Patents

Literature

61 results about "Mesityl oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

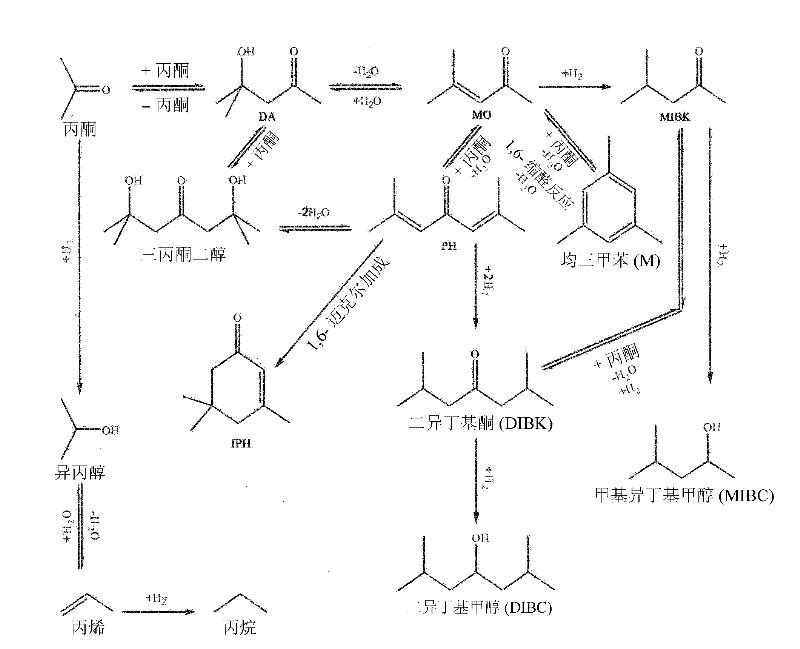

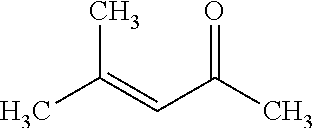

Mesityl oxide is a α,β-unsaturated ketone with the formula CH₃C(O)CH=C(CH₃)₂. This compound is a colorless, volatile liquid with a honey-like odor.

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Anti-aging agent TMQ and preparation method thereof

The invention provides an anti-aging agent TMQ and a preparation method thereof. The preparation method comprises preparing the anti-aging agent TMQ for rubber from aniline and acetone (or isopropylideneacetone) as raw materials in the presence of a catalyst through a one-step method. The catalyst comprises a titanate catalyst. The anti-aging agent TMQ for rubber is prepared through the preparation method. The preparation method utilizes a batch or continuous production process. A single-pass conversion of aniline is 80% or more. The content of the product TMQ effective bodies (such as dimer,trimer and tetramer) is 65% to 75%. Compared with the prior art, the preparation method utilizing the titanate catalyst to prepare the rubber anti-aging agent TMQ is an eco-friendly method having theadvantages of simple processes, low catalyst consumption, low cost and high effective body content.

Owner:CHINA PETROLEUM & CHEM CORP +1

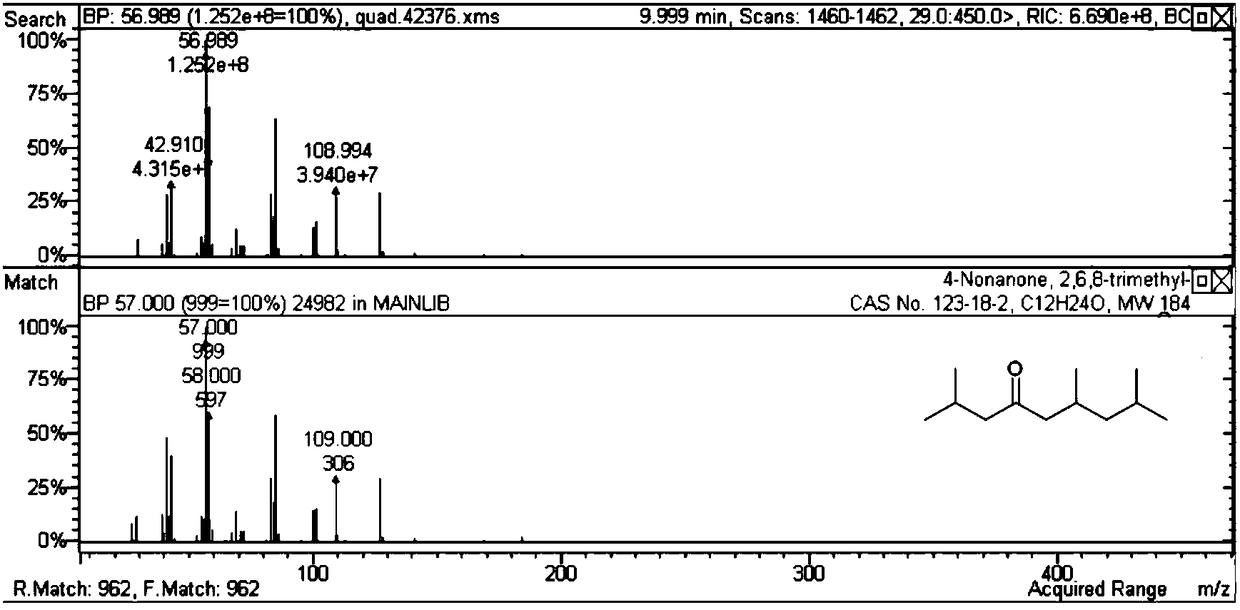

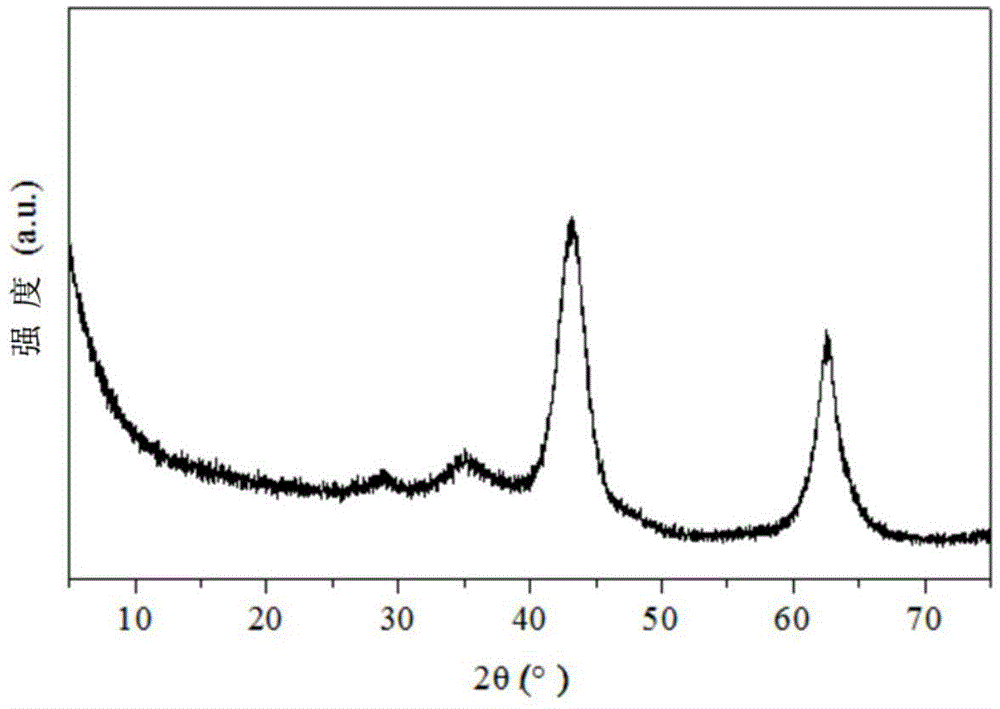

Synthesizing and utilizing novel nano-crystalline zinc chromite-supported nano-palladium catalyst

InactiveCN102371153AOrganic compound preparationCatalyst regeneration/reactivationGas phaseDesorption

