Patents

Literature

3065 results about "Xylose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xylose (cf. Greek: ξύλον, xylon, "wood") is a sugar first isolated from wood, and named for it. Xylose is classified as a monosaccharide of the aldopentose type, which means that it contains five carbon atoms and includes an aldehyde functional group. It is derived from hemicellulose, one of the main constituents of biomass. Like most sugars, it can adopt several structures depending on conditions. With its free aldehyde group, it is a reducing sugar.

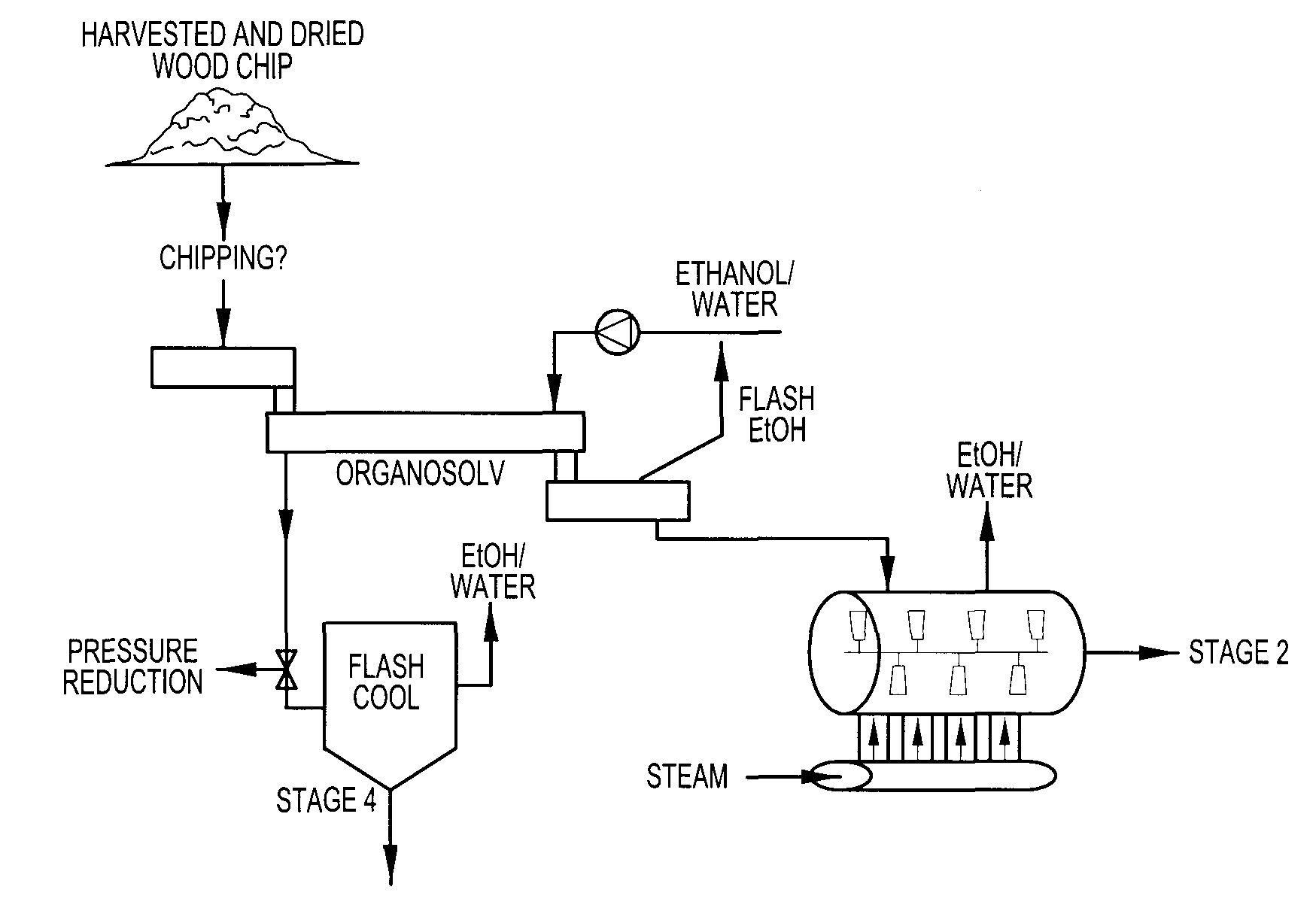

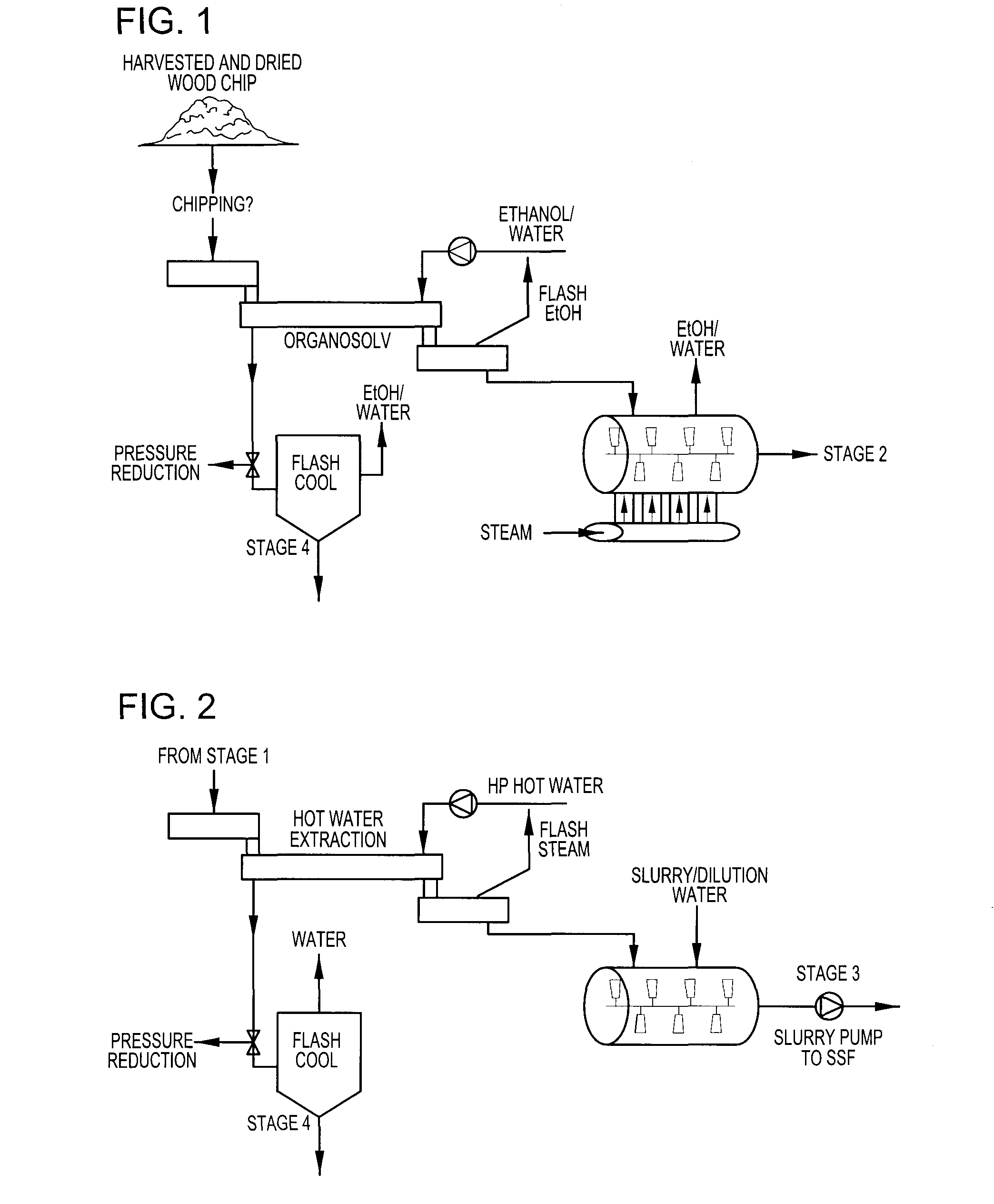

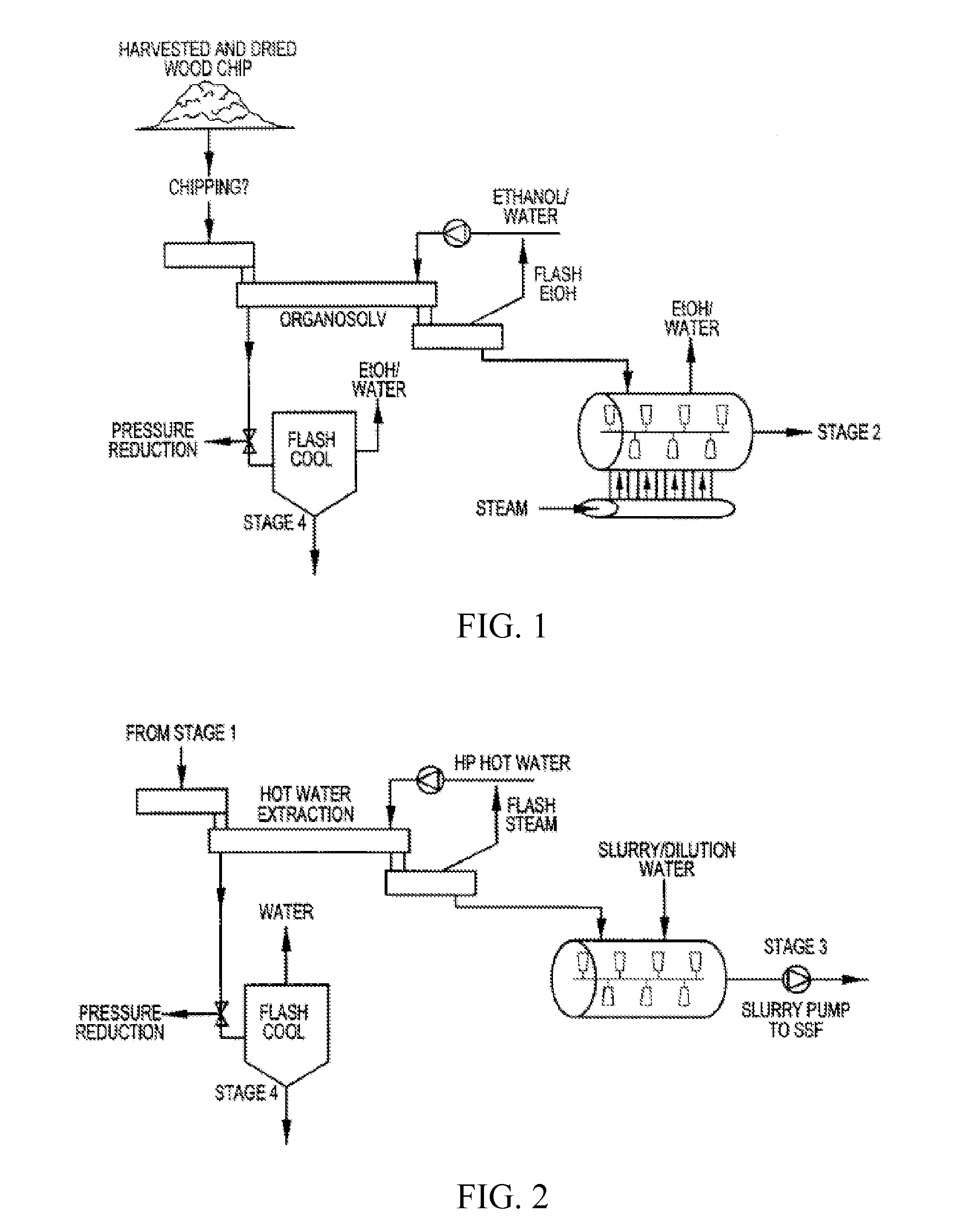

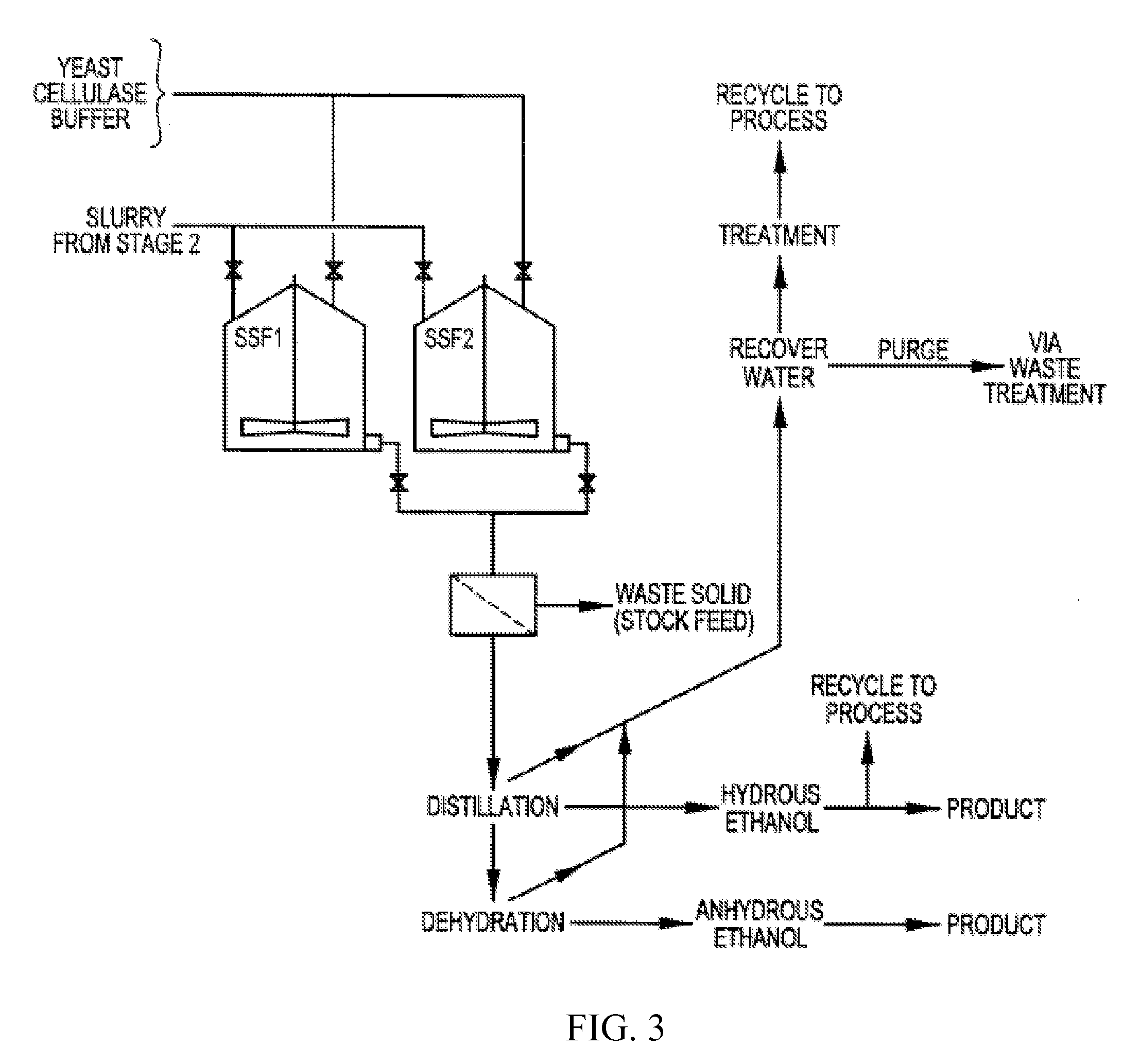

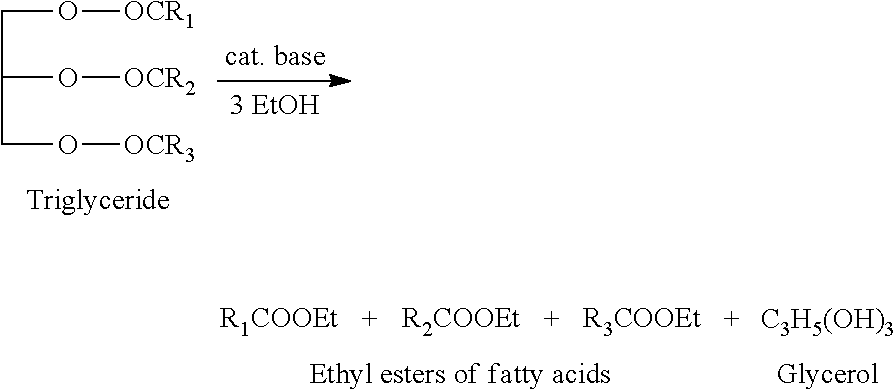

Process for the production of biofuel from plant materials

InactiveUS20070259412A1Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseBiofuel

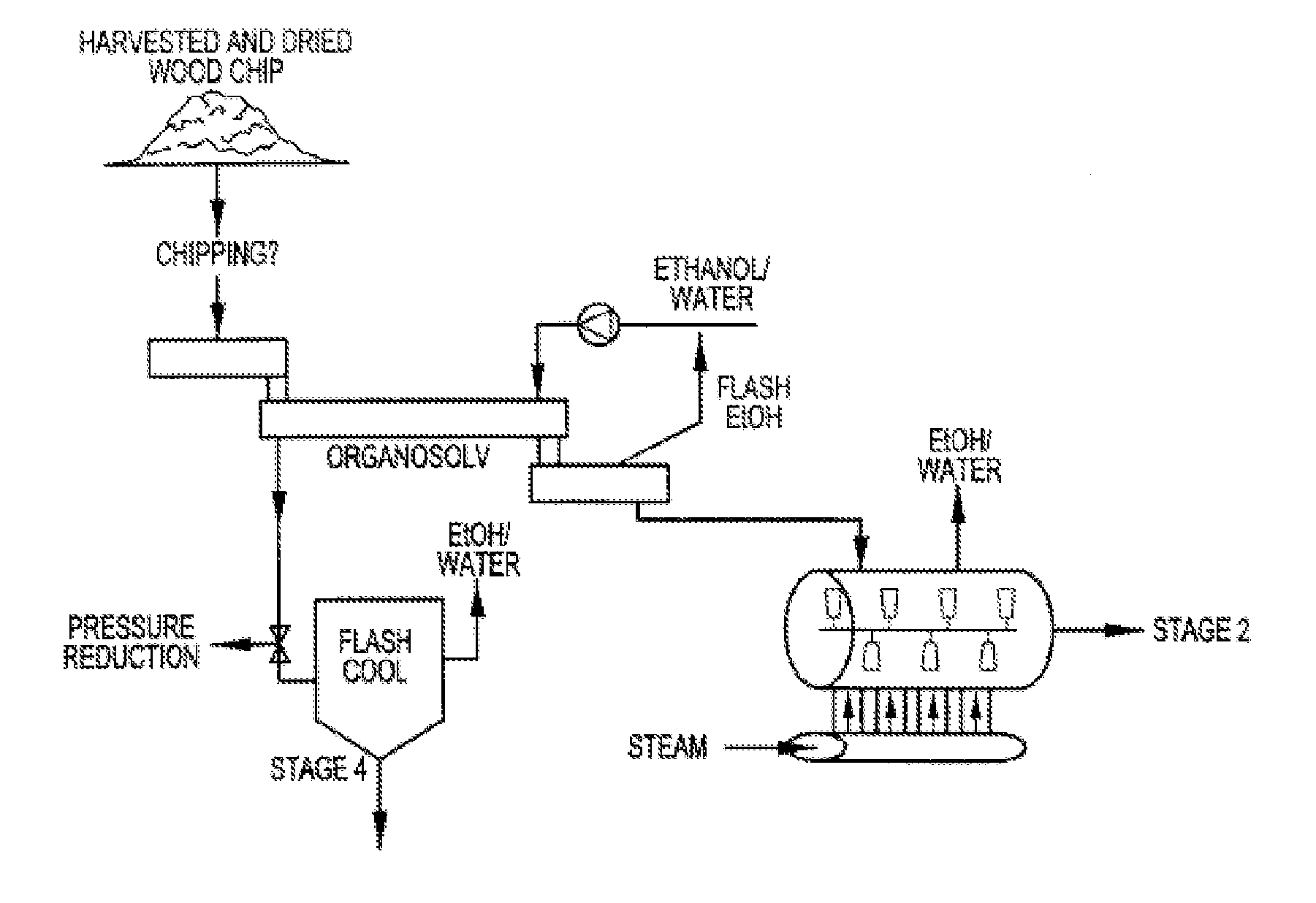

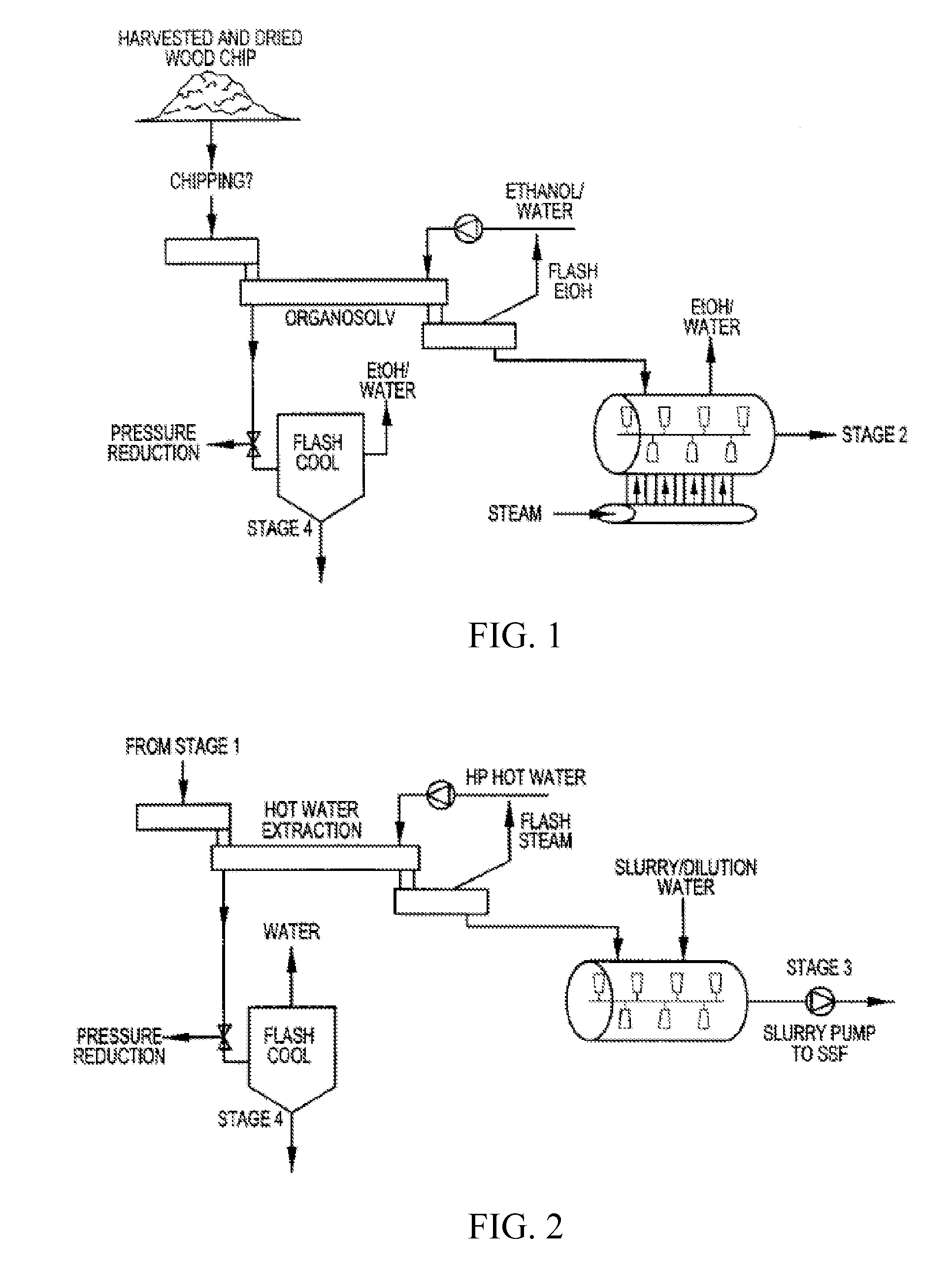

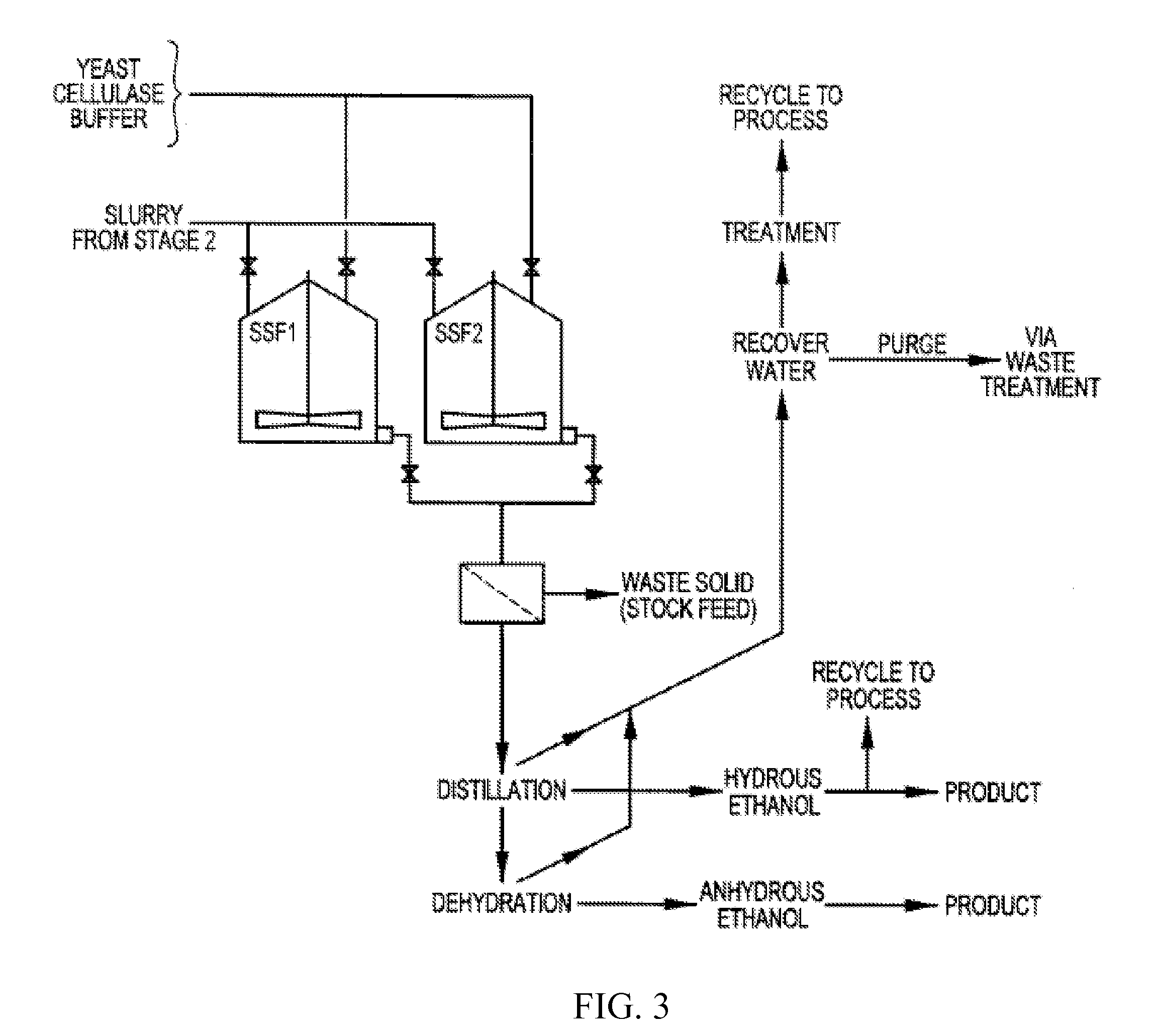

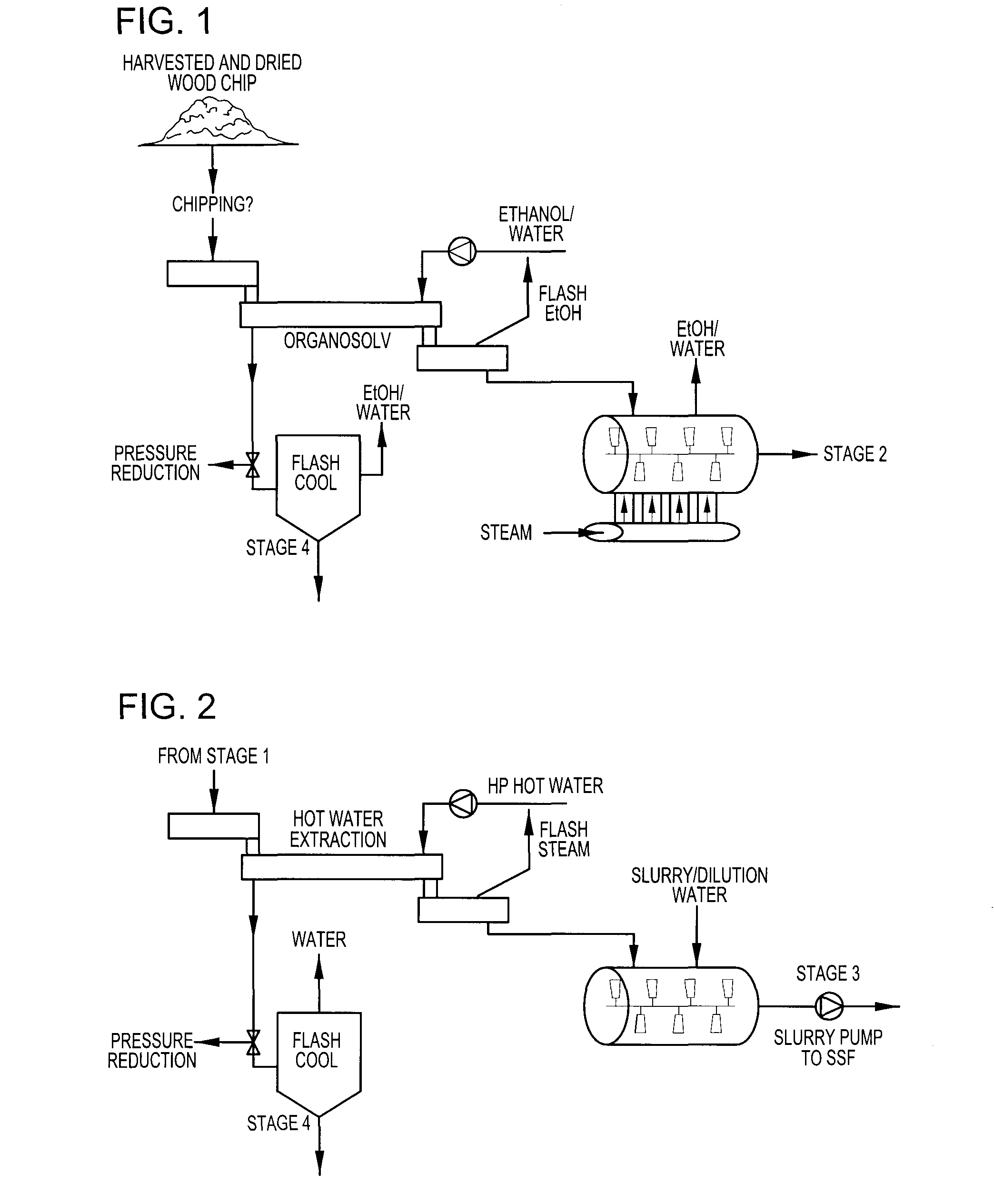

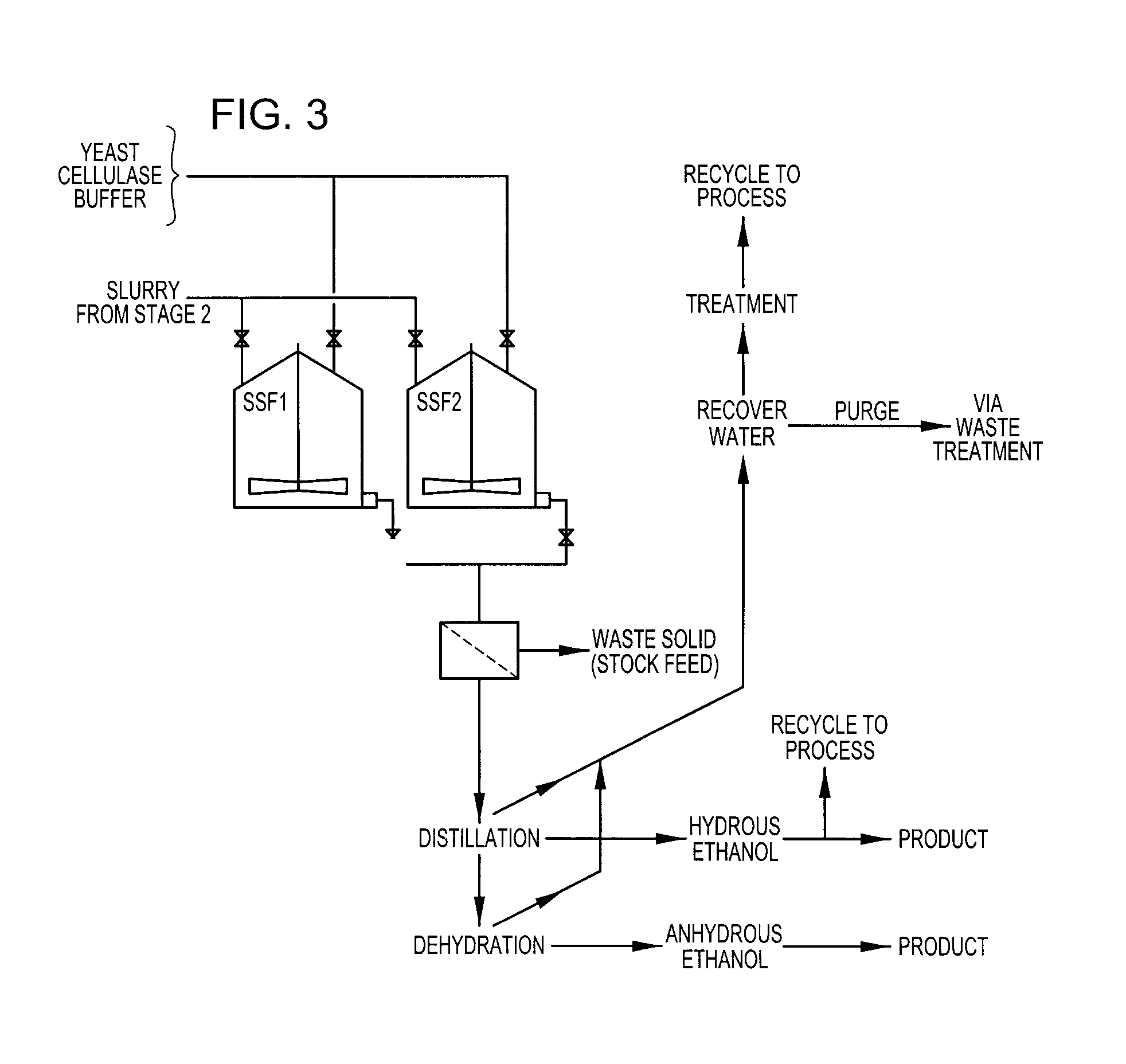

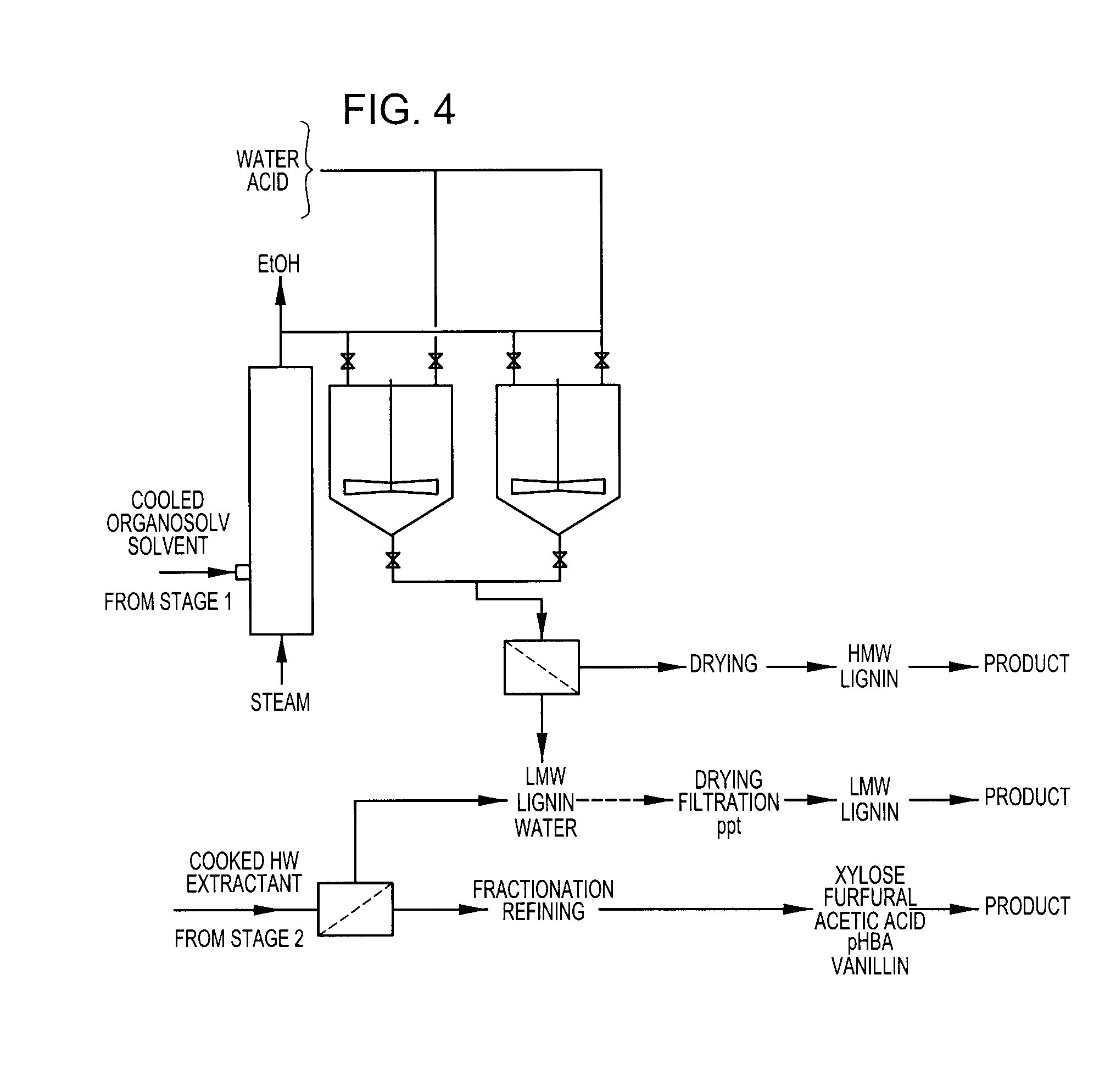

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

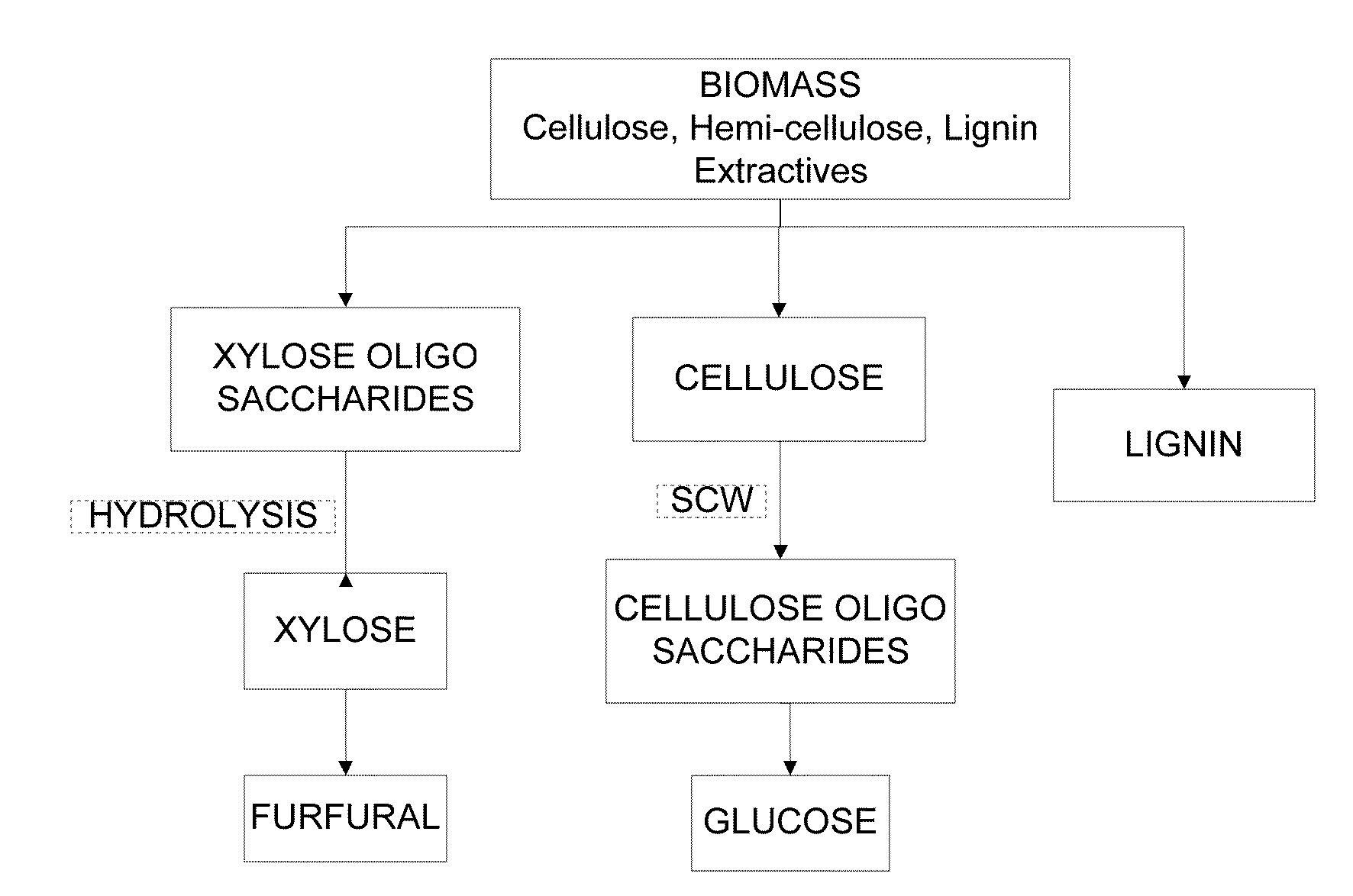

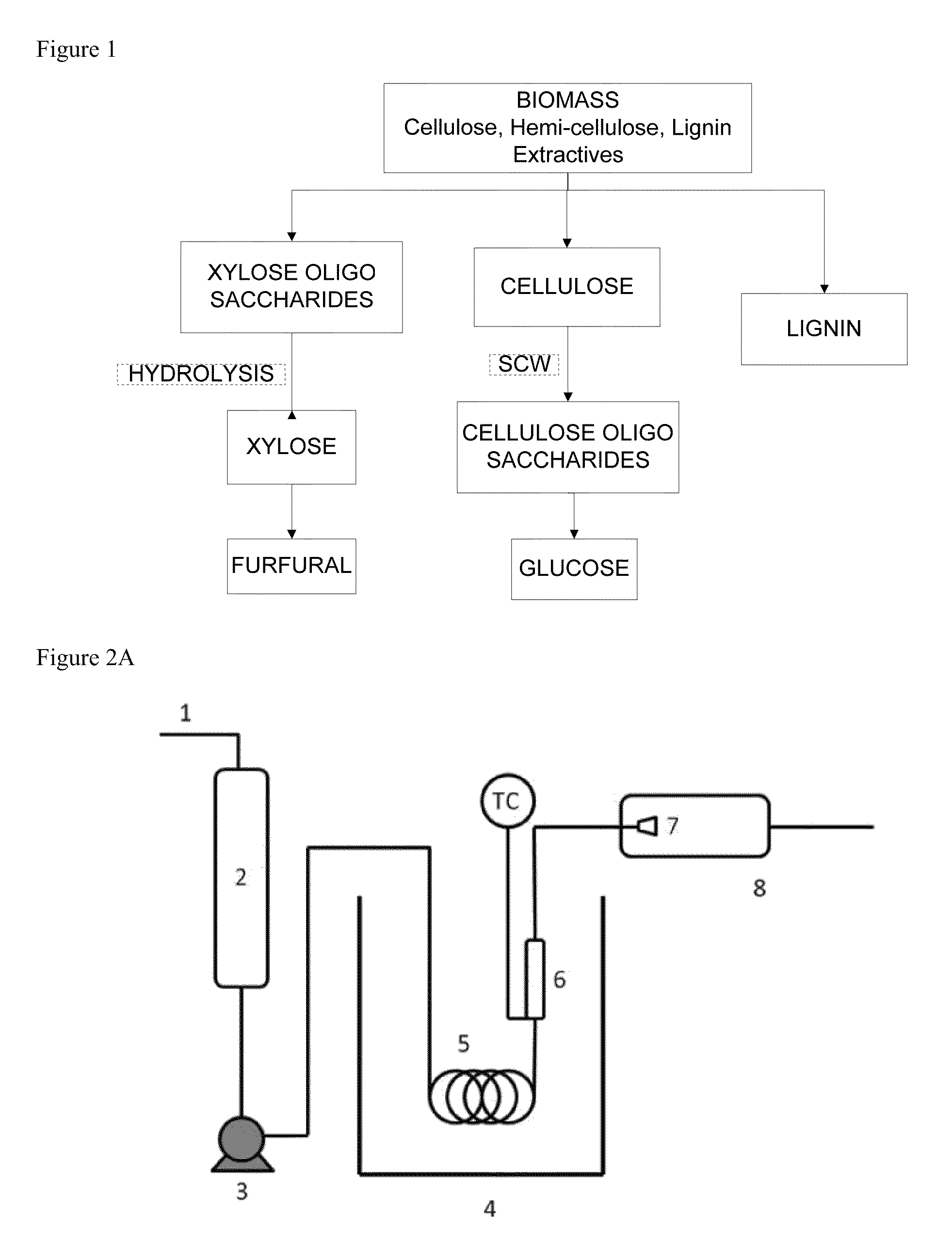

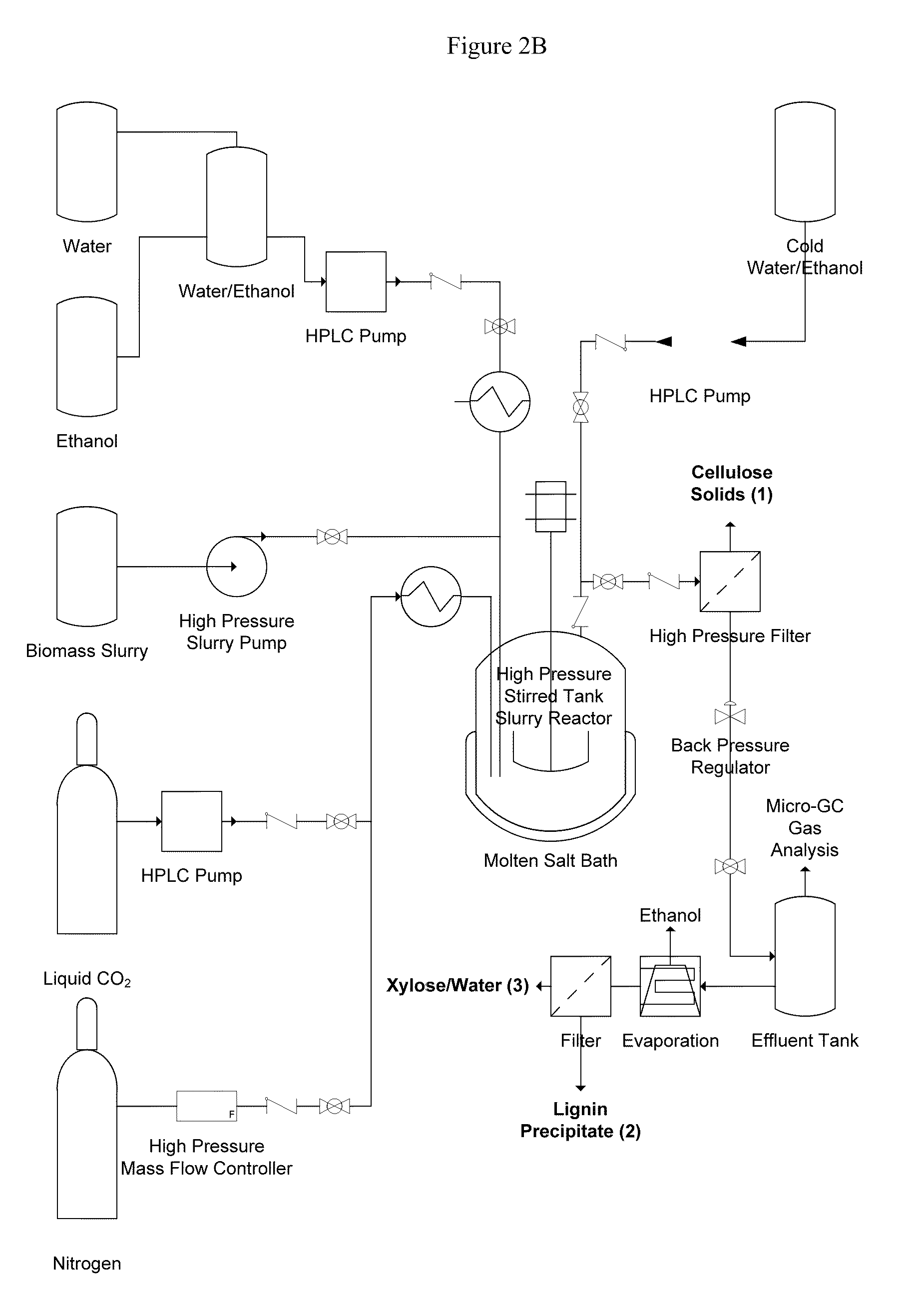

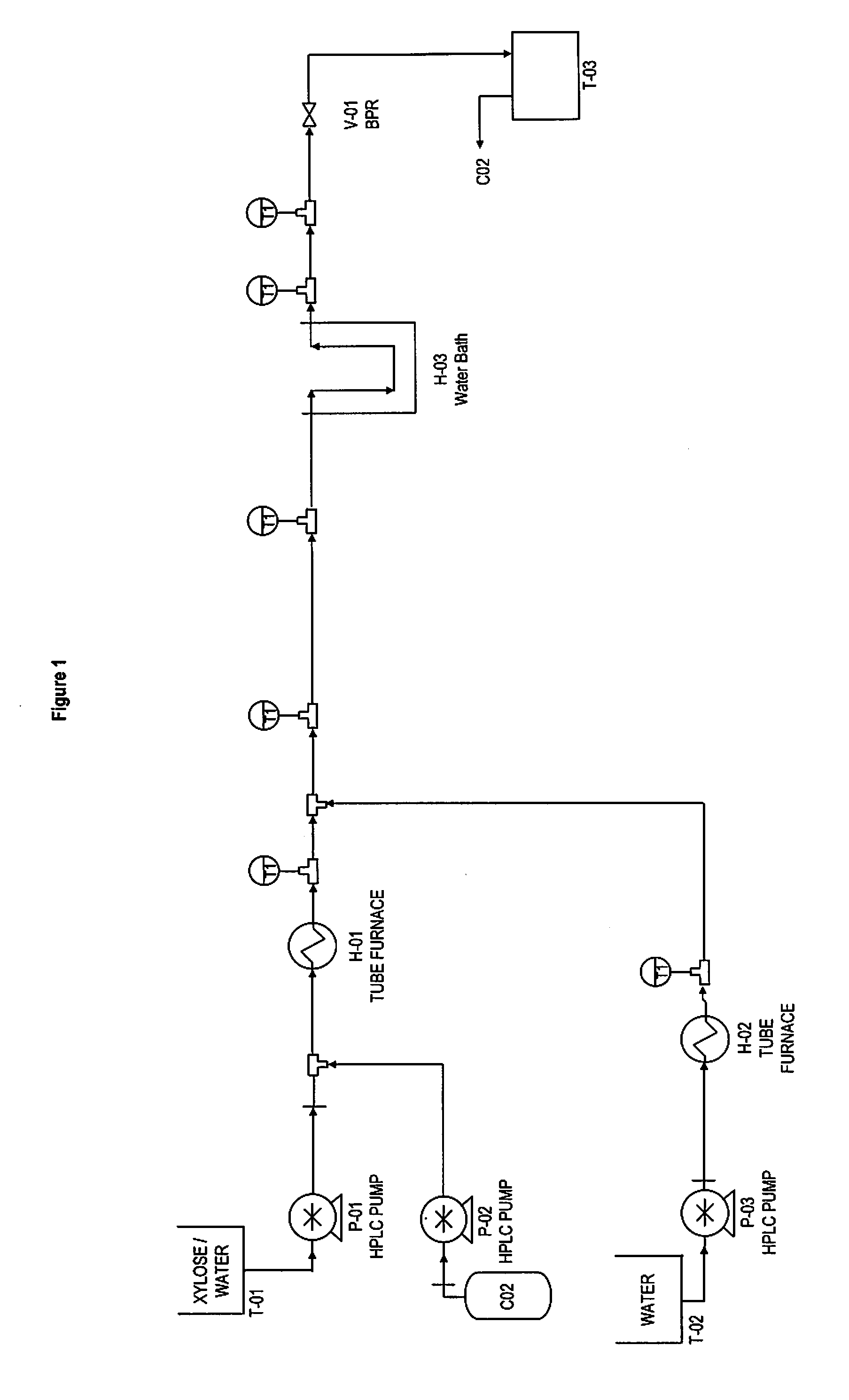

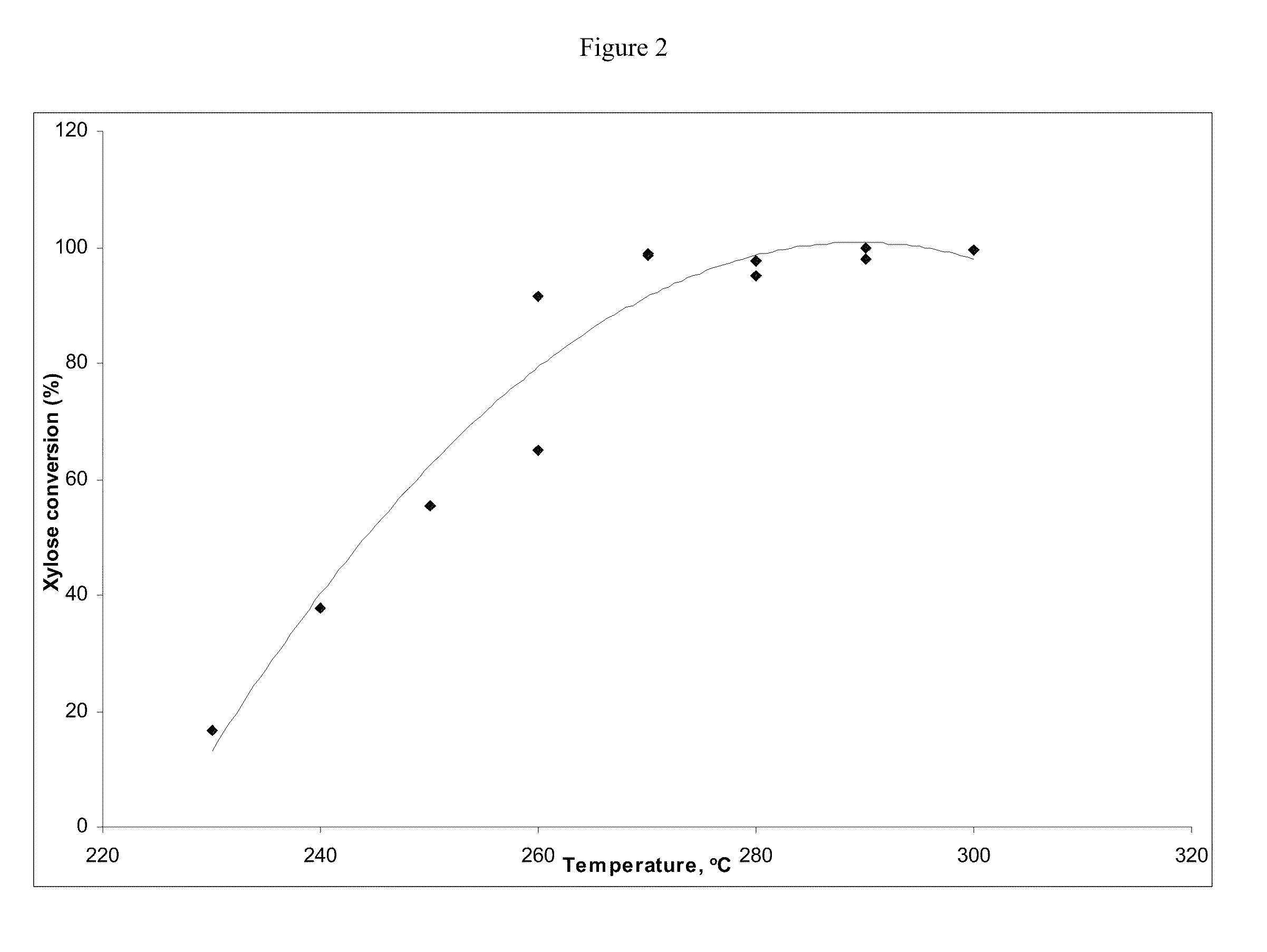

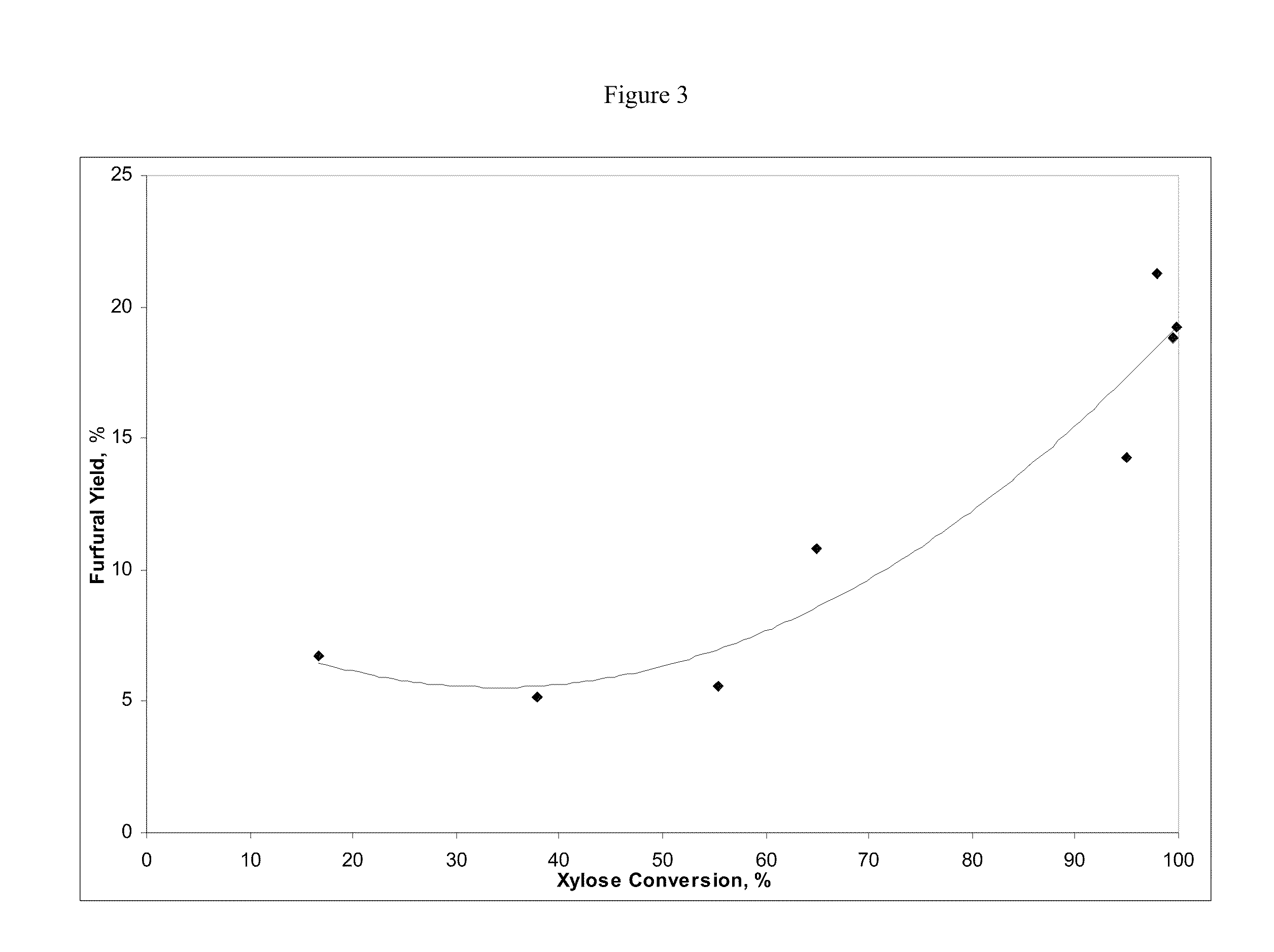

Nano-catalytic-solvo-thermal technology platform bio-refineries

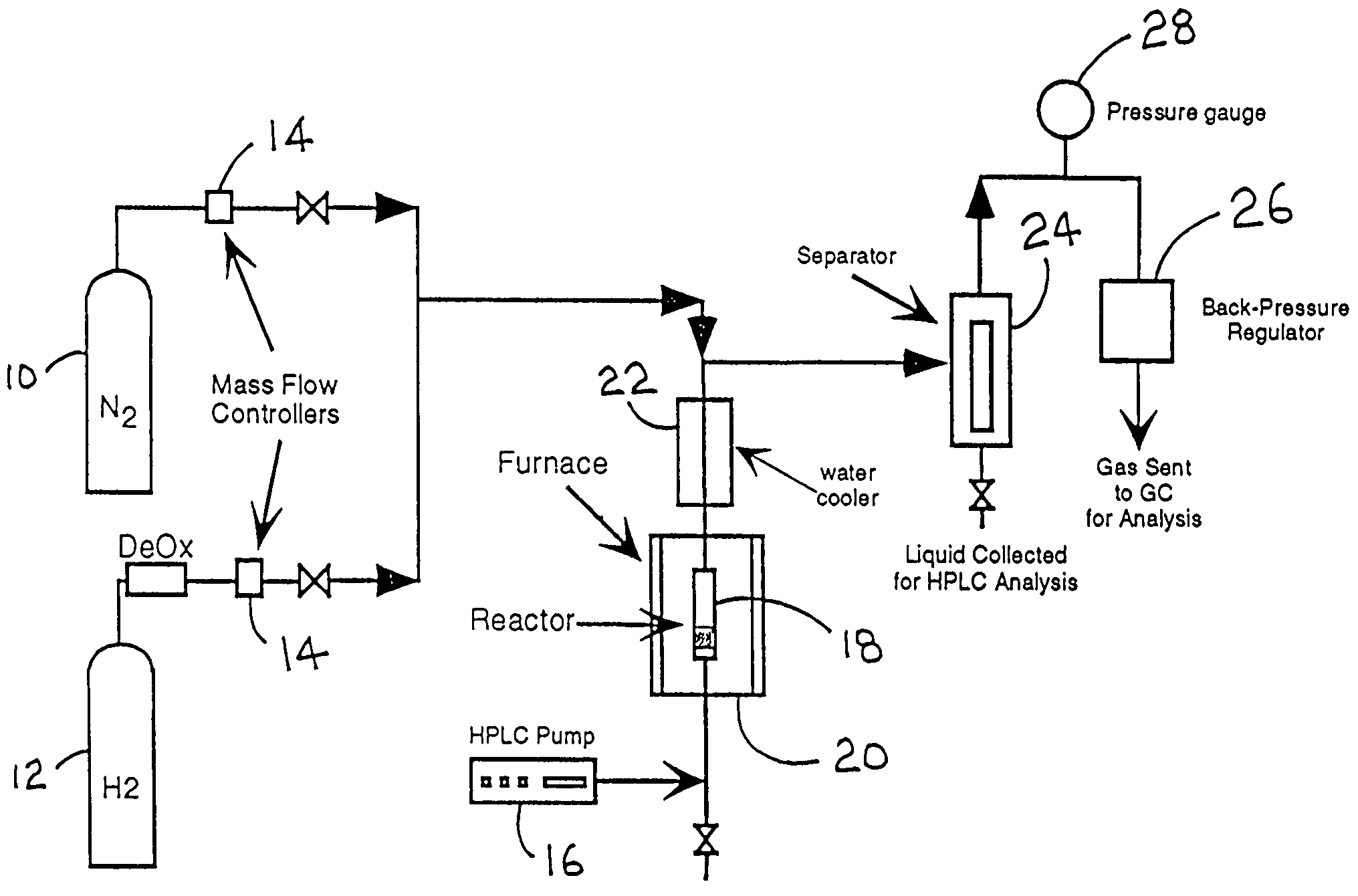

Methods of making glucose and / or furfural from biomass require one or more supercritical fluids that may be used to process biomass, cellulose from the biomass, and / or xylose from the biomass. Examples of supercritical fluids for use in processing biomass include ethanol, water, and carbon dioxide at a temperature and pressure above the critical points for ethanol and carbon dioxide but at a temperature and / or pressure below that of the critical point for water. A supercritical fluid containing carbon dioxide and water may be used to convert cellulose to glucose or convert xylose to furfural. The fluid has a temperature and pressure above the critical point of carbon dioxide, but at least one of the temperature and pressure is below the critical point for water.

