Method and equipment for carrying out deamination treatment on high-concentration wastewater containing ammonia nitrogen

A technology for ammonia nitrogen wastewater and its treatment method, which is applied in metallurgical wastewater treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problems that ammonia stripping efficiency is difficult to meet the requirements and the removal rate is high, reaching Effects of protecting the surrounding environment, improving efficiency and stability, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

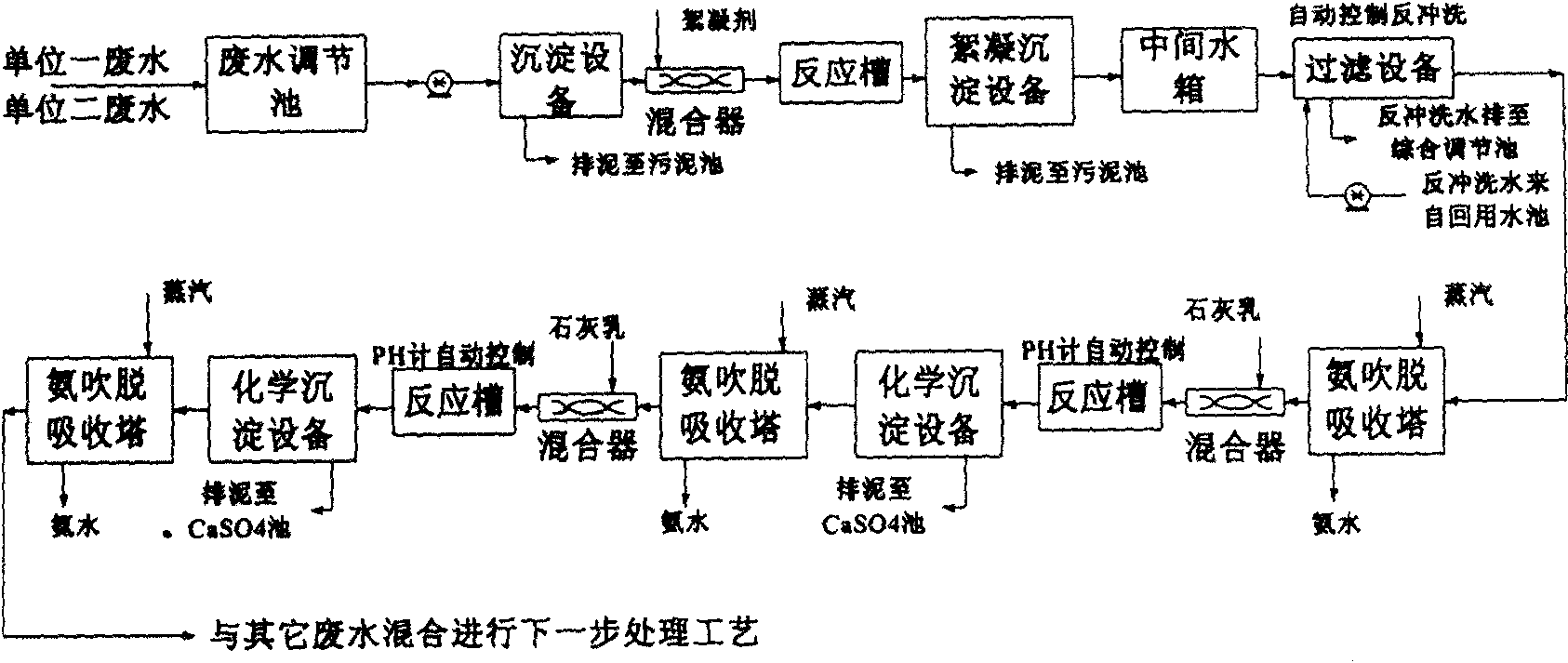

[0025] Example 1. Wastewater enters the regulating tank for water quality and water volume balance. The wastewater enters the sedimentation equipment. The wastewater is lifted to the flocculation sedimentation tank by the lift pump to add flocculant for flocculation and sedimentation. The mixing time of flocculant and wastewater is 3 minutes, and the reaction time is 30 minutes. , the precipitated wastewater is then lifted to the first-level stripping tower by the lifting pump, and the wastewater in the first-level stripping tower moves from top to bottom in the form of spraying, and is blown off by steam with a pressure of 0.5MPa, and the second-level ammonia blowing is carried out. For stripping, first use milk of lime to adjust the pH value of the wastewater to 11, after mixing, reaction, and chemical precipitation, after precipitation and separation, the wastewater is lifted to the stripping tower by a lift pump again, and steam stripping with a pressure of 0.4MPa is used in...

