Patents

Literature

1929results about How to "Achieve drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water-saving drum washing machine

ActiveCN105696248AReduce the amount of waterRealize the purpose of saving waterOther washing machinesWashing machine with receptaclesWater savingMechanical engineering

The invention provides a water-saving drum washing machine comprising an outer drum, an inner drum disposed in the outer drum and a water inlet pipeline communicating with the inner drum. The inner drum and the outer drum are installed on a central shaft coaxially. The inner drum is a holeless inner drum. The inner wall of the inner drum is provided with a plurality of lifting devices; the central shaft is internally provided with a hollow structure; the water inlet pipeline and the lifting devices communicate with the hollow structure. The lifting devices are provided with a plurality of water outlets. The technical objective of saving water is mainly achieved by using the holeless inner drum and making the space between the inner drum and the outer drum free of water in a washing process. Since the holeless inner drum is used, the structure of the water-saving washing machine is redesigned for water feeding and water drainage of the washing machine; further a water feeding and drainage system, a washing and spinning system and an airing drying and drying system are improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

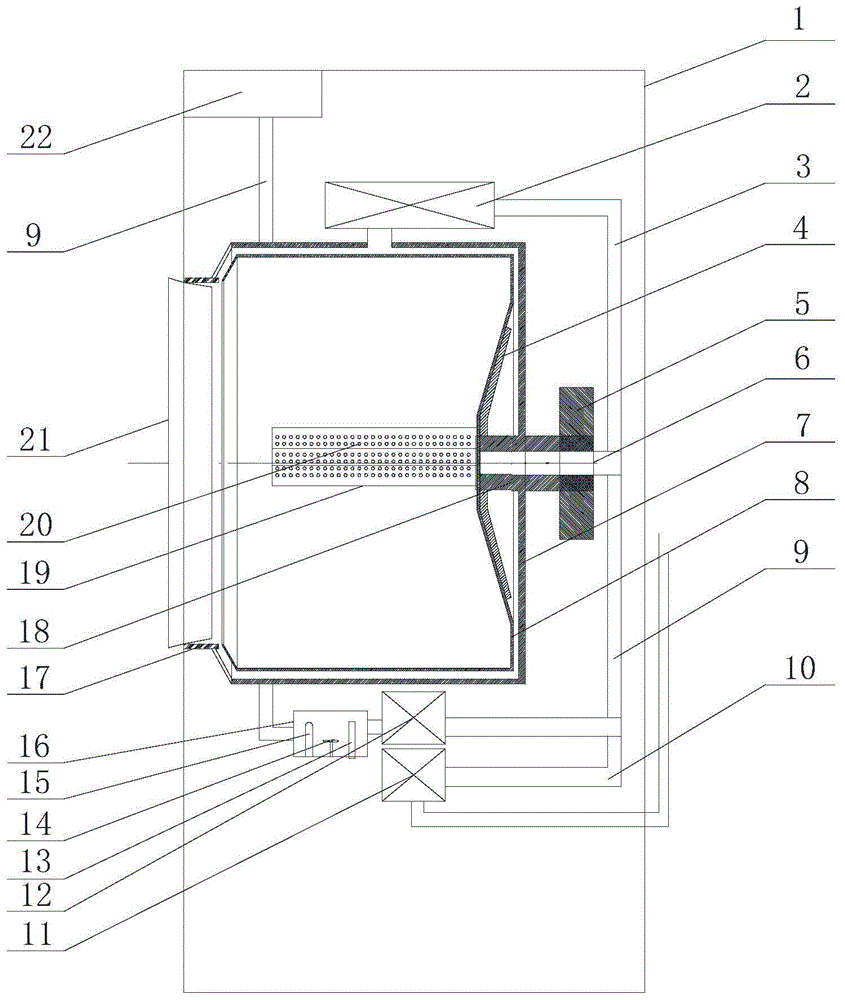

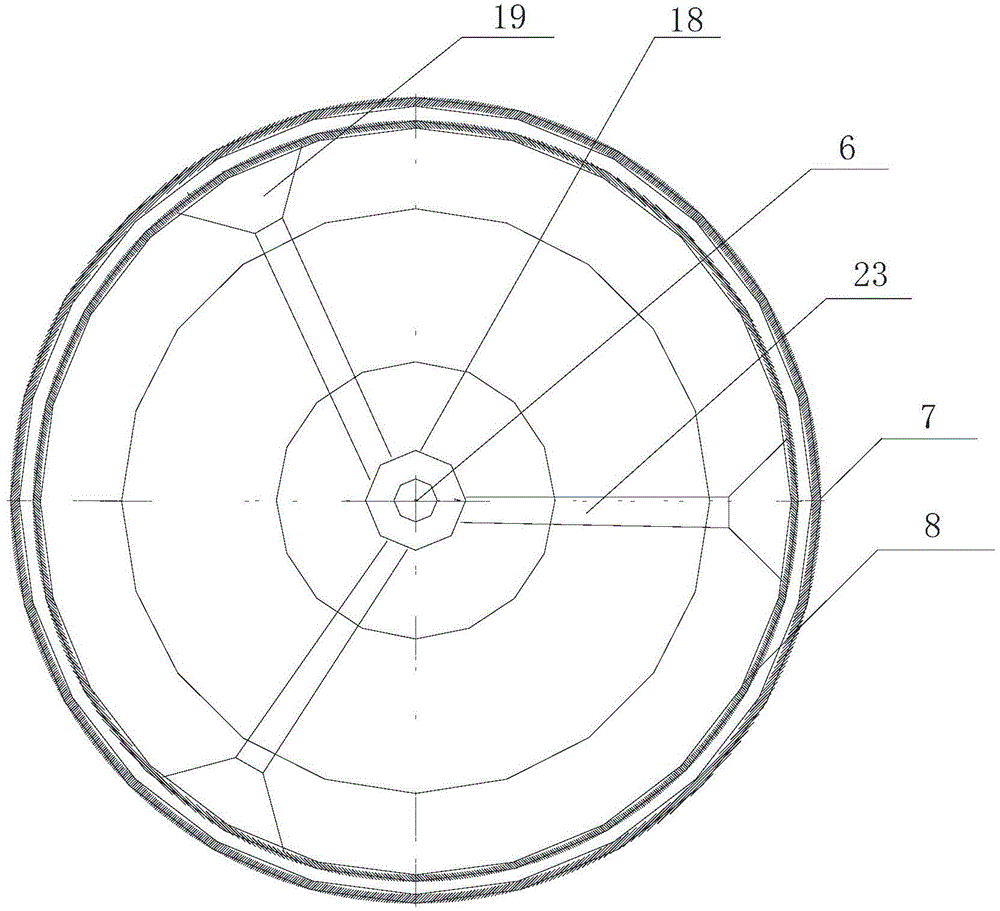

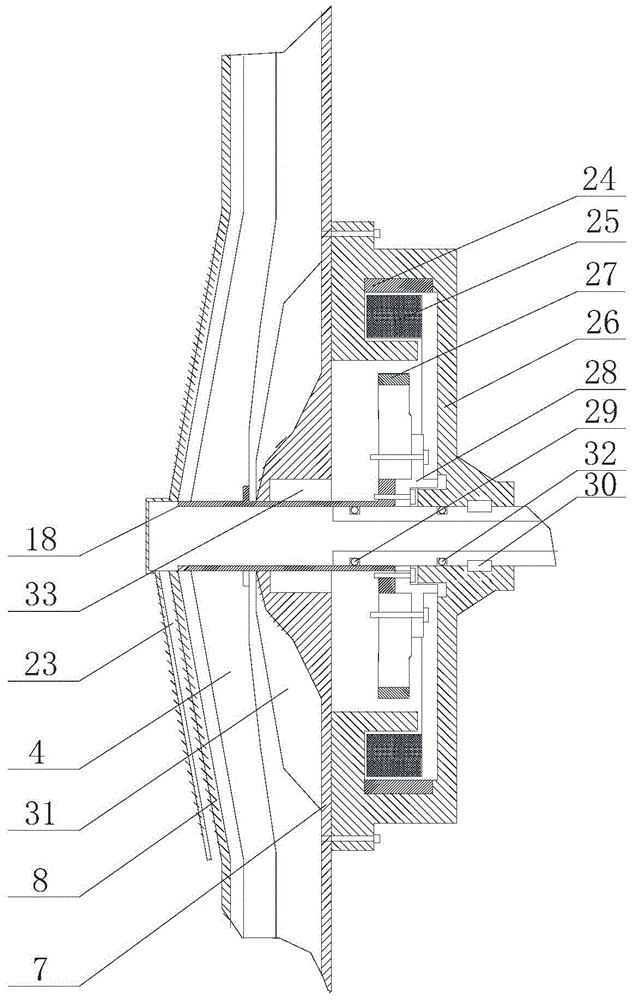

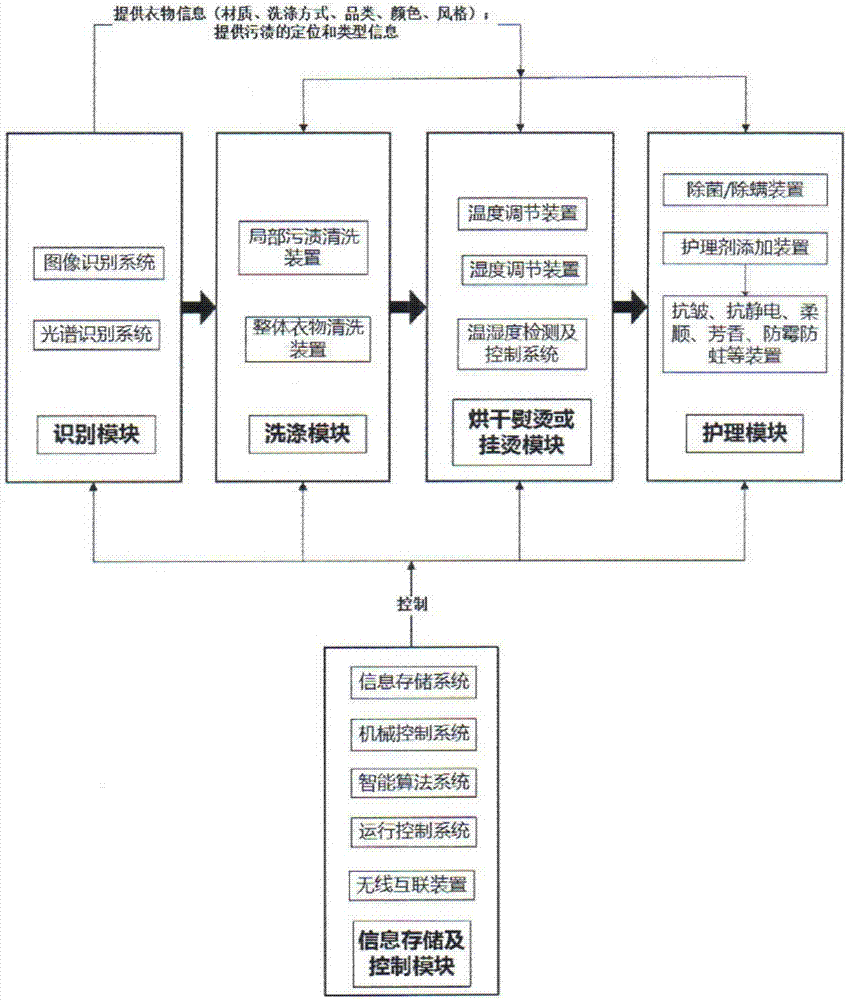

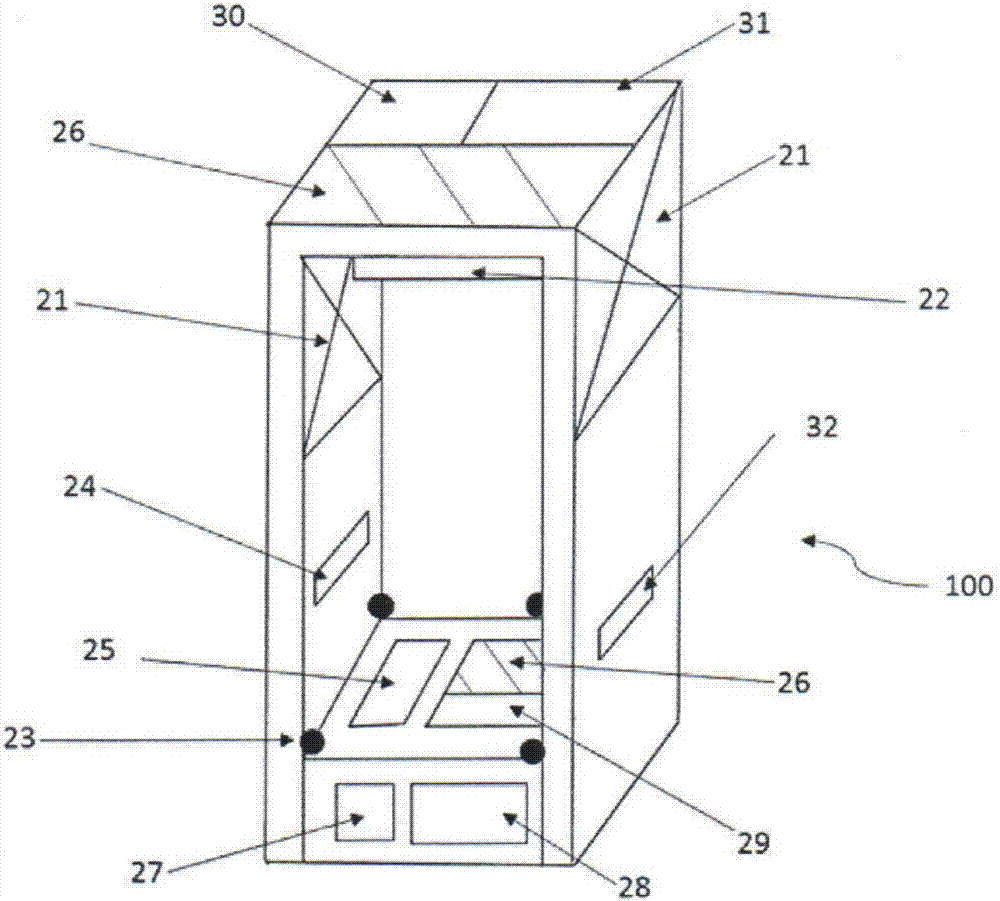

Multifunctional intelligent clothing care machine

InactiveCN106884278AHigh pixel gray levelFast sampling speedControl devices for washing apparatusIroning apparatusEngineeringCare program

The invention discloses a multifunctional intelligent clothing care machine. The machine is characterized by comprising a box body, wherein an air exhaust port is formed in the top part of the box body; a water tank and a water draining box which intercommunicate are arranged at the bottom part of the box body; a recognizing module, a washing module, a drying ironing or hanging ironing module provided with an intelligent algorithm system, and a caring module are arranged in the box body and are connected to an information storing and control module. According to the multifunctional intelligent clothing care machine, proper clothing stain removing program, washing program, drying program, ironing or hanging ironing program and casing program are accurately set; the clothing information recognizing and the stain type recognizing are intelligently combined; the care efficiency can be increased based on washing protecting models and intelligently-matched caring program, and meanwhile, the damage to the clothing appearance and physical and chemical performances can be decreased to the maximum. Therefore, common clothing and high-level clothing can be handled, and moreover, some clothing to be subjected to dry cleaning can be handled. The machine is high in automation degree; after a use puts clothing into the machine, the machine can automatically perform all tasks such as washing, drying, ironing and caring.

Owner:DONGHUA UNIV

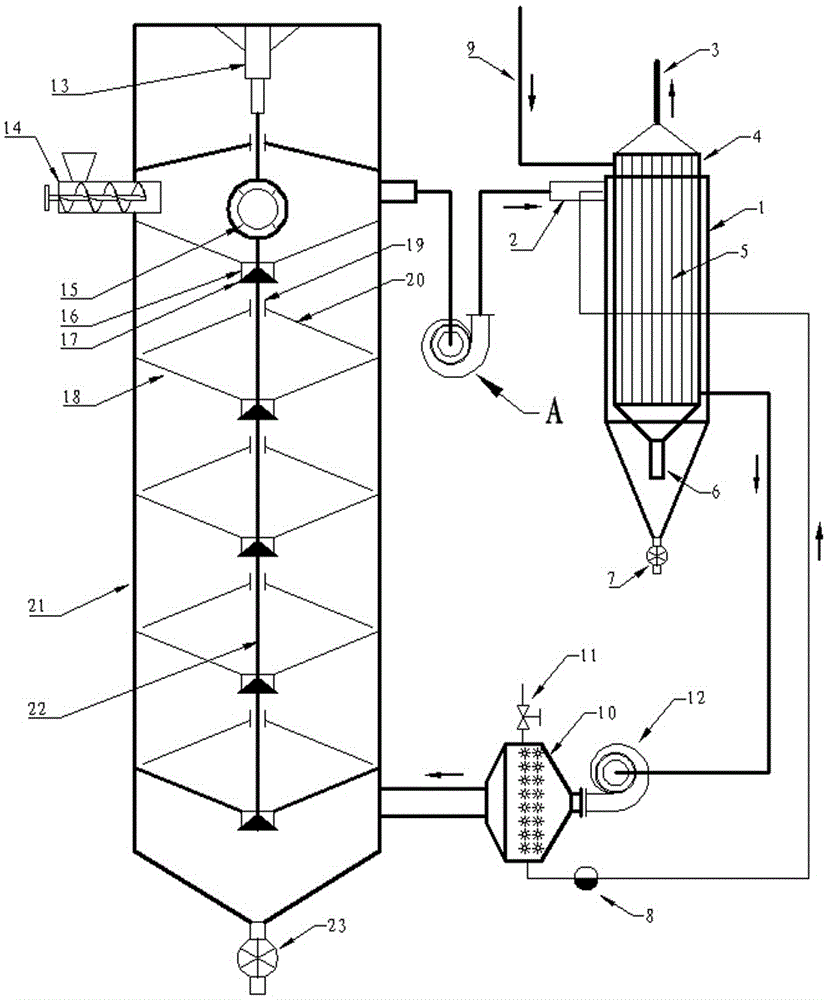

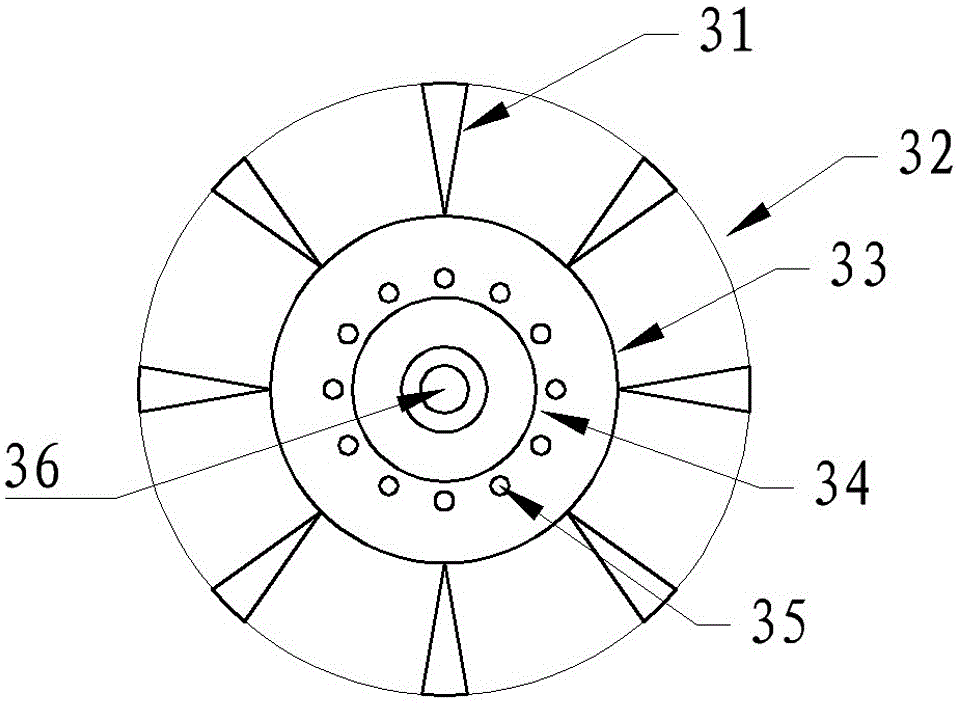

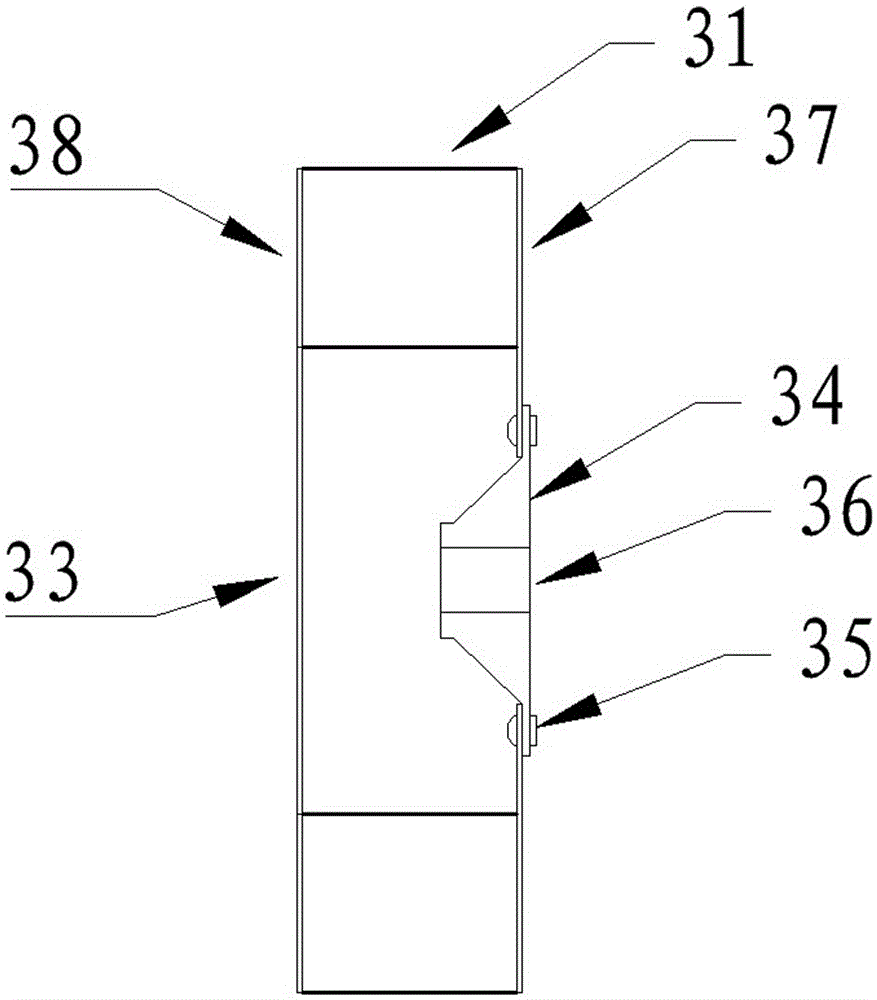

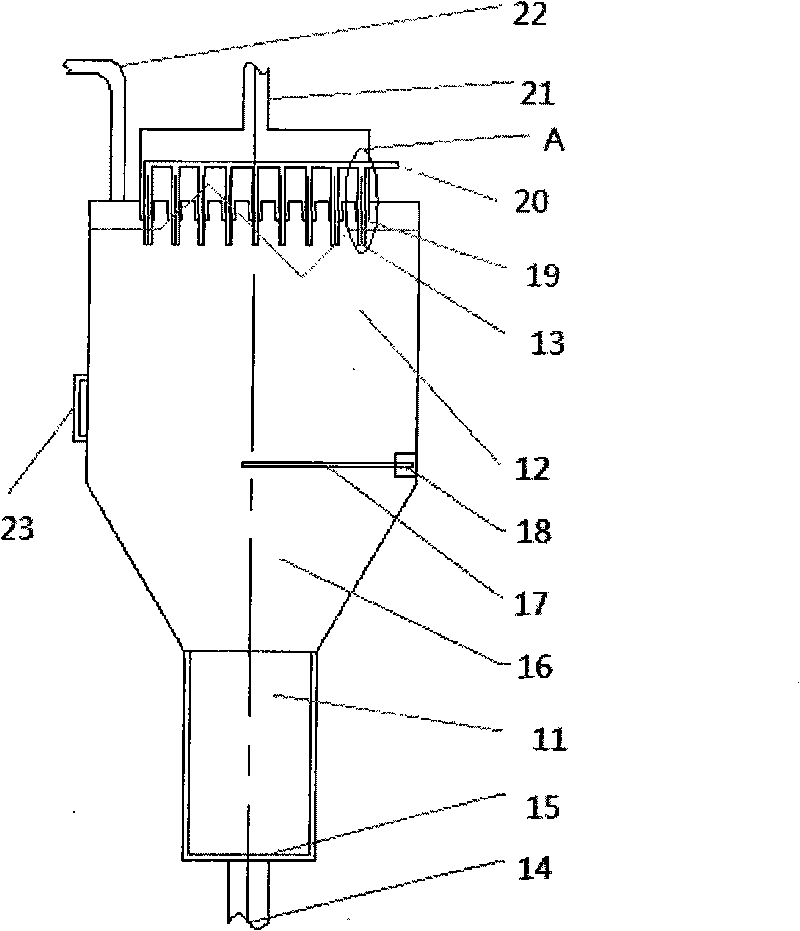

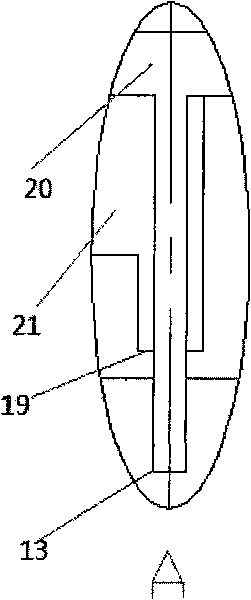

Hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization

ActiveCN105021012AReduce equipment investmentImprove work efficiencyDrying gas arrangementsImpellerWhirlwind

The invention discloses a hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization. The upper portion of a drying tower is connected with an induced draft fan, and the induced draft fan is connected with a cyclone dust removing waste heat efficient recoverer formed by a tube-type heat exchanger and a cyclone dust collector in an overlapped manner in the tangent direction and then is emptied; the air inlet end of the shell side of the tube-type heat exchanger is communicated with the atmosphere, and the air outlet end of the shell side of the tube-type heat exchanger is connected with the lower portion of the drying tower through an air blower and a steam finned heater; and an impeller of the induced draft fan is of a structure that blades are in a hollow and wedged shape, and the contour line of the appearance of the induced draft fan is an involute. According to the hot-air drying machine capable of utilizing the waste heat and achieving the penetrating countercurrent fluidization, creative integration is conducted on waste heat utilization and dust removal, the cyclone dust removing waste heat efficient recoverer is designed out, the equipment input is reduced, and the work efficiency is improved; and due to the fact that sieve mesh cone covers, sieve mesh cone discs, discharging tubes, a stretching vibration transmission shaft and conical plugs are arranged, penetrating, countercurrent, boiling and fluidization drying of materials are exquisitely and perfectly achieved, more energy is saved, the drying quality is higher, the power consumption of the induced draft fan is lower, and the application prospect is wider.

