Patents

Literature

366results about How to "Improve coating uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

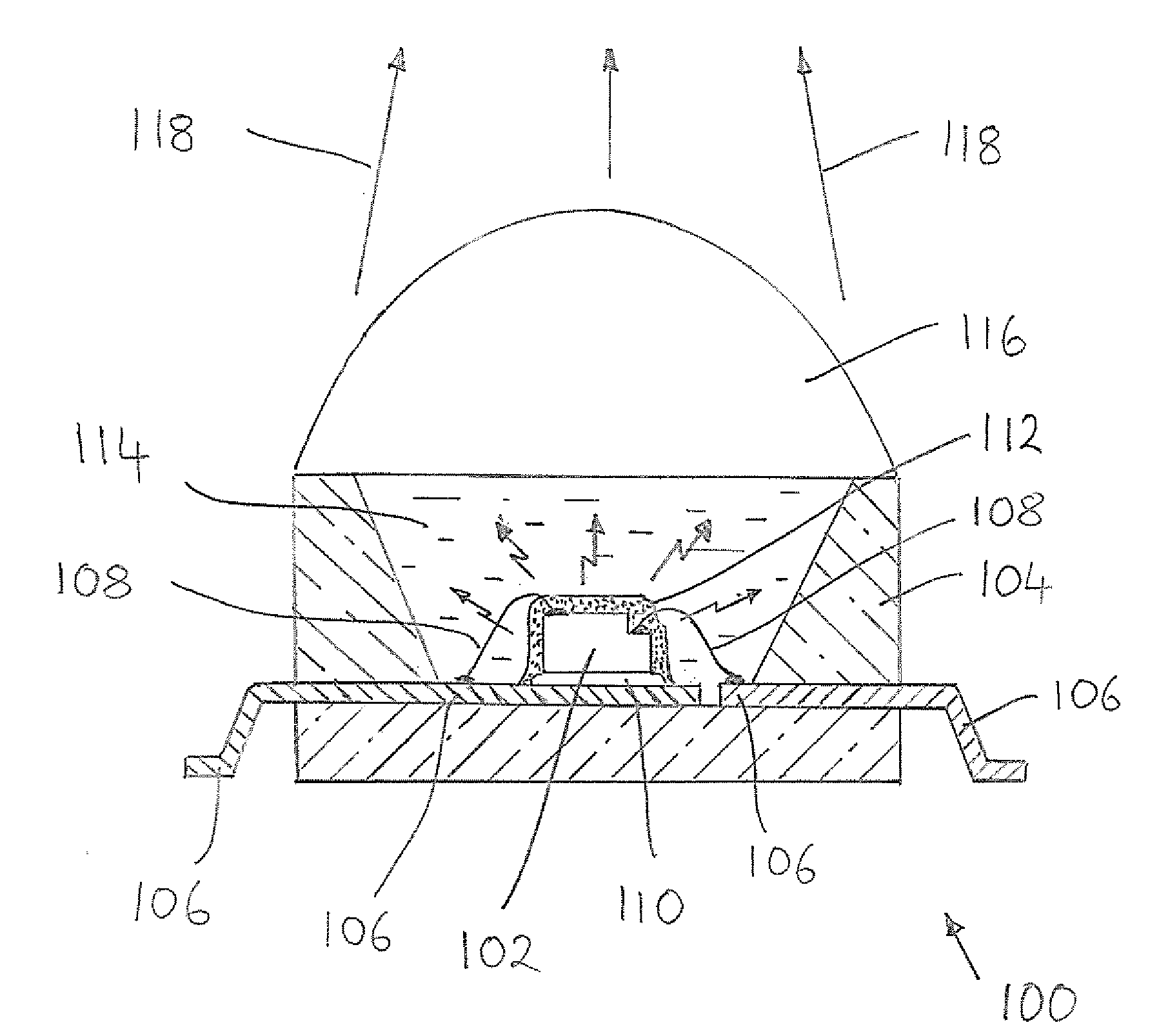

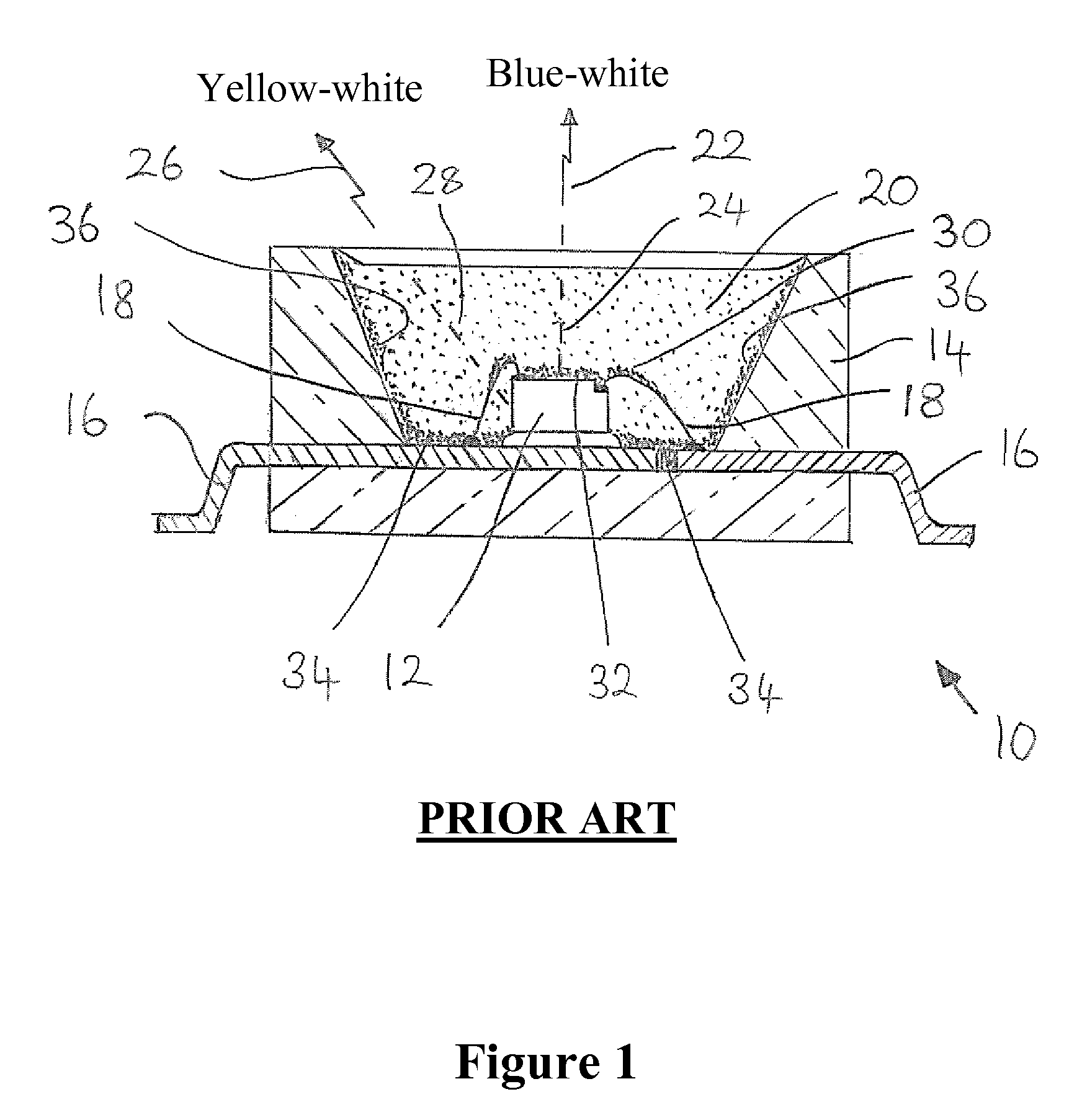

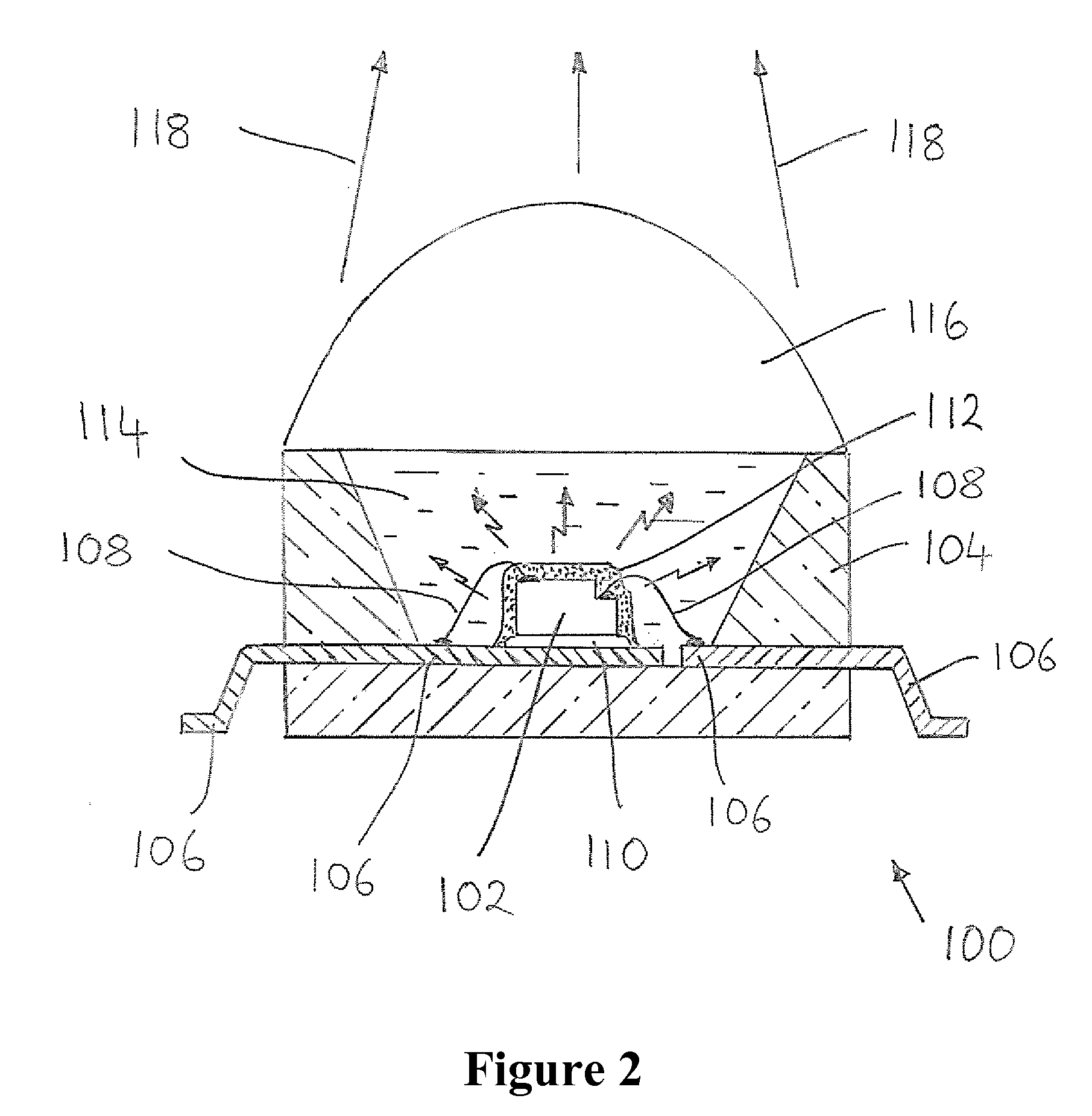

Light emitting device with phosphor wavelength conversion and methods of producing the same

ActiveUS20090134414A1Improve uniformityImprove coating uniformitySolid-state devicesOptical articlesEpoxyPhosphor

A method of fabricating a light emitting device comprises: mounting a light emitting diode chip in a package; heating the light emitting diode chip package assembly to a pre-selected temperature; and dispensing a pre-selected volume of a mixture of at least one phosphor and a light transmissive thermosetting material (silicone, epoxy) on a surface of the chip. The pre-selected volume and temperature are selected such that the phosphor / material mixture flows over the entire light emitting surface of the chip before curing. In an alternative method, using a light transmissive UV curable material such as an epoxy, the phosphor / material mixture is irradiated with UV radiation after a pre-selected time to cure the material. The pre-selected volume and pre-selected time are selected such that the phosphor / material mixture flows over at least the light emitting surface of the chip before curing.