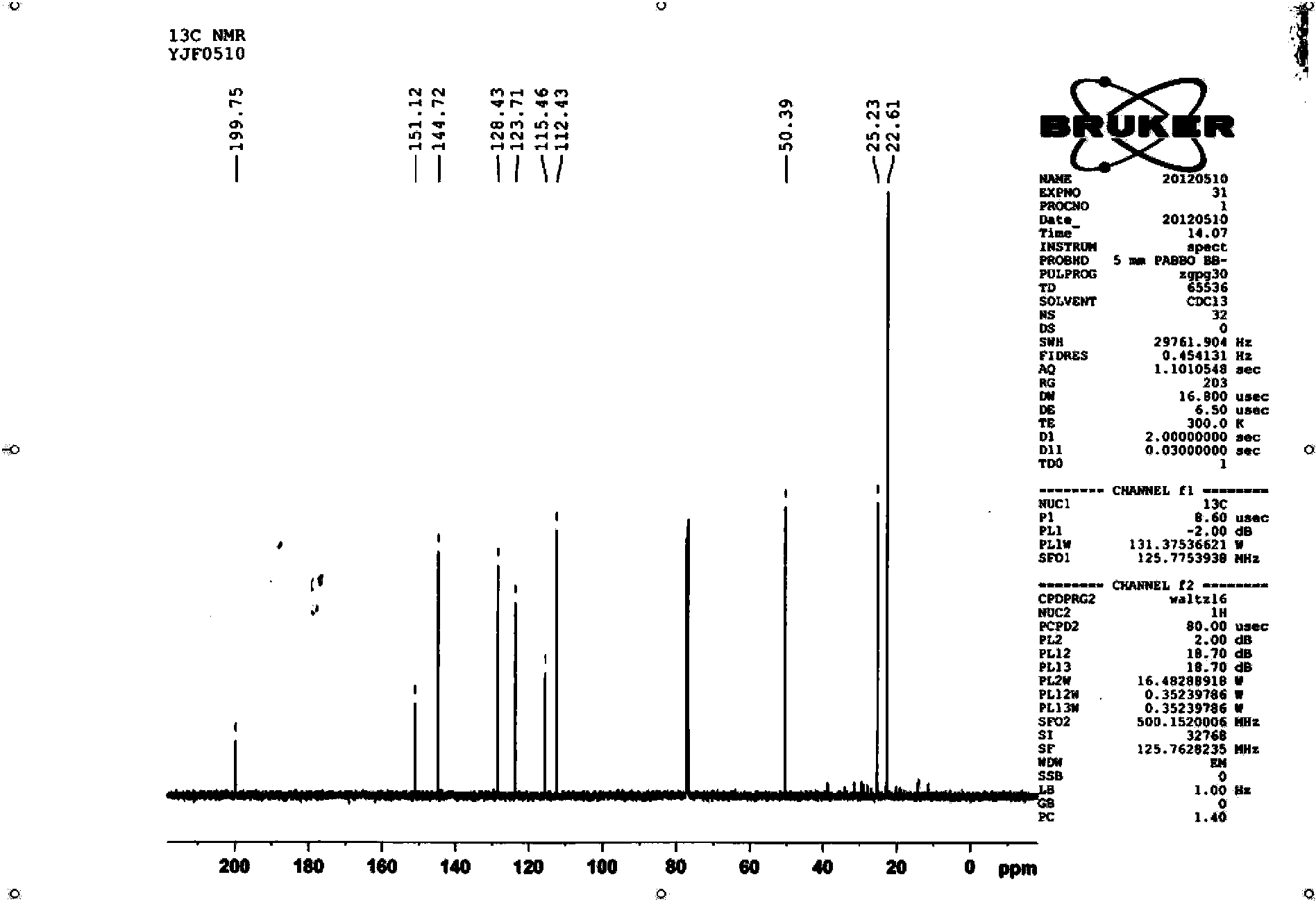

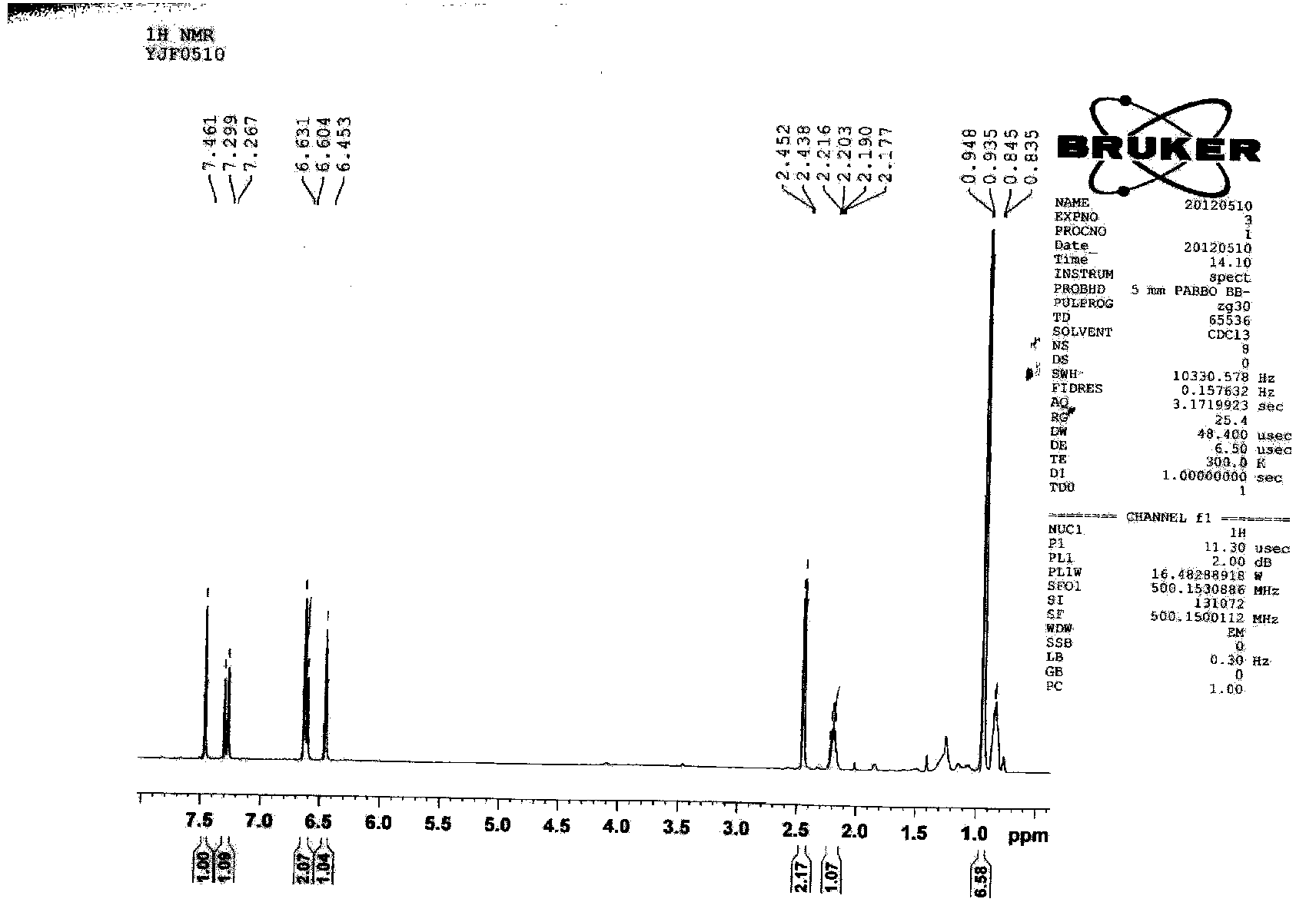

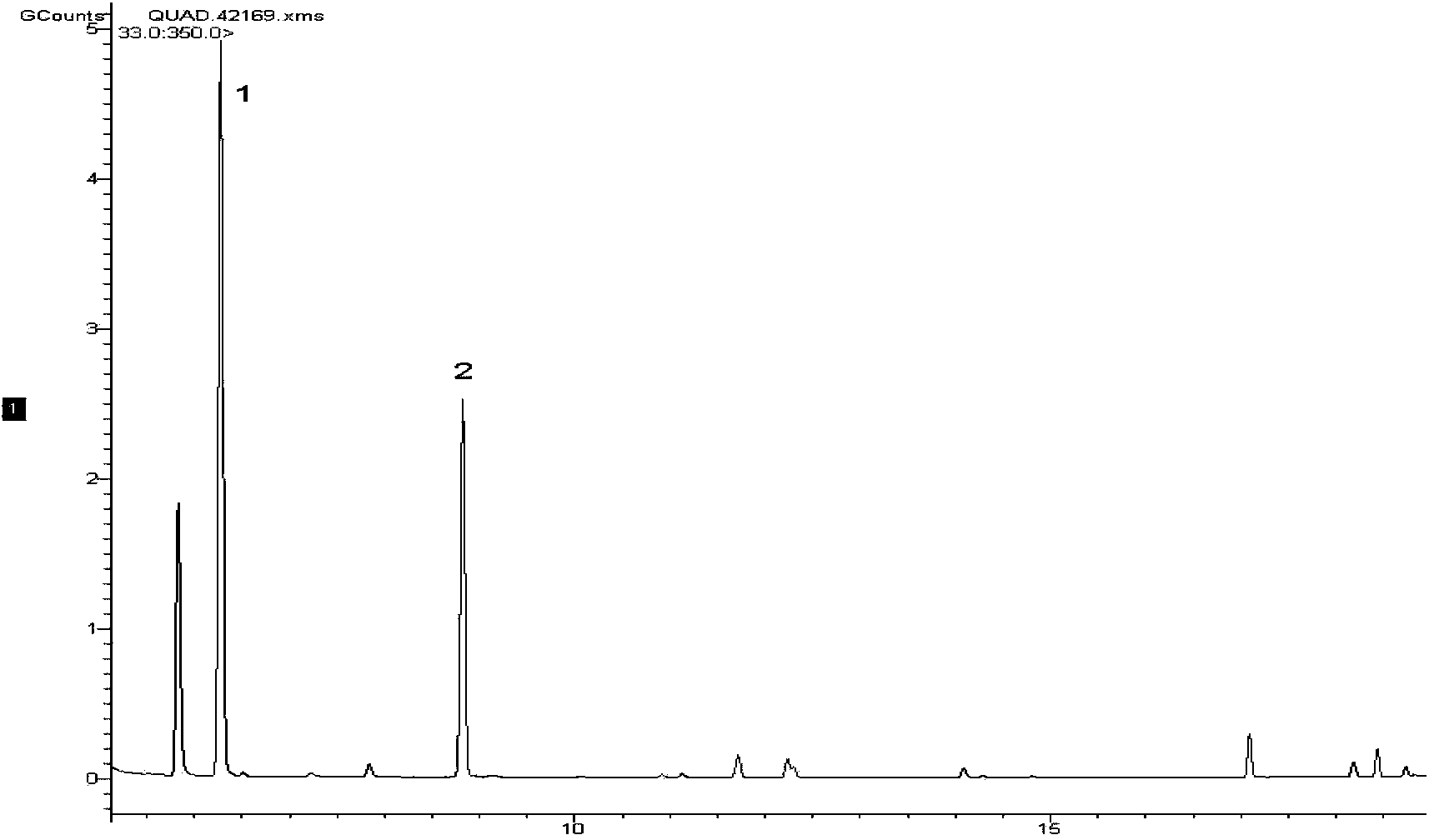

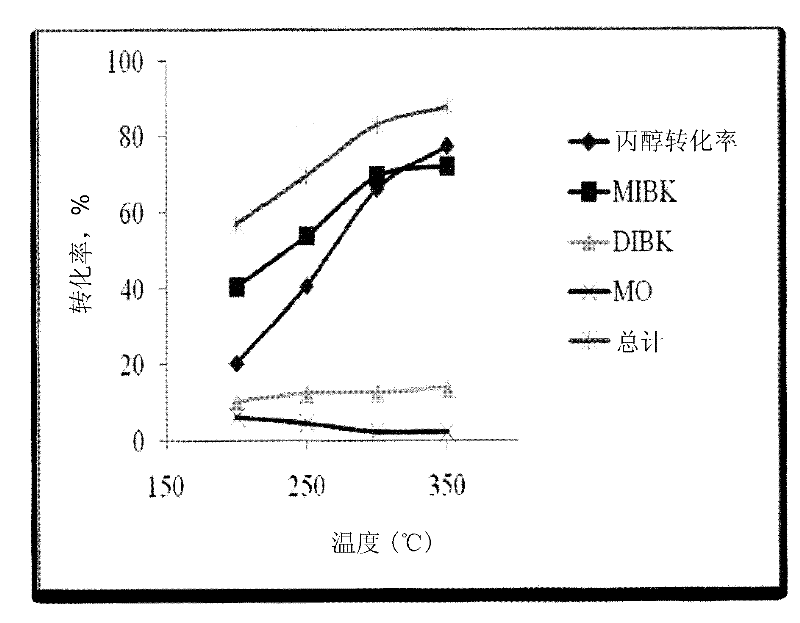

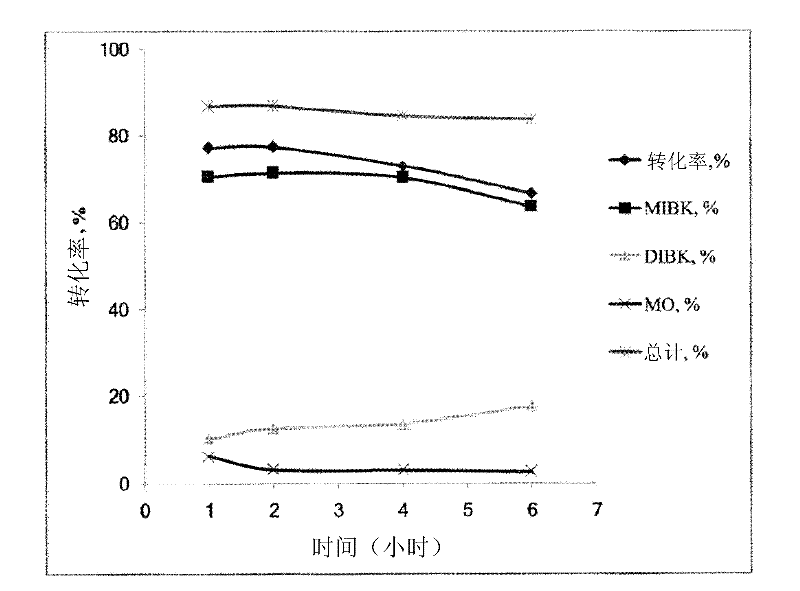

Several metal-supported catalyst compositions based on nano-crystalline zinc oxide were synthesized and characterized by X-ray powder diffraction (XRD), Carbon dioxide temperature programmed desorption (CO2 TPD), and nitrogen adsorption at -196 DEG C. The Pd-supported nano-ZnO mixed with different oxides such as Cr2O3, CrO3, MgO, and [gamma]-Al2O3 showed high catalytic activity in acetone condensation in gas-phase process under hydrogen flow. This reaction involves the base-acid coupling of acetone to form mesityl oxide, followed by its hydrogenation to methyl isobutyl ketone (MIBK). The novel catalyst 1% wt. n-Pd / n-ZnCr2O4 was utilized during gas-phase reaction during production of MIBK. MIBK selectivity was 70-72% at 66-77% acetone conversion at 300-350 DEG C. Diisobutyl ketone (DIBK) was the main by-product, with a total MIBK+DIBK selectivity up to 88%. The prepared catalysts showed stable activity and may be used repeatedly and for a longer period of time.

Owner:KING ABDULAZIZ CITY FOR SCINCE & TECH (KACST)

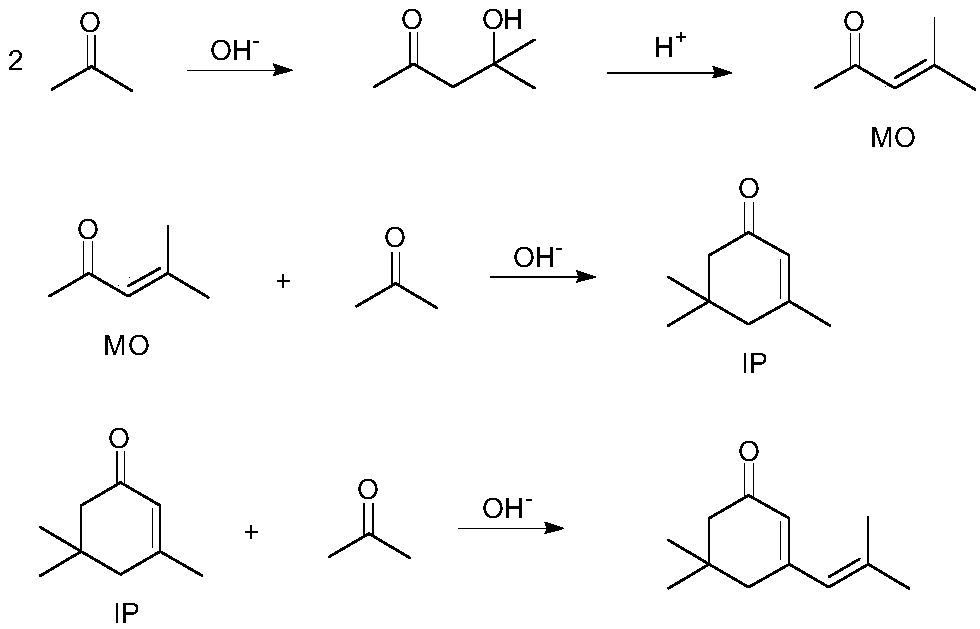

Catalyst for preparing isophorone using condensation of acetone and preparation method thereof

InactiveCN101462043AOrganic compound preparationCarbonyl compound preparationIsophoroneMesityl oxide

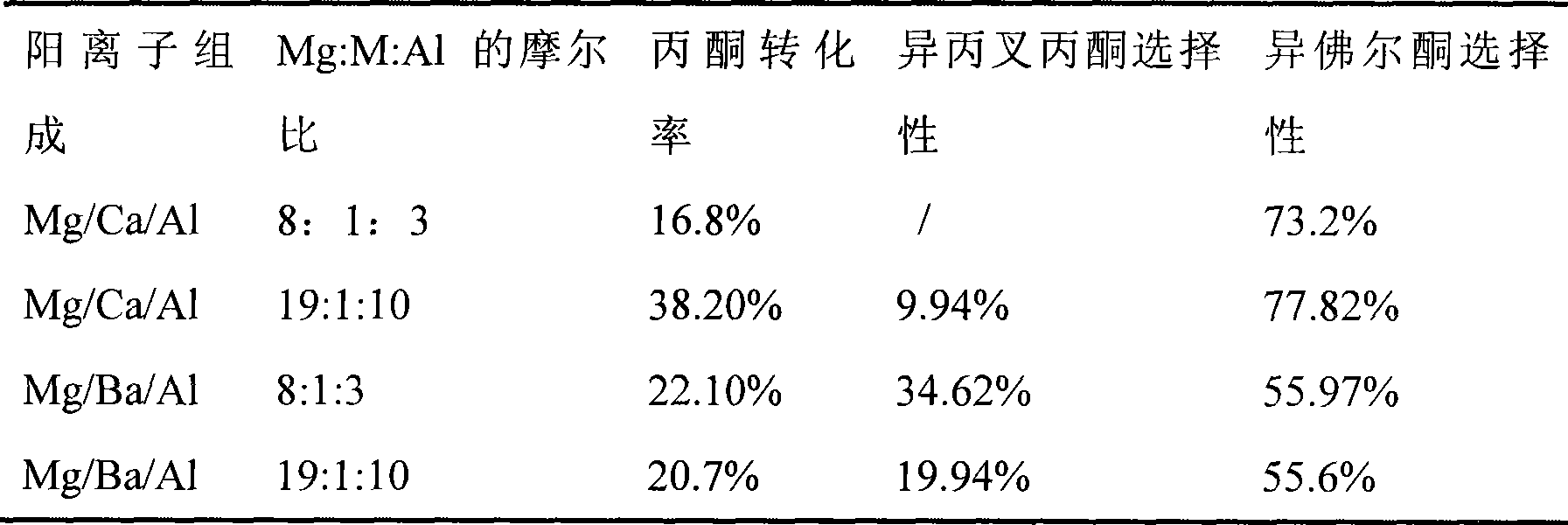

The invention discloses a catalyst for preparing isophorone by condensing acetone and a preparation method thereof. The catalyst is composite oxide Mg(M)AlO, a molecular general formula of the catalyst is represented by Mg(Mx)AlyOz, wherein M represents lithium, barium or calcium, x is more than or equal to 0.05 and is less than or equal to 0.3, y is more than or equal to 0.25 and is less than or equal to 0.75, z is equal to 1+nx / 2+3y / 2, and n is a chemical valence of the doped metal element M. The catalyst is used for a reaction that the acetone is condensed to prepare the isophorone, the highest conversion rate under normal pressure reaches 38.2 percent, the selectivity of the isophorone is 77.8 percent, and the total selectivity of the isophorone and mesityl oxide reaches 87.8 percent.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

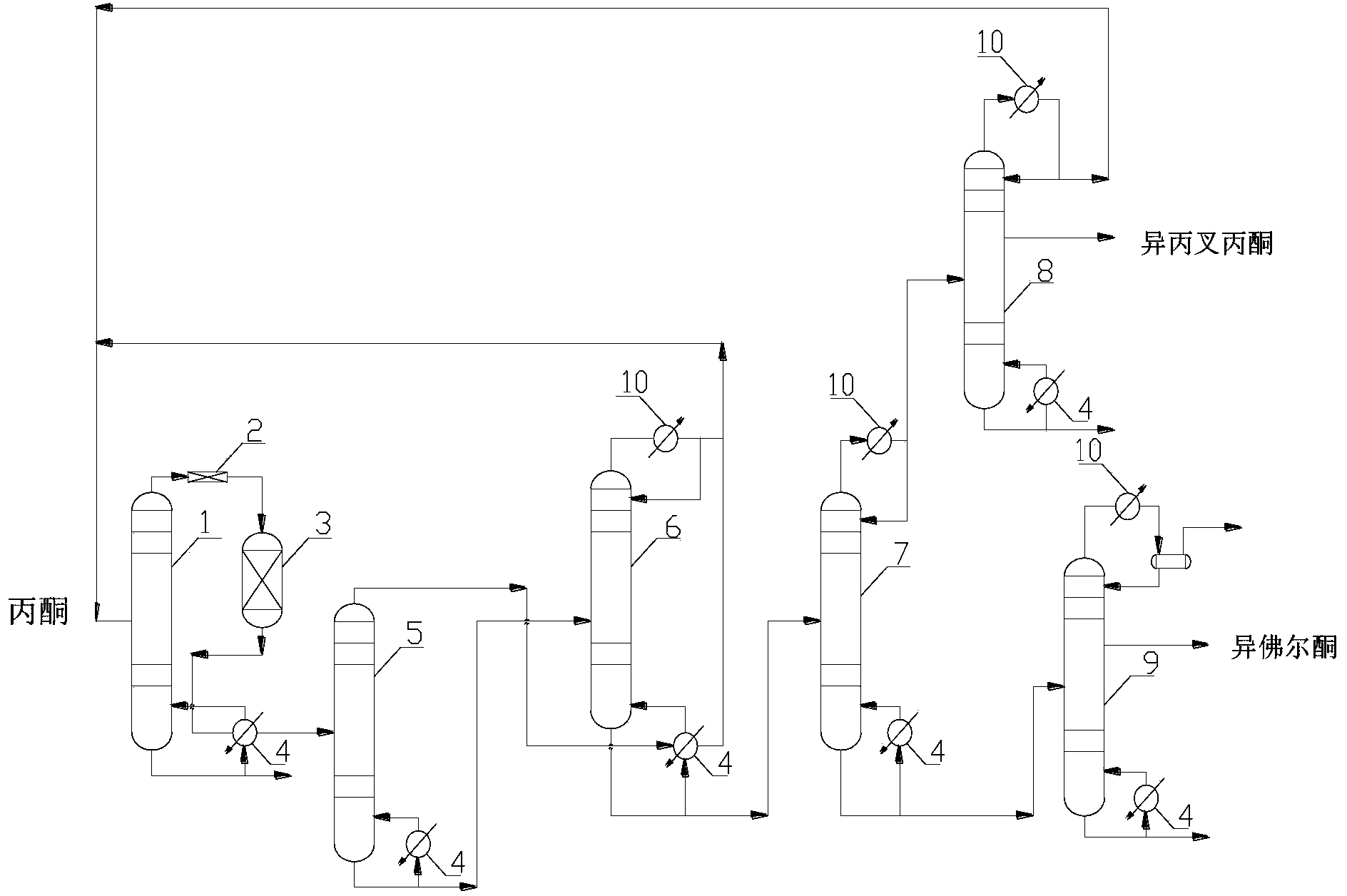

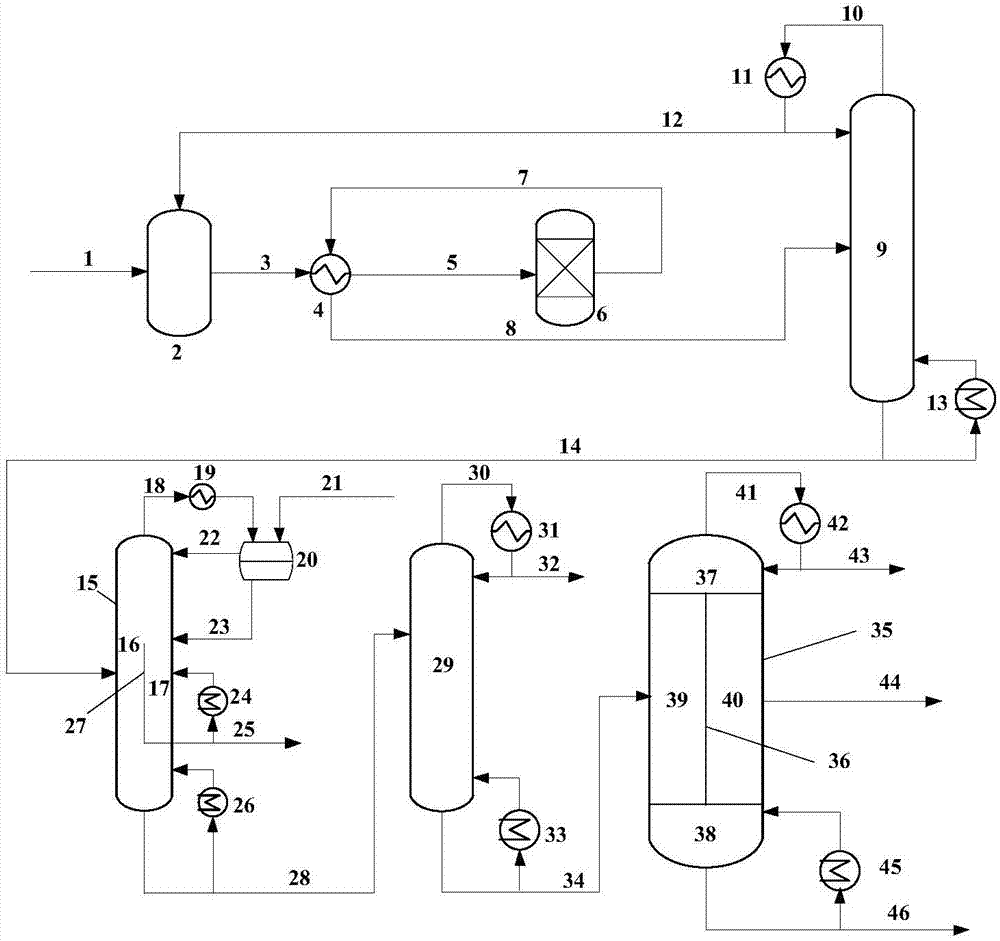

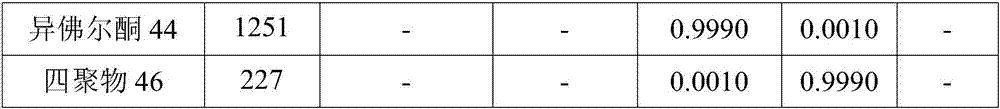

Production technology for isophorone

ActiveCN103435461AOutstanding FeaturesHighlight significant progressOrganic compound preparationChemical industryHigh energyReaction temperature

The invention relates to a production technology for isophorone which belongs to an unsaturated compound with a keto group as a constituent part of the six-membered ring. The production technology comprises the steps: introducing acetone subjected to vaporization and heating into a fixed bed reactor loaded with an alkali catalyst for a condensation reaction with a reaction temperature of 200-350 DEG C and a reaction pressure of 100-500 KPa, wherein the fixed bed reactor is filled with the alkali catalyst, the reaction products is a mixture mainly comprising water, mesityl oxide, mesityl oxide isomer, mesitylene, isophorone and a tetramer product; placing the reaction product obtained in acetone condensation polymerization after acetone is recovered in a cutting tower to cut isophorone, the tetramer product and light components in the reaction product, to obtain heavy components from the bottom of the tower, making the heavy components enter into a refining tower with a side line by a self-compaction mode, and drawing the product isophorone with a mass percent concentration of more than 99% from the side line of the refining tower. The production technology of the invention overcomes the disadvantages in the prior art of high production cost, easily-caused auto-agglutination problem and high energy consumption.

