Patents

Literature

17644results about "Liquid carbonaceous fuels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

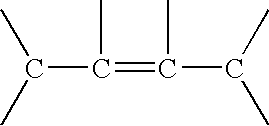

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

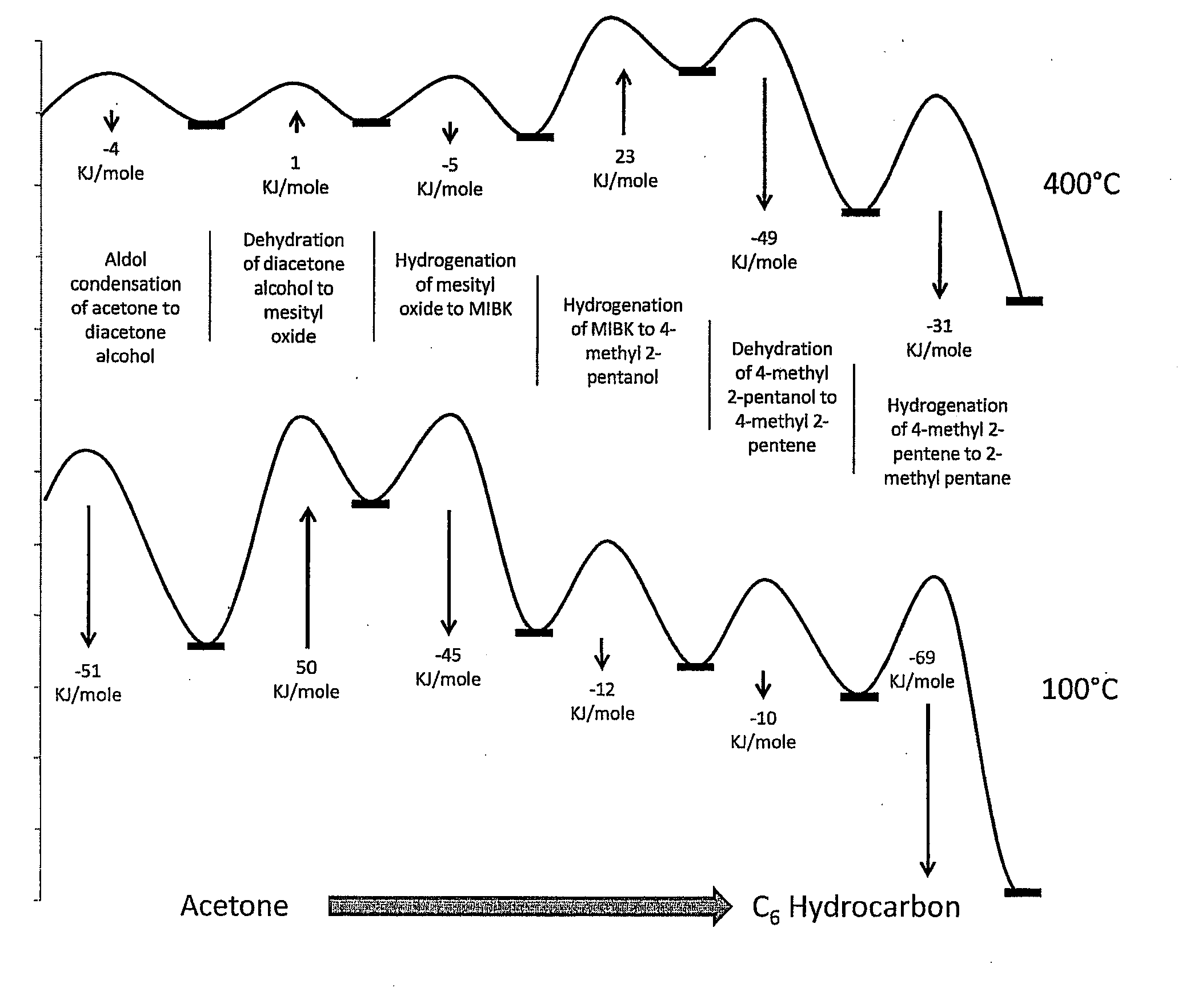

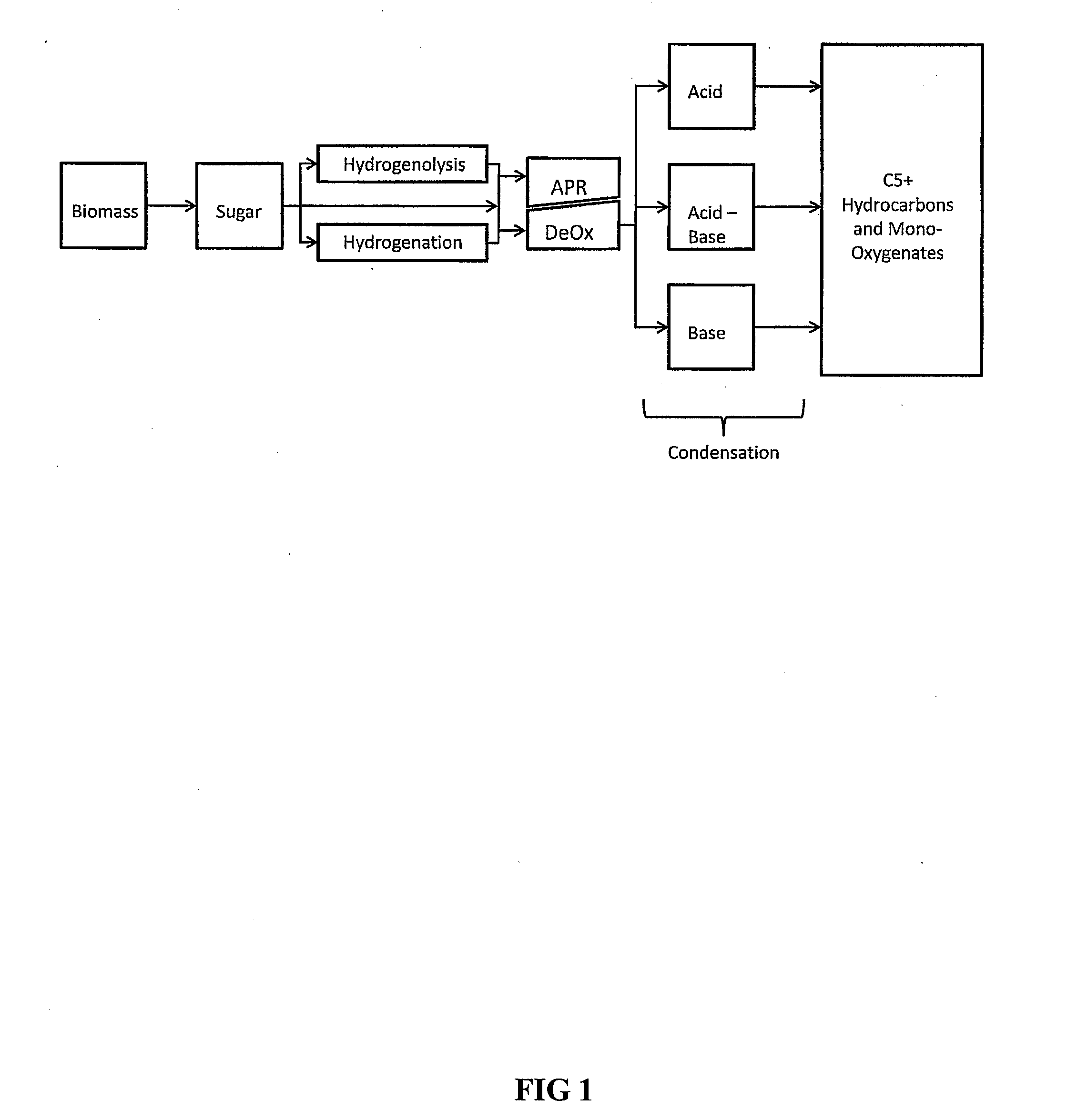

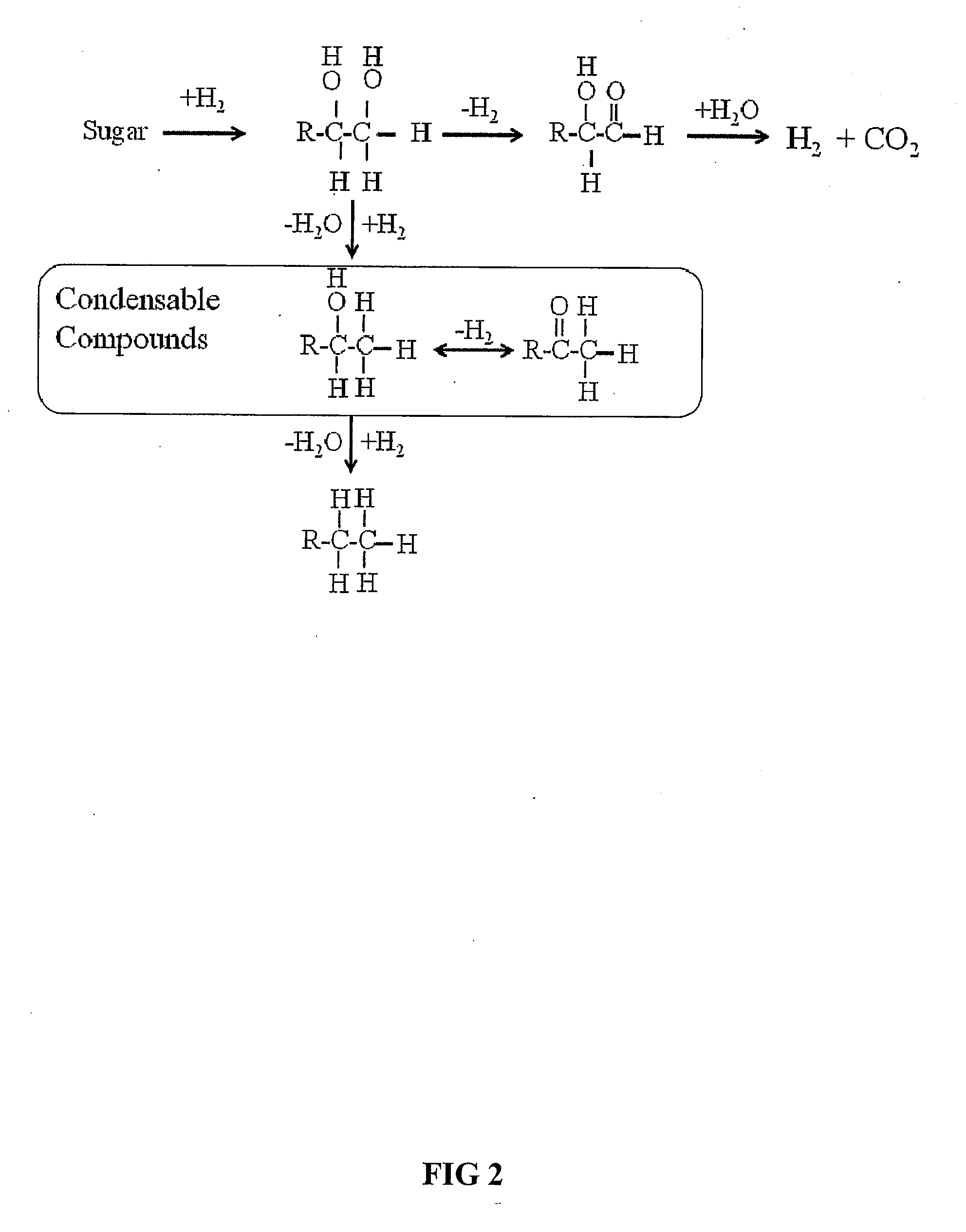

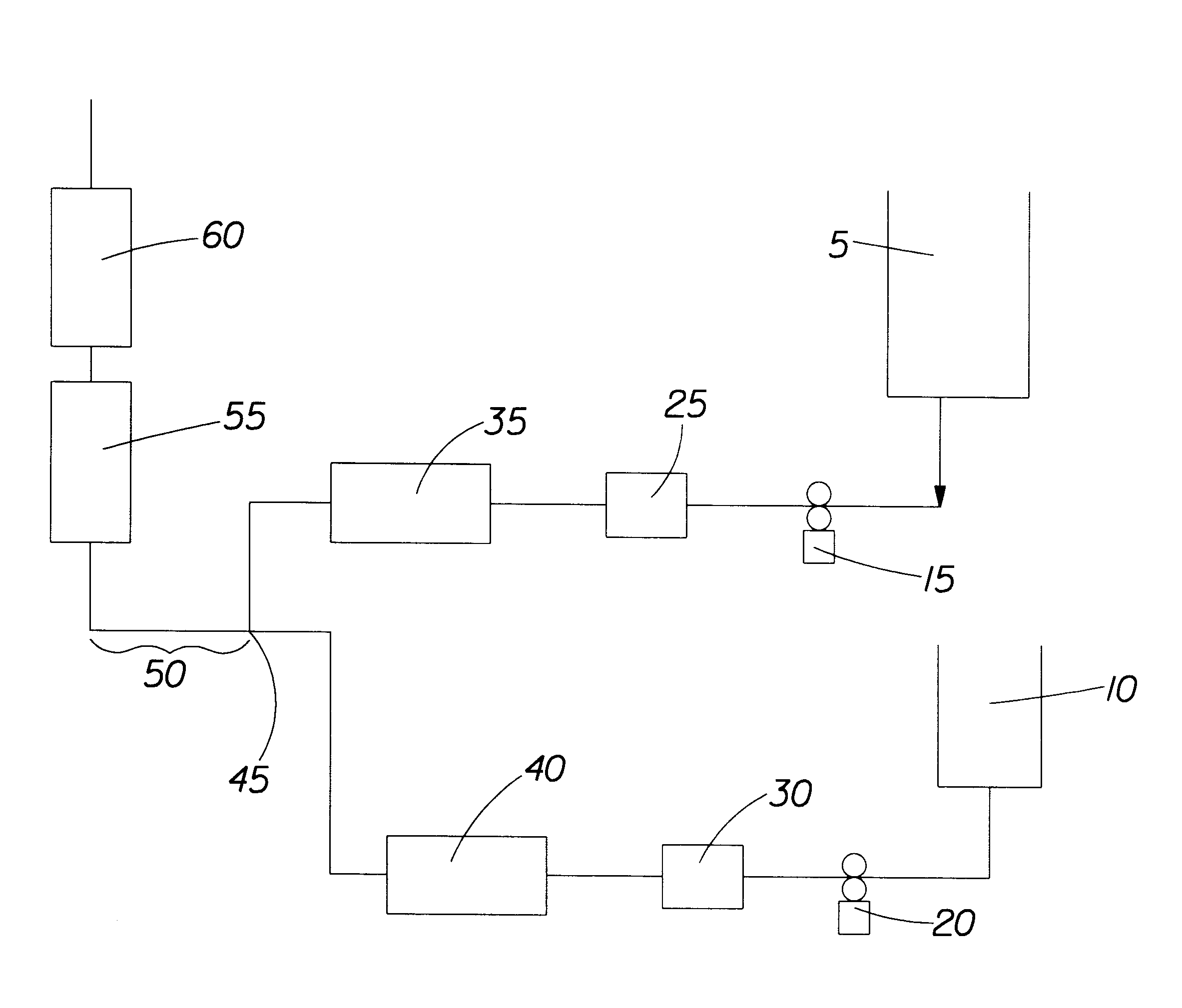

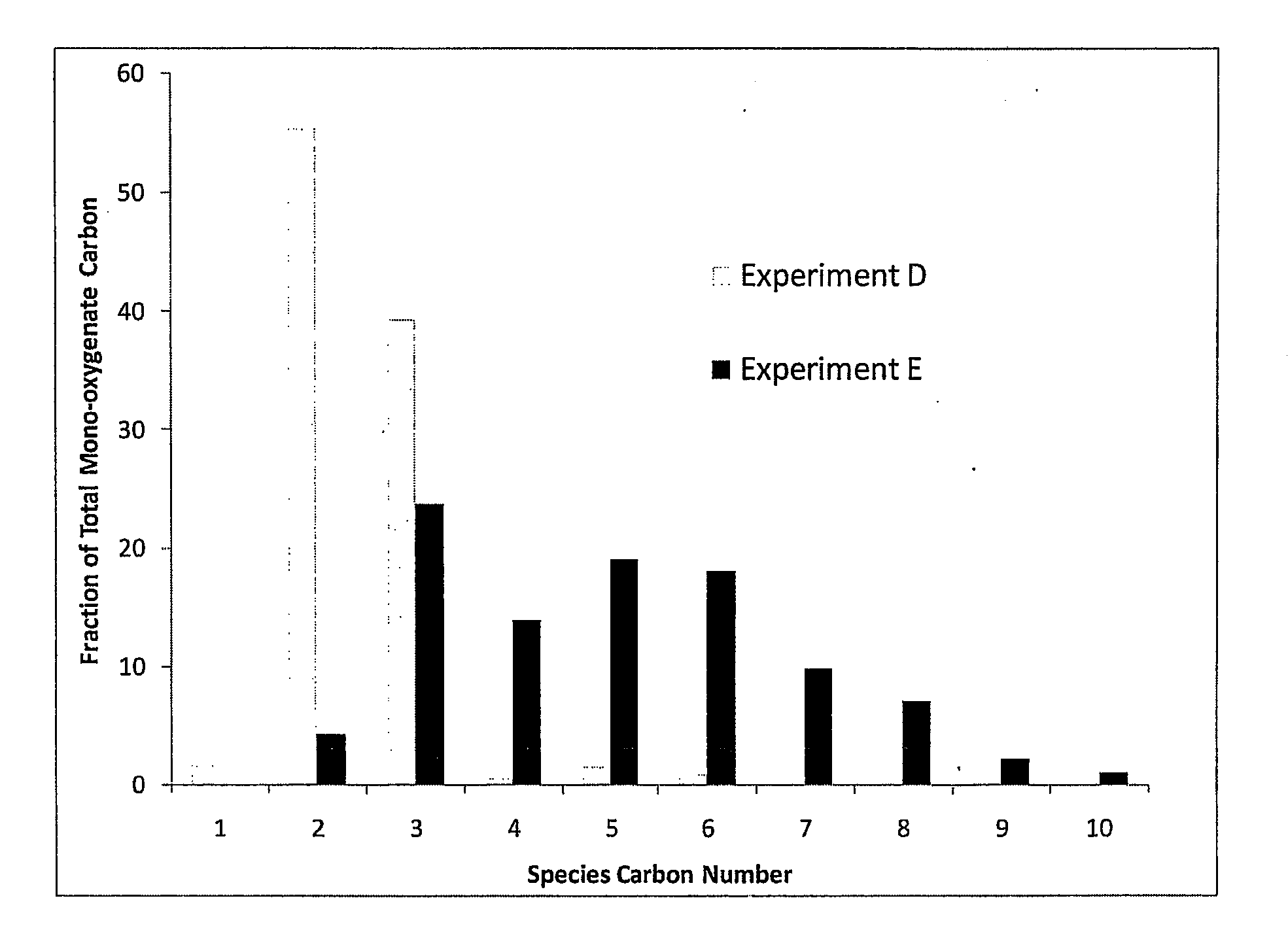

