Patents

Literature

47results about How to "Improve coal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

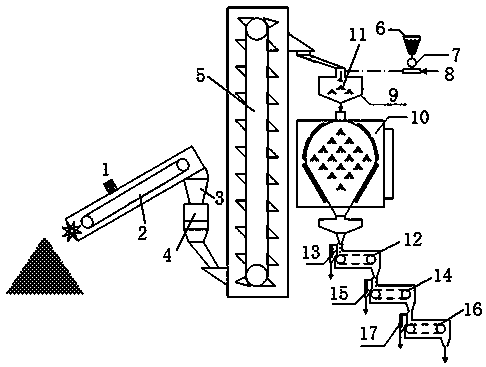

Brown coal drying and dehydrating device

InactiveCN101738077AAchieve dryingImprove coal qualityDrying solid materials with heatDrying machine combinationsComing outBrown coal

The invention relates to a brown coal drying and dehydrating device and an application method. The hot-air drying and dehydrating device dries and dehydrates brown coal at high speed and low energy consumption by main means of high-power microwaves and infrared. The application method for the device comprises the steps of: crushing raw coal; pretreating the coal through a hot-air drying system to remove external water; and then drying and dehydrating the coal further by microwaves, wherein an infrared scanning system is adopted in the drying and dehydrating process in order to prevent the brown coal from backwater. By applying the device, the water in the brown coal can be removed by over 98 percent in short time. The brown coal drying and dehydrating device has the advantages of simpleness and easy operation of process flow, quick dehydration and low energy consumption. The device and the method have no negative effect on the environment, the water coming out through drying can also be recycled, and the device and the method are economic and effective.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH +1

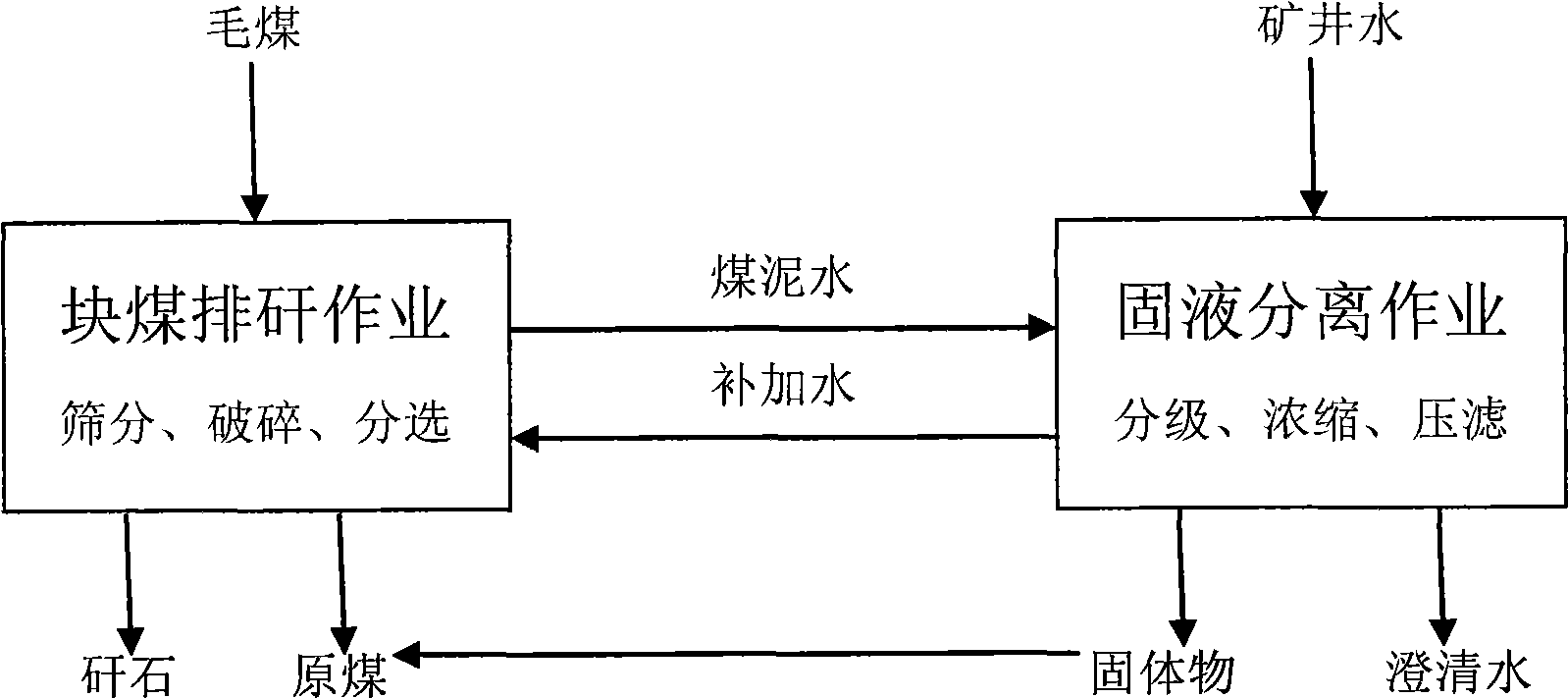

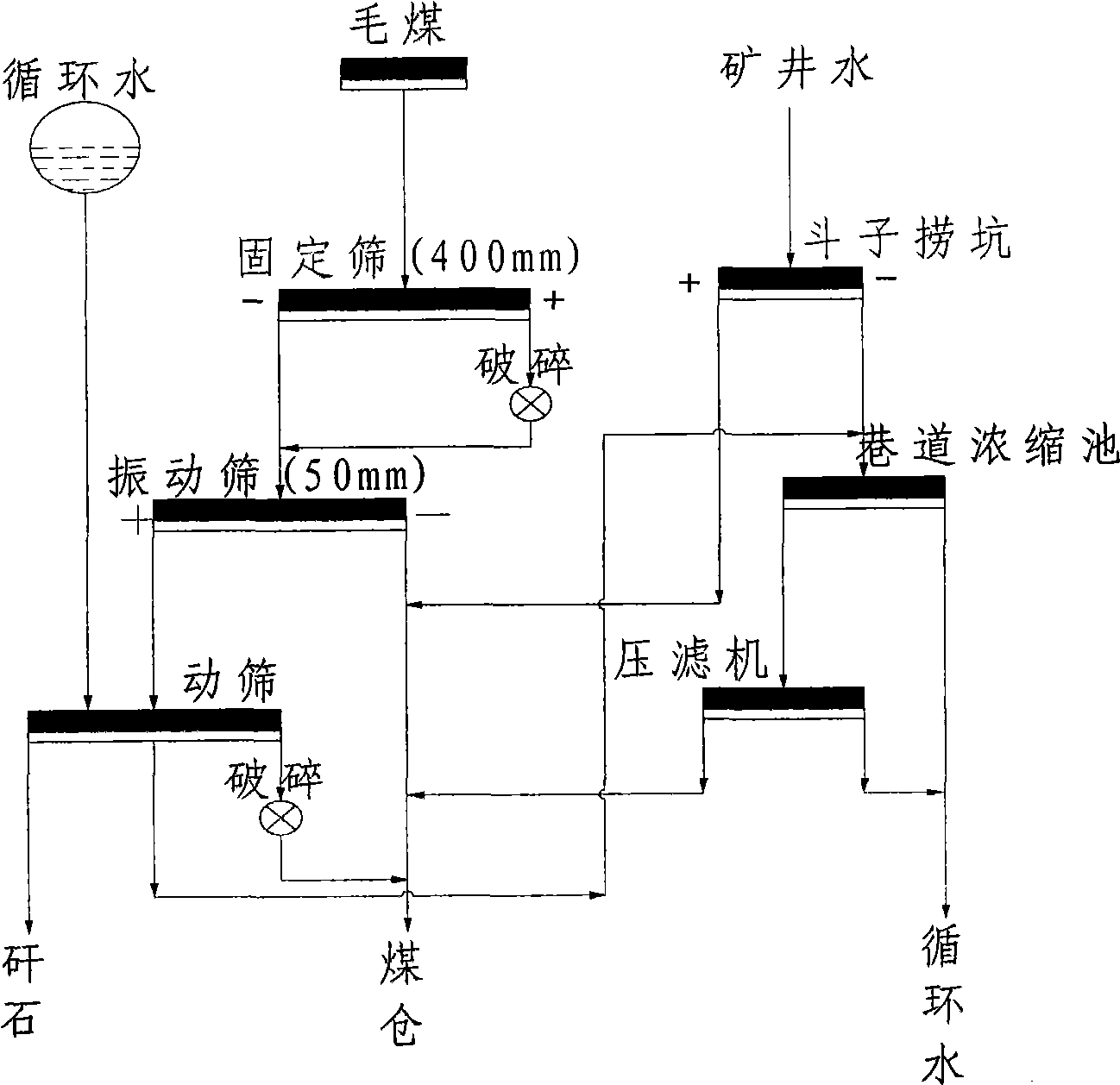

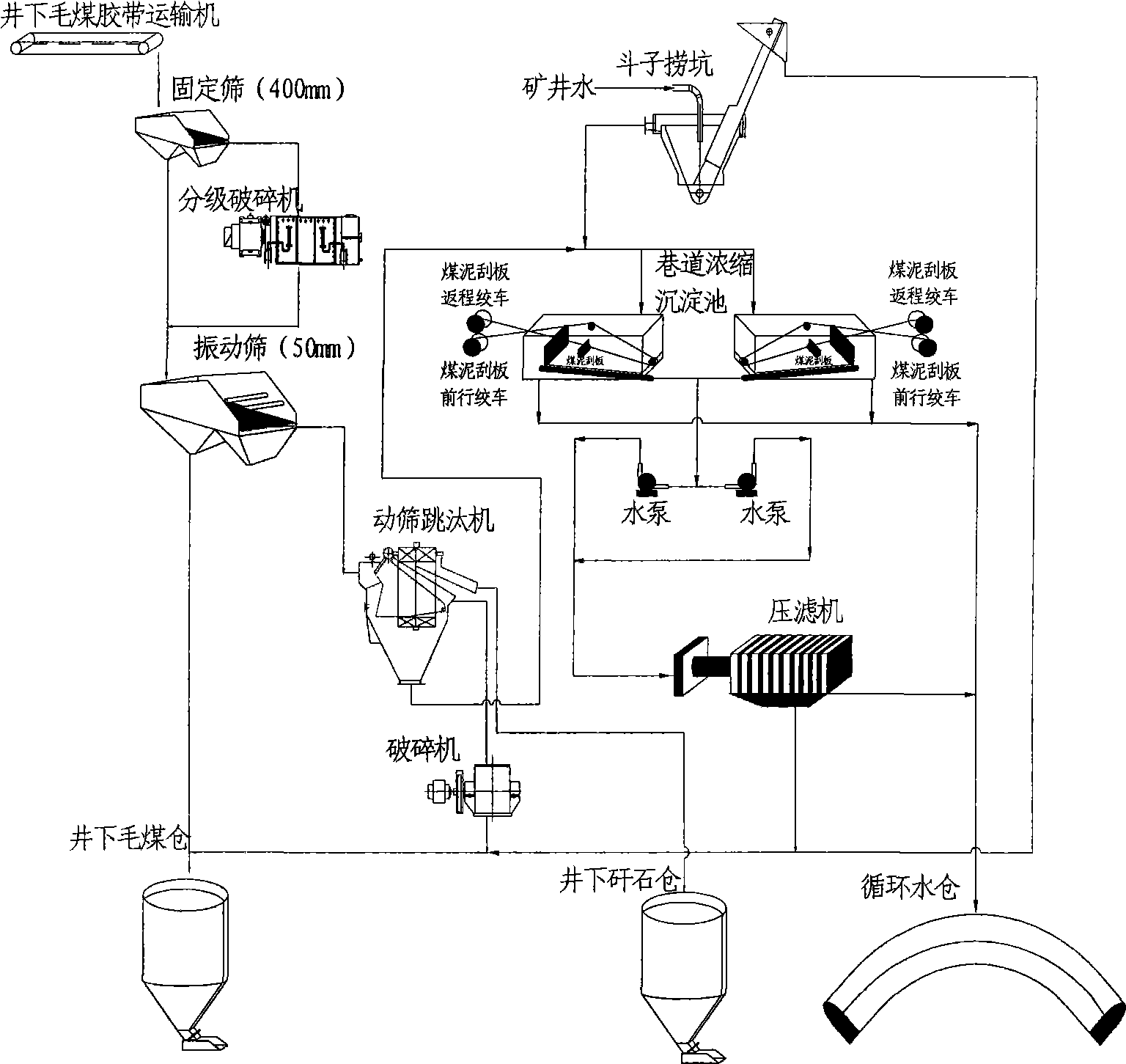

Down-hole gross coal dirt-discharging and mine water treating combined process

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solid-liquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solid-liquid separation operation comprises hydraulic classification, concentration and pressure filtration steps; by the gangue removal operation from lump coal, chunks of gangues in the gross coal are removed, and simultaneously the large particles thereof are crushed into appropriate size; by the mine water solid-liquid separation operation, the solid substances in the mine water are recycled to a coal streamline, and simultaneously the clear overflow water is delivered to a underground water sump; the coal muddy water generated by the gangue removal operation from lump coal is delivered to a mine water solid-liquid separation system for treatment and the mine water solid-liquid separation system provides water for washing and selection for the gangue removal operation from lump coal, so the coal muddy water and the water for washing and selection are combined into an organic whole.

