Patents

Literature

37results about How to "Lower reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

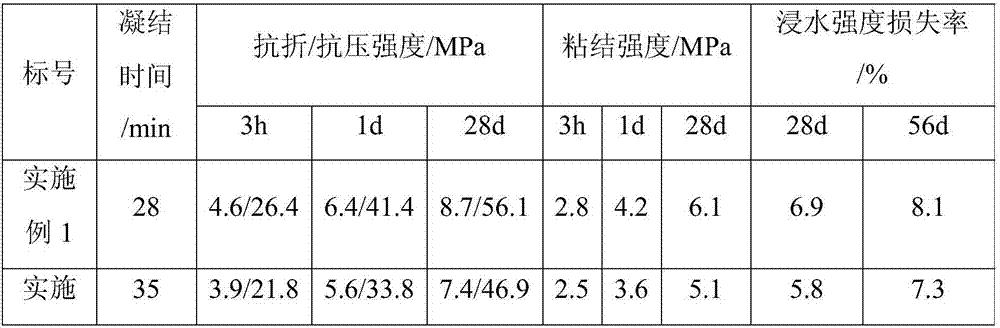

Phosphate cement based patching material and preparation method thereof

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

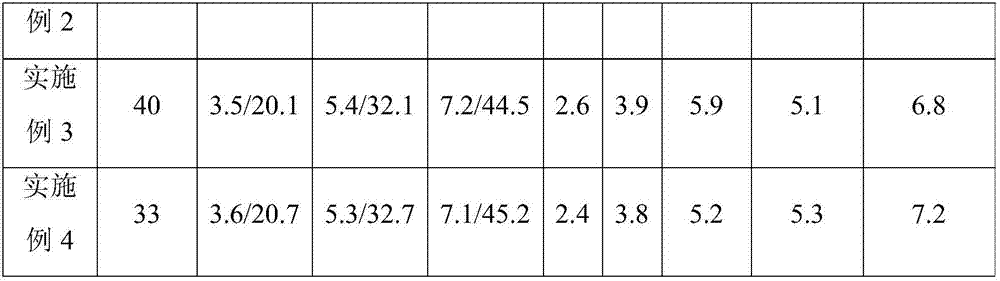

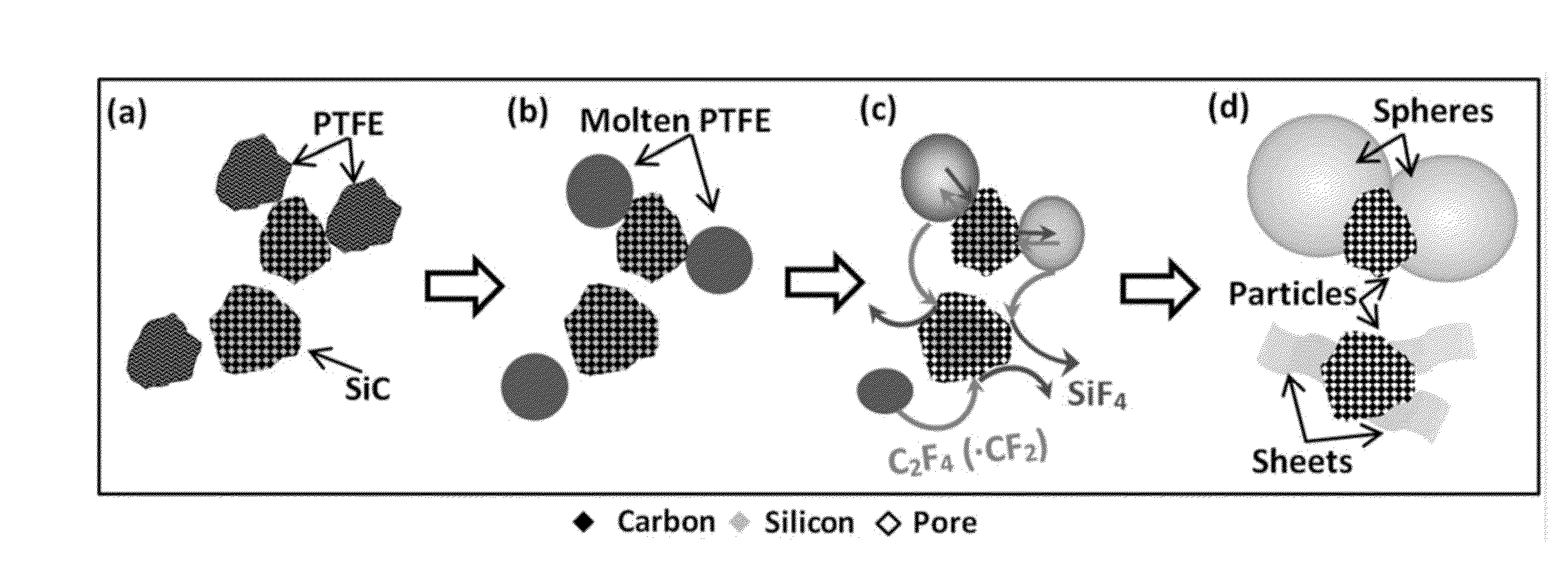

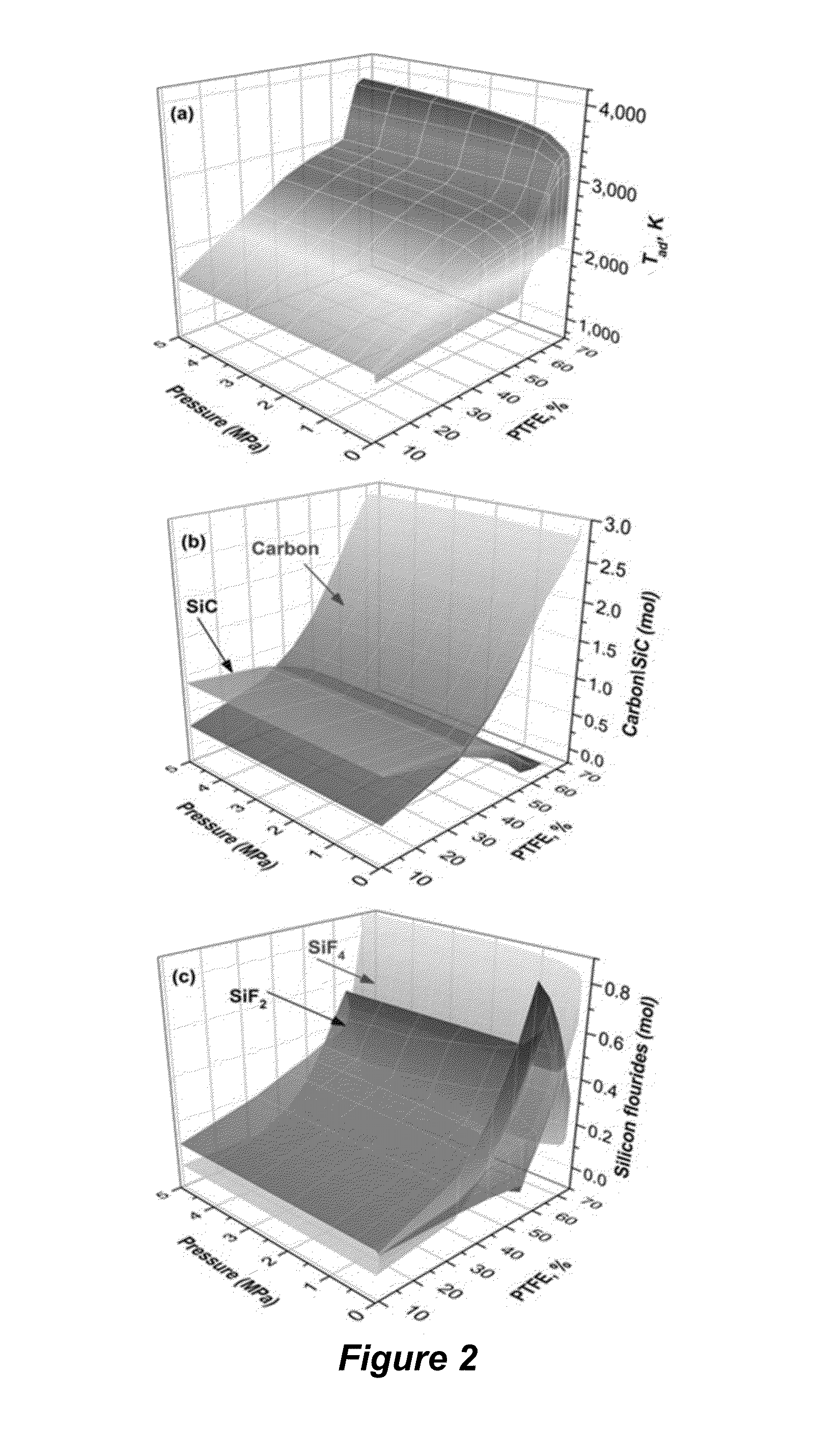

Combustion synthesis of graphene and carbonous nanomaterials

InactiveUS20140377160A1Raise the ratioIncrease surface areaGrapheneCarbon preparation/purificationExternal energyDecomposition

The invention provides methods for the combustion synthesis (CS) of graphene by a novel exothermic self-sustained reaction between a refractory ceramic compound and a carbon-containing polymer under an inert gas atmosphere. The synthesis of graphene was confirmed by both transmission electron microscopy and Raman spectroscopy. The graphene produced has very low (<1 wt. %) oxygen content. Fluorocarbon gases released due to decomposition of the carbon-containing polymer in the combustion wave can reduce the ceramic to a gas and mesoporous carbon particles and graphene layers. The method does not require an external energy source because it occurs in a self-sustained synergetic manner after ignition. The methods are flexible in terms of tuning the synthesis conditions for desired products, and the method can be scaled to provide kilogram quantities.

Owner:UNIV OF NOTRE DAME DU LAC

Process for producing chlorine

InactiveUS6852667B2High activityEasy to controlCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentOxygen

A process for producing chlorine by oxidizing hydrogen chloride with oxygen. The process uses various supported ruthenium catalysts or a catalyst system containing (A) an active component of a catalyst and (B) a compound having thermal conductivity of a solid phase measured by at least one point within a range from 200 to 500° C. of not less than 4 W / m. ° C.

Owner:SUMITOMO CHEM CO LTD

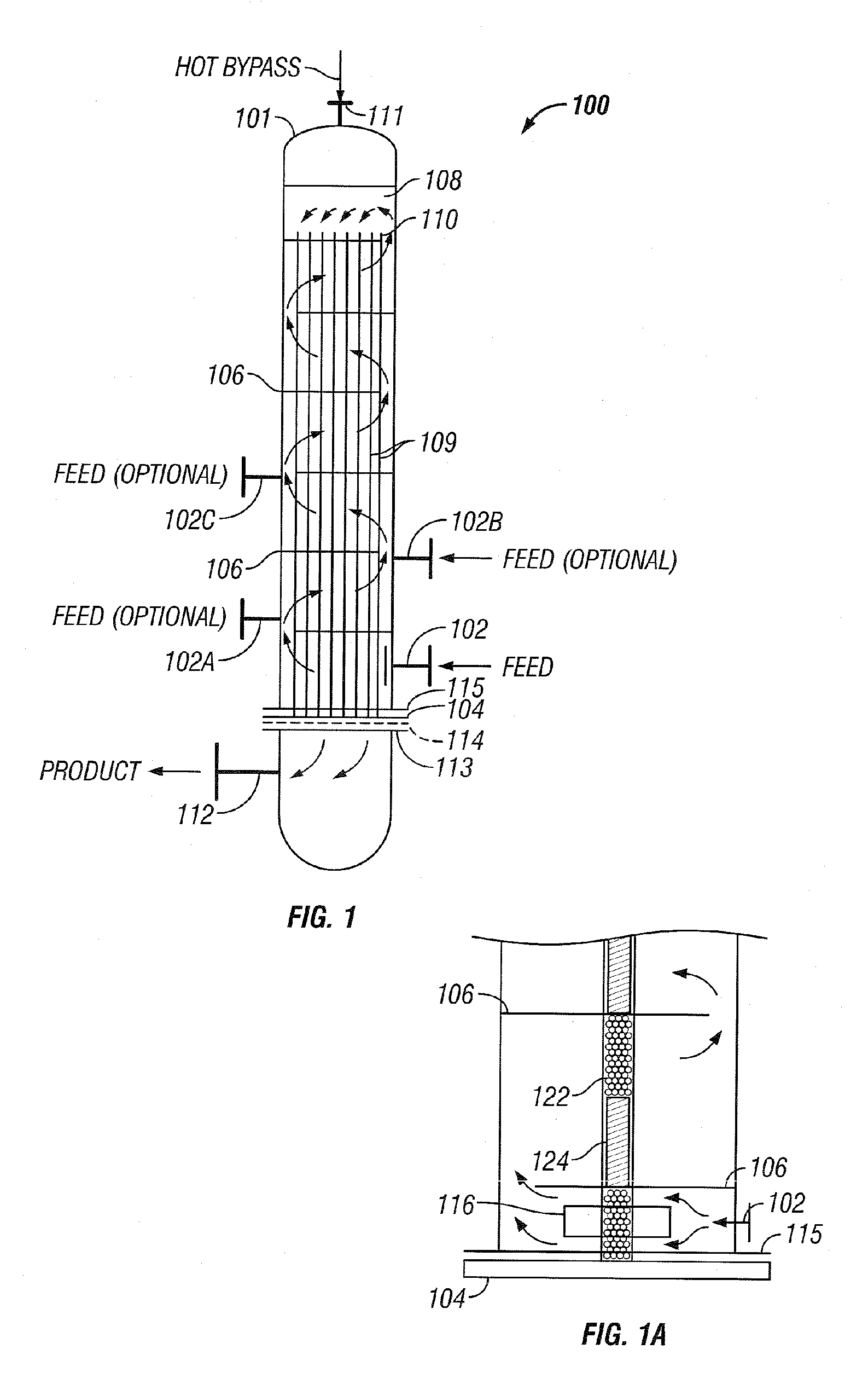

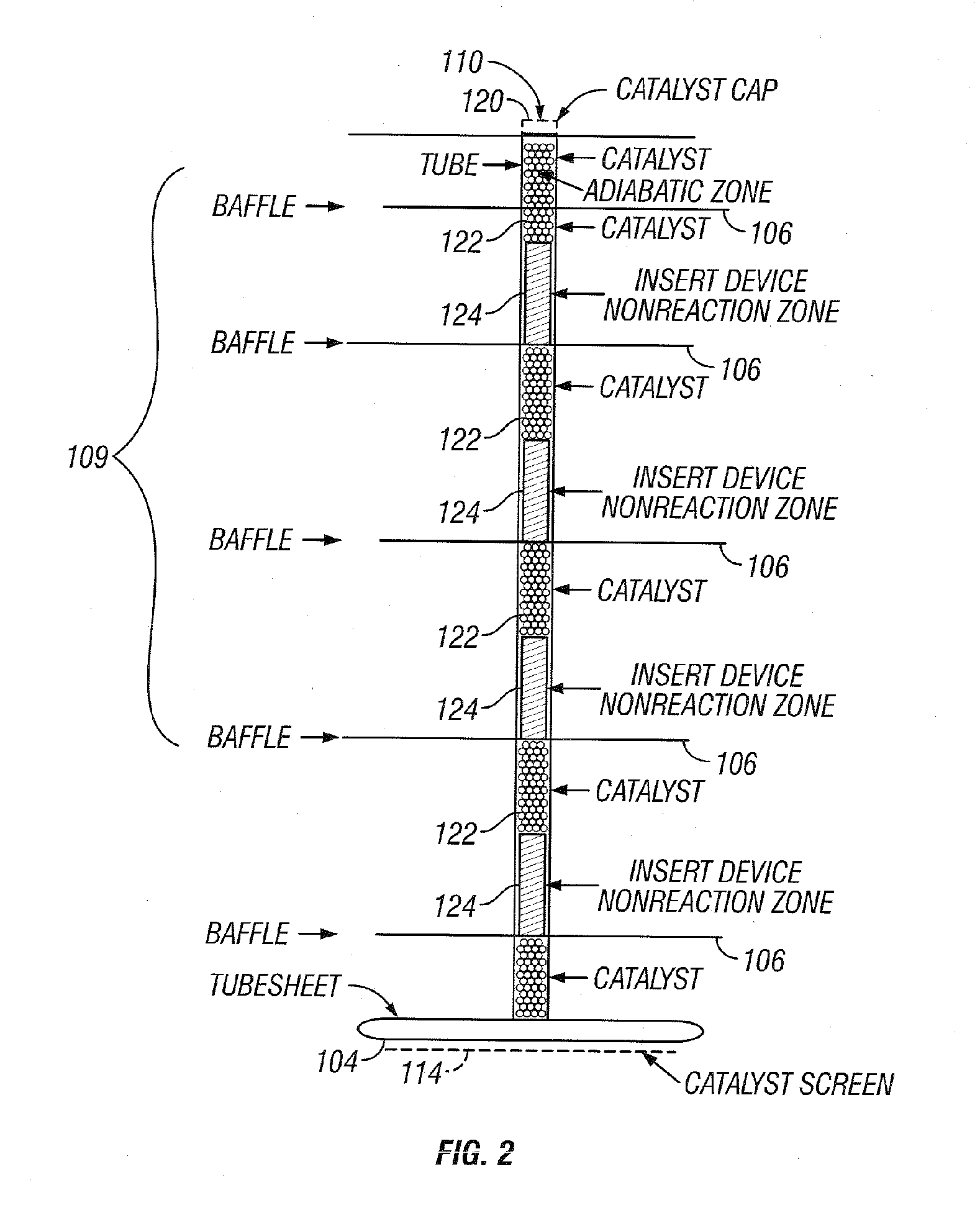

Maximum reaction rate converter system for exothermic reactions

ActiveUS20060099131A1Reduction in catalyst volumeSpeed up the conversion processMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionReaction temperatureEquilibrium curve

An ammonia converter system and method are disclosed. The reactor can alter the conversion of ammonia by controlling the reaction temperature of the exothermic reaction along the length of the reactor to parallel the equilibrium curve for the desired product. The reactor 100 can comprise a shell 101 and internal catalyst tubes 109. The feed gas stream enters the reactor, flows through the shell 101, and is heated by indirect heat exchange with the catalyst tubes 109. The catalyst tubes 109 comprise reactive zones 122 having catalyst and reaction limited zones 124 that can comprise inert devices that function to both separate the reactive zones, increase heat transfer area, and reduce the temperature of the reaction mixture as the effluent passes through the catalyst tube 109.

