Patents

Literature

71 results about "Enhanced selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibodies with Enhanced or Suppressed Effector Function

ActiveUS20130089541A1Inhibition is effectiveStrong specificityAntipyreticAnalgesicsFc receptorFc(alpha) receptor

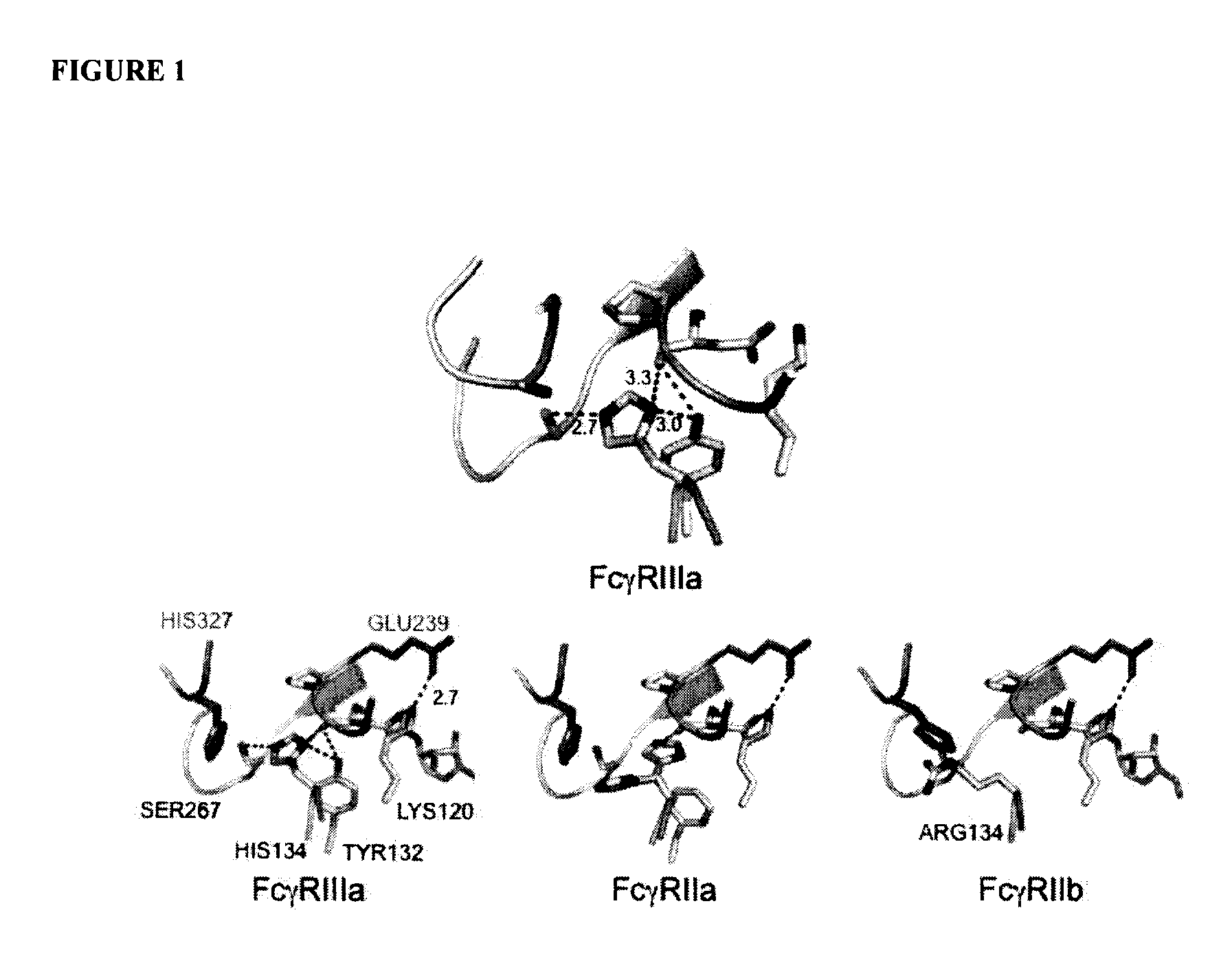

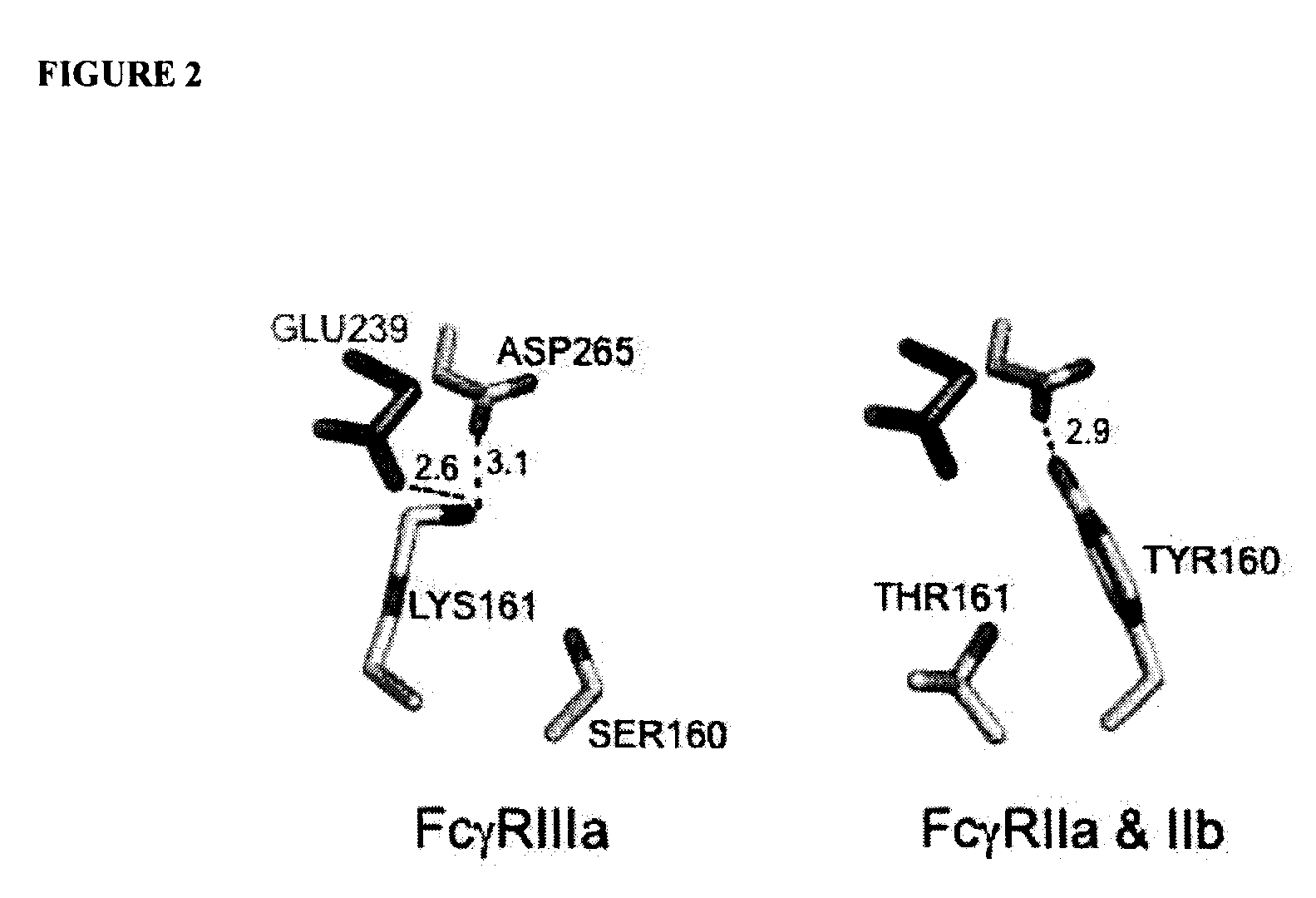

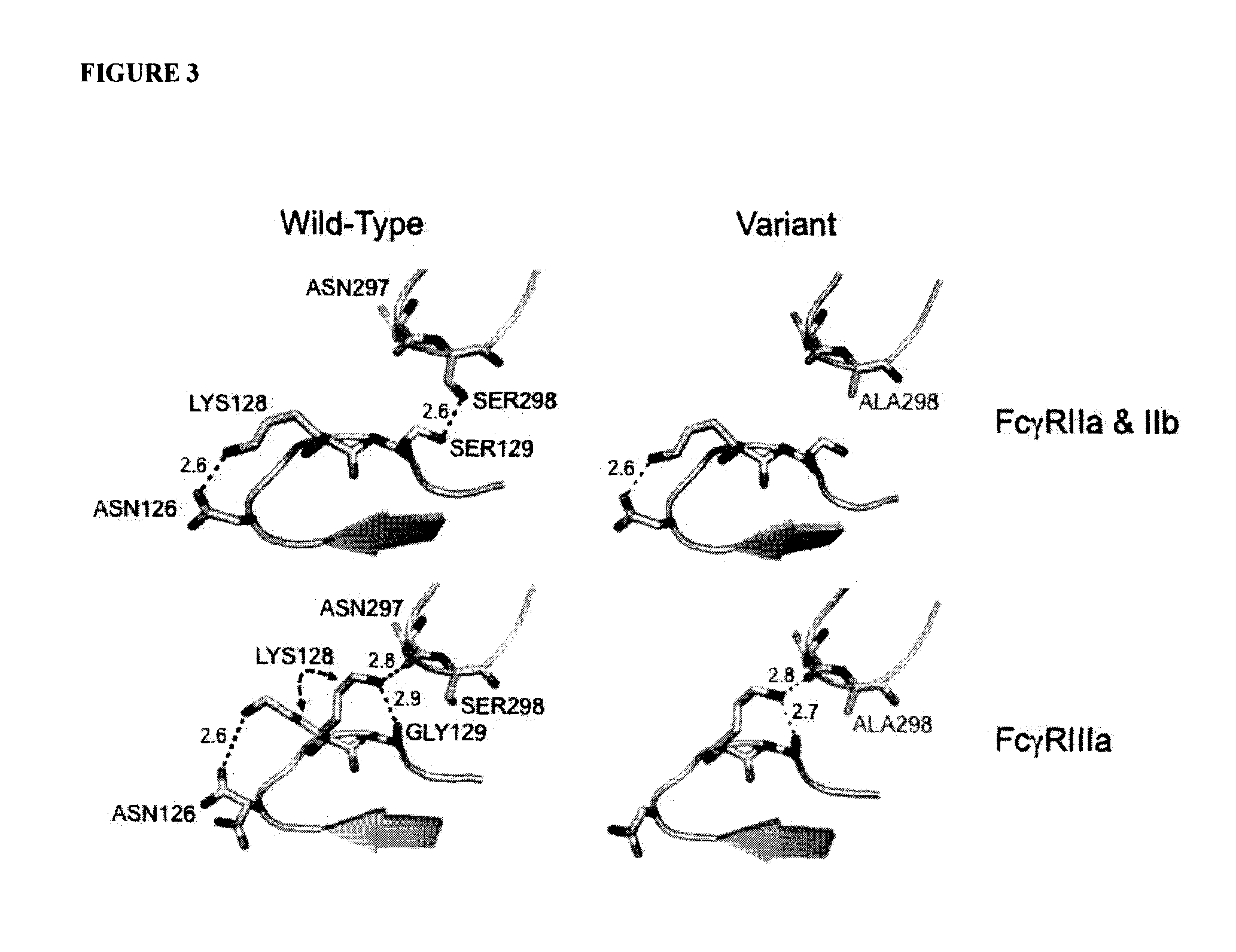

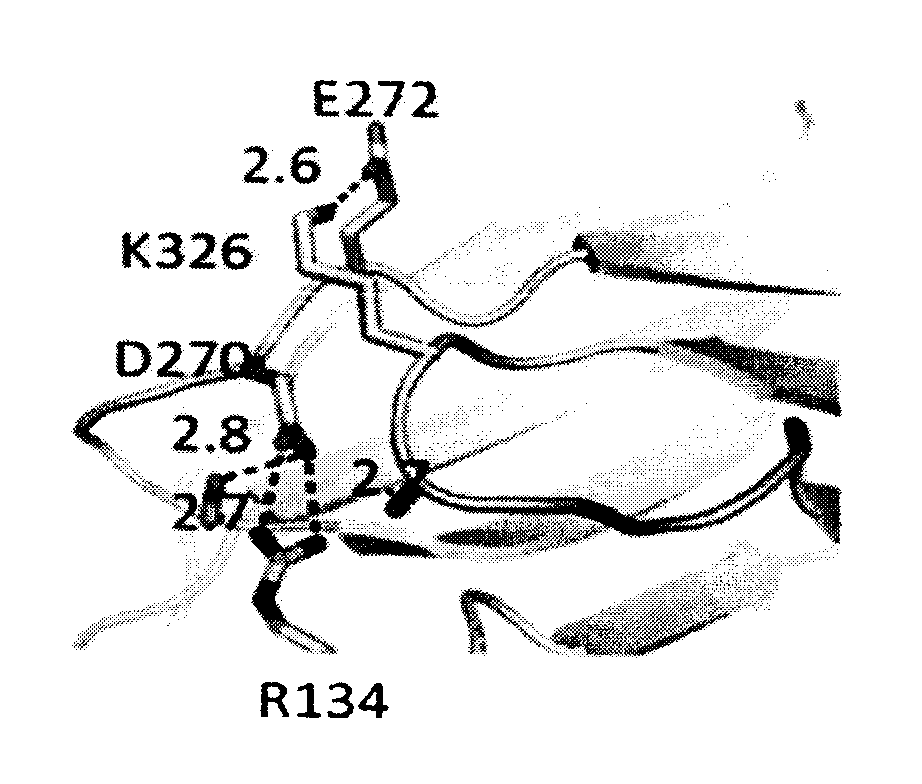