Owner:HENAN POLYTECHNIC UNIV

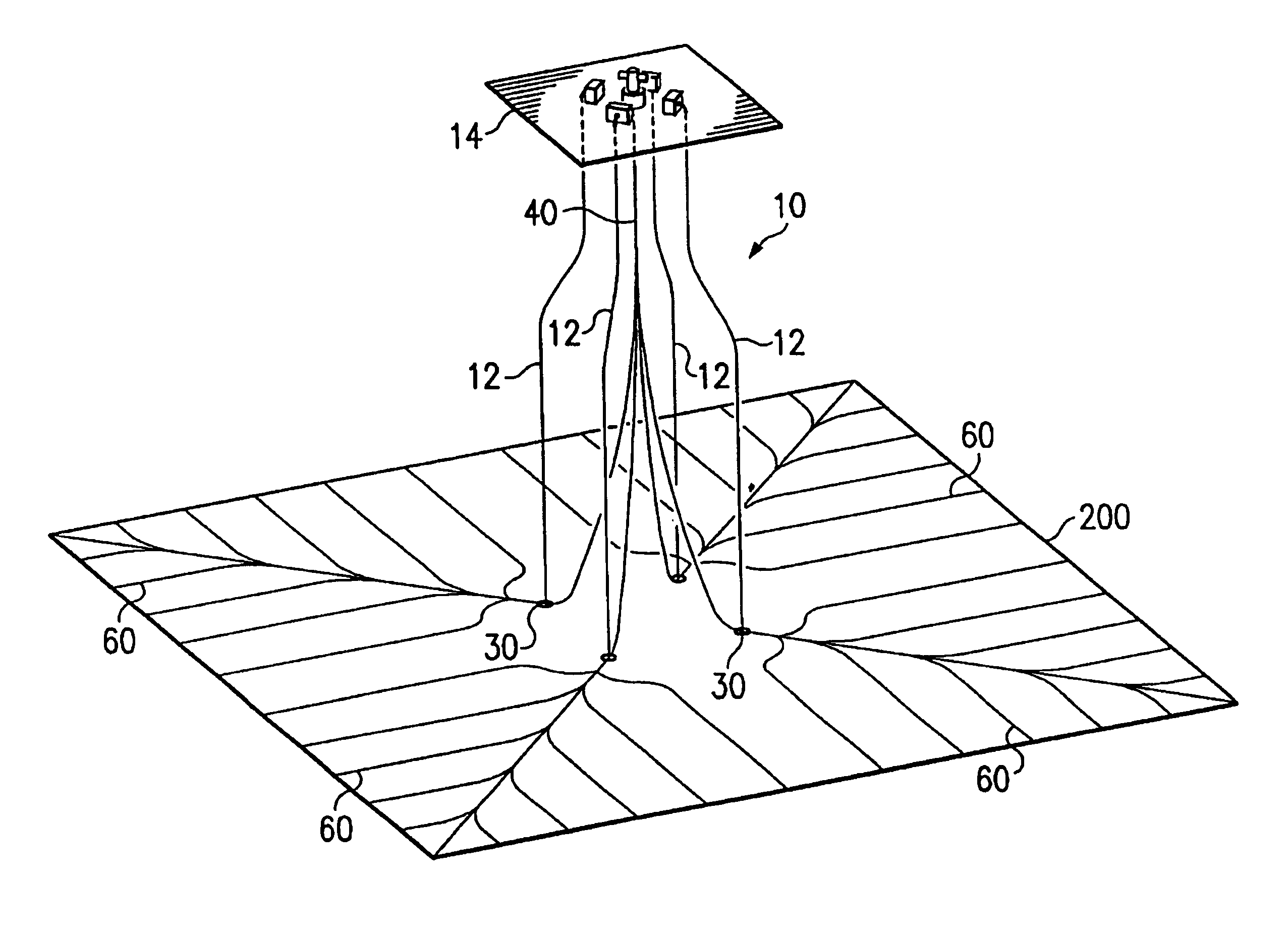

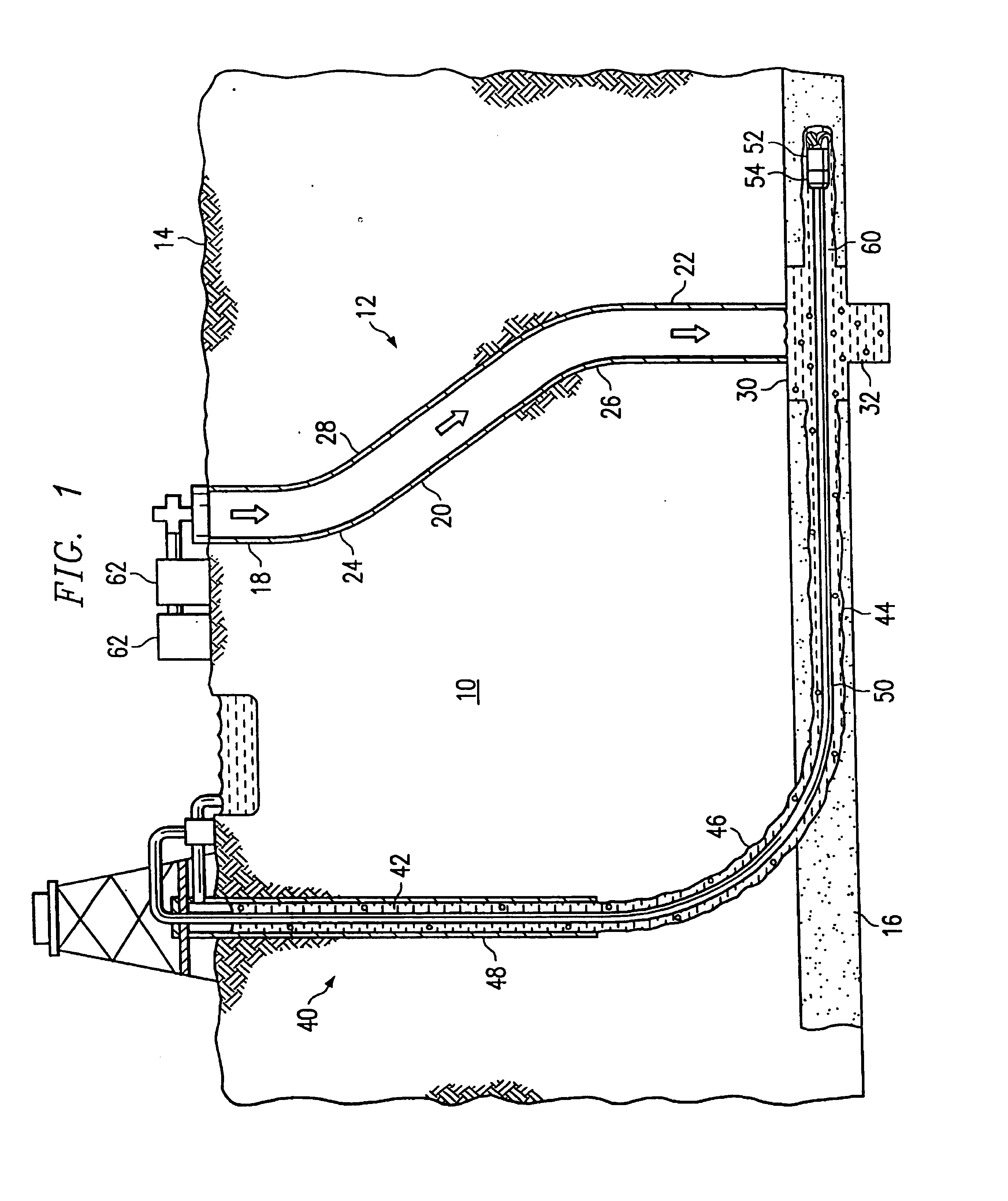

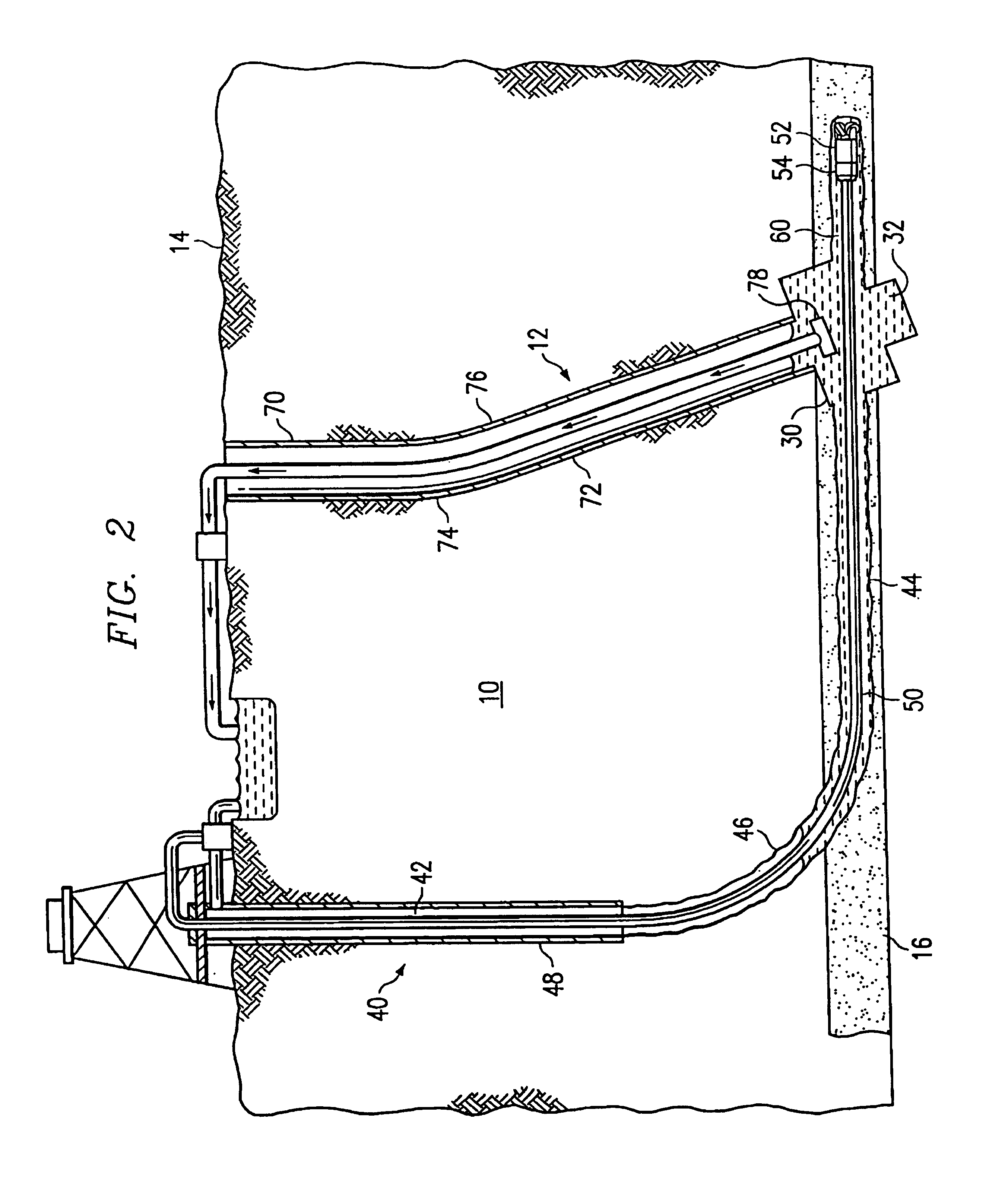

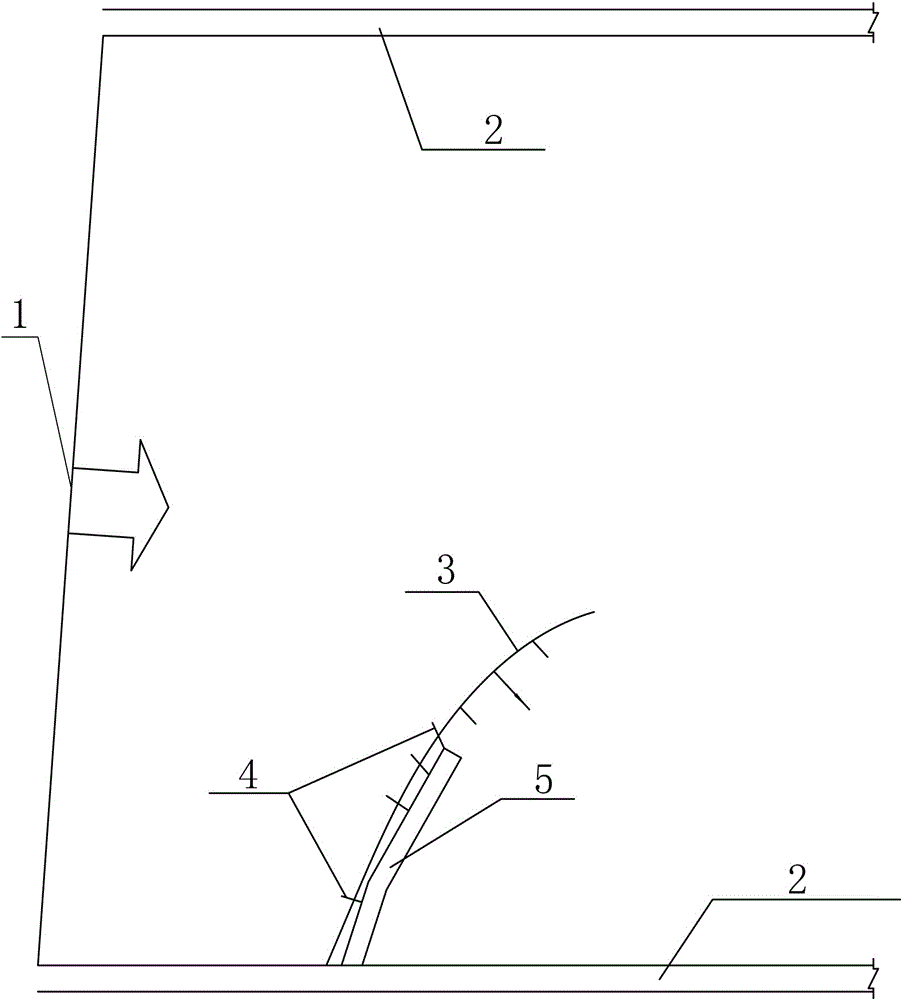

Method and system for accessing a subterranean zone from a limited surface area

InactiveUS7036584B2Shorten the timeImprove mining efficiencyFluid removalDirectional drillingWellboreEnvironmental geology

A method and system for accessing subterranean resources from a limited surface area includes a first well bore extending from the surface to the target zone. The first well bore includes an angled portion disposed between the target zone and the surface to provide an offset between a surface location of the first well bore and an intersection of the first well bore with the subterranean resource. The system also includes an articulated well bore extending from the surface to the target zone. The articulated well bore is offset from the first well bore at the surface and intersects the first well bore proximate the target zone. The system further includes a well bore pattern extending from the intersection of the first well bore and the articulated well bore in the target zone to provide access to the target zone.

Owner:EFFECTIVE EXPLORATION

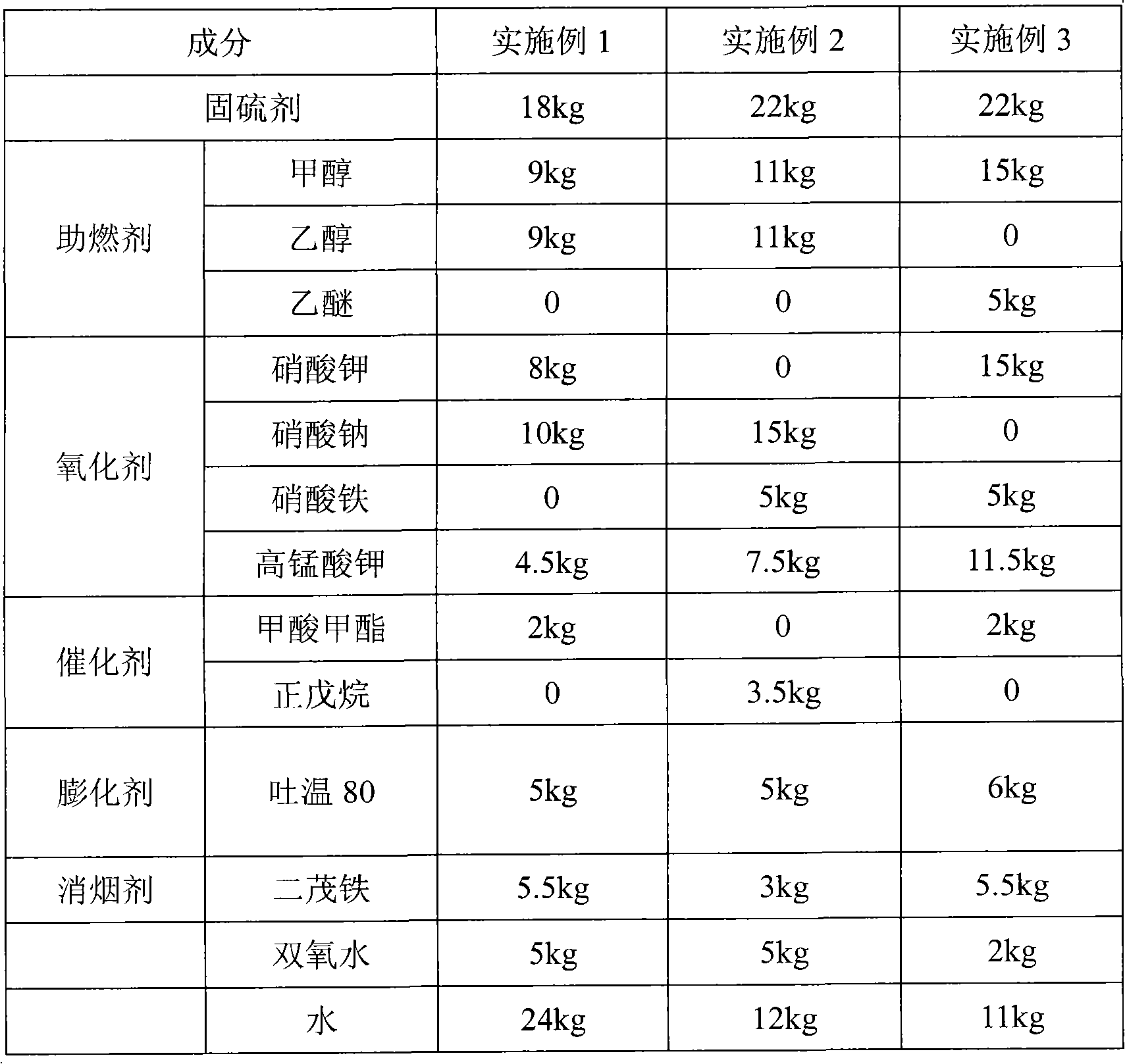

High-efficiency environmental-friendly coal-saving sulphur-fixing antismoke agent and production technology thereof

InactiveCN101658757AImprove efficiencyImprove coal qualityDispersed particle separationSolid fuelsChemistryCoal

The invention discloses a high-efficiency environmental-friendly coal-saving sulphur-fixing antismoke agent and a production technology thereof. The high-efficiency environmental-friendly coal-savingsulphur-fixing antismoke agent comprises the following components in percentages by weight: 18%-22% of the sulphur-fixing agent, 18%-22% of the combustion improver, 22.5%-27.5% of the oxidizing agent,4%-6% of the swelling agent, 2%-3.5% of the catalyst, 3%-5.5% of the antismoke agent, 2%-5% of the hydrogen peroxide and the balance of water. The invention also provides the production technology ofthe high-efficiency environmental-friendly coal-saving sulphur-fixing antismoke agent. The obtained high-efficiency environmental-friendly coal-saving sulphur-fixing antismoke agent has convenient use and good sulphur-fixing and denitration effect, can eliminate partial smoke dust without generating secondary pollution, has low operation cost and outstanding coal consumption saving and can also enhance the heat efficiency of a boiler, thereby playing a positive role on reducing the atmospheric pollution of cities and saving energy sources.

Owner:HENAN JUNENG ENERGY TECH

Gel foam for coal seam fire control

The invention discloses a gel foam for coal seam fire control, wherein the gel foam comprises 1.5%-0.7% of foaming agent, 1%-0.4% of synthetic super absorbent foam stabilizer and the balance of water by weight percentage. Compared with the traditional water slurry and gel, the gel foam is wider in coverage and can be piled up in the vertical direction quickly; the gel foam is capable of bringing more water and solid incombustible matters into a fire preventing and extinguishing region; as a result, the foam intensity is enhanced and the fire preventing and extinguishing efficiency is greatly improved; the foaming agent is formed by compounding surfactants such as an alkyl glycoside and an alkane sulfonate; the synthetic super absorbent resin is good in salt resistance; the gel foam is also obviously improved in water absorption capability in contrast with other gel foam; besides, the time taken to separate out 50 ml of water by standing the gel foam ranges from 4 to 5 hours; the time of the half foam life period is more than 18 hours; the stability of the foam and the persistence of foam plugging are improved; and moreover, the gel foam can be piled up in the vertical direction and is capable of achieving the prevention and treatment effects on high-position and medium-position coal.

Owner:SHANDONG UNIV OF SCI & TECH

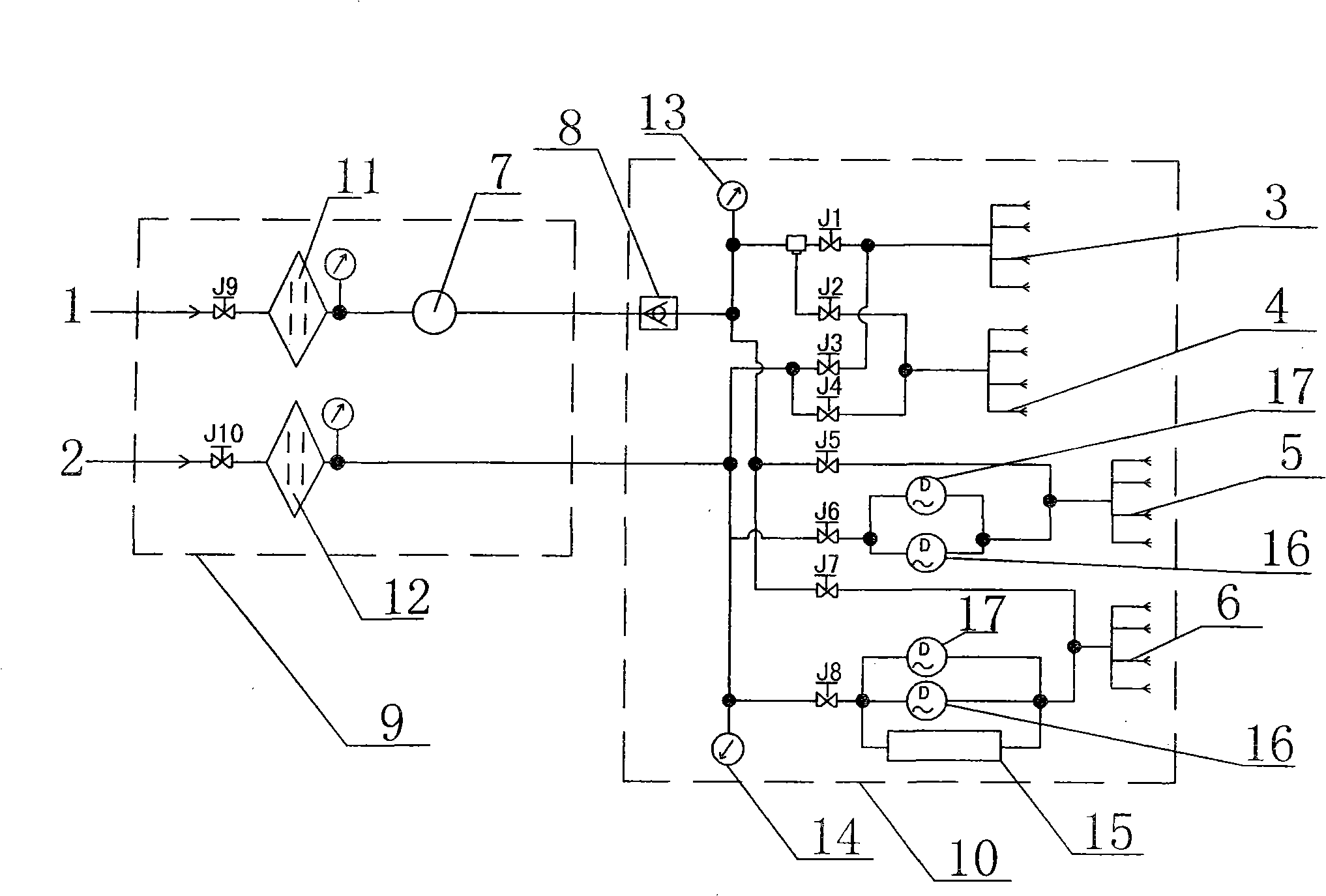

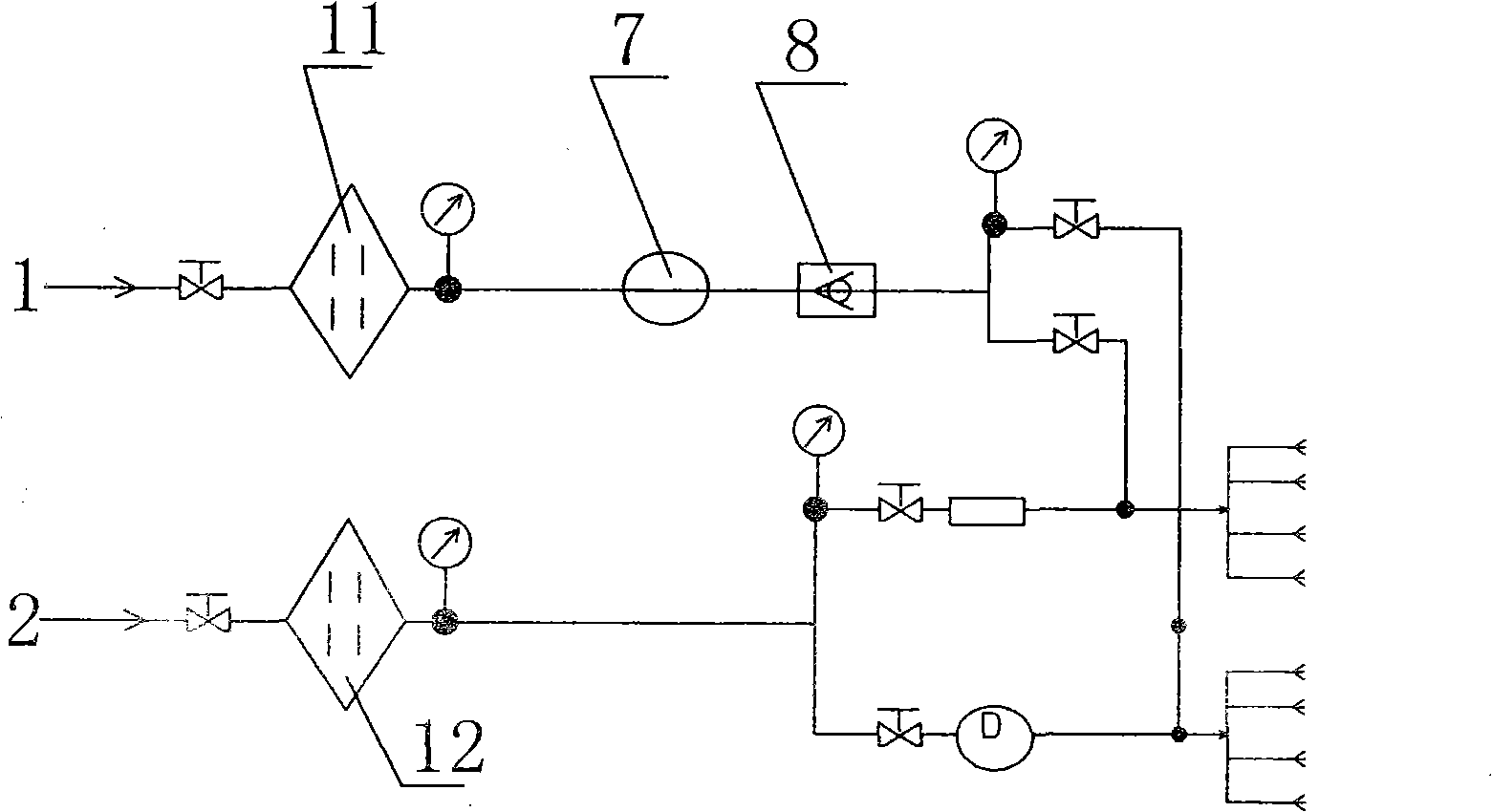

Wind water mixed atomizing method for down-hole coal cutter fully-mechanized coal winning machine

InactiveCN101307691AEfficient captureSolve slippageDust removalFire preventionWater sourceWater vapor

The invention belongs to a wind-water mixing spray technology which can be applied in underground comprehensive mining, comprehensive digging and in places requiring settling dust so as to improve safe production of a coal mine. The invention is characterized in that the technology is realized through the steps as follows: a wind source pipeline which is connected from a ground forcing fan to an extraction working surface with a selectable wind pressure of between 0.5 and 0.7MPa is in parallel connection with a water source pipeline which has certain pressure with a selectable hydraulic pressure of between 3 and 5MPa, and the volume ratio of the mixed wind and water is between 100-135 to 1; the wind source pipeline and the water source pipeline are both connected to nozzles of internal spraying and external spraying of a coal mining machine and a mechanical boring machine, so that wind-water mixing atomized water vapor is sprayed with a flow rate of between 15 and 20M<3> / minute; and the atomized water vapor captures coal dust, and disperses local gas generated during cutting a coal body. The invention aims to solve the problems caused by the local gas which is generated during settling dust and cutting coal and can not be dispersed in time, such as safety threat in production, water resource waste, affected coal quality, slipping belt, slipping goods, bin blockage or other problems.

Owner:李本学 +1

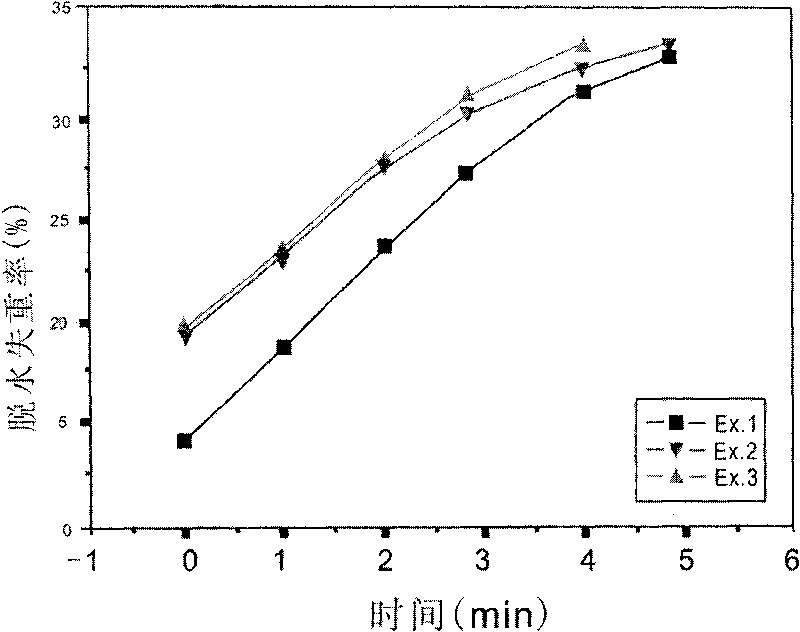

Microwave radiation preparation method of coal-based active carbon for removing pyrene

InactiveCN103896269AAbundant resourcesImprove coal qualityCarbon compoundsWater/sewage treatment by sorptionMicrowave radiometryMicrowave method

The invention discloses a method for removing a polycyclic aromatic hydrocarbon, namely pyrene, in simulated wastewater by virtue of adsorption by using coal-based active carbon which is prepared by taking Xinjiang anthracite as a carbon source and by use of a microwave radiation method. The coal-based active carbon is prepared through the steps of mixing activators with the anthracite, putting the mixture in a microwave reaction device, and finally carrying out one-step carbonization and activation in the presence of the activators KOH, ZNCl2 and H3PO4 under the conditions of an agent-to-material ratio of 1: 1 to 1:5, microwave time of 4-20 minutes, microwave power of 100W to 900W and N2 protection. The coal-based active carbons prepared in different embodiments have an average pore size of 28.22-42.54 angstroms, and also have relatively large specific surface area; the specific surface area is 623.84-1770.49 m<2> / g, and the total pore volume is 0.32-0.99 cm<2> / g. The adsorbing capacity of the coal-based active carbon to the pyrene reaches 89.43mg / g, and the removal rate of the pyrene is 99.37%. For removing the pyrene in wastewater, the coal-based active carbon prepared by use of a microwave method is characterized in that energy saving and high efficiency are shown in the preparation process of the active carbon, the active carbon has the advantages of large adsorption capacity, high adsorption rate, remarkable treatment efficiency and the like, and thus has excellent economic benefit and environmental benefit.