Owner:INTEMATIX

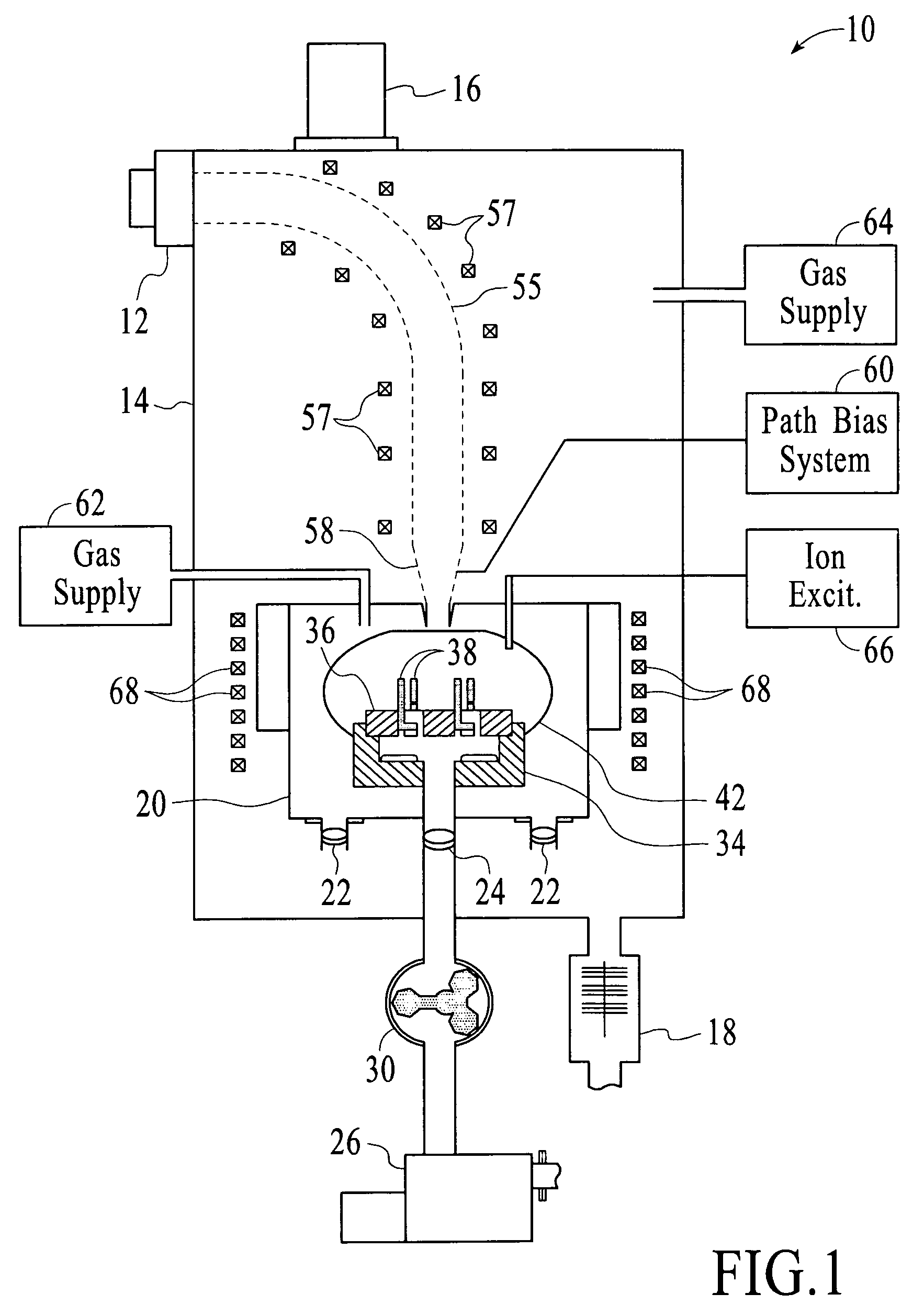

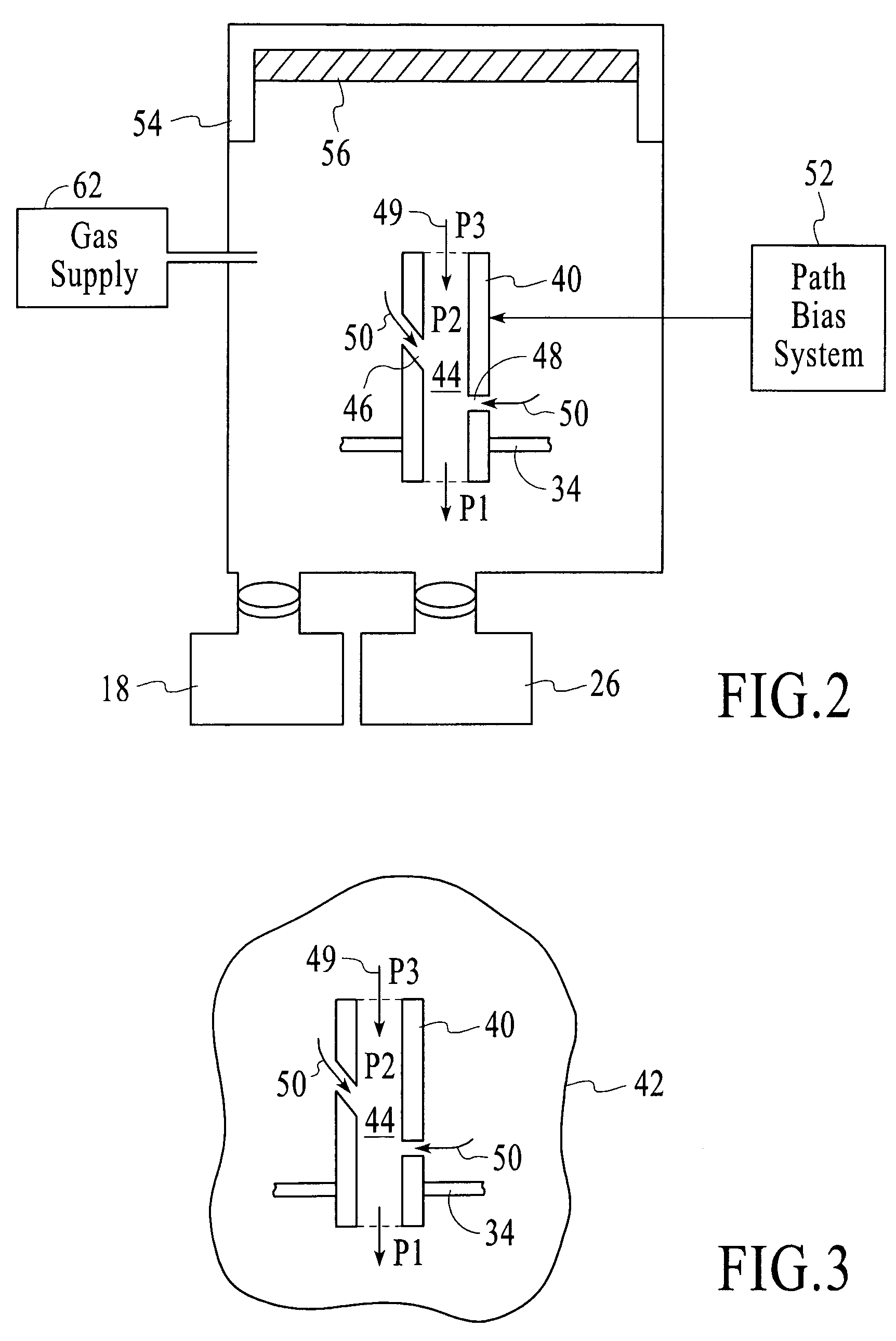

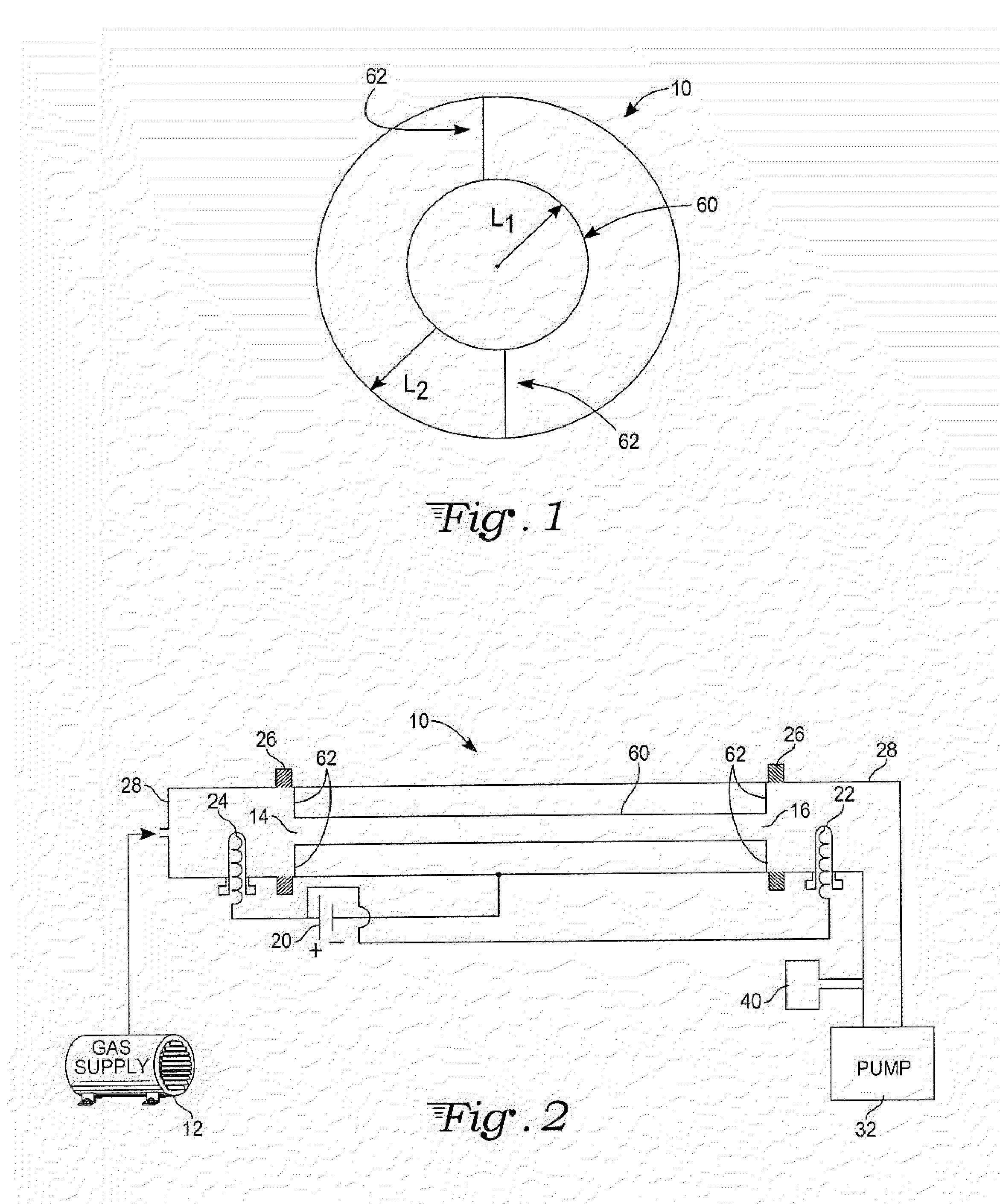

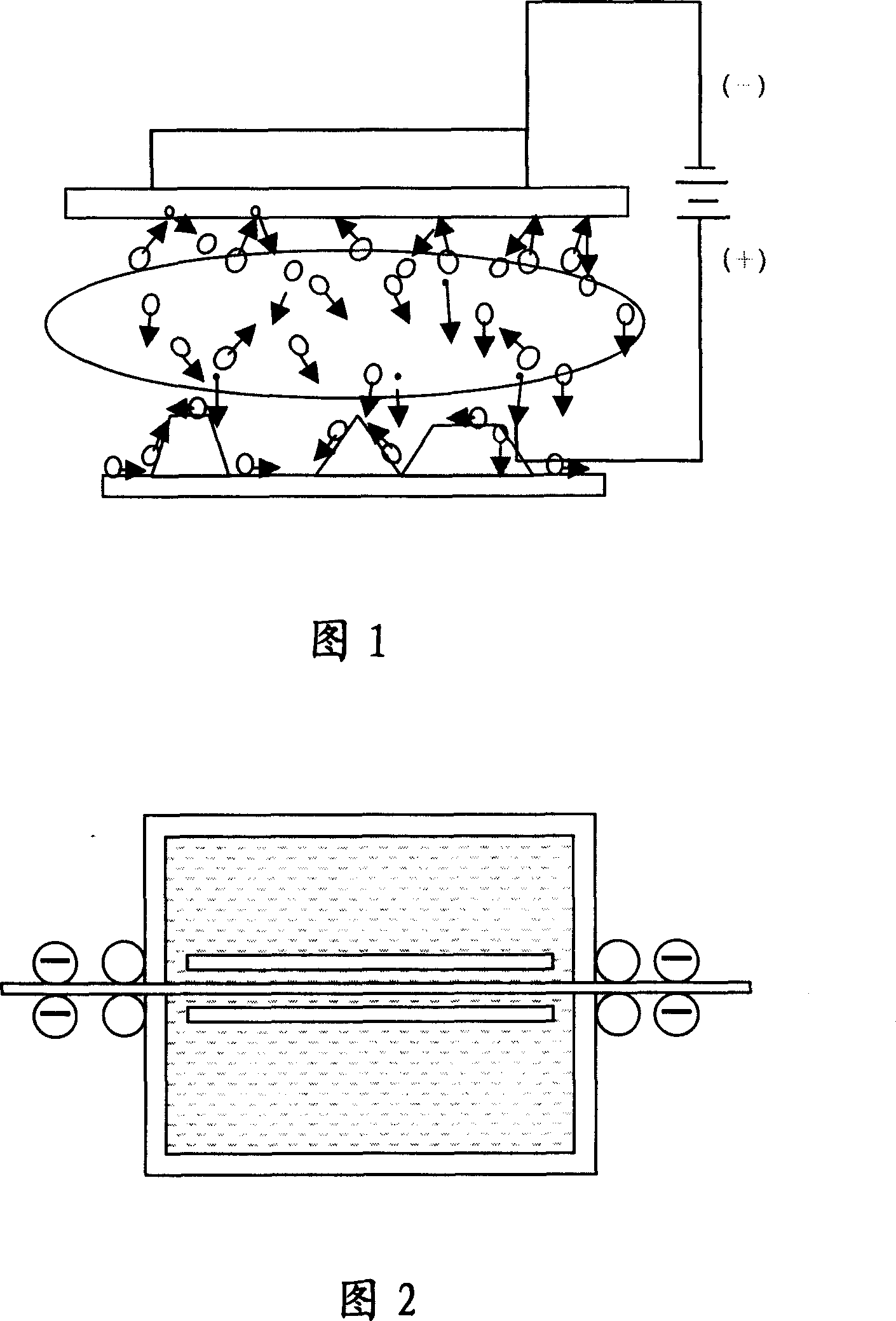

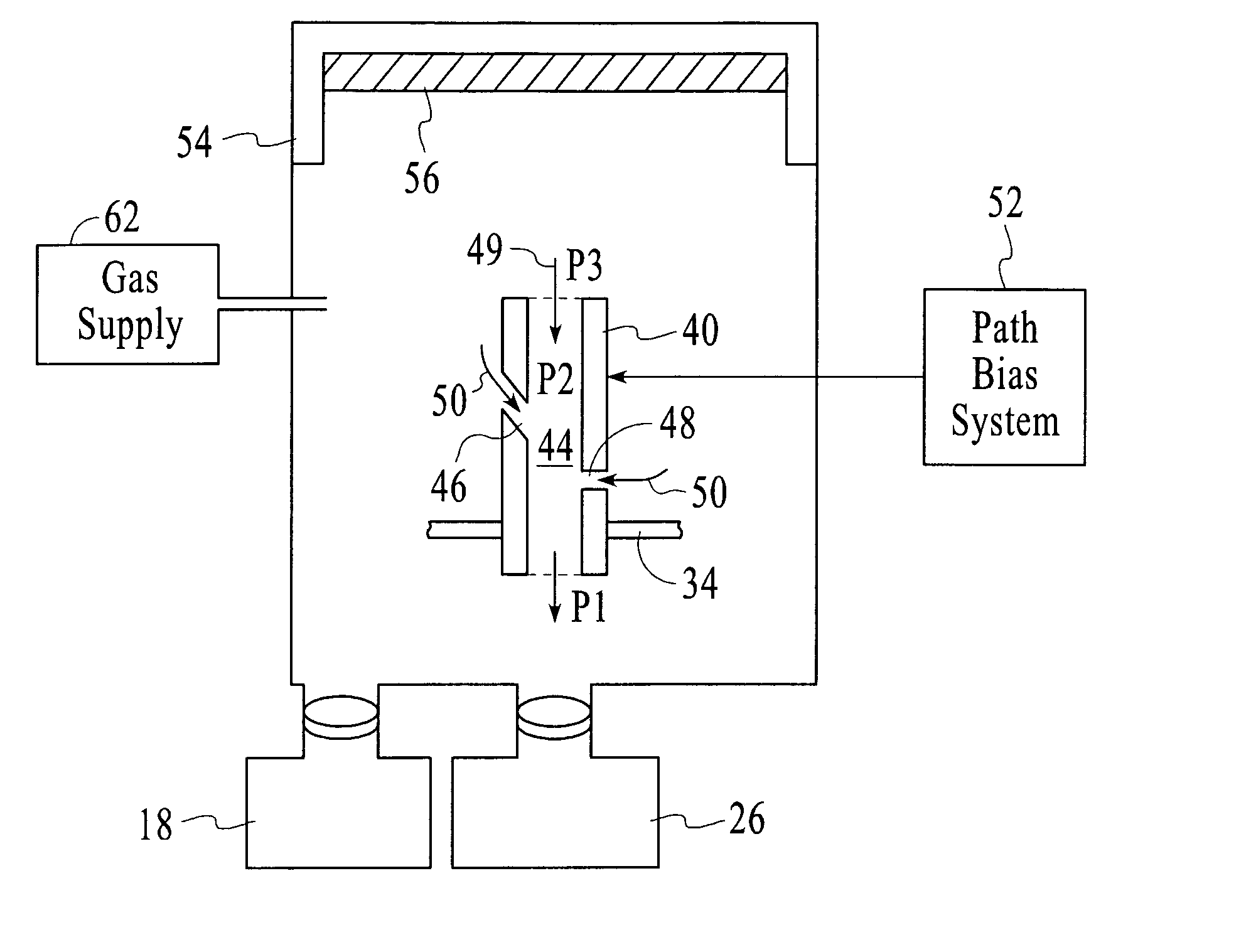

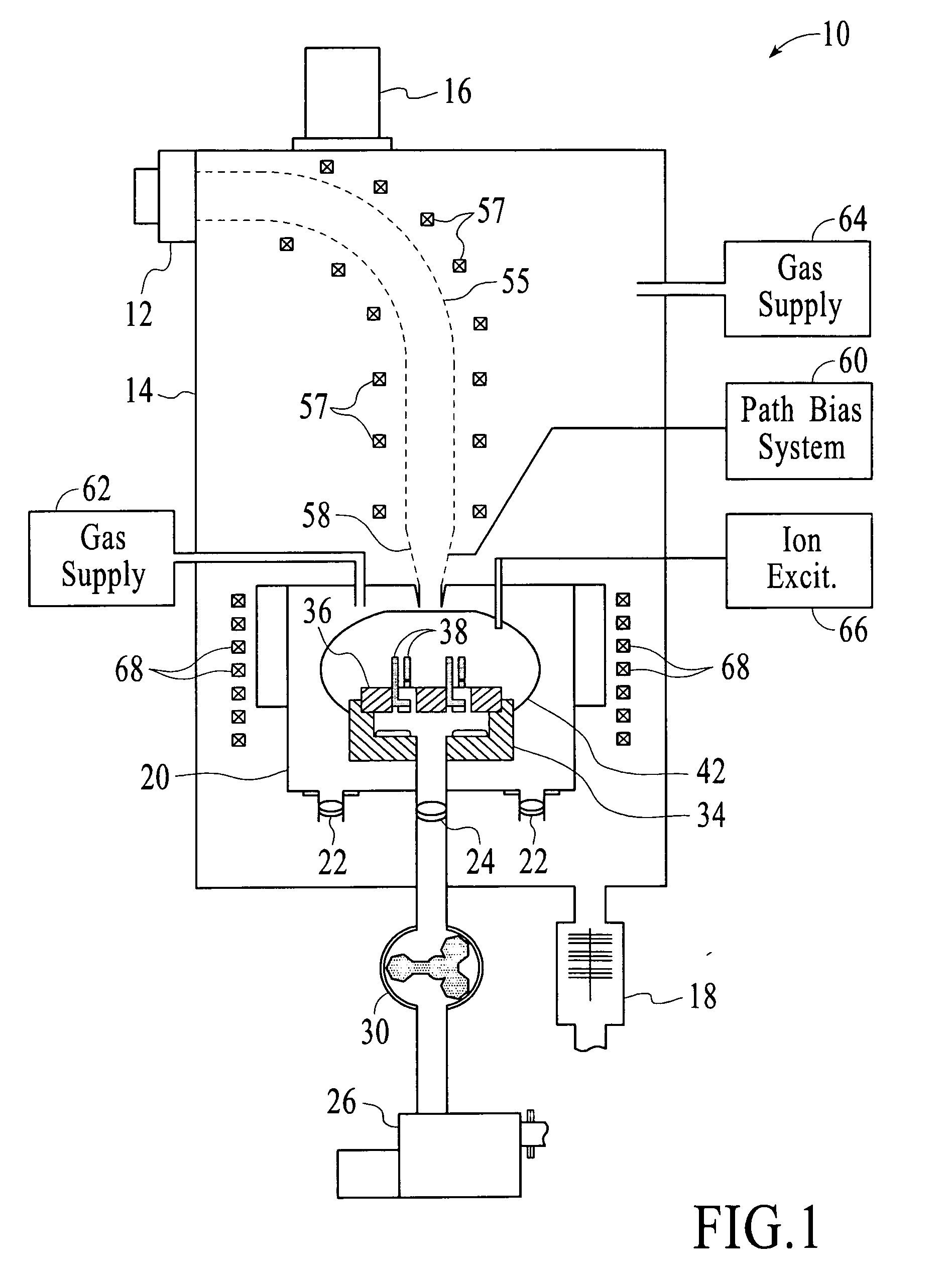

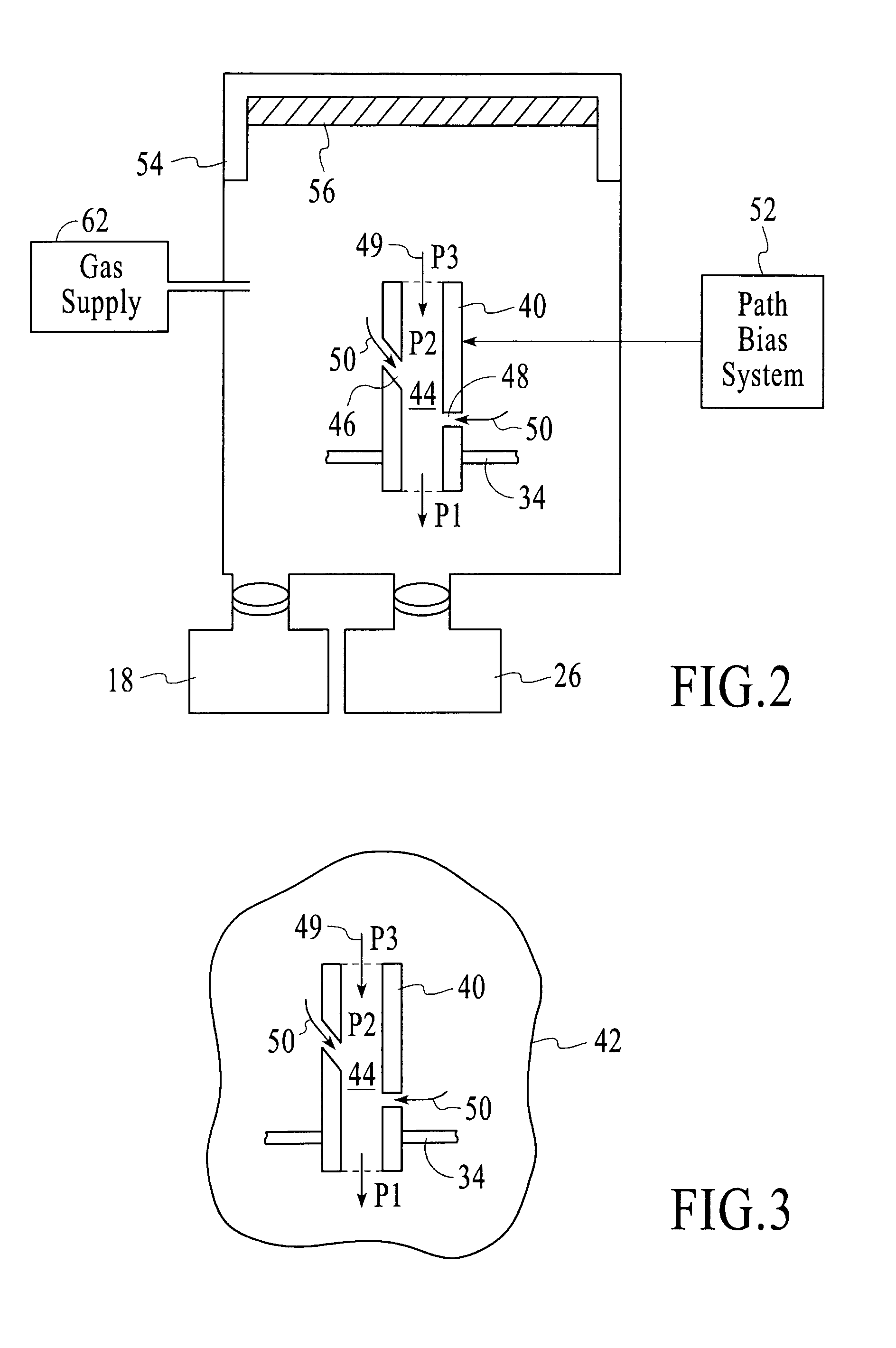

Apparatus for directing plasma flow to coat internal passageways

InactiveUS7444955B2Improve integrityLess expensiveCellsElectric discharge tubesSupporting systemHardness

An apparatus for coating surfaces of a workpiece is configured to establish a pressure gradient within internal passageways through the workpiece, so that the coating within the internal passageways exhibits intended characteristics, such as those relating to smoothness or hardness. The coating apparatus may include any or all of a number of cooperative systems, including a plasma generation system, a manipulable workpiece support system, an ionization excitation system configured to increase ionization within or around the workpiece, a biasing system for applying a selected voltage pattern to the workpiece, and a two-chamber system that enables the plasma generation to take place at a first selected pressure and the deposition to occur at a second selected pressure.

Owner:SUB ONE TECH

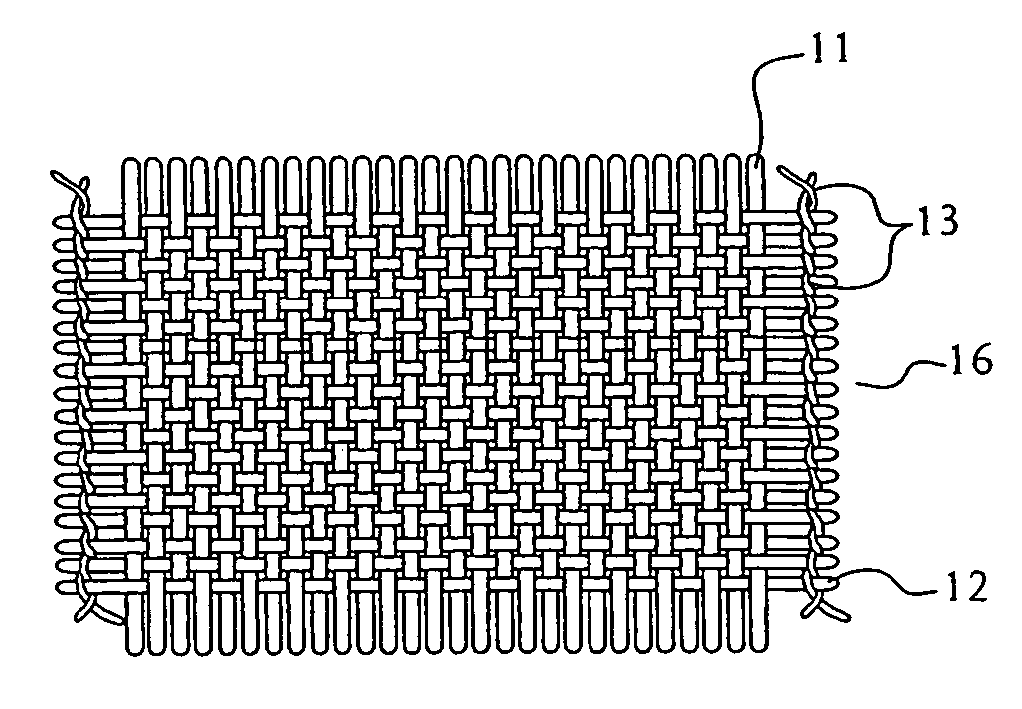

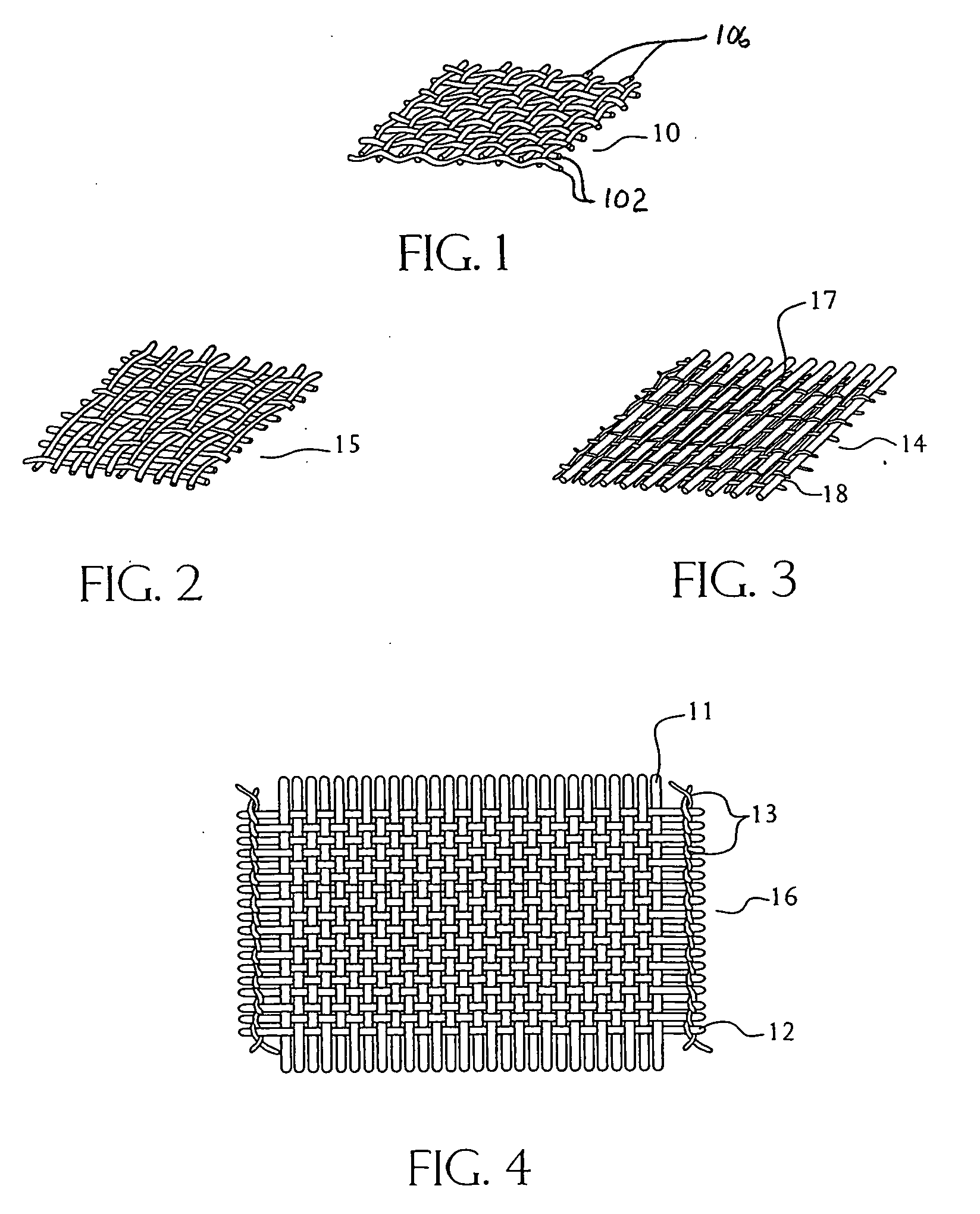

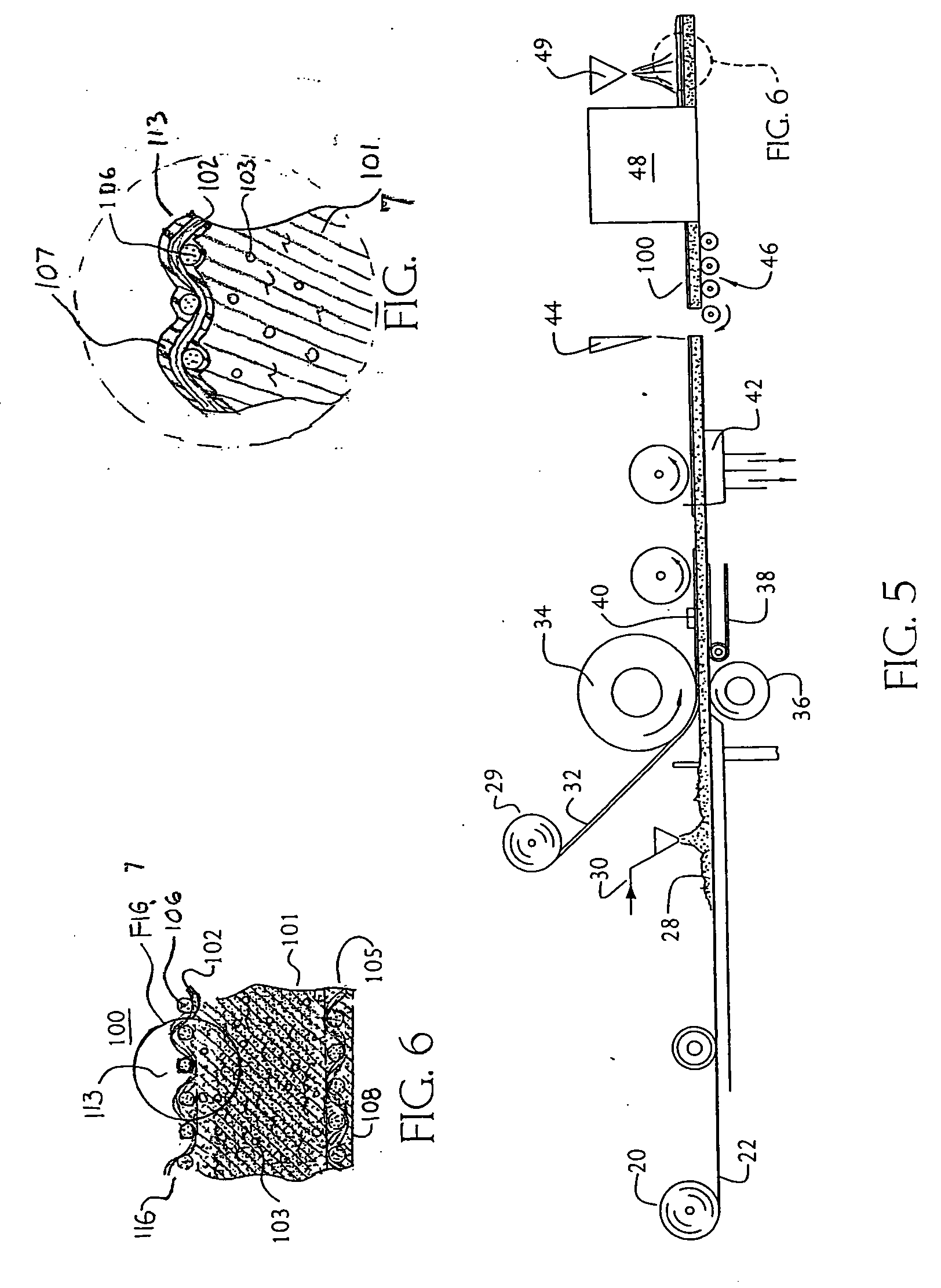

Fabric reinforcement and cementitious boards faced with same

ActiveUS20060013950A1Improve coating uniformityConvenient coatingPretreated surfacesWood working apparatusCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

