Patents

Literature

245 results about "Material Break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

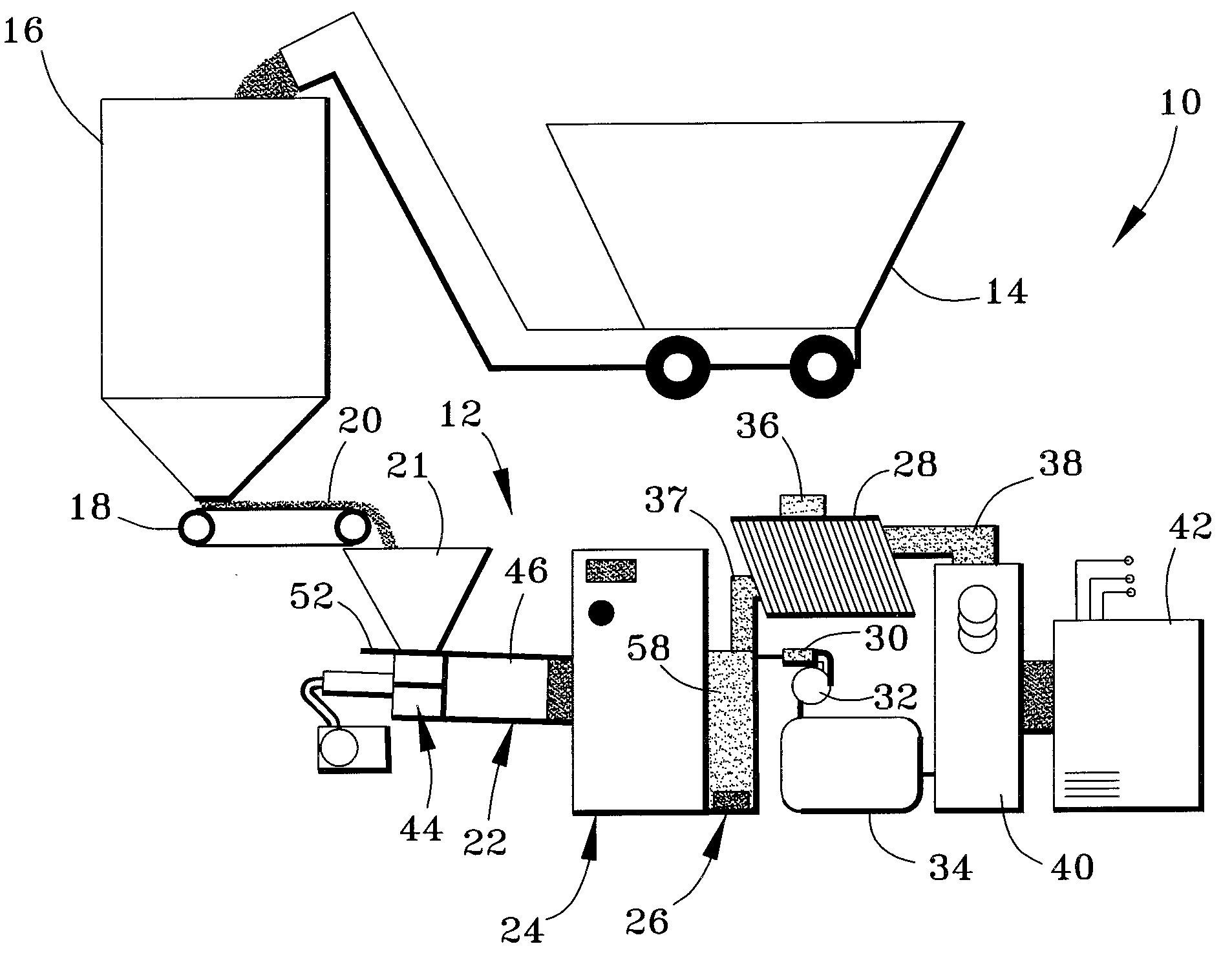

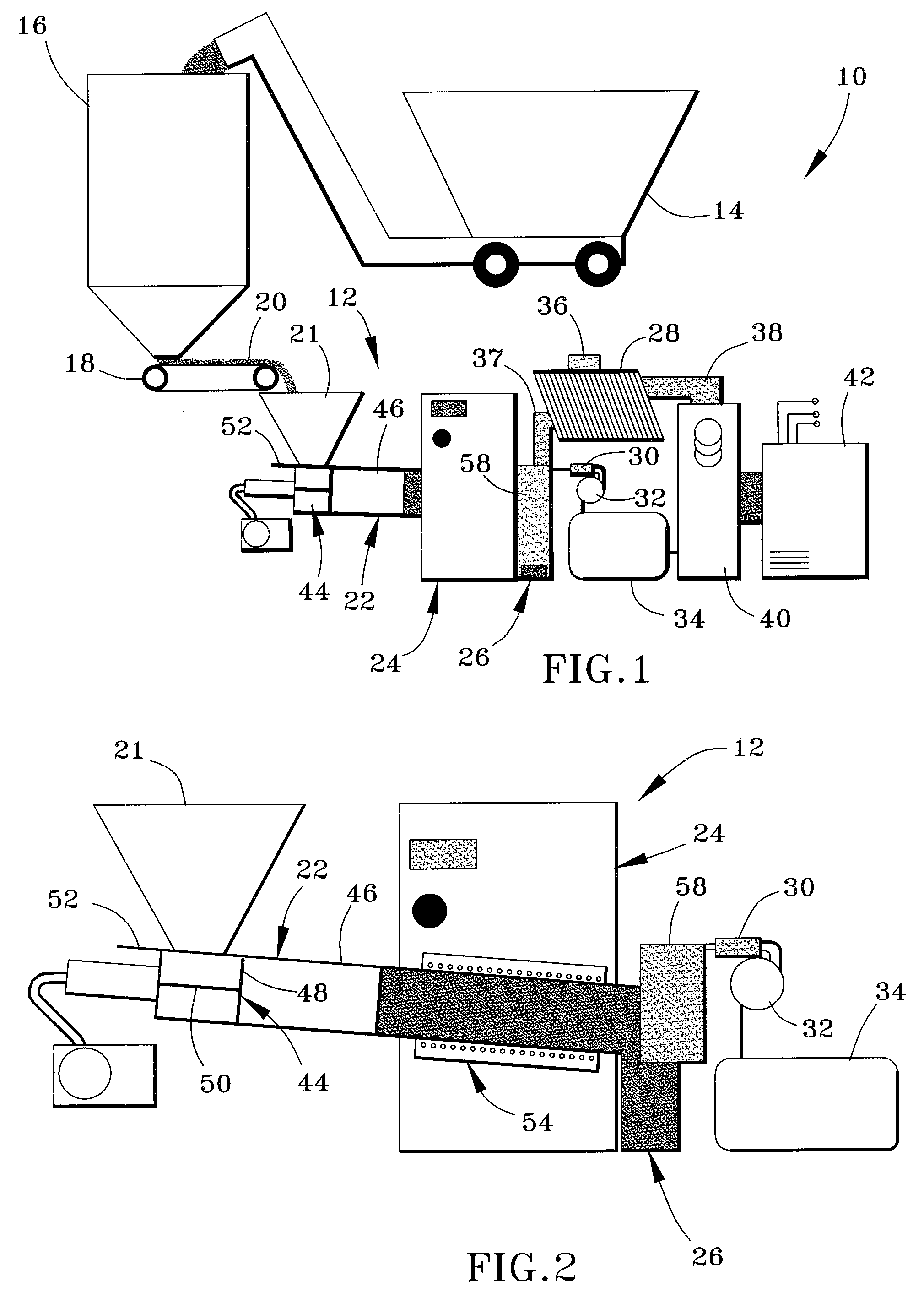

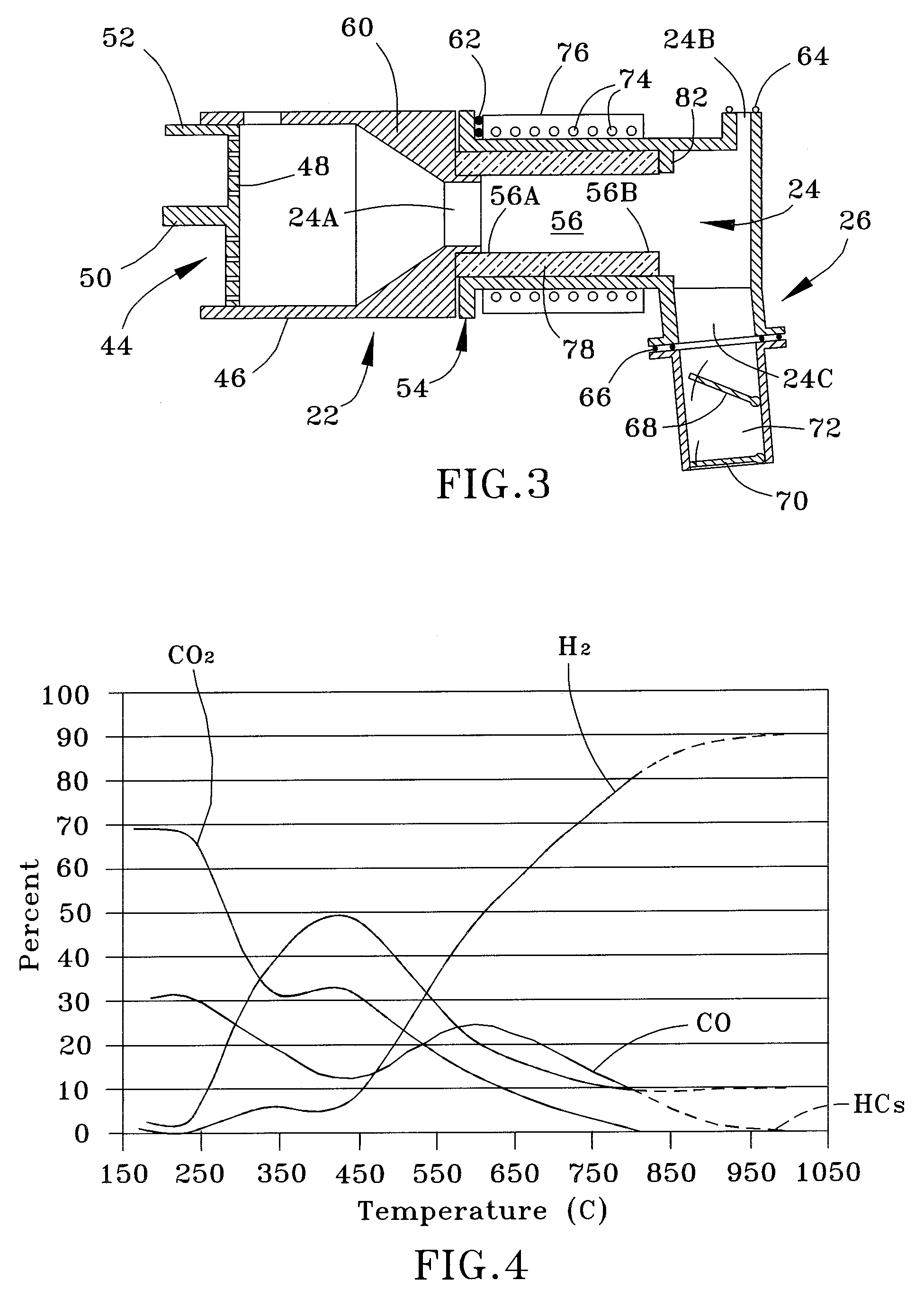

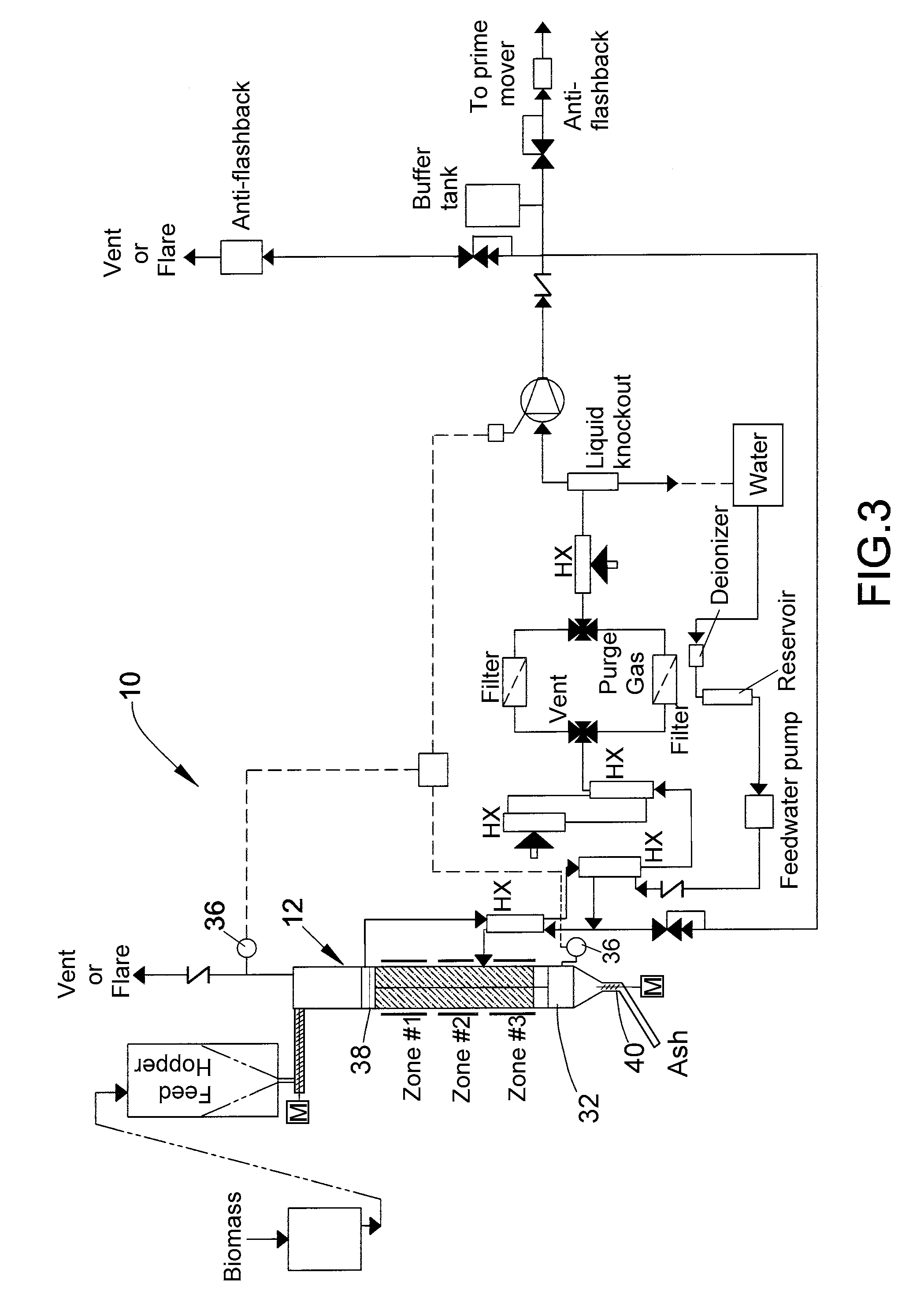

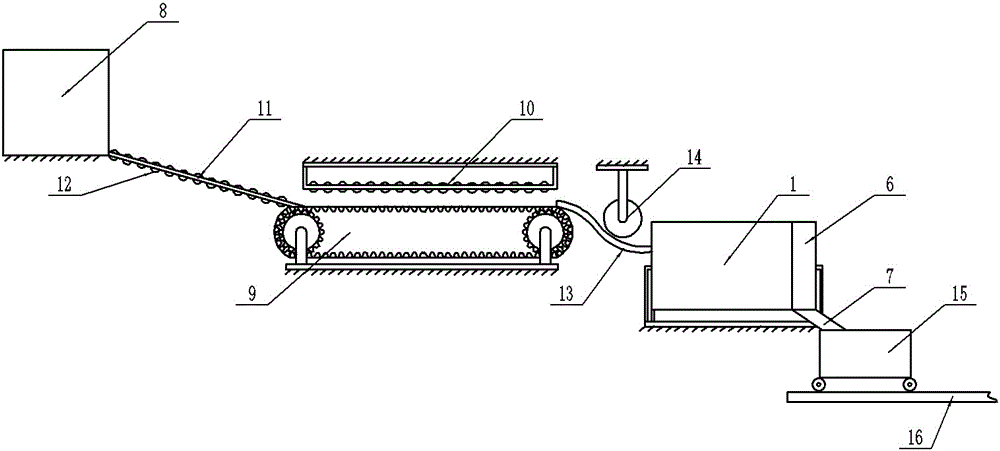

Process and system for syngas production from biomass materials

A process and system suitable for producing syngas from biomass materials. The process and system entail the compaction of a loose biomass material to remove air therefrom and form a compacted biomass material. The compacted biomass material is then introduced into a reactor and heated in the substantial absence of air so as not to combust the compacted biomass material. Instead, the compacted biomass material is heated to a temperature at which organic molecules within the compacted biomass material break down to form ash and gases comprising carbon monoxide and hydrogen gas. Thereafter, the carbon monoxide and hydrogen gas are released from the reactor, and the ash is removed from the reactor.

Owner:GREEN FORTRESS ENG INC

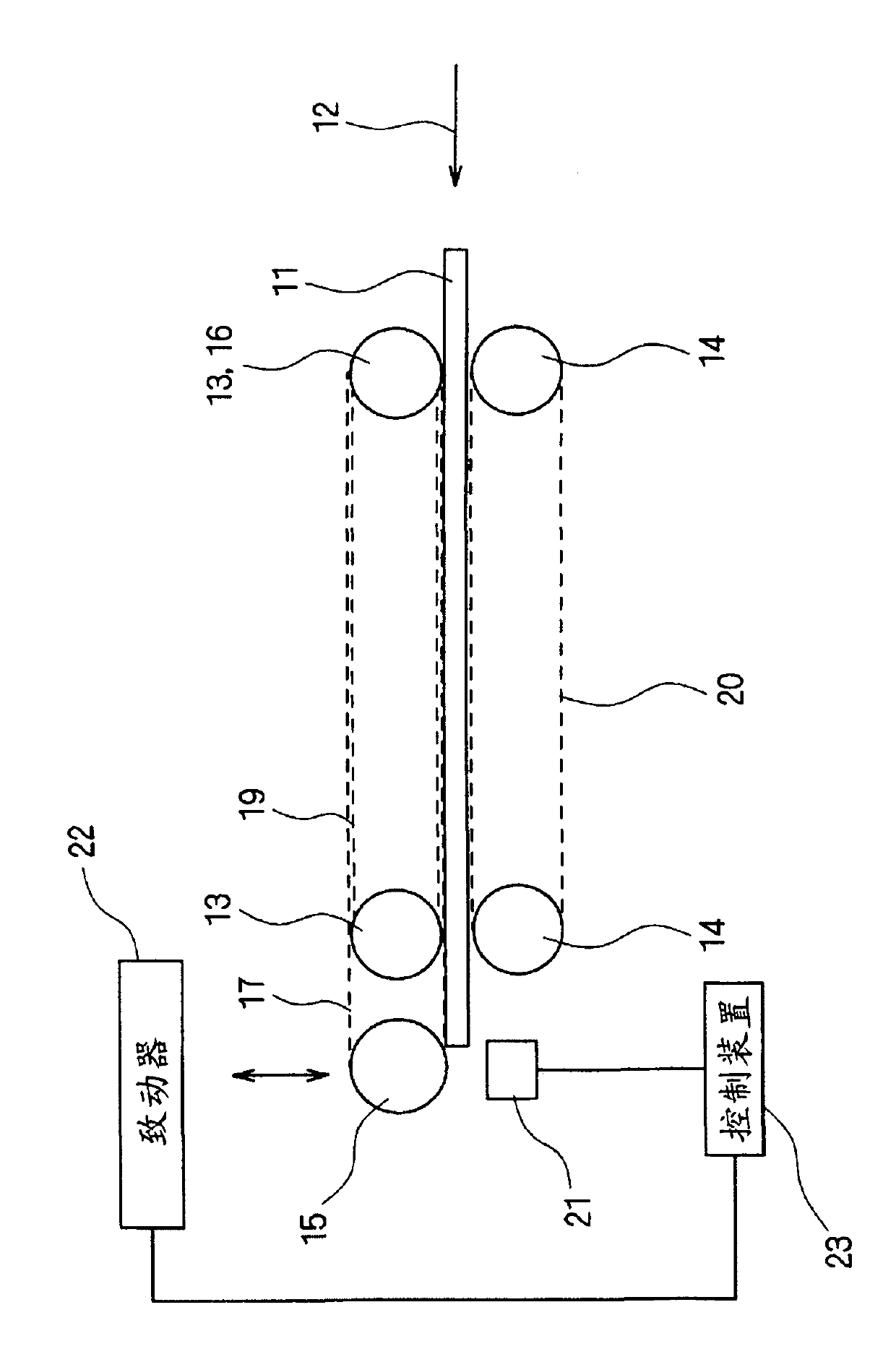

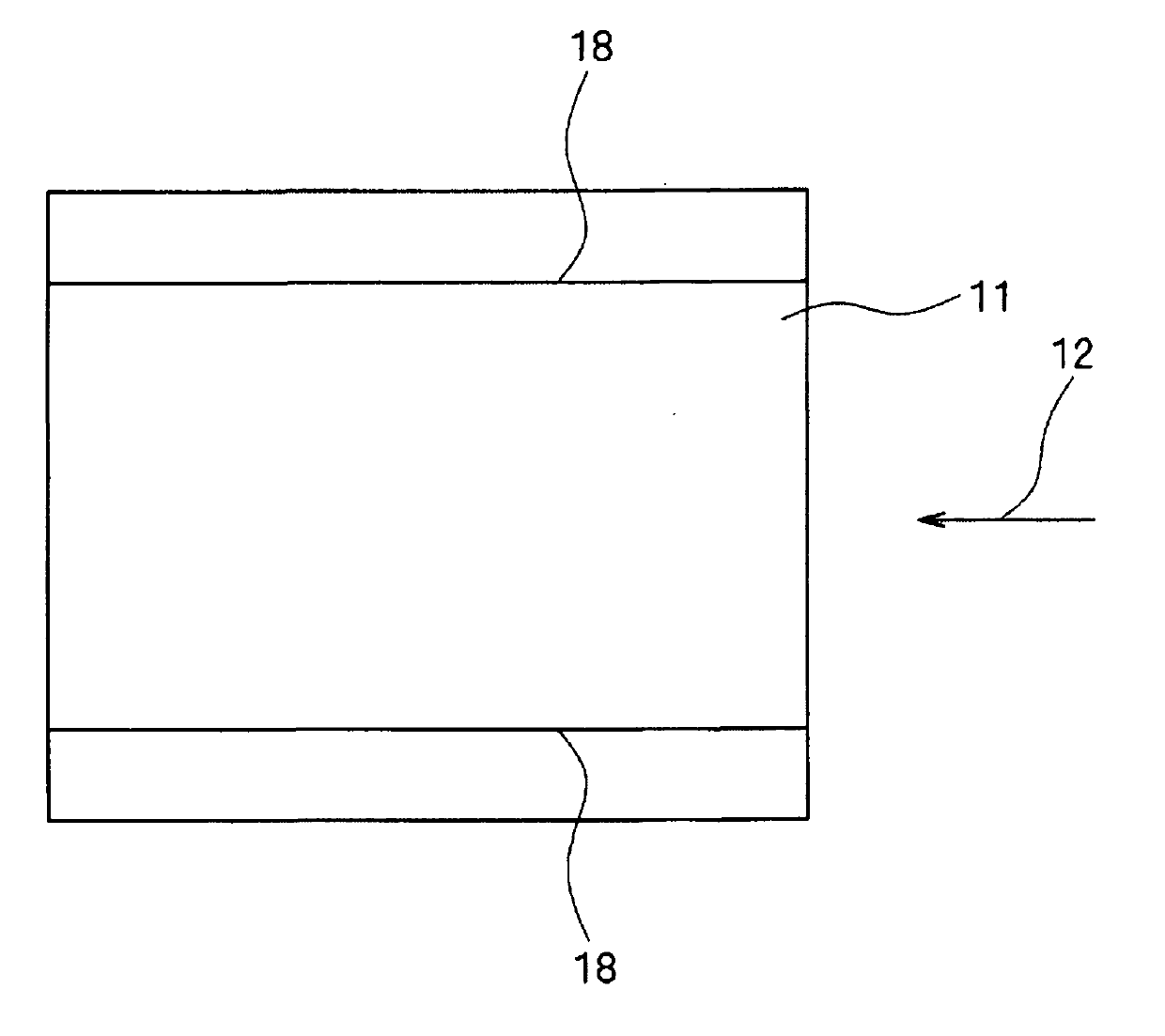

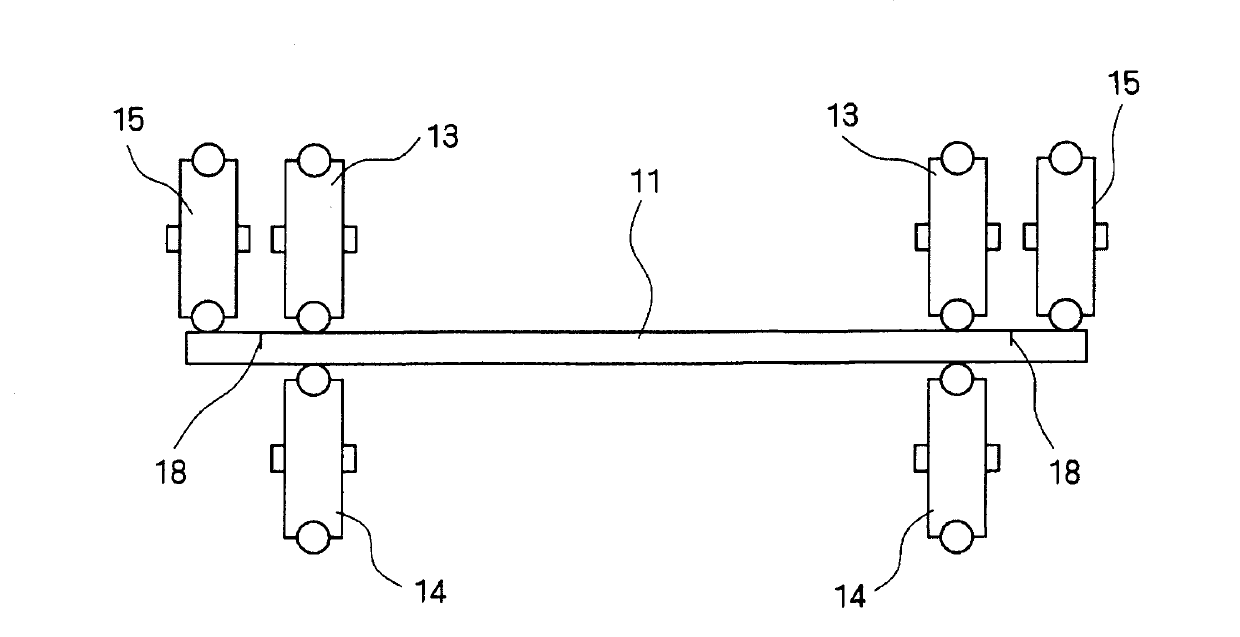

Dynamic Adjustment of Wrap Force Parameter Responsive to Monitored Wrap Force and/or For Film Break Reduction

ActiveUS20150197360A1Improve performanceReduce the possibilityWrapper folding/bending apparatusWeb rotation wrappingEngineeringMaterial Break