Owner:SHIHEZI UNIVERSITY

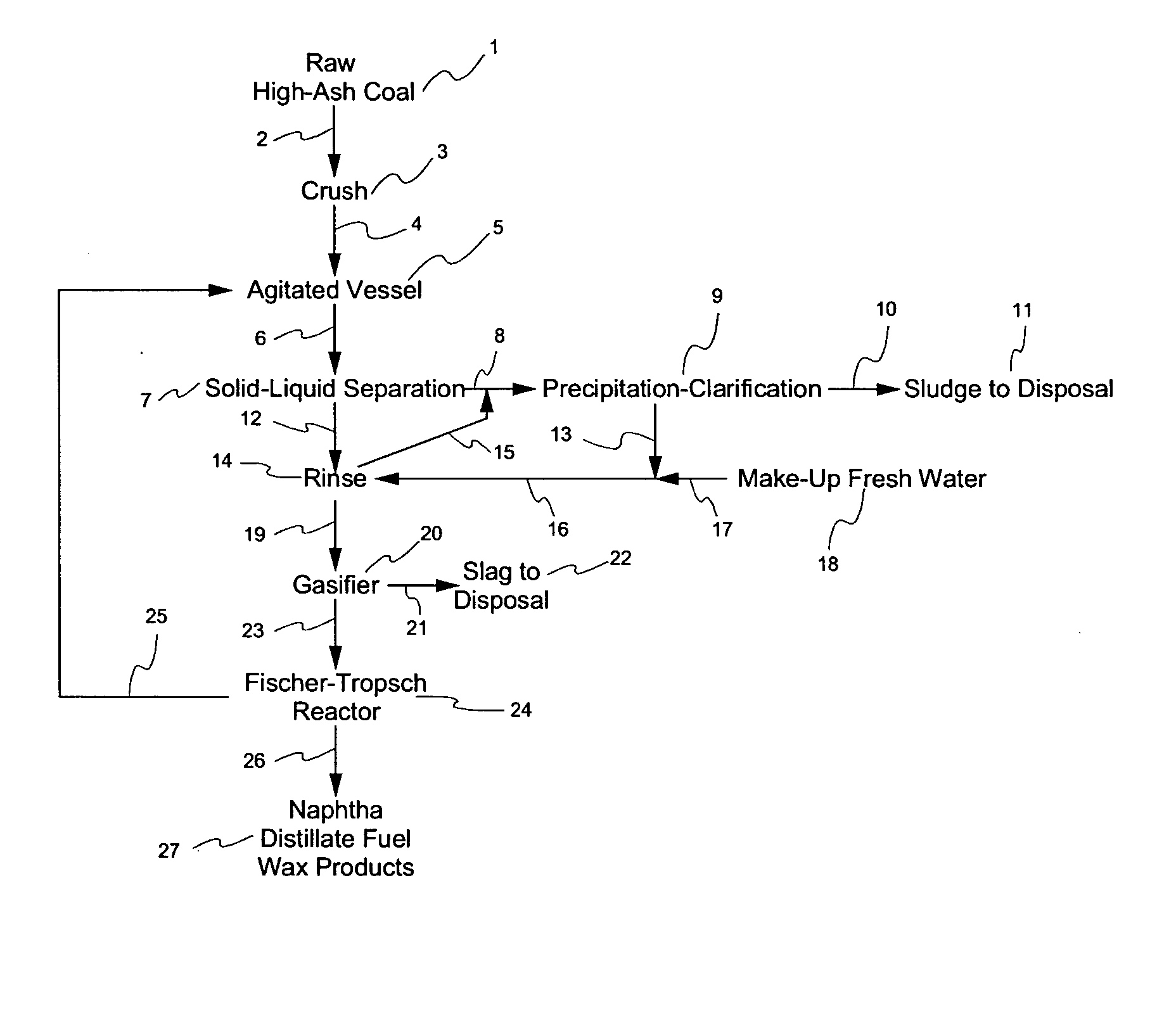

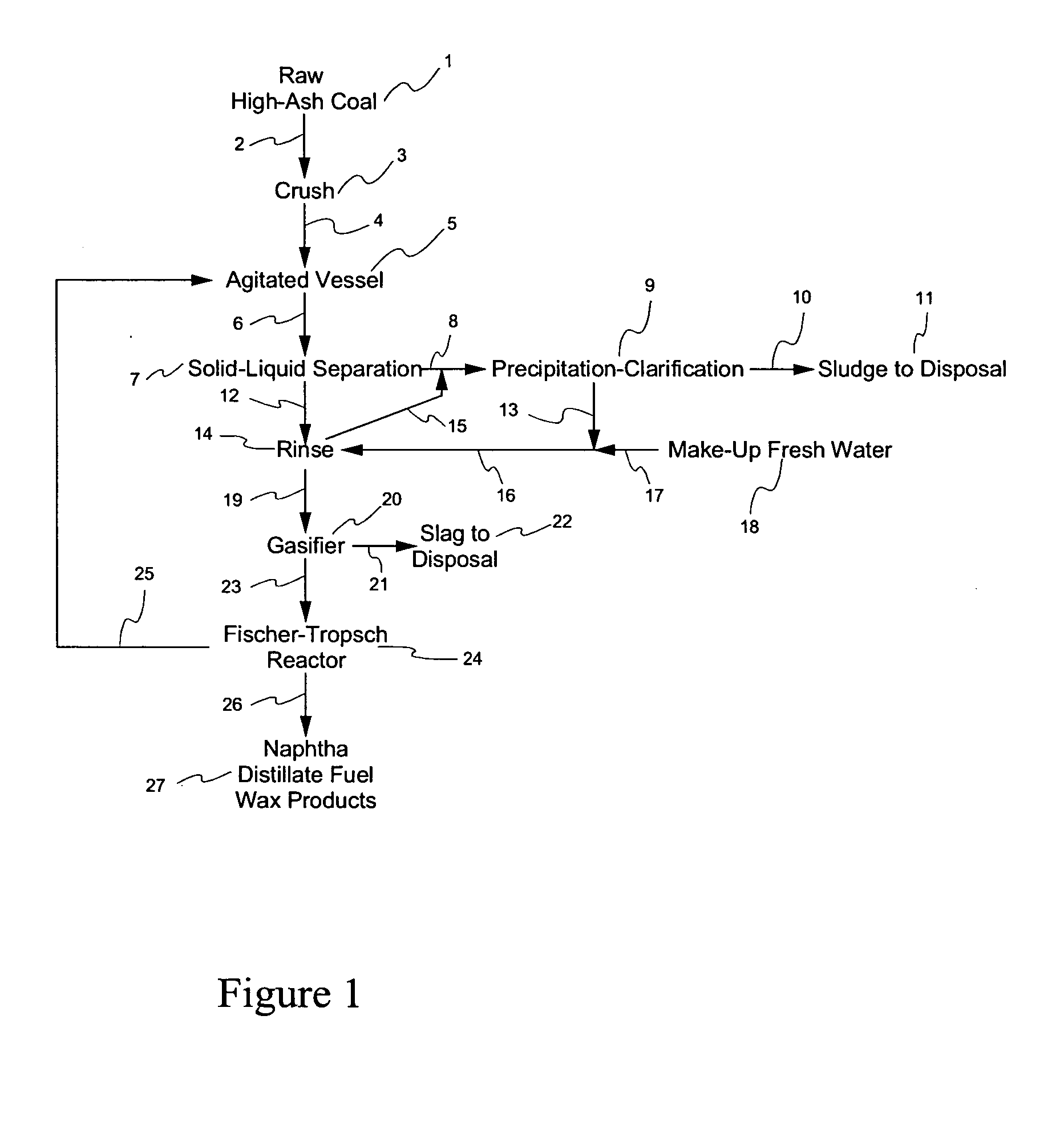

Method to upgrade low rank coal stocks

ActiveUS20050039386A1Improve coal qualityCheap sourceCoke ovensGas modification by gas mixingPower stationCombustion

The ash content of raw coals, lignite, and other carbonaceous materials is reduced by leaching the high-ash material with an aqueous acidic waste product produced by a Fischer-Tropsch reaction. The acidic aqueous waste is mixed with coal and process conditions are described. The claim takes advantage of using otherwise uneconomic coal, lignite or other carbonaceous material by upgrading the material to a suitable feedstock for combustion in a power plant or gasifier.

Owner:GTL ENERGY LTD

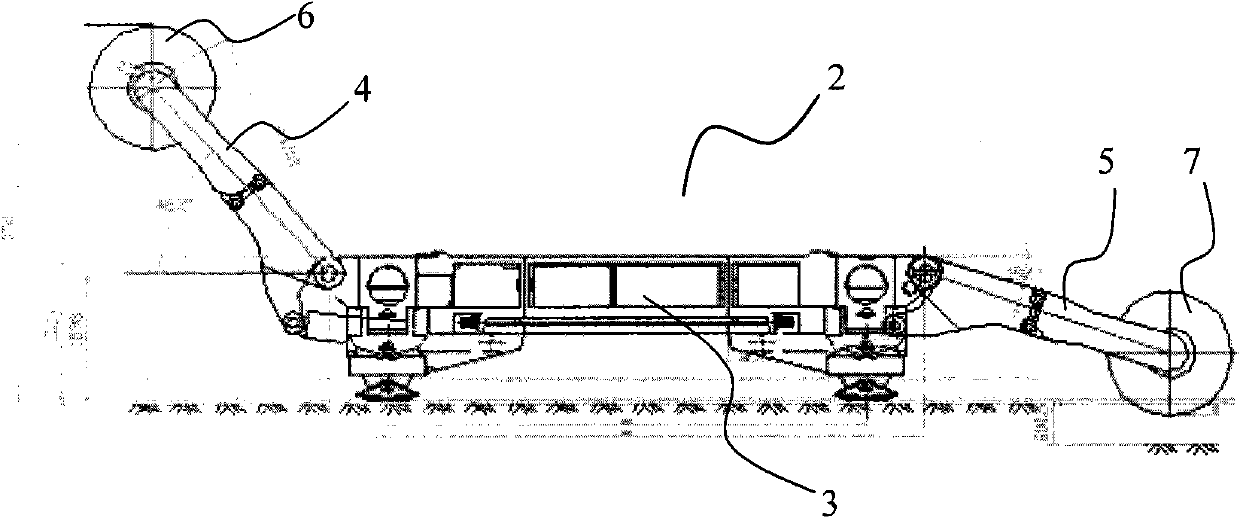

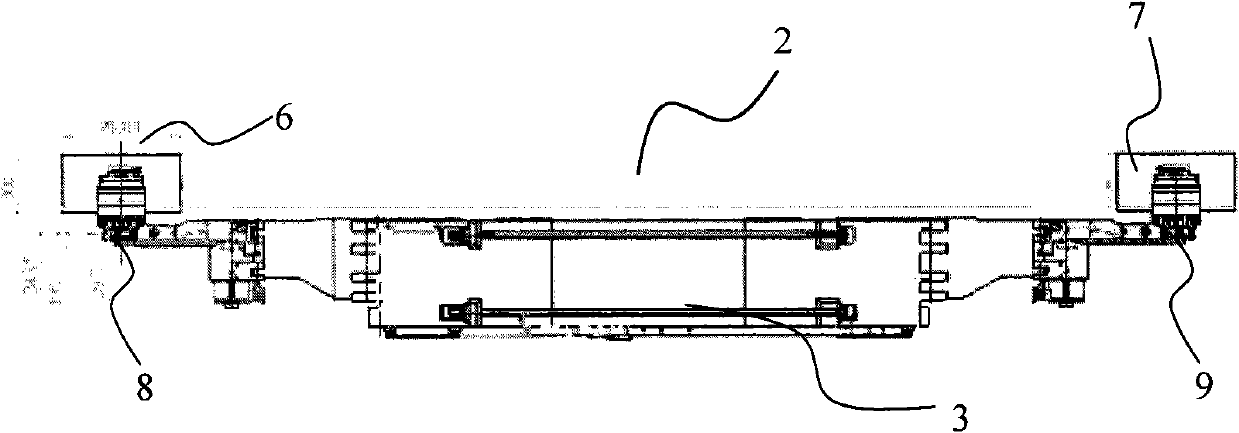

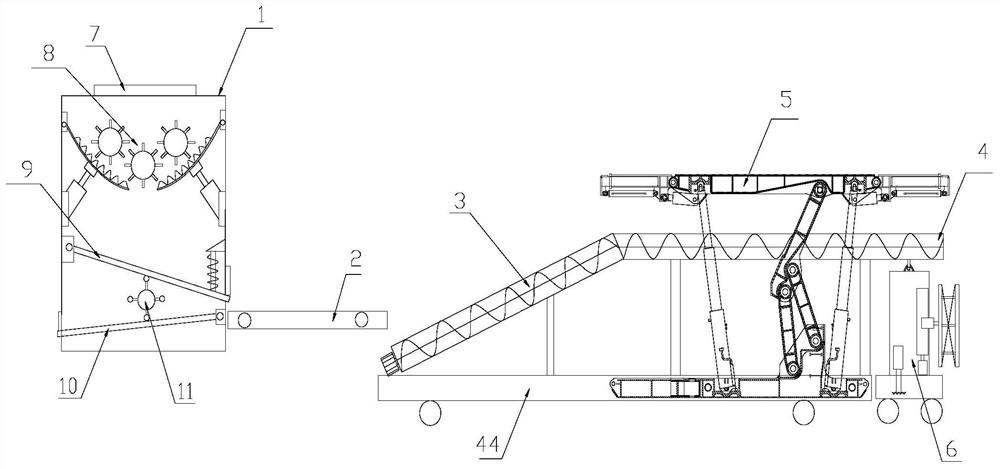

Slice mining technology and coal winning machine thereof

InactiveCN102373927ALow costImprove coal qualityUnderground miningSurface miningFree rotationEngineering

The invention relates to a coal winning machine for a slice mining technology. The coal winning machine comprises a coal loading device. The coal loading device comprises a rotating seat, a coal loading plate and a hydraulic drive system. The coal loading device is rotatably fixed on a cutting head part of the coal winning machine by the rotating seat, and performs a free rotation movement by adopting a cutting drum arranged on the cutting head part as the center. The coal loading plate is rotatably fixed on the main body of the coal loading device. The hydraulic drive system concurrently drives the rotating seat and the coal loading plate to perform rotation movements.

Owner:XIAN COAL MINING MACHINERY

Fully mechanized working face roadway pre-excavating type fault passing method

InactiveCN106837333AReduce gangue contentReduce lossUnderground miningSurface miningEngineeringFault occurrence

The invention relates to a method for pre-excavating a roadway through a fault in a fully mechanized mining face, comprising the following steps: 1) constructing a roadway for detecting faults; 2) drilling for coal exploration; 3) reinforcing and supporting the shed in the roadway; 4) during mining Control the inclination and pitch angle of the working face. The beneficial effects of the present invention are as follows: 1. The gangue can be extracted in advance in the pre-excavation roadway. On the one hand, the amount of gangue cut during mining can be reduced, the ratio of gangue in the raw coal can be reduced, the ash content can be reduced, and the coal quality can be improved; on the other hand, the mechanical and electrical equipment can be reduced. Reduce wear and tear, speed up the advancing speed of the working face, and improve the production efficiency of the working face. 2. The three elements of fault occurrence can be ascertained in advance, and detailed geological data can be provided for formulating scientific and reasonable measures for crossing faults. 3. Support and reinforce the surrounding rock at the fault in advance to reduce roof accidents during mining and improve the safety factor of the working face.

Owner:XIAOYUN COAL MINE JINING MINING IND GRP CO LTD

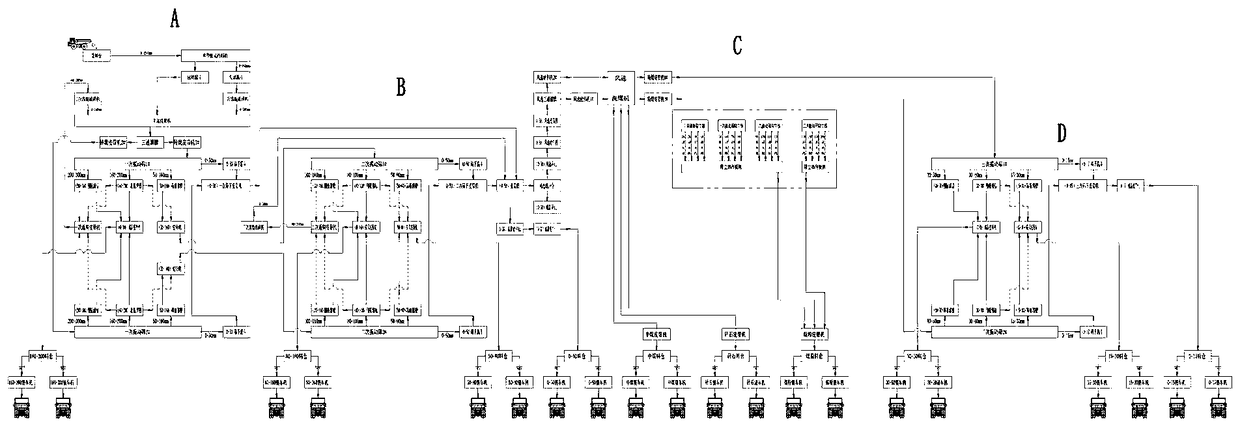

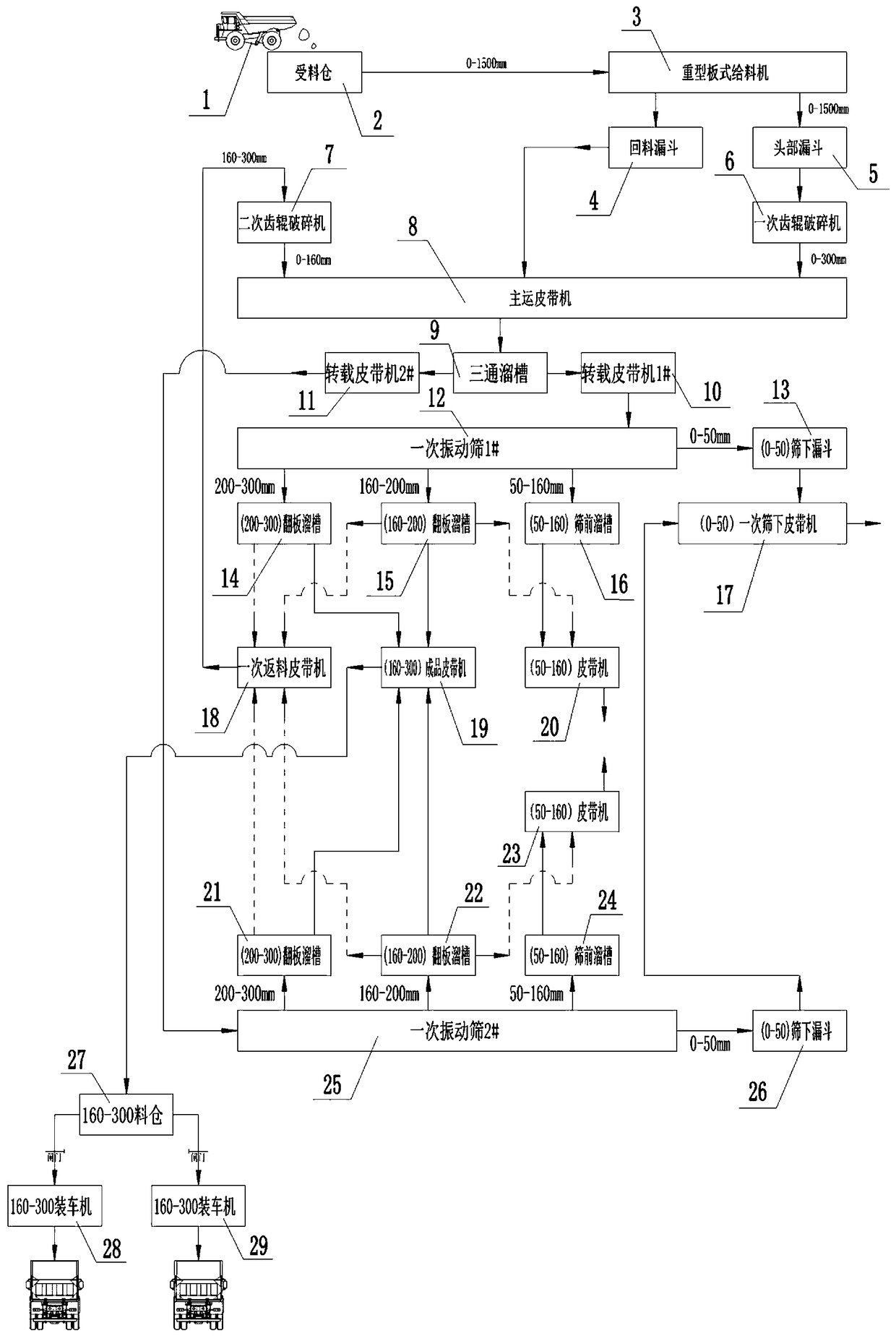

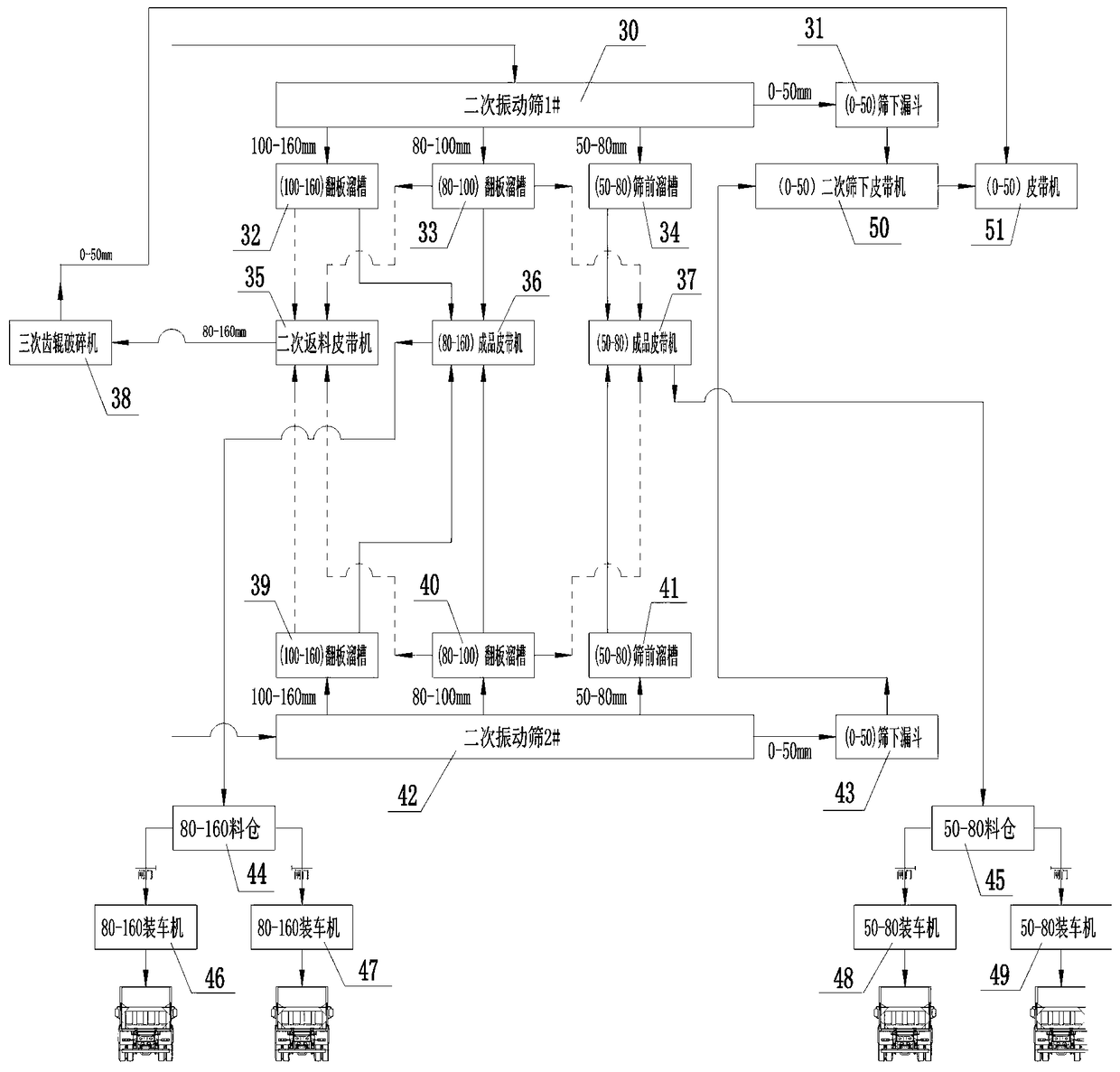

Grading production system for open coal breaking and sieving

The invention discloses a grading production system for open coal breaking and sieving. The grading production system comprises a mine car, a receiver bin, a heavy plate feeder, a feeder material returning hopper, a feeder head hopper, a tooth roller cracker, a main belt conveying machine, a three-way chute, a transshipment belt machine, a first-time vibrating screen, a hopper under a screen, a turning plate chute, a chute in front of the screen, a belt machine under the screen, a material returning belt machine, a finished product belt machine, a second-time vibrating screen, a winnowing buffer cabin, a winnowing gate, a winnowing feeder, a winnowing belt machine, a winnowing three-way chute, a winnowing coal washer, a clean coal belt machine, a loaded material breaking dust remover, a vibrating screen dust remover, a dust remover scraper, a middling coal belt machine, a gangue belt machine, a coal dust belt machine, a three-time vibrating screen, a middling coal stock bin, a gangue stock bin and a coal dust stock bin, wherein two adjacent devices are communicated through a material conveying pipeline. According to the grading production system disclosed by the invention, the first-time vibrating screen, the second-time vibrating screen, the winnowing coal washer, the three-time vibrating screen and the tooth roller cracker are arranged singly or arranged in parallel accordingto practical requirements.

