A process for preparing xylose by hydrolyzing hemicellulose with ozone acid

A technology of hemicellulose and ozone acid, which is applied in xylose production, sugar production, sugar production, etc., can solve the problems of long acid hydrolysis time, low xylose yield, and large xylose loss, and achieve xylose The effect of increasing yield, increasing xylose yield, and reducing xylose loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A process for preparing xylose by ozone acid hydrolysis of hemicellulose, comprising the following process steps:

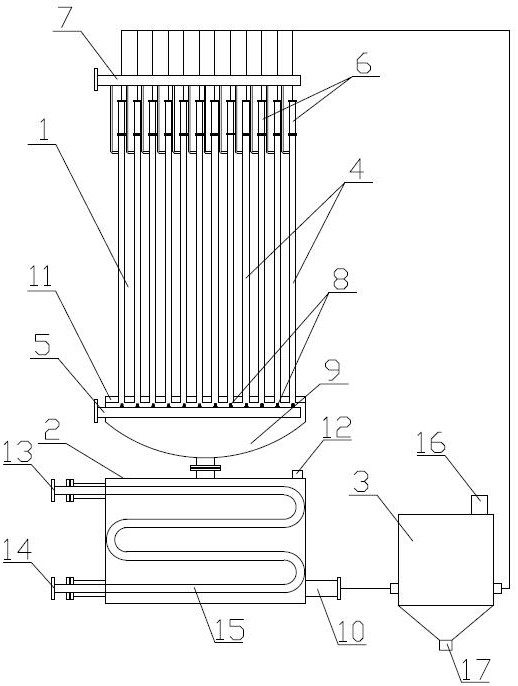

[0034] A, the hemicellulose solution containing hemicellulose is added to a plurality of vertical packing tubes 4, the top of each of the packing tubes 4 is provided with a tail gas collection pipe 6, and the top of the tail gas collection pipe 6 is provided with Raw material liquid inlet pipe 7, the raw material liquid inlet pipe 7 communicates with the upper part of each of the filler pipes 4 through a pipeline; the hemicellulose solution flows into the filler pipe 4 through the raw material liquid inlet pipe 7;

[0035] B, the bottom of the filler pipe 4 is provided with an ozone inlet pipe 5, and the ozone inlet pipe 5 is provided with a plurality of ozone nozzles 8 corresponding to the filler pipe 4, and the ozone flows from the ozone inlet pipe 5 enter, and then spray into the filler pipe 4 to treat the hemicellulose solution, and after the treatment...

Embodiment 2

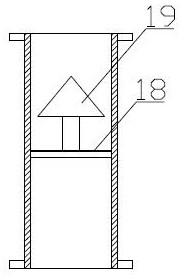

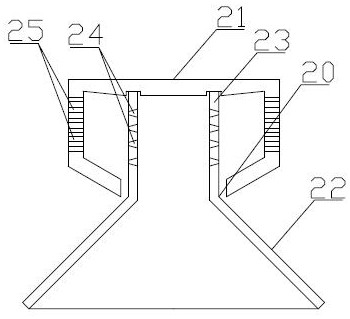

[0042]A device for producing xylose by ozone acid hydrolysis of hemicellulose, comprising an aeration device 1, a hydrolysis reaction box 2 and a xylose separation device 3; the aeration device 1 includes a plurality of vertically arranged packing pipes 4 and ozone inlet pipes 5. The top of each of the packing pipes 4 is provided with a tail gas collecting pipe 6, and the top of the tail gas collecting pipe 6 is provided with a raw material liquid inlet pipe 7, and the raw material liquid inlet pipe 7 communicates with each of the pipes through multiple pipes. The top of the filler pipe 4 communicates, the bottom of the filler pipe 4 is provided with the ozone inlet pipe 5, and the ozone inlet pipe 5 is provided with a plurality of ozone nozzles 8 corresponding to the filler pipe 4; The bottom of the stuffing pipe 4 communicates with the raw material liquid collection kettle 9, and the bottom of the raw material liquid collection kettle 9 communicates with the hydrolysis reacti...

Embodiment 3

[0063] A process for preparing xylose by ozone acid hydrolysis of hemicellulose, comprising the following process steps:

[0064] A, the hemicellulose solution containing hemicellulose is added to a plurality of vertical packing tubes 4, the top of each of the packing tubes 4 is provided with a tail gas collection pipe 6, and the top of the tail gas collection pipe 6 is provided with Raw material liquid inlet pipe 7, the raw material liquid inlet pipe 7 communicates with the upper part of each of the filler pipes 4 through a pipeline; the hemicellulose solution flows into the filler pipe 4 through the raw material liquid inlet pipe 7;

[0065] B, the bottom of the filler pipe 4 is provided with an ozone inlet pipe 5, and the ozone inlet pipe 5 is provided with a plurality of ozone nozzles 8 corresponding to the filler pipe 4, and the ozone flows from the ozone inlet pipe 5 enter, and then spray into the filler pipe 4 to treat the hemicellulose solution, and after the treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com