Patents

Literature

146 results about "Phenol product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenol can be made from the partial oxidation of benzene or benzoic acid, by the cumene process, or by the Raschig process. It can also be found as a product of coal oxidation. Other technical names for Phenol include Benzenol, Carbolic Acid, Hydroxybenzene, Liquid Phenol, Oxybenzene, and Phenyl Alcohol.

Method of extracting phenolic compound from coal liquefied oil or coal tar

ActiveCN102219649AHigh extraction rateHigh purityOrganic chemistryOrganic compound preparationWater vaporCoal chemical industry

The invention relates to the field of coal chemical industry, and more specifically relates to a method of extracting phenolic compounds from coal liquefied oil or coal tar. The method comprises the following steps: 1) distilling coal liquefied oil or coal tar and cutting to obtain fractions at a temperature of 260 DEG C; 2) mixing an extractant with the obtained fractions and layering the extractant; 3) separating and collecting the extractant layer which contains phenolic compounds; 4) carrying out multistage back extraction on the phenolic compounds so as to obtain a stripping agent-phenol solution and an extractant; 5) separating the stripping agent-phenol solution by rectification, recovering the stripping agent for cyclic utilization, and carrying out separation to obtain crude phenols; 6) removing entrained neutral oil in phenolic compounds by water vapour so as to obtain crude phenol products. The method of extracting phenolic compounds from coal liquefied oil or coal tar provided in the invention avoids the usage of soda acid, exerts no influence on subsequent treating processes, and guarantees high recovery rate and purity of phenols.

Owner:CCTEG CHINA COAL RES INST

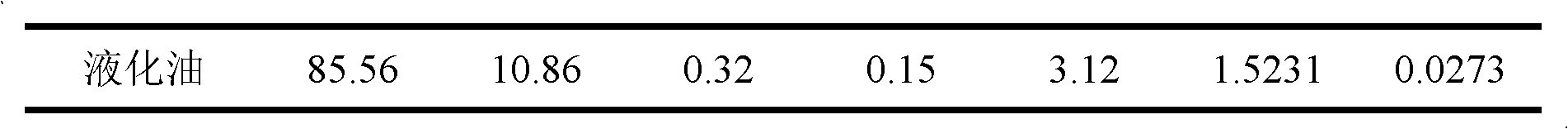

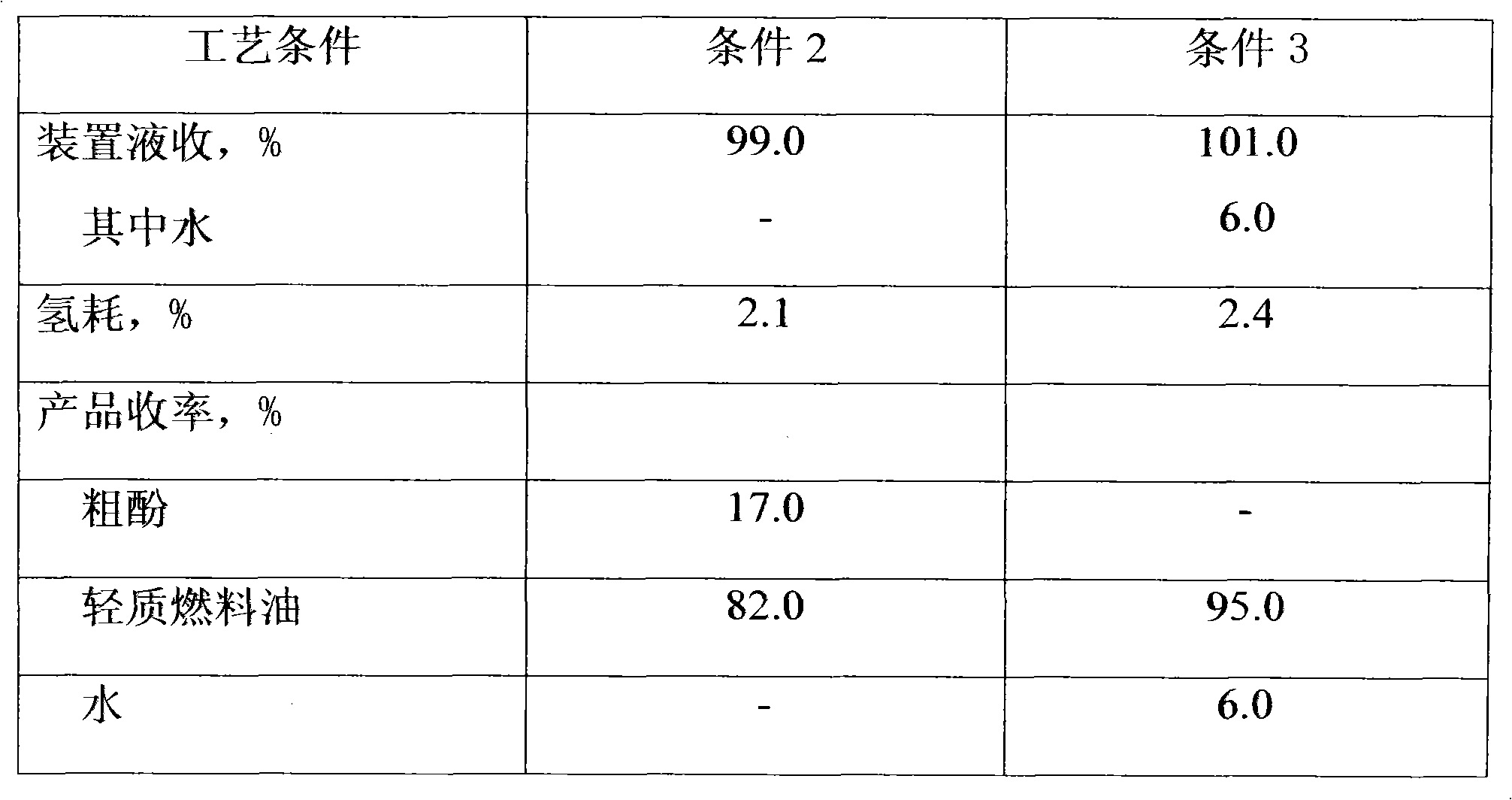

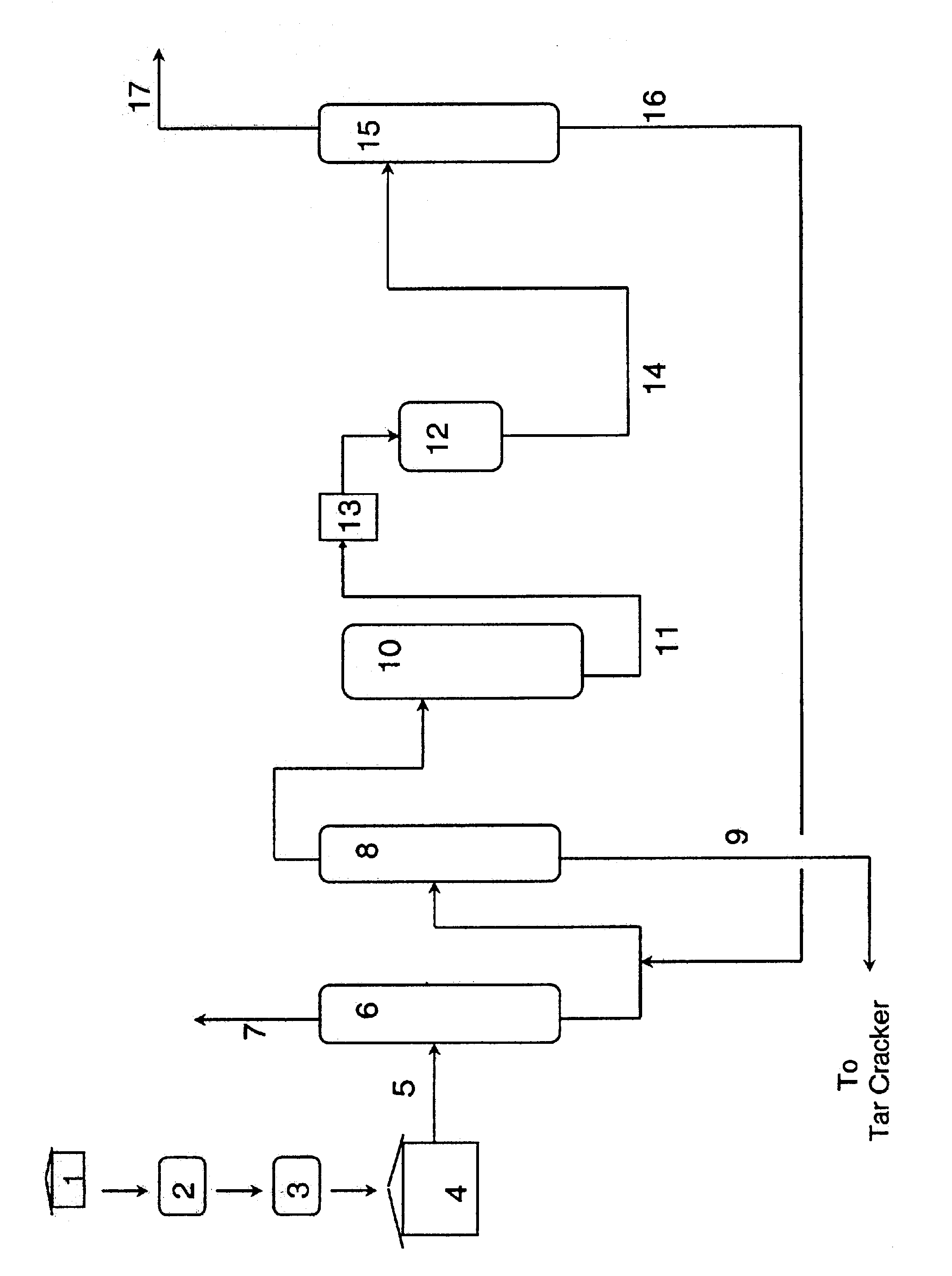

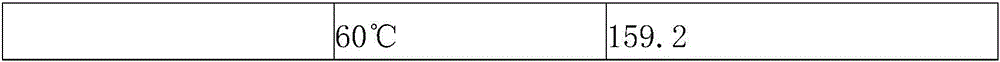

Medium and low temperature coal tar deep processing method

InactiveCN101538482AImprove performanceEfficient use ofThermal non-catalytic crackingCatalytic naphtha reformingCatalytic reformingFractionation

The invention discloses a medium and low temperature coal tar deep processing method. Medium and low temperature coke material is pretreated and fractionated to obtain light fraction, carbolic oil and heavy fraction, dephenolization treatment is carried out on the carbolic oil to obtain phenols product and dephenolized oil, the dephenolized oil and the above heavy fraction carry out pyrogenetic reaction jointly to obtain various carbonized products, wherein carbonized naphtha, at least one of carbonized diesel oil and carbonized wax oil is mixed with the light fraction obtained by material fractionation to carry out hydrofining and hydrocracking reaction, hydrogenated naphtha obtained by hydrocracking carries out catalytic reforming-aromatics extraction to obtain benzene, toluol, xylene, solvent oil and other products. Compared with the prior art, gasoline fraction and diesel oil fraction obtained by the inventive method are clean and stable in properties. In addition, the invention can produce a plurality of chemical products with high added value, truly realizes the effective utilization of medium and low temperature coal tar, and greatly improves the service life of devices.

