Patents

Literature

833 results about "Hydrodeoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodeoxygenation (HDO) is a hydrogenolysis process for removing oxygen from oxygen containing compounds. Typical HDO catalysts commonly are sulfided nickel-molybdenum or cobalt-molybdenum on gamma alumina.

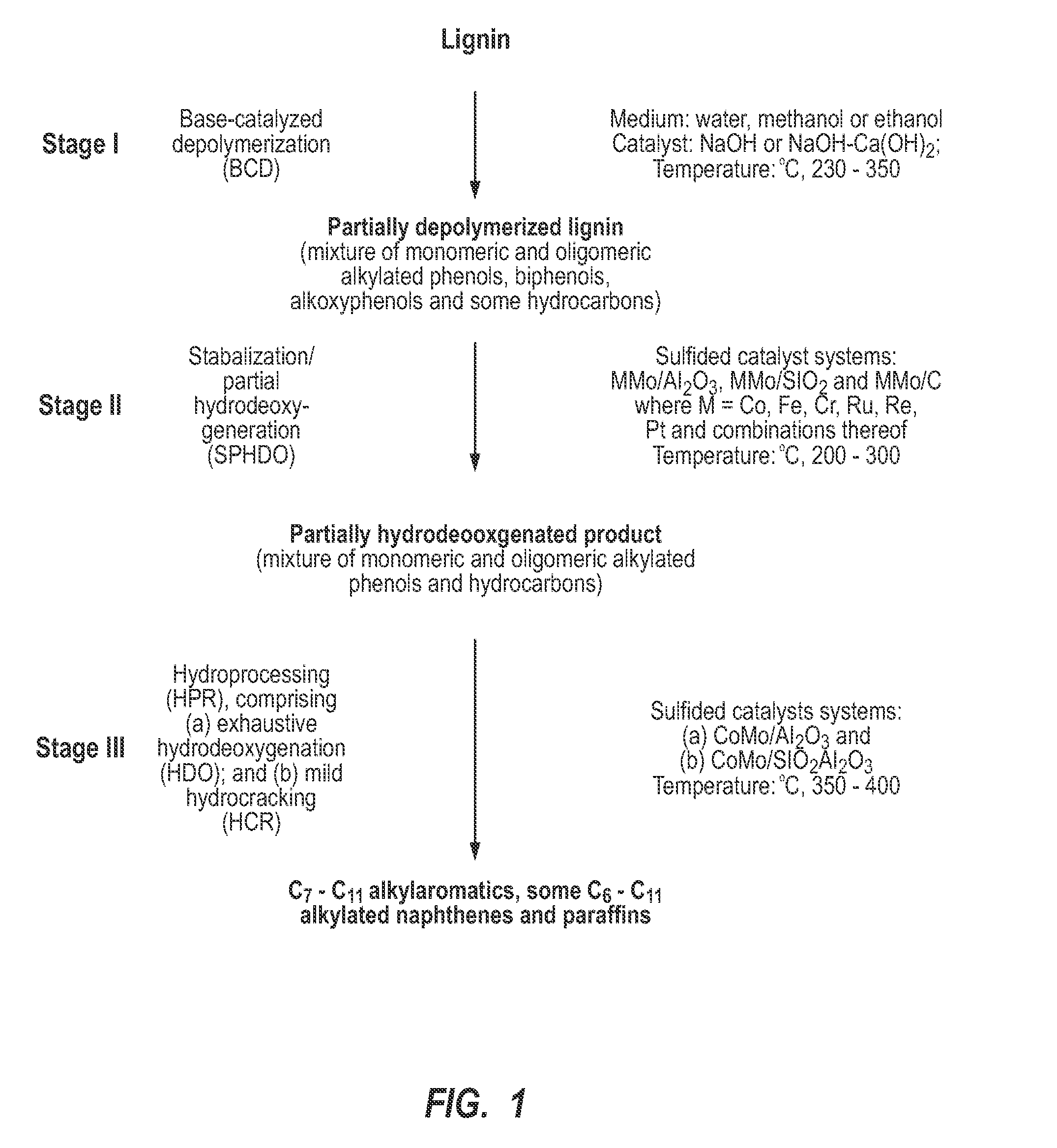

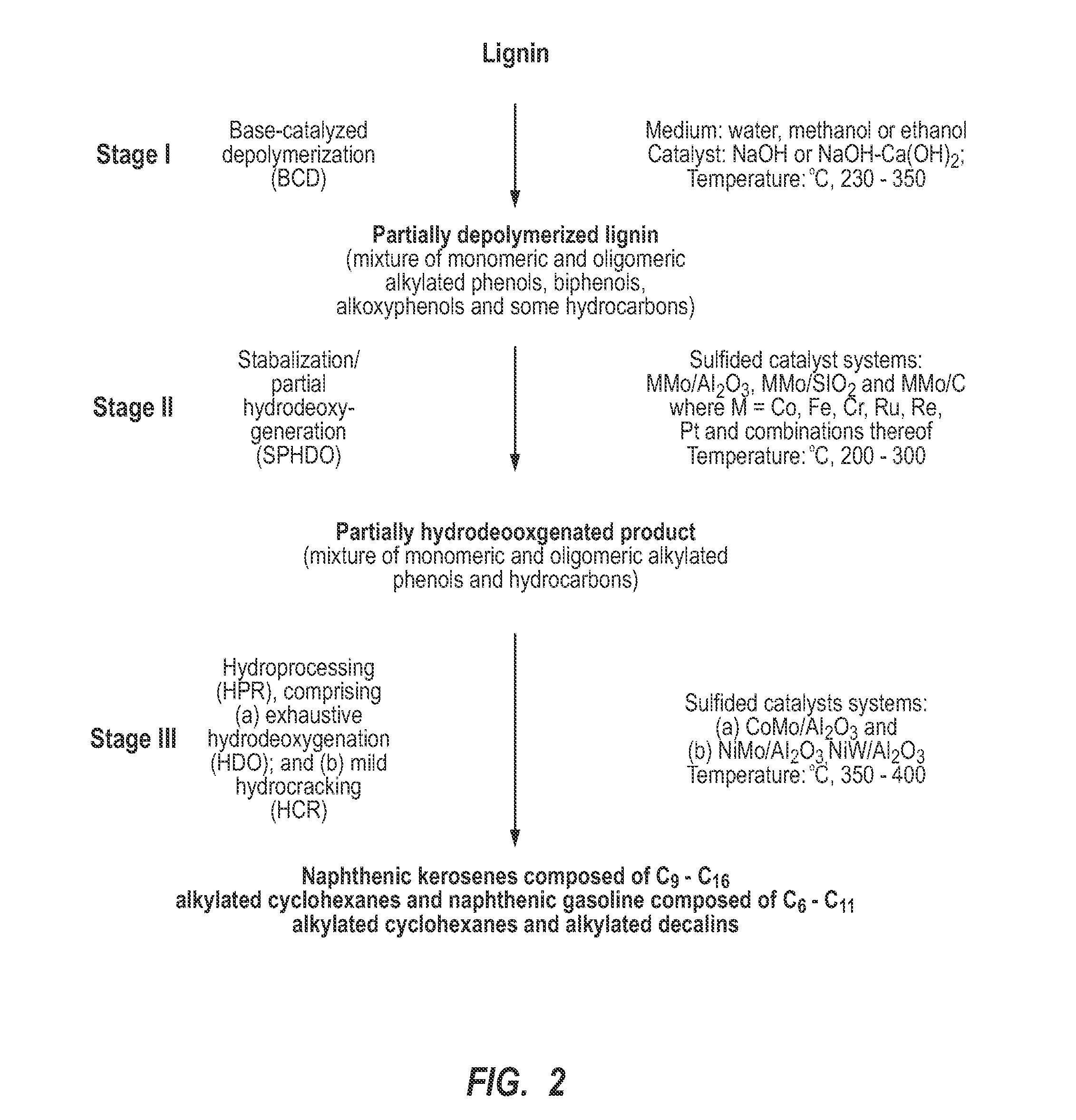

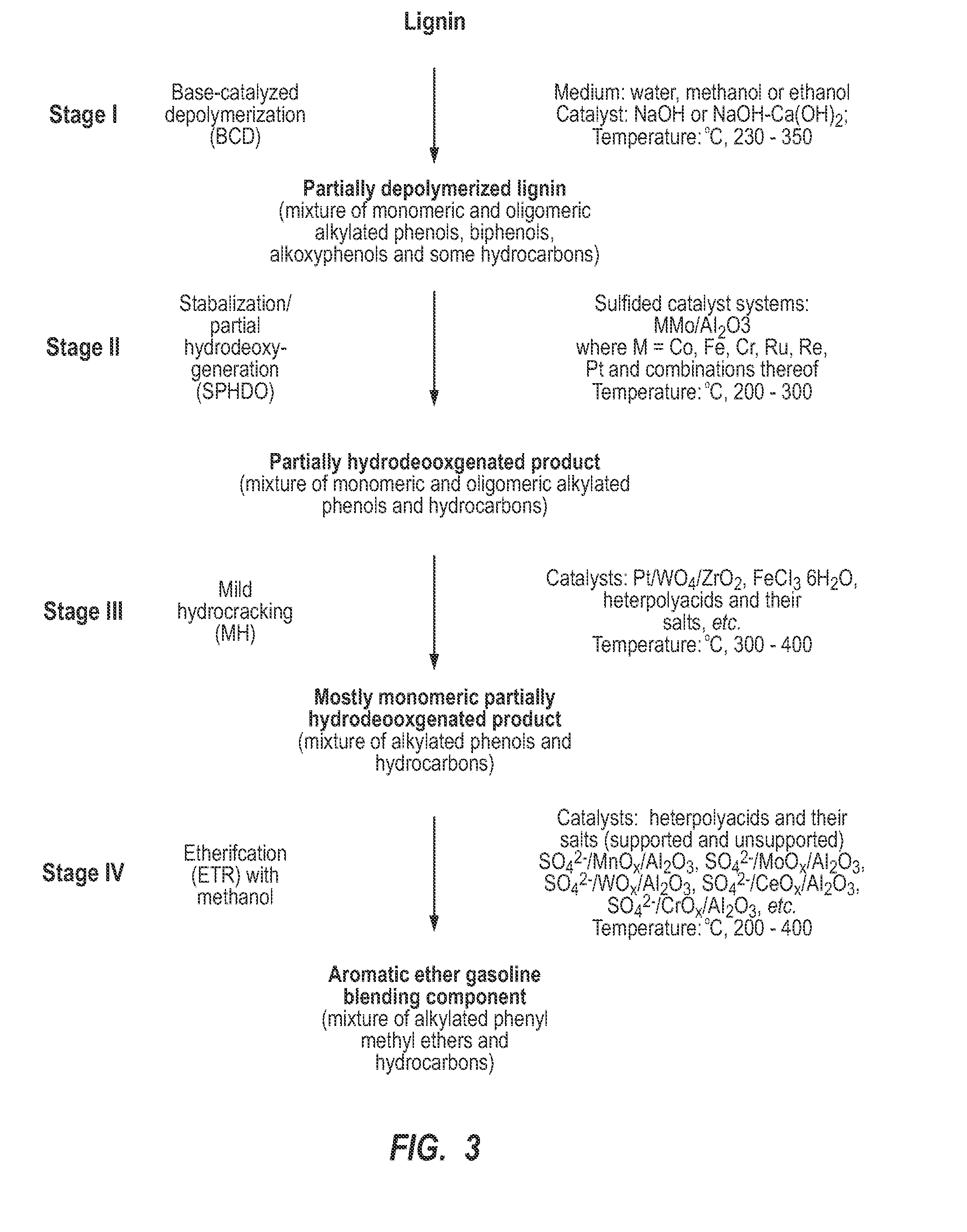

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

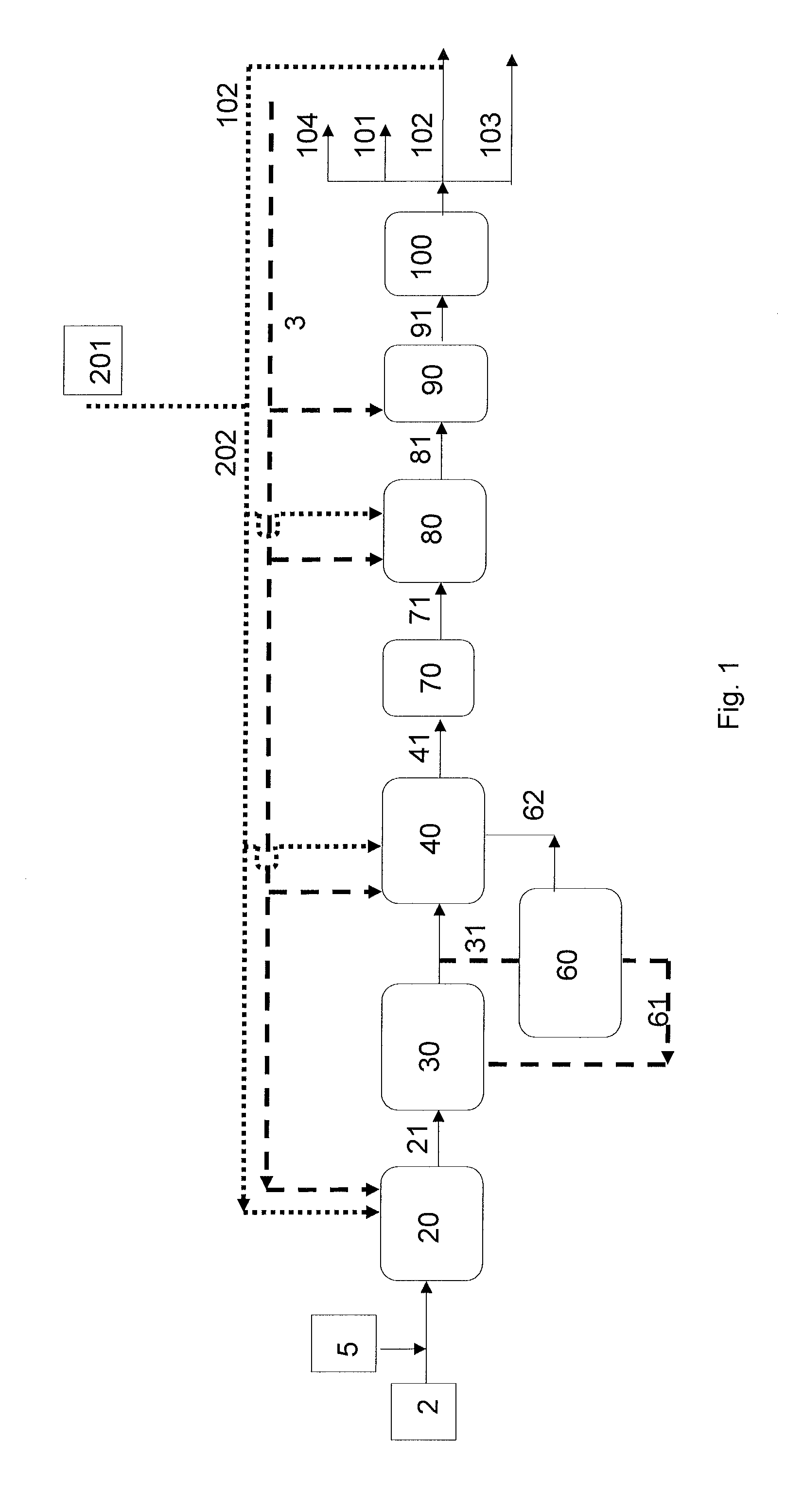

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

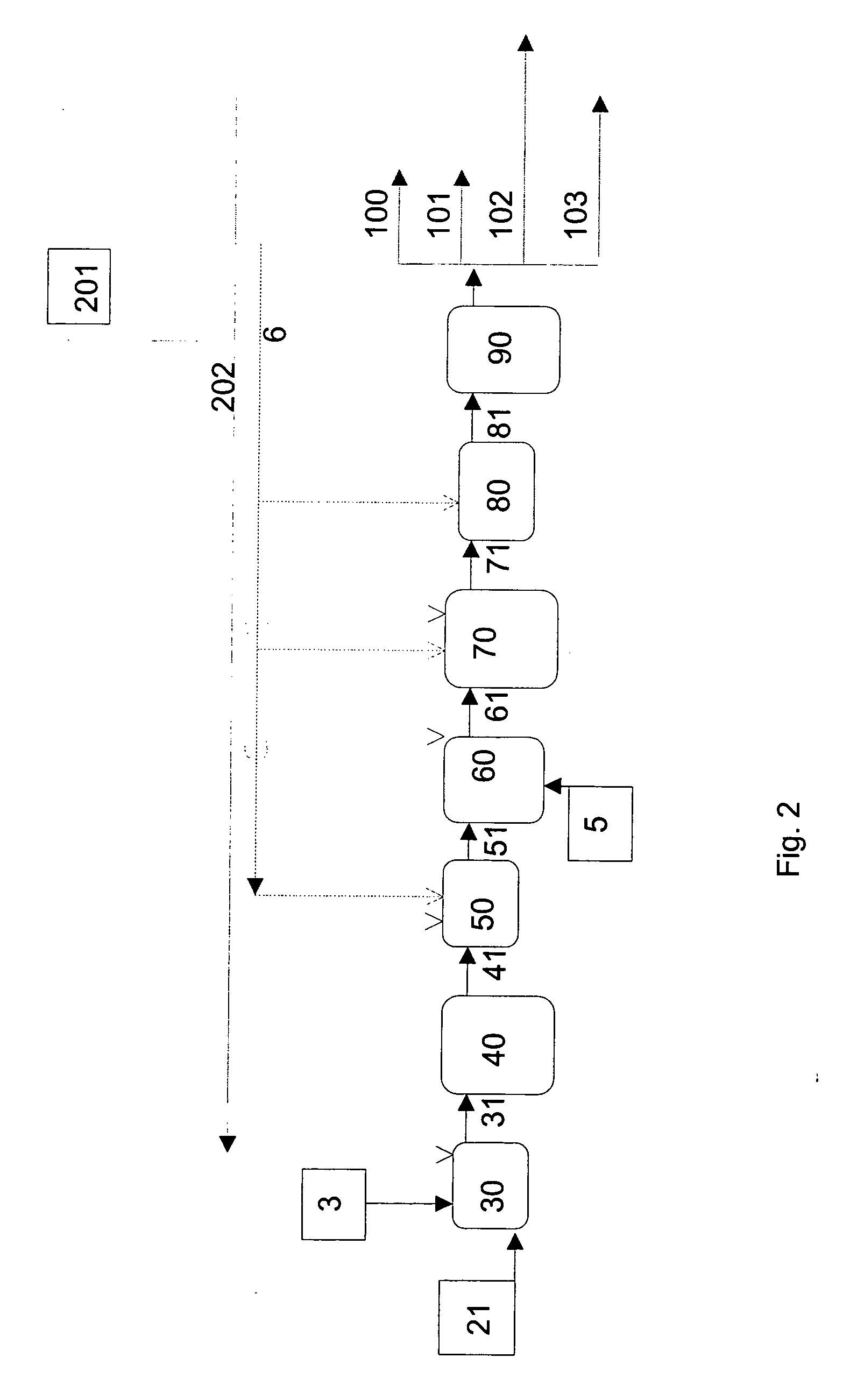

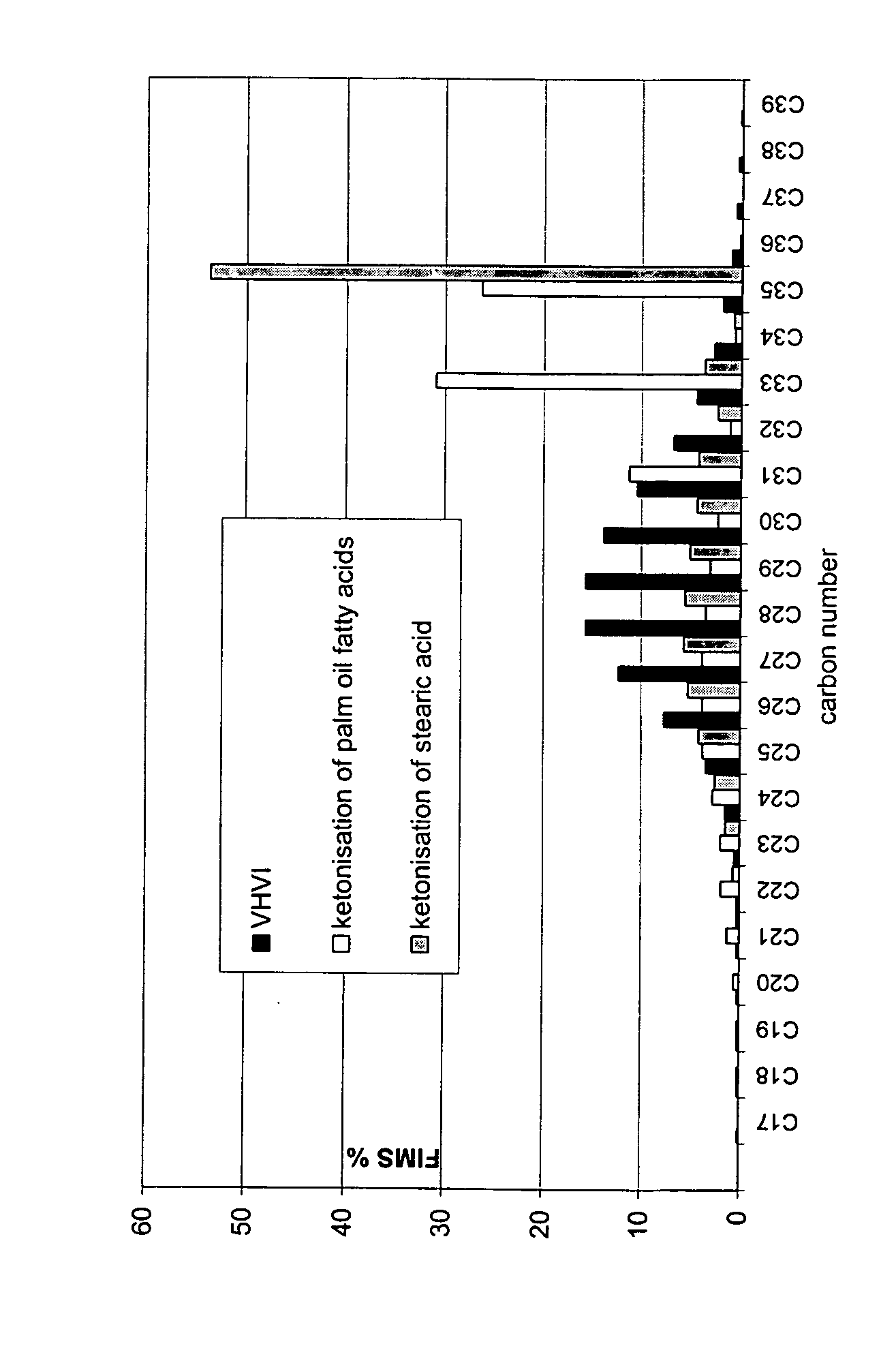

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

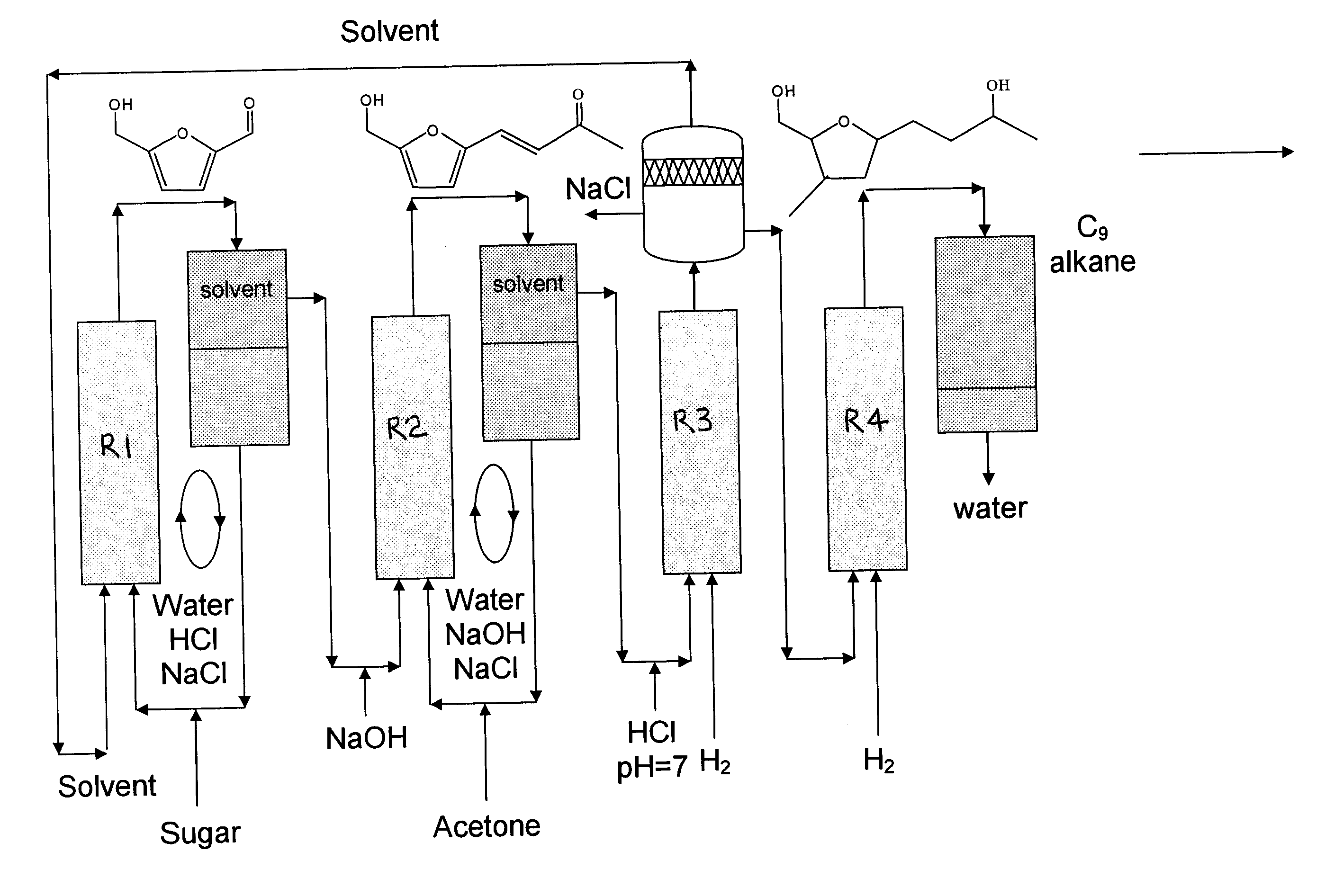

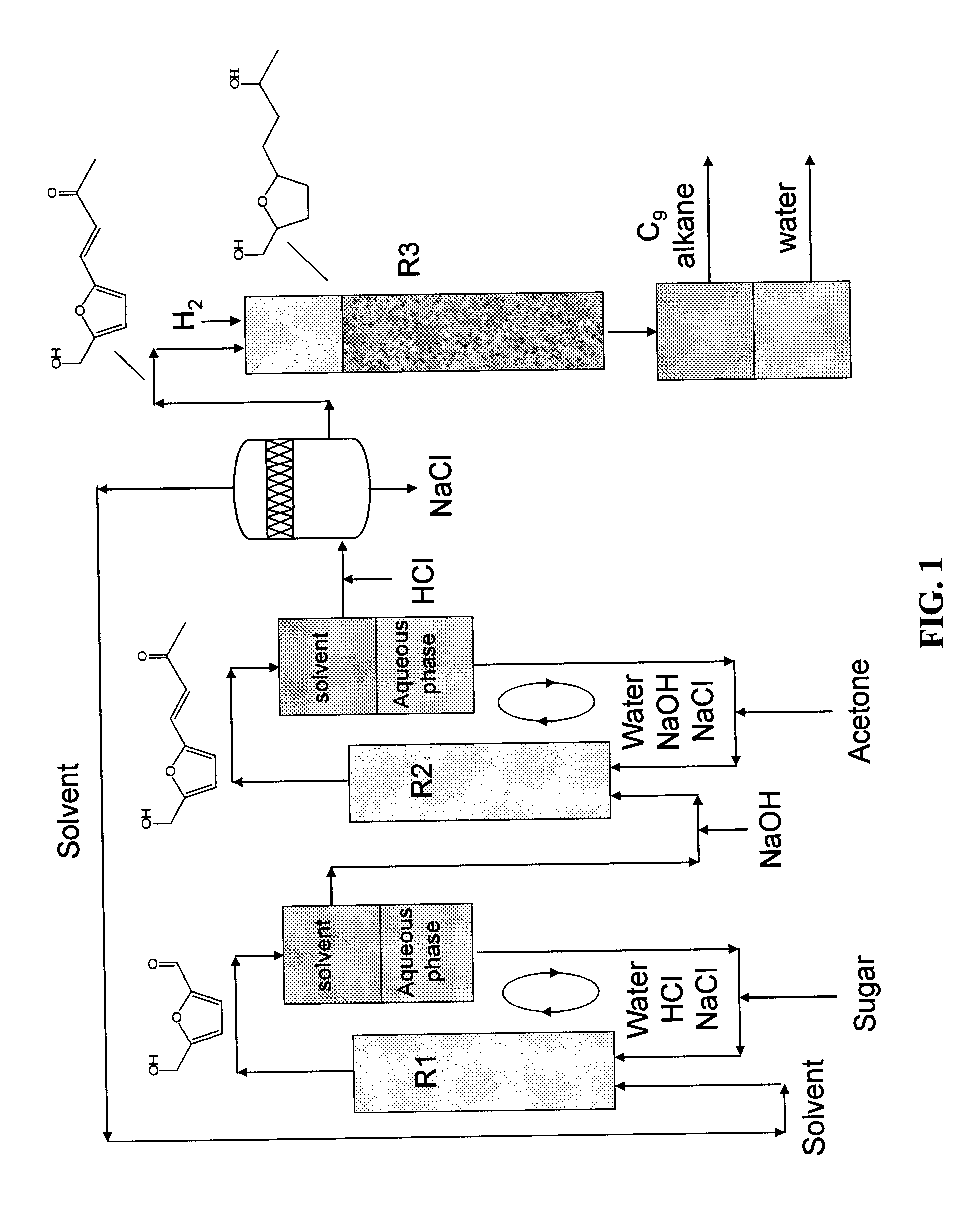

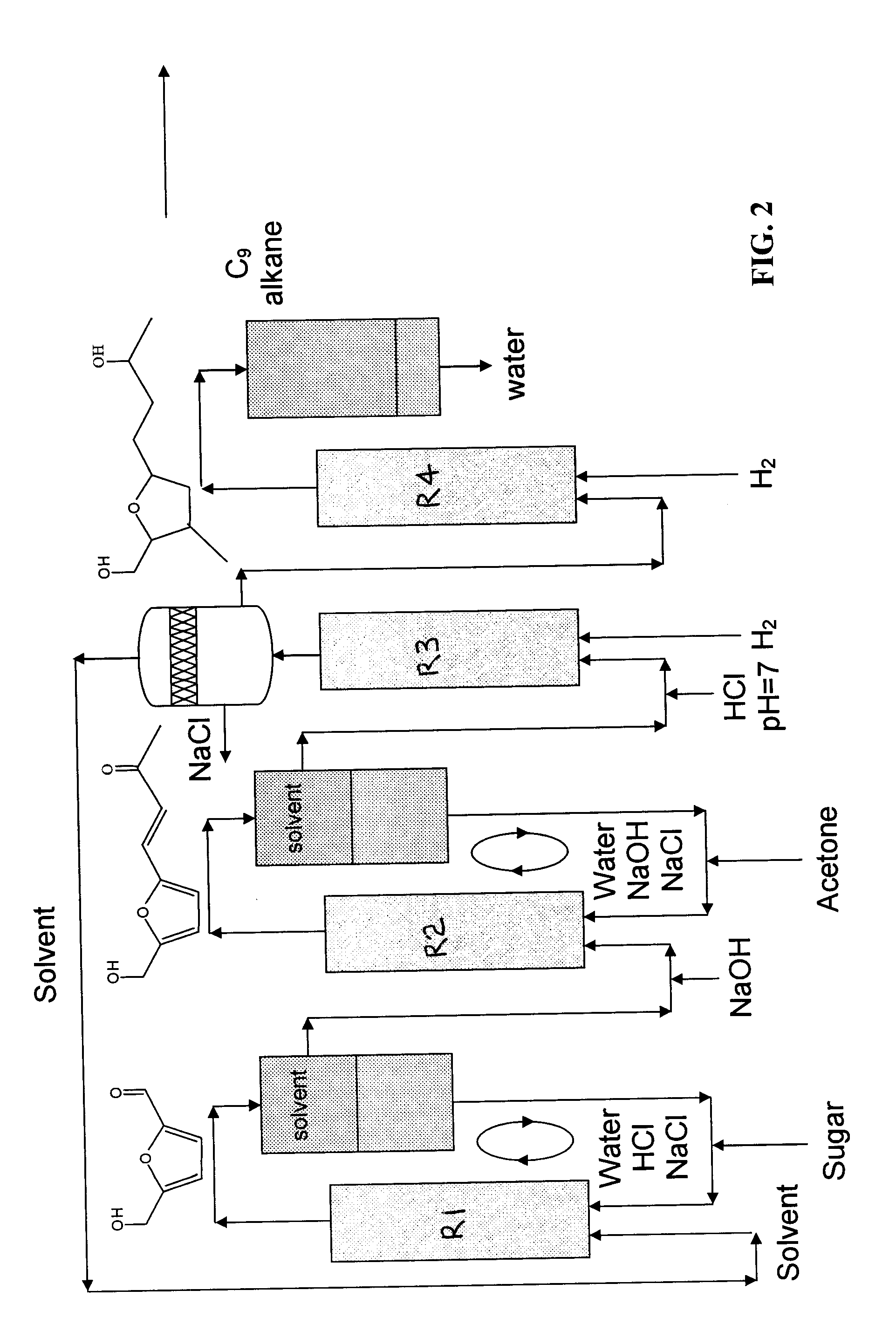

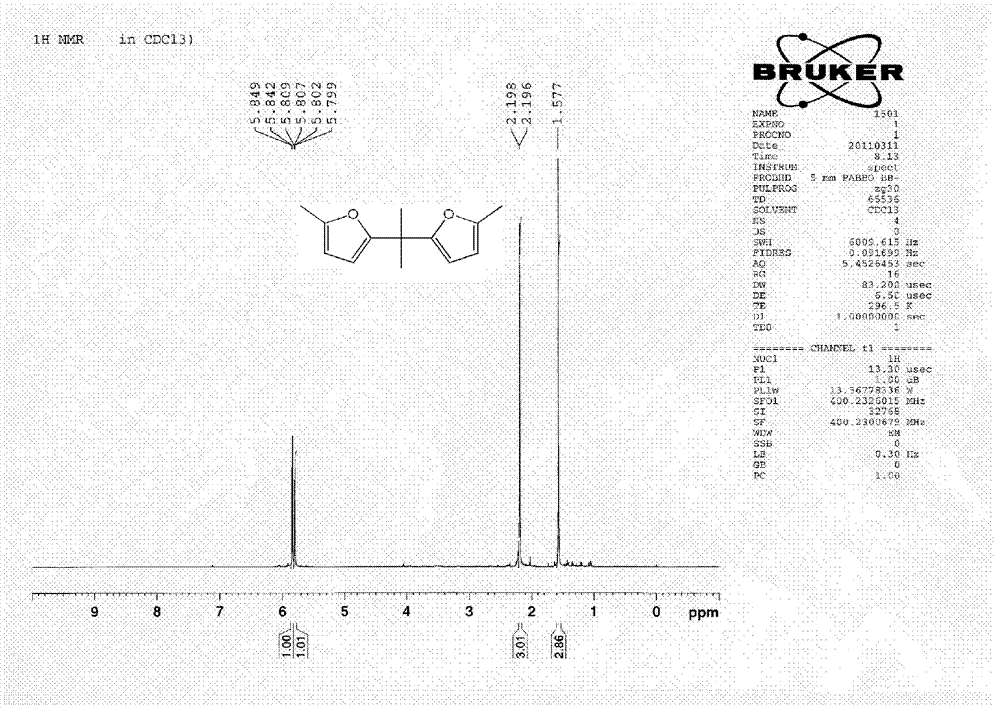

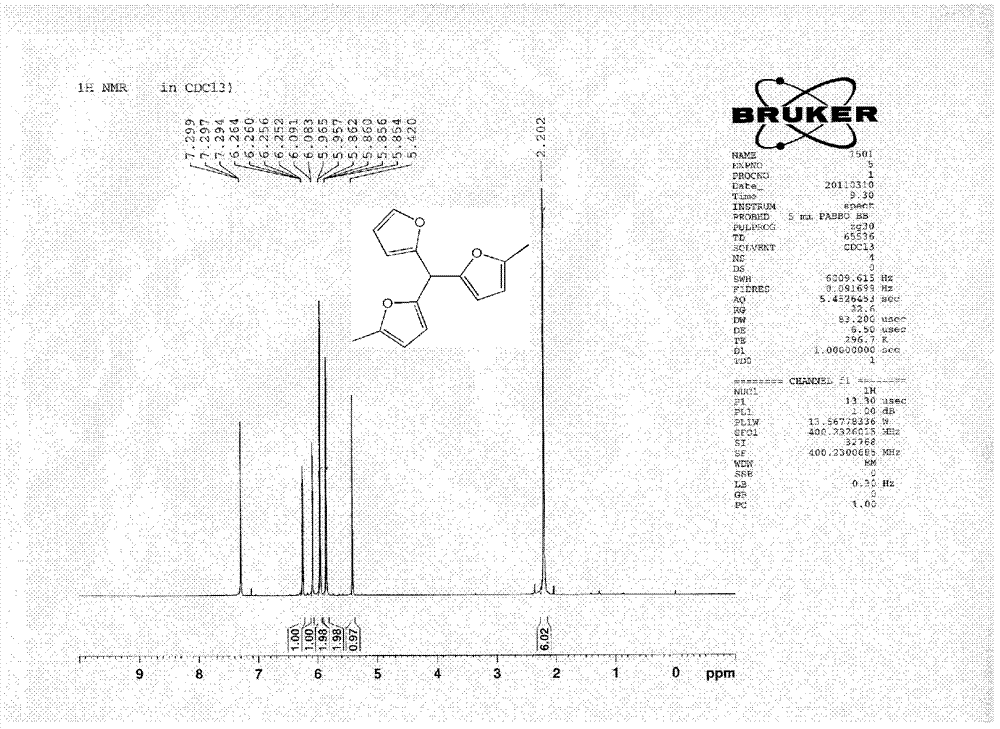

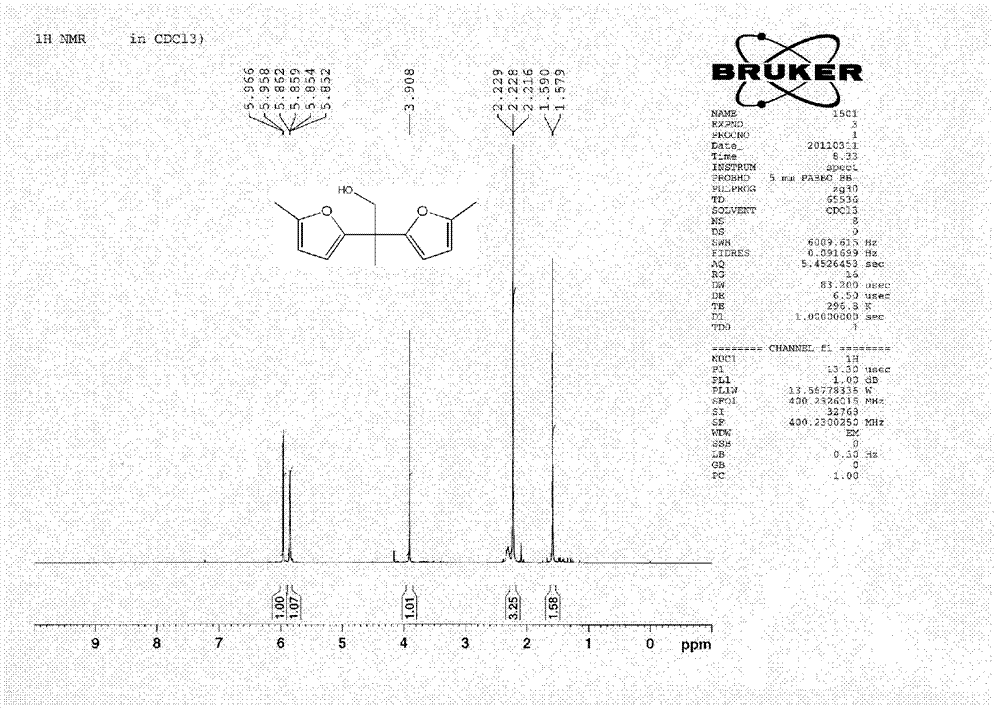

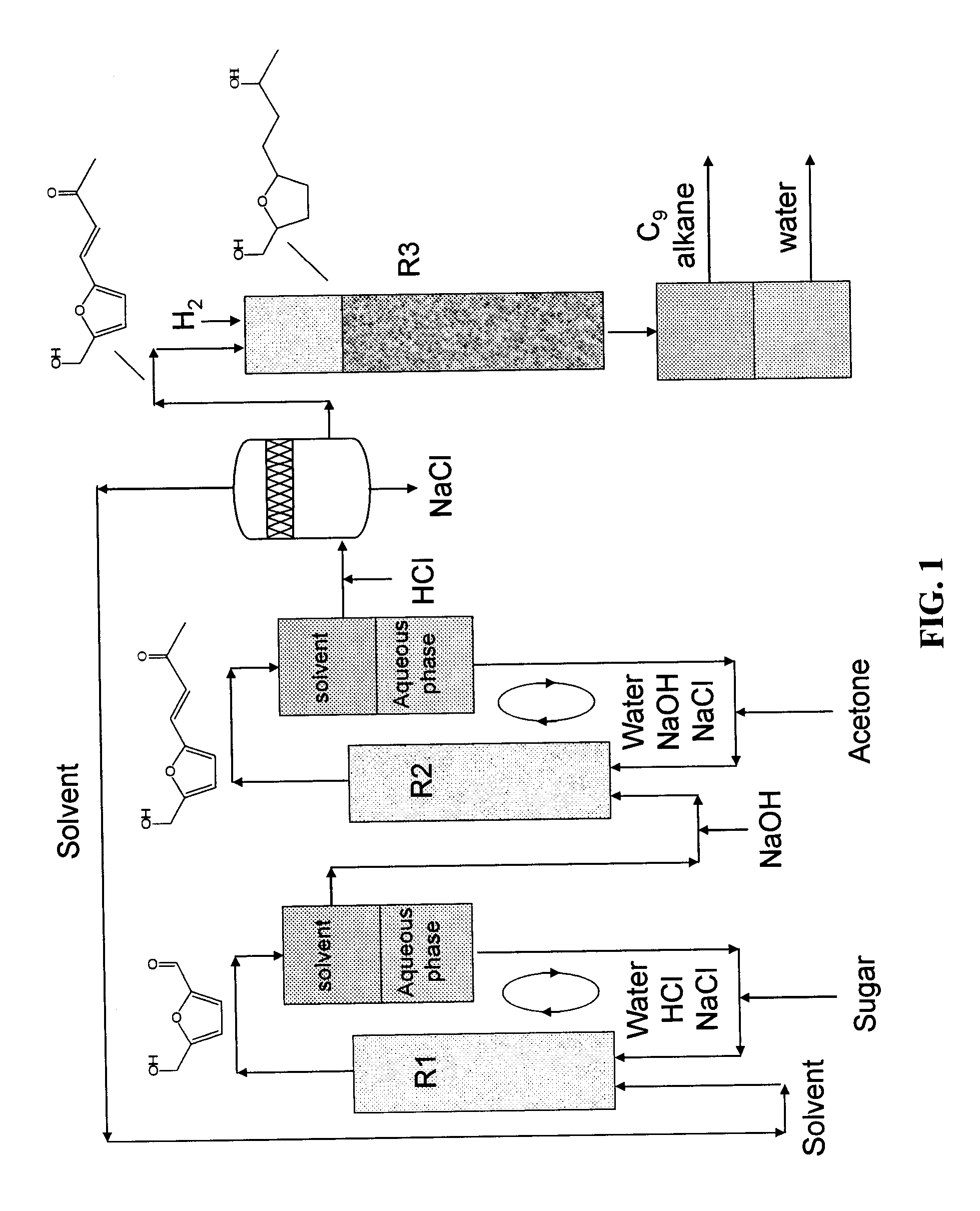

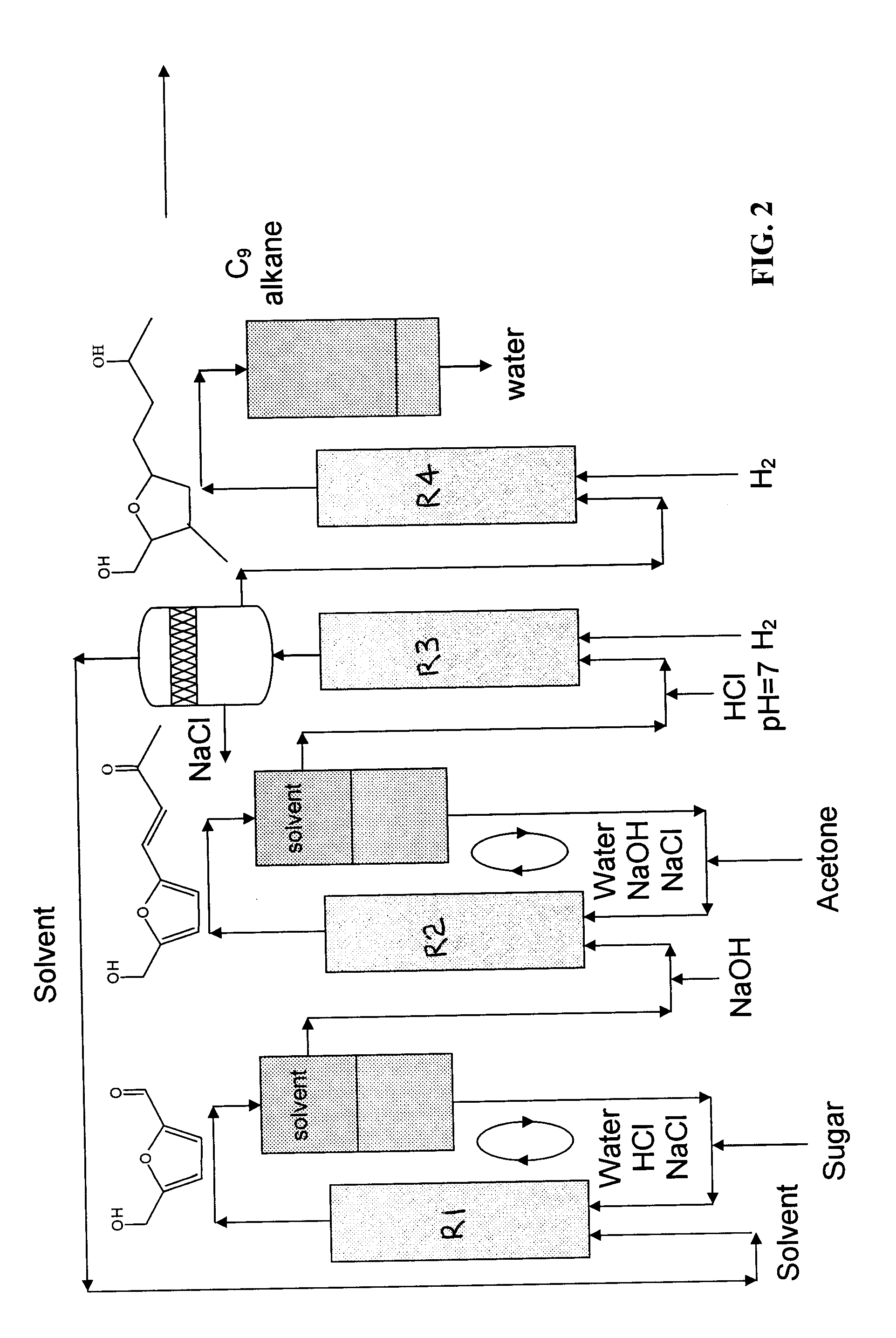

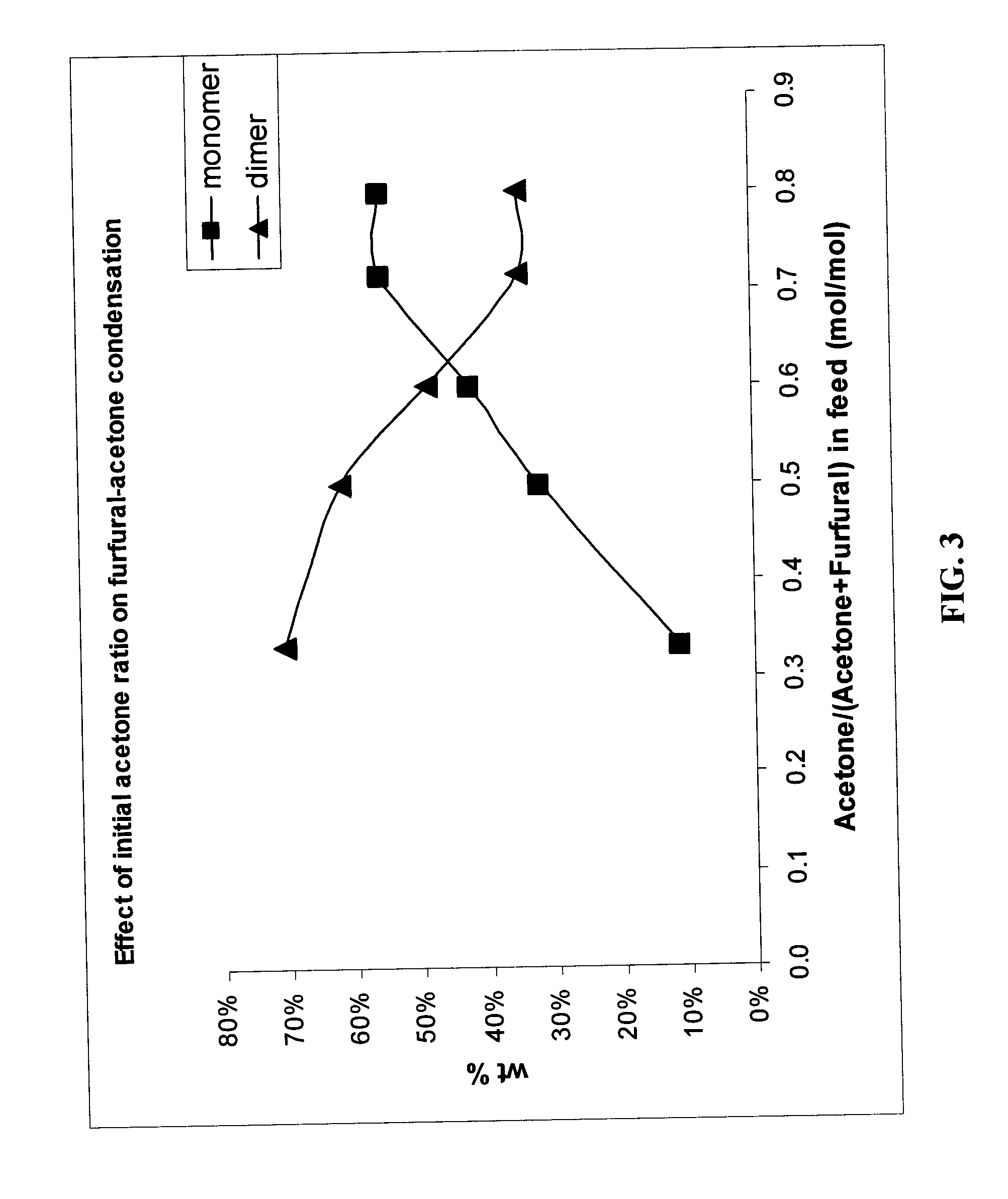

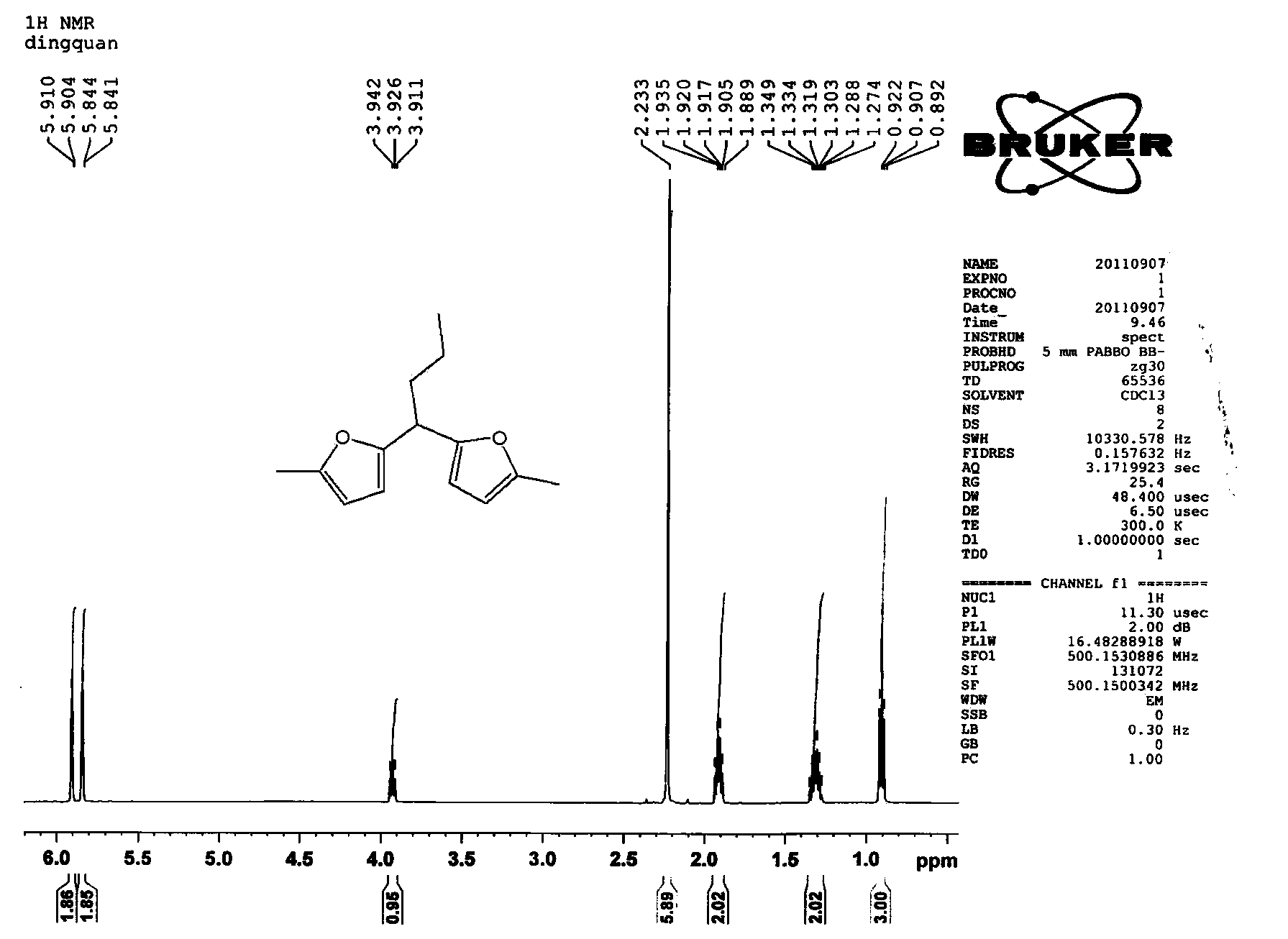

Production of liquid alkanes in the jet fuel range (c8-c15) from biomass-derived carbohydrates

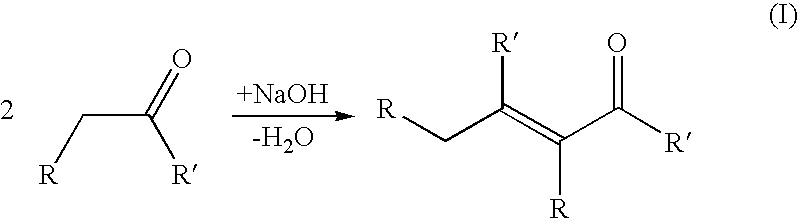

Described is a method for making a composition comprising alkanes. The composition is suitable for use as a liquid transportation fuel in general, and jet fuel in particular. The method includes dehydrating a feedstock solution comprising a carbohydrate, in the presence of an acid catalyst, to yield at least one furan derivative compound, in a reaction vessel containing a biphasic reaction medium: an aqueous reaction solution and a substantially immiscible organic extraction solution. The furan