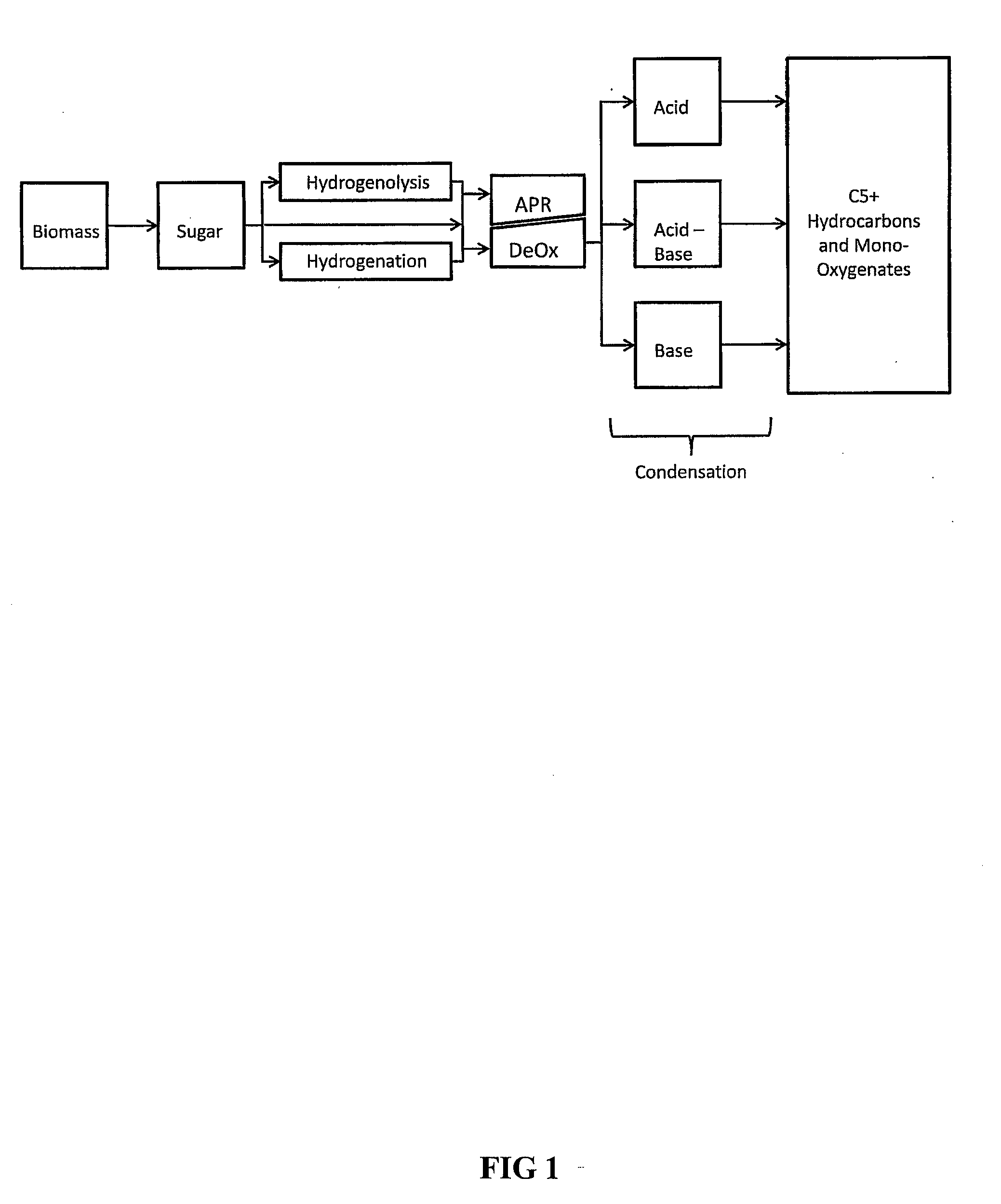

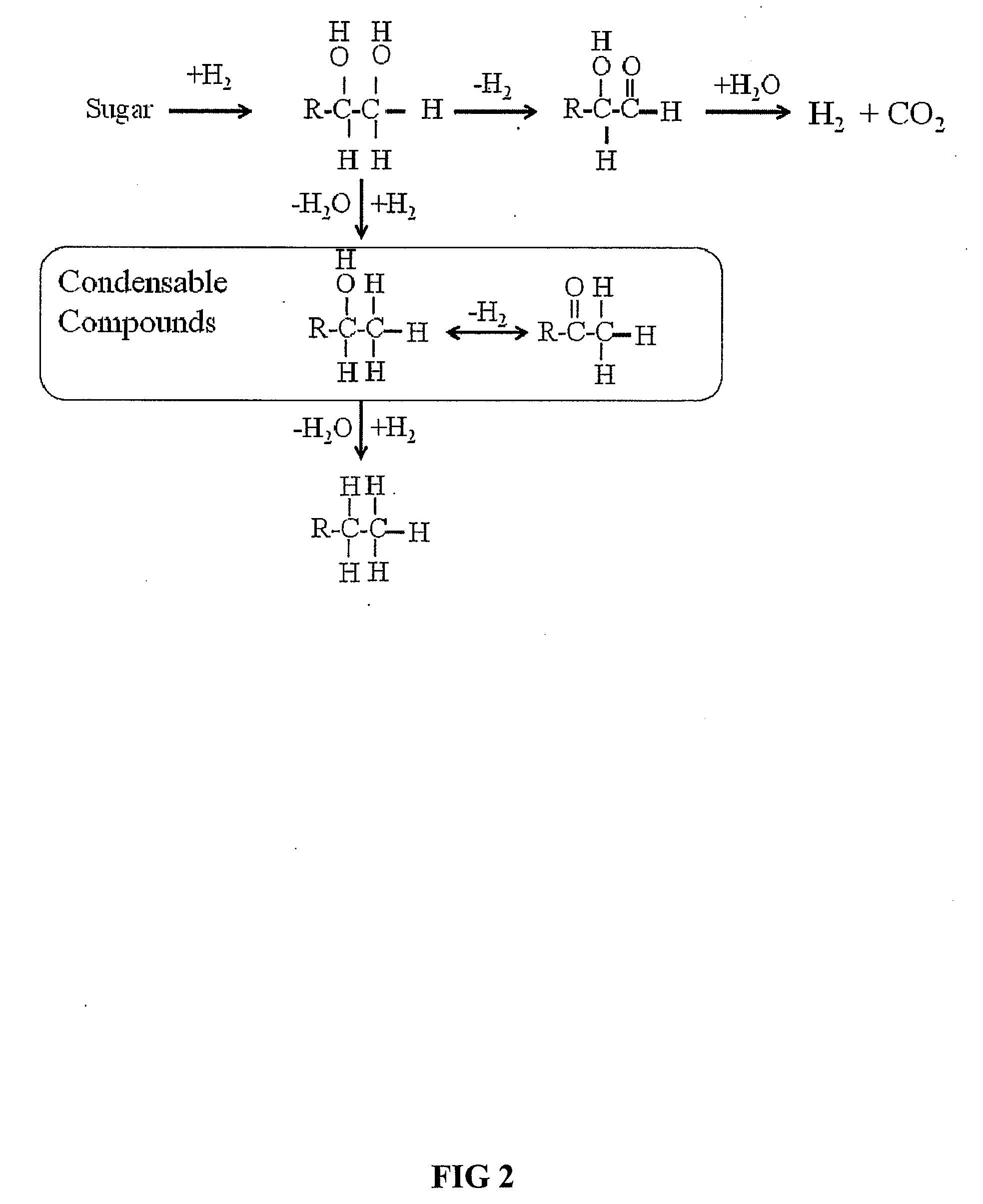

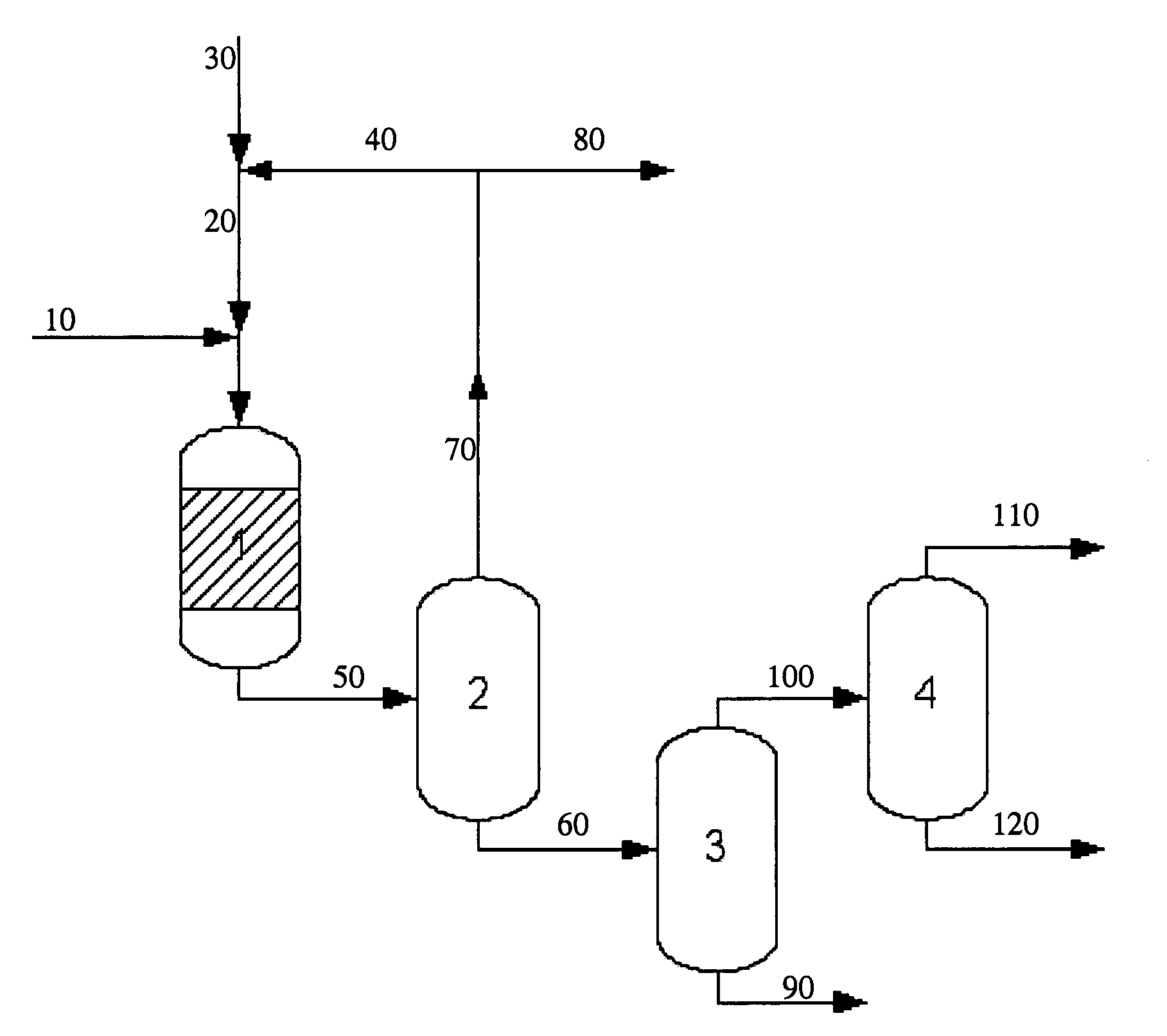

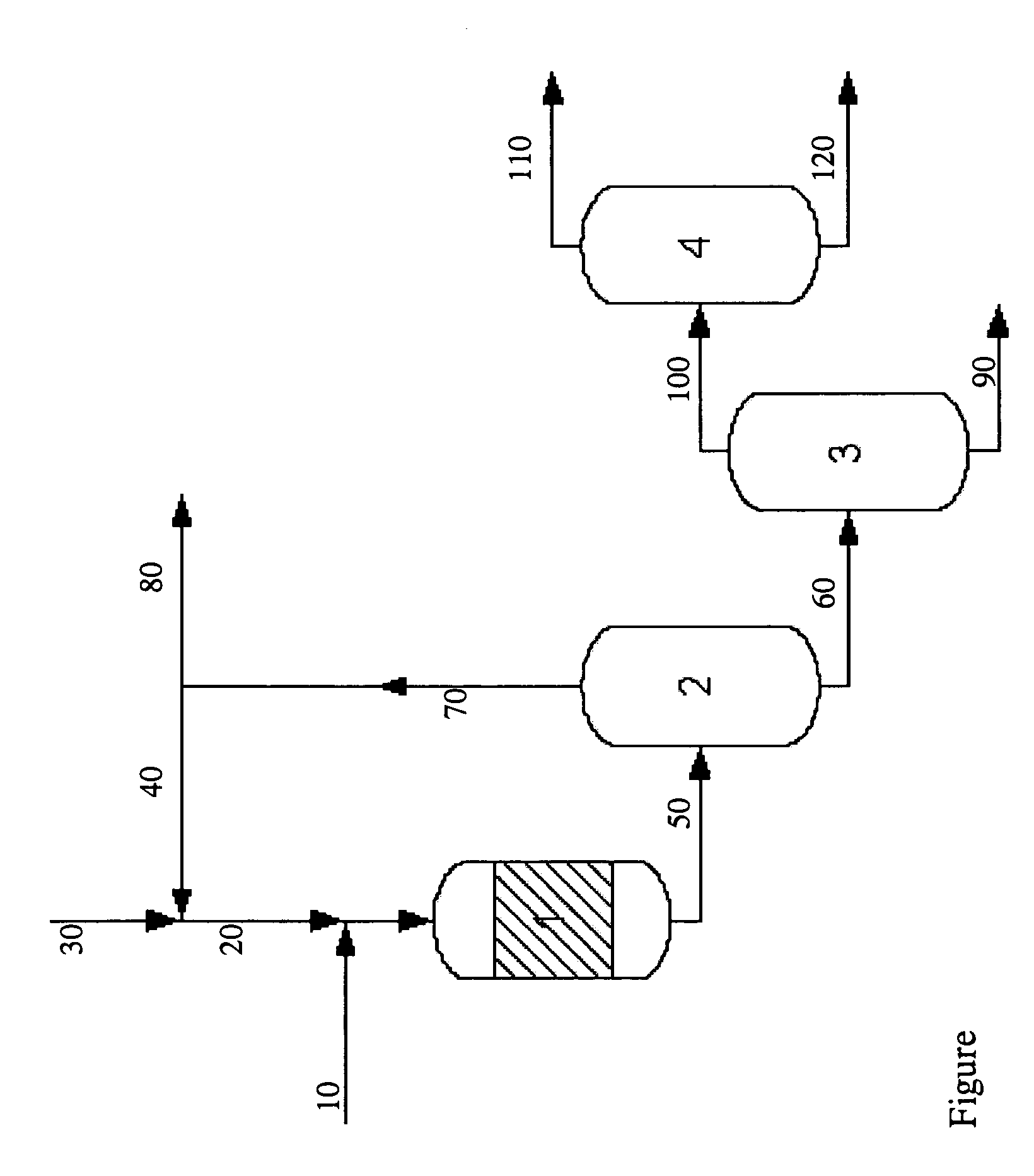

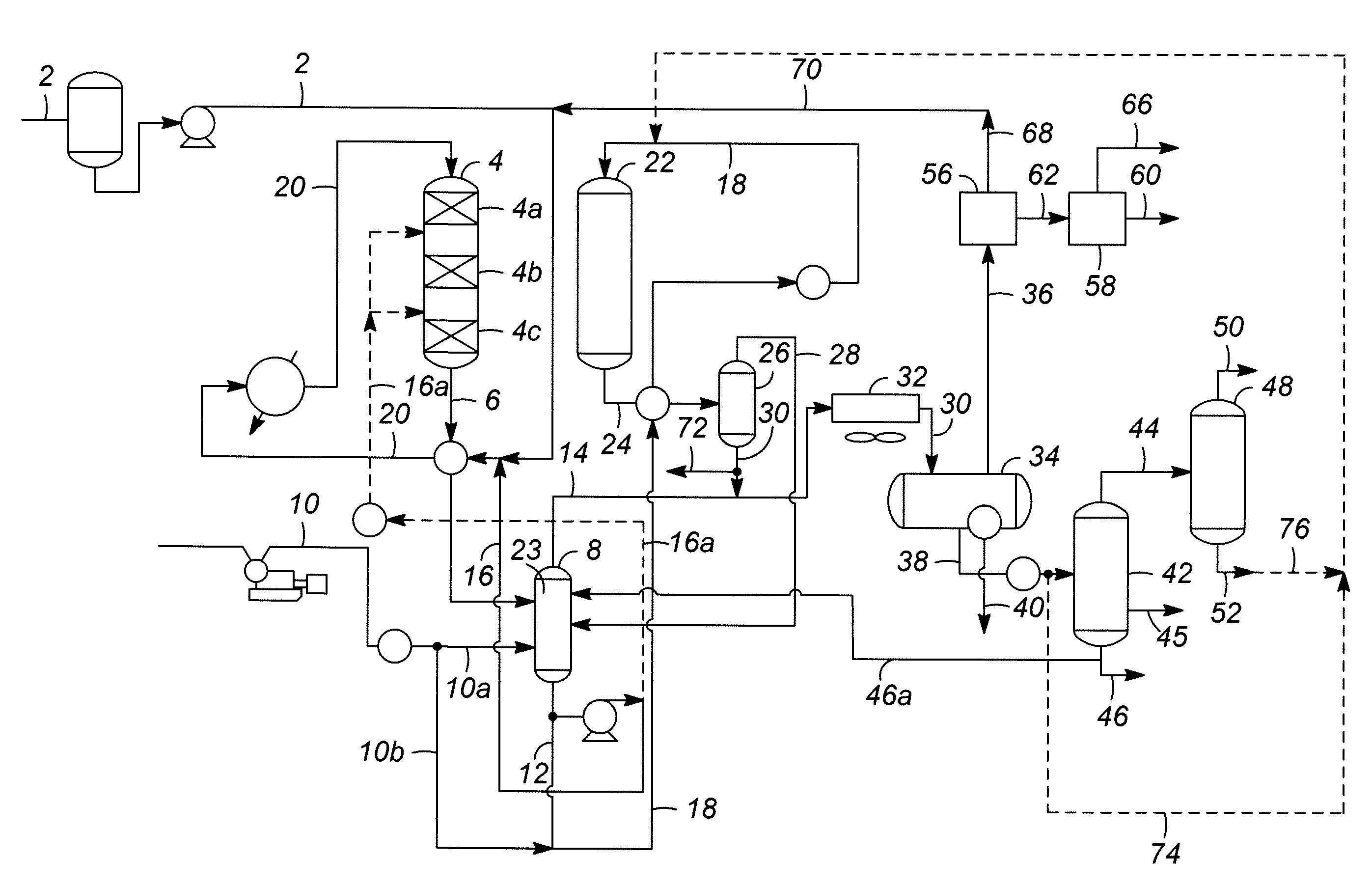

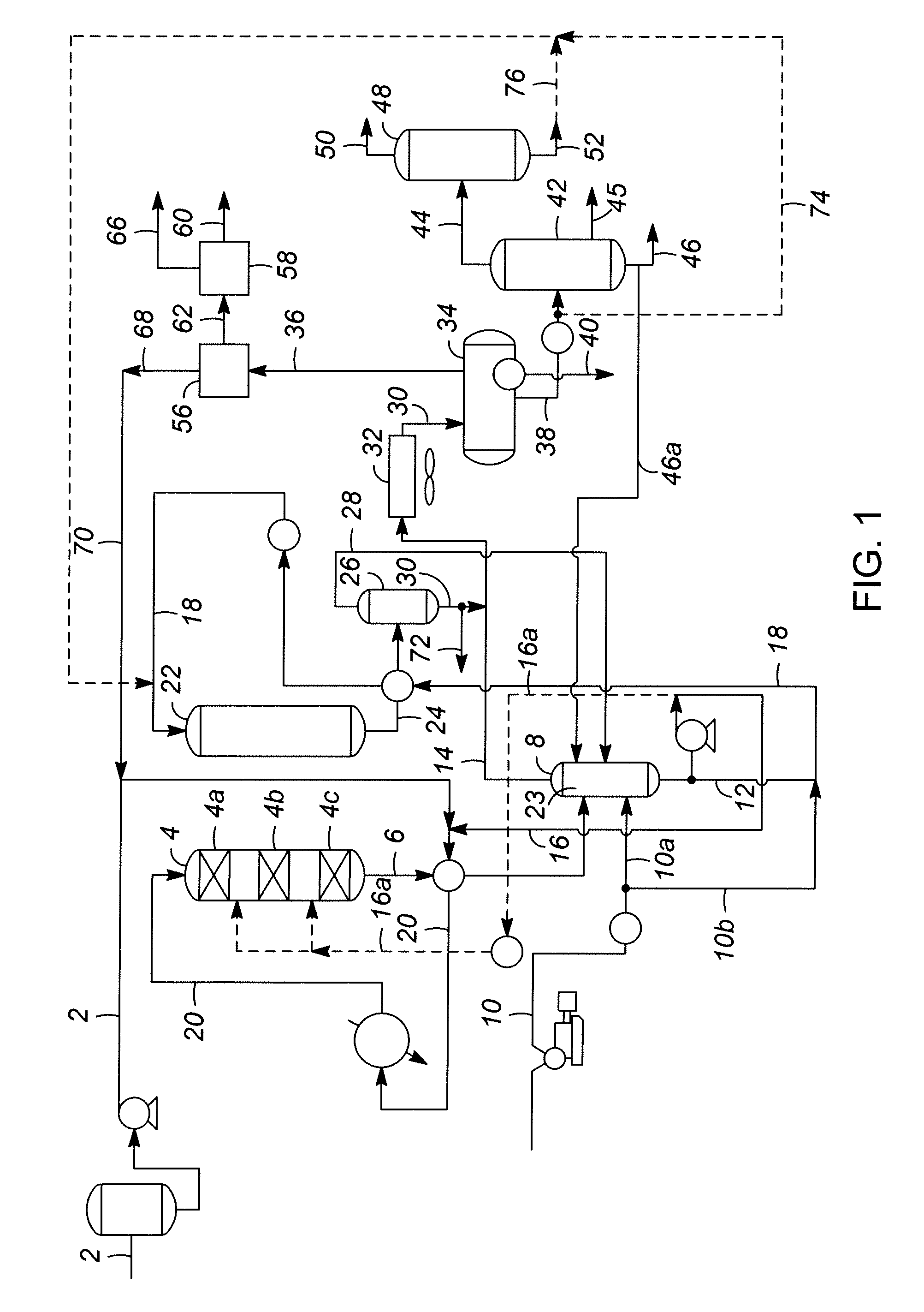

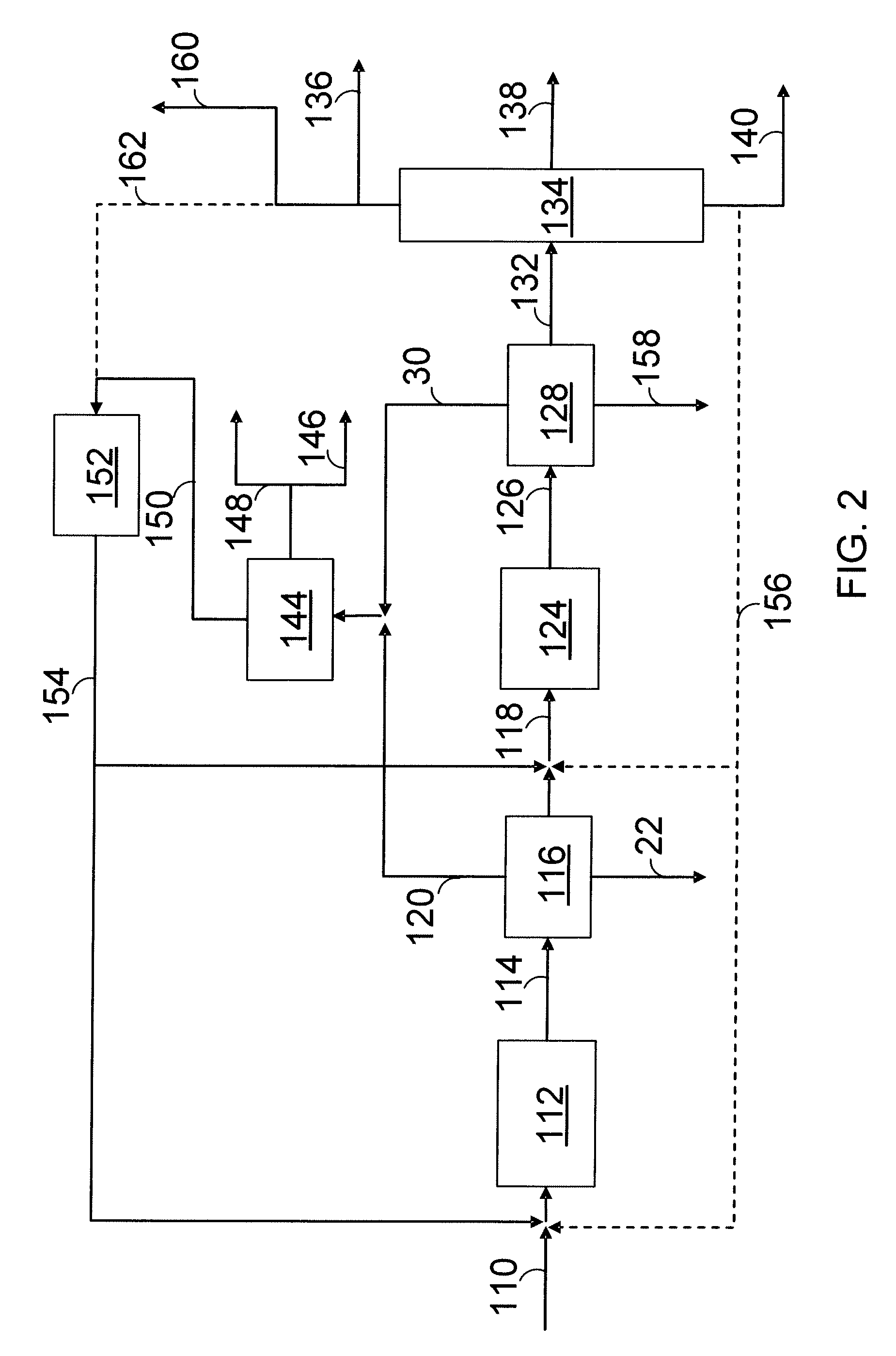

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080216391A1Organic compound preparationHydrocarbon from oxygen organic compoundsFuranLiquid fuel