Owner:KELLOGG BROWN & ROOT LLC

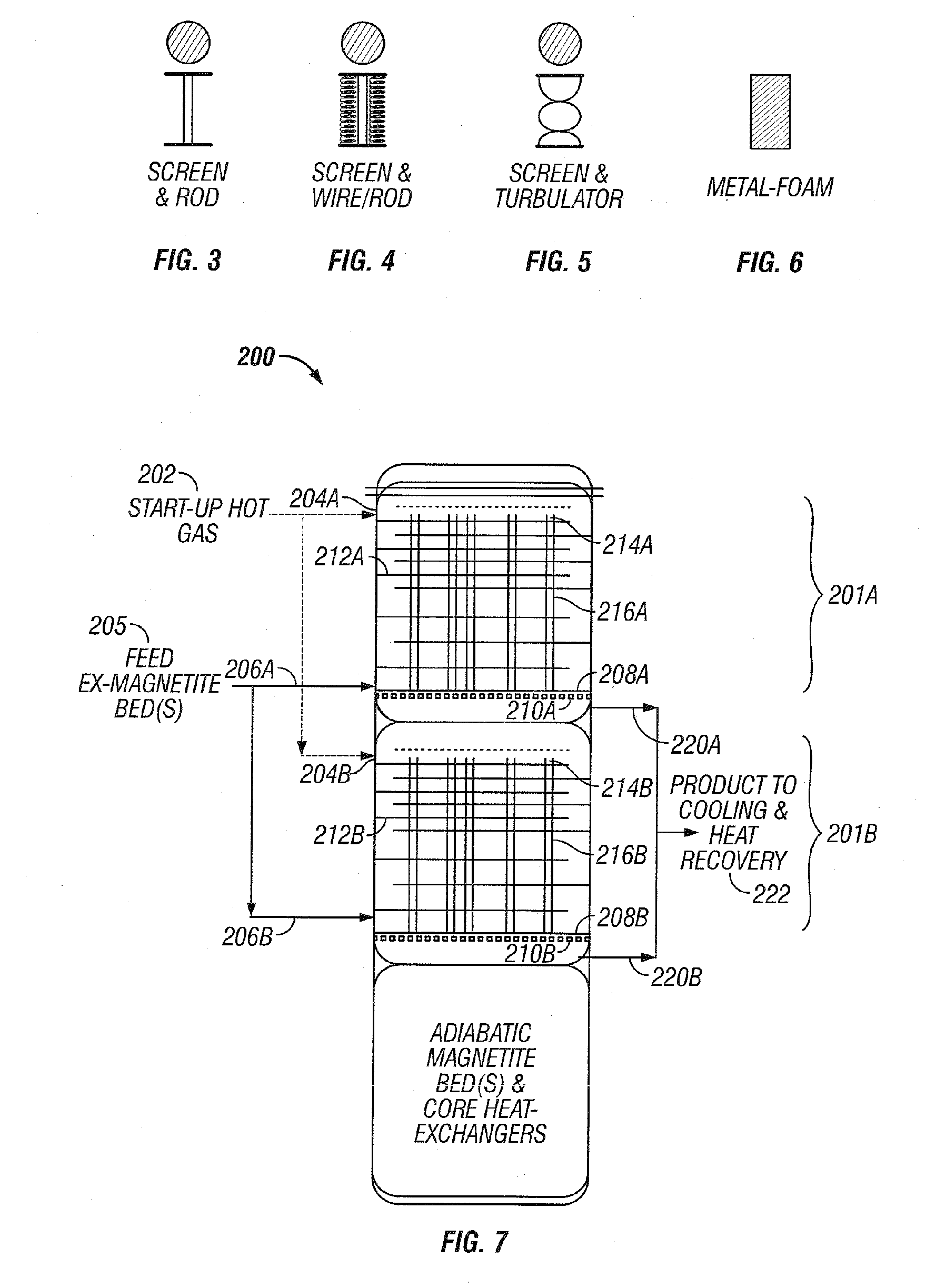

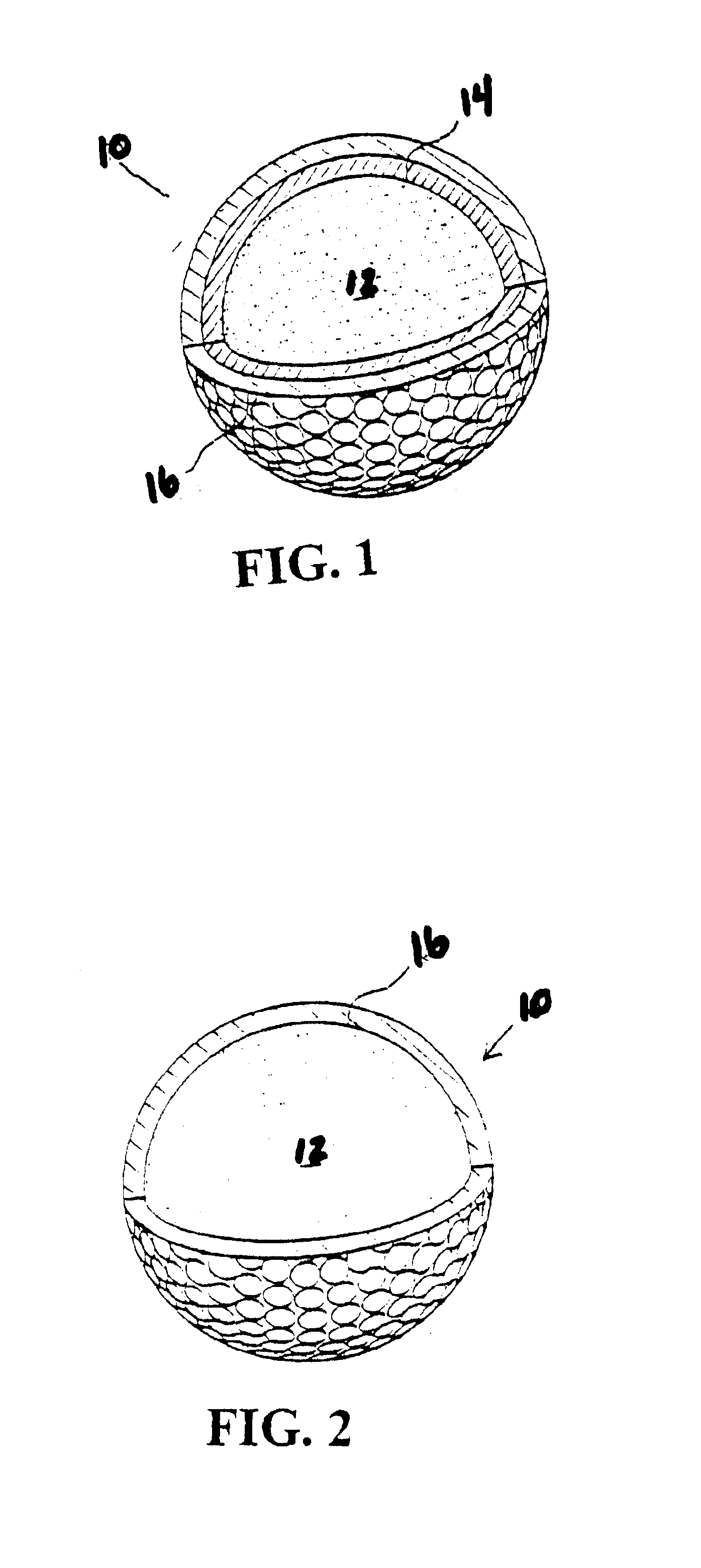

Thermosetting polyurethane material for a golf ball cover

A prepolymer blend for a thermosetting polyurethane material that allows for control of the reaction time is disclosed herein. The prepolymer blend is preferably composed of a polyurethane prepolymer and dimethyl methylphosphonate. The thermosetting polyurethane is preferably utilized as a cover for a golf ball. The cover is preferably formed over a core and boundary layer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Process for Producing Hydrorefined Gas Oil, Hydrorefined Gas Oil, and Gas Oil Composition

InactiveUS20080308459A1Increase cetane numberSufficient efficiencyTreatment with hydrotreatment processesRefining by aromatic hydrocarbon hydrogenationDistillates petroleumMolecular sieve

A process of the present invention for producing a hydrotreated gas oil has a step for obtaining a product oil having a total aromatic content of 3% by volume or less by hydrogenating a hydrotreated oil including 95% by volume or more of fraction having a boiling point range of 150-380° C., a sulfur content of 2-15 ppm by mass, a total aromatic content of 10-25% by volume, and a naphthene of 20-60% by volume in the presence of a hydrogenation catalyst; and a step for obtaining, by hydrogenating the above-described product oil in the presence of a hydrogenation catalyst containing a crystalline molecular sieve component, a product oil satisfying the conditions that the content of petroleum fraction having a boiling point range of lower than 150° C. is 16% by volume or less, and the sum of the total aromatic content and the total naphthene content is 80% or less relative to the sum of these in the hydrotreated oil.

Owner:IKI HIDESHI +3

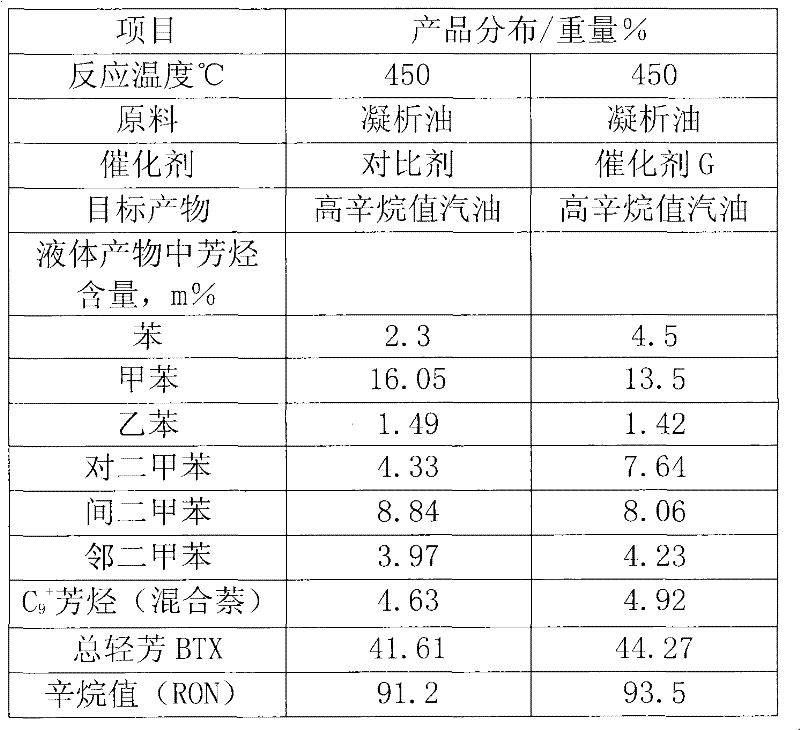

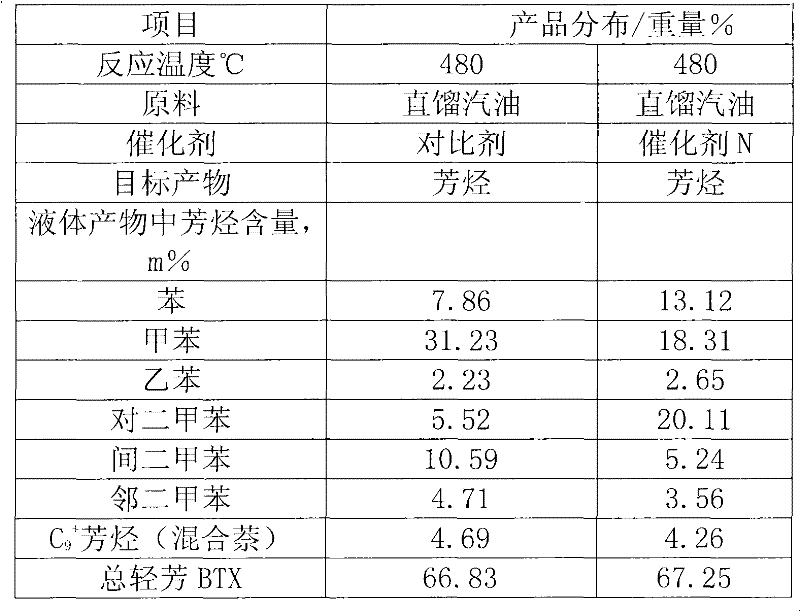

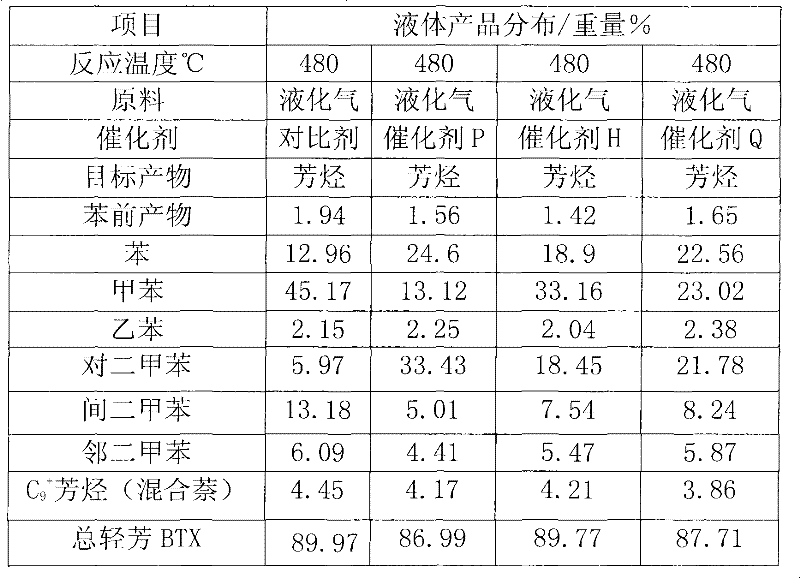

Aromatization catalyst and applications thereof

ActiveCN102218341AAdjust acid distributionIncrease total acidMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumAdhesive

The invention discloses an aromatization catalyst and applications thereof, and aims at solving the problems such as low yield of benzene and mixed xylene in the liquid outcomes and the like during the existing hydrocarbon aromatization reaction. The catalyst comprises the following components by weight percentage of 30-90wt% of molecular sieves, 0-60wt% of carriers and 10-20 wt% of adhesives, wherein the molecular sieves are mixtures of a molecular sieve I, a molecular sieve II, a molecular sieve III and a molecular sieve IV; the molecular sieve I is at least one modified HZSM-5 molecular sieve out of modified elements zinc, gallium and lanthanum; the molecular sieve II is at least one modified HZSM-5 molecular sieve out of modified elements bismuth, molybdenum, silver, copper, zirconiumand rhenium; the molecular sieve III is the HZSM-5 molecular sieve formed by modifying polysiloxane; and the molecular sieve IV is a modified hydrogenated mercerization type molecular sieve, a modified hydrogenated Beta-type molecular sieve, a hydrogenated ZSM-11 molecular sieve and a hydrogenated MCM-22 molecular or mixtures thereof.

Owner:CHINA PETROCHEMICAL CORP +1

Catalysts for low temperature selective oxidation of propylene, methods of making and using the same

InactiveUS6143928AIncrease productivityHigh yieldOrganic compound preparationOrganic chemistry methodsNiobiumLanthanum

A mixed metal oxide catalytic system consisting of molybdenum, vanadium, palladium, lanthanum, niobium and X, wherein X is copper and / or chromium, providing higher yields of acrylic acid and acrolein in the low temperature oxidation of propylene with a molecular oxygen-containing gas without the production of side products such as CO.

Owner:SAUDI BASIC IND CORP SA

Treating solution for forming fluoride coating film and method for forming fluoride coating film

InactiveUS20080241368A1Lower reaction temperatureAmount of timeDispersed particle filtrationSemiconductor/solid-state device manufacturingAlkaline earth metalX-ray

A conventional method for forming an insulating film on a magnet has a difficulty in achieving sufficient improvement in magnetic characteristics due to nonuniformity of a coating film, and an extended time and higher temperature which are required in a thermal treatment. In order to solve the problems, the present invention provides a treating solution composed of an alcohol based solvent and a rare earth fluoride or alkaline earth metal fluoride dispersing in the solvent. In the treating solution, at least one X-ray diffraction peak has a half-value width larger than 1°. The present invention also provides a method for forming an insulating film using the treating solution.