derivative compound is then subjected to a self-aldol condensation reaction or a crossed-aldol condensation reaction with another carbonyl compound to yield a beta-hydroxy carbonyl compound and / or an alpha-beta unsaturated carbonyl compound. The beta-hydroxy carbonyl and / or alpha-beta unsaturated compounds are then hydrogenated to yield a saturated or partially saturated compound, followed by hydrodeoxygenation (e.g., dehydrating and hydrogenating) of the saturated or partially saturated compound to yield a composition of matter comprising alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Process for the manufacture of hydrocarbons

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the diesel fuel distillation range by skeletal isomerisation and deoxygenation carried out by hydrodeoxygenation or alternatively by combined decarboxylation and decarbonylation reactions, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

Reduction catalysts

Disclosed are catalysts comprised of platinum and rhodium on a support selected from the group of zirconia, stabilized (doped) zirconia, zirconia-metal oxide composites, and mixtures thereof, wherein the outer surfaces of the support are selected from the group of zirconia, stabilized zirconia, and mixtures thereof. More particularly, the supported catalysts comprise platinum and rhodium, wherein the molar ratio of platinum to rhodium is in the range of about 3:1 to about 1:2. The average pore diameter of the catalyst supports is in the range of about 5 nm to about 70 nm and the surface area is in the range of about 15 m2 / g to about 200 m2 / g. Also disclosed are methods for the hydrodeoxygenation of carboxylic acids, mono- and / or di-lactones thereof having at least one hydroxyl group on the backbone thereof to corresponding acids where the backbone hydroxyl group has been reduced in the presence of the catalyst.