Owner:HEBEI UNIV OF TECH

Method for synthesizing methyl isobutyl ketone from acetone by two-step process

ActiveCN104355975AHigh purityEasy to purifyOrganic compound preparationCarbonyl compound separation/purificationMolecular sieveMethyl isobutyl ketone

The invention relates to a method for synthesizing methyl isobutyl ketone from acetone by a two-step process. The method comprises the following steps: a fixed bed catalytic condensation reactor is filled with a solid catalyst, and acetone used as a reaction raw material is subjected to condensation-dehydration reaction on the catalytic condensation reaction bed to generate mesityl oxide and water; the product from the reactor enters a molecular sieve adsorption dehydration tank; the organic oil phase after dehydration enters a second fixed bed catalytic condensation reactor, and the acetone is further subjected to condensation-dehydration reaction to generate mesityl oxide and water; and the product enters a fixed bed catalytic hydrogenation reactor, the mesityl oxide is subjected to selective hydrogenation reaction on a Pd / Al2O3 catalyst to generate methyl isobutyl ketone, and the hydrogenation product is sent into a subsequent rectification separation system and subjected to separation to obtain the methyl isobutyl ketone product with the purity of greater than 99%. The invention provides a method for producing methyl isobutyl ketone from dimolecular acetone by a condensation-hydrogenation two-step process; and the acetone conversion rate is greater than or equal to 30.0%, and the methyl isobutyl ketone selectivity is greater than or equal to 99.0%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Preparation method of isophorone

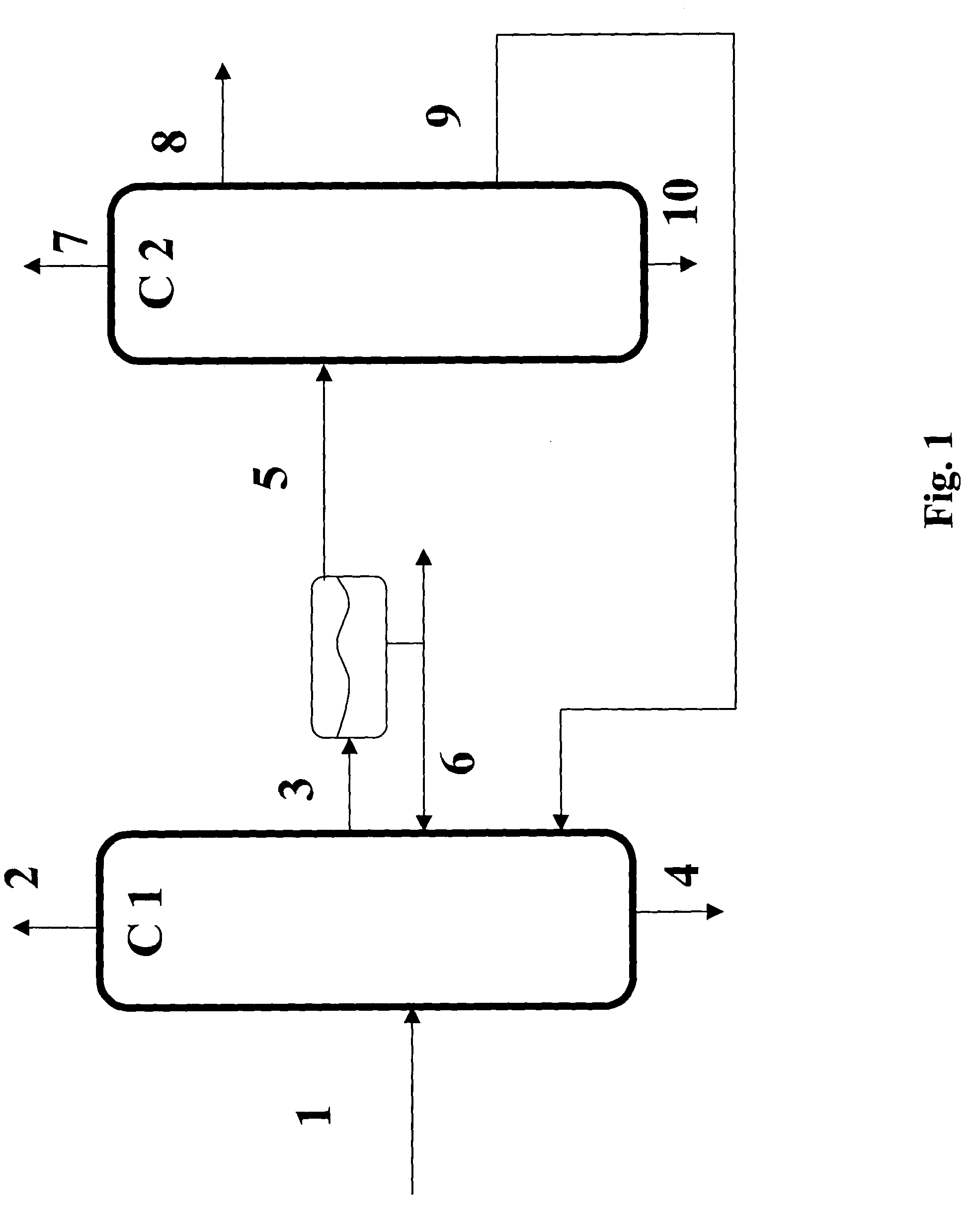

ActiveCN103467263AReduce usageThe reaction process conditions are mild and easy to controlOrganic compound preparationCarbonyl compound preparationDiacetone alcoholIsophorone

The invention discloses a preparation method of isophorone. The preparation method comprises the following steps: continuously sending acetone into a first reaction tower to perform a condensation reaction so as to generate a diacetone alcohol mixed solution; enabling the diacetone alcohol mixed solution to flow out of the first reaction tower and then flow into a heat exchanger through a charging pump to heat and perform a diacetone alcohol dehydration reaction so as to generate a mixture of the acetone and mesityl oxide; placing the mixture of the acetone and the mesityl oxide, the remaining diacetone alcohol mixed solution and a catalyst into a second reaction tower together for reaction, cooling a prepared reaction solution, and separating out a gas phase, an oil phase and a water phase, wherein the oil phase is an isophorone synthetic solution; and neutralizing and rectifying the isophorone synthetic solution to get the finished product isophorone. According to the preparation method, the use of solvents is avoided, the reaction process conditions are mild and easy to control, and the product yield is obviously increased in comparison with that of the prior art.

Owner:JIANGSU HUANXIN NEW MATERIAL CO LTD

Combined technique for synthesizing iso-propylidene acetone and sec-butyl alcohol

ActiveCN103772175ABreak the reaction balanceImprove conversion rateOrganic compound preparationPreparation by hydroxy group additionPtru catalystFluid phase

The invention relates to a combined technique for synthesizing iso-propylidene acetone and sec-butyl alcohol. According to the technique, a fixed bed reactor is adopted, solid acid is used as a catalyst, feedstock includes acetone and n-butene, and acetone is subjected to condensation reaction at a catalytic reaction bed to generate iso-propylidene acetone and water; n-butene and water react to generate sec-butyl alcohol; products from the reactor are sent into a high-pressure separator after being cooled and depressurized, and unreacted n-butene is gasified, subjected to gas-liquid separation and recycled to the reactor; the liquid phase is separated to obtain corresponding substances. The technique provided by the invention provides a new method for producing MO at one step by condensation of bimolecular acetone, and can break reaction balance and improve the conversion rate so as to reduce energy consumption and the production cost of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

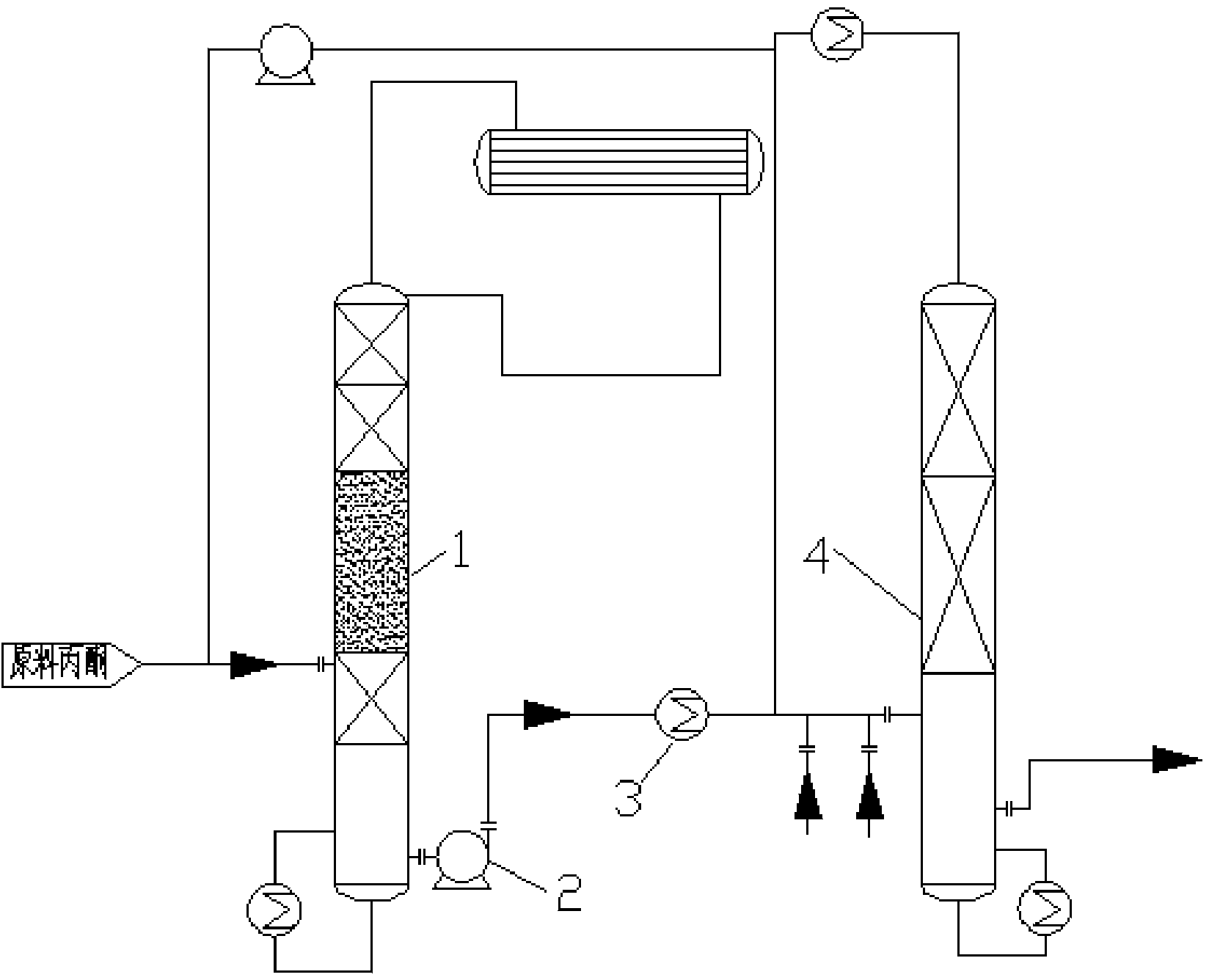

Equipment and method for preparing isophorone through acetone gas phase condensation

ActiveCN107573227AHigh selectivityNo pollution in the processOrganic compound preparationDistillation purification/separationIsophoroneSeparation technology

The invention relates to equipment and a method for preparing isophorone through acetone gas phase condensation. The equipment comprises an acetone recovery tower, a first partition wall tower, an isopropyl acetone tower and a second partition wall tower; in the first partition wall tower, a partition plate is positioned on a central axis in the tower, an azeotropic rectification zone is positioned on the left side of the partition plate, and a water purification zone is positioned on the right side of the partition plate; and in the second partition wall tower, a partition plate is positionedon a central axis in the tower, a primary distillation zone is positioned on the left side of the partition plate, a lateral line zone is positioned on the right side of the partition plate, a publicrectifying section is positioned at the upper part of the partition plate, and a public stripping section is positioned at the lower part of the partition plate. The equipment and the method providedby the invention have the benefits that with the adoption of the partition wall towers and other novel separation technologies, all products in the acetone condensation reaction can be effectively separated and recovered, namely isopolone as a main product, isopropyl acetone as a by-product, sym-trimethylbenzene, a tetramer and the like, and the quality purity of each of the products is higher than or equal to 99.60%; and in addition, the technical process of preparing the isophorone by the acetone condensation is significantly simplified, so that the equipment investment and the energy consumption are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of reproducible dodecanol and branched paraffin in range of aviation kerosene

ActiveCN108102683AHigh selectivityOrganic compound preparationHydroxy compound preparationKeroseneSolid acid

The invention relates to a preparation method of biomass-based dodecanol and branched paraffin in a range of aviation kerosene. The preparation method comprises two parts: 1), mesityl oxide, diacetonealcohol and methyl isobutyl carbinol or a mixture of two or more of the compounds is subjected to a condensation reaction on a first catalyst bed layer of a fixed bed continuous reactor under catalysis of an acid catalyst, a base catalyst, a metal doped solid acid catalyst or a metal doped solid base catalyst, and an oxygen-containing organic compound with carbon chain length being 12 is obtained; 2), a condensation product produced on the first catalyst bed layer and unreacted hydrogen are subjected to a hydrogenation reaction on a second catalyst bed layer of the fixed bed continuous reactor at lower reaction temperature under the acceleration of a metal catalyst, and dodecanol is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

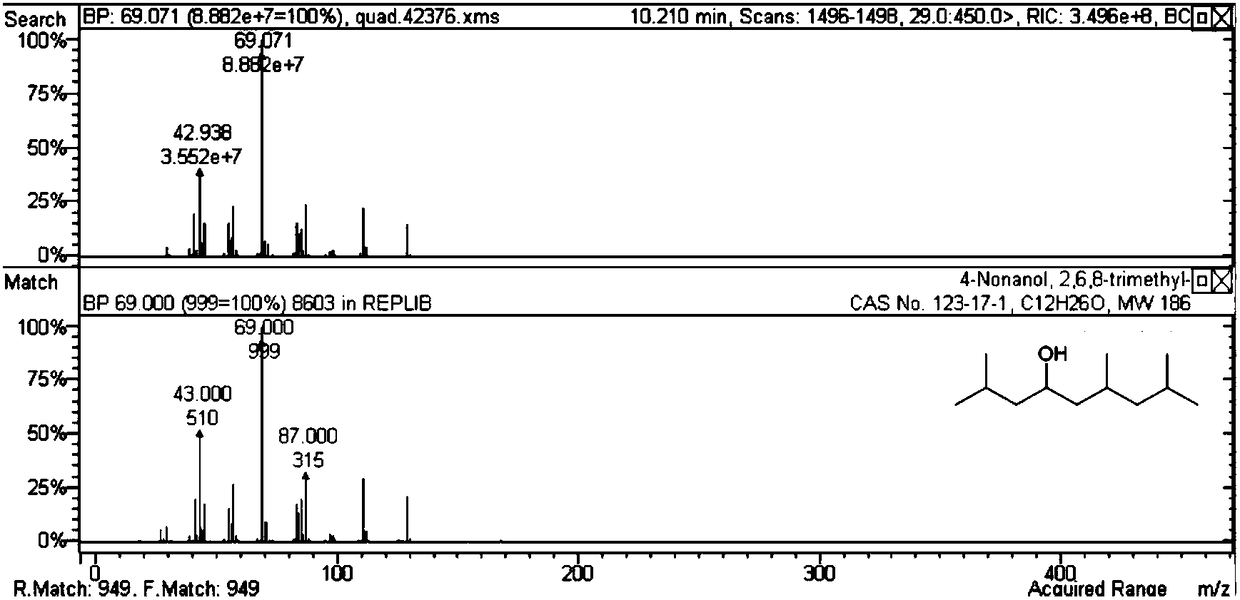

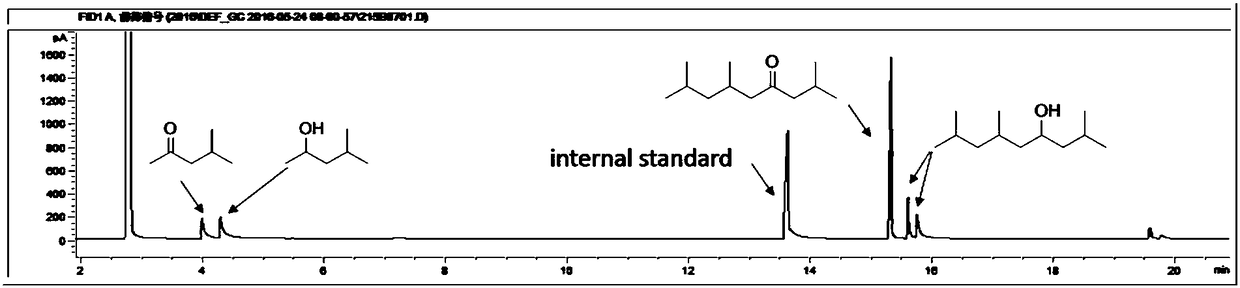

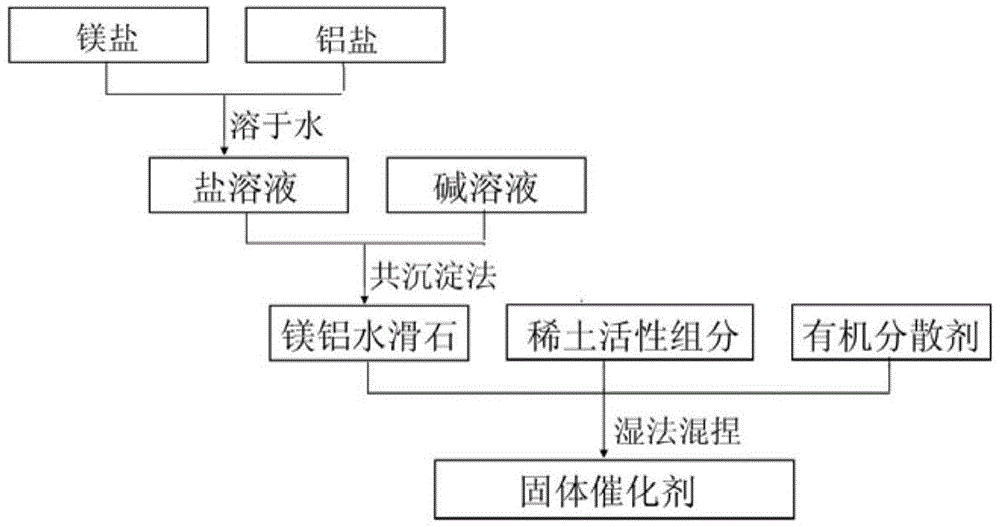

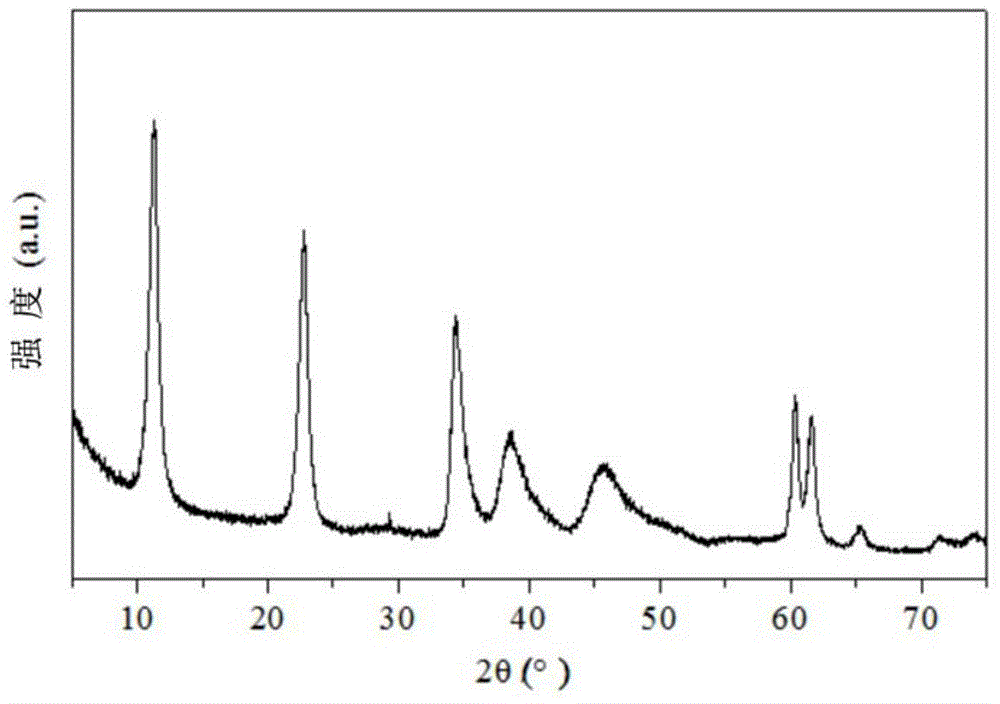

Solid catalyst used in acetone self-condensation reaction, and preparation method and application thereof

ActiveCN104923209AHigh density of basic sitesLarge specific surface areaOrganic compound preparationCarbonyl compound preparationFixed bedReaction temperature

The invention discloses a solid catalyst used in an acetone self-condensation reaction, and a preparation method and an application thereof. The invention relates to the technical field of acetone self-condensation catalysts. According to the invention, magnesium-aluminum hydrotalciteis first prepared with a co-precipitation method, and is adopted as a catalyst precursor; the catalyst precursor is well mixed with a rare earth component and an organic dispersing agent; the mixture is formed by wet kneading and extrusion; and roasting is carried out, such that the solid catalyst is obtained. A fixed bed continuous reaction device is adopted, and the catalyst is applied in an acetone self-condensation reaction. A reaction temperature is 100-450 DEG C, a reaction pressure is 0.1-2.0MPa, the liquid hourly space velocity is 0.1-5h<-1>, an acetone single-pass conversion rate is 20-50%, and an effective selectivity (mesityl oxide+isophorone) is 90-99%, wherein an isophorone selectivity is higher than 70%. The catalyst has acid-alkali dual active center on the surface, and can be flexibly modulated. The catalyst has good activity and stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing diacetone acrylamide from temperature-controlled phase-change type heteropoly acid ionic liquid catalyst

ActiveCN109331873AImprove catalytic abilityRapid responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTemperature controlPhase splitting

The invention relates to a method for preparing diacetone acrylamide from a temperature-controlled phase-change type heteropoly acid ionic liquid catalyst. In the method, mesityl oxide and acrylamideare taken as raw materials, temperature-controlled phase-change type heteropoly acid ionic liquid is used as a catalyst, phosphotungstate is added as an auxiliary gent, the selectivity of the productcan be improved remarkably, and the problem that a traditional homogeneous heteropoly acid catalyst is not easy to separate and reuse is solved by the characteristics of 'phase homogenizing at a hightemperature and phase splitting at a low temperature' of the disclosed ionic liquid.