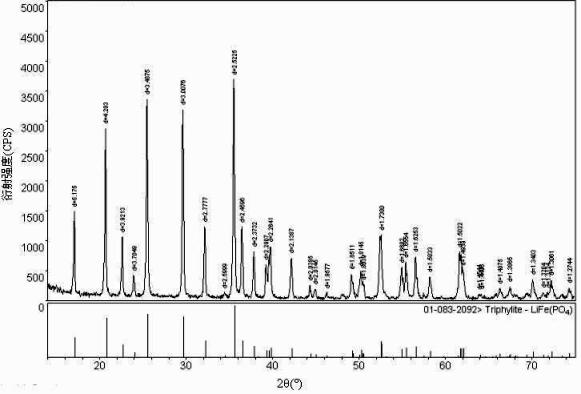

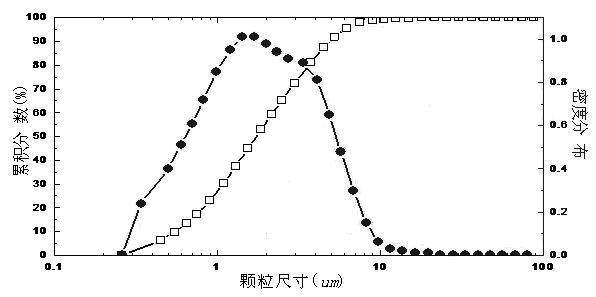

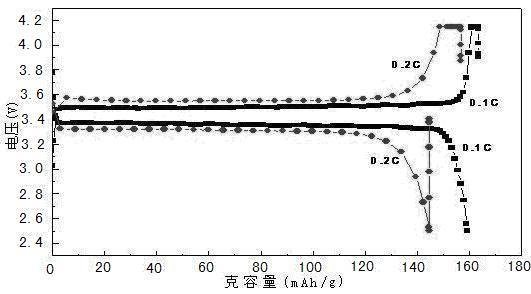

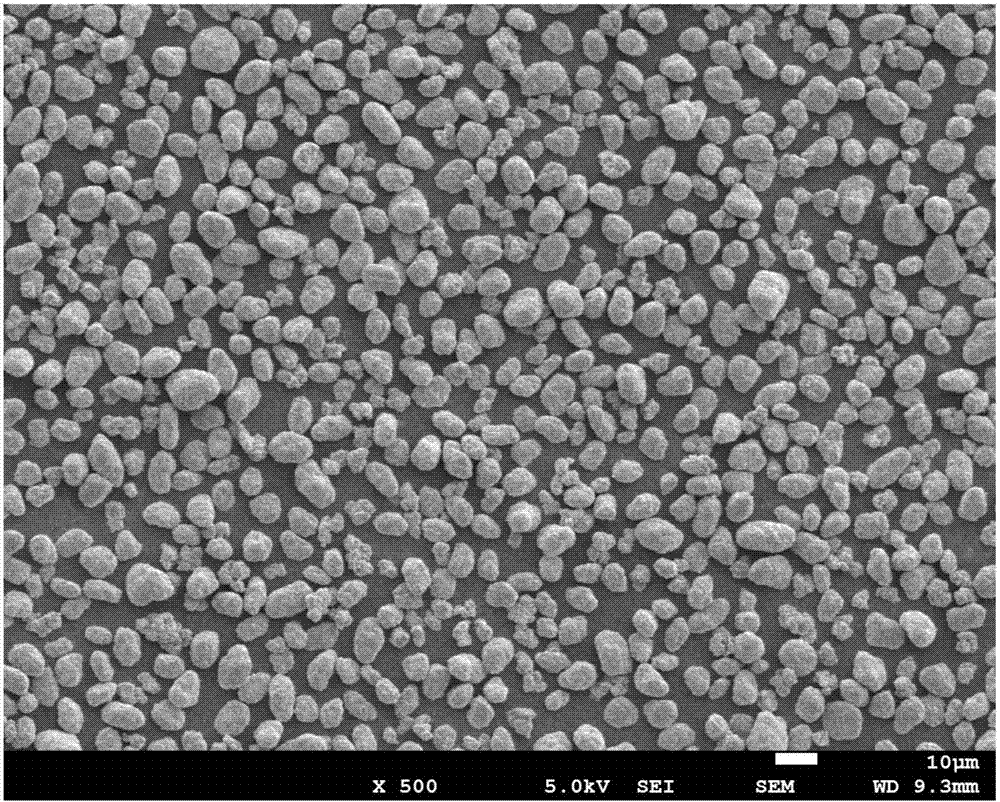

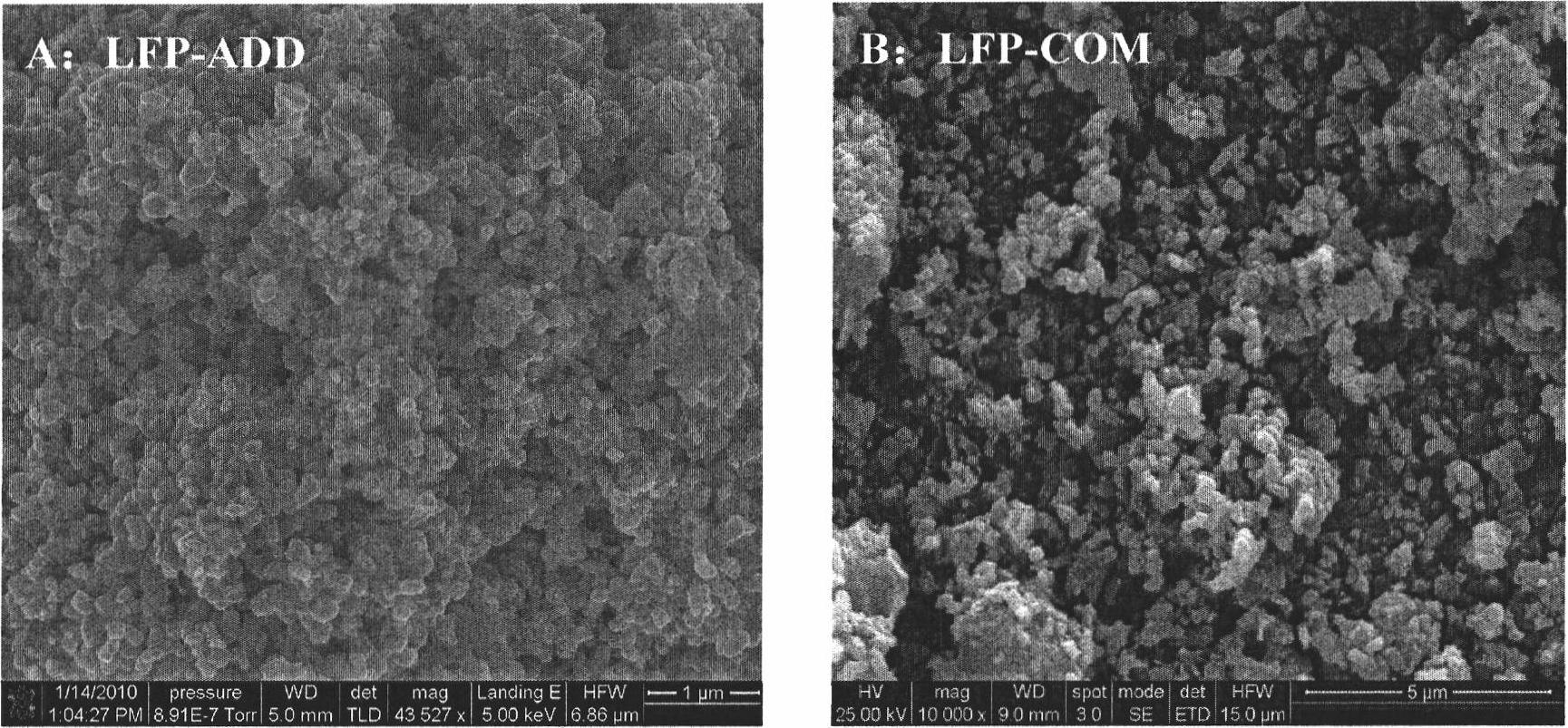

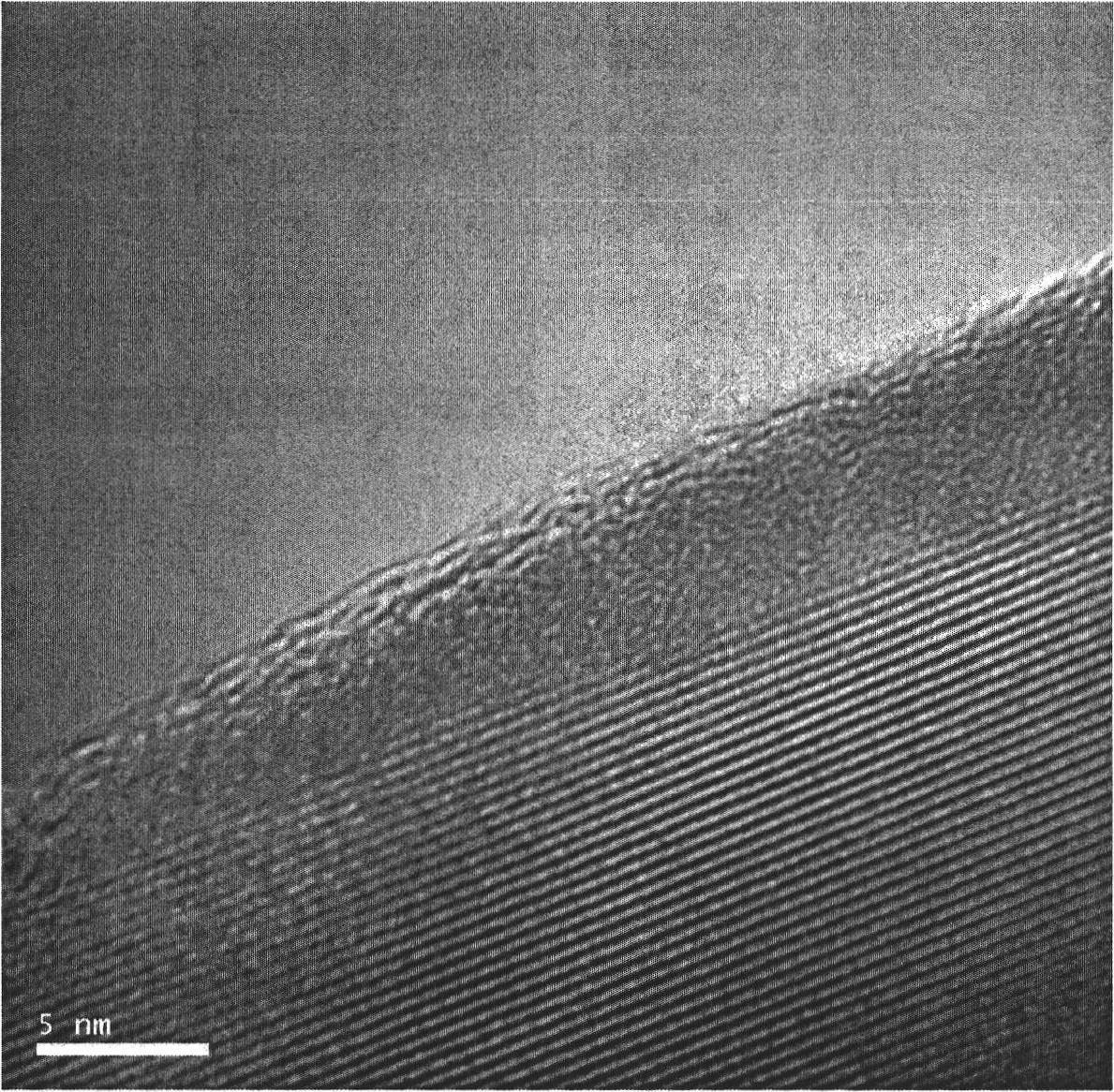

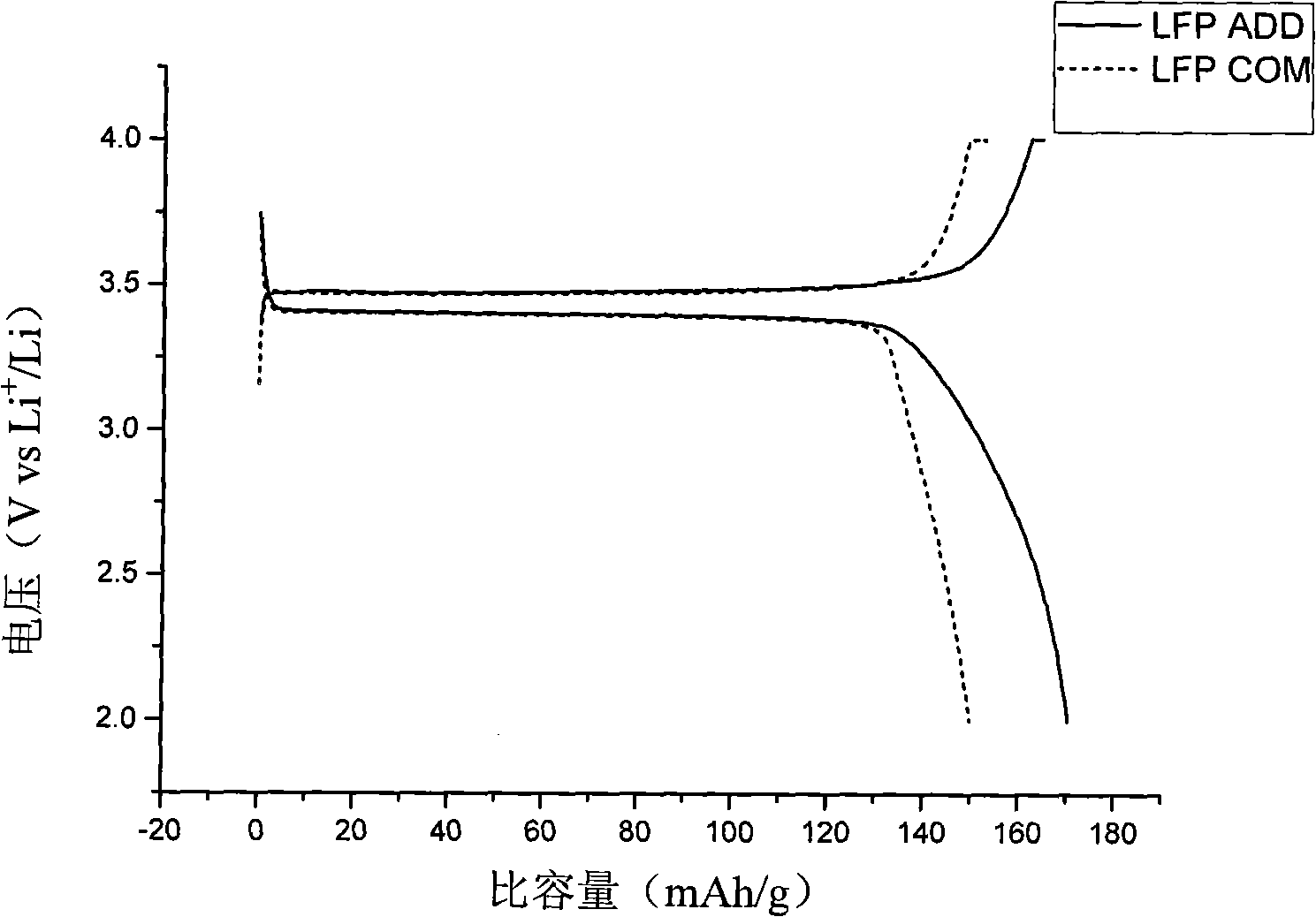

A kind of preparation method and product thereof of lithium iron phosphate material with high capacity and high compaction density

InactiveCN102275887ASolve the problem of impurityReduce manufacturing costCell electrodesPhosphorus compoundsElectrical batteryPhosphate

The invention belongs to the field of positive electrode materials for lithium ion batteries, and discloses a method for preparing lithium iron phosphate materials with high capacity and high compaction density, including (1) combining lithium source, Fe3+ source, phosphate, dopant and organic carbon source Mixing, and then spray granulation, (2) prepare calcined product, (3) mix and sand the calcined product and inorganic carbon source, and then spray dry to obtain secondary spray powder, (4) secondary spray The powder is heat-treated in vacuum or in a protective atmosphere, and sintered at a constant temperature; (5) After the above-mentioned sintered semi-finished product is passed through secondary ball milling or jet milling, a lithium iron phosphate product is obtained. The invention solves the defects of increased product cost, difficult coating and low compaction density of pole pieces caused by the use of divalent iron source, and has the characteristics of low production cost and good processability, electrical conductivity and electrochemical performance of prepared pole pieces .

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

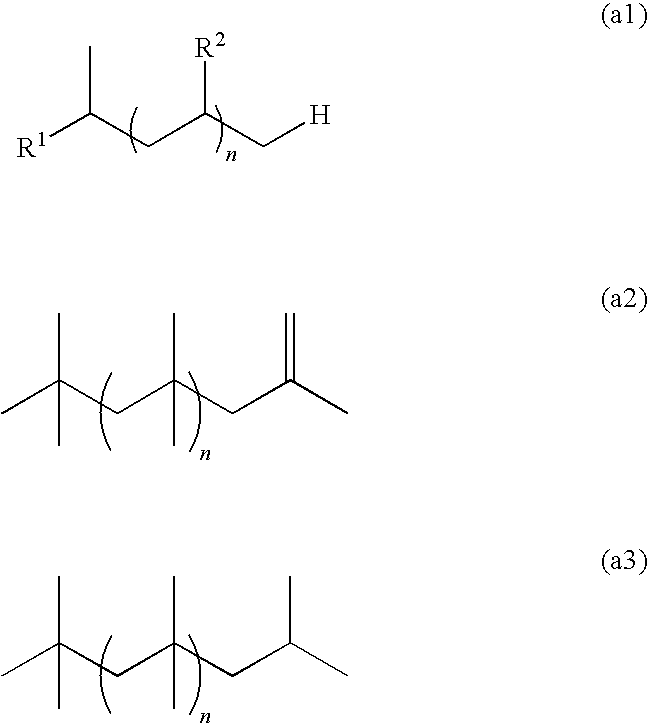

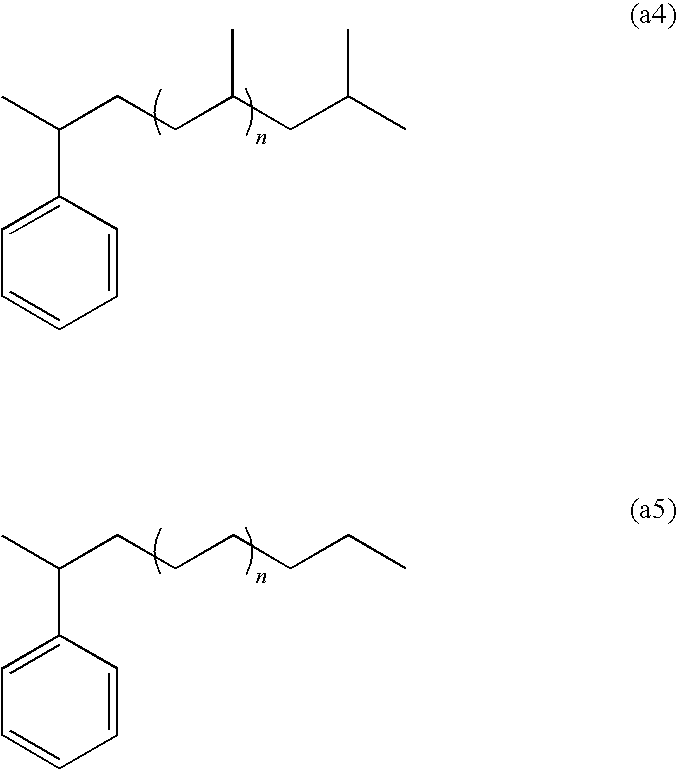

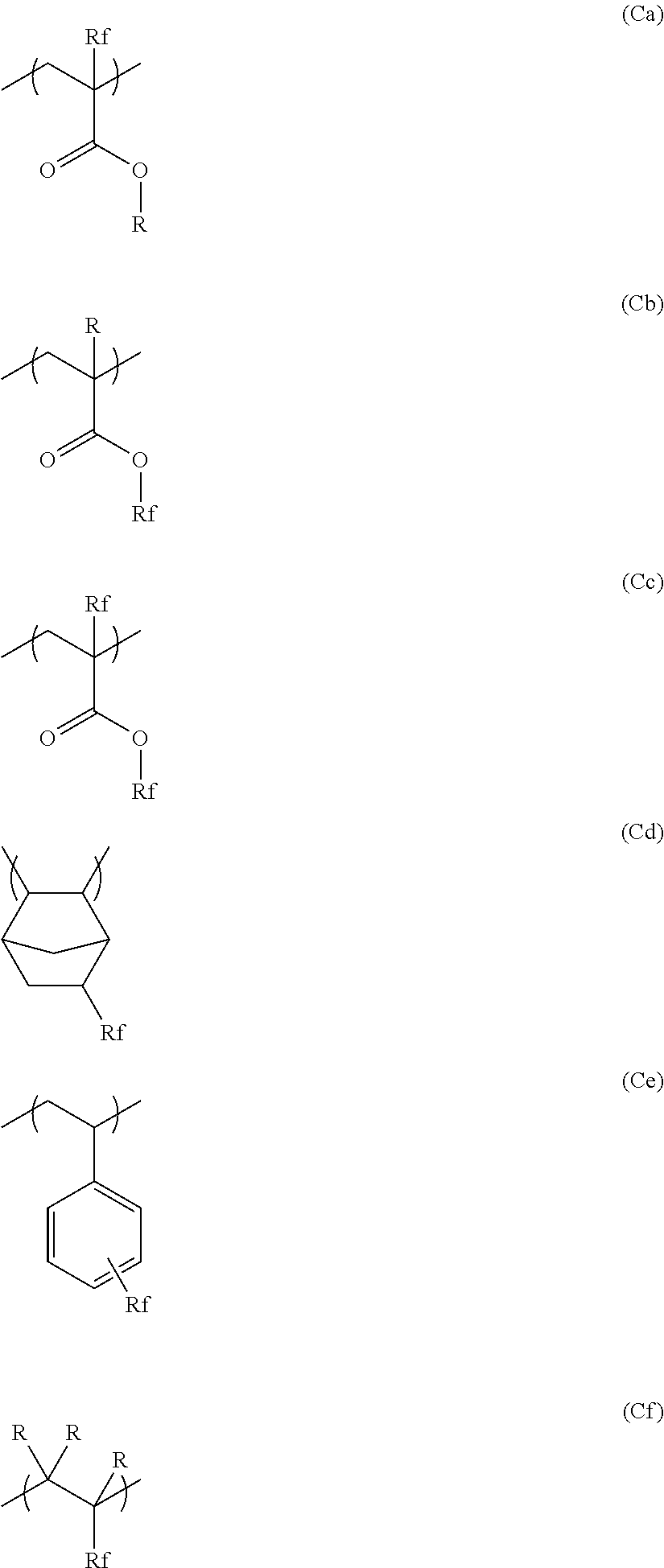

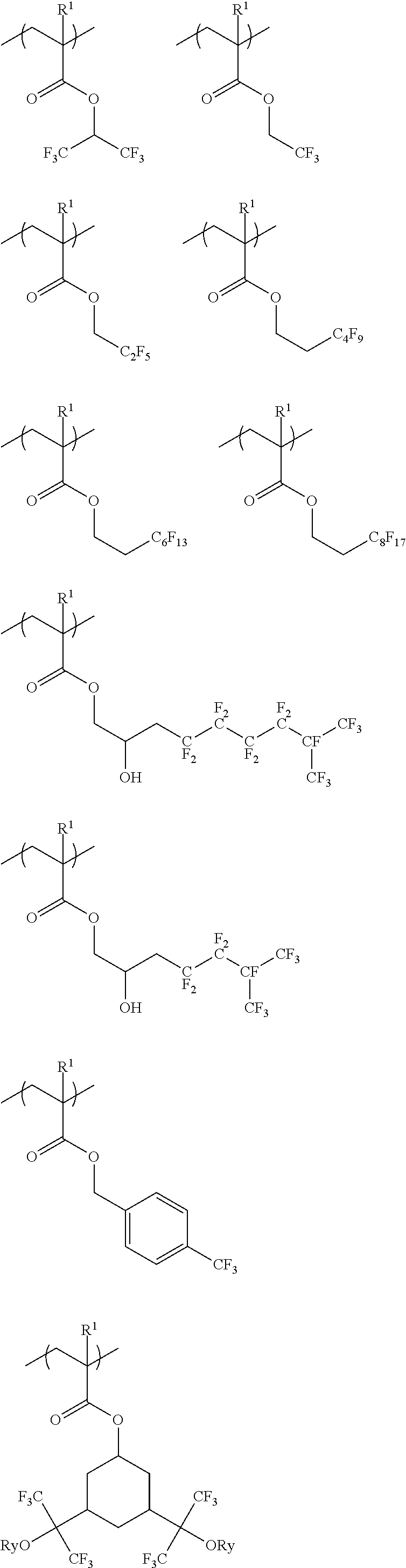

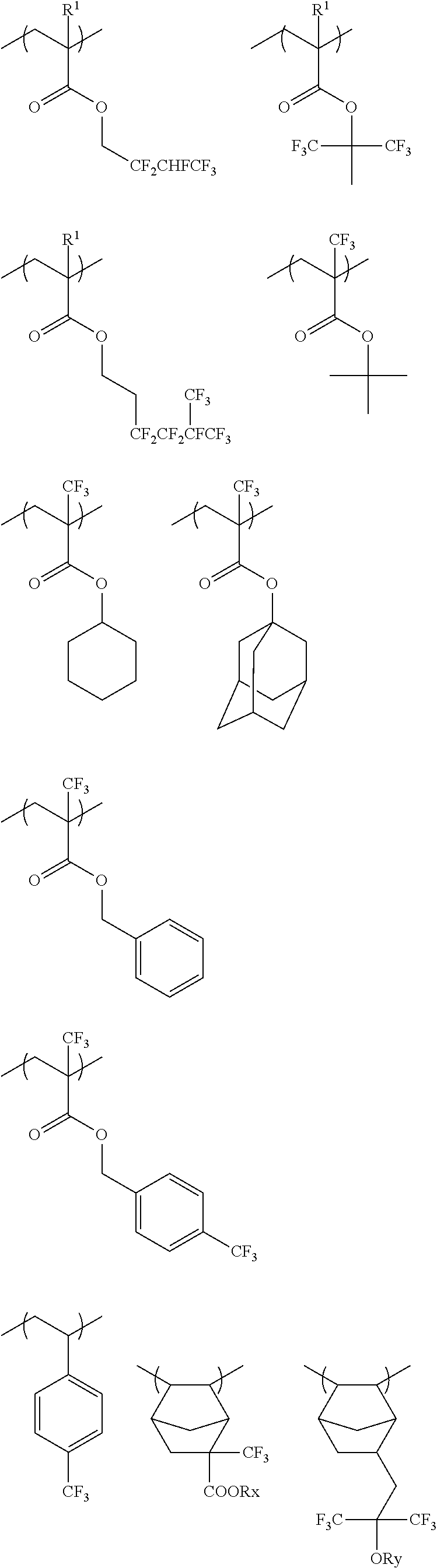

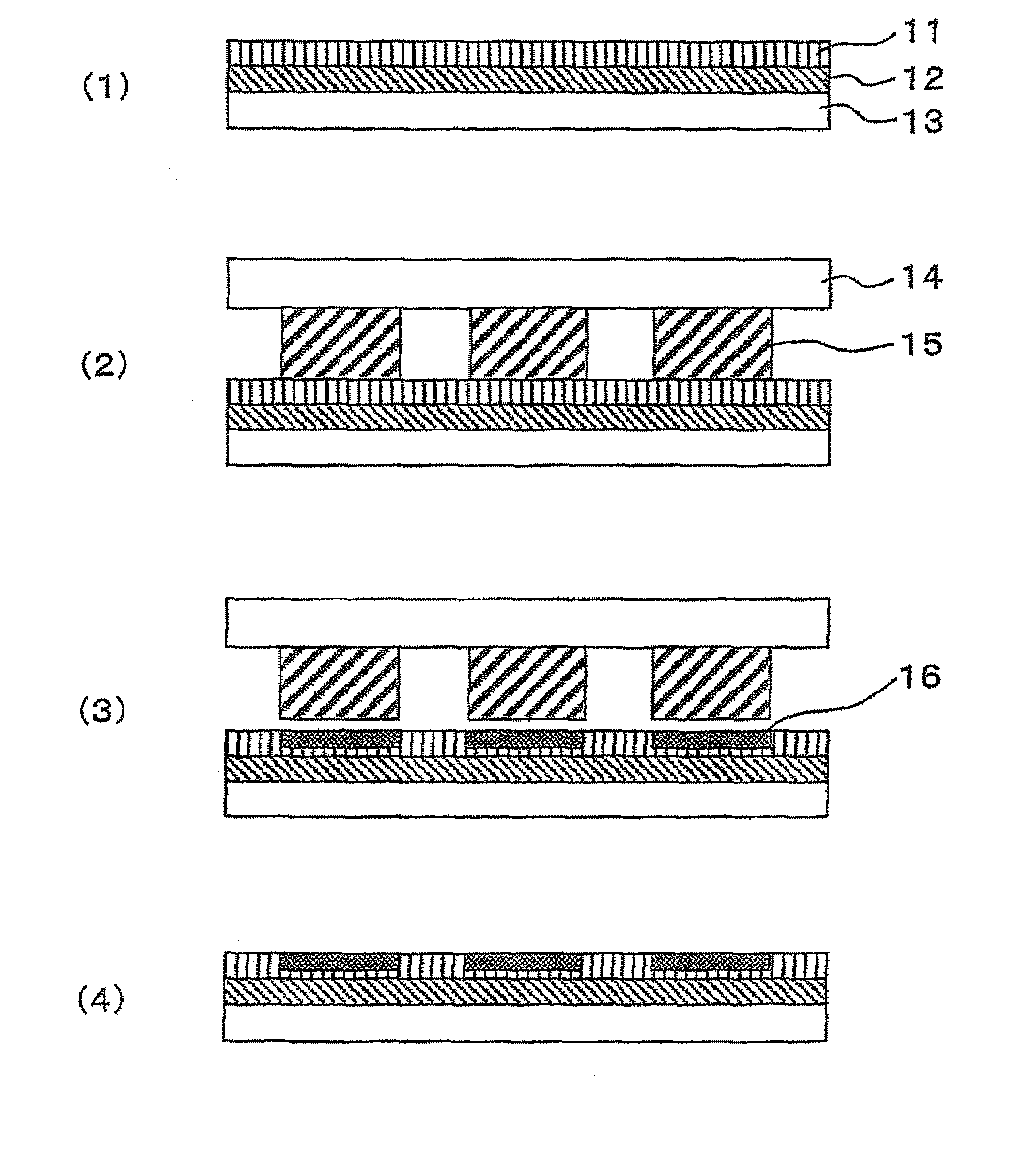

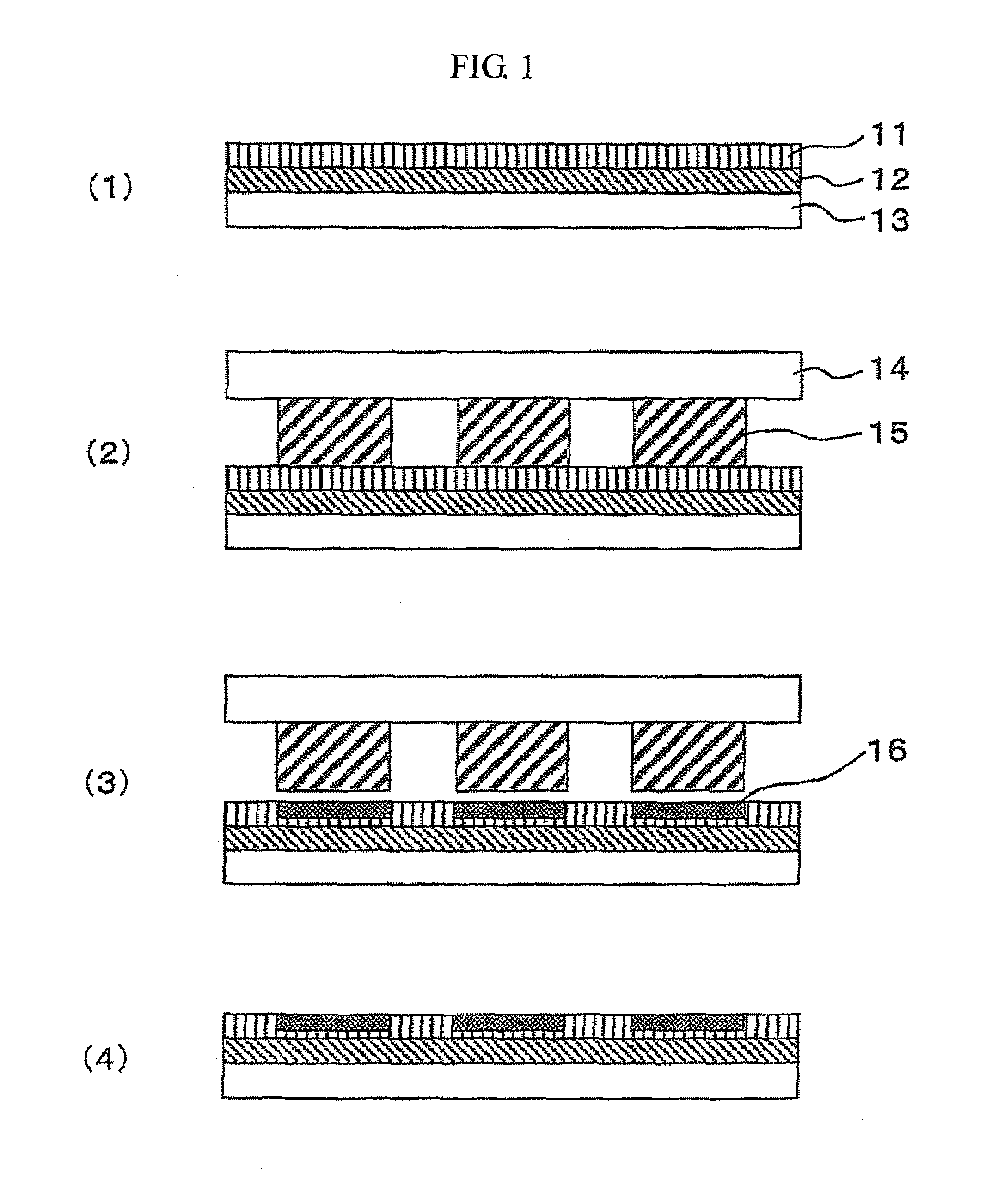

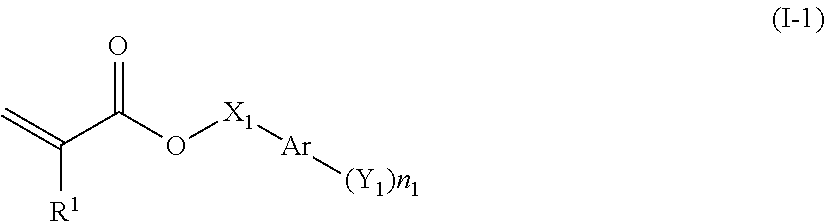

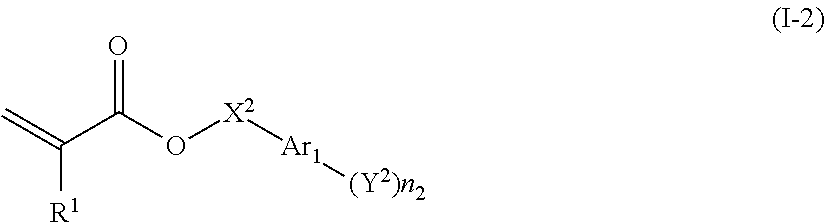

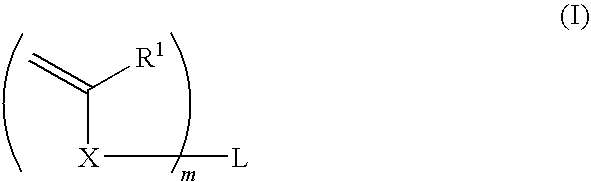

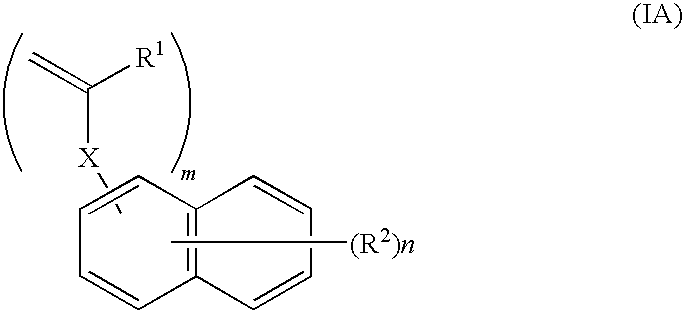

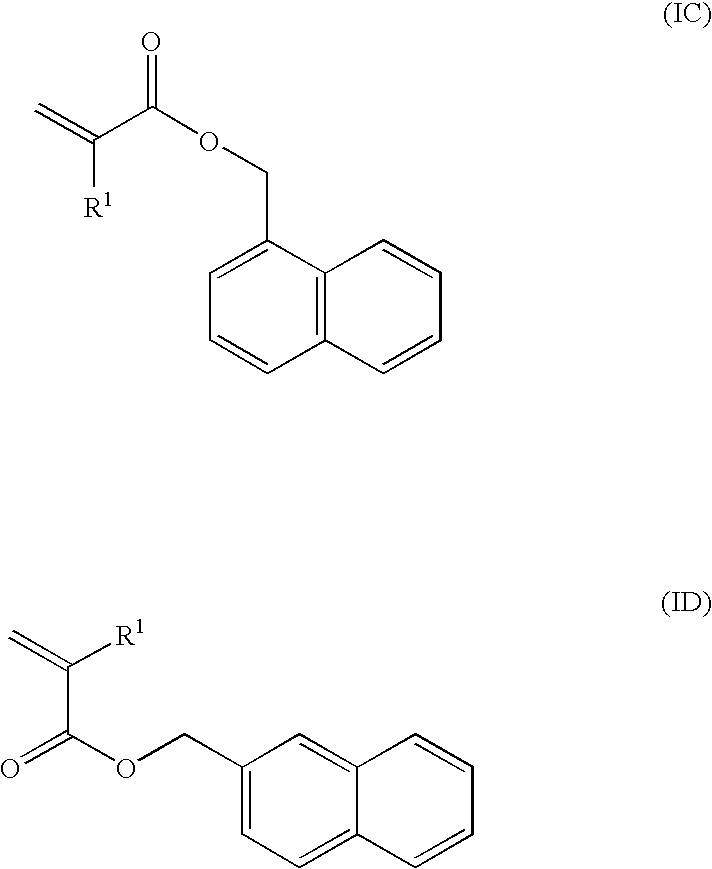

Composition for imprints, pattern and patterning method

InactiveUS20100009137A1Hardly worsening mold transferabilitySolve the real problemDecorative surface effectsLayered productsMonomerLubricant

A lubricant-containing composition for imprints comprising a polymerizable monomer and a photopolymerization initiator in combination or a resin component is excellent in patternability and mold releasability. The composition can form a pattern having a small line edge roughness after etching.