Owner:ARCHER DANIELS MIDLAND CO

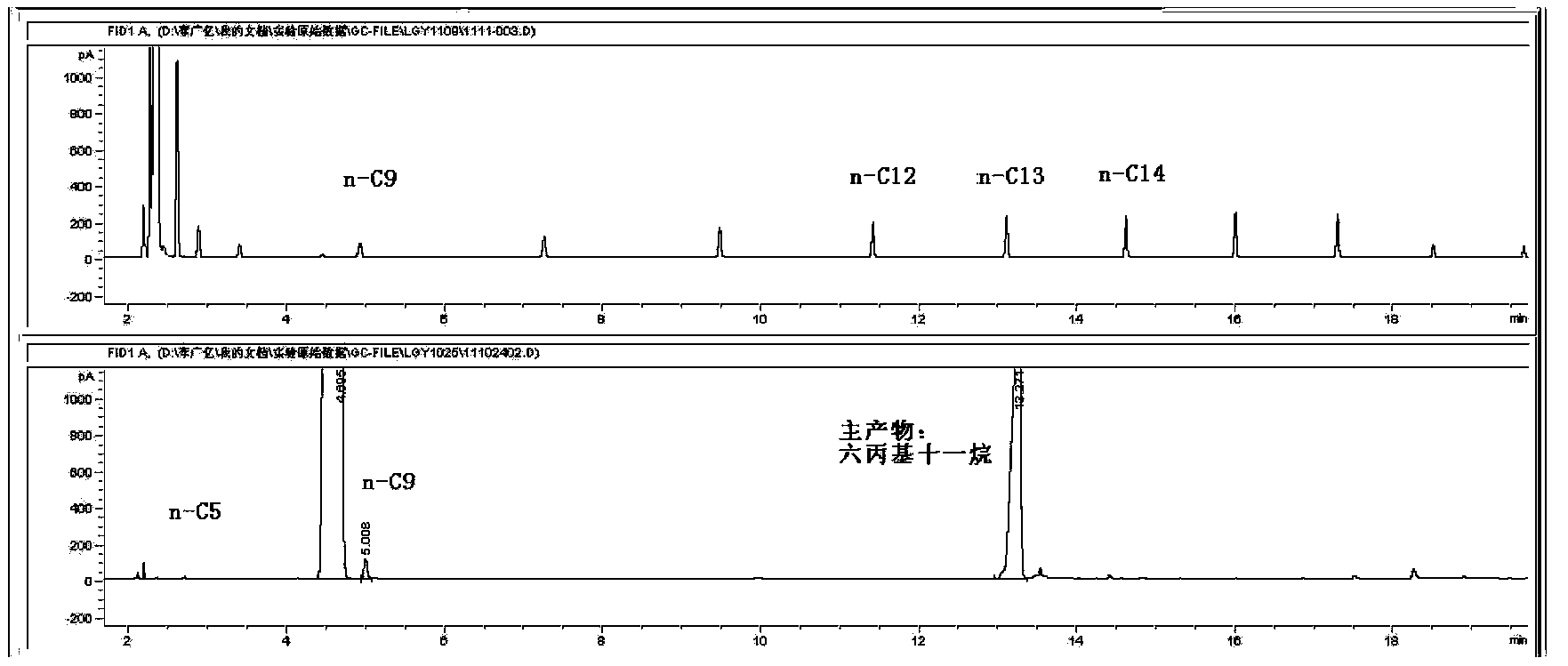

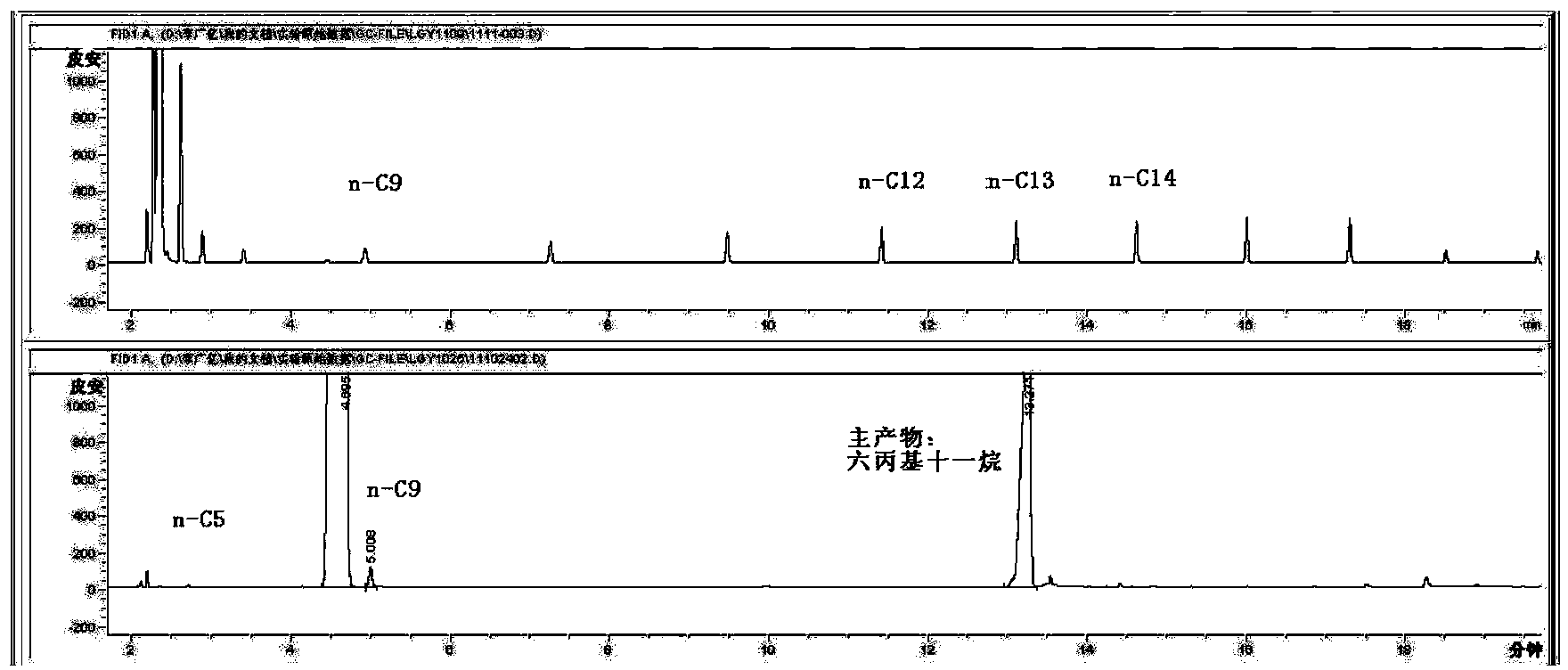

Preparation method of aviation kerosene or diesel

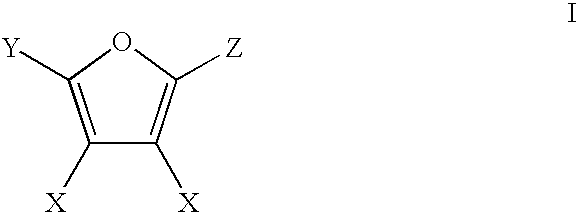

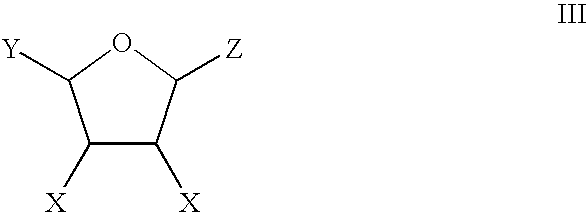

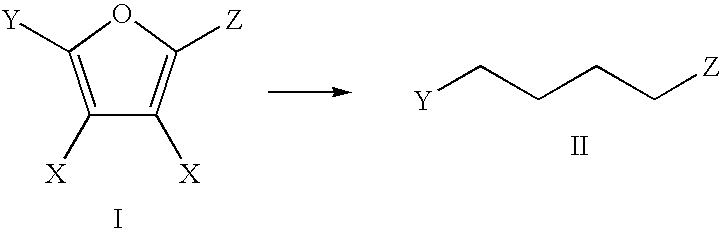

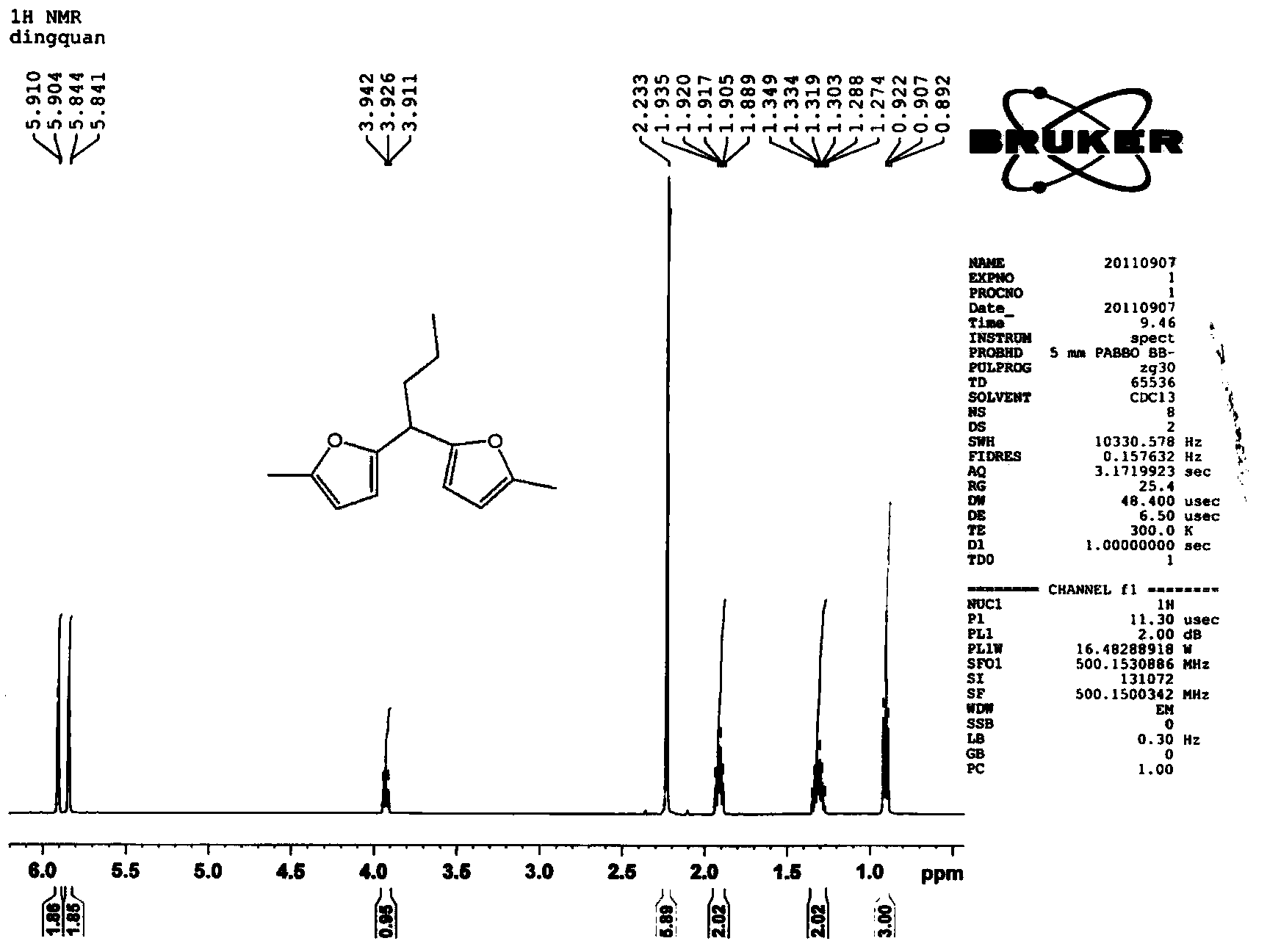

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for producing a branched hydrocarbon component

InactiveUS20070135316A1Reduce carbon dioxide emissionsImprove stabilityOrganic compound preparationCatalytic naphtha reformingIsomerizationHydrodeoxygenation

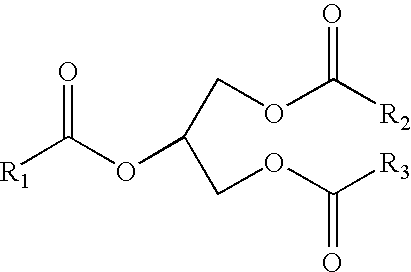

The invention relates to a process for producing high-quality hydrocarbon base oil particularly of biological origin. The process of the invention comprises aldol condensation, hydrodeoxygenation, and isomerization steps. Aldehydes and / or ketones, preferably of biological origin are used as the feedstock.

Owner:NESTE OIL OY

Paraffinic Biologically-Derived Distillate Fuels With Bio-Oxygenates For Improved Lubricity And Methods Of Making Same

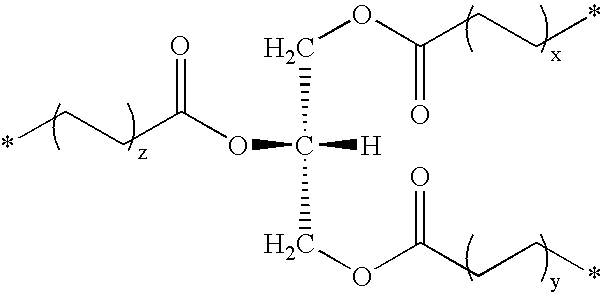

ActiveUS20090031617A1Improve the lubrication effectImprove efficiencyFatty acid chemical modificationRefining to change hydrocarbon structural skeletonParaffin waxIsomerization

The present invention is generally directed to methods for making fuels from biomass comprising triglyceride species, whereby the biomass is subjected to partial hydrodeoxygenation and (optionally) catalytic isomerization. The partial-hydrodeoxygenation of the triglyceride species produces a fuel that retains some oxygenates for enhanced lubricity.

