Patents

Literature

8203 results about "Weft yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

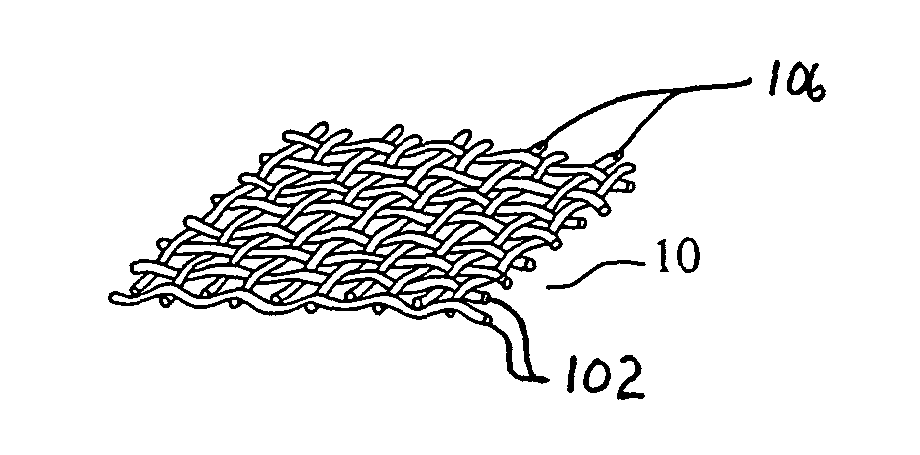

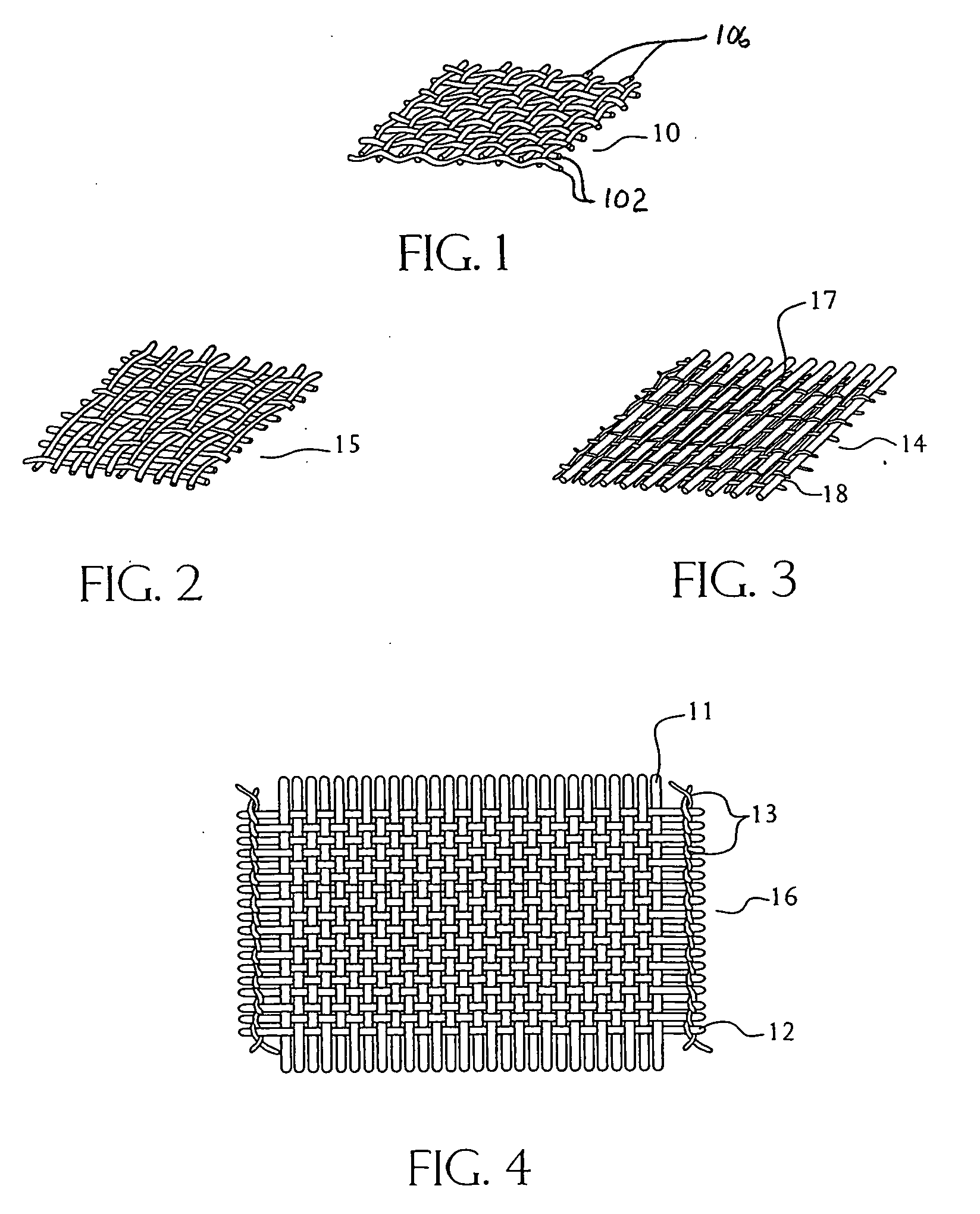

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

Carpet Construction and Carpet Backings for Same

Owner:PROPEX OPERATING

Turbomachine blade, in particular a fan blade, and its method of manufacture

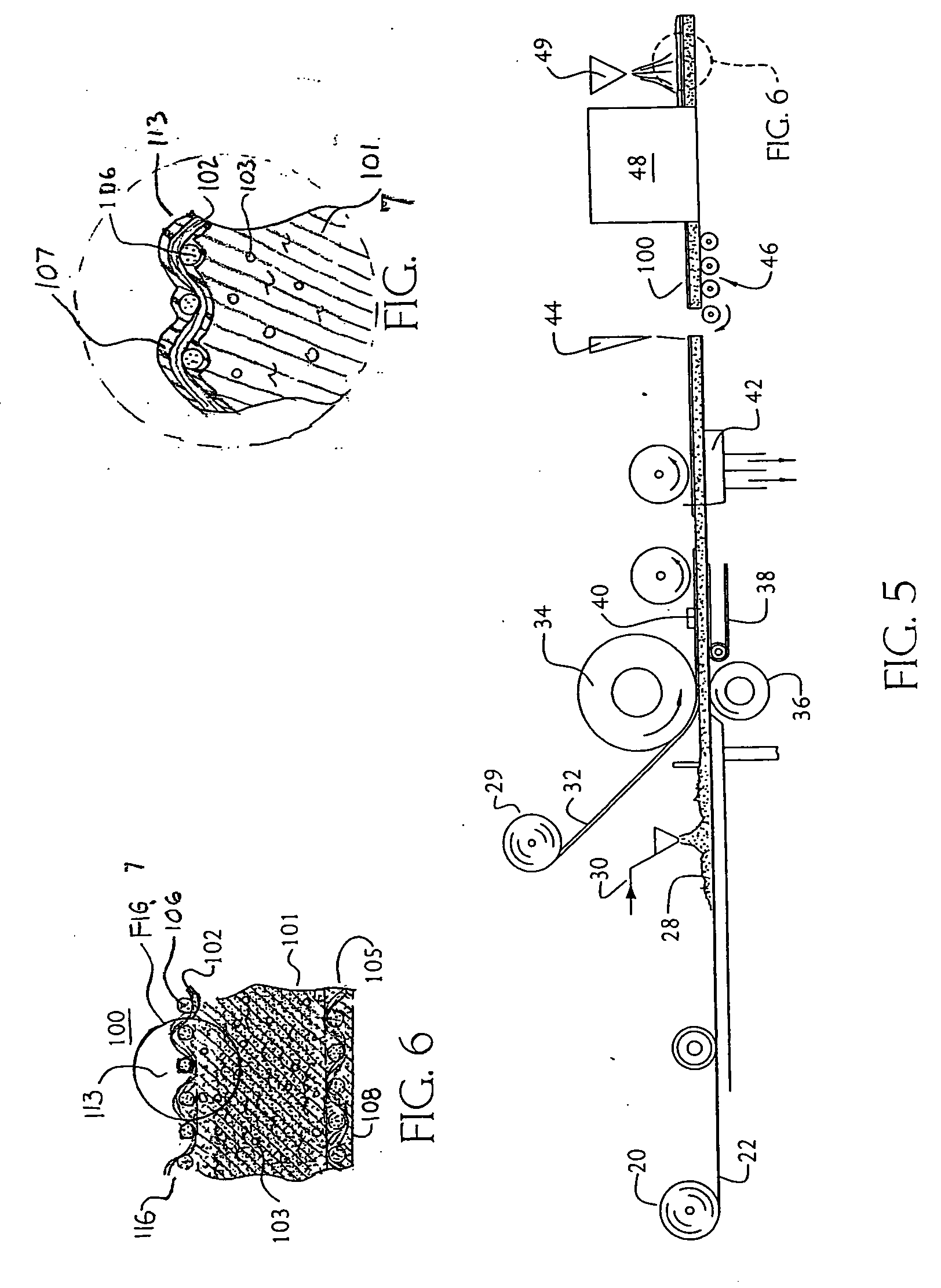

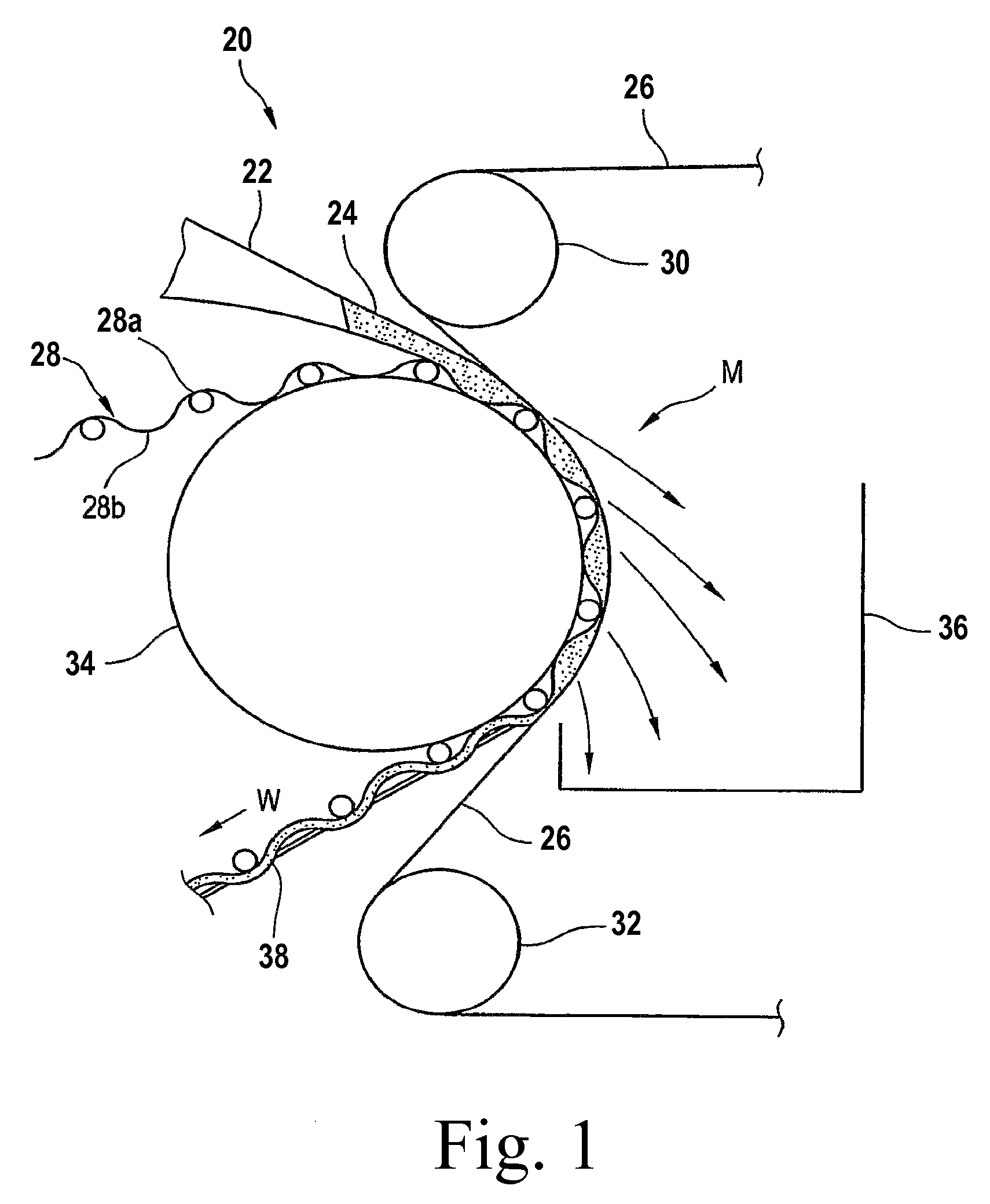

The composite turbomachine blade of the present invention comprises a preform made of yarns or fibers woven in three dimensions and a binder maintaining the relative disposition between the yarns of the preform. Said preform is made up of warp yarns and of weft yarns, the direction of the warp yarns forming the longitudinal direction of the preform. In characteristic manner, said preform comprises at least a first portion made using a first weave forming the airfoil of the blade, and a second portion made using a second weave forming the root of the blade, and the first and second portions are united by a transition zone in which the first weave is progressively modified to end up with the second weave, thereby obtaining a reduction at least in the thickness of the blade between the second portion and the first portion. The invention is applicable to making a fan blade for a turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Fabric reinforcement and cementitious boards faced with same

ActiveUS20050009428A1Improve coating uniformityConvenient coatingDecorative surface effectsPretreated surfacesCement boardEngineering

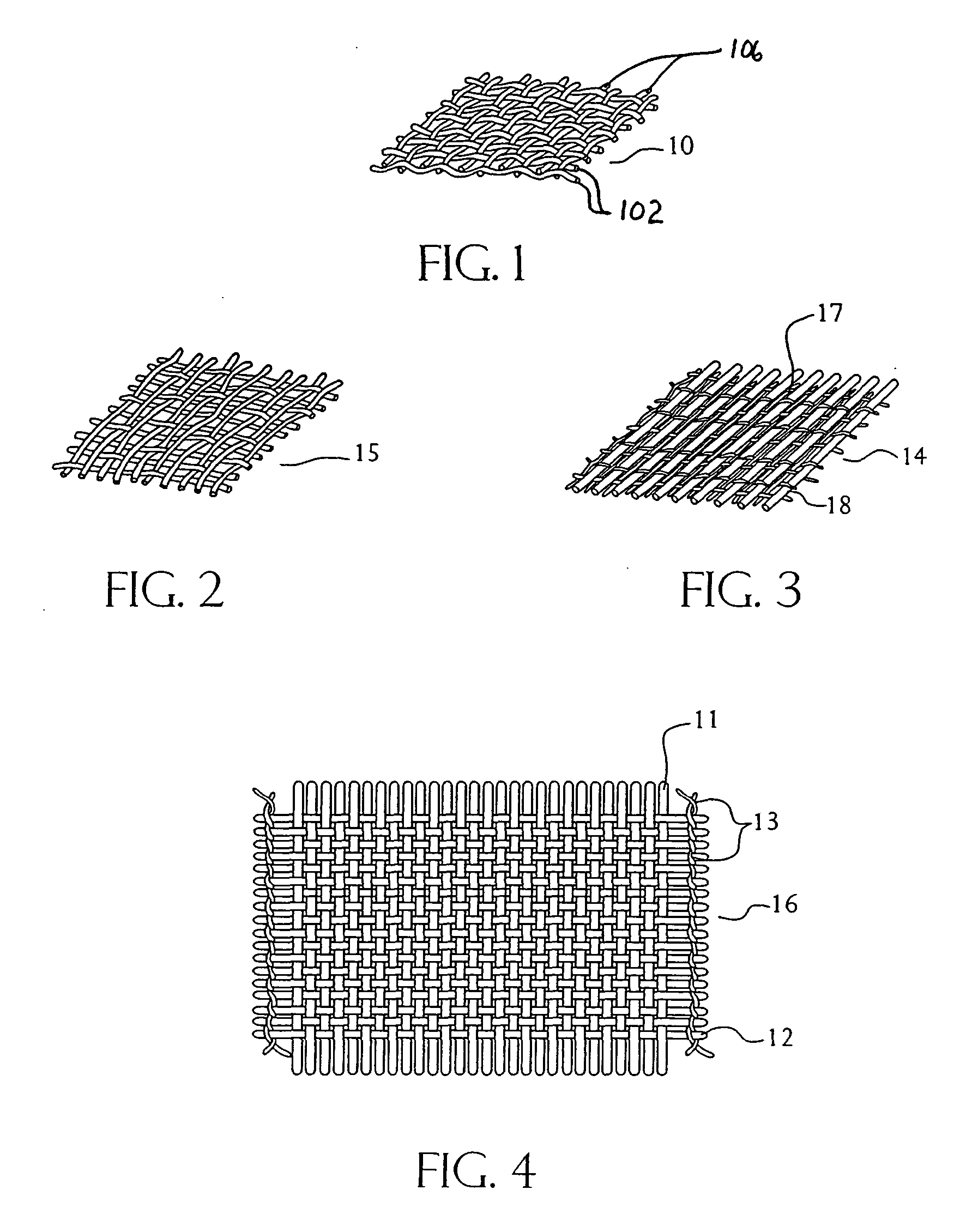

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Turbomachine blade, in particular a fan blade, and its method of manufacture

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

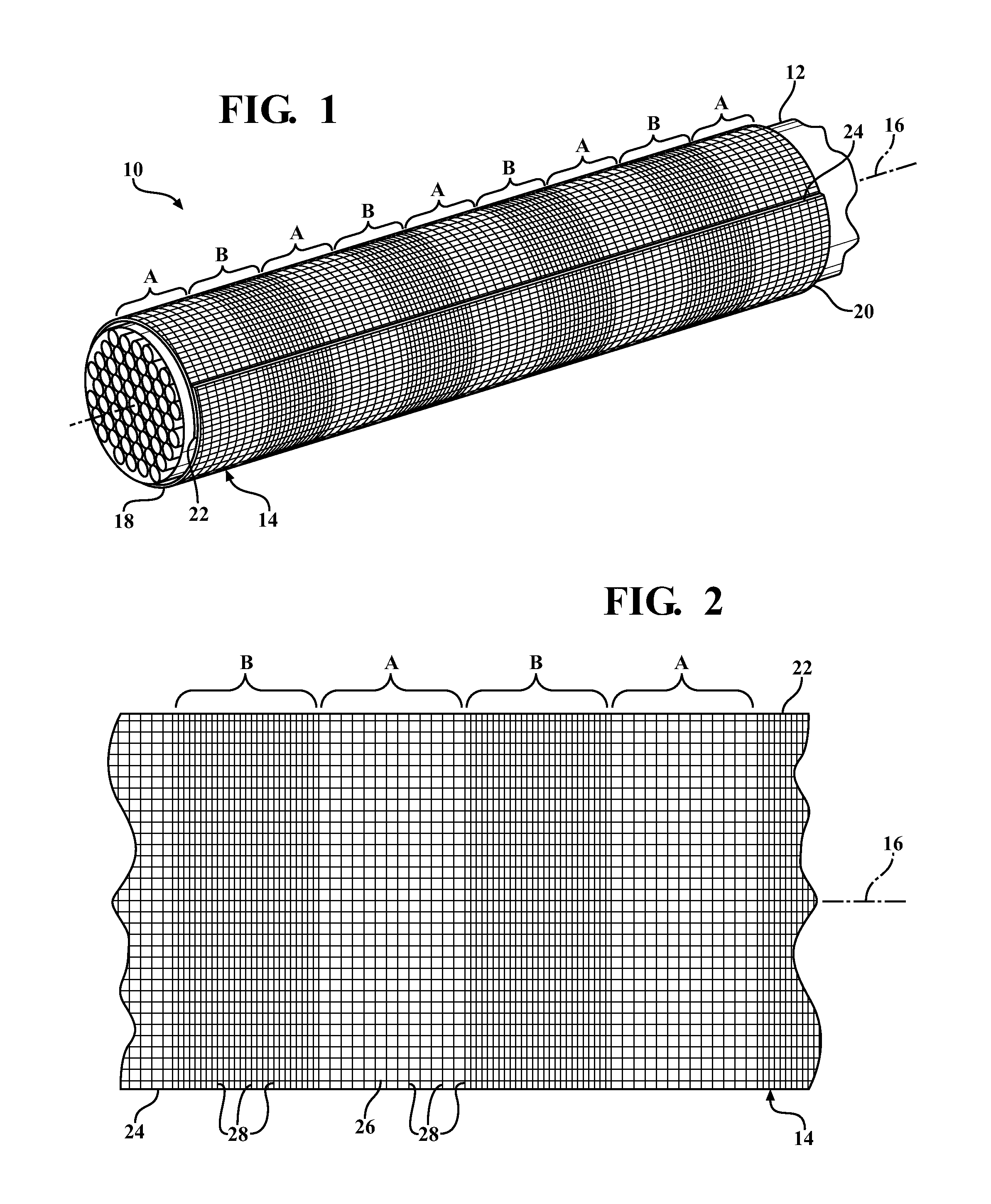

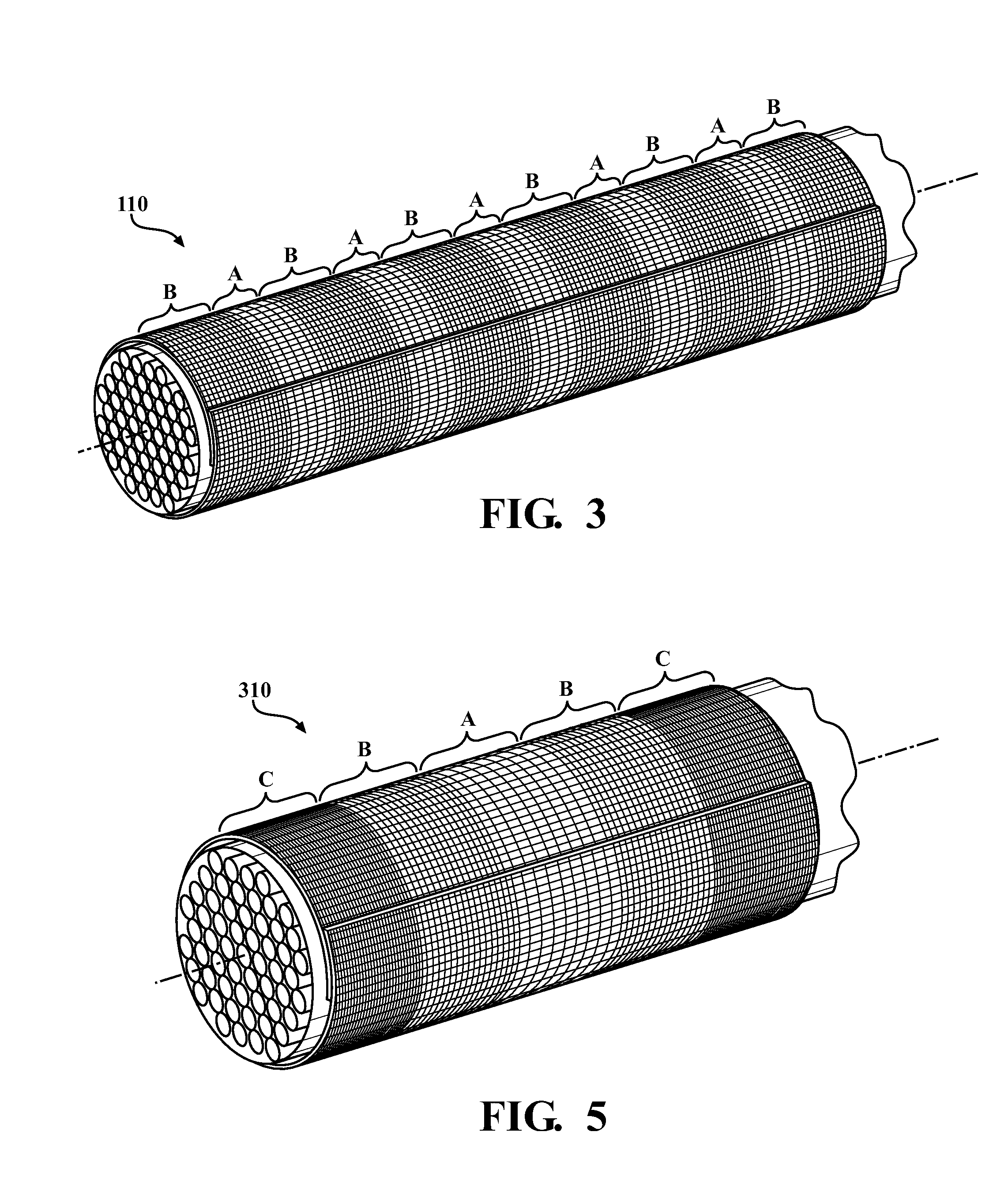

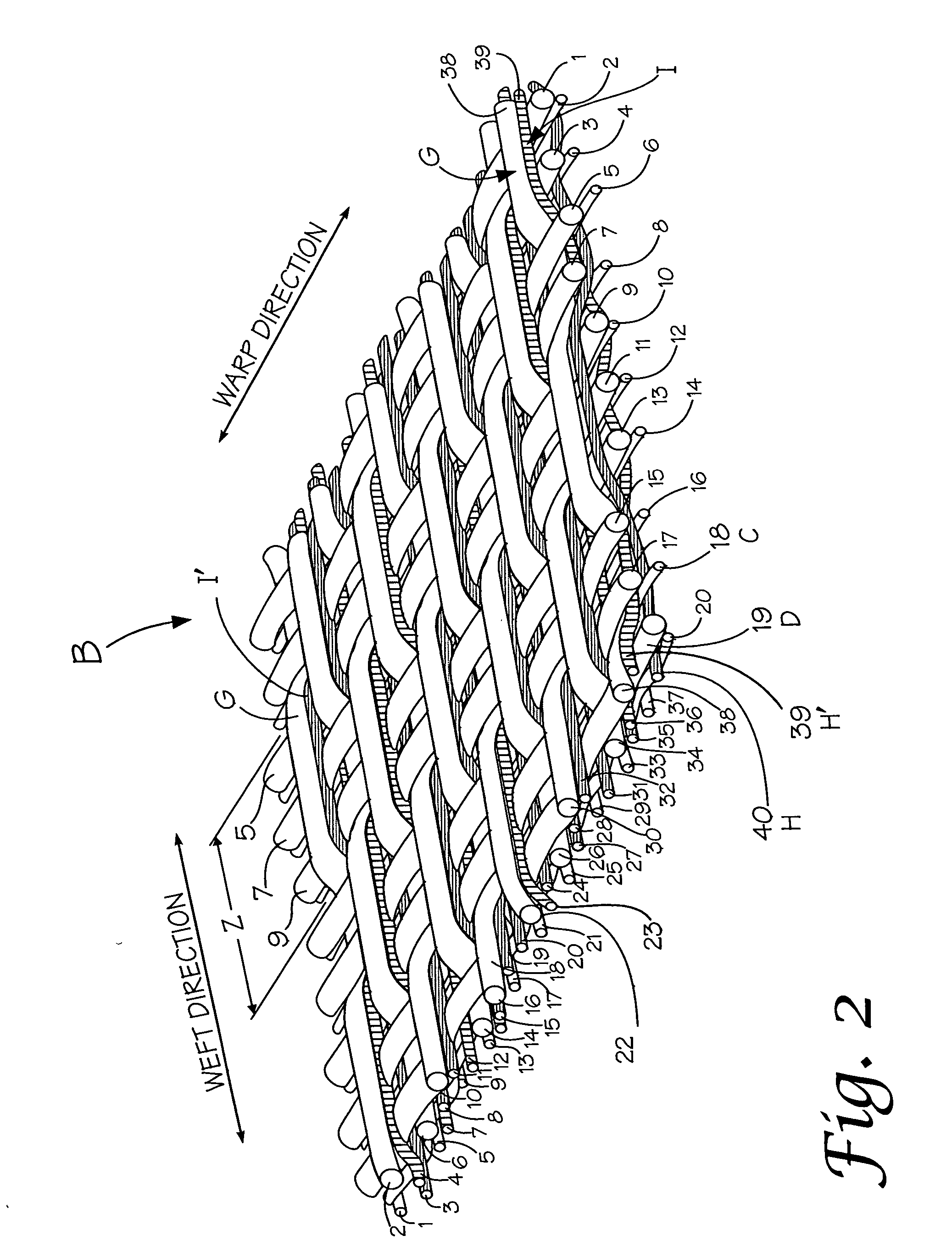

EMI Shielding Textile Fabric, Wrappable Sleeve Constructed Therefrom and Method of Construction Thereof

ActiveUS20140262478A1Improve abilitiesClose proximityShielding materialsLoomsArchitectural engineeringWeft yarn

A textile fabric, sleeve formed therefrom, and methods of construction thereof are provided. The fabric forms an elongate wall constructed from lengthwise extending warp yarns woven with widthwise extending weft yarns. At least some of the warp yarns are electrically conductive and have a first diameter. The weft yarns have a second diameter that is at least 25 percent less than the first diameter of the warp yarns. As such, the conductive warp yarns are brought into closer proximity with one another than if the weft yarns were the same diameter as the warp yarns. Accordingly, the ability of the fabric and sleeve formed therewith to provide shielding protection against EMI is enhanced.

Owner:FEDERAL MOGUL POWERTAIN LLC

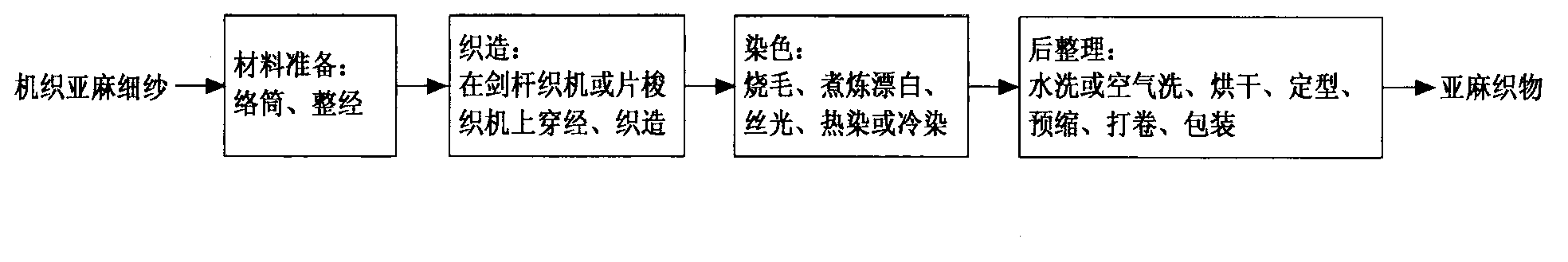

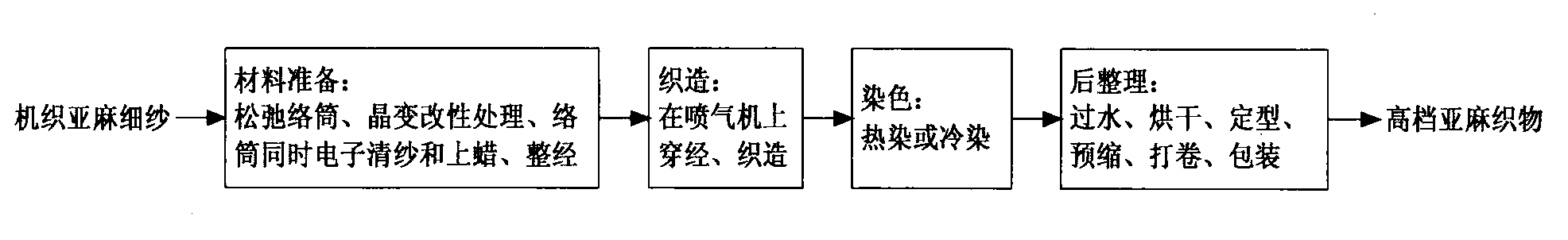

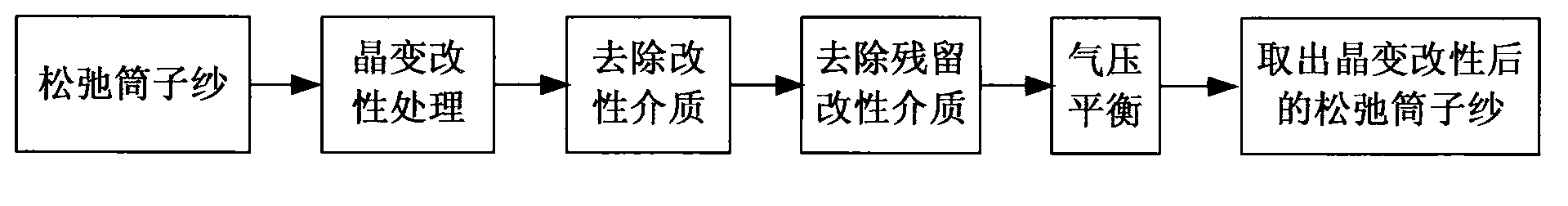

High-grade flax fabric weaving method based on crystallized and modified flax yarns

InactiveCN102839508ASoft textureImprove evennessLiquid/gas/vapor treatment of definite length materialsWoven fabricsAir-jet loomPulp and paper industry

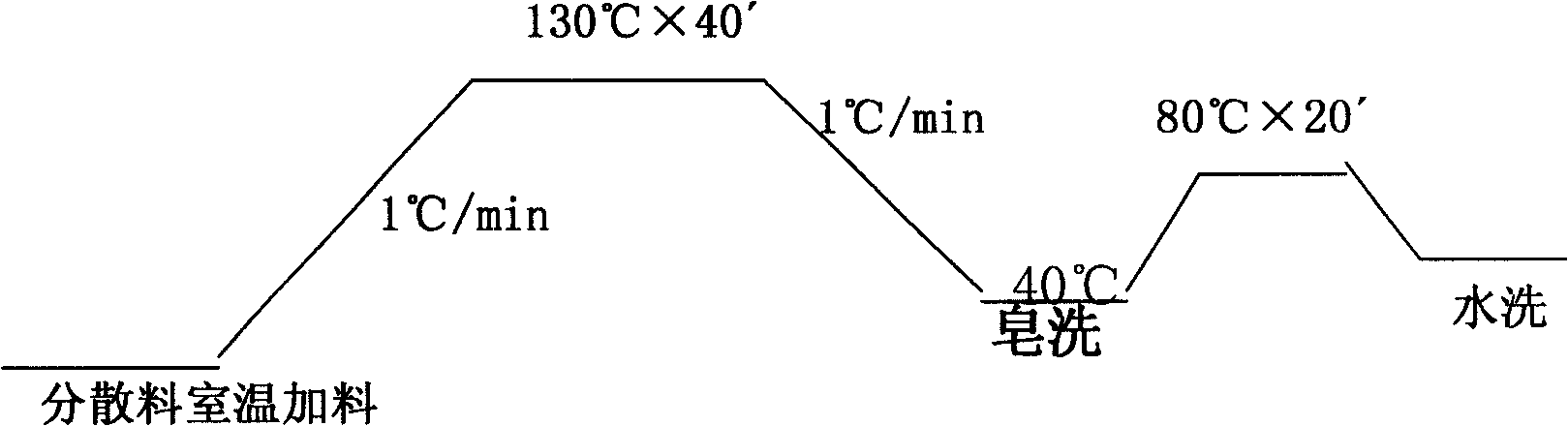

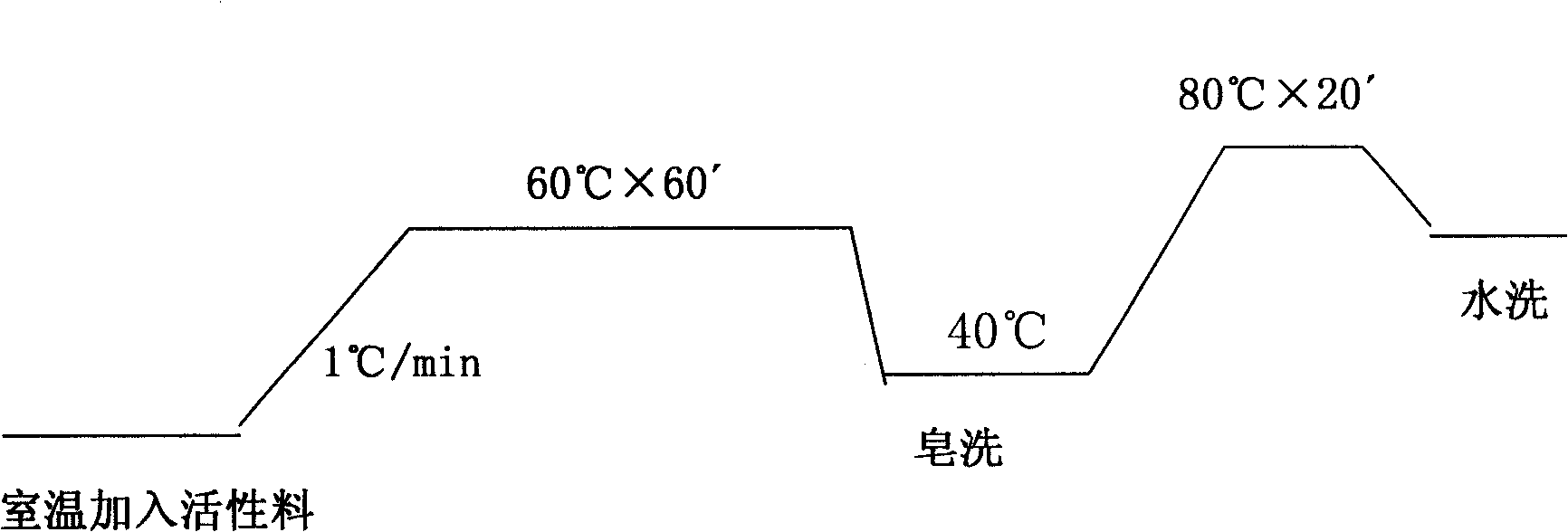

The invention provides a high-grade flax fabric weaving method based on crystallized and modified flax yarns. The method comprises the following steps: in the material preparing stage, woven flax spun yarns are subjected to relaxation and winding, so as to form relaxed yarns on cones; the relaxed yarns on cones are subjected to crystallization and modification treatment; the crystallized and modified relaxed yarns on cones are simultaneously subjected to winding, electronic yarn clearing and waxing, so that weaving yarns on cones are obtained; the weaving yarns on cones are subjected to warping according to the quantity of warp yarns; in the weaving stage, flax grey cloth is woven by taking the weaving yarns on cones as weft yarns, the warp yarns after warping as warp yarns, and drawing weft and warp yarns in an air jet loom; in the dyeing stage, the woven flax grey cloth is subjected to hot dyeing or cold dyeing; in the after finishing stage, the dyed flax grey cloth is rinsed, dried, finalized, preshrunk, wound and packaged to form the high-grade flax fabric. According to the high-grade flax fabric weaving method, the bottleneck of wearability of traditional flax fabric is solved, the flax fabric is enabled to obtain the sense of cotton, the production efficiency is improved, the production cost is reduced, and the energy conservation and emission reduction in the production process are realized.

