Patents

Literature

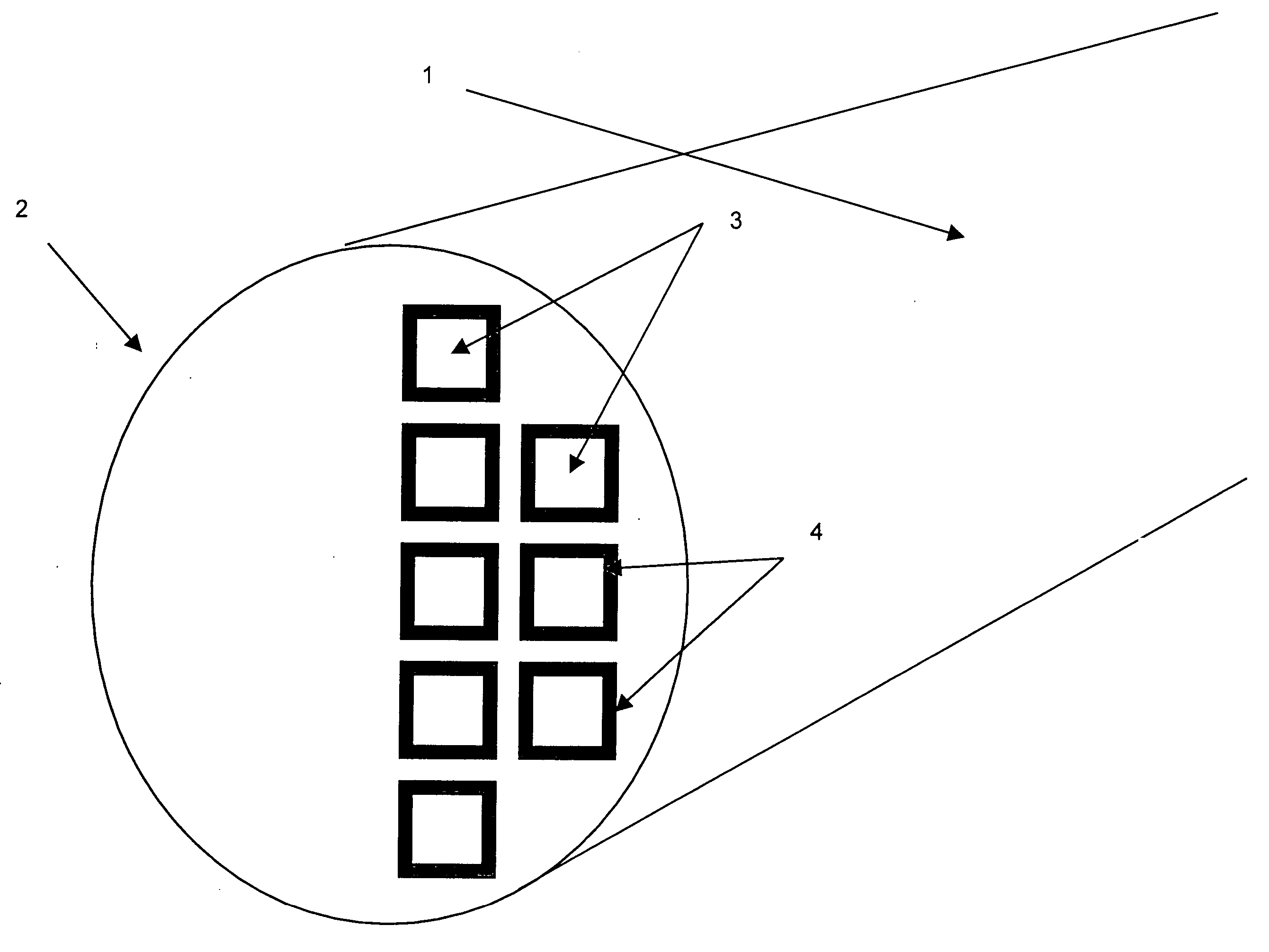

602 results about "Pervaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pervaporation (or pervaporative separation) is a processing method for the separation of mixtures of liquids by partial vaporization through a non-porous or porous membrane.

Pervaporation composite membranes

The present application discloses a composite membrane comprising (a) a support member that has a plurality of pores extending through the support member and (b) a cross-linked copolymer comprising (i) a cationic monomer and an anionic monomer and / or (ii) a zwitterionic monomer, which cross-linked copolymer fills the pores of the support member, the cross-linked copolymer having a permeability for a fluid that is dependent on the polarity of the fluid, wherein the permeability increases with increasing polarity.The present application also discloses a process for the preparation of the composite membrane, a pervaporation apparatus comprising the composite membrane, and methods for the use of the composite material in separation and dehydration processes.