Owner:HENAN ZHENYUAN TECH

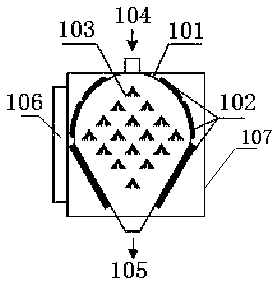

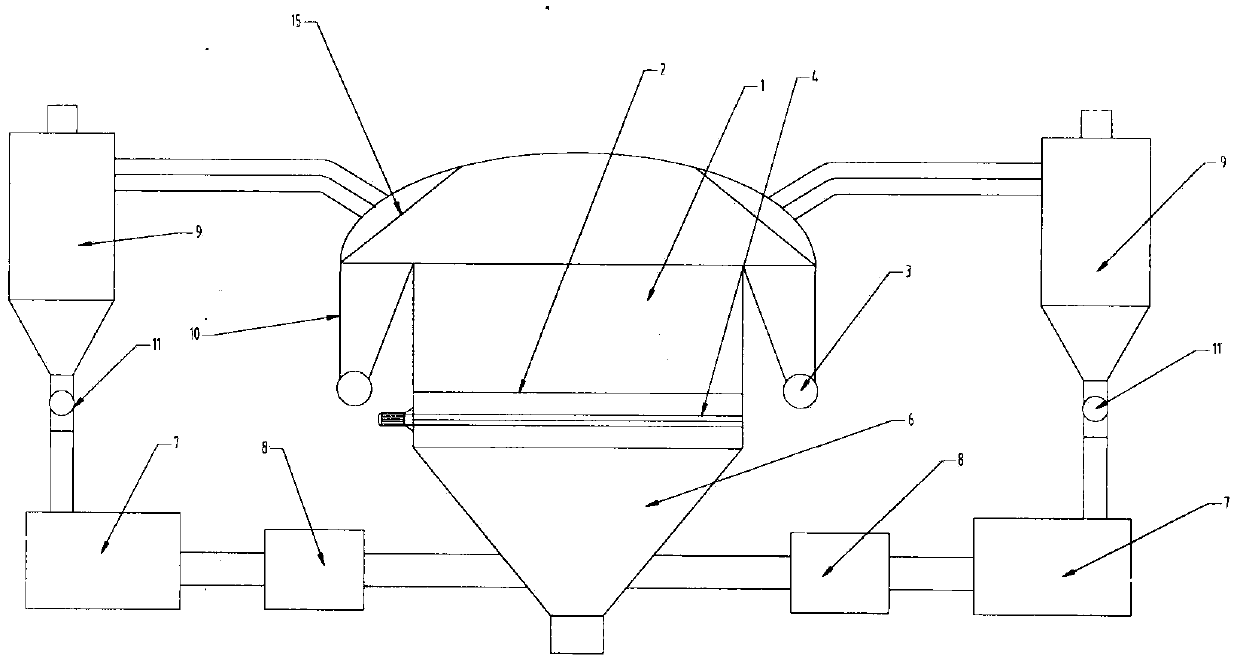

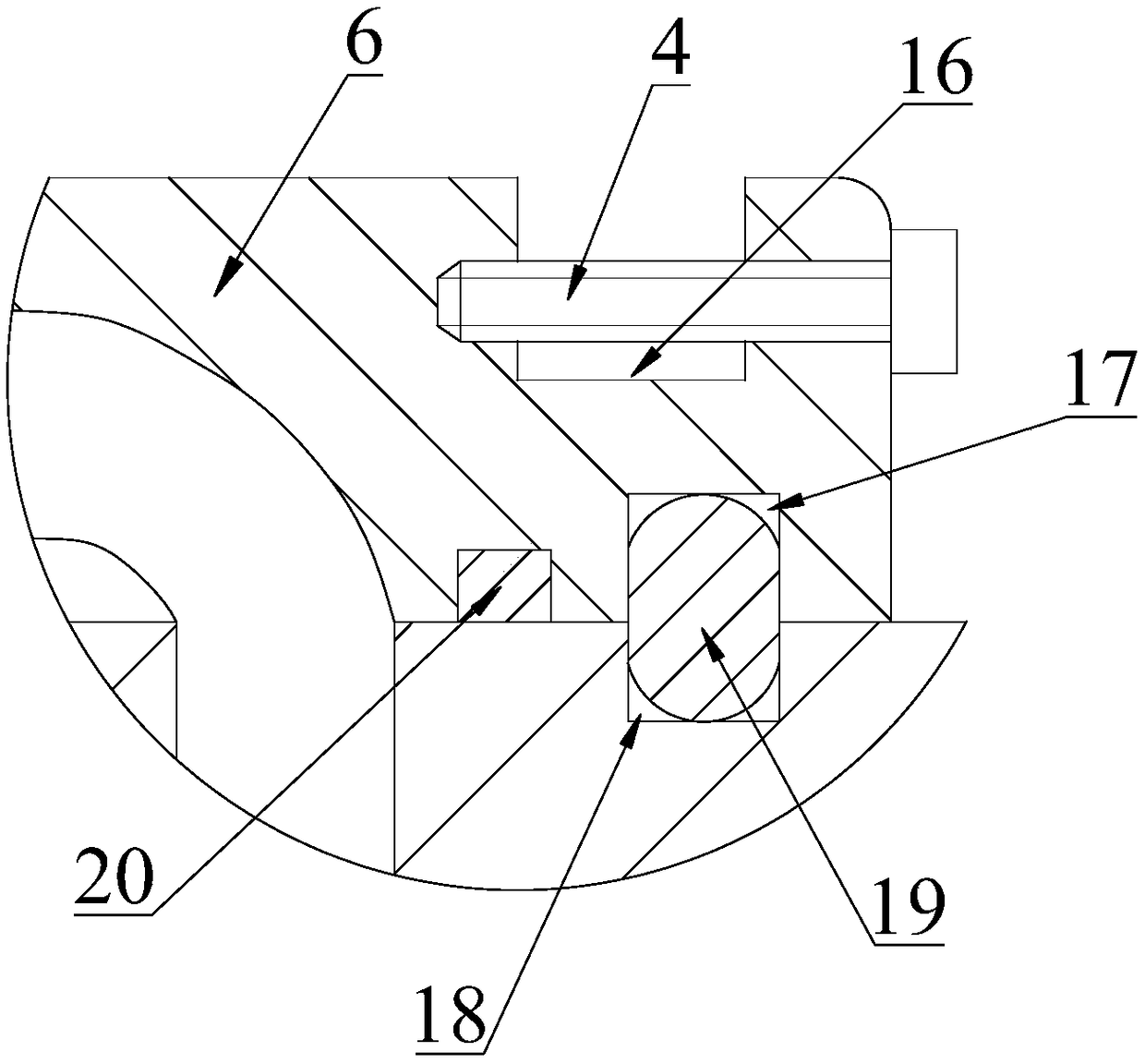

Drying and separation integrated machine for vibrating fluidized bed

ActiveUS20160054056A1Simple structureGuaranteed uptimeDrying solid materials with heatPneumatic tablesFiberWater vapor

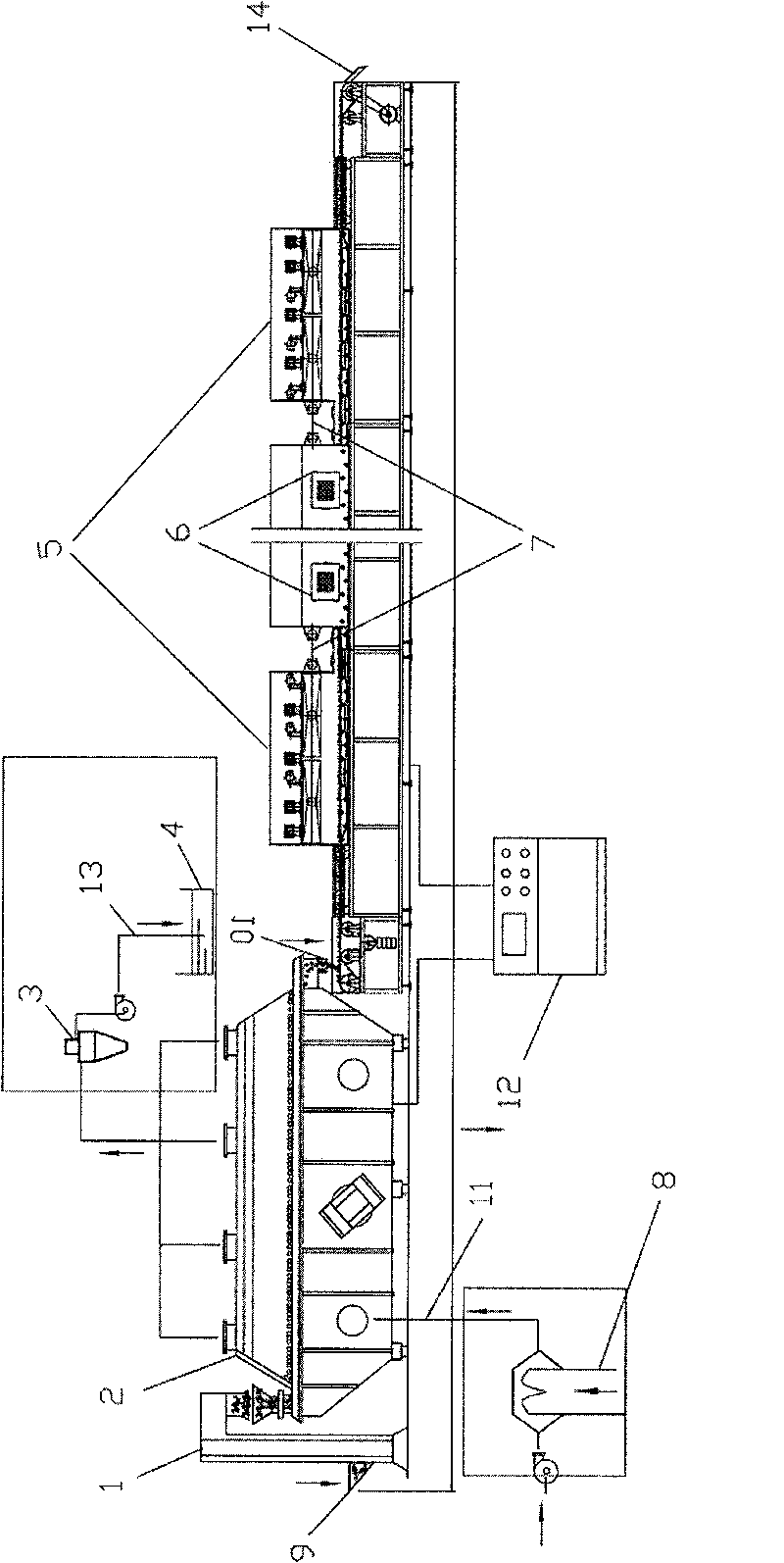

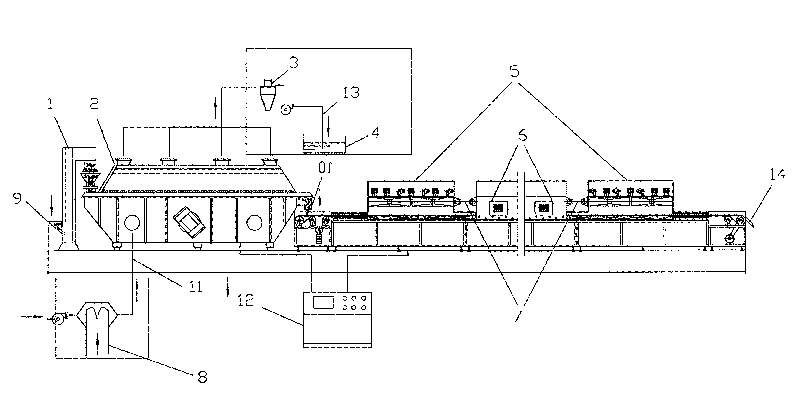

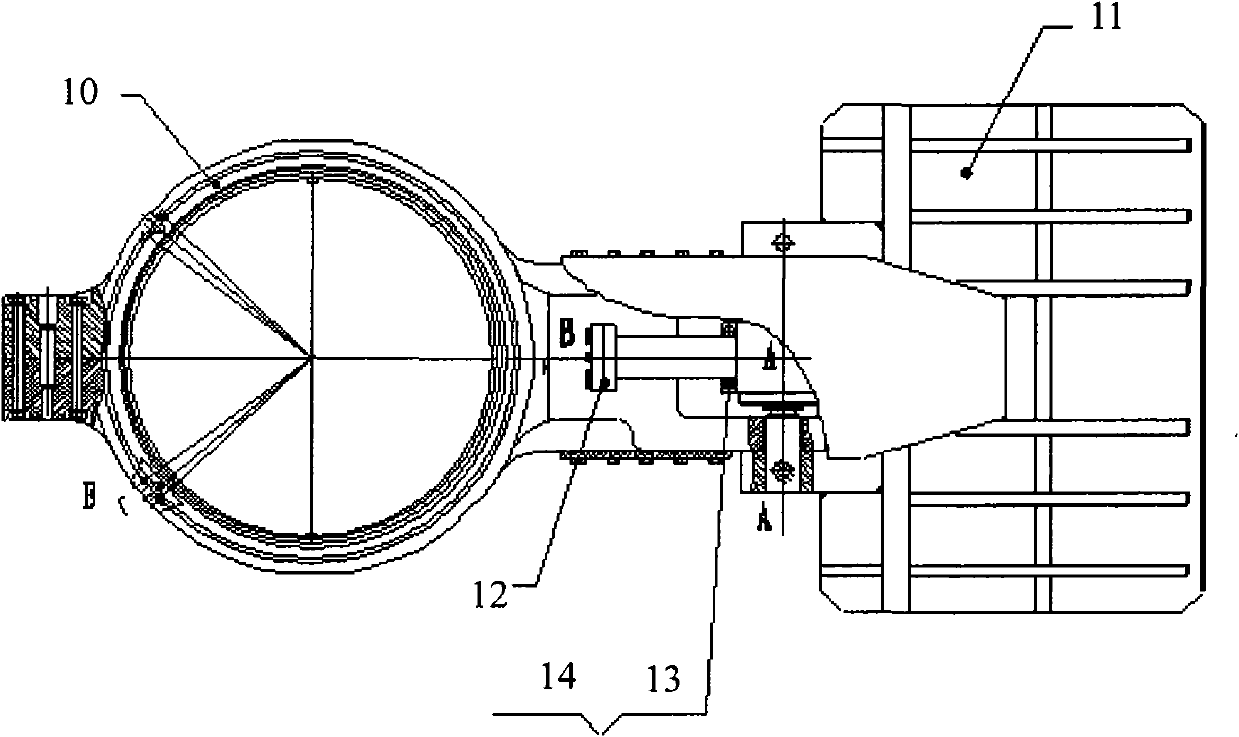

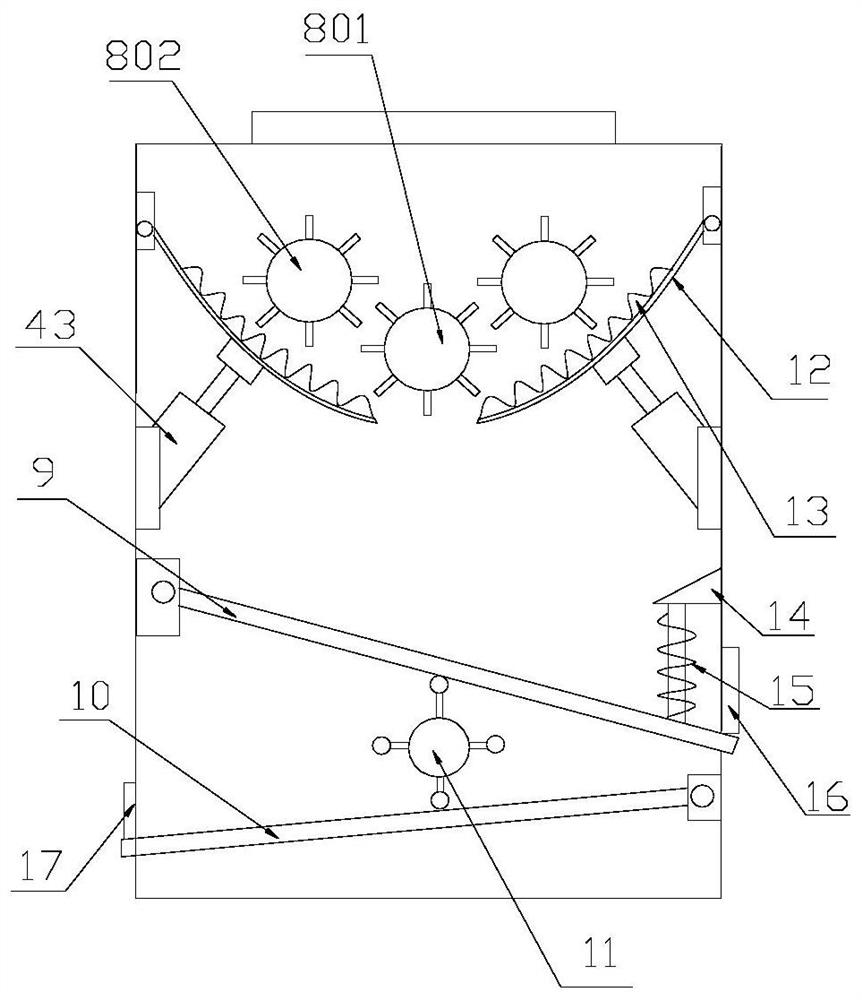

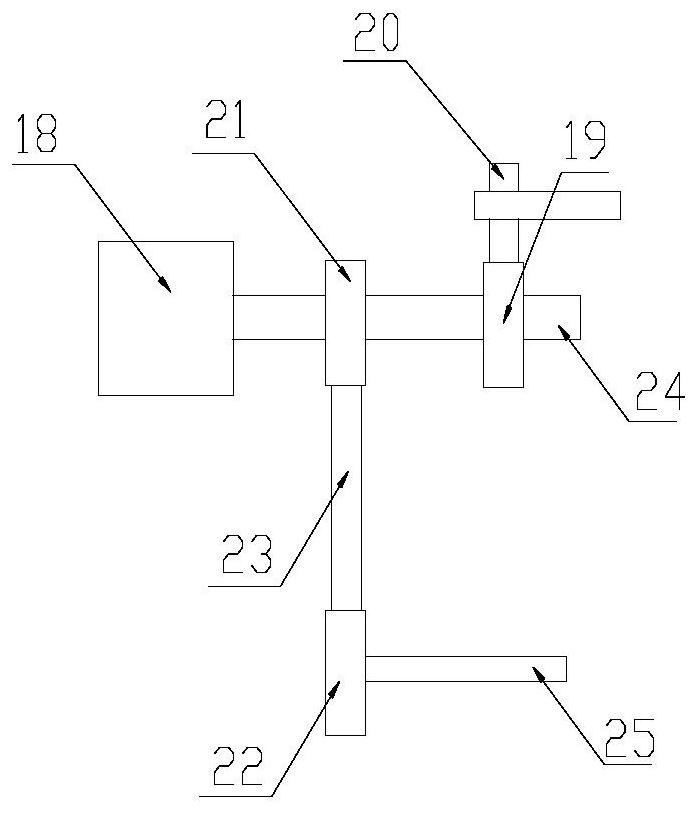

A drying and separation integrated machine for a vibrating fluidized bed comprises a front rack (10), a rear rack (12), a separation bed (6), and a rotary plow feeder (1) disposed at the upper portion at the front end of the separation bed (6). The tail end of the separation bed (6) is provided with a waste-rock rotary plow feeder (14) and a fine-coal rotary plow feeder (8), the upper portion of the separation bed (6) is provided with a dust-removing air-induced hood (4), the bottom thereof is provided with an air distribution chamber (3), the upper portion of the air distribution chamber (3) is provided with an air distribution plate (15), and the front rack (10) and the rear rack (12) are connected to the separation bed (6) by a spring (17) and a spring support (16). The bottom of the rear rack (12) is provided with a hydraulic cylinder (13), the lower portion of the rotary plow feeder (1) is provided with a feeding distribution device (2), two dust-removing air-induced hoods (4) and two air distribution chambers (3) are respectively provided on the top and the bottom of the separation bed (6), a heat-insulation coating is sprayed on the outer surfaces of the dust-removing air-induced hood (4) and the air distribution chamber (3), and the lower portion at the front end of the separation bed (6) is provided with a separating eccentric shaft vibration exciter (9). The air distribution plate (15) is formed of upper and lower porous metal plates and asbestos-fiber filter cloth sandwiched between the porous metal plates, the bottom of each air distribution chamber (3) is provided with a gas separator (5), and the gas separators (5) are connected to a hot-air pipe (19) sprayed with a heat-insulation coating. The wet coal in the vibrating fluidized bed is fluidized by high-temperature hot air, heat transfer and mass transfer proceed between the high-temperature air and the wet coal particles, and the moisture in the coal is taken out of the vibrating fluidized bed by the fluidization gas in a form of water vapor. During drying, the coal particles are fluidized by air flow together with vibration. The drying and separation integrated machine for a vibrating fluidized bed is of a simple structure, operates stably, and has high reliability.

