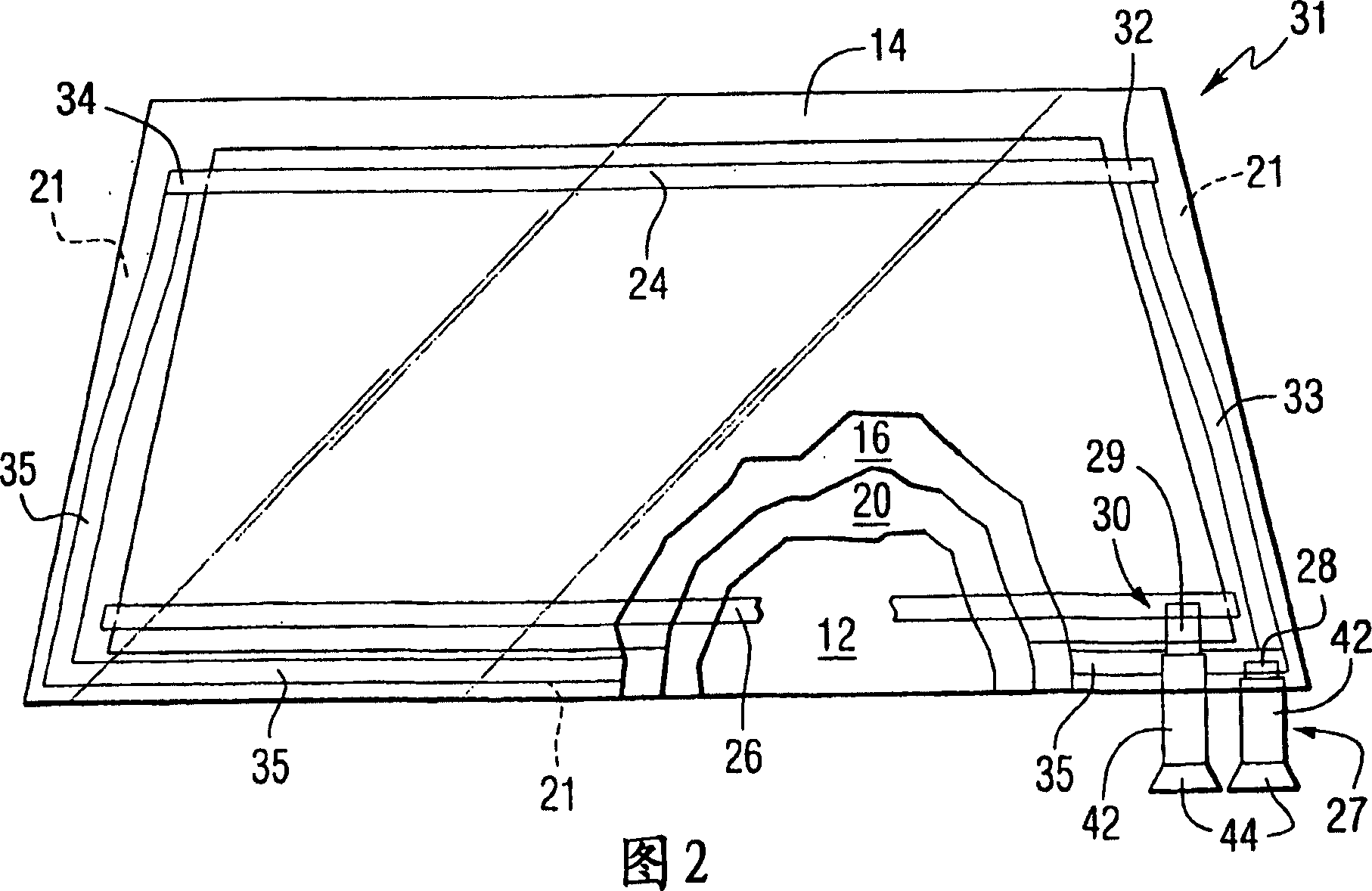

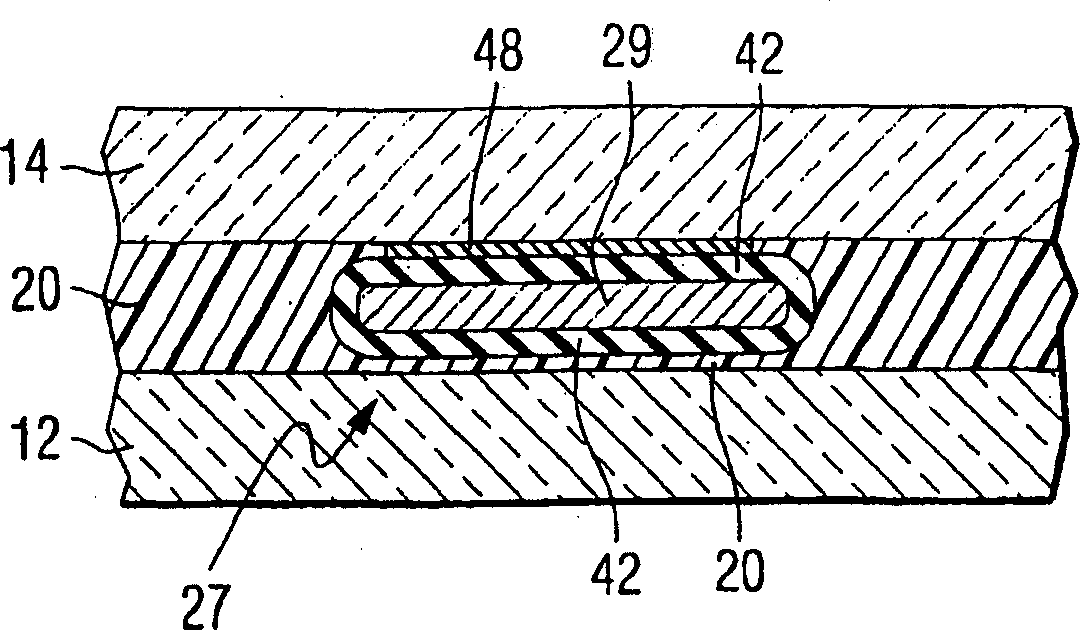

Method of soldering and solder compositions

InactiveCN1842415ATransparent/reflecting heating arrangementsGlass/slag layered productsEngineeringSoldering

The invention relates to using the heat generated during thermal treatment of one or more glass sheets to melt solder. In one nonlimiting embodiment, a lead providing external access to an electrical conductive arrangement, e.g. a conductive member between and connected to spaced bus bars between laminated sheets has an end portion of a connector, e.g. a lead soldered to each of the bus bars during thermal processing of the sheets, e.g. during the lamination of the sheets during a windshield manufacturing process. In another nonlimiting embodiment, the connector is soldered to the electrically conductive arrangement during the annealing of glass blanks following the heating and shaping of the glass blanks. Soldering the leads during the annealing or laminating process eliminated possible thermal damage to the sheet by having the sheet heated during the soldering operation instead of only a small surface portion of the sheet at and eliminates the cost of a separated soldering operation.