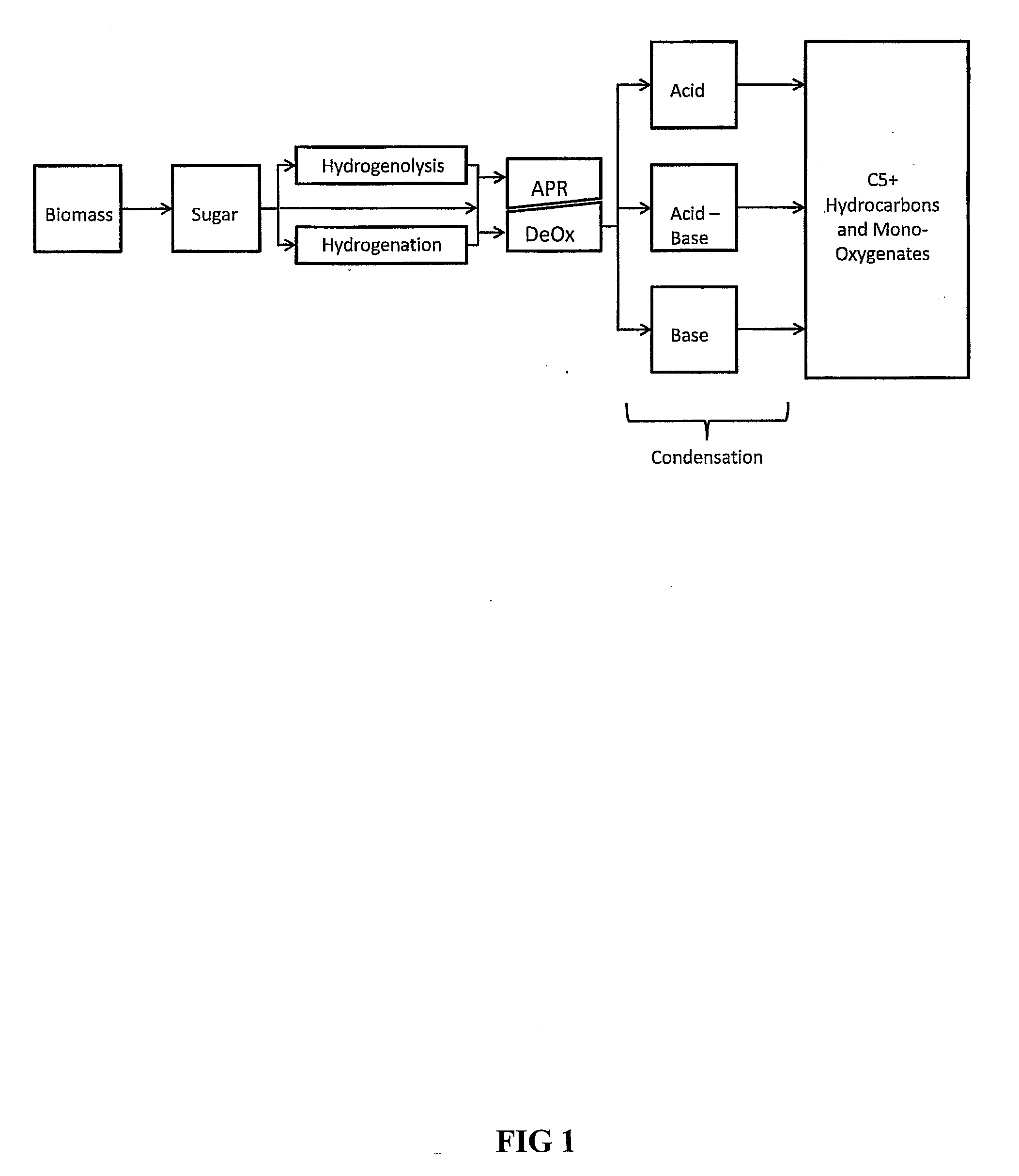

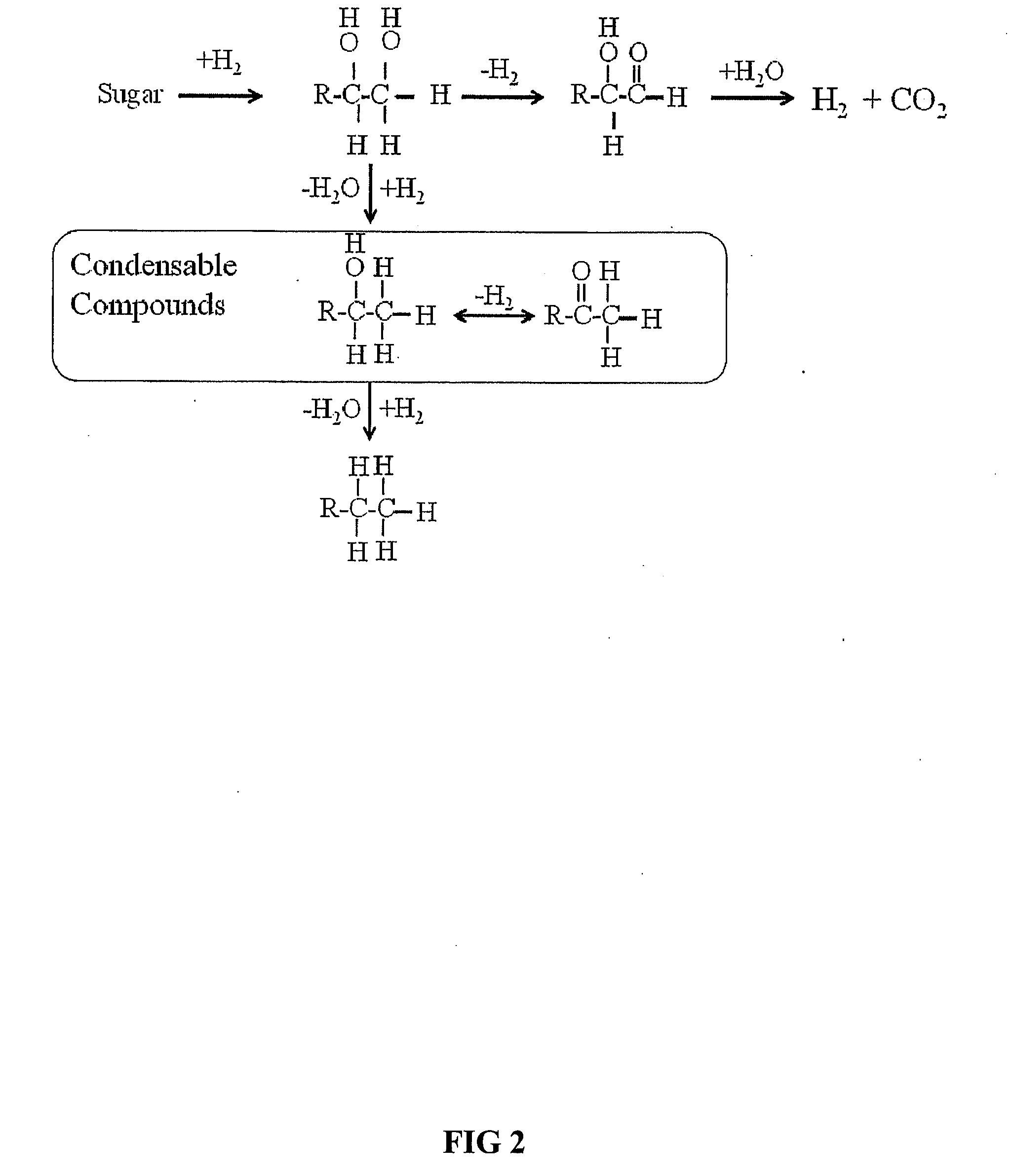

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

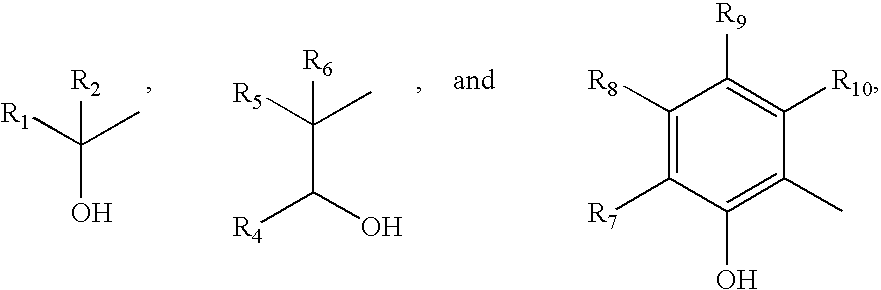

Lubricant and fuel compositions containing hydroxy carboxylic acid and hydroxy polycarboxylic acid esters

InactiveUS20050198894A1Reduce the amount requiredWithout diminishing anti-wear performanceOrganic chemistryLiquid carbonaceous fuelsCarboxylic acidMedicinal chemistry

Disclosed herein is a composition comprising: (A) a lubricant or a hydrocarbon fuel; (B) at least one hydroxy carboxylic acid ester or hydroxy polycarboxylic acid ester having the generic formula defined herein; and (C) at least one phosphorus-containing additive.

Owner:CHEMTURA CORP

Apparatus and process for in-line preparation of HIPEs

A method of making high internal phase emulsions is described. The method forms high internal phase emulsion (HIPE) using a single pass through the static mixer. In alternative embodiments, the HIPE may be further processed to farther modify the size of dispersed phase droplets, to incorporate additional materials into the HIPE, to alter emulsion temperature, and the like.