Owner:DONGHUA UNIV +1

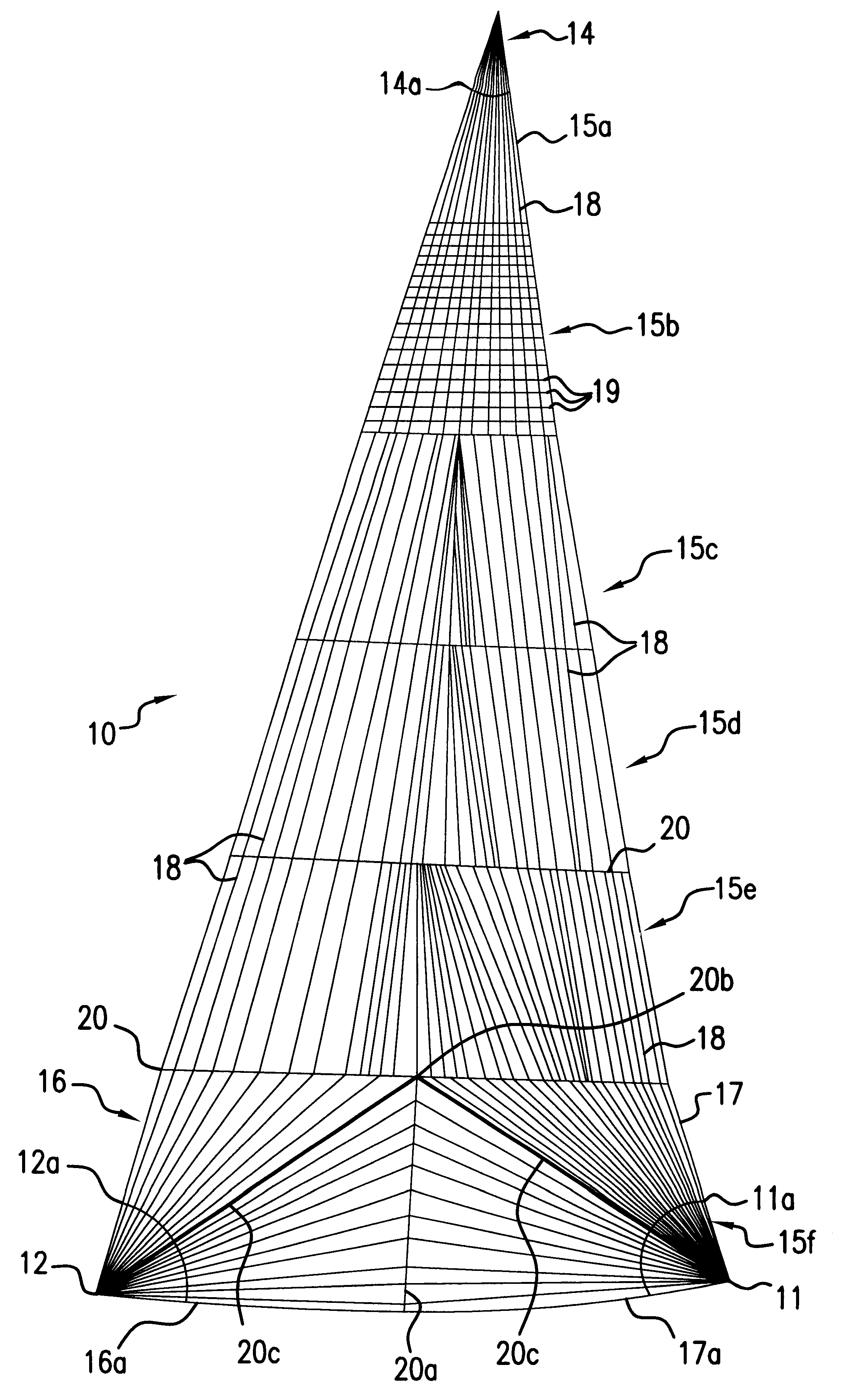

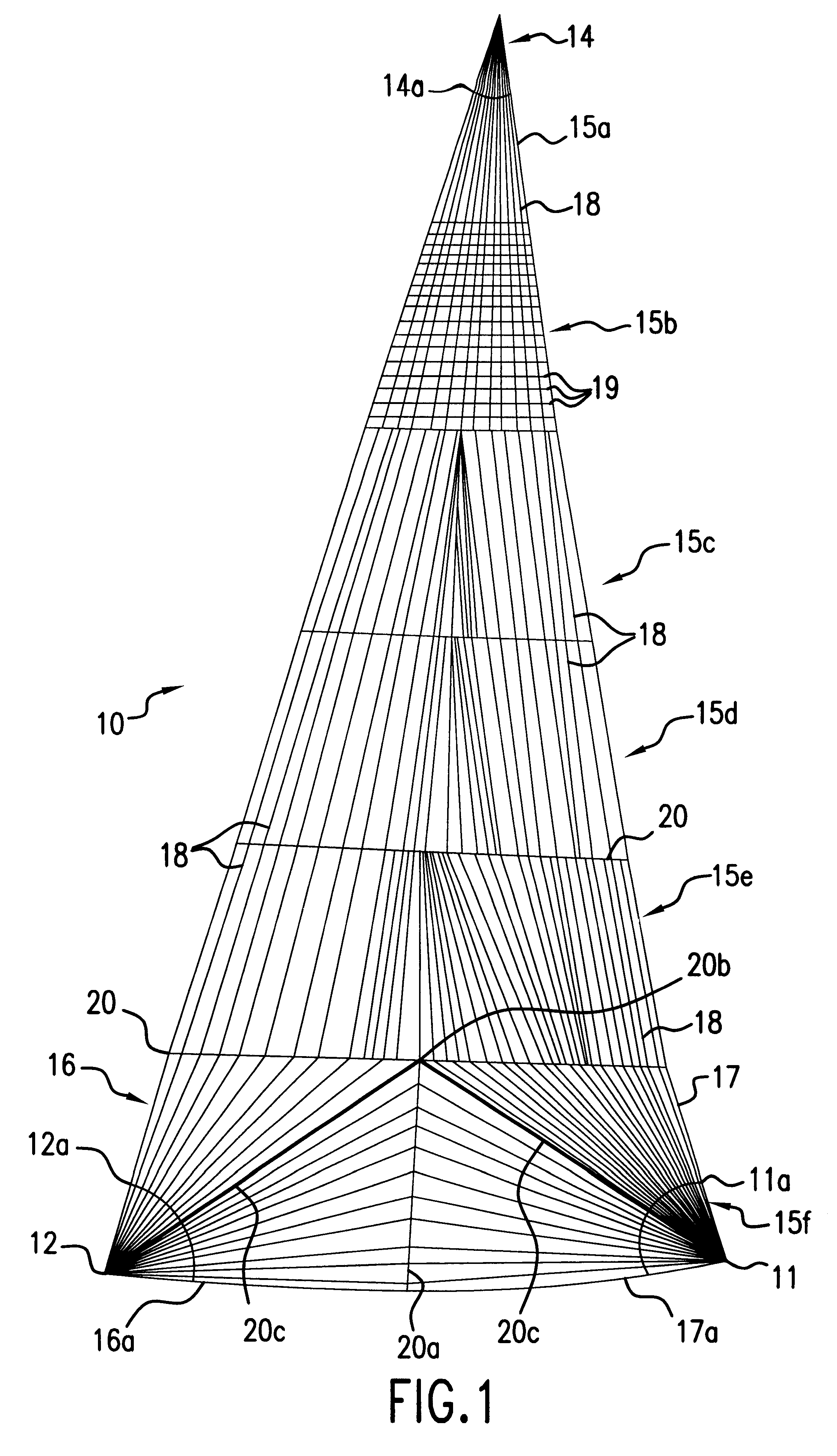

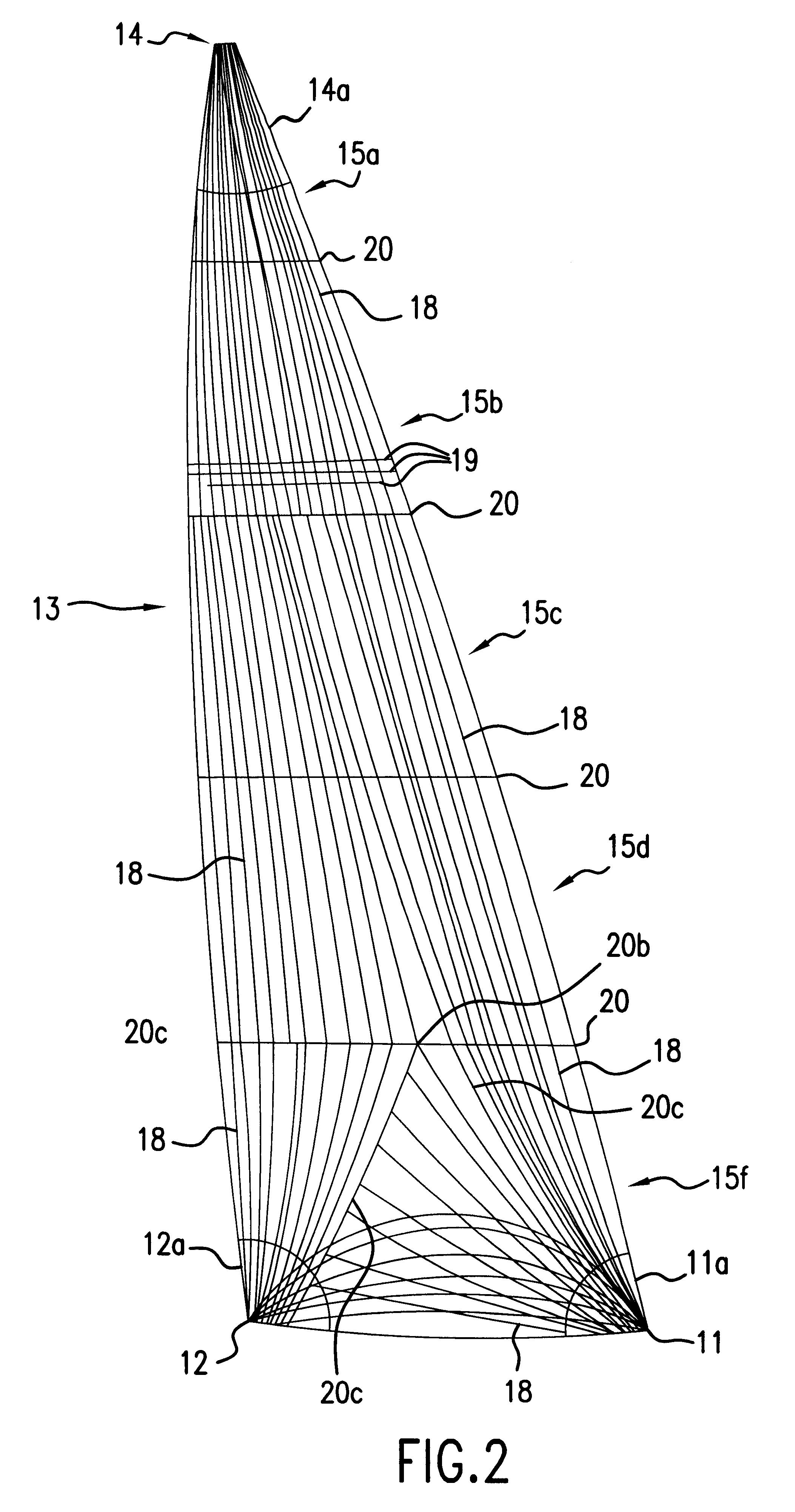

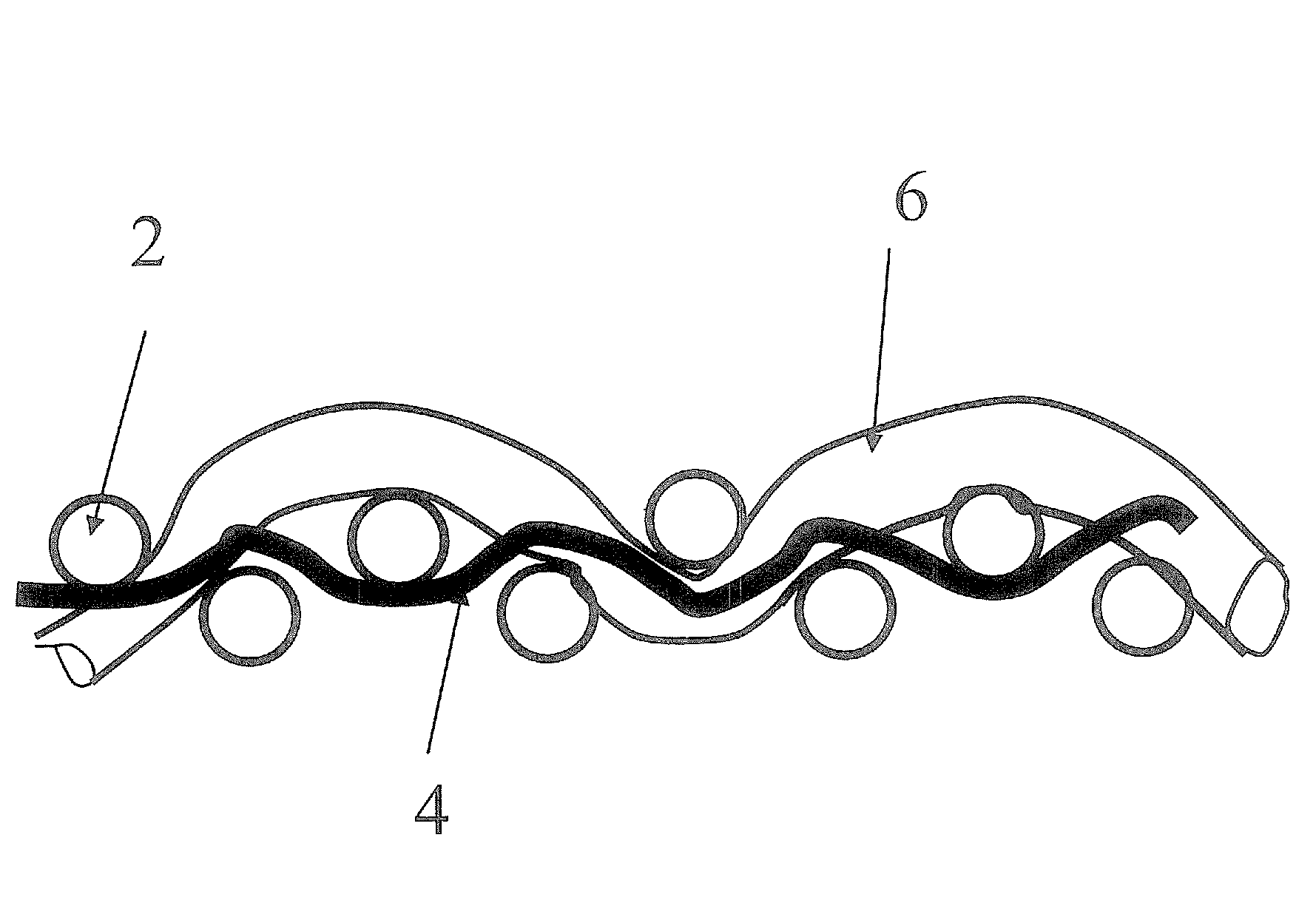

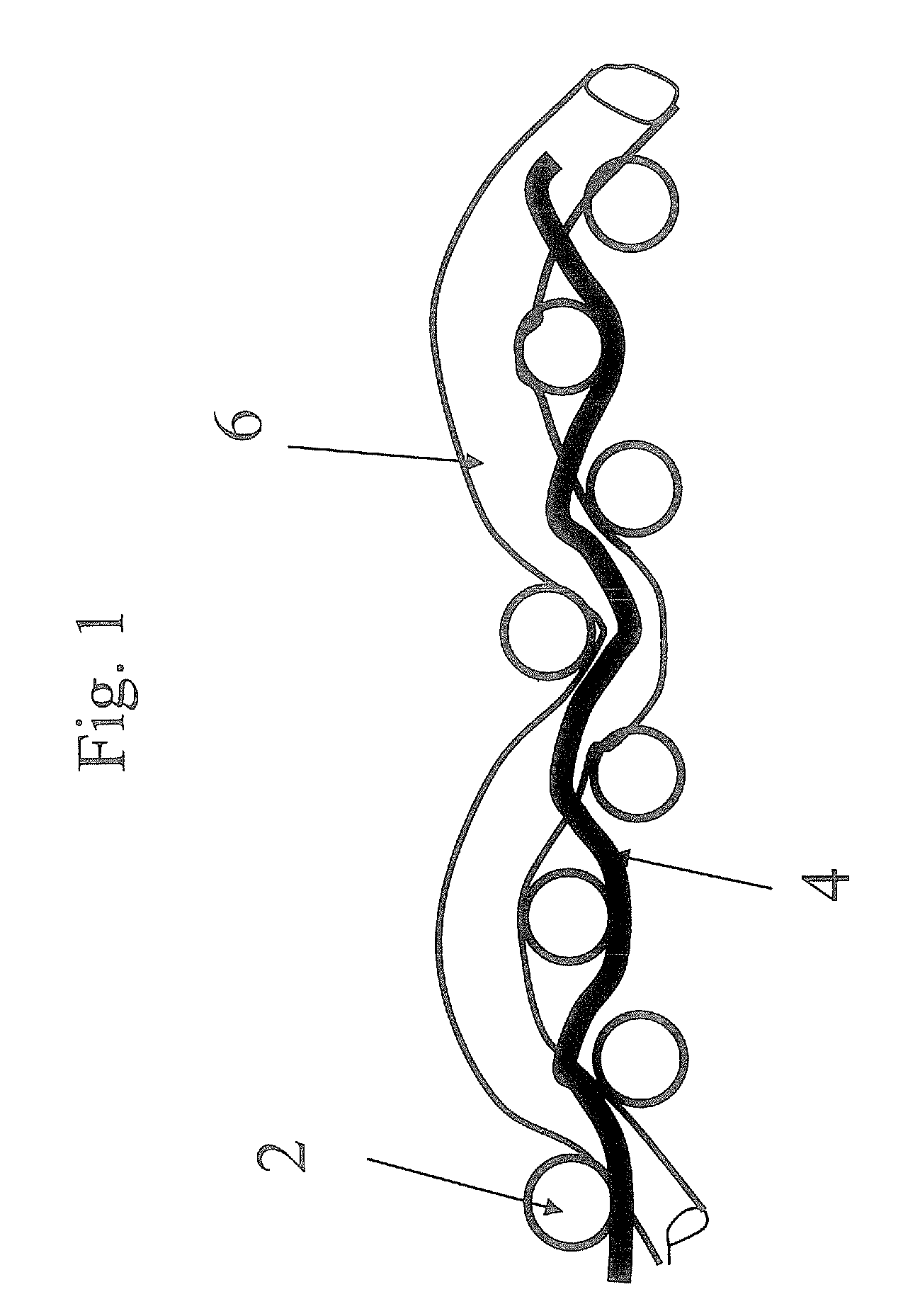

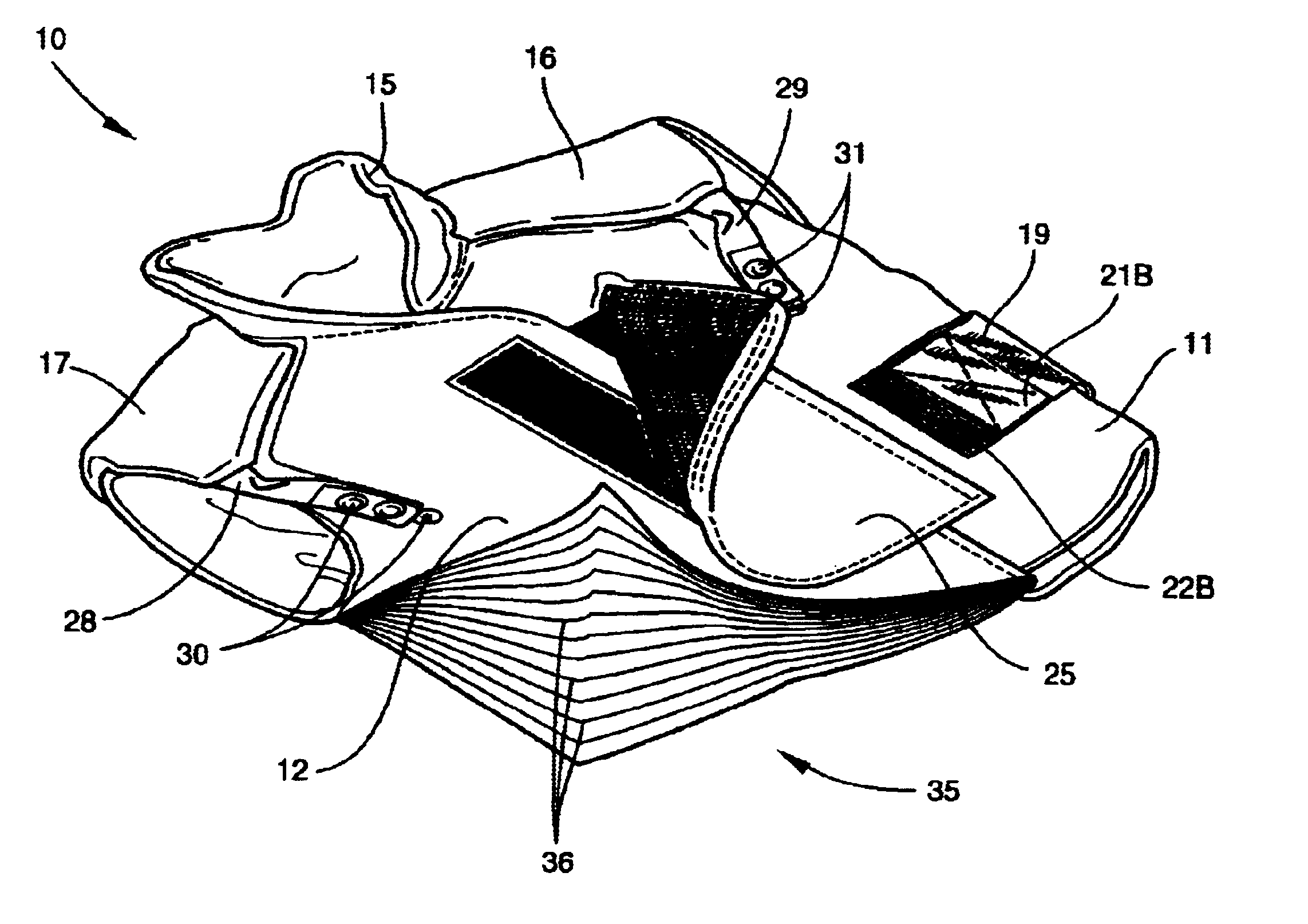

Woven fiber-oriented sails and sail material therefor

InactiveUS6311633B1Simple materialUniform processSynthetic resin layered productsWoven fabricsYarnFiber