Owner:常州新舜干燥工程有限公司

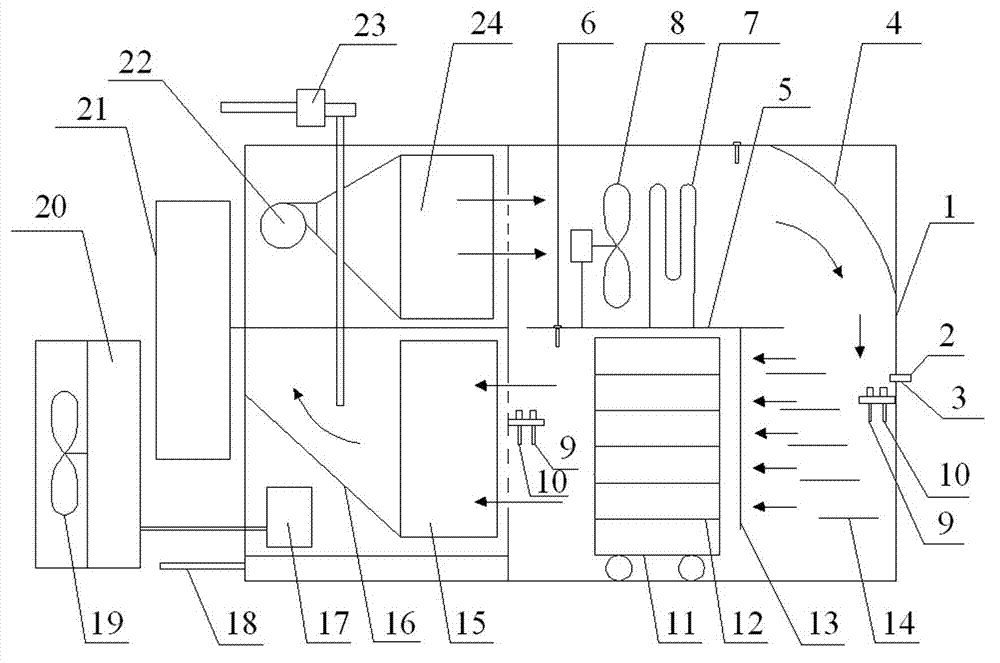

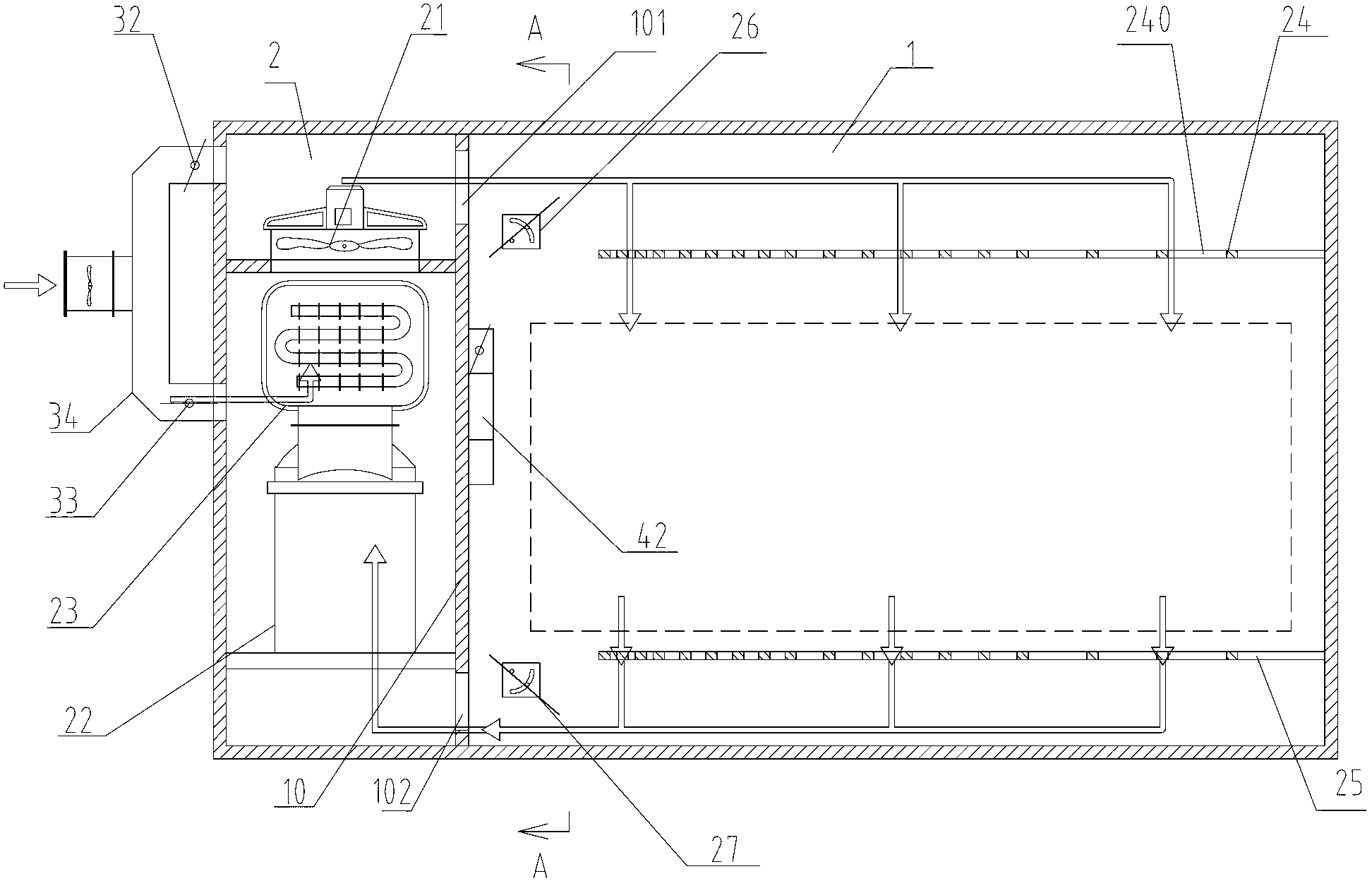

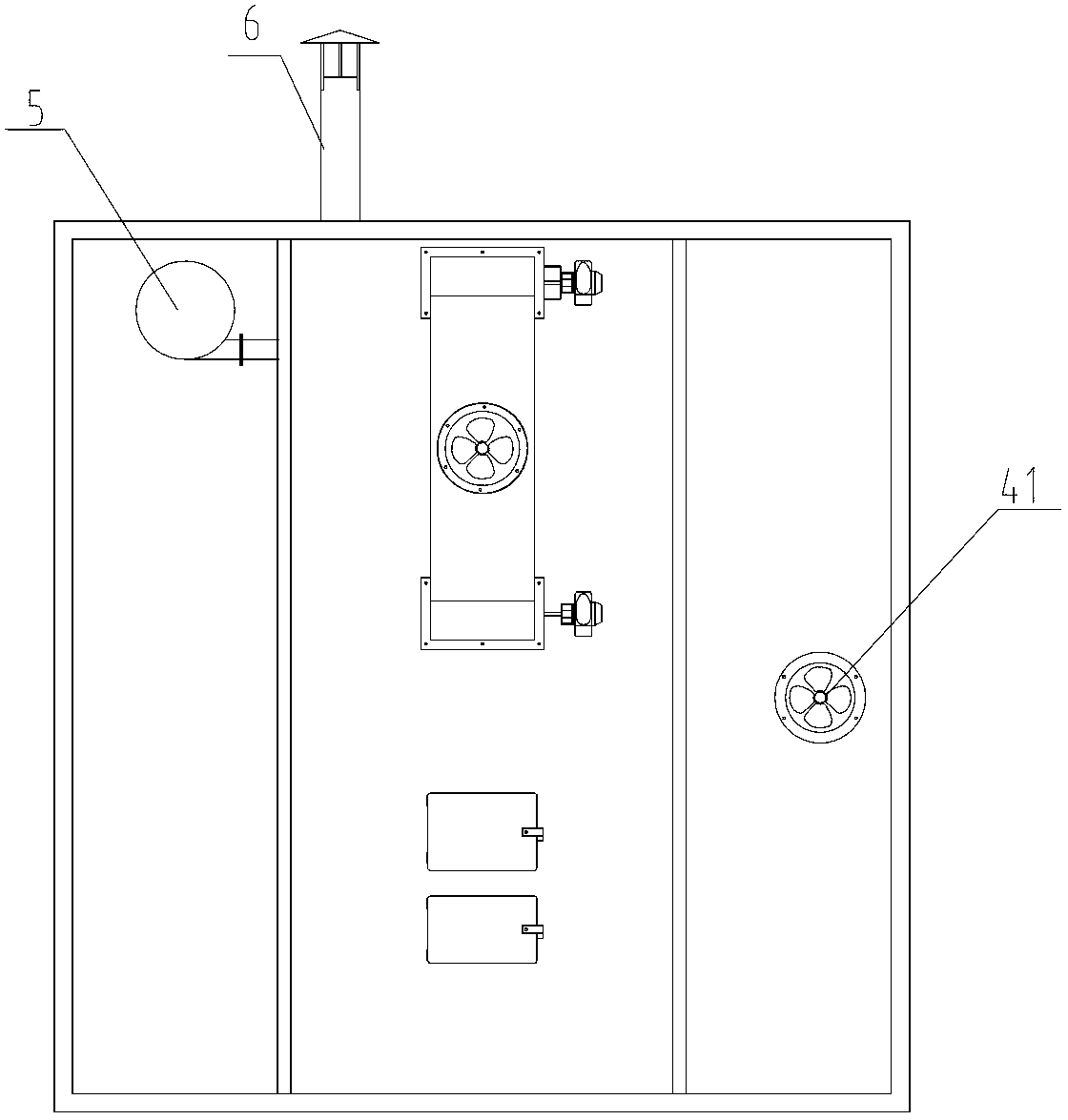

Drying unit of nitrogen-source heat pump

InactiveCN102818434ALow energy consumptionPrevent oxidationDrying gas arrangementsDrying machines with local agitationProcess engineeringDry gas

The invention discloses a drying unit of a nitrogen-source heat pump, comprising a drying box, a control system and an outdoor condenser, wherein the drying box comprises a box body, a heat pump chamber and a drying chamber; and the heat pump chamber and the drying chamber are arranged in the box body. The drying unit forms drying gas adjusting equipment with a nitrogen source, heat-pump equipment and a nitrogen device form a nitrogen heat-pump combining device so as to construct a closed circulation loop which adopts nitrogen as a medium to dry materials and effectively control the content of nitrogen in the drying chamber; and high-viscosity glass cement is used for sealing internal and external gaps of a drying room, a ventilating channel is modified, and a baffle, an arc-shaped air guide plate and an air uniformizing plate are added to enable the gas drying medium to be uniformly distributed in the drying chamber under certain air speed. The drying unit disclosed by the invention has the beneficial effects that the heat pump and a nitrogen combining device are used, the advantages of no pollution and low energy consumption of the heat pump can be fully utilized, the materials are dried under the condition of adopting nitrogen as a drying medium, the oxidation of the materials is prevented, the nutritional ingredients of the materials are retained, and the quality of dried products is improved.

Owner:HENAN UNIV OF SCI & TECH

UV-oxide hybrid drying type engraving intaglio printing ink

ActiveCN101250354AAchieve dryingWell mixedInksOther printing apparatusPulp and paper industryPrinting ink

The invention relates to UV-oxidation mixing drying type incising gravure printing ink, which is prepared through firstly producing by rolling UV drying components and oxidation drying components assisting volatilization drying, penetration drying and complex drying effect, and evenly mixing according to 1%-99% proportion of UV drying component and 99%-1% oxidation drying components assisting volatilization drying, penetration drying and complex drying effect. The printing ink of the invention conducts UV drying in the process of printing, instantly realizes partial drying of printing ink to form a drying ink film, can finish oxidation drying and assisting volatilization drying, penetration drying and complex drying effect to achieve the complete drying of printing ink. The printing ink solves the technical problems that thick ink film existing in current UV drying incising gravure printing ink is incomplete, complete drying can not be realized in the natural storage process, and has the advantages of economical, energy-saving and environment-friendly.

Owner:CHINA BANKNOTE PRINTING & MINTING

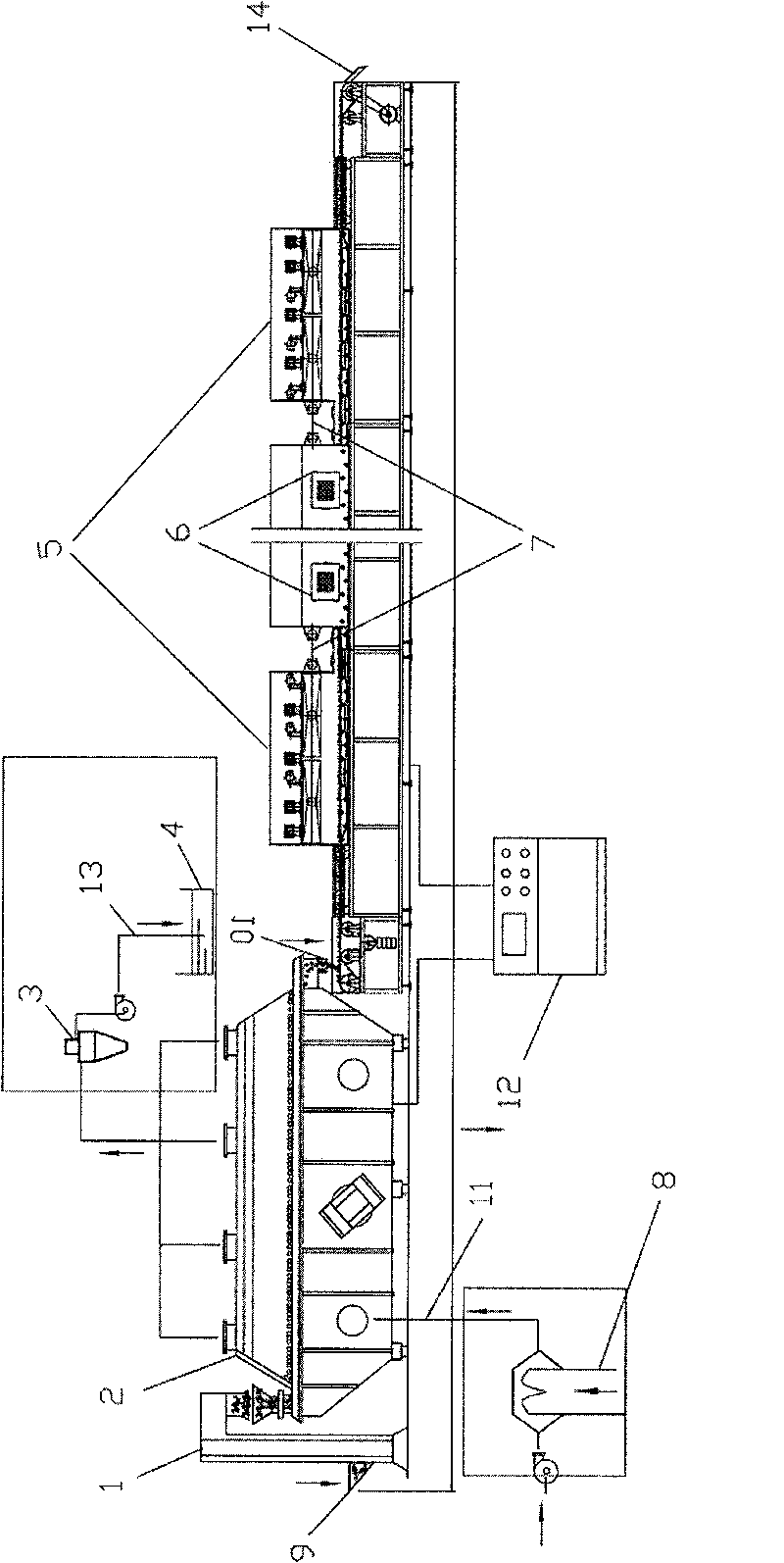

Brown coal drying and dehydrating device

InactiveCN101738077AAchieve dryingImprove coal qualityDrying solid materials with heatDrying machine combinationsComing outBrown coal

The invention relates to a brown coal drying and dehydrating device and an application method. The hot-air drying and dehydrating device dries and dehydrates brown coal at high speed and low energy consumption by main means of high-power microwaves and infrared. The application method for the device comprises the steps of: crushing raw coal; pretreating the coal through a hot-air drying system to remove external water; and then drying and dehydrating the coal further by microwaves, wherein an infrared scanning system is adopted in the drying and dehydrating process in order to prevent the brown coal from backwater. By applying the device, the water in the brown coal can be removed by over 98 percent in short time. The brown coal drying and dehydrating device has the advantages of simpleness and easy operation of process flow, quick dehydration and low energy consumption. The device and the method have no negative effect on the environment, the water coming out through drying can also be recycled, and the device and the method are economic and effective.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH +1

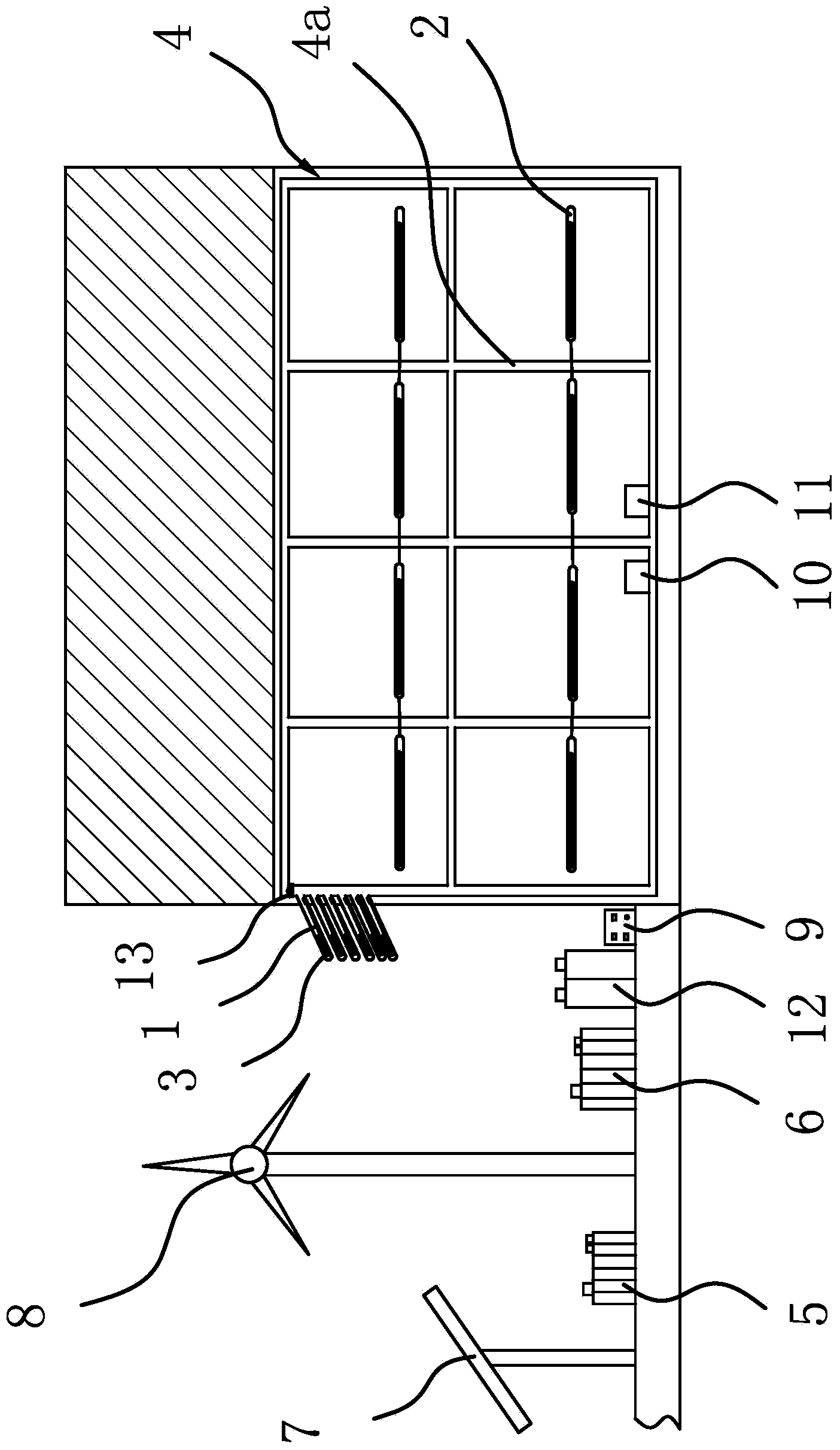

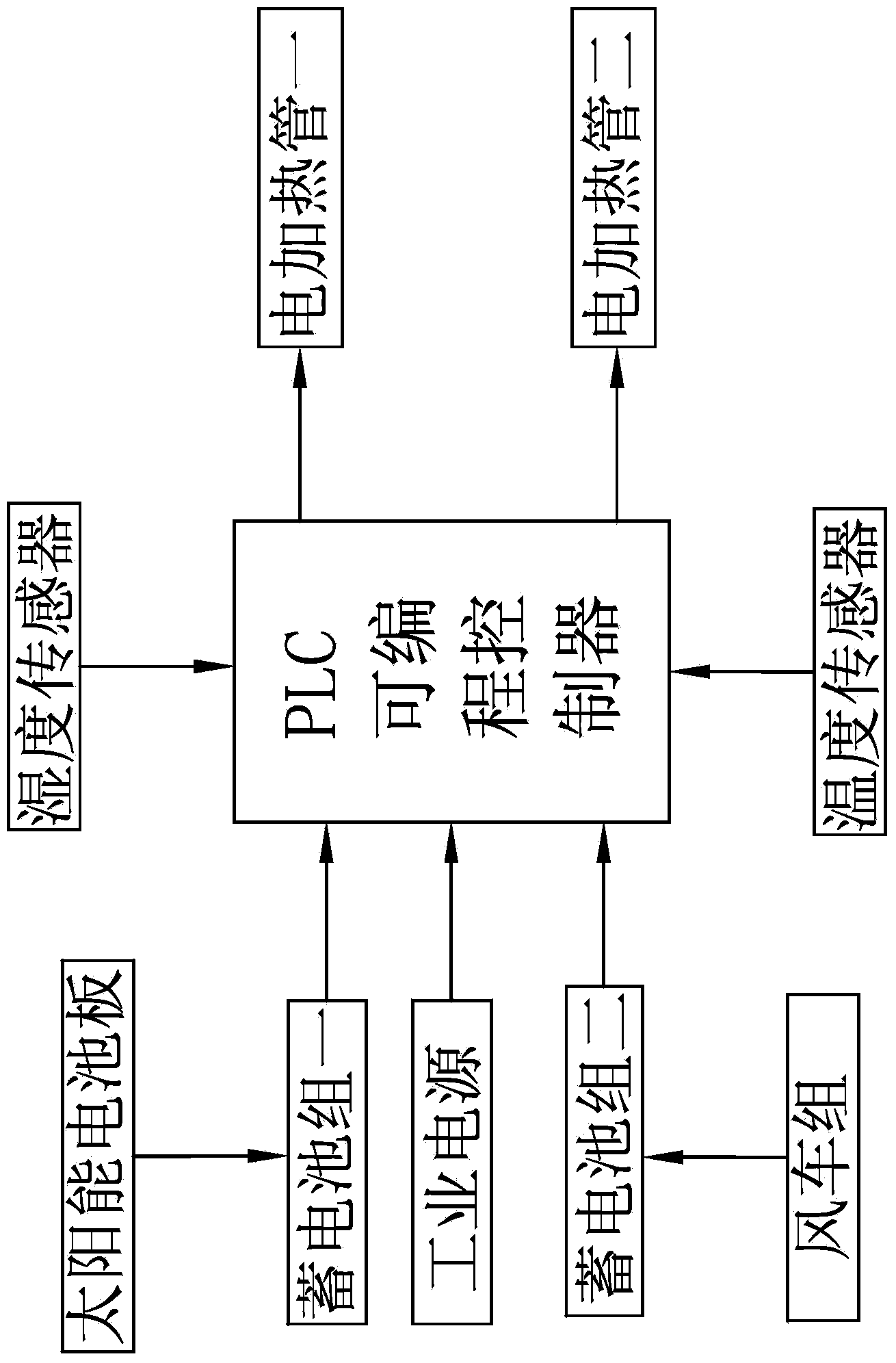

Tunnel anti-freezing dehumidification system

InactiveCN103437799APrevent frostbiteFreezing damage will not occurUnderground chambersTunnel/mines ventillationElectricityAnti freezing

The invention provides a tunnel anti-freezing dehumidification system, and belongs to the technical field of tunnel engineering. The tunnel anti-freezing dehumidification system solves the problems that an existing tunnel is low in temperature and high in humidity. The tunnel anti-freezing dehumidification system comprises a plurality of solar heat collection pipelines and a plurality of electric heating pipes I, wherein the solar heat collection pipelines are arranged at a tunnel portal, the electric heating pipes I are arranged inside a tunnel, one end of each solar heat collection pipeline is a closed end, and the other end of each solar heat collection pipeline is connected with a heating pipeline; electric heating pipes II are further arranged in the solar heat collection pipelines and connected with a storage battery pack II; the electric heating pipes I are evenly arranged on the two side walls inside the tunnel and connected with a storage battery pack I; a solar cell panel and a windmill set are also arranged at the tunnel portal, wherein the solar cell panel is connected with the storage battery pack I, and the windmill set is connected with the storage battery pack II. The tunnel anti-freezing dehumidification system can heat the tunnel so as to prevent rails from freeze injury and can dehumidify the tunnel so as to prevent the rails from rotting at the same time.

Owner:ZHEJIANG OCEAN UNIV

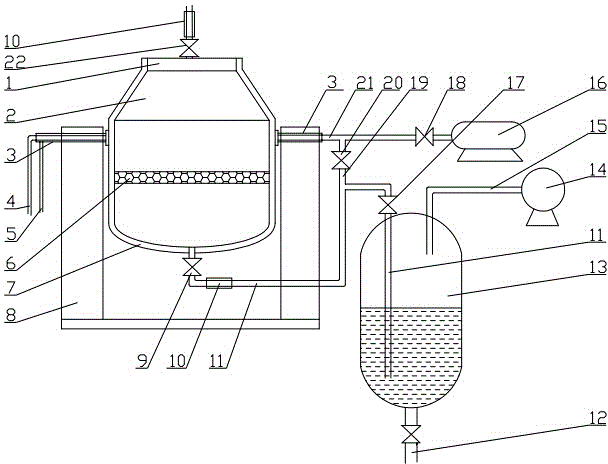

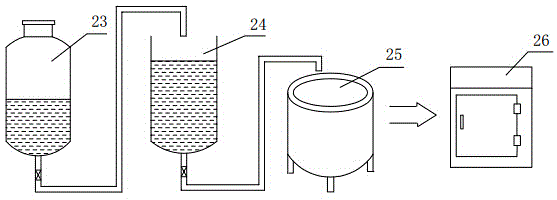

Solid-liquid separation device and method for producing Hopcalite

ActiveCN104689637AReasonable structureRealize solid-liquid separationFiltration circuitsMetal/metal-oxides/metal-hydroxide catalystsAir compressionVapor–liquid separator

The invention discloses a solid-liquid separation device and a method for producing Hopcalite, relating to the field of solid-liquid separation devices of chemical reaction products and catalyst preparation. The device comprises a sealed tank, wherein a feed opening is formed in the top of the sealed tank, a filtering layer is arranged at the lower middle part in the sealed tank, a rotating shaft is arranged on the outer side of the sealed tank, and the rotating shaft is a hollow shaft and is connected with a power overturning device; the upper side of the filtering layer in the sealed tank is connected with an air compressor through the rotating shaft and an air compression pipeline; a drain valve and a drain pipeline are arranged at the bottom of the sealed tank, the other end of the drain pipeline is connected with a gas-liquid separator, the top of the gas-liquid separator is connected with a vacuum pump through a vacuum pipeline, and a liquid outlet is formed in the bottom of the gas-liquid separator; the air compression pipeline is connected with the drain pipeline through a pipeline, and valves, liquid inlet valves and air compression valves are respectively arranged on the pipeline, the drain pipeline and the air compression pipeline. The device is good in solid-liquid separation effect and is high in production efficiency; when the device is used for producing Hopcalite, the cost is low, the production cycle is short, potassium sulfate and sodium sulfate can be respectively recovered, and thus the potassium sulfate and the sodium sulfate can be recycled.