Owner:胜帮科技股份有限公司

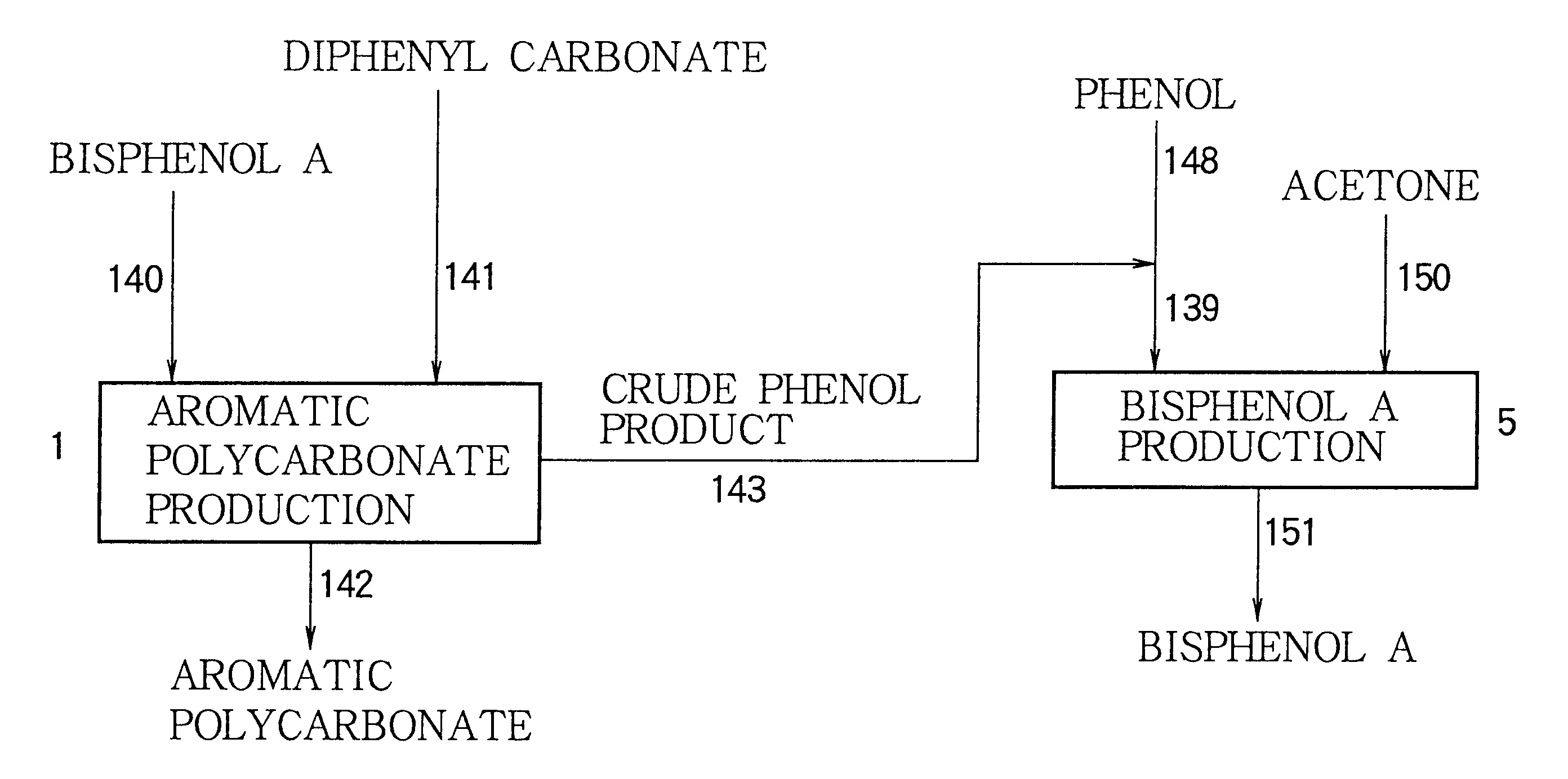

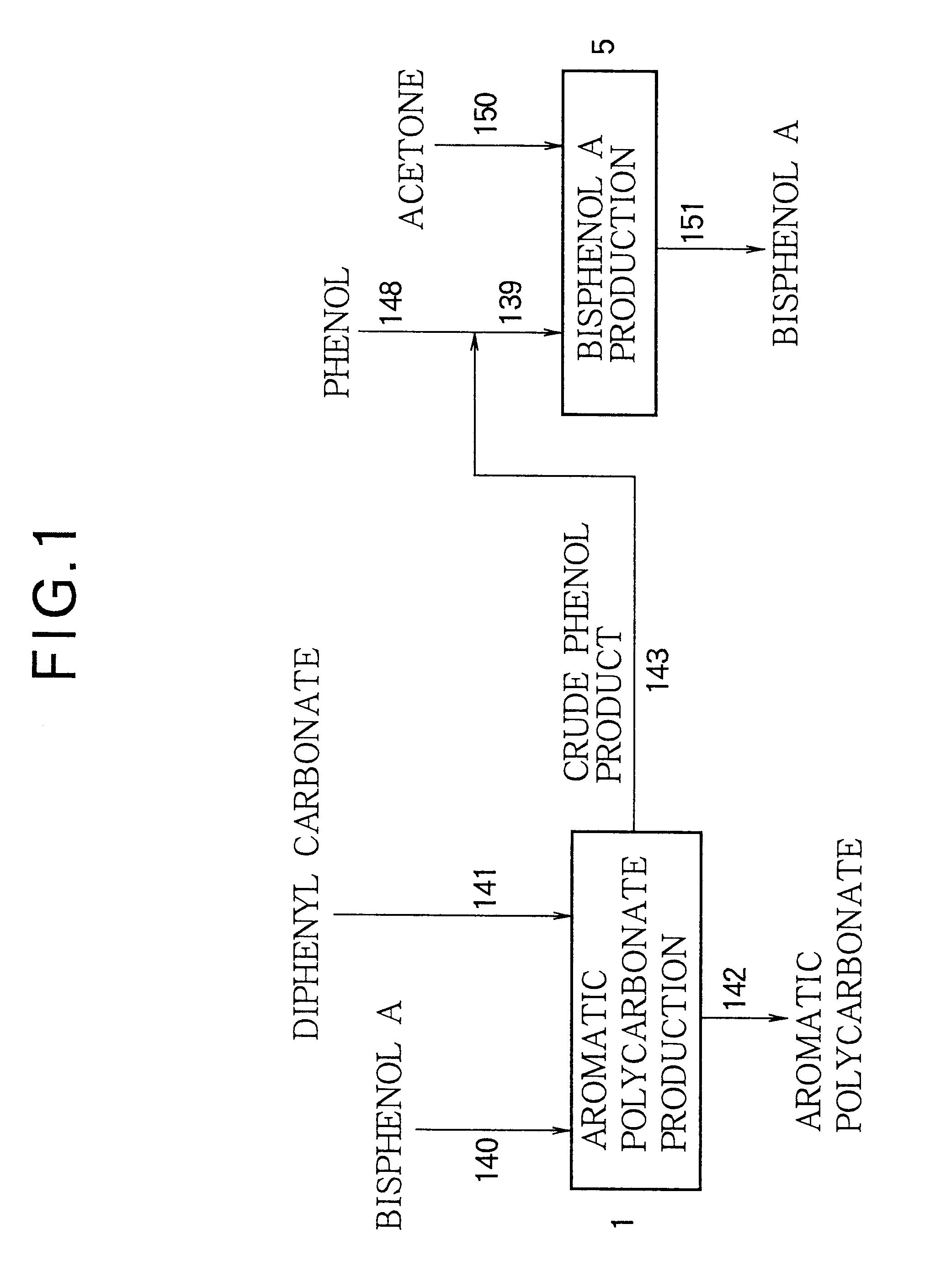

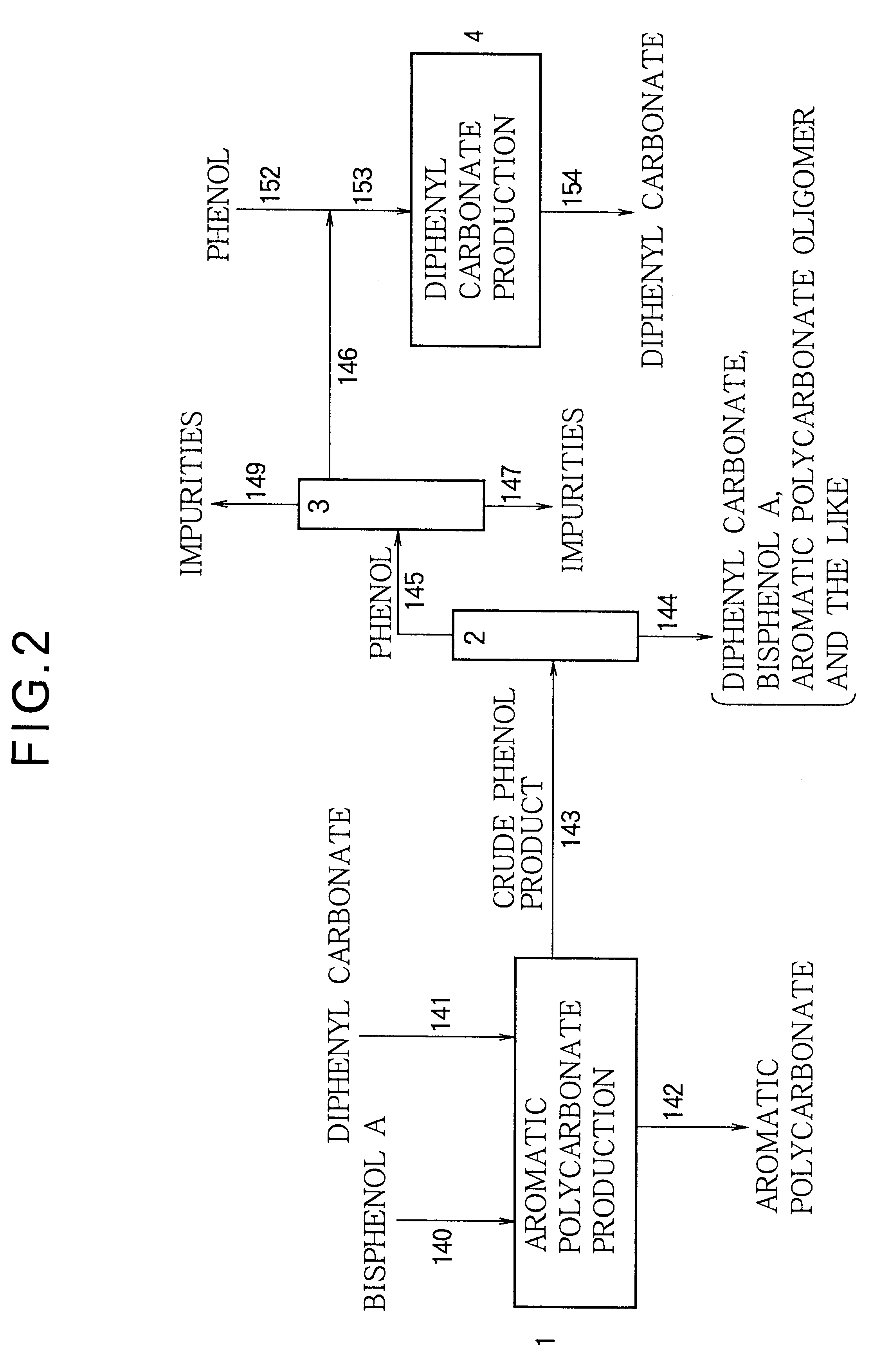

Method for producing an aromatic polycarbonate

Disclosed is a method for producing an aromatic polycarbonate, which comprises reacting acetone with a phenol material, thereby producing bisphenol A, and polymerizing the resultant bisphenol A with diphenyl carbonate to produce an aromatic polycarbonate while producing phenol as a by-product, wherein the by-product phenol is recovered as a crude phenol product containing the by-product phenol as a main component and containing impurities, and the crude phenol product is used as at least a part of the phenol material for producing bisphenol A. According to the method of the present invention, a crude phenol product as such, containing, as a main component, a by-product phenol which is by-produced during the polymerization reaction for producing an aromatic polycarbonate, and containing impurities, can be utilized for producing an aromatic polycarbonate, without any purification or the like. In the method of the present invention, not only can a necessity for complicated operations, such as a purification treatment, be reduced, but also the amount of wastes can be reduced and the yield of the aromatic polycarbonate, based on any of phenol and bisphenol A, can be improved.

Owner:ASAHI KASEI KK

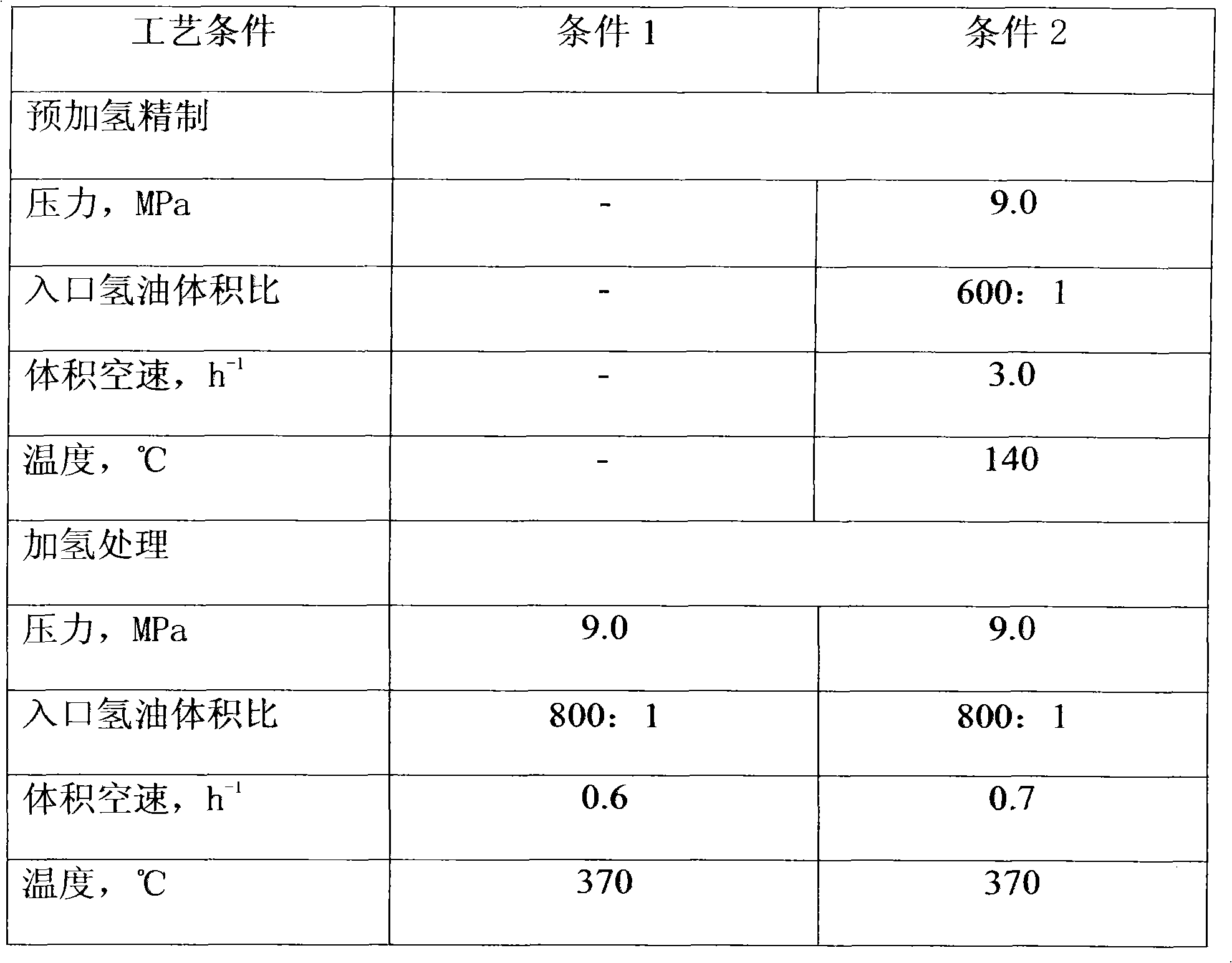

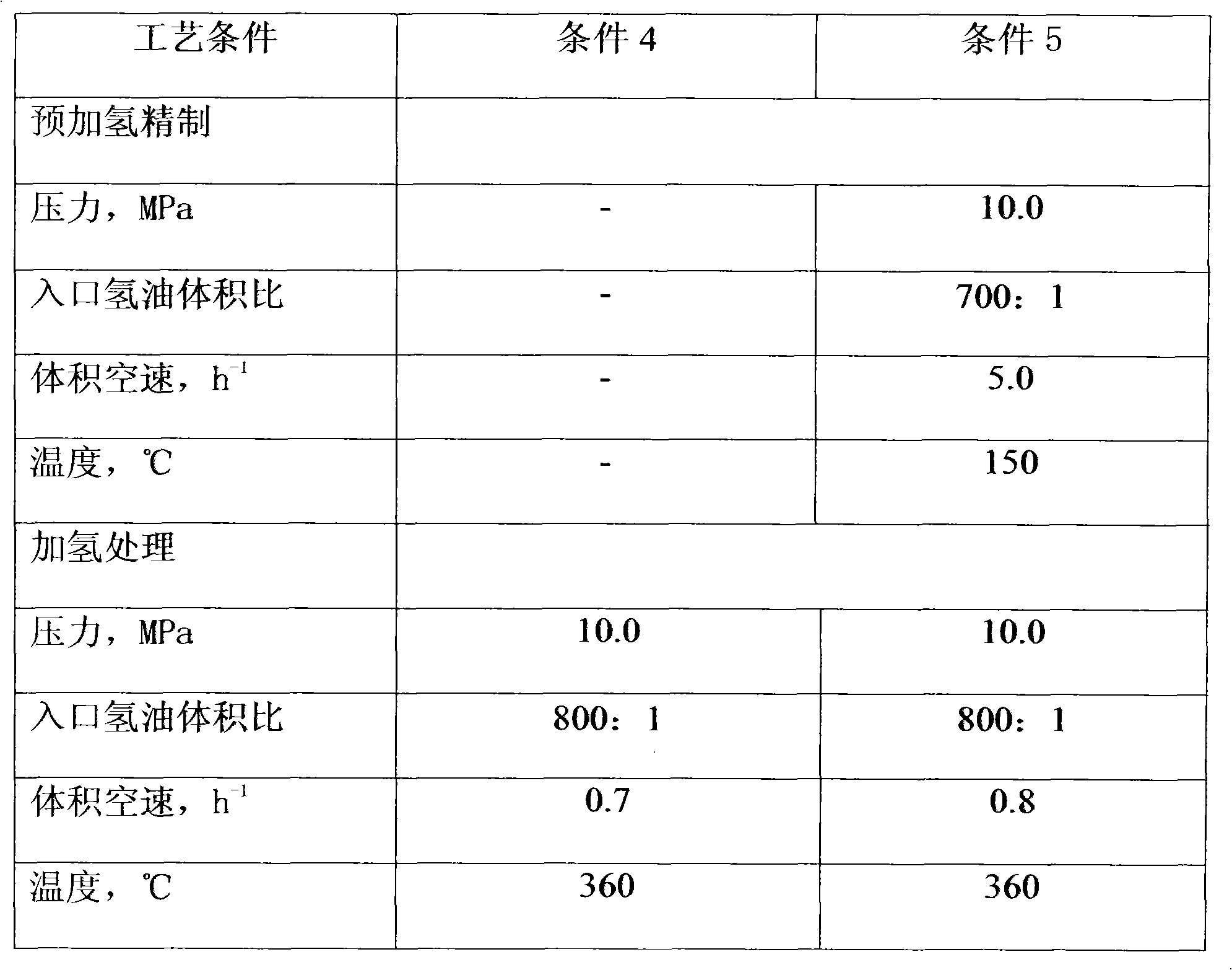

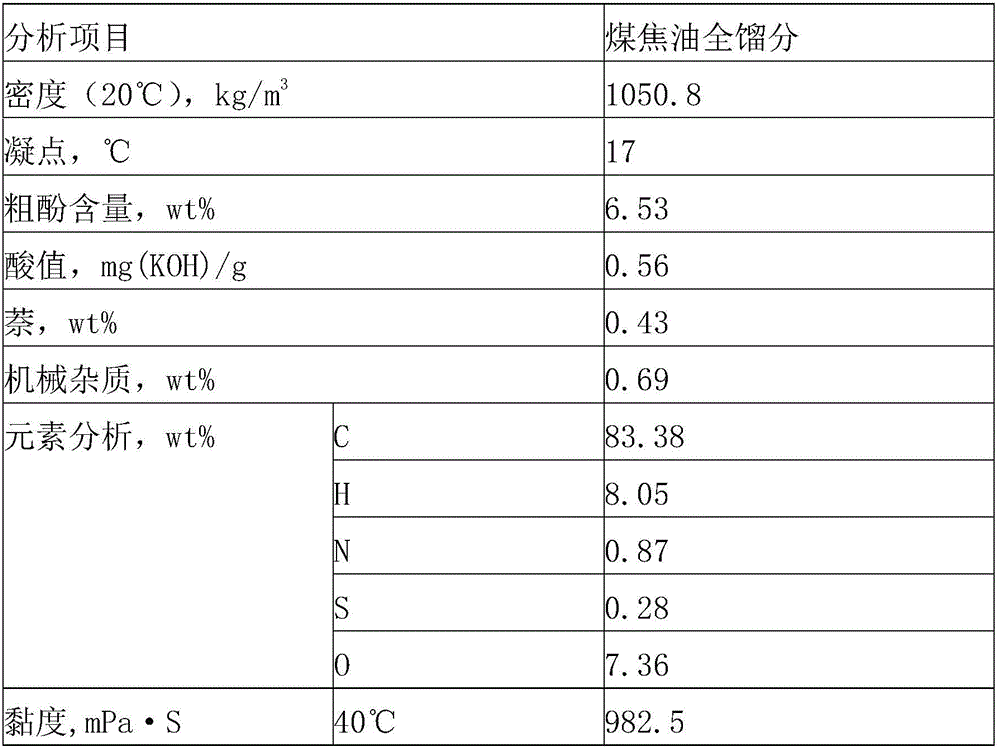

Processing method of medium-low temperature coal tar

ActiveCN102465033AImprove economyOperation cycle solutionOrganic chemistryOrganic compound preparationSlagFuel oil

The invention discloses a processing method of medium-low temperature coal tar. According to the method, whole fraction of the medium-low temperature coal tar which has been undergone dehydration and slag removal is firstly distilled to obtain a light fraction and a heavy fraction. The heavy fraction is used as modified asphalt or heavy fuel oil and the like. A phenolic compound is separated from the light fraction by an acid-base extraction method so as to obtain a crude phenol product. Hydrogenation saturation of alkene from dephenolized raw oil is carried out by a hydro-pretreating method. The prehydrogenation raw oil contacts with a main hydrofining catalyst for desulphurization, nitrogen removal, aromatic saturation and other reactions. In comparison with the prior art, by the adoption of the method provided by the invention, components which influence long-term operation of a hydrogenation device can be fundamentally removed; the operation period of the device can be obviously prolonged; the crude phenol product can be obtained; and the utilization rate of raw materials and the whole economy of a processing device can be raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

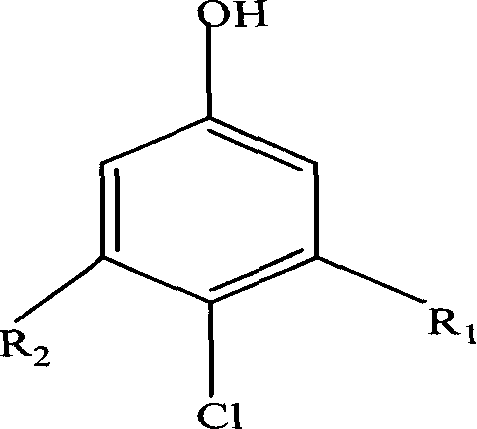

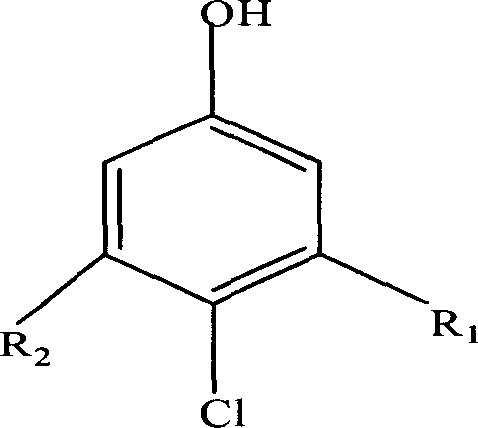

Industrial preparation method for p-chloroalkylphenols

ActiveCN101085722AHigh yieldReduce generationOrganic chemistryOrganic compound preparationElectrophilic additionMetal chloride

The invention provides an industrial method for preparing chloro- alkyl- phenol. It takes alkyl- phenol and chlorizating agent for addition reaction to prepare said product. Said reaction is carried out at -10- 100 Deg. C under co-catalytic action. Said co- catalyst comprises metallic chloride, organic sulfide and alkyl ether. The invention is characterized by greatly reduced production cost and side production production, increased purity and yield.