Owner:WANHUA CHEM GRP CO LTD

Method for synthesizing methyl isobutyl ketone from acetone through one-step method

ActiveCN102557904ALow in mesityl oxideMeet production requirementsOrganic compound preparationCarbonyl compound preparationHydrogenMethyl isobutyl ketone

The invention relates to a method for synthesizing methyl isobutyl ketone from acetone through a one-step method. Acetone and hydrogen gas are taken as raw materials; a three-phase trickle bed reactor is adopted; the reaction conditions are that: the temperature is 120-160 DEG C, and the pressure is 2.5-4.0 MPa; the liquid air speed is 0.8-2.0 h<-1>; in a catalyst, gamma-Al2O3 is taken as a carrier after being modified by using a lanthanum salt for carrying metal palladium; the mass percentage content of lanthanum is 0.5-3.0 percent; and the mass percentage content of Pd is 0.03-0.10 percent. The preparation method comprises the following specific steps of: soaking a lanthanum component in an isometric way for gamma-Al2O3 to obtain modified gamma-Al2O3; and soaking metal palladium in an isometric way to obtain a catalyst, wherein the content of palladium serving as a catalyst is very low; the content of mesityl oxide serving as a byproduct is less than or equal to 0.07 percent; stability is kept for a long time; the acetone transformation rate is more than or equal to 30.0 percent; and the selectivity of methyl isobutyl ketone is more than or equal to 93.0 percent.

Owner:PETROCHINA CO LTD

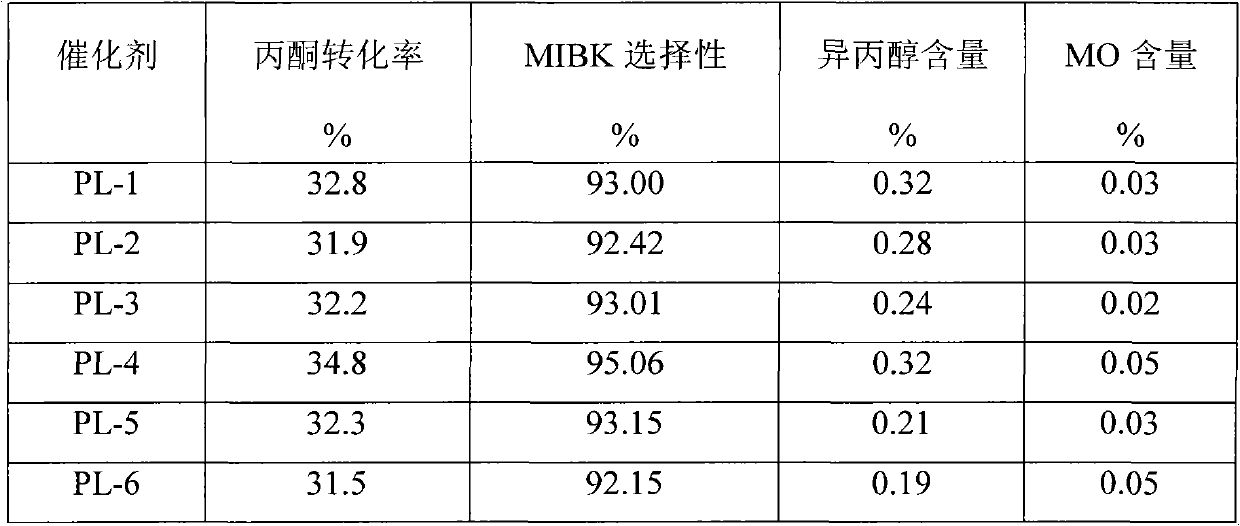

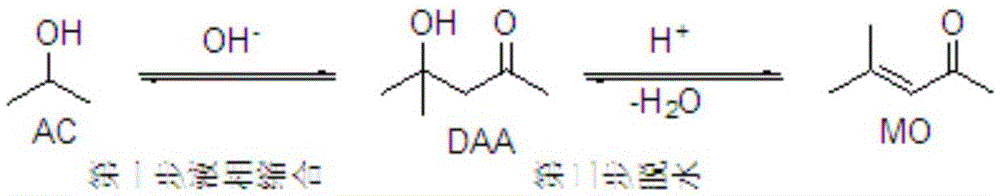

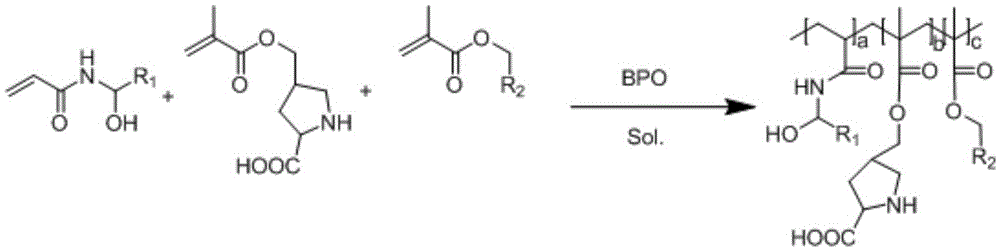

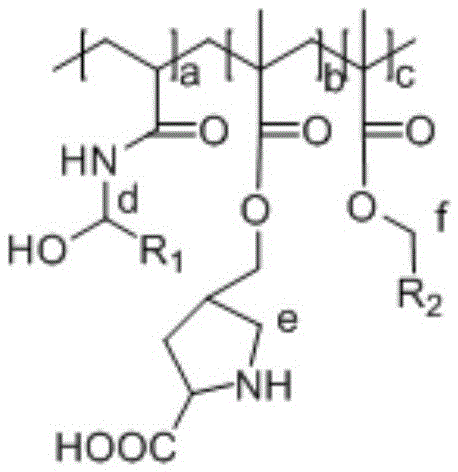

Preparation method of polymer catalyst for acetone condensation

ActiveCN105728040APromote formationImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOxygenMethyl group

The invention relates to a preparation method and applications of a polymer catalyst. The catalyst is applied to acetone condensation and dehydration for preparing mesityl oxide and is capable of improving the conversion rate of acetone. The preparation method comprises the following steps: adding N-hydroxymethyl acrylamide, 2-methyl-2-acrylic acid-4-L-methyl proline ester, 2-methyl-2-acrylic acid-4-methyl piperidine ester, an initiator namely benzoperoxide (BPO), and a solvent into a pressure resistant reaction flask in sequence, wherein the solvent can be methanol (MA), N,N-dimethyl formamide (DMF), dimethyl sulfoxide (DMSO), or N,N-dimethyl acetamide (DMA), stirring to dissolve the components mentioned above, removing oxygen; carrying out reactions at a certain polymerization temperature, after reaction, precipitating the reaction product, subjecting the reaction production to centrifugation, and drying the reaction product to obtain the catalyst (PNL).

Owner:NANJING UNIV +1

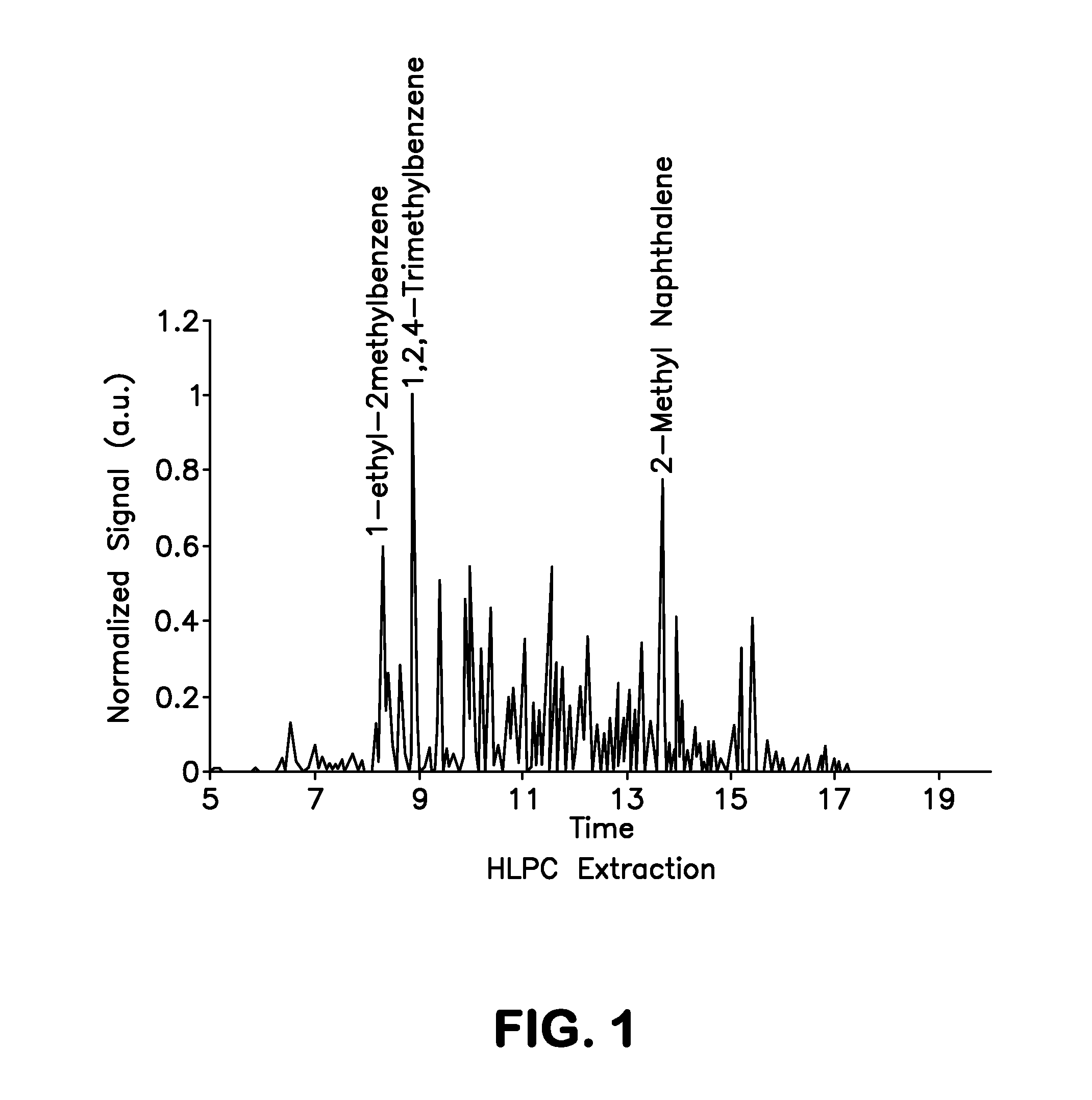

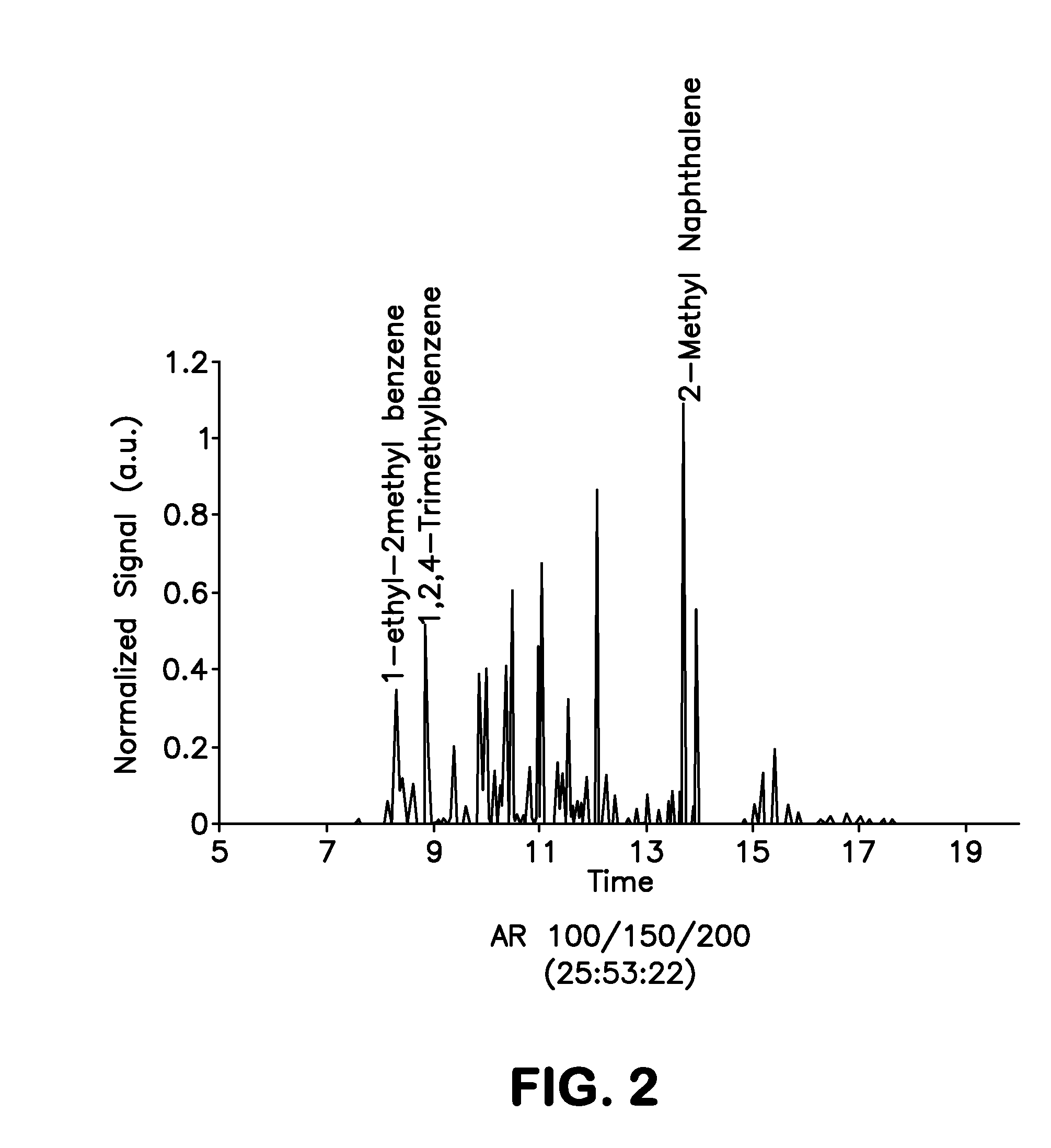

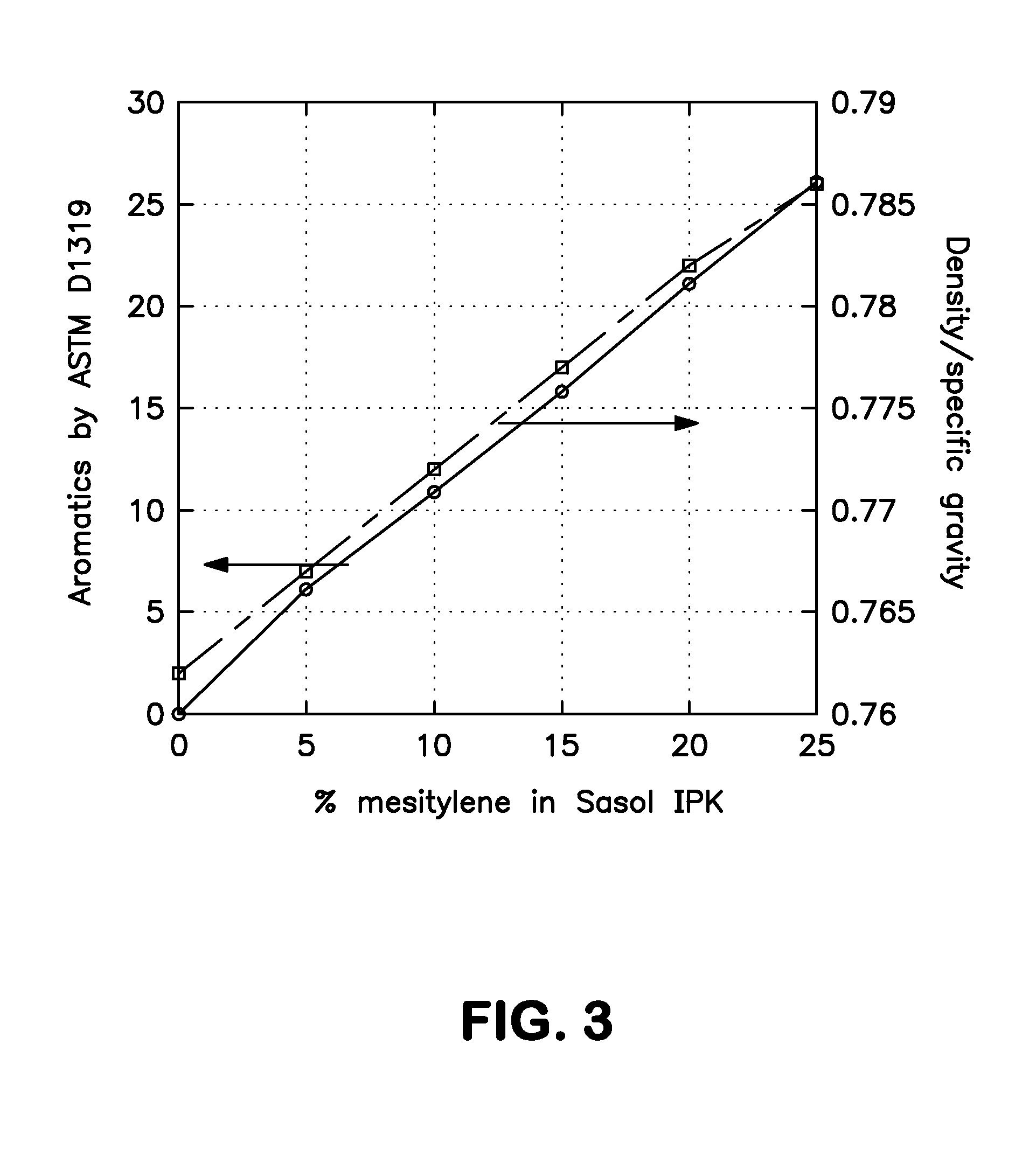

Biogenic Fuel And Method Of Making Same

ActiveUS20120059205A1Increase energy contentHydrocarbon by hydrogenationBiofuelsNiobiumMesityl oxide