Owner:LANTECH COM

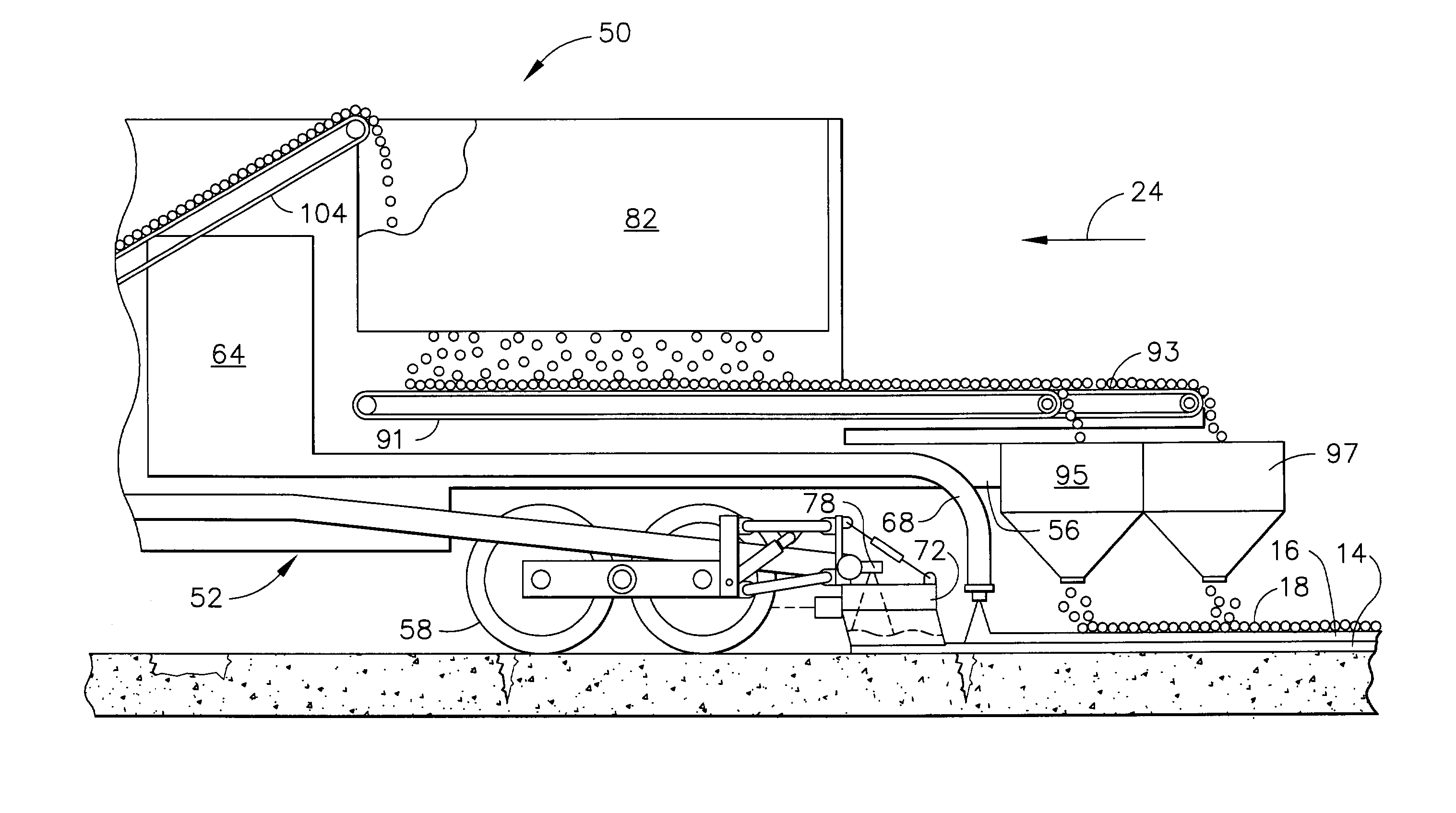

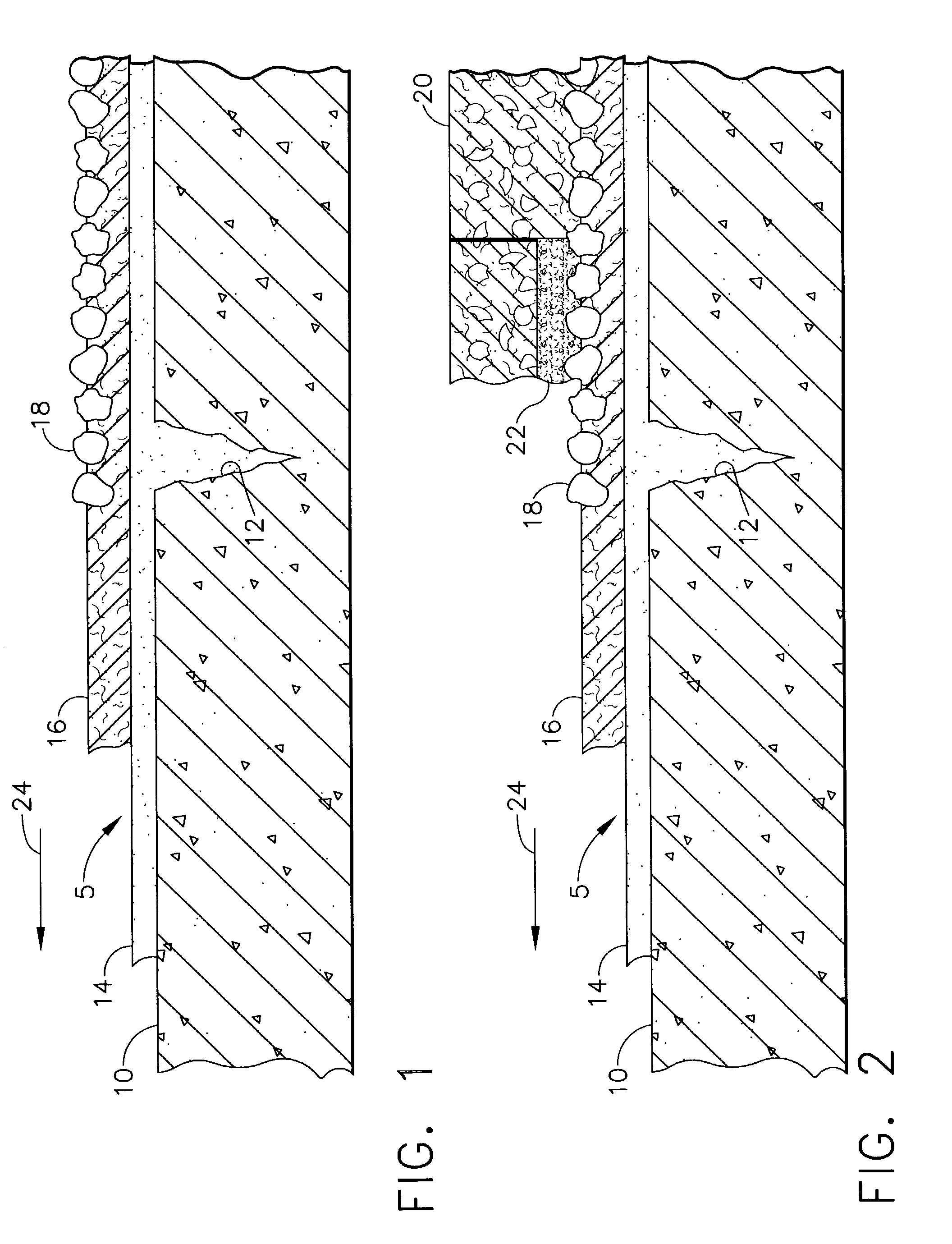

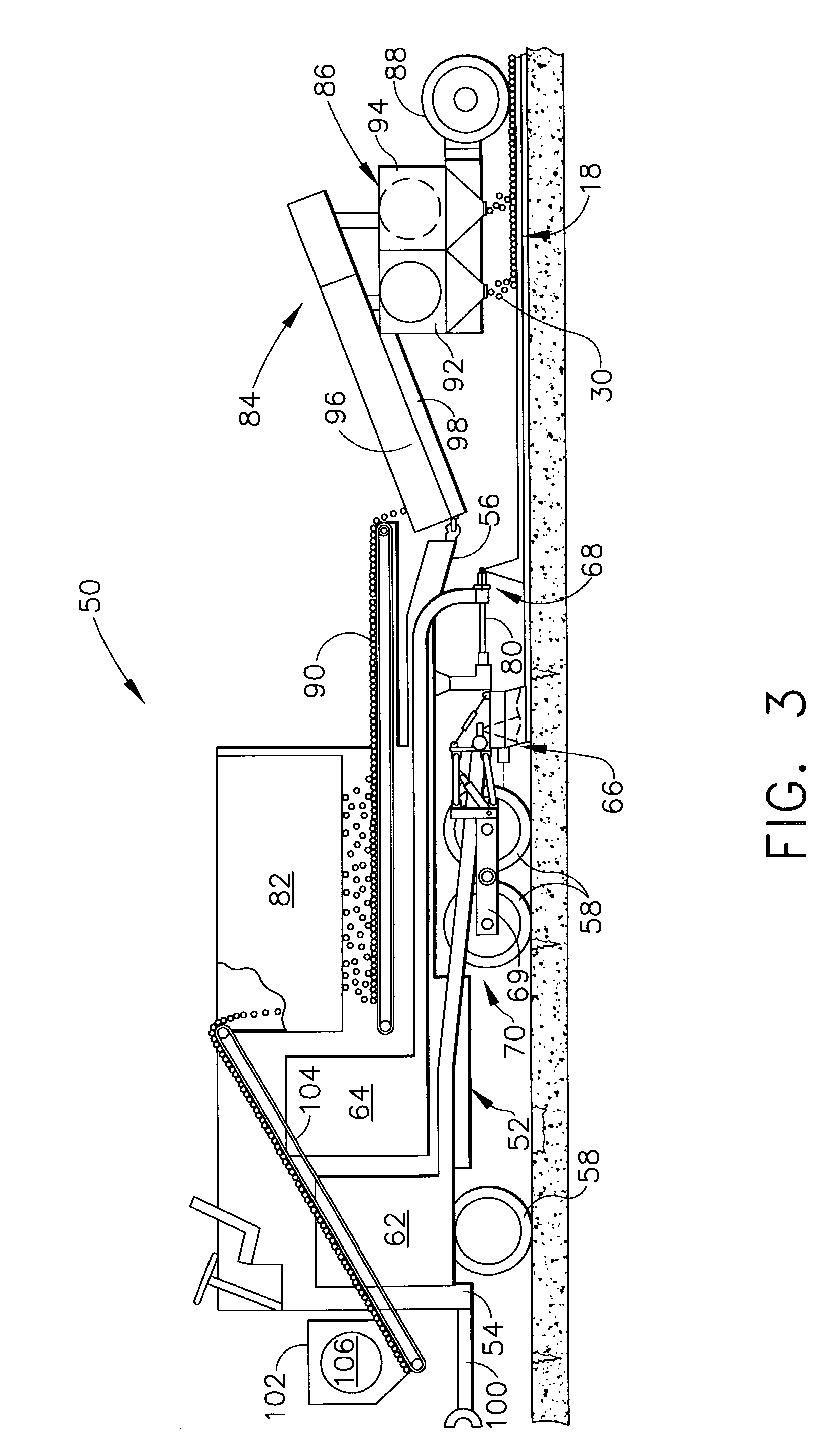

Apparatus for treating a pavement surface

An apparatus for treating a pavement surface with a plurality of layers in a single pass, including: a chassis having a forward end and a rear end; a plurality of rolling means spaced longitudinally along the chassis for supporting the chassis so it can roll along a particular direction of advance; a powerplant for moving the chassis along the direction of advance; a first storage tank mounted on the chassis for containing bituminous sealant; a second storage tank mounted on the chassis for containing bituminous emulsion; a main hopper mounted on the chassis for storing aggregate particles; a first mechanism in flow communication with the first storage tank for applying a layer of bituminous sealant at a predetermined temperature and application rate on the pavement surface; a second mechanism in flow communication with the second storage tank for applying a layer of bituminous emulsion at a predetermined temperature and application rate on the layer of bituminous sealant, wherein a thermal reaction occurs between the bituminous sealant and the bituminous emulsion so as to accelerate a material break and cure time for the layers; and, a third mechanism in flow communication with the main hopper for providing a layer of aggregate particles at a predetermined application rate on the layers of bituminous sealant and bituminous emulsion during the thermal reaction.

Owner:TERRY ASPHALT MATERIALS

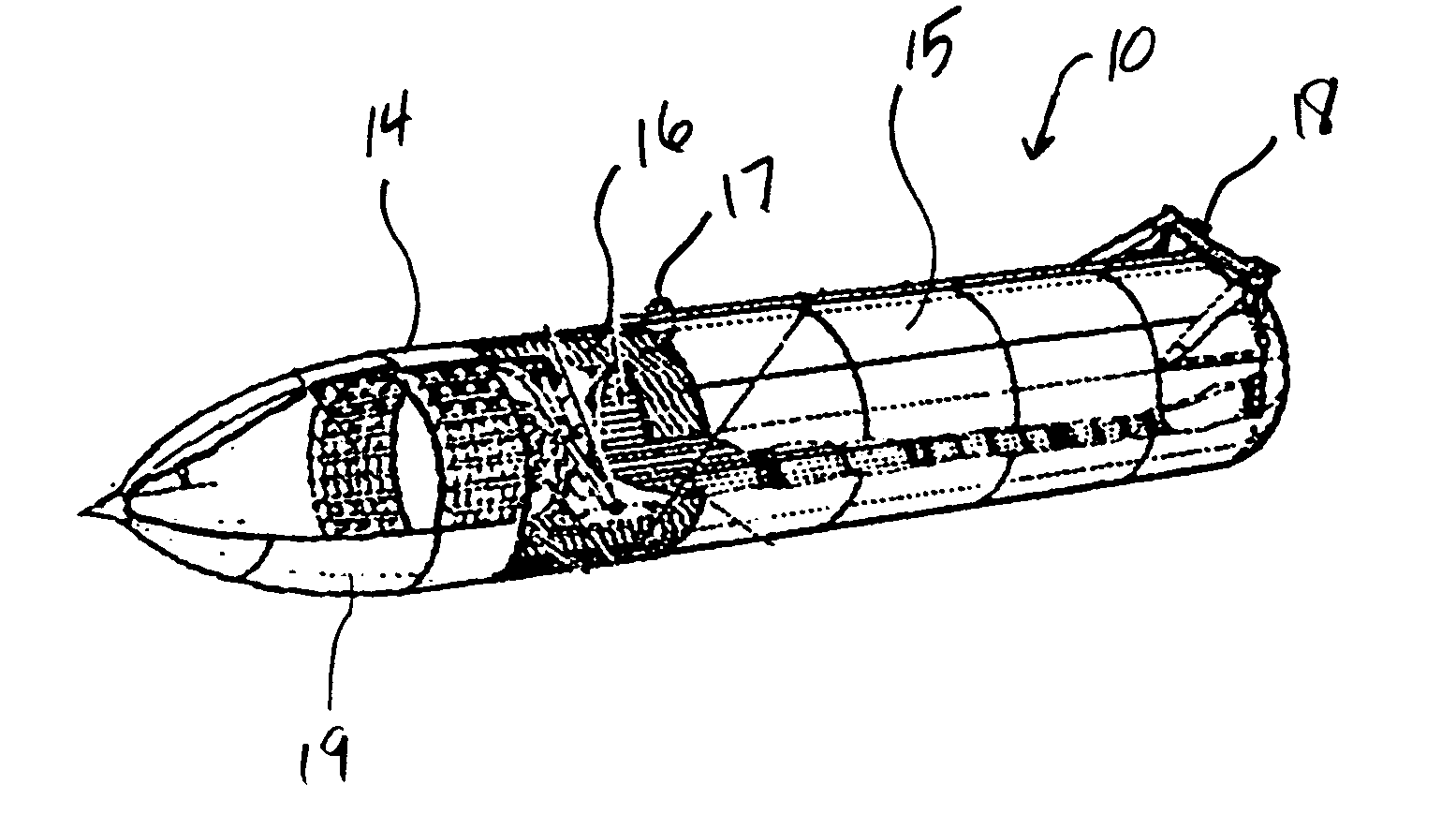

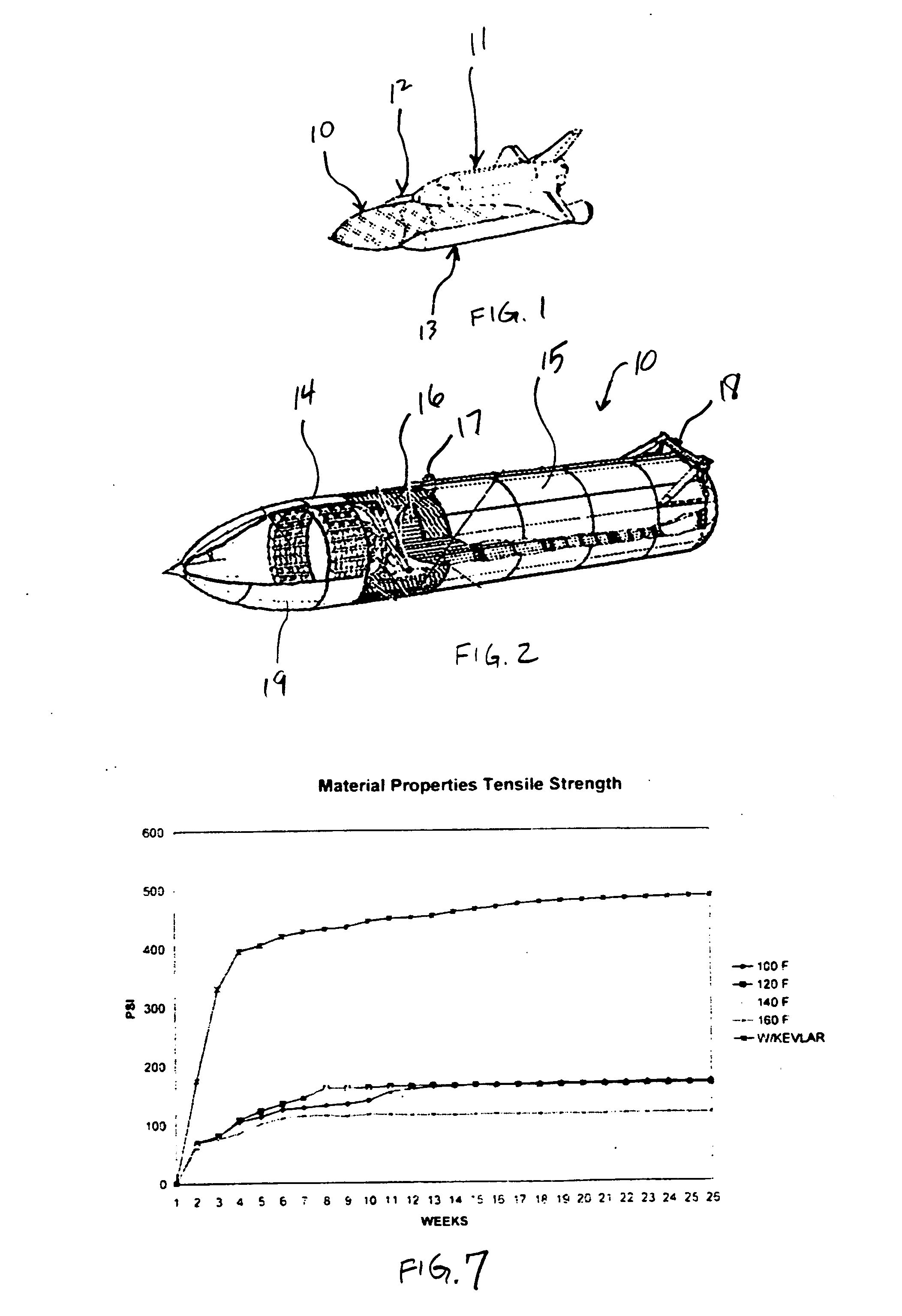

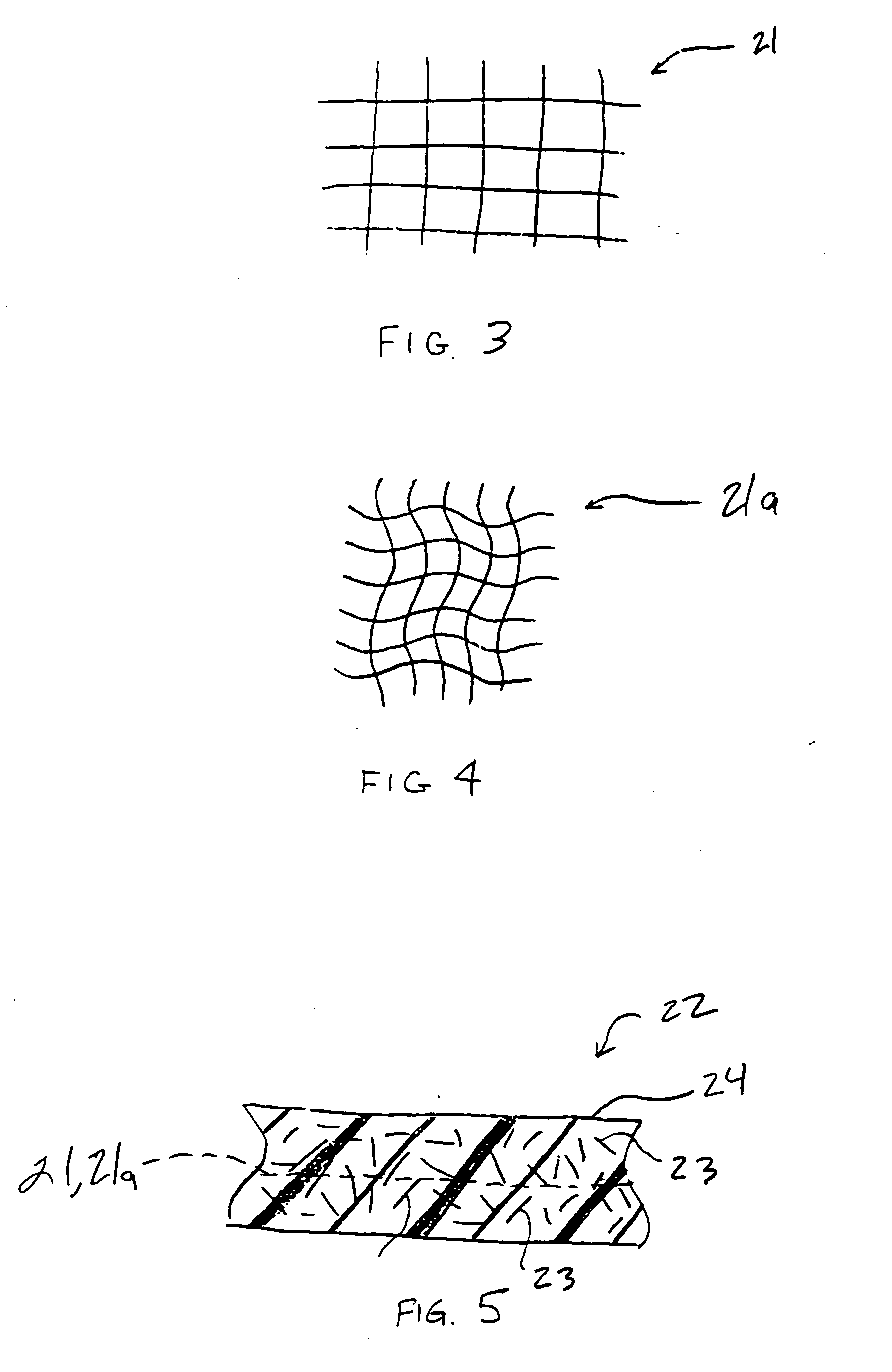

Reinforced foam covering for cryogenic fuel tanks

InactiveUS20050001100A1High strengthMaterial nanotechnologyCosmonautic vehiclesFuel tankCarbon nanotube

A cryogenic fuel tank adapted for attachment to an aerospace vehicle includes an exterior layer of reinforced composite insulating foam. The insulating foam is reinforced with an aramid fiber mesh or a closed cell foam may be reinforced with one or more of carbon nanotubes, graphite whiskers, silicon carbide fibers or graphite fibers. The improved composite insulating structure disclosed herein provides a remedy for insulating material breaking off the large external fuel tank attached to the space shuttle during launch and ascent into space.