Owner:湖南瑞冠生物化工科技有限公司

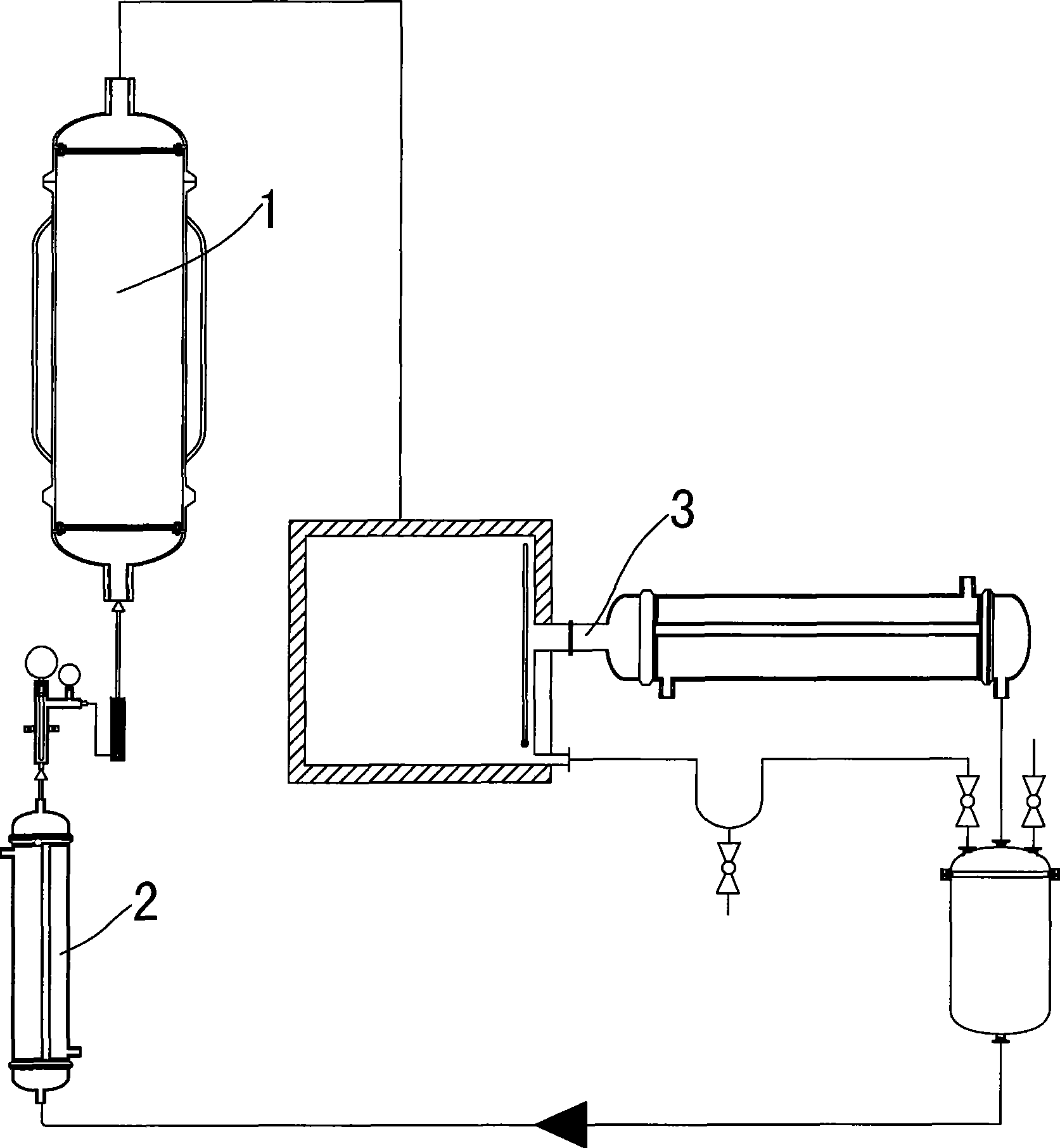

Production and purification of phenol: hydroxyacetone removal by hydrotalcite

InactiveUS6486365B1High mechanical strengthLose significant efficiencyOrganic compound preparationCatalystsDistillationBoiling point

A process for converting carbonyl-type impurities contained in a phenolic solvent to high-boiling derivatives is provided by contacting the phenolic solvent with a hydrotalcite-type material (HTM). The phenol can be separated from the high-boiling derivatives using conventional separation techniques, such as distillation, so the invention also provides a process for separating carbonyl-type impurities, such as hydroxyacetone (HA), from a phenolic solvent. The process can be applied in the conventional industrial process for converting cumene to phenol to remove carbonyl-type impurities from the phenol product. A process and a facility for producing purified phenol by converting cumene to phenol are provided. In the conversion of cumene to phenol, the phenol often contains carbonyl-type impurities. The phenol and carbonyl-type impurities are reacted in the presence of an HTM to produce phenol and high-boiling derivatives. The phenol may be further purified using conventional separation techniques, such as distillation, to remove the high-boiling derivatives.

Owner:SABIC GLOBAL TECH BV

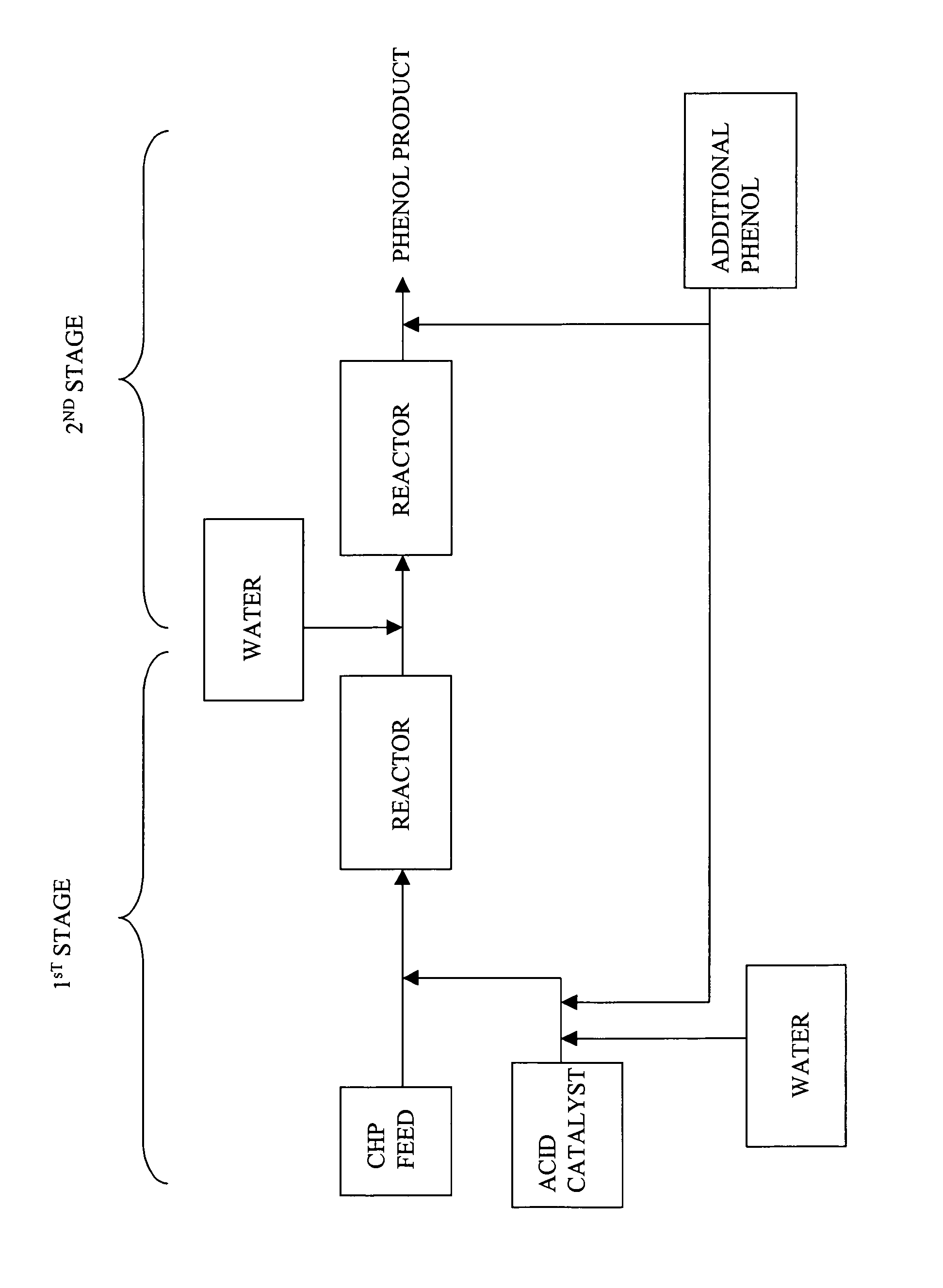

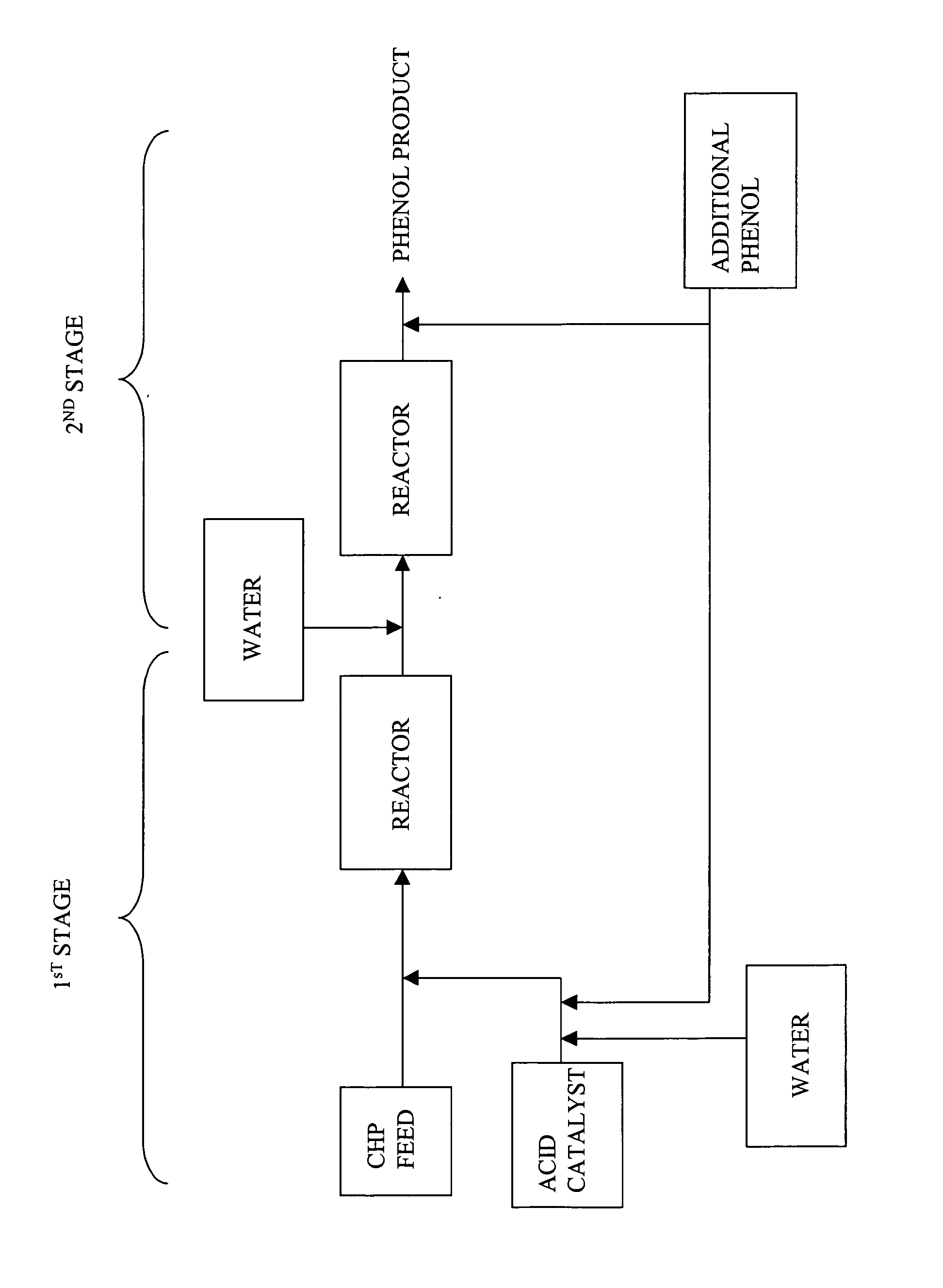

Process for producing phenol

A process for producing a phenol product generally comprises a first step comprising reacting in a first reactor a feed stream comprising cumene hydroperoxide and water with an acid catalyst to produce an effluent comprising the phenol product, acetone, and at least 1% by weight residual cumene hydroperoxide, and a second step comprising passing the effluent into a second reactor and decomposing the residual cumene hydroperoxide, wherein during said process the ratio of phenol to acetone is maintained at a molar ratio of greater than 1:1, and wherein the water in each of the first and second steps is present in an amount more than 0 and less than or equal to 5 weight percent based on the total weight of the feed stream or effluent, and wherein the process is continuous.

Owner:SABIC GLOBAL TECH BV

Technique for extracting and separating tea polyphenol from tea-leaf

InactiveCN101386631AReduce consumptionReduce energy consumptionOrganic chemistryLiquid liquid partitionFeed additive

The invention discloses a novel process for extracting and separating tea phenol, which comprises the steps of extracting, liquid-liquid partition chromatography, and column chromatography integrated separation or the steps of extracting, liquid-liquid partition chromatography, and concentration integrated separation. The process comprises the following steps of: firstly, mixing water and tea at the mass ratio of between 0.2 and 1 to 1 uniformly, using extractant to extract the solution to obtain extraction liquid; then performing column chromatography or concentration drying to obtain tea phenol products with various specifications. During the extraction process, water-soluble impurities such as tea polysaccharide are retained in the tea and no tea polysaccharide waste water is produced. The tea polysaccharide, protein, fibrin, microelements and other compositions are retained in dried tea dregs after extraction, which can be used as good feed additives. The process can adopt integrated separation so as to improve the stability and the degree of automation greatly and reduce the number of workers and the labor intensity.

Owner:CHUNTIAN BIOTECH DEV XIANGXI AUTONOMOUS COUNTY

Method for producing phenolic compound

InactiveUS7547799B1Organic compound preparationPreparation by ester-hydroxy reactionCompound aWaste stream

A method is provided for producing an ester-substituted phenol product stream from an ester-substituted diaryl carbonate manufacturing waste stream. The method includes the steps of obtaining a waste stream containing an ester-substituted diaryl carbonate from an ester-substituted diaryl carbonate manufacturing facility and creating a reaction mixture by combining the waste stream with a solvent and with a transesterification catalyst. The reaction mixture is maintained at a reaction pressure at or below atmospheric pressure, and at a reaction temperature for a period of time sufficient to produce ester-substituted phenol by solvolysis of the ester-substituted diaryl carbonate. Ester-substituted phenol is removed from the reaction mixtures in an ester-substituted phenol stream. The solvent, the reaction temperature, and the reaction time are selected in combination such that less than 1,000 ppm of acid-substituted phenol is present in the ester-substituted phenol stream.