Owner:FUJIFILM CORP

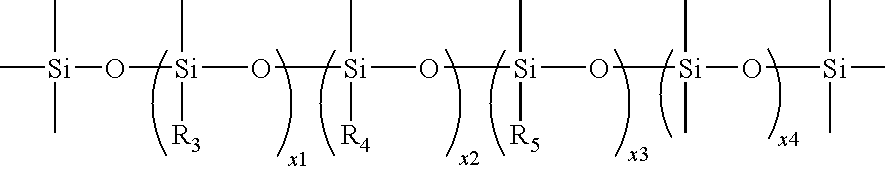

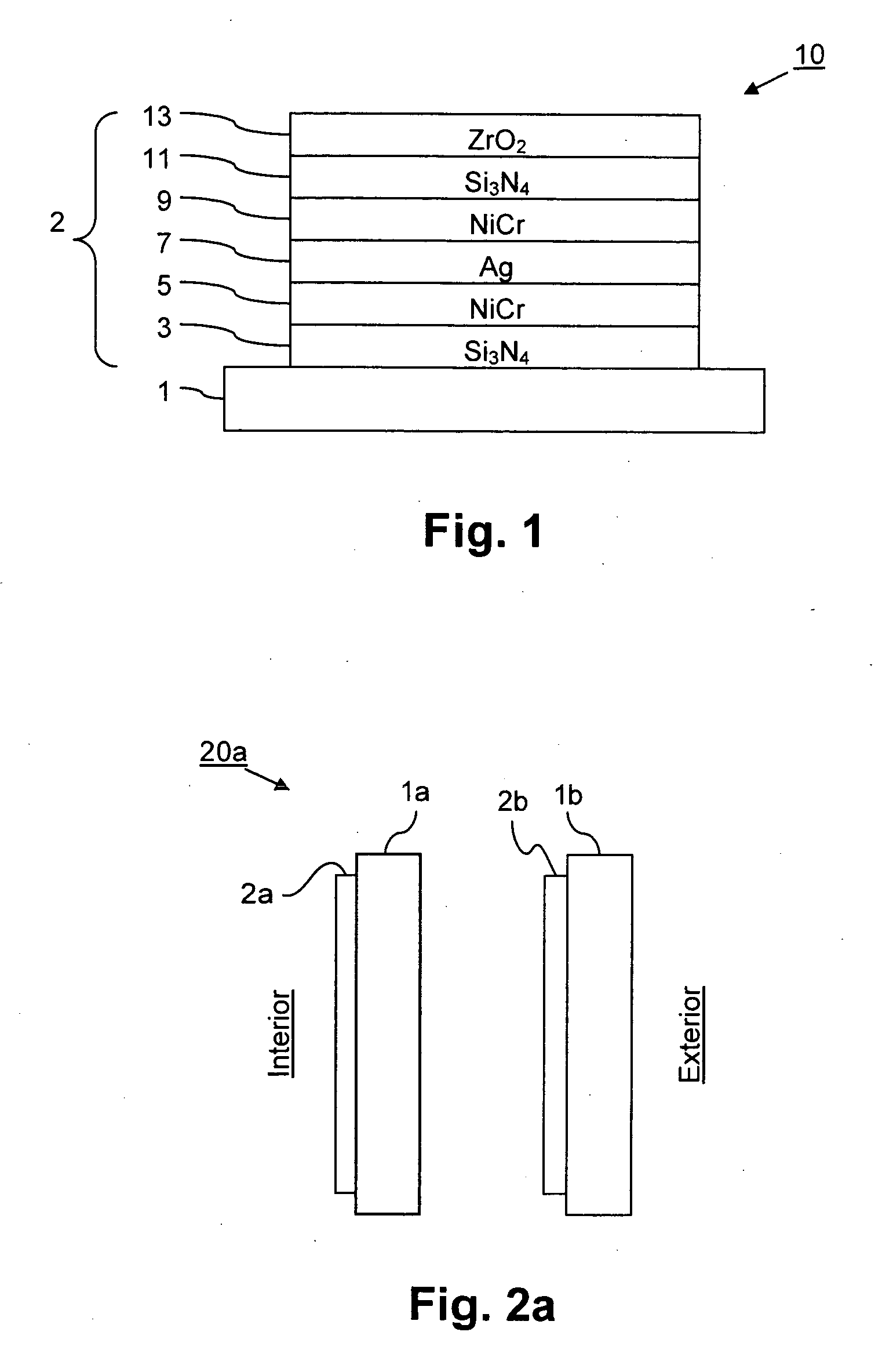

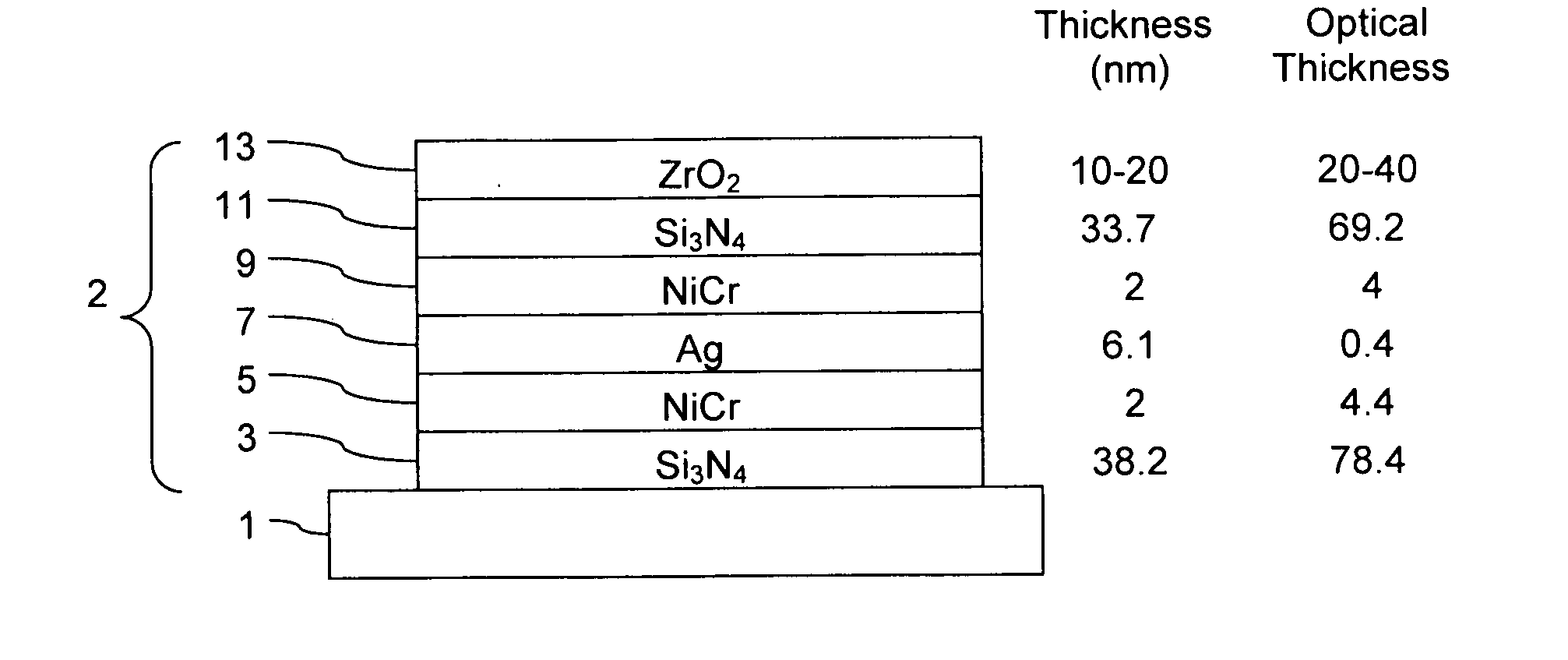

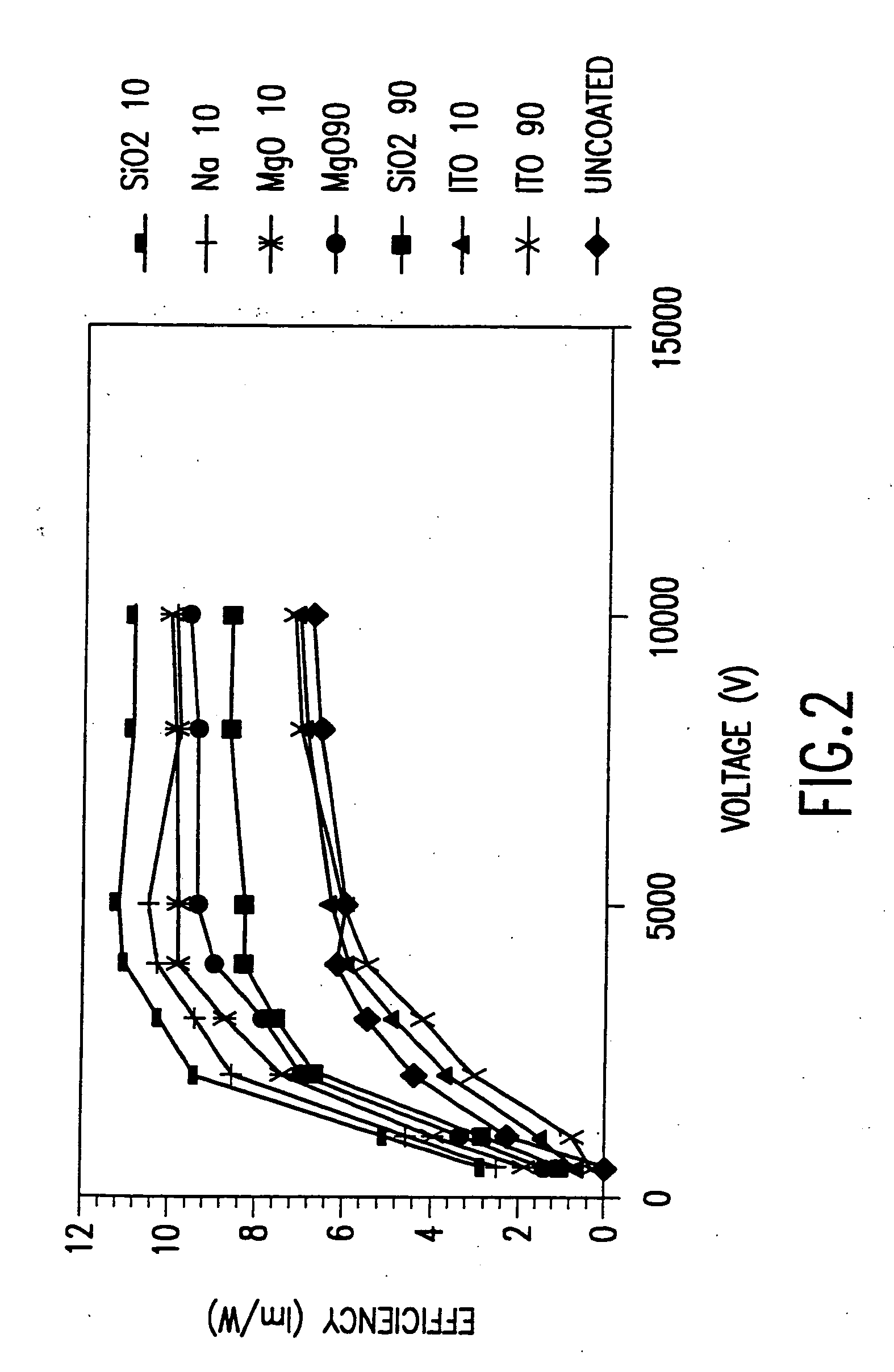

Coated article with sputter-deposited transparent conductive coating for refrigeration/freezer units, and method of making the same

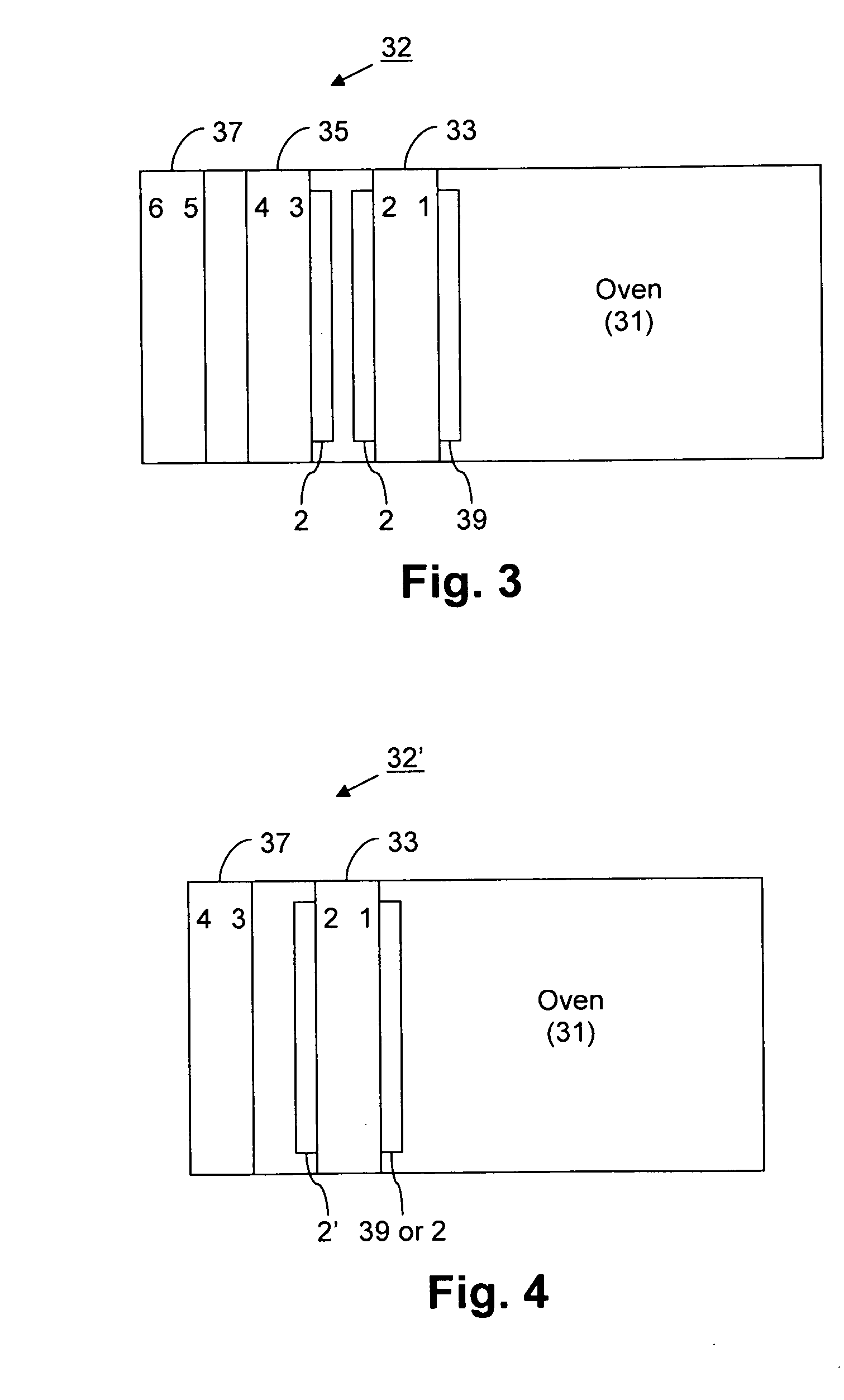

InactiveUS20100209730A1Reduce transmissionSuperior optical and thermal performance characteristicDoors for stoves/rangesLighting and heating apparatusConductive coatingSputter deposition

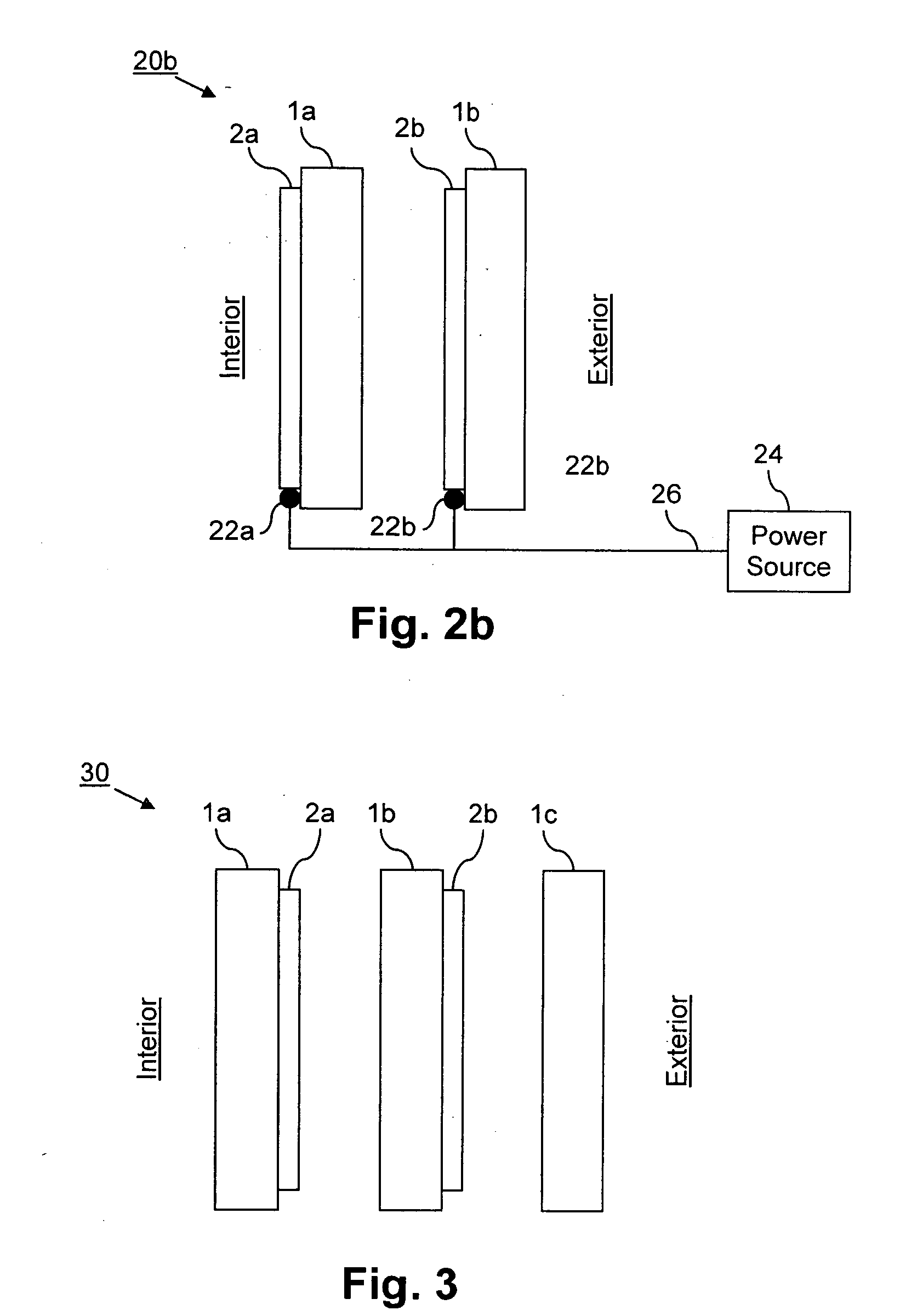

Certain example embodiments relate to sputter-deposited transparent conductive coatings (TCCs) for use in, for example, refrigeration and / or freezer units (e.g., as doors, windows, etc.). The TCC may include a silver-based conductive layer, at least partially protected by a zirconium oxide overcoat. Such TCCs may be provided in connection with monolithic or multi-substrate arrangements in different example embodiments. Certain example embodiments may involve “active” modes, where a silver-based layer in the TCC may receive a voltage, e.g., to reduce the likelihood of frosting, freezing, fogging, condensation, and / or the like, on the glass substrate that supports the TCC.

Owner:GUARDIAN GLASS LLC

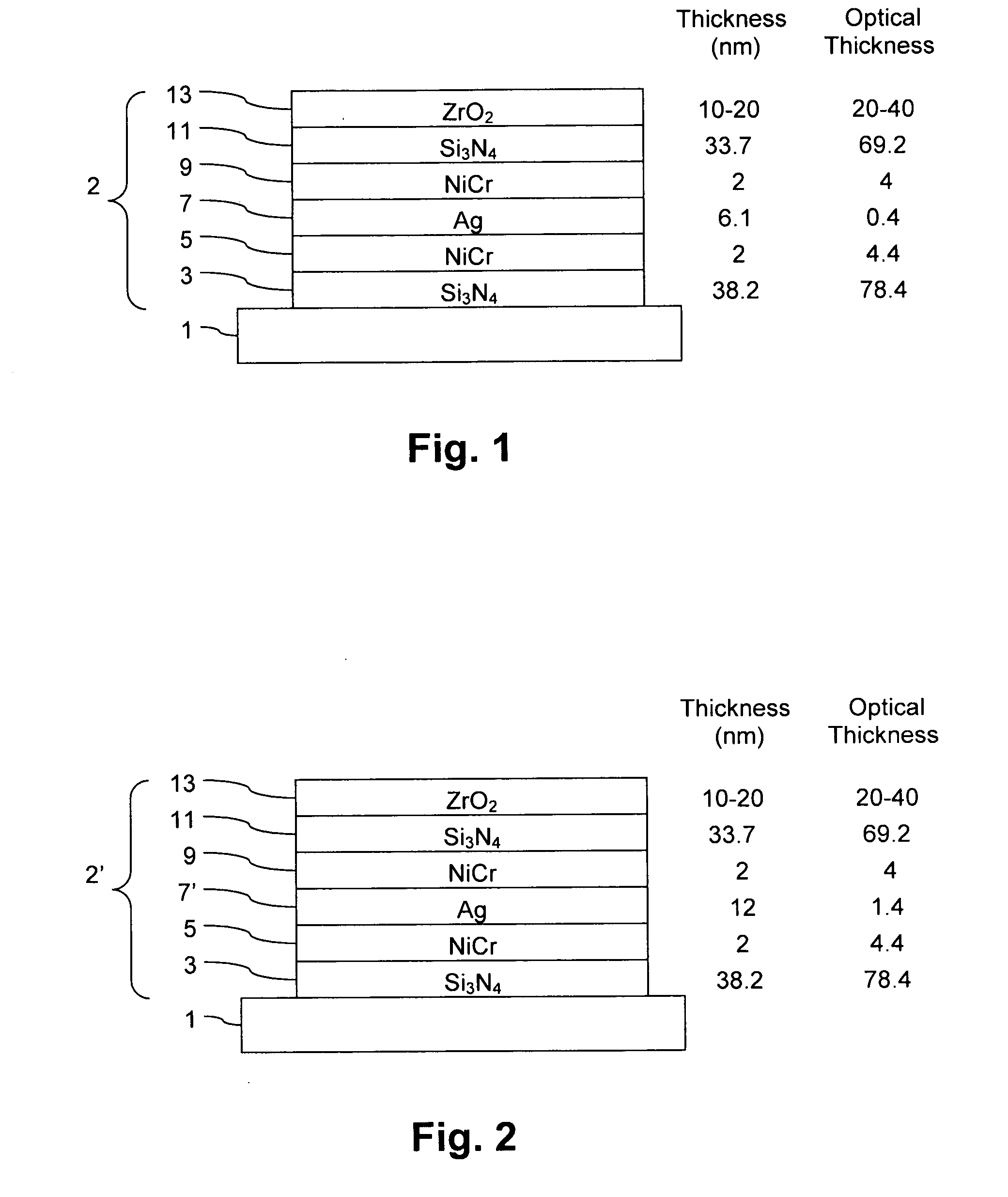

Coated article with sputter-deposited transparent conductive coating capable of surviving harsh environments, and method of making the same

InactiveUS20100209729A1Reduce heat transferSuperior optical and thermal performance characteristicDoors for stoves/rangesDomestic stoves or rangesConductive coatingEngineering

Certain example embodiments relate to sputter-deposited transparent conductive coatings (TCCs) that are capable of surviving the harsh environments of ovens so that they can be included, for example, in oven door applications. In certain example embodiments, zirconium oxide (e.g., ZrO2 or other suitable stoichiometry) may be used as a protective overcoat to protect an underlying Ag layer from corrosion in the atmosphere. In three lite oven door example embodiments, surface 1 has a TCC pyrolytically disposed thereon, surface 2 has a TCC sputter-deposited thereon and, optionally, surface 3 has a TCC sputter-deposited thereon. In two lite oven door example embodiments, surface 1 has a TCC pyrolytically disposed or sputter-deposited thereon, and surface 2 has a TCC sputter-deposited thereon.

Owner:GUARDIAN GLASS LLC

Lithium ion battery pole piece with high multiplying power and production thereof

ActiveCN1819308AGood coating uniformityUltra-thinElectrode manufacturing processesElectrode carriers/collectorsPolyvinylidene fluorideCarbon nanotube

The cell pole piece includes electrode active substance, collector, adhesive and conducting agent. The thickness of said pole piece is 40~100mum. The active substance of anode is selected from one of LiCoO2and LiMnO2 or the mixture of the both. The active substance of cathode is electrographite with grain size D50 distributed between 5~11mum. The said adhesive is polyvinylidene fluoride or Teflon. The conducting agent is selected from one of conducing carbon black, super-conduct carbon black, conductance graphite, acetylene black and carbon nano tube, or mixture of two of them above, or the mixture of more than two of them above. The weight percentage of electrode active substance, adhesive and conducting agent are 85~96%, 2~8%, 1~10% respectively.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Core-shell structured lithium nickel manganese cobalt precursor, fabrication method thereof and application thereof in lithium ion battery

ActiveCN107968198AHigh nickel content insideIncrease contentCell electrodesSecondary cellsDischarge efficiencyManganese

The invention relates to a core-shell structured lithium nickel manganese cobalt precursor, a fabrication method thereof and application thereof in a lithium ion battery. The precursor is nickel manganese cobalt carbonate and sequentially comprises an inner core and more than one shell layer from inside to outside, and mole concentration of the corresponding Ni is gradually reduced from the innercore to the shell layers sequentially arranged outside. The invention also provides a surface coated lithium nickel manganese cobalt composite material prepared by employing the precursor and the lithium ion battery employing the composite material as a positive electrode material. By the precursor, the problems that the synthesis process of a ternary nickel manganese cobalt positive electrode material is not mature and is complicated, the precursor research is neglected and the improvement of the performance of the ternary nickel manganese cobalt material is limited are solved. In the batteryprepared from a nickel-rich gradient-concentration ternary nickel manganese cobalt positive electrode material, the initial discharge specific capacity under 0.1C rate is larger 194mAh / g, the initialcharge-discharge efficiency is larger than 92%, and the capacity retention rate after circulation for 300 times under 1C rate is larger than 80%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

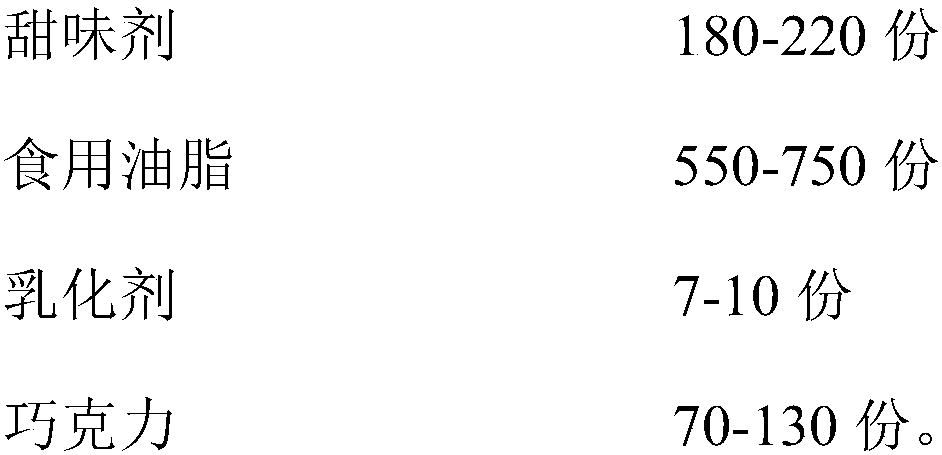

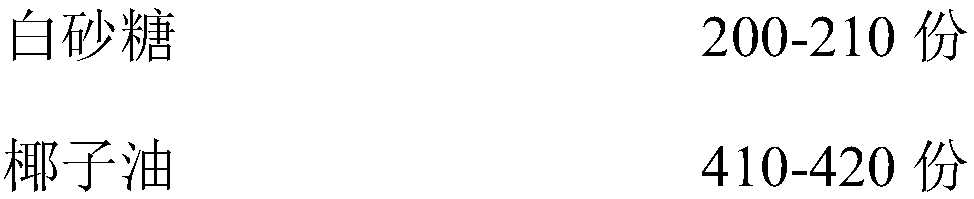

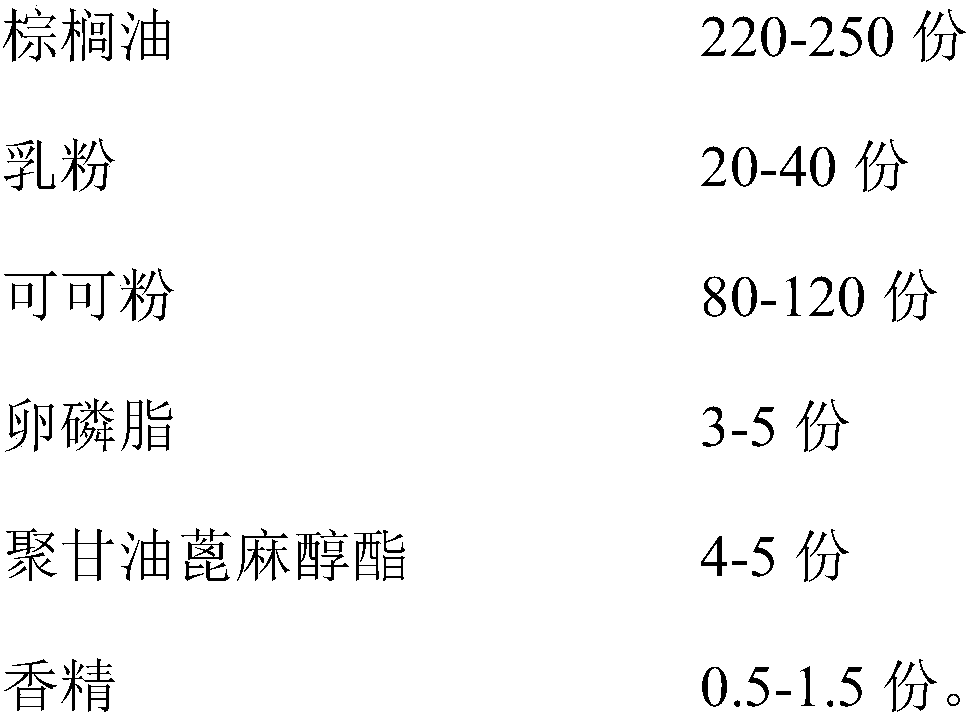

Chocolate composition, coating layer and preparation method thereof and frozen drink coated with the coating layer

