Patents

Literature

1121 results about "Contaminated water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contaminated water refers to any water that is polluted with harmful compounds. It may be polluted with any of the following types of contaminants including sewage: Biological: Also known as microbiological contaminants or microbes, biological contaminants refer to harmful organisms in water.

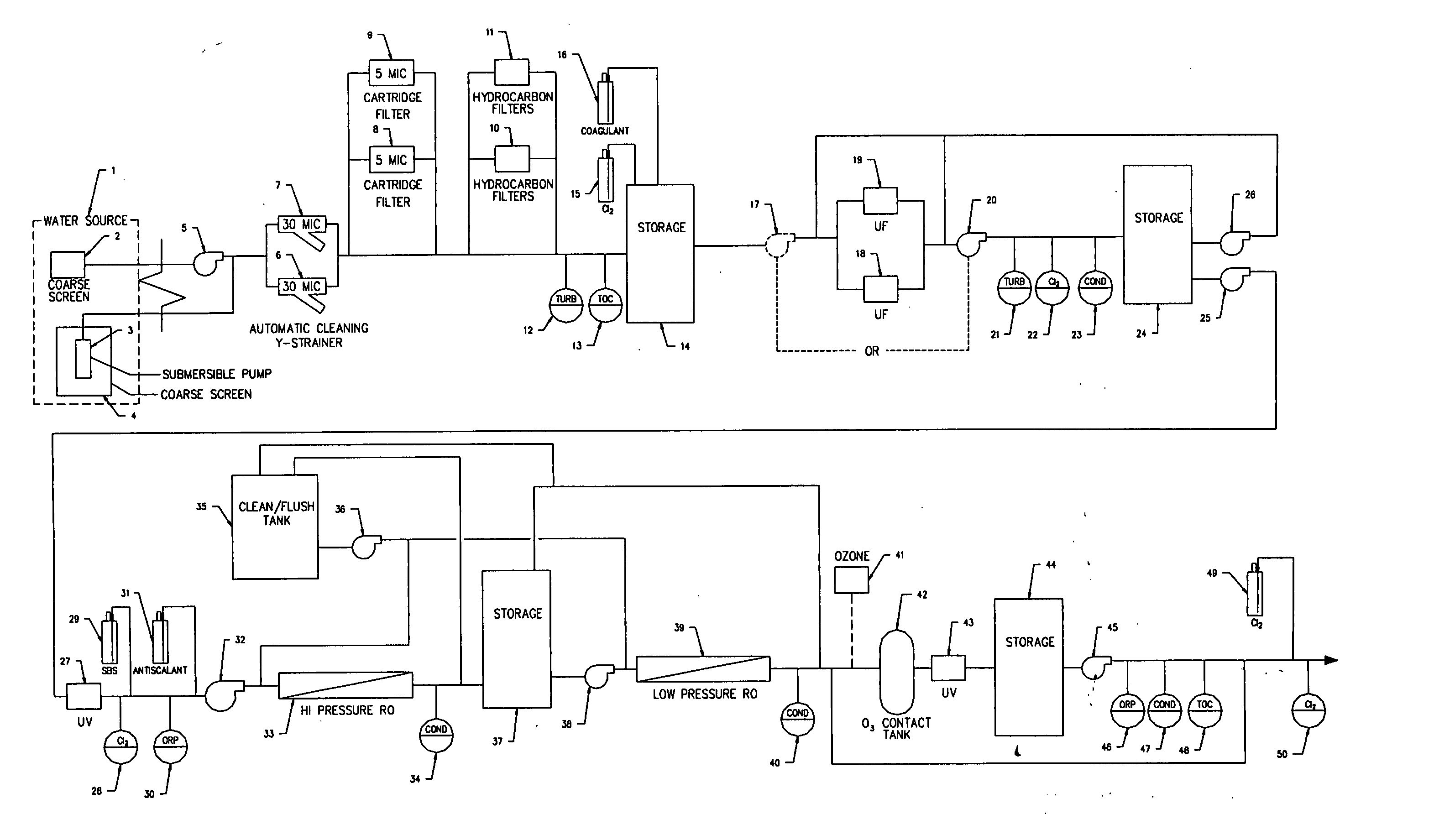

Water purifier and method of making and using the same

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

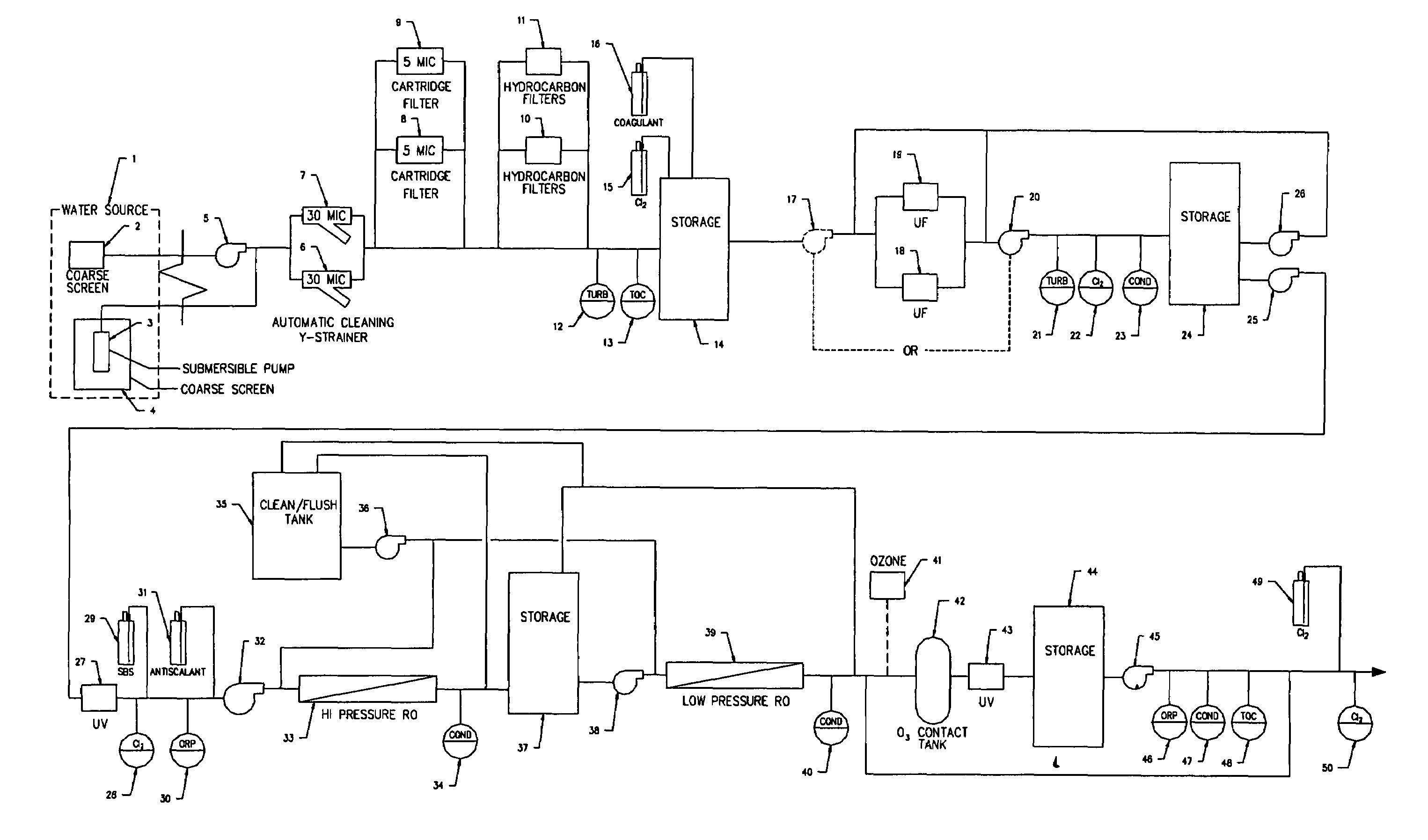

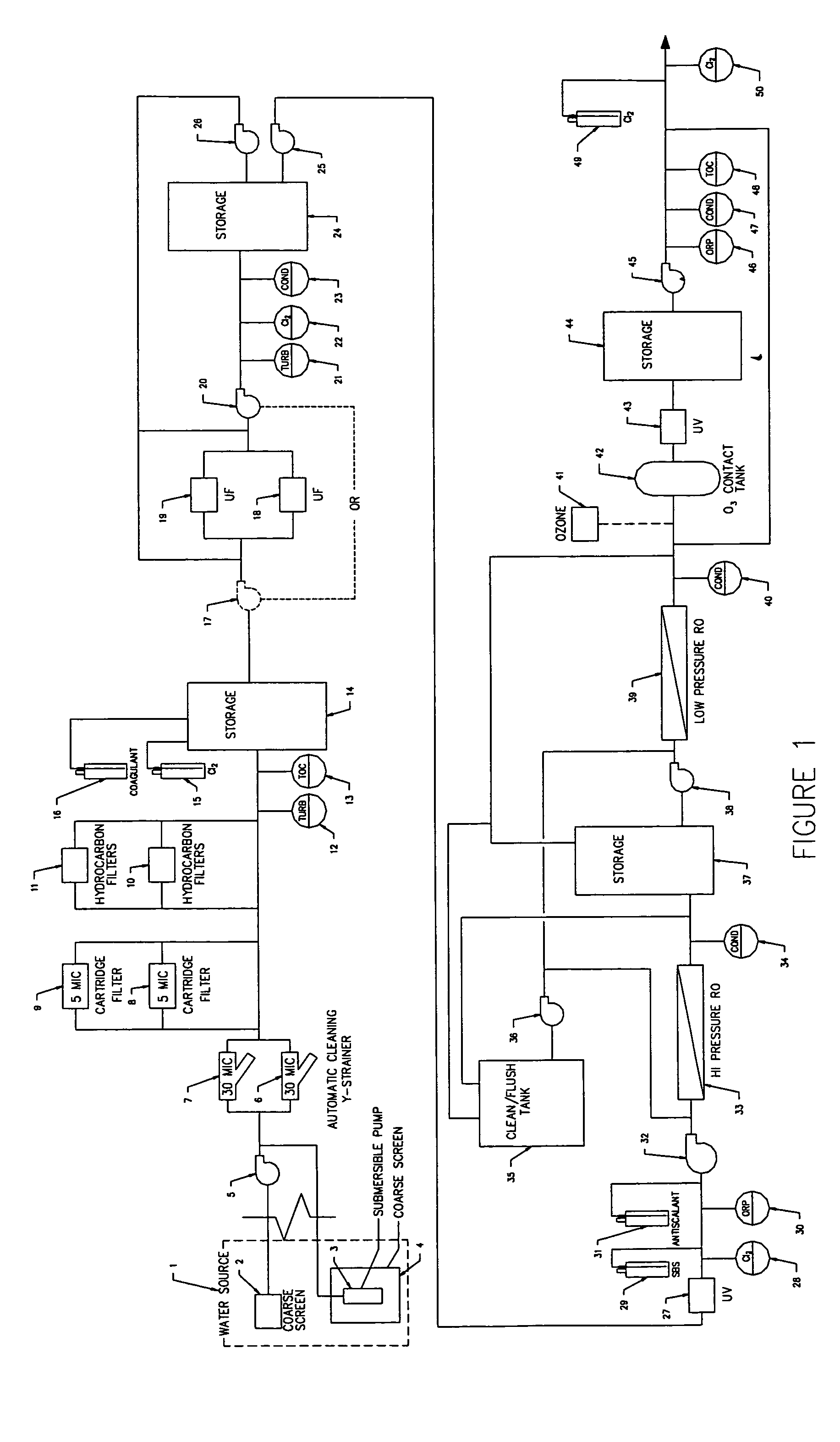

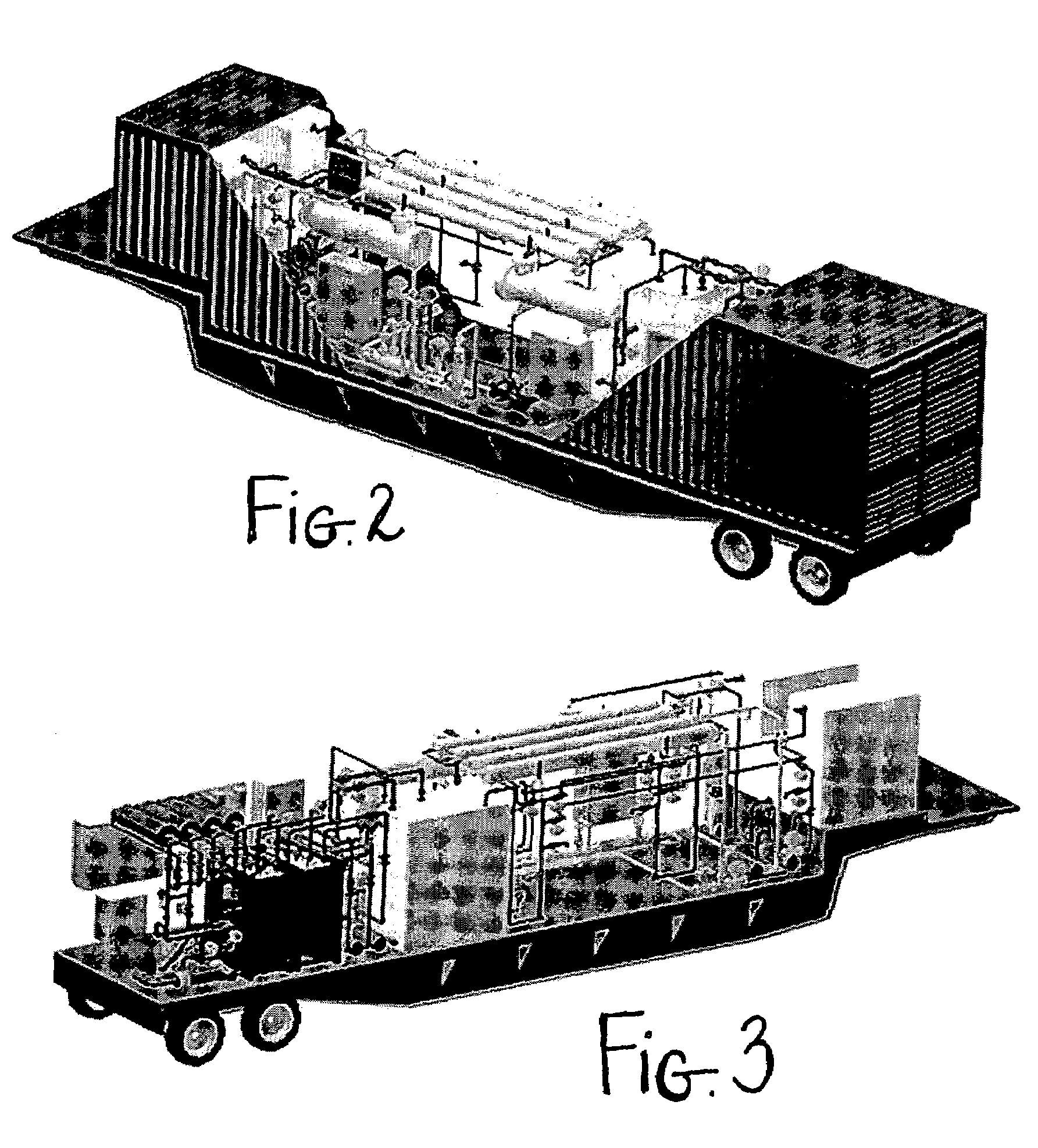

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

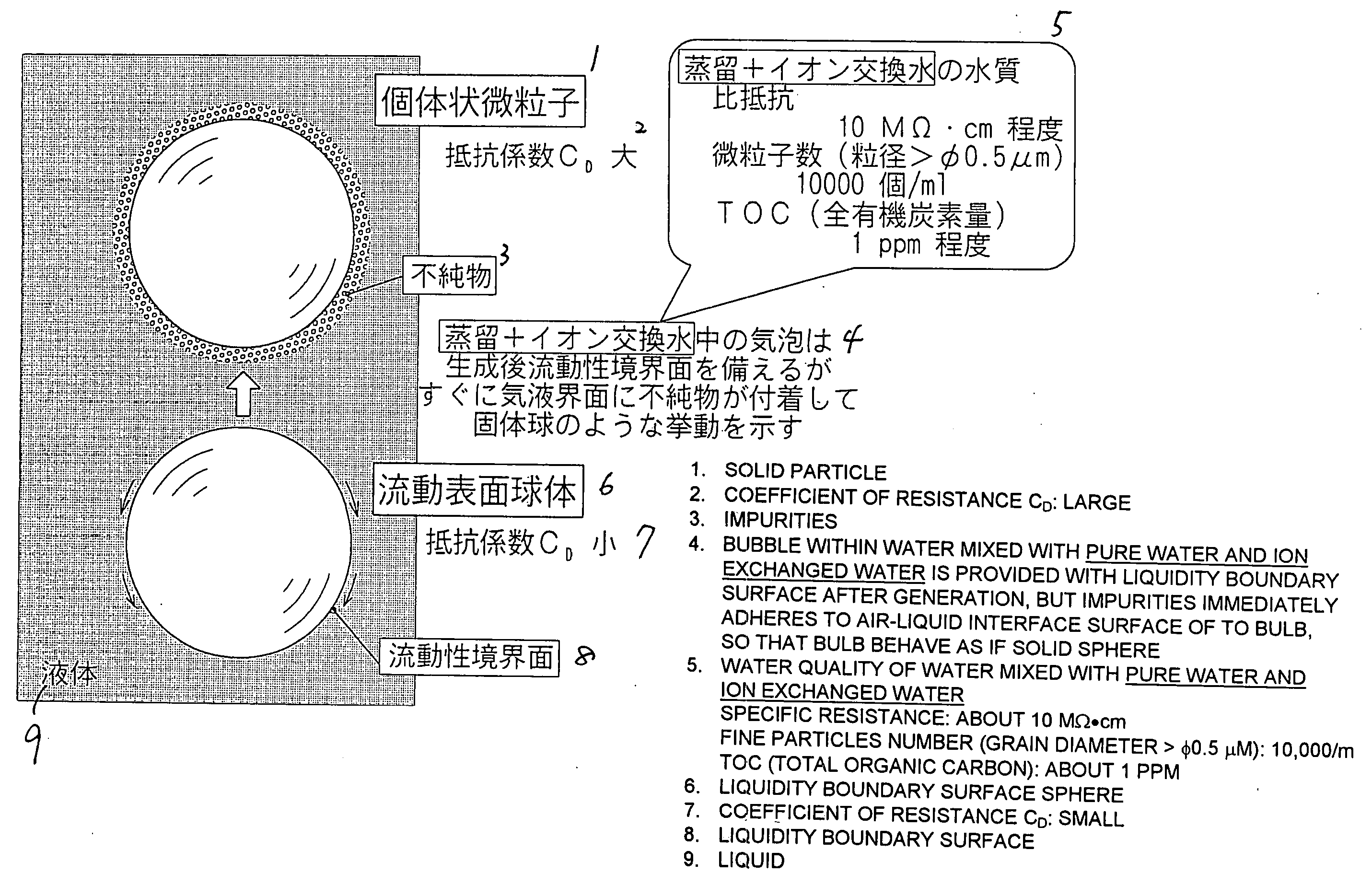

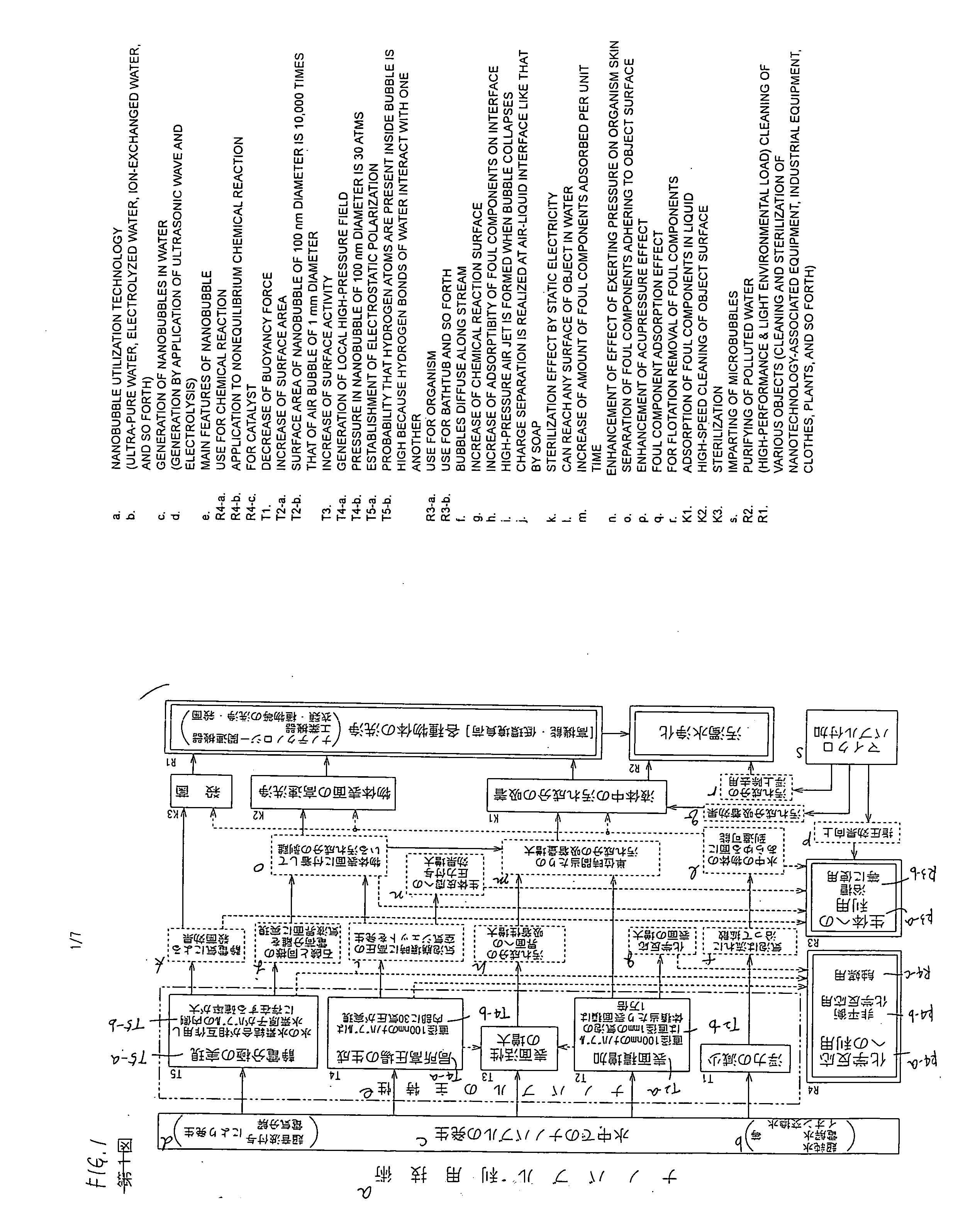

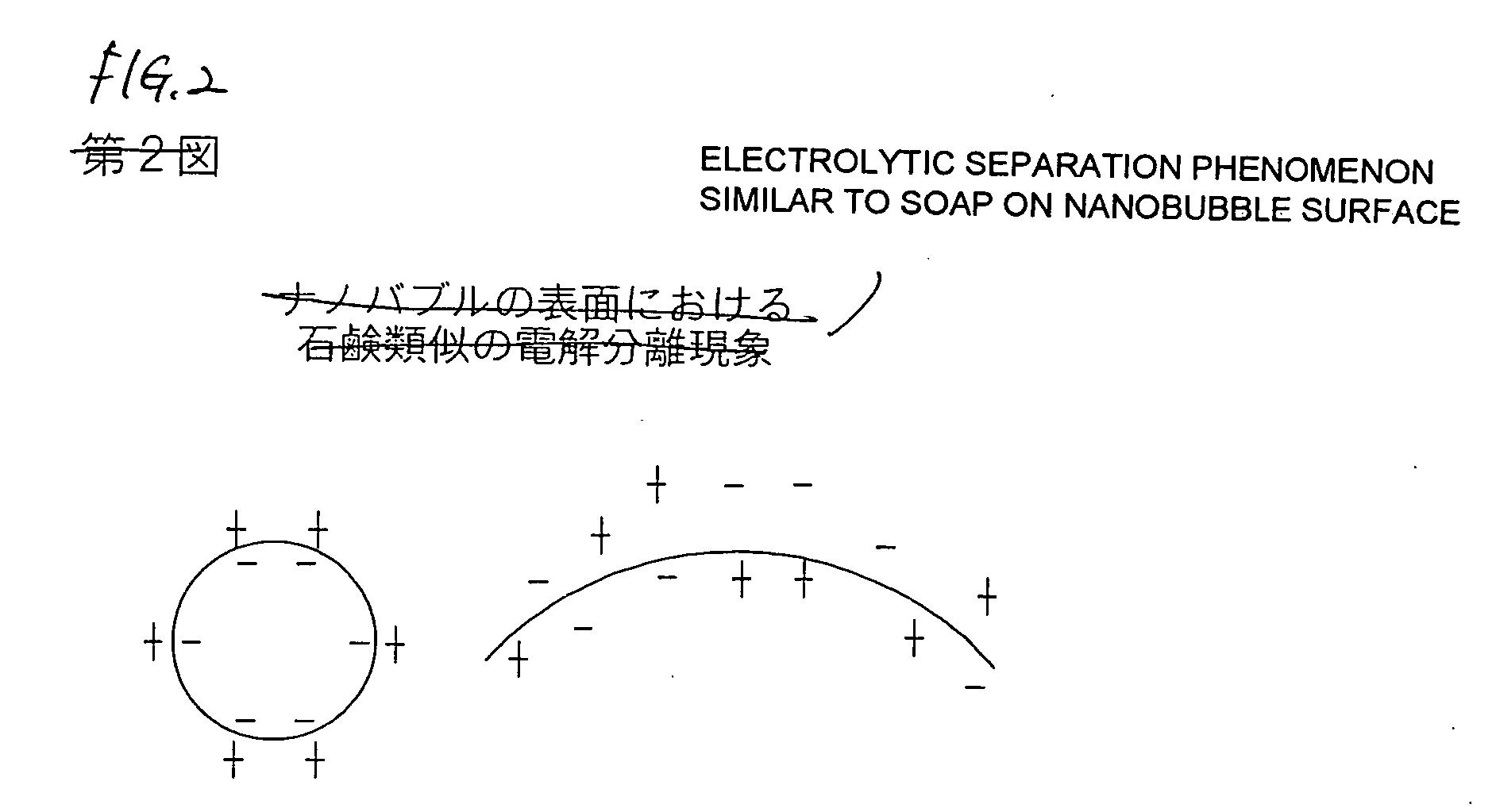

Nanobubble utilization method and device

InactiveUS20060054205A1Efficient use ofFast cleaningMaterial nanotechnologyVibration massageBiological bodyChemical reaction

The present inventors have found the presence of a nanobubble that has not been confirmed conventionally, and established a method for producing nanobubbles. The inventors have determined the theoretically expected characteristics of the produced nanobubbles, found new characteristics by analyzing data experimentally collected, and elucidated the relationship among the characters. Specifically, the inventors have found that a nanobubble has features such as decrease of the buoyant force, increase of the surface area, increase of the surface activity, generation of a local high-pressure field, interface activating action, and sterilizing action thanks to electrostatic polarization. By the association among the features, any of wide variety of objects can be cleaned with high performance and with light environmental load thanks to the function of adsorbing foul components, the function of cleaning the surface of an object quickly, and the sterilizing function, and polluted water can be purified. Nanobubbles can be applied to an organism to recover from fatigue and effectively used for chemical reactions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

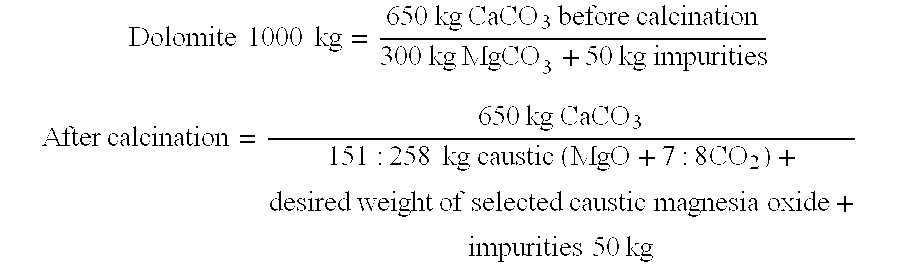

Settable composition and uses therefor

InactiveUS6200381B1Decrease decarbonisation temperaturePromote decompositionSolid waste managementWaste productSlurry

A dry powdered flowable cement composition contains calcium carbonate and a partially decarbonated magnesium carbonate. A slurry of the composition will set hard with various organic fillers including waste products and toxic waste. The composition can be slurried with contaminated water such as sea water, mineral laden ground water and muddy water. A high percentage of filler can be added while still having an acceptable set.

Owner:DOLOMATRIX INT LIMITED ACN 091 340 920

Method for removing oil from water coalescing in a polymer particle/fiber media

ActiveUS7297279B2Increase the liquid flow rateBig contactLiquid suspension thickening by filtrationSolid sorbent liquid separationFiberWater flow

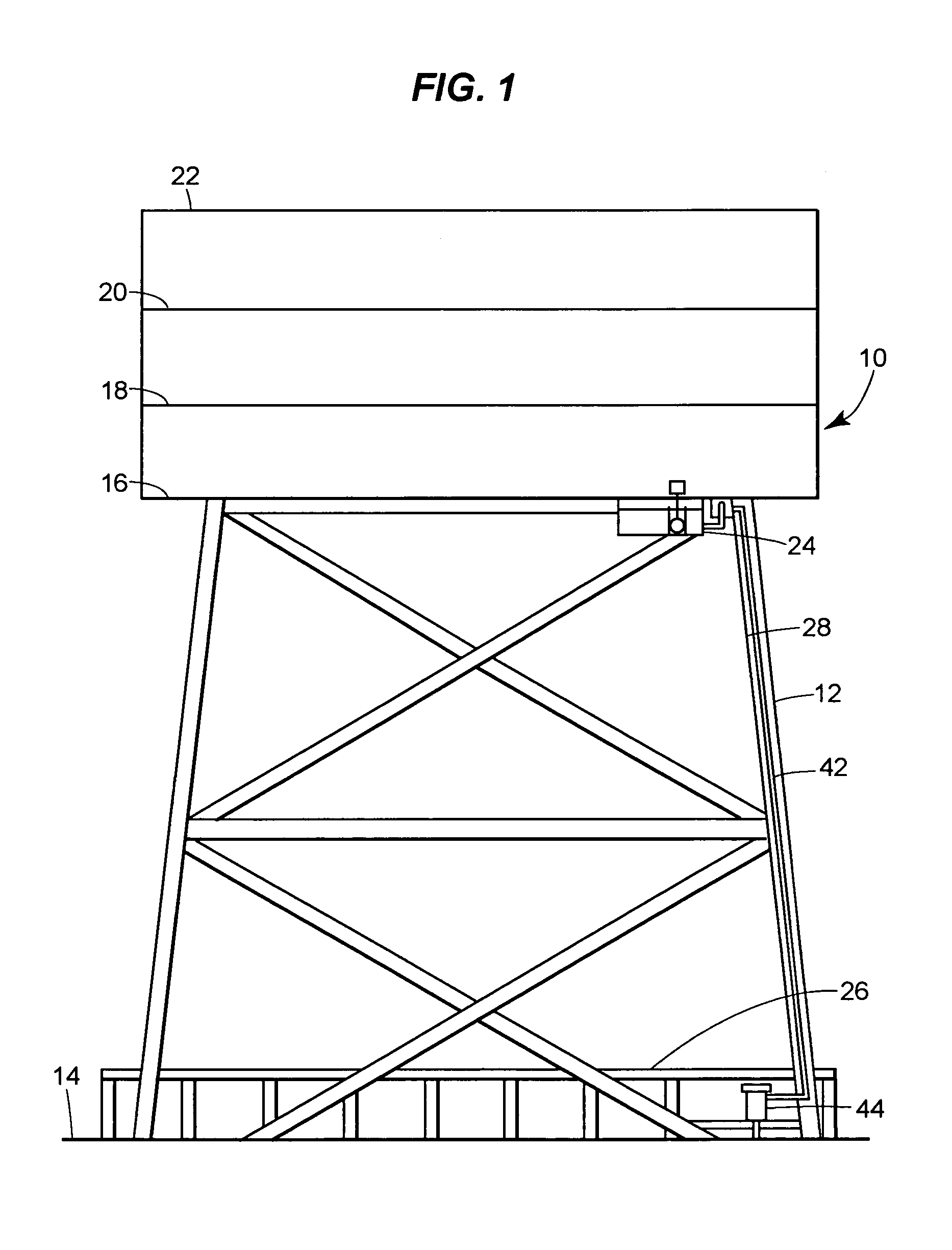

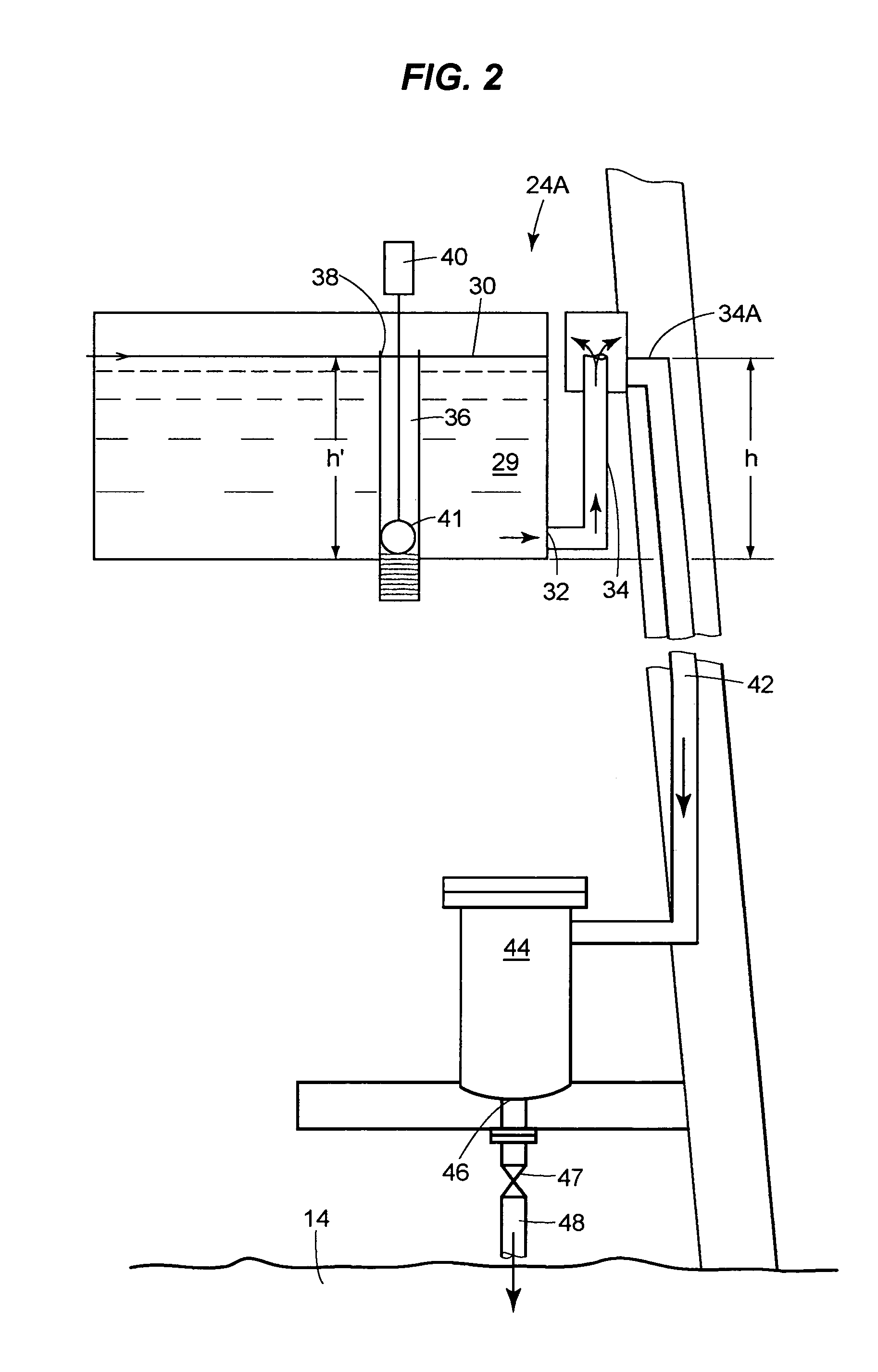

Apparatus in fluid communication with a water leg portion of a hydrocarbon-contaminated water, e.g., a water leg portion of a produced water stream or an offshore drilling or production platform sump tank for conveying water, separated from oil, into contact with non-woven fiber / particulate polymer coalescing media-containing canisters such that the hydrocarbon droplets and other organic material droplets commingled with the sump tank or produced water will be coalesced by passage through the coalescing media. The canisters preferably are provided in a plurality of stacks in each vessel. Solids that do not pass through the canisters are accumulated at the bottom of the vessel and easily drained through a drain port. The water and hydrocarbons will pass through the coalescing media within the canisters and will be separated easily from each vessel, e.g., by gravity separation, sot that the water can be conveyed back to the ocean water without contamination.