Owner:THE PROCTER & GAMBLE COMPANY

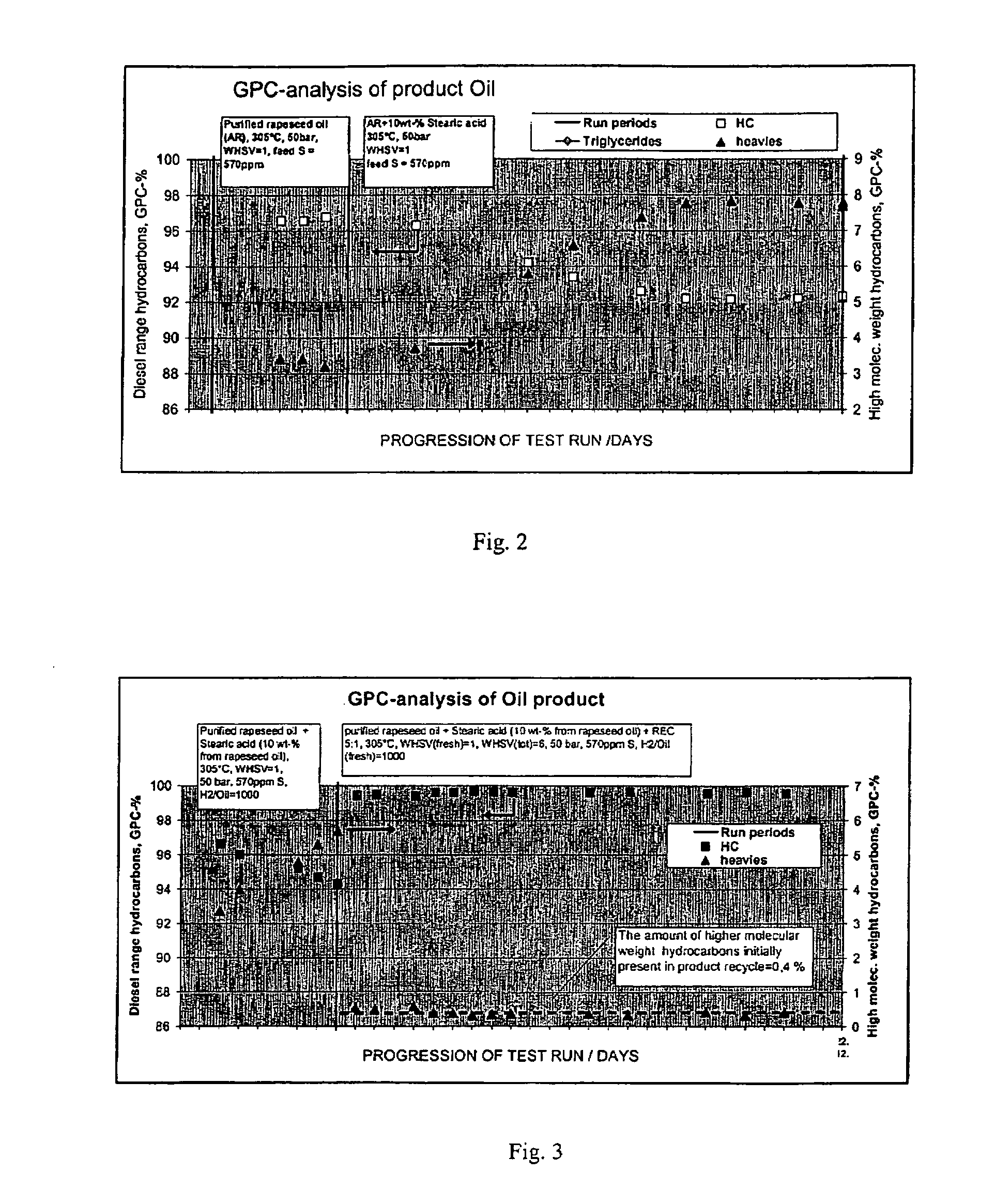

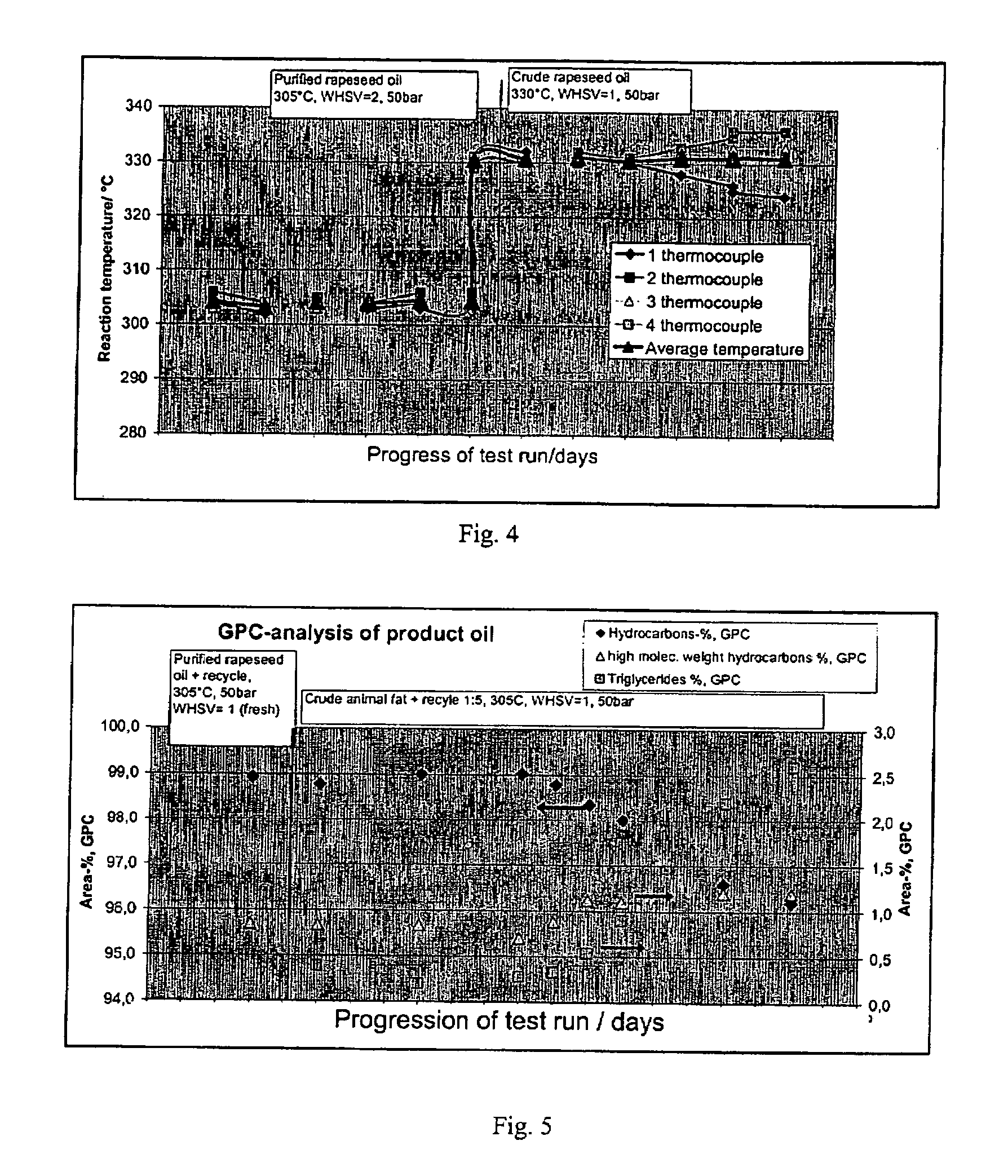

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

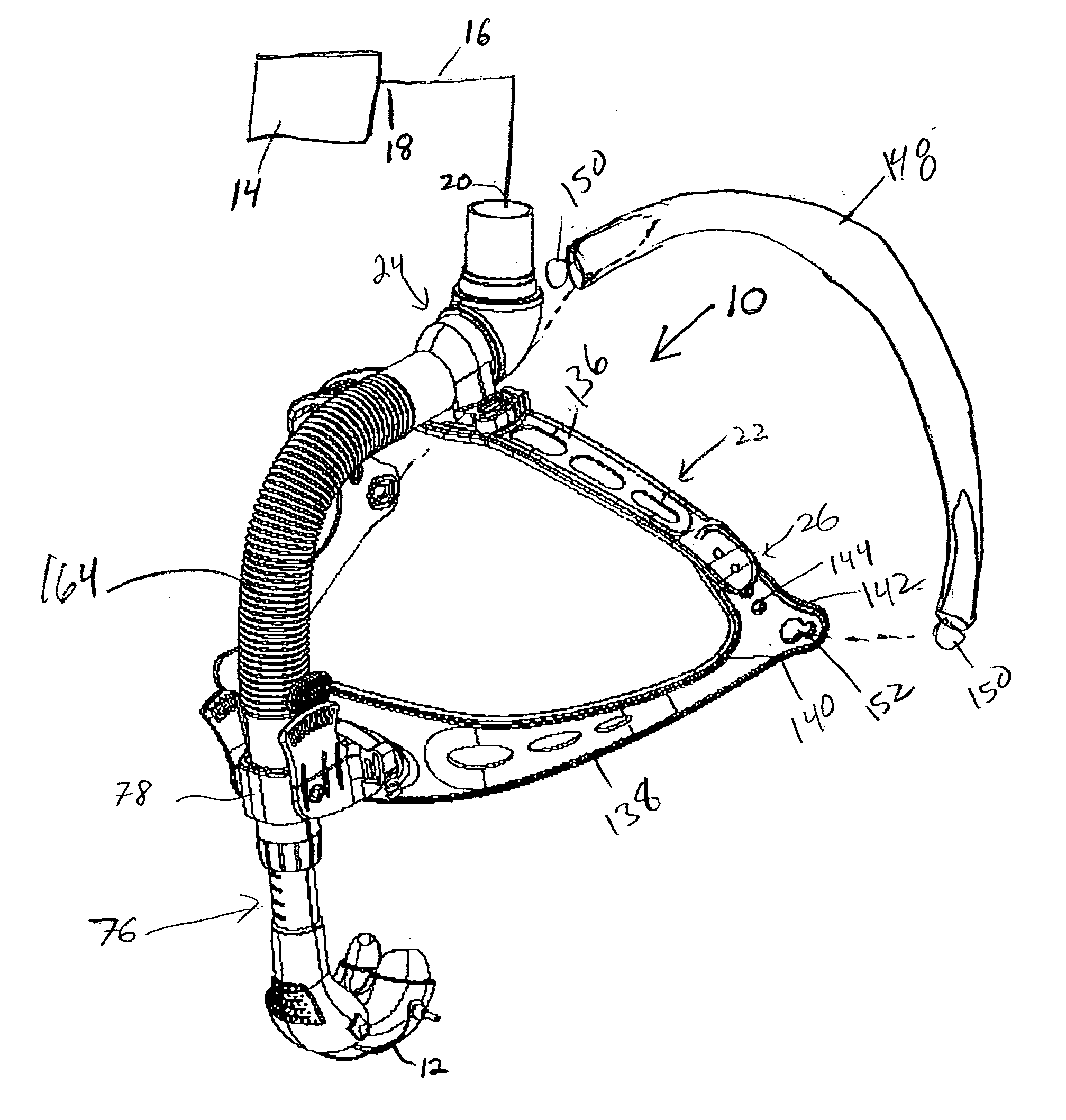

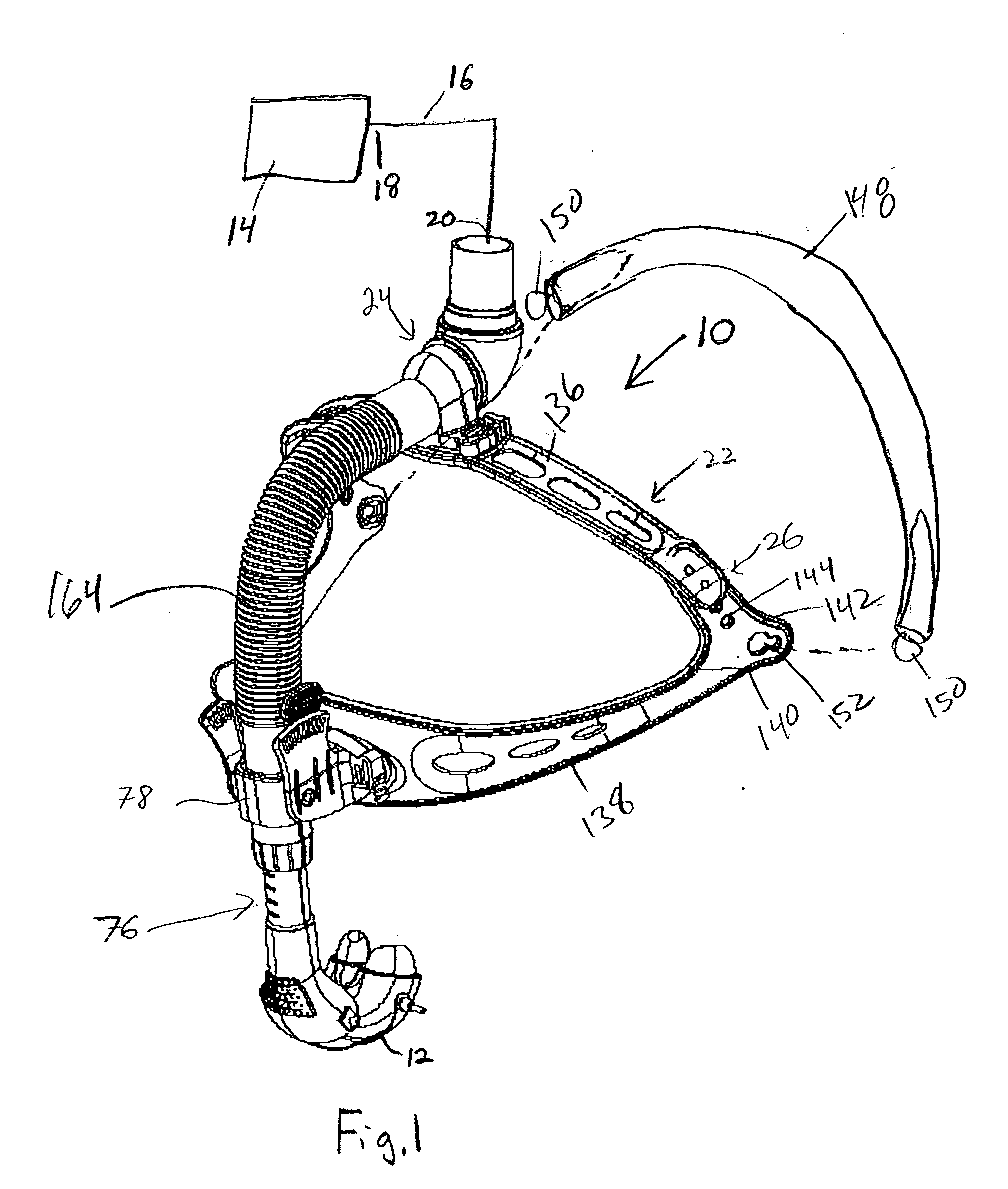

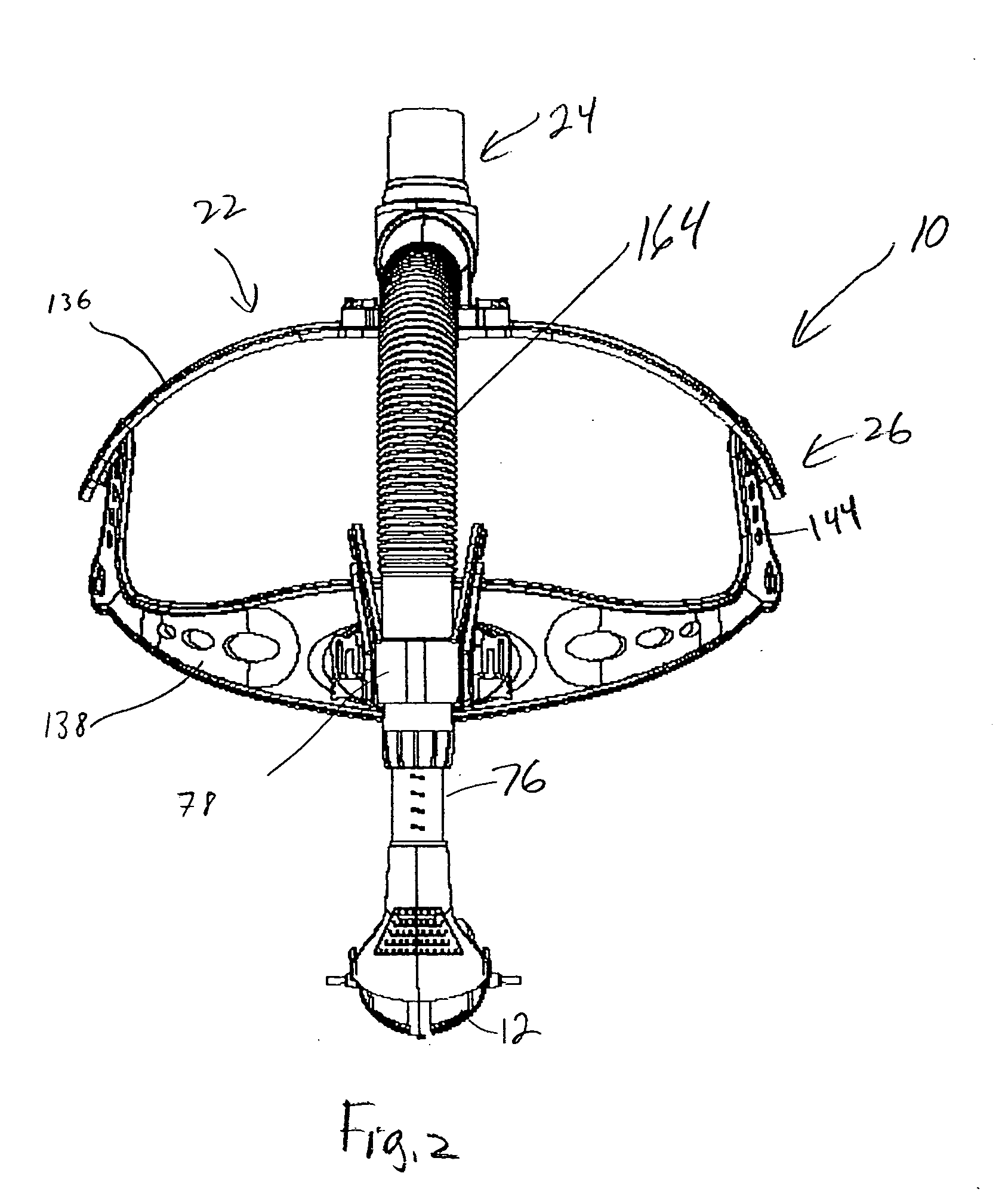

Patient inteface assembly and system using same

ActiveUS20050076913A1Improved patient interface stability and overall comfortOvercomes shortcomingPhysical therapyBreathing filtersNasal cavityMinimal contact

A patient interface assembly that includes a patient interface device, a headgear, and coupling member joining the interface device to a headgear assembly. In one embodiment, a spring biases the patient interface device against the patient's face when in use. In a further embodiment, the patient interface device is a nasal cushion that includes a formable support mounted to the nasal cushion for providing support and adjustment of the nasal cushion to improve fit and comfort. The headgear assembly in one embodiment is a semi-rigid, minimal contact harness assembly and includes an adjustment assembly that allows for a simultaneous adjustment of multiple straps. An adjustment assembly on the headgear provide a gross adjustment of the position of the interface relative to the patient and a biasing force to urge the patient interface device against the patient's face. In a further embodiment, a pair of rigid connecting members coupling the patient interface device to the headgear.

Owner:RIC INVESTMENTS LLC

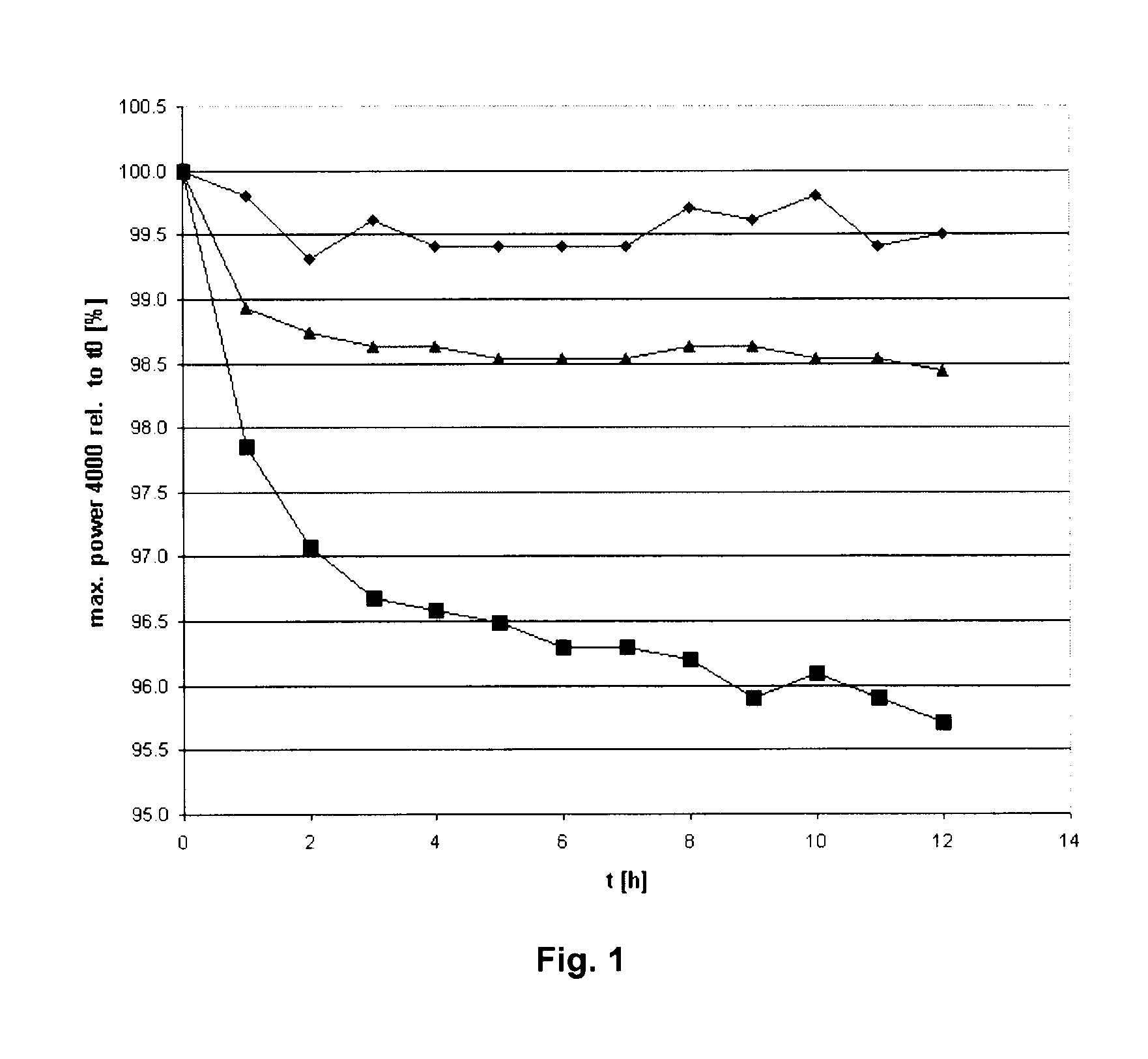

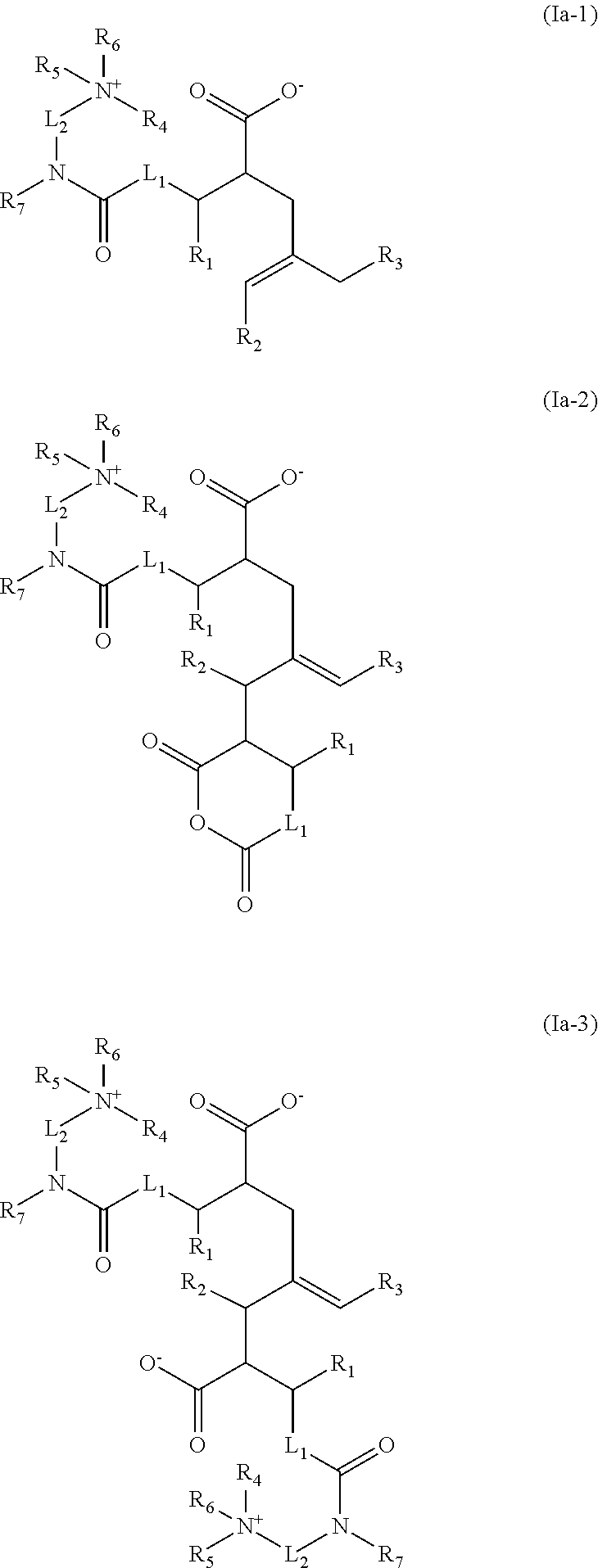

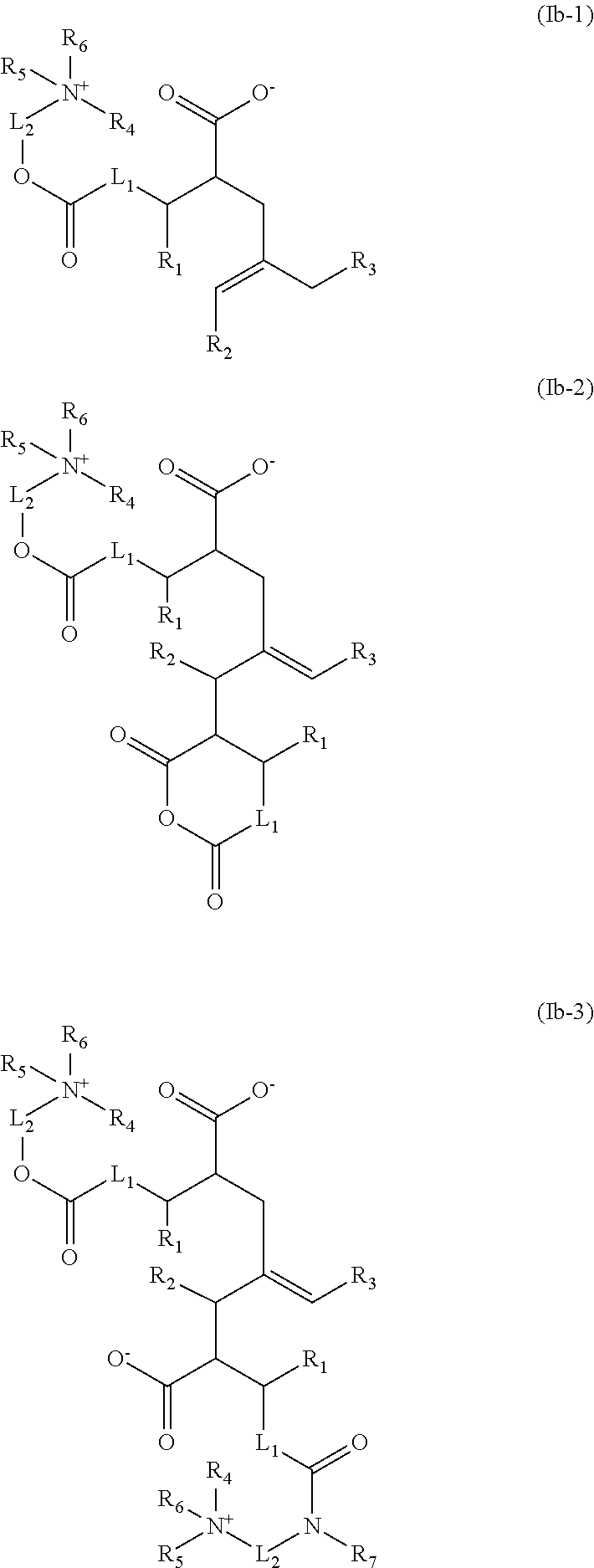

Acid-free quaternized nitrogen compounds and use thereof as additives in fuels and lubricants

The present invention relates to novel acid-free quaternized nitrogen compounds, to the preparation thereof and to the use thereof as a fuel and lubricant additive, more particularly as a detergent additive, as a wax antisettling additive (WASA) or as an additive for reducing internal diesel injector deposits (IDID); to additive packages which comprise these compounds; and to fuels and lubricants thus additized. The present invention further relates to the use of these acid-free quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct-injection diesel engines, especially in common-rail injection systems, for reducing the fuel consumption of direct-injection diesel engines, especially of diesel engines with common-rail injection systems, and for minimizing power loss in direct-injection diesel engines, especially in diesel engines with common-rail injection systems.

Owner:BASF AG

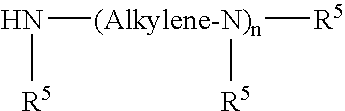

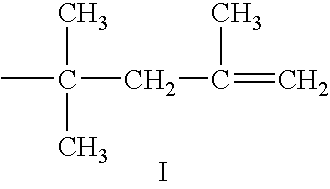

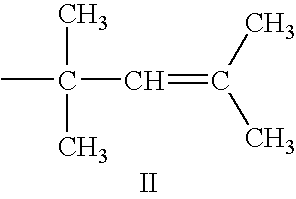

Quaternary Ammonium Salt of a Polyalkene-Substituted Amine Compound

InactiveUS20080113890A1Organic compound preparationTransportation and packagingCompound aQuaternary ammonium cation

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) polyalkene-substituted amine having at least one tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

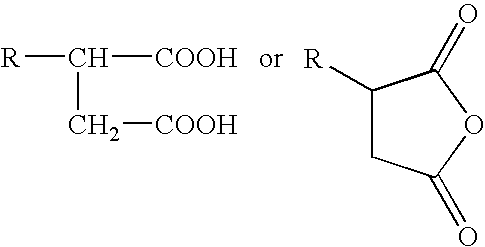

Process for the preparation of polyalkenyl succinic anhydrides

A polyalkenyl succinic anhydride is prepared with low amounts of resinous or chlorinated byproducts in a two-step process whereby a polyalkene is first reacted with an unsaturated organic acid in a thermal ene reaction, followed with exposure to a gaseous halogen in presence of an additional amount of the unsaturated organic acidic reagent. The foregoing process produces a polyisobutenyl succinic anhydride having a high ratio of succinic anhydride functional groups to polyisobutenyl backbone groups. Such a polyisobutenyl succinic anhydride is particular suitable for the production of oil-soluble hydrocarbyl succinimides that have good dispersant properties when added to lubricating oil compositions.

Owner:AFTON CHEMICAL

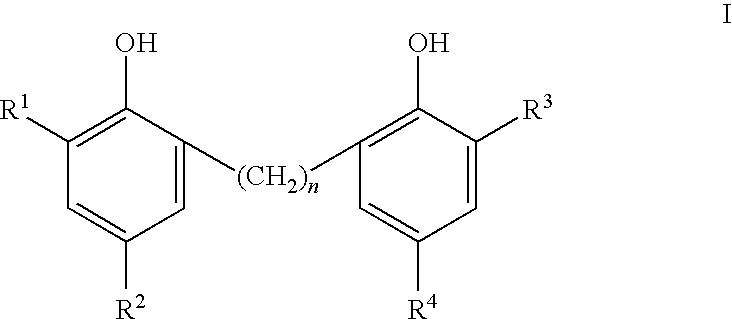

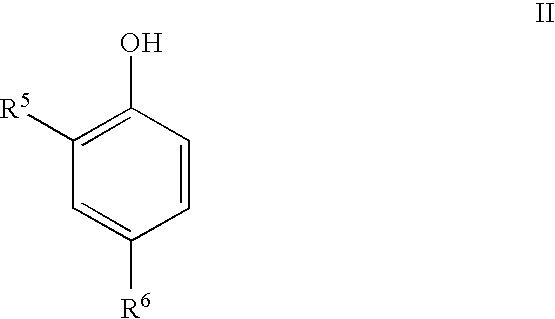

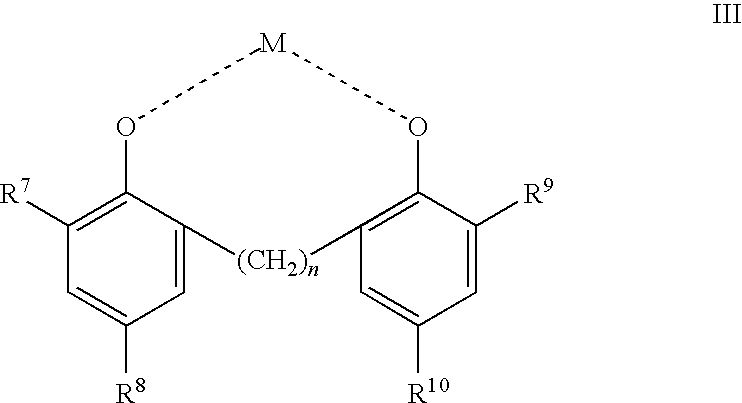

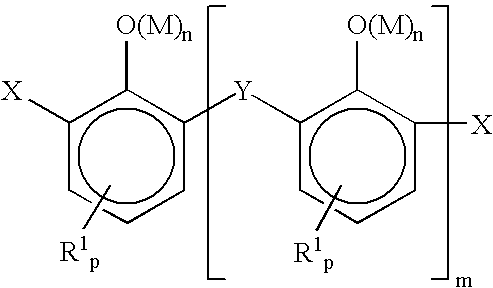

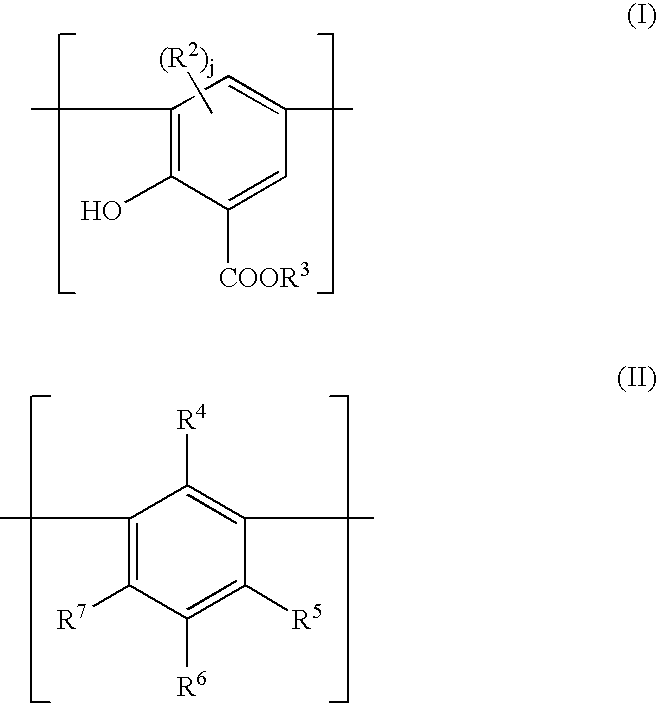

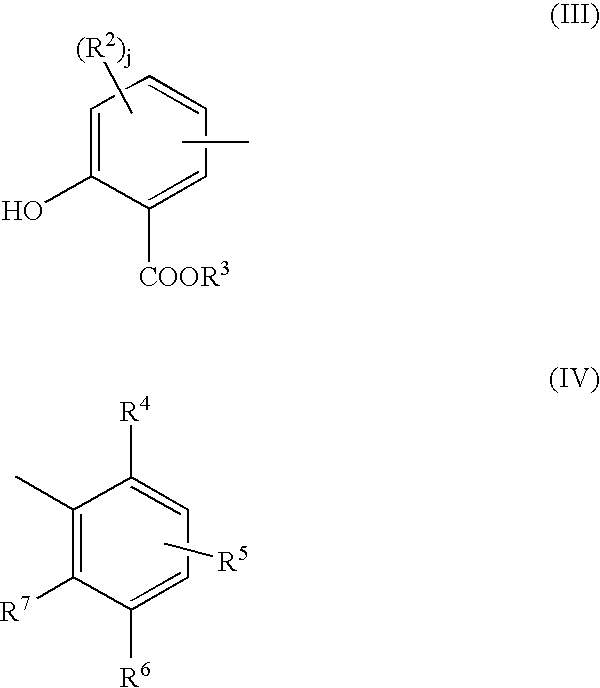

Phenolic dimers, the process of preparing same and the use thereof

Owner:AFTON CHEMICAL

Biomass Char Compositions for Catalytic Gasification

InactiveUS20090217575A1Efficient utilization of carbonEfficient comprehensive utilizationProductsReagentsParticulatesHydrogen

Particulate compositions are described comprising an intimate mixture of a biomass char producedfrom the combustion of a biomass, such as switchgrass or hybrid poplar, with at least a second carbonaceous material, such as petroleum coke or coal, and, optionally a gasification catalyst, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

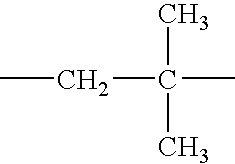

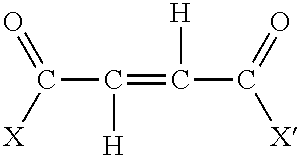

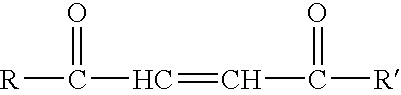

Low-chlorine, polyolefin-substituted, with amine reacted, alpha-beta unsaturated carboxylic compounds

A composition of matter comprising an amine acylated with a hydrocarbyl group substituted carboxylic acylating agent containing an average of from 1.3 to 1.6 groups derived from α,β-unsaturated carboxylic compounds per Mn of the hydrocarbyl group, wherein the hydrocarbyl group has Mn determined by GPC ranging from 1500 to 3000, the amine comprises polyamine bottoms and said acylated amine has total base number (TBN) ranging from 17 to 35. A method for preparing the composition, lubricating oils containing the composition and, in another embodiment, lubricating oil compositions of this invention further comprising a metal overbased sulfonate detergent.

