Patents

Literature

4648results about "Water/sewage treatment by degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

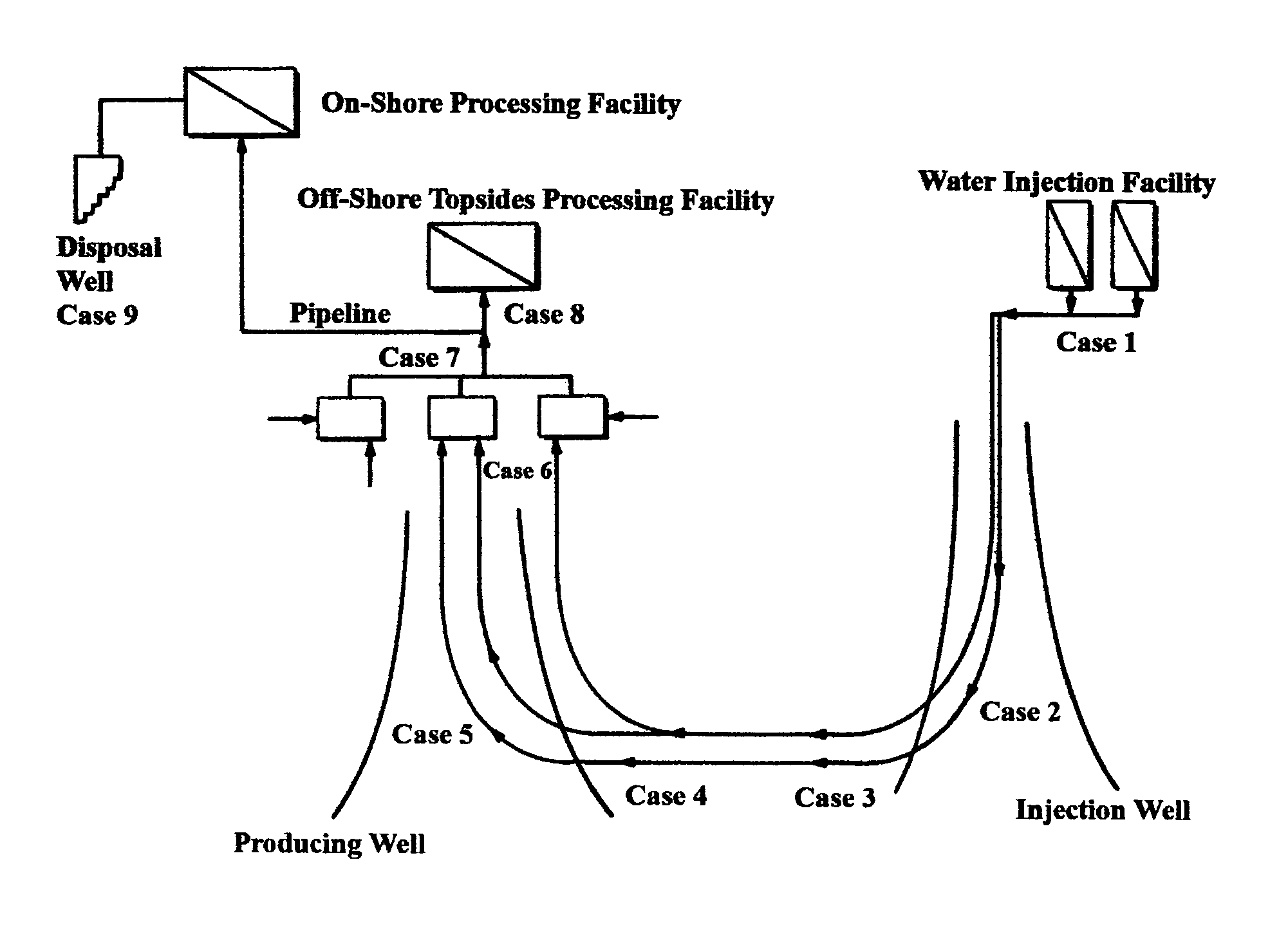

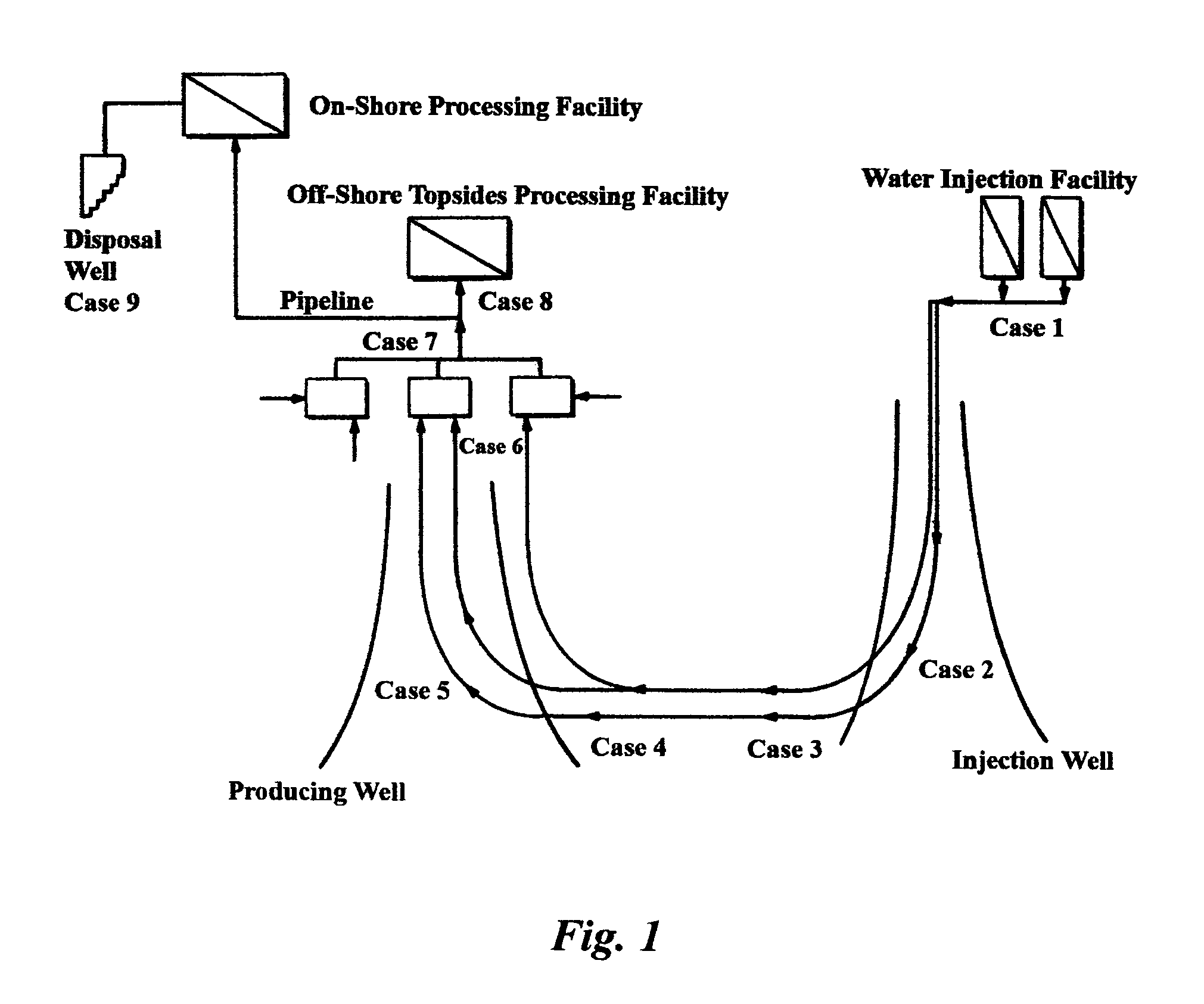

Treating produced waters

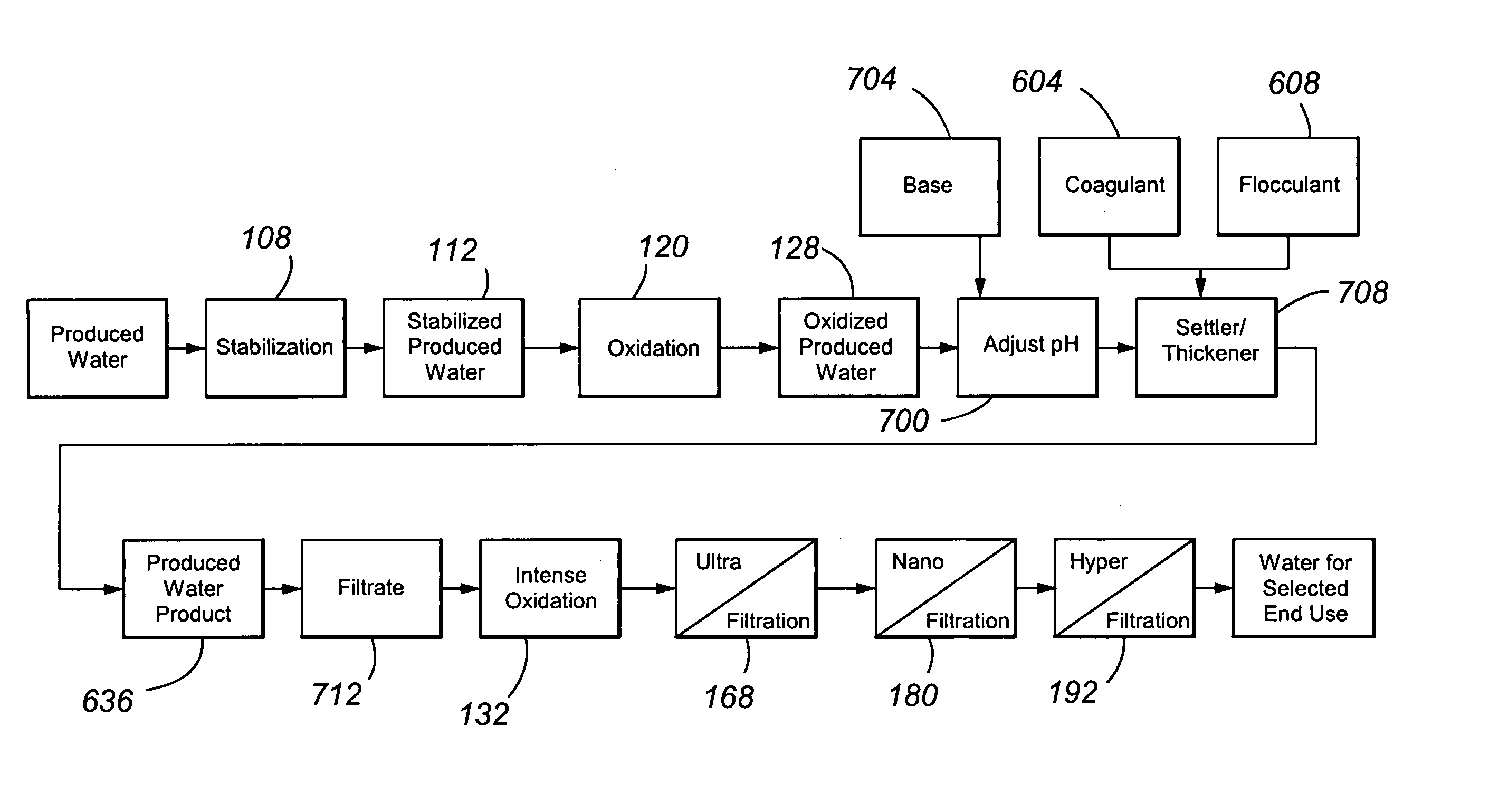

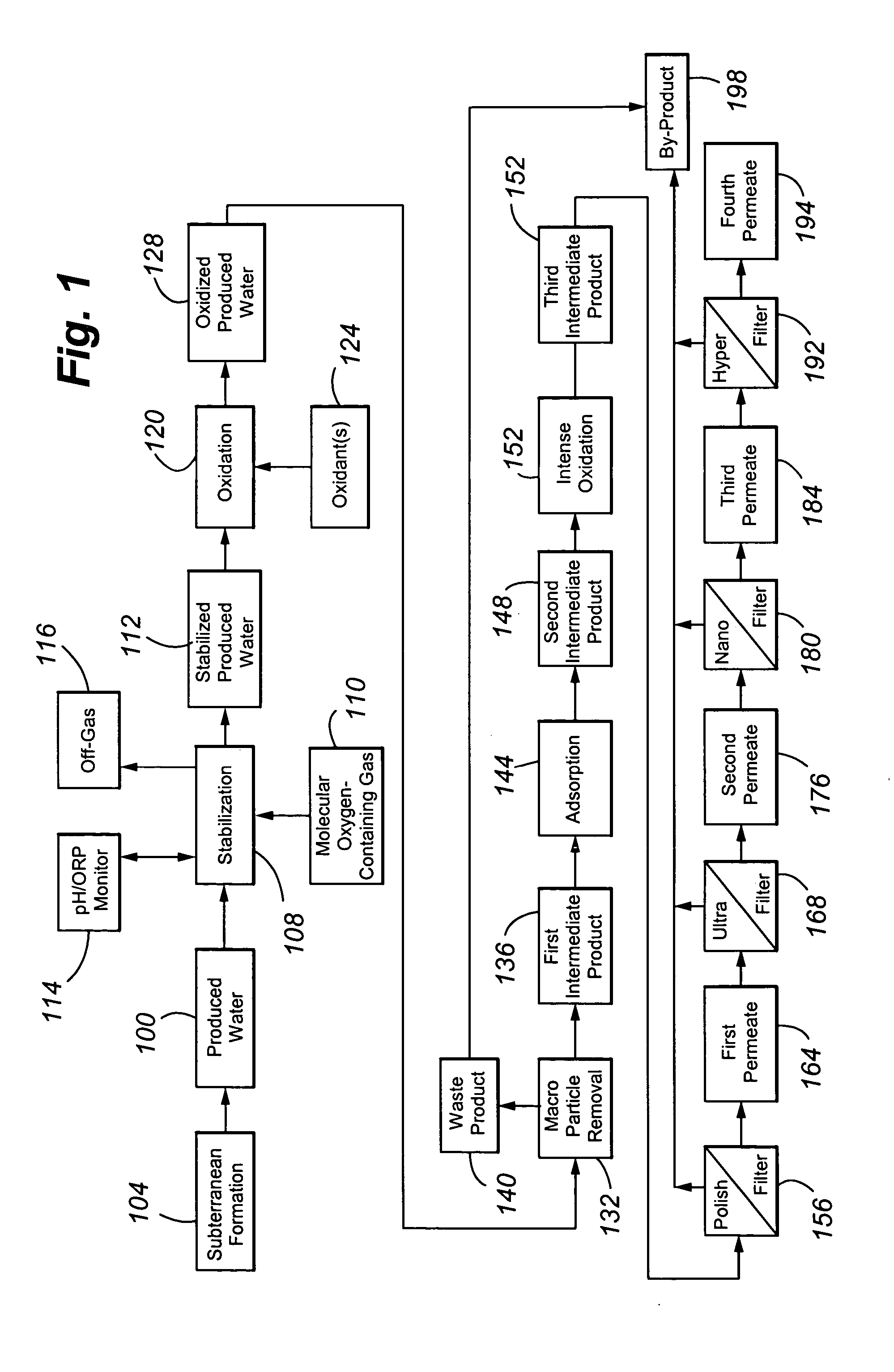

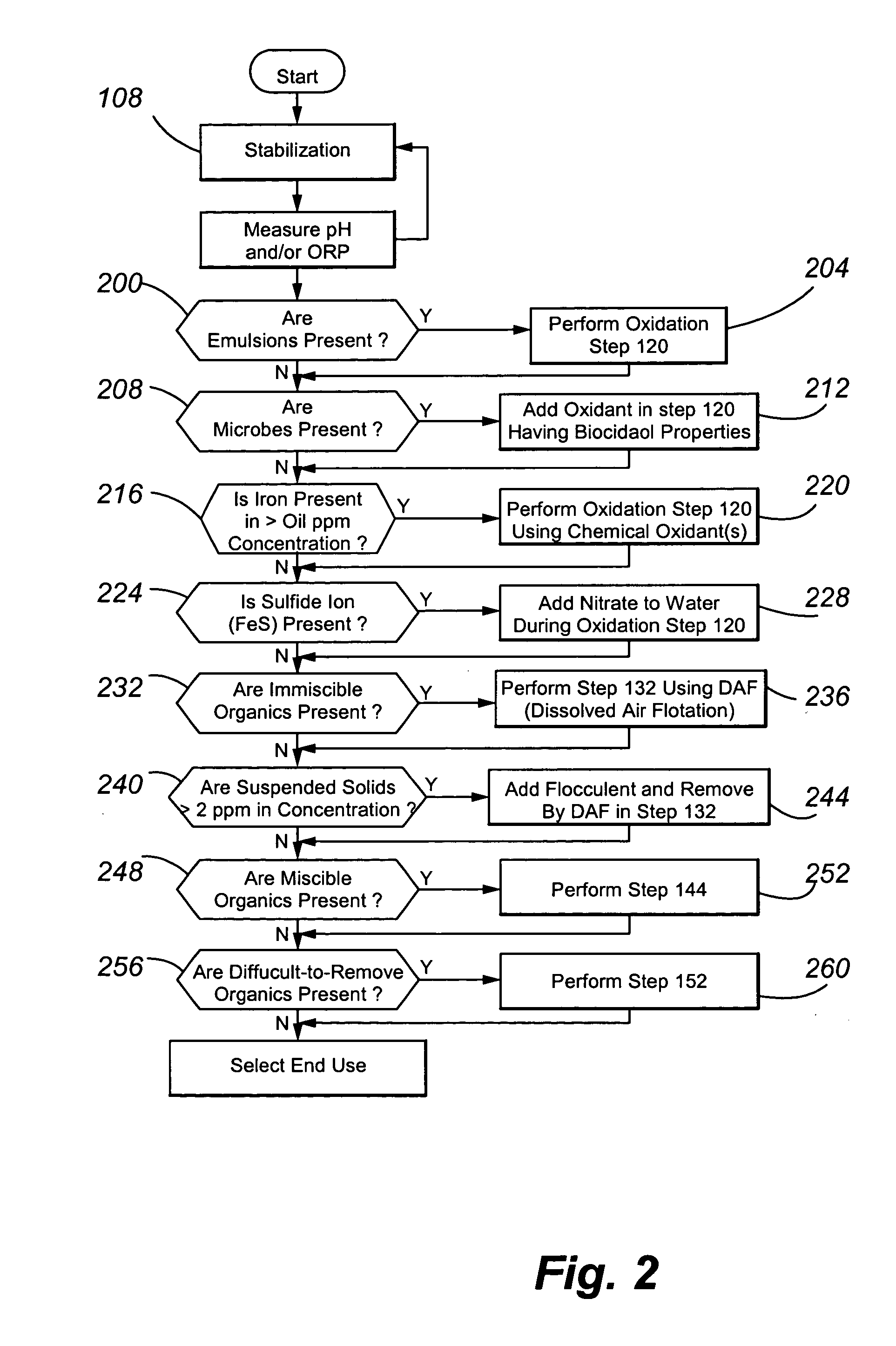

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

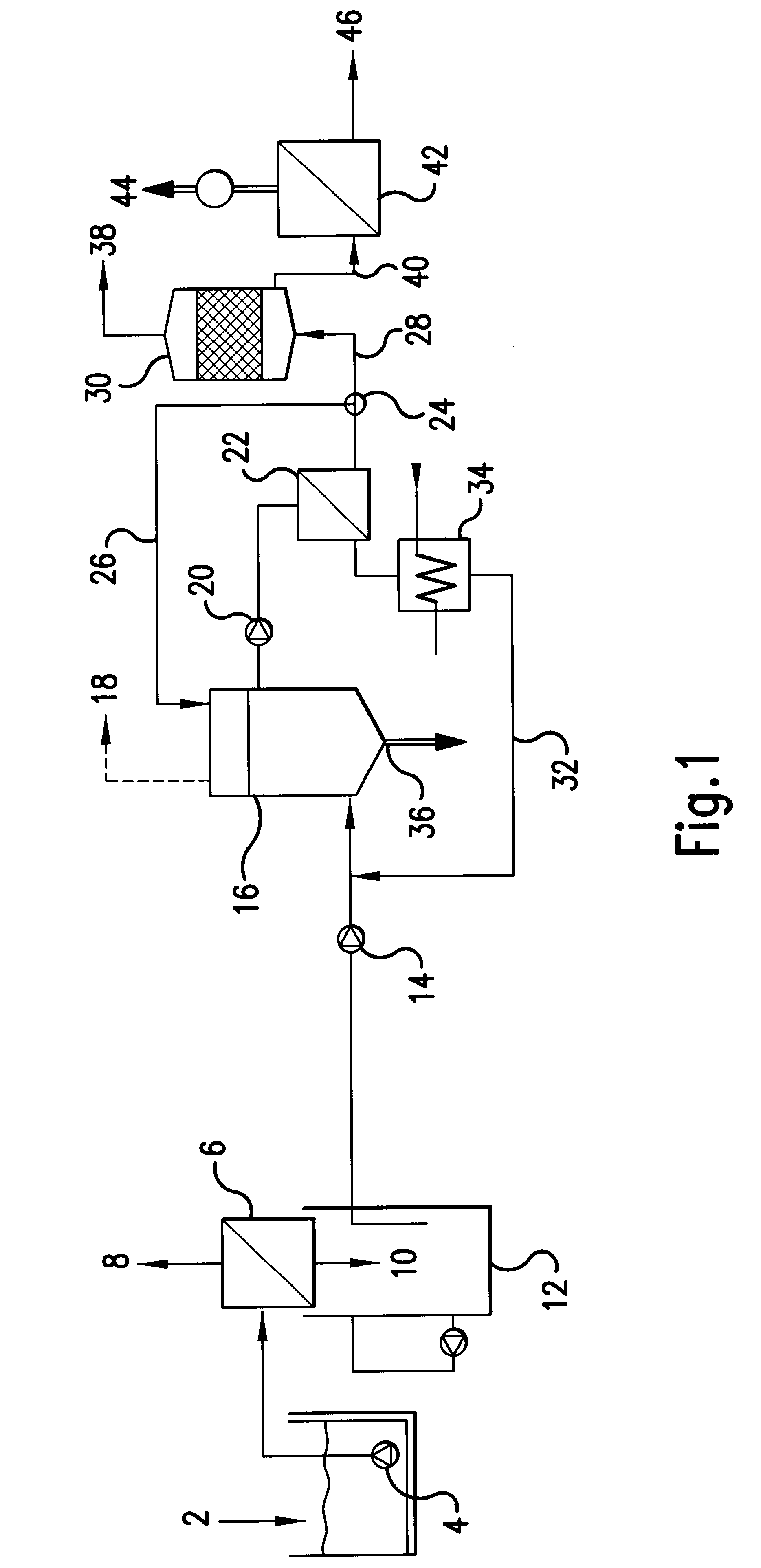

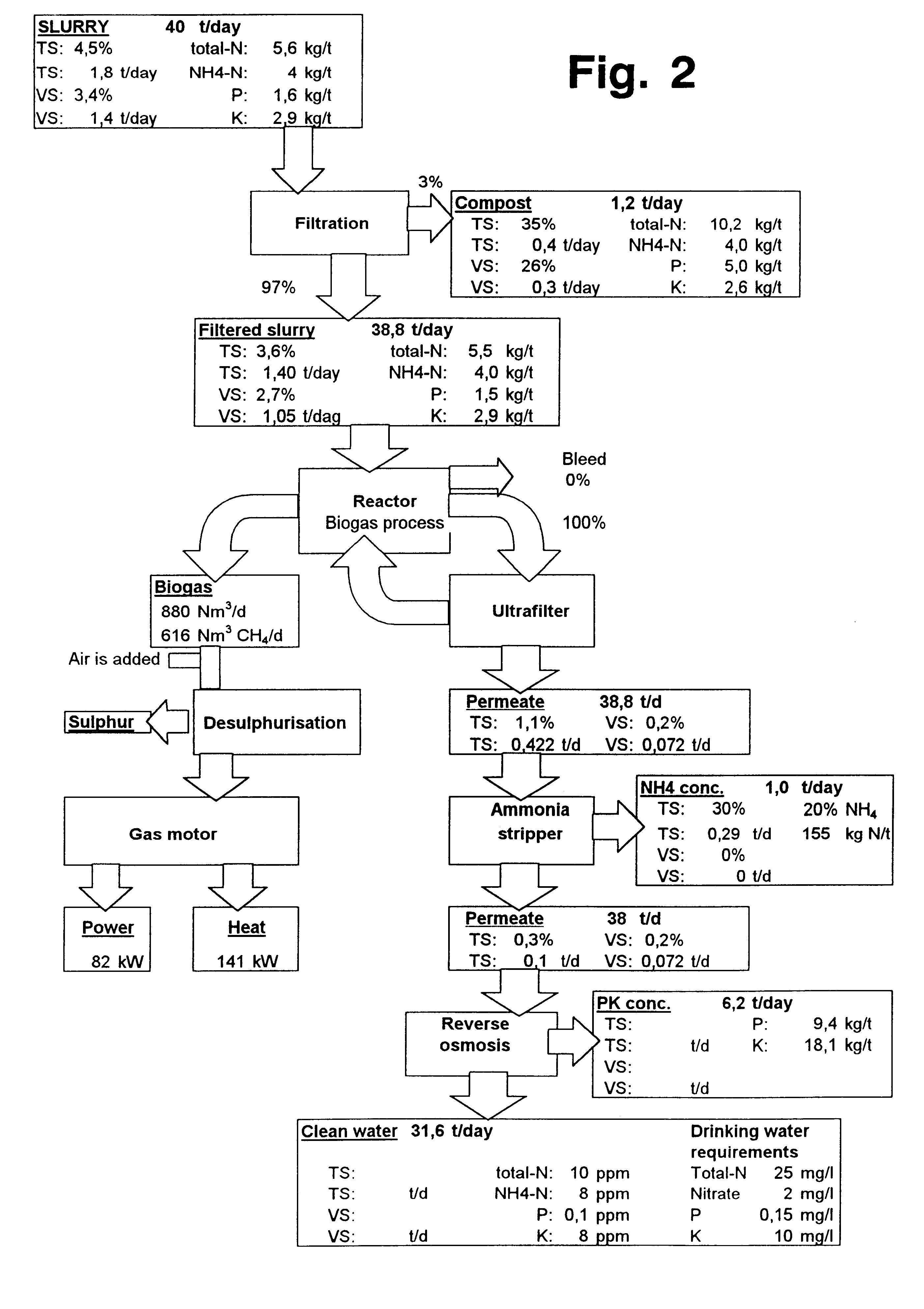

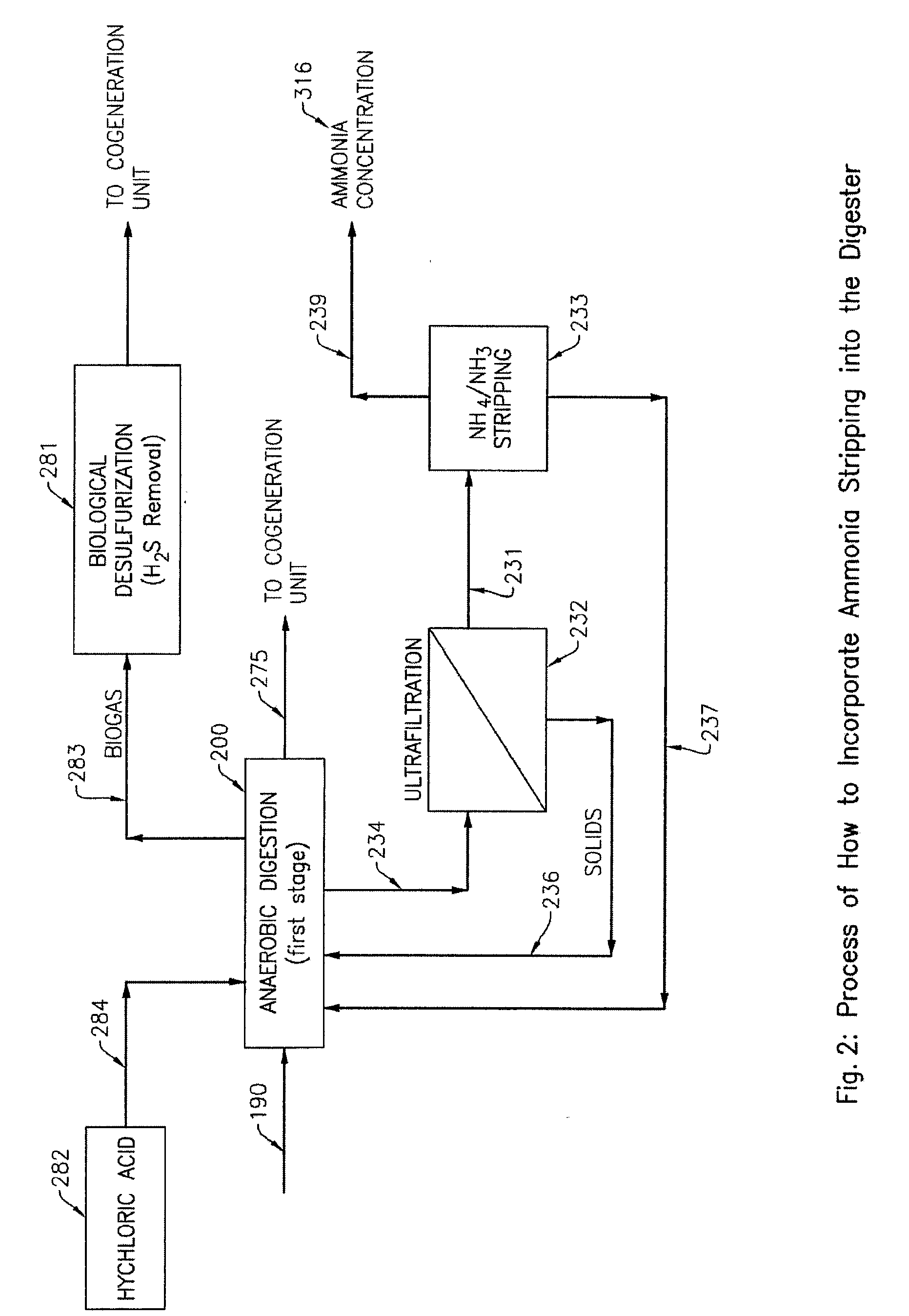

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

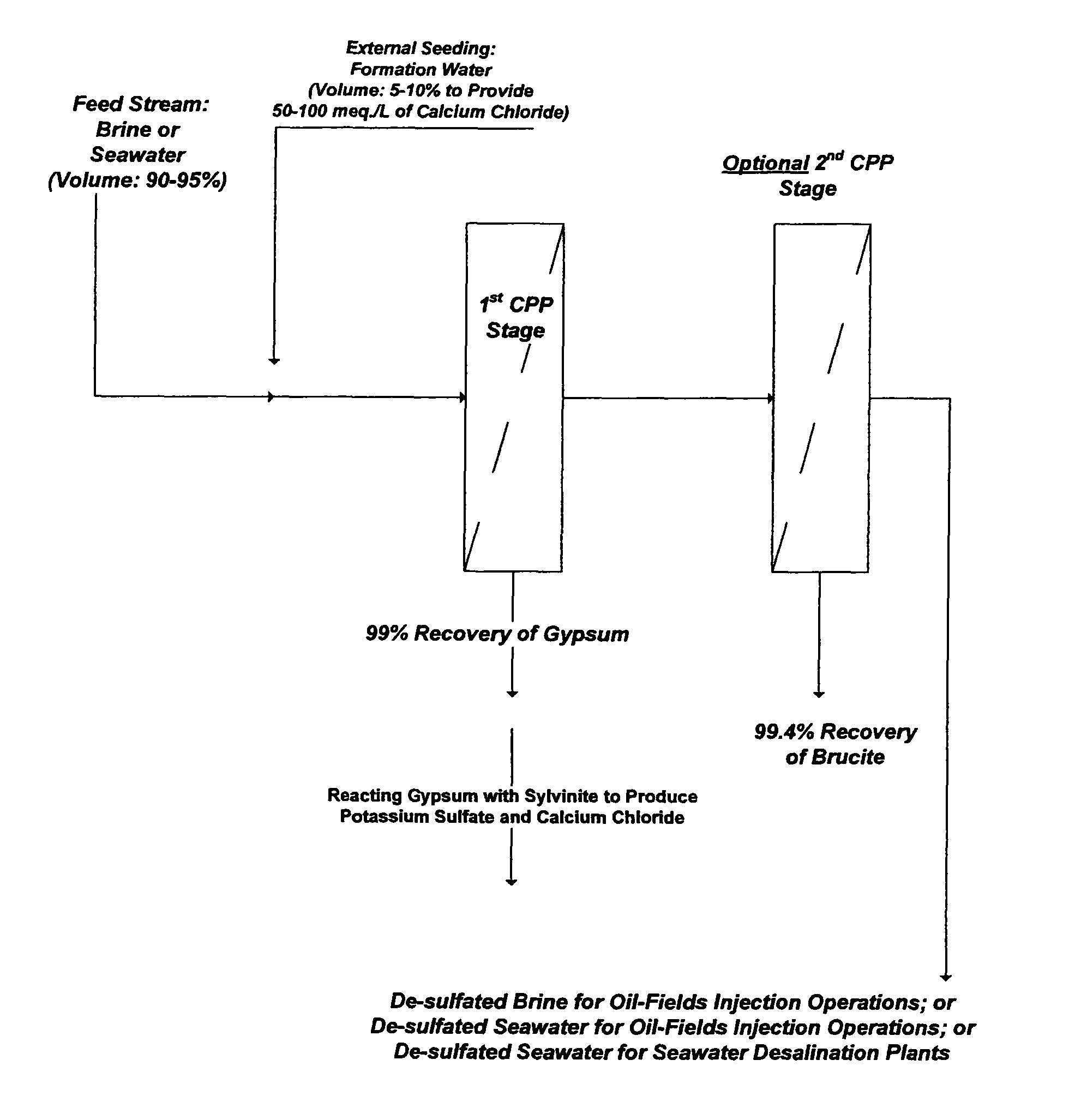

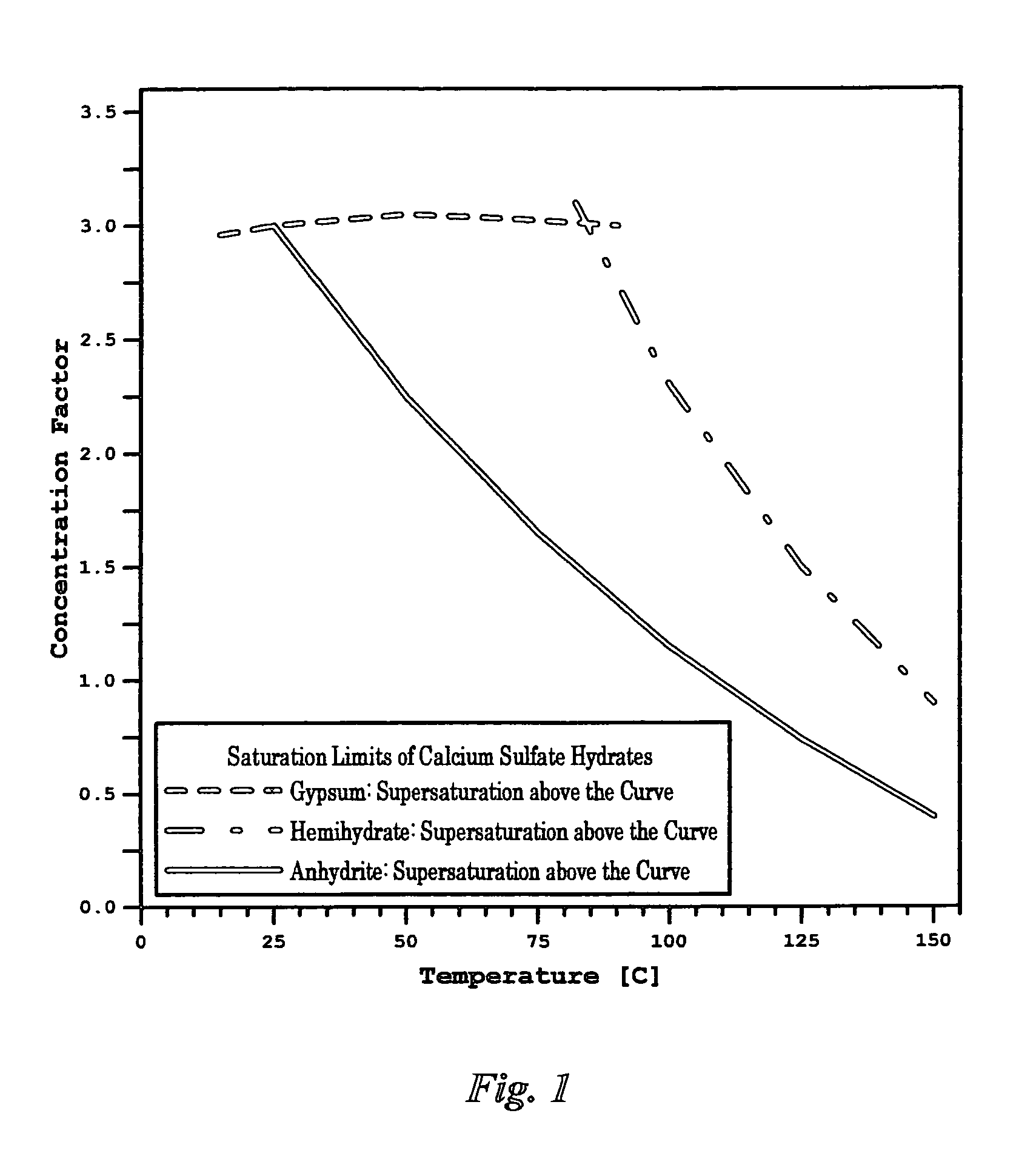

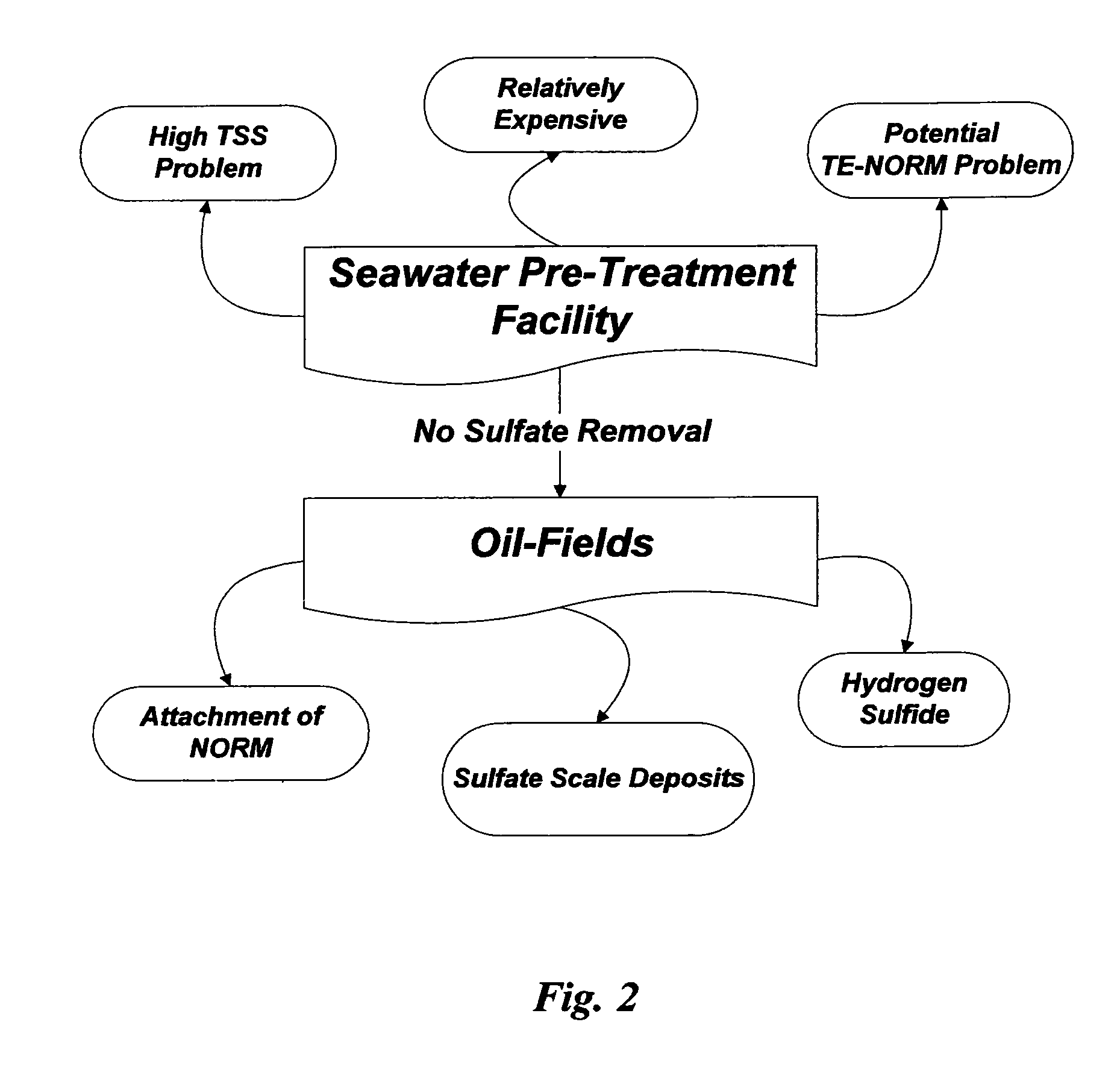

Methods to de-sulfate saline streams

ActiveUS7789159B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterInorganic materials

Methods are disclosed to de-sulfate saline streams such as seawater, brine from seawater desalination plants, and the like. The disclosed methods can also co-produce de-ionized water and inorganic materials from such de-sulfated saline streams.