Owner:AMCOL INTERNATIONAL CORPORATION

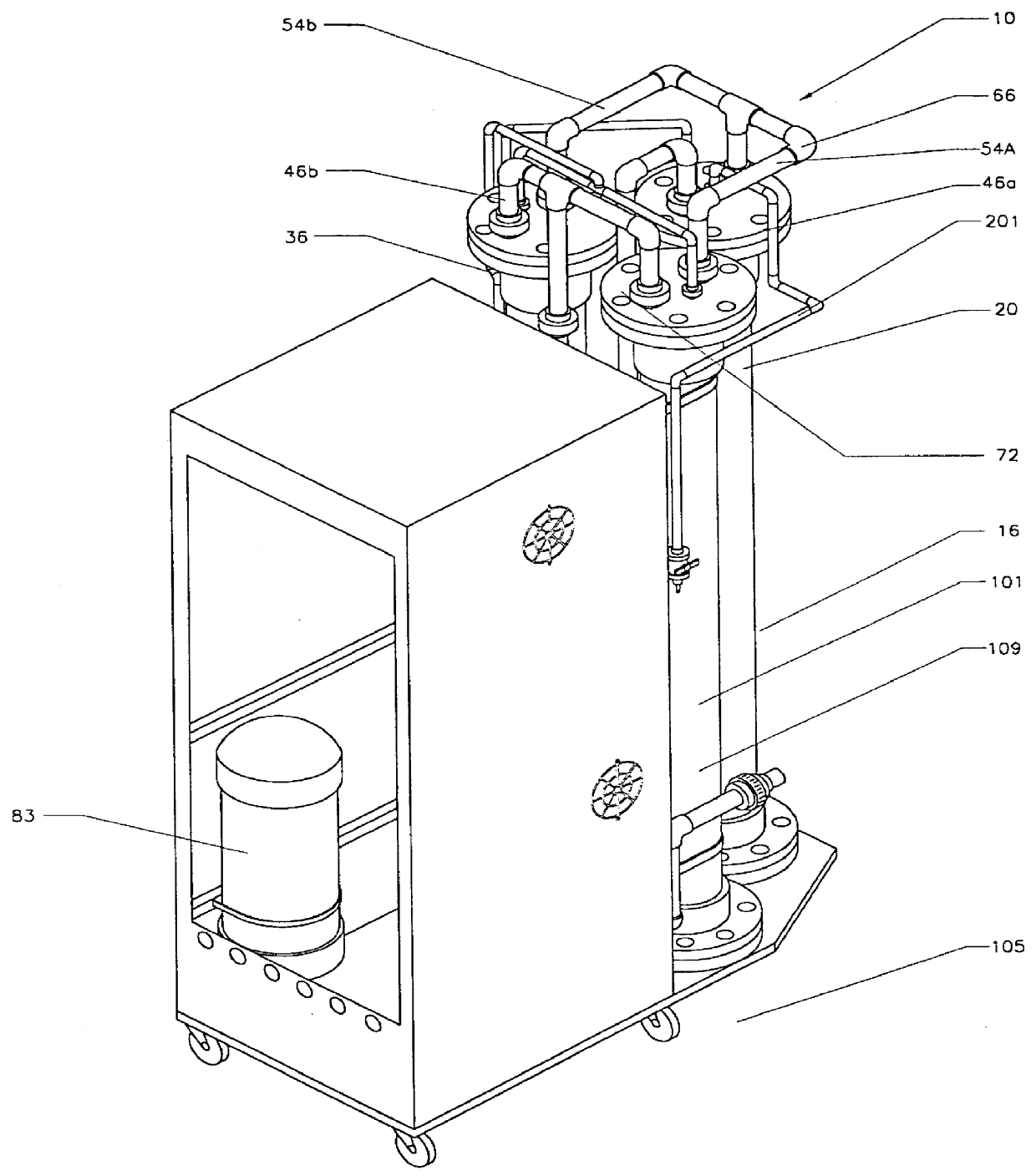

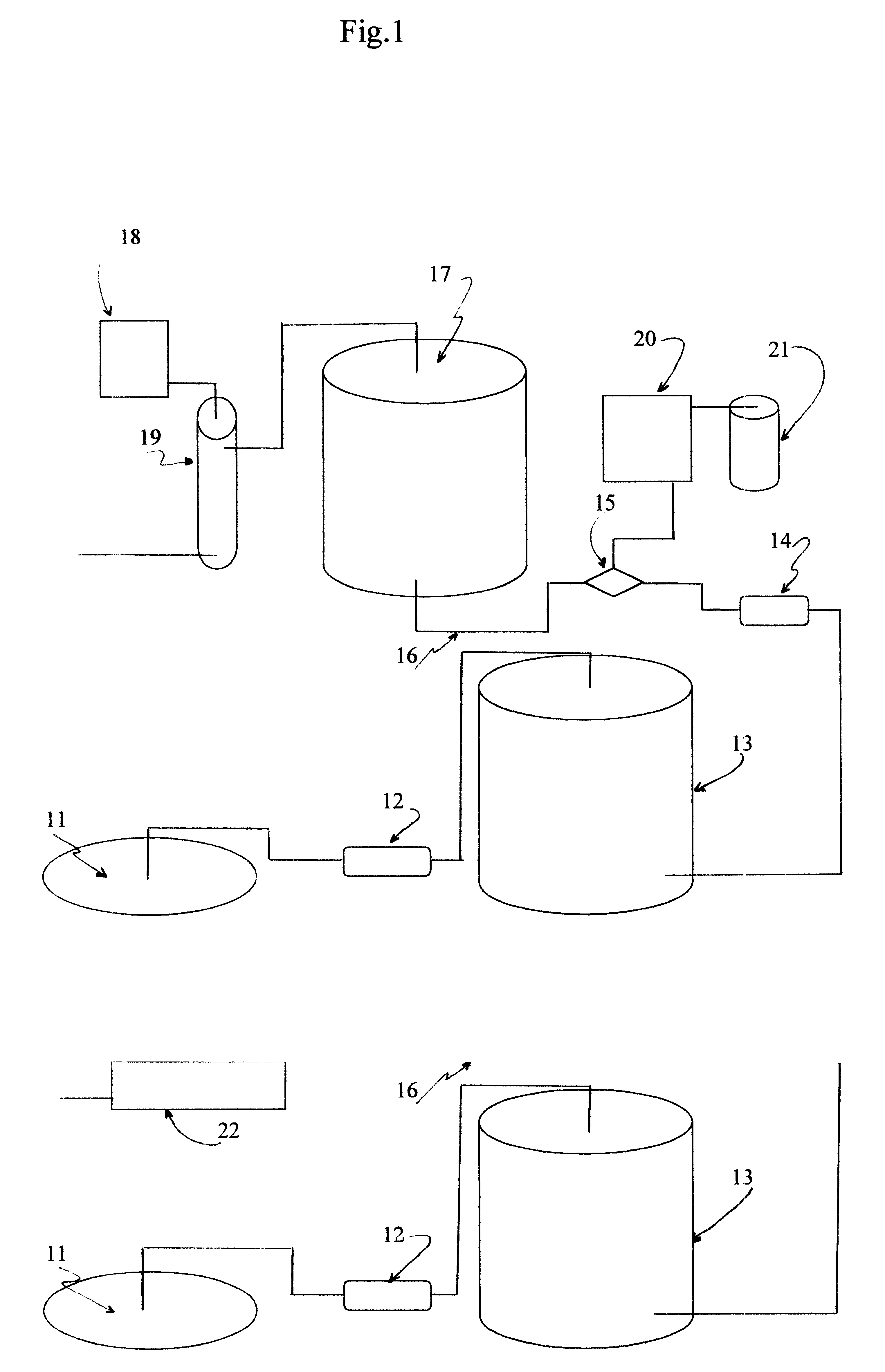

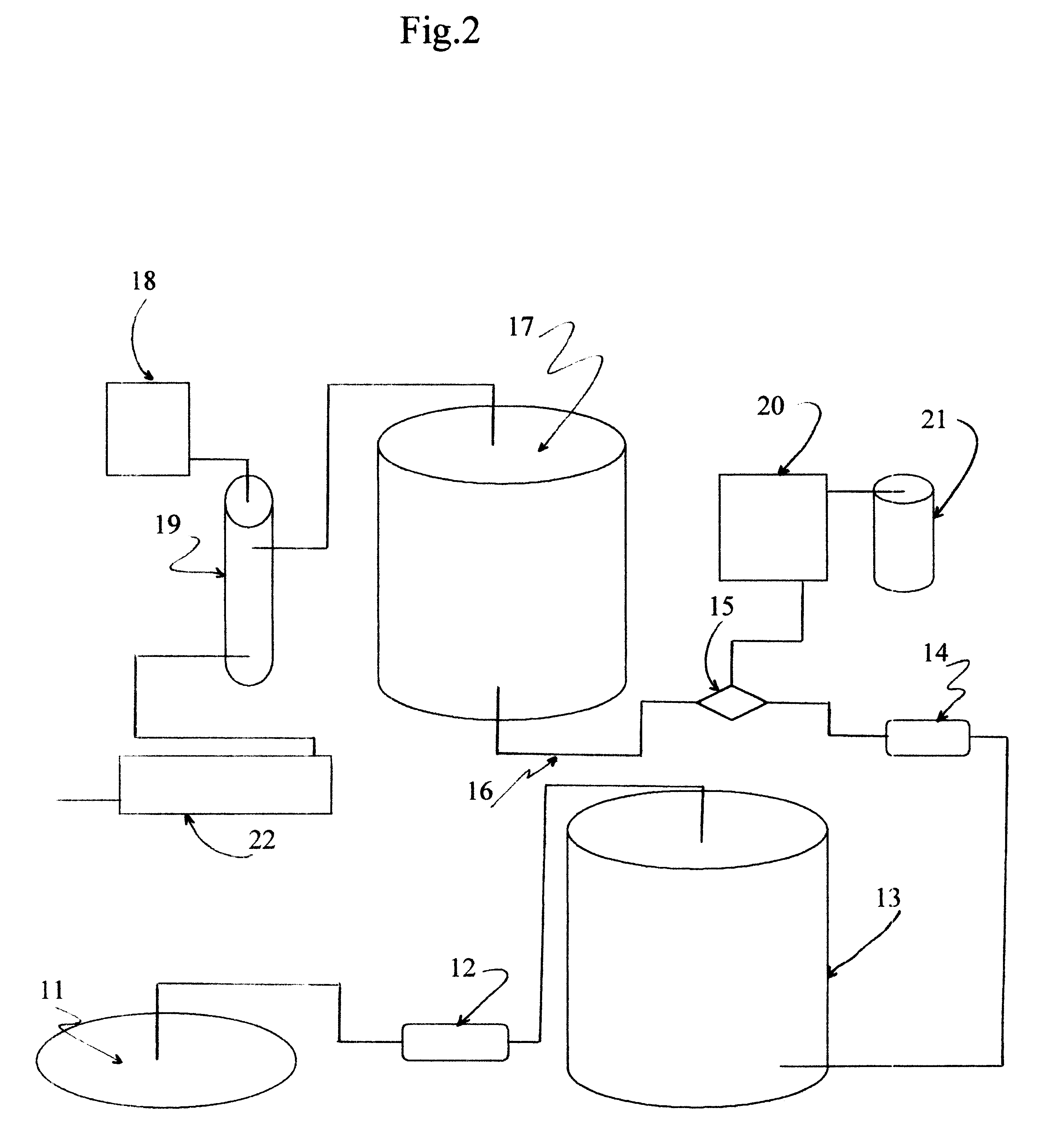

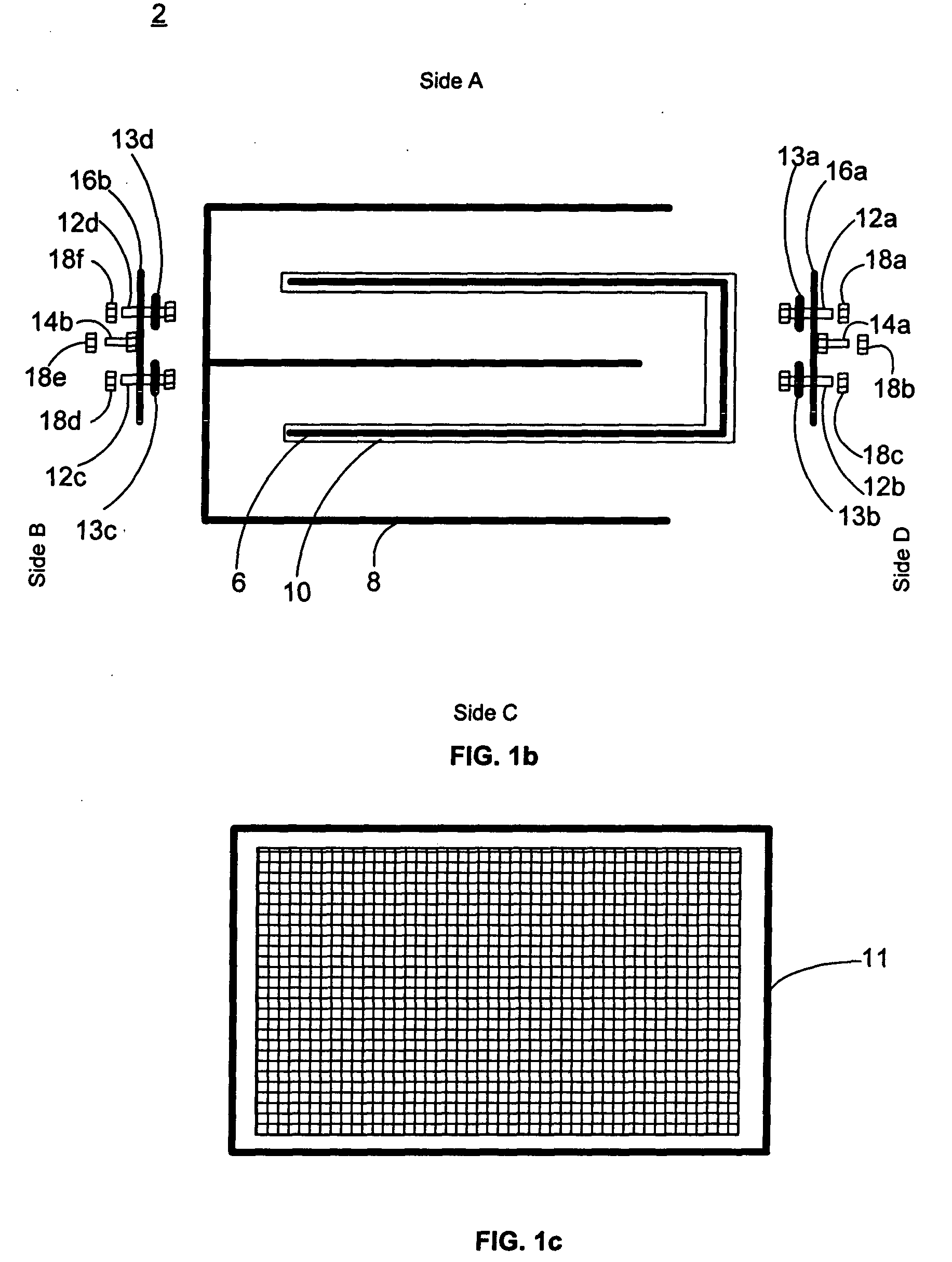

Apparatus for the purification of water and method therefor

InactiveUS6090294AComprehensive understandingSignificant utilityOther chemical processesIon-exchanger regenerationSolubilityGas phase

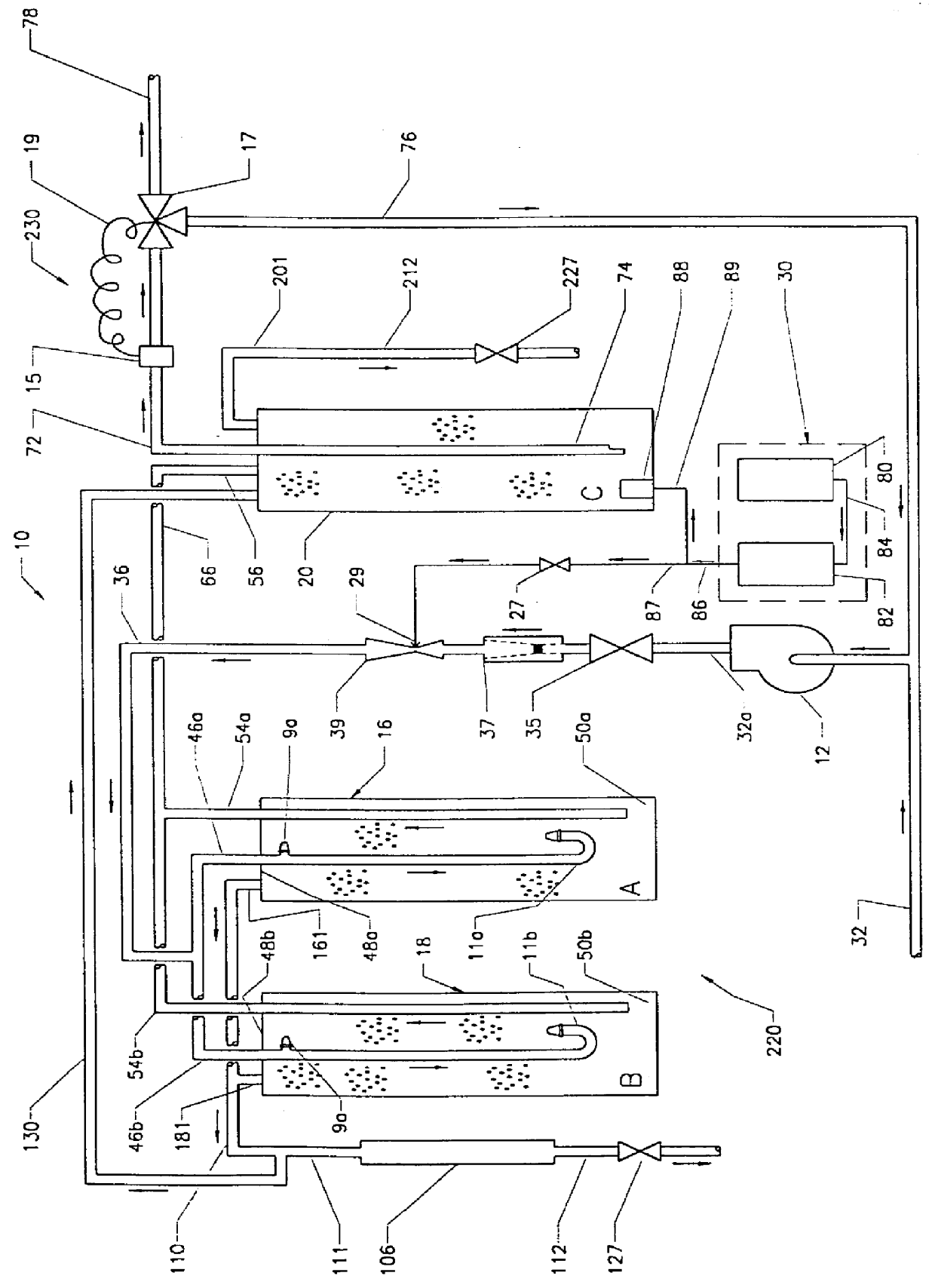

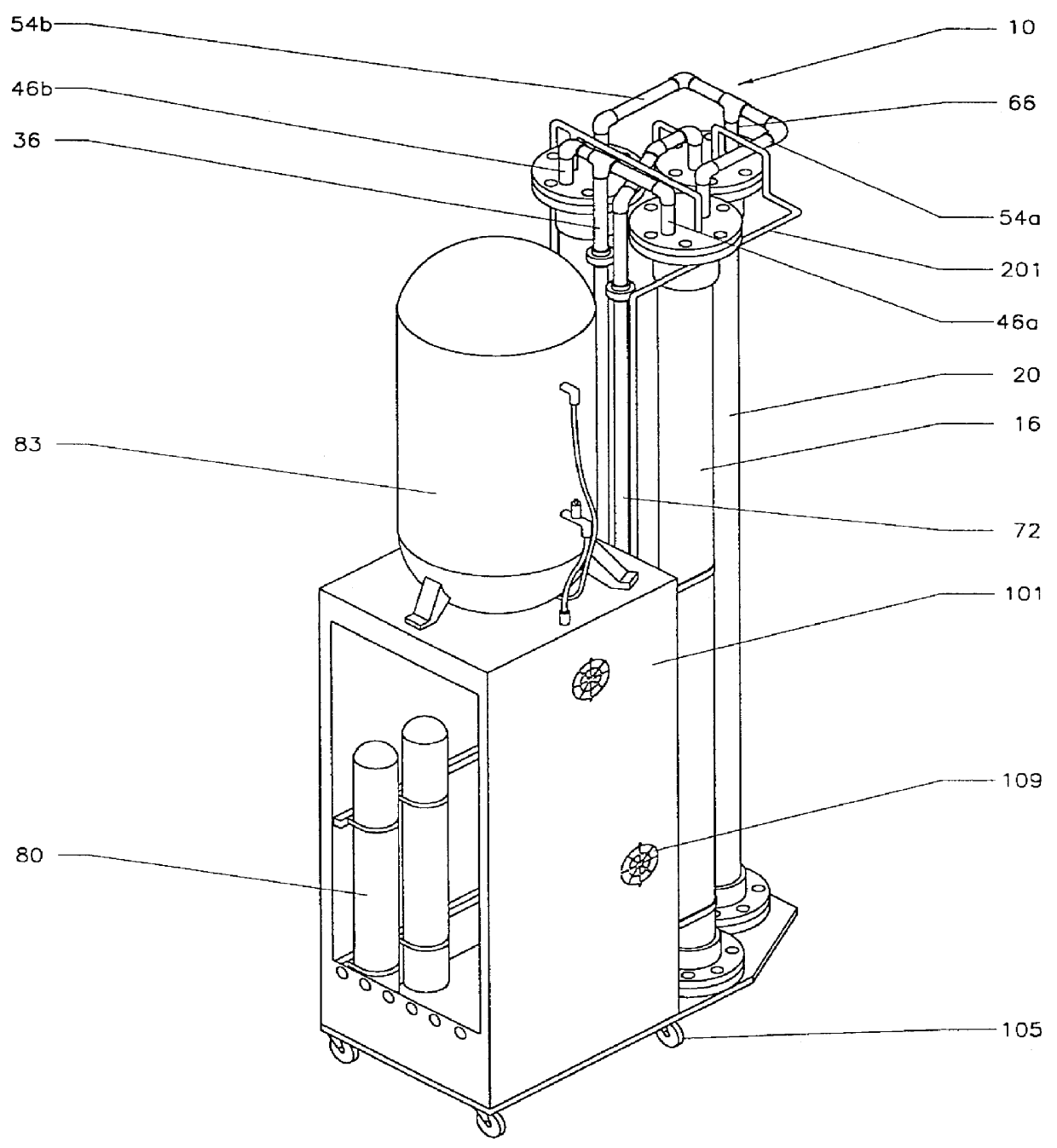

An apparatus and method for the purification of contaminated water whereby the contamination level of the wastewater is automatically monitored and treatment self-adjusted and continued until the desired level of purification is reached. Specifically, if upon treatment a pre-set purification level is not obtained a water recycle control means completely precludes the uptake of additional contaminated water and recycles wastewater within the apparatus until the desired level of purification is obtained. The present invention more particularly pertains to an efficient, turn key, economical, movable, automatic and compact apparatus and method for treating a fluid with ozone comprising multiple pressurized contact columns which are arranged in a hybrid parallel and series column configuration, which utilizes a unique water recycle control system and piping arrangement to improve the efficiency of the mass transfer of ozone into the water and increase its solubility by increasing the contact time between the water phase and the gas phase. The apparatus and method of the present invention has the further advantage that it requires minimal installation and may be used to fulfill the clean and safe water needs of any hotel, resort, restaurant, hospital, light industry, commercial business, apartment complex or small city.