Owner:CHINA UNIV OF MINING & TECH

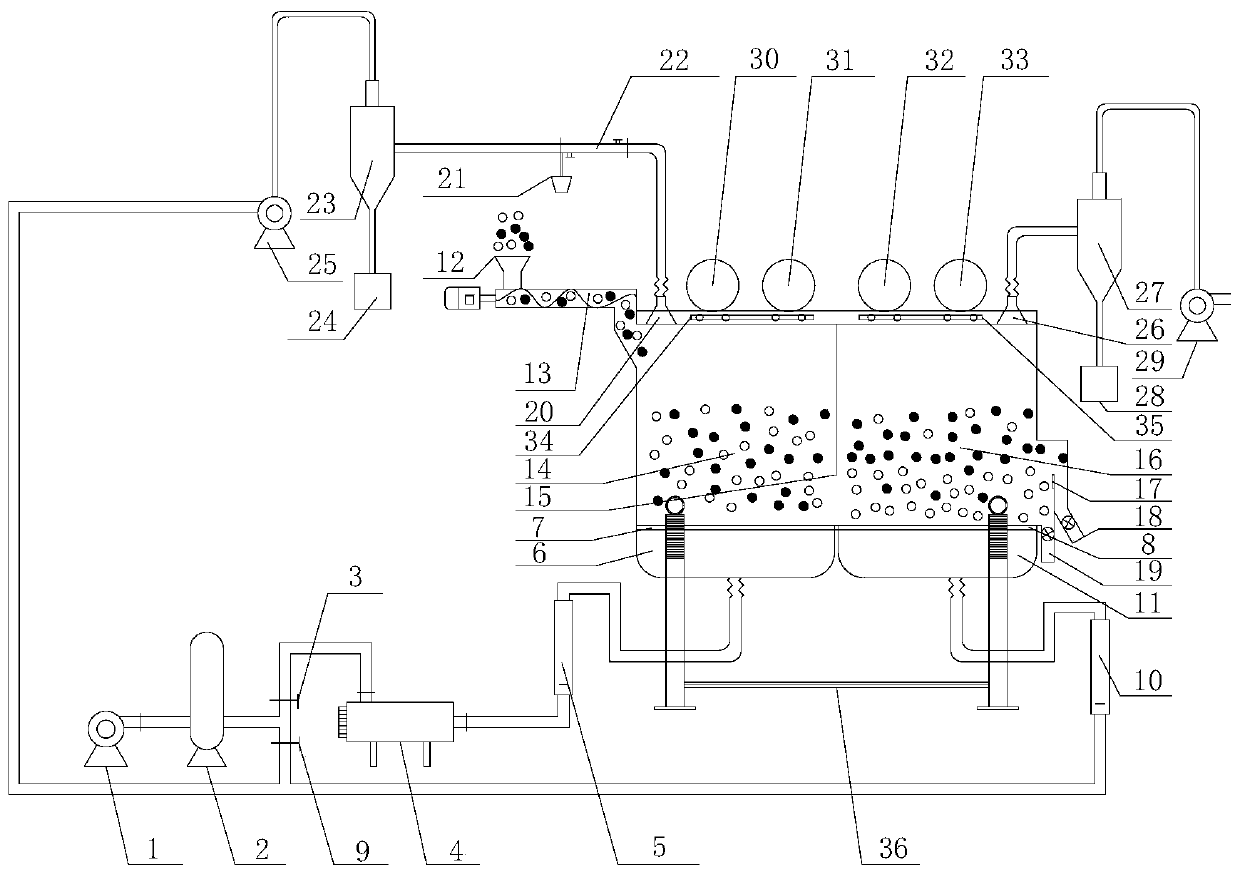

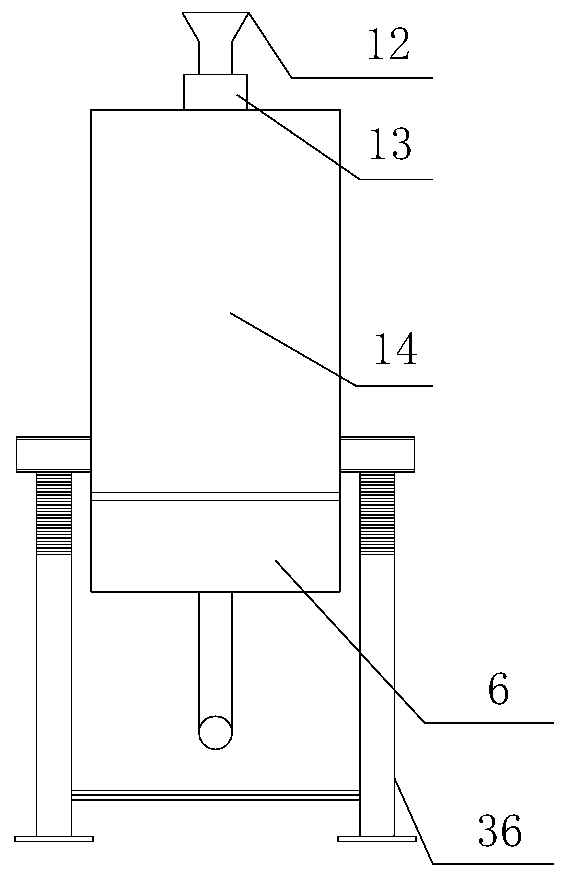

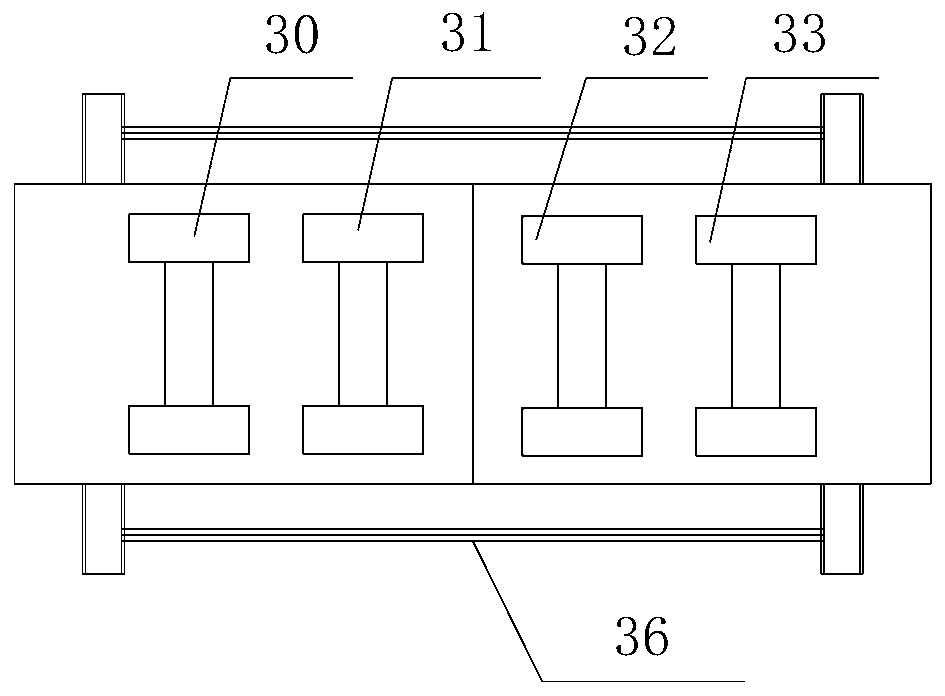

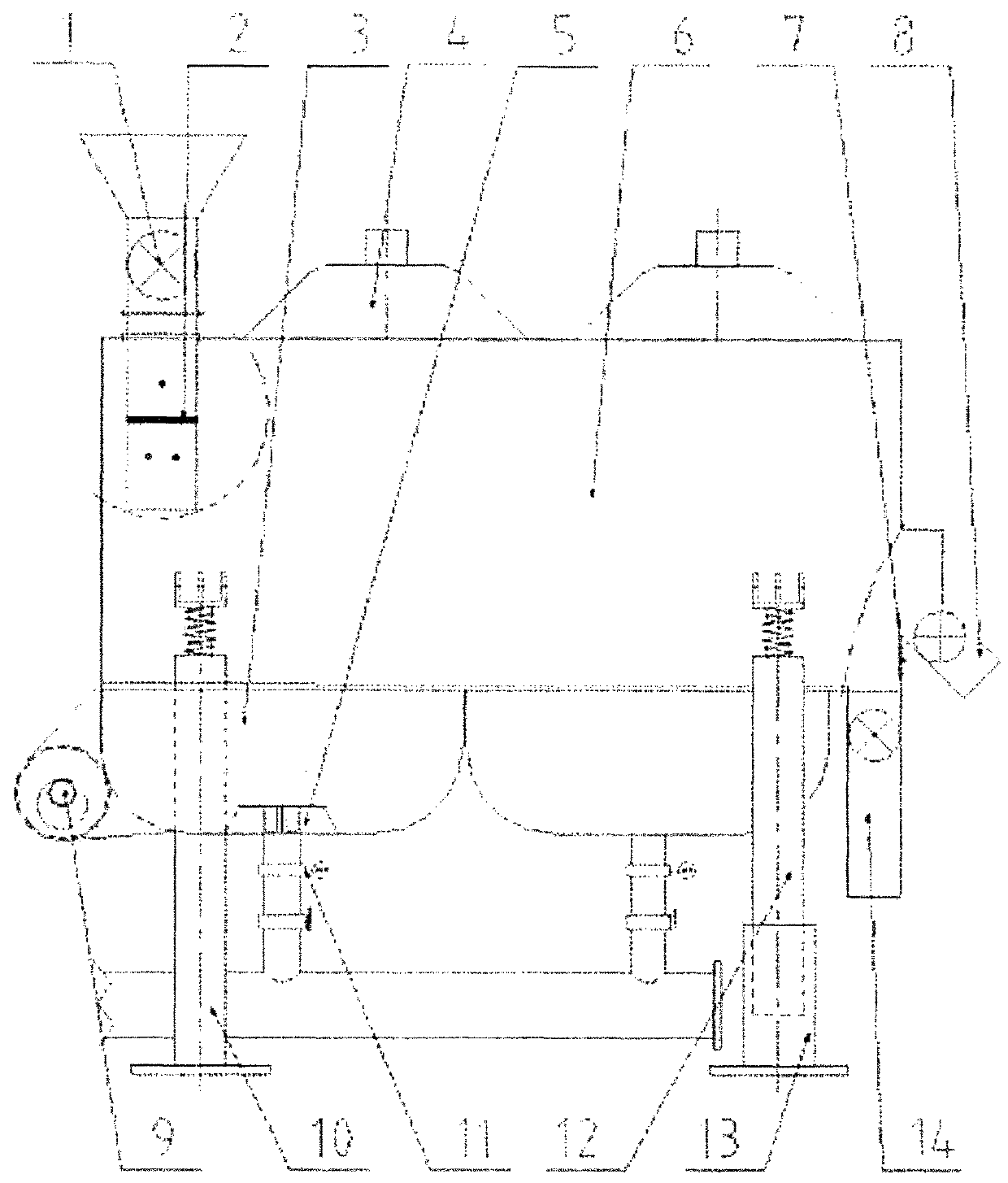

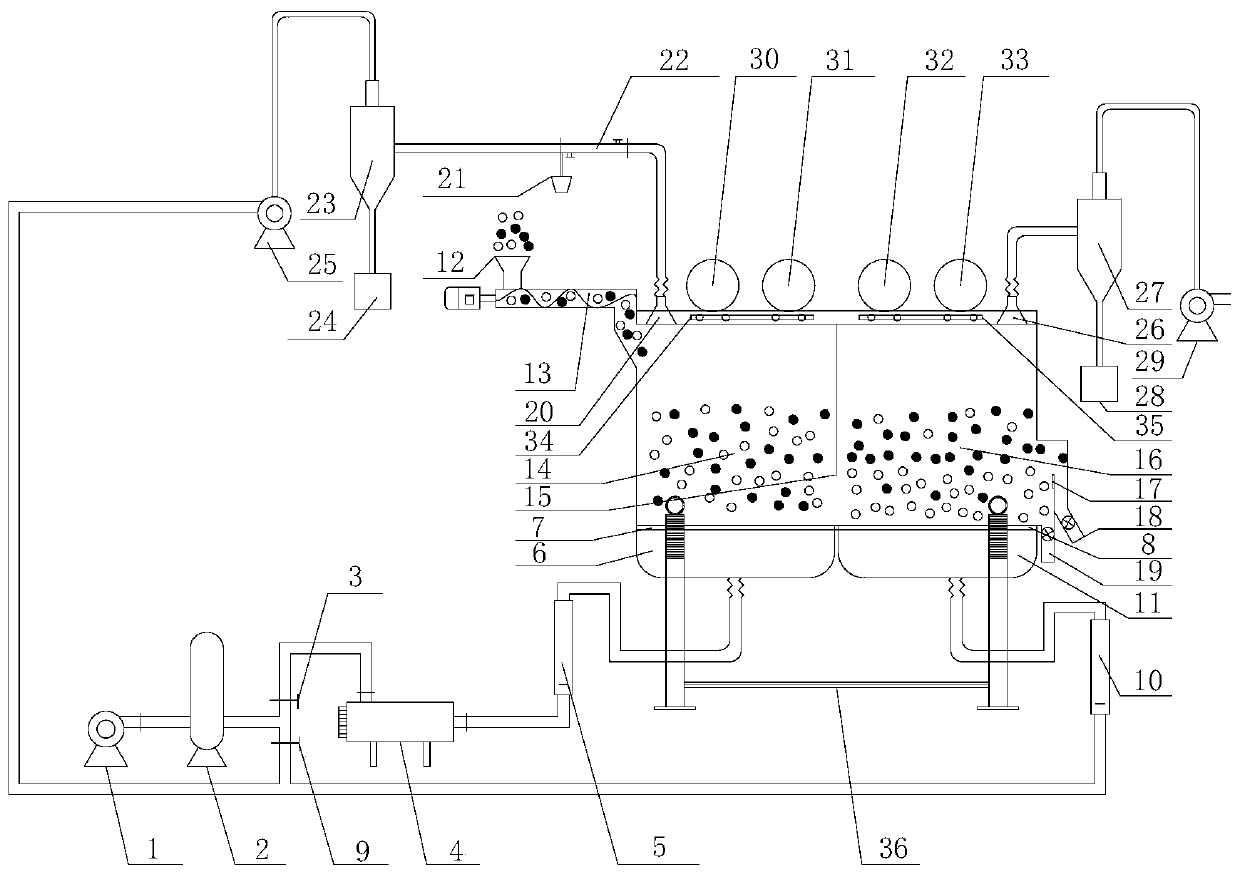

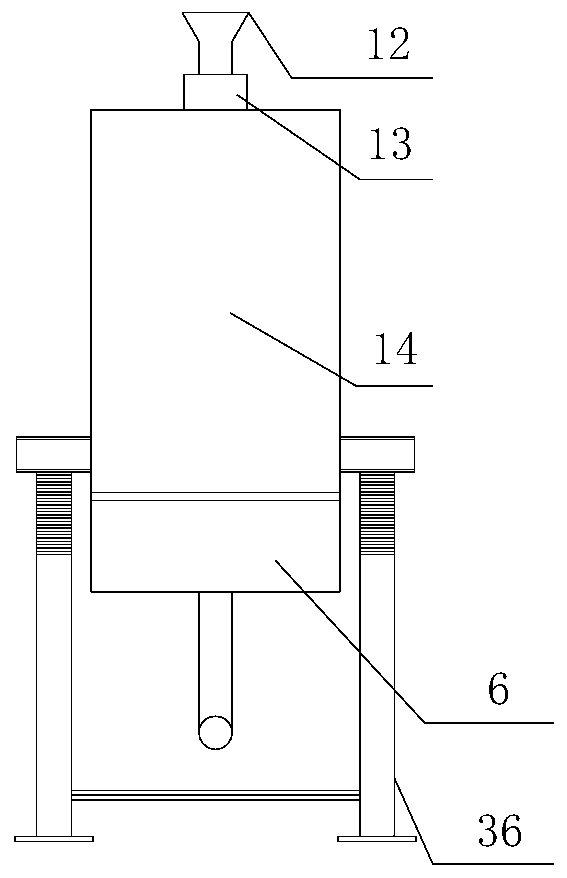

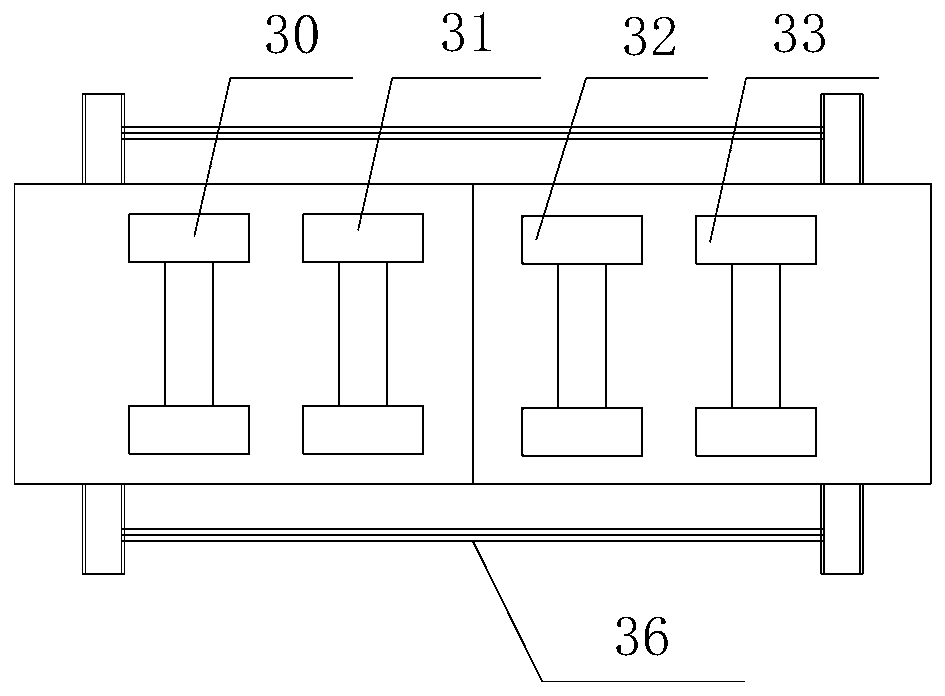

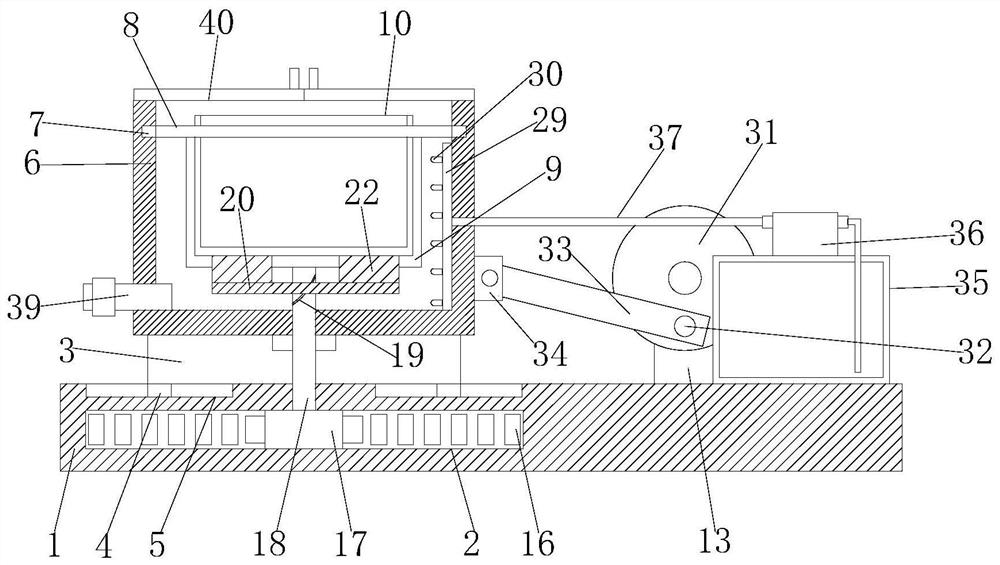

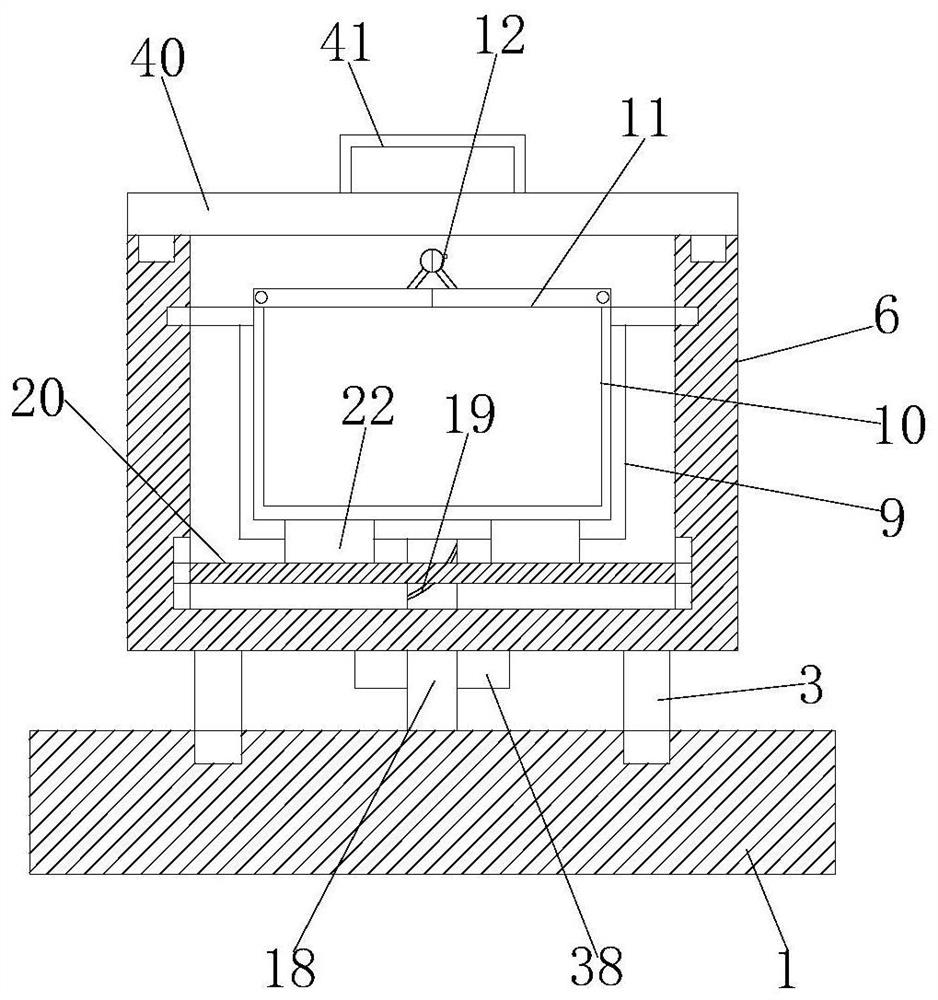

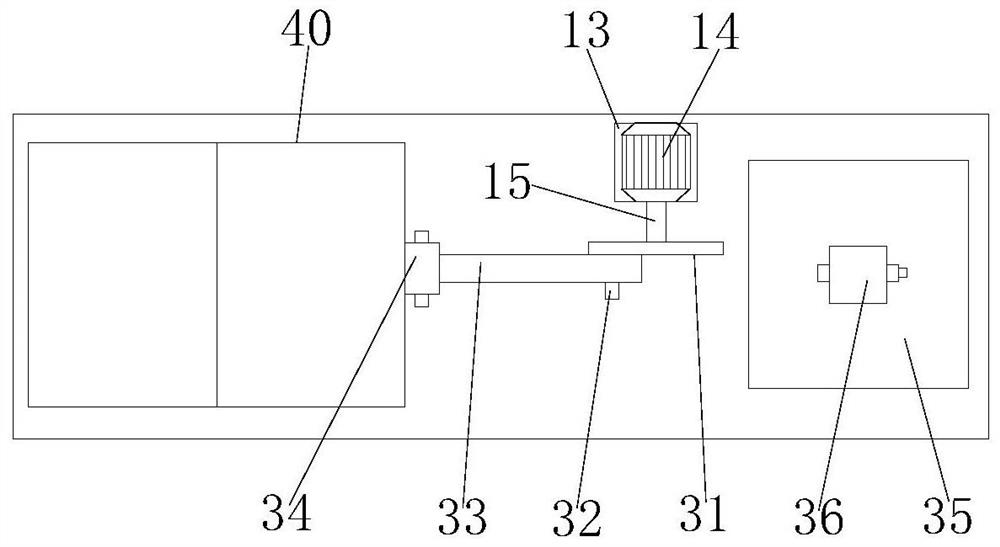

Coal variable-amplitude vibration fluidized bed drying and sorting system and sorting method

ActiveCN109731667AConvey evenlyStable deliveryDrying solid materials with heatPneumatic tablesVibration amplitudeFluidized bed drying

The invention relates to a coal variable-amplitude vibration fluidized bed drying and sorting system and a sorting method and belongs to the technical field of coal drying and sorting devices. The coal variable-amplitude vibration fluidized bed drying and sorting system is used for solving the technical problem that an existing coal drying device is poor in drying effect, and the sorting efficiency is difficult to improve. The drying and sorting system comprises a drying and sorting unit, an air supply unit, a feeding unit, a discharging unit, an induced draft dust-removing unit and a supporting unit. The air supply unit and the induced draft dust-removing unit are connected with the bottom and the top of the drying and sorting unit correspondingly. The supporting unit is used for supporting the drying and sorting unit. The drying and sorting unit is internally provided with a dividing plate and is divided into a drying section bed body and a sorting section bed body, wherein the top of the drying section bed body and the top of the sorting section bed body are provided with a drying section vibration exciting device and a sorting section vibration exciting device correspondingly,and the vibration amplitude of the drying section vibration exciting device is larger than that of the sorting section vibration exciting device. The coal variable-amplitude vibration fluidized bed drying and sorting system achieves integration of drying and sorting and has the characteristics of a good drying effect, high sorting efficiency, low cost, wide application range, convenient operationand the like.