Owner:HITACHI CHEM CO LTD

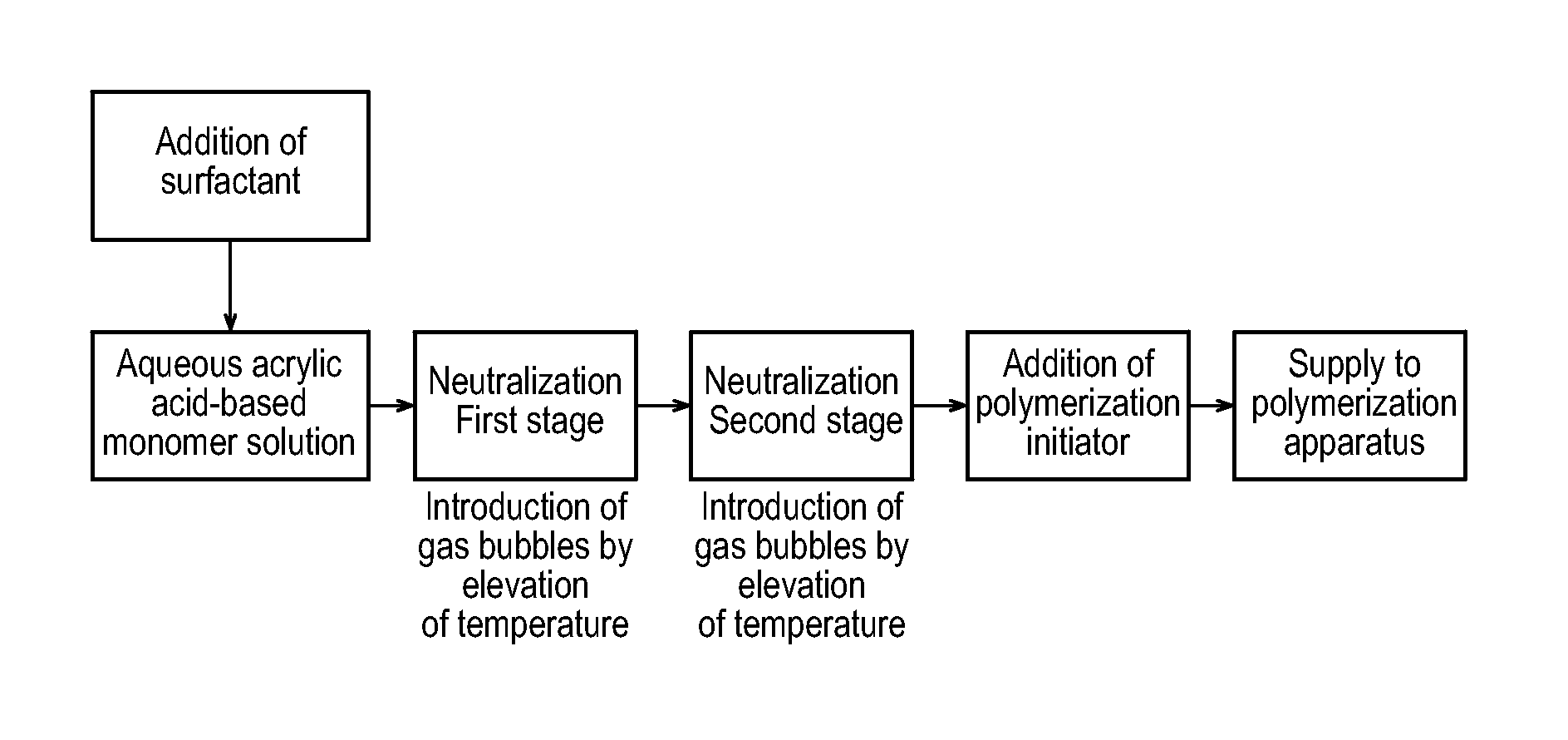

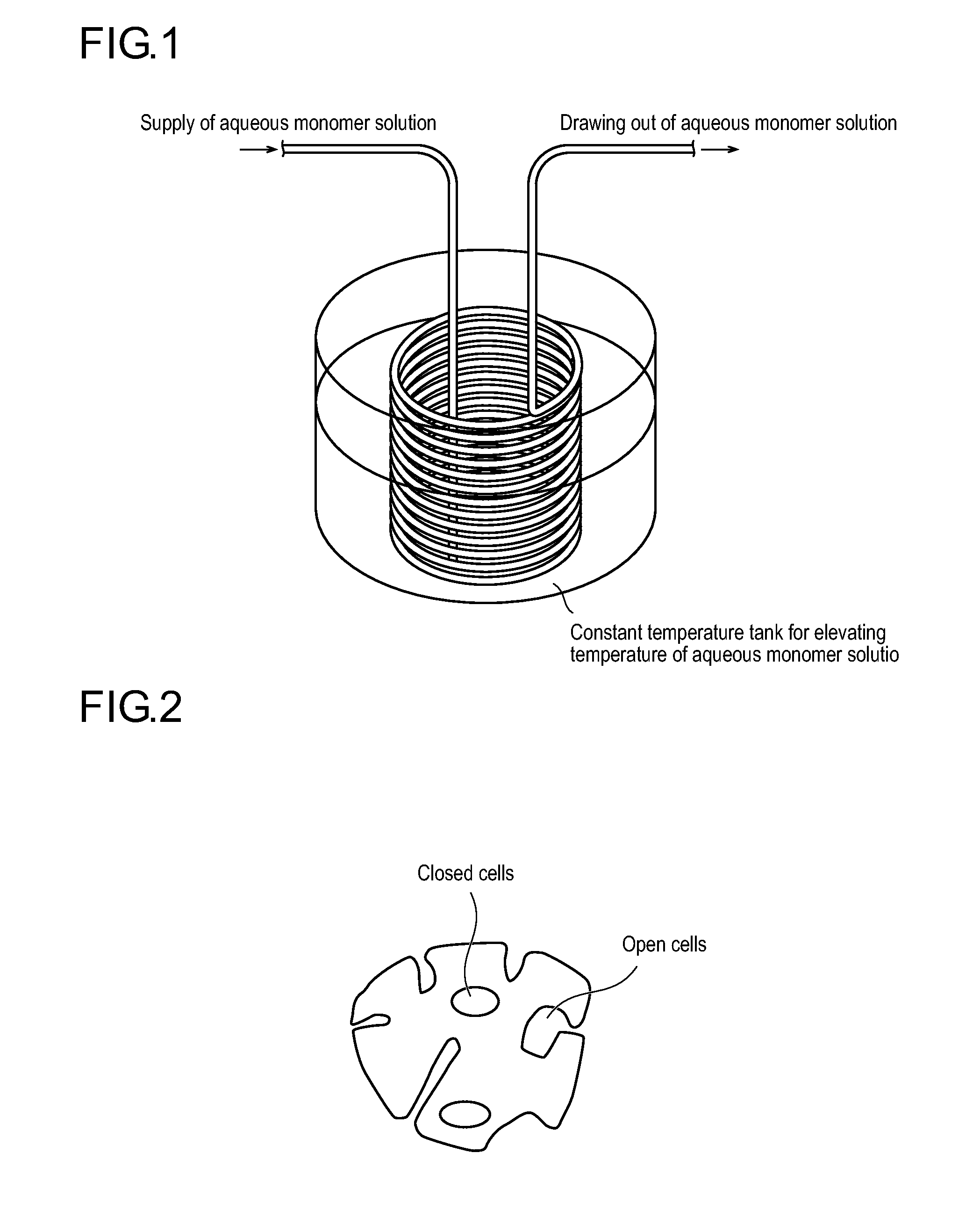

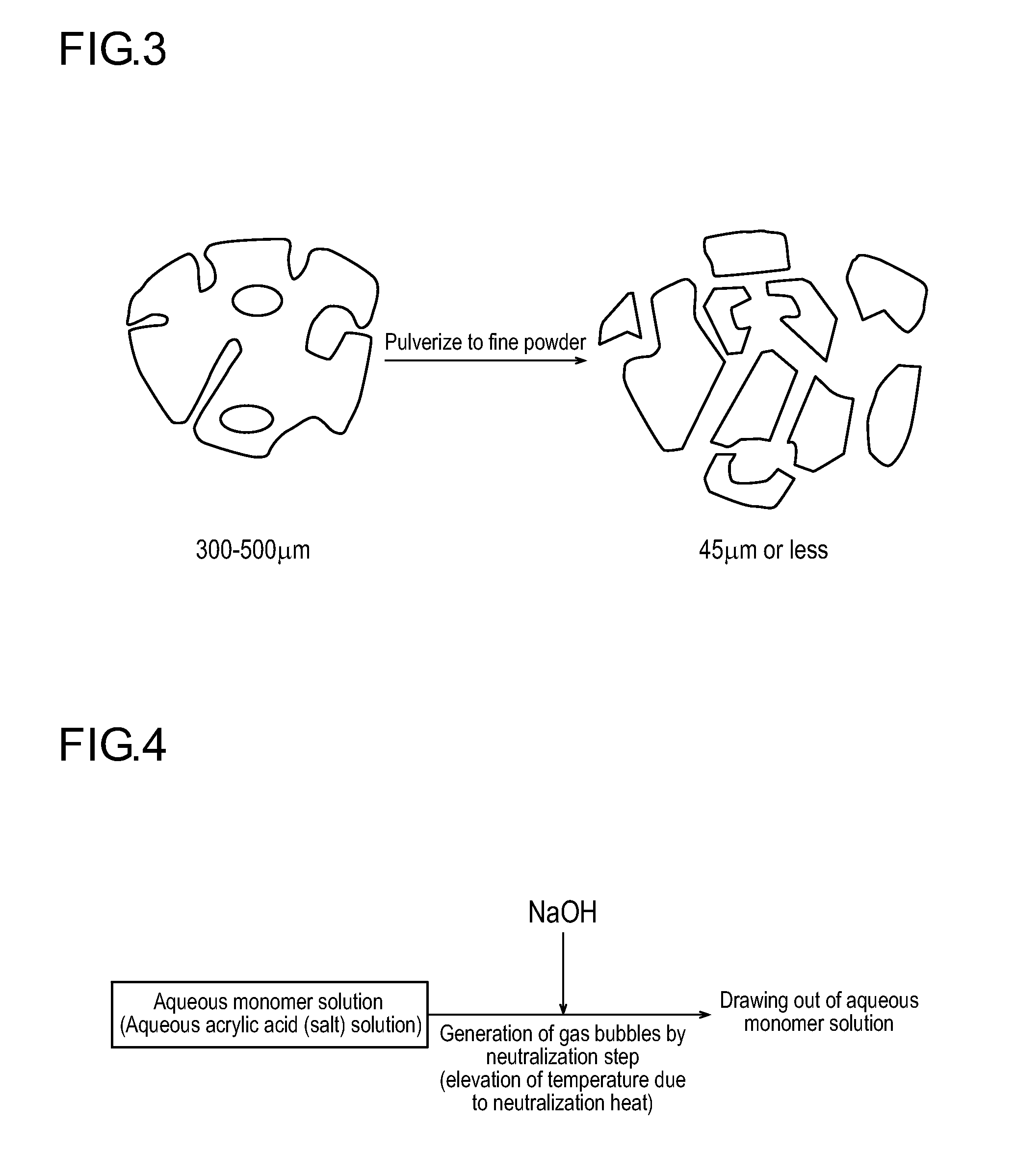

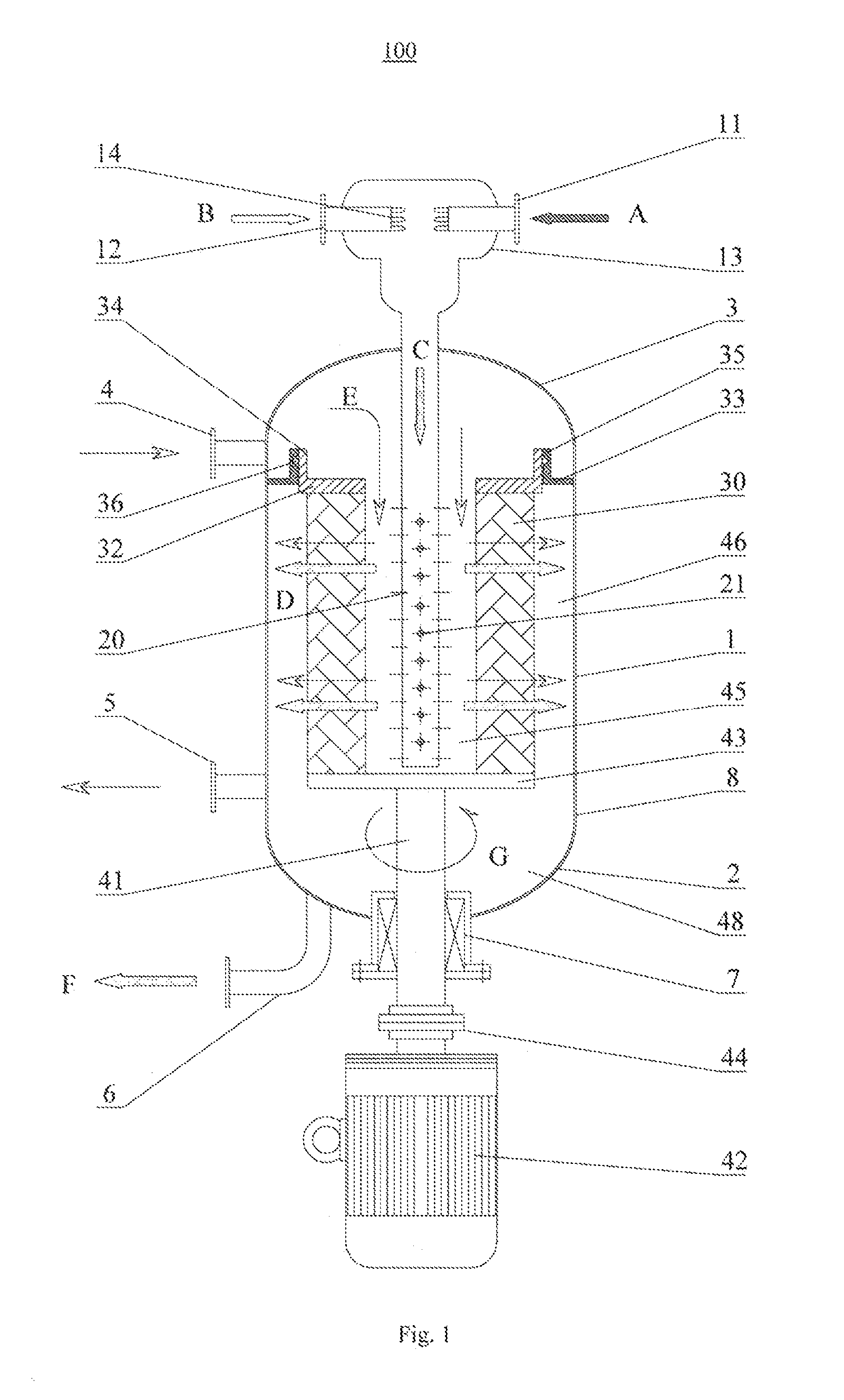

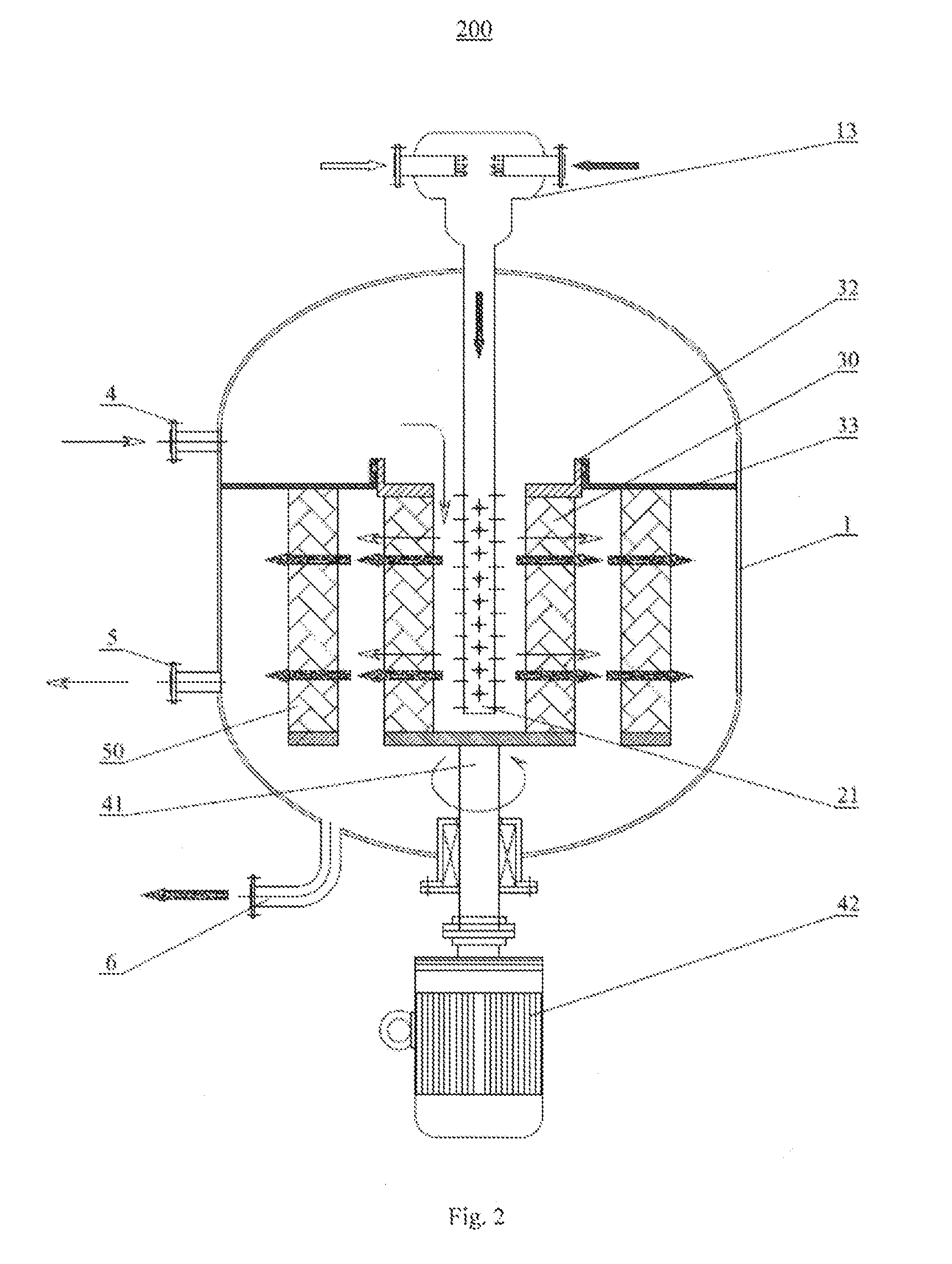

Method for producing polyacrylic acid (SALT)-based water absorbent resin powder

From a viewpoint of reduction in an out of spec product after surface crosslinking, particularly, when an alkylene carbonate compound is used as a surface crosslinking agent, influence by an air temperature is great, and it is necessary to reduce ethylene glycol which is produced as a byproduct, and there is provided a process for producing a polyacrylic acid (salt)-based water absorbent resin powder, comprisinga step of polymerizing an aqueous acrylic acid (salt)-based monomer solution,a step of drying the resulting polymer,an optional grinding•classifying step, anda surface crosslinking step,wherein in the surface crosslinking step,(1) a surface crosslinking agent containing an alkylene carbonate compound and a polyhydric alcohol compound is mixed into a water absorbent resin powder, the mixture is heat-reacted and, further, simultaneously with, or separately from the mixing, an ion reactive surface crosslinking agent is mixed, and / or(2) mixing treatment of mixing a surface crosslinking agent solution into a water absorbent resin powder containing at least one or more kinds of ion reactive surface crosslinking agents is performed two or more times.

Owner:NIPPON SHOKUBAI CO LTD

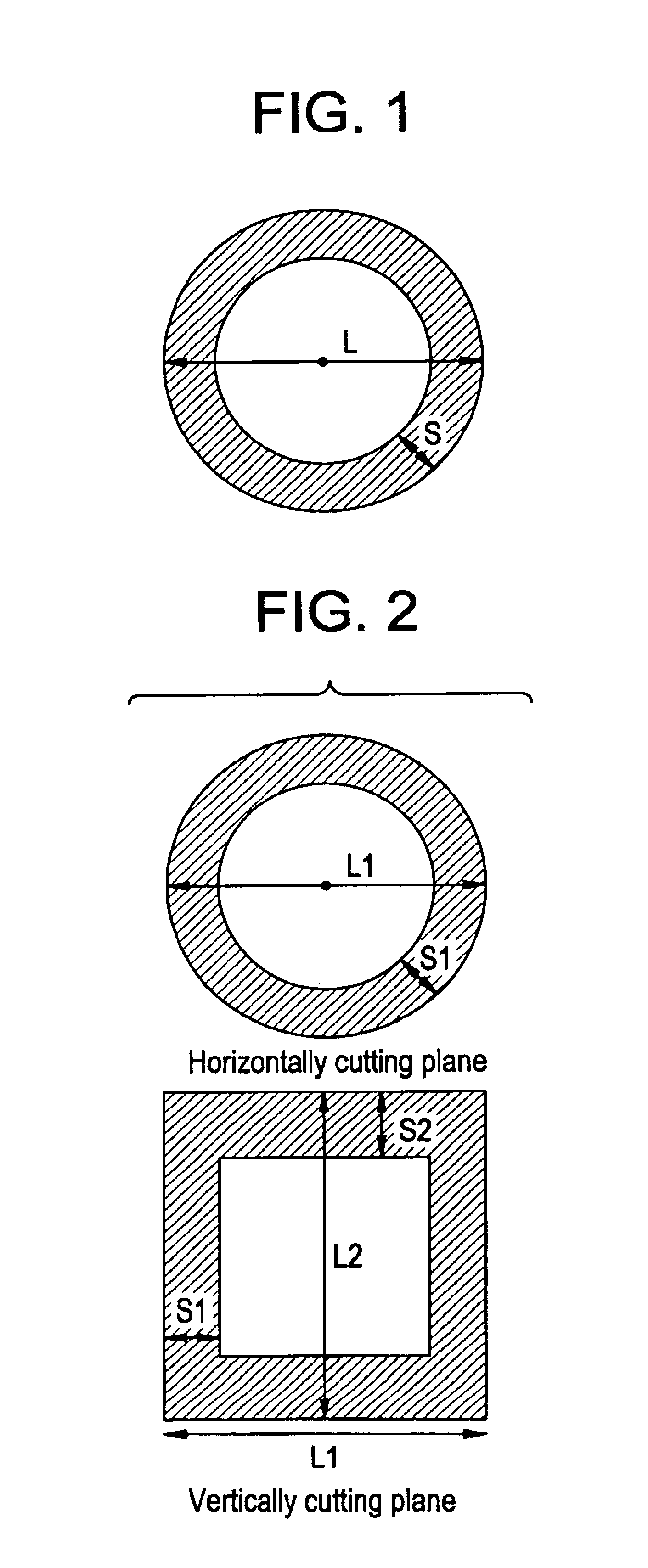

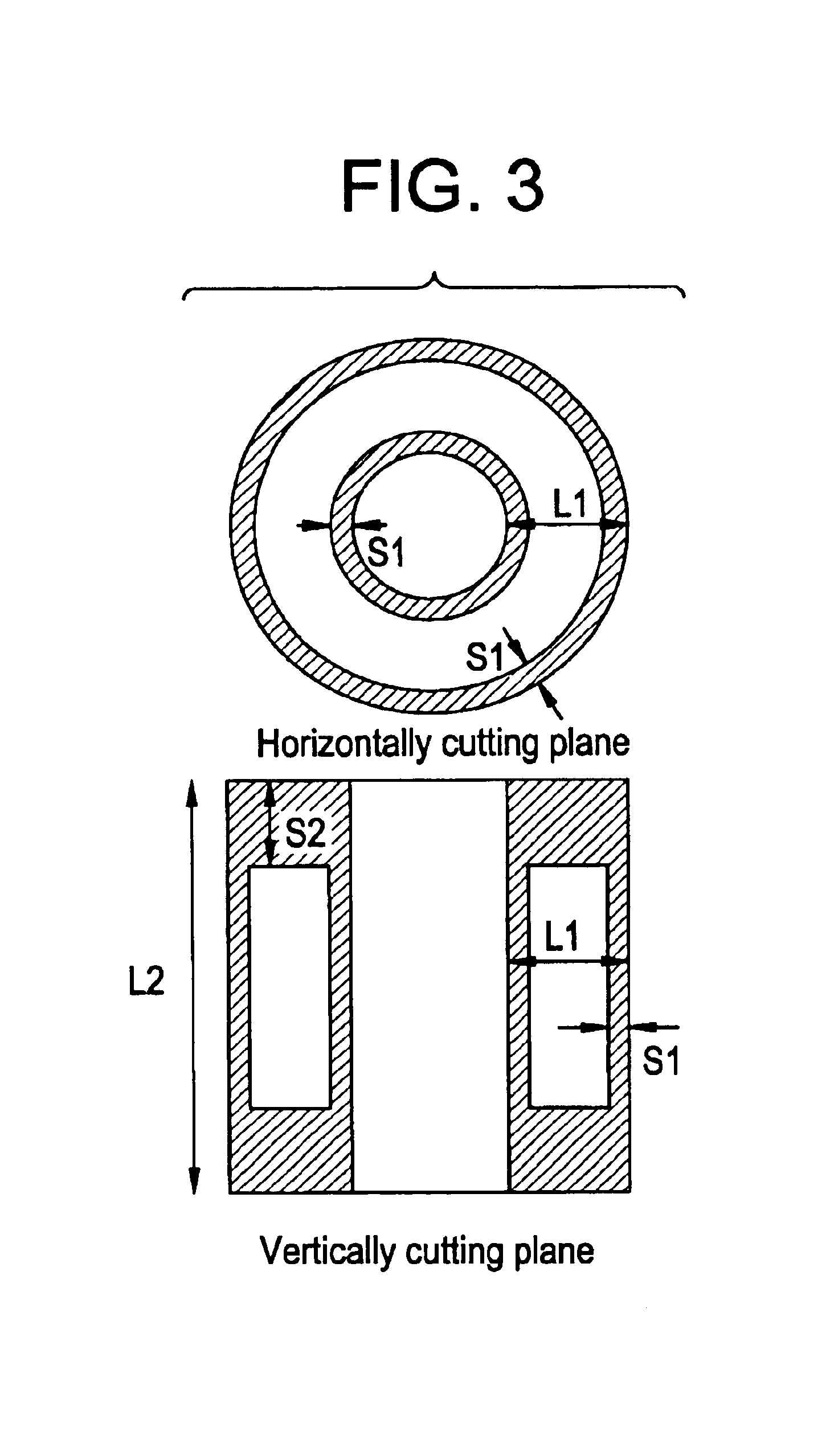

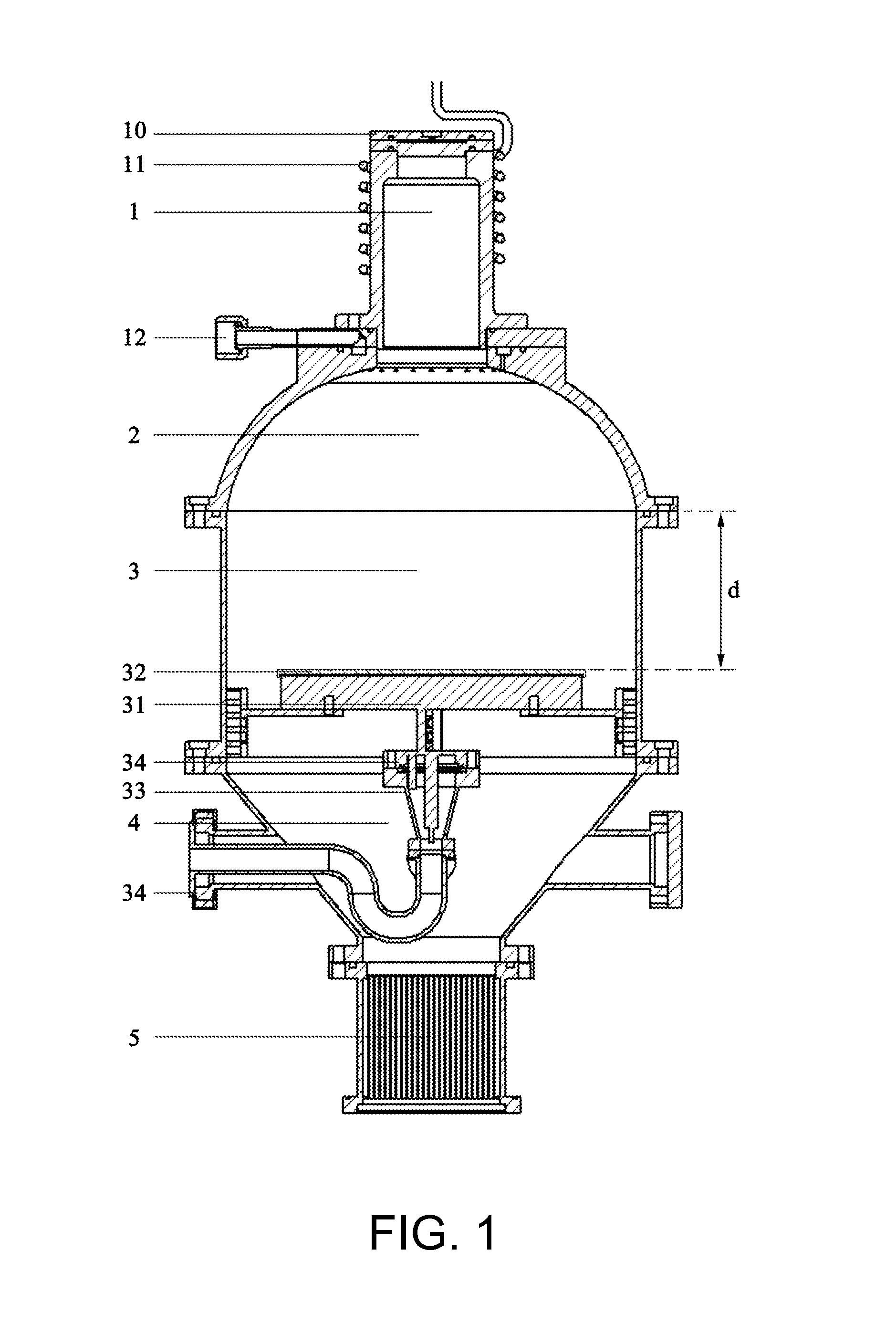

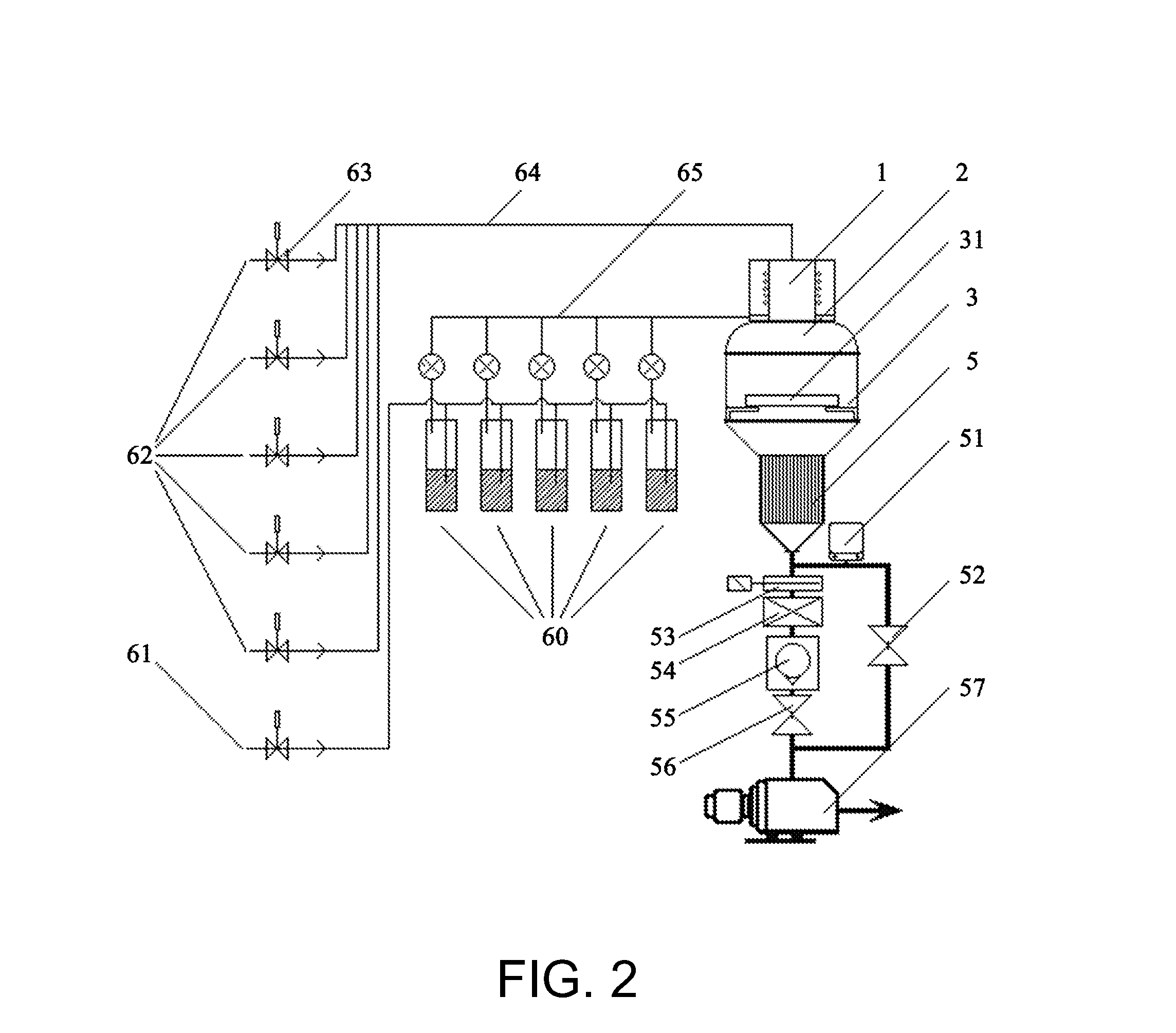

Reactor and Alkylation Process Using the Reactor

ActiveUS20140128654A1High catalytic efficiencyLower reaction temperatureHydrocarbons from unsaturated hydrocarbon additionCatalystsAlkyl transferEngineering

The present disclosure provides a reactor for at least two liquid materials, comprising an enclosed reactor housing; a feeding tube having liquid material inlets for receiving corresponding liquid materials respectively; a distribution tube communicating with the feeding tube and extending into the reactor housing, the distribution tube being provided with a plurality of distribution holes in the region thereof extending into the reactor housing; a rotating bed in form of a hollow cylinder, which is disposed in the reactor housing via a fixing mechanism, thus dividing inner cavity of the reactor housing into a central area and an outer area, the rotating bed being capable of rotating driven by a driving mechanism; and a material outlet provided in a lower portion of the reactor housing for outputting product after reaction. The distribution tube extends into the central area spaced from inner surface of the rotating bed, so that materials can enter into the outer area from the central area through the rotating bed and can be output via the material outlet.