Owner:邯郸市同俊达矿山设备股份有限公司

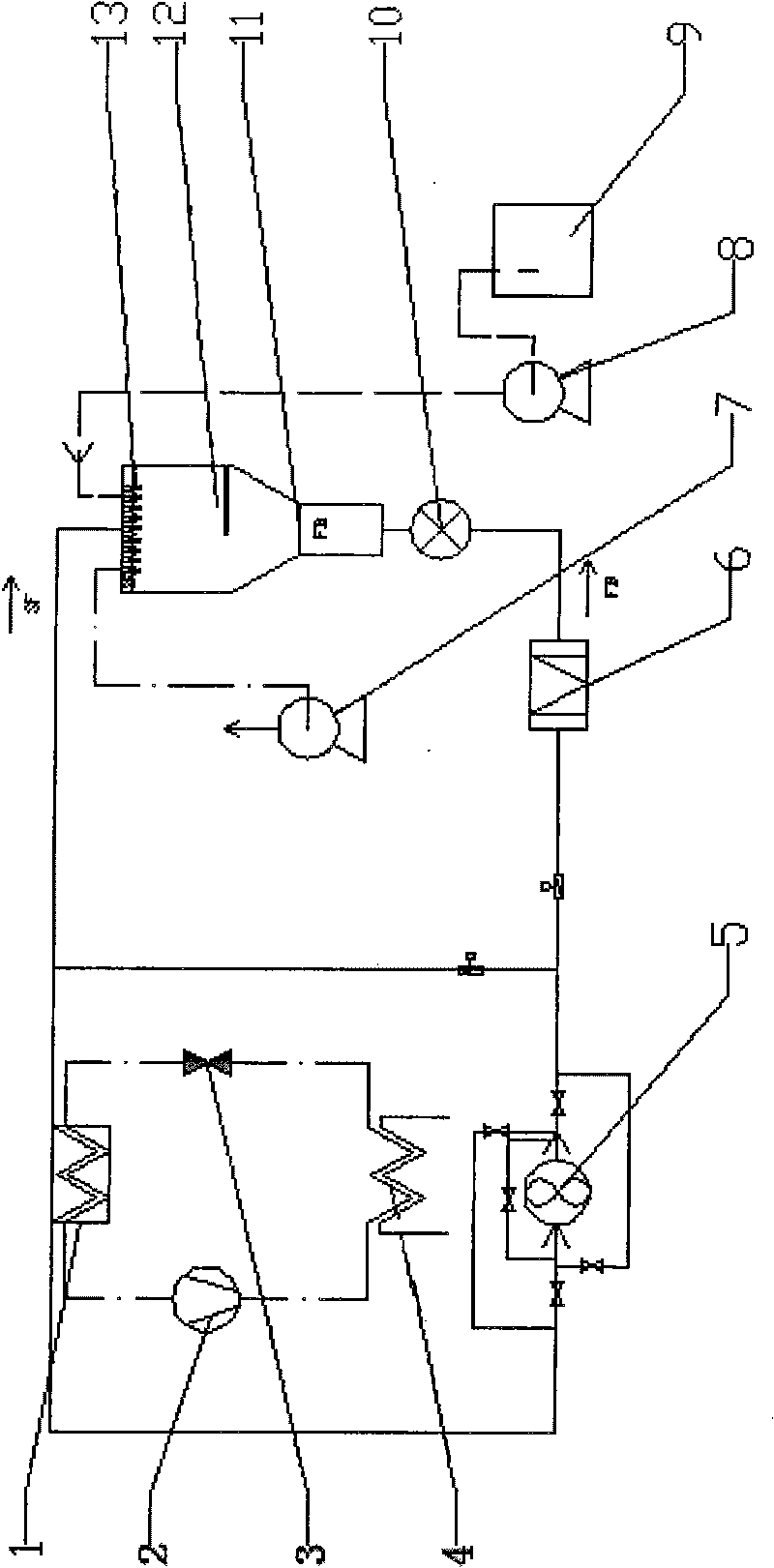

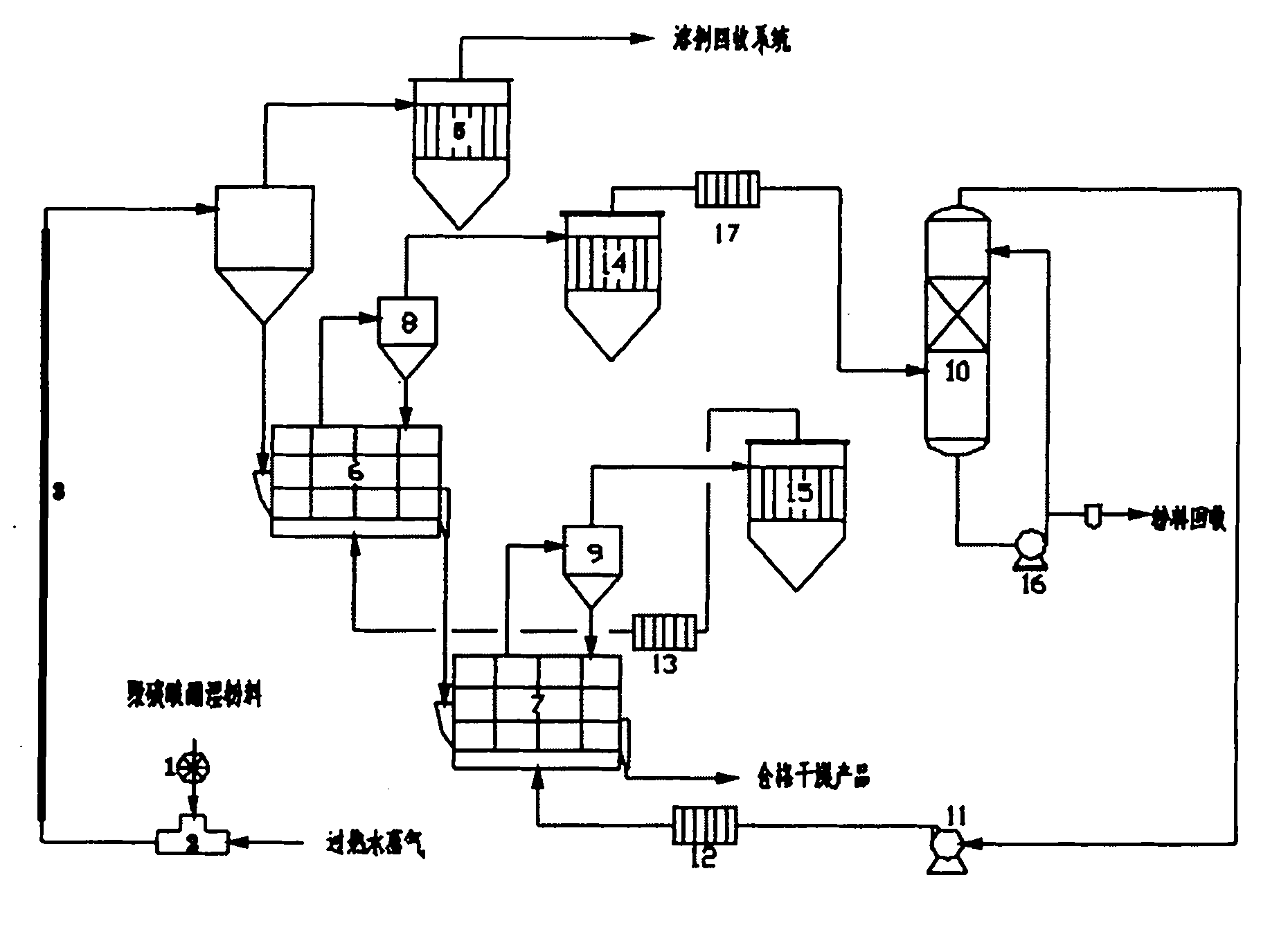

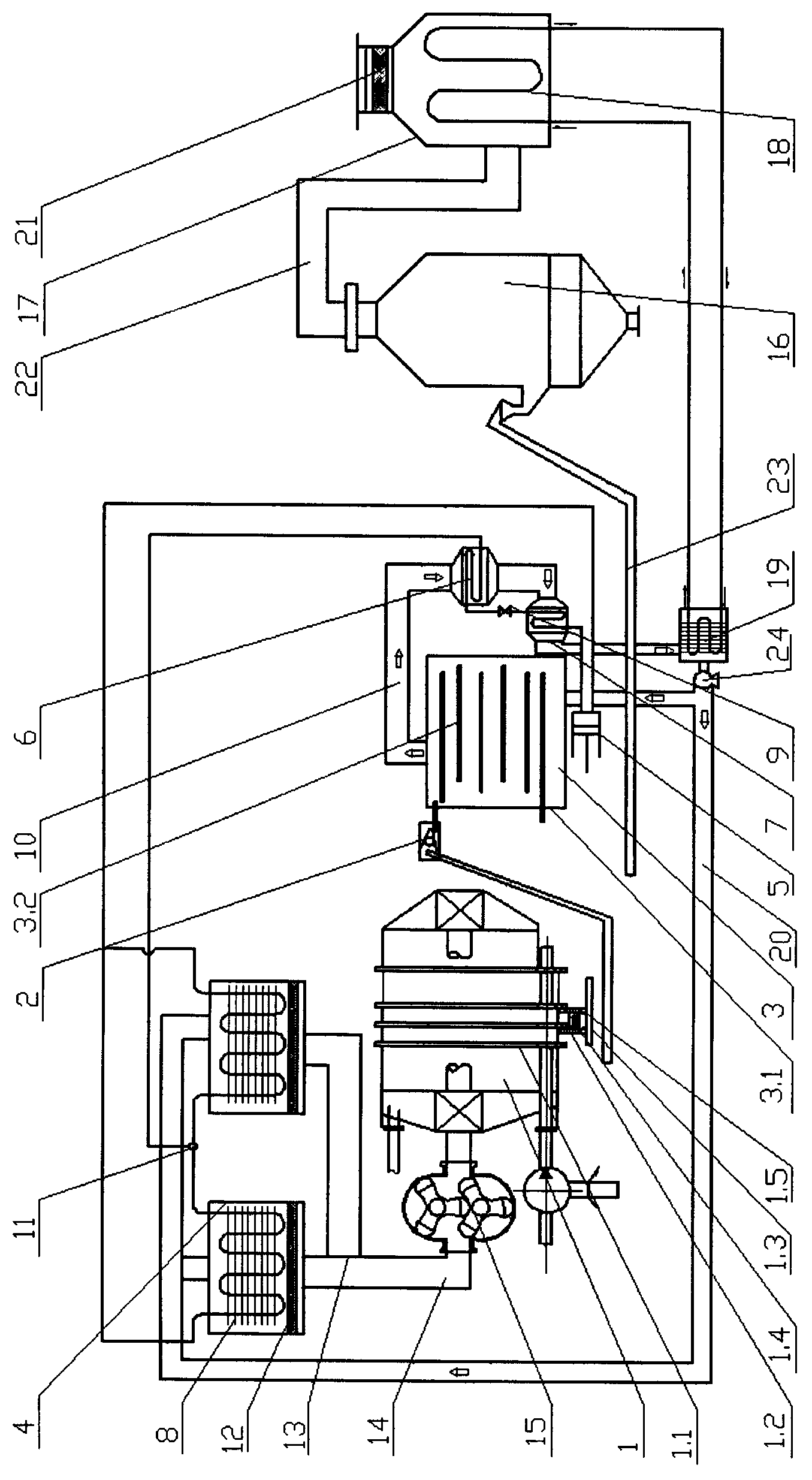

Intermittent drying system and method of multifunctional fluidized bed for freezing, spraying and pelleting

ActiveCN101738063AReduce damageReduce quality degradationDrying solid materials without heatProcess engineeringLiquid food

The invention discloses intermittent drying system and method of a multifunctional fluidized bed for freezing, spraying and pelleting, which has the advantages of flexible structure, variety methods, low use cost and the like. The structure is characterized by comprising a refrigeration system and a fluidized bed drying system for spraying and freezing in vacuum, wherein a vacuum spraying drying system is connected with a feeding system, the refrigeration system is connected with the feeding end of the vacuum spraying drying system, the other path of pipeline of the refrigeration pipeline is connected with a fluidized device of the vacuum spraying drying system through a pulse adjusting device to form a closed ring system, thereby flexible switch among different drying methods can be realized, and intermittent operation is carried out. The invention is mainly used for dewatering storage of products with high additional value, such as liquid foods, medicines, biological products and the like and development operation of new techniques of dewatering products such as liquid foods, medicines and biological products.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

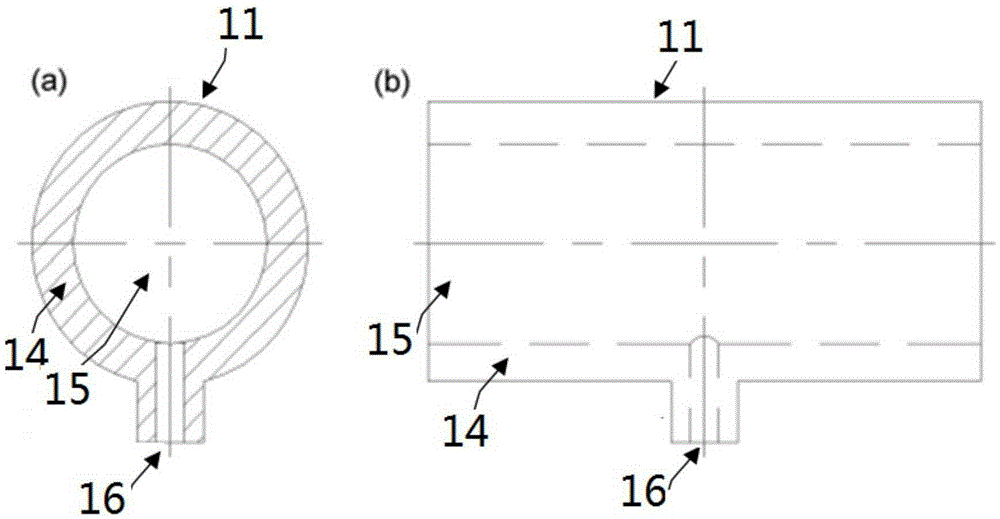

Preparation method and device for carbon fiber-reinforced thermoplastic resin composite material

The invention provides a manufacturing method for a carbon fiber-reinforced thermoplastic resin composite material. The method comprises the steps of firstly removing a sizing agent on a carbon fiber surface, then performing metallic coating treatment, water scrubbing and surface heat treatment, leading into a dipping die head containing melt thermoplastic resin in a splitting state, enabling the melt thermoplastic resin to wrap the carbon fiber surface, then performing cooling and grain-size dicing, so that the carbon fiber-reinforced thermoplastic resin composite material is prepared. The method has the advantages of simple and practical process, low cost, stable quality, good mechanical property, good electromagnetic protective property and light weight.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

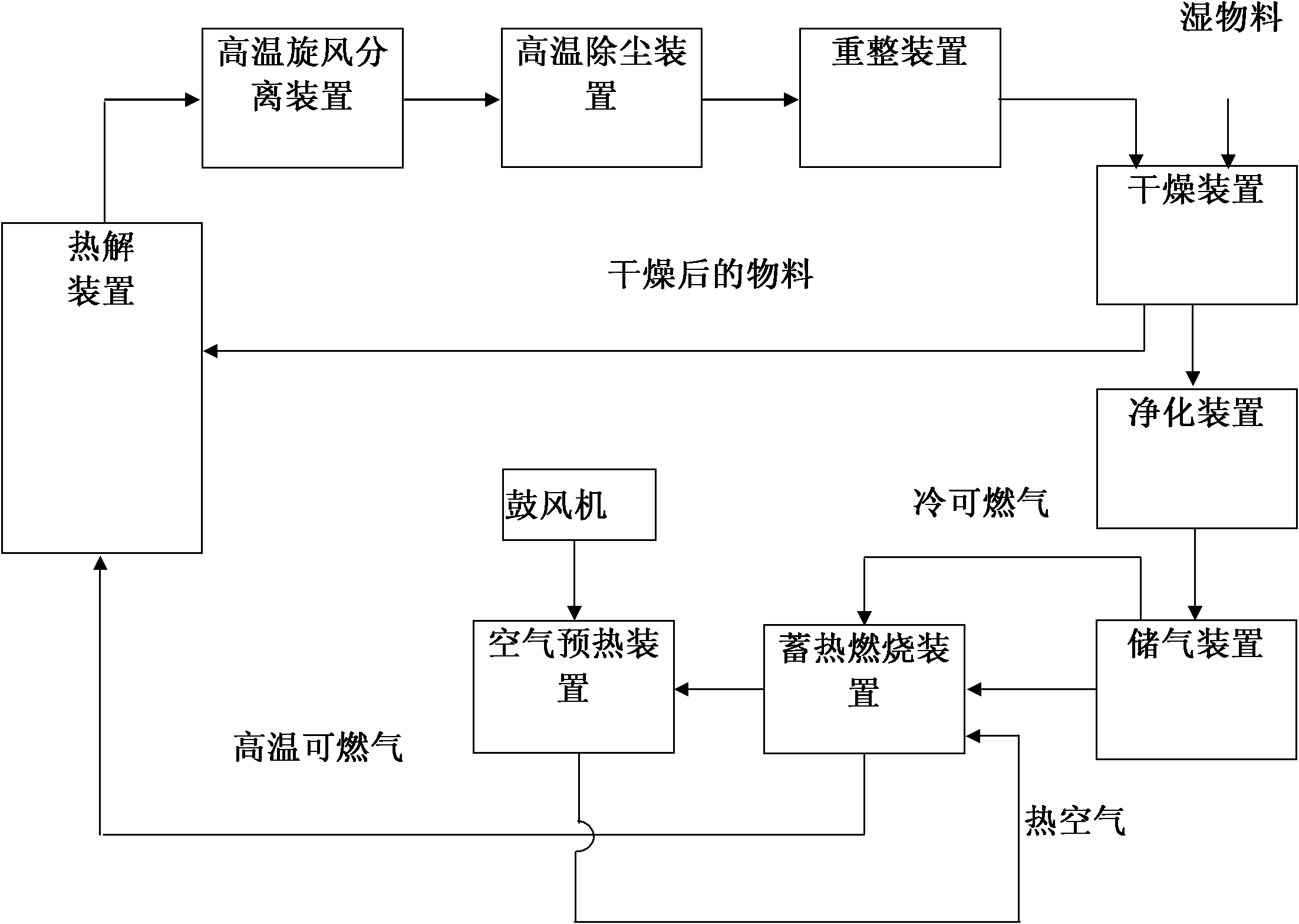

Method for preparing activated carbon by pyrolysis of organic matters

ActiveCN102134071ARealize zero supplyRealization of regenerative combustionCarbon compoundsEnergy inputActivated carbonCombustible gas

The invention relates to a method for preparing activated carbon by pyrolysis of organic matters, comprising a pyrolyzing device, a reforming device, a drying device, a purifying device, a gas storage device and a high-temperature heat-storage combustion device, wherein pyrolysis reaction is carried out on organic matters by the pyrolyzing device so as to generate combustible gas, tar and coke, the combustible gas enters the drying device after passing through the reforming device so as to dry the organic matters, a part of the purified combustible gas combusts in the direction of a combustion passage of the high-temperature heat-storage burning device so as to generate combustion heat, and simultaneously, the other part of the combustible gas exchanges heat by the heat-storage combustion device in the direction of a heat-exchange passage, and then enters the pyrolyzing device for pyrolysis and activation reaction as pyrolyzing and activating medium. In the process of pyrolysis, the coke forms the activated carbon by activation of the combustible gas. The combustible gas generated by pyrolysis is dried by the drying device, and then sensible heat in the gas is fully released; a part of the combustible gas combusts to release heat as the energy source needed in the process of pyrolysis, and the combustible gas is a pyrolysis medium, and is also an activating agent in the process that the coke generates the activated carbon.

