Patents

Literature

874 results about "Deamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

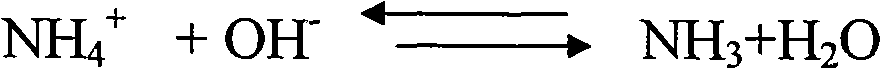

Deamination is the removal of an amino group from a molecule. Enzymes that catalyse this reaction are called deaminases. In the human body, deamination takes place primarily in the liver, however glutamate is also deaminated in the kidney. In situations of excess protein intake, deamination is used to break down amino acids for energy. The amine group is removed from the amino acid and converted to ammonia. The rest of the amino acid is made up of mostly carbon and hydrogen, and is recycled or oxidized for energy. Ammonia is toxic to the human system, and enzymes convert it to urea or uric acid by addition of carbon dioxide molecules (which is not considered a deamination process) in the urea cycle, which also takes place in the liver. Urea and uric acid can safely diffuse into the blood and then be excreted in urine.

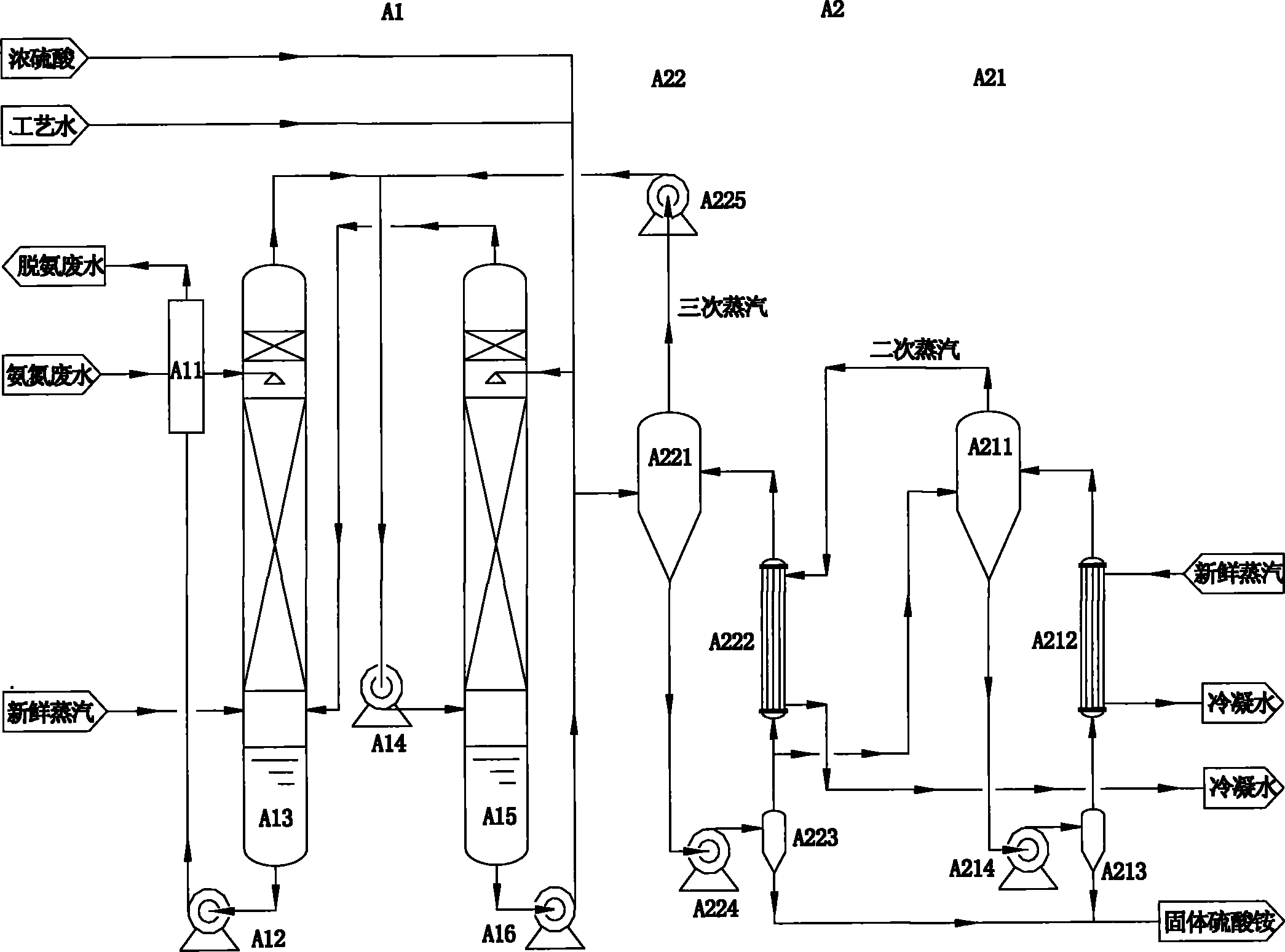

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

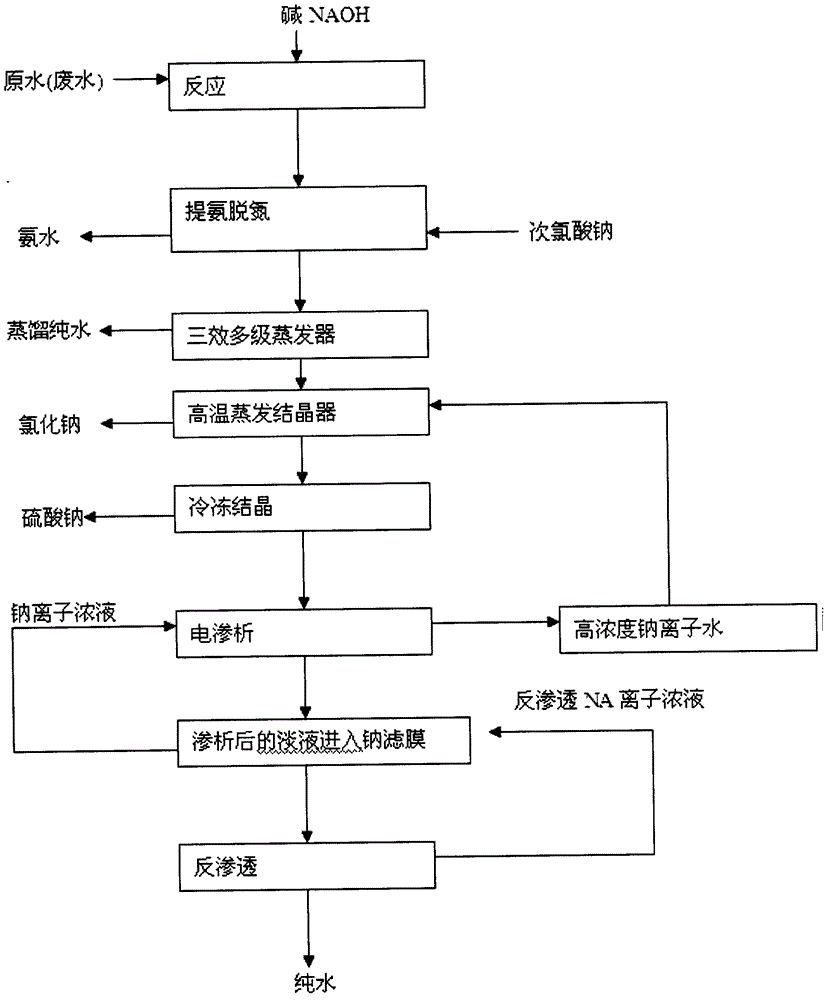

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

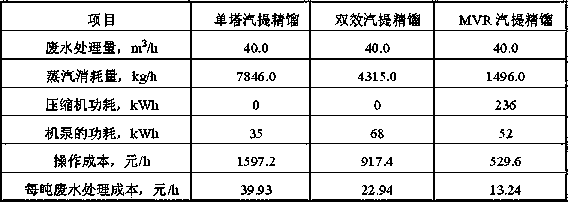

MVR (Mechanical Vapor Recompression) vapor-stripping deamination system and application method thereof

InactiveCN103408086AIncrease pressureIncrease temperatureWater/sewage treatment by degassingAmmonia preparation/separationAxial-flow pumpWater discharge

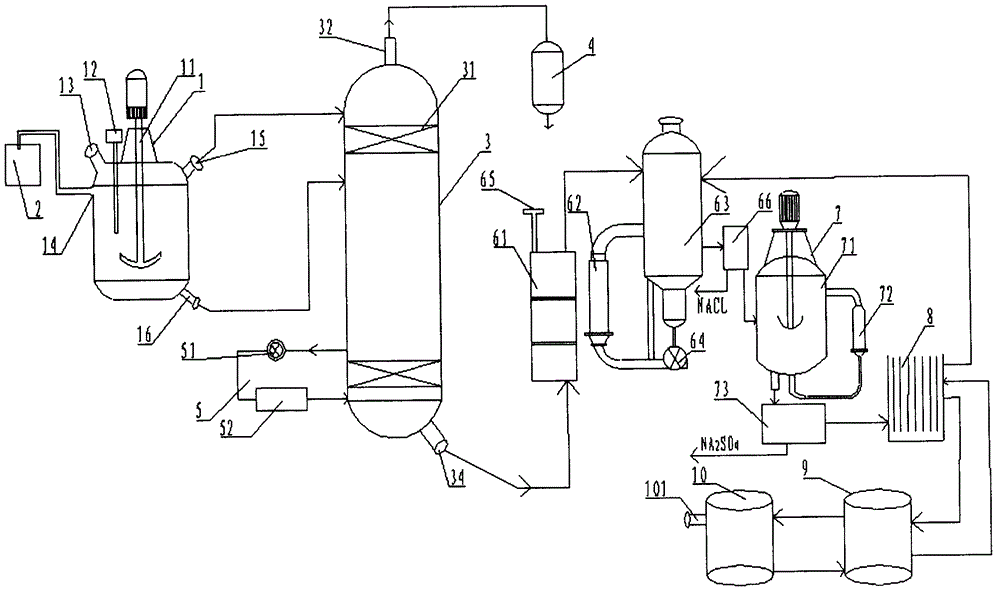

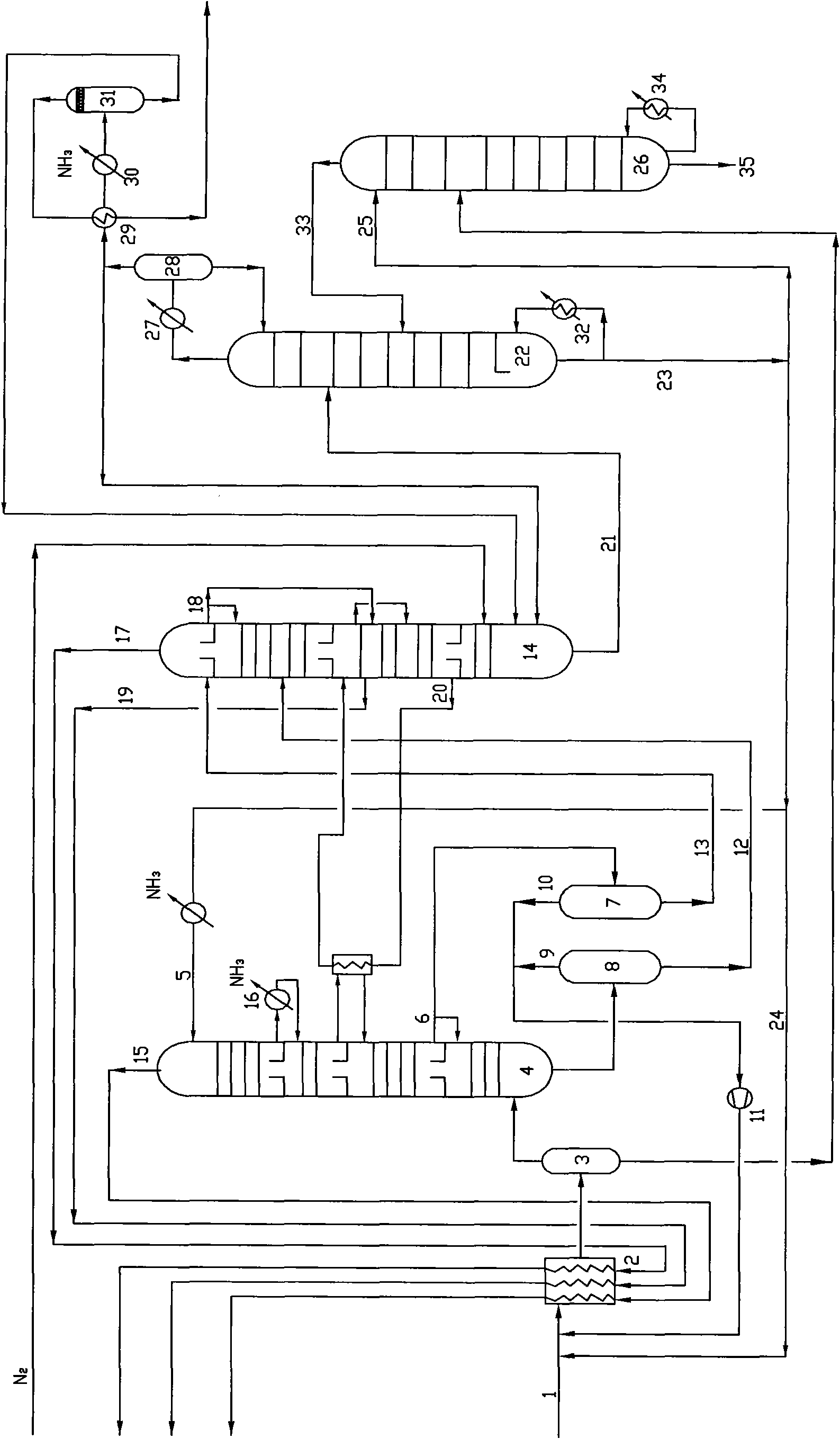

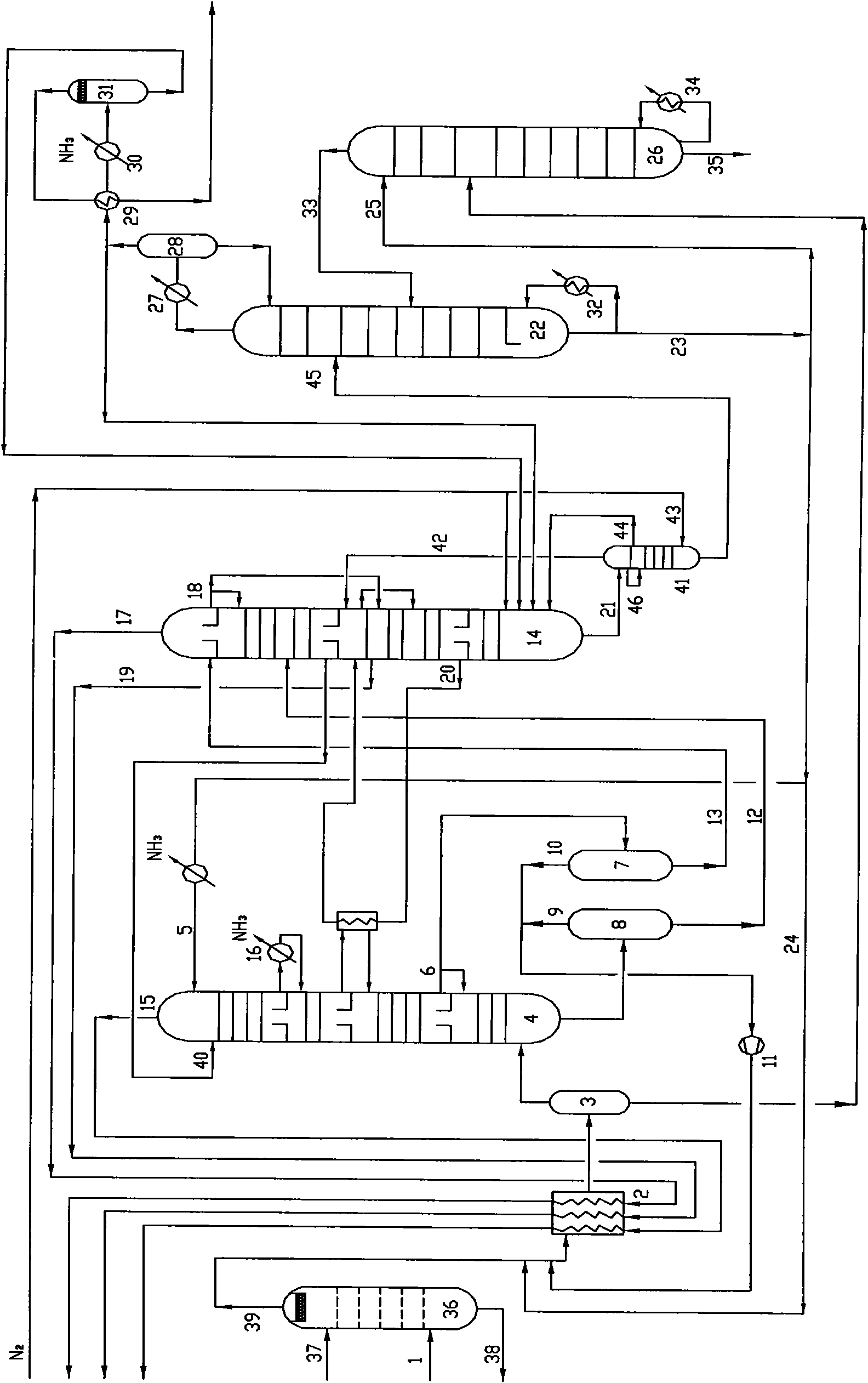

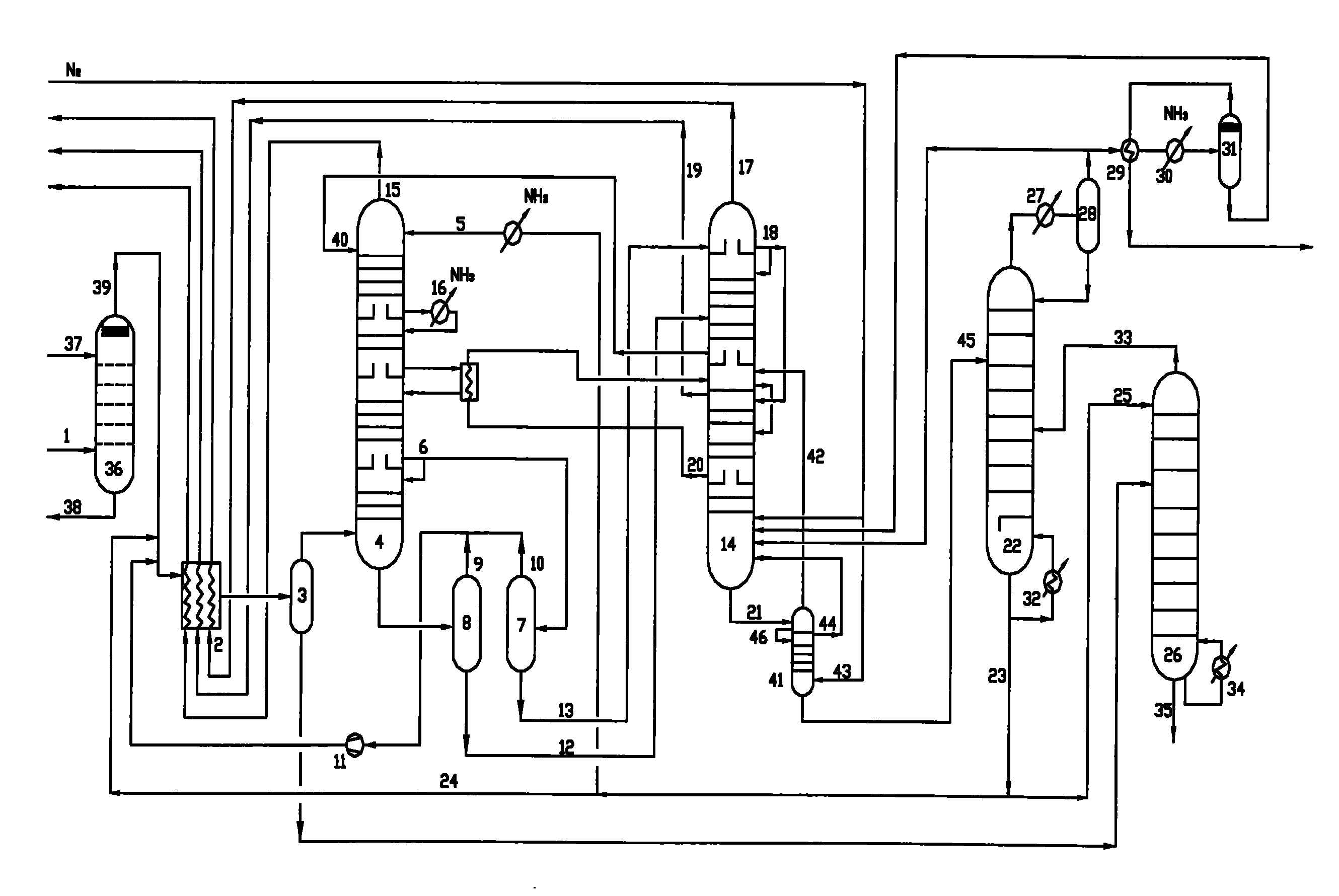

The invention relates to an MVR vapor-stripping deamination system. The MVR (Mechanical Vapor Recompression) vapor-stripping deamination system comprises a vapor-stripping deamination tower, an ammonia water rectification tower and a condenser, wherein a high-ammonia-nitrogen sewage input pipe, a vapor input pipe I, a post-deamination waste water discharge port and an ammonia-containing vapor discharge port I are arranged on the vapor-stripping deamination tower; the vapor-stripping deamination tower is connected with a reboiler; the high-ammonia-nitrogen sewage input pipe is connected with waste water feed preheaters (II and I); the post-deamination waste water discharge port is connected with the waste water feed preheater I and an axial flow pump respectively; the ammonia-containing vapor discharge port I is connected with the reboiler through a mechanical vapor compressor; the reboiler is connected with a dilute ammonia water storage tank connected with the ammonia water rectification tower; a discharge port, an ammonia-containing vapor discharge port II and a vapor input pipe are arranged on the ammonia water rectification tower; the discharge port is connected with a rectification tower kettle discharge pump and the waste water feed preheater II; the ammonia-containing vapor discharge port II is connected with the condenser; a strong ammonia water discharge port is connected with a strong ammonia water storage tank connected with the ammonia water rectification tower. Meanwhile, the invention further discloses an application method of the MVR vapor-stripping deamination system. The MVR vapor-stripping deamination system has the advantages of less investment, high feasibility and high comprehensive utilization ration.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