Owner:CHINA PETROCHEMICAL CORP +1

Simplified process to prepare polyolefins from saturated hydrocarbons

InactiveUS20070249793A1Lower reaction temperatureAvoid equilibrium limitationLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionPolyolefinDehydrogenation

A simplified process for preparing polyolefins from saturated hydrocarbons is provided. The process involves partial and selective dehydrogenation of a saturated hydrocarbon in the presence of oxygen to form an olefin, unreacted hydrocarbon, and water, and optionally other by-products and oxygen. The water, other by-products (if present), and oxygen (if present) are separated from the olefin and unreacted hydrocarbon. No other separation is performed. The olefin and unreacted hydrocarbon are polymerized in the presence a polymerization catalyst or initiator to make polyolefin. Solid polyolefin is separated from unreacted hydrocarbon, which is recycled to the dehydrogenation reaction.

Owner:WESTLAKE LONGVIEW

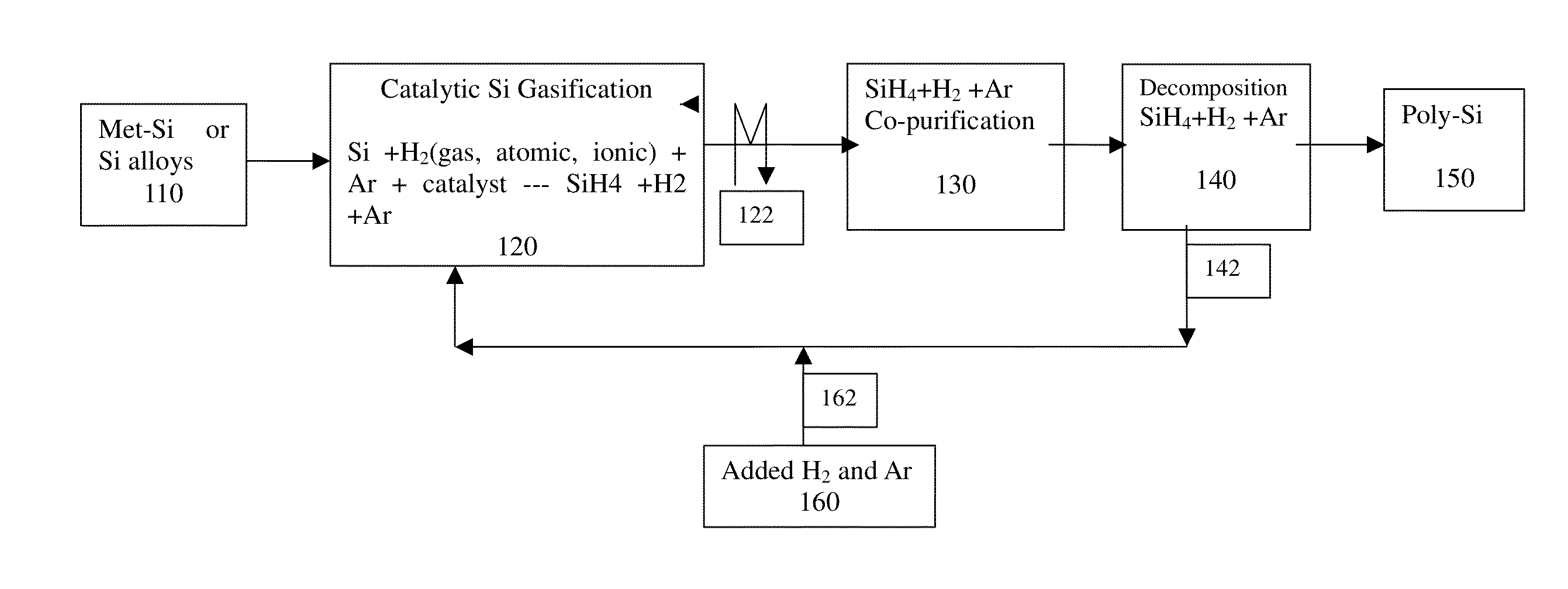

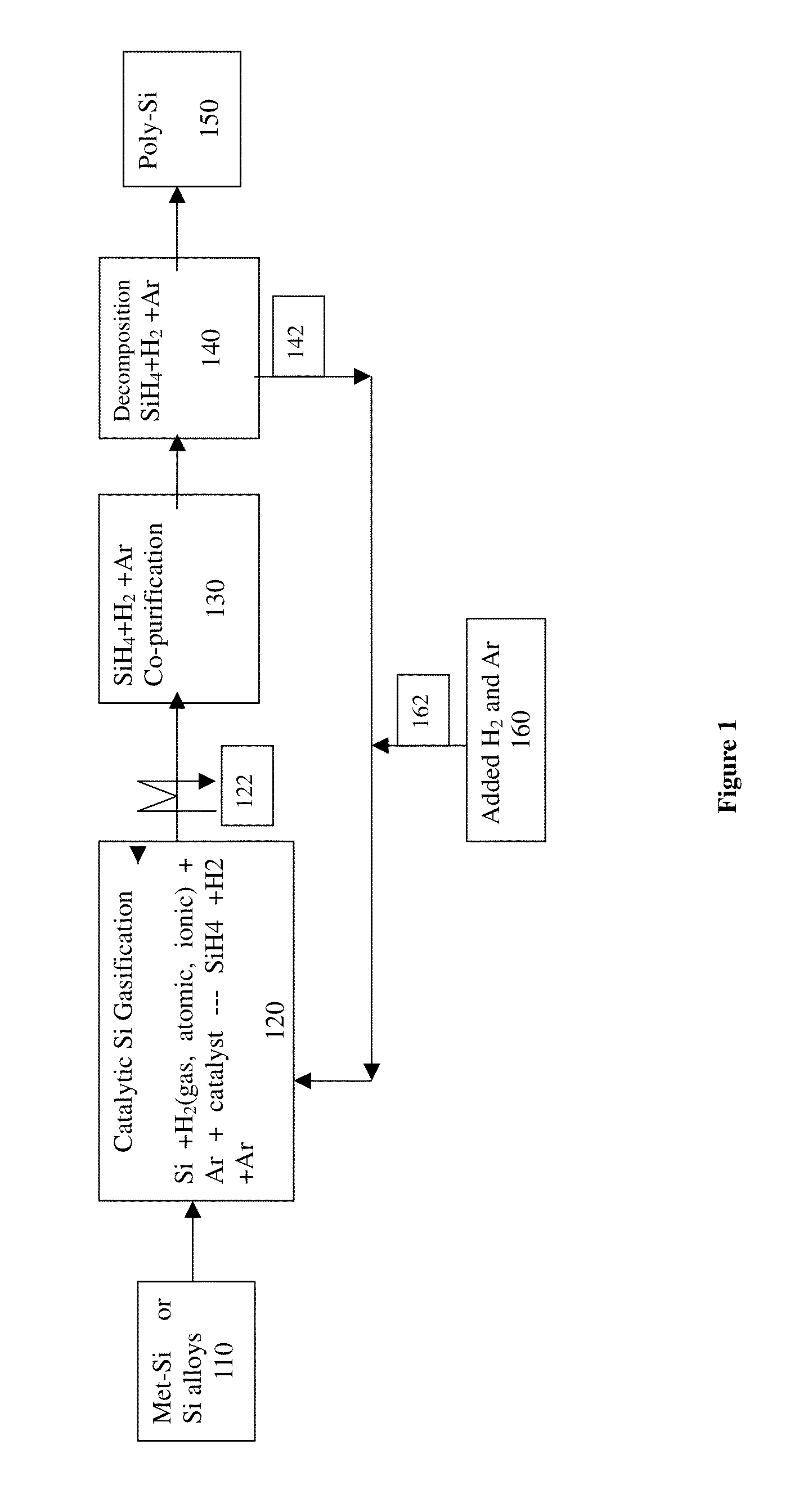

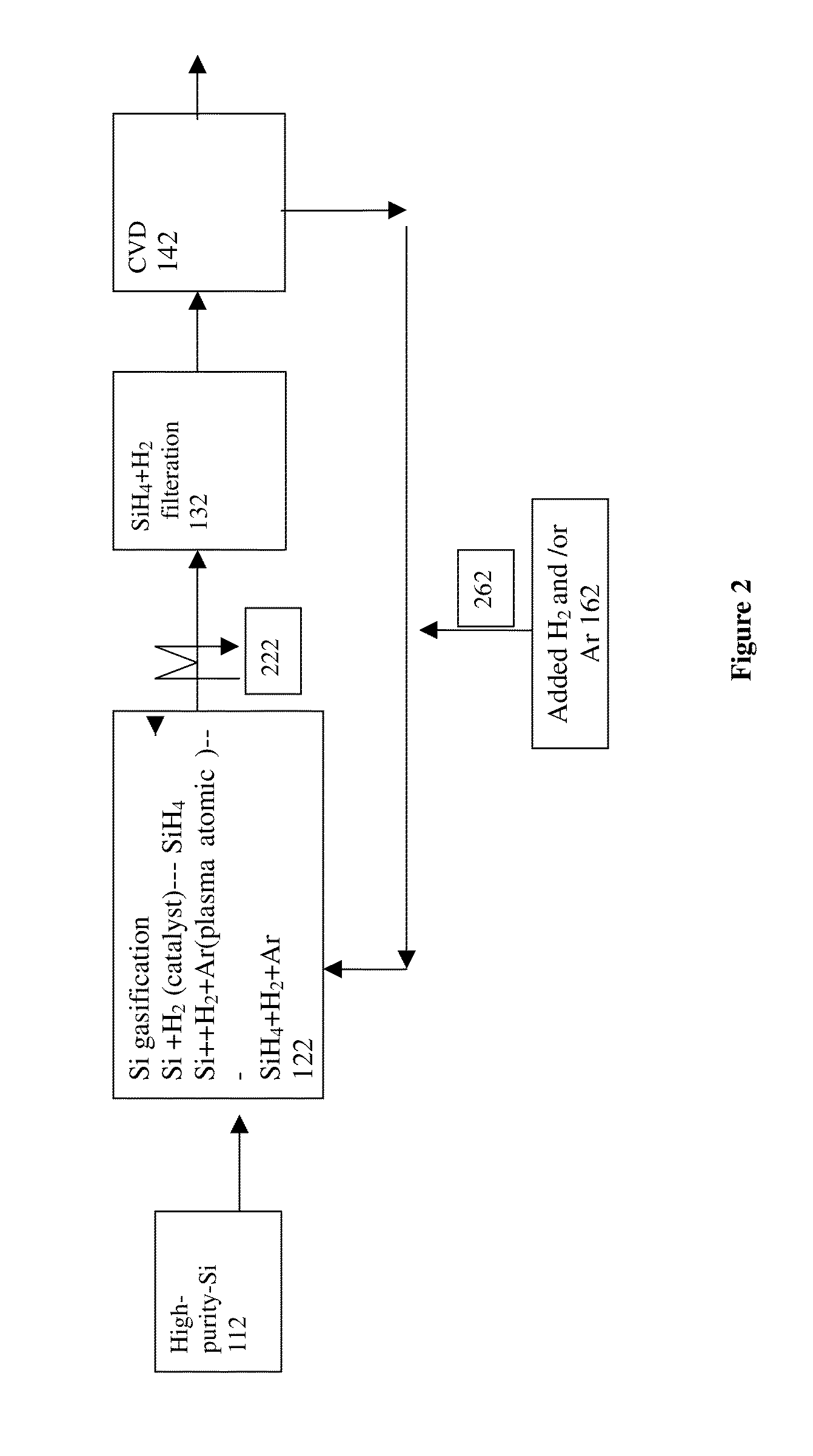

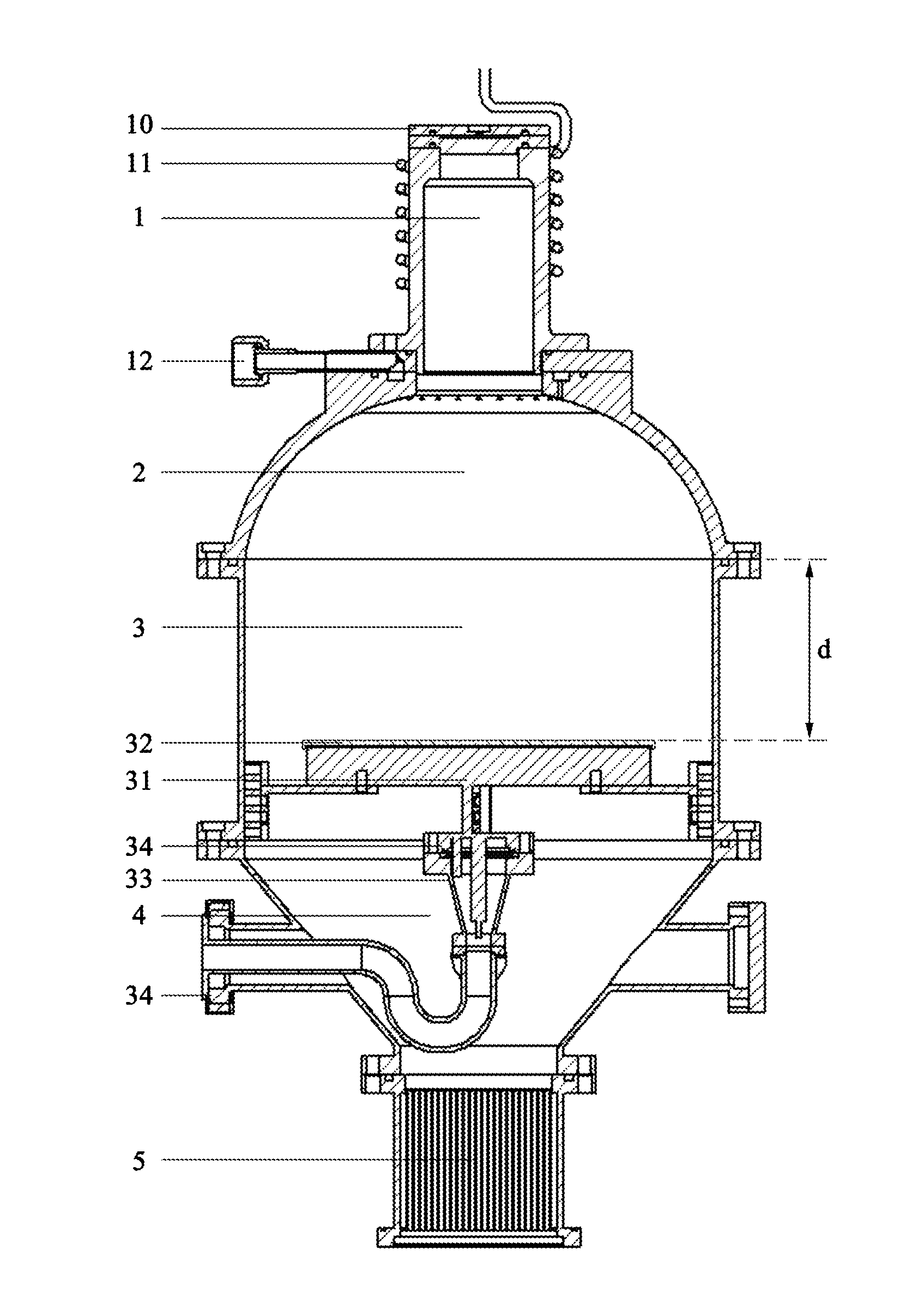

Method and system for production of silicon and devicies

InactiveUS20130195746A1Lower reaction temperatureSimple manufacturing processSilicon hydridesFluidised-bed furnacesHydrogenSilanes

In one embodiment of the invention, the silane and hydrogen (and inert gas) mixture is produced using catalytic gasification of silicon (or si-containing compounds including silicon alloys) with a hydrogen source such as hydrogen gas, atomic hydrogen and proton. By not separating silane from hydrogen and co-purifying all the gases (silane and hydrogen, inert gas) in the gas mixture simultaneously, the mixture is co-purified and then provide feed stock for downstream application without further diluting the silane gas. One aspect of the invention addresses the need for an improved production method, apparatus and composition for silane gas mixtures for large scale low cost manufacturing of high purity silicon and distributed on-site turnkey applications including but not limited to the manufacture of semiconductor integrated circuits, photovoltaic solar cells, LCD-flat panels and other electronic devices. Thus, various embodiments of the invention can greatly reduce the cost and simplify the process of manufacturing silicon.