Owner:DALIAN UNIV OF TECH +1

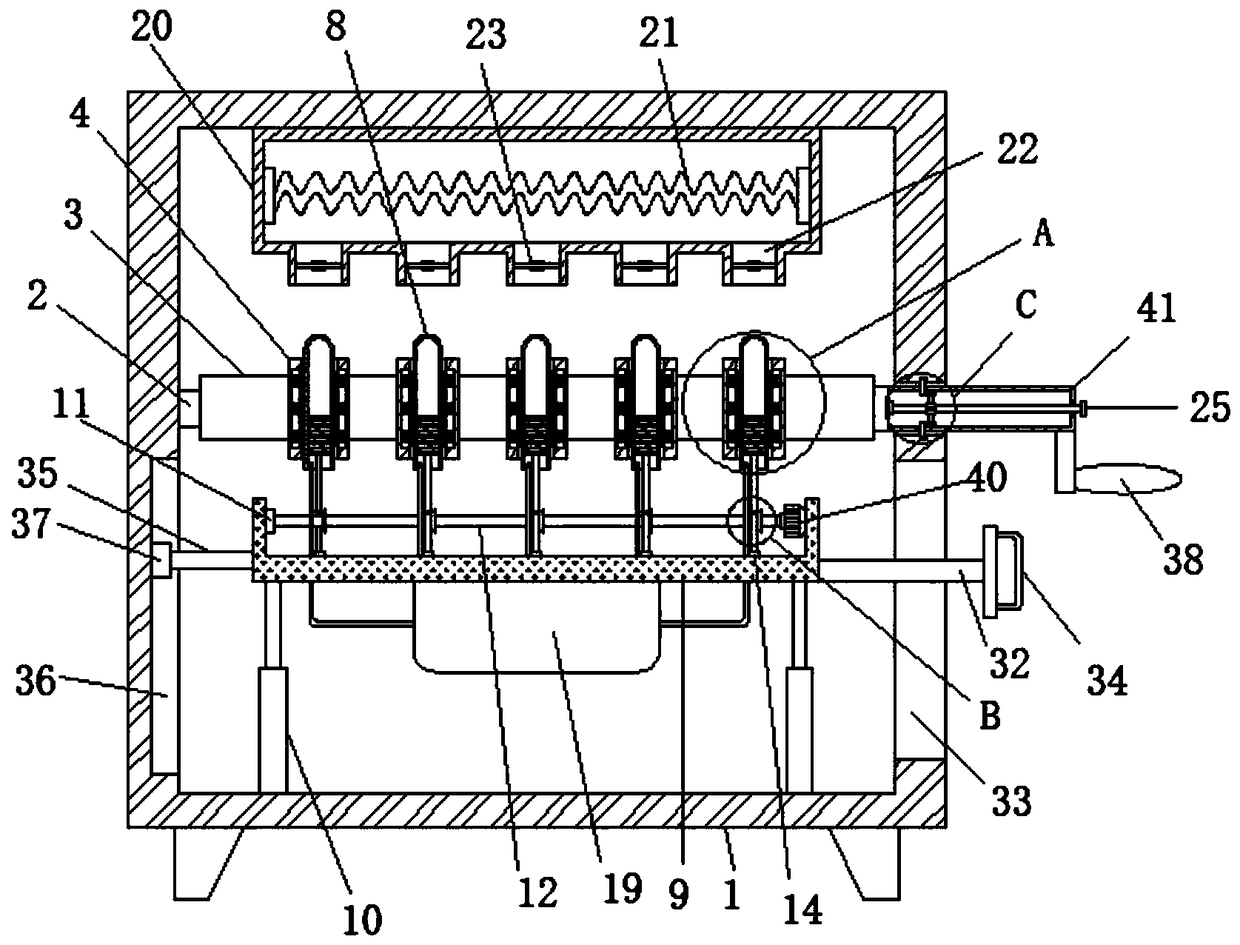

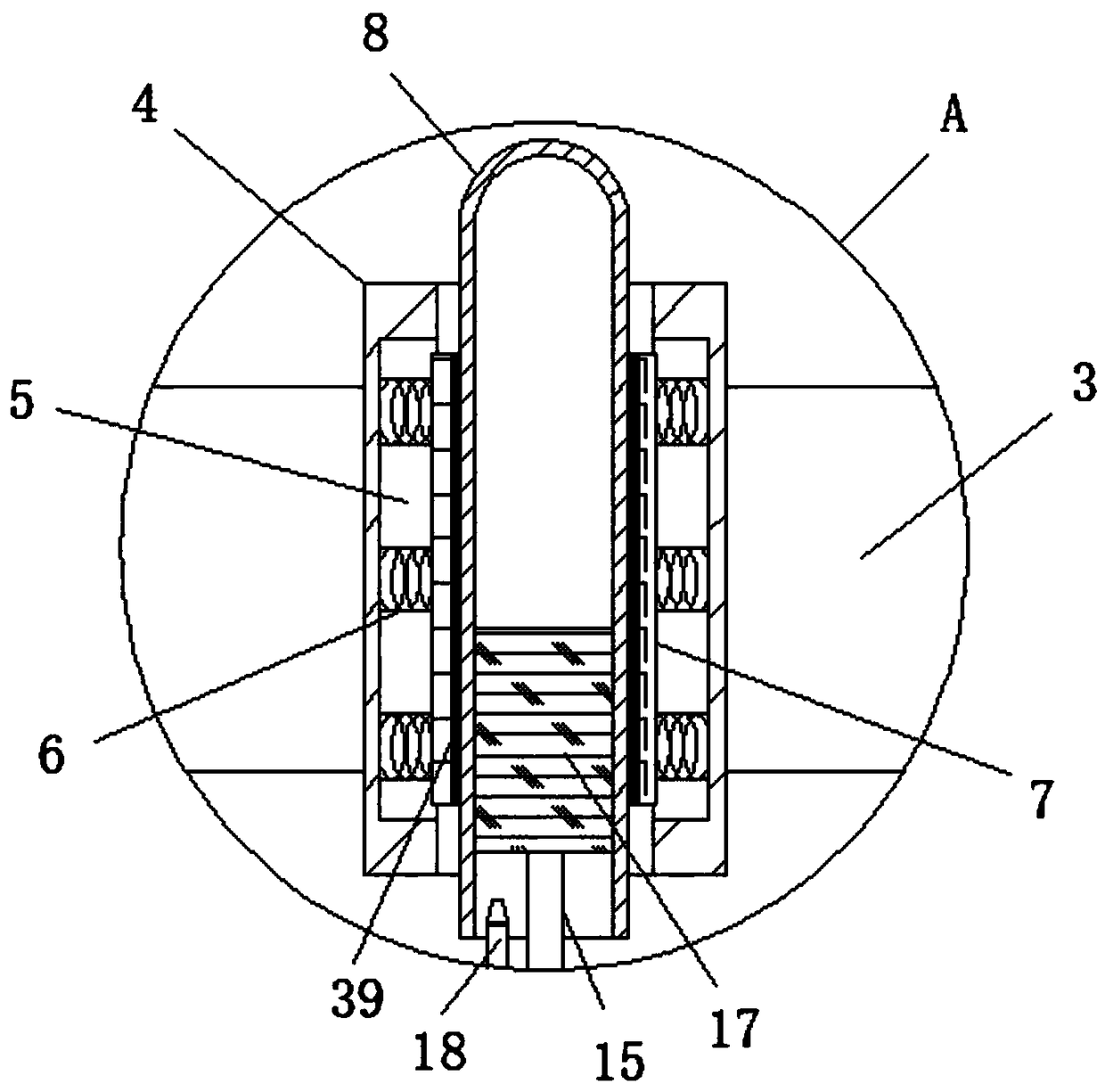

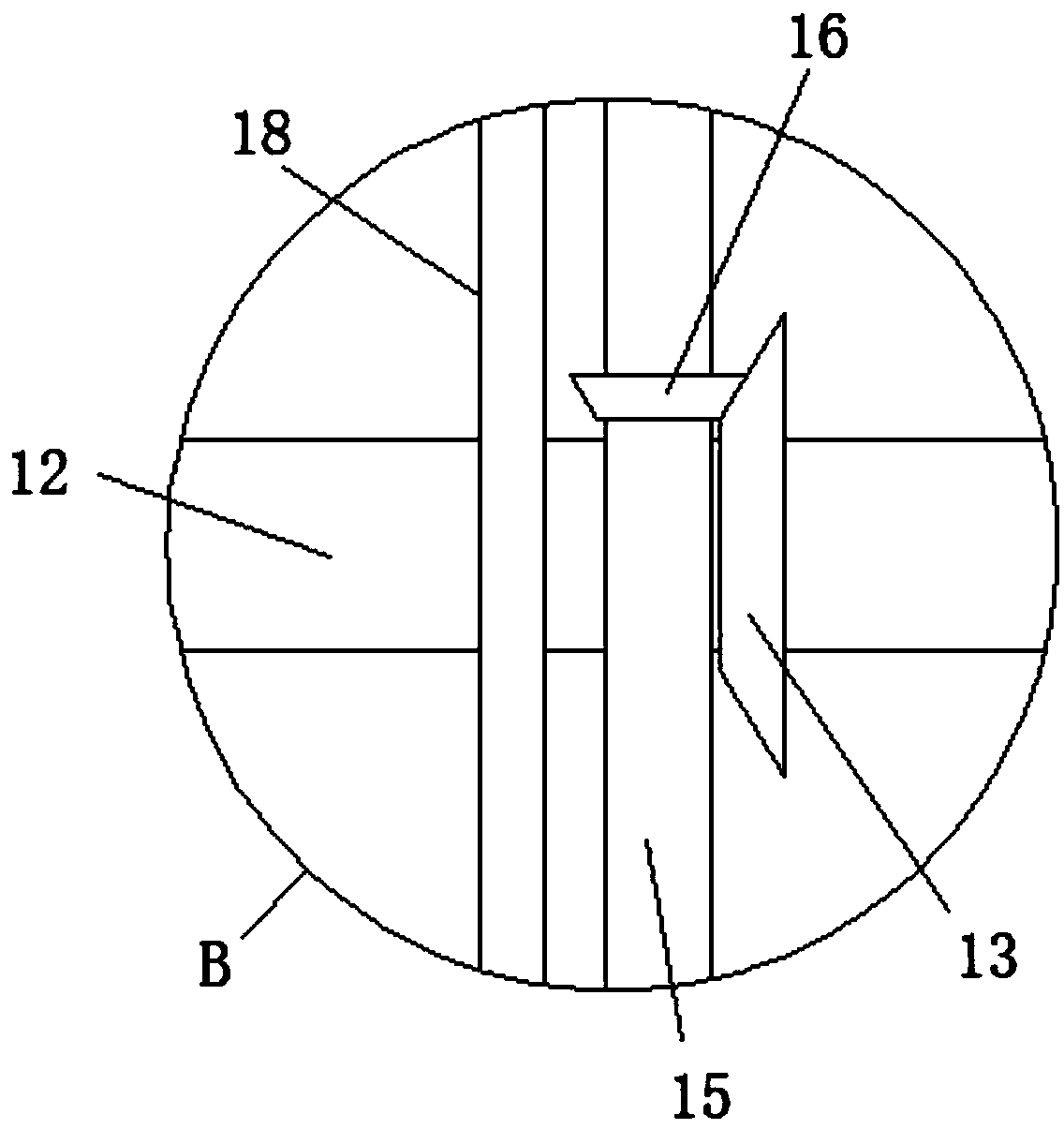

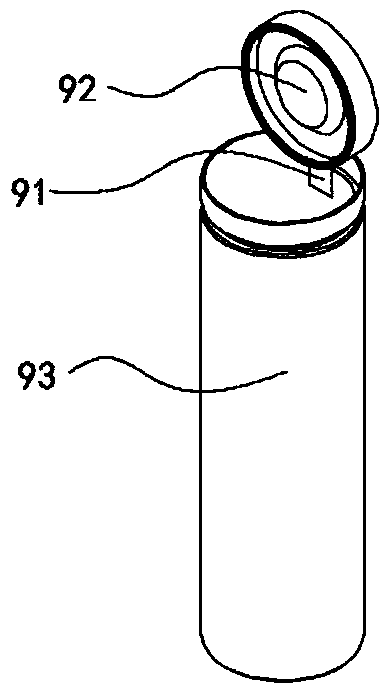

Drying and cleaning integrated device of medical test tube

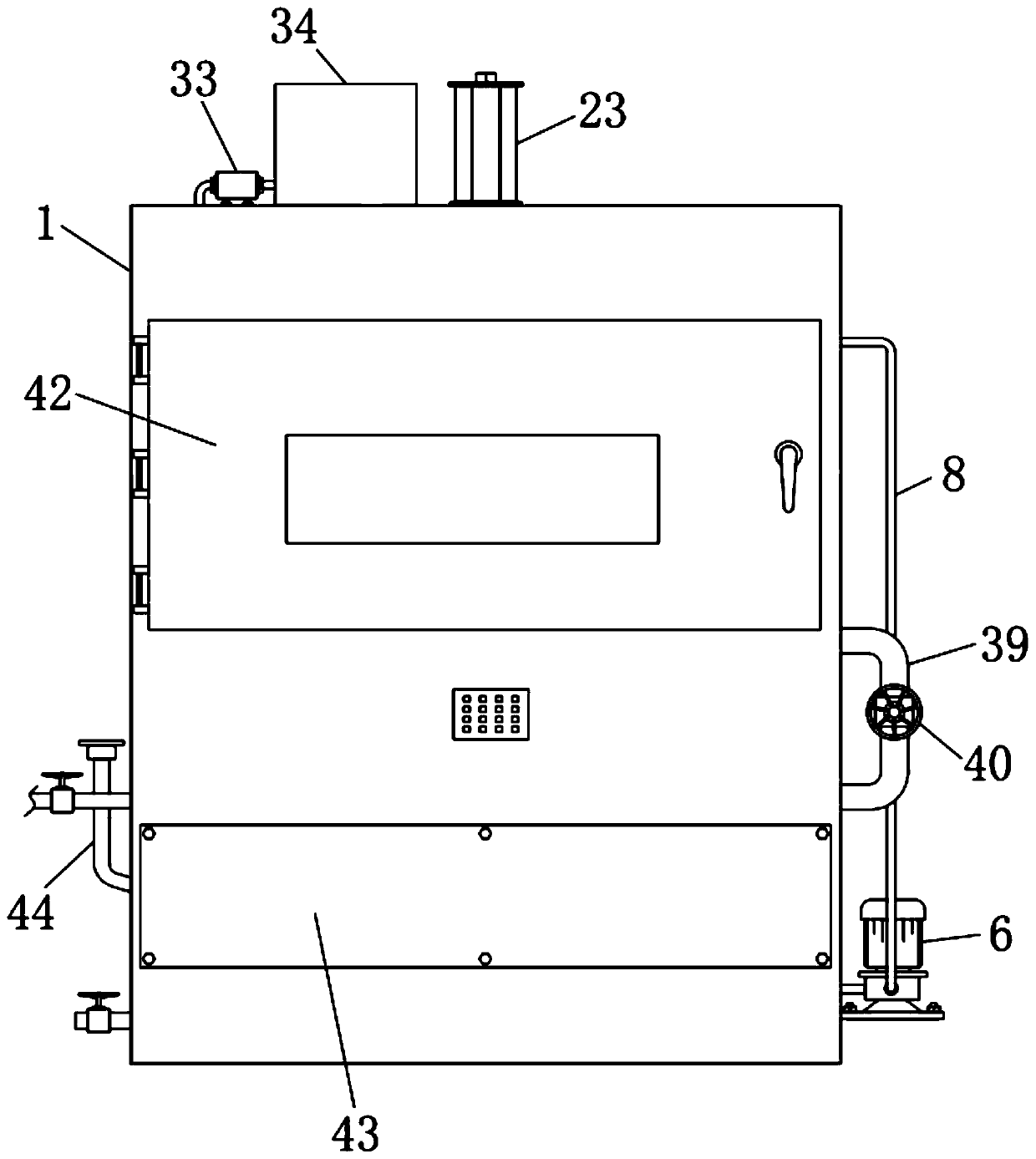

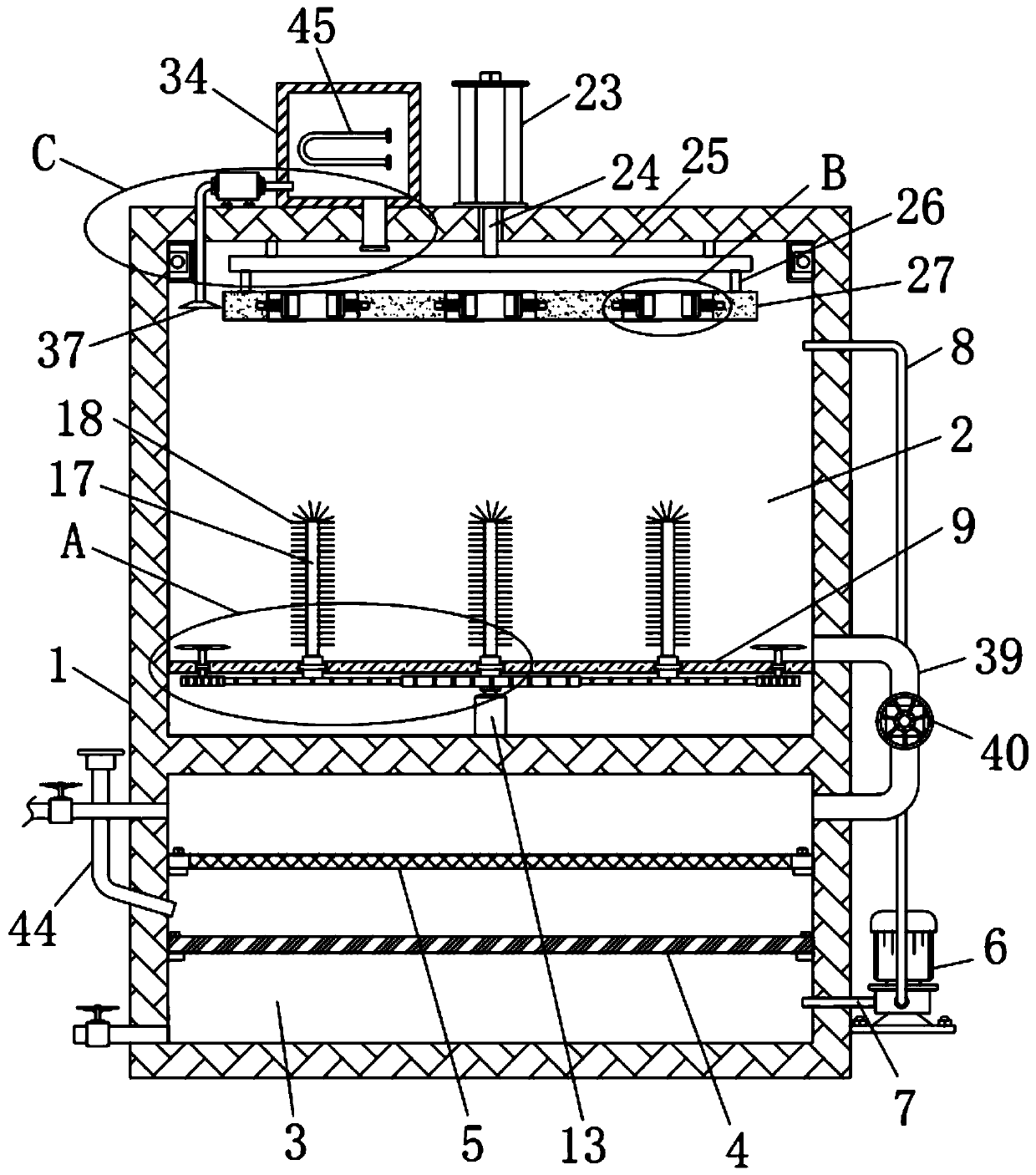

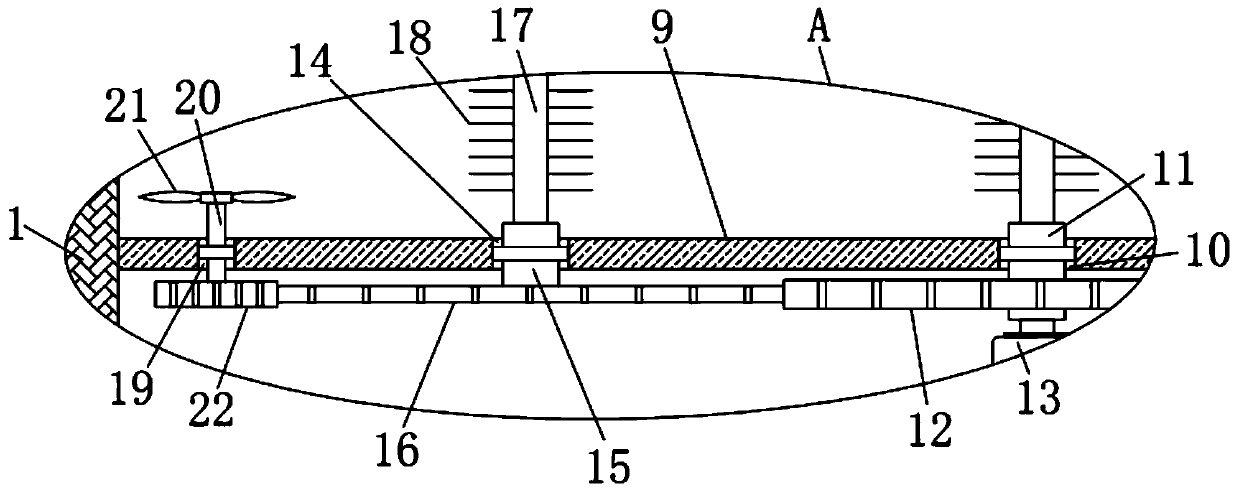

InactiveCN108655143AAchieve dryingRealize integrated cleaningHollow article cleaningDrying gas arrangementsEngineeringMedical treatment

The invention discloses a drying and cleaning integrated device of a medical test tube. The device comprises a box body, the box body is of a hollow structure, the inner wall of one side of the box body is rotationally connected with a transversely arranged mounting rod through a first rotating piece, one end, far away from the first rotating piece, of the mounting rod is transversely provided with a rotating rod, and the rotating rod penetrates through the side wall of the box body to be arranged; a plurality of vertically arranged fixing seats are fixedly connected to the side wall of the mounting rod, grooves are formed in the side walls of the two sides of the fixing seats, and the side walls of the grooves are connected with vertically arranged clamping plates through a plurality of springs; and the test tube is vertically arranged between the two clamping plates, a bearing plate is transversely arranged in the box body, moreover, the bearing plate is arranged below the rotating rod, and the side wall of the two sides of the bearing plate are connected with the inner wall of the lower end of the box body through telescopic rods which are vertically arranged. According to the device, the automatic cleaning and drying of the medical test tube can be realized, the workload of a medical staff is reduced, and the cleaning efficiency is improved.

Owner:SOUTHWEST MEDICAL UNIVERISTY

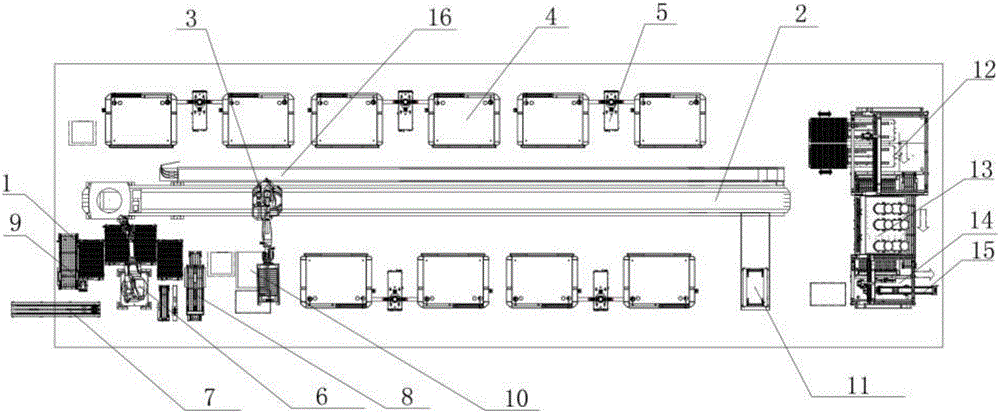

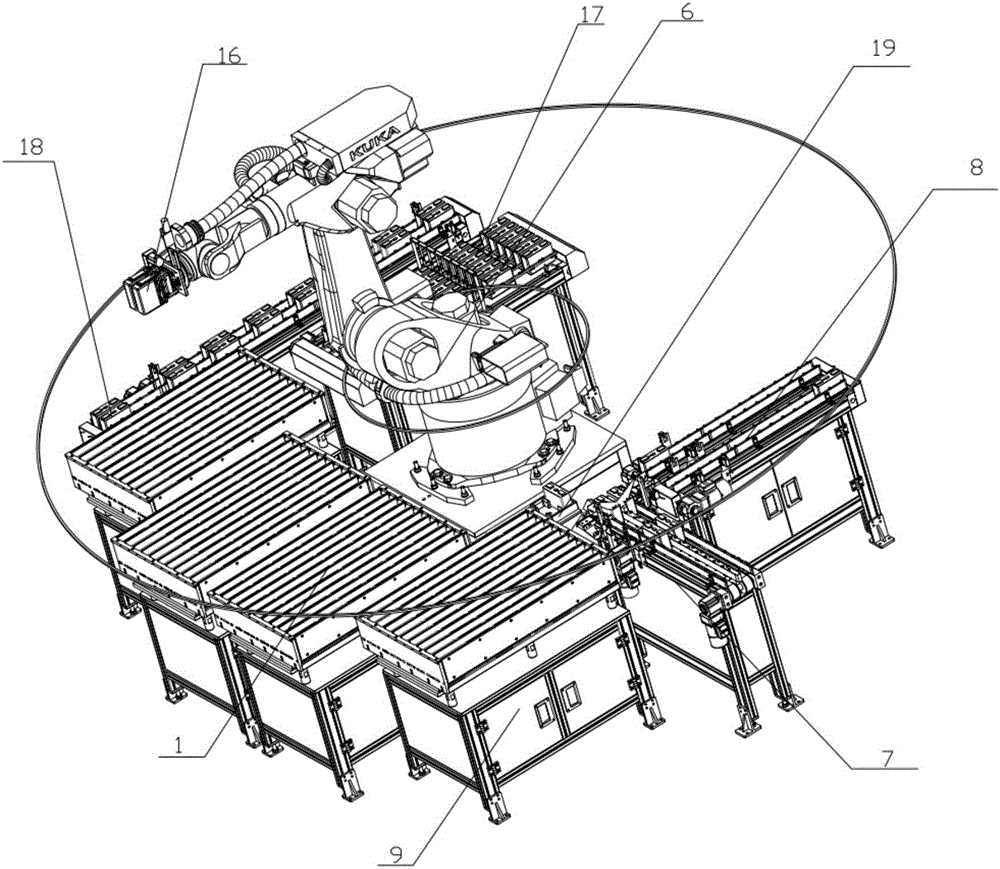

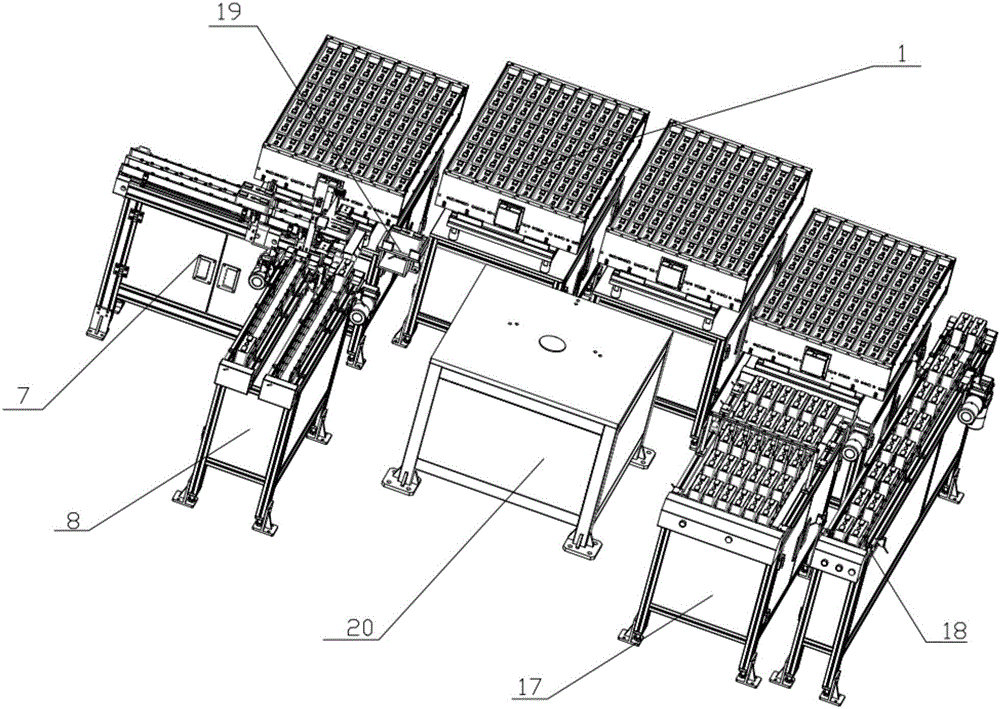

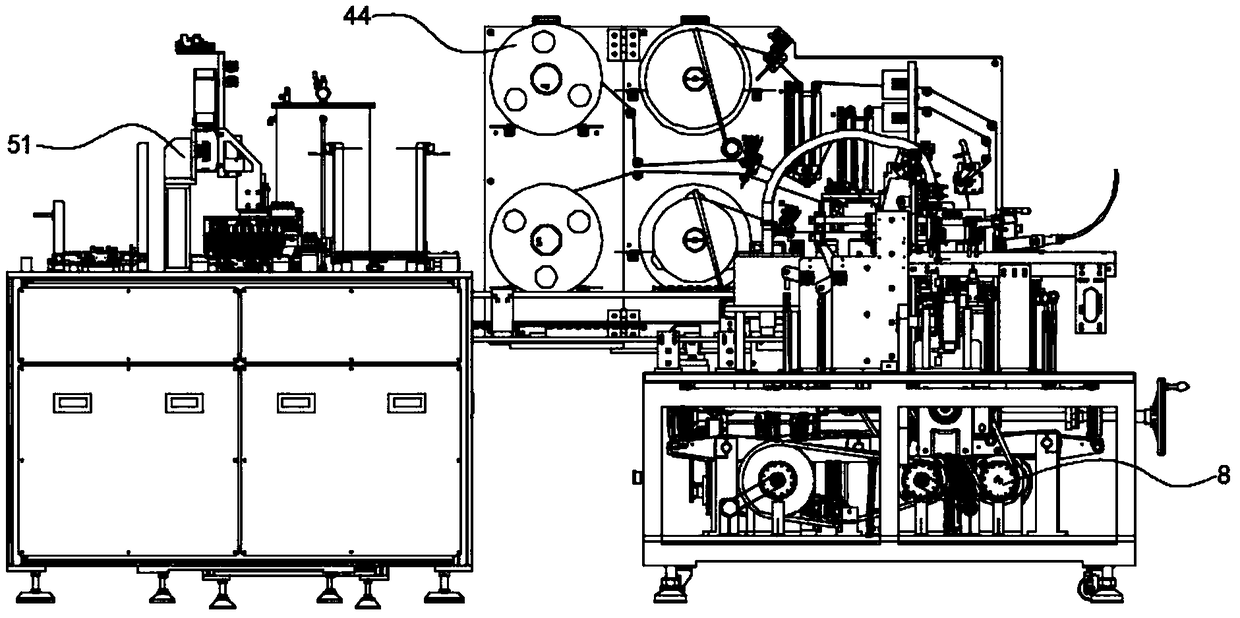

Automatic lithium battery drying and cooling processing system

ActiveCN106384845AAchieve dryingAchieving processing powerFinal product manufactureElectrolyte accumulators manufactureEngineeringManipulator

The invention discloses an automatic lithium battery drying and cooling processing system which comprises a main moving line, drying furnaces, a carrying six-axis manipulator and a cooling furnace, wherein multiple drying furnaces are mounted on the two sides of the main moving line; the carrying six-axis manipulator is mounted on the main moving line; a fixture clamping component is mounted on the working end of the carrying six-axis manipulator; an automatic loading unit is arranged at one end of the main moving line, and a cooling unloading unit is arranged at the other end; the automatic loading unit comprises an input conveying line, a loading six-axis manipulator and a fixture bearing table; the cooling unloading unit comprises a cooling loading platform, the cooling furnace, a cooling unloading platform and an output conveying line; the cooling loading platform and the cooling unloading platform are arranged at the two ends of the cooling furnace respectively; and the output conveying line is connected with the cooling unloading platform. The system disclosed by the invention can be used for automatically loading and unloading lithium batteries and automatically finishing the drying and cooling treatment processes of the lithium batteries.

Owner:深圳市新伟创实业有限公司

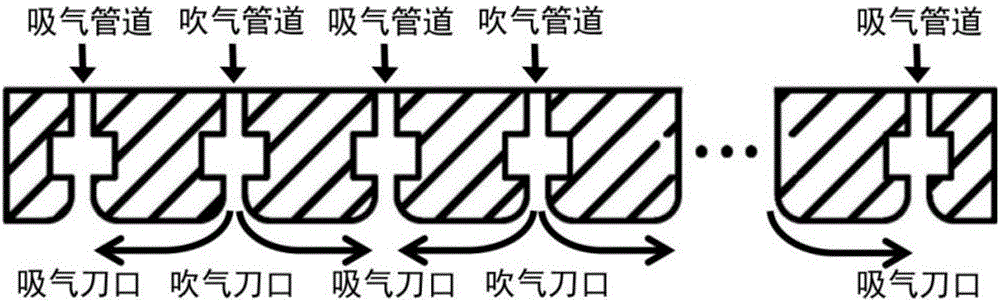

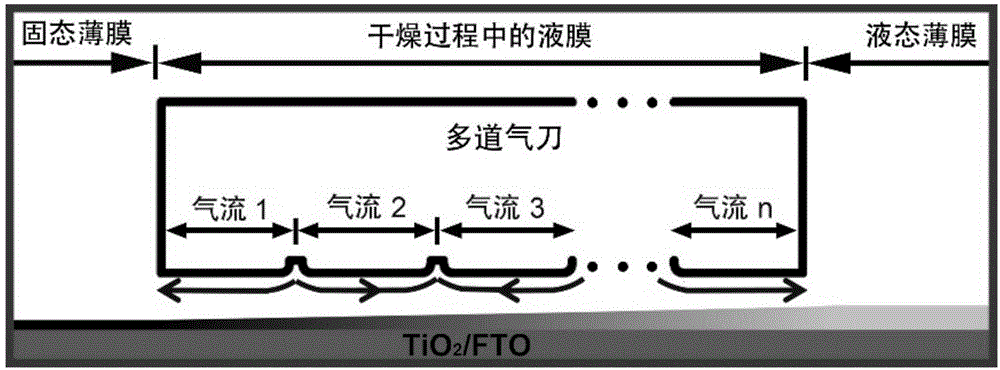

Multi-flow drying air knife and method used for preparing perovskite thin film in perovskite solar cell by using same

ActiveCN106252520AQuality improvementDry fastFinal product manufactureSolid-state devicesPerovskite solar cellEngineering

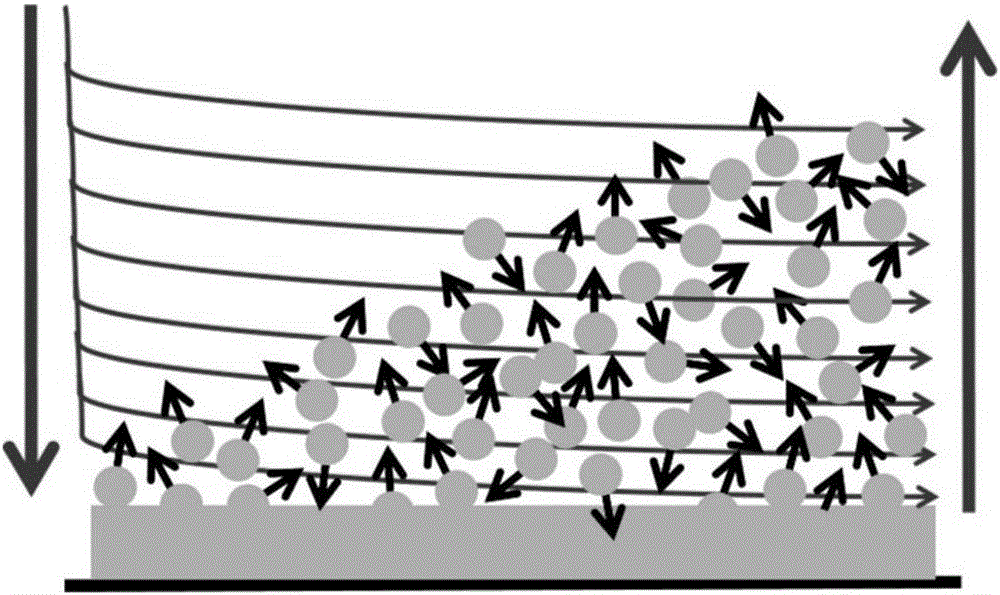

The invention provides a multi-flow drying air knife and a method used for preparing a perovskite thin film in a perovskite solar cell by using the same. A perovskite liquid film coated on the surface of a substrate is arranged under the multi-flow drying air knife, wherein several blowing passages and suction passages are alternatively arranged at intervals. Dilution airflow blown out by the blowing passages absorbs a solvent component when flowing through the surface of the perovskite liquid film to realize liquid film drying. The airflow leaves the liquid surface, enters the multi-flow drying air knife through the suction passages, and flows out. The solvent component in a solution is rapidly evaporated. The high-quality perovskite thin film in the perovskite solar cell is prepared by controlling the conditions of a drying process. According to the invention, the perovskite thin film with uniform and compact structure is acquired; leakage current caused by perovskite thin film holes is avoided, which is favorable for the preparation of the solar cell which has the advantages of high efficiency and large area; and the multi-flow drying air knife and the method have the advantages of simple operation, easy operation, low cost, high repeated accuracy, easy industrialization, continuous production and so on.