Owner:RENMATIX INC

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090069550A1Great potentialTotal calories lowLignin derivativesPulp by-products recoveryFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

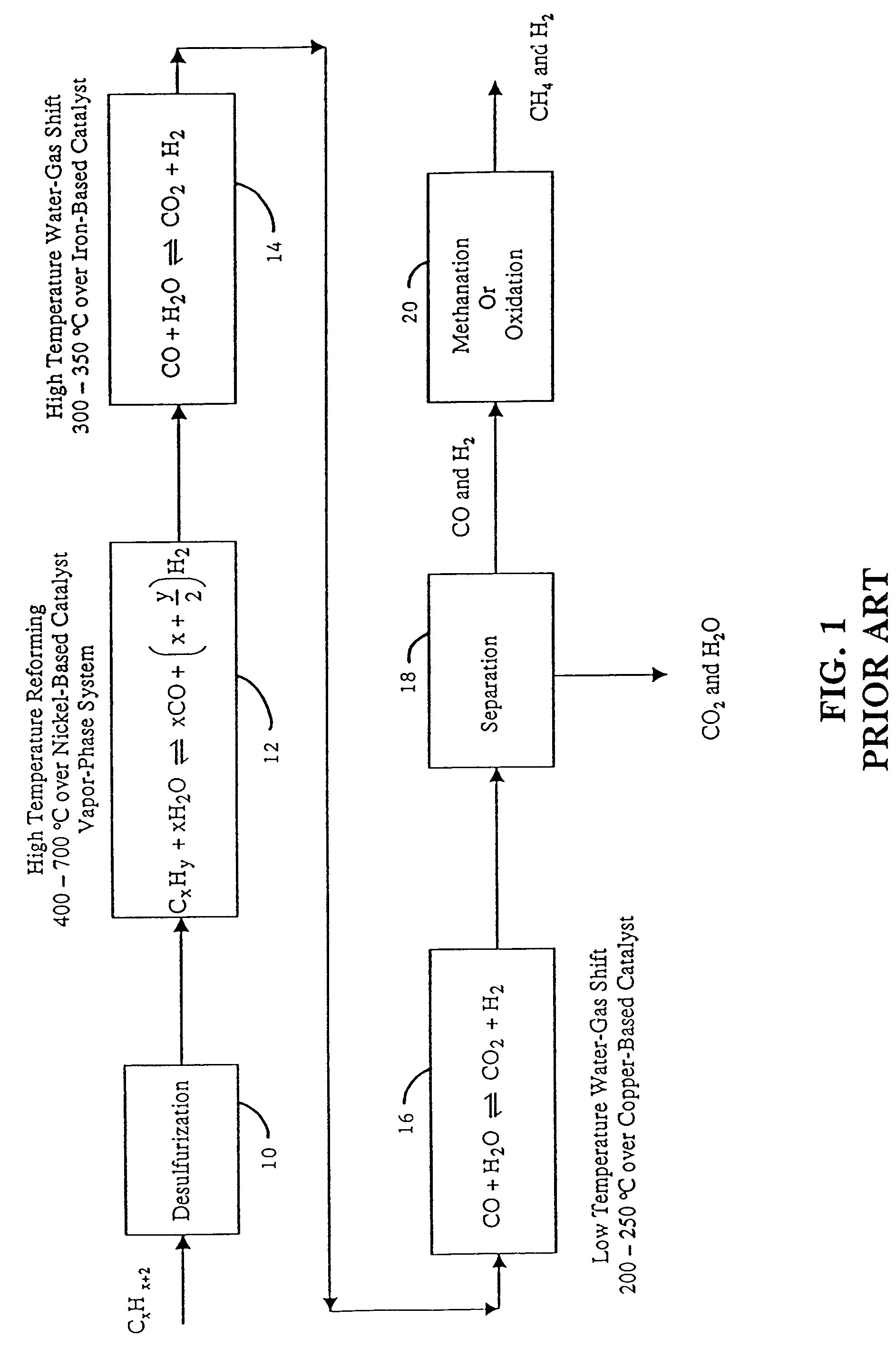

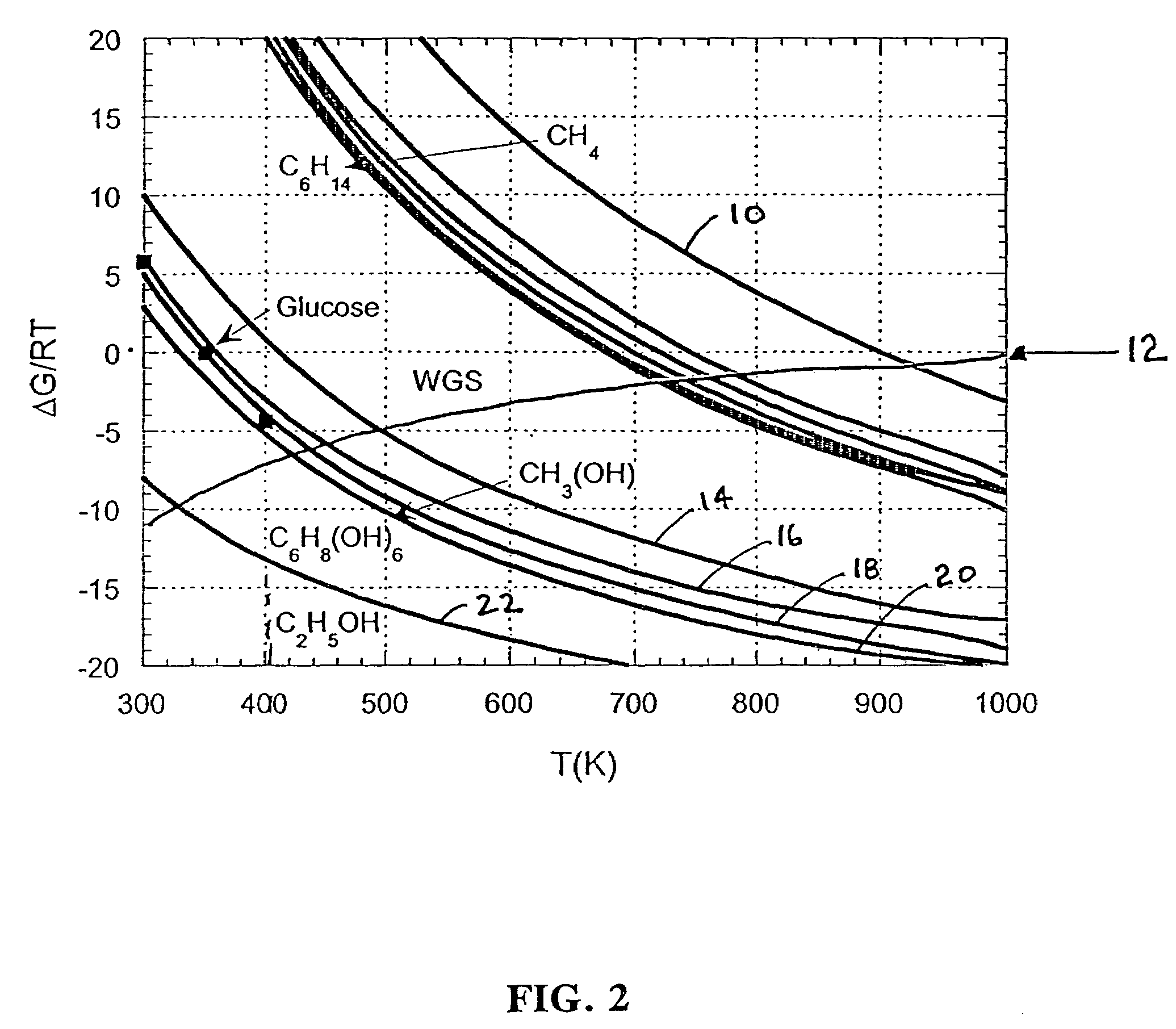

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS7618612B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Fruit and vegetable soybean milk drink and preparation method thereof

InactiveCN104997103AGreat tasteRetain nutritional valueFood ingredient functionsOligosaccharide food ingredientsBiotechnologyNutritive values

The present invention discloses a fruit and vegetable soybean milk drink which is prepared from the following raw materials in parts by weight: fruit juice 10-15 parts, vegetable juice 5-10 parts, Chinese red date soybean milk 3-5 parts, white granulated sugar 3-5 parts, high glucose syrup 2-3 parts, xylo-oligosaccharide 1-2 parts, malic acid 2-5 parts, citric acid 0.1-0.2 part, stabilizer 0.1-0.15 part and pure water 77.15-87.3 parts. The preparation method of the fruit and vegetable soybean milk drink comprises the following steps: (1) preparing the fruit juice; (2) preparing the vegetable juice; (3) preparing the Chinese red date soybean milk; (4) blending; (5) homogenizing and degassing; and (6) sterilizing and bottling. The prepared fruit and vegetable soybean milk drink increases the taste, improves the mouthfeel, maintains the nutritional values and increases the nutrients of the soybean milk, not only satisfies the people's pursuit for taste preferences, but also maintains and adds more nutrients, and has higher nutritional values.

Owner:HEILONGJIANG TIANYI AGRI TECH DEV

Integrated processing of plant biomass

InactiveUS7649086B2Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseWoody plant

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

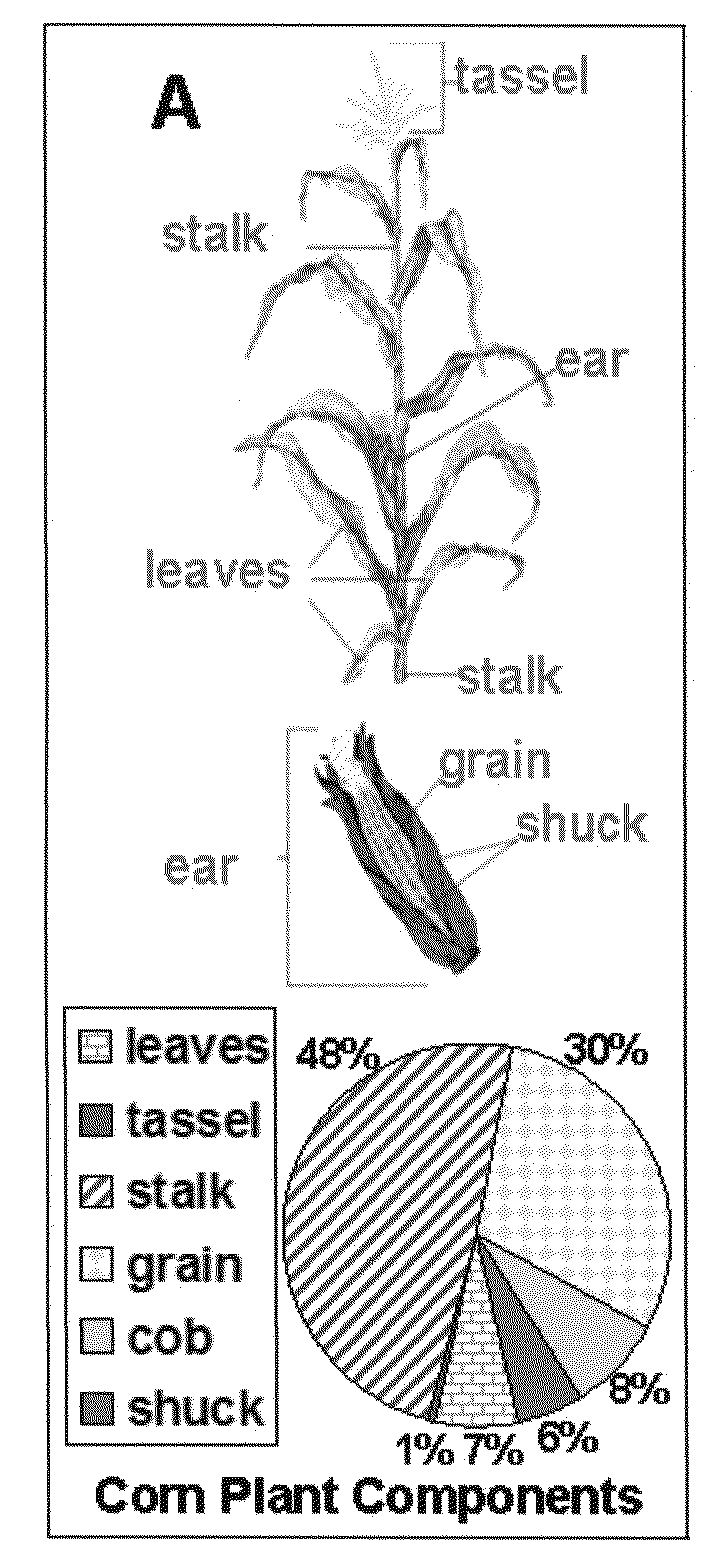

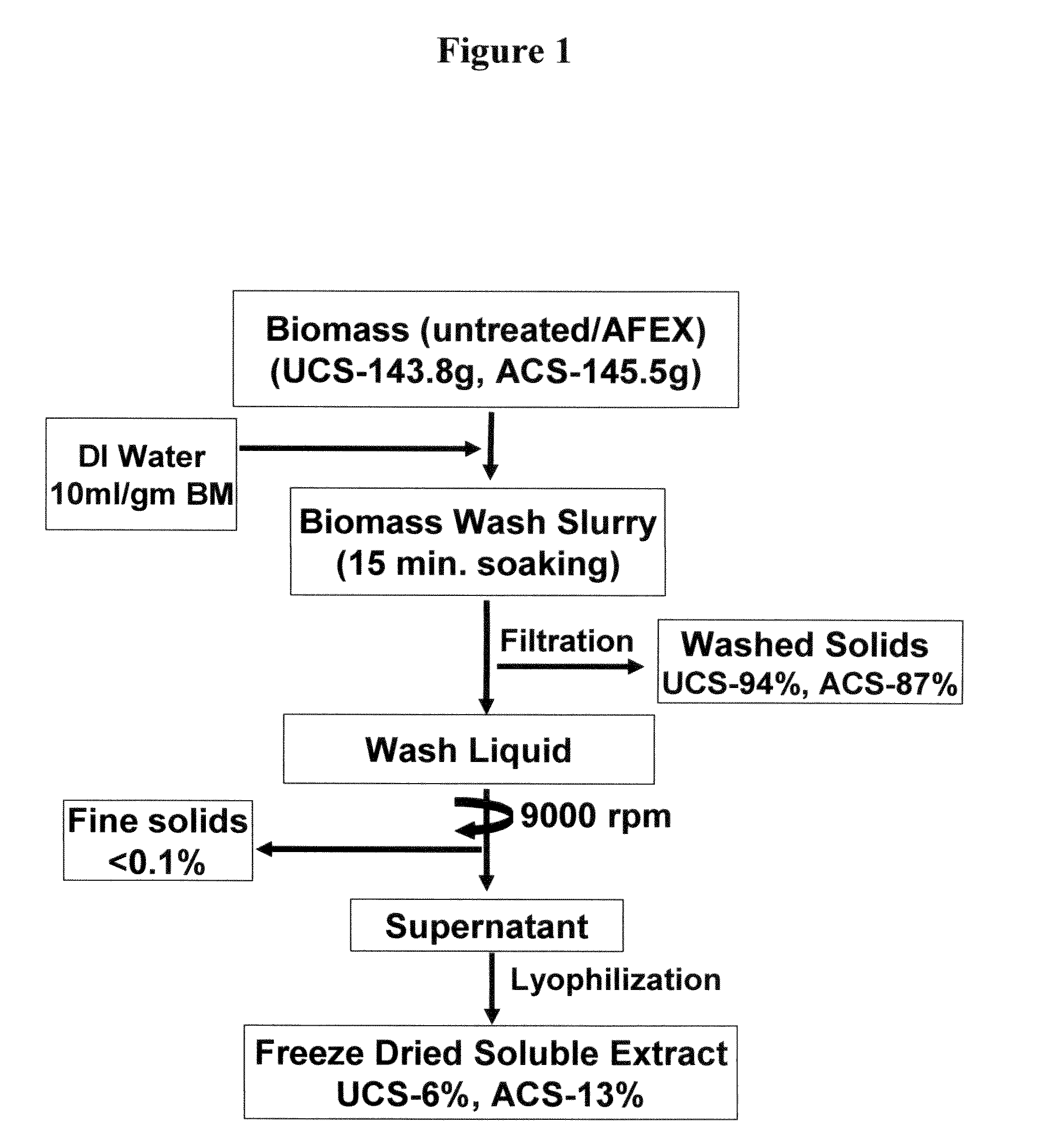

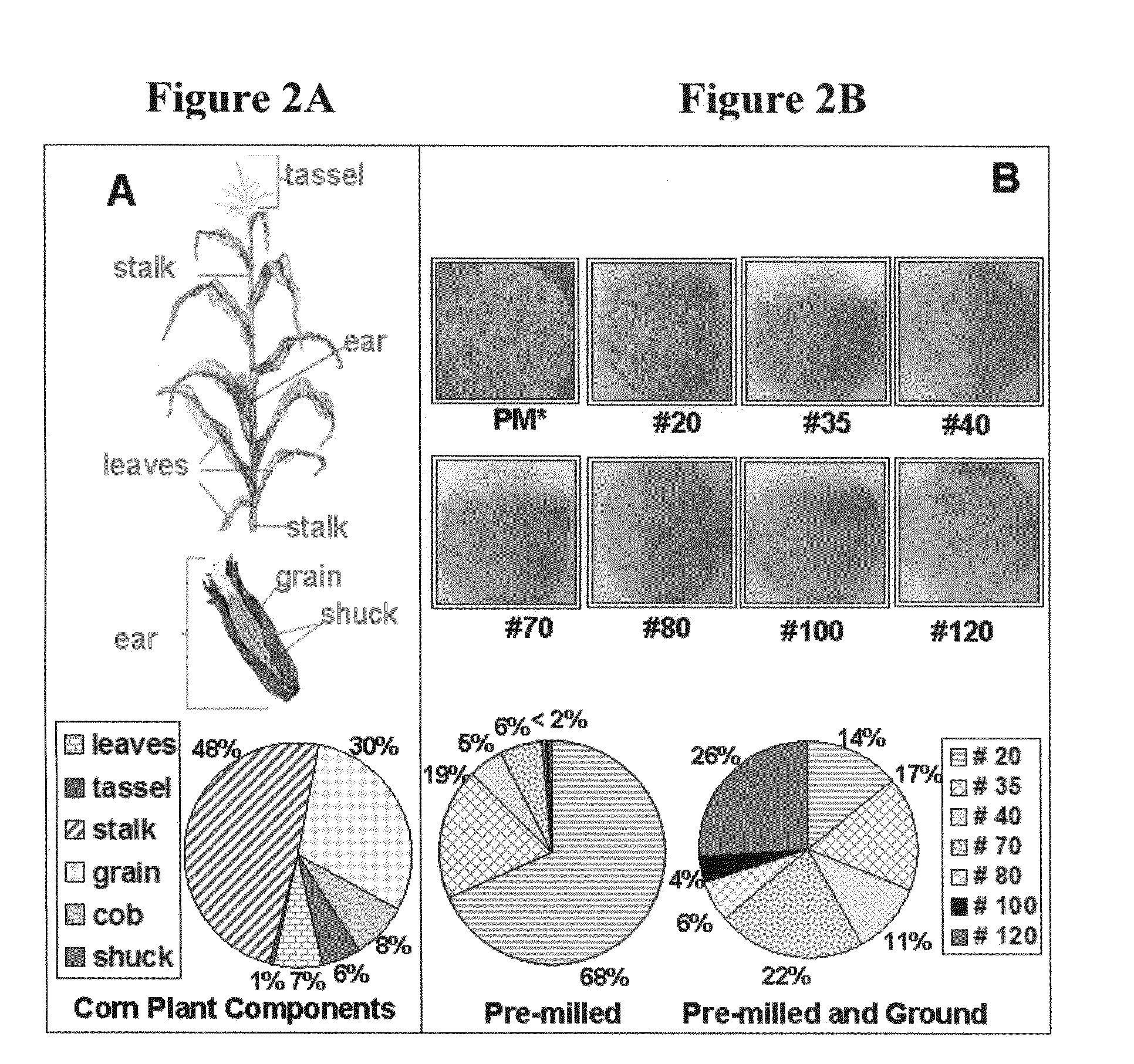

Process for enzymatically converting a plant biomass

The present invention describes a process for at least a 90% conversion of a plant biomass preferably by a reduction of the units of cellulase needed and by using a xylanase which acts synergistically with the cellulase to improve the yield of xylose and glucose as sugars. The process enables greater conversion of a lignocellulosic plant biomass to glucose and xylose for use as animal feeds and as fermentation as medium for producing ethanol.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Comprehensive utilization process of wood cellulose