Owner:THE LUBRIZOL CORP

Mixed dispersants for lubricants

A dispersant composition comprising the product of an amine, an alcohol, or an amino alcohol, with a hydrocarbyl-substituted succinic anhydride component exhibits improved viscosity stability and reduced chlorine content, when the hydrocarbyl-substituted succinic anhydride component comprises: (a) 10 to 95 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the presence of chlorine; and (b) 5 to 90 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the substantial absence of chlorine.

Owner:THE LUBRIZOL CORP

Single-source precursors for ternary chalcopyrite materials, and methods of making and using the same

InactiveUS6992202B1Effective yieldFurnaces without endless coreMaterial nanotechnologyChalcopyriteQuantum dot

A single source precursor for depositing ternary I-III-VI2 chalcopyrite materials useful as semiconductors. The single source precursor has the I-III-VI2 stoichiometry “built into” a single precursor molecular structure which degrades on heating or pyrolysis to yield the desired I-III-VI2 ternary chalcopyrite. The single source precursors effectively degrade to yield the ternary chalcopyrite at low temperature, e.g. below 500° C., and are useful to deposit thin film ternary chalcopyrite layers via a spray CVD technique. The ternary single source precursors according to the invention can be used to provide nanocrystallite structures useful as quantum dots. A method of making the ternary single source precursors is also provided.

Owner:OHIO AEROSPACE INST +1

Additive formulation for lubricating oils

InactiveUS7285516B2Reduce the amount requiredOrganic chemistryOrganic compound preparationSulfurPhosphorus

Lubricating oils containing an additive formulation including at least one sulphonate, saligenin and salixarate detergent provide improved wear performance and decreased sulphur and phosphorus emissions.

Owner:THE LUBRIZOL CORP

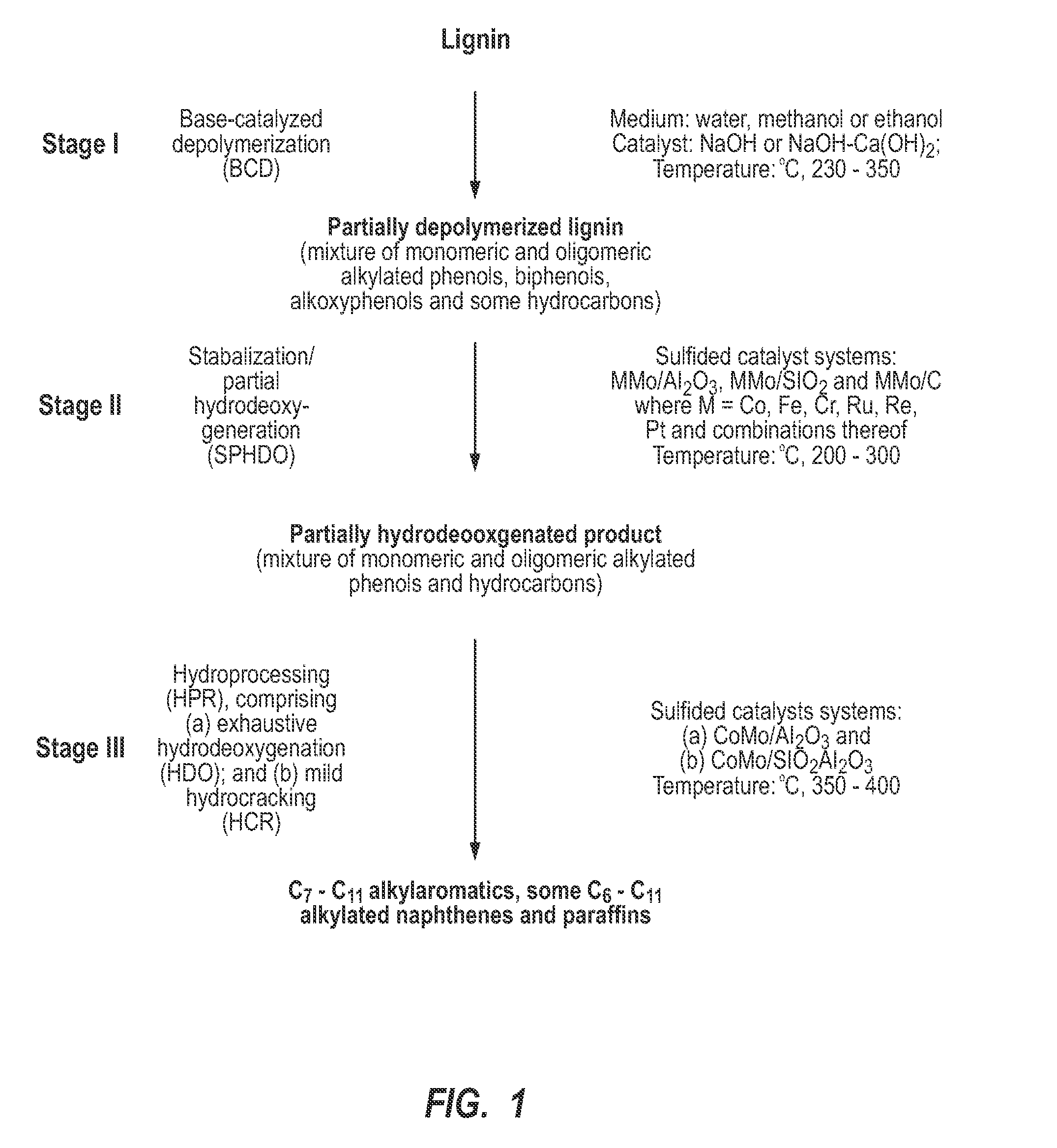

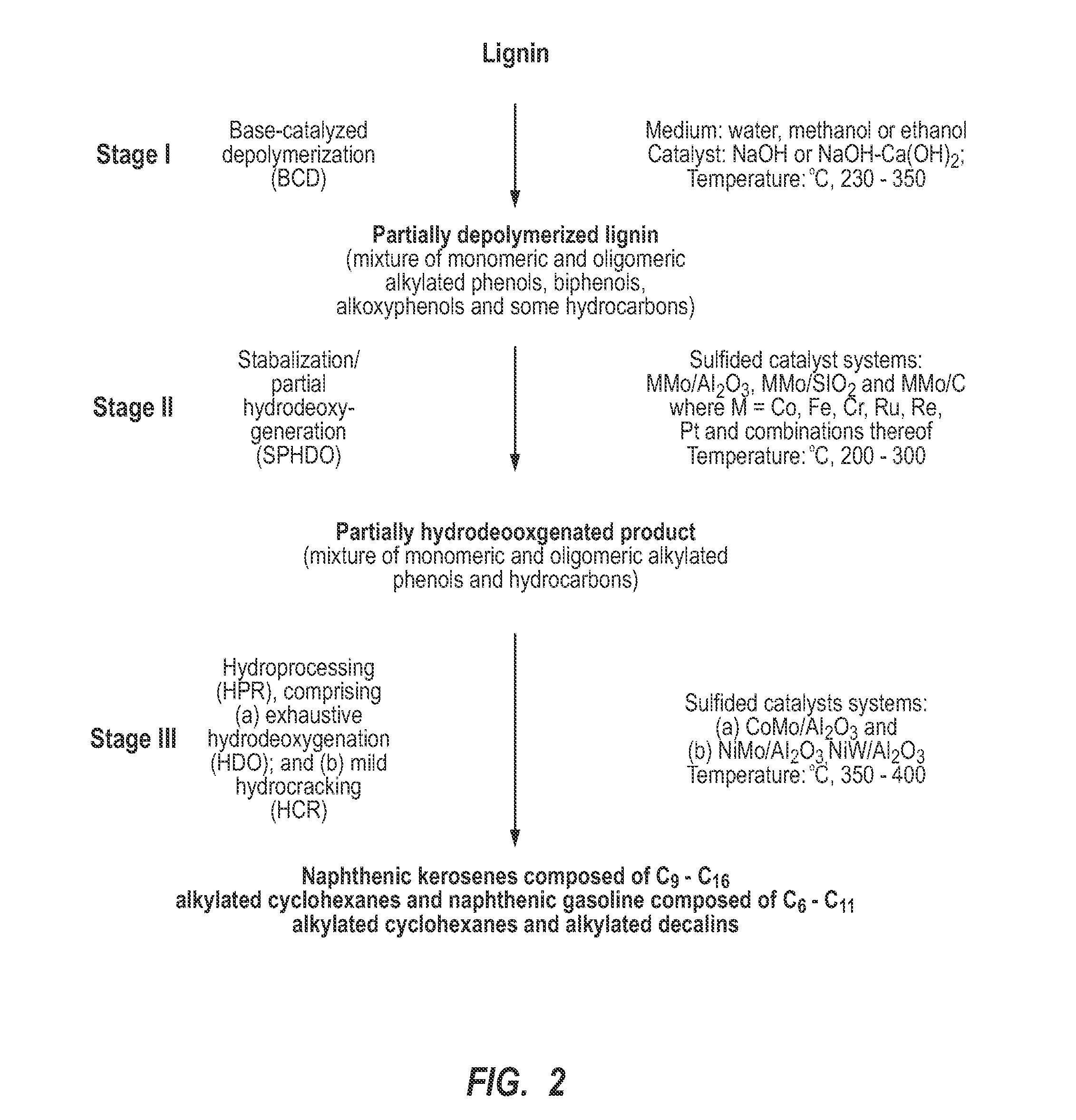

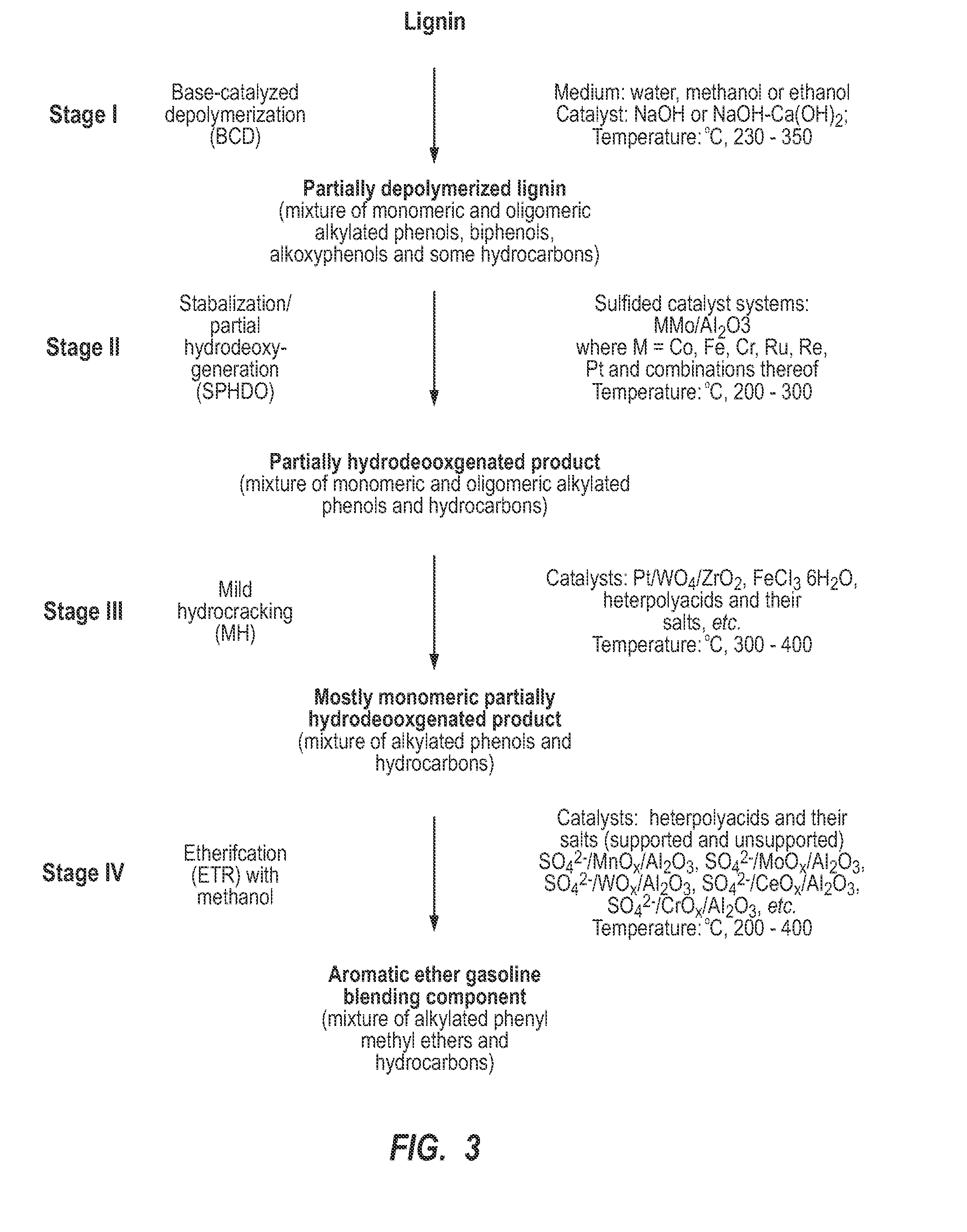

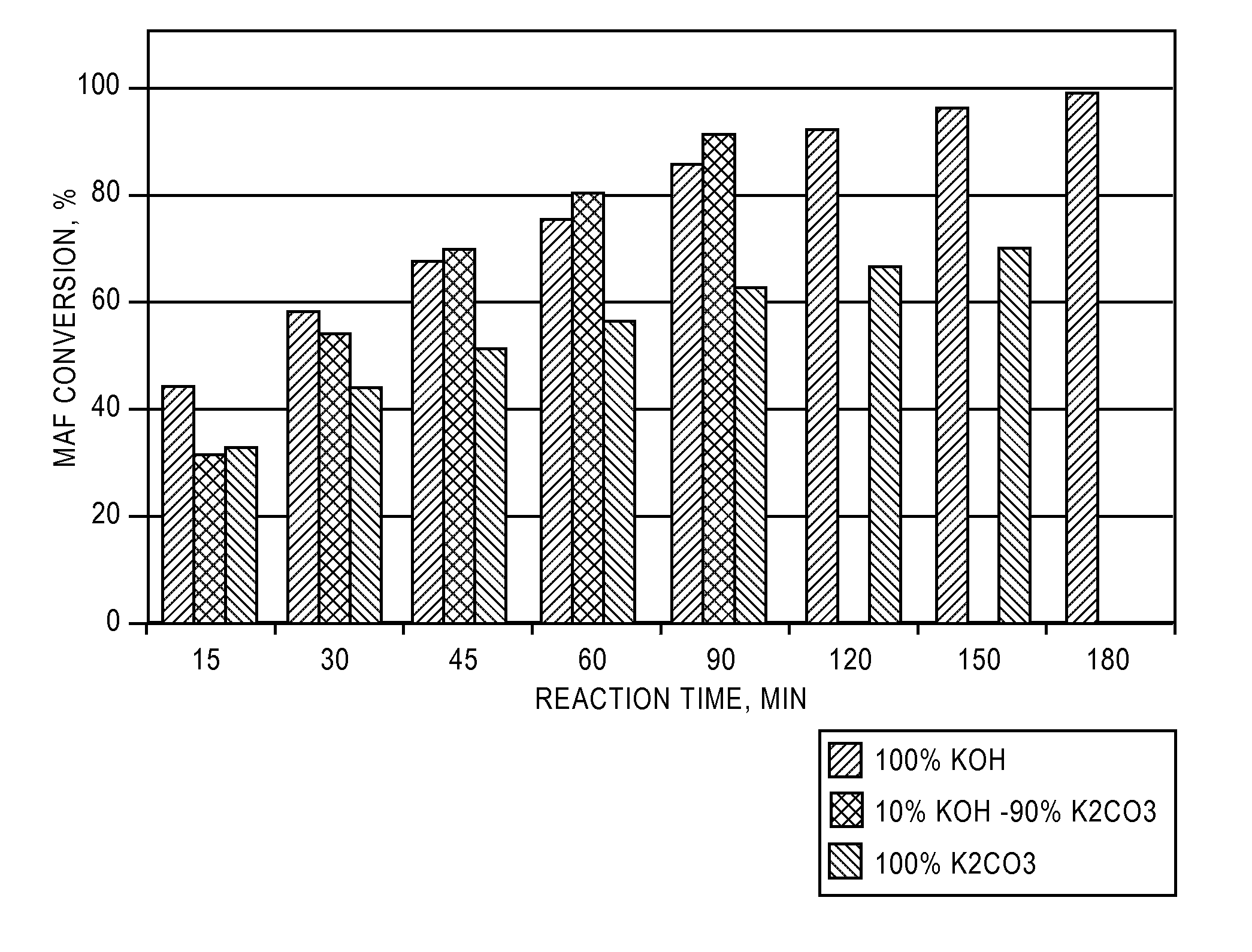

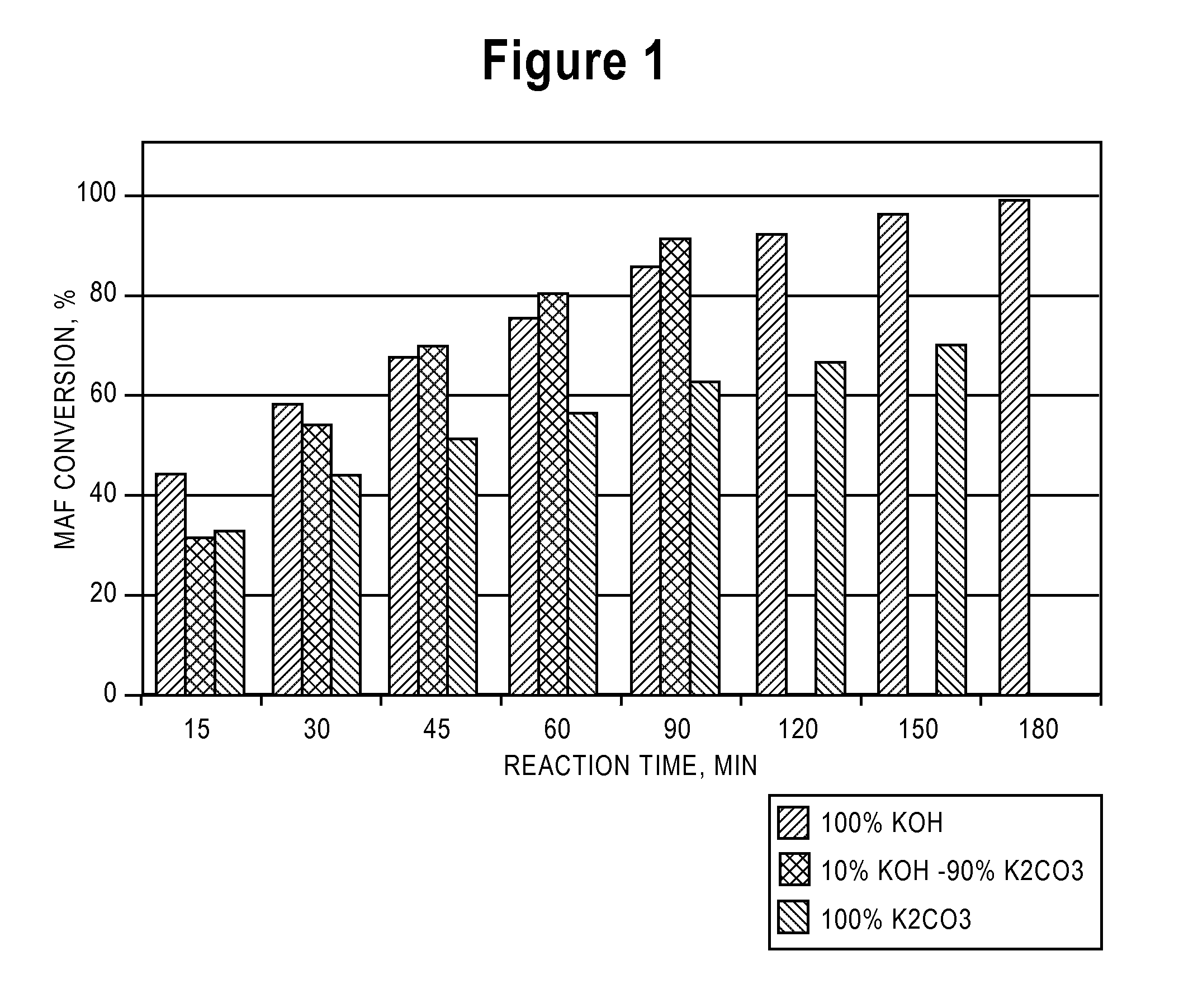

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

Lubricant additive

ActiveUS20120101017A1Good viscosity performanceIncrease VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