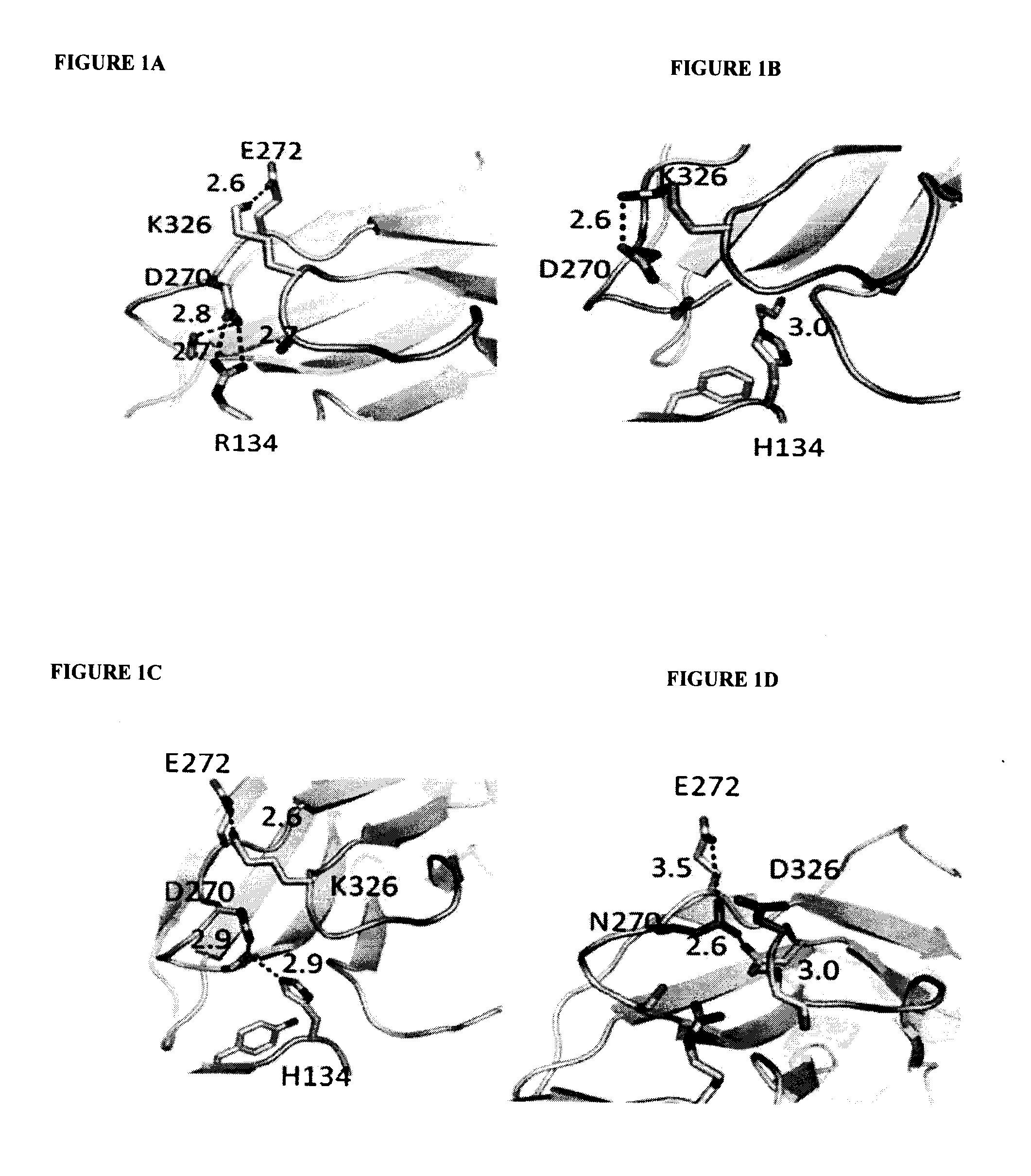

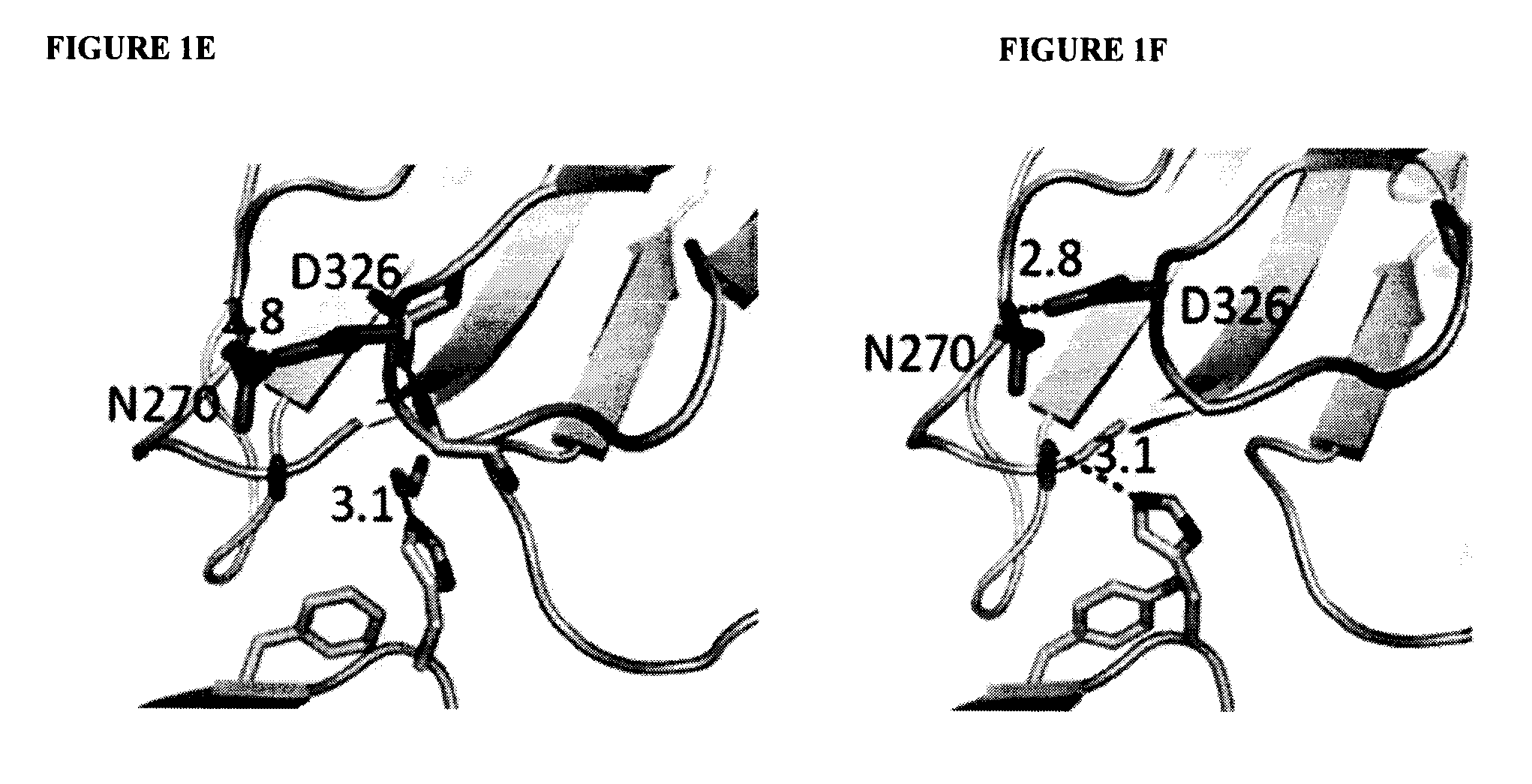

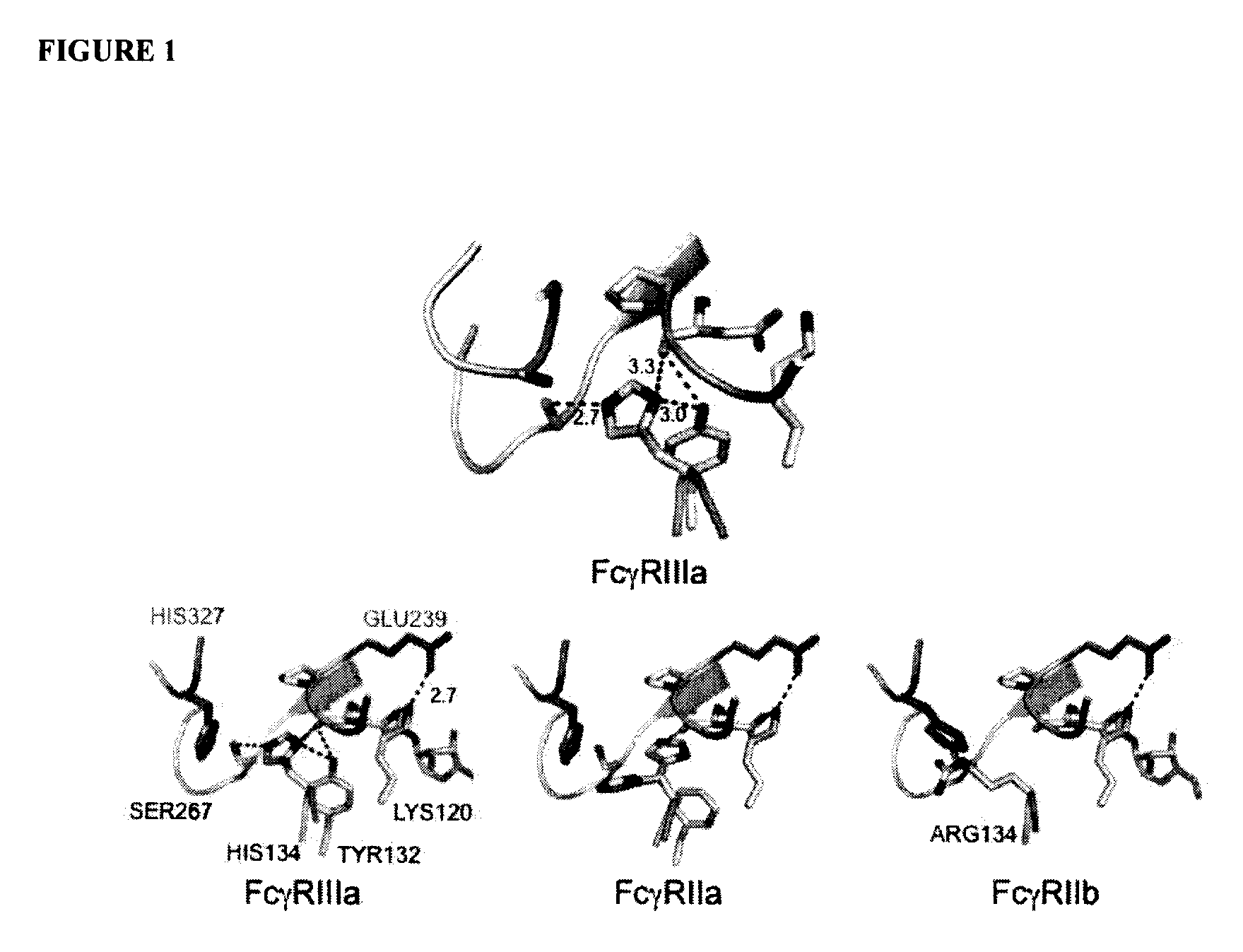

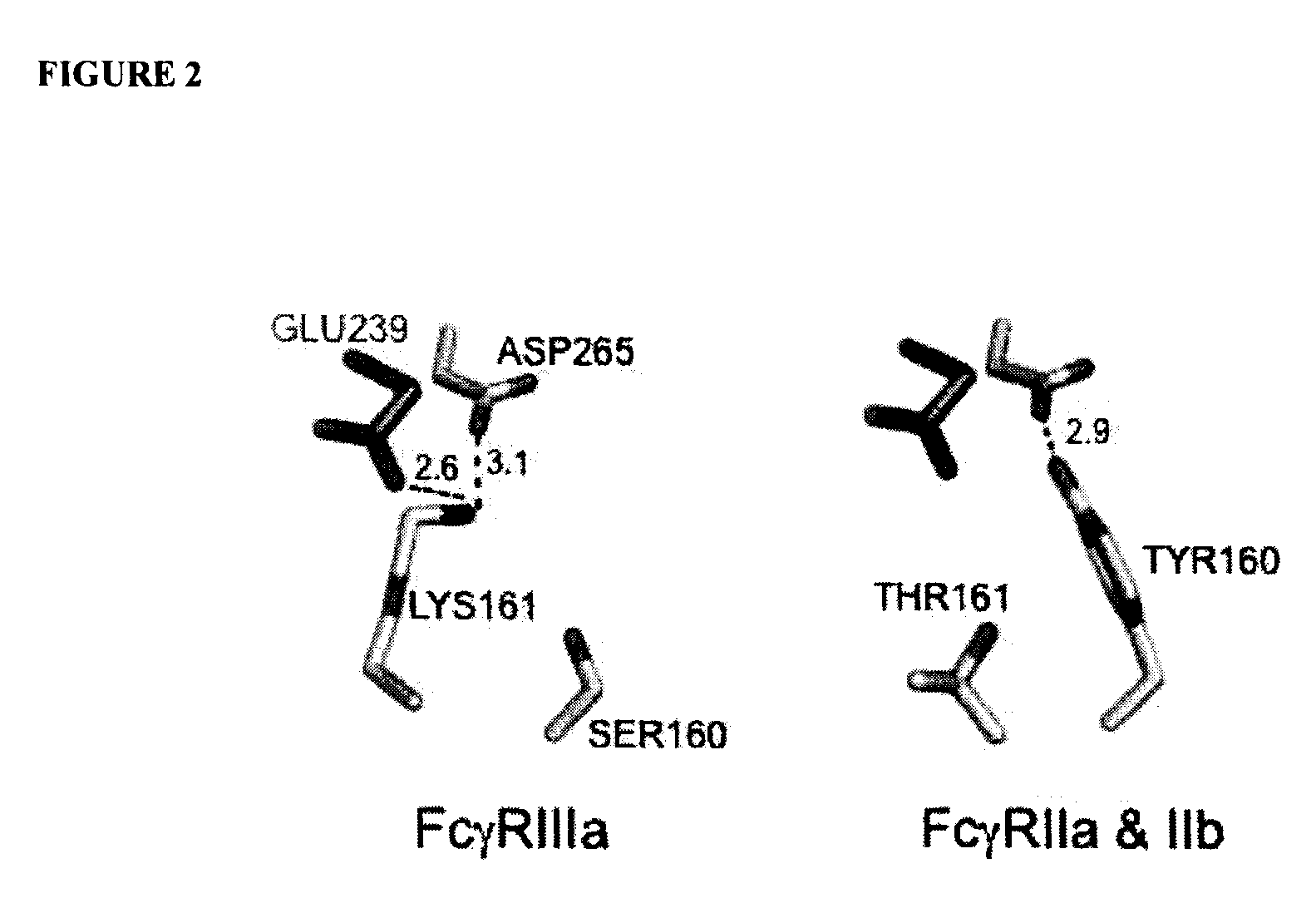

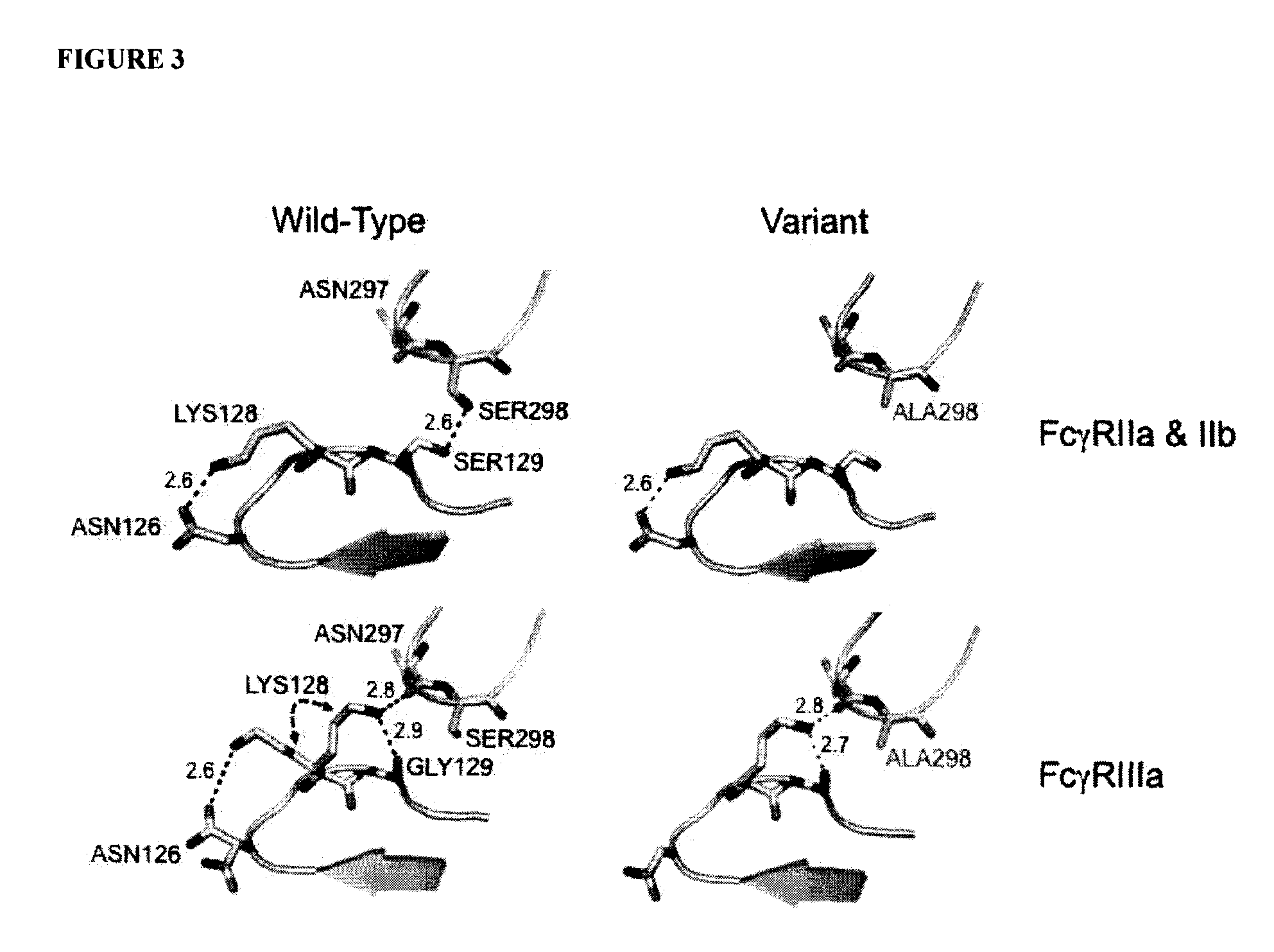

Rationally designed antibodies and polypeptides that comprise multiple Fc region amino acid substitutions that synergistically provide enhanced selectivity and binding affinity to a target Fc receptor are provided. The polypeptides are mutated at multiple