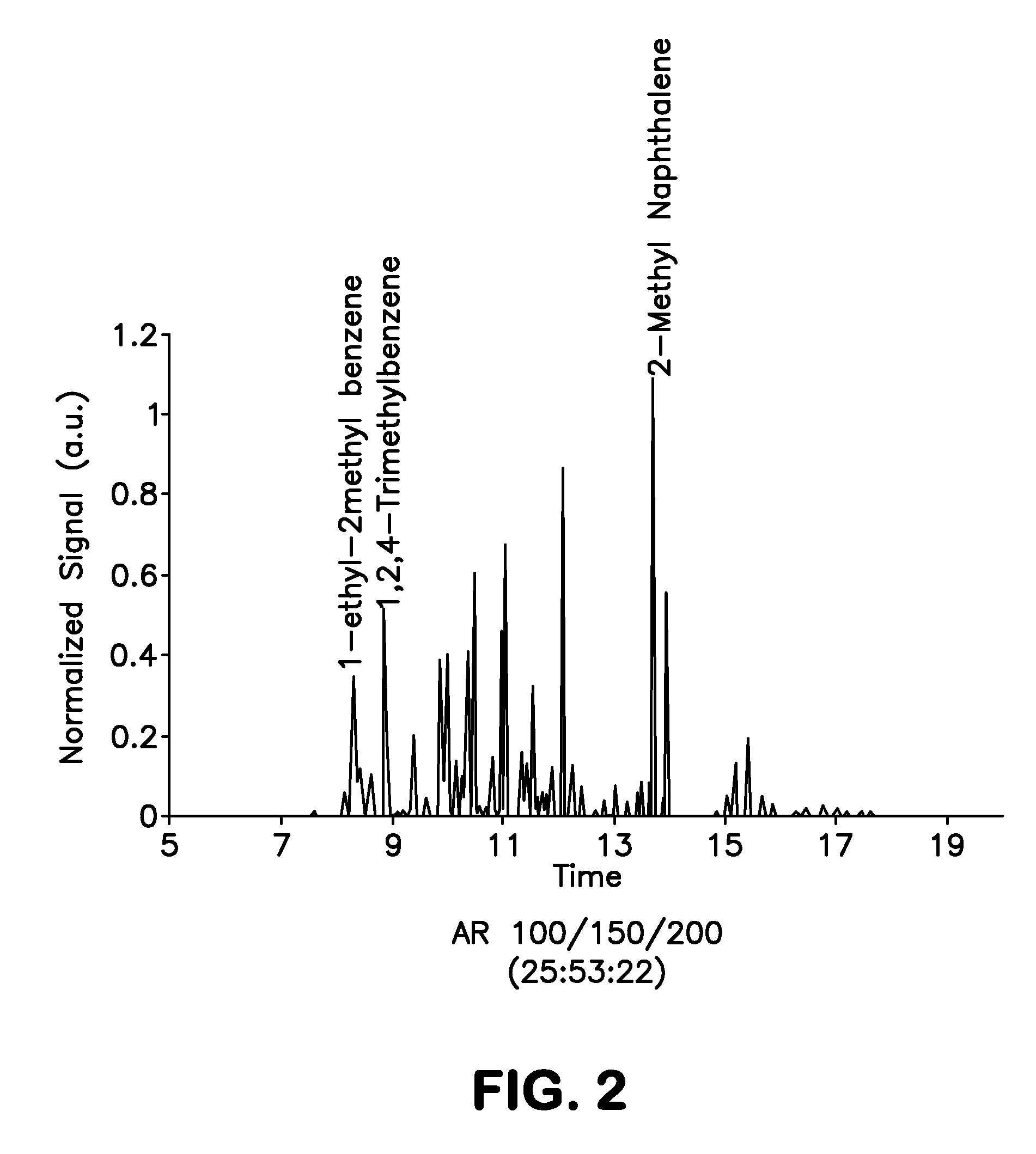

A method of producing from a biomass mesitylene-isopentane fuel is provided. A biomass may be fermented to form acetone. The acetone is converted in a catalytic reactor to mesitylene and mesityl oxide. The mesitylene is separated in a phase separator and the organic face containing mesityl oxide is sent to a dehydration reactor, then to a demethylation reactor, and finally to a hydrogenation reactor from which isopentane is recovered. This isopentane is then mixed with the mesitylene to form the final mesitylene-isopentane fuel. The catalytic reaction with acetone employs catalysts of either niobium, vanadium or tantalum.

Owner:SWIFT ENTERPRISES

Continuous process for recovering acetone from a waste stream resulting from acetone purification

The present invention provides a continuous process for recovering acetone from a waste stream from an acetone purification stage. The waste stream contains mesityl oxide and optionally acetone. The process for recovering acetone includes separating the waste stream in a separating device at least in one stream containing mesityl oxide and optionally a further stream containing acetone, then concentrating mesityl oxide in the mesityl oxide containing stream, and finally recycling the concentrated mesityl oxide stream to the separating device and bringing it into contact with a basic or acidic aqueous medium or with an acidic catalyst in the presence of water whereby mesityl oxide is at least partially hydrolyzed to acetone.

Owner:INEOS PHENOL GMBH & CO DE

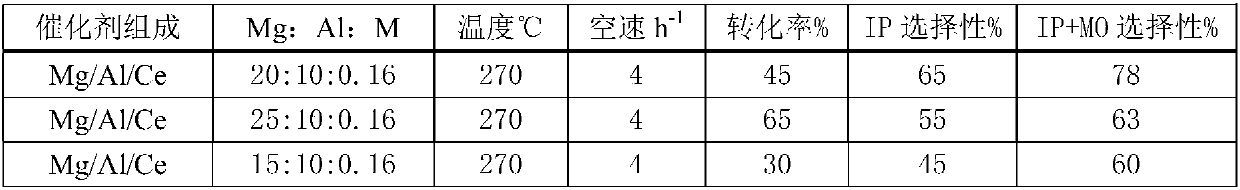

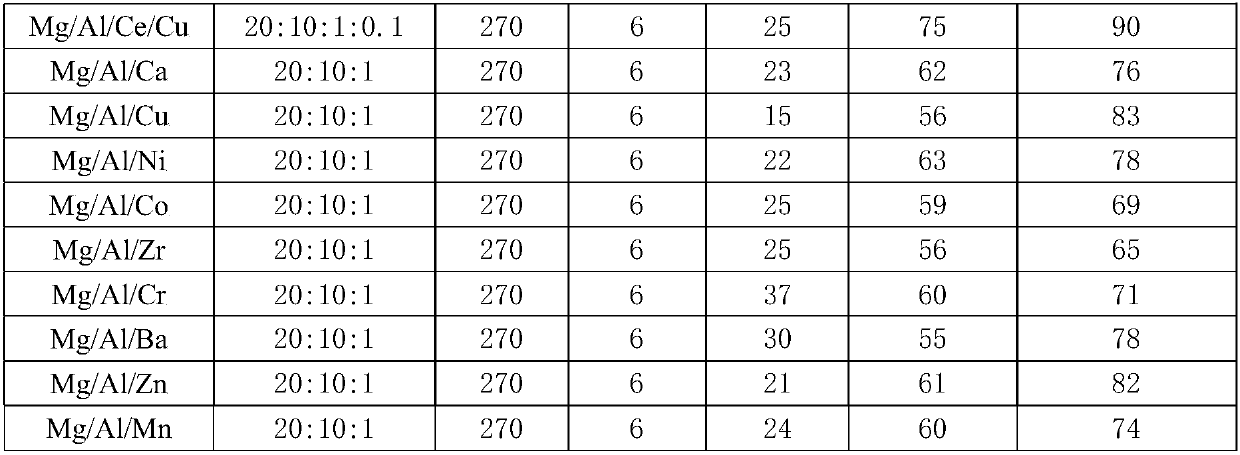

Heterogeneous catalyst for preparing isophorone, preparation and applications thereof

ActiveCN109926040AEasy to prepareLow priceOrganic compound preparationCarbonyl compound preparationIsophoroneMesityl oxide

The present invention provides a method for preparing a heterogeneous catalyst in the presence of a templating agent, wherein the heterogeneous catalyst is used for preparing isophorone through acetone condensation, and is a modified composite oxide (MgO-Al2O3-M<x+>Ox / 2) based on a magnesium aluminum oxide. The preparation method comprises: weighing a certain amount of a mixed salt, dissolving ina certain amount of water, adding a certain amount of a templating agent, adding a certain amount of a precipitating agent to the mixed salt solution in a dropwise manner at a certain temperature, aging, filtering, washing, drying, and calcining to obtain the catalyst. Compared with the catalyst in the prior art, the catalyst of the present invention has advantages of simple preparation method, low price, low bulk density, high activity, high selectivity and good stability. According to the present invention, in the reaction for preparing isophorone through acetone condensation, the reaction temperature is 250-300 DEG C, the mass space velocity of acetone is 1-8 h<-1> under normal pressure, the conversion rate of acetone is up to 45%, the isophorone selectivity is 75%, the mesityl oxide and isophorone selectivity is 90%, and the technology is suitable for the industrial production of isophorone.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

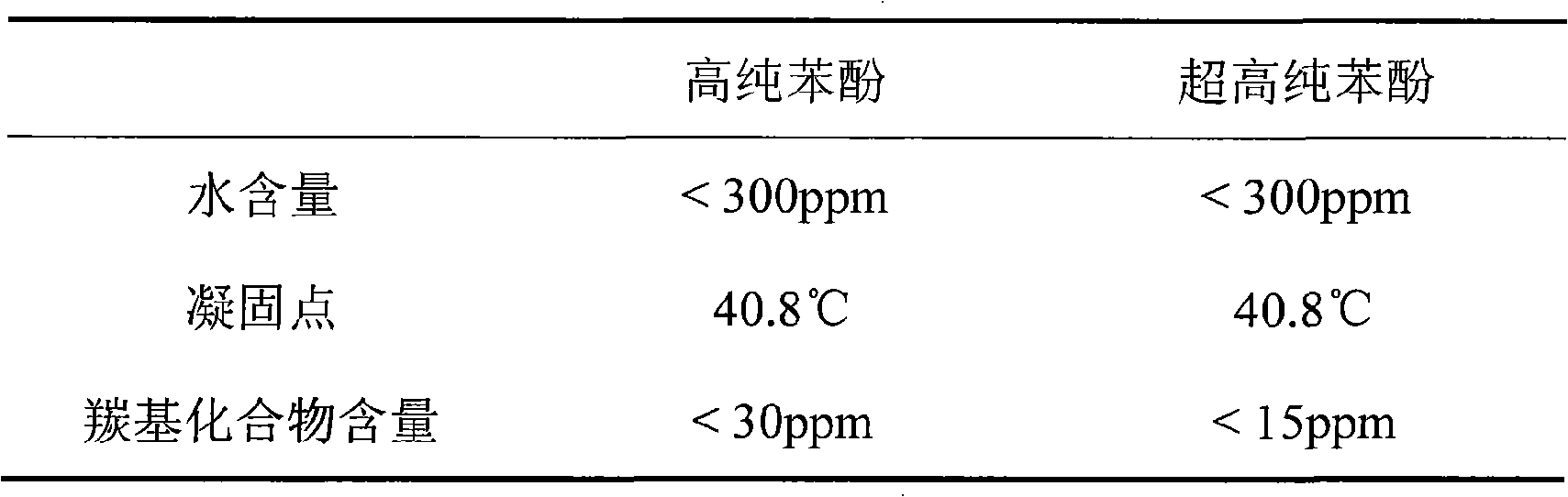

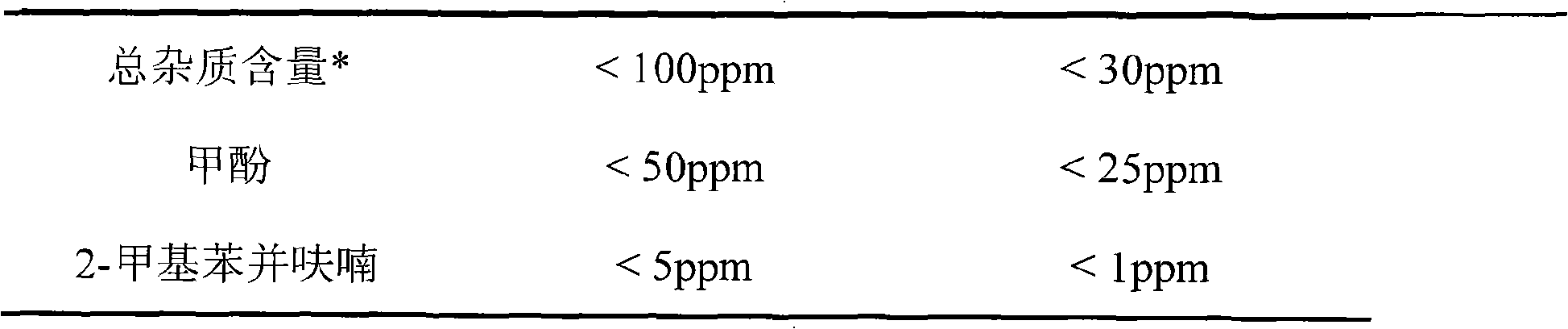

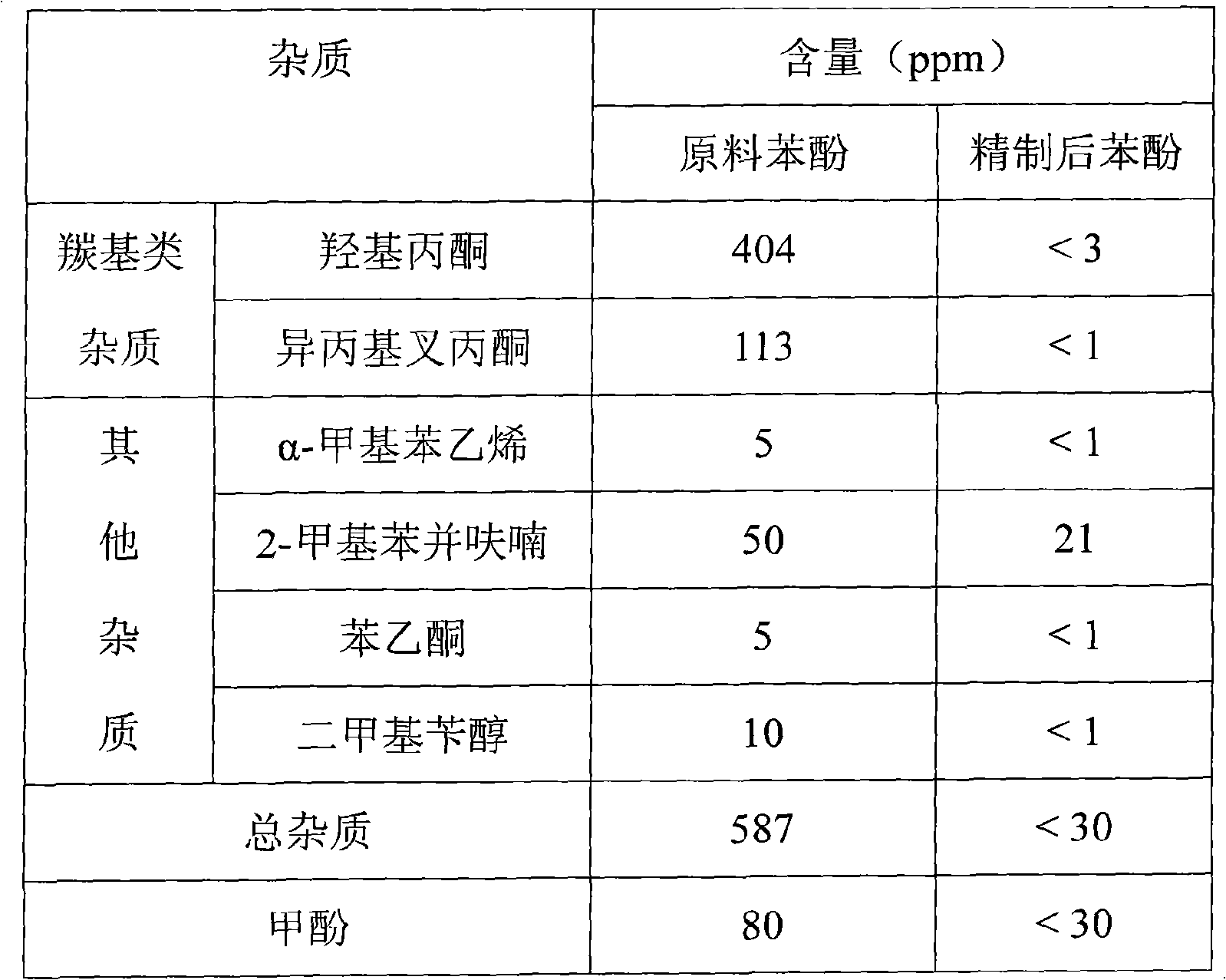

Method for refining phenol by acid-treated aluminium cross-linked montmorillonite catalyst

InactiveCN101575266AImprove adsorption capacityImprove catalytic performanceOrganic chemistryPhysical/chemical process catalystsCross-linkMesityl oxide

The invention provides a method for refining phenol by an acid-treated aluminium cross-linked montmorillonite catalyst, which comprises the following steps: acidizing Na-montmorillonite by sulfuric acid to obtain montmorillonite slurry; preparing an aluminium cross linking agent from aluminium choride; dripping the aluminium cross linking agent solution in the same volume into the montmorillonite slurry to prepare the acid-treated aluminium cross-linked montmorillonit catalyst; and intermittently or continuously catalyzing and refining the raw material phenol by the acid-treated aluminium cross-linked montmorillonite catalyst. The method of the invention adopts the acid-treated aluminium cross-linked montmorillonite catalyst which has B acid and L acid centers, multiple active spots, strong acidity, can effectively remove impurities such as acetol, mesityl oxide and the like, simultaneously can reduce contents of methylbenzofuran impurities, and has wide applicable raw material range.