Owner:SABIC INNOVATIVE PLASTICS IP BV

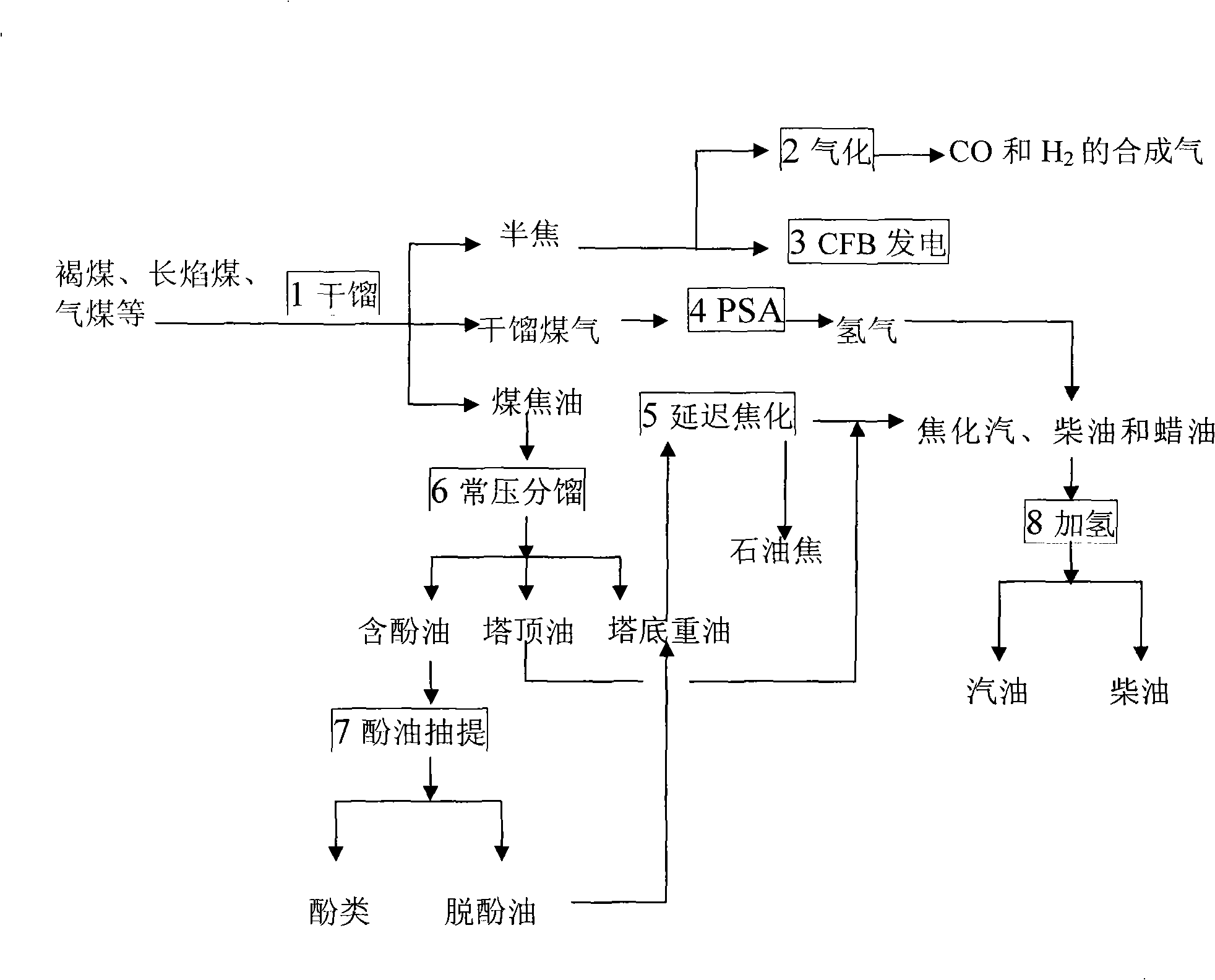

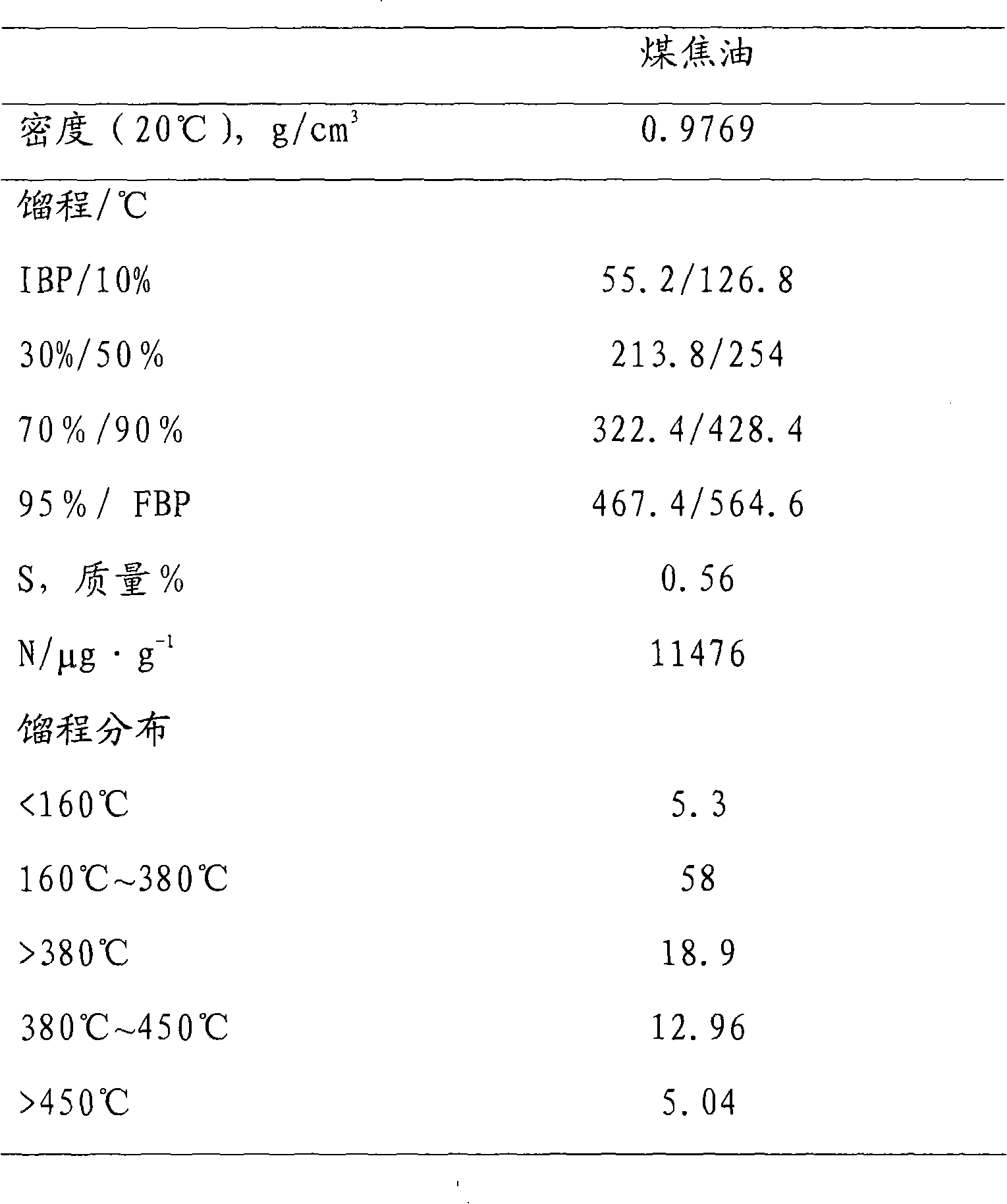

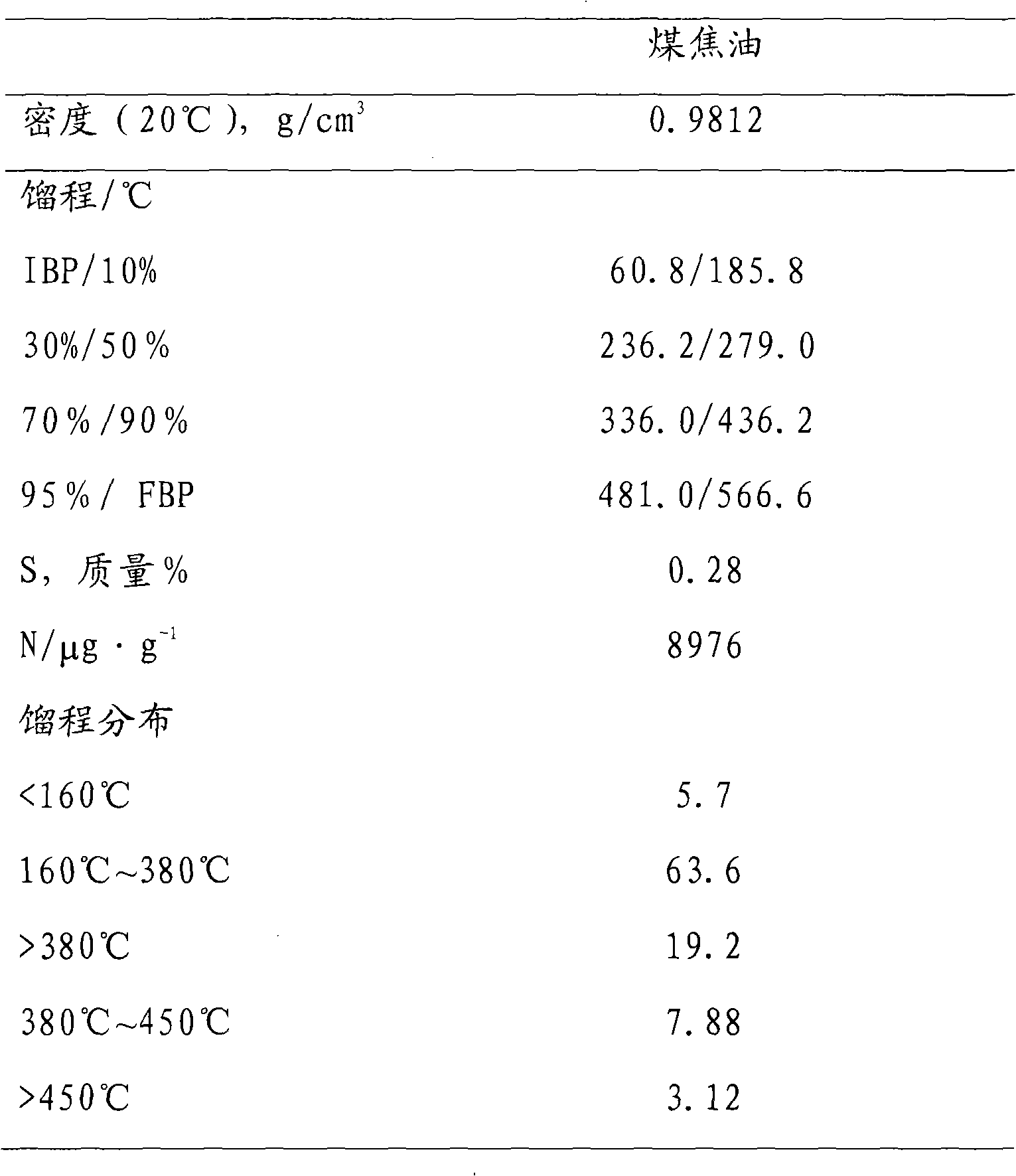

Incoherence or weak caking coal deep processing method

InactiveCN101538473ASave investment in environmental protectionReduce processing costsTreatment with hydrotreatment processesSpecial form destructive distillationWater vaporCarbonization

The invention discloses an incoherence or weak caking coal deep processing method. Firstly, coking coal is fed into a carbonization reactor to carry out carbonization reaction, thus generating coal gas, carbocoal and coal tar; hydrogen in the coal gas is extracted out by pressure swing absorption; the carbocoal is fed into a coal gas generator and reacts with oxygen and water vapour to generate synthesis gas and coal ash; or the carbocoal is fed into a circulating fluid bed boiler to carry out generating; the coal tar enters a normal pressure fractionating tower to obtain creosoted oil, oil at the top of the tower and heavy oil at the bottom of the tower; wherein the creosoted oil is extracted to obtain crude phenol product and dephenolized oil, the dephenolized oil and heavy oil at the bottom of the tower enter a delayed coking device to carry out thermal cracking reaction. Through the optimization design of the flow, the invention realizes the deep processing of incoherence or weak caking coal such as ignite, long flame coal, gas coal and the like, and effectively improves the utilization factor of the materials.

Owner:胜帮科技股份有限公司

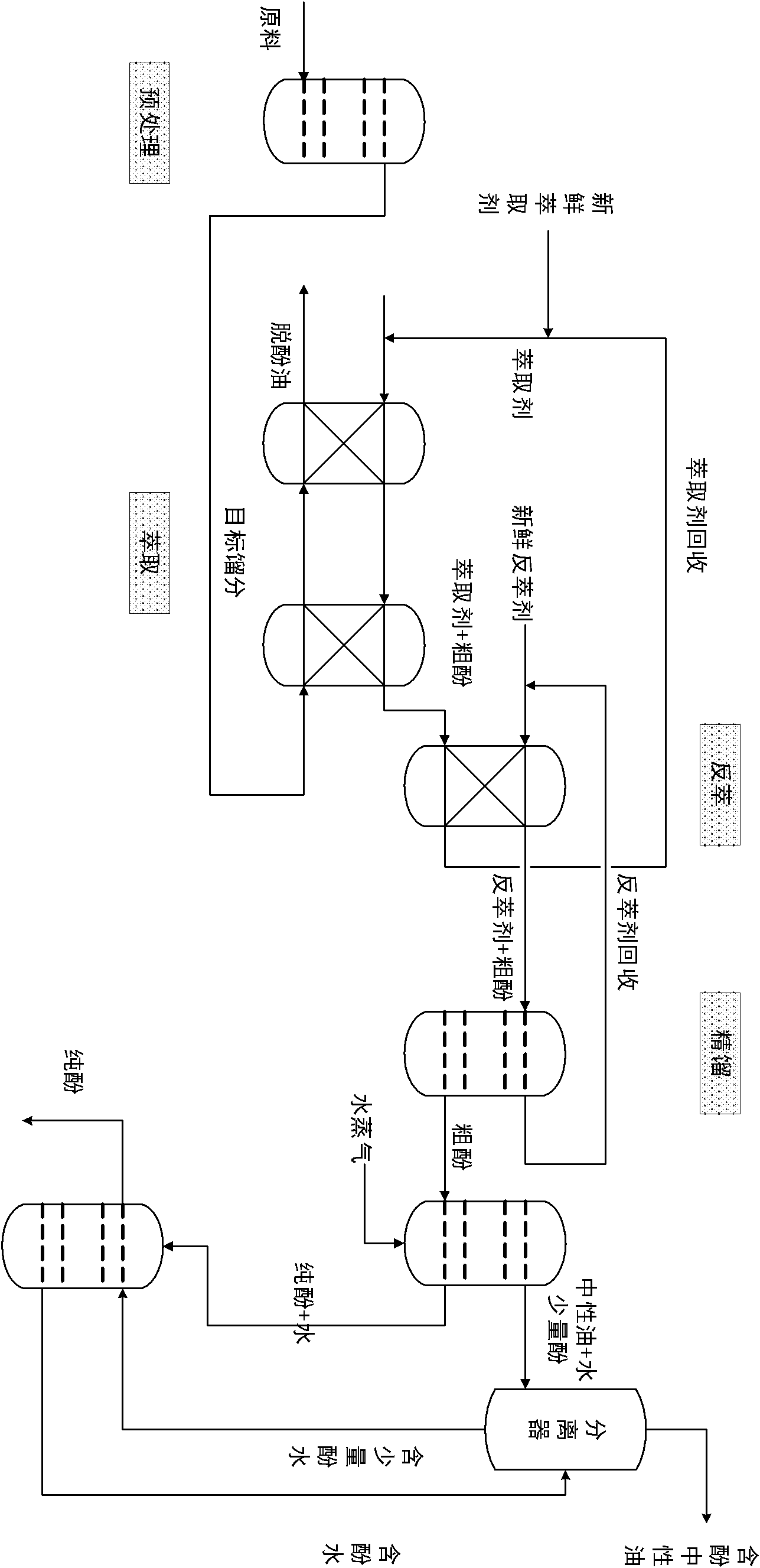

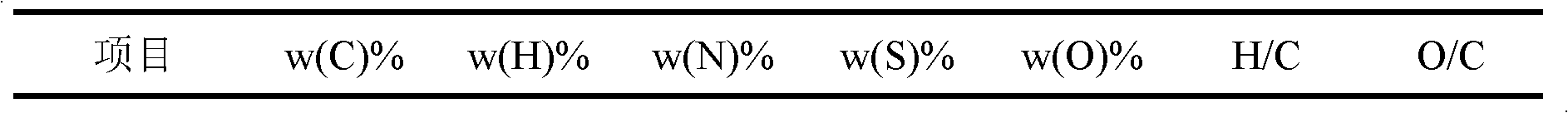

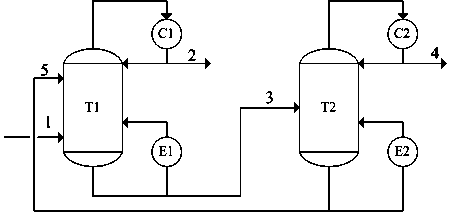

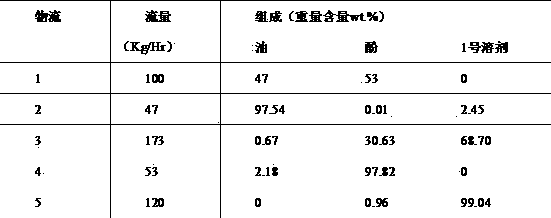

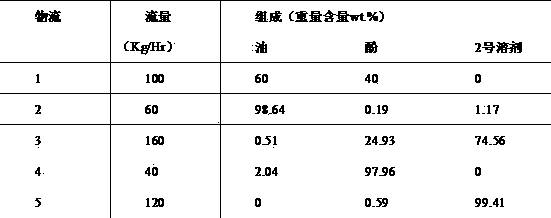

Method for extracting phenol compounds from direct coal liquefied oil through extractive distillation

ActiveCN103896739AHigh recovery rateIncrease relative volatilityOrganic chemistryOrganic compound preparationSulfolaneExtractive distillation

The invention relates to a method for extracting phenol compounds from direct coal liquefied oil through extractive distillation. An extractive distillation solvent (hereinafter referred to as solvent) adopted in the method is glyceryl triacetate and / or sulfolane, or a mixed solvent formed by mixing glyceryl triacetate and / or sulfolane and one or more selected from glycerol, triethanolamine, triethylene glycol, tetraethylene glycol, dimethyl sulfoxide and diethanol amine according to any proportion. The method is used for extracting phenol compounds from direct coal liquefied oil in an extraction distillation tower by using the solvent, then, a solvent flow rich in the phenol compounds enters a recovery tower and is separated, the phenol compounds discharged from the top of the recovery tower are recovered after being cooled to obtain phenol products, and the solvent is recycled after being discharged from the bottom of the recovery tower. The method has the characteristics of high product purity, low system energy consumption, no wastewater generation, no acid and alkaline waste and no corrosion to equipment.