Owner:CHU XI

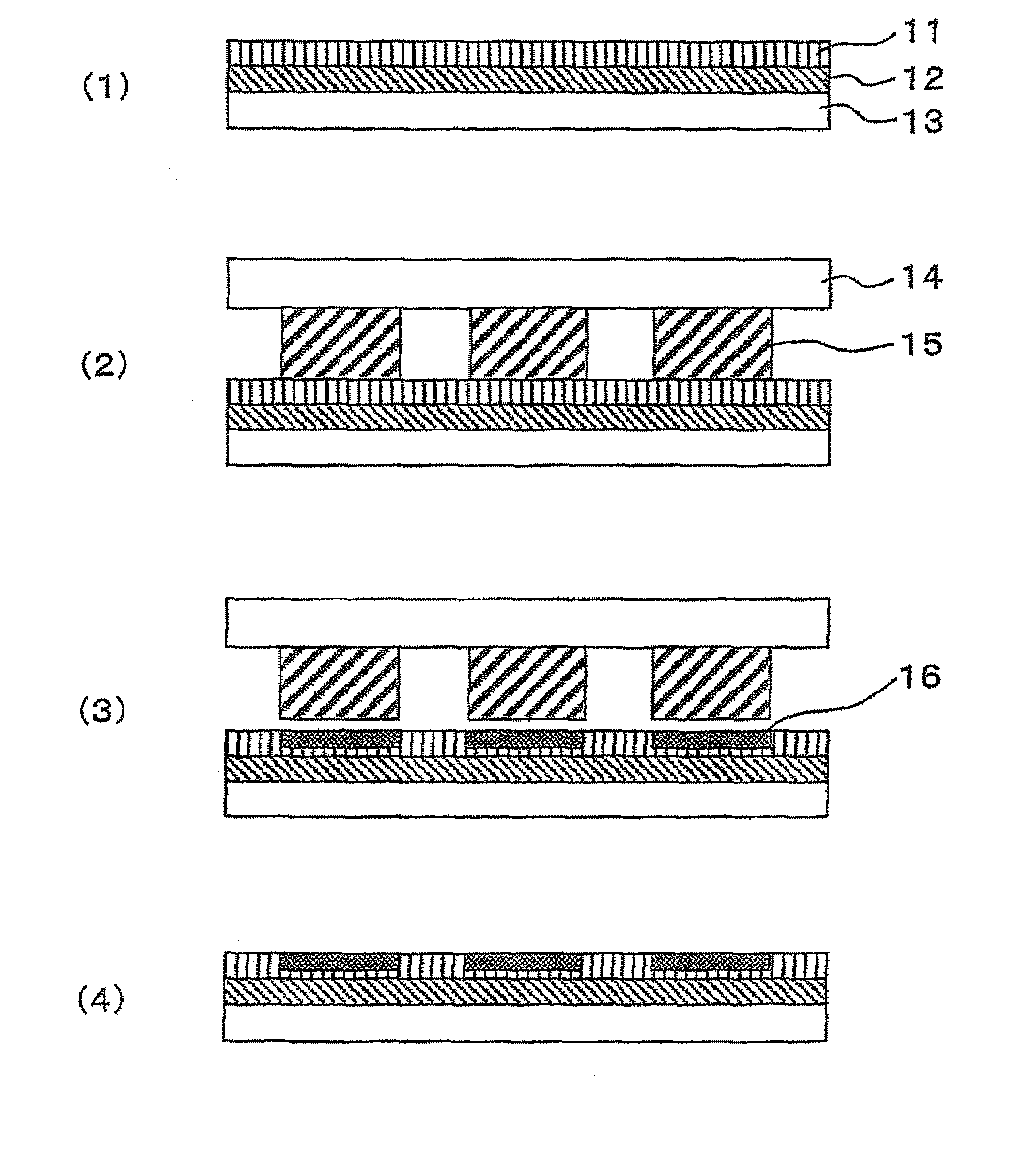

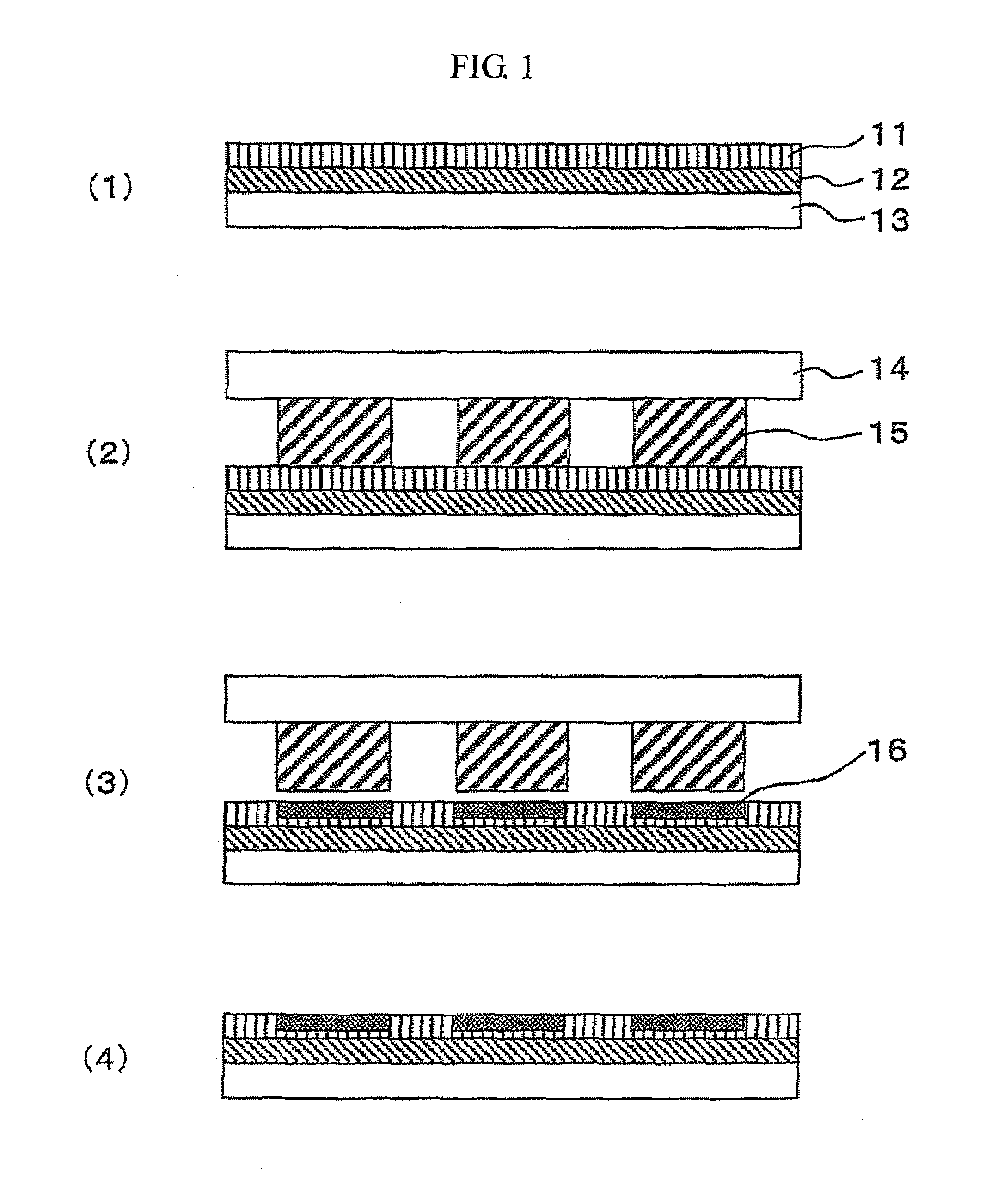

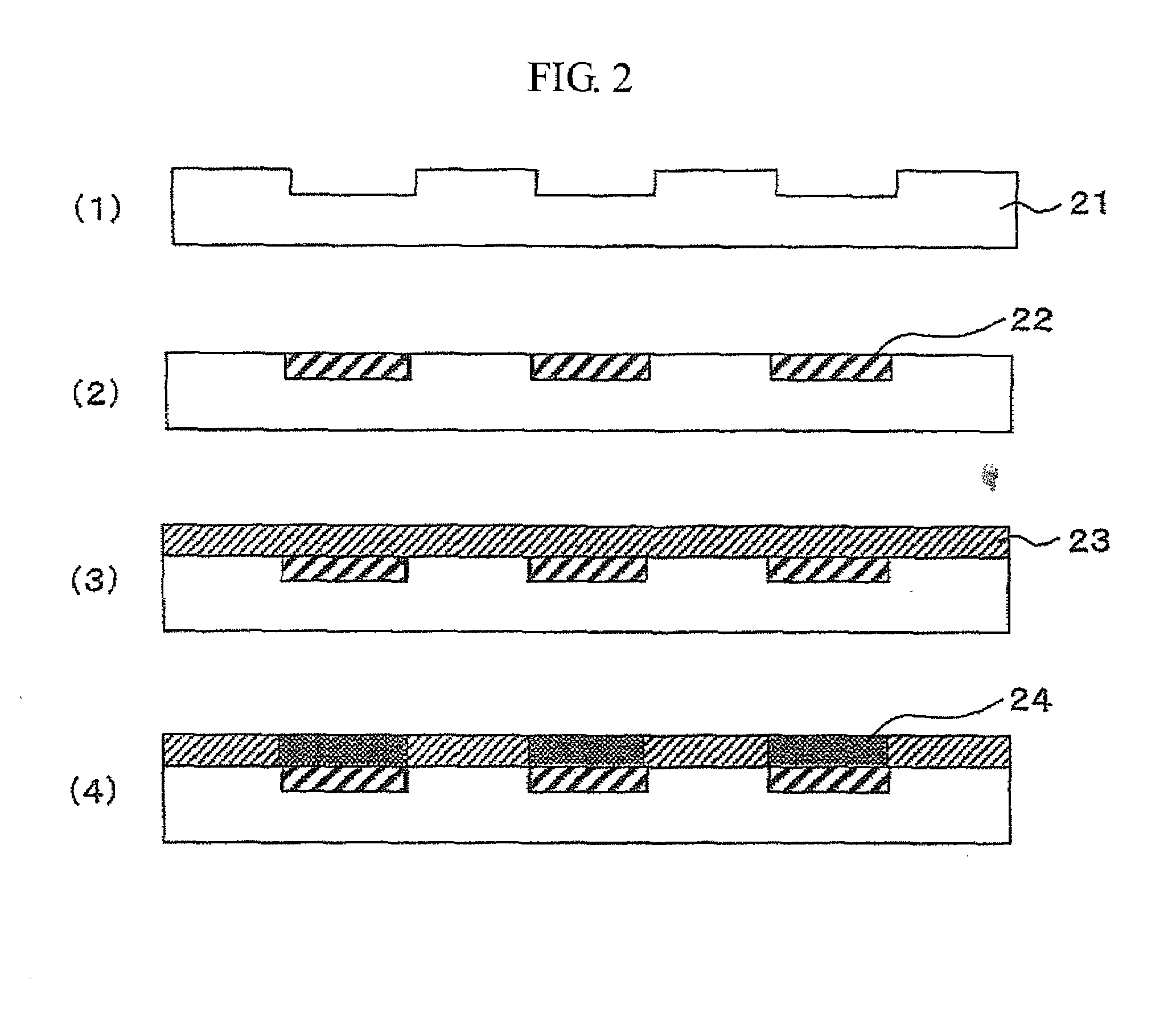

Plasma-Enhanced Atomic-Layer Deposition System and Method

InactiveUS20160010207A1Improve uniformityImprove film qualityElectric discharge tubesChemical vapor deposition coatingPump chamberAtomic layer deposition

In one example, we describe a type of plasma-enhanced atomic layer deposition equipment including: fluidly connected plasma generation chamber, diffusion chamber, reaction chamber, and pumping chamber, wherein the plasma generation chamber includes a plasma generation gas inlet and a plasma generation device that enables the generation of plasma from the plasma generation gas coming from the plasma generation gas inlet. A precursor inlet is disposed between the plasma generation chamber and the diffusion chamber. Precursors coming from the precursor inlet and generated plasma diffuse uniformly inside the diffusion chamber. A sample stage, for the placement of sample to be deposited on, is disposed inside the reaction chamber. The pumping chamber is sequentially connected to an exhaust trap and pumping system. The equipment has enabled high quality atomic layer thin film deposition.

Owner:WANG DONGJUN

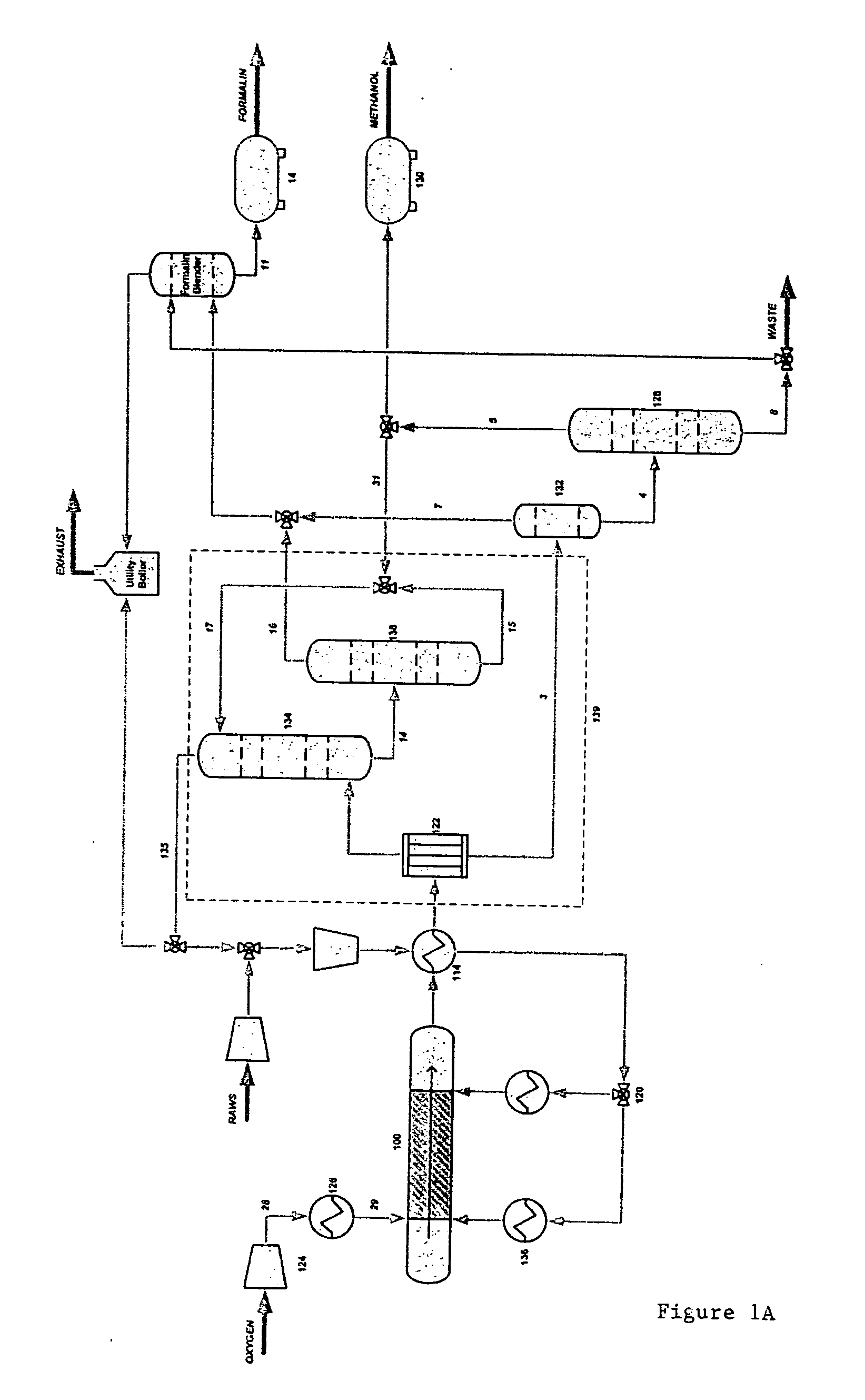

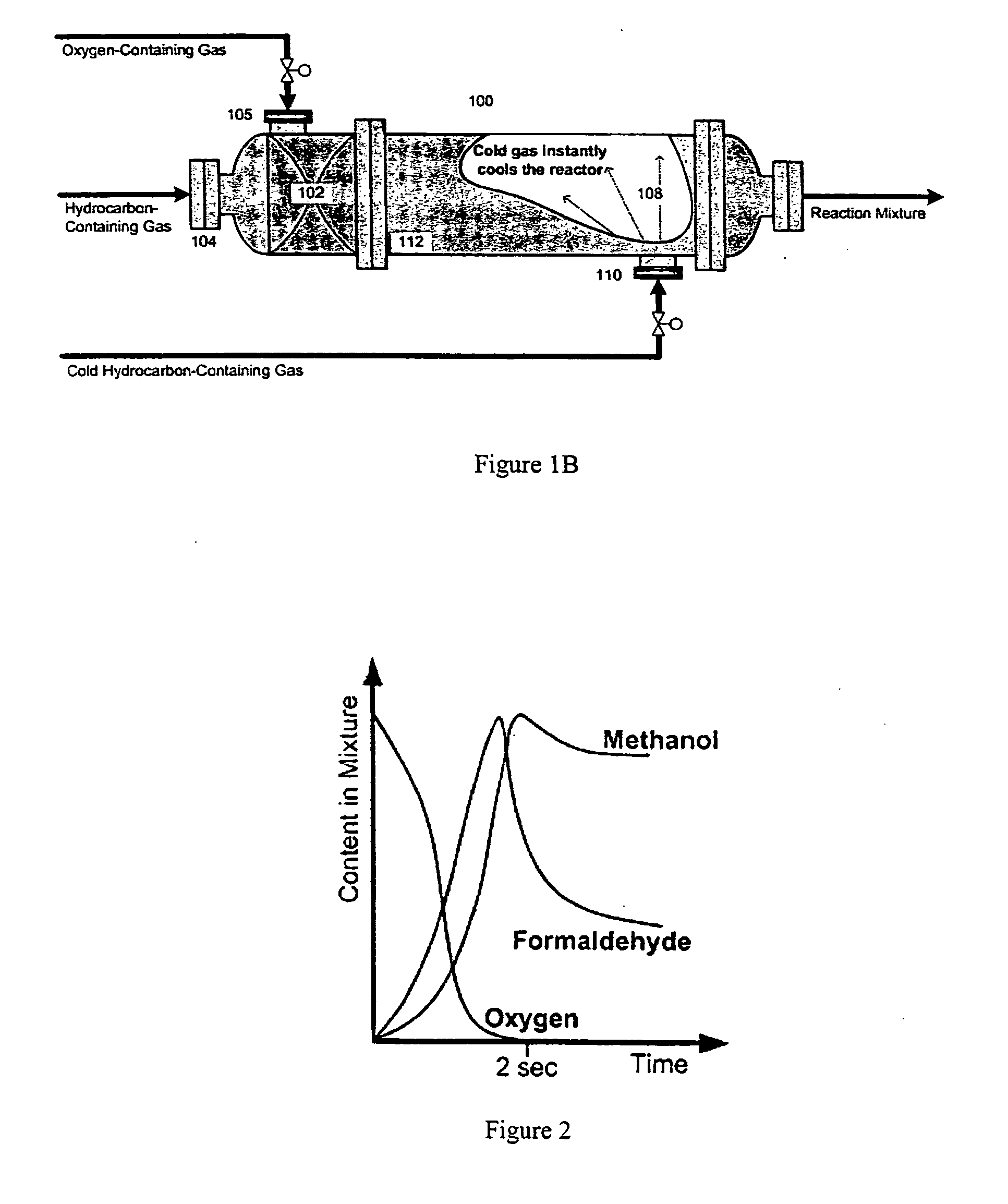

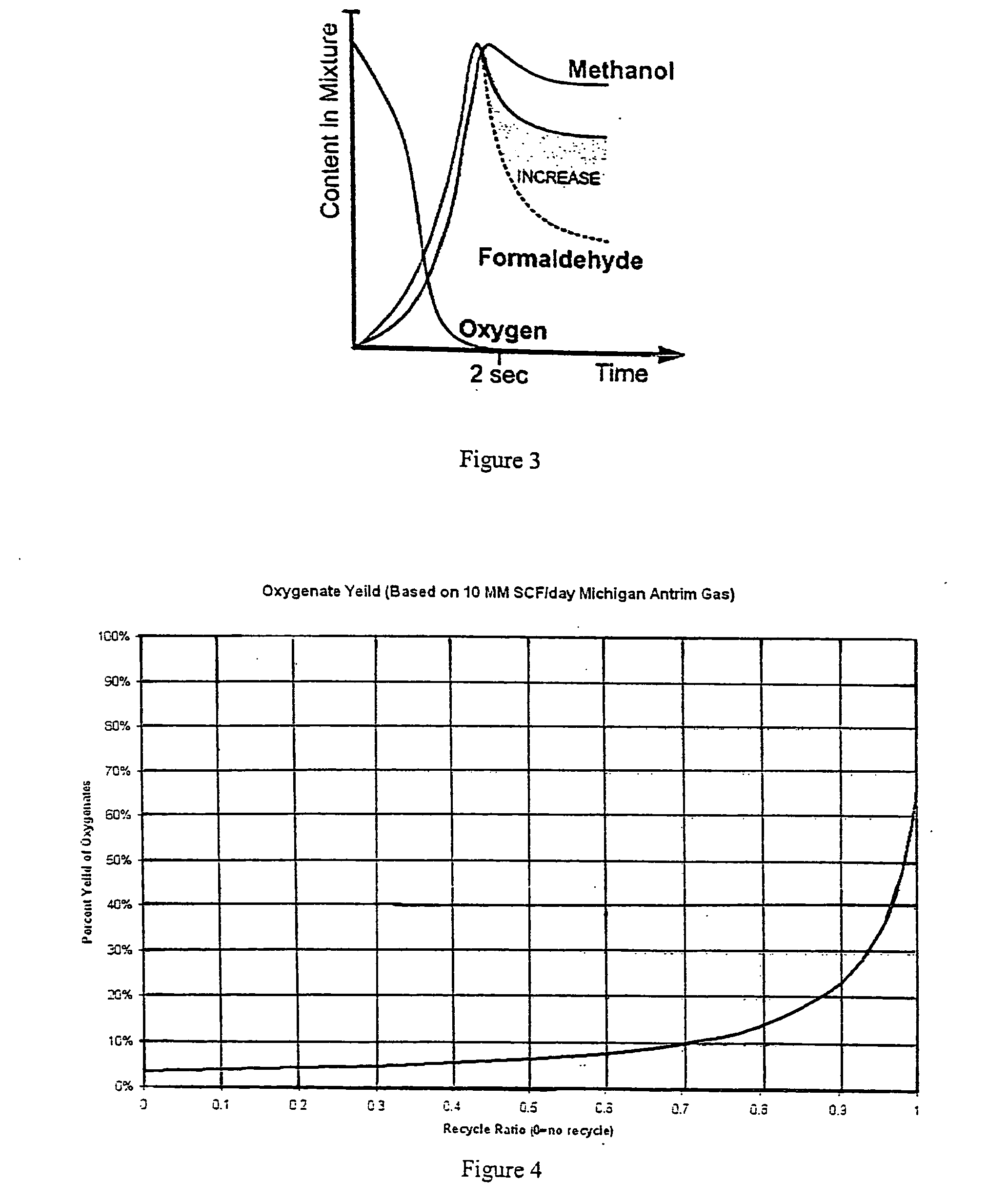

Method and apparatus for producing methanol

ActiveUS20060204413A1Avoid decompositionPrevent oxidationPreparation by oxidation reactionsOrganic compounds purification/separation/stabilisationOxygenHydrocarbon

An apparatus and method of producing methanol includes reacting a heated hydrocarbon-containing gas and an oxygen-containing gas in a reactor; to provide a product stream comprising methanol; and transferring heat from the product stream to the hydrocarbon-containing gas to heat the hydrocarbon containing gas. After removing methanol and CO2 from the product stream, unprocessed hydrocarbons are mixed with the hydrocarbon containing gas fro reprocessing through the reactor.