Owner:BADER MANSOUR S

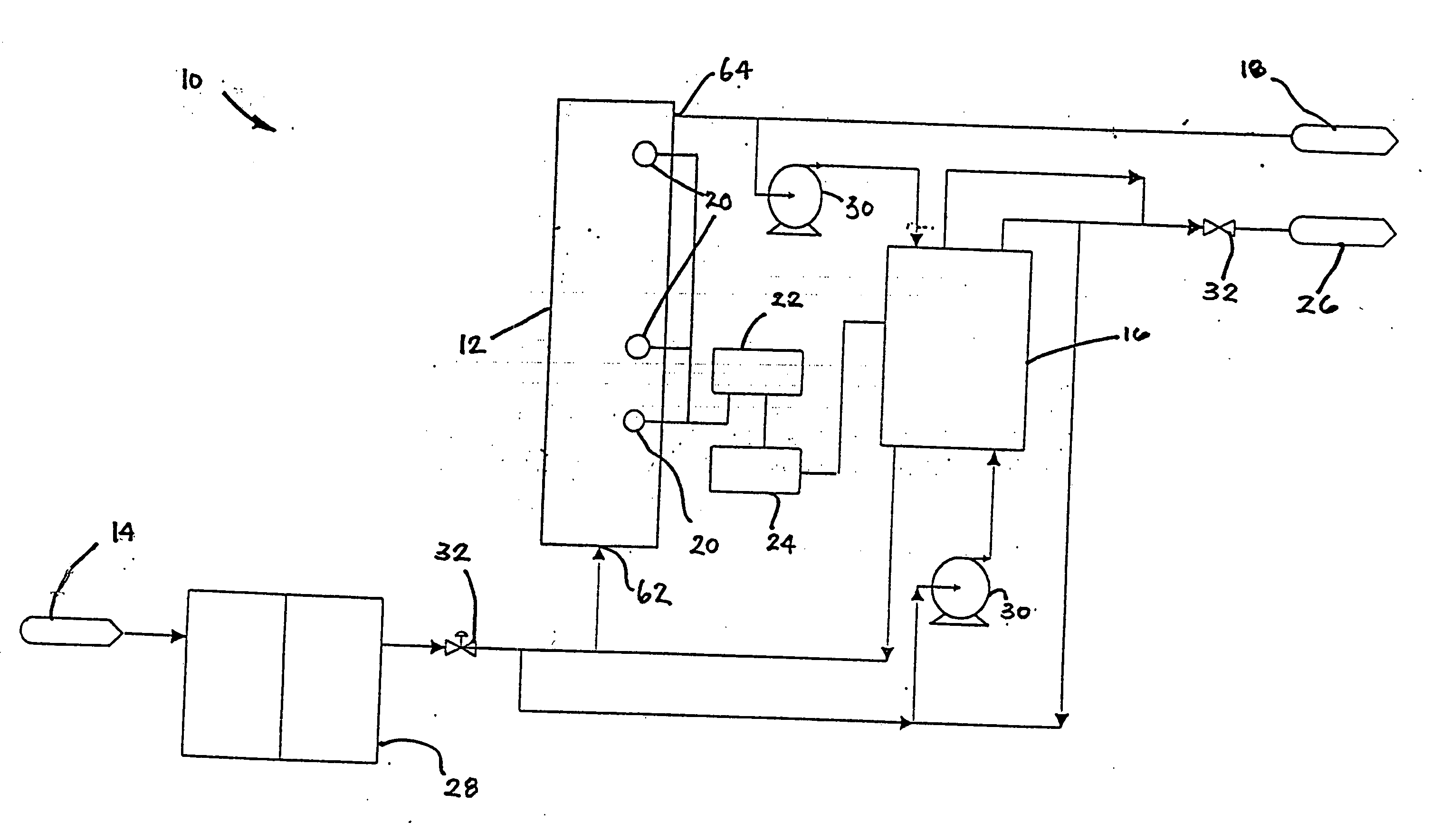

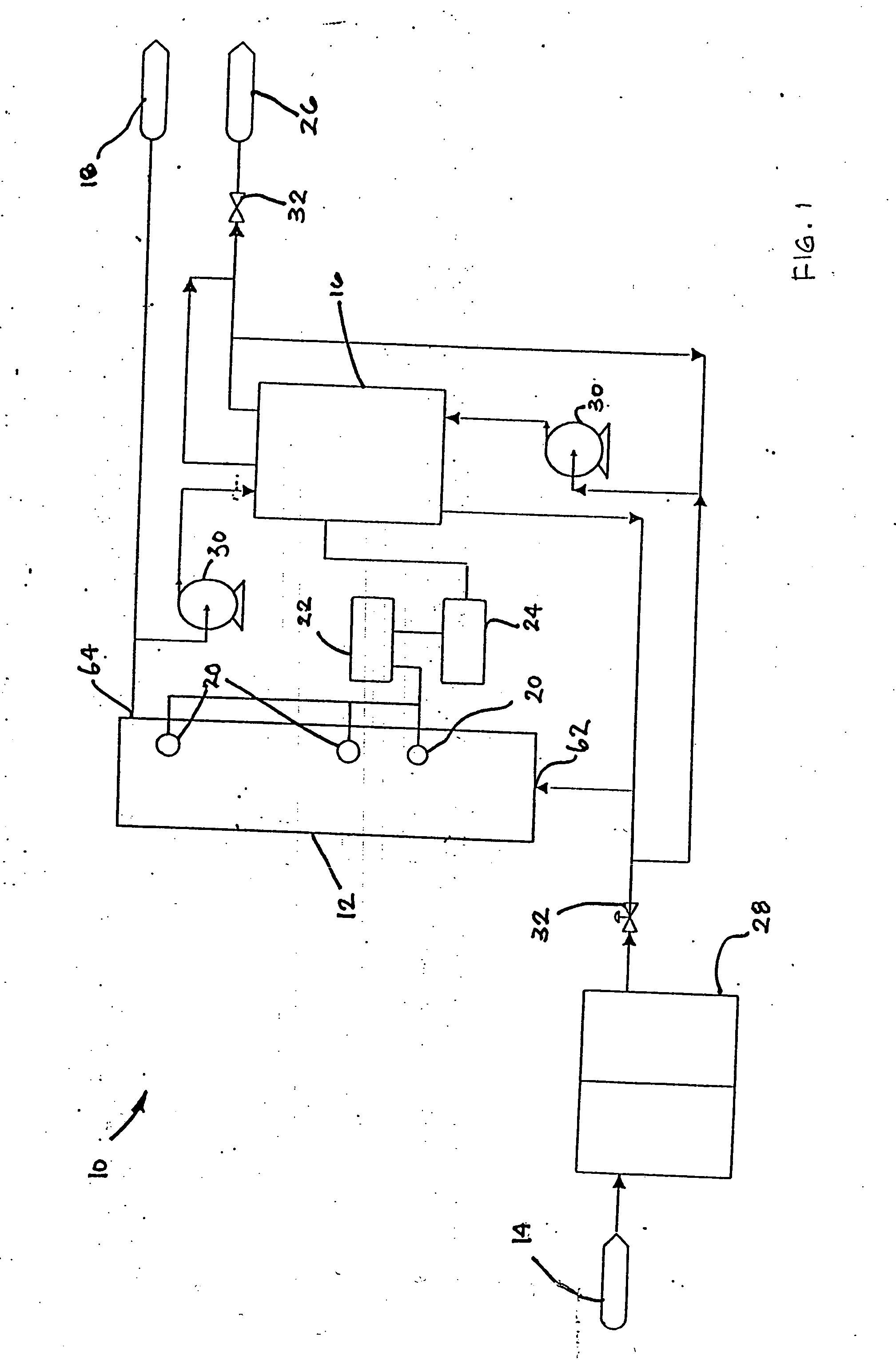

Water treatment system and method

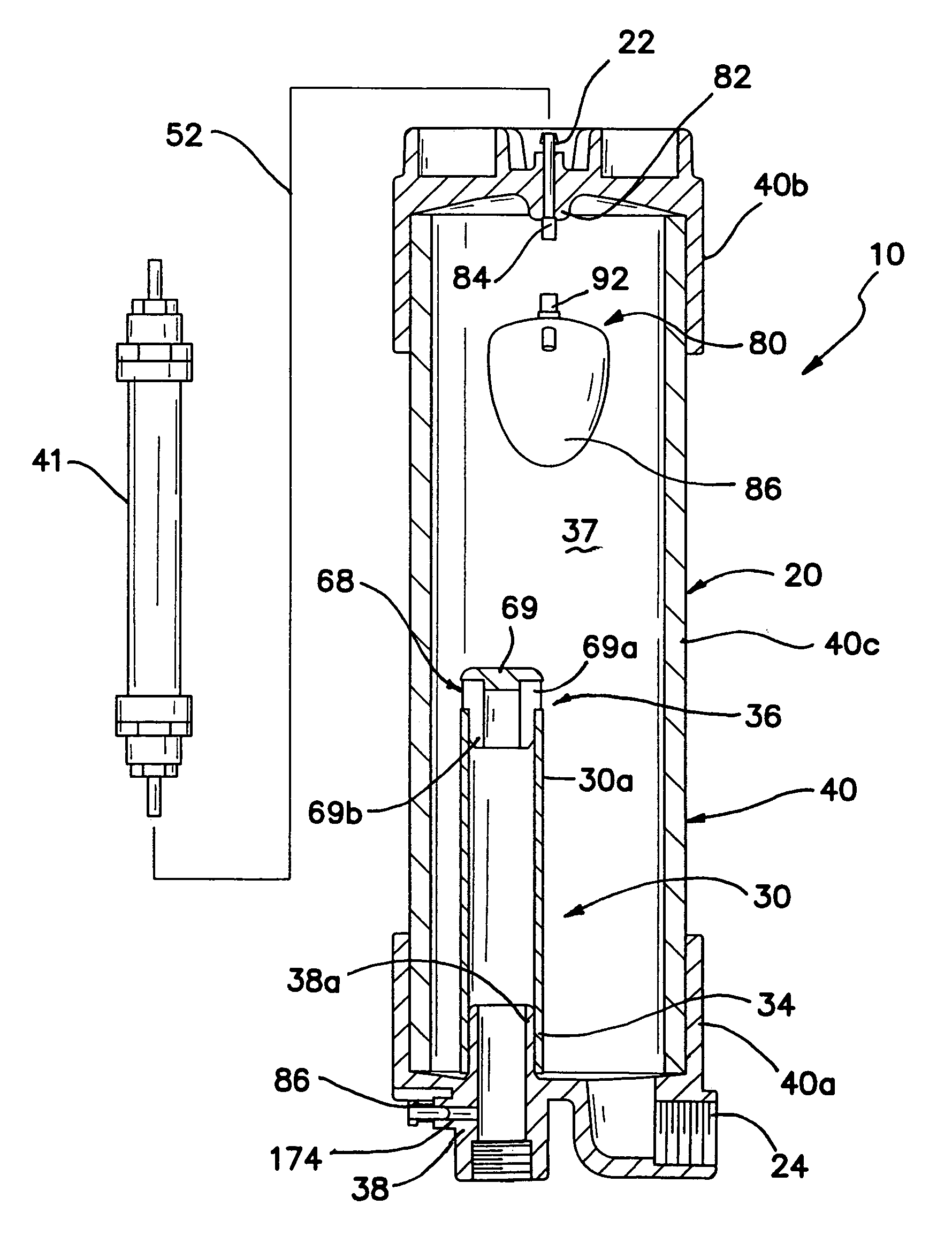

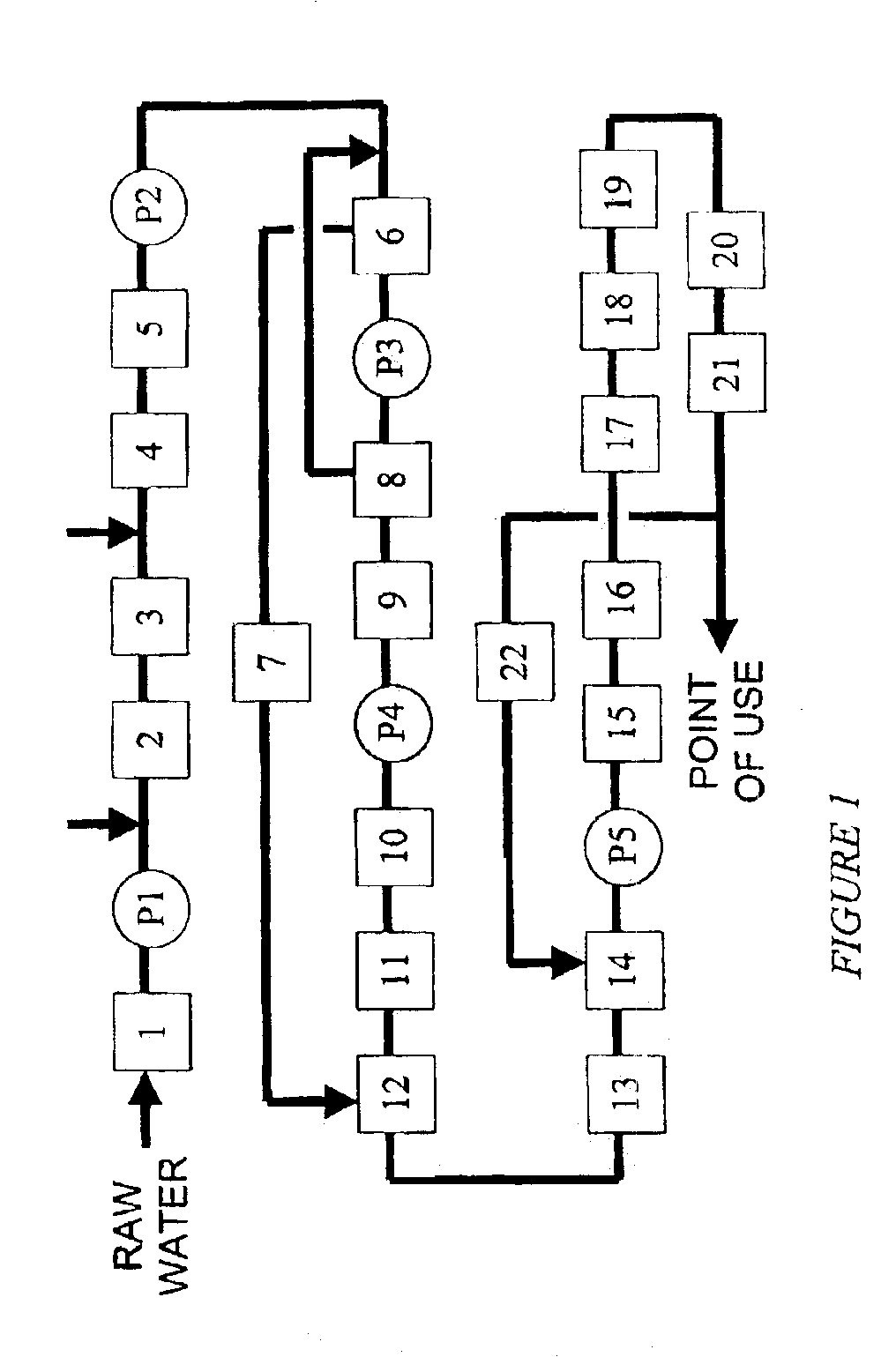

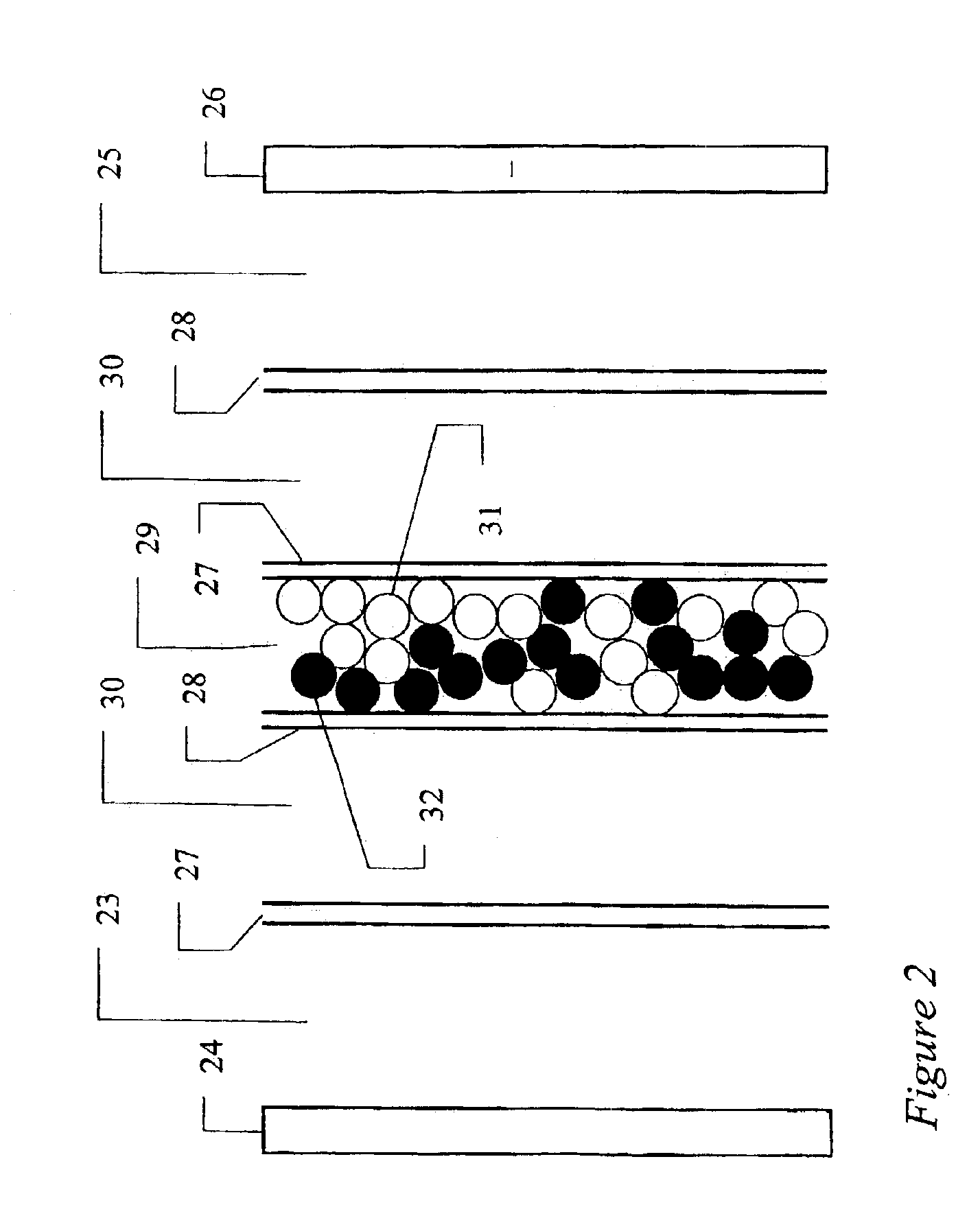

ActiveUS20050103722A1Water treatment parameter controlIon-exchange column/bed processesWater treatment systemWater source

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

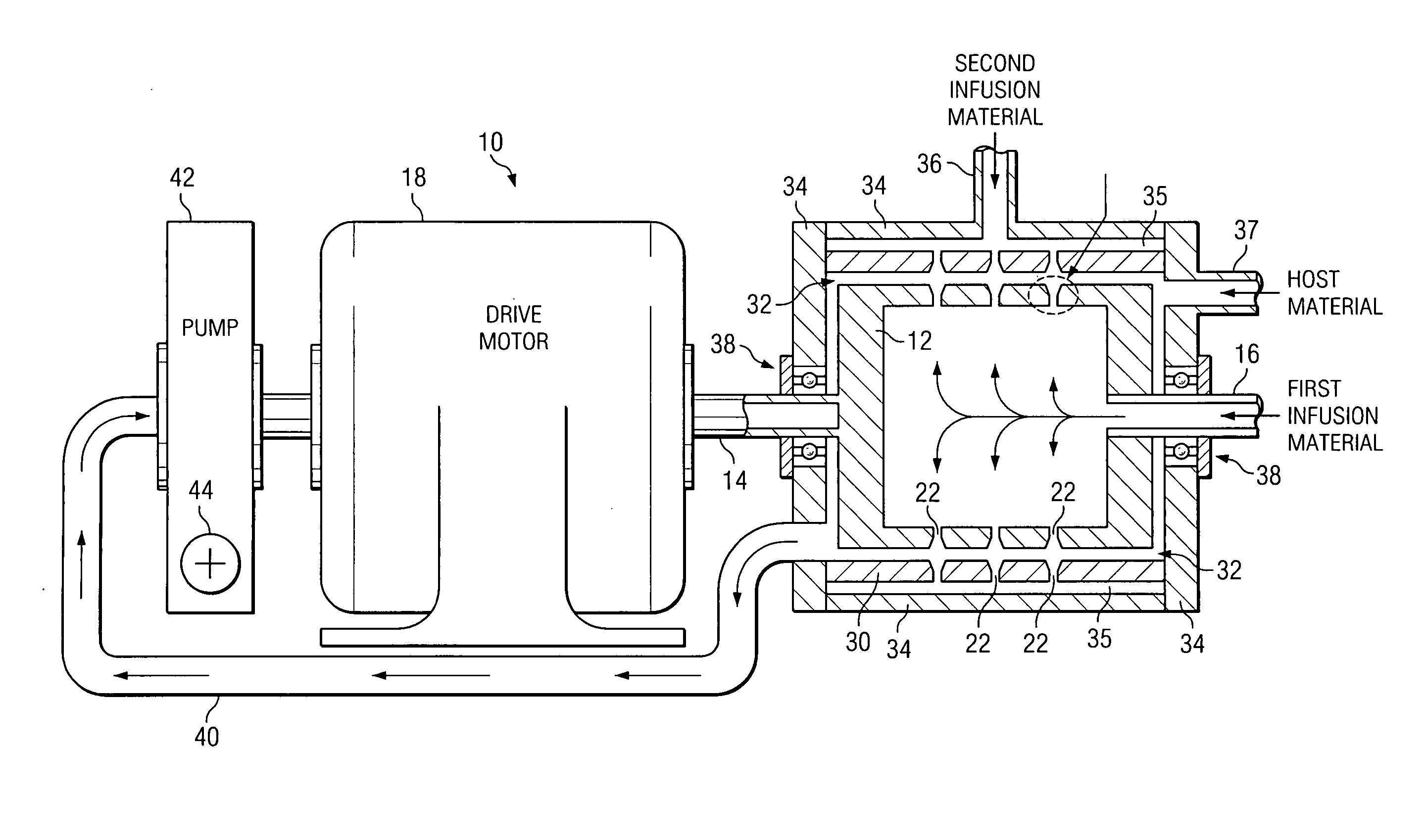

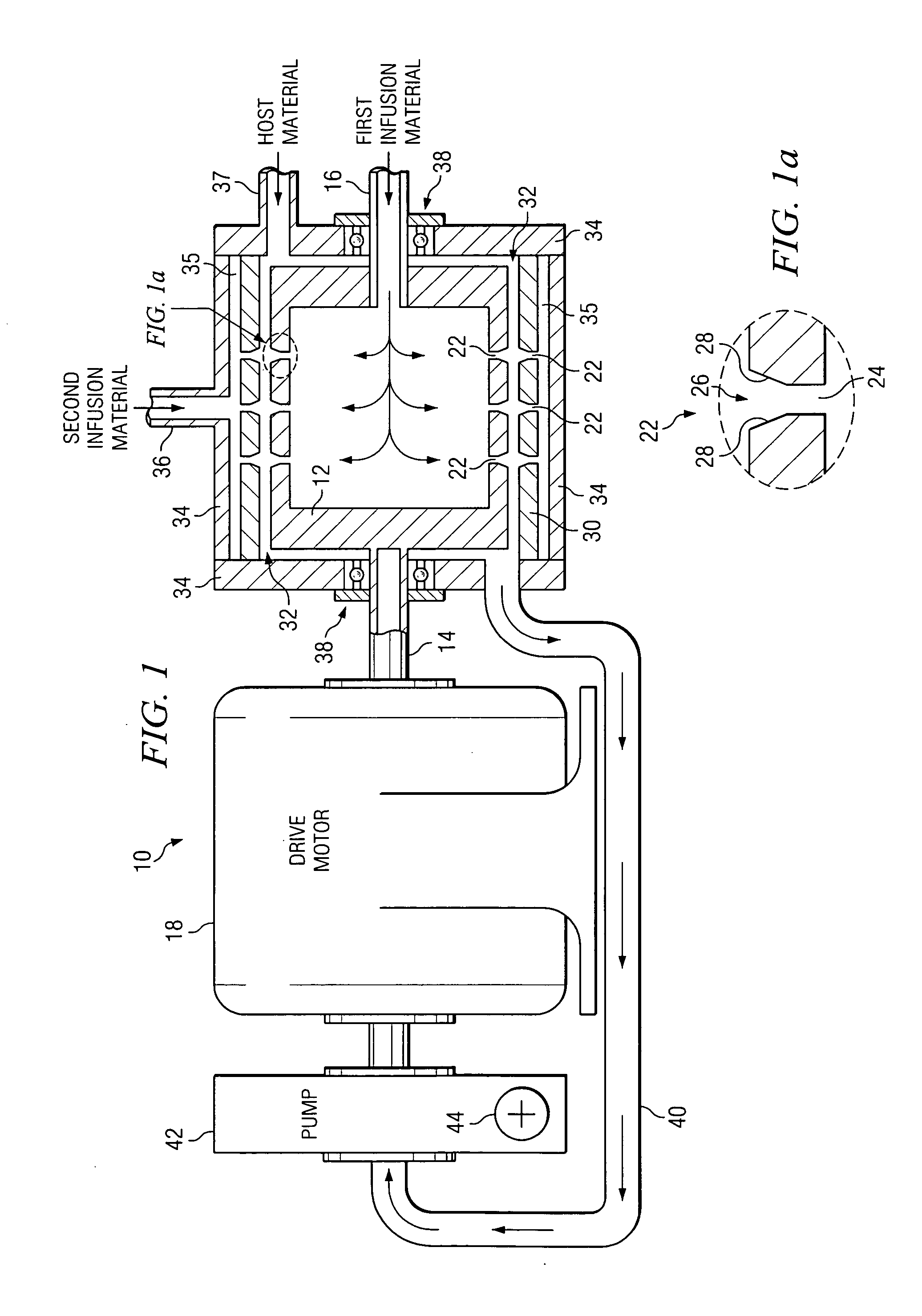

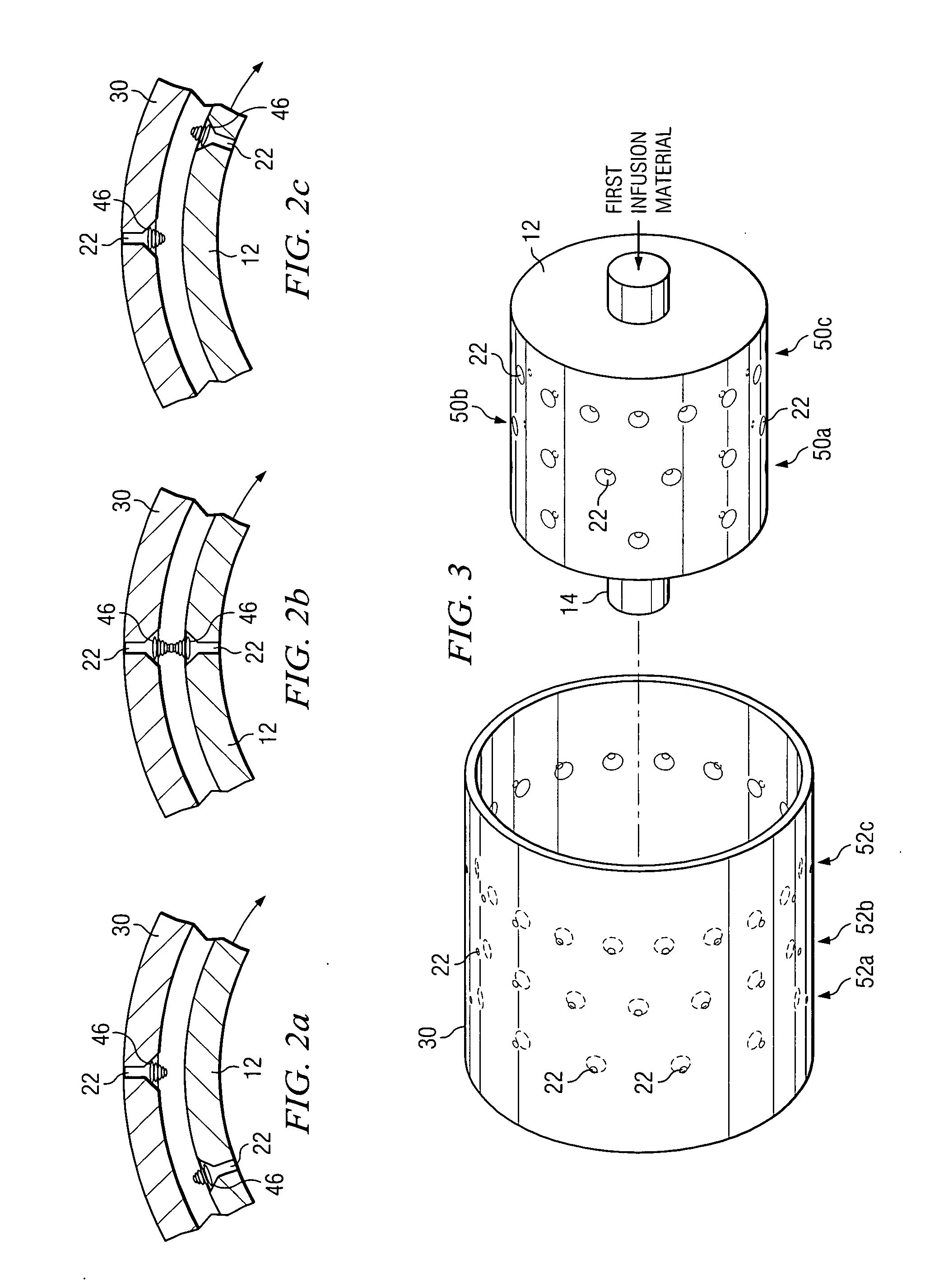

System and method for therapeutic application of dissolved oxygen

InactiveUS20050047270A1Rotary stirring mixersUsing liquid separation agentCavitationAqueous solution

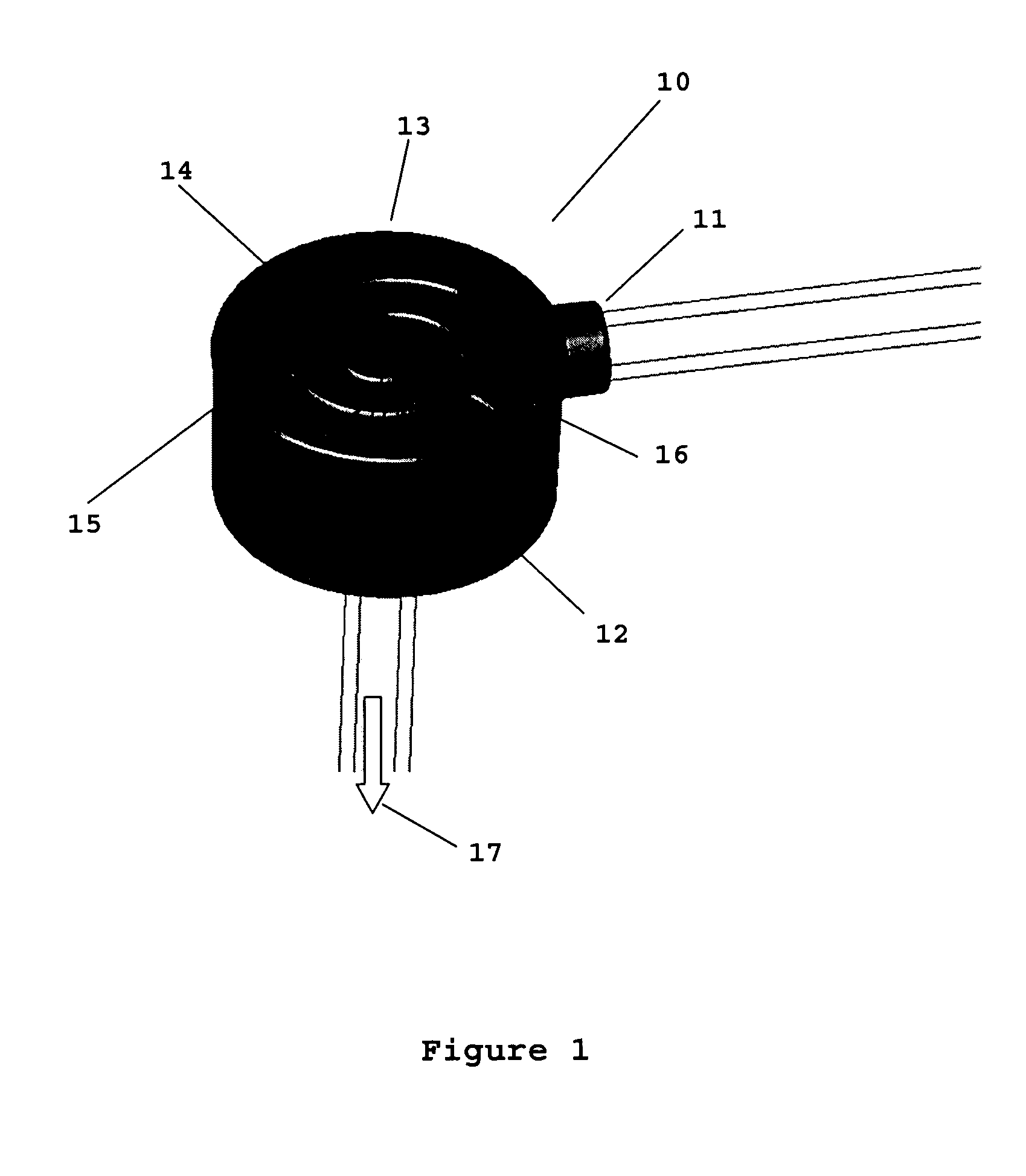

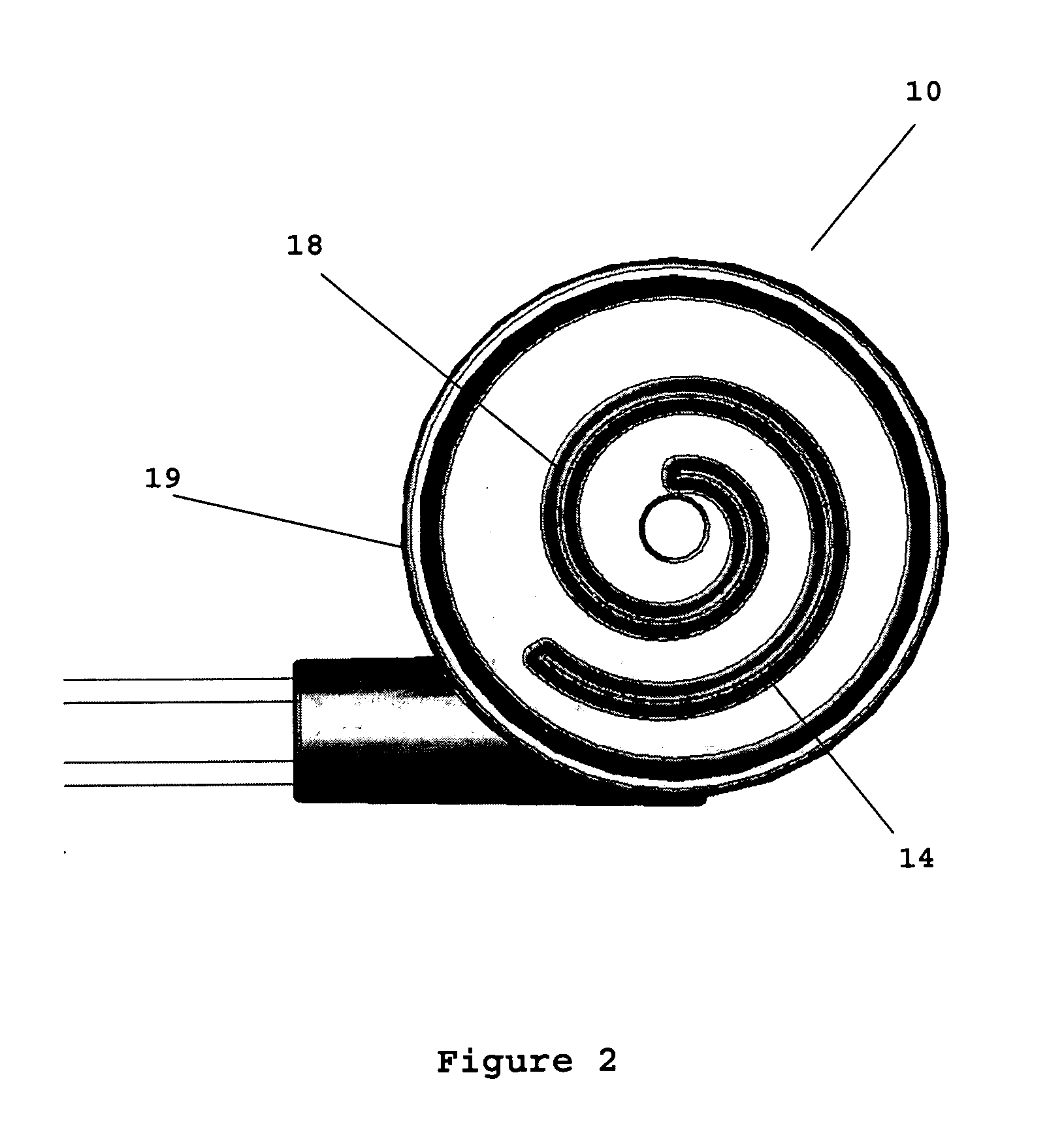

A system and method for generating an oxygen enriched aqueous solution for therapeutic application includes a diffuser comprising a first diffusing member having a surface incorporating surface disturbances, and a second diffusing member positioned relative to the first diffusing member to form a channel through which an aqueous solution and oxygen gas may flow. A reservoir containing the aqueous solution is connected to a pump that draws the aqueous solution from the reservoir and inputs the aqueous solution into the diffuser. The aqueous solution is moved through the channel relative to the surface disturbances to create cavitation in the aqueous solution to diffuse the oxygen gas into the aqueous solution to produce an oxygen enriched aqueous solution.