Owner:MCMASTER UNIV

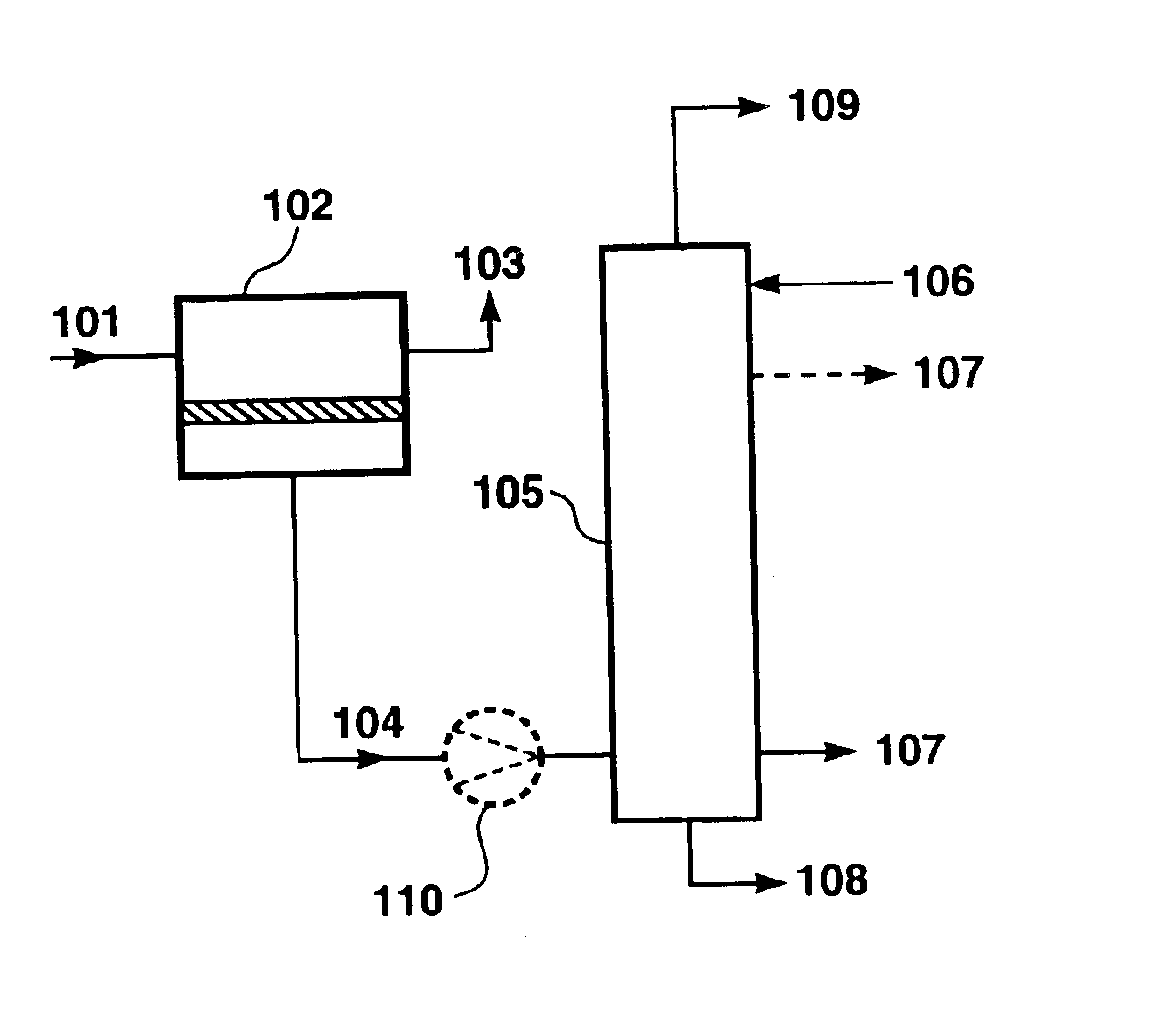

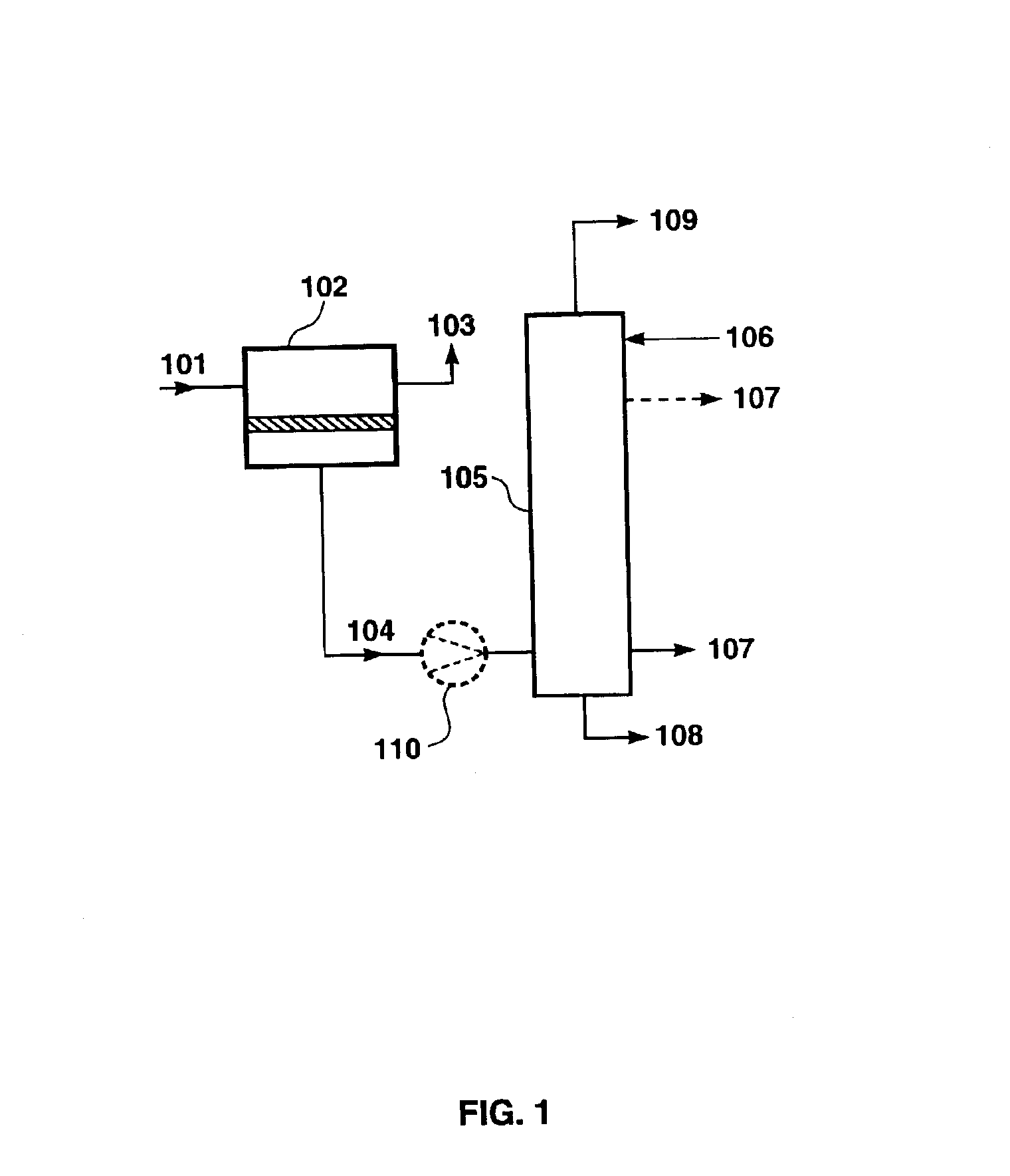

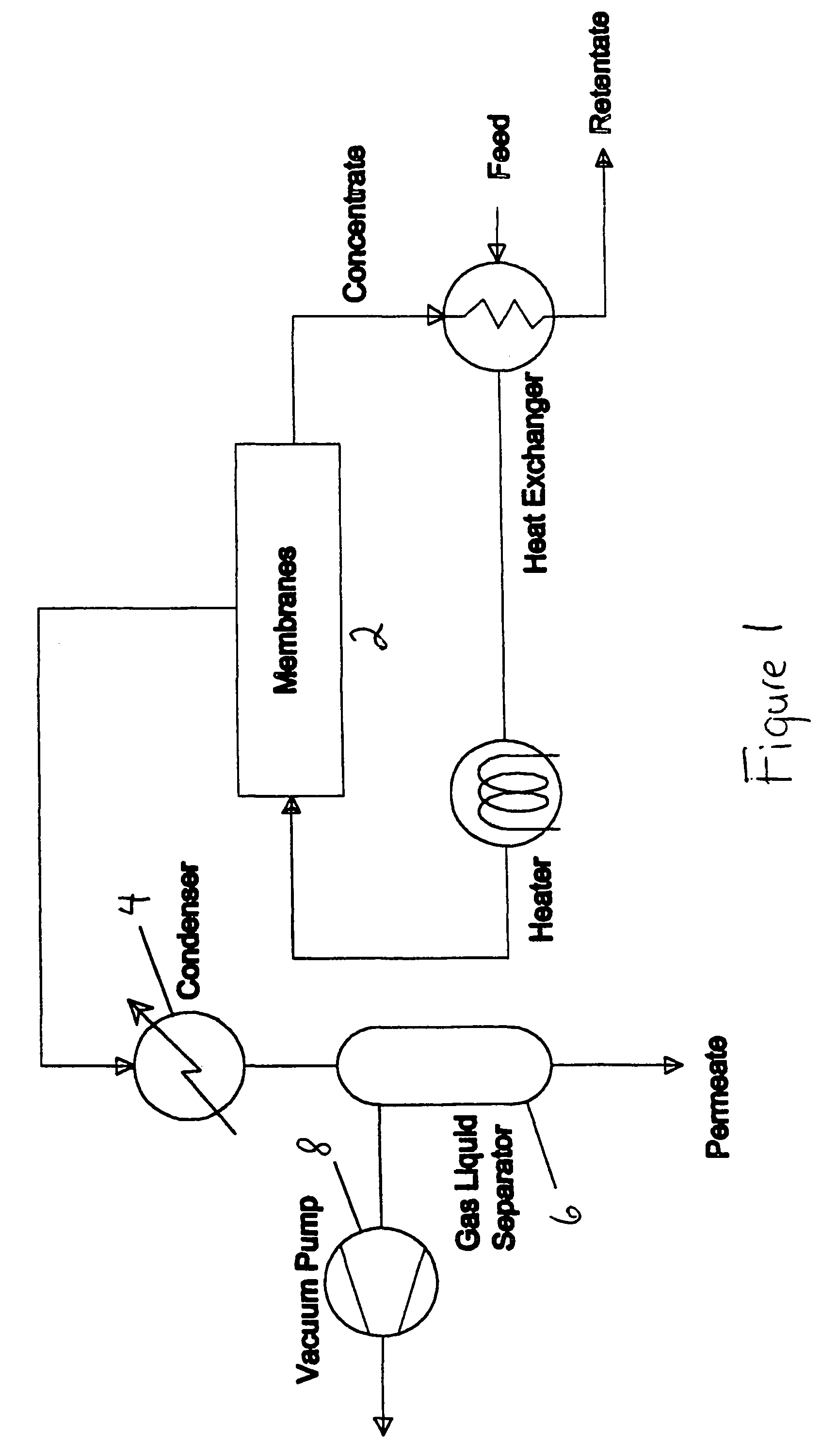

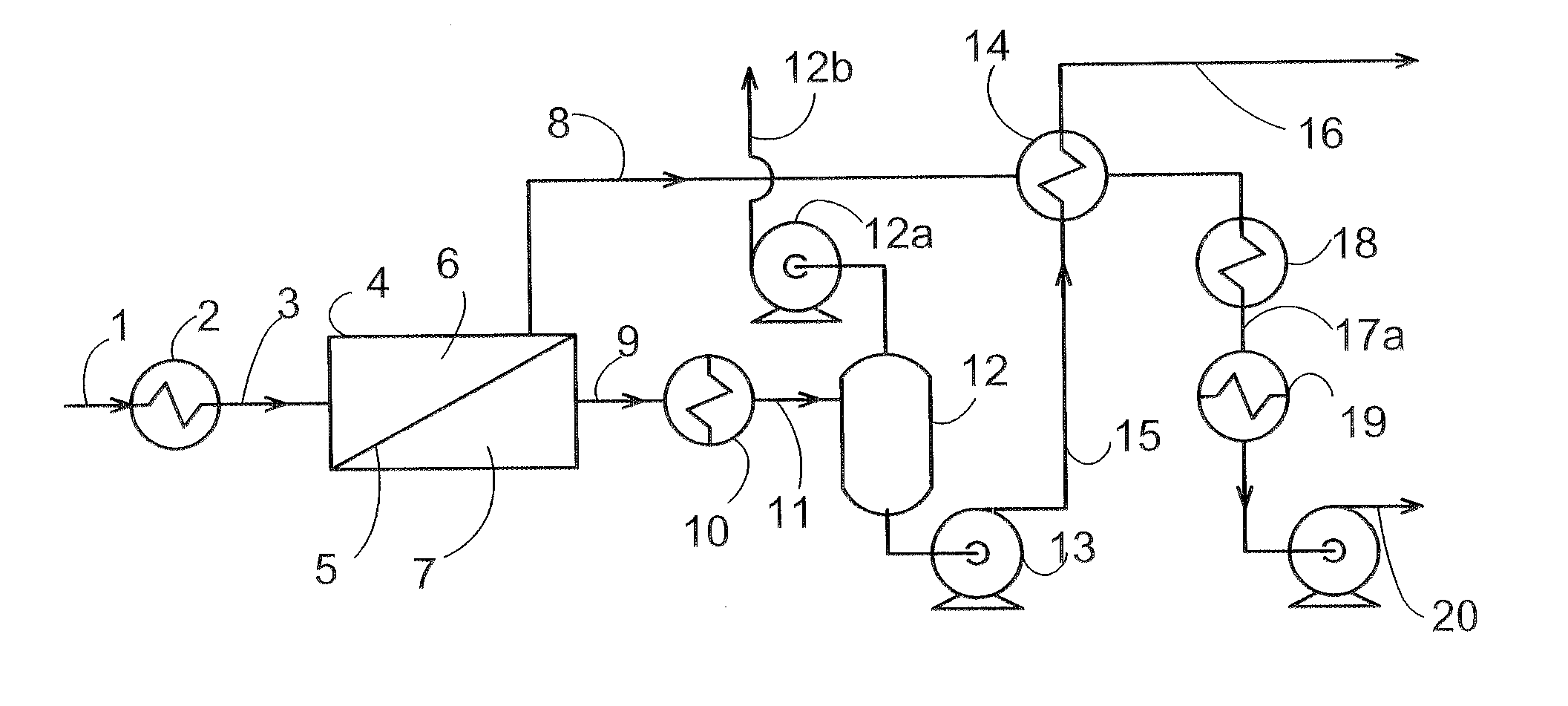

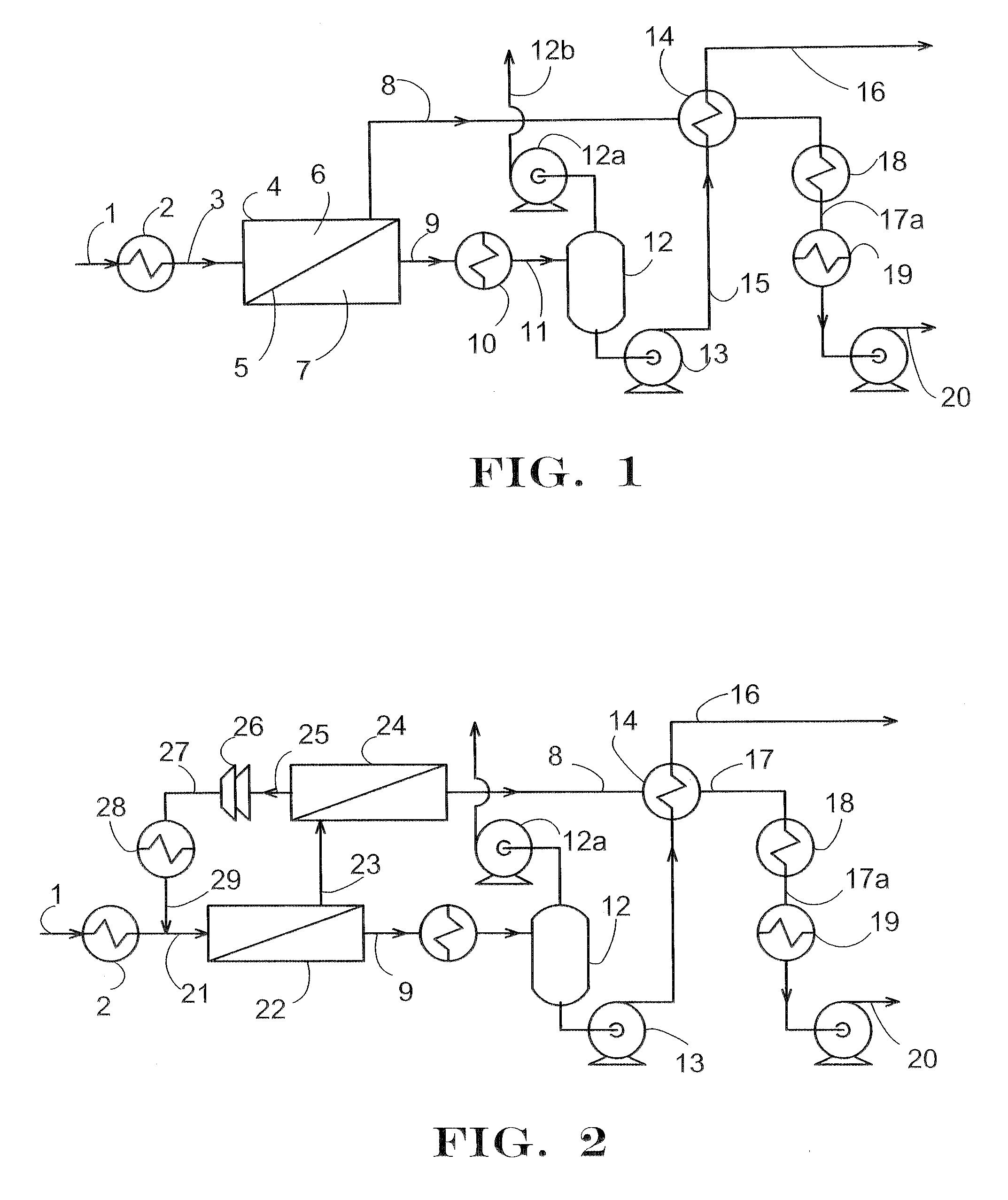

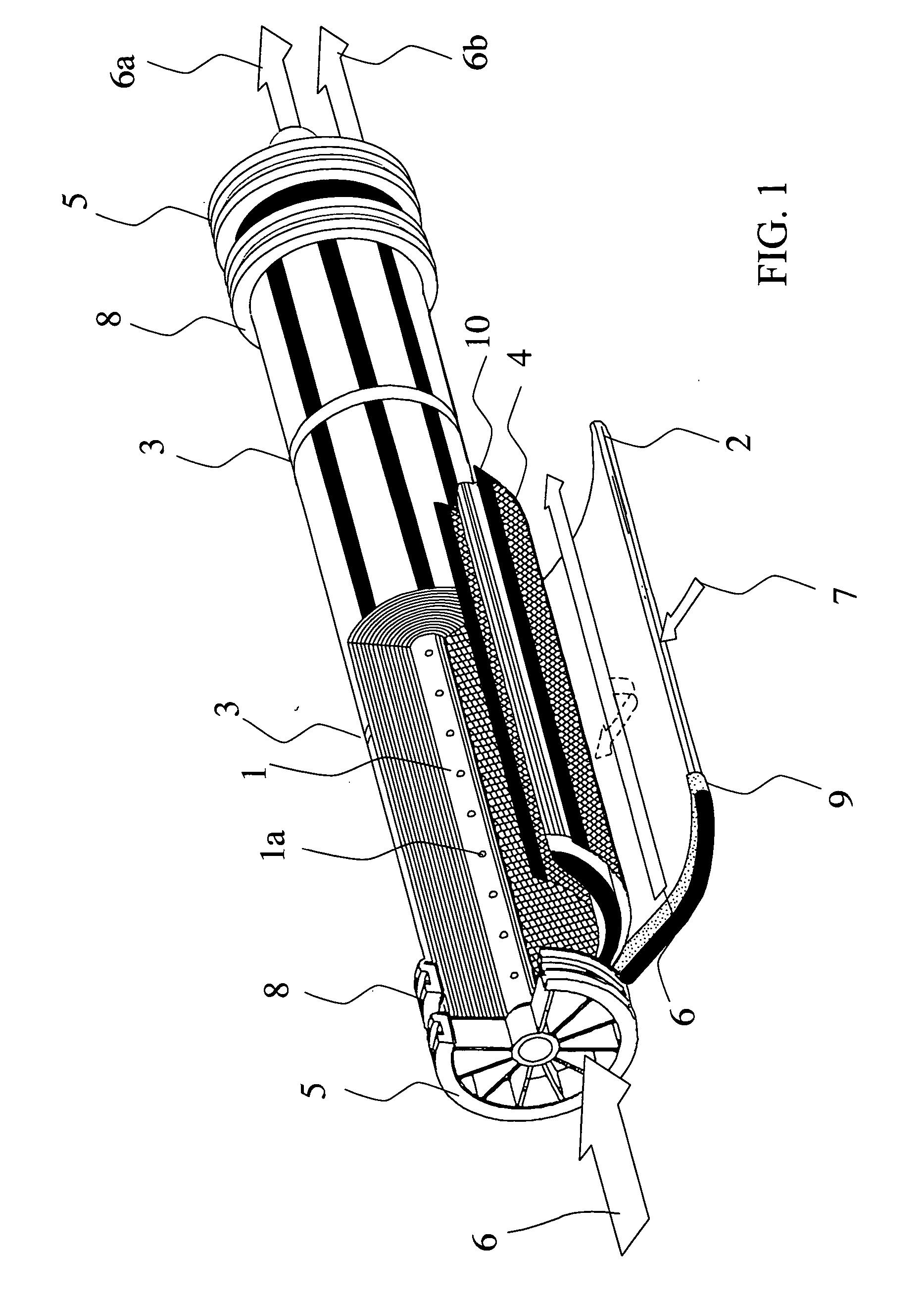

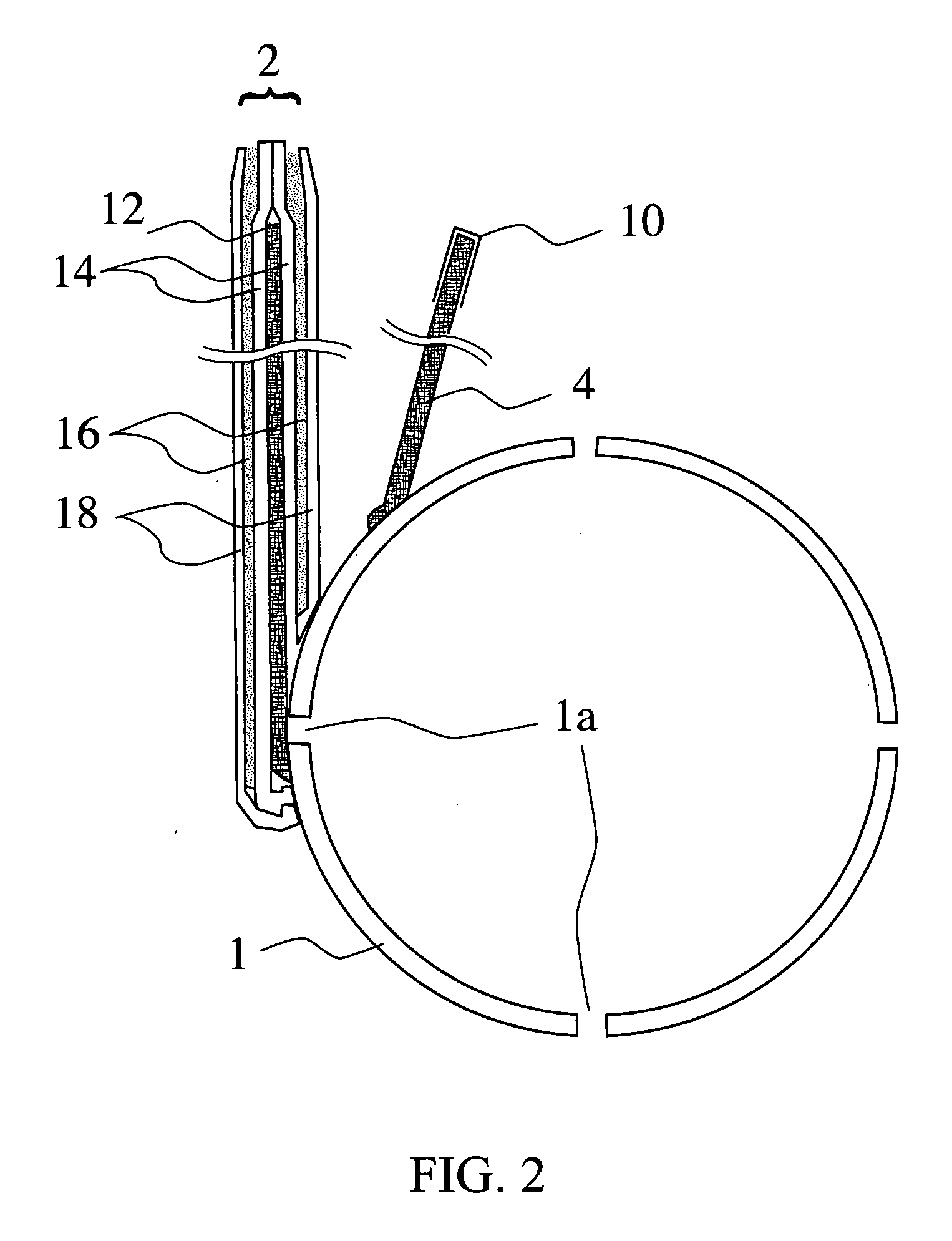

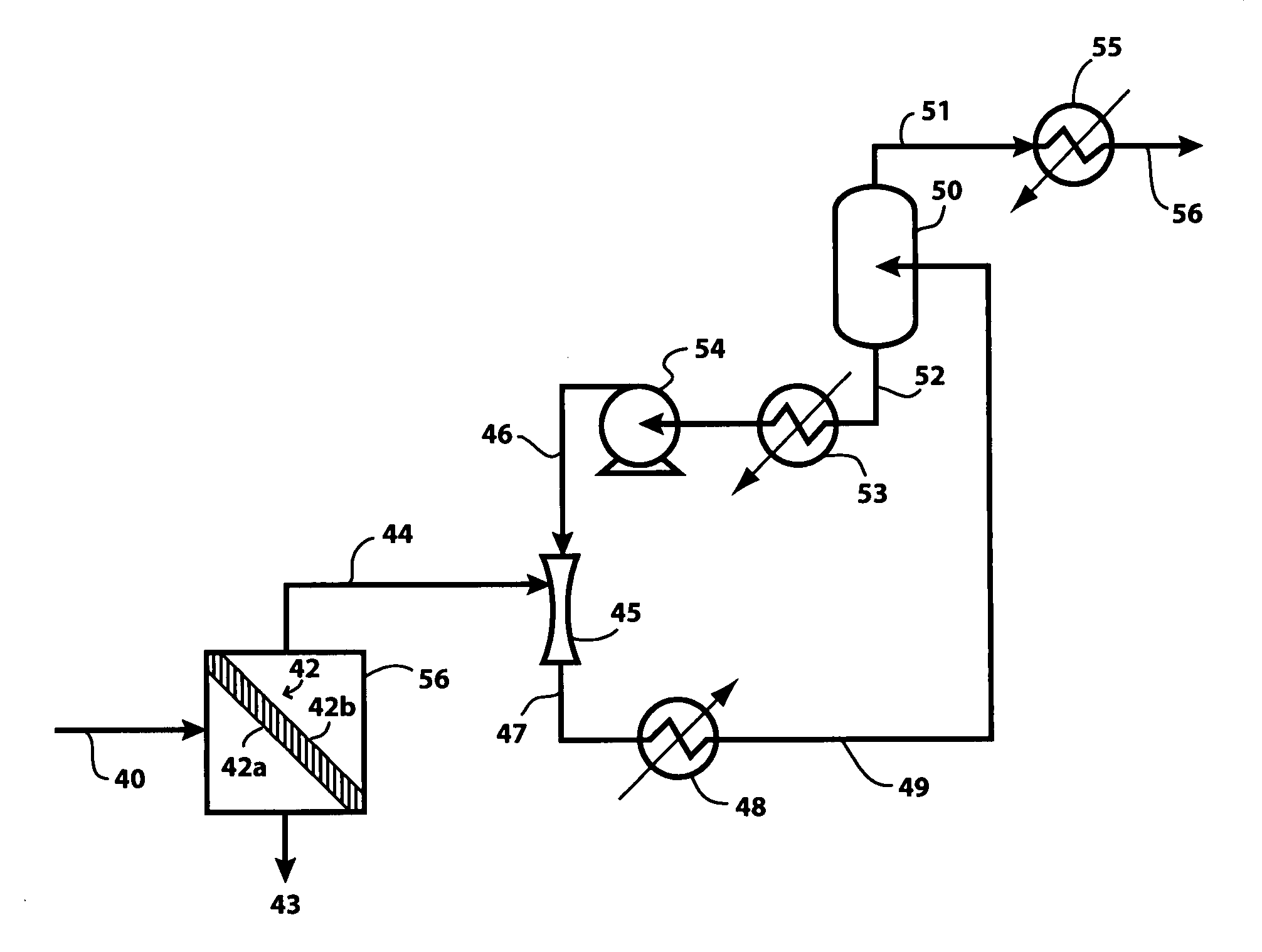

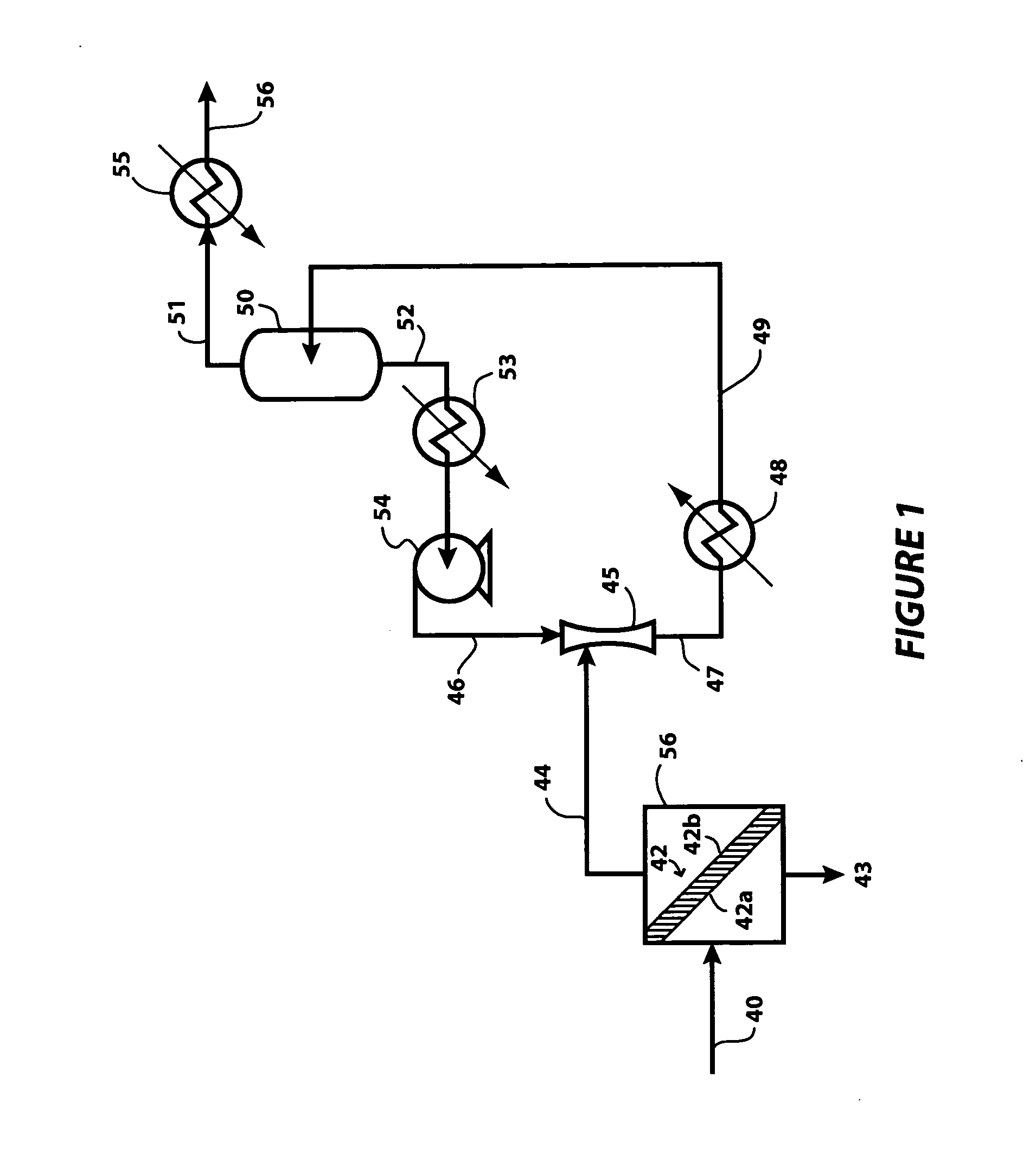

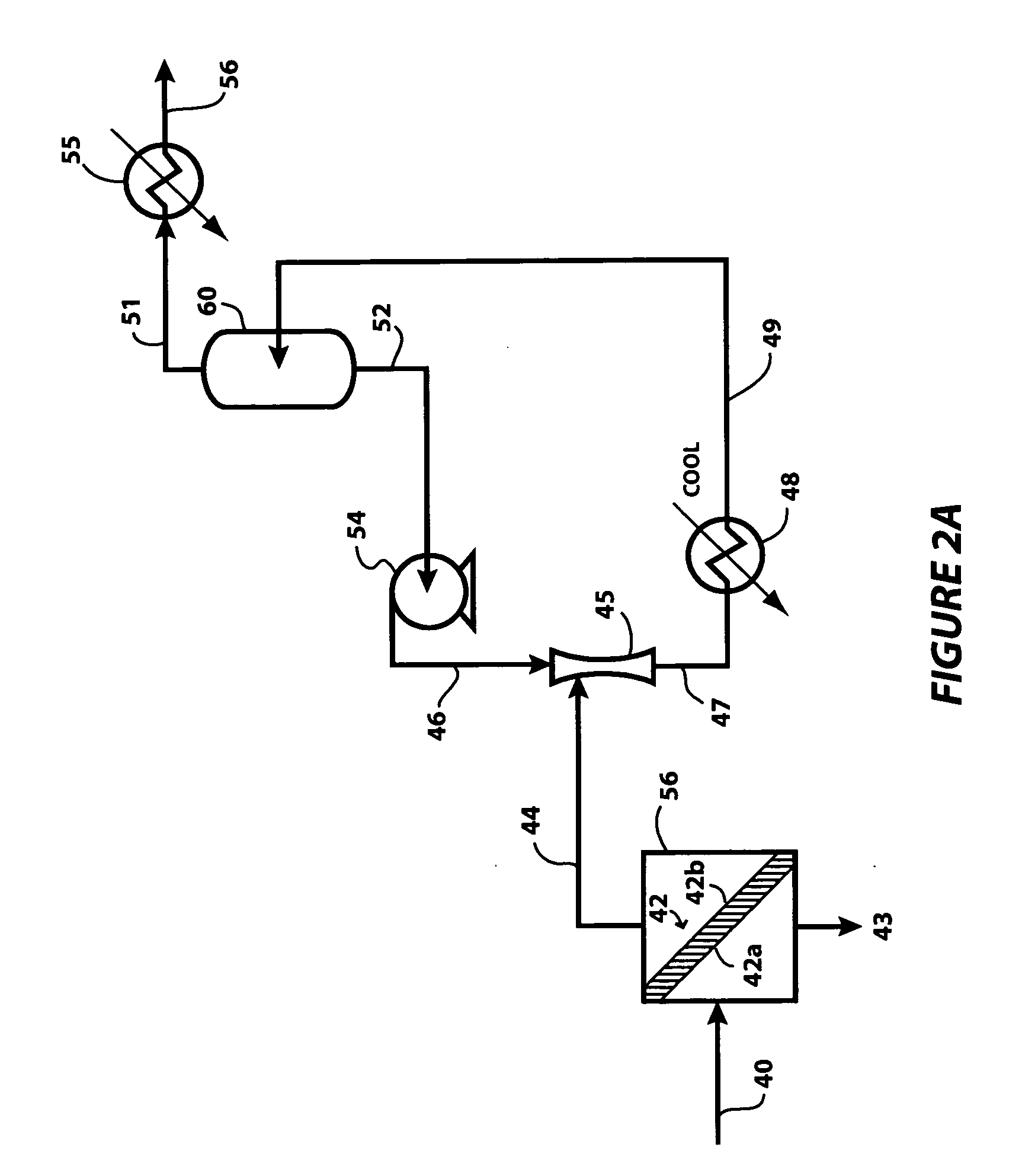

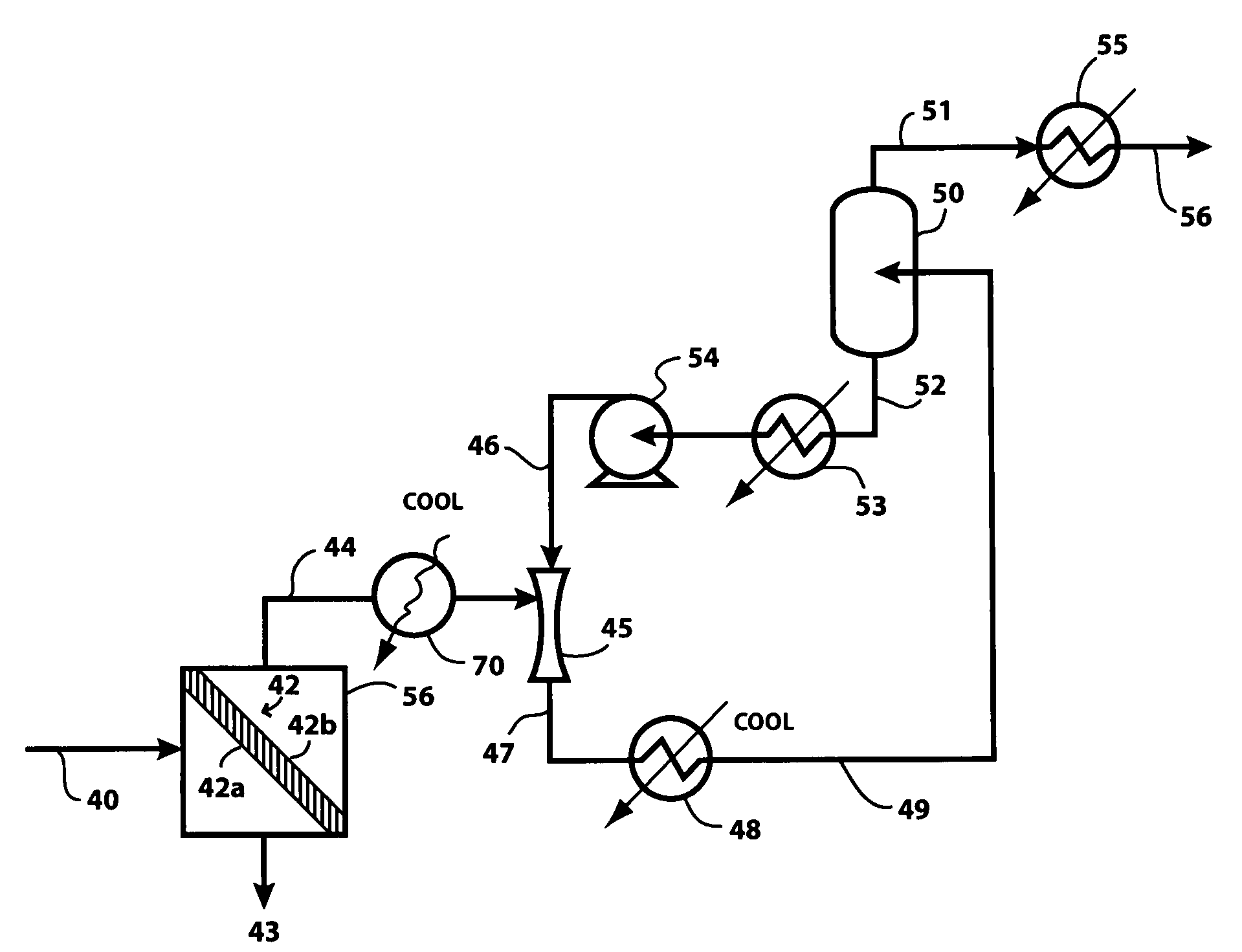

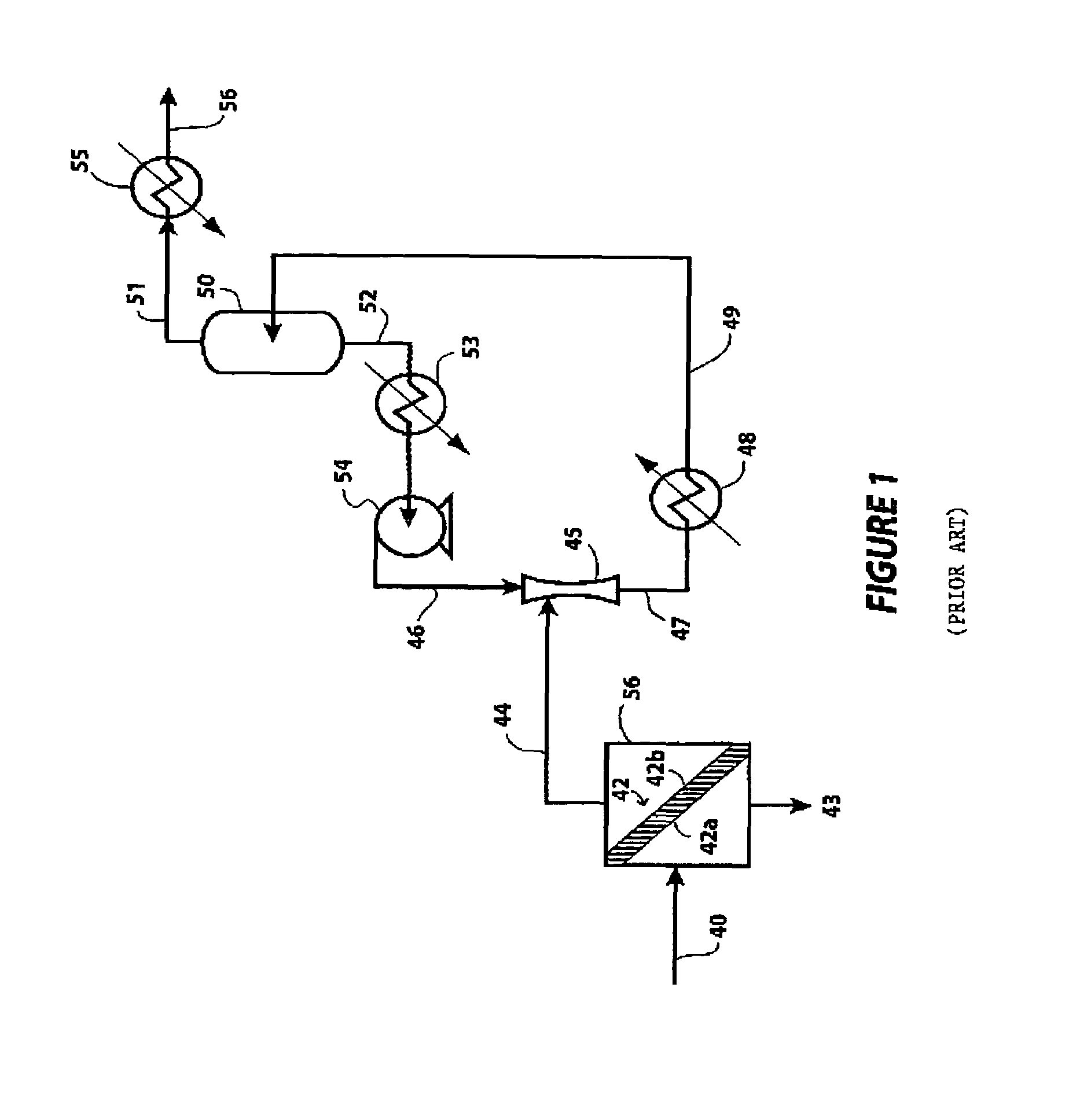

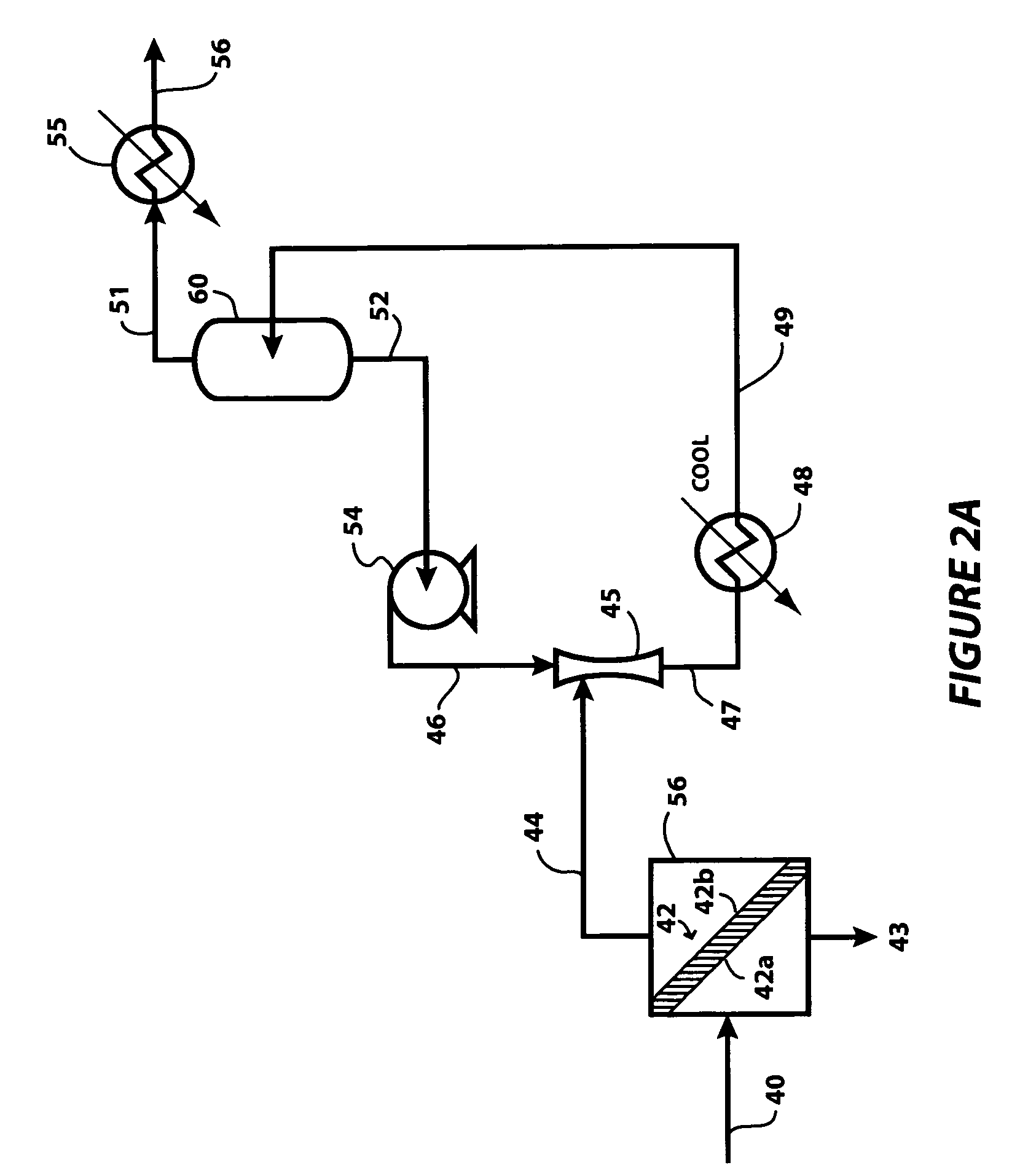

Separation of organic mixtures using gas separation or pervaporation and dephlegmation

InactiveUS6899743B2Easy to separateLow costSemi-permeable membranesSolid sorbent liquid separationZeotropic mixtureGas phase

A process for treating mixtures of organic components, including azeotropic mixtures. The process includes a gas- or liquid-phase membrane separation step in conjunction with a dephlegmation step to treat at least a portion of the permeate vapor from the pervaporation step. The process yields a membrane residue stream, a stream enriched in the more volatile component as the overhead stream from the dephlegmator and a condensate stream enriched in the less volatile component as a bottoms stream from the dephlegmator. Any of these may be the principal product of the process.

Owner:MEMBRANE TECH & RES

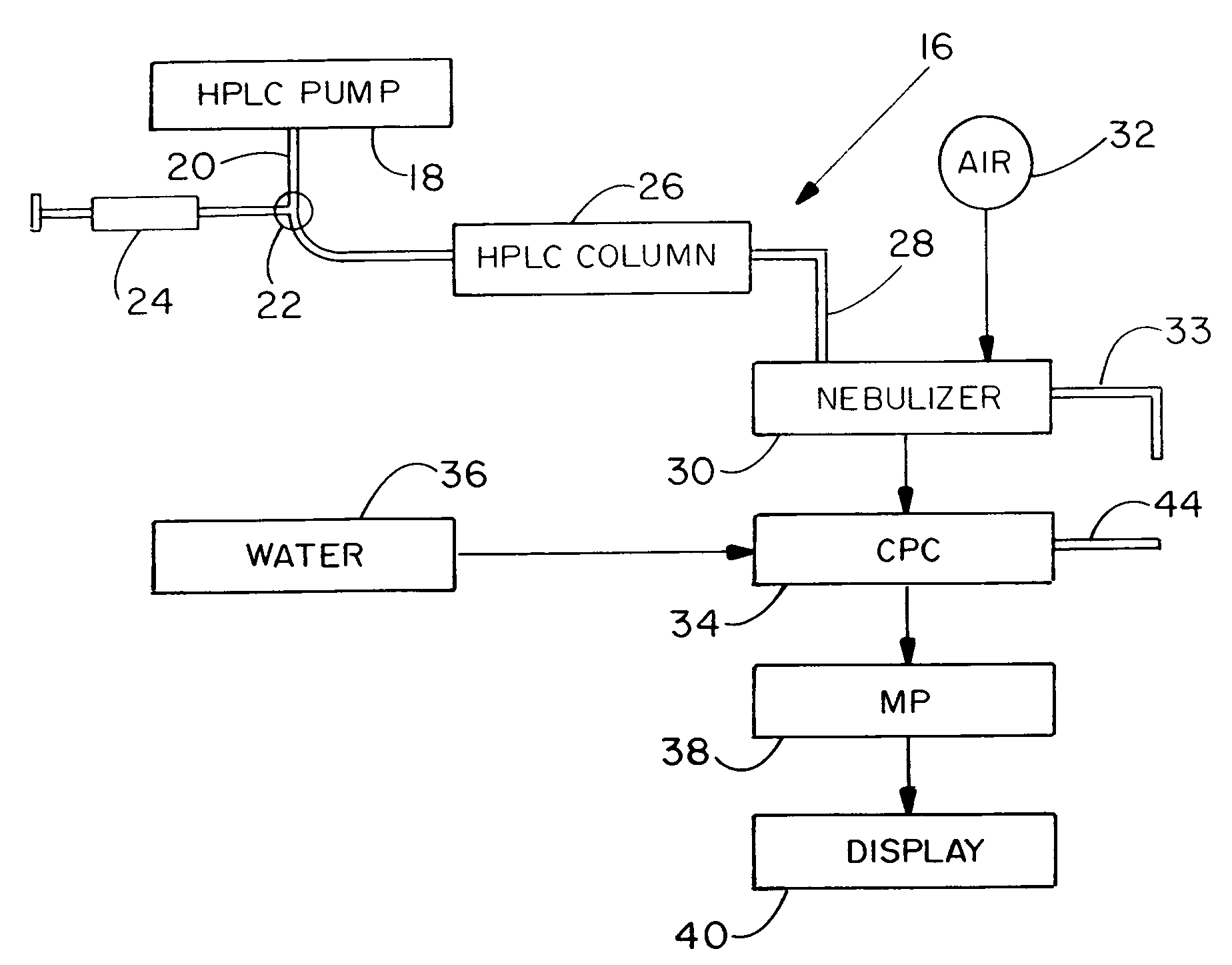

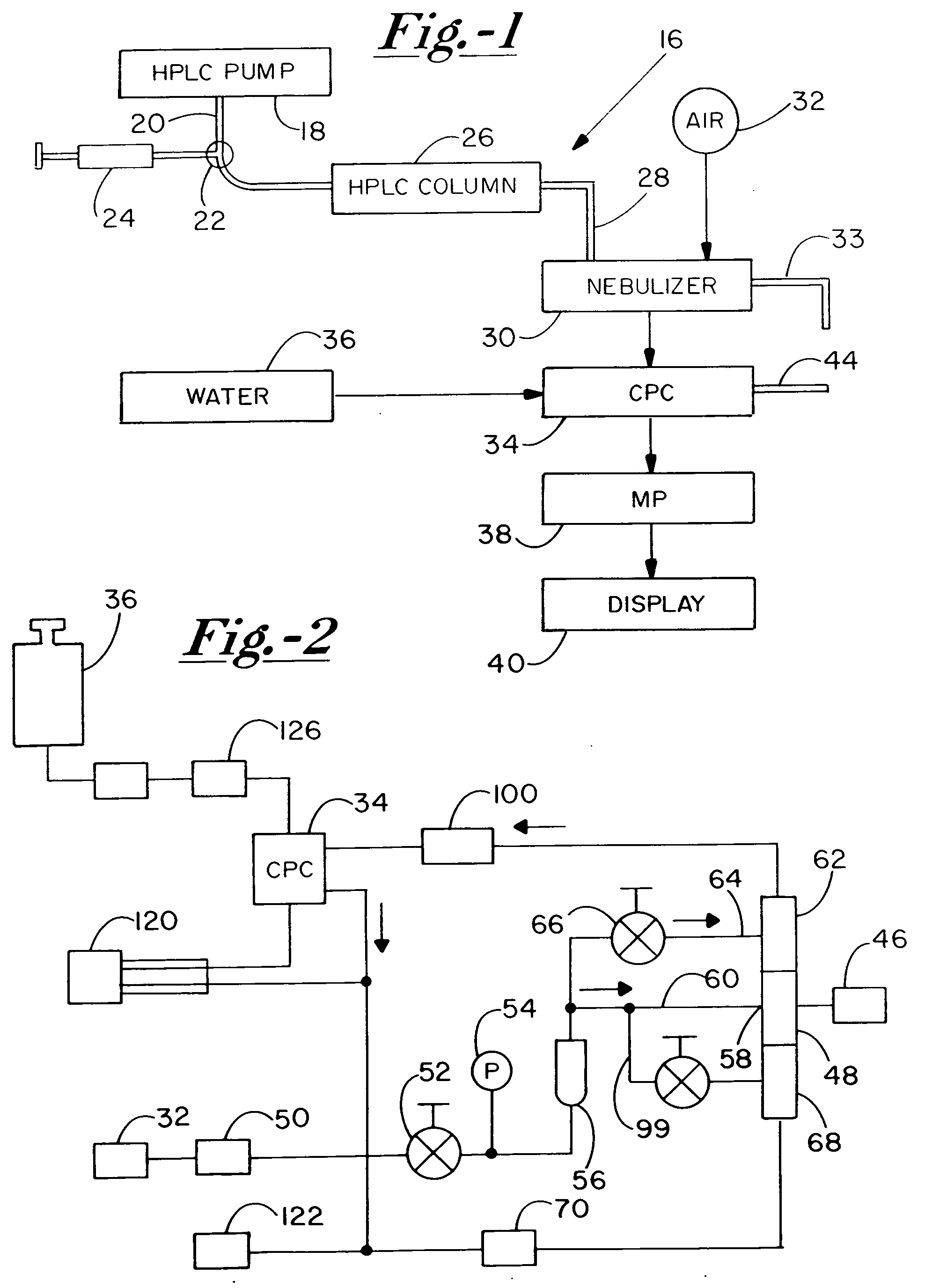

Measuring Analyte Concentrations in Liquids

InactiveUS20080137065A1Higher kinetic energy mixingSmall dropletSamplingComponent separationElectrical mobilityDroplet size

A high performance liquid chromatography system employs a nebulizer with a flow restriction at the exit of its mixing chamber to produce finer droplets, and an adjustable impactor for increased control over droplet sizes. Downstream of the mixing chamber, the nebulizer can incorporate tubing that is permeable to the sample liquid, to promote aerosol drying through perevaporation. A condensation particle counter downstream of the nebulizer uses water as the working medium, and is adjustable to control threshold nucleation sizes and droplet growth rates. A particle size selector employing diffusion, electrostatic attraction or selection based on electrical mobility, is advantageously positioned between the nebulizer and the CPC.

