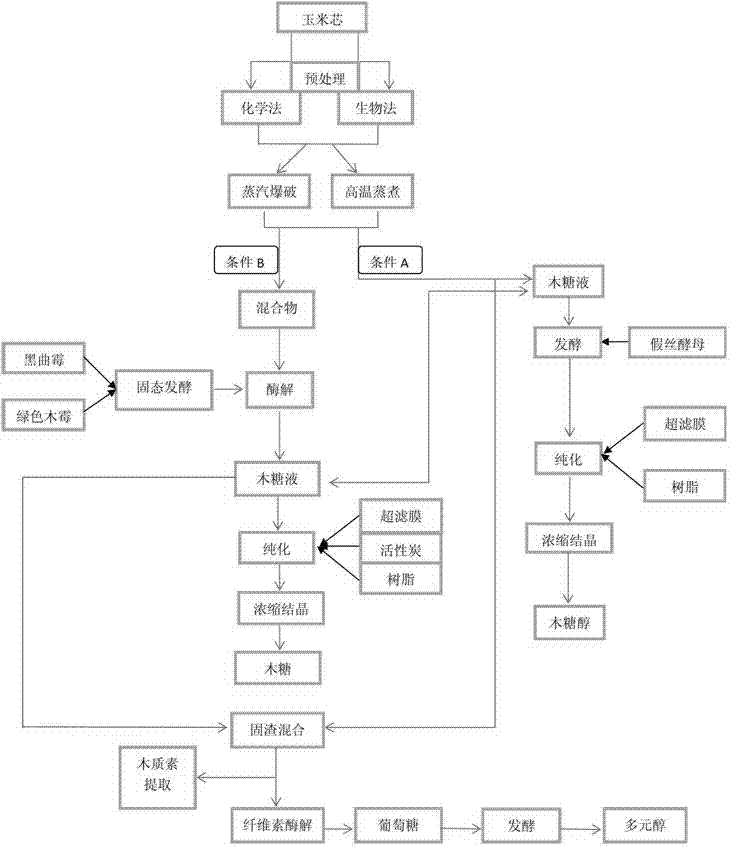

Process for producing polyatomic sugar alcohol and lignin by comprehensively using agricultural and forestry wasters of corncobs

A technology of agricultural and forestry waste and polysaccharide alcohol, applied in the field of biochemical industry, can solve the problems of only being burned or discarded, and lack of application channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] 1. Example of corn cob pretreatment

[0058](1) Choose agricultural and forestry waste corncobs as raw materials, crush the corncobs to 10% and add dilute sulfuric acid solution with a mass fraction of 0.2%, the solid-liquid ratio is 1:4, the soaking temperature is 30°C, and the soaking time is After soaking for 24 hours, use plate-and-frame filtration to separate the soaking system from solid to liquid to obtain pretreated raw materials and soaking liquid. The soaking liquid can be used repeatedly, and the solid raw materials are washed with water until nearly neutral.

[0059] (2) Insert the pre-cultivated white rot fungus seed liquid into the wet corncob, keep the humidity at 75%, the volume-to-mass ratio of the seed liquid to the corncob is 0.05ml / g corncob (dry weight), and the culture temperature is 28°C, pretreatment time is 40 days, in which the content of lignin is reduced by 40%, which is beneficial to the next step of degradation of hemicellulose; the medium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com