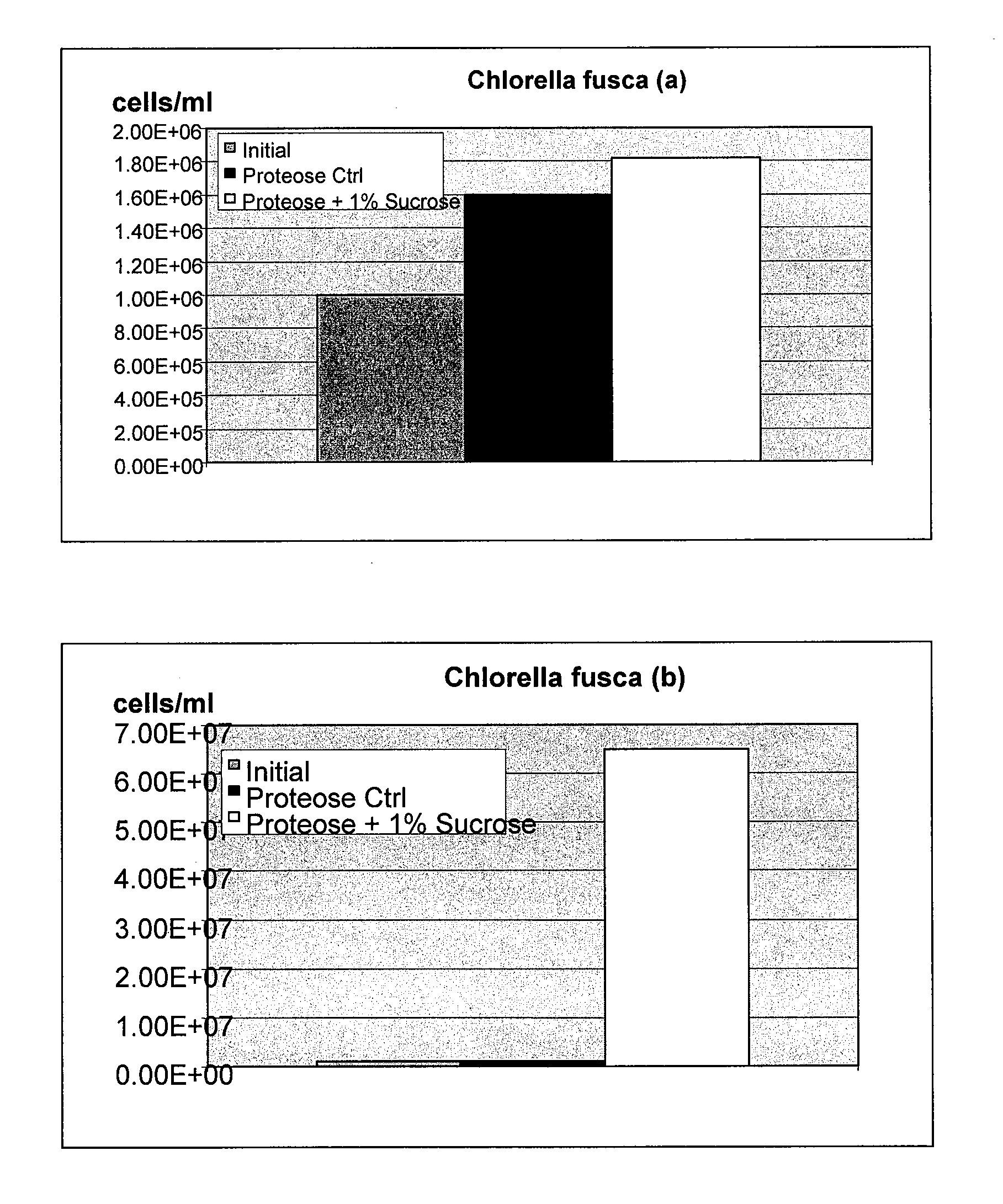

Use of Cellulosic Materials for Cultivation of Microorganisms

Owner:CORBION BIOTECH INC

Petroleum Coke Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a petroleum coke and an alkali metal gasification catalyst, where the alkali metal gasification catalyst comprises a combination of an alkali metal hydroxide and one or more other alkali metal compounds are loaded onto coke for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