Owner:PPG IND OHIO INC

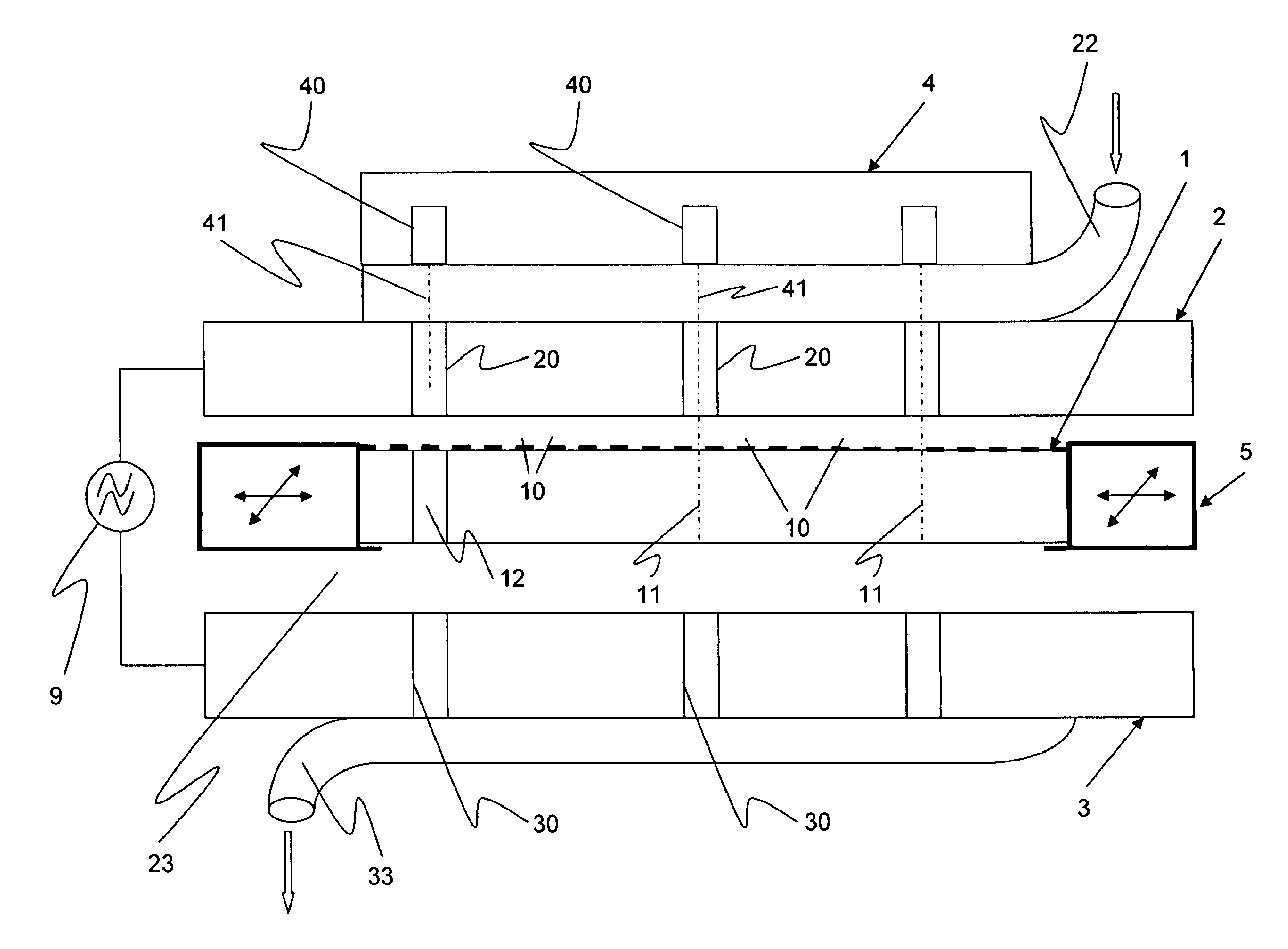

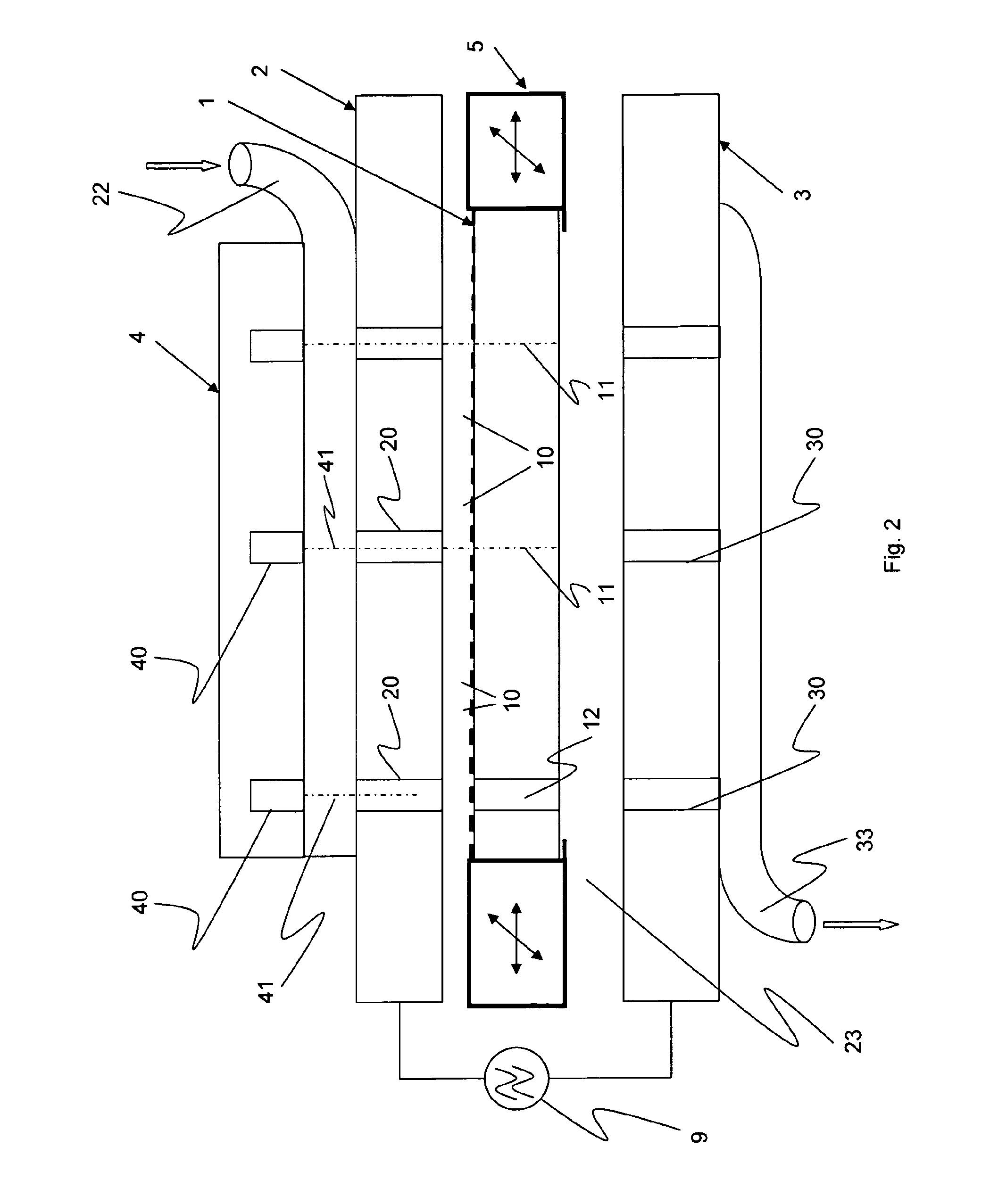

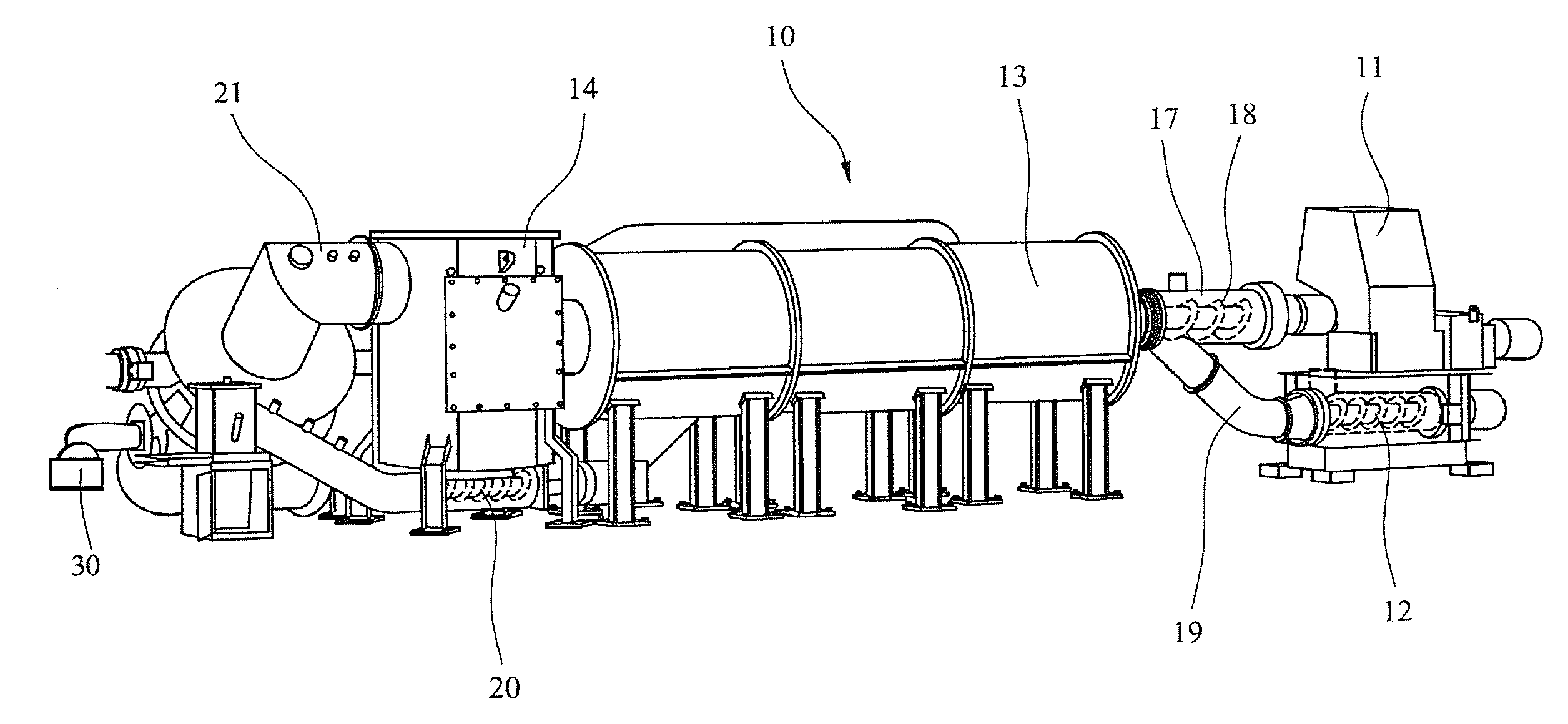

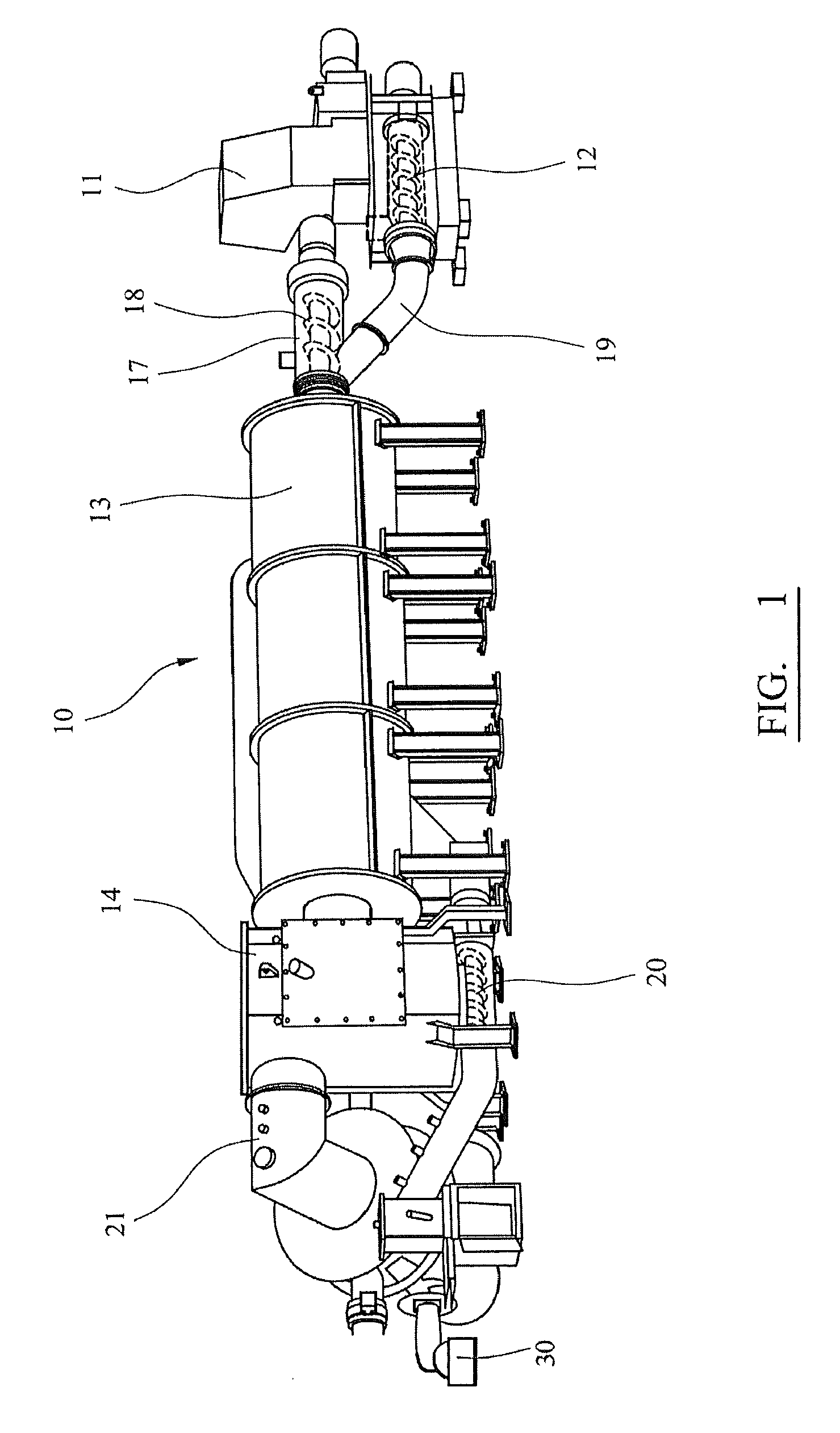

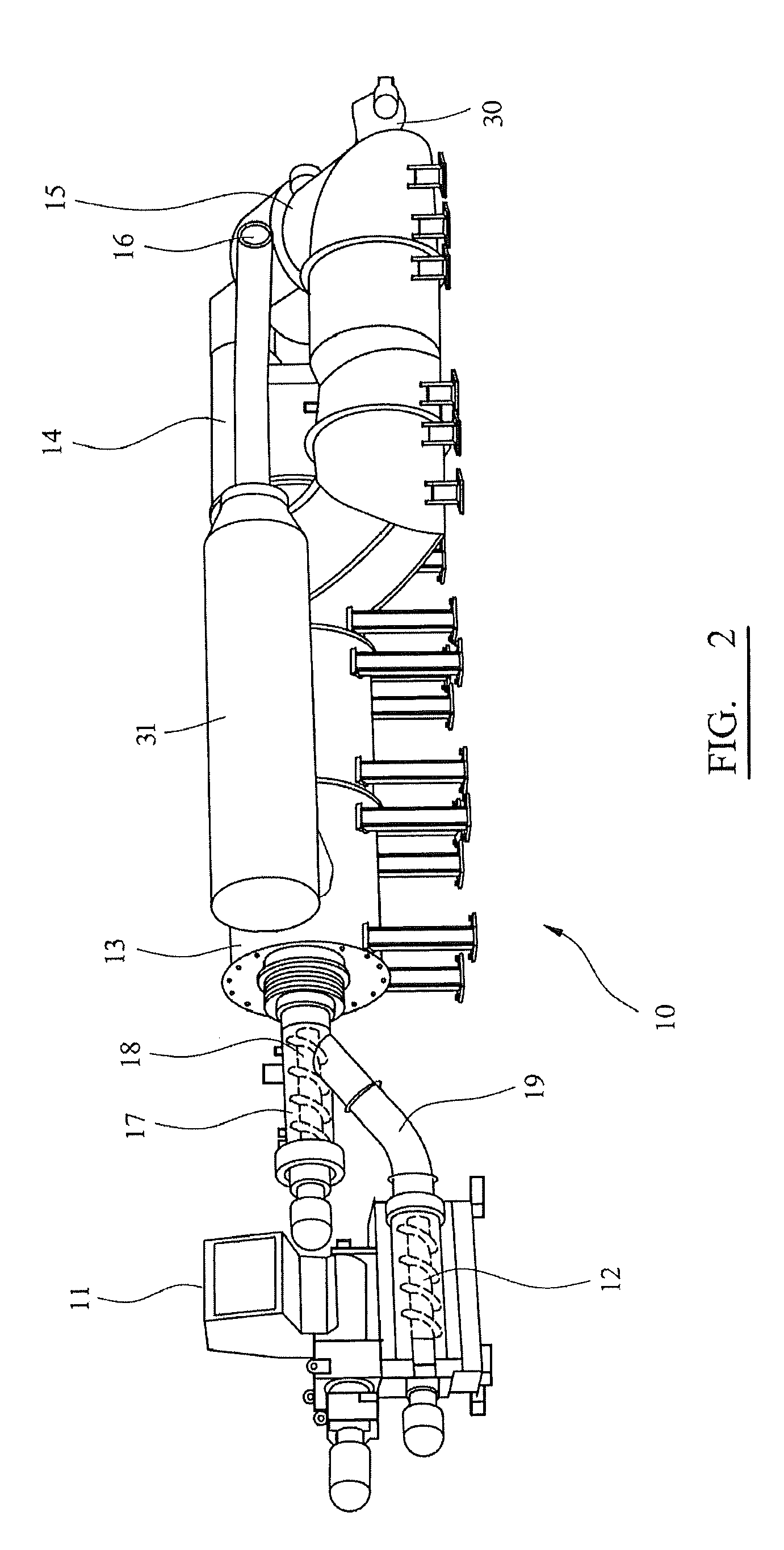

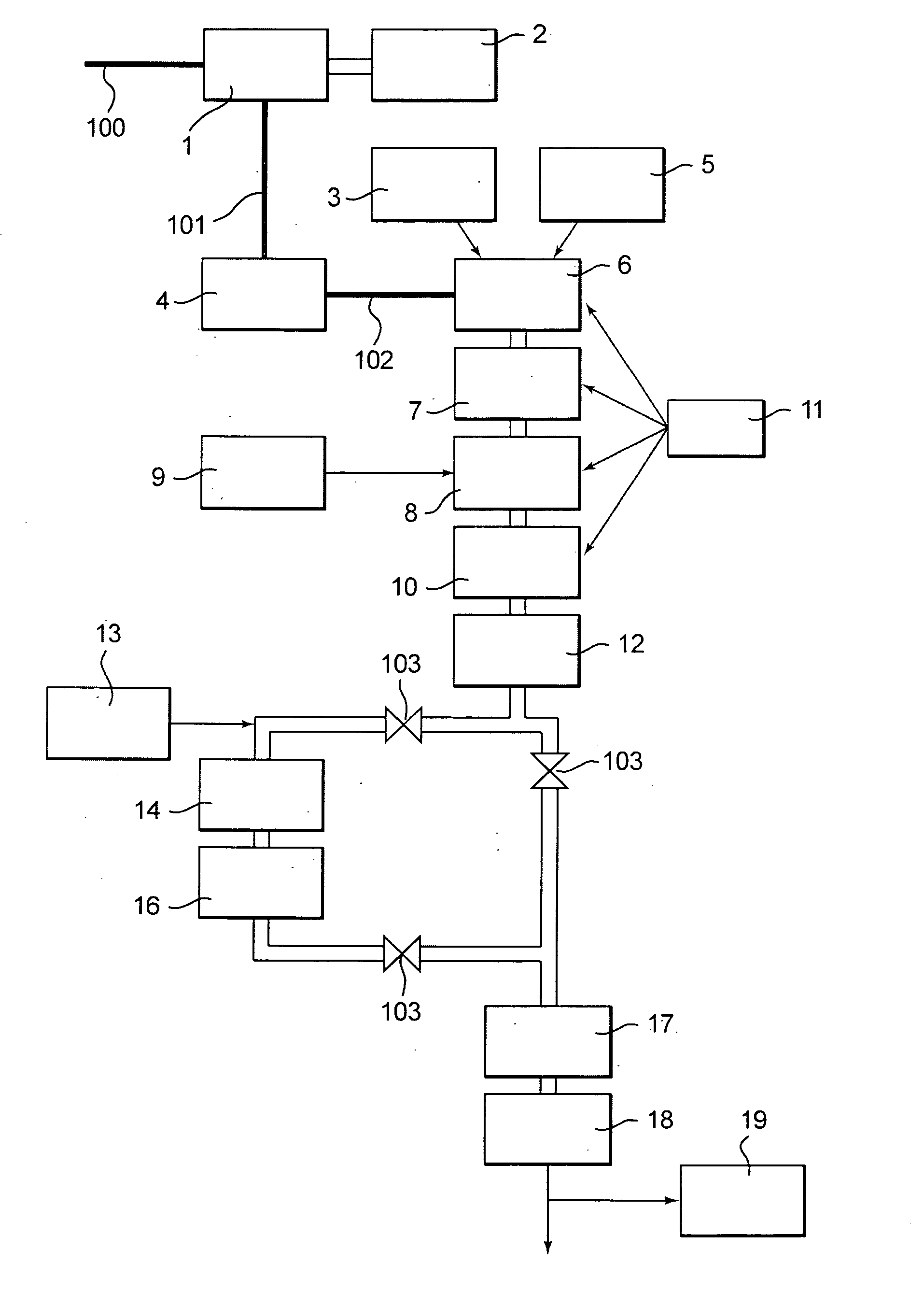

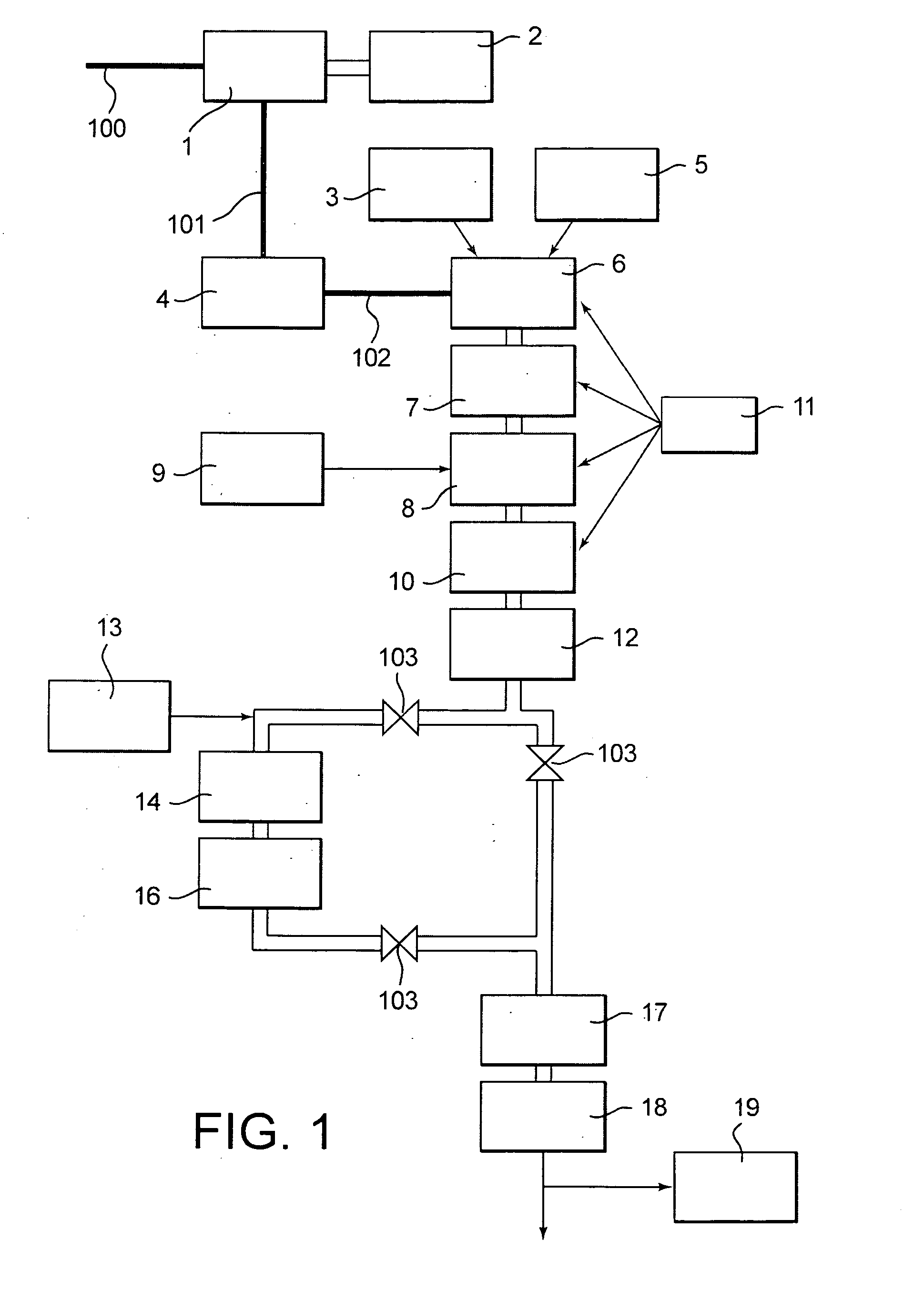

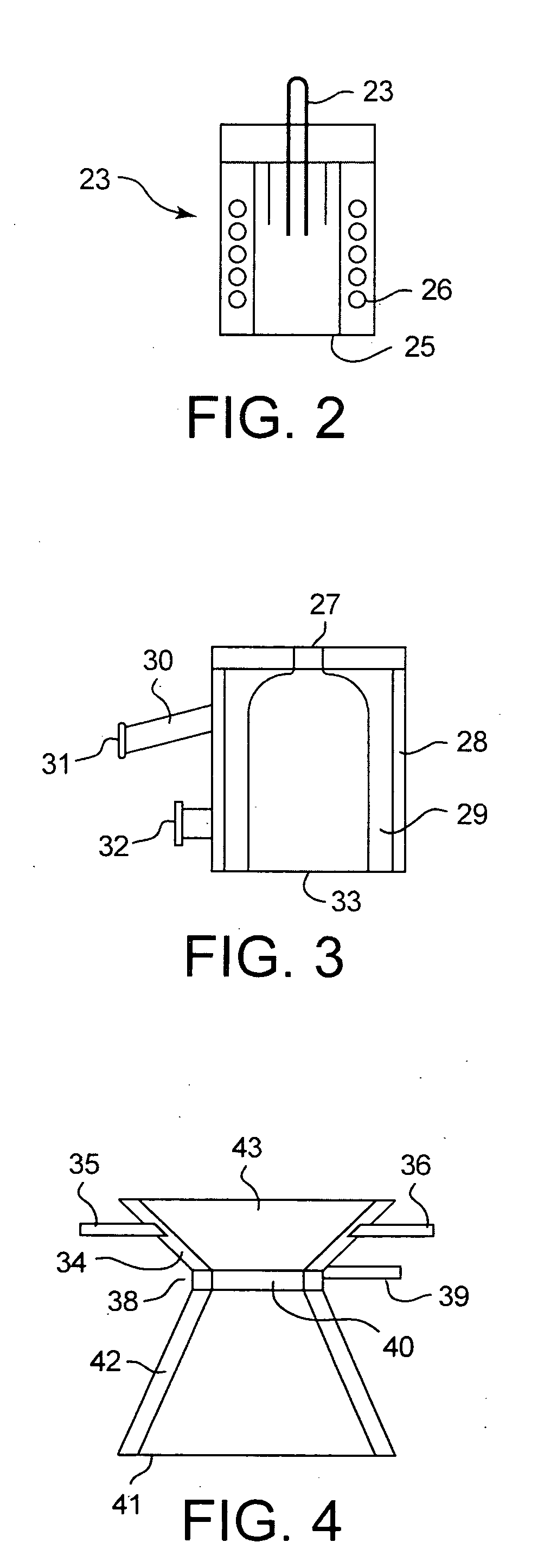

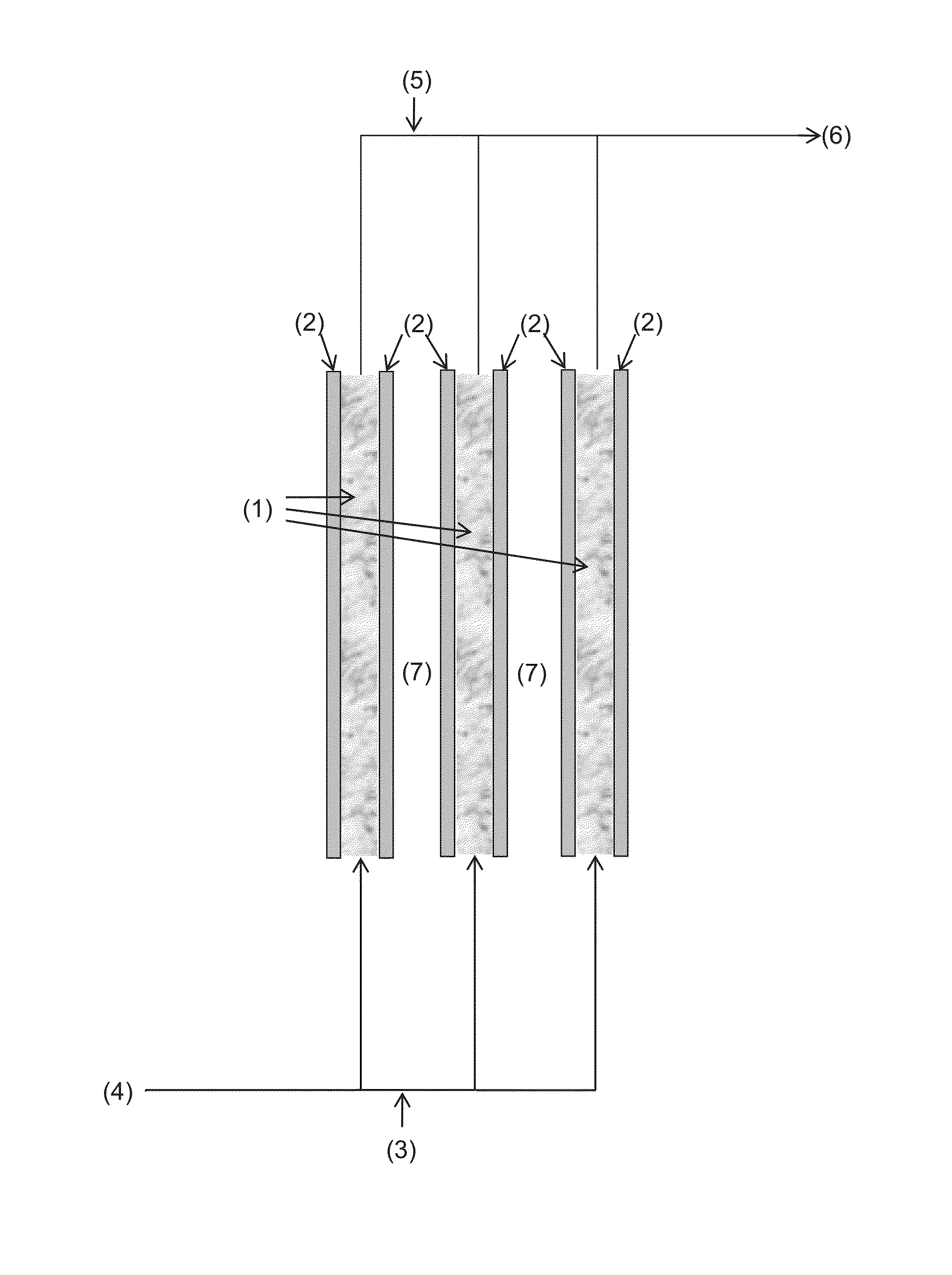

Waste processing system

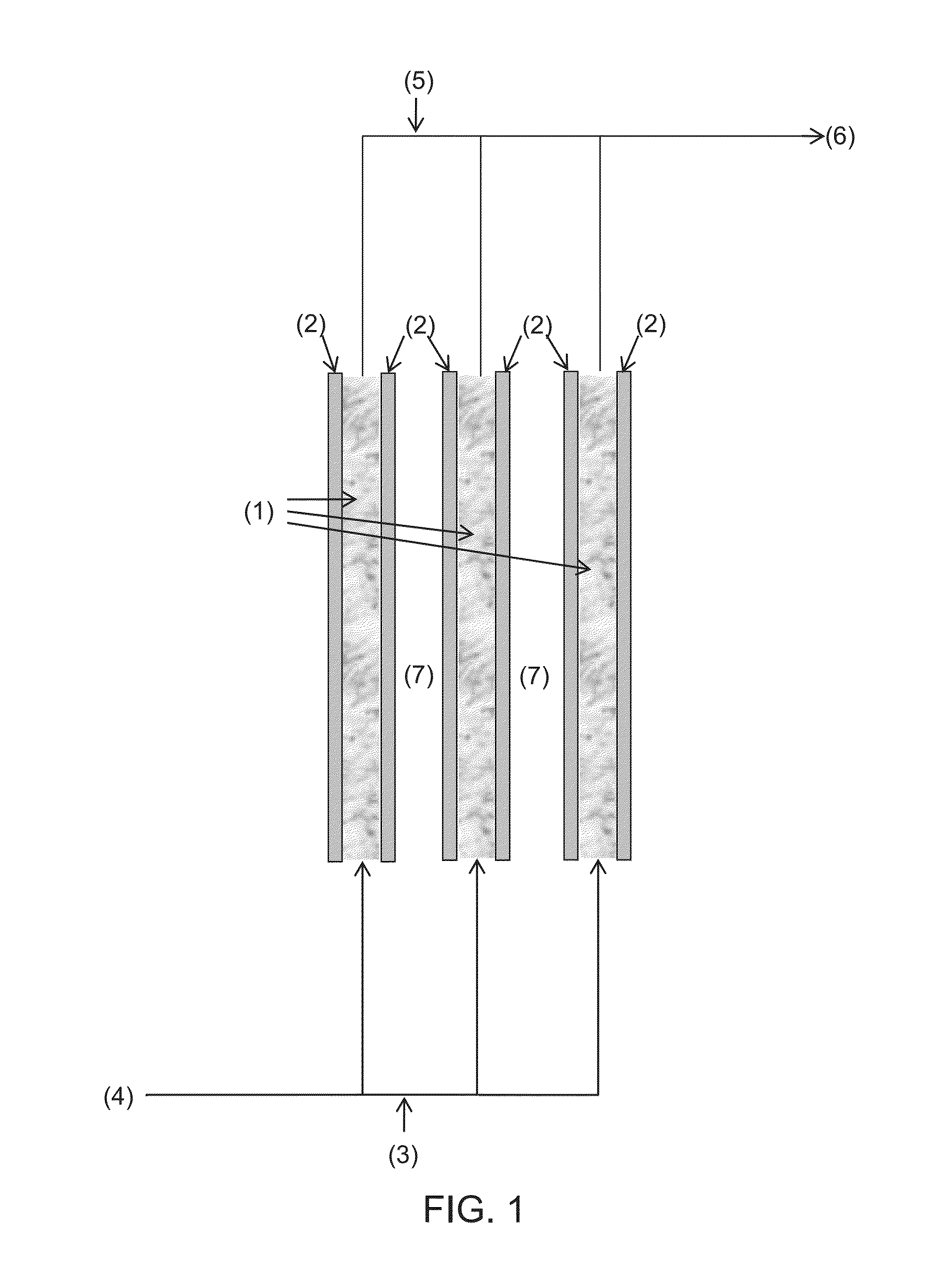

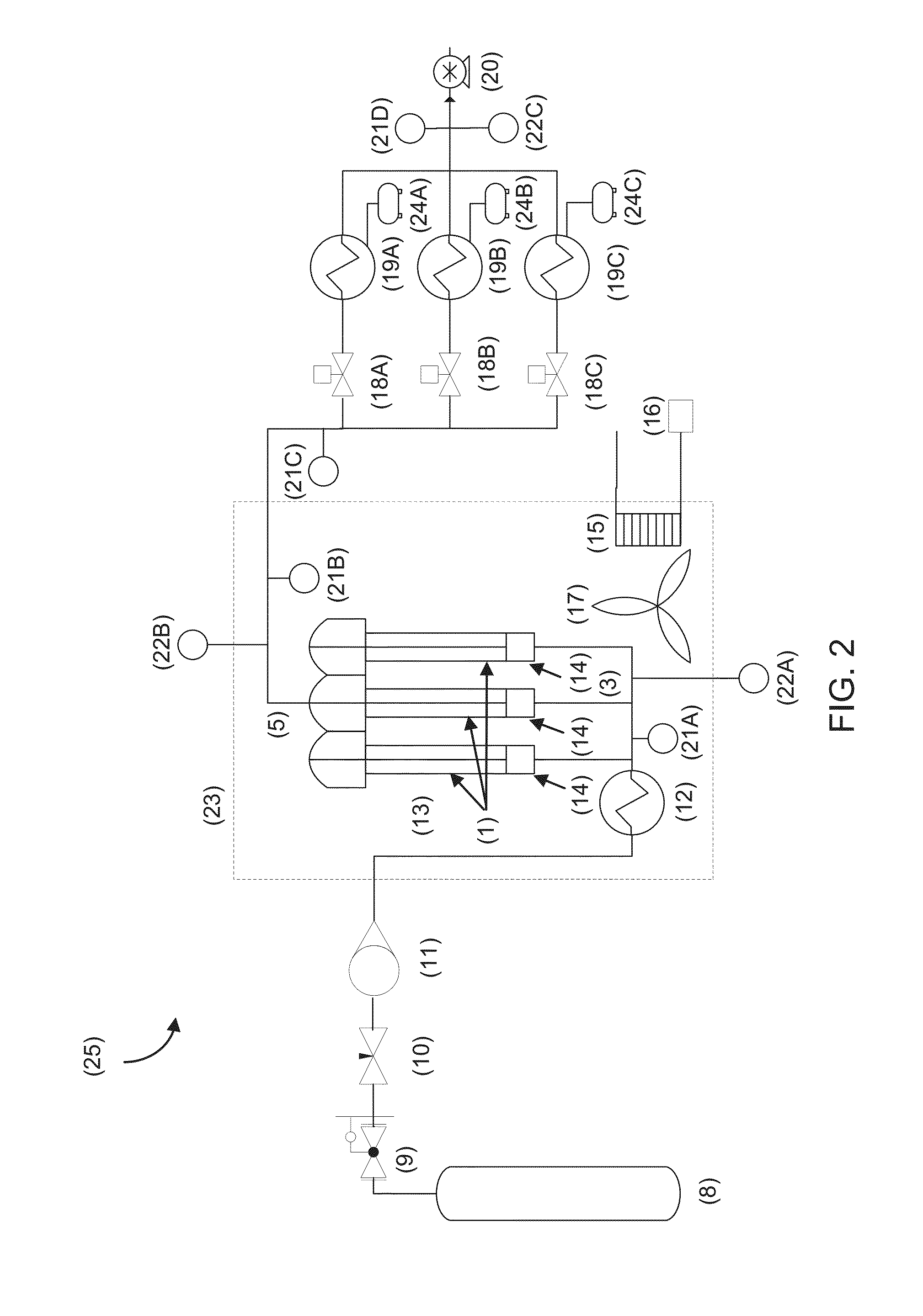

InactiveUS20110036280A1Easy to integrateSmall footprintSolid waste disposalIncinerator apparatusWaste processingThermal Destructions

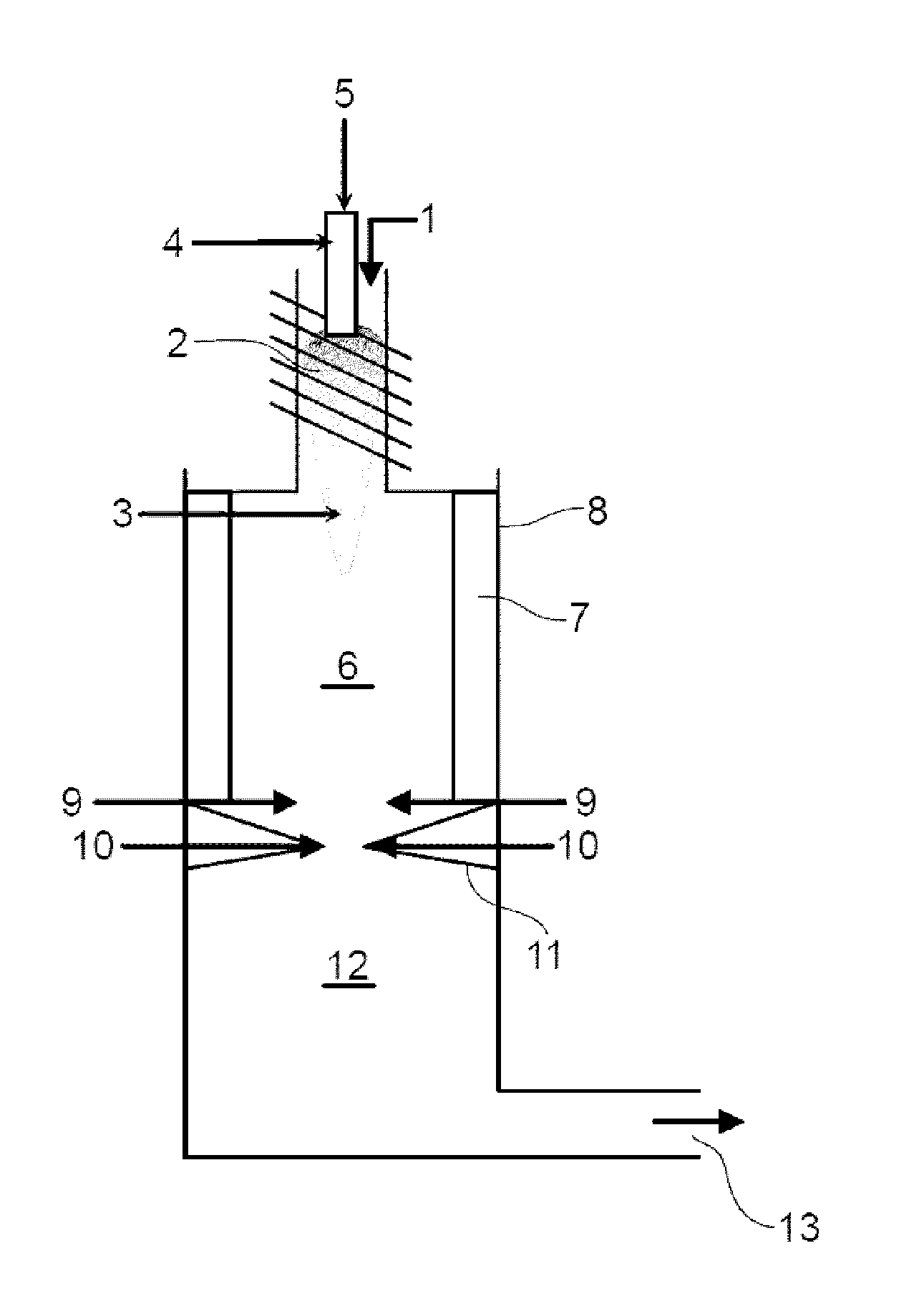

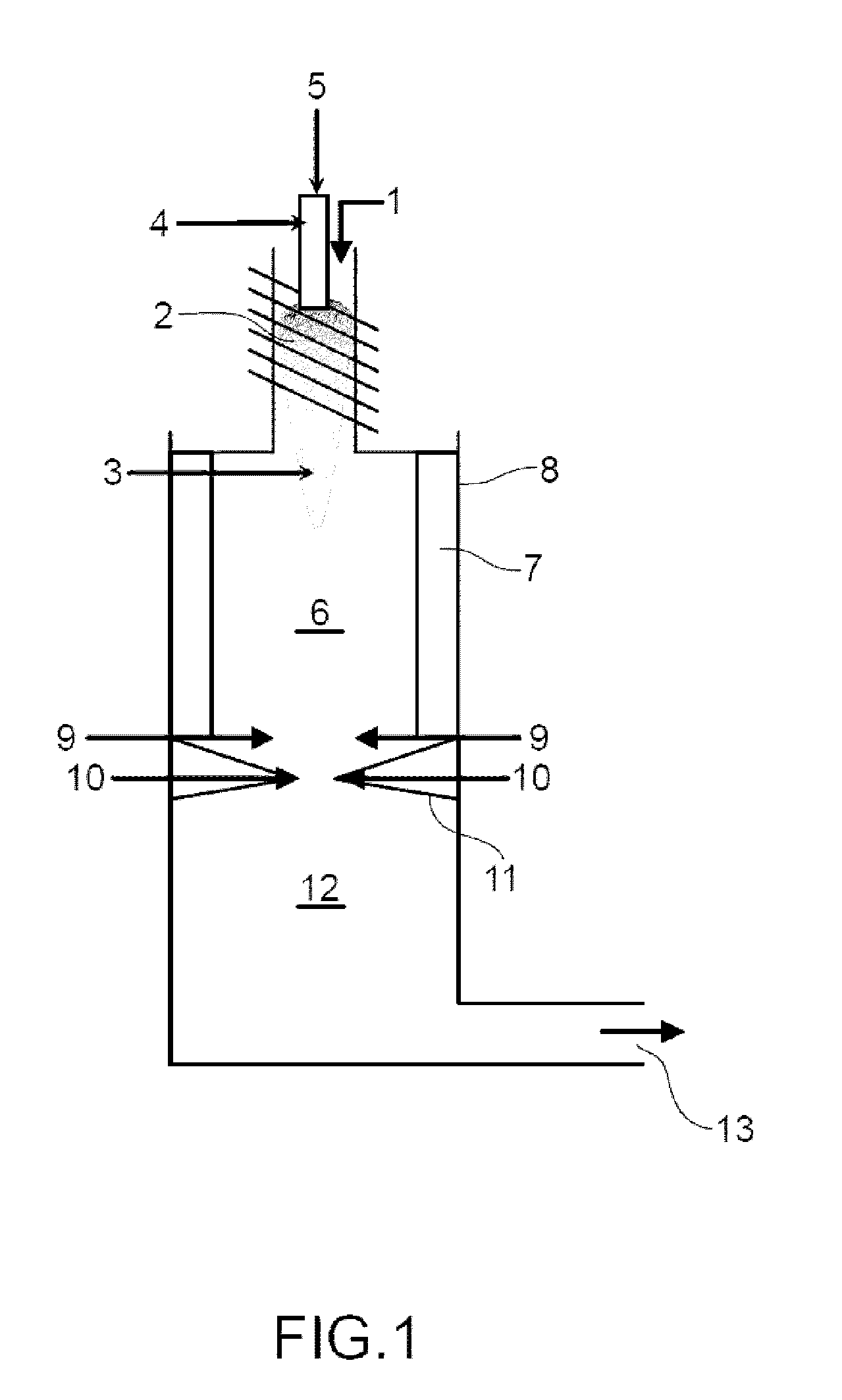

A small scale integrated waste processing system for the thermal destructions of waste. The system comprises a compactor (12) for densifying waste and expressing air, a pyrolyzer (13) to receive waste delivered from the compactor, a gasifier (14) with an ash vessel (23) that receives dried waste, and an oxidizer (15) receiving gas from the gasifier to be combusted. Heat energy from the oxidizer can be routed back to the pyrolyzer.

Owner:ETHOS ENERGY WORLDWIDE LTD

Monitor and methods for characterizing airborne particulates

InactiveUS7947503B2Readily moved and carried and attachedLess intrusiveMaterial analysis by electric/magnetic meansMaterial analysis by optical meansParticulatesAnalyte