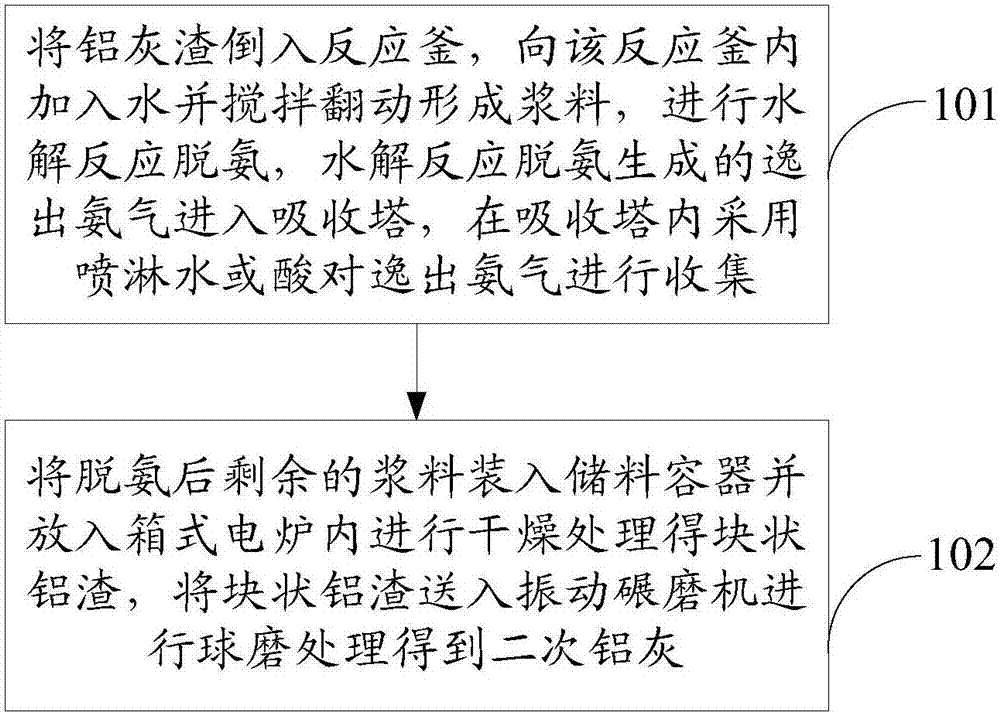

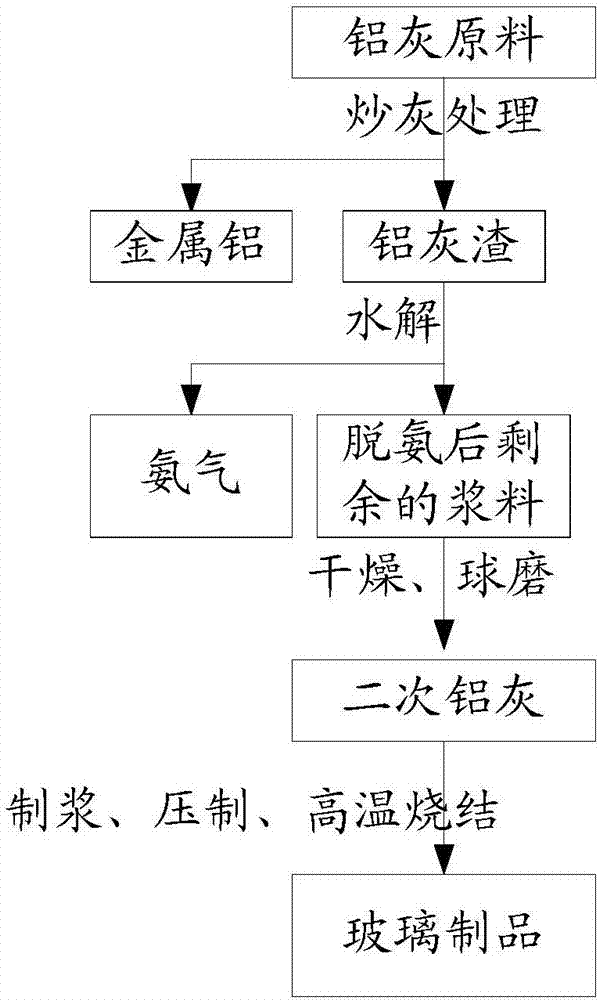

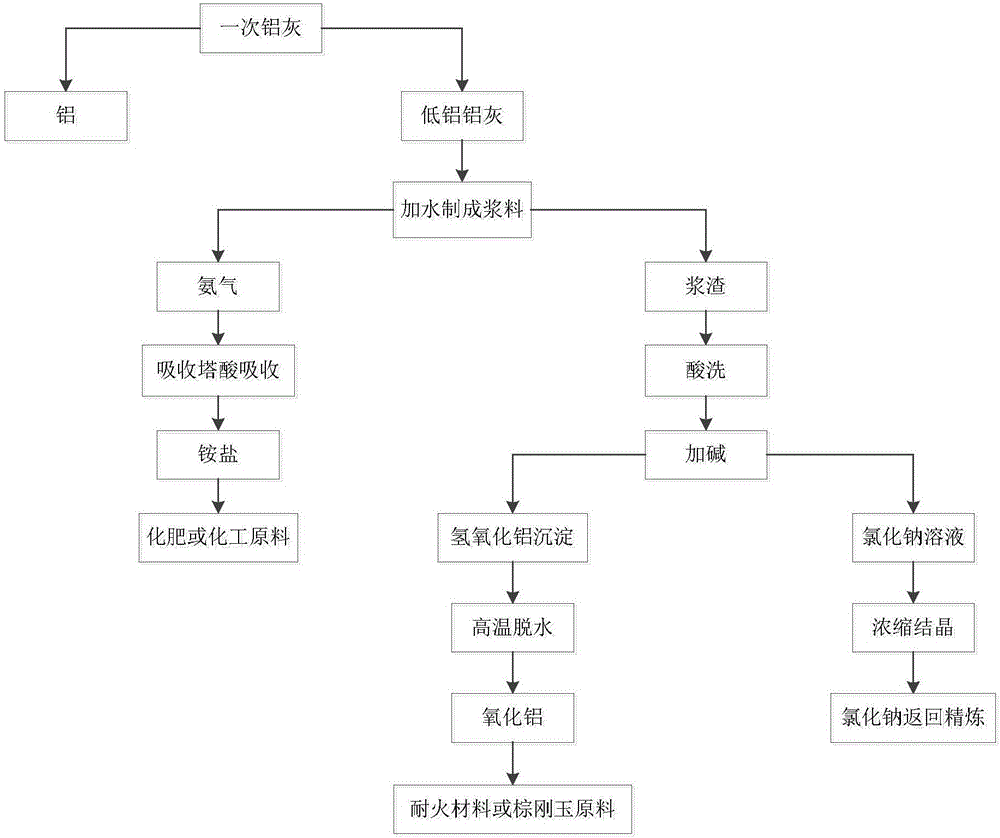

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

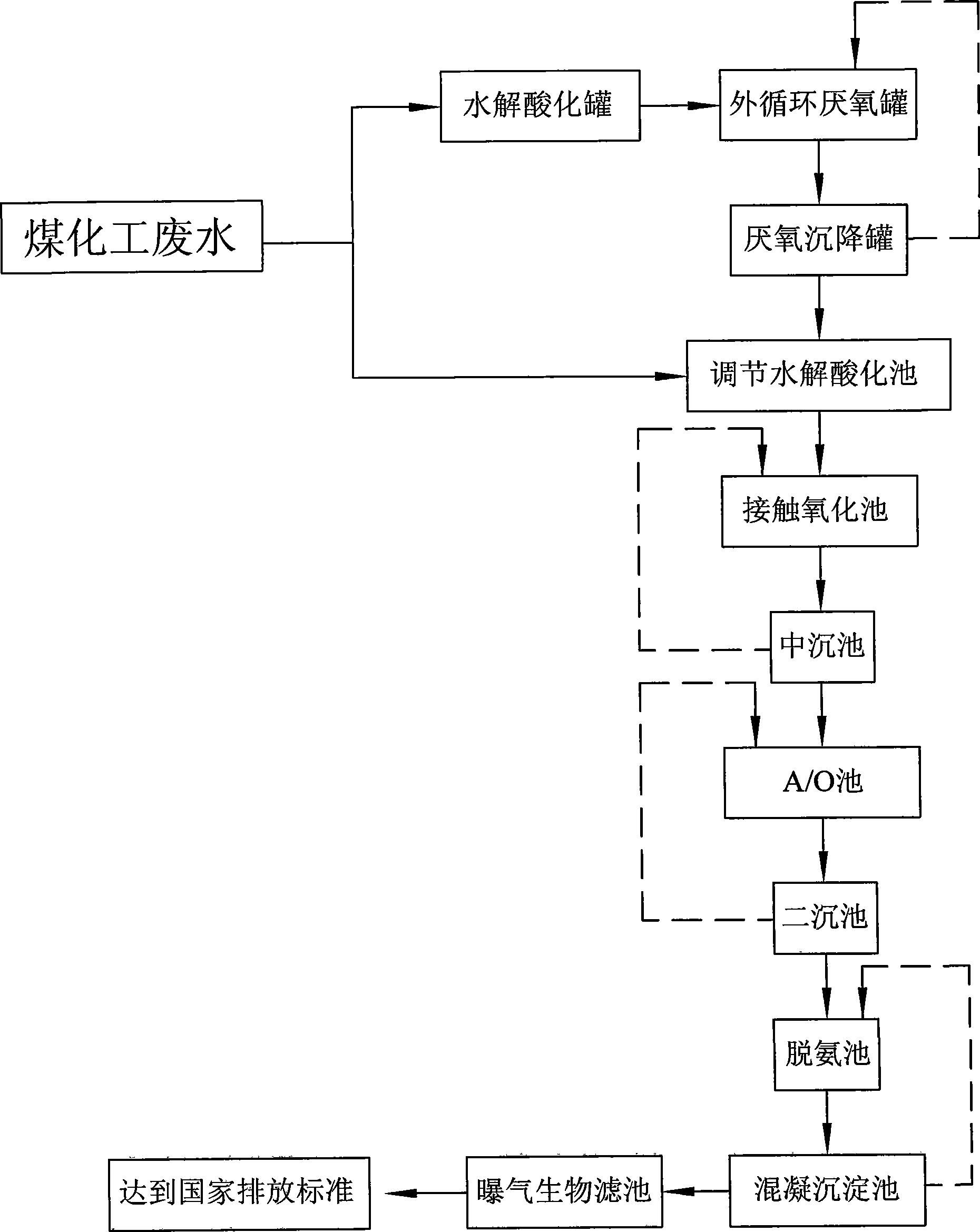

Coal chemical industry wastewater treating method

InactiveCN101503267AEasy to handleImprove the water effectWater contaminantsTreatment with aerobic and anaerobic processesOperational costsBiological filter

The invention relates to a coal chemical wastewater treatment method, in particular to a chemical wastewater treatment method. The invention aims to solve the problems of the chemical wastewater treatment method such as bad outlet water quality and high operational cost. The method comprises the following steps: pretreating coal chemical wastewater to be treated; then carrying out hydrolytic acidification treatment, external circulating anaerobic treatment, anaerobic sedimentation treatment, adjusting hydrolytic acidification treatment, contact oxidation treatment, sedimentation treatment, A / O treatment, sedimentation treatment, deamination treatment, coagulating sedimentation treatment and aeration biological filter tank treatment, wherein the temperature in an external circulating anaerobic tank is controlled within the scope of 32 to 35 DEG C; the hydraulic detention time is 24 to 36 h; the sludge concentration is controlled between 50 and 100 g / L; the volume load is 5 to 10 kg COD / m.d ; and the pH value is controlled between 7.0 and 7.5. The invention has the advantages of flexible operation, impact load resistance, low operating cost and good treatment effect; after the coal chemical wastewater is treated by the treatment method, the outlet water quality completely can achieve the wastewater comprehensive discharge standard regulated by the State.

Owner:HARBIN INST OF TECH

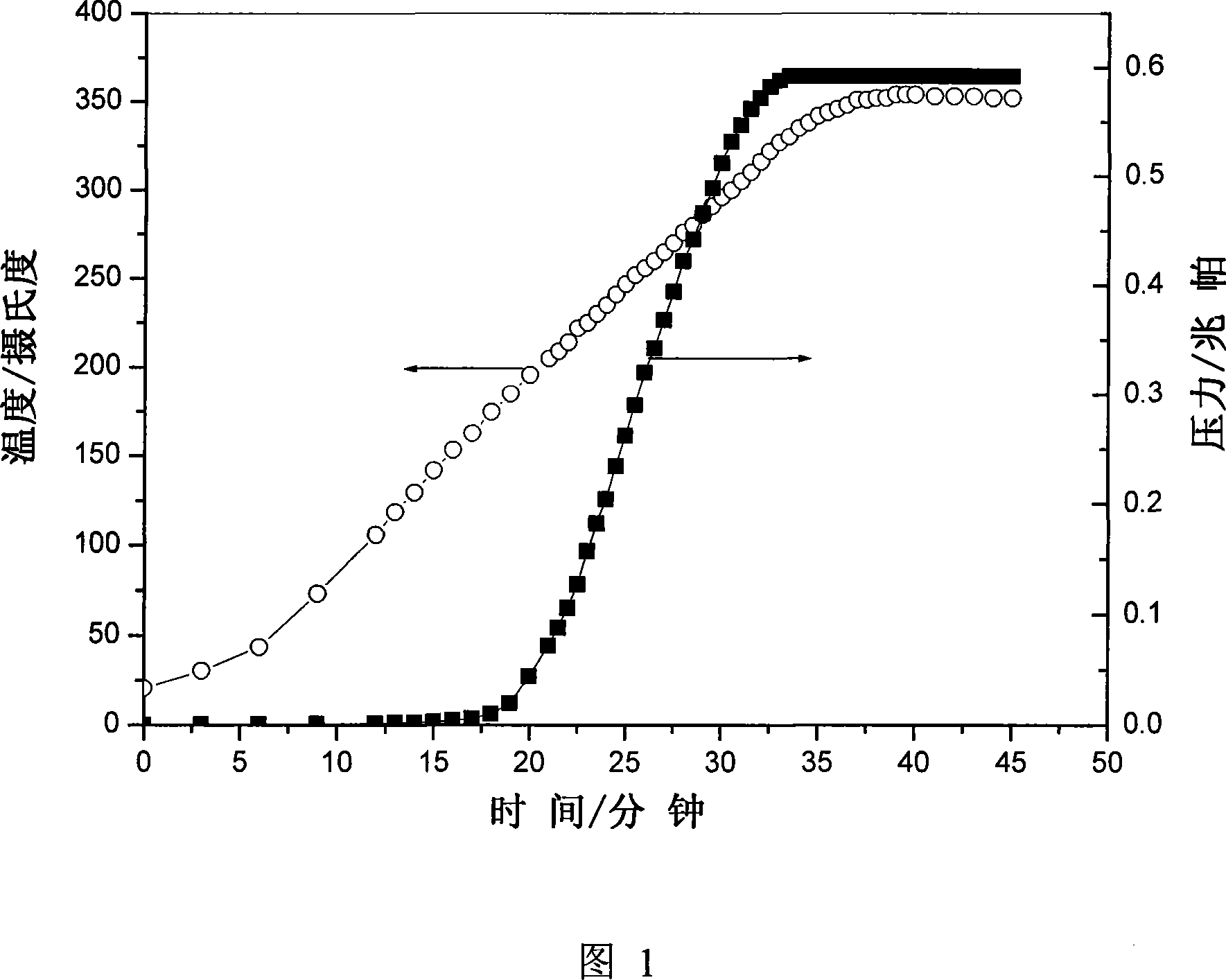

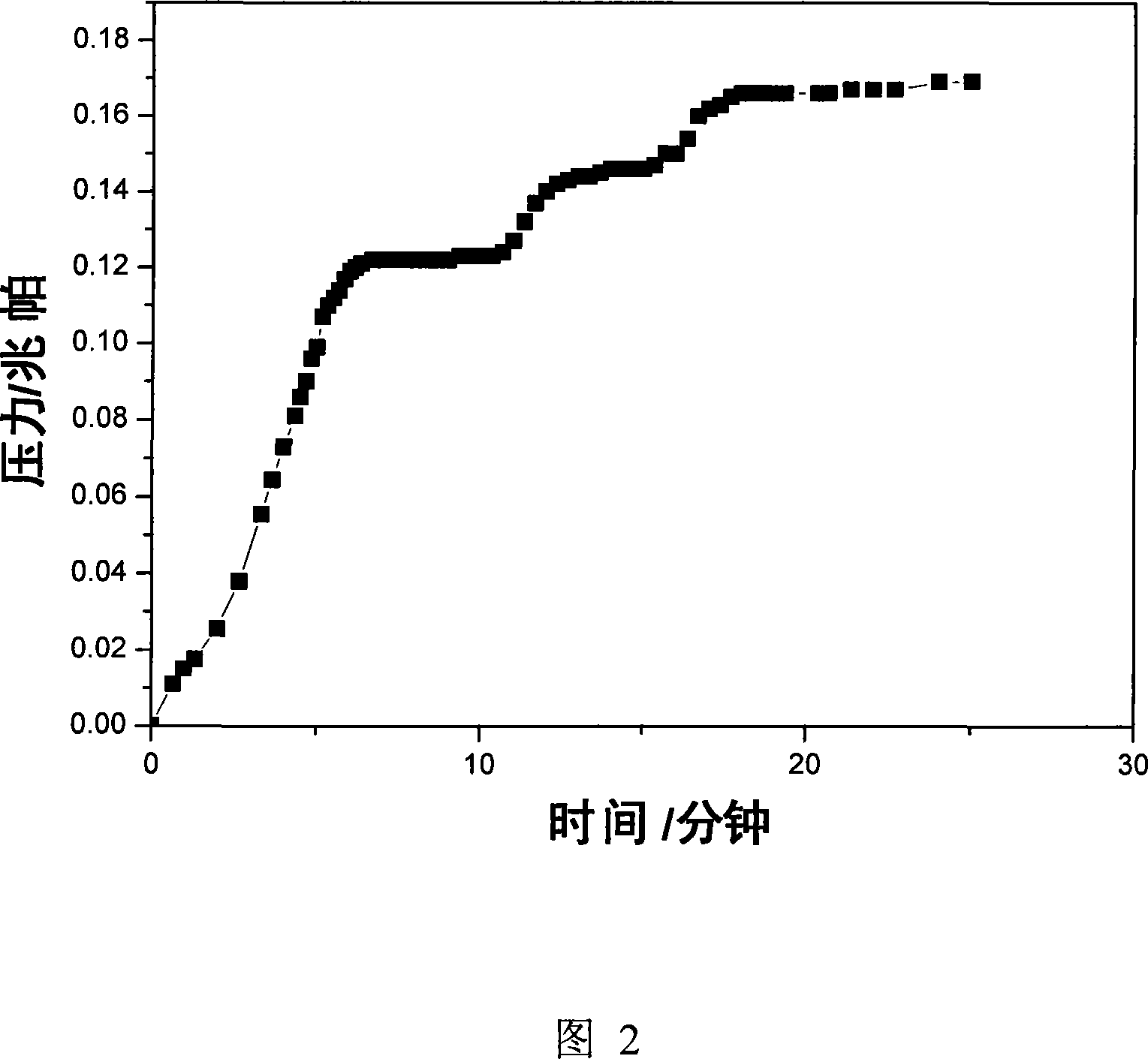

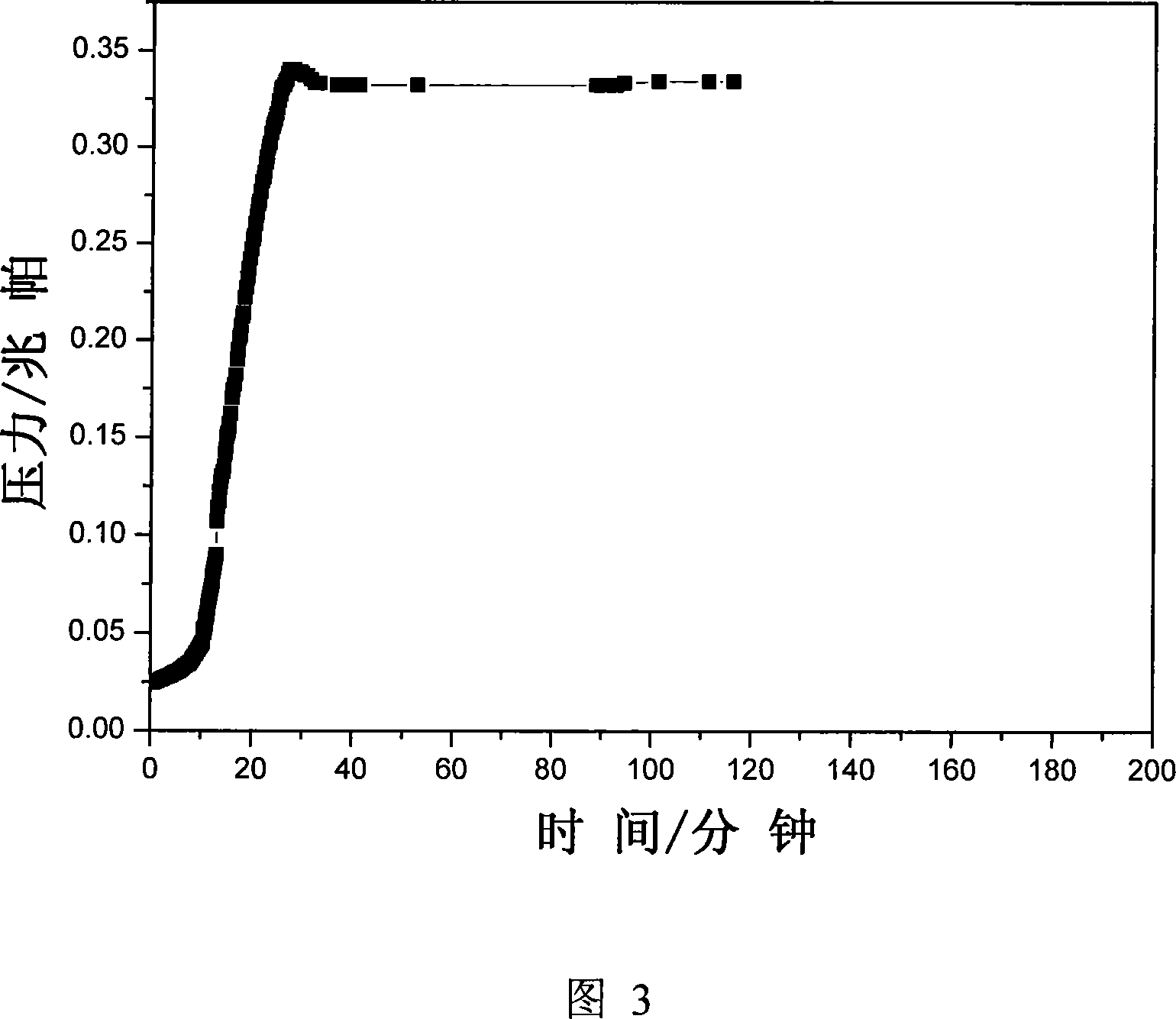

Amido complex compound and preparation method and usage

InactiveCN101182006AFast separationImprove conversion efficiencyAmmonia compoundsTransformation efficiencyAmmonia

The invention discloses an amino complex compound and a preparation method and application thereof. The components of the amino complex compound are MX (NH3)n, wherein, M is one or a plurality of Li, Mg, Al, Ca, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Sr, Ba, Sn; X is one or a plurality of F, Cl, Br, NO3, SO4; m is determined according to chemical valence, which is less than or equal to 5 and more than or equal to 1; n is determined according to coordination number, which is less than or equal to 15 and more than or equal to 1. The amino complex compound is used as an absorbent of amino after deamination and realizes separation, purification, storage and transporting of ammonia gas through low-temperature ammonia absorption and high-temperature ammonia discharge. The ammonia in circulating gas used in a synthetic ammonia technique of the invention has fast separation speed and the ammonia content entering into a tower can be reduced below 0.1 percent, thus remarkably promoting the ammonia net value and improving the transformation efficiency of the synthetic ammonia technique; furthermore, the invention can be suitable for different ammonia synthesis systems, in particular to a low-pressure ammonia synthesis system and realize the solidification of the ammonia gas during storage and transporting processes; the ammonia storage quantity can reach 40 to 70wt percent with safety and high efficiency.

Owner:ZHEJIANG UNIV

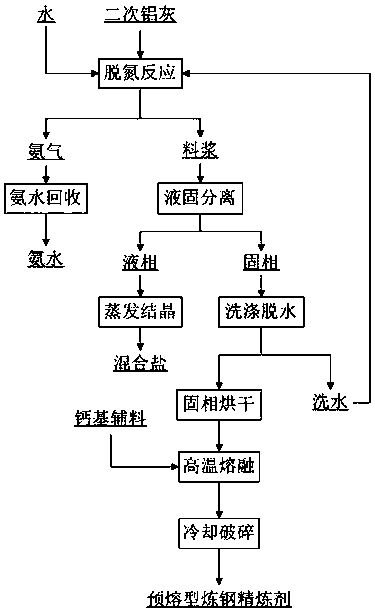

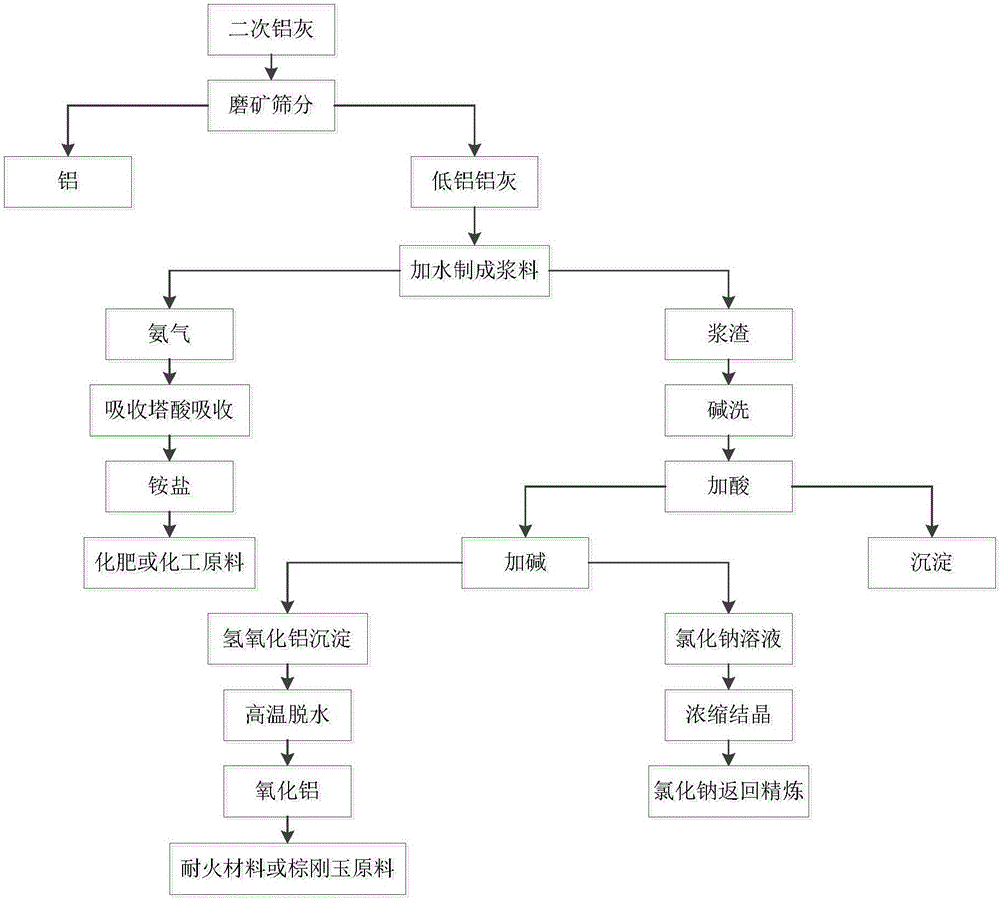

Harmless and comprehensive utilization method of secondary aluminum dross

InactiveCN107555447ARealize harmless treatmentTo achieve the purpose of "zero emission" utilizationChloride preparationFluoride preparationSlurryLiquid solid

The invention provides a harmless and comprehensive utilization method of secondary aluminum dross and relates to a harmless and comprehensive utilization method of secondary aluminum dross produced in an aluminum dross treating process. The harmless and comprehensive utilization method is characterized in that slurry is prepared from the secondary aluminum dross produced in the aluminum dross treating process and water, a stirring deamination reaction is performed, and ammonia gas formed through the reaction is condensed or absorbed by water; slurry after the reaction is subjected to liquid-solid separation, separated liquid phase is subjected to evaporative crystallization, and a chlorate and fluoride salt mixture is obtained; separated solid phase is used for producing a calcium aluminate material. With adoption of the method, the aluminum dross can be treated harmlessly, useful components in the aluminum dross are recovered efficiently, the harmless secondary aluminum dross can replace high-alumina bauxite for preparing a calcium aluminate product, production cost is reduced greatly, zero-release utilization of the aluminum dross is realized, the process is simple, the operation is convenient, the cost is low, environmental protection is realized, and the method has wide applicability.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