positions to make them more effective when incorporated in antibody therapeutics than those having wild-type Fc components.

Owner:ZYMEWORKS INC

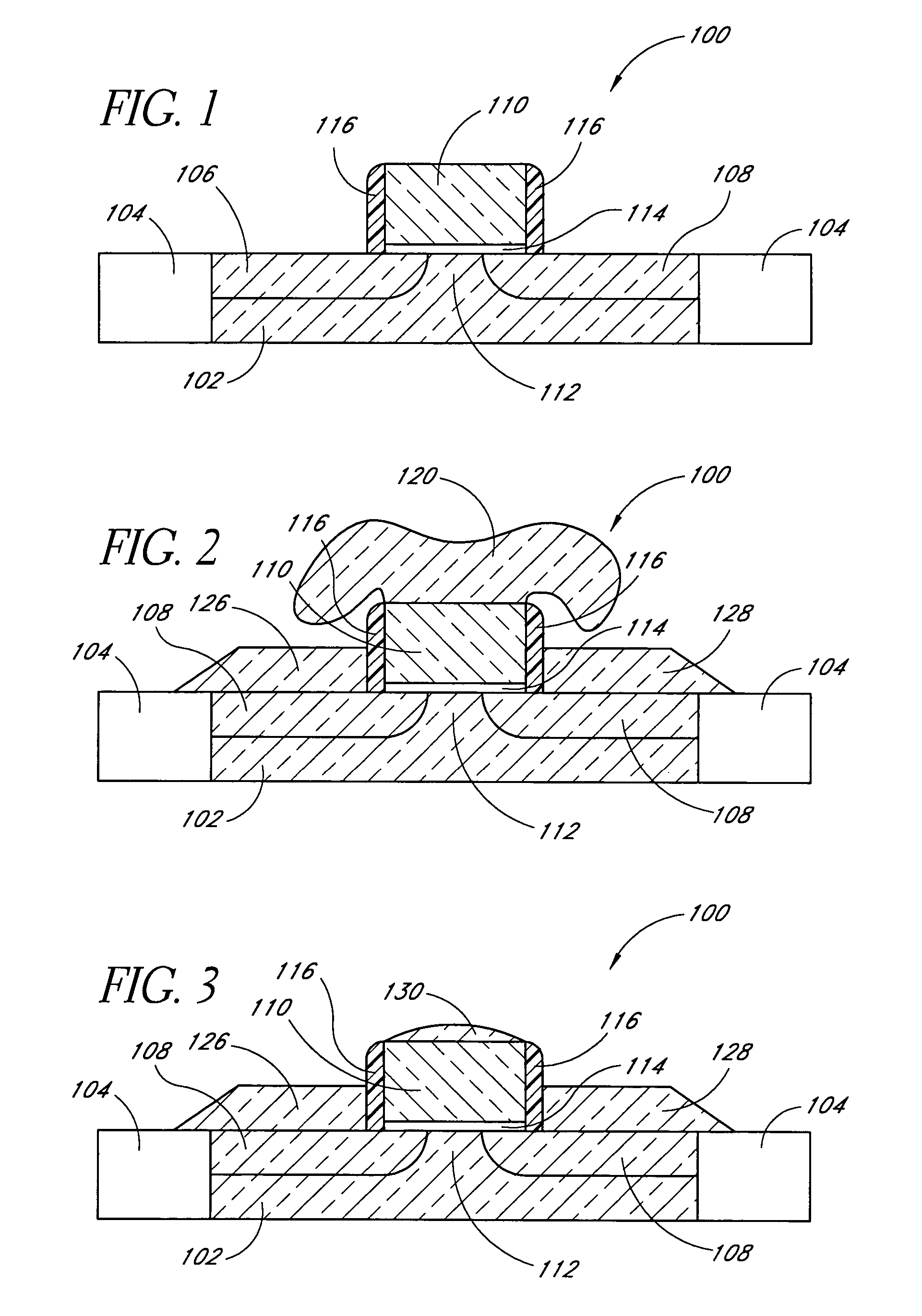

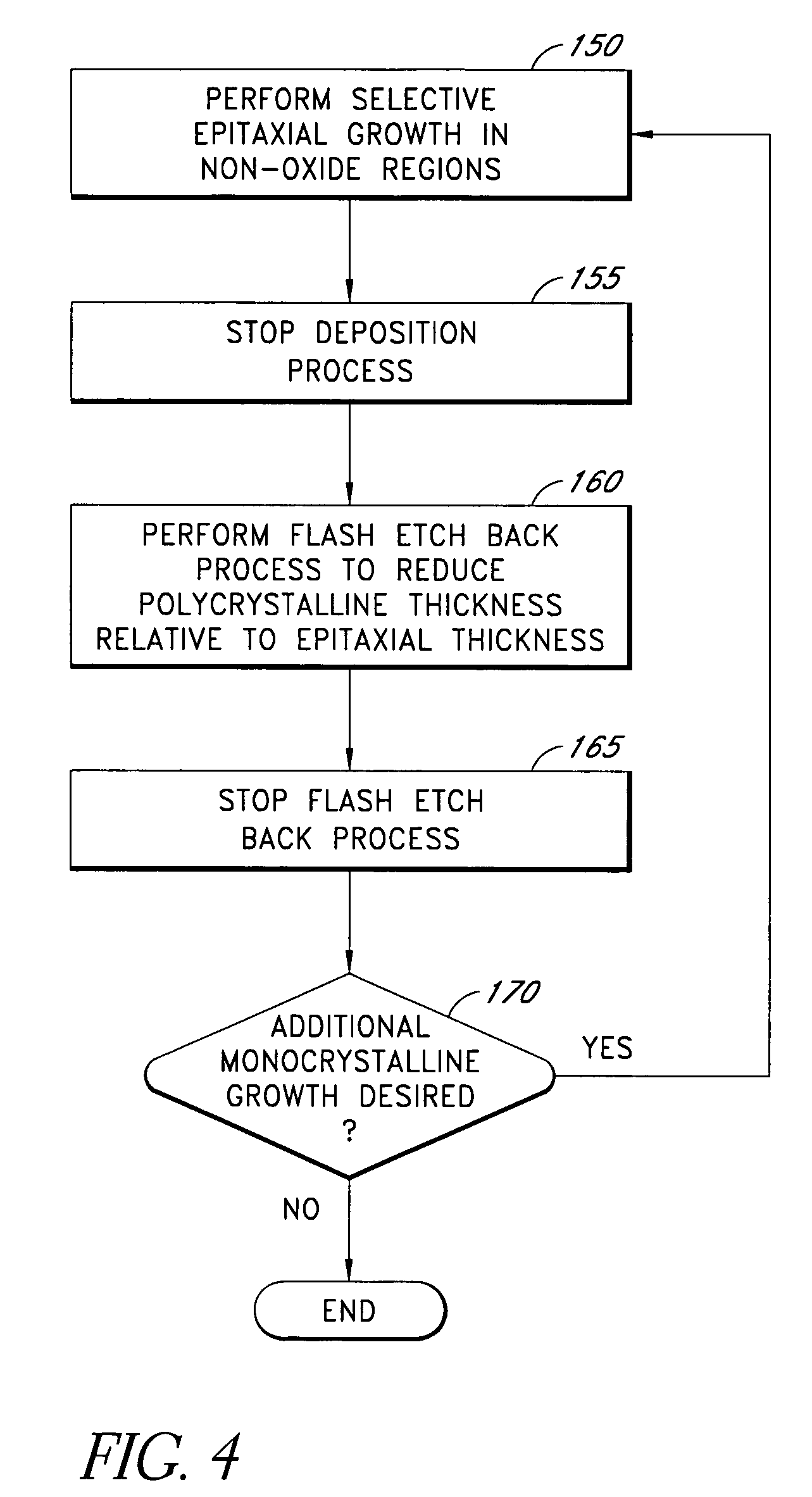

Enhanced selectivity for epitaxial deposition

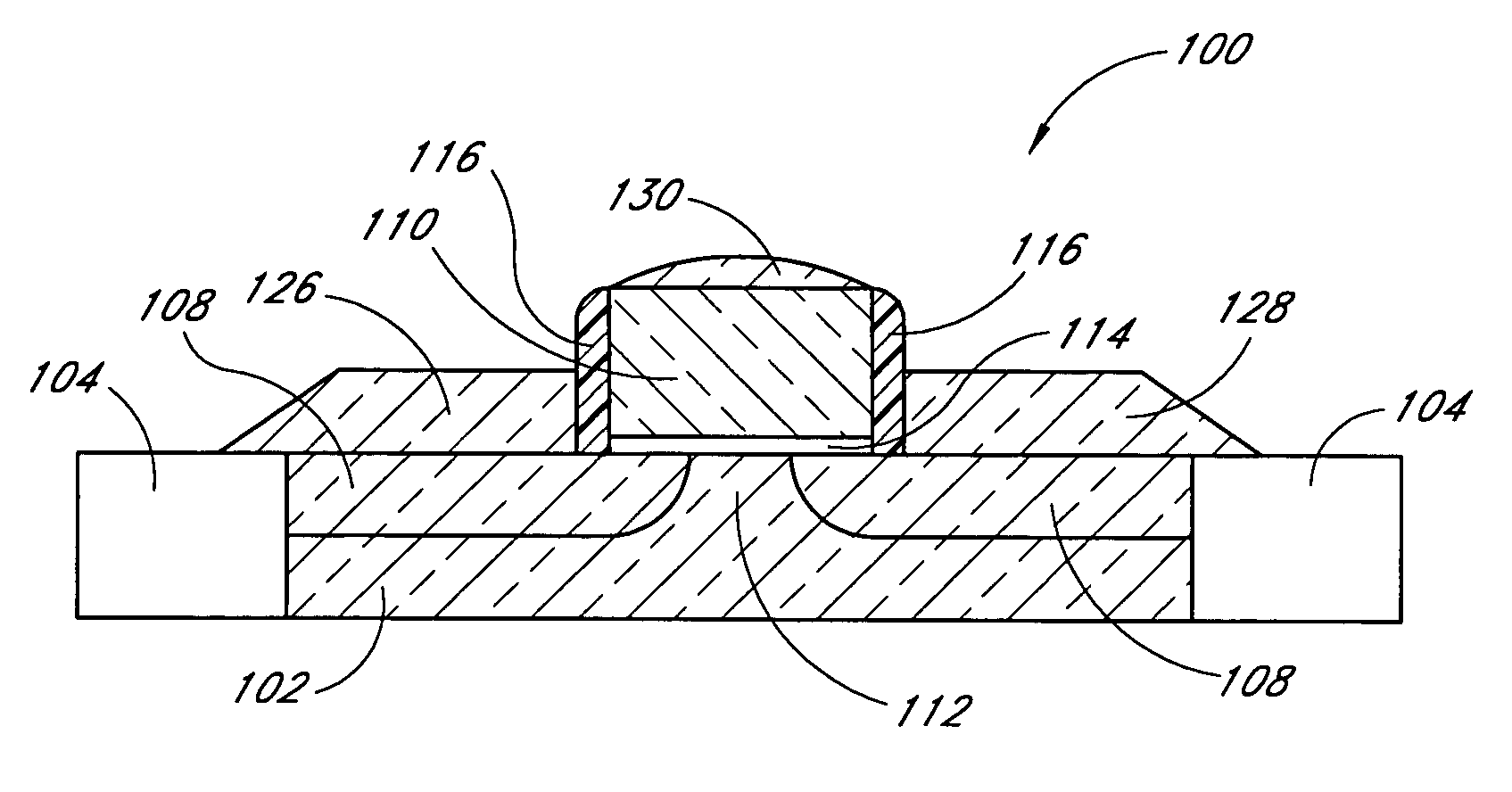

ActiveUS6998305B2Increase activity areaFrom solid stateSemiconductor/solid-state device manufacturingElectronic componentDeposition process