Owner:CHEVROU USA INC

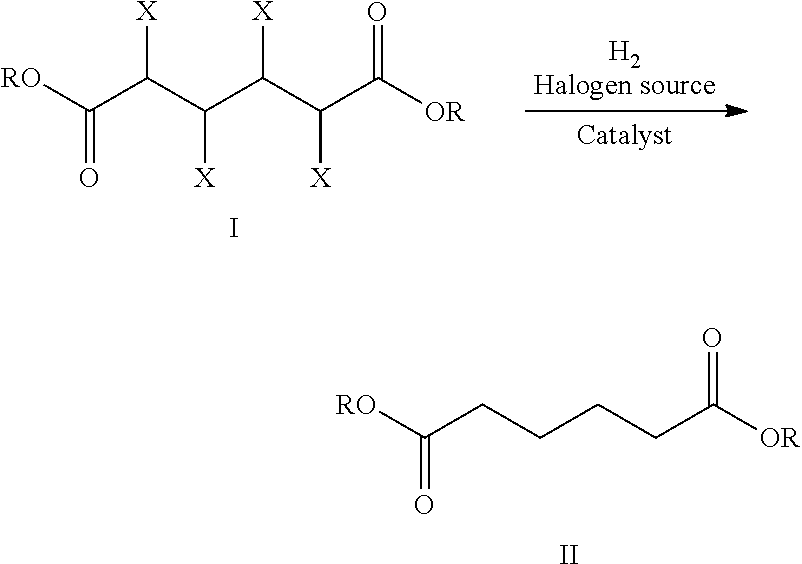

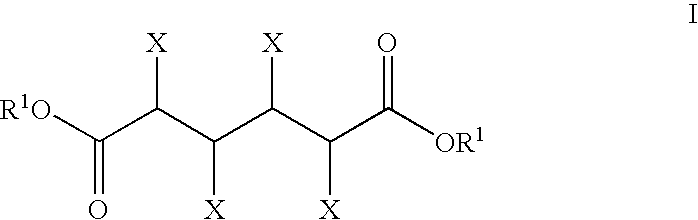

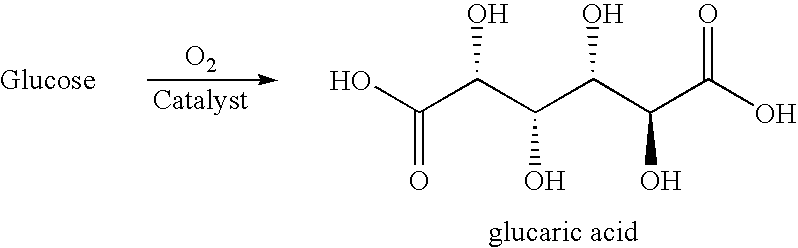

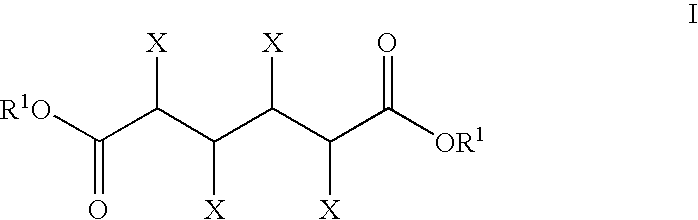

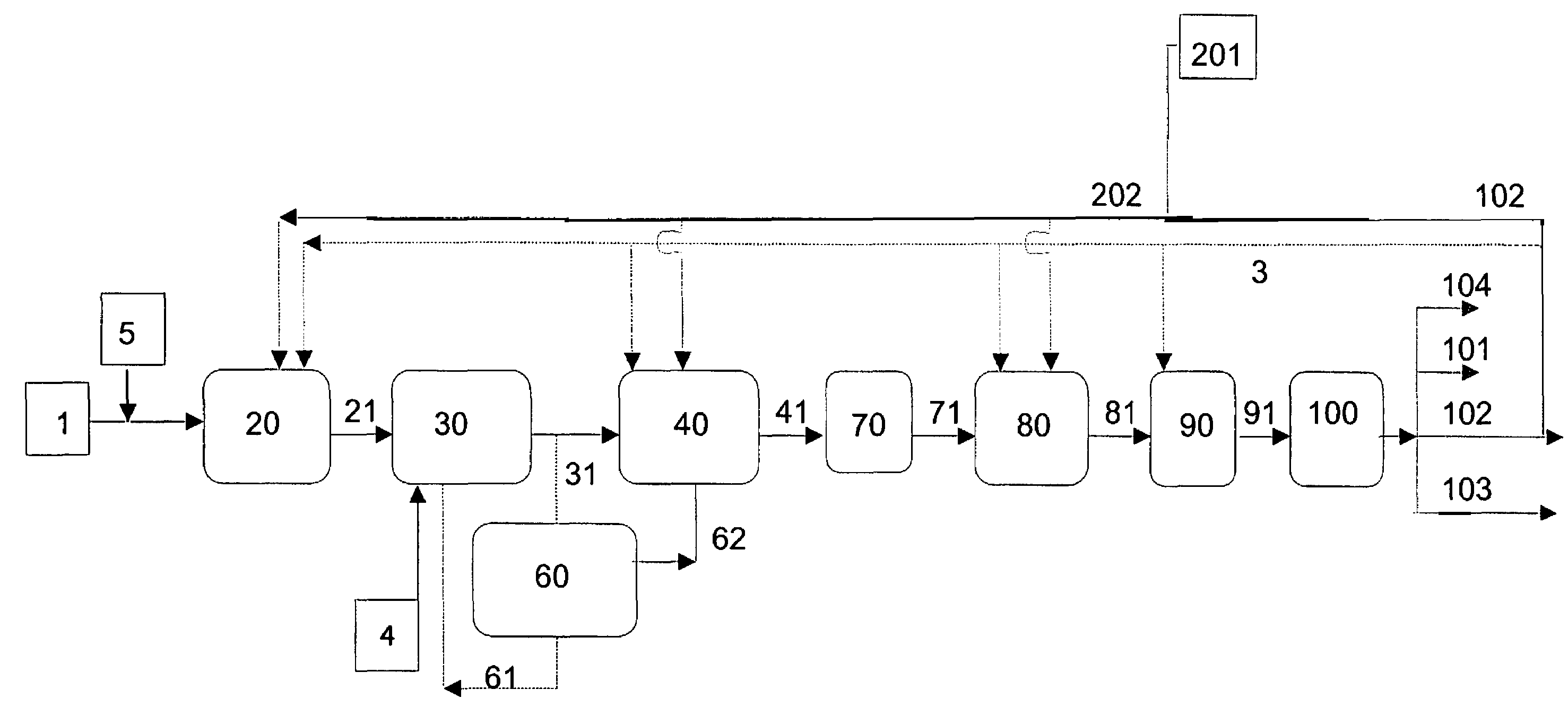

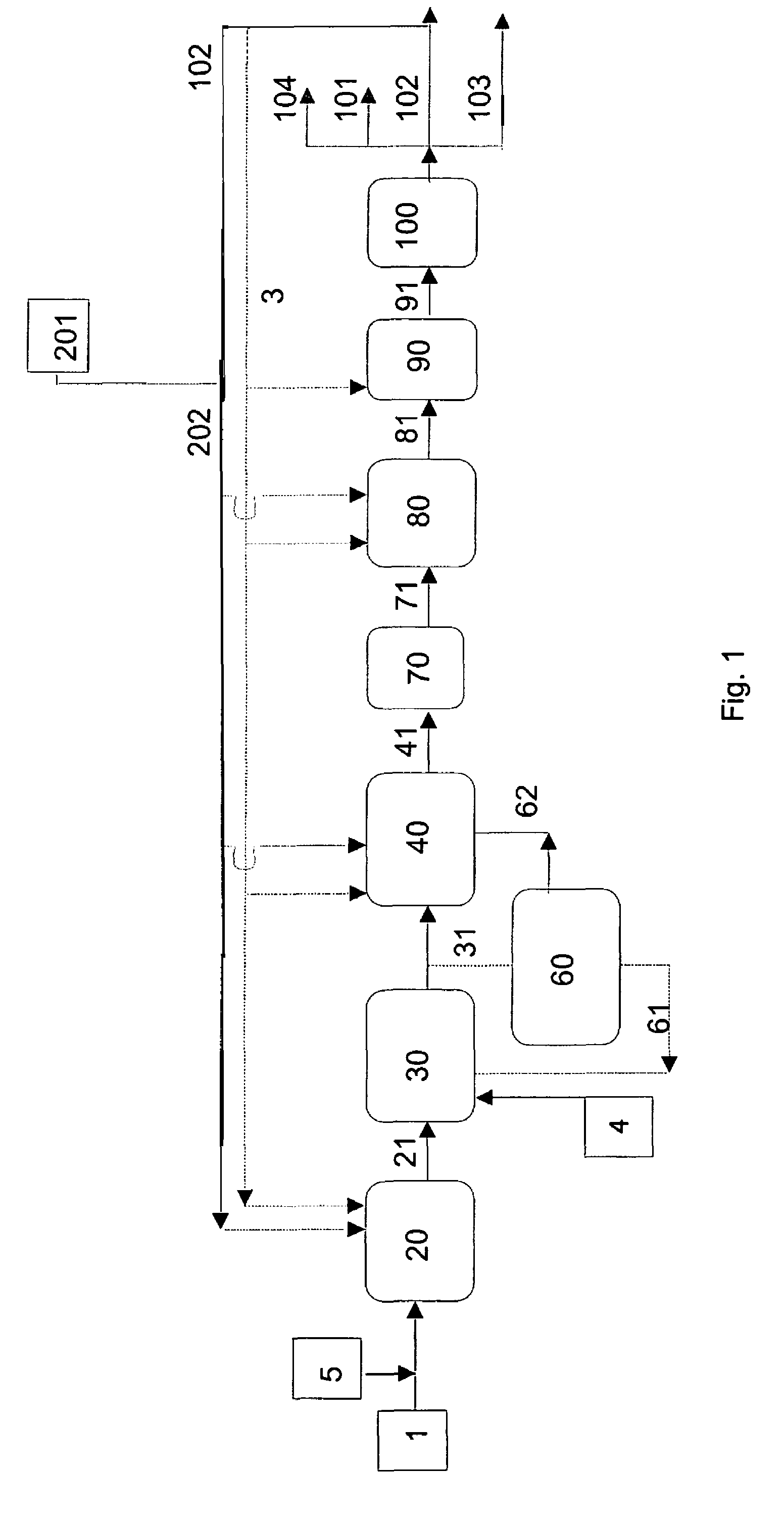

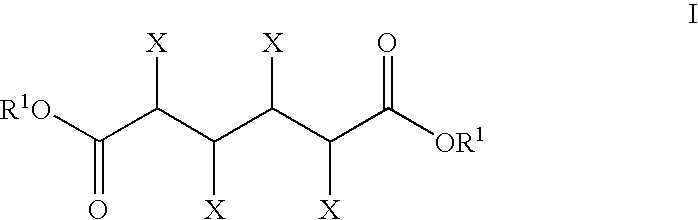

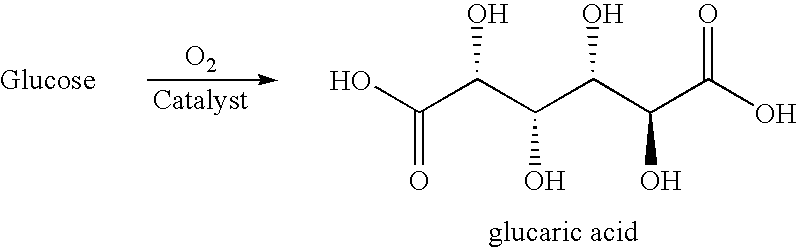

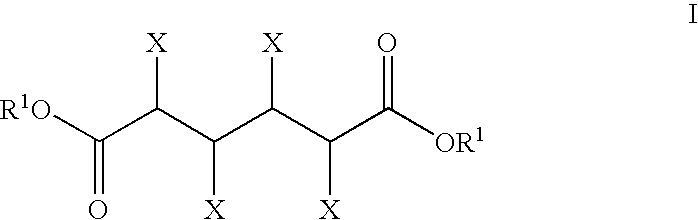

Production of adipic acid and derivatives from carbohydrate-containing materials

ActiveUS8669397B2Low costLactams preparationCarboxylic acid nitrile preparationCatalytic oxidationHydrodeoxygenation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

ActiveUS20080308458A1Fatty acid chemical modificationMolecular sieve catalystsParaffin waxVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal a first oxide and optionally a second oxide wherein at least one of the first oxide or second oxide comprises a zeolite, through hydrodeoxygenation and one or both of hydroisomerization and hydrocracking.

Owner:REFINING TECH SOLUTIONS LLC

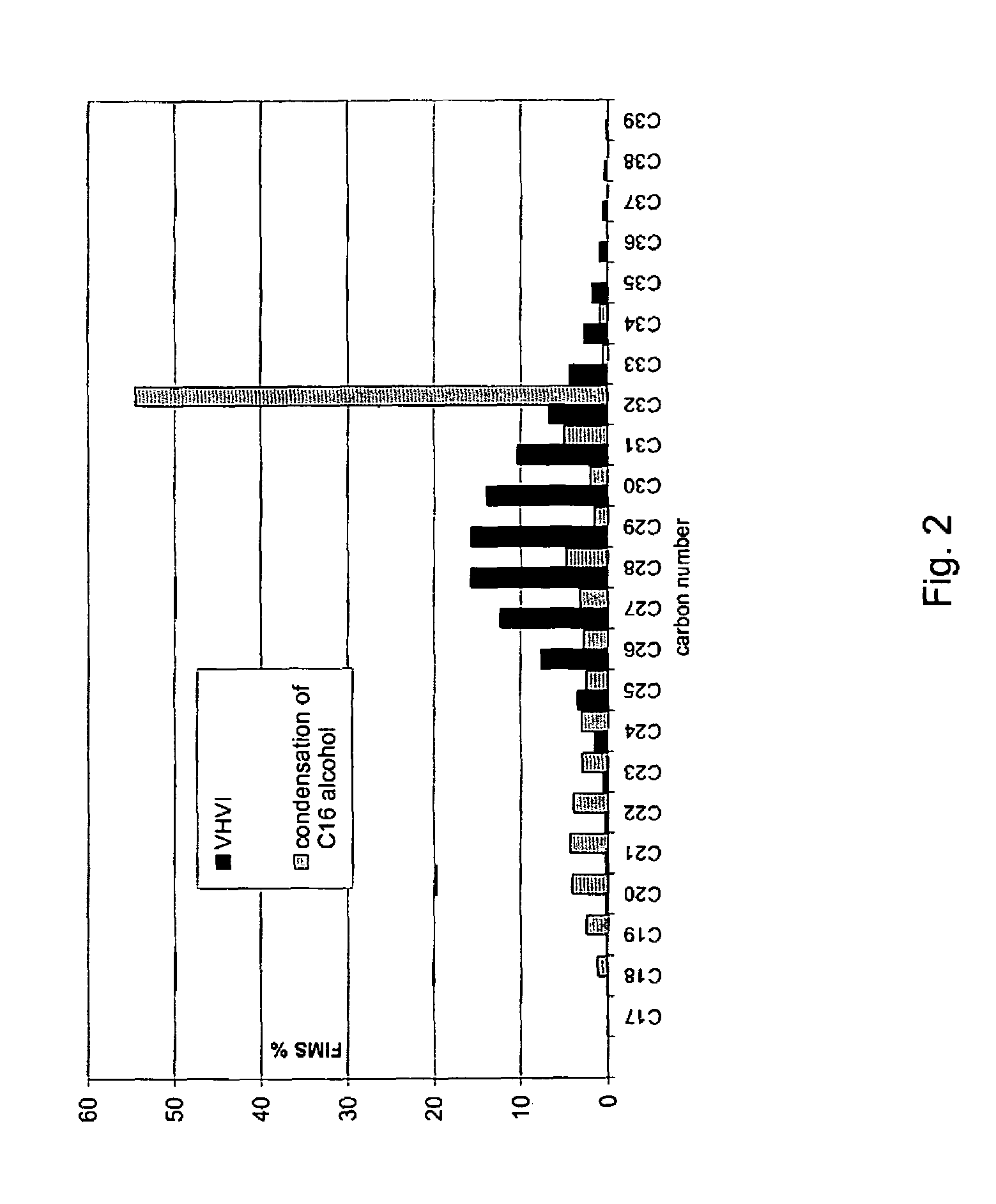

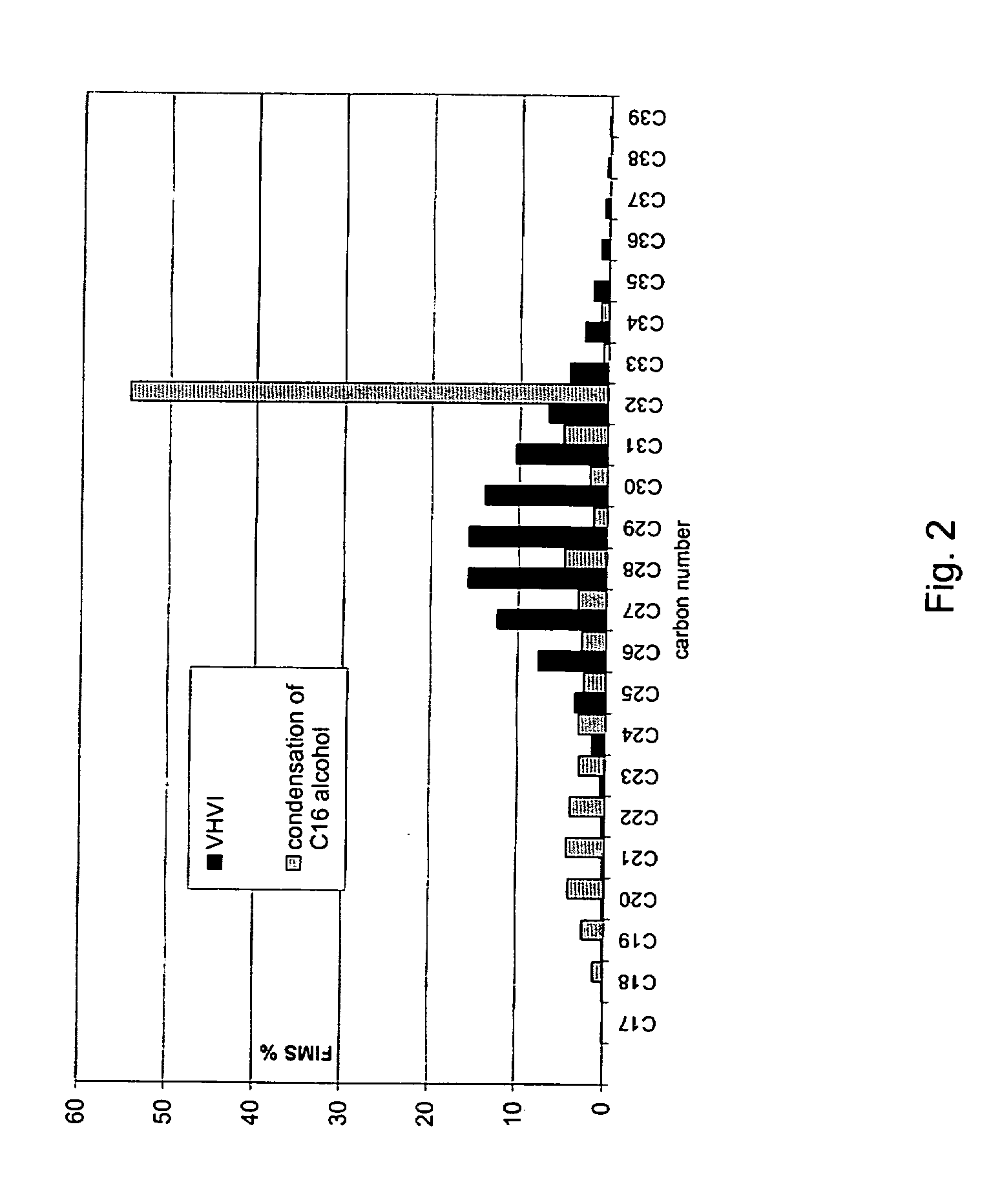

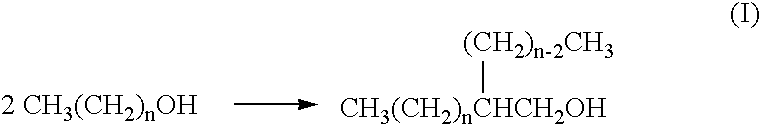

Process for producing a branched hydrocarbon component

The invention relates to a process for producing high-quality hydrocarbon base oil of biological origin. The process of the invention comprises alcohol condensation, hydrodeoxygenation, and isomerization steps. Alcohols, preferably fatty alcohols of biological origin are used as the feedstock.

Owner:NESTE OIL OY

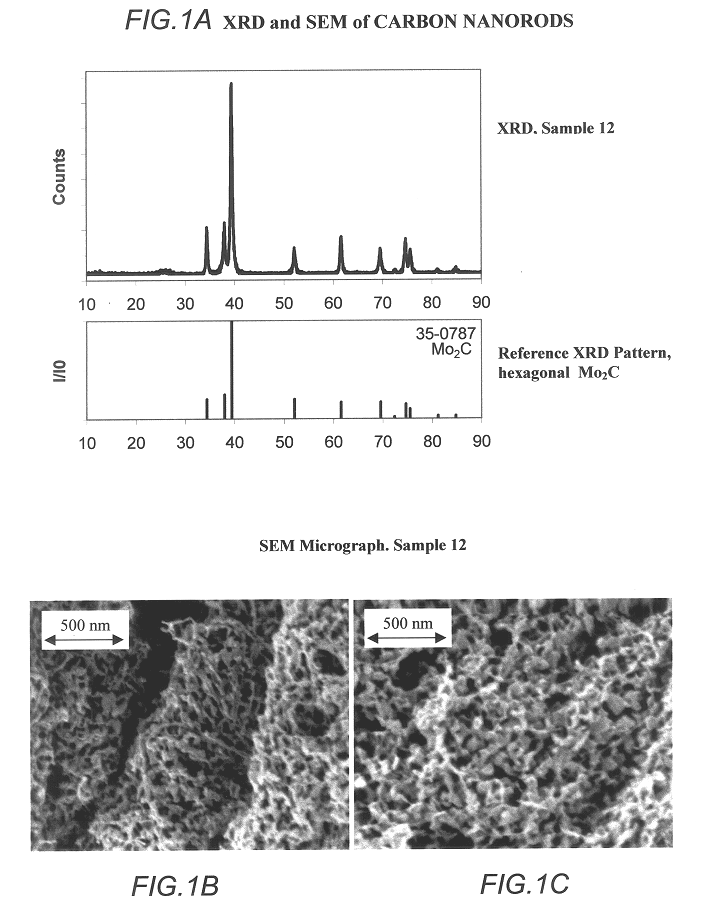

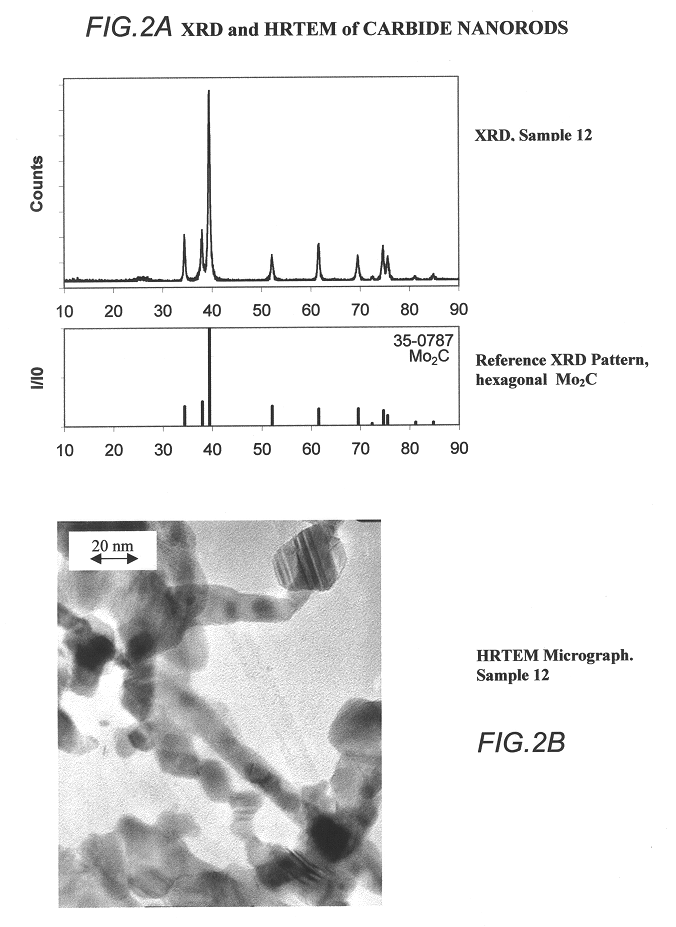

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

Production of liquid alkanes in the jet fuel range (C8-C15) from biomass-derived carbohydrates

ActiveUS7880049B2High selectivityHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlkaneFuran

Described is a method for making a composition comprising alkanes. The composition is suitable for use as a liquid transportation fuel in general, and jet fuel in particular. The method includes dehydrating a feedstock solution comprising a carbohydrate, in the presence of an acid catalyst, to yield at least one furan derivative compound, in a reaction vessel containing a biphasic reaction medium: an aqueous reaction solution and a substantially immiscible organic extraction solution. The furan derivative compound is then subjected to a self-aldol condensation reaction or a crossed-aldol condensation reaction with another carbonyl compound to yield a beta-hydroxy carbonyl compound and / or an alpha-beta unsaturated carbonyl compound. The beta-hydroxy carbonyl and / or alpha-beta unsaturated compounds are then hydrogenated to yield a saturated or partially saturated compound, followed by hydrodeoxygenation (e.g., dehydrating and hydrogenating) of the saturated or partially saturated compound to yield a composition of matter comprising alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