Owner:杨冠军

Biological test tube cleaning, disinfecting and drying equipment

InactiveCN111515201AStable clampingIncrease frictionHollow article cleaningTreatment involving filtrationActivated carbonWater resources

The invention discloses biological test tube cleaning, disinfecting and drying equipment. The biological test tube cleaning, disinfecting and drying equipment comprises a box. The box is provided witha cleaning cavity and a water cavity. An activated carbon plate and a filter plate are fixedly mounted in the water cavity. The activated carbon plate is located under the filter plate. A water pumpis fixedly mounted on one side of the box. The suction end of the water pump is fixedly connected with a water suction pipe. The end, far away from the water pump, of the water suction pipe extends into the water cavity and is located below the activated carbon plate. The discharge end of the water pump is fixedly connected with a drain pipe. The end, far away from the water pump, of the drain pipe extends into the cleaning cavity. A partition plate is fixedly mounted in the cleaning cavity. The biological test tube cleaning, disinfecting and drying equipment is reasonable in design, good in practicality, capable of realizing integration operation of cleaning, drying and disinfecting of test tubes without manual cleaning and capable of saving time and labor, improves the working efficiency, has the good cleaning, drying and disinfecting effects on the test tubes and can filter and purify waste water obtained after cleaning for recycling and save water resources.

Owner:顾海燕

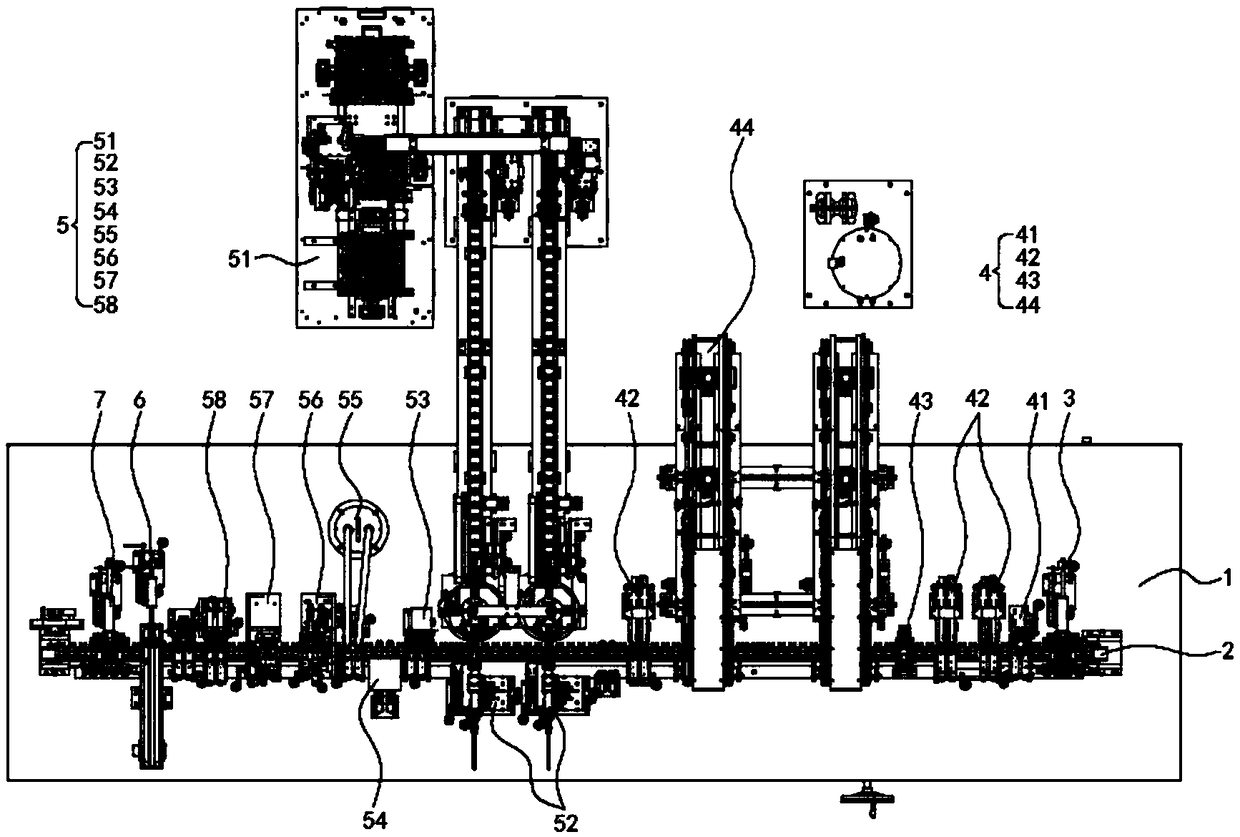

Full-automatic lithium battery production line

ActiveCN109301333AGuaranteed positioning accuracyEnsure consistencyFinal product manufactureElectrolyte accumulators manufactureProduction lineBiochemical engineering

The invention discloses a full-automatic lithium battery production line, which includes a machine frame, a circular transporting mechanism arranged on the machine frame, lithium batteries, and a loading mechanism, a lug shaping mechanism, an end cap shaping mechanism, a rejected product retrieve mechanism, a delivery mechanism, and a multi-station cam transmission mechanism, which are arranged successively on the machine frame. The multi-station cam transmission mechanism supplies power to the loading mechanism, the lug shaping mechanism, the end cap shaping mechanism, the rejected product retrieve mechanism and the delivery mechanism, so that production efficiency of the full-automatic lithium battery production line is increased. Lithium battery semi-products are transplanted to the work stations by means of the loading mechanism, then successively pass through the lug shaping mechanism, the end cap shaping mechanism, the rejected product retrieve mechanism and the delivery mechanism by being held by the circular transporting mechanism; through a series of online processing on the lithium battery semi-products, performance consistency of the lithium batteries is guaranteed by means of online detection and calibration on the mechanisms.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

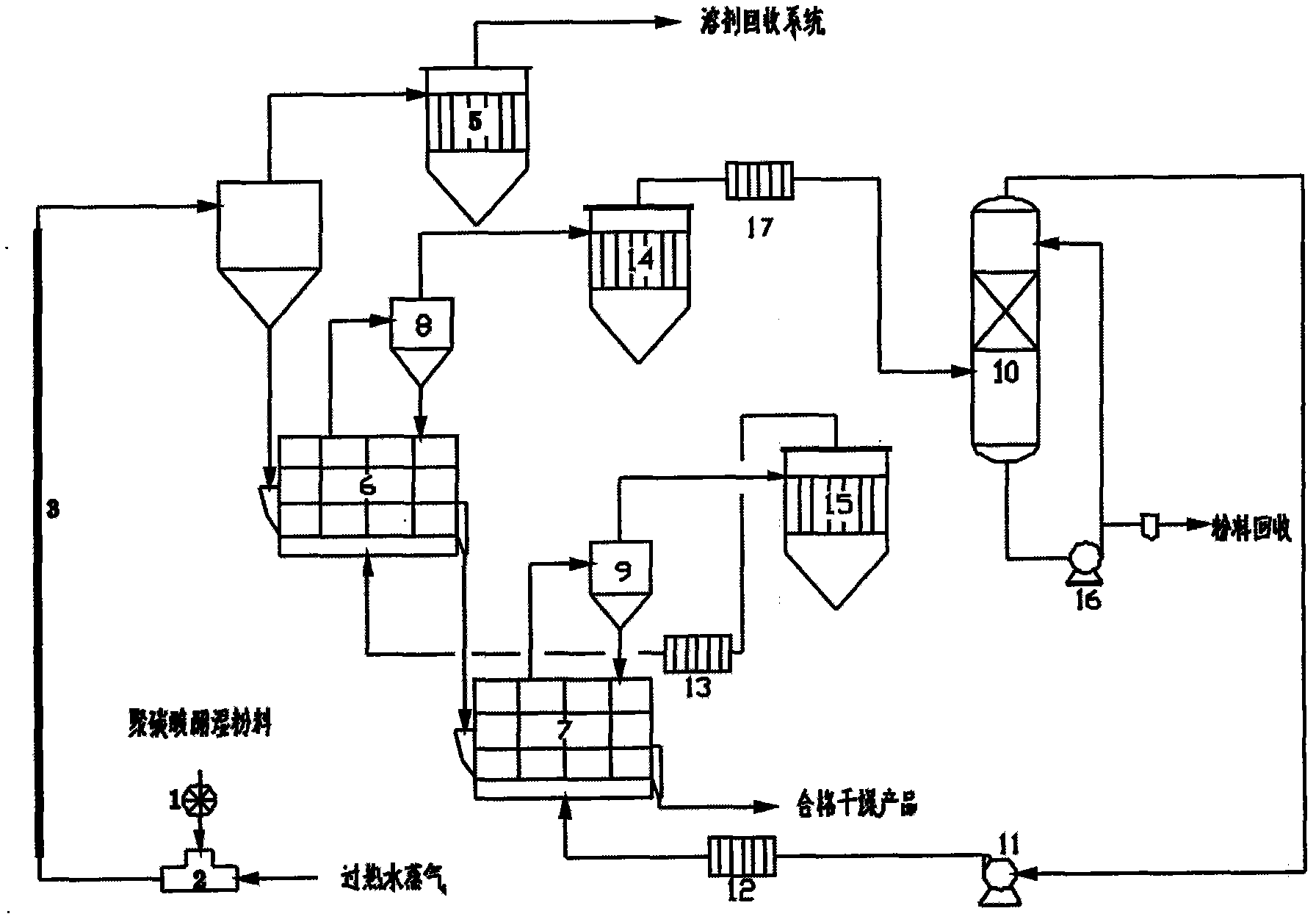

Method for drying poly carbonate (PC)

InactiveCN102620526ASolving Recycling ProblemsAvoid accident hazardsDrying solid materials with heatHearth type furnacesFluidized bed dryingThree stage

The invention relates to a method for drying polycarbonate (PC), which is characterized in that PC powder is subjected to drying treatment by adopting a one-stage pneumatic drying and two-stage fluid bed drying combined way, and overhot vapor is used as the drying medium in the one-stage drying process; and hot nitrogen gas is used as the drying medium in the fluid bed drying process, the nitrogen gas is recycled through processes such as washing, cooling, dehumidifying, pressurizing, heating and the like, and the PC powder in washing water is recycled. The water content of a product dried in the three-stage draying combined way can meet the later processing requirement, accident potentials such as dust explosion and the like caused in the drying process of the PC powder can be effectively solved, and the quality of the product can be improved.

Owner:甘肃银光聚银化工有限公司 +1

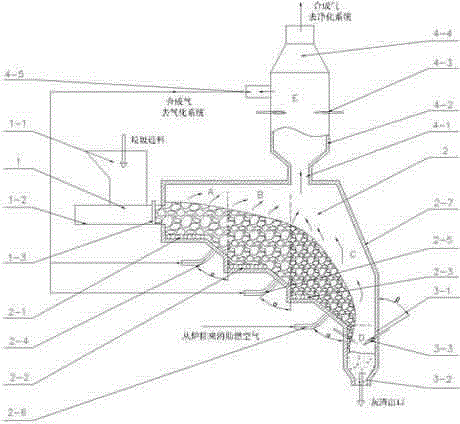

Plasma auxiliary-heating melting and gasifying reactor

ActiveCN104449875ASolve the emission problemFix issues that require reprocessingGasification processes detailsCombustible gas productionOperational costsReaction sequence

The invention relates to a plasma auxiliary-heating melting and gasifying reactor. The plasma auxiliary-heating melting and gasifying reactor comprises a feeder and a reaction chamber, wherein the feeder is connected with the reaction chamber; the reaction chamber sequentially comprises a drying area, a pyrolysis and gasification area, a burn-out area and an ash melting area according to a reaction sequence along a horizontal direction; the drying area is connected with the feeder through a charge port; the bottom of the pyrolysis and gasification area is lower than that of the drying area; the bottom of the burn-out area is lower than that of the pyrolysis and gasification area; the bottom of the ash melting area is lower than that of the burn-out area; the top of the burn-out area is connected with a synthesis gas reforming area through a throat opening; plasma torches are arranged in both the ash melting area and the synthesis gas reforming area. According to the plasma auxiliary-heating melting and gasifying reactor disclosed by the invention, the plasma torches are used as a high-quality external heat source for melting the ash generated after pyrolysis and gasification for household garbage, and the gasified synthesis gas is reformed, thus removing all harmful substances which are possibly generated by the household garbage in pyrolysis and gasification processes, reducing the one-time investment cost and operation cost of garbage plasma gasification, and enabling the synthesis gas to be purer.

Owner:中国东方电气集团有限公司

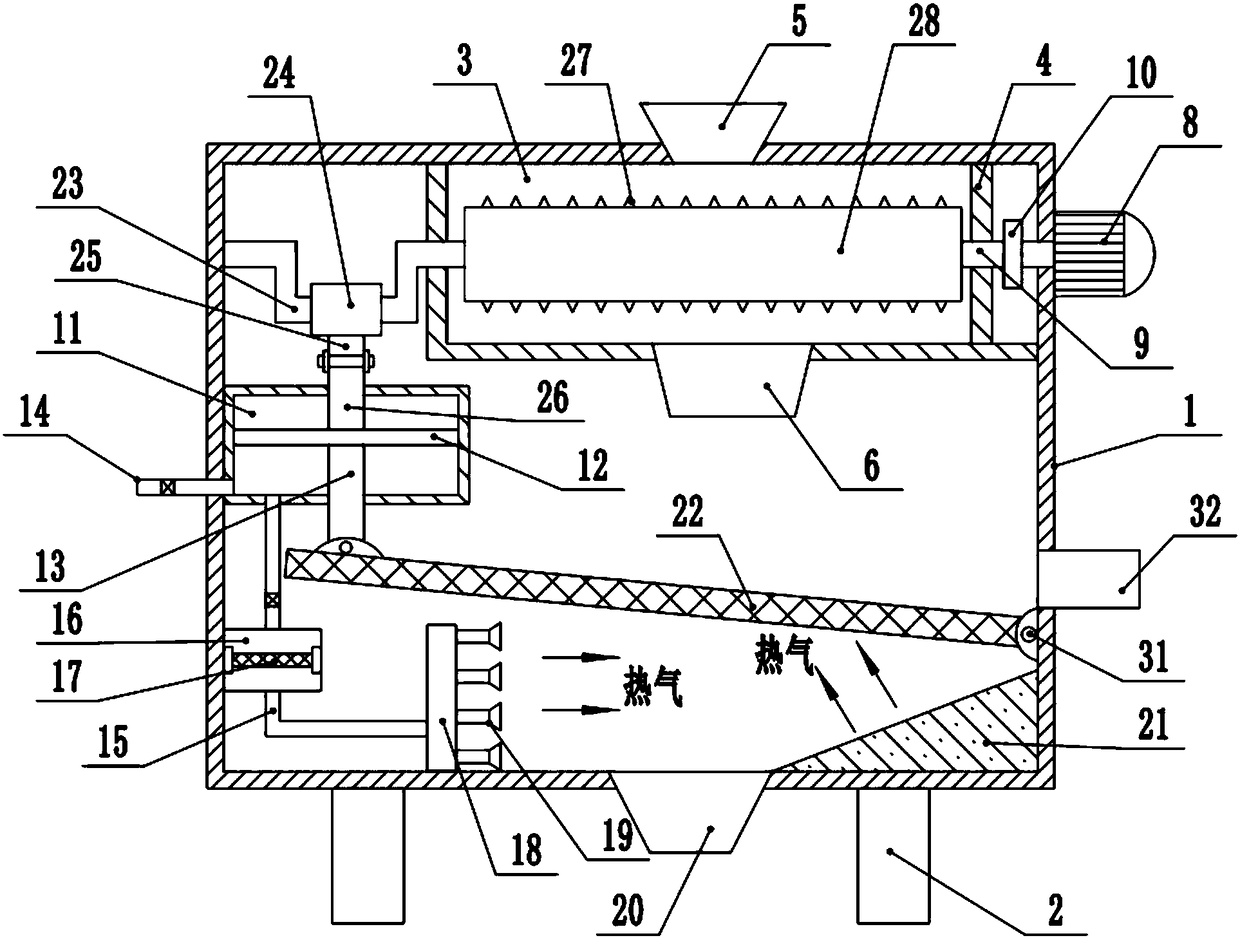

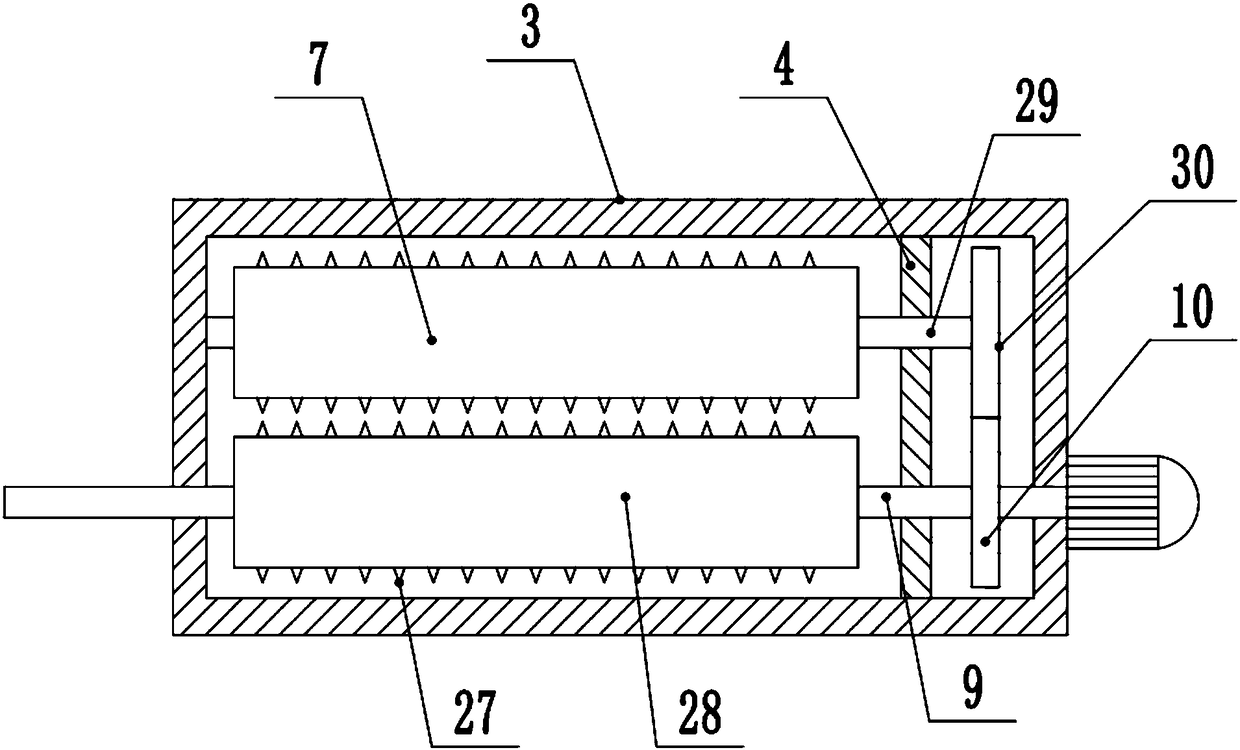

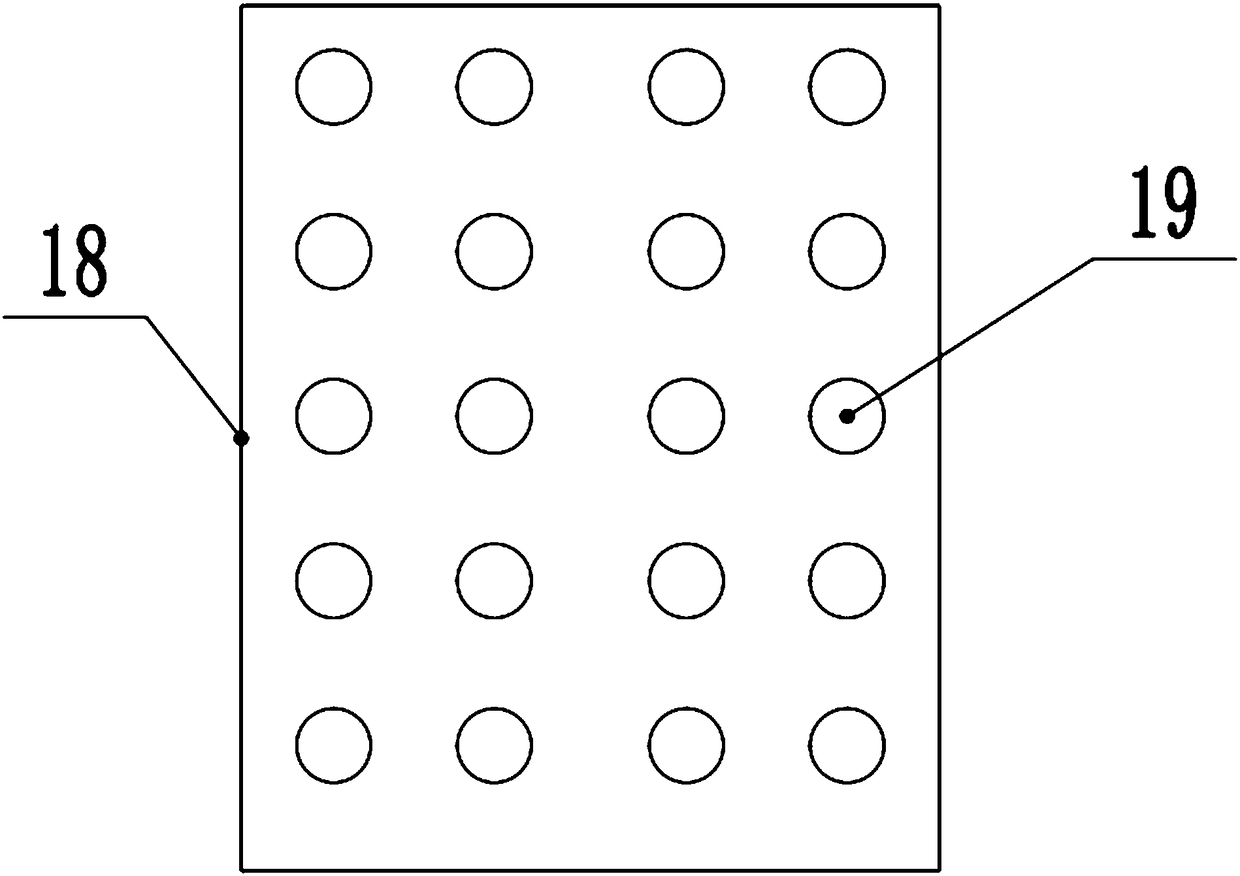

Fruit/vegetable drying device and working method thereof

InactiveCN102697154AAchieve dryingOmni-directional dryingFood treatmentProcess engineeringCounter rotation

The invention discloses a fruit / vegetable drying device and a working method thereof. With the fruit / vegetable drying device and the working method thereof, more fruit / vegetable windswept area is provided, the drying effect is better, the temperature at a baking area is uniform, and temperature jump can be avoided during the humidity elimination, so that the product quality is ensured. The fruit / vegetable drying device comprises a box body and a bidirectional circular drying system, wherein a baking area and a heating area are formed in the box body; a separation plate is arranged between the baking area and the heating area; an upper air vent is arranged at the top of the separation plate and a lower air vent is arranged at the bottom; a heating device and an air feeding device are arranged in the heating area; the bidirectional circular drying system comprises a counter-rotation circulating fan which is arranged in the heating area and located above the heating device; and the upper air vent, the counter-rotation circulating fan, the heating device and the lower air vent are communicated in sequence. The fruit / vegetable drying device provided by the invention is capable of ensuring that the temperature at each point in the baking area is more even.