Owner:CHINA UNIV OF MINING & TECH

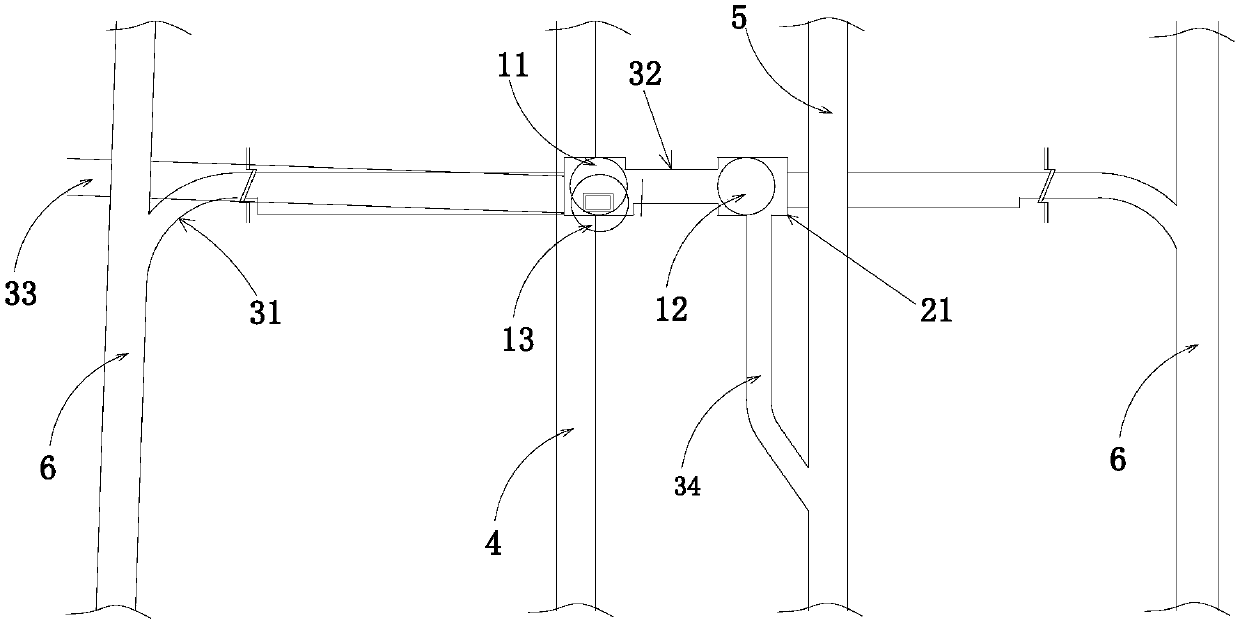

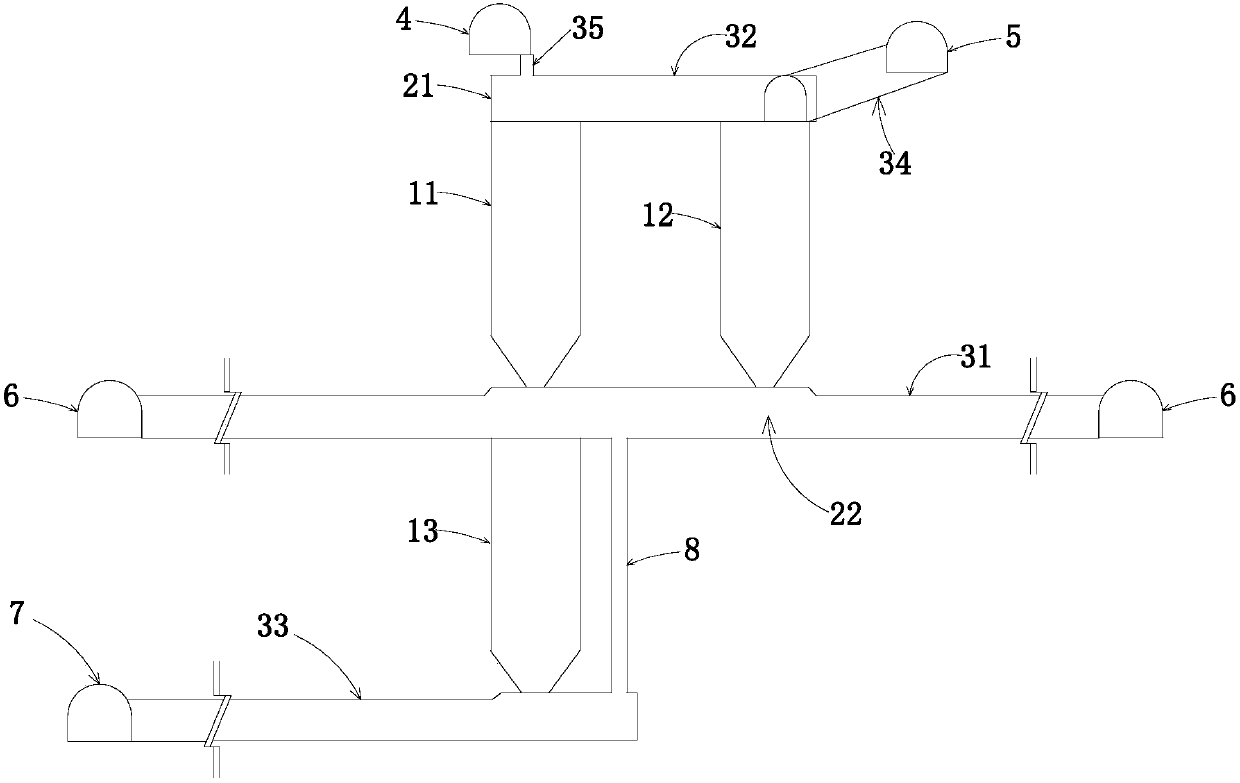

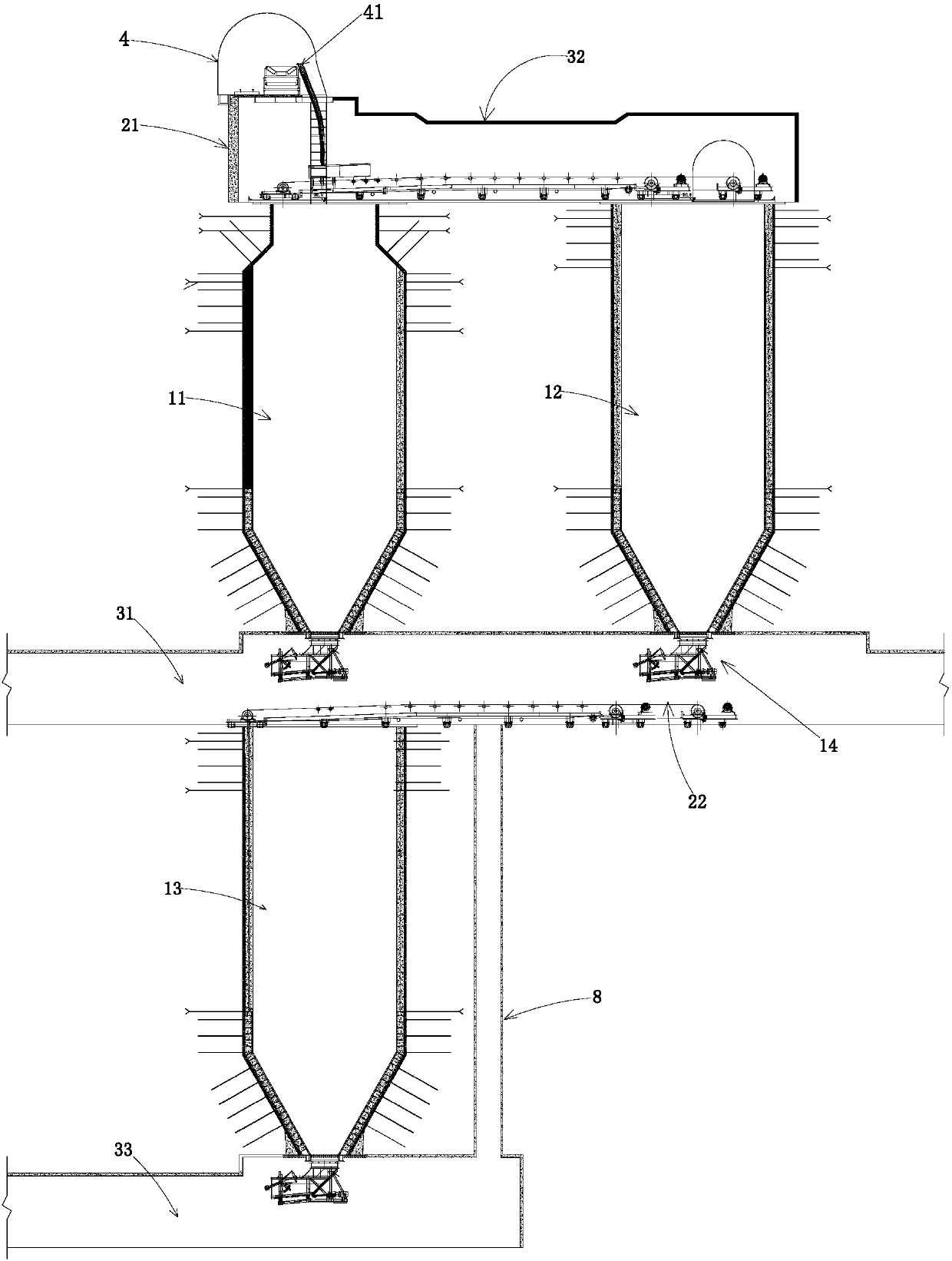

Comprehensive treatment system for underground coal gangue of coal mine

InactiveCN107905837AImprove project qualityShorten construction timeUnderground chambersMaterial fill-upMining engineeringIntegrated processing

The invention discloses a comprehensive treatment system for coal and gangue underground in coal mines, which solves the problems of separation of coal and gangue and utilization of gangue. The connecting lane of the top chamber, the air inlet hole and the track alley, the comprehensive gangue body warehouse includes the gangue bin, the gangue bin and the filling gangue bin. Underneath, the gangue bin roof chamber connects the gangue bin and the gangue bin entrance, and the outlets of the gangue bin and gangue bin are set on the top of the gangue bin connection lane, which connects the two track lanes and fills the gangue bin The entrance is set in the gangue storage lane, the outlet is set in the filling lane, and the air inlet connects the filling lane and the gangue bin lane. The underground coal and gangue comprehensive processing system of coal mine also has the advantages of strong gangue storage and transportation capacity, alleviating the transportation conflict between coal and gangue, improving coal quality, and collecting and utilizing gangue.

Owner:临沂矿业集团菏泽煤电有限公司

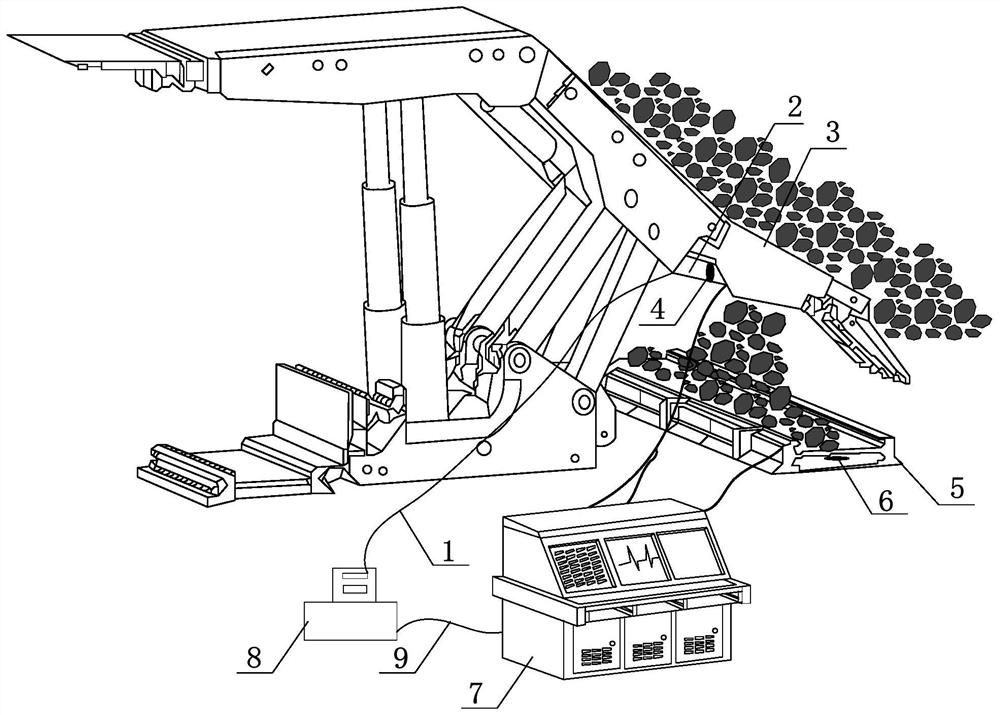

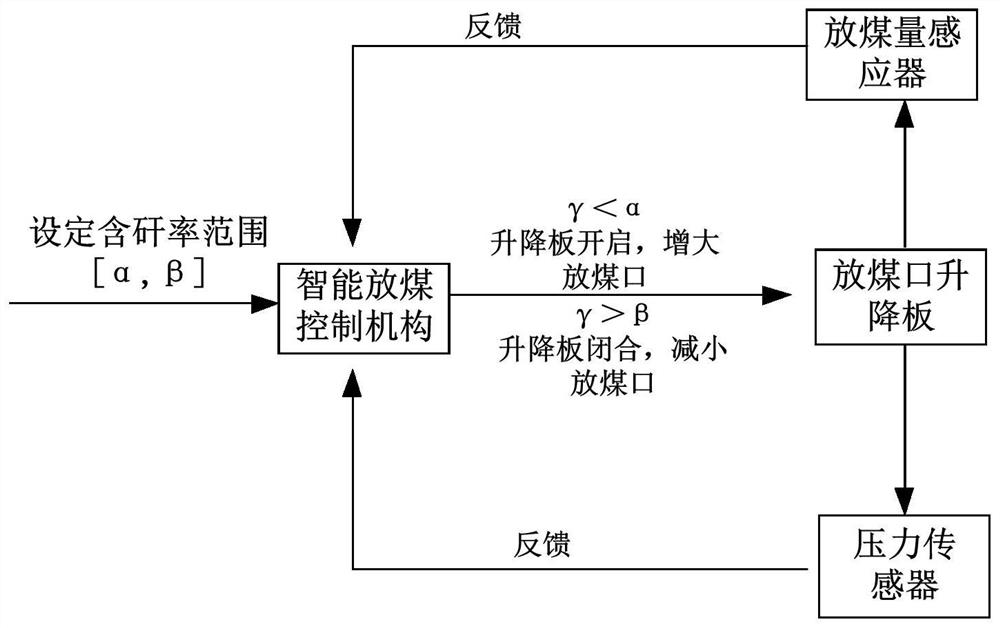

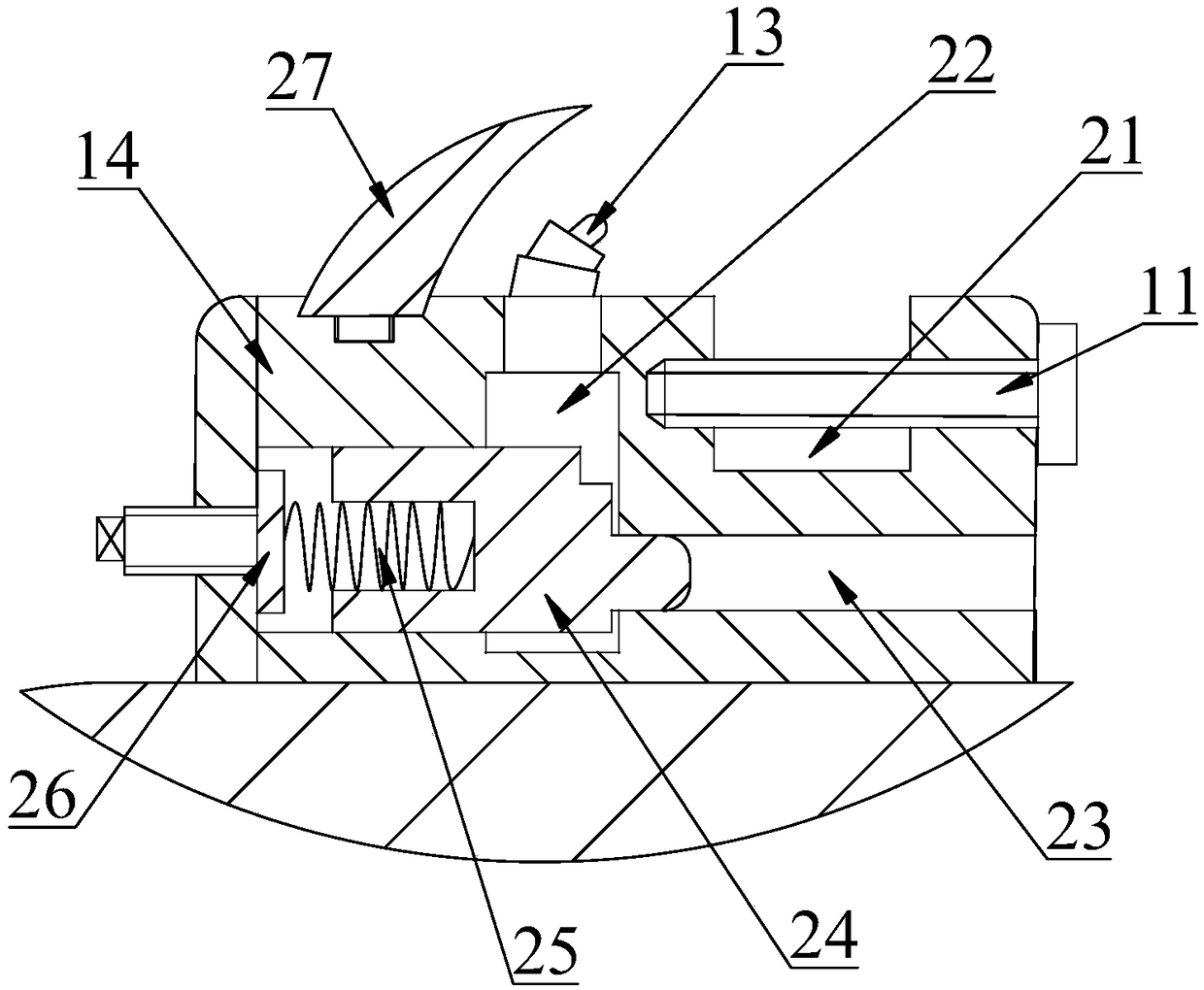

Intelligent coal control device and method for full-mechanized caving mining bracket of thick coal seam

InactiveCN111980739AImprove coal qualitySafe and efficient productionMine roof supportsUnderground transportControl systemStructural engineering

The invention provides an intelligent coal control device and method for a full-mechanized caving mining bracket of a thick coal seam, relates to the technical field of underground mining methods, andaims to solve the technical problems that a caving control system is complex in structure, is low in caving quality and the like. A caving control device comprises a caving mechanism, a coal carryingmechanism and a control mechanism, wherein the caving mechanism is arranged on the rear part of a full-mechanized caving hydraulic bracket, and comprises a hydraulic pipeline, a lifting movable column, a caving hole lifting plate and a caving amount inductor, and is used for controlling caving and monitoring the volume of outlet coal; the coal carrying mechanism is arranged below a hydraulic bracket, and comprises a scraping plate conveyor and a pressure sensor for conveying coal gangues and monitoring weight; and the control mechanism comprises a computer, an electric-hydraulic controller and a control cable for monitoring and judging caving quality and controlling caving. After coal refuse content is set by the device, monitored data of the caving amount inductor and the pressure sensorare combined to judge and regulate opening and closing of a caving hole. The device and the method provided by the invention further have the advantages of being simple in structure, flexible in operation, safe and efficient, and the like.

Owner:中煤能源研究院有限责任公司

A kind of microwave radiation preparation method of coal-based activated carbon for removing pyrene

InactiveCN103896269BAbundant resourcesImprove coal qualityCarbon compoundsWater/sewage treatment by sorptionMicrowave radiometryMicrowave method

The invention discloses a method for removing a polycyclic aromatic hydrocarbon, namely pyrene, in simulated wastewater by virtue of adsorption by using coal-based active carbon which is prepared by taking Xinjiang anthracite as a carbon source and by use of a microwave radiation method. The coal-based active carbon is prepared through the steps of mixing activators with the anthracite, putting the mixture in a microwave reaction device, and finally carrying out one-step carbonization and activation in the presence of the activators KOH, ZNCl2 and H3PO4 under the conditions of an agent-to-material ratio of 1: 1 to 1:5, microwave time of 4-20 minutes, microwave power of 100W to 900W and N2 protection. The coal-based active carbons prepared in different embodiments have an average pore size of 28.22-42.54 angstroms, and also have relatively large specific surface area; the specific surface area is 623.84-1770.49 m<2> / g, and the total pore volume is 0.32-0.99 cm<2> / g. The adsorbing capacity of the coal-based active carbon to the pyrene reaches 89.43mg / g, and the removal rate of the pyrene is 99.37%. For removing the pyrene in wastewater, the coal-based active carbon prepared by use of a microwave method is characterized in that energy saving and high efficiency are shown in the preparation process of the active carbon, the active carbon has the advantages of large adsorption capacity, high adsorption rate, remarkable treatment efficiency and the like, and thus has excellent economic benefit and environmental benefit.