Owner:TAIYUAN UNIV OF TECH

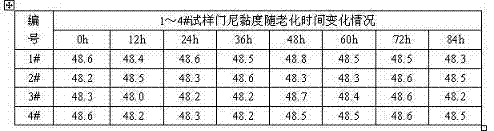

Preparation method of styrenated hindered phenol or styrenated phenol antioxidant product

ActiveCN102267876AImprove antioxidant capacityAvoid pollutionOrganic chemistryOrganic compound preparationTert butyl phenolButadiene-styrene rubber

The invention discloses a preparation method of a styrenated hindered phenol or styrenated phenol antioxidant product, belonging to the field of preparation process methods of polymer antioxidant products. The preparation method is characterized in that: o-tert-butyl phenol or phenol, p-cresol, o-cresol and m-cresol are used as raw materials, styrene is used as an alkylation reagent, an organic acid compound is used as a catalyst, a small amount of polymerization inhibitor is added, and the styrenated hindered phenol product or styrenated phenol product is prepared through catalytic alkylation reaction; a neutralizing and decolorizing agent is added to the styrenated product to deactivate the acidic catalyst and remove the coloring source material, thus obtaining a white-like or light yellow viscous liquid namely the styrenated phenol antioxidant product which has clear and transparent appearance, pH value of 6.5-7.5, storage stability and high use efficiency; and the styrenated phenol antioxidant product is free of water-soluble pollutants such as free phenol or methyl phenol, thereby solving the problem of environmental pollution caused by the use of the product in styrene butadiene rubber latex.

Owner:CHANGZHOU UNIV

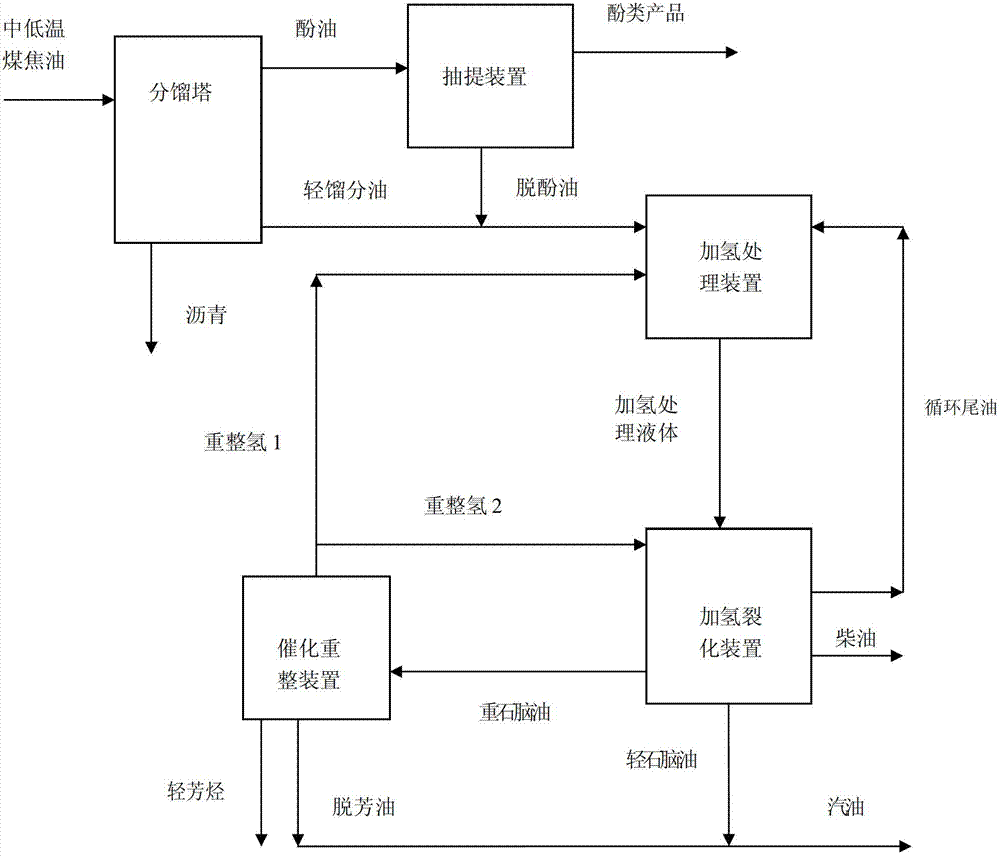

Hydrogenation method for medium and low temperature coal tar

InactiveCN102899088AReduce consumptionRaw materials are simpleTreatment with hydrotreatment processesCatalytic reformingNaphtha

The invention discloses a hydrogenation method for medium and low temperature coal tar. The medium and low temperature coal tar is pretreated and fractionated to obtain carbolic oil, light distillates and asphalt; the carbolic is subjected to dephenolization to obtain phenol products and dephenolized oil; the light distillates and the dephenolized oil are mixed and sent into a hydrotreating reaction zone; liquid generated from hydrotreatment is sent into a hydrocracking reaction zone; the liquid generated from hydrotreatment is fractionated to obtain intermediate distillate oil used as diesel; the tail oil obtained from fractionation is recycled to the hydrocracking reaction zone or the hydrotreating reaction zone; naphtha obtained from fractionation is sent into a catalytic reforming reaction zone; hydrogen obtained from catalytic reforming is used in a hydrogen system; and the obtained liquid is extracted and fractionated to obtain premium gasoline or light aromatic products. Compared with the prior art, the method provided by the invention employs a combined process comprising fractionation, dephenolization, hydrotreating, hydrocracking and catalytic reforming to obtain phenol products, light aromatic products and high-quality motor fuel, and greatly prolongs operation cycle of the device.

Owner:王小英

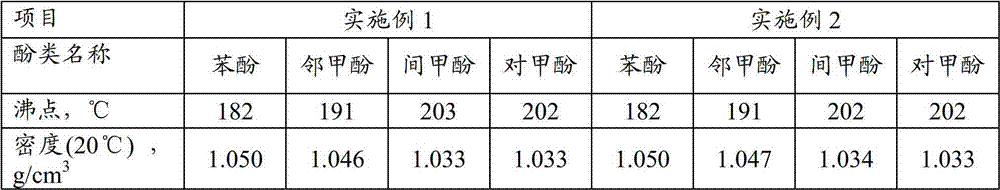

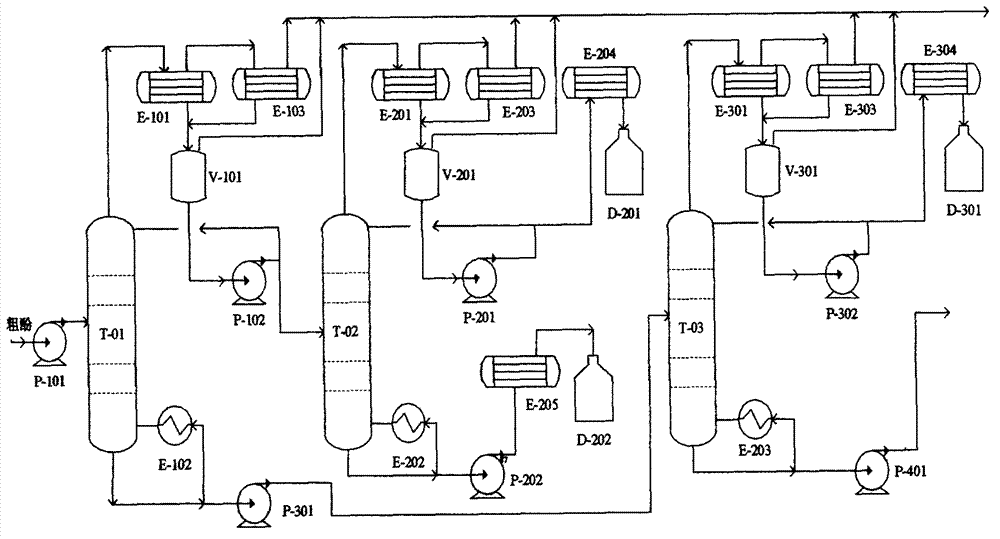

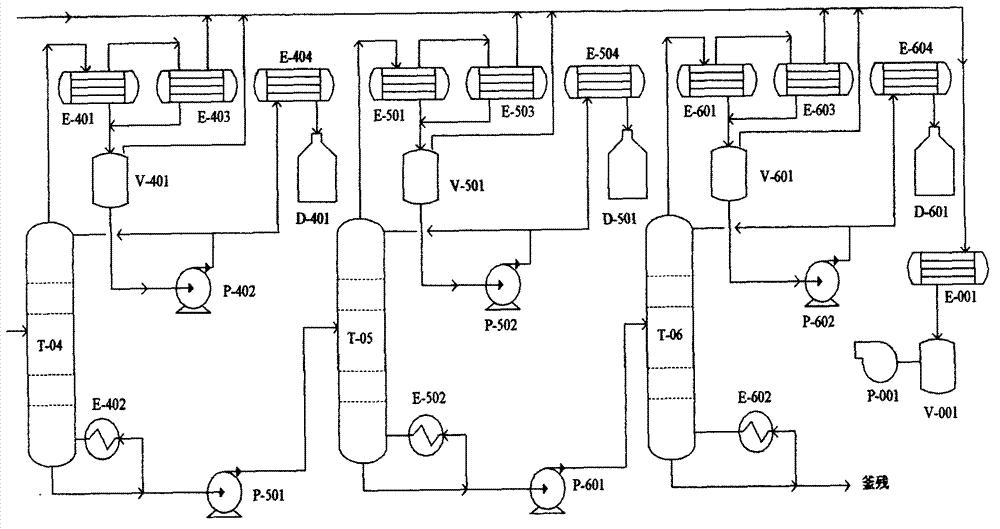

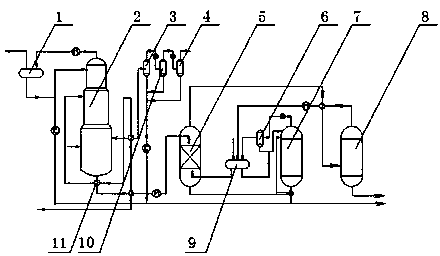

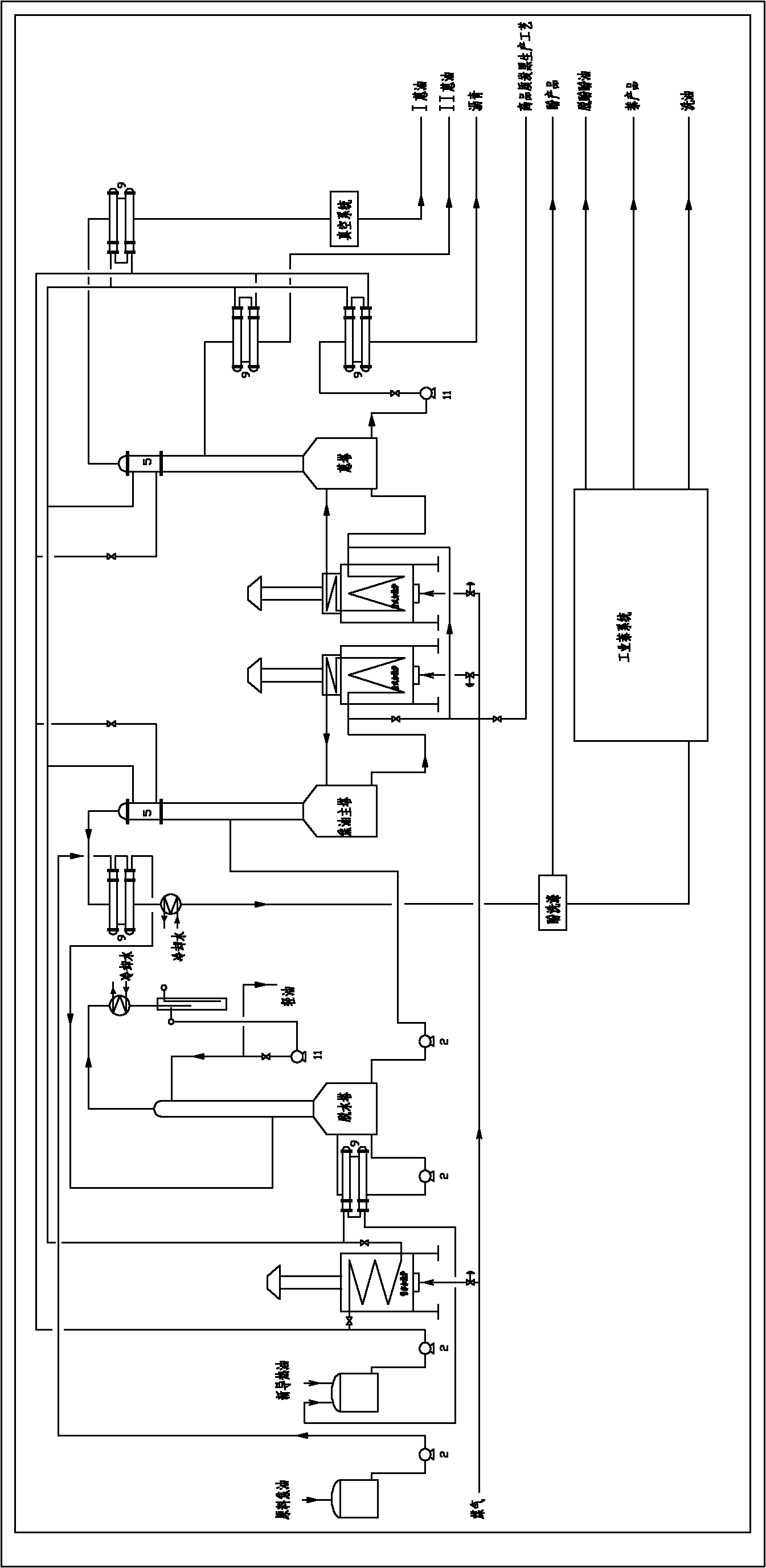

Method and device for continuously rectifying and separating medium/low-temperature coal tar crude phenols

ActiveCN102731264AEfficient separationImprove product qualityOrganic chemistryOrganic compound preparationTowerCoal tar

The invention discloses a method and device for continuously rectifying and separating medium / low-temperature coal tar crude phenols. The method is implemented in a way that: crude phenols extracted from medium / low-temperature coal tar as raw materials are subjected to six-tower continuous rectification to effectively perform impurity removal and separation, thereby obtaining a mixed phenol product containing phenol and orthocresol of which the purities are higher than 99.5% and 2,6-dimethylphenol, 4-methylphenol, 3-methylphenol and 2-methylphenol of which the contents are higher than 99%, a mixed phenol product containing 2,4-dimethylphenol, 2,5-dimethylphenol, 4-methyl-2-ethylphenol and 6-methyl-2-ethylphenol of which the contents are higher than 96%, and the like. The device comprises a light component removal unit, a phenol-orthocresol unit, a meta-paracresol unit, a dimethyl phenol unit a trimethyl phenol unit, a decolorization unit and a vacuum system which are connected through pipelines. In view of the composition characteristics of medium / low-temperature coal tar crude phenols, the invention obtains optimized technique and parameters for separating phenol products; and the whole technical process is reasonable and continuous, has the characteristics of low energy consumption, high product quality, high stability, low production cost and the like, and thus, is an efficient and feasible continuous technique for continuously rectifying and separating medium / low-temperature coal tar crude phenols.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Method for treating high-concentration phenol-ammonia wastewater