Owner:UNITED STATES OF AMERICA

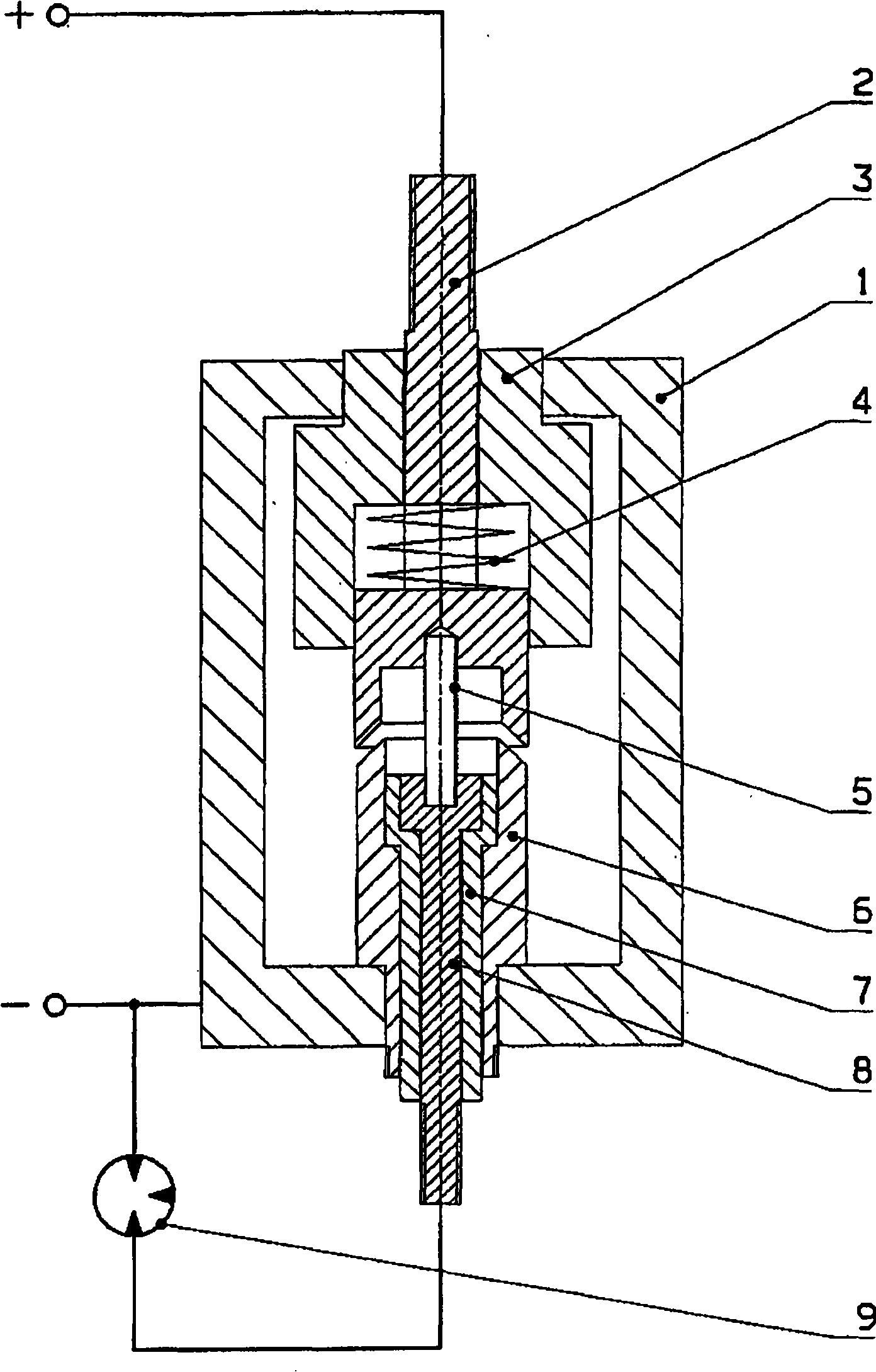

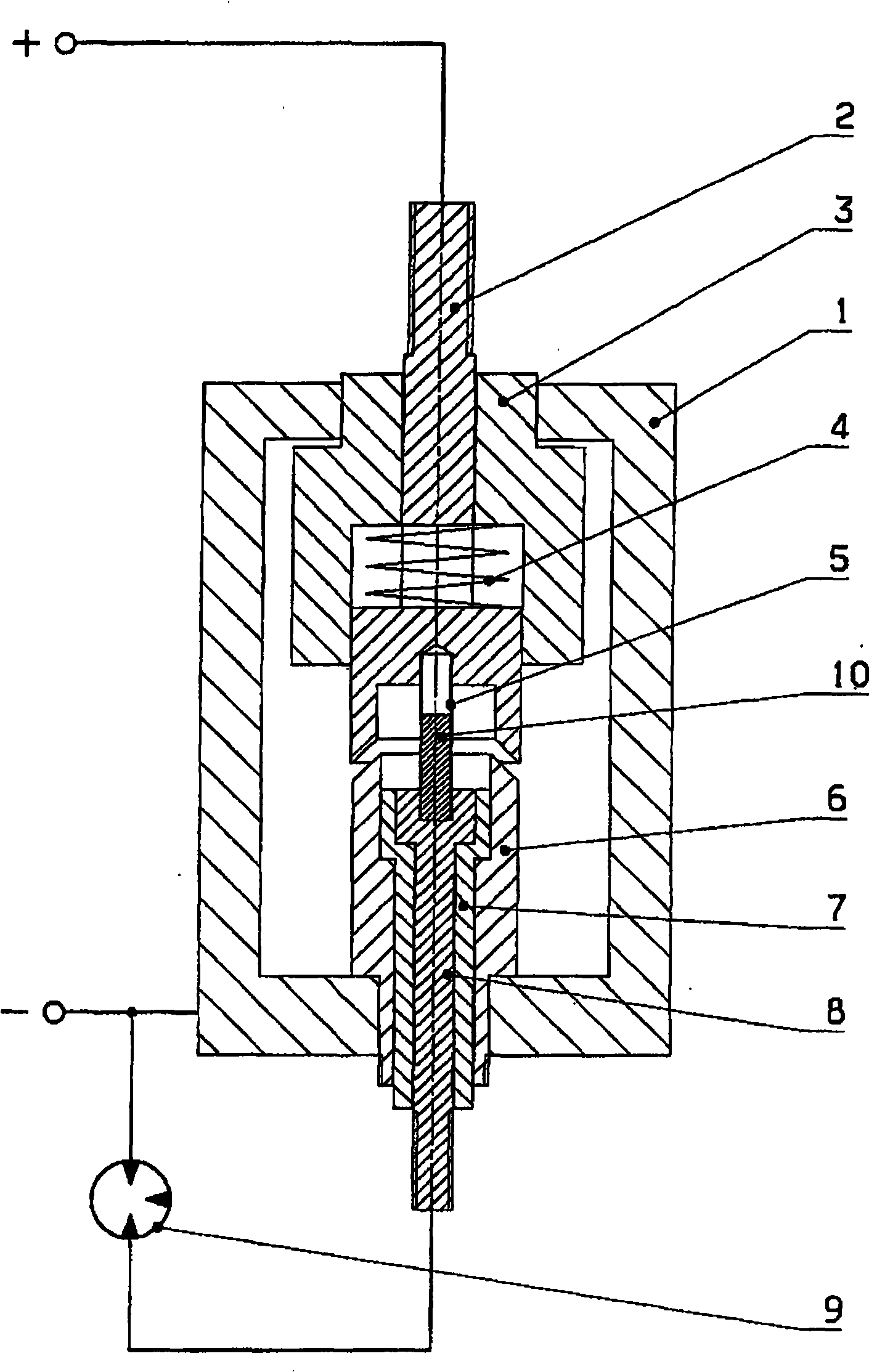

Device and Method for Destroying Liquid, Powder or Gaseous Waste Using an Inductively Coupled Plasma

ActiveUS20080286169A1Reduce the temperatureArc welding apparatusIndirect carbon-dioxide mitigationAtomic elementDecomposition

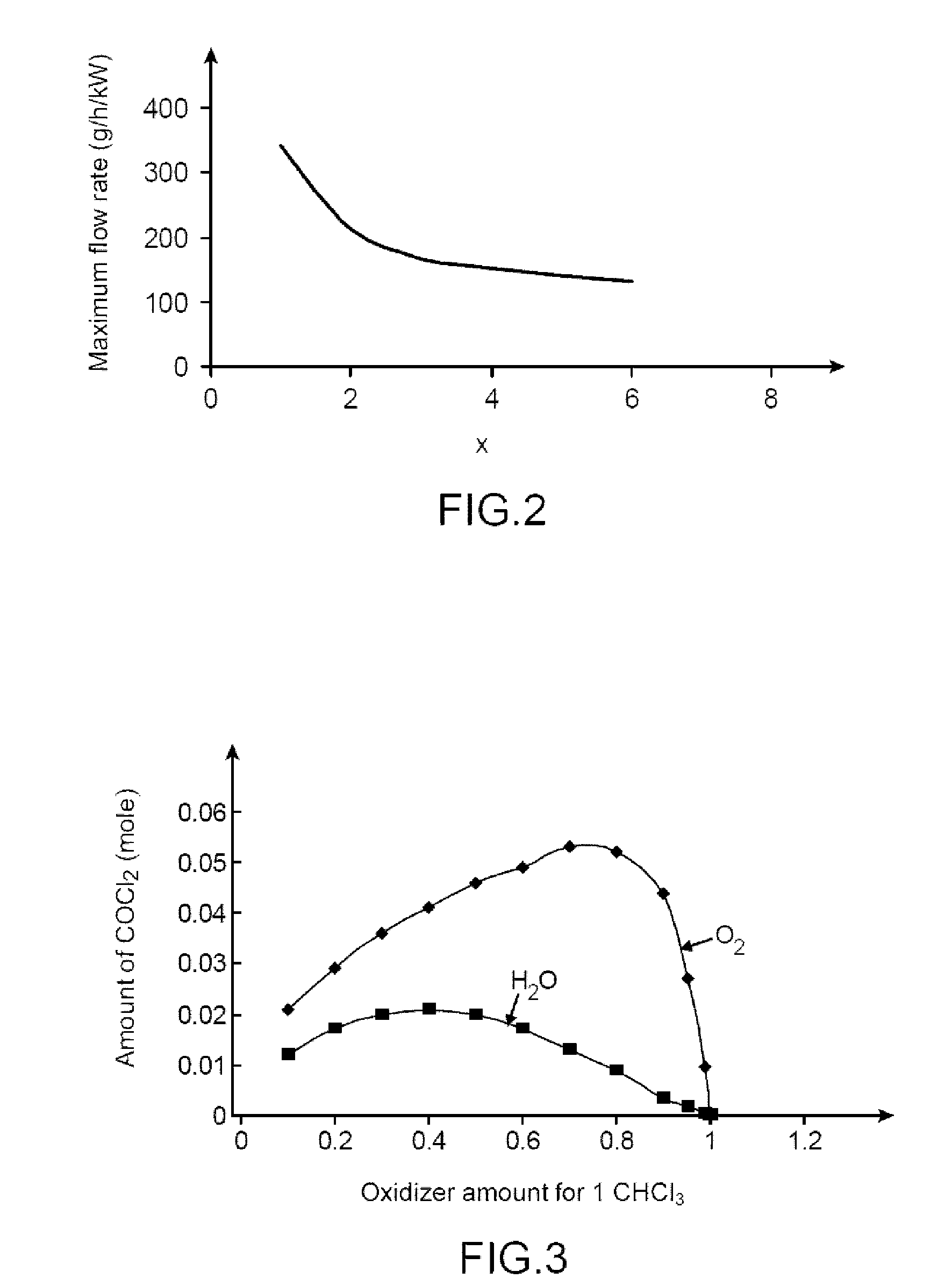

The invention relates to a thermal destruction process for at least one organic or halogenated organic product in liquid, gaseous or powder form. The process includesmixing:of the aforementioned one or more organic products with water in sufficient quantities to ensure that at least stoichiometric ratios between atoms of carbon and oxygen in the mixture are obtained, orof the aforementioned one or more halogenated organic products with water in sufficient quantities to ensure that at least the stoichiometric ratios for, on the one hand, atoms of carbon and oxygen in the mixture, and on the other hand, for hydrogen and halogen atoms in the mixture are obtained,introduction of this mixture and of plasmagenic gases into the coil of an inductively coupled plasma torch to produce gas in which decomposition into atomic elements has occurred,an initial thermal destruction operation of the aforementioned gas in which decomposition into atomic elements has occurred, this initial destruction operation taking place in a reaction chamber,a second thermal destruction operation of the gas that has undergone the initial destruction operation, this second destruction operation taking place in a stirring device with no energy being added, this gas which undergoes the second thermal destruction operation being stirred with air and / or oxygen,recombination by cooling of at least a part of the gas emerging from the stirring device,discharge of the gas that has been destroyed.The invention also relates to a device that allows this destruction process to be applied.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

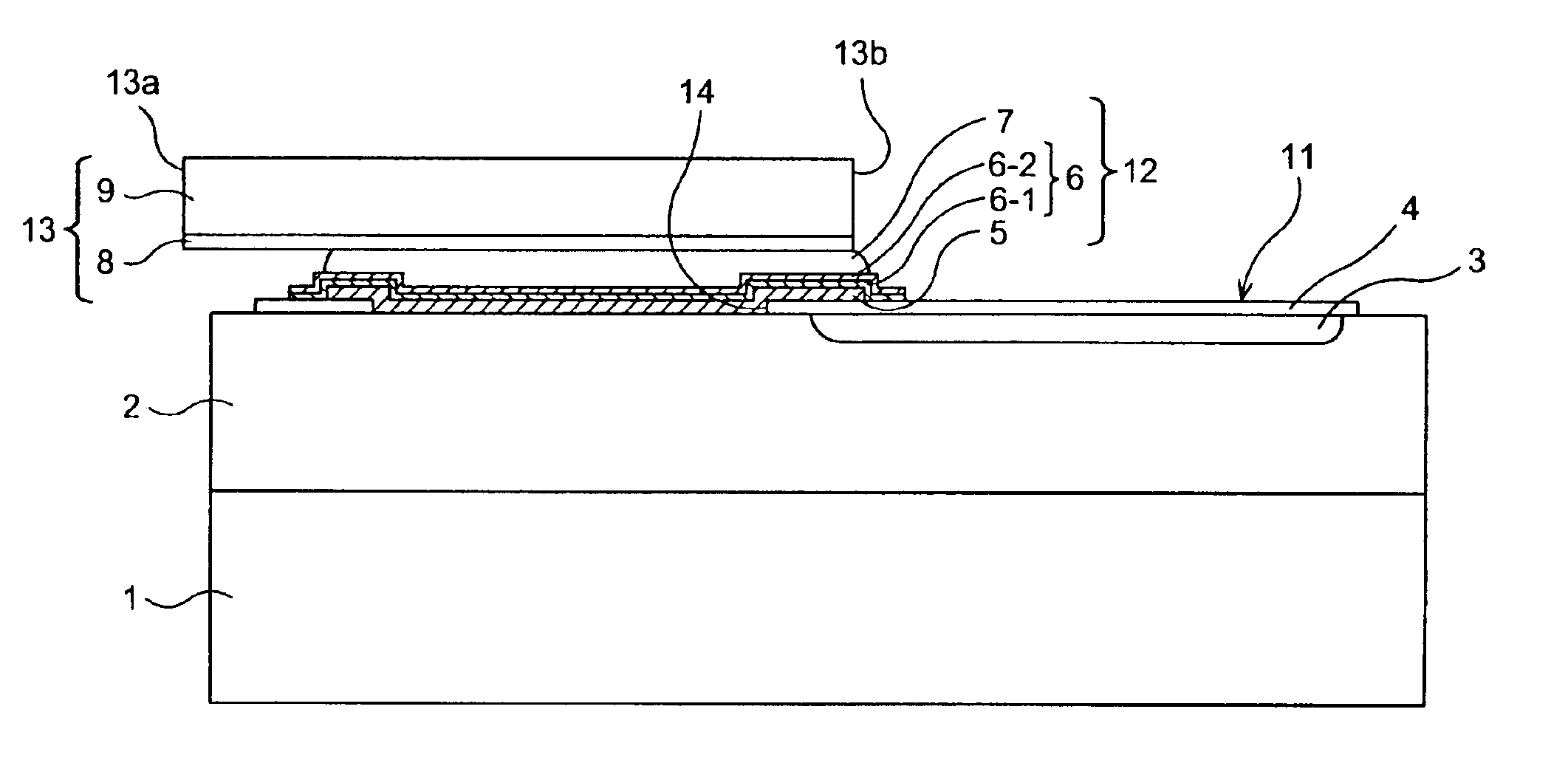

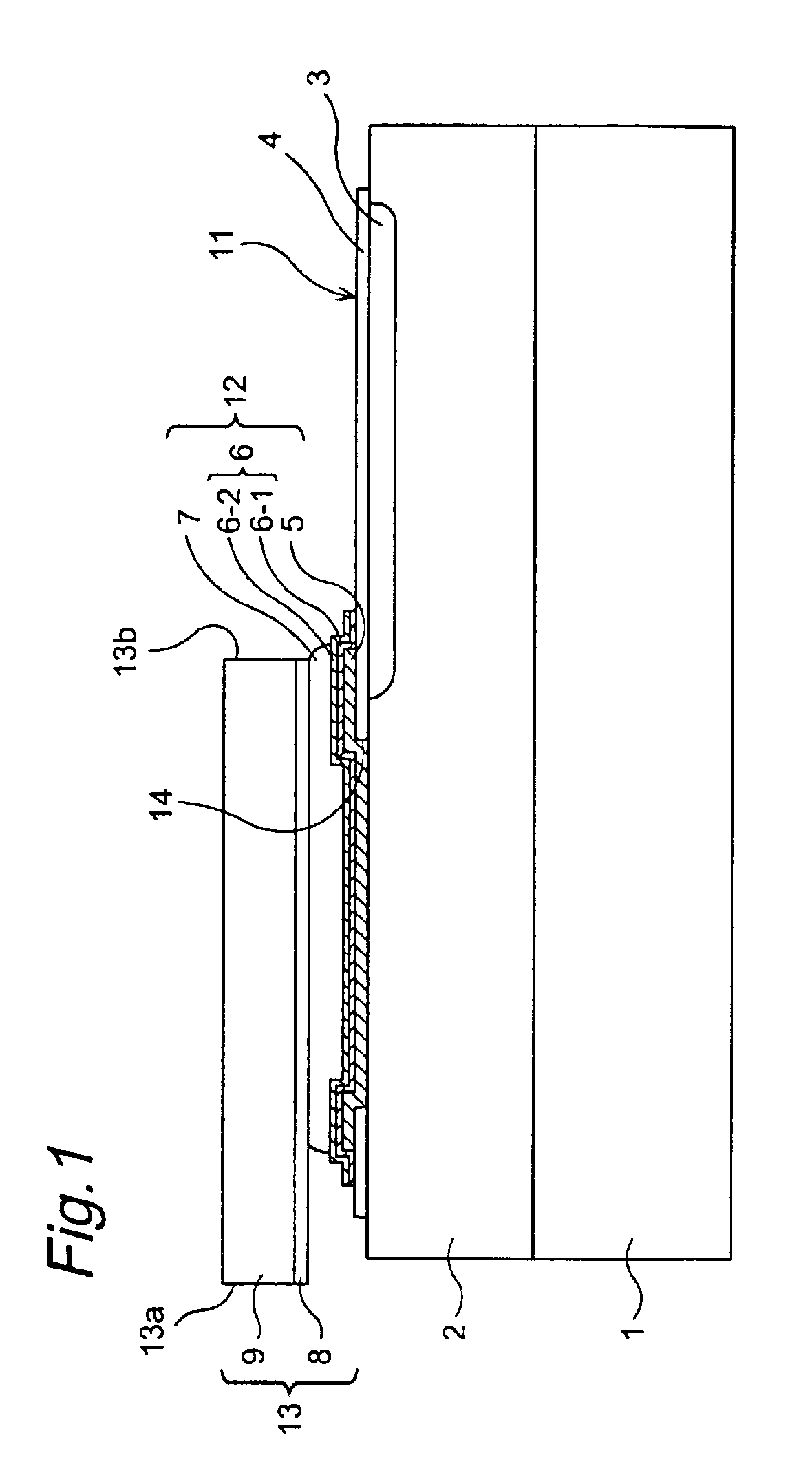

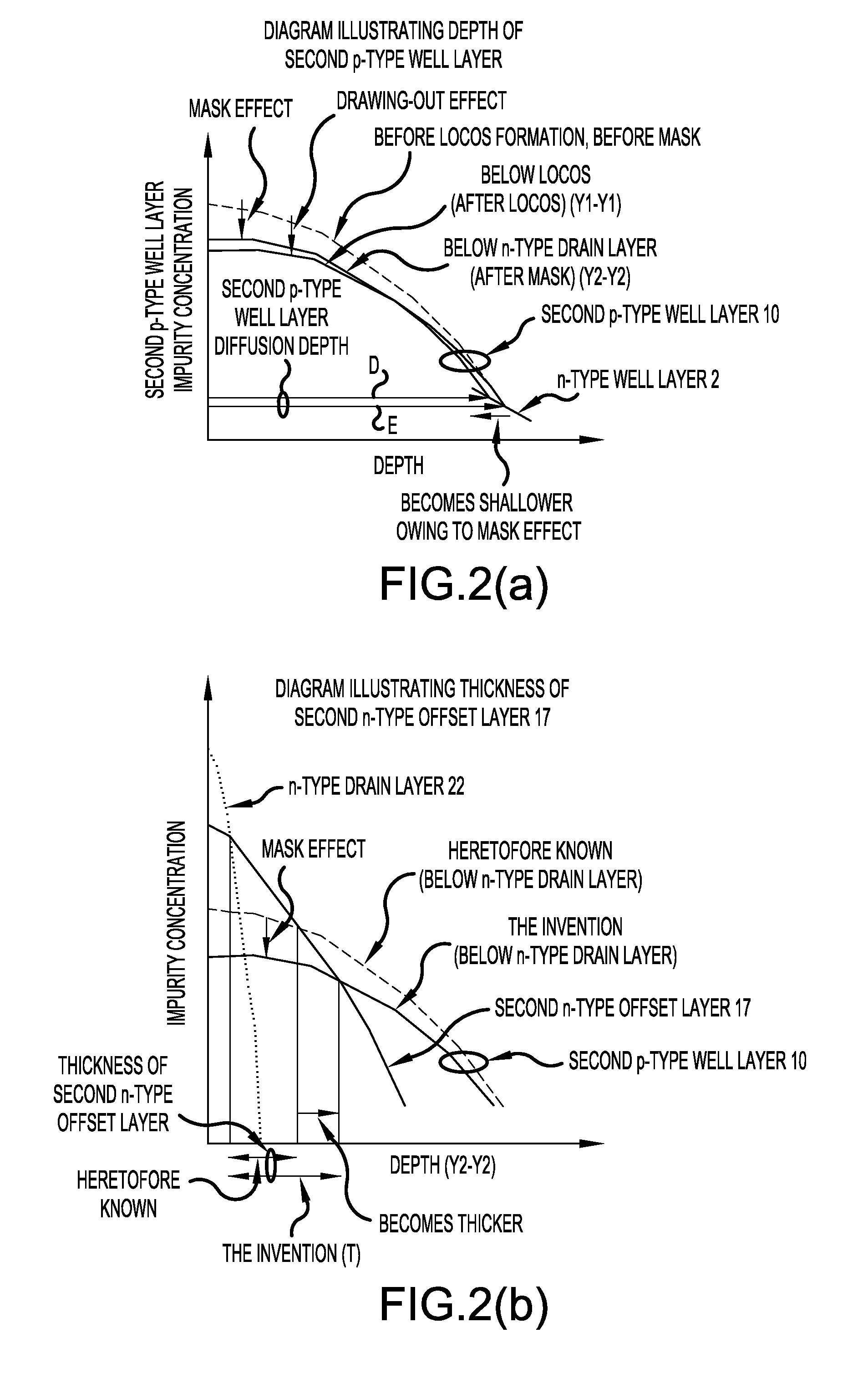

Semiconductor device and manufacturing method therefor

InactiveUS6858871B2Avoid thermal damageInhibits sufficient meltingSemiconductor/solid-state device detailsSemiconductor laser structural detailsThermal DestructionsPhotodiode

A red color laser diode 13 is die-bonded onto a silicon submount photodiode chip 11 having a insulating film 4 on the surface thereof. The silicon submount photodiode chip 11 receives a light beam radiated from a back side 13b of the red color laser diode 13 for monitoring an output of a light beam radiated from a front side 13a of the red color laser diode 13. The insulating film 4 of the silicon submount photodiode chip 11 is provided with a hole 14 located beneath an electrode 12 that die-bonds the red color laser diode 13 onto the silicon submount photodiode chip 11. Heat generated by the red color laser diode 13 is easily conducted to the silicon submount photodiode chip 11 through the hole 14 not covered with the insulating film 4 and discharged therefrom, which enables prevention of thermal destruction.