Owner:BEIJING UNIV OF CHEM TECH

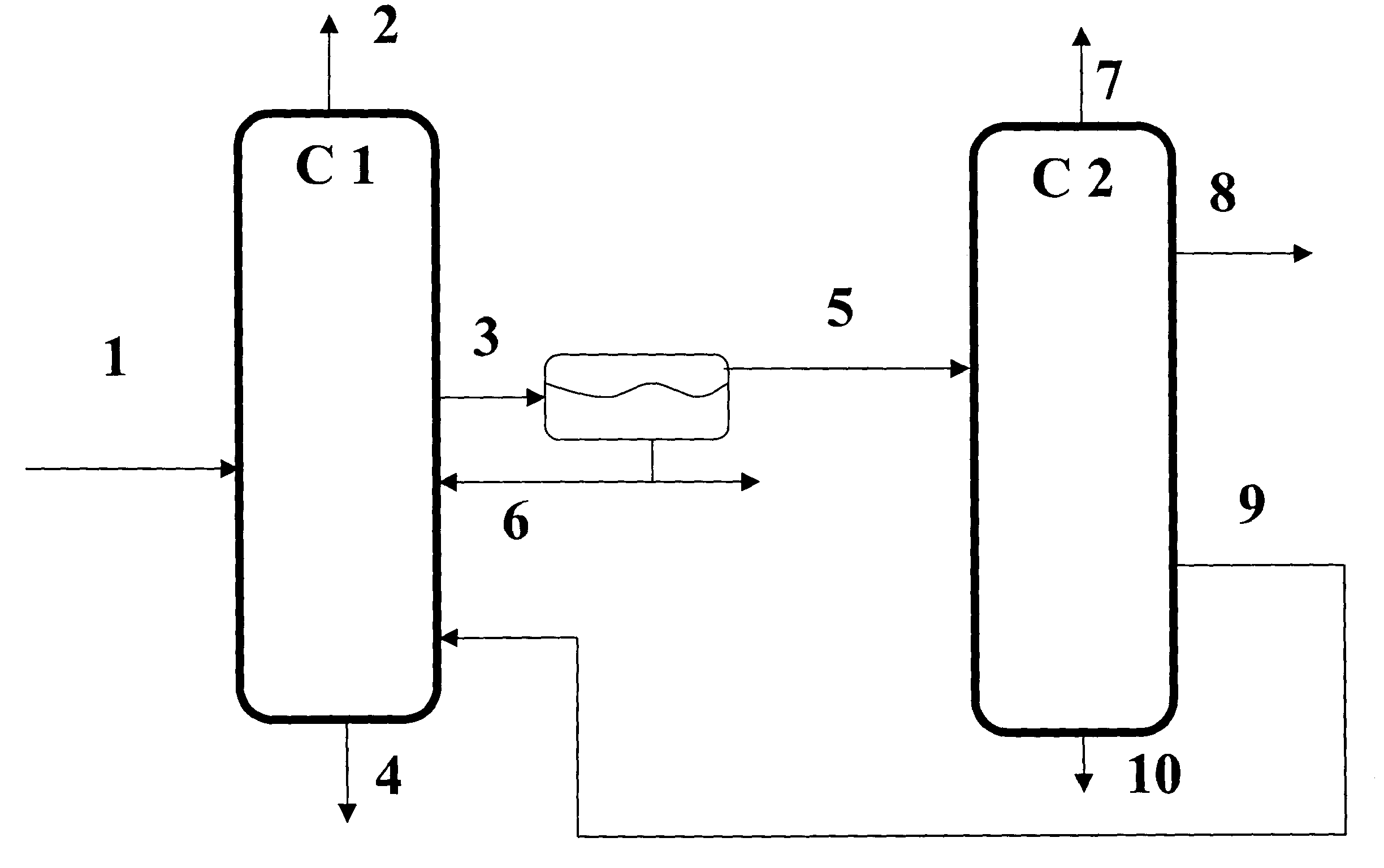

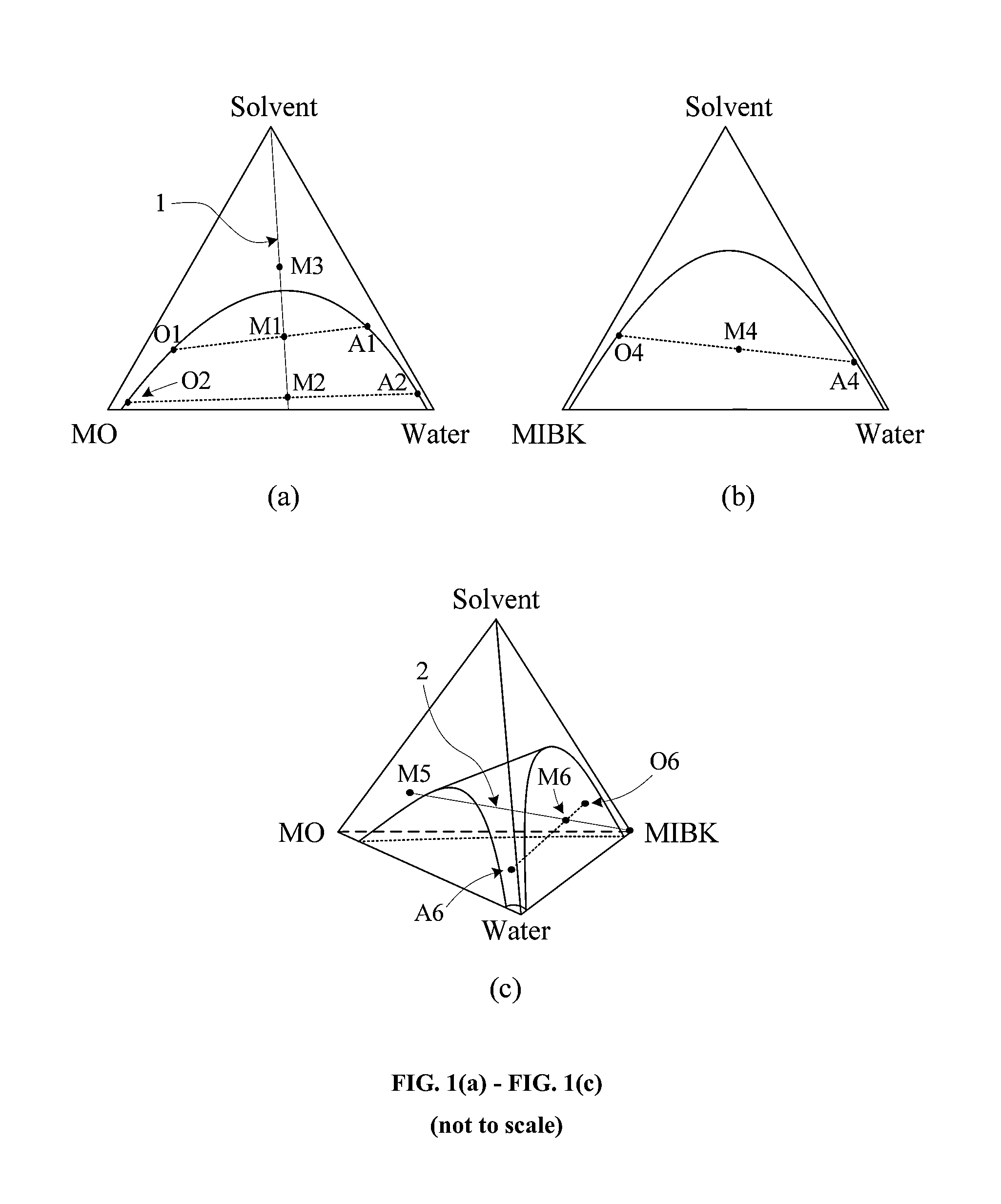

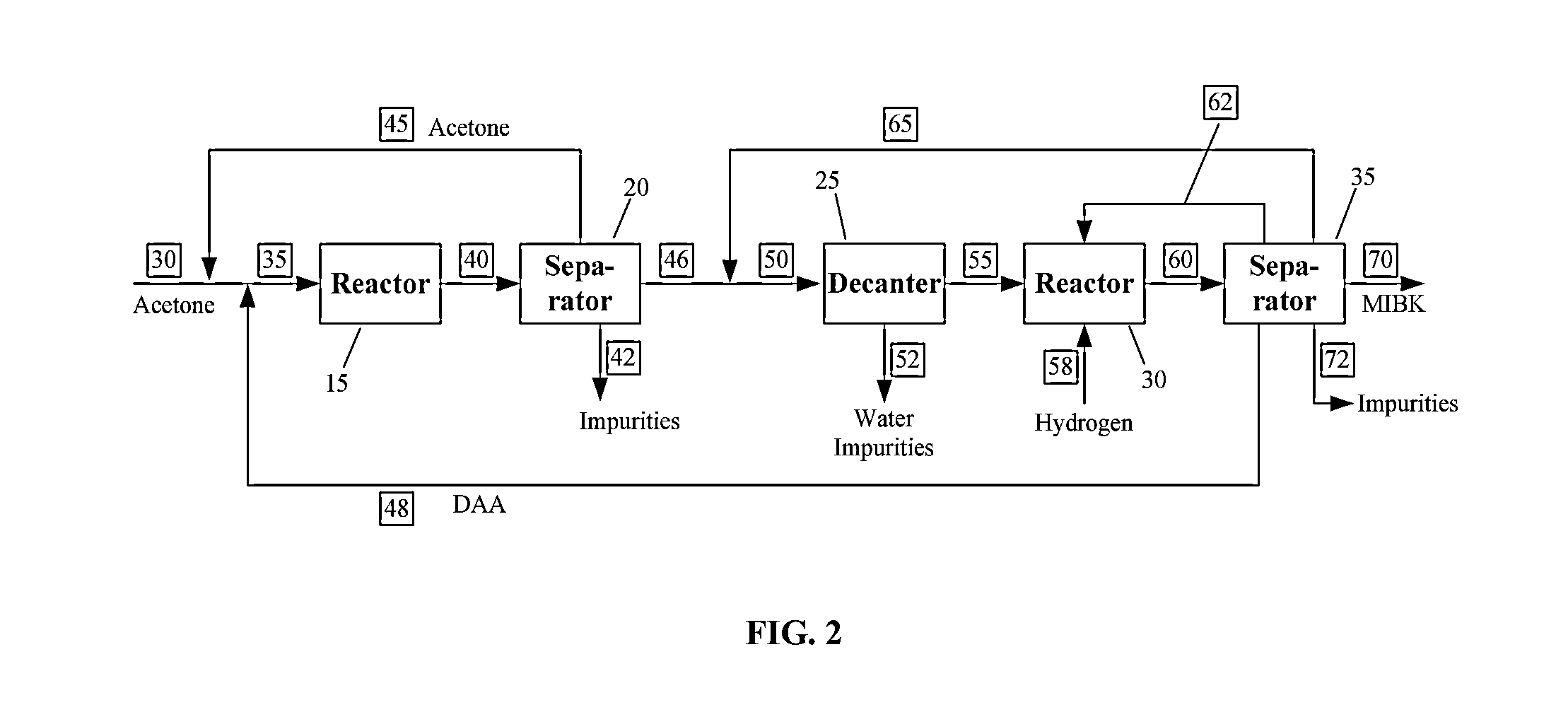

Two-step system and method for the production of methyl isobutyl ketone

ActiveUS9120734B2High puritySequential/parallel process reactionsOrganic compound preparationMethyl isobutyl ketoneHydrogen

Embodiments of the present invention describe systems and methods for production of methyl isobutyl ketone (MIBK) from acetone and hydrogen in a two-step process. In a first step, acetone is converted to a product stream containing mesityl oxide (MO) at a temperature in the range of about 0-120° C. and a pressure in the range of about 1-3 atm. The composition of the product stream from the first reaction step is adjusted so that the resulting stream can undergo a favorable liquid-liquid separation in a decanter, and an MO rich product stream can be recovered. The composition of the feed to the decanter is controlled by choosing the number of reactor stages for the first reaction step and their operating temperatures, and / or by recycling some MIBK to the decanter feed. The method does not require a substantially complete conversion of acetone in the first reaction step, nor does it require a removal of DAA from the product of the first reaction step by separation.

Owner:CLEARWATERBAY TECH

Method for synthesizing mesityl oxide from acetone by one-step process

ActiveCN104355976ABreak the reaction balanceImprove conversion rateOrganic compound preparationCarbonyl compound separation/purificationMolecular sieveMesityl oxide

The invention relates to a method for synthesizing mesityl oxide from acetone by a one-step process, which adopts a combination technique of series connection of a fixed-bed reactor and a molecular sieve adsorption dehydration tank. The method comprises the following steps: a reactor is filled with a solid catalyst, and acetone used as a reaction raw material is subjected to condensation reaction to generate mesityl oxide and water; the product enters a first molecular sieve adsorption dehydration tank; the organic oil phase after dehydration enters a second fixed-bed reactor, and the acetone is further subjected to condensation reaction to generate mesityl oxide and water and passes through a second molecular sieve adsorption dehydration tank; the number of stages of series connection of the reactors and dehydration tanks is 2-3; the acetone and mesityl oxide oil phase after dehydration are sent into a rectification separation system, and the unreacted acetone is circulated back to the reactor; and the liquid phase on the tower bottom is separated to obtain the mesityl oxide with the purity of greater than 99%. The method provides a method for producing mesityl oxide from dimolecular acetone by a condensation one-step process, breaks reaction equilibrium, enhances the conversion rate, acquires the high-purity mesityl oxide product, and lowers the energy consumption and production cost of the product.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Device for extracting mesityl oxide from dilute acetone solution

ActiveCN102698457AAdjustable thicknessSolve the problem that the temperature inconsistency affects the stability of the distillation columnDistillation regulation/controlLiquid separationMesityl oxidePhysical chemistry

The invention provides a device for extracting mesityl oxide from a dilute acetone solution, which comprises a rectifying tower, a cooler, a chromatographic tank, a dilute acetone storage tank, a mesityl oxide storage tank and other components, wherein the chromatographic tank comprises a cooling coil and guide partitions staggered vertically; one or more overflow ports A for mesityl oxide are formed on the sides of the chromatographic tank and can overflow the mesityl oxide to the mesityl oxide storage tank; and an overflow port B for dilute acetone is formed below the overflow port A and can overflow the dilute acetone to the dilute acetone storage tank; a liquid level sensor can be arranged on a side of each of the dilute acetone storage tank and the mesityl oxide storage tank, and a liquid level alarm can be arranged on the top of each of the dilute acetone storage tank and the mesityl oxide storage tank. In the device, the chromatographic tank can implement layering automatically without being supplied with process water or tower bottom liquid; the dilute acetone can return to the rectifying tower after being heated to solve the problem that the stability of the rectifying tower is affected due to different temperatures of the solutions entering the tower. The storage tank can either alarm or open and close a valve automatically when being full so as to reduce labor cost and prevent operation error.

Owner:NANTONG CELLULOSE FIBERS CO LTD

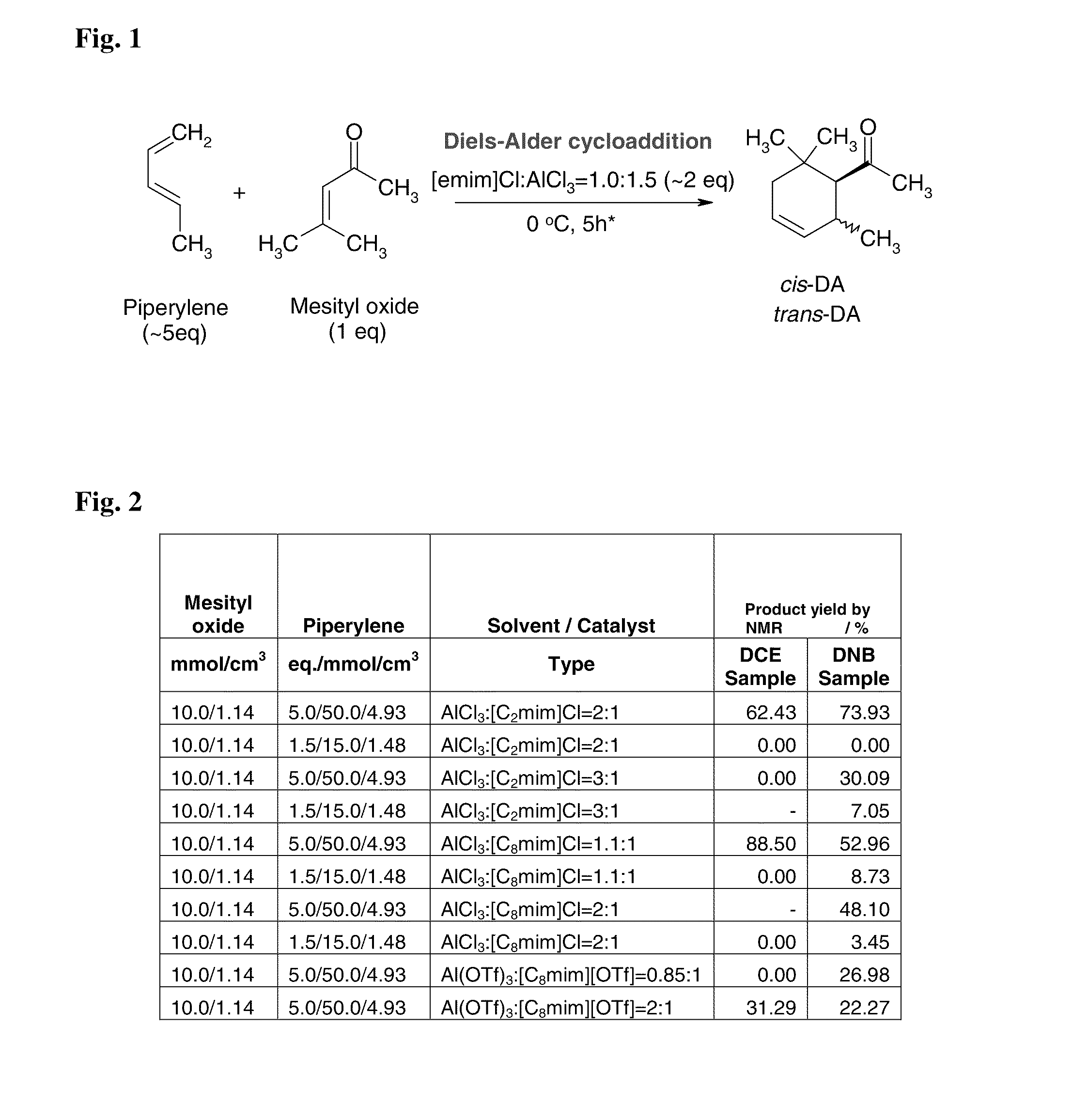

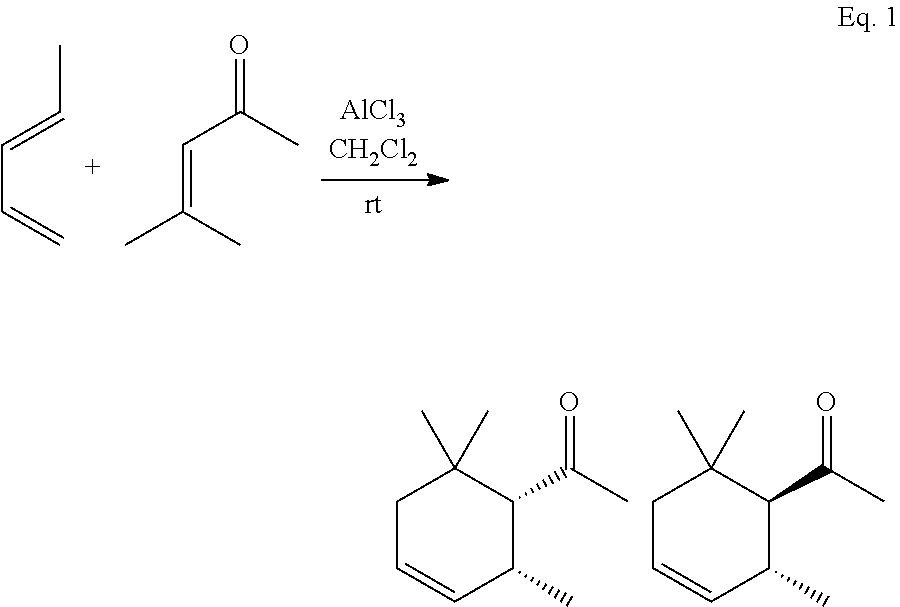

Process for conducting an organic reaction in ionic liquids

InactiveUS8067644B2High yieldSuitable for industrial scaleOrganic compound preparationCarbonyl compound preparationMesityl oxideCyclohexene