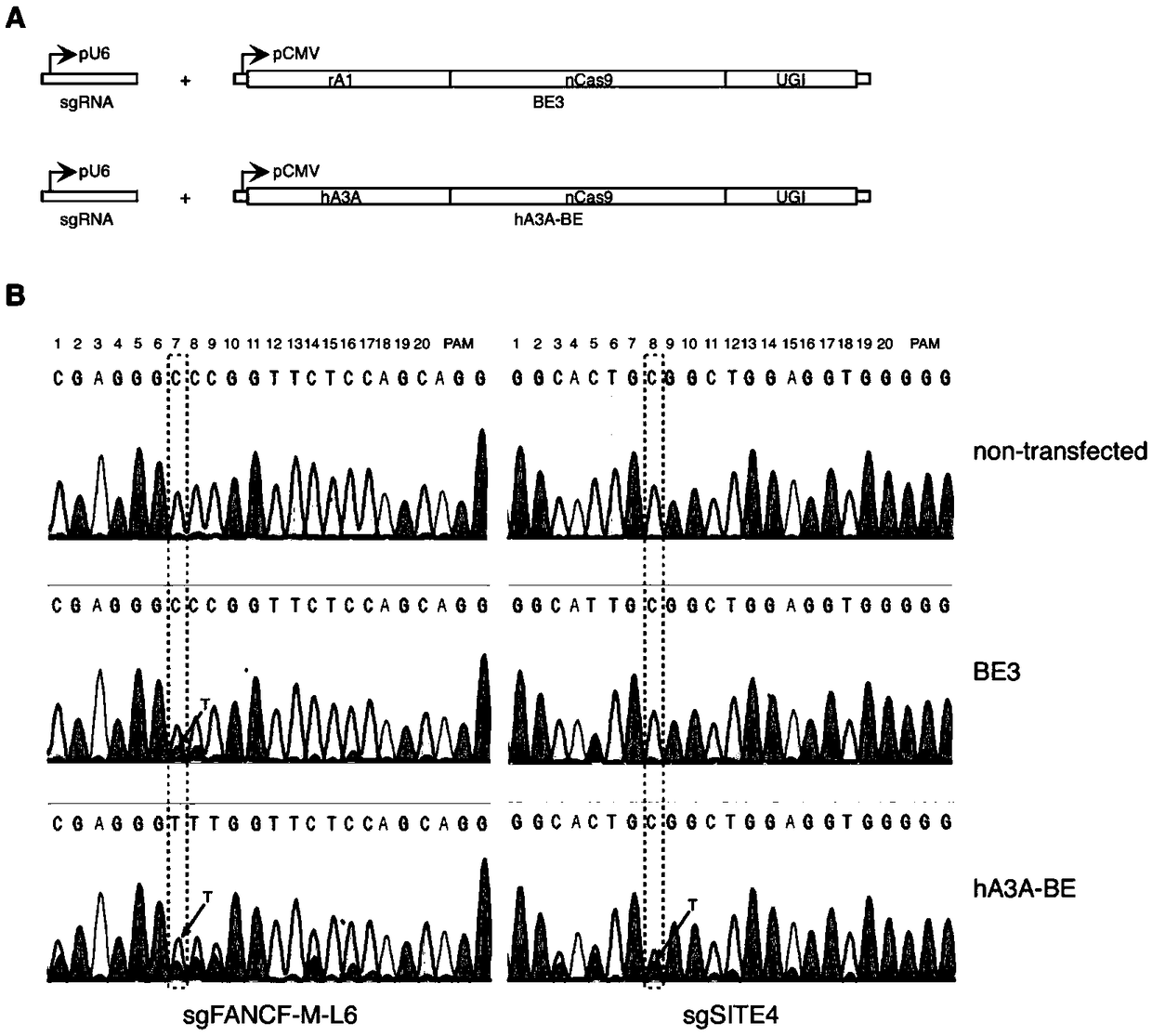

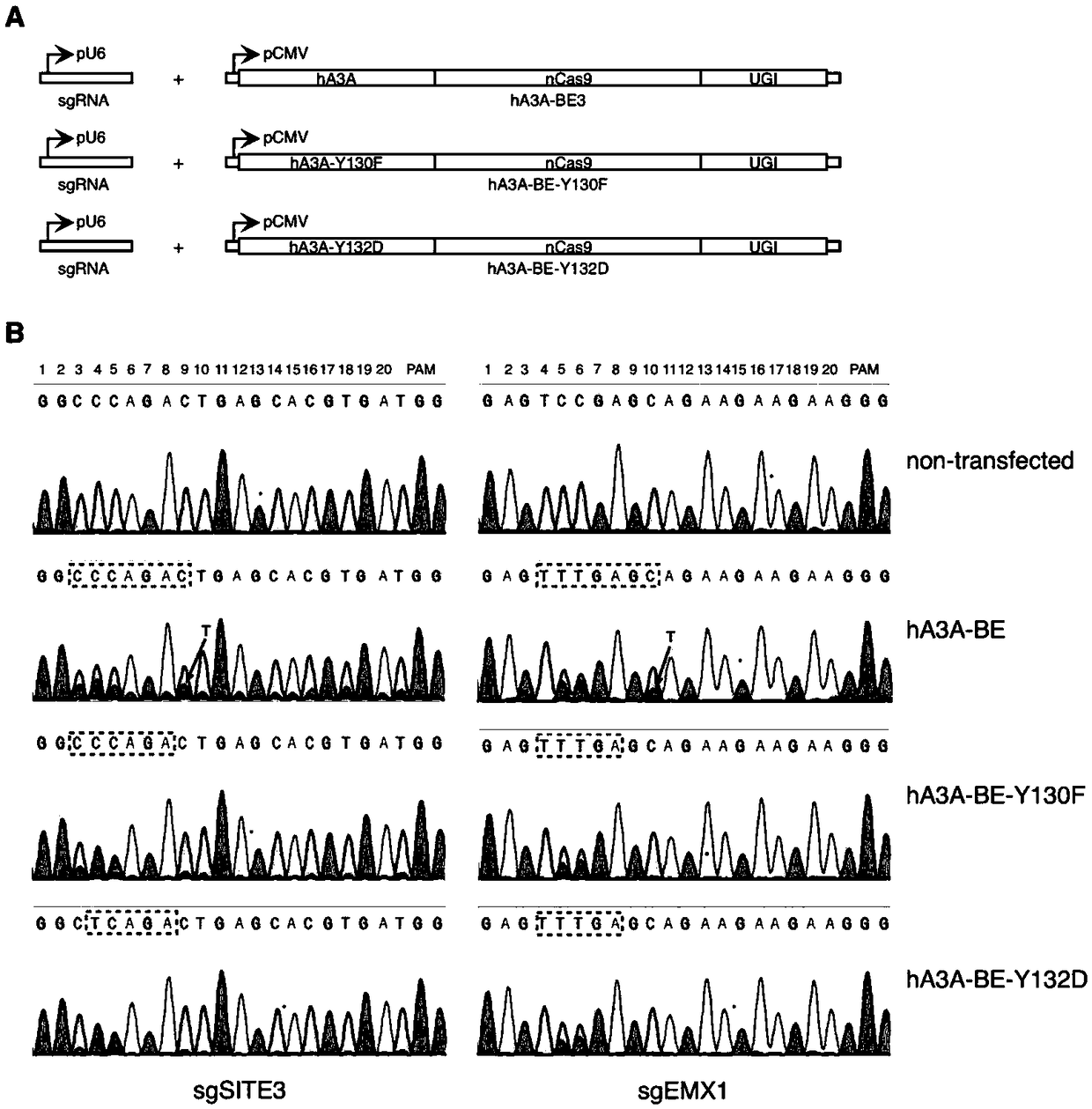

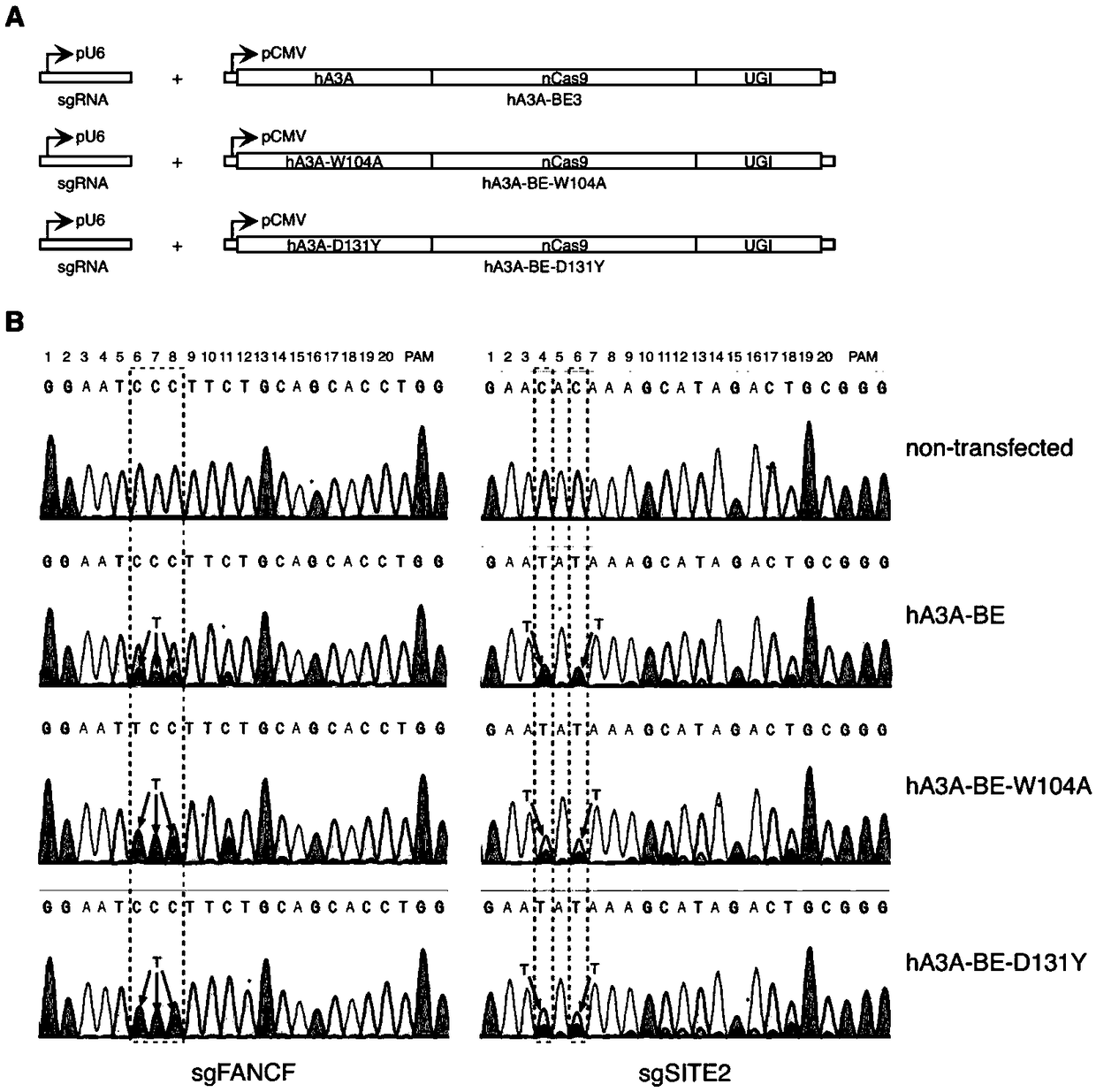

Gene base editor

The invention provides a gene base editor, in particular relates to fusion protein. The fusion protein is characterized by comprising two fragments. The first fragment comprises APOBEC3A and the second fragment comprises CRISPR-related Cas protein. The base editor is capable of performing base edition in DNA and performing deamination on cytosine to be uracil, and the base editor still has higherediting efficiency even if cytosine is located at a GpC site or in a hypermethylated state.

Owner:SHANGHAI TECH UNIV

Process for removing acid gas with low-temperature methanol solution

ActiveCN101874967AReduce ammonia contentSolve the blockageDispersed particle separationBy absorptionIncreased carbon dioxideProduct gas

The invention relates to a process for removing an acid gas with a low-temperature methanol solution, solving the problem that a low-temperature rectisol plant enriches ammonia and has lower recovery rate of CO2, lower concentration of H2S in acid gases and large solution circulating volume in the traditional process. The process comprises feed gas preprocessing, desulfuration and decarbonization by an absorption tower, CO2 analysis and gas stripping and hydrogen sulfide concentration by a desorber, regeneration by a heat regenerator and deficient methanol separation by a methanol / water separation tower, wherein the feed gas is conveyed into an ammonia scrubber for deamination and preprocessing. The process can reduce the ammonia enrichment in the low-temperature rectisol plant, increase the recovery rate of CO2, improve the concentration of H2S in acid gases, reduce the circulating volume of the solution and ensure the quality of purified gas products.

Owner:WUHUAN ENG

Method for extracting vanadic anhydride from stone coal vanadium ore

InactiveCN101451199AReduce pollutionLow costVanadium oxidesProcess efficiency improvementSlagFiltration

The invention relates to a method for extracting V2O5 from stone coal vanadium ores, which is characterized in that the stone coal vanadium ores are grinded, subjected to high-temperature roasting, and directly leached out by a dilute sulfuric acid; slag is washed and filtered by water; and a leached solution is extracted by extract containing an N235 extractant, and subjected to back-extraction, ammonium metavanadate precipitation, filtration, washing, deamination and roasting to obtain the V2O5. The method greatly reduces pollution of waste gas and waste water. Compared with the prior salt roasting (sodium modification) technology, the technology has a reasonable design structure, high comprehensive utilization rate of resources, proper material consumption, strong controlled ability of the process, high product quality and high automation degree of the technological flow, and is convenient for large-scale industrial production. The technology does not have exact demands on the raw ores and has good adaptability. The overall yield of the technology is high, reaches more than 85 percent, is on the advanced level in China currently, and is improved by approximately 25 percent compared with the overall yield of sodium modification roasting technology of other vanadium smelting plants in Hunan province.

Owner:CNMC NINGXIA ORIENT GRP

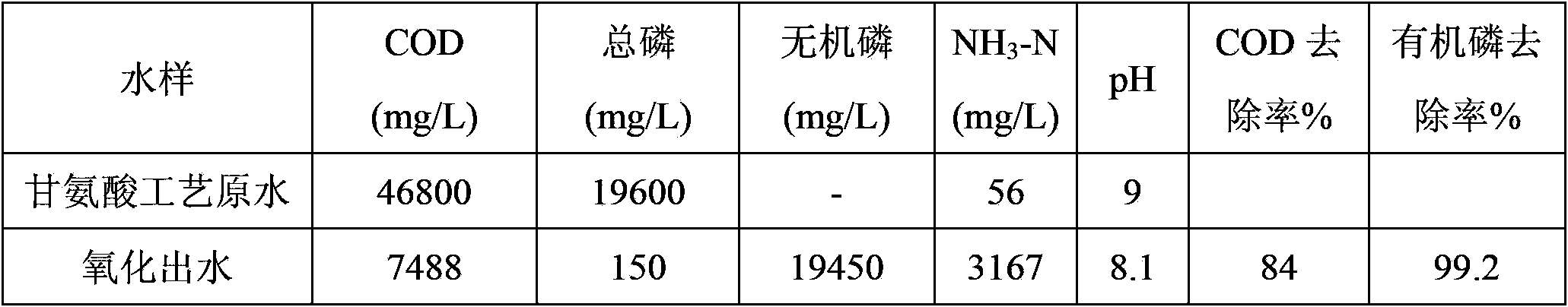

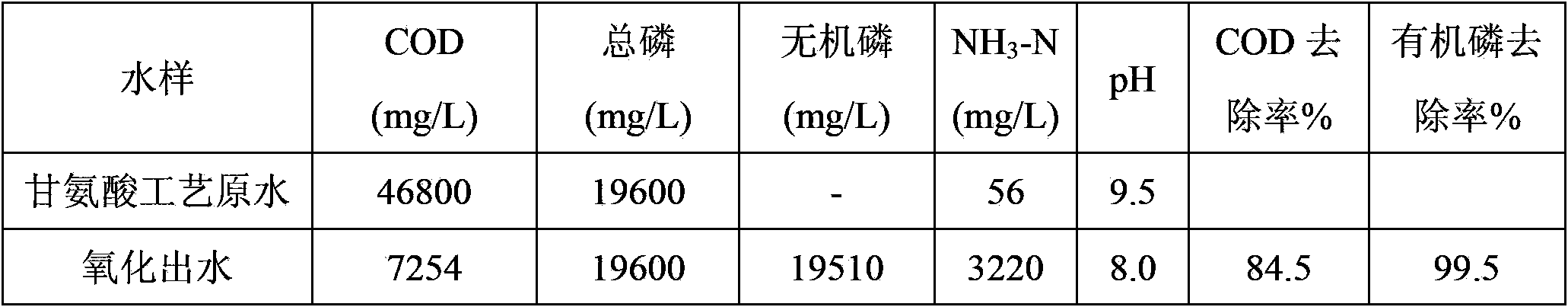

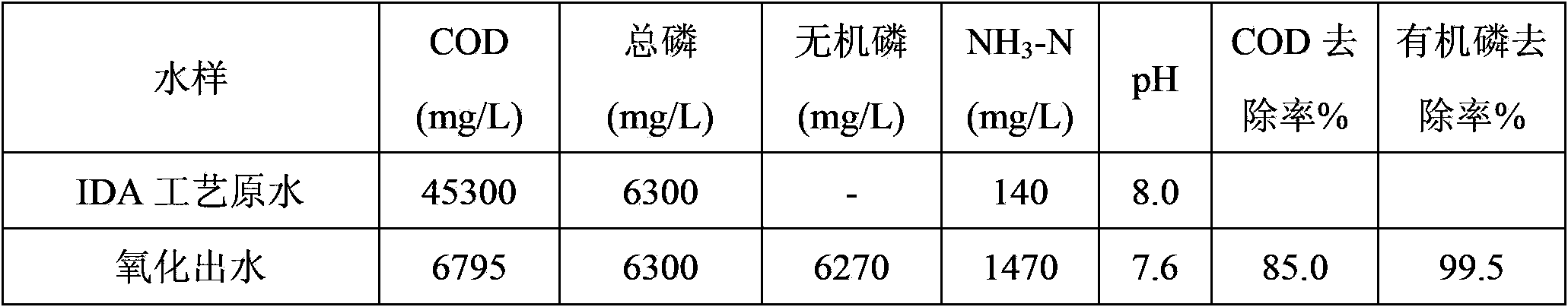

Catalytic wet oxidation pretreatment method of glyphosate production wastewater

ActiveCN103663667AHigh activityReduce dosageMultistage water/sewage treatmentWater/sewage treatment by oxidationPretreatment methodChemical oxygen demand

The invention relates to a catalytic wet oxidation pretreatment method of glyphosate production wastewater, comprises the following steps: firstly regulating pH value to be more than 8 and less than 10, adding a multi-component homogeneous catalyst and carrying out oxidative degradation on pollutants in wastewater for 0.3-2 hours by using a continuous catalytic wet oxidation device with air as an oxidizing agent at the reaction temperature of 210-230 DEG.C and the reaction pressure of 2-4MPa, wherein the catalyst is a soluble transition metal salt mixture. By adopting the method for treating the glyphosate production wastewater, the organic phosphorus conversion rate is high, the COD (chemical oxygen demand) removal rate is high, the biodegradability of the wastewater can be improved, and the secondary pollution is avoided. The method has the advantages that the catalyst activity is high, low in cost and easy to get, reaction conditions are relatively mild, and continuous operation is easily implemented; the glyphosate production wastewater can be discharged in standard through the combined process of catalytic wet oxidation pretreatment-routine technical dephosphorization and deamination-biochemistry, and the industrialized application prospect is great.

Owner:中国中化股份有限公司 +2

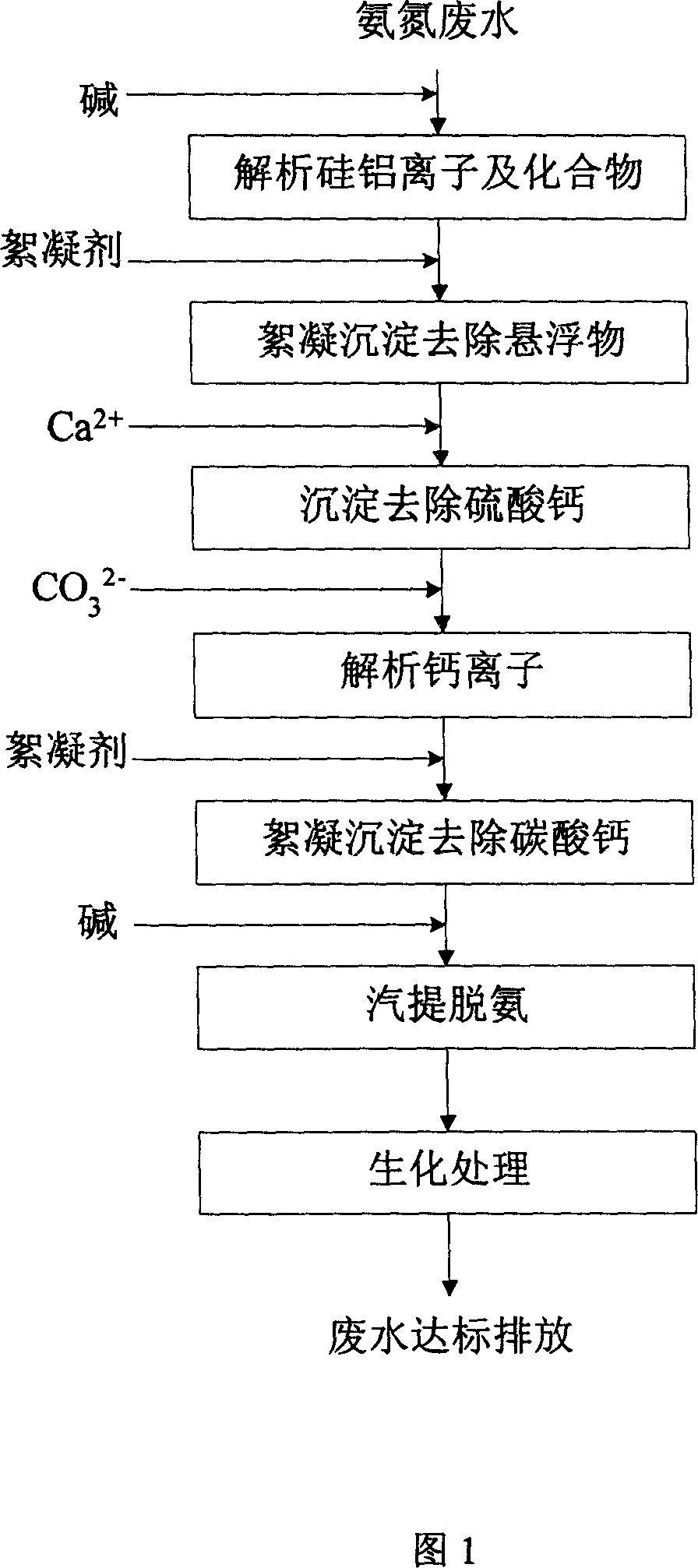

Method for treating ammonia nitrogen wastewater

ActiveCN1958471APrevent scalingAvoid problems such as tower blockageTreatment using aerobic processesMultistage water/sewage treatmentHigh concentrationTherapeutic effect

This invention relates to a method for treating ammonia nitrogen wastewater, especially high-concentration ammonia nitrogen wastewater produced during manufacture of oil-refinery catalyst. The method comprises: (1) adjusting the pH value of the wastewater, and solid-liquid separating to remove suspended matters and dissolved Si2+, Al3+ and their compounds; (2) adding Ca2+ to form CaSO4 precipitate, and solid-liquid separating to reduce acidic matters in the wastewater; (3) adding CO32- to form CaCO3 precipitate, and solid-liquid separating to remove Ca2+ in the wastewater; (4) steam-stripping for deamination, and performing biochemical treatment so that wastewater reaches state discharge standards. The method can solve the problems of low effect on removing suspended matters and dissolved Si2+, Al3+ and their compounds, scaling and column blockage during steam-stripping process, and the need for a large amount of alkali added, and can improve wastewater treatment effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