A method of forming an electronic component having elevated active areas is disclosed. The method comprises providing a semiconductor substrate in a processing chamber. The semiconductor substrate has disposed thereon a polycrystalline silicon gate and exposed active areas. The method further comprises performing a deposition process in which a silicon-source gas is supplied into the processing chamber to cause polycrystalline growth on the gate and epitaxial deposition on the active areas. The method further comprises performing a flash etch back process in which polycrystalline material is etched from the gate at a first etching rate and the epitaxial layer is etched from the active areas at a second etching rate. The first etching rate is faster than the second etching rate. The deposition process and the flash etch back process can be repeated cyclically, if desired. In certain other embodiments, the deposition process is a selective epitaxial deposition process, wherein growth occurs in non-oxide regions, but not in oxide regions.

Owner:ASM IP HLDG BV

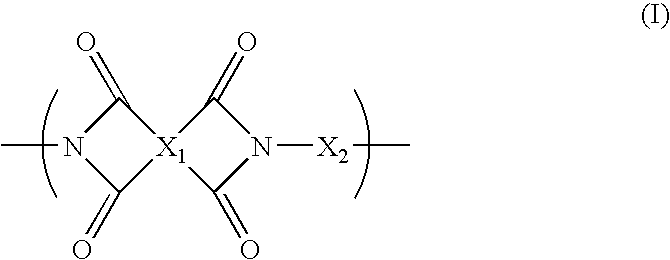

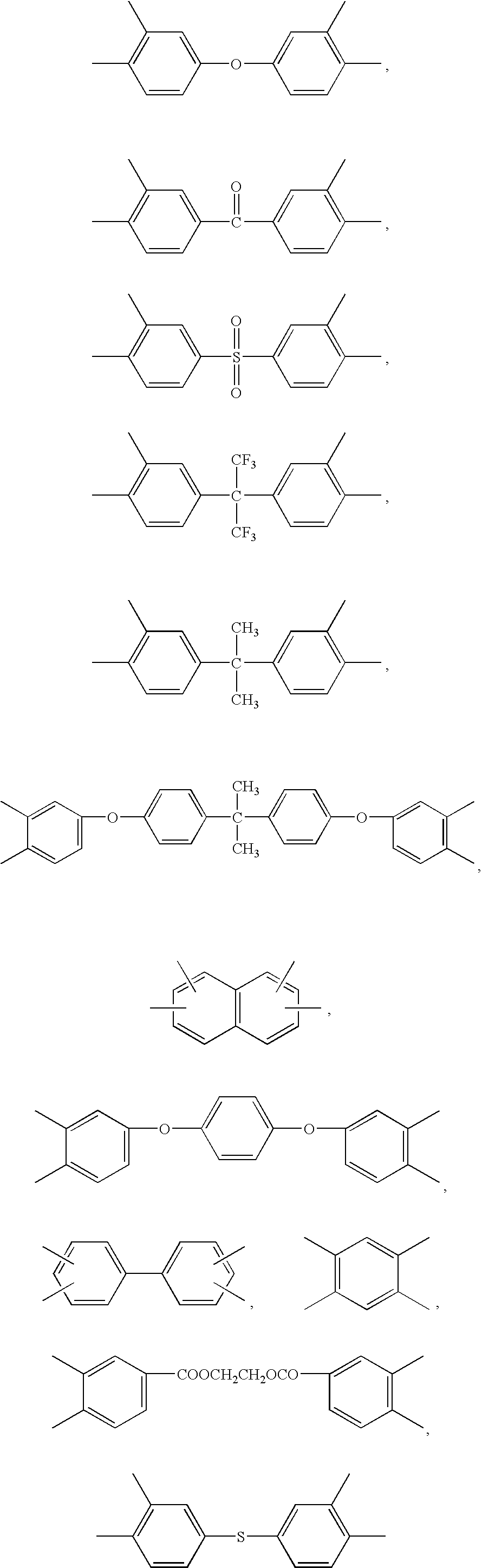

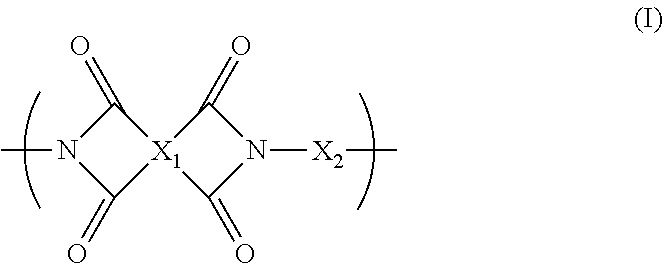

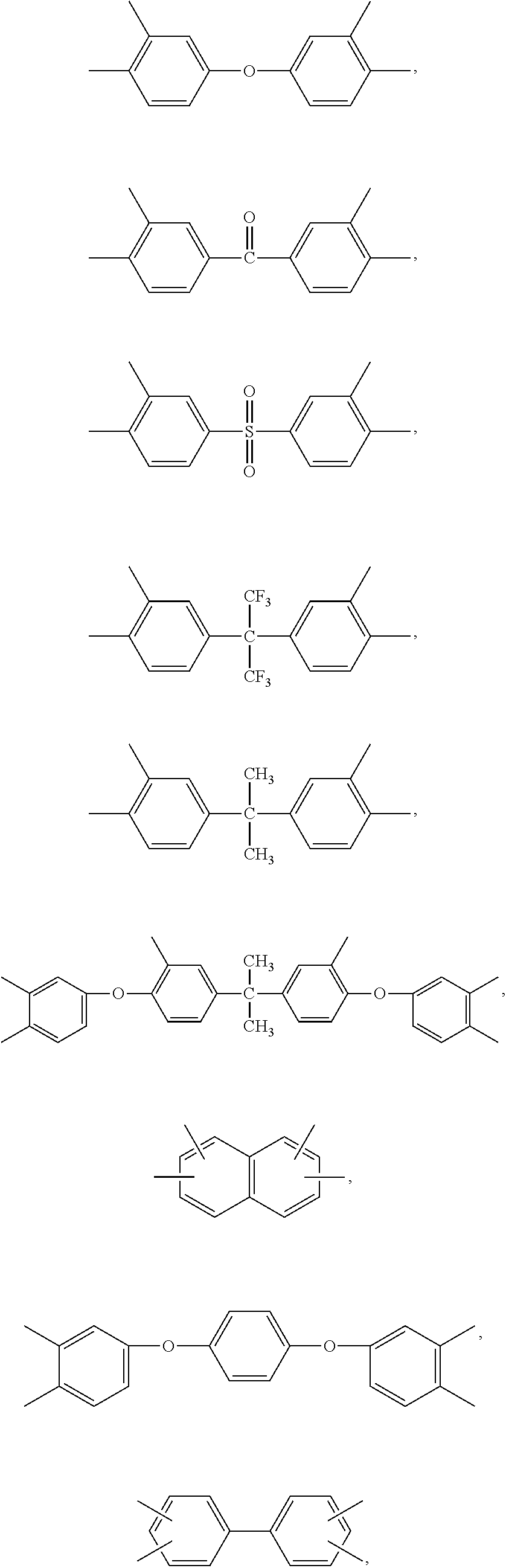

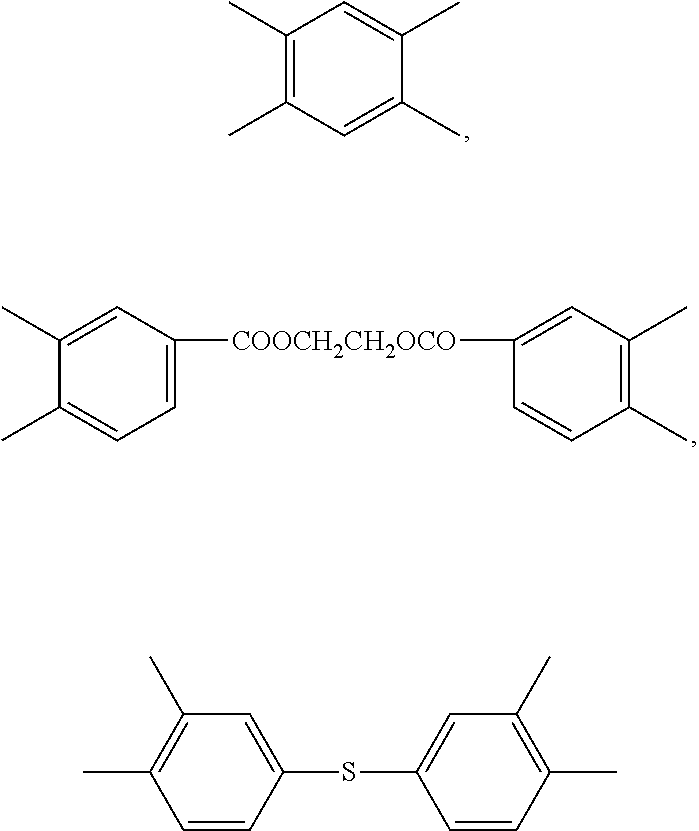

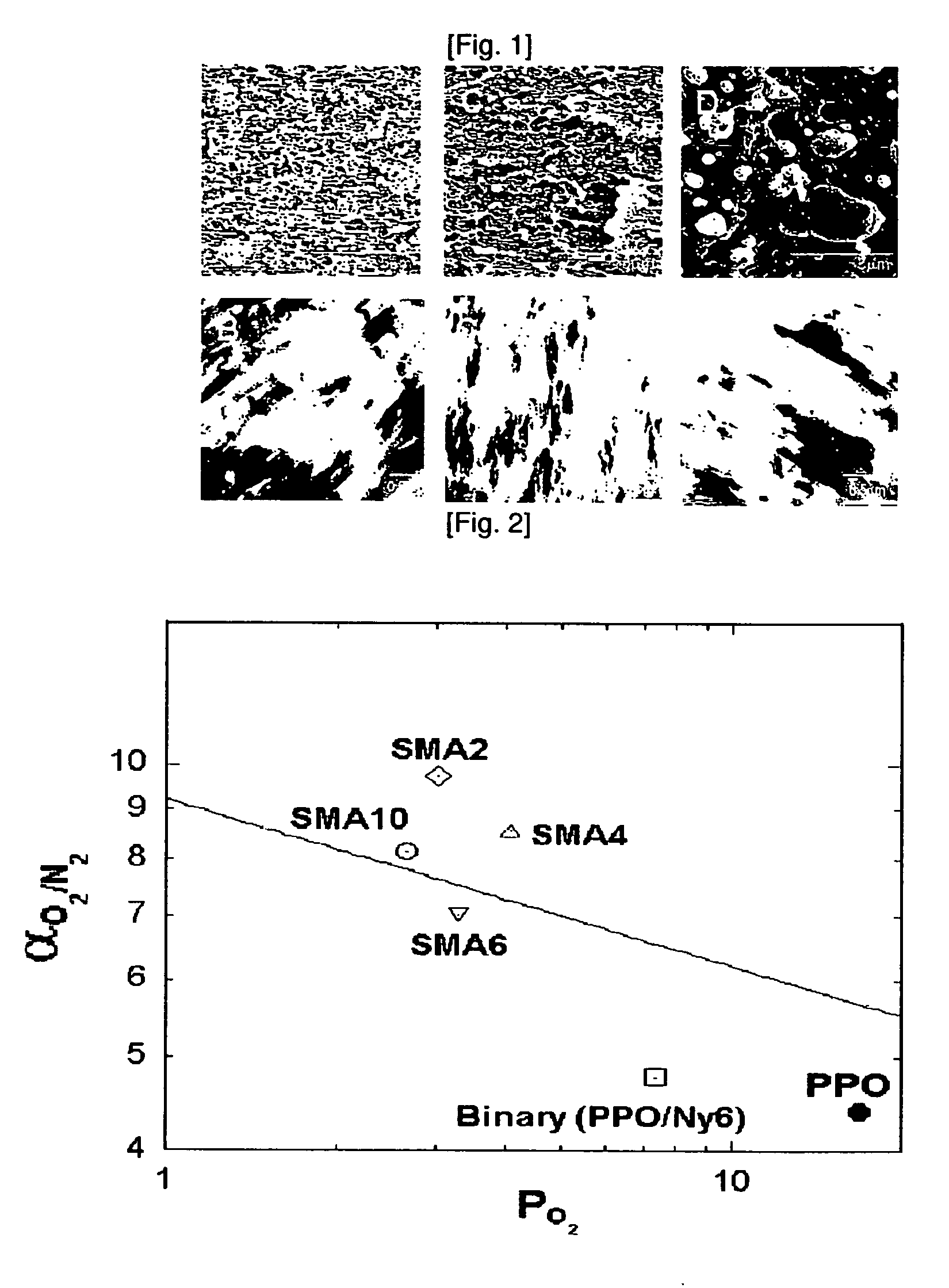

Blend Polymer Membranes Comprising Thermally Rearranged Polymers Derived from Aromatic Polyimides Containing Ortho-Positioned Functional Groups