Owner:扬州福尔喜果蔬汁机械有限公司

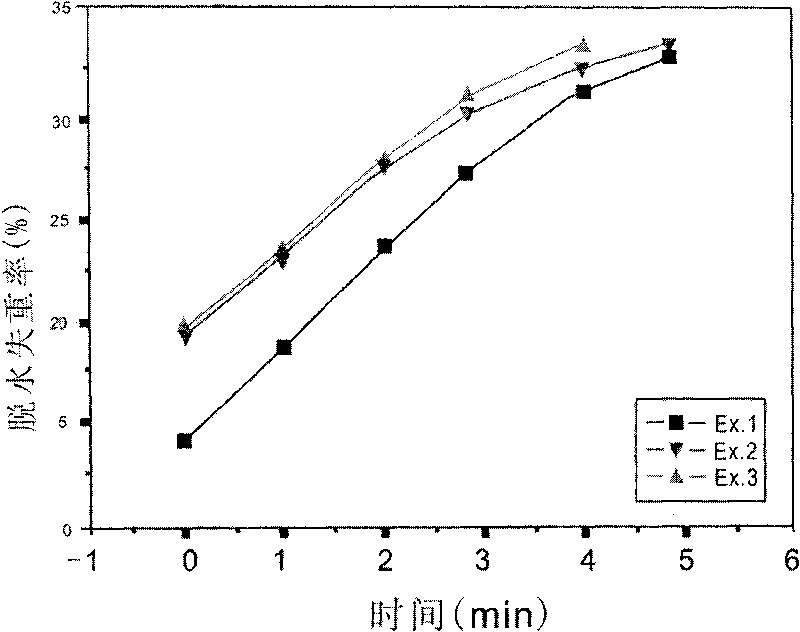

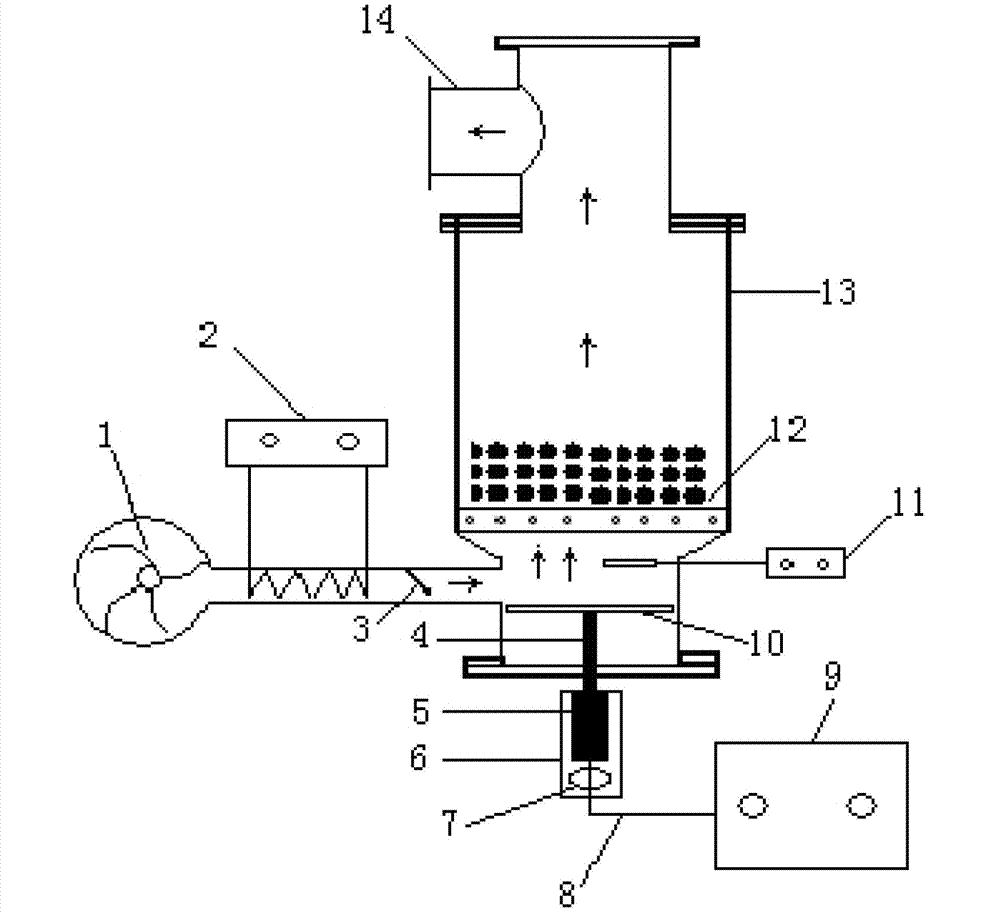

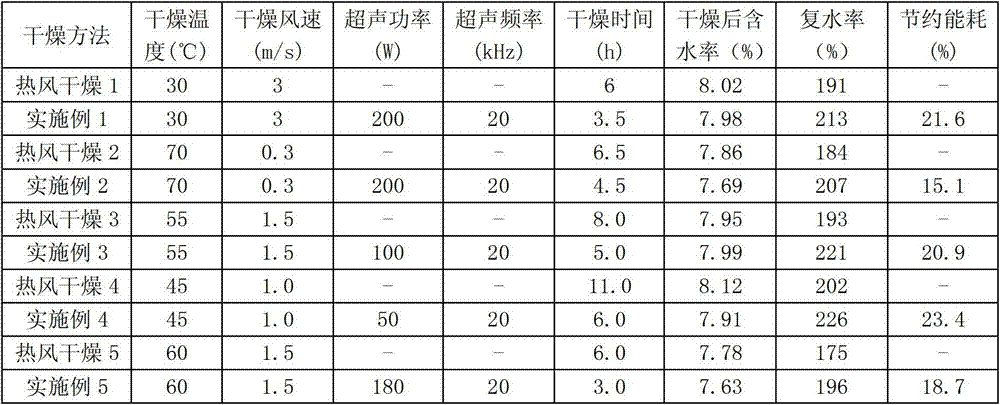

Ultrasonic and hot air combined carrot drying method and ultrasonic and hot air combined drying device

InactiveCN103109919AChange traitsIncrease the gapFood processingFruits/vegetable preservation by dehydrationProcess engineeringUltrasonic irradiation

The invention discloses an ultrasonic and hot air combined carrot drying method and an ultrasonic and hot air combined drying device. The ultrasonic and hot air combined carrot drying method comprises the following steps of: (1) pretreatment of a carrot raw material, namely washing and slicing fresh carrots; and (2) ultrasonic and hot air combined drying, namely, putting carrot slices on a sieve, sequentially starting a heating and blowing device and an ultrasonic irradiation device, and carrying out ultrasonic and hot air combined drying on the carrot slices, wherein the drying temperature is 30-70 DEG C, the drying air speed is 0.3-3m / s, the ultrasonic power is 100-200W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the sieve is 5-15cm and the drying time is 3-6 hours. According to the ultrasonic and hot air combined carrot drying method, an ultrasonic technology is directly and effectively coupled to a hot air drying process, so that the heat transfer and mass transfer efficiencies in the drying process are improved, the drying time is shortened, the energy consumption is saved and the product quality is improved.

Owner:HENAN UNIV OF SCI & TECH

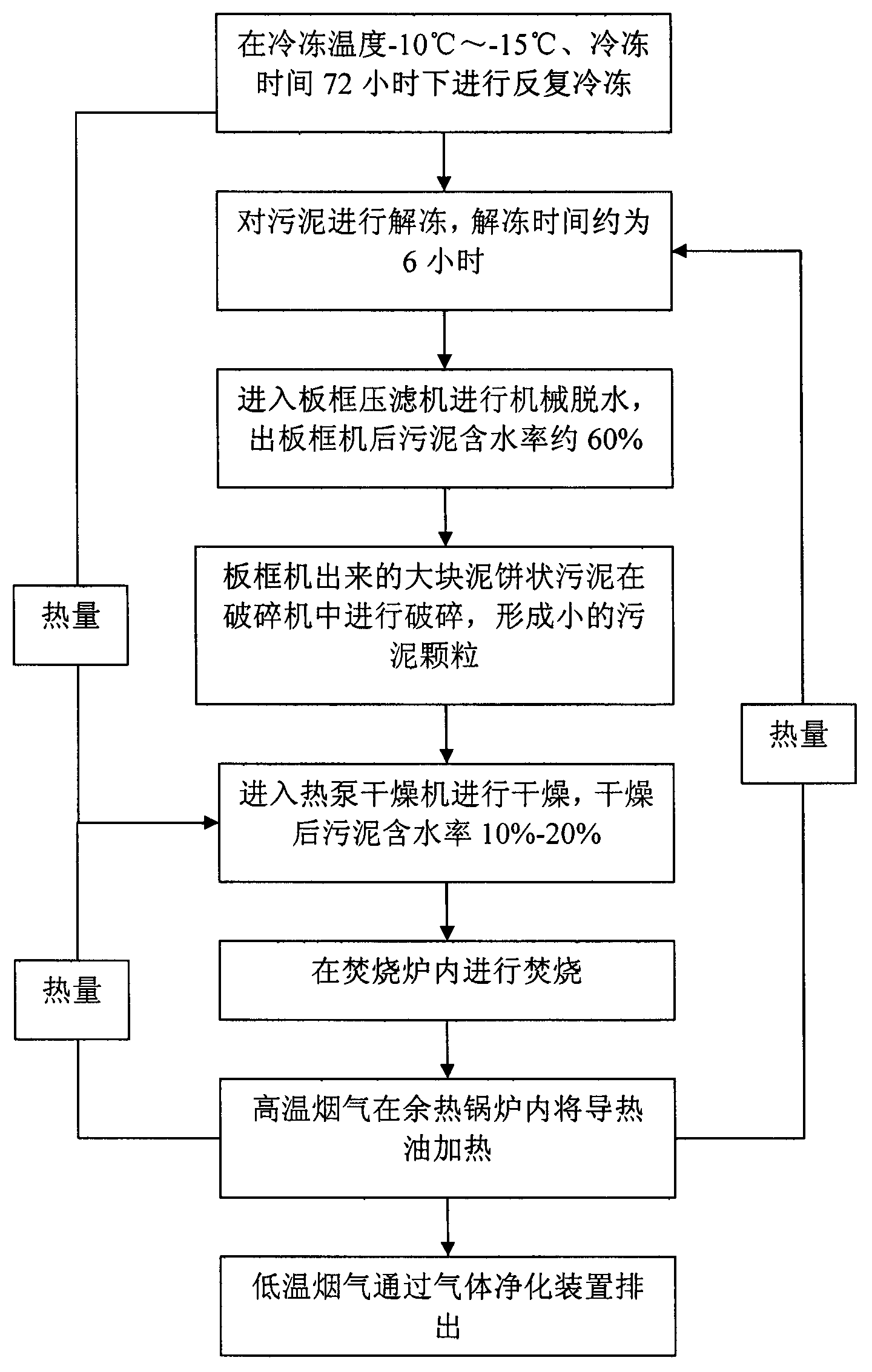

Sewage sludge advanced treatment method

InactiveCN104098242AAchieve dryingDoes not increase throughputSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWaste heat recovery unitPlate heat exchanger

The invention discloses a sewage sludge advanced treatment method which is based on a sewage sludge advanced treatment device. The sewage sludge advanced treatment device comprises a sludge freezing container, a freeze drying energy circulating system and a waste heat recovery device. The freeze drying energy circulating system comprises a compressor, an evaporator, a condenser and a first heat exchanger arranged in the sludge freezing container. The air outlet end of the compressor is connected with the condenser, the condenser is connected with the evaporator through a throttling element, and the evaporator is connected with the air inlet end of the compressor through the first heat exchanger. The waste heat recovery device comprises a waste heat boiler and a heat conduction oil pipe arranged in the waste heat boiler, the heat conduction oil pipe is connected with a second heat exchanger, oil conduction oil enters the second heat exchanger to transfer heat to air, and the air heated is respectively conveyed to a drying device and the sludge freezing container to be used for sludge drying and unfreezing. According to the sewage sludge advanced treatment method, the sludge treatment amount is not increased in the treatment process, and recycling of working medium energy improves sludge freezing efficiency and heat utilization rate.

Owner:CHINA JILIANG UNIV

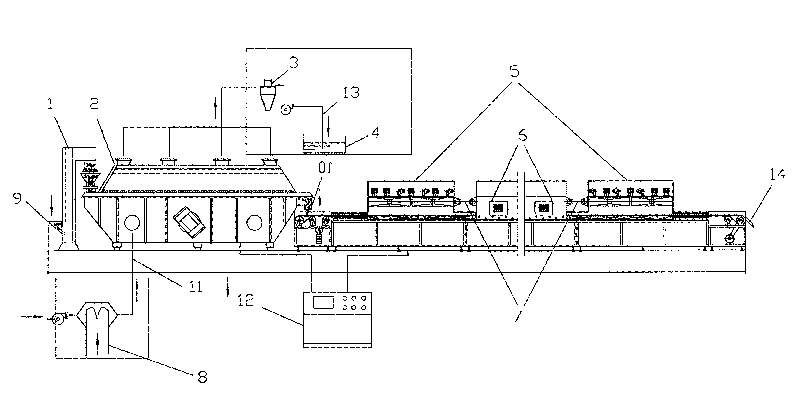

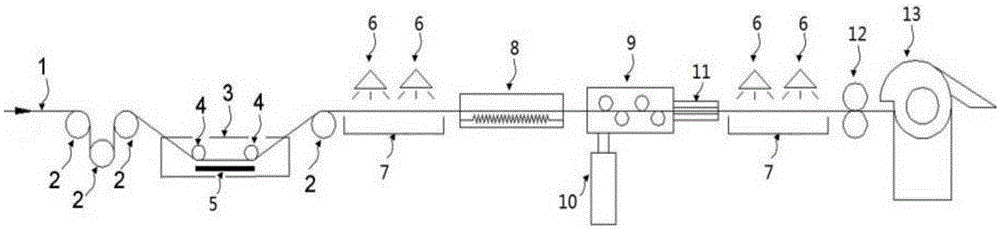

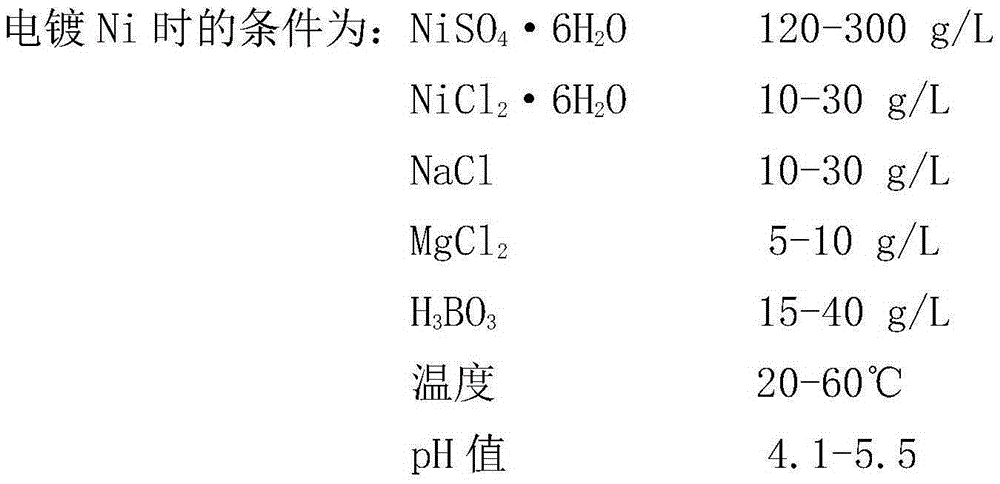

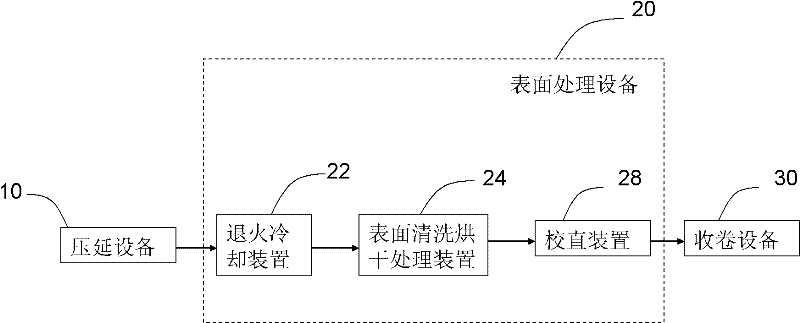

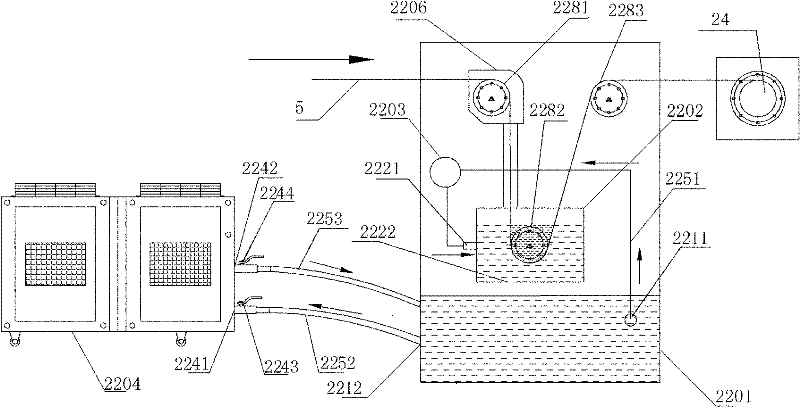

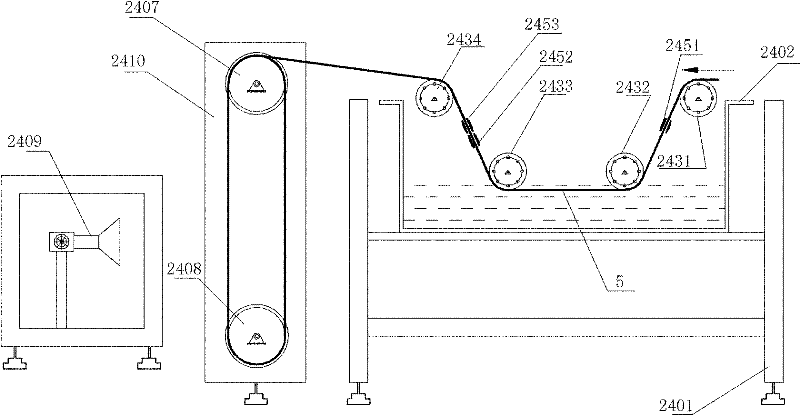

Copper base belt surface treatment device of solar photovoltaic welding belt and processing method thereof

InactiveCN102479880AAchieve cleaningSimple structureFinal product manufactureSemiconductor devicesProduction lineSurface cleaning

The invention discloses a copper base belt surface treatment device of a solar photovoltaic welding belt. The device can be used in a solar photovoltaic welding belt production line and installed behind rolling equipment and in front of rolling-up equipment. The device comprises an annealing and cooling device, a surface cleaning and drying processing device and a straightening device. The invention also discloses a processing method using the copper base belt surface treatment device. According to the processing method, the copper base belt is rolled by the rolling equipment and then annealed and cooled by the annealing and cooling device; the copper base belt after being annealed and cooled enters into the surface cleaning and drying processing device for surface cleaning and drying; the copper base belt after being cleaned and dried enters into the straightening device for improving the straightness; and the copper base belt after being straightened enters into the rolling-up equipment for rolling up. By adopting the device and the method, wires can be cleaned in real time, weldability of the copper base belt can be improved, tinplating rejection rate caused by the poor surfacequality of the copper belt can be reduced and the problems such as the poor straightness of the copper base belt and the like can be solved.

Owner:BRUKER SPALECK SOLAR TECH TAICANG

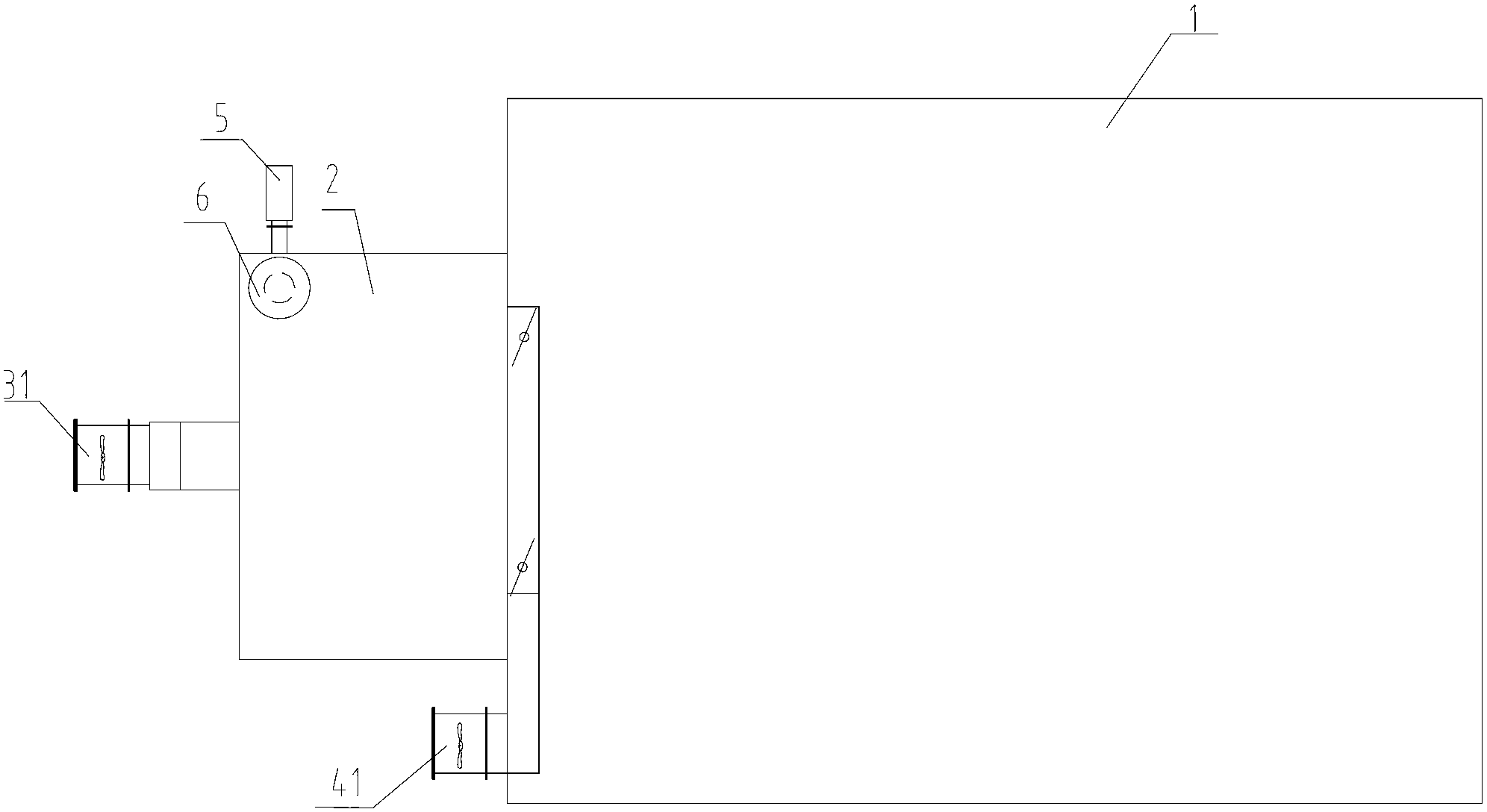

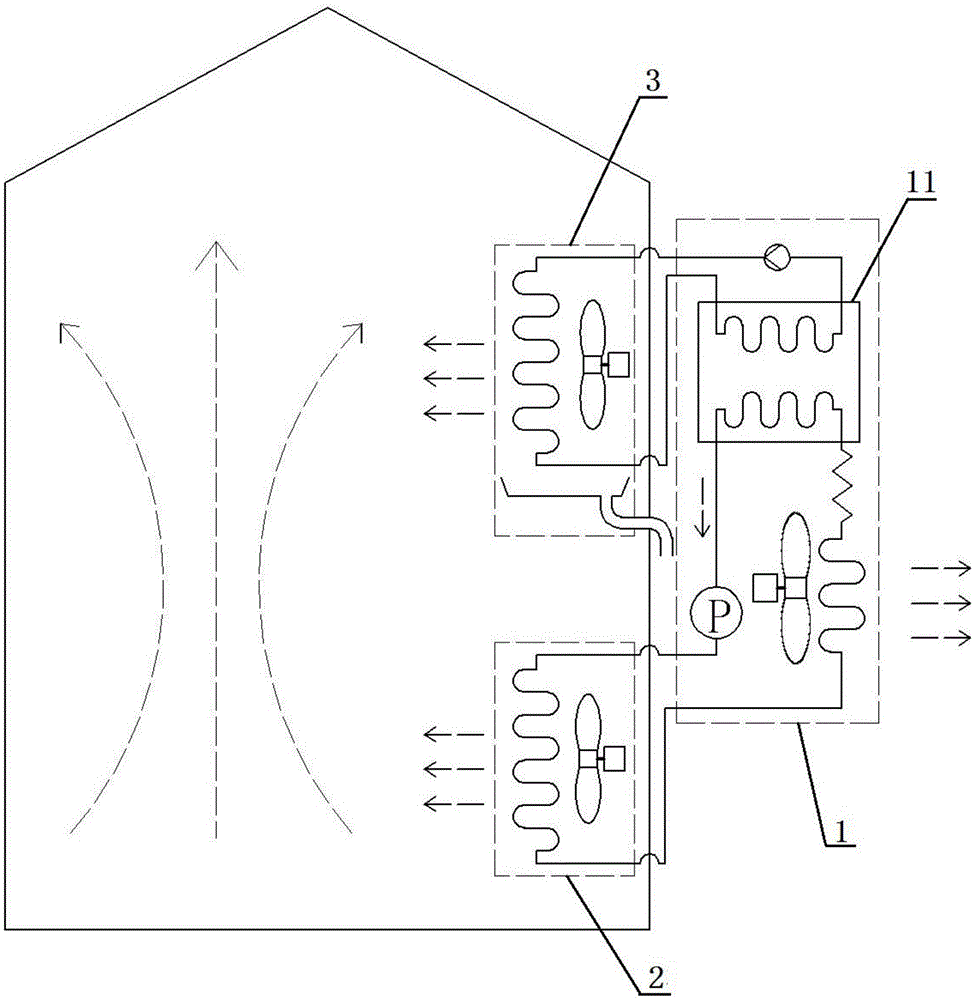

Dehumidifying house

ActiveCN105546940AAchieve dryingTea dryingCompression machines with several condensersCold airCoolant flow

The invention relates to a dehumidifying house. The dehumidifying house mainly comprises a house and a drier. A heating fan inhales air in the house, and the air is blown over a first condenser, so that water in articles enters the air to become hot humid air; a coolant flows back into a second condenser and a throttle in a main machine to be further cooled, and then the cooled coolant enters a third condenser in a cold storage box; the coolant in the third condenser flows back to a compressor to be squeezed into a high-temperature high-pressure coolant, and then the high-temperature high-pressure coolant flows back to a heating machine, so that cold storage fluid in the cold storage box is kept within a preset temperature range; a fourth condenser soaked in the cold storage fluid in the cold storage box is affected by the cold storage fluid to be cooled; the cooled coolant in the fourth condenser is conveyed to an evaporator through a high-pressure pump; a condensing fan inhales the indoor hot humid air which is blown to the evaporator, water in the hot humid air is separated out to downwards drop into a water pan under the evaporator, dry cold air is blown out from a condensing machine, and after the temperature of a cold drive of the evaporator rises, the dry cold air flows back to the fourth condenser, and then is cooled by the cold storage fluid to flow to the evaporator.