Owner:REVALESIO CORP

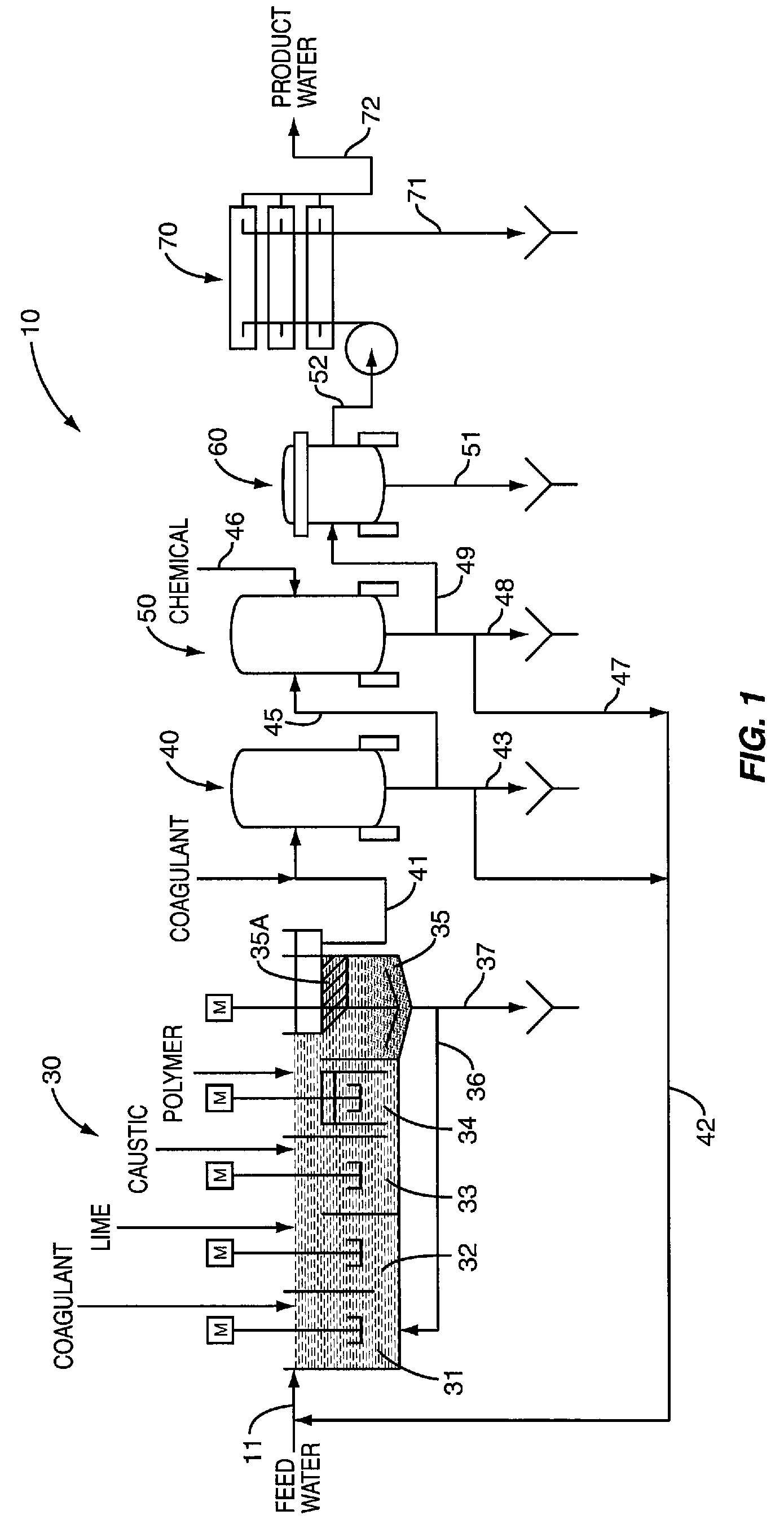

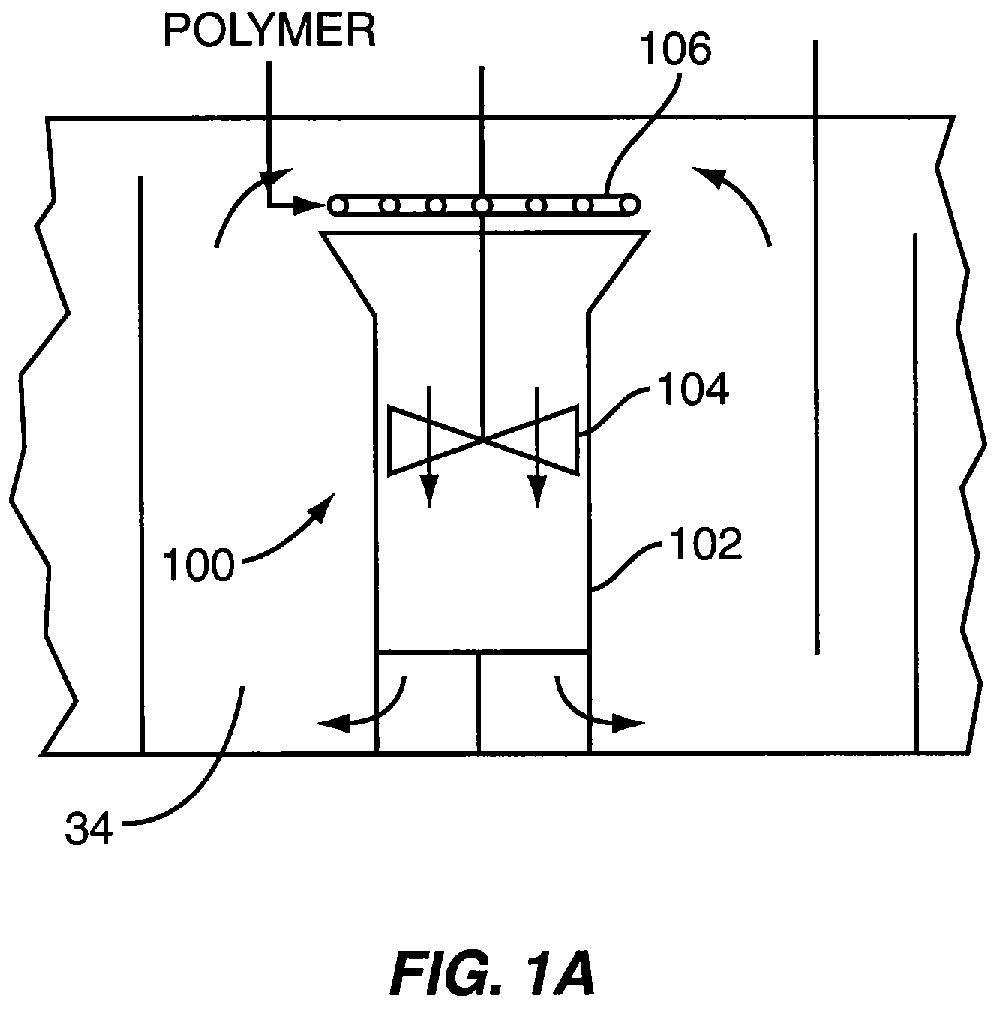

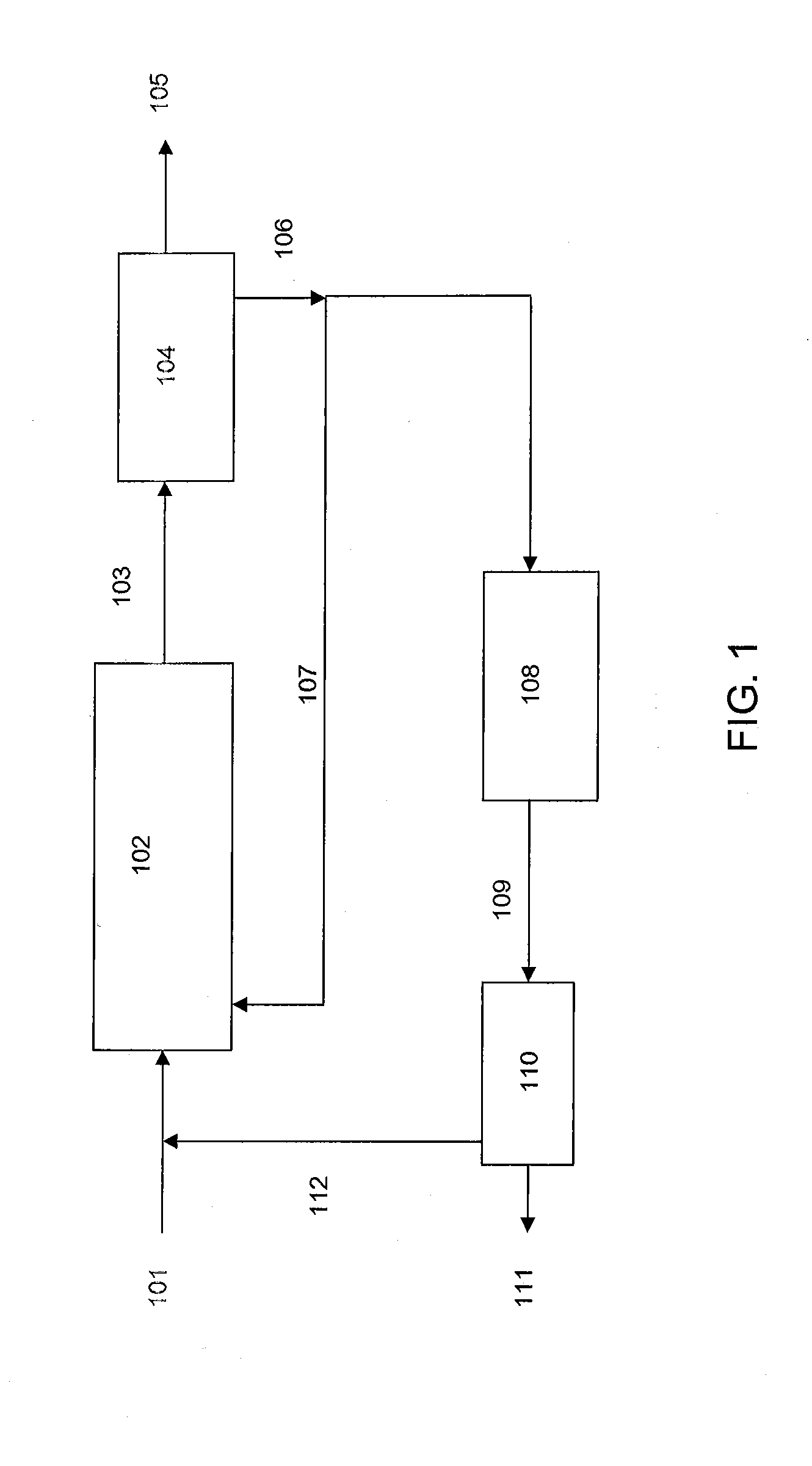

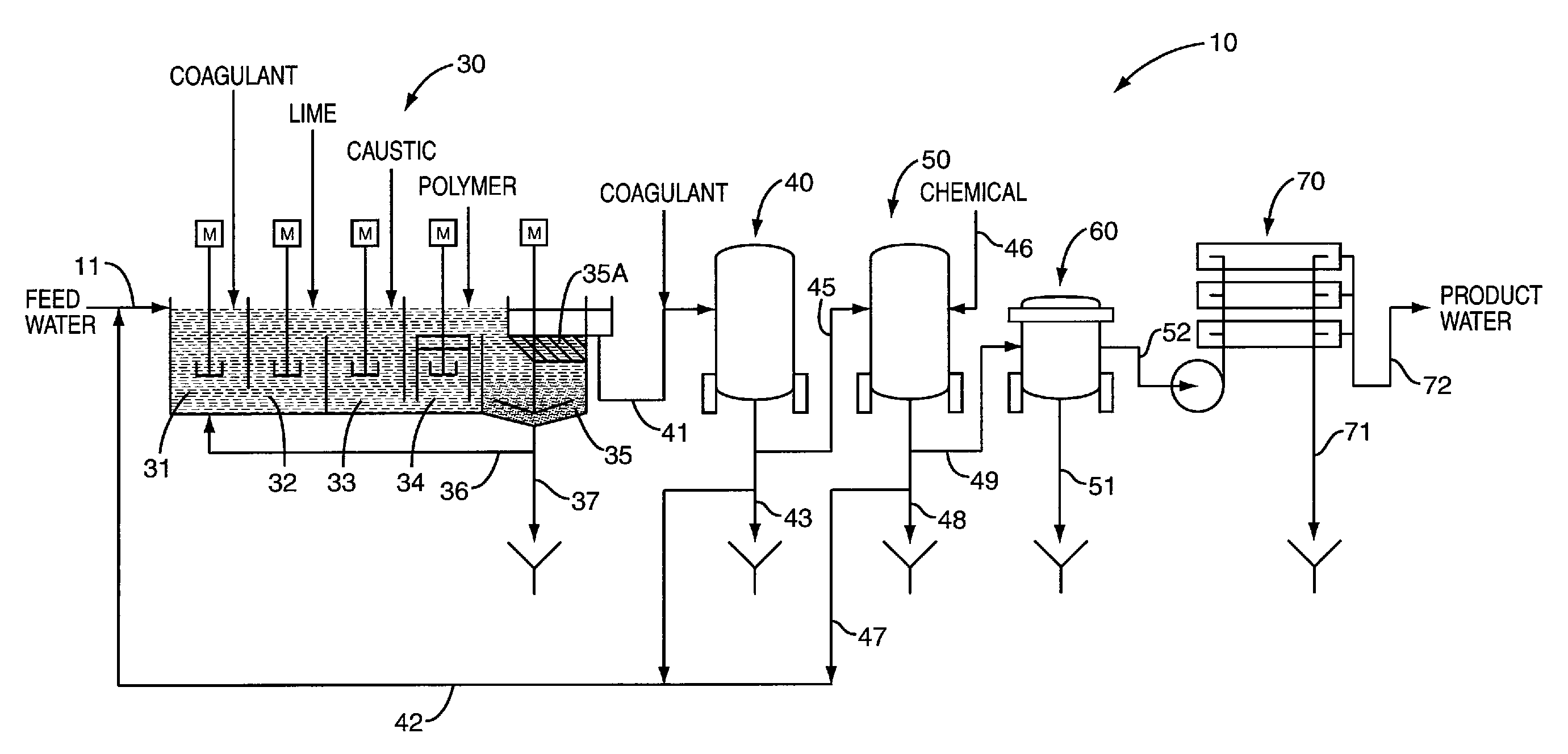

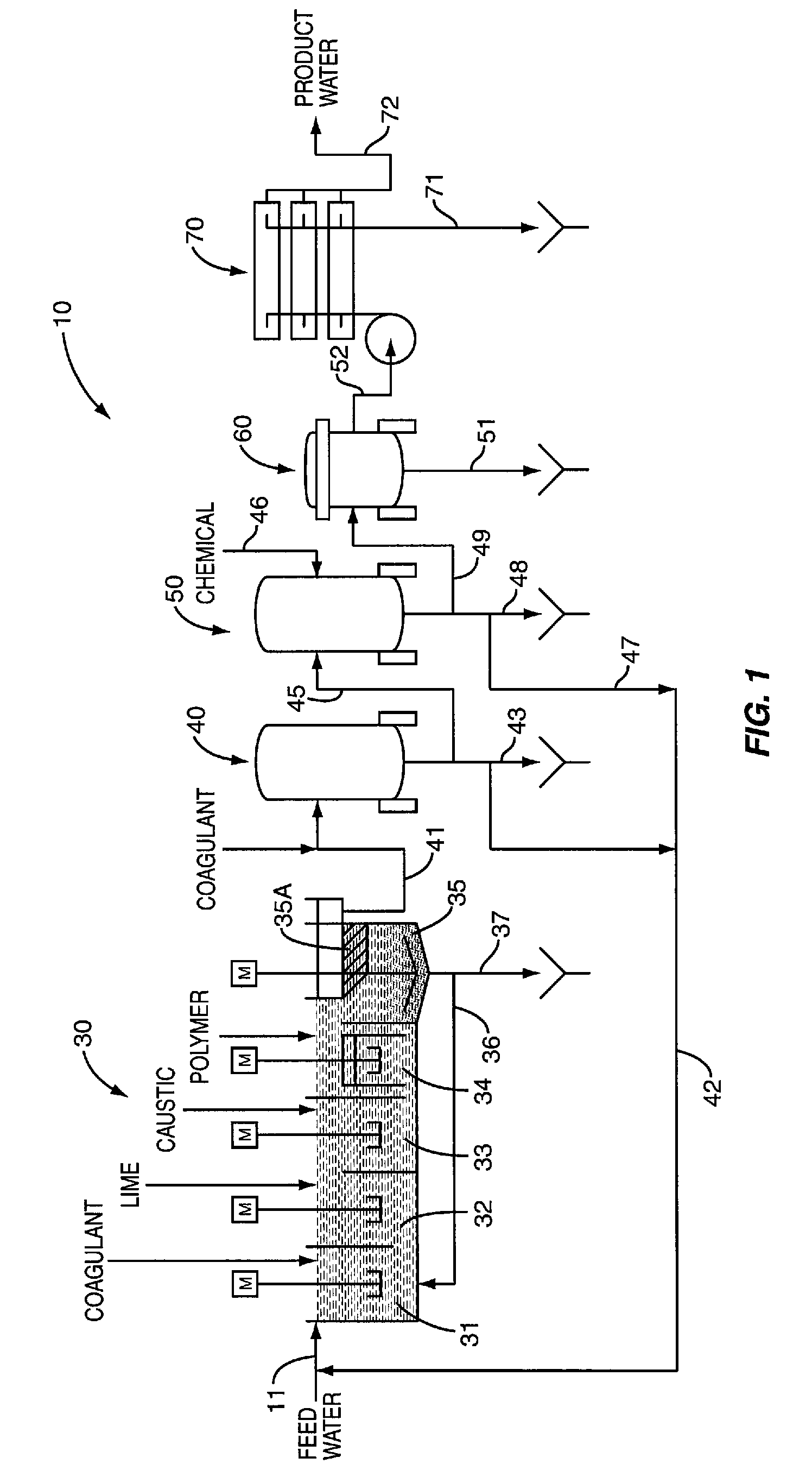

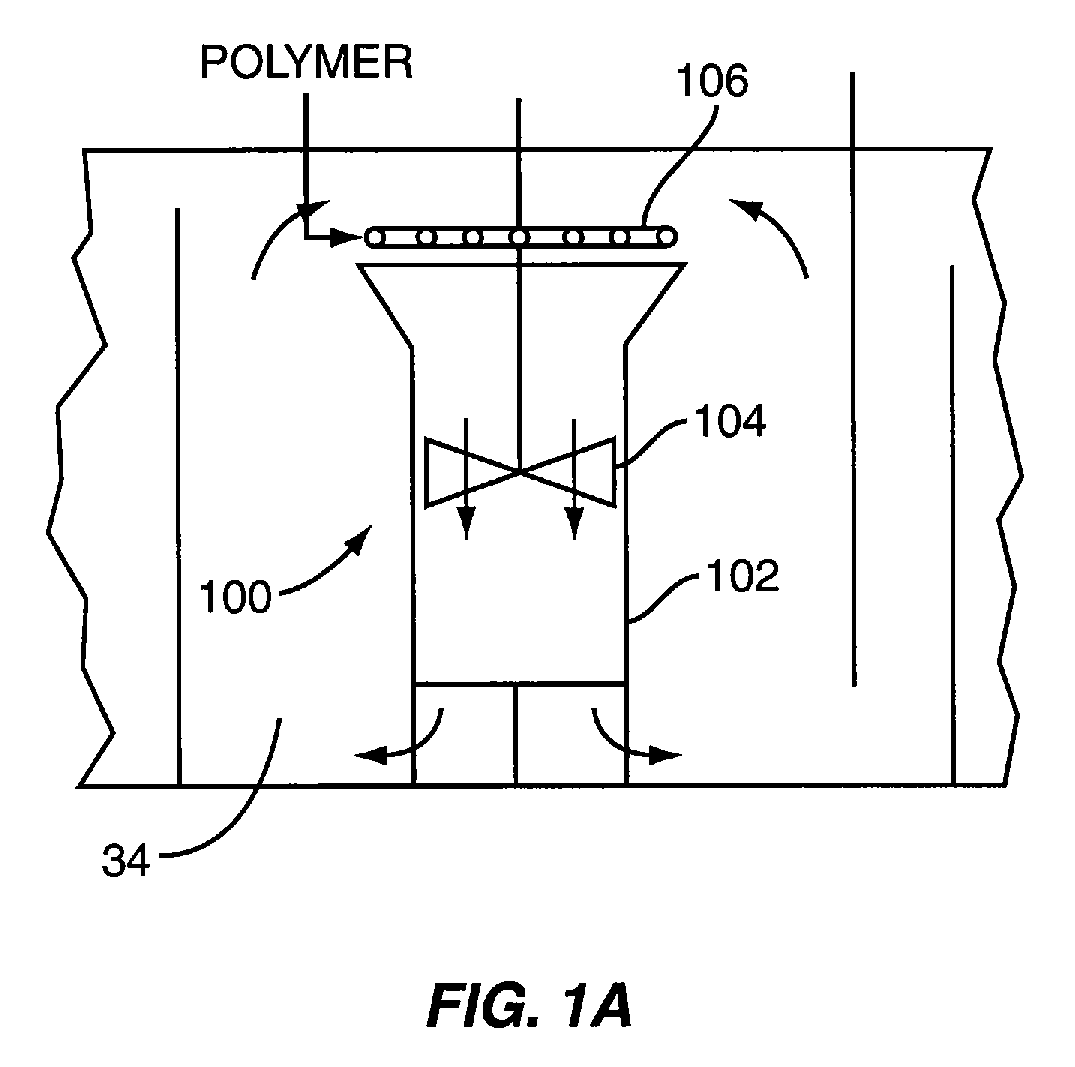

Method for treating wastewater or produced water

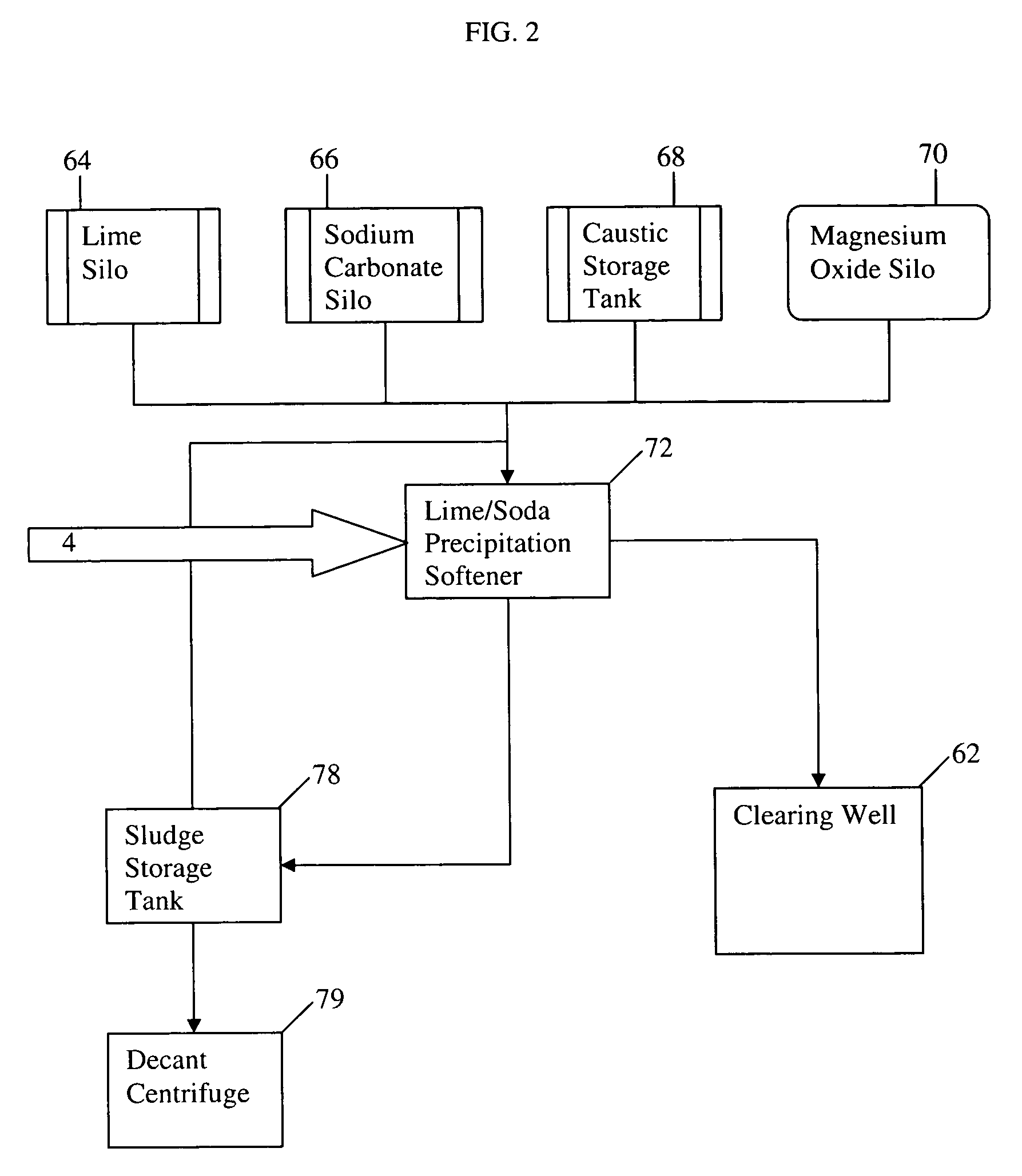

ActiveUS7815804B2Reduce hardnessReduce dissolved solidWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