Owner:KEIRE FRED AIVARS

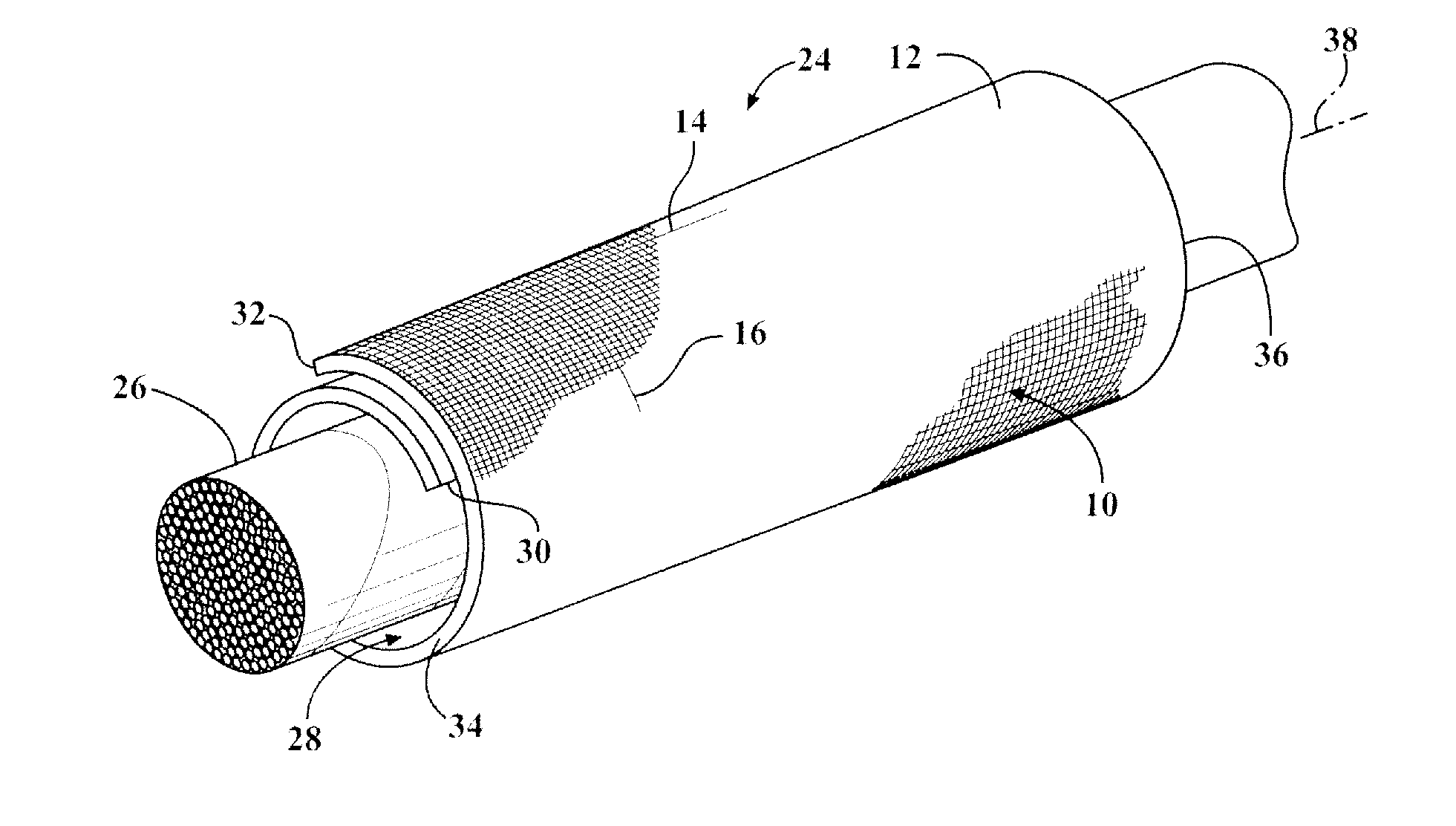

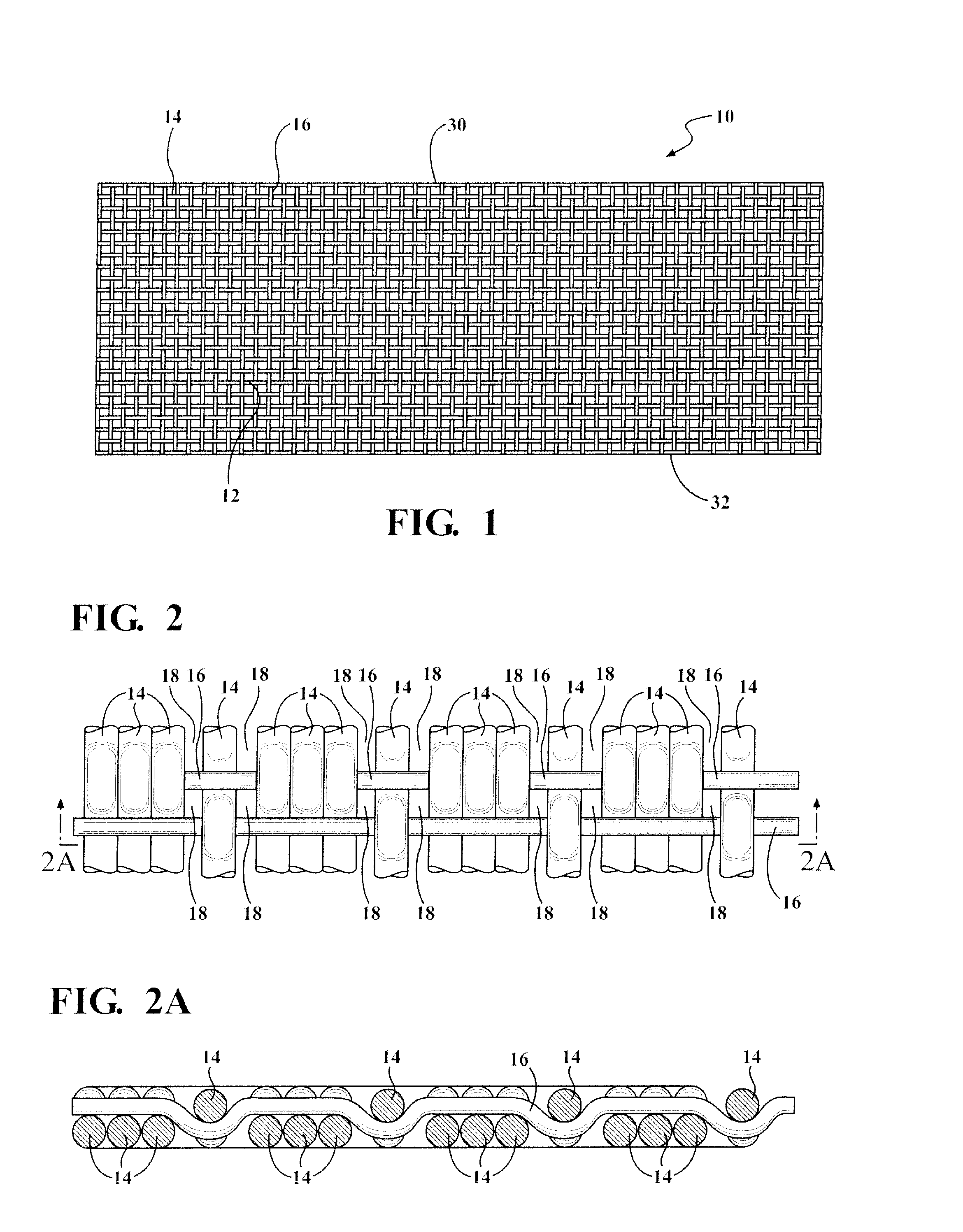

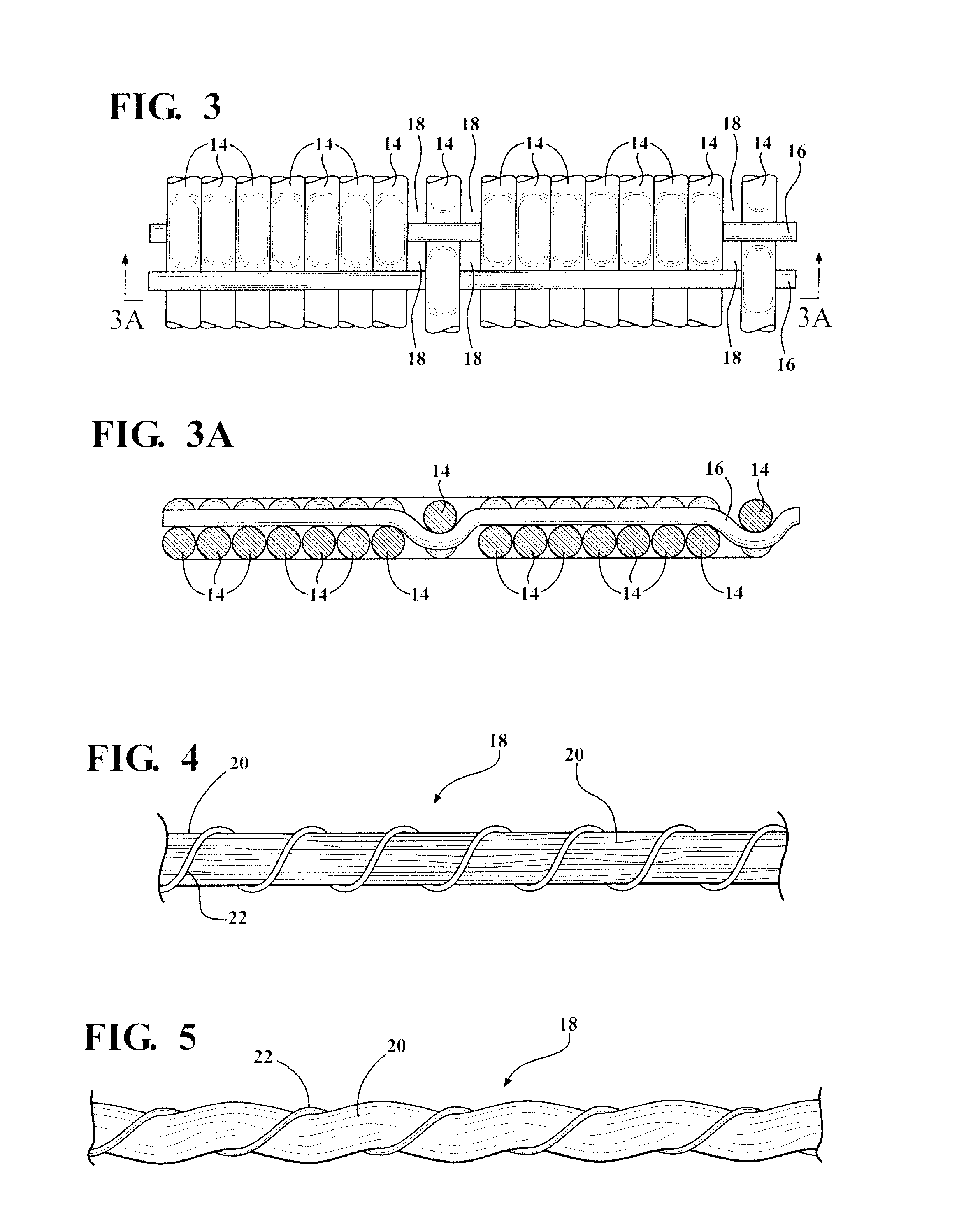

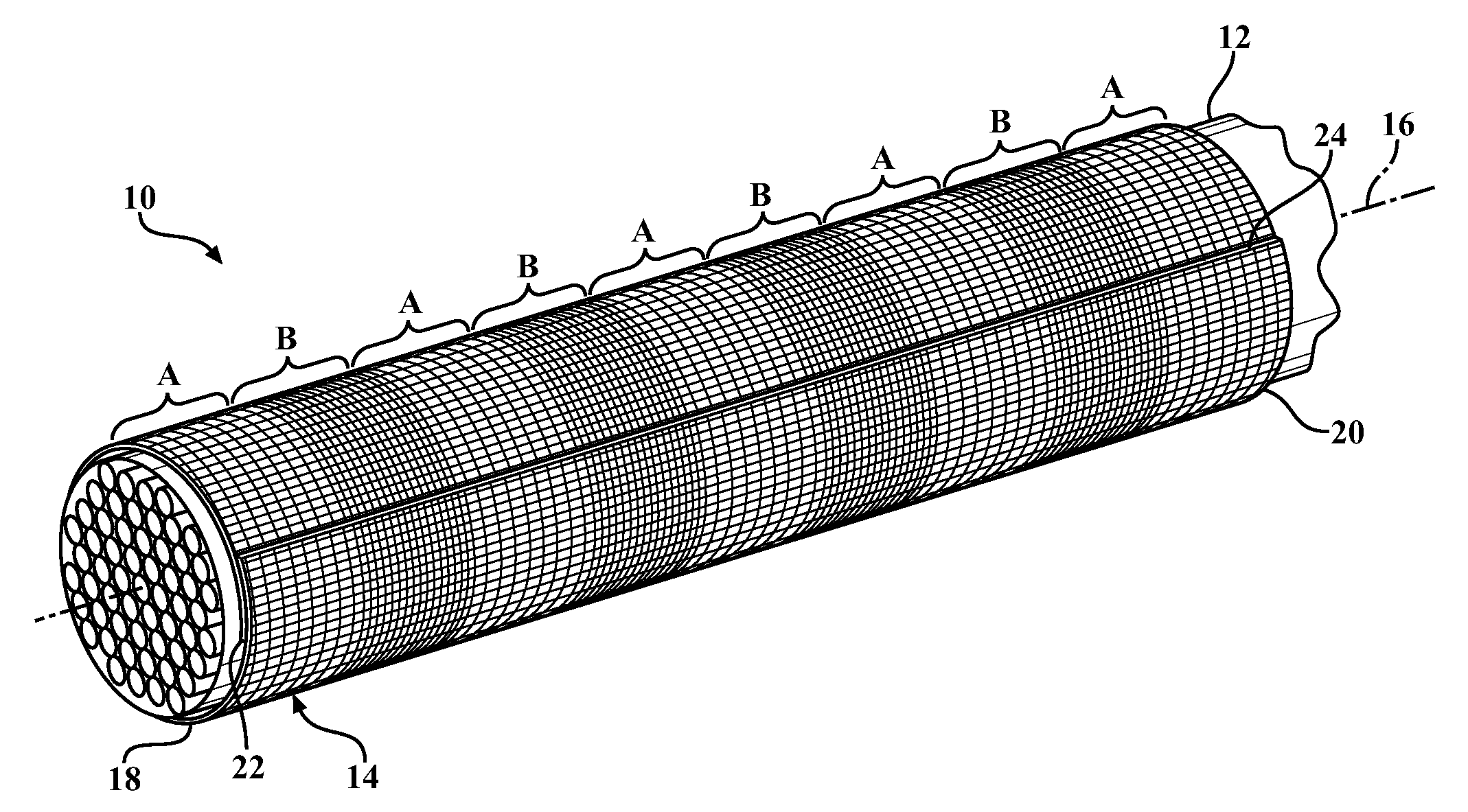

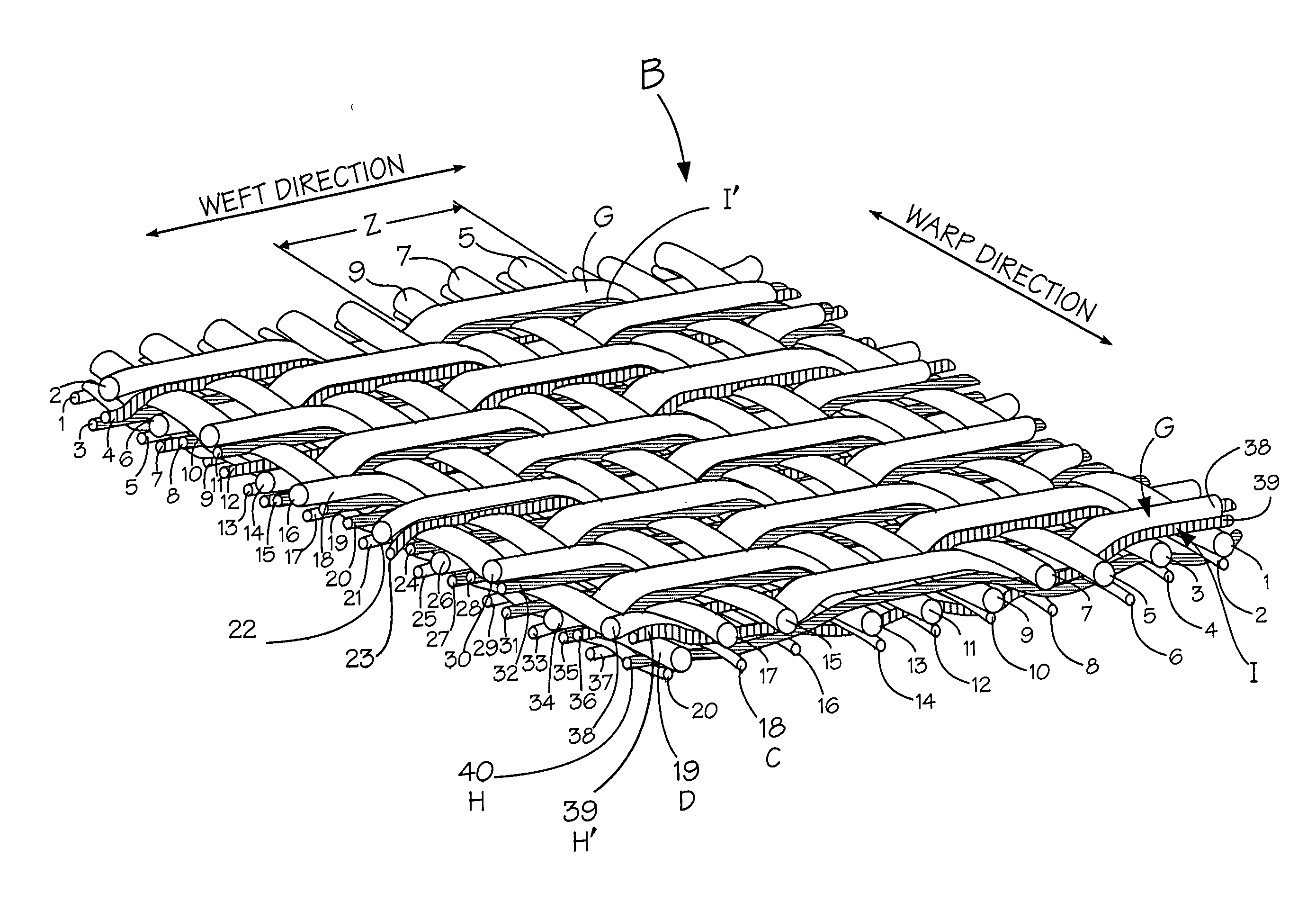

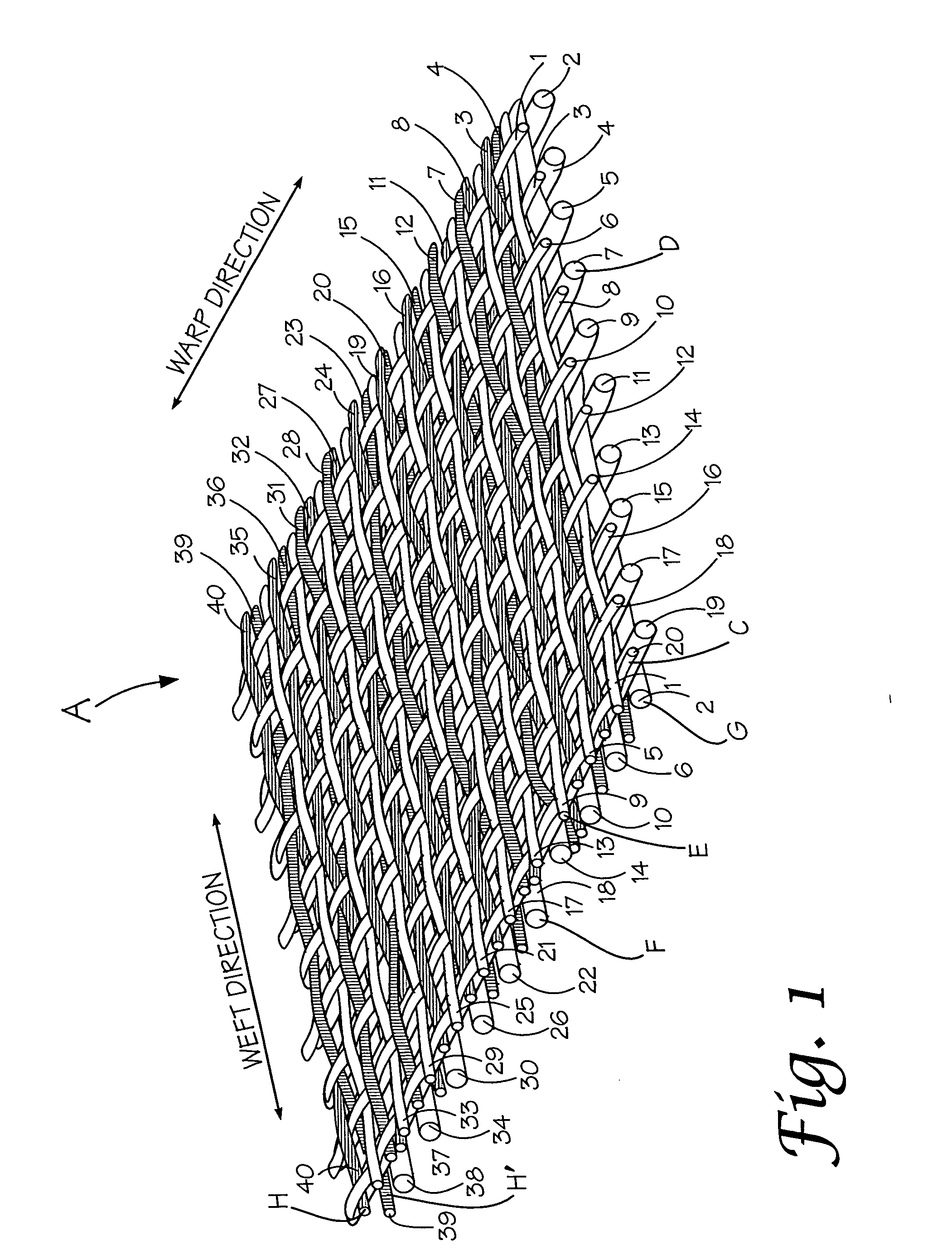

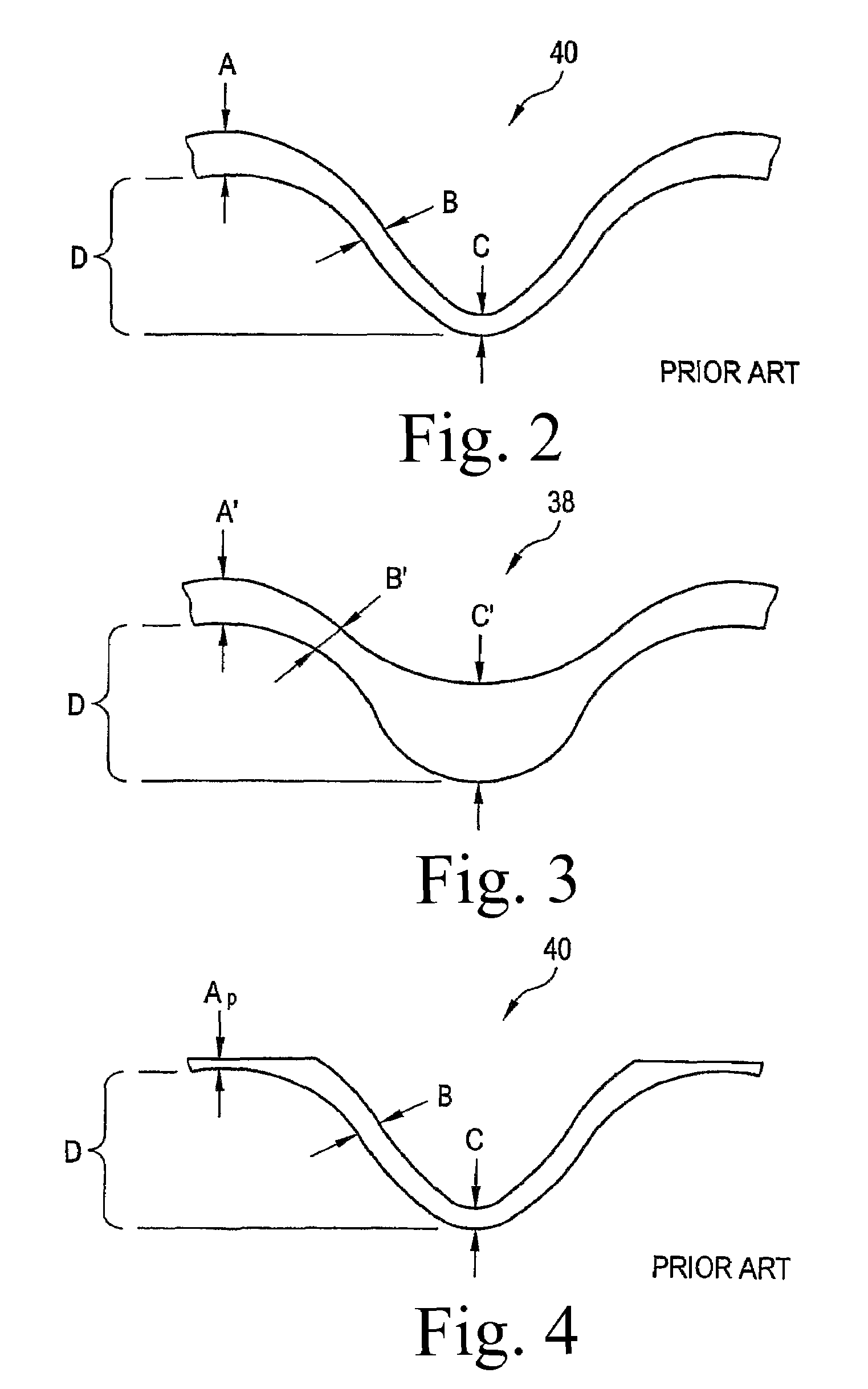

Non-kinking self-wrapping woven sleeve and method of construction thereof

ActiveUS20120037263A1Increase flexibilityRaise countElectrical apparatusLoomsUltimate tensile strengthWeft yarn

A wrappable textile sleeve and method of construction thereof is provided. The textile sleeve includes an elongate wall extending along a longitudinal axis between opposite ends with lengthwise extending edges extending along the longitudinal axis between the opposite ends. The wall is woven from lengthwise extending warp yarns and circumferentially extending weft yarns with at least some of the weft yarns being heat-set to impart a self curling bias on the wall to bring the edges into overlapping relation with one another. Further, the weft yarns form a plurality of discrete annular bands that extend circumferentially about the longitudinal axis with adjacent bands having different picks-per-inch from one another to provide the sleeve with enhance regions of flexibility, self-curling bias and hoop strength.

Owner:FEDERAL MOGUL POWERTAIN LLC

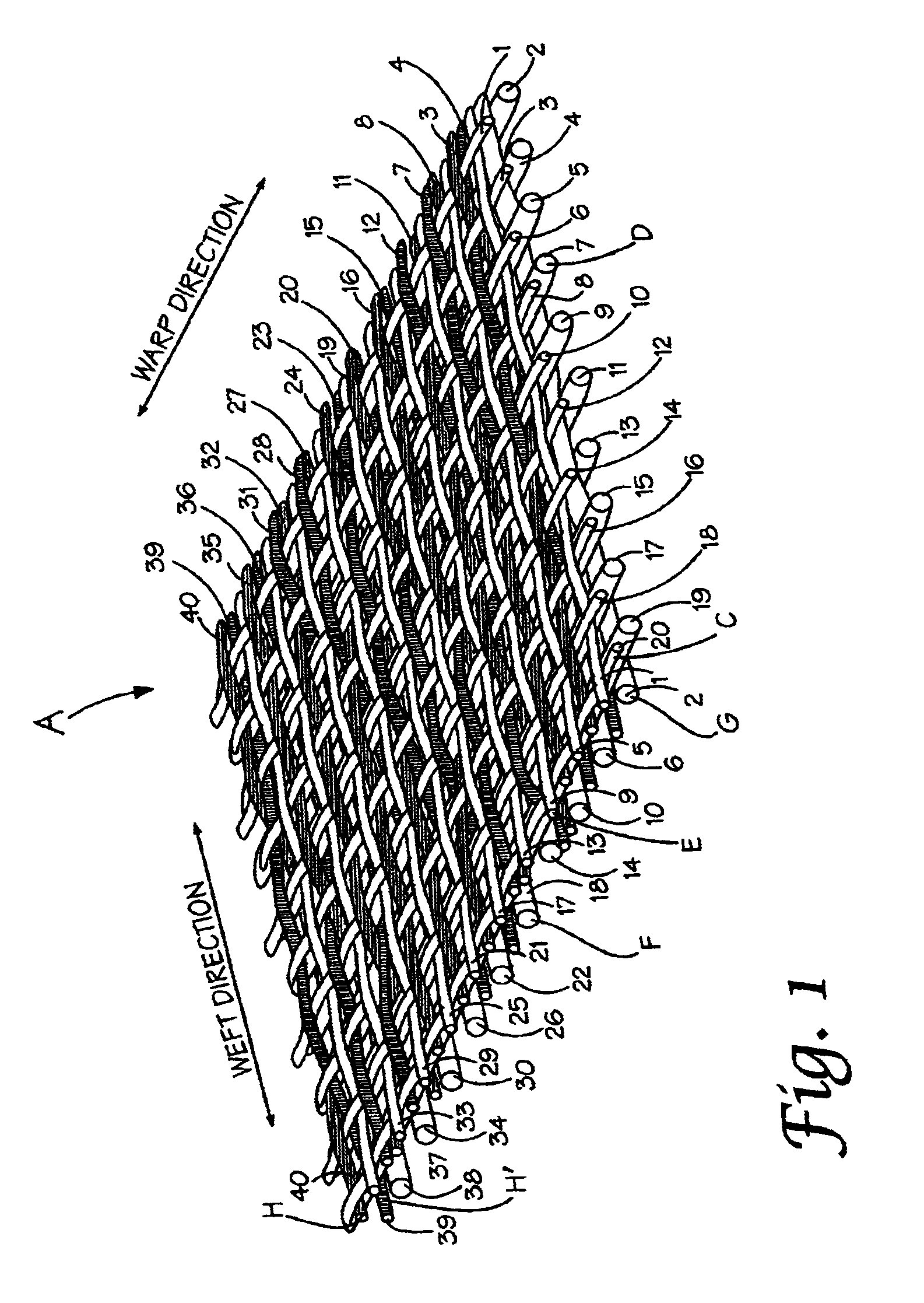

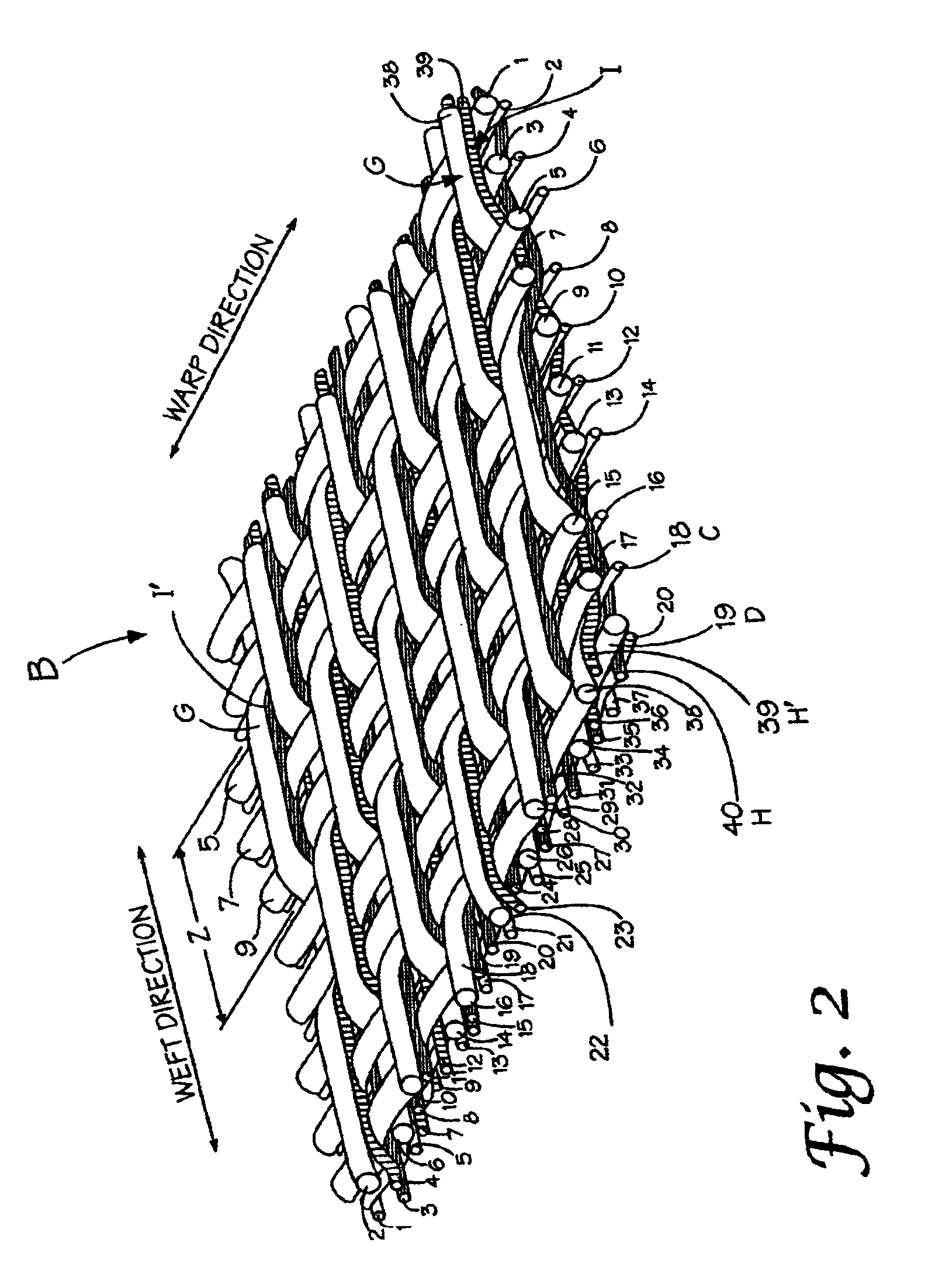

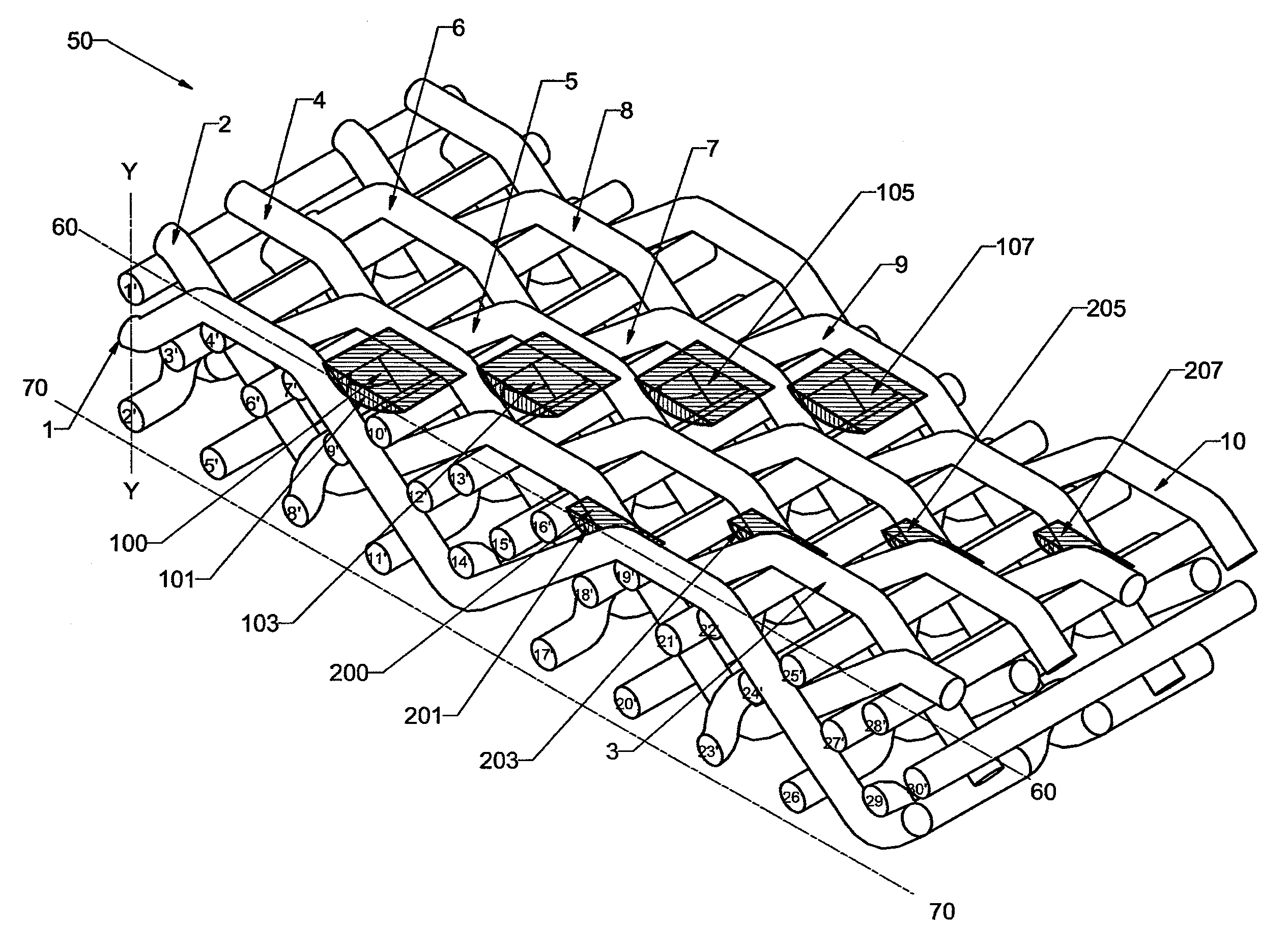

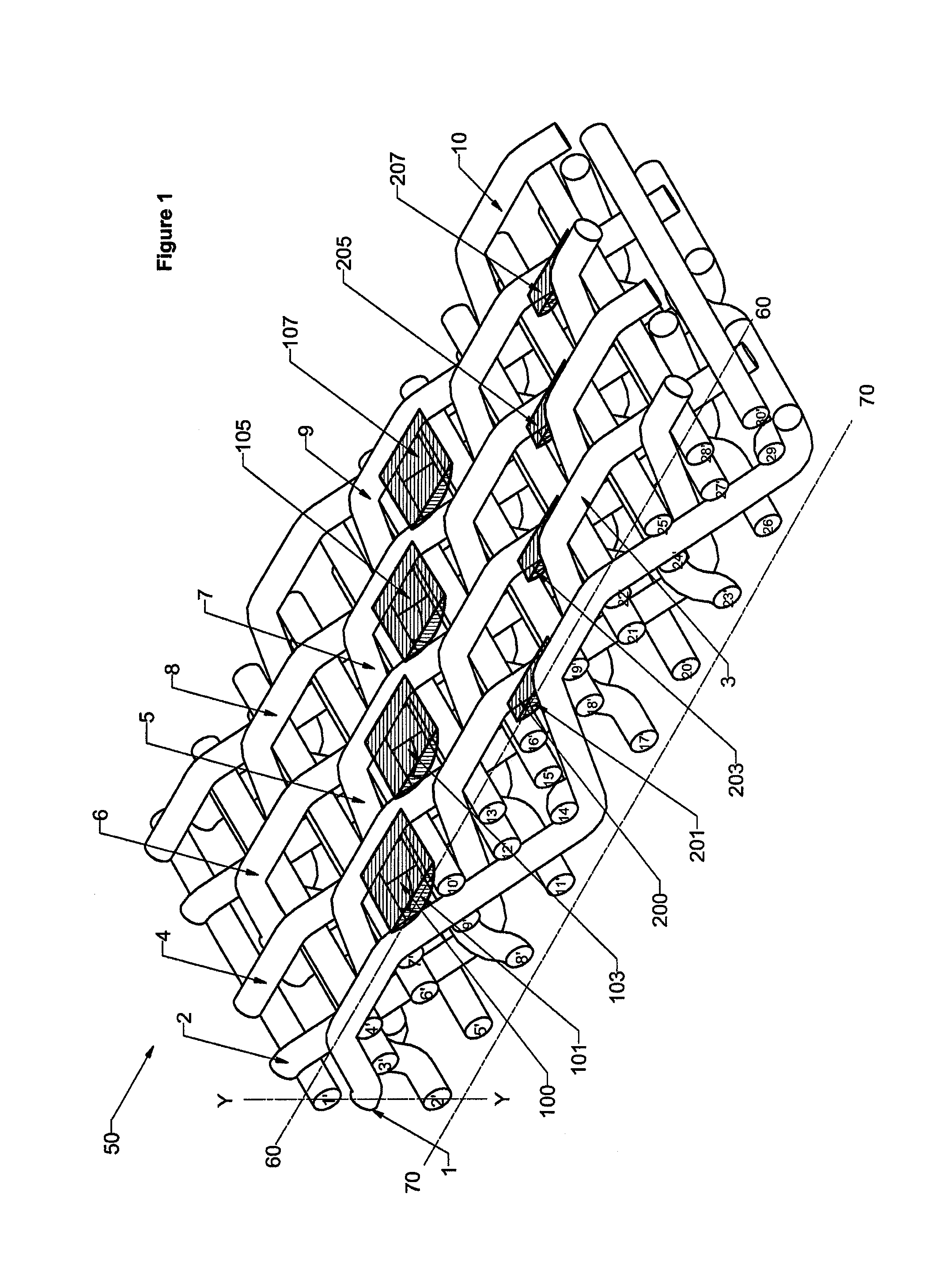

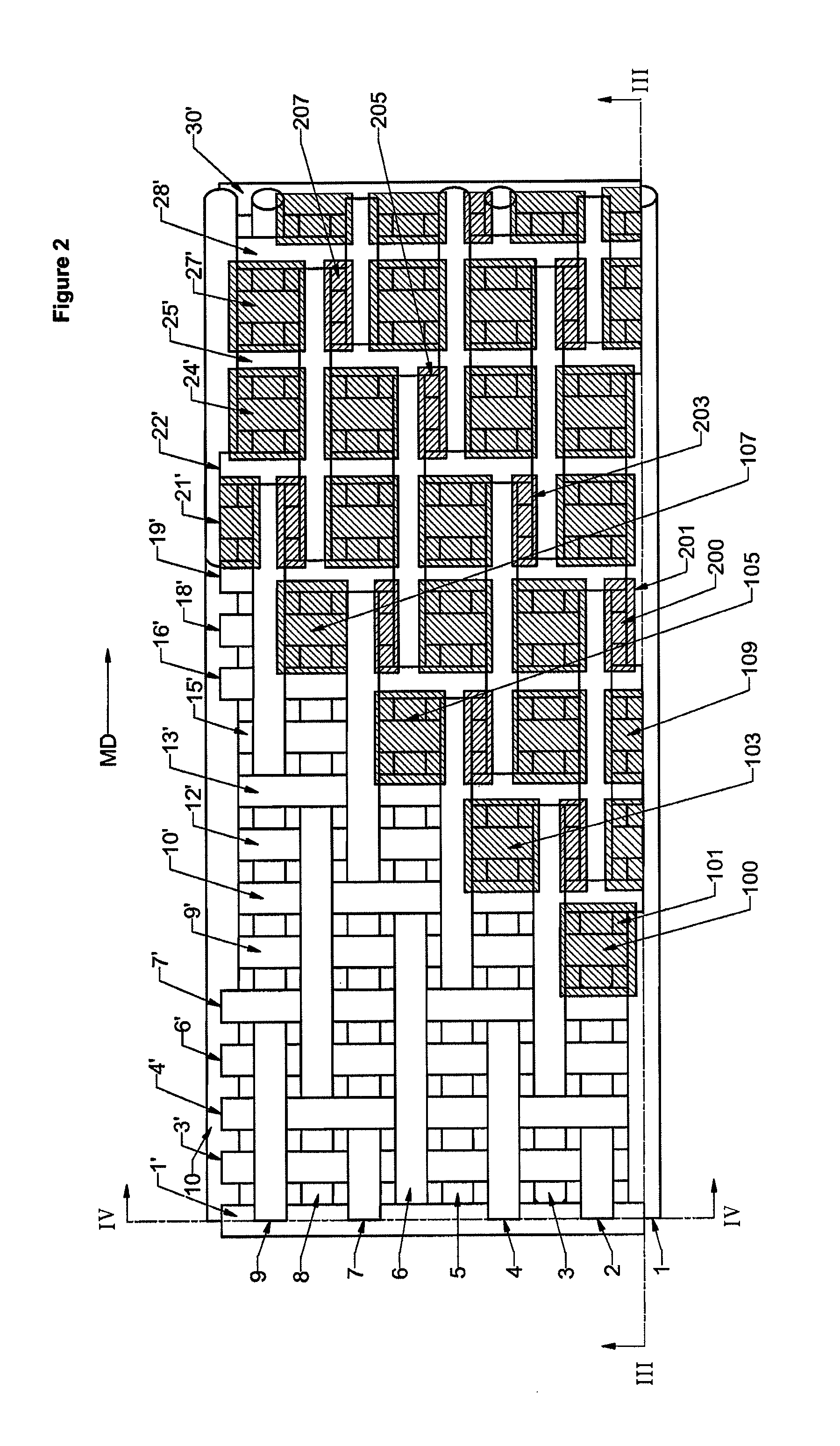

Warp-stitched multilayer papermaker's fabrics

InactiveUS7059357B2Easy to drainImprove joint strengthCellulosic pulp after-treatmentNon-fibrous pulp additionWeft yarnWarp knitting

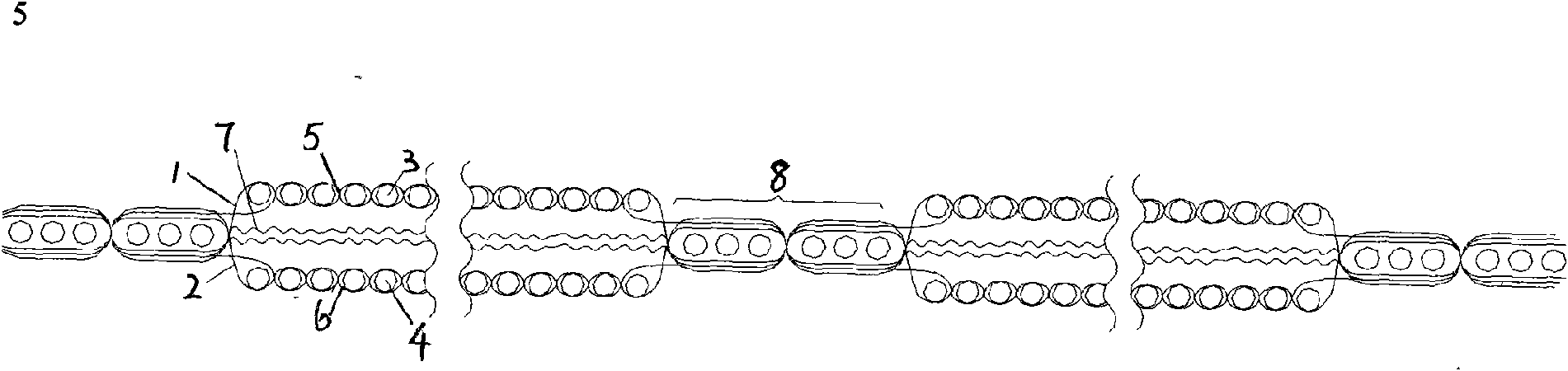

A warp-stitched multilayer papermaker's fabric has a set of bottom warp yarns, a set of bottom weft yarns, a set of top weft yarns and a set of warp stitching yarn pairs. The bottom warp yarns are interwoven with the bottom weft yarns. The stitching warp yarns interweave with both the bottom weft yarns and the top weft yarns, and are woven such that at locations where the first of the stitching warp yarns in a pair weaves in the top fabric layer, the second stitching warp yarn in the pair drops below the top fabric layer to interweave with one or more bottom weft yarns to bind the top fabric layer and the bottom fabric layer together. The first stitching warp yarn of the stitching warp yarn pair may weave on a first side of one of the bottom warp yarns while the second stitching warp yarn of each stitching yarn pair may weave on the other side of that bottom warp yarn. Each stitching yarn pair may be substantially stacked above a bottom warp yarn. The fabric may further include a set of top warp yarns that interweave with the top weft yarns in the top fabric layer. The set of top warp yarns may be woven from a first warp beam, the set of bottom warp yarns may be woven from a second warp beam and the set of stitching warp yarns may be woven from a third warp beam.