example 2

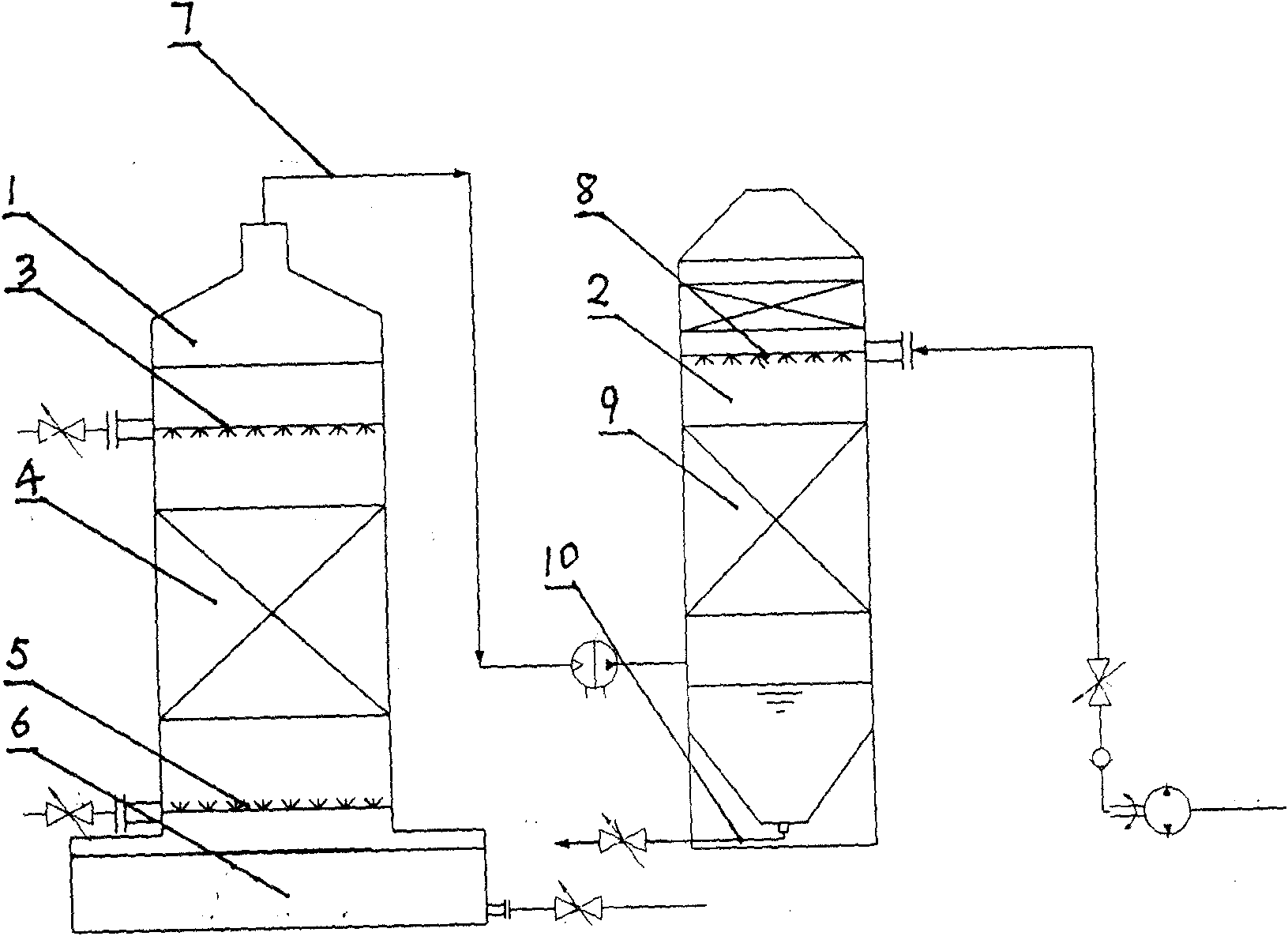

[0029]Example 2, the ammonia stripping absorption tower of the device of the present invention consists of stripping tower 1, absorption tower 2, waste water sprayer 3, waste water packing layer 4, aeration pipe 5, drainage box 6, exhaust pipe 7, clear water spray 8, clear water packing layer 9 and recovery pipe 10, wherein waste water sprayer 3, waste water packing layer 4 and aeration pipe 5 are housed in stripping tower 1, waste water packing layer 4 is in the middle part of stripping tower 1, waste water spraying The device 3 is above the waste water packing layer 4, the aeration pipe 5 is below the waste water packing layer 4, the drainage tank 6 is at the bottom of the stripping tower 1, the top of the stripping tower 1 is connected with an exhaust pipe 7, and the upper part of the absorption tower 2 inner cavity is installed There is a clear water sprayer 8 with a clear water packing layer 9 in the middle, the other end of the exhaust pipe 7 is connected to the absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com