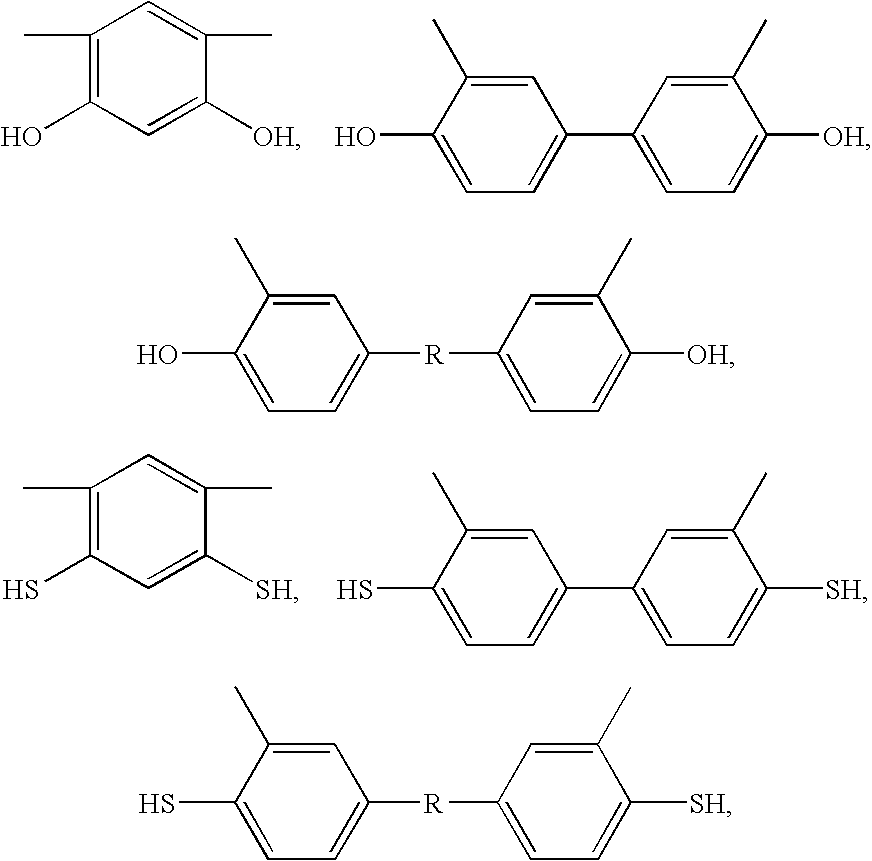

ActiveUS20100242723A1Increase flexibilityLow costSemi-permeable membranesMembranesPolymer scienceOrtho position

The present invention discloses blend polymer membranes comprising thermally rearranged polymers derived from aromatic polyimides containing ortho-positioned functional groups and methods for making and using these blend polymer membranes. The blend polymer membranes described in the current invention are prepared by heat treatment of blend polymer membranes comprising aromatic polyimides containing ortho-positioned functional groups such as —OH or —SH groups. In some instances, an additional crosslinking step is performed to improve the selectivity of the membrane. These blend polymer membranes have improved flexibility, reduced cost, improved processability, and enhanced selectivity and / or permeability compared to the comparable polymer membranes that comprise a single polymer.

Owner:UOP LLC

Antibodies with Enhanced or Suppressed Effector Function

InactiveUS20130108623A1Increase free energyLow affinitySugar derivativesAntipyreticFc receptorAntiendomysial antibodies

Rationally designed antibodies and polypeptides that comprise two Fc region amino acid substitutions that synergistically provide enhanced selectivity and binding affinity to a target Fc receptor are provided. The polypeptides comprise Fc region mutations at two positions that synergistically make the polypeptides more effective when incorporated in antibody therapeutics than those having wild-type Fc components.