Owner:WEAVEXX

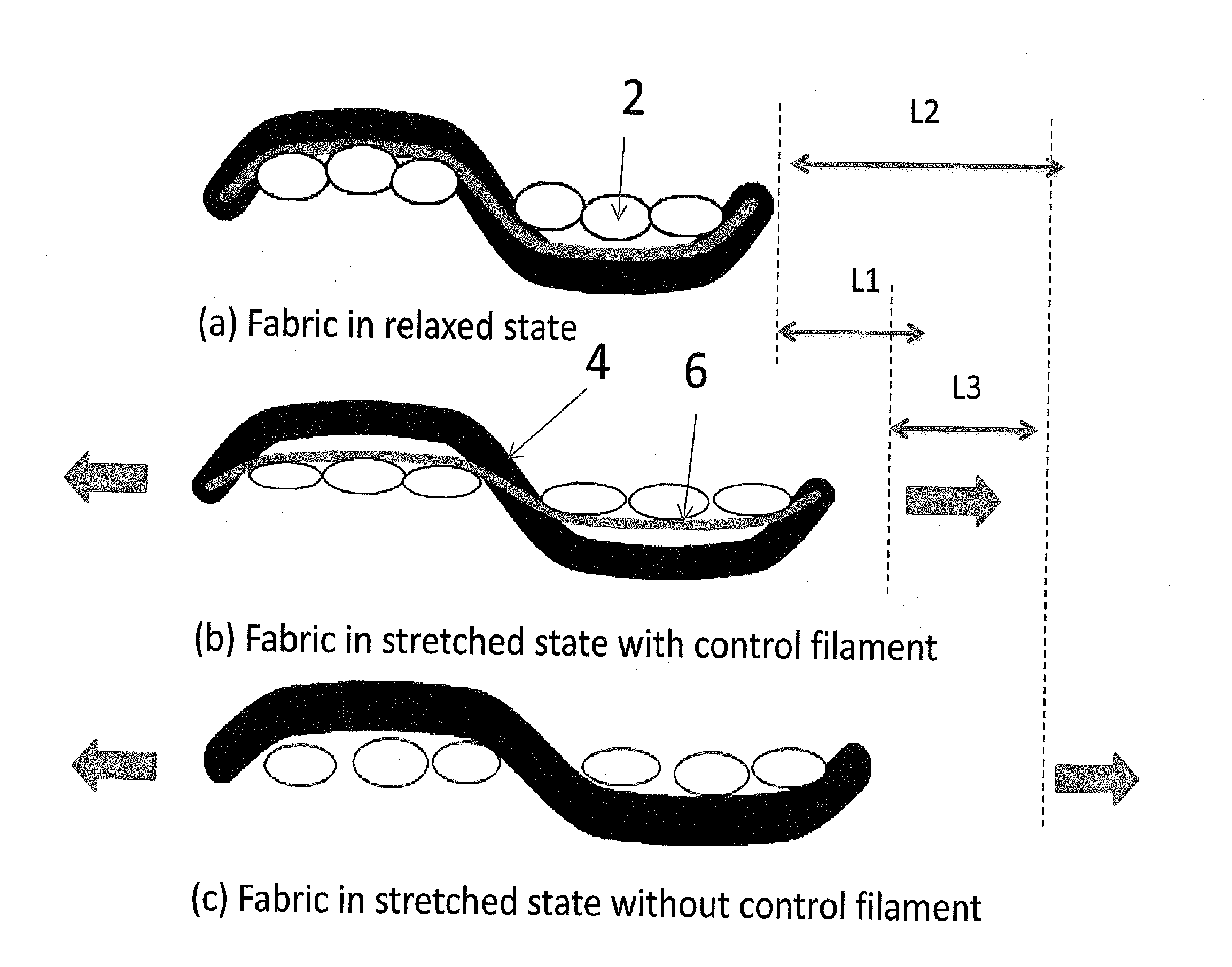

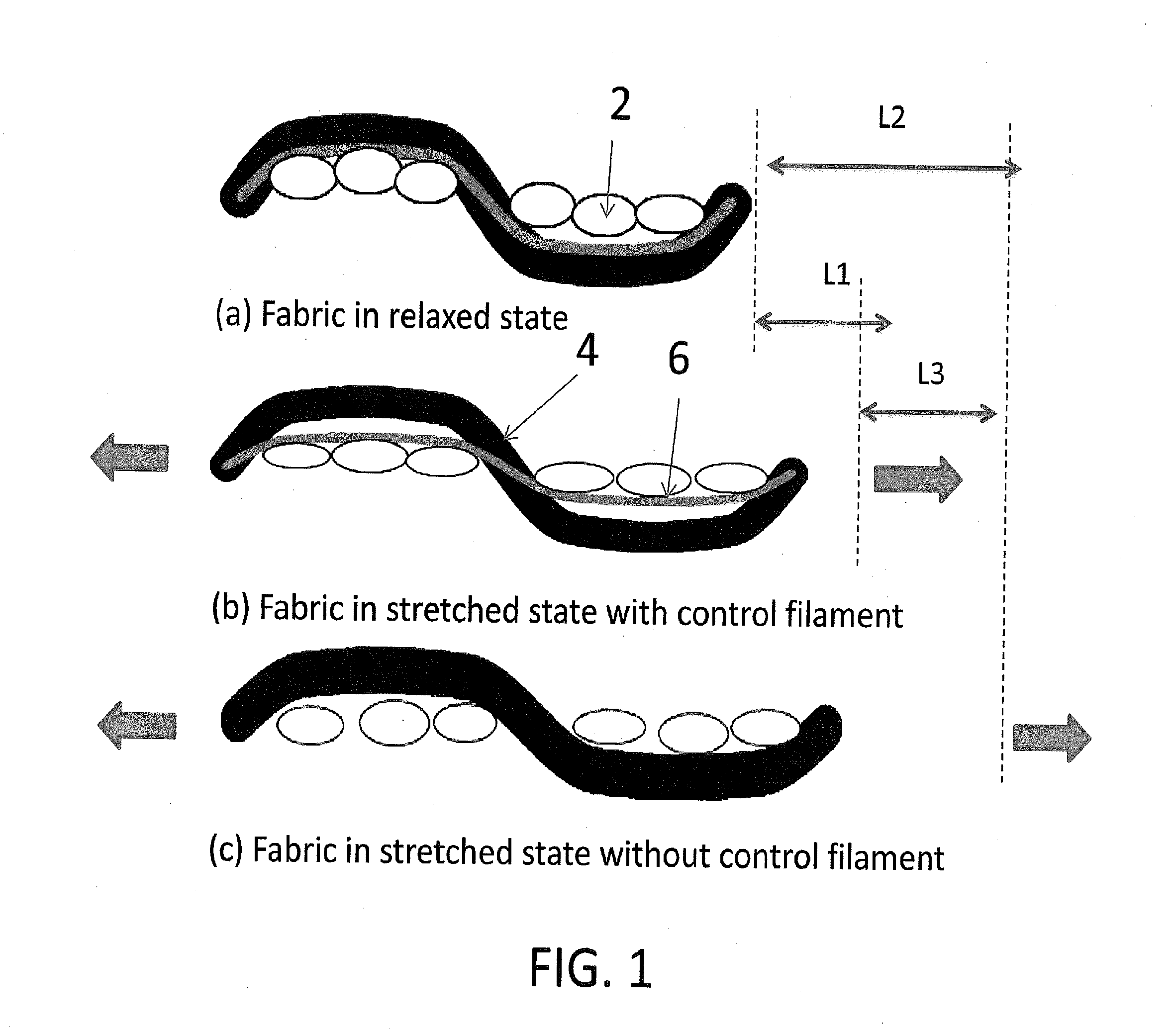

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

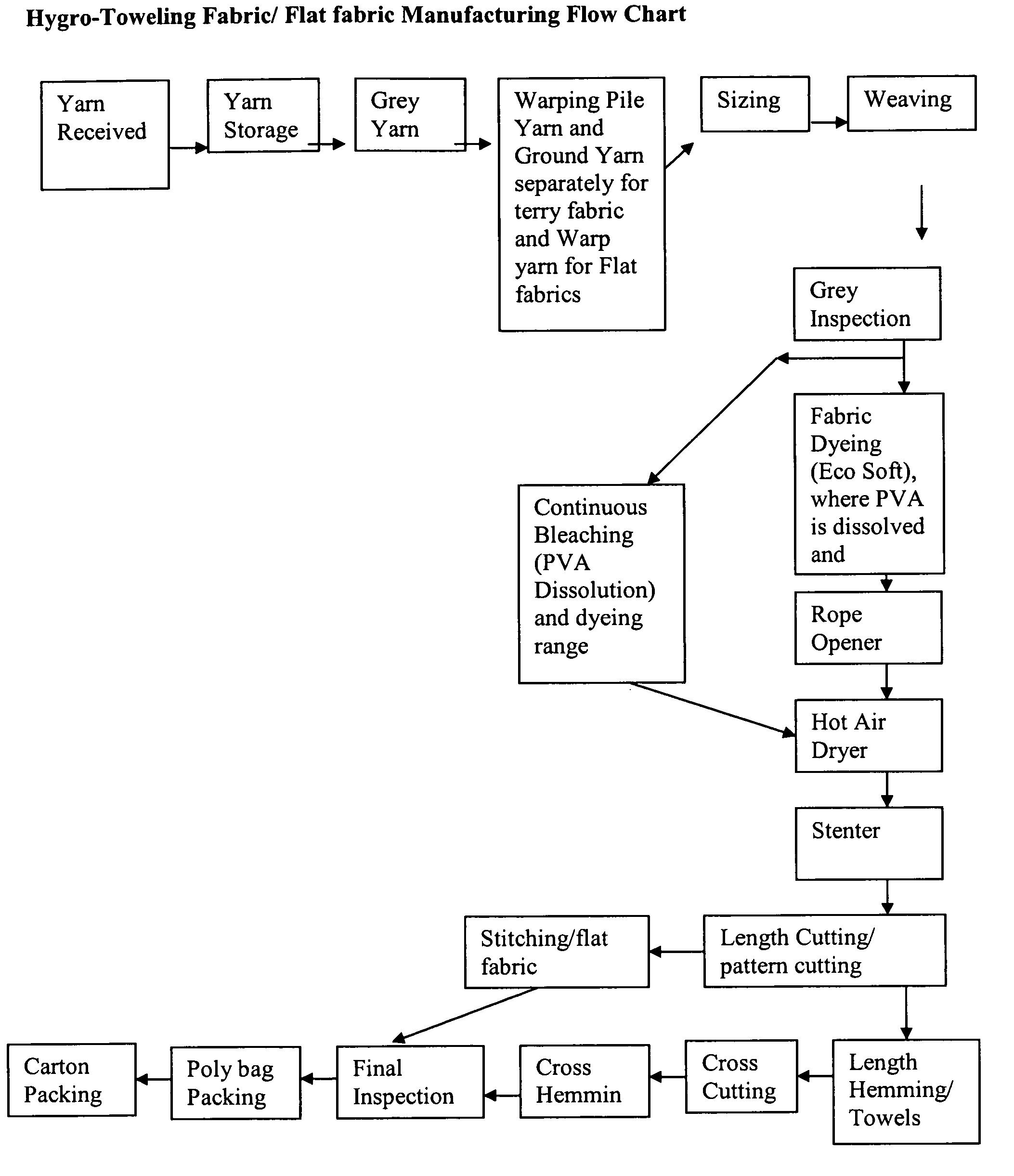

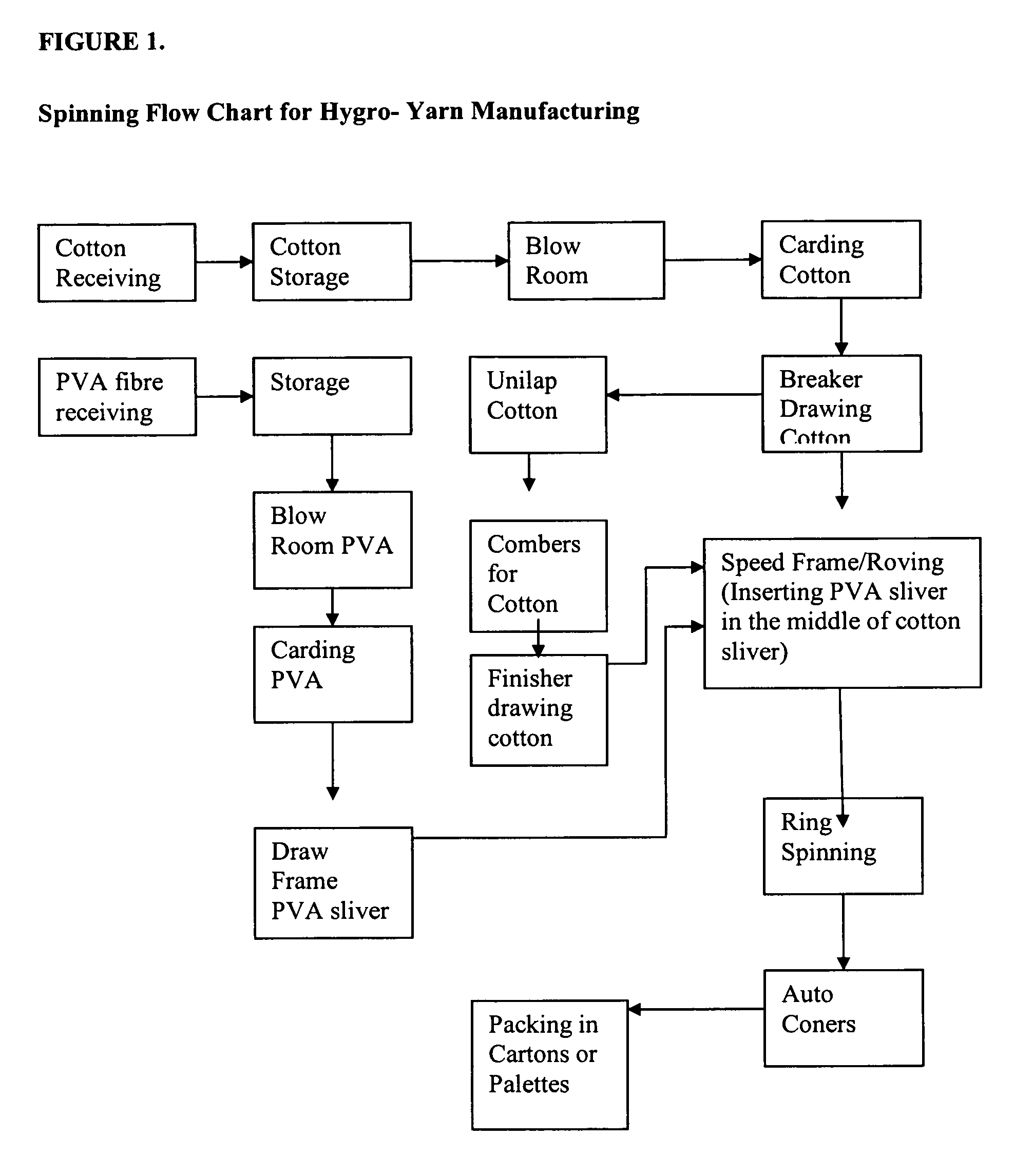

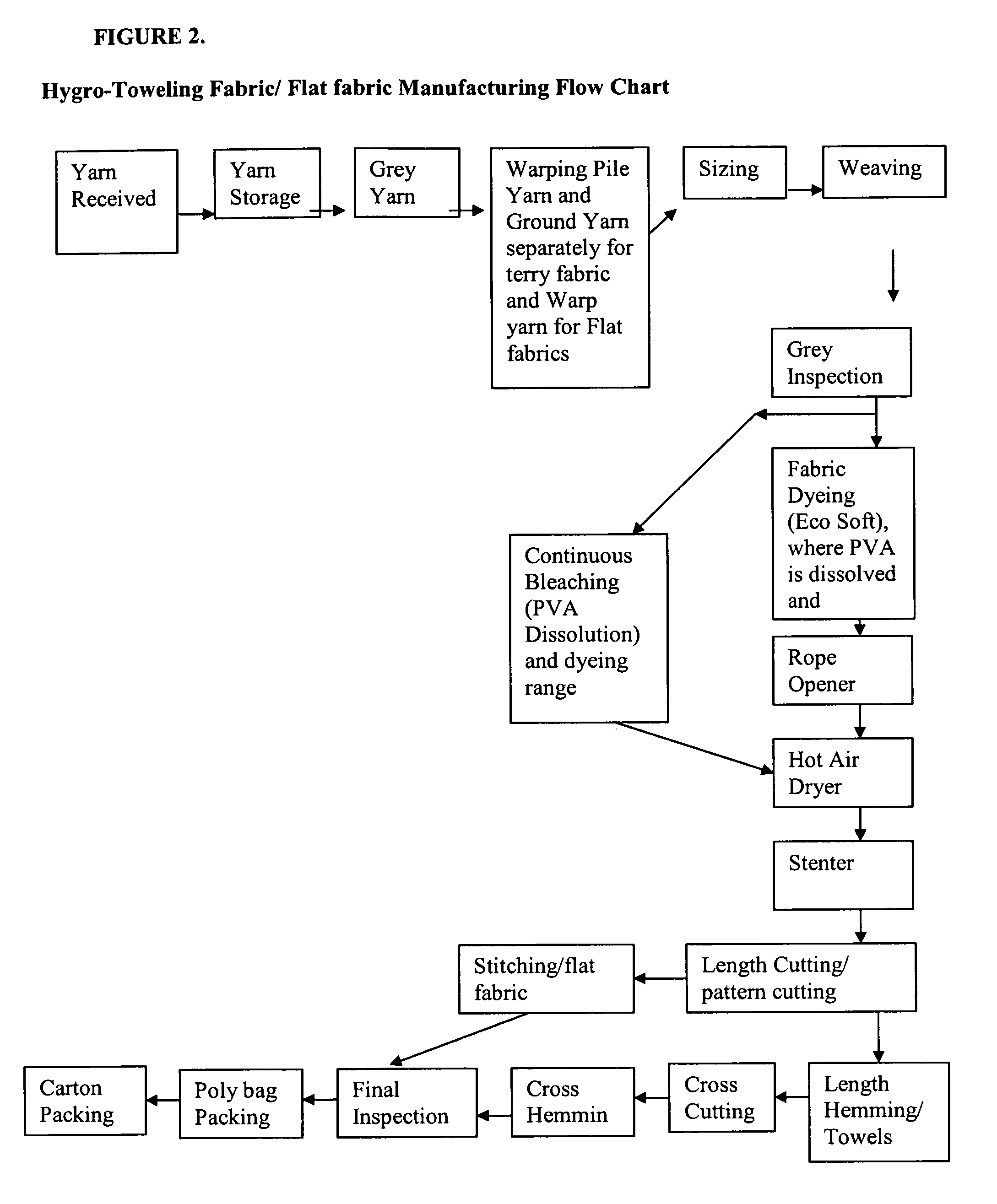

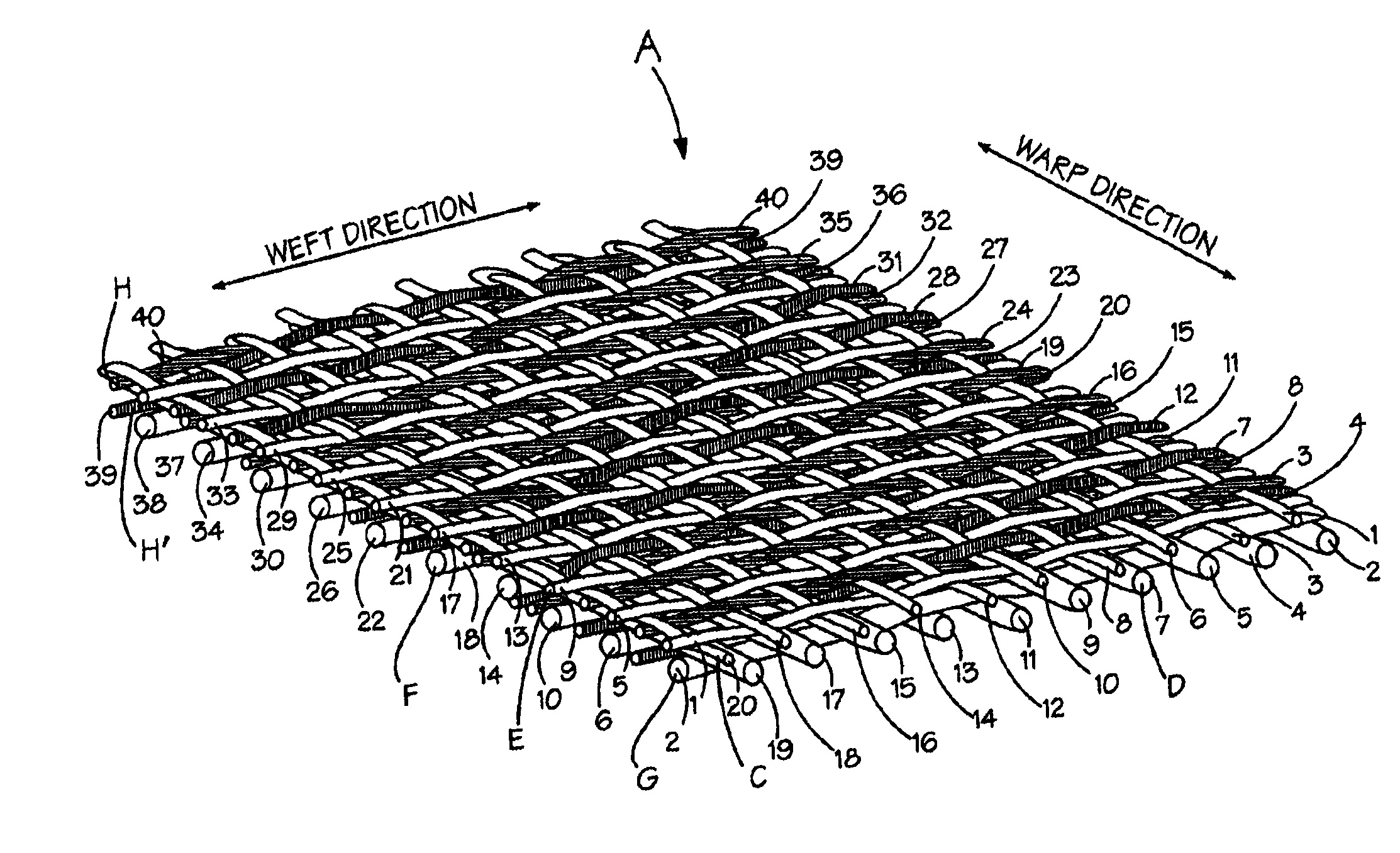

Hygro materials for use in making yarns and fabrics

ActiveUS20070087162A1Fast dryingIncrease in sizeFabric breaking/softeningLayered productsFiberWarm water

A process is described wherein pile yarn is woven with cotton weft and warp yarns to produce terry fabrics, such as towels. The fabric is then washed in warm water to dissolve the PVA fibers. The amount of fibers dissolved, depends upon the count of the yarn or yarns used. By dissolving the PVA fibers, a hollow air space is produced throughout the pile yarn, corresponding to an increase in the air space in the pile yarn. By increasing the air space in the pile yarn, the resulting towels are softer and bulkier than standard cotton towels. The present invention further relates to pile yarn in terry woven fabric (warp yarn), or weft yarn, in the case of flat fabrics.

Owner:WELSPUN INDIA LTD

Composite papermaking fabric

A composite papermaking fabric having an upper support fabric including upper warp and weft yarns and a lower contact fabric including lower warp and weft yarns. The upper fabric is woven in a first weave pattern which forms a support surface and the lower fabric is woven in a broken twill weave pattern which forms the contact surface. The composite fabric includes paired binder yarns which weave in alternating sequences with the upper and lower fabrics binding them together. The broken twill weave pattern provides plural floats of cross-machine direction yarns passing outwardly of a plurality of adjacent lower warp yarns forming a plurality of adjacent cross-machine direction floats. Certain of the paired floats comprise a lower weft yarn and a binder yarn while others may comprise two lower weft yarns. The lower weft yarn floats are positioned to shield and protect the binder yarn floats along their entire length.

Owner:VOITH FABRICS

Stretch wovens with separated elastic yarn system

In some embodiments are an article including a woven fabric having warp yarns and weft yarns. Either warp yarn or weft yarn or both warp and weft yarns have two separate systems of yarns. The systems of yarns include a hard yarn forming the main body of fabric and a composite covered elastic yarn with an elastic fiber core; wherein the fabric has an outer face side, a back side, and the fabric includes at least one of: (a) a weaving pattern where the composite yarn and at least one adjacent hard yarn pass over the same pick when the composite yarn is on the outer surface; (b) the ratio of hard yarn denier to composite yarn denier is at least 1:1; and (c) the composite yarn floats over no more than 5 picks on the outer face side.

Owner:THE LYCRA CO LLC

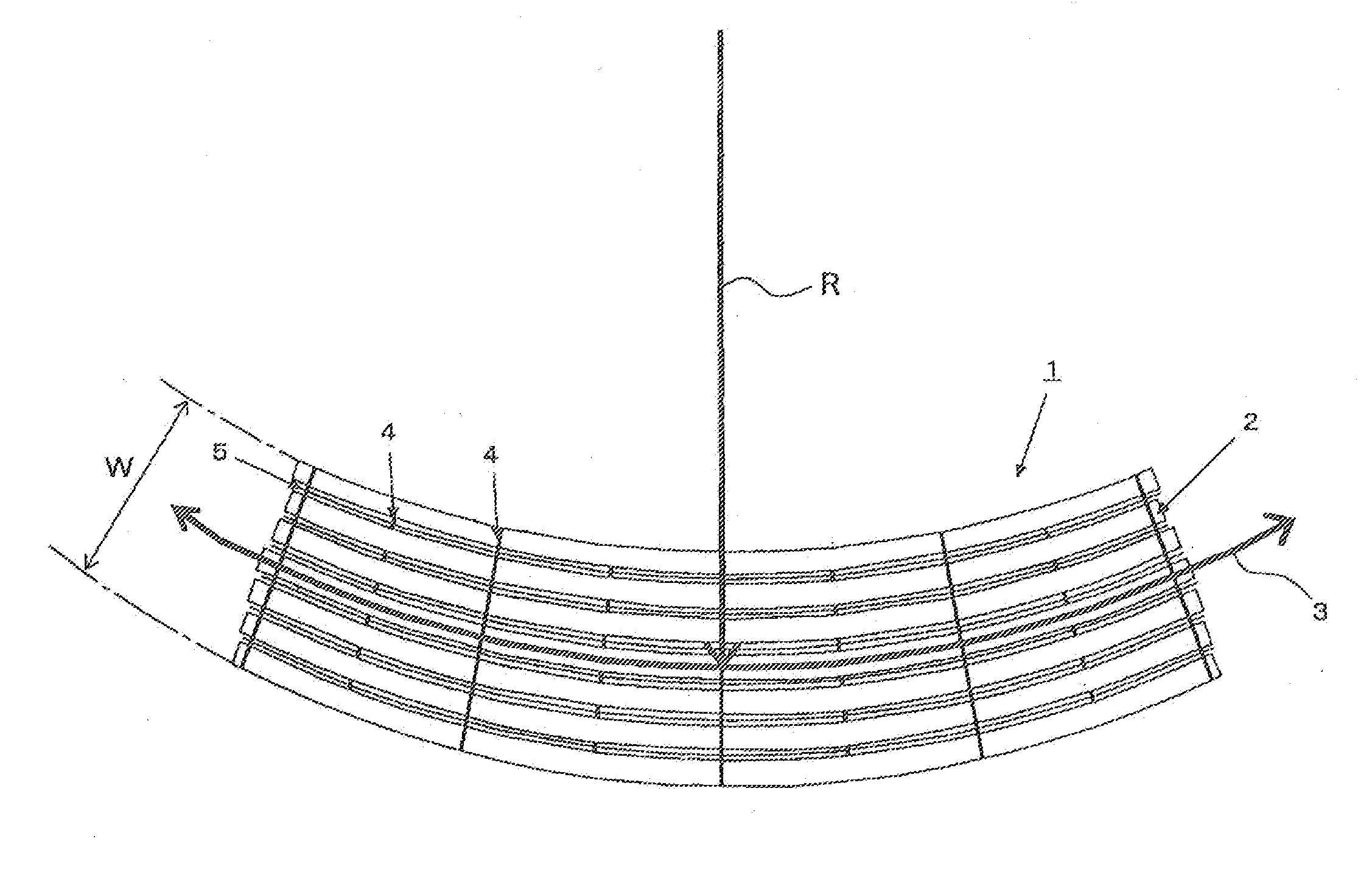

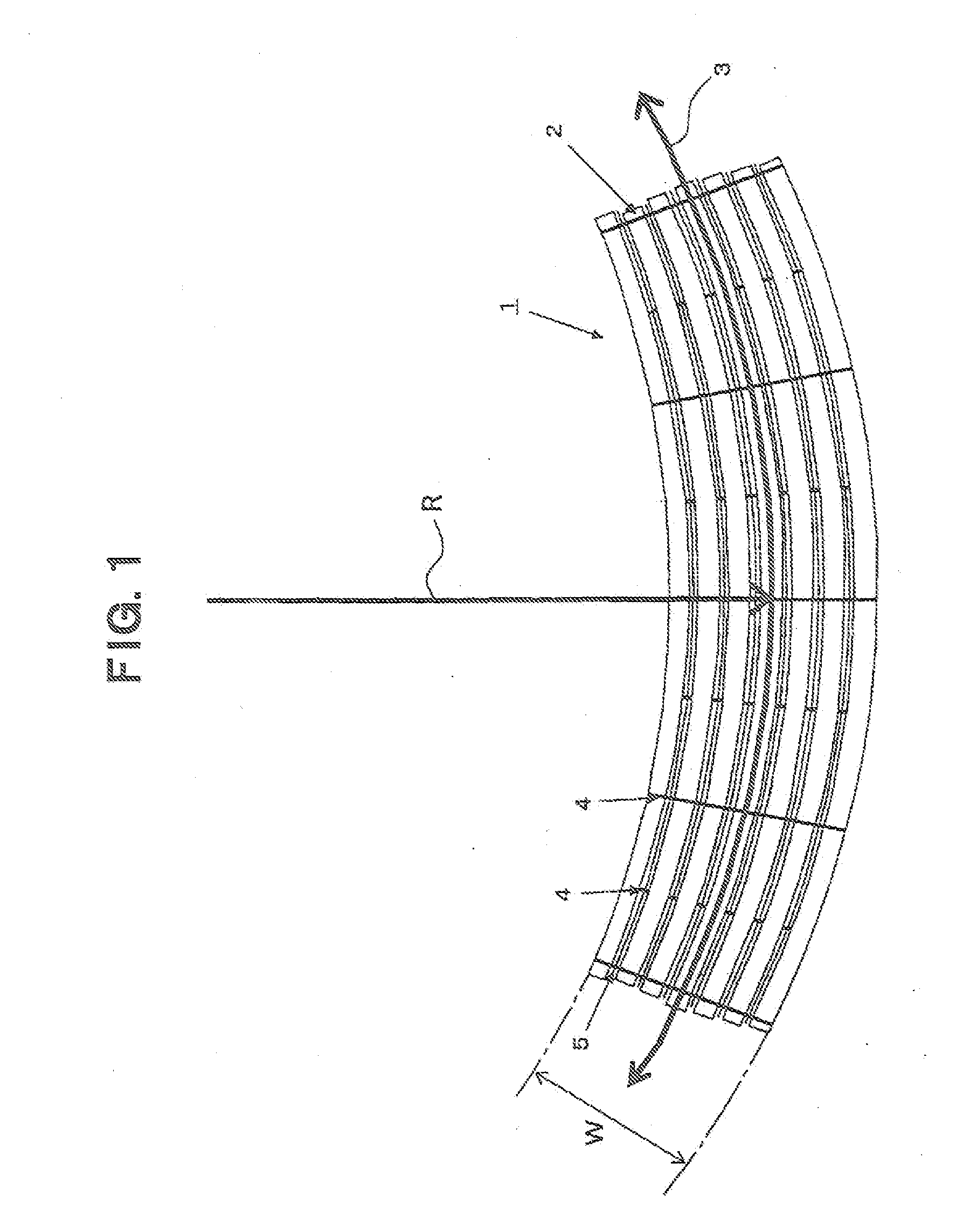

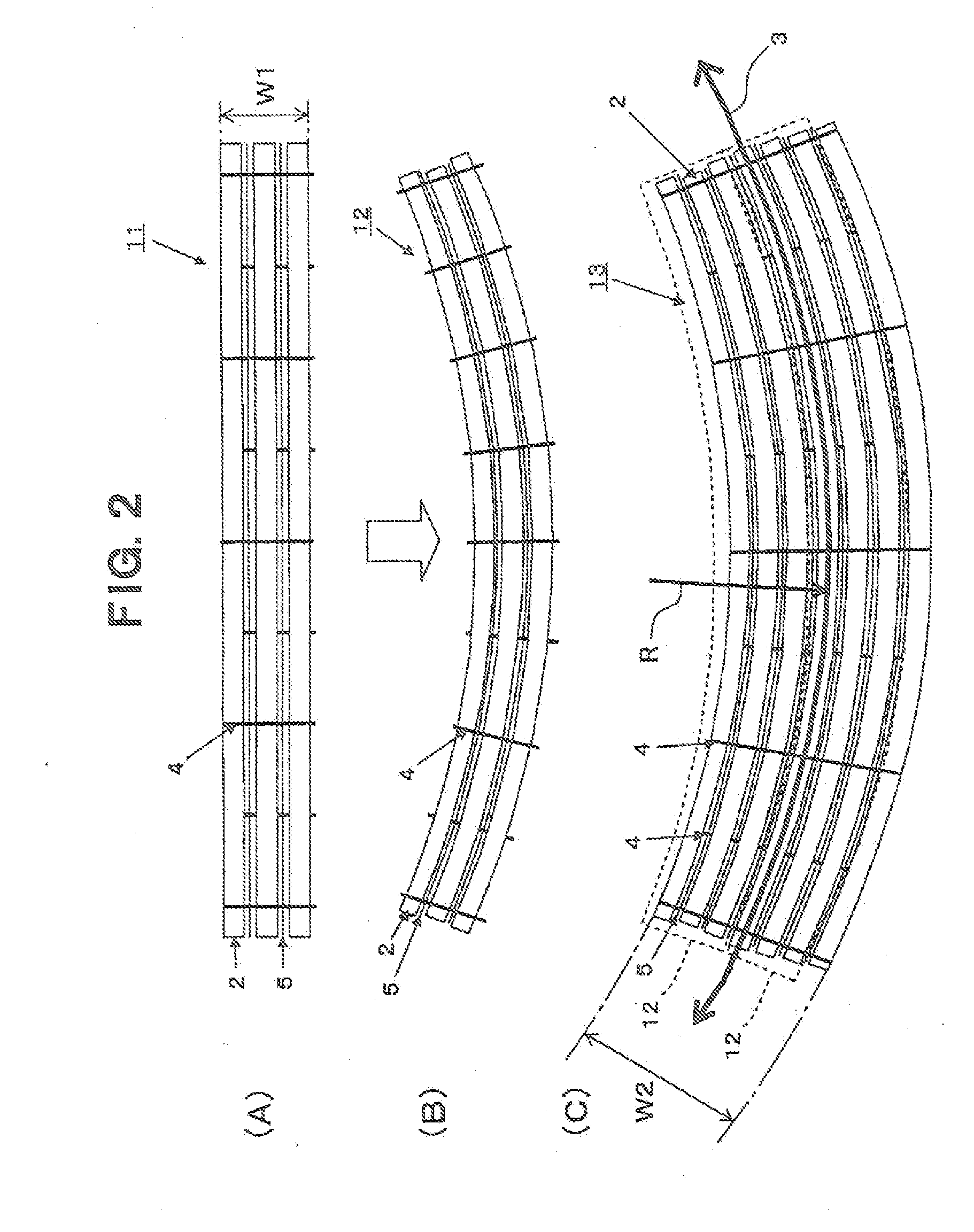

Reinforcing fiber substrate of curved shape, layered product using the same, preform, fiber-reinforced resin composite material, and processes for producing those

InactiveUS20100285265A1Efficient formationSimple structureLoomsSynthetic resin layered productsYarnCurve shape

A curved reinforcing fiber substrate having a curved planar shape comprising a plurality of reinforcing fiber yarns arranged parallel to a direction along a circumferential direction of the curved shape, and auxiliary weft yarns arranged in directions crossing the plurality of reinforcing fiber yarns each arranged in one direction of the circumferential direction.