Owner:SHARP KK

Treatment of pigmented tissue using optical energy

InactiveUS20060095097A1Improve efficiencySurgical instrument detailsLight therapyThermal DestructionsOptical energy

A method and apparatus for selectively photobleaching or killing pigmented tissues by photochemically converting pigments in the tissues using light and specifically two-photon excitation. Phototoxic products thereby produced then kill pigmented cells. Hyperthermia or an exogenous agent can also be added to augment efficacy. The present invention is also directed to selective thermal destruction of pigmented tissues using related optical means.

Owner:PROVECTUS DEVICETECH

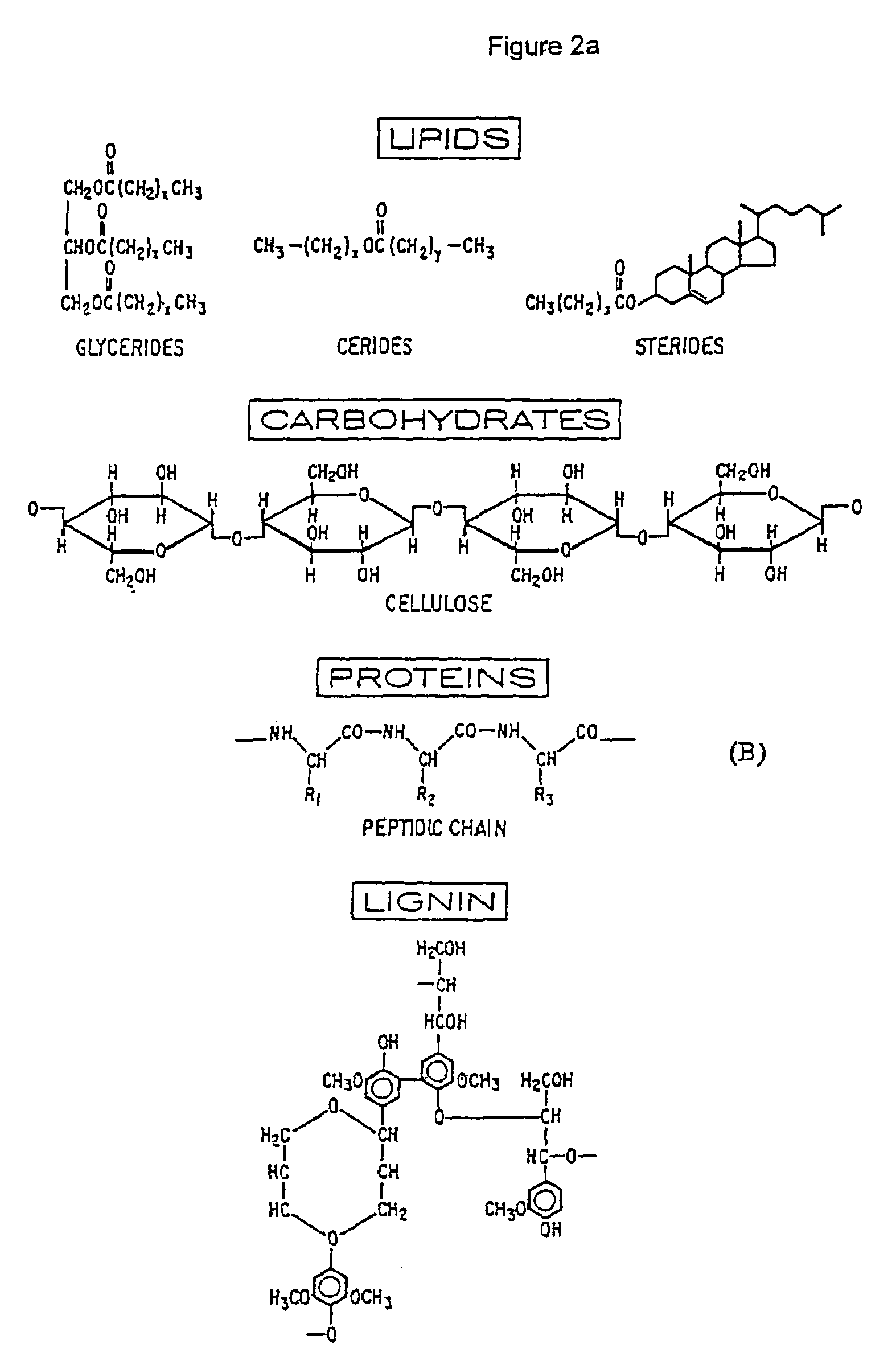

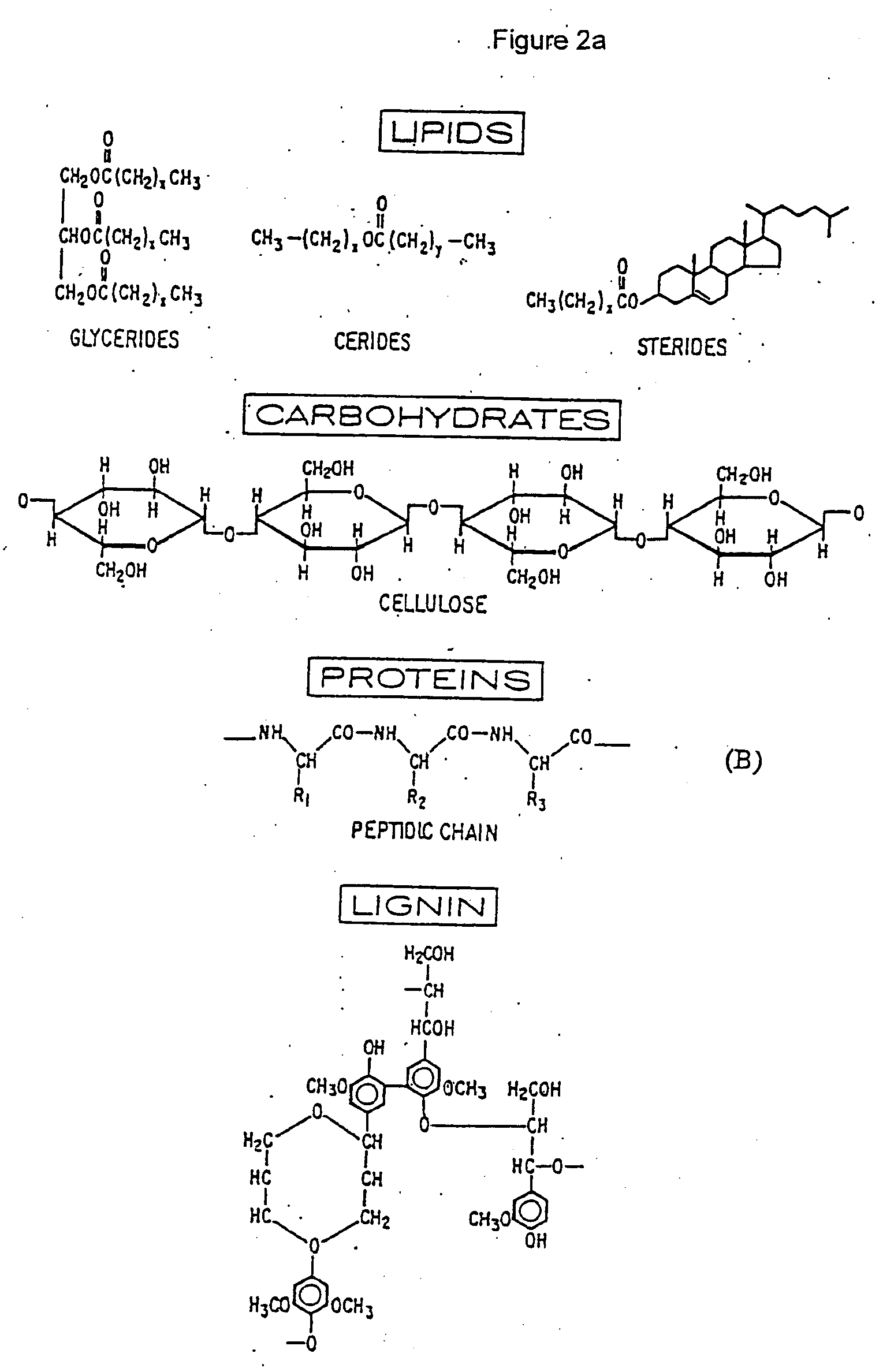

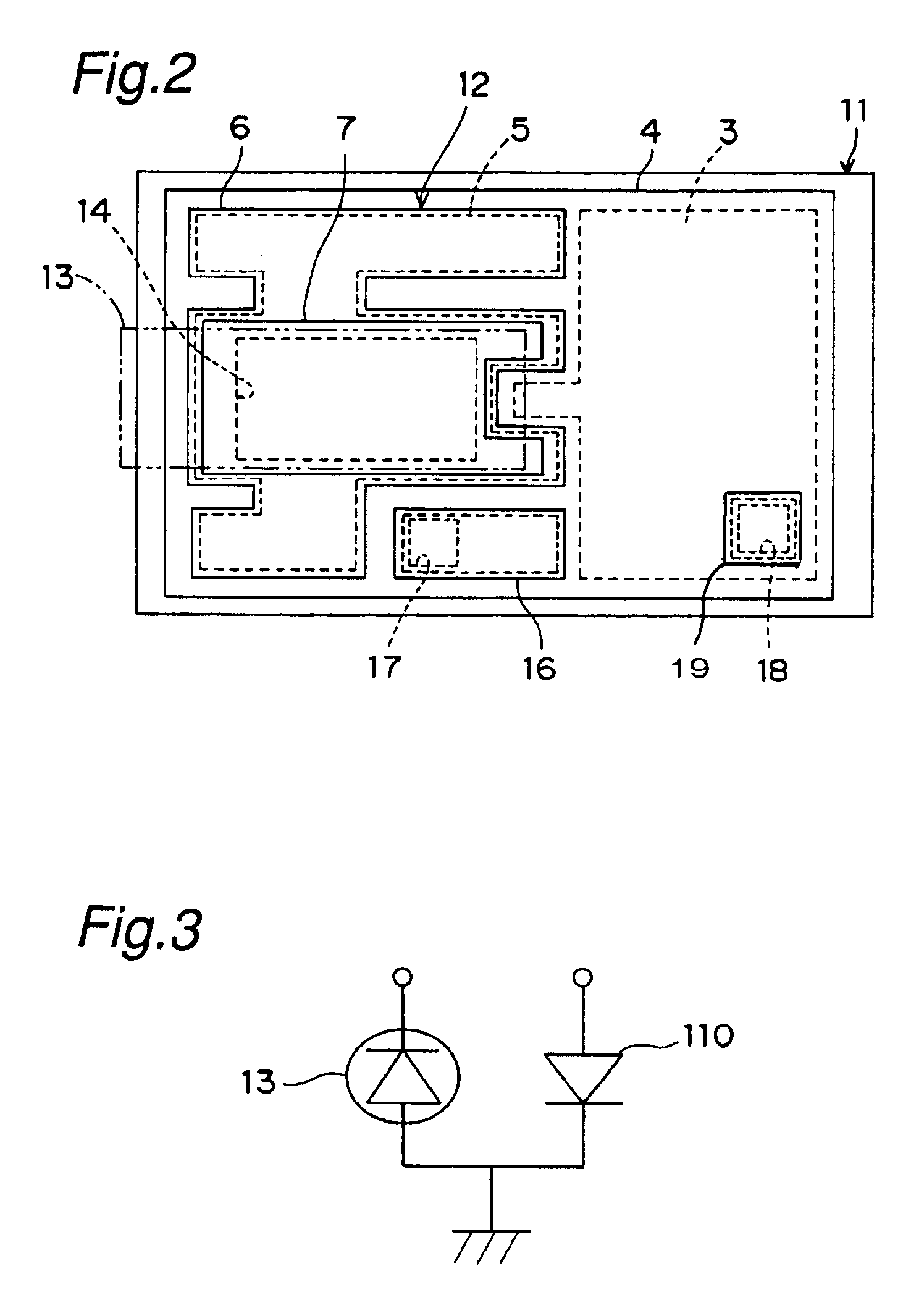

Thermal Fractionation Of Plant Material

InactiveUS20160243460A1Hydrocarbon active ingredientsHydroxy compound active ingredientsHigh rateDistillation

A highly controllable thermal distillation reactor system (25) and method (30) allow volatile compounds to be efficiently removed from the plant matter without use of solvents, and can separate compounds with different vapor pressure characteristics. The system has a Thermal Distillation Reactor (TDR) (13) into which the plant material is charged. The TDR provides for high rates of heat transfer coupled with small thermal diffusion length scales to allow substantially all of the plant material to be within a narrow temperature range, which enhances the separation purity cuts. The system provides high removal efficiencies whilst minimizing any impurities resulting from pyrolysis or thermal destruction to the cellulose, hemi-cellulose or lignin within the plant material.

Owner:BIOFRACT LLC

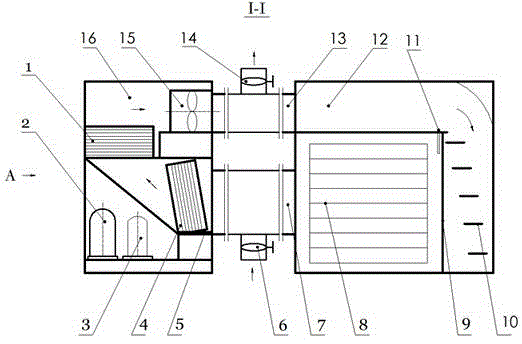

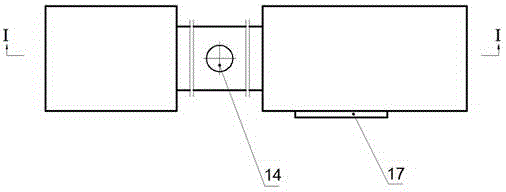

Variable-temperature drying device of medium and high temperature heat pump

InactiveCN104807318AAchieve dryingMeet the requirements of different drying processesDrying gas arrangementsHeat sensitiveMoisture

The invention discloses a variable-temperature drying device of a medium and high temperature heat pump. According to the variable-temperature drying device, the technical advantages of wide drying temperature zone (0 to 80 DEG C) and controllable humidity of a drying media (air) of the medium and high temperature heat pump are utilized, an electric temperature and moisture control air valve is regulated to obtain a controllable sealed, semi-open or fully-open heat pump system, the variable-temperature and variable-moisture segmental drying of agricultural products is realized, and the purposes of low energy consumption of a drying process and high quality of dried products can be achieved. Materials can be prevented from thermal destruction in a high moisture environment by variable-temperature drying, and variable-moisture drying can be used for preventing the surfaces of materials from crusting or hardening and is favorable for inside moisture from transferring to the surfaces. The variable-temperature drying device adopts an intermittent drying mode. Compared with hot air drying equipment which gives priority to power consumption, the variable-temperature drying device has prominent energy efficiency, and the quality of a product dried by the variable-temperature drying device can be more easily controlled. The variable-temperature drying device can be widely applied to the drying of heat sensitive materials, such as agricultural products and aquatic products, and can be used for drying in industries, such as biological products, Chinese patent medicines and chemical engineering.

Owner:江西省科学院食品工程创新中心

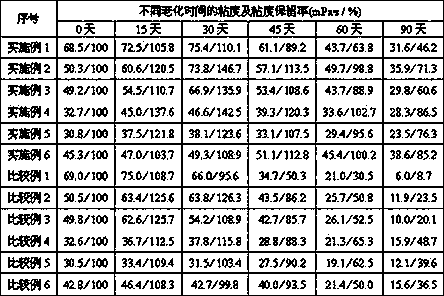

Method for increasing high temperature aging stability of polyacrylamide

ActiveCN103421482AImprove stabilityImprove high temperature aging stabilityDrilling compositionThioureaThermal Destructions

The present invention relates to a method for increasing high temperature aging stability of polyacrylamide, wherein the problem that stability of polyacrylamide can become poor in a high temperature stratum due to oxidation, thermal destruction and other reasons so as to cause failure during a tertiary oil recovery technology is mainly solved with the present invention. The technical scheme comprises that: a stabilizer is added to a polymer solution so as to substantially increase stability of the solution during a high temperature aging process, wherein the stabilizer comprises, by mass concentration, (a) 50-300 mg / L of thiourea, and (b) 100-1000 mg / L of a small molecule alcohol compound, and the polyacrylamide is partially hydrolyzed polyacrylamide, sulfonated polyacrylamide or hydrophobically associated polyacrylamide. With the technical scheme, the problem in the prior art is well solved, and the method can be used for industrial production of tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