The invention discloses a comprehensive utilization process of wood cellulose, which comprises the processes of comprehensive treatment, oligosaccharide preparation, lignin preparation, fiber ethanol preparation and the like. The invention has the advantages of decomposing a biomass macromolecular natural compact structure by using a high-pressure instant steam exploding technology, being beneficial to the separation and the extraction of the lignin, the cellulose and the cellulose, reducing the consumption of the energy sources and the materials, such as acid, alkali, heat, catalyst and the like for preprocessing, reducing the emission of pollutants and lightening the pollution of the environment. Secondly, the cogeneration of oligosaccharide and lignin realizes the comprehensive utilization of the energy sources, especially the application of the steam exploding technology ensures that the quality of the two products of the oligosaccharide and the lignin is greatly improved and the yield is greatly increased; and alcohol and the lignin of production fuels of sugar residues can be extracted irrespective of the order.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

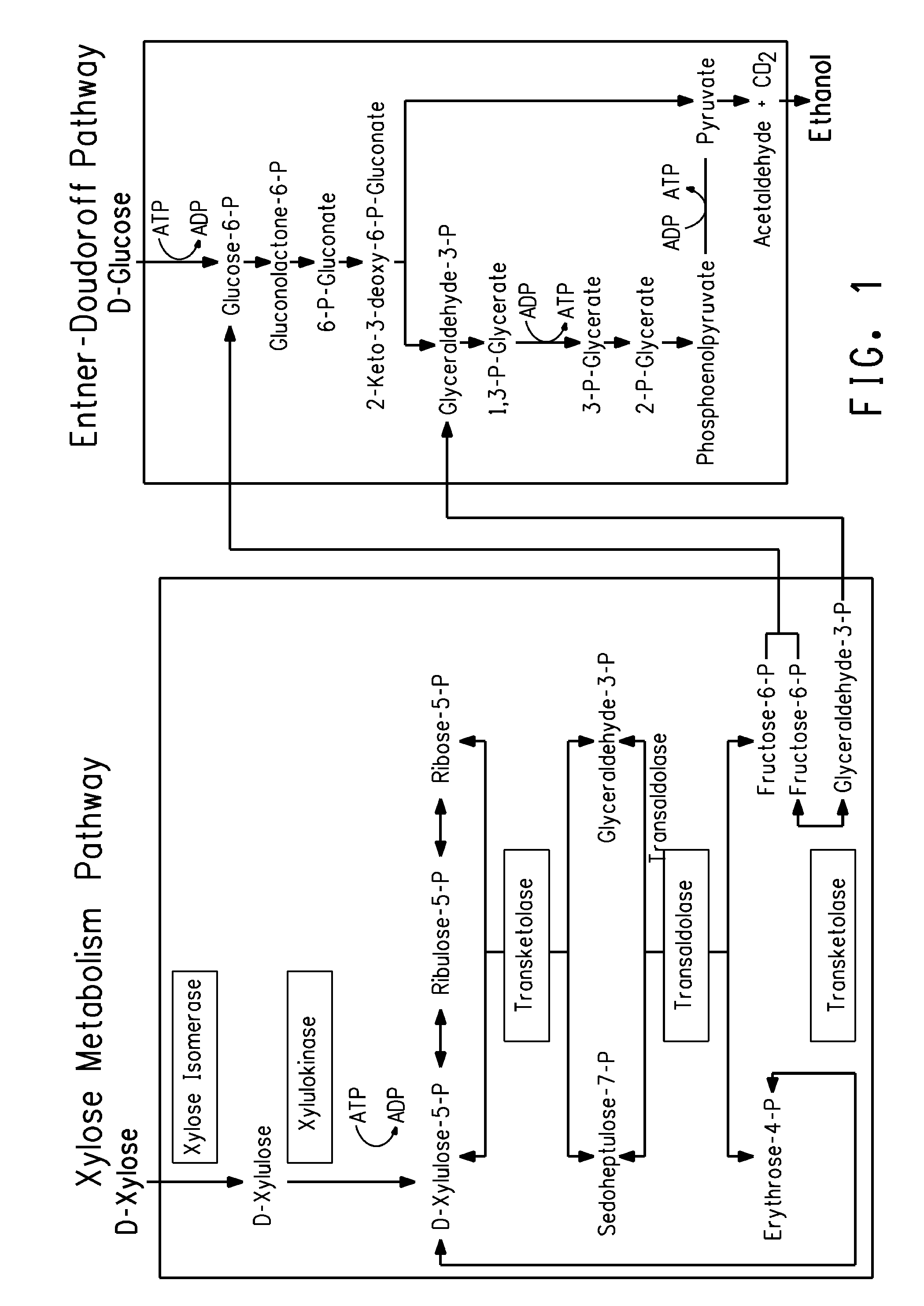

Ethanol production in fermentation of mixed sugars containing xylose

Xylose-utilizing Z. mobilis strains were found to have improved ethanol production when grown in medium containing mixed sugars including xylose if sorbitol or mannitol was included in the medium. The effect was seen in concentrations of mixed sugars where no growth lag period occurs, as well as in higher sugars concentrations.

Owner:SUSTAINABLE TECH CORP +1

Durable thermoset binder compositions from 5-carbon reducing sugars and use as wood binders

ActiveUS20110263757A1Minimize formaldehyde contentWeaken energyCosmetic preparationsOrganic detergent compounding agentsTris(2-aminoethyl)amineParticle board

The present invention provides thermosetting aqueous binder compositions of (i) one or more diprimary diamine, e.g. lysine, or poly(primary amine), e.g. polyethylenimine and tris(2-aminoethyl)amine, and (ii) one or more 5-carbon reducing sugar, such as xylose. The binders are at least substantially formaldehyde free and cure rapidly at temperatures sufficiently low and with sufficiently little swelling to enable one to provide wood or woody material containing articles, such as particle board, oriented strand board and bamboo boards or articles.

Owner:ROHM & HAAS CO

Pre-treatment of bales of feedstock

The present invention is directed to a method of pre-treating a lignocellulosic feedstock. The lignocellulosic feedstock comprises cereal straw, stover, or grass. One or more than one bale of lignocellulosic feedstock is conveyed into a pre-treatment reactor. Steam and acid are added to the bales and are maintained at a temperature, acid concentration, and for a time sufficient to hydrolyze hemicellulose to xylose and increase susceptibility of cellulose to digestion by cellulase enzymes, thus producing a pre-treated feedstock. The pre-treated feedstock is then removed from the pre-treatment reactor.

Owner:IOGEN ENERGY CORP

Method for preparing xylose by using squeezed waste alkali in viscose fiber production process

ActiveCN102643935AReduce preprocessingAvoid events that pollute the environmentSaccharides productionHazardous substanceIon exchange

The invention relates to a method for preparing xylose by using squeezed waste alkali in the viscose fiber production process. According to the method, xylose finished products are obtained through work procedures of hemicellulose solution preparation, hemicellulose extraction, hemicellulose hydrolysis, neutralization and deacidification, preconcentration, decoloration, ion exchange, ordinary concentration, crystallization, separation and drying. When the technical scheme provided by the invention is adopted, harmful environment-pollution substances such as waste alkali and waste water generated in the viscose production process can be thoroughly eliminated, the standard of full-flow-process clean production can be reached, viscose production enterprises can also produce xylose in the viscose production process, the goal of environment protection is reached, and meanwhile, the waste reutilization is also realized.

Owner:YIBIN GRACE +2

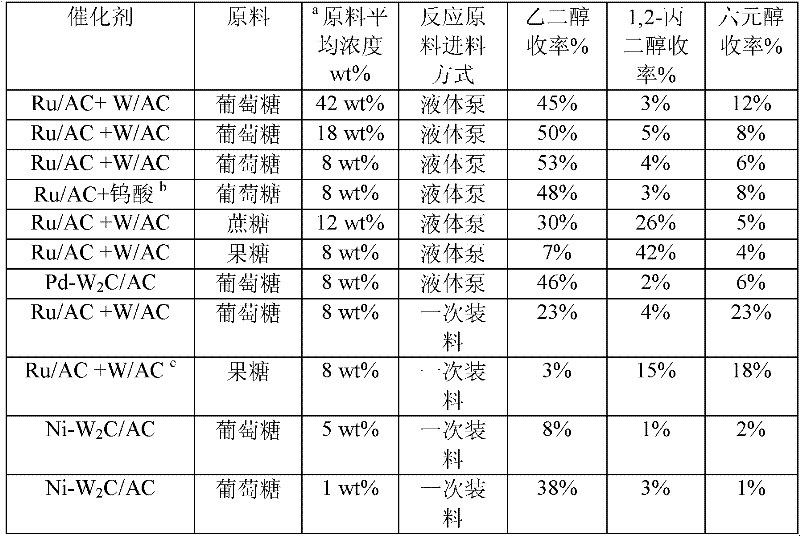

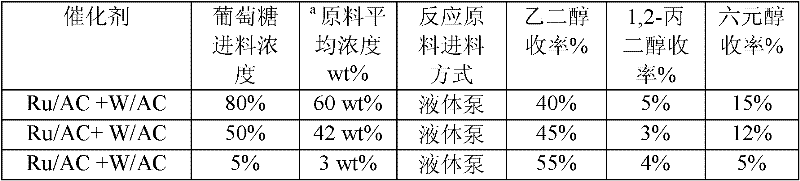

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

Zymomonas with improved ethanol production in medium containing concentrated sugars and acetate

InactiveUS20090203099A1Improve performanceIncreased acetate toleranceBacteriaBiofuelsAcetic acidSugar

Through screening of a Zymomonas mutant library the himA gene was found to be involved in the inhibitory effect of acetate on Zymomonas performance. Xylose-utilizing Zymomonas strains further engineered to reduce activity of the himA gene were found to have increased ethanol production in comparison to a parental strain, when cultured in mixed-sugars medium comprising xylose, and, in particular, in the presence of acetate.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Method of processing lignocellulosic feedstock for enhanced xylose and ethanol production

ActiveUS20070148751A1Improve accessibilityHigh yieldBiofuelsFermentationAqueous solutionHemicellulose