Owner:TORAY IND INC

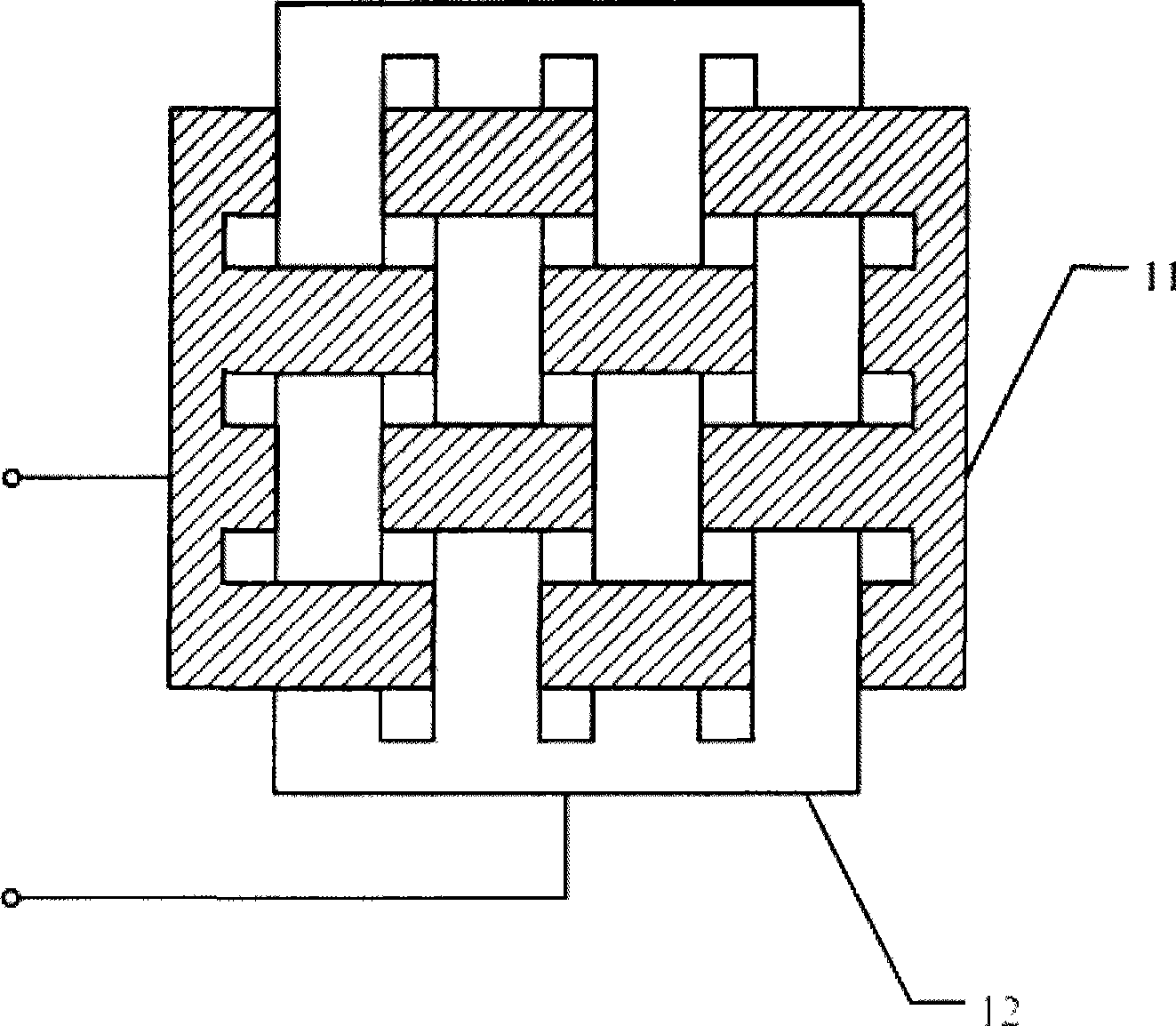

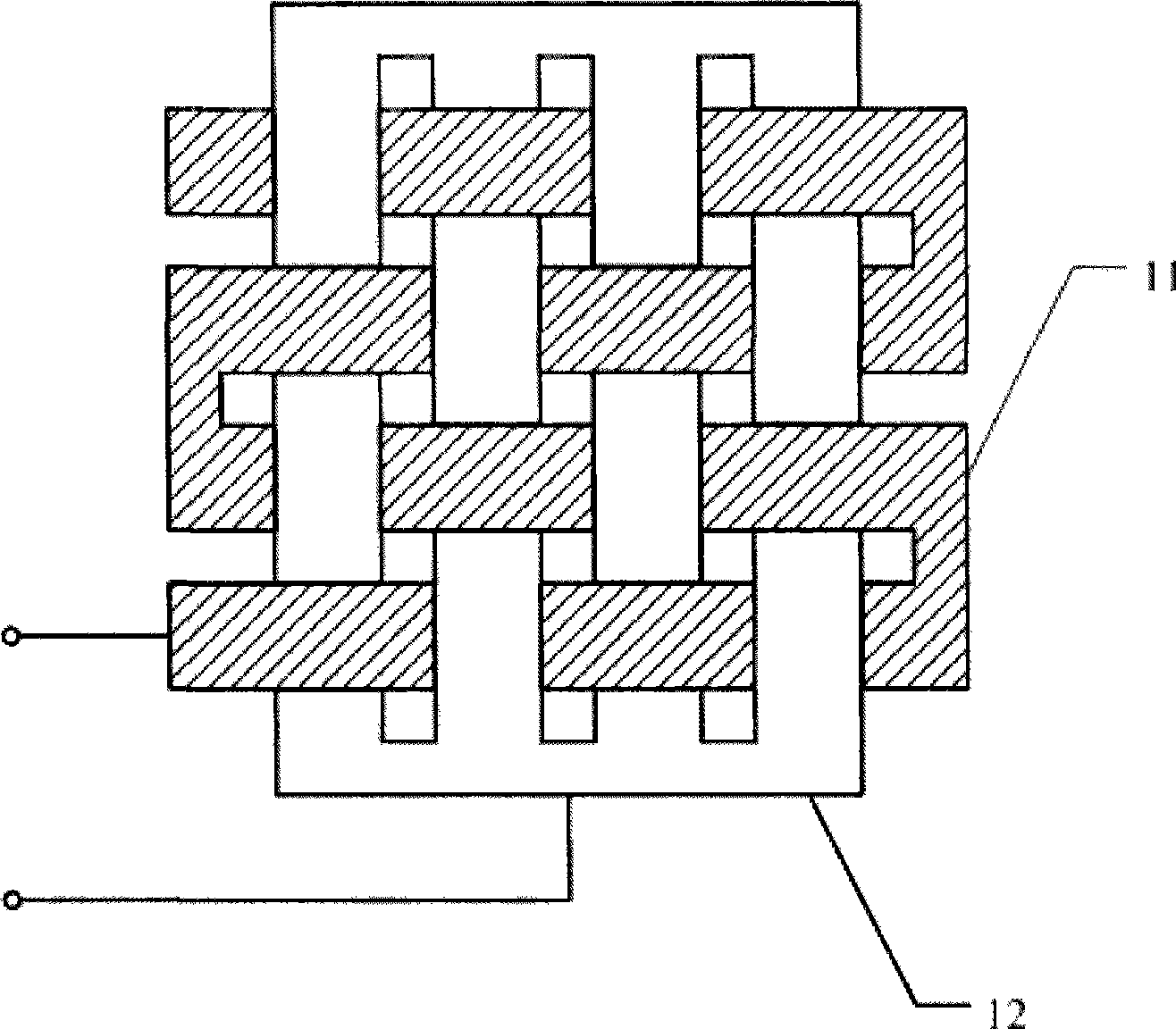

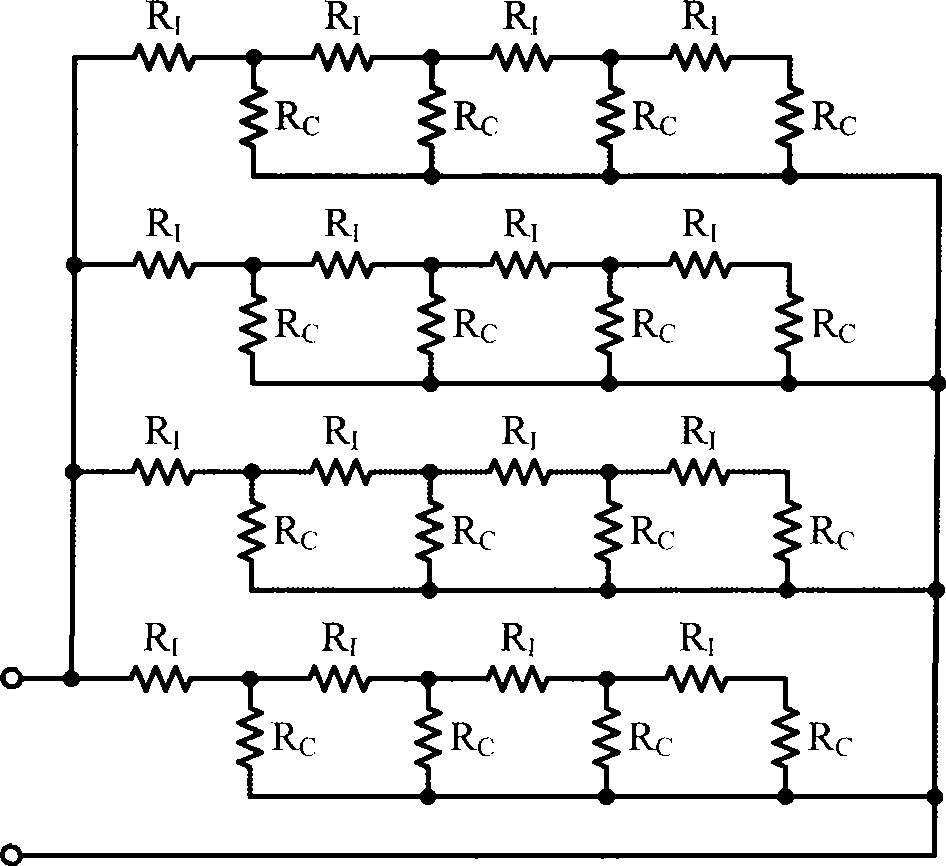

Flexible resistance type pressure sensor with machine-weaved structure and use thereof

InactiveCN101393058AHas a bendableWith foldableForce measurementDiagnostic recording/measuringFiberElectrical resistance and conductance

The invention provides a flexible resistance type pressure sensor with a woven structure, which consists of conductive fibers. The pressure sensor is characterized in that the conductive fibers are mutually interwoven into a woven fabric, all warp yarns of the woven fabric are connected with each other, all weft yarns of the woven fabric are connected with each other, and an integral resistor between all the warp yarns and all the weft yarns changes with the pressure on the woven fabric. The technical proposal of the flexible resistance type pressure sensor provides application of the flexible resistance type pressure sensor with the woven structure, which is characterized in that the flexible resistance type pressure sensor with the woven structure is applied to sleeping posture detection costume. The pressure sensor has the characteristics of flexibility, foldability and launderability, and is suitable for the detection of wearable personal physiological information and state.

Owner:DONGHUA UNIV

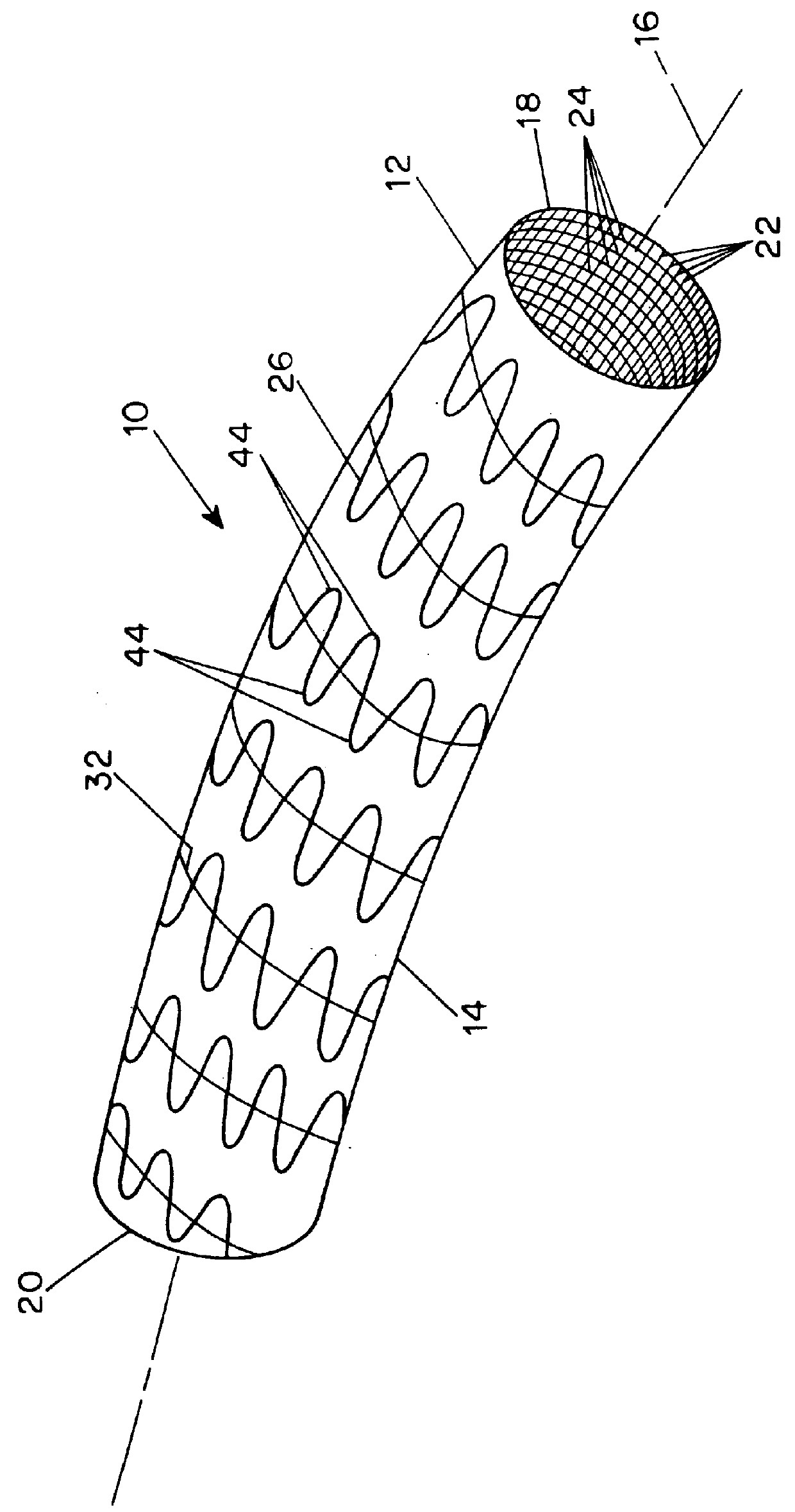

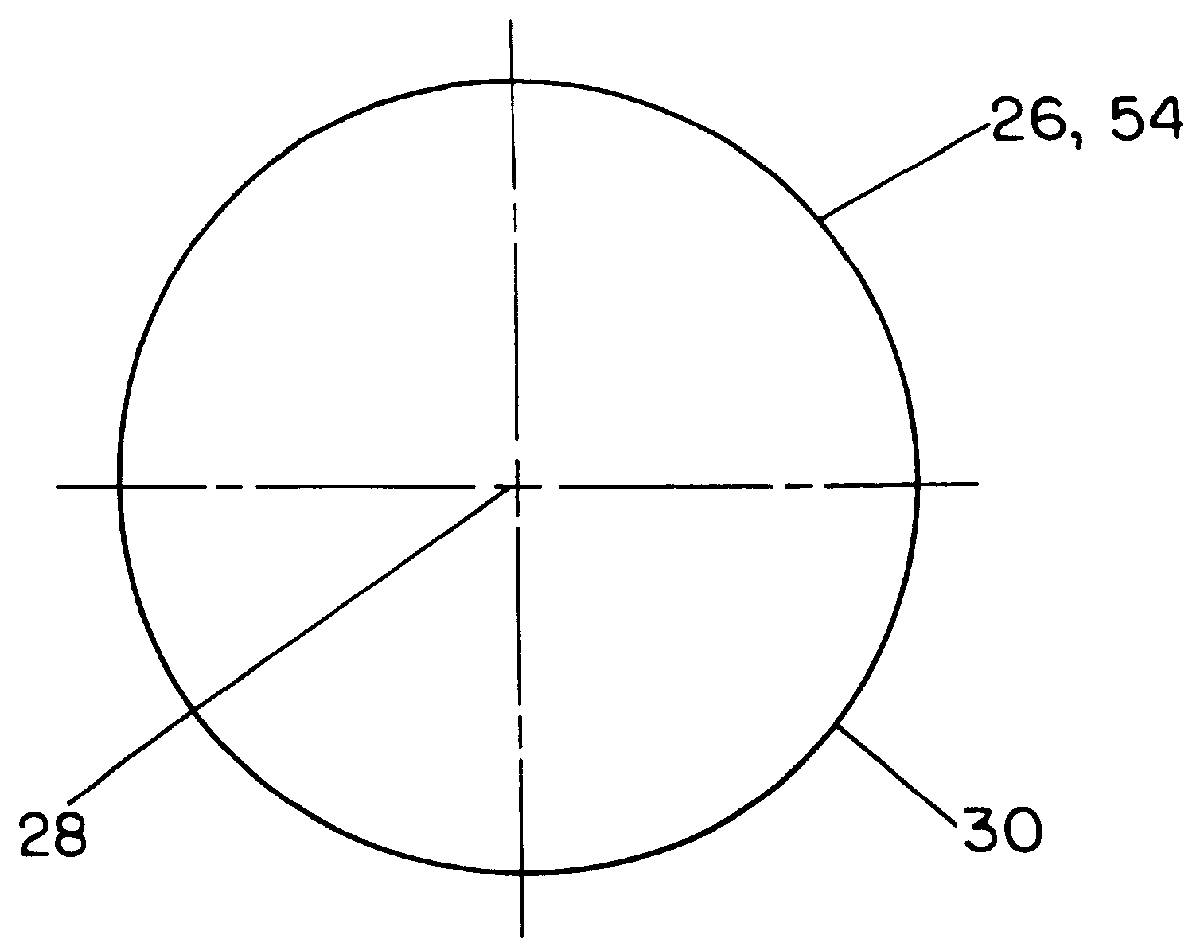

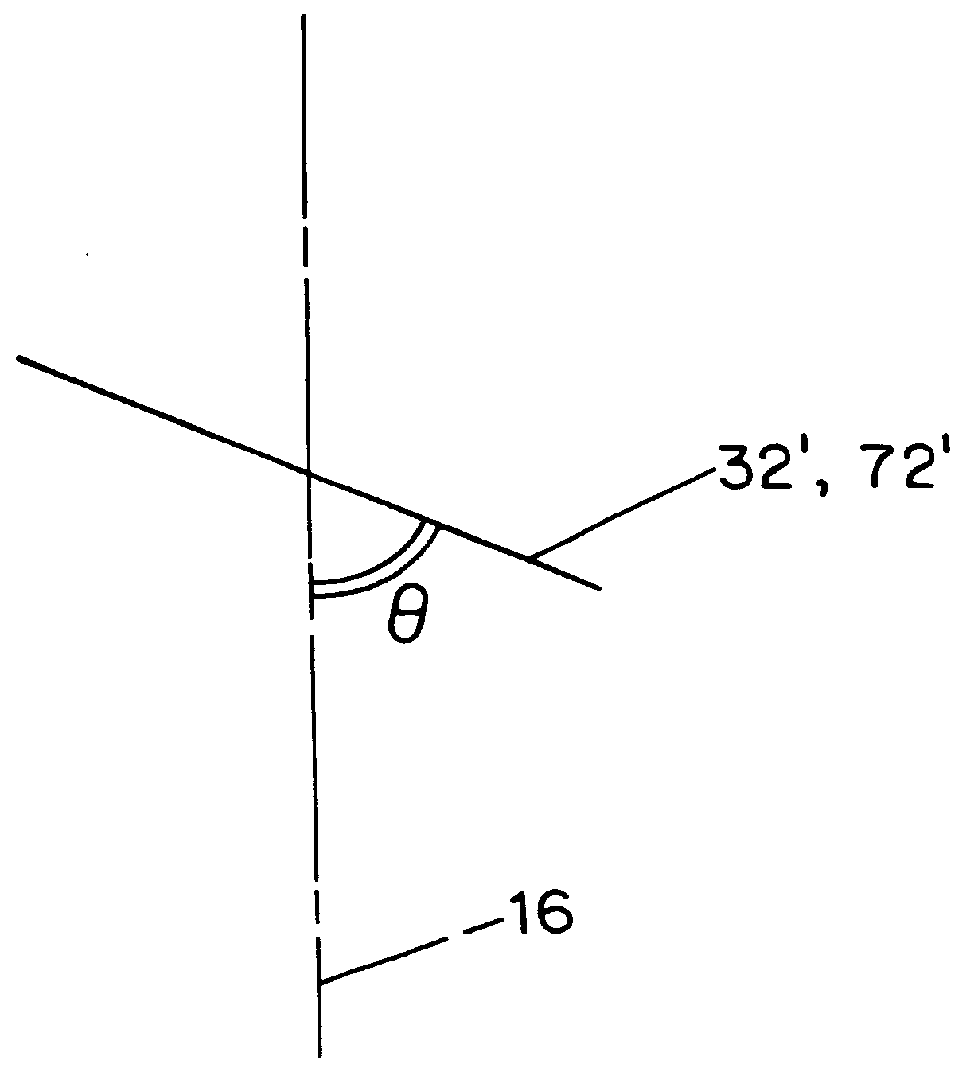

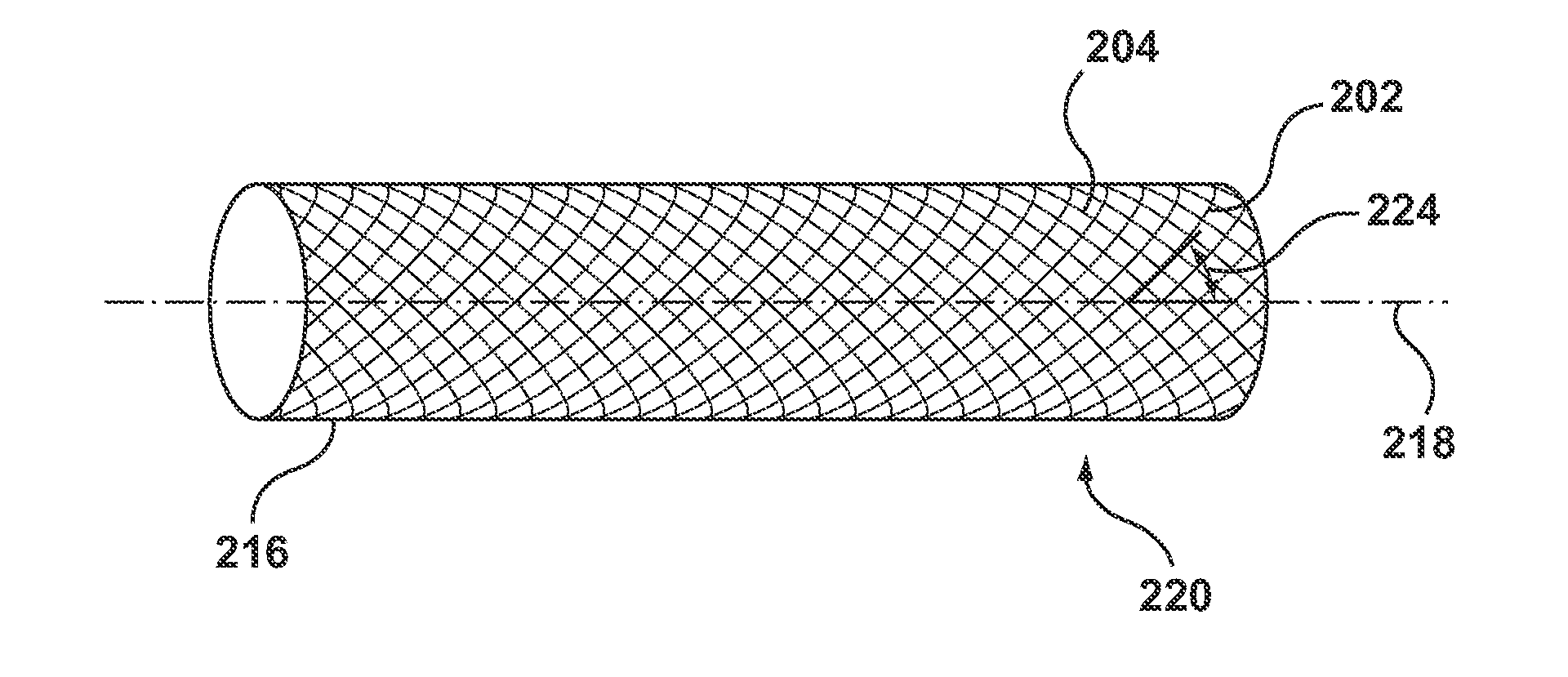

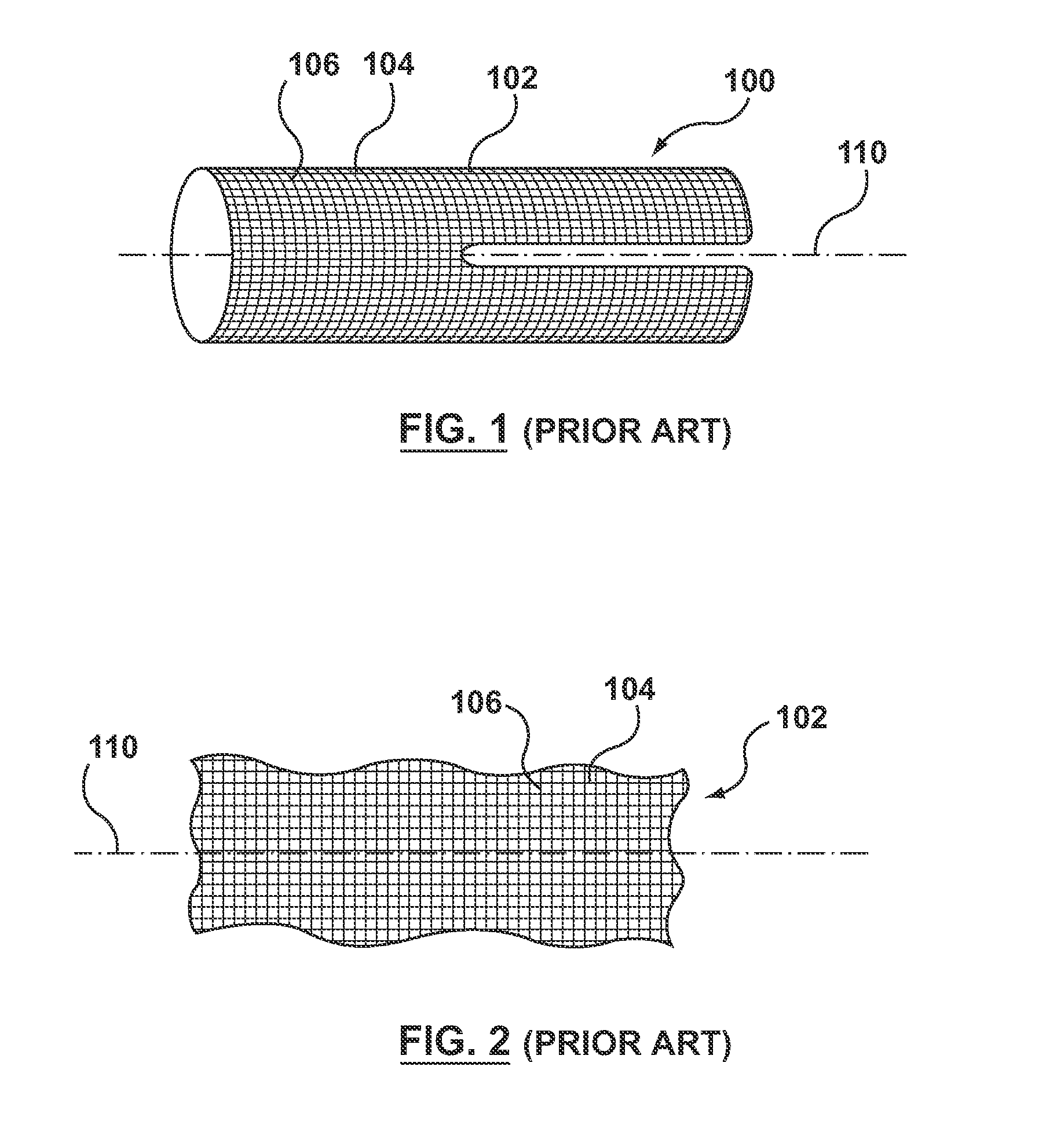

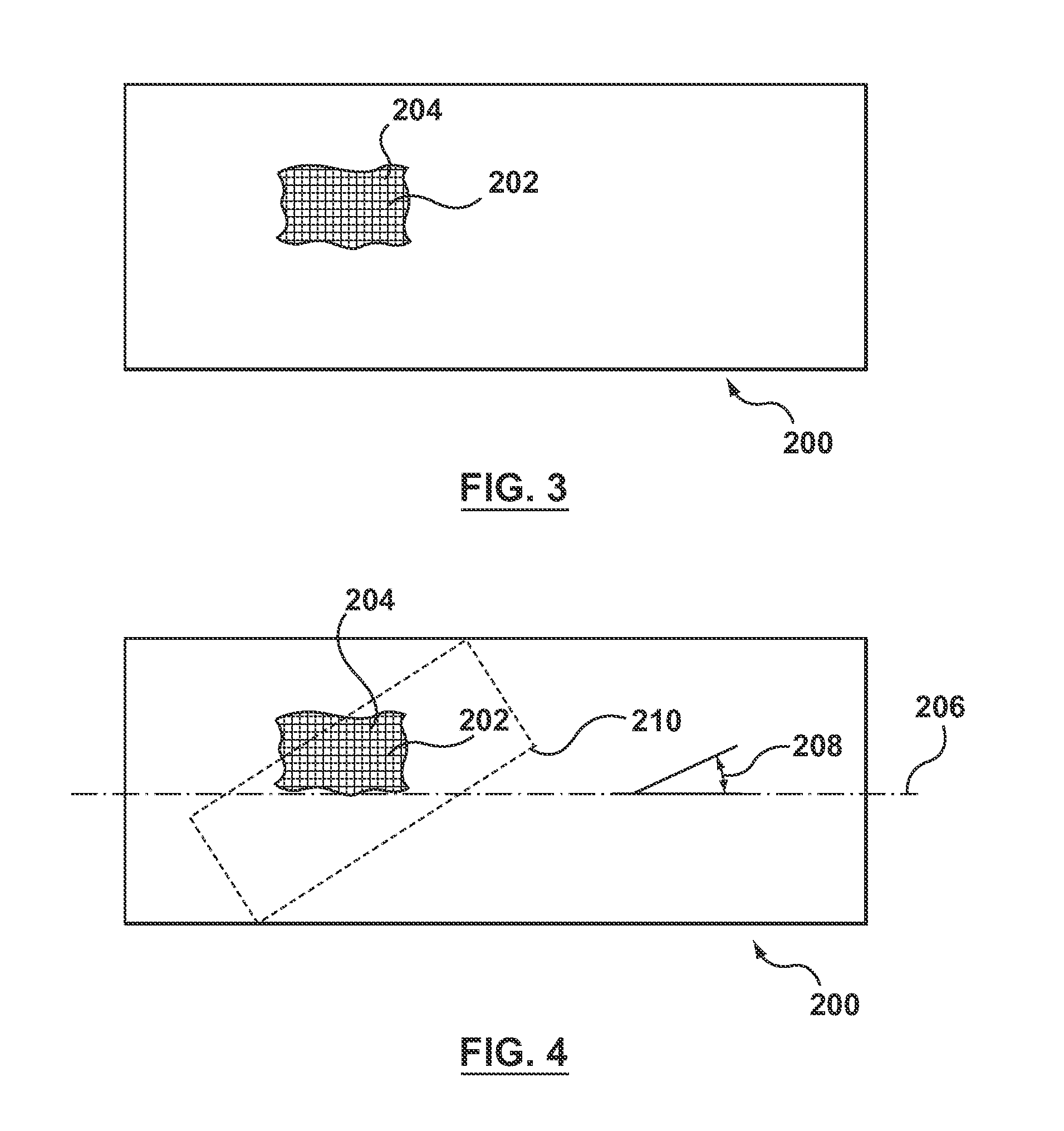

Method of Making an Endoluminal Vascular Prosthesis

A flat sheet of woven material includes warp yarns and weft yarns interlaced at substantially right angles to each other. A graft material is cut from the flat sheet of woven material such that the graft material includes a graft material longitudinal axis and the warp yarns are disposed at an angle relative to the graft material longitudinal axis. The warp yarns and weft yarns are not parallel to or perpendicular to the graft material longitudinal axis. The graft material is formed into the shape of an endoluminal prosthesis, such as by rolling opposing edges towards each other and securing the opposing edges to each other. The endoluminal prosthesis thus includes warp yarns disposed at an angle relative to the prosthesis longitudinal axis.