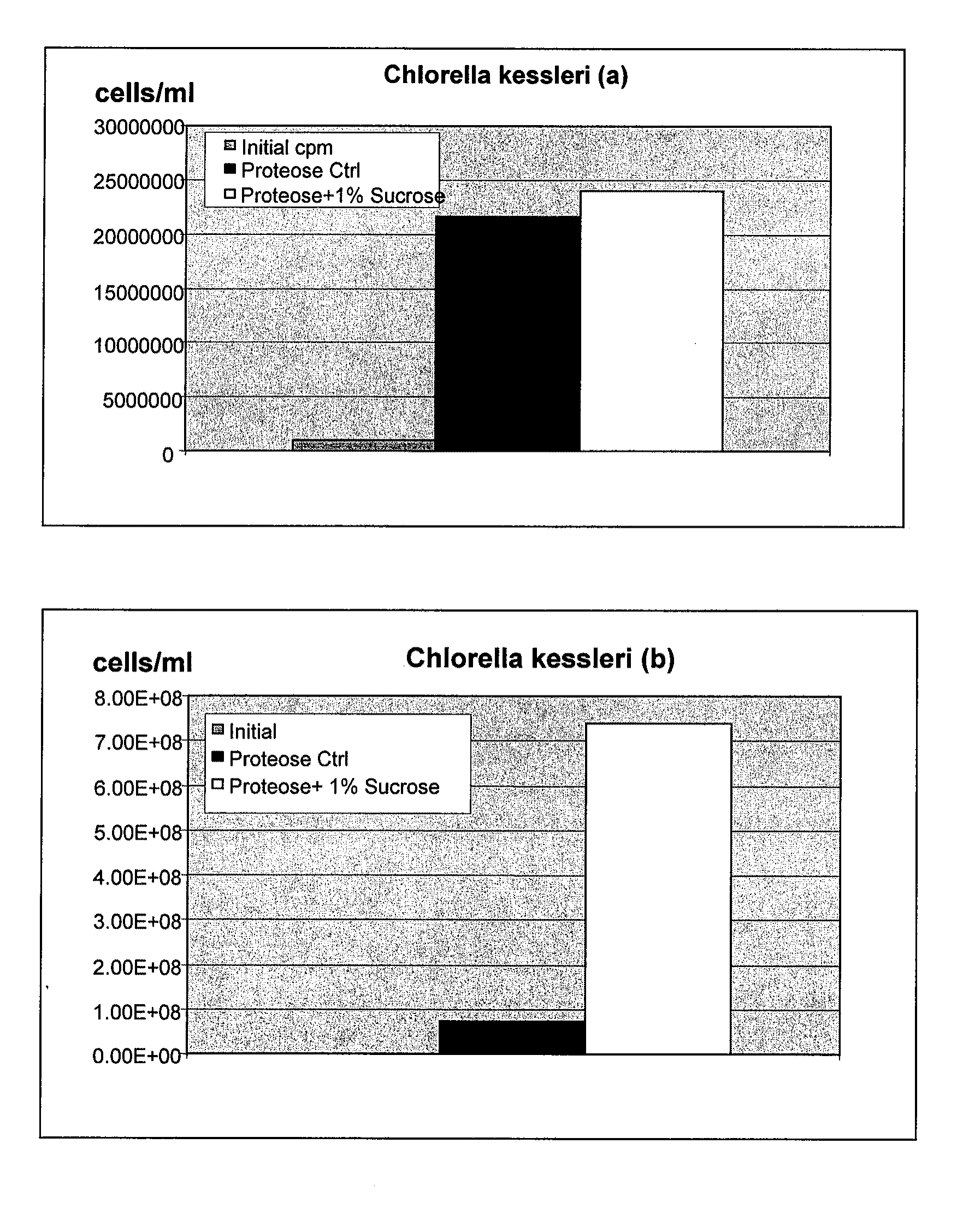

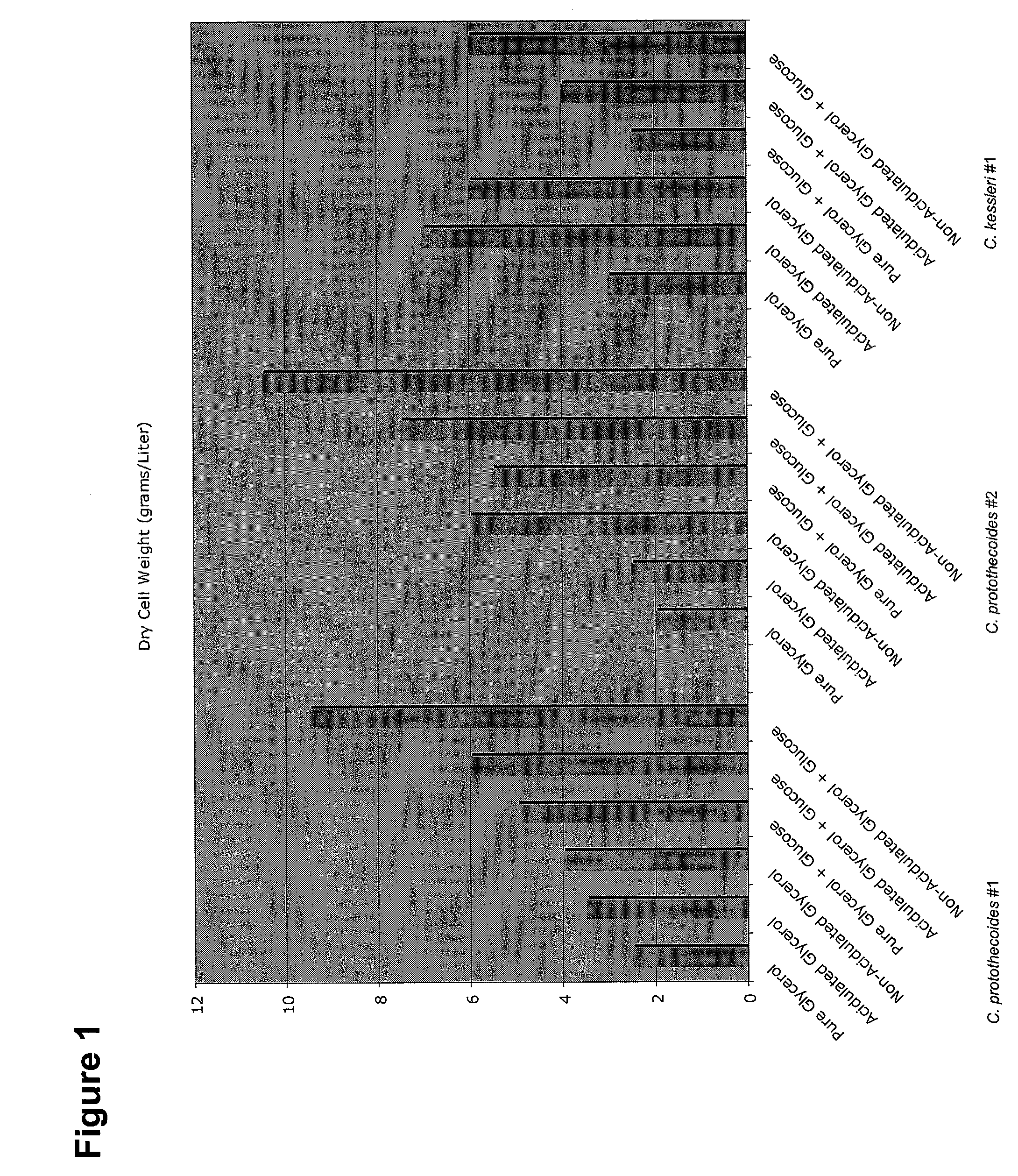

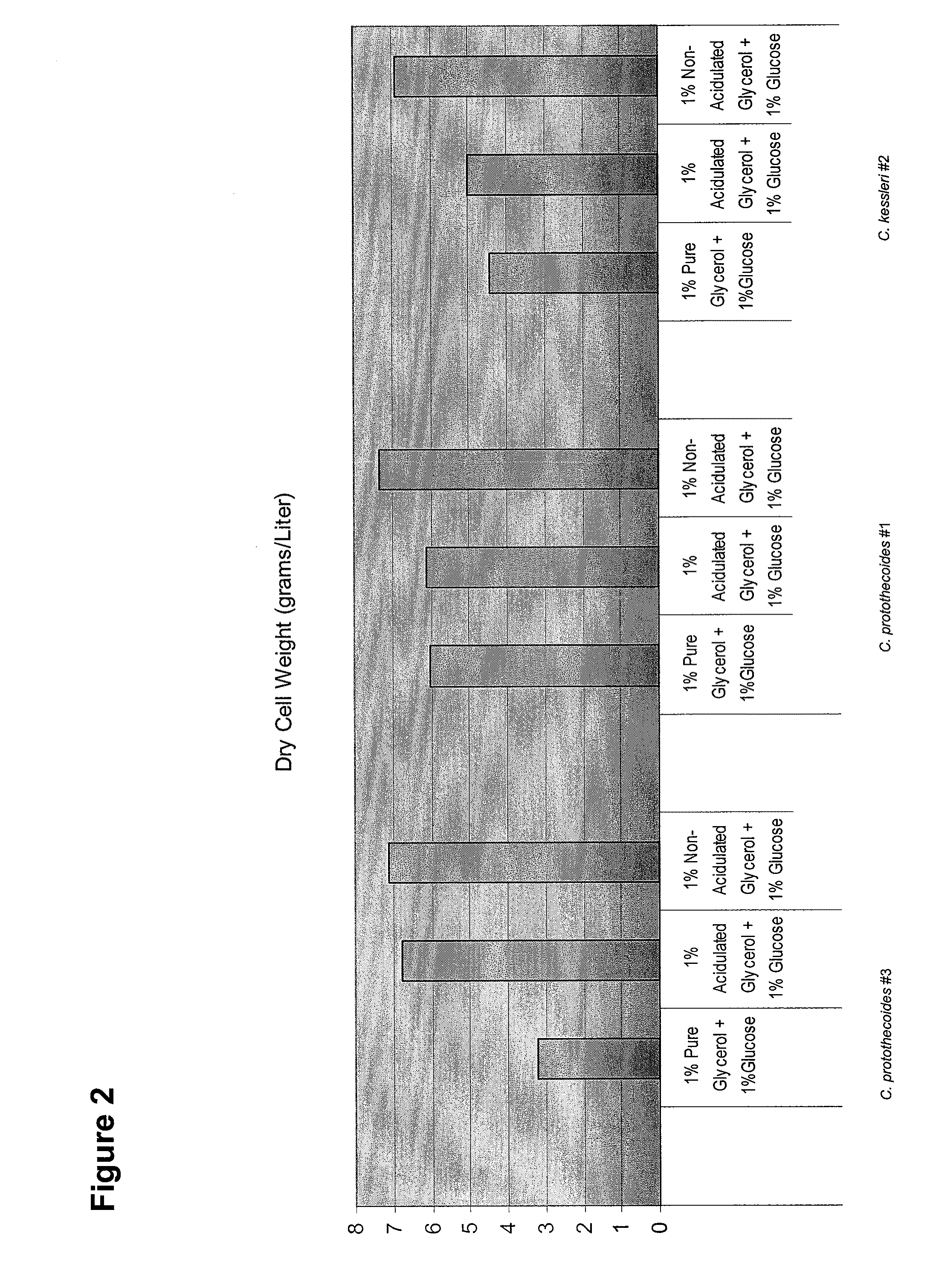

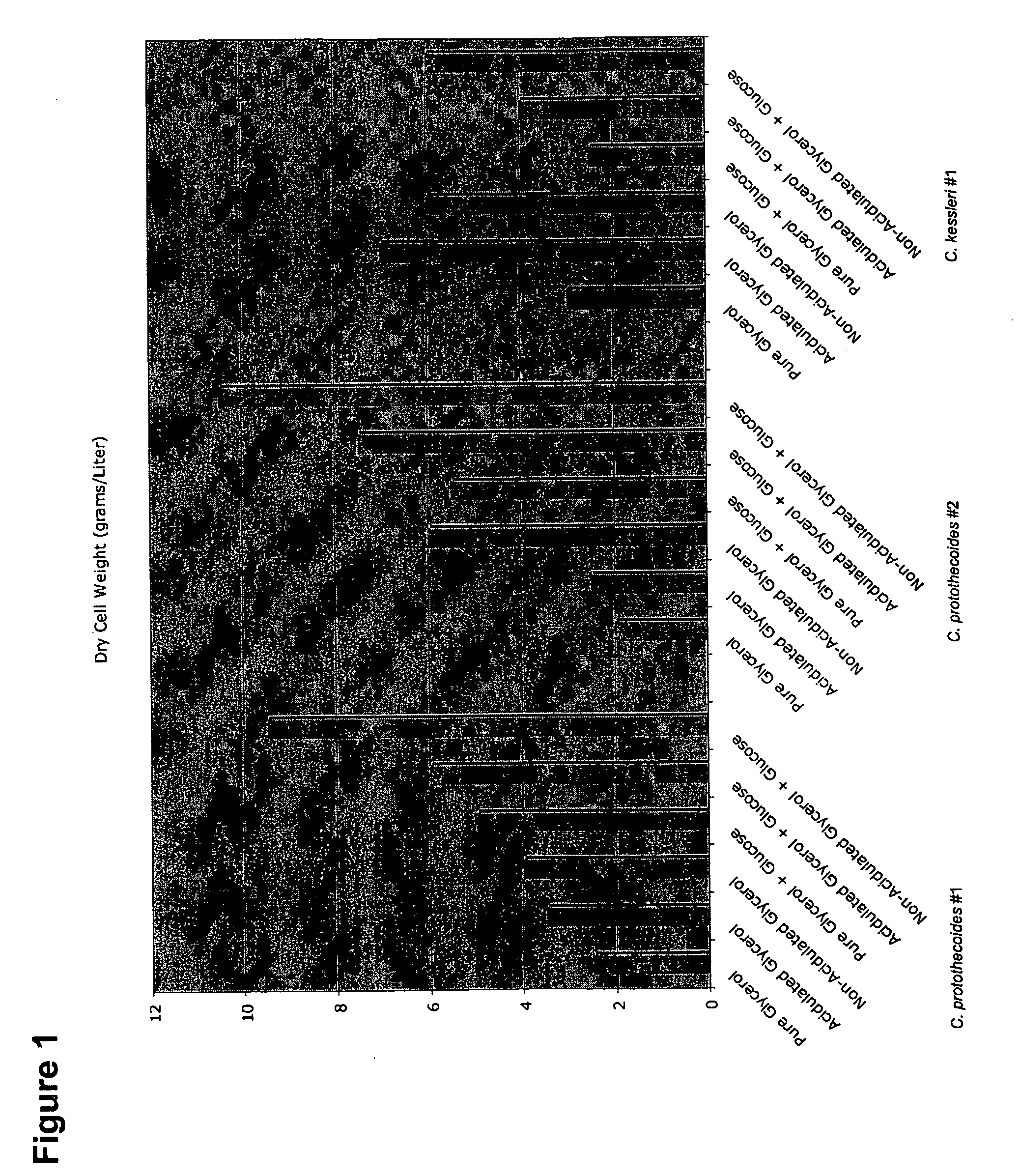

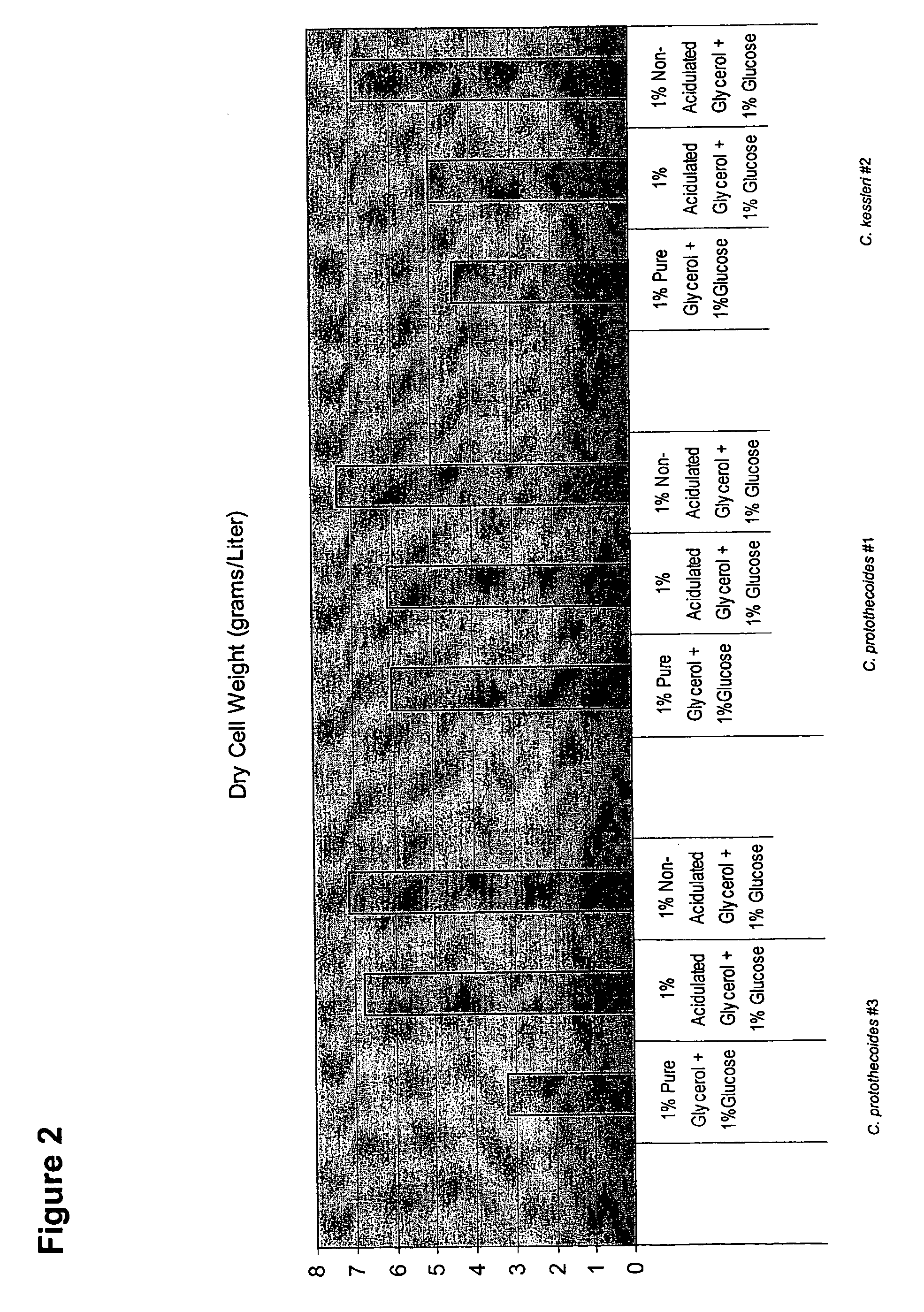

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

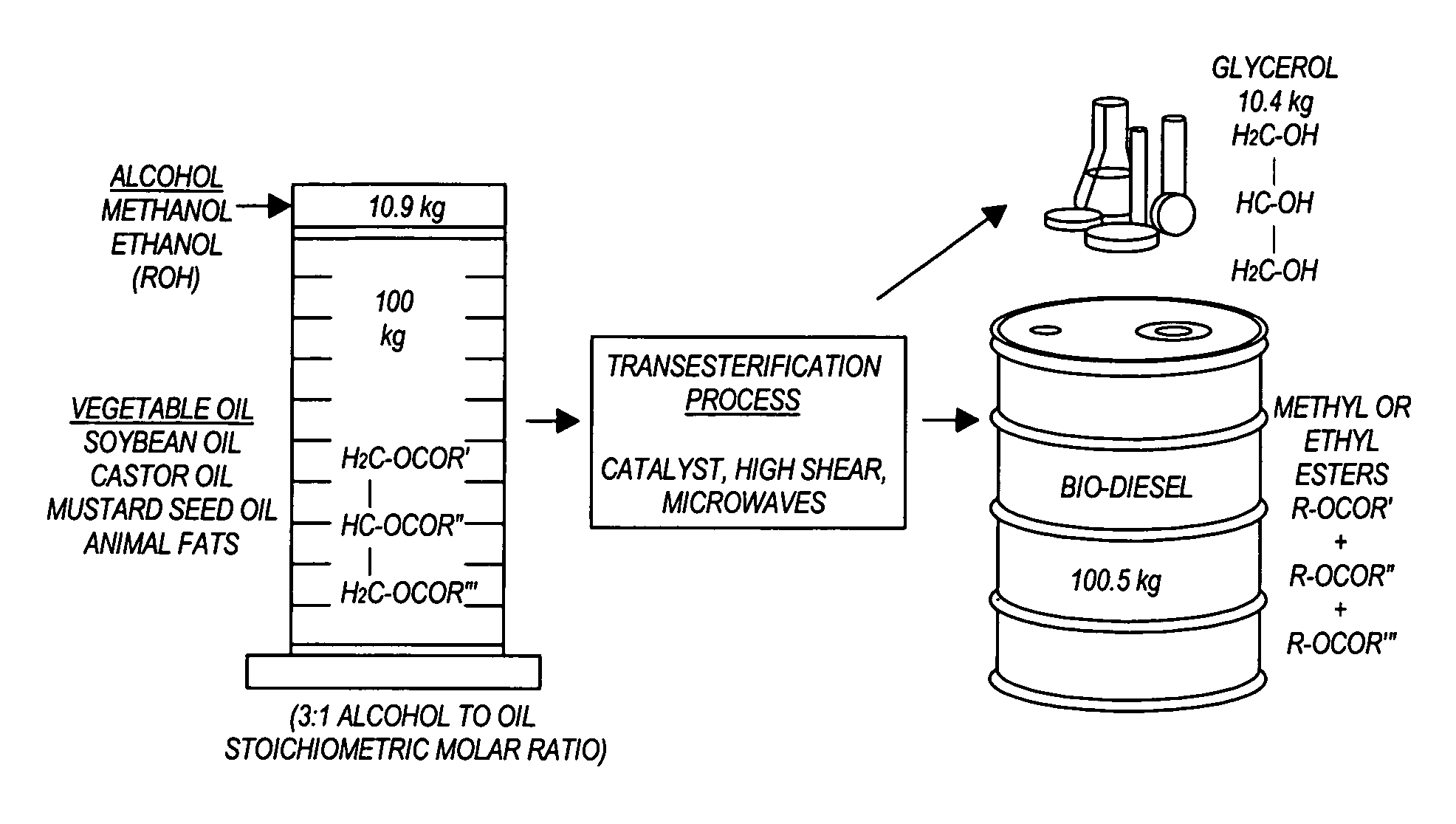

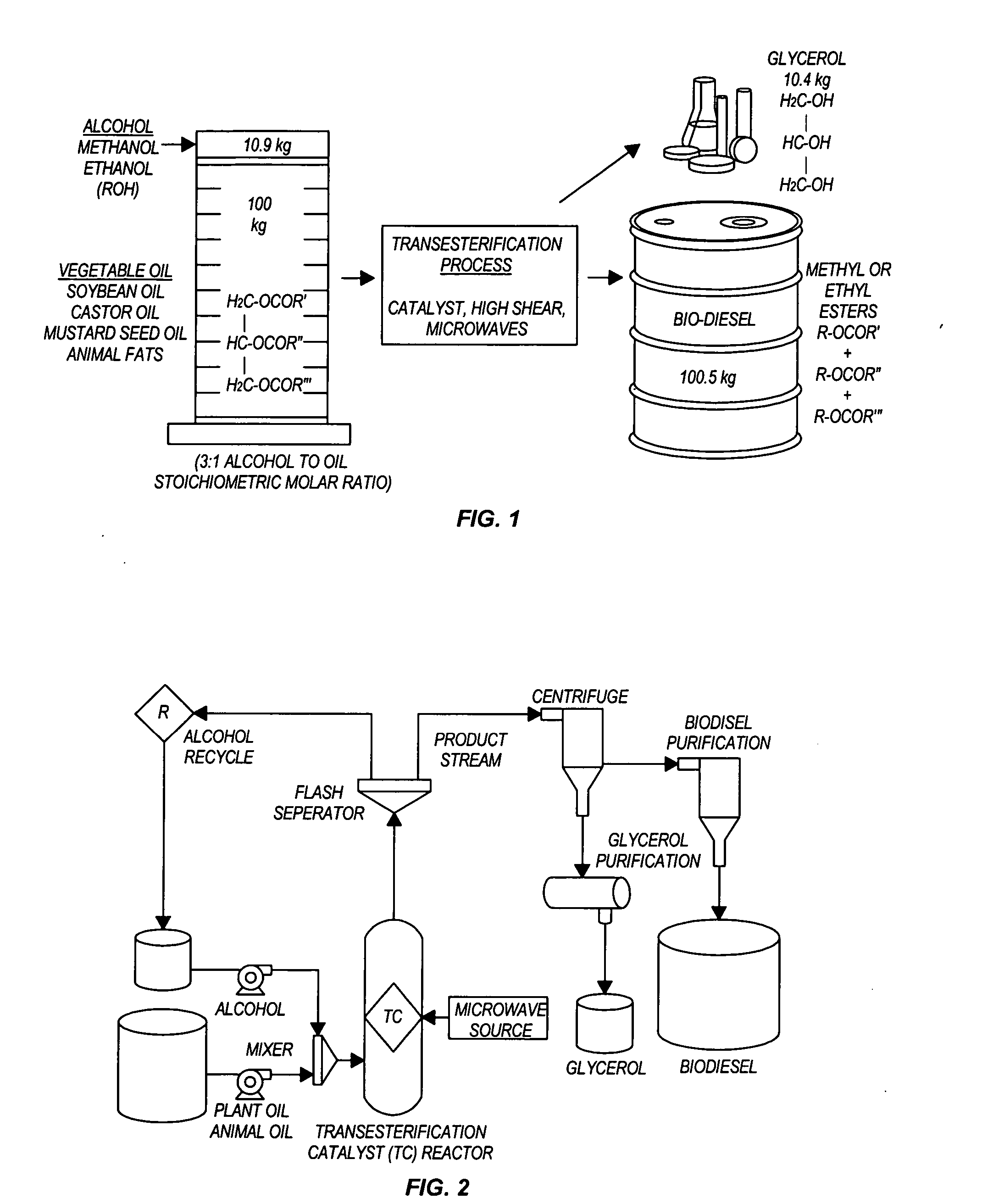

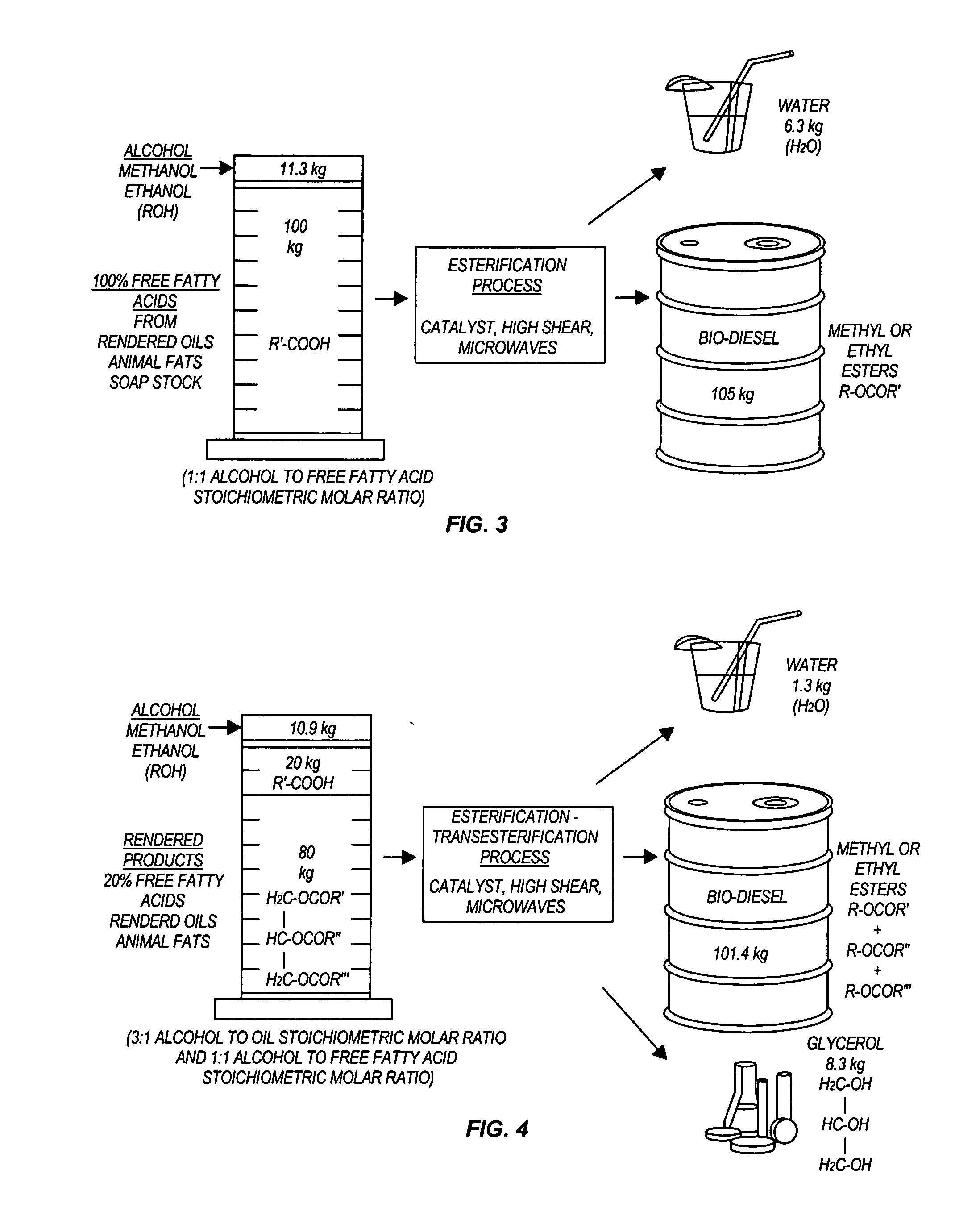

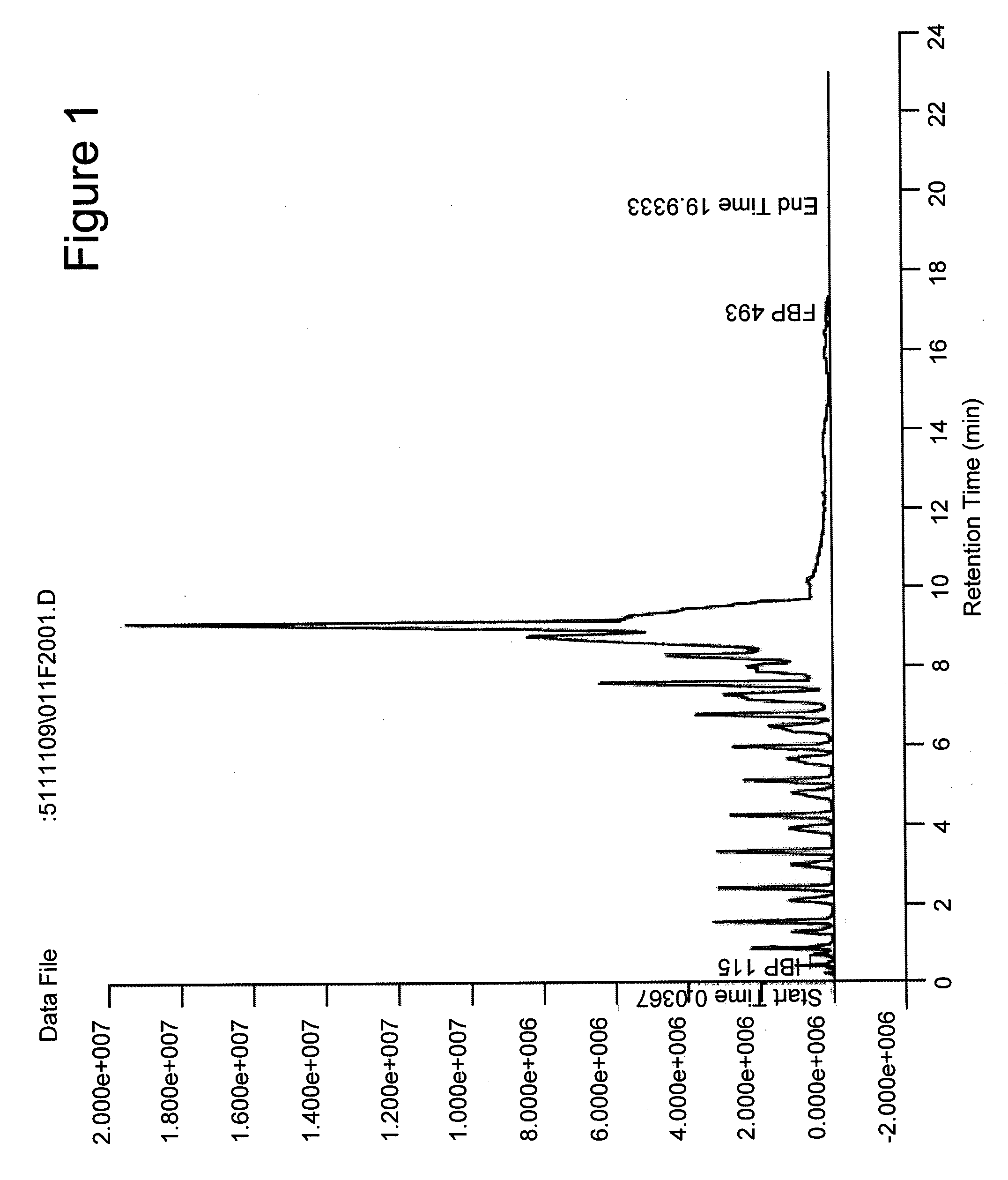

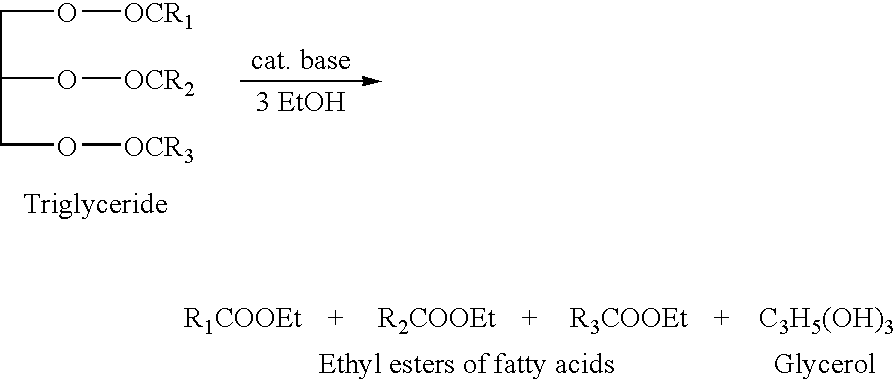

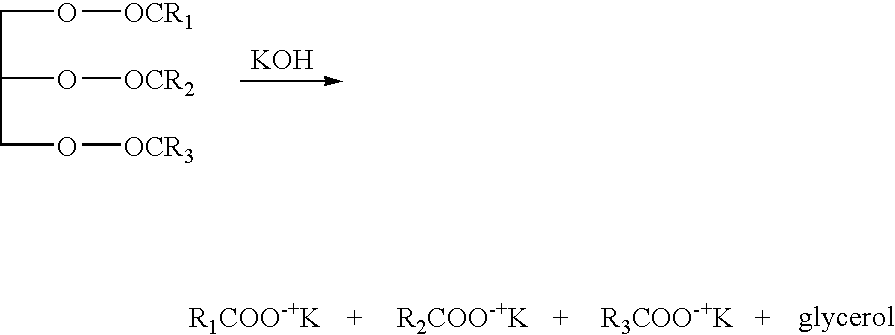

Methods for producing biodiesel

InactiveUS20050274065A1Fatty acid esterificationPreparation by ester-hydroxy reactionMicrowaveTransesterification

Transesterification, esterification, and esterification-transesterification (both one-step and two-step) for producing biofuels. The process may be enhanced by one or more of the following: 1) applying microwave or RF energy; 2) passing reactants over a heterogeneous catalyst at sufficiently high velocity to achieve high shear conditions; 3) emulsifying reactants with a homogeneous catalyst; or 4) maintaining the reaction at a pressure at or above autogeneous pressure. Enhanced processes using one or more of these steps can result in higher process rates, higher conversion levels, or both.

Owner:CARNEGIE MELLON UNIV

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

Hydroprocessing Microalgal Oils

InactiveUS20100170144A1Improve efficiencyLow costHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

Fuels and other valuable compositions and compounds can be made from oil extracted from microbial biomass and from oil-bearing microbial biomass via hydroprocessing and / or other chemical treatments, including the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts.