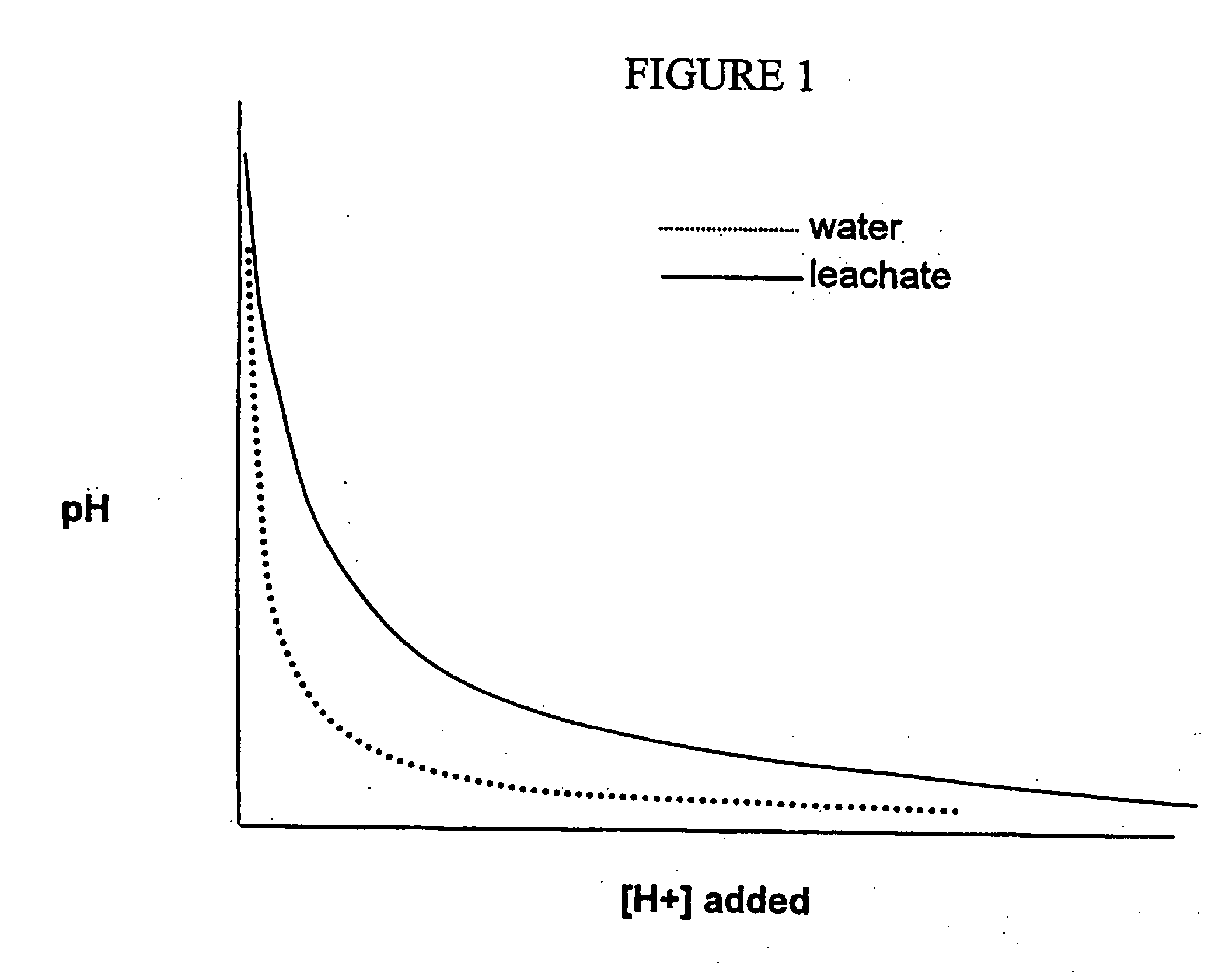

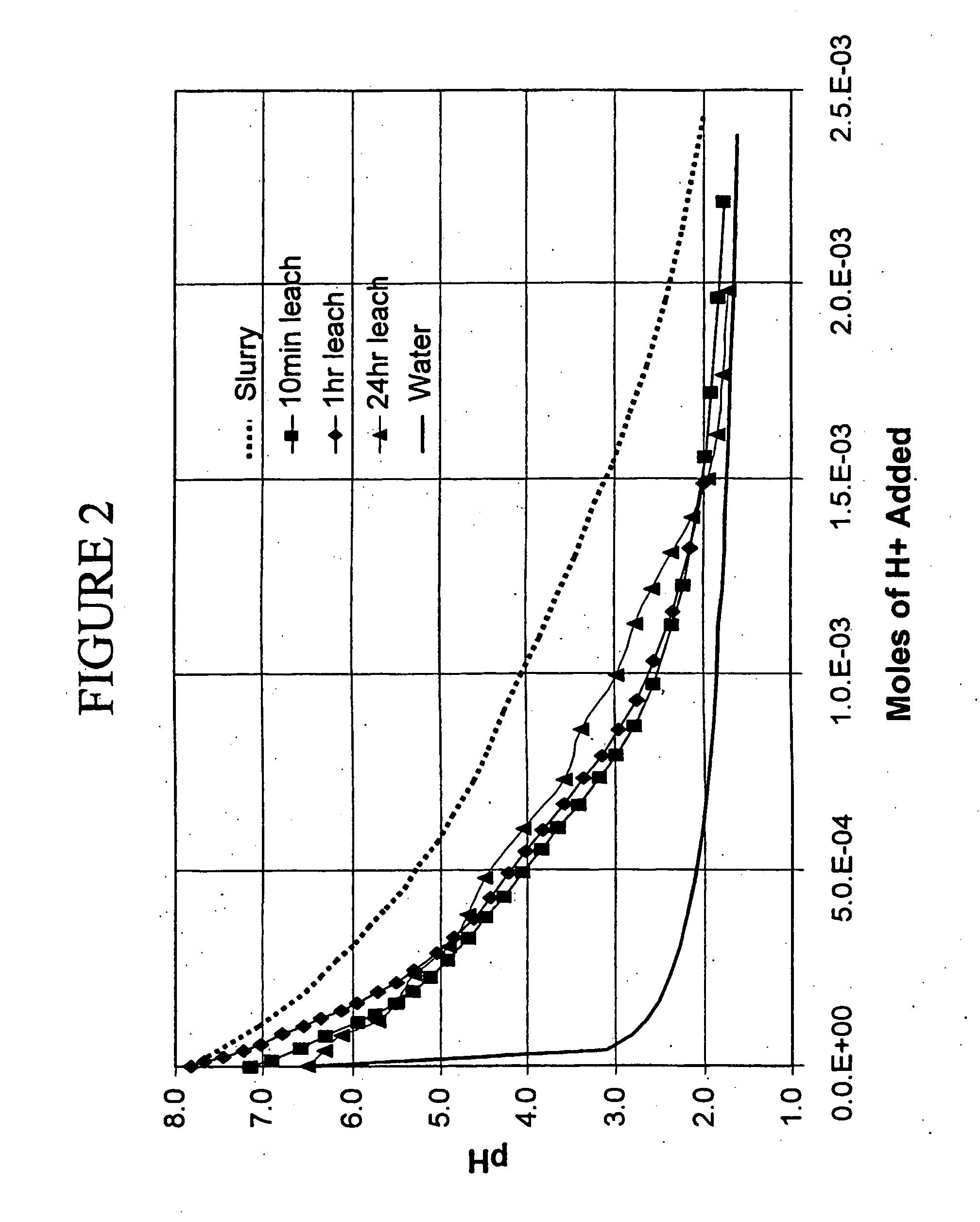

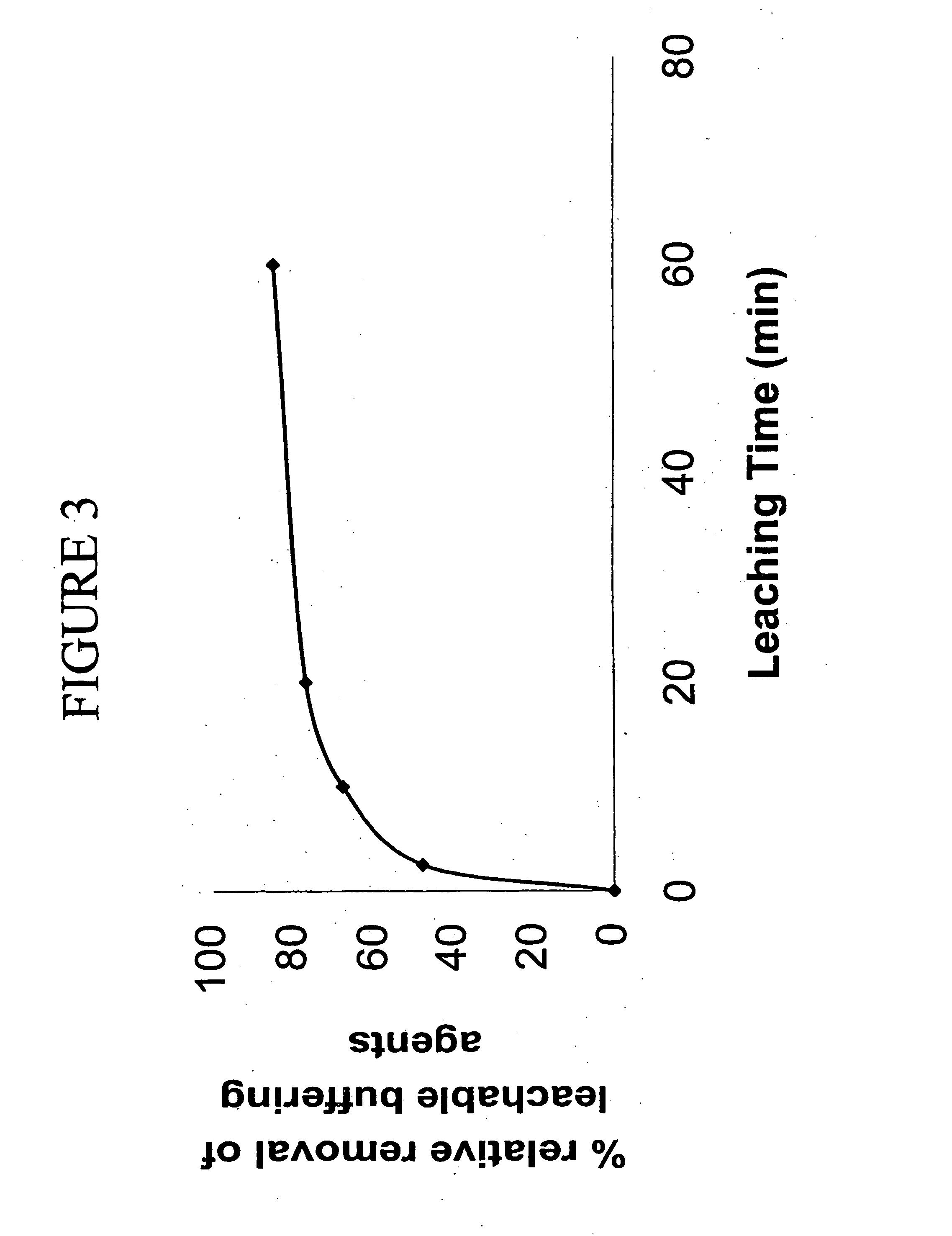

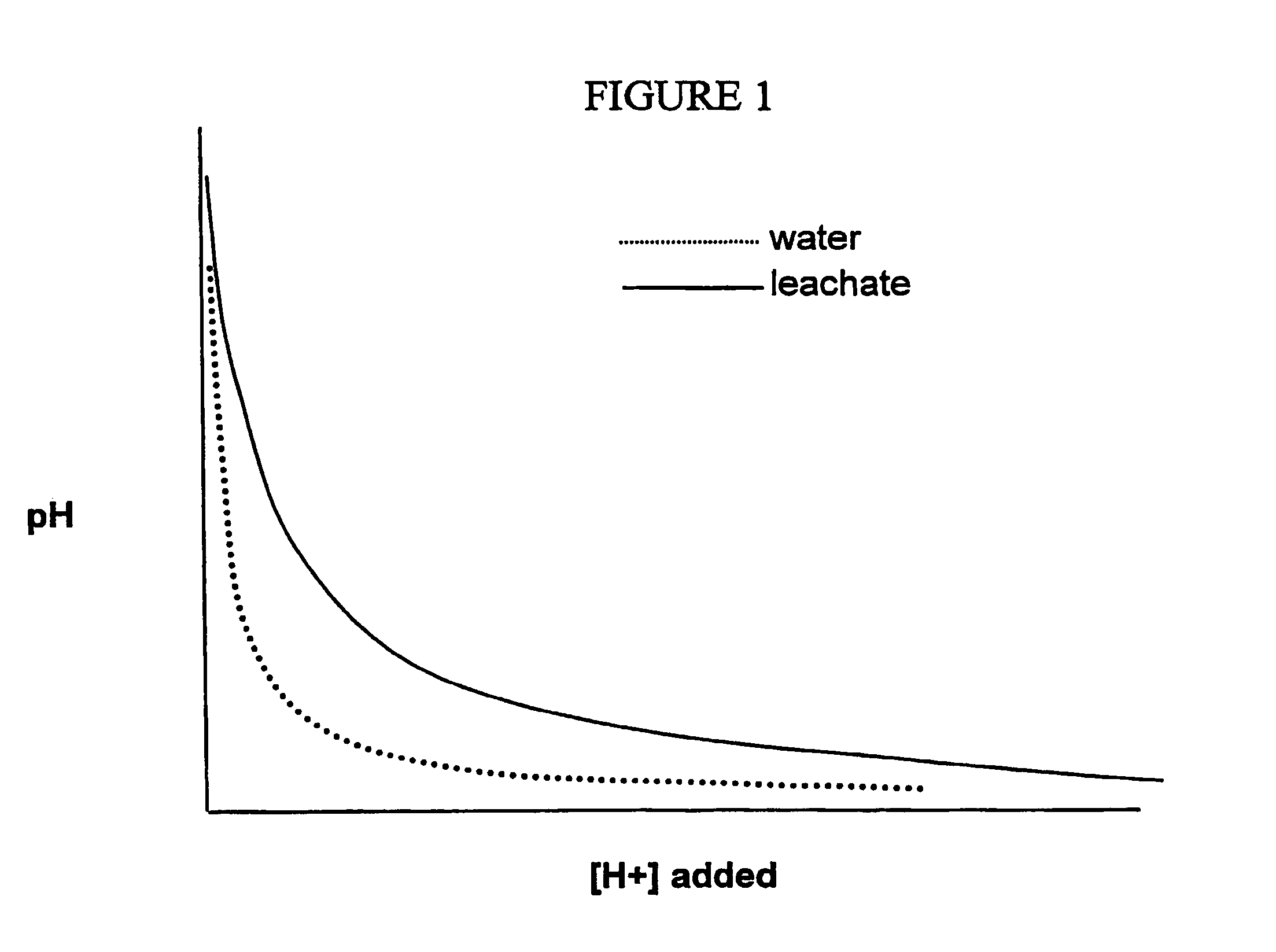

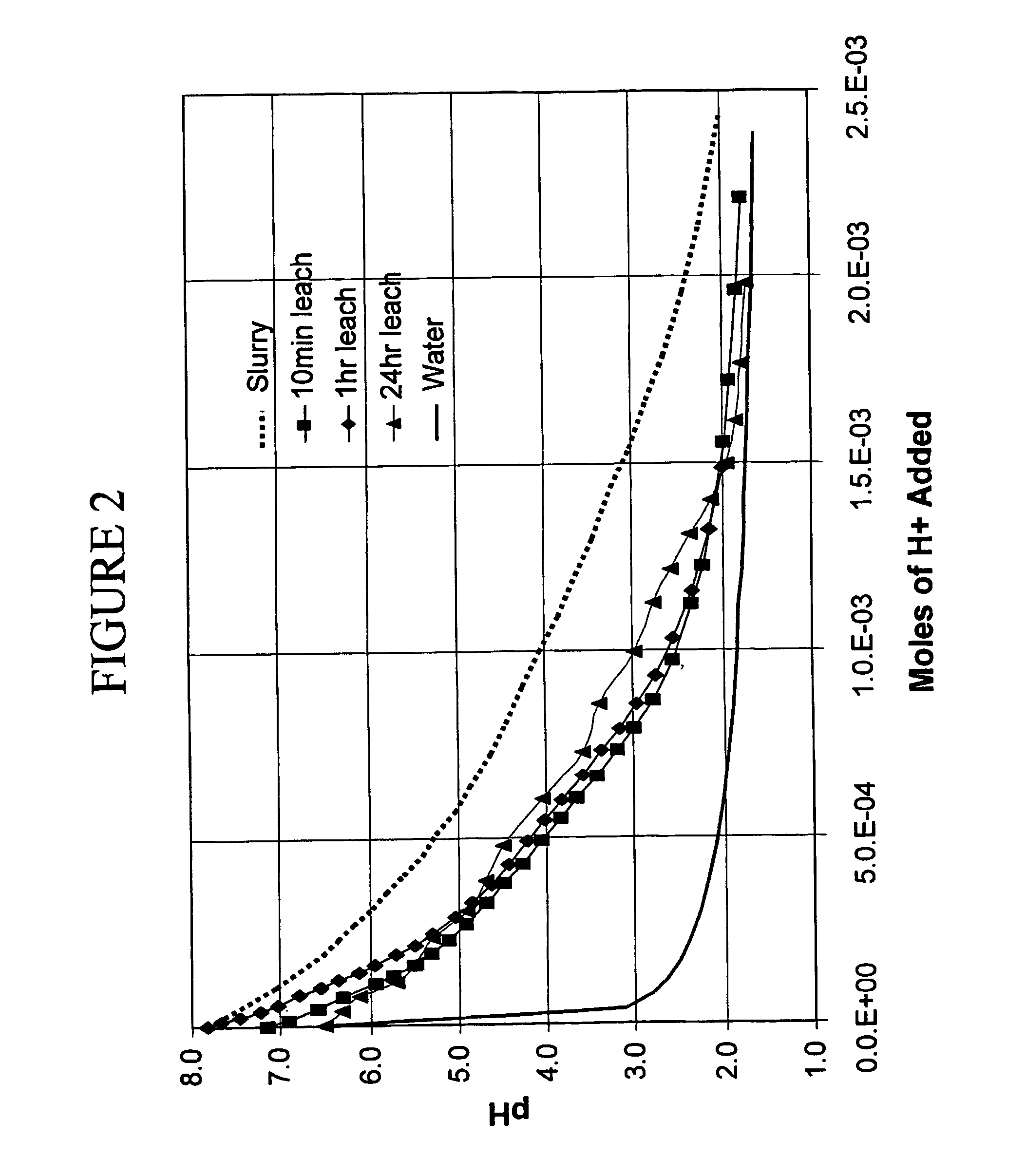

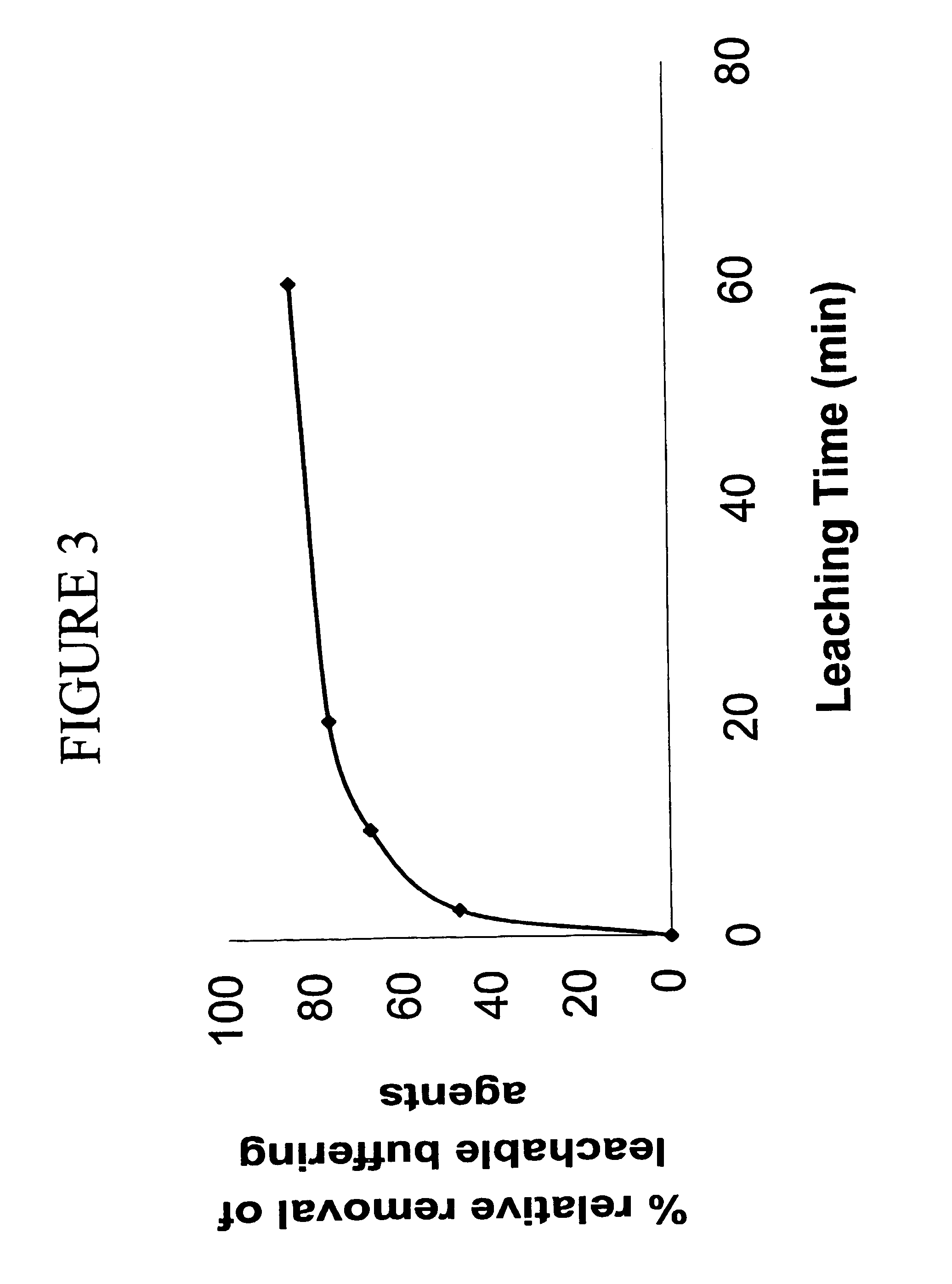

The present invention provides a method of producing xylose from lignocellulosic feedstock. The method comprises disrupting lignocellulosic feedstock; leaching the lignocellulosic feedstock by contacting the feedstock with at least one aqueous solution for a period greater than about 2 minutes to produce a leached feedstock and a leachate; removing the leachate from the leached feedstock; acidifying the leached feedstock to a pH between about 0.5 and about 3 to produce an acidified feedstock, and; reacting the acidified feedstock under conditions which disrupt fiber structure and hydrolyze a portion of hemicellulose and cellulose of the acidified feedstock, to produce a composition comprising xylose and a pretreated feedstock. The xylose may be purified from the pretreated feedstock or it may be converted to ethanol with the pretreated feedstock.

Owner:IOGEN ENERGY CORP

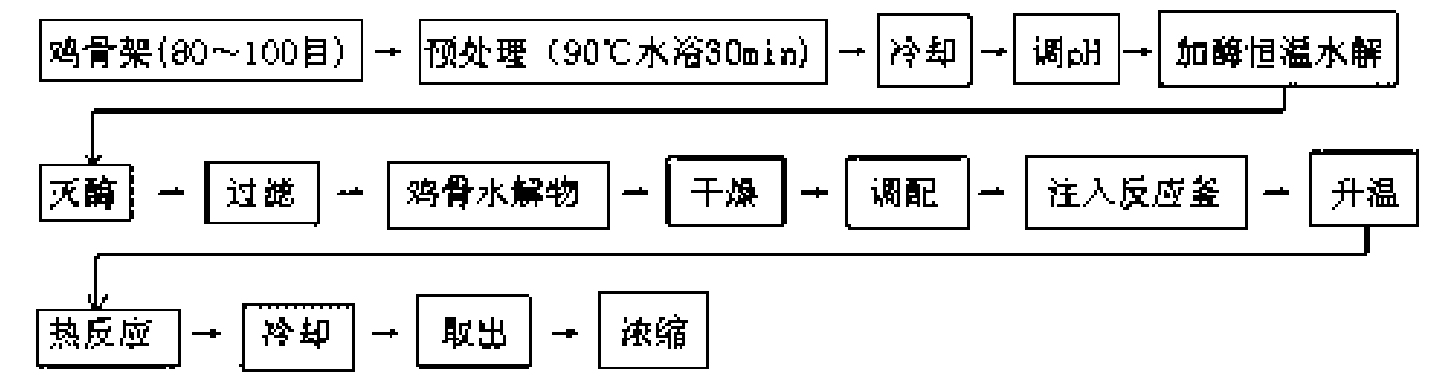

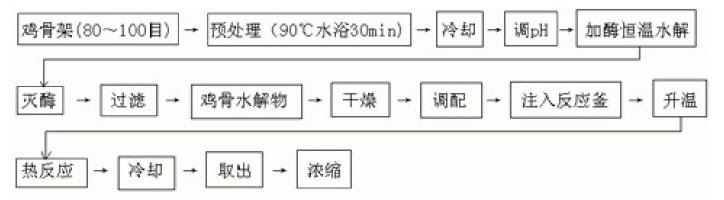

Chicken bone protein zymolyte and chicken essence substrate prepared by same

The invention provides a chicken bone protein zymolyte and a chicken essence substrate prepared by the chicken bone protein zymolyte, belonging to the technical field of poultry processing. The invention solves the problems of high cost for producing a chicken essence substrate, limited raw material sources, unavailable effective utilization generally by discarding leftovers, such as chicken bone, and the like, and the like in the prior art. In the invention, a novel chicken essence substrate is developed by adopting the cheap leftovers, namely chicken bone as a raw material and utilizing a biological enzymolysis technology and a hot reaction spice research technology; the chicken essence substrate is prepared by the following steps of: adopting the chicken bone zymolyte obtained after the chicken bone is subjected to double enzymolysis by pancreatic enzyme and Flavourzyme composite flavor protease as a main material, mixing the main material with hydrolyzed vegetable protein (HVP), a yeast extract, glucose, xylose, thiamine, chicken oil and propylene glycol according to a certain proportion; and carrying out Maillard reaction in a high-pressure reactor to prepare the chicken essence substrate with vivid chicken fragrance. The chicken essence substrate has vivid chicken fragrance, rich and strong chicken fragrance and long aftertaste.

Owner:FUZHOU UNIV

Method of processing lignocellulosic feedstock for enhanced xylose and ethanol production

The present invention provides a method of producing xylose from lignocellulosic feedstock. The method comprises disrupting lignocellulosic feedstock; leaching the lignocellulosic feedstock by contacting the feedstock with at least one aqueous solution for a period greater than about 2 minutes to produce a leached feedstock and a leachate; removing the leachate from the leached feedstock; acidifying the leached feedstock to a pH between about 0.5 and about 3 to produce an acidified feedstock, and; reacting the acidified feedstock under conditions which disrupt fiber structure and hydrolyze a portion of hemicellulose and cellulose of the acidified feedstock, to produce a composition comprising xylose and a pretreated feedstock. The xylose may be purified from the pretreated feedstock or it may be converted to ethanol with the pretreated feedstock.

Owner:IOGEN ENERGY CORP

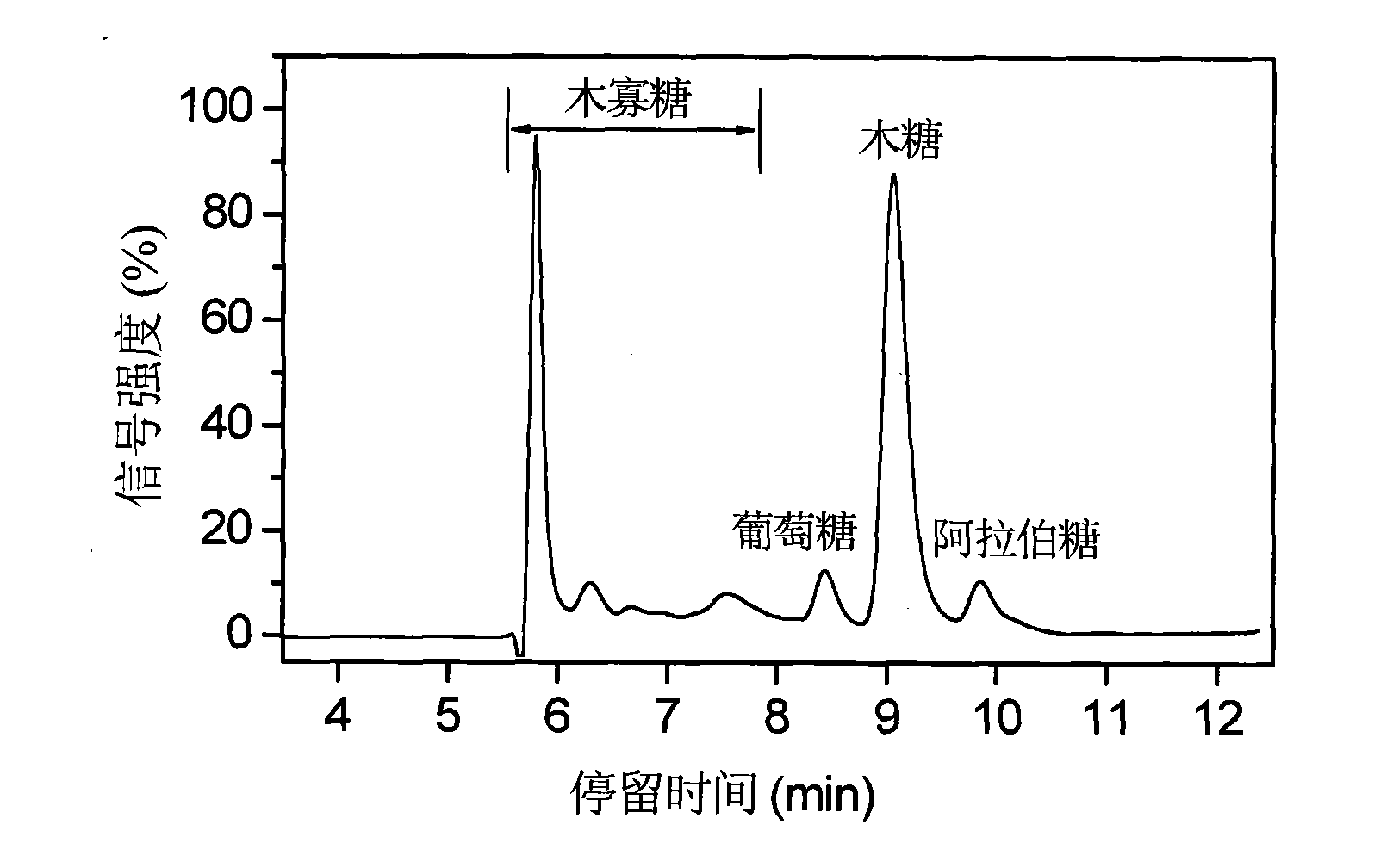

High-Purity Xylooligosaccharide Compositions

To provide a high-purity xylooligosaccharide composition while preventing the formation of UV-absorbing substances and coloring matters.A high-pure xylooligosaccharide composition containing reduced UV-absorbing substances and reduced coloring matters and a method of producing the same which comprises alkali-treating or pressure- and heat-treating a plant material such as wood, corn cob, cotton seed hull, bagasse or rice straw, further enzymatically treating the same, and purifying the crude saccharide solution containing the residues thus obtained, wherein the solution is concentrated and then optionally subjected to desalting and active carbon-treatment. According to the method of the invention, the saccharified solution is concentrated followed by the desalting and active-carbon treating so that a high-purity xylooligosaccharide composition can be produced while preventing the formation of UV-absorbing substances and coloring matters.