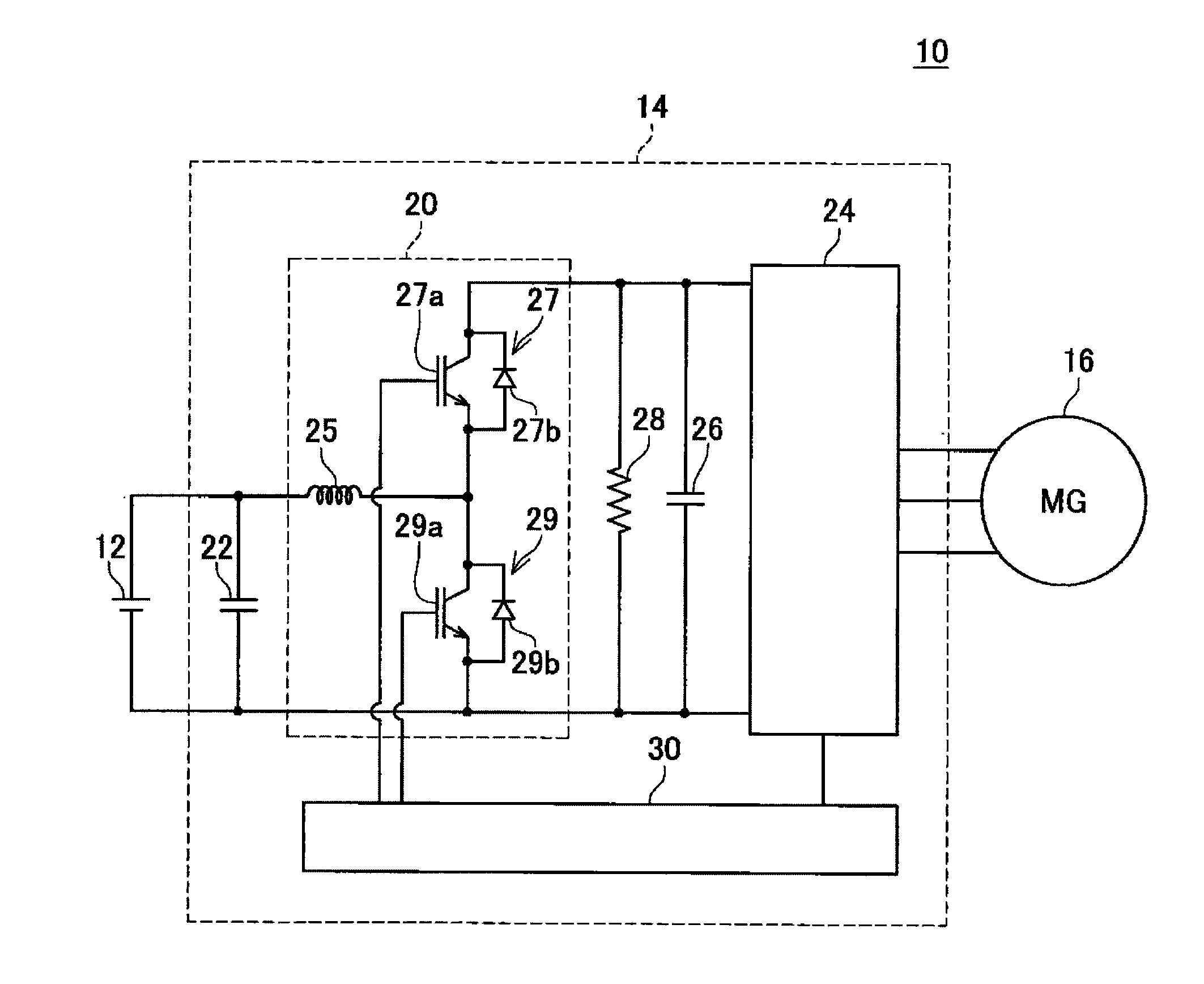

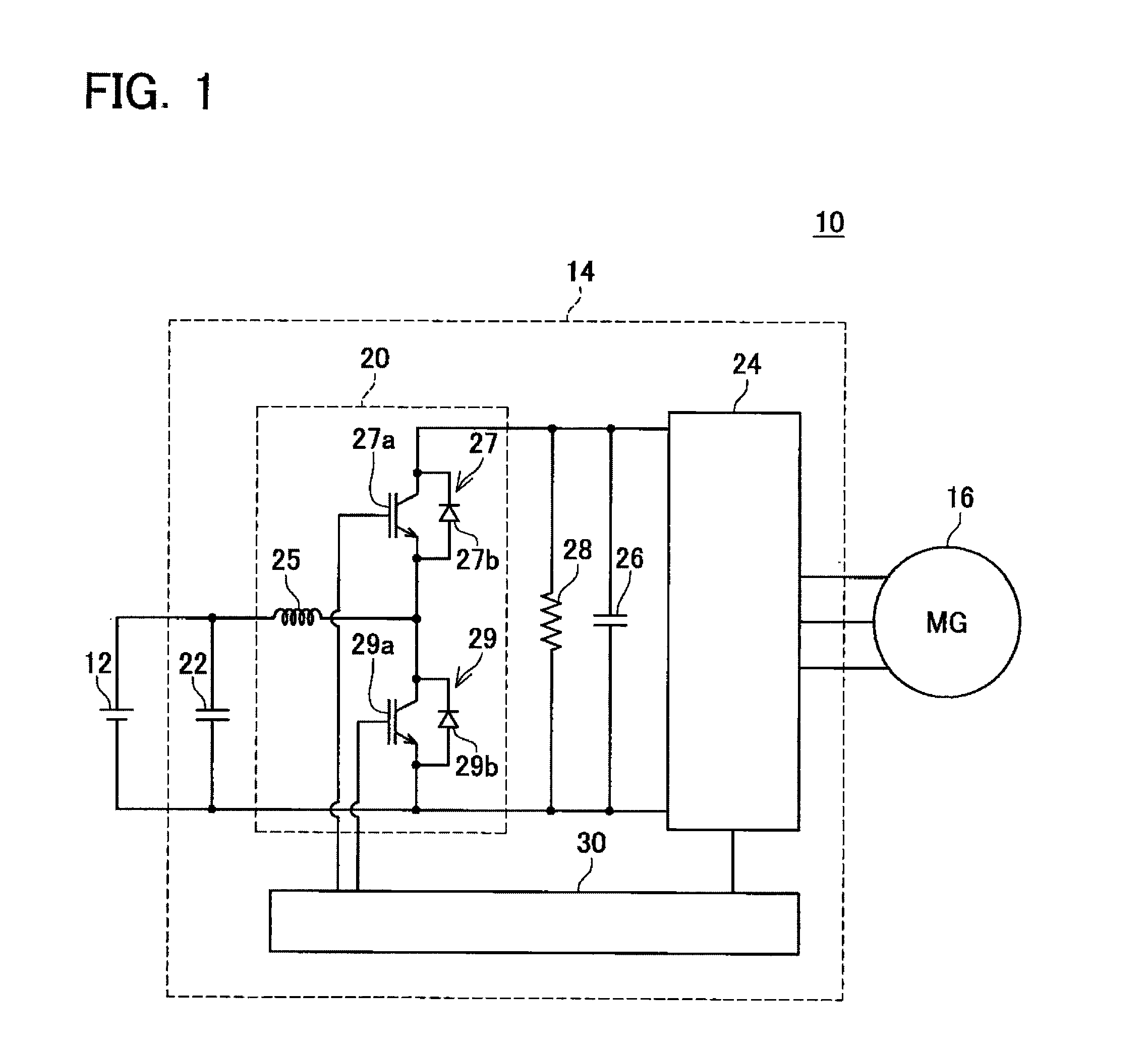

Motor controller

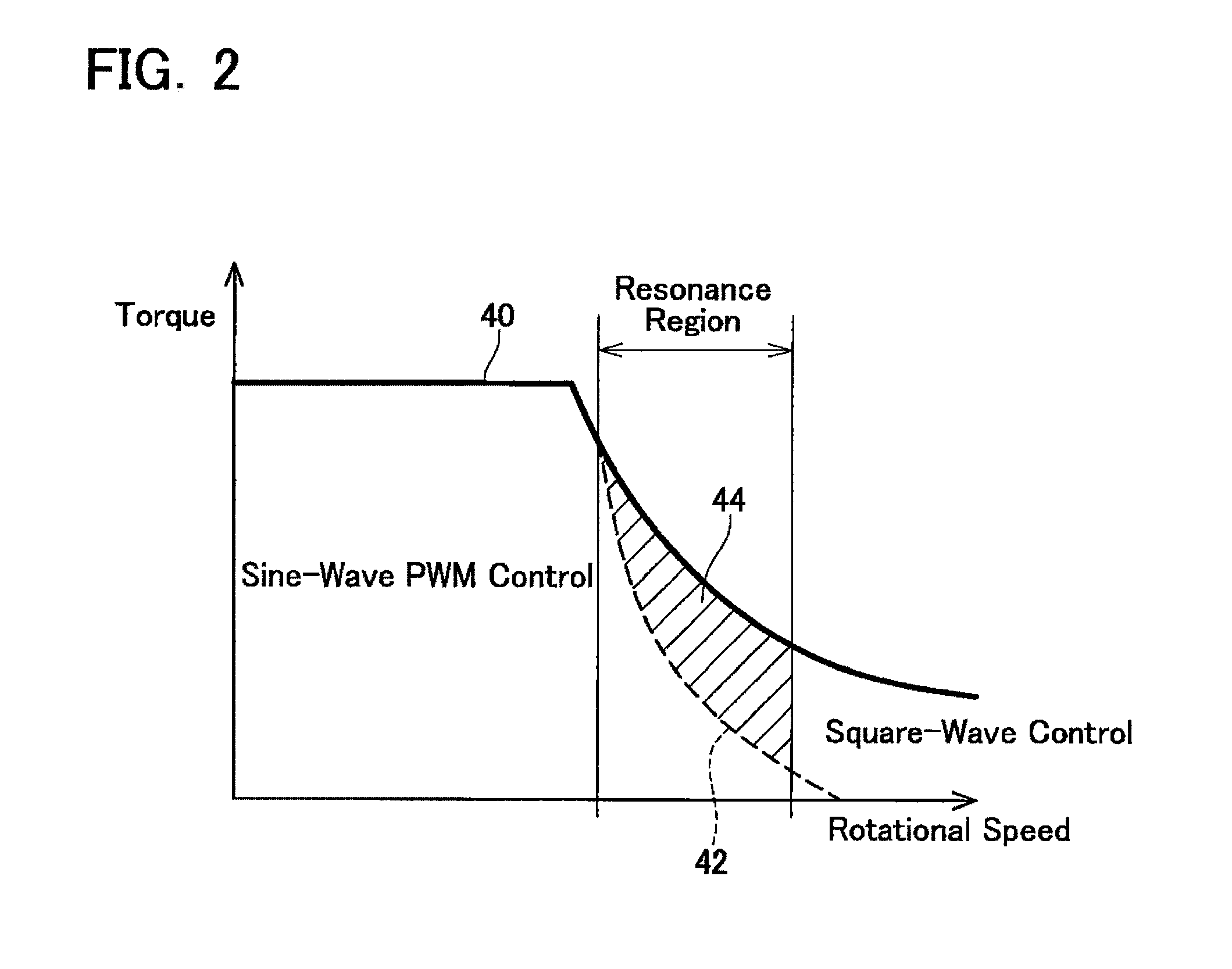

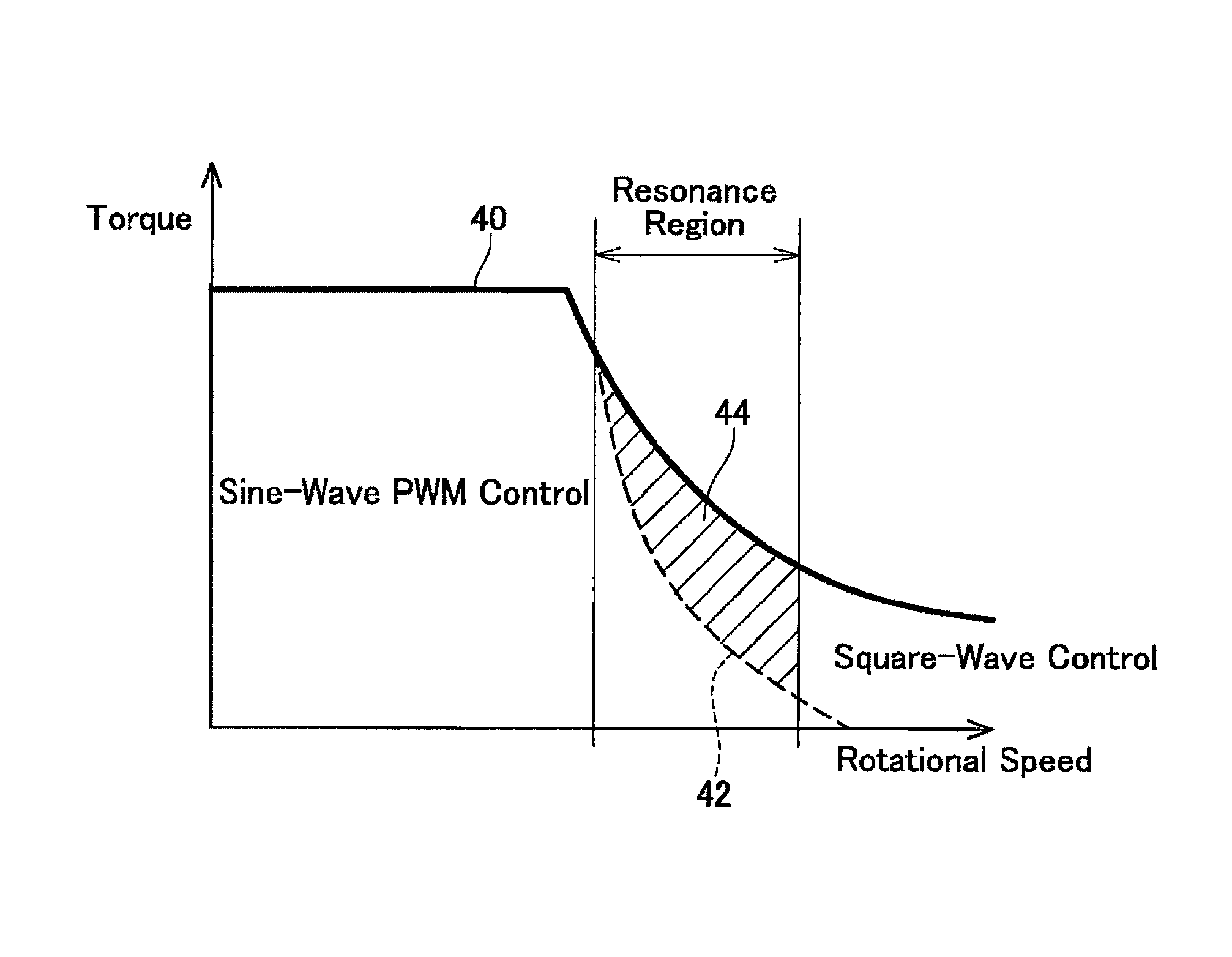

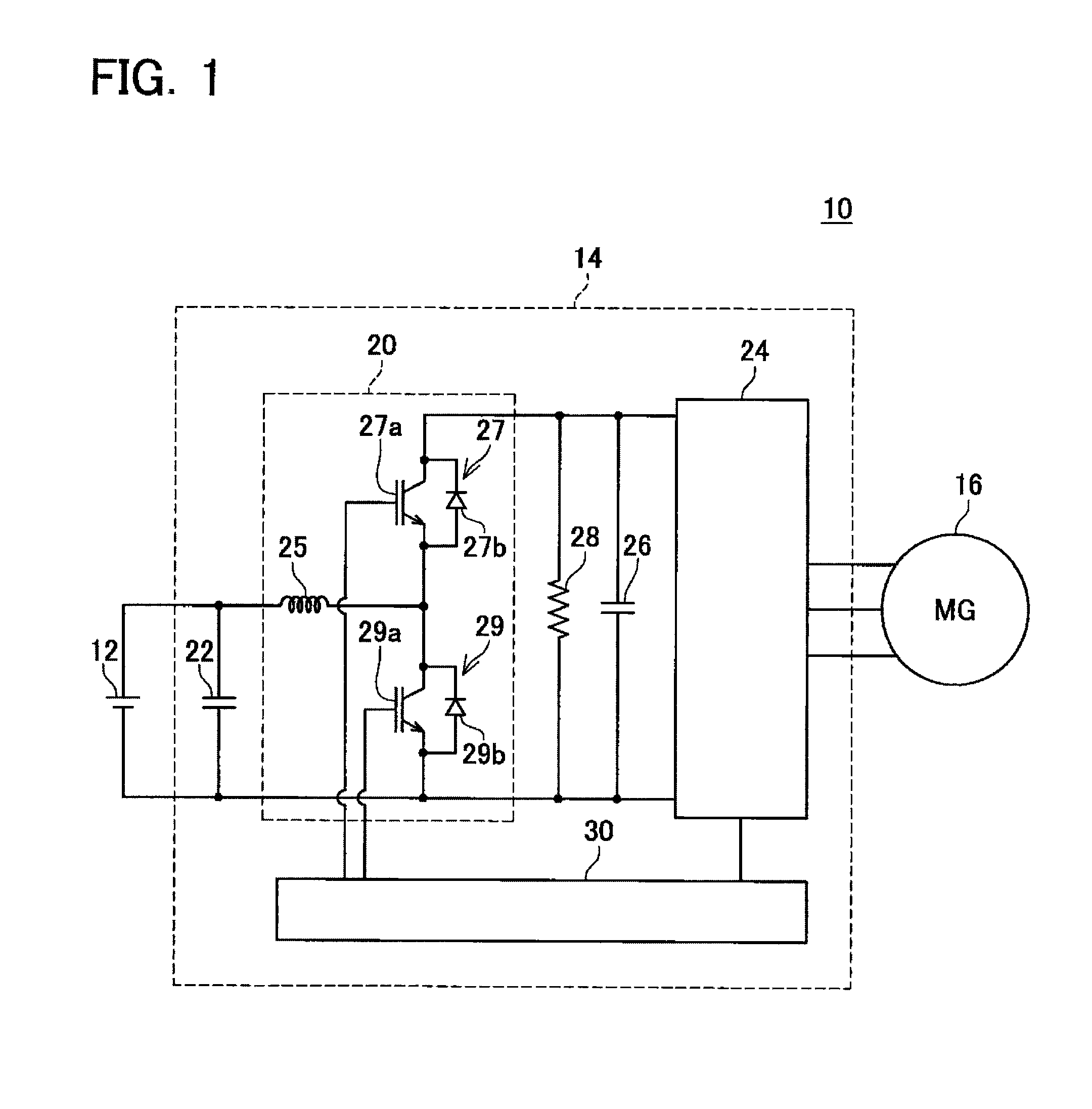

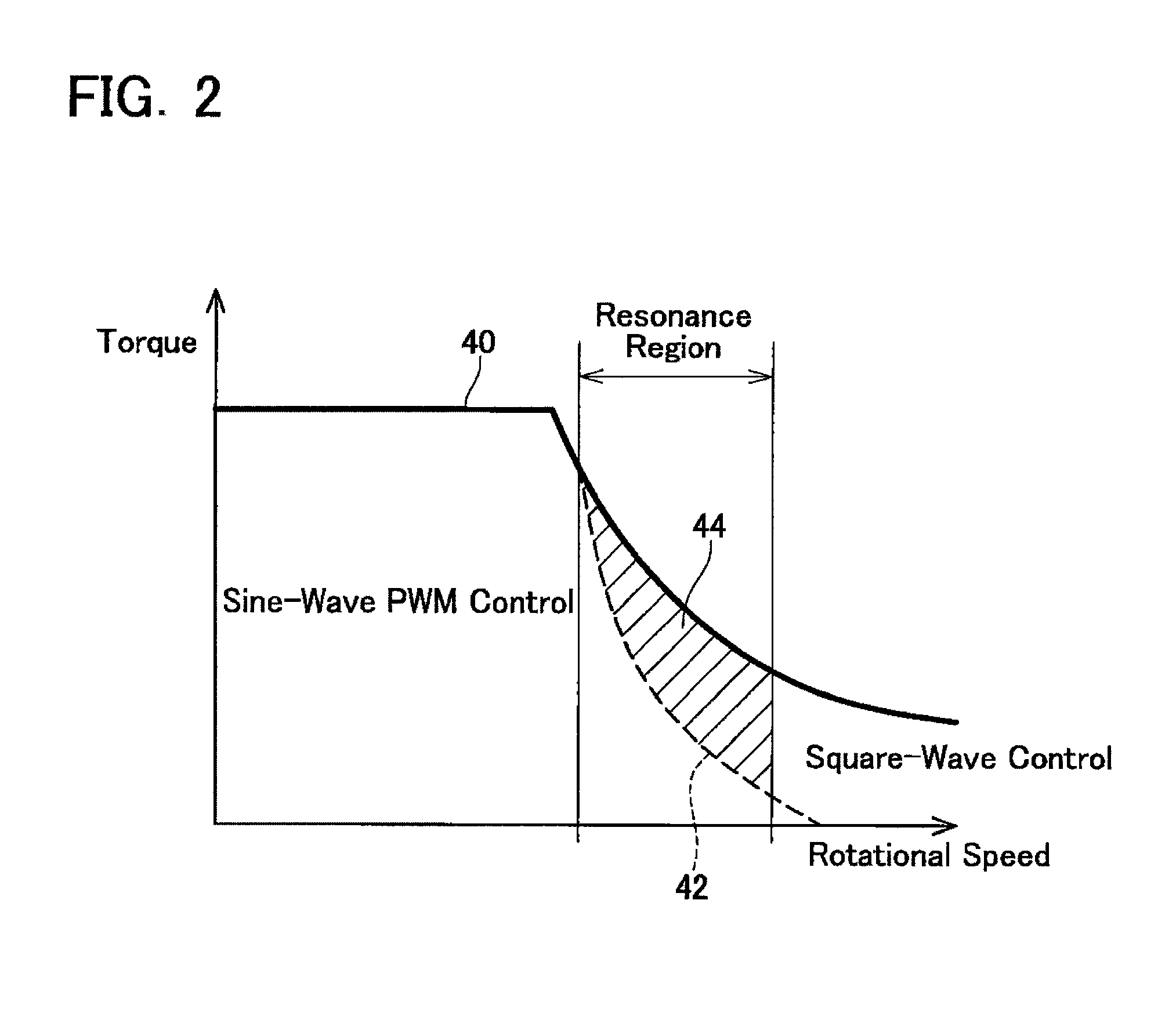

ActiveUS20130110334A1Degraded drivabilityEnsure drivabilitySpeed controllerDigital data processing detailsOperating pointElectrical battery

Provided is a technology capable of ensuring drivability of an electric vehicle while preventing thermal destruction of its parts and deterioration of a battery, caused by an LC resonance. The present specification discloses a motor controller for an electric vehicle having a battery, a converter circuit, an inverter circuit, a smoothing capacitor, and a motor, the motor controller configured to control a drive of the motor by controlling an operation of the inverter circuit. In this motor controller, an operating region of the motor that causes a resonance of an LC circuit configured by a reactor of the converter circuit and the smoothing capacitor is set as a resonance region. In this motor controller, execution of square-wave control on the motor is permitted only over a predetermined time period, when the converter circuit is not boosting the DC power and an operating point of the motor is included in the resonance region.