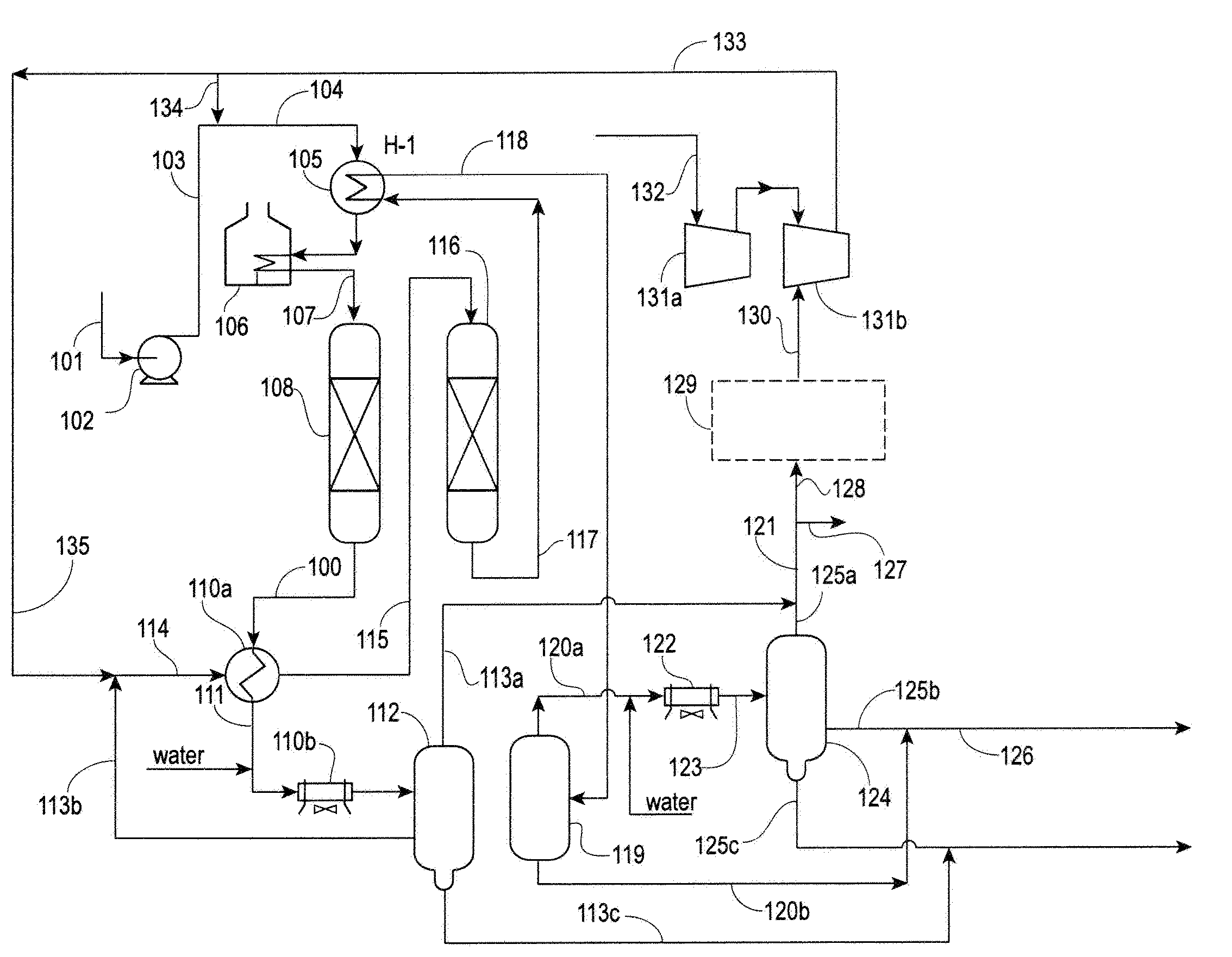

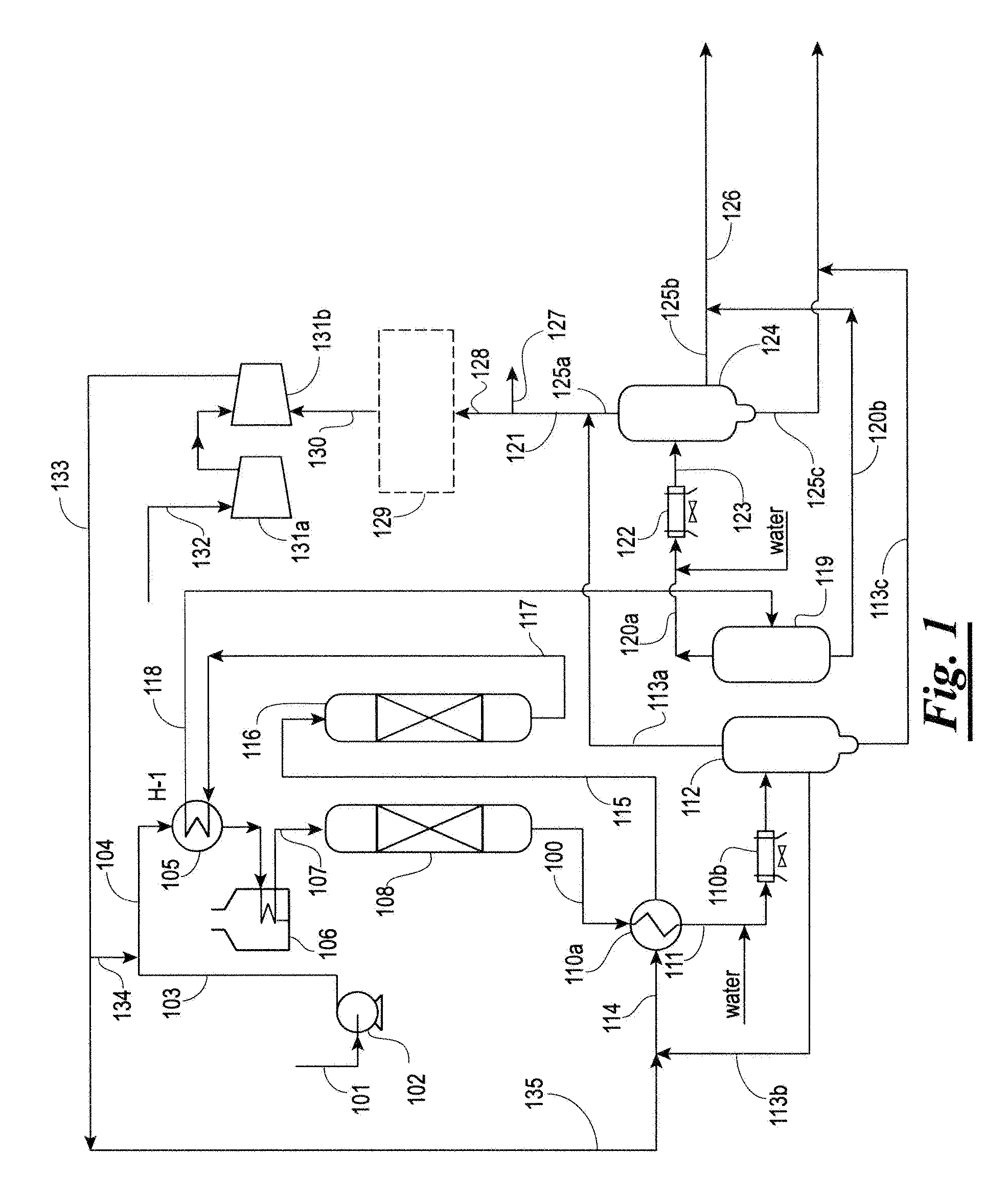

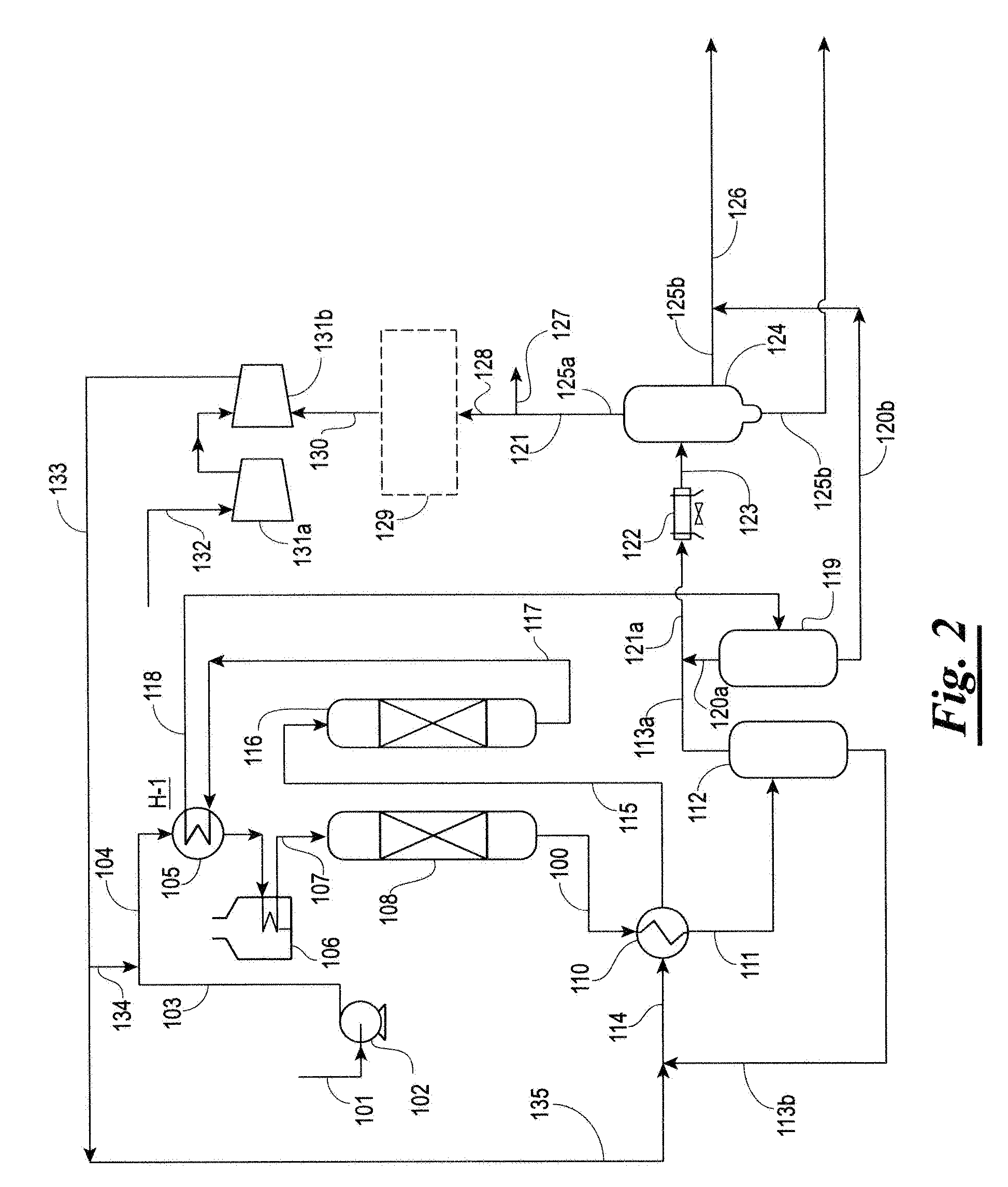

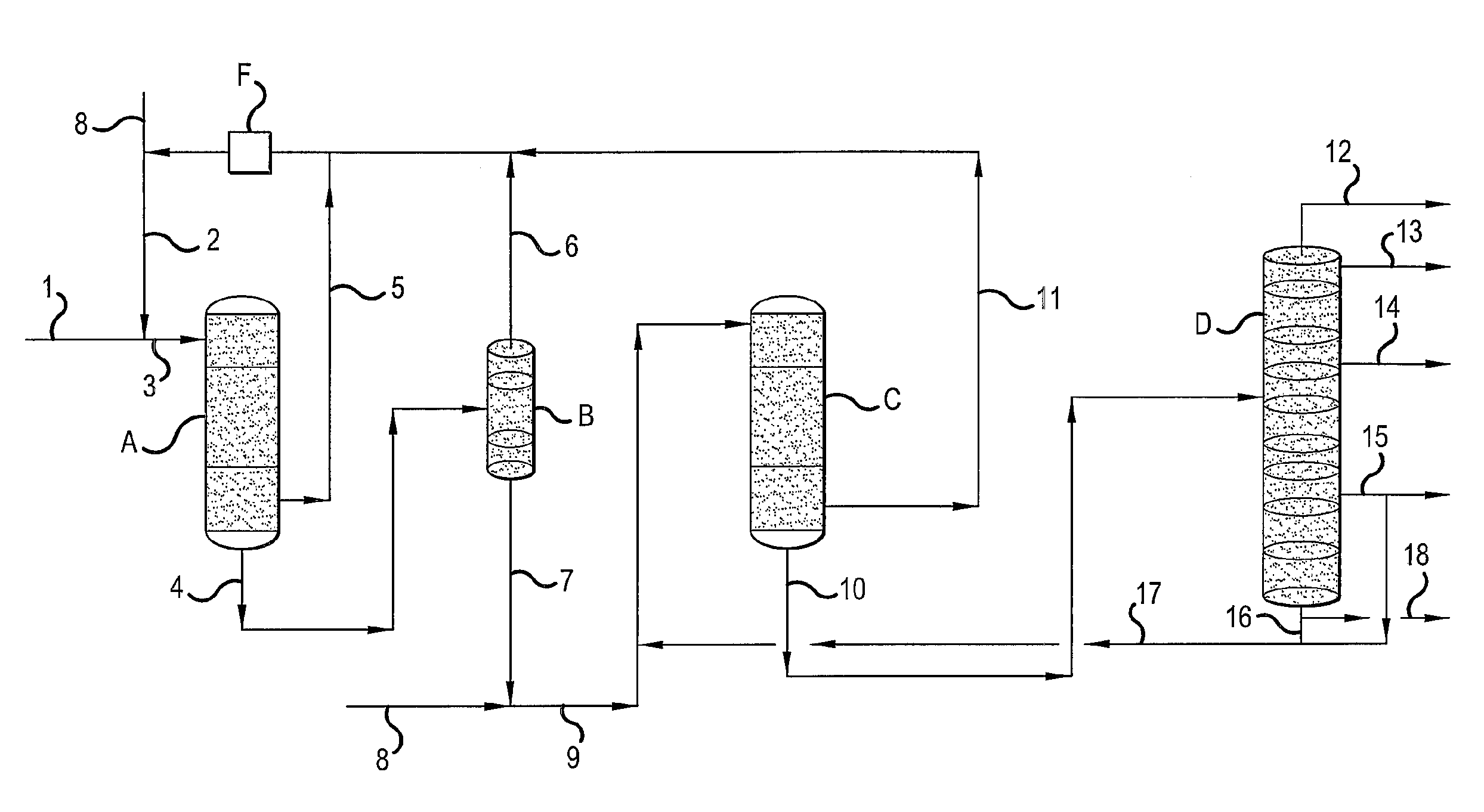

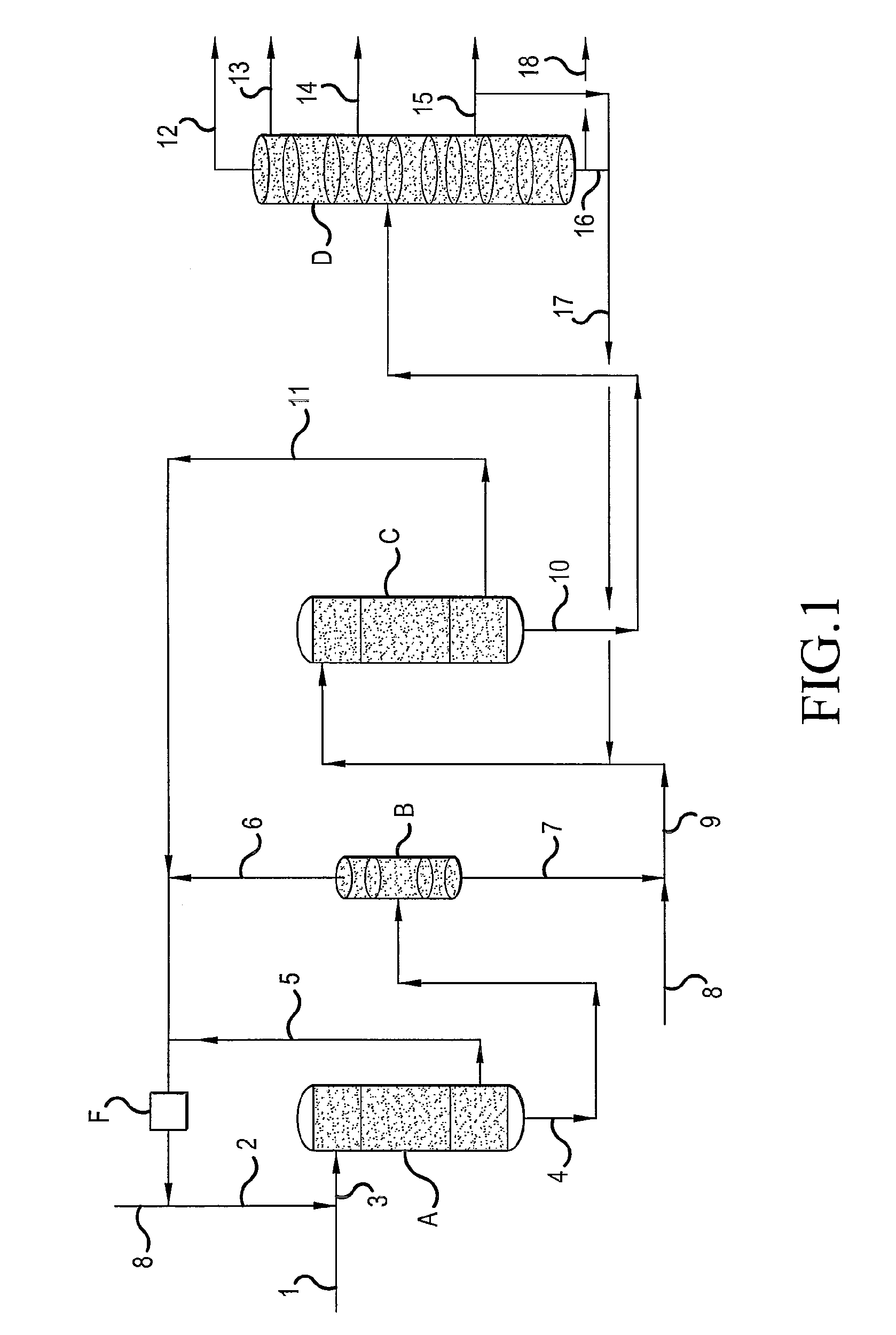

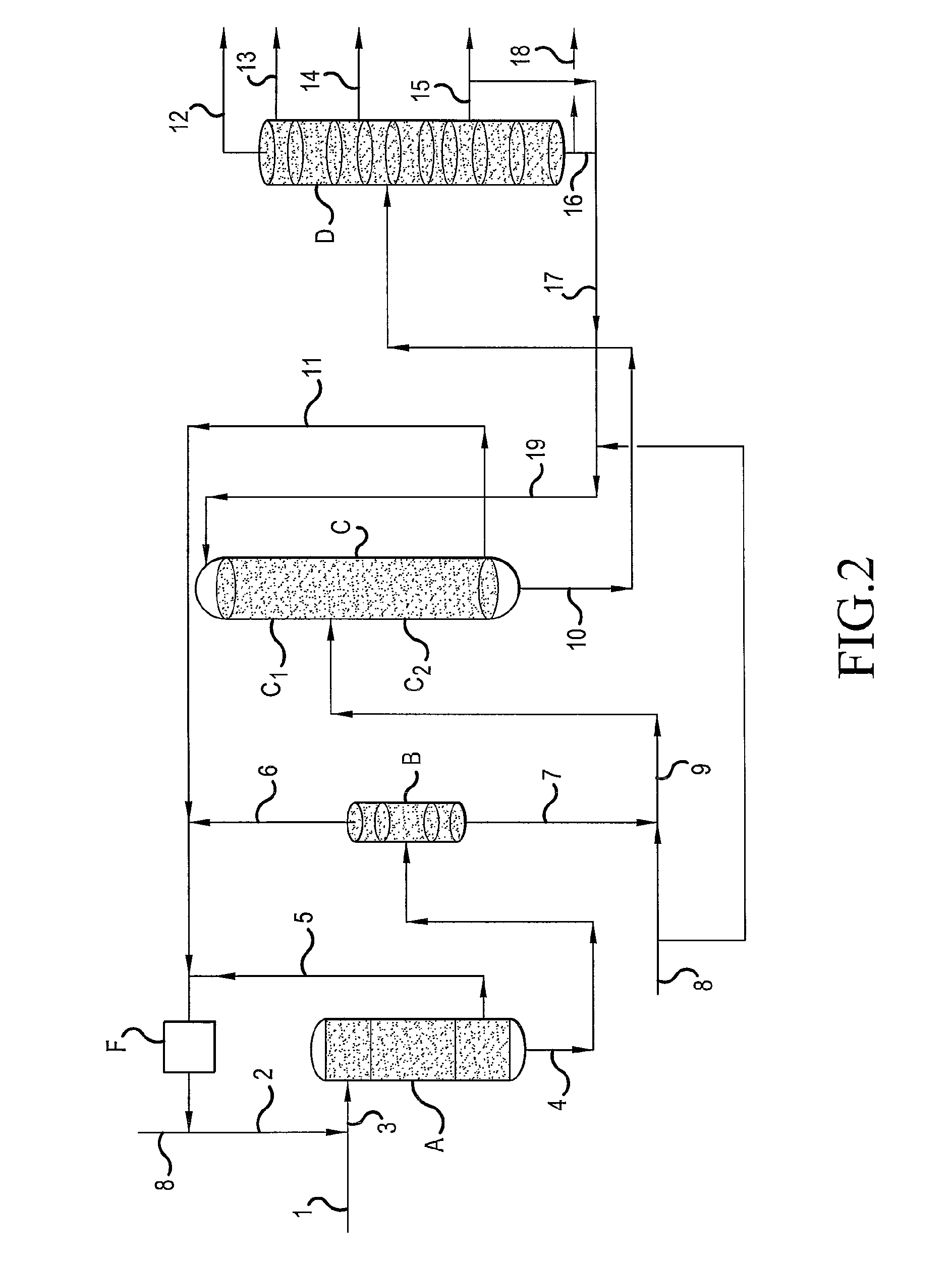

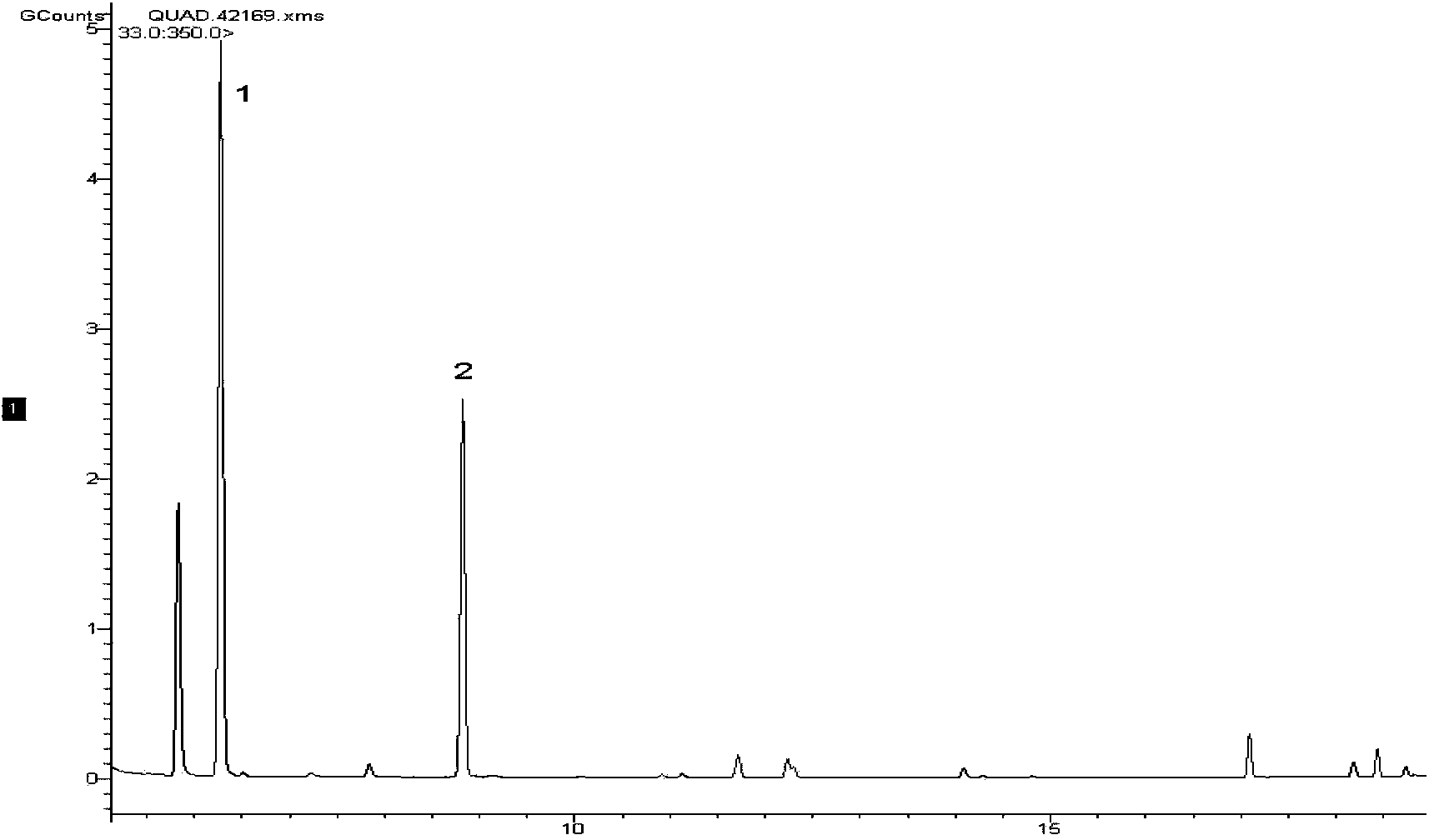

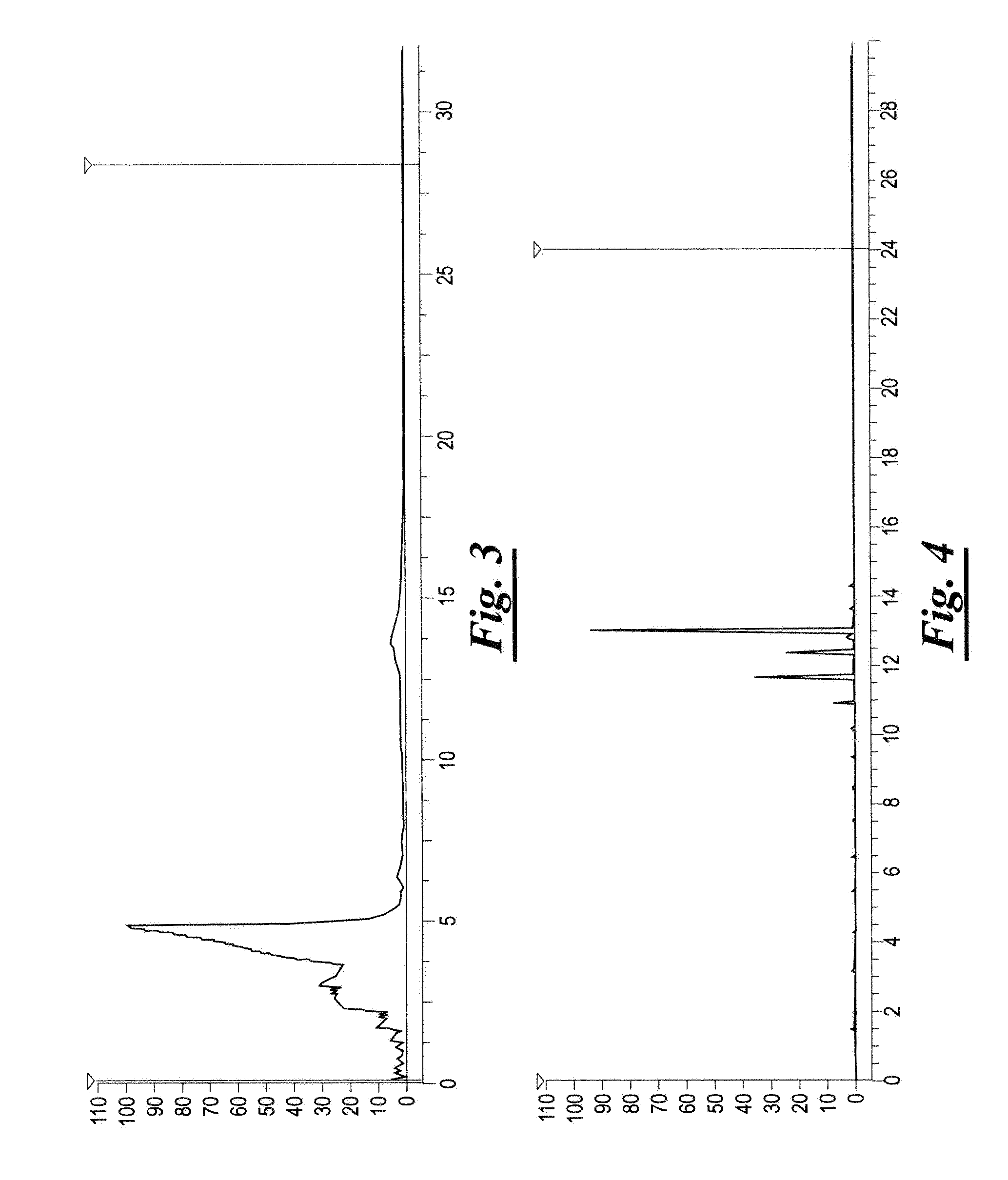

Hydrodeoxygenation process

A process for producing a hydrocarbon from biomass. A feed stream having free fatty acids, fatty acid esters or combinations thereof is provided. The feed stream is heated in the presence of a first catalyst to produce a partially hydrodeoxygenated stream. The partially hydrodeoxygenated stream is heated in the presence of a second catalyst to produce an effluent stream containing the hydrocarbon.