Owner:SUNTORY HLDG LTD +1

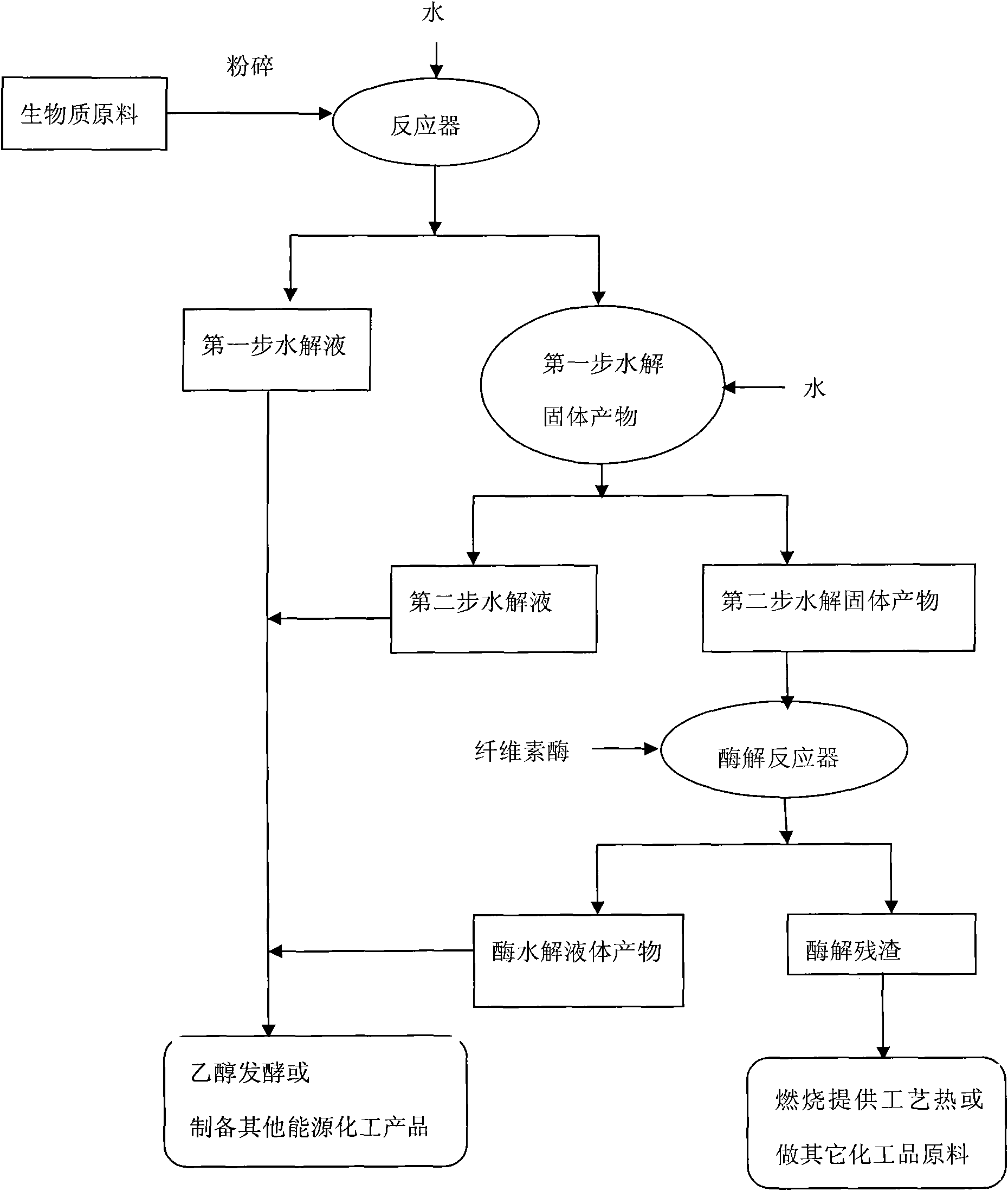

Method of high-efficiency pretreatment on biomass

InactiveCN101586136AReduce degradationHigh recovery rateLignin derivativesOligosaccharidesPretreatment methodLiquid water

The invention discloses a method capable of carrying out green high-efficiency hydrolysis pretreatment on lignocellulose biomass. The method in the invention comprises the steps of hydrolyzing the hemicellulose in the cellulose biomass into saccharide products mainly containing xylose and oligose thereof using a two-step temperature-changing segmentation hydrolysis method so as to accomplish the pretreatment, and adding the pretreated solid raw material mainly containing cellulose and lignin to cellulase so as to accomplish enzymatic hydrolysis and recover the saccharide products to the utmost extent. The invention uses high-temperature liquid water as reaction medium, has the advantages that the method has low cost and is environment-friendly and green. The reaction conditions are moderate, the saccharide products are degraded less, and the recovery rate is high. By adopting the two-step temperature-changing segmentation hydrolysis method, the method not only hydrolyzes the hemicellulose to the utmost extent to obtain the saccharide products, but also further pre-treats the raw material such that the cellulose is made into glucose through enzymatic hydrolysis, reaching the purpose of protecting environment and hydrolyzing the lignocellulose biomass highly effectively. The raw material is capable of realizing waste utilization and promotes the development of green industries.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

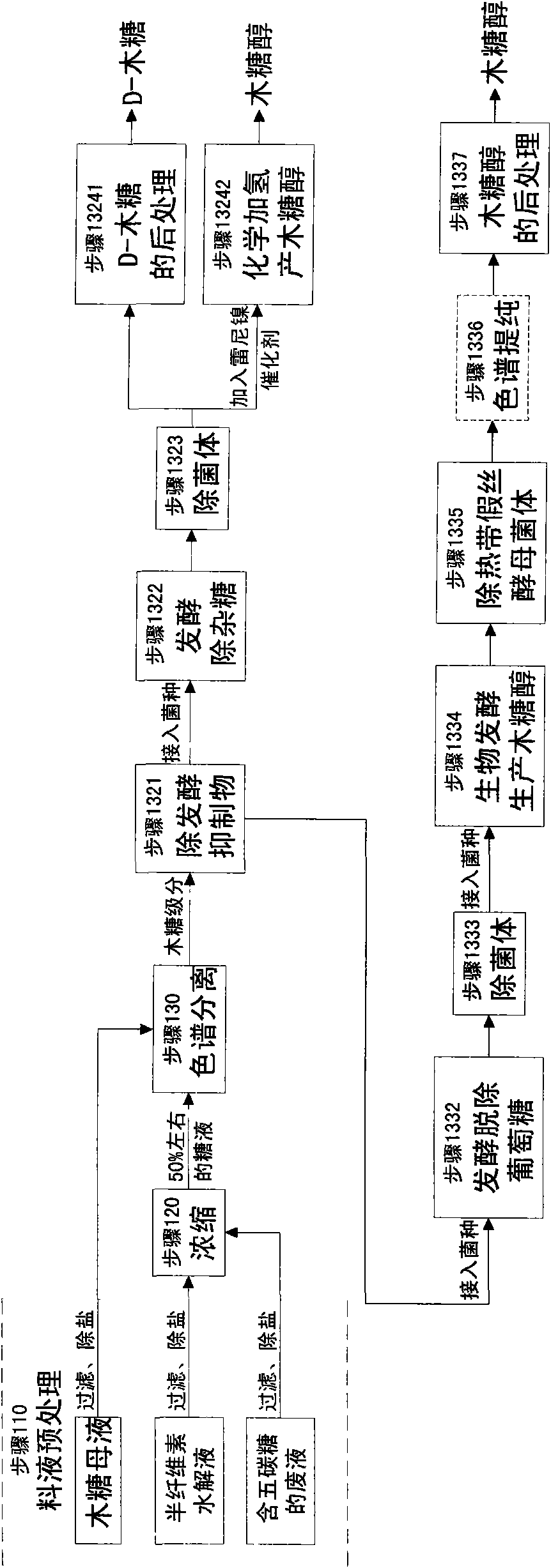

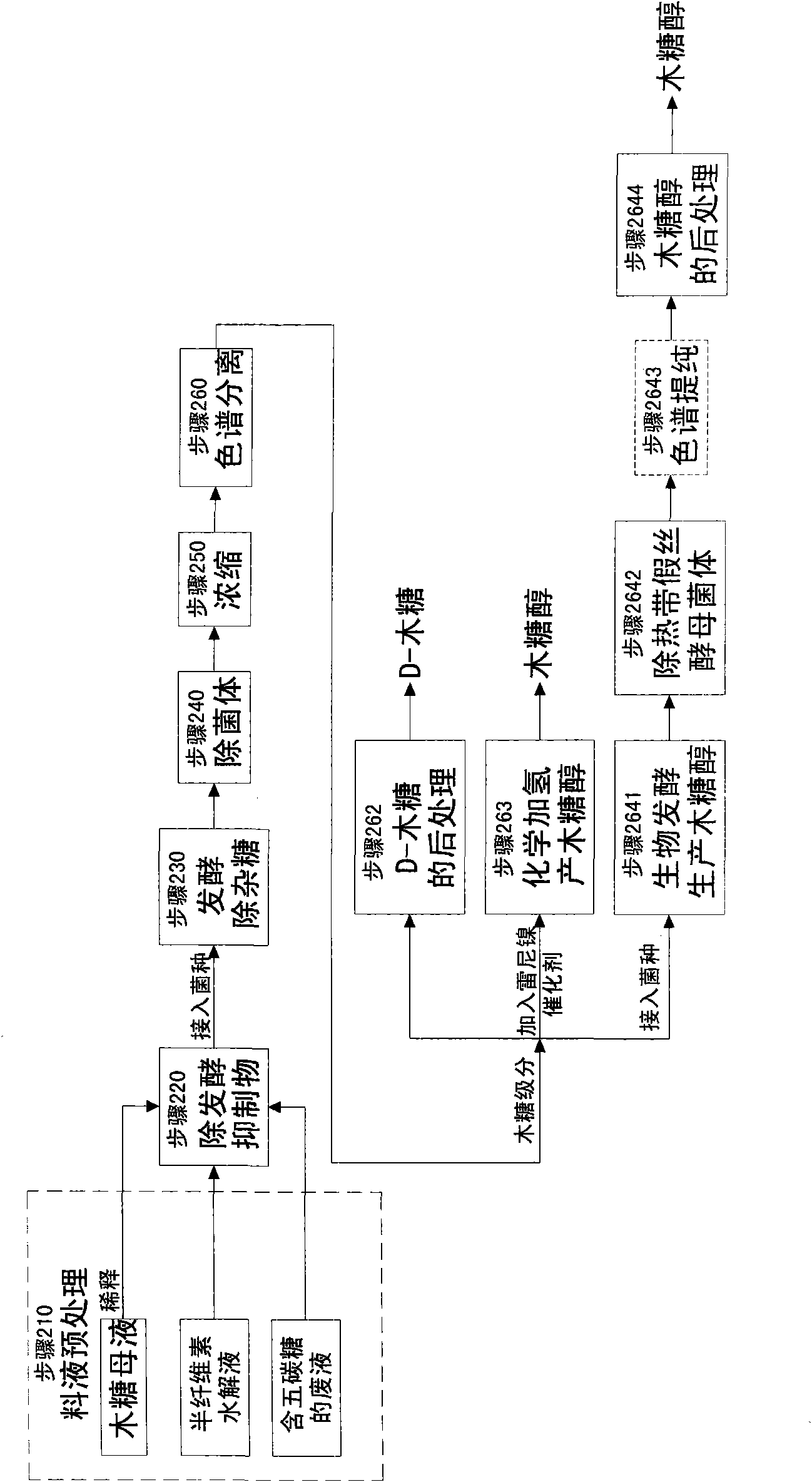

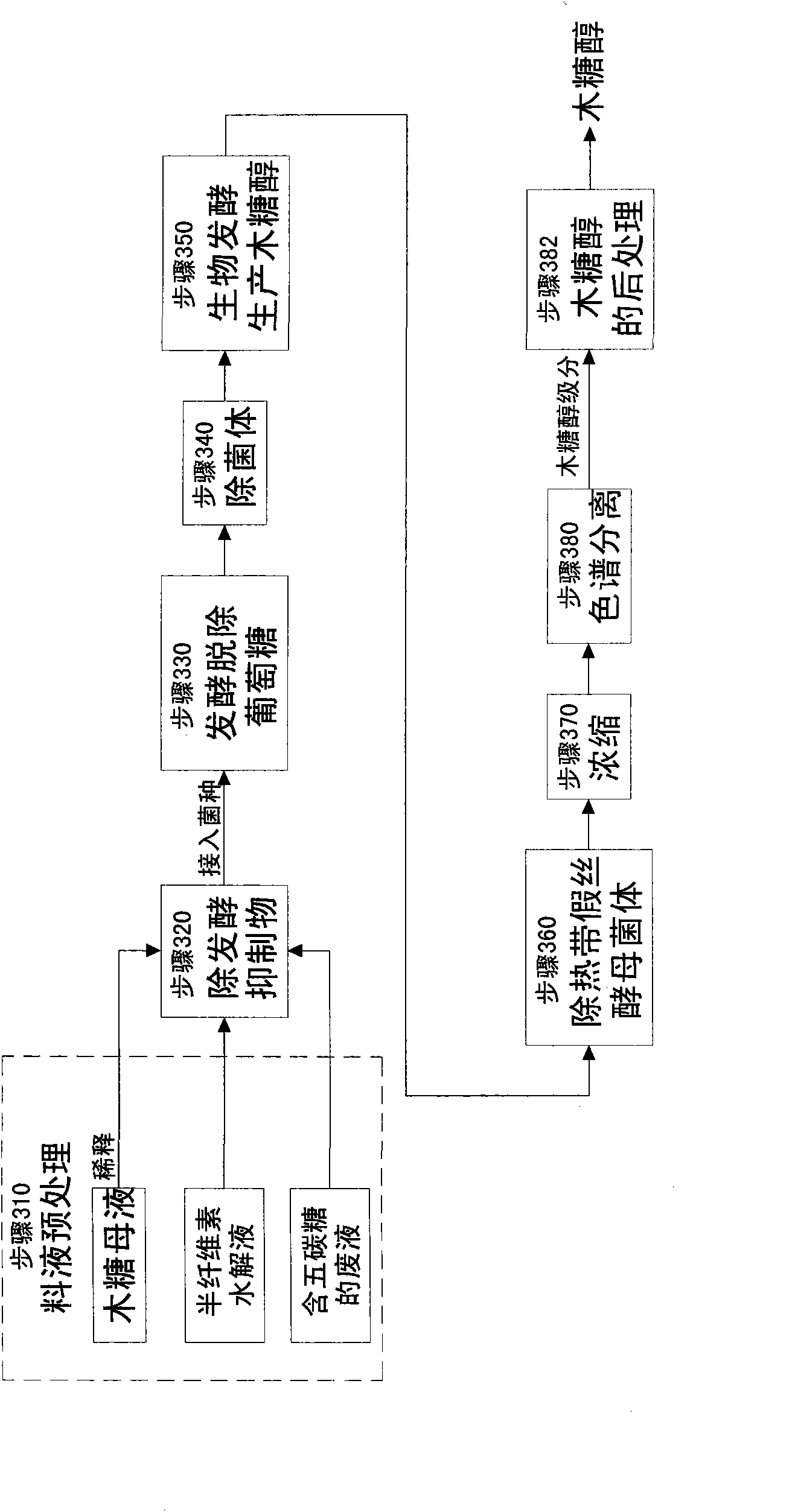

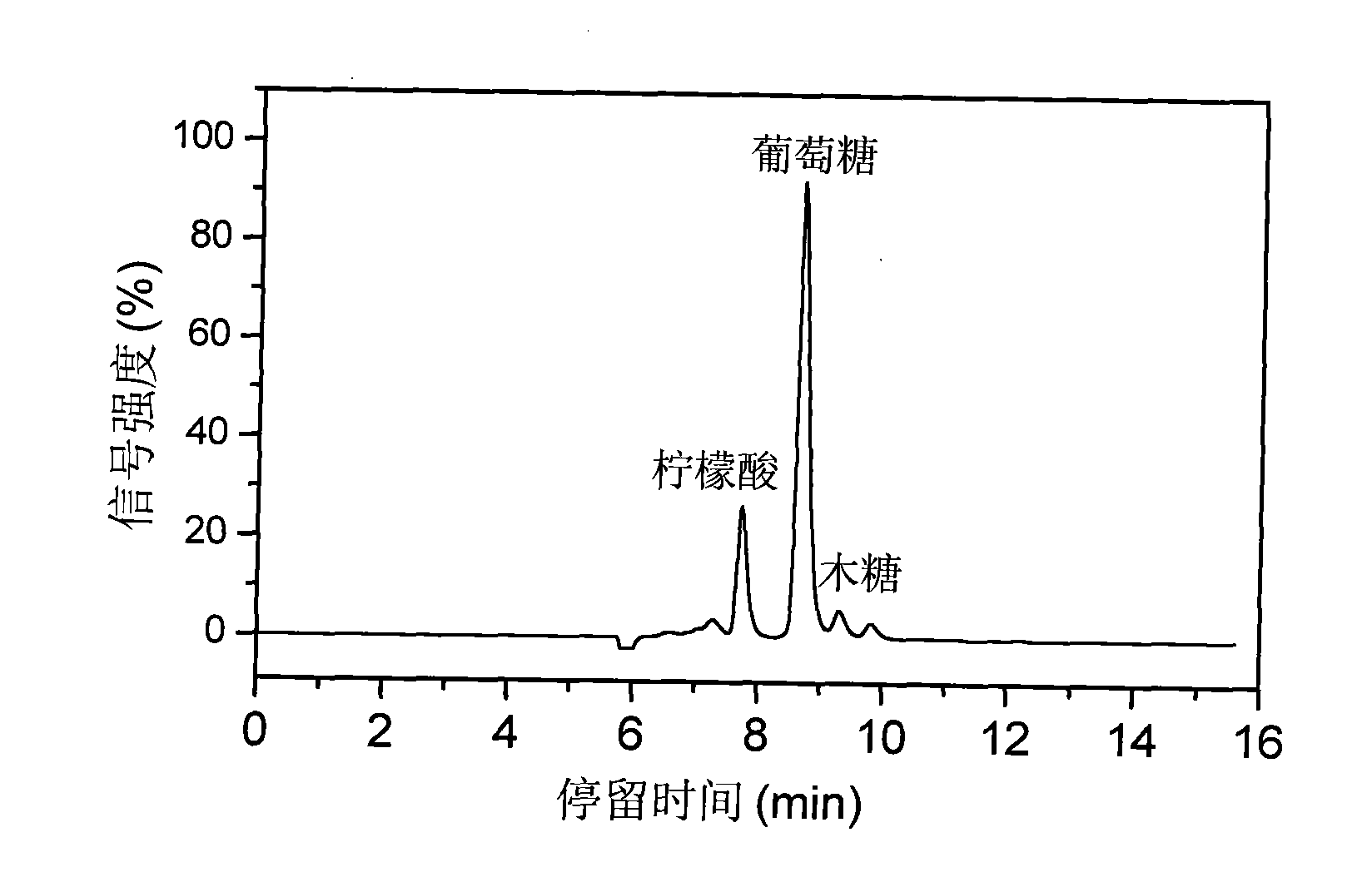

Method for producing wood sugar product

ActiveCN101659681AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationHydrolysis

The invention relates to a method for producing a wood sugar product and a byproduct of ethanol or D-ribose or citric acid. The method takes hydrolysis liquid, wood sugar mother liquor and / or production waste liquid containing pentose of agricultural or forestry waste as the raw materials, comprising the following steps: (a) preprocessing feed liquid; (b) colour spectrum separation: separating thefeed liquid into arabinose fraction feed liquid and wood sugar fraction feed liquid; (c) removing mixed sugar at least containing glucose and galactolipin; and (d) carrying out aftertreatment on thewood sugar fraction feed liquid to obtain the wood sugar product. The wood sugar product comprises xylitol and D-wood sugar. The invention has low production cost and high efficiency and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

Methods for preparing ethylene glycol from polyhydroxy compounds

ActiveUS20120172633A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureHeteropoly acid

This invention provides methods for producing ethylene glycol from polyhydroxy compounds such as cellulose, starch, hemicellulose, glucose, sucrose, fructose, fructan, xylose and soluble xylooligosaccharides. The methods uses polyhydroxy compounds as the reactant, a composite catalyst having active components comprising one or more transition metals of Groups 8, 9, or 10, including iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, as well as tungsten oxide, tungsten sulfide, tungsten hydroxide, tungsten chloride, tungsten bronze oxide, tungsten acid, tungstate, metatungstate acid, metatungstate, paratungstate acid, paratungstate, peroxotungstic acid, pertungstate, heteropoly acid containing tungsten. Reacting at a temperature of 120-300° C. and a hydrogen pressure of 1-13 MPa under hydrothermal conditions to accomplish one-step catalytic conversion. It realizes efficient, highly selective, high yield preparation of ethylene glycol and propylene glycol from polyhydroxy compounds. The advantage of processes disclosed in this invention include renewable raw material and high atom economy. At the same time, compared with other technologies that converts biomass raw materials into polyols, methods disclosed herein enjoy advantages including simple reaction process, high yield of targeted products, as well as easy preparation and low cost for the catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solvo-thermal hydrolysis of xylose

ActiveUS20100048924A1Rapid coolingOrganic chemistryChemical/physical/physico-chemical processesSolventFurfural

The invention relates to a process for producing furfural from xylose comprising: (a) mixing an aqueous xylose solution containing xylose oligosaccharides with sub-critical or near-critical water to form a mixture at a first temperature and a first pressure; (b) maintaining the mixture at the first temperature and the first pressure for a first time period; and (c) rapidly cooling the mixture to a second temperature and a second pressure, wherein furfural is produced by the process (d) process can also be carried out with or without mixing of carbon dioxide with aqueous xylose solution before it is mixed with sub-critical or near-critical water to form a mixture at a first temperature and pressure.