Owner:DENSO CORP

Method for extracting lipid components

ActiveCN102311869AChemically stableEfficient use ofFatty substance recovery/refiningEssential-oils/perfumesAlkaneLipid formation

The invention discloses a method for extracting lipid components. By employing a subcritical extraction technology with a polyfluoroalkane low pressure liquefied gas as an extraction medium, the method can conduct lipid component extraction in various raw materials. Making use of the polyfluoroalkane characteristics of stable chemical property, safety and nontoxity, noncombustibility and existence of dissolved lipid components after liquefaction, the method extracts lipid components (oil, lipoid, oil-soluble pigment, essential oil, wax, etc.) from some raw materials with low energy consumption, and also can select an extraction medium with similar polarity. Characterized by high extraction efficiency and good product quality, the method of the invention can realize room temperature or lowtemperature operation in the overall process, and ensure every functional component in the raw materials free from thermal destruction to the utmost. And degreased meal can undergo secondary deep development, thus benefiting for comprehensive utilization of raw materials and realization of high value-added processing. Therefore, the method provided in the invention is of important application value.

Owner:SOUTH CHINA UNIV OF TECH

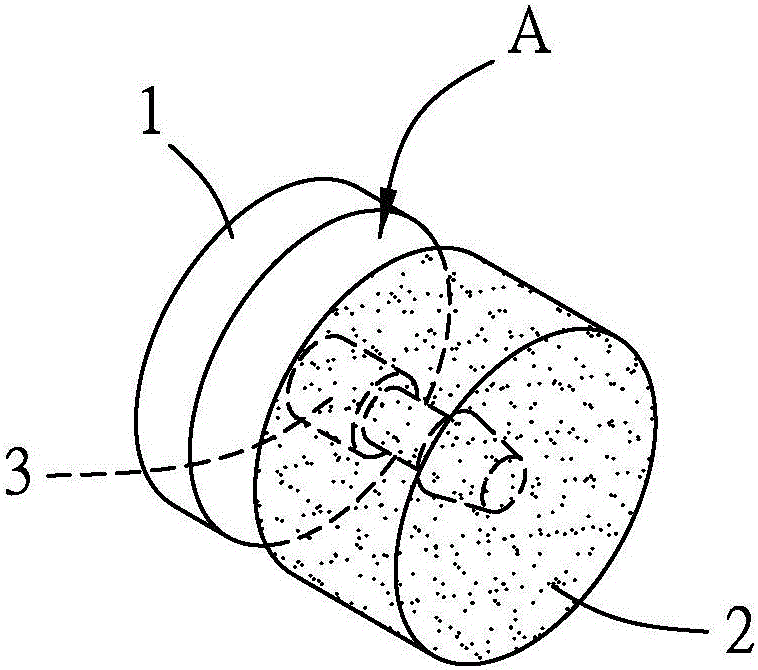

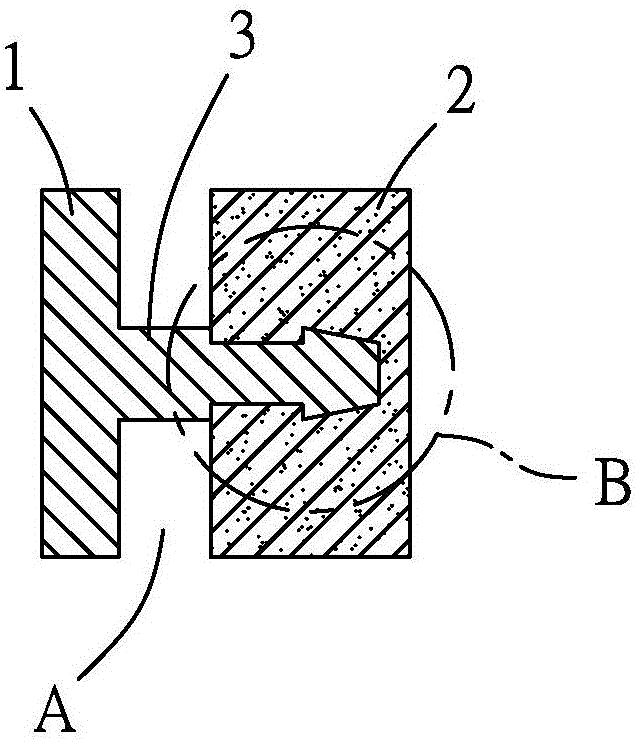

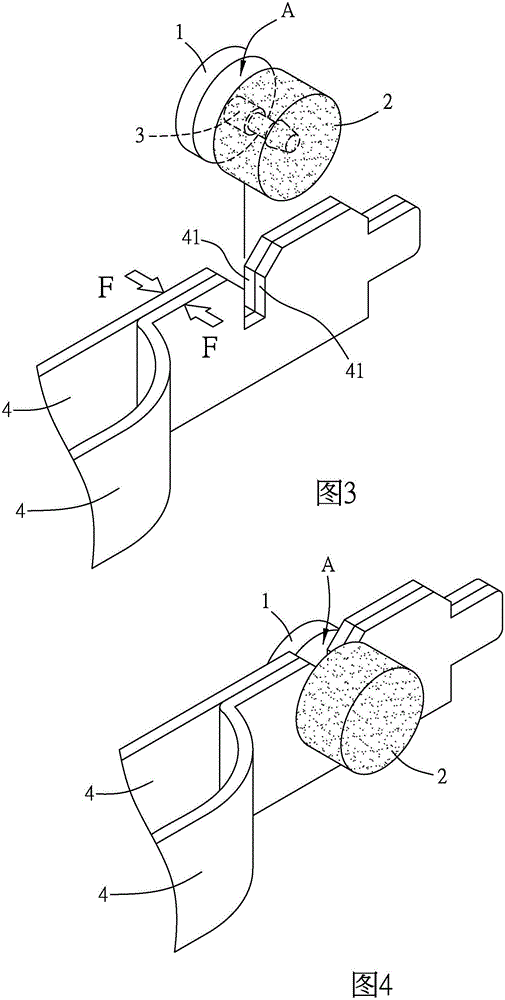

Thermal-destruction conductive sheet fuse clip, plug and socket

InactiveCN107437711AIndeed power offEnsure electricity safetyCoupling device detailsPlastic materialsThermal Destructions

The invention relates to a thermal-destruction conductive sheet fuse clip, a plug and a socket. The thermal-destruction conductive sheet fuse clip is used for allowing two conductive sheets to be contacted and limited with each other to form a path and destroying the conductive sheets during overheat, so that the two conductive sheets are expanded to form a breakage path due to an elastic force. The thermal-destruction conductive sheet fuse clip comprises a first limitation piece, a second limitation piece and a connection piece, wherein at least one of the first limitation piece, the second limitation piece and the connection piece is a plastic material, at least one of the first limitation piece and the second limitation piece is a metal material, and a part to be destroyed is formed at a connection position of the plastic material and the metal material.

Owner:GREEN IDEA TECH INC

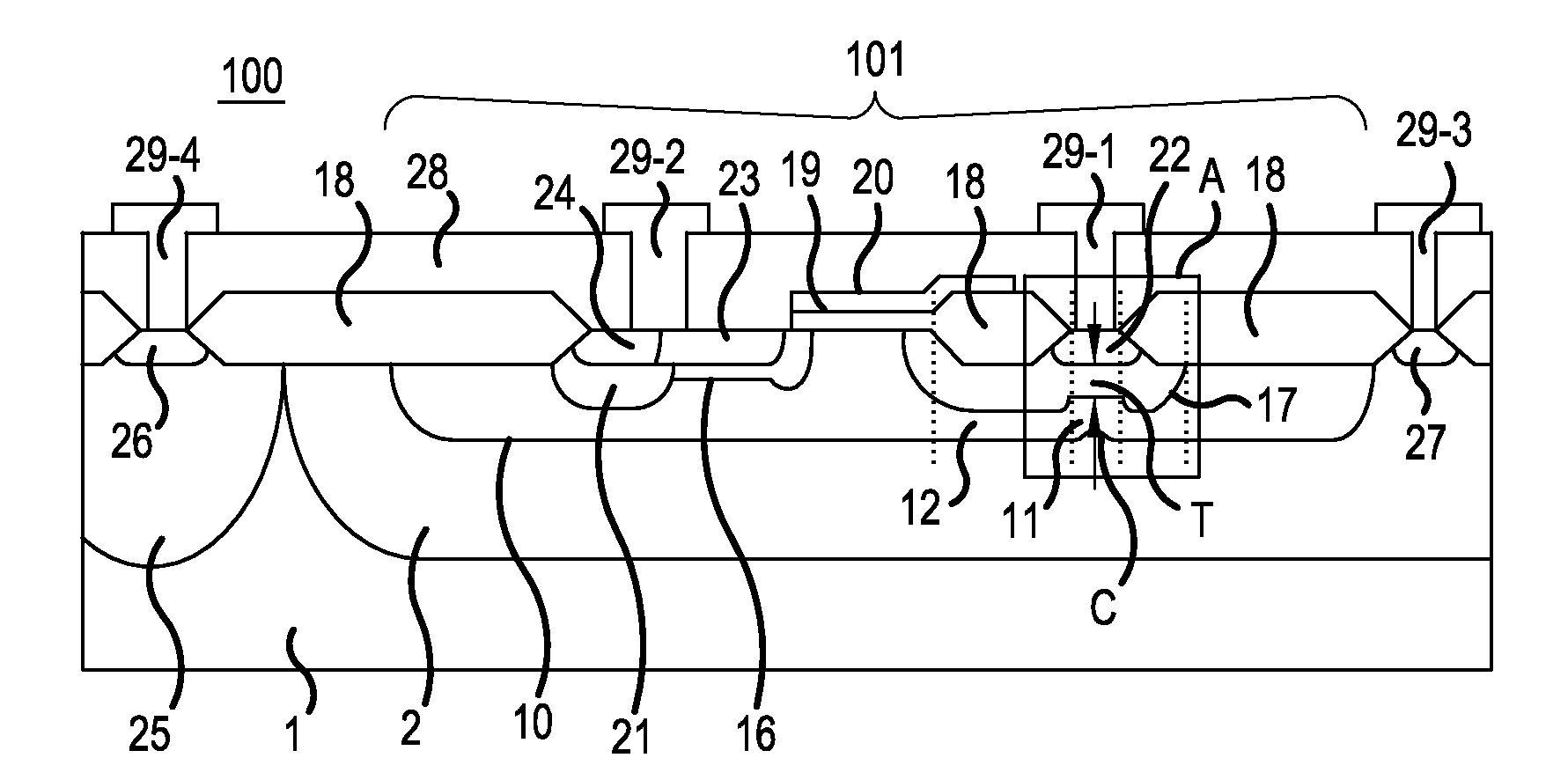

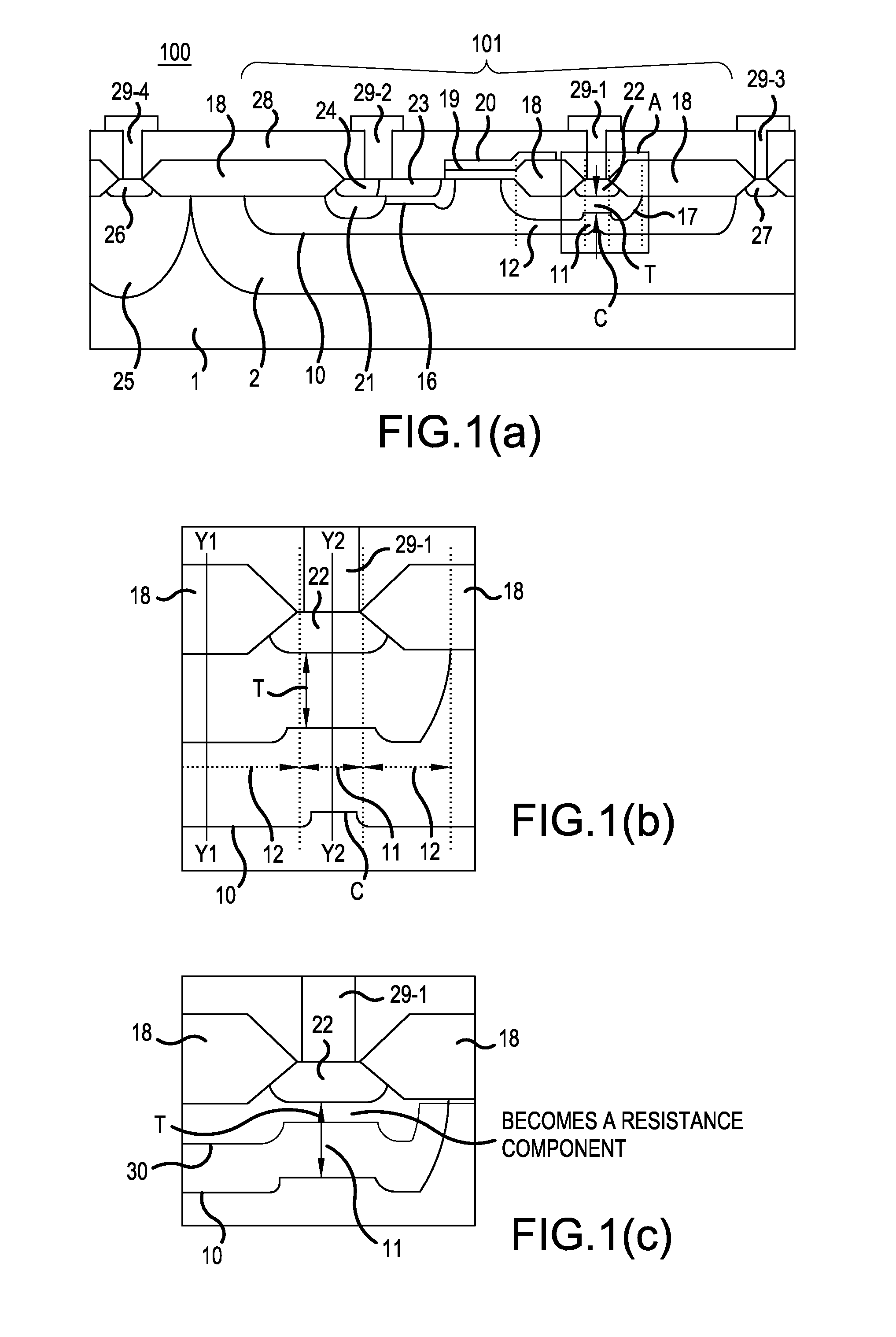

Semiconductor device and manufacturing method thereof

ActiveUS20140197491A1Improve antistatic performanceReduce chip sizeTransistorSemiconductor/solid-state device detailsLow voltageDevice material

A semiconductor device and manufacturing method are disclosed which provide increased ESD resistance. By disposing a slit mask when forming a second p-type well layer, impurity concentration of the second p-type well layer is partially reduced. By forming a second n-type offset layer in the second p-type well layer having decreased impurity concentration, it is possible to increase thickness of the second n-type offset layer in this place compared with that heretofore known. By increasing thickness of the second n-type offset layer, a depletion layer does not reach an n-type drain layer at a low voltage when reverse bias is applied to the drain. It thus is possible to prevent thermal destruction caused by localized electrical field concentration. As a result, it is possible to increase ESD resistance. As it is sufficient to replace a photoresist mask, there is no increase in the number of processes.