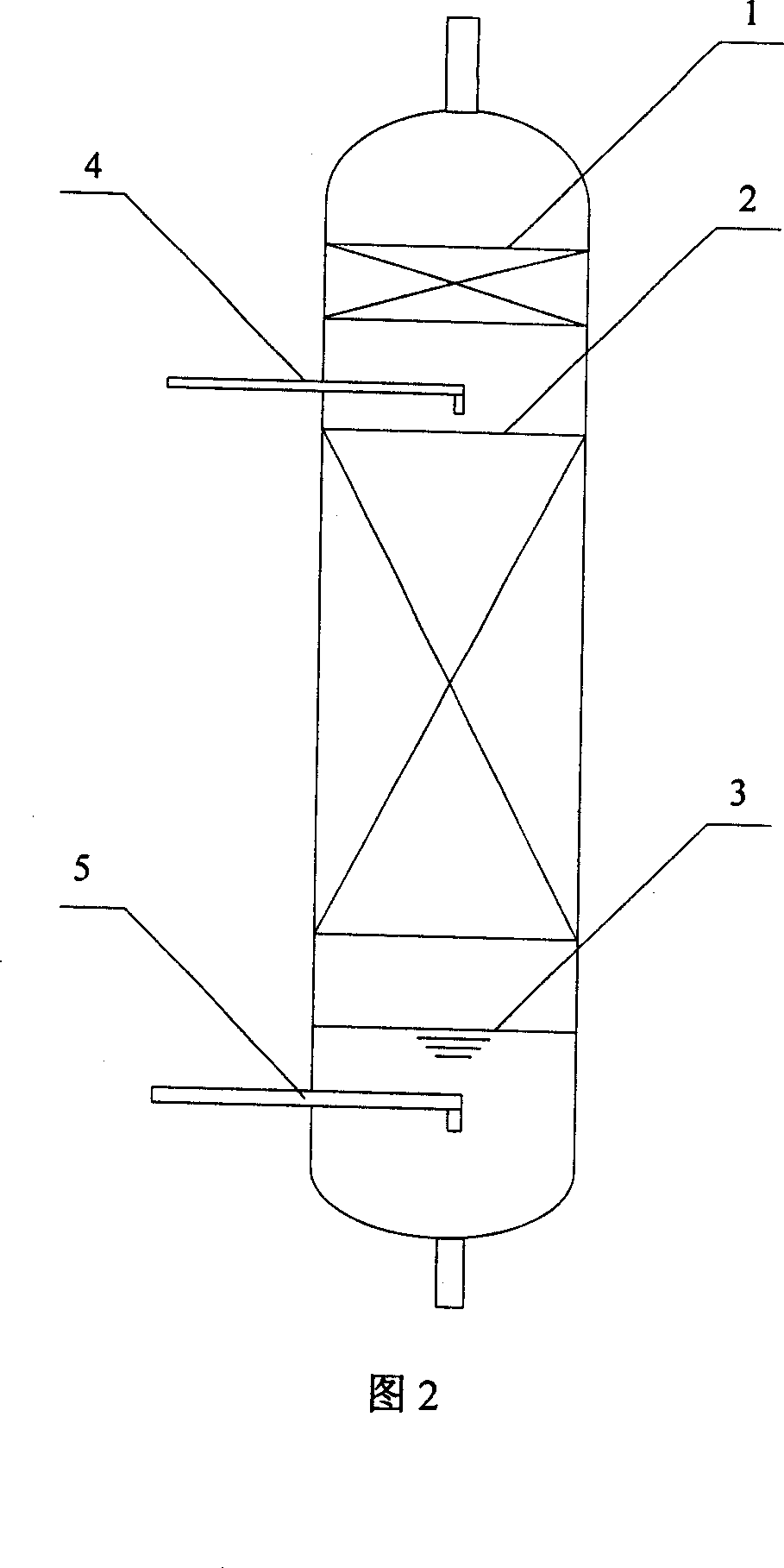

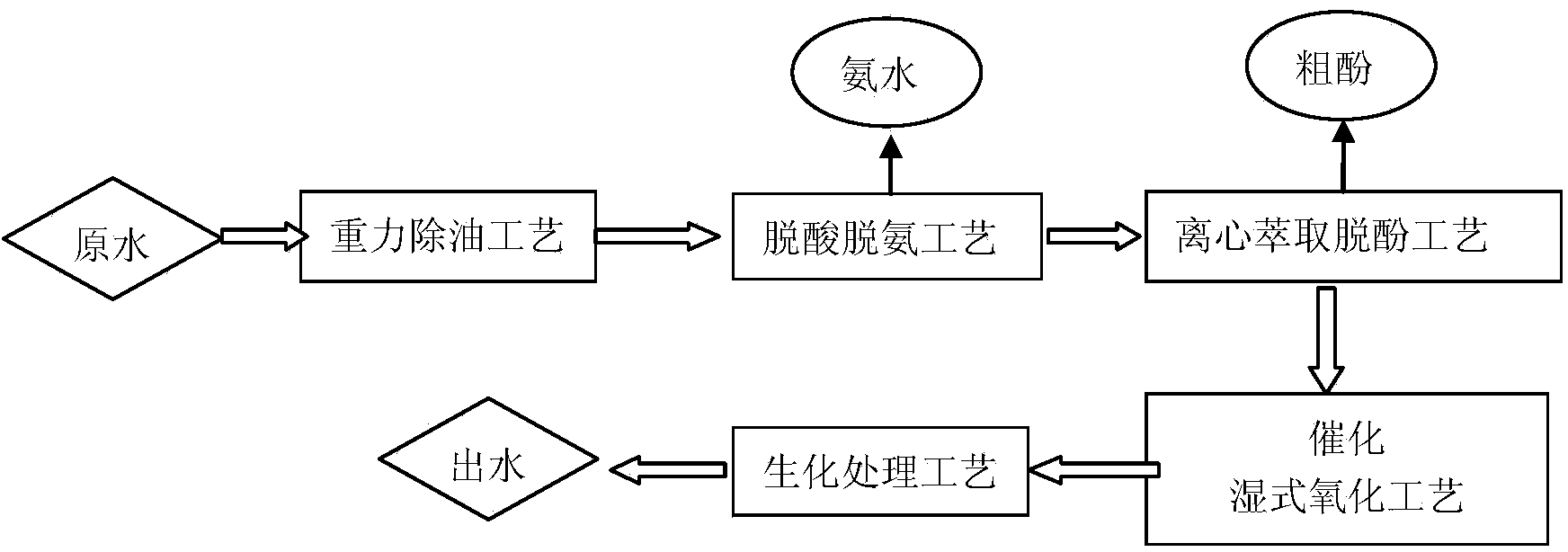

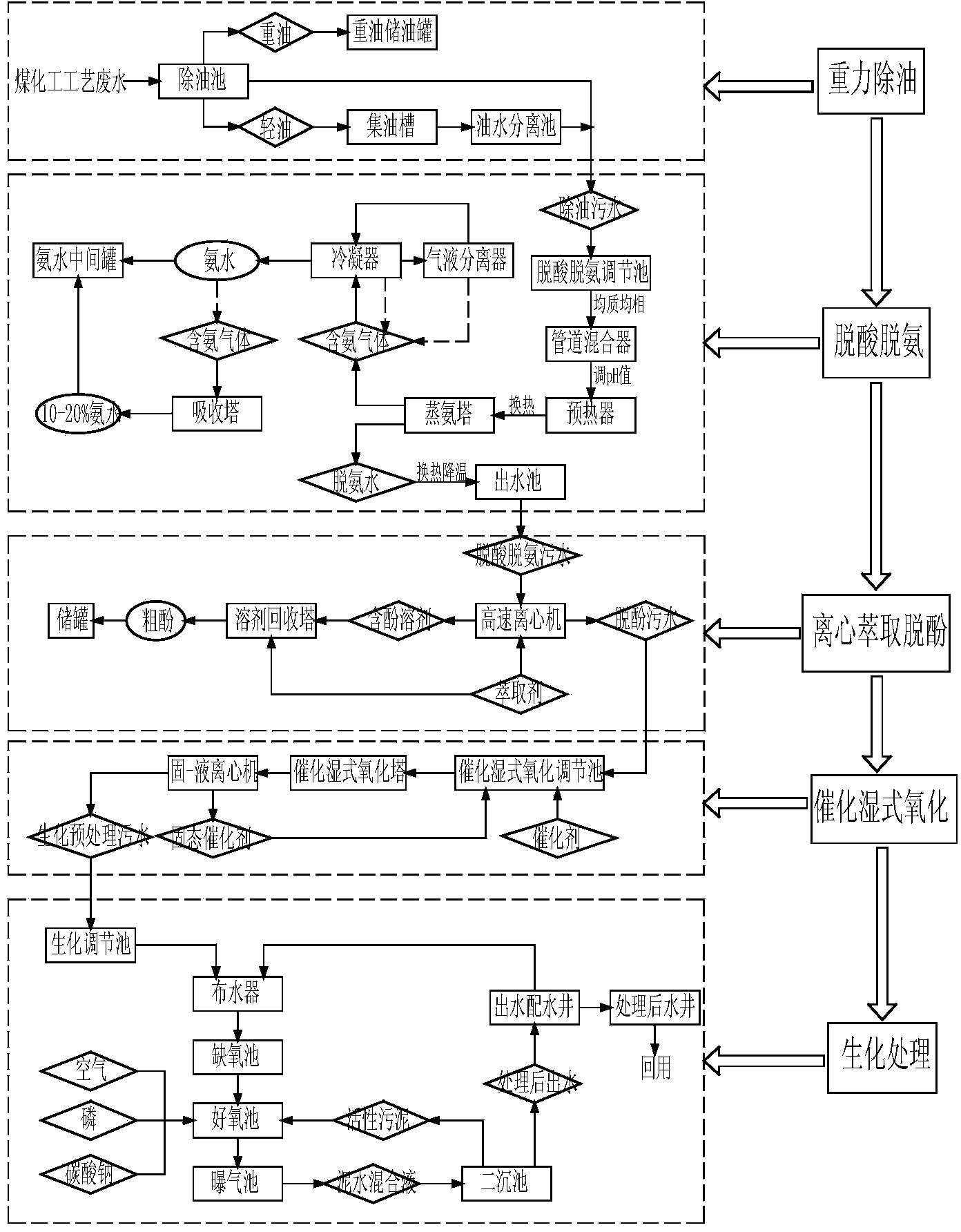

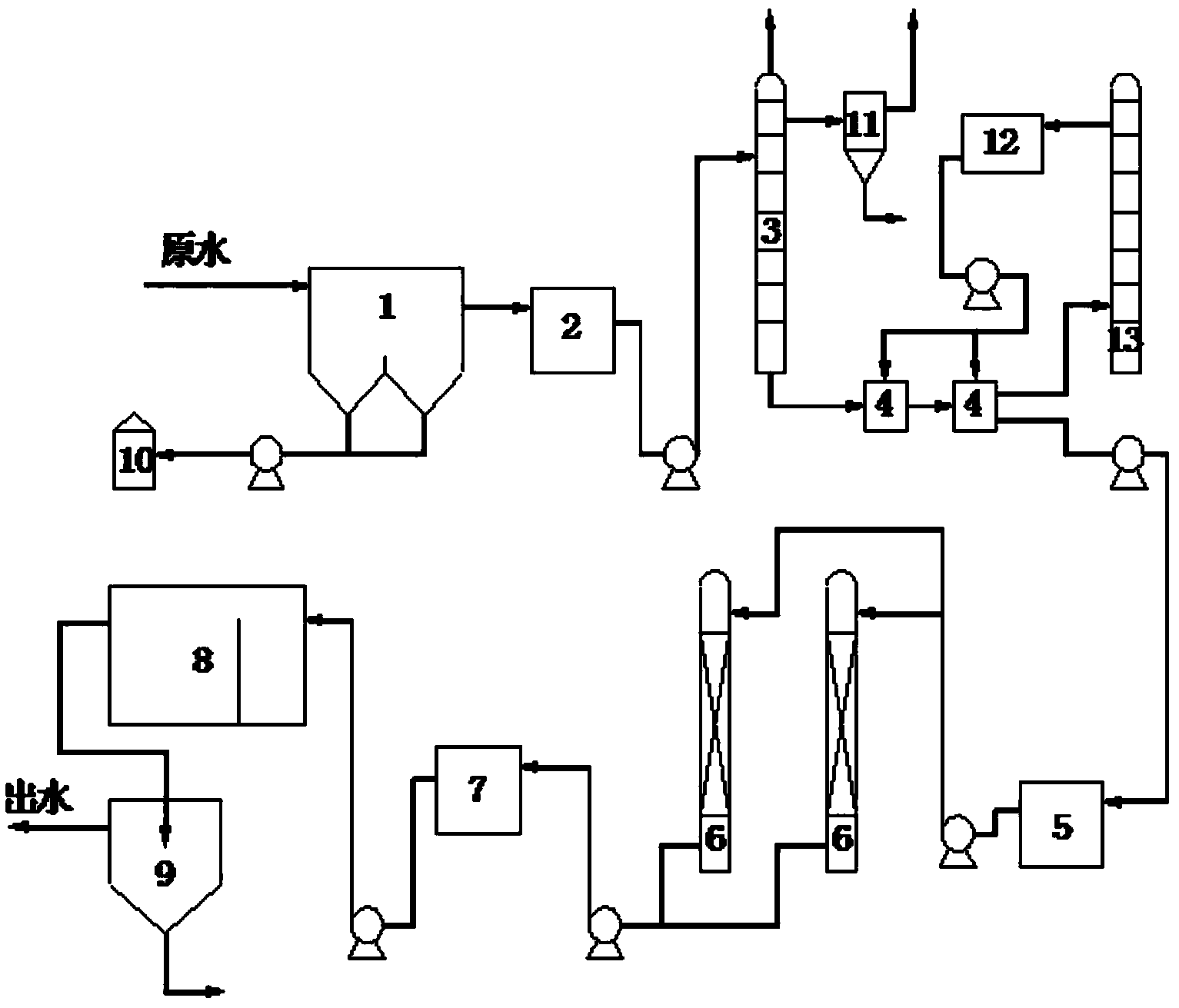

Advanced treatment process of coal chemical industry wastewater

ActiveCN103880242AAchieve water balanceMultistage water/sewage treatmentChemical industryEmission standard

The invention relates to an advanced treatment process and device of coal chemical industry wastewater. The process comprises the following steps: removing oil, performing deacidification and deamination, performing centrifugal extraction and dephenolization, performing catalytic wet oxidation and performing biochemical treatment. The device comprises an oil removal pool, a deacidification and deamination regulating reservoir, an ammonia still, a high speed centrifuge, a catalytic wet oxidation regulating reservoir, a catalytic wet oxidation tower, a biochemical regulating reservoir and an A / O biochemical system which are connected with one another sequentially. The indirect emission standard requirements in the national coking chemical industrial pollutant discharge standard (GB16171-2012) can be met after main pollutants such as chemical oxygen demand (COD), oil, ammonia nitrogen and phenol in coal chemical industry wastewater are treated, and ammonia water and crude phenol can be recovered. Compared with the prior art, the advanced treatment process of coal chemical industry wastewater has the beneficial effects that sewage produced in coal chemical industry is treated with a clear target on the basis of characteristics of the coal chemical industry production process, so that the indirect emission standard requirements are met, available resources in the sewage are recovered, and sewage resource treatment is really realized.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

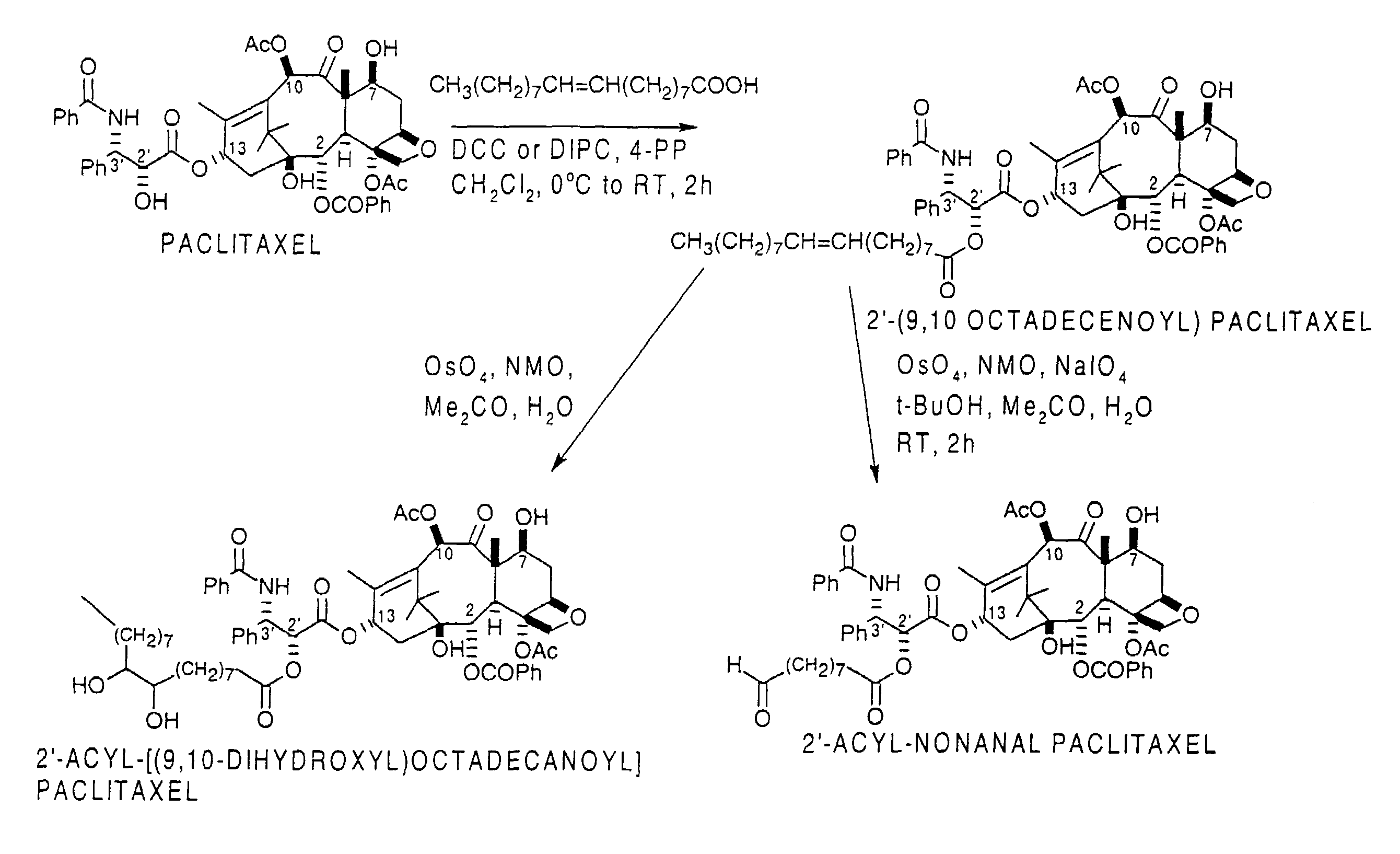

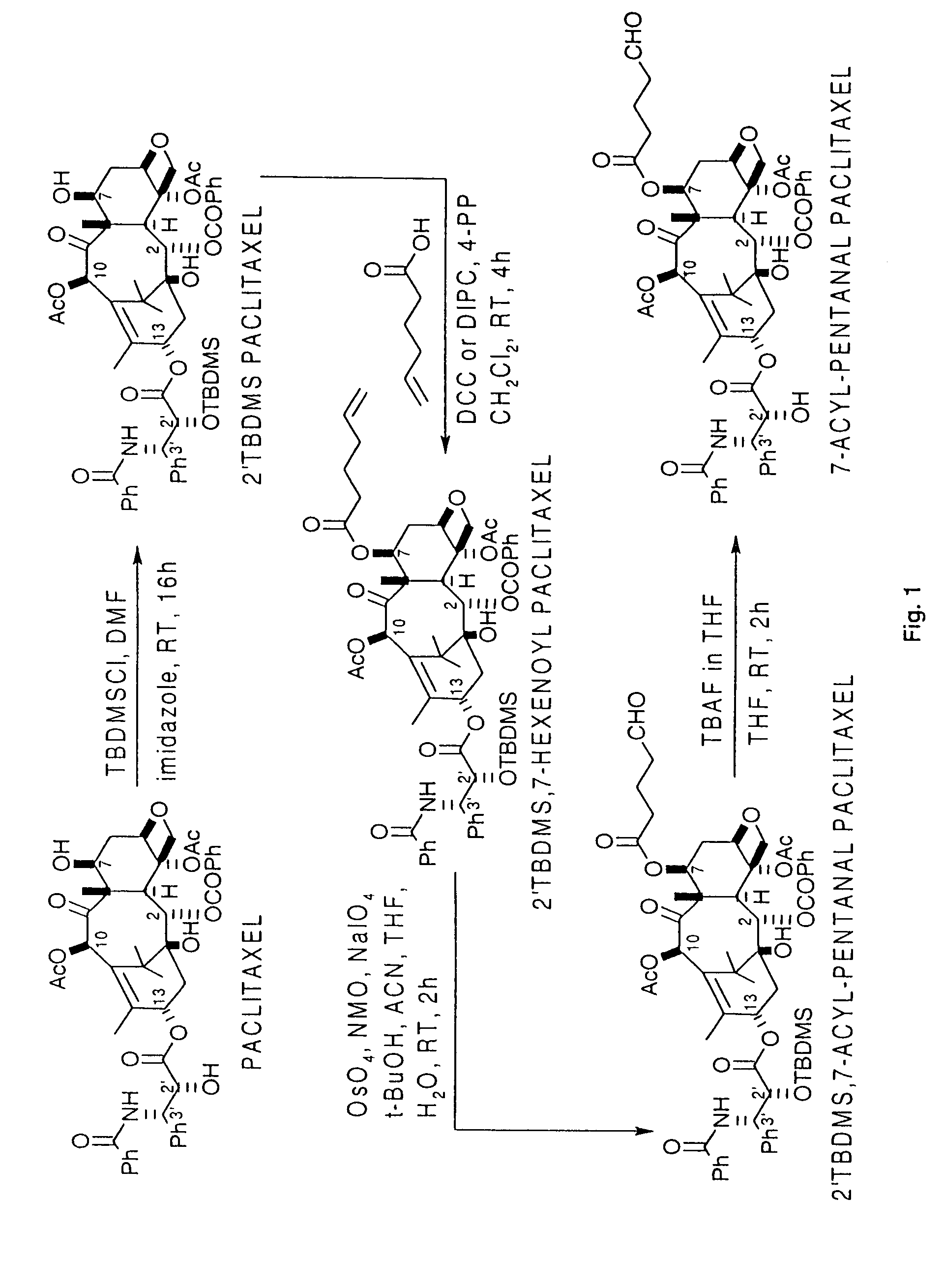

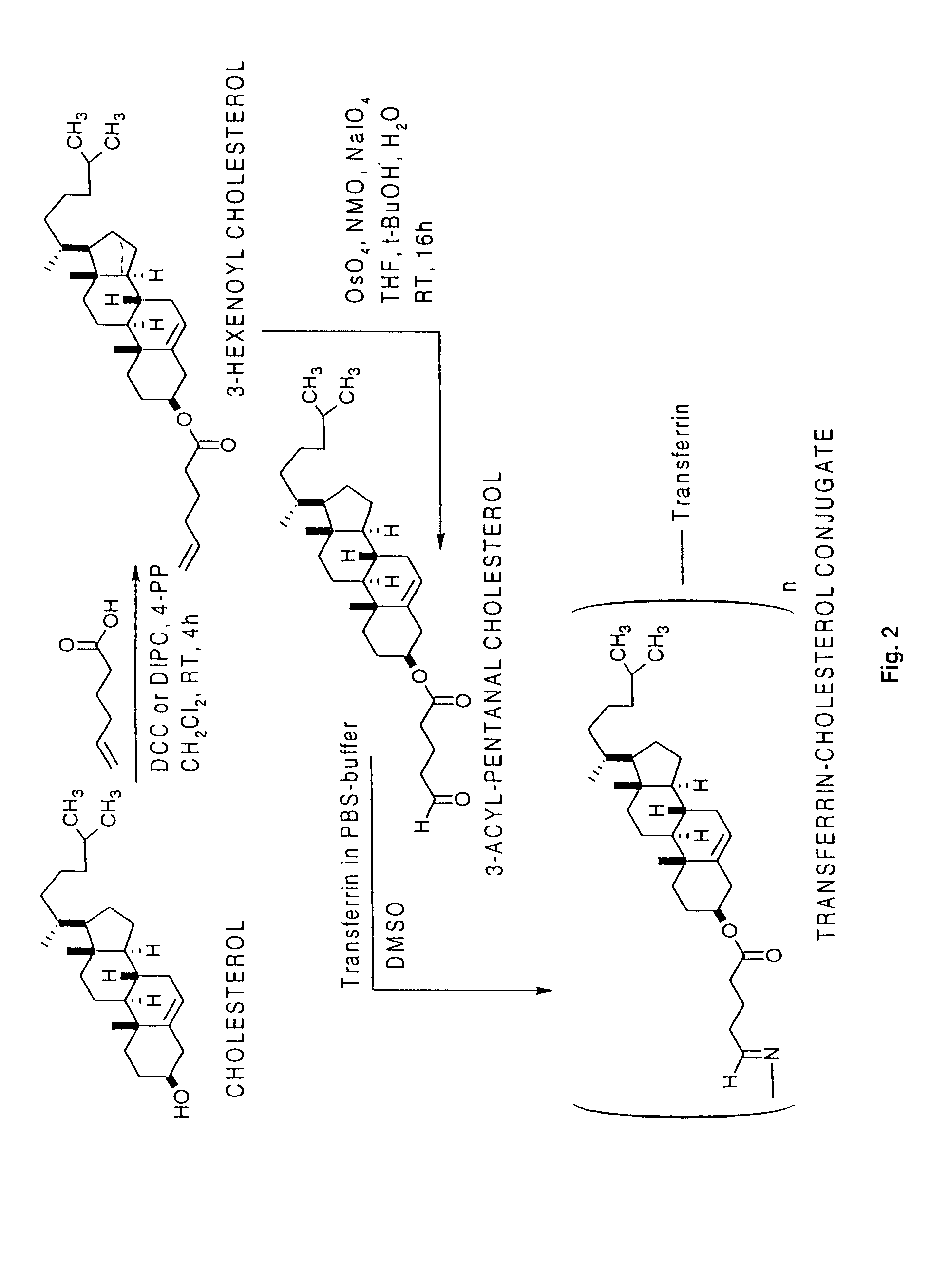

Molecular conjugates for use in treatment of cancer

InactiveUS7153946B2Reduce and eliminate side effectEfficient ConcentrationBiocideSugar derivativesMoietyOncology

A molecular conjugate is provided having the formula:wherein R1 is a de-hydroxyl or de-amino moiety respectively of a hydroxyl-bearing or amino-bearing biologically active molecule or an analog or derivative thereof, and Z is —O— or —NH—, respectively, Y is a straight or branched alkyl having 1 to 20 carbons that may be optionally substituted with one or more phenyl, a cycloalkyl optionally substituted with one or more alkyl or phenyl, or an aromatic group optionally substituted with one or more alkyl groups, electron-withdrawing groups, or electron-donating groups; and R2 is —CH═CH(W), —CH(OH)CH(OH)W, or —C(O)H, where W can be H, a straight or branched alkyl having 1 to 20 carbons that may be optionally substituted with one or more phenyl, a cycloalkyl optionally substituted with one or more alkyl or phenyl, or an aromatic group optionally substituted with one or more alkyl groups, electron-withdrawing groups, or electron-donating groups.

Owner:TAPESTRY PHARMACEUTICALS INC

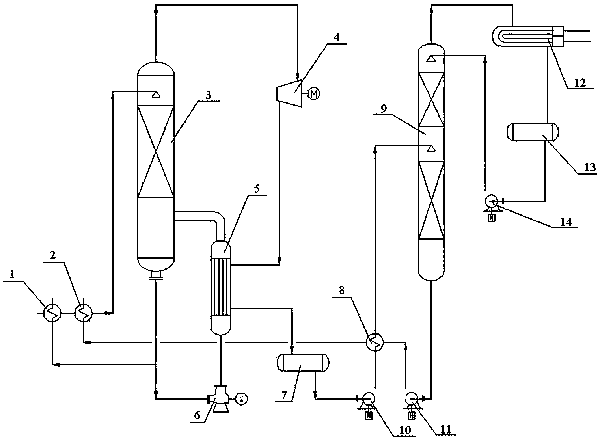

Efficient energy-saving coupling stripping deamination equipment and method

ActiveCN102030386AReduce ammonia nitrogen contentWater/sewage treatment by degassingEvaporationEngineering

The invention discloses efficient energy-saving coupling stripping deamination equipment and method. The equipment mainly comprises an I-effect evaporator, an II-effect evaporator, an inlet / outlet heat exchanger, a stripping deamination tower, an ammonia absorption tower and a circulation pump. The method comprises the following steps: heating the ammonia-nitrogen wastewater through the inlet / outlet heat exchanger and then feeding the heated ammonia-nitrogen wastewater into the stripping deamination tower; performing stripping deamination by utilizing circulating steam and fresh steam; feeding the ammonia steam contained in the top of the stripping deamination tower into the ammonia absorption tower by a steam circulator; absorbing the ammonia in the circulating steam by utilizing sulfuric acid to obtain ammonium sulfate solution; returning the purified steam to the stripping deamination tower for cyclic use; and feeding the ammonium sulfate solution to a double-effect evaporation section, and heating the ammonium sulfate solution by utilizing the fresh steam serving as a heat source for evaporation, obtaining solid ammonium sulfate, wherein the steam obtained by evaporating the ammonium sulfate solution in the II-effect evaporator is returned to a steam circulation efficient stripping deamination section by a steam conveyer and used as deamination steam. Through the invention, the wastewater with high ammonia nitrogen content can be treated, the ammonia nitrogen content in the discharged wastewater after treatment is low, and the steam consumption is low.