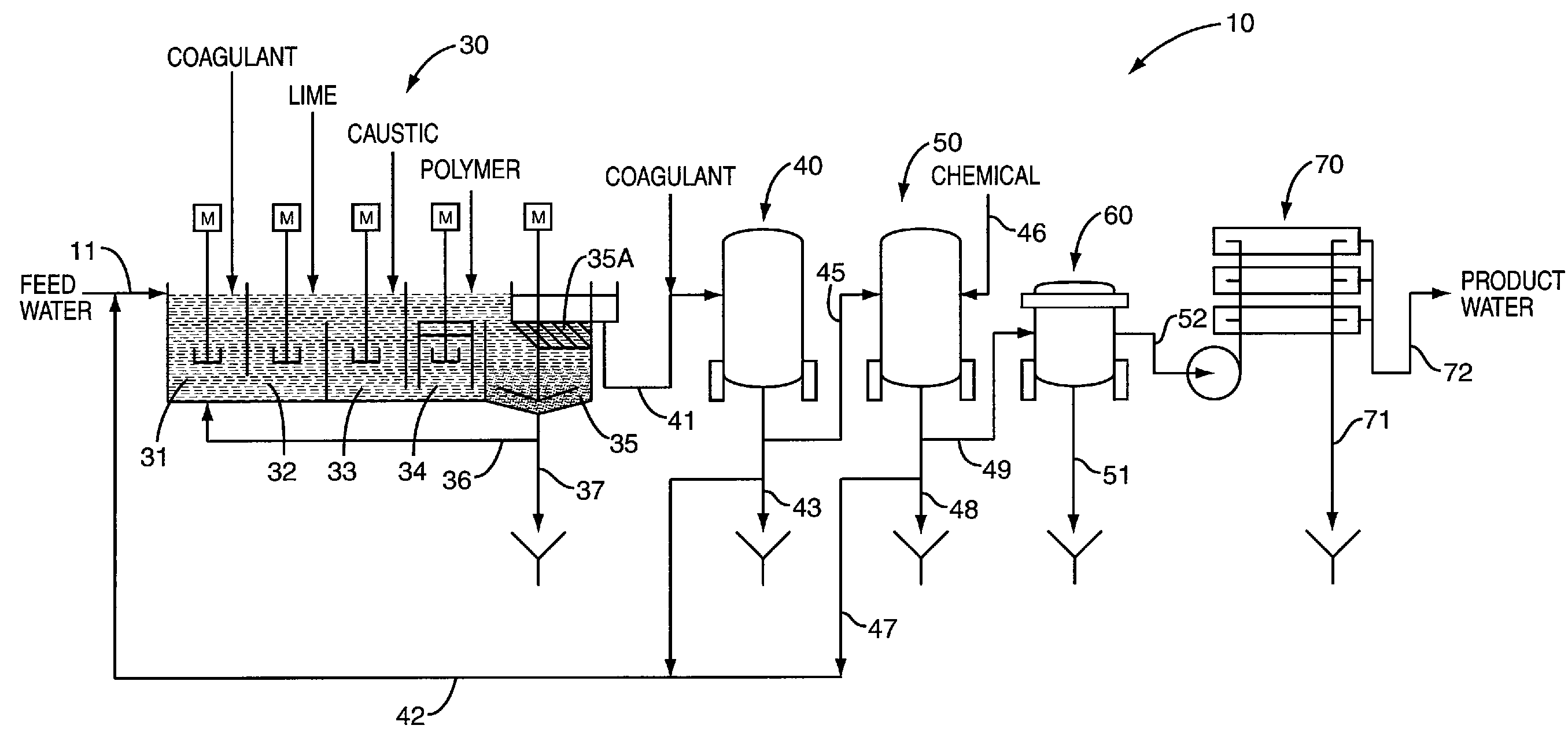

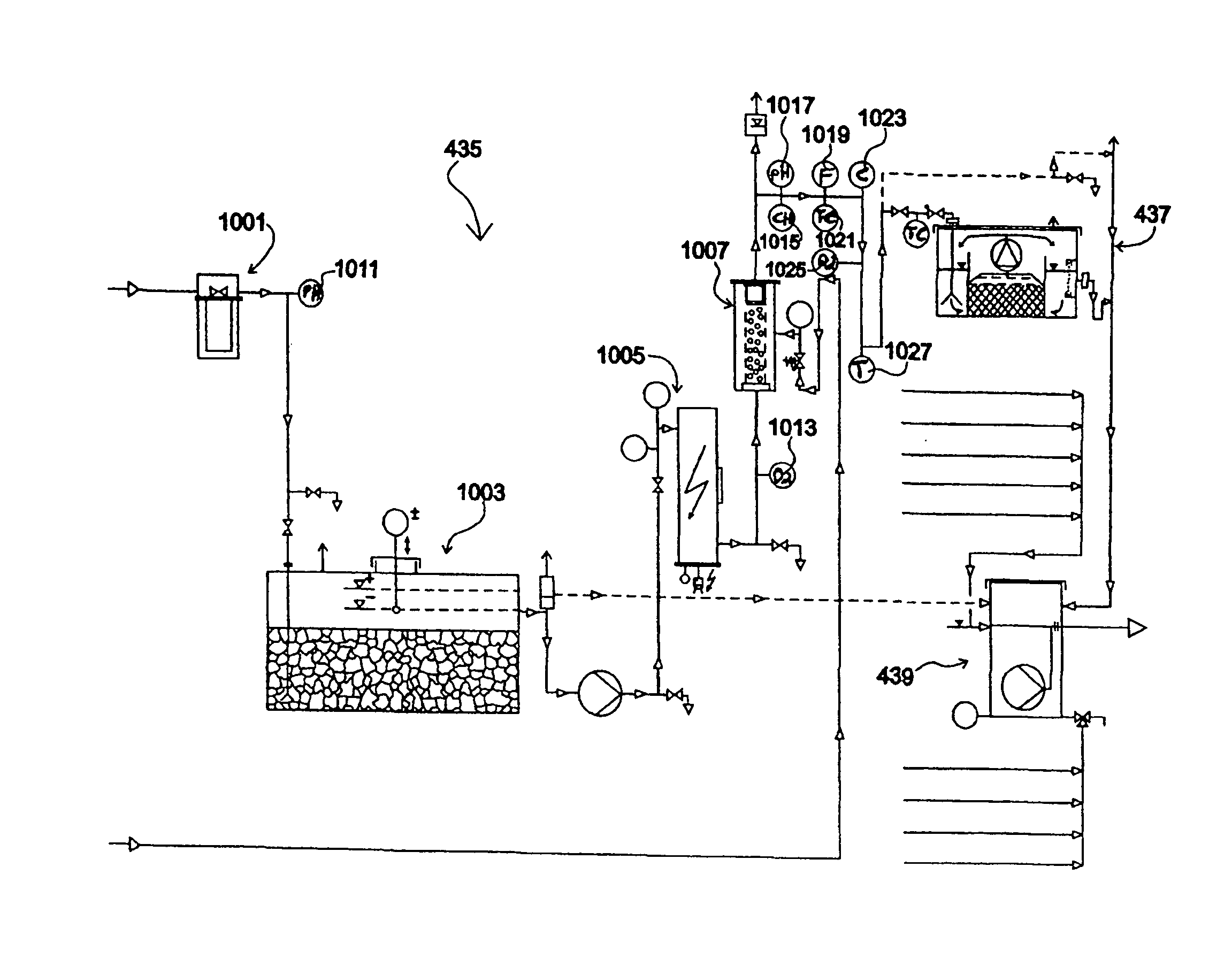

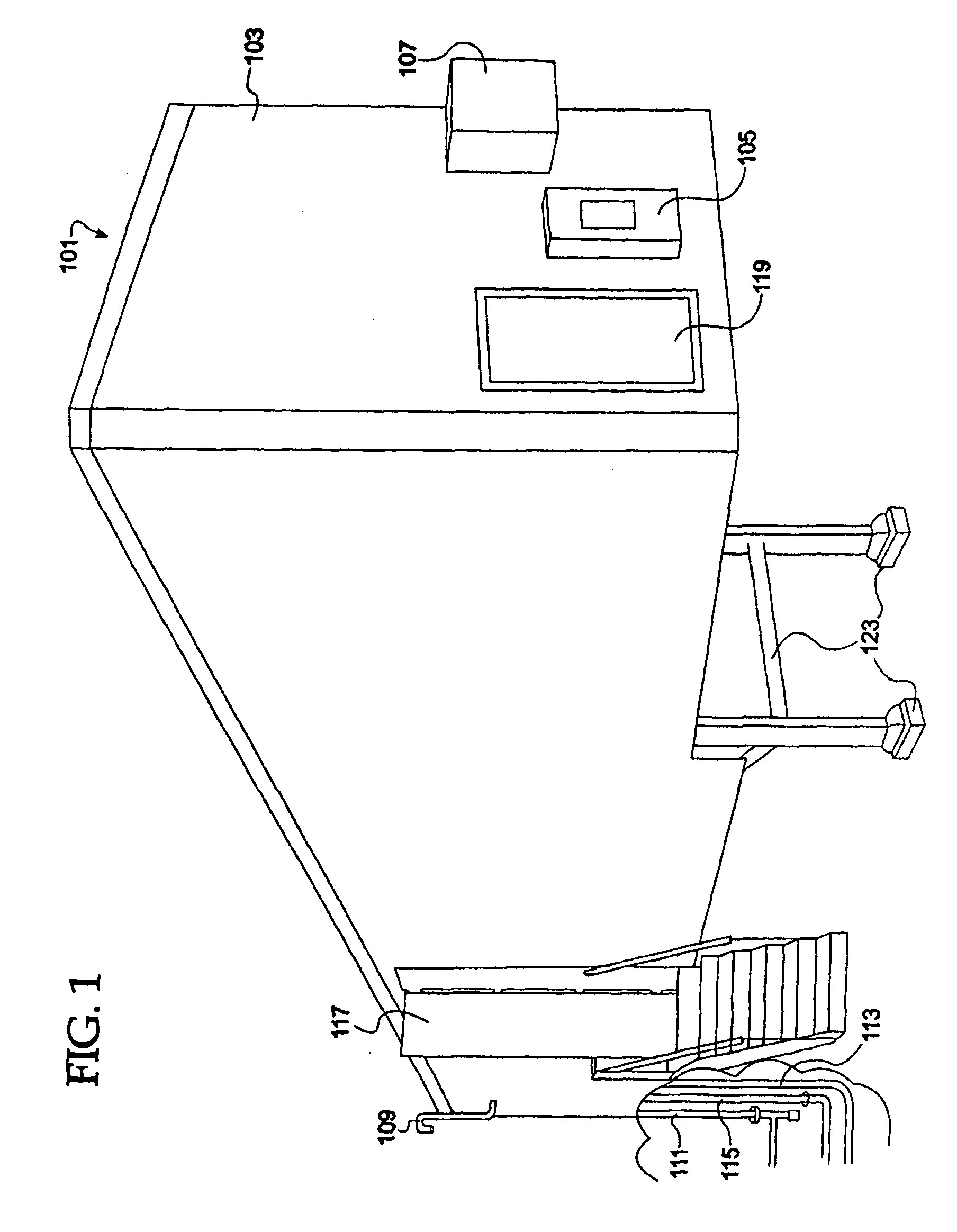

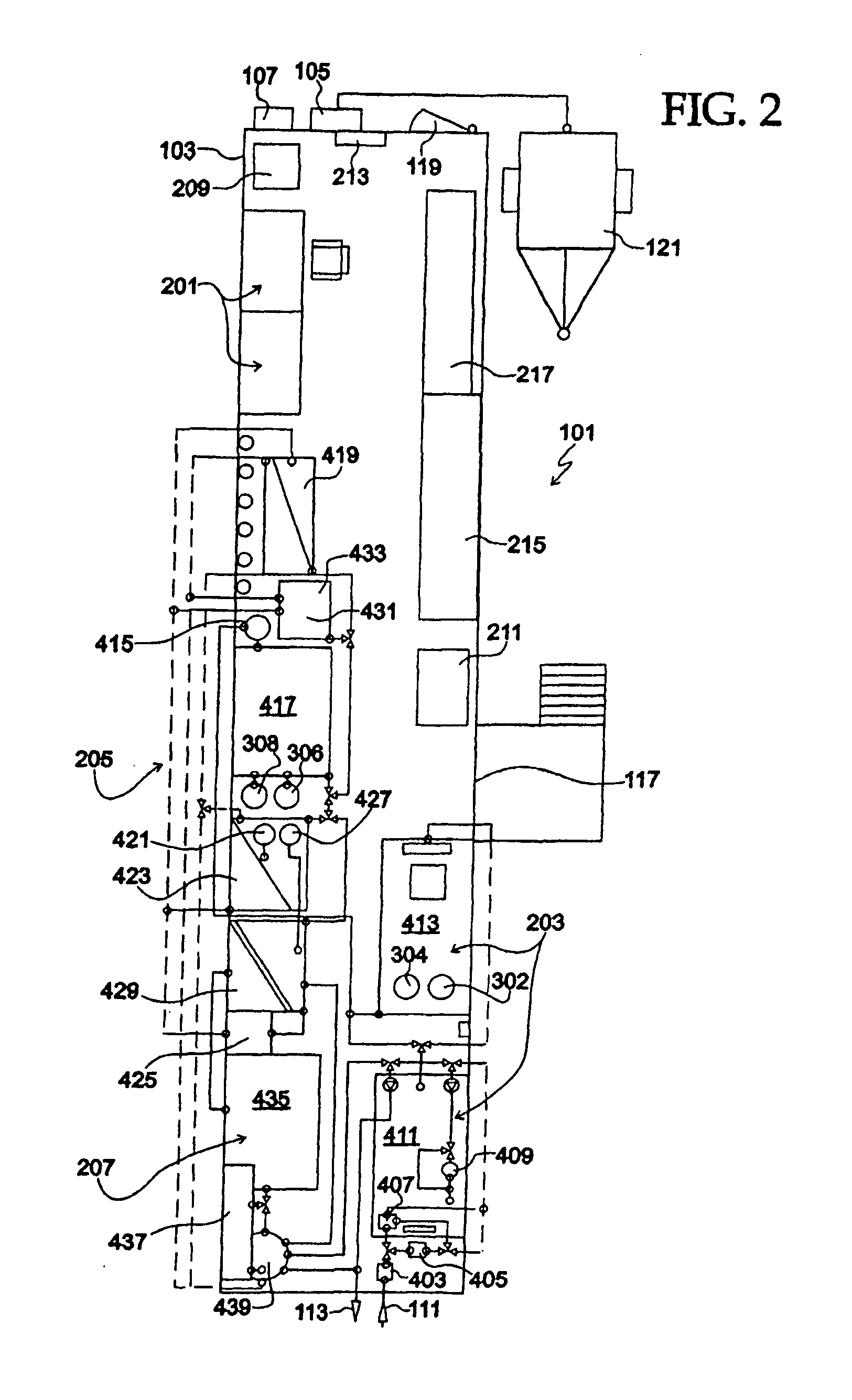

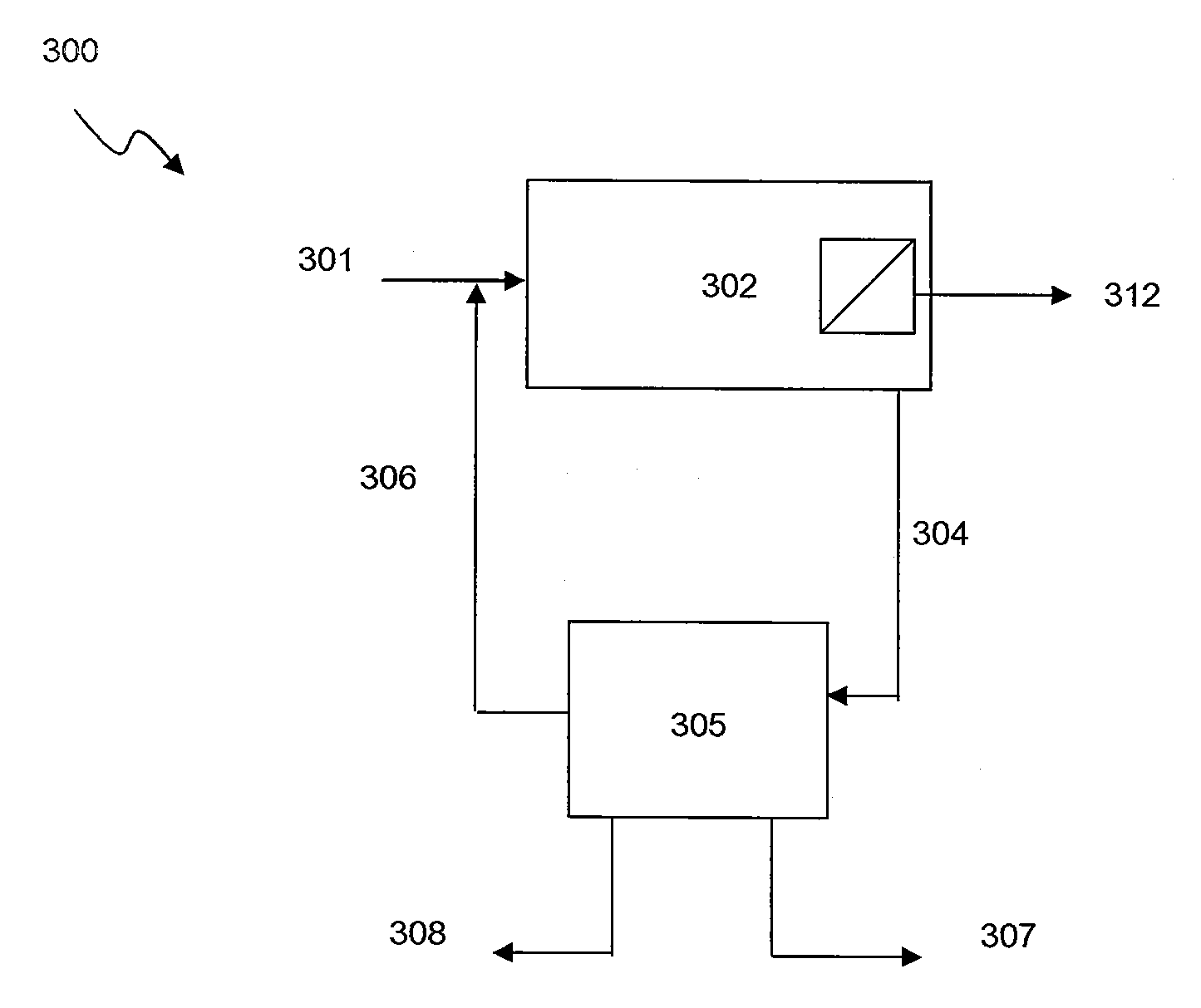

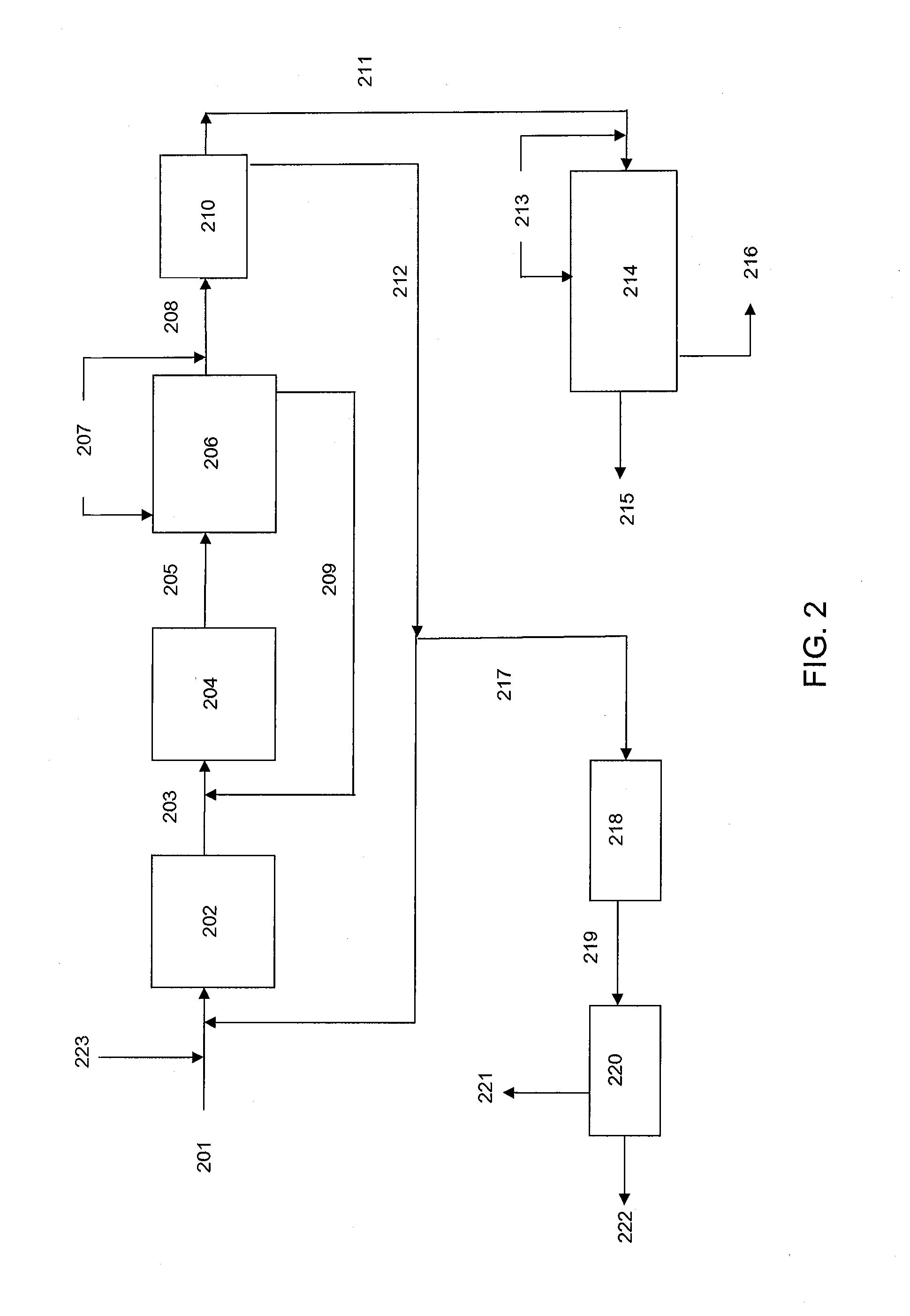

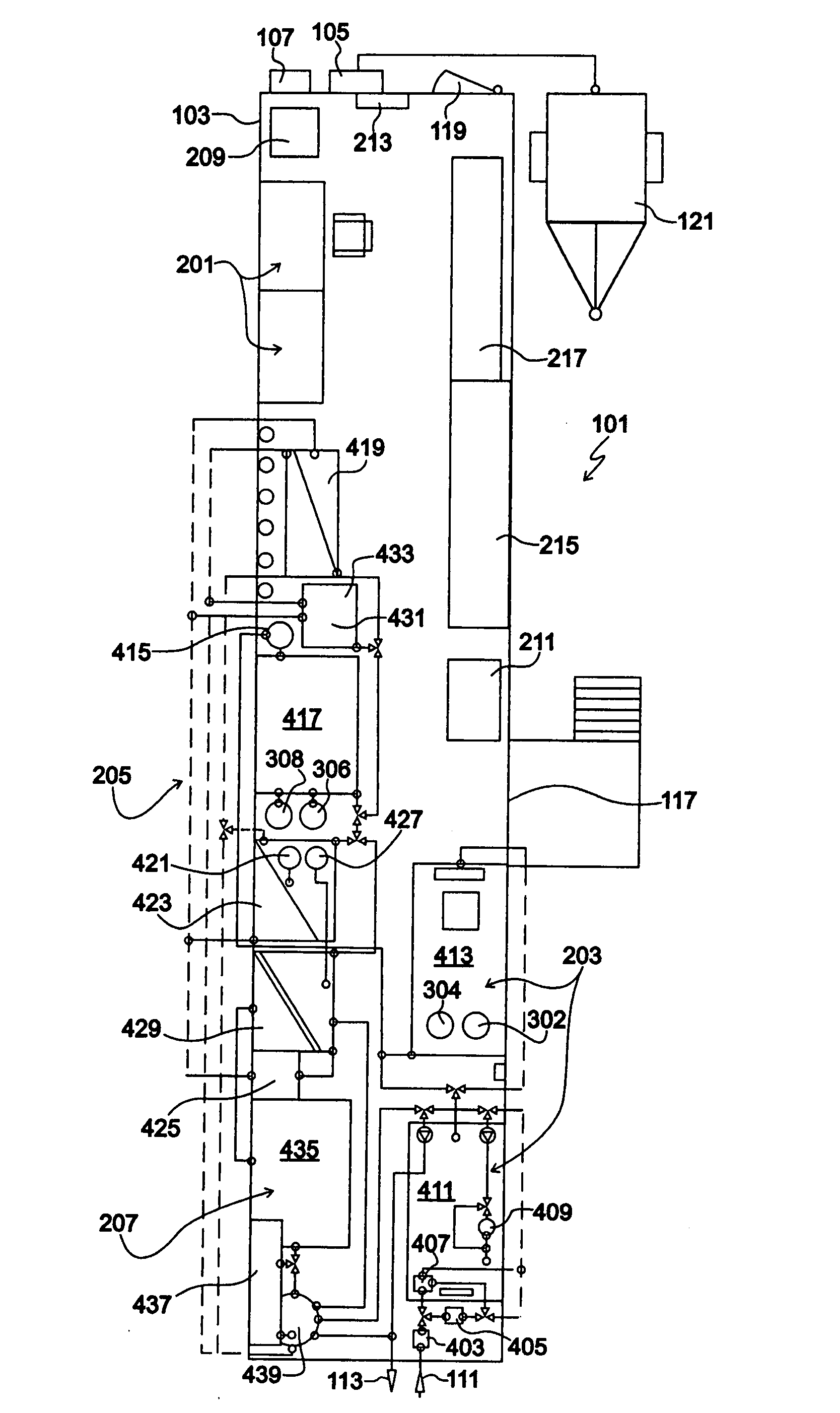

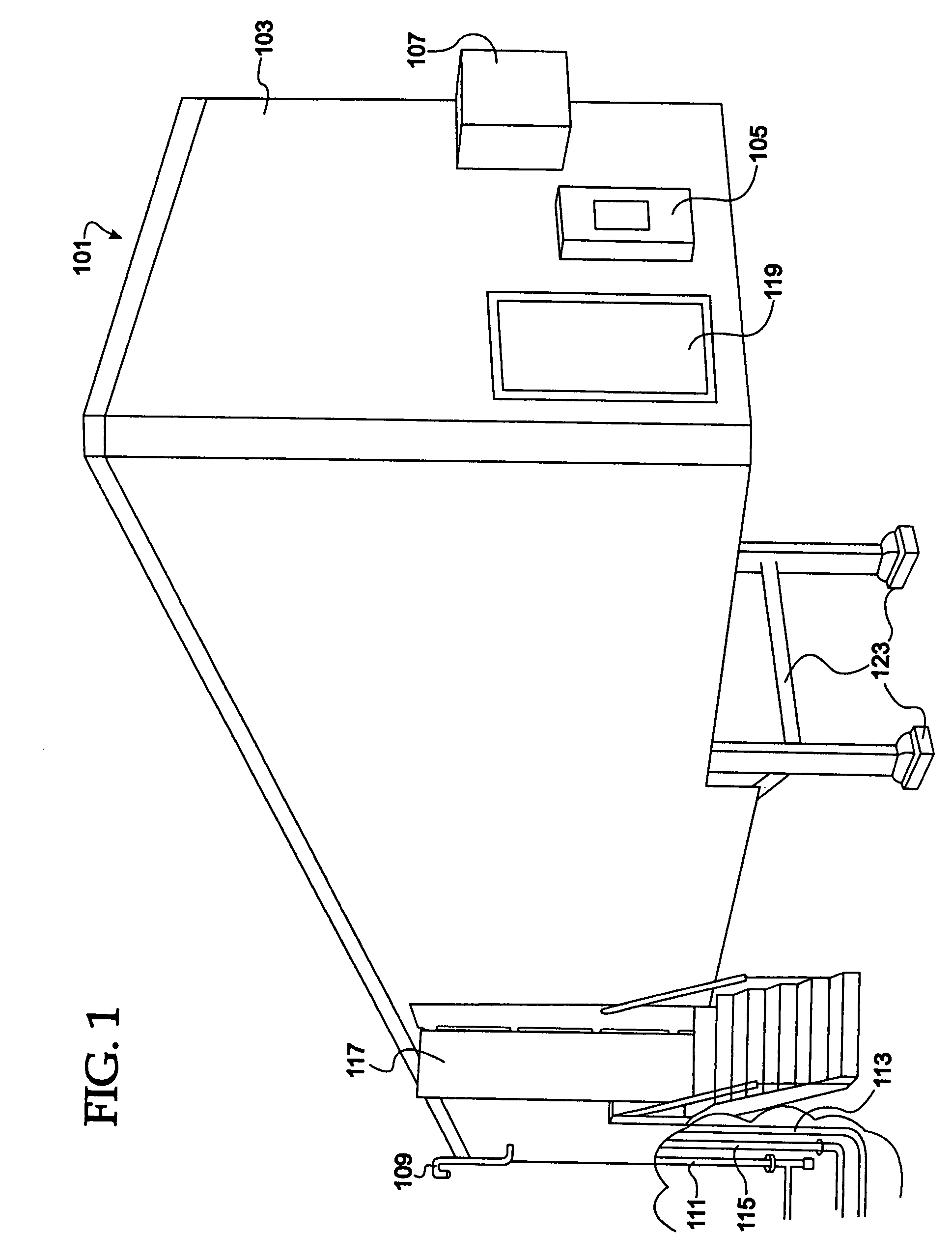

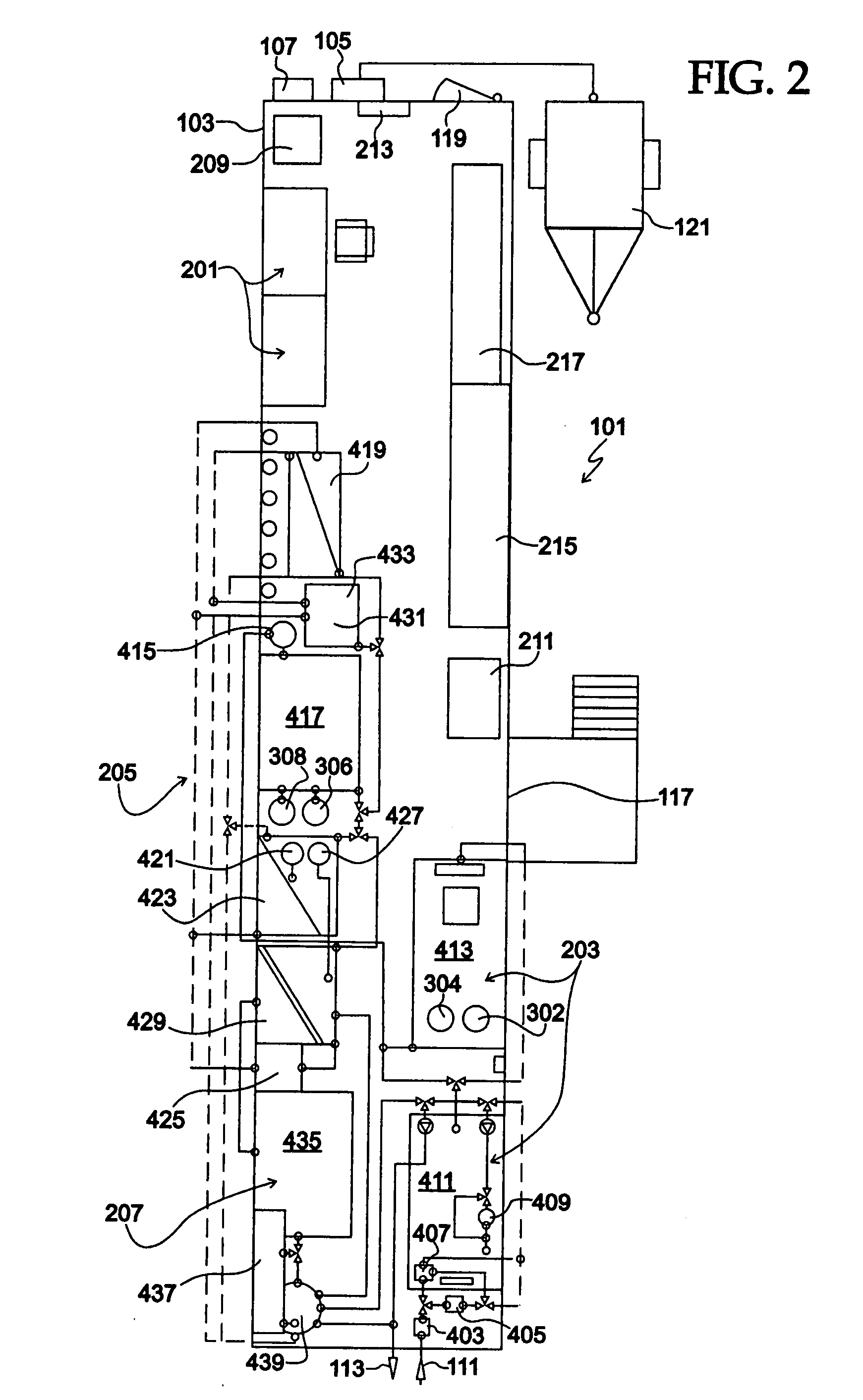

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

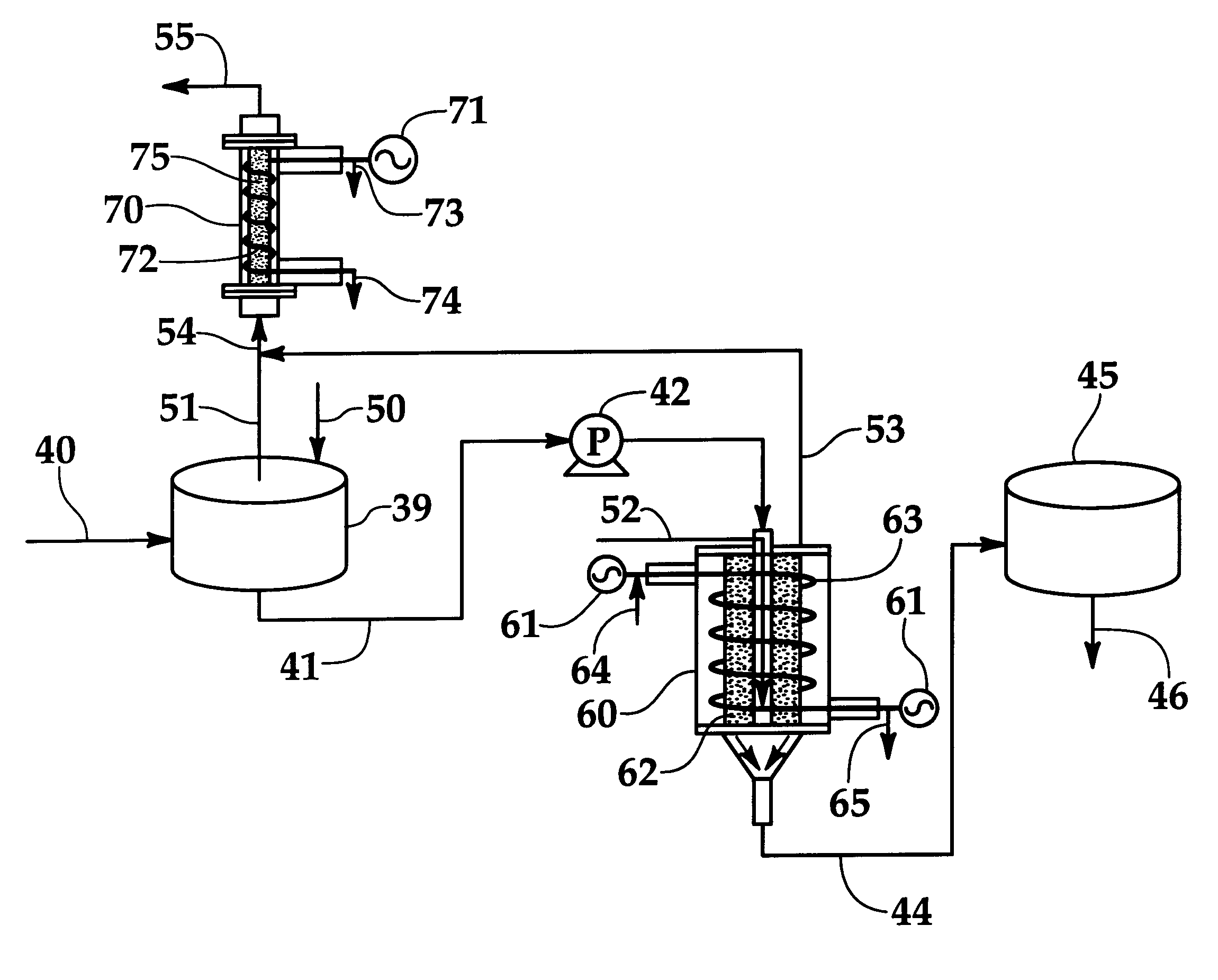

InactiveUS20110257788A1Reduce financial riskHigh continuity of operationWater/sewage treatment by neutralisationSustainable biological treatmentInitial treatmentIon exchange

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

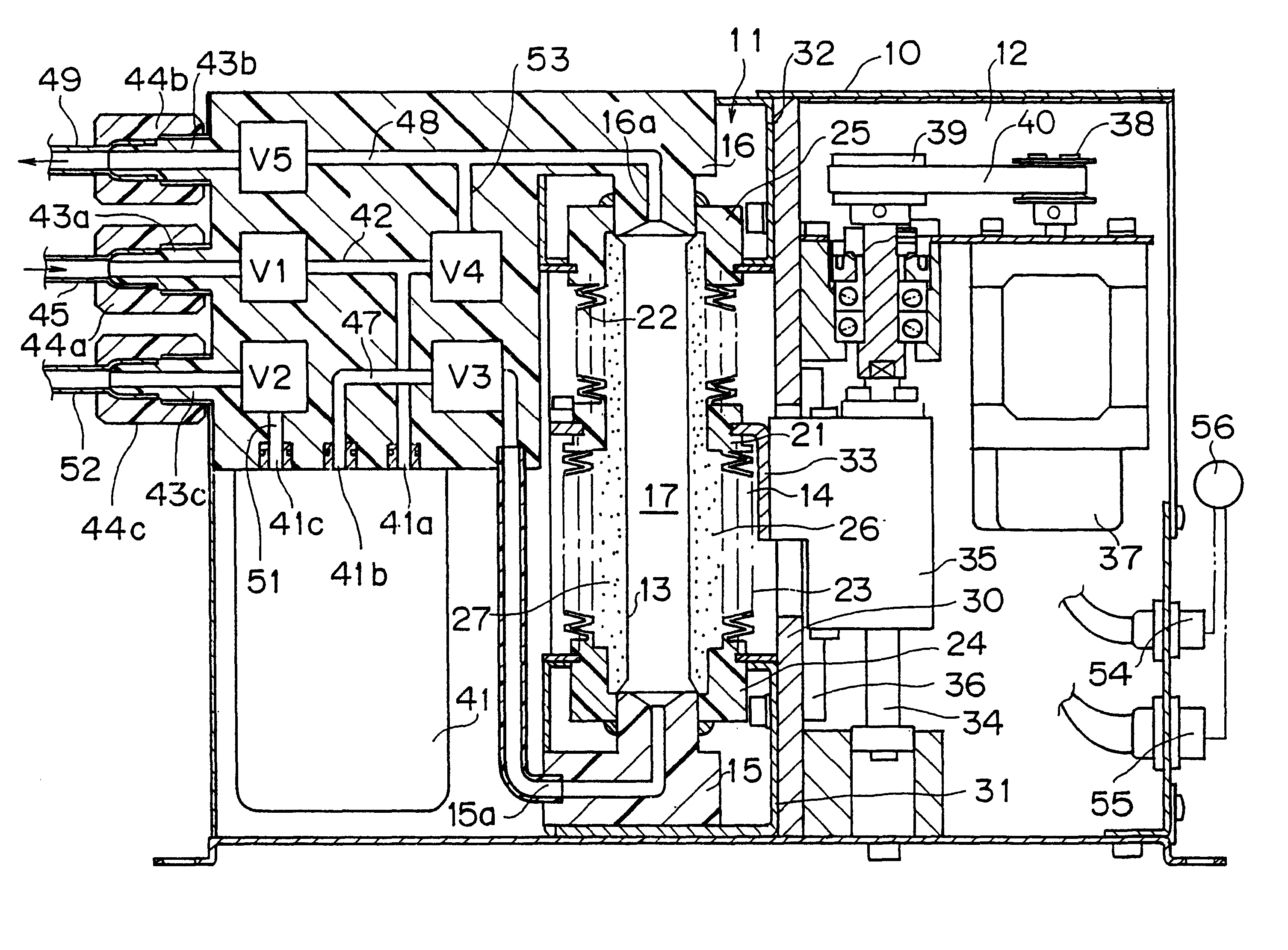

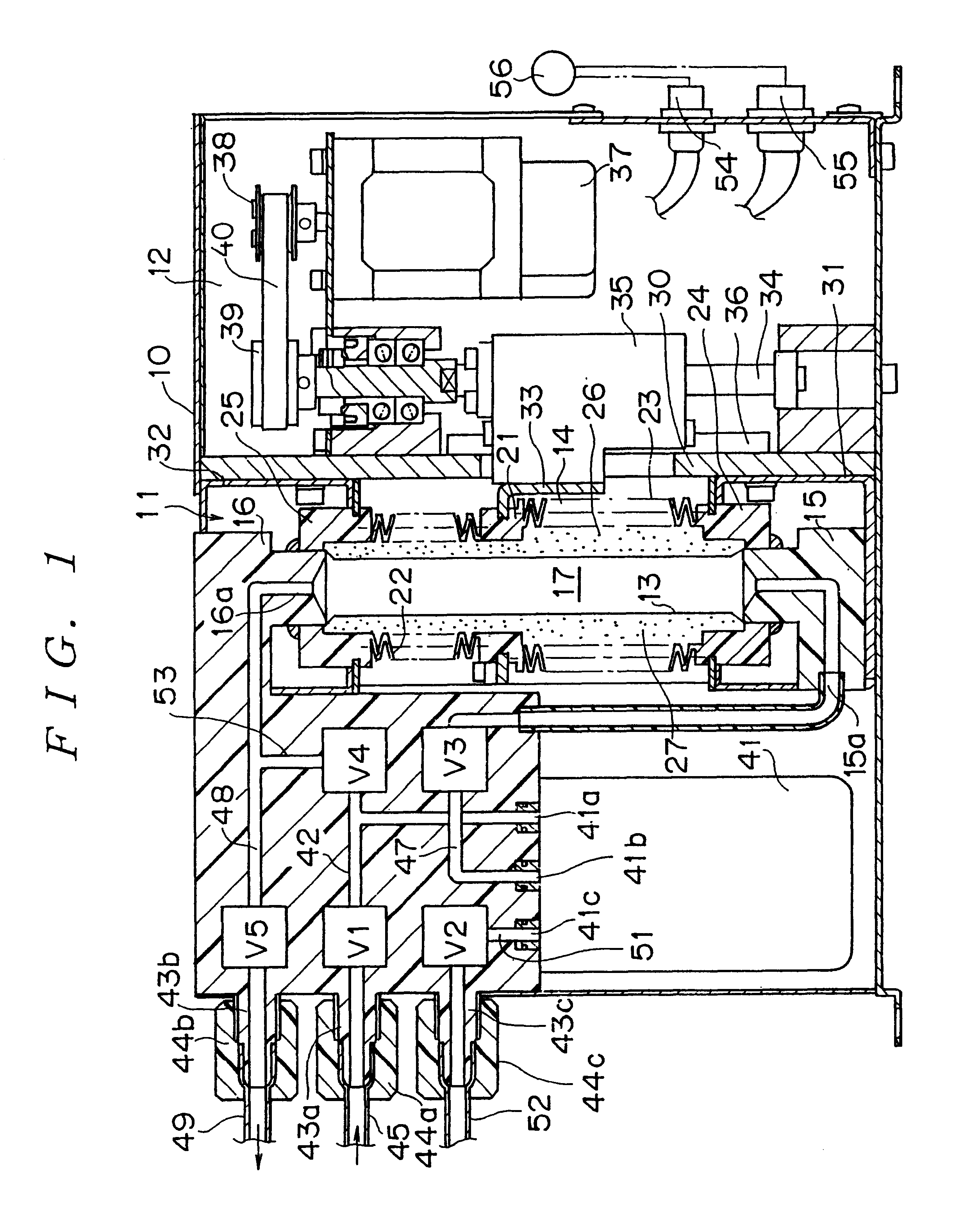

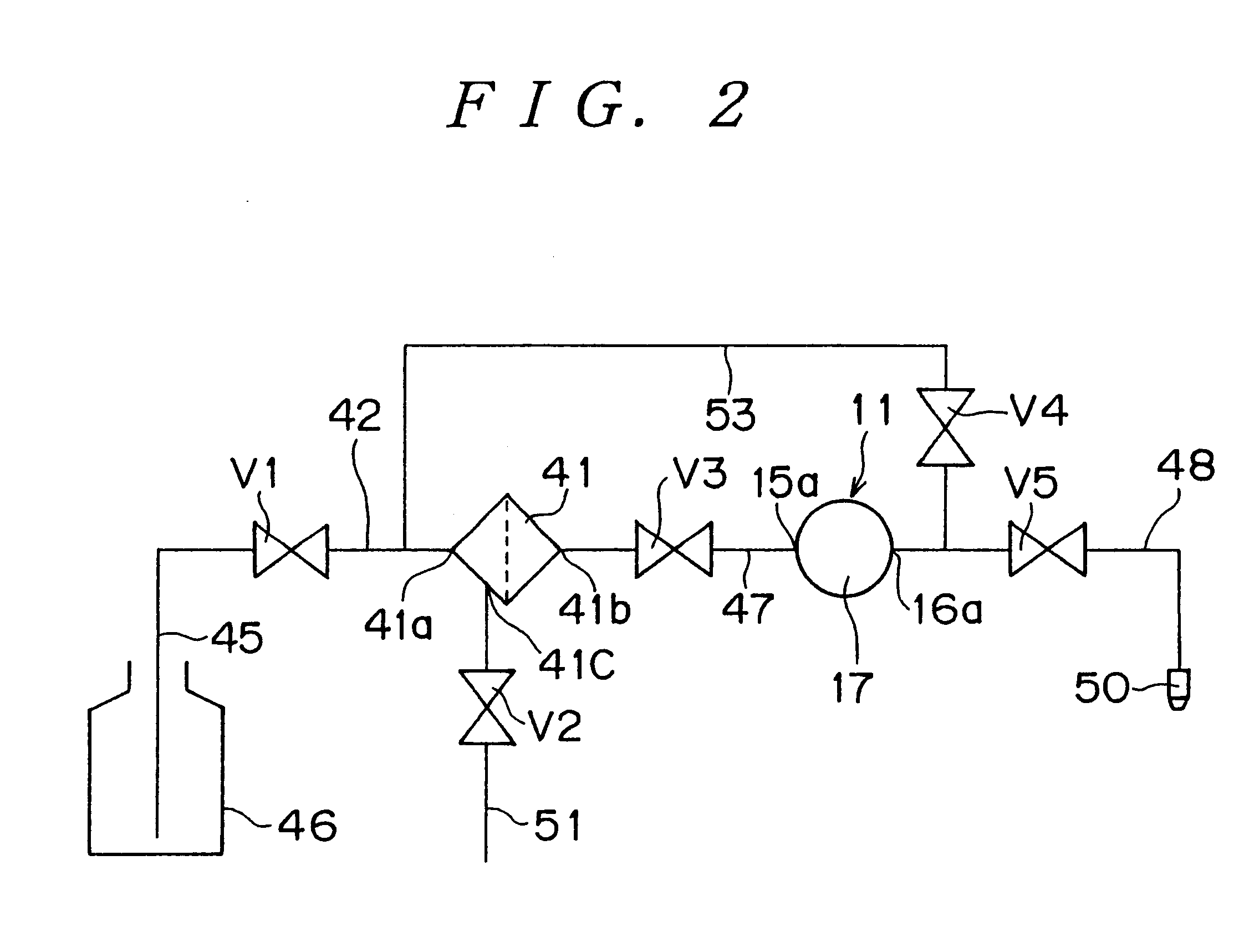

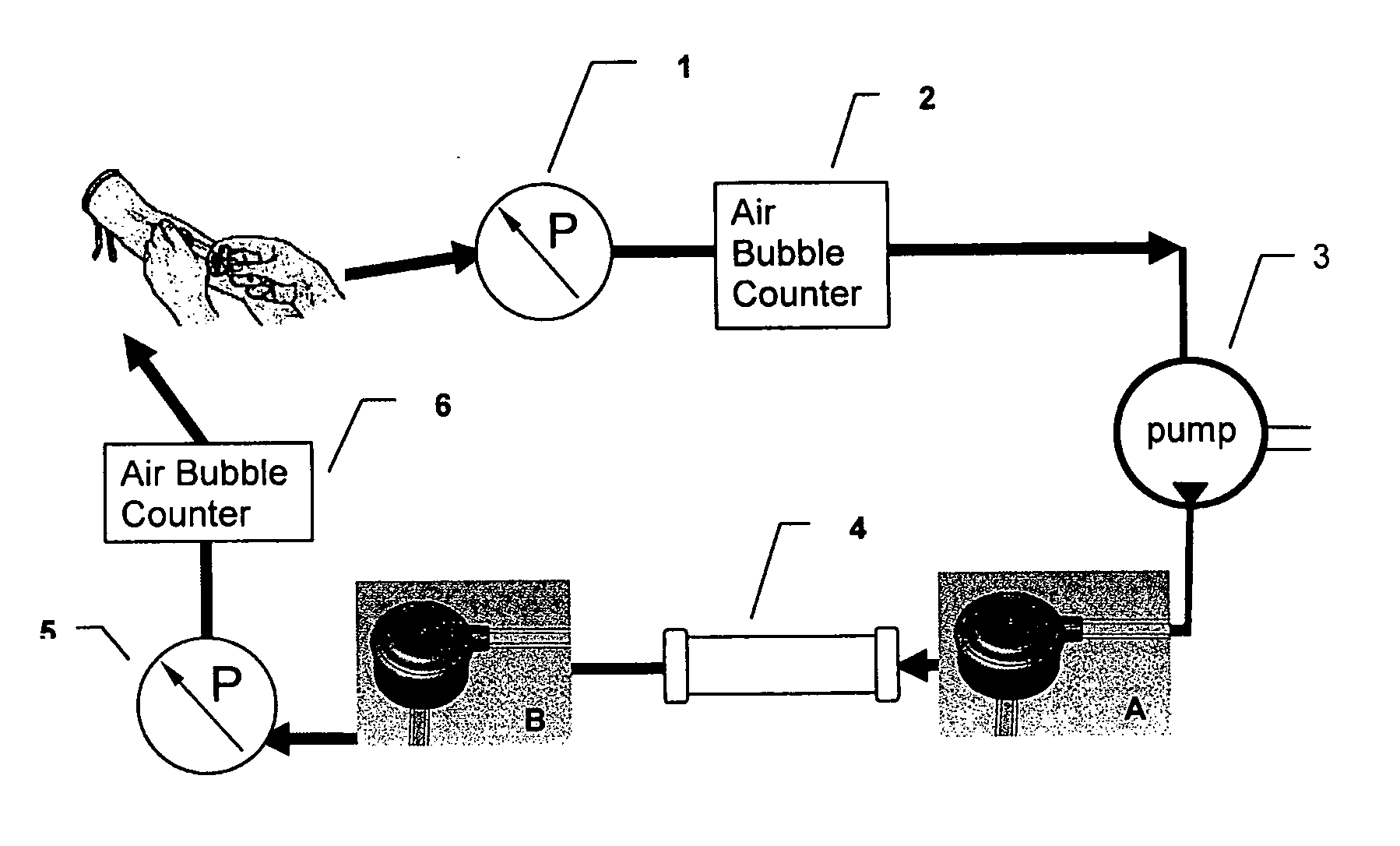

Chemical liquid supply method and apparatus thereof

InactiveUS6238576B1Improve cleanlinessPrevent penetrationLiquid separation auxillary apparatusFlexible member pumpsPump chamberInlet flow

Impure portions such as air bubbles and gelled portions in a liquid are removed so that the liquid can be discharged with improved cleanliness. Under condition that a return flow path and a liquid discharge flow path are closed, a pump chamber is expanded, thereby sucking the liquid in a liquid container portion into a pump chamber through a filter. Under condition that a vent port of the filter and the return flow path are opened and a liquid introducing flow path, the liquid discharge flow path, and a pump inlet flow path are closed, the pump chamber is contracted, thereby returning the liquid in the pump chamber toward the filter so that air in the filter is exhausted to the outside. Under condition that the return flow path and the pump inlet flow path are closed, the pump chamber is contracted, thereby discharging the liquid from the nozzle.

Owner:KOGANEI

High performance, energy efficient system and method for wastewater treatment with resource recovery and reduced residual solids generation

ActiveUS20080223783A1Treatment with anaerobic baffled reactorsWater treatment parameter controlRetention timeCell mass

A wastewater treatment system is provided including an aerobic membrane bioreactor and an anaerobic digester system connected to receive wasted solids continuously from the aerobic membrane bioreactor and also connected to return effluent from the anaerobic digester system continuously to the aerobic membrane bioreactor. Further, a process is provided for treating wastewater including the step of wasting a volume fraction of organic cell mass from an aerobic membrane bioreactor to an anaerobic digester system and maintaining a solids retention time (SRT) in the bioreactor that is (1) greater than a time needed to achieve growth of organisms suitable for converting carbonaceous biochemical oxygen demand (CBOD) into cell mass and (2) less than a time at which substantial decay of the organisms occurs. The system and process may further include optional pretreatment and / or phosphorus and / or nitrogen removal downstream of the membrane bioreactor system.

Owner:HSBC BANK

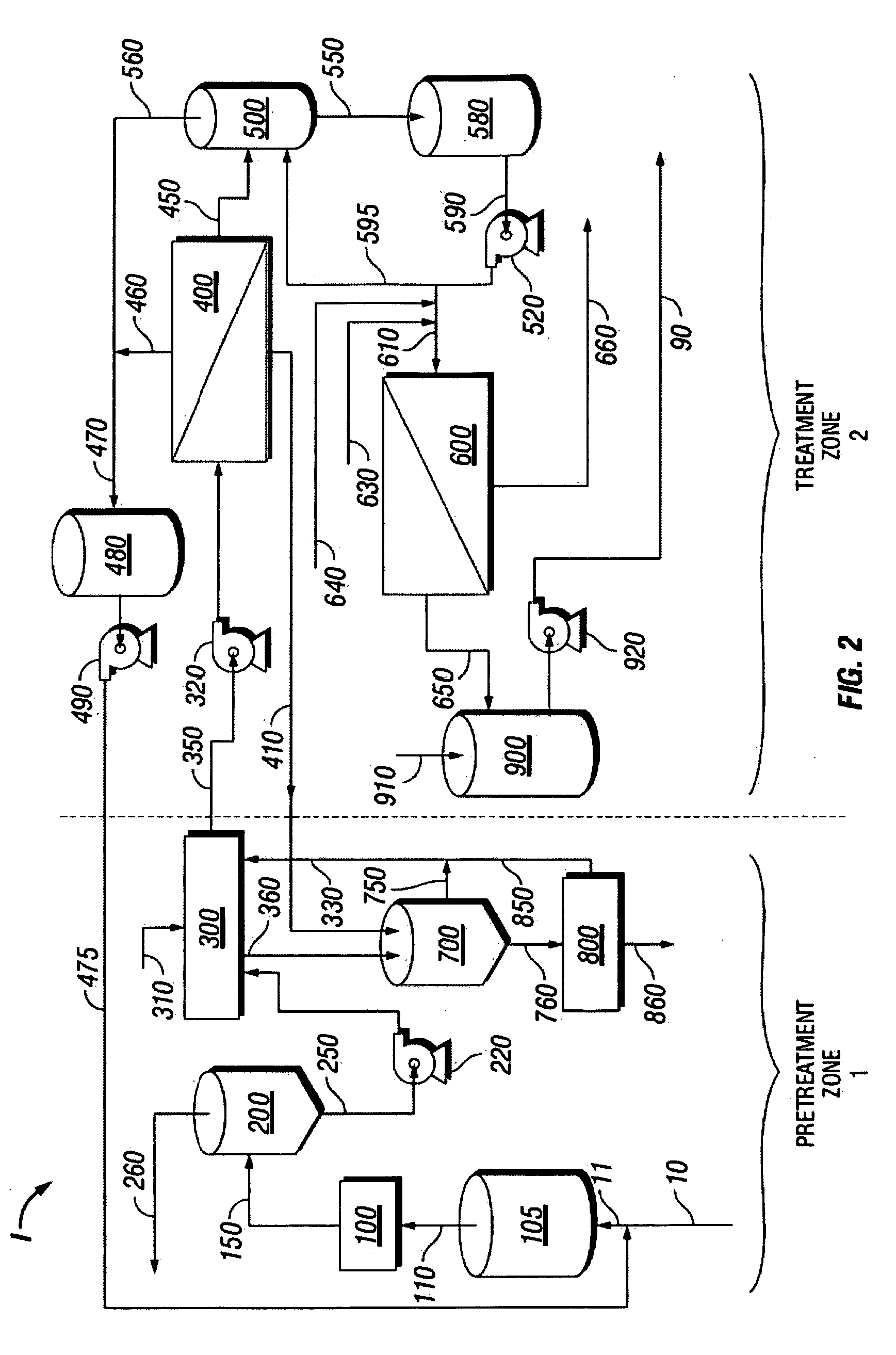

Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

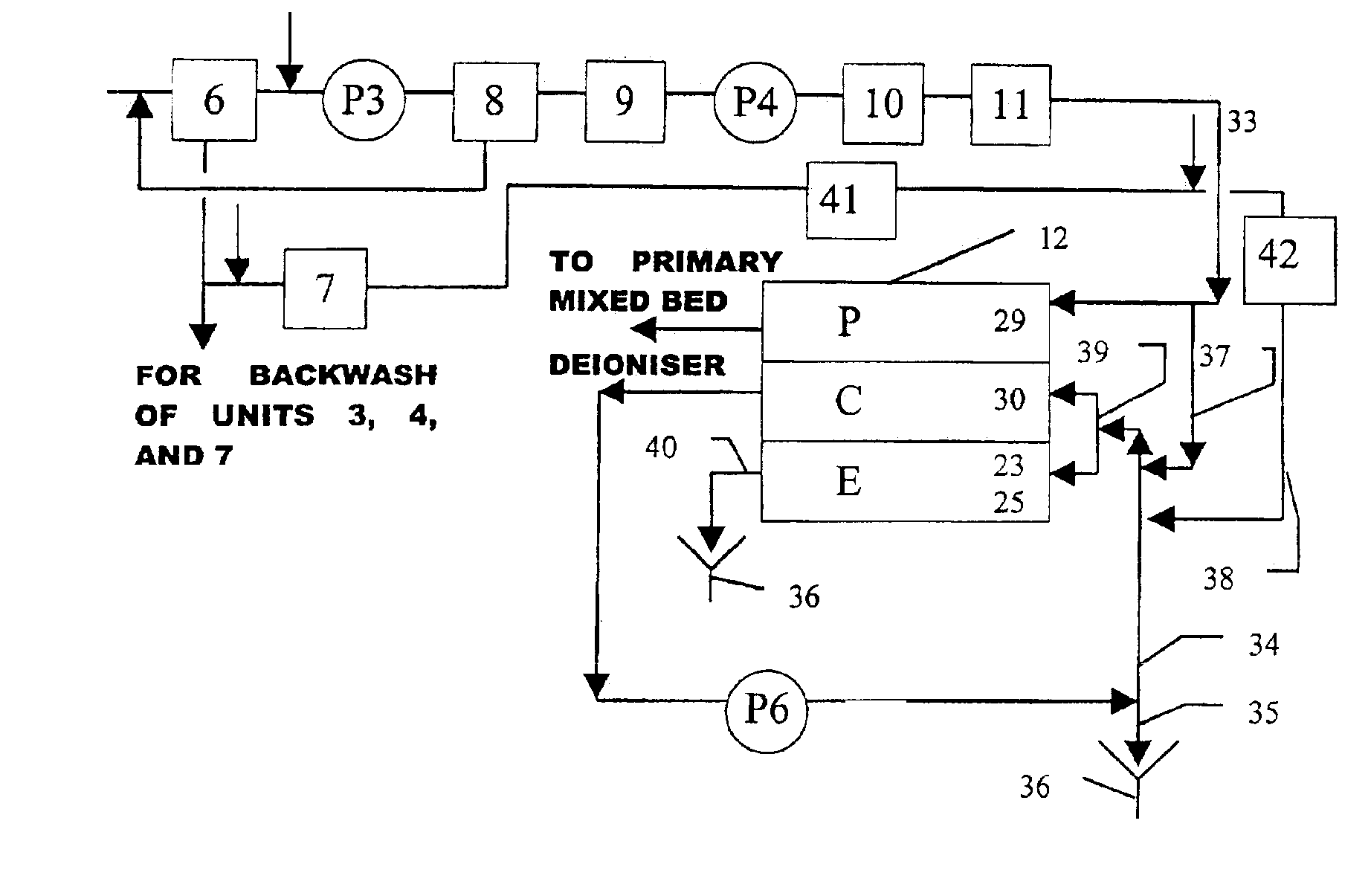

InactiveUS20090032446A1Reduce financial riskHigh continuity of operationReverse osmosisFlash degasificationIon exchangeReverse osmosis

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus are housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies are also disclosed.