Owner:AGRIMOND USA CORP

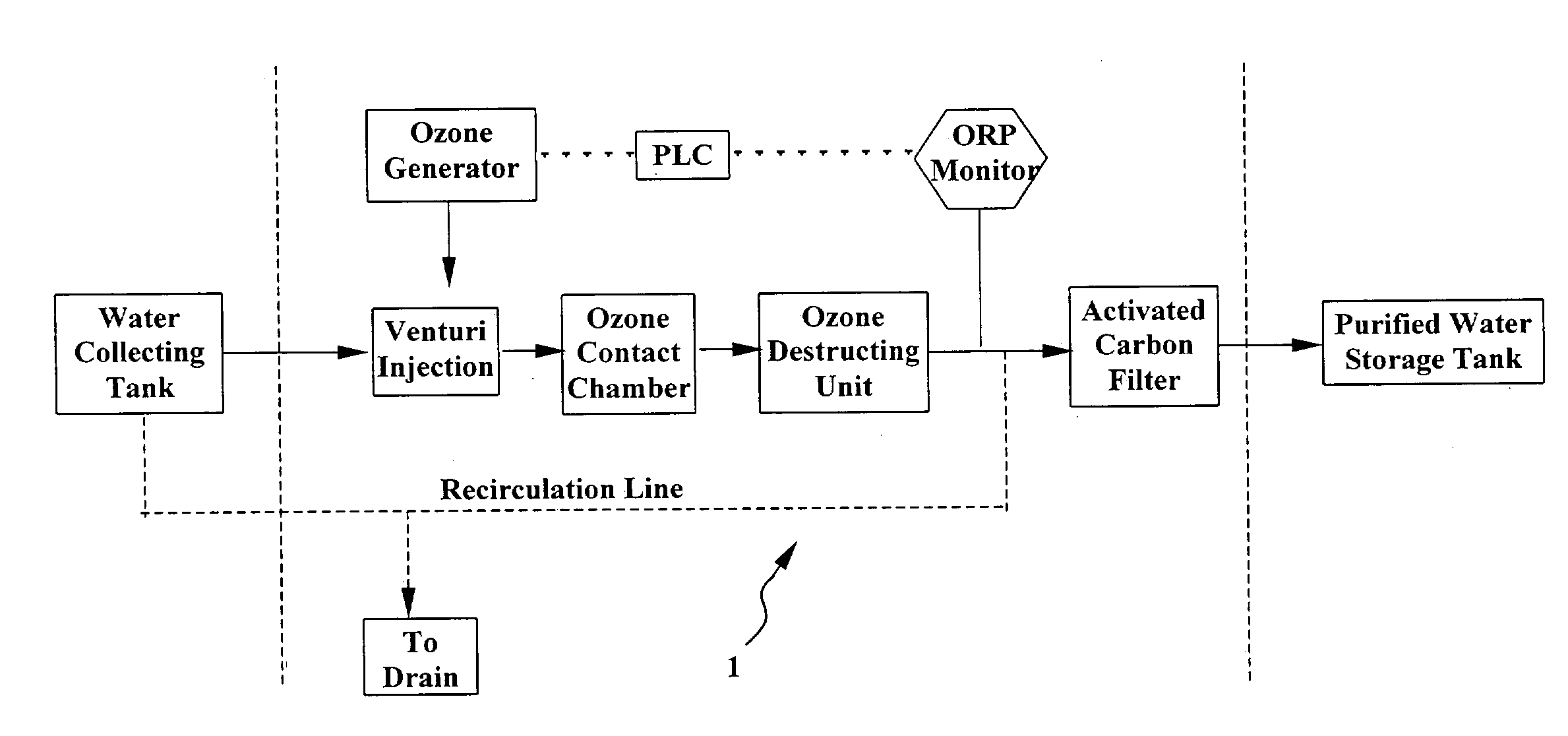

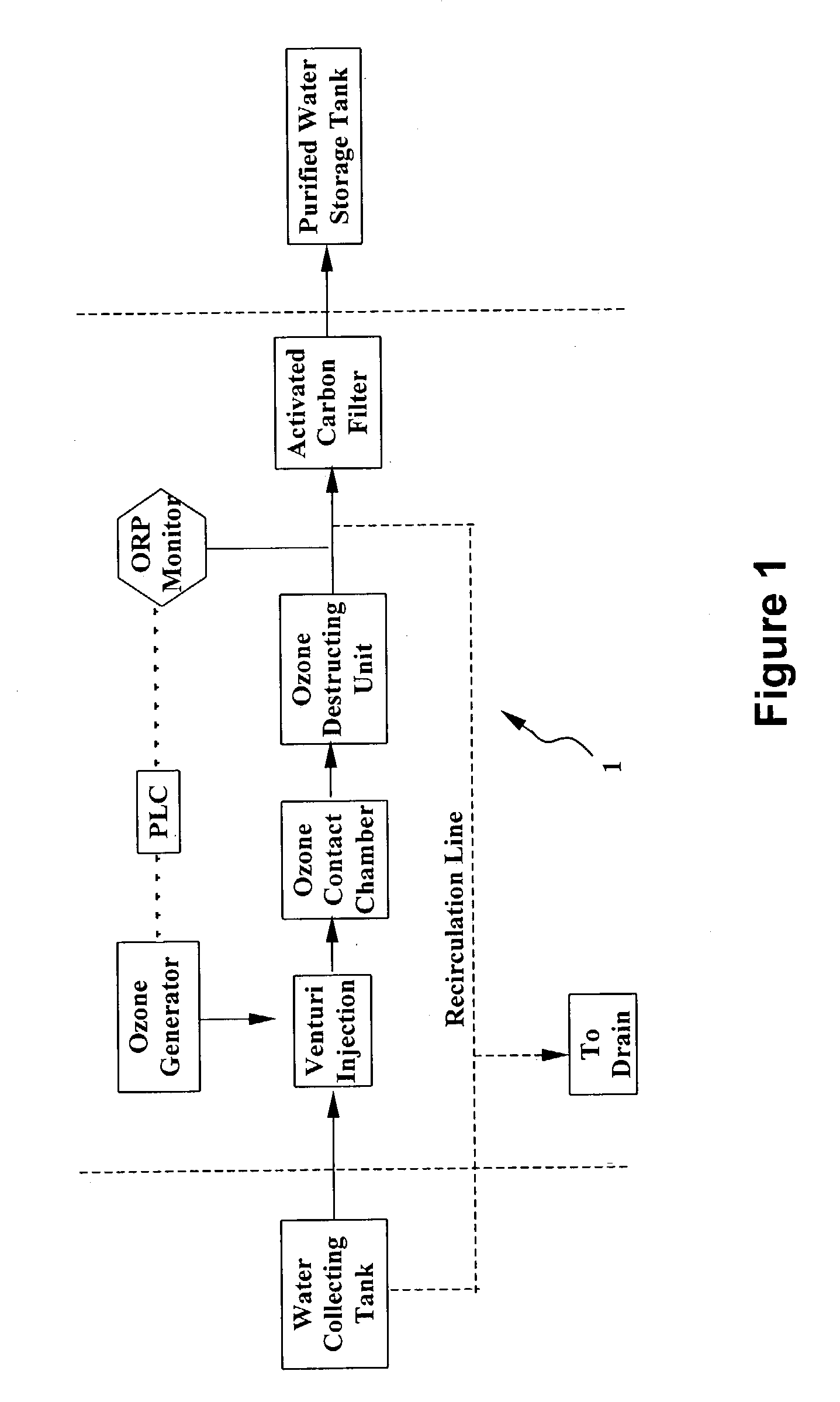

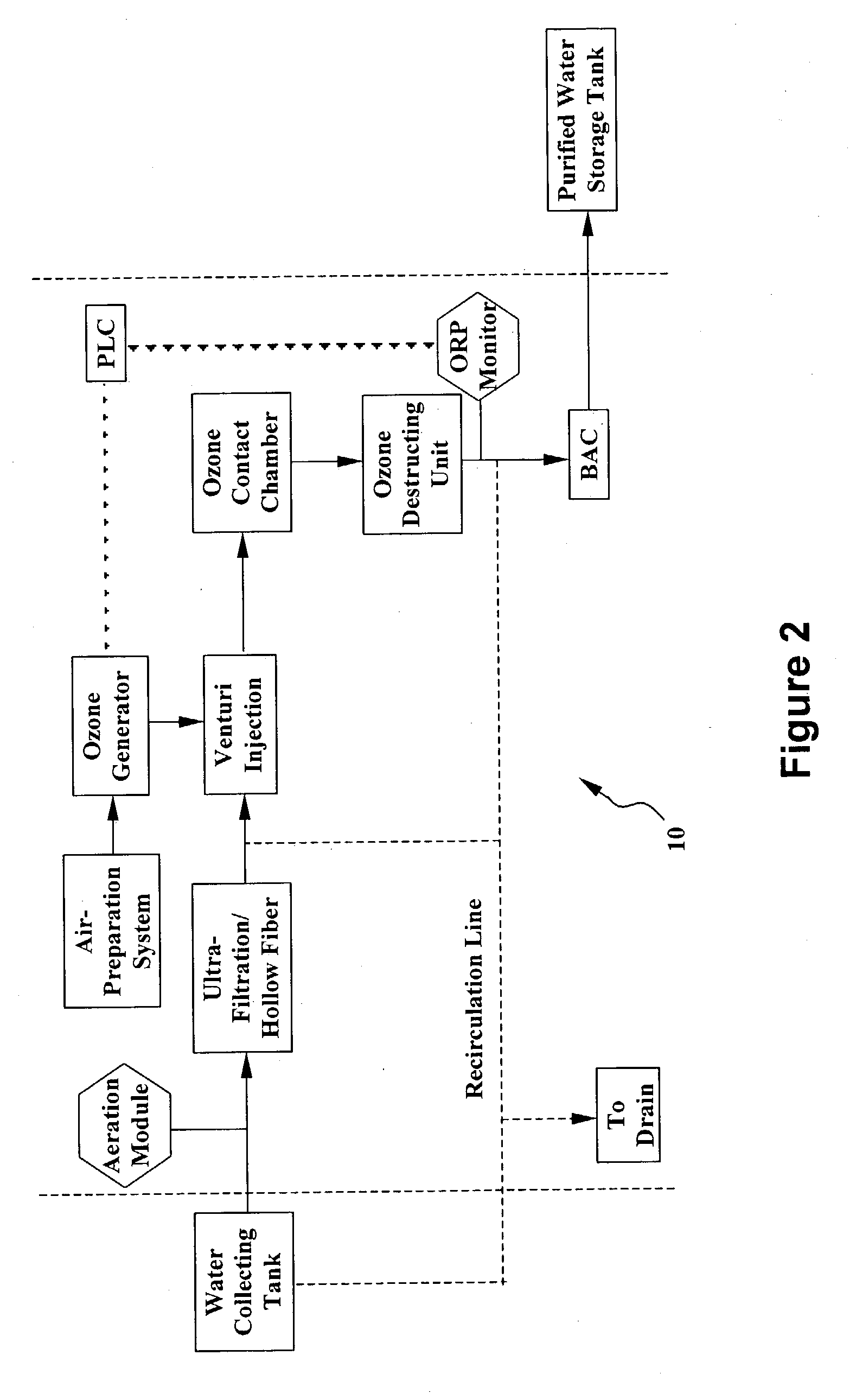

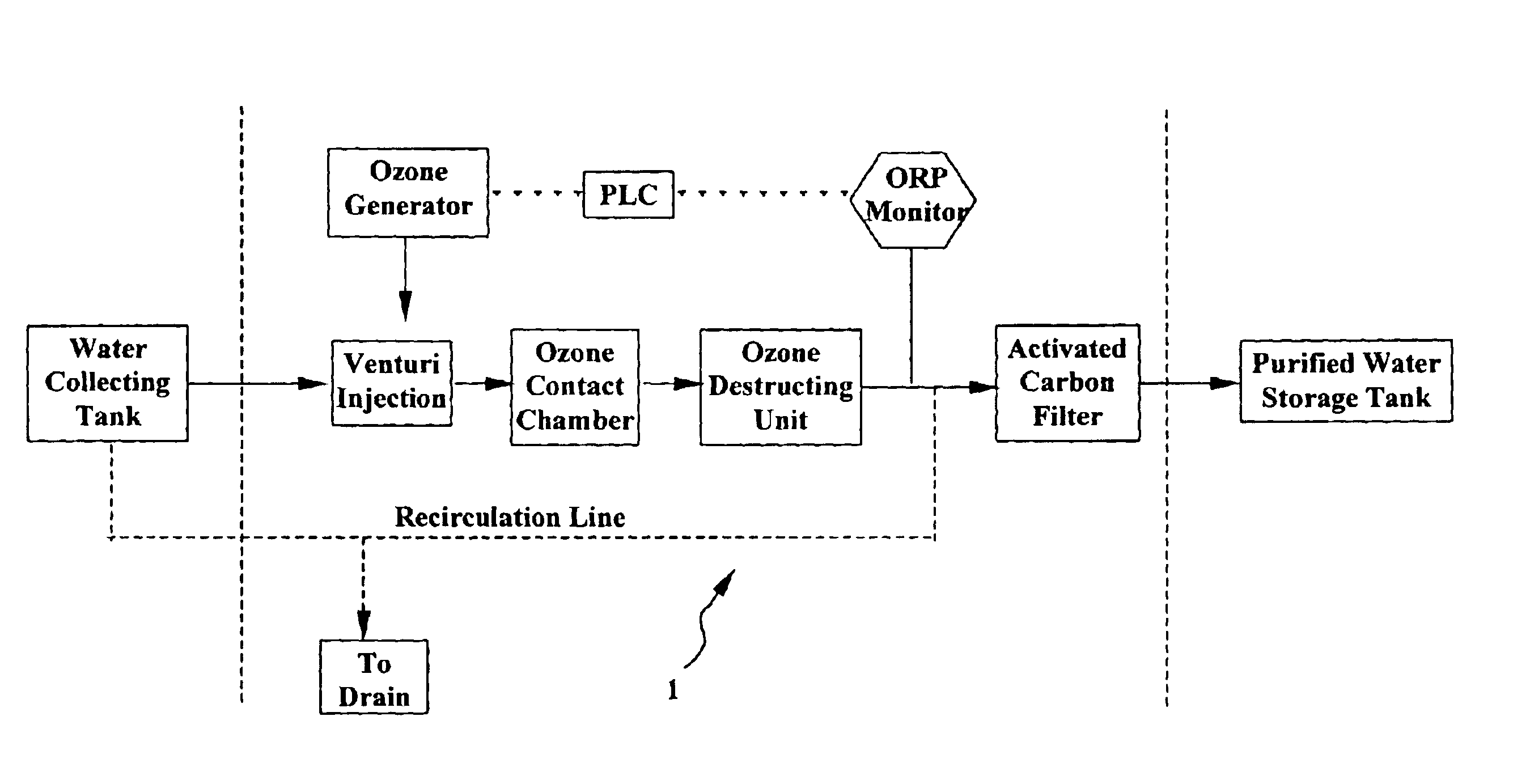

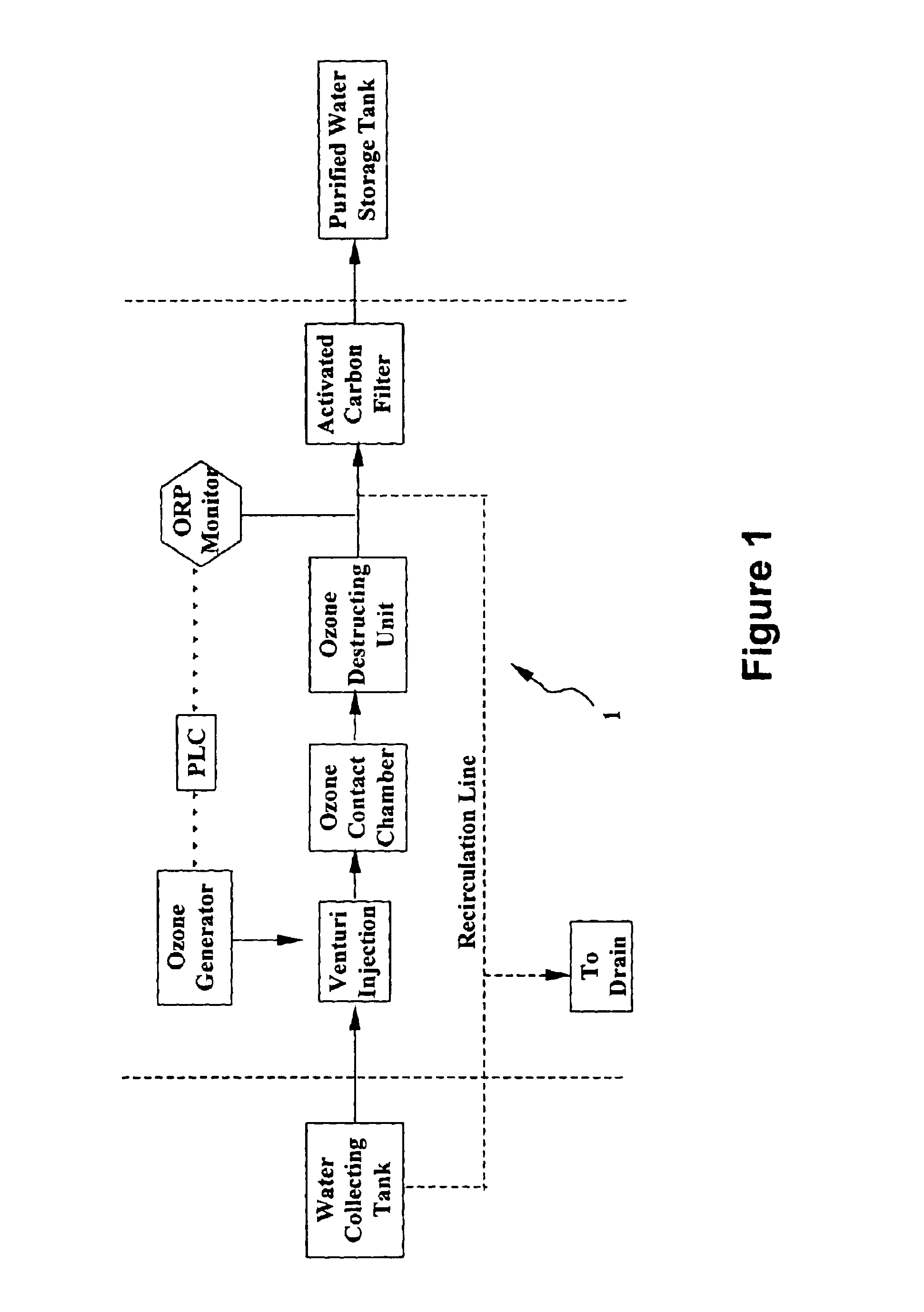

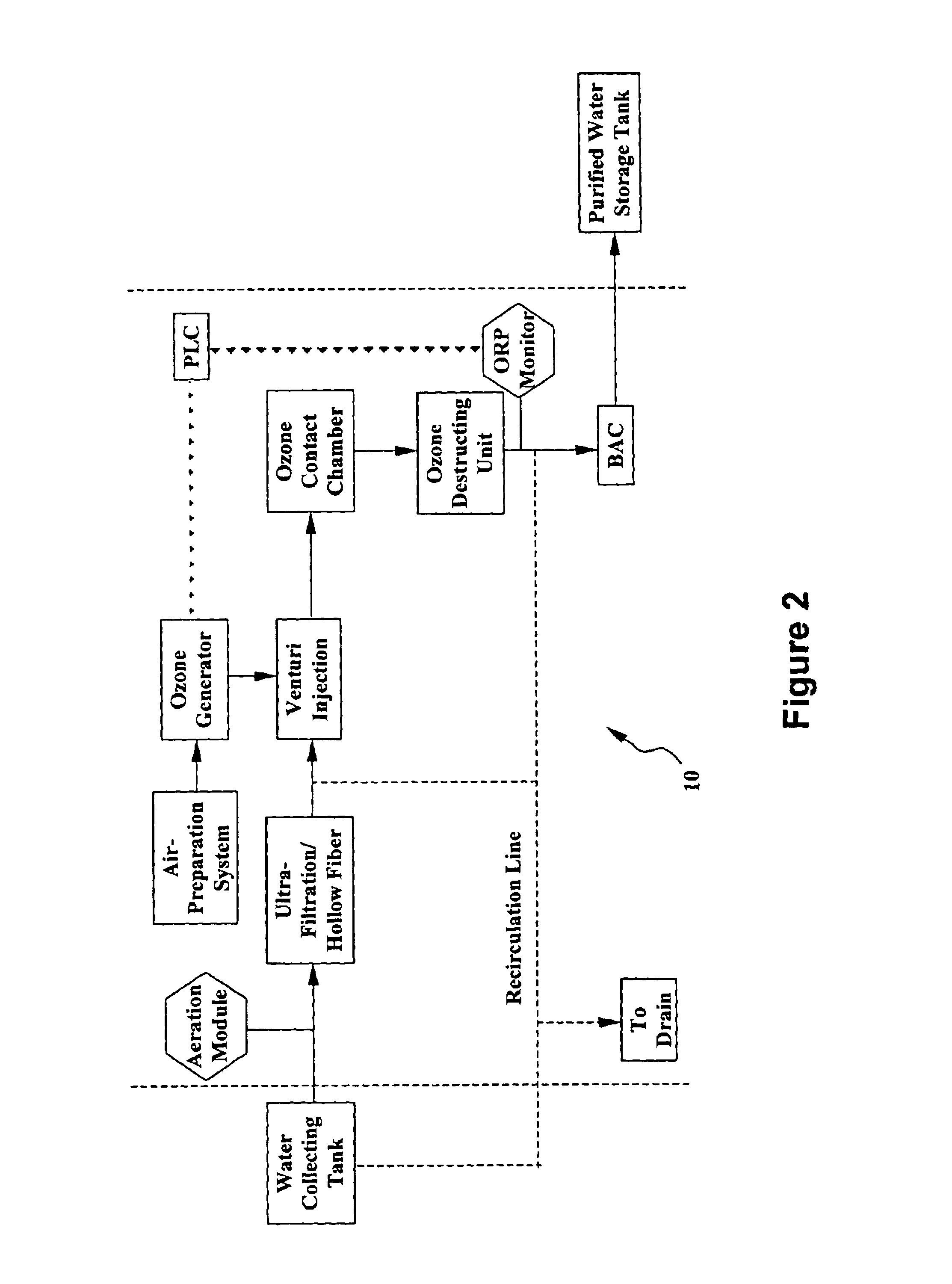

System and method for water purification

InactiveUS20040168989A1Treatment using aerobic processesSedimentation separationBiological activated carbonActivated carbon filtration

A self-contained, portable water purification system, including (a) an ozone supply, (b) an ozone contact chamber for mixing a contaminated or potentially contaminated water stream with ozone generated by such ozone supply, (c) an ozone destruction unit for destructing ozone contained in the water stream and converting said water stream into an oxygen-rich and ozone-depleted water stream, and (d) a downstream biologically active carbon filter, for receiving such oxygen-rich and ozone-depleted water stream and biologically destructing at least a portion of contaminants contained therein.

Owner:TEMPEST ENVIRONMENTAL SYST

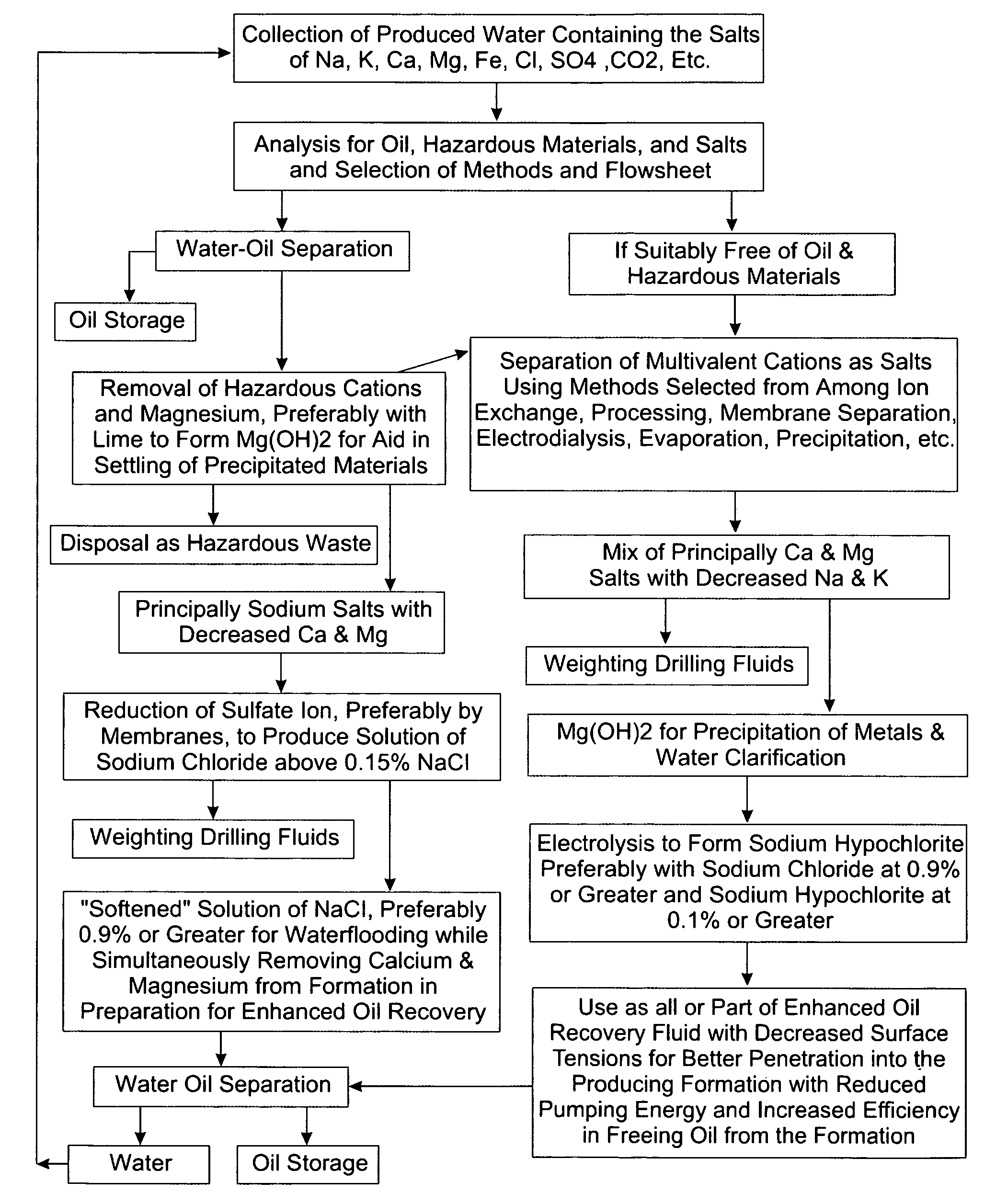

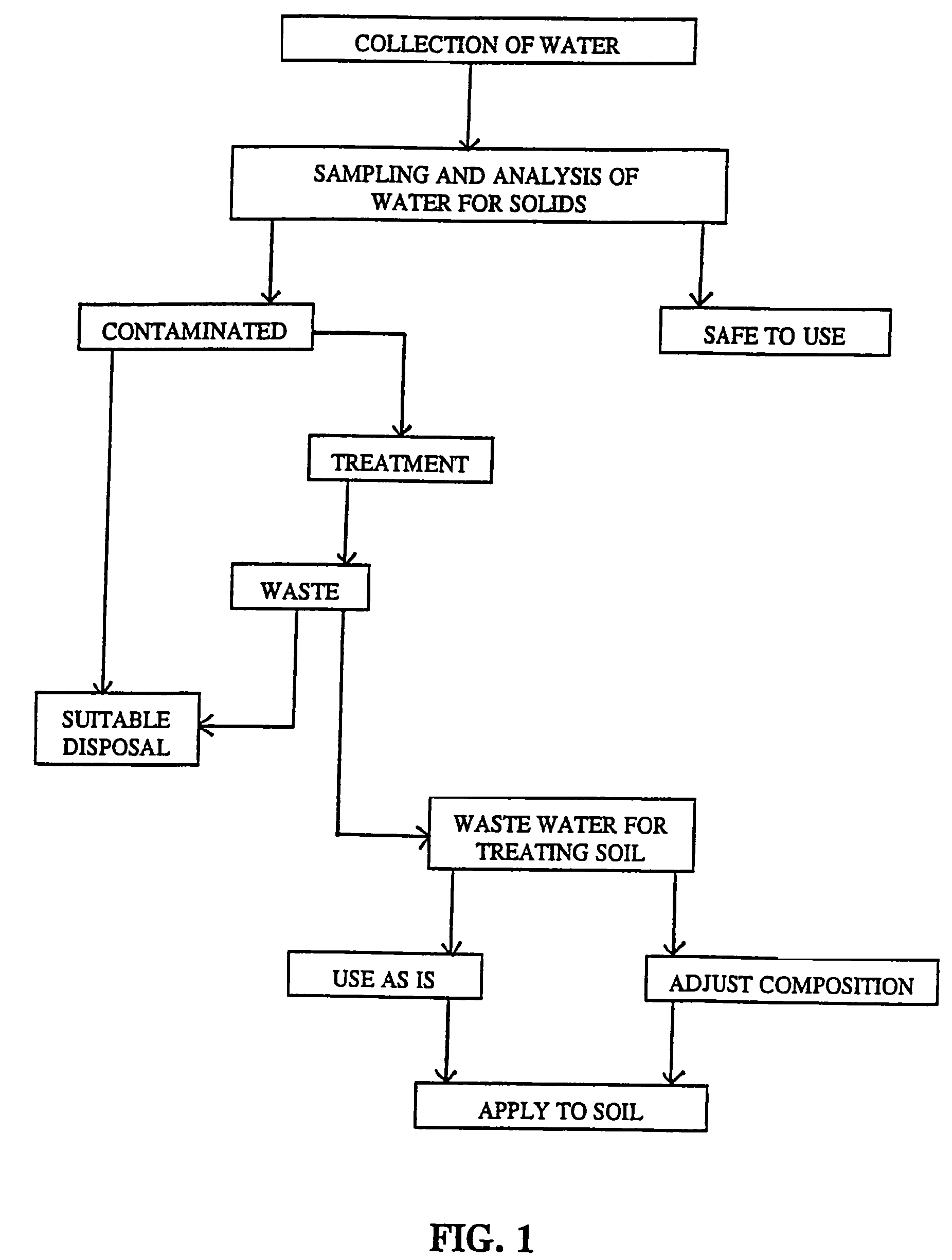

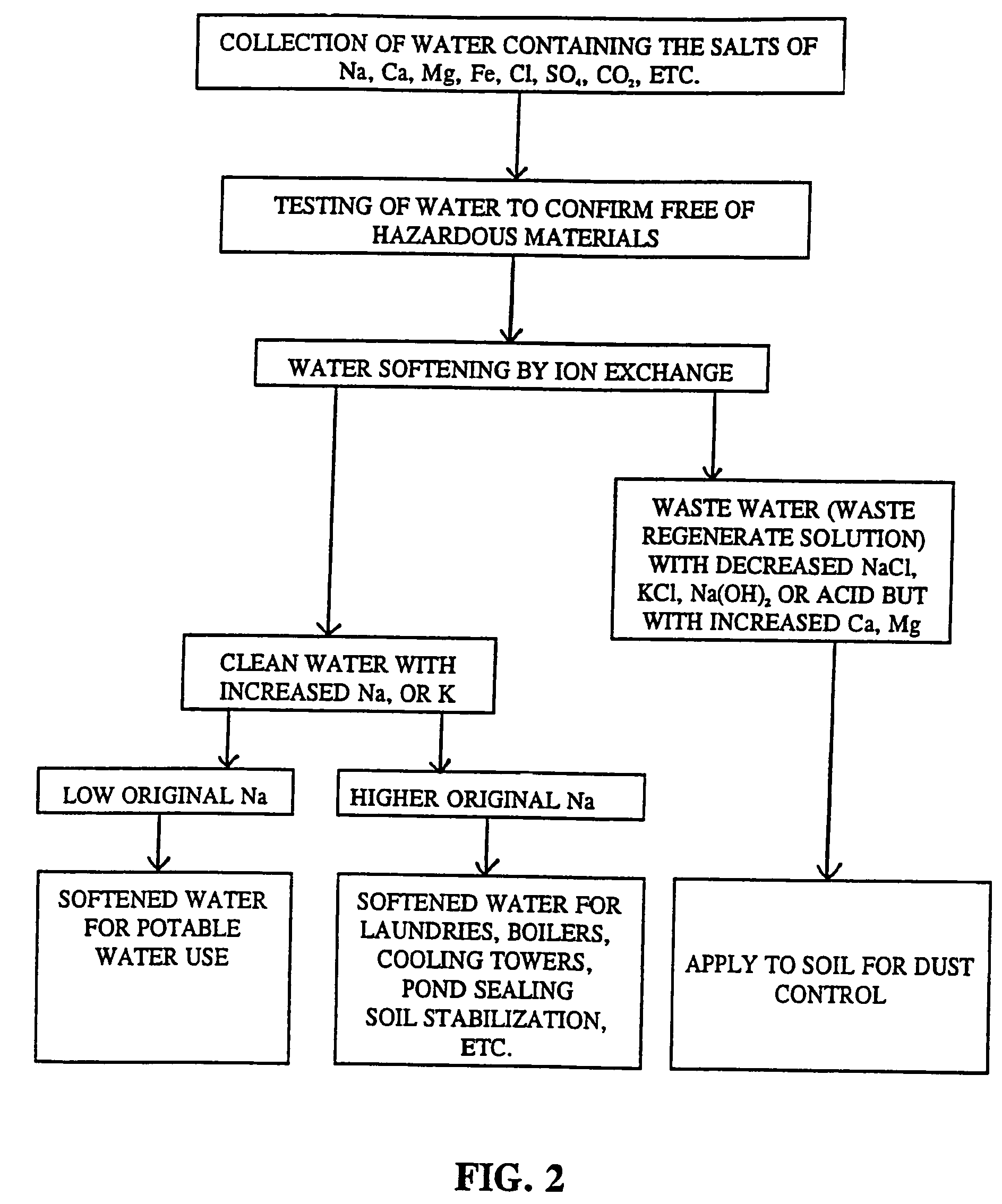

Methods of improving oil or gas production with recycled, increased sodium water

InactiveUS7717173B2Reduction tendencySpecific water treatment objectivesScale removal and water softeningLiquid productEnvironmental engineering

A method of improving oil or gas well production has the steps of (a) collecting contaminated water having 0.15% or more by weight of the salts of Na, Ca, Mg, K, Cl, SO4 or CO3 or combinations thereof (b) separation processing the contaminated water to produce i.) a first separated liquid product having increased sodium chloride and decreased magnesium chloride and calcium chloride or combinations thereof than the collected water, and ii) a second solid or liquid product having decreased sodium chloride and increased magnesium chloride and calcium chloride or combinations thereof than the collected water, and (c) injecting the first liquid product into an oil or gas well formation to improve production.

Owner:ECYCLING

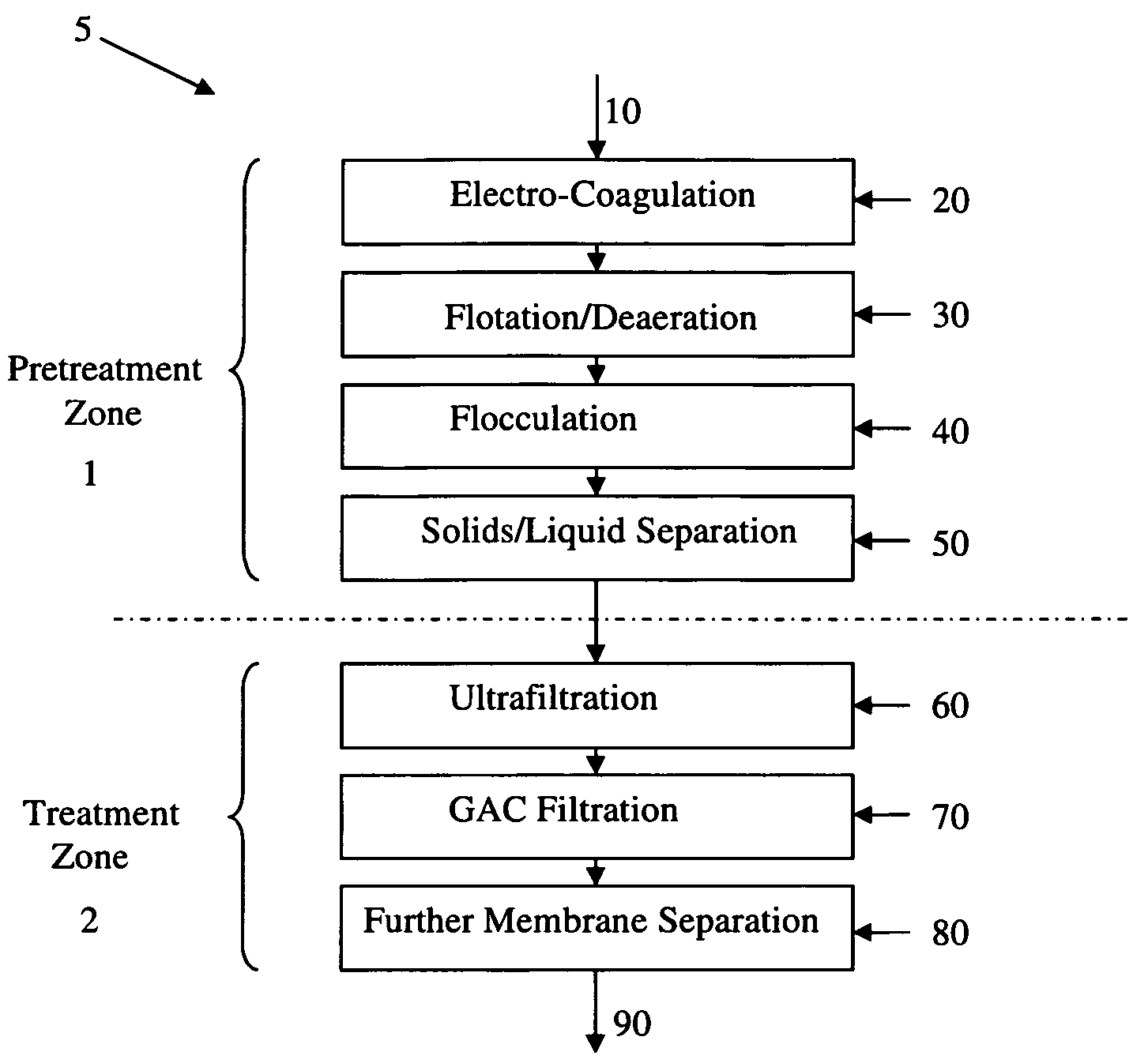

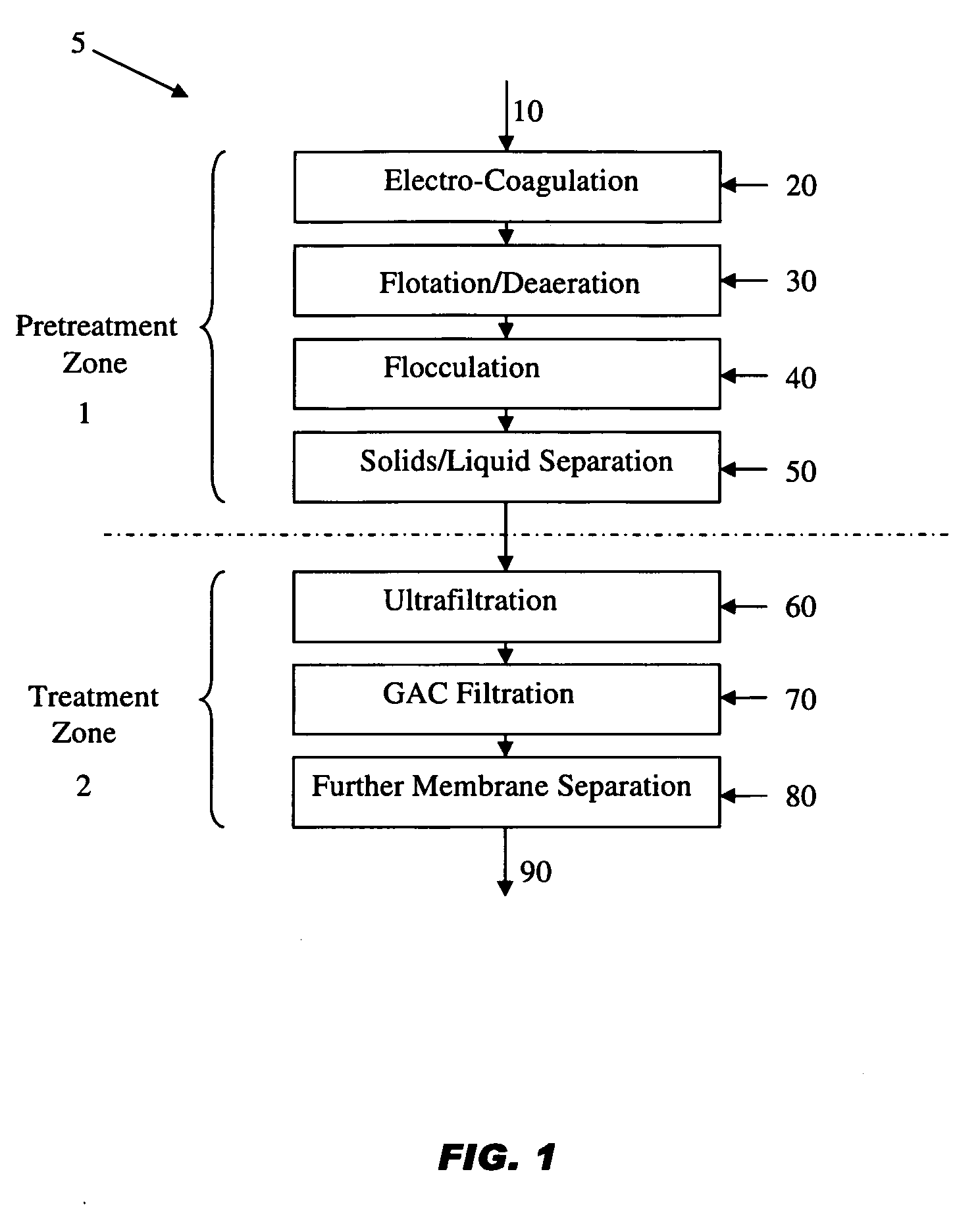

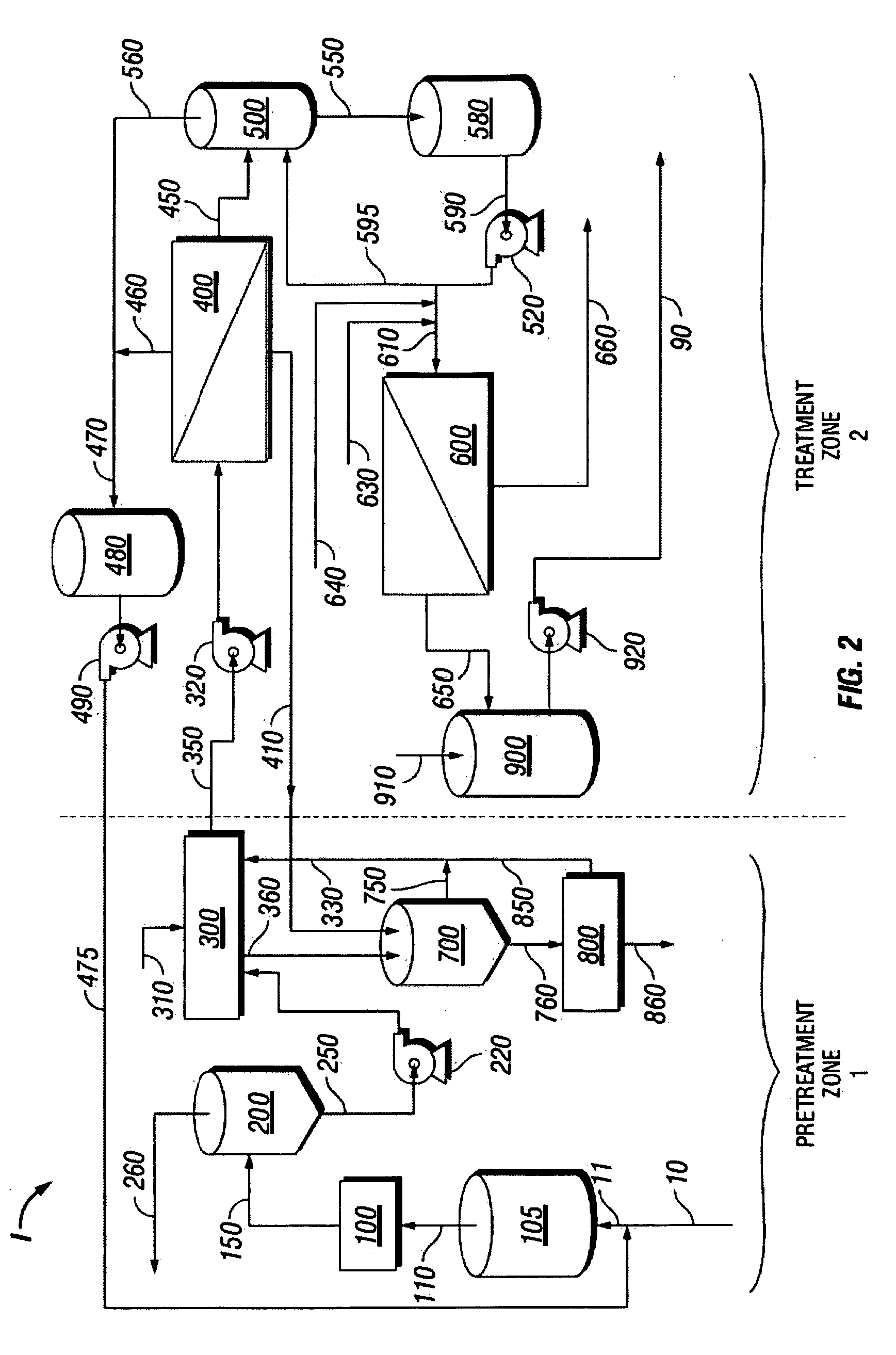

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

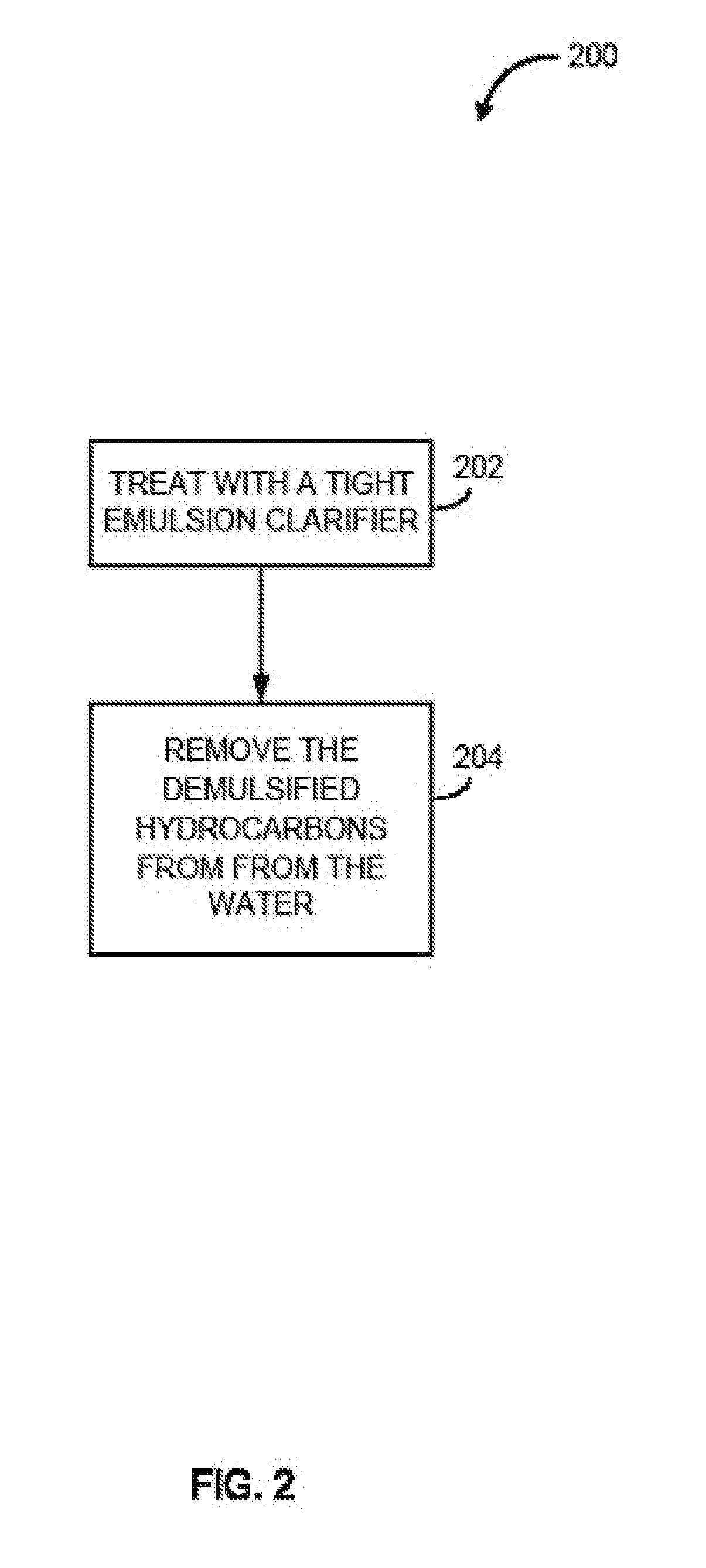

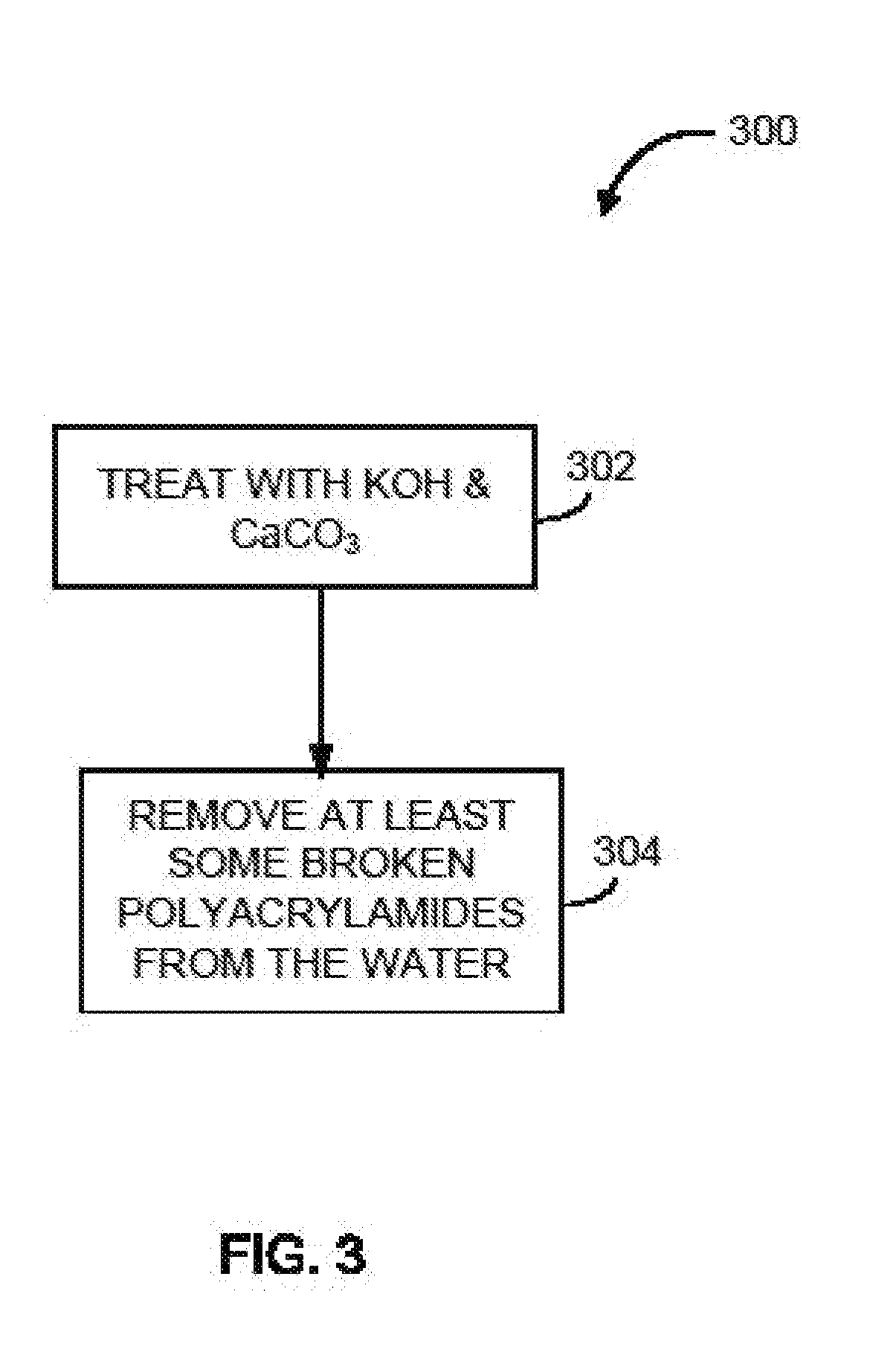

Oil field water recycling system and method

InactiveUS20110017677A1Reduce water hardnessReduce chain lengthSpecific water treatment objectivesWater contaminantsChemical treatmentAnaerobic bacteria

The disclosure describes a novel approach for treating water, such as oilfield production waste. The disclosure describes novel methods for chemically treating contaminated water, such as chemical processes for softening water, demulsifying hydrocarbons, destroying a sequestering effect on divalent cations, destroying any detectable amount or over 99% of aerobic and anaerobic bacteria, and breaking long chain polymers. The disclosure further describes novel methods for clarifying contaminated water to remove suspended solids.