InactiveCN103496812AShort process flowImprove processing efficiencyWater contaminantsMultistage water/sewage treatmentCoal gasification wastewaterButyl acetate

The invention relates to a method for treating high-concentration phenol-ammonia coal gasification wastewater. The method takes butyl acetate as an extraction agent and comprises the steps of firstly extracting by use of a phenol extraction tower to remove phenols contained in the wastewater, removing the acid gas and ammonia in the wastewater by use of an acid and ammonia removal tower, and recovering the extraction agent in the extraction phase by use of a solvent stripping tower so as to obtain a crude phenol product from the bottom of the tower. The method provided by the invention realizes high-purity removal of the phenols, acid gas, free ammonia and solid ammonia in the coal gasification wastewater so as to meet the requirement of biochemical treatment on the inflow water quality, and obtains the crude phenol product and high-concentration ammonia gas. Compared with the prior art, the method provided by the invention has the advantages of good extraction effect, high phenol removal efficiency, short process flow and low treatment cost; the method is simple and convenient to operate, and the treatment quality is reliable.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

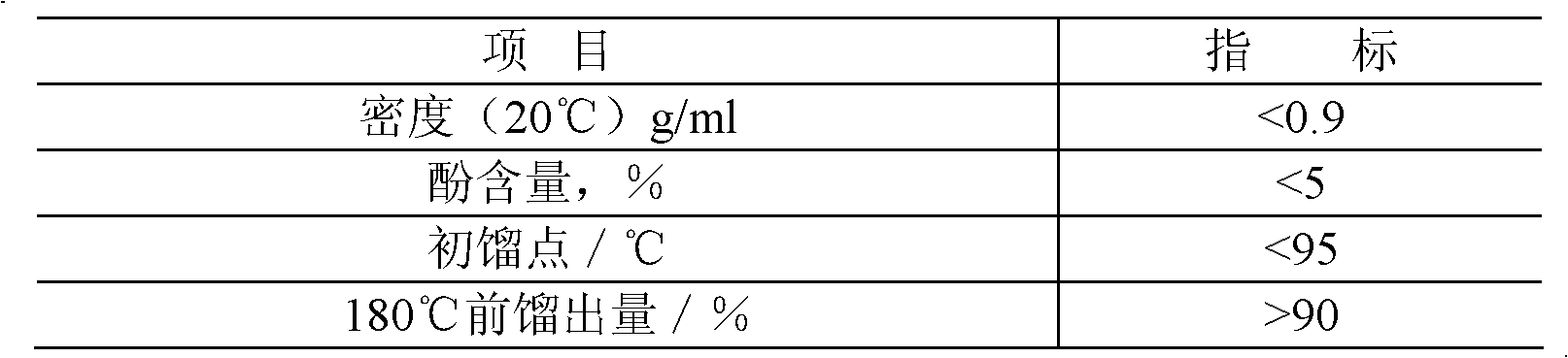

Production process of phenol products

InactiveCN1974517ALess investmentSmall footprintOrganic chemistryOrganic compound preparationTheoretical plateSlag

The present invention relates to coal chemical technology, and is especially process of producing phenol products. By using crude phenol after dewaterig and eliminating slag as material and through once intermittent rectifying process in a rectifying tower with theoretical plate number of 60-90, phenol, o-cresol fraction, m, p-cresol and industrial xylenol are obtained, with the o-cresol fraction is intermittently decompression rectified to obtain o-cresol product. Compared with tower type process, the present invention has low cost, small area and low power consumption.

Owner:ANGANG STEEL CO LTD

Process for producing phenol

InactiveUS20050222466A1Easy to understandOrganic compound preparationCarbonyl compound preparationPHENOL LIQUIDPhenol product

A process for producing a phenol product generally comprises a first step comprising reacting in a first reactor a feed stream comprising cumene hydroperoxide and water with an acid catalyst to produce an effluent comprising the phenol product, acetone, and at least 1% by weight residual cumene hydroperoxide, and a second step comprising passing the effluent into a second reactor and decomposing the residual cumene hydroperoxide, wherein during said process the ratio of phenol to acetone is maintained at a molar ratio of greater than 1:1, and wherein the water in each of the first and second steps is present in an amount more than 0 and less than or equal to 5 weight percent based on the total weight of the feed stream or effluent, and wherein the process is continuous.

Owner:SABIC GLOBAL TECH BV

High-concentration phenol-ammonia sewage treatment method

ActiveCN103466874AImprove removal efficiencyImprove processing qualityMultistage water/sewage treatmentAmmonia preparation/separationHigh concentrationSolubility

The invention relates to a high-concentration phenol-ammonia sewage treatment method. The high-concentration phenol-ammonia sewage treatment method includes the steps of conducting deacidification and deamination by conducting alkali injection and pressure stripping through a single tower conducting extraction dephenolization by using butyl acetate as an extraction agent, recycling the extraction agent in an extraction phase through a solvent recovery tower and a solvent stripping tower, and obtaining a crude phenol product at the bottoms of the towers. Due to the characteristics that the butyl acetate is low in price, low in solubility, less in loss in the whole production process, low in energy consumption in the recycling process and the azeotropy point of the butyl acetate and water is high, the dephenolization efficiency can be greatly improved, or the operation expenses spent in the extraction period can be reduced.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

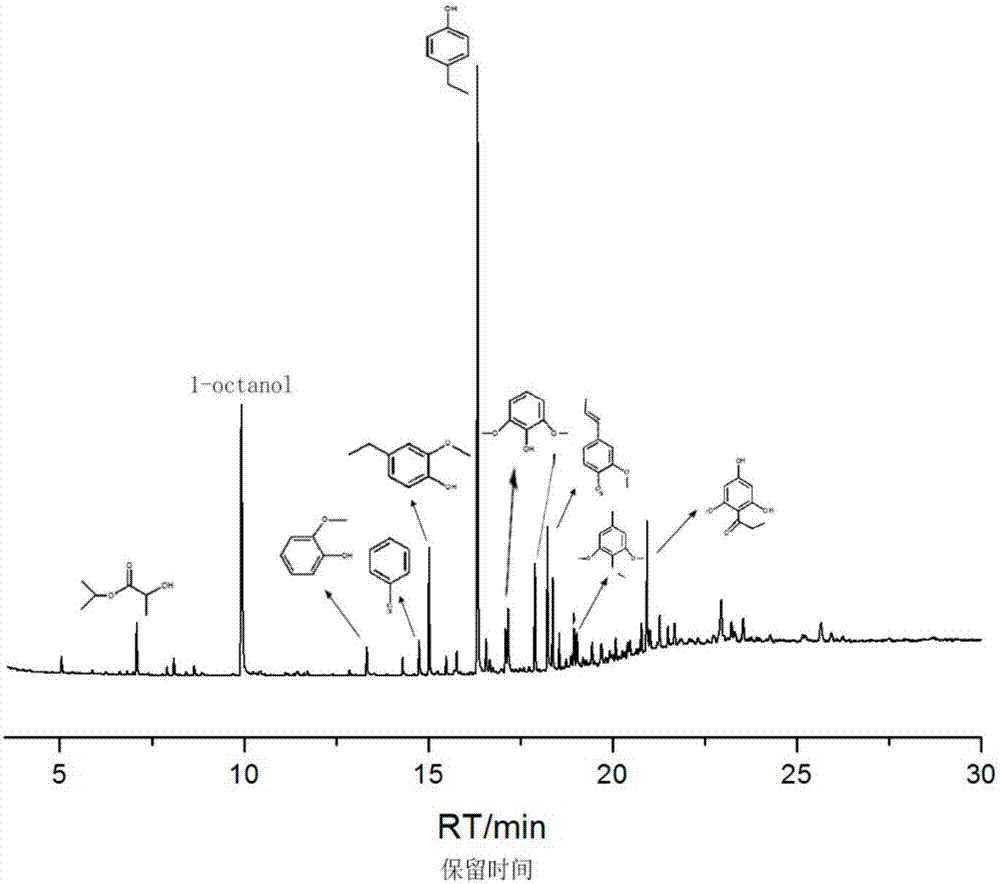

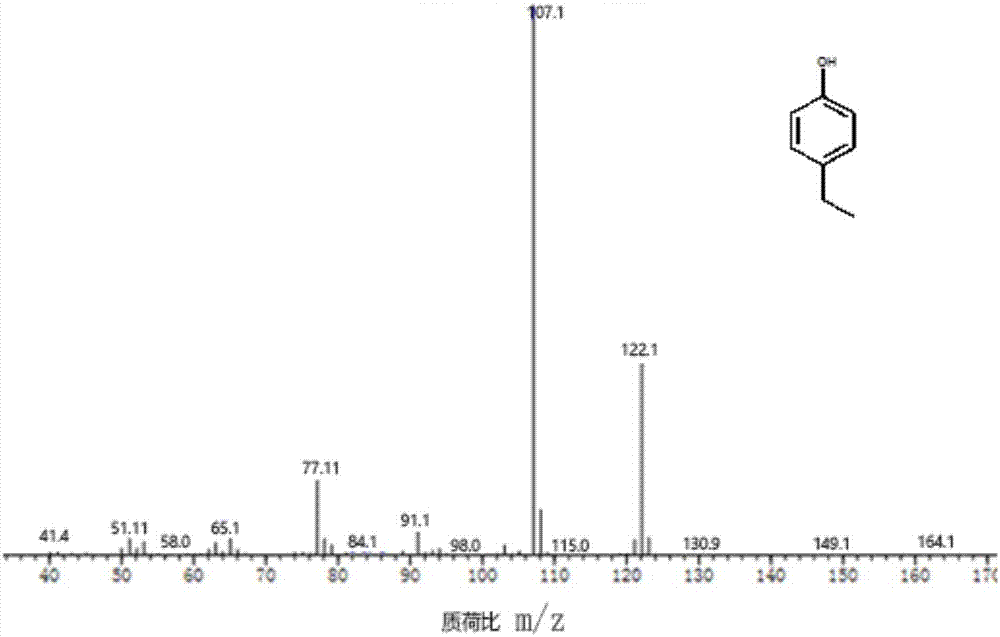

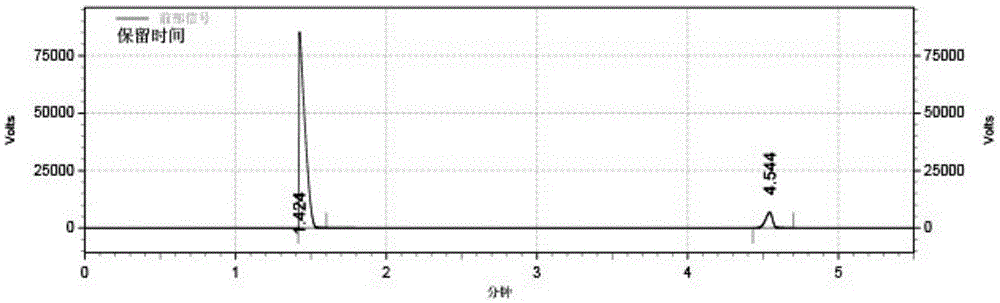

Method for preparing 4-ethyl phenol by selective lignin hydrogenolysis

ActiveCN107235829APromote generationHigh selectivityOrganic chemistryOrganic compound preparationLiquid productDepolymerization

The invention discloses a method for preparing 4-ethyl phenol by selective lignin hydrogenolysis. According to the method, lignin, nickel-based catalysts and reaction solvents are added into a reactor, the reactor is sealed and filled with hydrogen, the internal pressure of the reactor is controlled to be 0-4MPa, and reaction is performed for 1-5 hours at the temperature of 210-290 DEG C. After reaction, reaction liquid is filtered to obtain a liquid product containing the 4-ethyl phenol and recovered catalysts. The nickel-based catalysts comprise carriers and nickel metal loaded on the carriers. Generation of the 4-ethyl phenol in the hydrogenolysis process of lignin can be greatly promoted by the catalysts, formation of carbon deposits and other phenol products in the lignin depolymerization process is inhibited, and the generated 4-ethyl phenol is high in selectivity. The yield of the 4-ethyl phenol reaches 6.31%, the content of the 4-ethyl phenol in the organic liquid product is 38.83%, and the yield and selectivity simultaneously reach the current highest level.

Owner:SOUTH CHINA UNIV OF TECH

Lignin-modified urea resin or foamed plastic and preparation method thereof

The invention discloses lignin-modified urea resin or foamed plastic and preparation methods thereof. The preparation method of the lignin-modified urea resin comprises the following steps of: performing a urea resin preparation process by taking a lignin phenol product, formaldehyde and urea as raw materials, so as to obtain the lignin-modified urea resin. The formaldehyde emission amount of the lignin-modified urea resin provided by the invention is low. The lignin-modified urea foamed plastic is good in flame-retardant performance and can be used for external wall insulation, building decoration and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

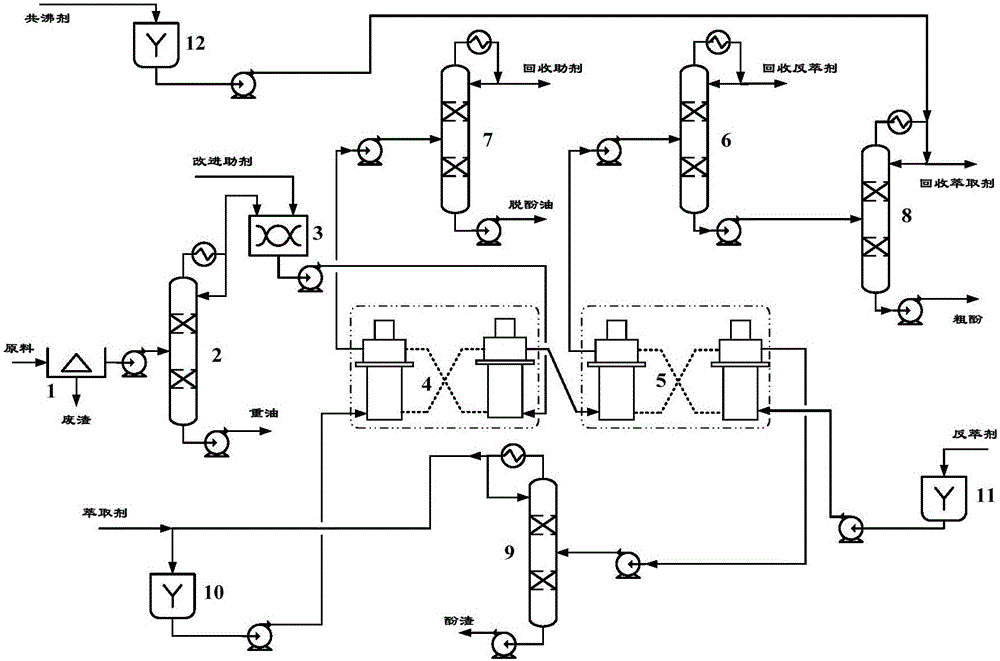

Method and device for extracting and separating phenolic compounds from coal derived oil

InactiveCN106278827AAvoid it happening againGood quality indexOrganic chemistryOrganic compound preparationAzeotropic distillationCoal

The invention discloses a method and device for extracting and separating phenolic compounds from coal derived oil. The method comprises the following steps of performing distillation and cutting to obtain phenol-enriched distillation fractions: performing distillation, distillation fraction and cutting on the coal derived oil, and cutting out a phenol-enriched distillation fraction of a certain temperature segment; performing centrifugation, extraction and separation on a solvent: performing centrifugation and separation on the phenol-enriched distillation fraction, an extraction agent and an addition agent so as to obtain a liquid phase containing an extraction agent, wherein a light phase of the liquid phase containing the extraction agent is a dephenolization oil-addition agent solution, a heavy phase of the liquid phase containing the extraction agent is an enriched phenolic compound, and the extraction agent is an aqueous solution of one or more selected from butanone, cyclohexanol, dihydric alcohol and glacial acetic acid; performing centrifugation, backward extraction and separation; recovering the addition agent; recovering reverse extraction agents; and refining crude phenols: performing azeotropic distillation and separation on crude phenol raw materials containing a few extraction agents so as to obtain the extraction agent and crude phenol products.

Owner:CCTEG CHINA COAL RES INST +1

Production and purification of phenol

InactiveUS6635789B2Efficiently employedReduce the amount requiredOther chemical processesOrganic compound preparationDistillationSolvent

A process for separating sulfonic acid compounds from a phenolic solvent is provided by contacting the phenolic solvent with a hydrotalcite-type material (HTM). The process can be applied in the conventional industrial process for converting cumene to phenol to remove sulfonic acid compounds from the phenol product. A process and a facility for producing purified phenol by converting cumene to phenol are provided. In the conversion of cumene to phenol, the phenol often contains carbonyl-type impurities. The phenol and carbonyl-type impurities are reacted in the presence of a sulfonic acid cation exchange resin catalyst (IER) to produce a reaction product that may contain sulfonic acid compounds. The reaction product is contacted with an HTM to reduce the amount of sulfonic acid compounds which may be present and to produce a purified phenol-containing stream. The purified phenol-containing stream may be further purified using conventional separation techniques, such as distillation.