Owner:PROCTER & GAMBLE CO

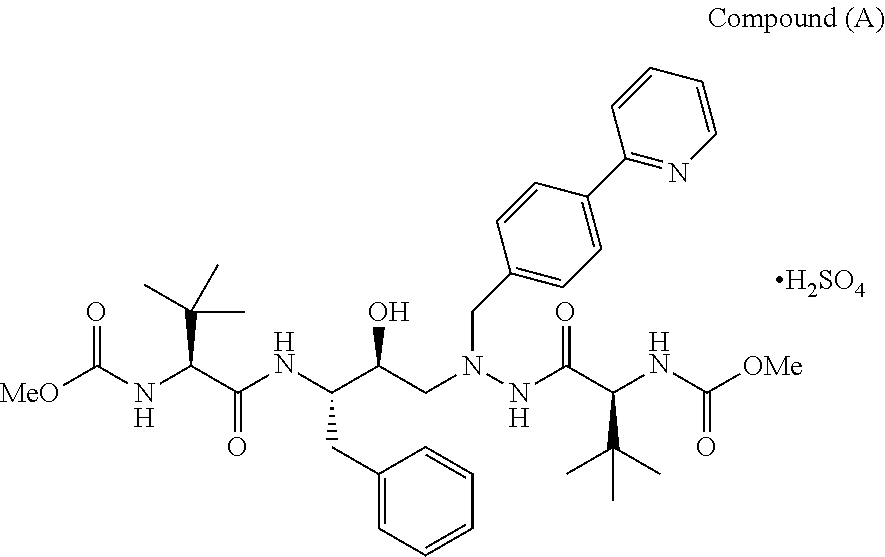

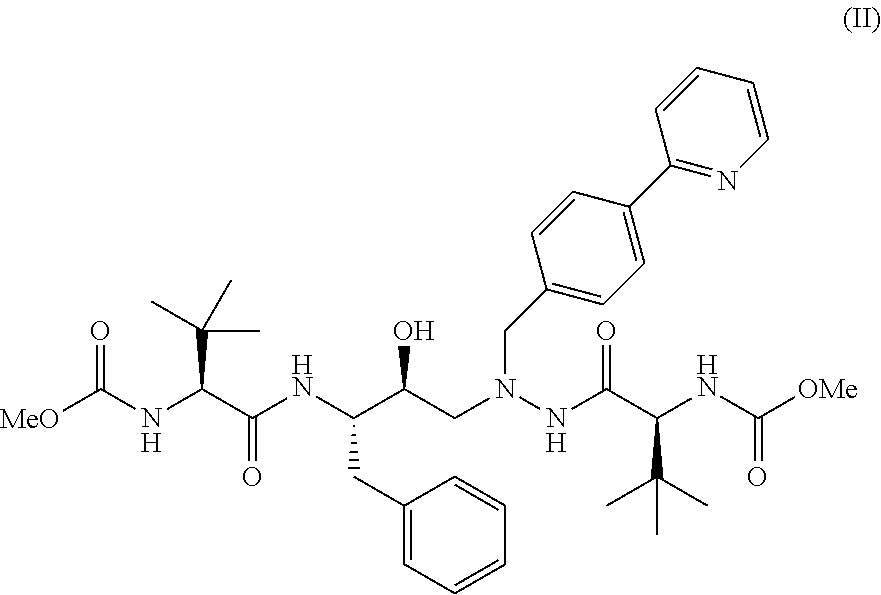

Process for Preparing Atazanavir Sulphate

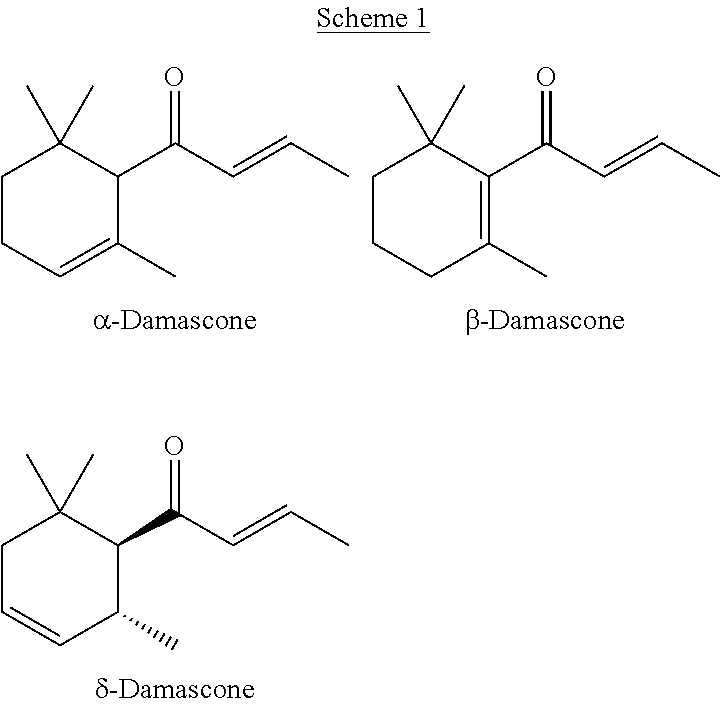

The present invention relates to a process for the preparation of Compound (A):wherein the process comprises contacting atazanavir base (Compound (II))with sulphuric acid in a combination of two or more solvents and isolating compound (A). The present invention also relates to substantially pure Compound (A), and to Compound (A) devoid of mesityl oxide impurity. Mesityl oxide has the following formula:

Owner:CIPLA LTD

Catalyst used for synthesizing isophorone and preparation method thereof

InactiveCN105126801AHigh catalytic activityImprove catalytic selectivityPhysical/chemical process catalystsOrganic compound preparationHigh activityPolyvinylpyrrolidone

The invention relates to isophorone, in particular to a catalyst used for synthesizing isophorone and a preparation method thereof. The catalyst used for synthesizing isophorone is prepared from components including MgO and ZrO2, wherein the mole ratio of MgO to ZrO2 is (0.1-2):1. The preparation method includes the steps that 1, polyvinylpyrrolidone K30 is dissolved in absolute ethyl alcohol, then magnesium nitrate hexahydrate is added into the solution to prepare a solution A, and zirconium propoxide and acetylacetone are added into absolute ethyl alcohol to prepare a solution B; 2, the solution B is added into the solution A to be stirred, then deionized water is added to obtain a thick solution, and the thick solution stands to be converted into gel; 3, reflux and filtration are performed on the gel in ammonia water, a filter cake is dried and then calcined, and then the catalyst used for synthesizing isophorone is obtained. The catalyst has high activity and selectivity, the conversion rate of acetone can reach 54.6%, and the overall selectivity of isophorone and mesityl oxide can reach 96.8%. The catalyst is easy to prepare and good in stability.

Owner:XIAMEN UNIV

A kind of preparation method of aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

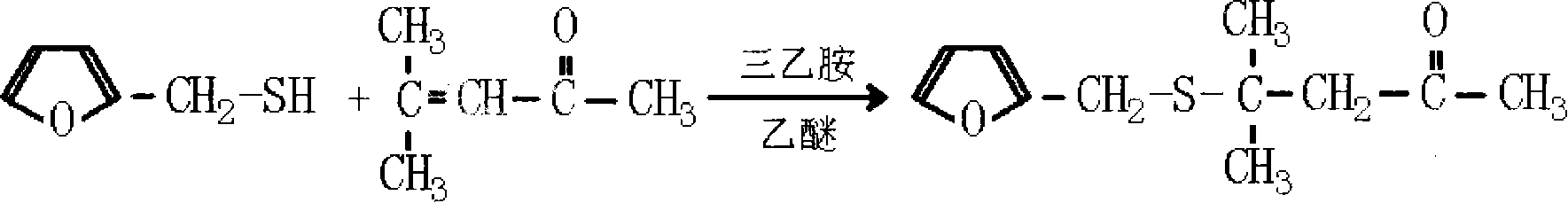

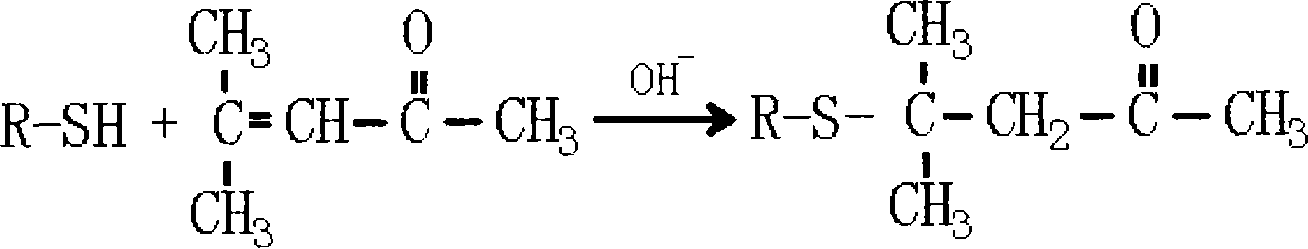

Method for preparing 4-methyl-4-(2-furanmethylthio)-2-pentanone

InactiveCN101607948AEliminate the recycling stepImprove securityOrganic chemistry2-furanmethanethiolMesityl oxide

The invention relates to a method for preparing 4-methyl-4-(2-furanmethylthio)-2-pentanone, which comprises the steps of: (1) performing the reaction of alkaline aqueous solution and 2-furanmethanethiol at a temperature of between 10 and 20 DEG C, and then mixing the obtained product with mesityl oxide; (2) increasing the temperature of the mixture to be between 50 and 70 DEG C, and performing a reflux reaction for 1.5 to 3.5 hours; (3) cooling a reaction liquid to be between 5 and 15 DEG C after the reaction is finished, and using sulfuric acid to neutralize the reaction liquid until the pH value is between 6 and 7; and (4) separating to obtain an organic phase, and then obtaining the 4-methyl-4-(2-furanmethylthio)-2-pentanone through washing, separation, drying and distillation. The method adopts water as a reaction solvent, remarkably improves the safety of the operation of a reaction system, saves a solvent recovery step at the same time, and simplifies the operation; the yield of products is improved to 80 percent from 60 percent at the same time, which reduces the waste of raw materials; and at the same time, no other miscellaneous gas substances are introduced during the preparation, which has more reliable guarantee on the sensory quality of perfume compounds.

Owner:TIANJIN CHEM REAGENT RES INST

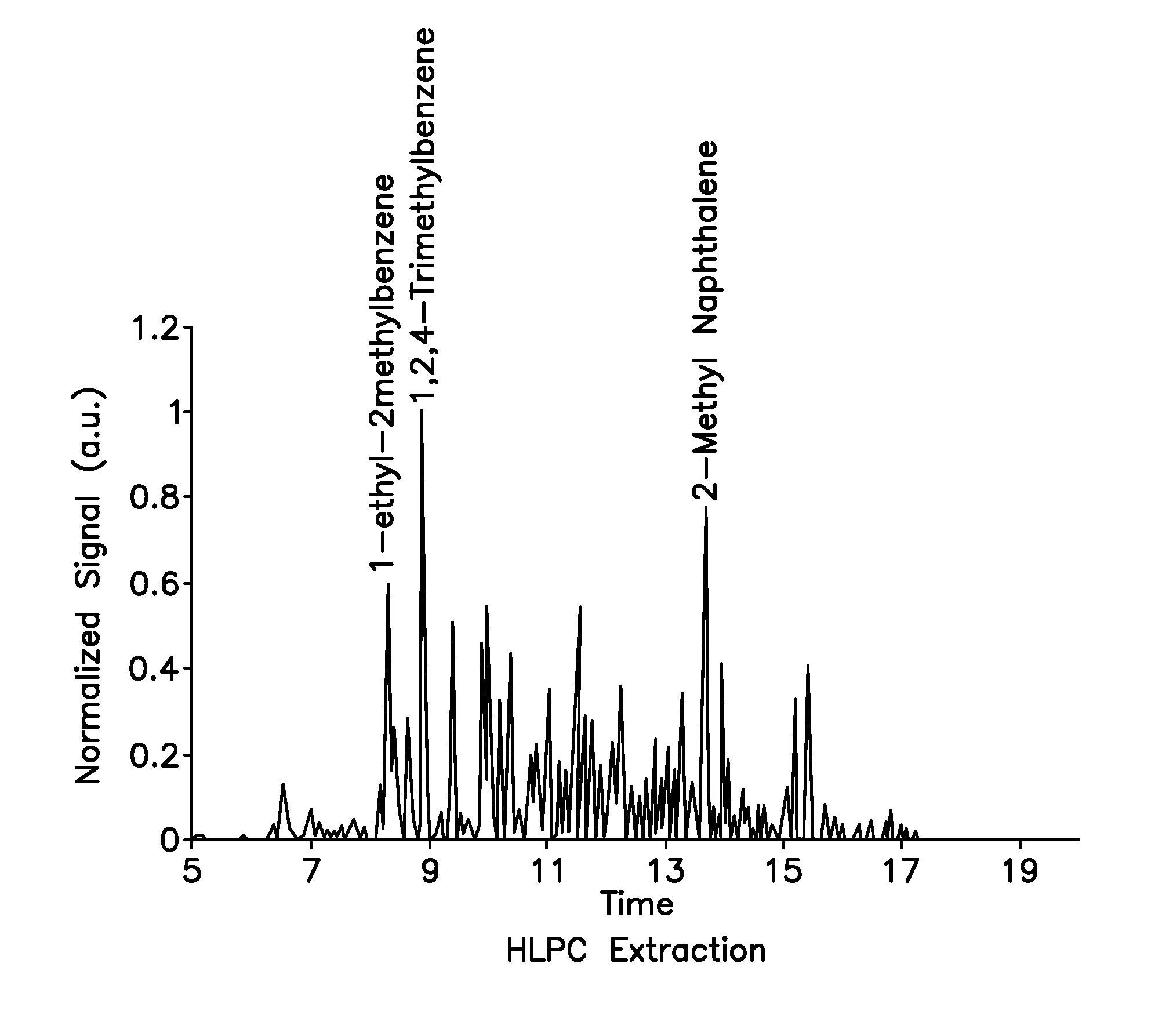

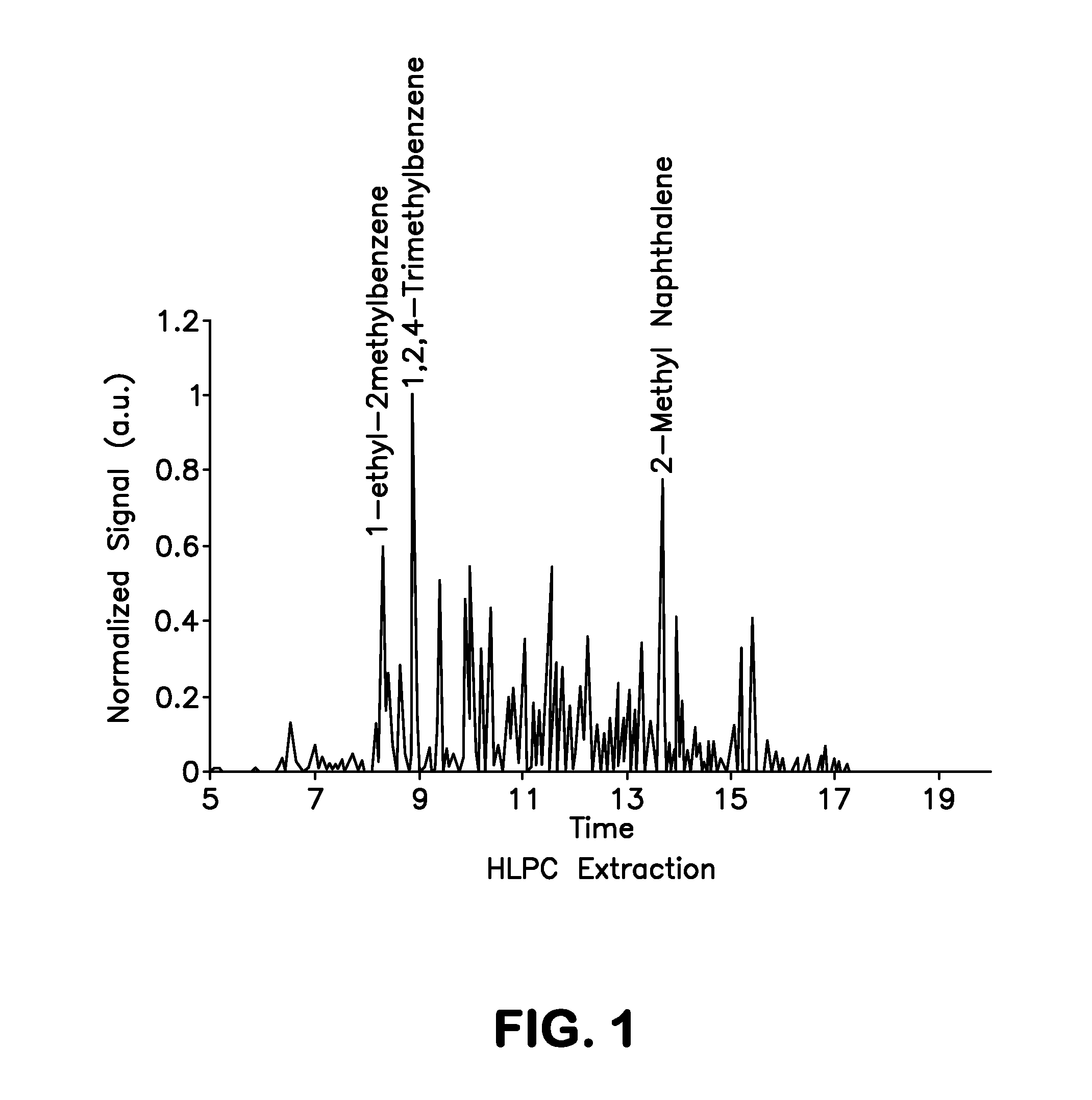

Biogenic fuel and method of making same

ActiveUS8907150B2Hydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystMesityl oxide

A method of producing from a biomass mesitylene-isopentane fuel is provided. A biomass may be fermented to form acetone. The acetone is converted in a catalytic reactor to mesitylene and mesityl oxide. The mesitylene is separated in a phase separator and the organic face containing mesityl oxide is sent to a dehydration reactor, then to a demethylation reactor, and finally to a hydrogenation reactor from which isopentane is recovered. This isopentane is then mixed with the mesitylene to form the final mesitylene-isopentane fuel. The catalytic reaction with acetone employs catalysts of either niobium, vanadium or tantalum.

Owner:SWIFT ENTERPRISES

Method for preparing alpha-isophorone

InactiveCN103664560ASelective stabilityLittle effect on selectivityOrganic compound preparationCarbonyl compound preparationIsophoroneMesityl oxide

The invention discloses a method for preparing alpha-isophorone. The method comprises the step of generating the condensation reaction by acetone under the alkaline catalysis to obtain the alpha-isophorone. The method is characterized in that the condensation reaction is performed in a water and dimethylbenzene mixed solvent system. According to the method, the condensation reaction is performed in the water and dimethylbenzene mixed solvent system; after the condensation reaction is performed for certain time, the selectivity of the alpha-isophorone is basically stabilized; even if the condensation reaction continues to be performed, the influence on the selectivity of the alpha-isophorone, mesityl oxide and isopropyl-ketol is very small; the phenomenon that a reaction endpoint is required to be controlled by the conventional synthesis method is avoided, and the method disclosed by the invention is suitable for industrial production. According to the method disclosed by the invention, the acetone conversion rate is 25-55 percent; the selectivity of the alpha-isophorone is 65-80 percent, and the total selectivity of the mesityl oxide and the isopropyl-ketol is 0.5-10 percent.