Owner:ROCKWATER RESOURCE

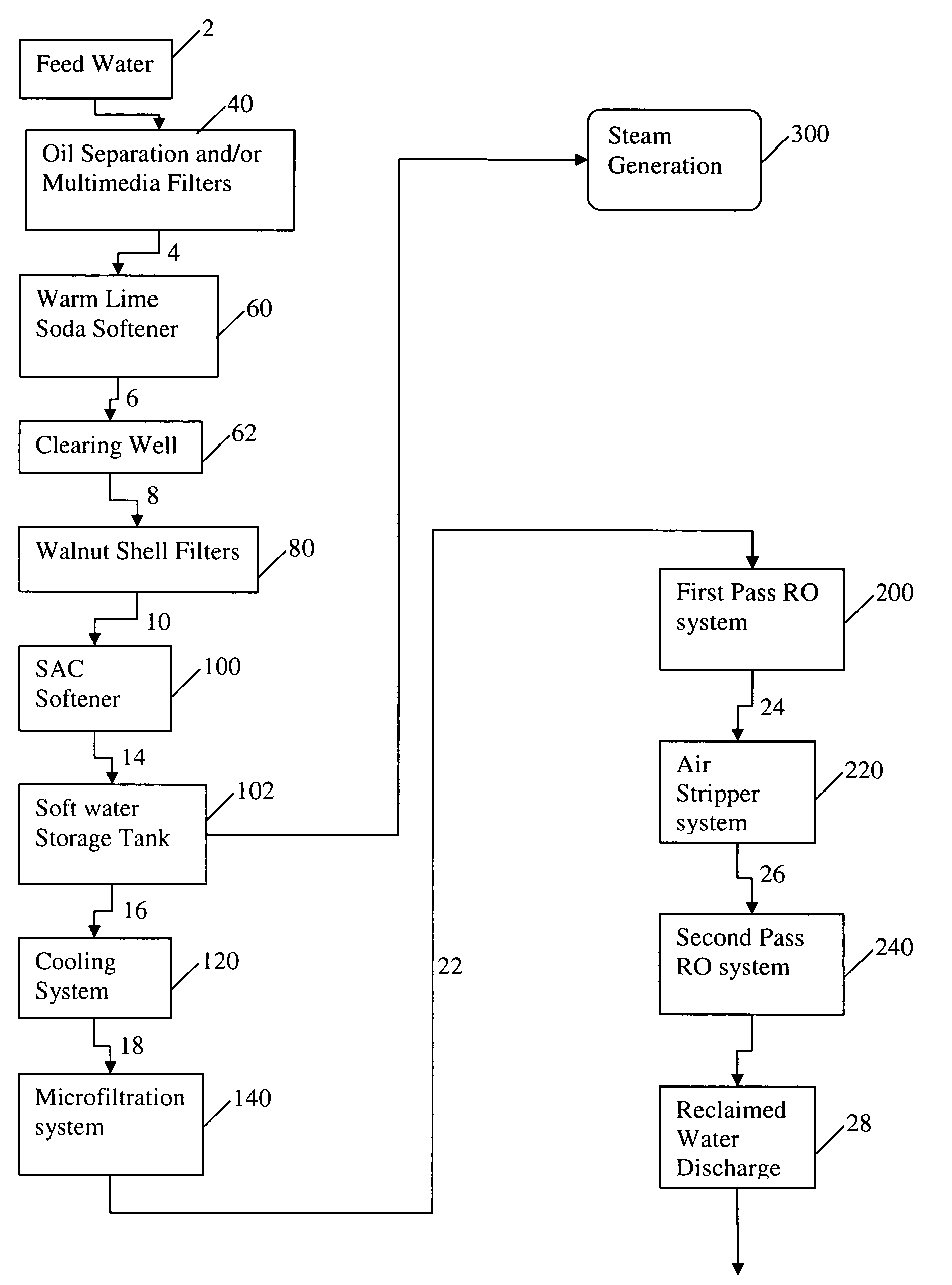

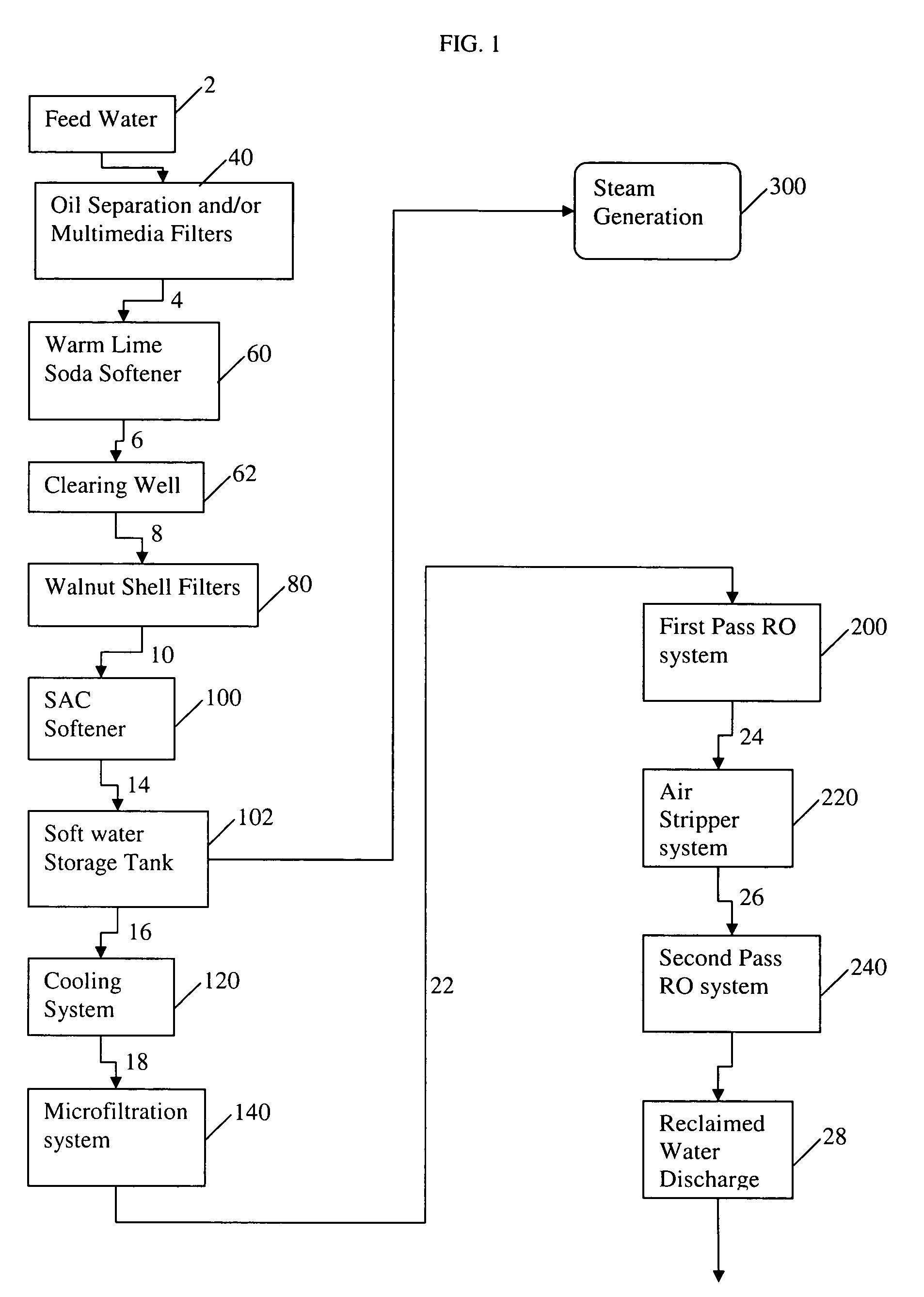

Water treatment process for oilfield produced water

ActiveUS7520993B1Minimize continued precipitationLiquid separation auxillary apparatusUsing liquid separation agentSludgeTreatments water

The invention relates to a method and system for treating an aqueous liquid containing dissolved minerals and dissolved hydrocarbons. Method steps and apparatus for treating a waste water feed stream are disclosed which utilize a warm lime softening system in fluid communication with the waste water feed stream, wherein sludge from the warm lime softening system is recycled to improve lime utilization and enhance silica and boron removal without the addition of an external source of magnesium. In addition, a microfiltration system and / or an air stripper system may be used in fluid communication with at least one reverse osmosis system to produce a treatment water that meets state and federal guidelines for surface discharge.

Owner:WATER & POWER TECH

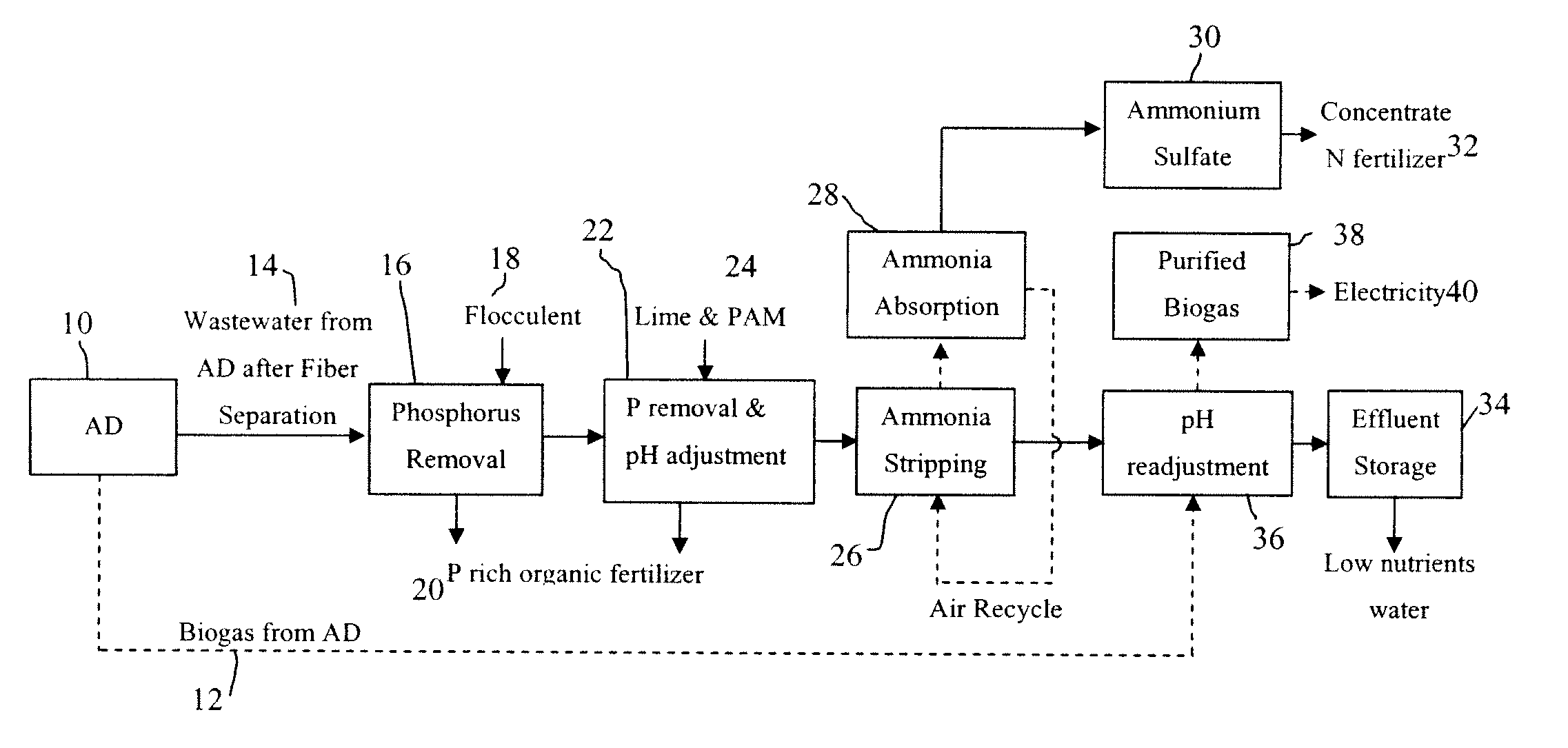

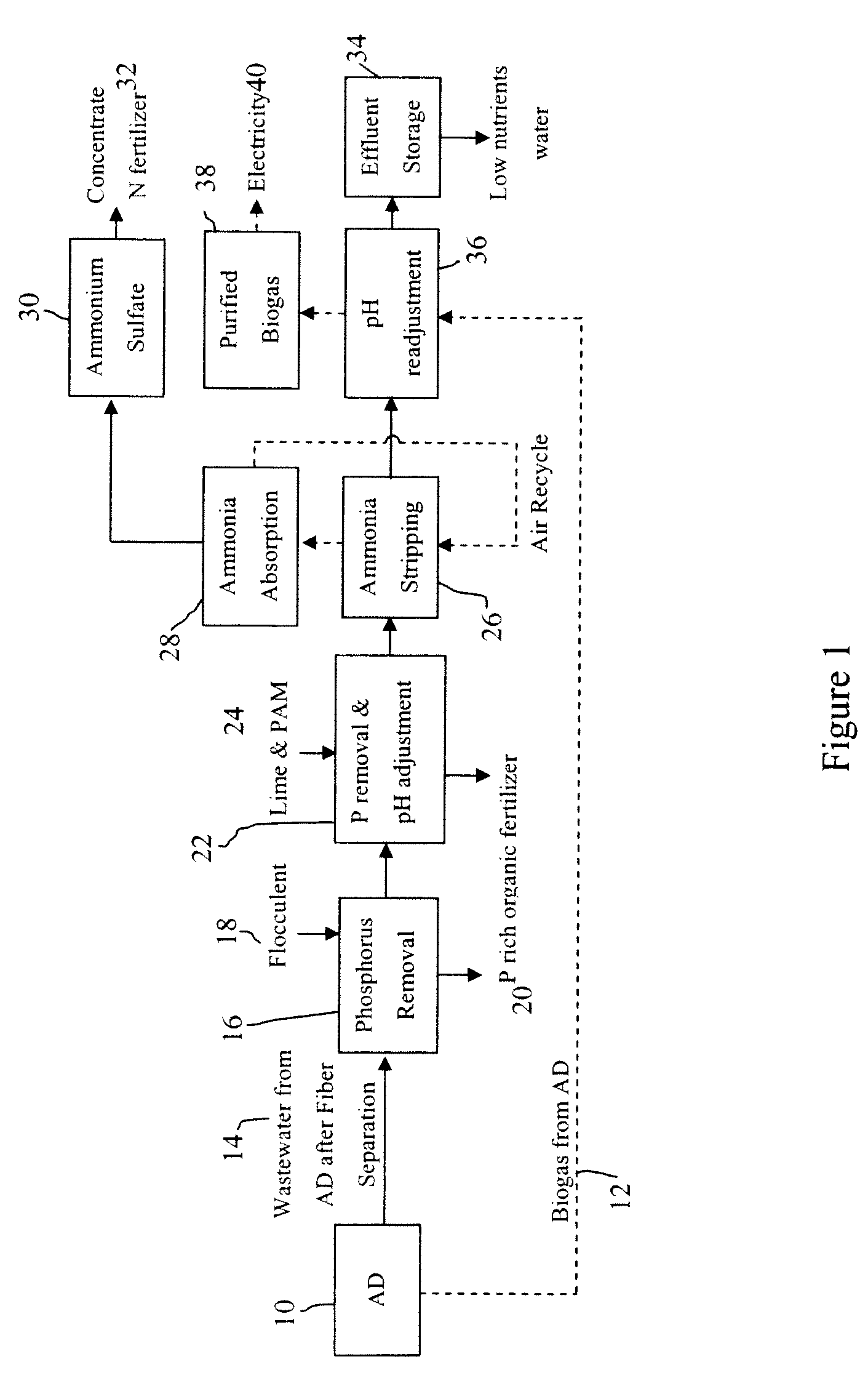

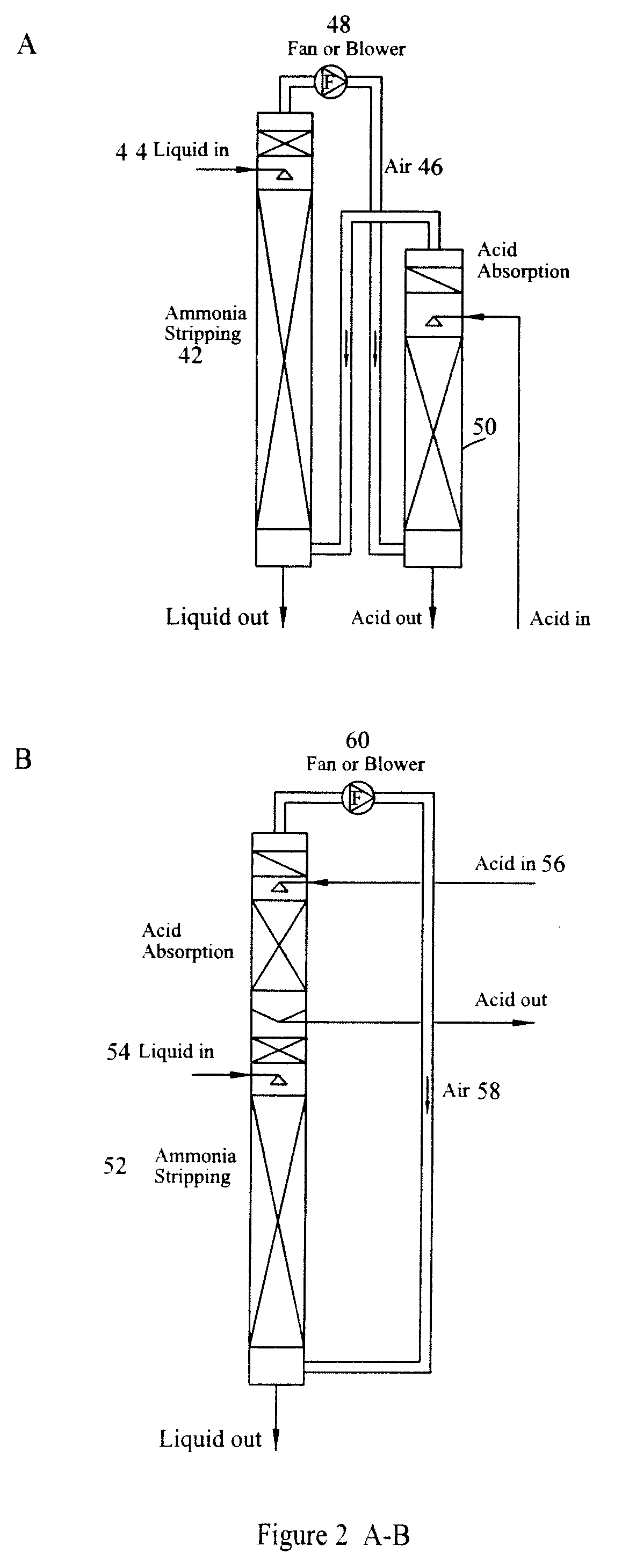

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

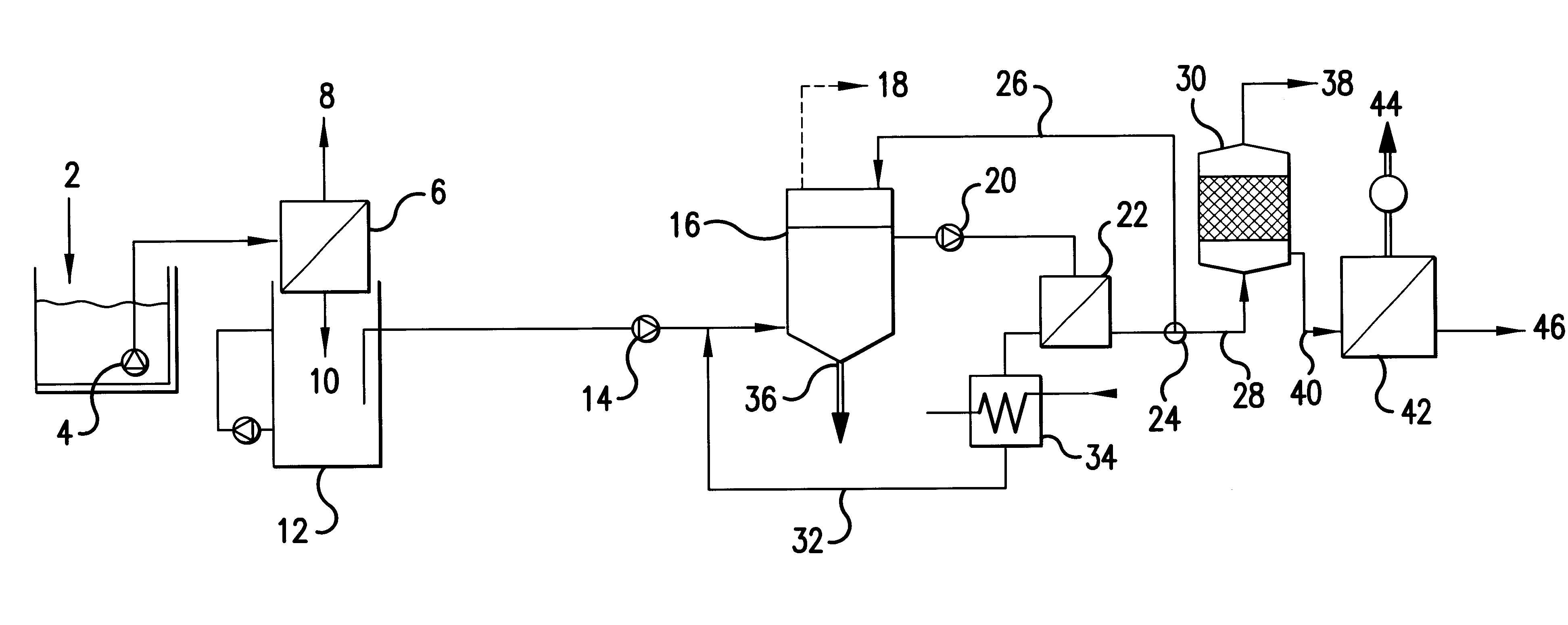

Method for Treating Wastewater or Produced Water

ActiveUS20080135478A1Reduce hardnessReduced silica concentrationWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Degassing device

ActiveUS20110092875A1Maximize advantageReduced effectivenessDialysis systemsMedical devicesHaemodialysis machineEngineering

Owner:GAMBRO LUNDIA AB

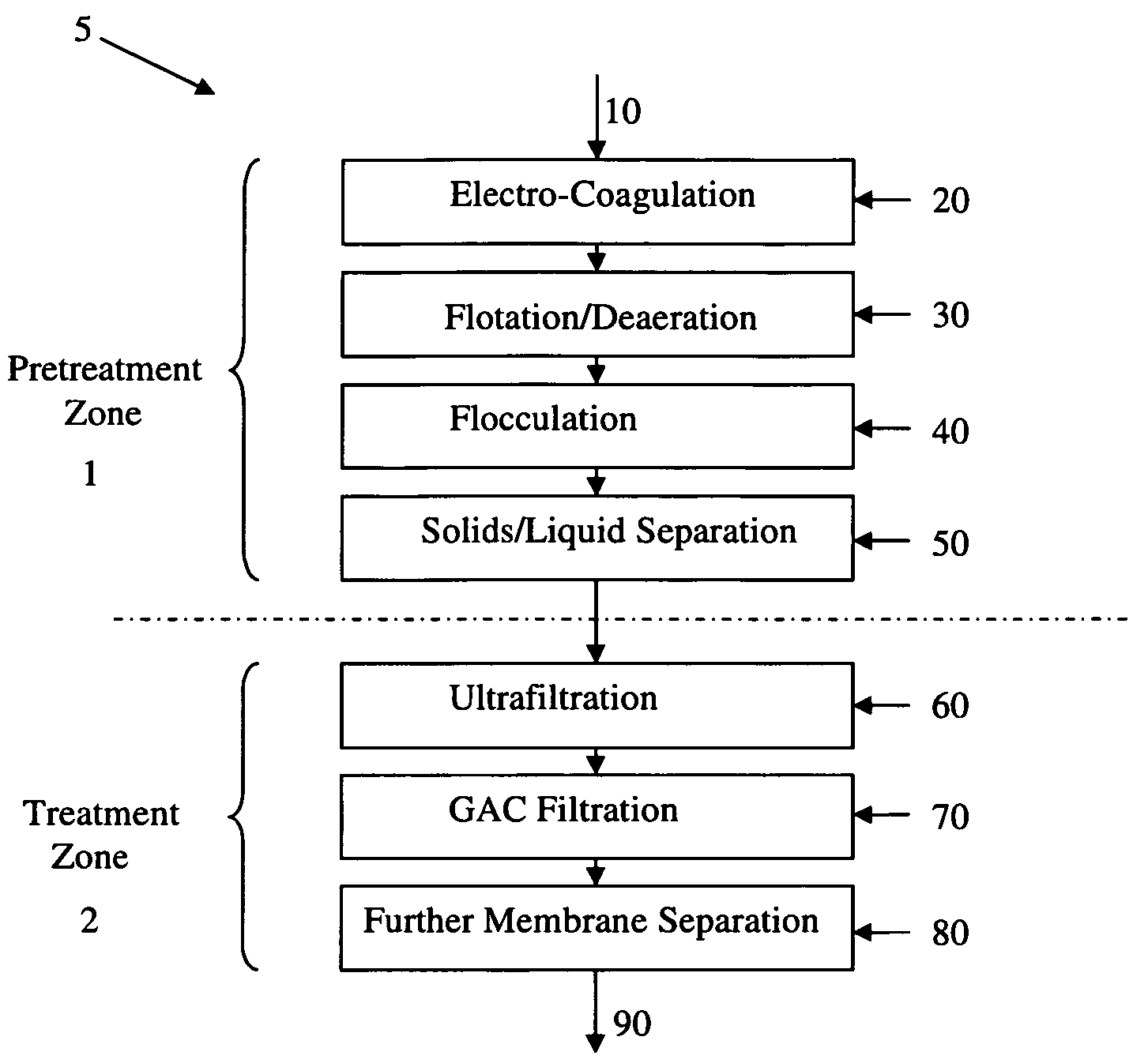

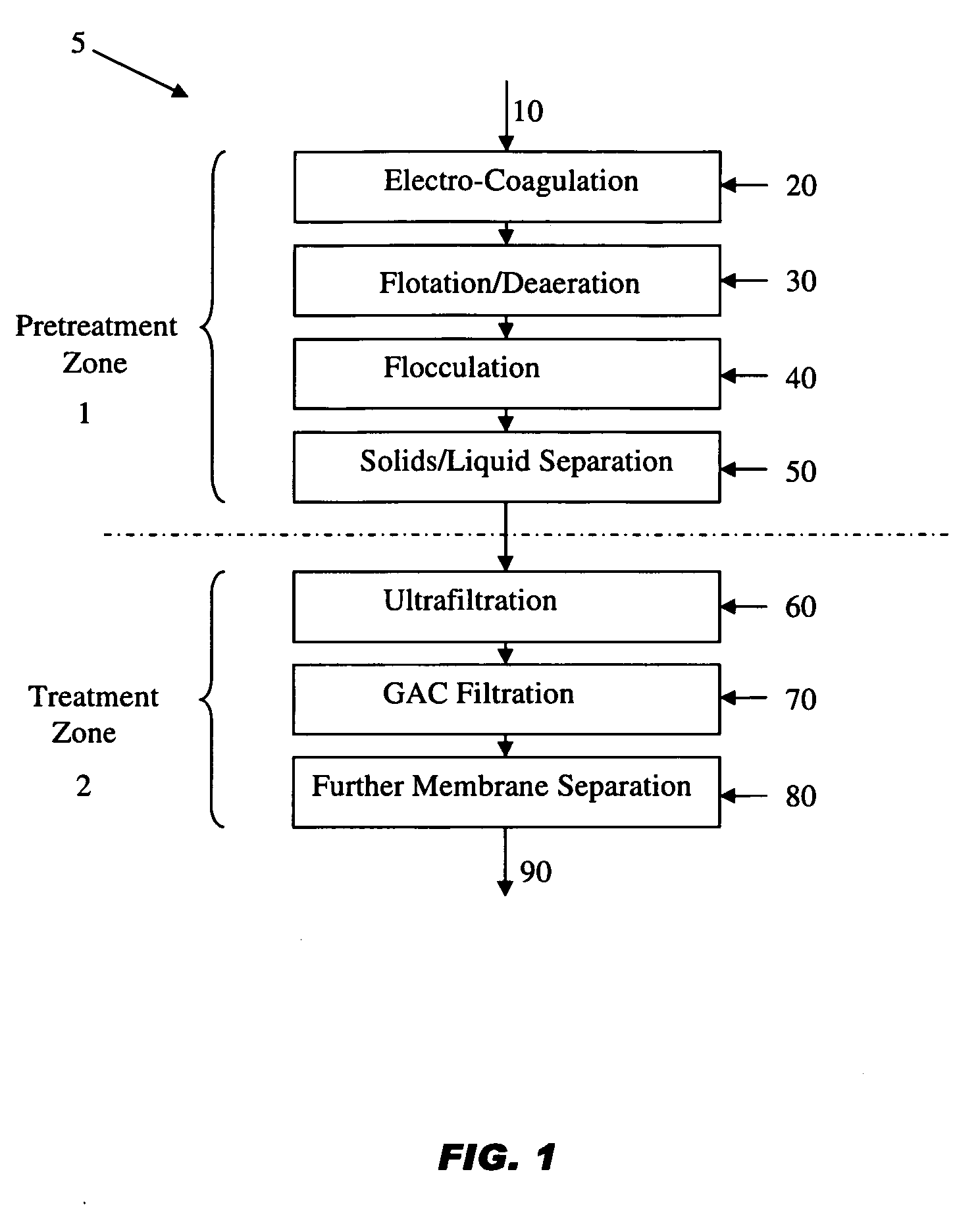

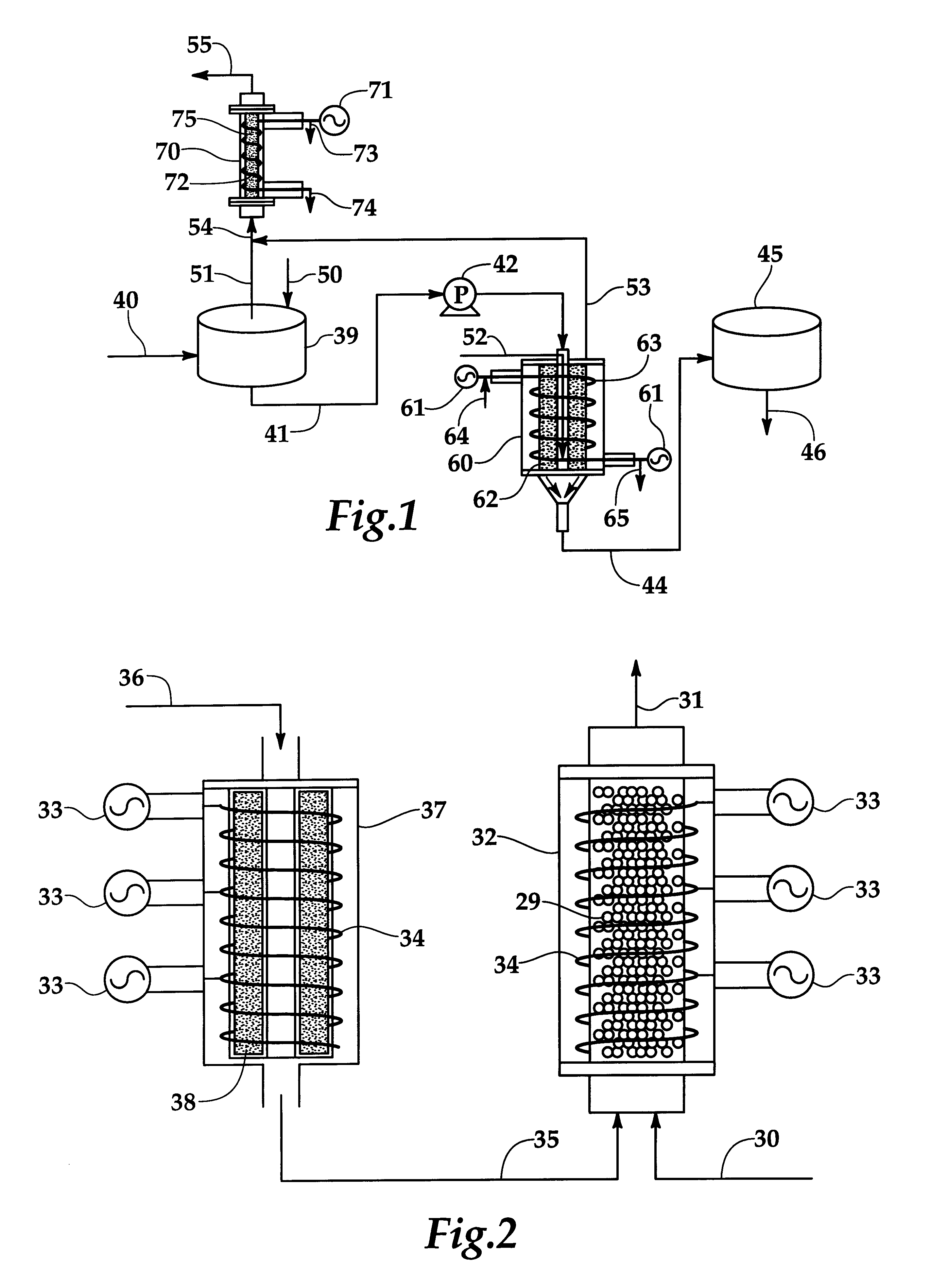

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

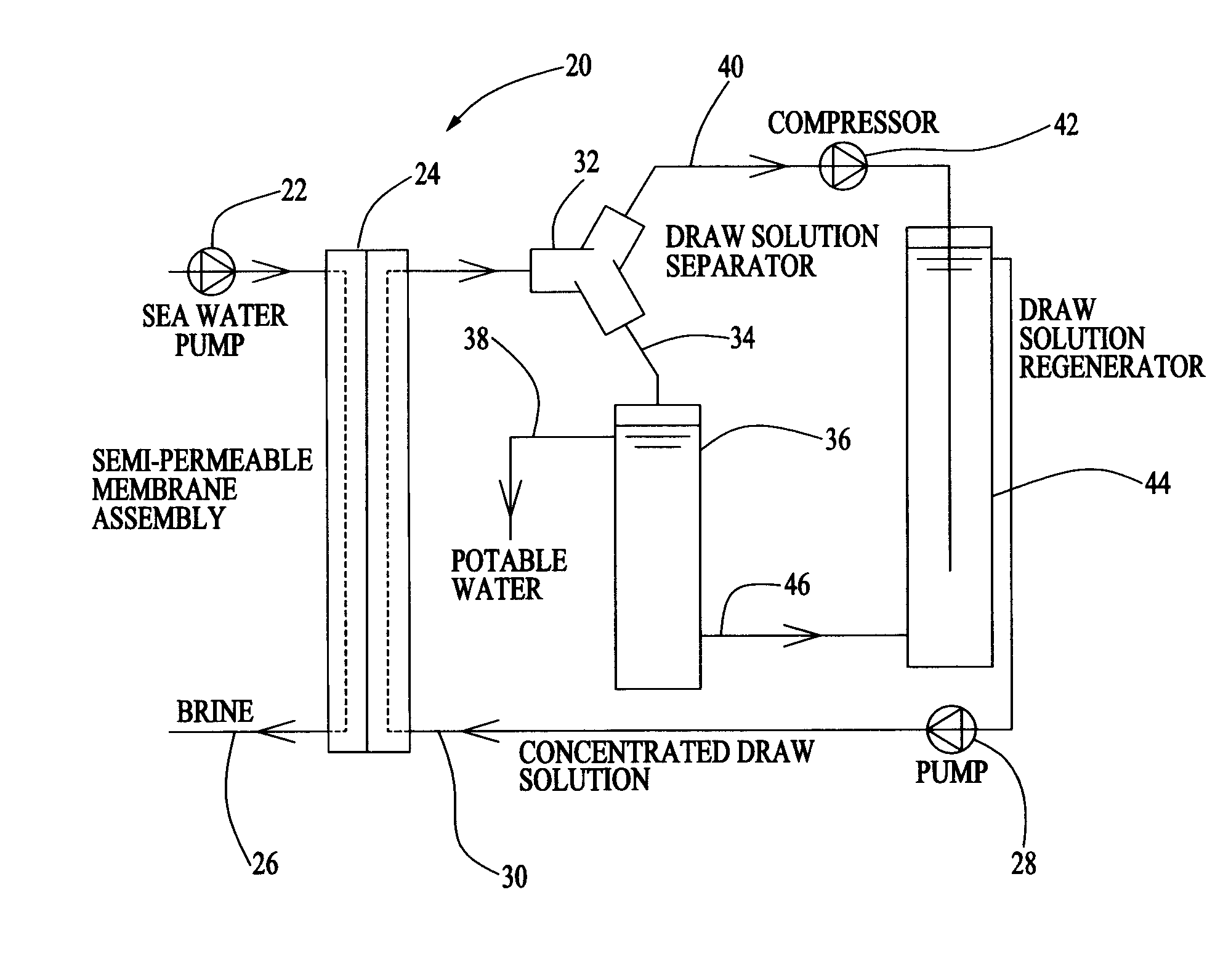

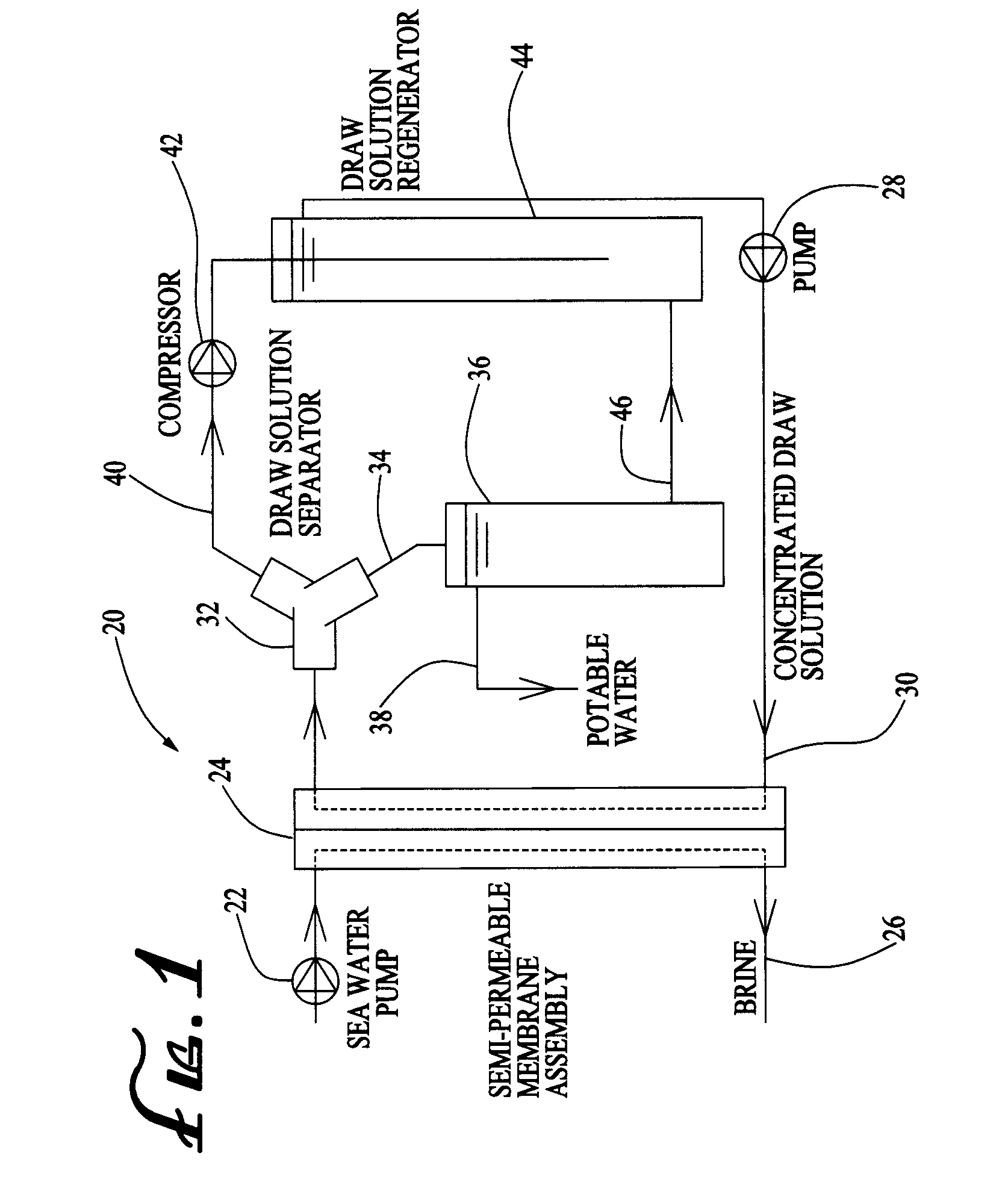

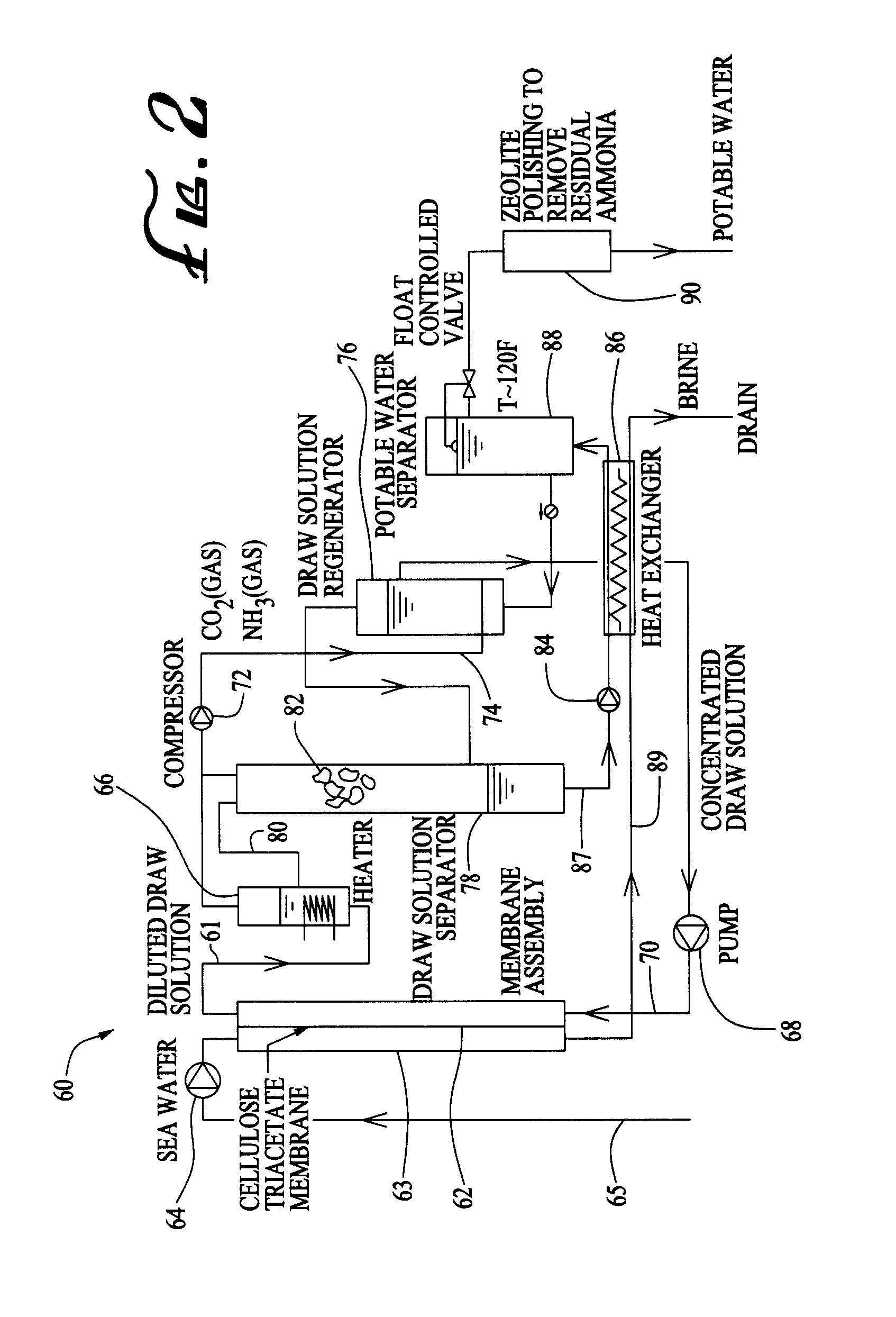

Method and Apparatus for Producing Potable Water from Seawater Using Forward Osmosis