Owner:FUJI ELECTRIC CO LTD

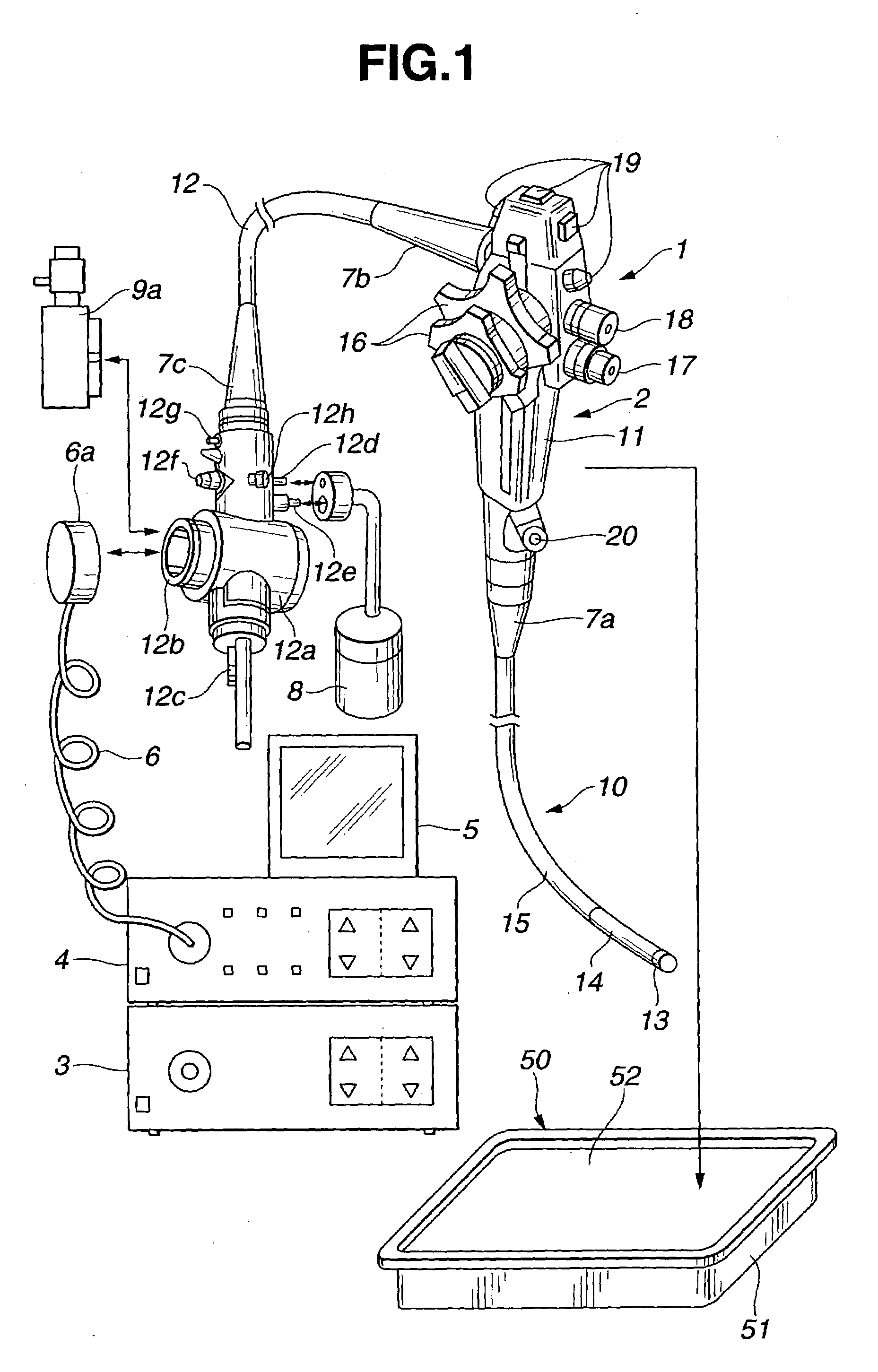

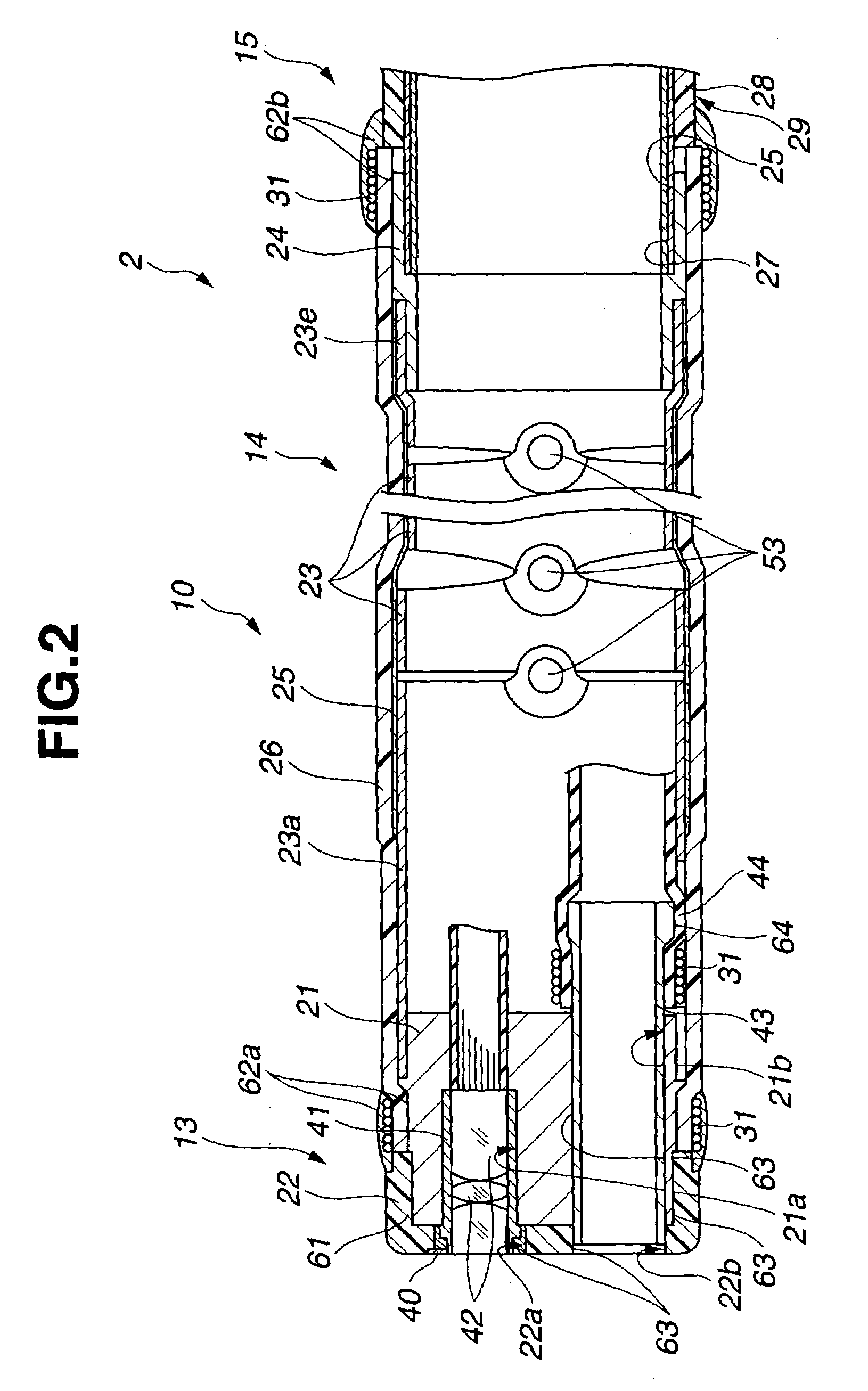

Diassembly of endoscope having adhesively bonded parts

An endoscope comprises a plurality of members constituting the endoscope, and parts-bonded sections each having at least members thereof bonded together using an adhesive. The temperatures of thermal destruction at which the adhesives included in the parts-bonded sections are thermally destroyed are made equal to or higher than the maximum temperature attained during a high-pressure steam sterilization process. At the same time, the temperatures of thermal destruction are made equal to or lower than the heat-resistance temperatures above which members bonded using the adhesives or members located near the bonded members included in the parts-bonded sections fail to resist heat.

Owner:OLYMPUS CORP

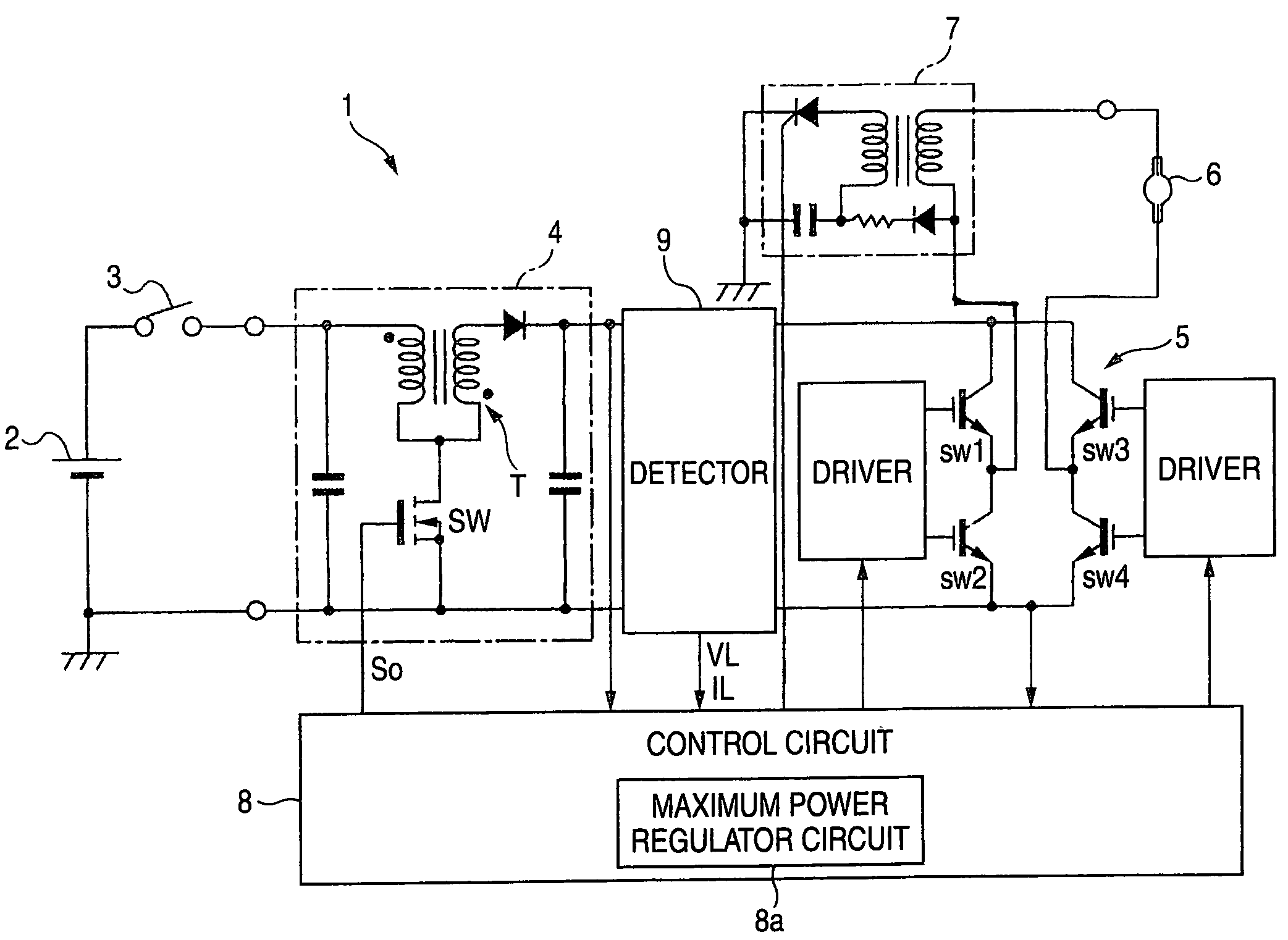

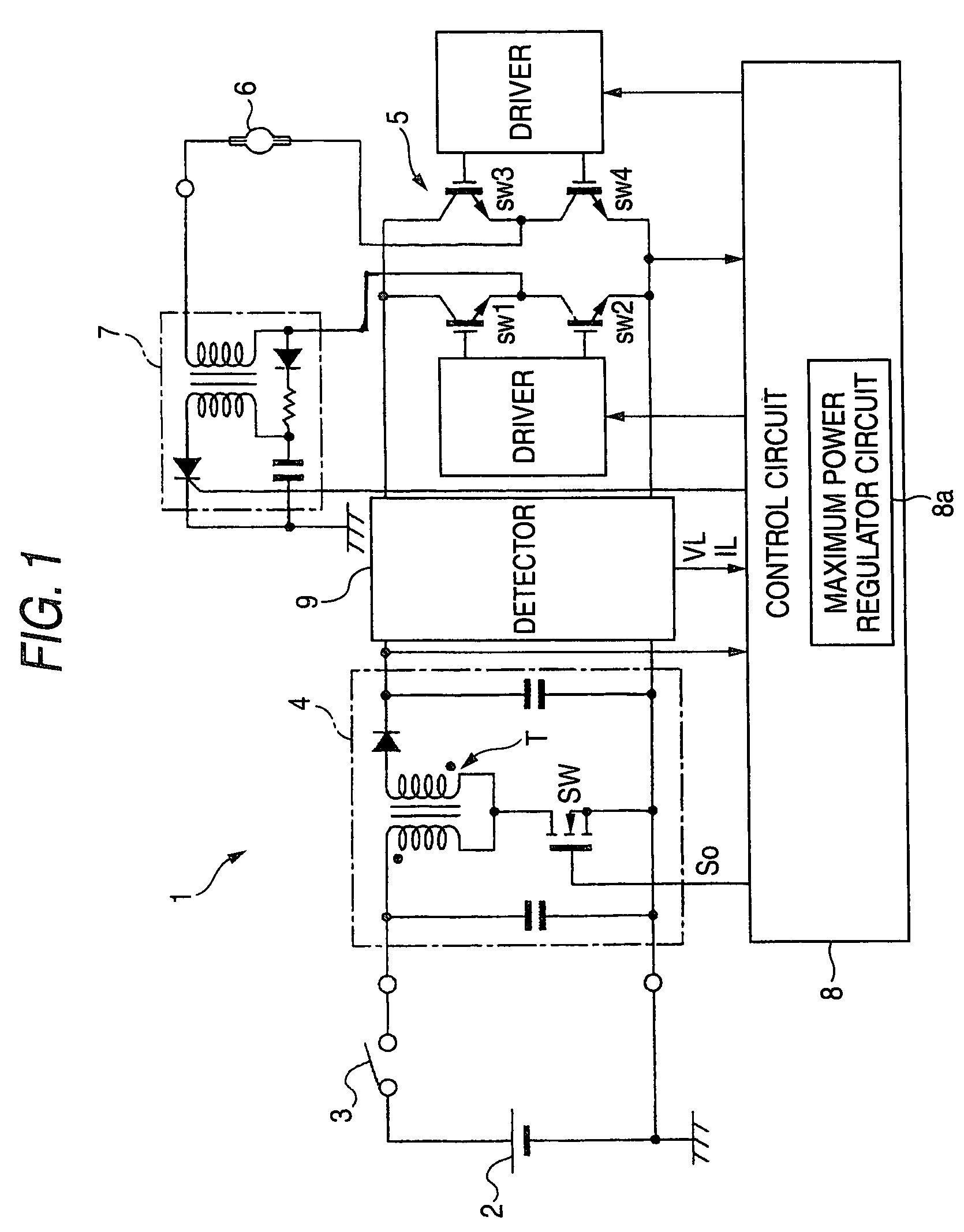

Lighting apparatus for discharge lamp

InactiveUS7332876B2Preventing continued applicationReduce total powerSemiconductor lamp usageElectric light circuit arrangementGas-discharge lampThermal Destructions

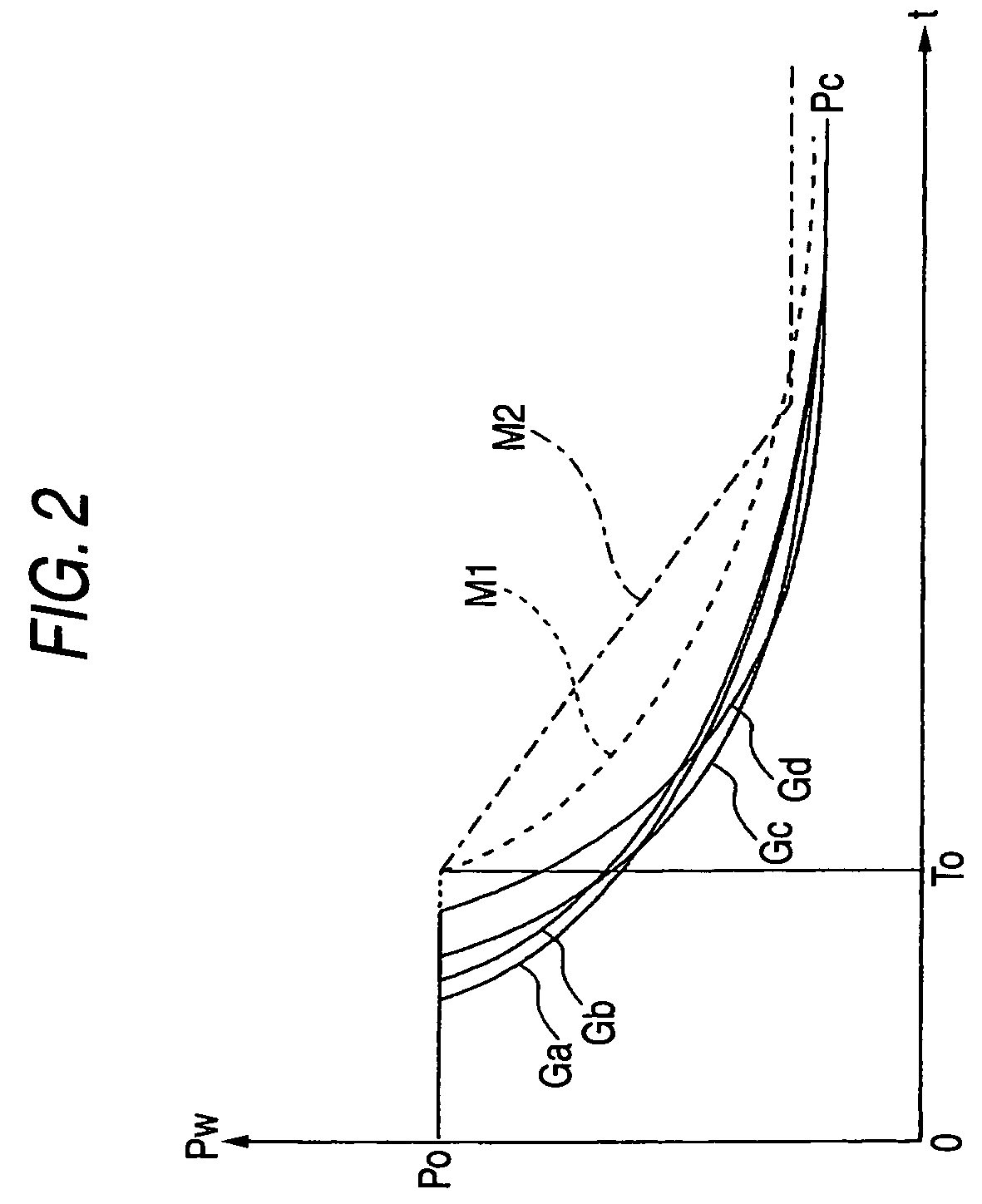

In a discharge lamp lighting apparatus, in a transient period from the time a discharge lamp is lit in a cold state to the time the discharge lamp reaches a static lighting state, the power applied to the discharge lamp is reduced over time after an initial maximum power that exceeds the rated power. A maximum power regulator circuit is provided to regulate the applied power in the transient period such that the applied power does not exceed an upper limit power line M1 or M2 that is reduced over time after the application of the initial maximum power. In this way, the application of excessive transient power is prevented from continuing longer than necessary in the event of a failure in a load, thus limiting the amount of generated heat and preventing thermal destruction.

Owner:KOITO MFG CO LTD

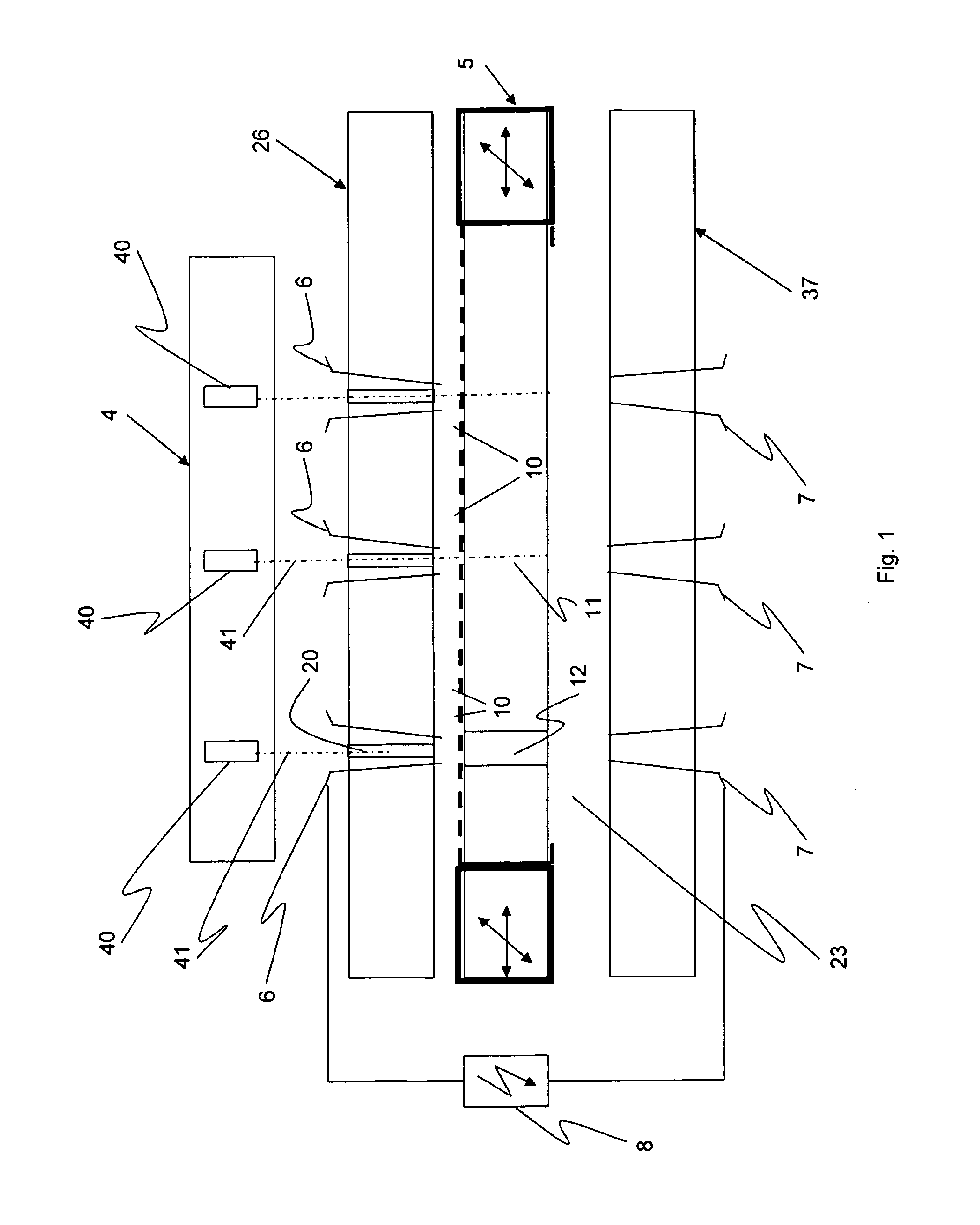

Method and device for thermal destruction of organic compounds by an induction plasma

ActiveUS20120277515A1Easy to handleHigh yieldSolid waste disposalDirect carbon-dioxide mitigationForming gasInduction plasma technology

A method and device for chemical destruction of at least one feed comprising at least one organic compound are provided. The device comprises at least one inductive plasma torch, means for introducing at least one plasma-forming gas into the torch, optionally when the plasma gas(es) comprise(s) no or little oxygen, means for bringing oxygen gas into the plasma or into the vicinity of the plasma, means for introducing the feed into the torch, a reaction enclosure capable of allowing thermal destruction of the gases flowing from the torch, a device allowing mixing of the gases flowing out of the reaction enclosure to be carried out, means for introducing air and / or oxygen gas into the mixing device, a device allowing recombination by cooling of at least one portion of the gases from the mixing device, the torch, the reaction enclosure, the mixing device and the recombination device being in fluidic communication.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Motor controller

ActiveUS8818596B2Degraded drivabilityEnsure drivabilityDigital data processing detailsPropulsion by batteries/cellsOperating pointElectrical battery

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com