The present invention discloses a chocolate composition, a coating layer and a preparation method thereof and frozen drink coated with the coating layer. The chocolate composition is prepared by a combined use of oil and an emulsifier at a specific ratio, reduces viscosity, improves fluidity of slurry, finally improves uniformity of coating of the chocolate coating layer, can flexibly adjust thickness of the chocolate coating layer, can prepare the chocolate coating layer of 2 mm or more, and can also prepare the chocolate coating layer with the thickness of 1 mm or less. At the same time, through combined cooperation and synergistic effects of a sweetener, edible oil, an emulsifier and chocolate at a specific ratio, the preparation method also avoids problems of cracking, material discharging and waxing feeling problems caused by too thin thickness of the chocolate coating layer, improves coating effects of the chocolate coating layer, and also improves taste and mouthfeel of the chocolate coating layer.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

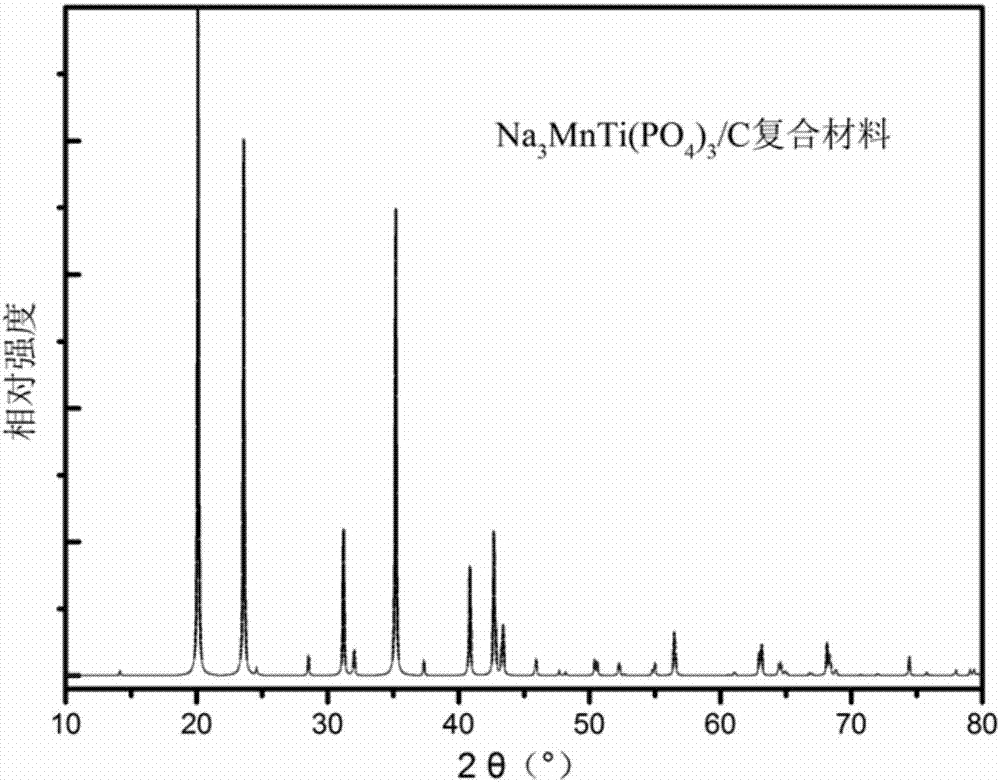

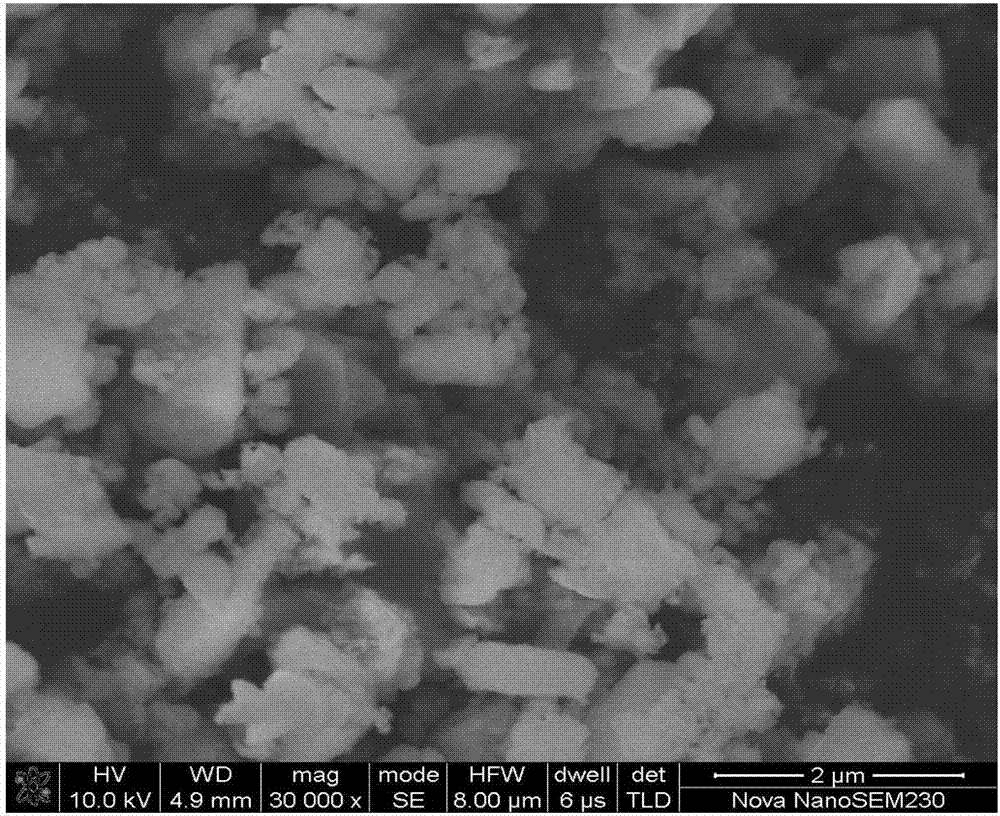

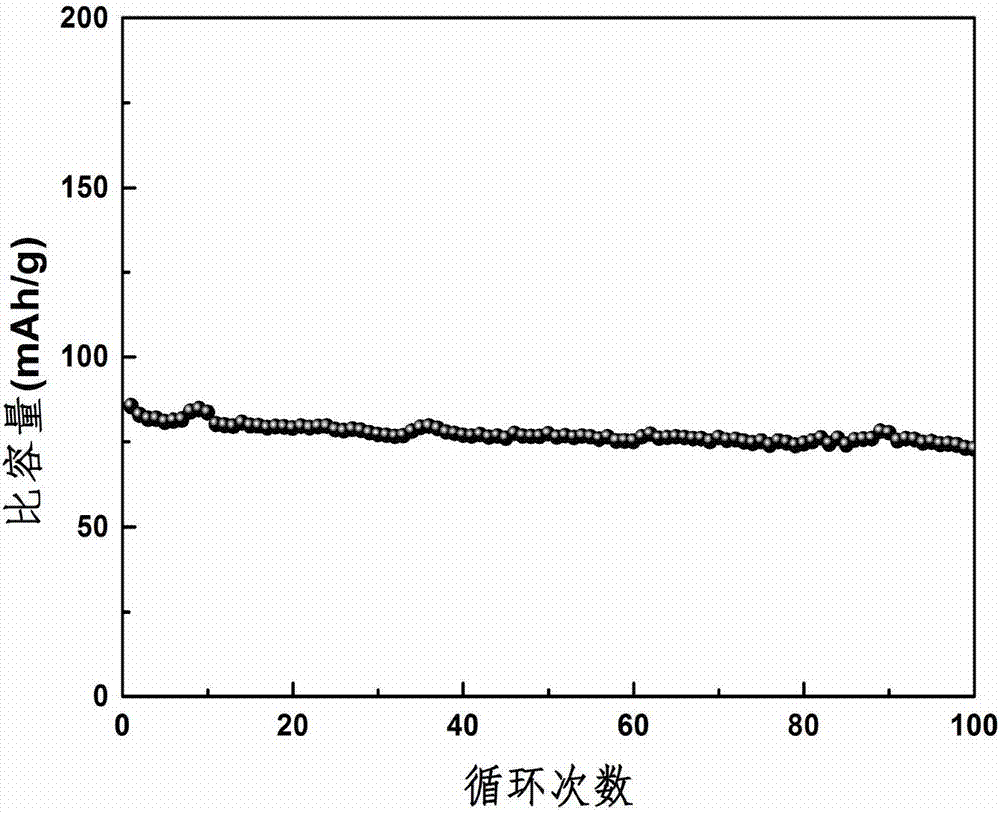

Carbon coated titanium manganese sodium phosphate composite material, preparation method and application thereof in sodium-ion battery

ActiveCN106981641AImprove stabilityImprove conductivityCell electrodesSecondary cellsSodium phosphatesHigh energy

The invention discloses a Na3MnTi(PO4)3 / C composite material, a preparation method and an application thereof in a sodium-ion battery. The composite material is composed of carbon coated Na3MnTi(PO4)3 particles. The preparation method comprises the following steps: utilizing an organic matter as a reducing agent and a carbon source, taking low-cost manganese source and titanium source as raw materials and adopting a solid phase method for synthesizing a carbon coated Na3MnTi(PO4)3 composite anode material with an excellent performance. The preparation method is simple and practicable, the condition is mild and the yield is high. When the prepared composite material is used as an anode material of the sodium-ion battery, the anode material shows high energy density, high working voltage, excellent circulatory stability and excellent rate capability.

Owner:湖南钠邦新能源有限公司

Composition for imprints, pattern and patterning method

InactiveUS20110183127A1Hardly worsening mold transferabilityImprove coating uniformityLayered productsDecorative surface effectsSiliconContamination

A composition for imprints comprising a polymerizable monomer, a photopolymerization initiator, and a polymer having a functional group with at least one of a fluorine atom or a silicon atom and having a polymerizable functional group, wherein the polymer has a weight-average molecular weight of at least 2000 and the amount of the polymer is from 0.01 to 20% by mass relative to the polymerizable monomer, is excellent in patternability and mold releasability, capable of forming good patterns and free from a problem of mold contamination.

Owner:FUJIFILM CORP

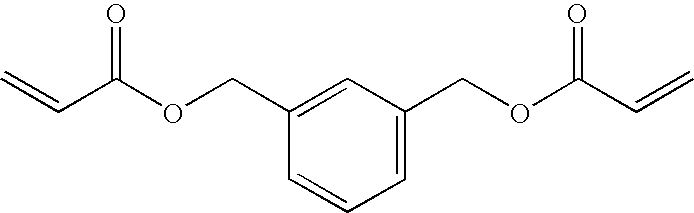

Curable composition for imprints, patterning method and pattern

ActiveUS20100009287A1Worsening mold transferabilitySolve the real problemPhotosensitive materialsLayered productsOrganic chemistryViscosity

A curable composition for imprints, comprising at least one polymerizable monomer and a photopolymerization initiator, wherein the content of a polymerizable monomer having a viscosity at 25° C. of 7 mPa·s or more is 80% by mass or more, relative to all the polymerizable monomers contained in the composition. The curable composition for imprints has low volatility of the components even in a thin film coating on a substrate and is thus capable of forming a good pattern.

Owner:FUJIFILM CORP

Composite carbon material, modified electrode material prepared from composite carbon material and lithium ion battery

ActiveCN107706403AImprove stabilityImprove coating uniformityCell electrodesCarbonizationSodium-ion battery

The invention discloses a composite carbon material, a modified electrode material prepared from the composite carbon material and a lithium ion battery. The composite carbon material contains a firstcarbon material, a second carbon material and a carbon source, wherein the first carbon material and the second carbon material are doped carbon materials. Compared with a conventional manner for firstly coating by virtue of a carbon source for carbonization to obtain a carbon material coating layer, the composite carbon material has the advantages that by introducing a proper amount of the firstcarbon materials and a proper amount of the second carbon materials, on one hand, the use amount of a common carbon source is reduced, and on the other hand, the electrochemical properties of structure stability, electrical conductivity, tap density, volume energy density, rate capability, cycle performance and the like of an electrode material modified by the composite carbon material can be cooperatively improved. By coating and modifying lithium iron phosphate by virtue of the composite carbon material, the rate capability and cycling stability of lithium iron phosphate can be substantially improved, the specific discharge capacity of lithium iron phosphate is more than or equal to 149mAh / g under a 6C rate condition, and the capacity retention ratio is more than or equal to 97% after 60 cycles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Treating solution for forming fluoride coating film and method for forming fluoride coating film

InactiveUS20080241368A1Lower reaction temperatureAmount of timeDispersed particle filtrationSemiconductor/solid-state device manufacturingAlkaline earth metalX-ray

A conventional method for forming an insulating film on a magnet has a difficulty in achieving sufficient improvement in magnetic characteristics due to nonuniformity of a coating film, and an extended time and higher temperature which are required in a thermal treatment. In order to solve the problems, the present invention provides a treating solution composed of an alcohol based solvent and a rare earth fluoride or alkaline earth metal fluoride dispersing in the solvent. In the treating solution, at least one X-ray diffraction peak has a half-value width larger than 1°. The present invention also provides a method for forming an insulating film using the treating solution.

Owner:HITACHI CHEM CO LTD

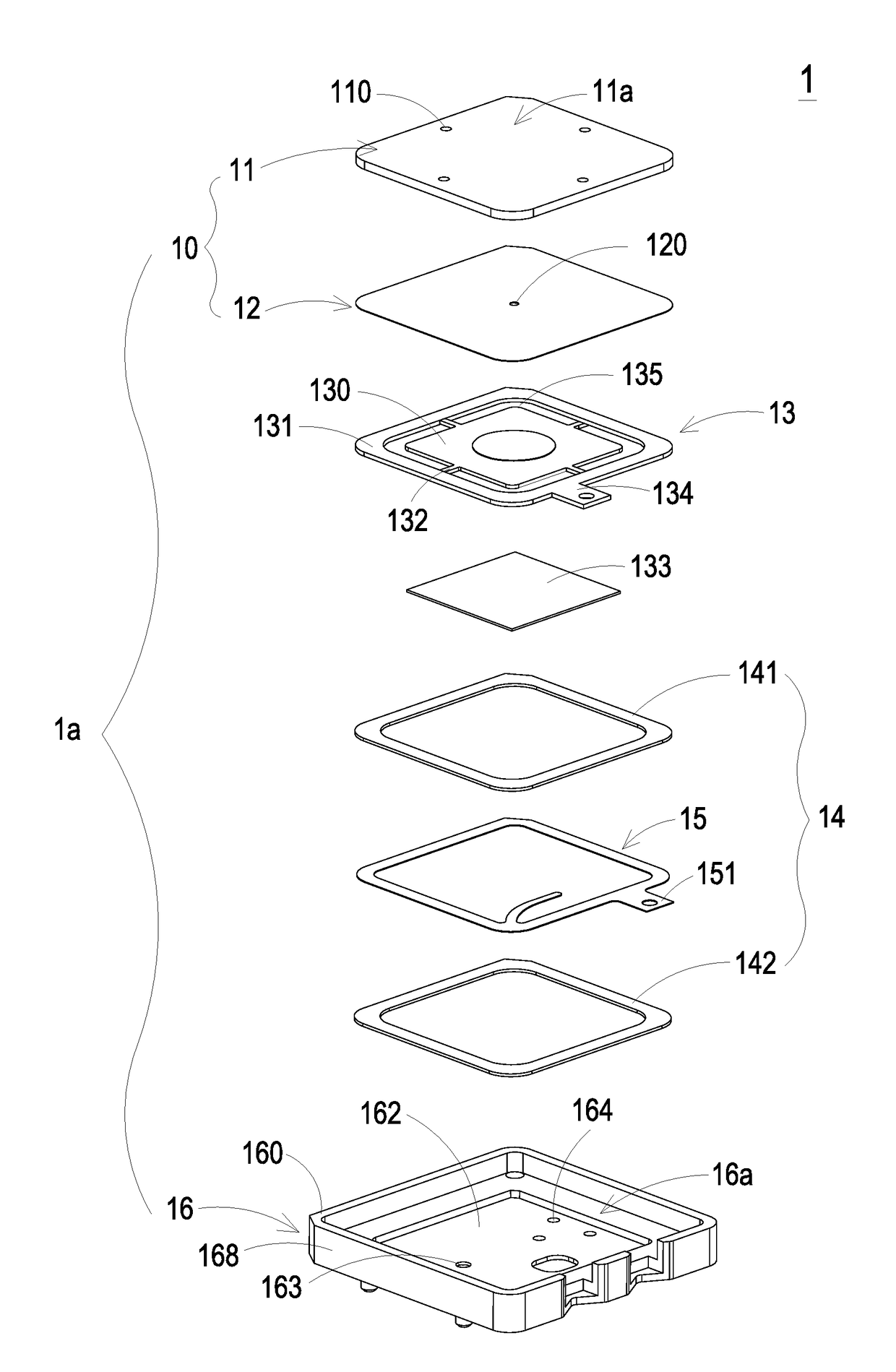

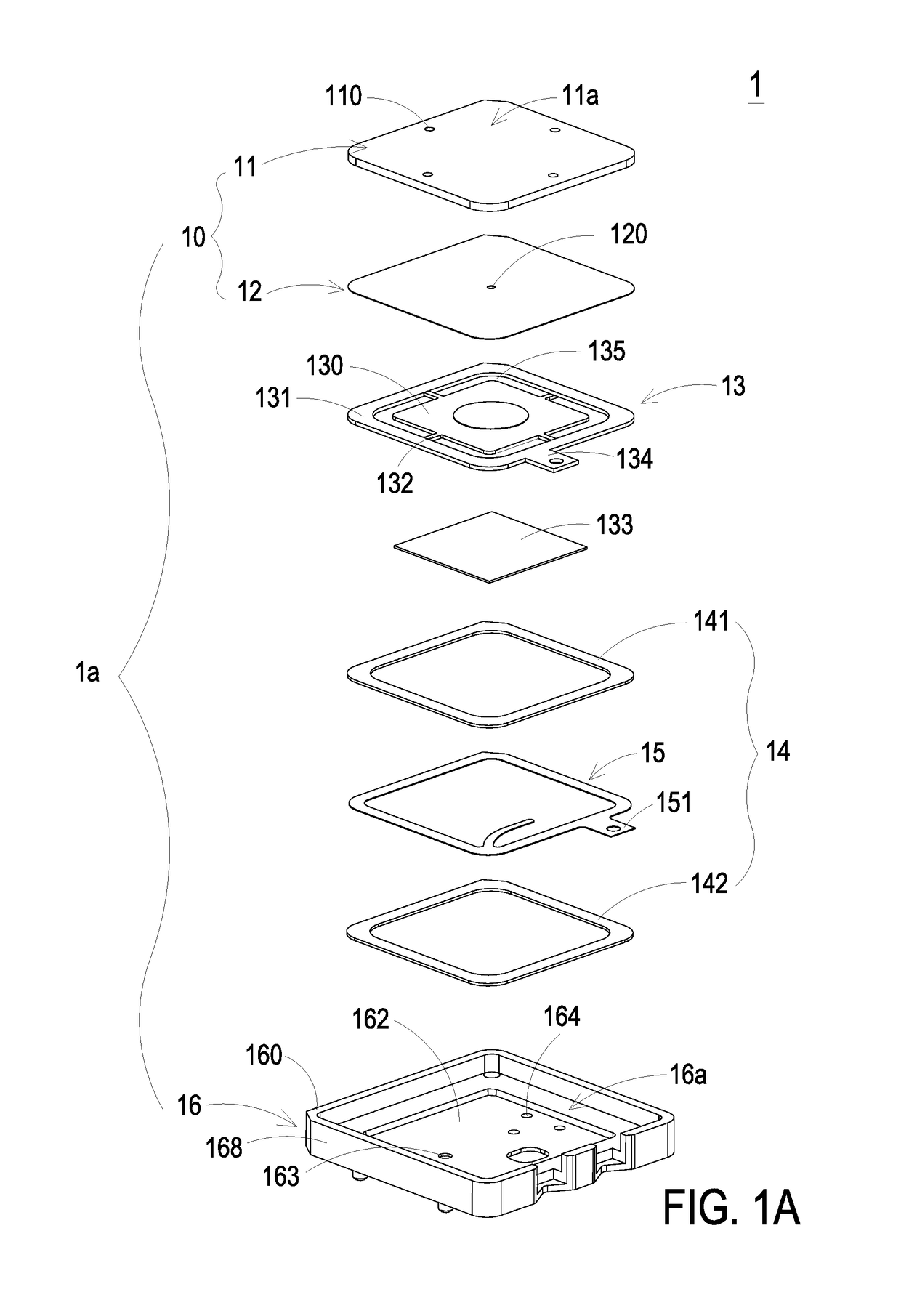

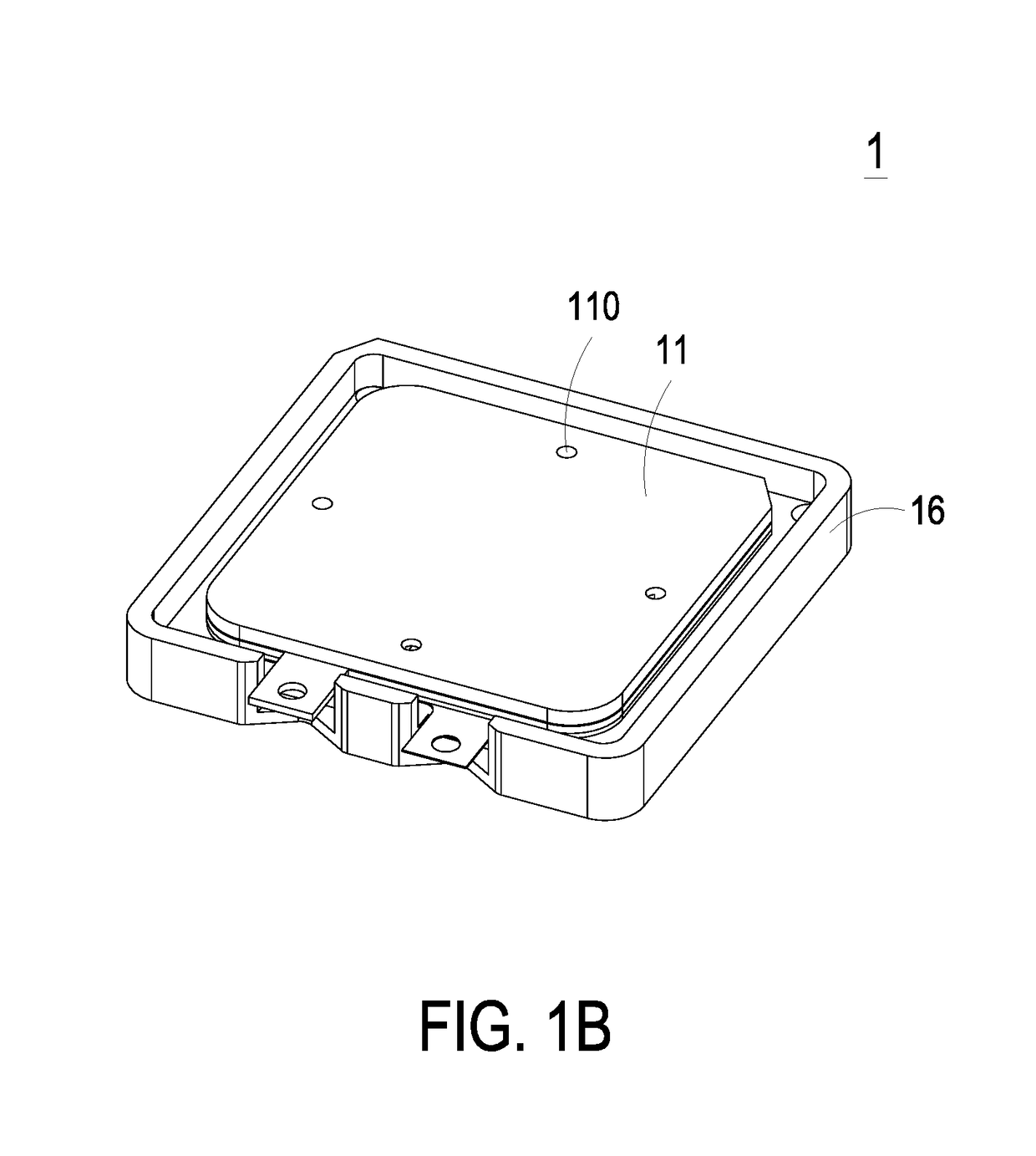

Miniature fluid control device and piezoelectric actuator thereof

ActiveUS20180066768A1Steadiness and performance be intensifyDecrease motionValve arrangementsPiezoelectric/electrostriction/magnetostriction machinesEngineeringPiezoelectric actuators

A piezoelectric actuator includes a square suspension plate, an outer frame, plural brackets and a square piezoelectric ceramic plate. The outer frame is arranged around the suspension plate. A second surface of the outer frame and a second surface of the suspension plate are coplanar with each other. The plural brackets are perpendicularly connected between the suspension plate and the outer frame for elastically supporting the suspension plate. Each bracket has a length in a range between 1.11 mm and 1.21 mm and a width in a range between 0.2 mm and 0.6 mm. A length of the piezoelectric ceramic plate is not larger than a length of the suspension plate. The piezoelectric ceramic plate is attached on a first surface of the suspension plate.

Owner:MICROJET TECH

Method for preparing polyanionic lithium ion battery anode material

InactiveCN101794878AMixed changeChange the physical and chemical properties of the surfaceCell electrodesDispersityCalcination

The invention discloses a method for preparing a polyanionic lithium ion battery anode material. The anode material is LixMXO4 / C compound, wherein M denotes a transition metal element and X denotes phosphorus, silicon or sulfur. Solid-liquid mixed dispersing agent is added in the material mixing of solid-phase synthesis to change the surface physical and chemical properties of the materials and to enable the dispersity of material particles to be good. The solid-liquid mixed dispersing agent can effectively inhibit the growth of the particles and the conglobation among particles in the process of high-temperature calcinations. The distribution of the grain size of the prepared anode material particles is even, carbon is evenly coated on the surface of the LixMXO4 particles, the electron and ion conductivity is high, the specific capacity is close to the theoretical capacity of the compound and the rate discharge performance is excellent.

Owner:PULEAD TECH IND

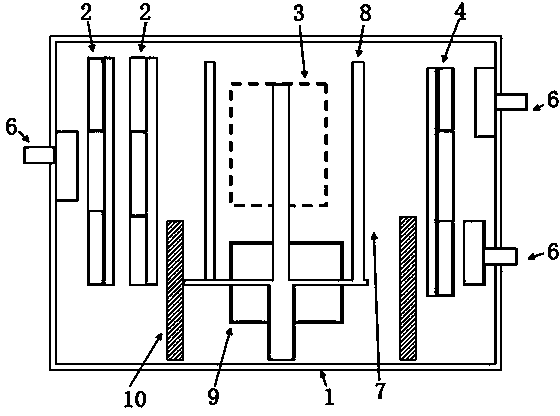

Multifunctional fully-automatic ion-plating machine for deposition of cutting tool coating and using method of multifunctional fully-automatic ion-plating machine

ActiveCN103695858AIncrease profitIncrease gas ionization rateVacuum evaporation coatingSputtering coatingAlloyOxygen

The invention relates to the technical field of thin film materials, in particular to a multifunctional fully-automatic ion-plating machine for the deposition of a cutting tool coating. The machine comprises a vacuum chamber, bipolar pulse magnetron sputtering targets, a rectangular anode layer gas ion source, a high-power pulse magnetron sputtering source, a bias power supply, cathode arc sources, a workpiece rack and a support, wherein the bipolar pulse magnetron sputtering targets, the anode layer gas ion source, the high-power pulse magnetron sputtering source, the bias power supply and the cathode arc sources are controlled through five groups of independent switches respectively. Due to the adoption of the structure, pure metal, alloy and reaction film layers can be prepared, and multi-element and multilayer nanometer composite coatings and oxygen-containing coatings can also be prepared to meet the requirements of metal cutting tools with different shapes and sizes on high-speed machining.