ActiveUS20090308727A1Efficient and effectiveAuxillariesGeneral water supply conservationDesalinationPotable water

A method and apparatus for desalinating seawater which uses an ammonia bicarbonate forward osmosis desalination process. Seawater is pumped through one side of a membrane assembly. A draw solution is pumped through the other side of the membrane assembly. The draw solution withdraws water molecules from the seawater through the membrane into the draw solution. A draw solution separator receives a heated draw solution which then decomposes into ammonia, carbon dioxide and water. Potable water is separated from ammonia has and carbon dioxide gas. The ammonia gas and carbon dioxide gas are recombined with a portion of the potable water stream to reform the ammonium bicarbonate draw solution.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

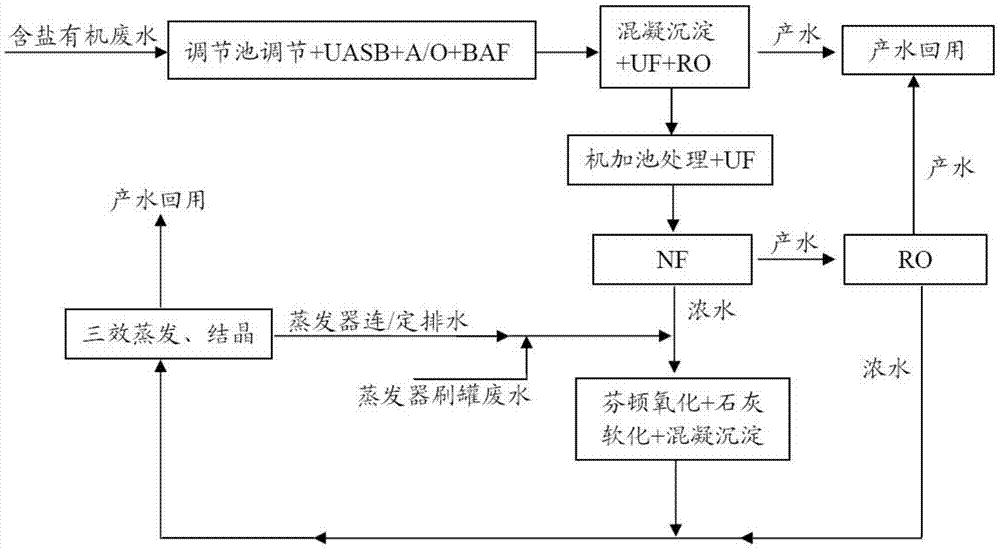

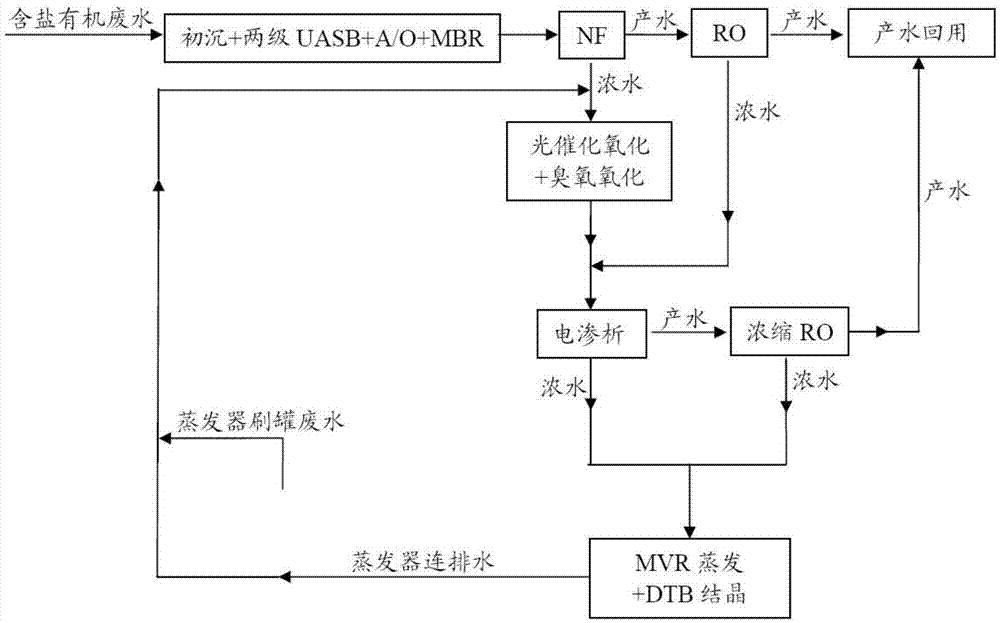

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

Methods to produce sulfate-free saline water and gypsum

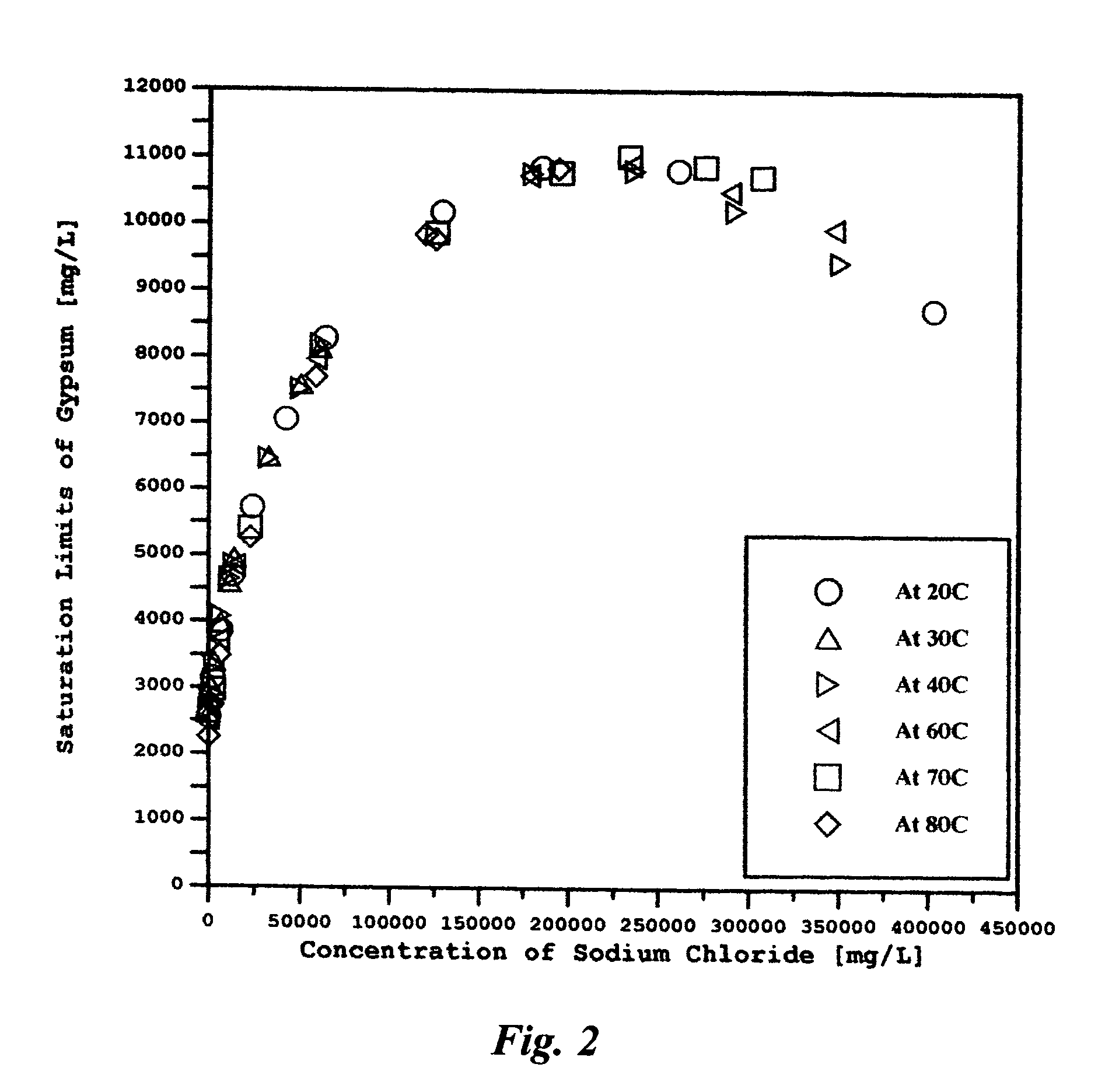

ActiveUS7392848B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterSulfate

Methods are disclosed for the selective separation of sulfate from a saline stream such as seawater to produce nearly sulfate-free saline stream for oil-fields water injection operations. The separated sulfate in the form of gypsum from the treated saline stream can be used in different applications.

Owner:BADER MANSOUR S

Process for microwave decomposition of hazardous matter

InactiveUS6187988B1Promote oxidationNitrogen compoundsLiquid separation by electricityActivated carbonHydrazine compound

This process occurs in the presence of activated carbon or its equivalent by decomposing adsorbed hazardous materials, such as hydrazine and microorganisms, on the carbon surface by radiofrequency energy in the microwave range at near ambient conditions of temperature and pressure. Further microwave oxidation to nonhazardous gases occurs in the presence of a microwaves enhanced oxidation catalyst.

Owner:CHA CHANG YUL

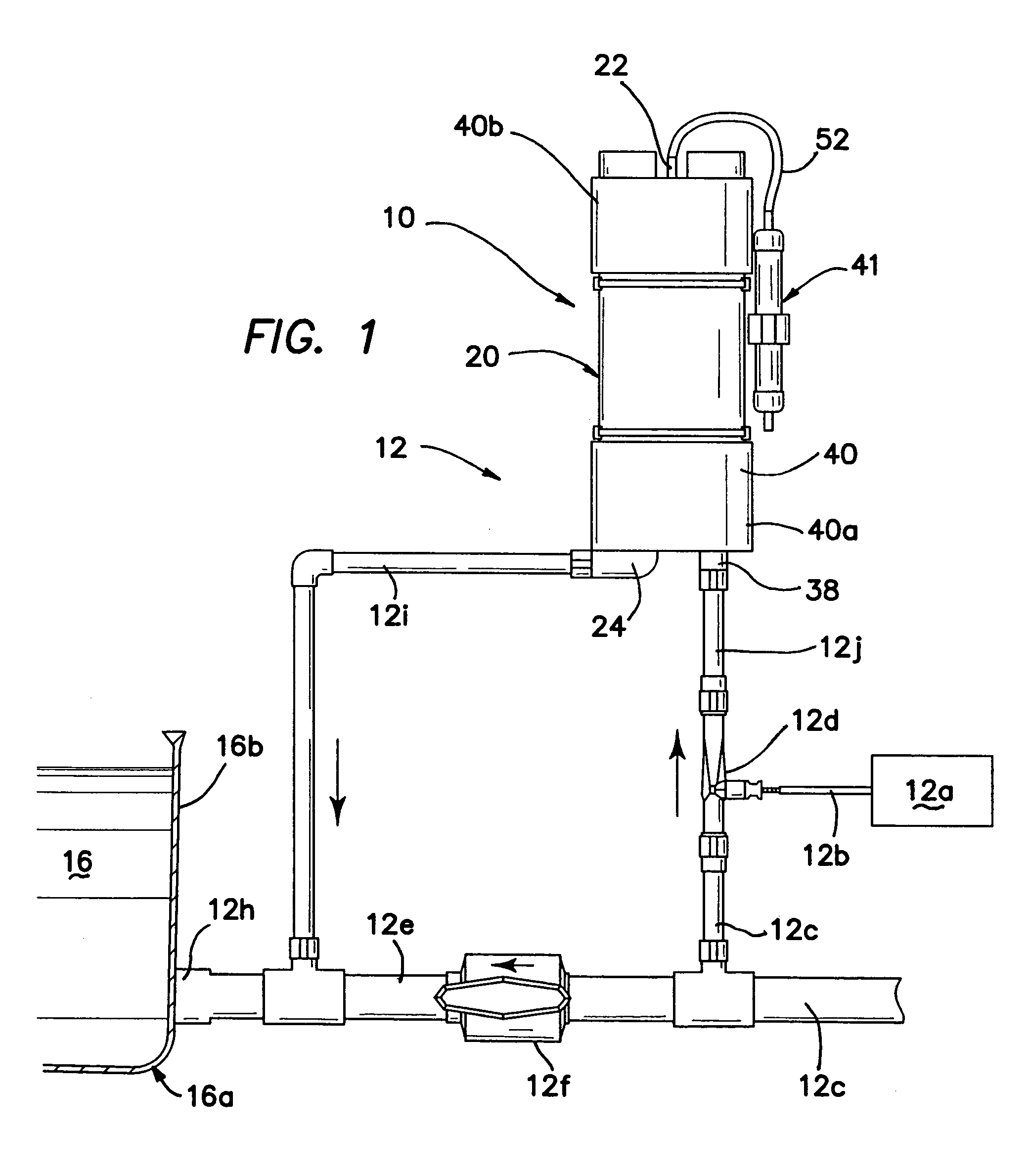

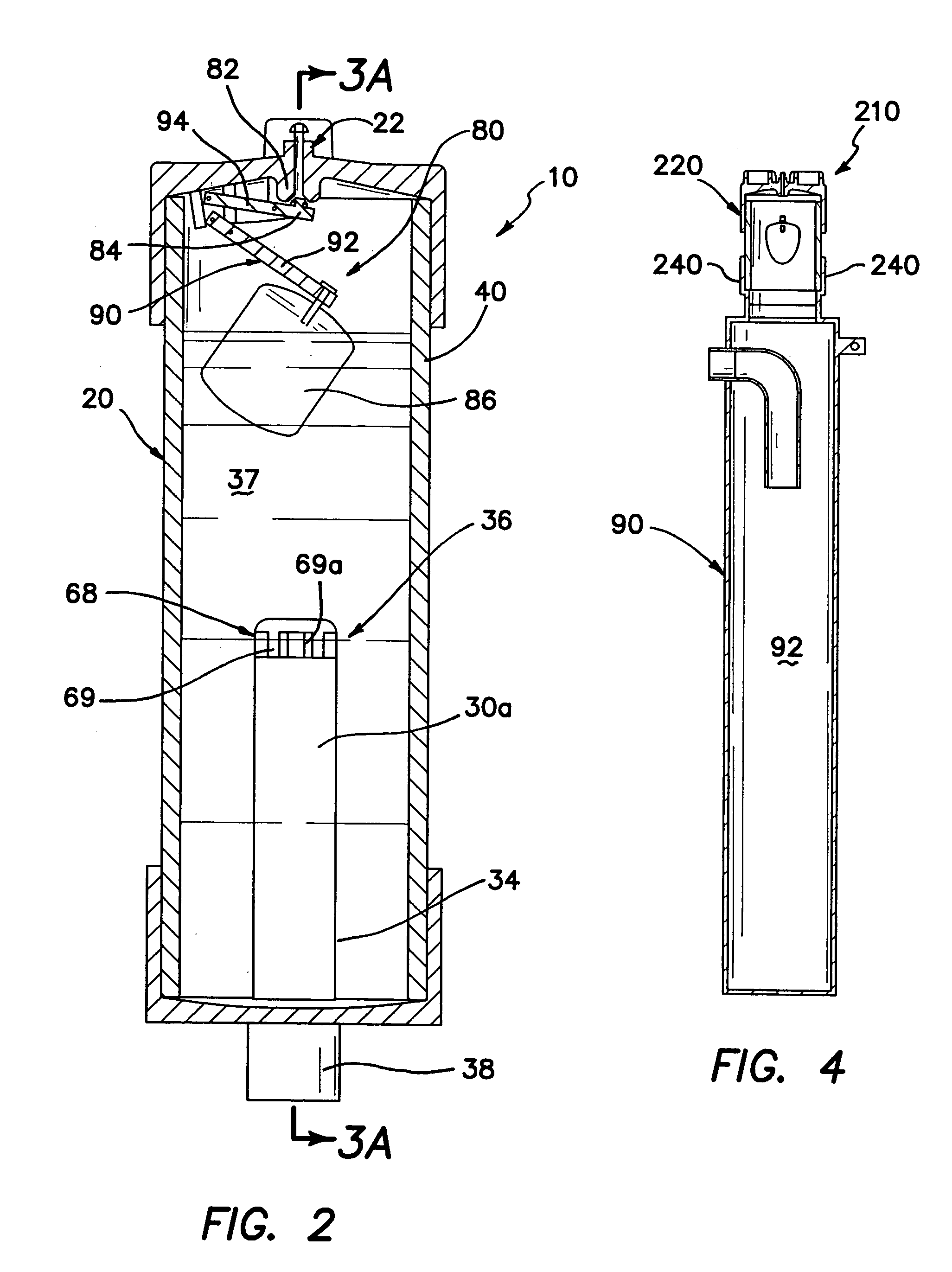

Water ozonation mixing and degassing system

ActiveUS7022225B1Straightforward in constructionEasy to useOther chemical processesDispersed particle separationLiquid waterExhaust fumes

An apparatus and system for mixing and separating ozonated water is provided. The apparatus is especially useful as a component of a system for cycling sanitizing ozonated water to a body of water such as a pool, spa or pond. The apparatus generally includes a separating vessel including a mixing tower, preferably located substantially entirely within the separating vessel and including a diffuser element for enhancing mixing of ozonated water without increasing turbulence in the separating vessel. Preferably, the apparatus includes a seal mechanism that substantially prevents liquid water from escaping the separating vessel with vented off-gas. The invention further provides an ozone destruct assembly including a condensate collection portion, and may also include a return line for passing a treated off-gas into the body of water.

Owner:CUSTOM MOLDED PROD

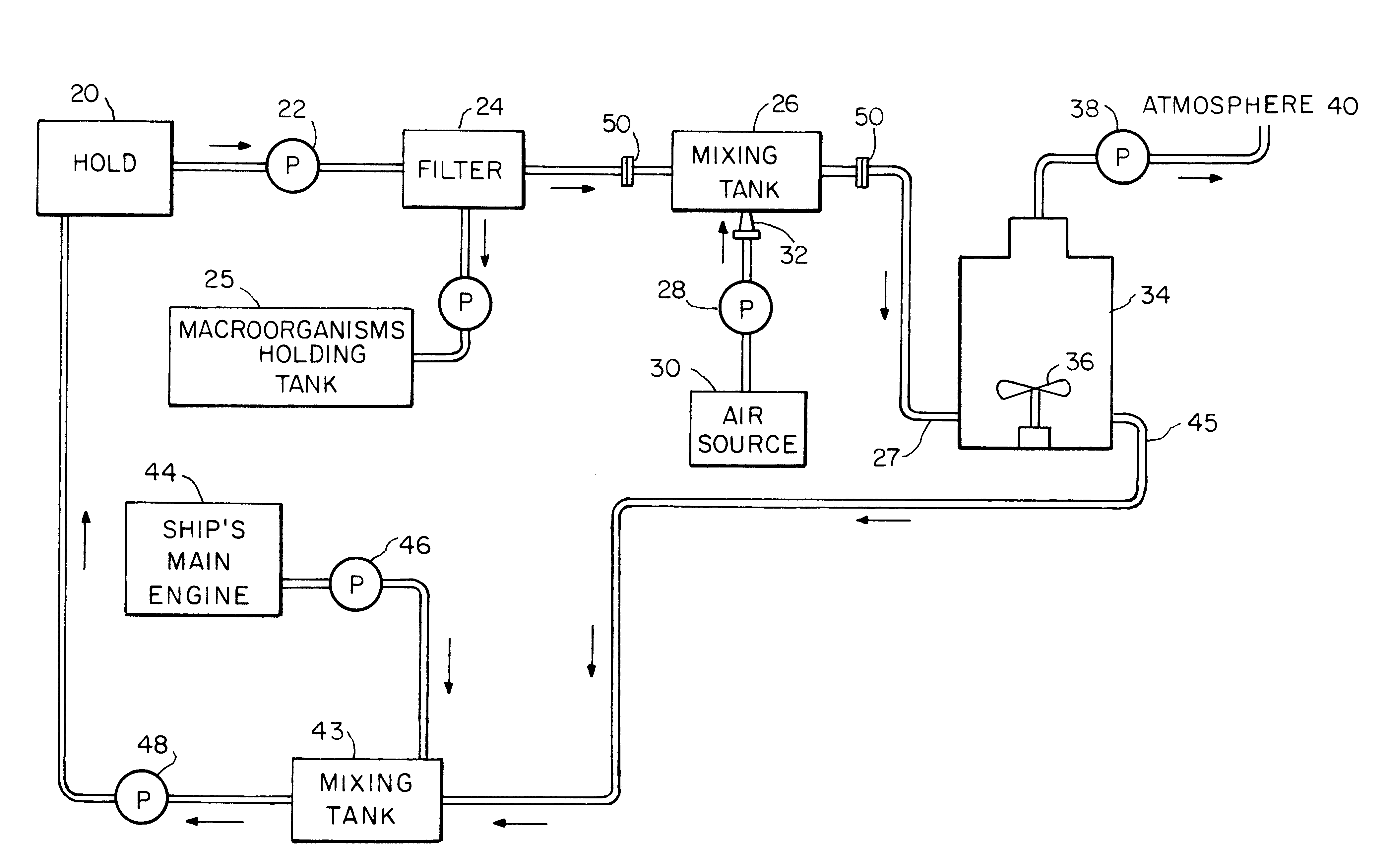

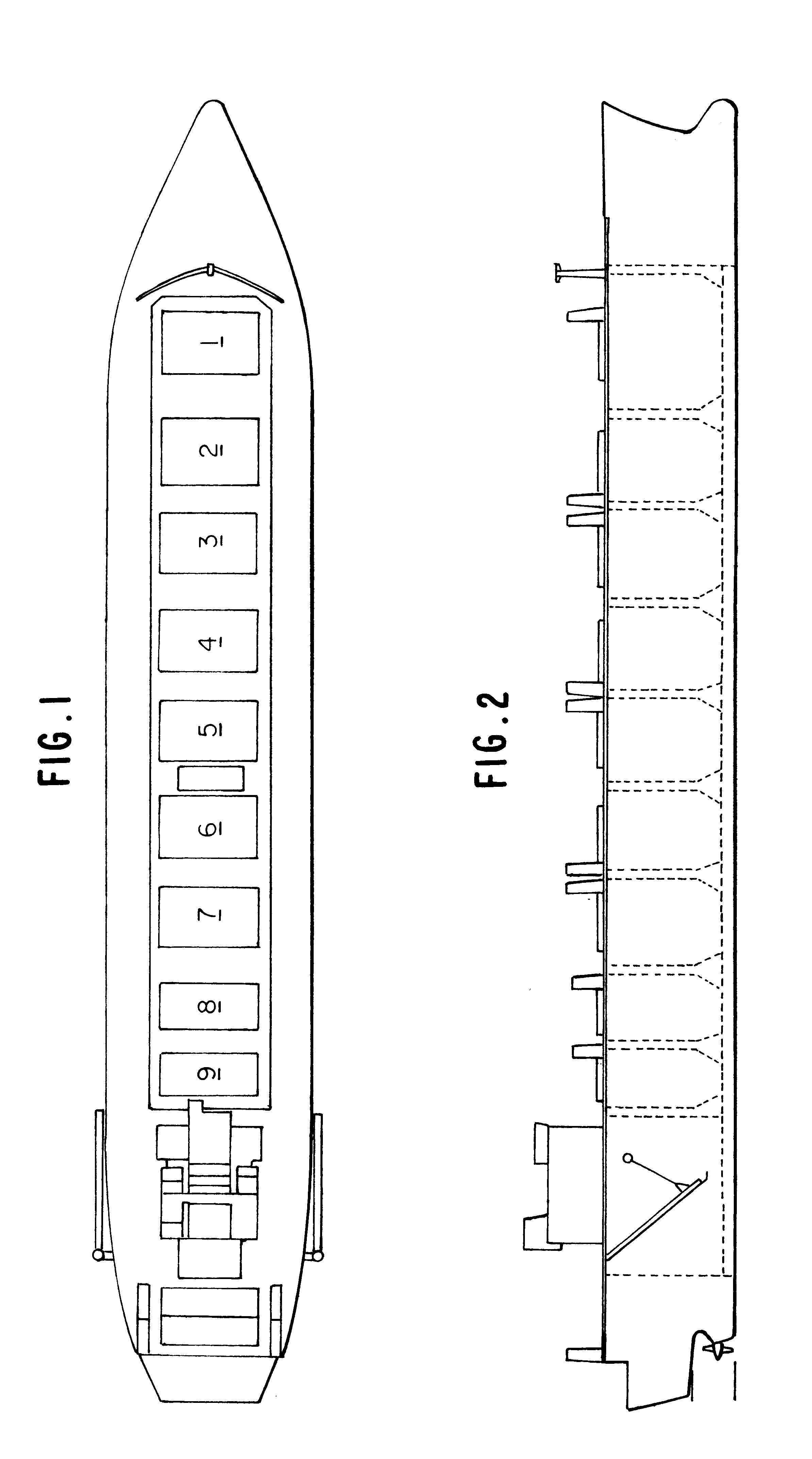

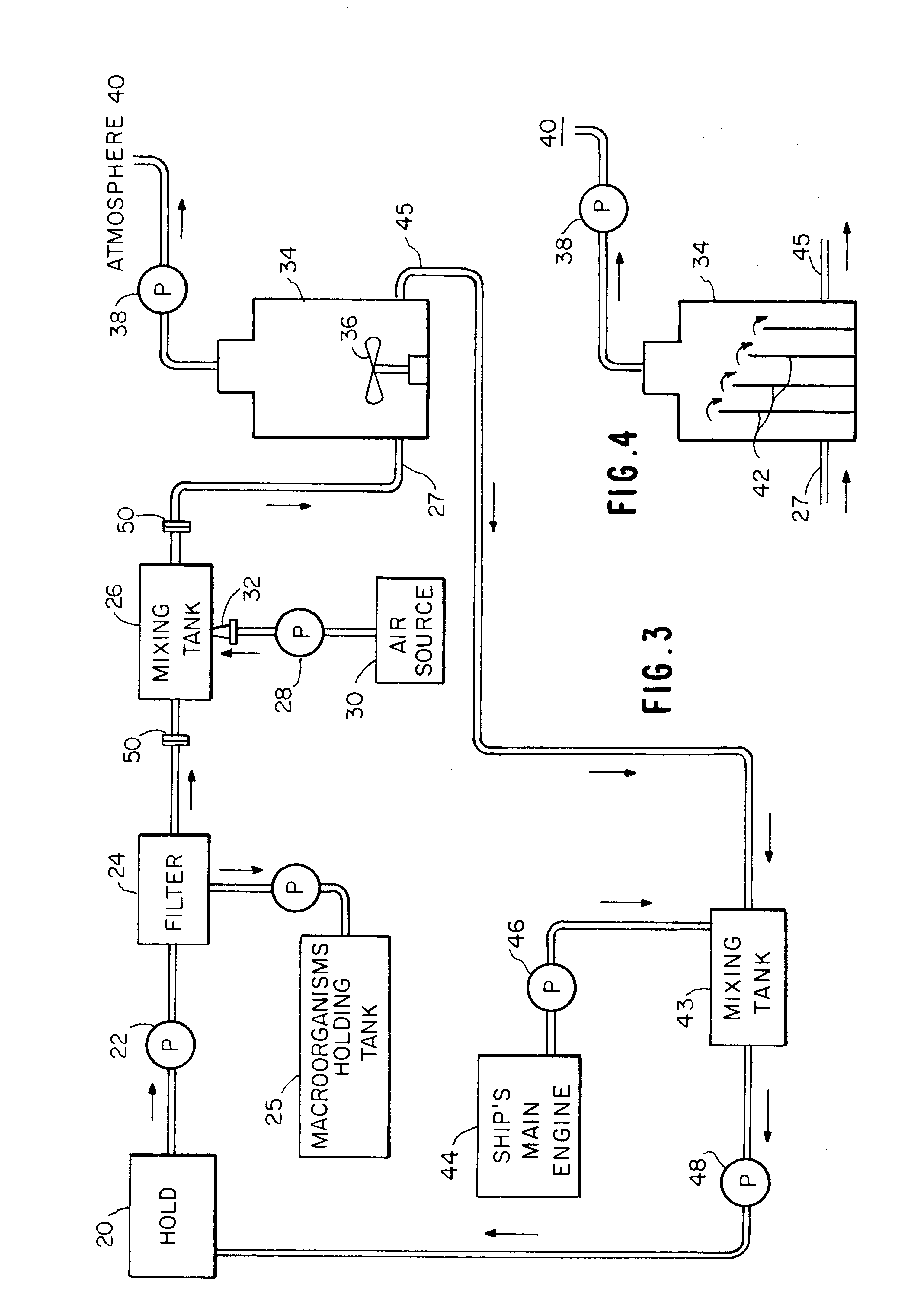

Method and apparatus for killing microorganisms in ship ballast water

InactiveUS6171508B1Rapidly reduce the DOTime requiredHull interior subdivisionWater treatment parameter controlOxygenAnaerobic microorganisms

A method and apparatus for treating ship ballast water before it is discharged into coastal waters. The ballast water may contain a generalized and diverse species population of harmful non-indigenous microorganisms. Before discharge, the ballast water is oxygenated and deoxygenated to reduce the populations of anaerobic and aerobic microorganisms, respectively. If anaerobic microorganisms are of no concern, the oxygenation step can be eliminated. Also, a method and apparatus for treating large volumes of any water, to reduce the population of a wide spectrum of diverse species of microorganisms wherein the water is deoxygenated, and then held in a sealed space for a period of time until the aerobic population has been reduced.