Owner:MEDTRONIC VASCULAR INC

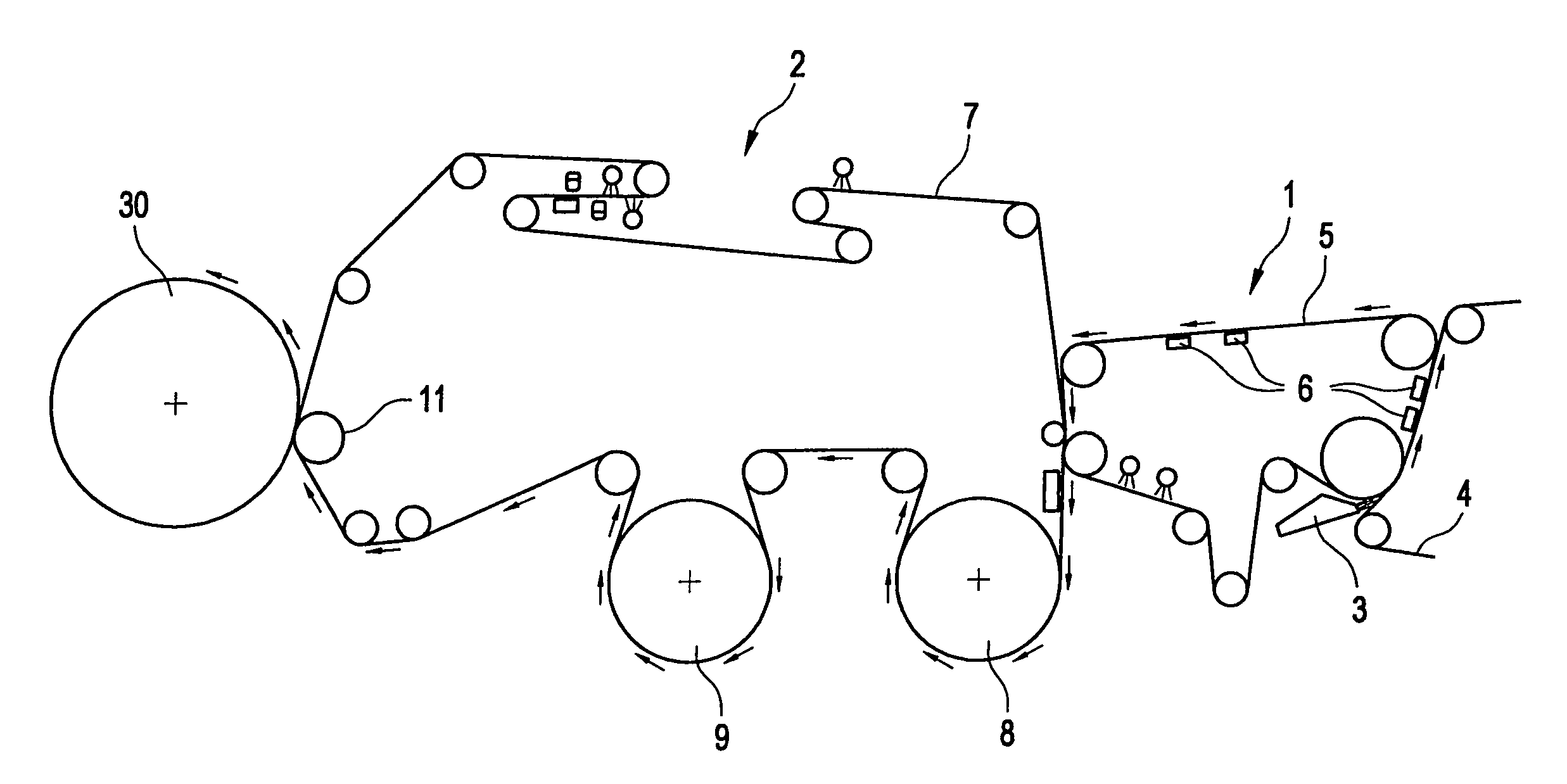

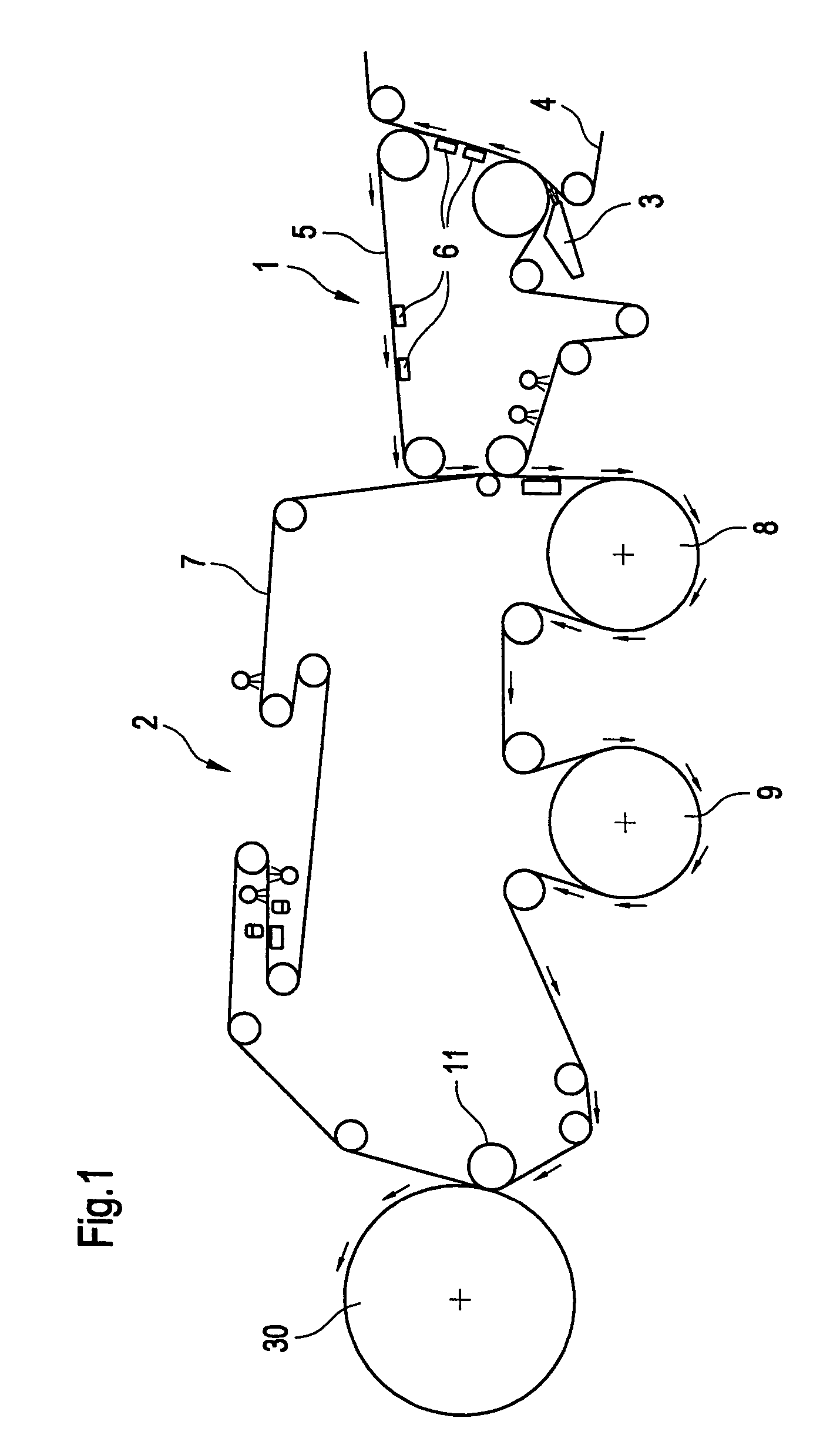

Through air dryer fabric

Owner:VOITH PATENT GMBH

Composite papermaking fabric

A composite papermaking fabric having an upper support fabric including upper warp and weft yarns and a lower contact fabric including lower warp and weft yarns. The upper fabric is woven in a first weave pattern which forms a support surface and the lower fabric is woven in a broken twill weave pattern which forms the contact surface. The composite fabric includes paired binder yarns which weave in alternating sequences with the upper and lower fabrics binding them together. The broken twill weave pattern provides plural floats of cross-machine direction yarns passing outwardly of a plurality of adjacent lower warp yarns forming a plurality of adjacent cross-machine direction floats. Certain of the paired floats comprise a lower weft yarn and a binder yarn while others may comprise two lower weft yarns. The lower weft yarn floats are positioned to shield and protect the binder yarn floats along their entire length.

Owner:VOITH FABRICS

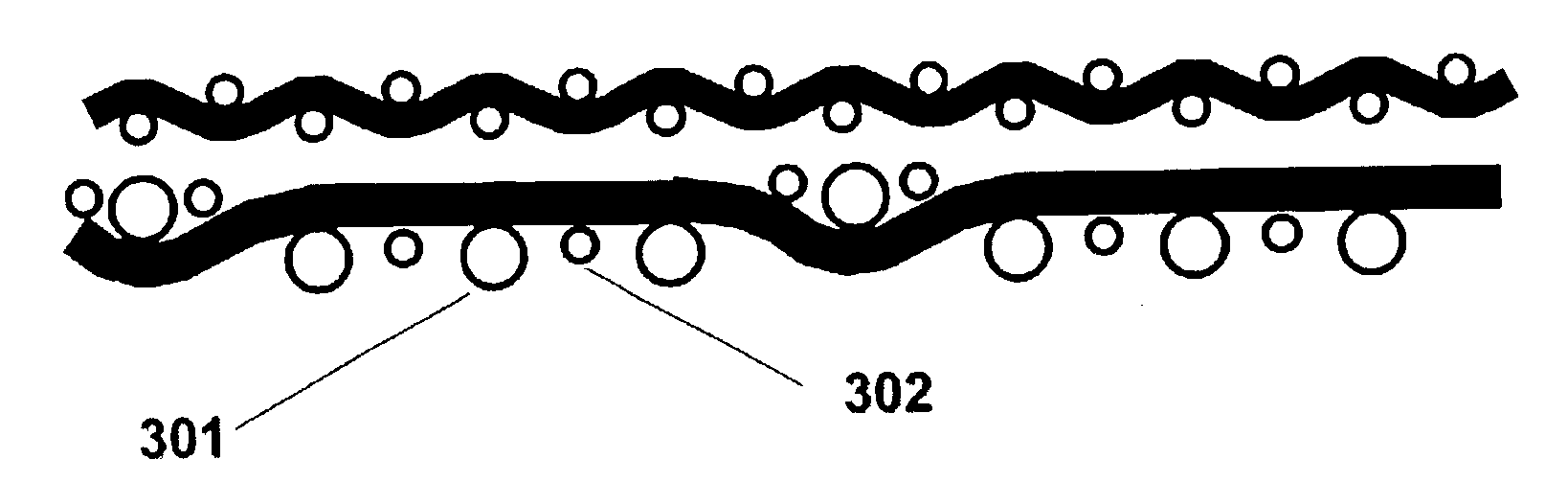

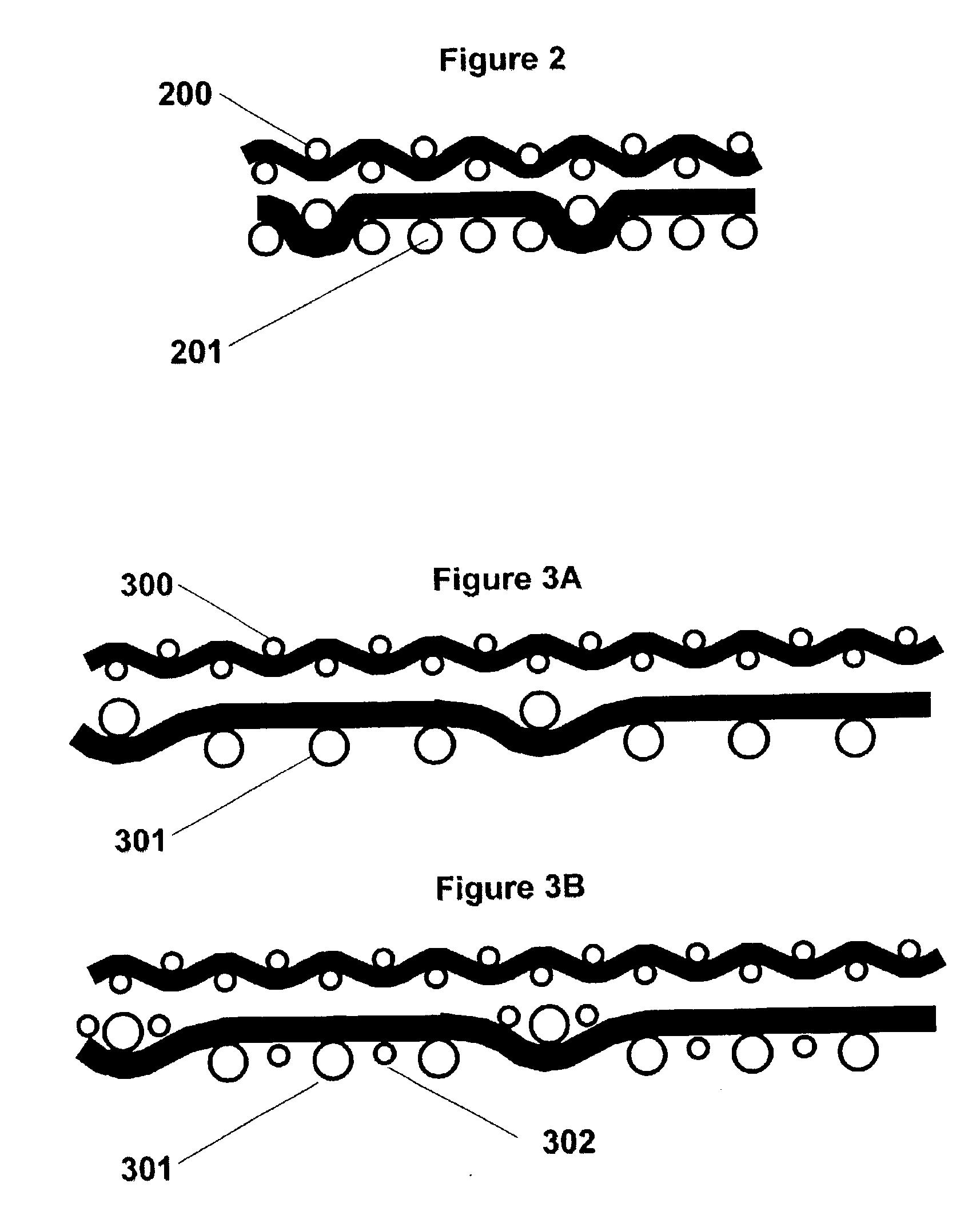

Double layer papermakers fabric with pockets for bulk enhancement

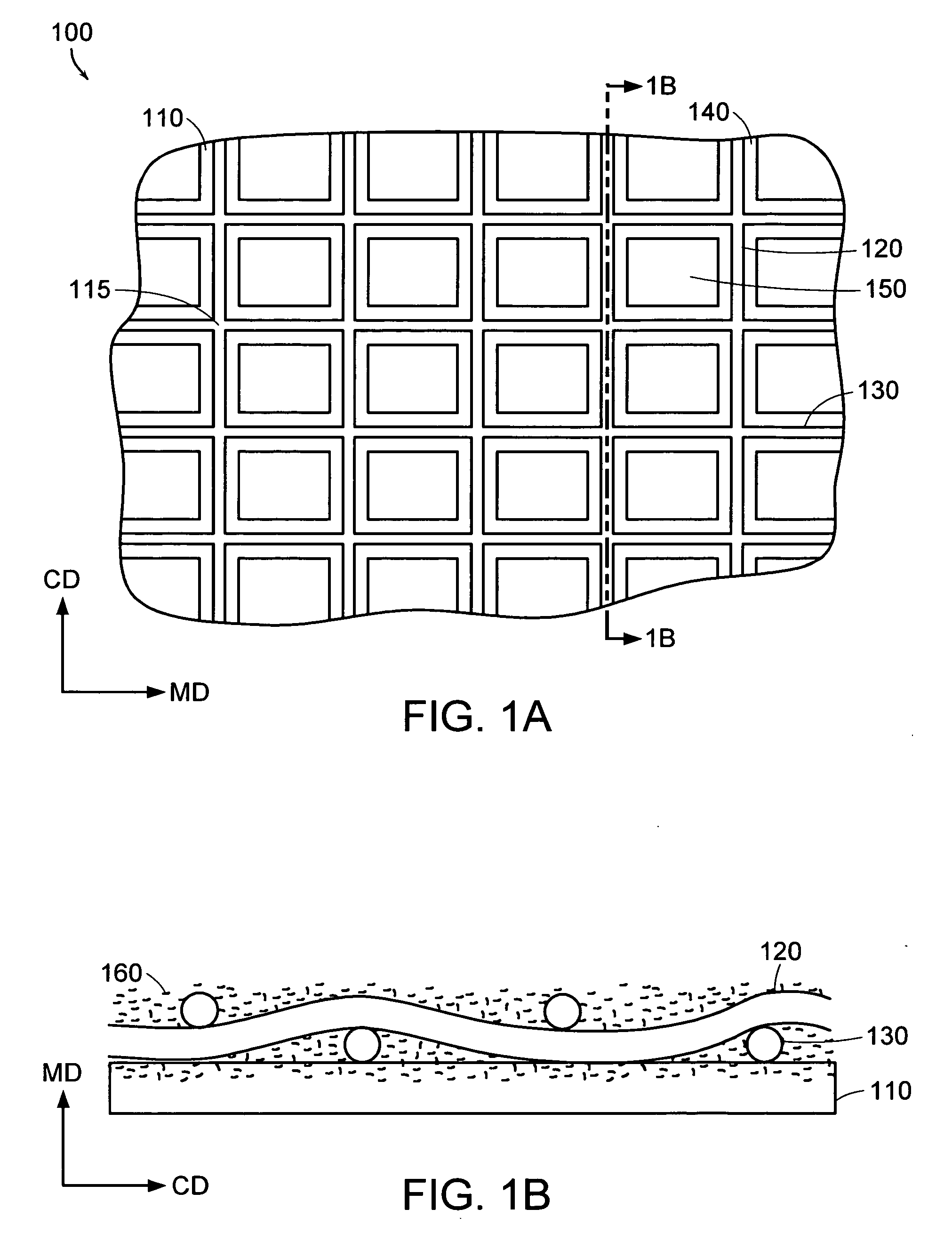

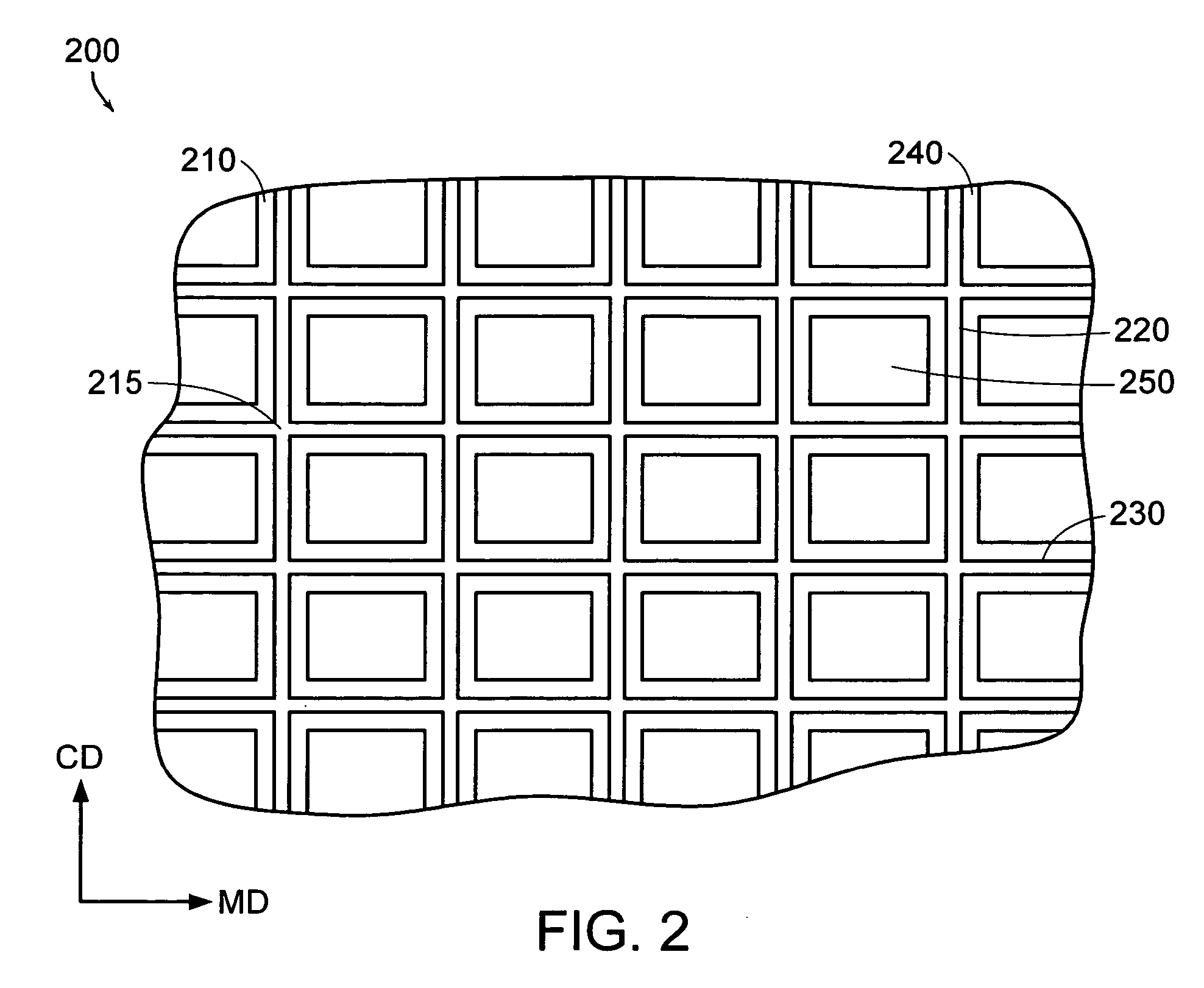

InactiveUS7493923B2Impart surface roughnessSignificant formMachine wet endPress sectionEngineeringWeft yarn

A double layer papermakers' fabric that is particularly suitable for forming or through-air drying (TAD) of high bulk tissue and towel product is provided. The fabric includes a single warp yarn system interwoven with three weft yarn systems such that: a first of the weft yarn systems is located on the paper side (PS) surface of the fabric; a second of the weft yarn systems is located on the machine side (MS) surface of the fabric; and the third weft yarn system is located intermediate between the first and second weft yarn systems. The yarns of the first and second weft yarn systems are interwoven with the warp yarn system such that they are vertically stacked with respect to one another in the fabric. The yarns of the third weft yarn system are interwoven so as to be located in a central plane of the fabric that is intermediate of the first and second weft yarn systems, and each yarn of the third yarn system is located in between the vertically stacked pairs of weft yarns of the first and second weft yarn systems. The warp and weft yarn systems are interwoven according to an asymmetric design which provides generally rectangular pockets on each of the PS and MS of the fabric with the yarns of the third weft yarn system forming the “bottom” of each pocket. There may be from about 50 to 750 pockets per sq. in. of fabric, each ranging in depth from about 0.1 mm to about 1.0 mm in depth; these pockets impart unevenness to the fabric surface which assists in creating bulk in the sheet formed or conveyed thereon. The fabrics of the invention also offer low sheet contact area, typically less than 30% of the total fabric surface, and generally in the range of from 15% to about 20%. The fabrics are also highly air permeable to ensure good air flow and drainage of the sheet.

Owner:ASTENJOHNSON

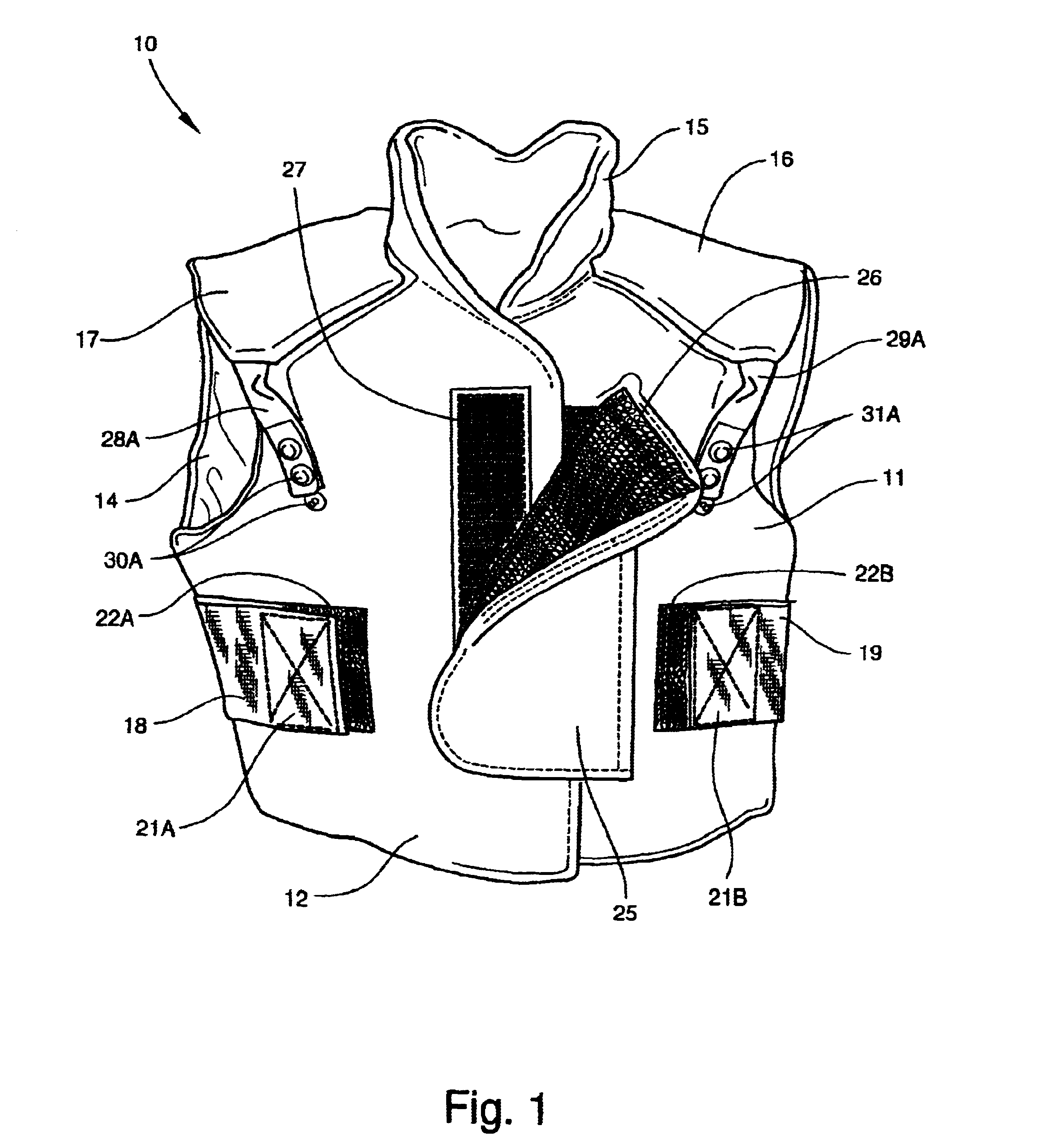

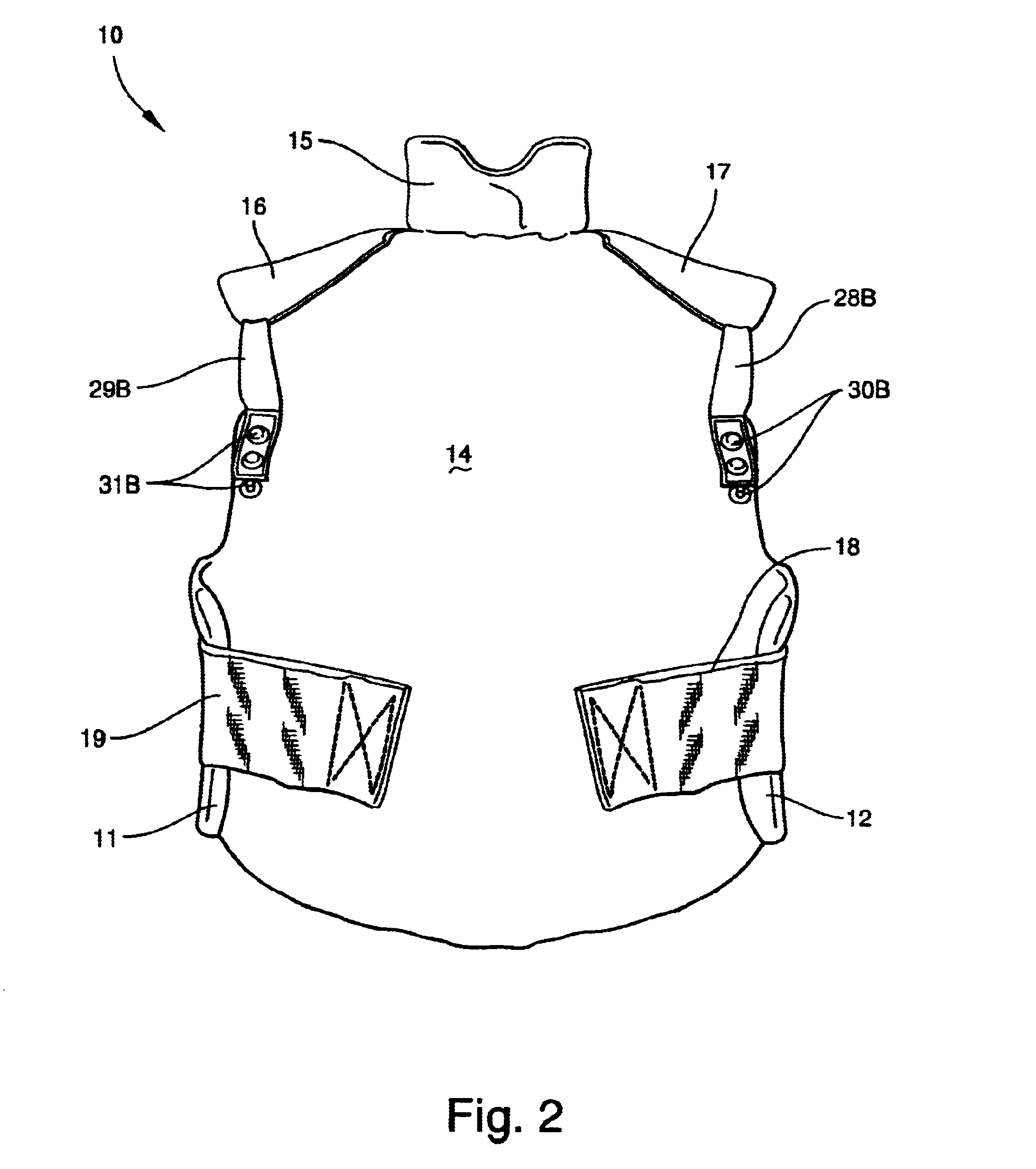

Lightweight soft body-armor product

InactiveUS6651543B2Improve the immunityReduce weightPersonal protection gearArmour platesYarnFoot per second

A ballistic panel is provided for being incorporated into a lightweight soft body-armor product adapted for covering an area of the body. The ballistic panel includes an assembly of woven fabric plies with warp and fill yarns formed of bundled aramid fibers. The plies have a collective areal density of no greater than 1.30 pounds per square foot, and a V50 ballistic limit of no less than 1925 feet per second using a .22 caliber, 17 grain FSP at 0 degrees obliquity.