Owner:LANZHOU UNIVERSITY +1

Combined technique for synthesizing iso-propylidene acetone and sec-butyl alcohol

ActiveCN103772175BBreak the reaction balanceImprove conversion rateOrganic compound preparationPreparation by hydroxy group additionPtru catalystFluid phase

The invention relates to a combined technique for synthesizing iso-propylidene acetone and sec-butyl alcohol. According to the technique, a fixed bed reactor is adopted, solid acid is used as a catalyst, feedstock includes acetone and n-butene, and acetone is subjected to condensation reaction at a catalytic reaction bed to generate iso-propylidene acetone and water; n-butene and water react to generate sec-butyl alcohol; products from the reactor are sent into a high-pressure separator after being cooled and depressurized, and unreacted n-butene is gasified, subjected to gas-liquid separation and recycled to the reactor; the liquid phase is separated to obtain corresponding substances. The technique provided by the invention provides a new method for producing MO at one step by condensation of bimolecular acetone, and can break reaction balance and improve the conversion rate so as to reduce energy consumption and the production cost of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

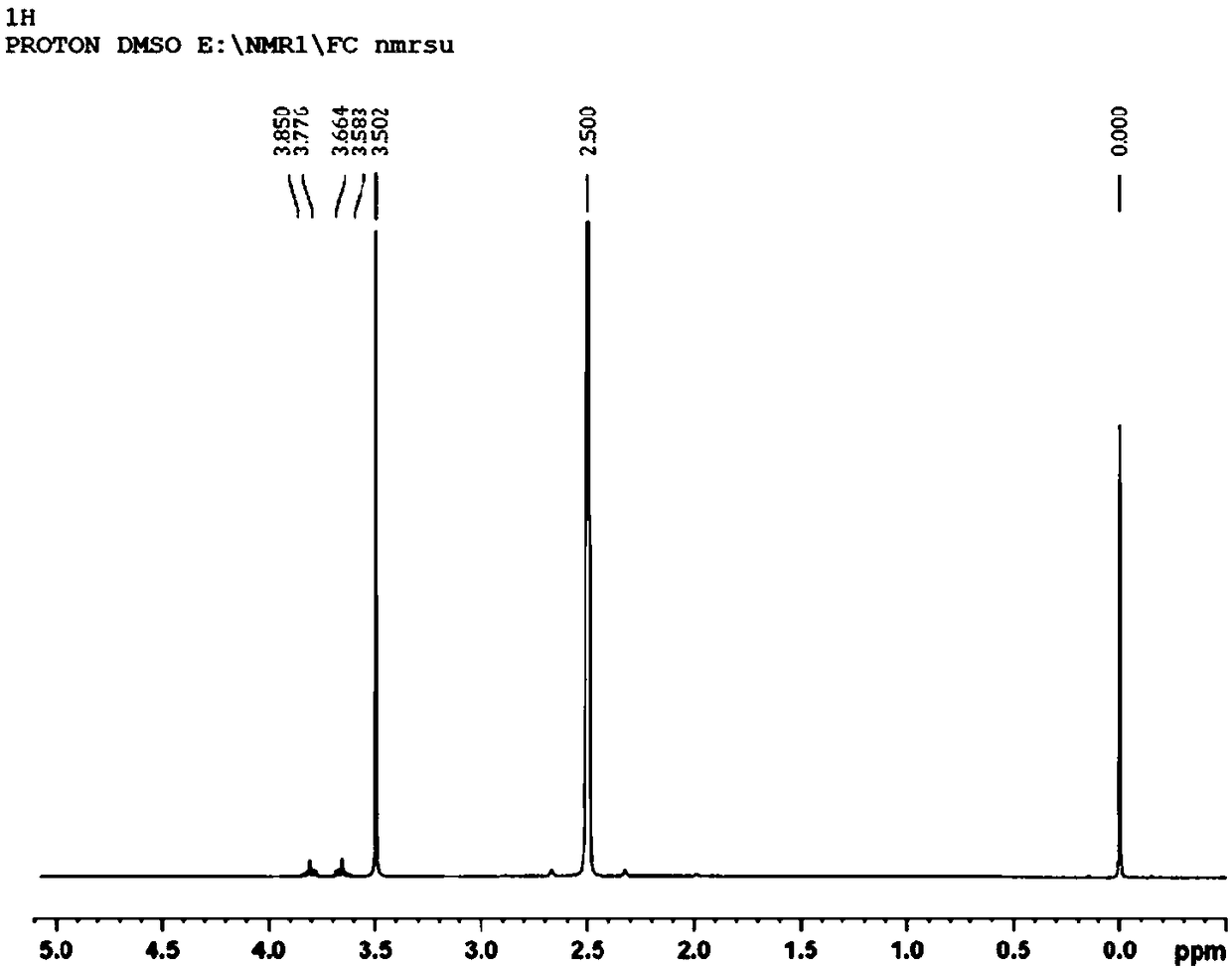

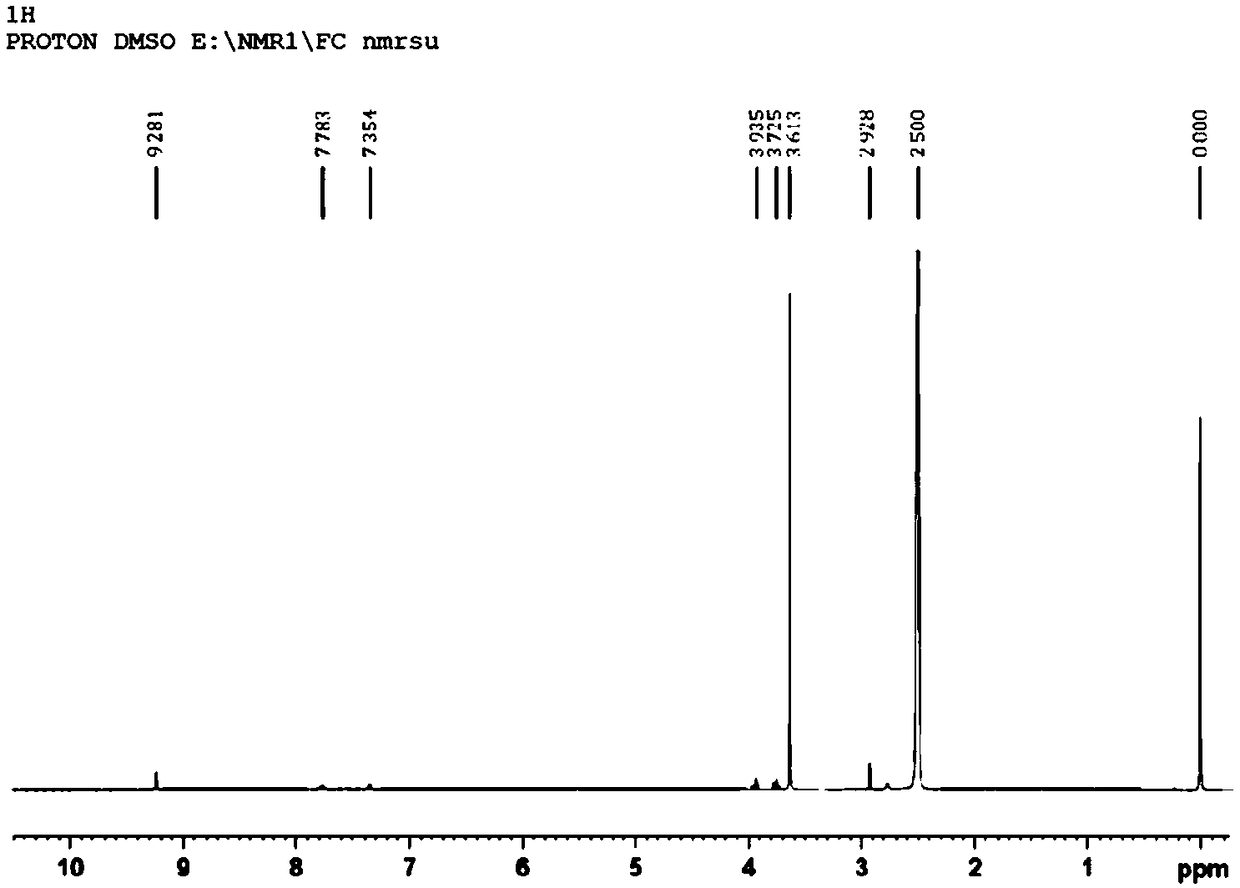

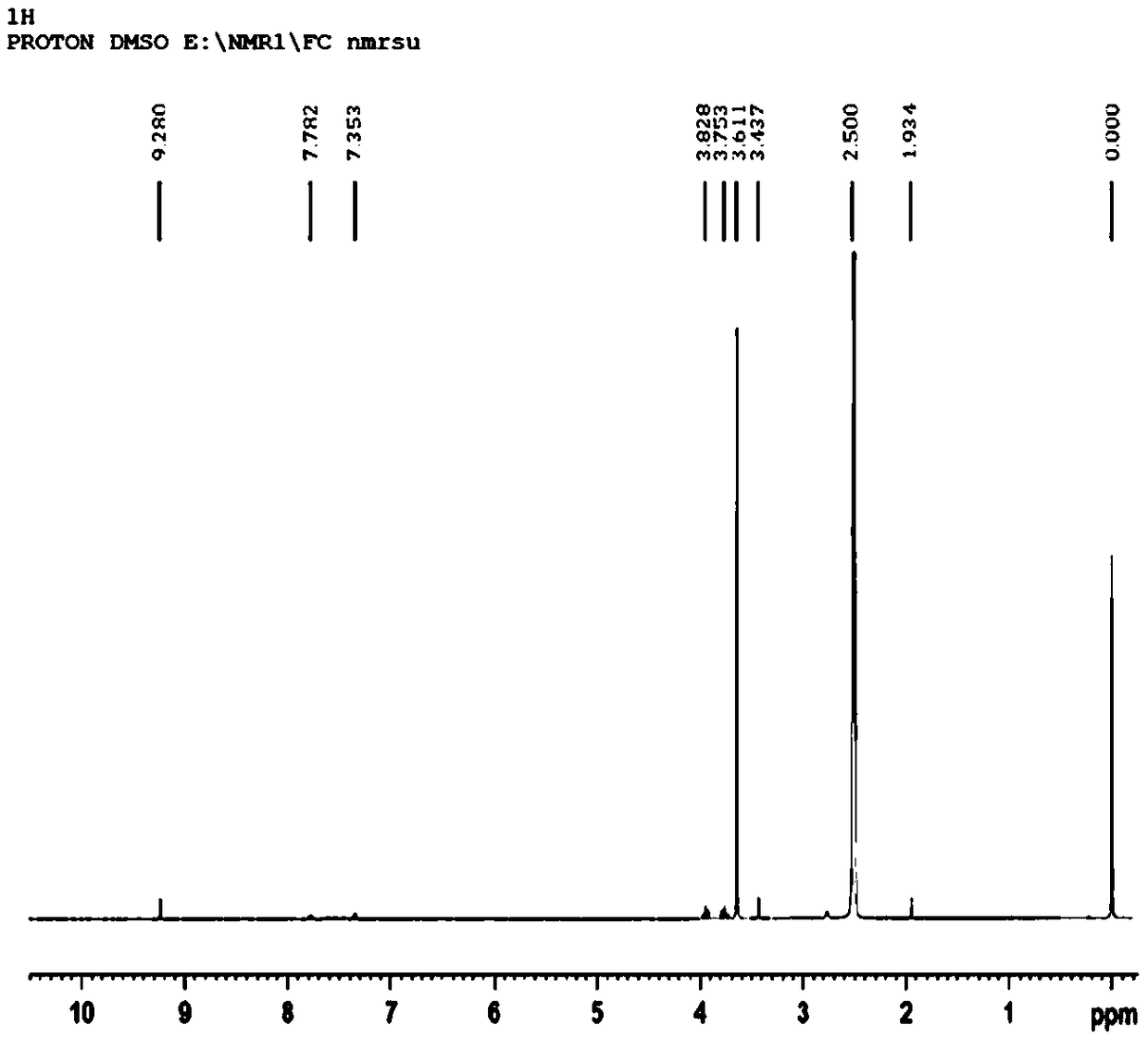

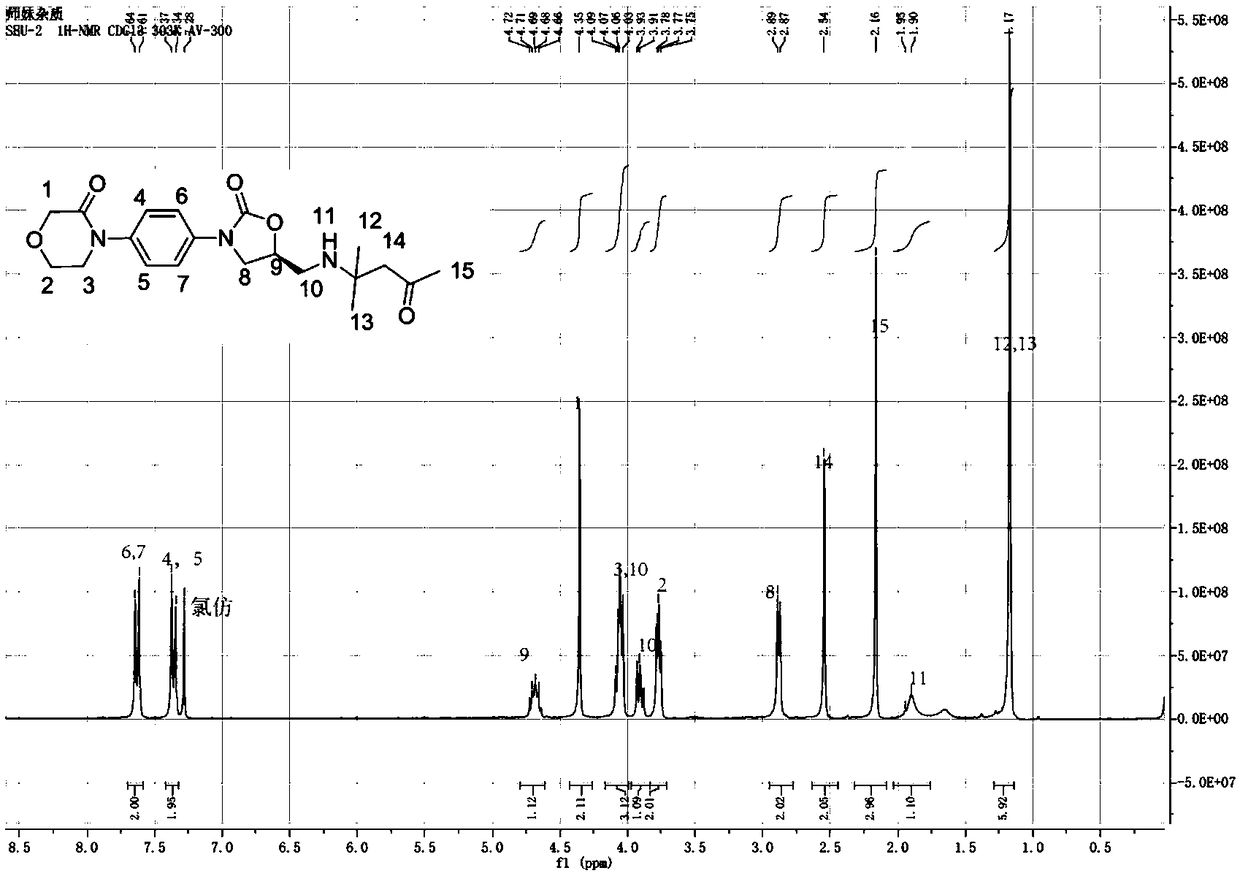

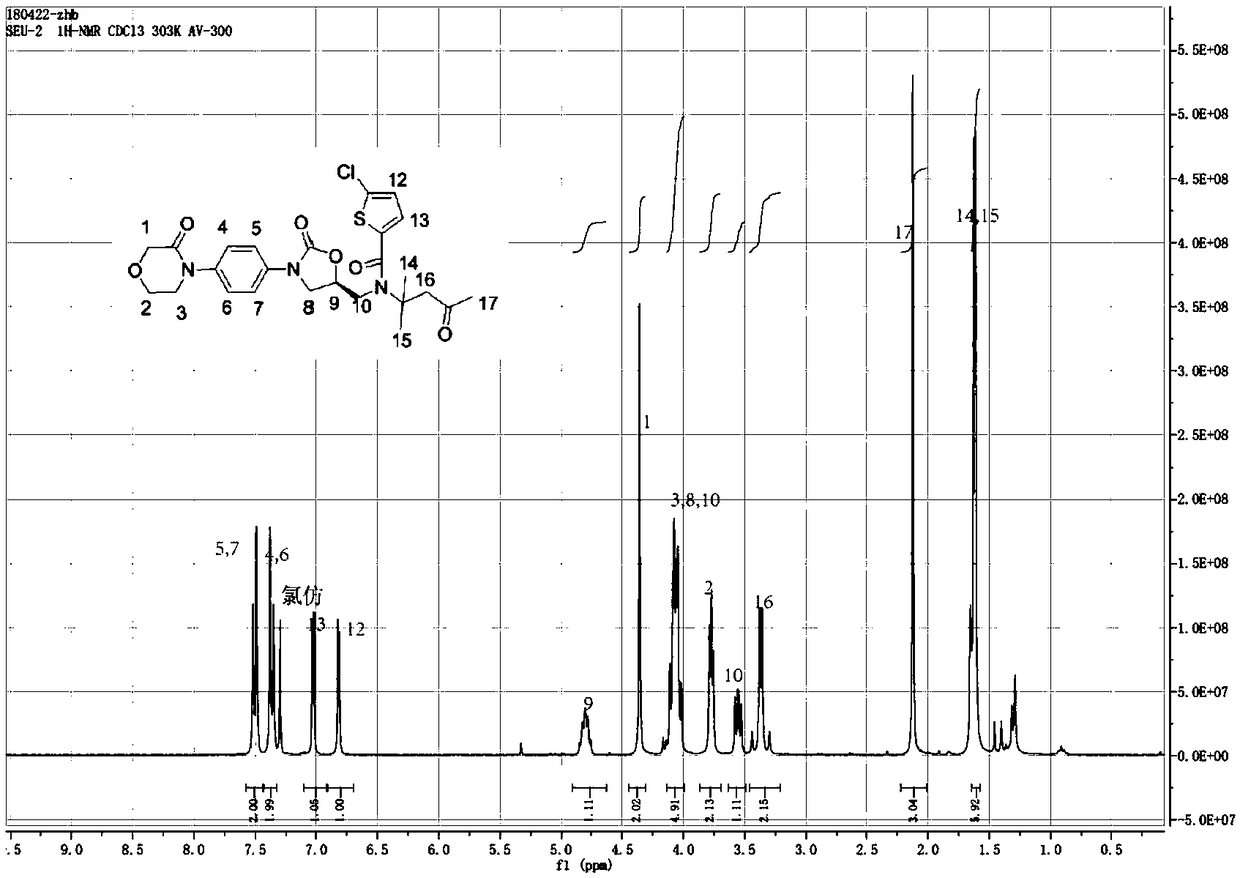

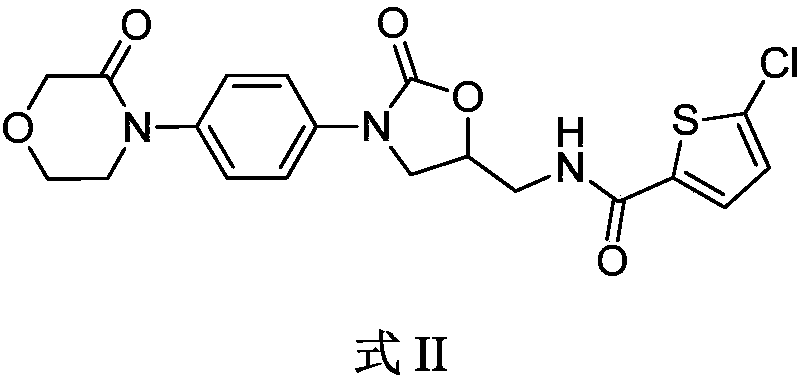

Rivaroxaban isopropylidene impurity reference substance and preparation method of reference substance

The invention discloses a rivaroxaban isopropylidene impurity reference substance, and a structural formula of the impurity reference substance is shown in the specification. The invention also discloses a preparation method for the impurity reference substance, comprising the following steps: 4-(4-(5-(aminomethyl)-2-oxo-3-oxazolidinyl)phenyl)-3-morpholine is reacted with mesityl oxide under basicconditions to obtain 4-(4-(5-(((2-methyl-4-oxypenta-2-yl)aminomethyl)-2-oxo-3-oxazolidinyl)phenyl)-3-morpholinone; 4-(4-(5-(((2-methyl-4-oxypenta-2-yl)aminomethyl)-2-oxo-3-oxazolidinyl)phenyl)-3-morpholinone is reacted with 5-chlorothiophene-2-formyl chloride under basic conditions to obtain the rivaroxaban isopropylidene impurity reference substance. The method provided by the invention achievesa simple process and high purity, and can provide qualified oxazolidine impurity reference substance for quality control of rivaroxaban.

Owner:南京海辰药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com