Owner:EVANS THOMAS S

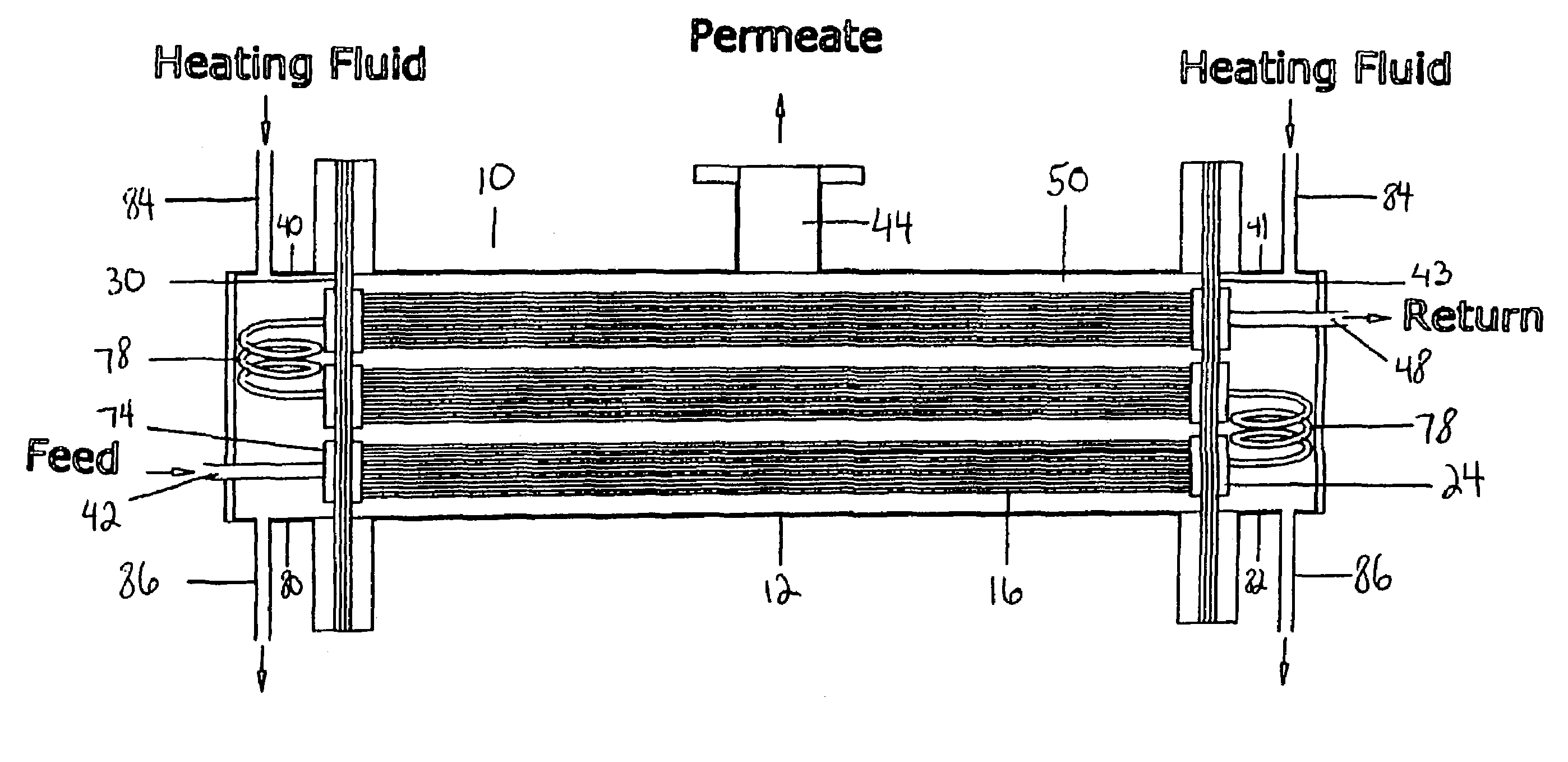

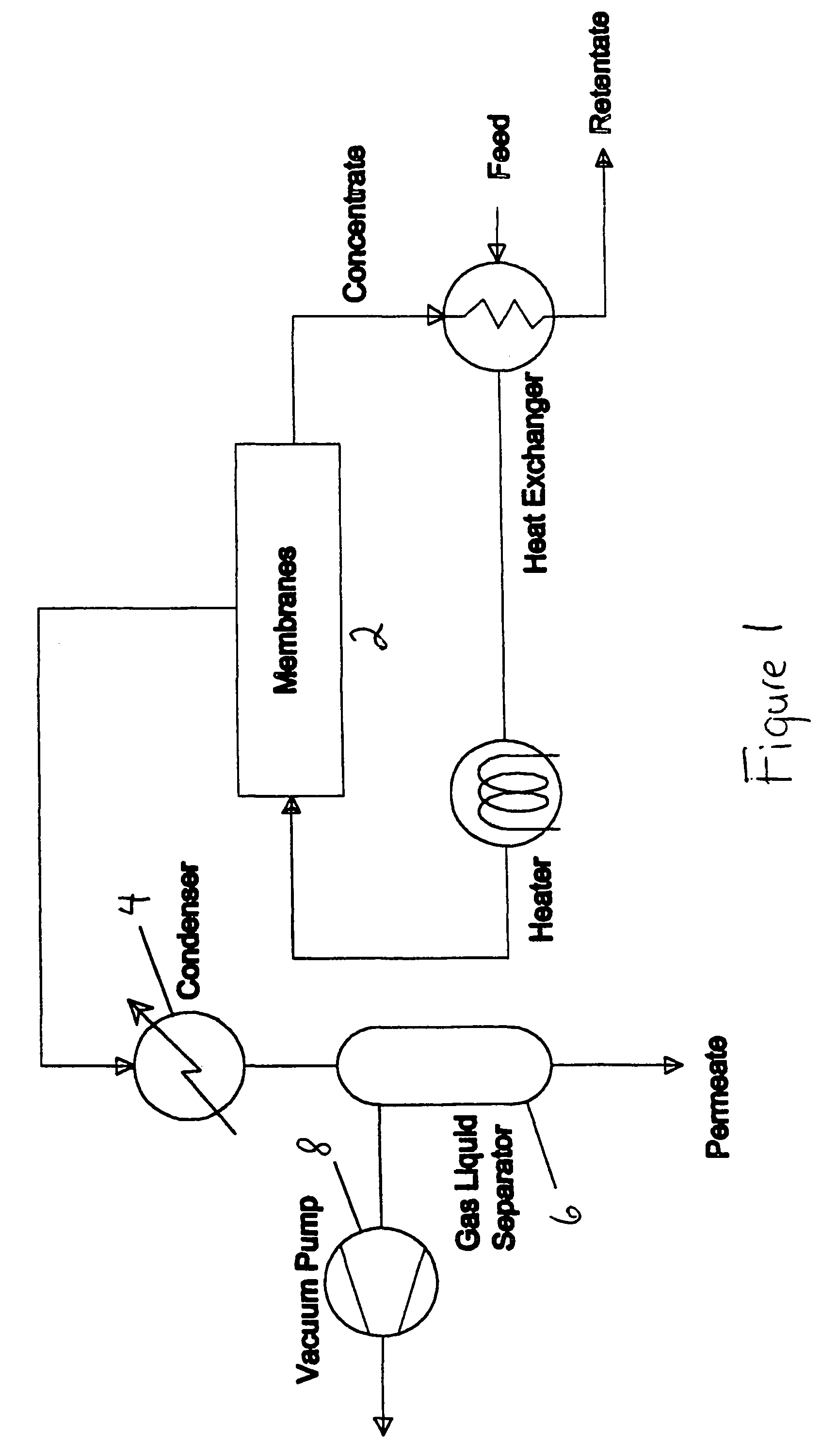

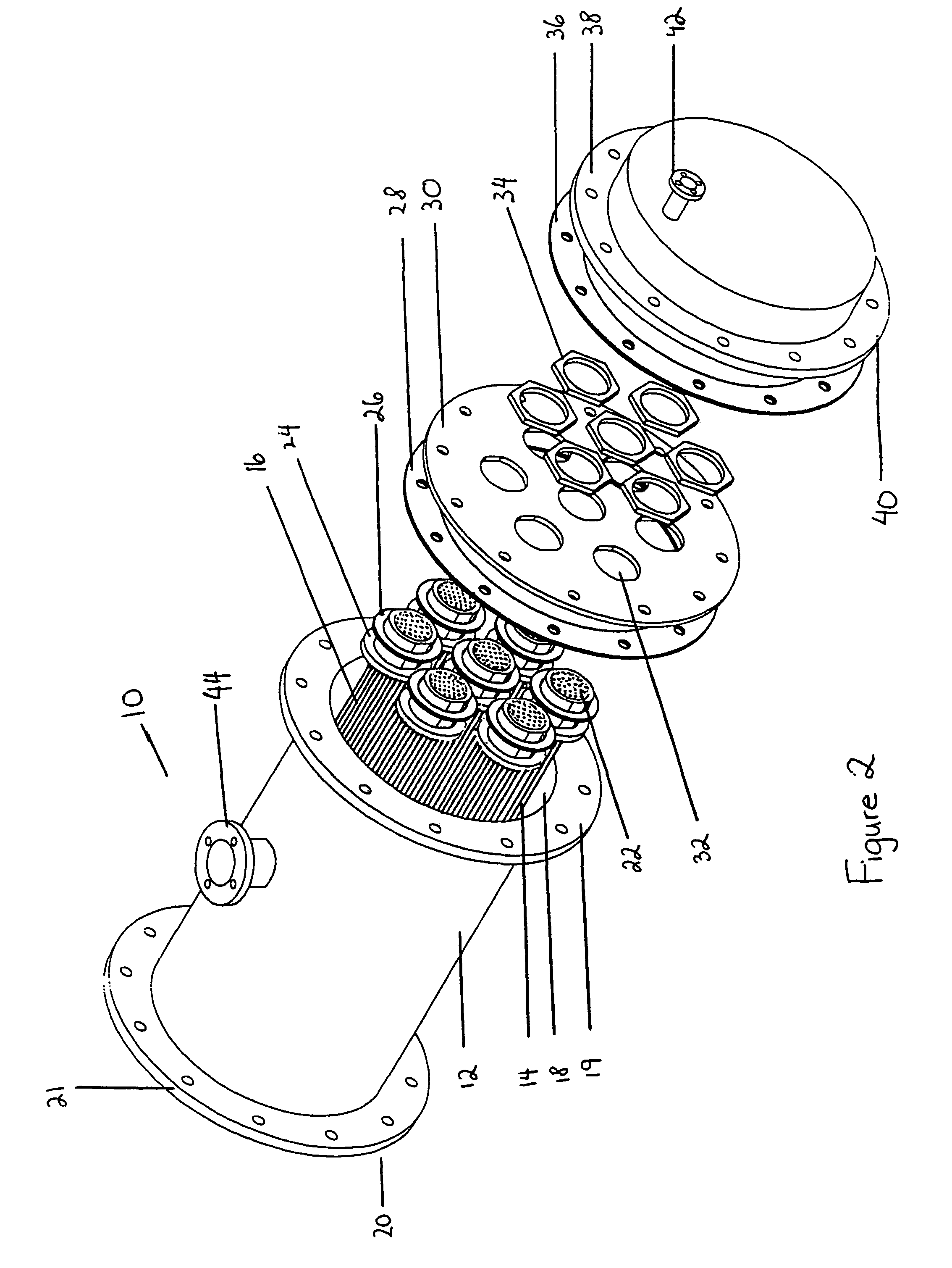

Membrane-assisted fluid separation apparatus and method

InactiveUS7459084B2Easy to disassembleReduce complexityMembranesGeneral water supply conservationFiberHigh concentration

This present invention relates to a fluid separation module adapted to separate a given fluid mixture into permeate and retentate portions using bundles of hollow fiber membranes. The membranes may be composed of different kinds of membranes depending on the application being used to separate the fluid mixture. The fluid separation module may be used to separate fluid mixtures by a number of different processes, including but not limited to, pervaporation, vapour permeation, membrane distillation (both vacuum membrane distillation and direct contact membrane distillation), ultra filtration, microfiltration, nanofiltration, reverse osmosis, membrane stripping and gas separation. The present invention also provides an internal heat recovery process applied in association with those fluid separation applications where separation takes place by evaporation through the membrane of a large portion of the feed into permeate. Desalination and contaminated water purification by means of vacuum membrane distillation are just two examples where the internal heat recovery process may be applied. In these two examples, large portions of the feed are separated by membranes into a high purity water permeate stream by evaporation through the membranes and into a retentate stream containing a higher concentration of dissolved components than present in the feed. In this process the permeate vapour that is extracted from the fluid separation module is compressed by an external compressor to increase the temperature of the vapour higher than the temperature of the feed entering the separation module. Heat from the permeate vapour at the elevated temperature is transferred back to the incoming feed fluid mixture entering the fluid separation module in a condenser / heat exchange.

Owner:LOEB INVESTORS CO 166 LP +1

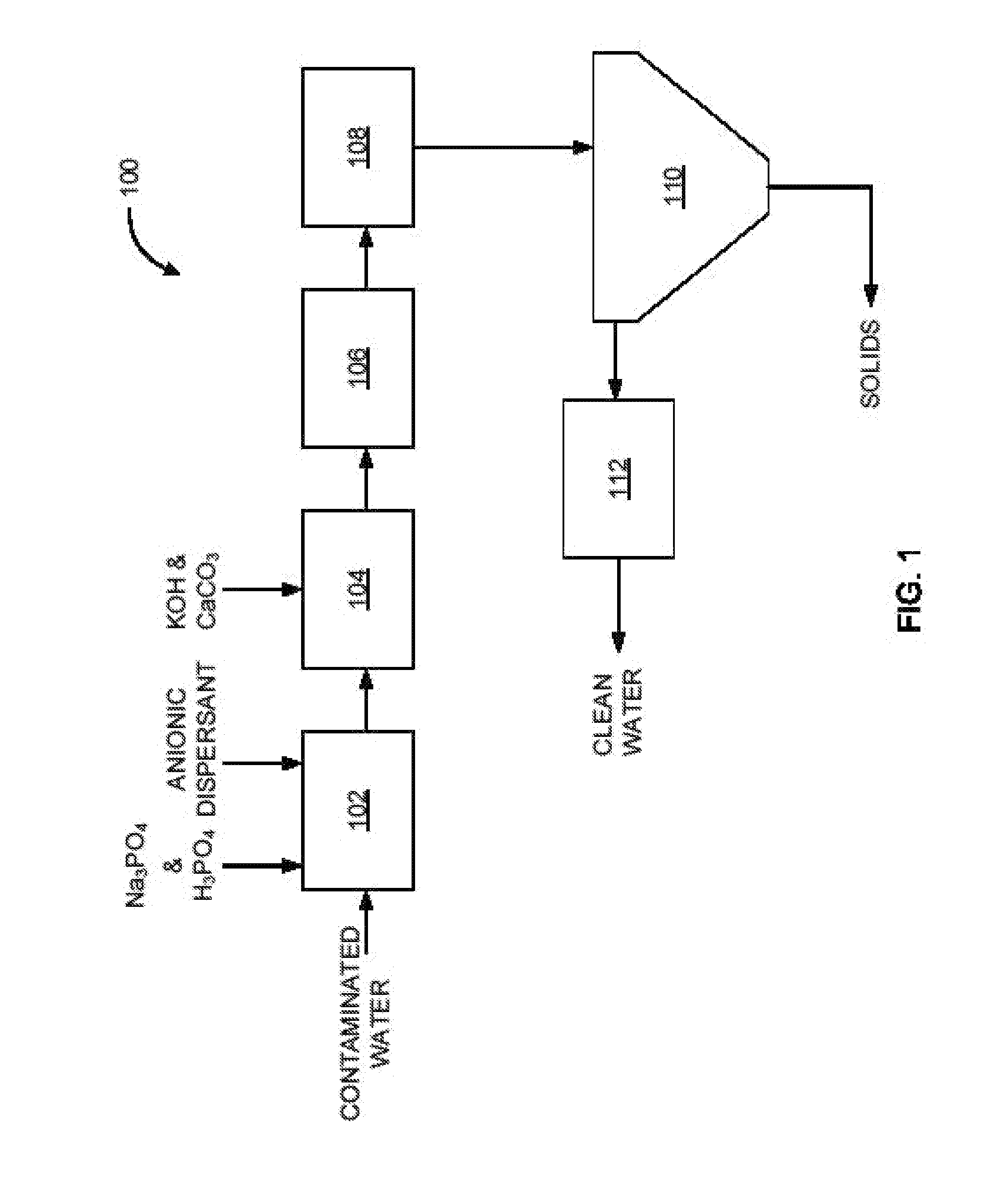

Methods for the purification of contaminated waters

InactiveUS20050061750A1Type of reductionReduce the presence of impuritiesSedimentation separationMultistage water/sewage treatmentContaminated waterChemistry

The present invention describes a method for the purification of waters containing high levels of contaminants by sequentially intermixing with the contaminated water a first anionic polymer, a cationic polymer, and a second anionic polymer, and then separating the contaminants from the water.

Owner:POLYMER VENTURES

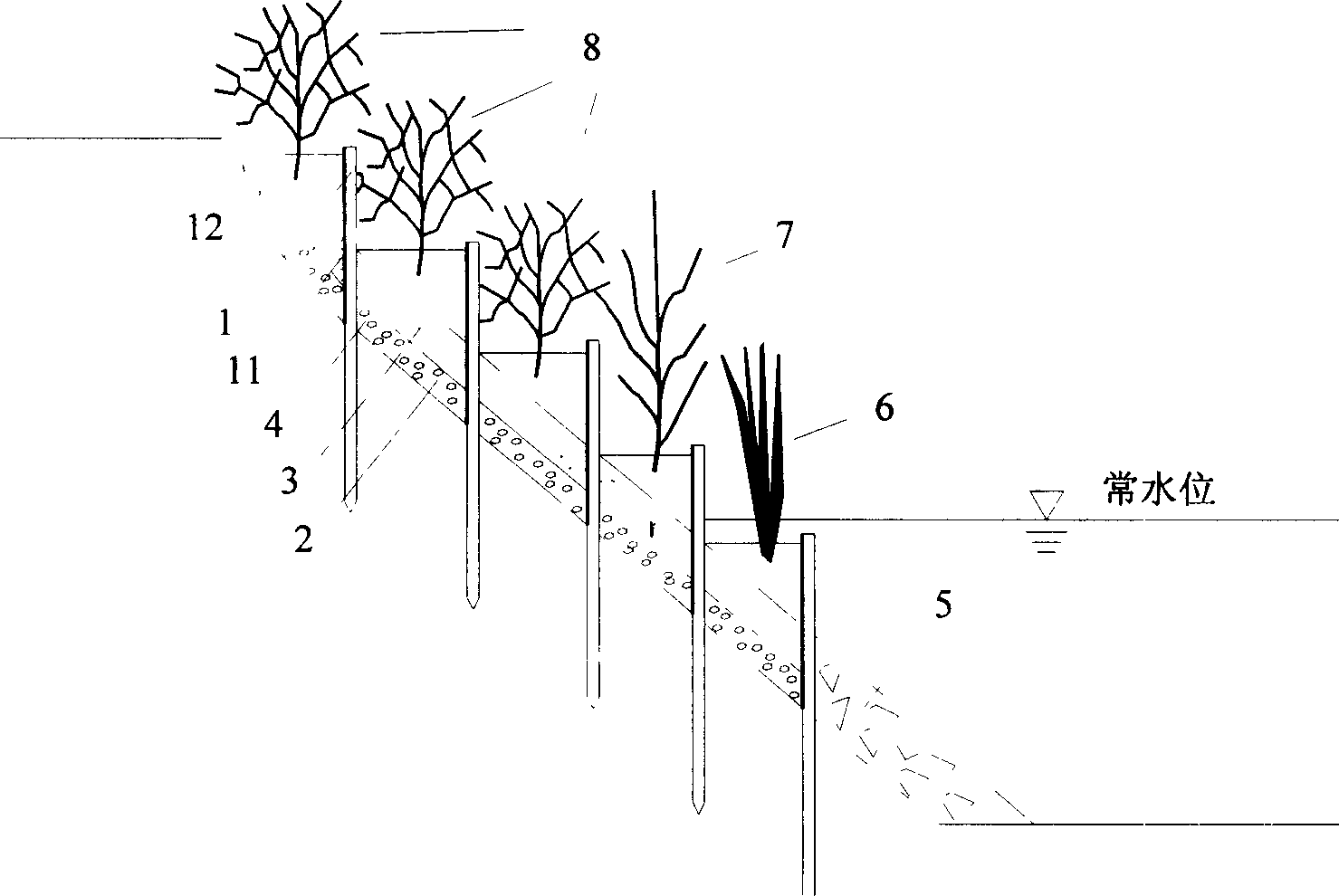

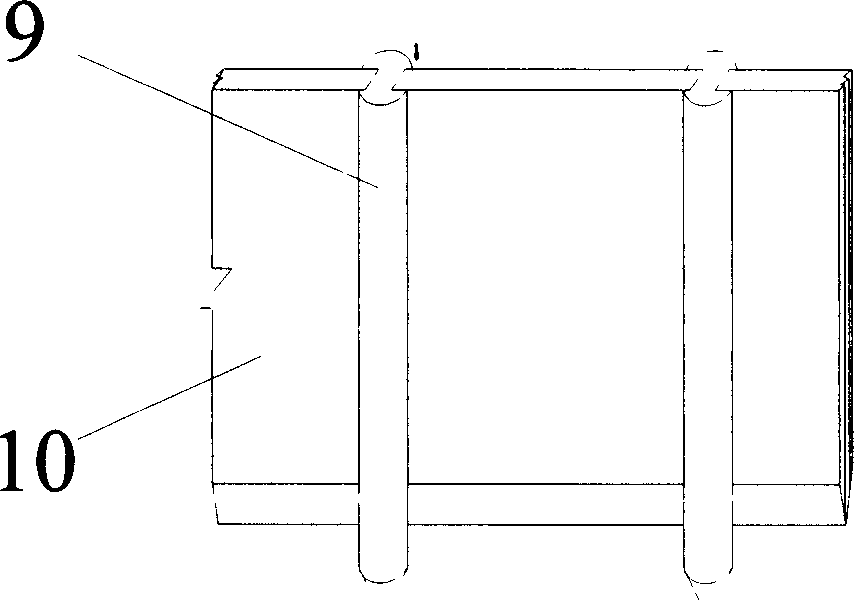

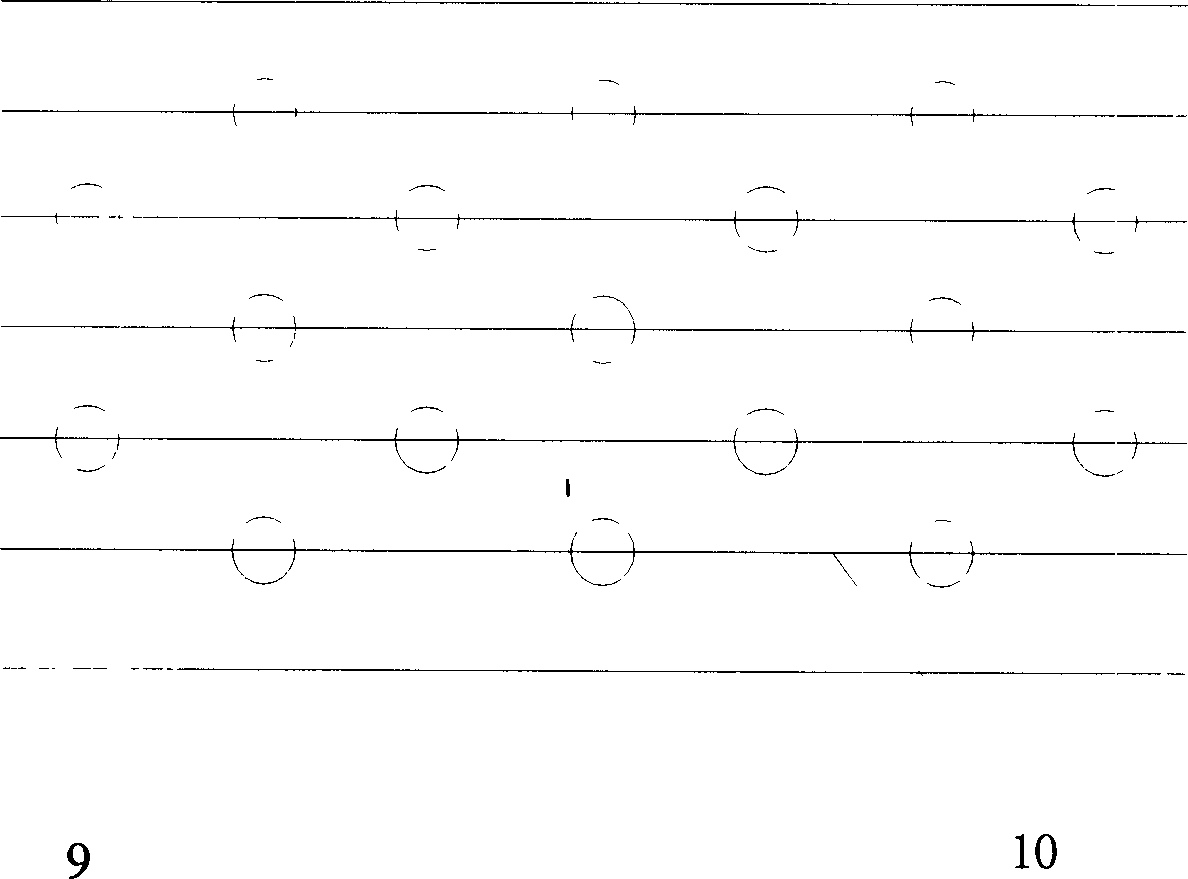

Landscape type multi-stage stepwise artificial wetland protection slope forming method

InactiveCN1632231AGood water permeabilityAvoid inconvenienceClimate change adaptationCoastlines protectionConstructed wetlandEutrophication

The invention relates to a slope protection forming method of a landscape-type multi-level stepped constructed wetland, which has the effect of intercepting and purifying pollutants entering river channels in the form of surface sources. Sand-free concrete piles and slabs are inserted to form pile-slab components, and a slope protection system from high to low is formed on the river bank slope from the bank slope to the river bed. Planting areas are set on the side of the pile slabs, and there are fillers inside. Geotextiles are installed on the bankside side of the slab, so that when the non-point source pollutants flow from the river bank to the river, the plants planted in the planting area absorb the eutrophication in the polluted water, and the biofilm is formed on the surface of the filler to absorb and degrade the pollutants. After this The sewage treated at the first stage continues to infiltrate or overflow, enters the second row, and goes down step by step. Finally, the sewage is purified to a greater extent and flows into the river. It solves the defects of natural, hard and ecological slope protection. The structure is simple, easy for industrial production, the construction amount is small, the land is saved, and the landscape is beautified.

Owner:HOHAI UNIV

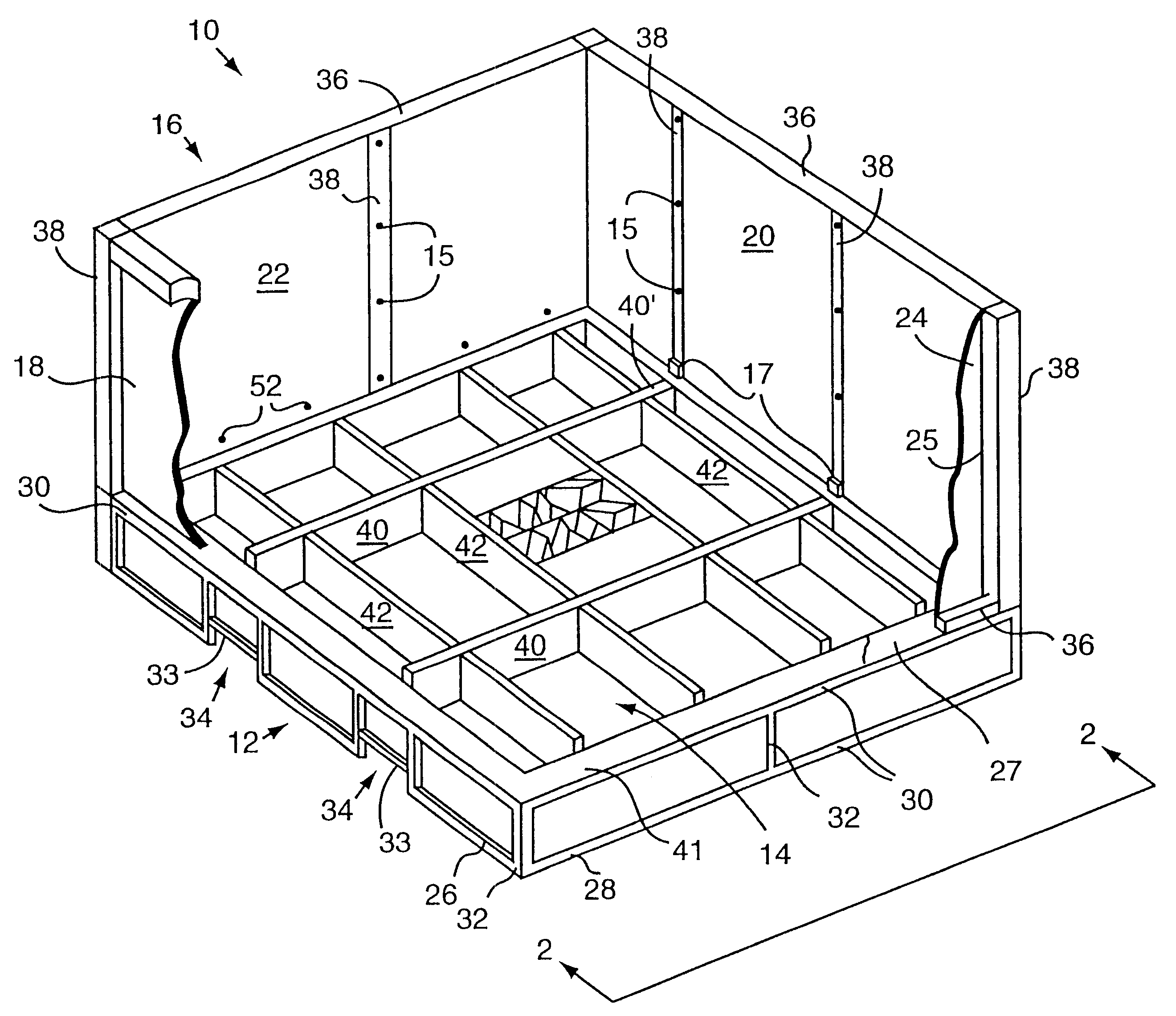

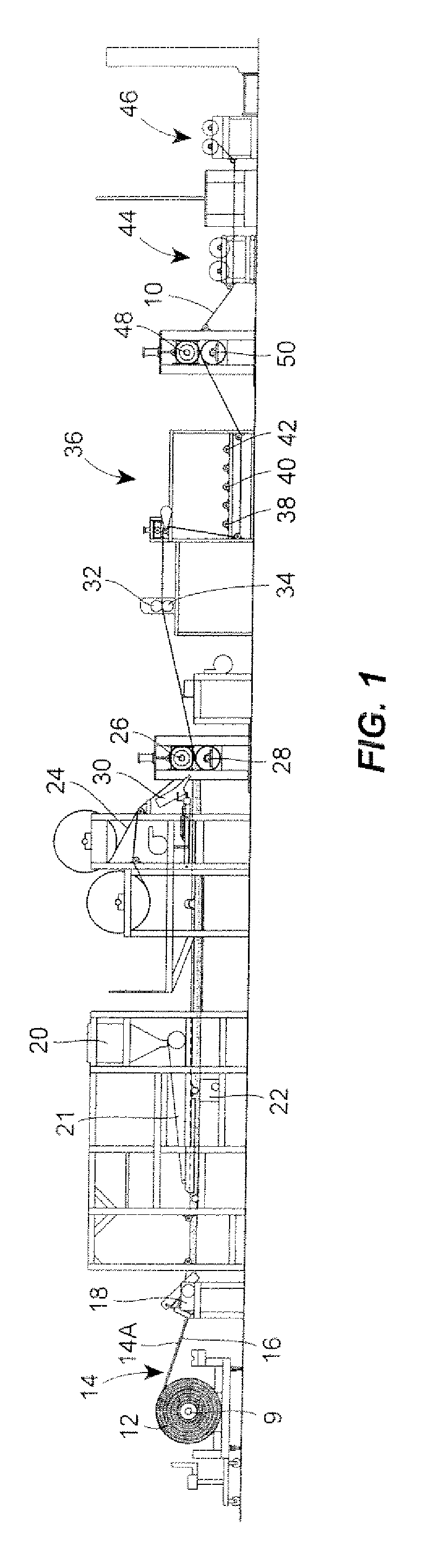

Method and apparatus for pressure washing

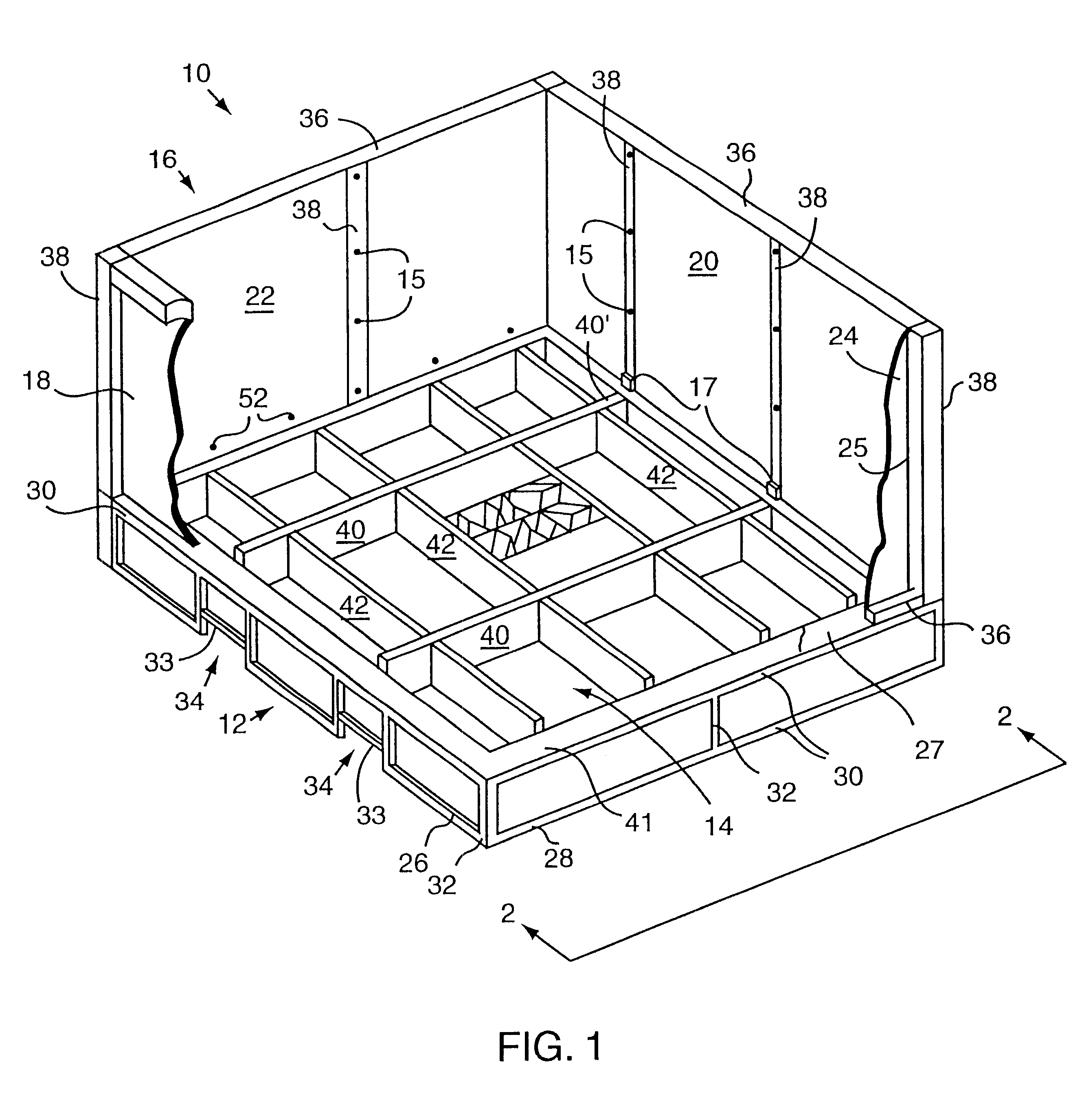

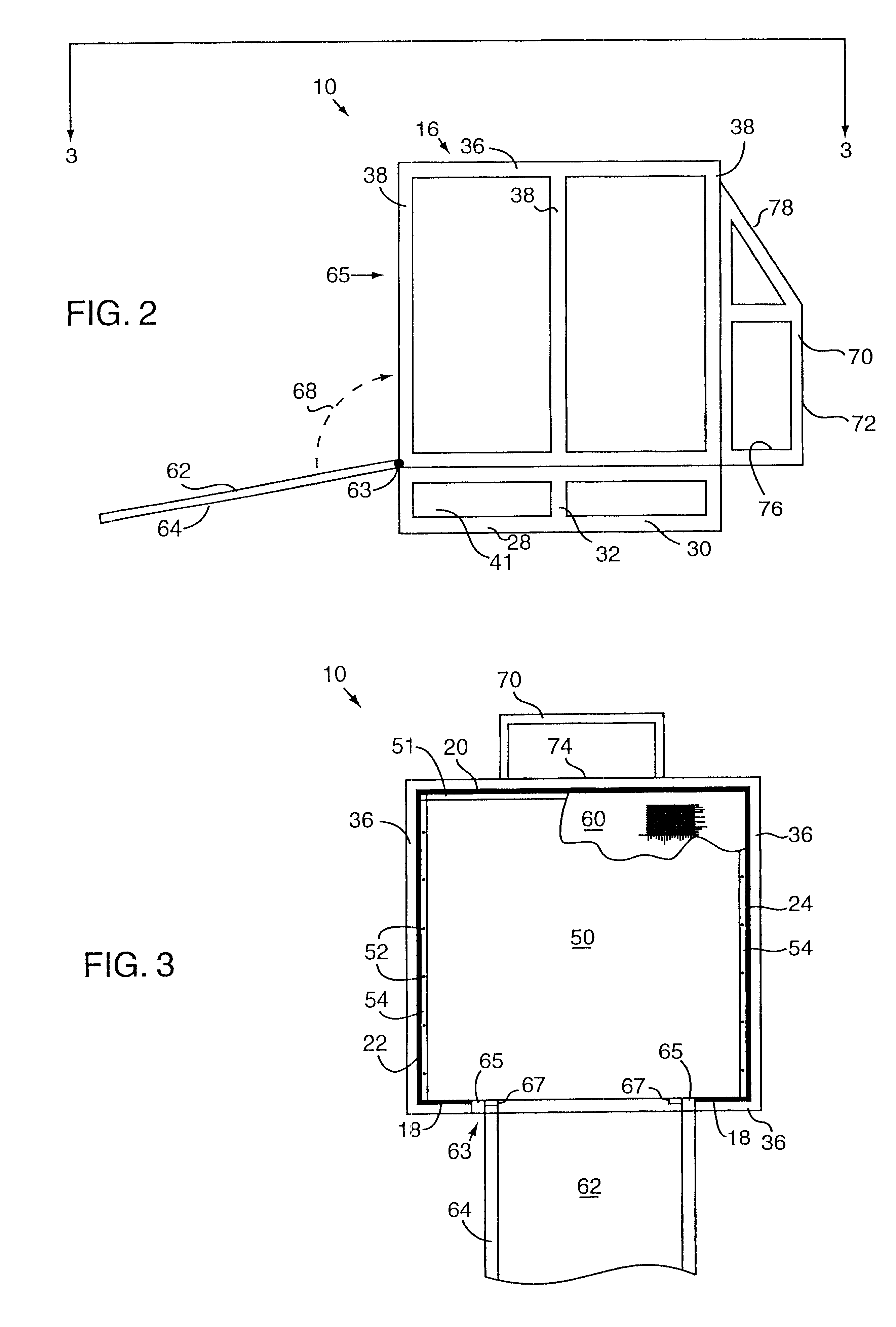

The present invention relates to methods and apparatus for removing a contaminant from an object. According to one aspect, an apparatus for washing an object which has contaminant is arranged to recover the contaminant. The apparatus includes a support floor that supports an object to be washed and a basin mounted below the support floor. The basin is divided into a plurality of chambers which include a clean water chamber, a secondary water chamber, an oil containment chamber, and a contaminated water receiving chamber which receives water which is contaminated after it is flowed over the object to remove the contaminant. The contaminated water received in the contaminated water receiving chamber must pass sequentially through the oil containment chamber and the secondary water chamber prior to entering the clean water chamber. The clean water chamber is flowably coupled to the secondary water chamber by a first flowpath near the operational water level, while the secondary water chamber is flowably coupled to the oil containment chamber by a second flowpath near the bottom of the basin. The oil containment chamber is flowably coupled to the contaminated water receiving chamber by a third flowpath near the operational water level. The apparatus also includes a first pump which draws and filters water from the secondary water chamber and returns the filtered water to the clean water chamber.