Owner:FLORIDA INT UNIV BOARD OF TRUSTEES

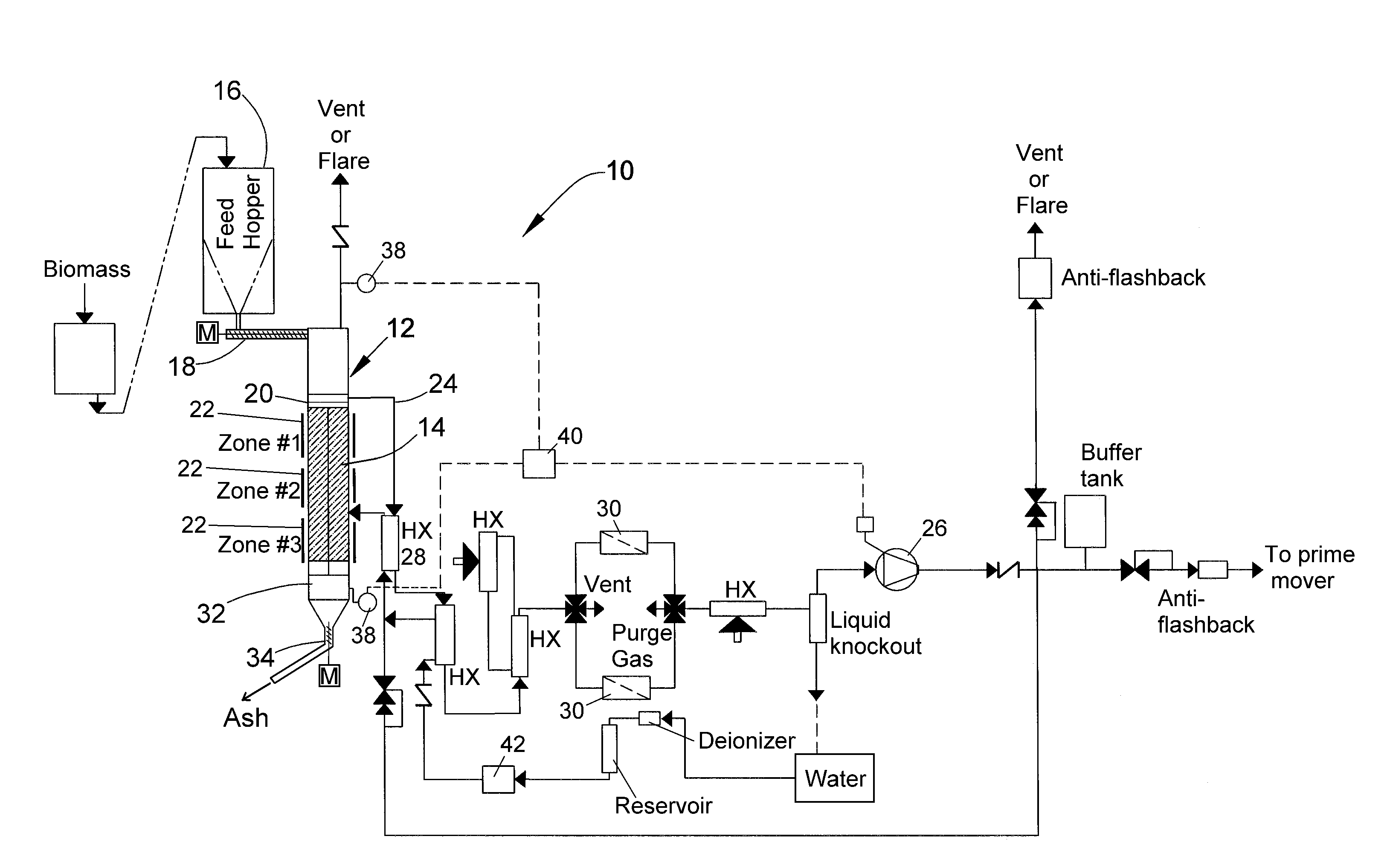

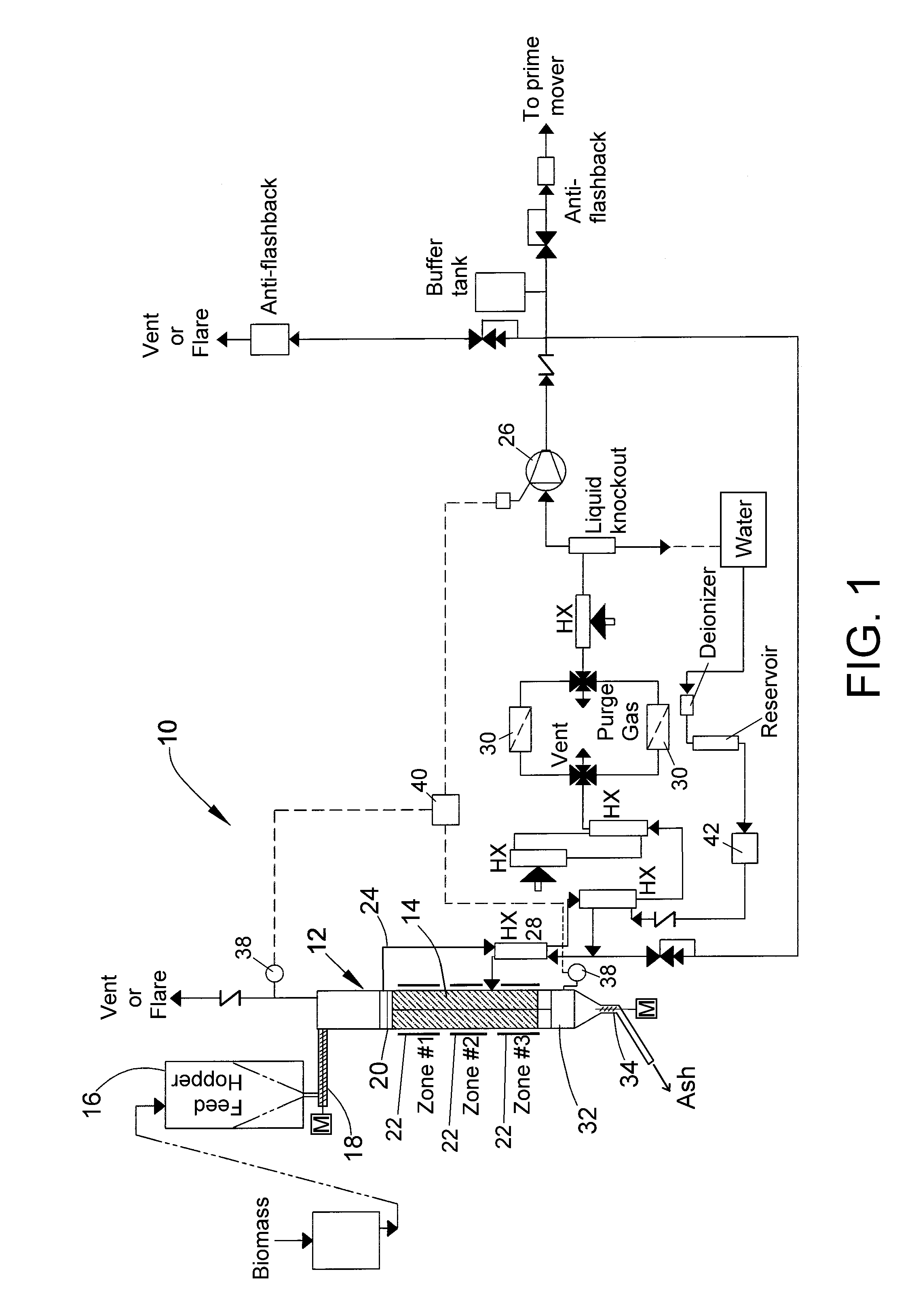

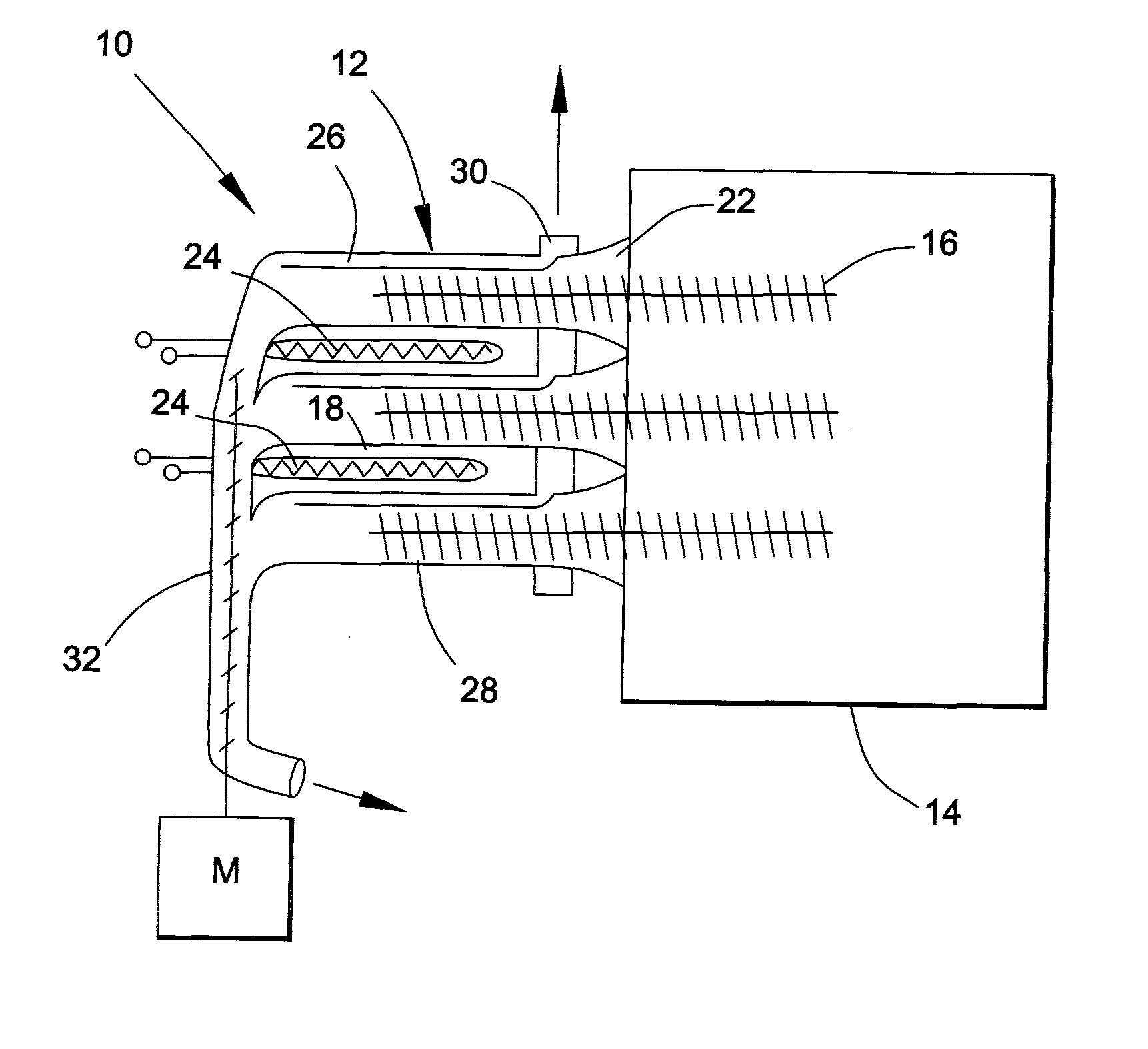

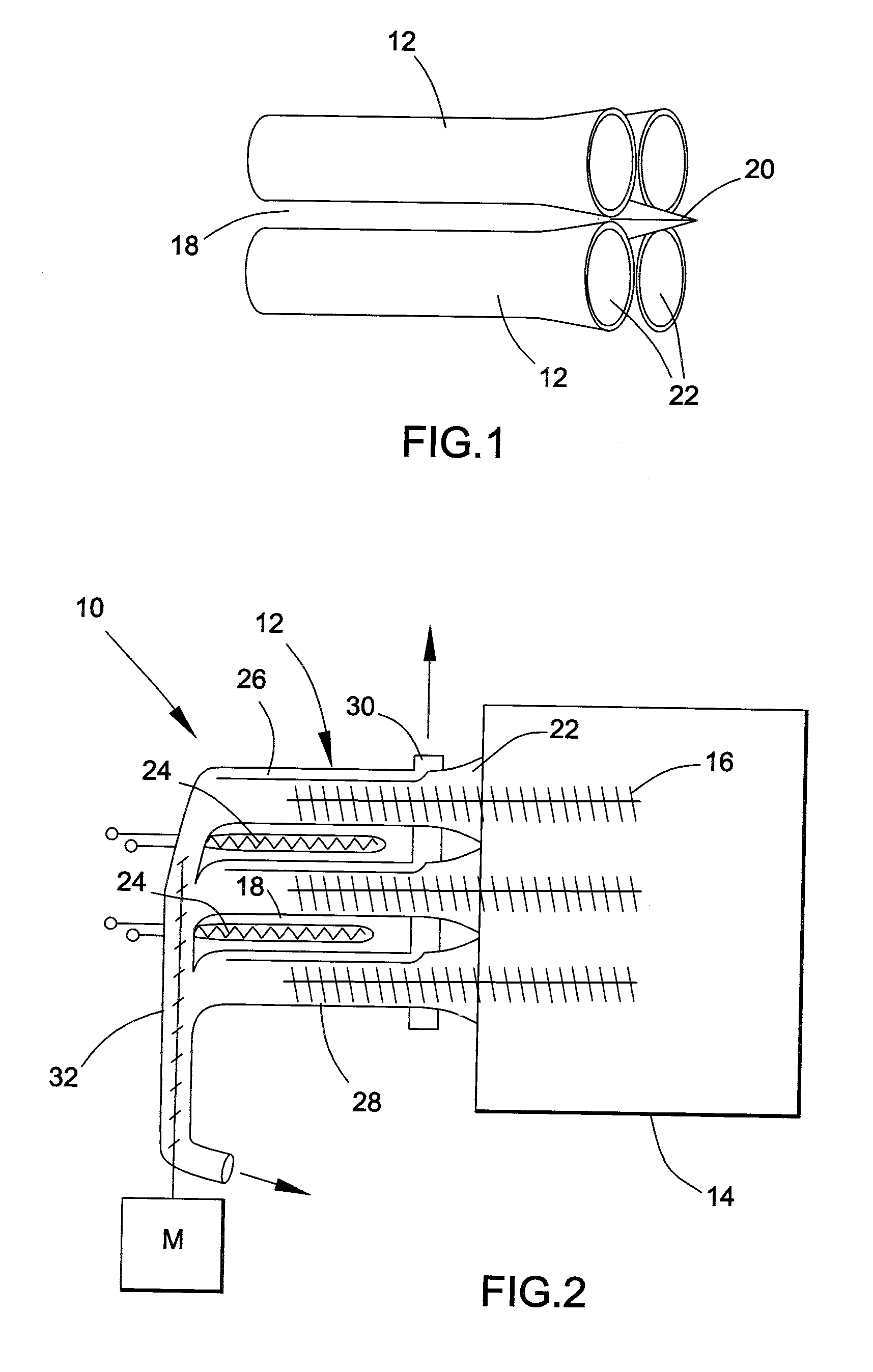

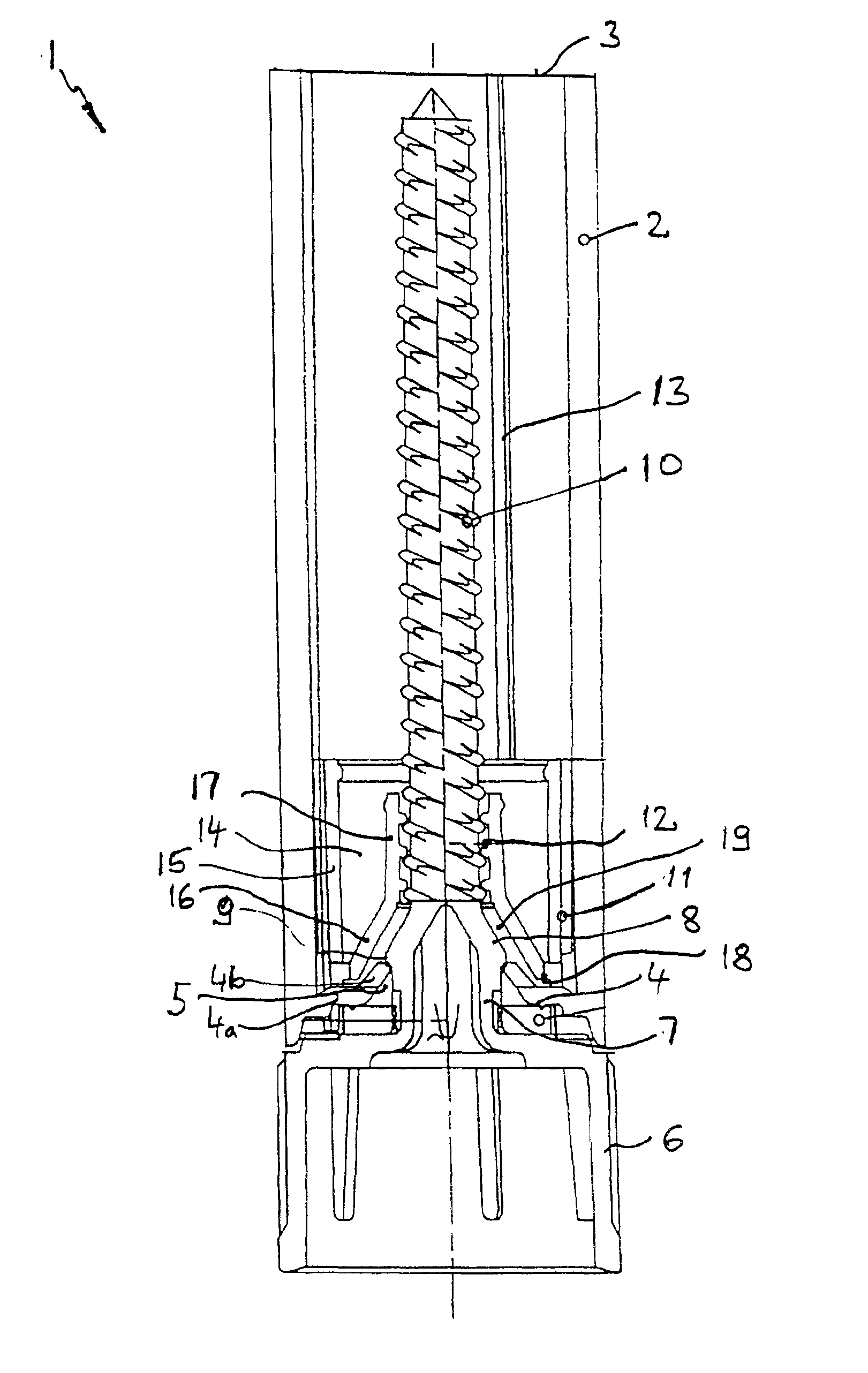

Biomass gasification/pyrolysis system and process

A system and process capable of promoting the energy content of a syngas produced from a biomass material. The system and process entail compacting a loose biomass material and simultaneously introducing the compacted biomass material into an entrance of a reactor tube, and then heating the compacted biomass material within the tube to a temperature at which organic molecules within the biomass material break down to form ash and a fuel gas mixture. The fuel gas mixture is withdrawn from the tube and the ash is removed from the tube through an exit thereof. The entrance and exit of the tube, the compaction step, and the removal step cooperate to inhibit ingress of air into the tube by forming a plug of the biomass material at the entrance of the tube and a plug of ash at the exit of the tube.

Owner:INDIANA UNIV RES & TECH CORP

High-elasticity bandage fabric and manufacture method thereof

ActiveCN101653621ATo achieve reliefIncrease elasticityHeating/cooling textile fabricsAbsorbent padsRetention timeEngineering

The invention relates to the field of textile, in particular to a medical and sport bandage. The bandage is technical characterized by fabrics and a processing method of the fabrics; the selected materials break through materials on the prior market, weft yarn which is 100 percent of all-cotton yarn is selected, and warp yarn adopts fabric of all-cotton yarn packed spandex yarn as base cloth; 55 percent of ultrahigh elasticity and long retention time which do not exist in the bandage fabric on the prior market are obtained by a special processing method, and a bandage finished product can be directly stuck to the skin part needing protection in a disposable way, has favorable lightness, ventilation and comfortable feeling and novelty.

Owner:NITTOBO CHINA CO LTD

Scalable biomass reactor and method

ActiveUS8465562B2Efficient productionLarge capacityBiofuelsIndirect heating destructive distillationHydrogenCombustion

Owner:INDIANA UNIV RES & TECH CORP

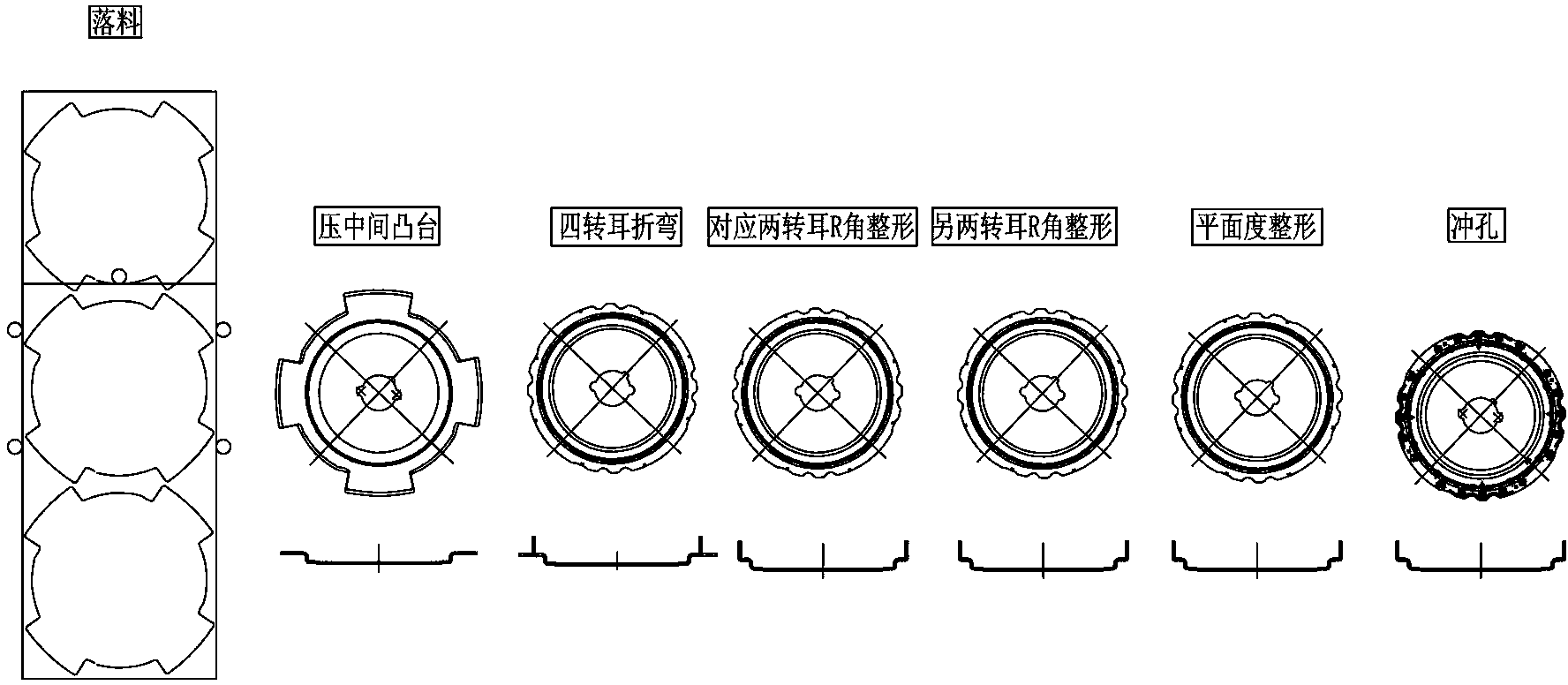

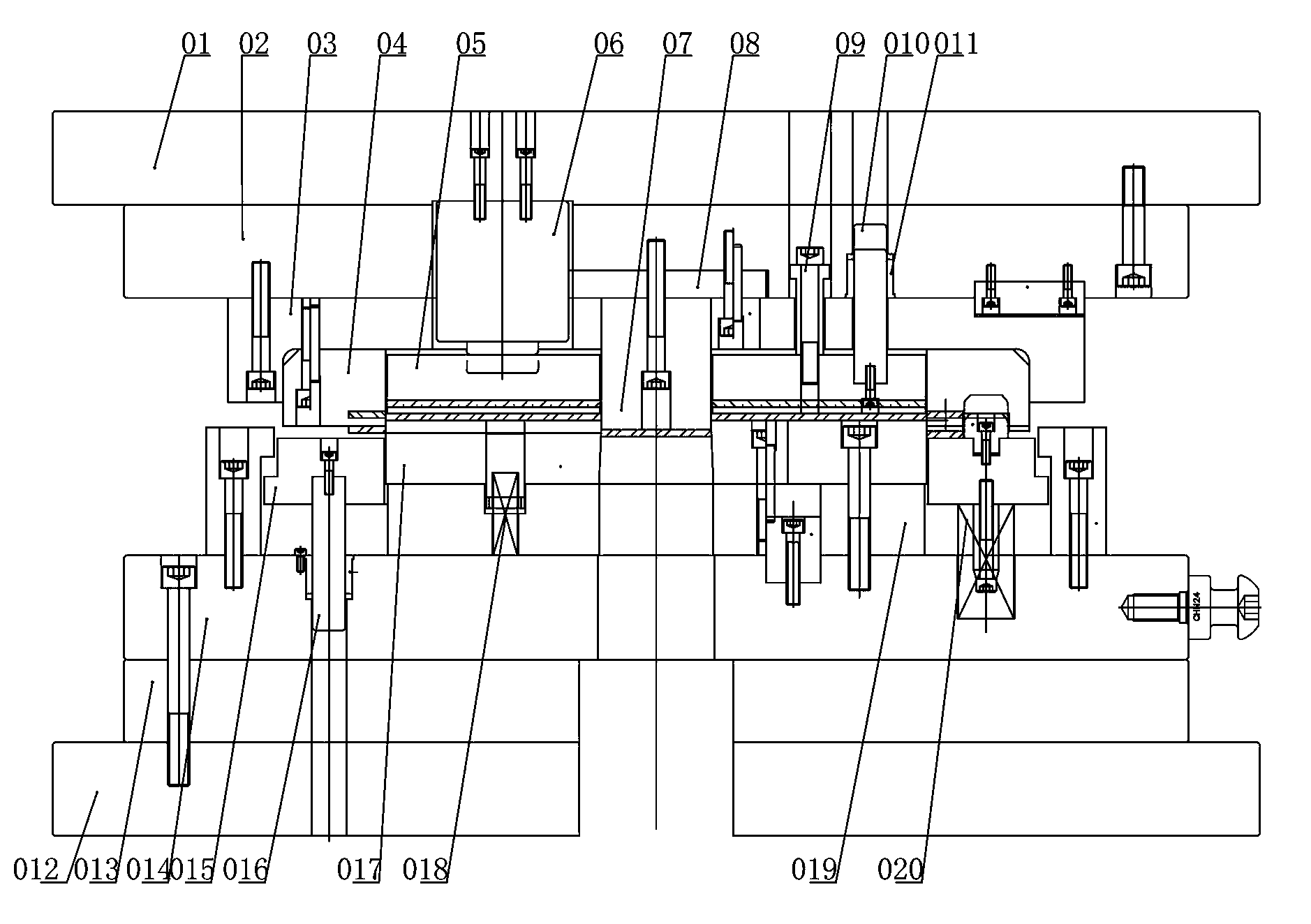

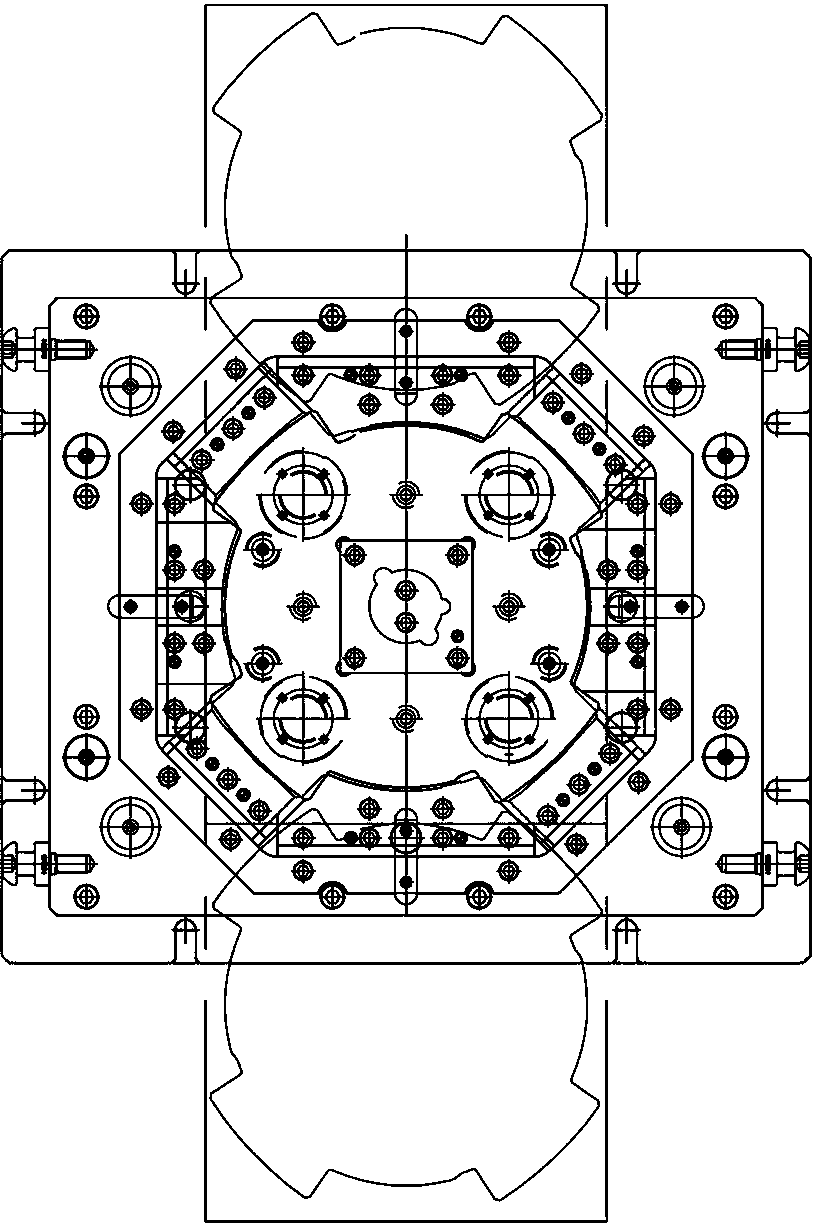

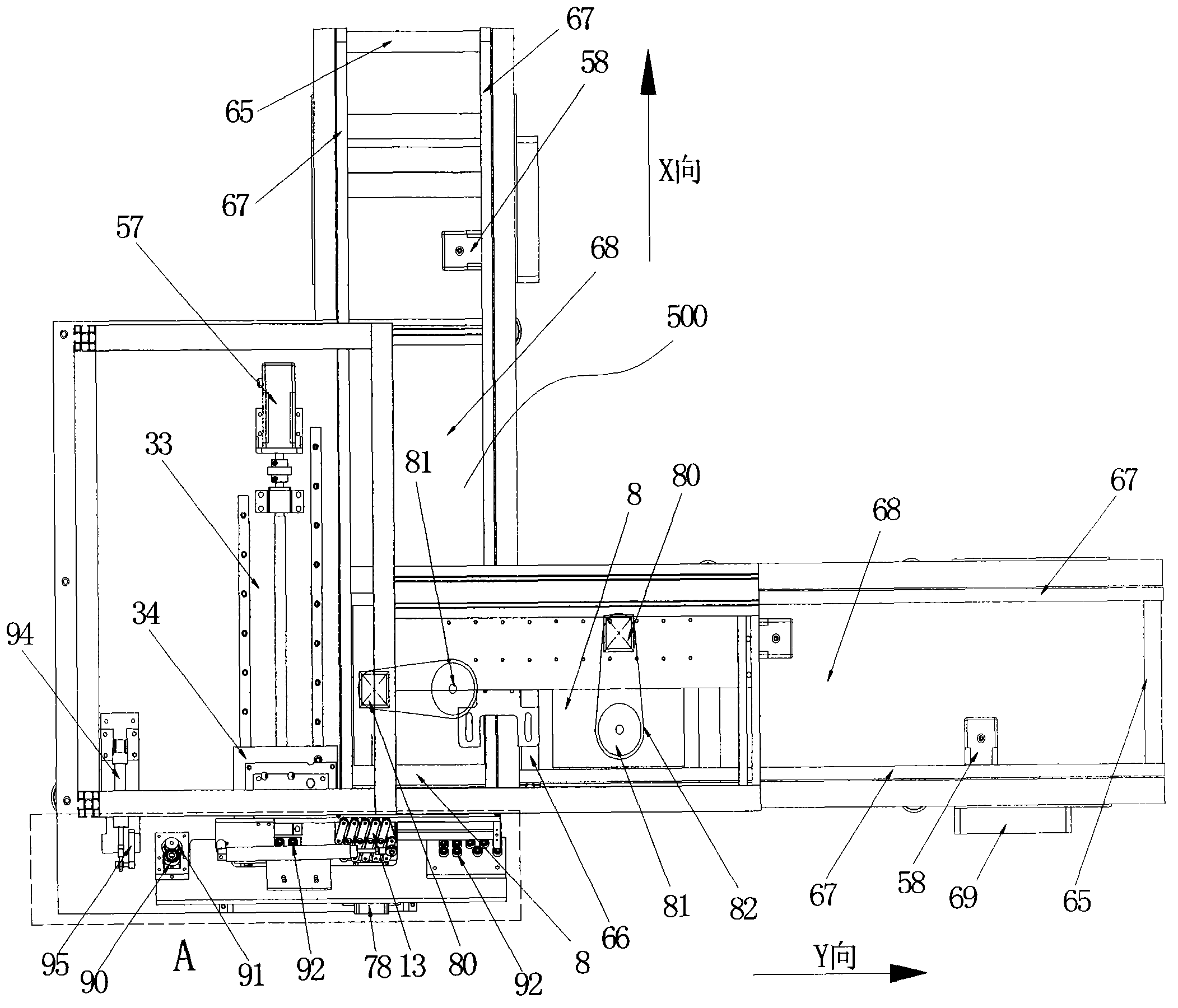

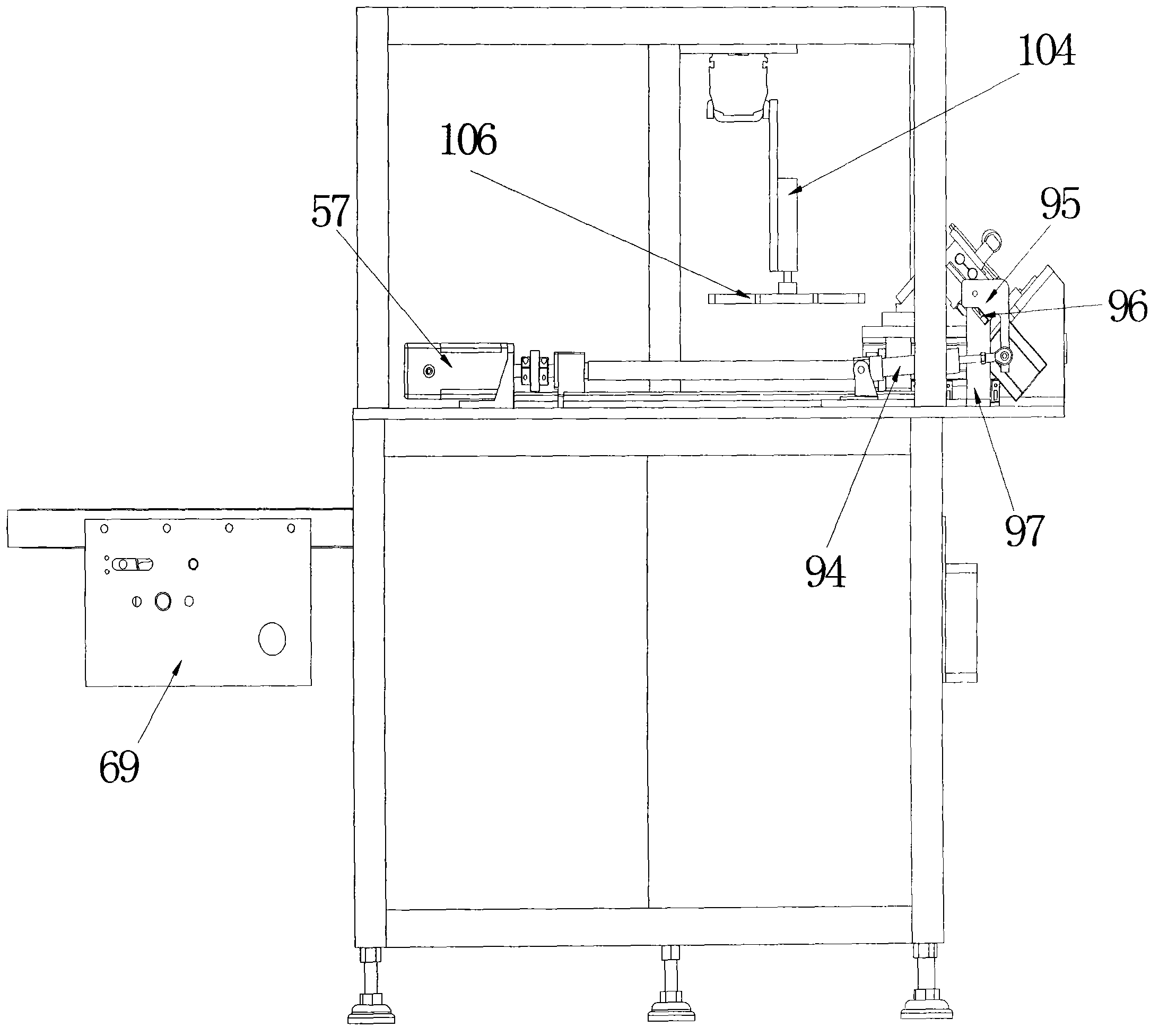

Clutch cap forming process and forming equipment thereof

The invention discloses a clutch cap forming process. The clutch cap forming process is characterized by including the following steps of (a) blanking, (b) pressing a middle boss, (c) bending four rotating lugs, (d) angle R shaping of two corresponding rotating lugs, (e) angle R shaping of the other two rotating lugs, (f) shaping flatness, and (g) punching. The invention further discloses clutch cap forming equipment which comprises a blanking die, a stretching die, a bending die, a first shaping die, a second shaping die and a punching die. According to the clutch cap forming process and the forming equipment thereof, the mode that pulling is carried out first and then folding is carried out is adopted, the thickness of a clutch can reach 6.35 mm, and the obtained bearing force of the clutch can reach 100000 newtons; meanwhile, a bending mode with an angle R is adopted, the probability that materials break during bending is reduced, and the bending success rate reaches 99.3%; angle R shaping of the rotating lugs is carried out twice, the angle R is eliminated, an assembling hole is convenient to form, and the best shaping effect is achieved; a flatness shaping procedure is arranged, accuracy of the formed hole is guaranteed, and meanwhile, a cap of the clutch and the clutch are accurately assembled.

Owner:RAINBOW METAL TECH

Flexible modified method for poly beta-hydroxybutyric butyrate and poly beta-hydroxybutyric butyrate-beta hydroxyl valerate

This invention relates to a toughness modify method of e. Poly-beta-hydroxybutyric acid ester and poly-beta-hydroxybutyric acid ester-beta-hydroxy valerate and poly- succinic acid butanediol ester or poly- lactic acid carry out vacuum drying, then according to a certainty weight proportion add to Banbury mixer for fusion and blending, after several minutes, add cross-linking agent to carry out dynamic co crosslinking. This materials breaking elongation rate can reach 425%, fracture strength can reach 33.5 MPa, notch impact strength reach 64 joule / m.

Owner:SHANGHAI JIAO TONG UNIV

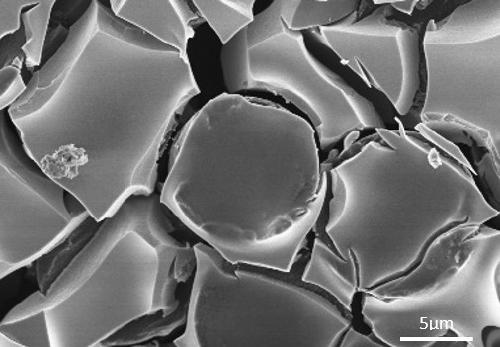

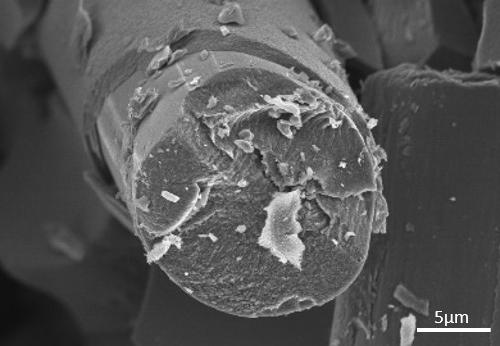

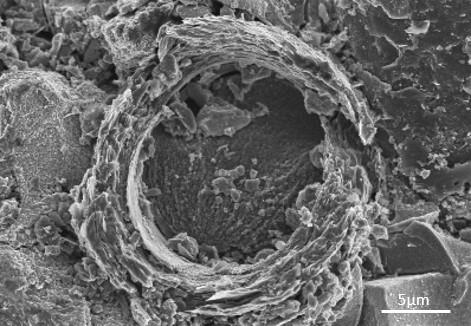

Cf/C-SiC-ZrC composite material and preparation method thereof

The invention relates to a Cf / C-SiC-ZrC composite material and a preparation method thereof, and belongs to the field of carbon fiber toughened ceramic matrix composite materials. The Cf / C-SiC-ZrC composite material with high fracture toughness property is prepared by using a process combining chemical vapor deposition and a precursor infiltration and pyrolysis method. The specific preparation method comprises the following steps: first, performing rubber discharge and pyrolysis carbon PyC interface layer deposition on a carbon fiber preform; then immersing in a mixed solution of PCS and PZC; performing impregnation, curing and cracking treatment; circulating the impregnation-curing-cracking process to obtain the Cf / C-SiC-ZrC composite material. The Cf / C-SiC-ZrC composite material prepared by the method of the invention can effectively reduce the physical and chemical damage to the carbon fiber during the cracking process under the protection of a PyC interface layer, and cracks transmitted from a ceramic matrix to the carbon fiber is deflected on the interface layer. In addition, the PyC interface layer is beneficial to the weakening of interface bonding force between the carbon fiber and the ceramic matrix; when the Cf / C-SiC-ZrC composite material breaks, energy is dissipated through the pull-out of the carbon fiber, so that the fracture toughness property of the Cf / C-SiC-ZrC composite material is improved.

Owner:UNIV OF JINAN

Composite material and preparation method thereof

ActiveCN108079934ALarge specific surface areaIncrease loadOther chemical processesAluminium silicatesCarbon filmMicrosphere

The invention relates to a composite material and a preparation method thereof, and can be widely applied to the fields of batteries, environmental protection, adsorptive dehumidification, air conditioning, refrigeration, heat pumps, pressure-variable separation purification, hydrogen storage production and the like. The composite material comprises a supporting framework material, carbon microspheres and / or a carbon film and a loading material, the loading material comprises salt, an electrode material and a physical adsorbent, the carbon microspheres and / or the carbon film are / is firmly attached to the wall surfaces of pores in the supporting framework material, and the loading material is uniformly distributed inside the carbon microspheres and / or the carbon film, so that direct embedment of the loading material between carbon atoms is achieved, the anti-agglomeration inactivation capacity is obviously enhanced, and the service life is effectively prolonged; the composite material breaks through a limitation of the specific surface area of the original skeleton material, so that the specific surface area of the composite material can be effectively increased under the premise ofincreasing the loading capacity, and the adsorption, reaction or electron migration rate can be increased; the composite material conveniently achieves close contact between the adsorbent and a heat-exchanging wall surface by an extruding, bonding or brazing method, so that the contact heat resistance between the two is effectively reduced.