Owner:SHIHEZI UNIVERSITY

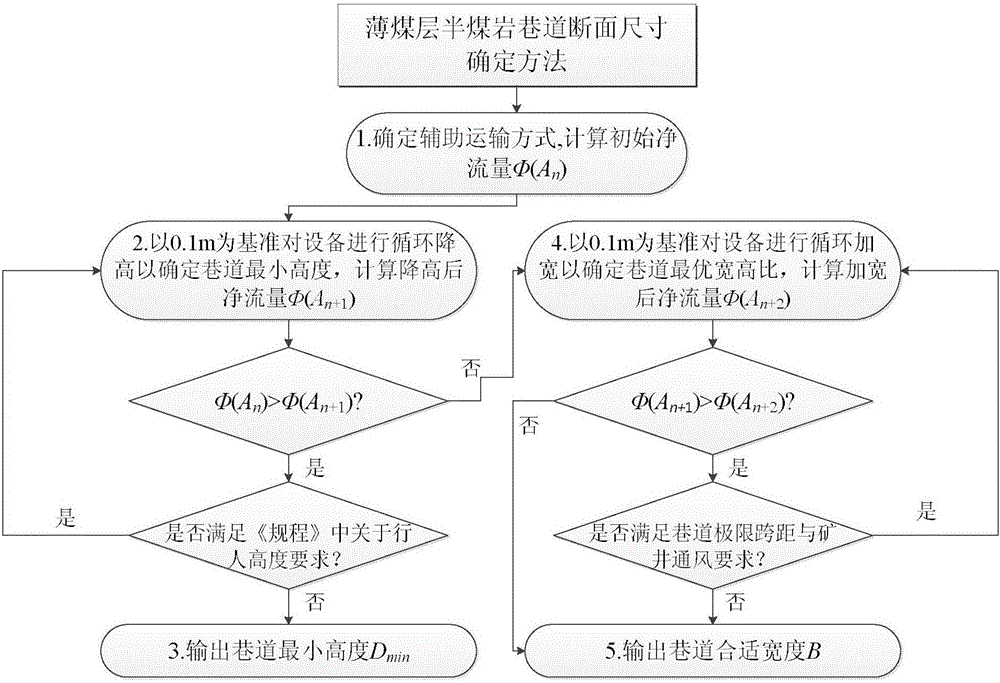

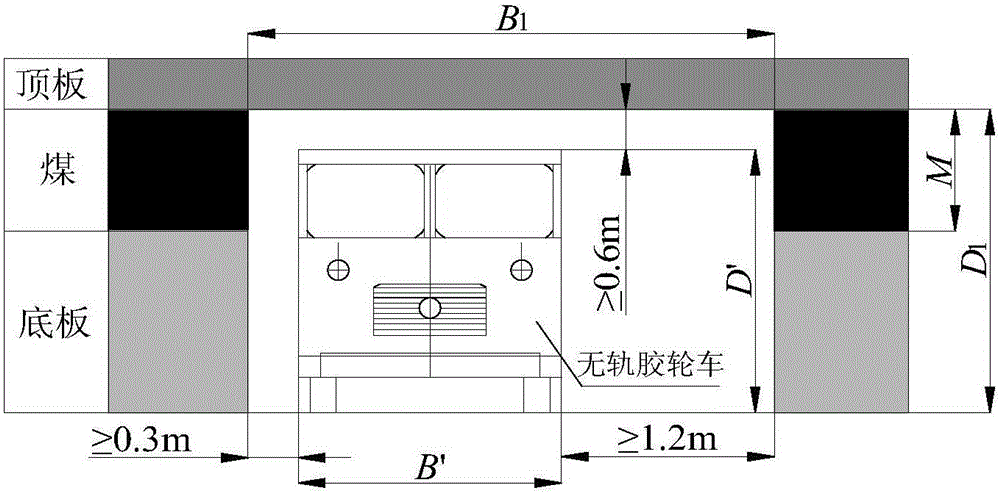

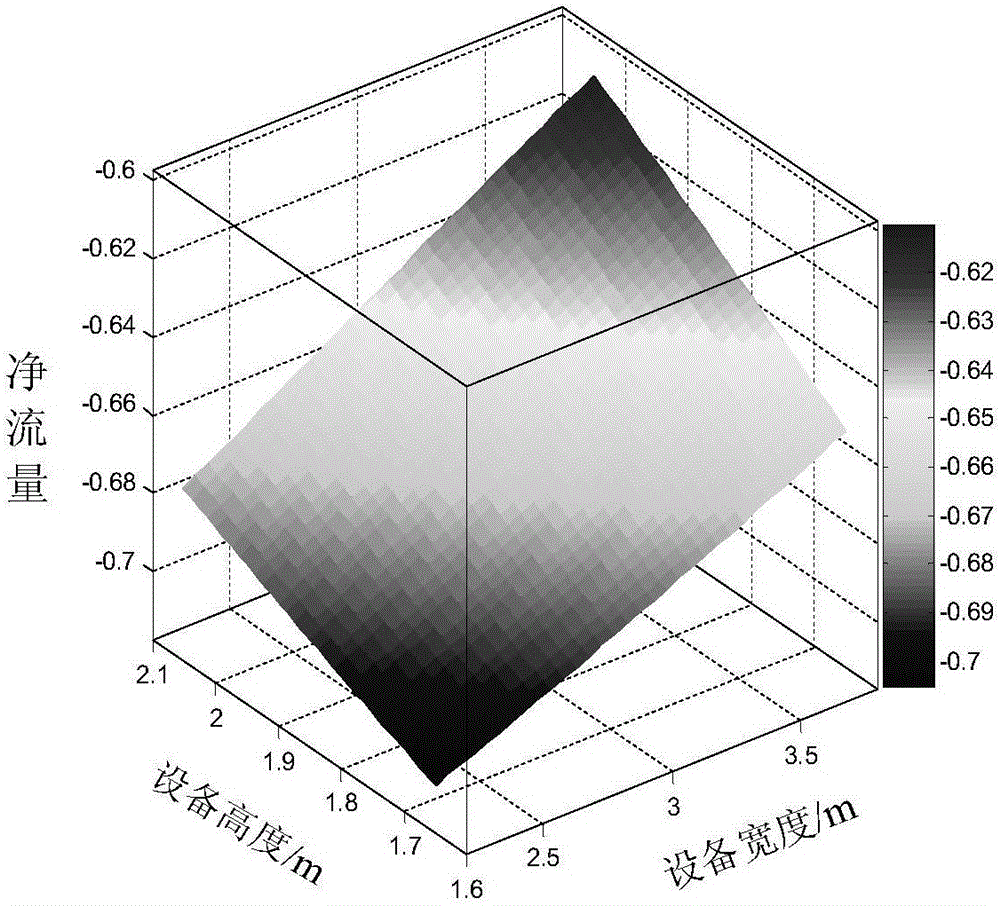

Method for determining section size of half coal rock roadway in thin coal seam

ActiveCN105956929ALow costReduce gangue contentGeometric CADData processing applicationsSize determinationCoal

The invention relates to a method for determining the section size of a half coal rock roadway in a thin coal seam, and belongs to a thin coal seam roadway section size determination method. The method comprises the steps of firstly preliminarily determining an appropriate section size of the half coal rock roadway; secondly, optimizing the section size of the roadway according to a principle of first height then width, that is, reducing the height of the roadway at first so as to determine the minimum height of the roadway, and widening the roadway so as to determine an optimal roadway width to height ratio; checking whether the reduced roadway height meets a pedestrian height requirement or not, and determining the minimum height of the roadway; and checking whether the widened roadway meets limit span and mine safety ventilation requirements or not, determining the optimal width to height ratio of the roadway, and acquiring the reasonable width of the roadway. The method provided by the invention combines various geological conditions of the thin coal seam, realizes the value engineering of exchanging rock for coal of the thin coal seam, reduces the tunneling working surface cost, reducing the percentage of shale content, improving the coal quality, and increasing single inlet and per unit yield under the condition of slightly breaking or not breaking rock.

Owner:CHINA UNIV OF MINING & TECH

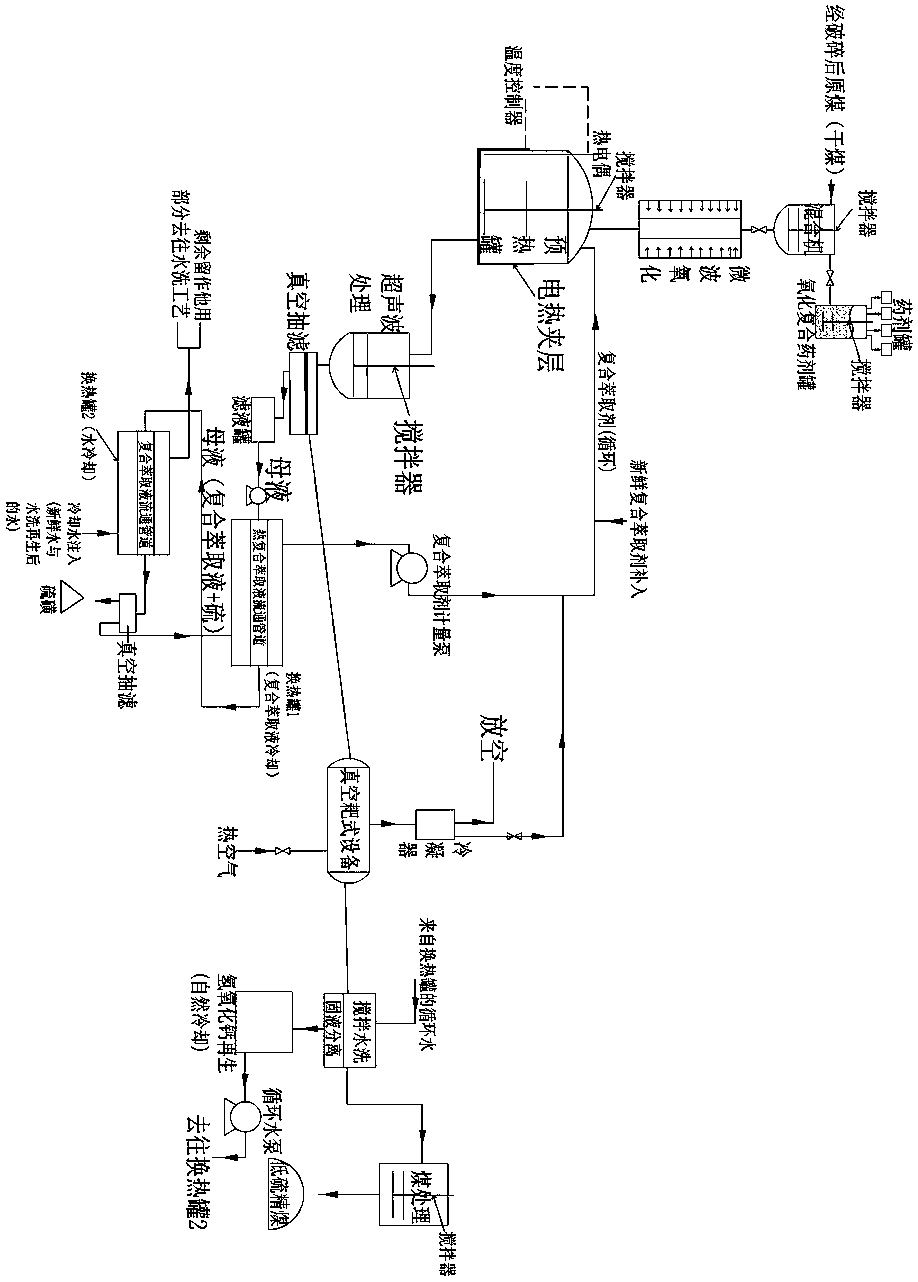

Coal electromagnetic radiation desulfurization upgrading system

The invention provides a coal electromagnetic radiation desulfurization upgrading system, aiming at reducing the content of sulfur in coal, improving the quality of sulfur coal resources and providingpreceding guarantee to ultralow emission. The system comprises a charge and delivery unit, a desulfurization medium feed unit, a mixing unit, an electromagnetic radiation unit and a magnetic separation unit, raw coal is delivered and upgraded through the charge and delivery unit and enters the feed valve of the mixing unit, enters the mixing cavity of the mixing unit with a desulfurization mediumof the desulfurization medium feed unit in the feed valve, is sufficiently mixed in the mixing cavity, enters the electromagnetic radiation unit, and enters the magnetic separation unit after radiation treatment.

Owner:GUODIAN SCI & TECH RES INST

Coal dressing method achieving whole-particle-size sorting

InactiveCN105750206ARealize full granularity sortingEffective sorting and dischargeGradingSulfurProcess engineering

The invention discloses a coal dressing method achieving whole-particle-size sorting. According to the scheme, sorting is performed on raw coal many times through a plurality of different-height and different-hole-diameter segmented bed surfaces; medium coal, gangue, ferrous disulfide and other impurities in the raw coal are sorted into a secondary bed surface, and clean coal is acquired; meanwhile, gangue, ferrous disulfide and other impurities of the secondary bed surface are sorted to a ternary bed surface, and medium coal is obtained; the clean coal and the medium coal are subjected to multiple times of sorting of a plurality of segments of different-height and different-hole-diameter bed surfaces so that the clean coal and the medium coal meeting the requirements can be acquired; finally, the clean coal, the medium coal, gangue and impurities are discharged in a classified mode. Whole-particle-size sorting of a dry coal-dressing machine is achieved, and gangue, ferrous disulfide and impurities in all particle sizes are effectively sorted and discharged. The gangue discharging, desulphurization, ash falling and coal quality improving purposes are achieved.

Owner:杨志辉

Drying and separation integrated machine for vibrating fluidized bed

ActiveUS9964357B2Simple structureImprove reliabilityDrying solid materials with heatPneumatic tablesImpellerFluidized bed drying

Drying and separation vibrating fluidized bed for processing wet coal by high-temperature hot air. Wet coal is fed into a vibrating separation chamber connected to a hot air supply duct. The wet coal is vibrated as it is dried and is layered as heat and mass transfer occur between the high-temperature air and the wet coal particles. Hot air enters the bottom of separation chamber through a distribution plate that includes asbestos fiber cloth sandwiched between clamping plates. The wet coal is fed through a feeding distribution device that separates the coal pieces as they enter the separation chamber. After the coal is dried and layered, the heavy and light material exits the separation chamber through two discharge impellers.

Owner:CHINA UNIV OF MINING & TECH

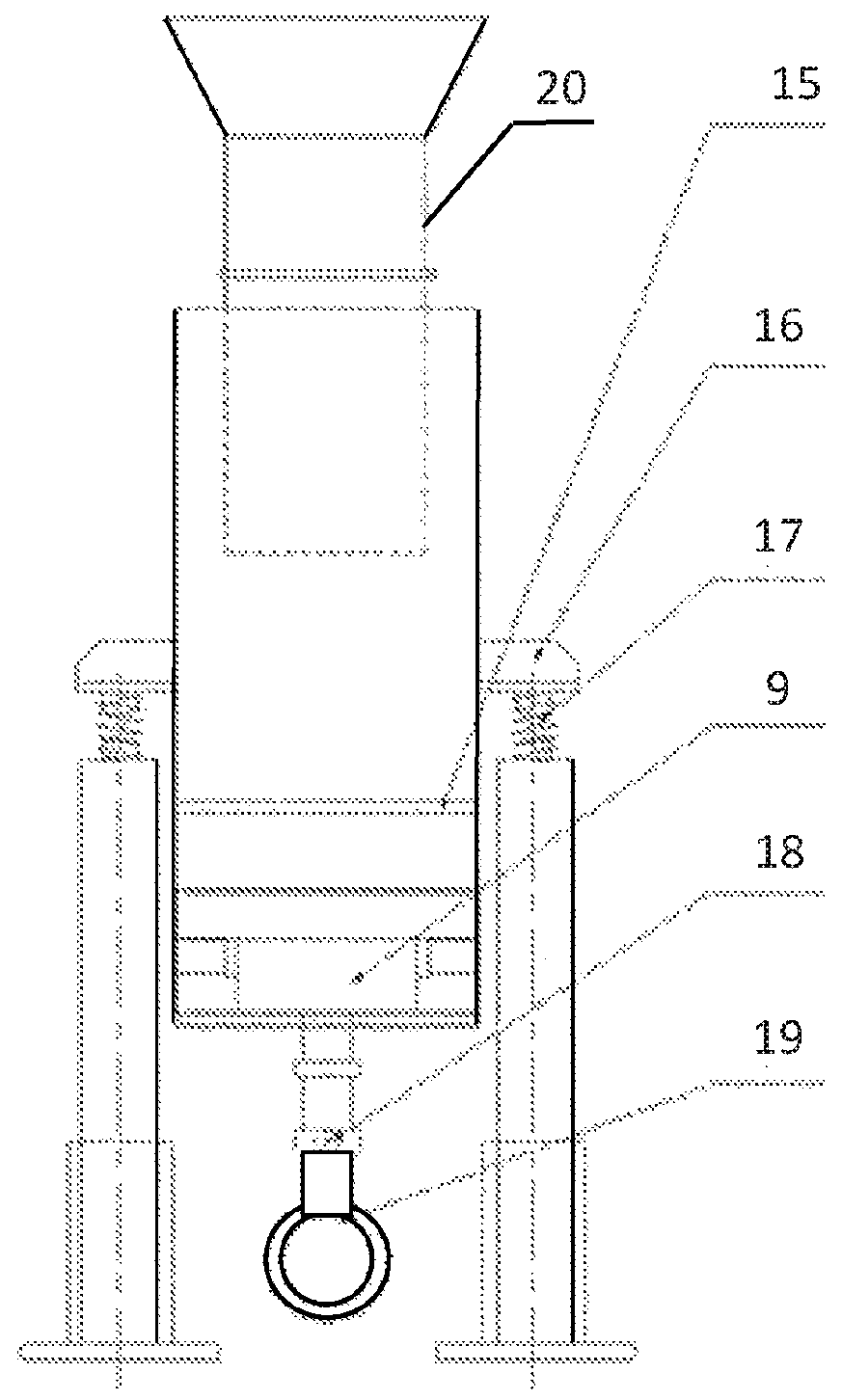

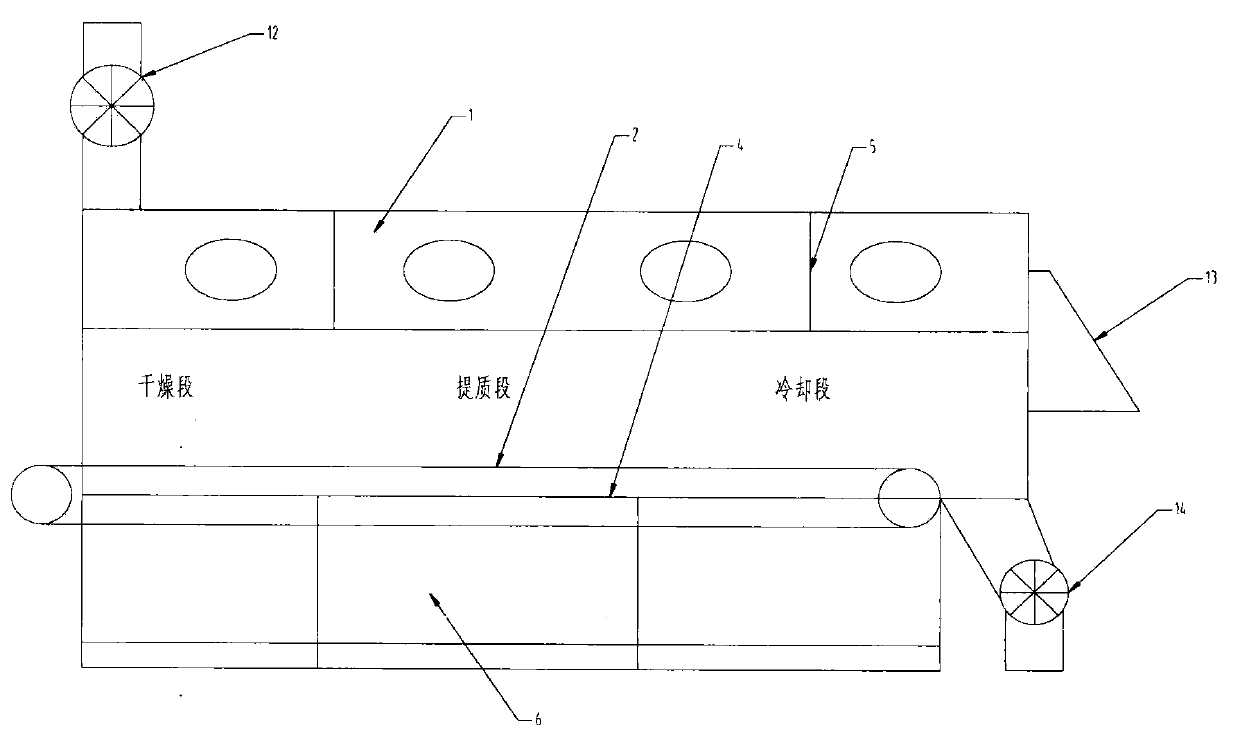

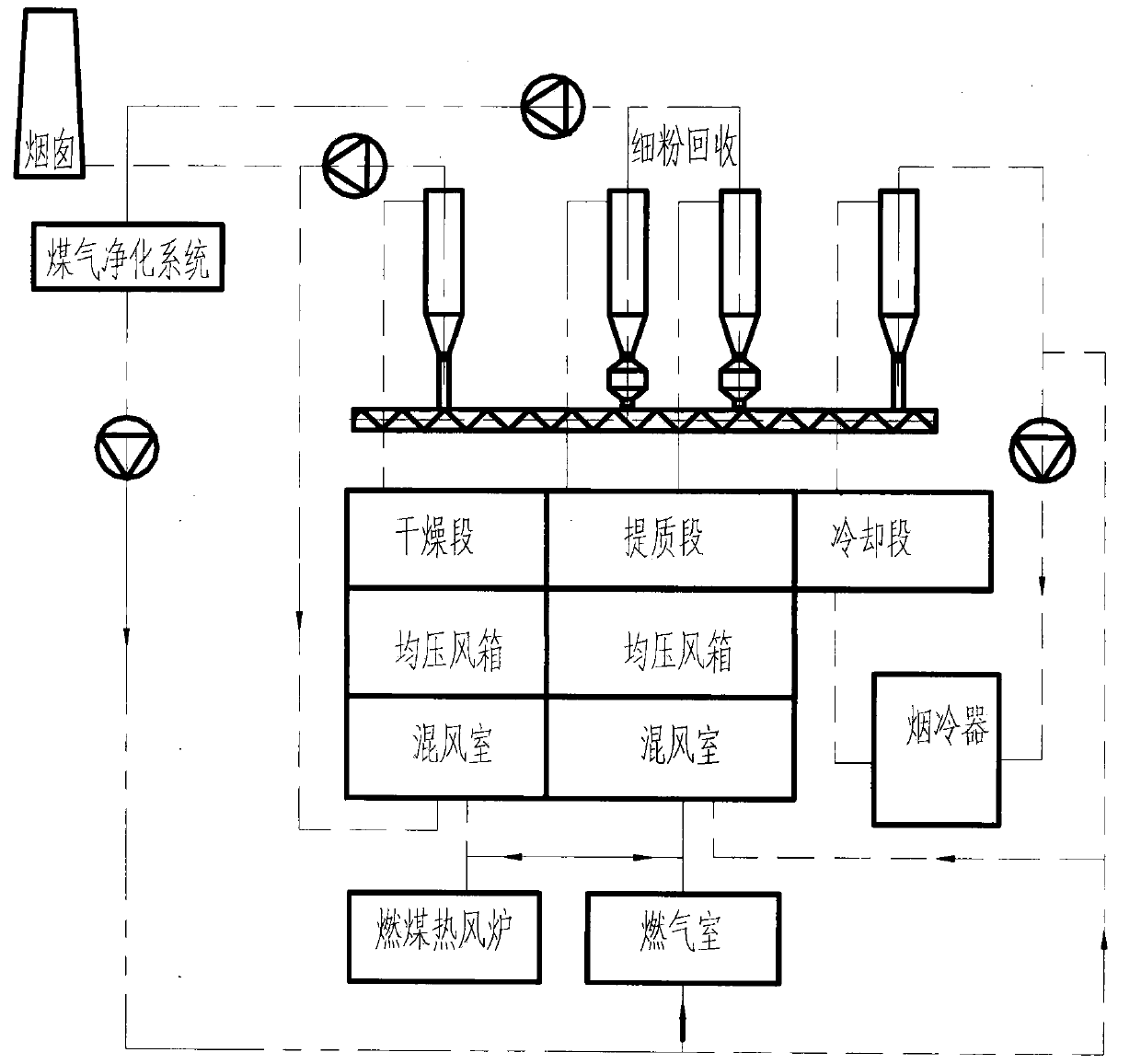

Large fluidized bed system and device for drying and upgrading lignite

InactiveCN104180609AEnsure quality improvementMove fastDrying solid materials with heatDrying gas arrangementsFluidized bedEngineering

The invention relates to a fluidized bed system for grading, drying and upgrading lignite. The fluidized bed system comprises a fluidized bed, coal-burning hot air furnaces and a hot air recycling system, and the hot air recycling system hermetically connects the coal-burning hot air furnace with the fluidized bed. The fluidized bed system is characterized in that broken lignite entering the fluidized bed is divided into upgrading coal granules and fine coal powder, the fine coal powder is sent into the coal-burning hot air furnaces for burning to provide heat for the fluidized bed system, the fluidized bed system further comprises a lignite grading and upgrading system, and the upgrading coal granules are graded according to granular size in the fluidized bed under action of the lignite grading and upgrading system and subjected to upgrading of different degrees according to difference in granular size of the coal granules. By the fluidized bed system, industrialized grading, drying and upgrading of lignite can be realized, and utilization rate of lignite is increased.