Owner:TSI INC

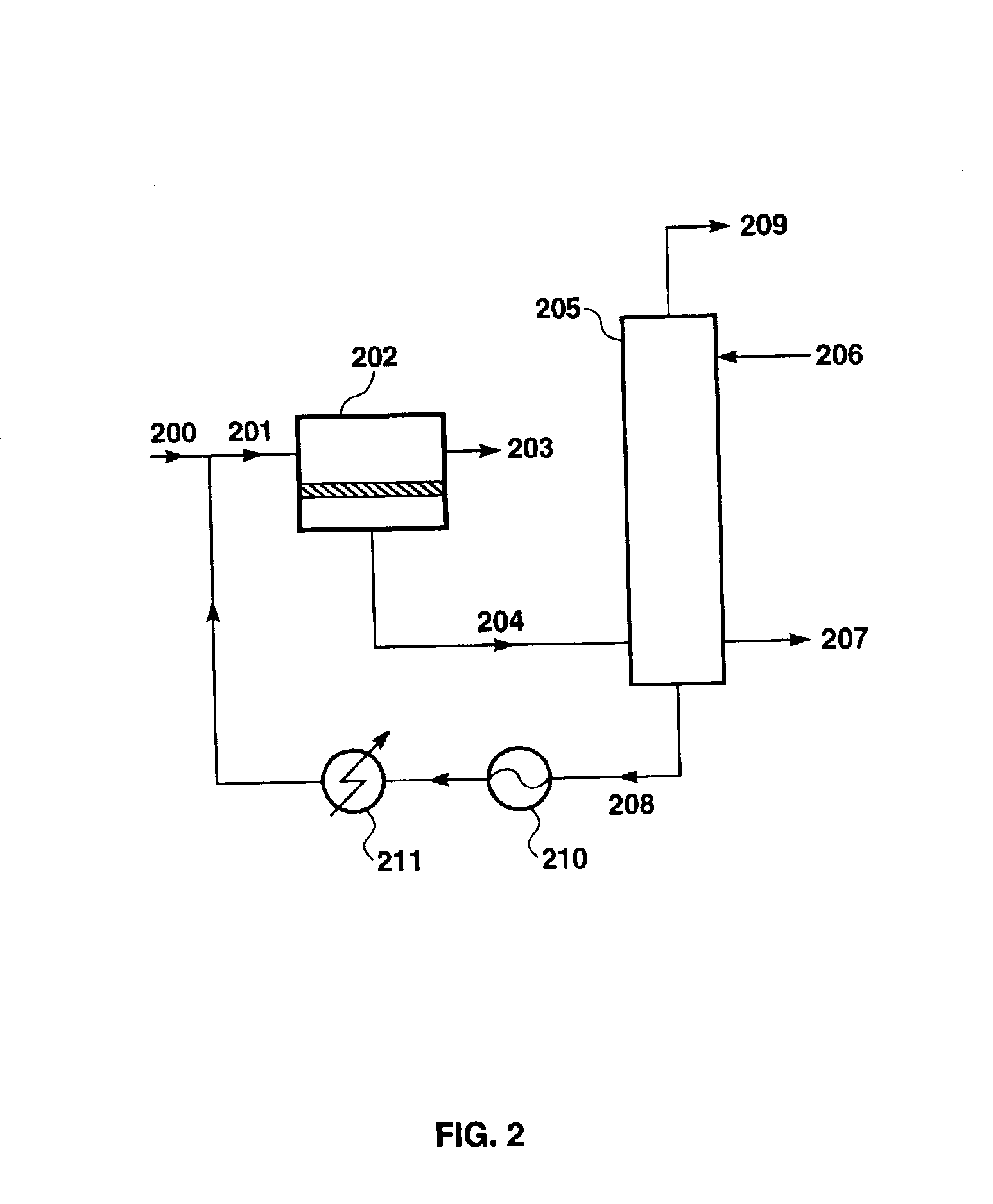

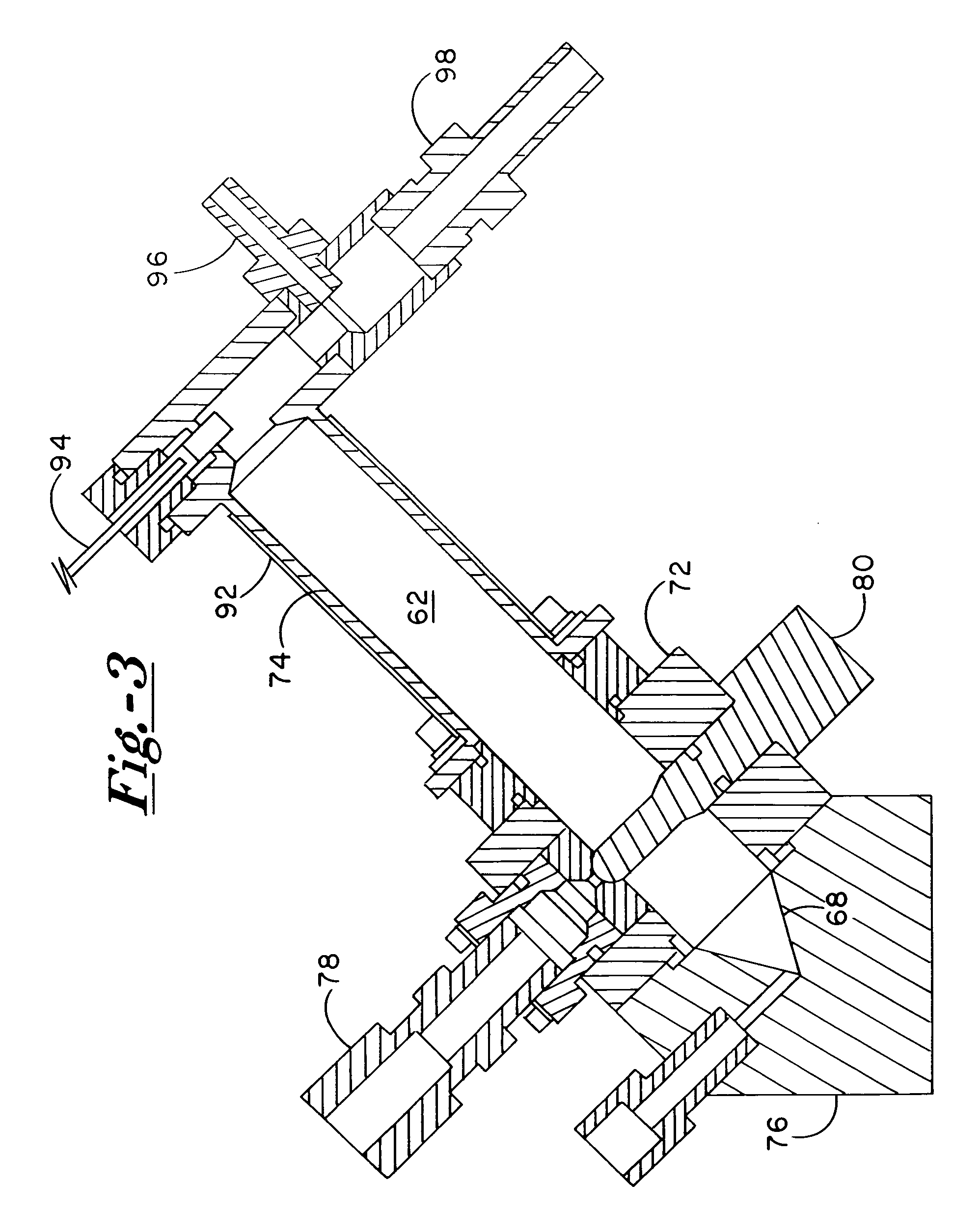

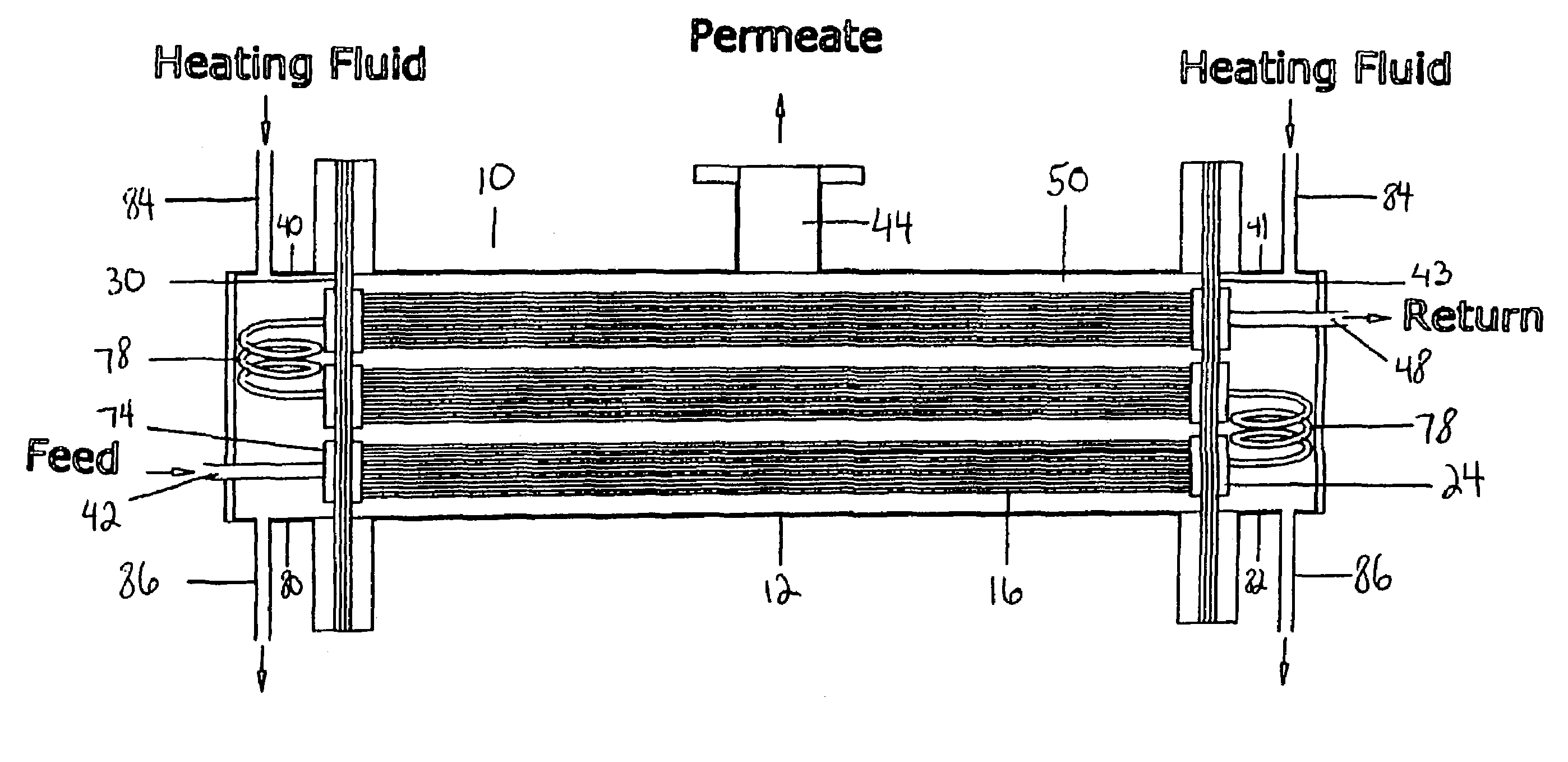

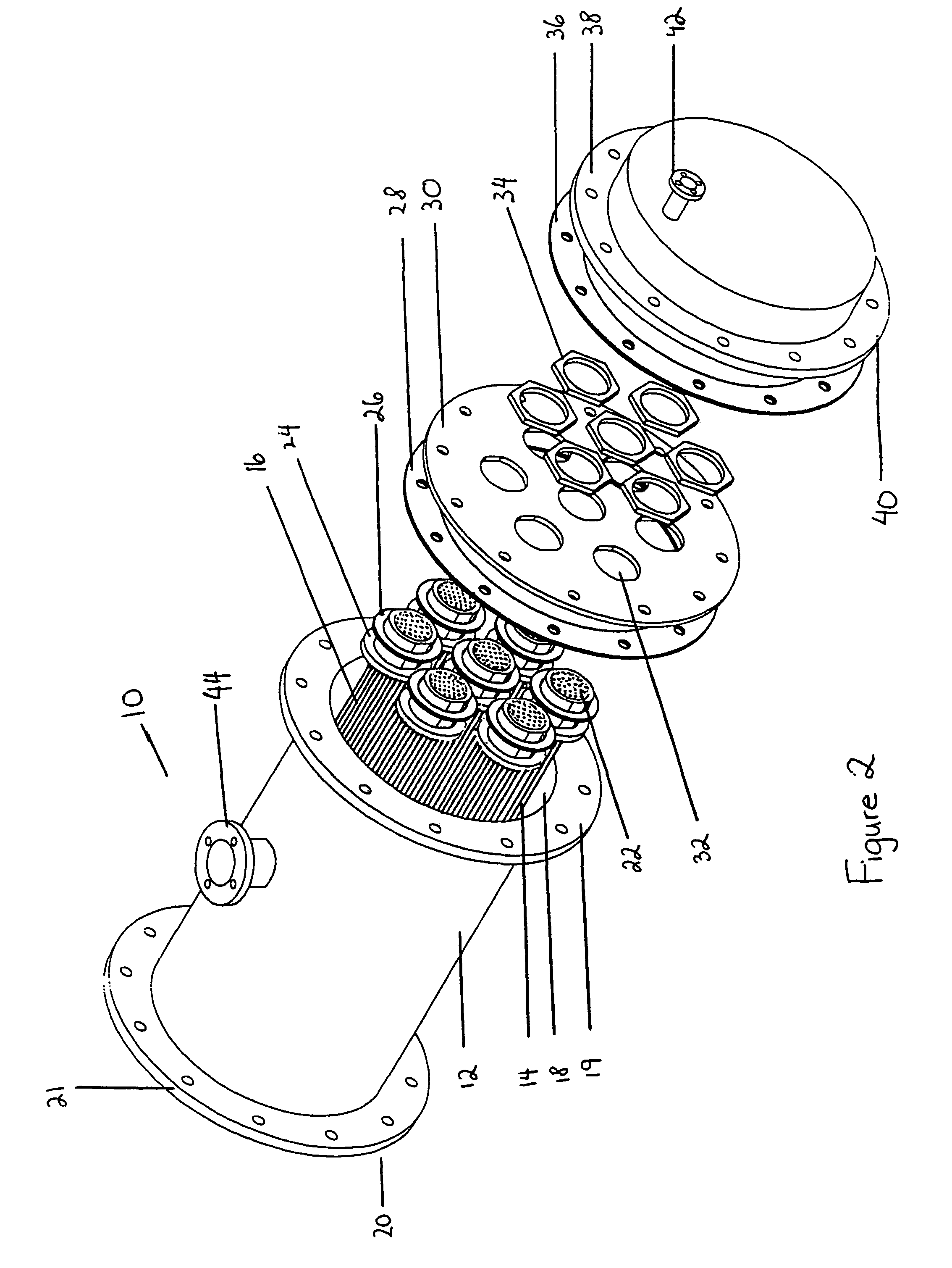

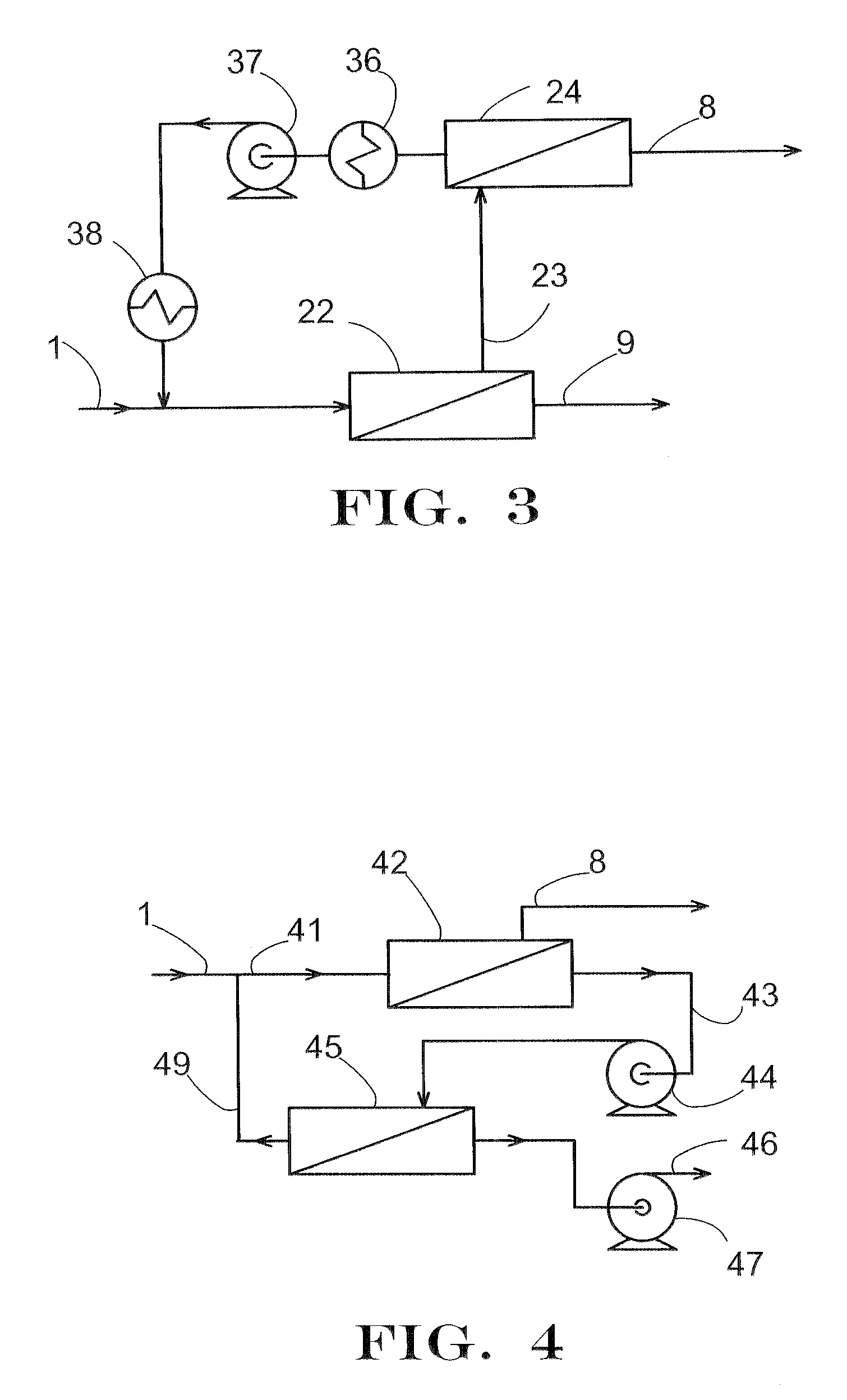

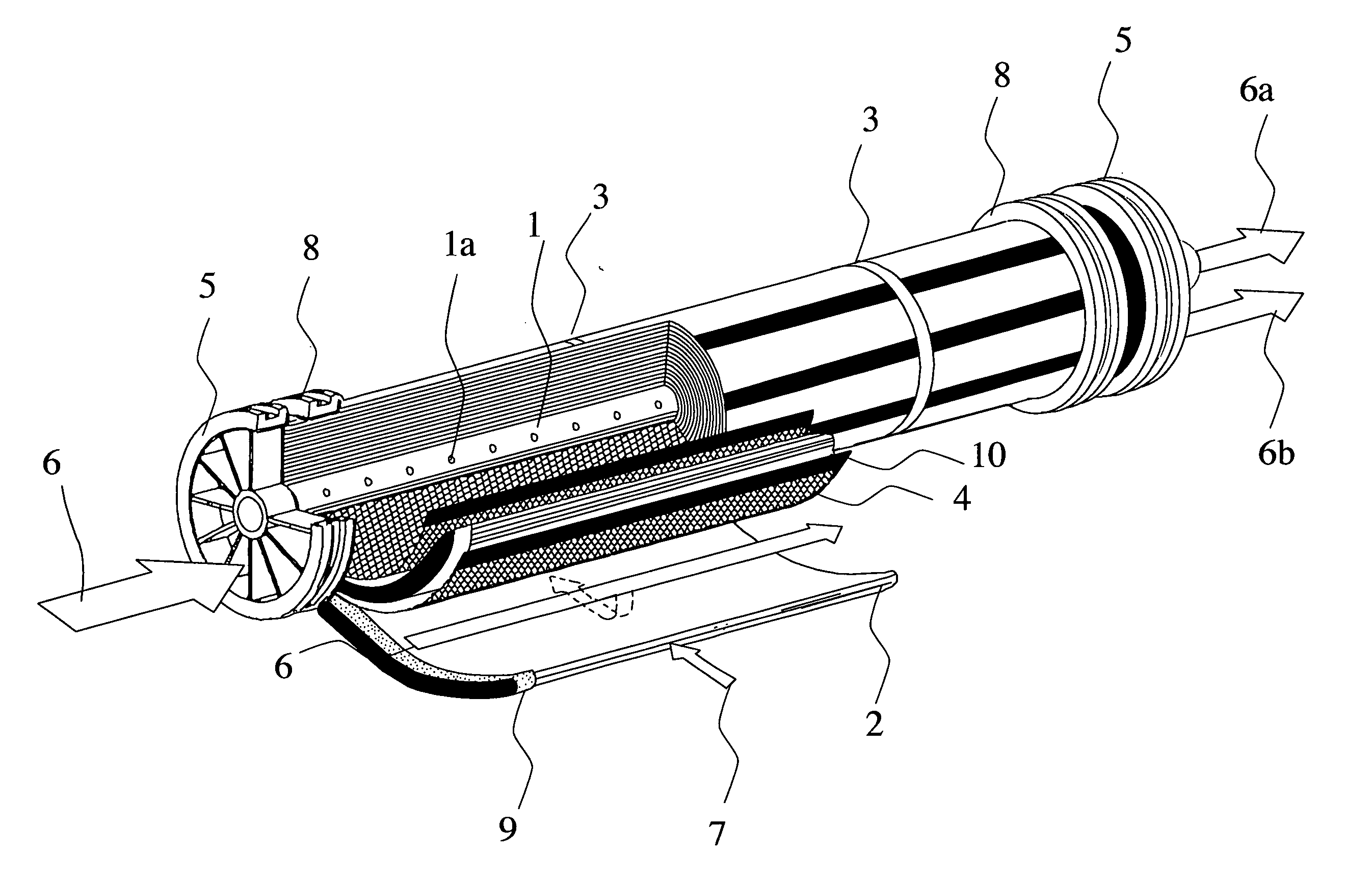

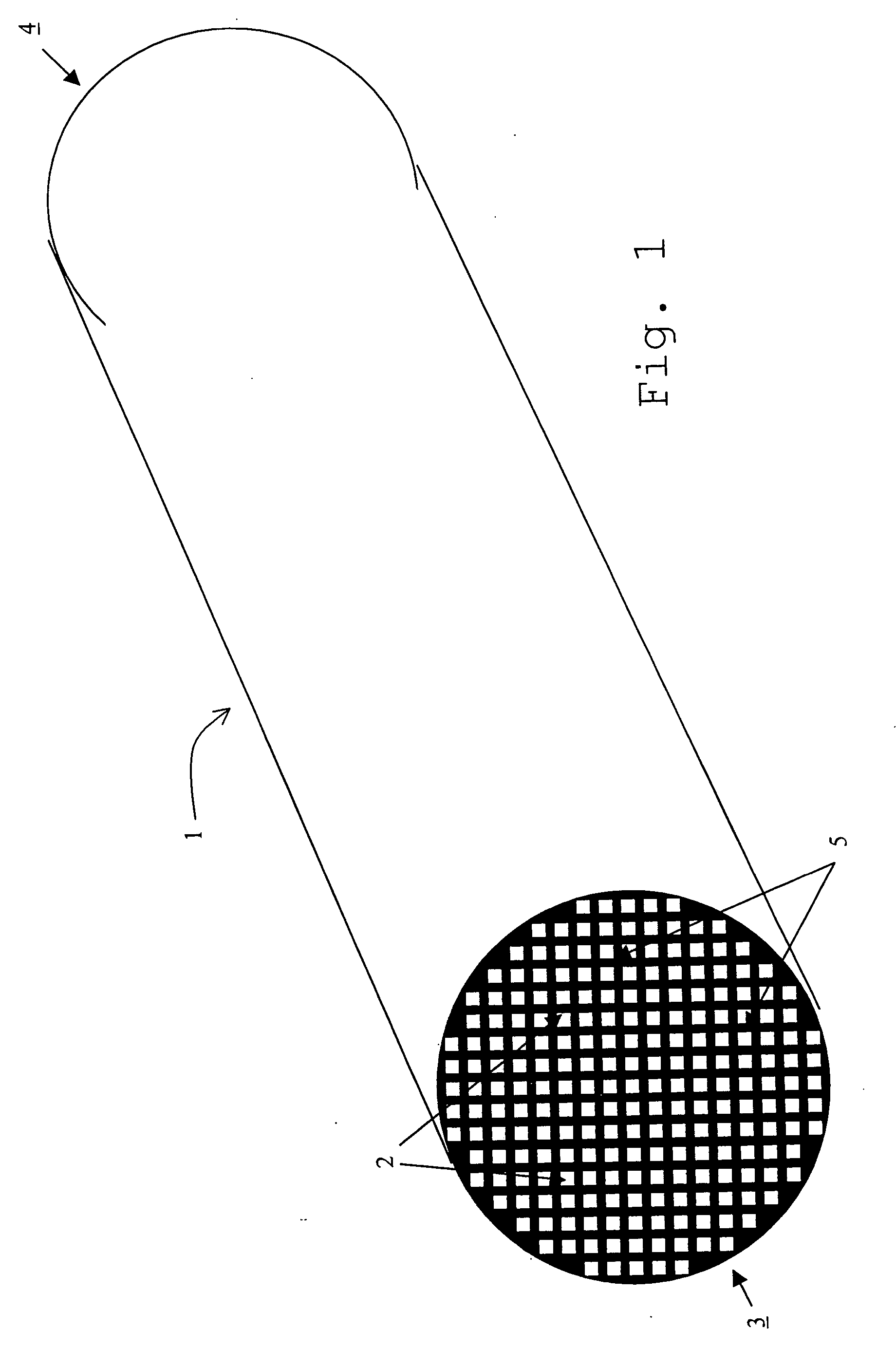

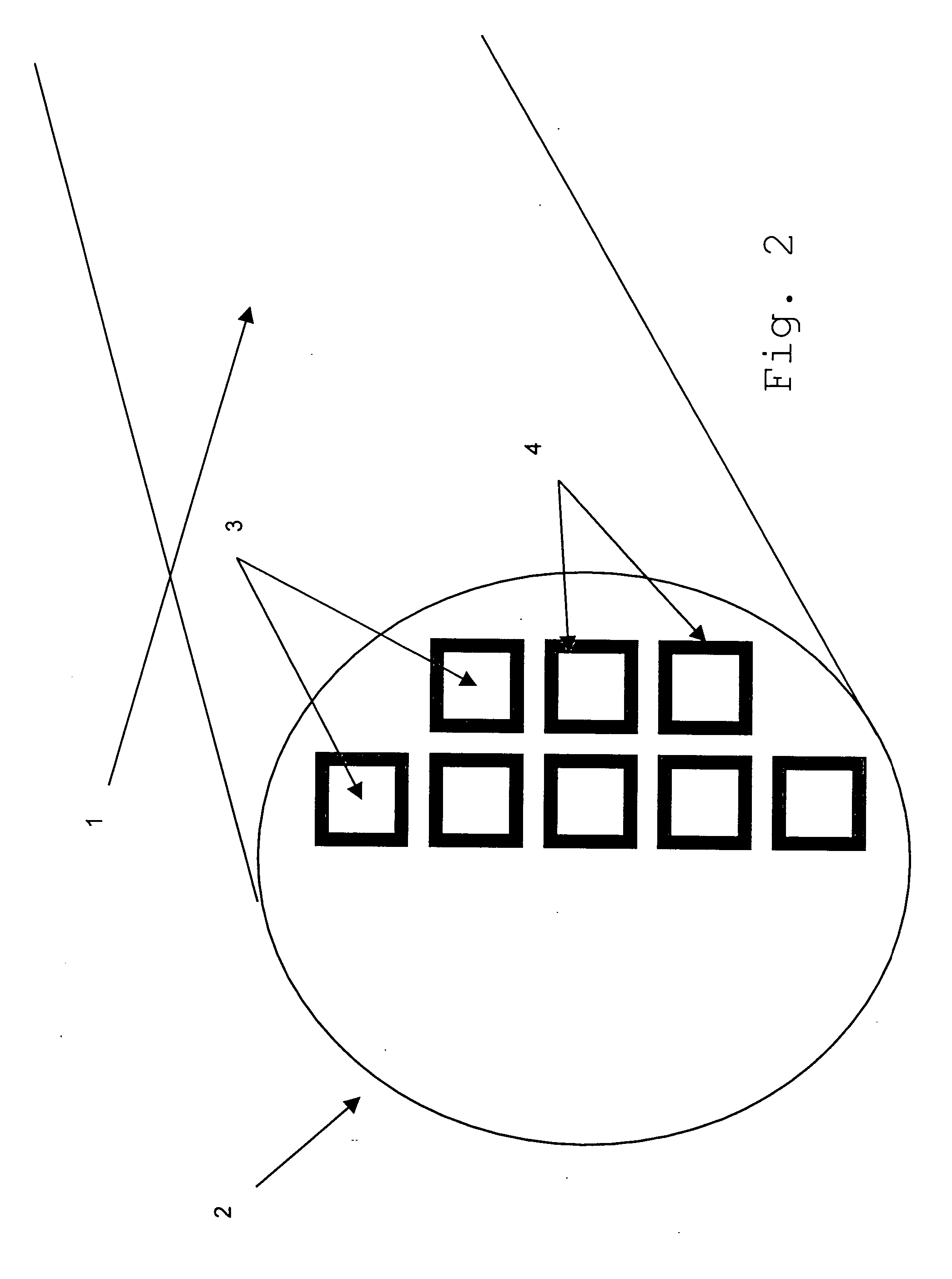

Membrane-assisted fluid separation apparatus and method

InactiveUS7459084B2Easy to disassembleReduce complexityMembranesGeneral water supply conservationFiberHigh concentration

This present invention relates to a fluid separation module adapted to separate a given fluid mixture into permeate and retentate portions using bundles of hollow fiber membranes. The membranes may be composed of different kinds of membranes depending on the application being used to separate the fluid mixture. The fluid separation module may be used to separate fluid mixtures by a number of different processes, including but not limited to, pervaporation, vapour permeation, membrane distillation (both vacuum membrane distillation and direct contact membrane distillation), ultra filtration, microfiltration, nanofiltration, reverse osmosis, membrane stripping and gas separation. The present invention also provides an internal heat recovery process applied in association with those fluid separation applications where separation takes place by evaporation through the membrane of a large portion of the feed into permeate. Desalination and contaminated water purification by means of vacuum membrane distillation are just two examples where the internal heat recovery process may be applied. In these two examples, large portions of the feed are separated by membranes into a high purity water permeate stream by evaporation through the membranes and into a retentate stream containing a higher concentration of dissolved components than present in the feed. In this process the permeate vapour that is extracted from the fluid separation module is compressed by an external compressor to increase the temperature of the vapour higher than the temperature of the feed entering the separation module. Heat from the permeate vapour at the elevated temperature is transferred back to the incoming feed fluid mixture entering the fluid separation module in a condenser / heat exchange.

Owner:LOEB INVESTORS CO 166 LP +1

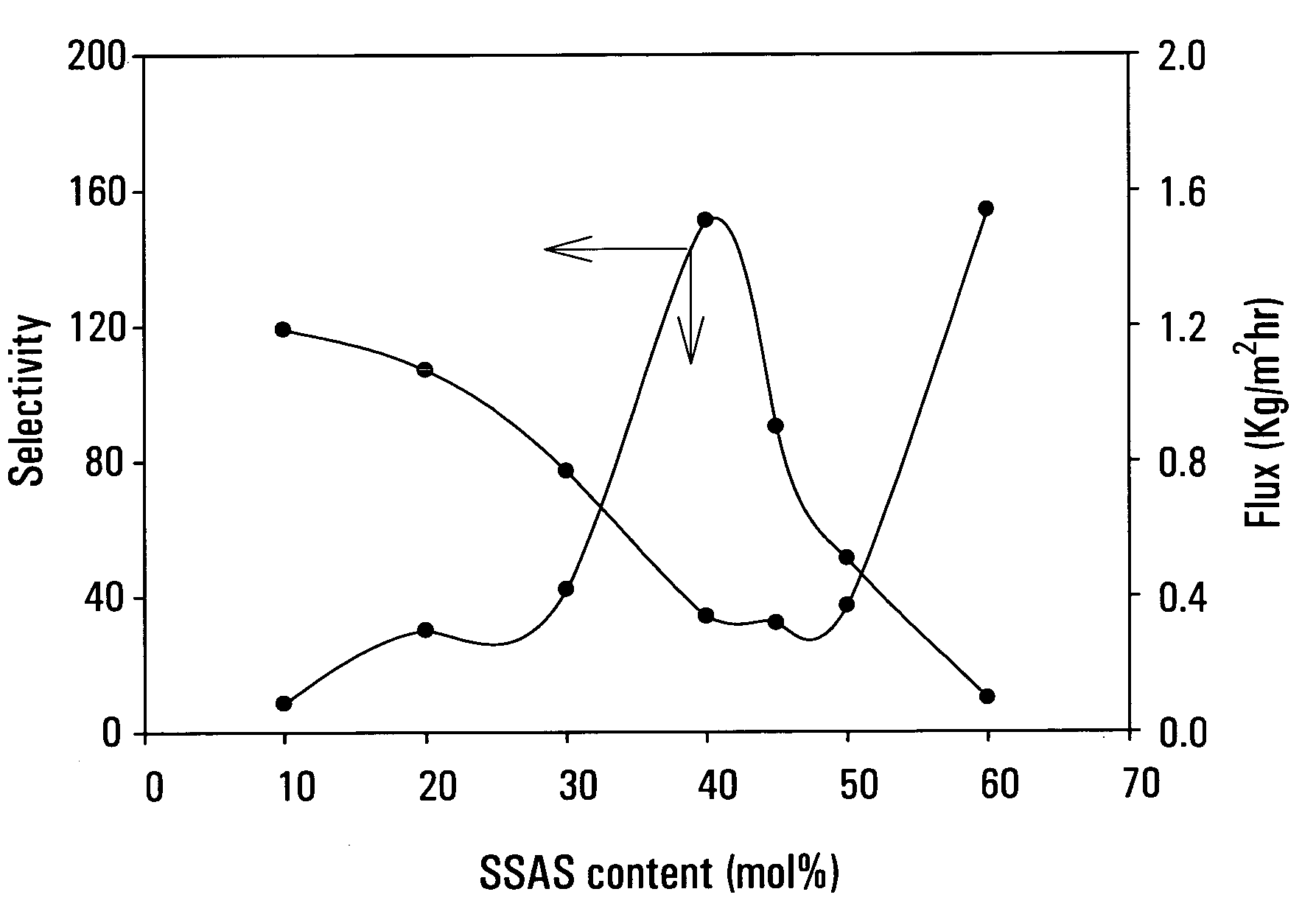

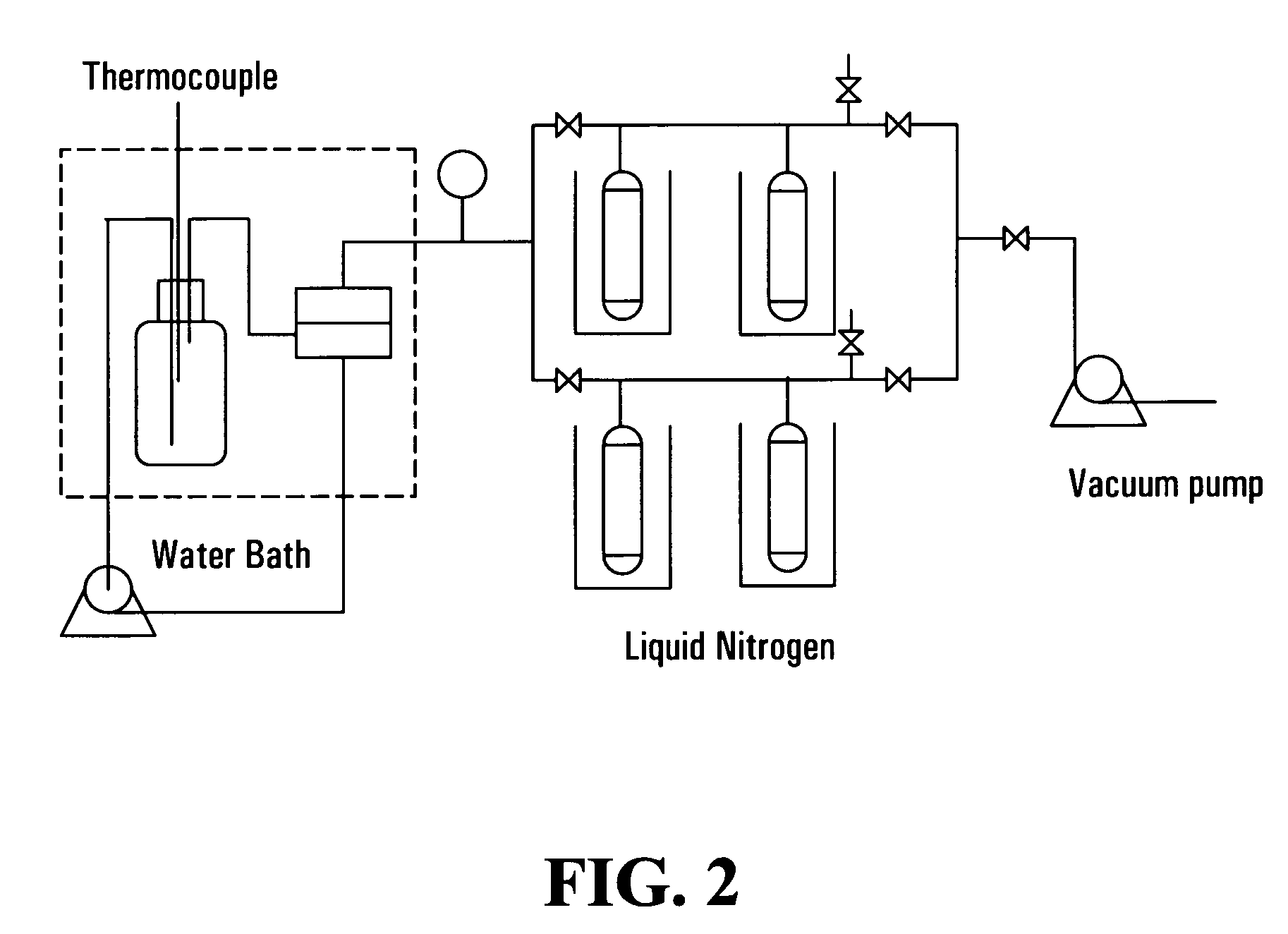

Pervaporation composite membranes

The present application discloses a composite membrane comprising (a) a support member that has a plurality of pores extending through the support member and (b) a cross-linked copolymer comprising (i) a cationic monomer and an anionic monomer and / or (ii) a zwitterionic monomer, which cross-linked copolymer fills the pores of the support member, the cross-linked copolymer having a permeability for a fluid that is dependent on the polarity of the fluid, wherein the permeability increases with increasing polarity. The present application also discloses a process for the preparation of the composite membrane, a pervaporation apparatus comprising the composite membrane, and methods for the use of the composite material in separation and dehydration processes.