Owner:BEIJING UNIV OF CHEM TECH

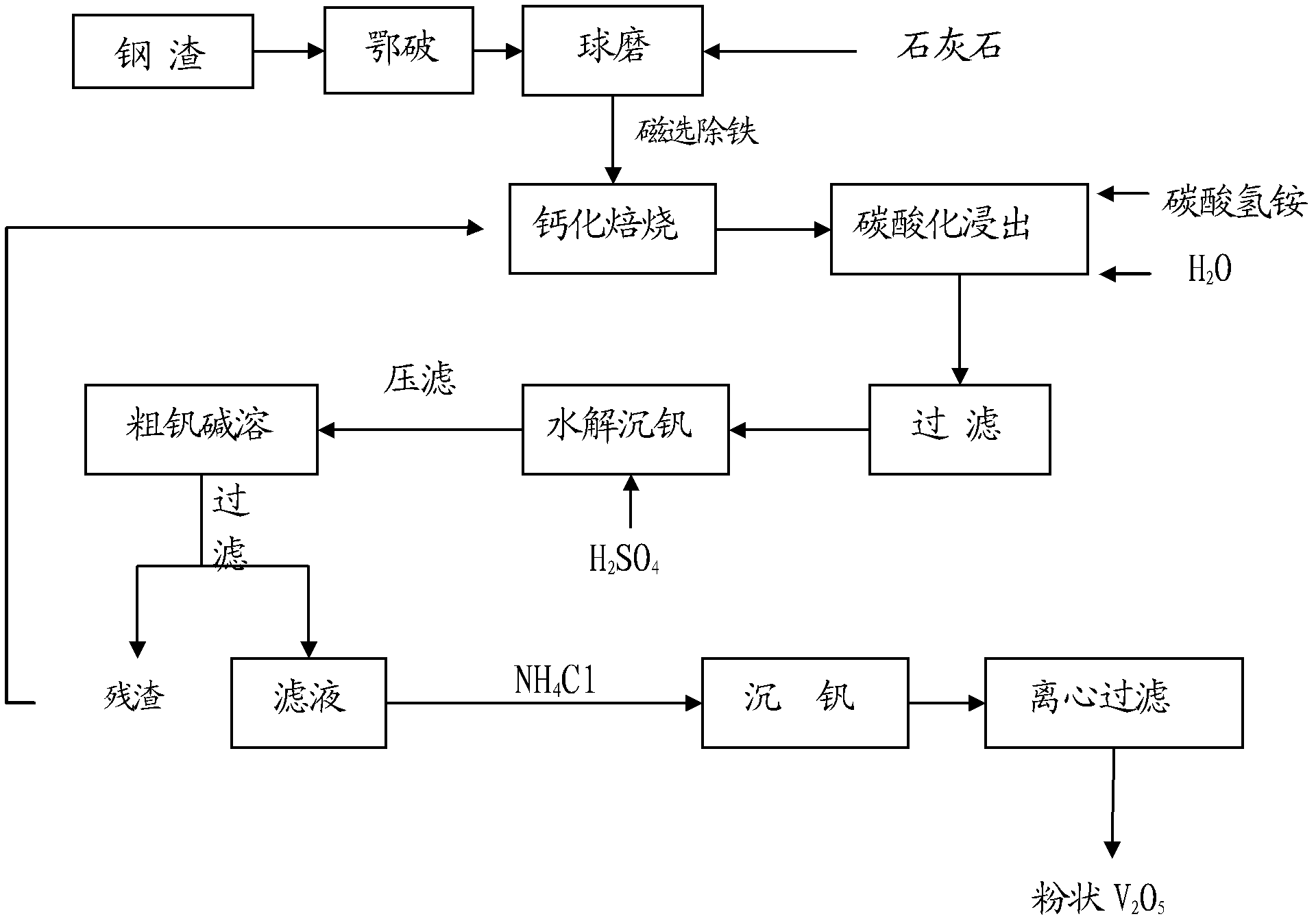

Vanadium extraction technology of low-grade high-calcium vanadium-containing steel slag

InactiveCN102534233AEfficient use ofEfficient recyclingProcess efficiency improvementSteelmakingCalcification

The invention discloses a vanadium extraction technology of low-grade high-calcium vanadium-containing steel slag. The technology comprises the following steps of: a, performing pretreatment of the low-grade high-calcium vanadium-containing steel slag; b, performing oxidation calcification roasting of the low-grade high-calcium vanadium-containing steel slag; c, performing carbonation leaching treatment of the vanadium-containing steel slag after the roasting to obtain vanadium-containing leachate; d, adding an acid to the vanadium-containing leachate to precipitate vanadium, and filtering to obtain coarse vanadium; e, performing alkaline solution treatment of the coarse vanadium, and filtering to obtain V<5+>-containing filtrate; and f, adding NH4Cl into the V<5+>-containing filtrate, reacting to generate NH4VO3, and performing deamination to obtain V2O5 finally. Through the vanadium extraction technology disclosed by the invention, the requirement on calcium content is reduced; high-purity vanadium pentoxide is produced from low-grade high-calcium vanadium-containing steel slag; and the vanadium resource in the vanadium-titanium magnetite is effectively recycled and utilized. The invention provides conditions for the vanadium extraction of a converter single-link method; and the vanadium-containing molten iron is directly used for steelmaking, the vanadium enters the low-grade high-calcium steel slag, and an additional converter for vanadium extraction is not needed, thereby avoiding the interference and influence on the steelmaking caused by the additional vanadium extraction converter for vanadium extraction.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

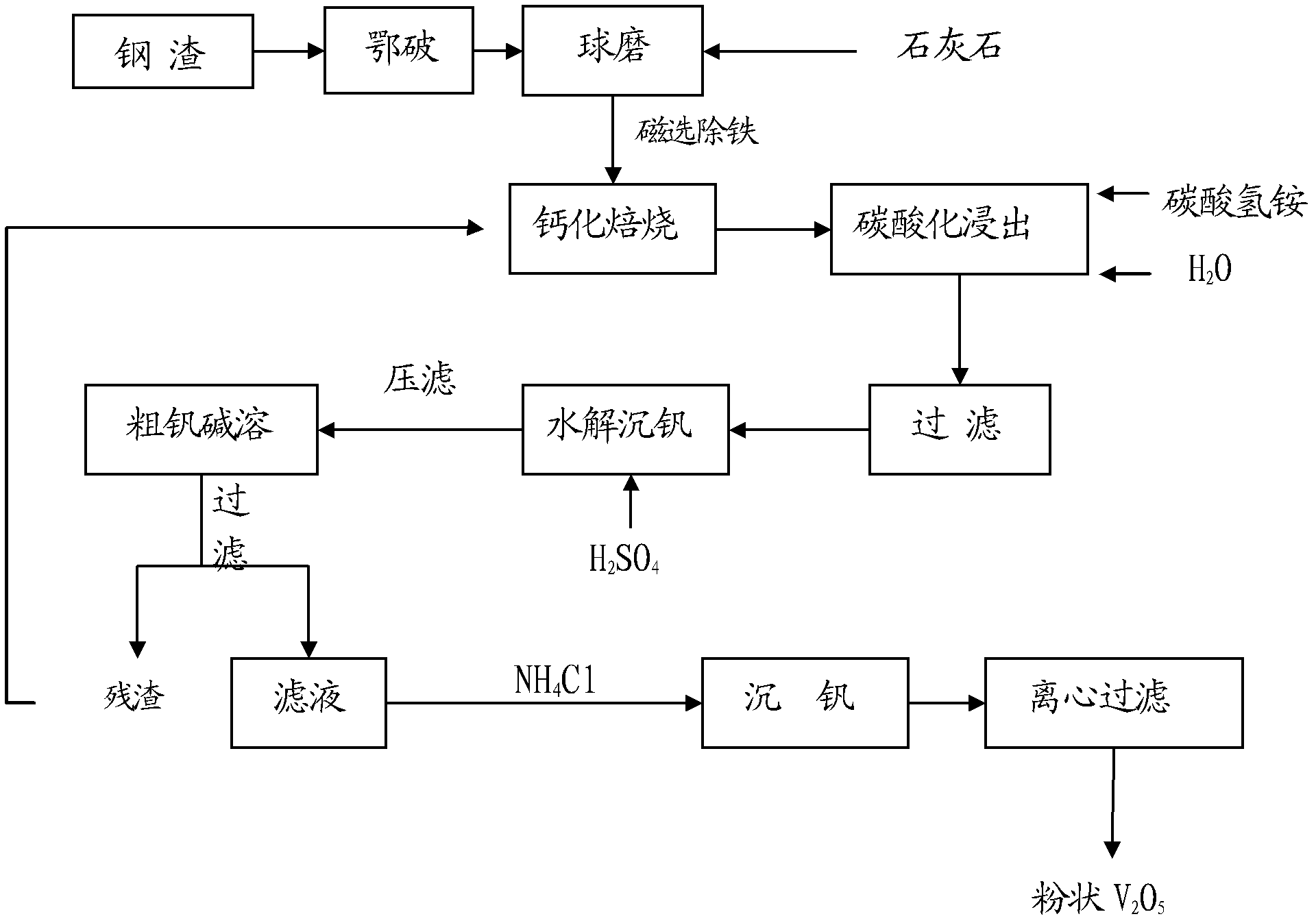

Aluminum ash utilizing method

InactiveCN106892441AIncrease added valueAvoid pollutionCement productionProcess efficiency improvementSlurryAdditional values

The invention discloses an aluminum ash utilizing method. The aluminum ash utilizing method comprises the following steps that S101, aluminum ash residues are poured into a reaction kettle, water is added into the reaction kettle and is stirred and turned to form slurry, hydrolysis reaction for deamination is performed, escaped ammonia gas generated during hydrolysis reaction for deamination enters an absorbing tower, and spraying water or acid is adopted in the absorbing tower to collect the escaped ammonia gas; S102, the slurry left after deamination is charged into a material storage container, the container is put in a box-type electric furnace, drying treatment is performed to obtain massive aluminum residues, the massive aluminum residues are fed into a mill, and ball-milling treatment is performed to obtain secondary aluminum ash. By adopting the aluminum ash utilizing method, the additional value of the aluminum ash is greatly improved, and environmental pollution caused by additional value piling and backfilling is avoided. The aluminum ash utilizing method is high in utilizing efficiency, simple in technological process, low in investment, low in cost and environmentally friendly and facilitates large-scale popularization and application.

Owner:NANTONG UNIVERSITY

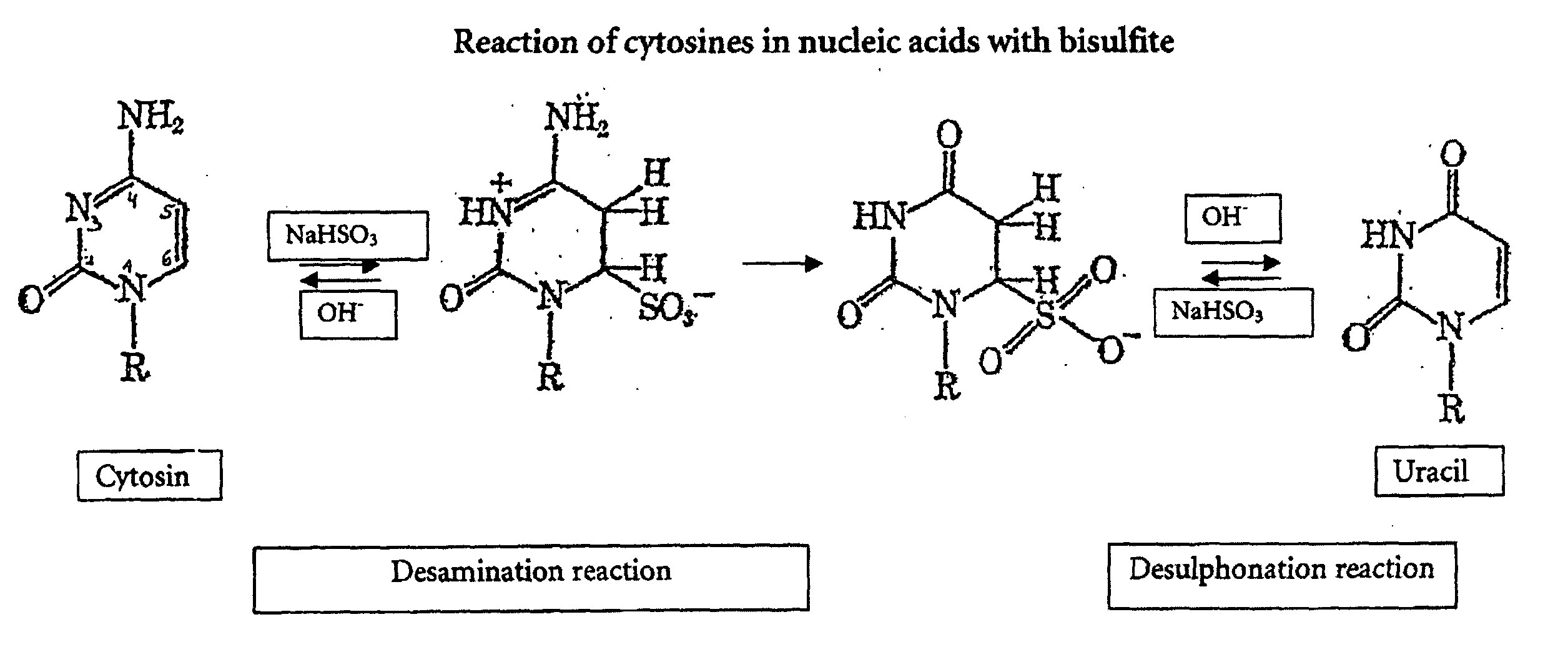

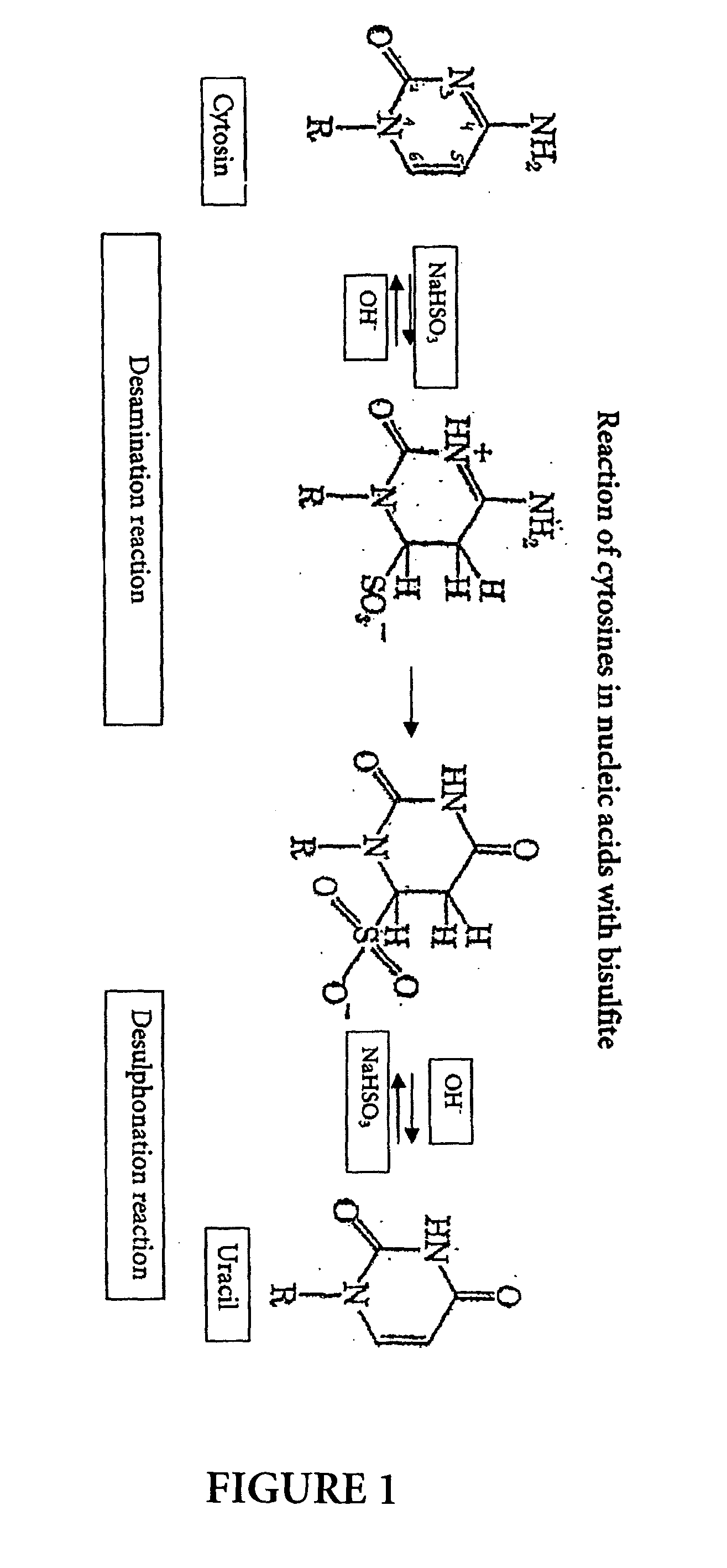

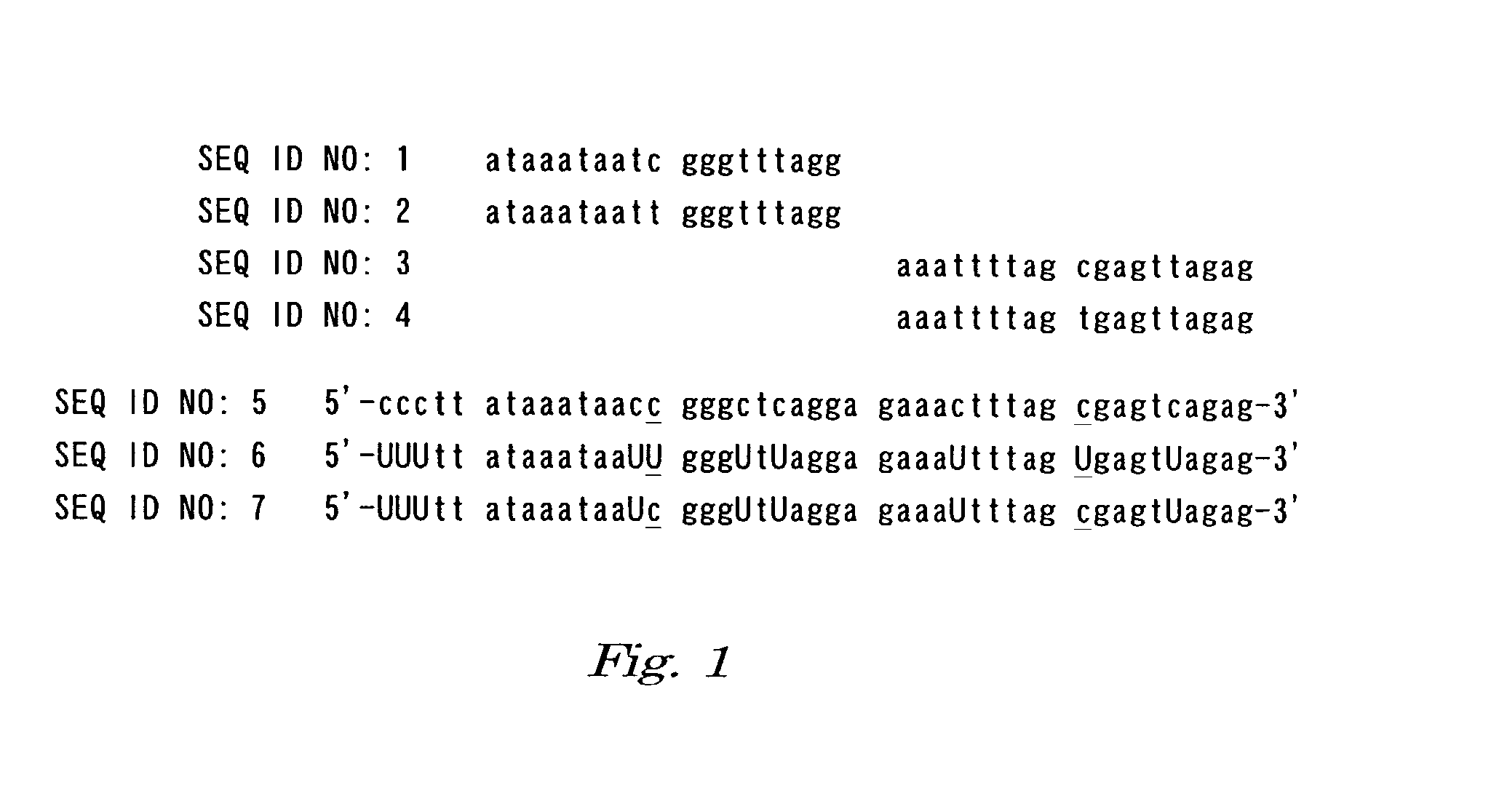

Method for bisulfite treatment

ActiveUS20040241704A1Increase speedImprove accuracySugar derivativesMicrobiological testing/measurementGlass fiberCytosine

The present application is directed to a method for performing a bisulfite reaction to determine methylation positions in a nucleic acid, i.e. methylated and non-methylated cytosines, whereby the nucleic acid is bound to a solid phase during the deamination and / or desulfonation step of the bisulfite reaction. The solid phase is preferably a material comprising glass or silica, more preferably a glass fleece, glass membrane or a magnetic glass particle. Further, the use of a solid phase for binding a nucleic acid during the deamination and / or desulfonation step of the bisulfite reaction is disclosed and a kit containing a bisulfite reagent and a solid phase.

Owner:QIAGEN GMBH

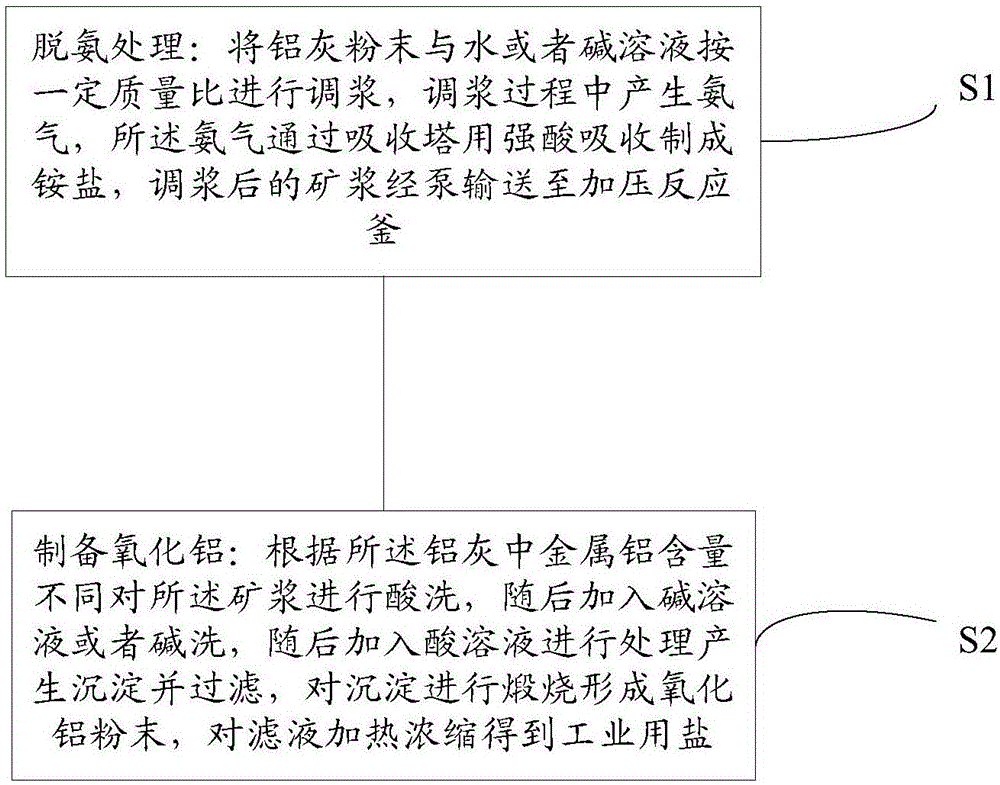

Aluminum ash recycling method

ActiveCN106830025AHarmlessImplement resourcesAmmonia preparation/separationAluminium oxides/hydroxidesStrong acidsAmmonia

The invention discloses an aluminum ash recycling method. The aluminum ash recycling method comprises the following steps: deamination: aluminum ash powder and water or aqueous alkali are subjected to pulp mixing in a certain mass ratio, ammonia is produced in the pulp mixing process and absorbed by an absorption tower with strong acid, ammonium salt is prepared, and pulp obtained through pulp mixing is delivered by a pump to a pressurized reactor; preparation of aluminum oxide: the pulp is pickled according to different aluminum contents in aluminum ash, then aqueous alkali is added or alkali washing is performed, an acid solution is added for treatment, precipitates are produced, filtered and calcined, aluminum oxide powder is formed, a filtrate is heated to be concentrated, and industrial salt is obtained. When the aluminum ash is recycled with the technical scheme, useful components in the aluminum ash can be recovered to the greatest extent, environmental pollution caused by aluminum ash processing is avoided, the recovered ammonia can be directly applied to flue gas desulfurization and denitrification forelectrolytic aluminum or aluminum fabrication enterprises, and harmlessness, recycling and benefits of aluminum ash treatment are realized.

Owner:NANTONG UNIVERSITY

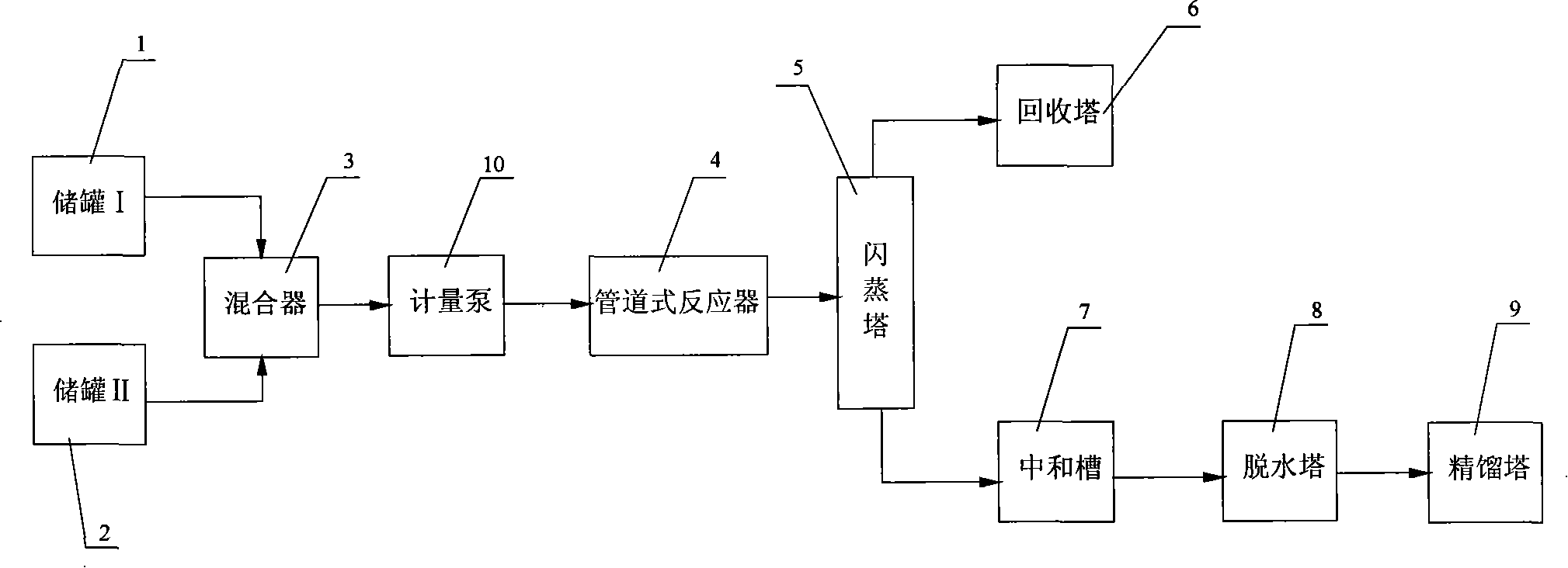

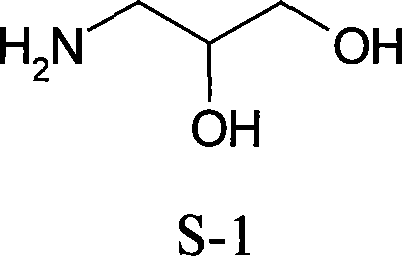

Method for synthesizing 3-amido-1,2-propanediol by pipe reactor

ActiveCN101250115AShort reaction timeHigh yieldChemical/physical/physico-chemical stationary reactorsAmino preparation by functional substitutionReaction temperatureGlycerol

The invention discloses a method for synthesizing 3-amino-1, 2-propanediol via a tubular reactor, which comprises (1) ammoniation such as premixing liquid chlorine glycerol and ammonia water via a mixer, and reacting in a tubular reactor while the reaction temperature is 60-100DEG C, the pressure is 3-6MPa and the time is 6-12min, and obtain the mixture solution of 3-amino-1, 2-propanediol and ammonia water, (2) purification such as treating the mixture solution by depressurizing, flash evaporation and deamination, and treating the liquid after the deamination by adding alkali to neutralize, dehydrating, depressurizing and distilling, to obtain 3-amino-1, 2-propanediol. The synthesized 3-amino-1, 2-propanediol has the advantages of high yield.