Owner:EZ ENVIRONMENTAL SOLUTIONS

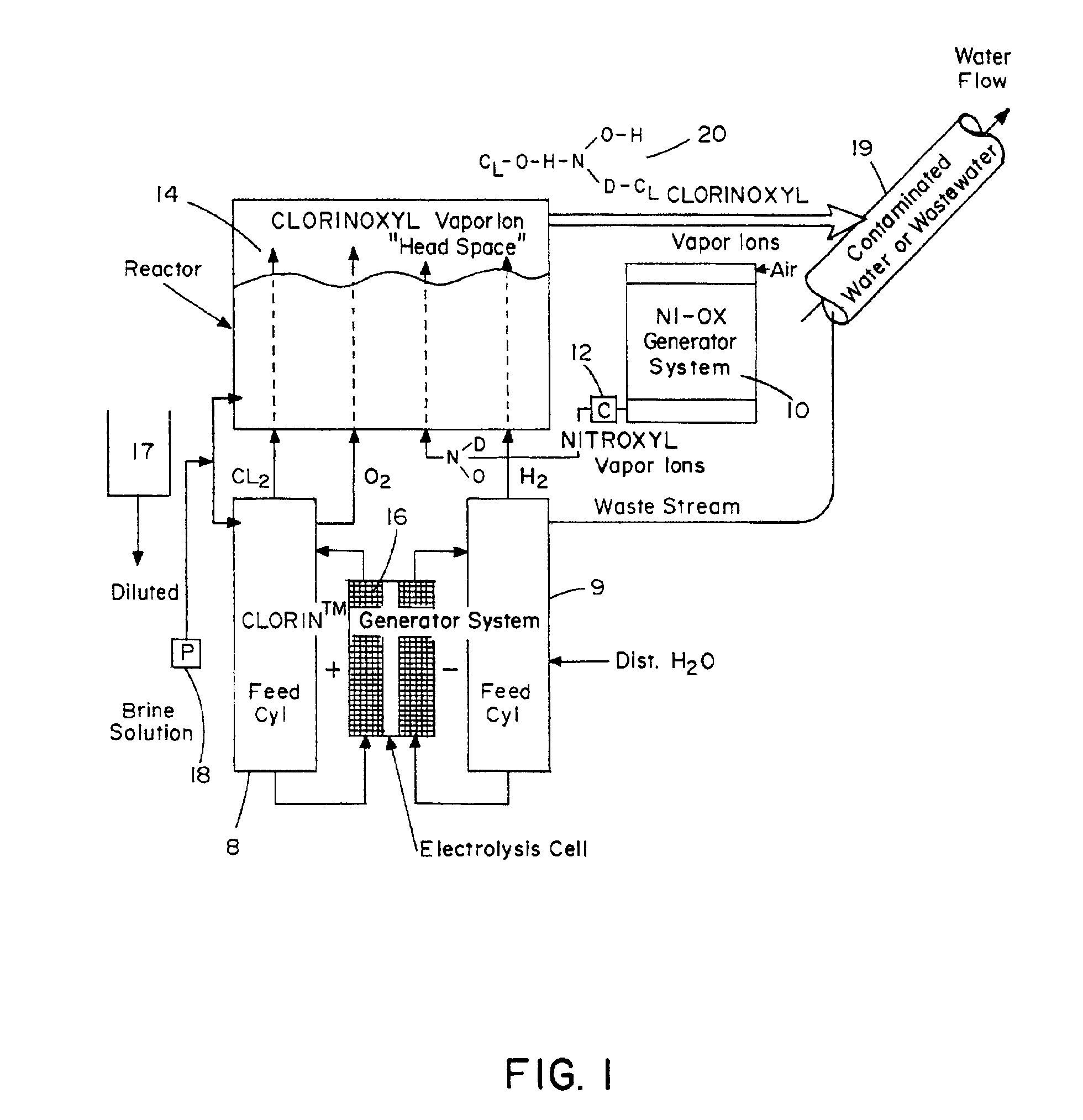

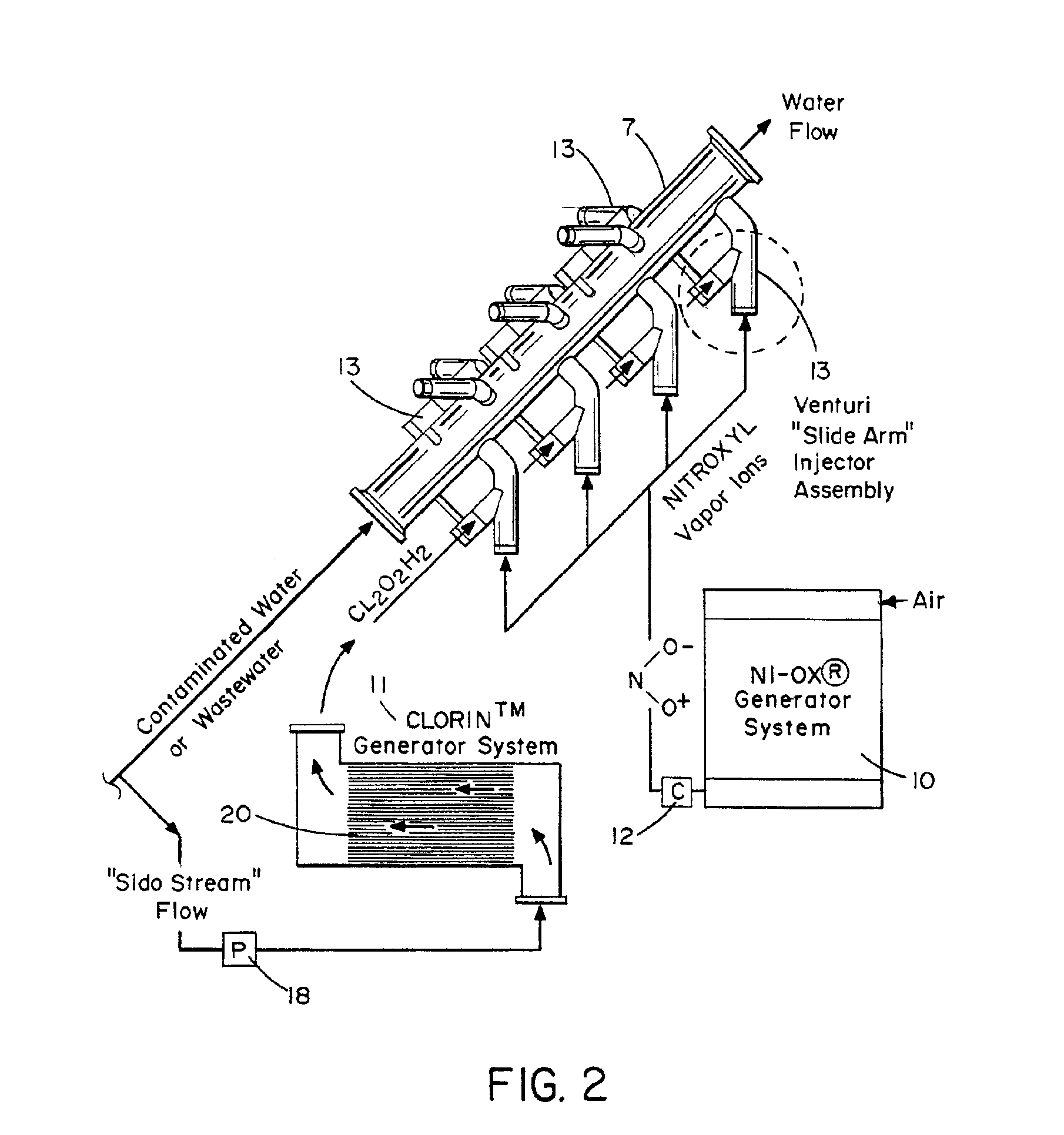

Non-chemical water treatment method and apparatus employing ionized air purification technologies for marine application

InactiveUS6923901B2Reduce maintenanceReduce energy costsCyanogen compoundsNitrogen compoundsElectrolysisDihydrogen oxide

Contaminated water, particularly, ballast water, blackwater, galley water, accommodation water, laundry water, fresh water and seawater, is disinfected by admixture of a highly reactive gas stream containing ions of oxygen and nitrogen, formed by exposure of air to short-wavelength ultraviolet radiation, and of chlorine, formed in situ by electrolysis of salt in the water. Solids removal can be accomplished by electrophoresis in the same unit employed for electrolysis to release chlorine, or in a separate unit. Heavy metals maybe removed by plating or sacrificing electrodes.

Owner:IONZ BLUEWATER SOLUTIONS +1

Filtration of hydrocarbon containing liquid

InactiveUS6503390B1Preventing back wash of any liquidLiquid suspension thickening by filtrationPaving gutters/kerbsExtreme weatherFiltration

An apparatus for and method of filtering hydrocarbon contaminated water is disclosed herein. The present invention may be used in drainage openings, particularly in parking lots and containment areas for large sources of hydrocarbons such as oil tanks or electrical transformers, to remove hydrocarbons from hydrocarbon contaminated water. The apparatus has a filtration compartment which filters out debris and sediment which may clog the treatment compartment. A pre-filter attachable to the apparatus may be used to further aid in filtering out sediment. A means for melting snow and ice may be incorporated within the filtration compartment such that liquid flow is not hindered during extreme weather conditions. The treatment compartment contains a hydrocarbon absorption media which absorbs any hydrocarbons present in the water rendering such water substantially hydrocarbon-free for discharge directly into a stream or groundwater. In the event of a hydrocarbon spill, the hydrocarbon absorption media forms a plug which seals off the flow of contaminated water. A hydrocarbon solubilizing material capable of effectively removing sheen in a first pass may be disposed as a top layer over the hydrocarbon absorption media. Preferably, each compartment is manufactured as a cartridge which may be dropped into a housing inserted into a drain opening.

Owner:SPI FILTRATION

Water purification method

InactiveUS20140175015A1Conveniently and efficiently purifyingInexpensivelyWaste water treatment from quariesWaste water treatment from ceramic industriesPurification methodsSorbent

A water purification method comprising adding a purification agent to water having a contaminant concentration of 1 μg / L to 10 g / L, the purification agent containing an adsorbent having an average particle size of 100 nm to 500 μm, an iron-based flocculant, and an alkaline substance; causing the adsorbent to adsorb at least a part of the contaminants in water; settling the adsorbent with the adsorbed contaminants by the iron-based flocculant; and removing the sediment from water, wherein the purification agent is added in an amount of 0.01 g to 20 g per liter of water, can purify contaminated water conveniently and efficiently.

Owner:FUJIFILM CORP

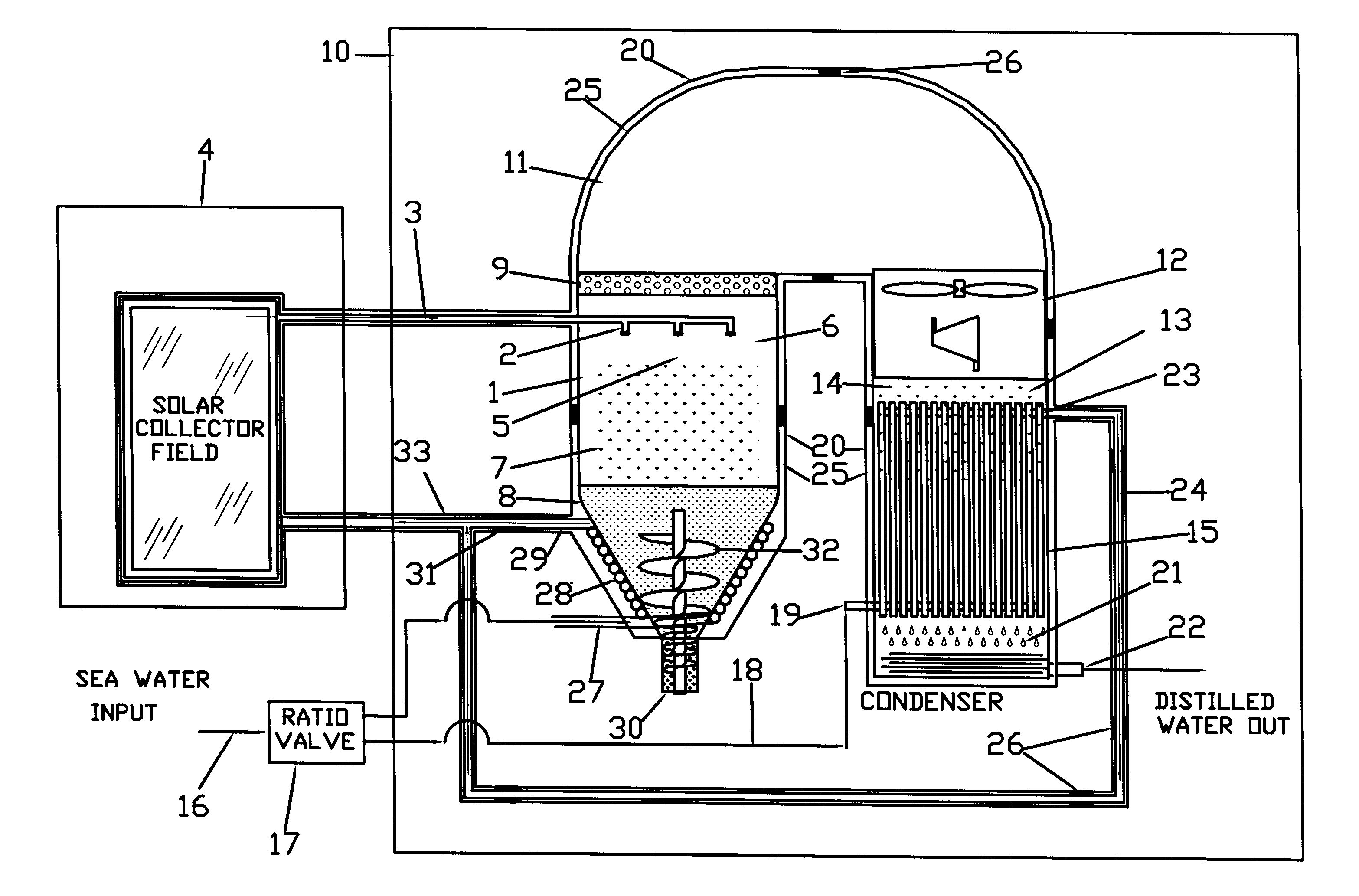

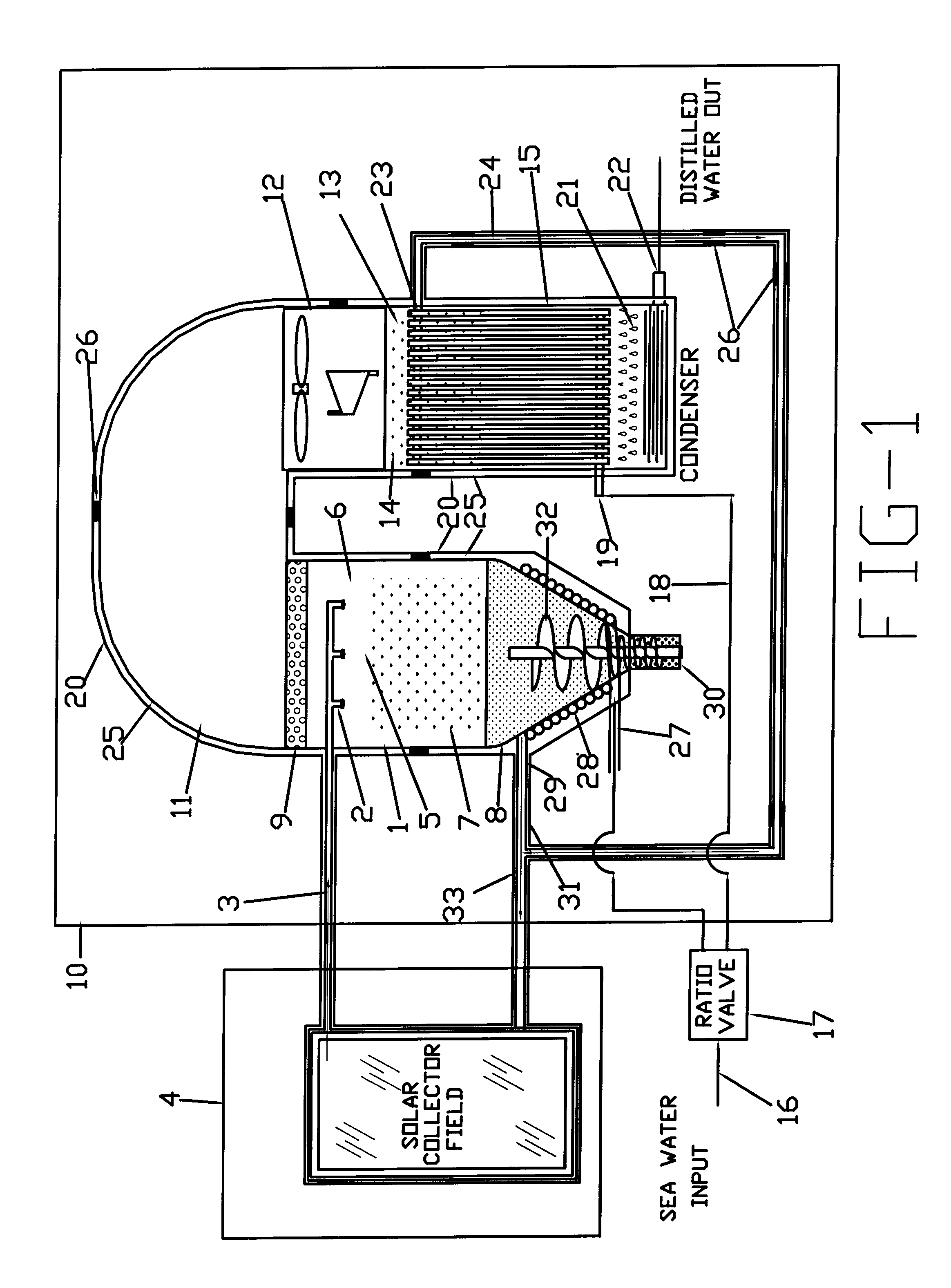

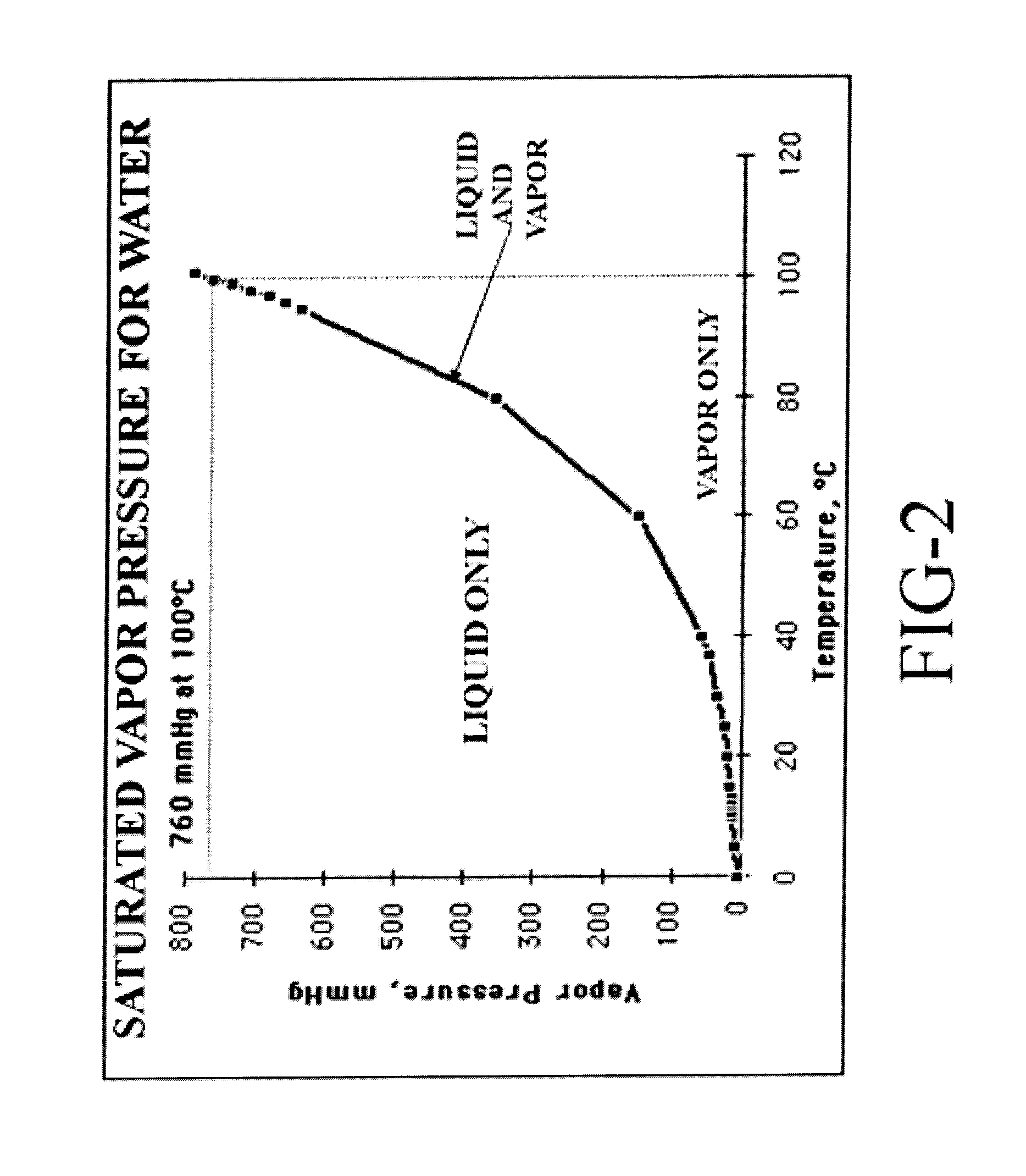

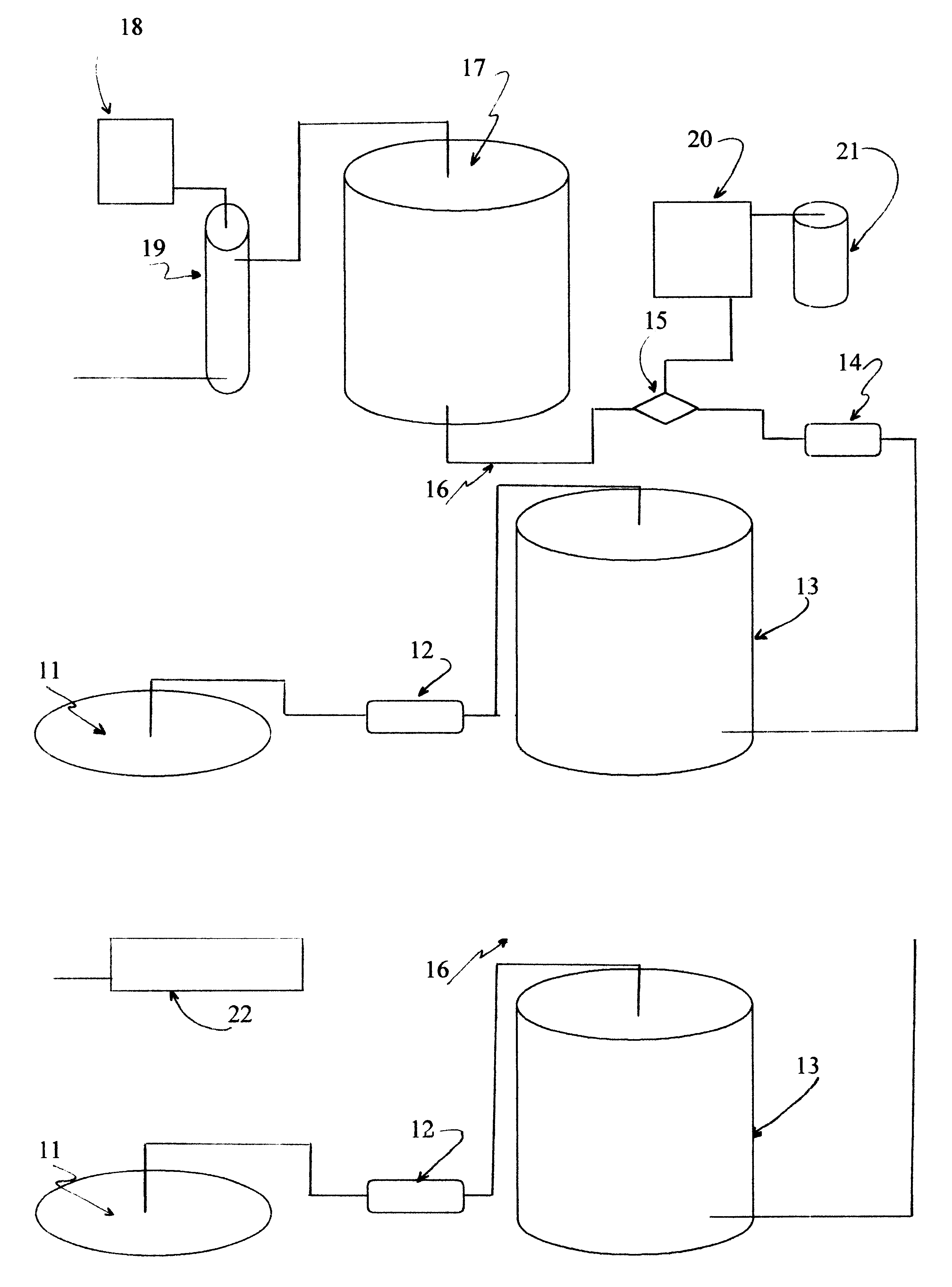

Large scale insulated desalination system

ActiveUS20120085635A1Improve distillation efficiencyLower energy requirementsGeneral water supply conservationAuxillariesDistillationBrackish water

An apparatus and method for the distillation of ocean and brackish water that includes insulation means for preventing heat from escaping to the atmosphere is disclosed. The insulation means comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system provides a means for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. A means for recapturing and using the heat of condensation as well as heat from the salt byproduct to preheat the input contaminated water is also disclosed.

Owner:FLO ONICS LLC

Process and apparatus for purifying methyl tert-butyl ether contaminated water

There is provided an efficient and effective method and apparatus for purifying methyl-tert butyl ether contaminated water by bubbling into the water an oxidizing gas and then stripping the oxidizing gas and MTBE from the water. A pressurized container is used to create microbubbles and to promote oxidation.

Owner:WASINGER ERIC M

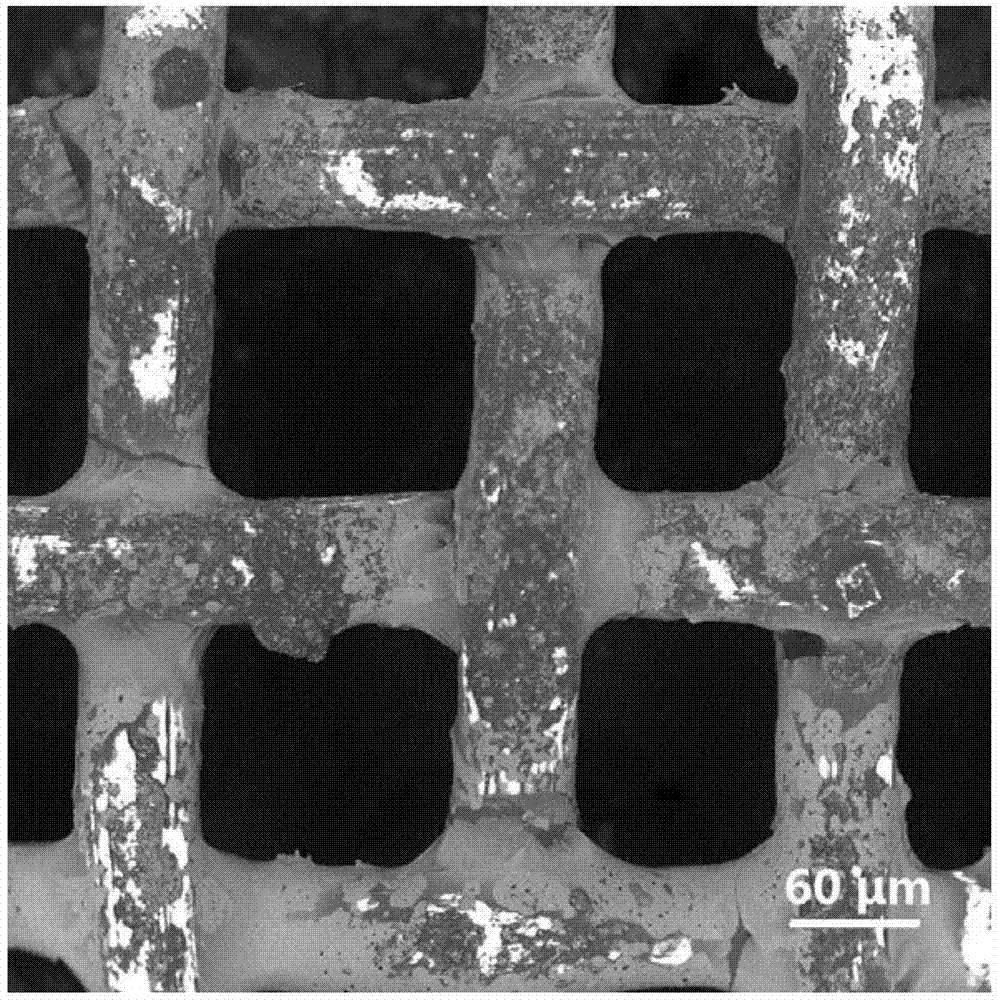

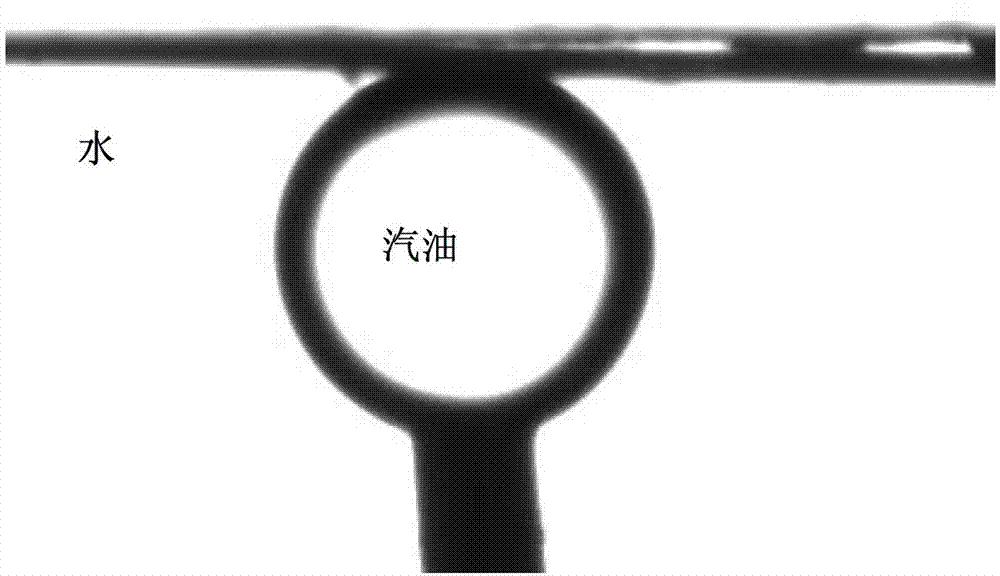

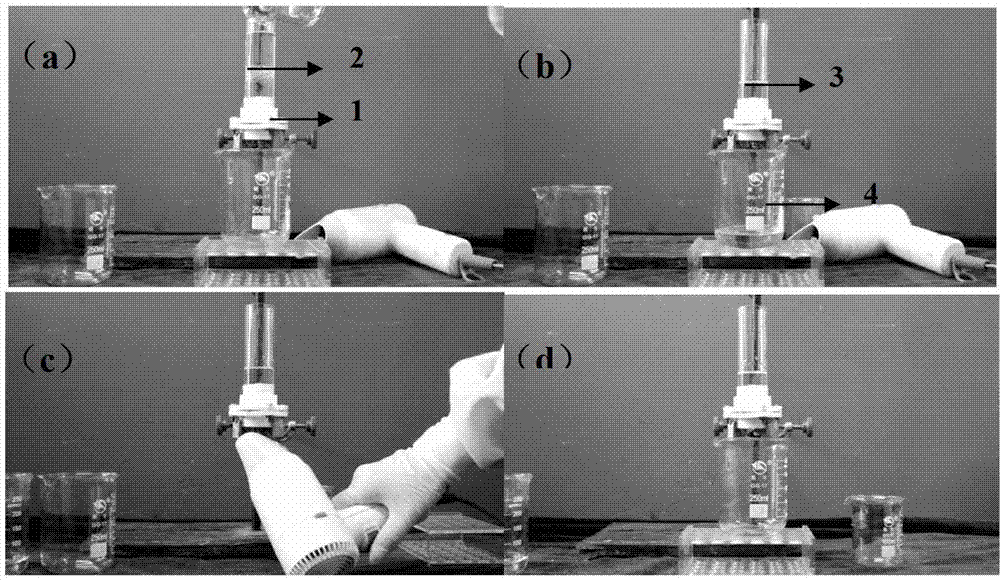

Responsive oil and water separation net film with underwater super lipophobicity property and preparation method thereof

ActiveCN103111096AIncrease speedReduce separation costsLiquid separationCross-linkUltraviolet lights

The invention discloses a responsive oil and water separation net film with an underwater super lipophobicity property and a preparation method thereof. The method comprises the following steps of: (1) dissolving a polymer monomer, a photoinitiator, a cross-linking agent and a thickening agent in water so as to obtain a mixed solution; (2) soaking a fabric net in the mixed solution; and (3) taking out the fabric net, carrying out a polymerization reaction on the soaked fabric net in ultraviolet light the wavelength of which is 365nm so as to obtain a polymer hydrogel coating layer in the fabric net, and then obtain the responsive oil and water separation net film with the underwater super lipophobicity property. The responsive oil and water separation net film with the underwater super lipophobicity property, provided by the invention, has the advantages that the oil-contaminated water can be separated, meanwhile, the temperature and pH dual responsive characteristics are realized, the controllable oil and water separation is realized, a separation device is simplified, and the separation cost is saved.