Owner:SHANDONG UNIV

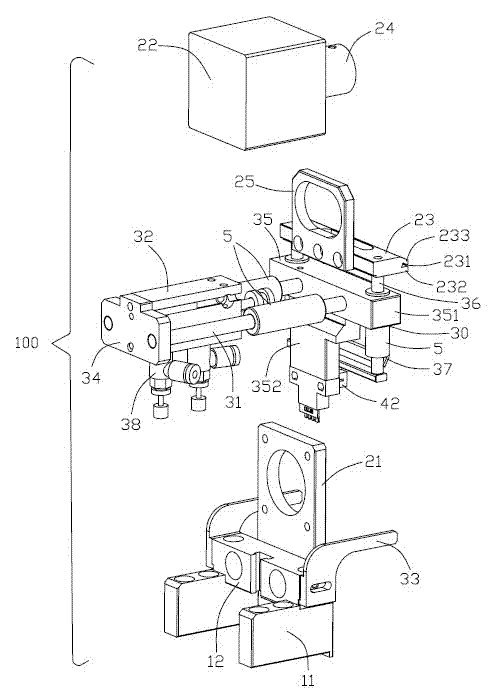

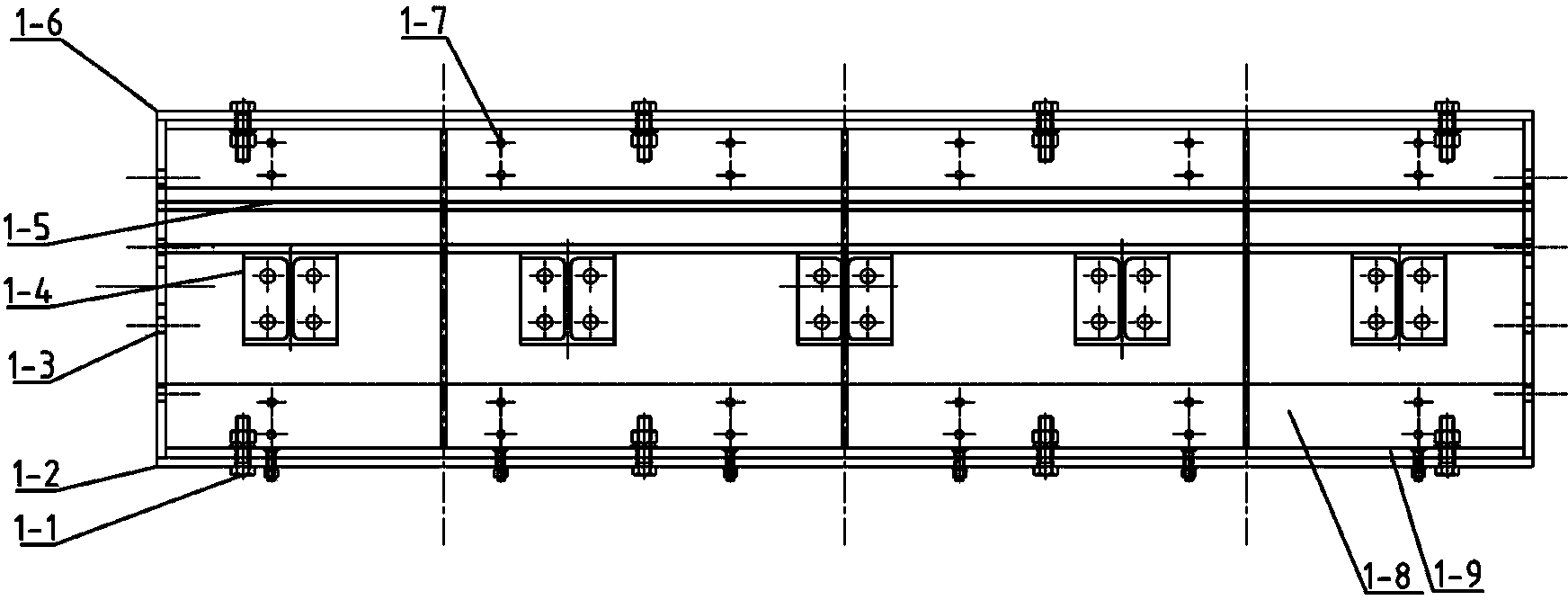

Material band breaking device

ActiveCN102969643AAvoid cloggingRealize intelligent automatic productionContact member manufacturingEngineeringMaterial Break

Owner:KUNSHAN JIAHUA ELECTRONICS

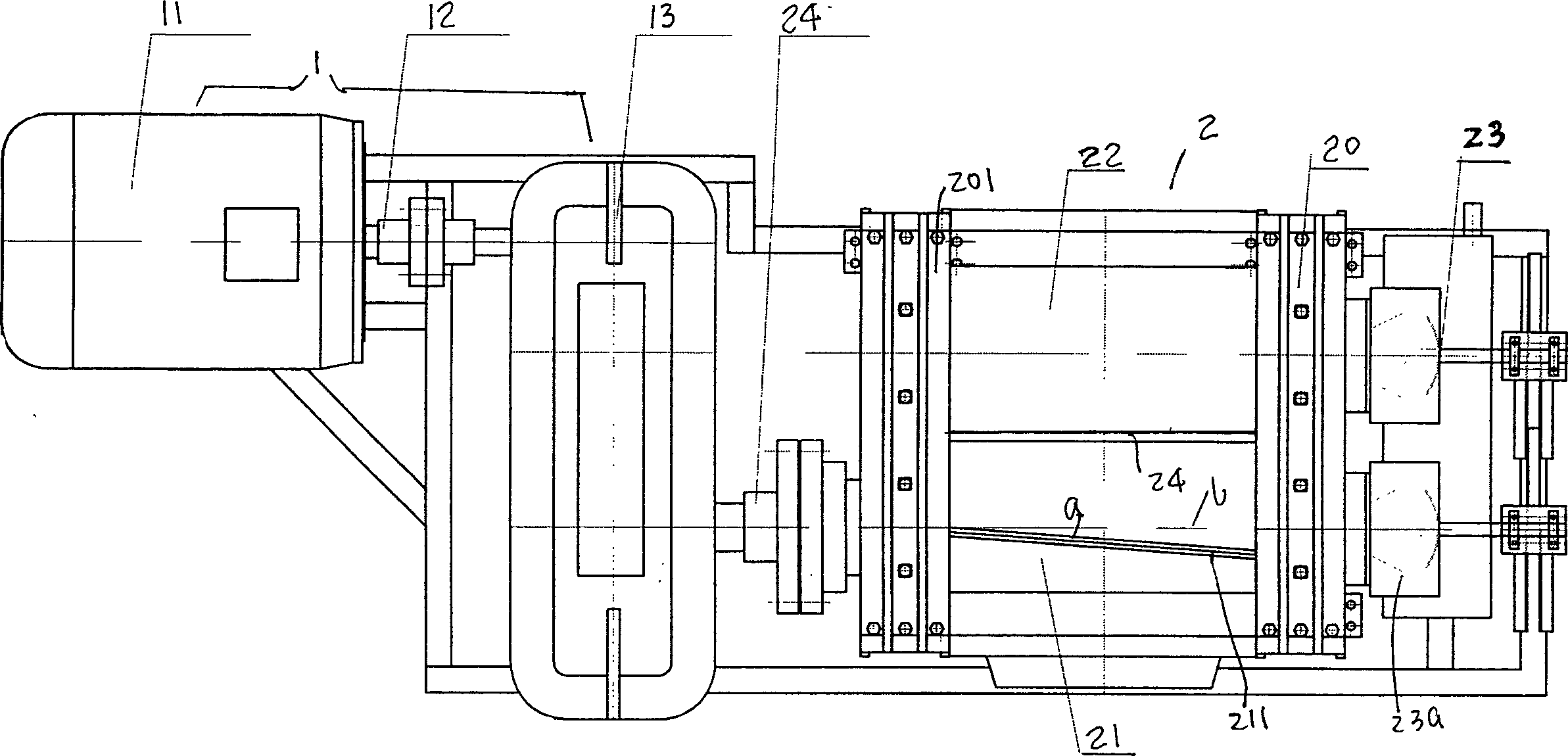

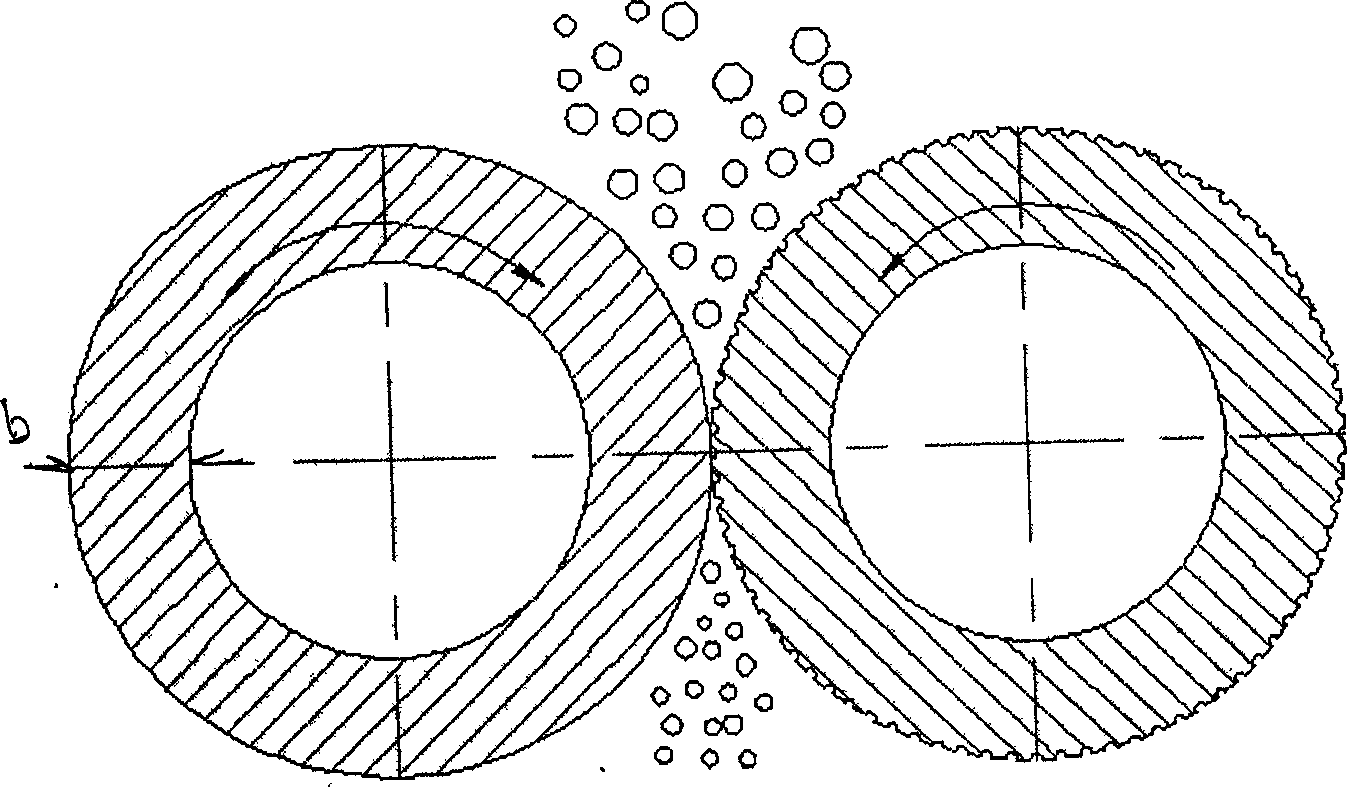

Materials crusher

InactiveCN1817460ASignificant advantagesSignificant beneficial effectPlastic recyclingGrain treatmentsCouplingReducer

A material breaking machine is composed of machine frame, speed reducer, power unit with motor linked with said speed reducer via the first shaft coupling, cooling system, and breaking unit consisting of hollow active and passive rollers parallelly installed on machine frame and communicated to said cooling system. It features that the gap between active and passive roller is preset to make the active roller to just drive the passive roller via the material to be broken.

Owner:天津市瑞德机械制造有限公司

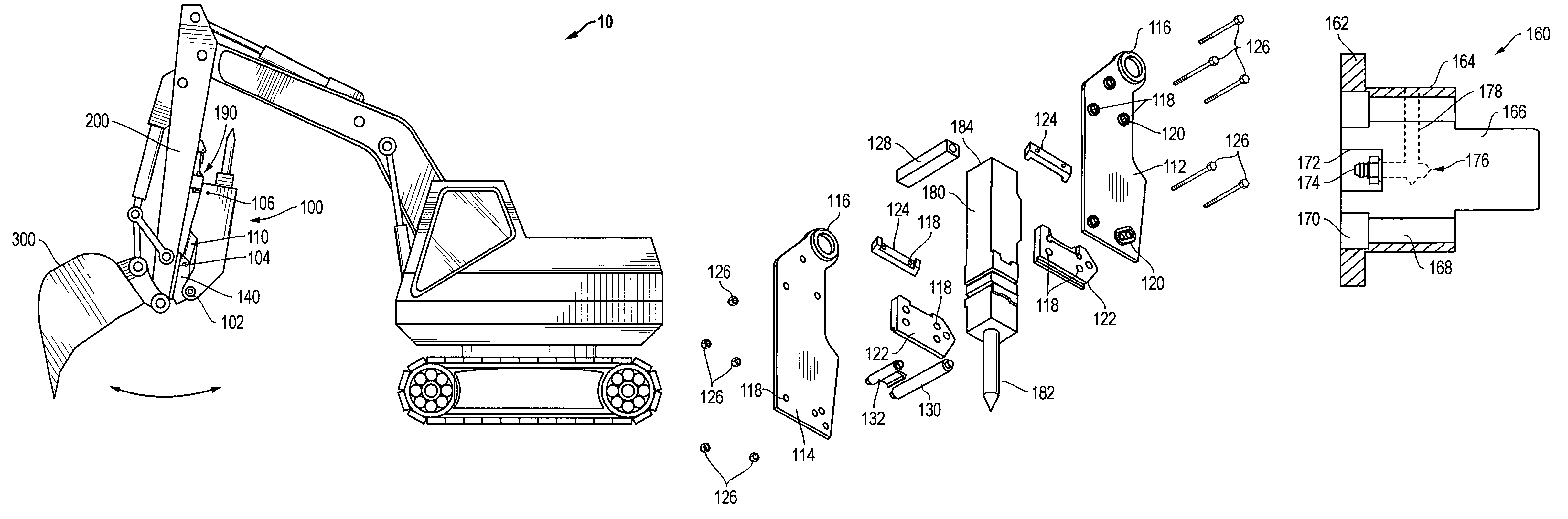

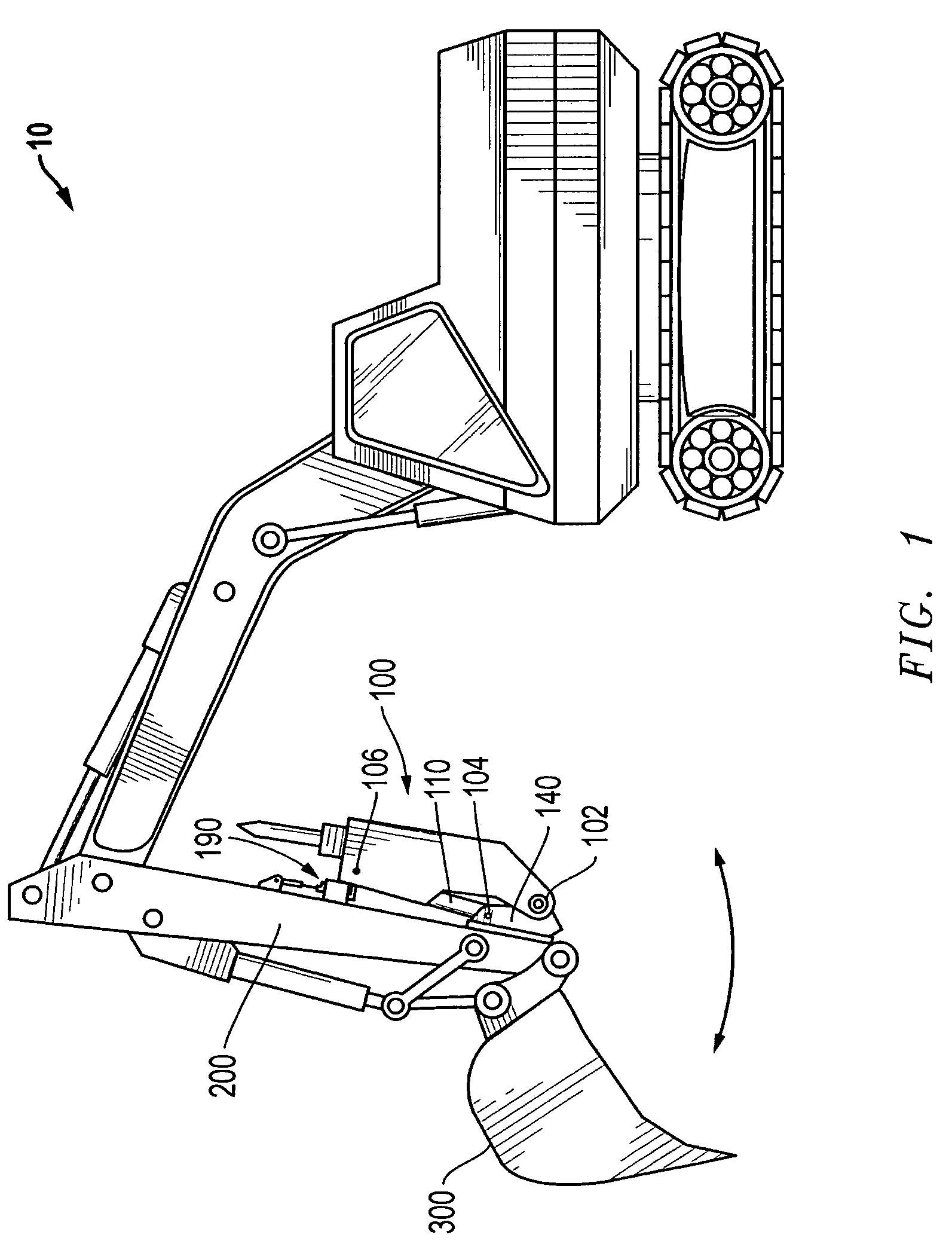

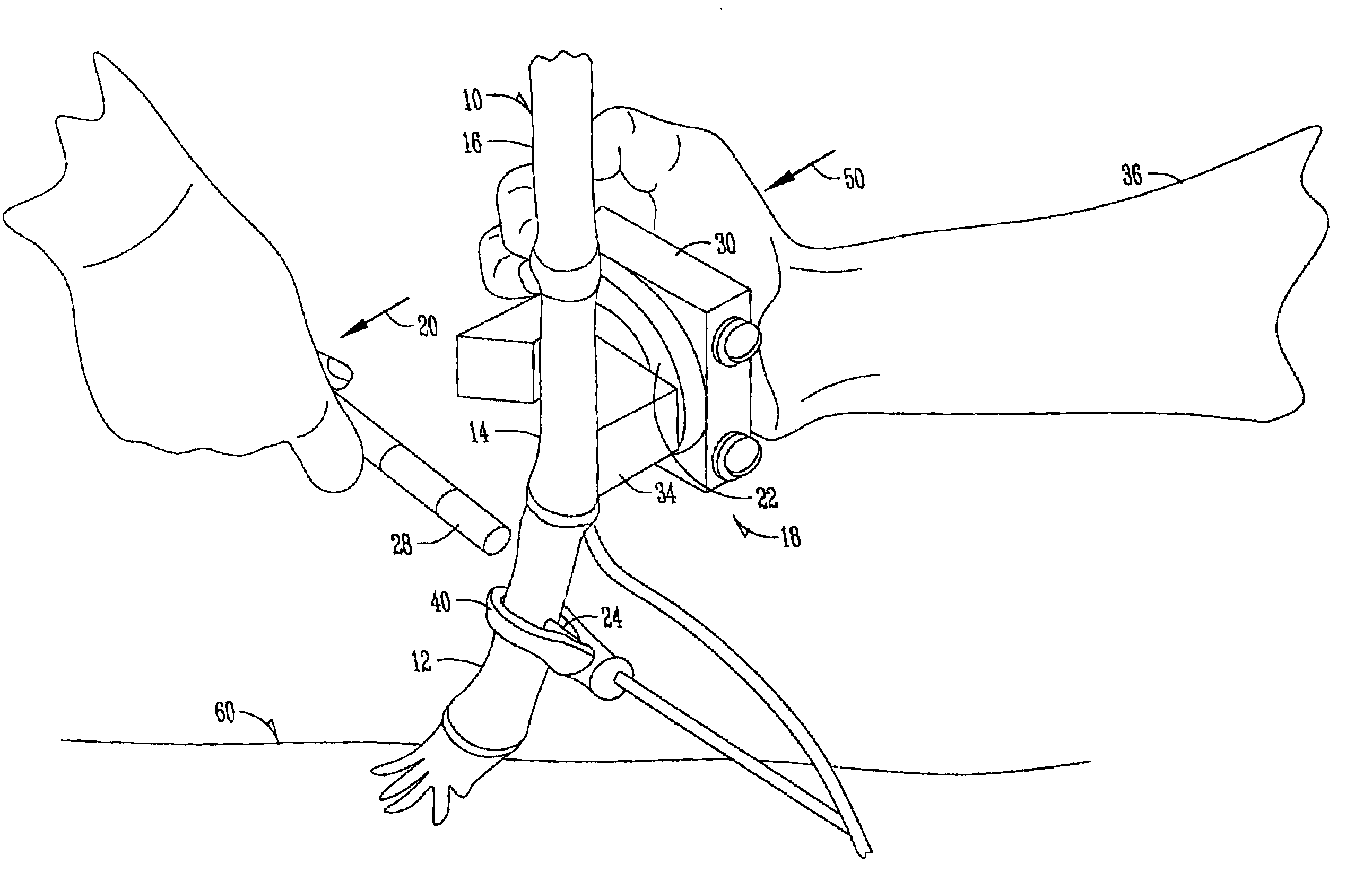

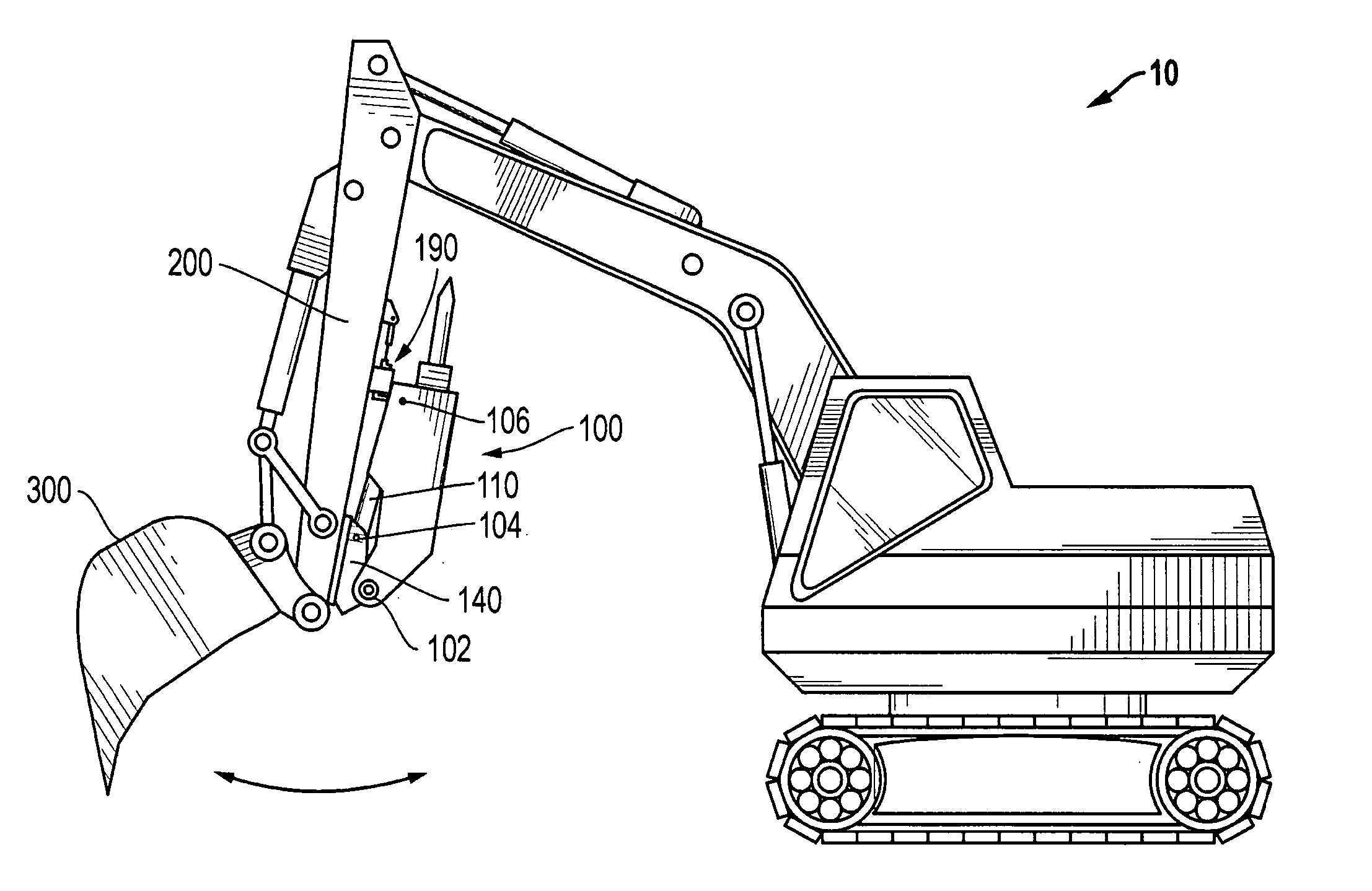

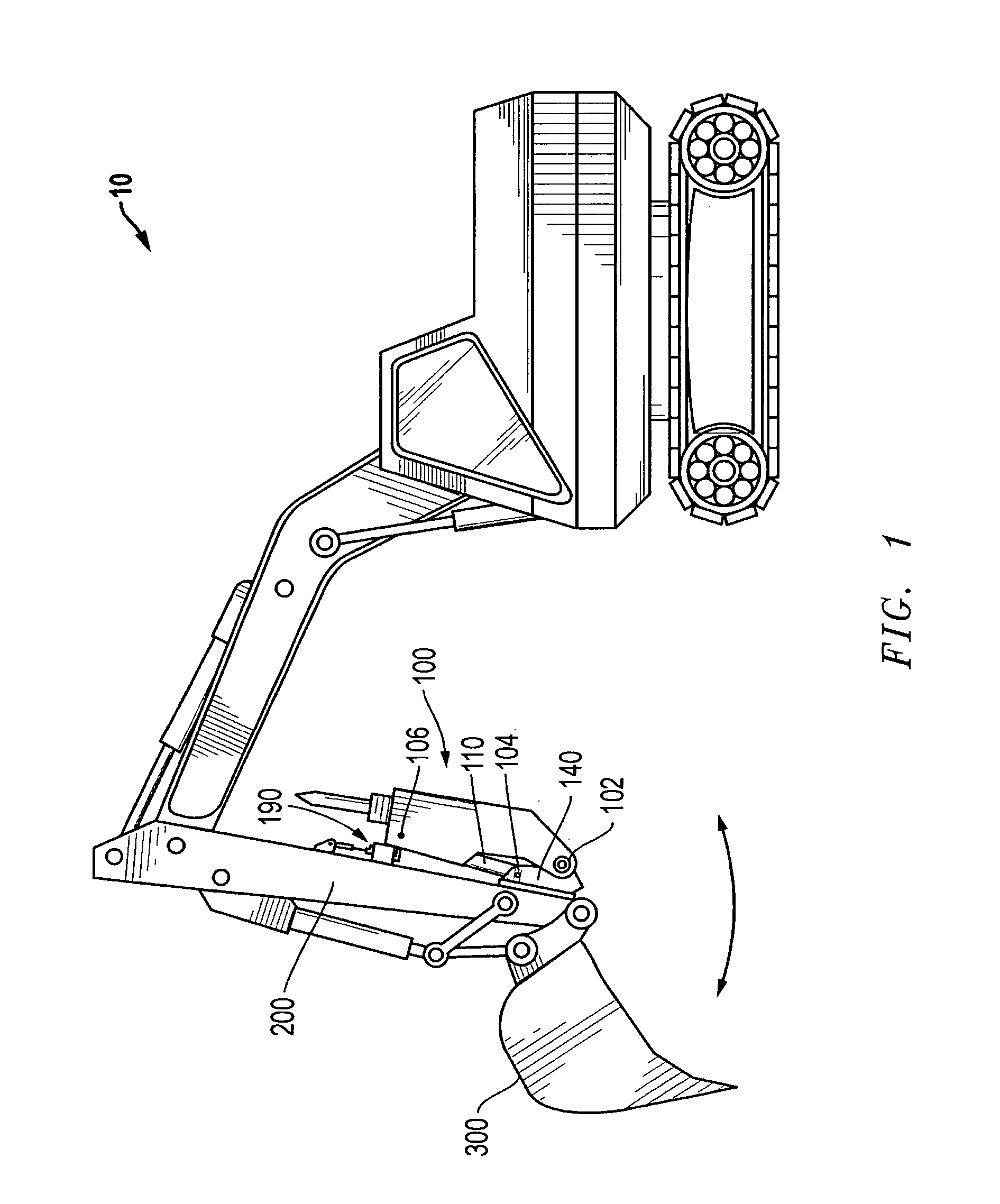

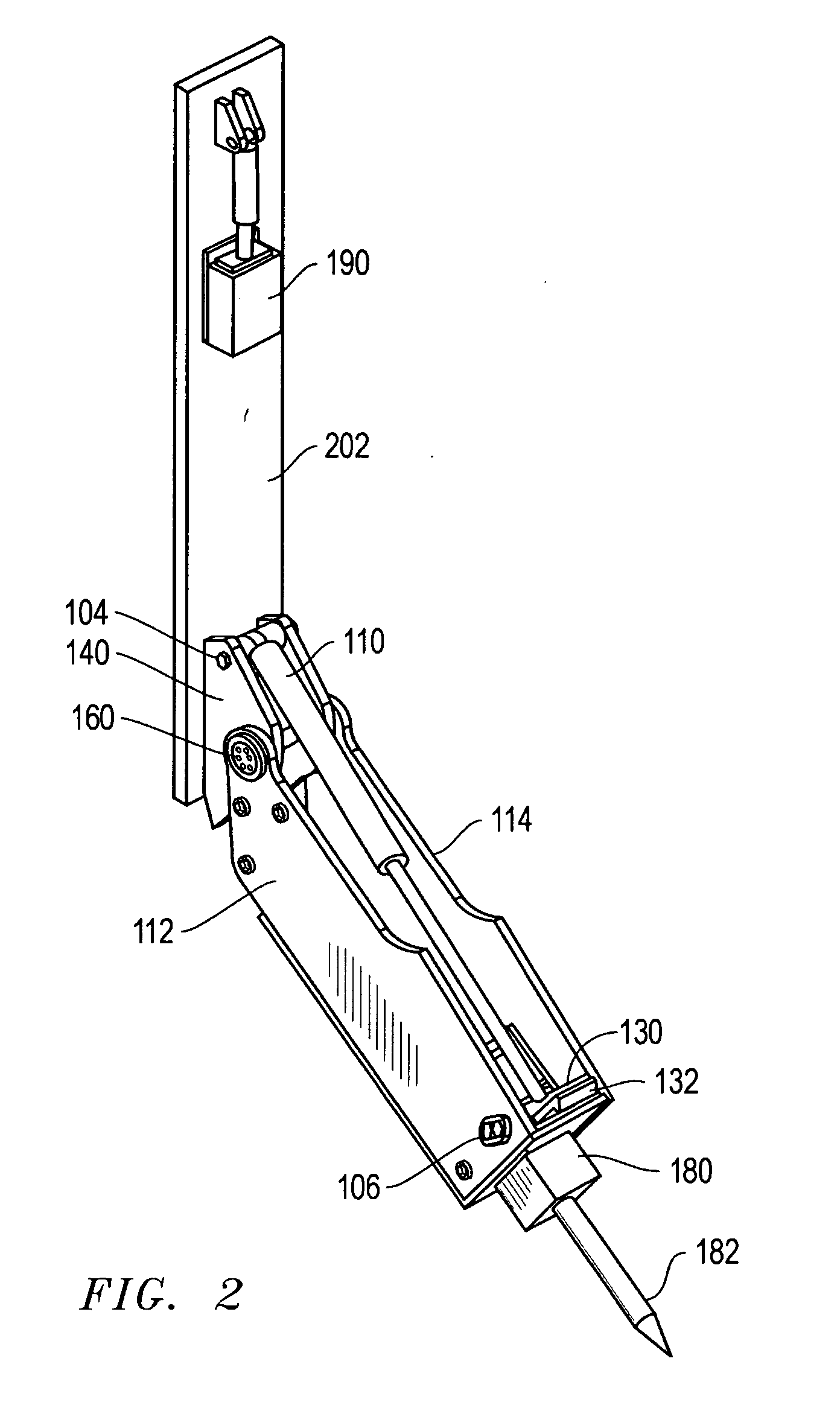

Impact resistant breaker deployment system for an excavating machine

InactiveUS7257910B2Avoid distortionEasy to disassembleMining devicesMechanical machines/dredgersCrusherExcavator

Disclosed is an excavating machine, representatively a tracked excavator, having a boom stick portion on which both an excavating bucket and a hydraulic breaker are mounted for hydraulically driven pivotal movement between first and second limit positions. The bucket may be operated independently of the breaker for digging operations. Similarly, the breaker may be operated independently of the bucket for refusal material-breaking operations. The same excavating machine may now use the bucket and breaker in a rapid and continuous exchange to permit frequent removal of small quantities of broken refuse material with the bucket, exposing the bucket and breaker to fresh refuse material. The excavating machine disclosed incorporates an impact resistant deployment system with bifurcated and lubricated trunnion pivots and an in-line pivot restriction, or stop. The system provides a breaker assembly connection that permits quick installation and removal of the breaker, and significantly greater durability.