Owner:GUANGDONG UNIV OF TECH

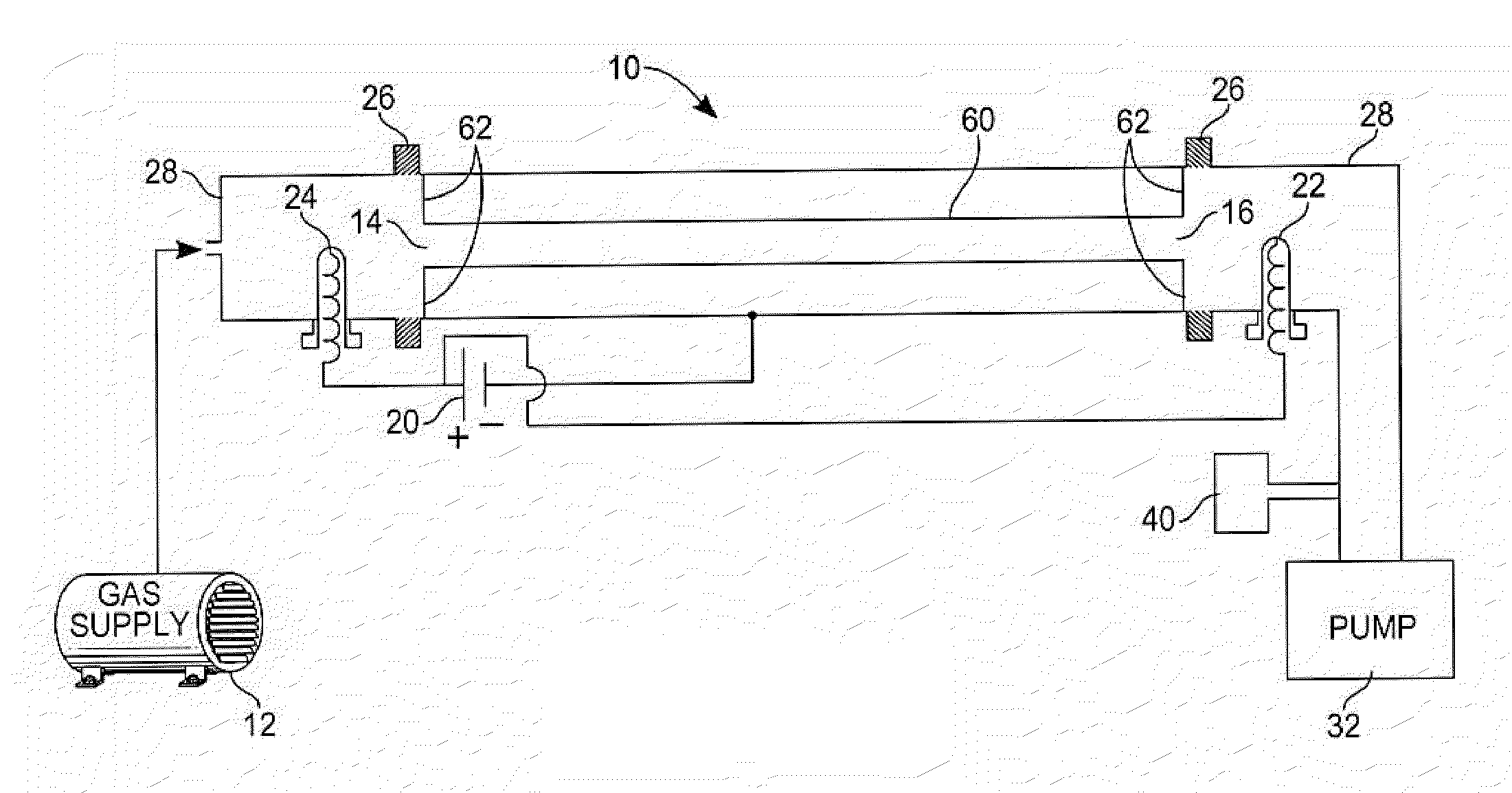

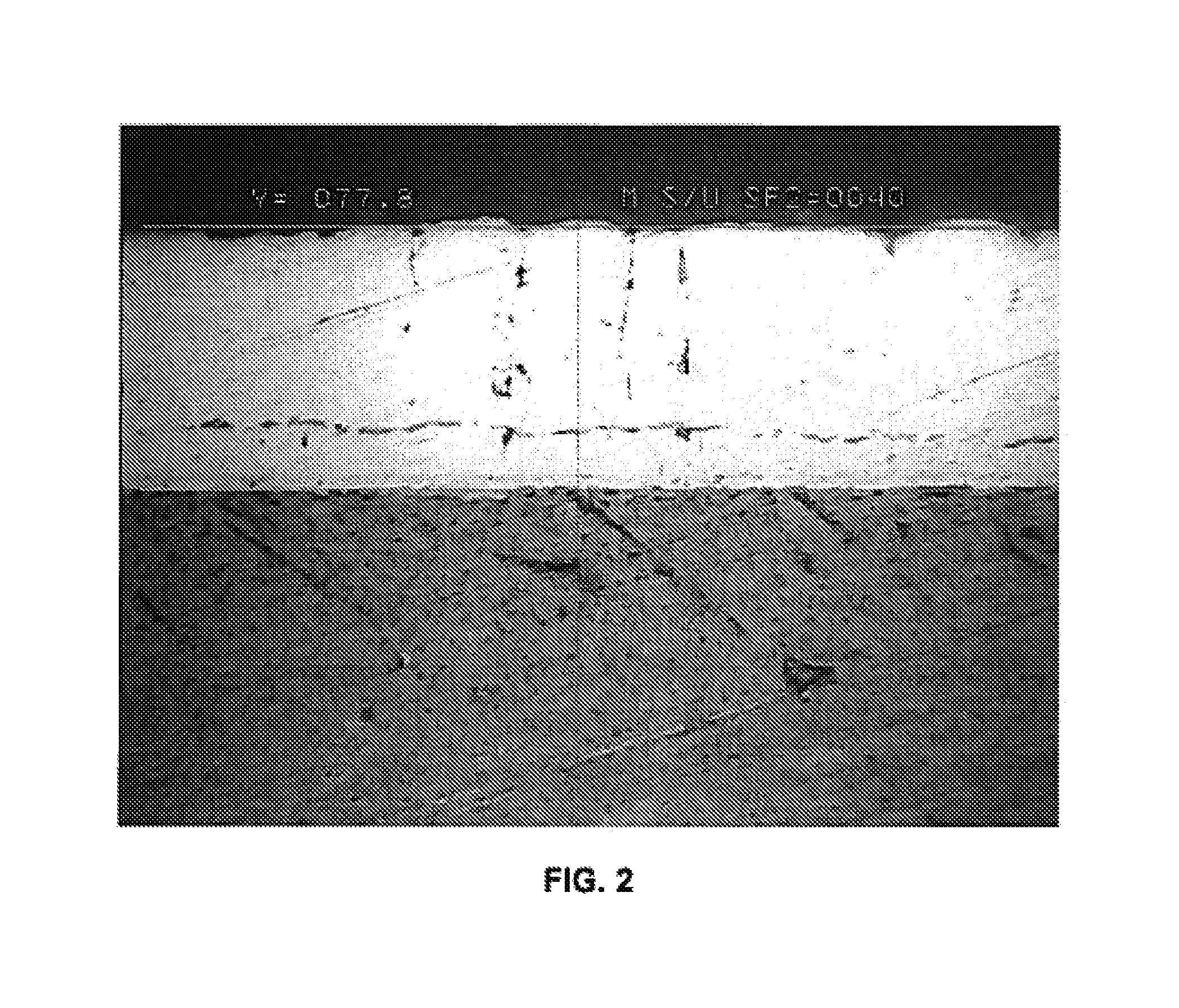

Method of coating inner and outer surfaces of pipes for thermal solar and other applications

ActiveUS20090311443A1Increase ionization rateReduce quality problemsSolar heating energyLiquid surface applicatorsMetallurgyMetal

In accordance with one embodiment of the invention, a workpiece having a smaller cross sectional dimension (e.g., diameter) is centered within a workpiece having a larger cross sectional dimension, with the workpieces being electrically connected. In this embodiment, surfaces of the two workpieces can be coated simultaneously, either with the same coating material or different coating materials. In another embodiment, holes are located along the length of an internal metal tube which functions as a gas distribution injector and anode holder. A ceramic liner may be placed inside the internal metal tube, with a conductive wire within the ceramic liner. The internal metal tube may be biased as a cathode, while the internal wire is biased as an anode. The hollow cathode effect is applied in all spaces directly adjacent to the surface or surfaces being coated. In some applications, different surfaces being coated are biased at different voltages.

Owner:AGM CONTAINER CONTROLS

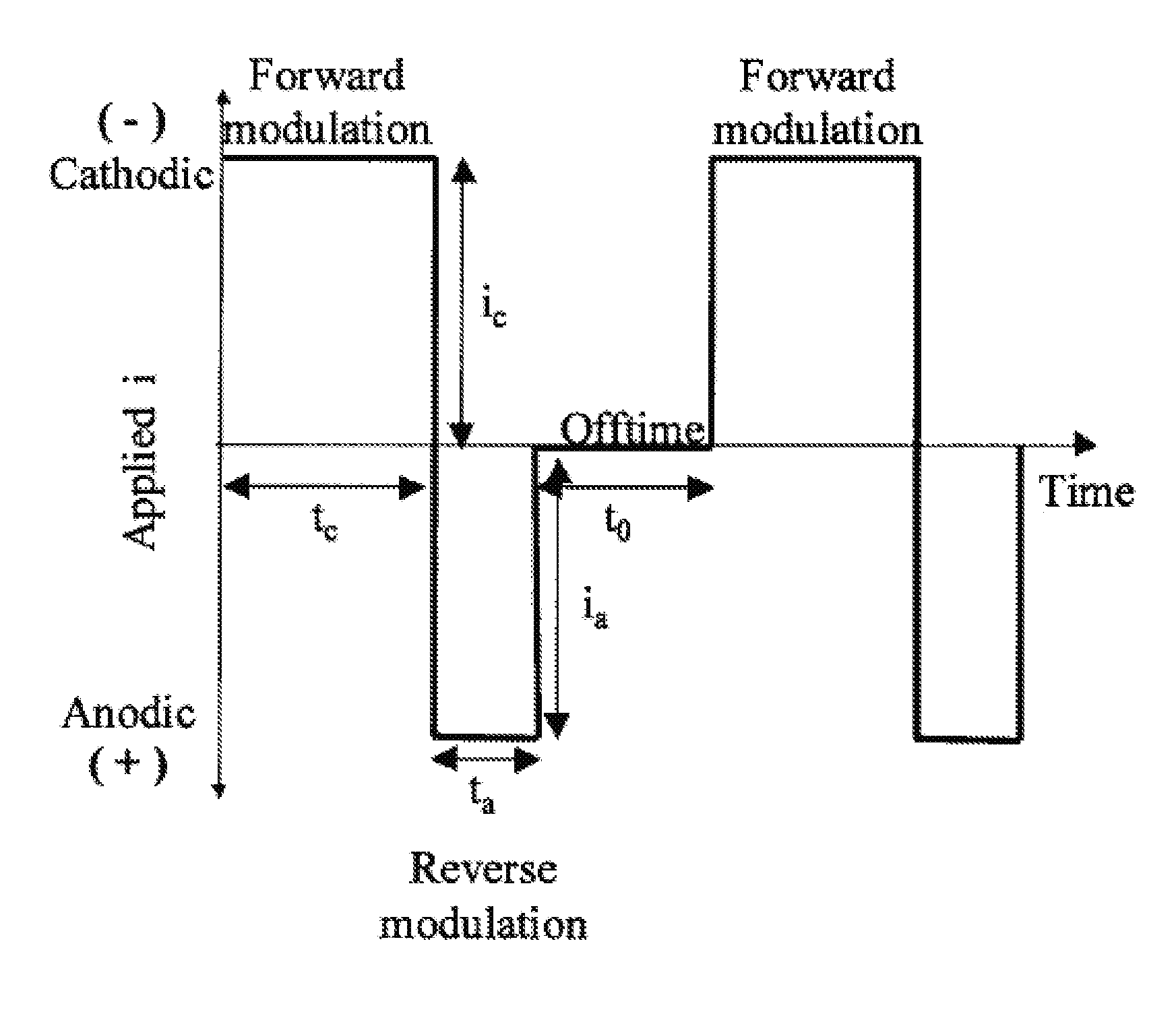

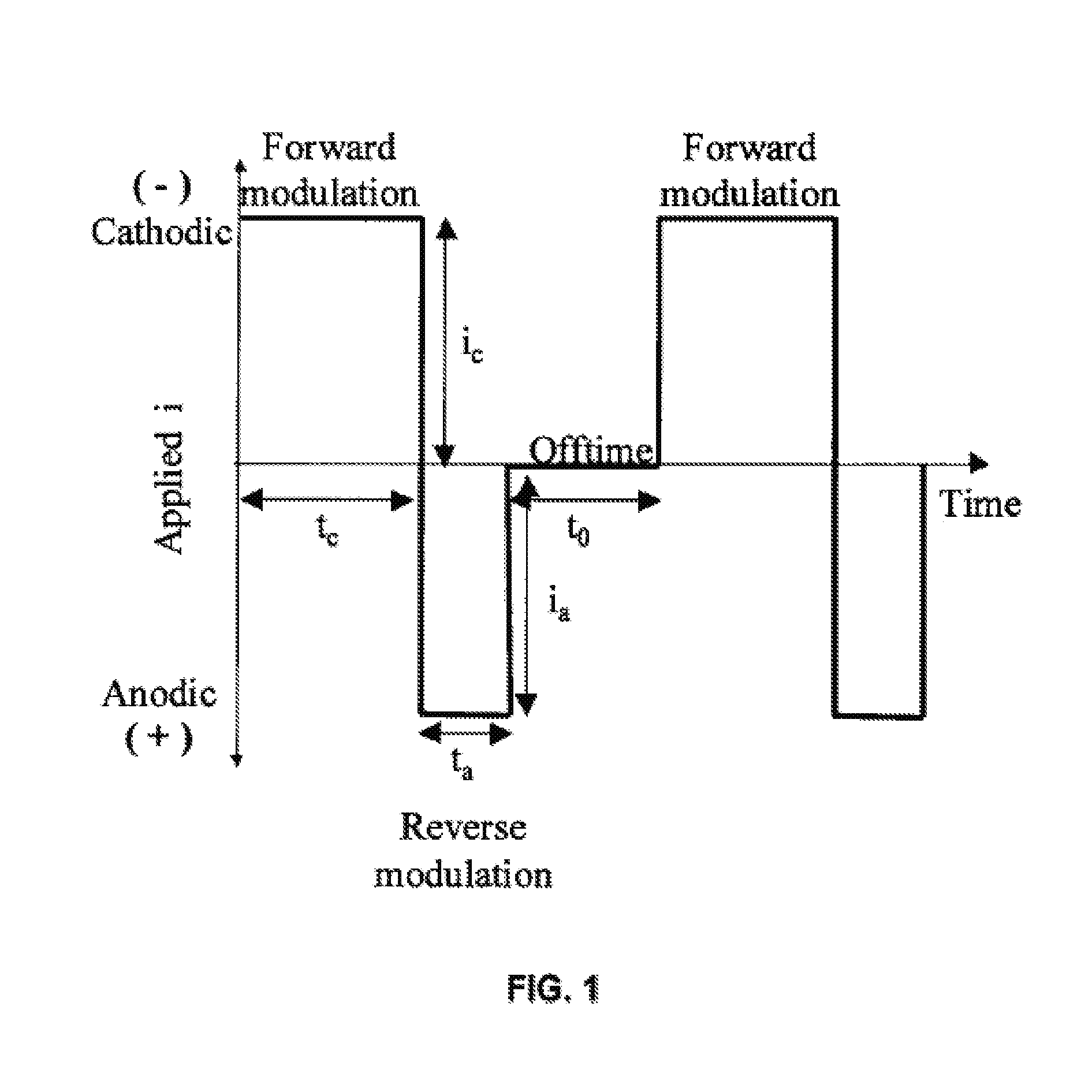

Electrodeposition of chromium from trivalent chromium using modulated electric fields

A layer of chromium metal is electroplated from trivalent chromium onto an electrically conducting substrate by immersing the substrate and a counter electrode in a electroplating bath and passing a modulated electric current between the electrodes. In one embodiment, the current contains pulses that are cathodic with respect to said substrate and in another embodiment the current contains pulses that are cathodic and pulses that are anodic with respect to said substrate. The cathodic pulses have a duty cycle greater than about 80%.

Owner:FARADAY TECH INC

Curable composition for imprints, patterning method and pattern

InactiveUS20130052431A1Solve the real problemImprove coating uniformityDecorative surface effectsLayered productsOrganic chemistryPolymerization

Provided is a curable composition for imprints capable of ensuring good patternability after repetitive transfer of pattern, and less causative of defects. The curable composition for imprints comprising a polymerizable compound (A), a photo-polymerization initiator (B) and a non-polymerizable compound (C); the non-polymerizable compound (C) dissolving into the curable composition for imprints in an exothermic manner.

Owner:FUJIFILM CORP

Curable composition for nanoimprint, and patterning method

ActiveUS8025833B2Hardly worsening mold transferabilitySolve the real problemOrganic chemistryPhotosensitive materialsMonomerChemistry

Owner:FUJIFILM CORP

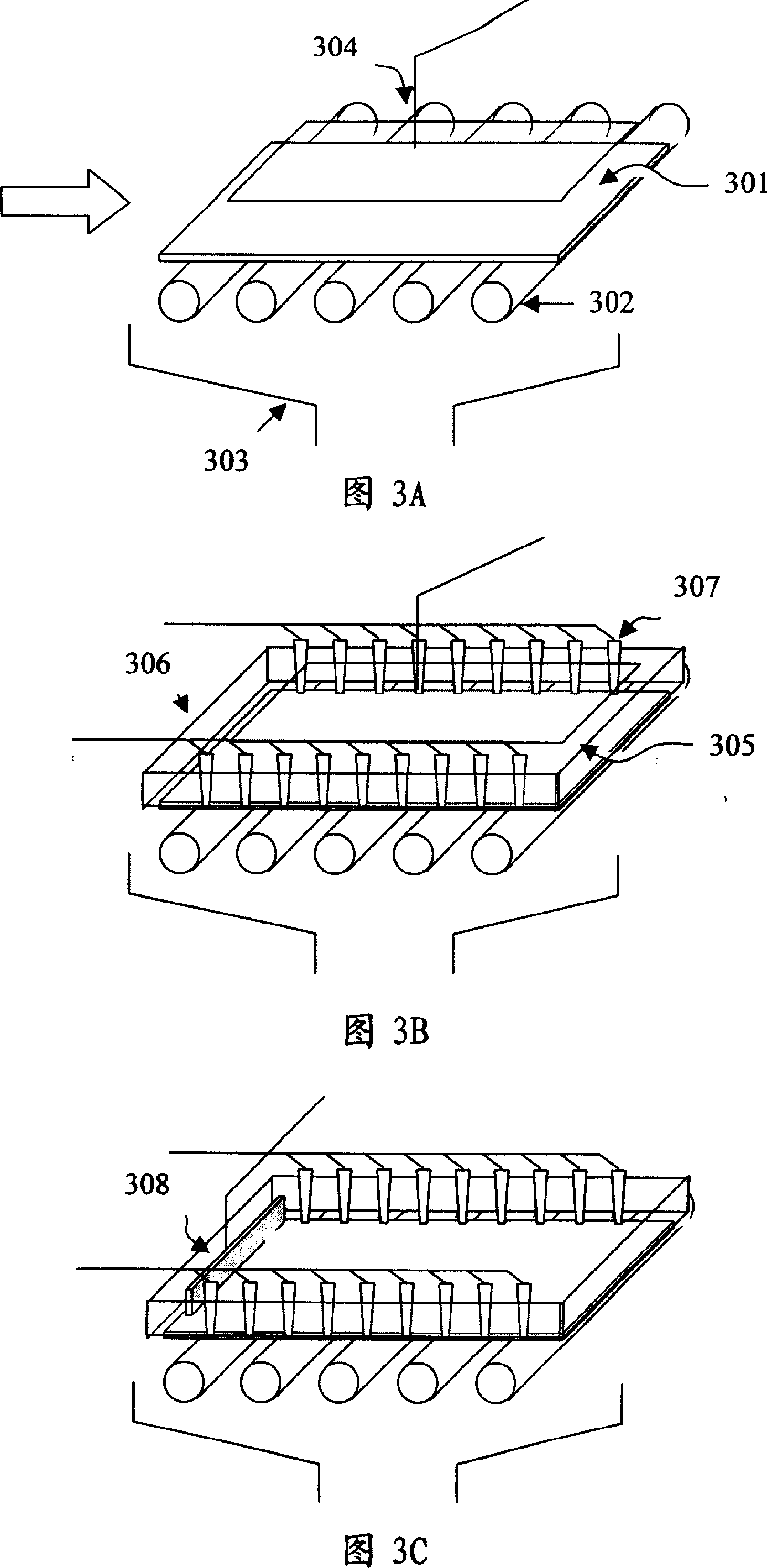

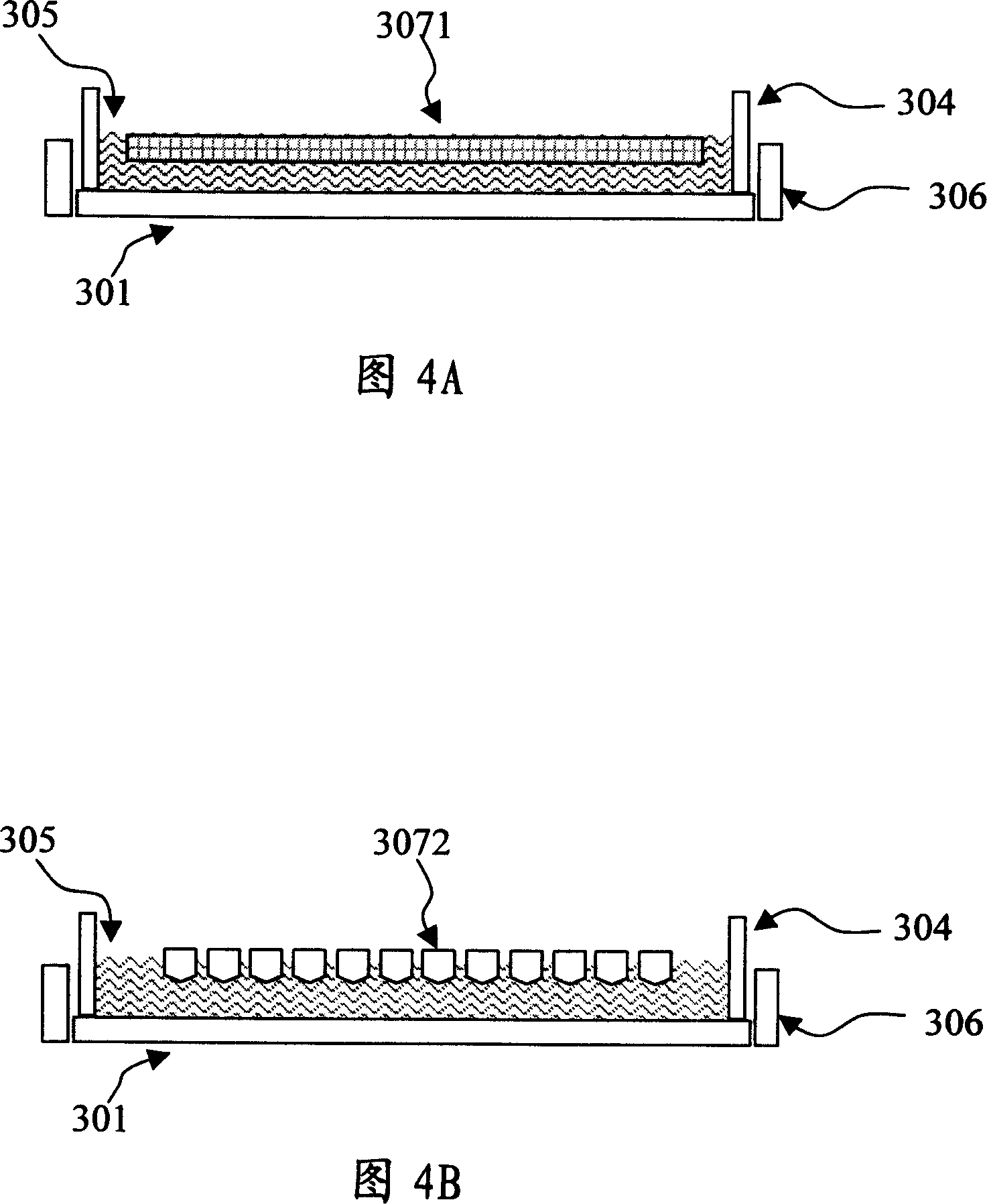

Method of horizontally plating, electrodepositing or electrodeless plating processing on substrate

InactiveCN101109094AAvoid scratchesImprove coating uniformityElectrolysis componentsOxidation reductionColor gel

A level electroplating equipment comprises essentially a group of plating-solution baffles, a group of first electrodes, a group of reticulated, surface-like or needle-like second electrodes, and an electrode regeneration and plating-solution recycling system. When the baseplate is sent horizontally for positioning, the plating-solution slowly flowing plate and the contact cathode will clamp and conduct electricity for the baseplate; then by filling plating solution and contacting with the anode at upper, an electro plating environment is formed so as to carry out one-side plating for the baseplate at the side of cathode; or by filling electro-deposition solution and contacting with the anode at upper, an electro-deposition environment is formed, so as to carry out one-side electro deposition at the side of the anode for color optic filter pigment, dyestuff, or electro conductive photoresistor. The invention provides a level electroplating / electro-deposition / electrode-free electroplating equipment, can be used for electroplating an one-side even and horizontal film on the upper surface of a baseplate, for electro deposition of color optic filter pigment, dyestuff, or electro conductive photoresistor, or for depositing metallic film on a single side by chemical oxidation-reduction method.