Owner:TSINGHUA UNIV

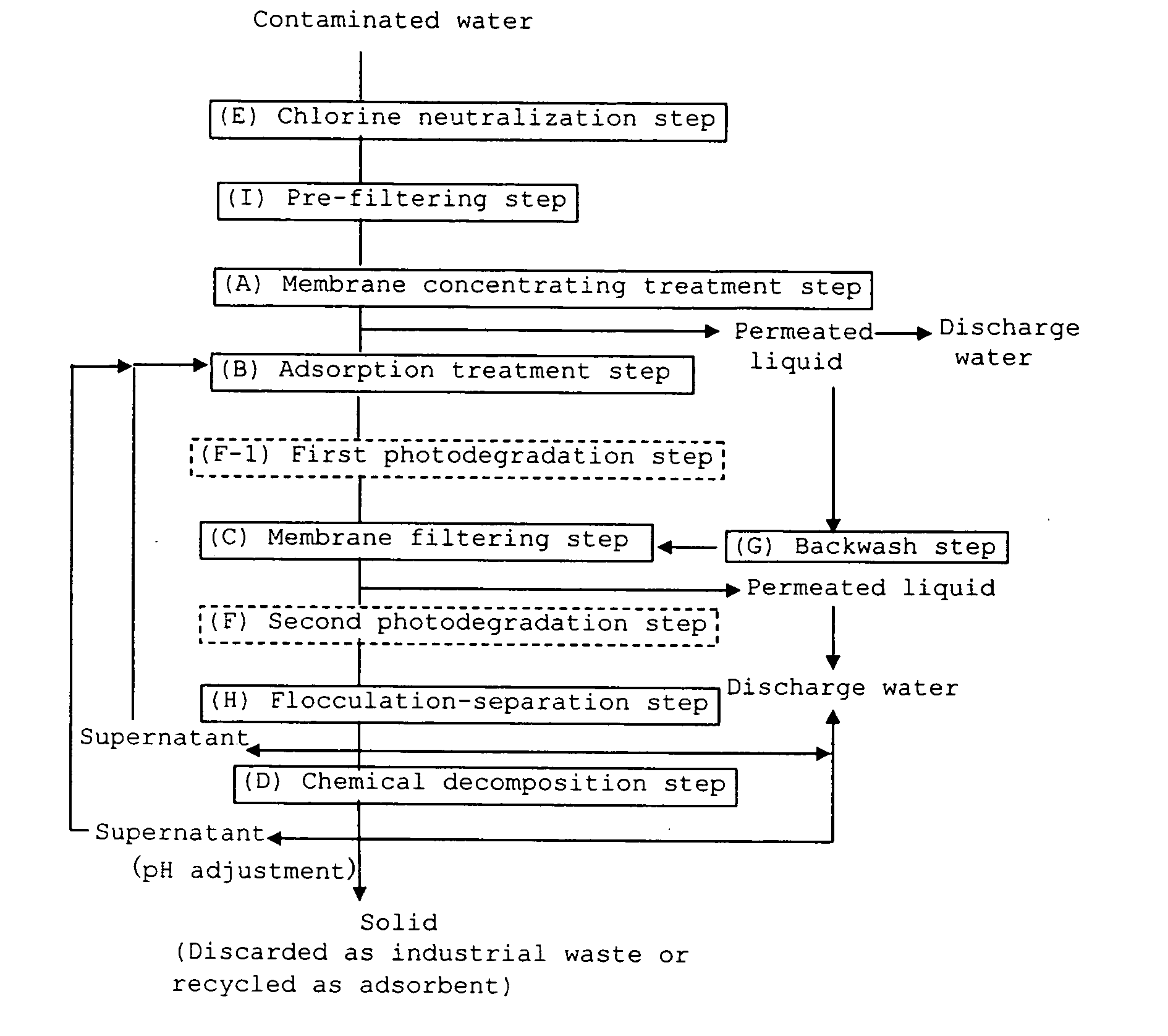

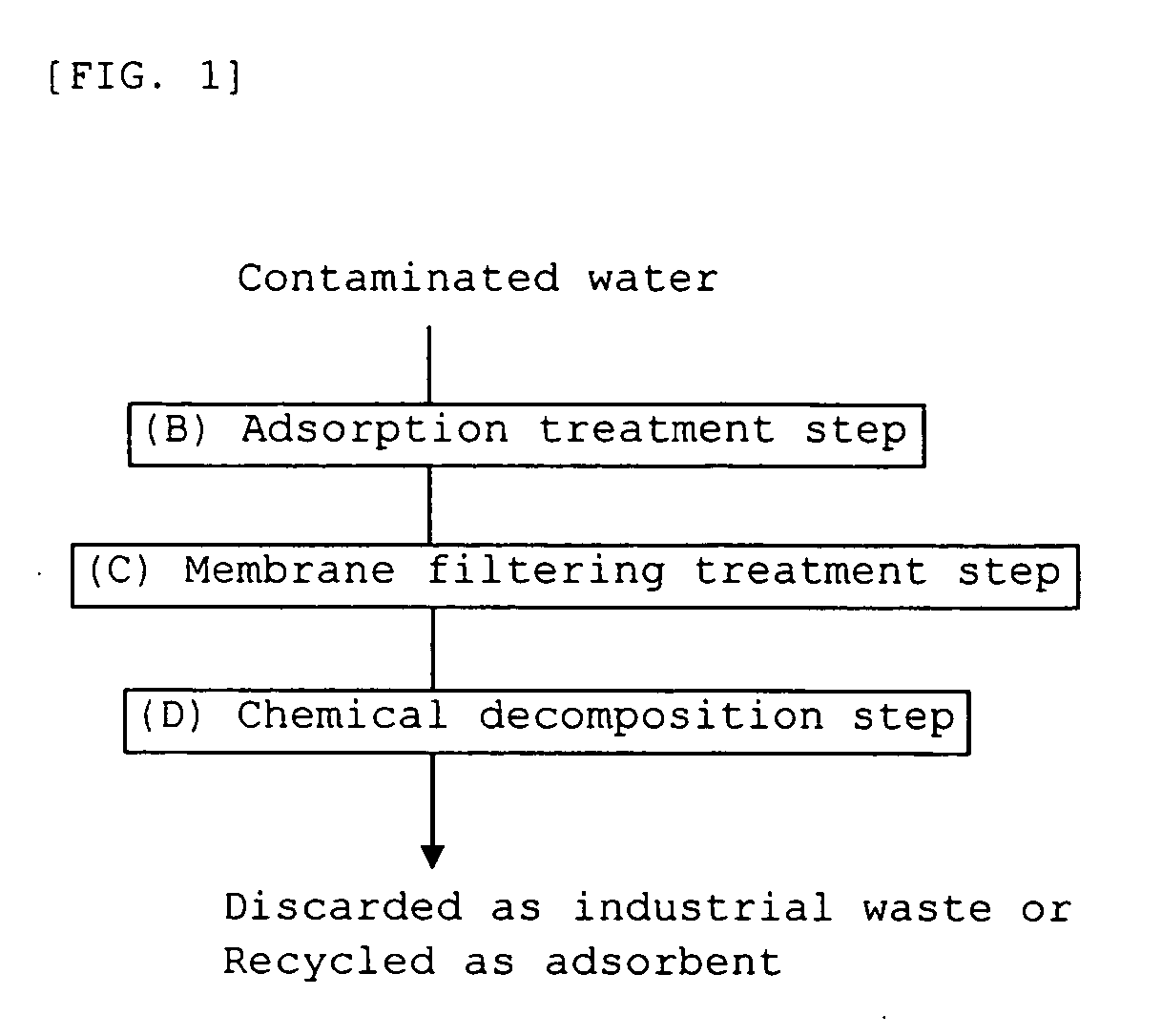

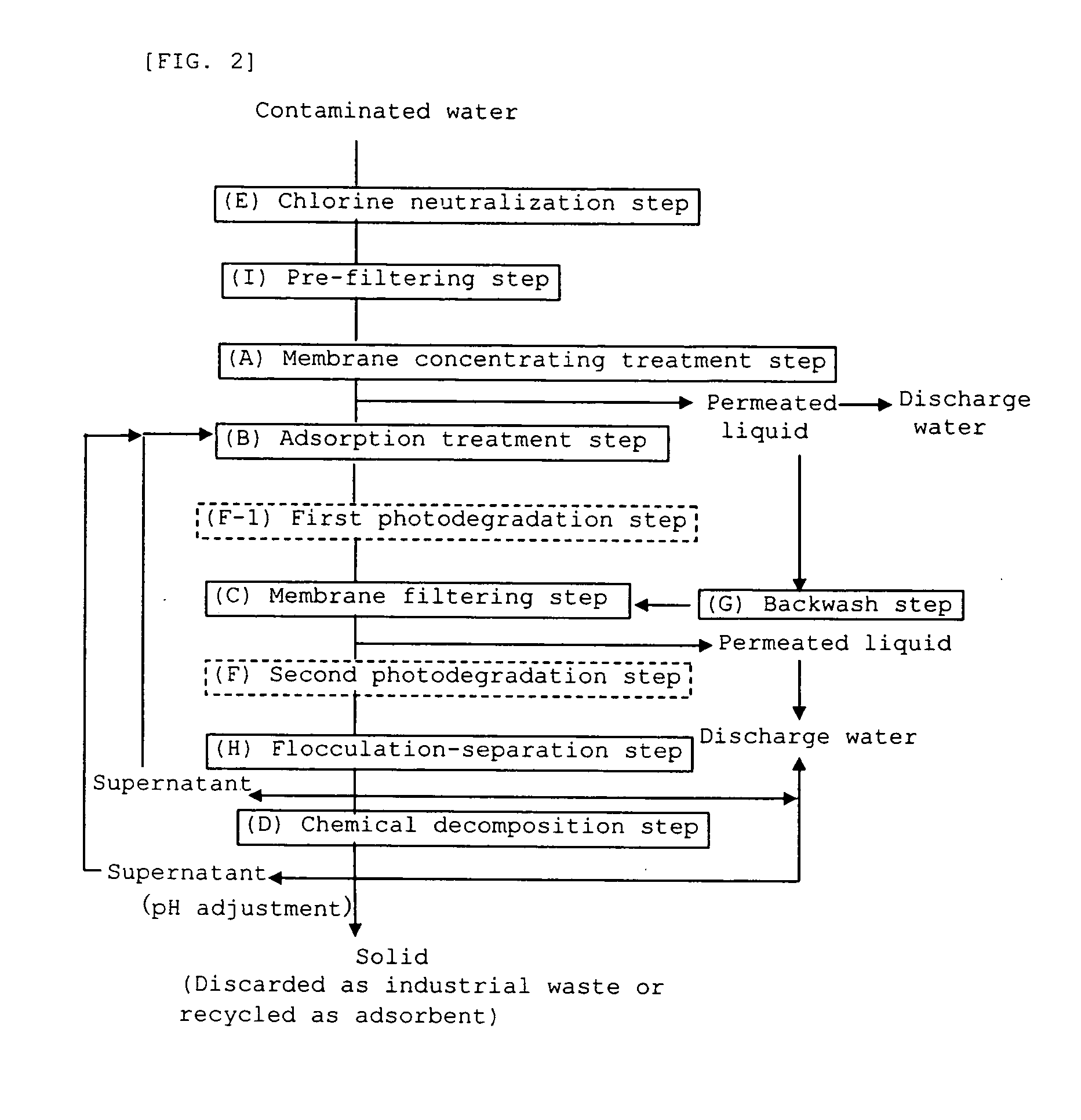

Method for treating raw water containing hardly decomposable substance

InactiveUS20070119779A1Efficient decompositionReduce concentrationUltrafiltrationSolid sorbent liquid separationDesorptionSorbent

Provided a method for treating hardly-decomposable-substance-containing water, in which hardly decomposable substances such as dioxins, contained in contaminated water (treatment raw water) are concentrated and rendered harmless by providing the steps of (B) adding an adsorbent to water containing a hardly decomposable substance (treatment raw water) to cause the hardly decomposable substance to be adsorbed on the adsorbent (adsorption treatment step), (C) separating a permeated liquid through a filter membrane to concentrate the adsorbent adsorbing the hardly decomposable substance (membrane filtering treatment step), and (D) chemically decomposing the hardly decomposable substance adsorbed on the concentrated adsorbent with a peroxide without any operation of desorption from the adsorbent (chemical decomposition step), and the method can be applied to water containing a reducing substance such as bisulfate that neutralize free chlorine and can render the hardly decomposable substances harmless efficiently at a low cost without being limited by properties of the hardly decomposable substances contained.

Owner:IDEMITSU KOSAN CO LTD

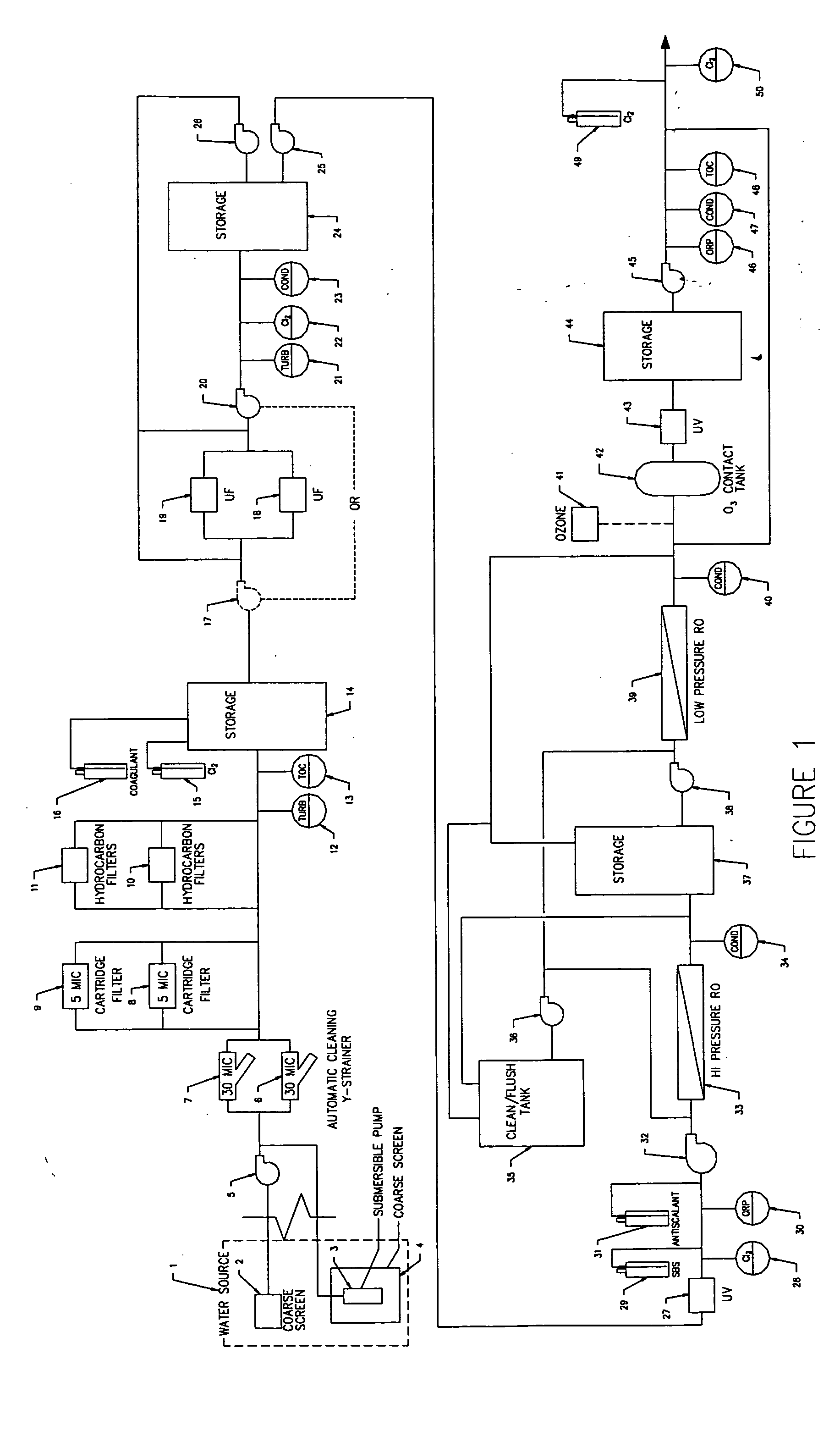

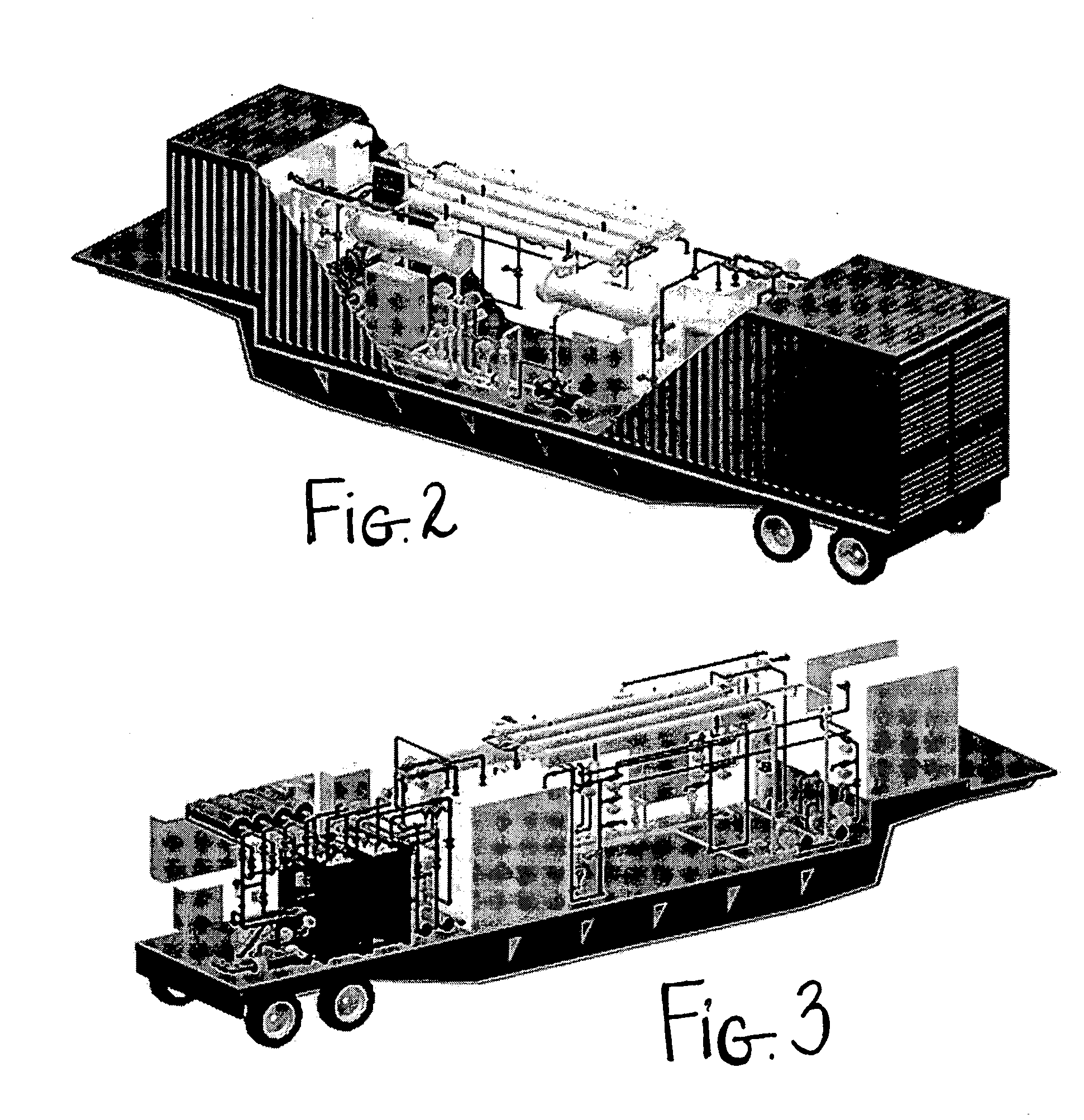

System and method for water purification

InactiveUS6824695B2Treatment using aerobic processesSedimentation separationBiological activated carbonActivated carbon filtration

A self-contained, portable water purification system, including (a) an ozone supply, (b) an ozone contact chamber mixing a contaminated or potentially contaminated water stream with ozone generated by such ozone supply, (c) an ozone destruction unit for destructing ozone contained in the water stream and converting said water stream into an oxygen-rich and ozone-depleted water stream, and (d) a downstream biologically active carbon filter, for receiving such oxygen-rich and ozone-depleted water stream and biologically destructing at least a portion of contaminants contained therein.

Owner:TEMPEST ENVIRONMENTAL SYST

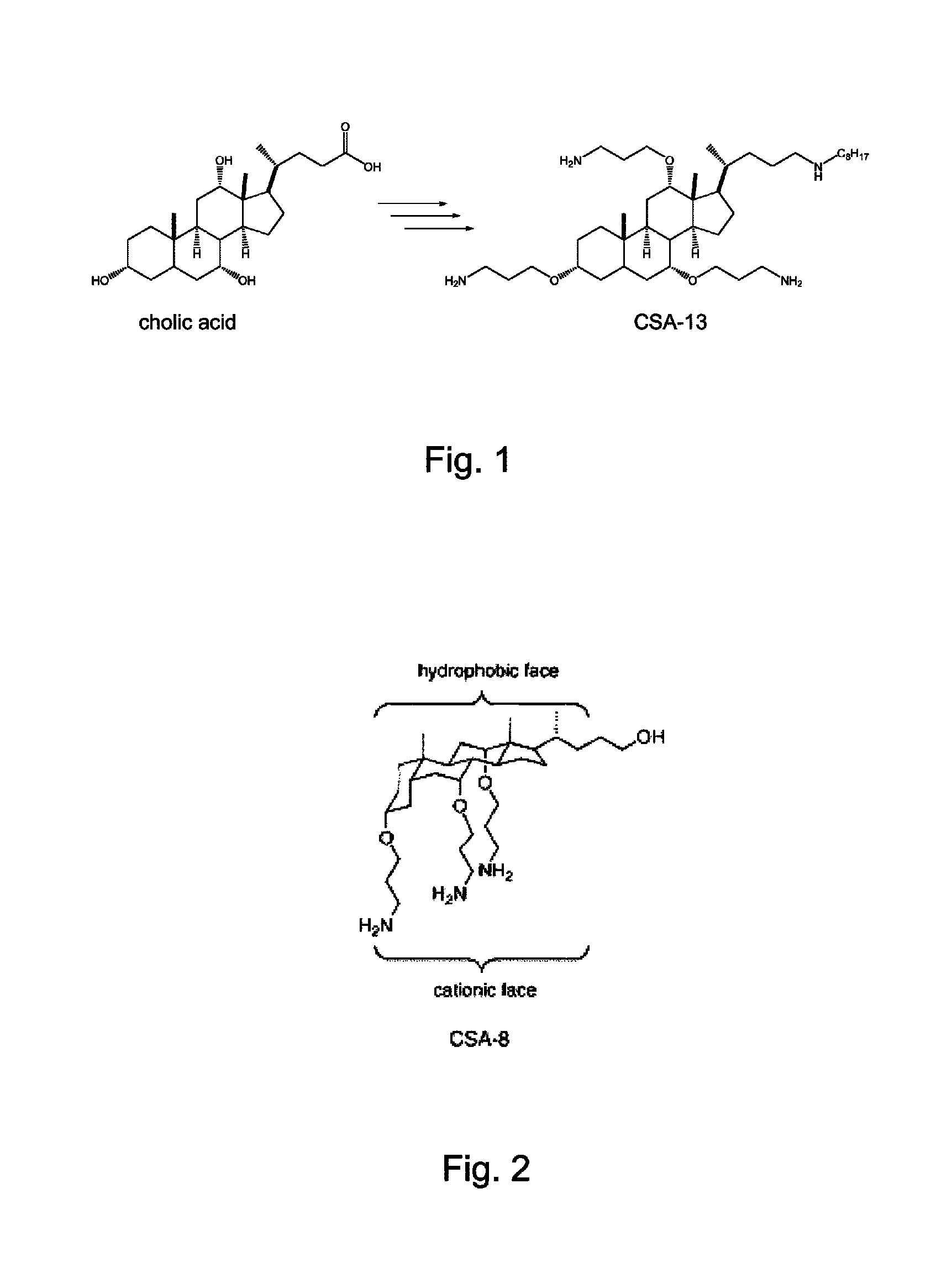

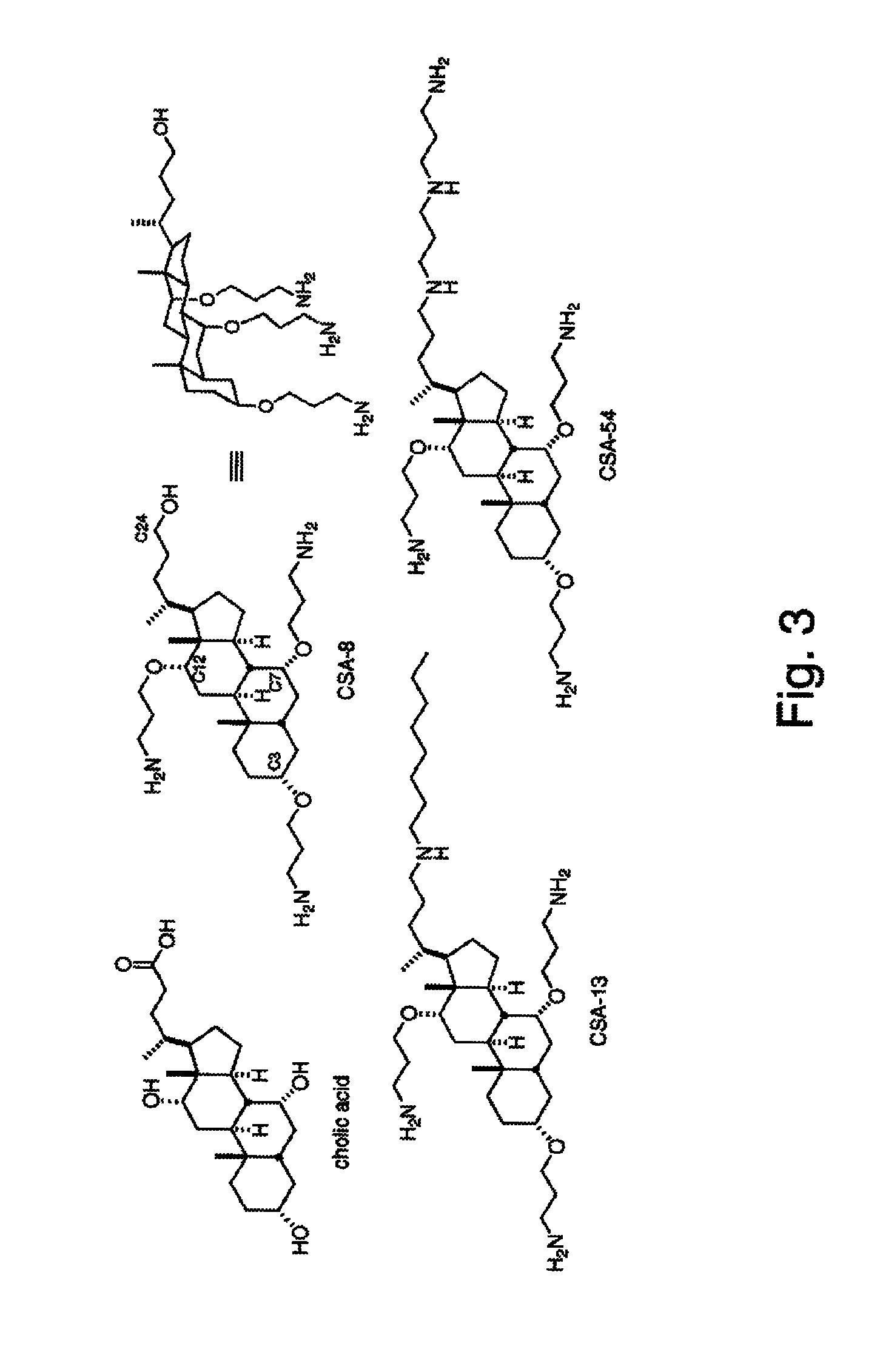

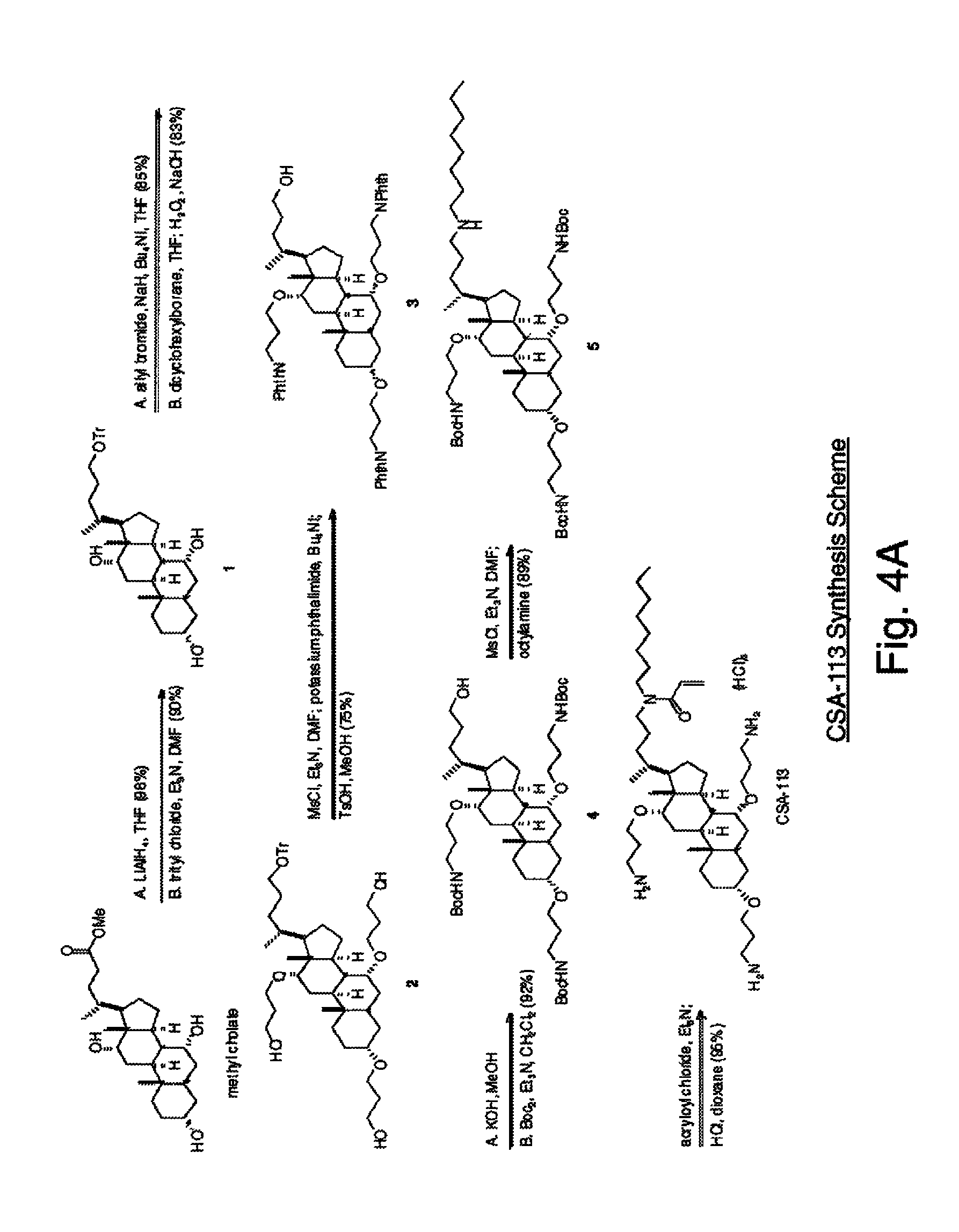

Biofouling-resistant ceragenin-modified materials and structures for water treatment

This invention relates to methods for chemically grafting and attaching ceragenin molecules to polymer substrates; methods for synthesizing ceragenin-containing copolymers; methods for making ceragenin-modified water treatment membranes and spacers; and methods of treating contaminated water using ceragenin-modified treatment membranes and spacers. Ceragenins are synthetically produced antimicrobial peptide mimics that display broad-spectrum bactericidal activity. Alkene-functionalized ceragenins (e.g., acrylamide-functionalized ceragenins) can be attached to polyamide reverse osmosis membranes using amine-linking, amide-linking, UV-grafting, or silane-coating methods. In addition, silane-functionalized ceragenins can be directly attached to polymer surfaces that have free hydroxyls.