Owner:REG SYNTHETIC FUELS LLC

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

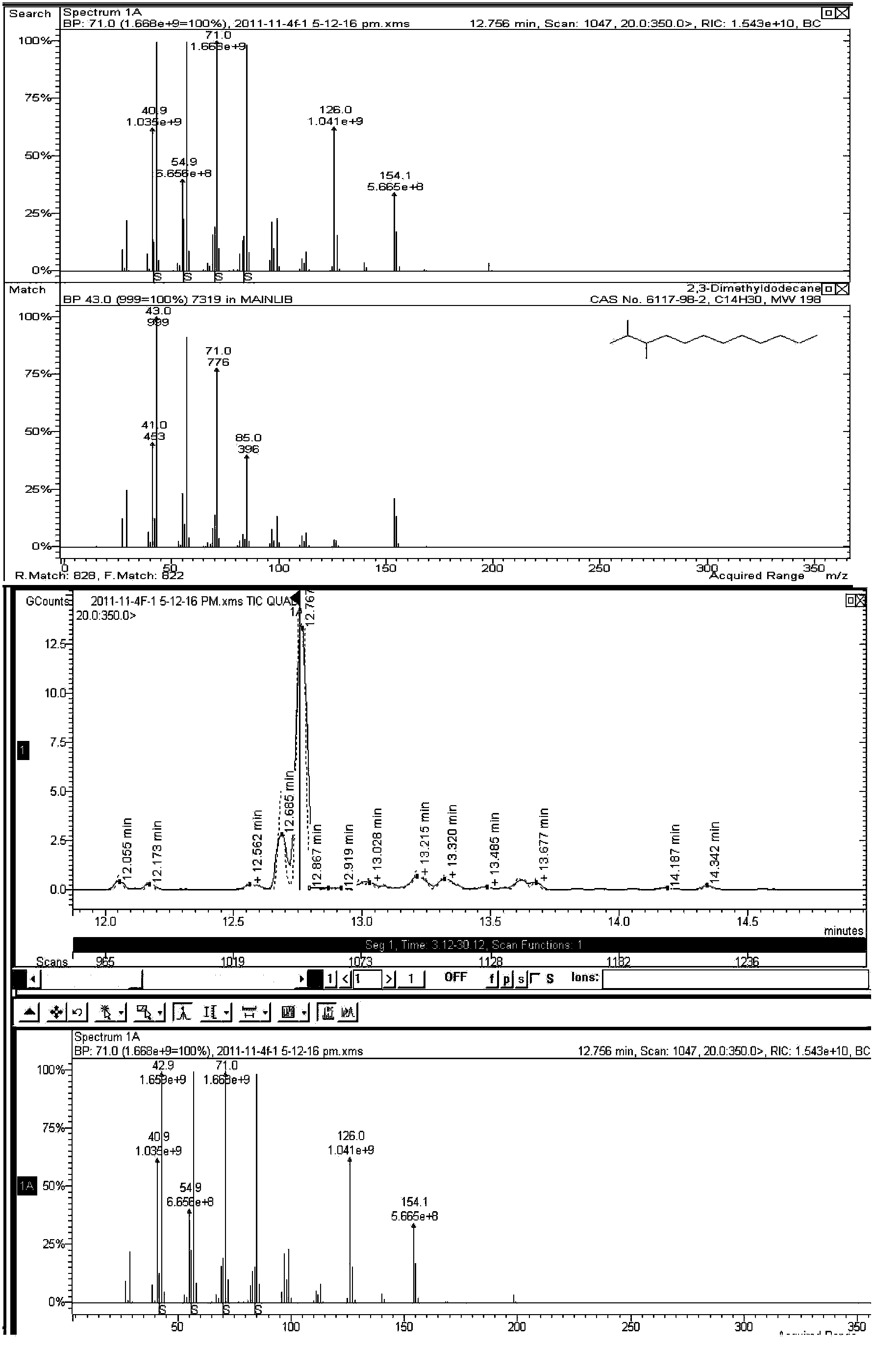

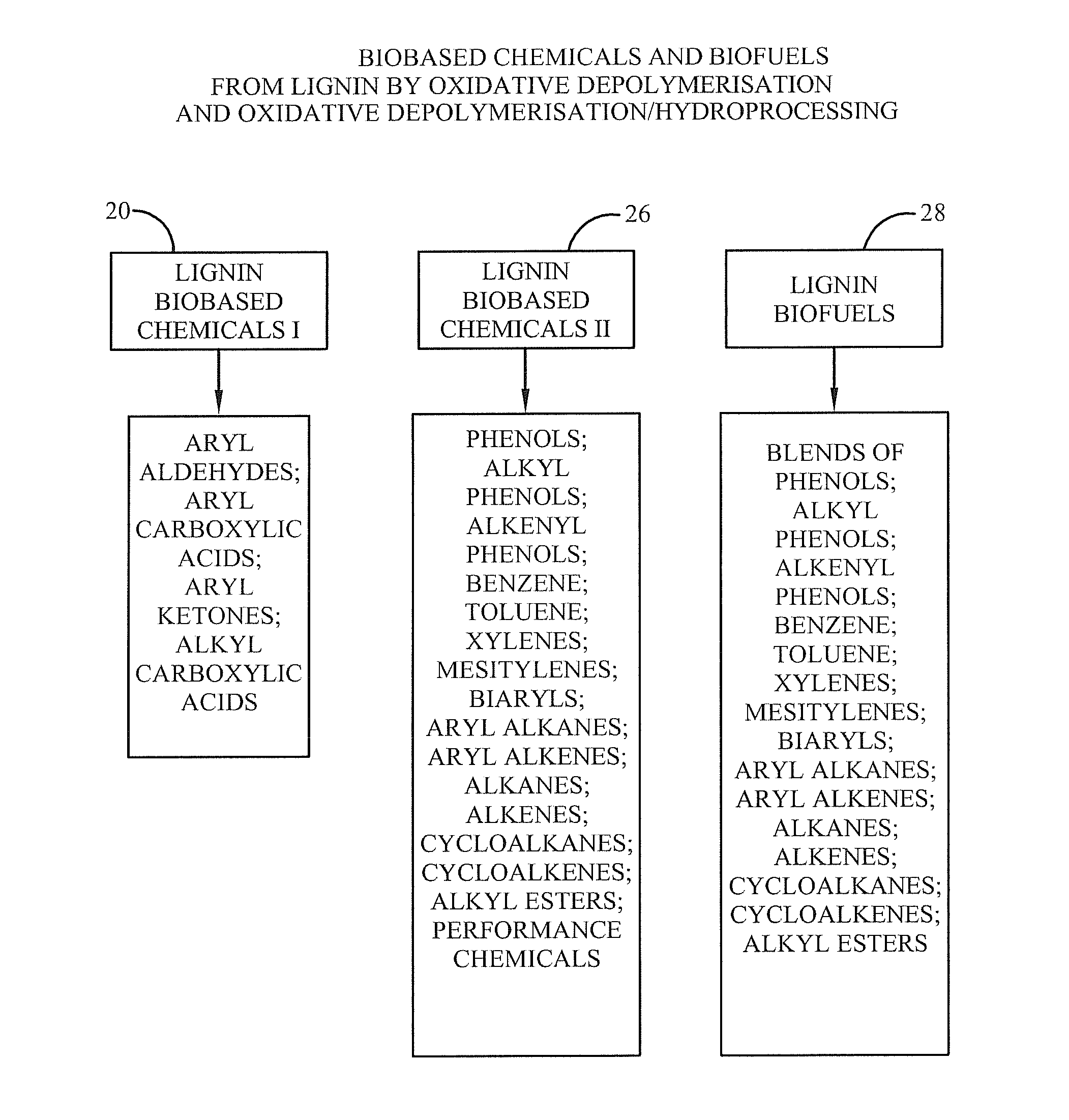

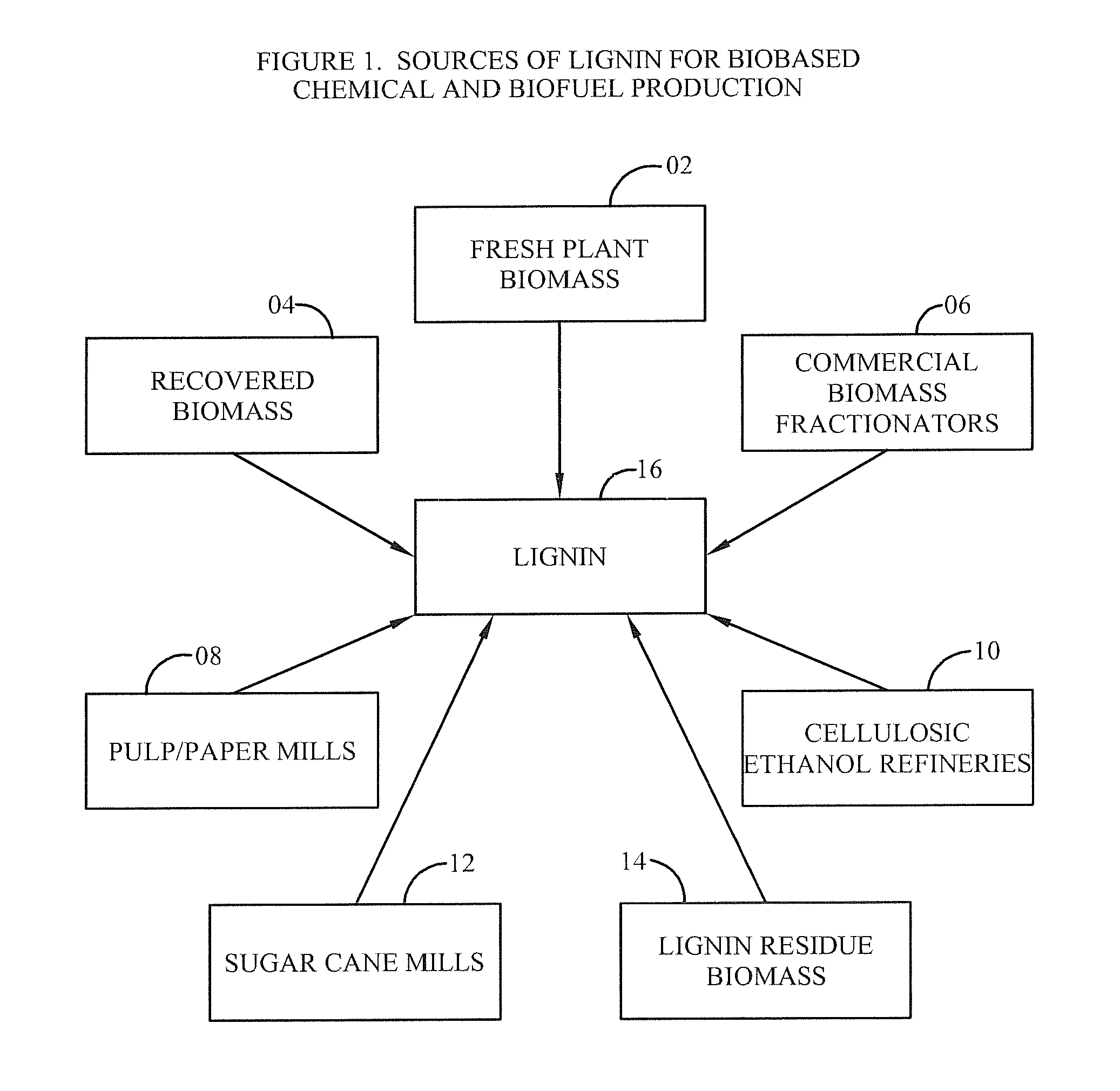

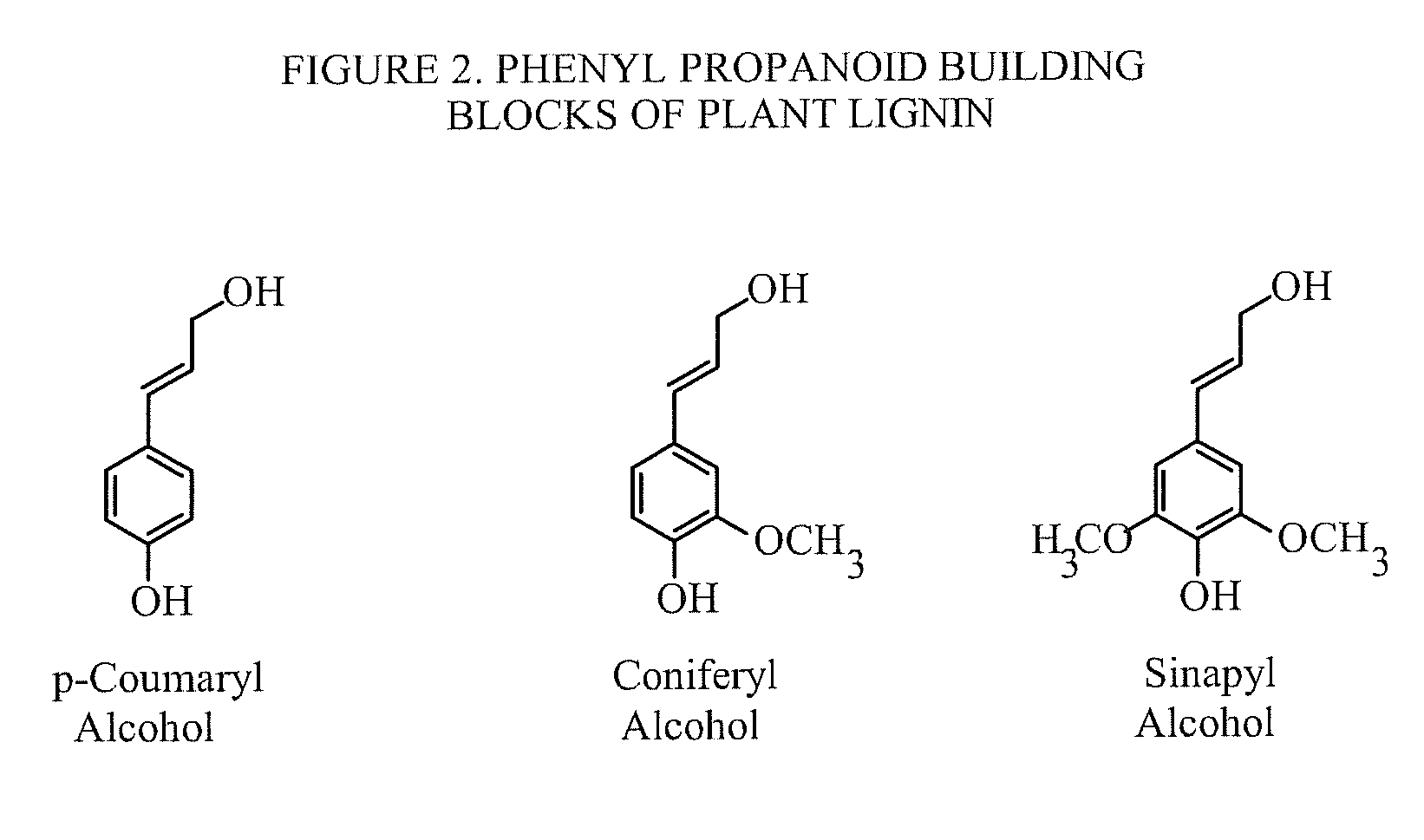

Method for selective production of biobased chemicals and biofuels from plant lignin

InactiveUS20130232853A1Easy to implementEasy to useCarboxylic acid nitrile preparationCarboxylic acid esters preparationBiofuelHydrodeoxygenation

The present invention is directed generally to a method of production of biobased chemicals, biofuels, and lignin residues from lignin sources, including waste lignin. This method may allow for selectively producing biobased chemicals, biofuels, and lignin residues from lignin sources using certain processing methods. The methods for production of these biobased chemicals, biofuels, and lignin residues may be provided by chemical-induced processing, catalytic oxidative lignin depolymerisation processing, and catalytic hydroprocessing. Further, the catalytic hydroprocessing from processes including catalytic reduction processing, catalytic hydrodeoxygenation processing, and / or catalytic / dehydrogenation processing may also be used. The method described herein also provides a means in which waste from the process(es) may be reduced and / or recycled.

Owner:VERTICHEM CORP

Process for the manufacture of hydrocarbon components

The present invention relates to hydrocarbons and particularly to the manufacture of hydrocarbon components suitable as aviation fuels or jet fuels and as blending stocks for aviation fuels. The process comprises the stages, wherein in the first stage an oil feed of biological origin and hydrogen gas are subjected to conditions sufficient to effect hydrodeoxygenation in the presence of a hydrodeoxygenation catalyst to yield n-paraffins;in the second stage the n-paraffins and hydrogen gas are subjected to conditions sufficient to effect isomerisation in the presence of an isomerisation catalyst to yield isoparaffins and separating fractions; andrecycling the fraction boiling at a temperature above 200° C. under atmospheric pressure obtained from the second stage to reisomerisation, where isomerisation is effected in the presence of an isomerisation catalyst.

Owner:NESTE OIL OY

Process for producing a branched hydrocarbon component

InactiveUS20070135666A1Reduce carbon dioxide emissionsImprove stabilityLiquid hydrocarbon mixture productionHydrocarbonsIsomerizationAlcohol

The invention relates to a process for producing high-quality hydrocarbon base oil of biological origin. The process of the invention comprises alcohol condensation, hydrodeoxygenation, and isomerization steps. Alcohols, preferably fatty alcohols of biological origin are used as the feedstock.

Owner:NESTE OIL OY

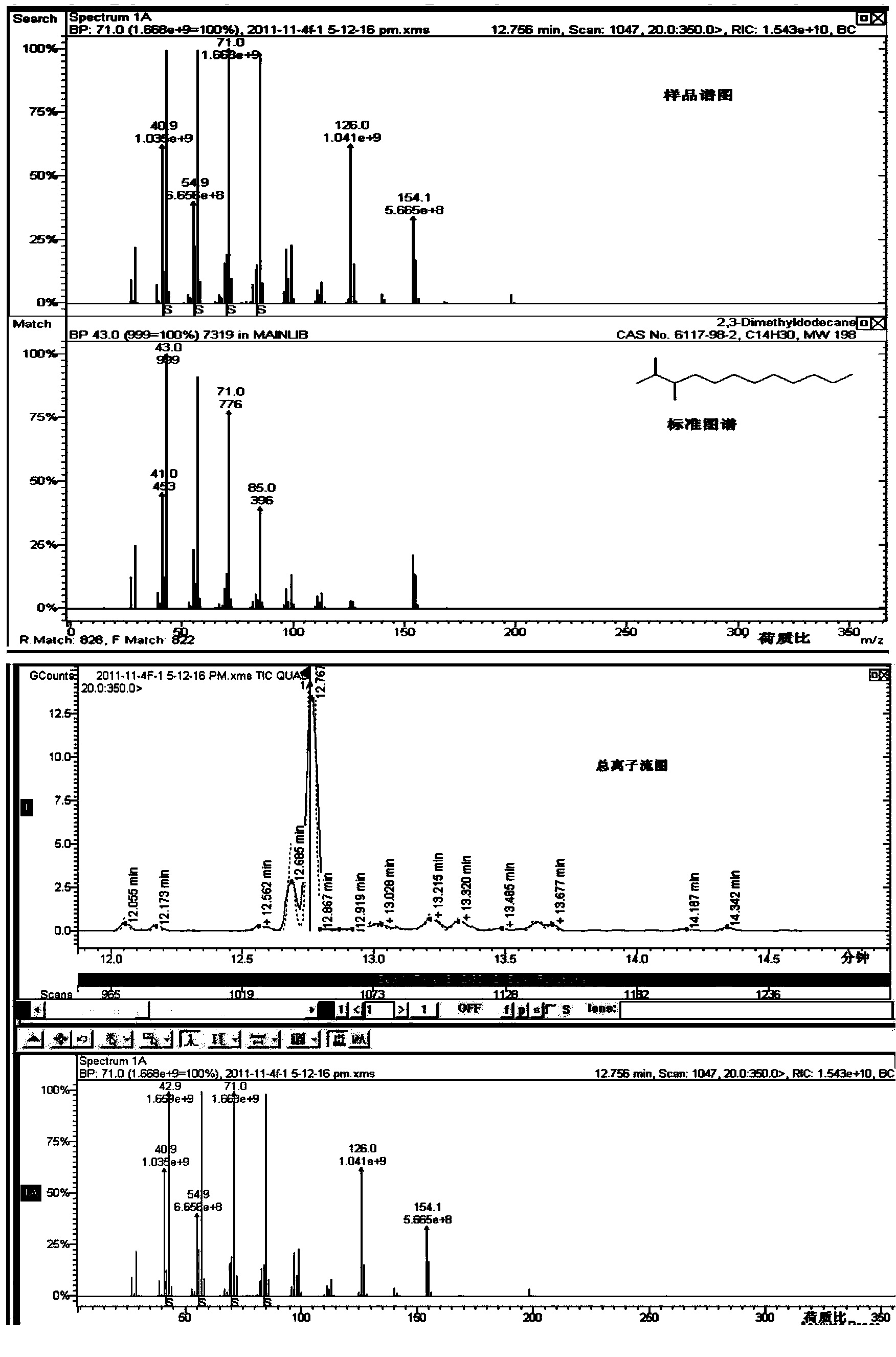

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrodeoxygenation process

ActiveUS20090163744A1Increase costOxygen-containing compound preparationCoke ovensHydrodeoxygenationHydrocarbon

A process for producing a hydrocarbon from biomass. A feed stream having free fatty acids, fatty acid esters or combinations thereof is provided. The feed stream is heated in the presence of a first catalyst to produce a partially hydrodeoxygenated stream. The partially hydrodeoxygenated stream is heated in the presence of a second catalyst to produce an effluent stream containing the hydrocarbon.