Owner:廖智良

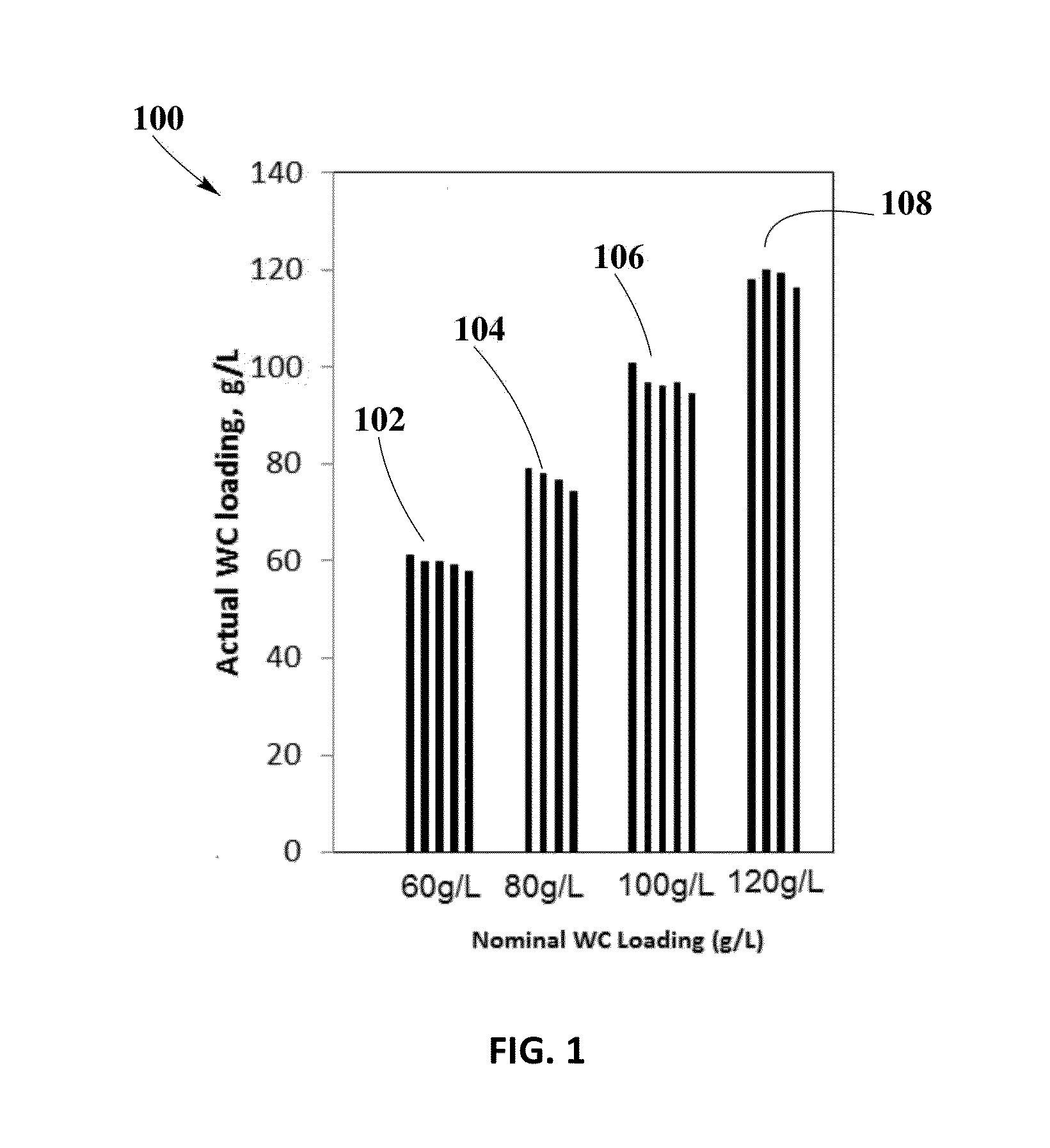

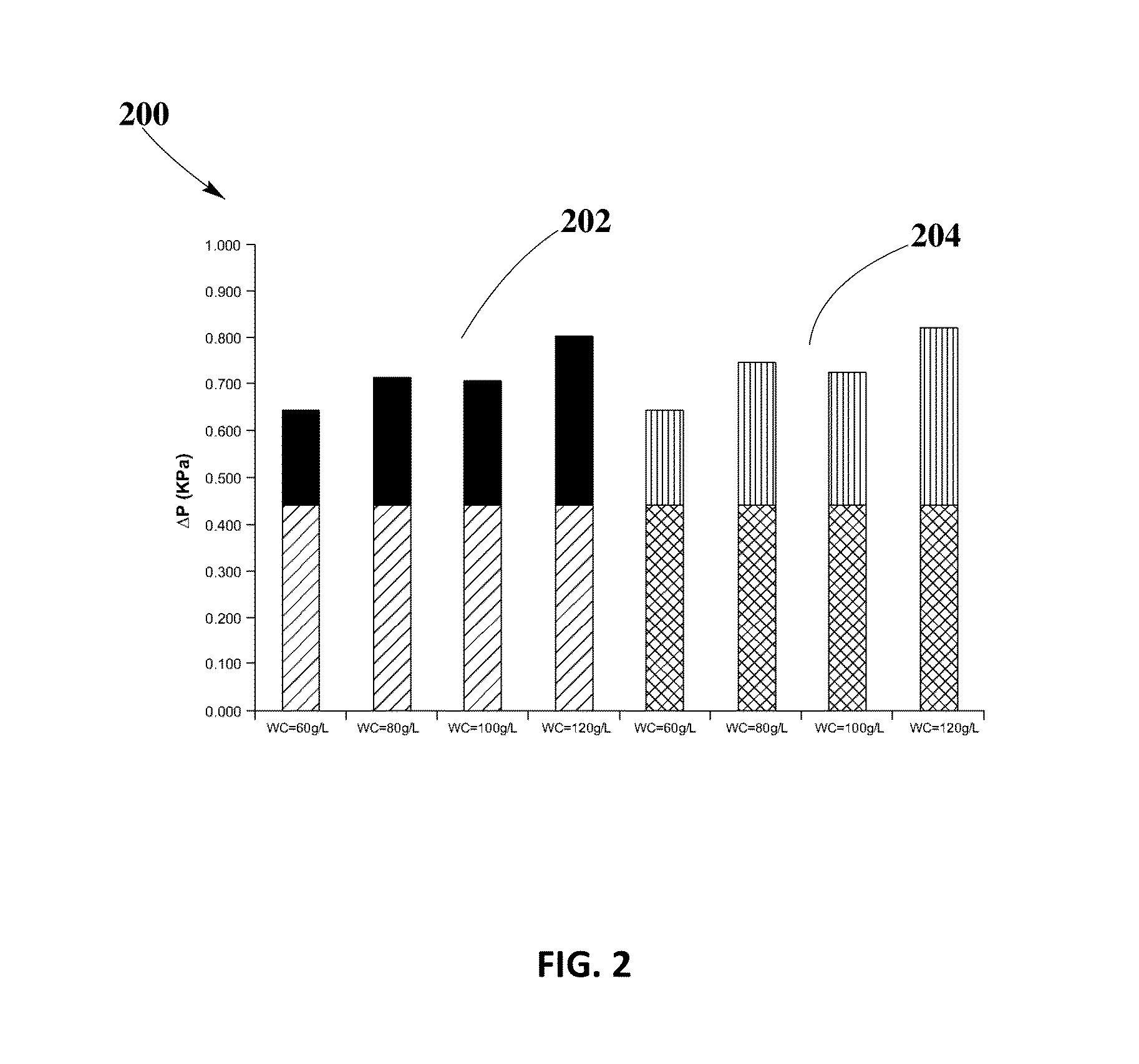

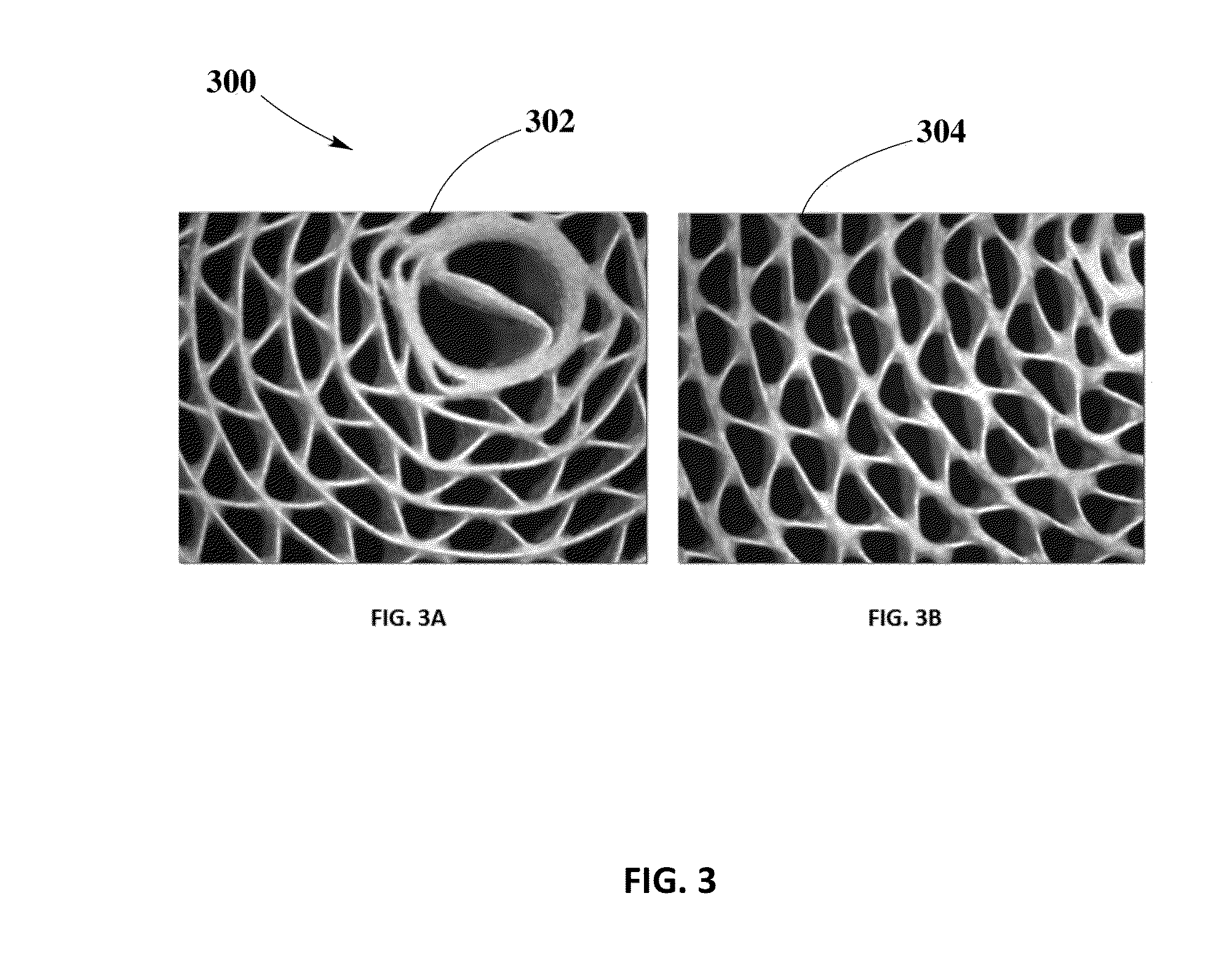

Variations of Loading of Zero-PGM Oxidation Catalyst on Metallic Substrate

InactiveUS20150018202A1Improve coating uniformityImprove catalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetallic substrateCatalytic test

The present disclosure refers to processes and formulations employed for optimization of variations of Zero-PGM catalyst coated on metallic substrates. Deposition of a uniform and well-adhered layer of catalyst on the metallic substrate may be enabled by the selection of a washcoat loading resulting from variation of metal loadings. Characterization of catalysts may be performed using a plurality of catalytic tests, including but not limited to washcoating adherence test, back pressure test, inspection of textural characteristics, and catalyst activity. Optimized variations may be applied to a plurality of metallic substrates for achieving coating uniformity, desired level of WCA loss, and optimized performance of catalyst activity.

Owner:CLEAN DIESEL TECHNOLOGIES

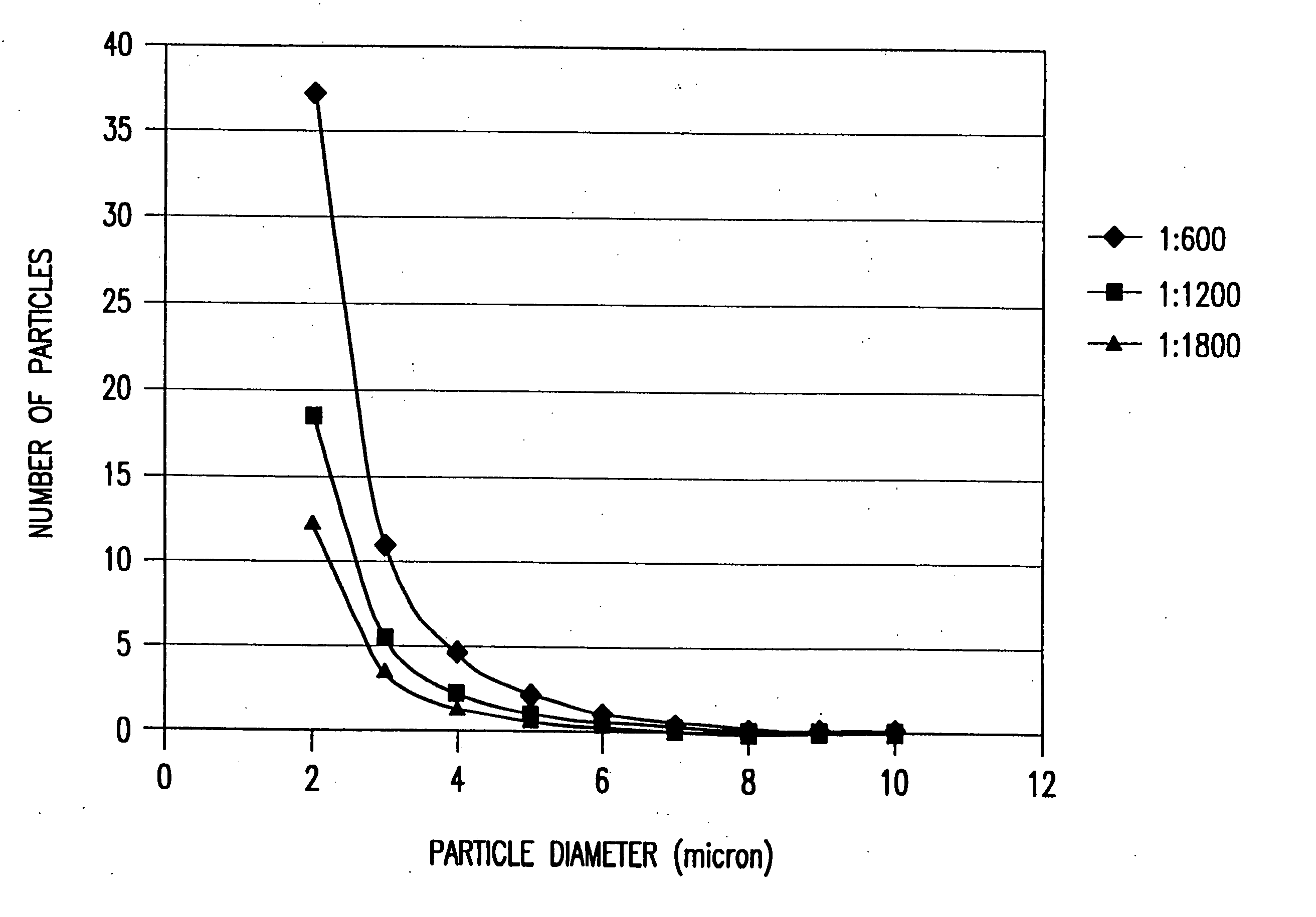

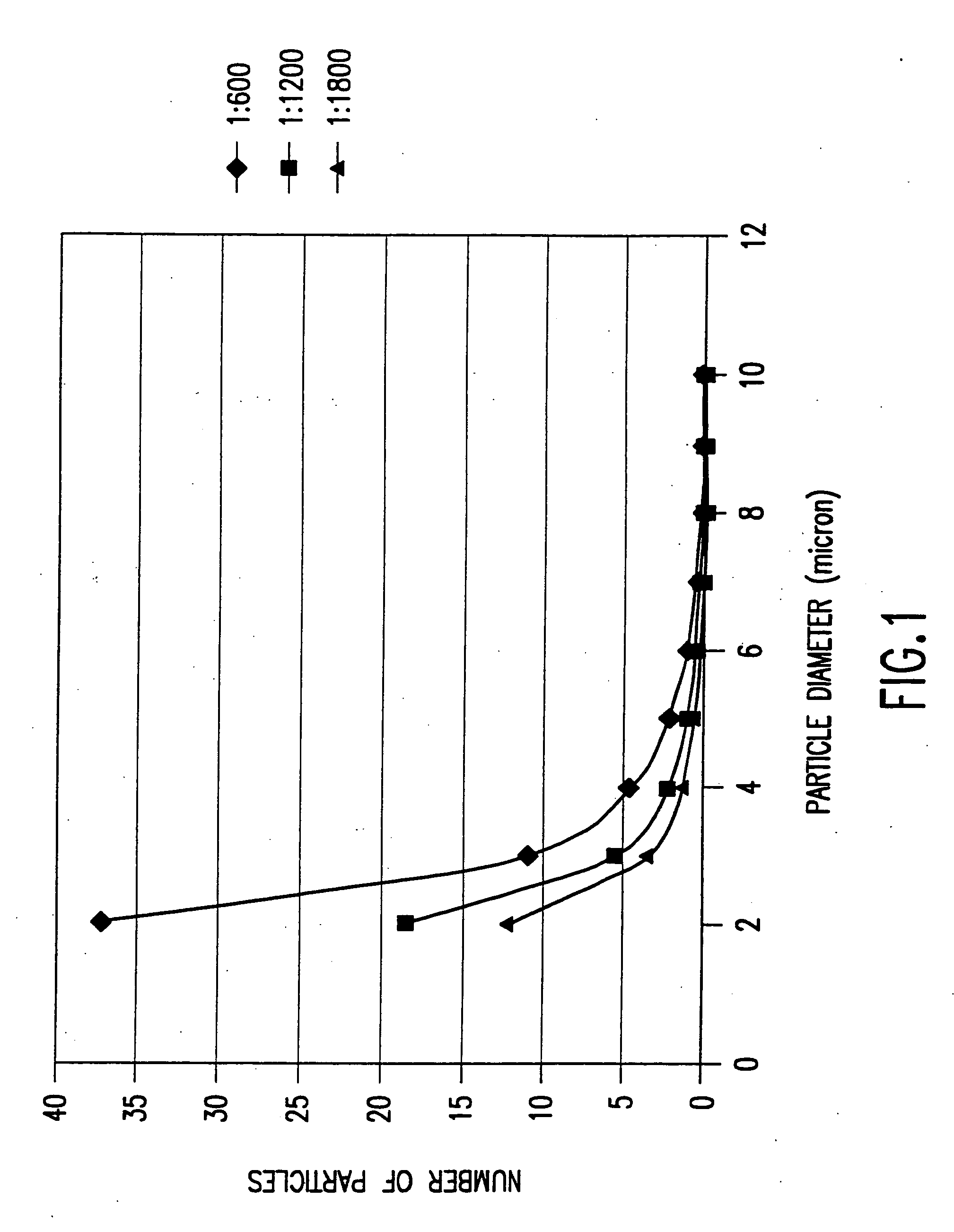

Method for coating small particles

InactiveUS20060024436A1Good coating uniformityReduce agglomerationLiquid surface applicatorsGranule coatingSolventSmall particle

The coating method includes the steps of dissolving coating precursor(s) in a solvent to form a precursor solution: adding with mixing a miscible diluent to the precursor solution to form a coating solution; admixing solid particles to the coating solution to form a coating slurry, with the particles surrounded with the coating solution; spraying the coating slurry to form droplets containing at least one particle; passing the droplets through a drying zone where the droplets are dried and form dry particles coated with a coating material formed from the coating precursor(s); heat-treating the coating material on the particles emanating from the drying zone to remove volatile matter on the coating material, to improve integrity of the coating material and / or to effect another objective; and collecting dry coated particles.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

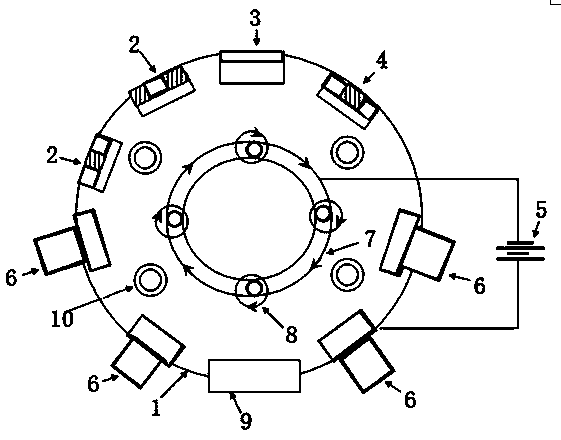

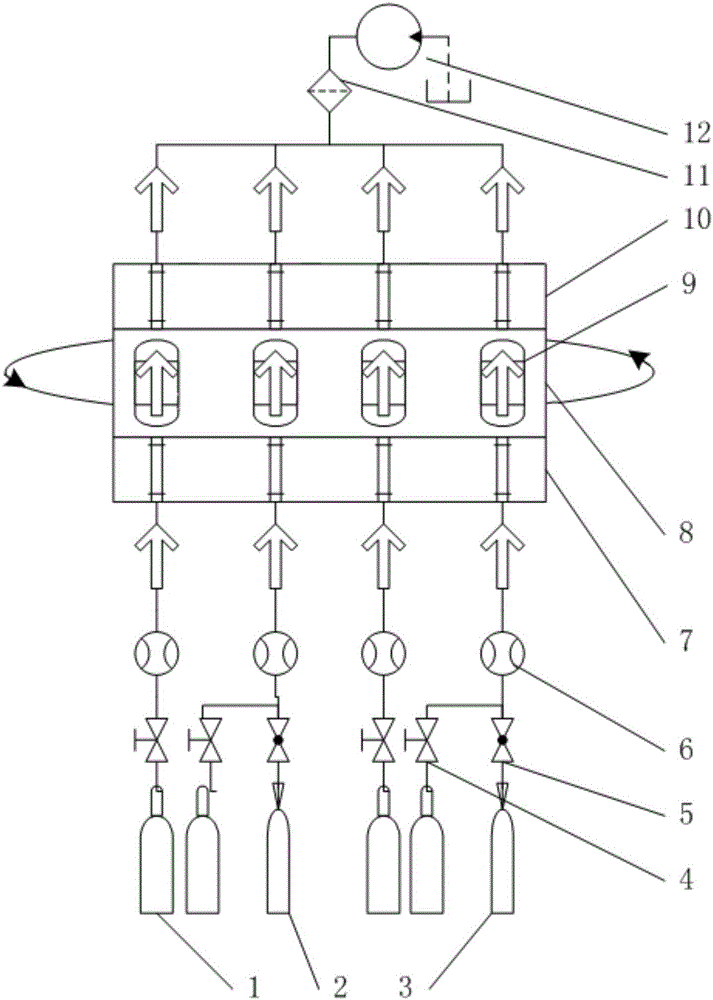

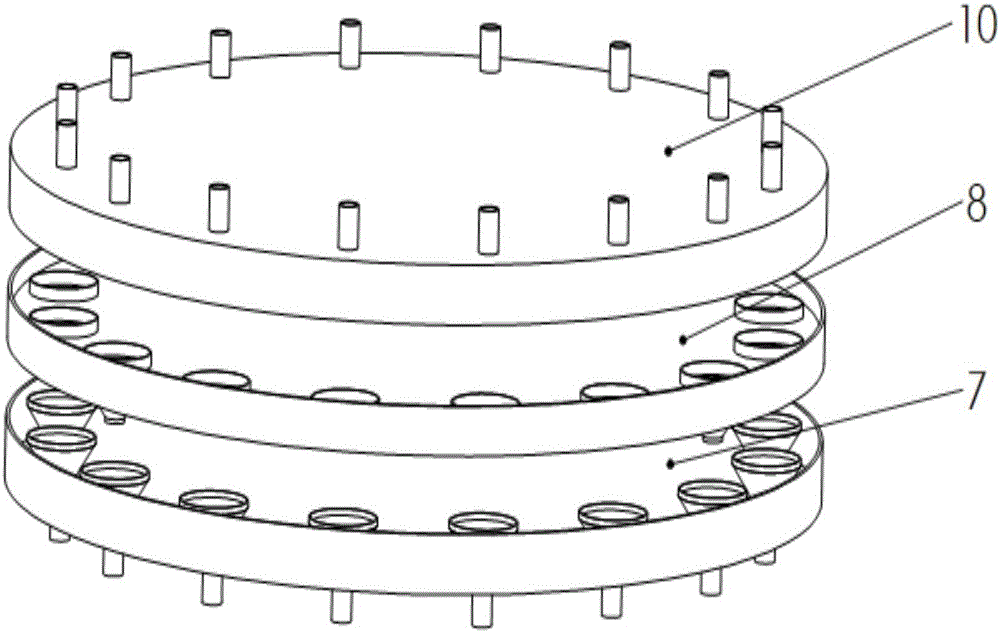

Nanoparticle space isolation atomic layer deposition equipment and method based on fluidized bed

ActiveCN105951058AImprove coating efficiencyShorten the timeNanotechnologyChemical vapor deposition coatingNanoparticleFluidized bed

The invention discloses nanoparticle space isolation atomic layer deposition equipment and a method based on a fluidized bed. Nanoparticles to be coated are put in a middle part of a powder reaction cavity; the middle part of the powder reaction cavity is driven to perform an intermittent peripheral motion under driving of a power supply to pass through a first cleaning area, an absorbing area, a second cleaning area and a reaction area in sequence; coating film layers are formed on the surfaces of the nanoparticles; and an ideal film thickness is obtained through circular motion. The equipment and the method can realize quick coating of the nanoparticles under normal pressure, and have such advantages as high coating rate, good coating uniformity and high coating efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

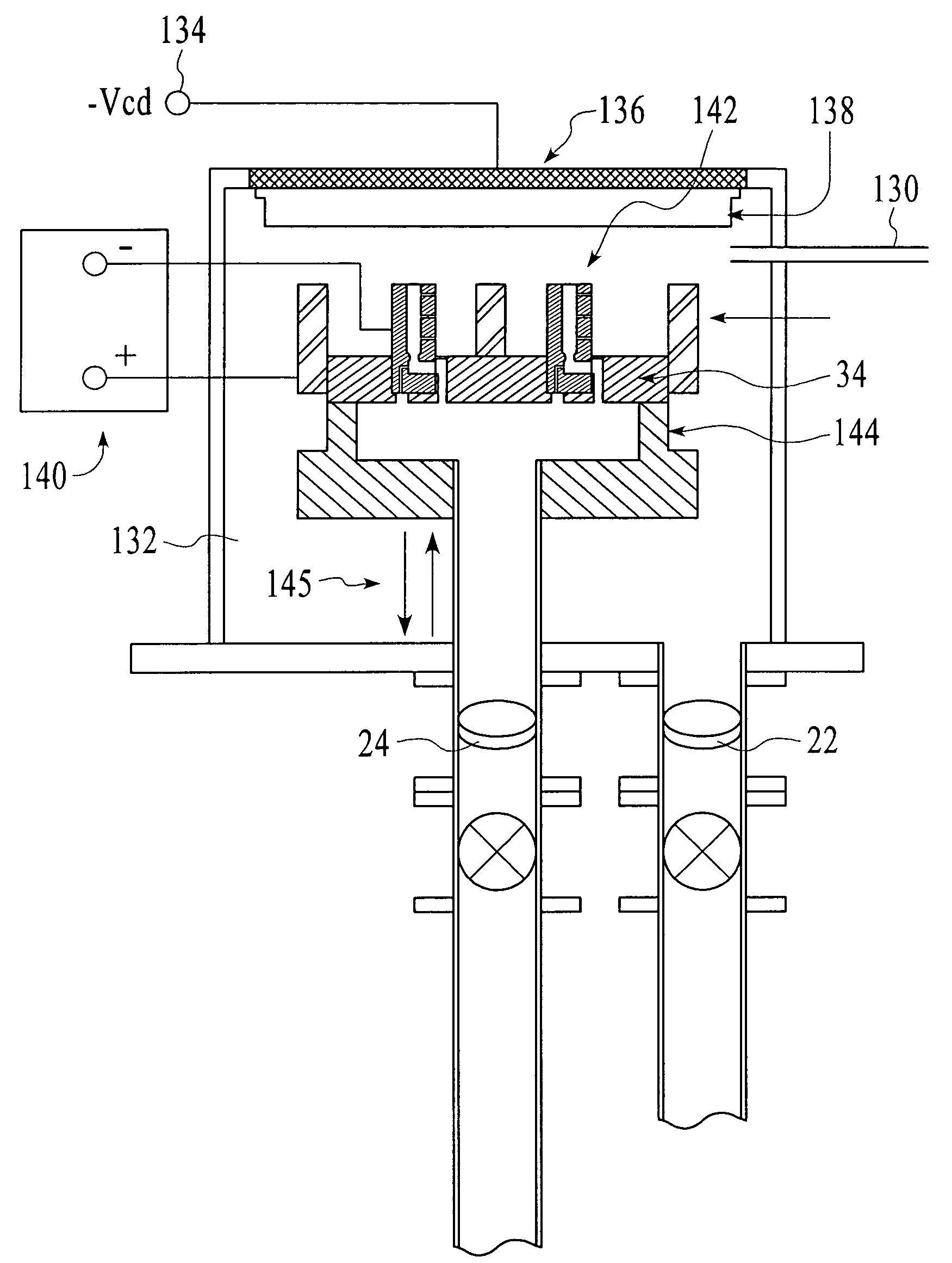

Apparatus for directing plasma flow to coat internal passageways

InactiveUS20050257744A1Improve coating uniformityHigh vacuum integrityCellsElectric discharge tubesSupporting systemEngineering

An apparatus for coating surfaces of a workpiece is configured to establish a pressure gradient within internal passageways through the workpiece, so that the coating within the internal passageways exhibits intended characteristics, such as those relating to smoothness or hardness. The coating apparatus may include any or all of a number of cooperative systems, including a plasma generation system, a manipulable workpiece support system, an ionization excitation system configured to increase ionization within or around the workpiece, a biasing system for applying a selected voltage pattern to the workpiece, and a two-chamber system that enables the plasma generation to take place at a first selected pressure and the deposition to occur at a second selected pressure.