Owner:BRIGHAM YOUNG UNIV +1

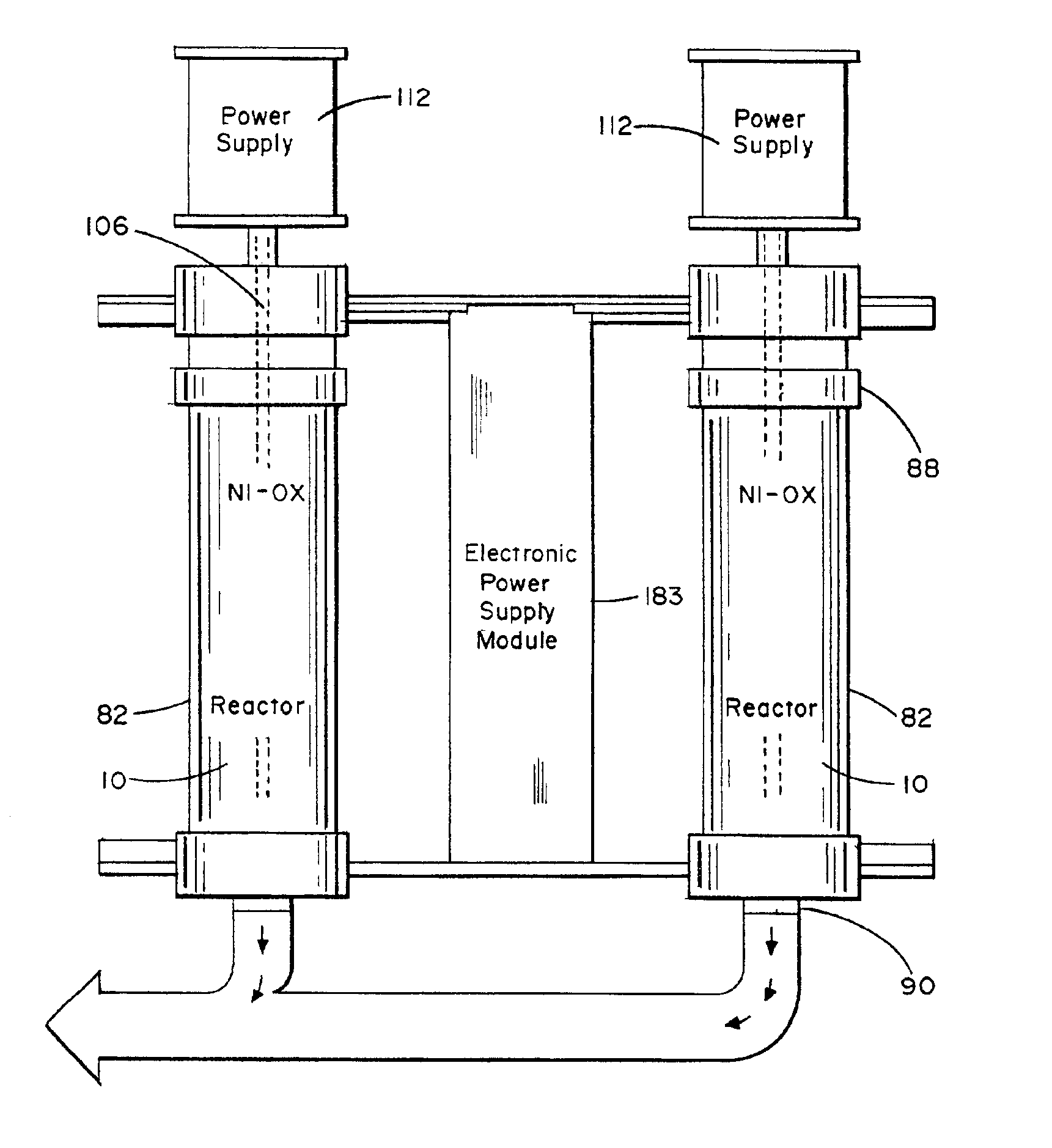

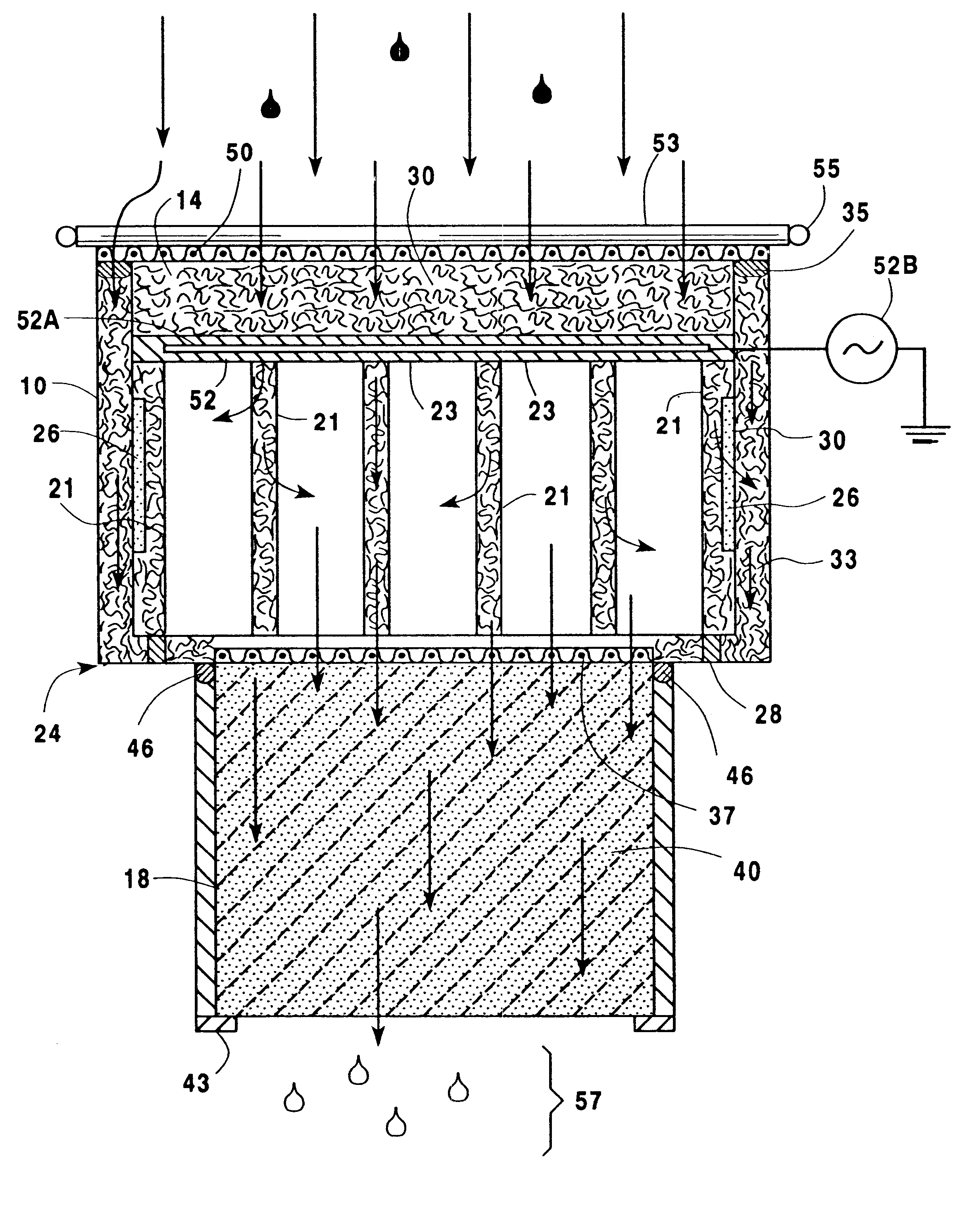

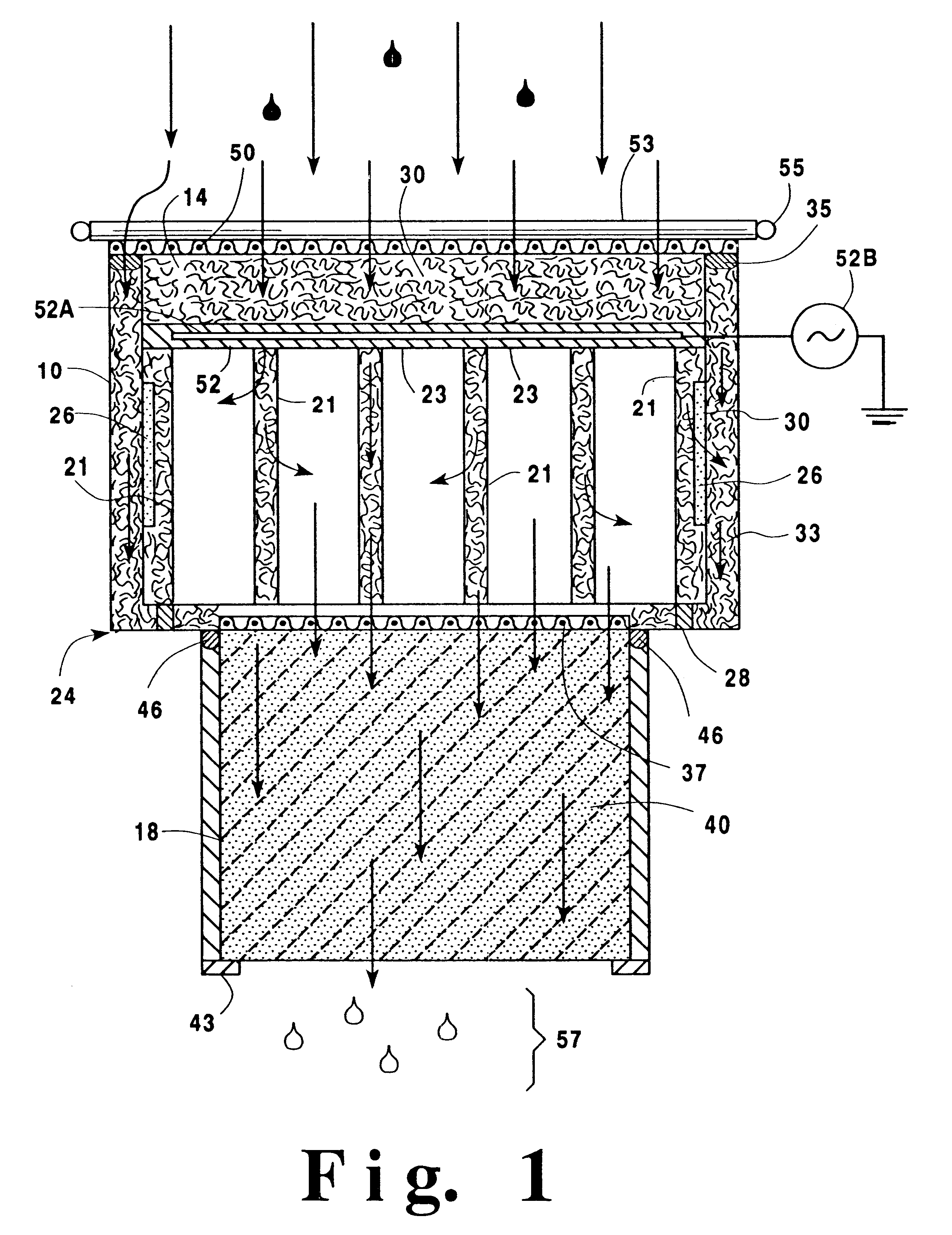

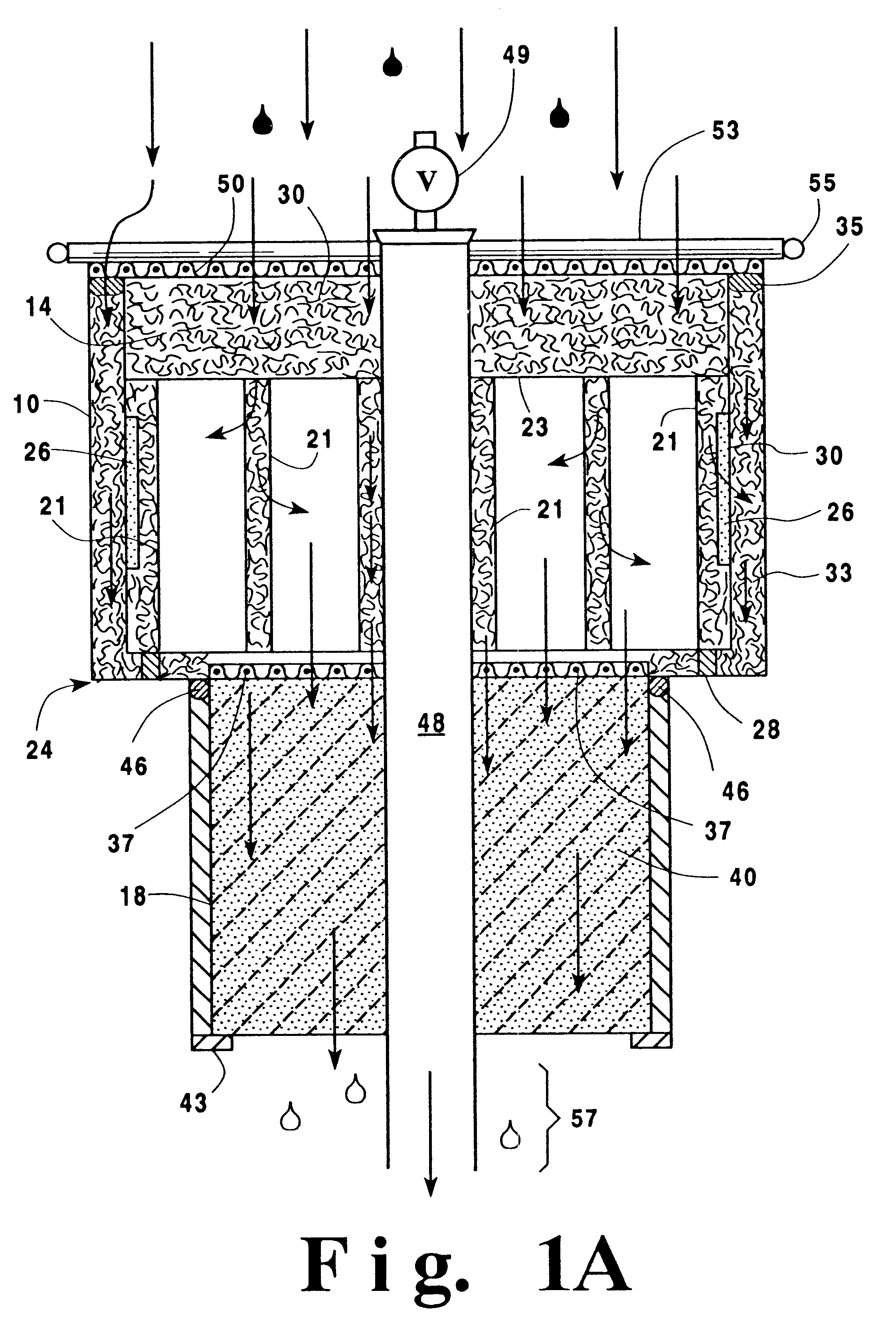

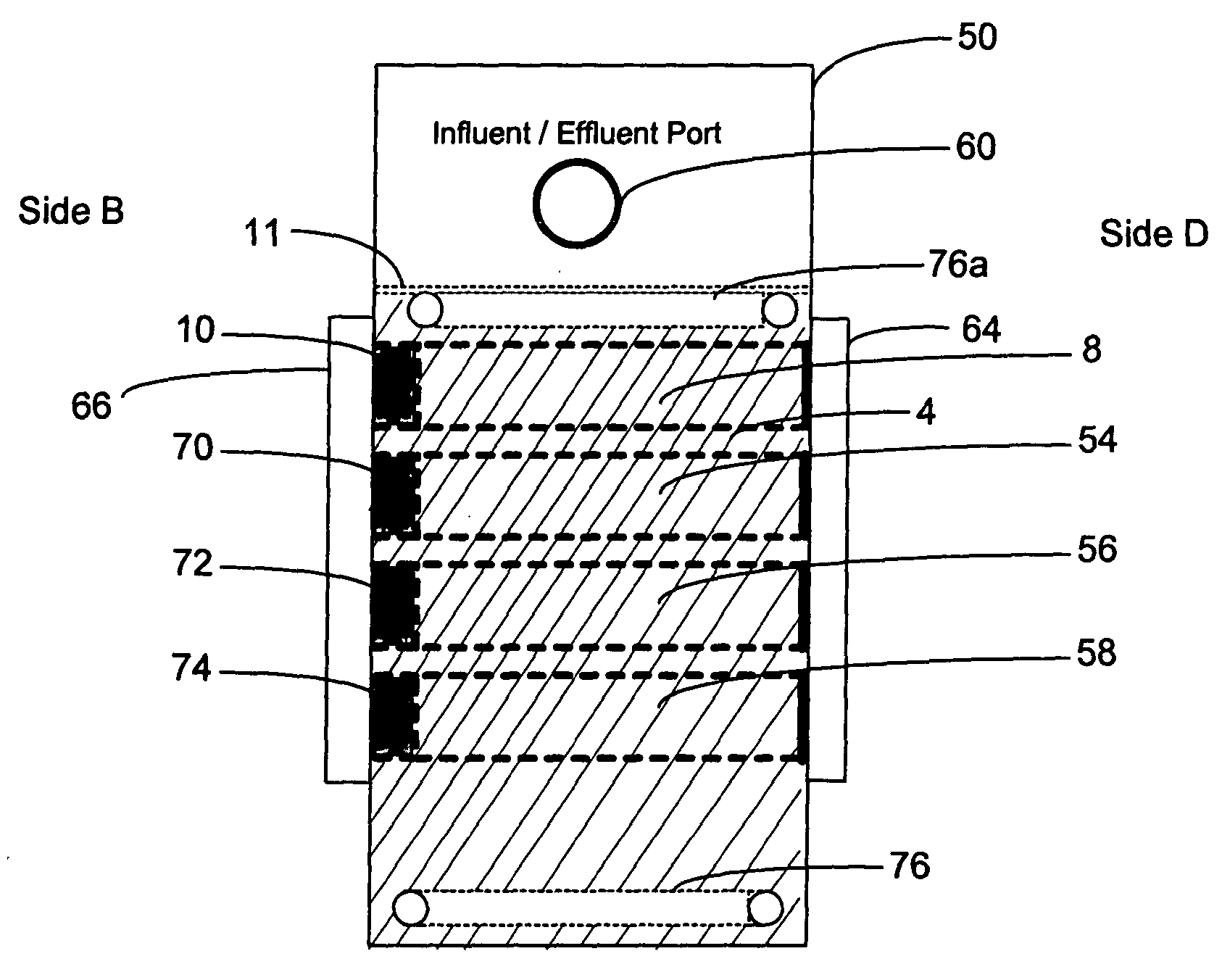

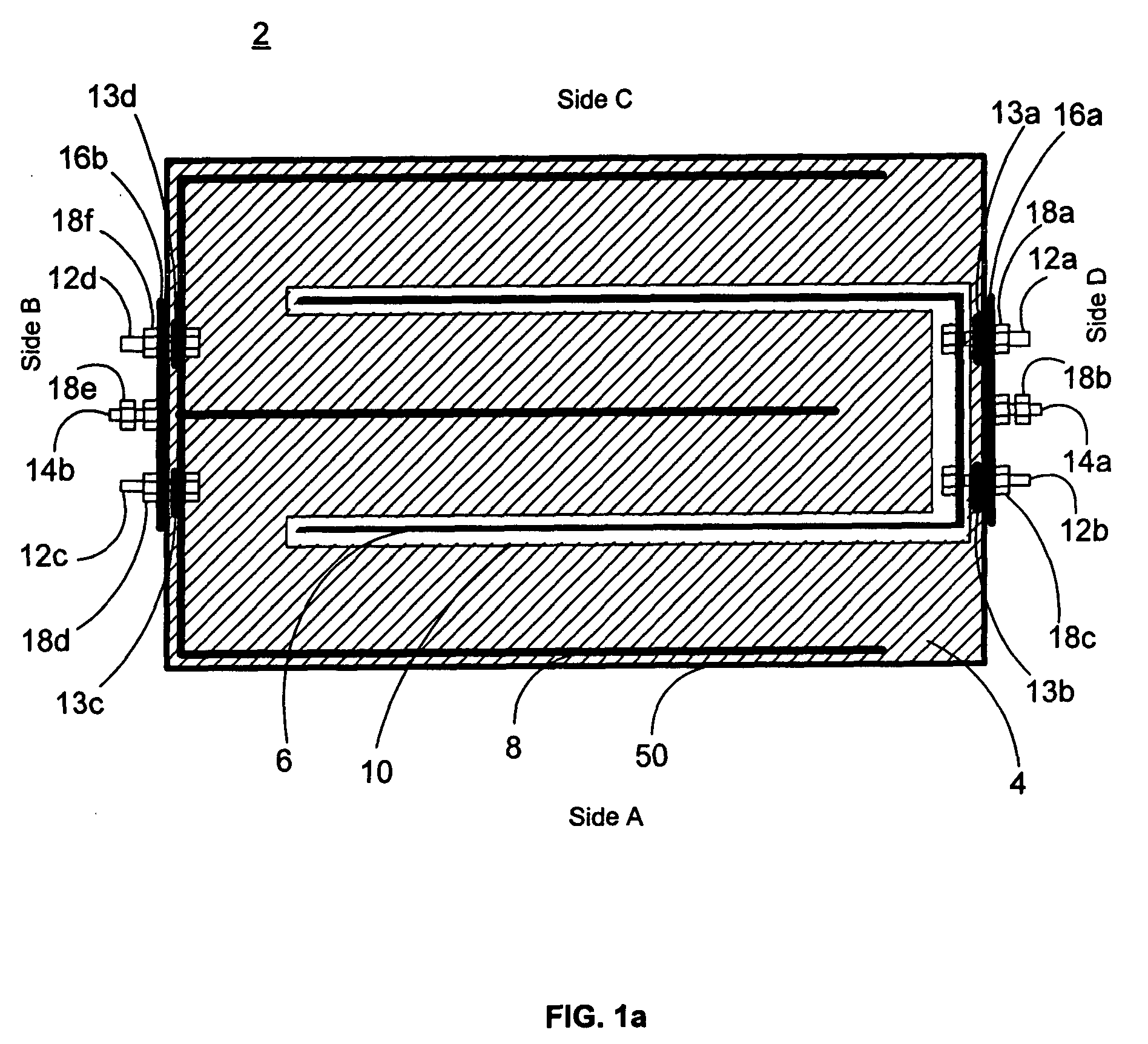

Electrolytic cell stack with porous surface active electrode for removal of organic contaminants from water and method to purify contaminated water

InactiveUS20050034978A1Overcome limitationsPromote repairCellsWater treatment compoundsWaste streamSurface water

A wet oxidation / reduction electrolytic cell stack, system, and method for the remediation of contaminated water is disclosed. A porous electrode of large surface area produces powerful oxidizing agents in situ without having to add any reagents, oxidizers, or catalysts to the water to be treated. Further, by the appropriate selection of electrode material, organic contaminants may be absorbed onto the surface of the electrode and subsequently oxidized to provide a dynamically renewable porous electrode surface. Flow rates, and power requirements may be tailored to the specific moieties to be removed, thus allowing local treatment of specific waste streams resulting in direct discharge to a publicly owned treatment works (POTW) or surface water discharge. A novel feature of this invention is the ability to remove both organic and metal contaminants without the addition of treatment reagents or catalysts.

Owner:EXTI

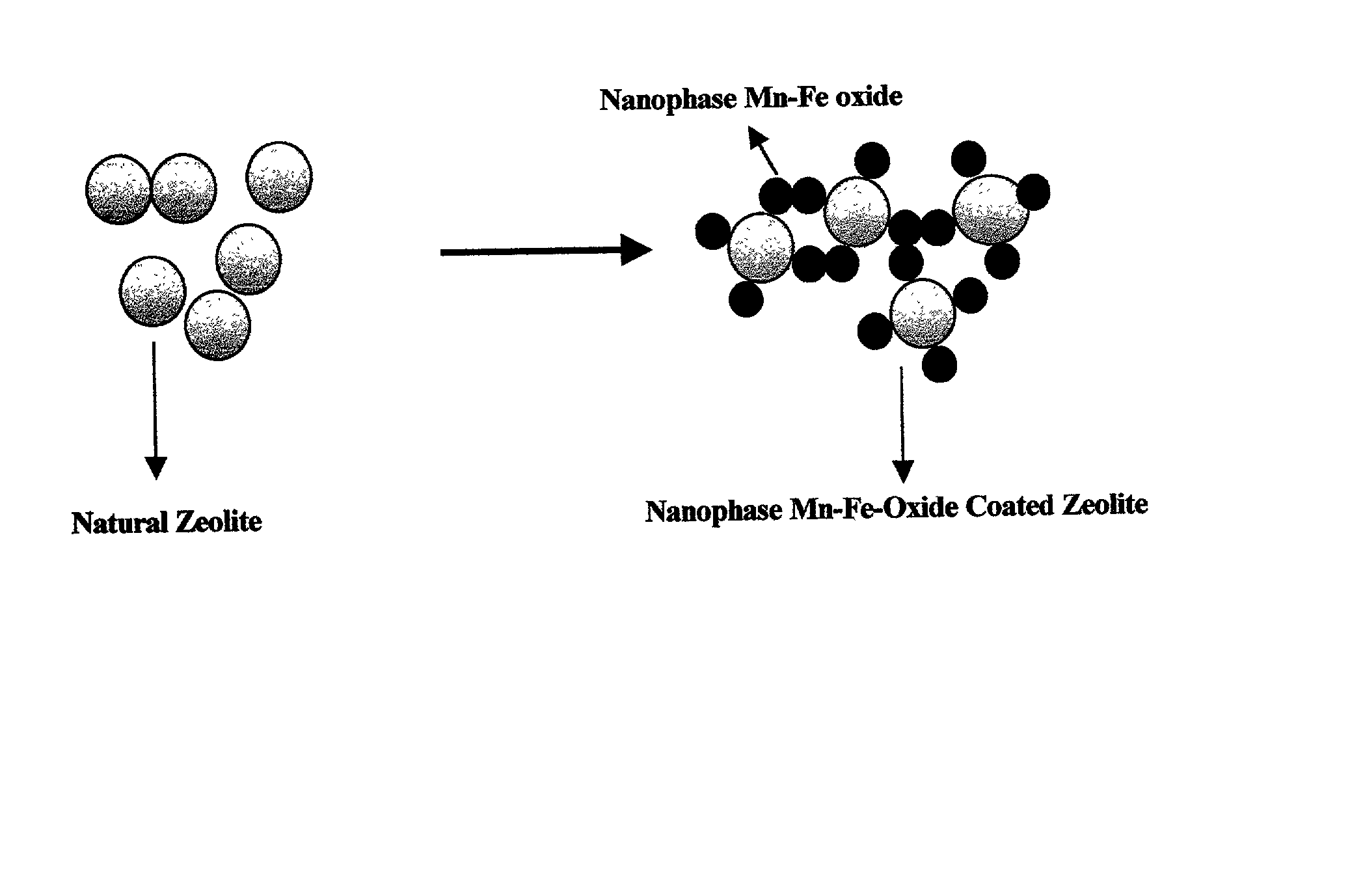

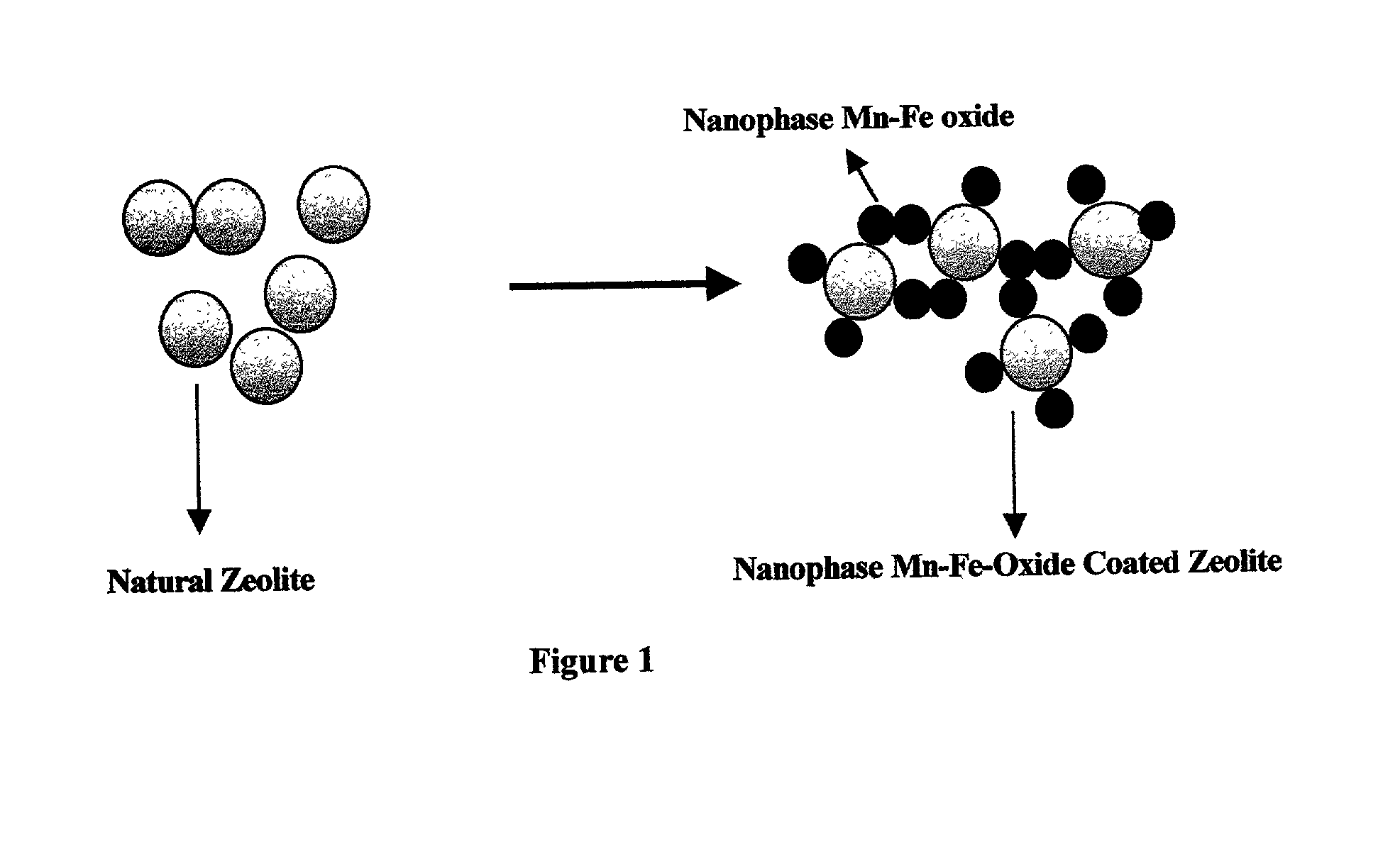

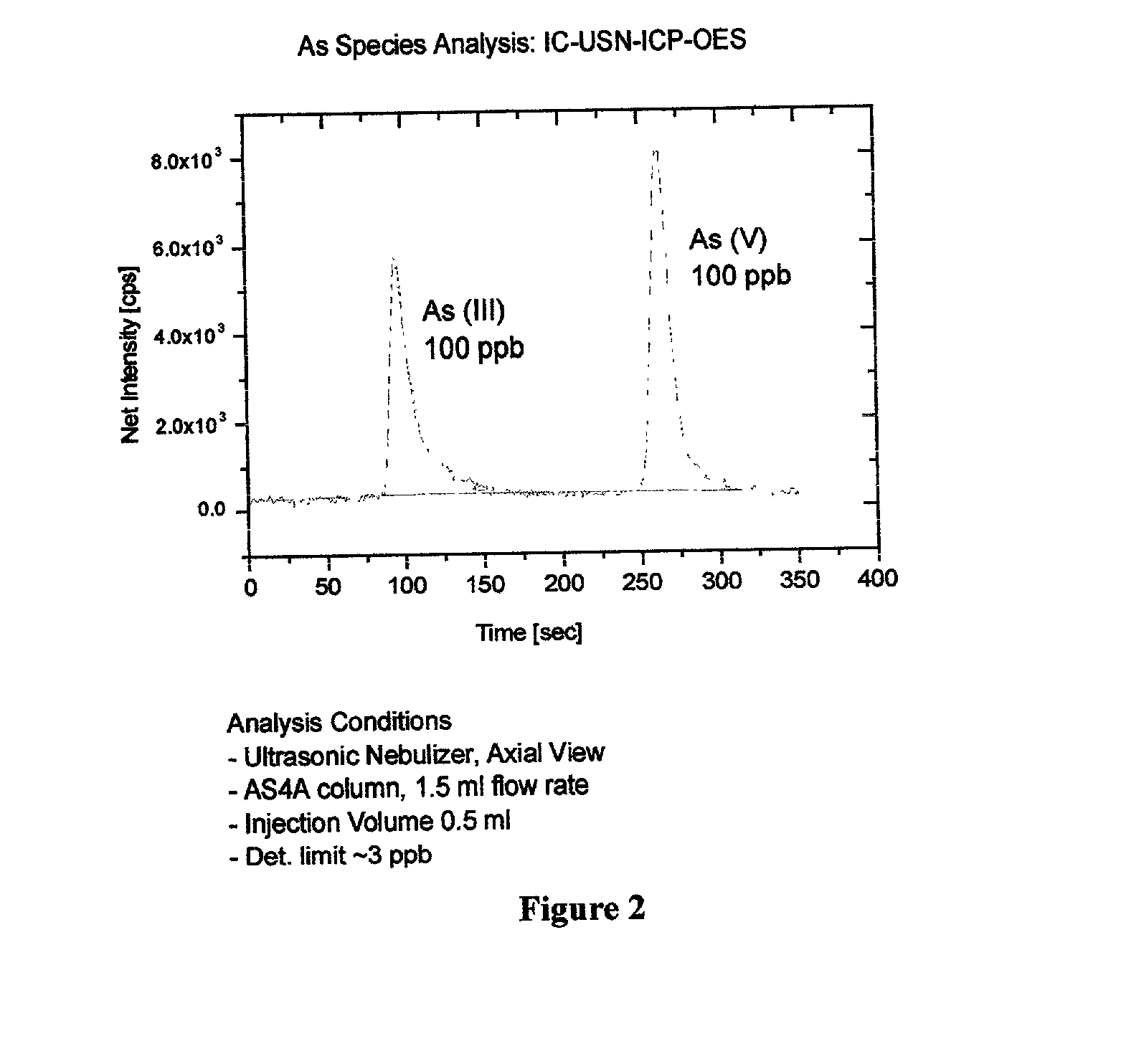

Absorbent for arsenic species and method of treating arsenic-contaminated waters

InactiveUS20030116504A1Maintain aestheticsReduce the amount requiredSolid sorbent liquid separationWater/sewage treatment by neutralisationArsenic pollutionPotable water

The present invention is directed to an adsorbent for removing arsenic species from ground water and / or surface water systems. Such adsorbent removes both As(III) and As(V), thereby providing potable water. Also provided is a method and / or device (e.g., filter) for removing arsenic species from contaminated waters utilizing such adsorbent.

Owner:CHK GROUP

Method for preparing salt-resistant stain-resistant bentonite with adsorption function

ActiveCN104030308AIncrease the areaHigh ion exchange capacitySilicon compoundsContaminated waterStain

The invention provides a method for preparing salt-resistant stain-resistant bentonite with adsorption function. The method comprises the following steps: performing sodium treatment, namely milling natural calcium bentonite to pass through a sieve with the granularity of 50-150 meshes, adding the bentonite into an aqueous solution of a sodium treatment agent, stirring, performing sodium treatment and reacting at the temperature of 50-90 DEG C for 1-4 hours, and drying to obtain sodium-based bentonite; and modifying, namely milling the sodium-based bentonite to pass through a sieve with the granularity of 150-250 meshes, drying and mixing with a modifier at normal temperature, and obtaining the product. The bentonite prepared by the method is high in expansibility, has high salt resistance, high stain resistance and good adsorption performance, can be used for underground seepage prevention of high salinity complex water bodies and also can be used for treating heavy metal ions and organic pollutants in contaminated water.

Owner:HOHAI UNIV

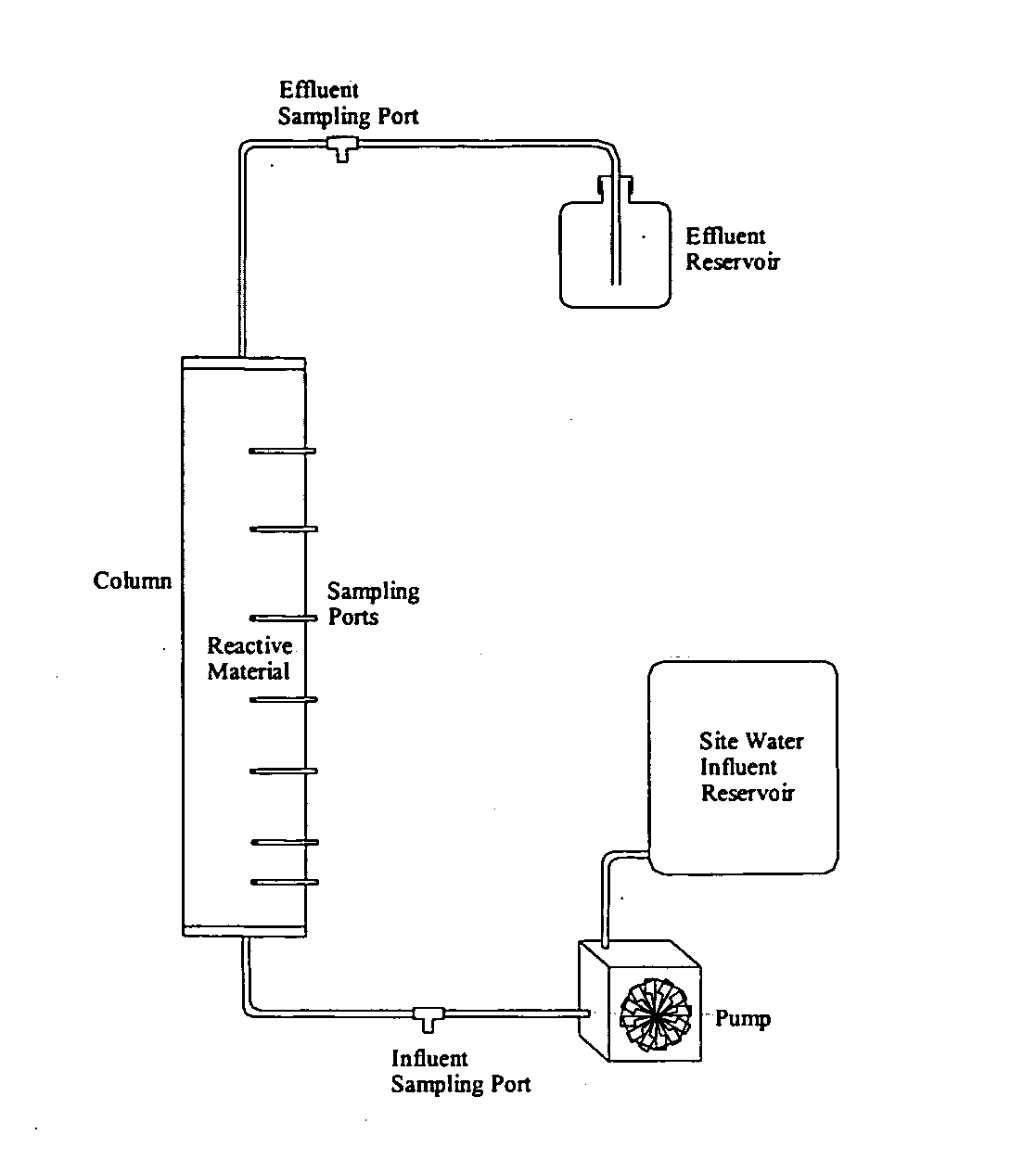

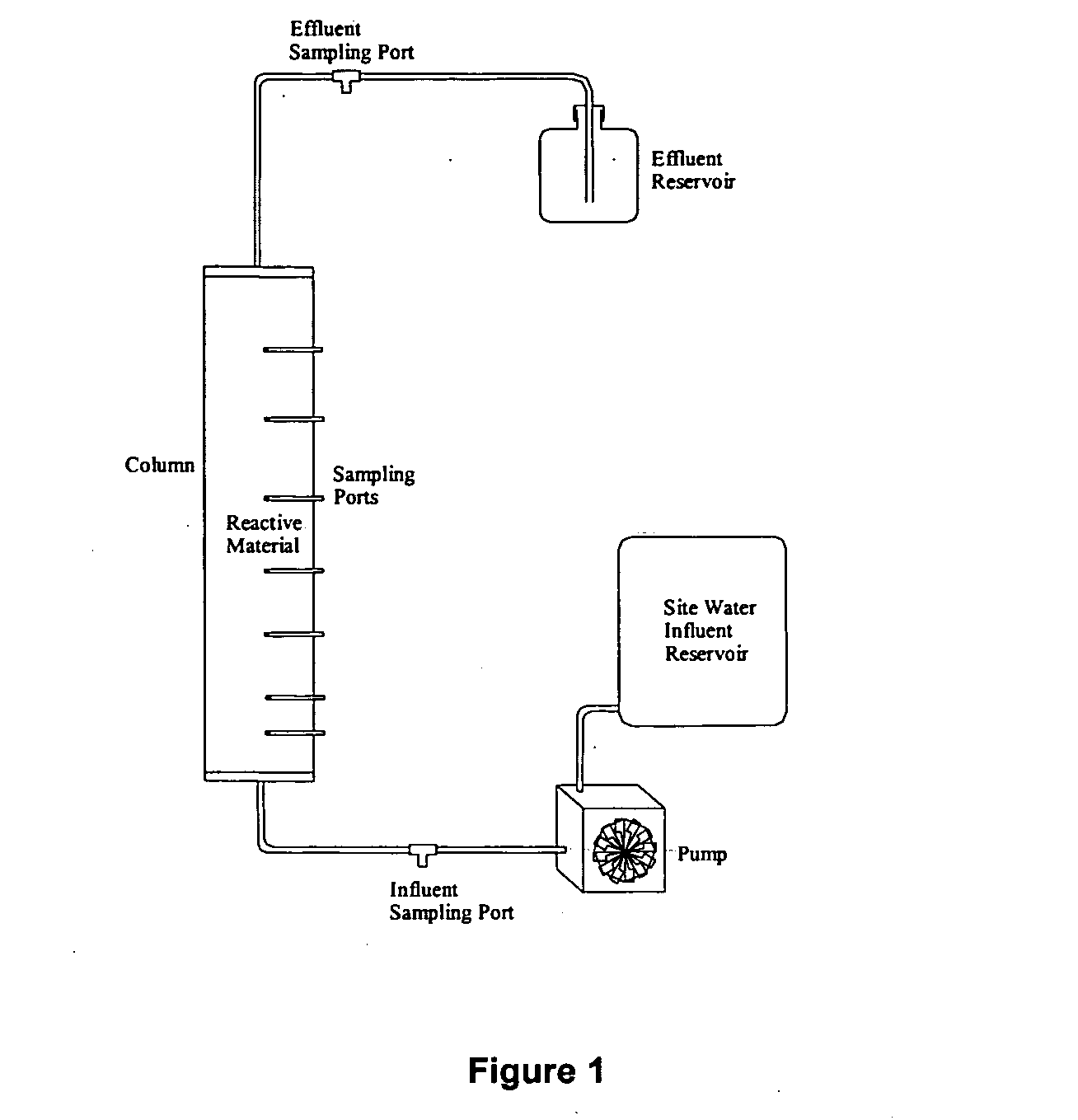

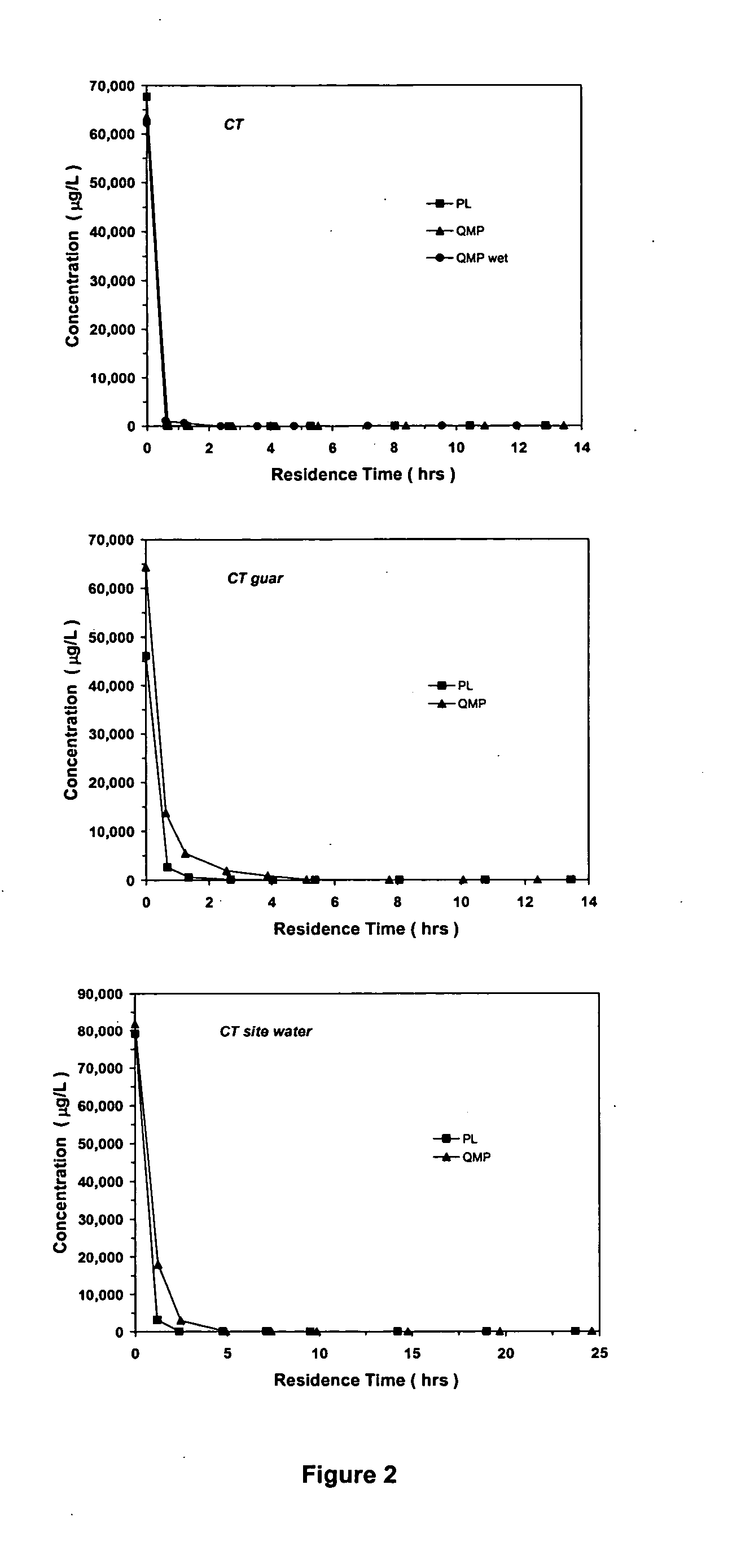

Process for treating water using atomized ferrous powders containing 0.25 to 4 wt% carbon and 1 to 6 wt% oxygen

A process for treating contaminated water in which water contaminated with a volatile organic compound is placed within a volume of iron powder granules which have been water atomized by striking a stream of molten iron with water jets and drying the resulting iron powder. The iron powder granules contain iron, carbon and oxygen, wherein carbon is contained from 0.25 to 4 wt. % and oxygen is contained from 1 to 6 wt. %. The contaminated water is passed through or contacts the iron powder granules, whereby the contaminant is remediated.

