Method for refining phenol by acid-treated aluminium cross-linked montmorillonite catalyst

A montmorillonite and catalyst technology, which is applied in the field of phenol purification, can solve the problems of undetermined product impurity composition, limited adsorption and catalytic performance, and small number of active sites, so as to increase the interlayer spacing and porosity of montmorillonite , many active sites, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of acidified aluminum crosslinked montmorillonite catalyst

[0024] (1) Prepare montmorillonite solution: acidify sodium-based montmorillonite with sulfuric acid with a mass concentration of 15% at 80° C., stir for 5 hours, and use deionized water to make the acidified sodium-based montmorillonite into a concentration of 5% wt The montmorillonite slurry;

[0025] (2) Preparation of aluminum crosslinking agent: Take 1.0 mol / L sodium hydroxide solution and add dropwise at a rate of 10 ml / min to a concentration of 0.5 mol / L aluminum trichloride solution, add dropwise at a constant temperature of 60°C and stir vigorously, then Aging at 70°C for more than 10 hours to prepare the aluminum crosslinking agent.

[0026] (3) Acidified aluminum cross-linked montmorillonite: drop an equal volume of aluminum cross-linking agent solution into the montmorillonite slurry at a rate of 5.0ml / min, stir for 4 hours, let stand, filter with a vacuum pump, and wash ...

Embodiment 2

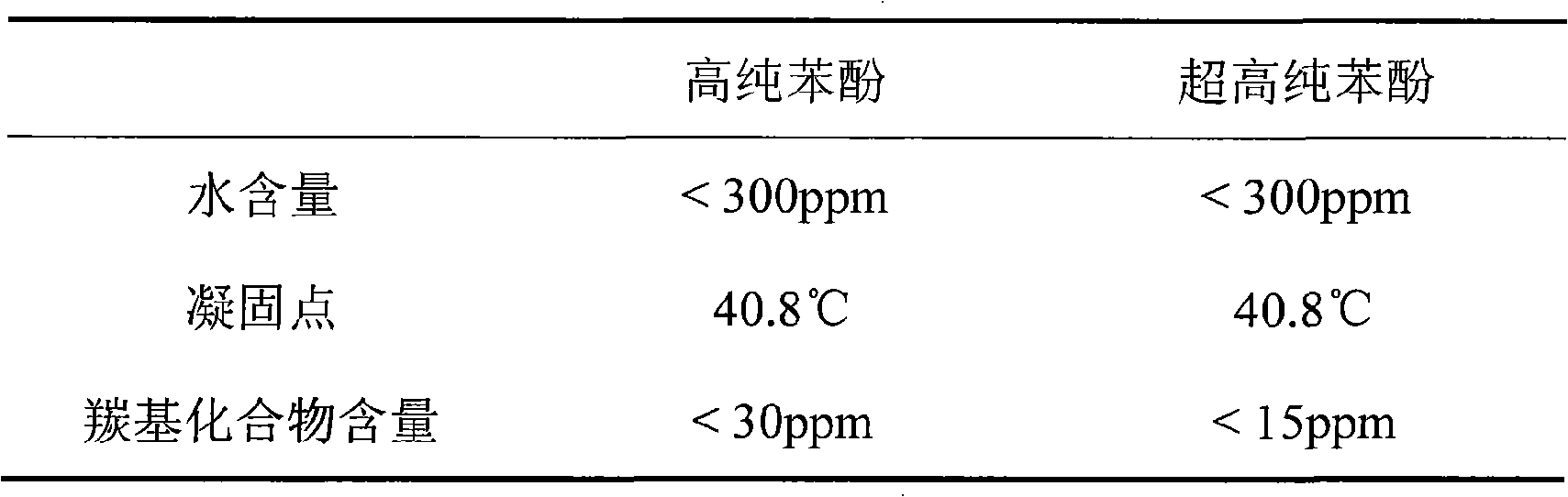

[0030] Example 2: The acidified aluminum cross-linked montmorillonite catalyst prepared in Example 1-A was added to a three-necked flask containing molten raw material phenol at a volume ratio of 4%, and reacted at 120° C. for 2 hours under nitrogen protection. After the reaction stopped, A syringe with a strainer was used to suck out the phenol, and the product was analyzed for impurity content by gas chromatography after simple distillation. (See Table 3)

[0031] table 3

[0032]