Owner:ZHEJIANG HAIZHOU PHARMA CO LTD

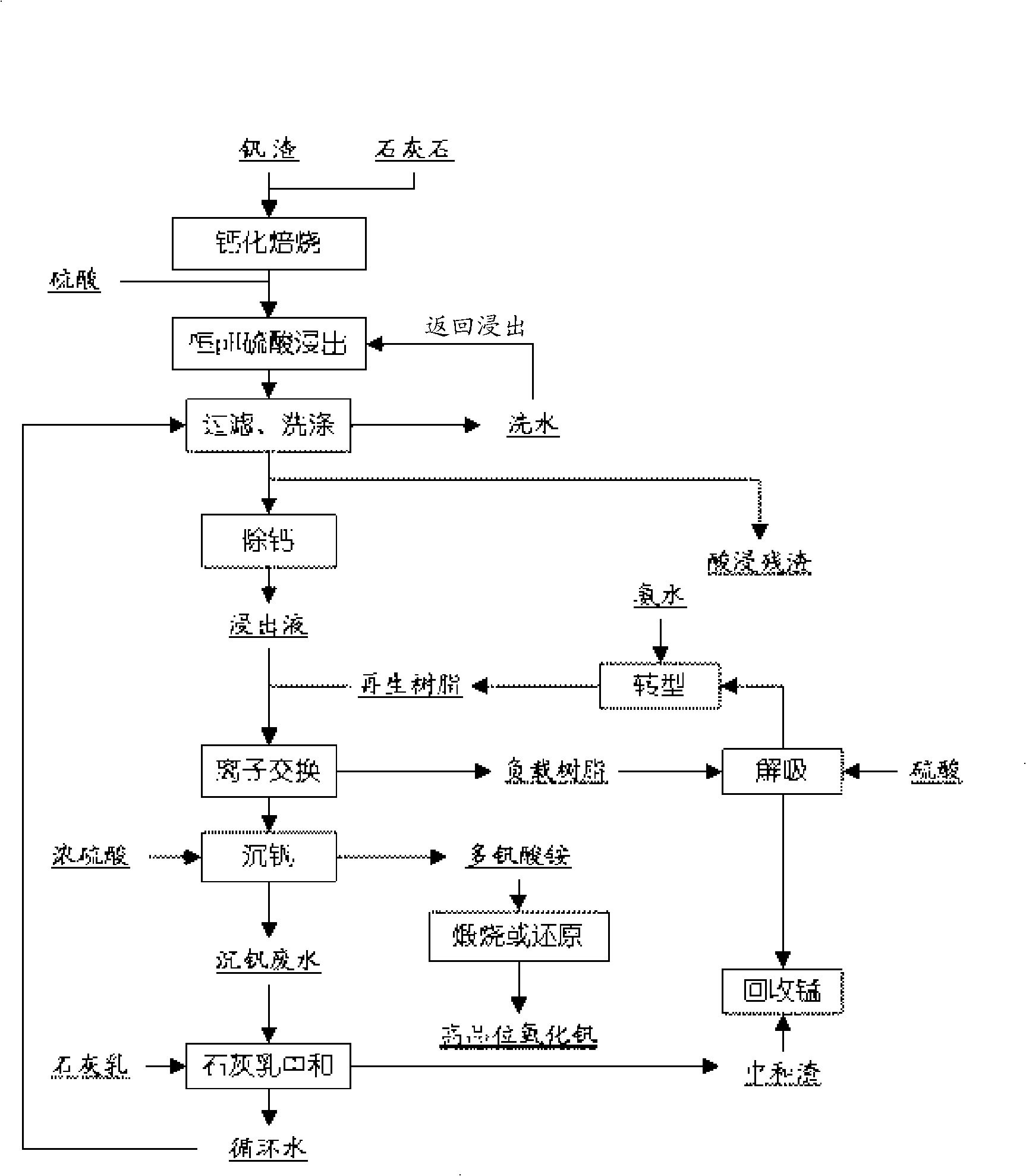

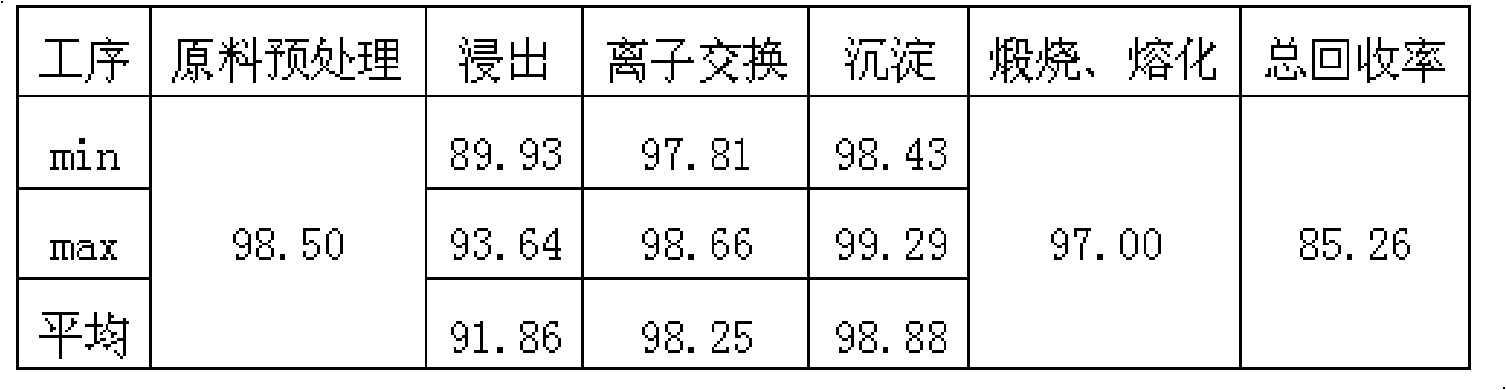

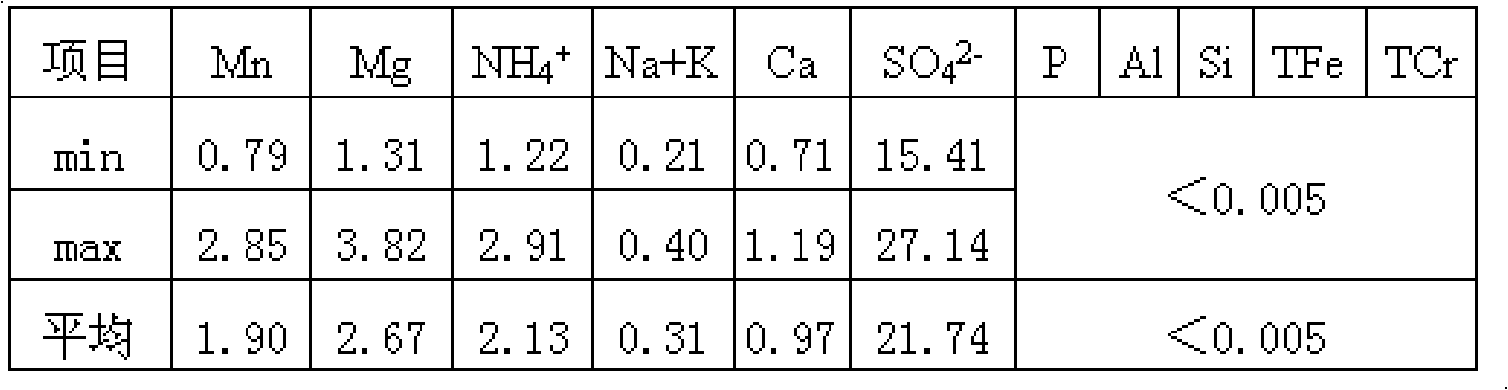

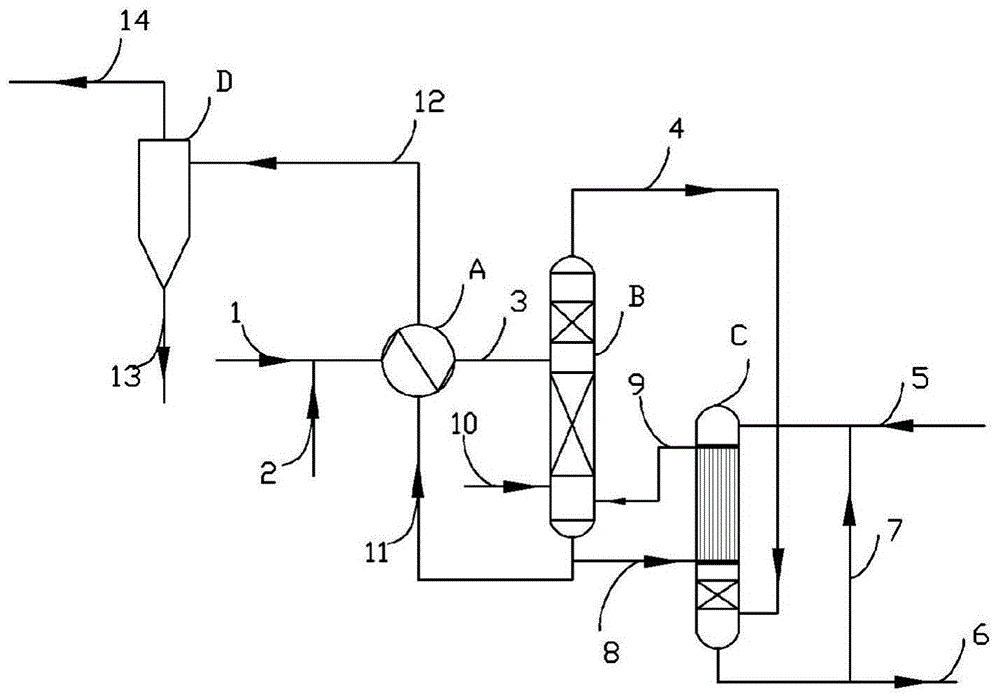

Process for producing vanadium oxide for implementing wastewater circulation with ionic exchange

ActiveCN101402470ASolve difficult environmental problemsQuality improvementVanadium compounds preparationVanadium oxidesEmission standardIon exchange

The invention relates to a method for producing vanadium oxide by utilizing ion exchange to realize wastewater circulation and belongs to the field of the extraction of the vanadium oxide. The technical problem which is solved by the invention is to provide a method for producing the vanadium oxide, in which a high-quality vanadium product can be obtained and the problems that vanadium extraction wastewater reaches the emission standard and is recycled are thoroughly solved. The method for producing the vanadium oxide comprises the following steps: the vanadium oxide is prepared by the steps of the preparation of raw materials, calcification and roasting, infiltration, solid-liquid separation, ion exchange and impurity removal, vanadium precipitation, calcination and deamination or deoxidation and other steps; and the vanadium extraction wastewater is subjected to neutralizing treatment by using lime cream and returns a system for recycling, thereby realizing the zero emission of the wastewater. The method also improves the reclaiming rate of vanadium which is higher than that of the current process, and reduces production cost. The method is combined with other technologies to convert residue and other wastes after vanadium extraction into secondary resource for reutilization, thereby realizing clean production.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Synthetic method of kyprolis

ActiveCN103641890AHigh reaction yieldHigh yieldPeptidesBulk chemical productionAcetic acidMorpholine

The invention relates to the technical field of drug synthesis, and particularly relates to a synthetic method of kyprolis. The synthetic method comprises the following steps: carrying out condensation reaction on morpholine-4-base acetic acid, L-homophenylalanine ester and salt, and then carrying out decarboxylation protection to generate a compound V; carrying out the condensation reaction on the decarboxylation, the salt and N-Boc-L-leucine, and then carrying out deamination protection to generate a compound VI; carrying out the condensation reaction on the compound V and the compound VI, and then carrying out decarboxylation protection to generate a compound VII; carrying out the condensation reaction on the compound VII and a compound VIII to obtain the kyprolis. The method disclosed by the invention can be used for enhancing the reaction yield by adopting a converging synthetic method; the used reagent is easy, convenient, easy to obtain and less in pollution. The process disclosed by the invention only relates to the condensation and deprotection between amino acids and is simple and controllable in reaction and suitable for industrial production.

Owner:重庆兴泰濠制药有限公司

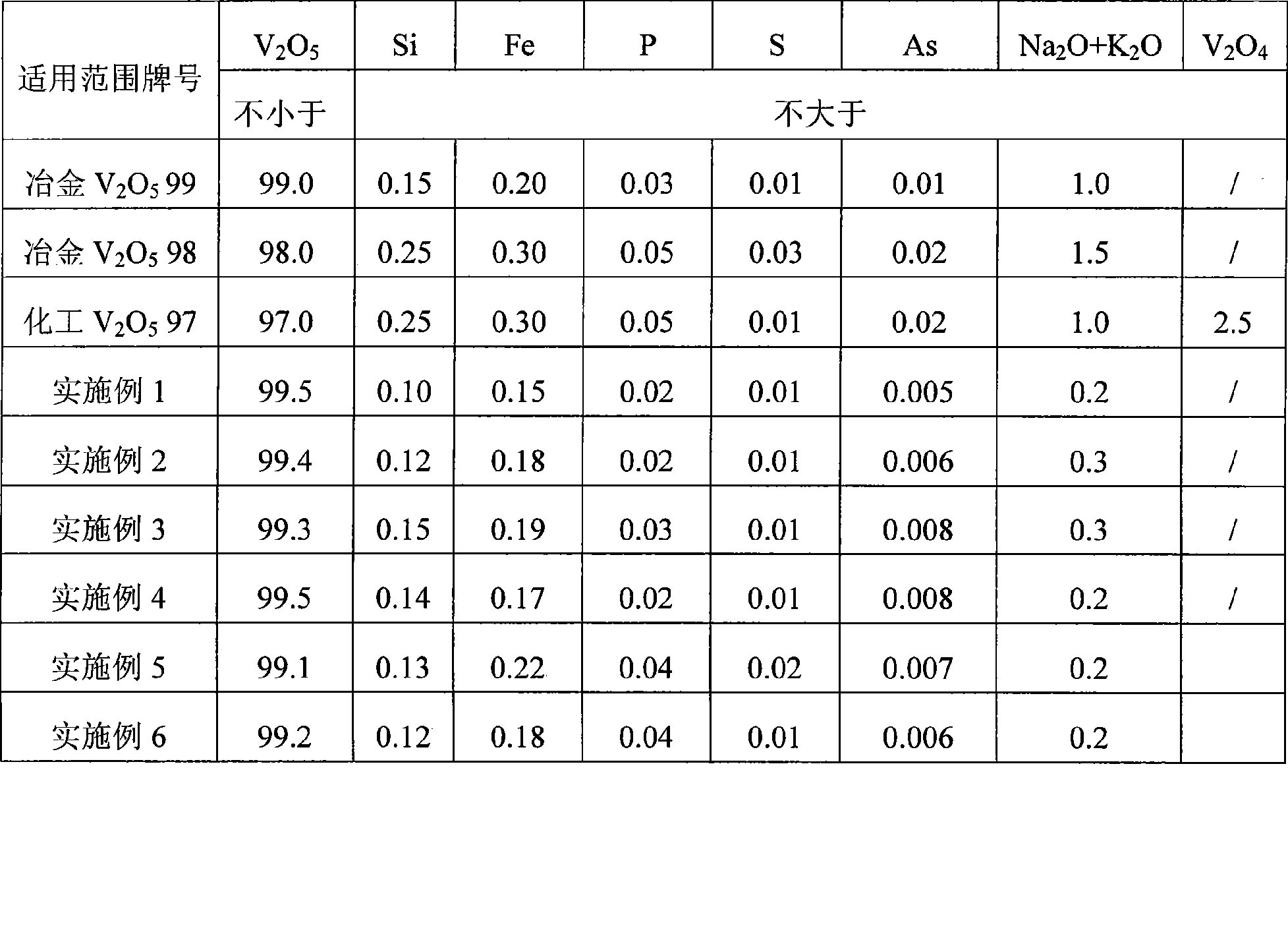

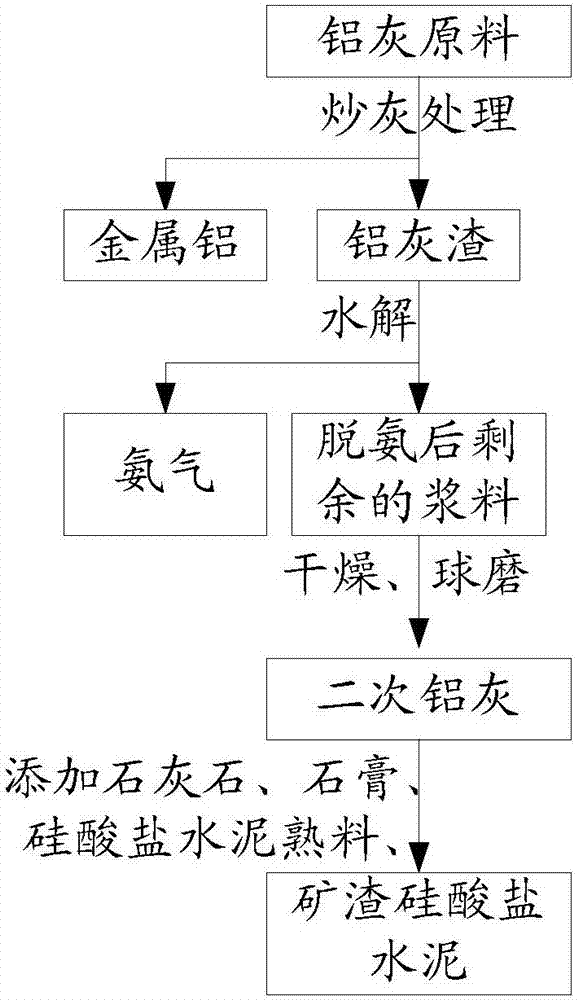

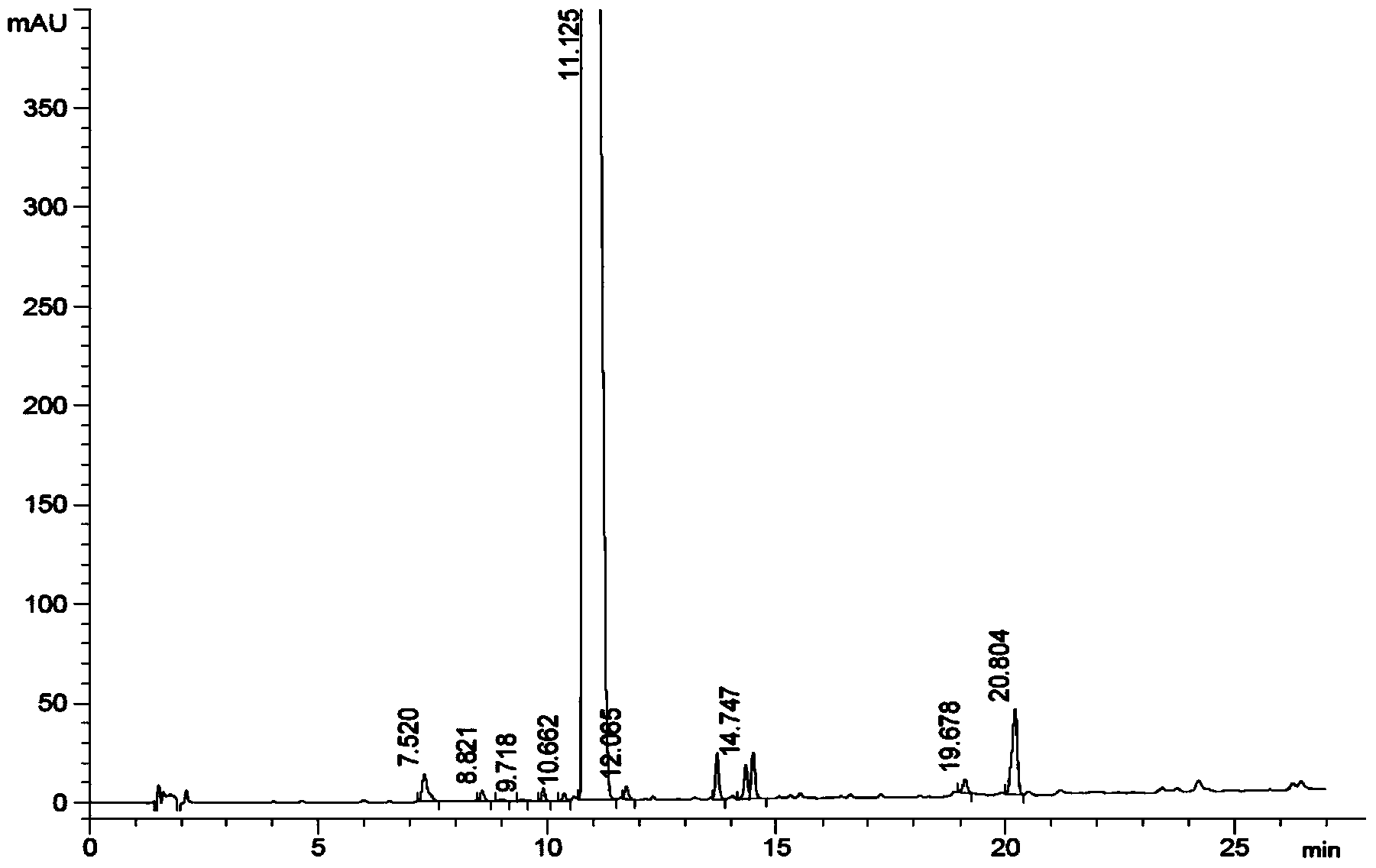

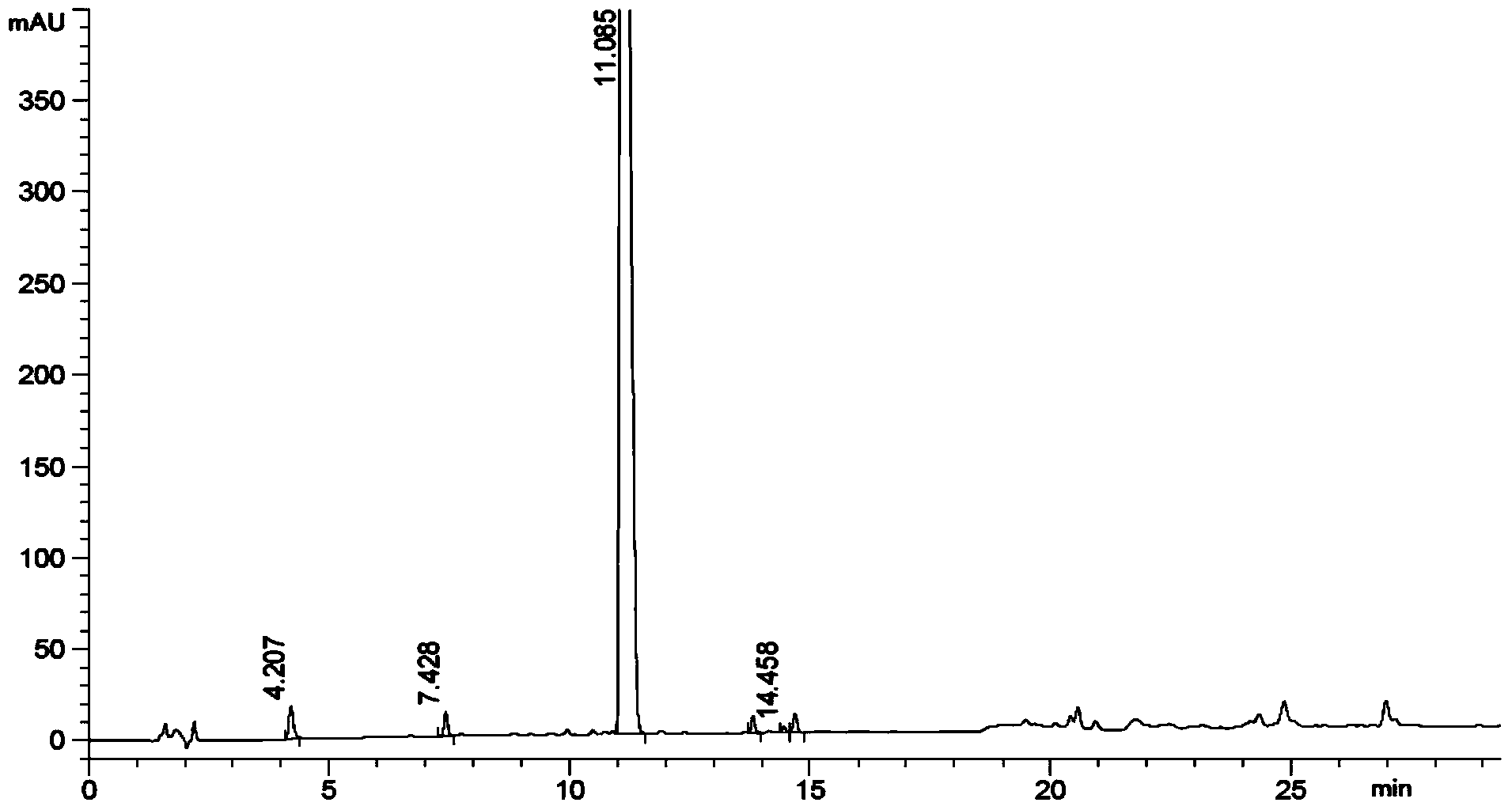

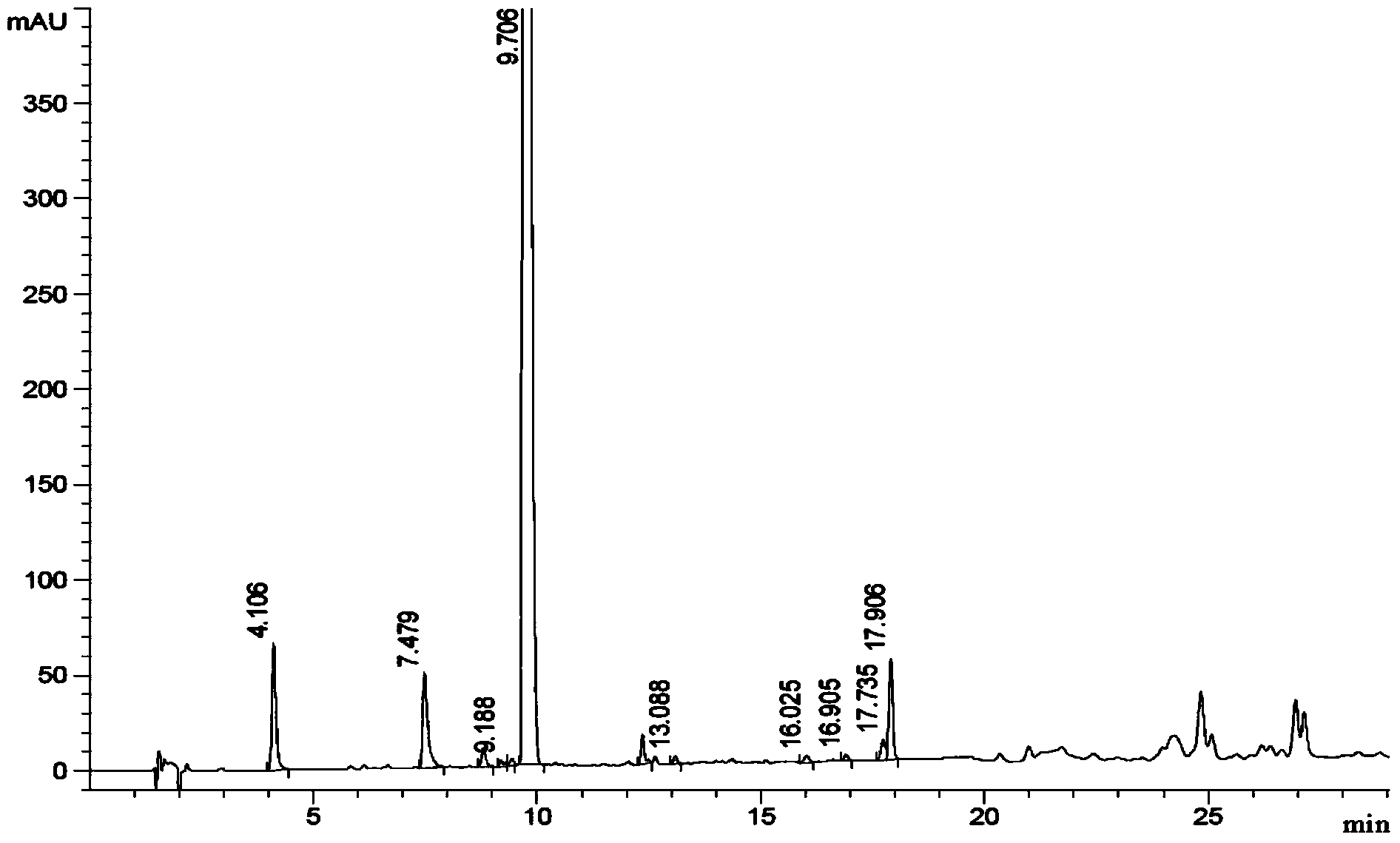

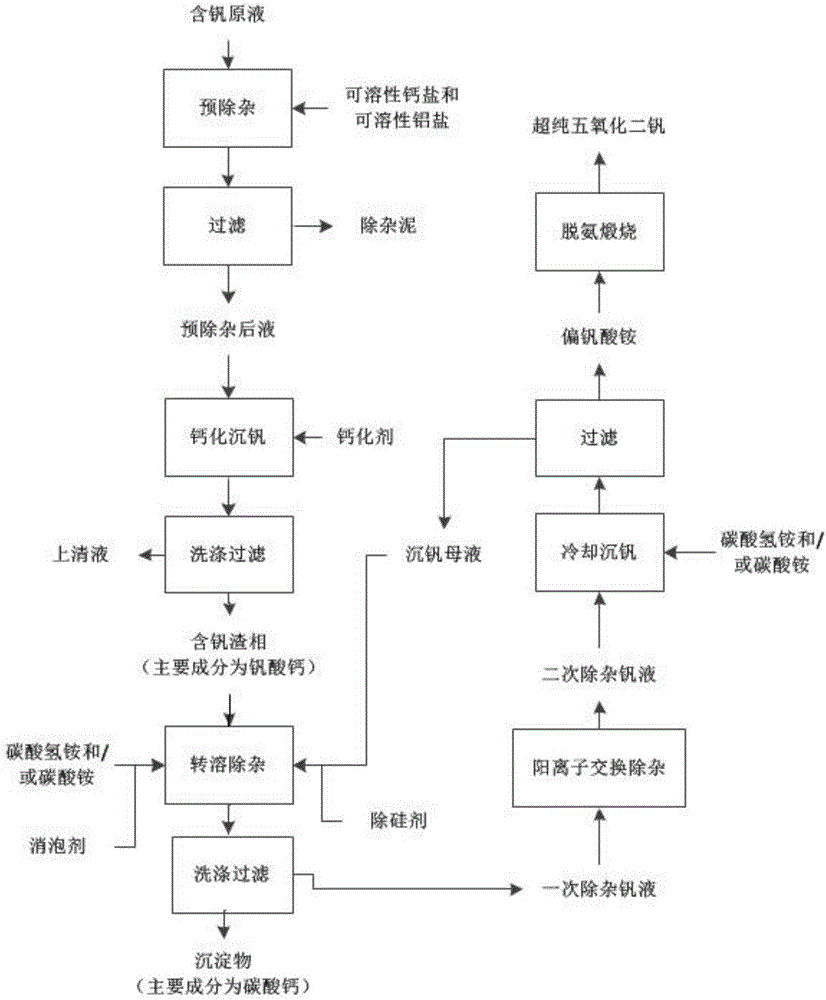

Preparation method of ultra-pure vanadium pentoxide

The invention discloses a preparation method of ultra-pure vanadium pentoxide. The preparation method comprises the following steps of: removing impurities in advance; transferring phosphorus and silicon in a vanadium-containing solution into a solid phase for removal; performing calcification and vanadium precipitation; transferring vanadium in a liquid phase into a calcium vanadate phase; leaving the impurities such as chromium, manganese, potassium and sodium in the liquid phase for removal; performing solubilization reaction of vanadium in the calcium vanadate into the liquid phase through ammonium bicarbonate and / or ammonium carbonate; leaving the calcium, phosphorus, silicon, iron and magnesium in the solid phase for removal; replacing residual trace cations of the liquid phase with ammonium ions by an ammonium type cation exchange system to realize deep purification; and performing cooling vanadium precipitation and deamination calcination to obtain vanadium pentoxide. In the invention, the process route is simple, the drug consumption is low, the vanadium pentoxide with purity of over 99.95% can be stably obtained, and the content of main impurities such as iron, chromium, manganese, silicon, phosphorus, calcium, sodium, magnesium, potassium and aluminum is all lower than 0.002%.