Owner:ZYMEWORKS INC

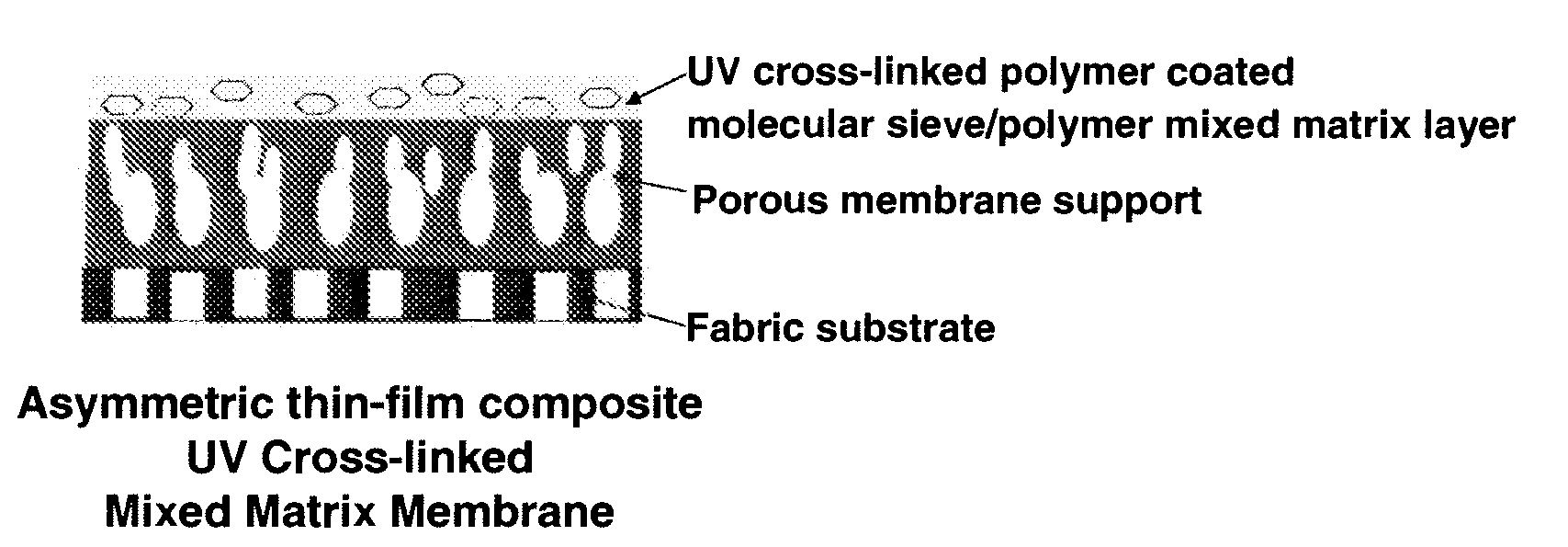

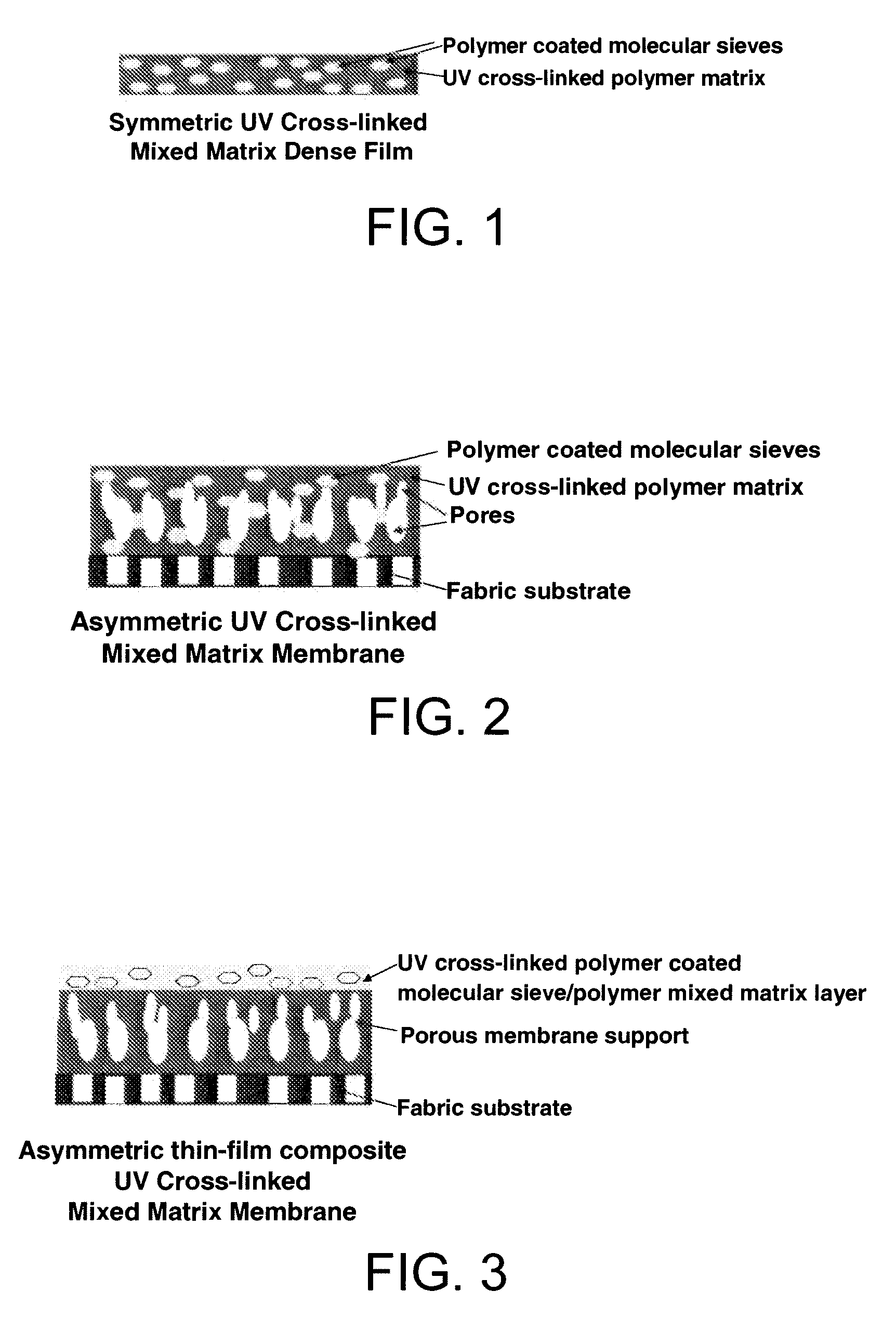

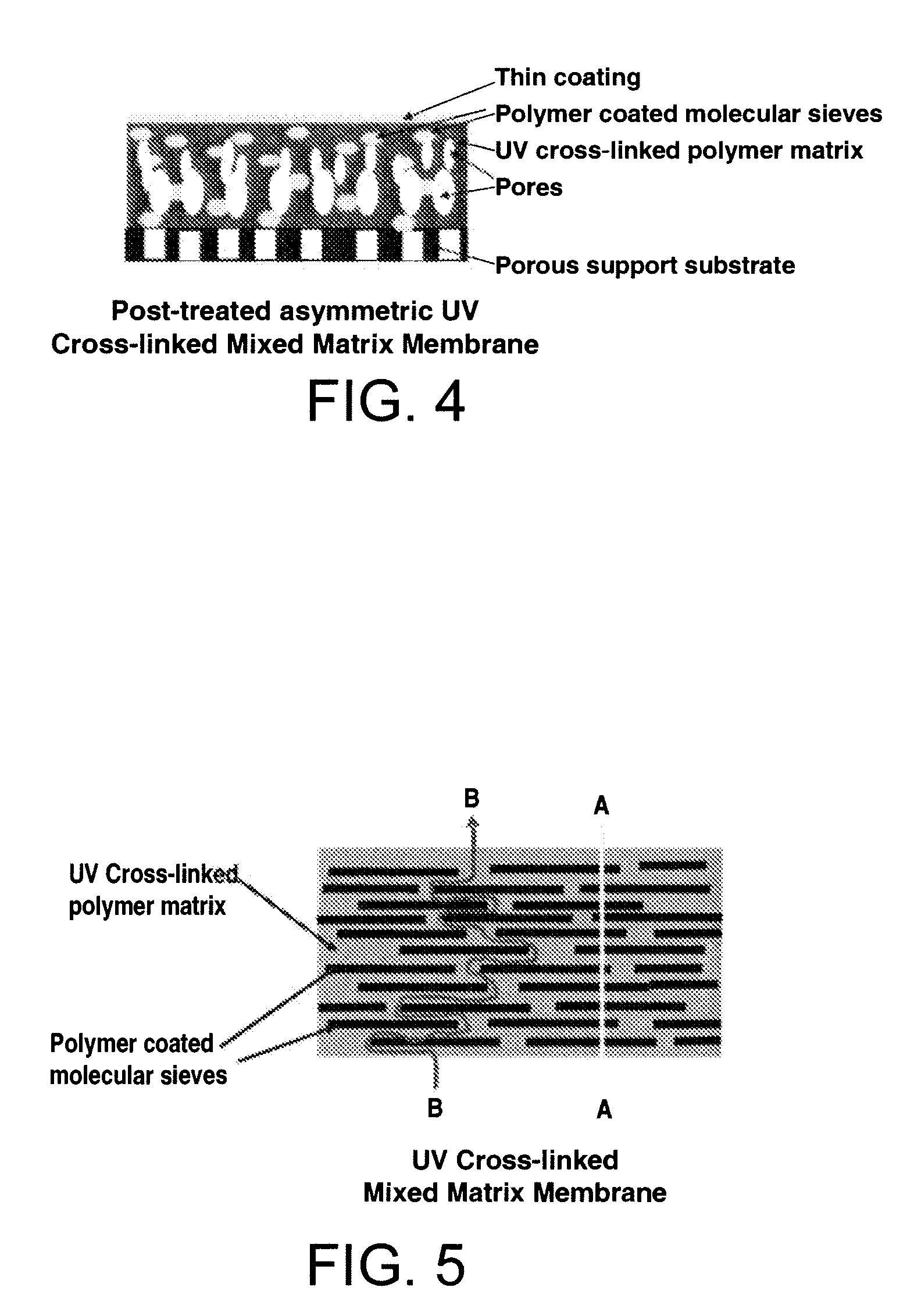

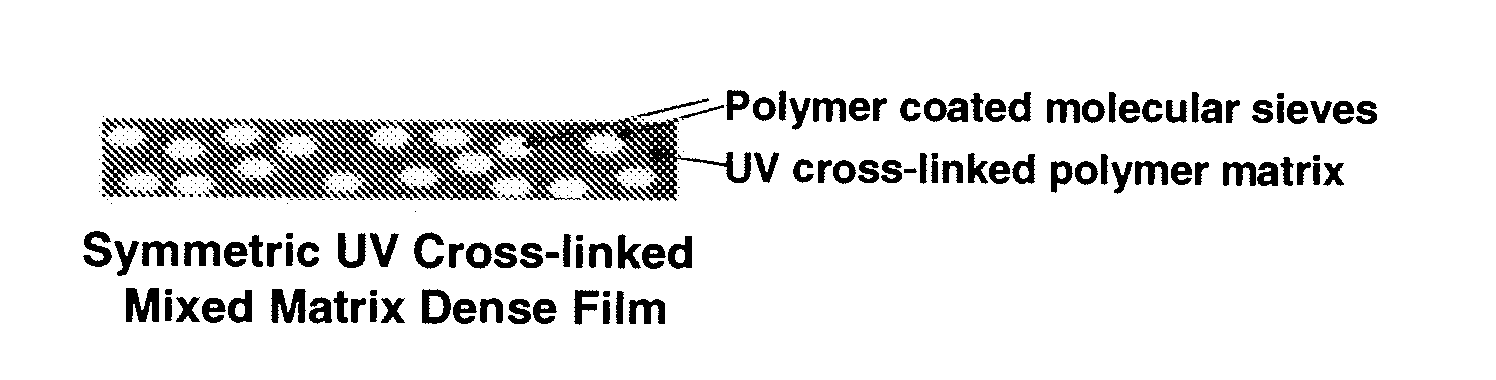

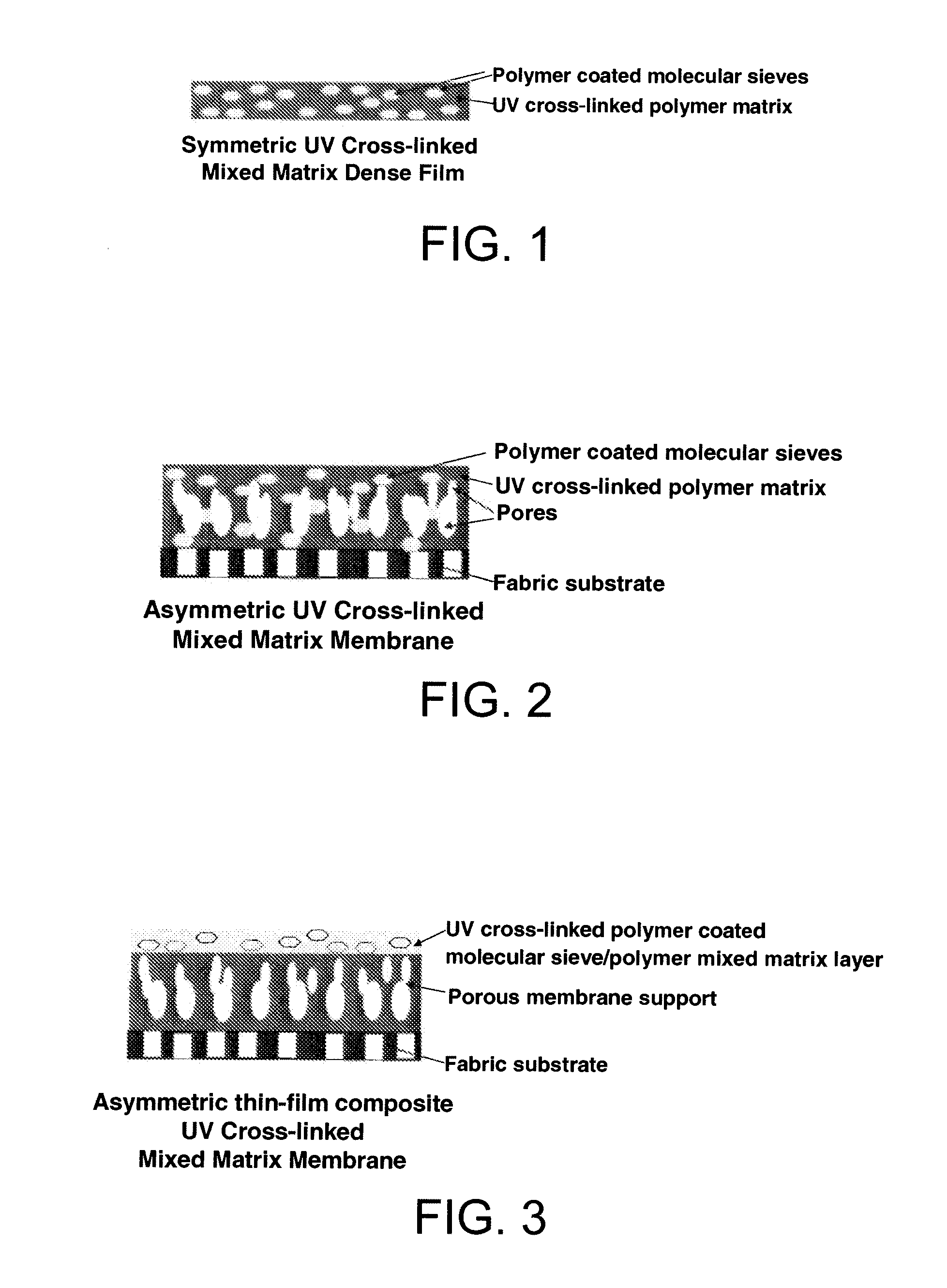

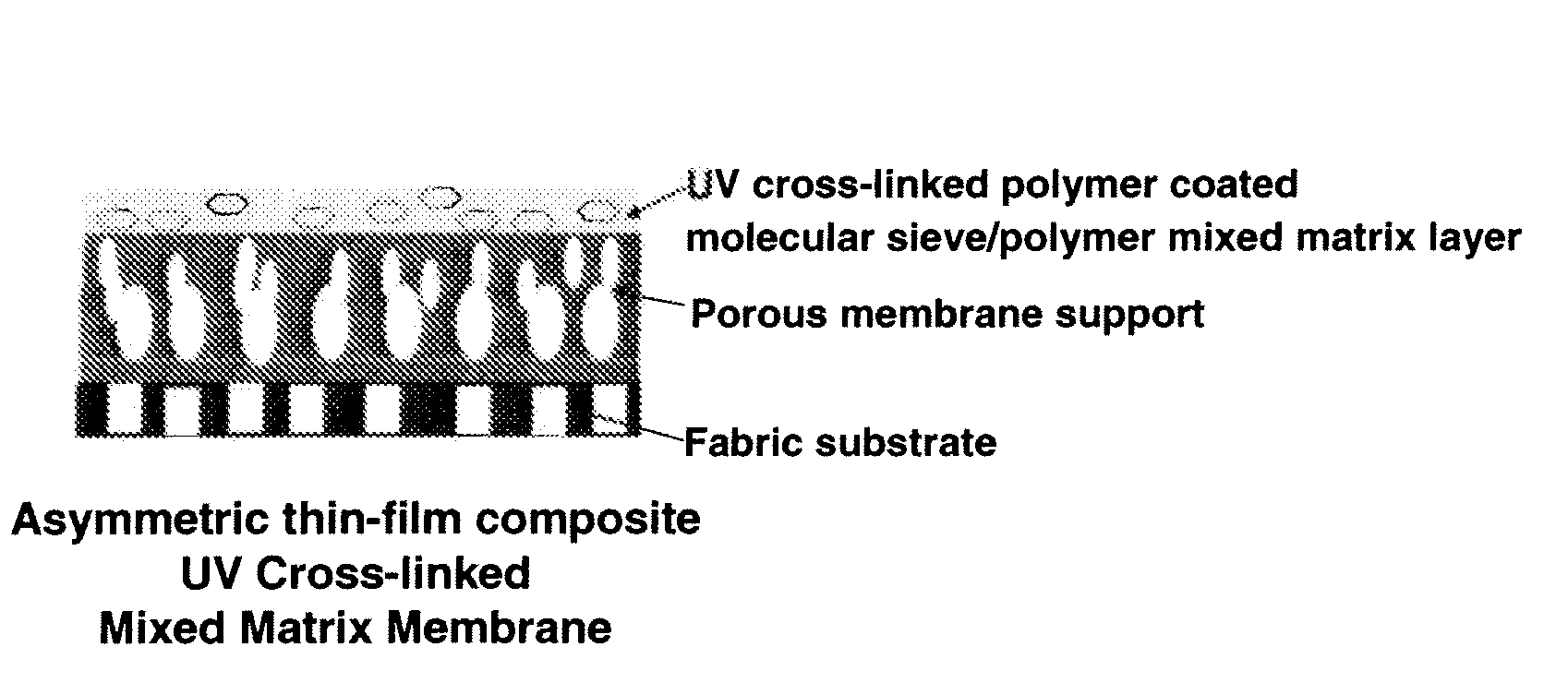

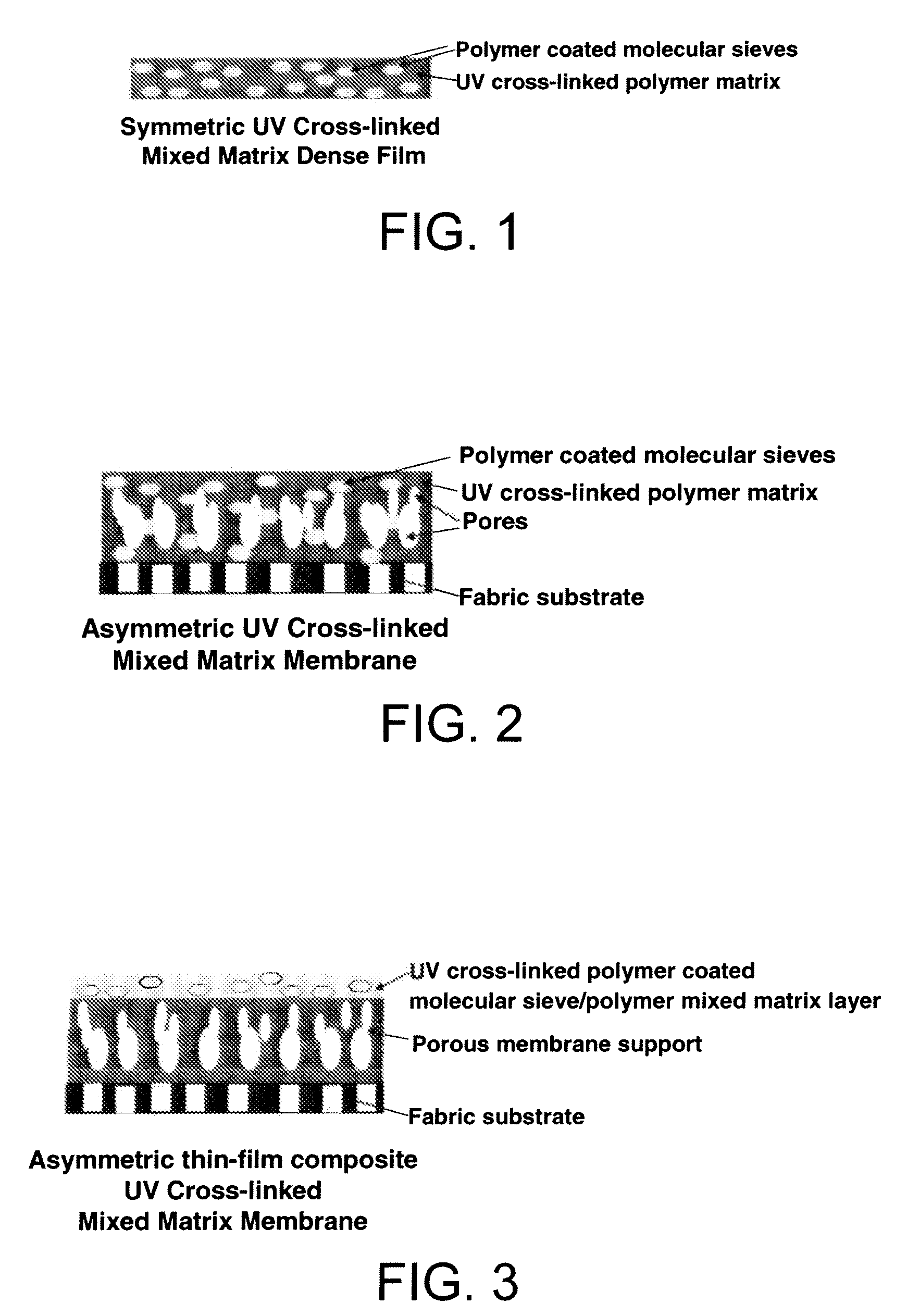

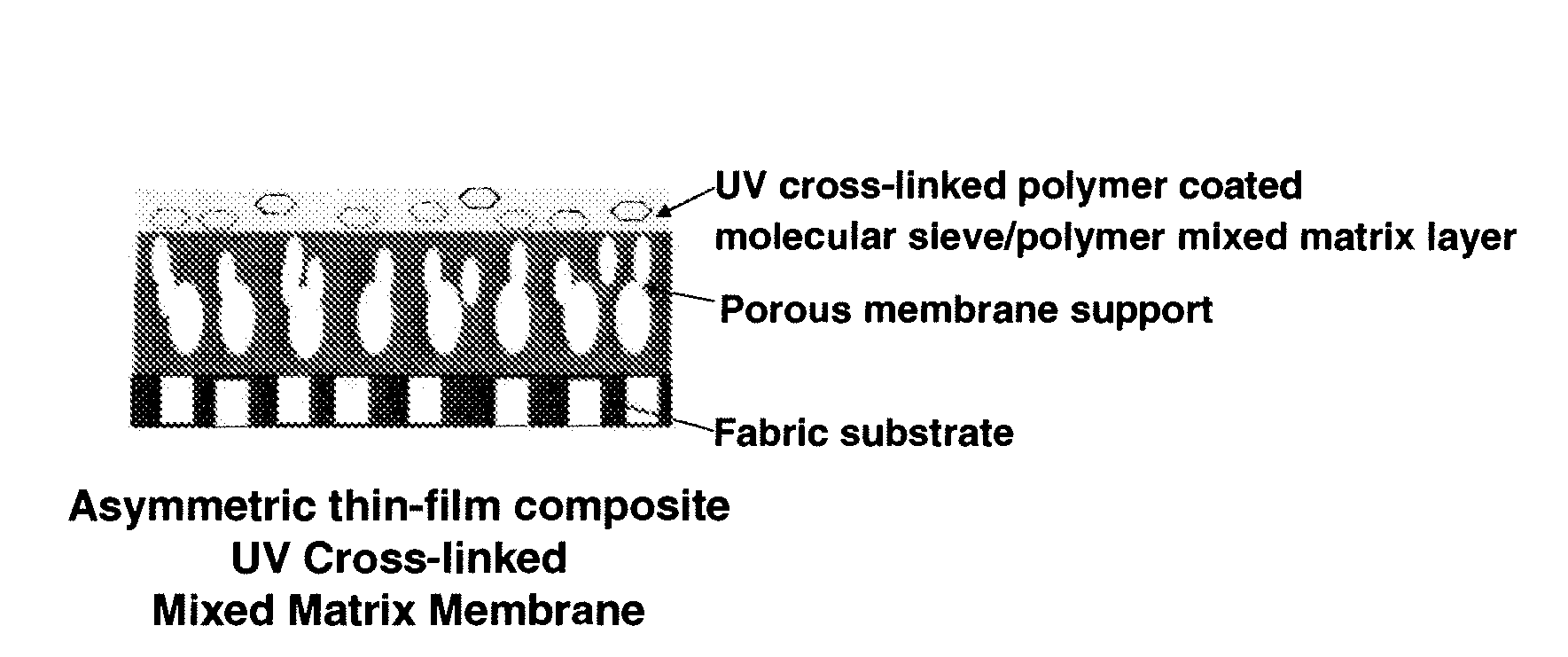