Owner:MCMASTER UNIV

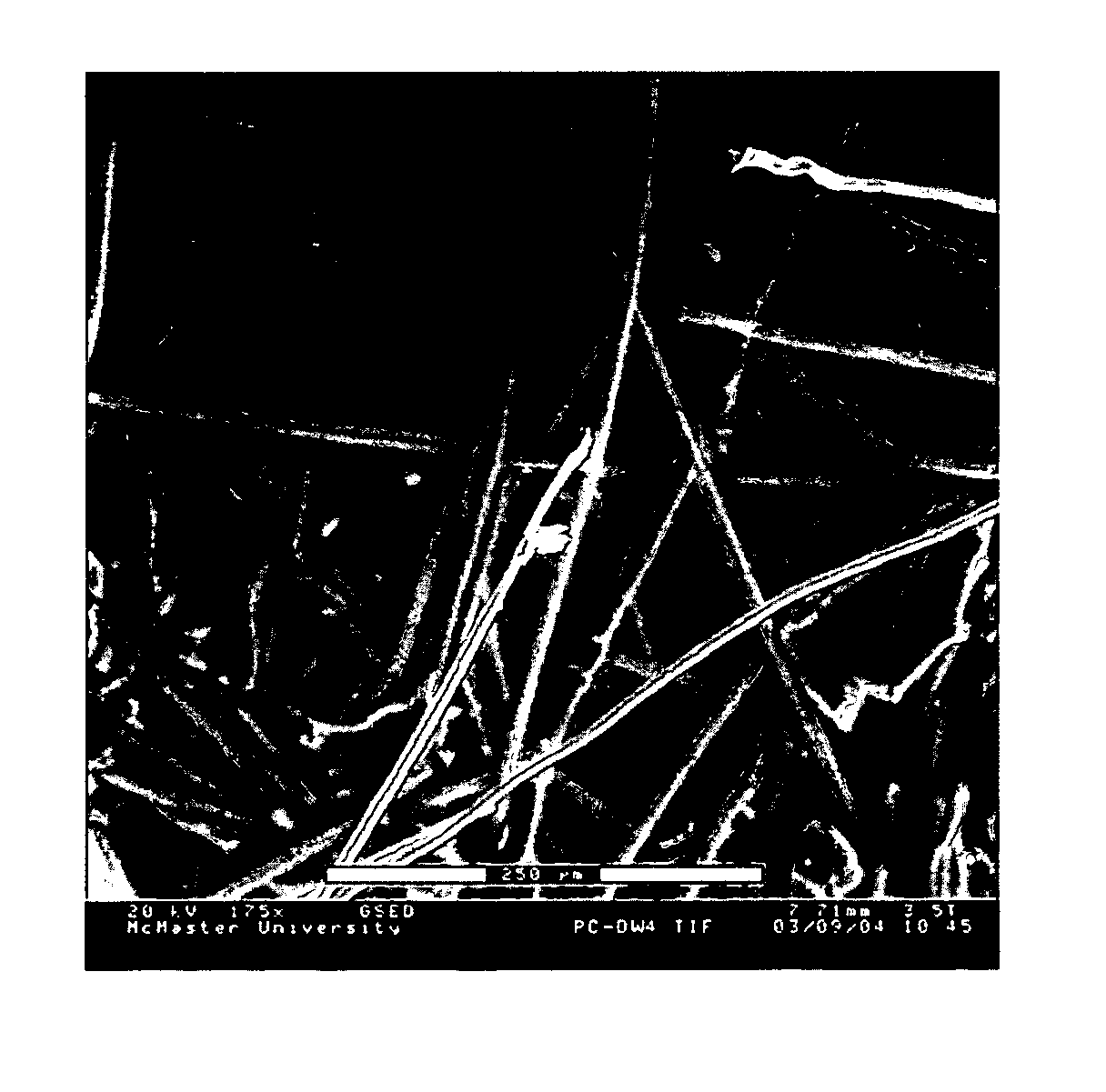

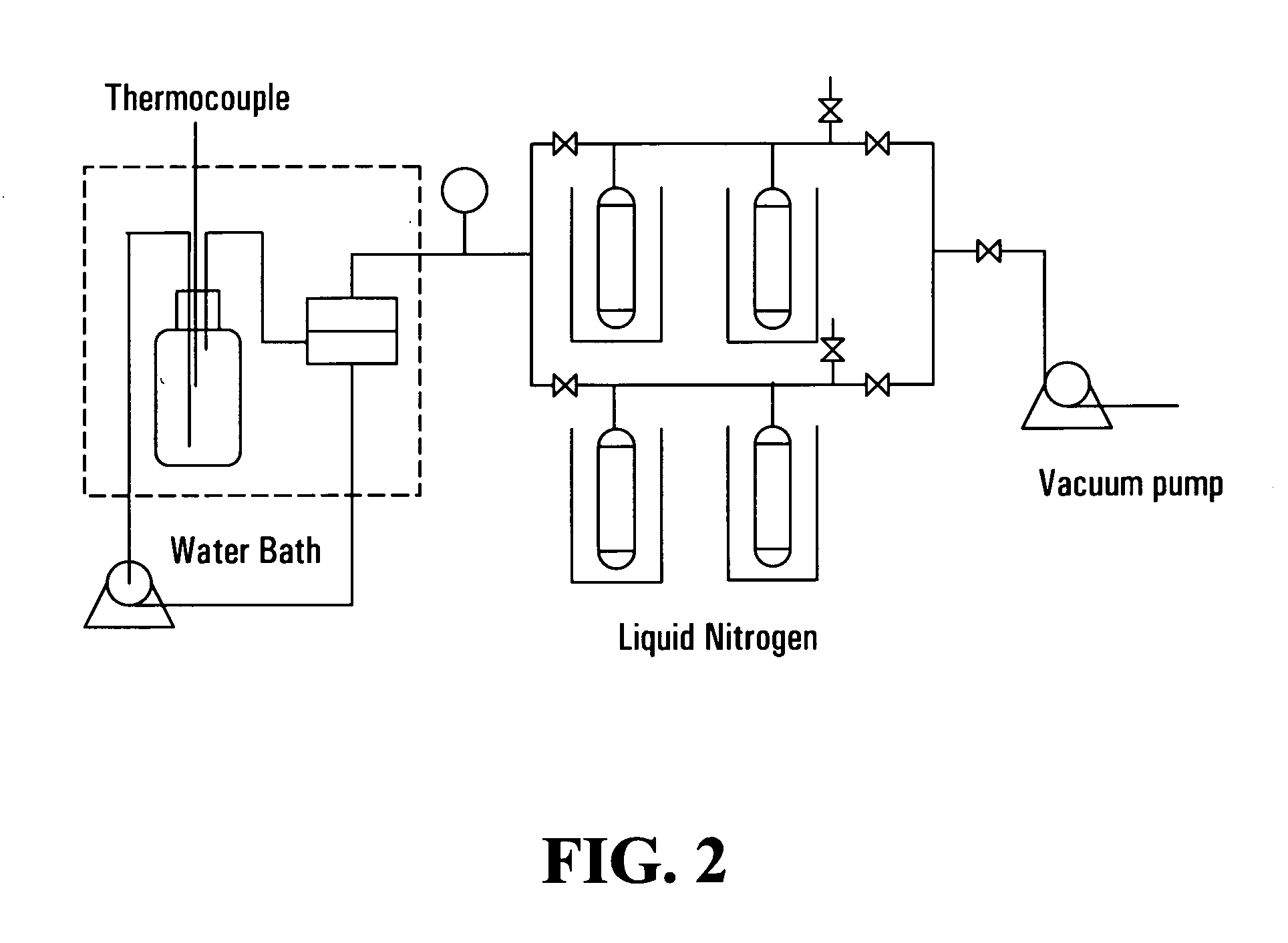

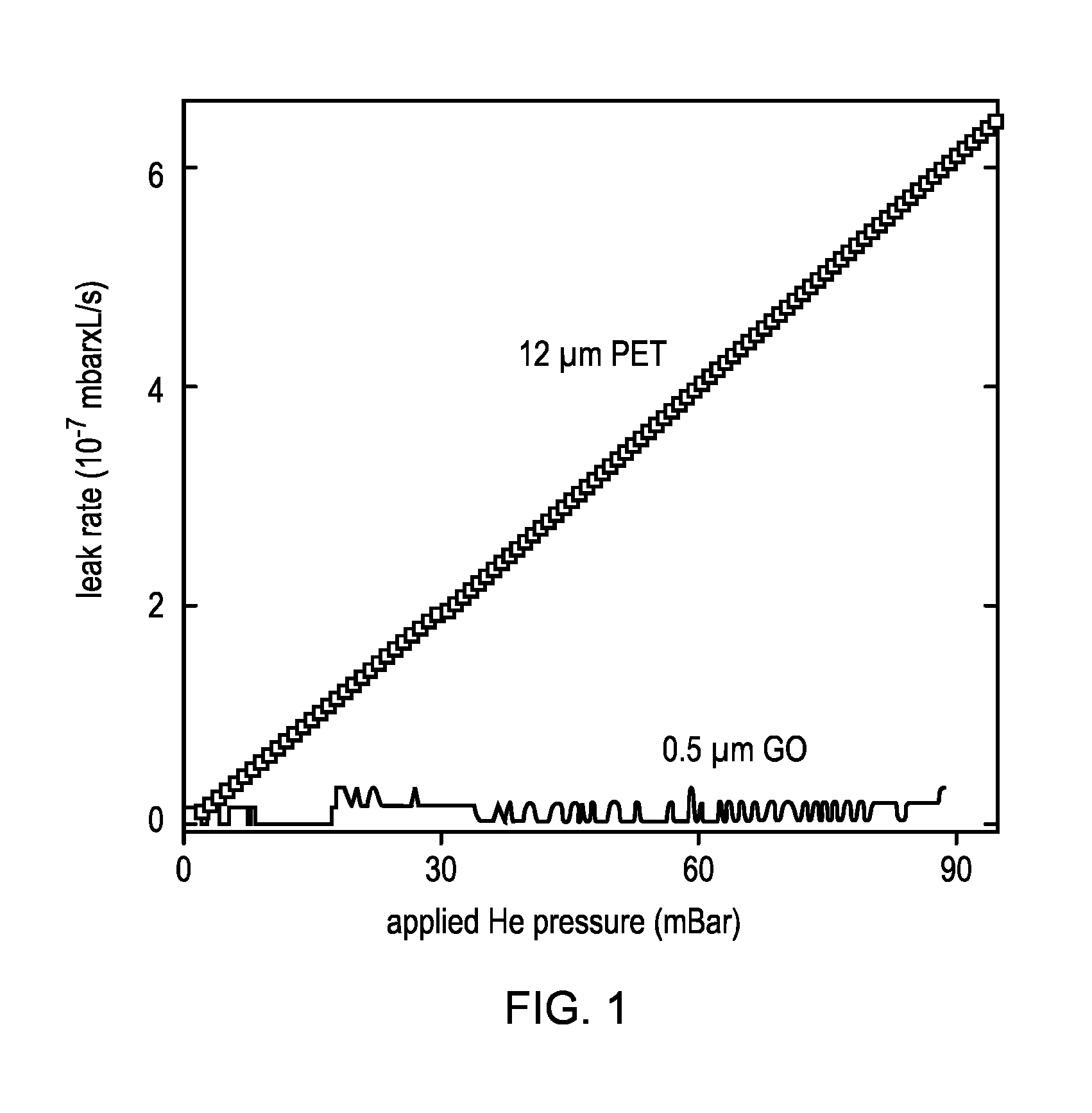

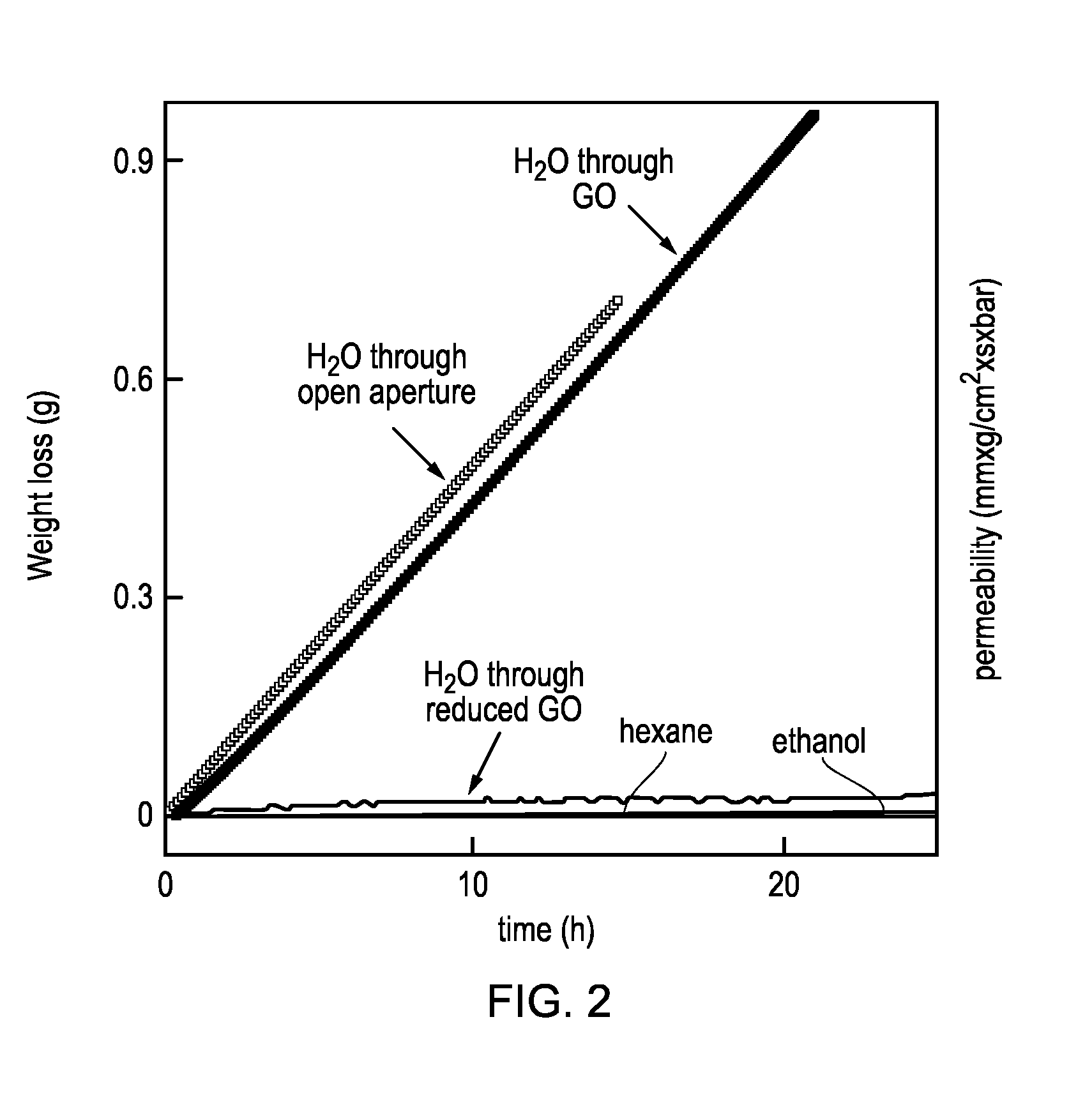

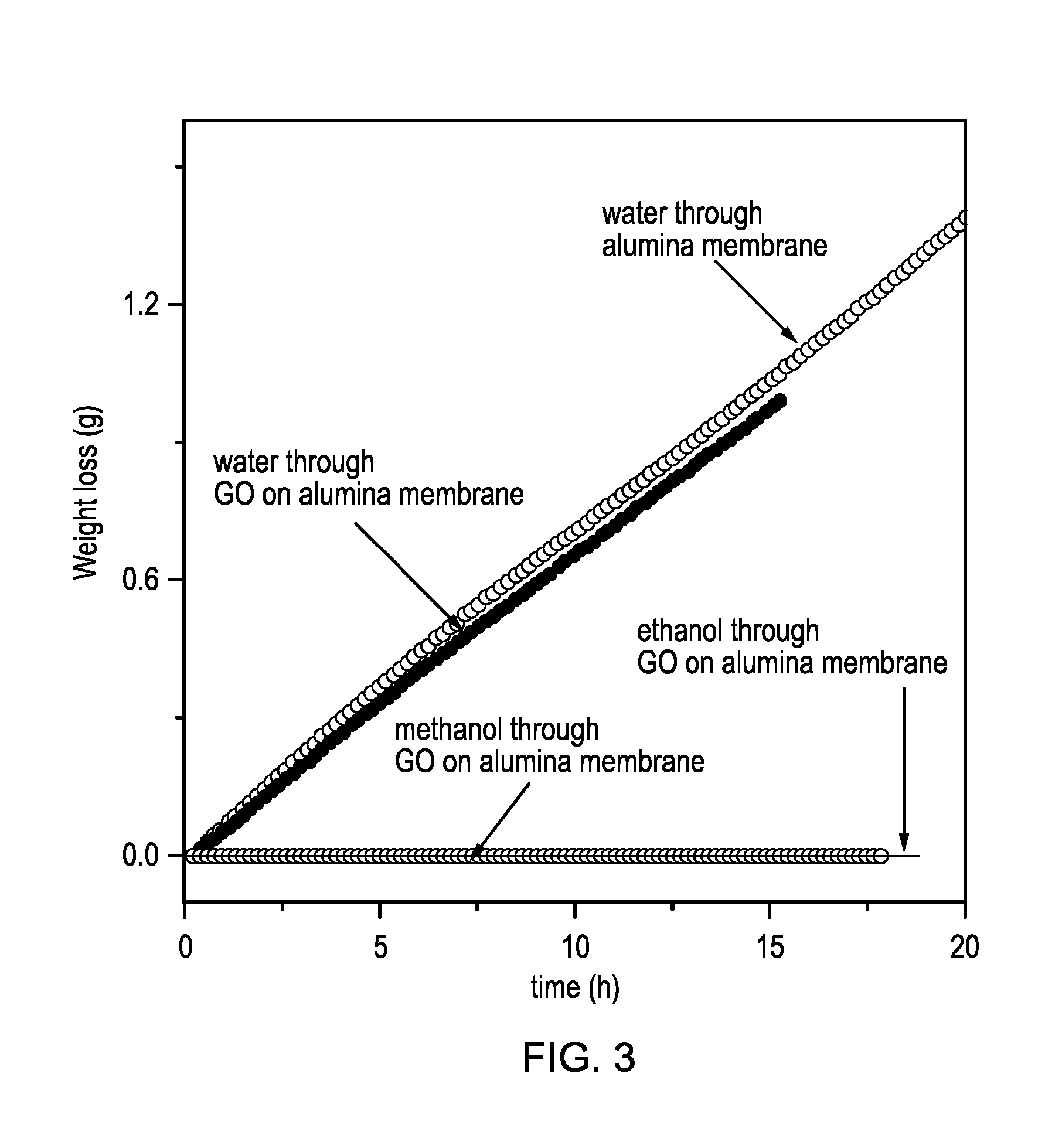

Separation of Water Using a Membrane

This invention relates to uses of graphene oxide, and in particular graphene oxide on a porous support, and a membrane comprising these materials. This invention also relates to methods of dehydration, which include vapour phase separation and pervaporation. Pervaporation is a method of separating mixtures of liquids using a membrane. Pervaporation consists of two basic steps: permeation of the permeate through the membrane and evaporation of the permeate from the other side of the membrane. Pervaporation is a mild which can be used to separate components which would not survive the comparatively harsh conditions needed for distillation (high temp, and / or low pressure).

Owner:UNIV OF MANCHESTER

Removal of Water and Methanol from Fluids

ActiveUS20080099400A1Efficient separationPowerfulMembranesUltrafiltrationChemical reactionInternal combustion engine

A method of removing water and / or methanol from fluid mixtures of the water or methanol with other compounds uses vapor permeation or pervaporation of the water or methanol, as the case may be, from the mixture through a membrane having an amorphous perfluoropolymer selectively permeable layer. The novel process can be applied in such exemplary embodiments as (a) removing water or methanol from mixtures of compounds that have relative volatility of about 1-1.1 or that form azeotropic mixtures with water or methanol, (b) the dehydration of hydrocarbon oil such as hydraulic fluid to concentrations of water less than about 50 ppm, (c) removing water and methanol byproducts of reversible chemical reactions thereby shifting equilibrium to favor high conversion of reactants to desirable products, (d) drying ethanol to less than 0.5 wt. % water as can be used in fuel for internal combustion engines, and (e) controlling the water content to optimum concentration in enzyme-catalyzed chemical reactions carried out in organic media.

Owner:COMPACT MEMBRANE SYST INC

Spiral-wound liquid membrane module for separation of fluids and gases

InactiveUS20060131235A1Lower energy requirementsEfficient separationMembranesSolid sorbent liquid separationChemical physicsSpiral wound

The present invention is a filtering and chemical separation device that performs the operations of solvent extraction and pervaporation in a single piece of equipment, configured as a spiral-wound membrane module, and provides for the replenishment of the solvent in the supported liquid membrane while the module continues in operation. It provides a solution to the problem of separating miscible compounds efficiently and with low energy requirements.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE

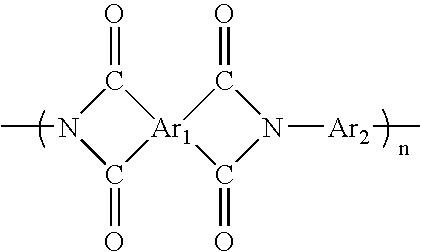

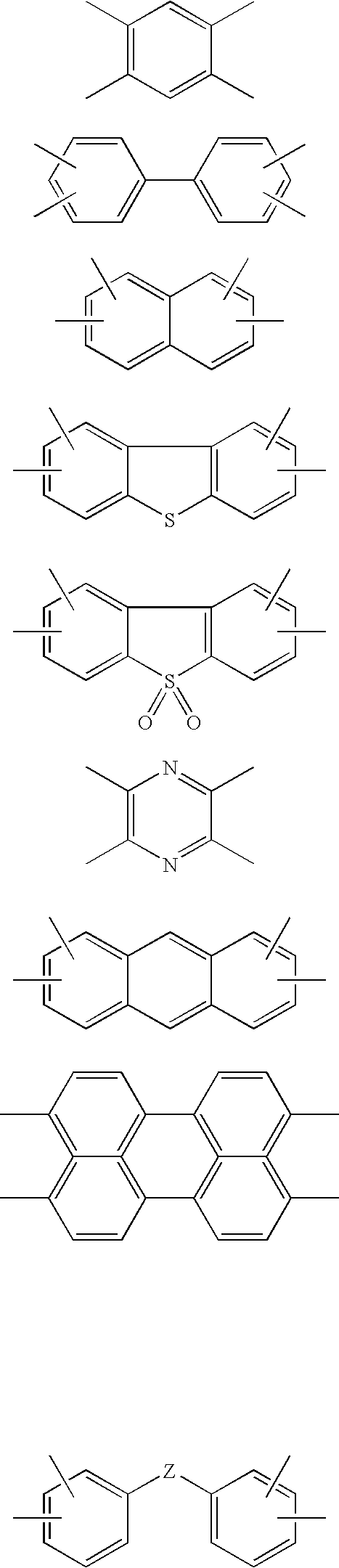

Polyimide membranes

InactiveUS20040177753A1Improve performanceStable membranes for gas/vapourMembranesIsotope separationDendrimerHydrocarbon mixtures

The present invention deals with a process for treating a polyimide comprising exposing said polyimide to a compound selected from the group consisting of dendrimers, hyperbranched polymers and mixtures thereof. The polyimide may be in the form of a membrane and the membrane, after treatment according to the process of the invention, may be suitable for use in a membrane-based separation technique, for example gas separation, filtration, microfiltration, ultrafiltration, reverse osmosis or pervaporation. The membrane may for example be suitable for separation of gas and hydrocarbon mixtures including mixtures of H2 / N2, H2 / CO2, He / N2, CO2 / CH4, and C2-C4 hydrocarbon mixtures.

Owner:NAT UNIV OF SINGAPORE

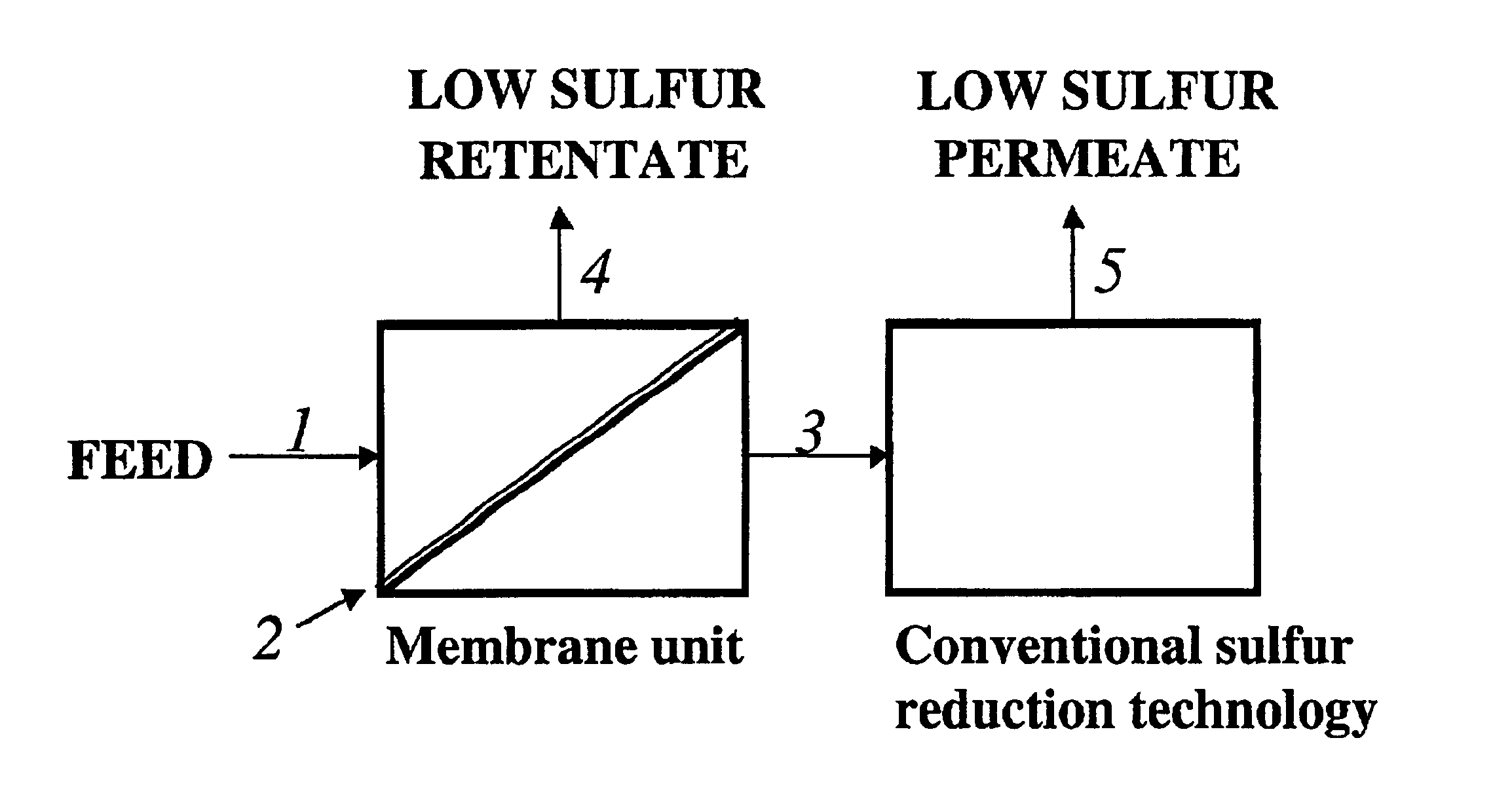

Membrane separation for sulfur reduction

InactiveUS6896796B2Improve economyMinimized volumeDialysisTreatment with plural serial refining stagesNaphthaGasoline

A membrane process for the removal of sulfur species from a naphtha feed, in particular, a FCC light cat naphtha, without a substantial loss of olefin yield is disclosed. The process involves contacting a naphtha feed stream with a membrane having sufficient flux and selectivity to separate a sulfur deficient retentate fraction from a sulfur enriched permeate fraction, preferably, under pervaporation conditions. Sulfur deficient retentate fractions are useful directly into the gasoline pool. Sulfur-enriched permeate fractions are rich in sulfur containing aromatic and nonaromatic hydrocarbons and are further treated with conventional sulfur removal technologies, e.g. hydrotreating, to reduce sulfur content. The process of the invention provides high quality naphtha products having a reduced sulfur content and a high content of olefin compounds.

Owner:WR GRACE & CO CONN

Membrane separation process

ActiveUS20070114177A1Organic compounds purification/separation/stabilisationMembranesSpray nozzlePervaporation

The invention relates to an improved membrane pervaporation and vapor permeation system in which the vacuum is produced by a fluid passing through a Venturi-type nozzle. The fluid is chosen from solvents that have little or no affinity for the permeate molecules. It is applicable over process feed rates, and can be used for the separation of aromatic species from hydrocarbon.

Owner:EXXON RES & ENG CO

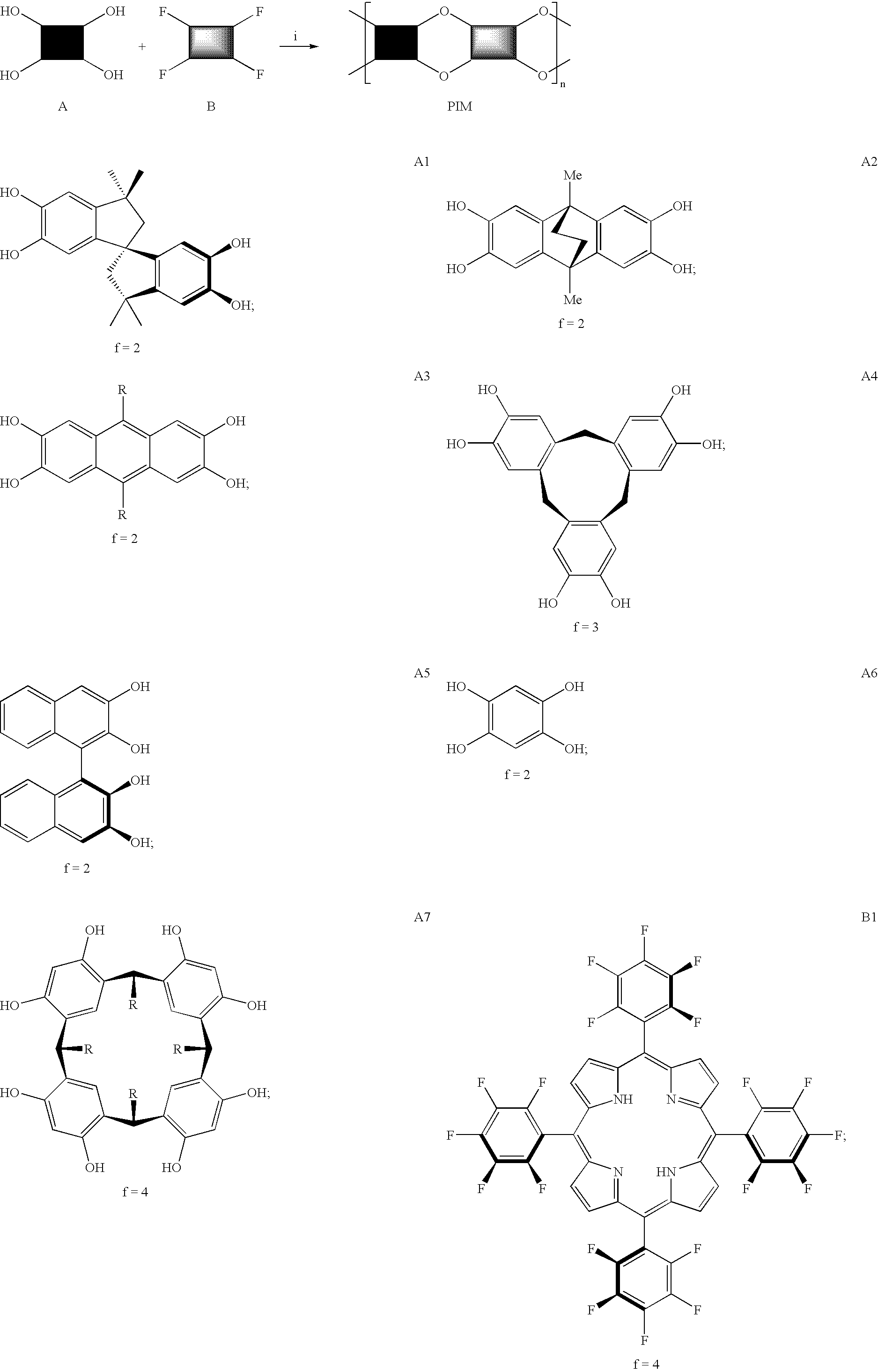

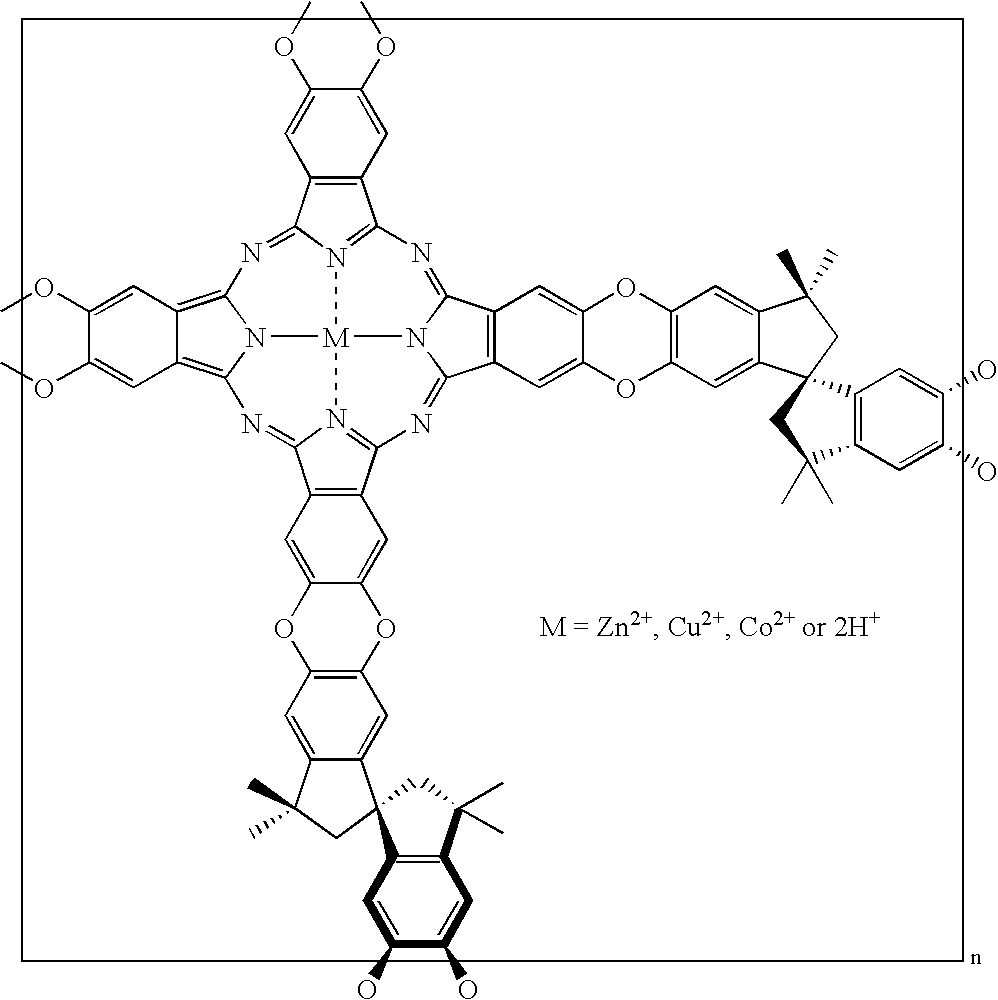

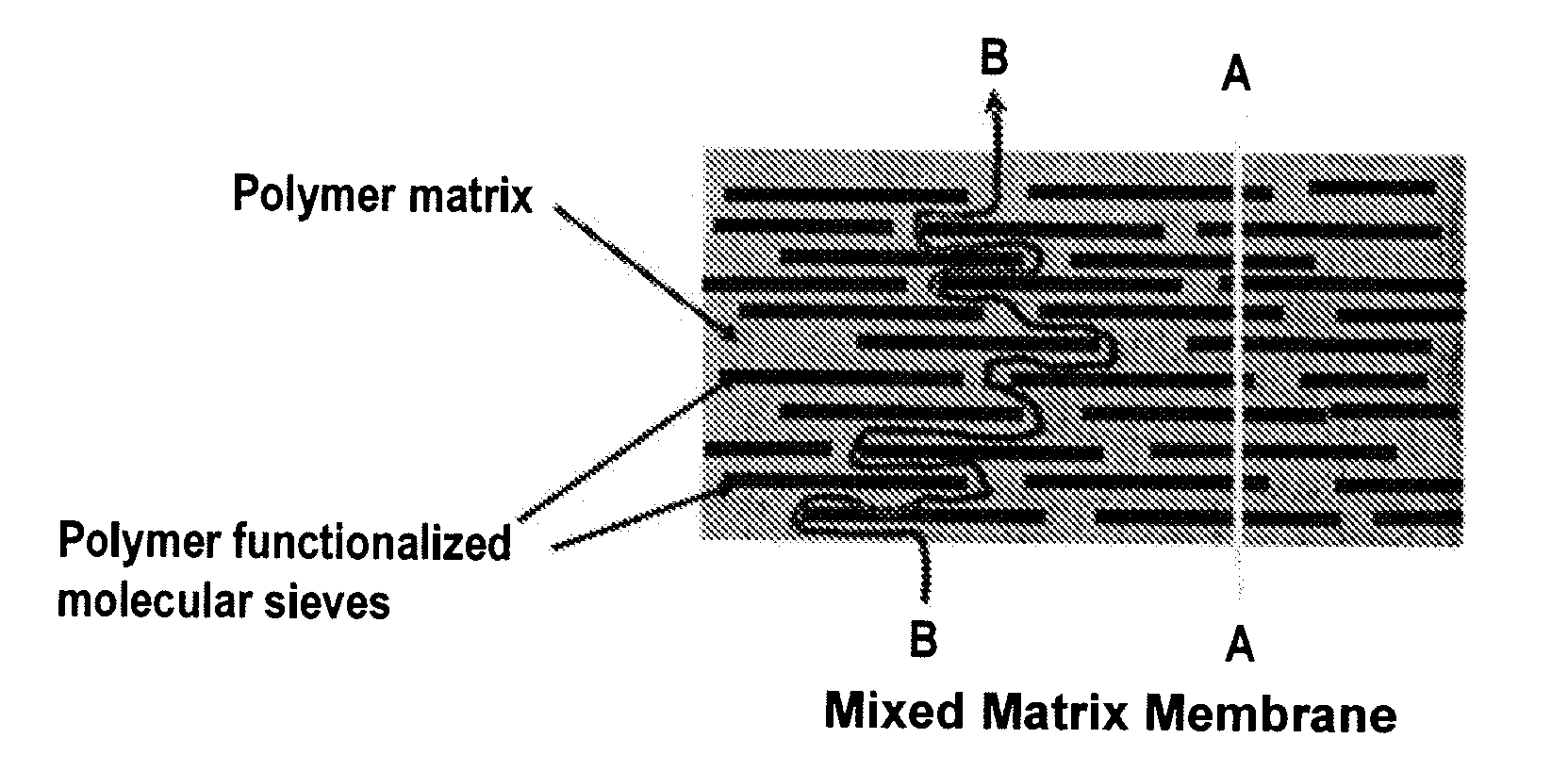

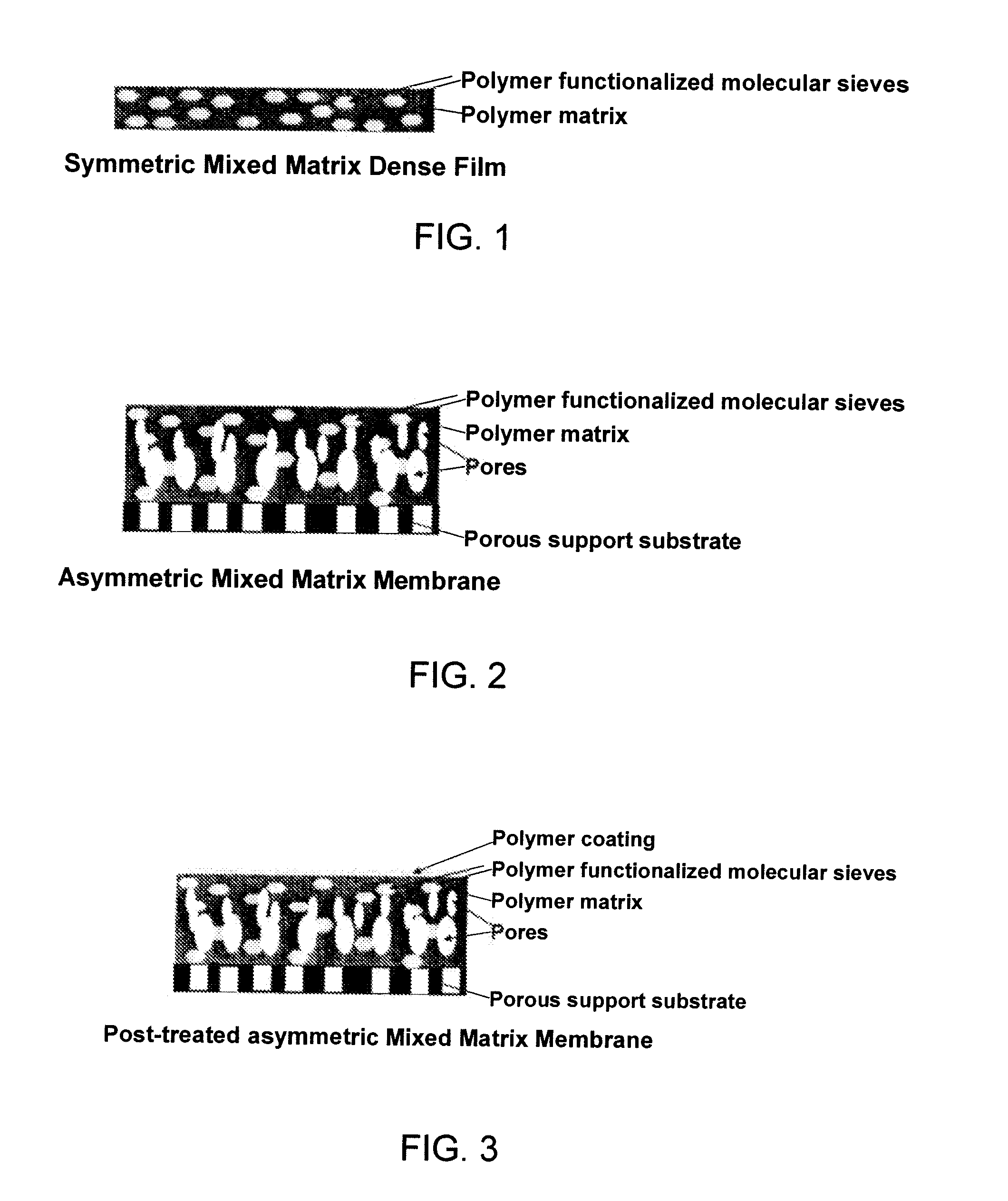

High Flux Mixed Matrix Membranes for Separations

InactiveUS20070209505A1High selectivityIncrease fluxSemi-permeable membranesIsotope separationParaffin waxPetrochemical

The present invention discloses a new class of high flux mixed matrix membranes that are made by incorporating porous inorganic fillers (e.g. microporous and mesoporous molecular sieves, carbon molecular sieves, porous metal-organic frameworks) into a high flux high surface area microporous organic polymer matrix. These microporous organic polymers are referred to as “polymers of intrinsic microporosity” or PIMs. The high flux membranes are promising for a wide range of separations including liquid separations such as pervaporation of phenol / water and also gas separations in the petrochemical, refinery, and natural gas industries such as methane / carbon dioxide, olefin / paraffin and iso / normal paraffins separations.