Owner:RECS

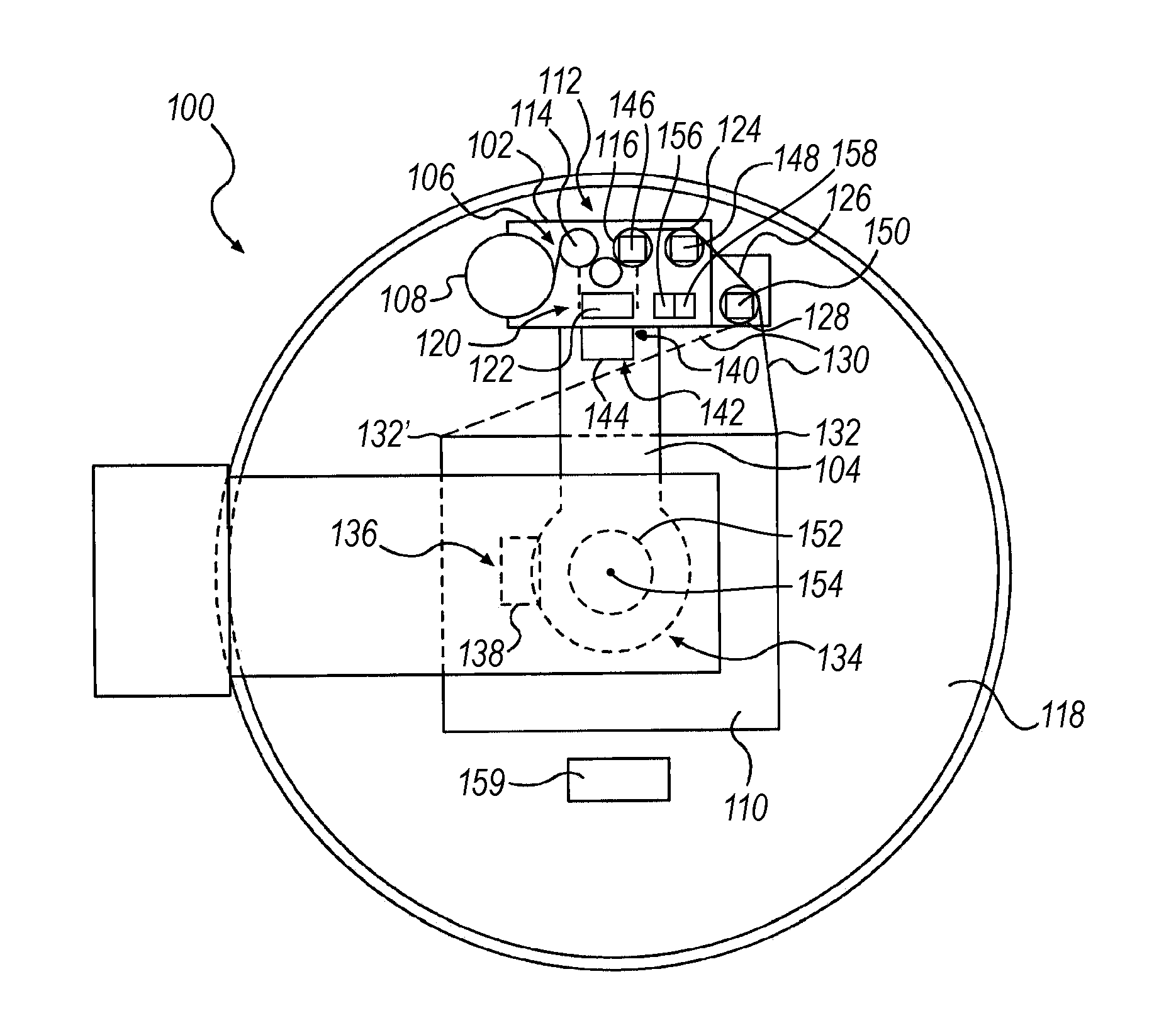

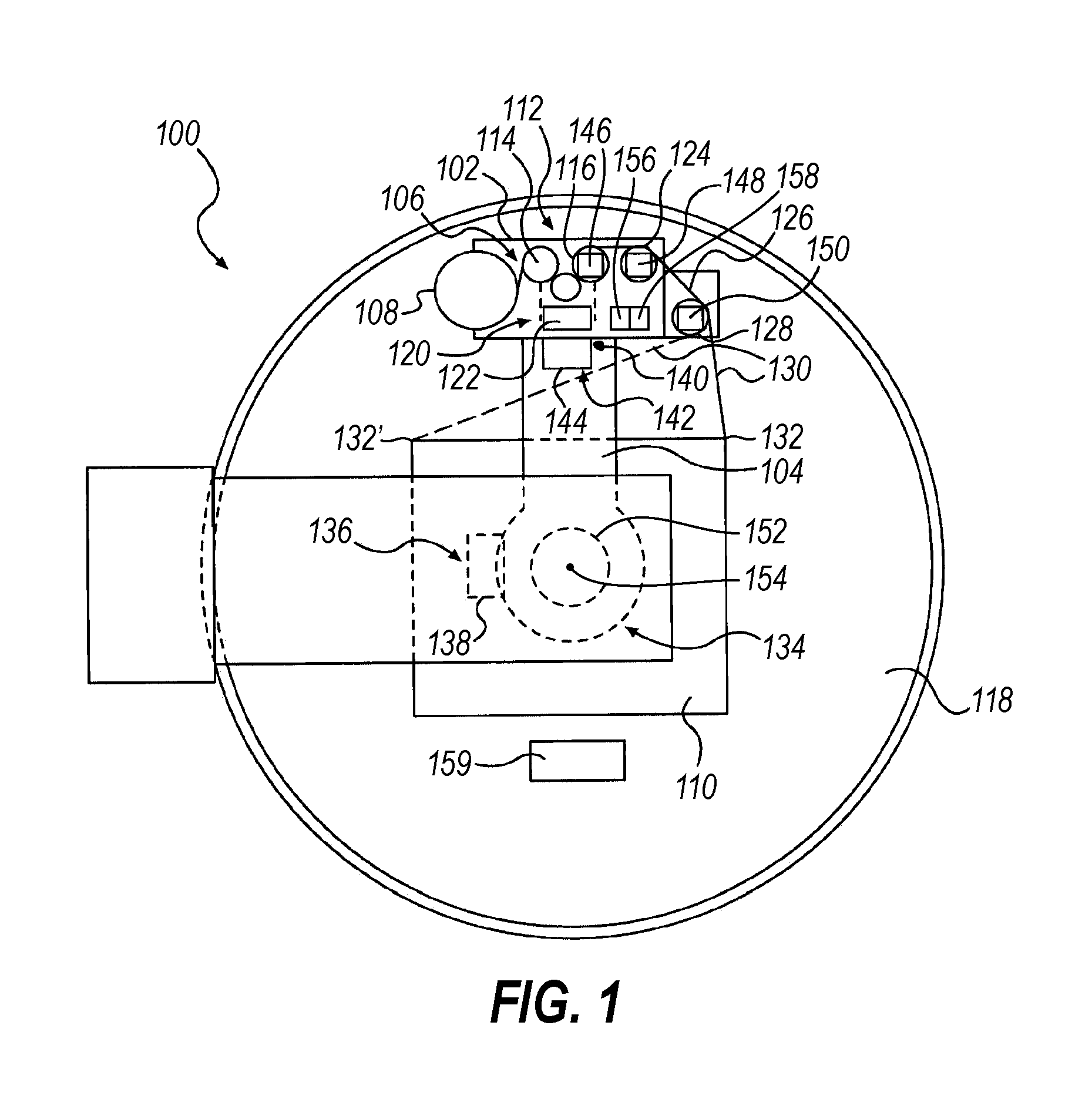

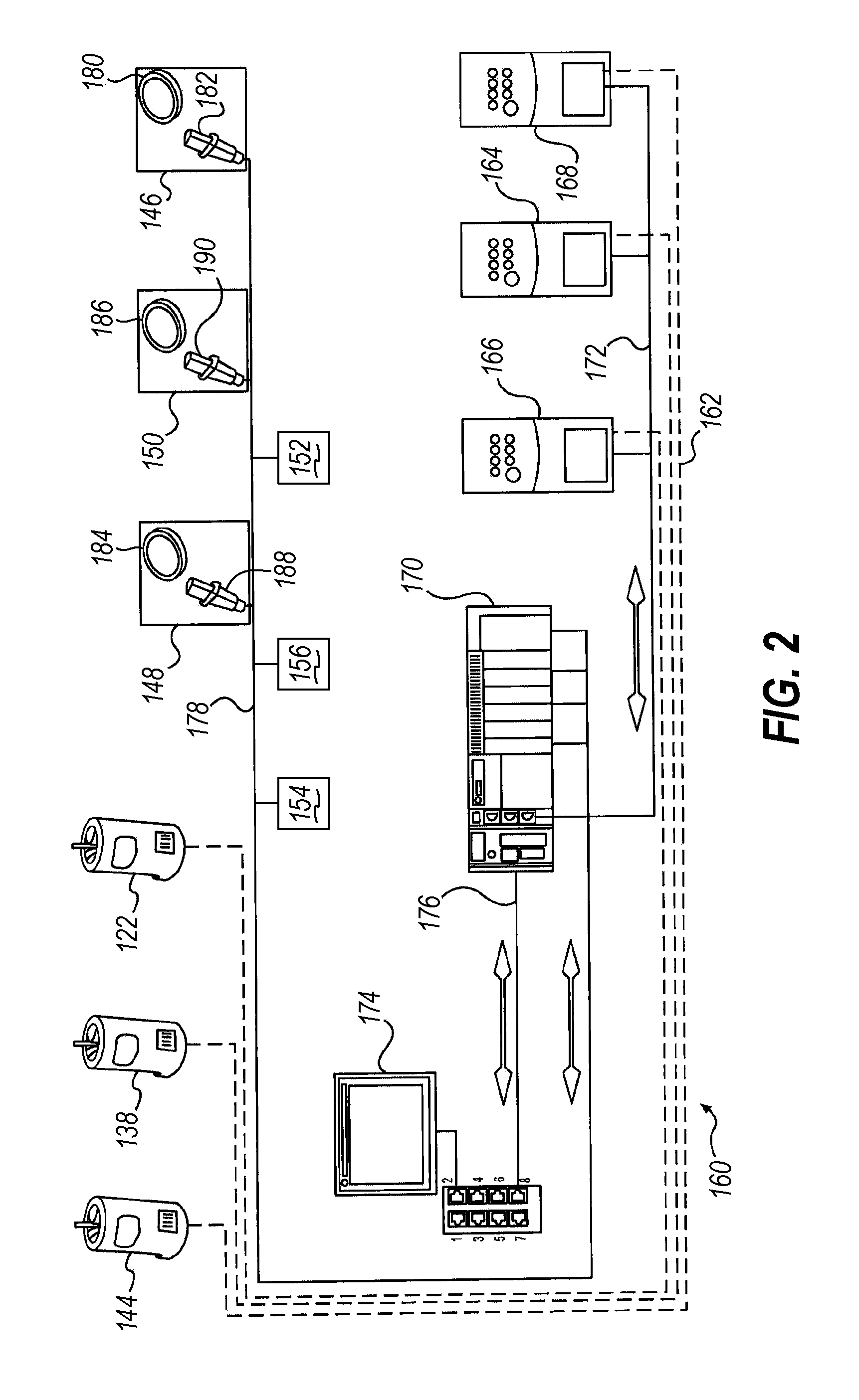

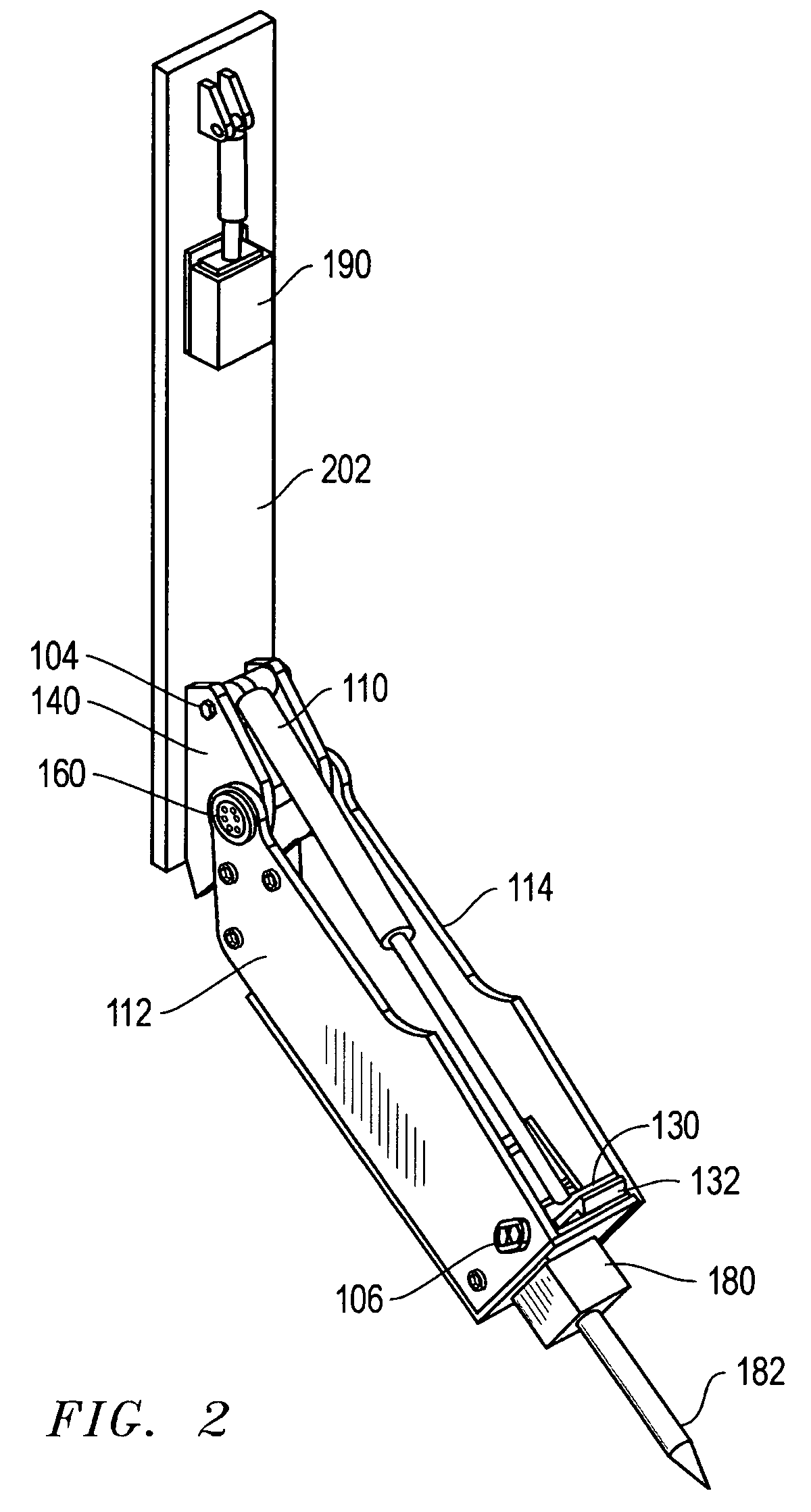

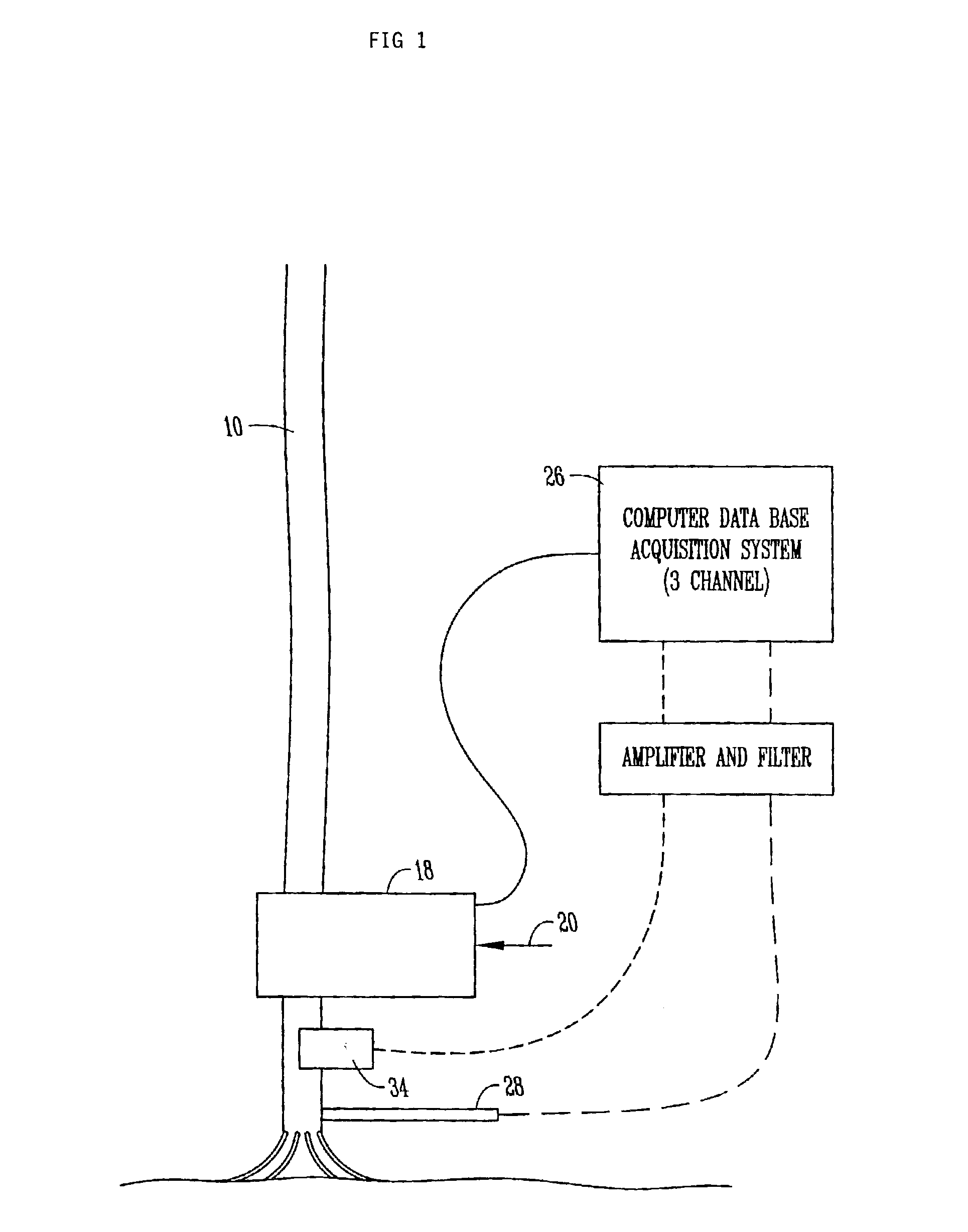

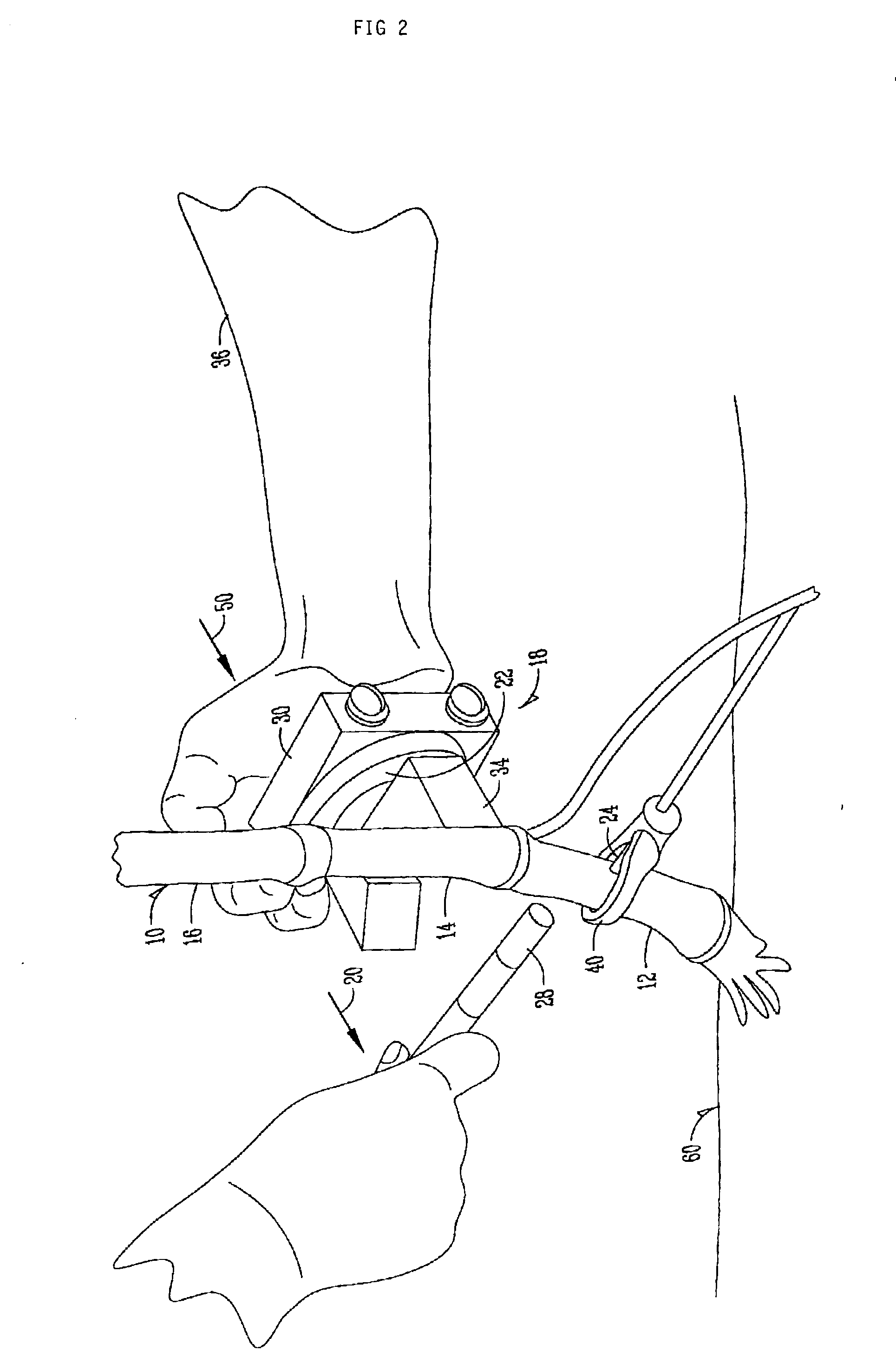

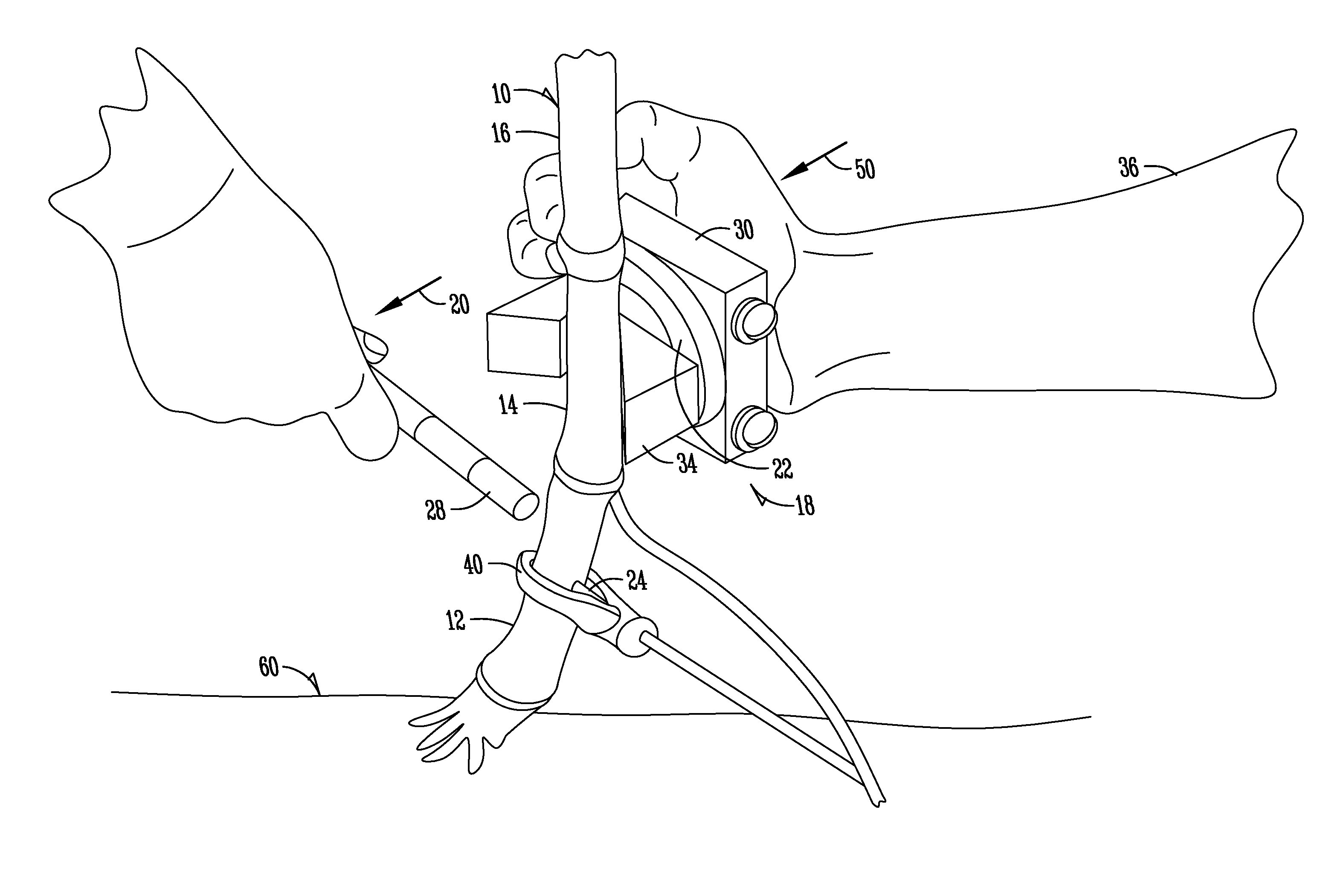

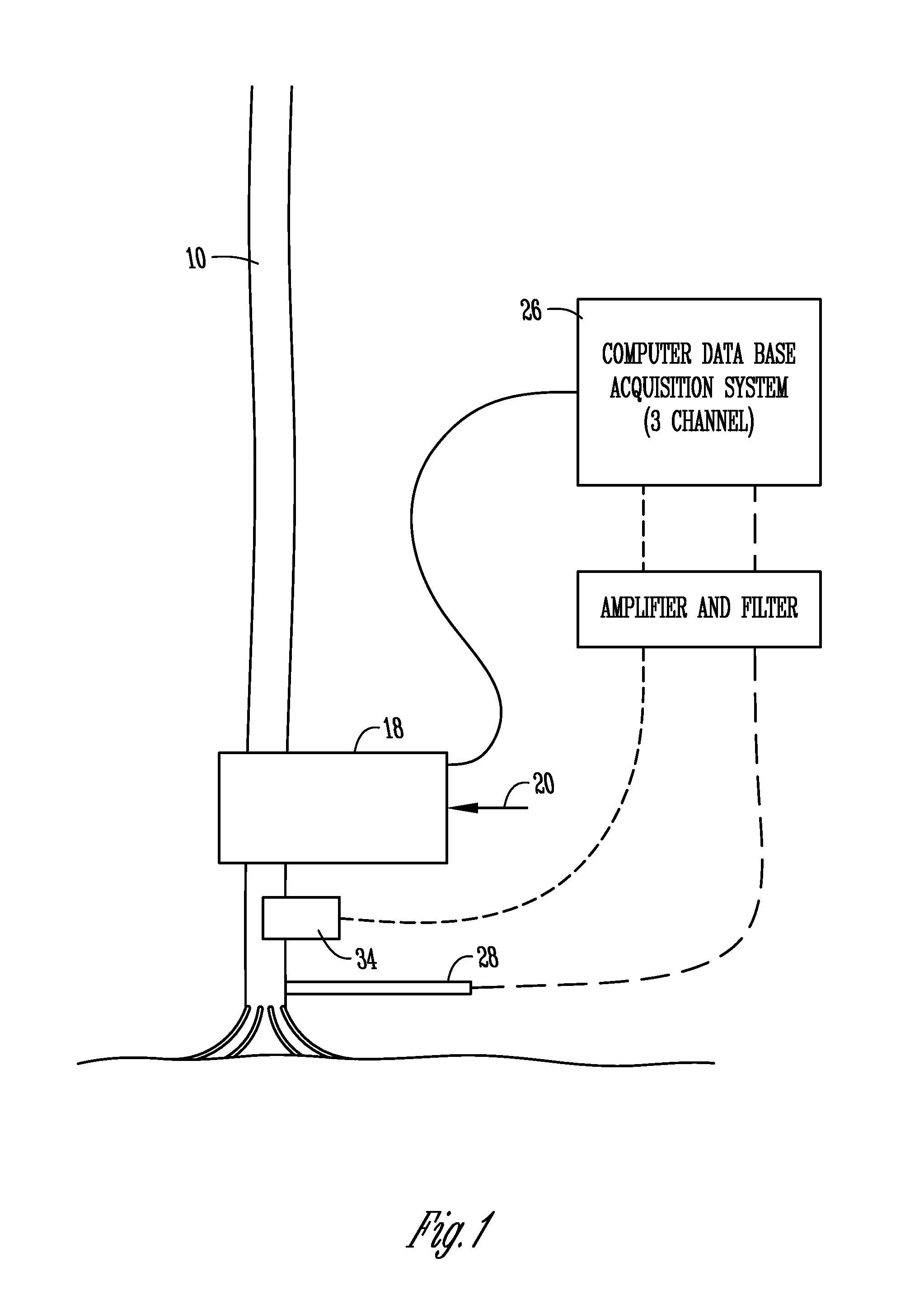

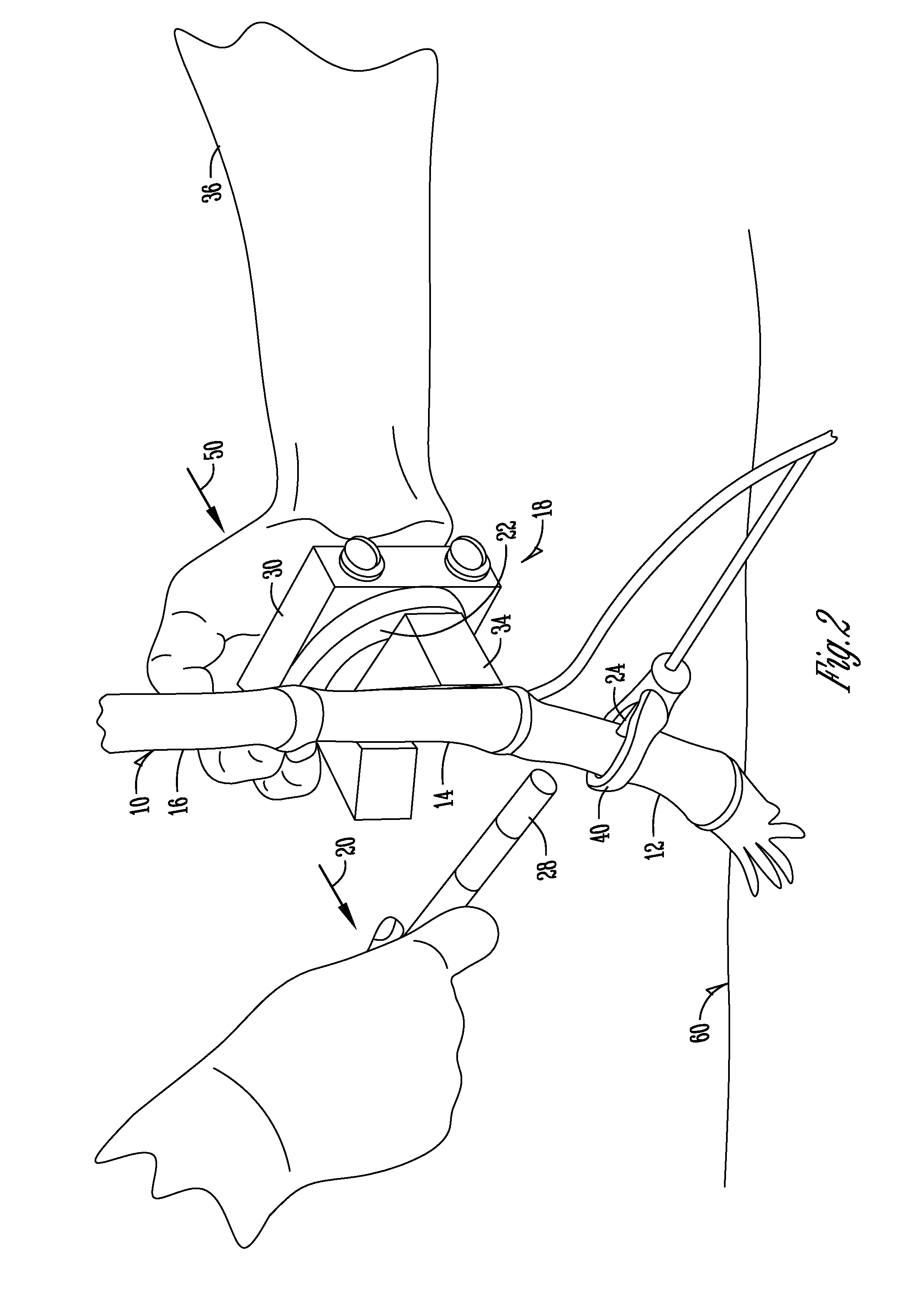

Correlating Push Force and Stalk Vibration to a Plant's Susceptibility to Stalk Lodging and Brittle Snap

InactiveUS20110083519A1Force measurement by measuring frquency variationsApparatus for force/torque/work measurementAccelerometerEngineering

The present device enables measurement of the susceptibility of corn plants to stalk lodging and brittle snap. The device is used to push over a corn stalk and the force used to push over the stalk, and the vibration of the stalk caused by the push are recorded. As material breaks in the stalk, an accelerometer, measures stalk vibration response to the breaking events; the data is then recorded to allow quantitative measurements of the susceptibility of corn plants to stalk lodging and brittle snap. This allows meaningful comparisons of various hybrids at early stages of hybrid evaluation and advancement.