Owner:ARMORWORKS ENTERPRISES

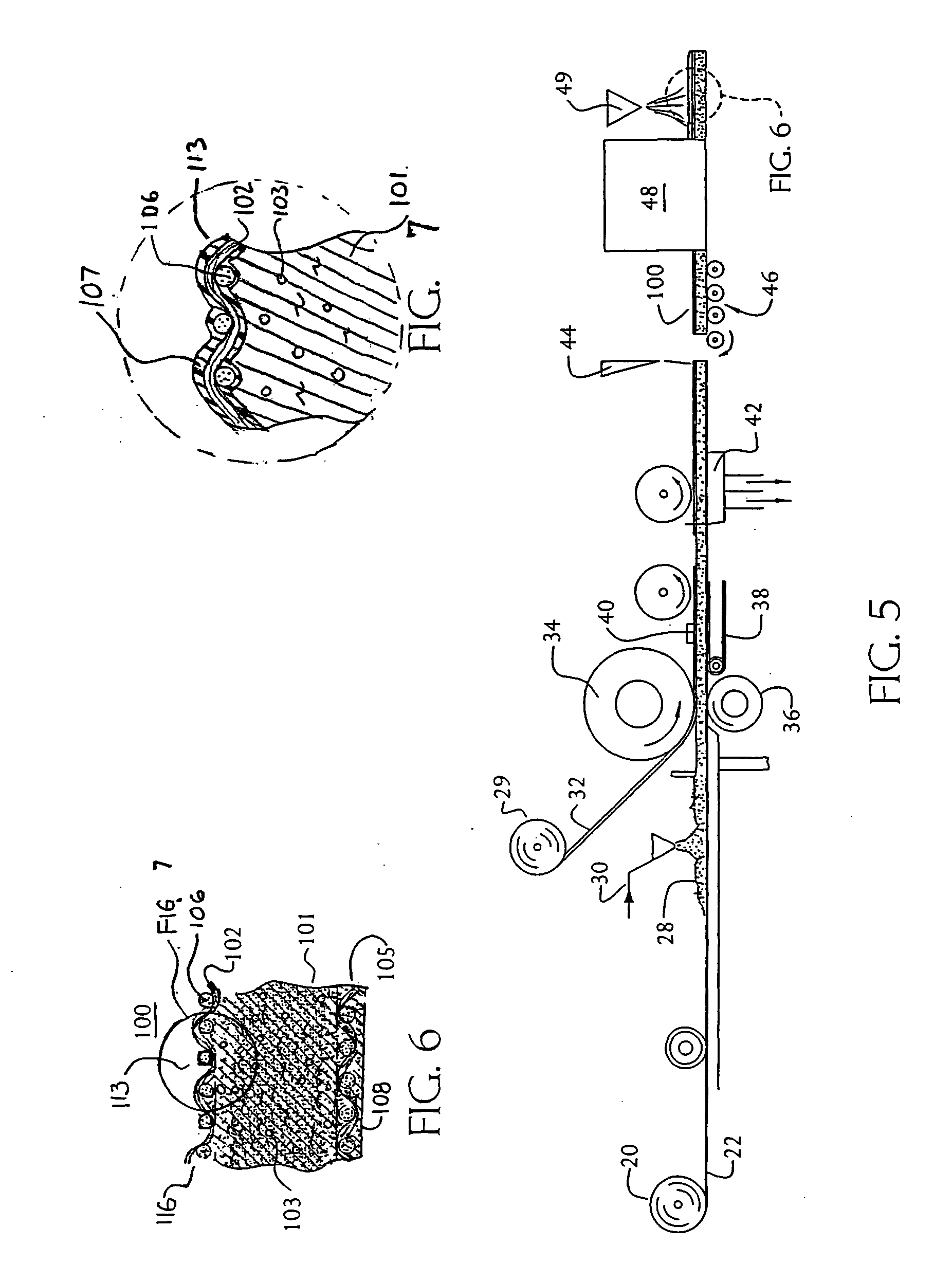

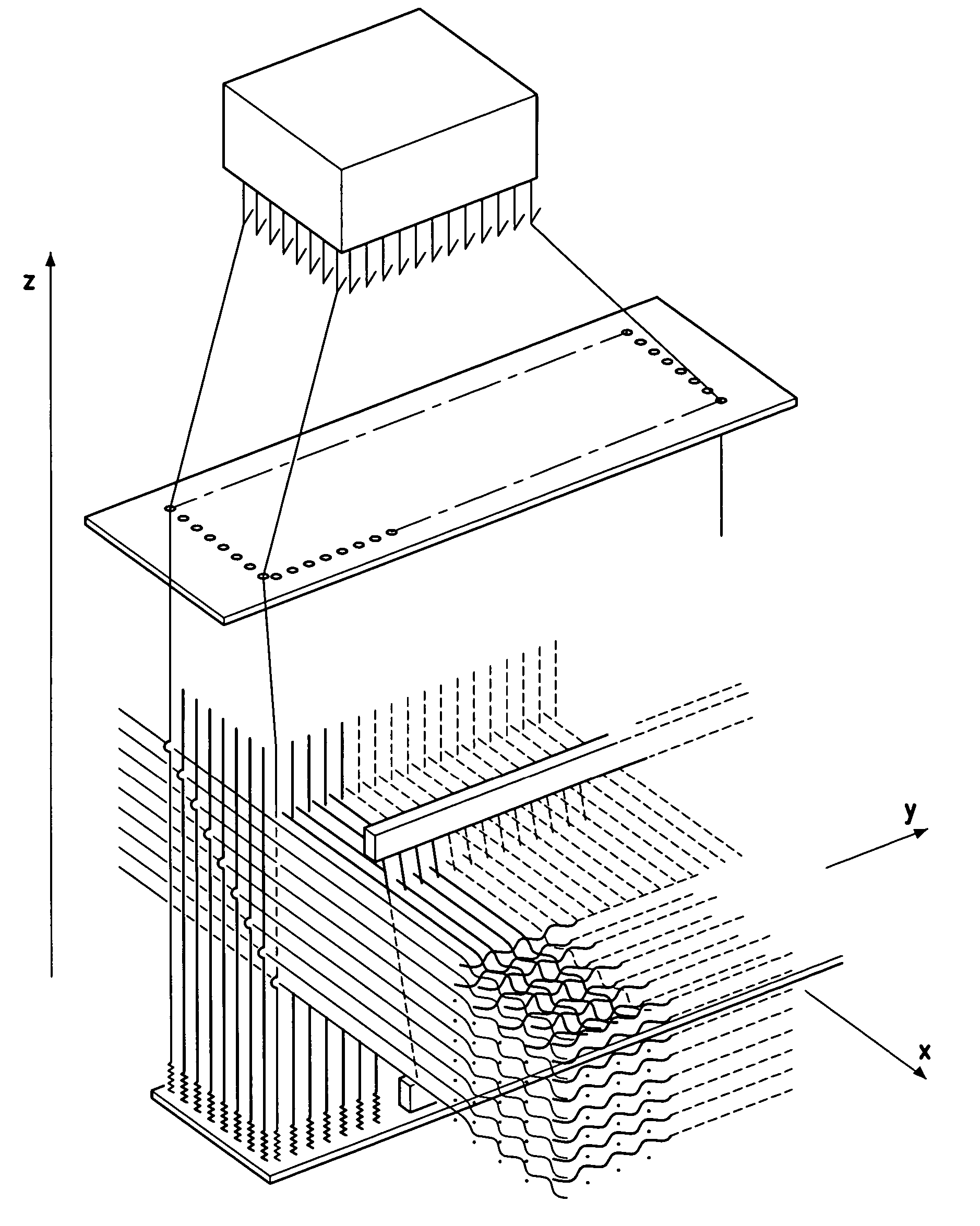

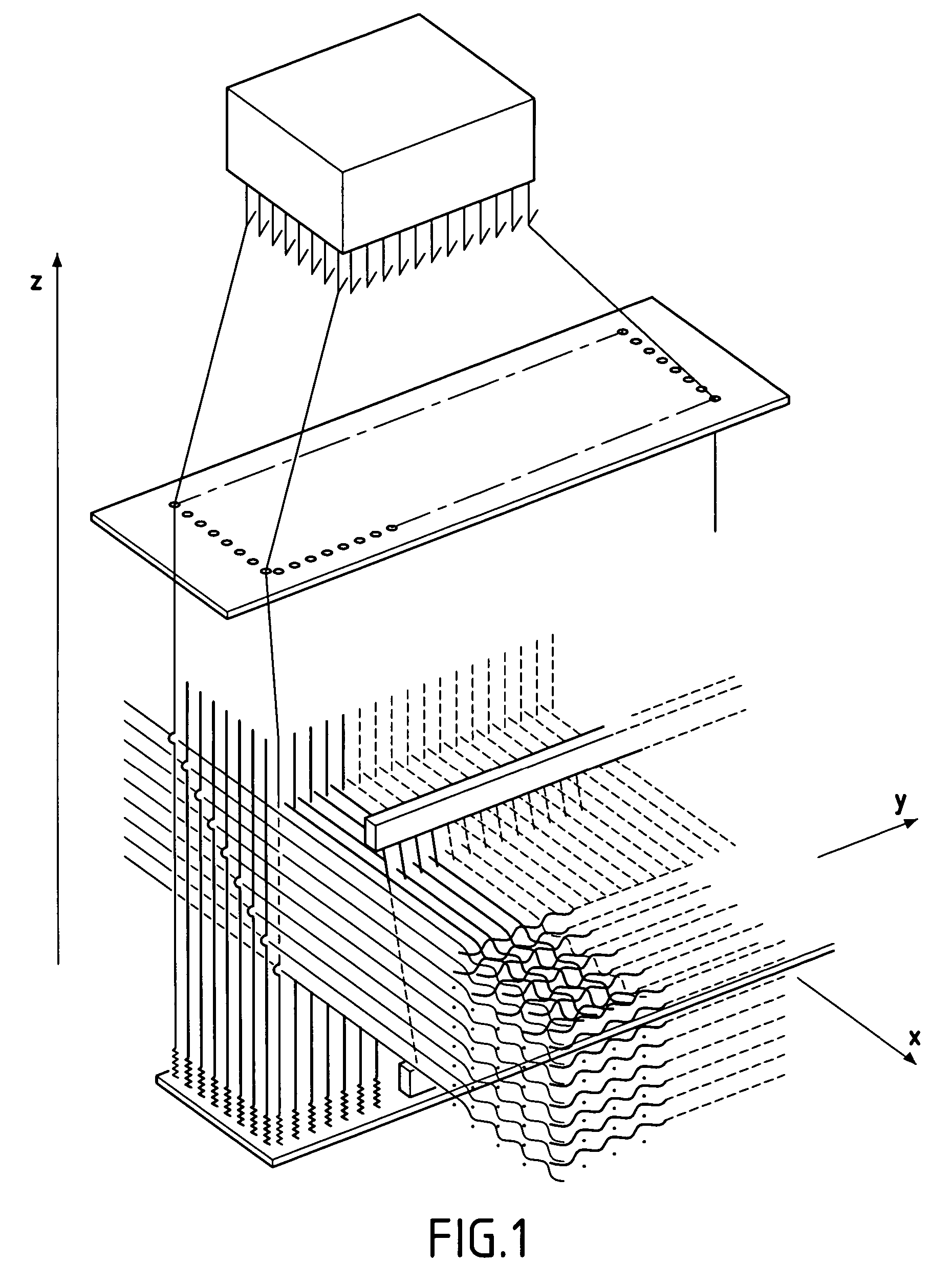

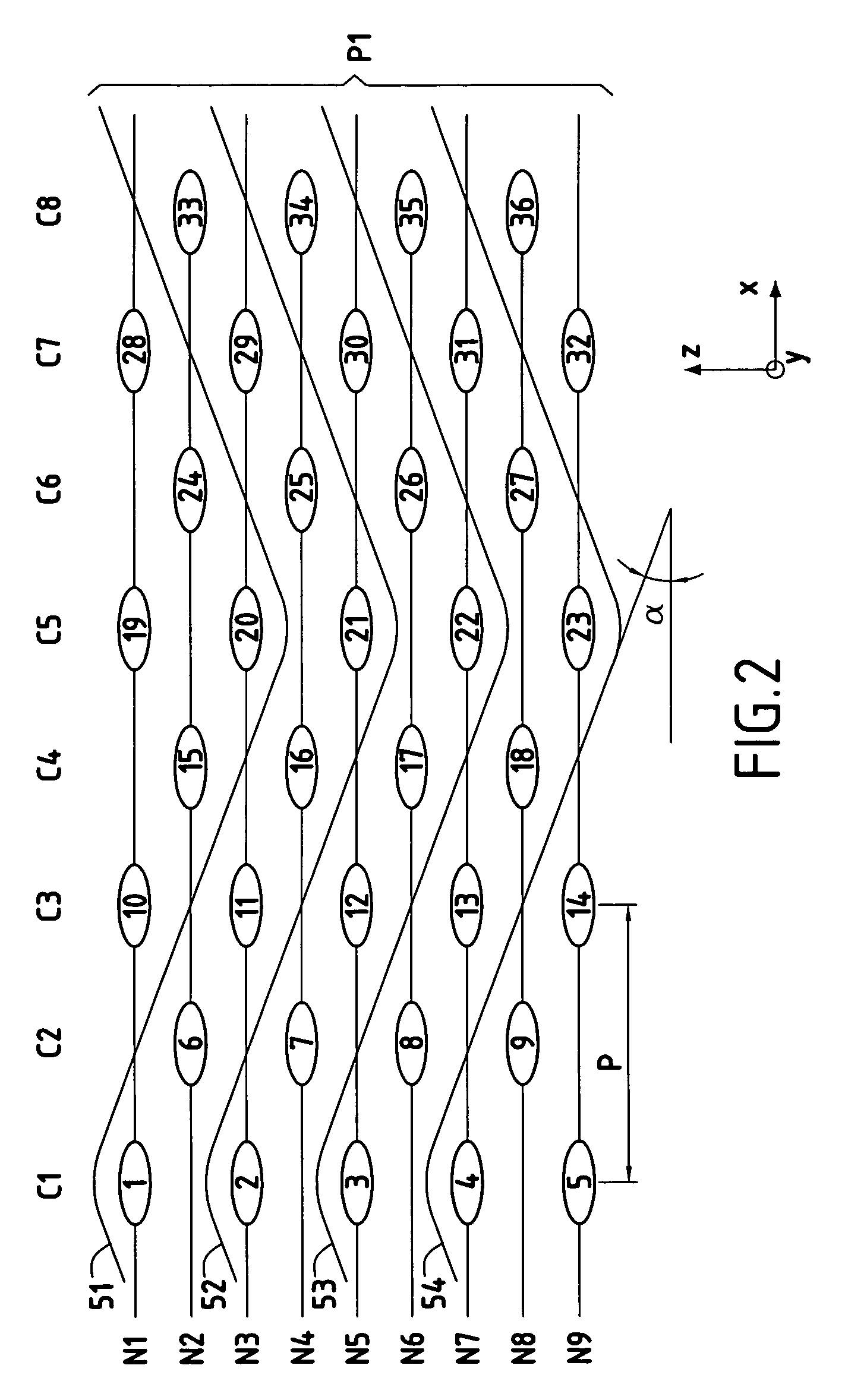

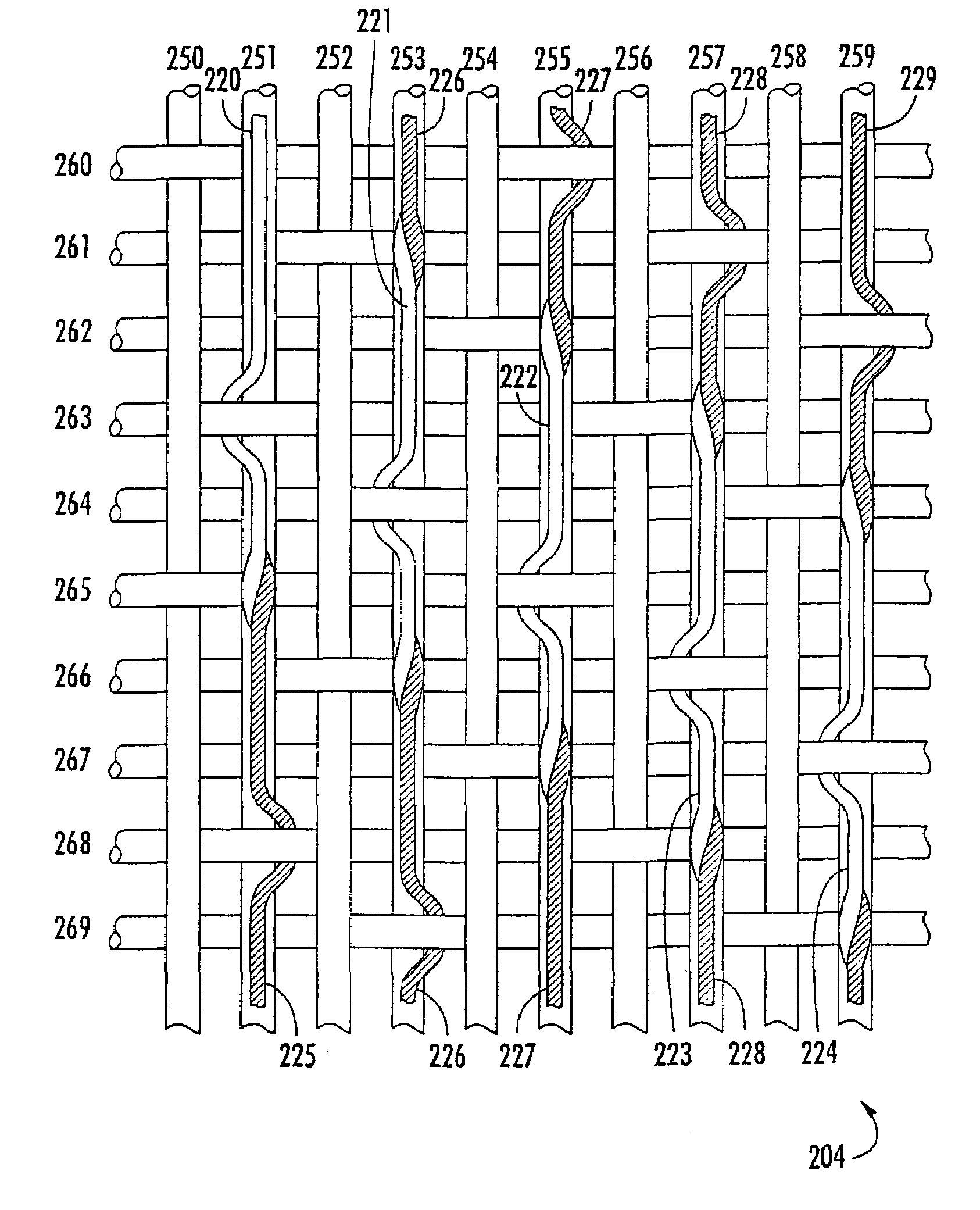

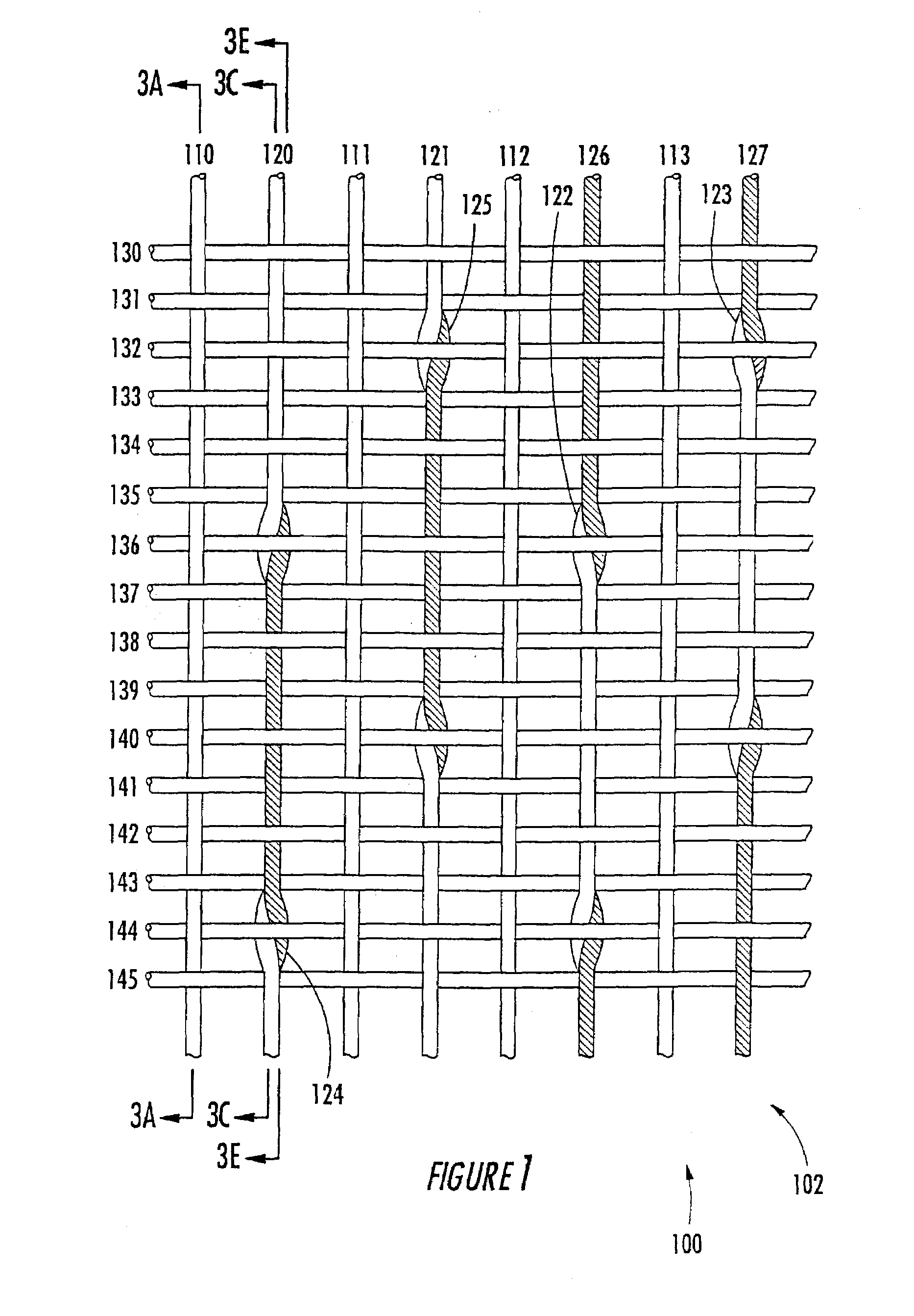

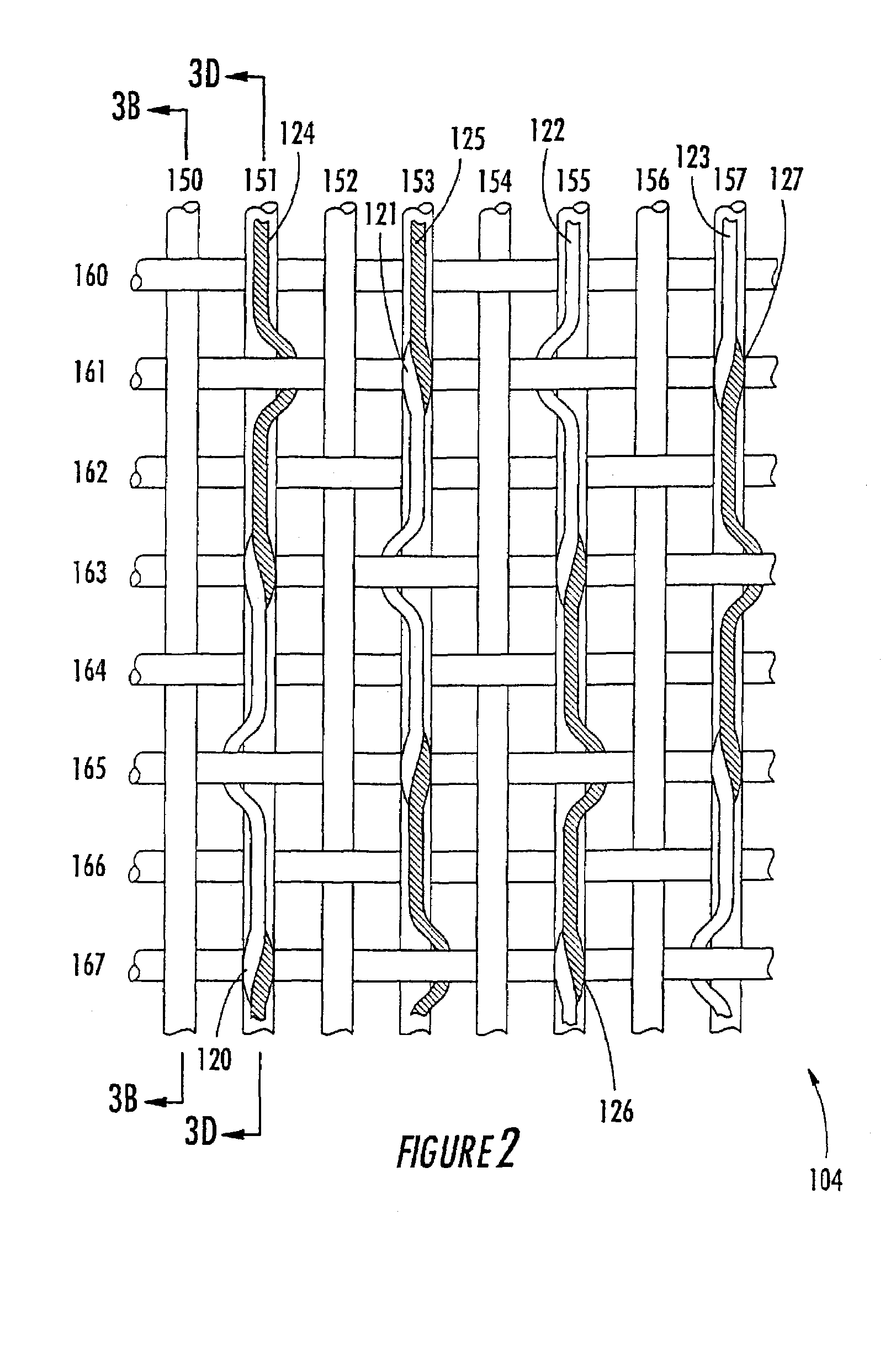

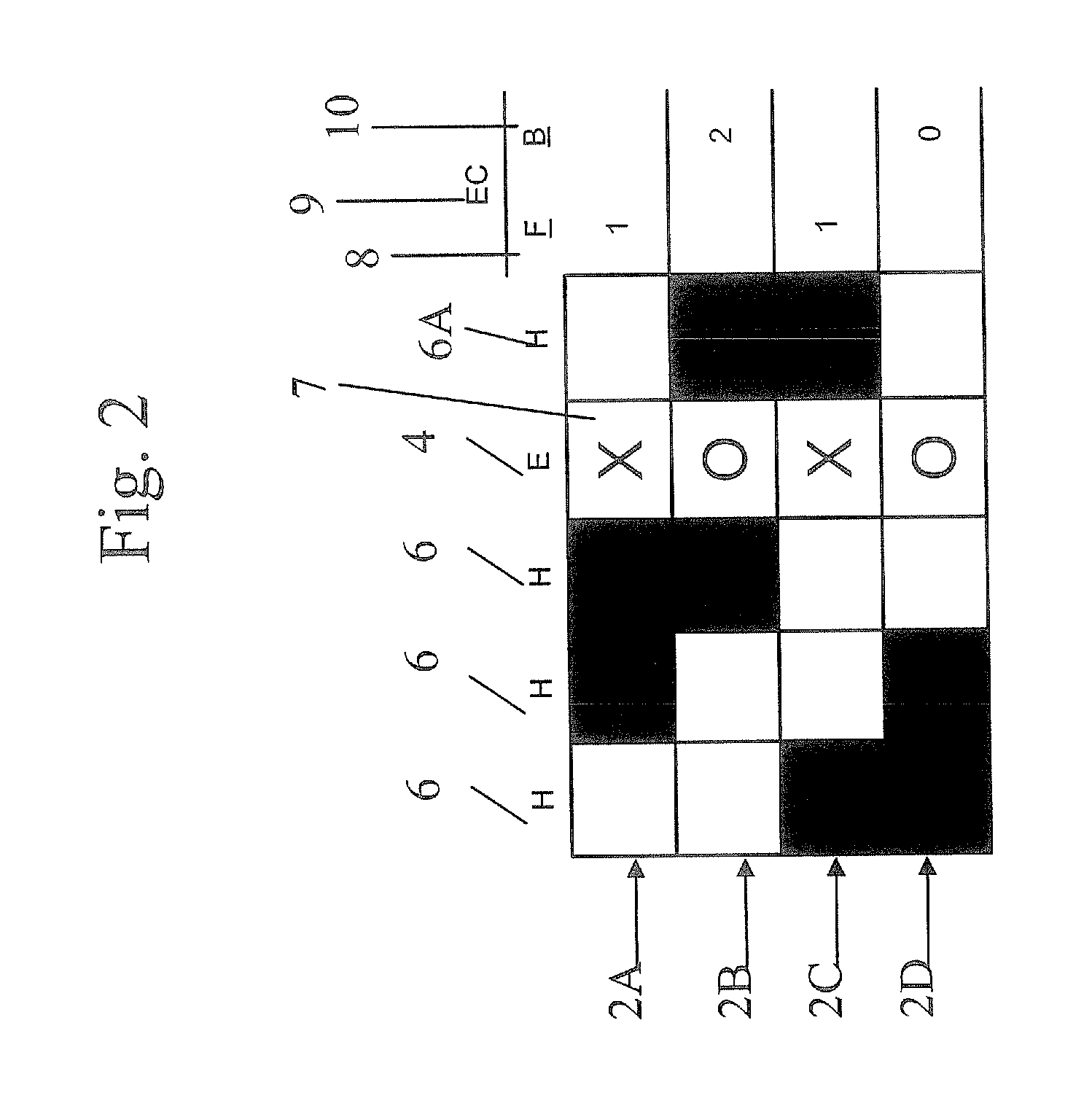

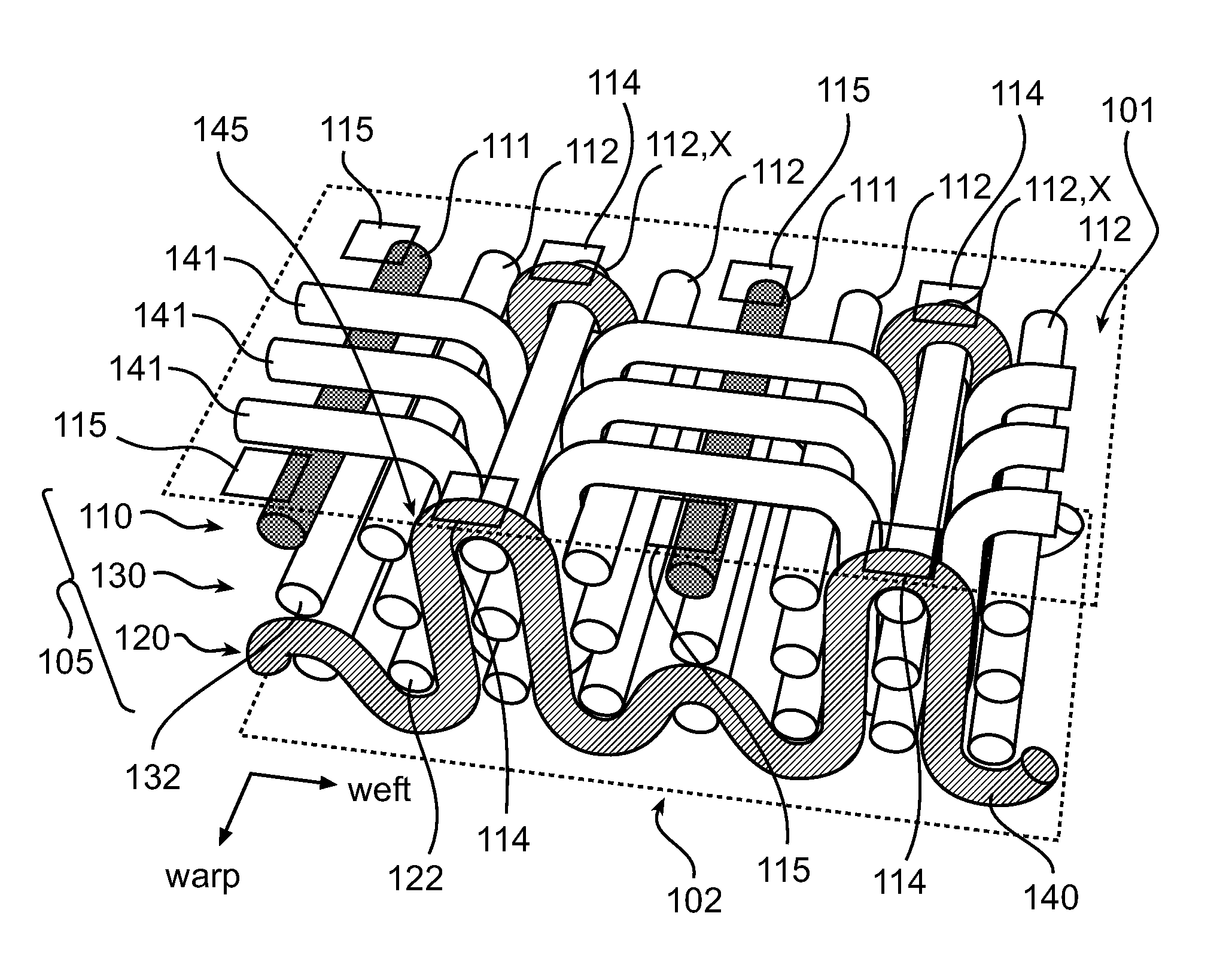

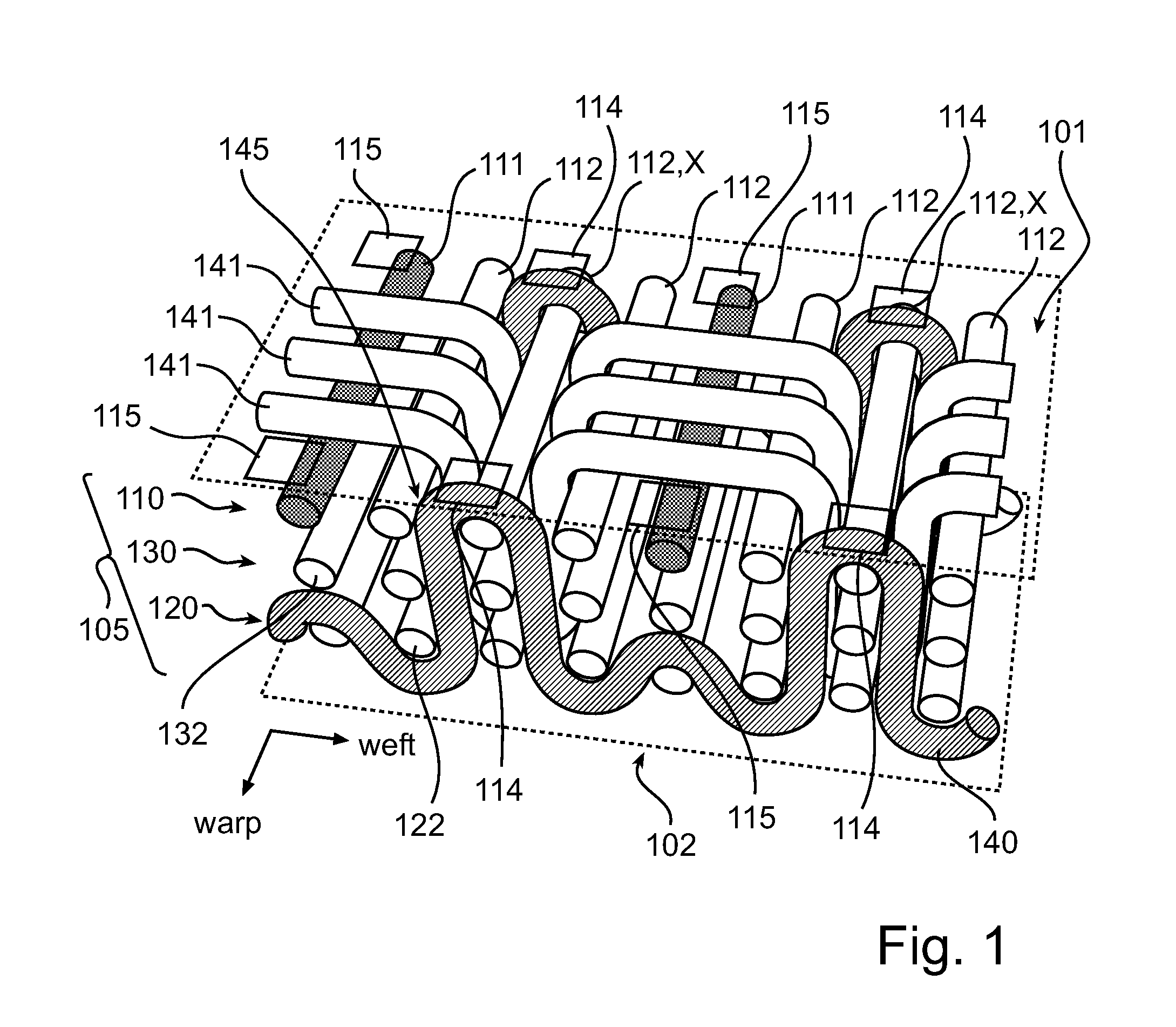

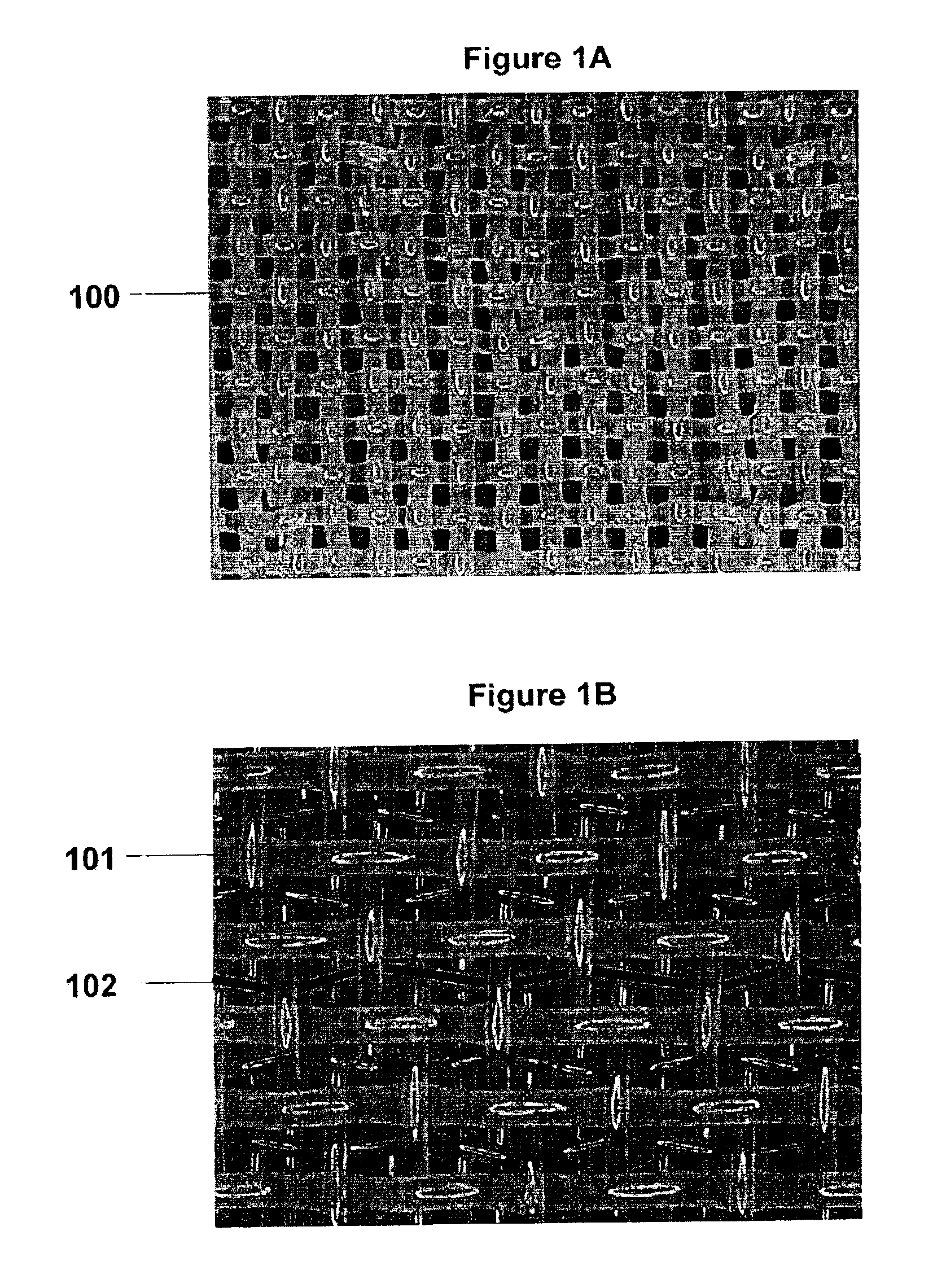

Multi-layer woven fabric display

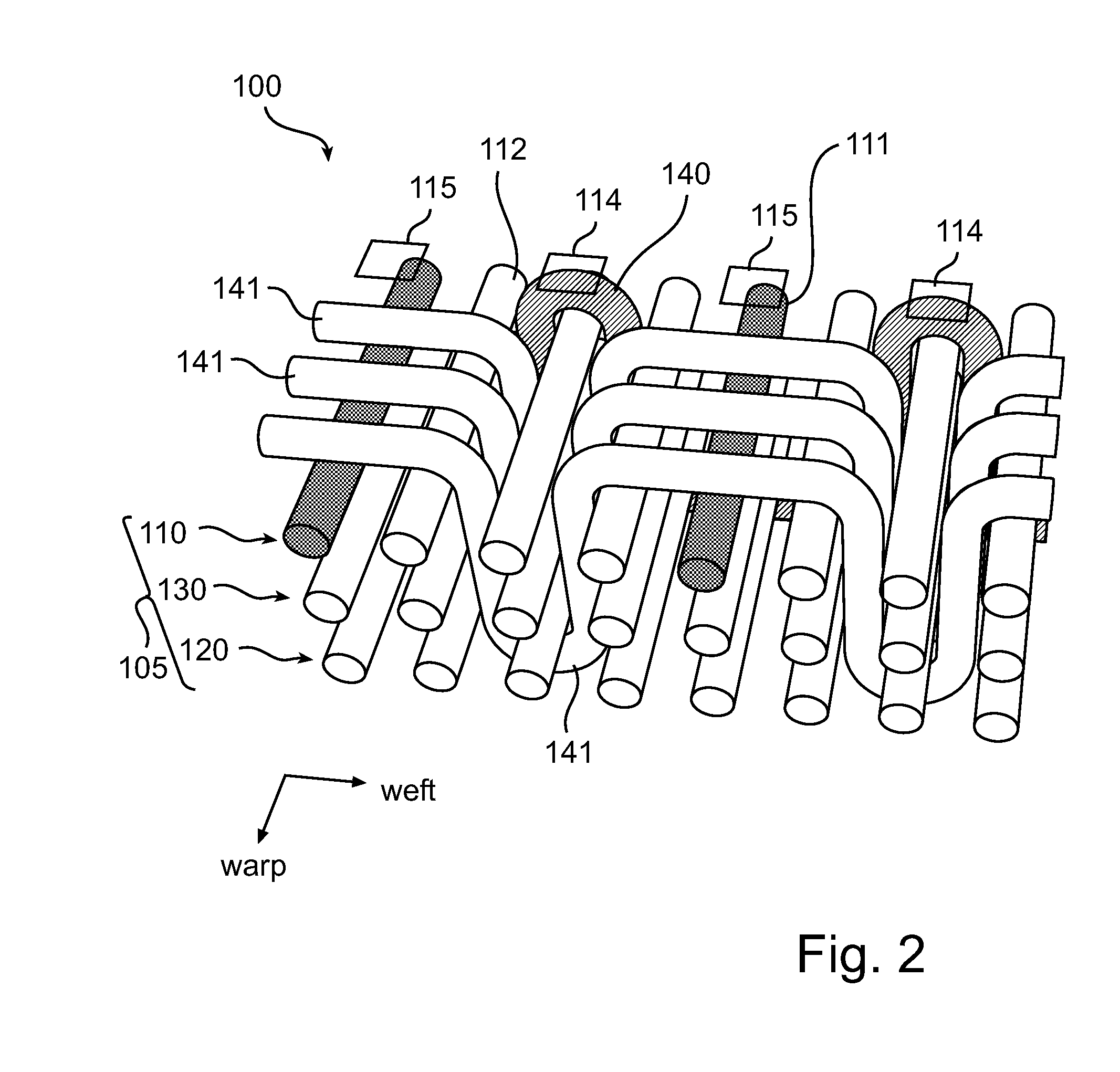

InactiveUS20100208445A1Reduce riskAvoid conducting electricityPrinted circuit aspectsMulti-ply fabricsPhotonicsEngineering

The present invention relates to textiles for photonic and electronic applications, particularly to multilayer textiles made of electrically conductive yarns for driving electrical components such as light emitting diodes connected to the textile. The light emitting diodes may be arranged in the form of an array in order to realize a flexible and foldable display. In the textile according to the present invention, insulating weft yarns are interwoven in a multilayer wrap (105) such that the electrically warp yarns (111) are partially covered by the insulating weft yarns (141), thereby preventing from short-circuit between electrically conductive yarns of the textile. In particular, the structure of the textile according to the present invention may be satin / sateen weave structure.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