Owner:UOP LLC

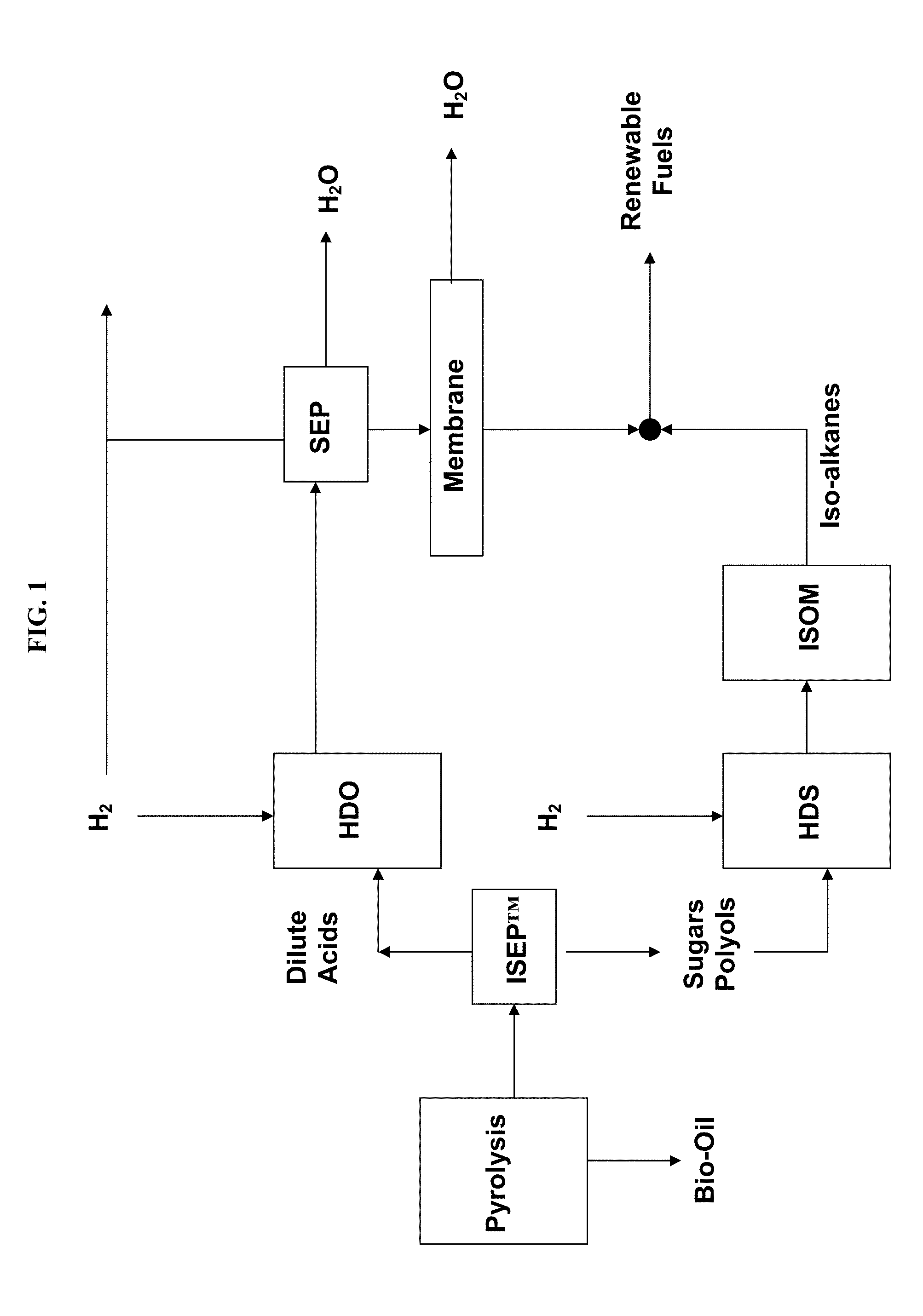

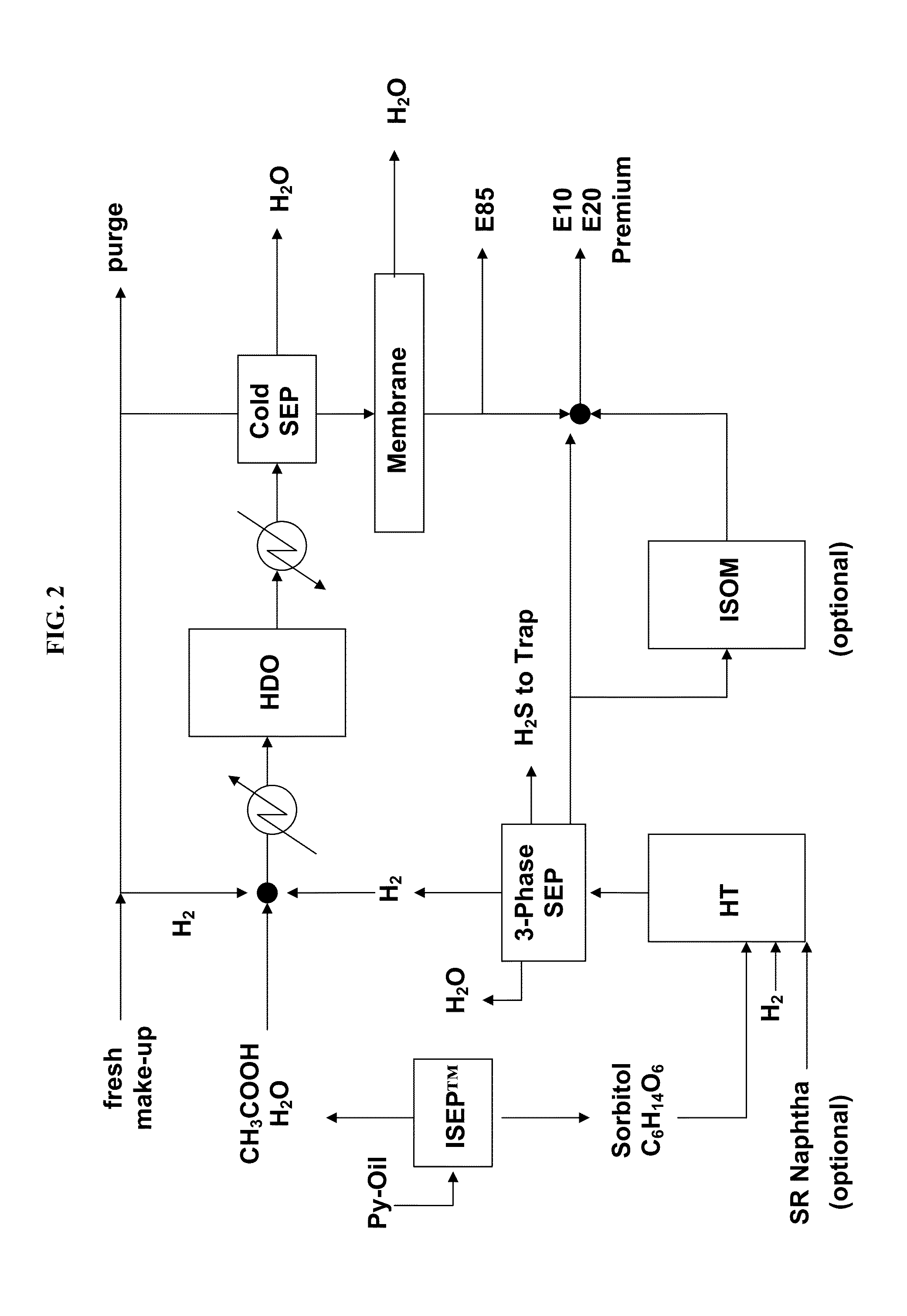

Advanced cellulosic renewable fuels

ActiveUS20130067803A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsOrganic acidCellulose

The invention relates to a process to manufacture advanced cellulosic gasolines. Dilute organic acids derived from pyrolized biomass are converted to their corresponding alcohols in a stand-alone hydrodeoxygenation unit followed by membrane pervaporation step to remove water. The alcohol product is blended directly into a neat hydrocarbon fuel basestock to make unadditized gasoline.

Owner:PHILLIPS 66 CO

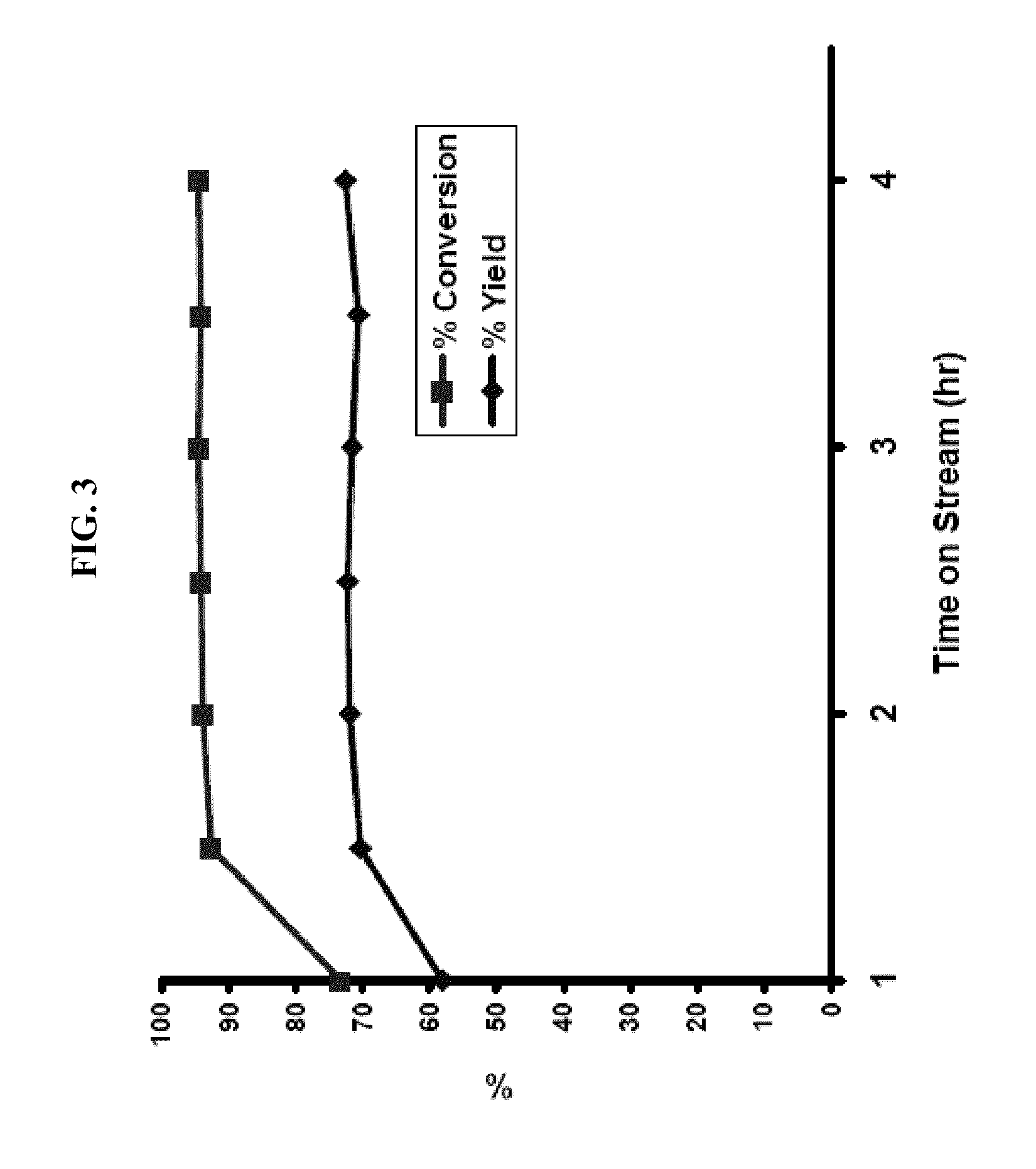

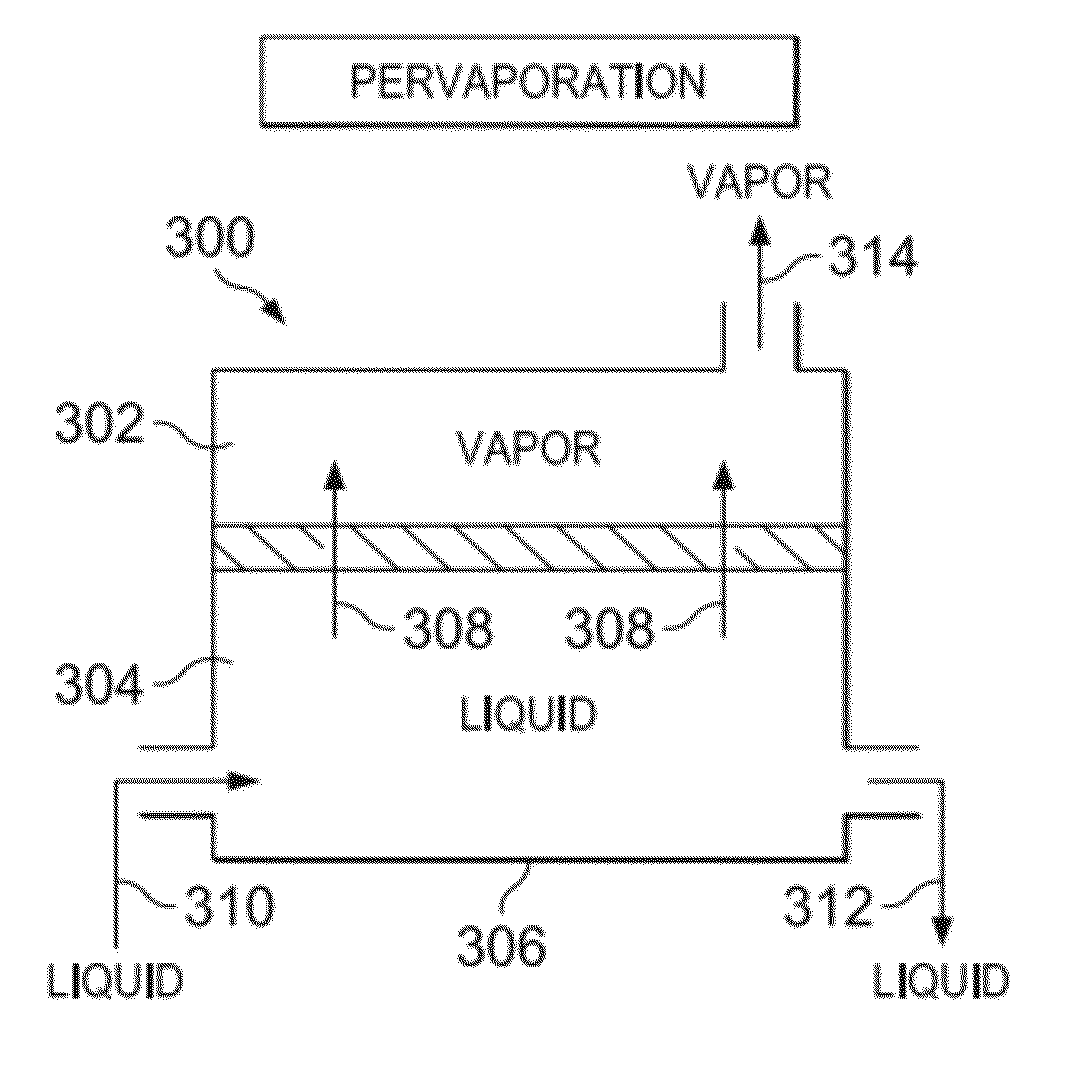

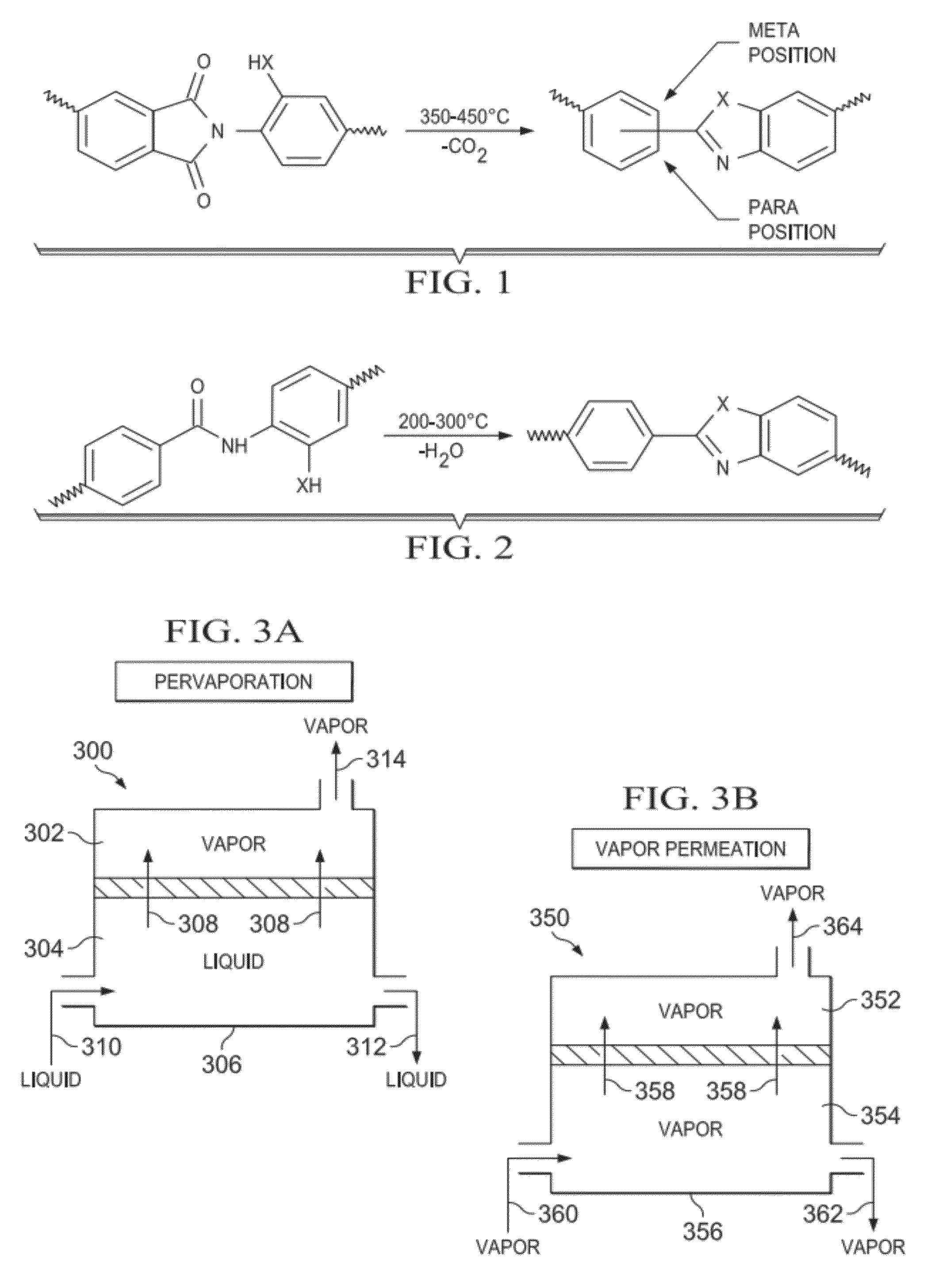

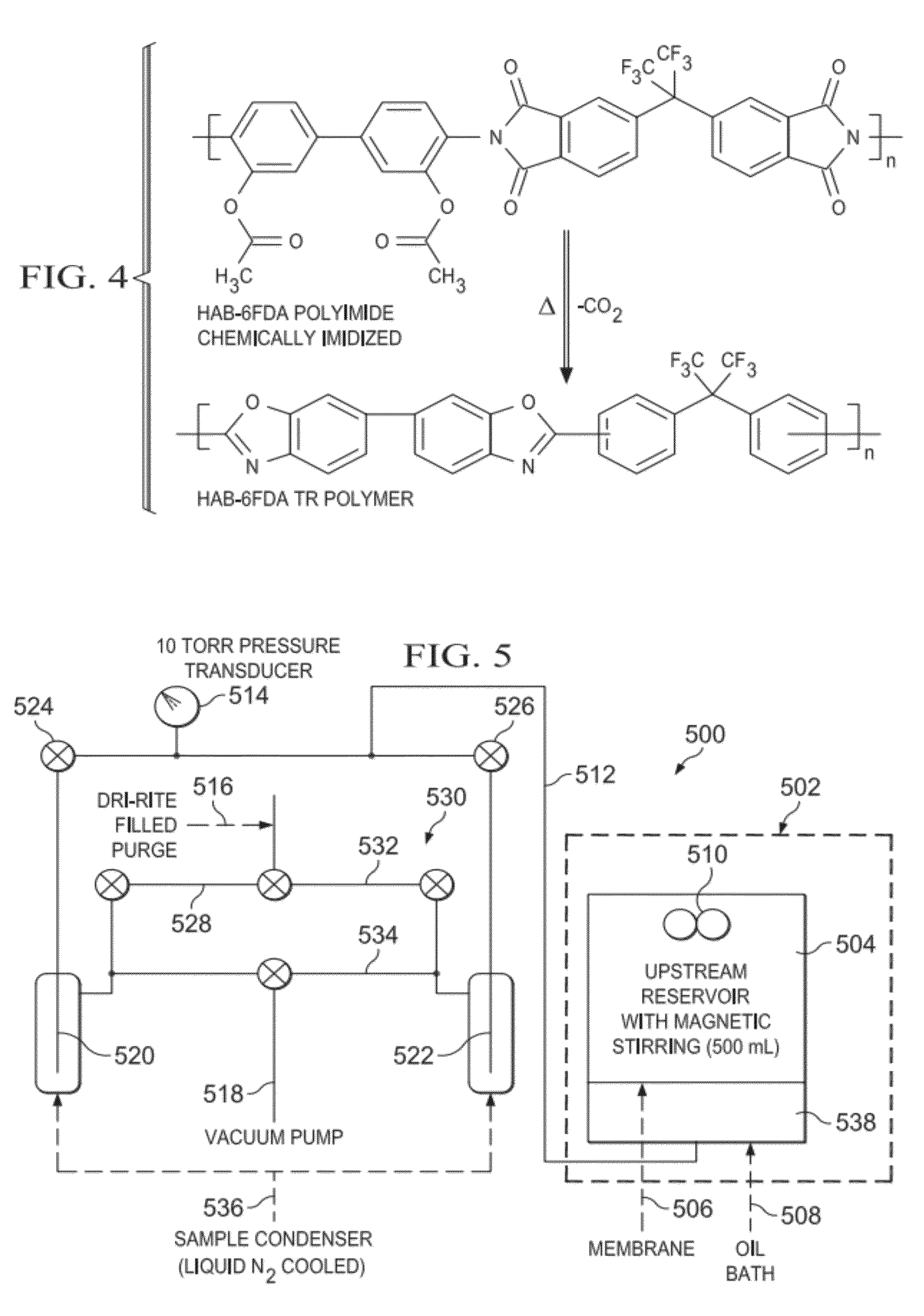

Thermally Rearranged (TR) Polymers as Membranes for Ethanol Dehydration

InactiveUS20120305484A1Improved separation propertiesGood chemical stabilityDewatering/demulsification with mechanical meansSolid sorbent liquid separationBiodieselOrganic solvent

Synthesis and use of a new class of polymeric materials with favorable separation characteristics for the dehydration of ethanol and other organic solvents is described herein. The thermally rearranged (TR) polybenzoxazole (PBO), polybenzimidazole (PBI) and polybenzothiazole (PBT) membranes of the present invention can be used for the dehydration of ethanol during processing to fuel grade biodiesel by either pervaporation or vapor permeation. The unique microstructure of the membranes provides excellent separation characteristics, and this, coupled with their inherent thermal and chemical stability, enables their usage in other separations, such as the dehydration of other organic solvents.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Membrane separation process

ActiveUS7497895B2Organic compounds purification/separation/stabilisationMembranesSpray nozzlePervaporation

The invention relates to an improved membrane pervaporation and vapor permeation system in which the vacuum is produced by a fluid passing through a Venturi-type nozzle. The fluid is chosen from solvents that have little or no affinity for the permeate molecules. It is applicable over process feed rates, and can be used for the separation of aromatic species from hydrocarbon.

Owner:EXXON RES & ENG CO

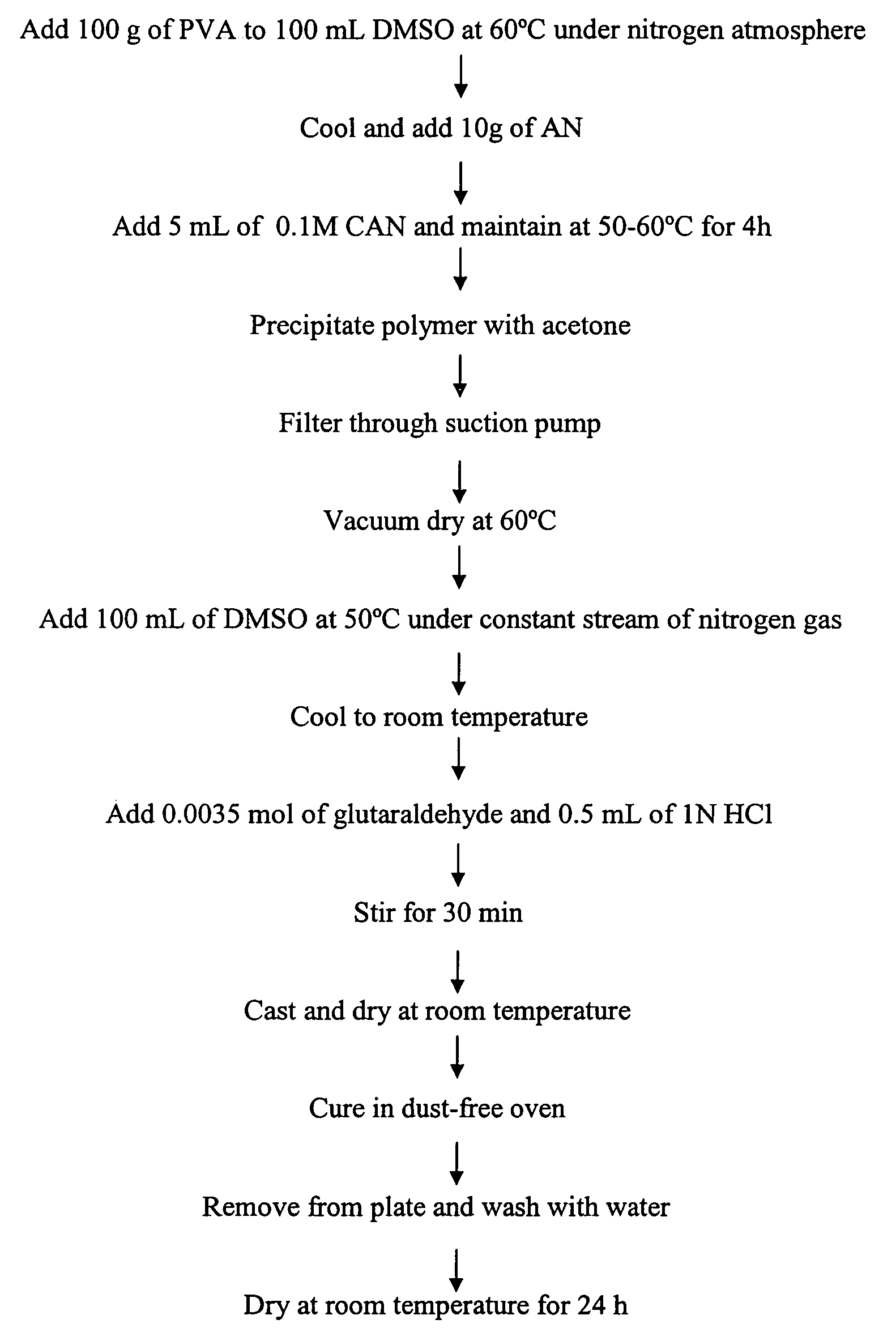

Pervaporation membranes and methods of use

InactiveUS7045062B1Easy to driveSemi-permeable membranesMembranesOrganic compoundToxic industrial waste