Owner:PIONEER HI BRED INT INC

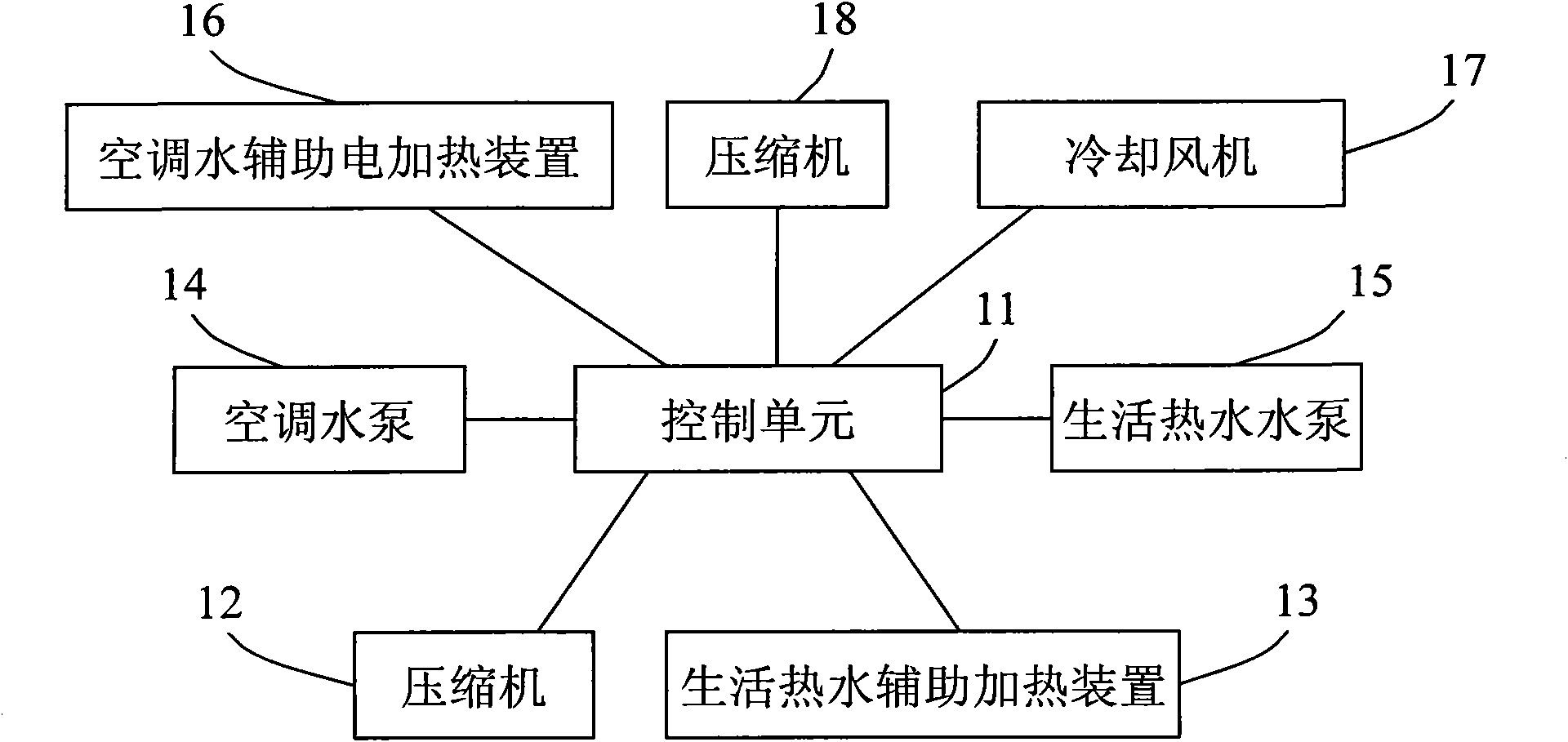

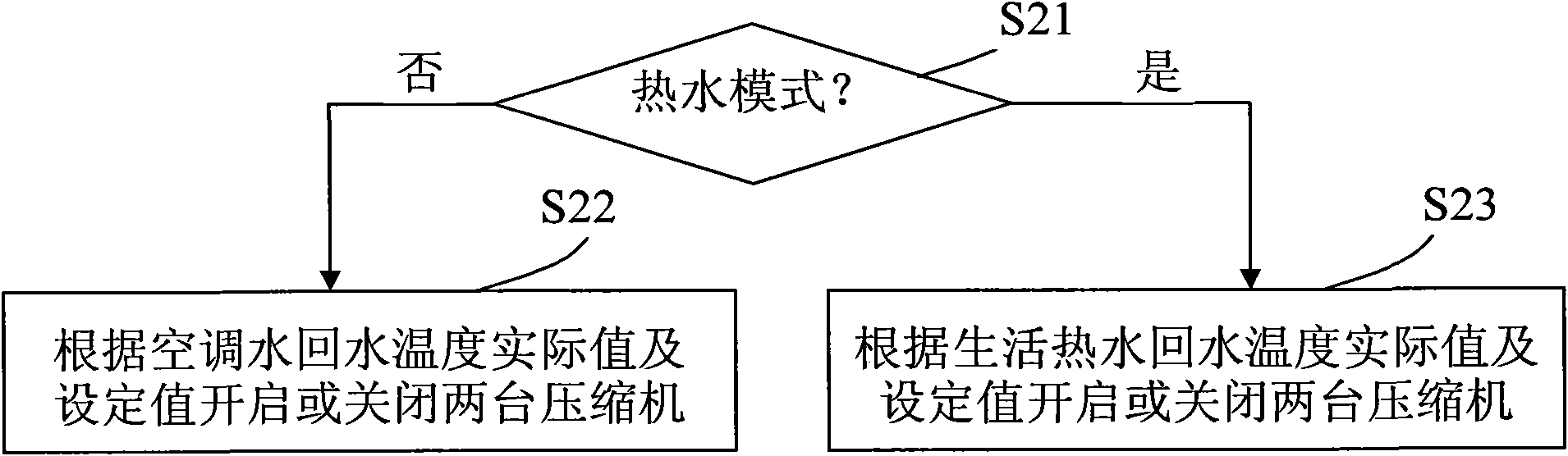

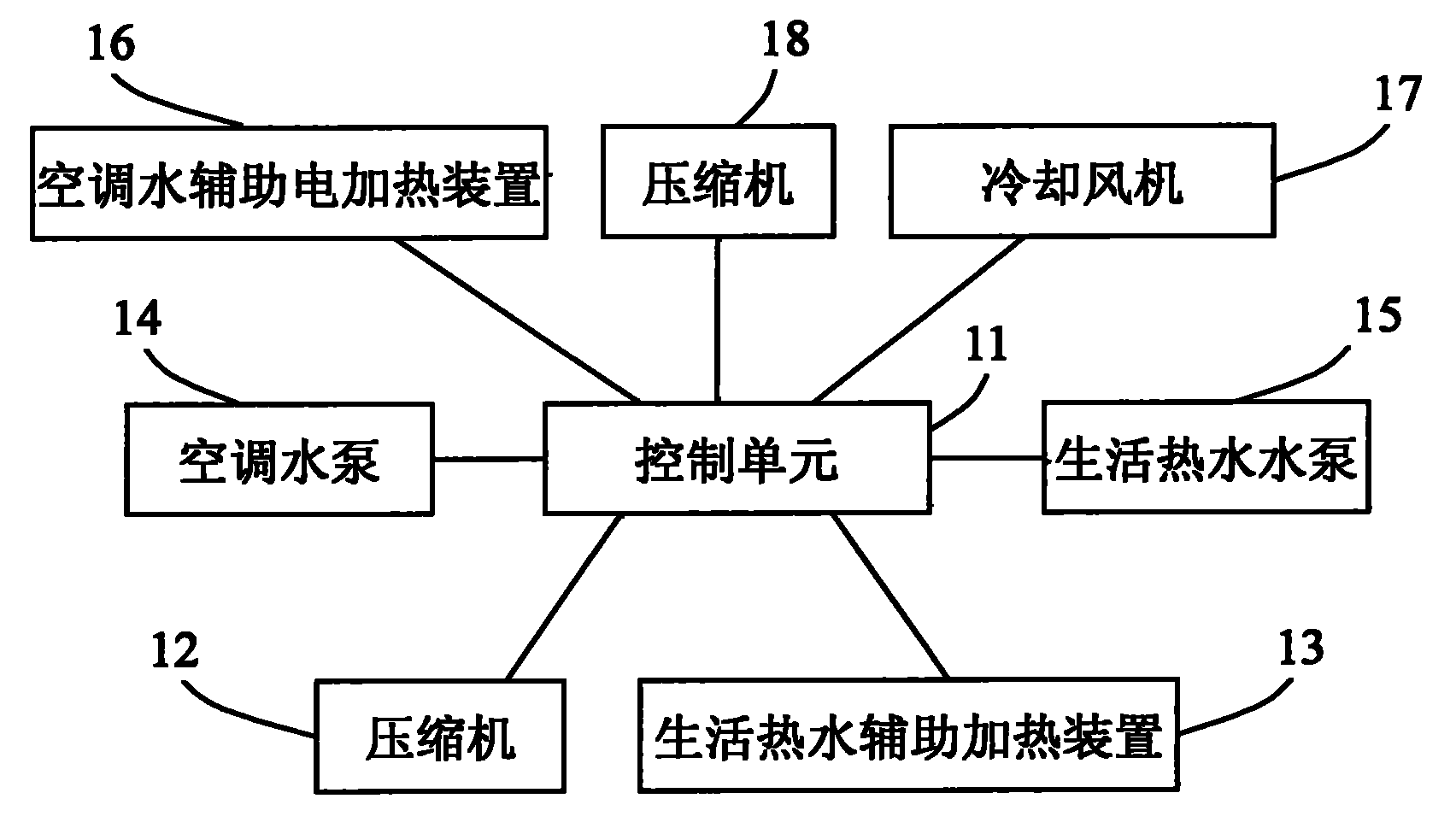

Combined cooling and heating supply system and control method

InactiveCN102109244AEnsure safetyAvoid damageRefrigeration safety arrangementHeating and refrigeration combinationsEngineeringAir conditioning

The invention relates to a combined cooling and heating supply system which comprises an air-conditioning water auxiliary electric heating device, a cooling fan, an air-conditioning water pump, a domestic hot water pump, at least two compressors and a domestic hot water auxiliary heating device and further comprises a control unit and a plurality of temperature sensors, wherein the temperature sensors are respectively used for measuring the actual value of the air-conditioning water return temperature and the value of the actual domestic hot water return temperature; when a material broken operating mode of the control unit is in an air-conditioning mode or a heating mode, the air-conditioning water pump is opened, and the compressors are opened or closed according to the actual value and the set value of the air-conditioning water return temperature; and when the operating mode is judged to be in a hot water mode, the domestic hot water pump is opened, and the compressors are opened or closed according to the value and the set value of the actual air-conditioning water return temperature. The invention also relates to a corresponding control method. With the combined cooling and heating supply system, the operation safety of equipment is ensured by controlling the opening or the closing of a high-power part in control equipment according to the air-conditioning water return temperature and domestic hot water return temperature as well as the set valve.

Owner:广东力优环境系统股份有限公司

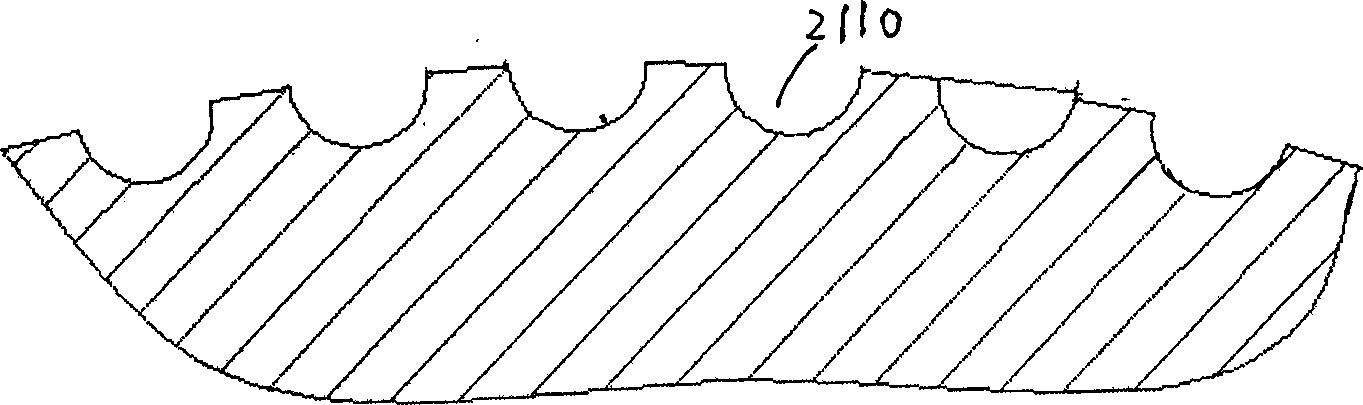

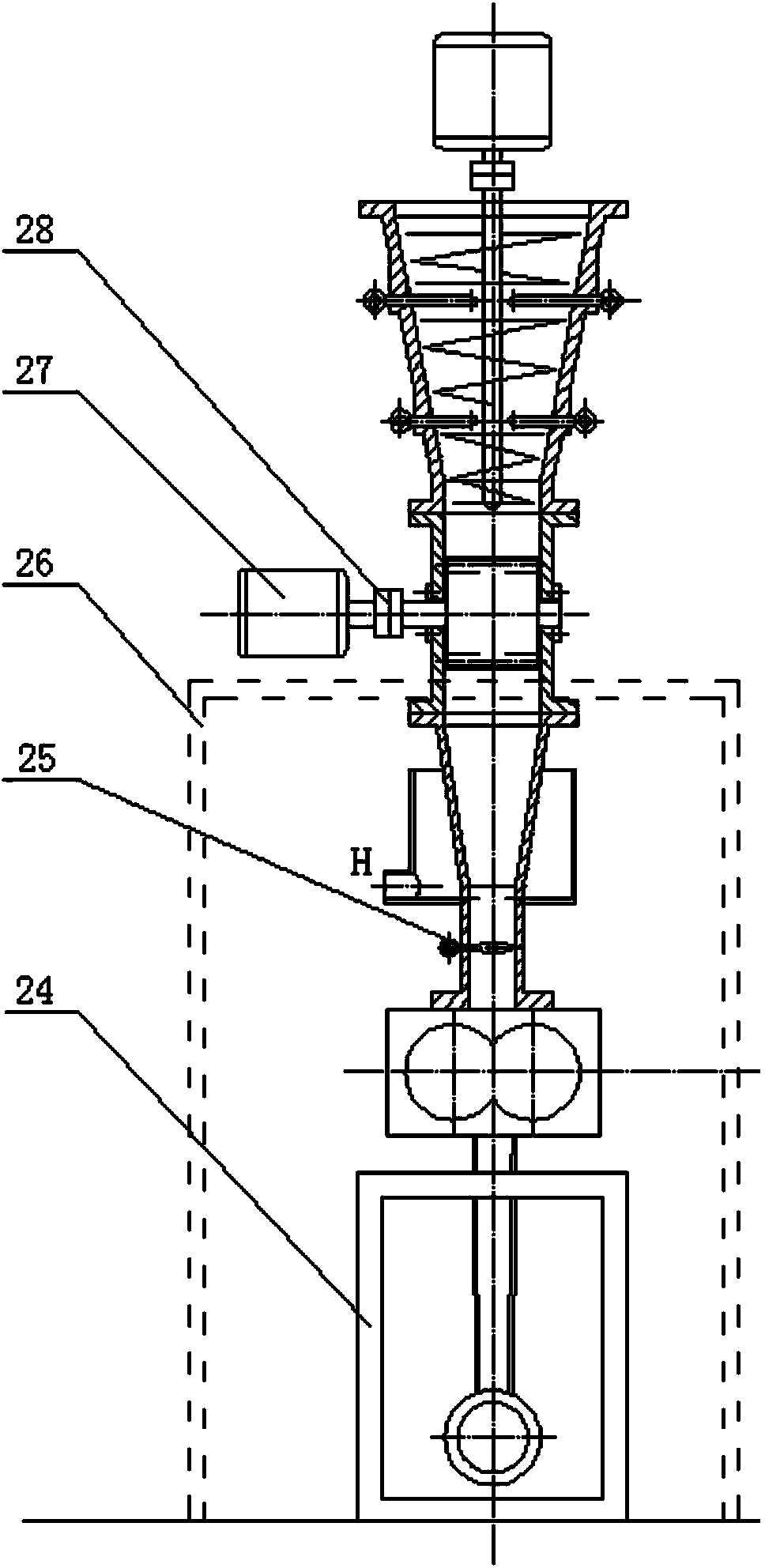

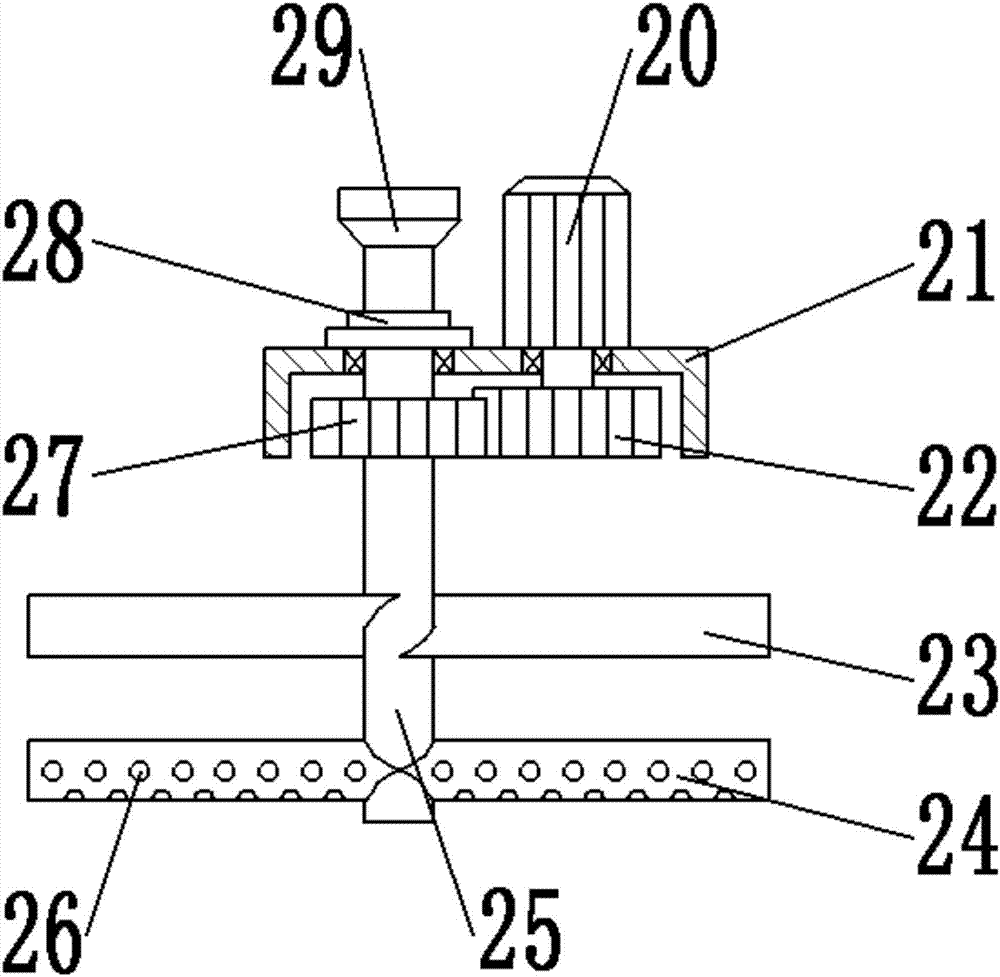

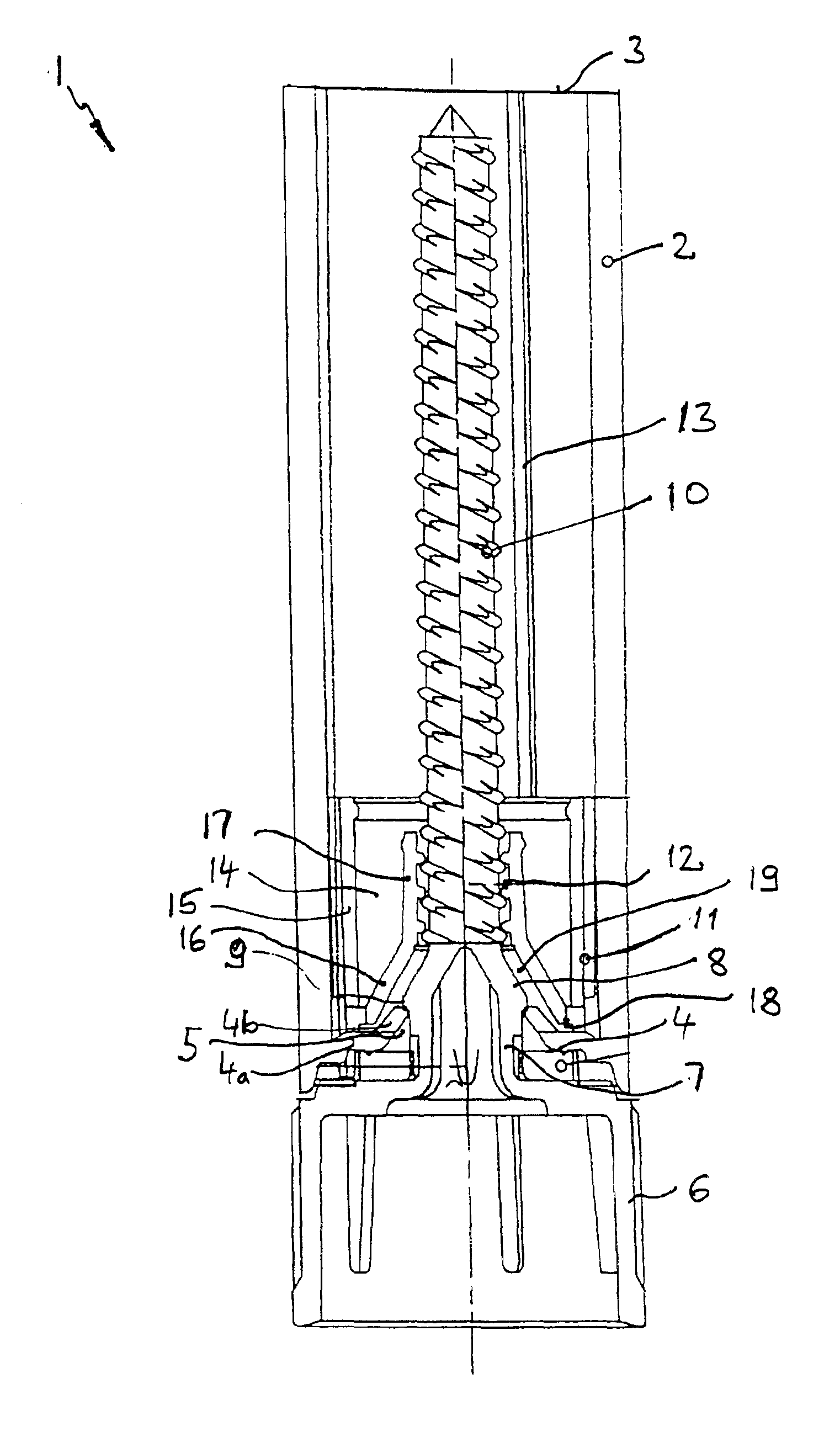

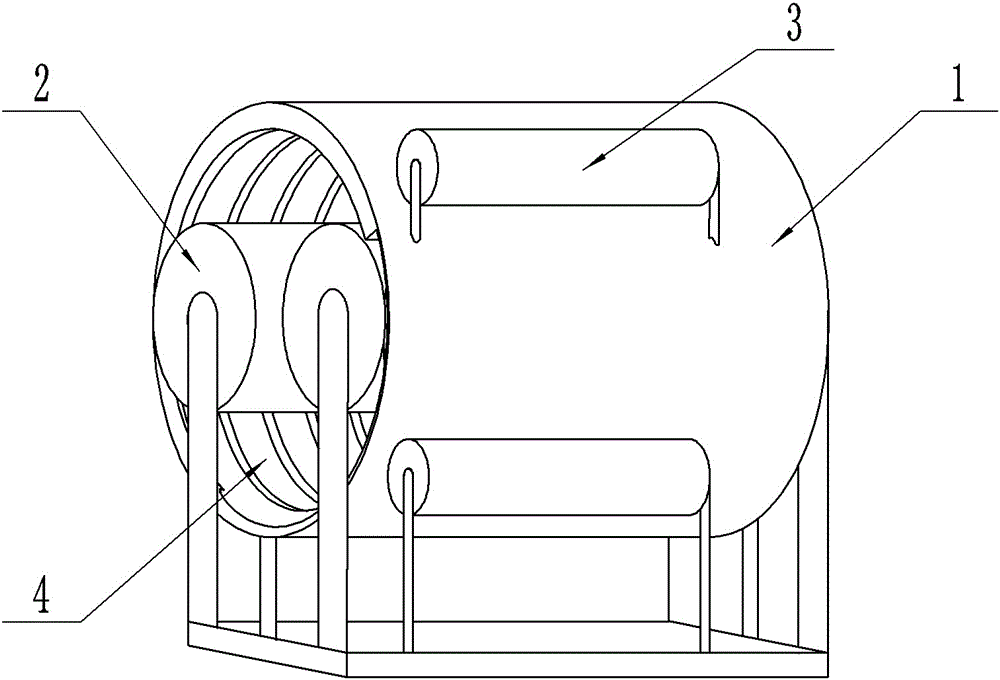

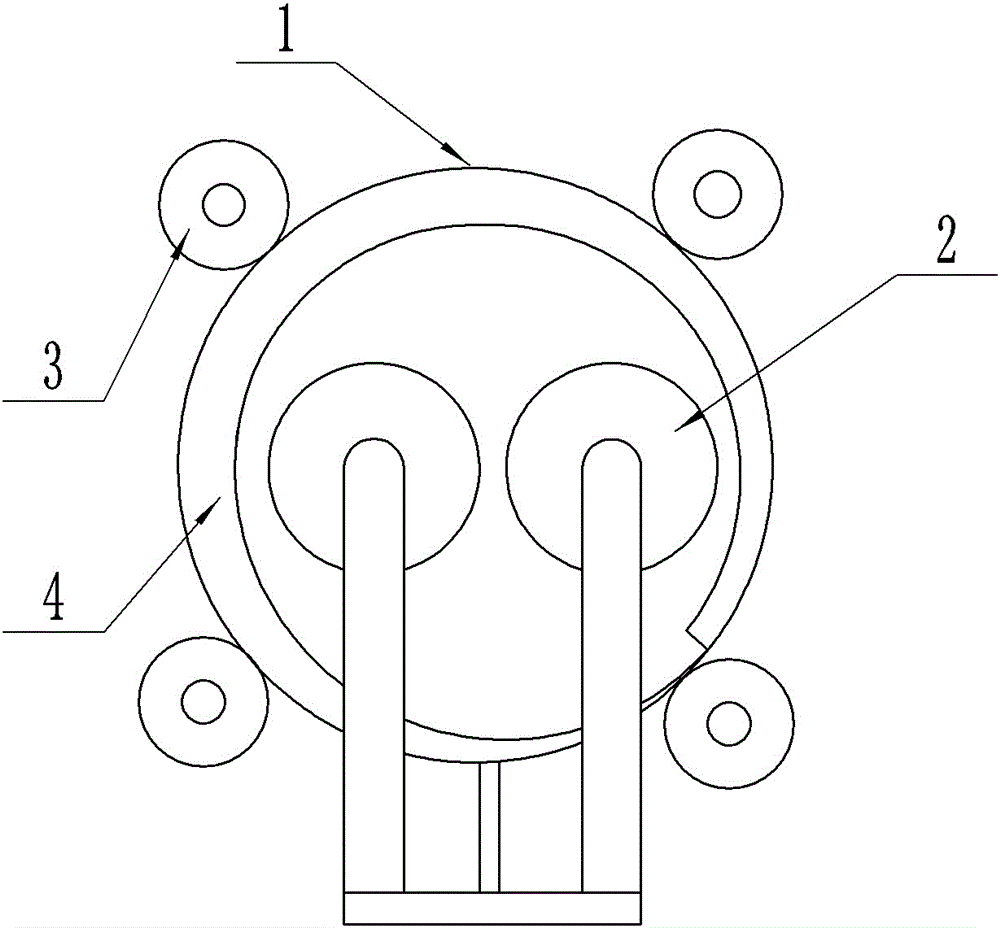

Twin screw breaking and dehydrating integrated processing equipment with gear pump

The invention belongs to the field of material breaking and dehydrating processing, and discloses a twin screw breaking and dehydrating integrated processing equipment with a gear pump; the equipment can be used for integrated processing of material friction breaking, extruding and forming, cell wall breaking, and solid-liquid extraction. The equipment comprises a main motor, a transmission belt, a reducing gear mechanism, a first coupling, a cylinder pair, a combined twin screw pair, connecting screws, an upper filtering cylinder fluid collecting device, the gear pump, a gear pump gear pair, a secondary breaking cutter, a forcing feeding spiral, a primary breaking cutter, a forcing feeder cylinder, a second coupling, a forcing feeding motor, a machine head covering plate, an indexing adjustment screw, a damping block, a dehydrating machine head, an auxiliary feeding cylinder, an upper filtering cylinder, upper filtering cylinder filtering plates, a frame, an upper filtering cylinder indexing adjusting mechanism, a support seat, a gear pump motor, a third coupling and an automatic control system. The forcing feeder breaks material primarily. The upper filtering cylinder is provided with two upper filtering cylinder filtering plates. The cylinder pair is provided with two feeding ports and four dehydrating ports, and the dehydrating machine head is provided with one four dehydrating port. Material breaking and dehydrating processing can be implemented efficiently.