Owner:TERRAVIA HLDG INC

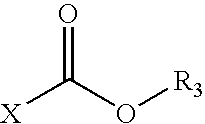

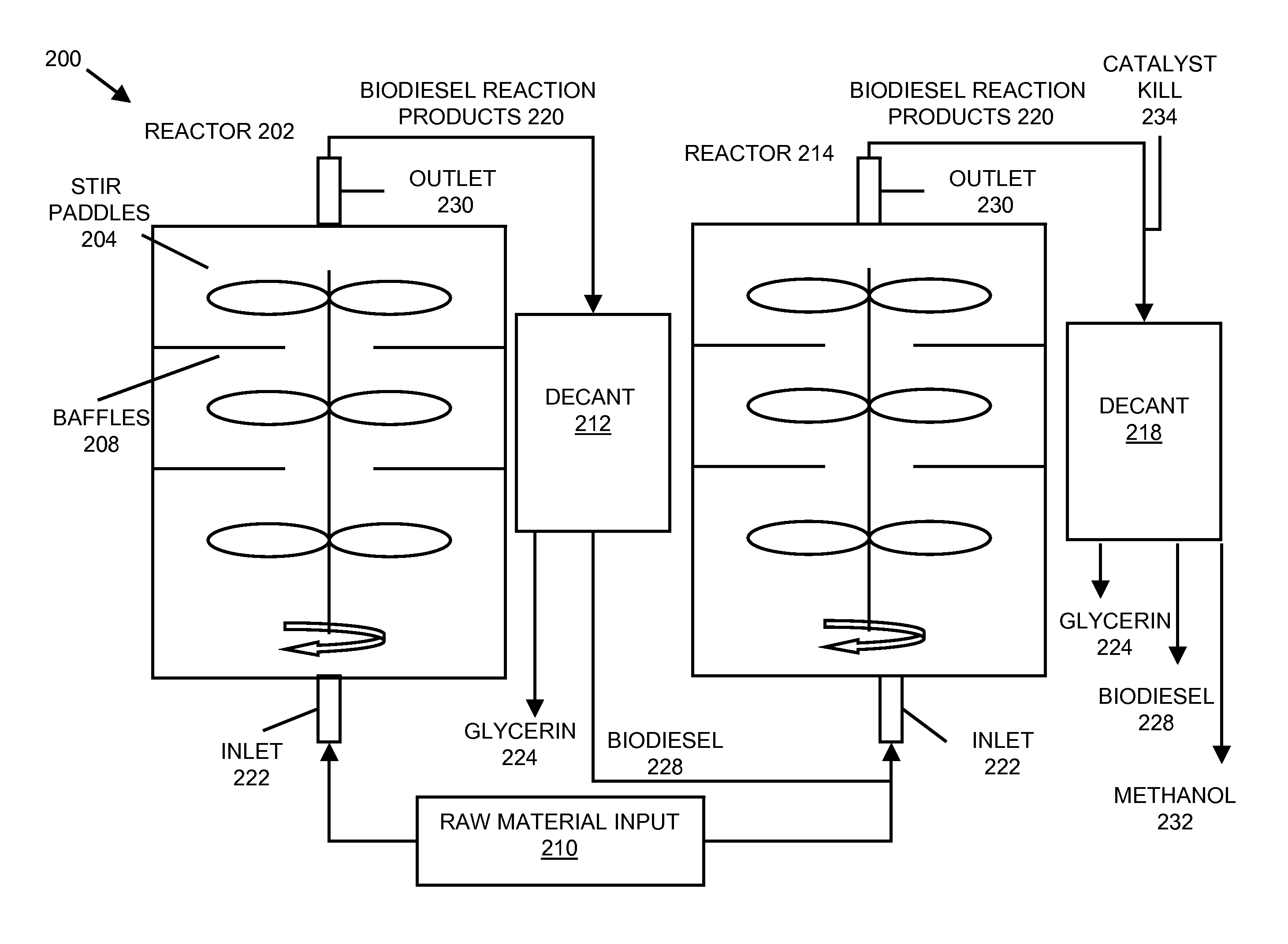

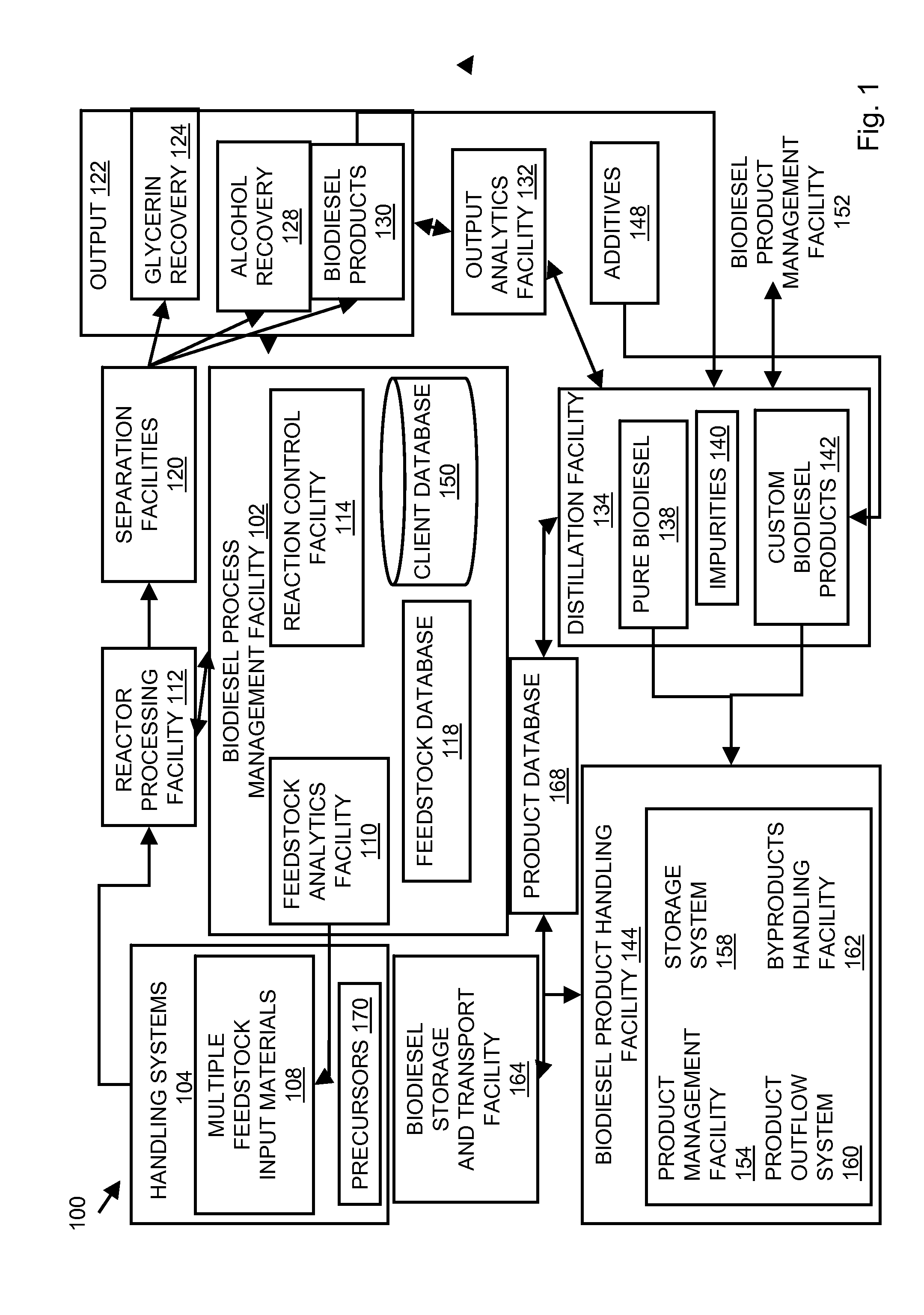

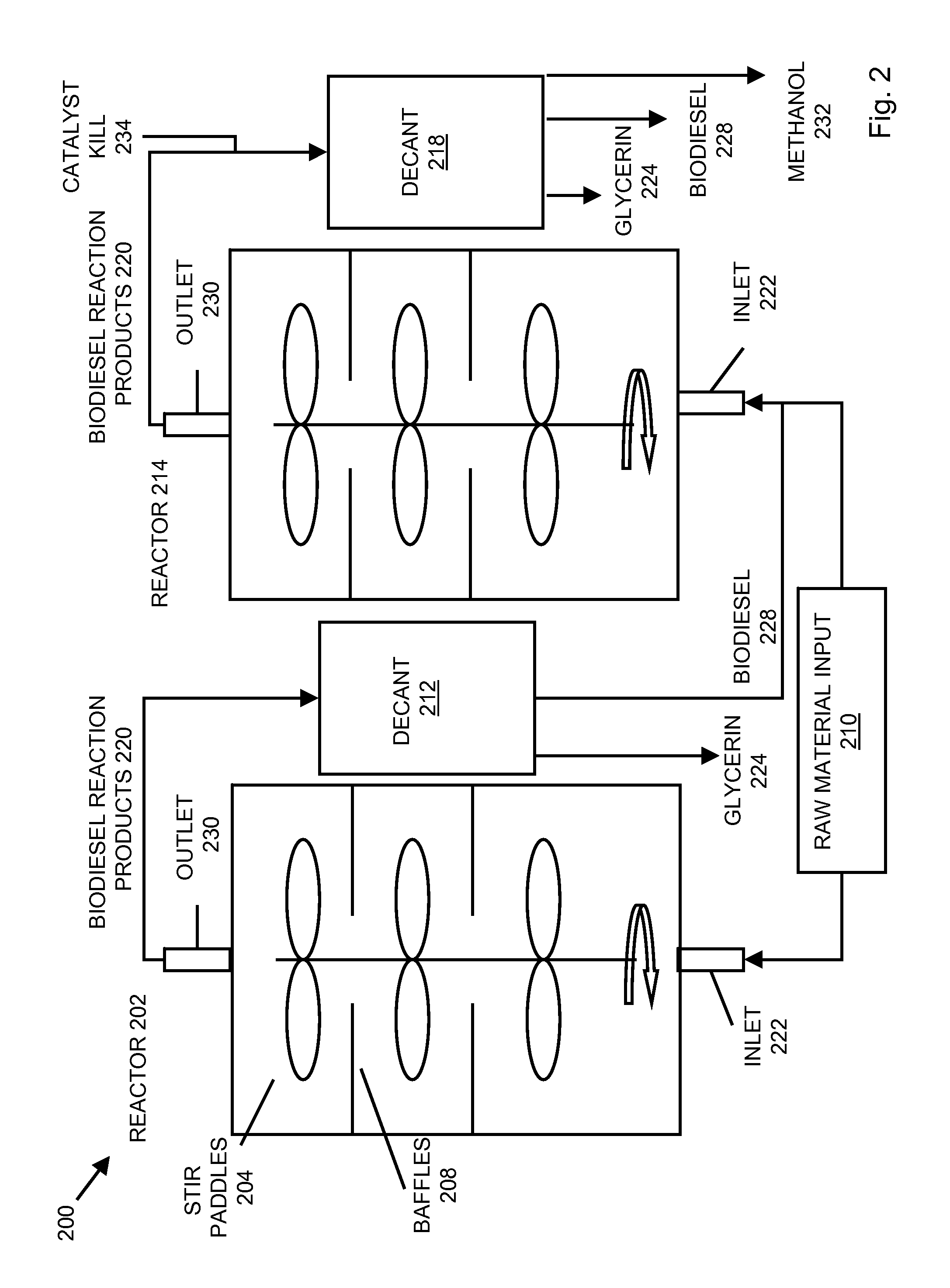

System and process for producing biodiesel

InactiveUS20080282606A1Reducing filter blocking tendencyEnhance biodiesel stabilityFatty acid esterificationFatty acids production/refiningBiodieselDistillation

In embodiments of the present invention, systems for producing a biodiesel product from multiple feedstocks may include a biodiesel reactor, a decanter, a flash evaporator and a distillation column. In other embodiments of the present invention, a process for producing a biodiesel comprises distilling a biodiesel reaction product to remove tocopherols and sterol glucosides and, optionally, adding biodiesel stabilizers to the resultant biodiesel to enhance thermal stability. The components of the system are interrelated so that parameters may be regulated to allow production of a custom biodiesel product.

Owner:IMPERIUM PROCESS TECH

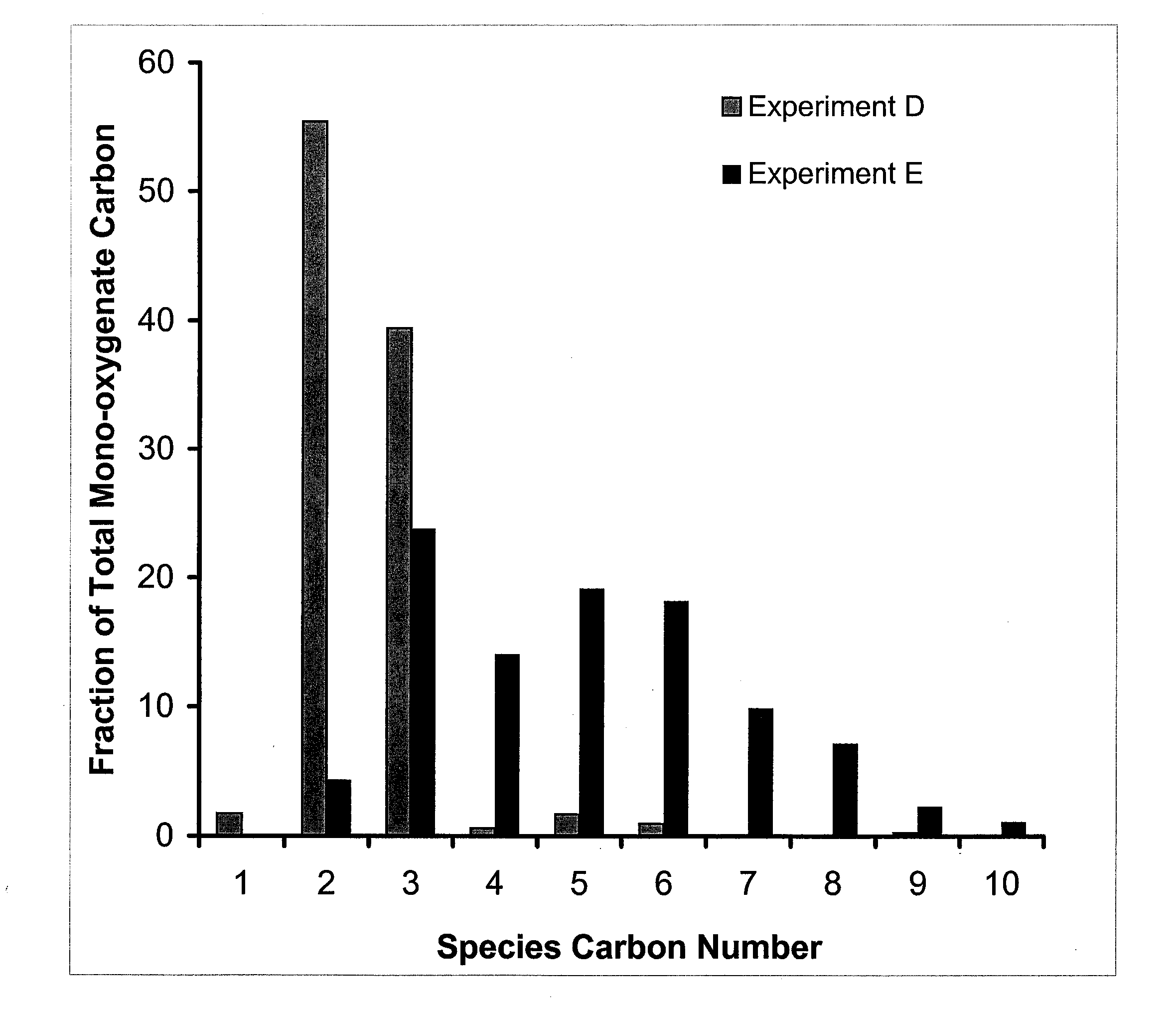

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

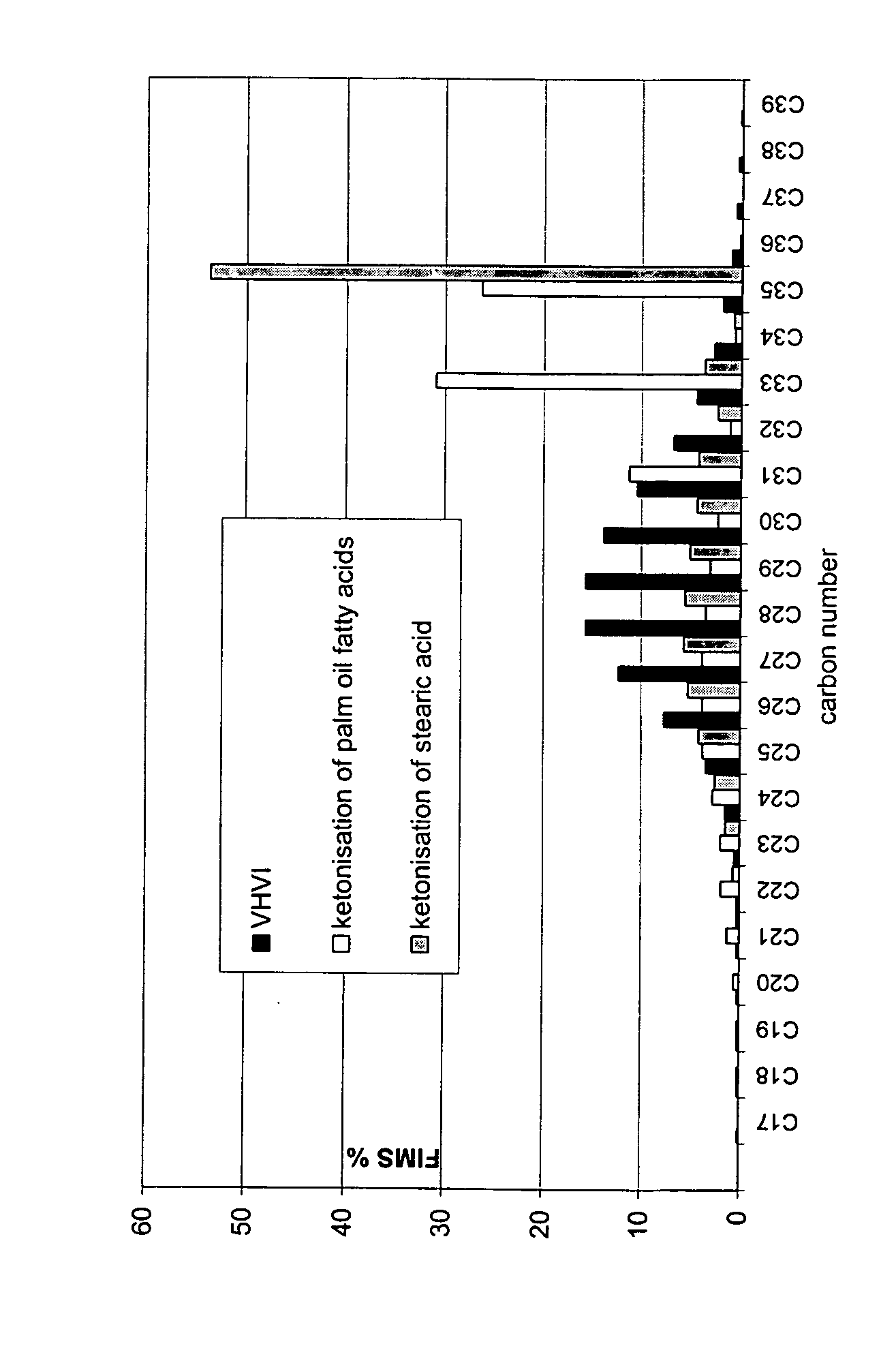

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

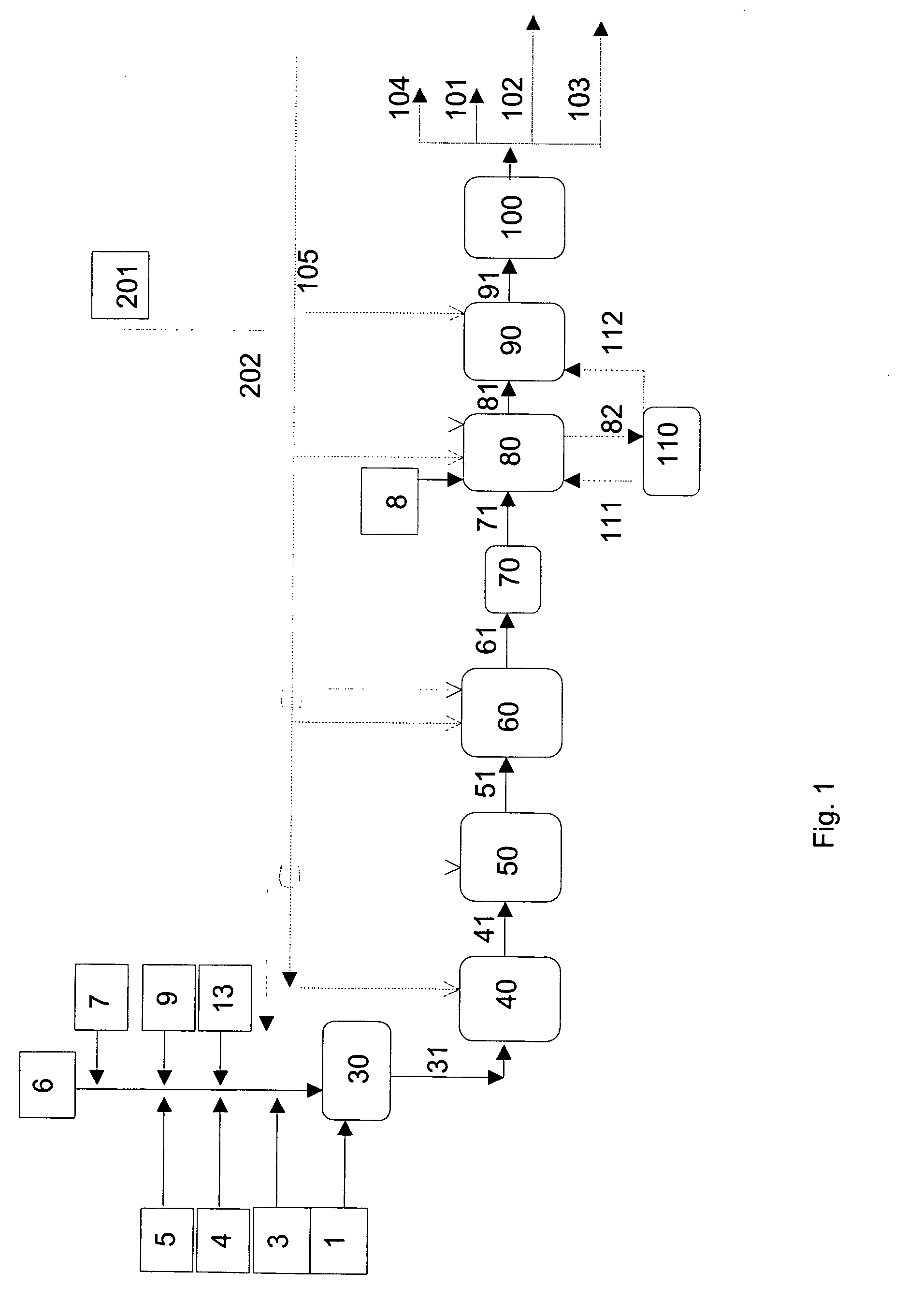

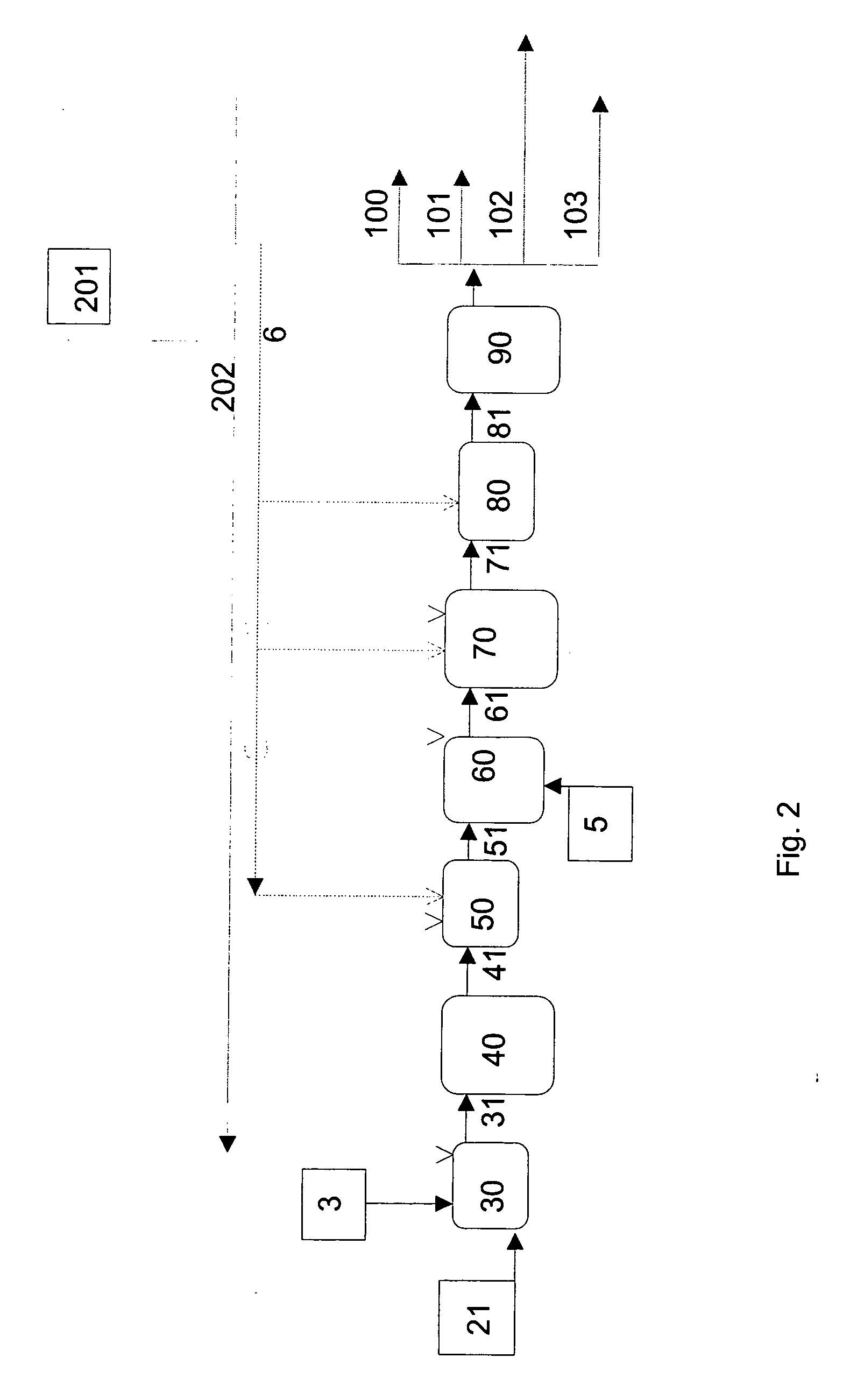

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates; (iii) contacting the pretreated biomass with hydrogen in the presence of a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co and / or Ni incorporated into a suitable support to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com