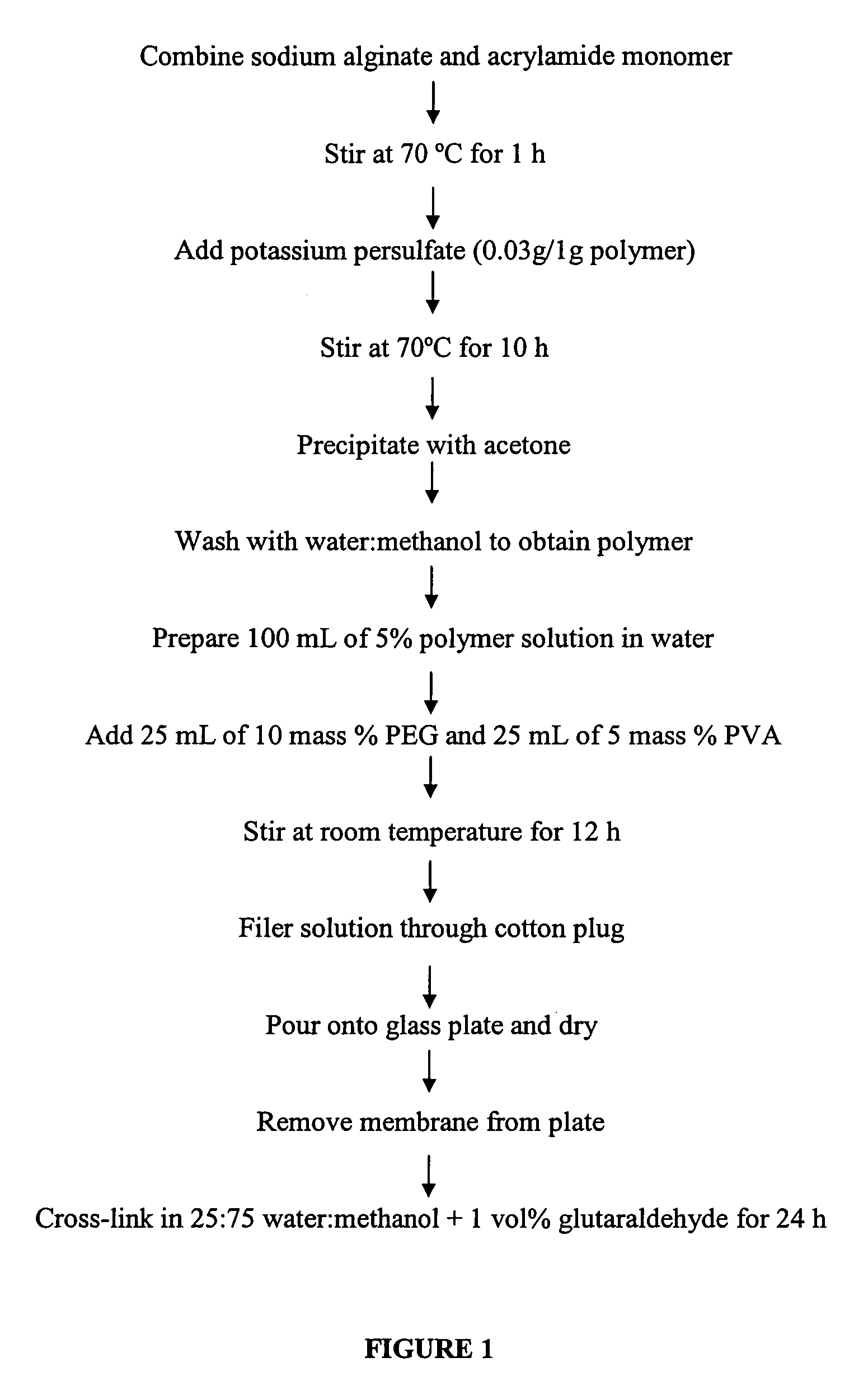

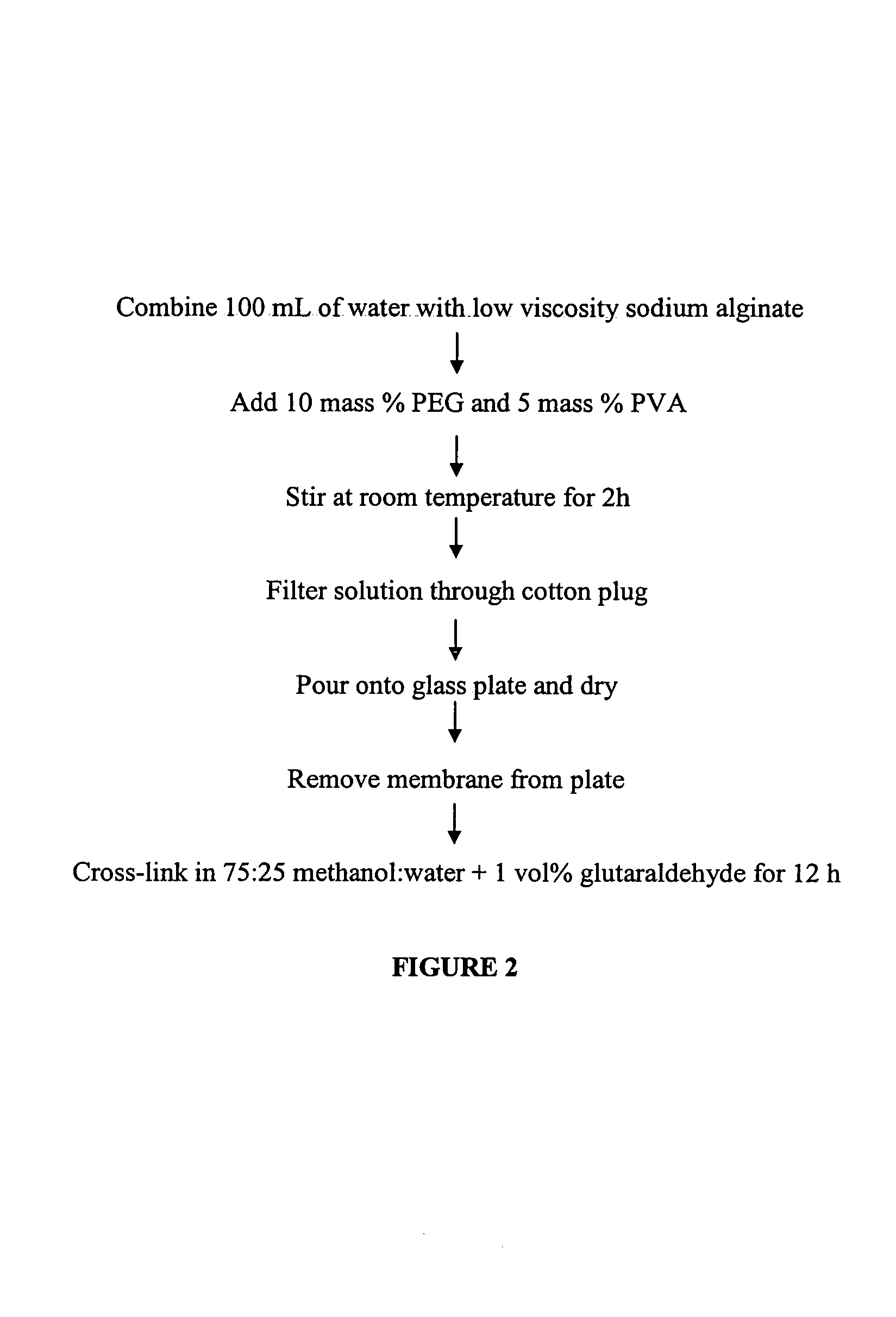

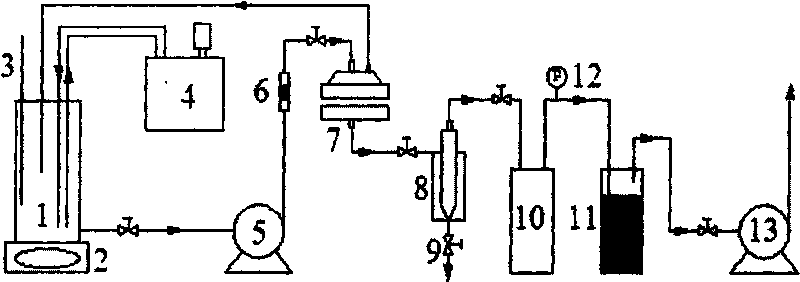

Pervaporation membranes including poly(acrylamide)-grafted alginate membranes, which may be optimized for the separation of alcohols from water, low viscosity sodium alginate membranes containing PEG and PVA, which may be optimized for the separation of organic acids from water, and copolymeric PAN-grafted PVA membranes, which may be optimized for the separation of DMF from water, and methods of making such membranes. Use of such membranes in pervaporation and pervaporation devices containing such membranes. Use of such membranes alone or in combination with ion-exchange membranes for recovery of organic compounds or for water purification applications such as production of potable water or industrial waste treatment. The membranes of the present invention may be used to remove trace amounts of water from organic compounds.

Owner:SEVENTY SEVENTH MERIDIAN CORP

Mixed Matrix Membranes Containing Ion-Exchanged Molecular Sieves

InactiveUS20100018926A1Improve permeabilityHigh selectivityMembranesIsotope separationFiberReverse osmosis

The present invention discloses mixed matrix membranes (MMMs) comprising ion-exchanged molecular sieves such as UZM-5 zeolite ion-exchanged with Li+ cation (Li-UZM-5) and a continuous polymer matrix and methods for making and using these membranes. These MMMs, comprising ion-exchanged molecular sieves, in the form of symmetric dense films, asymmetric flat sheets, asymmetric hollow fibers, or thin-film composites, have exhibited simultaneously increased selectivity and permeability (or permeance) over polymer-only membranes and the mixed matrix membranes made from molecular sieves that have not been ion exchanged for gas separations. These MMMs are suitable for a variety of liquid, gas, and vapor separations such as desalination of water by reverse osmosis, deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

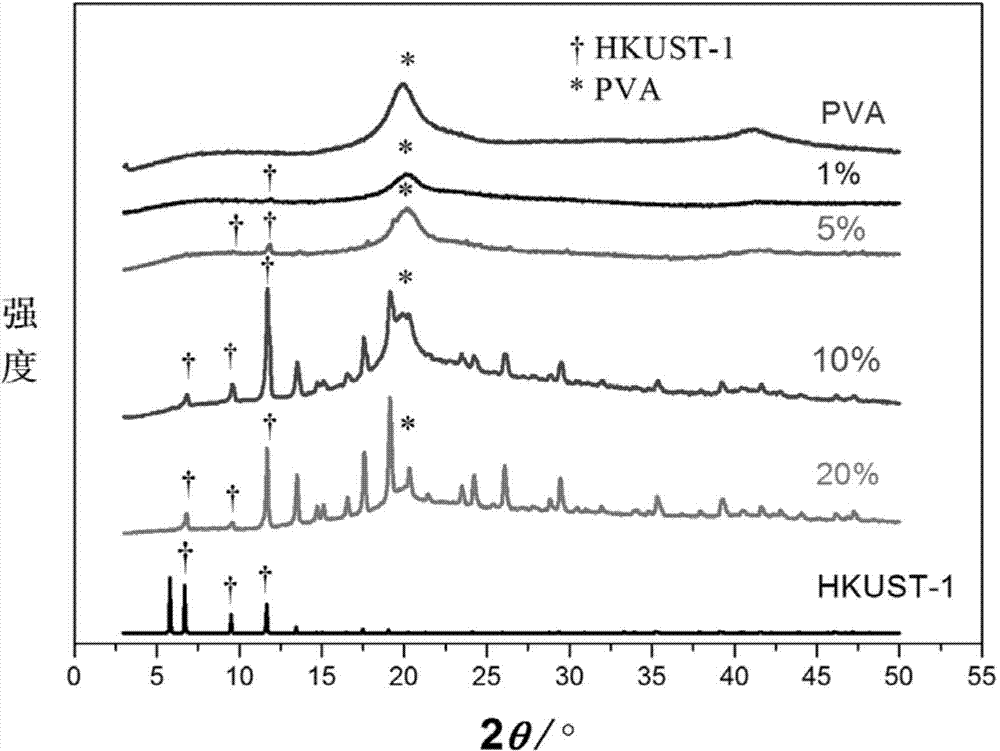

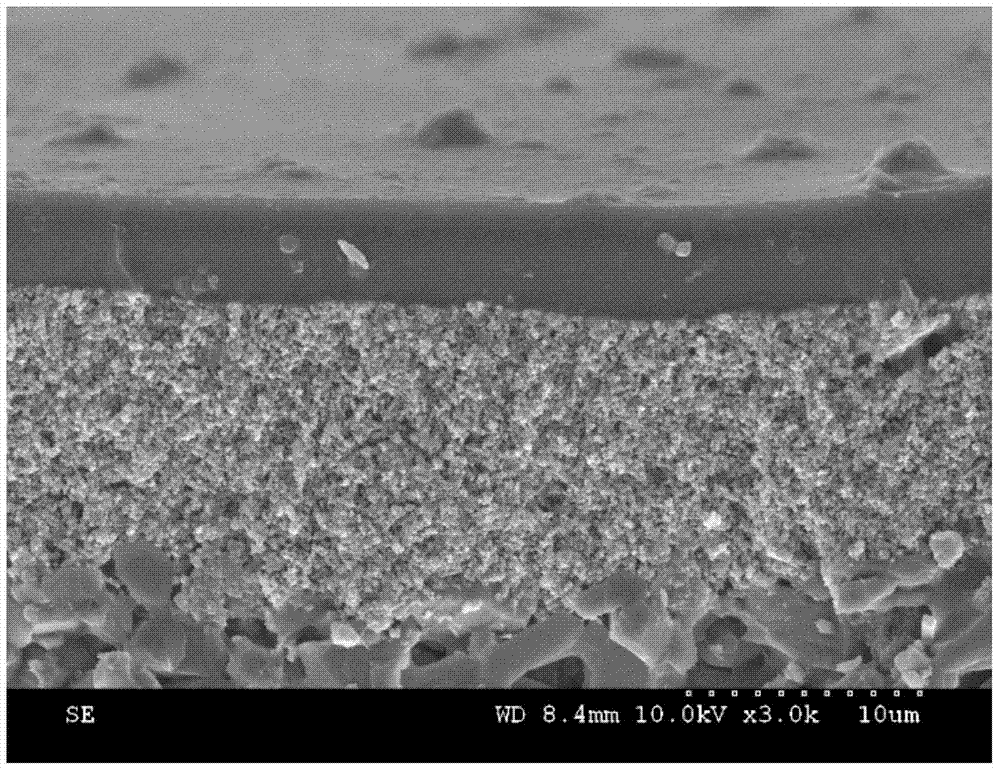

PDMS/PVDF pervaporation composite membrane, preparation method and application thereof

InactiveCN101703898AHigh permeation fluxEasy to prepareSemi-permeable membranesCarboxylic compound separation/purificationAcetic acidMicrofiltration membrane

The invention discloses a PDMS / PVDF (polydimethylsiloxane / polyvinylidence fluoride) pervaporation composite membrane which comprises a polyvinylidence fluoride supporting layer and a polydimethylsiloxane separating layer with different bore diameters. The composite membrane has high separating capability and separating efficiency when applied to separating acetic acid in an acetic acid water solution. The PDMS / PVDF pervaporation composite membrane comprises a separating layer and a supporting layer, wherein the separating layer is uniformly attached on the supporting layer, the total thickness of the composite membrane is 120-150 micrometers, the thickness of the skin separating layer is 30-40 micrometers, the supporting layer is made of polyvinylidence fluoride microfiltration membranes with bore diameters being respectively 0.1-2.0 micrometers, and the separating layer is made of the polydimethylsiloxane.

Owner:NANJING UNIV OF TECH

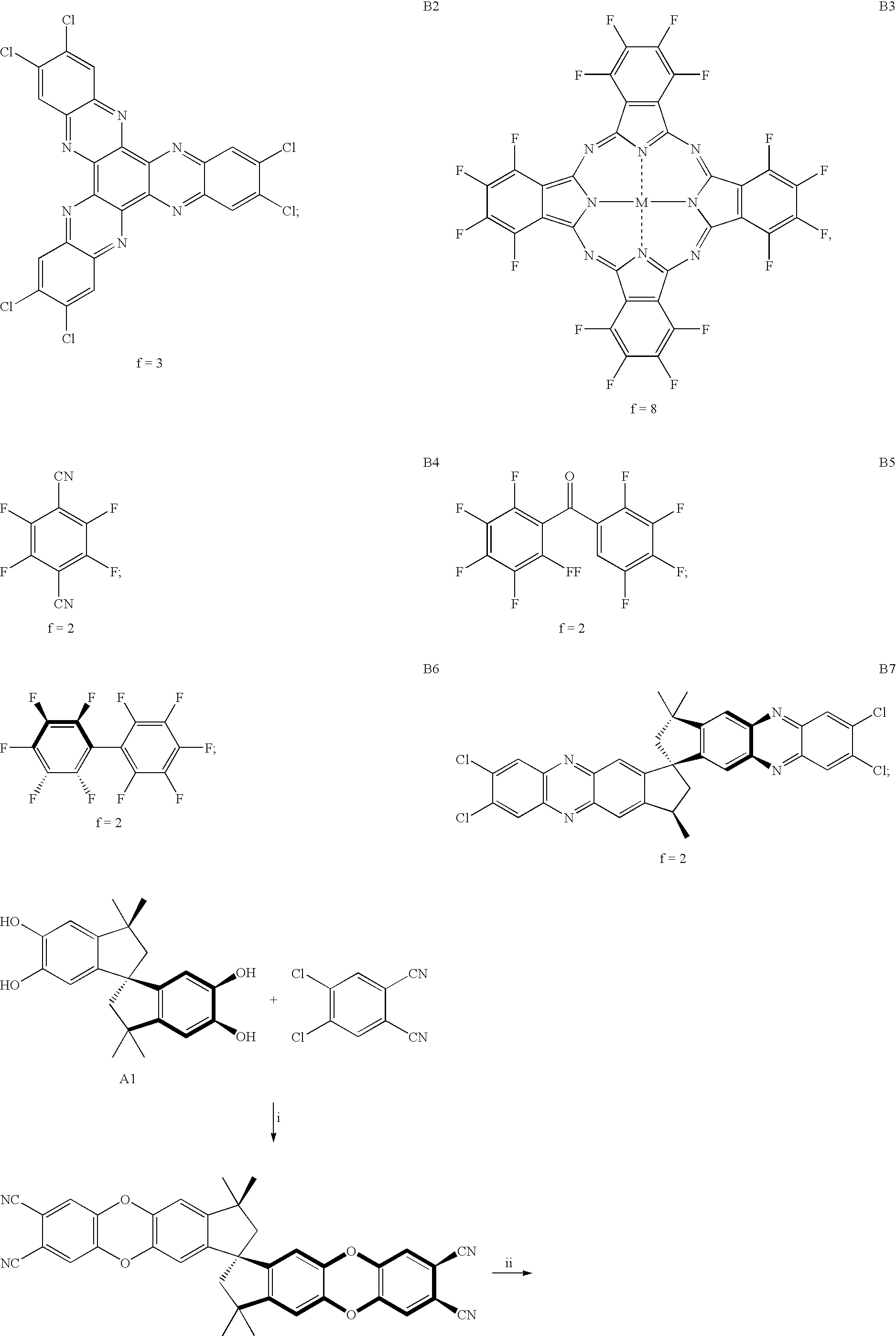

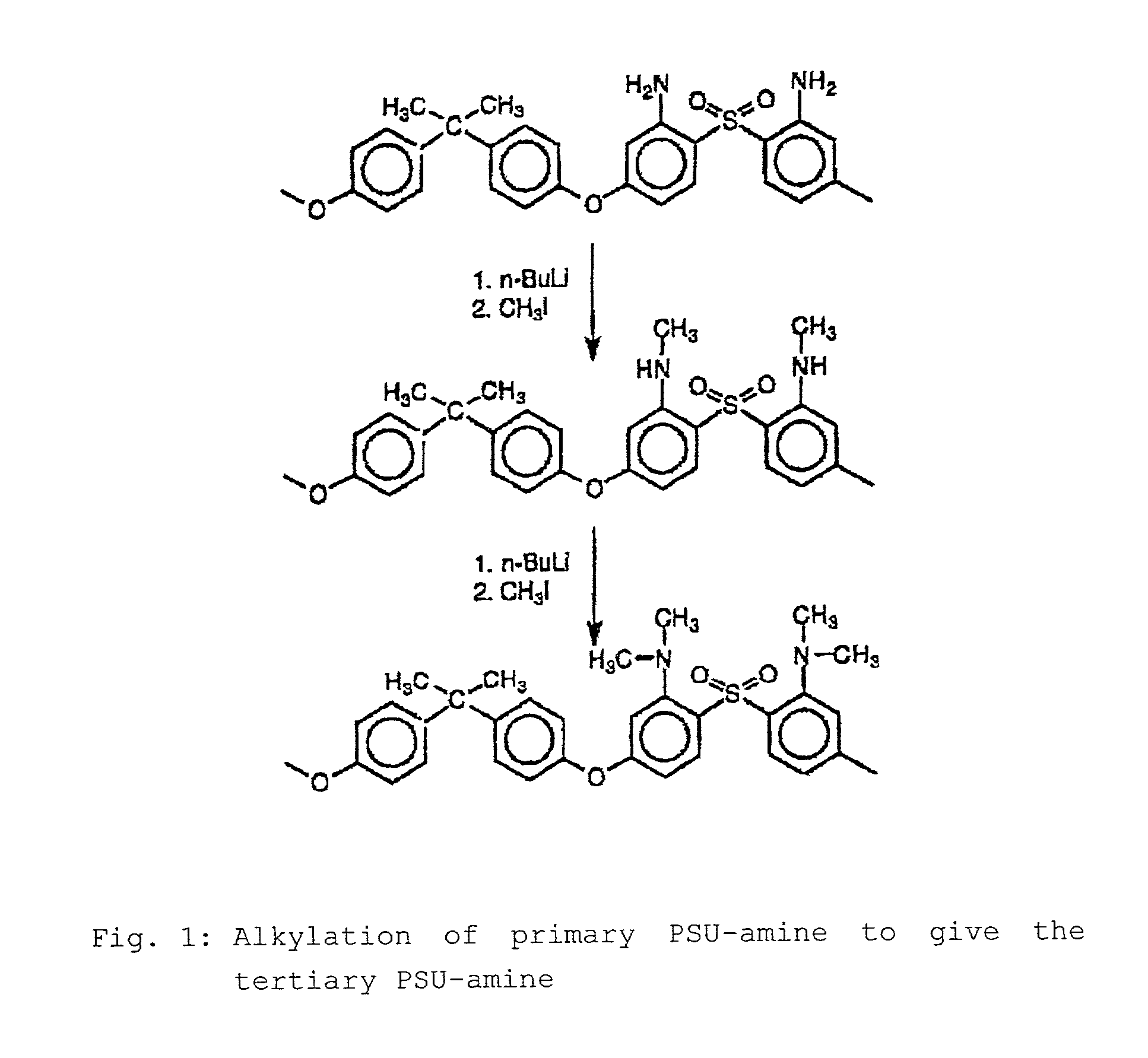

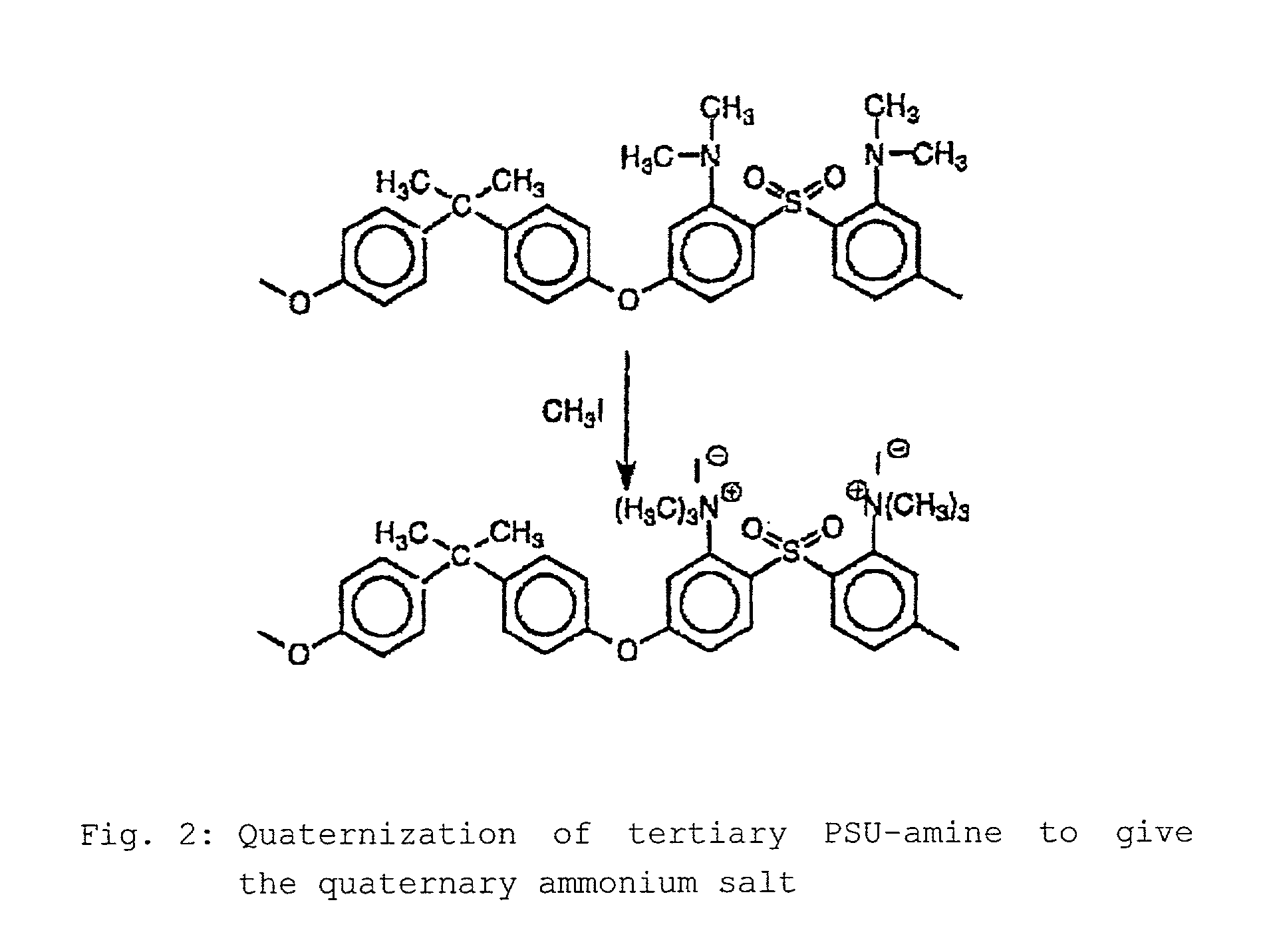

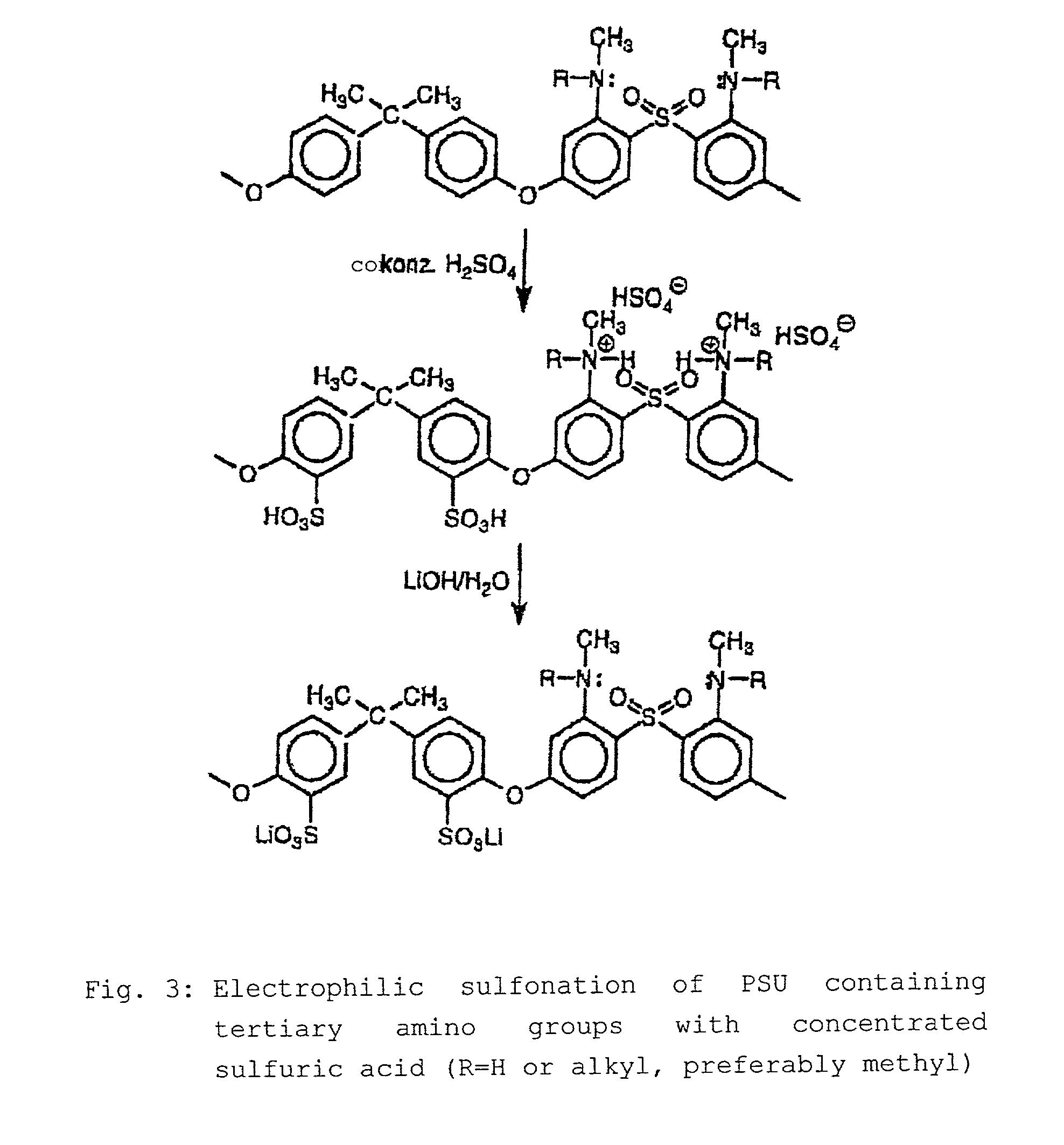

Step-by-step alkylation of polymeric amines

InactiveUS7132496B2Ion-exchange process apparatusNon-metal conductorsHydrophilic polymersOrganic base

The invention relates to the following: a method for step-by-step alkylation of primary polymeric amines by step-by-step deprotonation with a metallo-organic base and a subsequent reaction with an alkyl halide; a method for modifying tertiary polymeric amines with other functional groups; polymers with secondary / tertiary amino groups and with quaternary ammonium groups; polymers with secondary / tertiary amino groups and other functional groups, especially cation exchanger groupings; membranes consisting of the above polymers, either non-crosslinked or ionically or covalently cross-linked; acid-base-blends / membranes, and a method for producing same, consisting of basic polymers with polymers containing sulphonic acid, phosphonic acid or carboxyl groups; the use of ion exchanger polymers as membranes in membrane processes, e.g., polymer electrolyte membrane fuel cells, direct methanol fuel cells, redox batteries, or electrodialysis; the use of the inventive hydrophilic polymers as membranes in dialysis and reverse osmosis, nanofiltration, diffusion dialysis, gas permeation, pervaporation and perstraction.