Owner:BEIJING UNIV OF CHEM TECH

Impact resistant breaker deployment system for an excavating machine

InactiveUS20060272184A1Avoid distortionEasy to disassembleMining devicesMechanical machines/dredgersEngineeringCrusher

Disclosed is an excavating machine, representatively a tracked excavator, having a boom stick portion on which both an excavating bucket and a hydraulic breaker are mounted for hydraulically driven pivotal movement between first and second limit positions. The bucket may be operated independently of the breaker for digging operations. Similarly, the breaker may be operated independently of the bucket for refusal material-breaking operations. The same excavating machine may now use the bucket and breaker in a rapid and continuous exchange to permit frequent removal of small quantities of broken refuse material with the bucket, exposing the bucket and breaker to fresh refuse material. The excavating machine disclosed incorporates an impact resistant deployment system with bifurcated and lubricated trunnion pivots and an in-line pivot restriction, or stop. The system provides a breaker assembly connection that permits quick installation and removal of the breaker, and significantly greater durability.

Owner:RECS

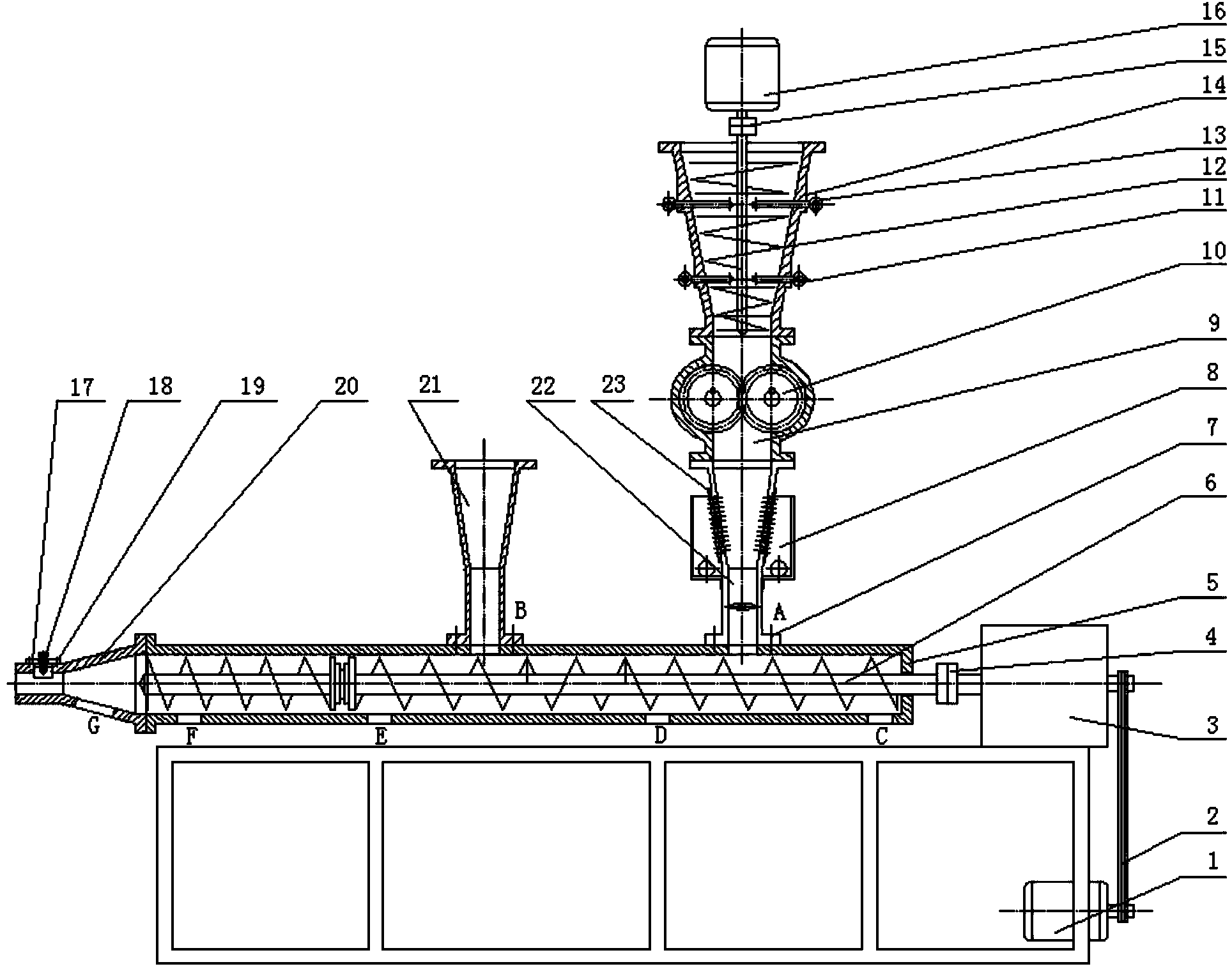

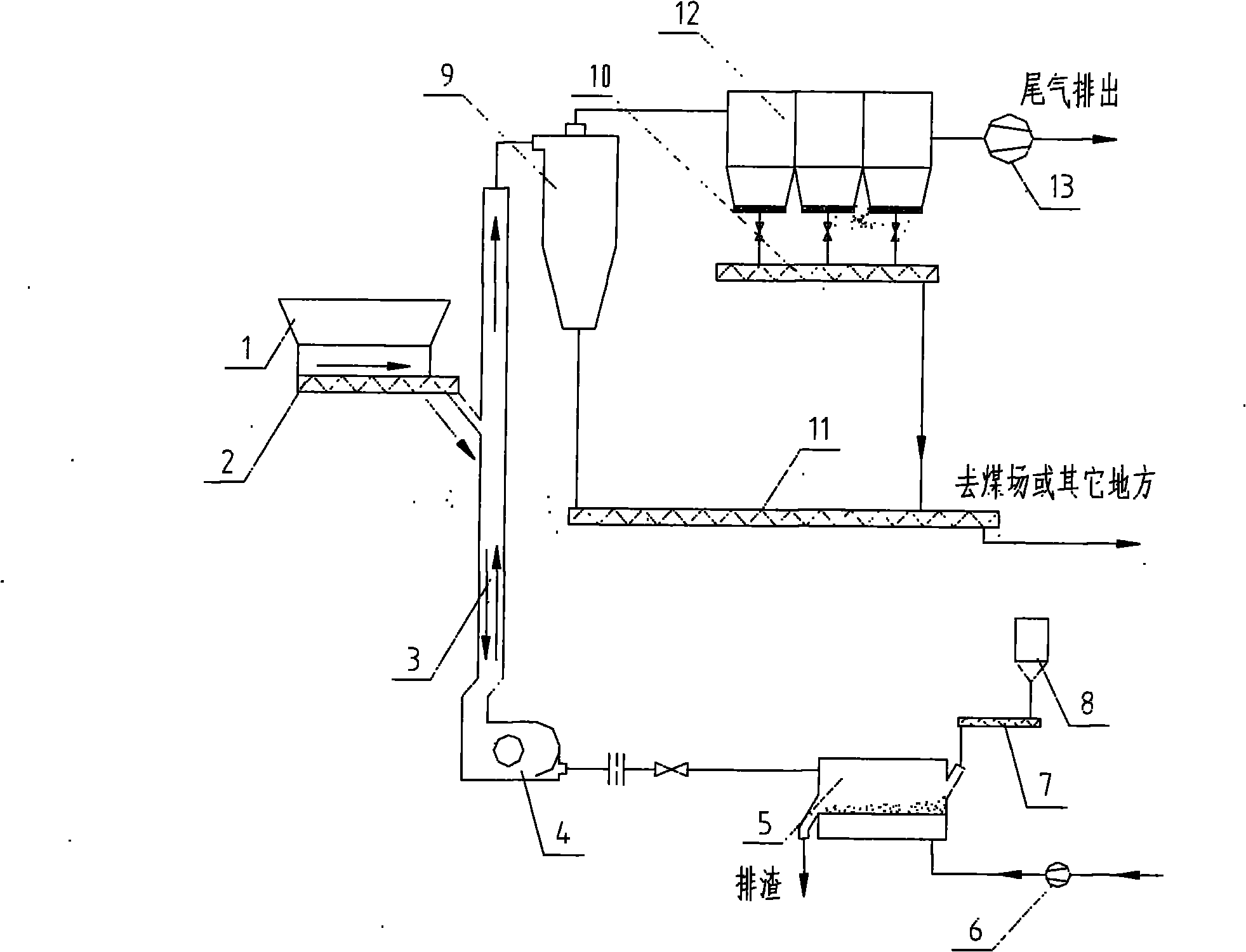

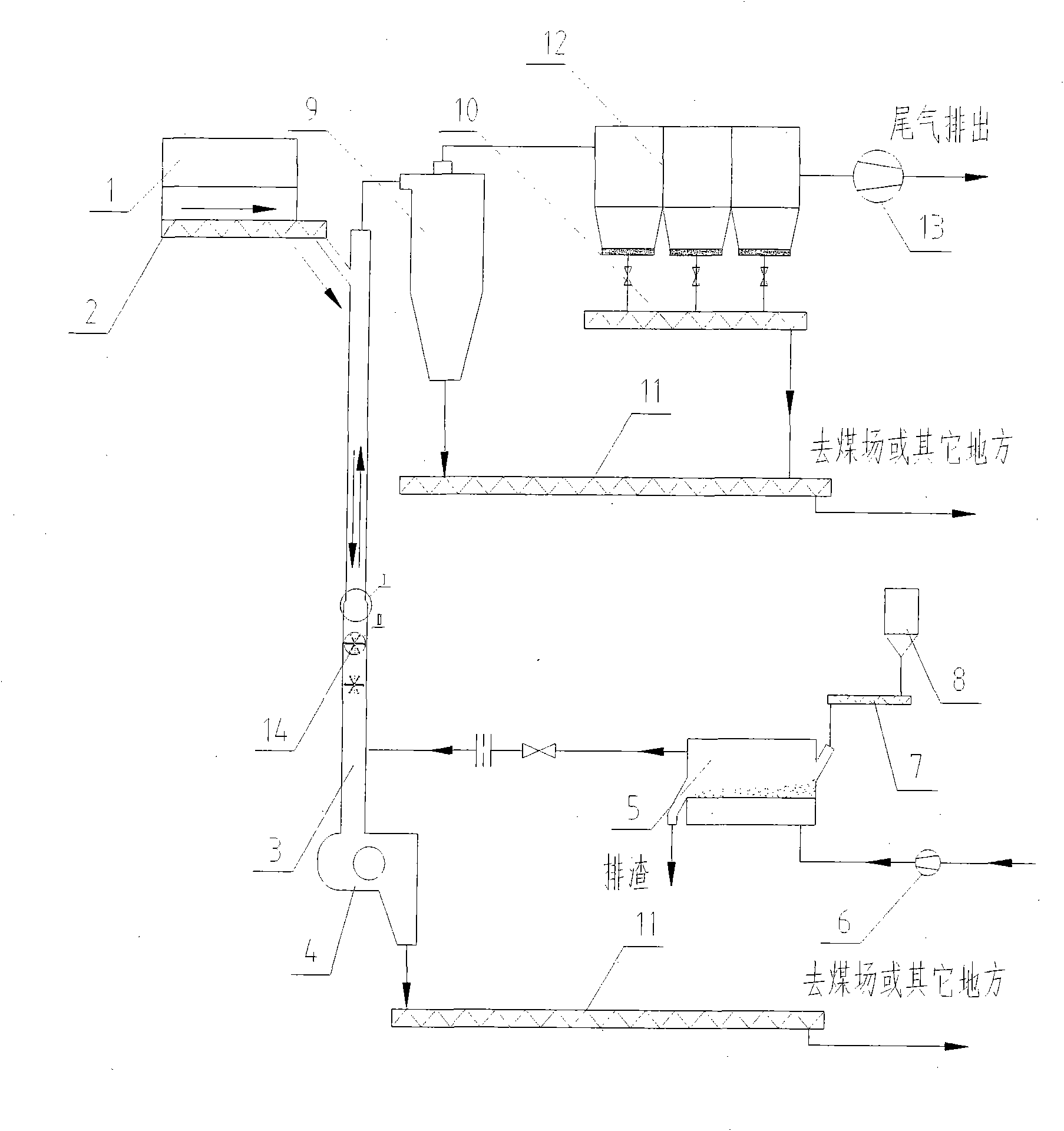

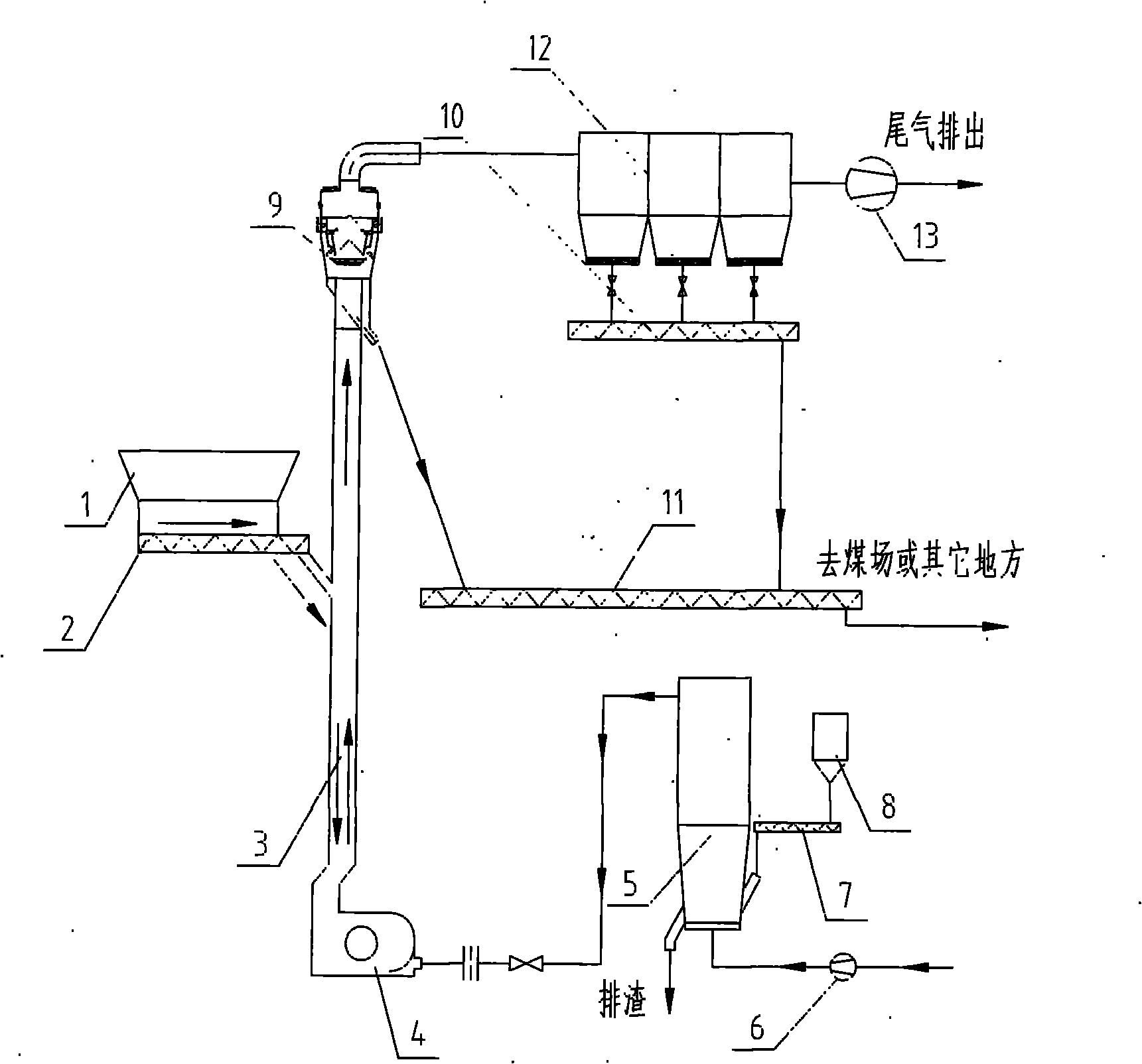

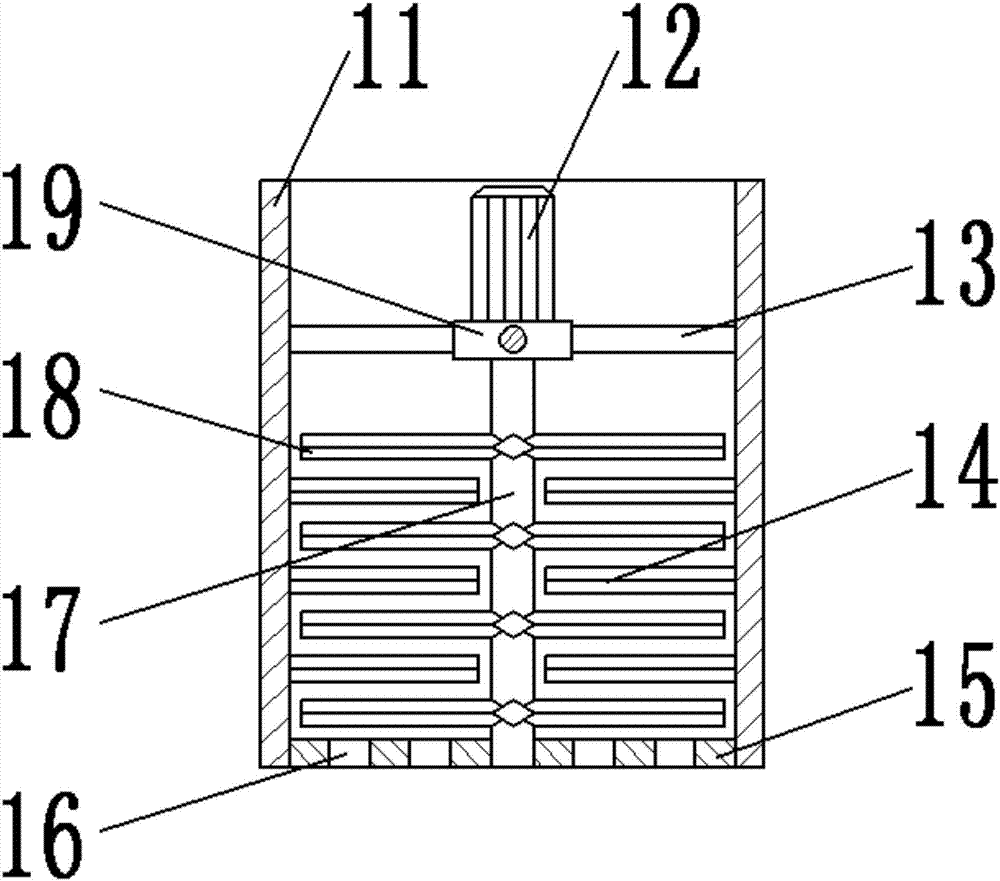

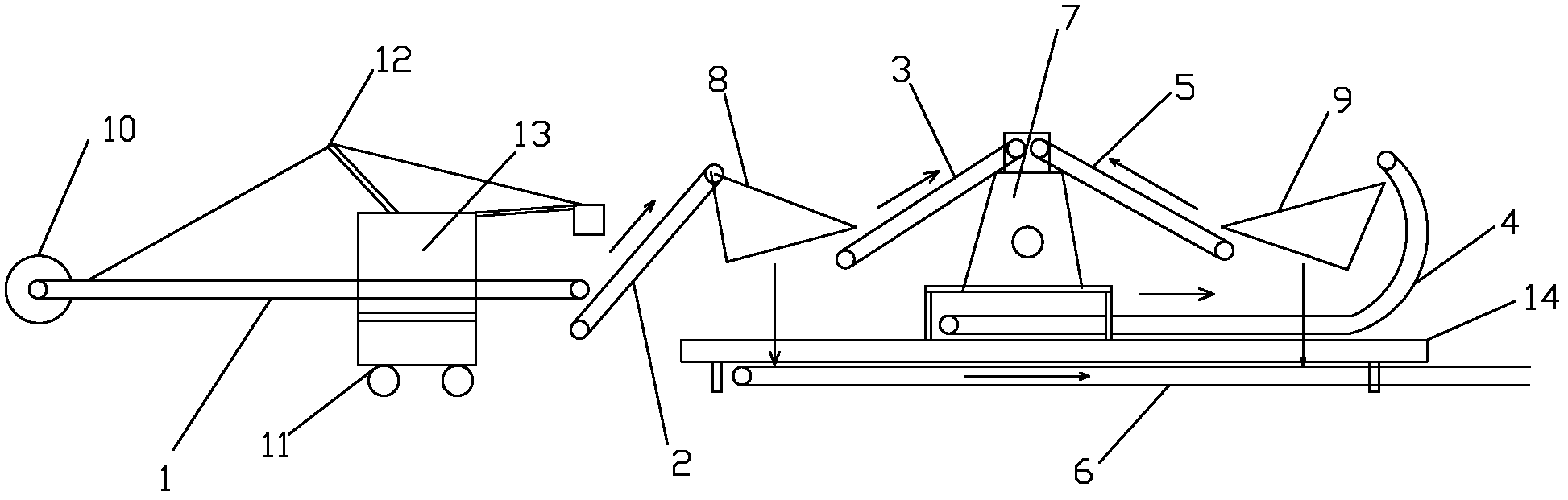

Drying and quality improvement apparatus for slime and sludge and technology thereof

ActiveCN101983942AStrong heat and mass transferAccelerates the rate of moisture diffusionSludge treatment by de-watering/drying/thickeningSludgeYard

The invention provides a drying and quality improvement apparatus for slime and sludge and technology thereof. The device mainly comprises a smoke producer, a feeder, a drying tube, a material breaking-apart device, a cyclone separator, a fine-grain conveying device, a finished-product handling device, a dust remover and a draft fan. The drying medium generated by the smoke producer and high-moisture materials to be dried administered by the feeder enter into the material breaking-apart device and the drying tube respectively. The high-moisture materials are subject to deep drying and air classification in the drying tube after being broke apart and preliminarily dried in the material breaking-apart device, wherein the particles of the size within the designed upper limit are carried into the separator by airflow and the particles of the size higher than the designed upper limit drop into the material breaking-apart device to be broke apart for a second time. Finished products collected by the separator are sent to coal yards or other places by the conveying device. Exhaust steam discharged by the separator is discharged into the atmosphere by the draft fan after being treated with the dust remover. The above apparatus has the advantages of better drying effect, reliable operation, simple system and compact structure.

Owner:HUANENG CLEAN ENERGY RES INST

Correlating push force and stalk vibration to a plant's susceptibility to root lodging

ActiveUS20100089176A1Testing starch susbtancesForce measurement by measuring frquency variationsAccelerometerBiology

The present device enables measurement of the susceptibility of corn plants to root lodging. The device is used to push over a corn stalk and the force used to push over the stalk, and the vibration of the stalk caused by the push are recorded. As material breaks in the stalk, an accelerometer, measures stalk vibration response to the breaking events; the data is then recorded to allow quantitative measurements of the susceptibility of corn plants to root lodging. This allows meaningful comparisons of various hybrids at early stages of hybrid evaluation and advancement.

Owner:IOWA STATE UNIV RES FOUND +1

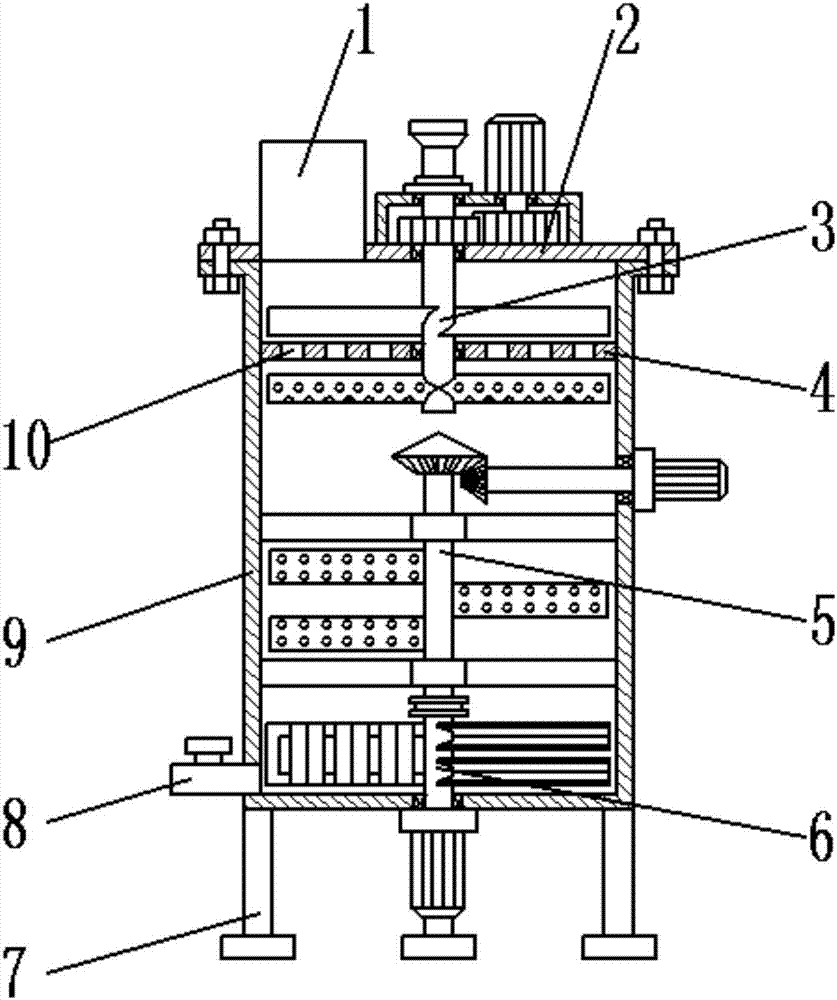

Chemical solid-liquid material stirring reaction equipment with solid material crushing function

InactiveCN107308901AIncrease surface areaExpand the drop areaChemical/physical/physico-chemical stationary reactorsGrain treatmentsEngineeringMaterial Break

The invention provides a solid-liquid material stirring reaction equipment for chemical industry with the function of crushing solid materials, which includes a tank body; the tank body is set as a hollow cylinder with an open top, and the tank body is vertically arranged; There is a cover plate; the solid material crushing device is welded and fixed on the left side of the cover plate surface; the discharge pipe is welded and fixed on the bottom side wall of the tank body; the bracket is welded and fixed on the bottom surface of the tank body; the cloth is welded and fixed at a distance of 20 cm from the top opening of the tank body The inside of the tank is equipped with a distributing device, a first stirring device and a second stirring device; the present invention uses a solid material crushing device to shear and break the agglomerated solid material to increase the surface area of the solid material; the material distributing device expands the solid-liquid The falling area of the material is convenient for the full contact of the solid-liquid material; the solid-liquid material in the tank is fully stirred and mixed through the first stirring device and the second stirring device, which is conducive to the full contact of the solid-liquid material and facilitates the efficient and sufficient reaction. .

Owner:合肥多智科技开发有限公司

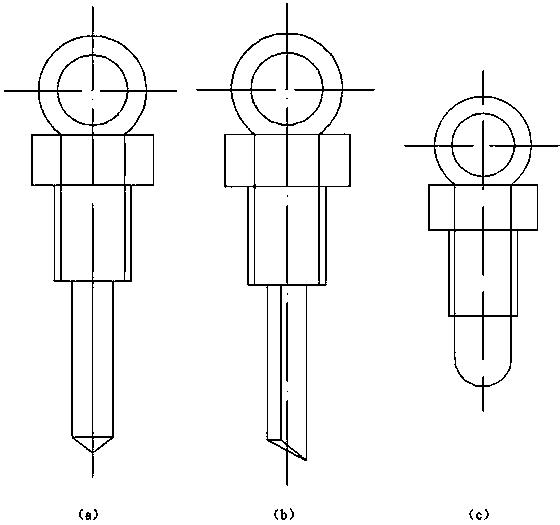

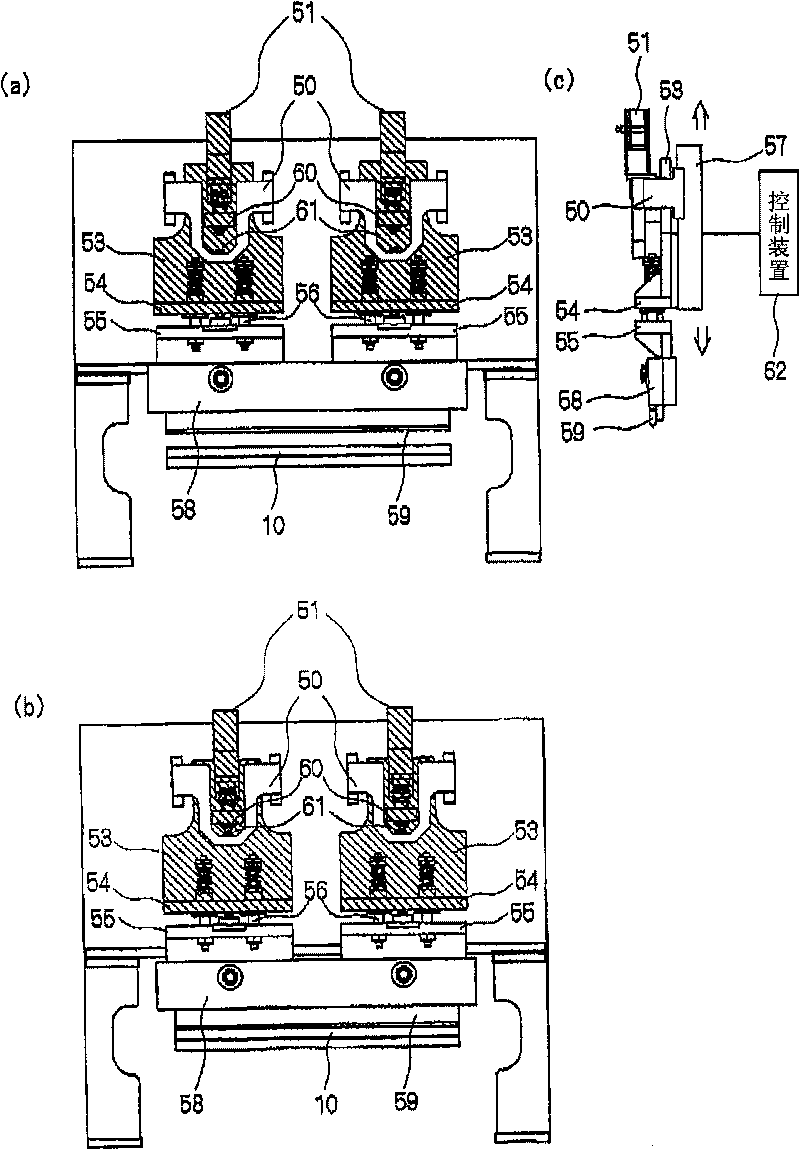

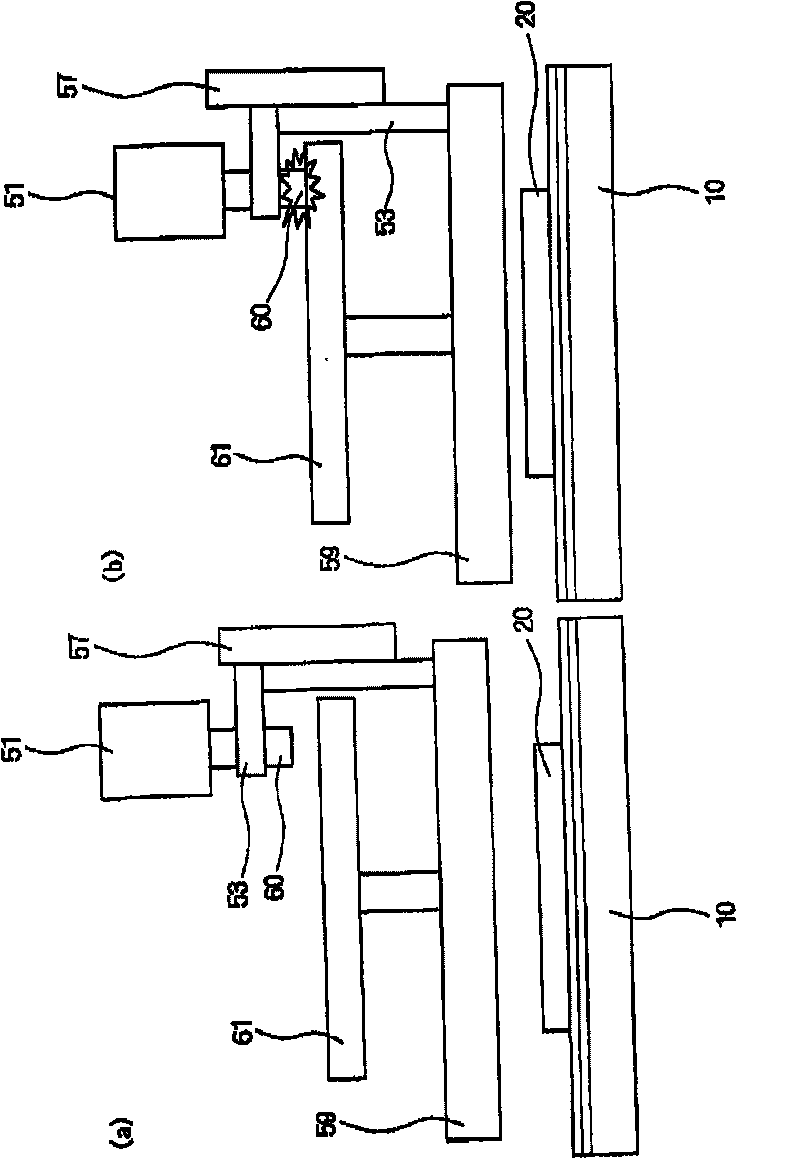

Brittle material breaking device

The invention provides a brittle material breaking device which is qualified to break the brittle material, no matter the breaking object is the thick plate or the thin plate. The brittle material breaking device includes: a support table for supporting a brittle material; and a breaking bar 59 for pressing down the brittle material on which a scribe line is formed and which is moved by a transfer means. And, the brittle material breaking device breaks the brittle material along the scribe line by using the breaking bar 59. The brittle material breaking device further comprises: a plurality of support members 53 for moving the breaking bar upward and downward; and liner servo motors 57 for moving a plurality of the support members 53. The support members 53 are arranged in a longitudinal direction of the breaking bar 59. The movements of the linear servo motors 57 are controlled so as to change an inclination angle of the breaking bar 59 in a nearly-vertical surface.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Device for receiving and dispensing a coatable material

A device for receiving and dispensing a coatable material such as adhesive, glue, cosmetics and the like. A sleeve-shaped receiving element has a piston-shaped element carrying the coatable material that is displaceable in longitudinal direction by a screw spindle operated by an external rotary grip at the base of the receiving element. The underside of the piston-shaped element is formed to complement the inwardly protruding shape of the sleeve base or grip element, such that there is virtually no free space in which air can collect between the piston-shaped element and the sleeve base when the piston element is fully retracted in the receiving element. Thus the device avoids undesired bubble formation during the filling process, and undesired material break off during use can be largely excluded.