Owner:GAS TECH

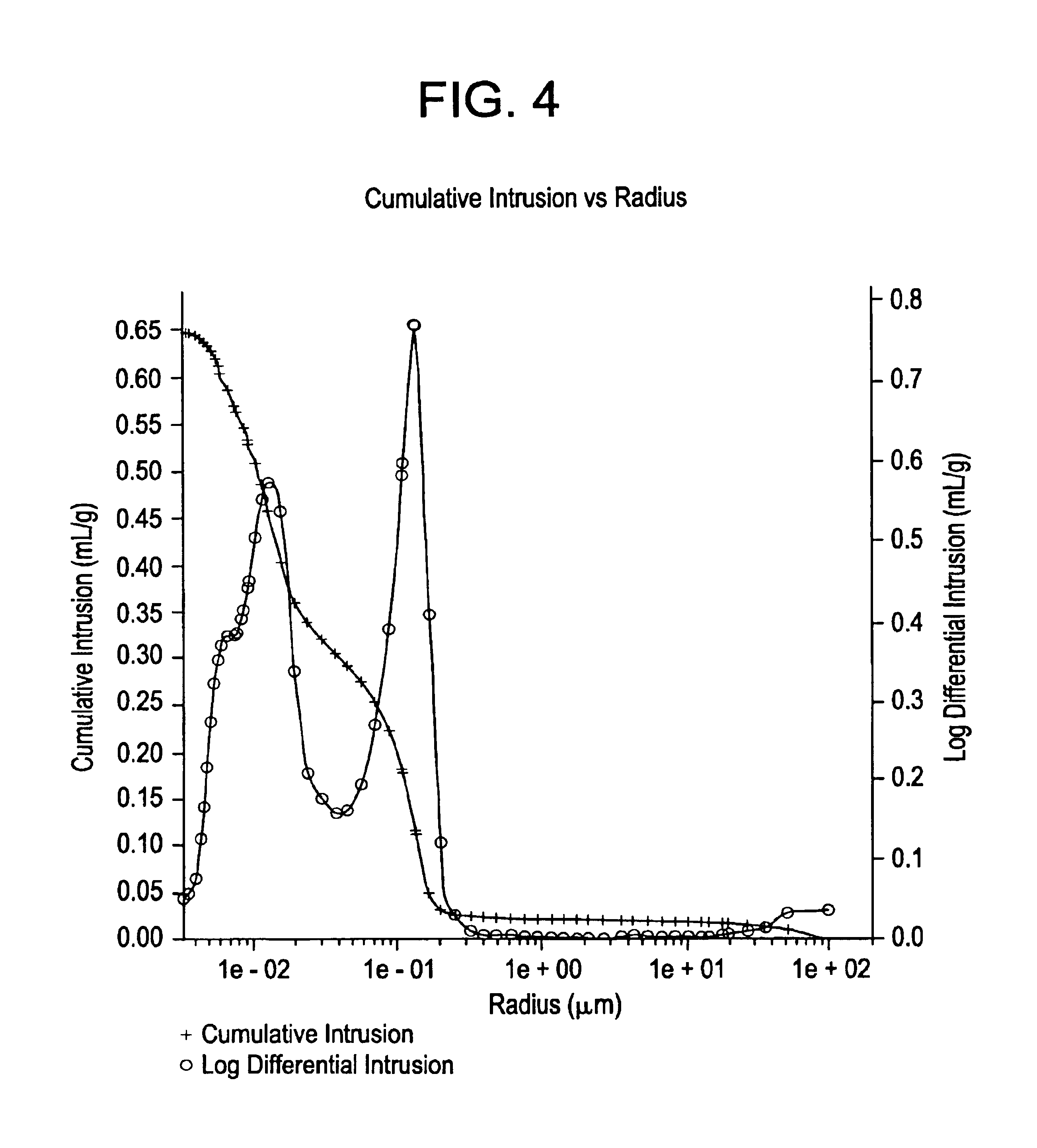

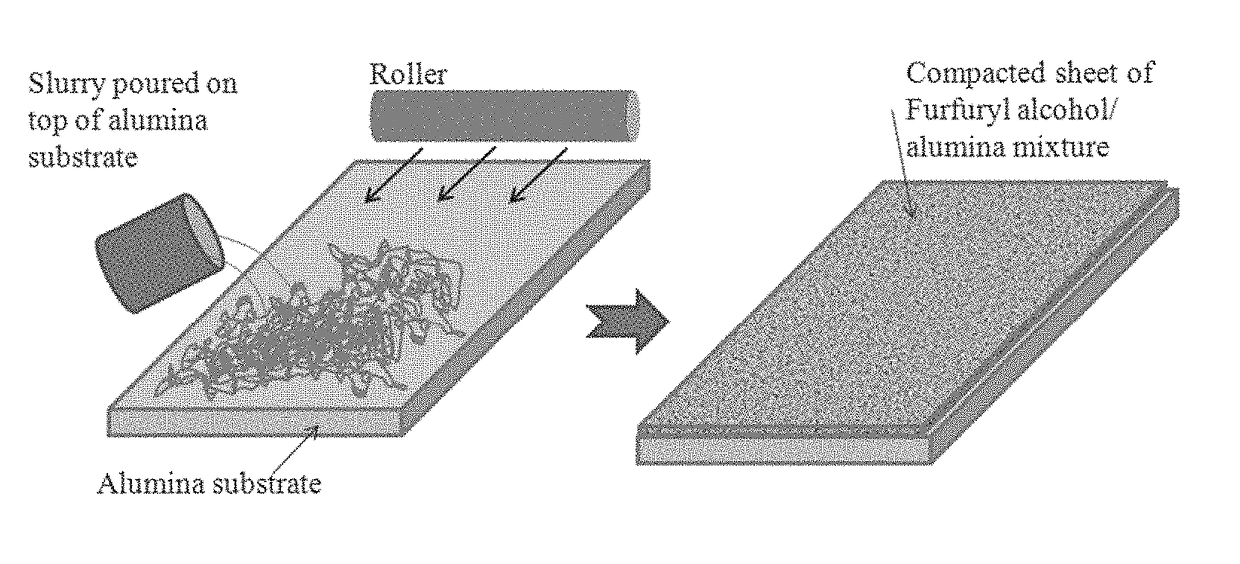

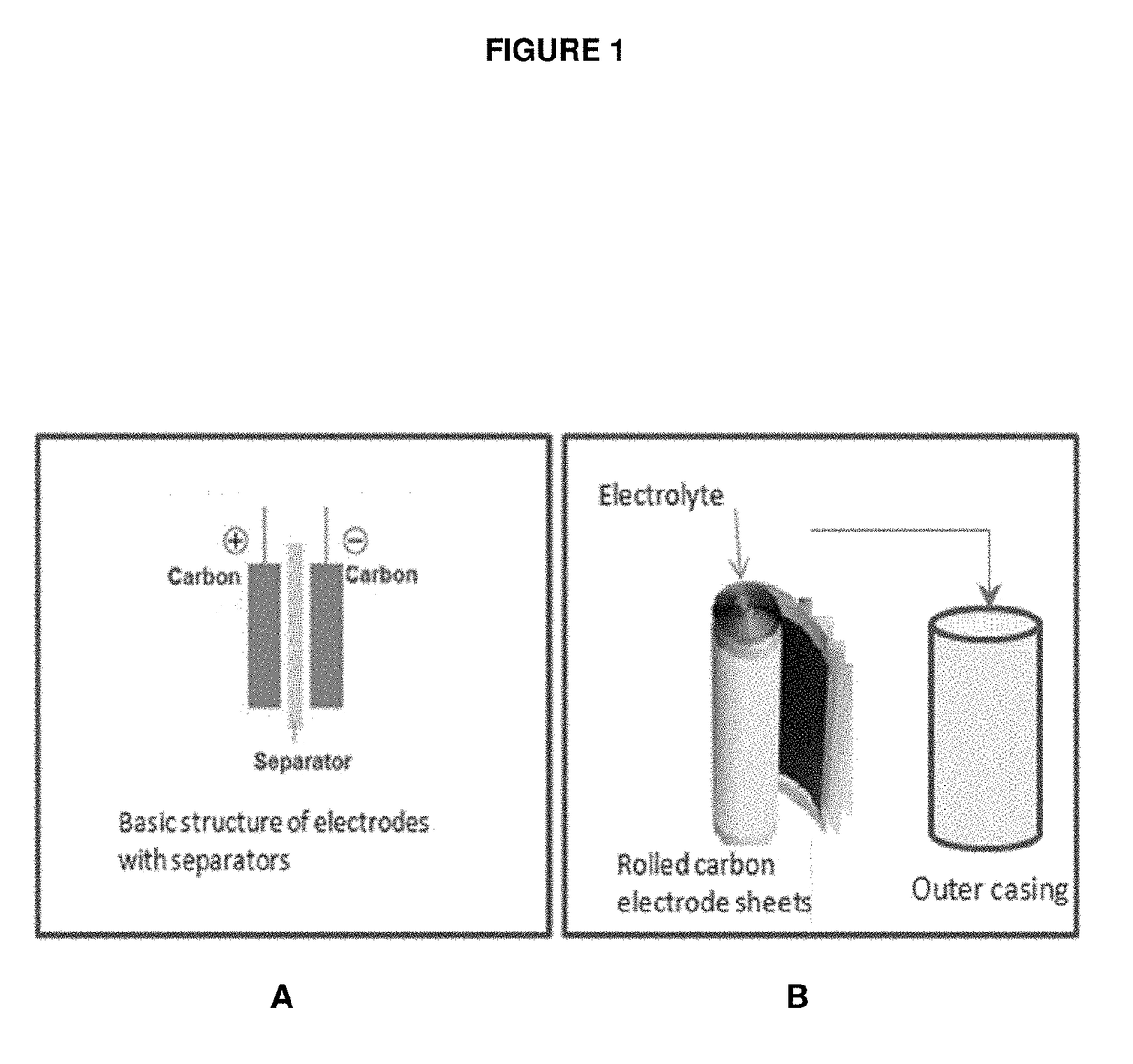

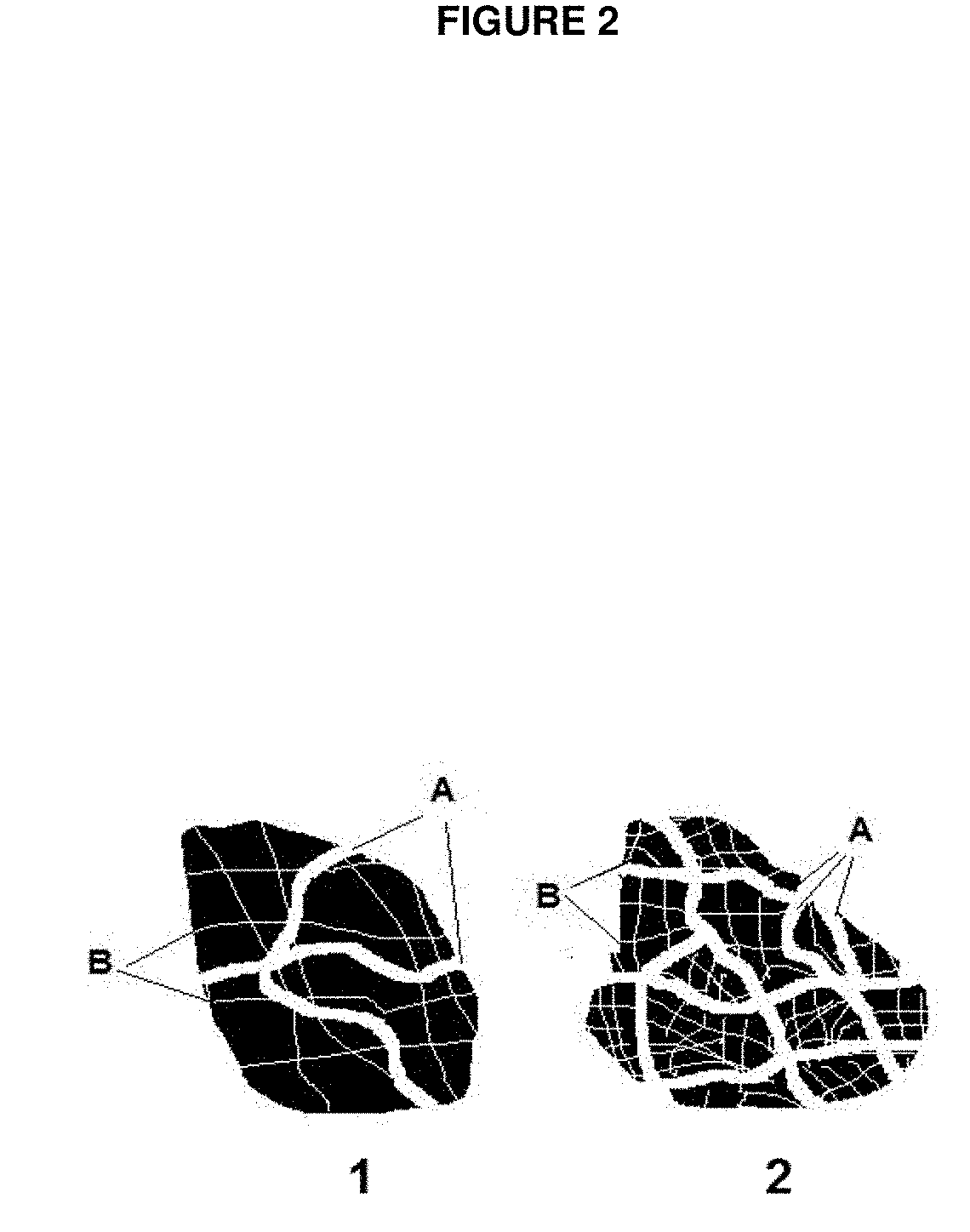

Porous carbon electrodes for energy storage applications

ActiveUS20170323738A1Large specific surface areaReduced stabilityCarbon compoundsHybrid capacitor electrodesPorous carbonNanoporous carbon

The present patent application discloses a method of producing nano-porous carbon, comprising mixing furfuryl alcohol or its fast-polymerizing derivatives with an aluminum-based solid polymerization catalyst, heating the mixture until a solid catalyst-carbon matrix forms, heating again under inert atmosphere and etching the powder to remove the matrix to produce a network of pores in the nano-porous carbon. The application further provides a method for making of fabricating tailor-made nano-porous carbon electrodes.

Owner:FARAD POWER

Process for producing acrolein and/or acrylic acid

ActiveUS20110015432A1High-temperature reactionImprove efficiencyOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationGas phaseReaction temperature

In industrial scale production of acrolen and / or acrylic acid by catalytic gas-phase oxidation of propylene or a propylene-containing gas with molecular oxygen or a molecular oxygen-containing gas or in industrial scale production of acrylic acid by catalytic gas-phase oxidation of acrolein or an acrolein-containing gas with molecular oxygen or a molecular oxygen-containing gas, this invention provides a process characterized in that the initial stage operation is carried out under advancedly elevated reaction temperature and thereafter the reaction temperature is lowered to carry out the steady state operation. According to this process, acrolein and / or acrylic acid can be produced in high yield stably over prolonged period.

Owner:NIPPON SHOKUBAI CO LTD

Silicate luminous material and preparation method thereof

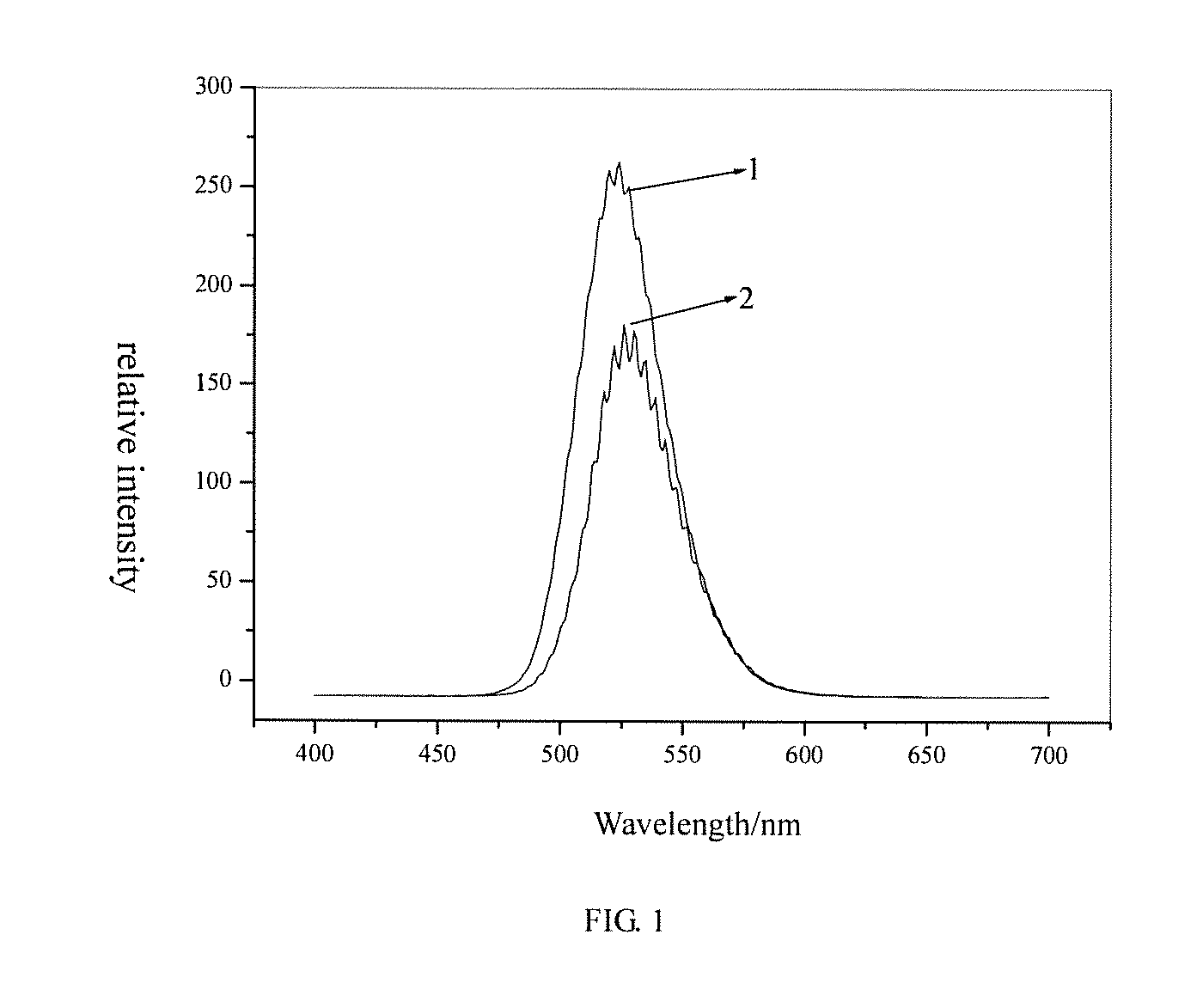

InactiveUS20130075661A1Improve quantum efficiencyHigh luminous intensityLuminescent compositionsQuantum efficiencyLuminous intensity

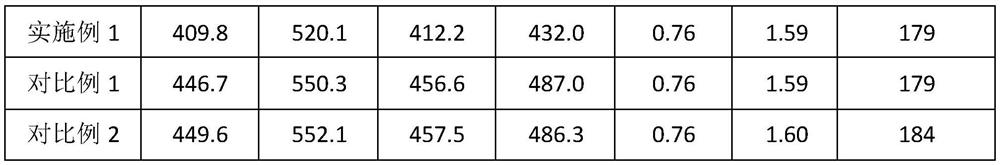

Silicate luminous material and preparation method thereof are provided. The luminous material is represented by the following chemical formula: Zn2−xSiO4:Mnx@SiO2@My, wherein M represents at least one element selected from the group consisting of Ag, Au, Pt, Pd and Cu, and y is molar ratio of M to Si in silicate luminous materials, and 0<x≦0.2, 0<y≦1×10−2. @ is coating; M is inner core; SiO2 is middle shell; Zn2−xSiO4:Mnx is outer shell. The core-shell luminous materials coating metal particle improve internal quantum efficiency, increase luminous intensity, and they are stable. The luminous materials can be controlled in the aspects of size and appearance and are appropriate to be used in coating screen process and improving display effect for sphere appearance with bulk density. Precipitation methods can not only decrease reaction temperature, but also have features of simple process, low equipment requirement, non-pollution and are controlled easily.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

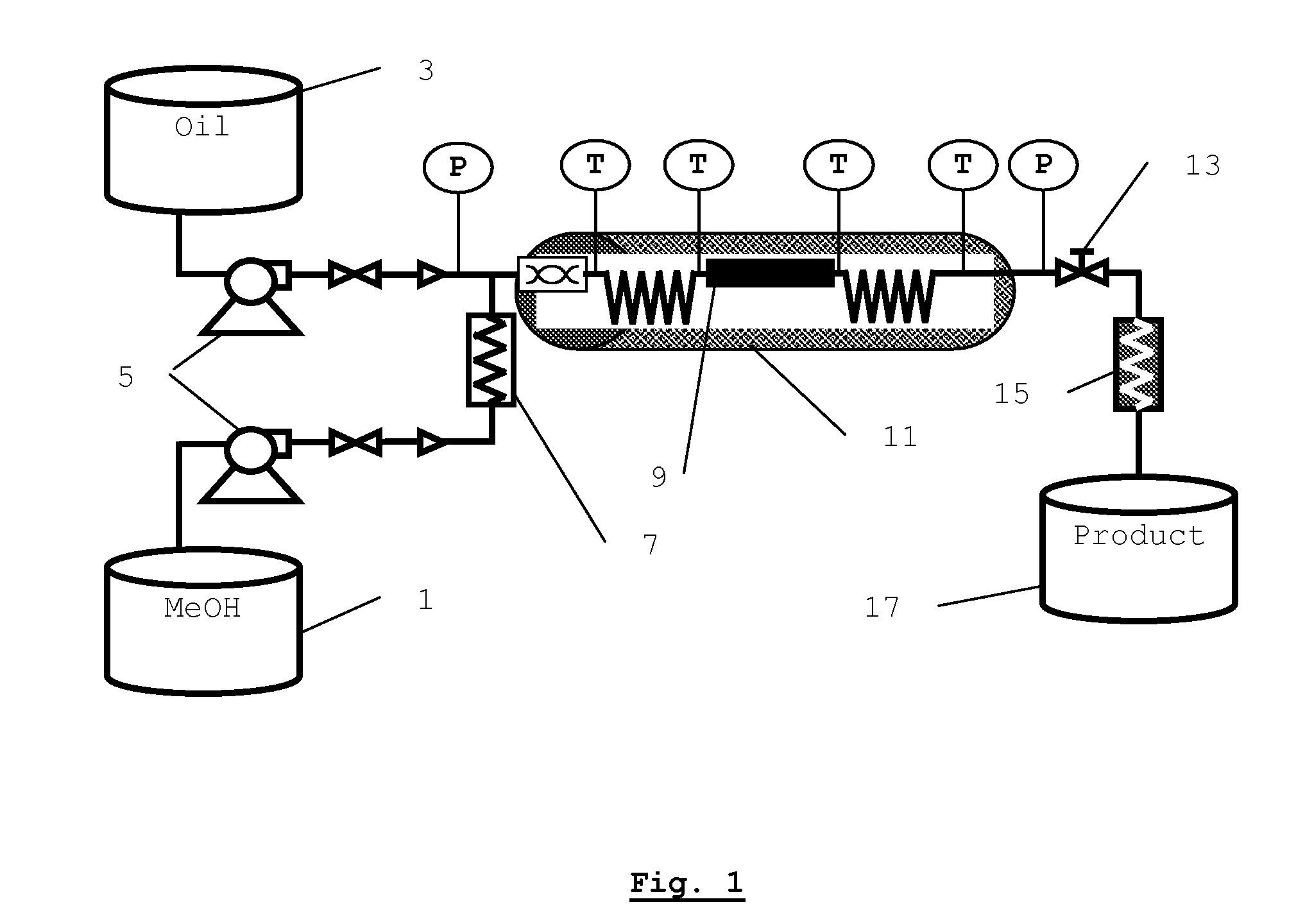

Novel method for producing biodiesel using an immobilised catalyst

ActiveUS20100010247A1Extended reaction timeRaise the reaction temperatureFatty oils/acids recovery from wasteFatty acid esterificationAlkaline earth metalContinuous flow

A method produces a fatty acid alkylester by transesterification of a fat or oil and an alcohol. The reaction is catalysed by a heterogeneous catalyst immobilised in a tubular reactor at a temperature between 260 and 420° C. and at a pressure higher than 5 bar. A mixture of the fat or oil and the alcohol is led in a continuous flow through the tubular reactor. The catalyst is preferably a metal oxide or a metal carbonate including an alkaline earth metal. The reaction takes place at reduced residence times and contact times compared to the prior art.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