Owner:HEBEI IRON AND STEEL

Resourceful treatment and cyclic utilization method of PCB circuit board waste etching liquid

The invention relates to a resourceful treatment and cyclic utilization method of PCB circuit board waste etching liquid. The resourceful treatment and cyclic utilization method comprises following steps: an alkali source is added into the waste etching liquid so as to promote decomposition of cuprammouium complex ions in the waste etching liquid, and transfer free ammonium ions into molecular state ammonia; waste water generated by the hybrid reaction is delivered into a deamination reaction tower, further decomposition of cuprammouium complex ions is realized in the deamination reaction tower, and free ammonia molecules in the waste water is exhausted via the top of the deamination reaction tower in gaseous state, is delivered into an ammonia absorption tower, is absorbed by concentrated hydrochloric acid, and is transferred into ammonium chloride solution so as to realize ammonium / ammonia resource recovery; and copper ions in the waste water is transferred into copper compounds to precipitate and realize recovery. According to the resourceful treatment and cyclic utilization method of PCB circuit board waste etching liquid, ammonia-nitrogen removal rate and ammonia recovery rate are both above 99.9%; copper recovery rate is more than 95%; coupling of ammonia recovery process and ammonium chloride synthetic process is realized; recoveries of ammonia / ammonium and copper are realized respectively; the ammonium chloride solution prepared by recycling can be recycled as a new etching solution after supplement of additives and deionized water; and all-component resourceful utilization of circuit board etching ammonia-nitrogen wastewater is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

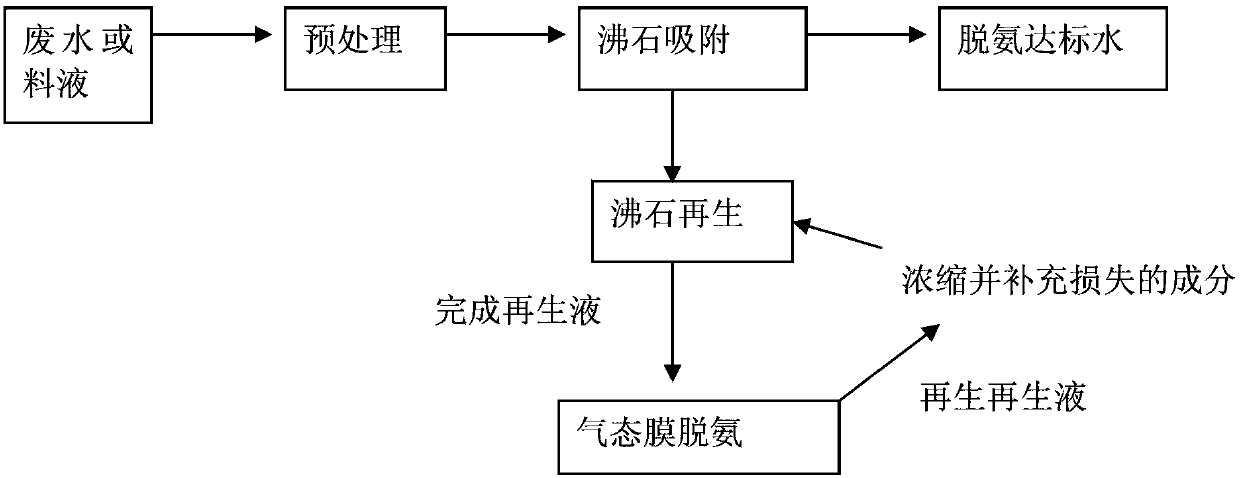

Method for treating low-concentration ammonia-nitrogen wastewater or feed liquid

ActiveCN104211246ACompliance with emission standardsDoes not increase processing difficultyMultistage water/sewage treatmentEnvironmental resistancePre treatment

The invention relates to a method for treating a low-concentration ammonia-nitrogen wastewater or feed liquid. The method comprises the steps: firstly, pre-treating the low-concentration ammonia-nitrogen wastewater or feed liquid, removing impurities in the wastewater or feed liquid, adjusting the pH of the wastewater or feed liquid to 6-7.5, and increasing the surface tension to 40 mN / m or even 65 mN / m or more; then carrying out selective adsorption treatment on the pretreated low-concentration ammonia-nitrogen wastewater or feed liquid with zeolite, making the ammonia-nitrogen average concentration of the wastewater or feed liquid subjected to adsorption less than a predetermined value, when the ammonia-nitrogen average concentration of the wastewater or feed liquid after the adsorption treatment reaches the predetermined value, carrying out regeneration treatment on zeolite by utilizing a regeneration liquid, and thus obtaining an ammonia-nitrogen enriched regeneration liquid; followed by allowing the ammonia-nitrogen enriched regeneration liquid to enter a gas membrane separation device, and carrying out deamination treatment; and finally carrying out concentration treatment on the ammonia-nitrogen removed regeneration liquid, and thus obtaining a recyclable regeneration liquid. The method has the advantages of simple operation, small energy consumption, low operation cost, no secondary pollution, economy and environmental protection.

Owner:TIANJIN PURESEA SPRING MEMBRANE TECH CO LTD

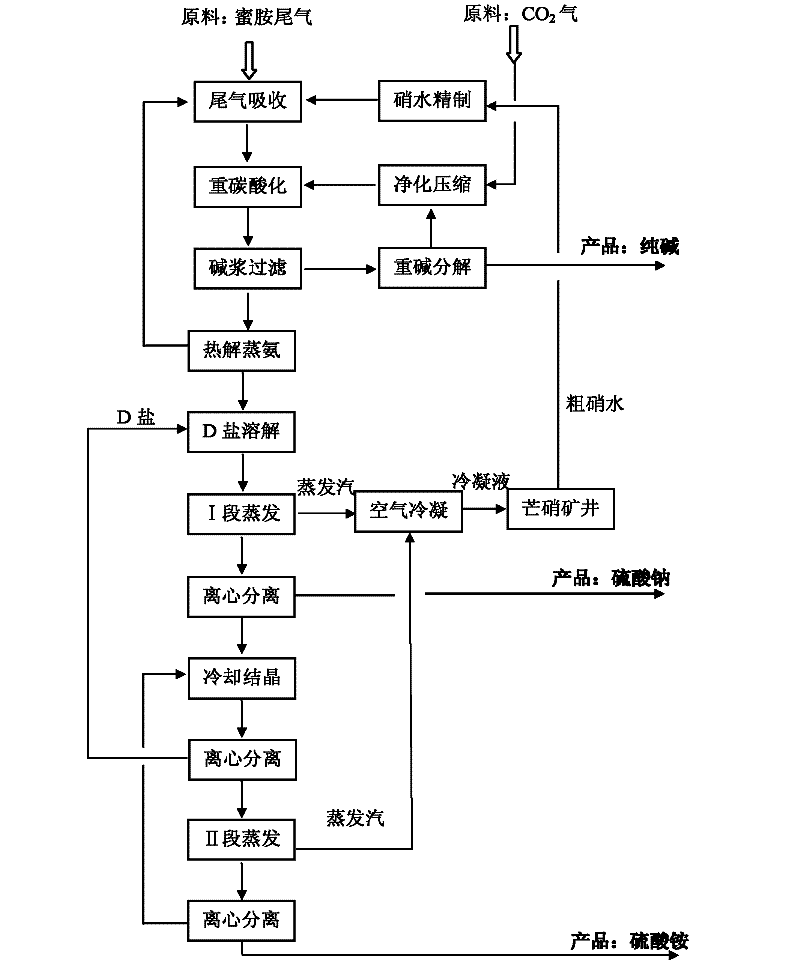

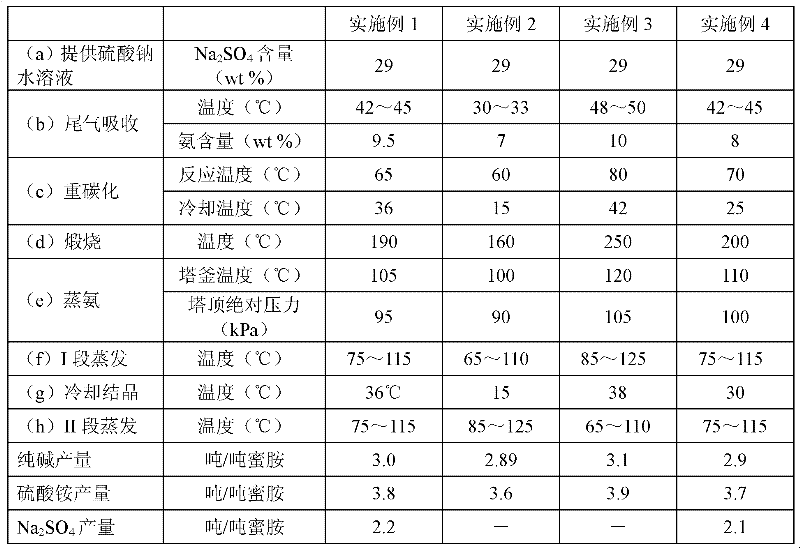

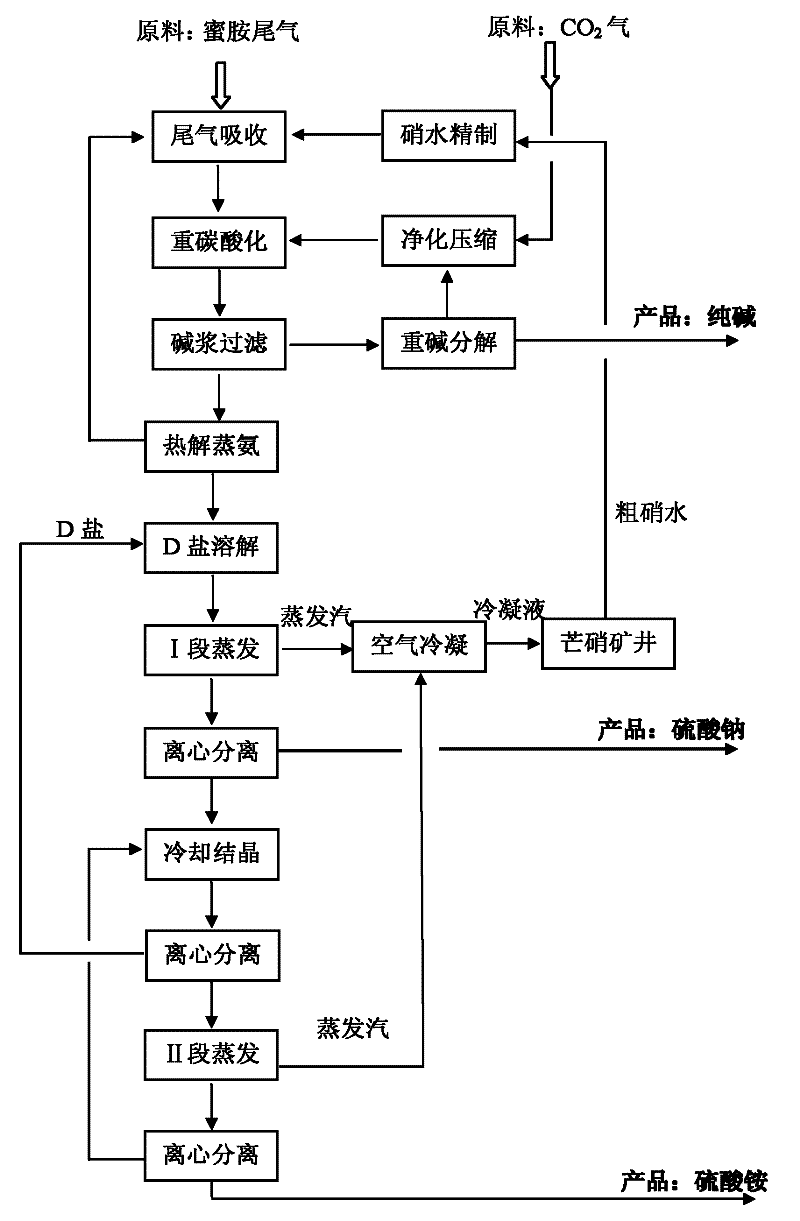

Methods for coproducing sodium carbonate and ammonium sulfate from melamine tail gas and mirabilite

InactiveCN102198953AIncrease profitReduce consumptionAmmonium sulfatesCarbonate preparationSodium bicarbonateSlurry

The invention relates to methods for coproducing sodium carbonate and ammonium sulfate from melamine tail gas and mirabilite. The method for producing the sodium carbonate comprises the following steps of: a, providing a sodium sulfate water solution; b, introducing melamine tail gas into the sodium sulfate water solution to form an ammonium carbonate-sodium sulfate water solution; c, introducing carbon dioxide into the ammonium carbonate-sodium sulfate water solution to obtain a suspension serous fluid of sodium bicarbonate crystals; and d, carrying out solid and liquid separation on the suspension serous fluid to obtain sodium bicarbonate and a mother solution I, calcining sodium bicarbonate solid to obtain the sodium carbonate. The method further comprises the following steps of: e, adding the mother solution I into an ammonia stilling tower, heating, forming tower top mixed gas containing ammonia and carbon dioxide, generating a deamination solution in the tower; f, evaporating the deamination solution for dewatering to obtain sodium sulfate crystals and a mother solution II; g, cooling the mother solution II for crystallizing to obtain Na2SO4.(NH4)2SO4.4H2O salt crystals and a mother solution III; and h, evaporating the mother solution III for dewatering, and separating out ammonium sulfate crystals. The methods have the advantages of high utilization rate of raw materials and low energy consumption.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD +1

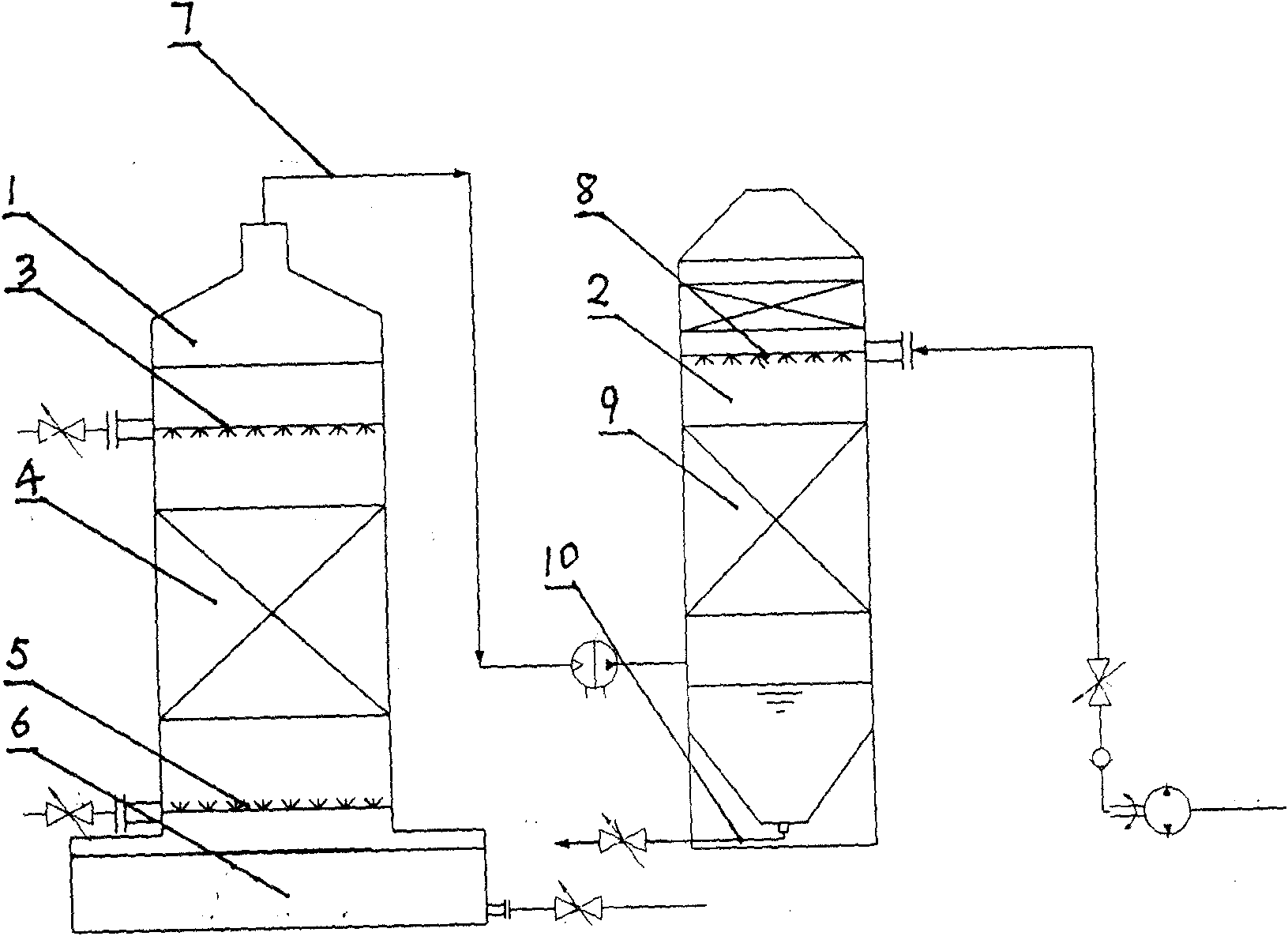

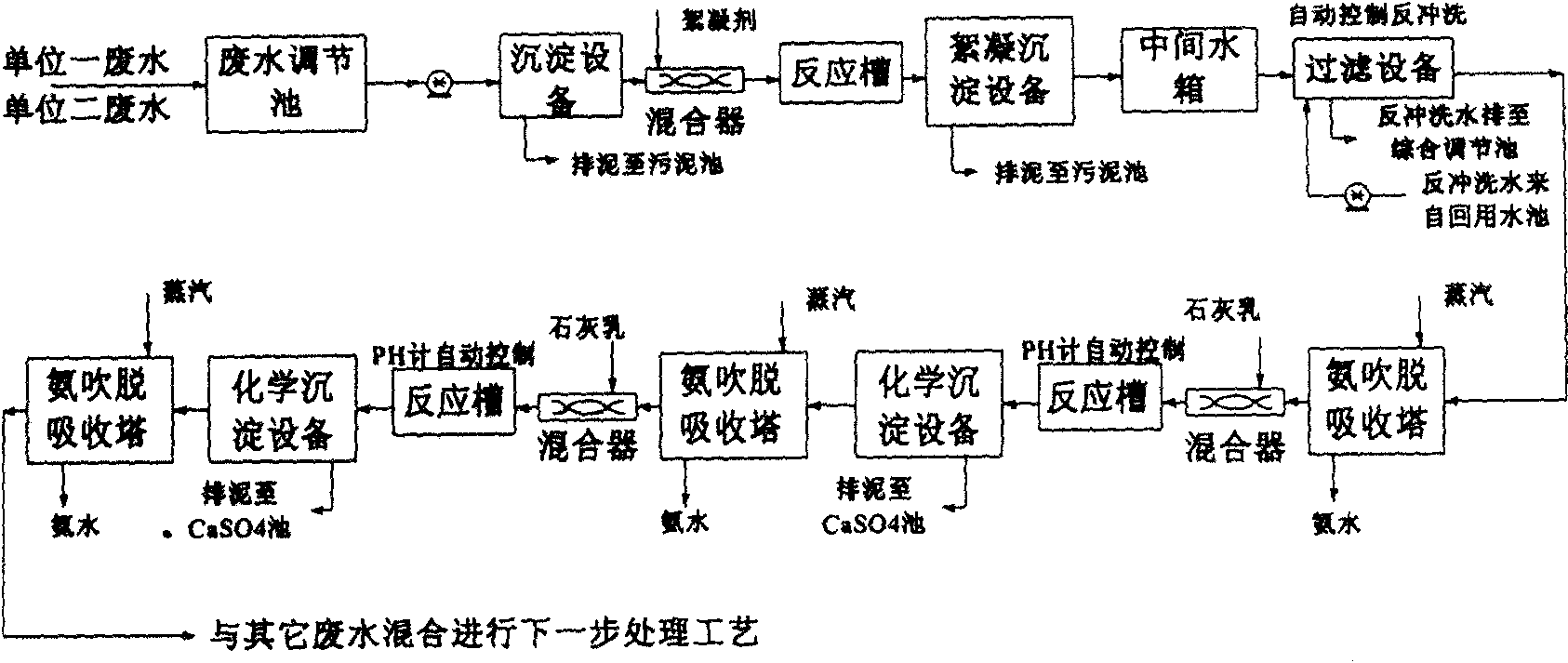

Method and equipment for carrying out deamination treatment on high-concentration wastewater containing ammonia nitrogen

InactiveCN101665294AReduce dosageLow running costWaste water treatment from metallurgical processMultistage water/sewage treatmentHigh concentrationThree level

The invention relates to a method and equipment for carrying out deamination treatment on high-concentration wastewater containing ammonia nitrogen, relating to industrial wastewater treatment. The method comprises the steps of preprocessing, three-level ammonia stripping, ammonia recycling, and the like, and limemilk is added in wastewater and the pH value is adjusted before two-level ammonia stripping and three-level ammonia stripping. The equipment mainly comprises a stripping tower and an absorption tower. By adopting a three-level ammonia stripping and absorbing process, the removing ratio of ammonia reaches over 98 percent, the efficiency and the stability for removing ammonia nitrogen are improved, the running cost of enterprises is reduced, the secondary pollution is prevented andthe periphery environment is protected.

Owner:CHANGCHUN INST OF TECH

Oligonucleotide-immobilized substrate for detecting methylation

InactiveUS20030096289A1Quick checkBioreactor/fermenter combinationsBiological substance pretreatmentsCytosinePyrimidine Nucleotides

Presence or absence of methylation of C located on 5' side of G in a sample DNA comprising a target sequence containing a dinucleotide consisting of C that may be methylated and a nucleotide on the 3' side of the C (CpN dinucleotide) is determined based on a result of hybridization performed for a plurality of capture oligonucleotides immobilized on a base material and including at least an oligonucleotide having a nucleotide sequence complimentary to or identical to a nucleotide sequence corresponding to the target sequence in which C other than C in the CpN dinucleotide is replaced with T and an oligonucleotide having a nucleotide sequence complimentary to or identical to a nucleotide sequence corresponding to the target sequence in which all of C's are replaced with T's and the sample DNA in which cytosines not methylated are converted into uracils by deamination or an amplification product thereof.