Owner:TIDEWATER BALLAST SOLUTIONS LLC

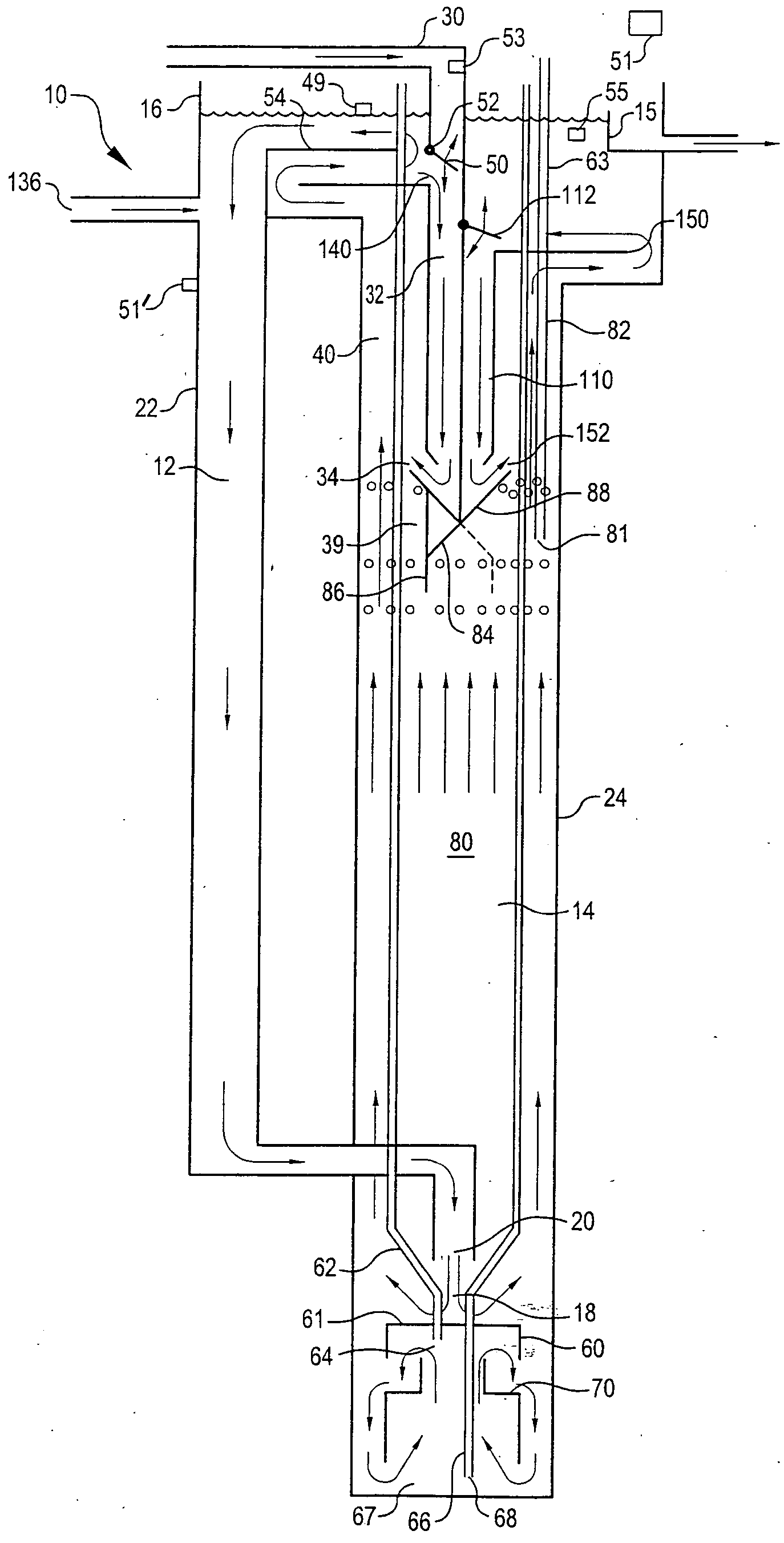

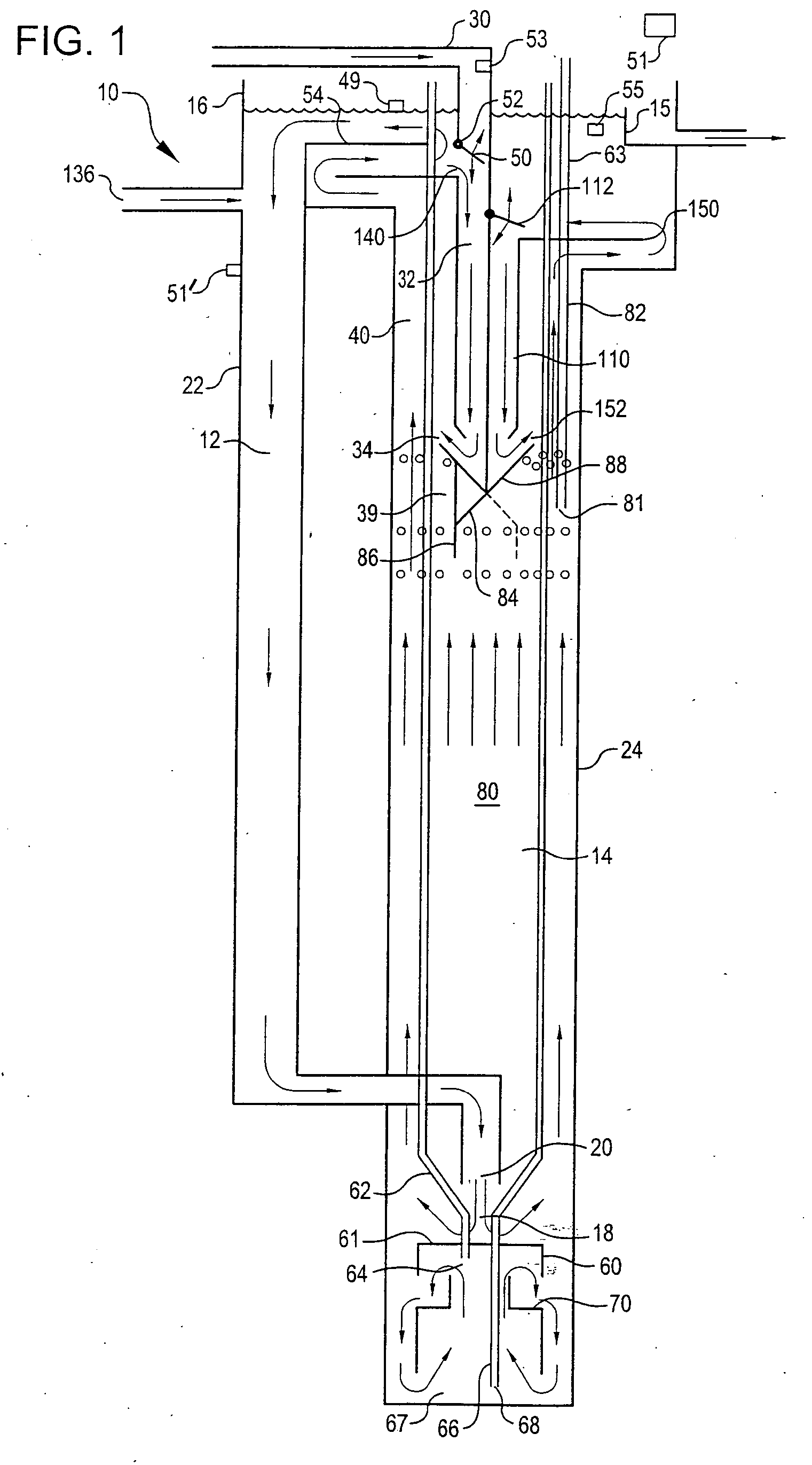

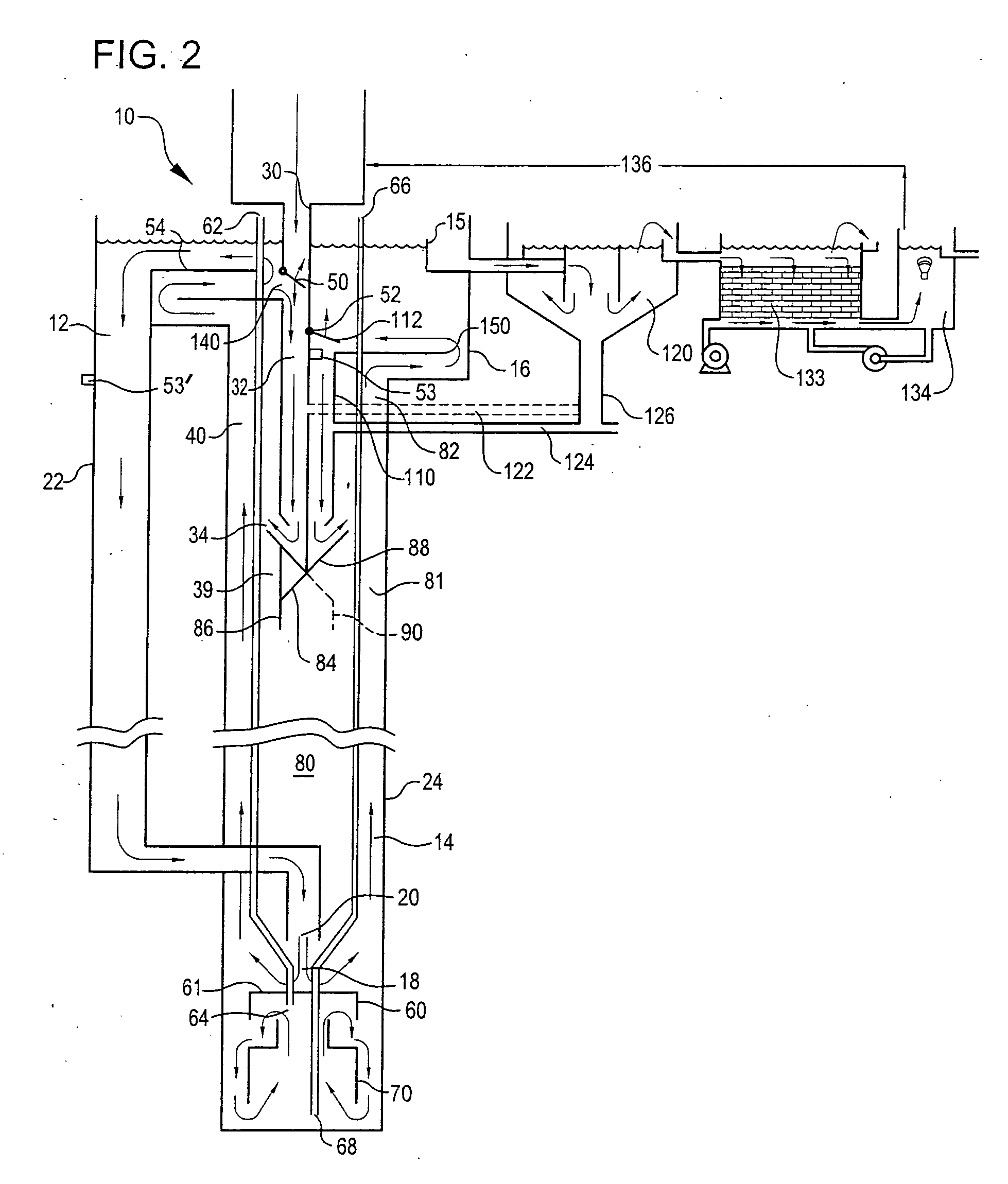

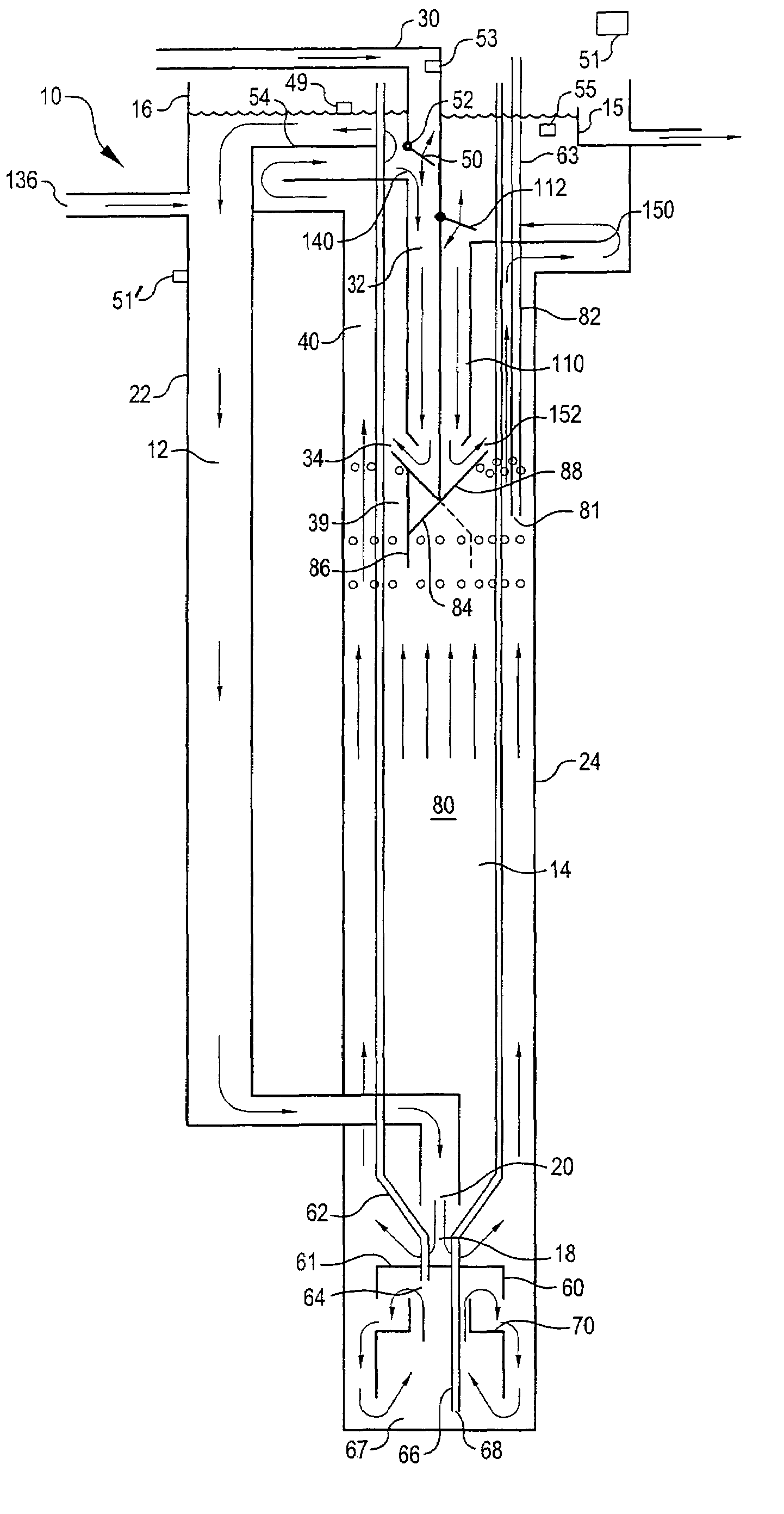

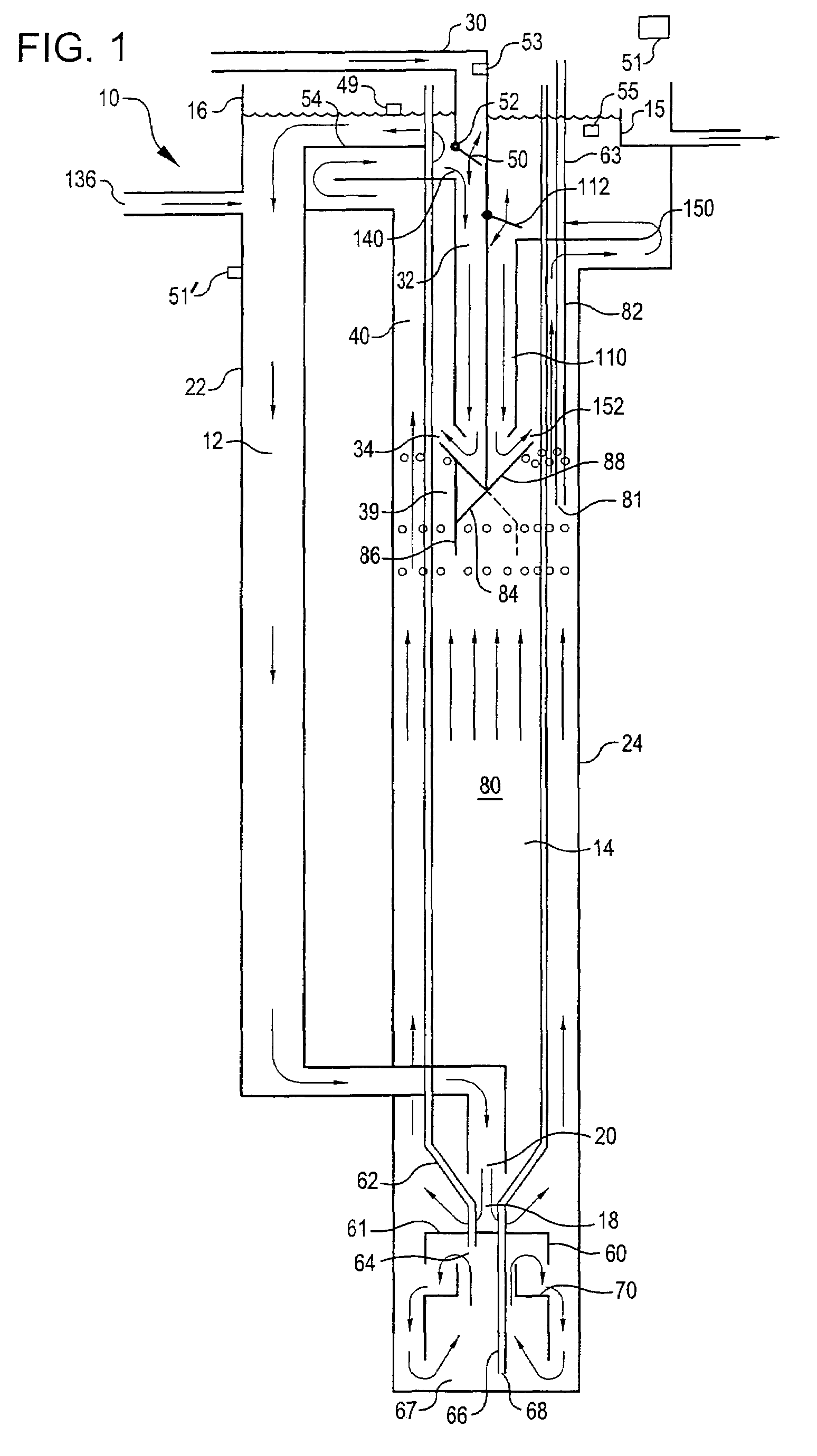

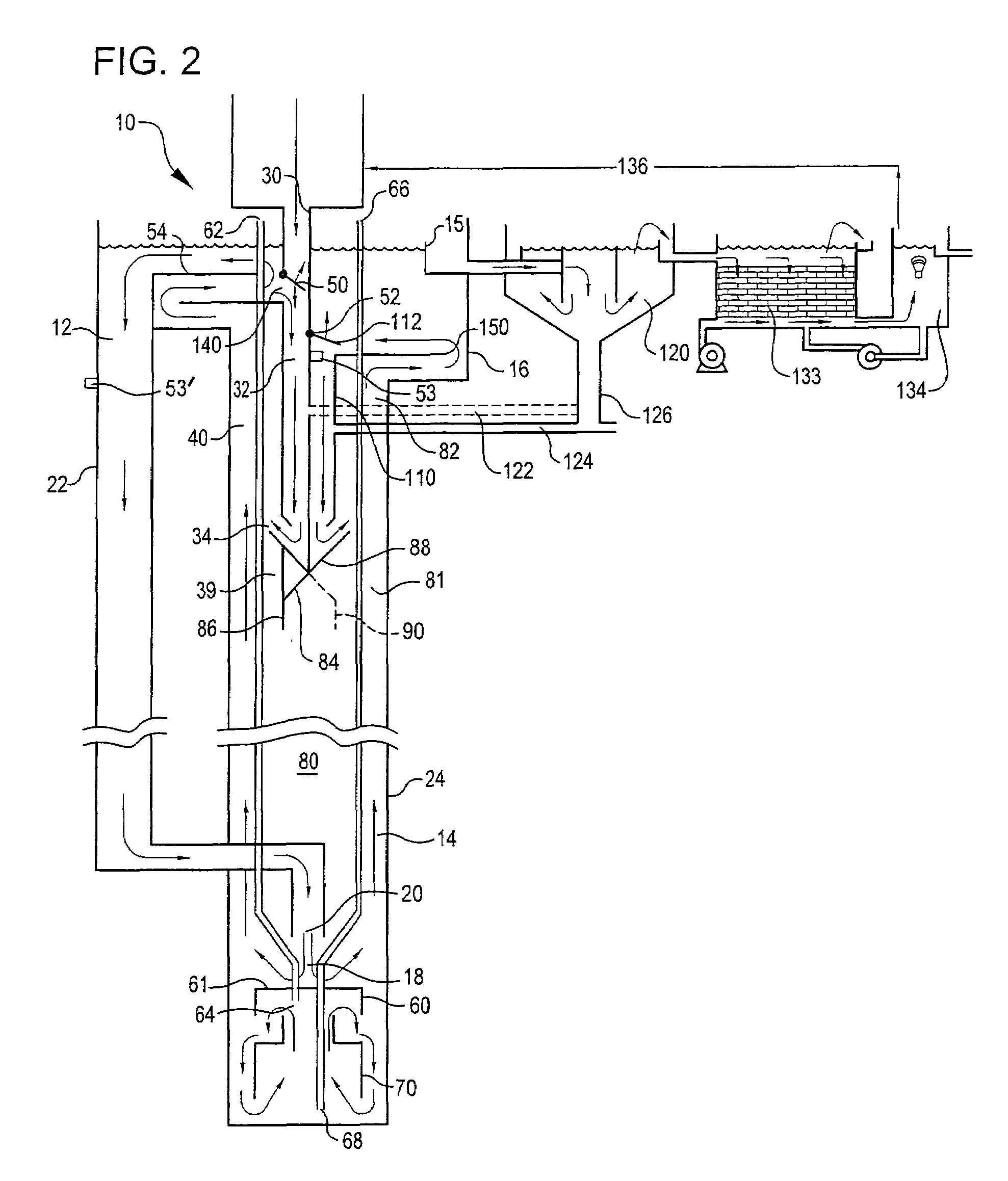

Methods and apparatus for biological treatment of waste waters

InactiveUS20050115880A1Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

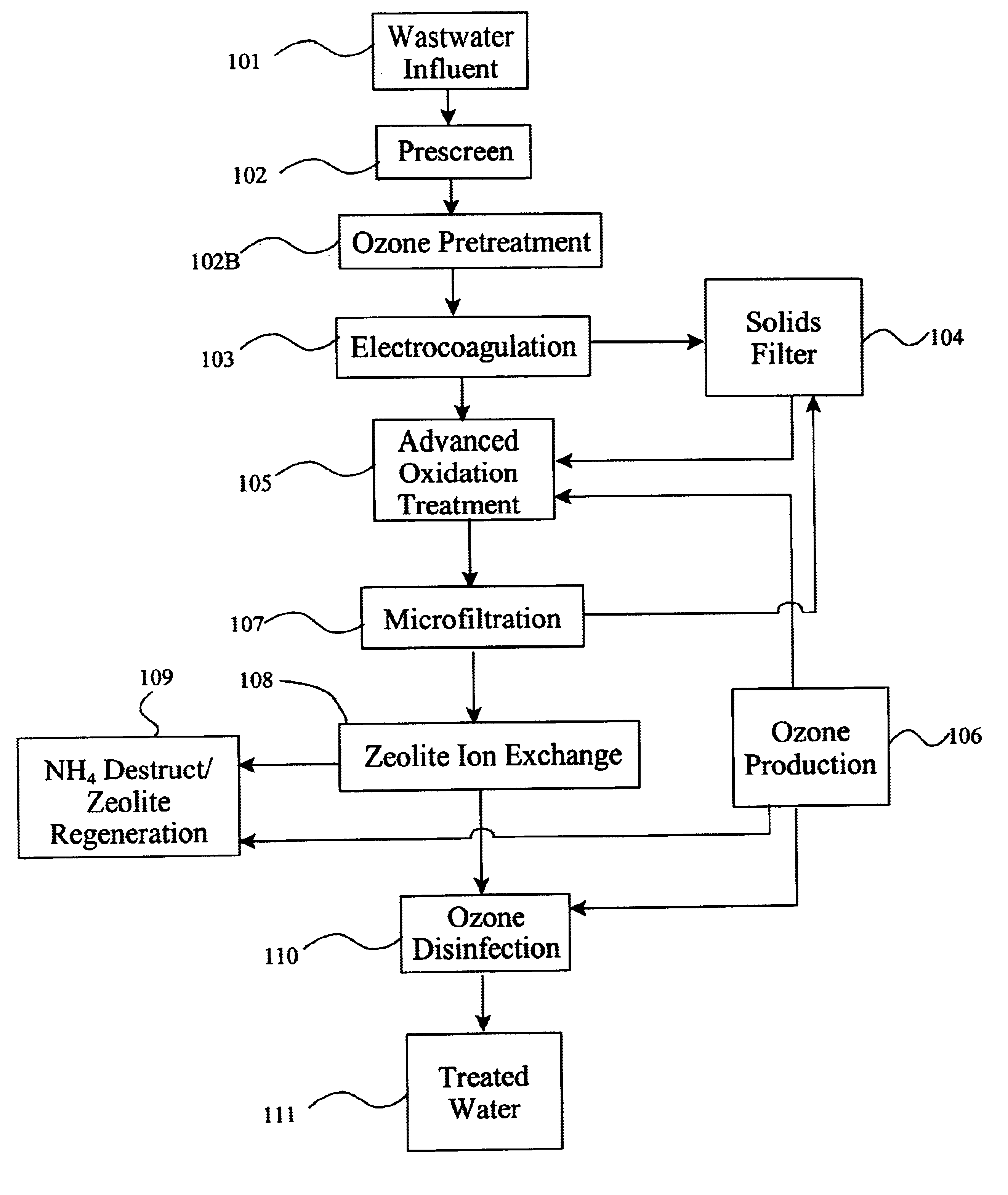

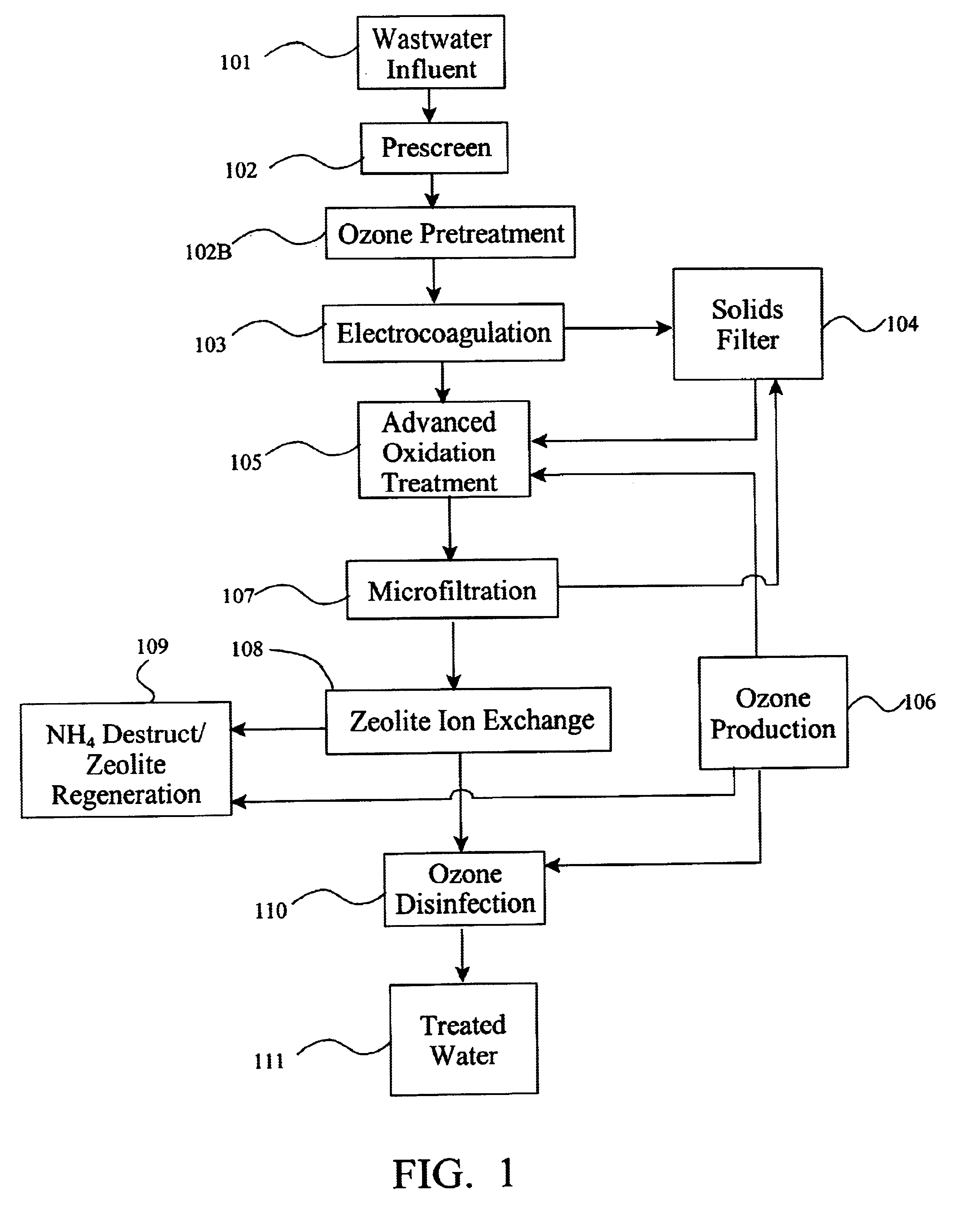

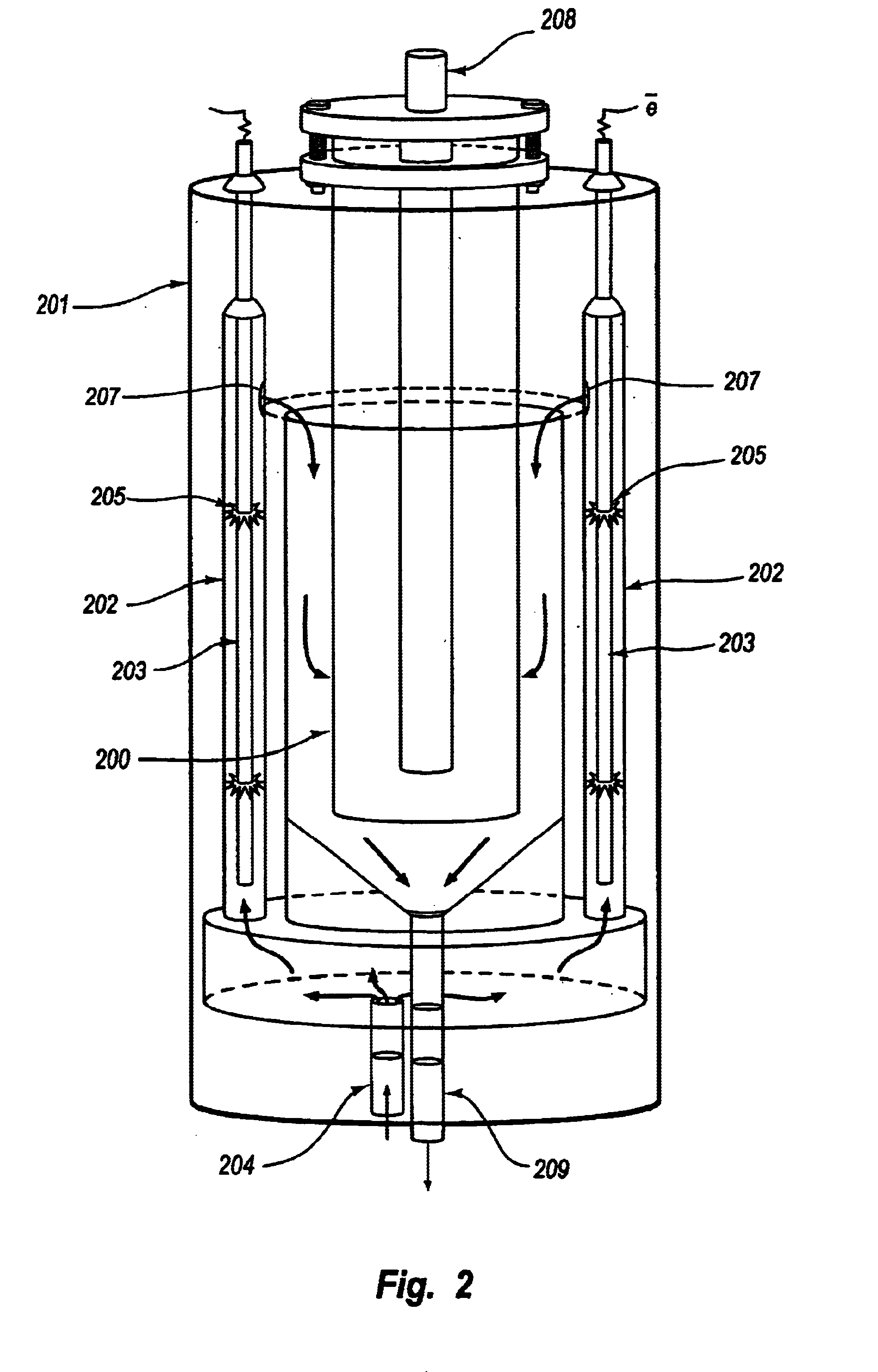

Leachate and wastewater remediation system

InactiveUS6960301B2Effective amount of reactionMany difficultyLiquid separation by electricityFlow mixersAdvanced oxidation processFiltration

A compact portable modular wastewater treatment system which integrates several processing technologies to provide a substantially purified water source. A wastewater stream is sent through an initial filtration step. The filtered wastewater is then subjected to electrocoagulation and then further filtered. The resulting stream containing substantially only organics is then treated in an advanced oxidation process which can include passing an electrical current through the water during the oxidation process. The partially treated water is then passed through ion-exchange columns to polish ammonium and other contaminants. The ion-exchange columns are cycled through regeneration cycles to provide continuous ion-exchange medium. The ammonium rich brine solution used in regeneration is subjected to an ammonium destruct process and then reused in regenerating ion-exchange columns. The water can then be sent through a final disinfection oxidation process to destroy or inactivate pathogens and / or remove any remaining colorants or odor to provide a water source suitable for almost any use.

Owner:NEW EARTH SYST

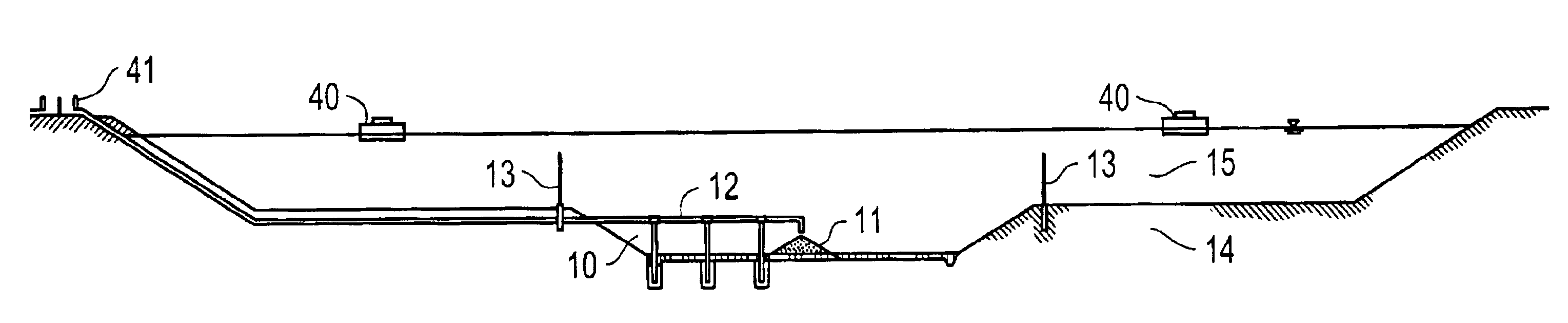

Apparatus to establish and optimize sedimentation and methane fermentation in primary wastewater ponds

InactiveUS6923906B2Raise the pHIncreases the rate of die-away of pathogenic bacteriaLiquid degasificationMixing methodsSludgeIncrease ph