Owner:HENKEL KGAA

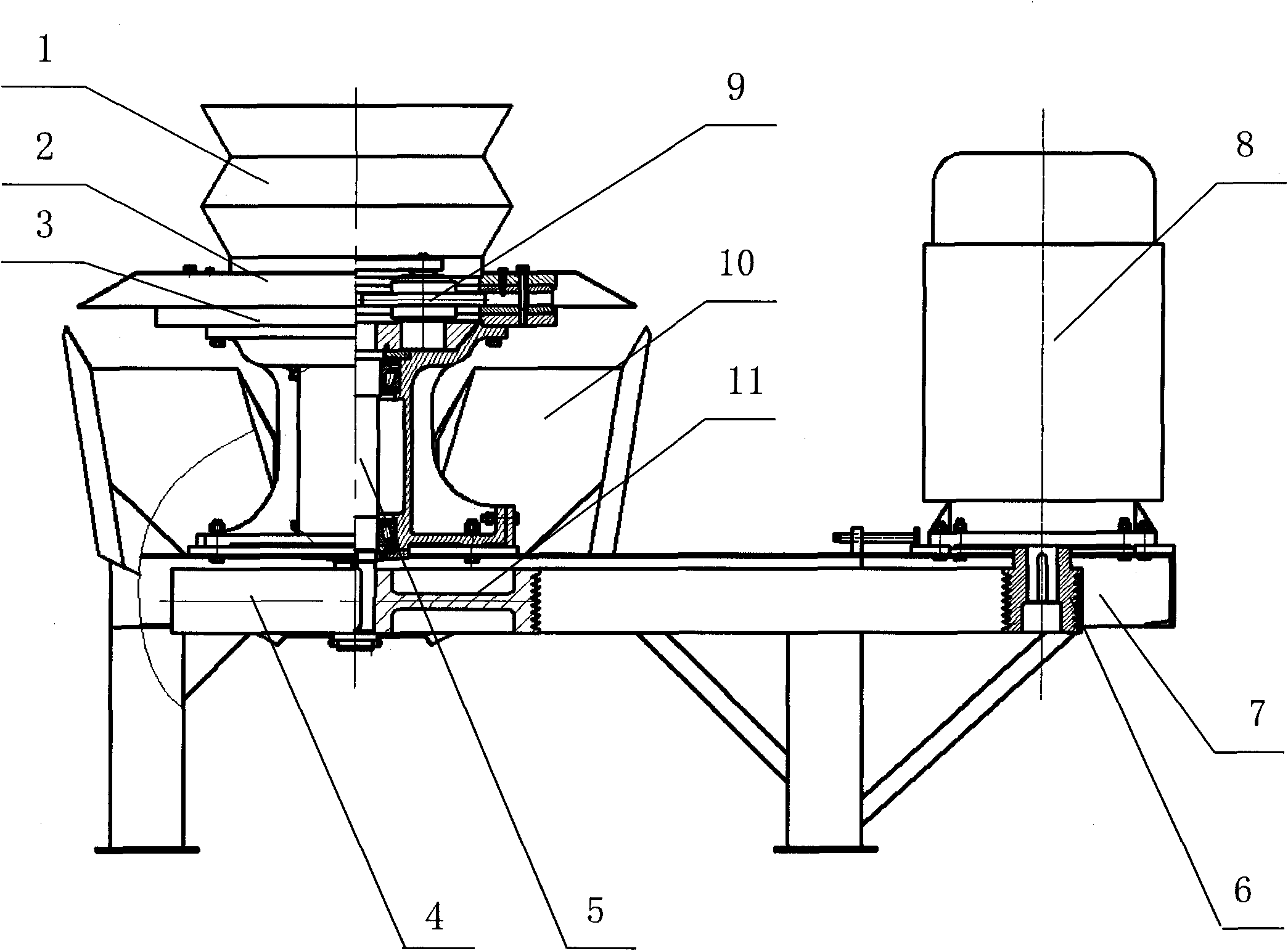

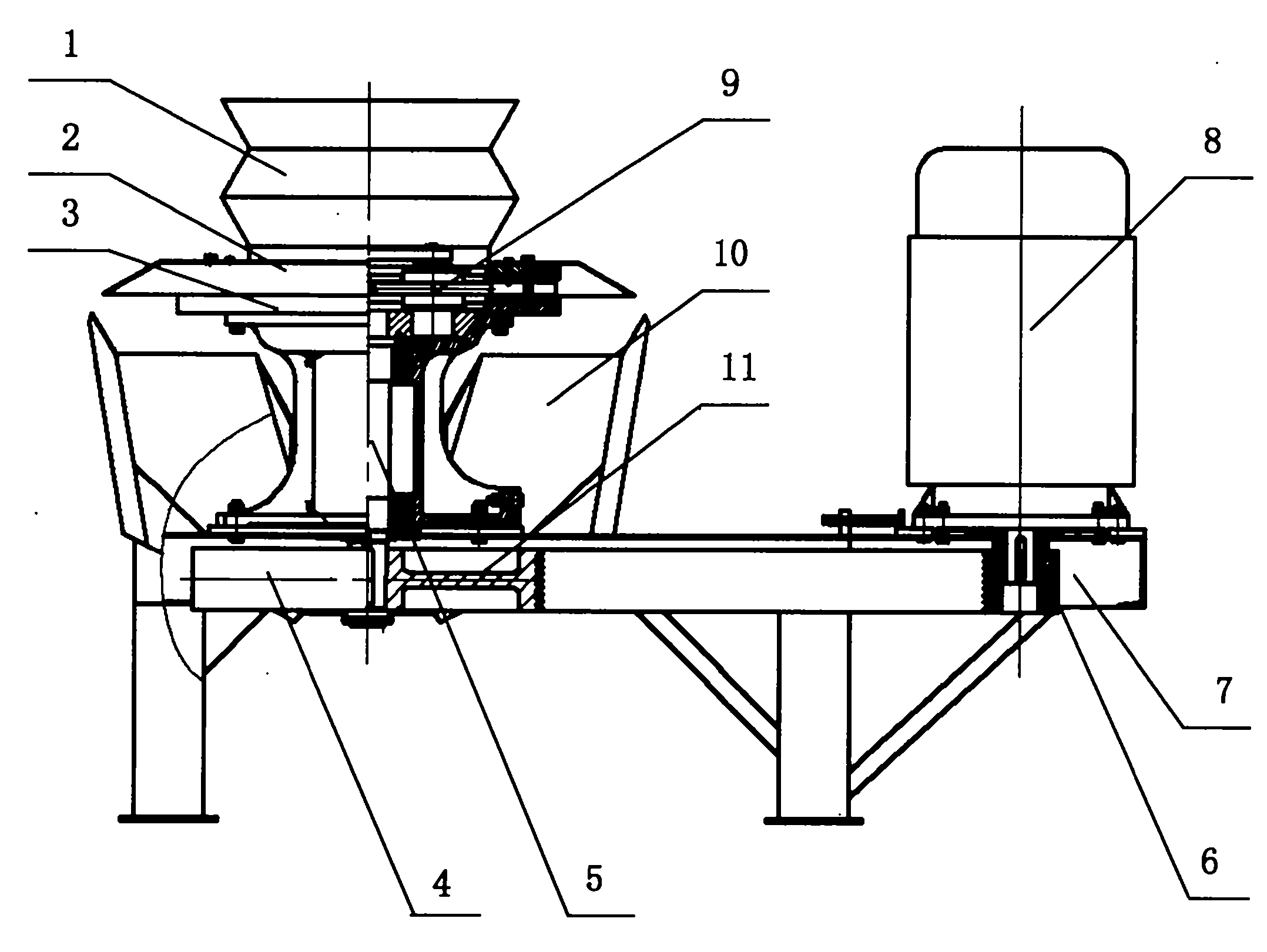

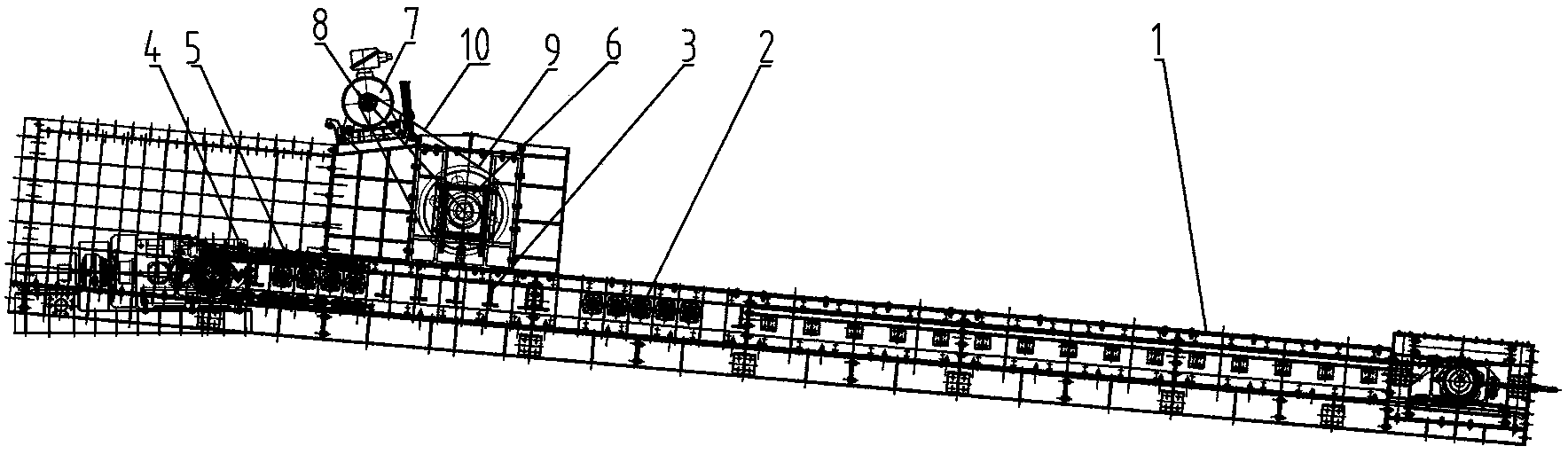

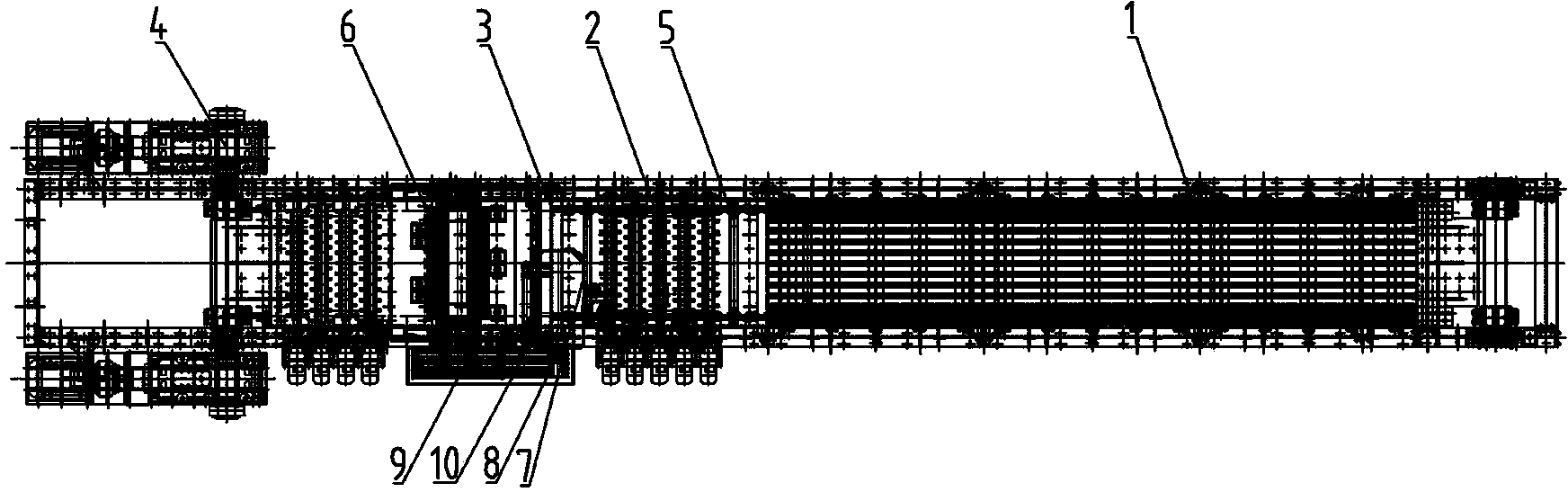

Circular mould flatwise type biomass extrusion moulding machine

InactiveCN101875245ASimple structureImprove efficiencyGranulation by material expressionShaping pressEngineeringBiomass

The invention relates to a circular mould flatwise type biomass extrusion moulding machine which is characterized by comprising a feed collection hopper, a material stopping shield, an extruding device, a drive device, a discharge collection hopper, a stand and a motor, wherein the extruding device is horizontally fixed on the stand and comprises an extruding wheel and a mould disk; and the mould disk is provided with a plurality of radial mould holes uniformly distributed in the horizontal direction. In the invention, all the mould holes can uniformly extrude materials without a stirrer or a material breaking cutter, the mould disk has small thickness, the moulding mould holes have wide selective range in dimensions, and the invention has good moulding effect, high efficiency and strong adaptability.

Owner:BEIJING AOKE RUIFENG NEW ENERGY

Brittle material breaking apparatus and brittle material breaking method

InactiveCN102015233AReliable disconnectionNo need for precise alignmentFine working devicesGlass severing apparatusMaterials scienceMaterial Break

Owner:MITSUBOSHI DIAMOND IND CO LTD

Novel pass-type screening crusher

The invention discloses a novel pass-type screening crusher. The novel pass-type screening crusher comprises a scraper conveyer slotted screen box body, a scraper conveyer rolling shaft type screening box body, a scraper conveyer crushing box body, a scraper conveyer driver, a scraper chain and a single roller breaking unit, when a scraper conveyer operates, and a material can enter from the tail of a scraper conveyer; mixed materials are uniformly distributed through the movement of a scraper, the qualified materials in the mixing material are preprocessed in advance, and the rest materials enter a roll screen and a slotted screen along with the movement of the scraper to be subjected to second-step processing; then the scraper can convey large materials into the single roller breaking unit, so that the unqualified large materials are crushed, the materials broken by the single roller breaking unit are reshipped or directly discharged by other equipment through a chute. The novel pass-type screening crusher provided by the invention can operate under the severe environment, the conveying capacity is high, the qualified materials are screened in advance, so that the material crushing efficiency is improved, the large materials being 1400-3000mm are transported and crushed through the single roller breaking unit, transportation, screening and crushing are performed simultaneously, the installation and the maintenance are convenient, and the novel pass-type screening crusher is widely applied on the transportation, screening and crushing operation of the large materials such as coal and metallurgy.

Owner:HENAN ZHENYUAN TECH

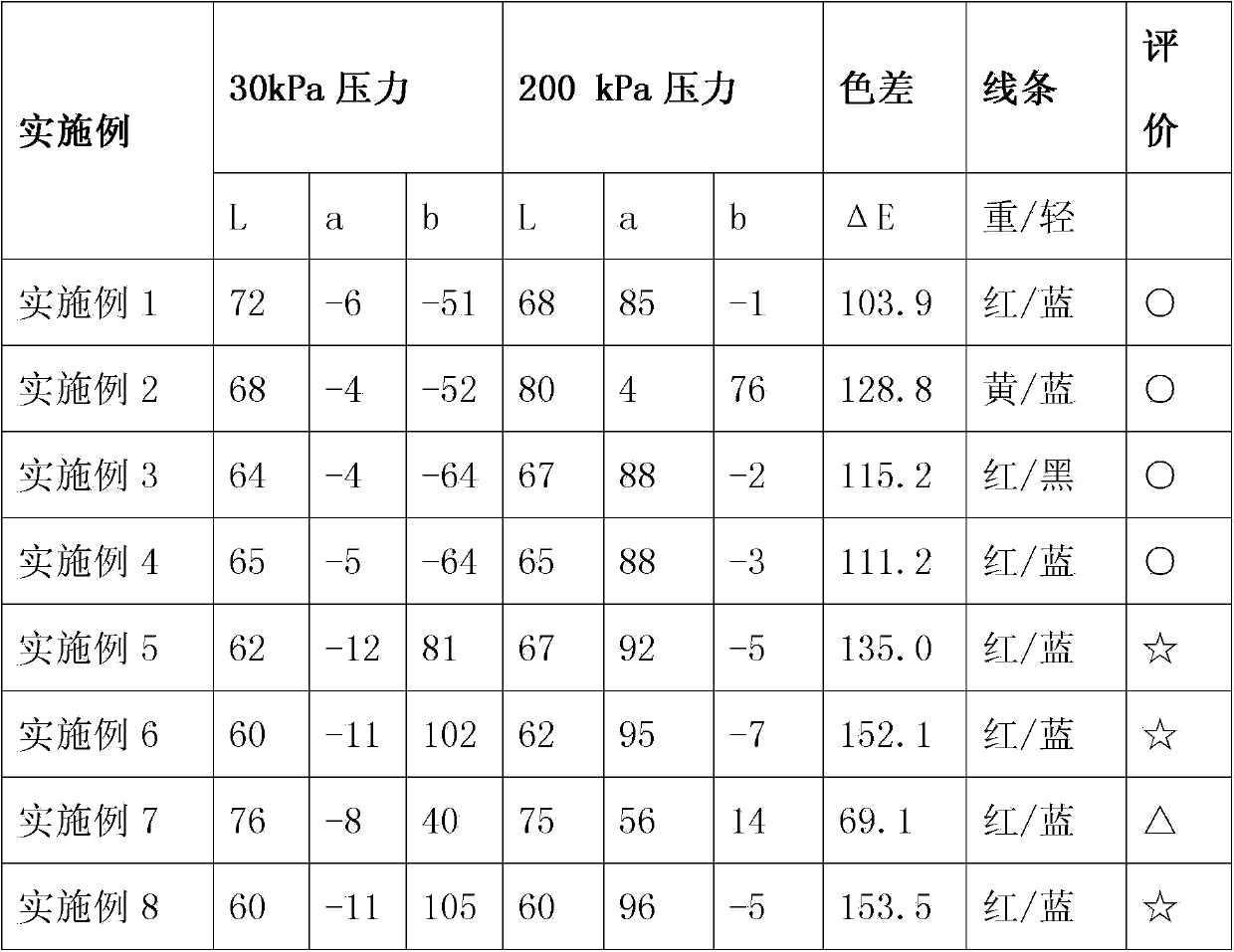

Double-color-line anti-counterfeiting paper and production method thereof

ActiveCN103628358ALower requirementEasy to prepareNon-fibrous pulp additionChemical reactionElectron donor

The invention provides double-color-line anti-counterfeiting paper and a production method thereof. According to the invention, a chromophoric material and a chromogenic material are added on raw paper; under normal circumstances, the chromophoric material and the chromogenic material are colorless chromophoric substances, one of the materials is wrapped by a microcapsule, and the other is ground. After slight scribing and friction of the paper, an electron donor substance in the chromogenic material and the chromophoric material which is granular after grinding fuse immediately by using generated tiny heat and undergo a chemical reaction so as to generate a color; after forceful scribing of the paper, the microcapsule containing another chromophoric material breaks, and the chromophoric material flows out and chemically reacts with the electron donor substance in the chromogenic material so as to generate another color; thus, two different color lines are generated on the paper through application of different scribing forces, thereby achieving an anti-counterfeiting purpose. The production method provided by the invention is easy and convenient; a discriminating means is simple; special physical conditions are not needed for discrimination, and hard substances like a finger are sufficient for completion of anti-counterfeiting authentication.

Owner:GUANGDONG GUANHAO HIGH TECH

Circularly breaking and sieving system and method thereof

InactiveCN102527484AGuaranteed GranularityEasy particle size controlGrain treatmentsEconomic benefitsCrusher

The invention discloses a circularly breaking and sieving system, which comprises a breaking device and a secondary sieving machine. A fourth conveying belt for conveying materials broken by the breaking device to the secondary sieving machine is arranged under the breaking device, and a fifth conveying belt for conveying materials which are not sieved out by the secondary sieving machine to the breaking device is arranged between the secondary sieving machine and the breaking device. The technical scheme of the circularly breaking and sieving system and the method thereof controls grain size of sieved materials through pore size of a sieving machine without controlling the grain size through the breaking device. Grain size control is simple and reliable. Through control of first sieving and second sieving of the materials, the phenomenon of over-breaking is avoided, carbon content of fly ash is greatly reduced, energy consumption is reduced, and economic benefit of boilers is greatly improved. An original coal manufacturing system is changed into horizontal technological distribution from vertical technological distribution, a technological route is shortened and simplified, floor area is reduced, and cost for investment of capital construction is greatly saved.

Owner:周杨

Glass processing production line

ActiveCN106732916AOvercome the problem of low crushing efficiencyQuality improvementCleaning using toolsGrain treatmentsProduction lineDrive wheel

The invention belongs to the technical field of glass processing and particularly discloses a glass processing production line. The glass processing production line comprises a material storing device, a cleaning conveying device, a preliminary breaking device, a rotary material breaking device and a glass collecting device which are sequentially arranged. A material storing box is enveloped by a discharging device, and a discharge outlet is formed in the material storing box. A plurality of sponge rollers are arranged on a cleaning plate and a cleaning passage. The preliminary breaking device comprises an S-shaped conveying passage and a preliminary pressing roller connected to a rack, and the preliminary pressing roller is arranged above the S-shaped conveying passage. The rotary material breaking device comprises a rotary feeding cylinder and a pair of breaking rollers arranged in the rotary feeding cylinder, driving wheels for driving the rotary feeding cylinder are arranged on the outer wall of the rotary feeding cylinder in the circumferential direction, and the rotary feeding cylinder, the driving wheels and the breaking rollers are all connected to the rack. The glass processing production line is integrally arranged, so that the problem that efficiency of glass breaking is low in the prior art is solved, and the quality of regeneration glass manufactured through recovered and broken is improved.

Owner:重庆美尔屋玻璃有限公司

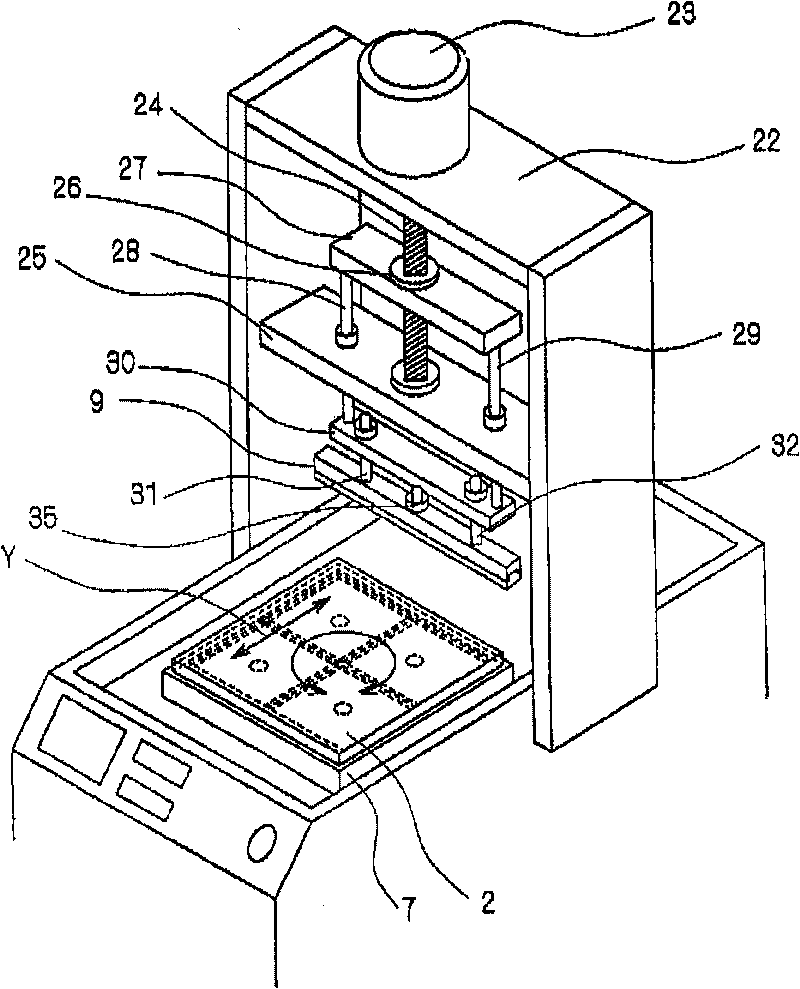

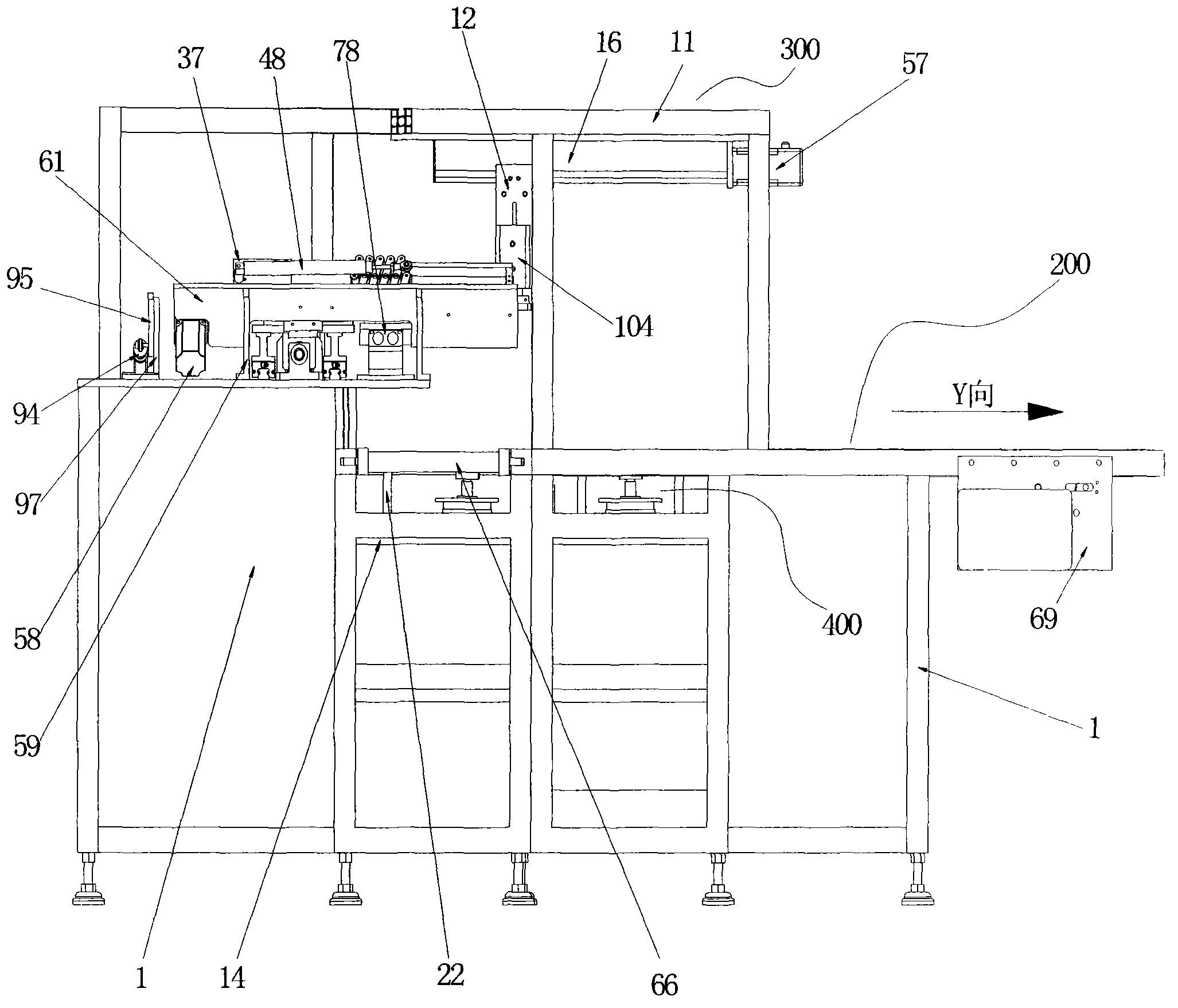

Automatic material break-off machine

The invention relates to an automatic material break-off machine. The automatic material break-off machine comprises a machine frame, a Y-direction translational system which enables a material plate stack to complete translational motion leftwards, a material plate conveying system, jacking devices, a material break-off system, a material clamping and placing system, an X-direction translational system which enables the material plate stack to complete translational motion backwards, and a circuit control system. The material plate conveying system comprises a support, a vacuum sucker, a first air cylinder which is arranged in a vertical direction and a left and right translational mechanism, wherein the support is fixedly connected onto the machine frame, the left and right translational mechanism is arranged on the support and above the machine frame, the first air cylinder is arranged on the left and right translational mechanism, and the vacuum sucker is arranged at a free end of a cylinder rod of the first air cylinder. The automatic material break-off machine is high in level of automation and can break off materials automatically, so that the production efficiency is improved, the labor intensity of workers is greatly reduced, and certain advantages are obtained.

Owner:QINGDAO TAIMENG AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com