Owner:李耀强

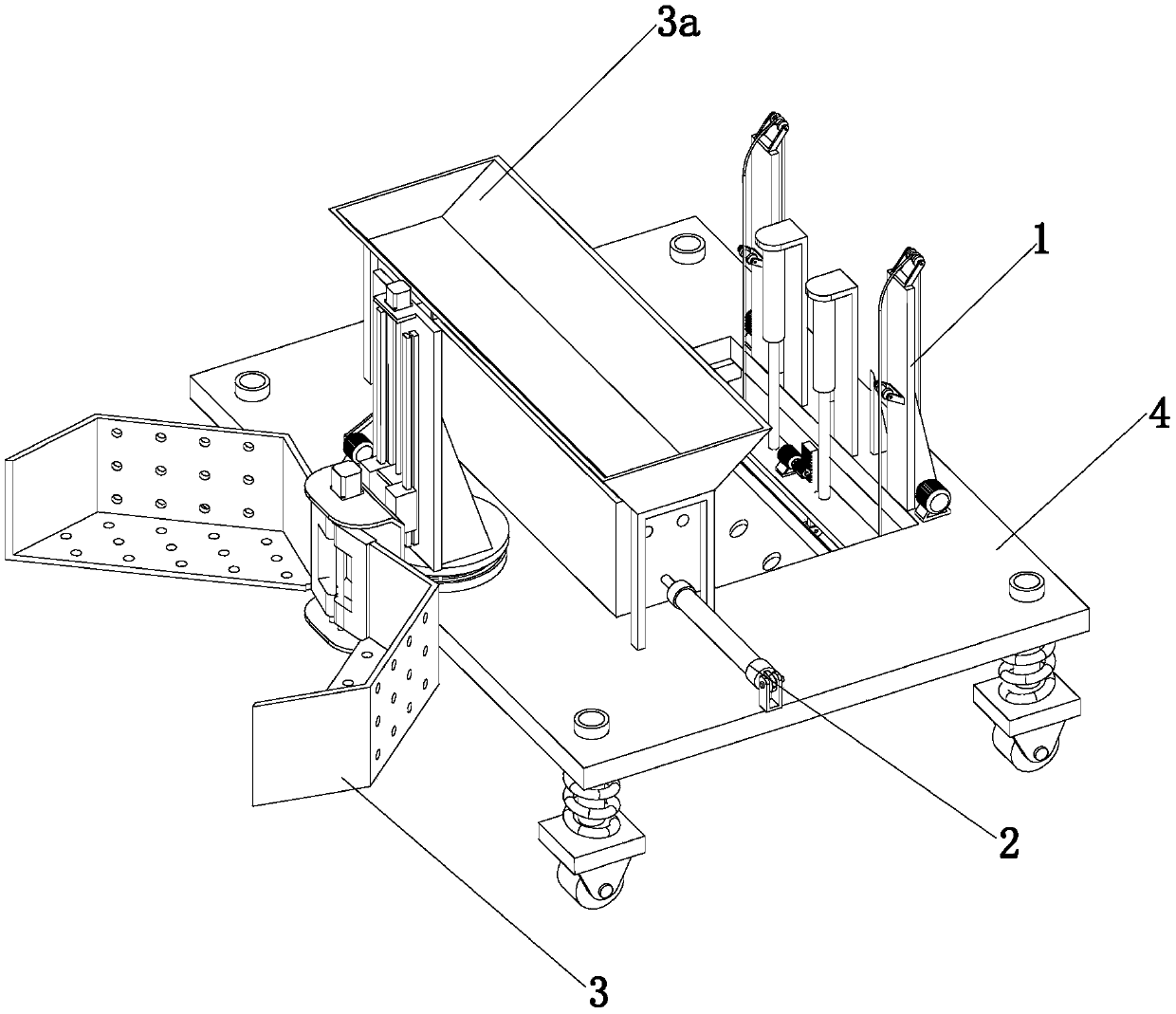

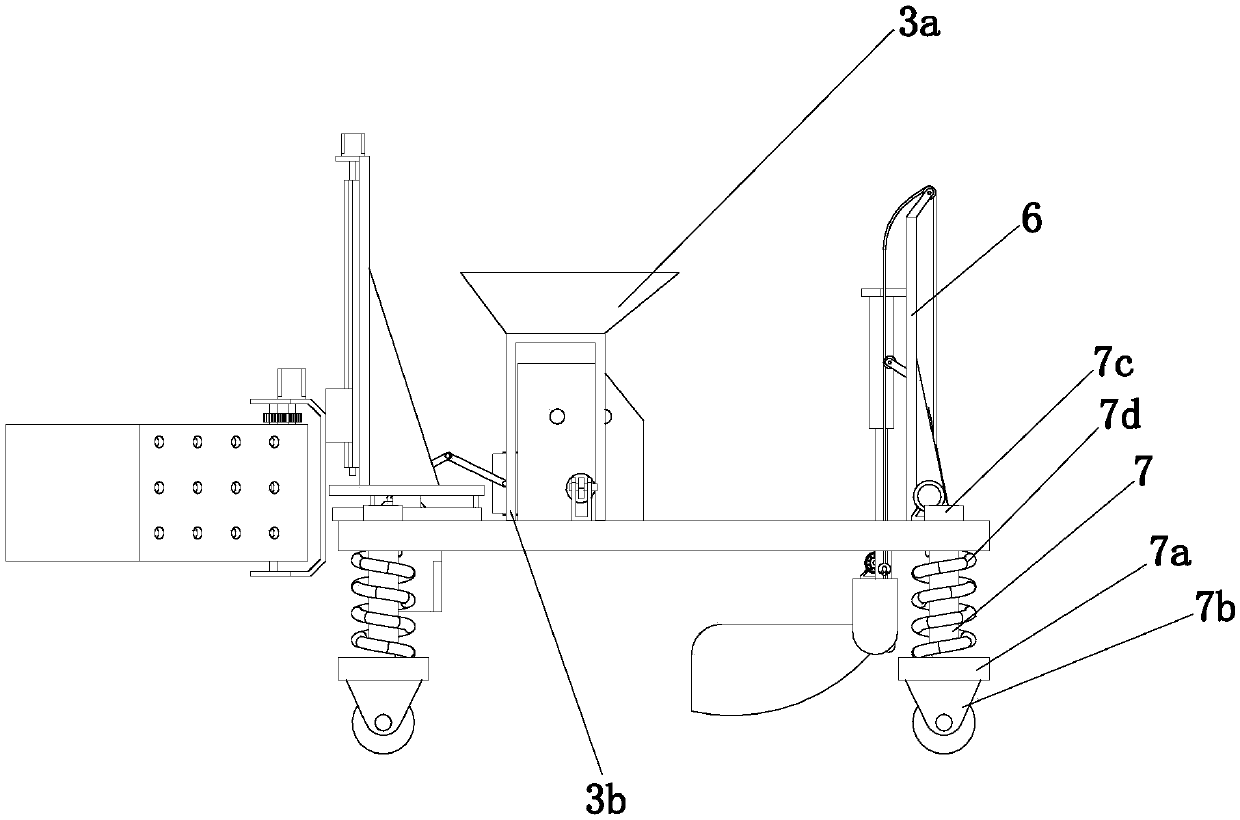

Silt cleaning device for watercourse treatment in municipal engineering

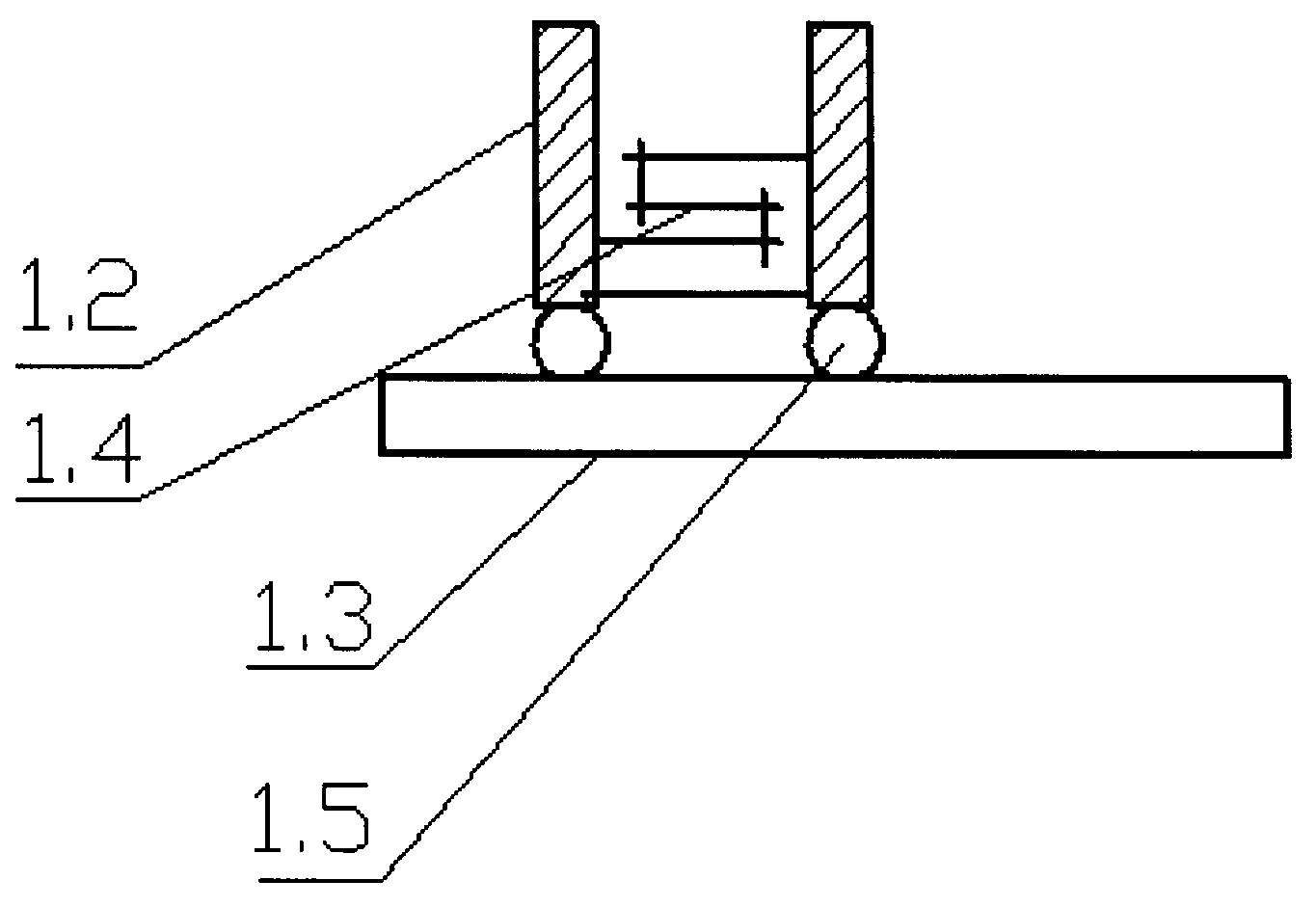

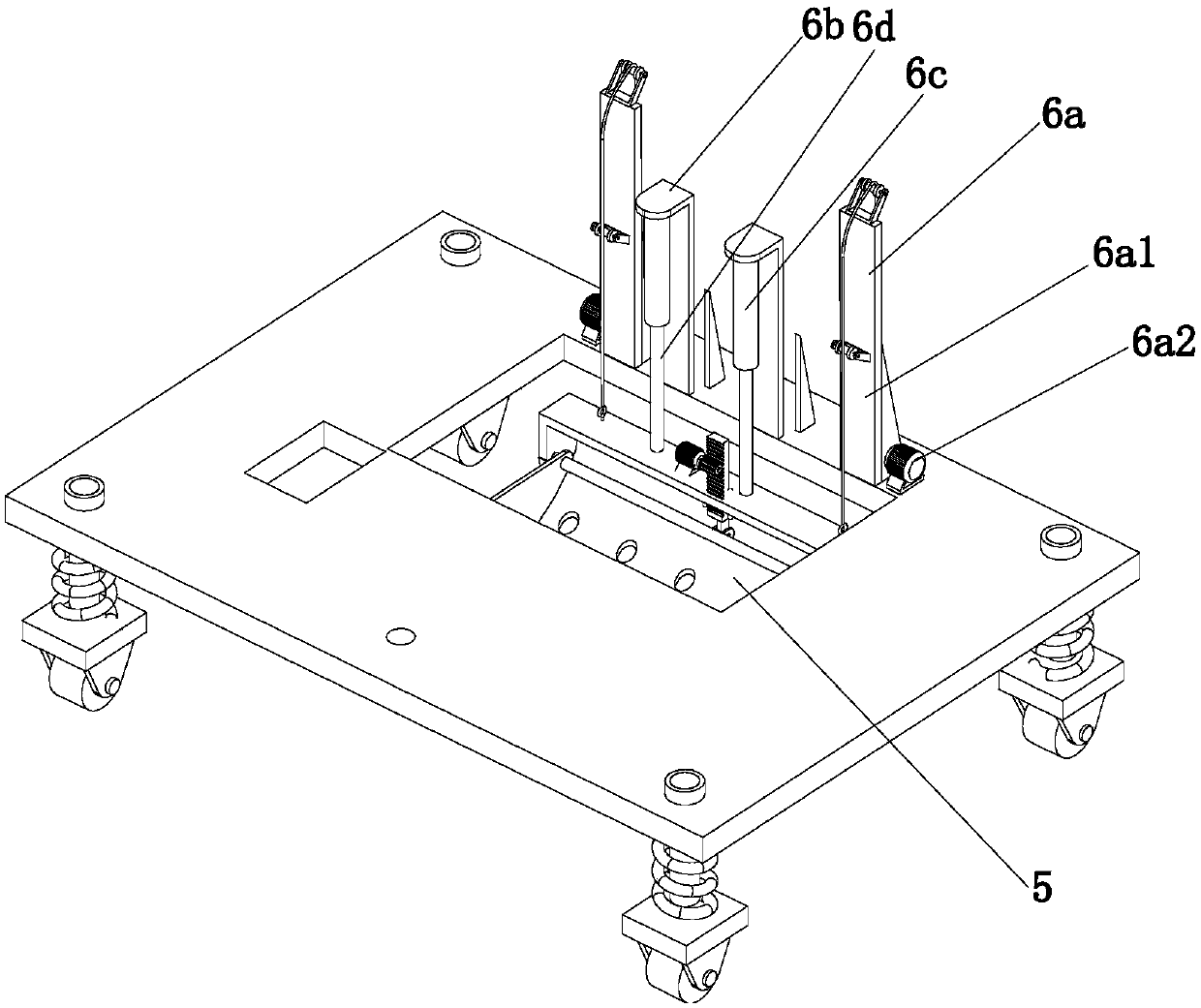

ActiveCN109098158AAvoid the hassle of follow-up processingAutomatically realize the lifting operationWater cleaningSoil-shifting machines/dredgersEngineeringSilt

The invention relates to the technical field of municipal machinery, in particular to a silt cleaning device for watercourse treatment in municipal engineering. The silt cleaning device for the watercourse treatment in the municipal engineeringcomprises a silt dredging mechanism, a silt treatment mechanism, a floating mattercollecting mechanism and a bottom plate arranged horizontally. The bottomplate is of a cuboid structure, and the silt dredging mechanism comprises a silt collecting assembly and a lifting assemblywhich is used for driving the silt collecting assembly to rise and fall. Thesilt collecting assembly comprises a U-shaped connecting plate and a rotary shaft. The rotary shaft is provided with an open upward dredging box in a sleeving mode. The silt cleaning device for the watercourse treatment in the municipal engineering has the beneficial effects that the dredging operation of watercourse silt can be realized automatically by the silt dredging mechanism, the drying andcrushing operations of the silt can be realized automatically by the silt treatment mechanism,the automatic collecting operation of floating matter can be realized by the floating matter collecting mechanism, manual dredging by workers is not required, and the work efficiency of municipality is improved.

Owner:义乌市富顺箱包有限公司

Feed for breeding cows

InactiveCN107373114AReduce the amount of solutionPromote absorptionFeeding-stuffFood processingAgricultural scienceFogera cattle

The invention belongs to the technical field of feed processing, and discloses a feed for breeding cows. The feed contains the following raw materials: corn, bean pulp, barley, hay, sorghum, fish meal, soybean, bean dregs, colza oil, lactic acid bacteria, salt, pericarpium citri reticulatae and hawthorn; a preparation method of the feed comprises the following steps: primary processing, grinding and mixing, feed palletization, packaging and sealing for storage. The feed solves the problems that the existing feed in the prior art can cause bloating in rumen of cows after being fed.

Owner:贵州万牛牧业科技发展有限公司

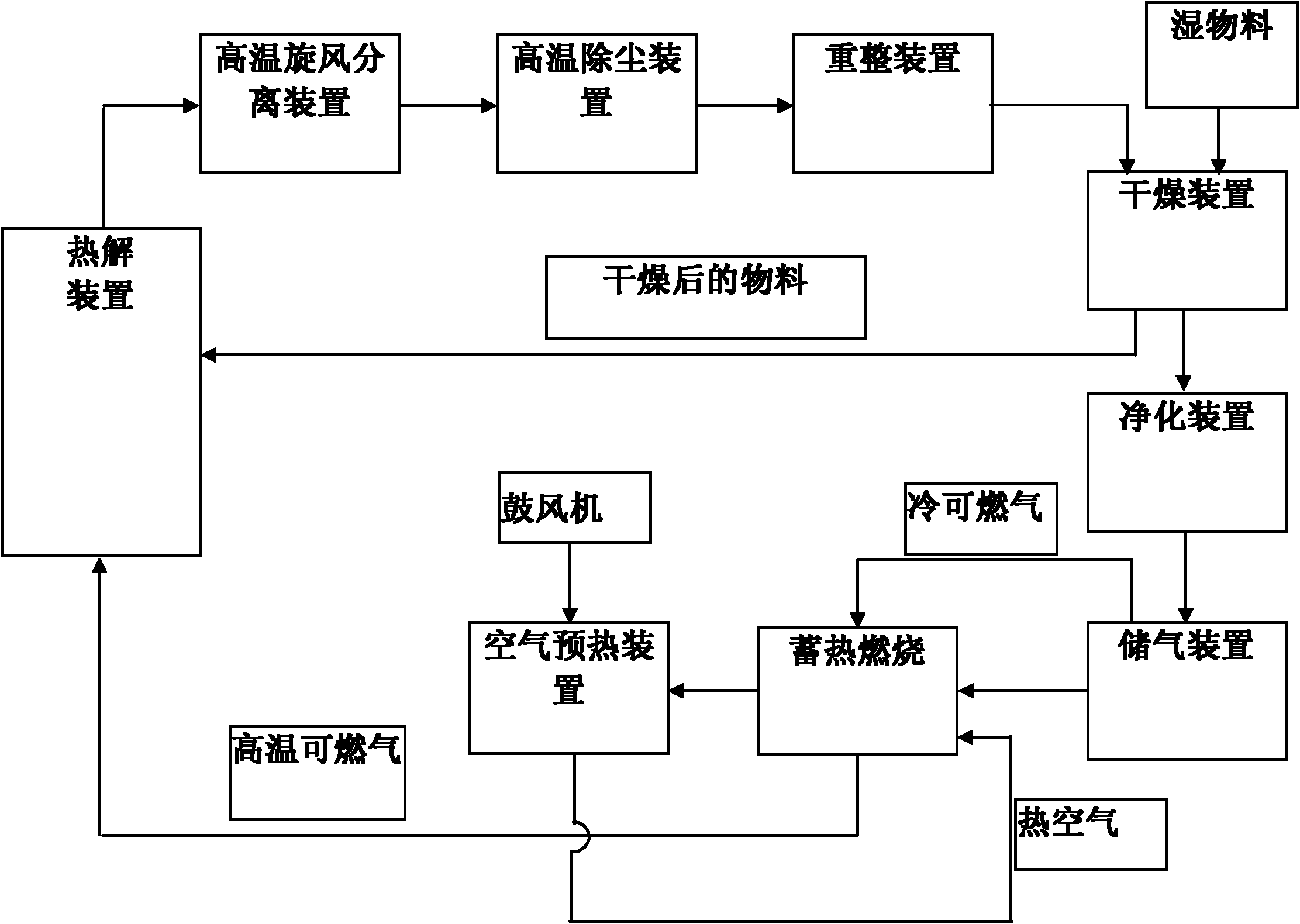

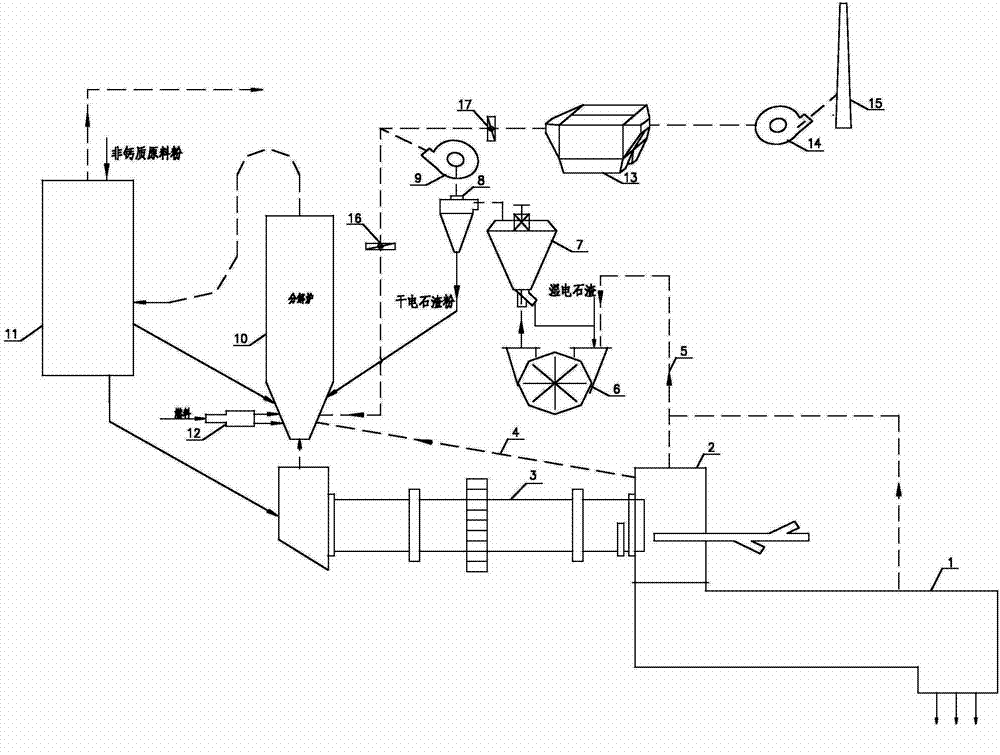

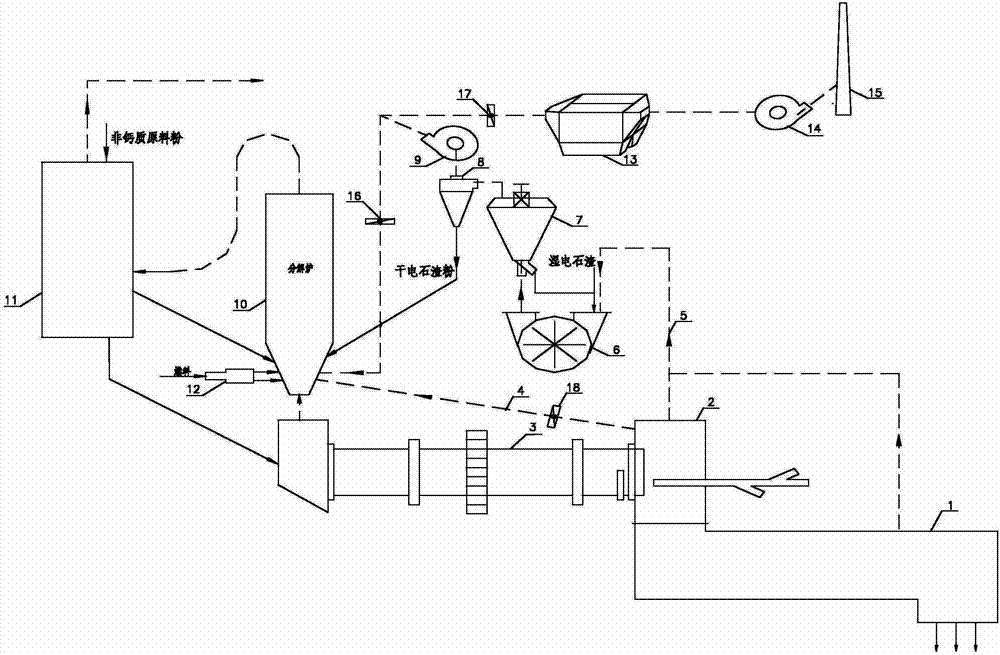

System for drying and decomposing wet acetylene sludge and firing cement clinker by using wet acetylene sludge as calcium raw material

The invention provides a system for drying and decomposing wet acetylene sludge and firing cement clinker by using the wet acetylene sludge as a calcium raw material. The system is characterized in that hot air drawn off from a clinker cooler and / or a kiln head cover is mixed in an air collecting pipe, then enters a drying crusher, exchanges heat with the calcium raw material fed into the drying crusher, finally passes through a powder concentrator, a cyclone dust collector and an exhaust gas draught fan and enters the bottom of a decomposing furnace for burning of fuel in the decomposing furnace; the calcium raw material is dried by hot air in a kiln head and subjected to powder concentration, then is directly and separately fed into the decomposing furnace and decomposed in the decomposing furnace, and finally is converged with non-calcium raw material powder preheated by a preheater system in the decomposing furnace, the calcium raw material and the non-calcium raw material powder enter a rotary kiln together so as to fire the cement clinker, and all the calcium raw material is the wet acetylene sludge. The system has the advantages that the wet acetylene sludge and the carbon dioxide reaction mechanism are fully combined, hot air mainly comprising nitrogen and oxygen is used as a drying hot source, and the acetylene sludge and the carbon dioxide are effectively prevented from being synthesized into calcium carbonate, so that the decomposition temperature and decomposition heat of calcium hydroxide are reduced.

Owner:NANJING KISEN INT ENG

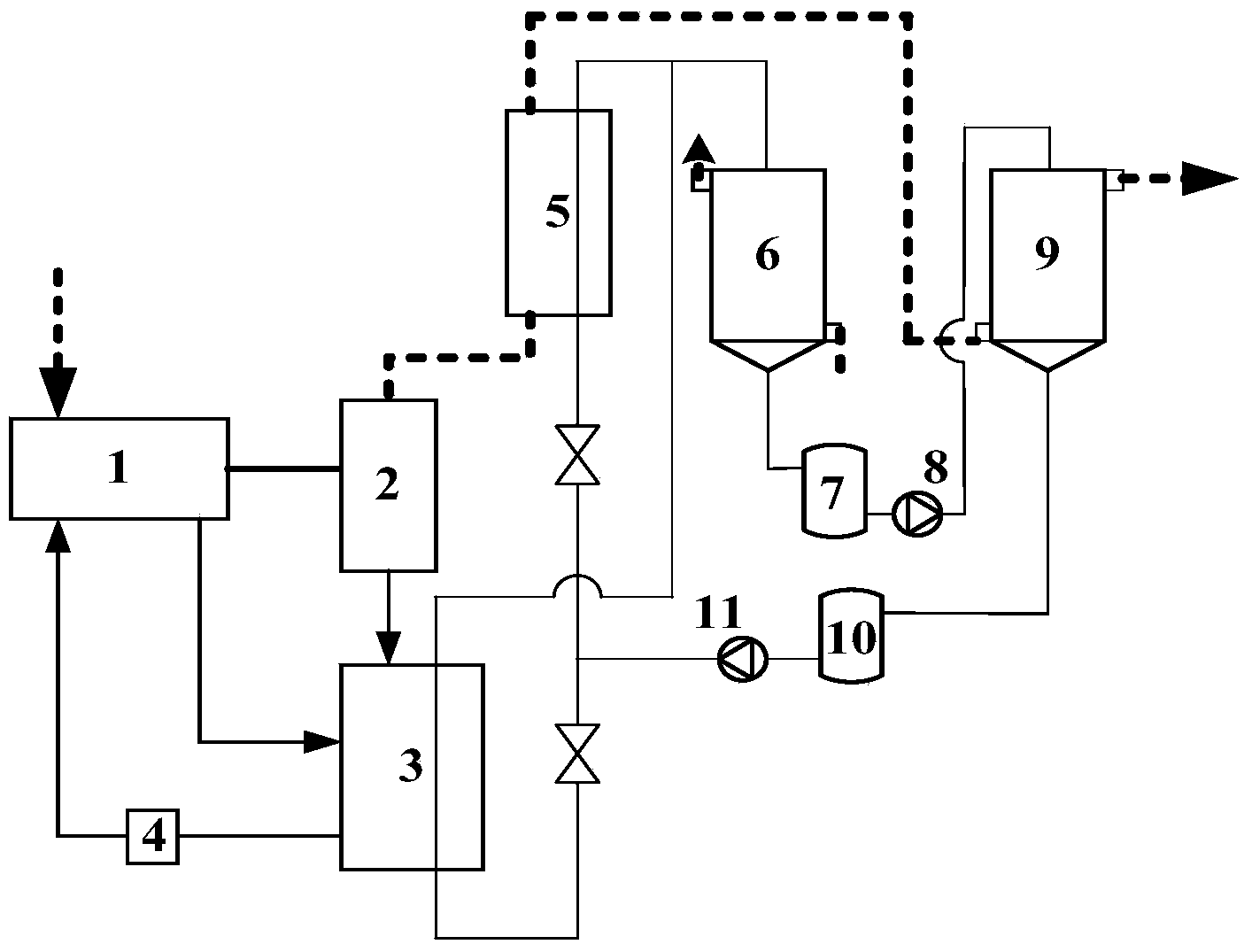

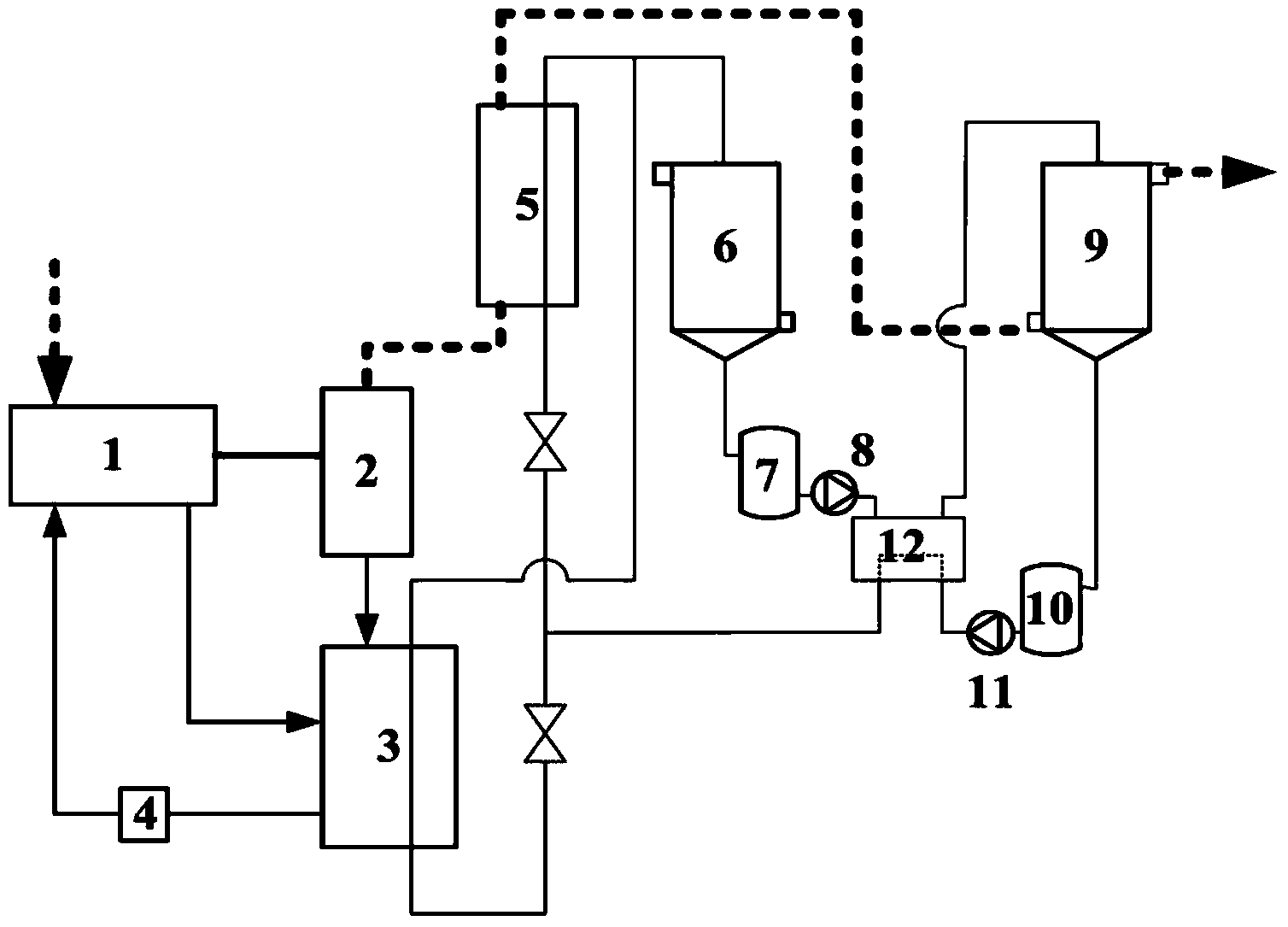

Gas drying apparatus removing heat by utilizing compressor and method

InactiveCN103657356AIncrease profitAchieve dryingDispersed particle separationRecuperatorProcess engineering

The invention discloses a gas drying apparatus removing heat by utilizing a compressor and a method. The apparatus comprises the compressor (1), an oil-gas separator (2), a lubricating-oil heat recovery exchanger (3), an oil filterer (4), a compressor exhaust heat exchanger (5), a heat source regenerator (6), a solution storage tank (7), a concentrated solution pump (8), a dehumidifier (9), a dilute solution tank (10) and a dilute solution pump (11), wherein the gas outlet of the compressor (1) is connected with the inlet of the oil-gas separator (2), and the gas outlet of the oil-gas separator (2) is connected with the gas inlet of the compressor exhaust heat exchanger (5). The advantages comprise that the gas drying apparatus is capable of effectively recovering waste heat generated when an inflator runs, and the waste heat is utilized for drying processing of compressor exhausted gas and other gas resources, so that the compressor exhausted gas and other gas resources can satisfy the technological requirements; and the technology not only helps to reduce the consumption cost of energy, but also helps to reduce environmental pollution.