Owner:QUEBEC METAL POWDERS

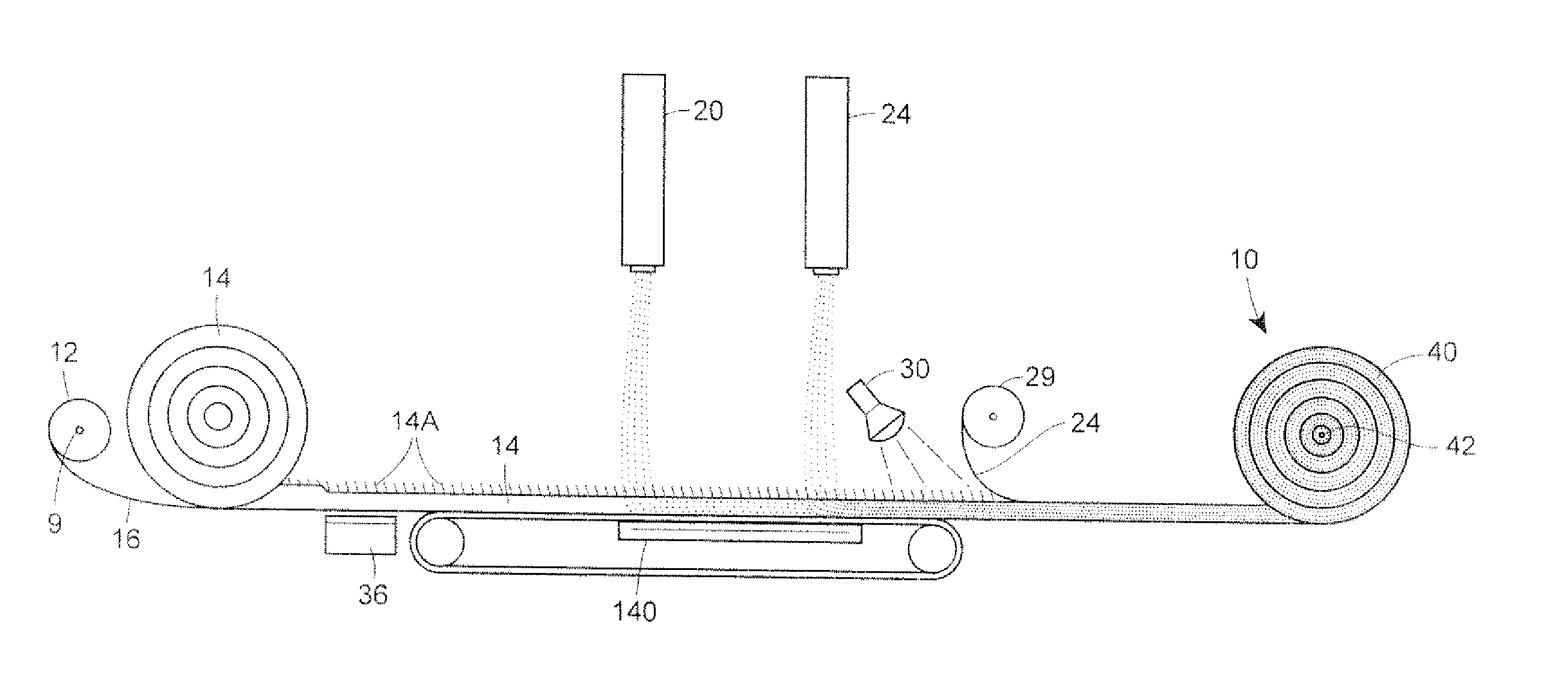

Contaminant-reactive geocomposite mat and method of manufacture and use

InactiveUS20070206994A1Minimize breakageHollow inflatable ballsHollow non-inflatable ballsPorosityFiber

Reactive geocomposite mats, and their method of manufacture, for treating contaminants in sediment, soil or water that allow the passage of essentially non-contaminated water therethrough. The geocomposite mat includes a pre-formed woven or non-woven geotextile, that is needlepunched to an outer geotextile sheet layer to provide a high loft, structurally secured, pre-formed geotextile having a thickness of about 6 mm to about 200 mm, and having, a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminant-sorptive material, or a contaminant-neutralizing material (hereinafter collectively referred to as “contaminant-reactant material” or “contaminant-reactive material”) throughout its thickness, or in any portion of the thickness across its entire major surface(s). The powdered or granular contaminant-reactive material is disposed within the pores of the previously formed, high loft geotextile mat to surround the fibers, e.g., by vacuum or vibrating the high loft mat while in contact with the contaminant-reactive material to allow the powdered or granular contaminant-reactive material to flow by gravity into the pores of the previously formed, needlepunched geotextile. A liquid-permeable outer geotextile sheet then is secured to the filled geotextile, preferably by heating upwardly extending fibers of the pre-formed geotextile mat to prevent the powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

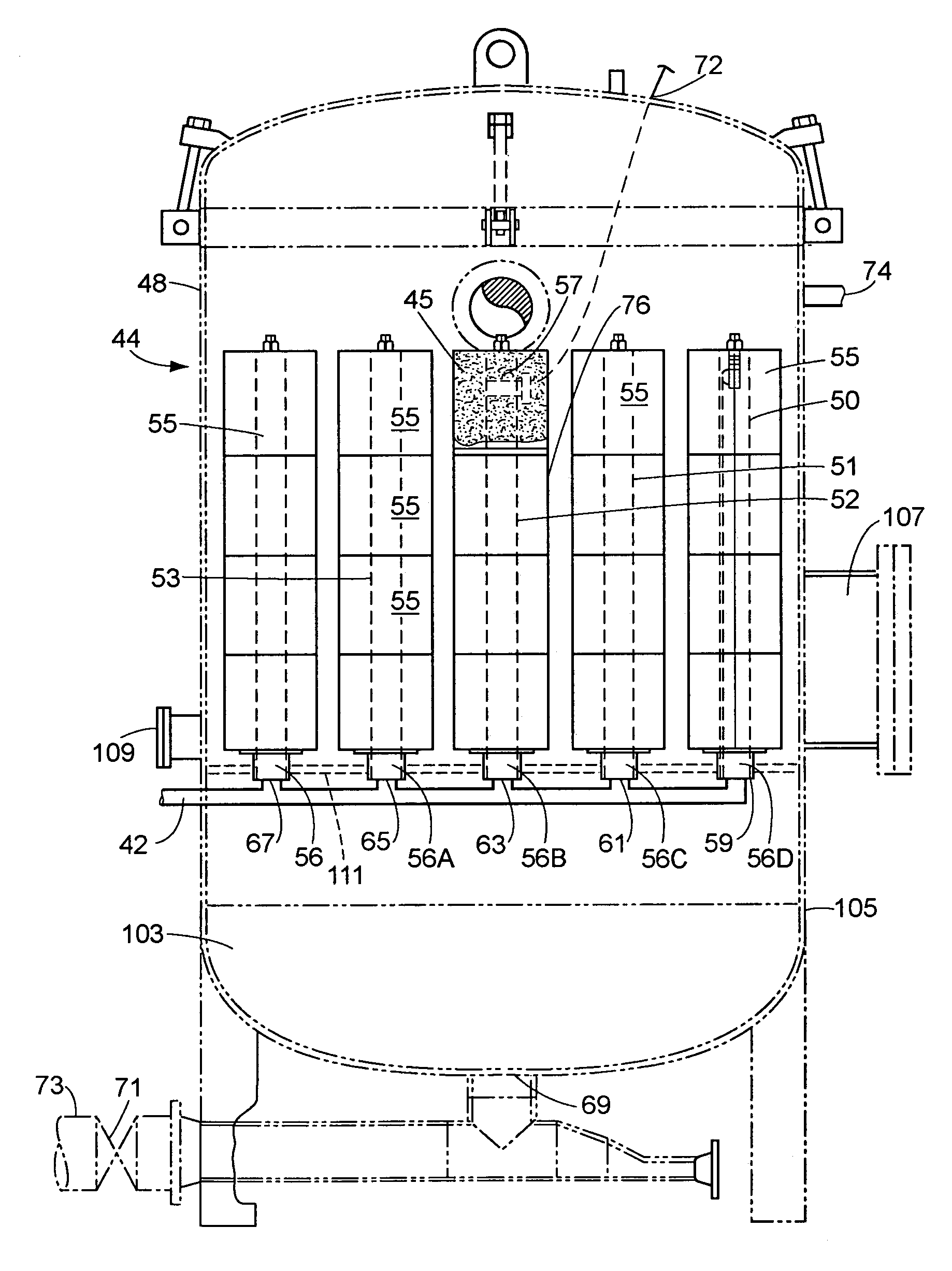

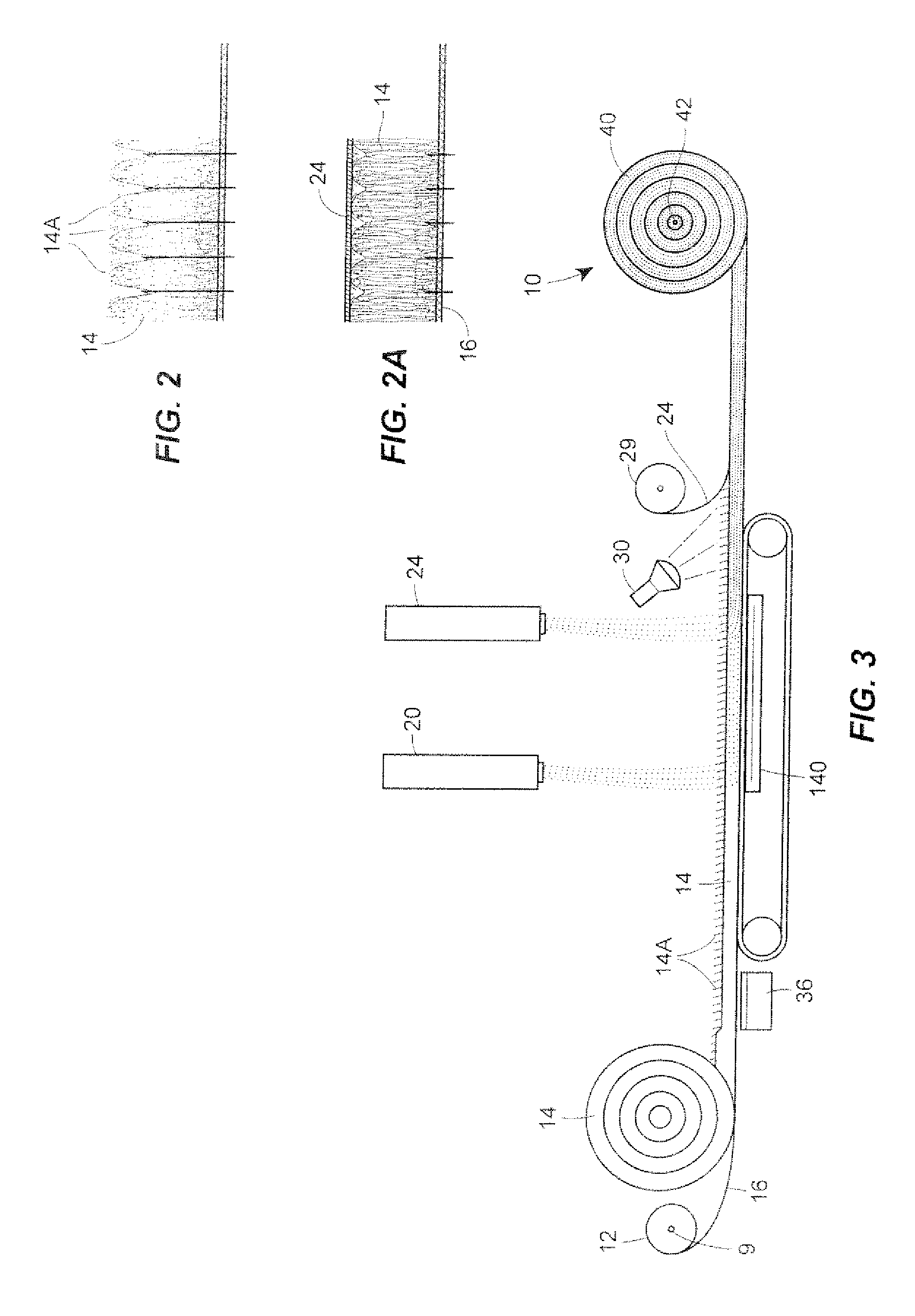

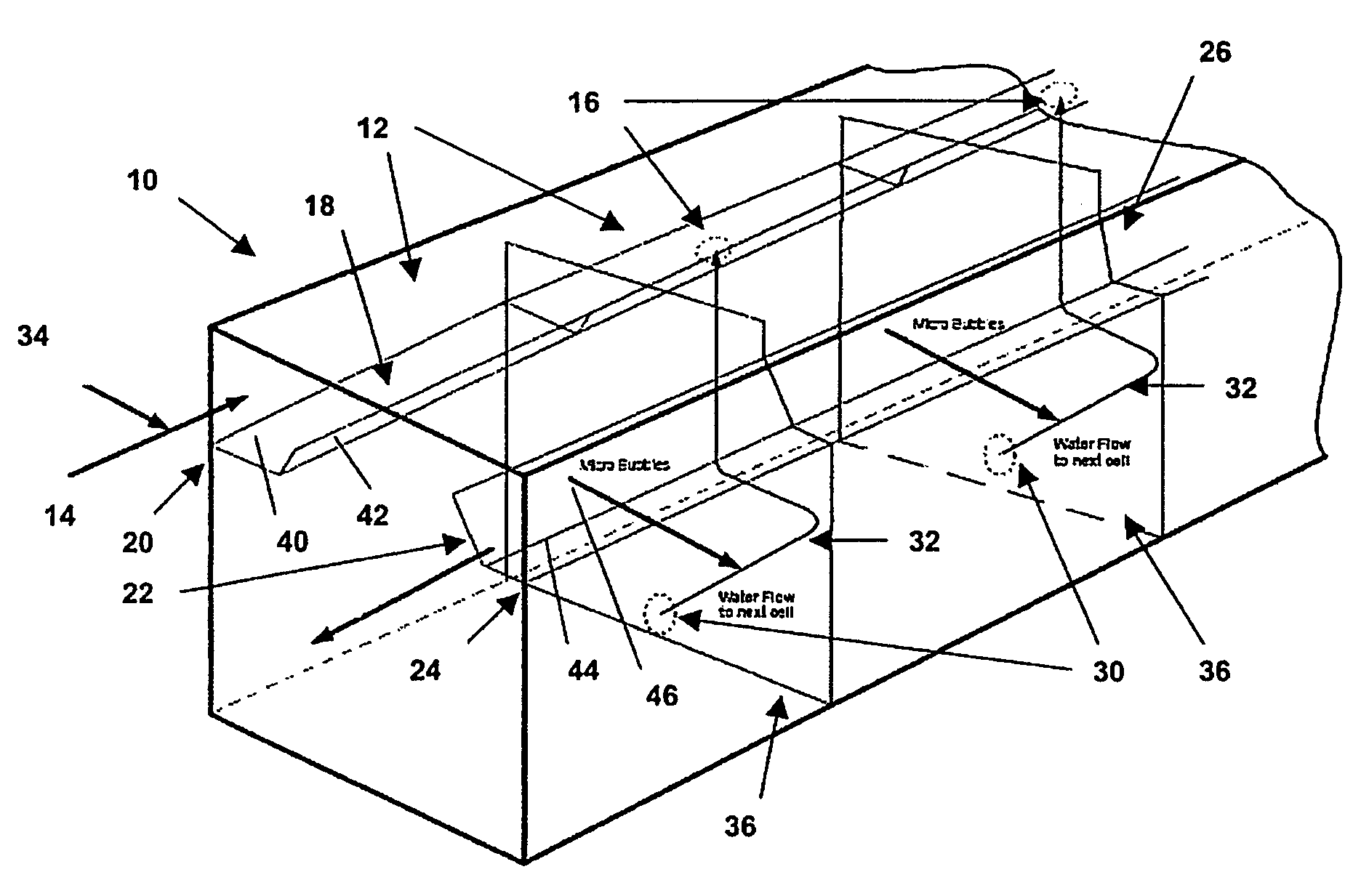

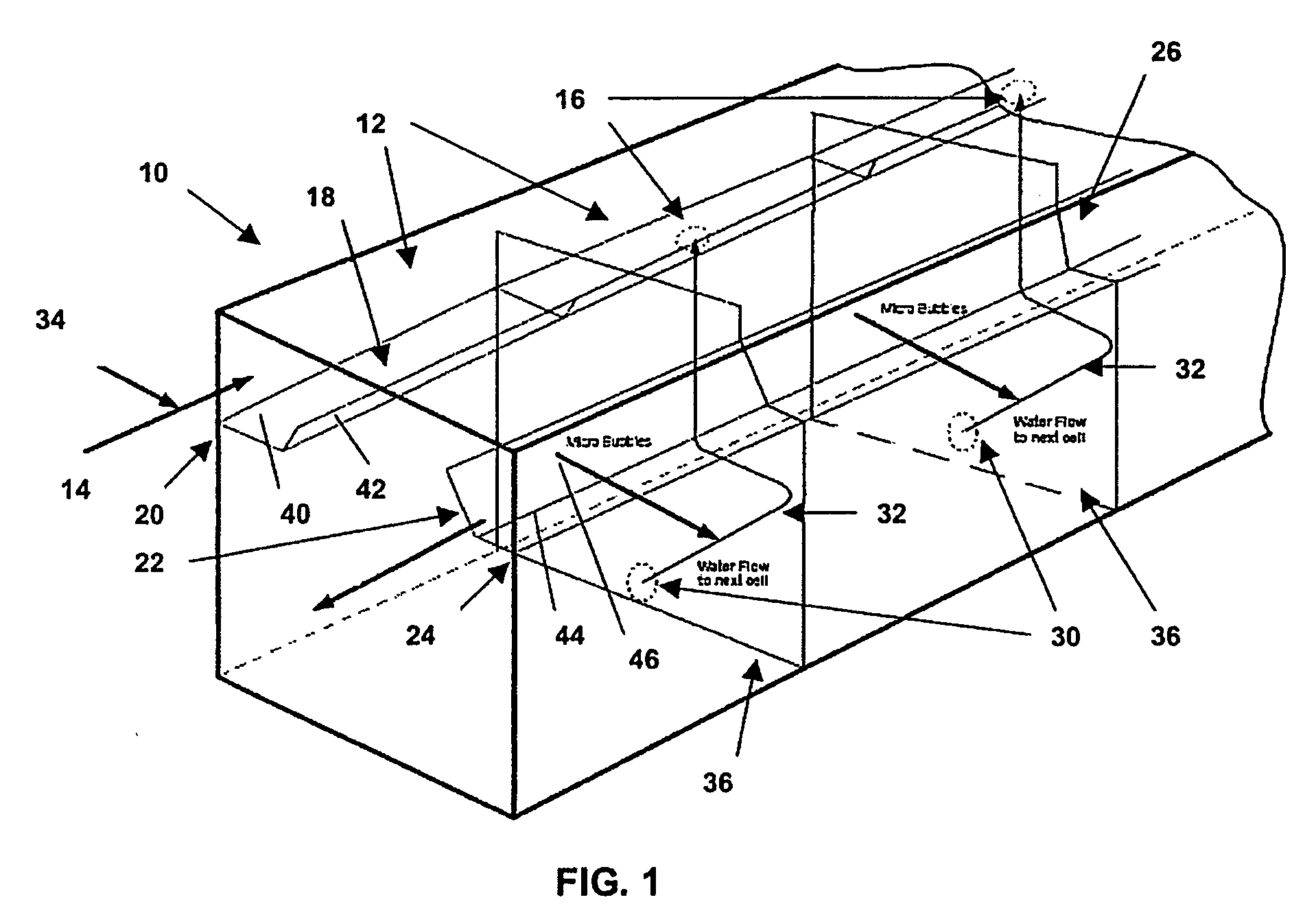

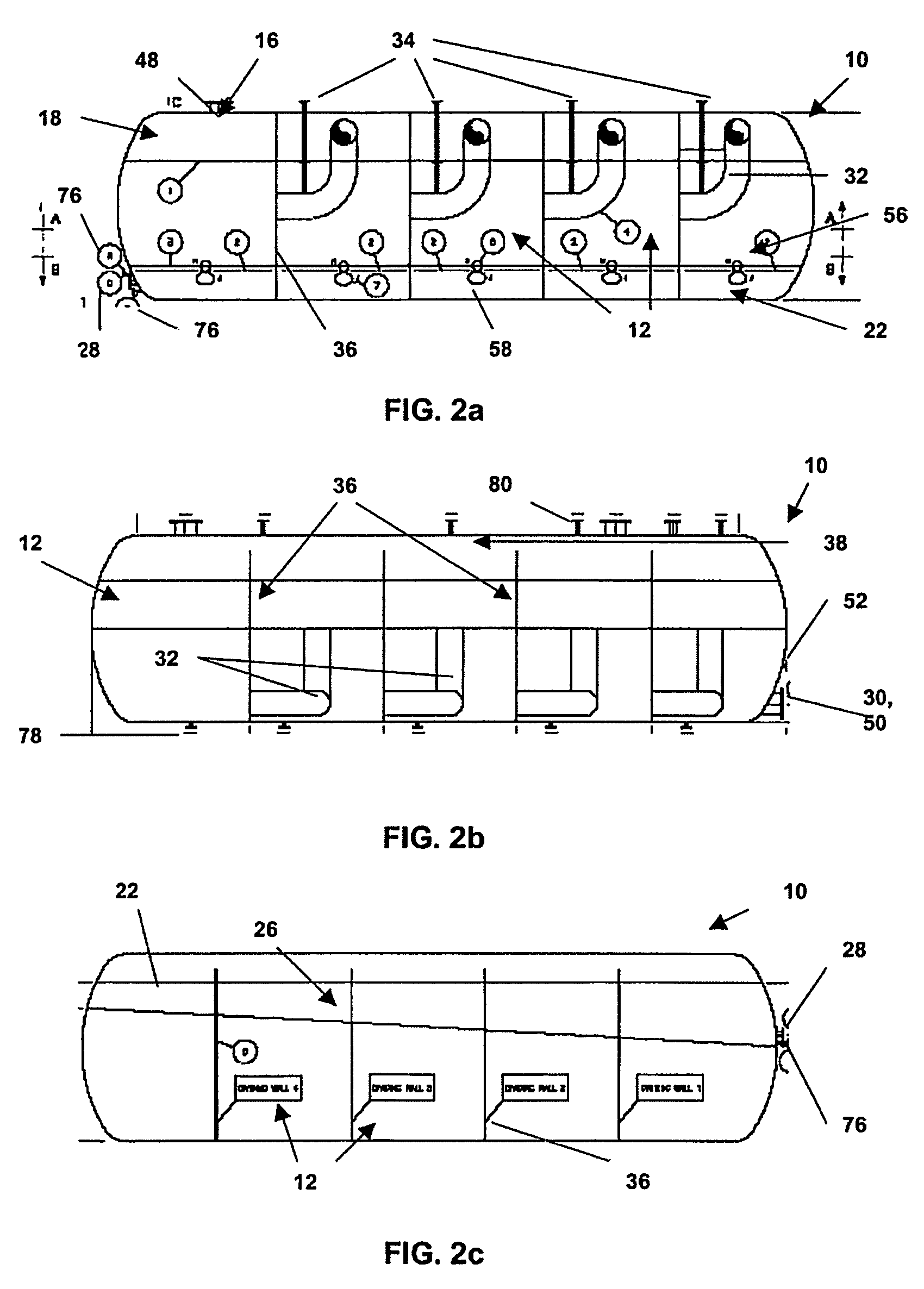

Vessel and method for treating contaminated water

ActiveUS20070114183A1Small footprintWaste water treatment from quariesWater contaminantsEnvironmental engineeringContaminated water

A vessel and method for removing immiscible fluid from contaminated water, the vessel comprising: at least one chamber; an injection line in fluid communication with an inlet of the one chamber; bubble generation means in fluid communication with the injection line for injecting gas bubbles into the injection line and allowing mixing in the injection line of the gas bubbles and the contaminated water to form an inlet fluid; an inlet weir within the chamber adjacent the inlet; an immiscible fluid weir within the chamber; a trough for collecting the immiscible fluid and allowing the immiscible fluid to flow out of the at least one chamber through an immiscible fluid outlet; and a cleaned water outlet generally at the bottom of the chamber; wherein when the inlet fluid is injected into the chamber, it passes through the inlet and over the inlet weir, the cleaned water flows downwardly toward the cleaned water outlet, and a remaining mixture of the immiscible fluid and the gas bubbles floats through the chamber to pass over the immiscible fluid weir and down the trough to the immiscible fluid outlet.

Owner:EXTERRAN WATER SOLUTIONS ULC

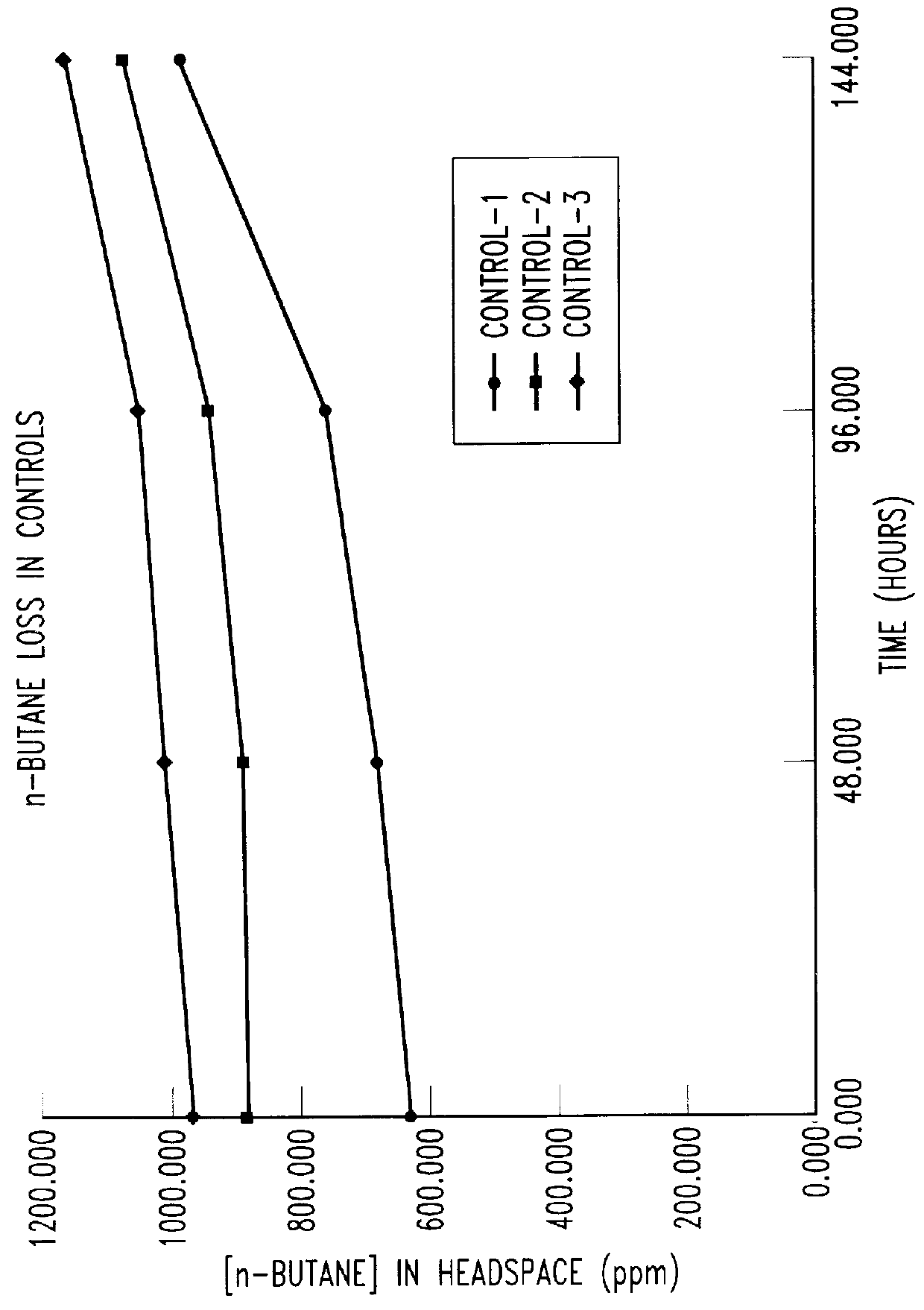

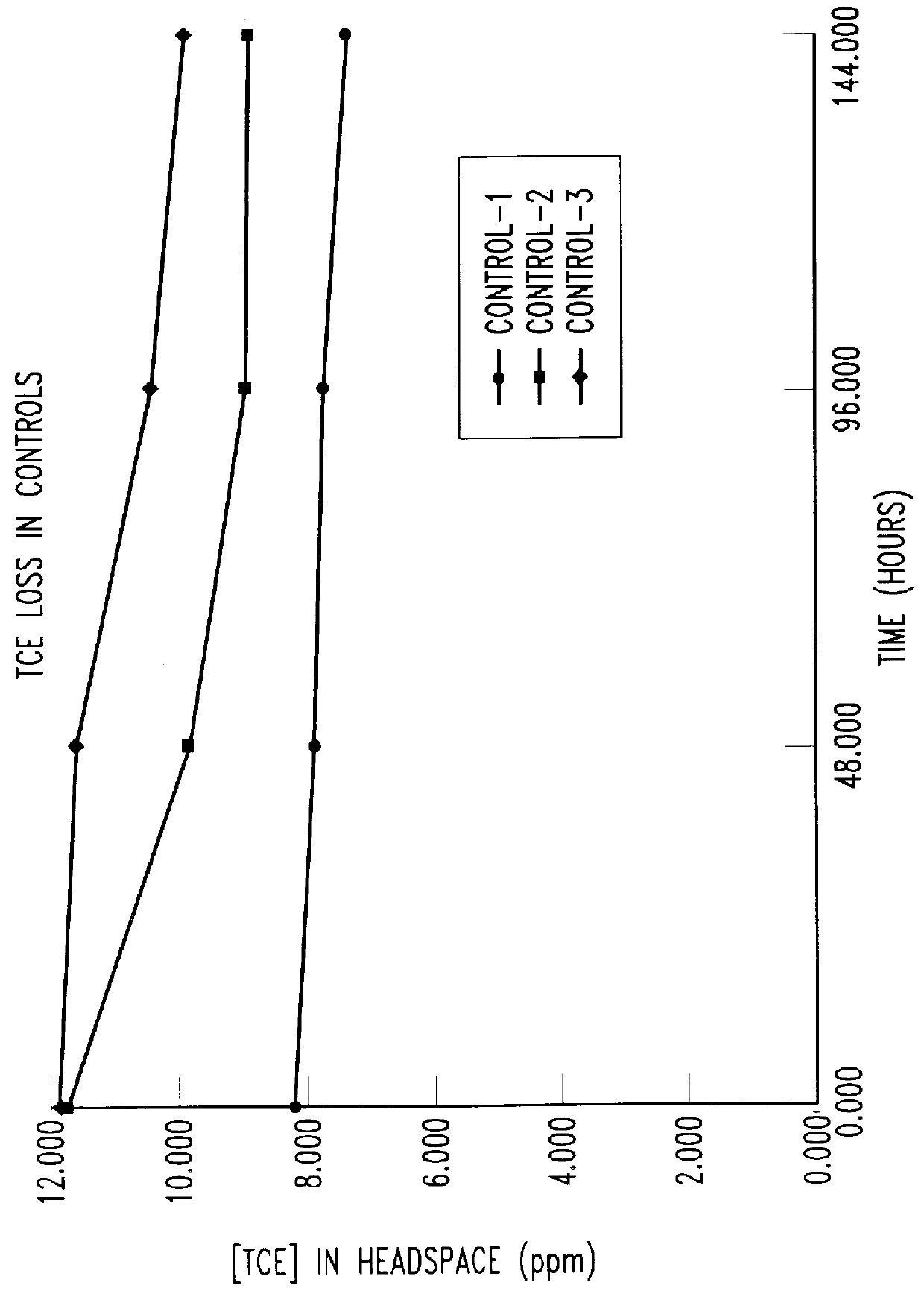

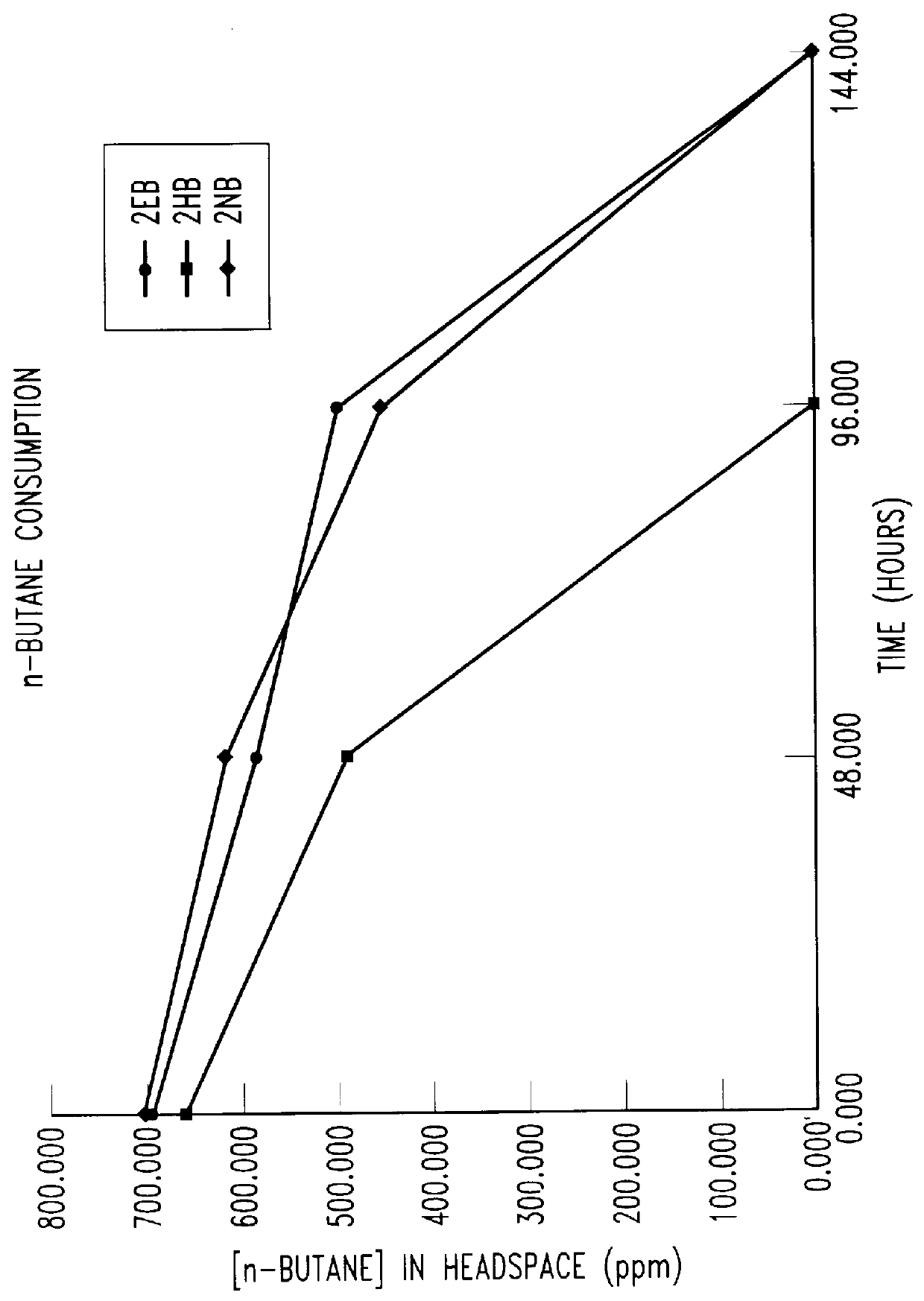

Bioreactor for remediation of pollutants with butane utilizing bacteria

InactiveUS6051130AReduce and eliminate hydrocarbon pollutantEasy to transportGas treatmentBacteriaBacteroidesComamonas

Butane-utilizing bacteria are used to degrade hydrocarbon pollutants such as trichloroethene (TCE). In-situ or ex-situ techniques may be used to reduce or eliminate hydrocarbon pollutants from liquid, gas and solid sources. In a preferred embodiment, TCE concentrations in various aqueous environments are reduced by contacting a contaminated water source with butane-utilizing bacteria in the presence of oxygen to degrade the TCE by cometabolism or direct metabolism. Suitable butane-utilizing bacteria include Pseudomonas, Variovorax, Nocardia, Chryseobacterium, Comamonas, Acidovorax, Rhodococcus, Aureobacterium, Micrococcus, Aeromonas, Stenotrophomonas, Sphingobacterium, Shewanella, Phyllobacterium, Clavibacter, Alcaligenes, Gordona, Corynebacterium and Cytophaga. The butane-utilizing bacteria have relatively low TCE toxicity in comparison with conventional methane-utilizing bacteria, and demonstrate an improved ability to degrade TCE.

Owner:GLOBAL BIOSCI

Universal water purification system

ActiveUS7632410B2General water supply conservationTreatment involving filtrationHigh concentrationPurification methods

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com