Owner:SABIC INNOVATIVE PLASTICS IP BV

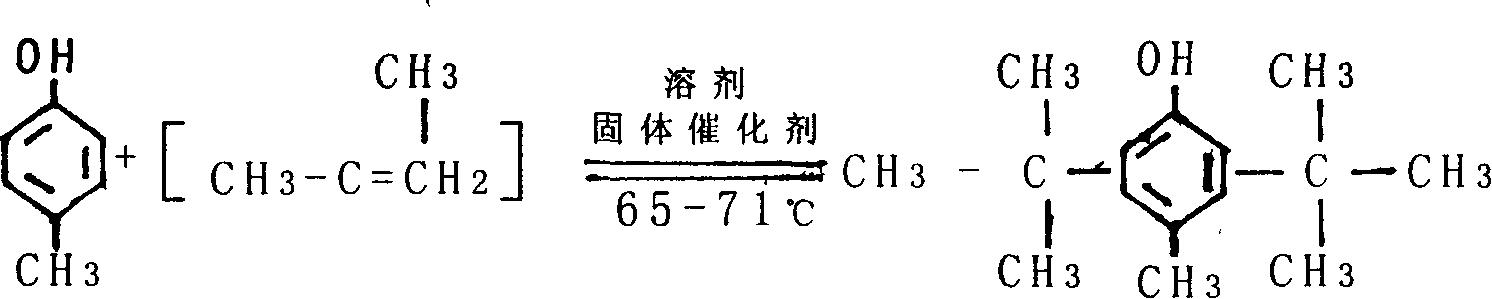

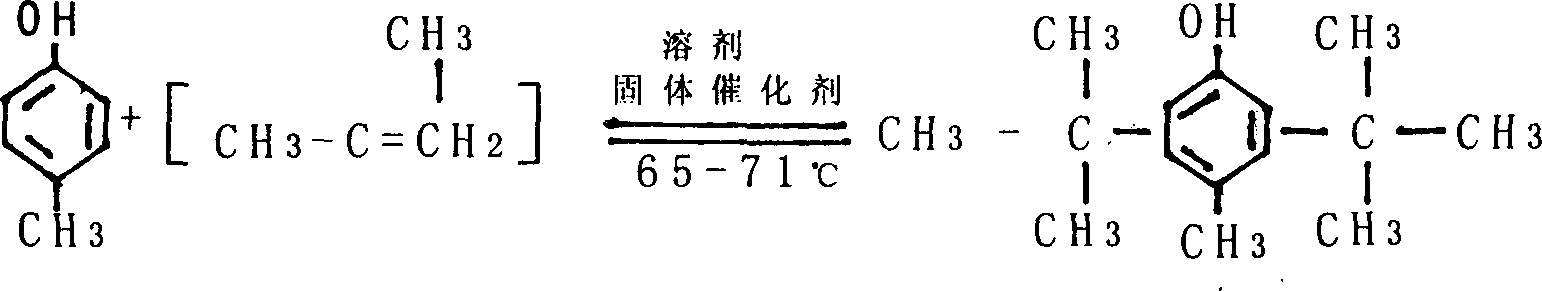

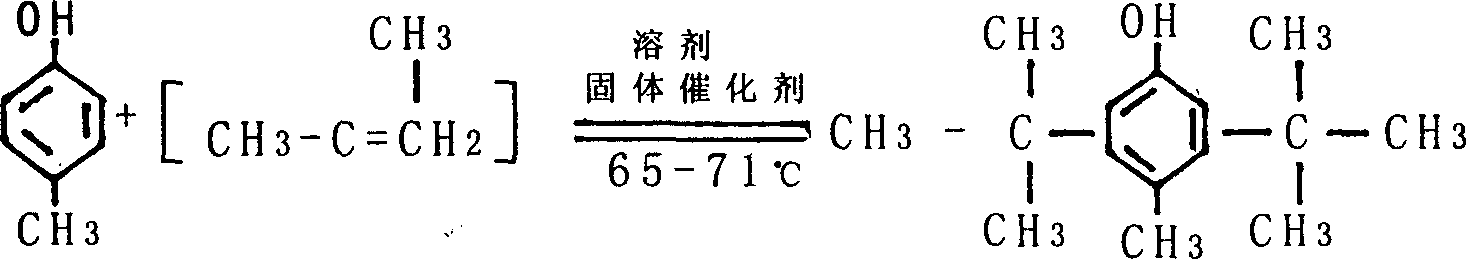

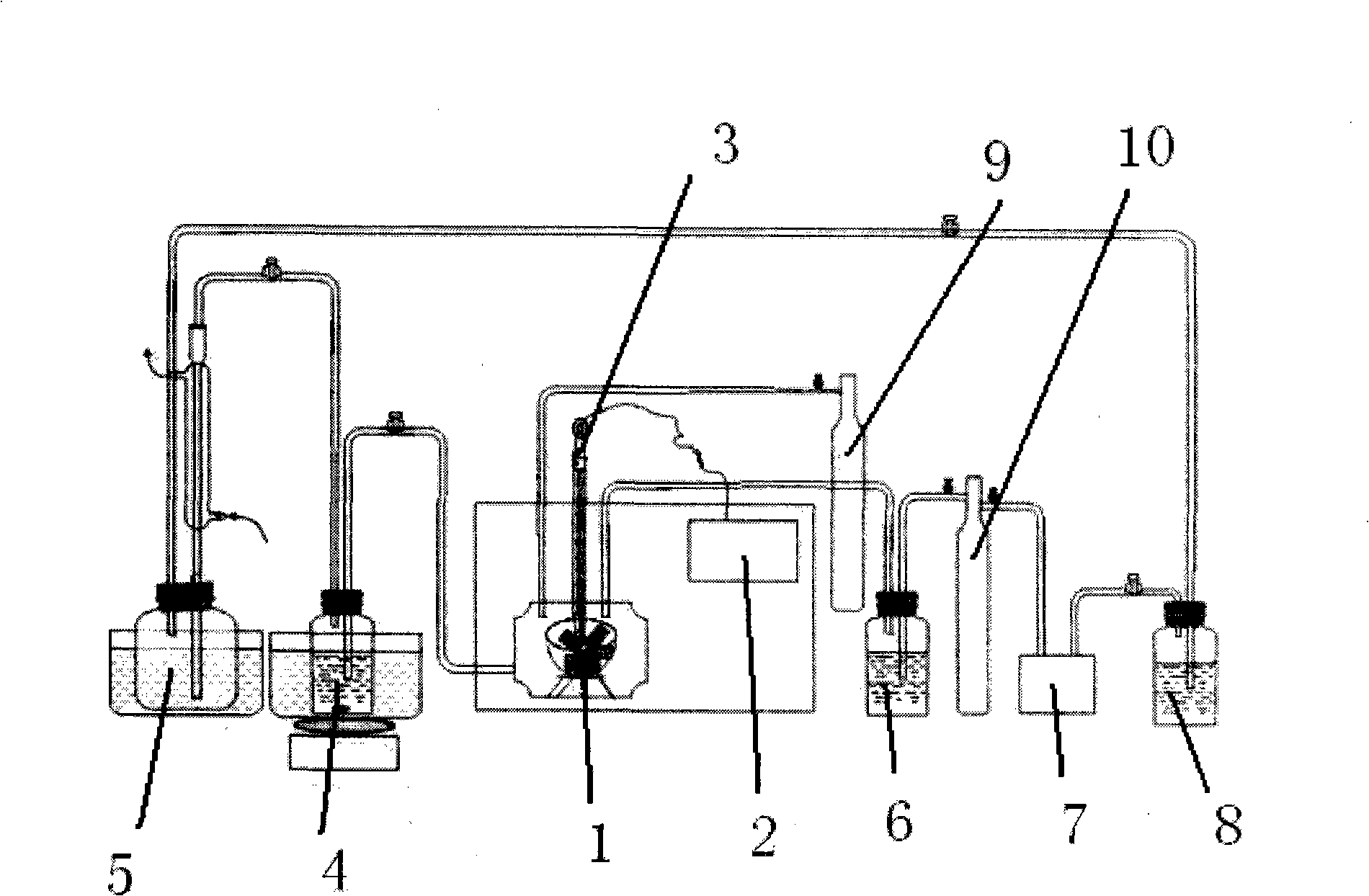

Production process of antioxidant 2,6-di-tert-butyl-4-methy phenol

The production process of 2, 6-di-tert-butyl -4-methyl phenol includes the following steps: the first alkylation reaction of paracresol, isobutene and solid catalyst; leading the reaction product to the crystallizing kettle while leaving the catalyst for further use and lowering temperature slowly to separate out crystal; repeating the foregoing steps; washing the initial crystal with water solution of sodium hydroxide and separating oily matter from the washed alkali solution for reuse; recovering ethanol from the mother liquid in a rectifying tower for reuse and separating out inferior 2, 6-di-tert-butyl -4-methyl phenol product from the residue; drying the re-crystallized product and packing. The present invention has the advantages of no drained waste water, no environmental pollution, high product quality, etc.

Owner:孟祥儒

Method for preparing biological diesel oil antioxidant additive with biomass microwave auxiliary directional thermal decomposition

InactiveCN101294076AImproves antioxidant activityReduced responseFuel additivesChemical inhibitorsSolubilityCellulose

A method for preparing an antioxidant additive of bio-diesel fuel by using microwave-assisted oriented pyrolysis of biomass is characterized in that the method comprises the following steps: cracking biomass such as plant cellulose with rich lignin in the presence of an inorganic acid as the catalyst and under controlled cracking process parameters and a microwave-assisted condition, fraction-collecting the cracking products, circularly using a reducible non-condensible gas component to maximally transform the lignin to phenol residues with small molecular weight, absorbing the phenol products by a functional ionic liquid, synchronously carrying out alkyl modification, and extracting in a solvent to obtain the antioxidant additive of bio-diesel fuel with good oil solubility, strong antioxidant effect and low cost. The method can achieve the green chemical goal of completely utilizing biomass such as plant cellulose.

Owner:NANCHANG UNIV

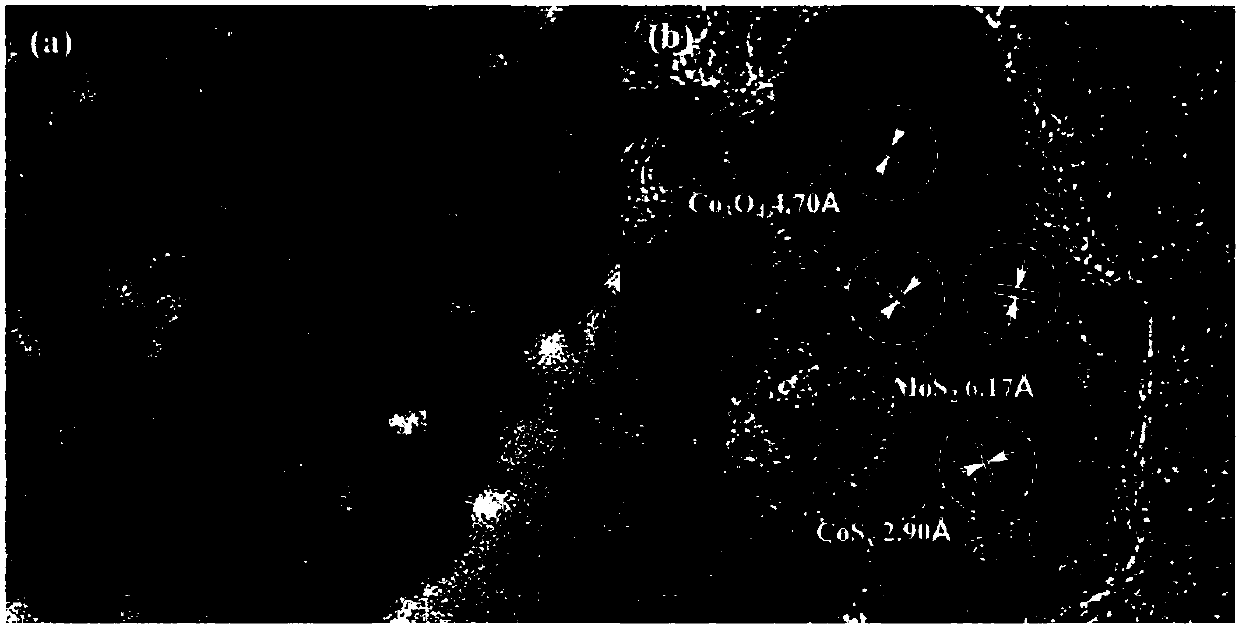

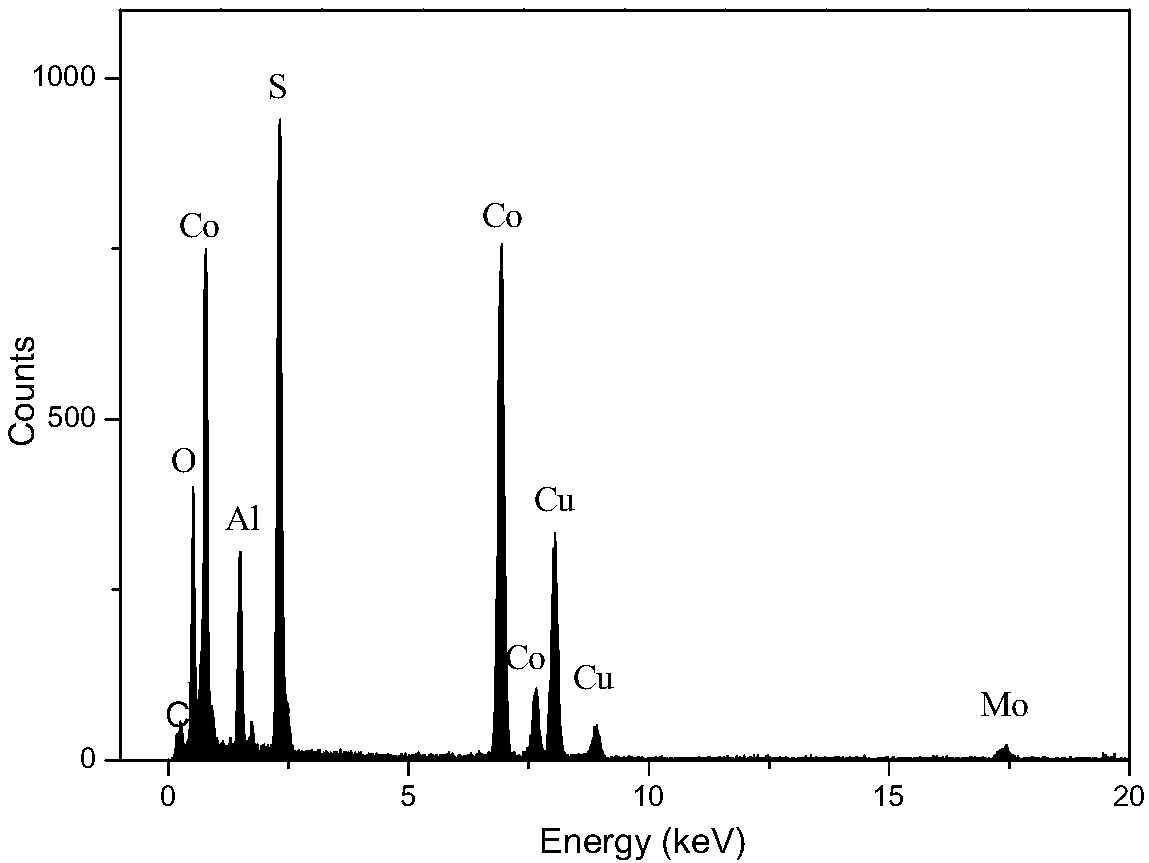

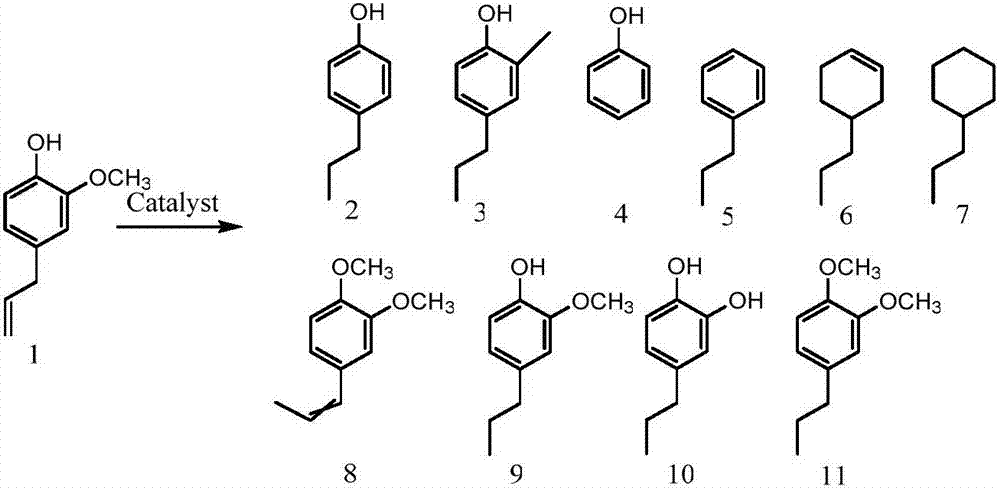

Co-based catalyst, preparation method thereof and application of Co-based catalyst in eugenol conversion

ActiveCN107812523ARealize optionalityHigh hydrodeoxygenation capacityOrganic compound preparationCatalystsEugenolHydrotalcite

The invention relates to a preparation method of a Co-based catalyst and application of the Co-based catalyst in eugenol conversion. The Co-based catalyst comprises a CoAl-O, CoAl-S or CoAlMo-S catalyst. CoAl hydrotalcite is taken as a precursor, and the Co-based catalyst in different existence forms, including cobalt oxide, cobalt sulfide and a Mo-doped cobalt molybdenum sulfide catalyst, is prepared, so that selectivity of catalyst activity is realized. The Co-based catalyst, taking activity of CoAlMo-S as an example, has the hydrodeoxygenation capability much higher than that of a commercially purchased CoMo / Al2O3 sulfide catalyst in catalytic conversion of a lignin model compound eugenol. Under the reaction conditions that pressure is at 3MPa, temperature is at 300 DEG C and time is 3hours, conversion rate of eugenol reaches 100%, a main product is a phenol product, and yield is higher than 60%. Stability of the catalyst is greatly improved, and the catalyst still maintains relatively high activity after beingrecycled many times.