Owner:REG SYNTHETIC FUELS LLC

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

The present invention generally relates to processes for the chemocatalytic conversion of a carbohydrate source to an adipic acid product. The present invention includes processes for the conversion of a carbohydrate source to an adipic acid product via a furanic substrate, such as 2,5-furandicarboxylic acid or derivatives thereof. The present invention also includes processes for producing an adipic acid product comprising the catalytic hydrogenation of a furanic substrate to produce a tetrahydrofuranic substrate and the catalytic hydrodeoxygenation of at least a portion of the tetrahydrofuranic substrate to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin

InactiveCN104744204AWide variety of sourcesRaw materials are renewableHydrocarbon from oxygen organic compoundsEthylene productionIridiumPtru catalyst

The invention relates to a method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin. A catalyst used in the method provided by the invention comprises two active components, namely an acid site being one or combination of more than one of transition metal elements niobium, tantalum, zirconium, molybdenum, tungsten and rhenium and a hydrogenation or hydrogen transfer active site being one or more than one of ruthenium, platinum, palladium, iridium, iron, cobalt, nickel and copper. According to the method provided by the invention, a phenol group, a guaiacol group, a syringa phenolic group compound, natural lignin and industrial lignin are taken as raw materials, water is taken as a solvent, high selectivity catalytic hydrodeoxygenation is carried out at the temperature of 180-350 DEG C and hydrogen pressure of 0.1-5MPa or with methyl alcohol, isopropyl alcohol and formic acid as hydrogen sources, so that C6-C9 aromatic hydrocarbon is obtained, the highest mass yield of aromatic hydrocarbon is 10%, and content of aromatic hydrocarbon in product oil can be up to more than 75%. The method provided by the invention has the advantages that reproducible natural biomass can be used as a raw material, and the raw material is cheap and available; the water is taken as the solvent, so that a reaction process is environment-friendly; and content of aromatic hydrocarbon in the product is high, and reaction conditions are mild.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing aviation kerosene from furyl oxygen-containing organic compounds by hydrogenation deoxidation

ActiveCN104119943AReduce energy consumptionSimple operation processMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneFuran

The invention relates to a new method for preparing hydrocarbons in the scope of aviation kerosene from C8-C16 furyl oxygen-containing organic compounds as raw materials by hydrogenation deoxidation reaction, wherein the C8-C16 furyl oxygen-containing organic compounds are obtained by C-C coupling of lignocellulose based platform chemical compounds; low temperature direct hydrogenation deoxidation under the condition of no solvent of the furyl oxygen-containing organic compounds can be realized by use of a metal-solid acid dual-functional catalyst to obtain a series of low freezing point branched alkanes having the chain in the length range of the aviation kerosene in high yield. The catalyst is composed of two parts of an active metal A and an acid vector X. The catalyst related in the method ahs the characteristics of being in no need of a solvent, simple in operation process, mild in reaction conditions, good in aviation kerosene (or diesel) selectivity, and the like, and is an ideal hydrogenation deoxidation catalyst for preparing liquid fuels from the furyl oxygen-containing organic compounds by the hydrogenation deoxidation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

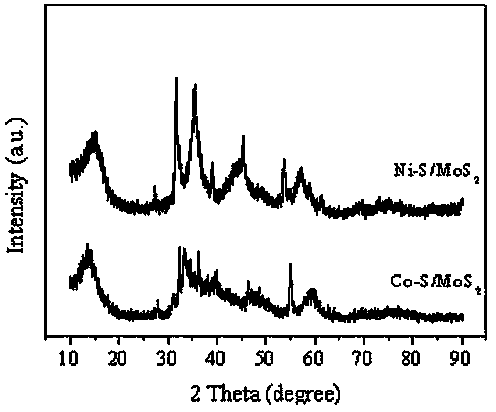

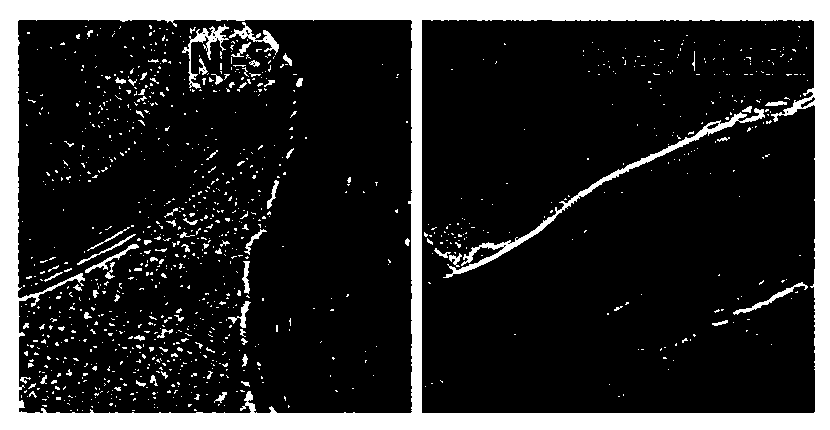

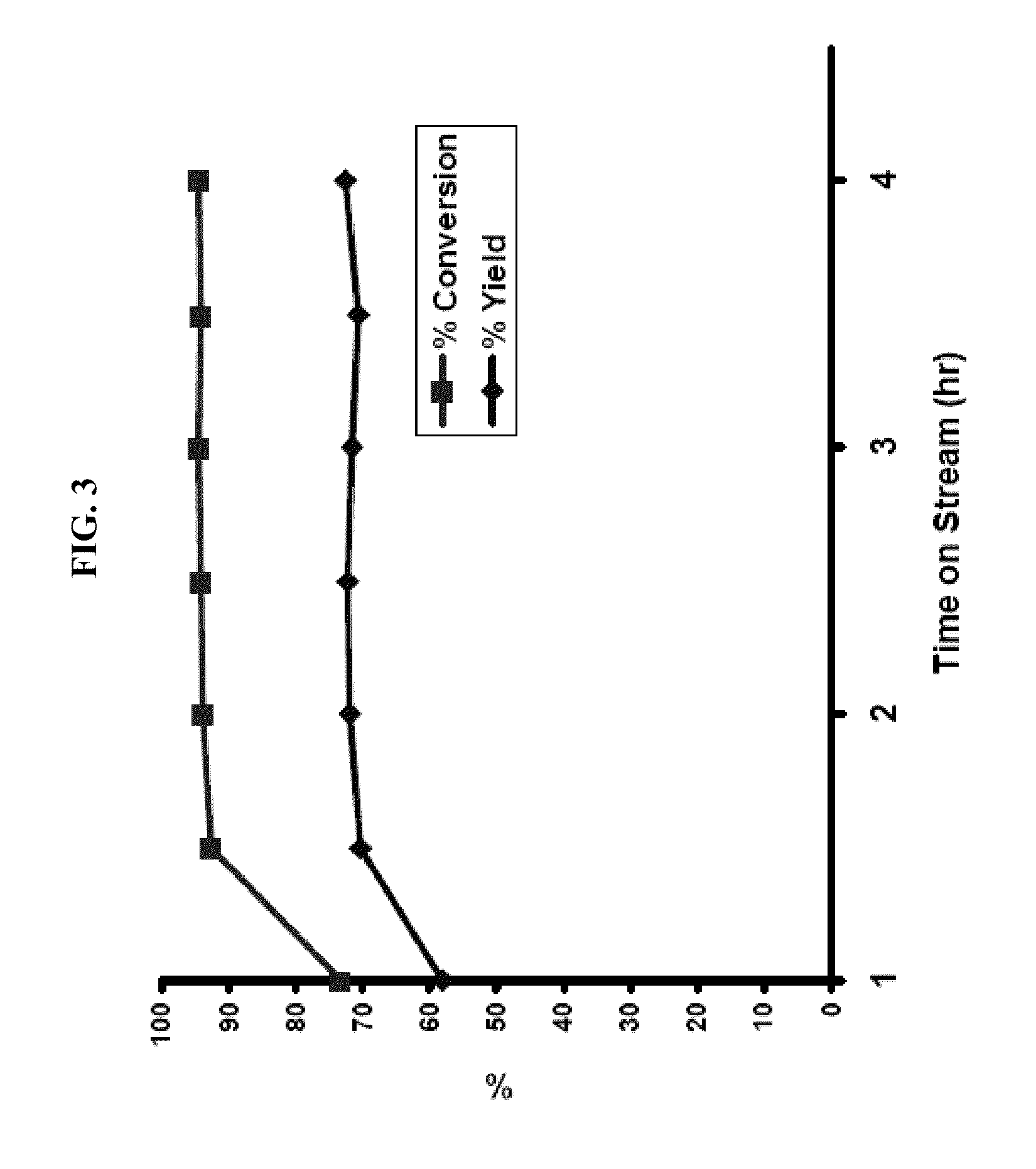

Double-metal-sulfide catalyst with high hydrodeoxygenation activity and preparation method thereof

InactiveCN103920506ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsRefining to eliminate hetero atomsNickel saltVulcanization

The invention relates to a preparation method for a double-metal-sulfide catalyst. Soluble molybdate and nickel salt or cobalt salt serves as a raw material, thiourea or thioacetamide serves as a sulfur source, and a Ni(Co)-S / MoS2 catalyst is prepared through a two-step hydrothermal method. The method particularly comprises the following steps: MoS2 is prepared in a high pressure reactor through the hydrothermal method first, then the nickel salt or cobalt salt and the sulfur source are added into the reactor of the obtained MoS2 to be evenly mixed, the reactor is sealed and heated, a reaction is conducted for a certain period of time, and Ni-S or Co-S is deposited on the MoS2, so that the Ni(Co)-S / MoS2 catalyst is prepared. The preparation method is characterized in that the specific area of the Ni(Co)-S / MoS2 catalyst prepared through the two-step hydrothermal method is large, high temperature vulcanization is not required in the preparation process, the preparation condition is mild, the catalyst is used for hydrodeoxygenation, a target product has high yield and good repeatability, and hydrodeoxygenation activity of the catalyst is high.

Owner:XIANGTAN UNIV

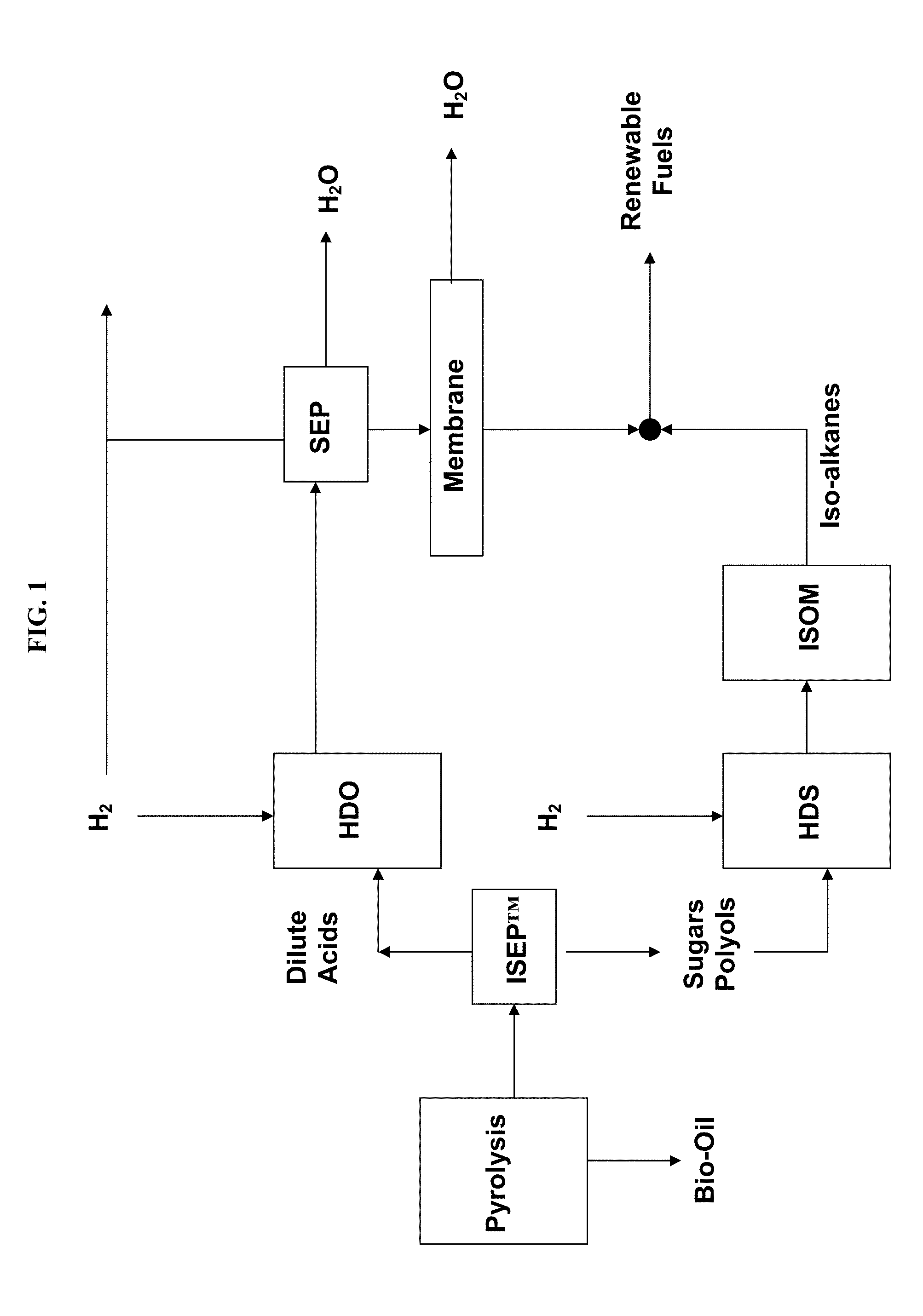

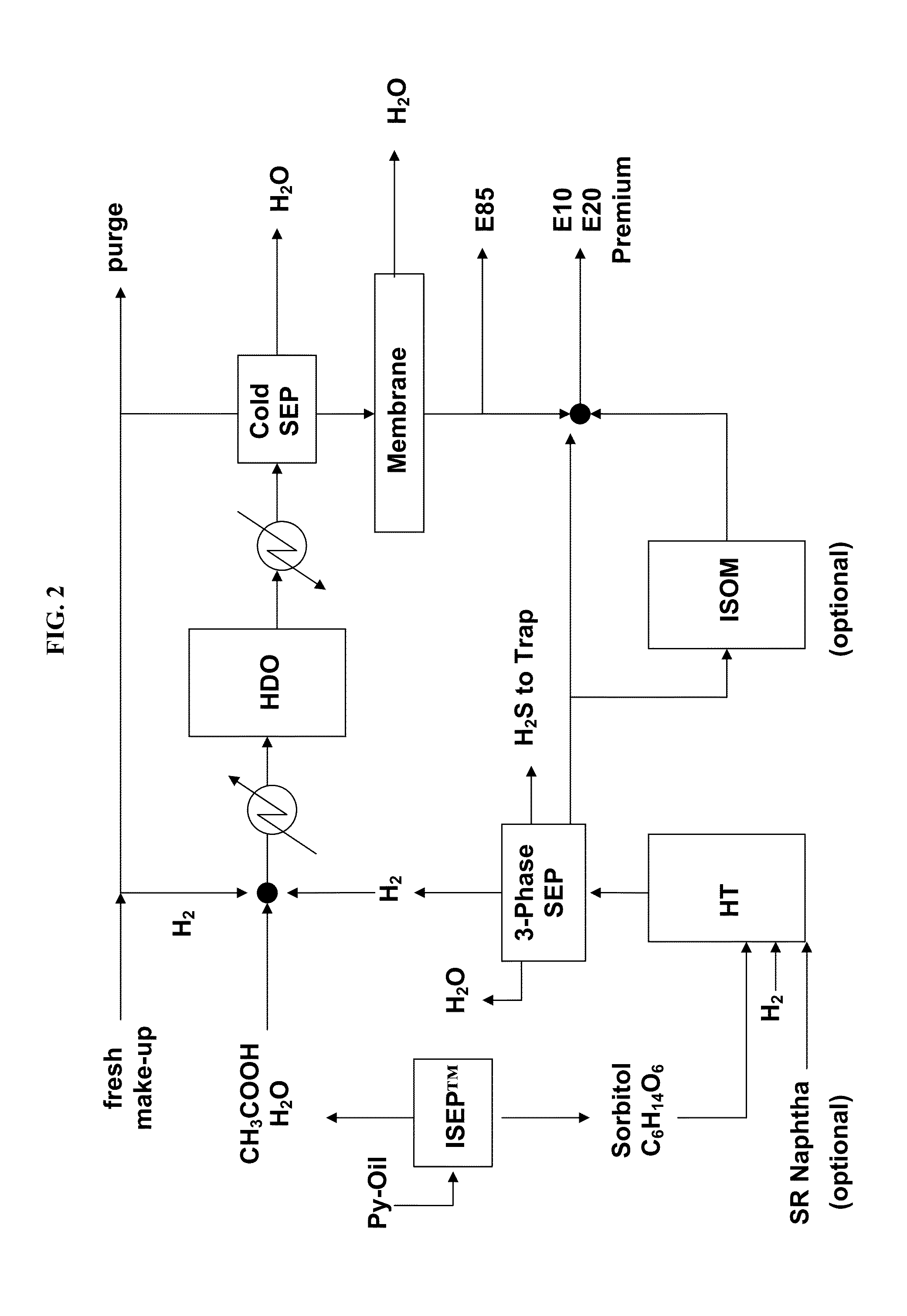

Advanced cellulosic renewable fuels

ActiveUS20130067803A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsOrganic acidCellulose

The invention relates to a process to manufacture advanced cellulosic gasolines. Dilute organic acids derived from pyrolized biomass are converted to their corresponding alcohols in a stand-alone hydrodeoxygenation unit followed by membrane pervaporation step to remove water. The alcohol product is blended directly into a neat hydrocarbon fuel basestock to make unadditized gasoline.