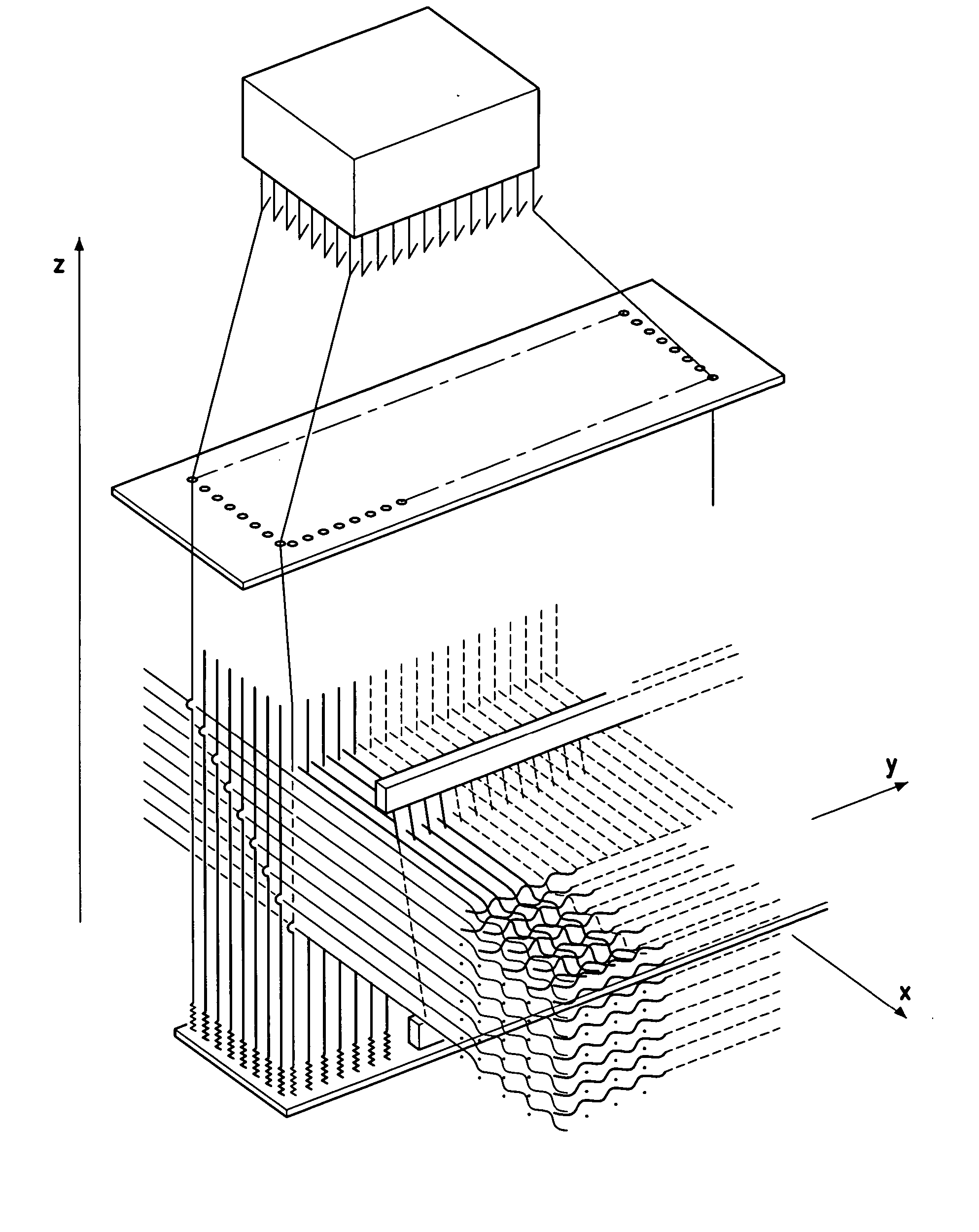

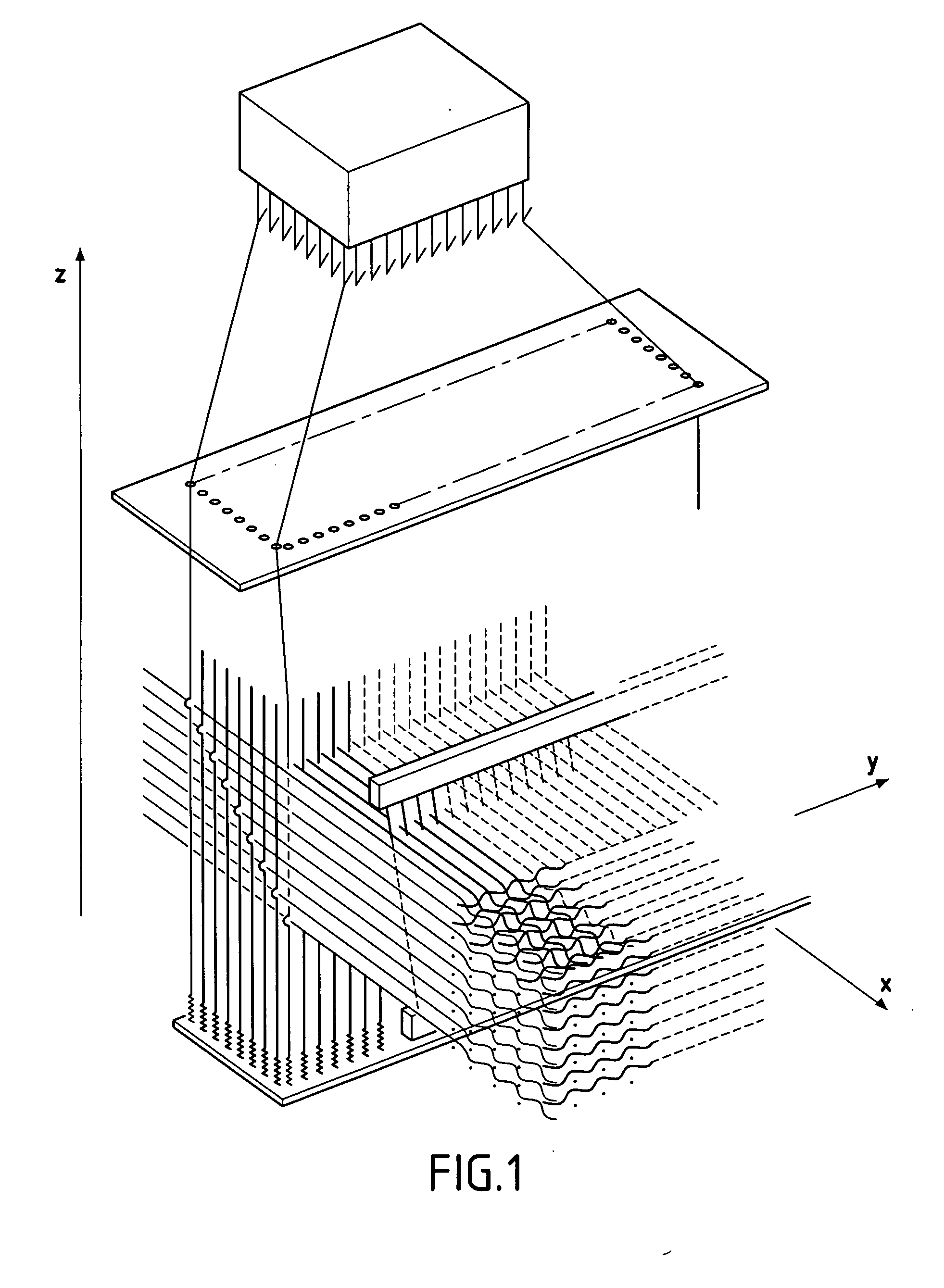

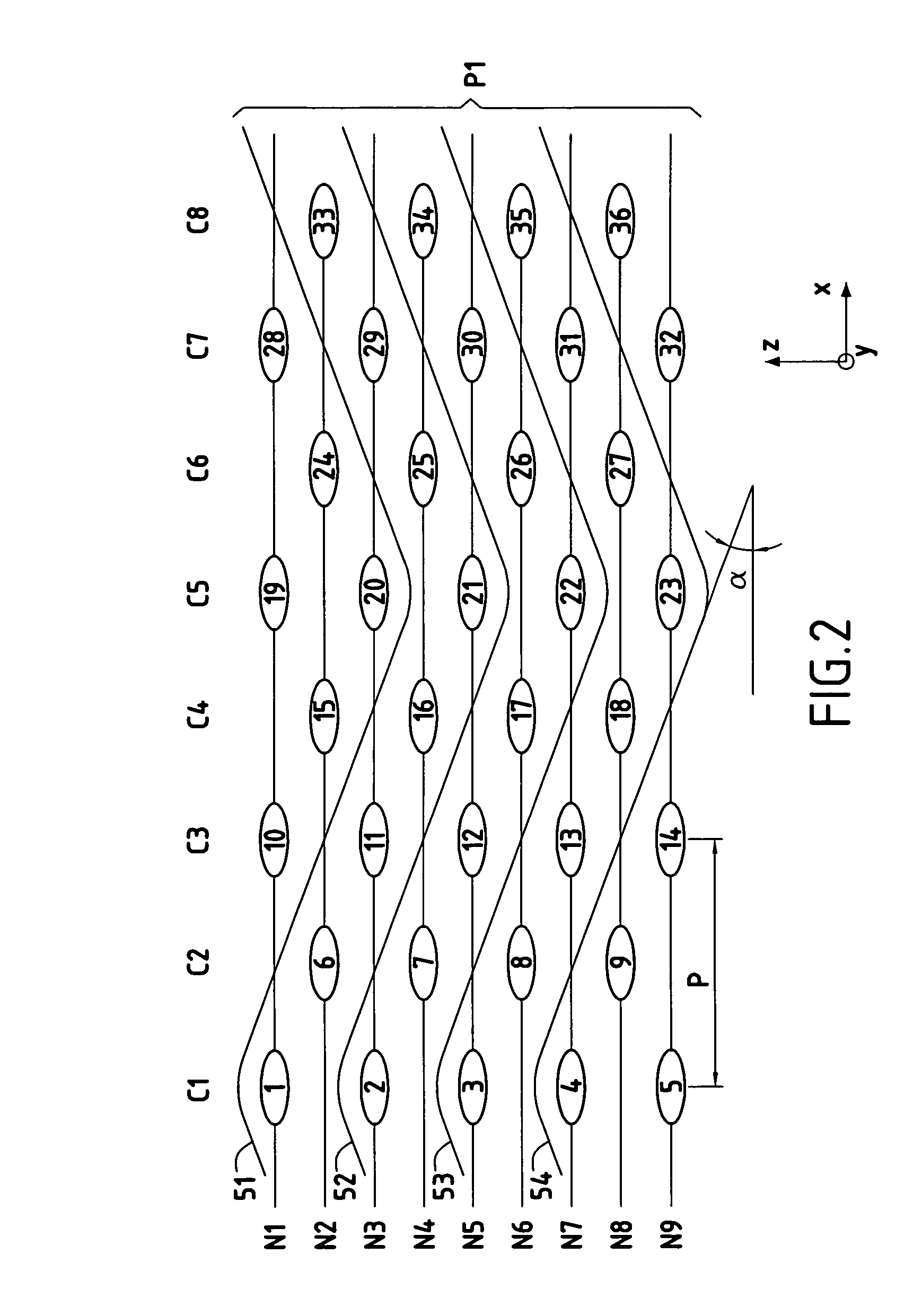

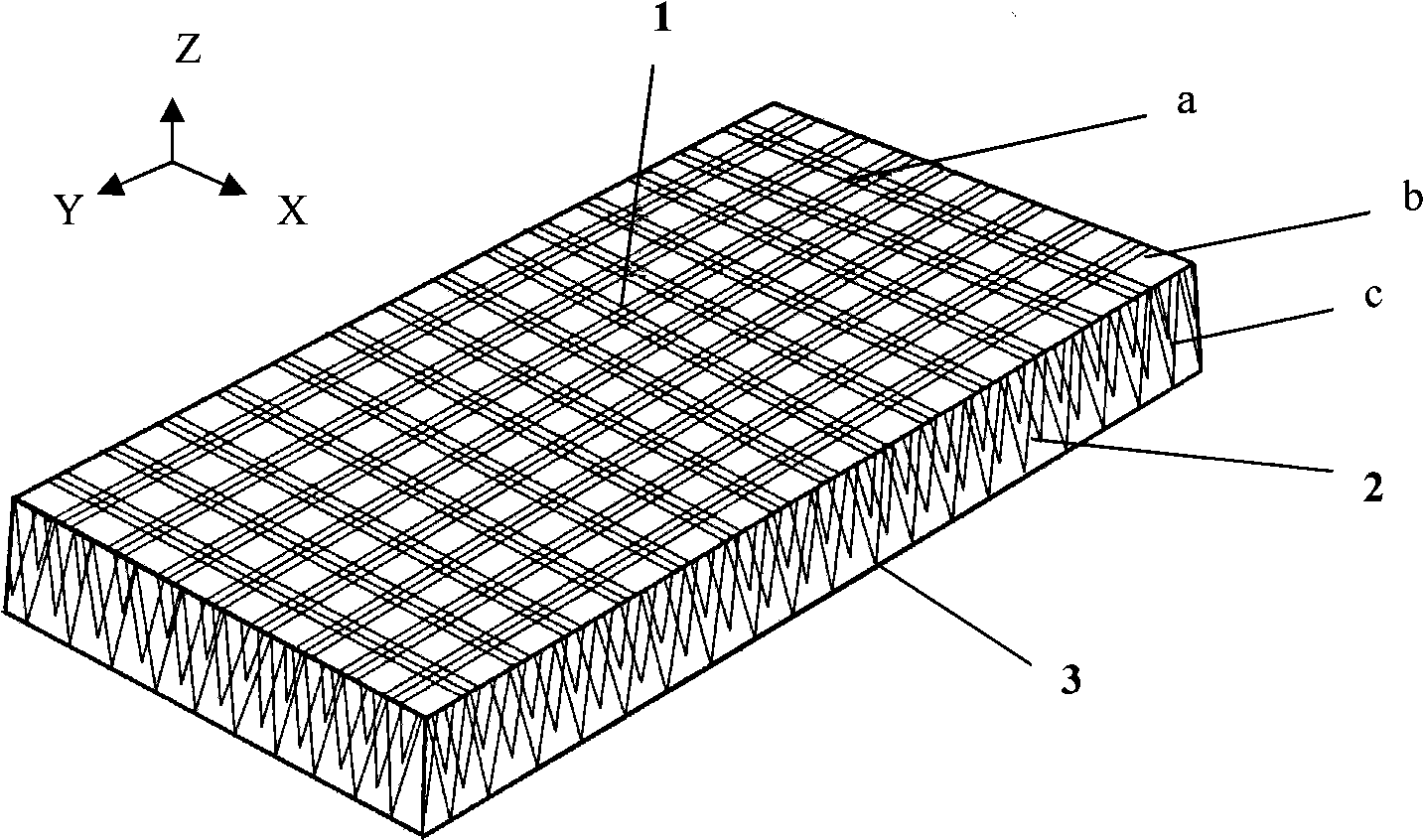

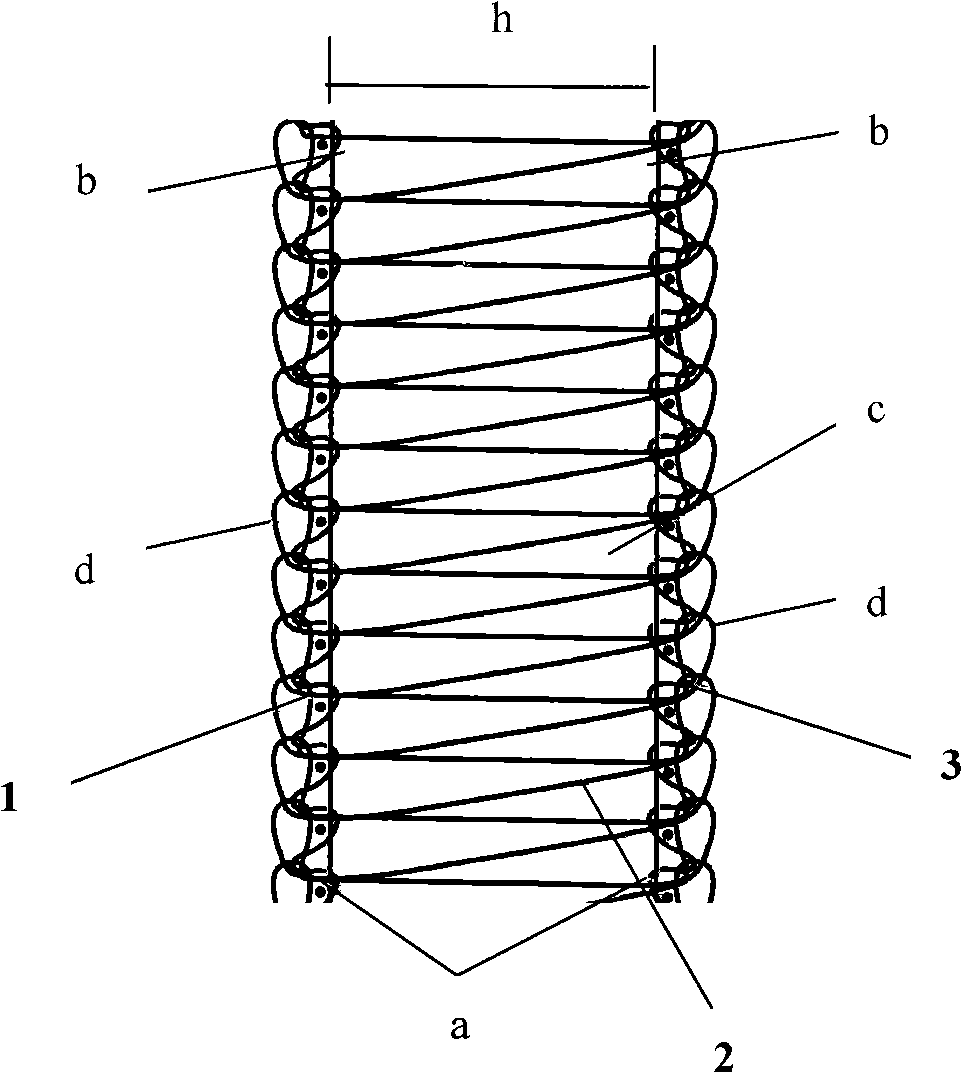

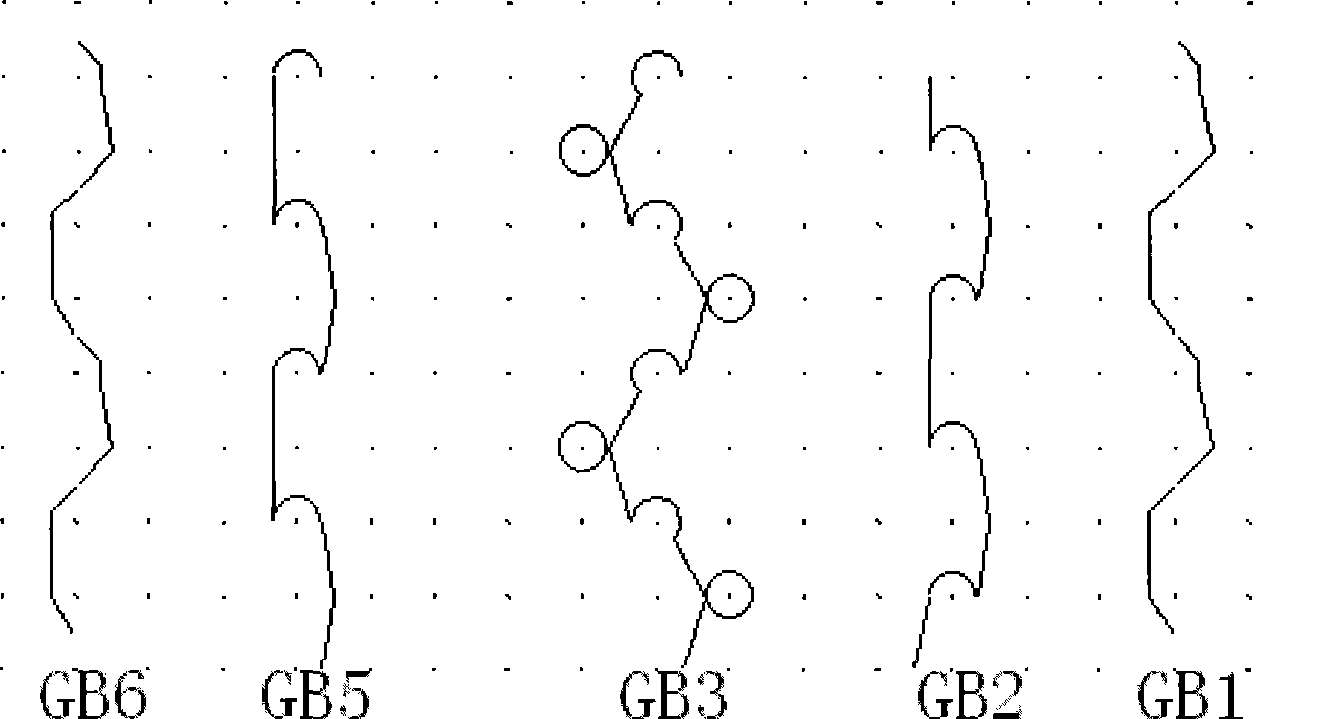

Production method for three-dimensional reinforced warp knitted spaced fabric

The invention relates to a manufacture method for three-dimensional reinforced warp knitted spaced fabric, and the warp knitted spaced fabric is produced on a modified double tricot raschel machine with full weft insertion devices. A main body of adopted raw materials is tows of high-performance fiber such as fiber glass, carbon fiber, aramid fiber, ultra high modulus polyethylene and the like. The manufacture method comprises the following steps: introducing high-performance fiber inserted weft yarns on the whole width of the machine in the X-axis direction through two weft insertion devices arranged on the front and the back of the machine; introducing high-performance fiber inserted warp yarns in the Y direction through guide bars; binding and fixing the inserted warp yarns and the inserted weft yarns through chain stitch or tricot stitch of common or high strength synthetic fiber filament yarns; adopting the high-performance fiber on upper and lower surface layer connecting yarns, ensuring the distance of 5 to 6 cm between the two surface layers, and providing reinforcing fiber in the Z-axis direction; and designing raw materials, densities, arrangement modes and interlayer thickness of the inserted warp and weft yarns of the surface layers and interlayer connecting yarns according to the requirements to form three-dimensional mesh structures with different mesh sizes and specifications. The manufacture method is characterized in that the high-performance fiber is extended and arranged in three-dimensional directions so as to overcome the defects and disadvantages of the prior spaced fabric taken as a reinforced material, and the manufacture method provides an ideal three-dimensional reinforced fabric for production of composite boards with good tensile, bending, shearing and compression properties and shock resistance.

Owner:JIANGNAN UNIV

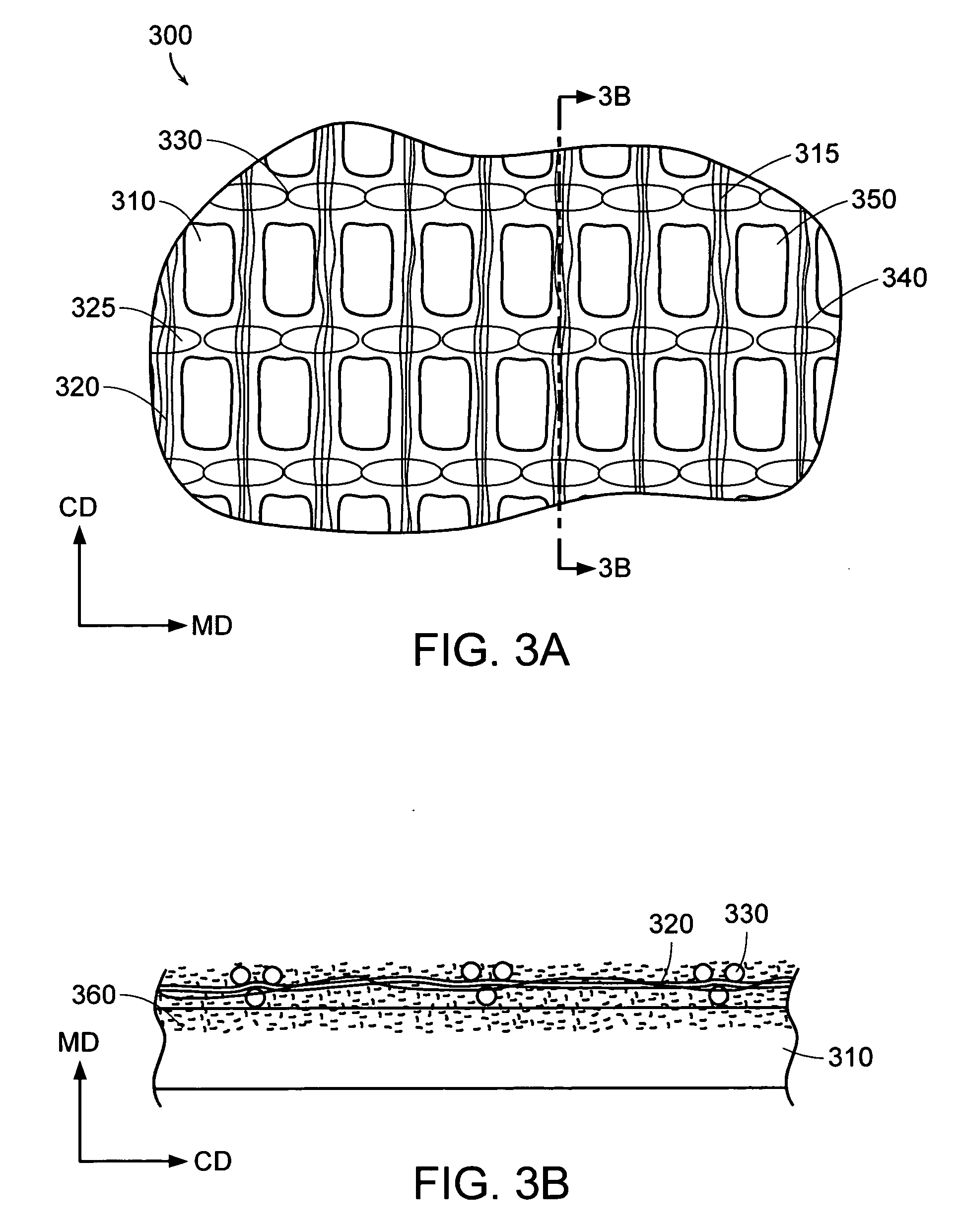

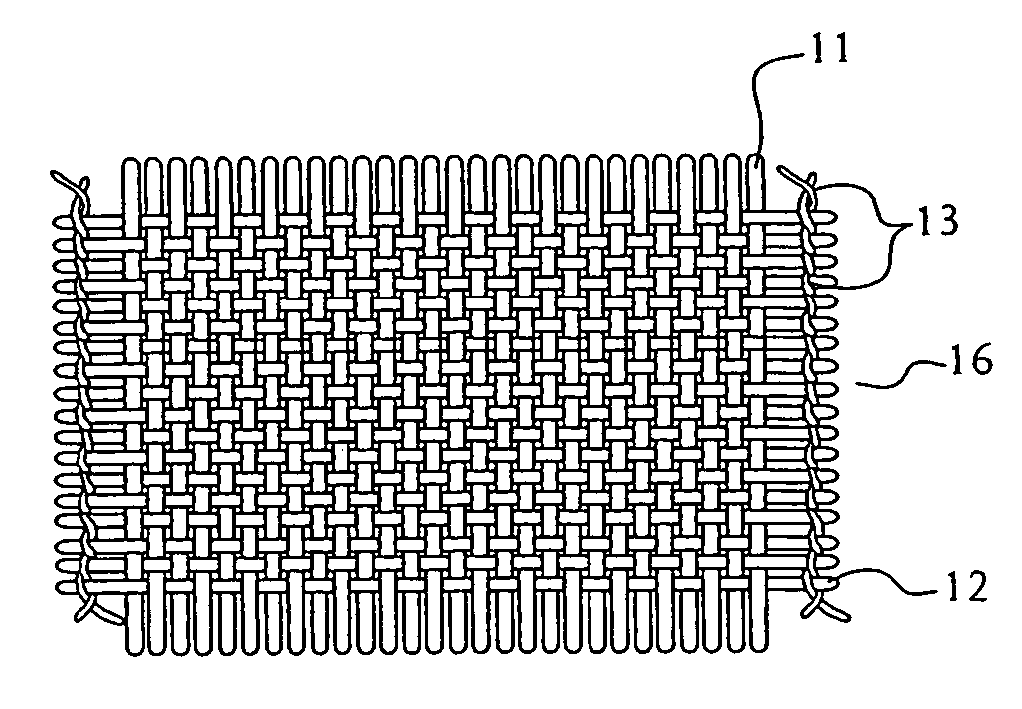

Multi-layer papermaker's fabrics with packing yarns

InactiveUS6902652B2Increasing caliperImproved seam strengthMachine wet endPaper/cardboardCotton materialLateral movement

A papermaker's fabric, usable in the forming section of a paper machine, having a top layer and a bottom layer of cross-machine direction (CD) wefts. The top (forming) layer and bottom (wear side) layer are woven together to form a multi-layer fabric. CD packing yarns are inserted between adjacent wear side weft yarns. The packing yarns reduce the void volume on the wear side of the cloth without significantly disrupting the air permeability or increasing the caliper of the fabric. The placement of the packing yarns also adds to the CD stability and seam strength of the fabric and reduces the lateral movement of the wear side weft yarns.

Owner:ALBANY INT CORP

Fabric reinforcement and cementitious boards faced with same

ActiveUS20060013950A1Improve coating uniformityConvenient coatingPretreated surfacesWood working apparatusCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

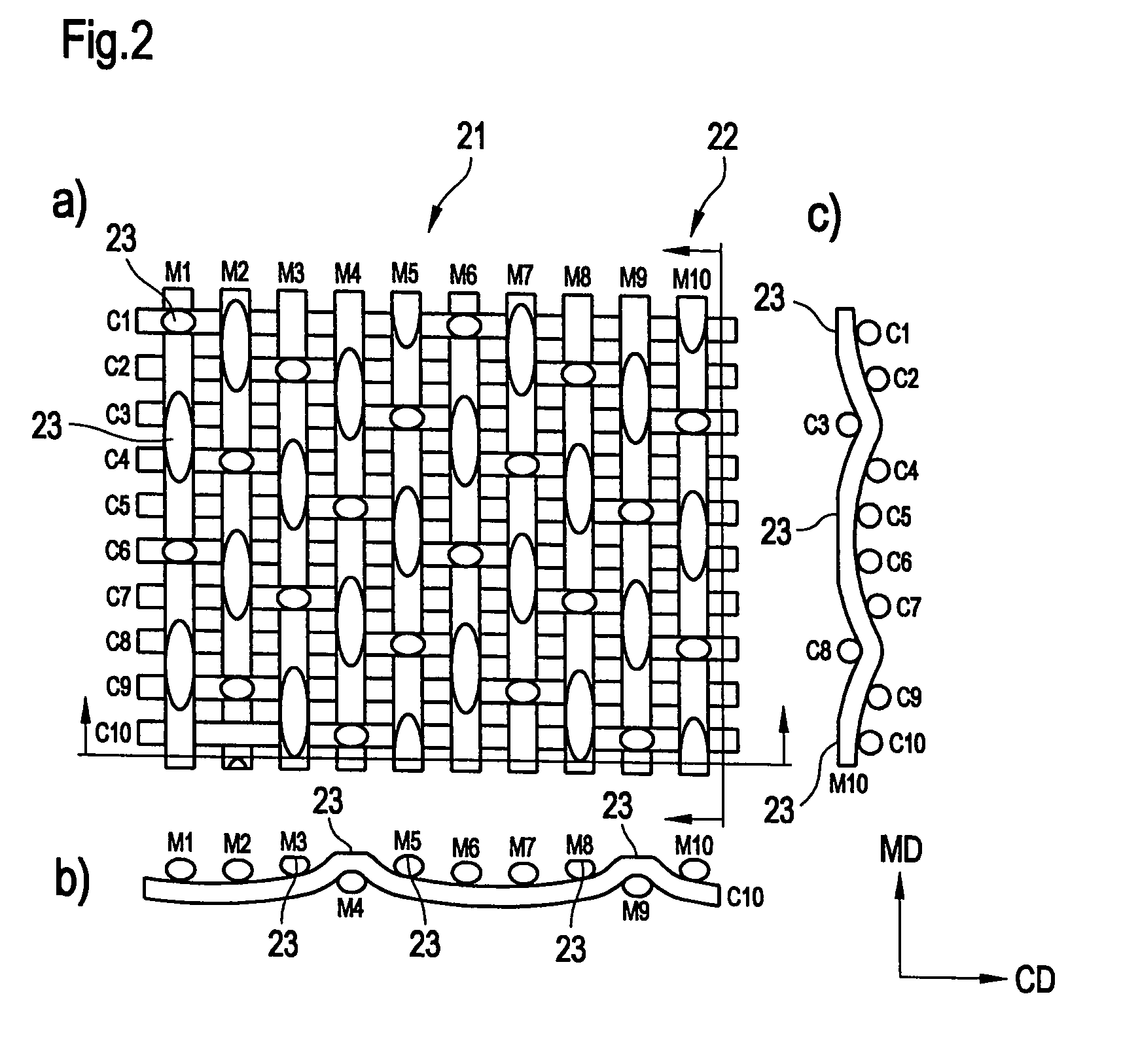

Structured forming fabric

InactiveUS7585395B2Increase surface areaImprove machine performanceFibreboardNon-fibrous pulp additionPulp and paper industryWeft yarn

A fabric for use by a papermaking machine, the fabric including a plurality of weft yarns, a plurality of warp yarns, and a woven fabric resulting from a repeating pattern of the weft yarns and warp yarns. Each of the weft yarn in the repeating pattern having a sequence of starting at a starting point then sequentially going over three adjacent warp yarns, under one warp yarn, over one warp yarn, under three warp yarns, over one warp yarn and under one warp yarn, the sequence then repeating.

Owner:VOITH PATENT GMBH

Flame Resistant Fabric With Anisotropic Properties

InactiveUS20110010827A1Increased durabilityChemical protectionHeat protectionFiberFire-retardant fabric

Flame resistant fabrics are formed by warp and fill yams having different fiber contents. The fabrics are constructed, for example, by selection of a suitable weaving pattern, such that the body side of the fabric and the face side of the fabric have different properties. The fabrics described herein can be printable and dyeable on both sides of the fabric and are suitable for use in military and industrial garments. Methods of forming flame resistant fabrics, and methods for forming garments from the fabrics, are also described.

Owner:SOUTHERN MILLS

Multicomponent fiber blended fabric and preparation thereof

InactiveCN101275327AComplementary advantage reductionReduce disadvantagesBiochemical fibre treatmentLoomsAntimicrobialWeft yarn

A multi-component fiber blended facing material is disclosed, whose weight proportion of spinning raw material is (the chaine is same with the weft yarn) 11-20% of tencel, 8-12% of ramee, 8-12% of bamboo fibre, 60-65% of terylene short fiber and 0.5-0.7% of conductive fibre. The invention implementing reasonable collocation and assembly of tencel, terylene, bamboo fibre, ramee and conductive fibre, which not only useds the large brute force and sticking dynam characteristic of terylene, but also full utilizes the superior characteristic and favorable wear behavior of tencel, bamboo fibre and ramee, thereby implementing ascendency complementary and inferior position elimination of various fibres, and meanwhile the conductive fibre has better and longer electrostatic resistance effect in the fibre blended yarns. The facing material has superior characteristics of moisture absorption, ventilating, electrostatic resistance, sticking, sliding, embonpoint hand feeling, good drapability, flokkit and pilling resistance, good model keeping performance, antimicrobial, etc. The invention has reasonable technique, resolve difficult problem of spinning and dyeing, and establish hardness foundation for the amenity and high-grade of the chemical fabrics facing material.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Weft-filled decorative fabrics in three-layer structure and production process thereof

InactiveCN101649522AStrong three-dimensional flower shapeObvious permanent bump effectWoven fabricsSurface layerEngineering

The invention discloses weft-filled decorative fabrics in a three-layer structure and a production process thereof. One of plain weave or twill weave is adopted as basic weave in a surface layer and aliner layer; warp yarns and weft yarns on the surface layer and the liner layer are woven into two-layer fabrics; 3 / 3 warp overlapped plain weave single-layer grid embedded strip yarns and 2 / 2 weft overlapped plain weave single-layer grid embedded strip yarns are respectively embedded and woven in an alternative arrangement mode on the surface layer and the liner layer in the warp direction and the weft direction; weft suspended filling yarns are woven between the surface layer texture of and the liner layer texture; the number R of full-texture circulating warp yarns of the whole fabrics satisfies an equation: R=10-16; and the decorative fabrics in the two-layer texture weft-filled three-layer structure are woven. The whole fabrics integrally have three-dimensional grid effect in a two-layer texture triple structure; under the supporting action of filled wefts in the weft direction, two-layer bag-shaped grids have permanent obvious swelling effect and form an air layer with a thickness of 1.2-1.8 mm in the fabrics, and the air layer has favorable functions of heat insulation, heat maintenance and sound shielding. Accordingly, the novel household decorative fabrics are ideal.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com