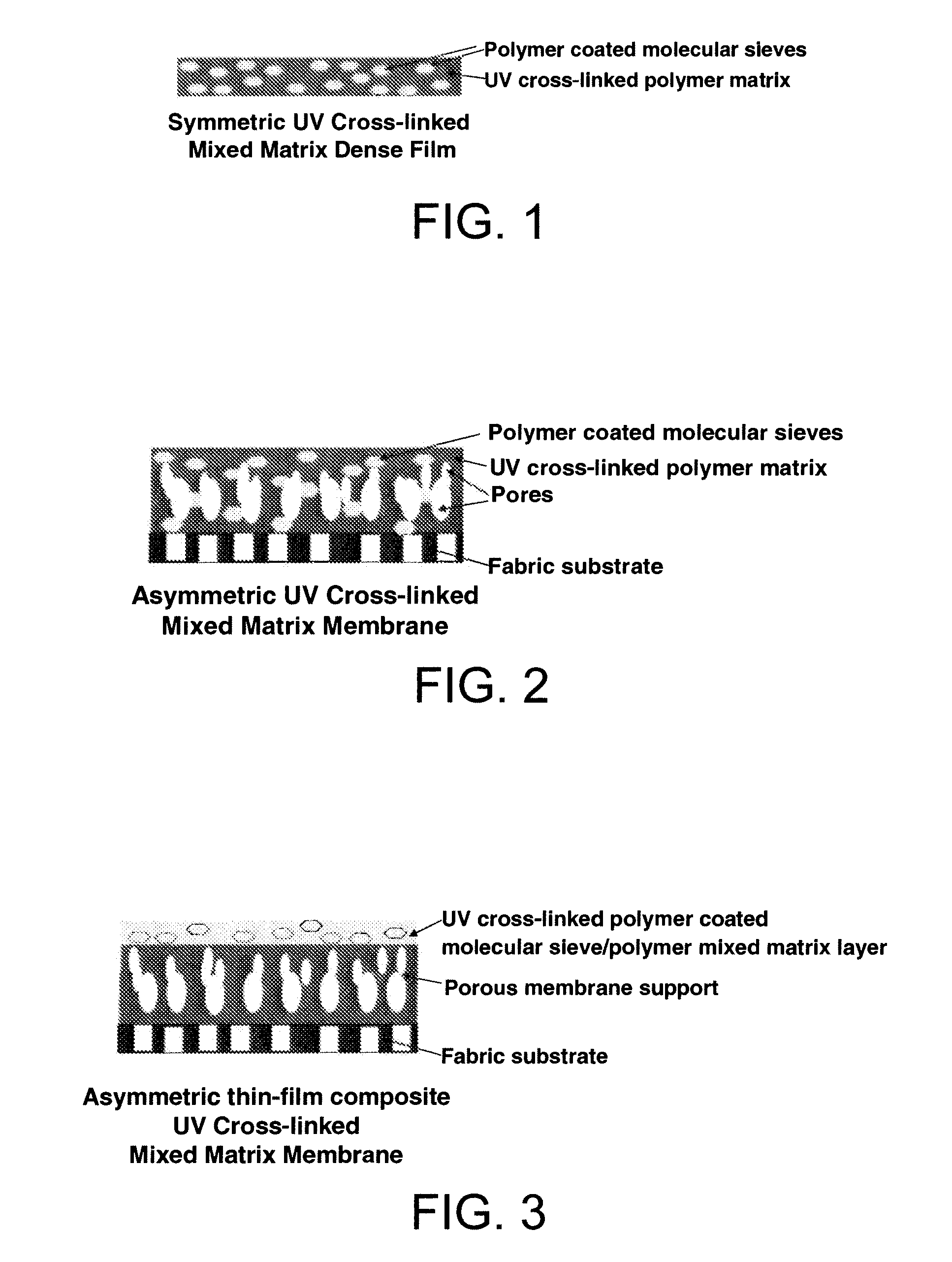

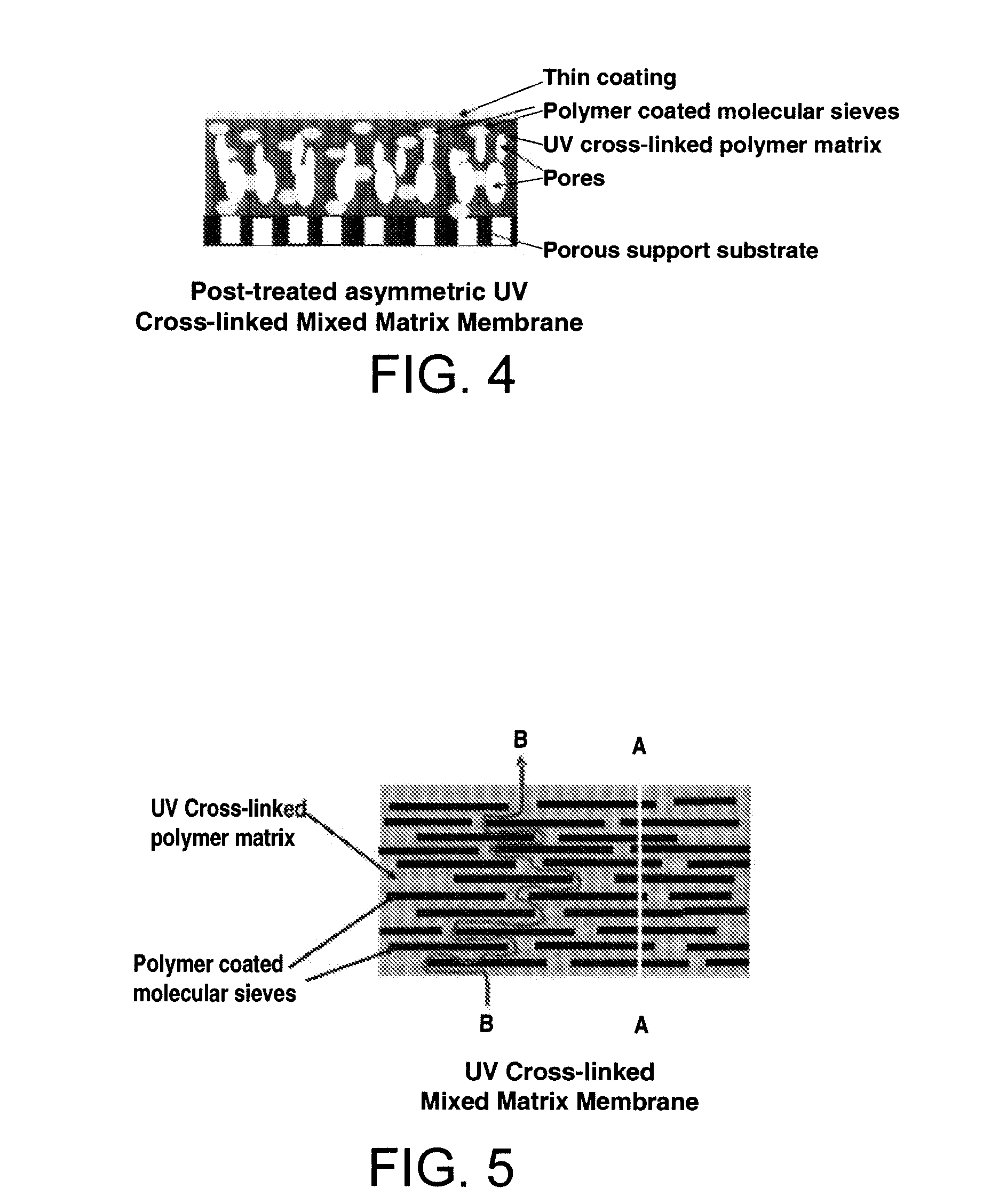

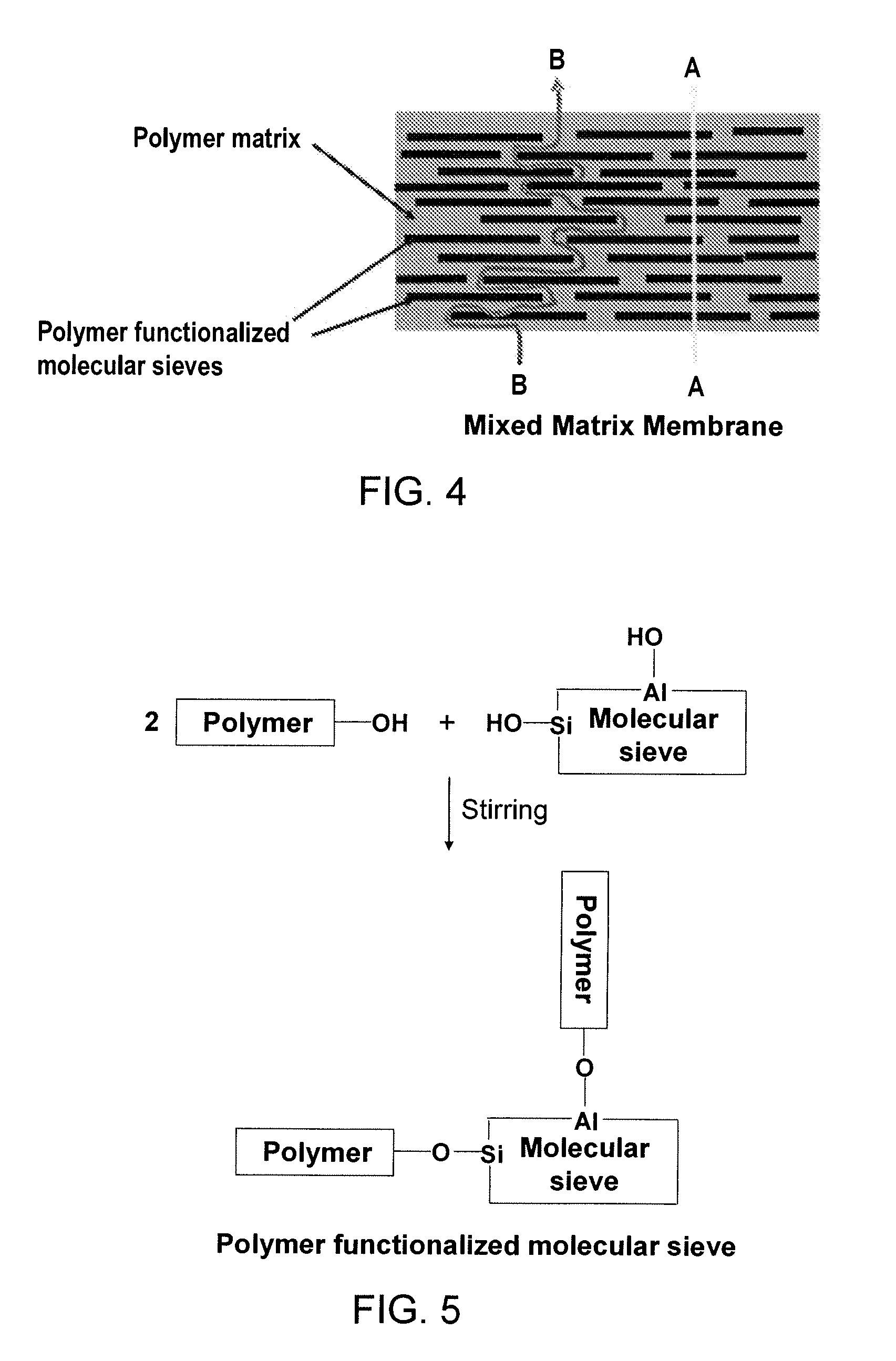

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes for sulfur reduction

InactiveUS20080295692A1Easy to separateAverage permeabilityMembranesSemi-permeable membranesCross-linkPolymer chemistry