Owner:PHILLIPS 66 CO

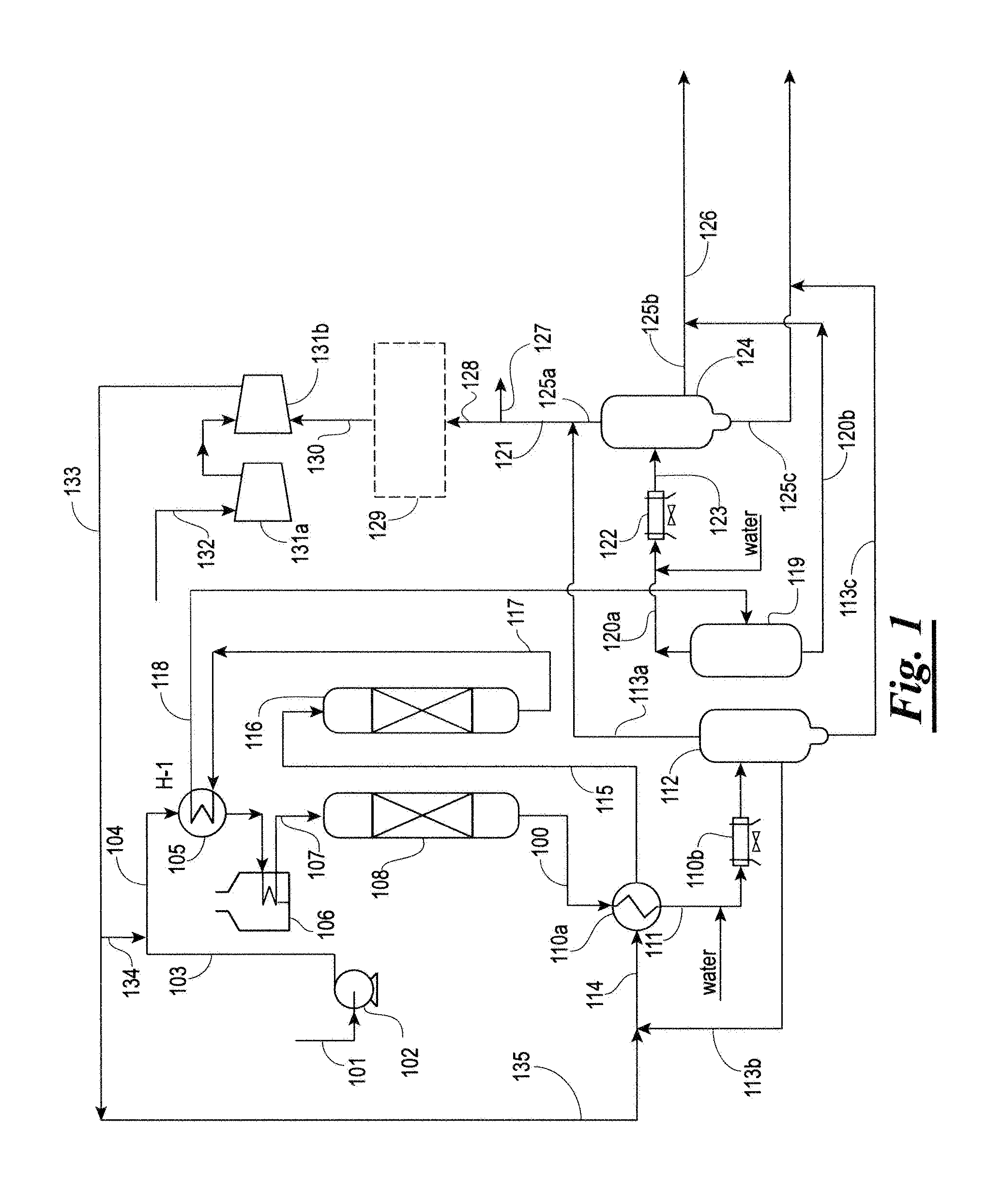

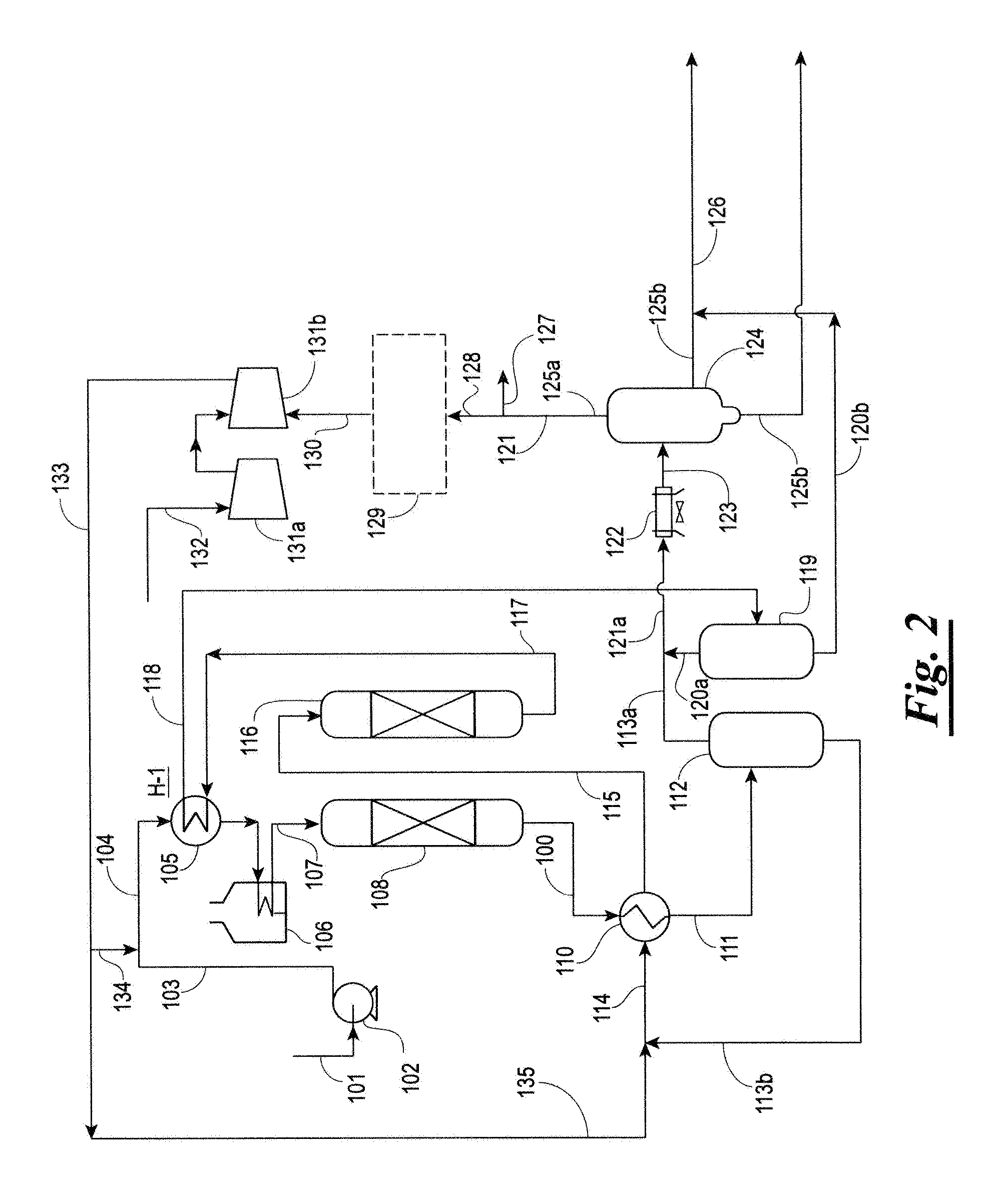

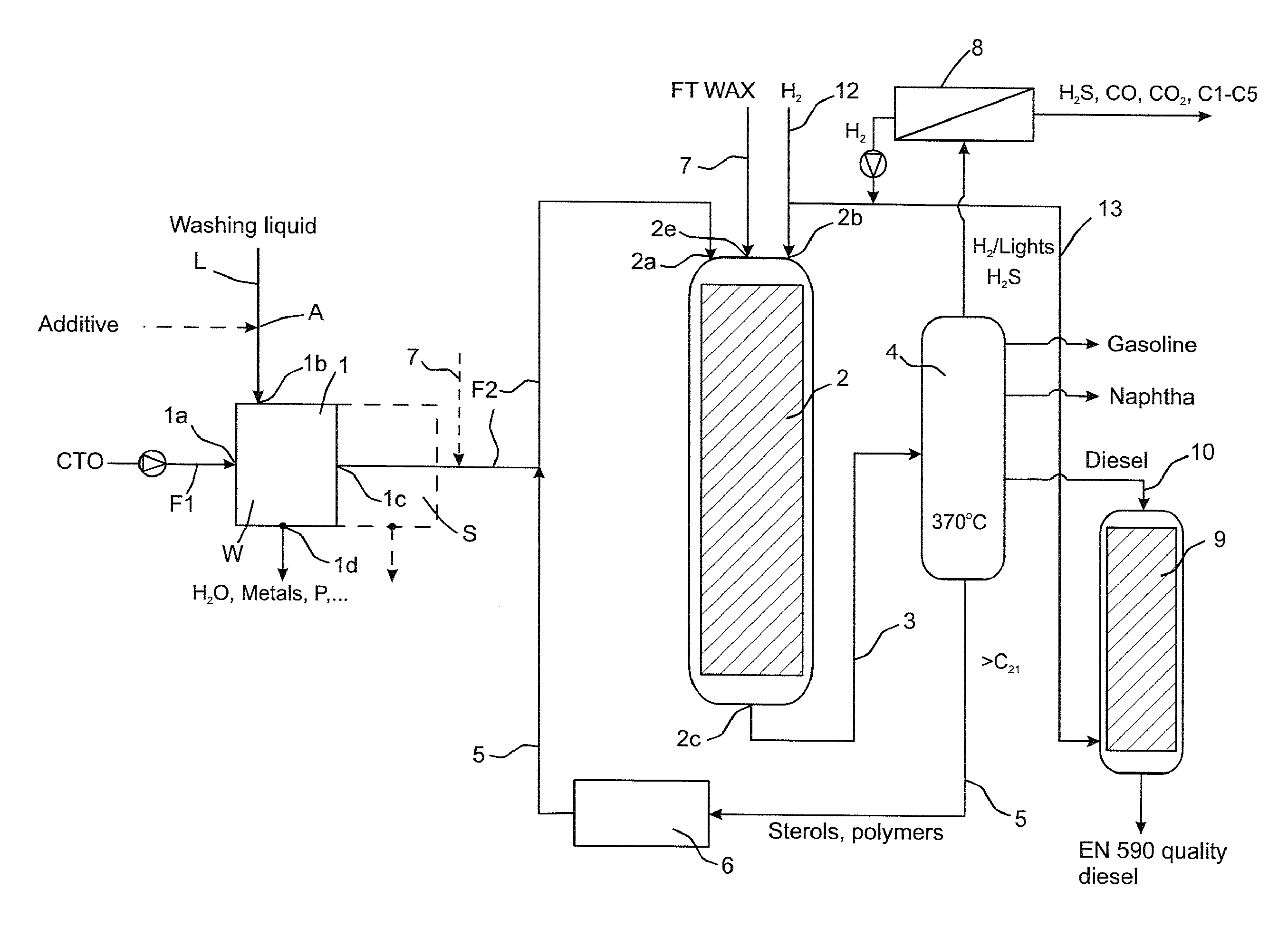

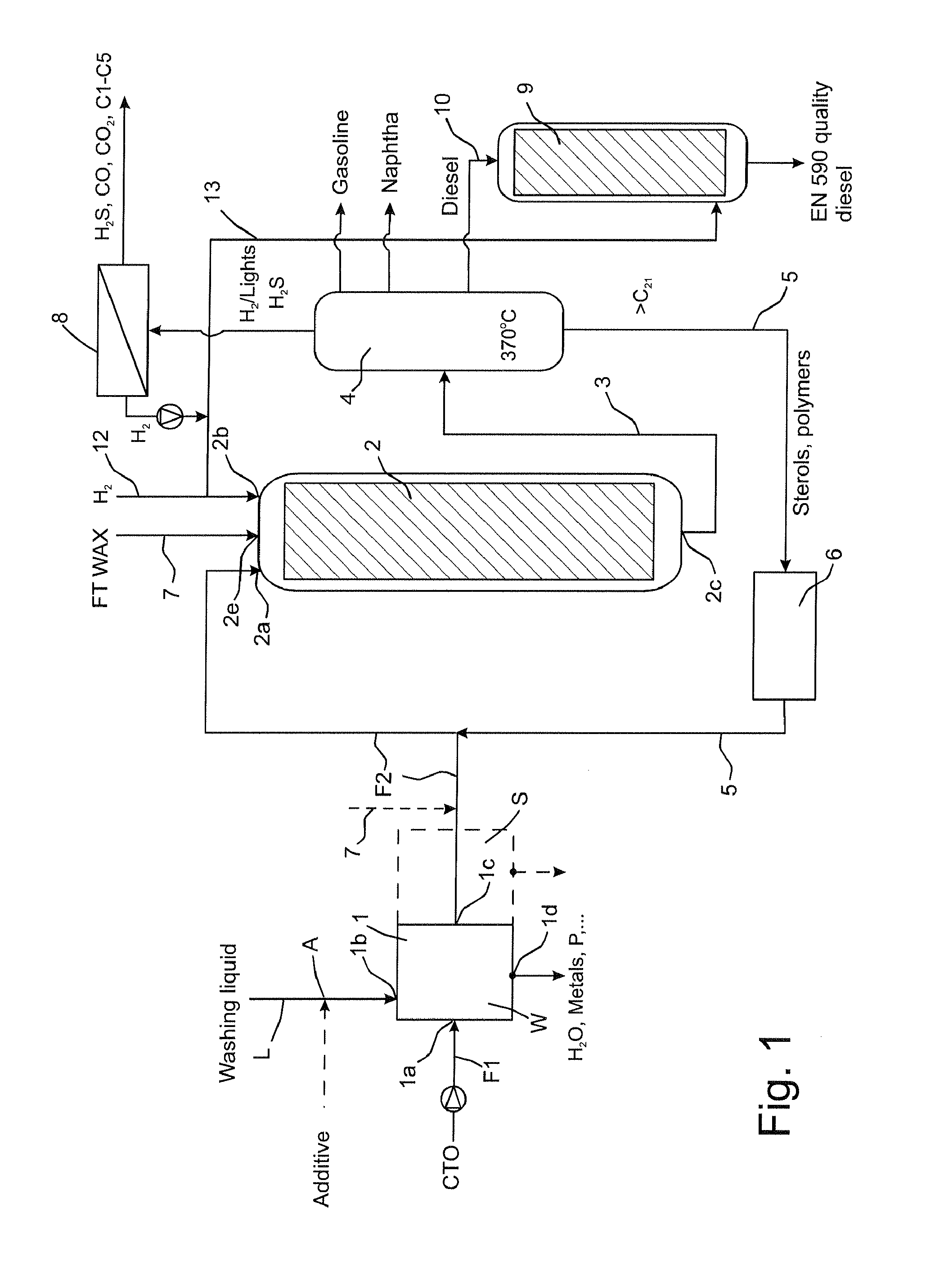

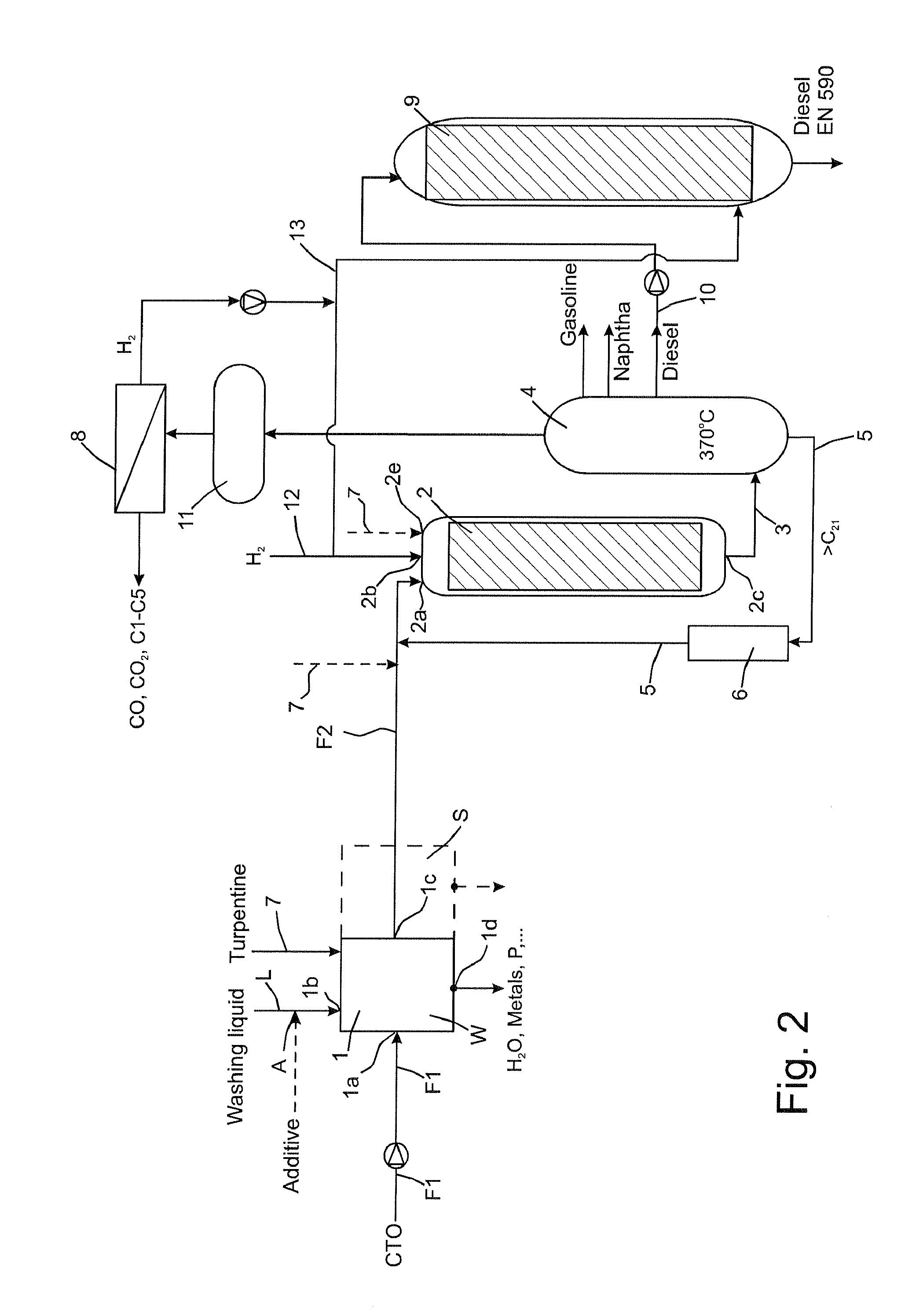

Method and apparatus for preparing fuel components from crude tall oil

ActiveUS20120088943A1For further processingExothermicity can be reducedRefining to change hydrocarbon structural skeletonFatty-oils/fats refiningHydrodeoxygenationTall oil

A method for preparing fuel components from crude tall oil. Feedstock containing tall oil including unsaturated fatty acids is introduced to a catalytic hydrodeoxygenation to convert unsaturated fatty acids, rosin acids and sterols to fuel components. Crude tall oil is purified in a purification by washing the crude tall oil with washing liquid and separating the purified crude tall oil from the washing liquid. The purified crude tall oil is introduced directly to the catalytic hydrodeoxygenation as a purified crude tall oil feedstock. An additional feedstock may be supplied to the catalytic hydrodeoxygenation.

Owner:UPM-KYMMENE OYJ

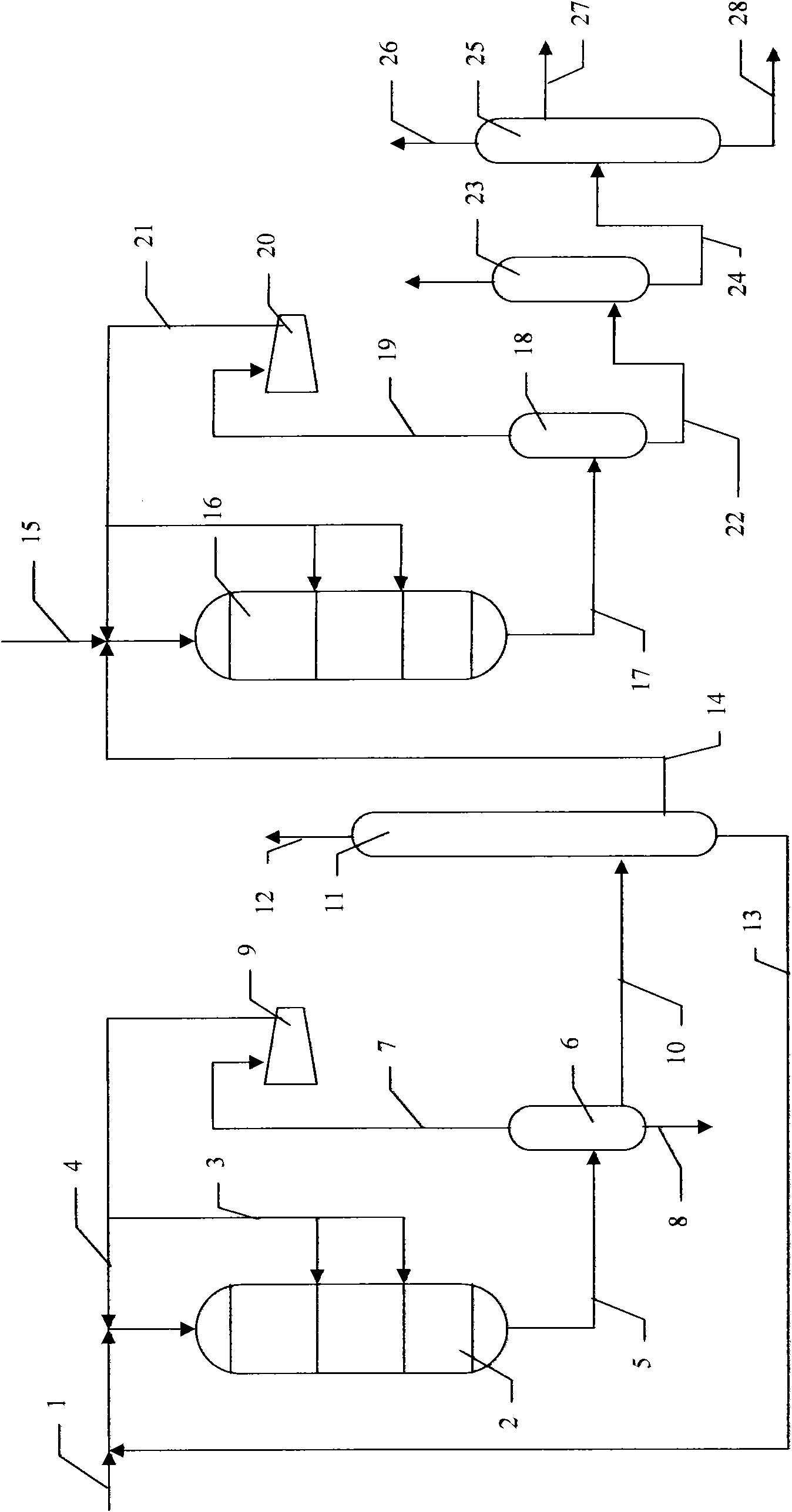

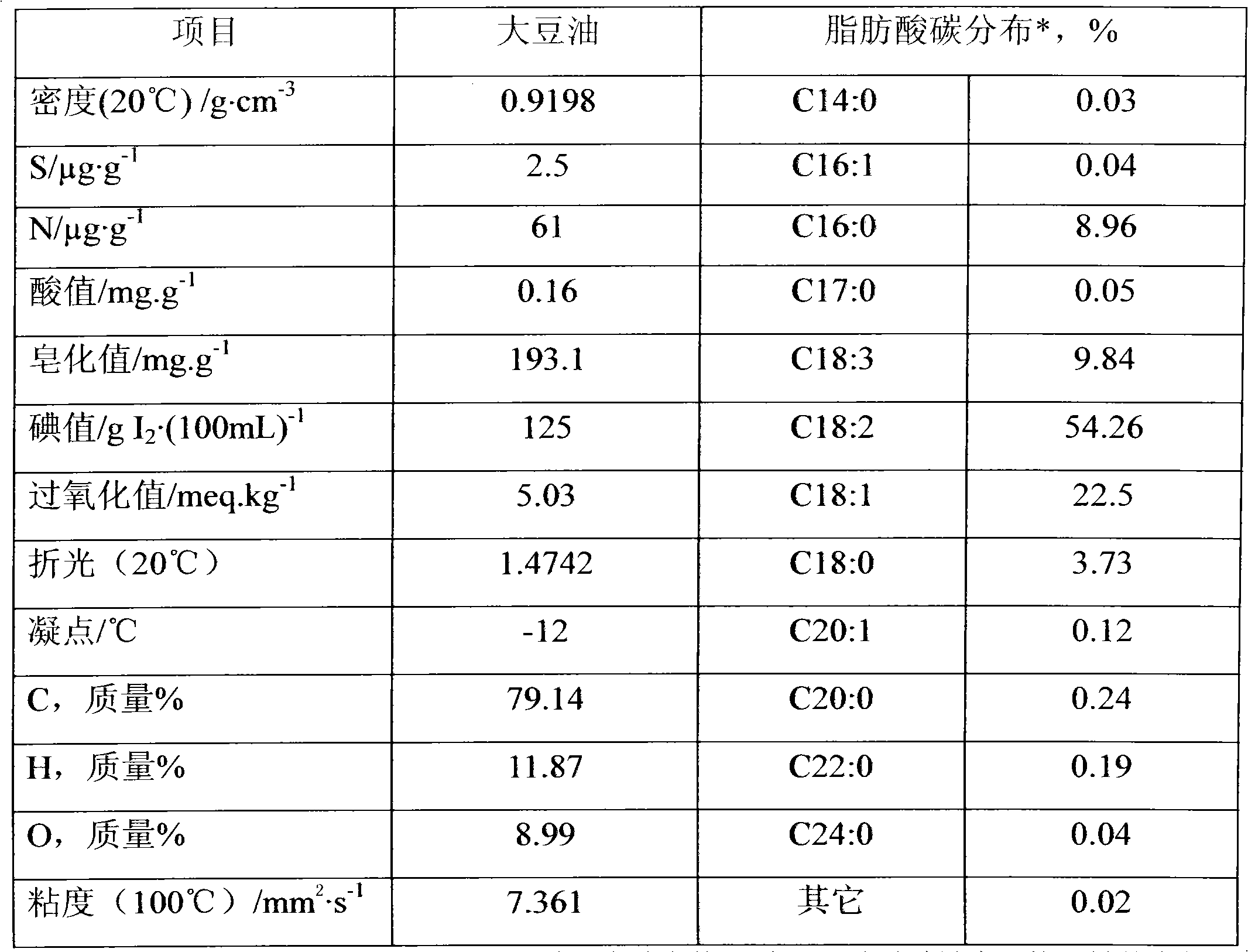

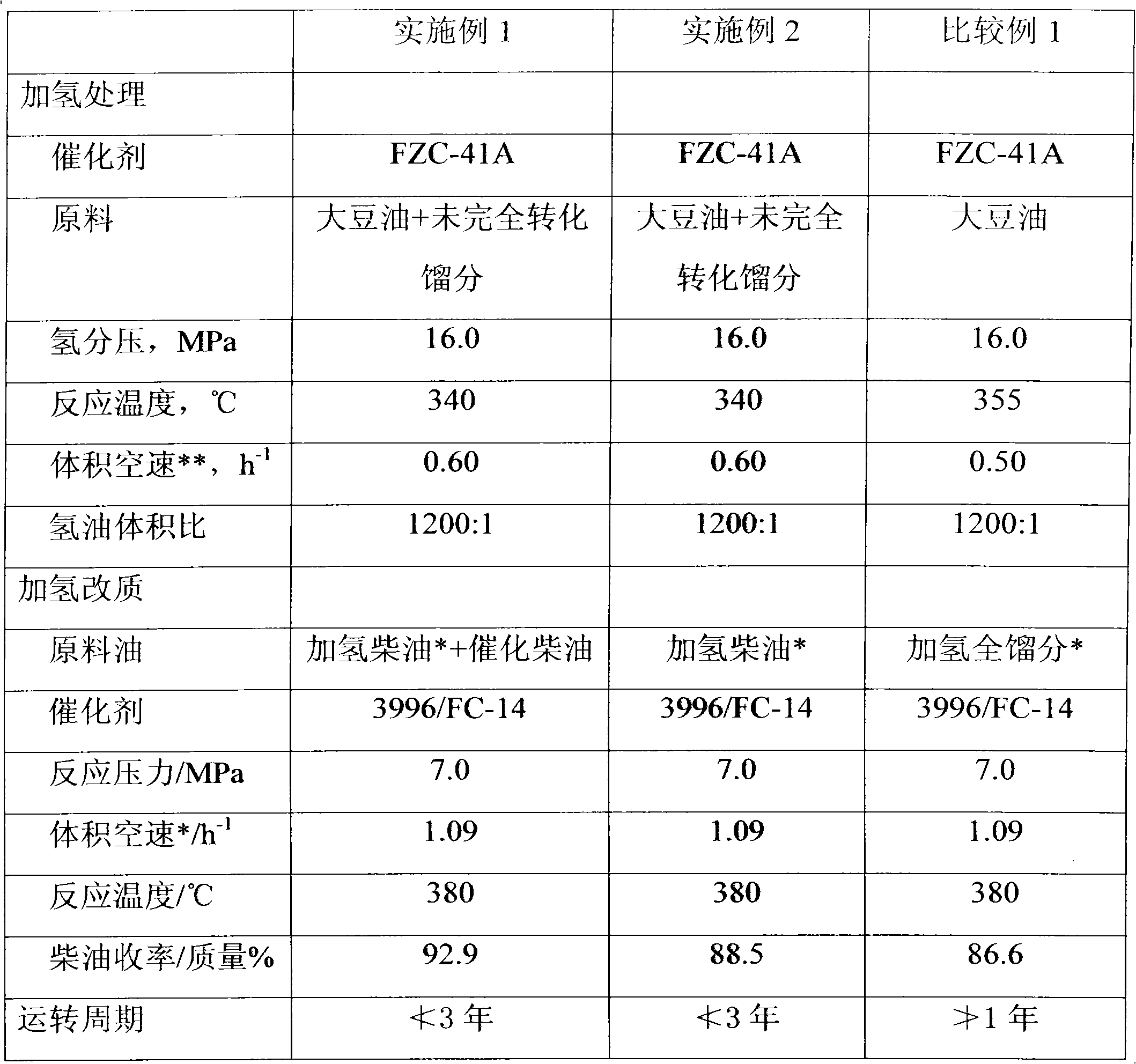

Method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel

ActiveCN102464998ANo reduction in activityStrong resistance to waterBiofuelsLiquid hydrocarbon mixture productionOil and greaseVegetable oil

The invention discloses a method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel. Animal and vegetable oil is subjected to hydrodeoxygenation and olefin saturation reaction with the existence of hydrogen and catalyst, gas and generated water are separated from effluents of hydrogenation reaction, gas, diesel fraction and incompletely-converted fraction are obtained by distilling the liquid, the incompletely-converted fraction is circulated back to a hydrogenation treatment reactor, the diesel fraction enters a hydrogenation modified reactor after being mixed with an optional modified raw material to be subjected to the modified reaction with the existence of hydrogen and modified catalyst, and gas products, naphtha and diesel fraction are obtained through the separation and distilling. Compared with the prior art, the hydrogenation reaction, hydrogenation modified reaction and / or pour point depression reaction of the animal and vegetable oil can be carried out under a relatively tempered technique condition, and the method has the advantages such as wide range of raw materials, high quality of products, high yield of diesel and fewer byproducts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing paraffinic hydrocarbons

ActiveUS20100076236A1Carry-outIncrease temperatureFatty acid chemical modificationBiofuelsAlkaneMonoglyceride

Process for producing paraffinic hydrocarbons, the process comprising the following steps: (a) contacting hydrogen and a feedstock comprising triglycerides, diglycerides, monoglycerides and / or fatty acids with a hydrogenation catalyst under hydro-deoxygenation conditions; and (b) contacting the whole effluent of step (a) with a hydroprocessing catalyst comprising sulphided Ni and sulphided W or Mo as hydrogenation components on a carrier comprising amorphous silica-alumina and / or a zeolitic compound under hydro-isomerisation conditions.

Owner:SHELL USA INC

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

ActiveUS20100317823A1Increase costLow costCarboxylic acid nitrile preparationOrganic chemistry methodsCatalytic transformationCatalytic oxidation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Catalyst for hyrogenating deoxidating and olefine saturating of Feather synthesizing oil and its mfg. process and application

ActiveCN1597859AImprove hydrogenation activityRefining by selective hydrogenationPtru catalystCopper oxide

The invention is a hydro-deoxidation and alkene-saturation catalyst of Fischer-Tropsch oil product and its components in weight percent: nickel oxide 5.0-18.0%, cobalt oxide 0-11.0%, copper oxide 0-6.0%, iron oxide 0-12.0%, titanium oxide 0-12.0%, lanthanum oxide 0-8.0% and carrier 46.0-85.0%. Its preparing method includes in turn carrier preprocessing and after-processing of supported active component and catalyst. It has higher activity to hydro-deoxidation and alkene saturation of the oil product, especially applied to the hydrofining process of the iron-base paste Fischer-Tropsch oil product with higher content of oxygen-containing compound and alkene.

Owner:SYNFUELS CHINA TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com