Owner:SOUTHEAST UNIV

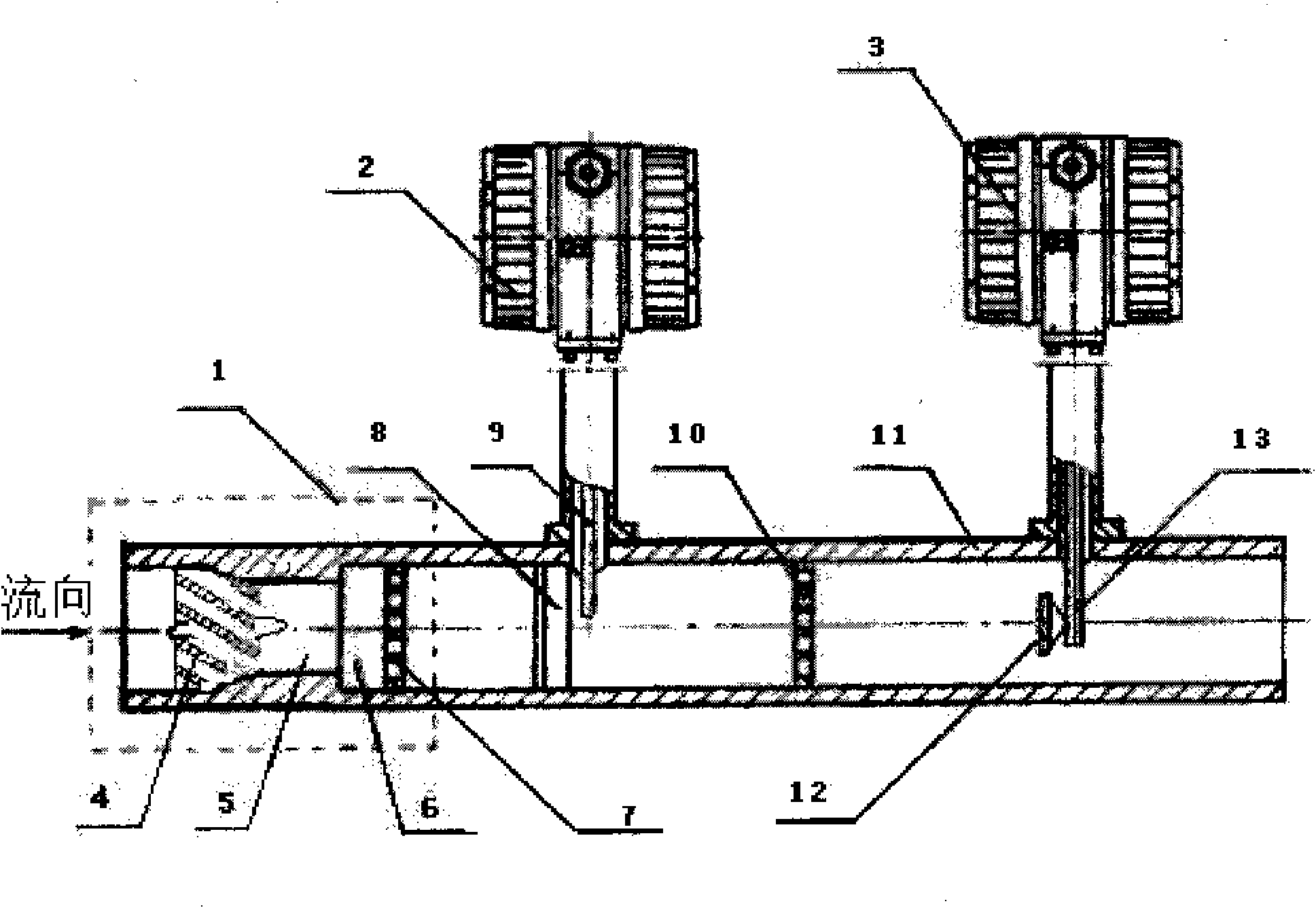

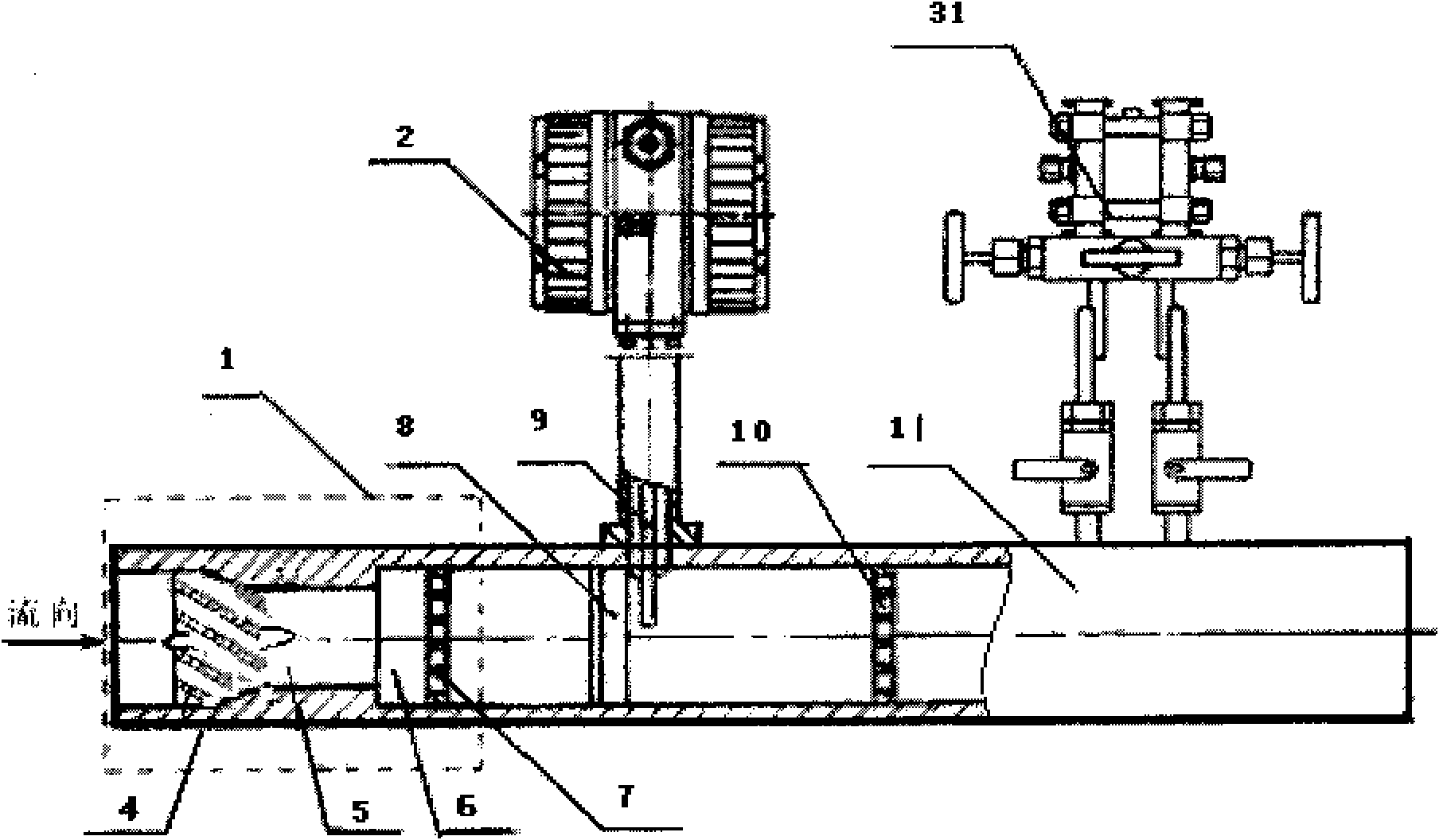

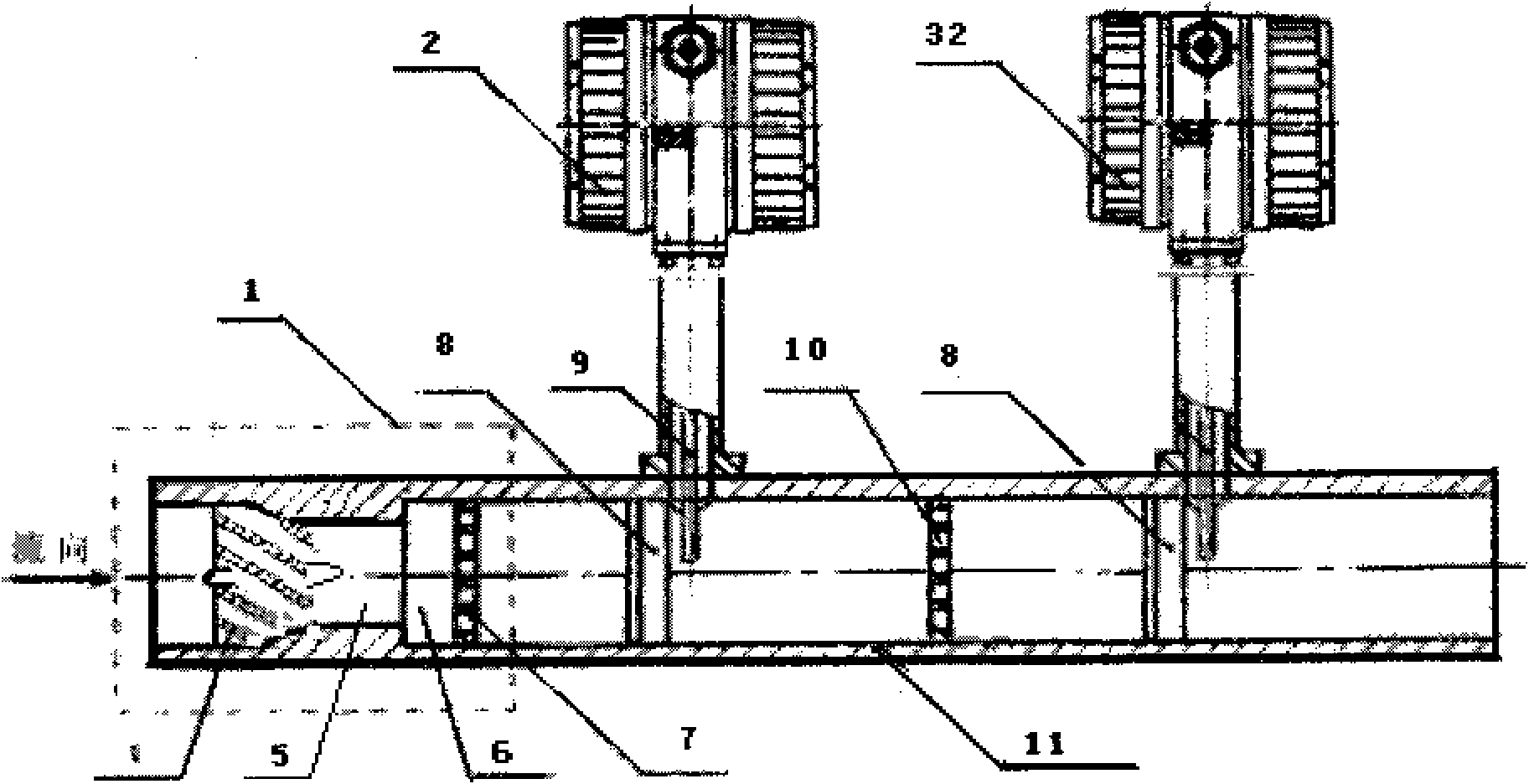

Composite mass flowmeter

InactiveCN101581589AAchieve dryingHigh densityIndirect mass flowmetersSpecific gravity measurementDifferential pressureEngineering

The invention relates to a composite mass flowmeter which comprises a pipeline meter body, a vortex flow sensor, a target flow sensor or a differential pressure flow sensor. The vortex street flow sensor for measuring a flow speed is used as a main body and mounted on the pipeline meter body, the vortex street flow sensor, the target flow sensor for measuring flow speed action force, or the differential pressure flow sensor for measuring flow differential pressure is mounted on the downstream of the pipeline meter body, and a multi-phase flow rectifying device is arranged on the upstream of the pipeline meter body. The invention utilizes the vortex street flow sensor to measure the flow speed, the target flow sensor to measure the flow speed action force or the differential pressure flow sensor to measure the flow differential pressure, and sensor signals are combined and collected, calculated and tabled by a microprocessor to measure the dryness, the density and the flow of fluid. The invention has reasonable structure, simple and convenient mounting and construction and high measurement precision and is particularly suitable for measuring the flow, the dryness and the density of two-phase or multi-phase fluid, thereby being an ideal measuring device for measuring fluid flow in a pipeline.

Owner:姚贤卿

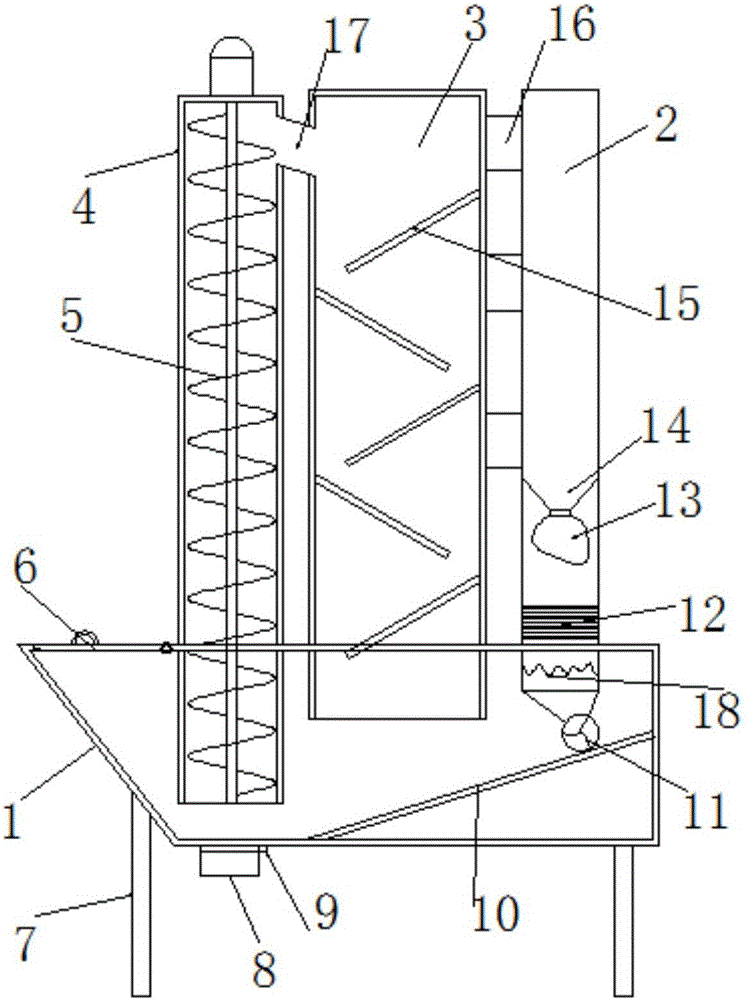

Environment-friendly and energy-saving type cereal drying, cooling and dust removing device

ActiveCN106403566AAchieve dryingAchieve dust removalFood processingDrying gas arrangementsEngineering

The invention discloses an environment-friendly and energy-saving type cereal drying, cooling and dust removing device. The environment-friendly and energy-saving type cereal drying, cooling and dust removing device comprises a box, a purifying barrel and a raise dust barrel. Landing legs are arranged on the two sides of the lower end of the box. A feeding barrel is arranged at the upper left end of the box and internally provided with a feeding packing auger. The lower end of the feeding barrel stretches into the box. The left end face of the box is an oblique face. An oblique material guiding plate with the low left part and the high right part is arranged in the part, on the right side of the feeding barrel, of the box. Through the arrangement of the oblique face and the oblique material guiding plate, materials are conveniently gathered to the position below the feeding barrel. A charging port and a charging cover plate located at the position of the charging port are arranged on the upper end face of the part, on the left side of the feeding barrel, of the box. The raise dust barrel is arranged at the upper end of the part, on the right side of the feeding barrel, of the box. The lower end of the raise dust barrel communicates with the box. A material guiding pipe is arranged between the upper end of the raise dust barrel and the feeding barrel. The left end of the material guiding pipe is higher than the right end of the material guiding pipe. A plurality of oblique raise dust plates are arranged in the raise dust barrel in a crossed manner. The environment-friendly and energy-saving type cereal drying, cooling and dust removing device is simple and reasonable in structure, energy saving and emission reduction are achieved, people can conduct drying and dust removal on cereal conveniently, and practicability is high.

Owner:绍兴上虞国风风机制造有限公司

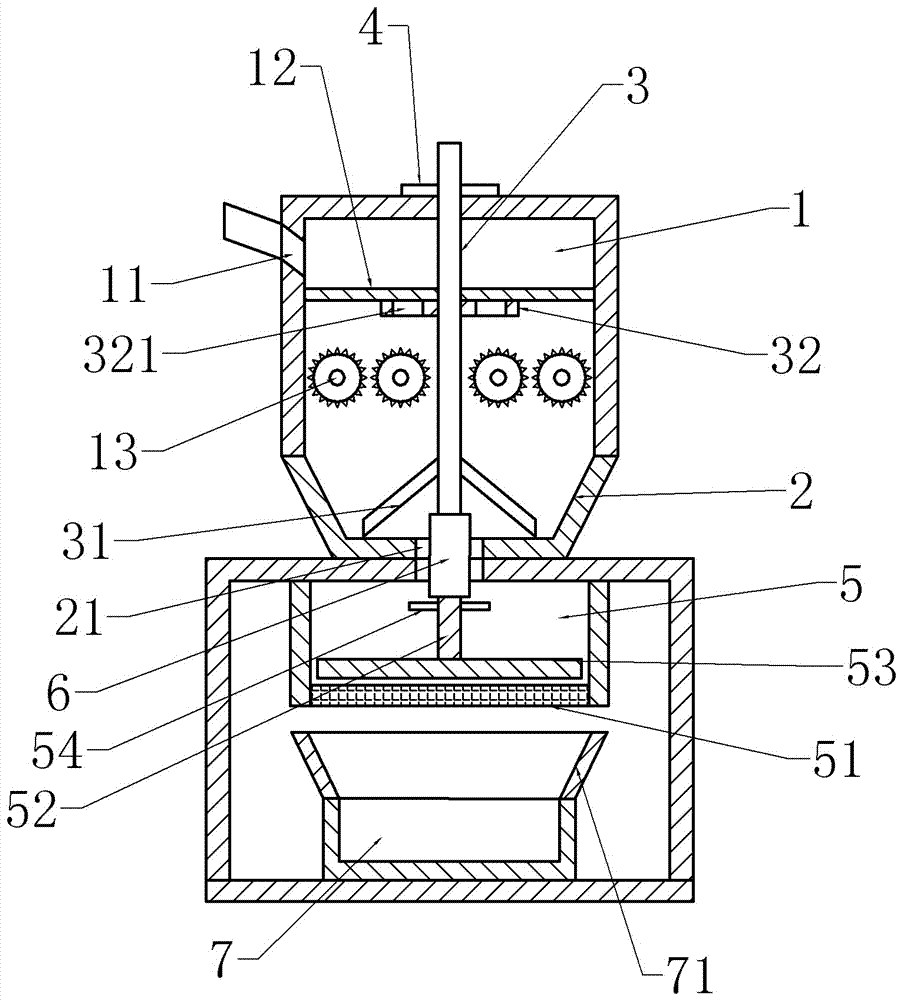

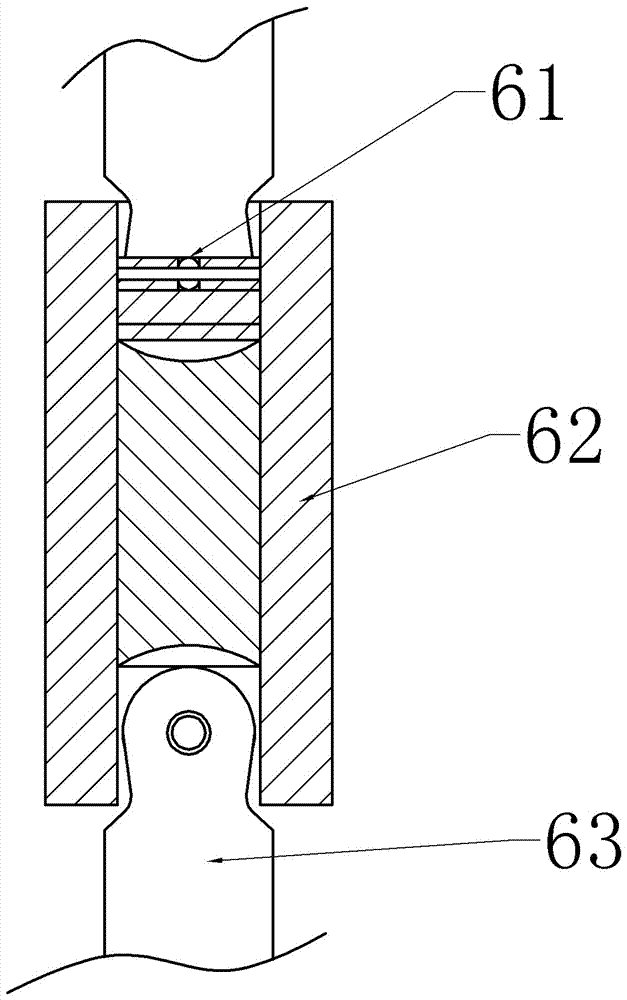

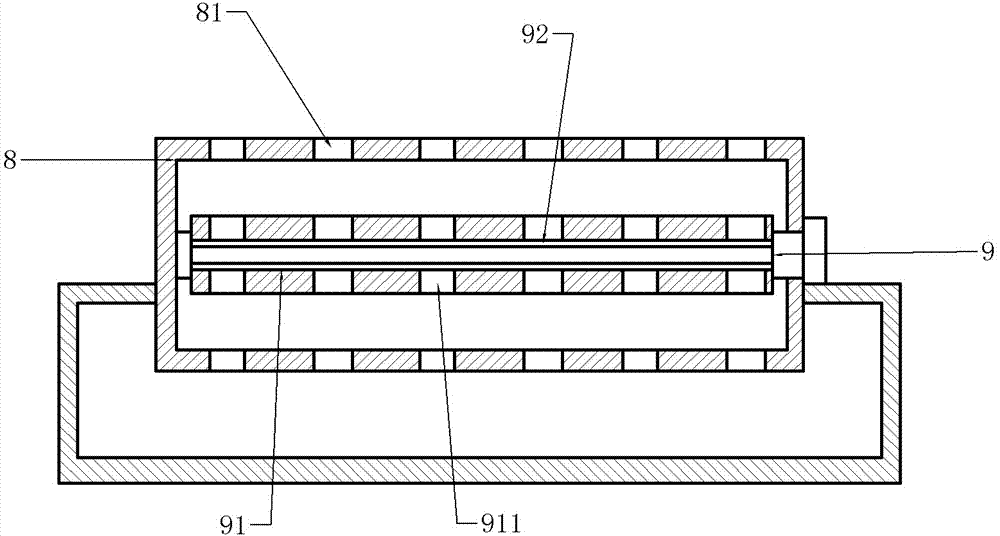

Crank type crushing, sieving and drying integrated device for seaweed polysaccharide extraction

The invention discloses a crank type crushing, sieving and drying integrated device for seaweed polysaccharide extraction; the device includes a treatment box; a crushing box is arranged on the rightside of the upper end of the treatment box, a driving shaft is arranged inside the crushing box, and a driving roller is arranged in the middle of the driving shaft; the right end of the driving shaftpasses through a separation plate and is connected with a driving gear; the back end of the driving gear is meshed with a driven gear; the left end of the driven gear is connected with a driven shaft; a driven roller is arranged in the middle of the driven shaft; the left end of the driving shaft passes through the left wall of the crushing box and is provided with a crank; a lifting sleeve is arranged in the middle of the crank; a connecting rod is connected at the lower end of the lifting sleeve; a piston rod is connected at the lower end of the connecting rod; a piston plate is connected at the lower end of the piston rod; a lifting rod is connected in the middle of the lower end of the piston plate; the right end of a swing sieve is hinged at the inner wall of the right end of the treatment box through a hinge; an air-induced box is arranged on the outer side of the piston plate. The crank type crushing, sieving and drying integrated device for seaweed polysaccharide extraction satisfies the integrative needs of crushing, sieving and drying in the pretreatment of seaweed polysaccharide, and only one power source is arranged in the whole device, so as to further reduce the processing cost.

Owner:吴芊葭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com