Embodiment 3

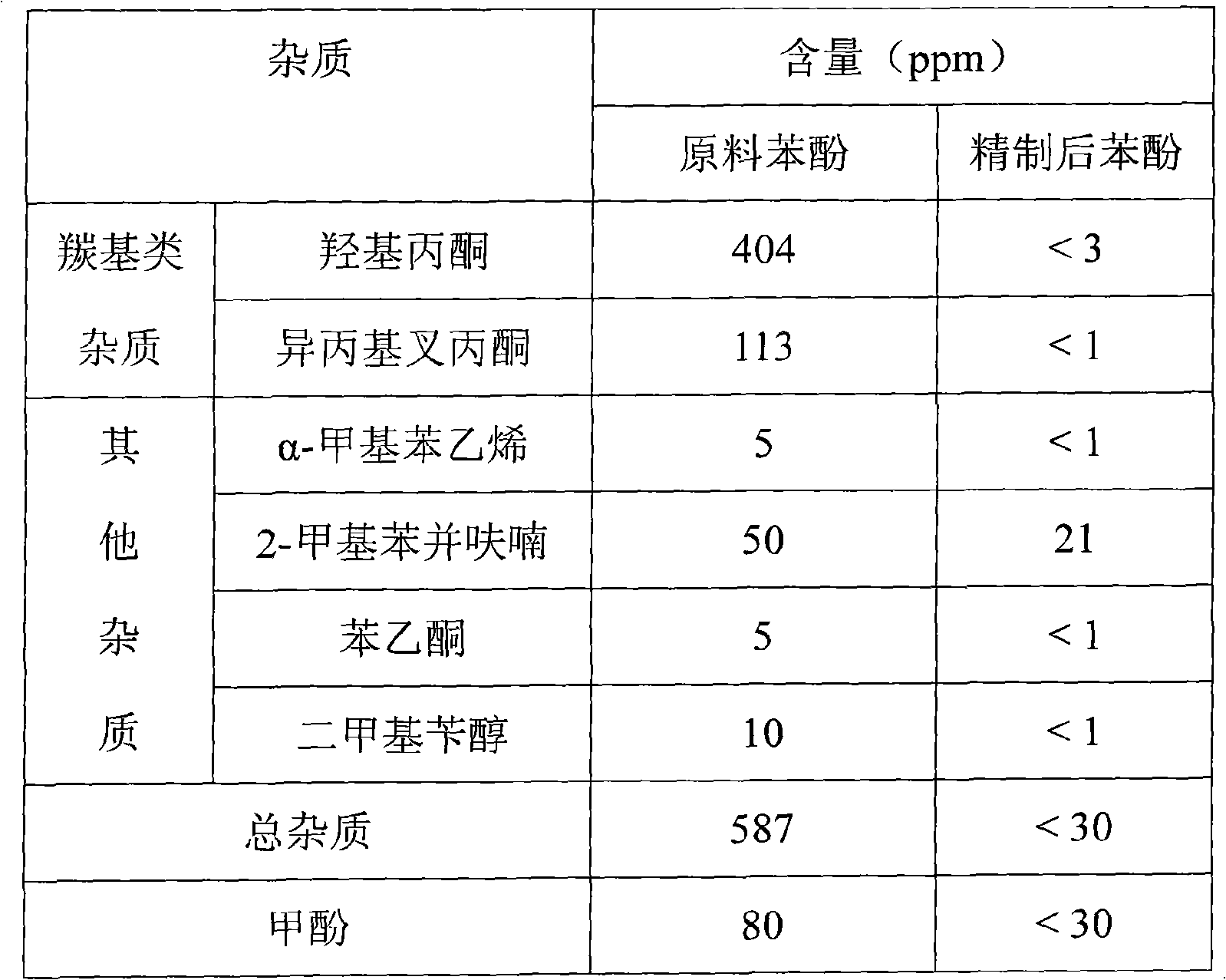

[0033] Embodiment 3 (acidified aluminum cross-linked montmorillonite continuous reaction process refining phenol)

[0034] Continuous reaction test adopts fixed-bed reactor, and the aluminum cross-linked montmorillonite catalyst (20~40) of 20ml acidification prepared in embodiment 1-B is housed in the reactor, and upstream raw material phenol directly enters catalyst bed layer without heat exchange, The reaction temperature is controlled at 150°C, and the volumetric space velocity of the phenol material is 1.0h -1 , the pressure is 1.0MPa. After the reaction was carried out for 1 day, the refined phenol product was analyzed for impurity content by gas chromatography. (See Table 4)

[0035] Table 4

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com