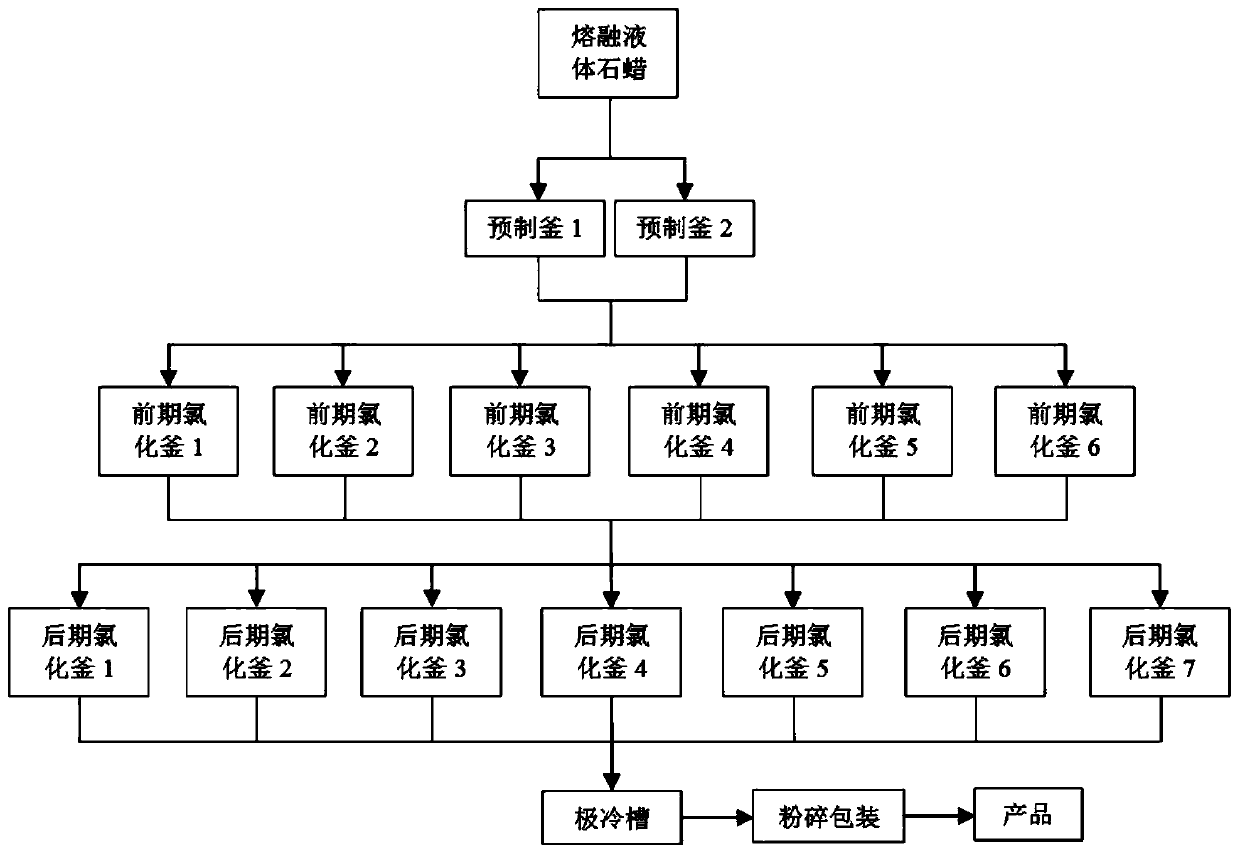

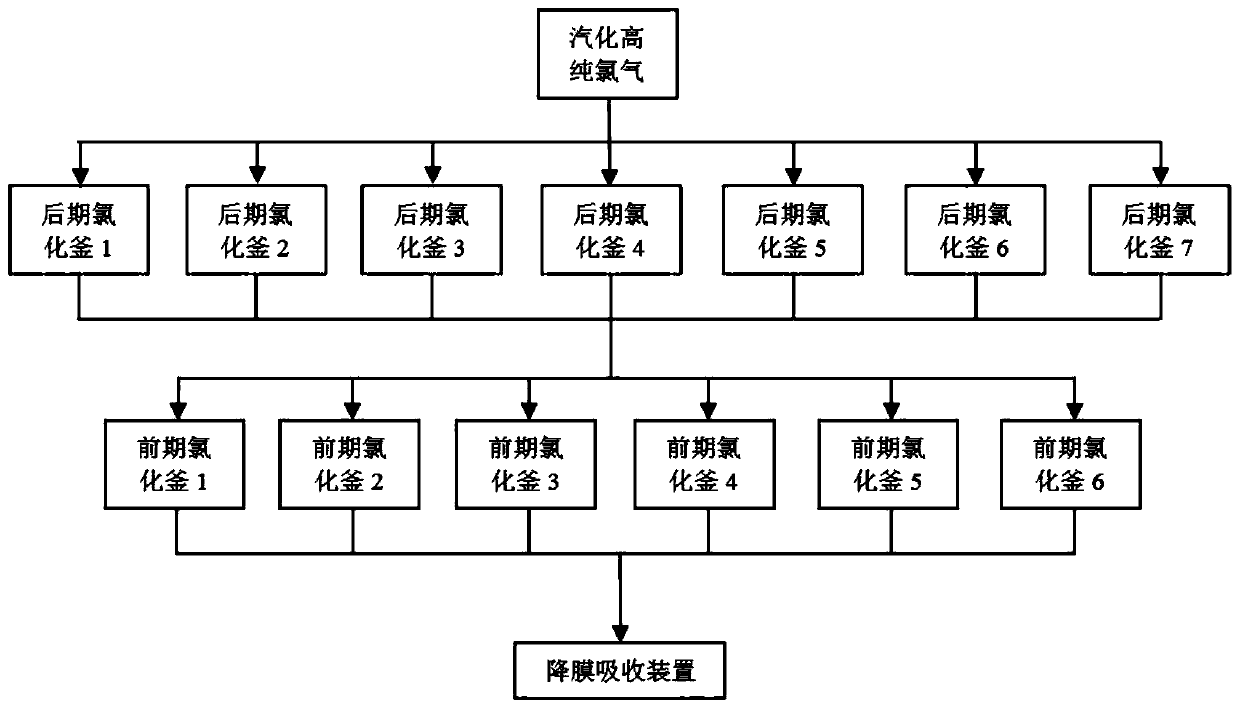

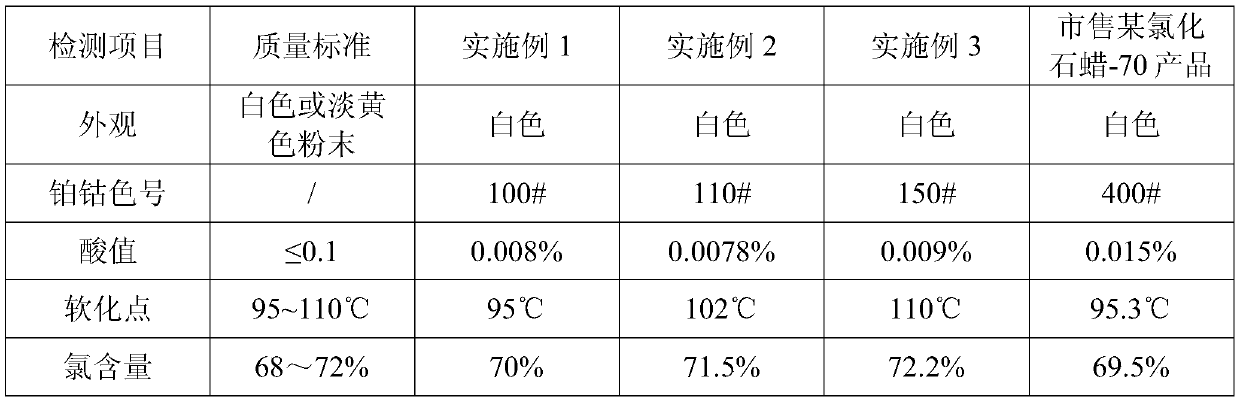

Method of producing chlorinated paraffin-70 through low temperature catalysis

InactiveCN110938470AAvoid the phenomenon of color deepeningQuick responseEnergy based chemical/physical/physico-chemical processesPetroleum chemical modificationParaffin waxReaction rate

The invention relates to a method of producing chlorinated paraffin-70 through low temperature catalysis and belongs to the technical field of synthesis of producing chlorinated paraffin-70 through low temperature catalysis. The method particularly includes: (1) feeding solid paraffin into a reaction kettle, and when the solid paraffin is molten completely, pressing the molten paraffin into a prefabricating kettle to perform a photo-induced reaction; (2) adding first and second additives to the molten paraffin; (3) feeding chlorine to perform early chlorination reaction; (4) according to the content of chlorine in the chlorinated paraffin, stepwise adding third and fourth additives, and performing a chlorination reaction; (5) after the reaction is finished, performing acid removal, water washing, addition of a stabilizer, refining, cooling and crushing to obtain the chlorinated paraffin-70. The method has following advantages: (1) the pressure is controlled stepwisely in the reaction process and the additives are added stepwisely, so that the reaction rate is increased, reaction temperature is reduced, reaction time is shortened and product quality is improved; (2) the method greatly reduces energy consumption than processes in the prior art.

Owner:山东沾化阳光化学有限公司

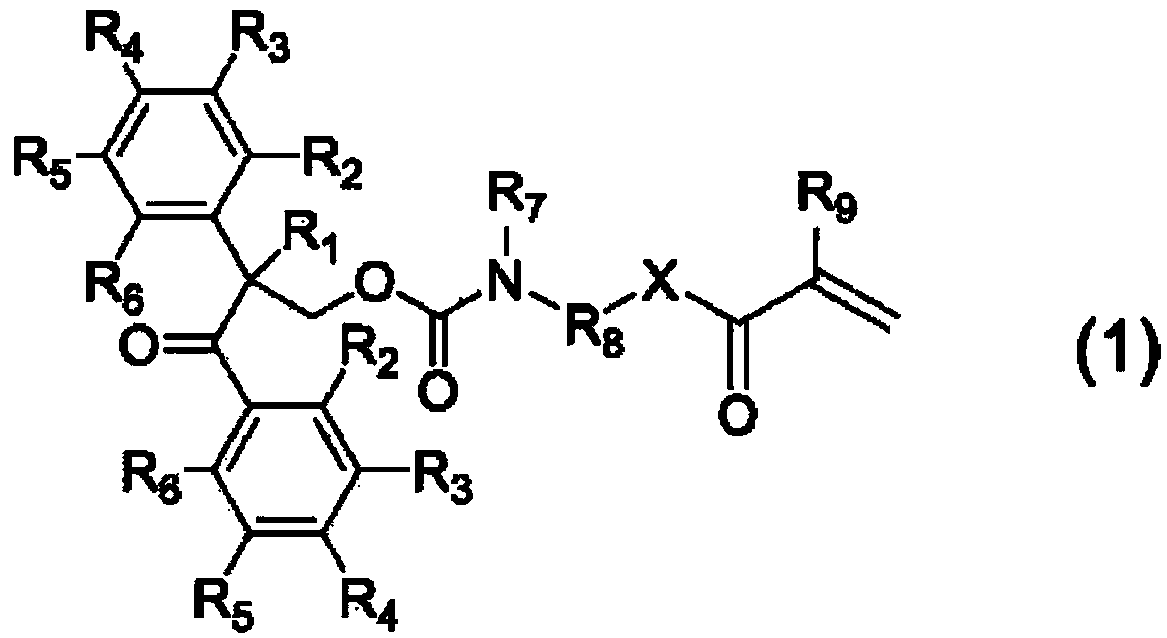

Novel compound, photopolymerization initiator containing said compound, and photosensitive resin composition containing said photopolymerization initiator

InactiveCN111448183AImprove solubilityHigh quantum yieldOrganic chemistryCarbon numberPolymer science

The purpose of the present invention is to provide: a novel compound which has excellent solvent solubility and compatibility with a resin, and which can generate bases and radicals with high efficiency by being irradiated with active energy rays; a photopolymerization initiator which contains said novel compound; and a photosensitive resin composition which contains said photopolymerization initiator and from which a cured product can be obtained that has high sensitivity and no metal corrosion. This novel compound is represented by formula (1). In formula (1), R1, R2, R3, R5 and R6 representa hydroxyl group or an alkoxy group. The R4's independently represent an organic group containing a thioether bond. R7 and R9 independently represent a hydrogen atom or an alkyl group with 1 to 4 carbons. R8 represents an alkylene group or an arylene group. X represents an oxygen atom or a sulfur atom.

Owner:NIPPON KAYAKU CO LTD

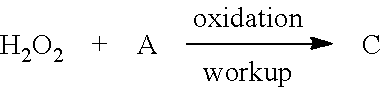

Online continuous flow process for the synthesis of organic peroxides using hydrogen peroxide as raw material

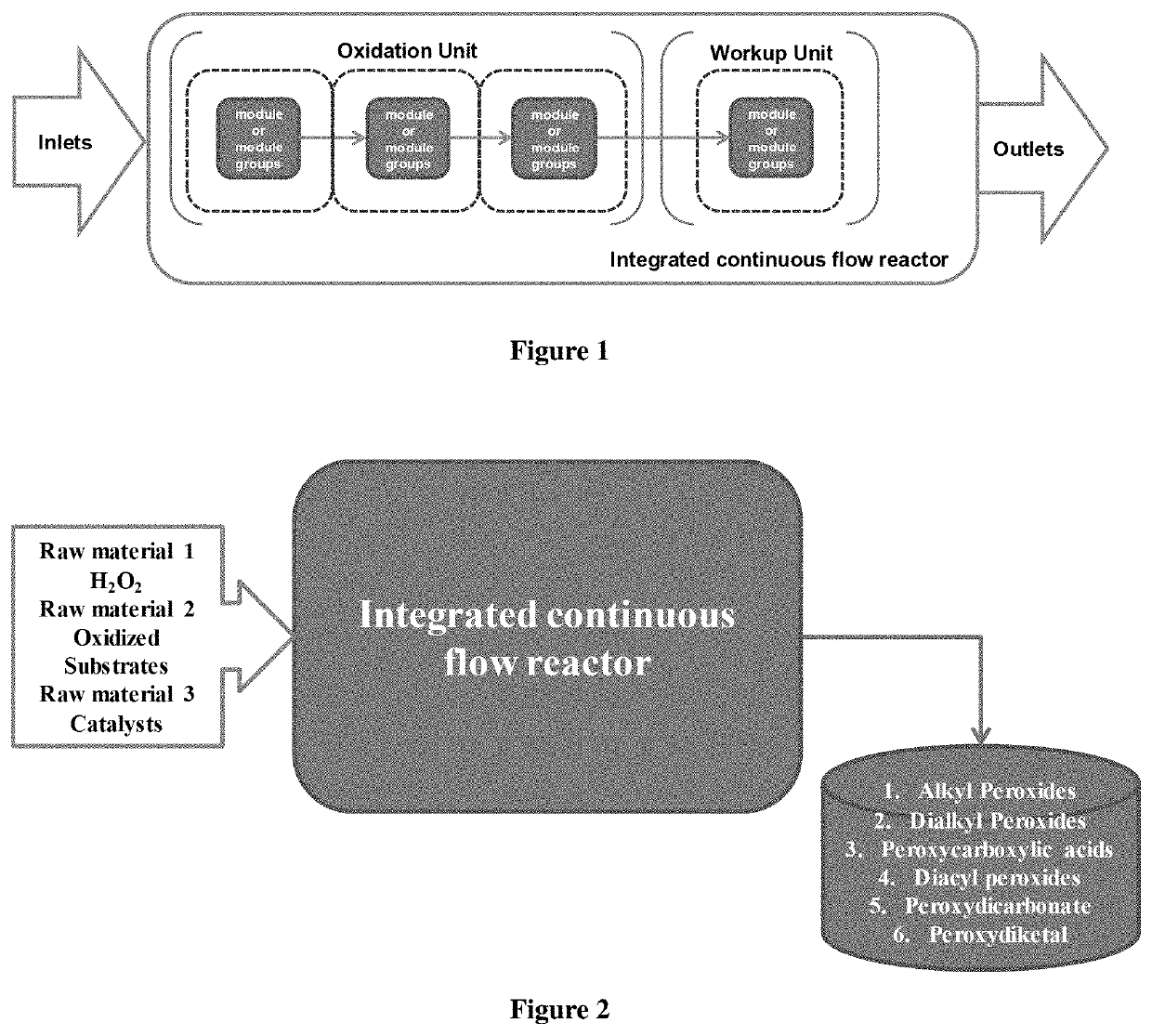

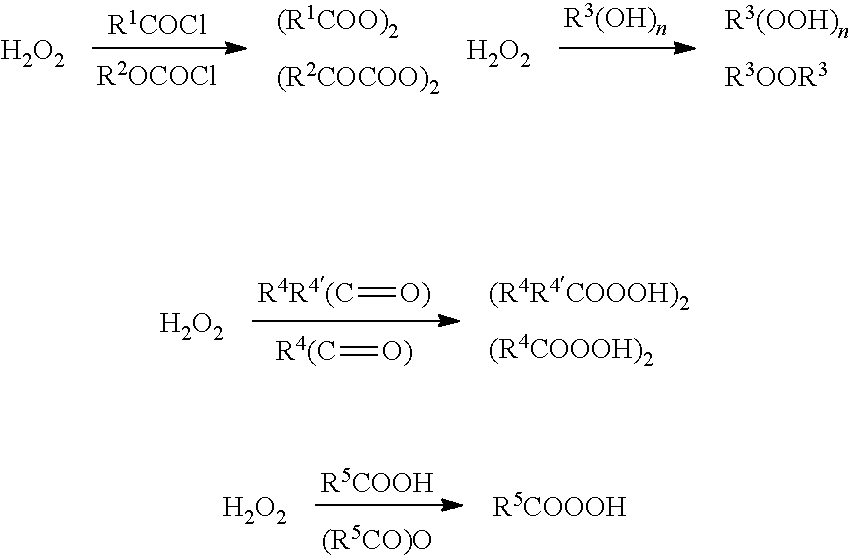

ActiveUS20200172478A1Long production timeLower reaction temperatureProcess control/regulationOrganic compound preparationPtru catalystProcess engineering

An online continuous flow production process for directly preparing organic peroxides by using hydrogen peroxide as a raw material. This production process uses hydrogen peroxide, catalyst, and an oxidation substrate as a raw material. Substrate will be turned to designated peroxides sequentially through oxidation and workup. This process is performed in a plug-and-produce integrated continuous flow reactor, and the raw materials are continuously fed to the reactor. So, specified peroxide can be continuously obtained at the outlet of the plug-and-produce integrated continuous flow reactor.