Owner:SUB ONE TECH

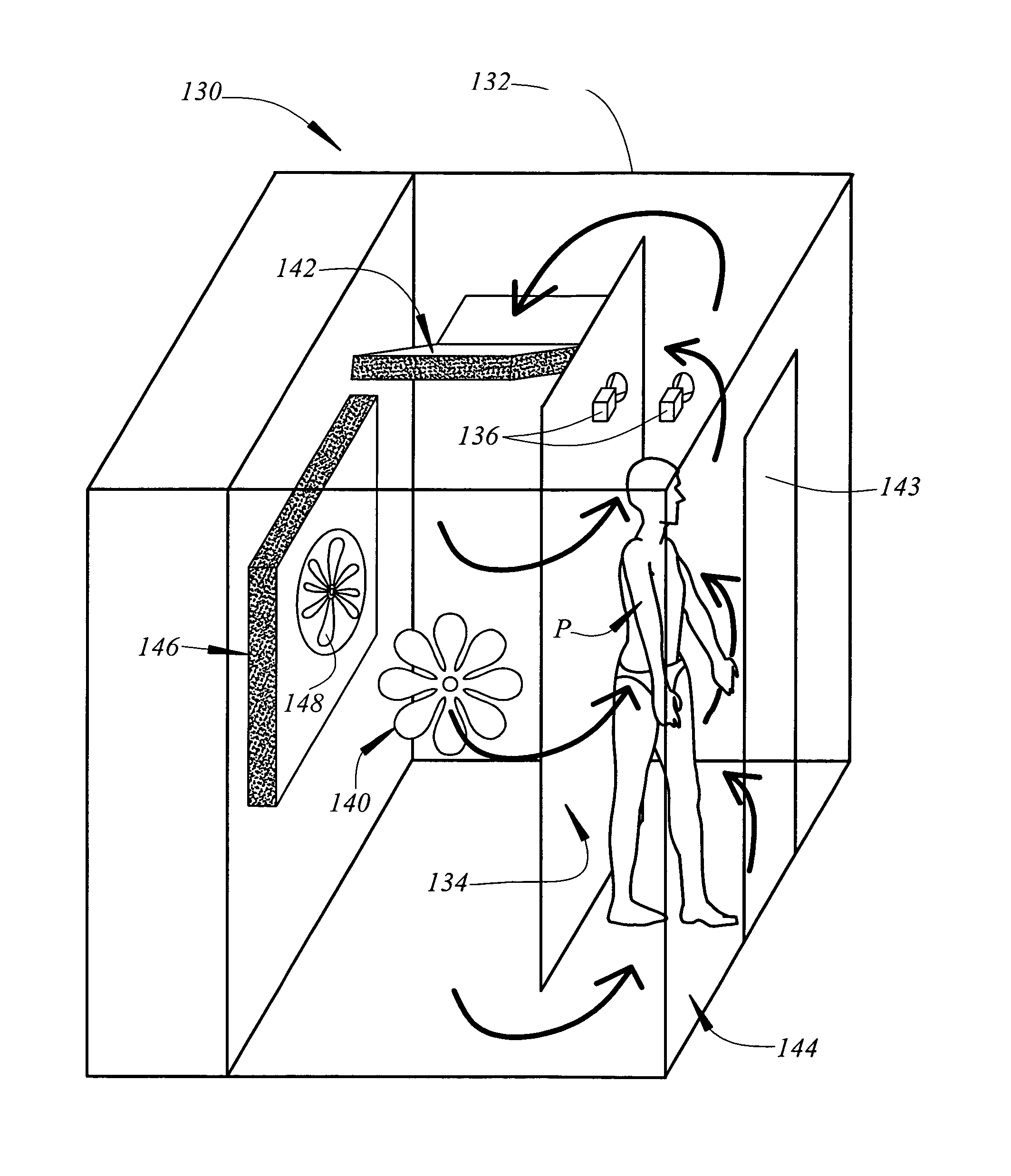

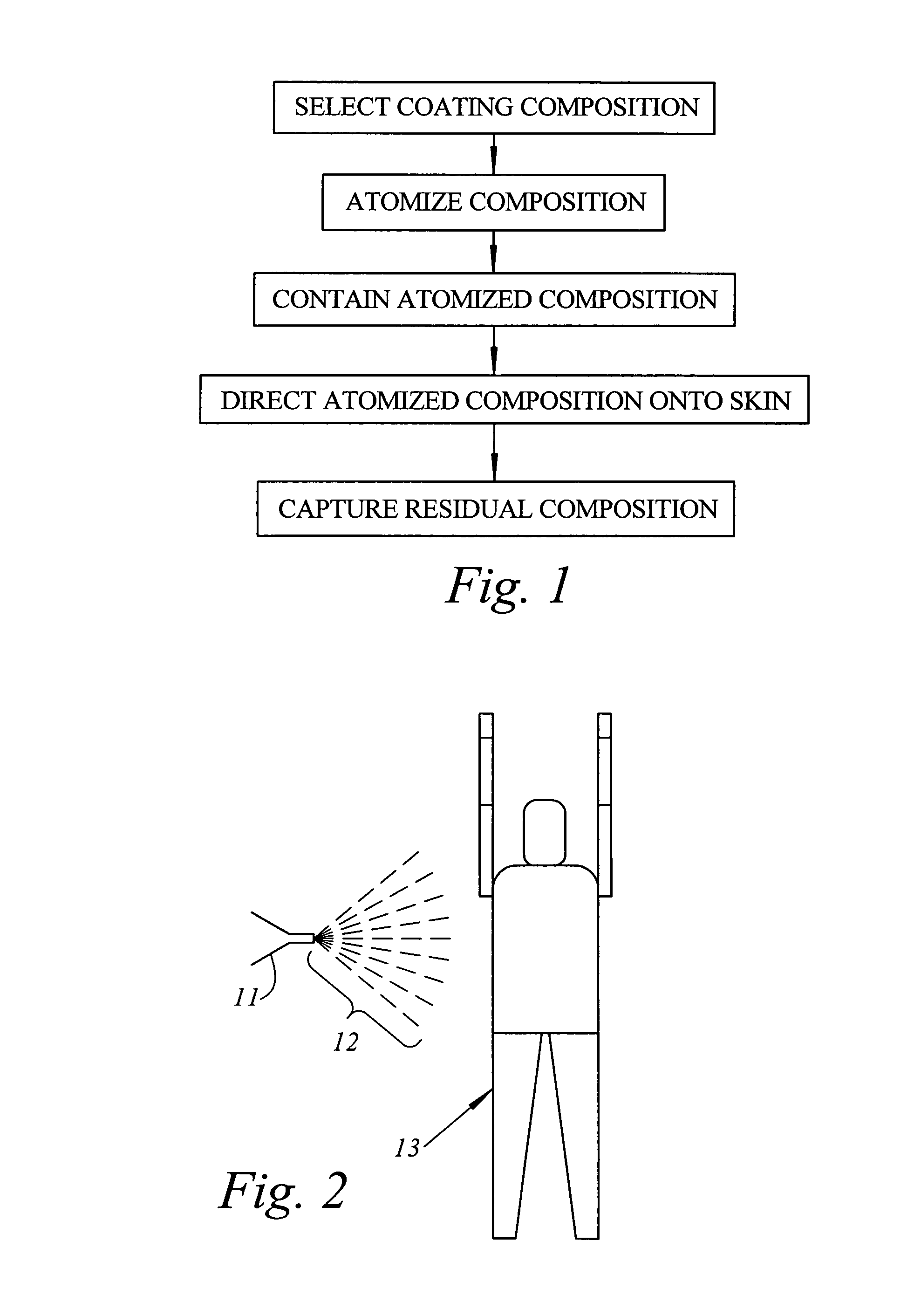

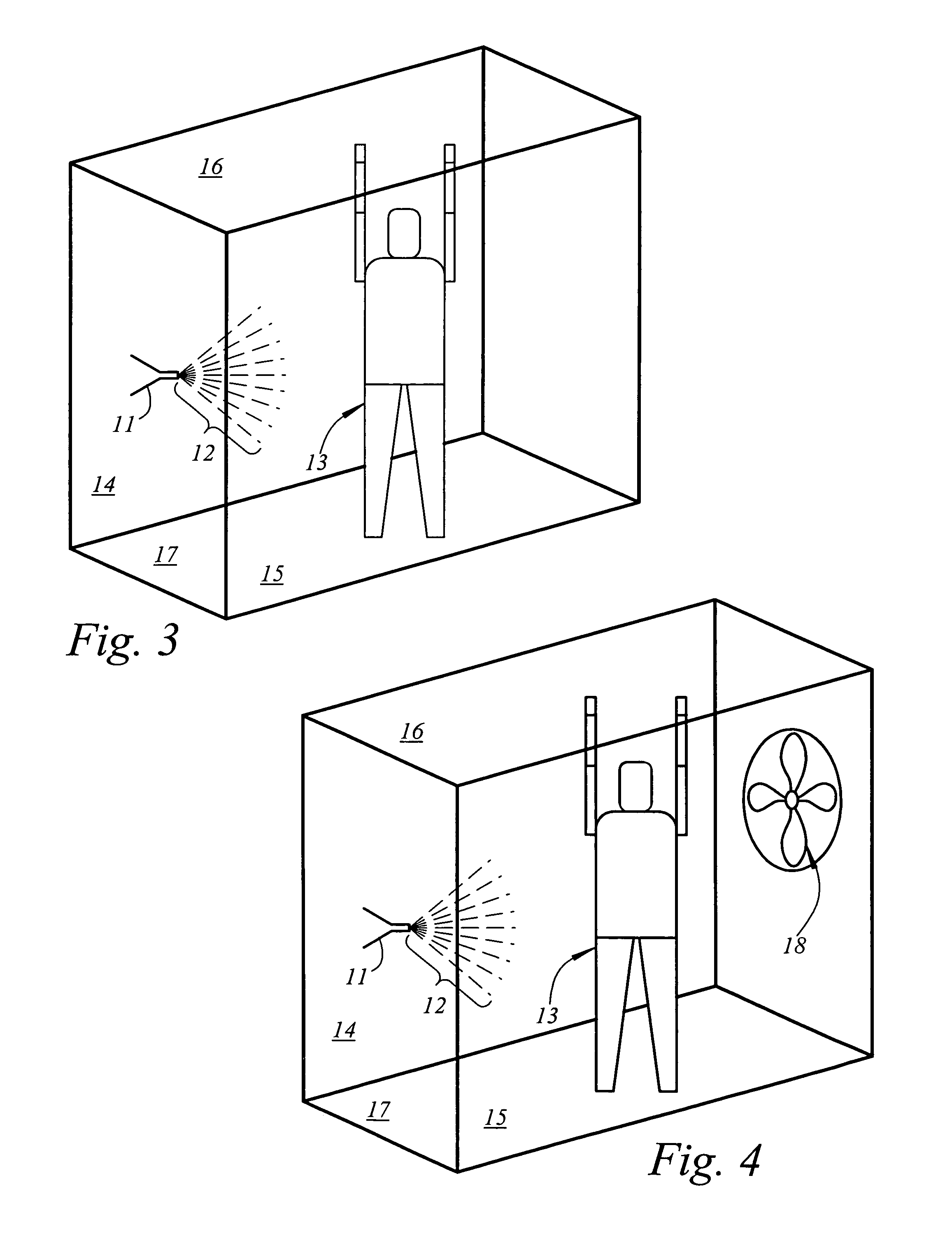

Automated system for coating the human body: virtual motion

InactiveUS7041089B2Improve coating uniformityImprove uniformityCosmetic preparationsLiquid surface applicatorsVirtual locomotionBiomedical engineering

In a system for coating human skin, a coating composition, such as a cosmetic or medical formulation, is uniformly coated over the entire body or selected parts of the body of the person being coated. The system includes atomization of the coating composition, containment of the atomized spray, and residual recovery which together yield a novel method for applying coating compositions.

Owner:LAUGHLIN PROD

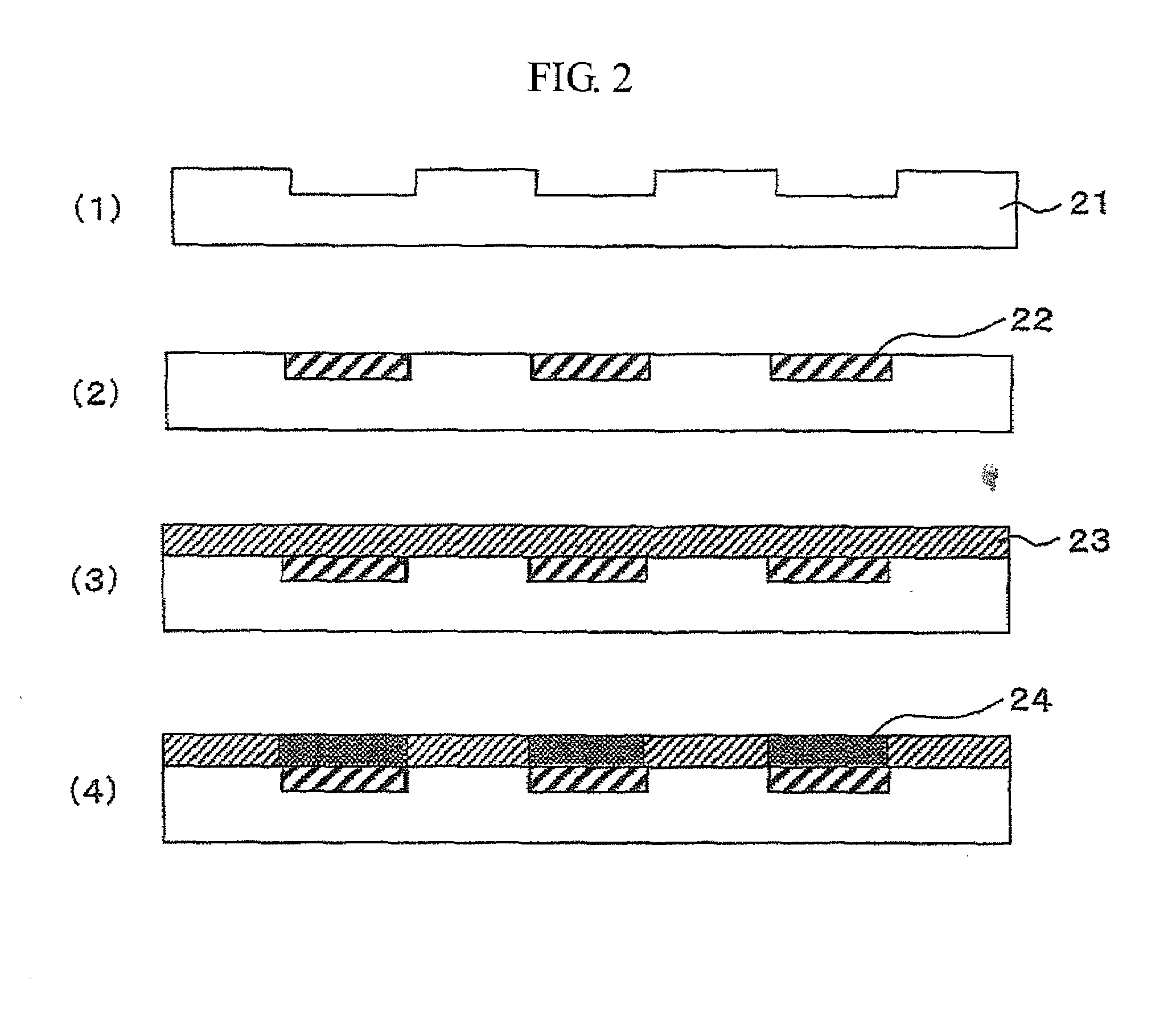

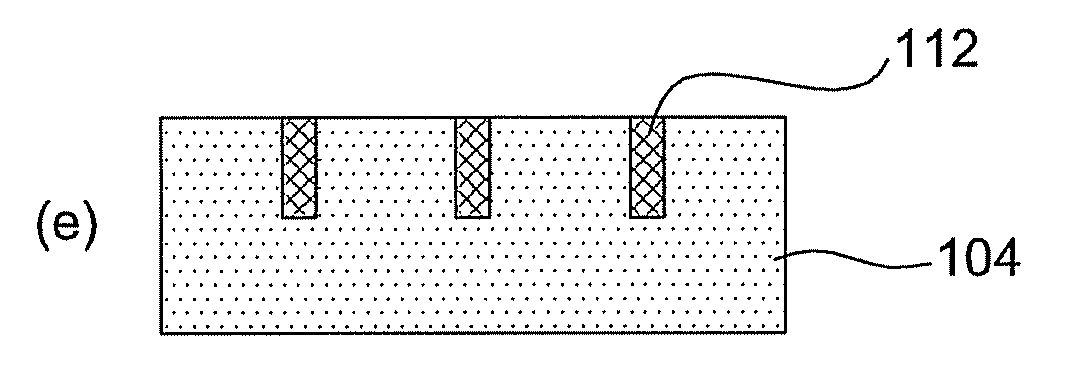

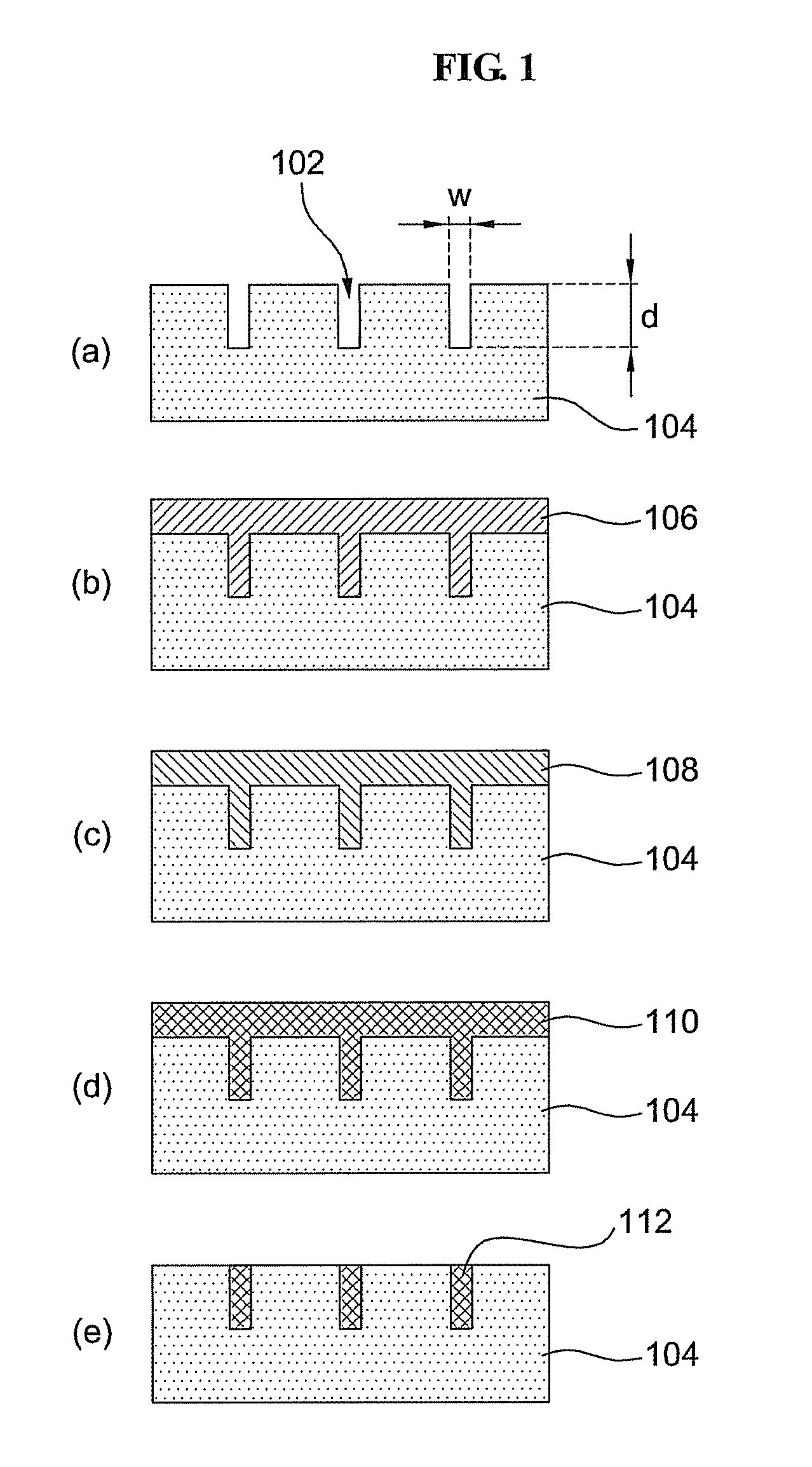

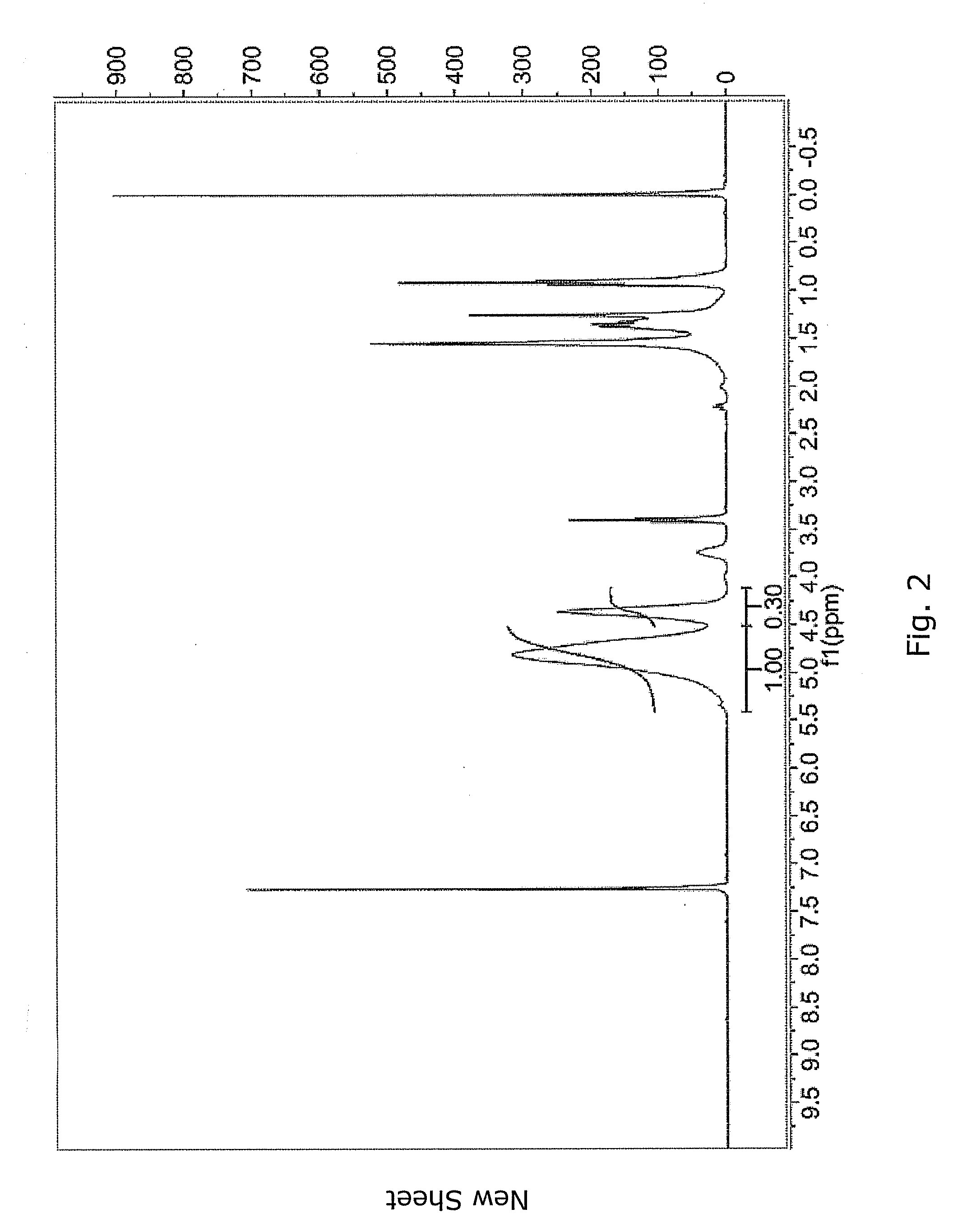

Polysilazane, method of synthesizing polysilazane, composition for manufacturing semiconductor device, and method of manufacturing semiconductor device using the composition

InactiveUS20100112749A1Excellent in groove-filling propertyHigh molecular weightSolid-state devicesSemiconductor/solid-state device manufacturingPolystyrenePolysilazane

Disclosed are polysilazane, a method of synthesizing the polysilazane, a composition for manufacturing a semiconductor device, and a method of manufacturing a semiconductor device using the composition. The polysilazane is synthesized through a reaction, under a catalyst, between dichlorosilane, trichlorosilane, and ammonia added in a reaction solvent as a reactant. In this instance, a polystyrene conversion weight average molecular weight of the polysilazane is about 2,000 to 30,000.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

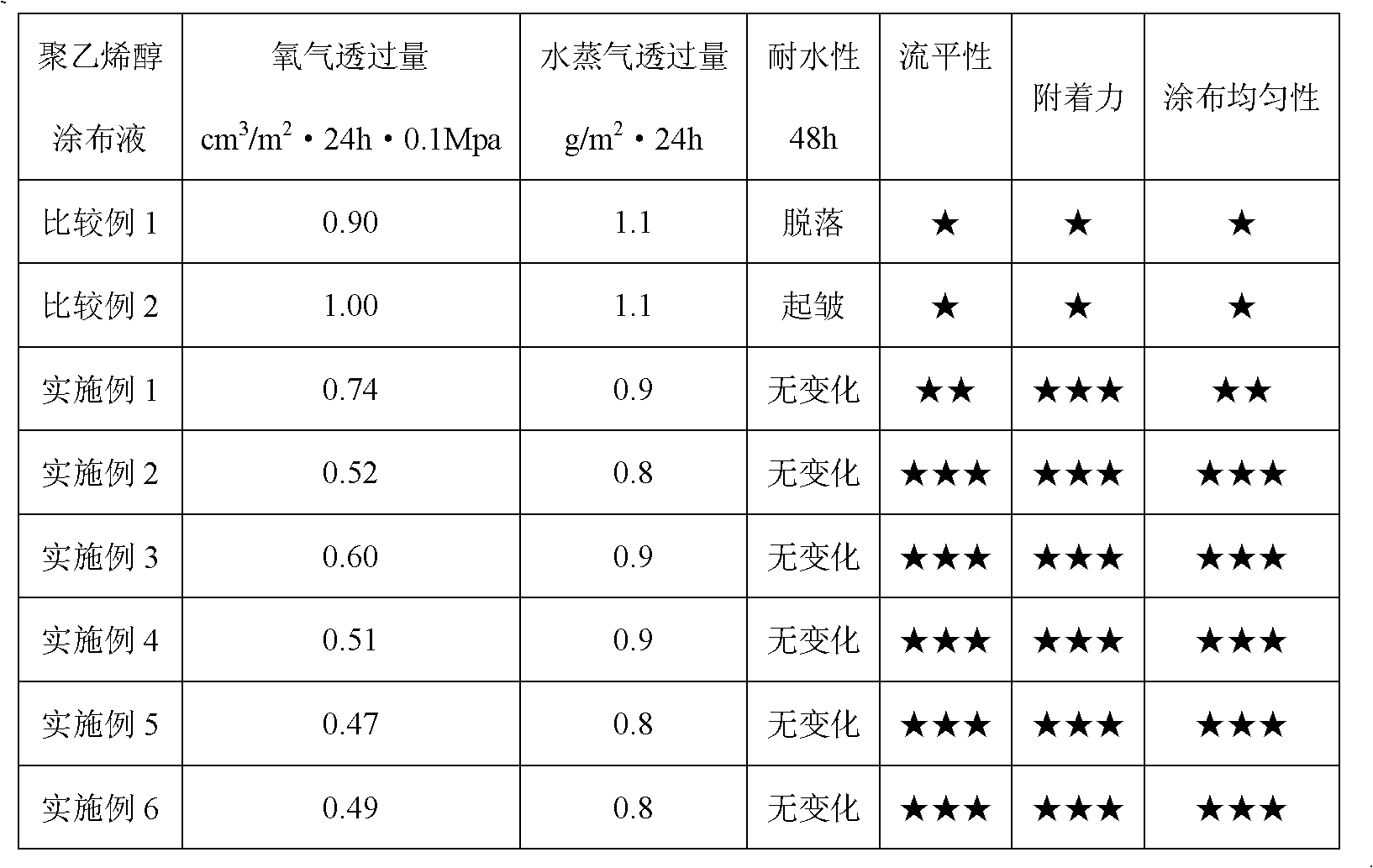

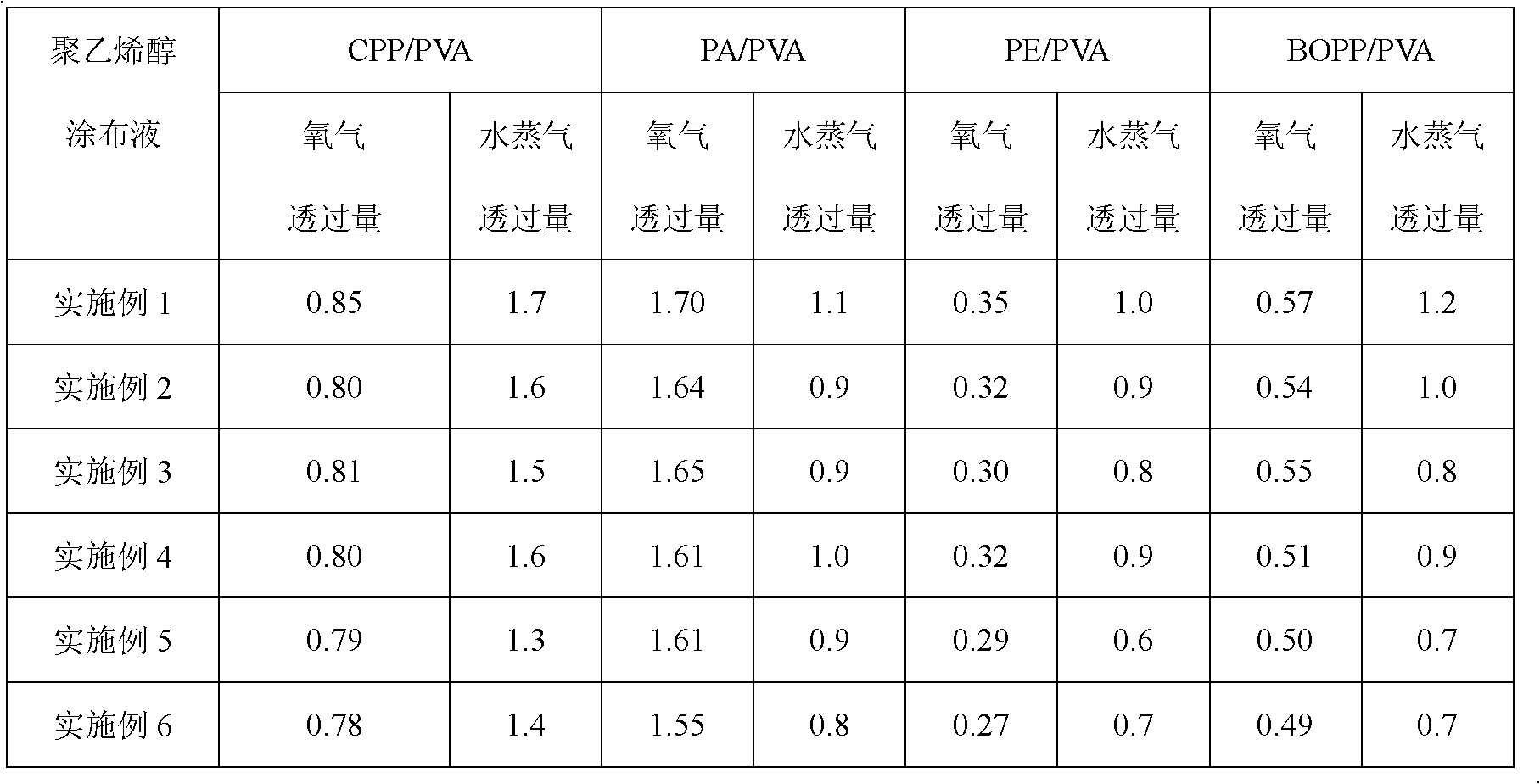

Water-resistant modified polyvinyl alcohol coating liquid and preparation method thereof, and coating formed by coating liquid

The invention discloses water-resistant modified polyvinyl alcohol coating liquid and a preparation method thereof, and a coating formed by the coating liquid. The water-resistant modified polyvinyl alcohol coating liquid comprises the following components in part by mass: 5 to 20 parts of polyvinyl alcohol, 45 to 95 parts of water, 0.1 to 3 parts of nano inorganic substance, 0.8 to 6 parts of modifier, 0.2 to 3 parts of catalyst, 0.05 to 1 part of coupling agent, 1 to 10 parts of regulating agent, 0.05 to 5 parts of adhesion accelerator, 0 to 0.5 part of leveling agent and 0 to 2 parts of wetting agent. The preparation method comprises the following steps of: adding the polyvinyl alcohol into water; heating and stirring; preserving the heat when the temperature is between 90 and 95 DEG C to ensure that the polyvinyl alcohol is dissolved completely; cooling to normal temperature; adding the nano inorganic substance, the catalyst and the modifier and completely stirring; and adding the coupling agent, the regulating agent, the adhesion accelerator, the leveling agent and the wetting agent during use and stirring uniformly. The coating formed by the water-resistant modified polyvinyl alcohol coating liquid prepared by the method has excellent properties.

Owner:南京红宝丽新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com