Owner:HARING THOMAS

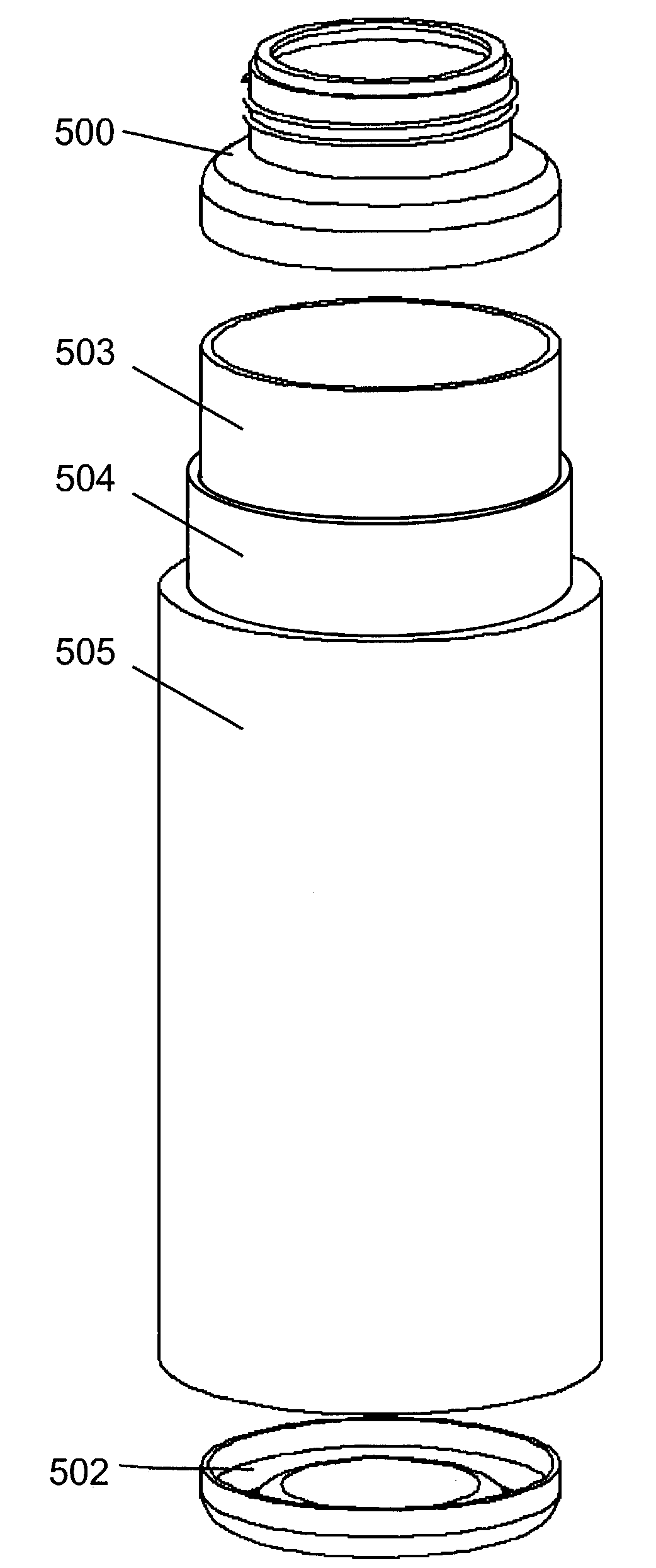

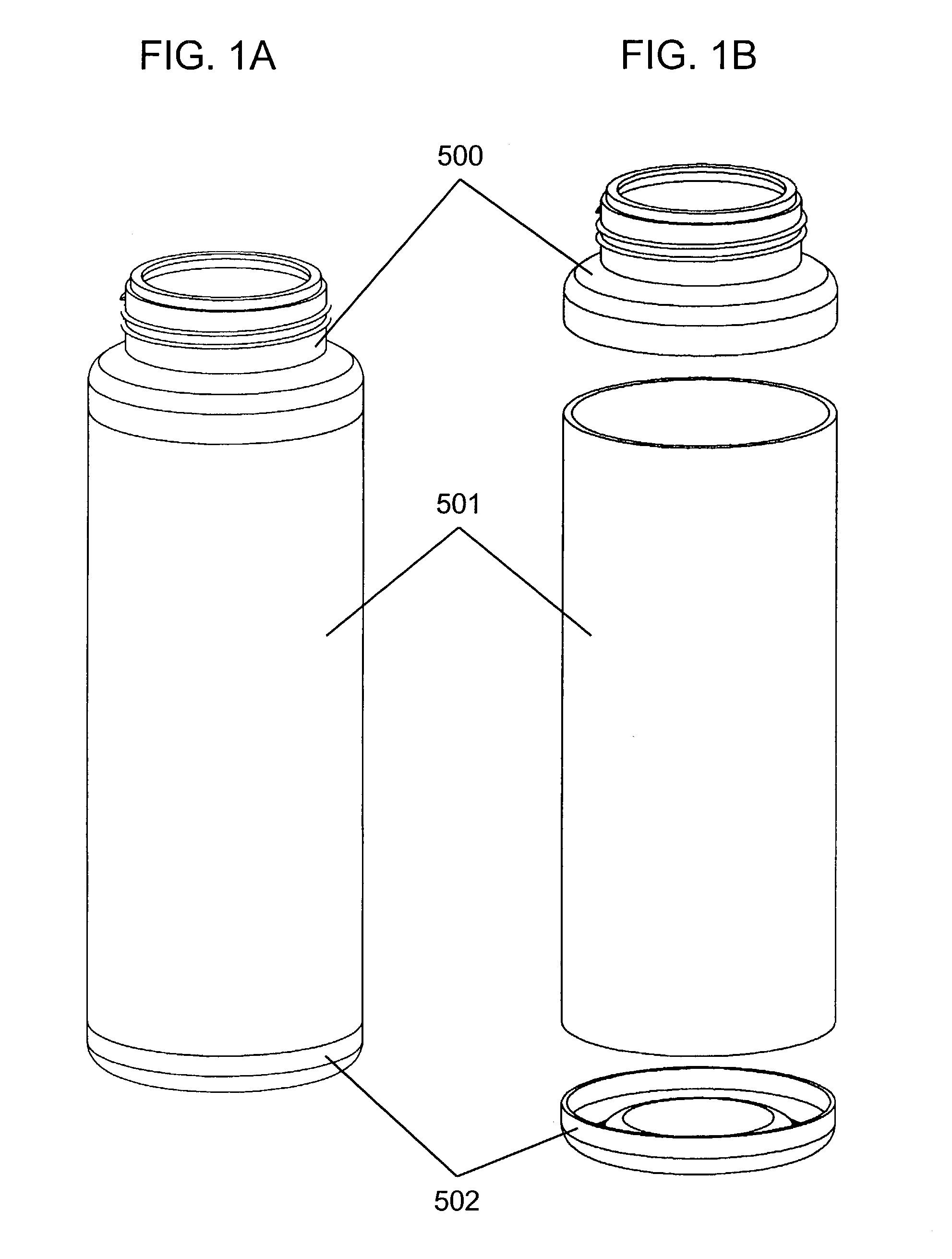

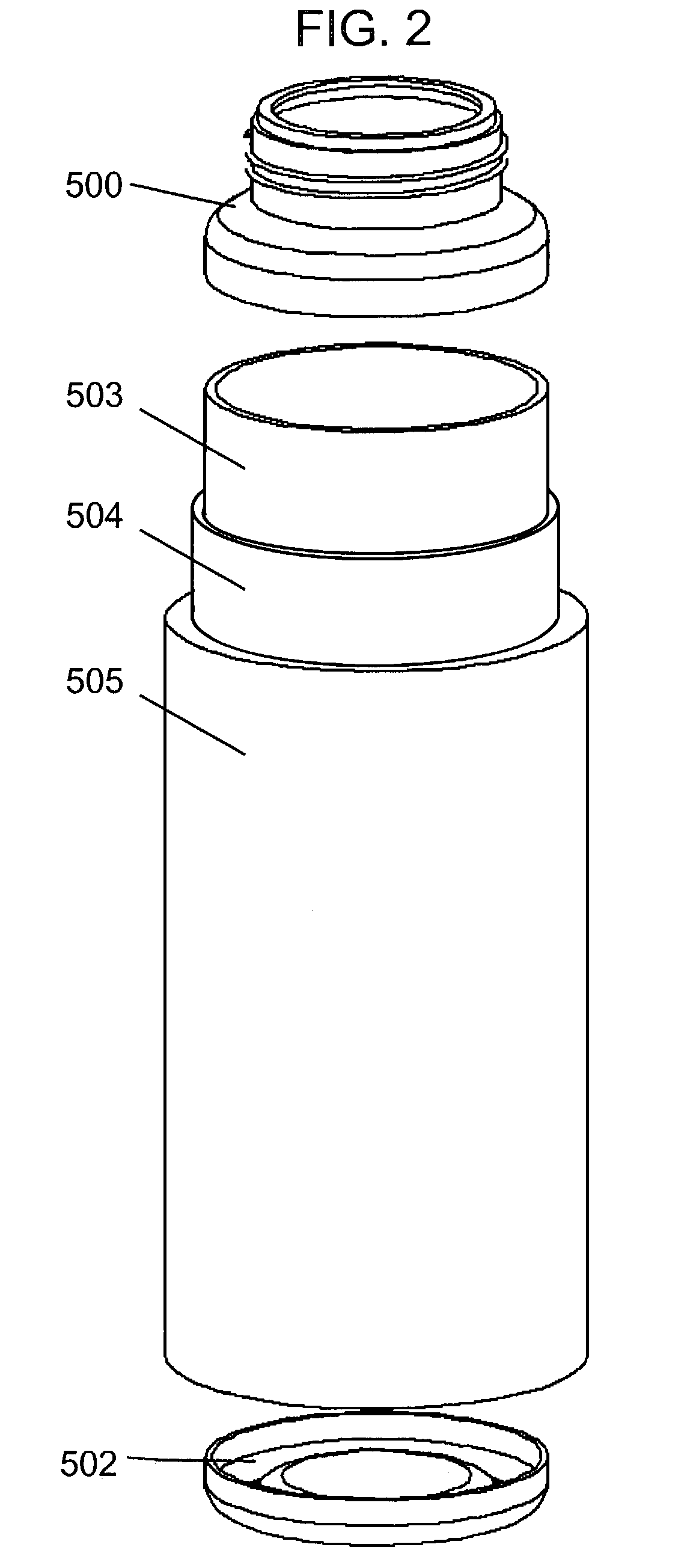

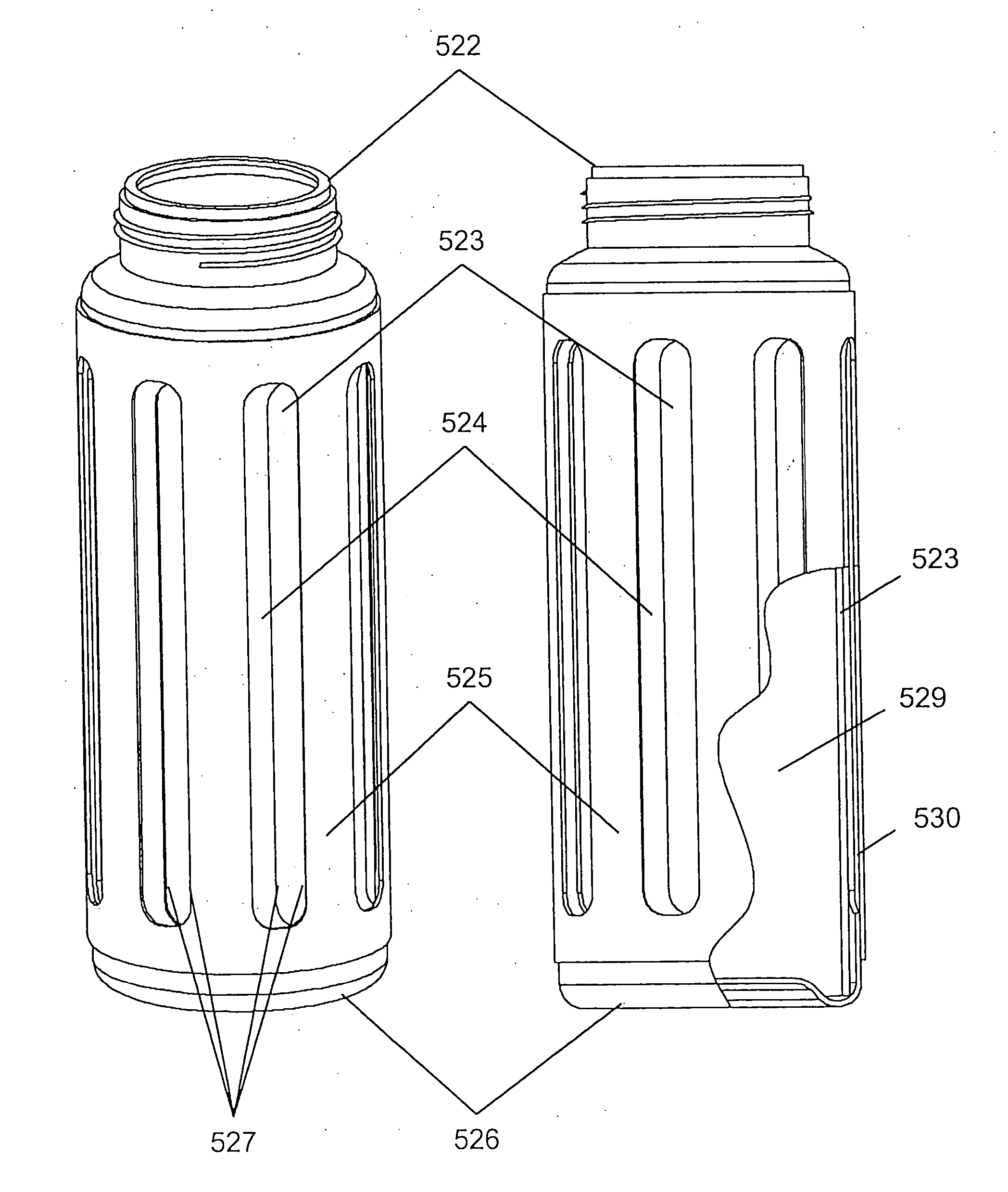

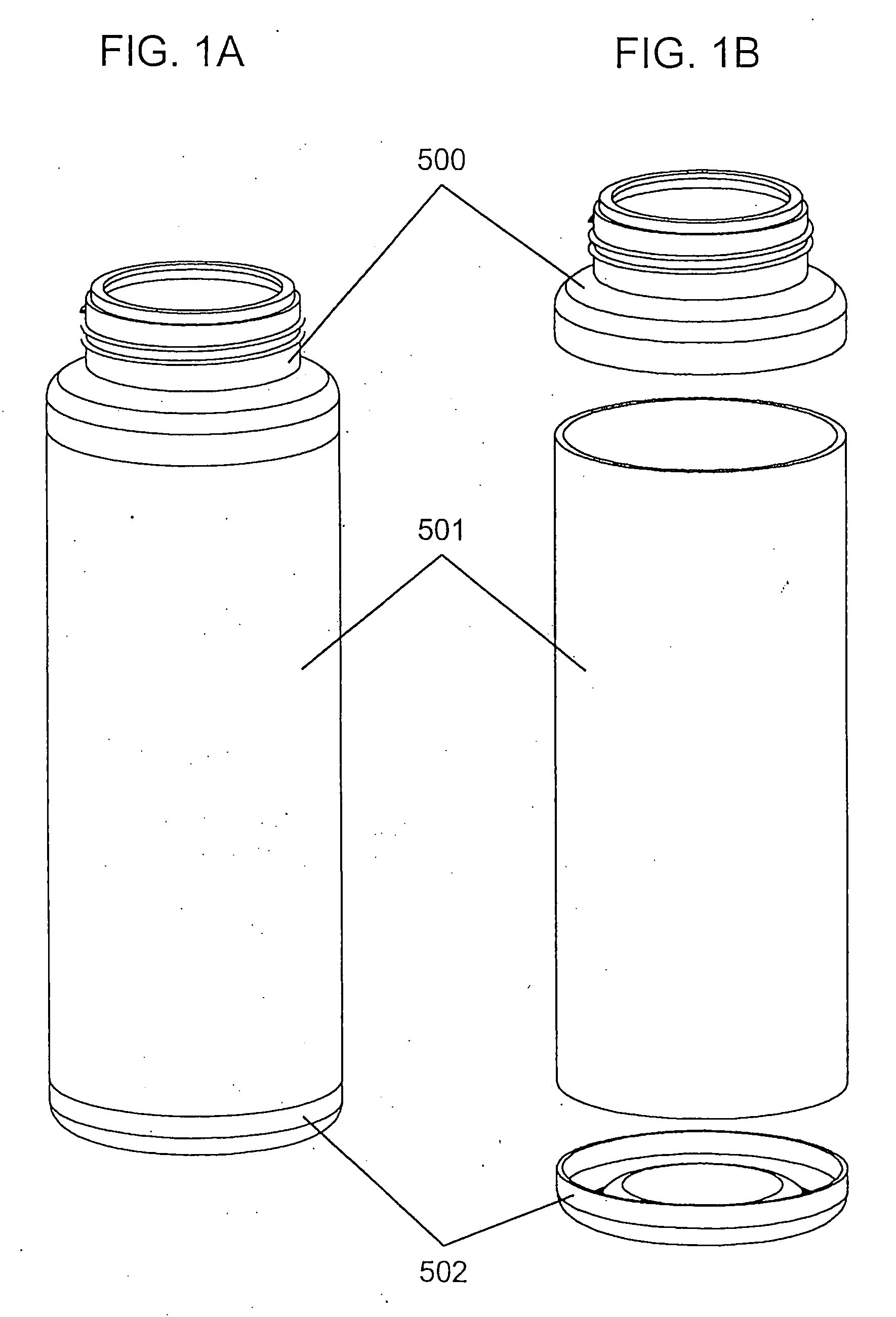

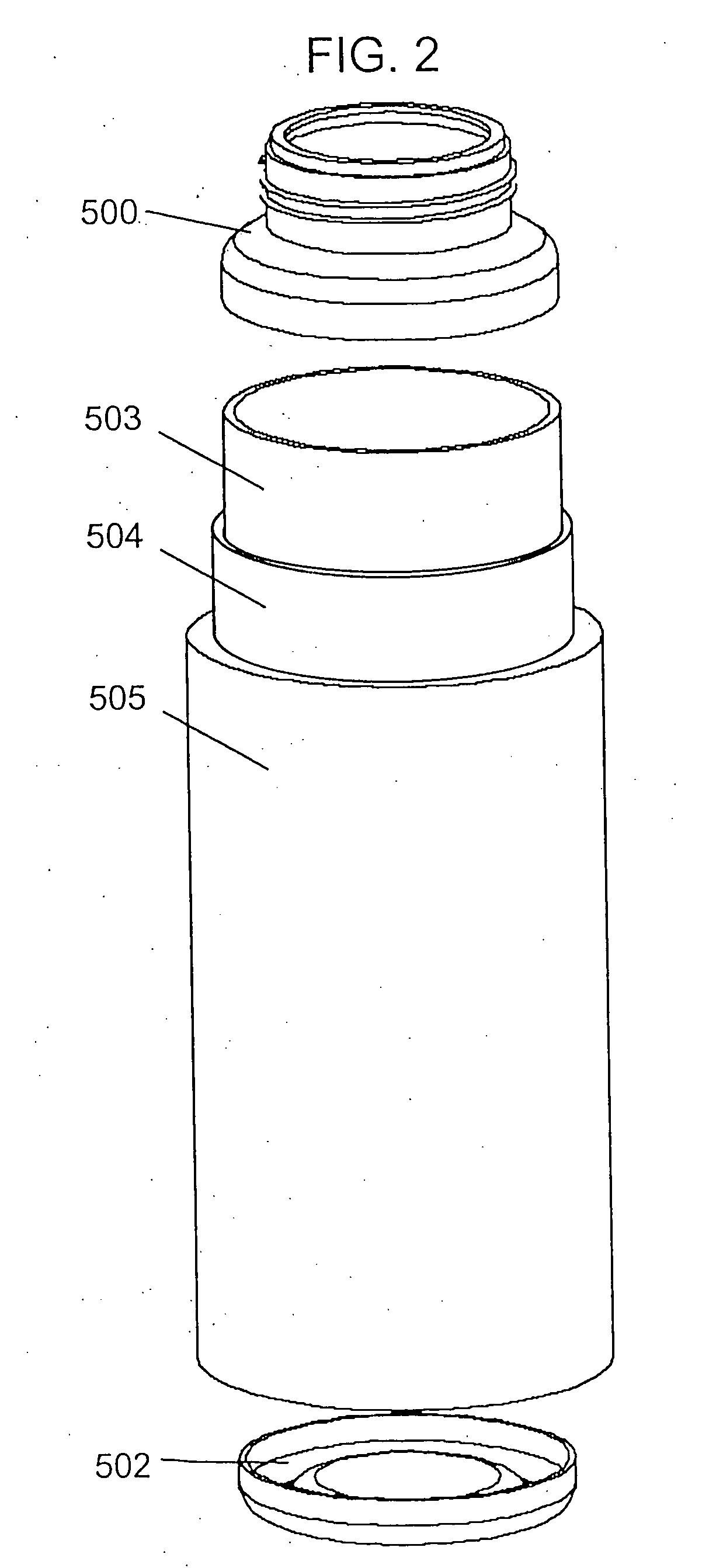

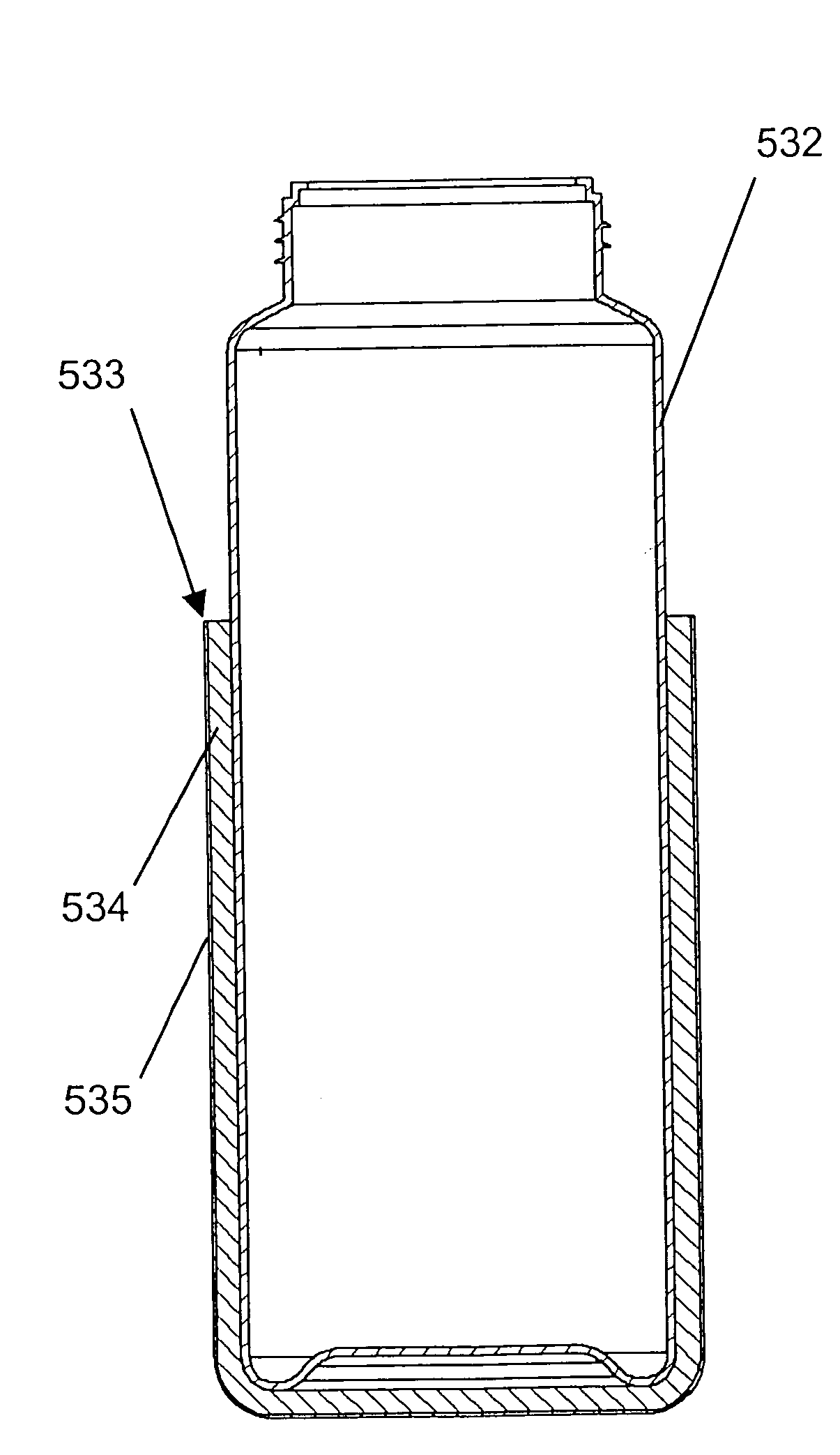

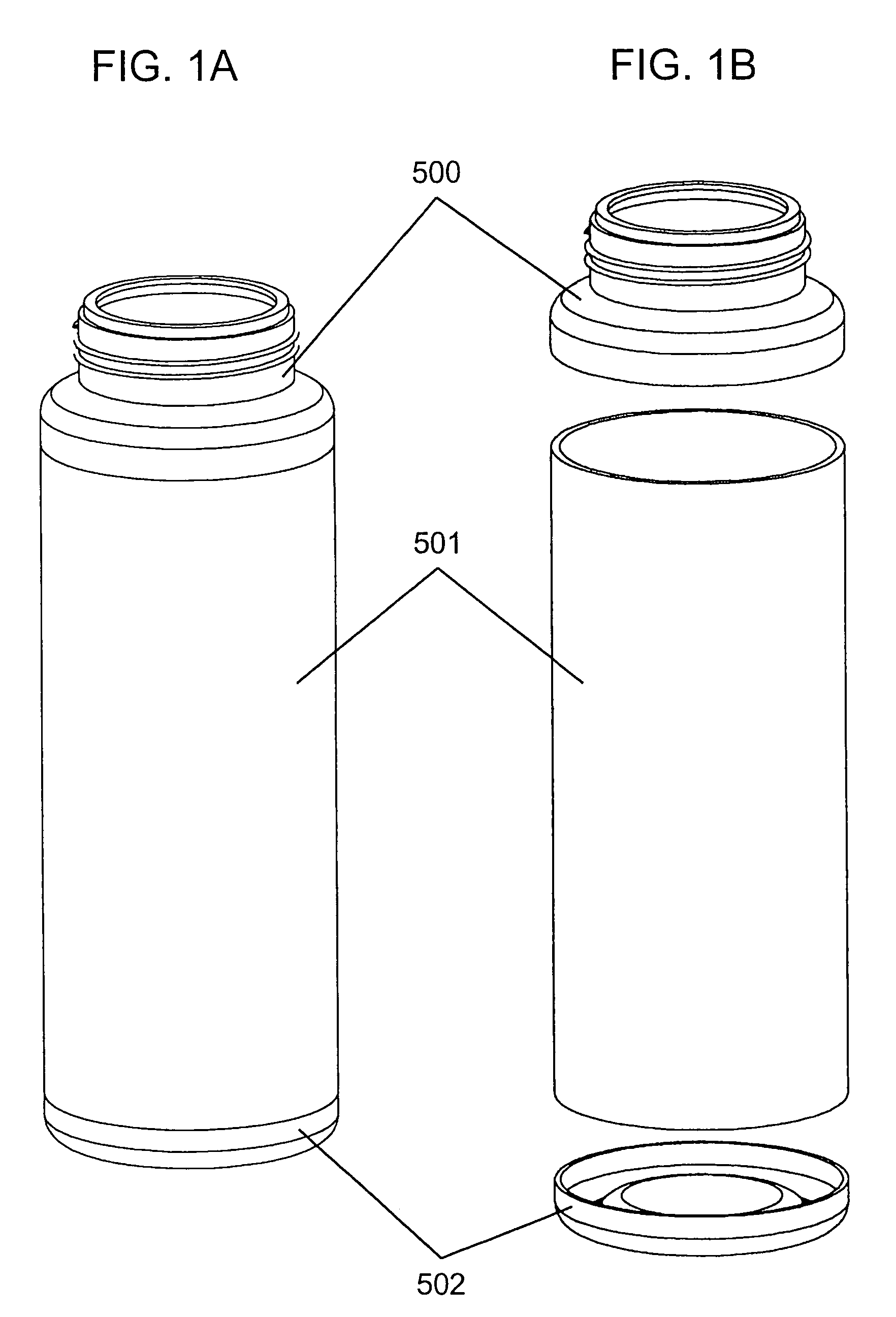

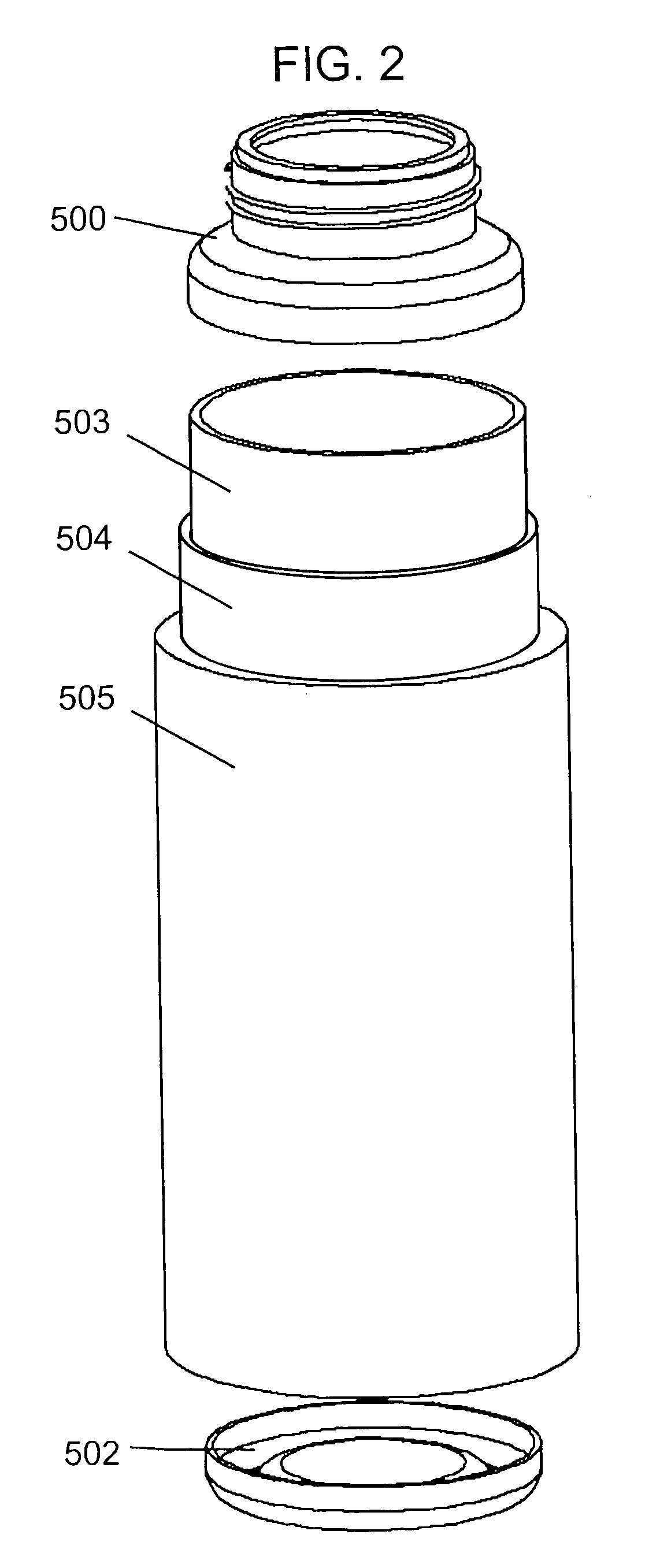

Self-cooling containers for liquids

InactiveUS7107783B2Improve cooling efficiencyTravelling sacksMedical devicesAs elementAbsorbent material

Disclosed are self-cooling containers for beverages and other liquids. Such containers comprise porous matrices as elements of the container bodies to effect the cooling of contained liquids by pervaporation. The liquid vapor can pass through the porous matrix directly to the environment or to a collector or trap comprising an absorbent material in contact with the container. Also disclosed are self-cooling containers incorporating insulative sleeves that reduce radiative warming of container surfaces yet permit sufficient pervaporative flux to cool containers residing within such sleeves.

Owner:ADVANCED POROUS TECH

Membrane devices using reaction bonded monolith supports

InactiveUS20050077226A1Excellent chemical durabilitySemi-permeable membranesIsotope separationSemipermeable membraneReverse osmosis

A membrane device comprised of a porous monolith support formed from a reaction-bonded ceramic powder, fired in an oxygen-free atmosphere, the monolith defining a plurality of passageways extending longitudinally from one end face of the monolith to an opposing end face. A semipermeable membrane suitable for separating a feedstock into permeate and retentate is applied to the passageway walls of said monolith. The semipermeable membrane can be selected from the group of membranes suitable for microfiltration, ultrafiltration, nanofiltration, pervaporation, reverse osmosis, and gas separations.

Owner:CERAMEM

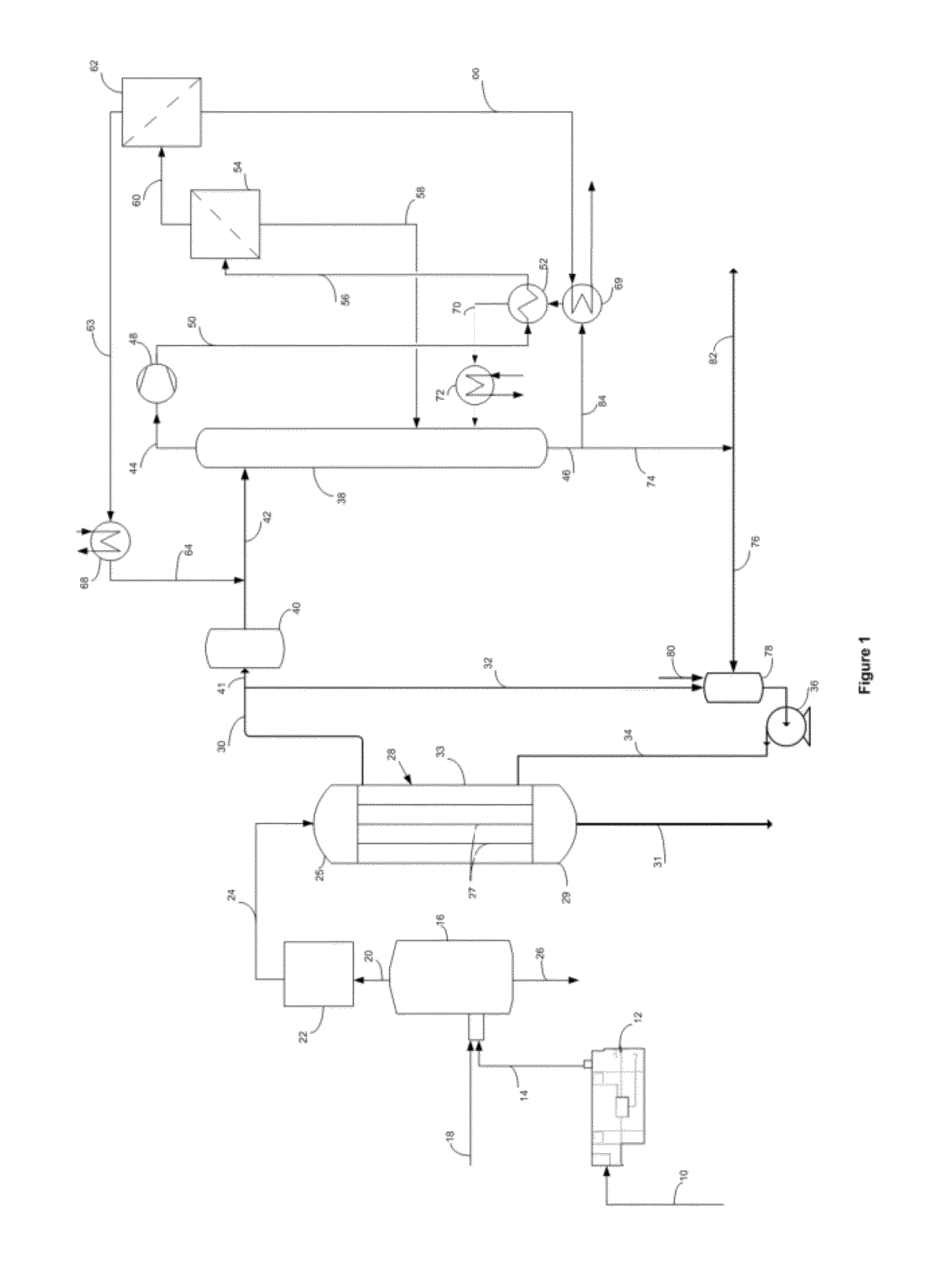

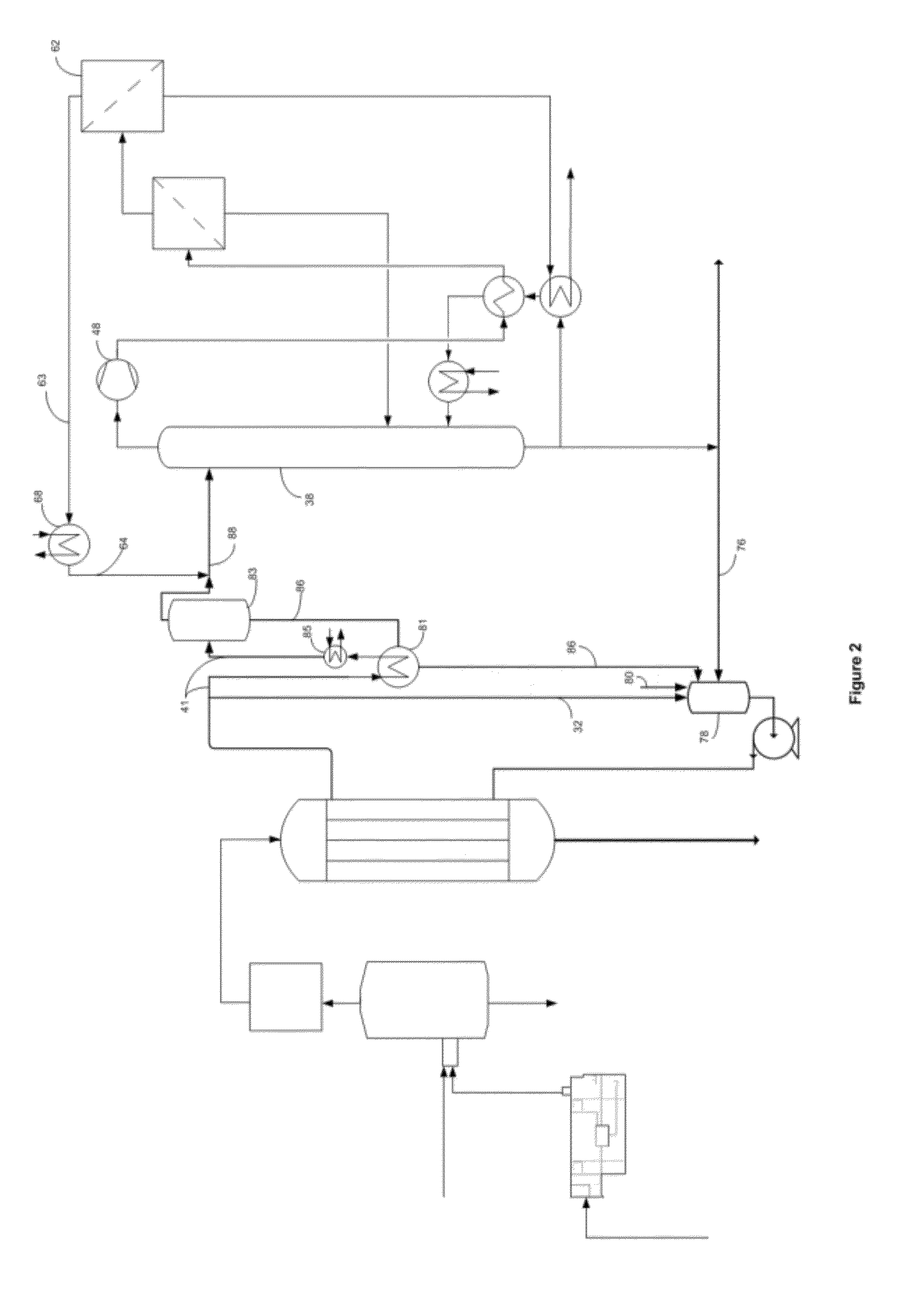

Process for producing ethanol

ActiveUS8211679B2Efficiently and economically separateEffective recoveryBiofuelsWaste based fuelLiquid productDistillation

Ethanol and other liquid products produced by contacting carbon monoxide (CO) and / or a mixture of CO2 (carbon dioxide) and H2 (hydrogen) with a microorganism in a bioreactor are separated using a combination of distillation and vapor permeation membranes. The bioreactor passes an effluent with an ethanol concentration of 1 to 6 wt % to a distillation column that produces an overhead vapor stream enriched in ethanol. A series of vapor permeation membranes retain ethanol as retentate and produce a 99 wt % or higher ethanol product. Ethanol depleted permeate streams flow back to the column and the bioreactor. Coupling a bioreactor with distillation and pervaporation efficiently and economically separates ethanol when present at low concentration in an aqueous fermentation broth. The separation arrangement may also include a flash zone ahead of the distillation column to raise the concentration of the ethanol in the input stream to the distillation column.