Owner:NISSHINBO IND INC

Copper-containing beta molecular sieve and preparation method thereof

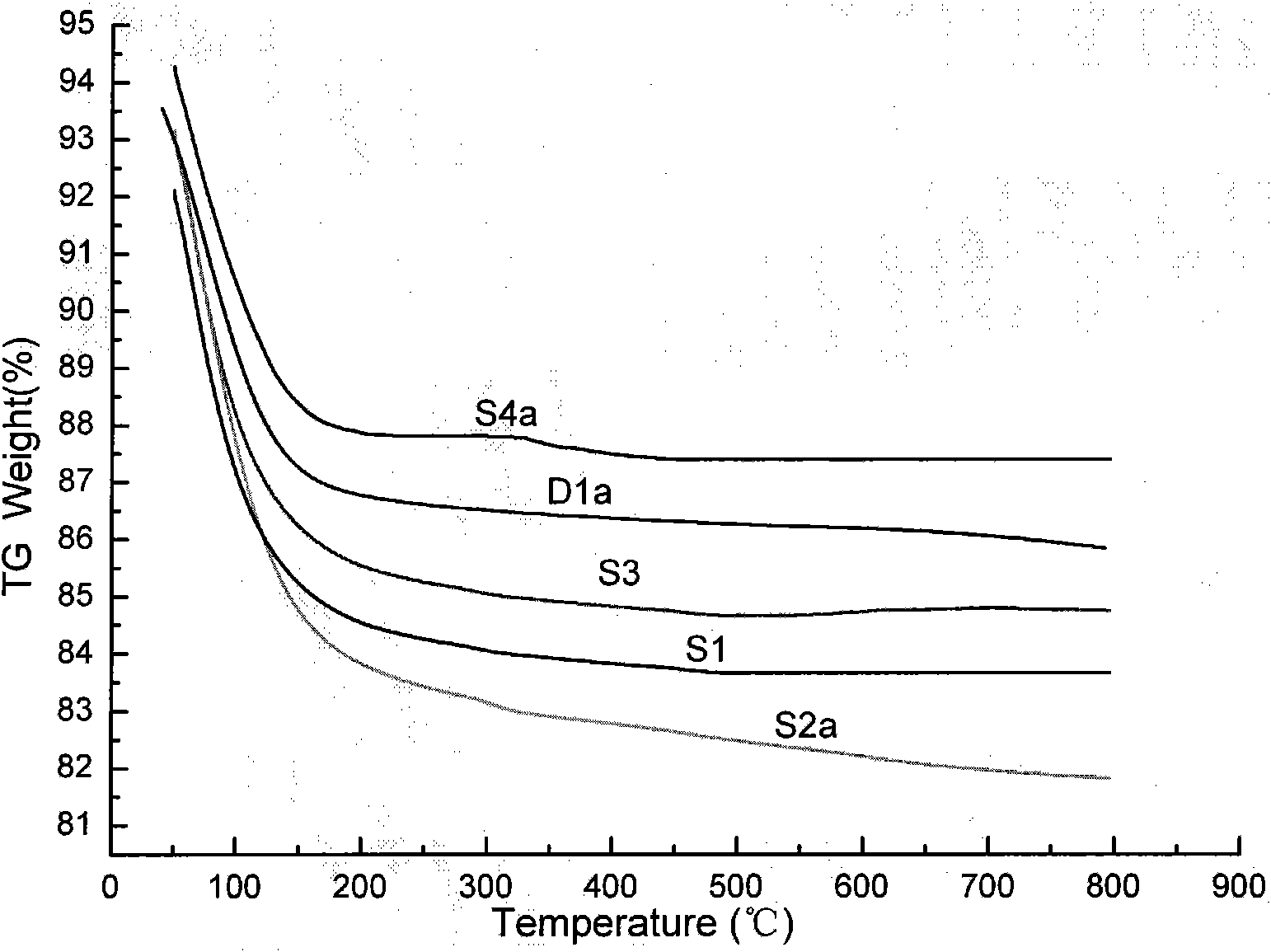

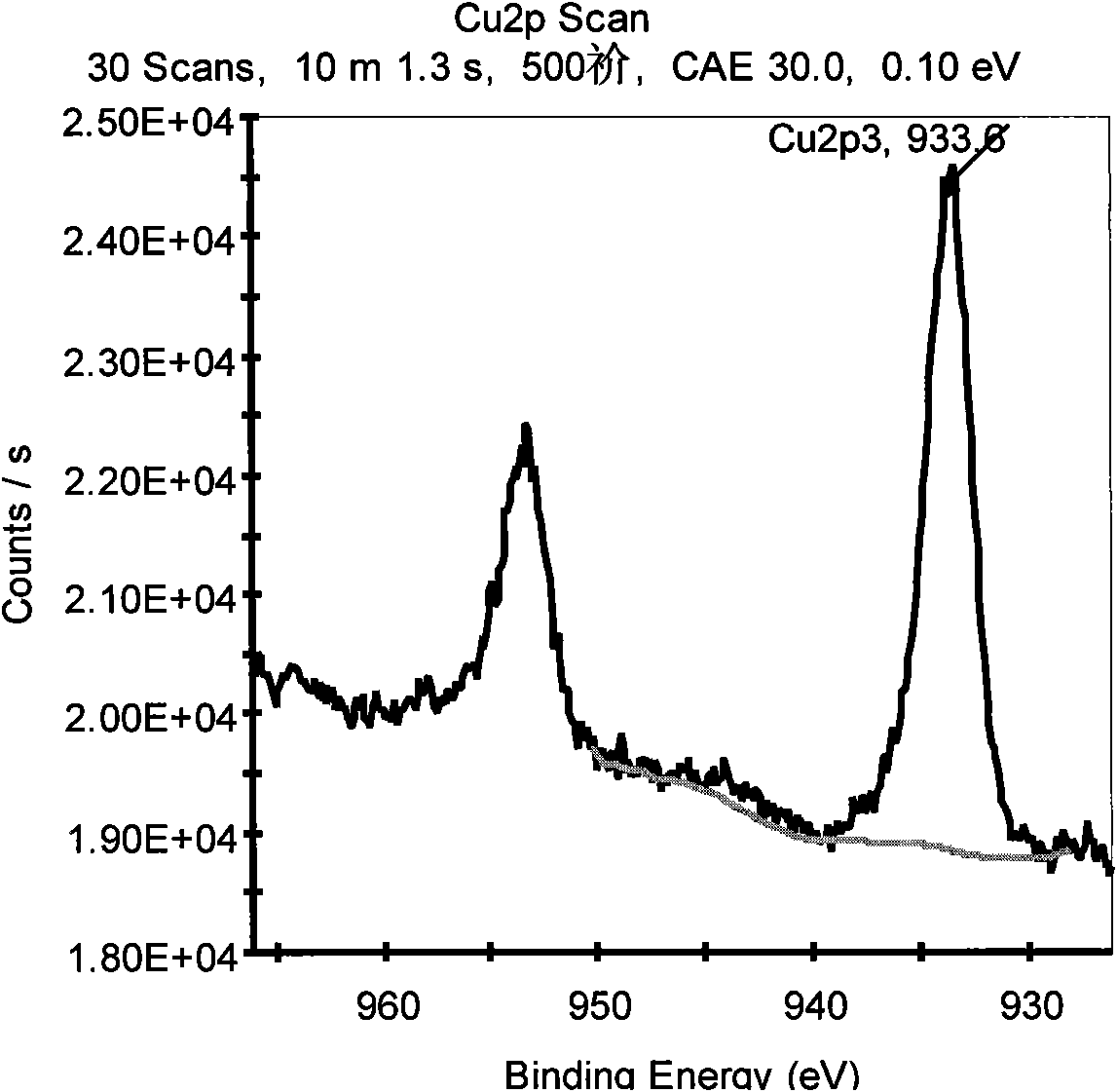

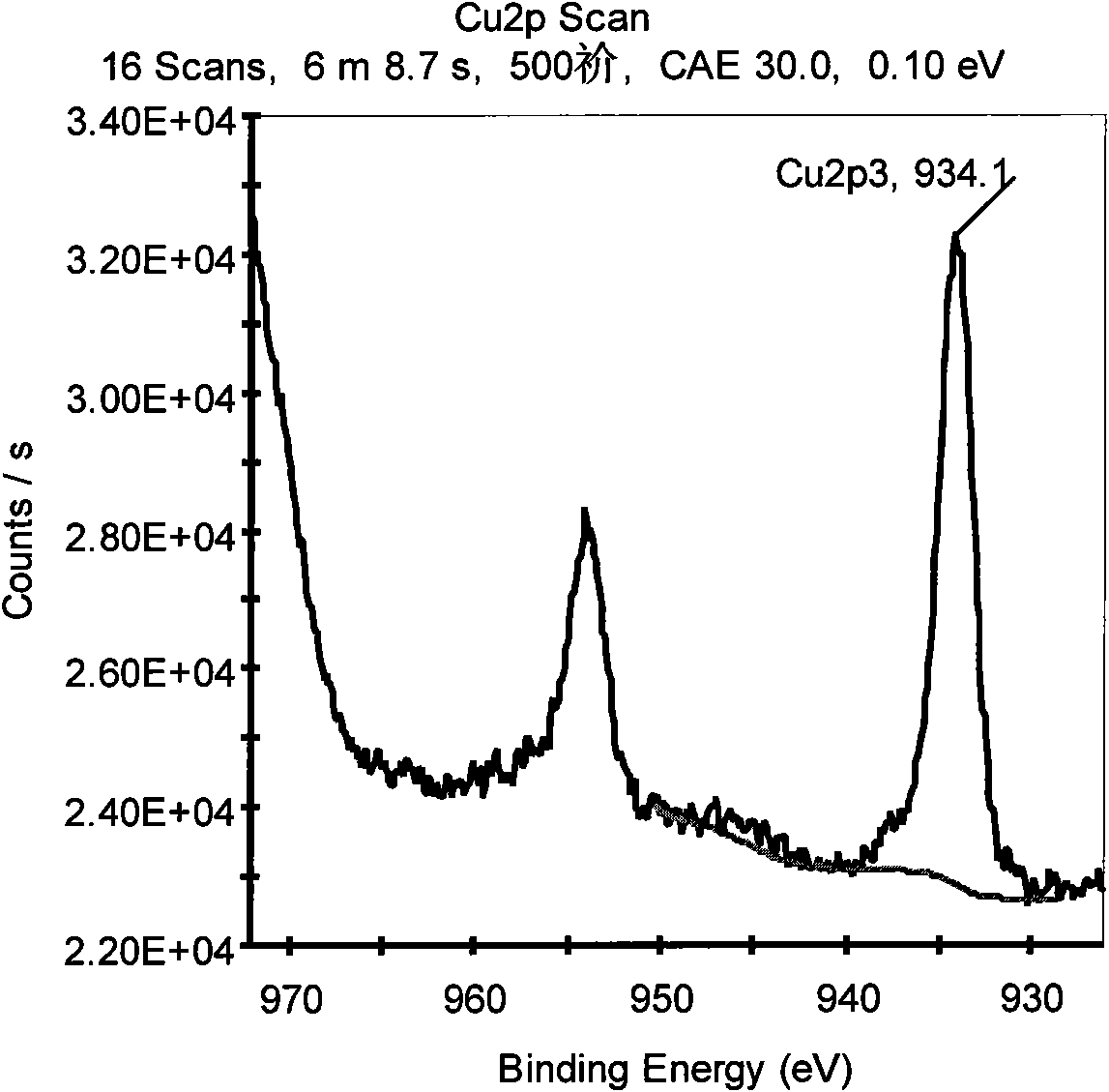

Copper-containing beta molecular sieve is characterized in that the beta molecular sieve comprises 0.01-10wt% of Cu (by CuO), the value of Cu<+> / ( Cu<+>+ Cu<2+>) of the surface of the beta molecular sieve is equal to or greater than 50wt%, and there is no deamination weight loss peak in a weight loss curve obtained through thermogravimetric characterization after 450DEG C. The molecular sieve of the invention is obtained by carrying out solid state ion exchange on copper ions and the molecular sieve while removing an organic amine template from the organic template-containing ammonium type beta molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

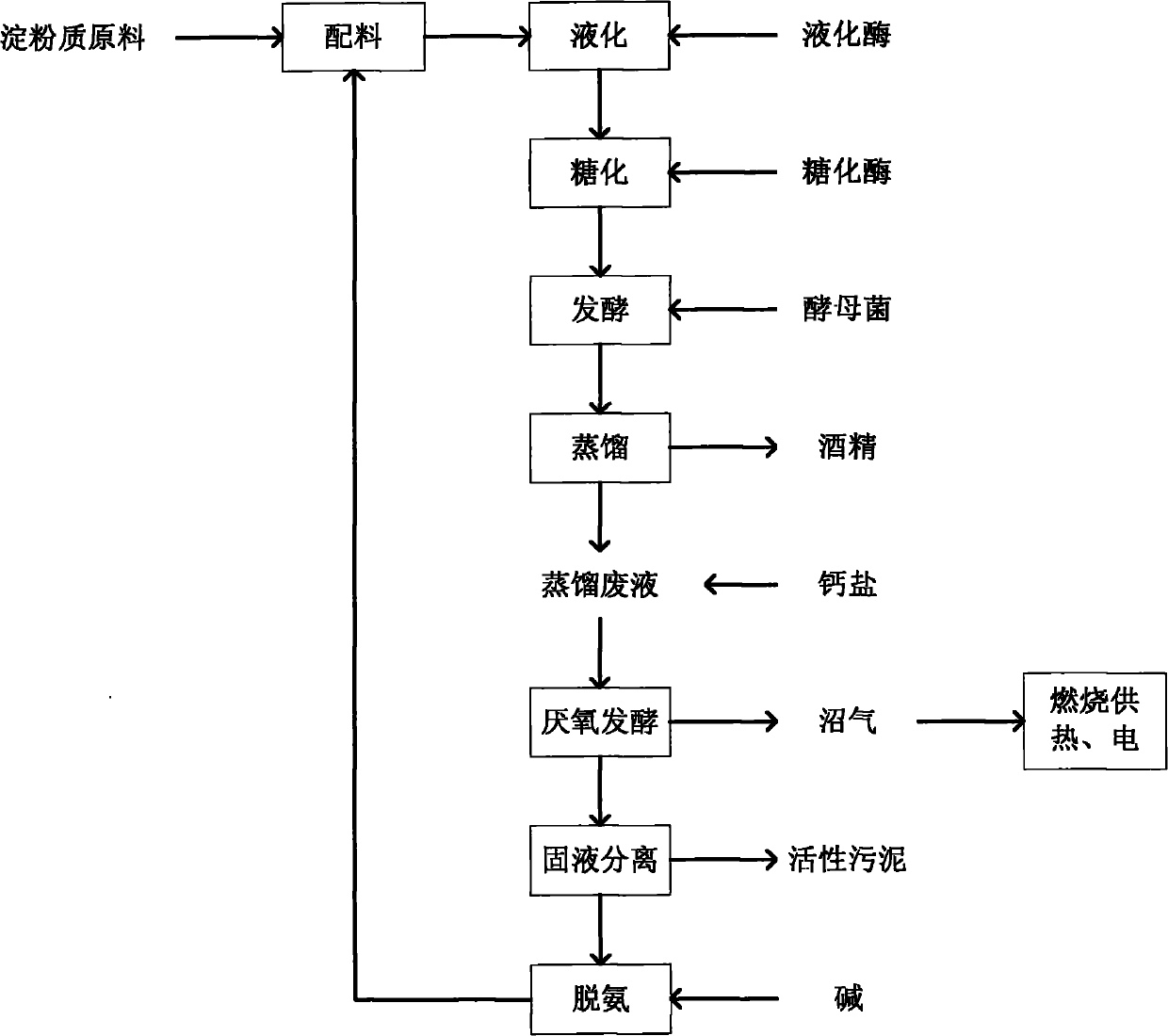

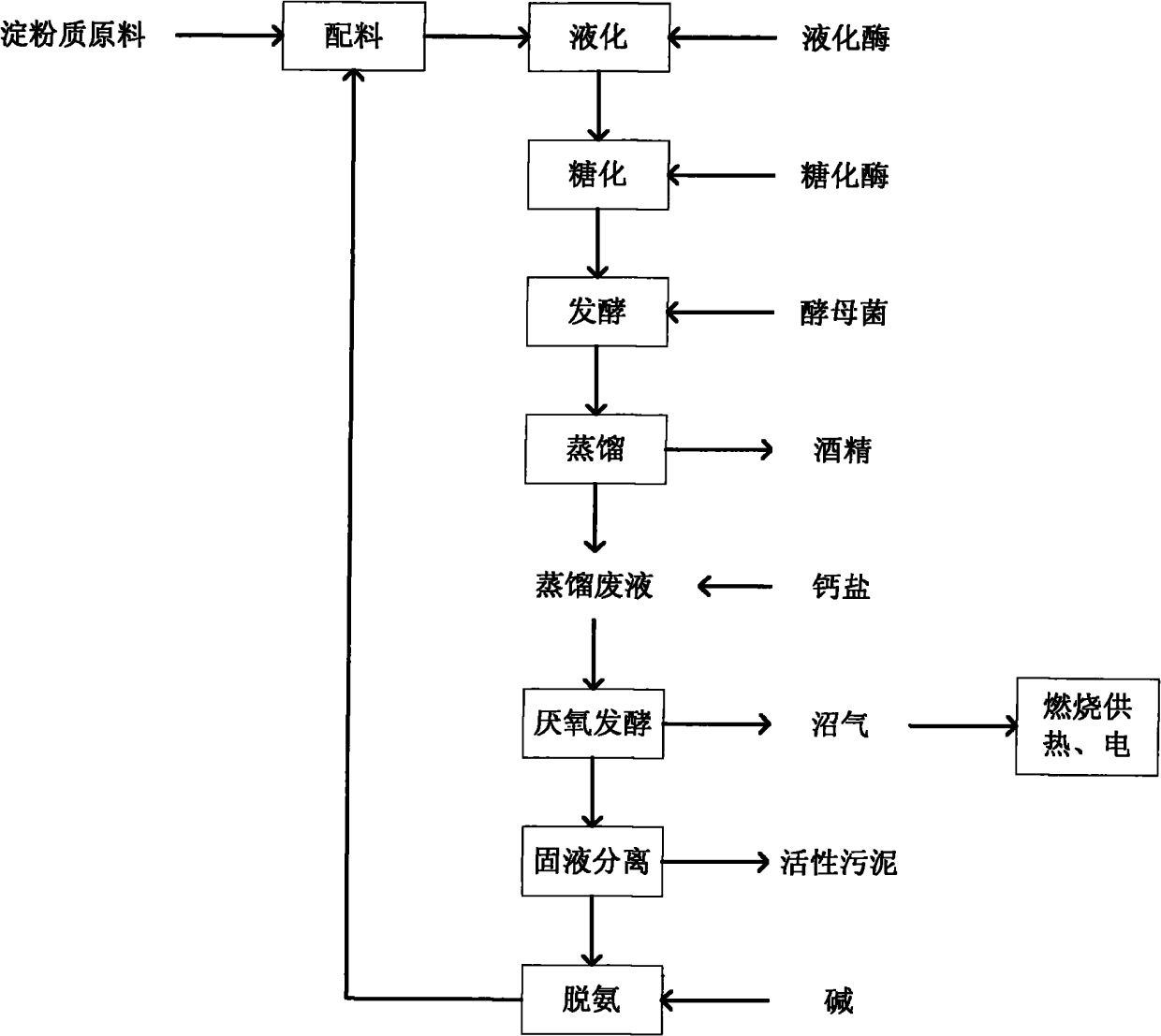

Method for producing alcohol by taking anaerobic effluent as ingredient water

ActiveCN102115764AEliminate potential hazardsImprove stabilityBiofuelsMultistage water/sewage treatmentLiquid wasteSulfate radicals

The invention relates to a method of an alcohol production process in which anaerobic effluent is taken as ingredient water. The method comprises the following steps of: mixing raw materials with deaminized anaerobic effluent in a specified material to water ratio; adjusting pH value and adding liquefied enzyme, heating, digesting and liquefying; cooling, and adding saccharified enzyme for saccharifying; lowering the temperature, inoculating and fermenting; distilling; precipitating sulfate radicals before performing anaerobic treatment on the distilled effluent obtained by distilling; and performing anaerobic treatment on the distilled effluent, and performing deamination treatment to obtain ingredient water for fermenting a next batch of alcohol. By adopting method, the running stability of the process in which the anaerobic effluent is taken as the ingredient water is enhanced, the content of hydrogen sulfide in marsh gas obtained by fermenting anaerobic marsh gas is lowered, and subsequent use of the marsh gas is facilitated.

Owner:JIANGNAN UNIV

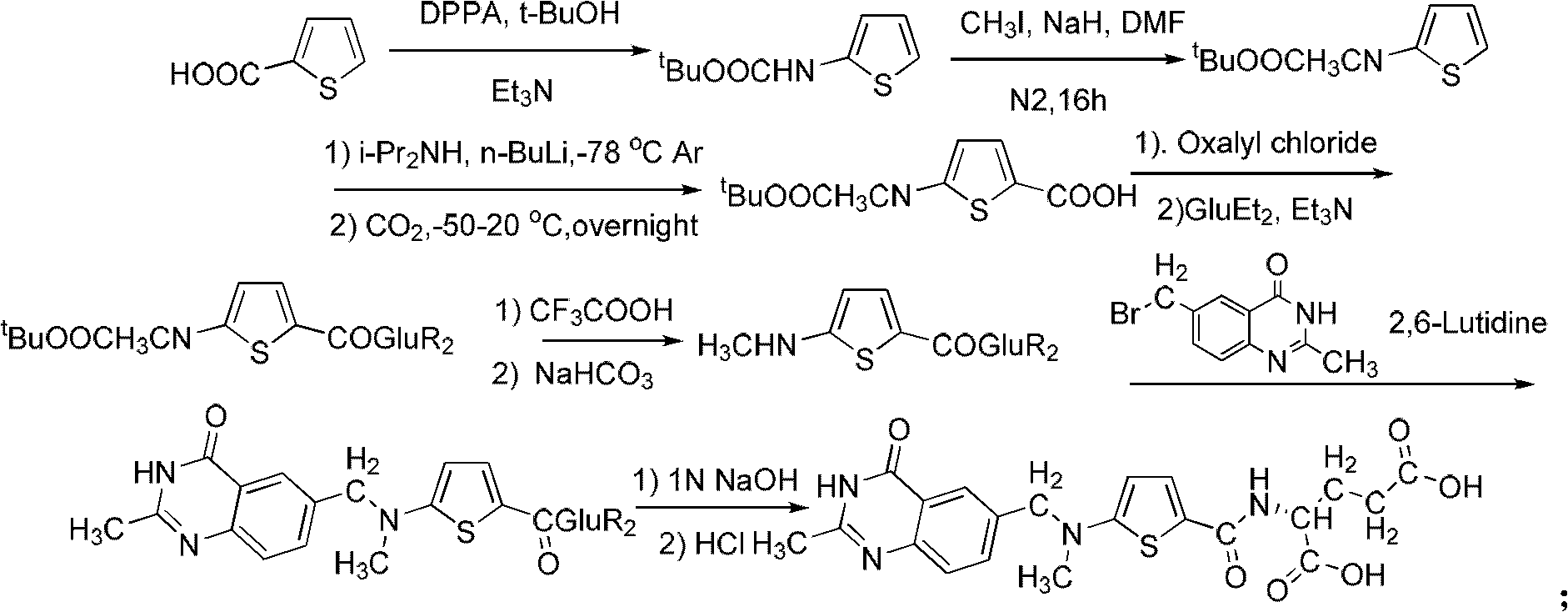

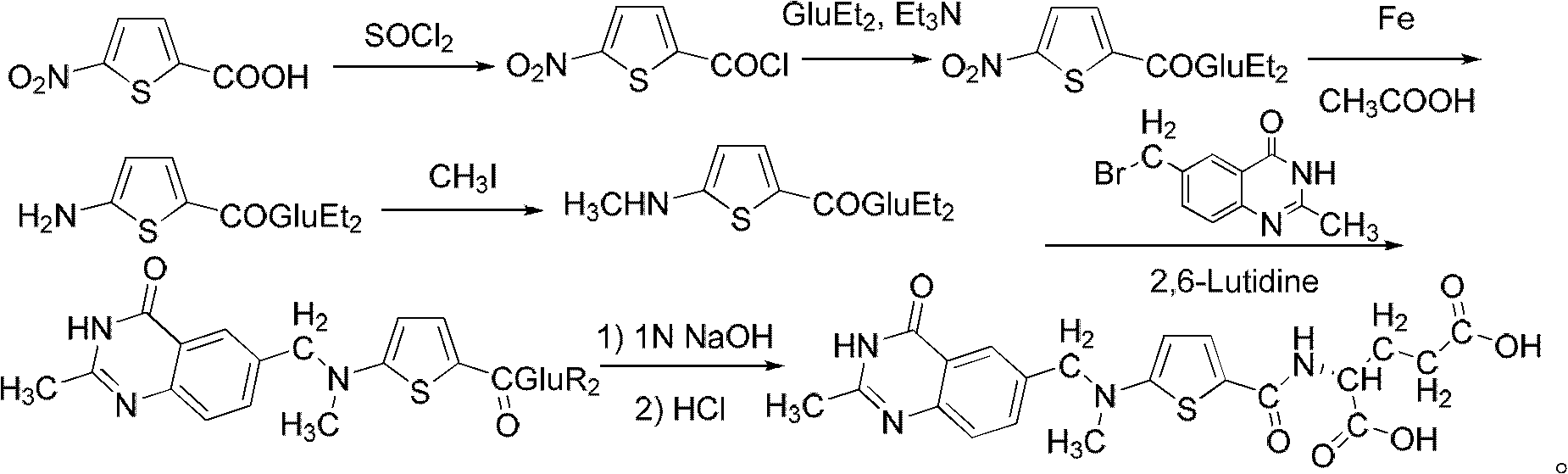

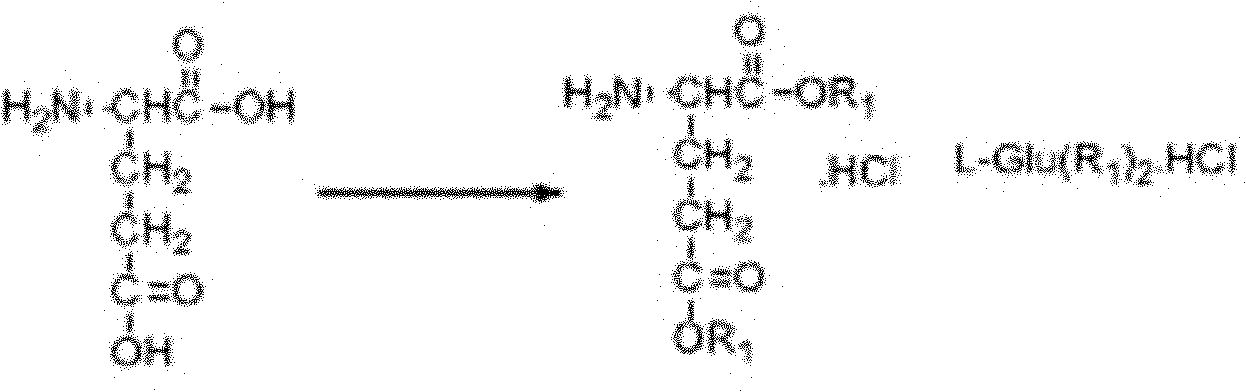

New synthesis technology of anti-cancer drug Raltitrexed

InactiveCN102127063ALow costOptimize the synthetic routeOrganic chemistryAntineoplastic agentsBenzoic acidTert-Butyloxycarbonyl protecting group

The invention relates to a new synthesis technology of anti-cancer drug Raltitrexed. The technology comprises the following steps: 1) using L-glutamic acid as raw material to perform esterification with alcohol under the action of halogenating agent and obtain L-glutamic acid diester hydrochloride; 2) using 2-amino-5-methyl-benzoic acid as raw material to prepare 6-bromomethyl-3,4-dihydro-2-methyl-4-oxo-6-quinazoline through cyclization, amination and bromination; 3) using 2-thienyl-propanedioic acid as raw material to prepare N-[5-[N-(tert-butoxycarbonyl)-N-methylamino]-2-thenoyl]-L-glutamic acid diethyl ester through nitrification, esterification, reduction, amino protection, N-methylation and device-esterification; 4) using L-glutamic acid diester hydrochloride and N-[5-[N-(tert-butoxycarbonyl)-N-methylamino]-2-thenoyl]-L-glutamic acid diethyl ester to prepare N-[5-(N-methylamino)-2-thenoyl]-L-glutamic acid diester through dehydrant condensation and deamination protection; and 5) using N-[5-(N-methylamino)-2-thenoyl]-L-glutamic acid diester and 6-bromomethyl-3,4-dihydro-2-methyl-4-oxo-6-quinazoline to perform condensation under the catalysis of alkali, recycling preparative chromatography, purifying, and performing de-esterification to obtain Raltitrexed.

Owner:深圳市普迈达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com