Owner:SHANGHAI HYBRID CHEM TECH

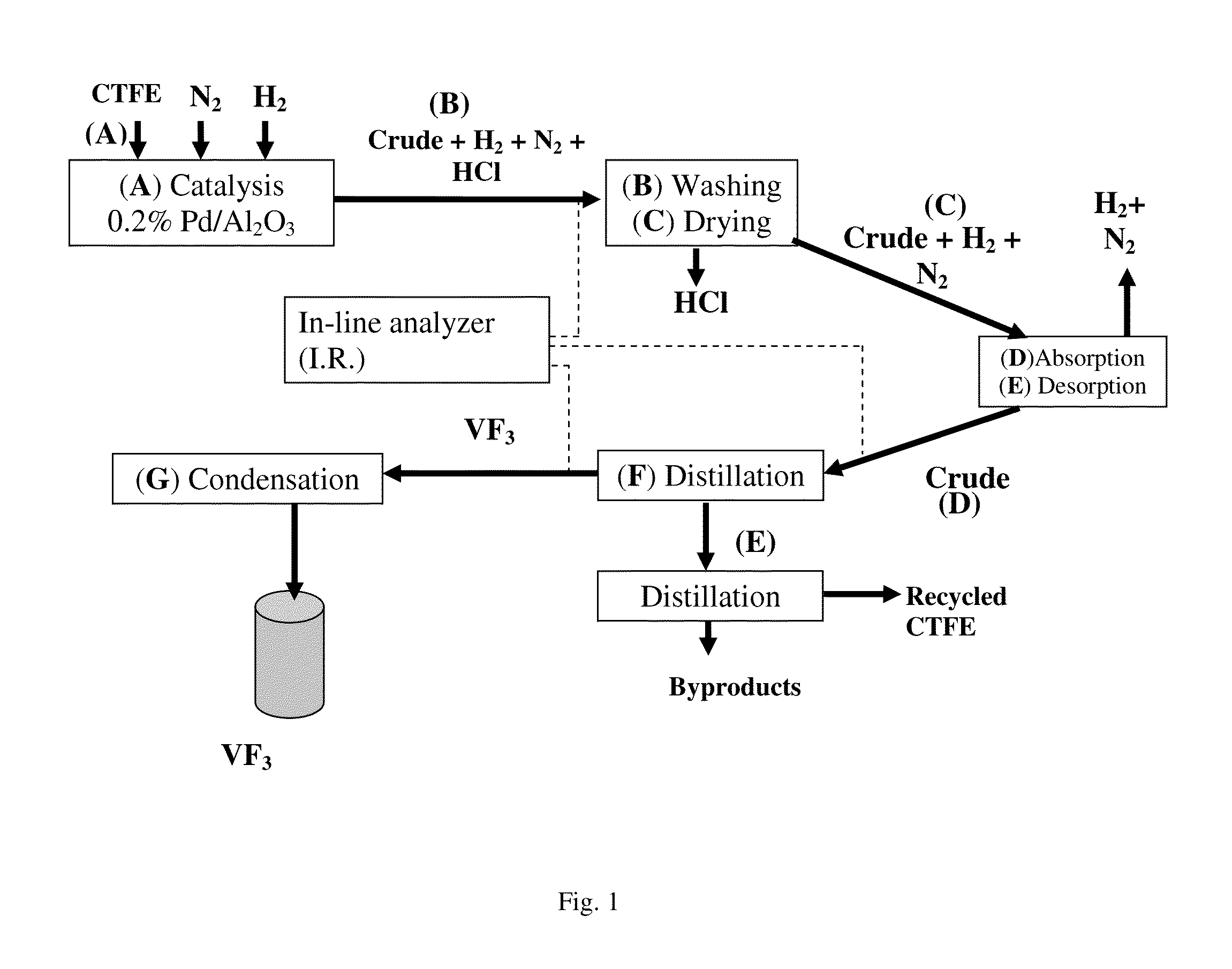

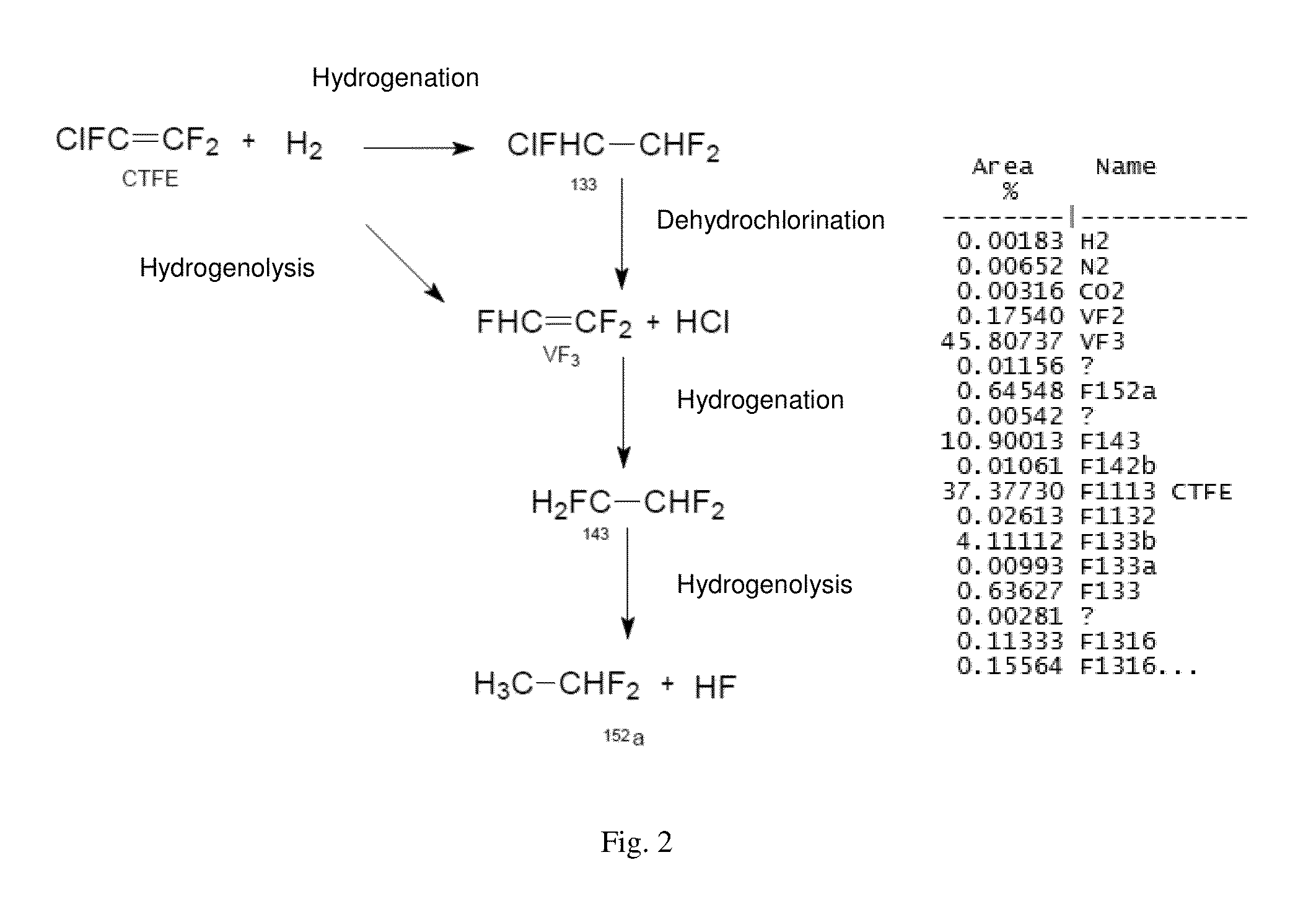

Method for synthesising trifluoroethylene from chlorotrifluoroethylene

ActiveUS20150094432A1High conversionLower reaction temperaturePreparation by dehalogenationPreparation by hydrogen halide split-offHigh selectivityHydrogenolysis

The present invention relates to the preparation of trifluoroethylene (VF3 or TrFE) by hydrogenolysis of chlorotrifluoroethylene (CTFE) in the gaseous phase over a group VIII metal catalyst deposited on a support. This method can be used to obtain VF3 in an economical manner in conditions which minimize the risk of explosion of this molecule. Using a catalyst containing a group VIII metal and, more specifically, containing Pd deposited on a support and a specific series of steps of separation and purification makes it possible to obtain excellent CTFE conversion rates and high selectivity in VF3 at atmospheric pressure and at low temperatures.

Owner:ARKEMA FRANCE SA

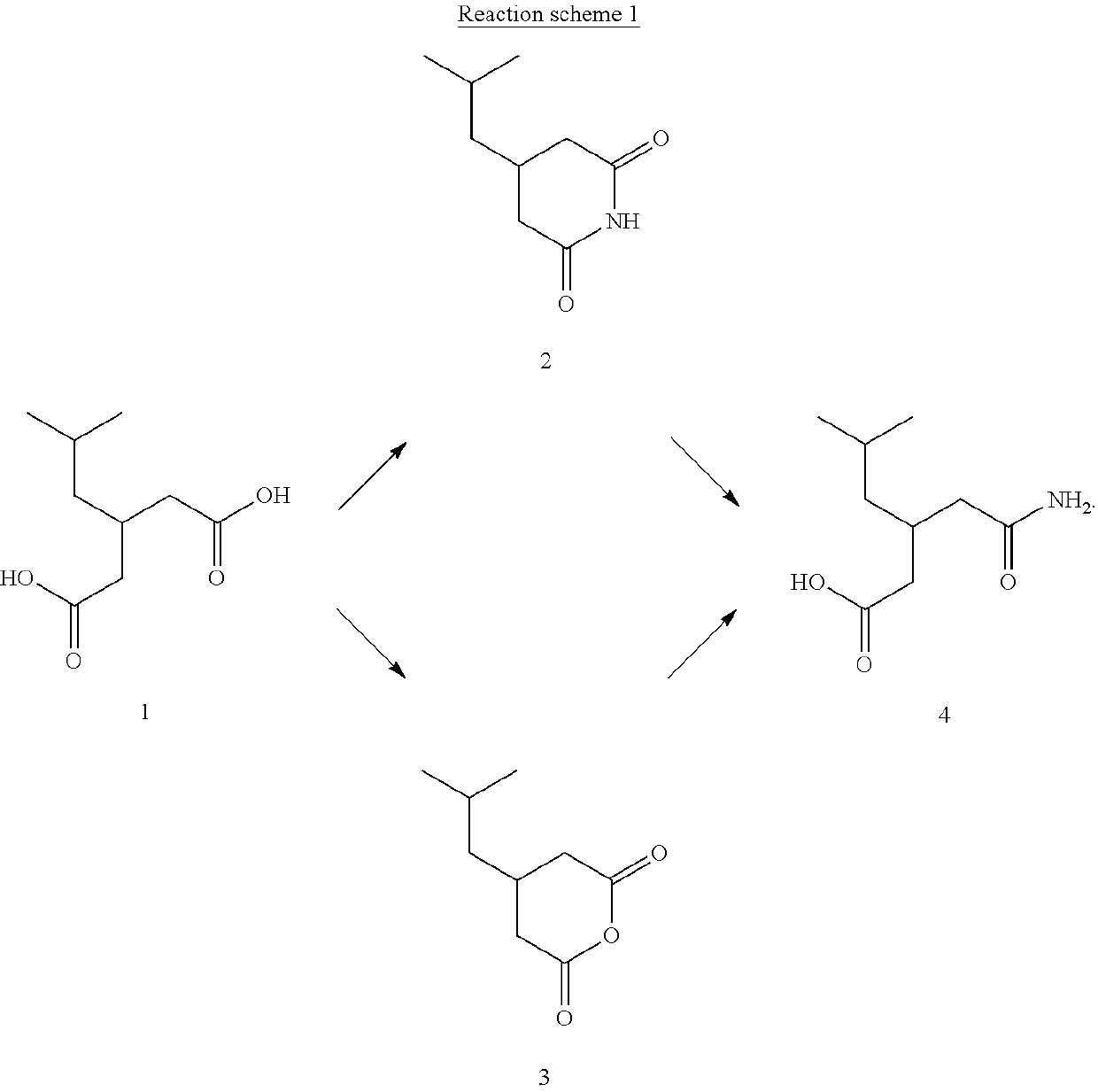

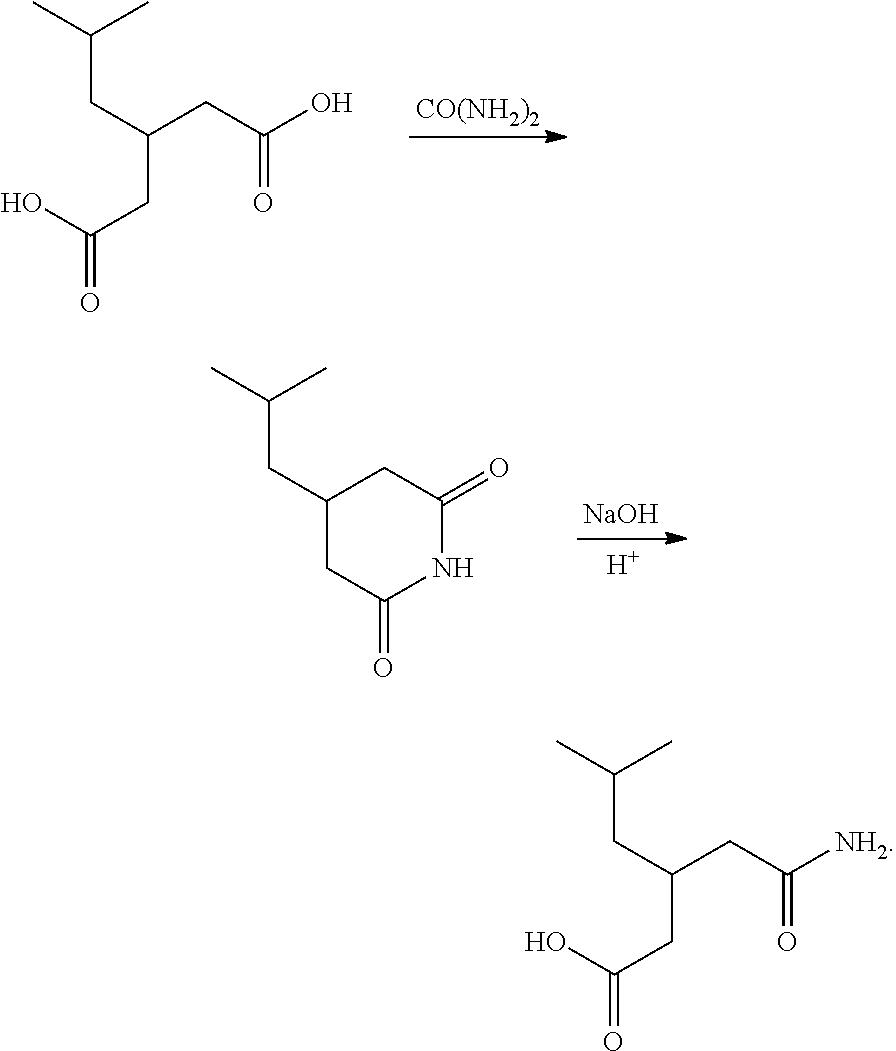

Method for preparing pregabalin intermediate 3-isobutylglutaric acid monoamide

ActiveUS20190152894A1The reaction steps are simpleAvoid cloggingOrganic compound preparationCarboxylic acid amides preparationOrganic solventPregabalin

Provided is a method for preparing a pregabalin intermediate 3-isobutylglutaric acid monoamide. The method comprises: 1) adding 3-isobutylglutaric acid and urea into a first organic solvent; 2) keeping warm and refluxing when heated to 100-140° C.; 3) adding water when cooled to 70-90° C.; 4) adding an ion membrane alkaline when cooled to 40-60° C., adjusting the pH to 11.0-14.0, then keeping warm at 40-60° C.; 5) when finished keeping warm, removing an organic layer; 6) adding an acid into the water layer to adjust the pH to 1.0-3.0; 7) extracting the solution acquired in step 6) by using a second organic solvent of a total volume of V, vacuum distilling 0.5-0.6 V of the organic solvent from an organic layer acquired by extraction; and 8) cooling to 0-15° C. and crystallizing to acquire 3-isobutylglutaric acid monoamide.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD +1

Fatty glyceride preparation method

ActiveUS20190256448A1Lower reaction temperatureHigh boiling pointFatty acid esterificationPreparation by ester-hydroxy reactionGlycerol DerivativesIodo fatty acid

The present invention provides a fatty glyceride preparation method, comprising converting fatty acid short-chain alcohol ester into fatty glyceride basic mixture by sequentially carrying out a normal-pressure reaction and a vacuum reaction in the nitrogen condition in the temperature of 80° C. to 150° C.; and meanwhile adding a basic catalyst and glycerin or adding a basic catalyst and a glycerin derivative into the fatty acid short-chain alcohol ester, so as to implement a conversion from the fatty acid short-chain alcohol ester to the fatty glyceride. Conditions of the preparation method are relatively moderate, and the structure of the fatty acid is not damaged in the reactions; the yield of the glyceride is high, compositions of the glyceride are stable and controllable, glyceride products having a high content of triacylglycerol can be obtained; the process is simple, costs are low, and the fatty glyceride is applicable to industrial production.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

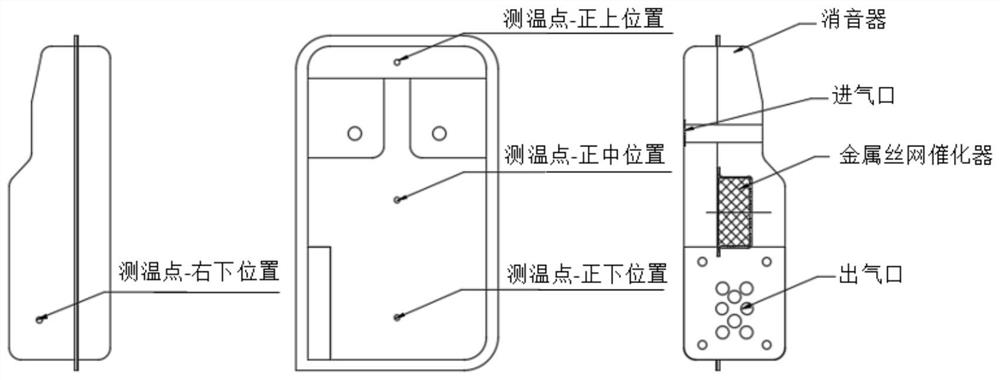

A low reaction temperature, low-deterioration wire mesh catalyst manufacturing process

ActiveCN109248714BLower working temperatureReduce the deterioration factorCatalyst activation/preparationPtru catalystReaction temperature

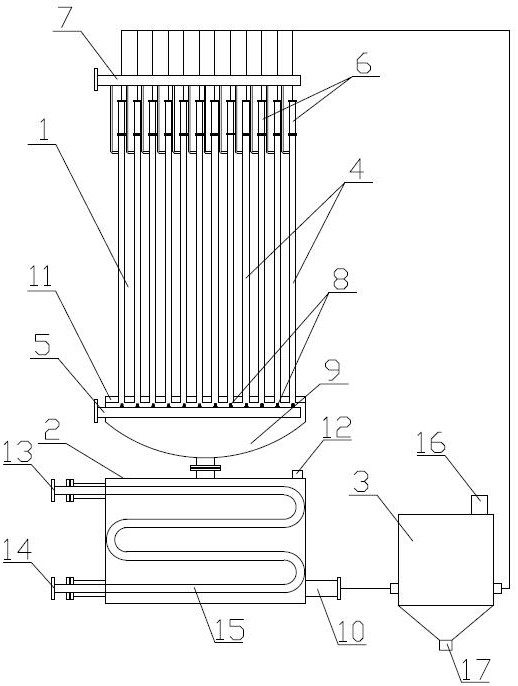

The invention relates to the technical field of catalysts, and relates to a manufacturing process of a low-reaction temperature and low-deterioration wire mesh catalytic converter. The first step of the manufacturing process is to coat a coating slurry containing a precious metal solution with a content of 60% to 80%, and then to bake the catalyst. Dry roasting and pre-aging treatment; the second step is to coat the remaining 20% to 40% of the precious metal solution on the surface coating of the produced semi-finished wire mesh catalyst. Beneficial effects: the forcible intervention destroys the microporous unstable structure of the coating, correspondingly reduces the specific surface area, reduces the initial conversion rate, reduces the reaction working temperature, and reduces the risk of being scalded by the plastic cover. At the same time, the high-temperature pre-aging catalyst has been carried out, and the unstable structure of the coating has been treated, and the deterioration coefficient will be correspondingly reduced after normal use; finally, coating the precious metal solution on the structurally stable coating can make up for the decrease in the specific surface area after pre-aging. The risk of reduced conversion efficiency, so as to ensure that the product meets the requirements of emission regulations.

Owner:南京德普瑞克环保科技股份公司

Oxide stannate luminescent material and preparation method thereof

ActiveUS20130075656A1Improve featuresExcellent bombardment resistanceLuminescent compositionsElectrical performanceElectron bombardment

A luminescent material and a preparation method thereof are provided. The said luminescent material is represented by the following chemical formula: Ln2−EuxSn2O7, wherein Ln is selected from one of Gd, Y and La, 0.1≦x≦1.5. The said luminescent material has good electrical performance, anti-electron bombardment and stable luminescent property. It is appropriate to be used in field emission light-emitting devices. The said preparation method has simple technique, no pollution, manageable process conditions, low preparation temperature and low equipment requirement, and is beneficial to industry production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

A process for preparing xylose by hydrolyzing hemicellulose with ozone acid

The invention relates to a technology for preparing xylose by using ozone for acid hydrolysis of hemicellulose, and belongs to the technical field of preparation of xylose. The technology is characterized in that the hemicellulose is performed with limited oxidizing by ozone in a particular aeration type, so that the ozone cannot react with the hemicellulose to generate carbon dioxide and water, and only one part of chemical bonds in the hemicellulose is damaged, thereby creating conditions for acid hydrolysis; the acid hydrolysis can complete the production of target product, namely D-xylose at lower temperature, thereby improving the productivity. The technology has the advantage that the hemicellulose is treated by the ozone and the acid hydrolysis, so that the acid hydrolysis time is shortened, and the environment-friendly and pollution-free effects are realized.

Owner:四川雅华生物有限公司

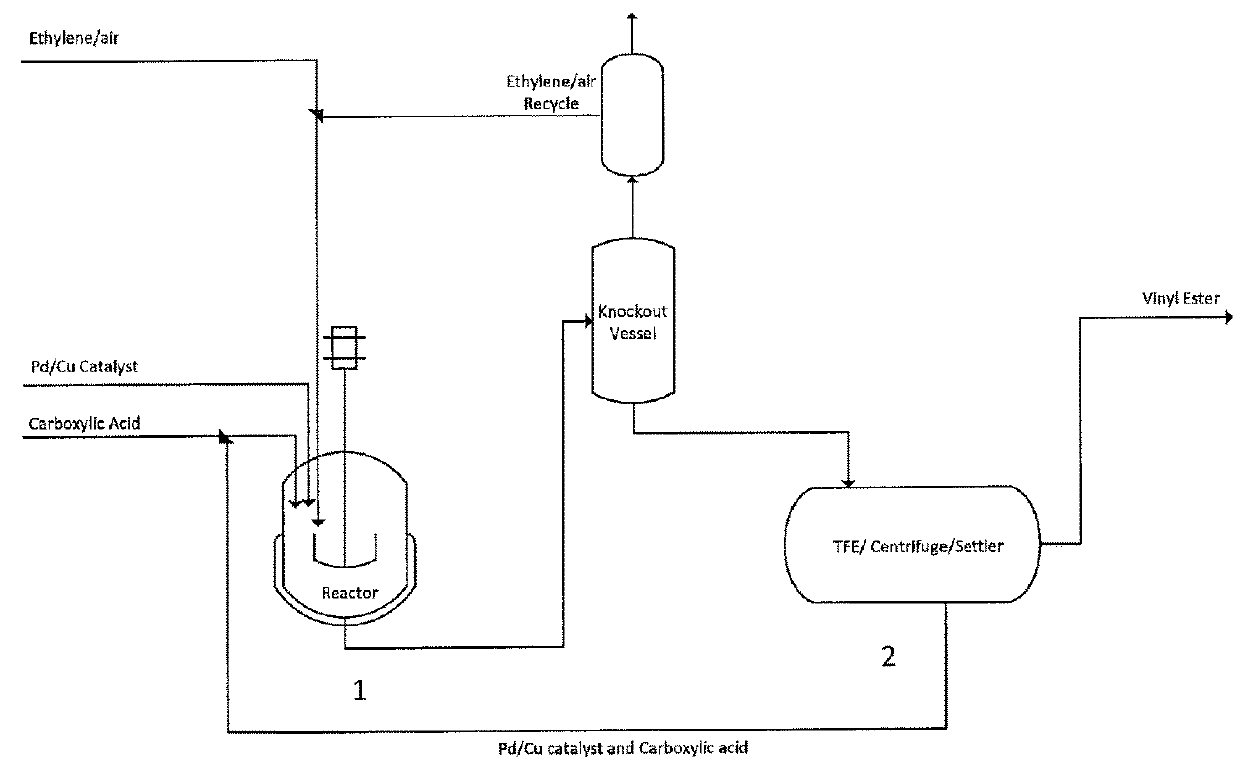

Process for the production of higher carboxylic acid vinyl esters

ActiveUS20180179140A1Lower reaction temperatureHigh recovery rateMolecular sieve catalystsOrganic compound preparationVinyl esterCarboxylic acid

Owner:HEXION INC

Hydrosilylation method

ActiveUS20090318724A1Reduce concentrationLess product coloration occursSilicon organic compoundsHydrolysateHydrosilylation

Compounds containing carbon-carbon double bonds and / or carbon-carbon triple bonds are hydrosilylated with linear organopolysiloxanes having diorganosiloxy units and Si—H groups, produced by reacting diorganodichlorosilanes and monochlorosilanes and optionally dichlorosilanes with water in a first step, where at least one of the monochlorosilanes or dichlorosilanes contain Si—H groups to give a partial hydrolysate and gaseous hydrogen chloride, and in a second step, treating the partial hydrolysate with water to remove SiCl groups still present to form hydrochloric acid, and producing a hydrolysate containing the organopolysiloxanes.

Owner:WACKER CHEM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com