Owner:赵建勋

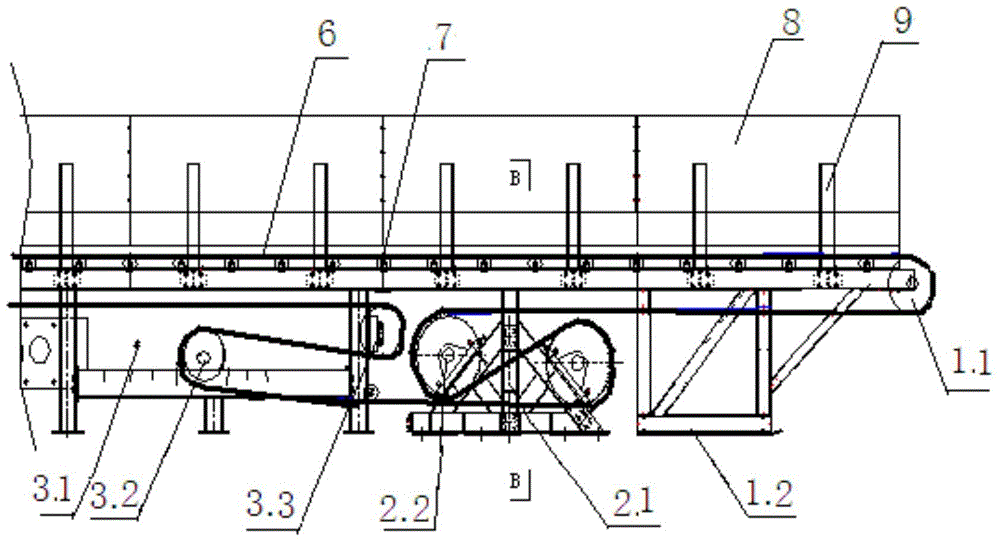

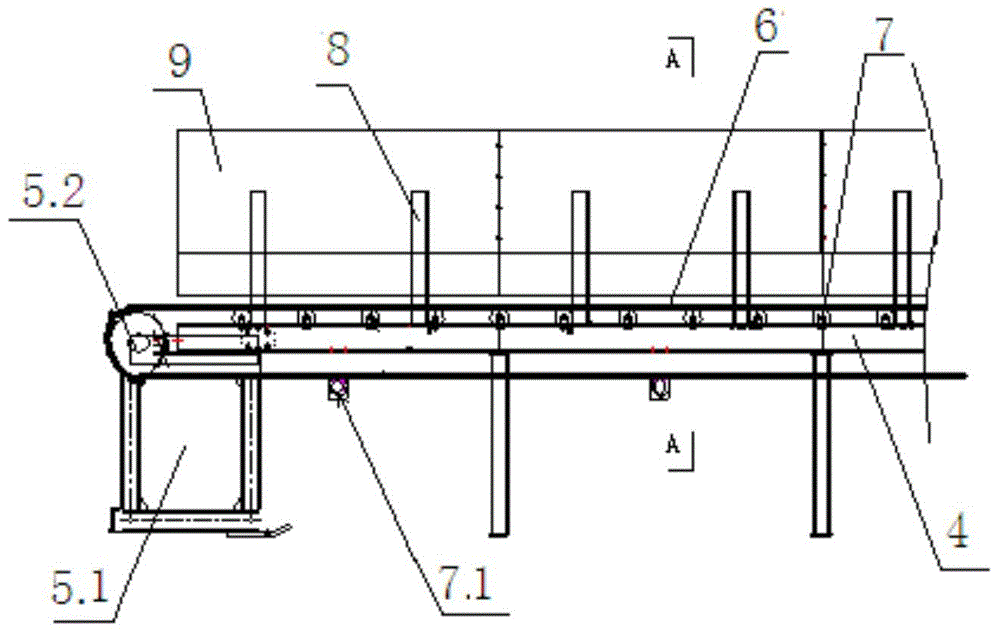

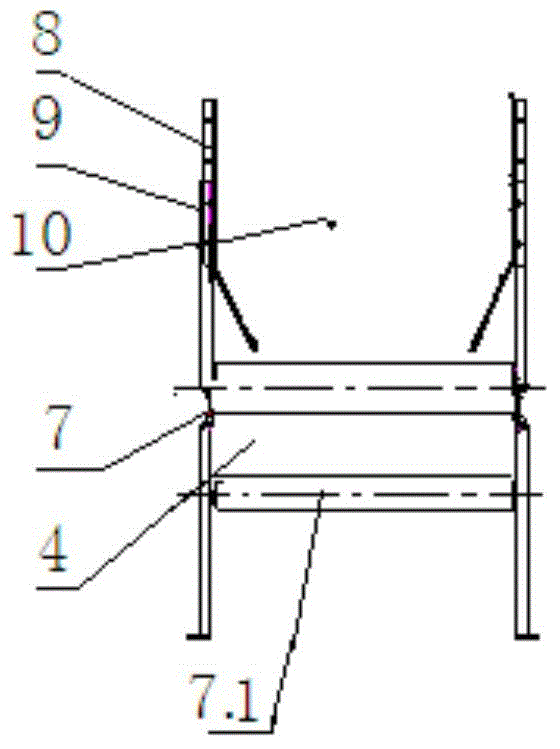

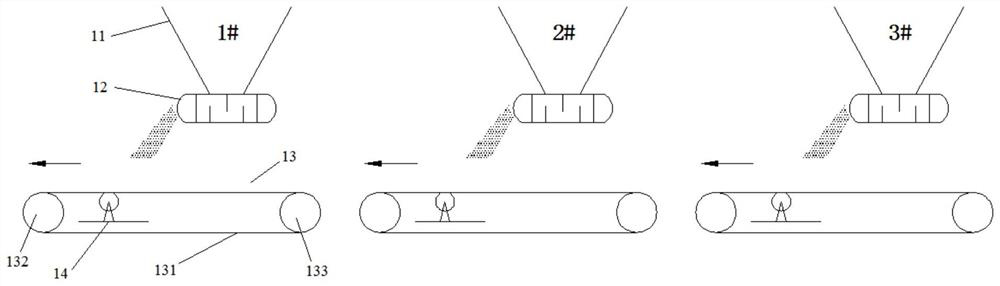

Belt type storing and conveying machine and method for storing and conveying gangue for underground heading face

The invention discloses a belt type storing and conveying machine and a method for storing and conveying gangue for an underground heading face. Upper carrier rollers and lower carrier rollers are arranged on a rack at intervals; rotary drums are arranged at the two ends of the rack; a pair of driving drums and tensioning drums are arranged below the rack; the driving drums are dragged by a driving device to rotate; vertical supports are fixedly connected to the two sides of the rack at intervals; material blocking plates are arranged on the vertical supports so as to enable groove-type spaces to be formed above the conveying belt; and the driving device is composed of a permanent magnet direct-current driving frequency conversion speed regulating motor and a frequency converter, wherein the motor is in rigid linkage with the driving rollers through elastic pin couplings. When the gangue is output from the heading face, the groove type spaces of the storing and conveying machine running at a low constant speed are filled with the gangue sent to the machine. When storage is full, the machine stops running and waits for being unloaded; when a tunnel conveying system is free in coal conveying, the stored gangue can be rapidly unloaded to the tunnel conveying system of, and therefore time conflict between outputting the gangue from the heading face and outputting coal of a working face is solved, and the tunneling efficiency is greatly improved.

Owner:XINWEN MINING GROUP ZHAI TOWN COAL MINE

A gel foam for coal seam fire control

InactiveCN103742186BImprove adhesionHigh strengthDust removalFire preventionCoal seam fireTherapeutic effect

The invention discloses a gel foam for coal seam fire control, wherein the gel foam comprises 1.5%-0.7% of foaming agent, 1%-0.4% of synthetic super absorbent foam stabilizer and the balance of water by weight percentage. Compared with the traditional water slurry and gel, the gel foam is wider in coverage and can be piled up in the vertical direction quickly; the gel foam is capable of bringing more water and solid incombustible matters into a fire preventing and extinguishing region; as a result, the foam intensity is enhanced and the fire preventing and extinguishing efficiency is greatly improved; the foaming agent is formed by compounding surfactants such as an alkyl glycoside and an alkane sulfonate; the synthetic super absorbent resin is good in salt resistance; the gel foam is also obviously improved in water absorption capability in contrast with other gel foam; besides, the time taken to separate out 50 ml of water by standing the gel foam ranges from 4 to 5 hours; the time of the half foam life period is more than 18 hours; the stability of the foam and the persistence of foam plugging are improved; and moreover, the gel foam can be piled up in the vertical direction and is capable of achieving the prevention and treatment effects on high-position and medium-position coal.

Owner:SHANDONG UNIV OF SCI & TECH

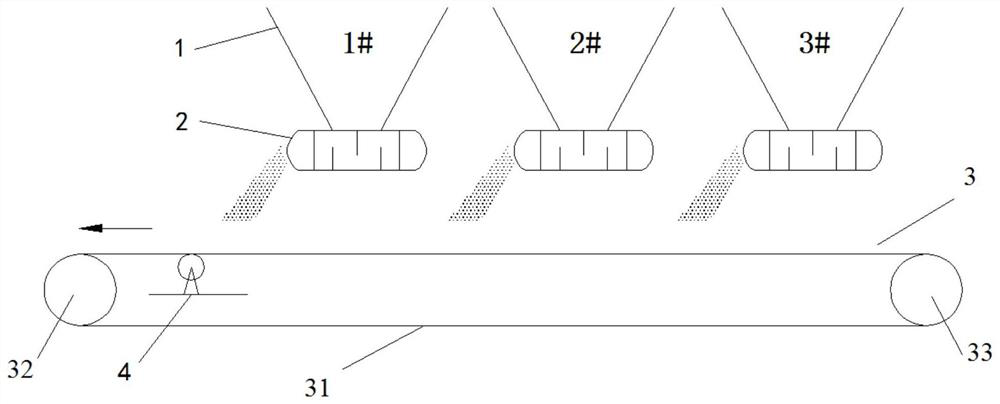

An optimization method to improve the accuracy of automatic coal blending in large-volume silos

ActiveCN110626820BImprove accuracyImprove pass rateConveyorsControl devices for conveyorsProcess engineeringCoal blending

The invention discloses an optimization method for improving the accuracy of automatic coal blending in large-volume silos, and belongs to the field of automatic instrument program control for coal blending production in large-volume silos in the coking industry. This method is based on the fact that every 3 feeding nozzles share a set of automatic coal blending weighing system, which can better solve the coal blending accuracy caused by the frequent start and stop of the main conveyor belt in the coal blending process, which causes a large number of low-accuracy running times to overlap. Falling puzzle. Moreover, the method of the present invention is simple, easy to operate, and has strong reliability. After use, the quality of mixed coal is significantly improved, which can effectively improve the accuracy of automatic coal blending and the qualified rate of mixed coal quality in large-volume silos, reduce invalid running time, and improve production efficiency. .

Owner:BAOTOU IRON & STEEL GRP

A Coal Variable Amplitude Vibration Fluidized Bed Drying and Separating System and Sorting Method

ActiveCN109731667BConvey evenlyStable deliveryDrying solid materials with heatPneumatic tablesFluidized bed dryingDust control

The invention relates to a coal variable-amplitude vibration fluidized bed drying and sorting system and a sorting method and belongs to the technical field of coal drying and sorting devices. The coal variable-amplitude vibration fluidized bed drying and sorting system is used for solving the technical problem that an existing coal drying device is poor in drying effect, and the sorting efficiency is difficult to improve. The drying and sorting system comprises a drying and sorting unit, an air supply unit, a feeding unit, a discharging unit, an induced draft dust-removing unit and a supporting unit. The air supply unit and the induced draft dust-removing unit are connected with the bottom and the top of the drying and sorting unit correspondingly. The supporting unit is used for supporting the drying and sorting unit. The drying and sorting unit is internally provided with a dividing plate and is divided into a drying section bed body and a sorting section bed body, wherein the top of the drying section bed body and the top of the sorting section bed body are provided with a drying section vibration exciting device and a sorting section vibration exciting device correspondingly,and the vibration amplitude of the drying section vibration exciting device is larger than that of the sorting section vibration exciting device. The coal variable-amplitude vibration fluidized bed drying and sorting system achieves integration of drying and sorting and has the characteristics of a good drying effect, high sorting efficiency, low cost, wide application range, convenient operationand the like.

Owner:CHINA UNIV OF MINING & TECH

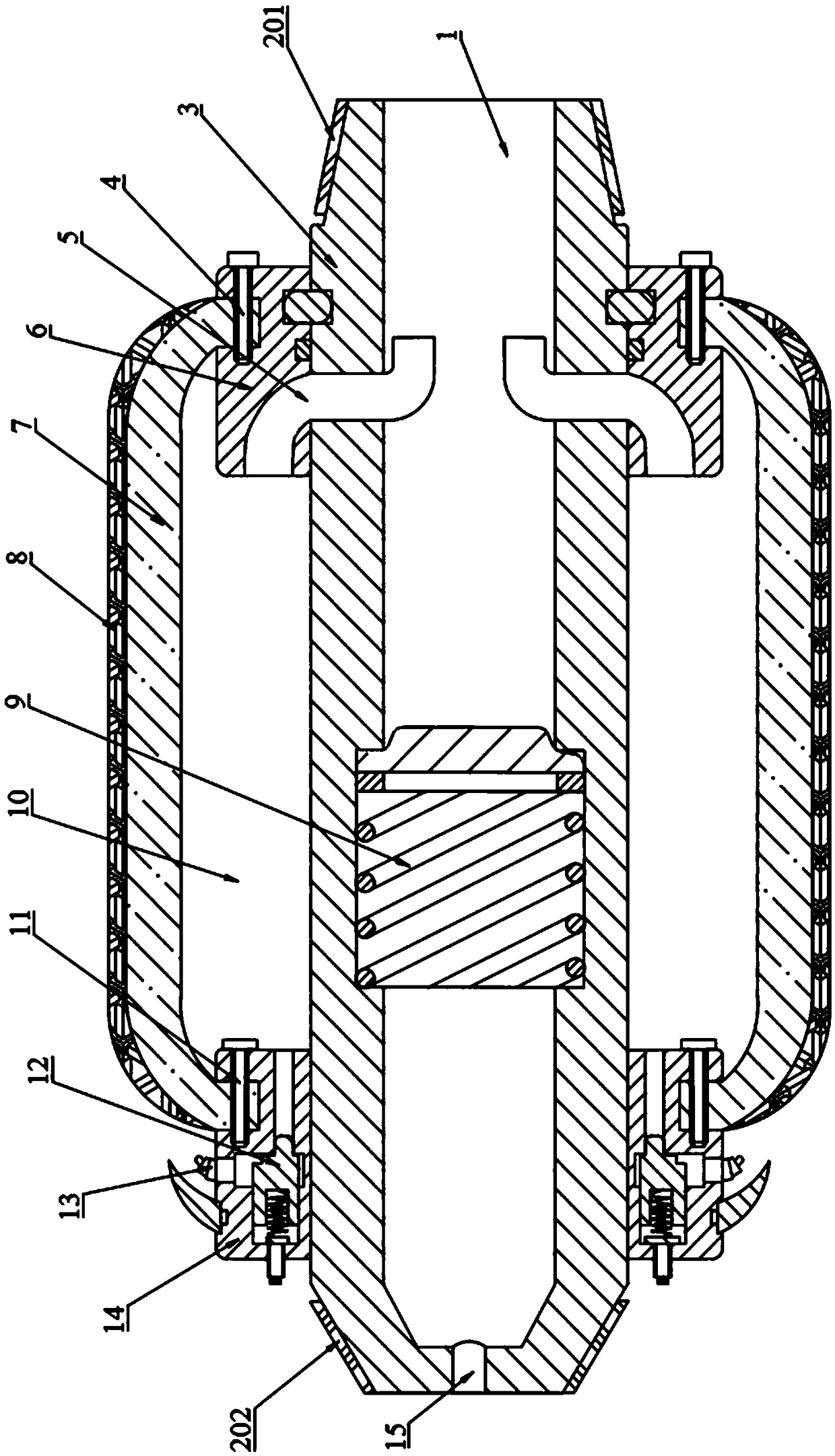

Centrifugal dewatering equipment used for coal processing and facilitating impurity removal

InactiveCN113304893AImprove coal qualityQuality improvementRotary centrifugesCleaning using liquidsEngineeringStructural engineering

The invention belongs to the technical field of centrifugal dewatering of coal processing, and particularly relates to centrifugal dewatering equipment used for coal processing and facilitating impurity removal. The centrifugal dewatering equipment comprises a base, wherein a transverse groove is formed in the base, two supporting plates are slidably connected to the top of the base, and two sliding blocks are fixedly connected to the bottoms of the two supporting plates respectively; first sliding rails are slidably connected to a plurality of sliding blocks, the first sliding rails are fixedly connected to the top of the base, the same fixing box is connected to the tops of the two supporting plates, an annular sliding way is formed in the fixing box, an annular plate is slidably connected into the annular sliding way, a fixing frame is connected to the bottom of the annular plate, and a filter box is connected to the inner ring of the annular plate; and sliding rods are fixedly connected to the two sides of the filter box, a second sliding rail is slidably connected to each of the two sliding rods, the two second sliding rails are fixedly connected to the inner ring of the annular plate, and two cover plates are rotationally connected to the top of the filter box. When the centrifugal dewatering equipment is used, impurities in coal can be effectively removed, the coal quality is improved, and the operation is simple.

Owner:谢森涛

Powerful extension bar

InactiveCN109025840AImprove sealingMeet water injectionDrilling rodsFlushingWater flowWater diversion

The application provides a powerful extension bar, comprising a body, a water diversion member, a fixed part, an elastic flexible pipe, a first control part and a movable part. End parts of two ends of the body are provided with a first connection part and a water injection hole communicated with a water inlet hole. The fixed part is fixed on the side wall of the body close to one end of the firstconnection part. The movable part is slidably mounted on the side wall of the body close to one end of a second connection part. The elastic flexible pipe is mounted on the fixed part and the movablepart. A cavity is formed between the elastic flexible pipe and the body. A polishing layer is arranged on the side wall of the elastic flexible pipe away from one side of the body. A first control part is used for controlling a water flow to flow from the water injection hole. The elastic flexible pipe of the present application can accumulate water to expand, thereby achieving sealing of the coal seam drilling; the water diversion member and the first control member simultaneously satisfy the requirements of coal seam water injection and sealing; the polishing layer is used to enable the powerful extension bar to have the function of polishing a coal seam sealing hole.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

A method for desulfurization of coal before combustion with ultrasonic equipment combined with composite extraction liquid

InactiveCN106244276BSimple reaction conditionsImprove pre-combustion desulfurization efficiencySolid fuelsCombined methodEngineering

The invention especially relates to an ultrasonic equipment and composite extract combined method for coal desulfurization before combustion. According to the ultrasonic equipment and composite extract combined method for coal desulfurization before combustion, microwave irradiation and ultrasonic cleaning are combined. Thus, coal reaction conditions can be improved, internal reaction speed of coal is accelerated, and selective modification and quality improvement of coal are realized. Meanwhile, the method has advantages of high efficiency, no corrosion, no pollution, direct treatment of 0-13 mm fine coal, no change of coking coal characteristic and further quality improvement of coal, and is of great significance for raising efficiency of coal desulfurization before combustion.

Owner:江苏鱼德水科技有限公司

Intelligent sorting and in-situ filling device and disassembly and assembly method

ActiveCN113171829AReduce lifting costsSolve pollutionSievingScreeningMining engineeringProcess engineering

The invention relates to an intelligent sorting and in-situ filling device and a disassembly and assembly method, and belongs to the technical field of filling engineering. The intelligent sorting and in-situ filling device comprises a sorting bin, a coal gangue conveying assembly and a compacting assembly, and a crushing assembly and a screening assembly are arranged in the sorting bin; the crushing assembly is used for crushing coal gangue; the crushed coal gangue are divided into coal powder and gangue through the screening assembly; the coal gangue conveying assembly is located on one side of the sorting bin and used for conveying the gangue output by the sorting bin to a goaf for backfilling; the compacting assembly is located in the goaf and used for compacting the backfilled gangue, and the compacting assembly and the coal gangue conveying assembly move synchronously. By means of the sorting bin, the coal gangue conveying assembly and the compacting assembly, the coal gangue is sorted underground and the gangue is filled in situ, the coal quality is effectively improved, the problems of environmental pollution and damage caused by emission of the gangue on the ground are solved, the lifting cost of the gangue is reduced, the economic benefits of coal mine enterprises are improved, and meanwhile disassembly and assembly are convenient and fast.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD

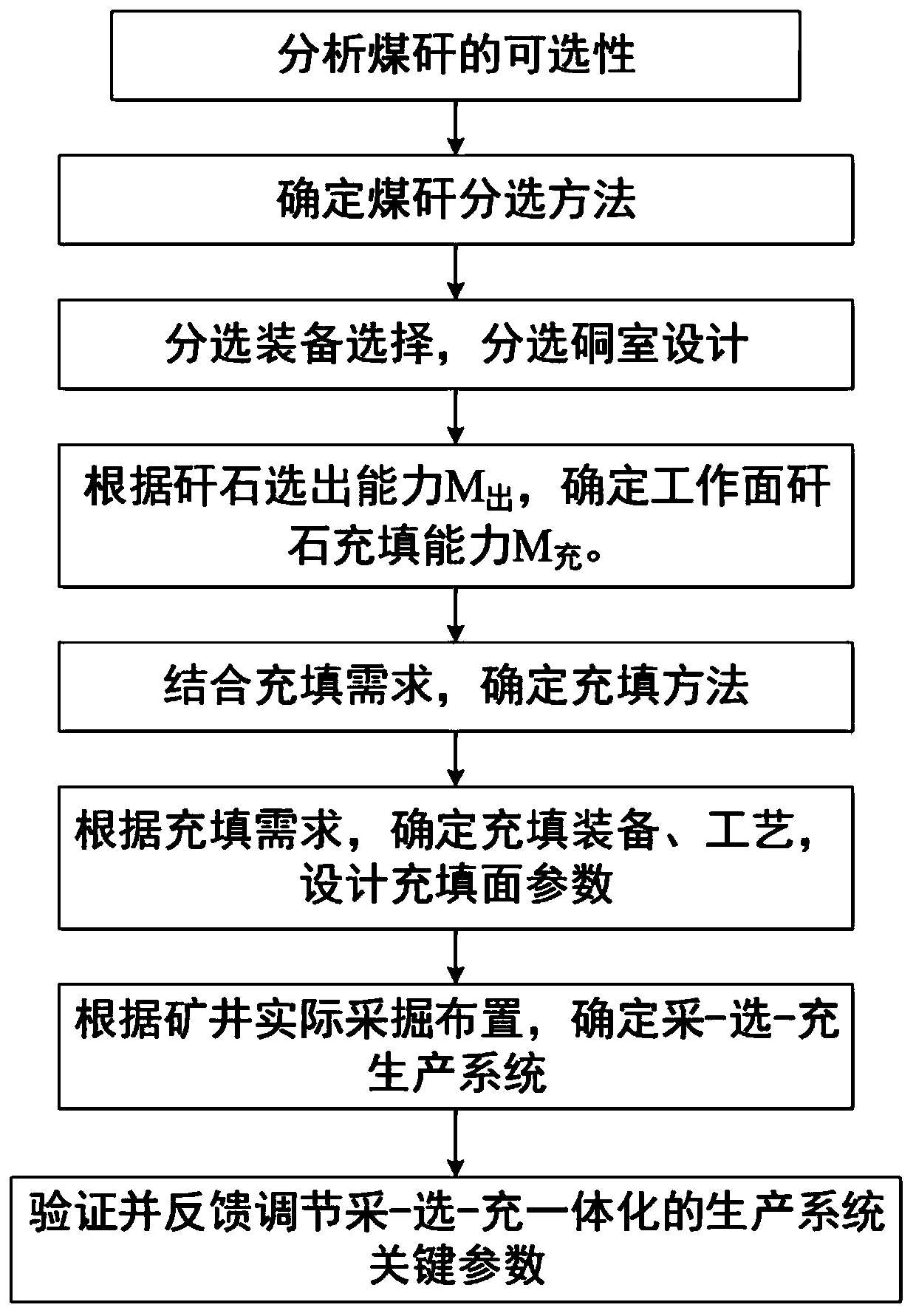

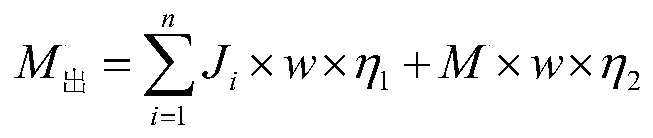

A design method for coal gangue underground sorting and in-situ filling engineering

ActiveCN109931095BReduce lifting costsPromote recoveryUnderground miningSurface miningMining engineeringProcess engineering

The invention discloses a design method for underground sorting and in-situ filling engineering of coal gangues. The design method comprises the following steps: analyzing the washability of underground coal gangues; determining a sorting method, sorting equipment and a sorting chamber of mines according to the washability and a washability scale of the underground coal gangues; determining the sorting amount of gangues and a working surface filling capability according to sorting scale; combining filling requirements to determine a final filling method; then determining filling equipment andtechnology through the needed filling amount and designing parameters of a filling surface; finally, designing a mining-sorting-filling production system according to actual mining arrangement of themines, and determining a mining-sorting-filling integration technology and verifying and feeding back key parameters for adjusting the mining-sorting-filling integration production system. By adoptingthe design method disclosed by the invention, the lifting cost of the coal gangues is reduced and environment pollution caused by the fact that the gangues are stacked and accumulated on the ground is avoided.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com