Owner:GREEN FRANKLIN BAILEY +2

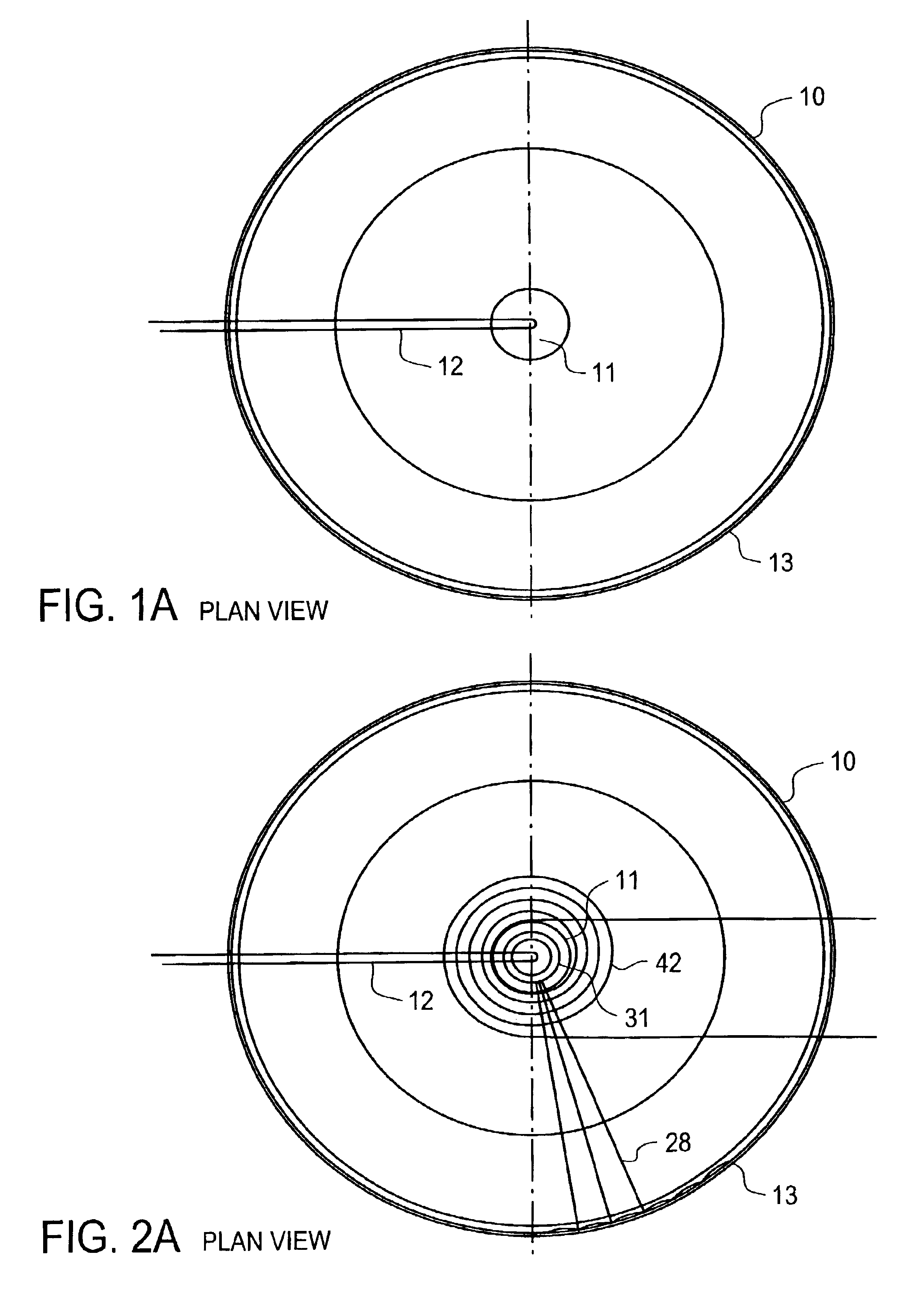

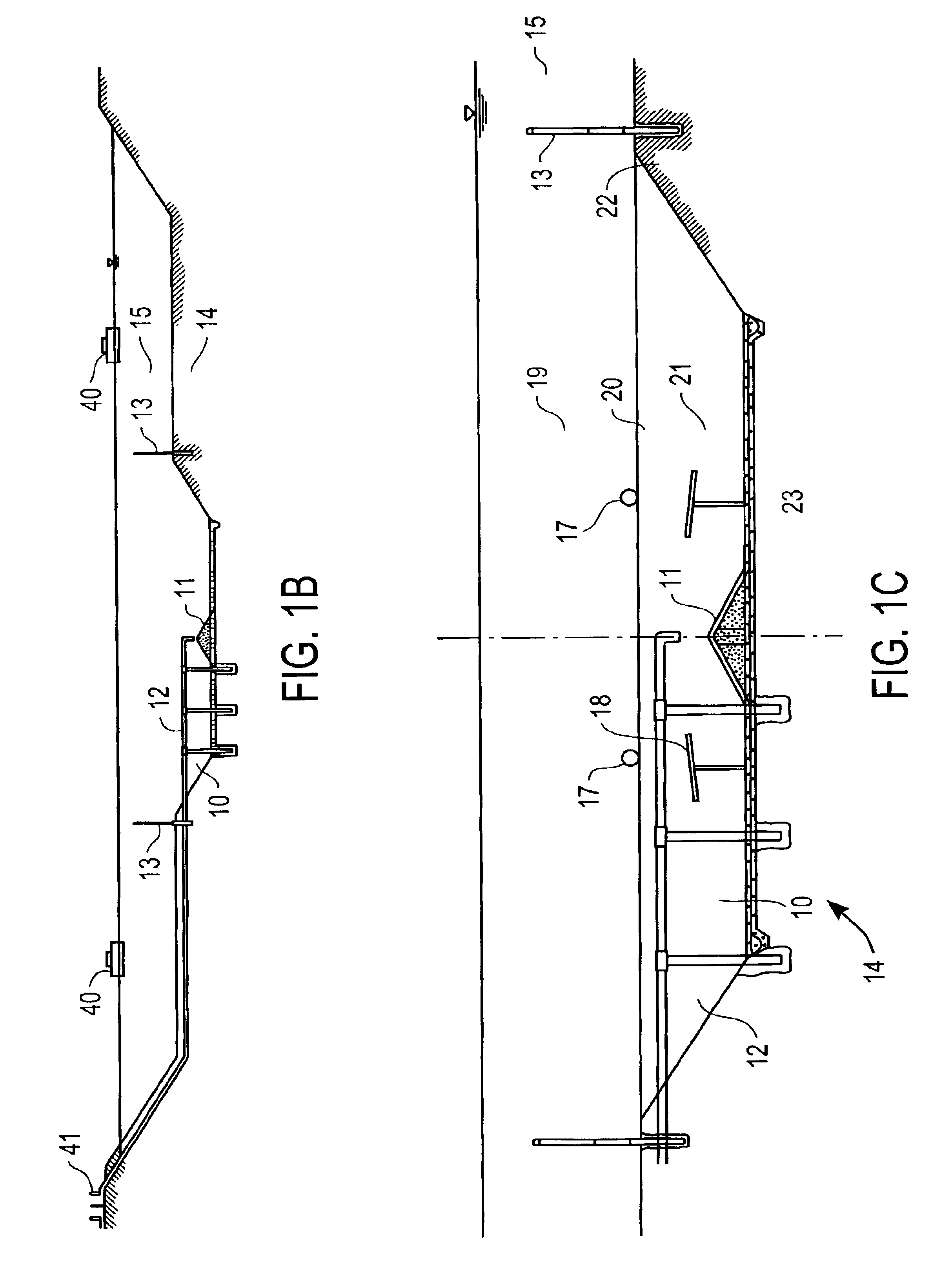

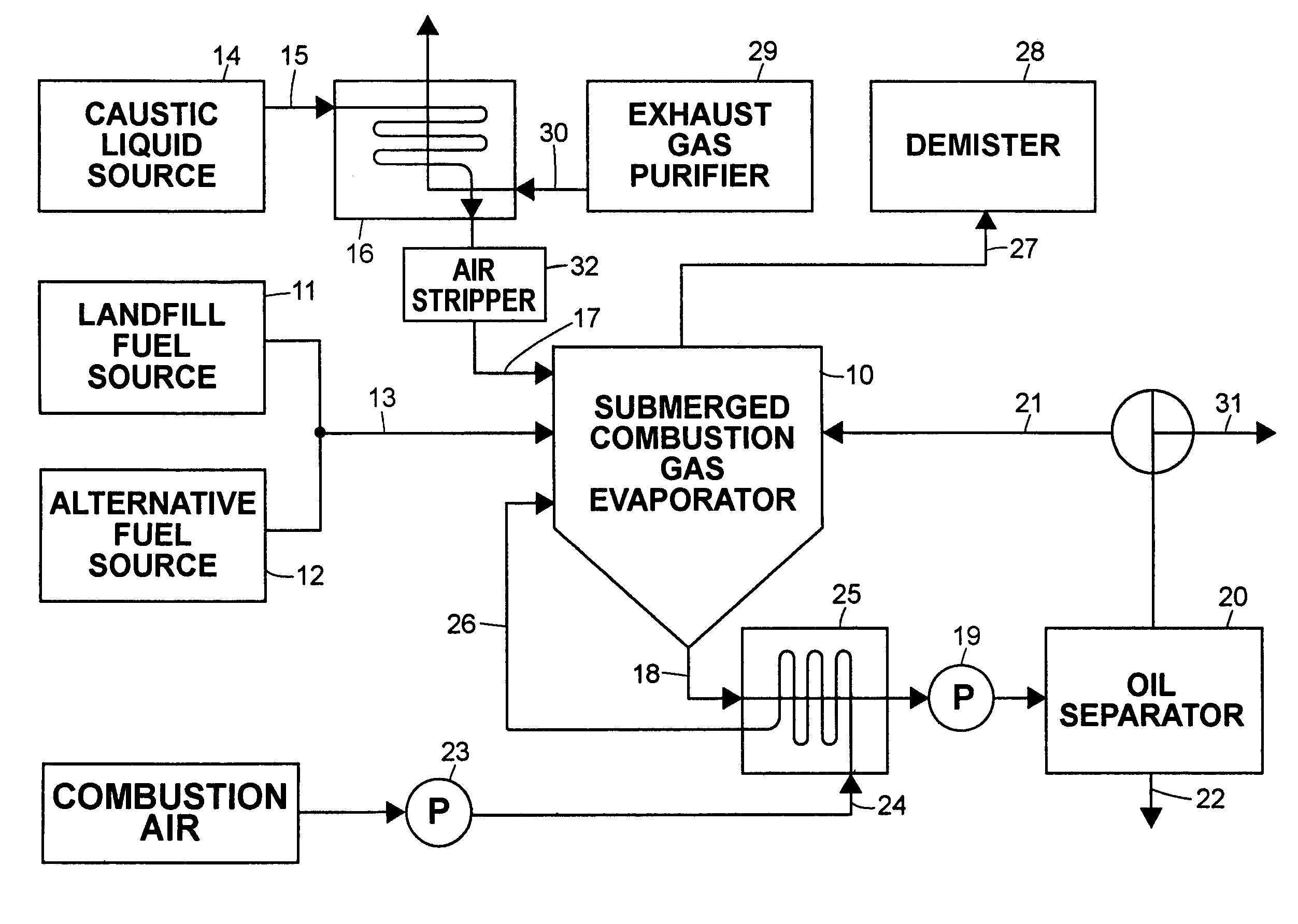

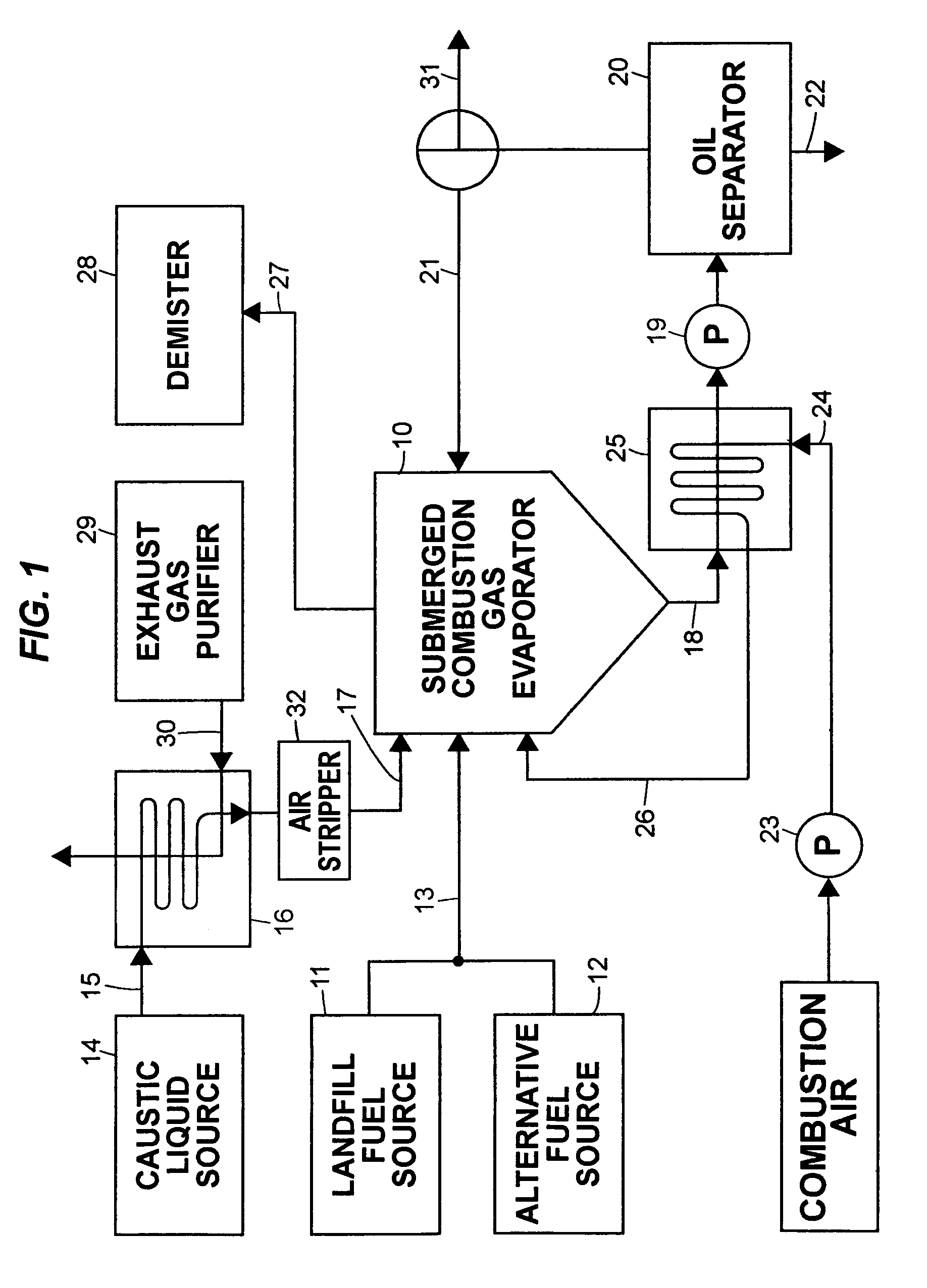

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

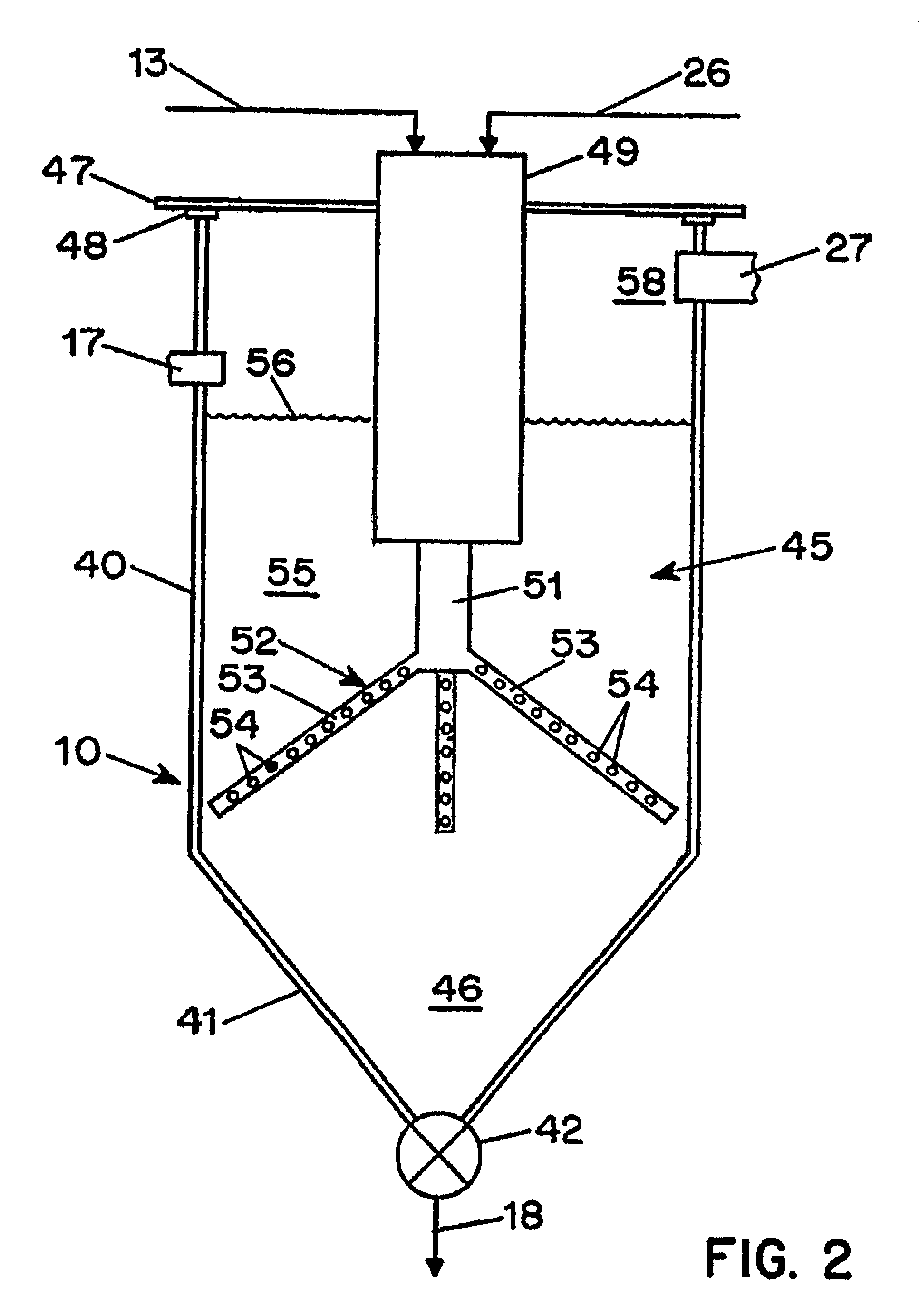

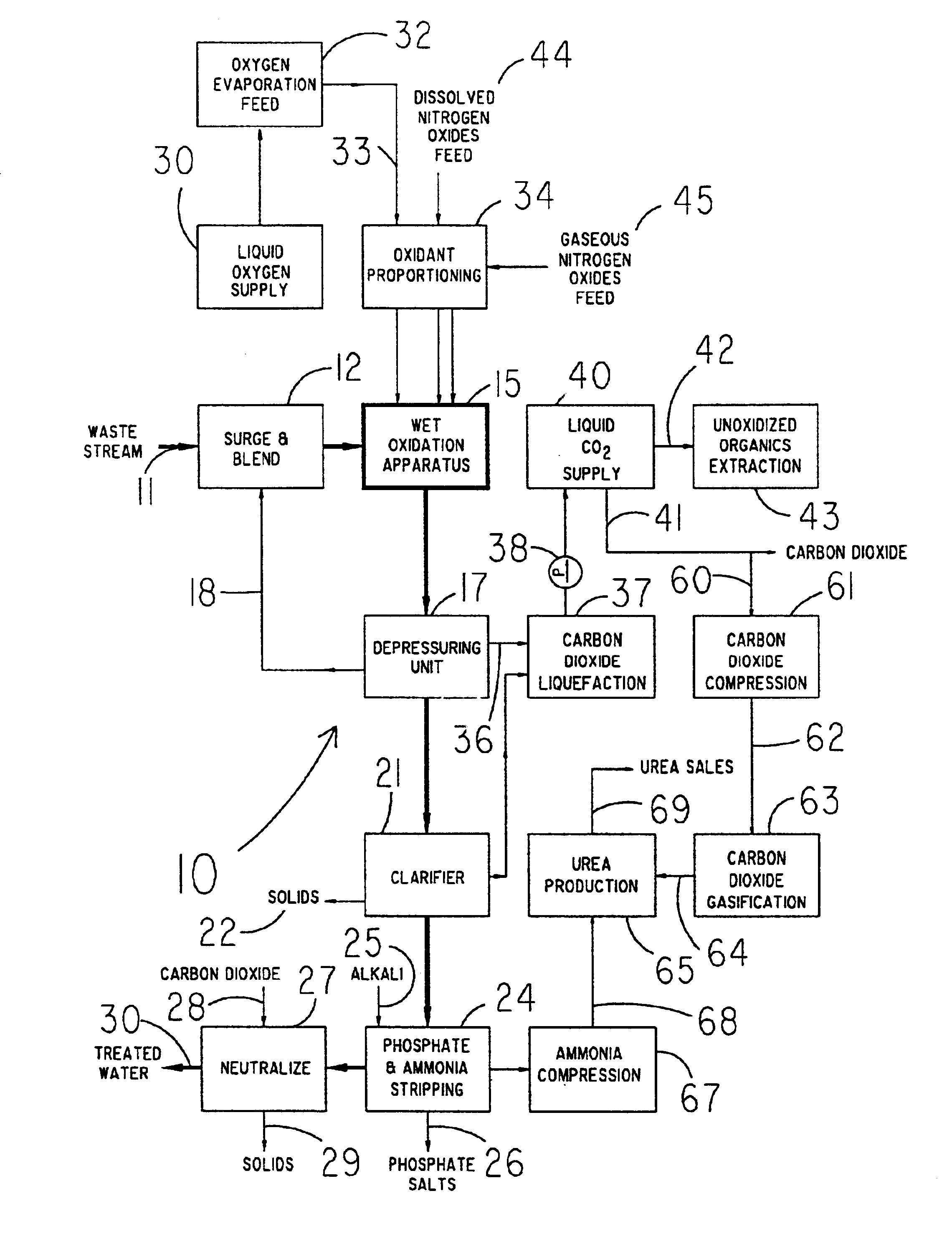

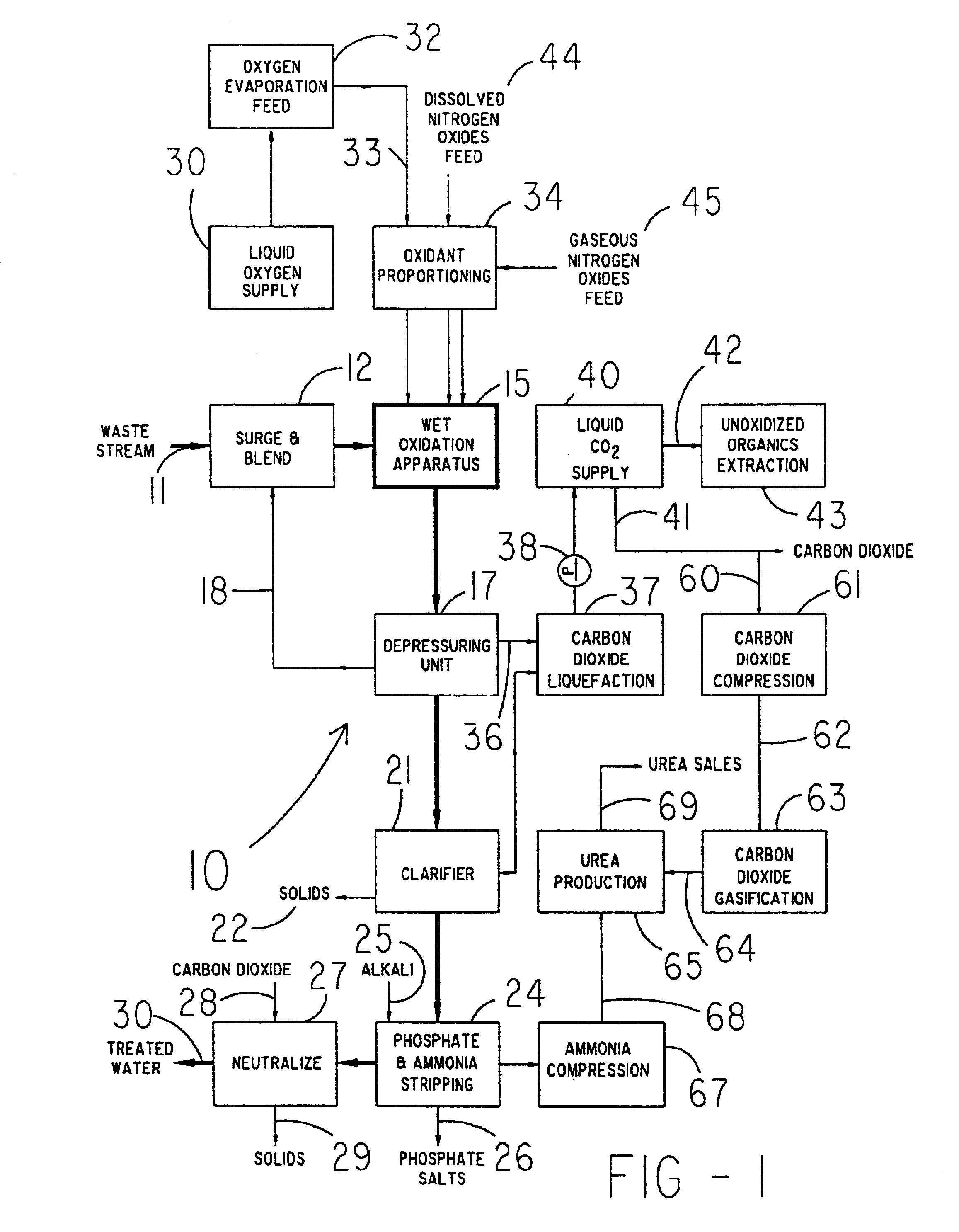

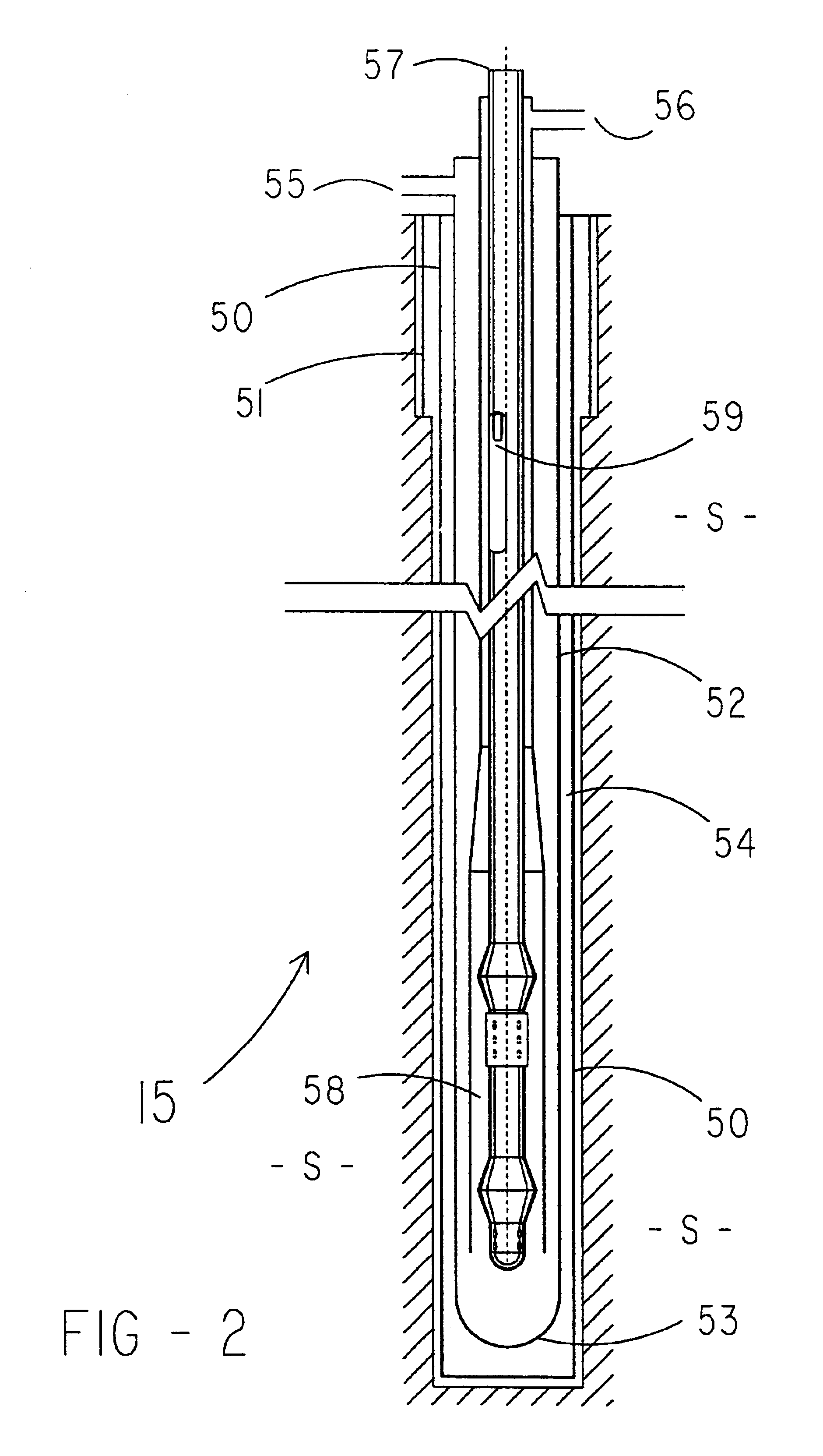

Method and apparatus for treating waste streams

InactiveUS6716360B2Overcome problemsUrea derivatives preparationSludge treatment by oxidationSufficient timeWaste stream

A method for treating a waste stream, the method including the steps of providing a waste stream that includes waste solids suspended in water, feeding the waste stream to the top of a hydraulic downdraft column, conducting the waste stream to the bottom of the hydraulic downdraft column, conducting the waste steam to a first reaction zone, introducing nitrogen-containing oxides into the first reaction zone so that the waste stream is contacted with the nitrogen-containing oxides, conducting the waste stream up a hydraulic updraft column into a second reaction zone, where the second reaction zone is configured to provide sufficient time so that a reaction between the nitrogen-containing oxides and waste solids can take place and substantially consume the nitrogen-containing oxides, introducing oxygen gas into the waste steam after the nitrogen-containing oxides are substantially consumed, thereby providing a second reactant that reacts with waste solids suspended within the stream, conducting the stream to the top of the hydraulic updraft column.

Owner:EAU VIRON

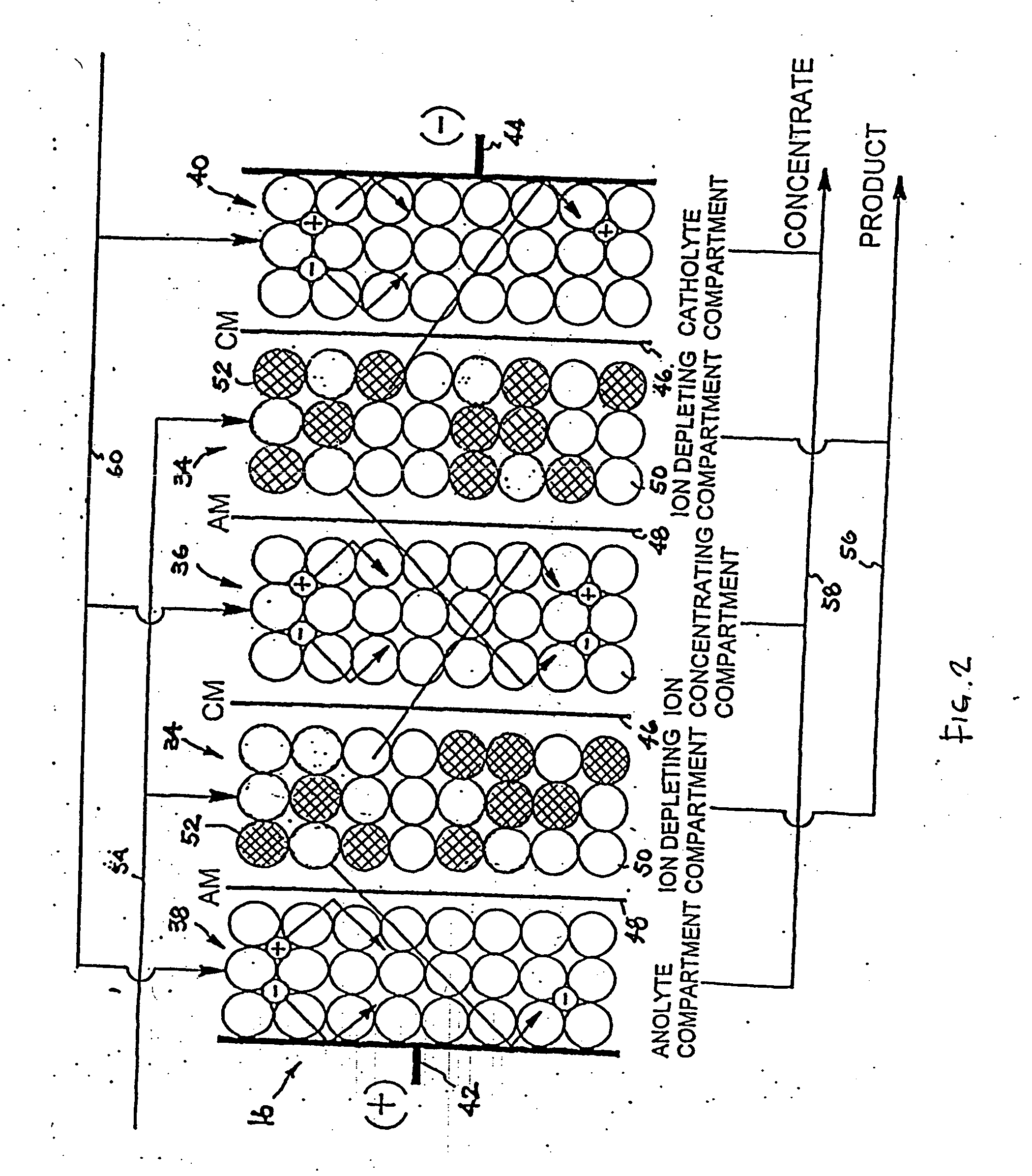

Apparatus and method for continuous electrodeionization

InactiveUS6929748B2Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectricityWastewater

Owner:EVOQUA WATER TECH PTE LTD

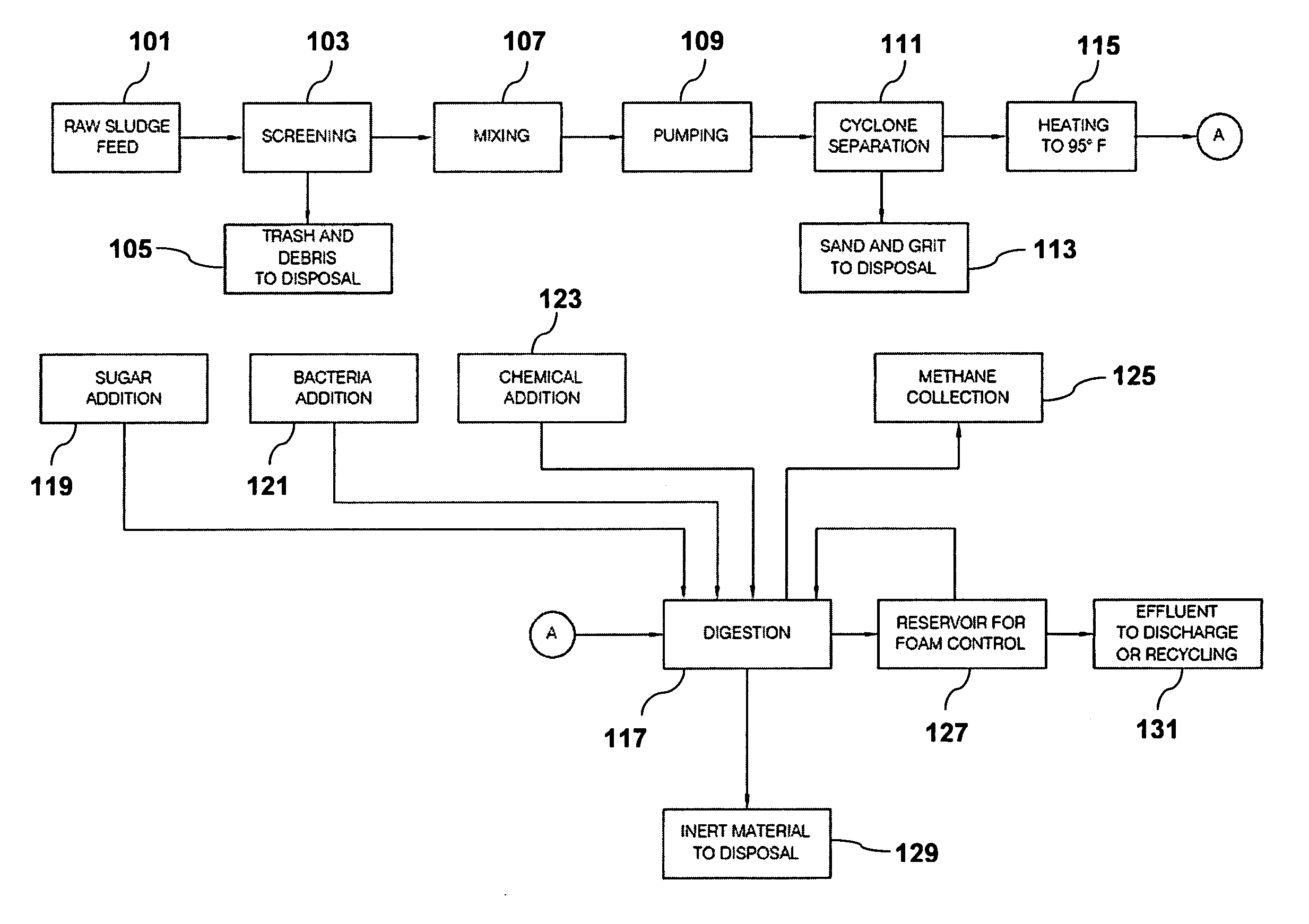

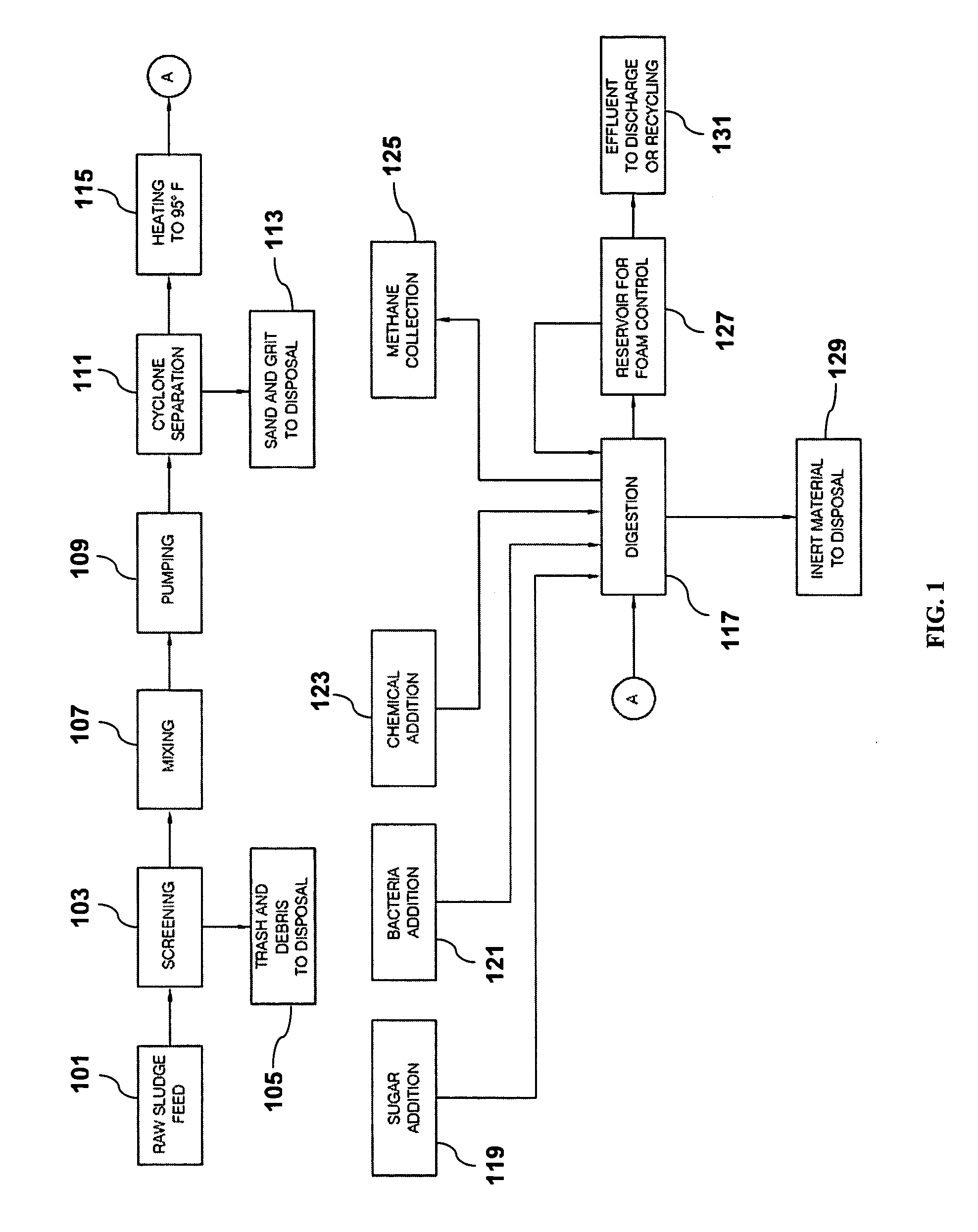

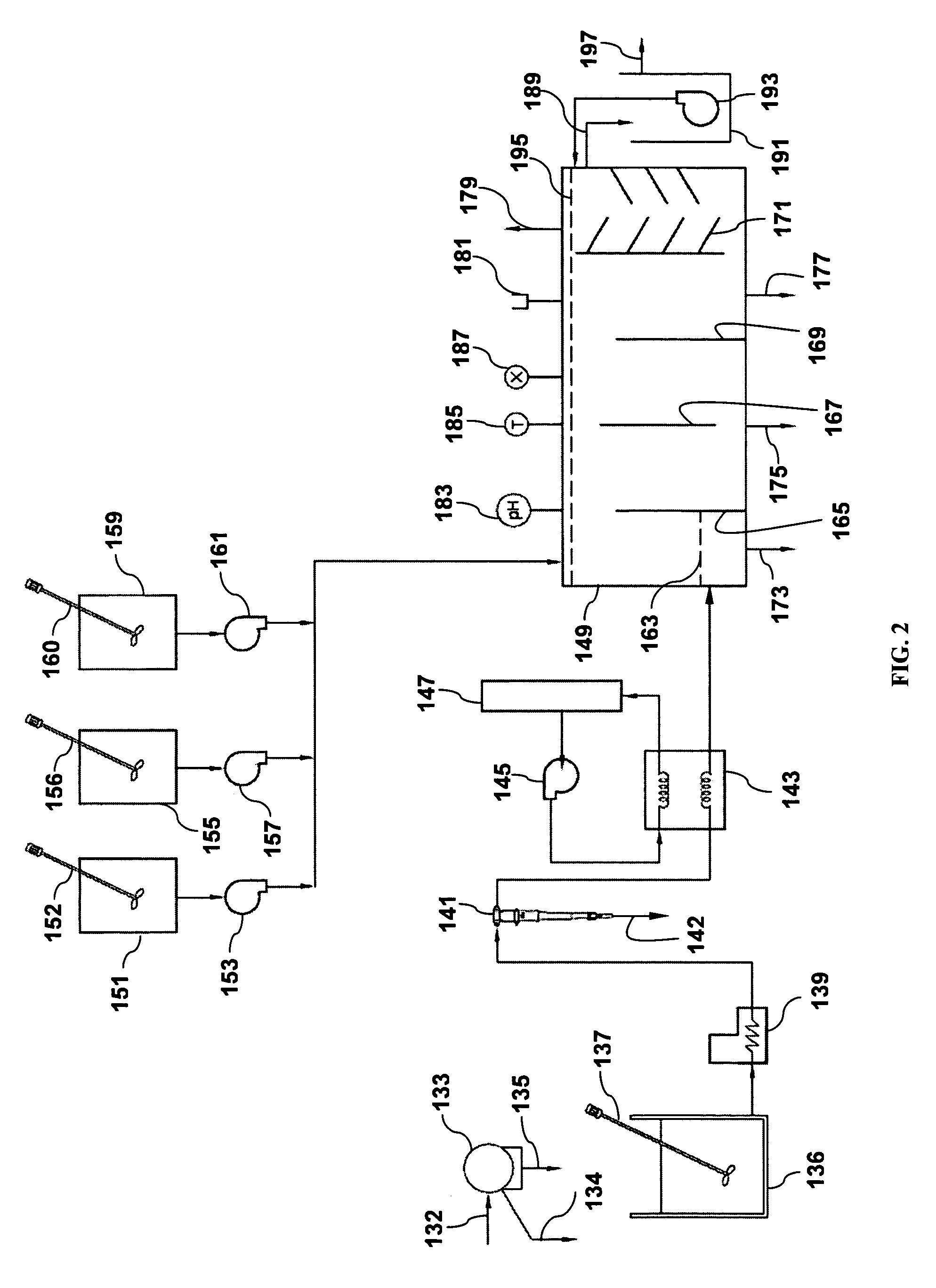

Digesters

Methods and devices are disclosed for converting predominantly organic waste materials, such as sludge, into useful byproducts.

Owner:TOLBERT & ASSOCS

Apparatus for biological treatment of waste waters

InactiveUS7018530B2Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

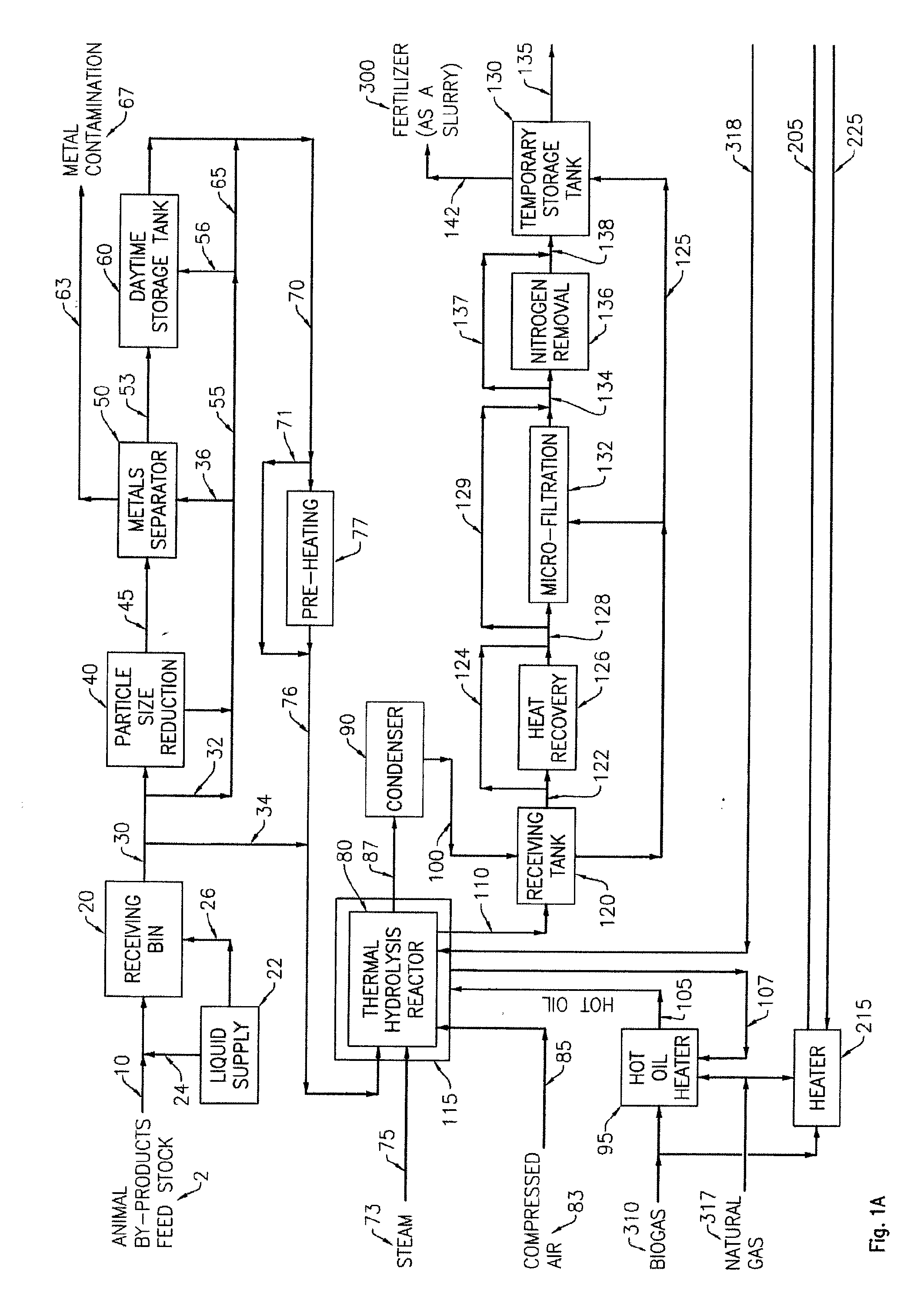

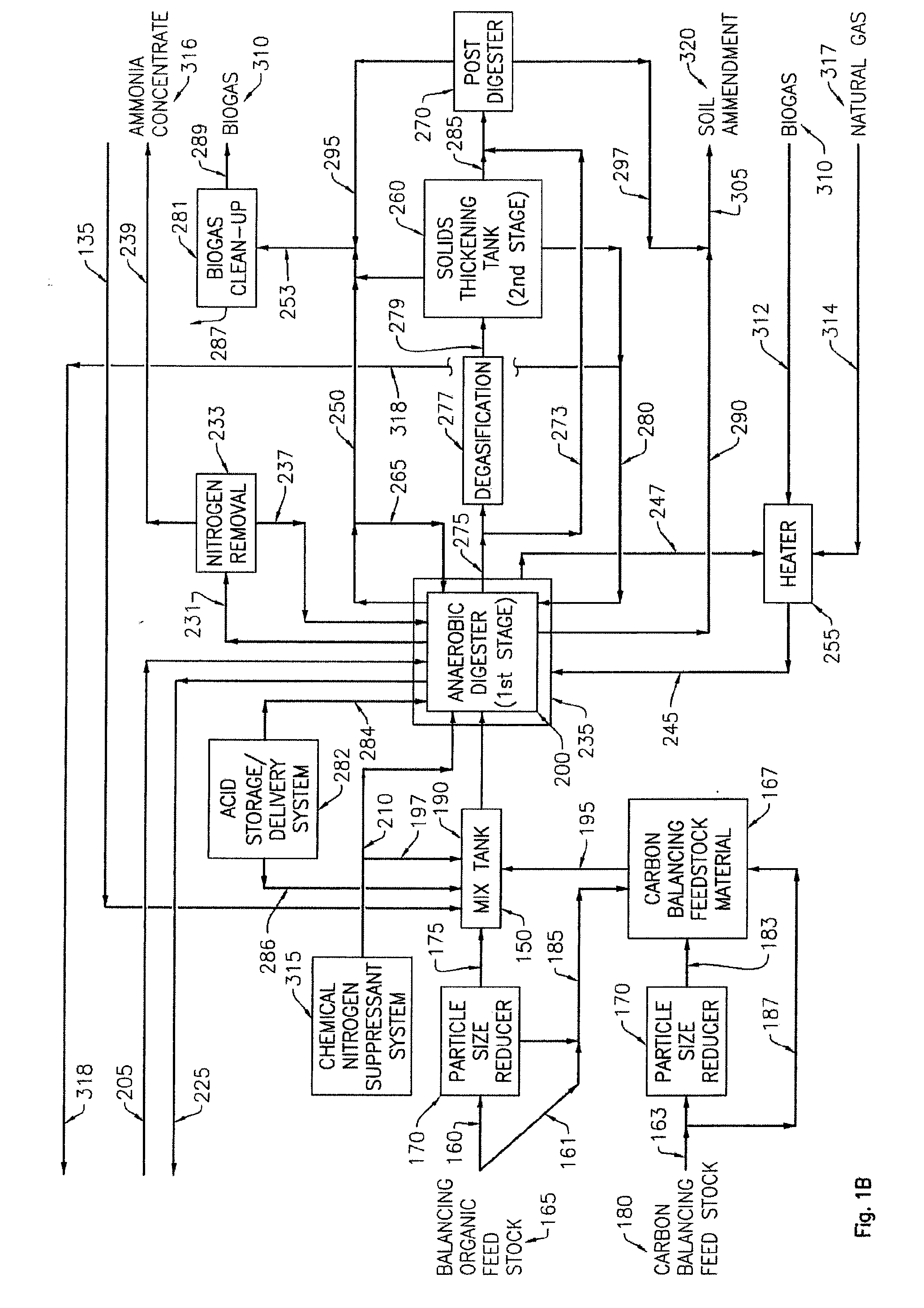

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

Popular searches

Solid sorbent liquid separation Water/sewage treatment by substance addition Liquid separation Water/sewage treatment by flocculation/precipitation Contaminated groundwater/leachate treatment Water/sewage treatment by oxidation Membranes Fatty/oily/floating substances removal devices Water/sewage treatment by irradiation Water treatment compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com