Owner:TIANJIN UNIV

High-phenol concentration waste water treatment method

ActiveCN105540969AReduce solubilityReduce lossesWater contaminantsTreatment involving filtrationWastewaterGravity flow

The invention discloses a high-phenol concentration waste water treatment method. The high efficiency and economic phenol-containing waste water extraction method comprises 1, removing impurities of high-phenol concentration waste water, 2, putting eudesmol and the high-phenol concentration waste water treated through the step 1 into an extraction container according to a volume ratio of 1: 1-10, carrying out fast stirring at a temperature of 10-50 DEG C for 5-20min and carrying out standing for 15-80min, 3, separating a raffinate phase in the lower layer and an extract phase in the upper layer from the stood solution through gravity flows, and analyzing phenol content of the raffinate phase through a gas chromatography method, 4, carrying out rectification on the extract phase obtained through the step 3 to obtain a phenol removal extraction agent and a crude phenol product and recycling the phenol removal extraction agent for extraction of high-phenol concentration waste water, and 5, carrying out rectification on the raffinate phase obtained through the step 3 to obtain the residual phenol removal extraction agent and the phenol-free waste water. The high-phenol concentration waste water treatment method belongs to the technical field of water treatment.

Owner:GUANGDONG UNIV OF TECH

Method for processing phenol-contained tar

ActiveCN101565182AReduce processing costsAchieve separationOrganic chemistryCarbon compoundsHydroquinone productsSolvent

The invention relates to a method for processing phenol-contained tar, in particular to a method for preparing an active carbon by utilizing a phenolic tar and simultaneously recycling the phenol product with high additional value therein. The method comprises the following steps of: adding the phenol-contained tar in a carbonizing furnace, heating the carbonizing furnace and leading the gas into the carbonizing furnace for sweeping and blowing; obtaining the active carbon after carbonizing; cooling and absorbing the hydroquinone product in the tail gas by utilizing a solvent; and returning the product to a separating and refining system of phenol hydroxylation process so as to recycle the hydroquinone product. The method has simple operation, converts the phenol-contained tar into the active carbon commodity with utilizable values, can recycle most of the hydroquinone product residual in the phenol-contained tar simultaneously, avoid resource wasting, reduce the processing expense of the solid wastes simultaneously and improve the yield of the product obviously.

Owner:SHANGHAI HUAYI NEW MATERIAL

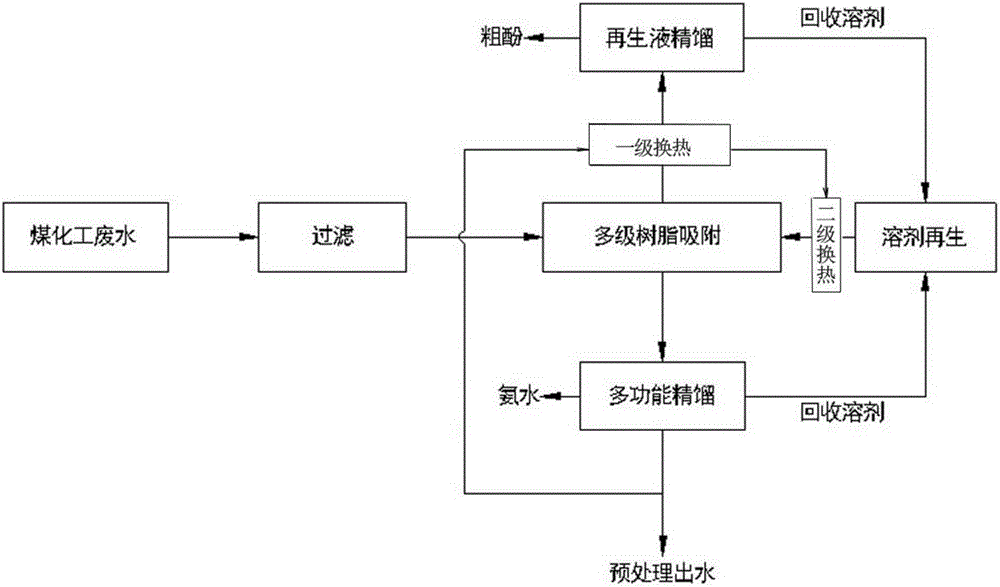

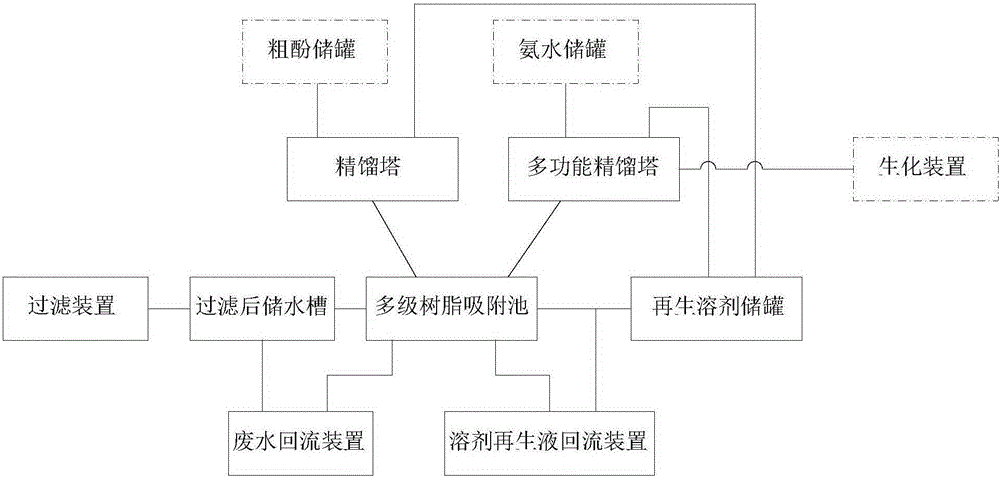

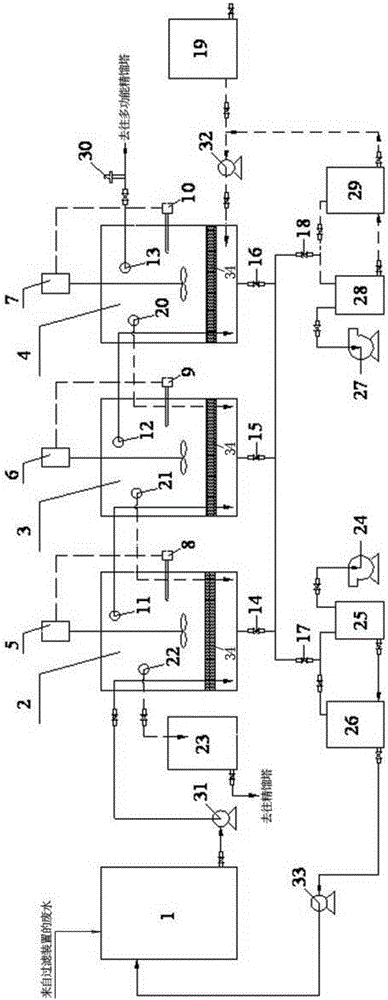

Coal chemical wastewater pretreatment process and device

ActiveCN105174577AIncrease profitFully contactedWater contaminantsMultistage water/sewage treatmentDistillationDesorption

The invention relates to a coal chemical wastewater pretreatment process and device. The process includes: filtering coal chemical wastewater, then subjecting the wastewater to adsorption in a multistage resin adsorption pool; increasing the wastewater BOD5 / CODcr value from less than 0.2 of raw water to more than 0.53; conducting ammonia distillation and separation and recovery of regenerated solvent by a multifunctional rectification tower to an effluent ammonia nitrogen content of less than 150mg / L; after resin adsorption saturation, performing regeneration by solvent regeneration technique, subjecting the solvent regeneration liquid to a rectification tower to recover the regenerated solvent, conducting separation to obtain the regenerated solvent with purity of more than 95% for recycling and a crude phenol product at the same time. According to the invention, the multistage stirring resin adsorption pool is employed to pretreat coal chemical wastewater, on the one hand the pollutant concentration can be reduced, the biodegradability of wastewater is greatly improved, and wastewater can directly enter the subsequent biochemical process to undergo treatment; and on the other hand, phenolic substances with economic value can be recovered. The cyclic regeneration solvent is employed to perform staged countercurrent desorption on resin, thus improving the resin regeneration rate and the utilization rate of regenerated solvent, shortening the technological process, and saving the equipment investment cost.

Owner:广东先能环保科技有限公司

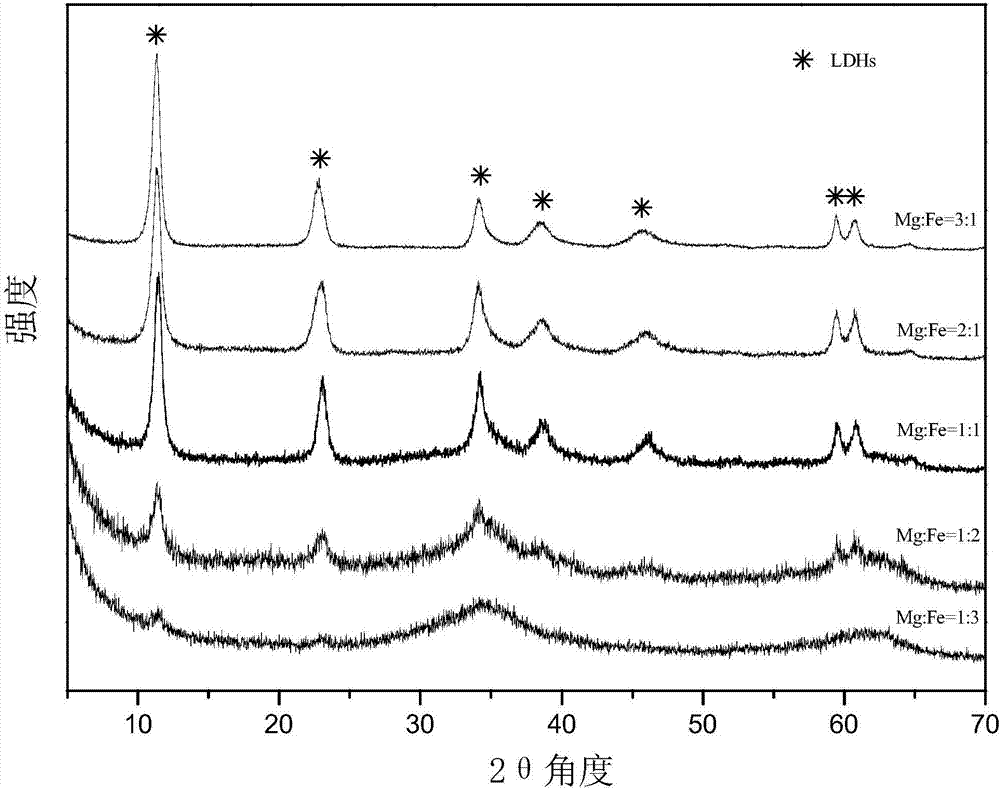

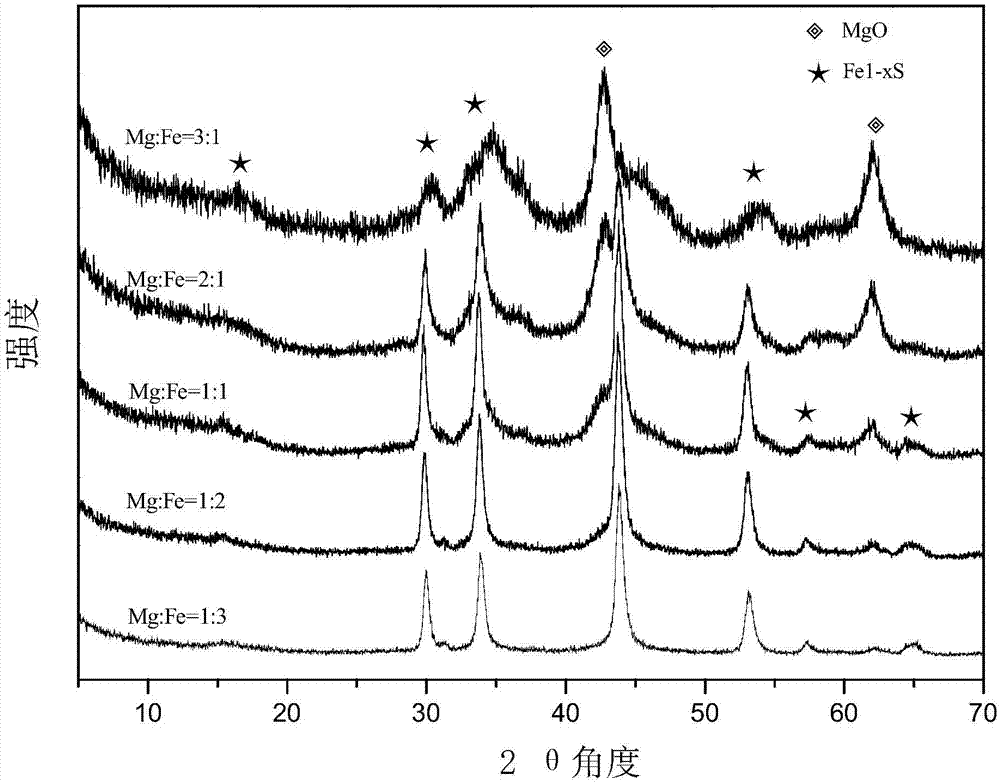

Combined alkaline iron-molybdenum sulfide catalyst, preparation method of catalyst and application of catalyst to aromatic phenol and ether conversion

ActiveCN107159267AGood dispersionHigh activityPhysical/chemical process catalystsOrganic compound preparationHydration reactionMixed gas

The invention provides a combined alkaline iron-molybdenum sulfide catalyst, a preparation method of the catalyst and an application of the catalyst to aromatic phenol and ether conversion. The catalyst is expressed by the aid of a molecular formula of MgxFey-Mo-S, x and y represent atomic ratio, and x: y = 3:1-1:3. MgxFey hydrotalcite serves as a precursor, the precursor is roasted at the temperature ranging from 350 DEG C to 500 DEG C to obtain oxide of MgxFey, the oxide and water solution with excessive MoO4<2>- ions are hydrated to obtain an MgxFey-MoO4<2> precursor of an intercalation layer, the MgxFey-MoO4<2> precursor is vulcanized through H2S / H2 mixed gas at the temperature ranging from 400 DEG C to 800 DEG C to finally obtain the MgxFey-Mo-S catalyst. The catalyst is effectively applied to aromatic phenol and ether conversion, cleavage of aryl-ether bands in a reactant is achieved, phenol products with low oxygen content are acquired, and the added value of the catalyst is improved.

Owner:TIANJIN UNIV

Coal tar deep processing technology based on four mixed fractions

InactiveCN102161902AReasonable designImprove product qualityTar working-up by water removalTar working-up by distillationTarEngineering

The invention discloses a coal tar deep processing technology based on four mixed fractions. The coal tar deep processing technology comprises the following steps: heating raw material tar by a coke tar heat exchanger to 105-130 DEG C and then entering into a dehydrating tower with 4-12 layers of trays; separating out water and partial light oil from the tower top of the dehydrating tower, and separating out anhydrous tar from the tower bottom of the dehydrating tower; processing the dehydrated tar through a conductive oil heat exchanger and heating to 240 DEG C-300 DEG C by a tubular heating furnace, and then entering into the lower middle part of a main tar tower which is provided with 15-35 layers of trays and is provided with 2-10 layers of trays in a stripping section; performing heating circulation by using the tubular heating furnace at the tower bottom; washing four mixed fractions with light phenol naphthalene cut at the tower top, cooling the four mixed fractions and dephenolizing to obtain a phenol product and a washed fraction, and processing the washed fraction in an industrial naphthalene processing device so as to obtain dephenolized phenol oil, an industrial naphthalene product and high-quality absorber oil; and obtaining mixed oil from the tower bottom, wherein the mixed oil can be directly used for producing high-quality carbon black or mesothermal pitch according to the market conditon.

Owner:上海同特化工科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com