Owner:RENMATIX INC

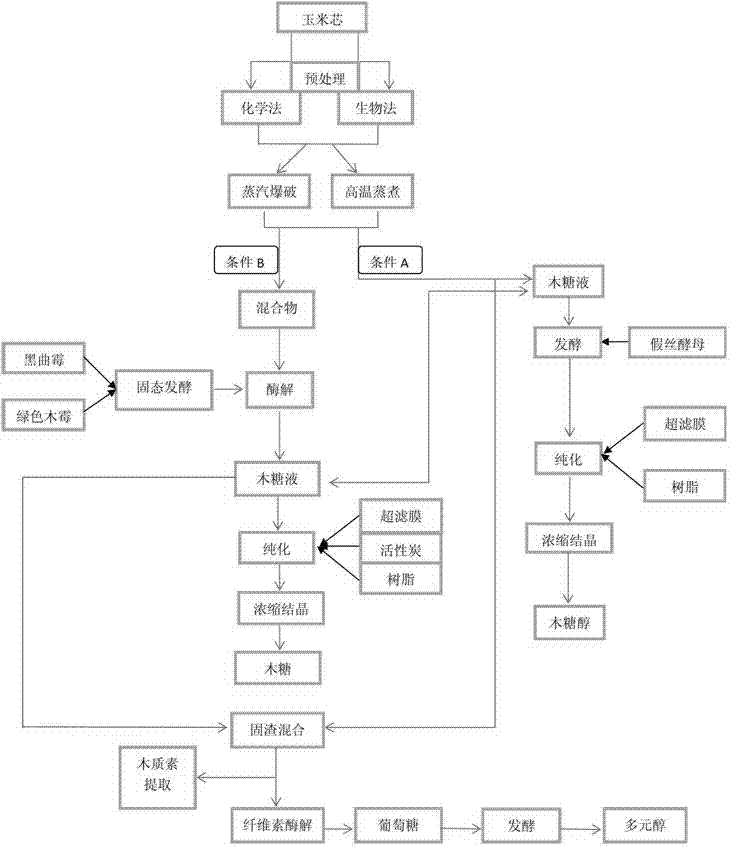

Process for producing polyatomic sugar alcohol and lignin by comprehensively using agricultural and forestry wasters of corncobs

The invention belongs to the biochemical industry field and particularly relates to a novel process for producing the polyatomic sugar alcohol and the lignin by comprehensively using agricultural and forestry wasters of corncobs. The process includes preprocessing raw materials by using a chemical or biological method, and producing a xylose hydrolysate in a high-temperature digesting or steam blasting mode to produce xylose products or xylitol products through a biological method. According to the process for producing the polyatomic sugar alcohol and the lignin by comprehensively using agricultural and forestry wasters of corncobs, ingredients of cellulose and lignin contained in the raw materials are fully used to develop and produce corresponding products.

Owner:BEIJING UNIV OF CHEM TECH

Dehydrated polysaccharide gel containing microorganisms, a sugar and a polyol for producing fermented drinks

Improved fermentation activity of microorganisms in a polysaccharide gel such as an alginate gel is obtained after dehydration, staorage and rehydration by soaking the gel containing the microorganisms prior to dehydration in a sugar solution to provide in the gel an amount of sugar of at least 100 g / kg and less than 500 g / kg of gel, preferably less than 300 g / k of gel. The dehydration may be carried out in a fluidized bed or by lyophilization. The gel may be in the form of beads or fibers having a double layer structure formed by an internal layer or core of gel containing the microorganisms and an external lay er or envelope of gel essentially devoid of the microoraganisms. The sugar is preferably xylose, glucose, fructose, lactose or sucrose, and the sugar solution may contain a polyol such as sorbitol, inositol or glycerol to provide in the gel an amount of polyol of at least 30 g / kg of gel. The sugar solution may also contain a non-ionic surfactant such as sorbitan monostearate as a protecting substance to fur ther improve fermentation activity. The microorganisms in the gel are preferably yeast, and after rehydration the yeast containing gel is used in producing a fermented drink such as in secondary fermentaion of wine to produce sparkling wine or champagne.

Owner:MOET & CHANDON

Ecological nutrition compound feed for meat chicken

InactiveCN1857105APromote growth and developmentReasonable nutritionFood processingAnimal feeding stuffXyloseMeat chicken

The ecological nutritive compound feed for meat chicken consists of corn, soybean dregs, corn protein powder, lysine, methionine, soybean oil, salt, sodium bicarbonate, stone powder, calcium biphosphate and other materials. It has the functions of promoting growth of meat chicken, raising immunity and raising disease resistance. The feed contains no antibiotic and has no drug residue.

Owner:缪淑华

Production of gasoline from fermentable feedstocks

ActiveUS20100137647A1High speedHigh oil contentOrganic compound preparationBiofuelsBiodieselKetonic acids

Methods are disclosed for forming heptan-4-one, and, optionally, heptan-4-ol, from fermentable sugars. The sugars are fermented using a bacteria or yeast that predominantly forms butyric acid. The butyric acid is subjected to catalytic ketonization conditions to form heptan-4-one, with concomitant loss of water and carbon dioxide. The heptan-4-one can be subjected to catalytic hydrogenation to form heptan-4-ol, an either of these can be included in gasoline compositions. In one aspect, the fermentable sugars are derived from lignocellulosic materials such as wood products, switchgrass, or agricultural wastes, which are delignified to form lignin, cellulose and hemicellulose. The cellulose and hemicellulose can be depolymerized to form glycose and xylose, either or both of which can be fermented by the bacteria. Thus, the methods described herein can convert biomass to a fuel composition or fuel additive, which can be used in a conventional gasoline engine, unlike traditional fuels such as ethanol or biodiesel.

Owner:CPS BIOFUELS INC

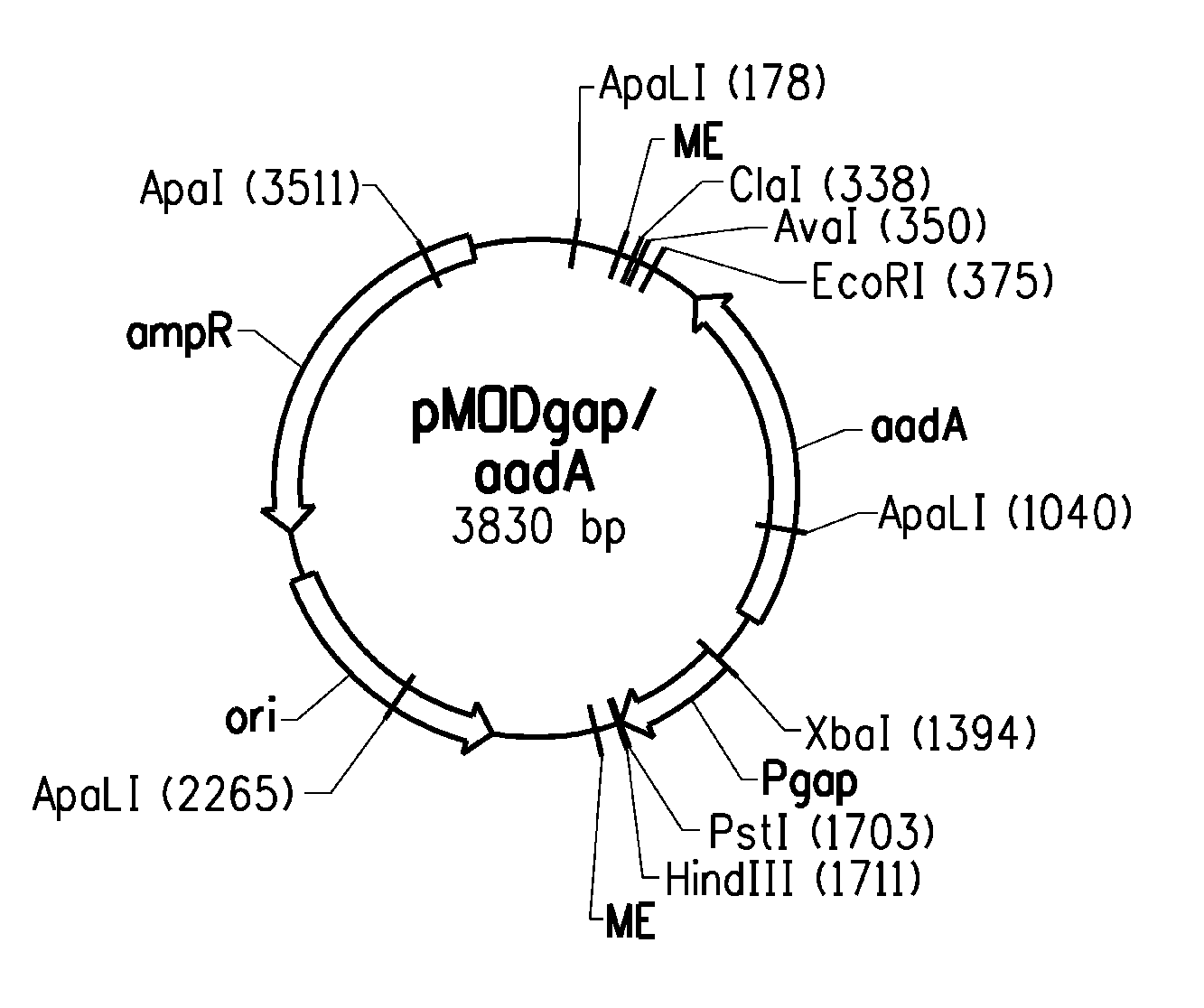

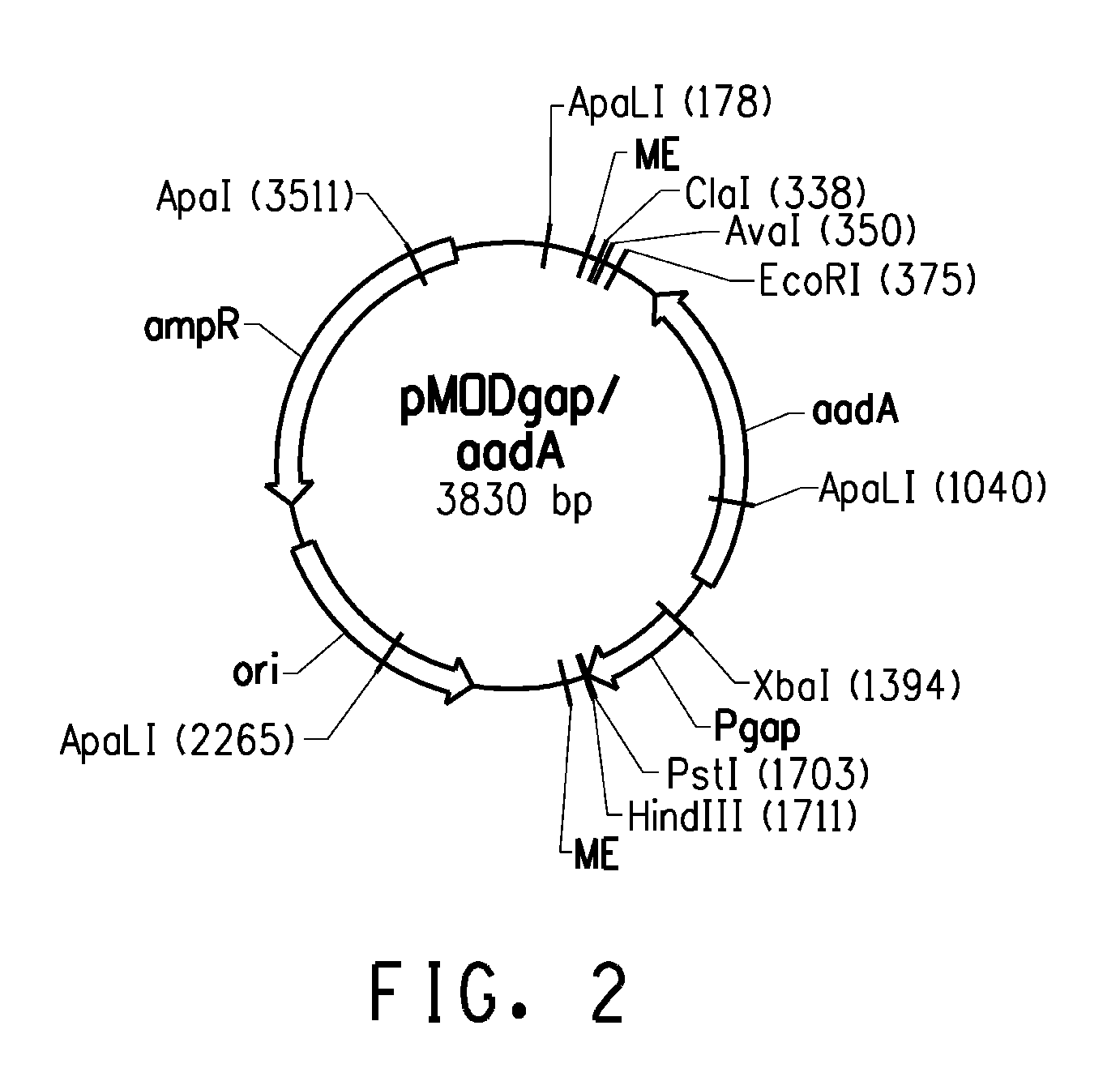

Genetically Engineered Microorganisms That Metabolize Xylose

The invention provides methods of cultivating oil-bearing microbes using xylose as a fixed carbon source. Also provided are microorganisms that have been genetically engineered to metabolize xylose as a fixed carbon source allowing them to convert xylose into oils. Particular advantages of the processes provided herein include production of oils rather than alcohols through the microbial fermentation processes utilizing xylose.

Owner:CORBION BIOTECH INC

Zymomonas with improved xylose utilization in stress conditions

ActiveUS20110014670A1Improved xylose utilizationBacteriaUnicellular algaeAcetic acidStress conditions

Strains of xylose utilizing Zymomonas with improved xylose utilization and ethanol production during fermentation in stress conditions were obtained using an adaptation method. The adaptation involved continuously growing xylose utilizing Zymomonas in media containing high sugars, acetic acid, ammonia, and ethanol.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

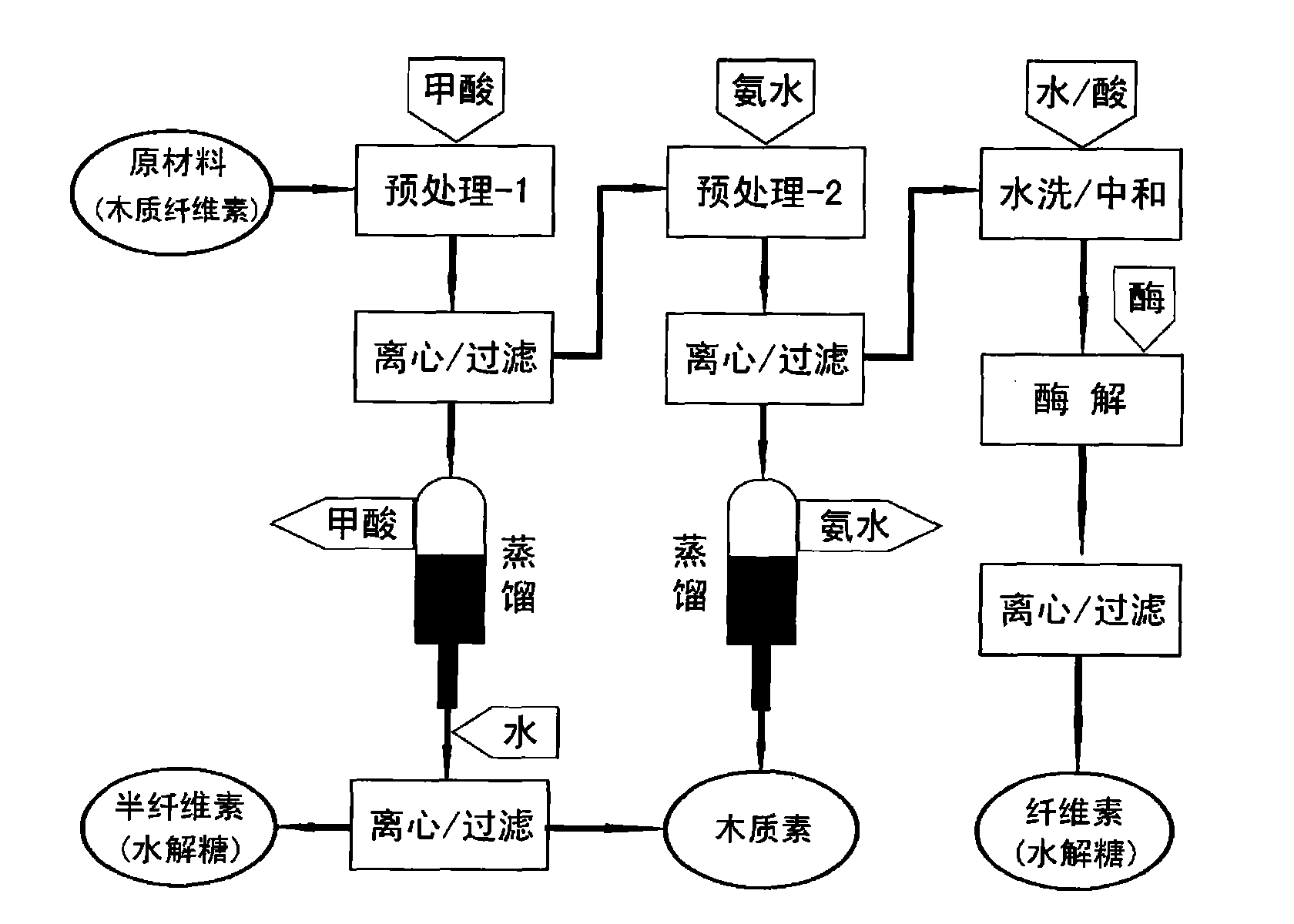

Lignocellulose acid/alkali coupling pretreatment method

InactiveCN102153763ARealize the separation of all componentsHigh purity of componentsFermentationSaccharides productionSolid componentPretreatment method

The invention relates to a lignocellulose acid / alkali coupling pretreatment method. Lignocellulose is separated into cellulose, hemicellulose and lignin by acid / alkali coupling pretreatment; and simultaneously, lignocellulose components are separated and subjected to high-efficiency enzymolysis and saccharification. The method comprises the steps of lignocellulose pretreatment, component separation, cellulose enzymolysis, solvent recovery and the like. The lignocellulose material is pretreated by formic acid or dilute sulphuric acid and is then subjected to solid-liquid separation, wherein the liquid component is used for recovering hemicellulose hydrolyzed sugar and part of lignin; and the solid component is further treated by ammonia water or a sodium hydroxide solution and is then subjected to solid-liquid separation, the liquid component is used for recovering lignin, and the solid component (cellulose) is subjected to enzymolysis and saccharification. By converting the lignocellulose into cellulose hydrolyzed sugar (glucose), hemicellulose hydrolyzed sugar (xylose and xylooligosaccharide) and lignin, the invention provides a basis for full-biomass utilization and develops a green process route for recovering the pretreatment solvent.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com