High-phenol concentration waste water treatment method

A treatment method and technology for phenol wastewater are applied to the treatment of phenol-containing wastewater and the treatment of high-concentration volatile phenol-containing wastewater, which can solve the problems of solvent loss, weak extraction ability of the extractant, high solubility, etc. Excellent extraction effect, low solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The phenol-containing wastewater with a concentration of 5000mg / L is first passed through the grid to remove impurities, and then the eucalyptol and phenol-containing wastewater are placed in the extraction vessel at a volume ratio of 1:1. Stir for 5 minutes, and separate layers in a constant temperature tank at a temperature of 10°C. After standing still for 60 minutes, separate the raffinate phase in the lower layer. The content of phenol in the raffinate phase is measured by gas chromatography. The extraction dephenolization rate is 96.2%.

Embodiment 2

[0040] Put the phenol-containing wastewater with a concentration of 20,000 mg / L first through the grid to remove impurities, and then put the eucalyptol and phenol-containing wastewater in the extraction vessel at a volume ratio of 1:4, and place them on a magnetic stirrer at 25°C Stir for 10 minutes, and separate layers in a constant temperature bath at 25°C. After standing still for 30 minutes, separate the lower raffinate phase. The phenol content in the raffinate phase is measured by gas chromatography. The dephenolization rate is 94.7%.

Embodiment 3

[0042] The phenol-containing wastewater with a concentration of 40000mg / L was first passed through the grid to remove impurities, and then the eucalyptol and phenol-containing wastewater were placed in the extraction vessel at a volume ratio of 1:8. Stir for 15 minutes, and separate layers in a constant temperature tank at a temperature of 40°C. After standing for 15 minutes, separate the raffinate phase in the lower layer. The content of phenol in the raffinate phase is measured by gas chromatography. The extraction dephenolization rate is 91.1%.

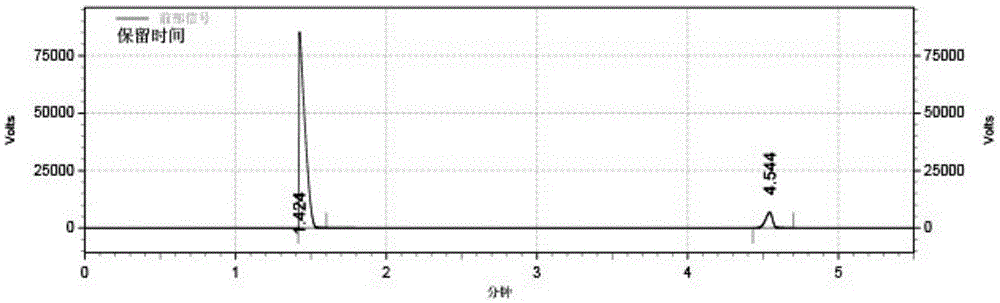

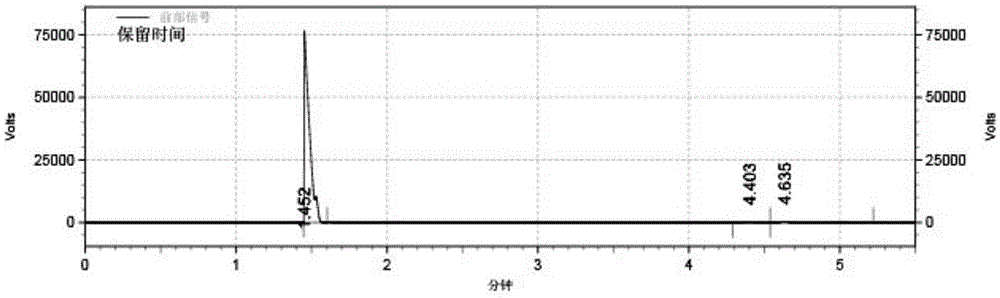

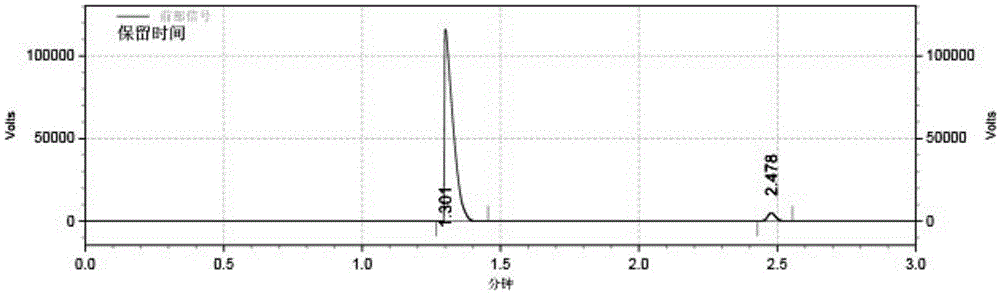

[0043] For specific chromatograms, see figure 1 It is the gas chromatogram before the extraction of 40000ppm phenol-containing wastewater; wherein, 1.42min is the ethanol peak (internal standard), and 4.54min is the phenol peak; figure 2 Be that concentration is the gas chromatogram after 40000ppm phenol-containing waste water is extracted with eucalyptus alcohol, explanation: 1.45min is ethanol peak (internal standard), 4.4min i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com