Owner:SYNATA BIO INC

Porous granule MCM-41-ZIF-8/PDMS pervaporation hybrid membrane, preparation and application

The invention relates to a porous granule MCM-41-ZIF-8 / PDMS pervaporation hybrid membrane, preparation and application, and belongs to the technical field of membrane separation. According to the invention, silicon hydroxyl enriched on the surface of a mesoporous molecular sieve MCM-41 is used, and a vacuum in-situ growth method is adopted to synthesize metal-organic framework material namely micropore ZIF-8 on the surface of the mesoporous molecular sieve MCM-41, so that porous granules containing mesoporous-micropore passages are prepared; silazane is adopted to further improve the hydrophobic modification of the porous granule MCM-41-ZIF-8, and the porous granule MCM-41-ZIF-8 is mixed with PDMS, then a membrane scraping method is adopted to prepare the pervaporation hybrid composite membrane on a polysulfone base membrane, the holes of which are blocked by deionized water, and the pervaporation hybrid composite membrane is used for the separation of ethyl alcohol / water system. The large aperture of MCM-41 and adsorbability of the ZIF-8 are used to promote alcohol molecules to adsorb on the surface of the membrane and to diffuse in the porous granule pore passages, and the defect of Trade-off phenomenon between separation factors and permeation flux is overcome, therefore, the separation performance of the hybrid membrane is improved. The porous granule MCM-41-ZIF-8 / PDMS pervaporation hybrid membrane has the advantages that the synthesis method of the porous granules is simple, the membrane preparation technology is simple and feasible, and a better industrial application prospect is achieved.

Owner:BEIJING UNIV OF TECH

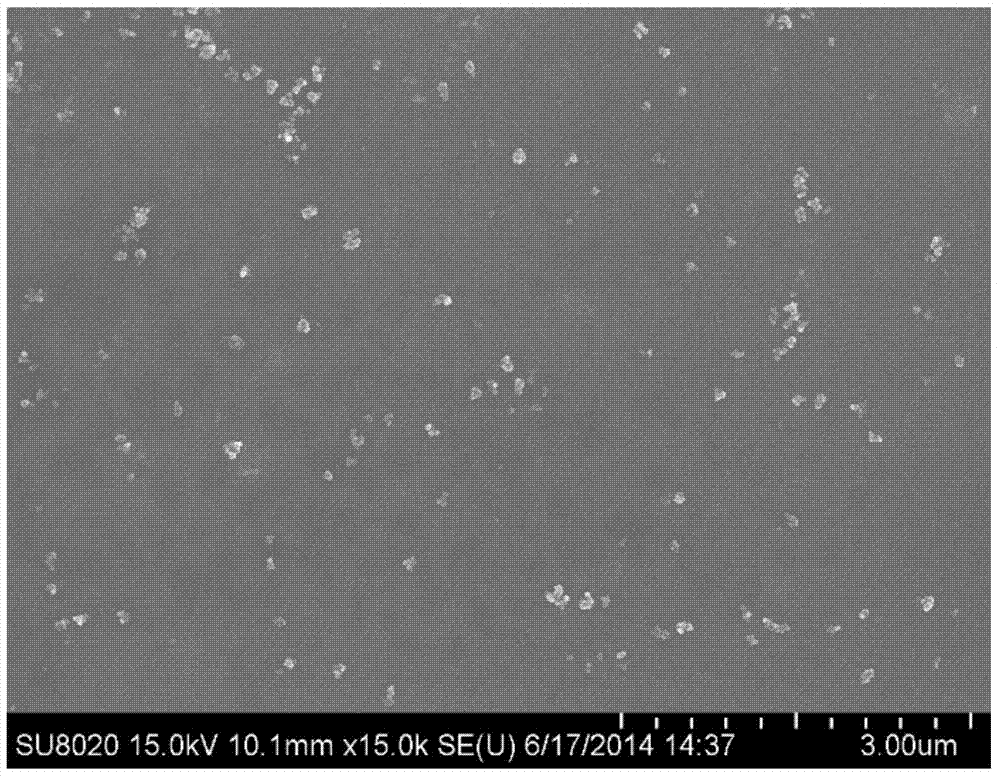

Preparation method of MOFs tube type hybrid membrane for separating aromatic hydrocarbons/alkyl hydrocarbons

InactiveCN104117290ALower feed temperatureHigh mechanical strengthSemi-permeable membranesAlkaneSolvent

A preparation method of an MOFs tube type hybrid membrane for separating aromatic hydrocarbons / alkyl hydrocarbons, and belongs to the technical field of membrane separation. The method comprises the steps: preparing MOFs particles by a solvent thermal method; preparing an MOFs / polymer membrane liquid by a co-mixing method, carrying out ultrasonic dispersion, and standing for defoaming; compounding the MOFs / polymer on the outer surface of a ceramic porous membrane modified by a silane coupling agent through a dynamic compression method, and forming a thin membrane separation layer; and drying the hybrid membrane for 0.1-4 h at the temperature of 30-120 DEG C, to enhance the stability of the separation layer. The invention provides the new preparation method of the MOFs hybrid membrane for separating the aromatic hydrocarbons / alkyl hydrocarbons, the process is simple, and the prepared hybrid membrane has good pervaporation performance, and the mechanical strength is improved to a larger degree.

Owner:BEIJING UNIV OF TECH

Self-cooling container for liquids

Disclosed are self-cooling pouches useful as containers for beverages and other liquids. Such pouches comprise a porous matrix as an element of the pouch body to effect the cooling of the pouch and a liquid contained therein by pervaporation of the liquid.

Owner:SMOLKO DANIEL D +1

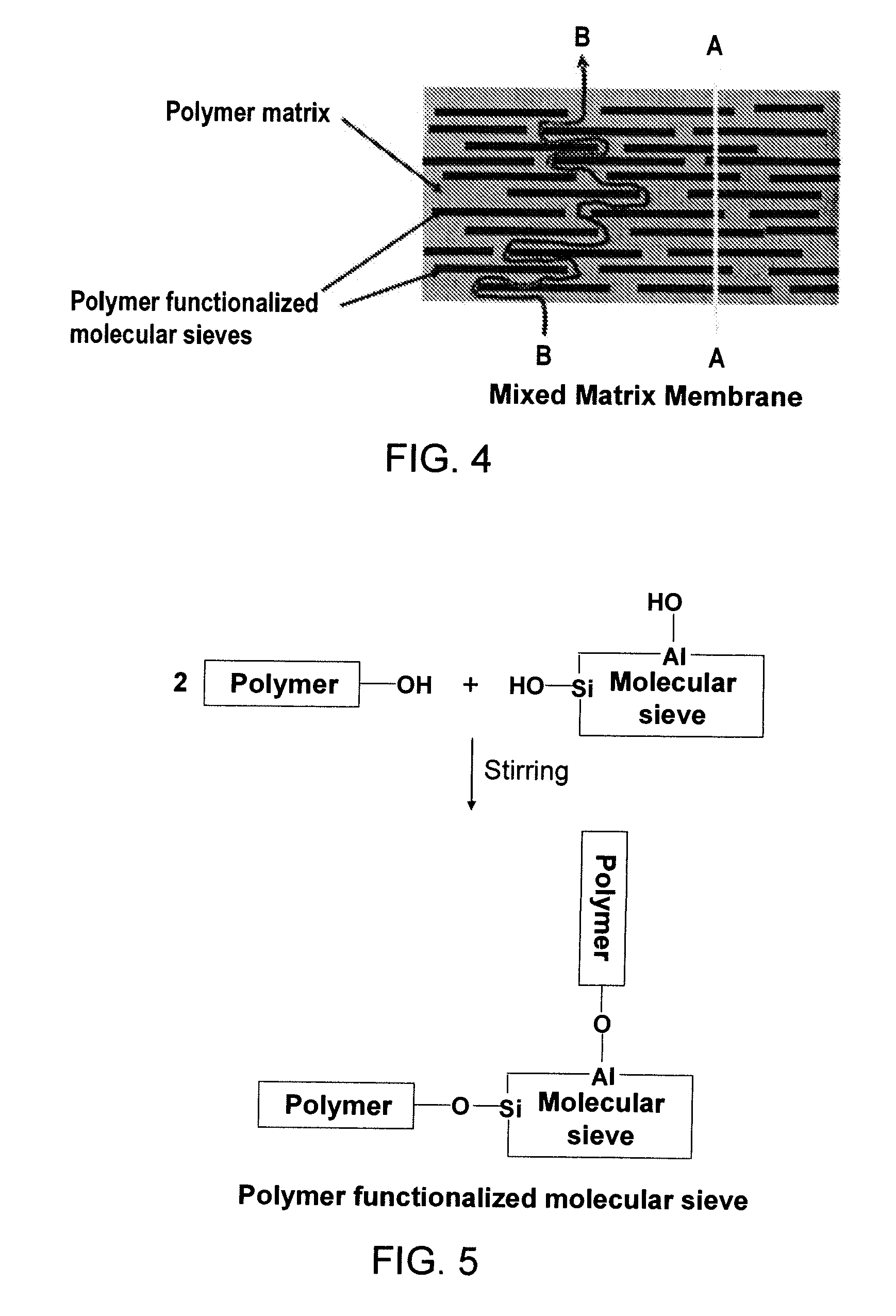

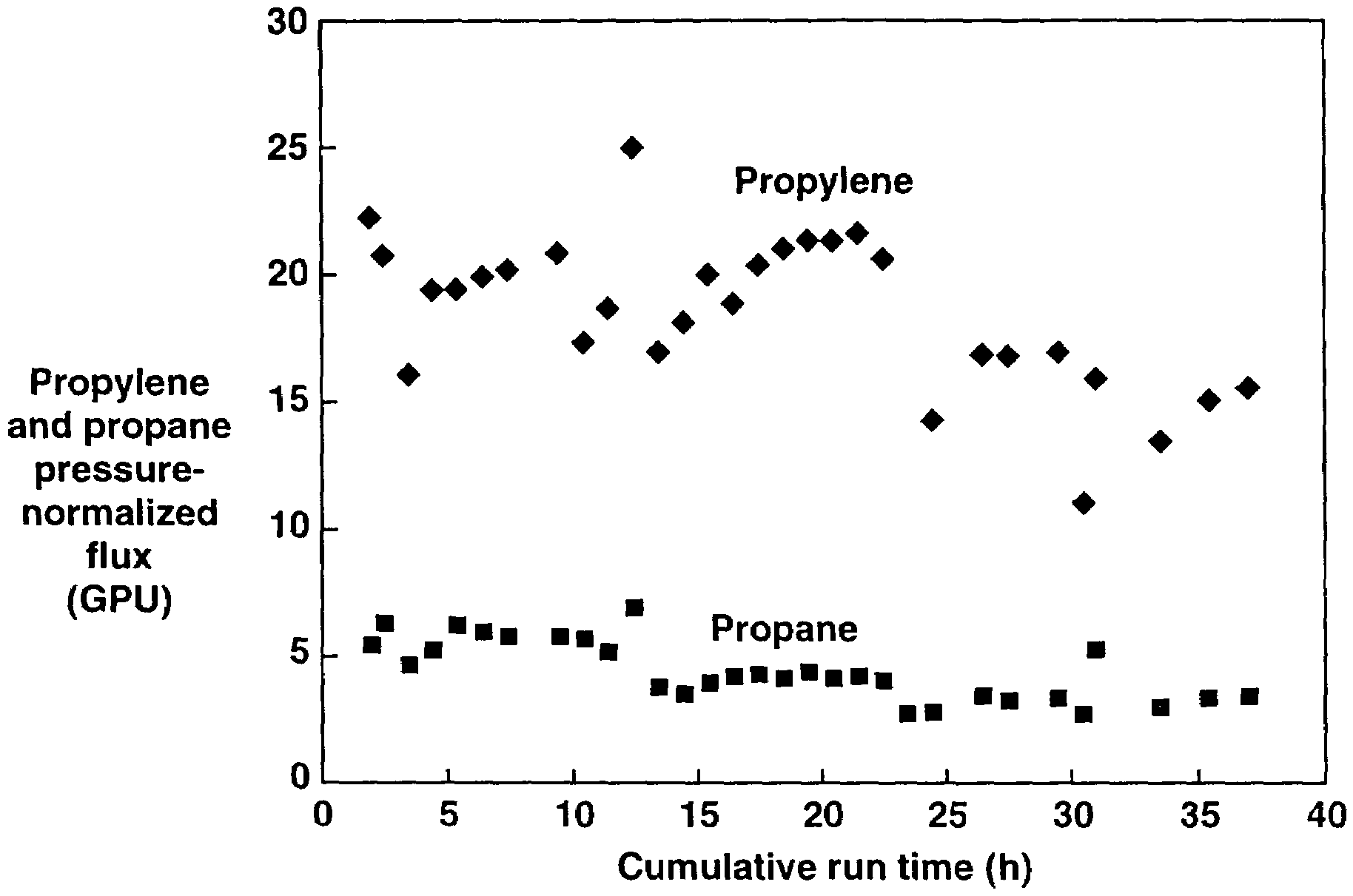

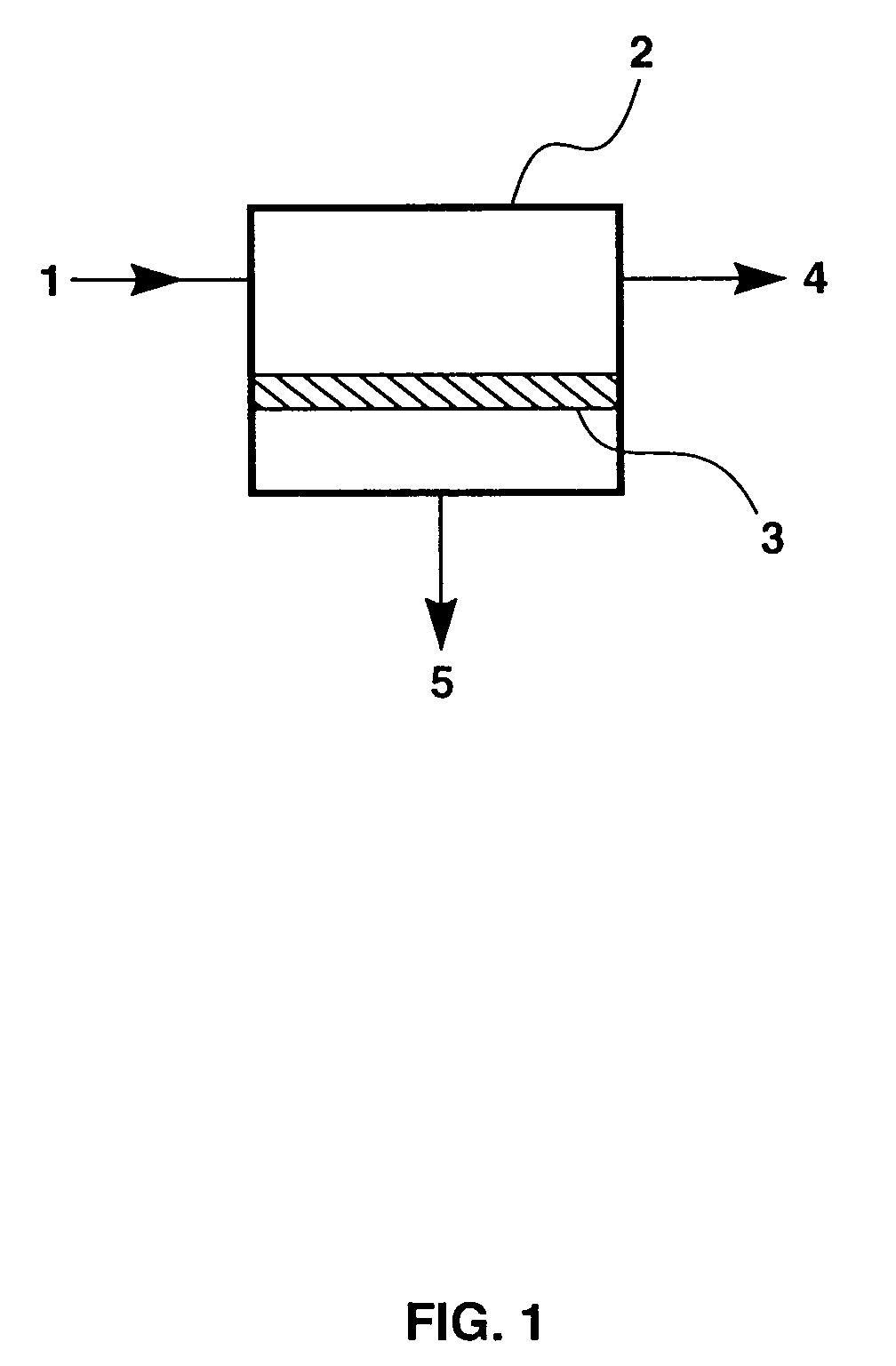

Method of Making Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090131242A1Easy to separateAverage permeabilitySemi-permeable membranesGas treatmentPolymer scienceCellulose acetate

The present invention discloses a method of making polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), and propylene / propane separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulphurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

Preparation method of porous-ceramic-supported graphene film

ActiveCN103611431AHigh strengthSimple and economical processSemi-permeable membranesOrganic solventComposite film

The invention relates to a preparation method of a porous-ceramic-supported graphene film. An inorganic ceramic material serves as a support body, and one side of a silane-modified inorganic ceramic support body is coated with a graphene film-forming material. The preparation method can be applied to removal of water in an organic solvent through a pervaporation method and separation of organic systems in other fields of industrial production. A composite film has the unique properties of a graphene material and the own advantages of a ceramic material. The inherent limitations of common organic and inorganic materials are overcome. The preparation method is simple and economic in process, and wide in application range.

Owner:NANJING UNIV OF TECH

Liquid-phase separation of low molecular weight organic compounds

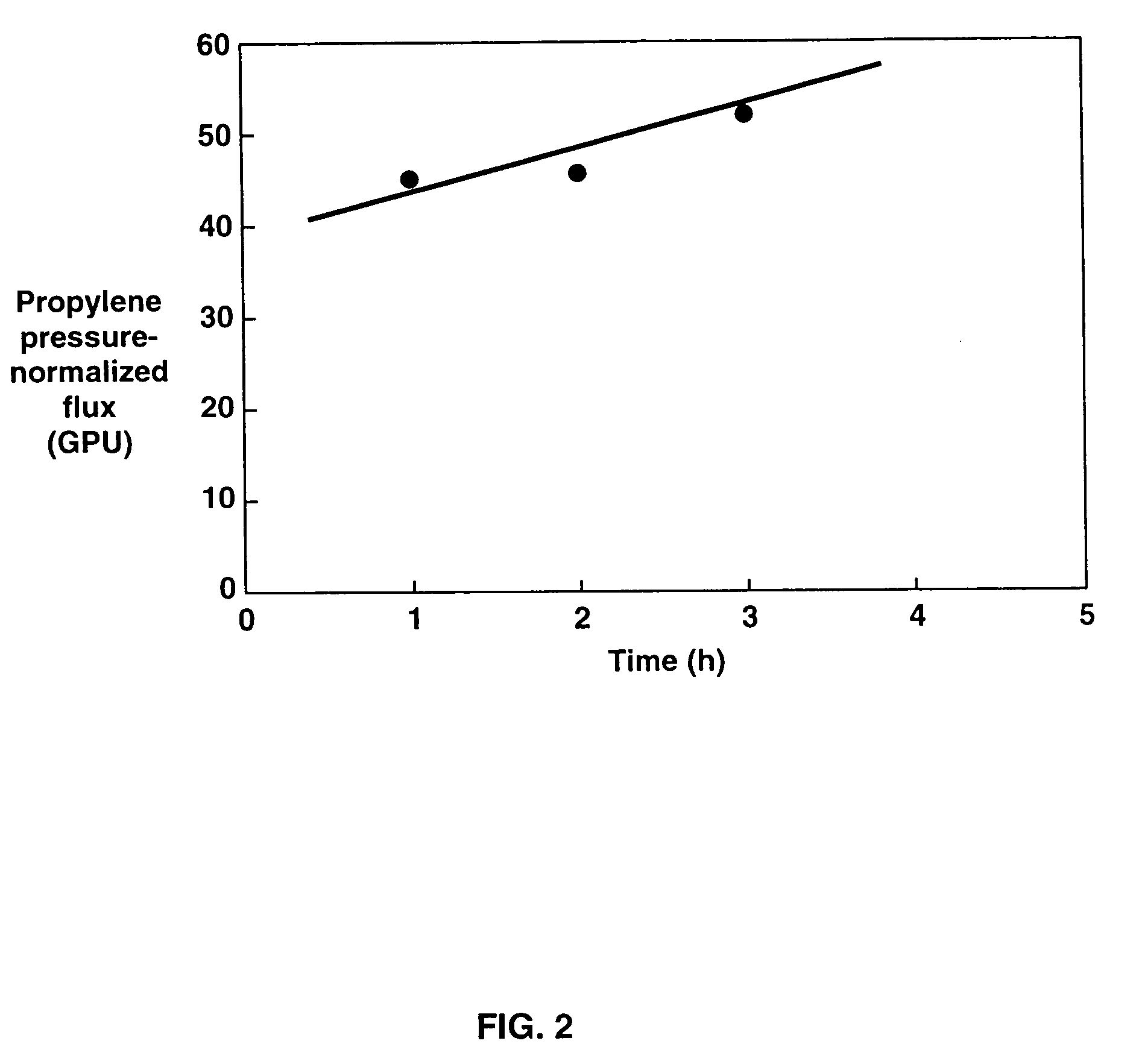

InactiveUS7479227B2Good chemical resistanceSimplifies recovery and further treatmentMethane captureOrganic compound preparationPervaporationOrganic compound

A process for separating a component from a low molecular weight organic mixture by pervaporation. The process uses fluorinated membranes and is particularly useful for treating mixtures containing light organic components, such as methane, propylene or n-butane.

Owner:MEMBRANE TECH & RES

Cooling jacket for containers

Disclosed are cooling jackets for containers for beverages and other liquids. Such a jacket comprises a porous matrix as an element of the jacket body to effect the cooling of the jacket by pervaporation of a liquid contained within the jacket body. The jacket therefore cools a liquid within a container maintained in direct contact with the jacket.

Owner:ADVANCED POROUS TECH

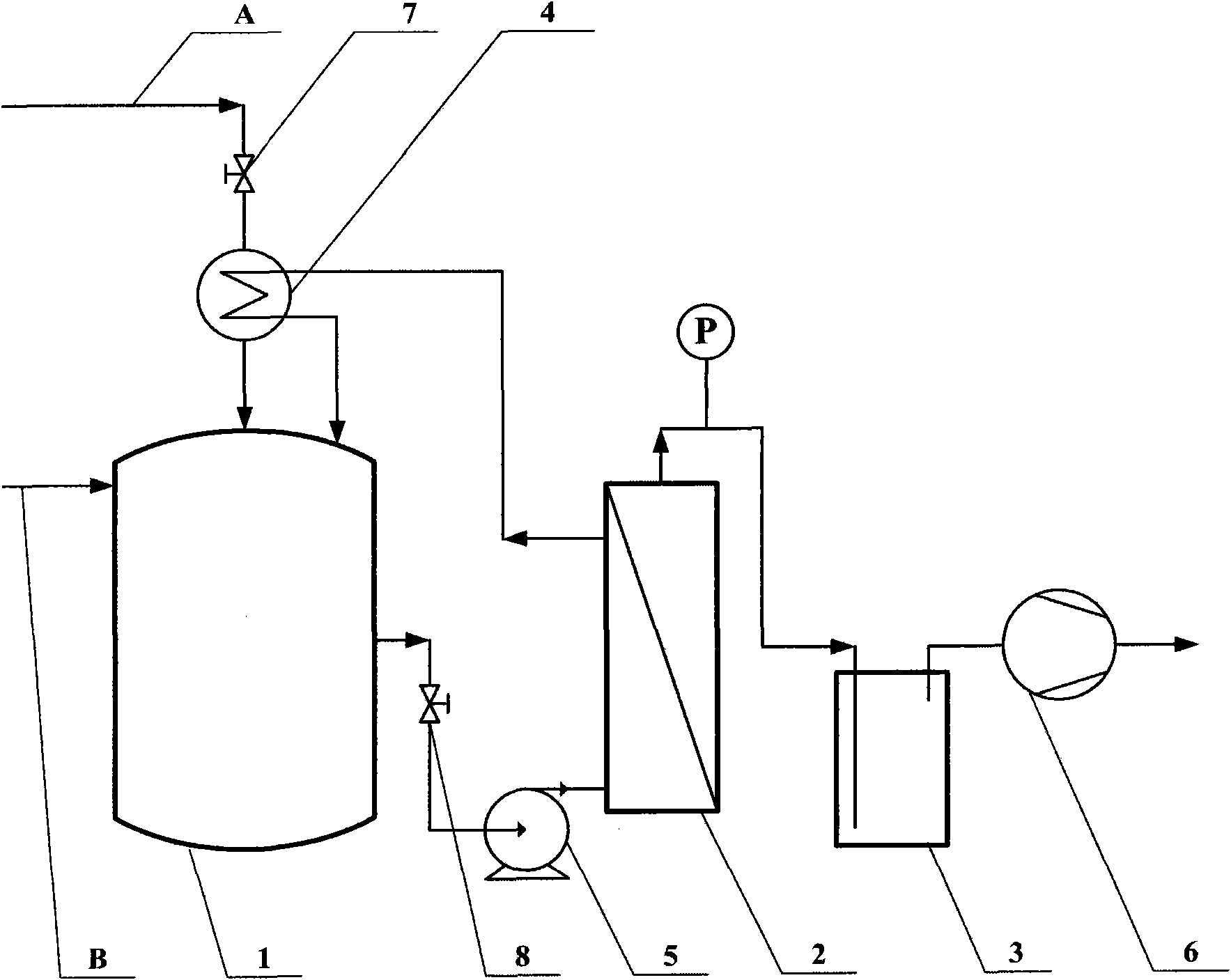

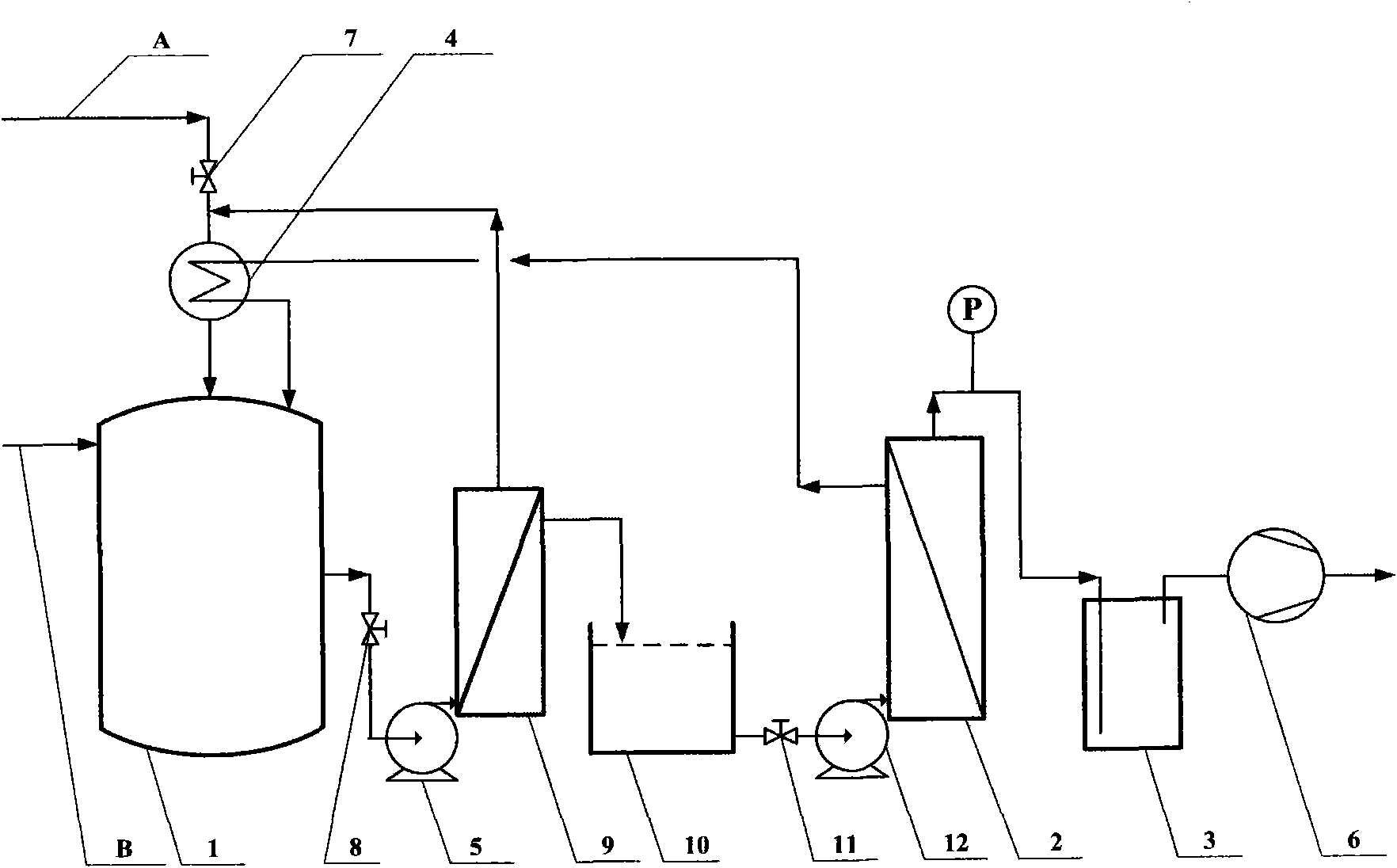

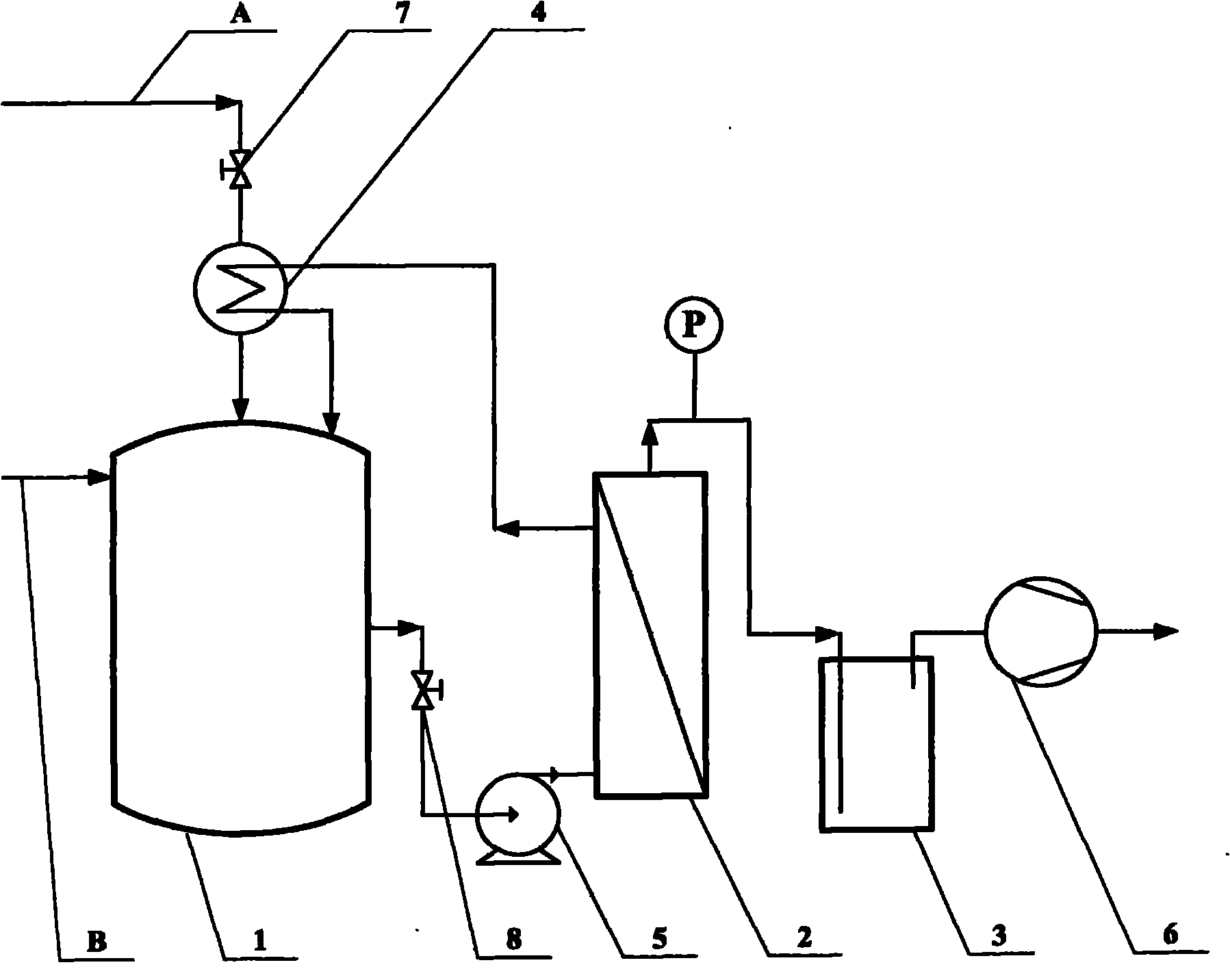

Process for separating acetone, butanol and ethanol in situ by coupling biomass fermentation and pervaporation

ActiveCN101805754AHigh strengthHigh yieldBiofuelsMicroorganism based processesMicroorganismPervaporation

The invention relates to a process for separating acetone, butanol and ethanol in situ by coupling biomass fermentation and pervaporation. A pervaporation separation process is coupled with a fermentation process, and ABE (acetone, butanol and ethanol) solvents produced by fermentation are removed in situ and in time through a pervaporation film, so inhibiting effects of the ABE solvents produced in the fermentation process on the growth of microbial cells are greatly reduced and production intensity and efficiency of ABE fermentation are enhanced. Simultaneously, compared with an ordinary rectification process, the process also greatly lowers energy consumption for separating the ABE solvents produced by biomass fermentation, shortens production time and greatly lowers production cost of fuel butanol.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com