Biological oils and production and uses Thereof

a technology of biodiesel and biological oils, applied in biochemical equipment and processes, biofuels, biochemical instruments and processes, etc., can solve the problems of high price of many oilseed crops, inability to realize the goal, and inability to produce biodiesel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

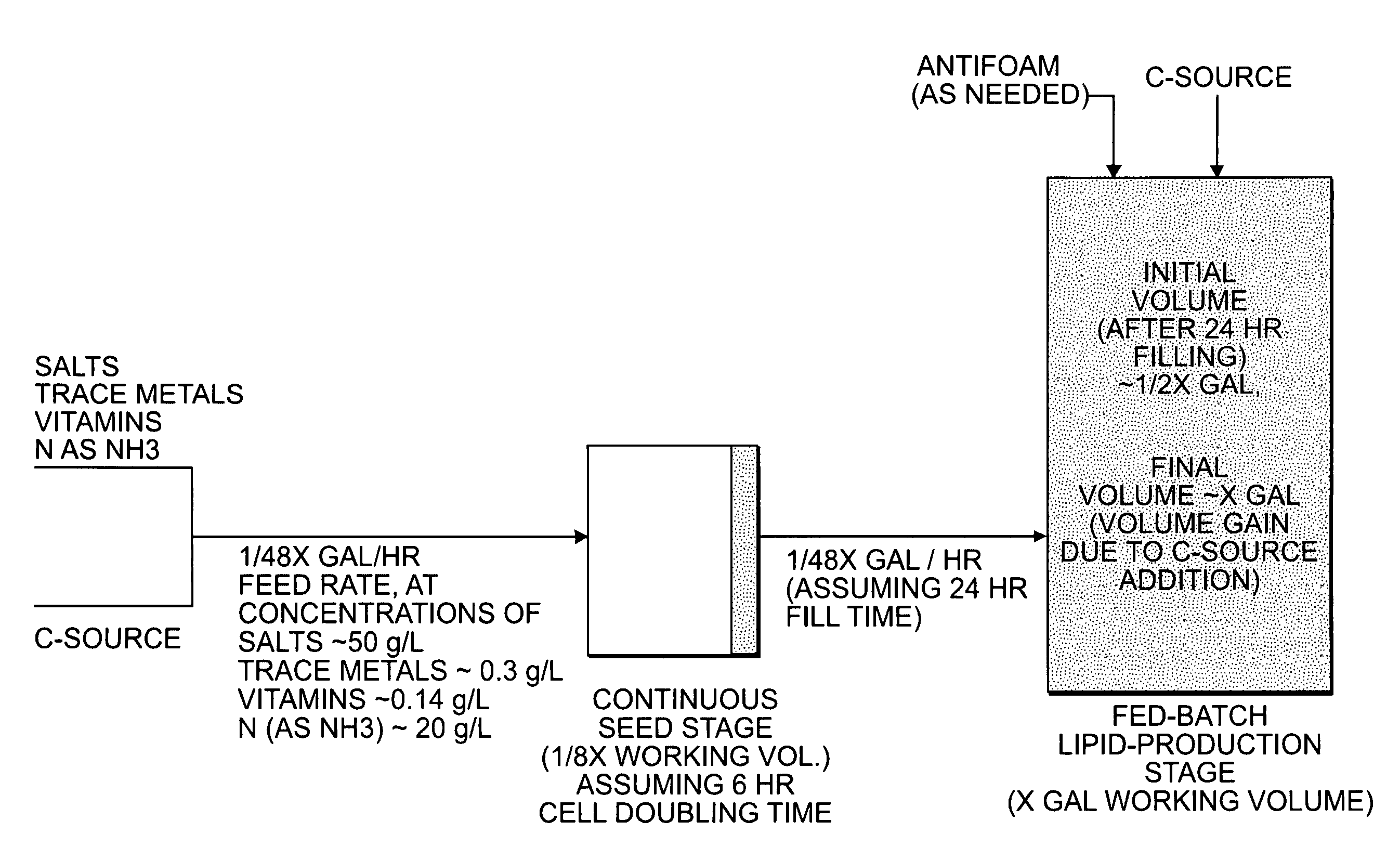

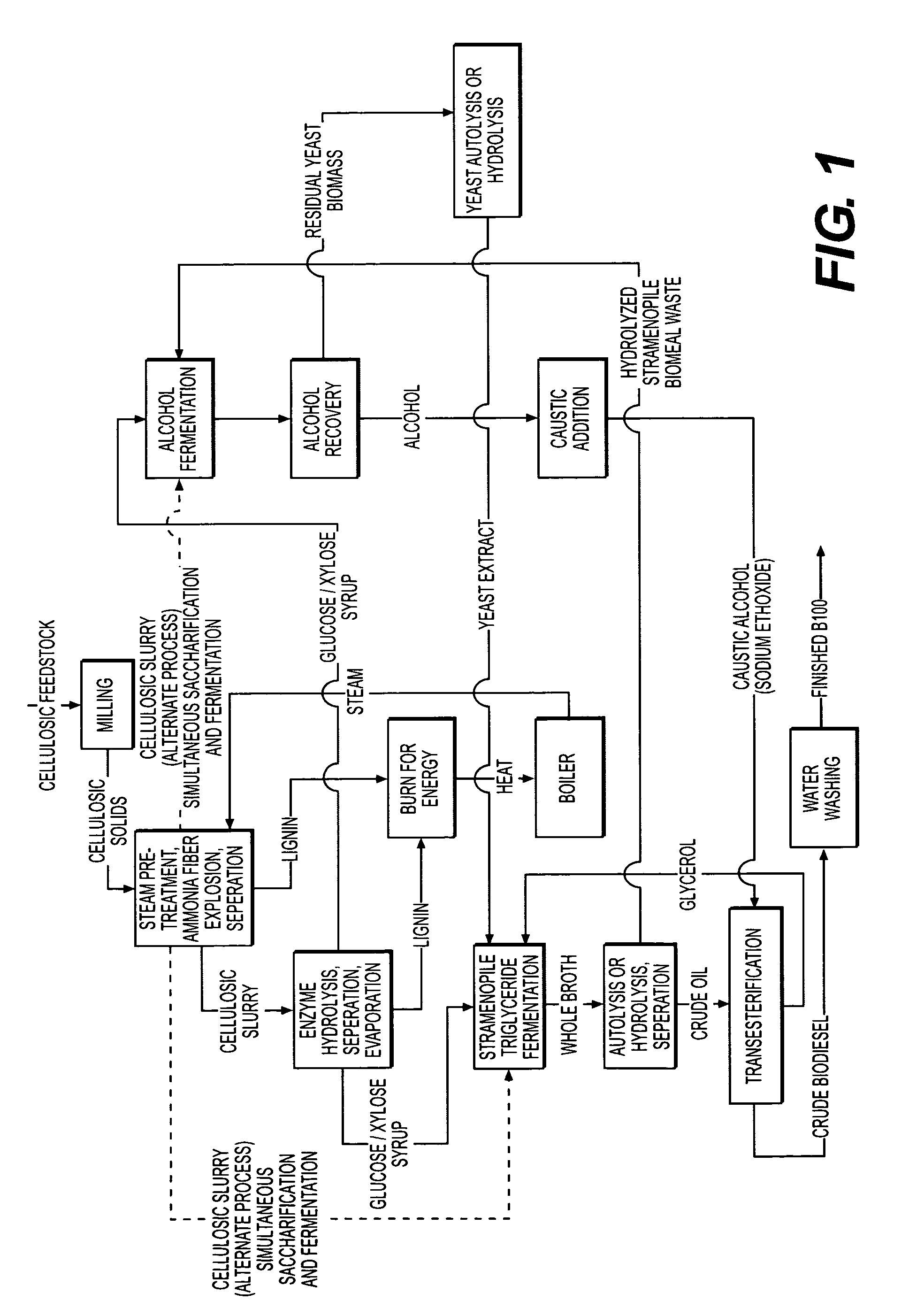

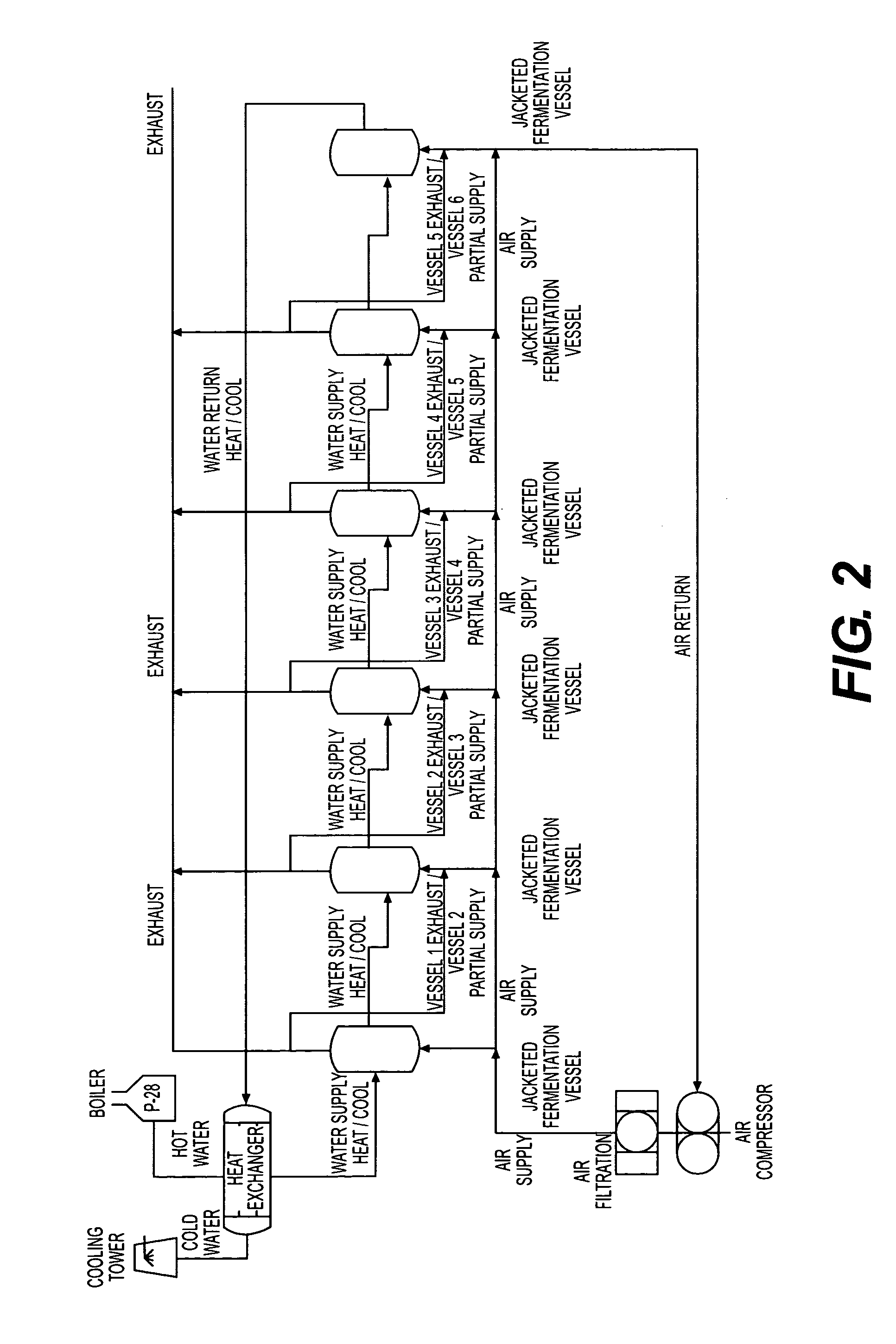

[0132]Using 2-liter fermentors, under typical fermentation conditions, cultures of a wild-type Schizochytrium or Thraustochytrium would be cultivated using a saccharified source of cellulose. Each fermentor would be batched with a media containing carbon (saccharfied cellulose), nitrogen, phosphorus, salts, trace metals, and vitamins. Each fermentor would be inoculated with a typical seed culture, then cultivated for 72-120 hours, and fed both a carbon (saccharified cellulose) feed and a nitrogen feed during cultivation. The nitrogen feed would be fed and consumed only during the growth phase, while the carbon (saccharified cellulose) would be fed and consumed throughout the fermentation. After 72-120 hours, each fermentor would be harvested and autolyzed or hydrolyzed. The hydrolyzed material would be separated into oil and biomass fractions. The oil would then be transesterified and separated from the glycerol. The mono alkyl ester would be water washed to produce a finished produ...

example 2

[0139]Using 10-liter fermentors, under typical fermentation conditions, a culture of wild-type or transgenic Schizochytrium or Thraustochytrium would be cultivated on a liquefied cellulose source. The organism would produce the necessary enzymes to simultaneously saccharify the cellulose and metabolize the glucose, xylose, hemicellulose, and lignin. Each fermentor would be batched with a media containing carbon (liquefied cellulose), nitrogen, phosphorus, salts, trace metals, and vitamins. Each fermentor would be inoculated with a typical seed culture, then cultivated for 72-120 hours, and fed both a carbon feed (liquefied cellulose) and a nitrogen feed during cultivation. The nitrogen feed would be fed and consumed only during the growth phase, while the carbon (liquefied cellulose) would be fed and consumed throughout the fermentation. After 72-120 hours, each fermentor would be harvested and autolyzed or hydrolyzed. The hydrolyzed material would be separated into oil and biomass ...

example 3

[0146]The transgenic Schizochytrium or Thraustochytrium of Example 2 would be developed using an exiting transformation system (such as that disclosed in published patent application no. WO 2002 / 083869 A2) to express genes encoding known and appropriate cellulases, hemicellulases, ligninases, saccharide transporters, epimerases, and saccharide isomerases. Alternately, previously uncharacterized cellulases, hemicellulases, ligninases, saccharide transporters, epimerases, and saccharide isomerases could be isolated from existing genome databases or via standard gene discovery strategies with uncharacterized or less characterized organisms, including PCR with degenerate primers based on conserved regions of homologous genes, or mass sequencing and mining of Expressed Sequence Tags (ESTs) or genome sequences, or other techniques. Appropriate gene expression and gene product activities would be validated using standard techniques such as gel electrophoresis, northern and western blots, E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| cell density | aaaaa | aaaaa |

| cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com