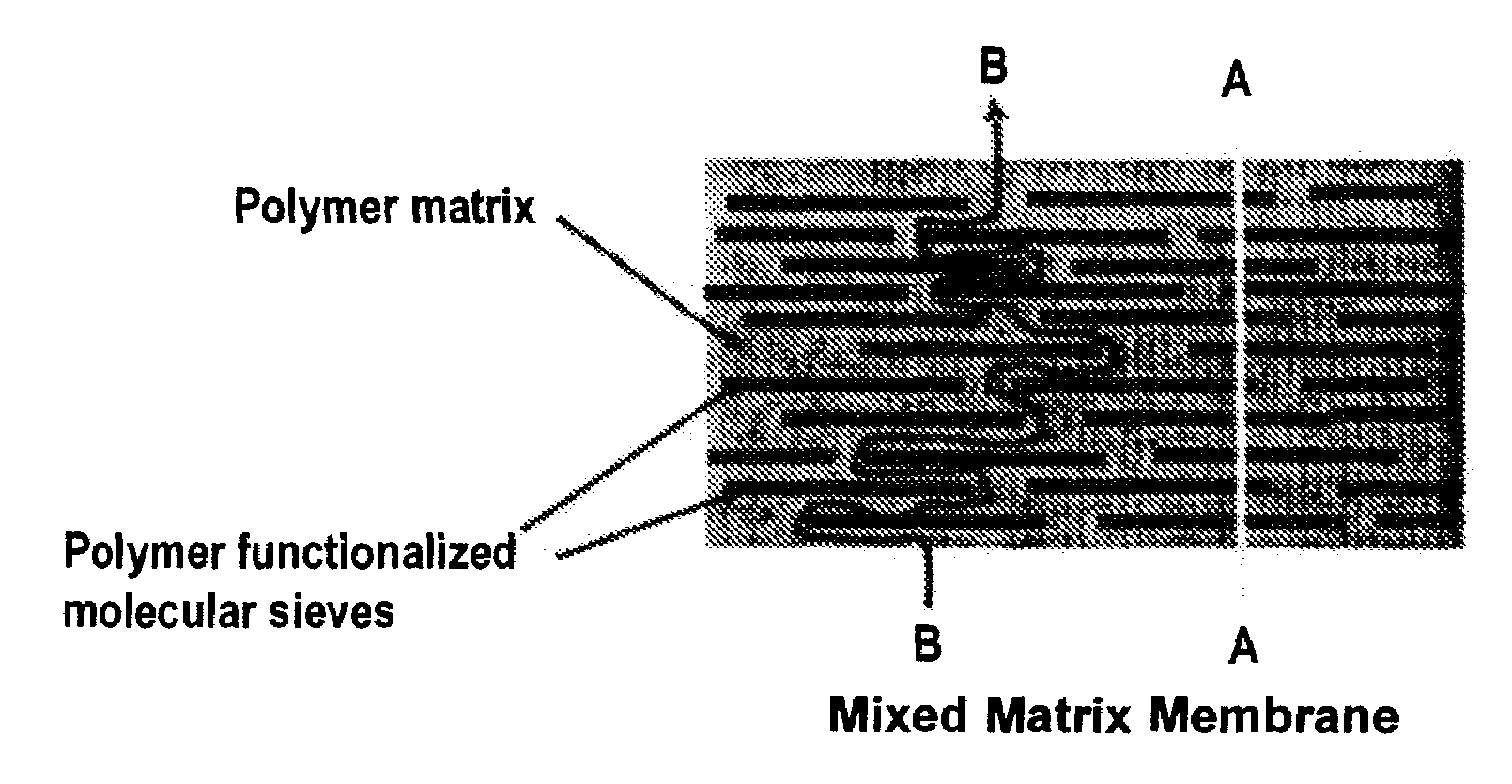

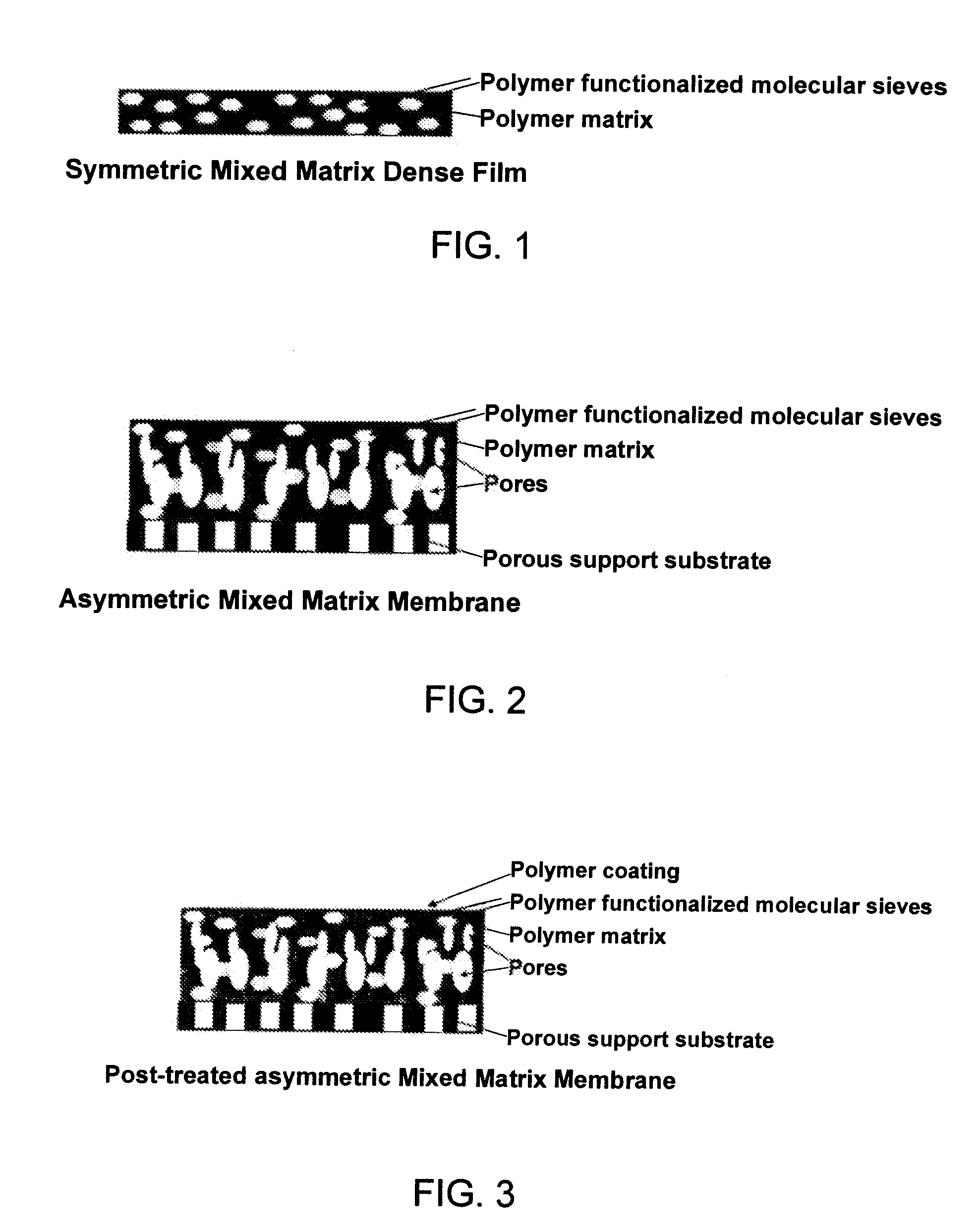

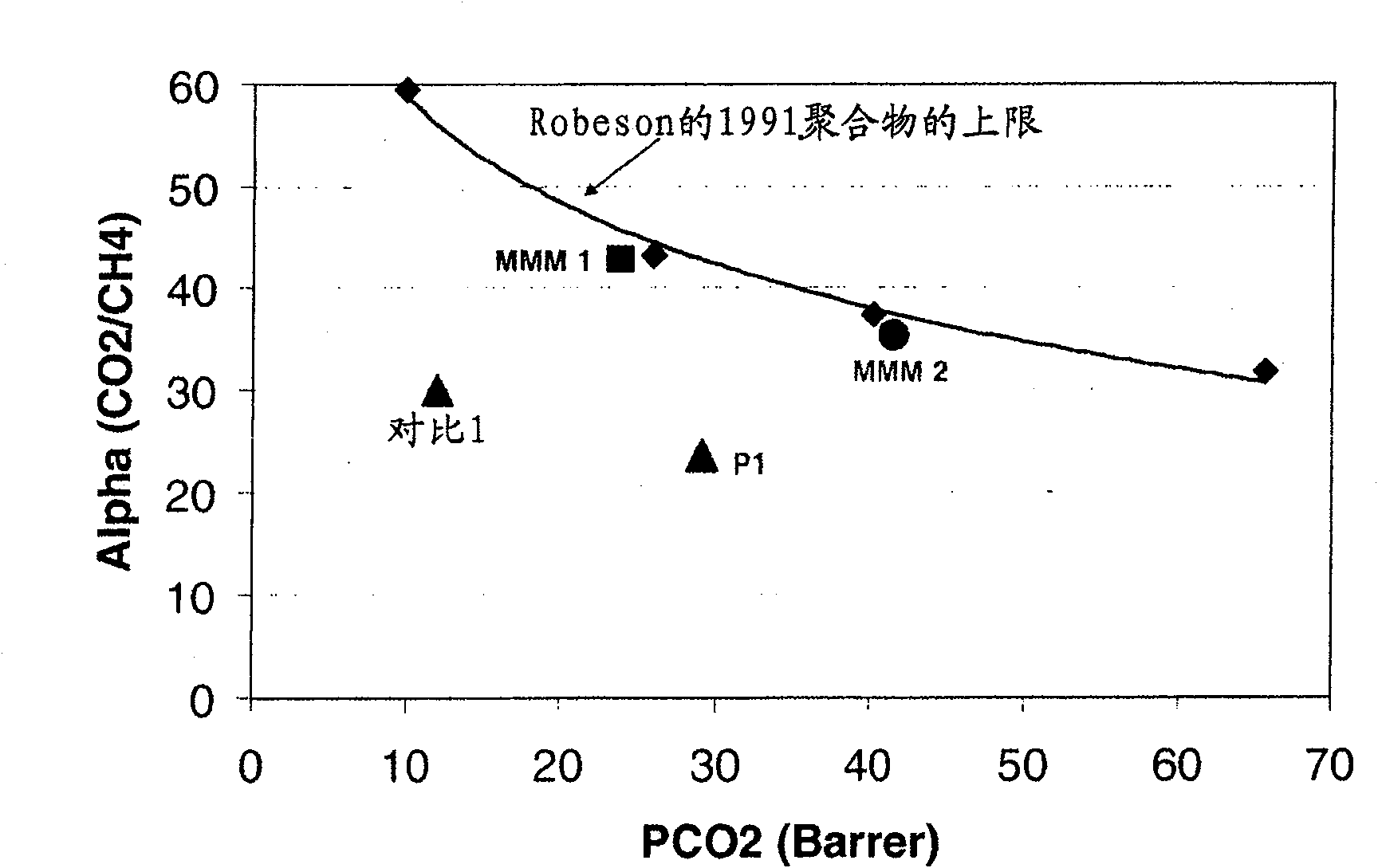

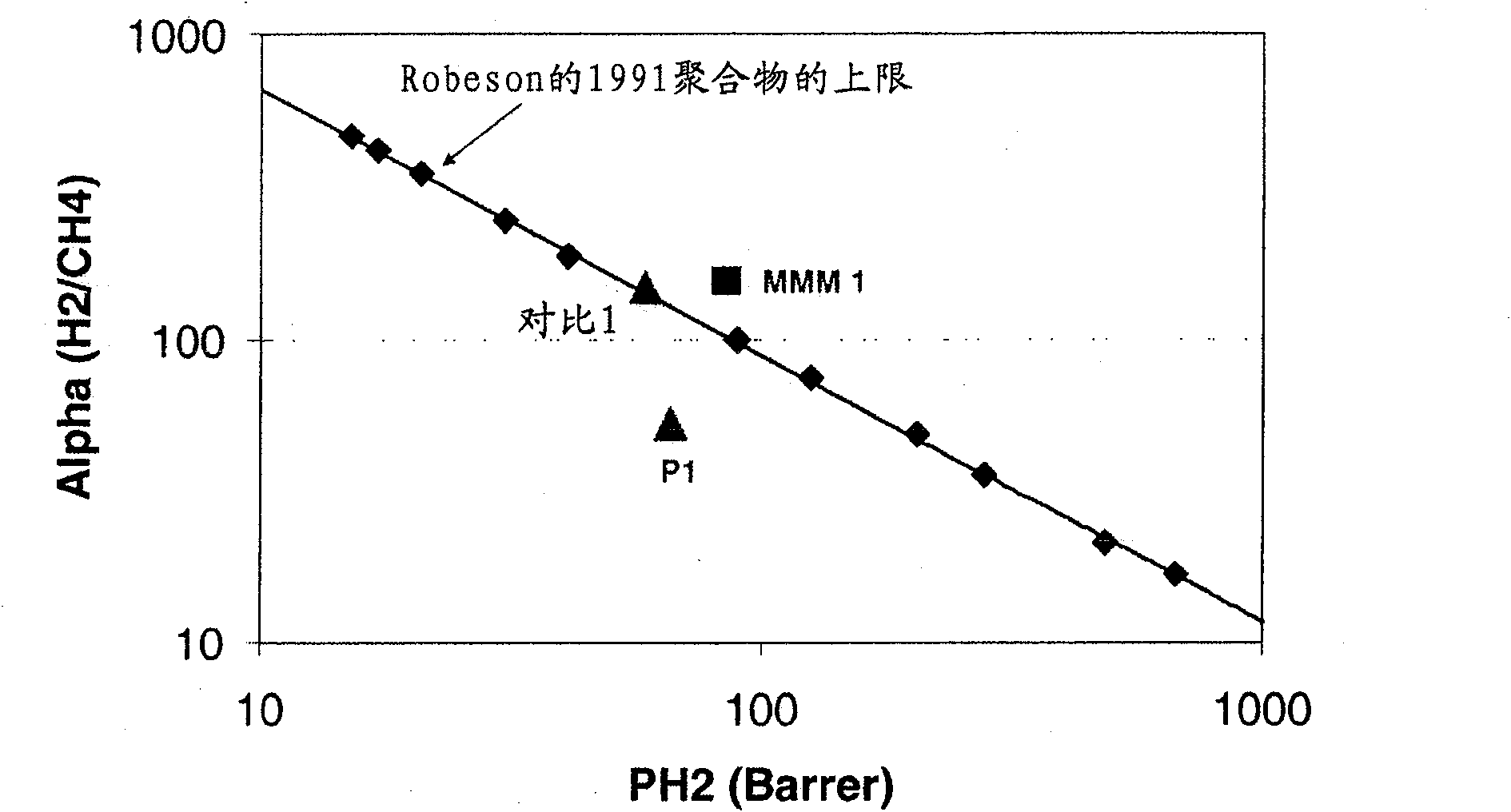

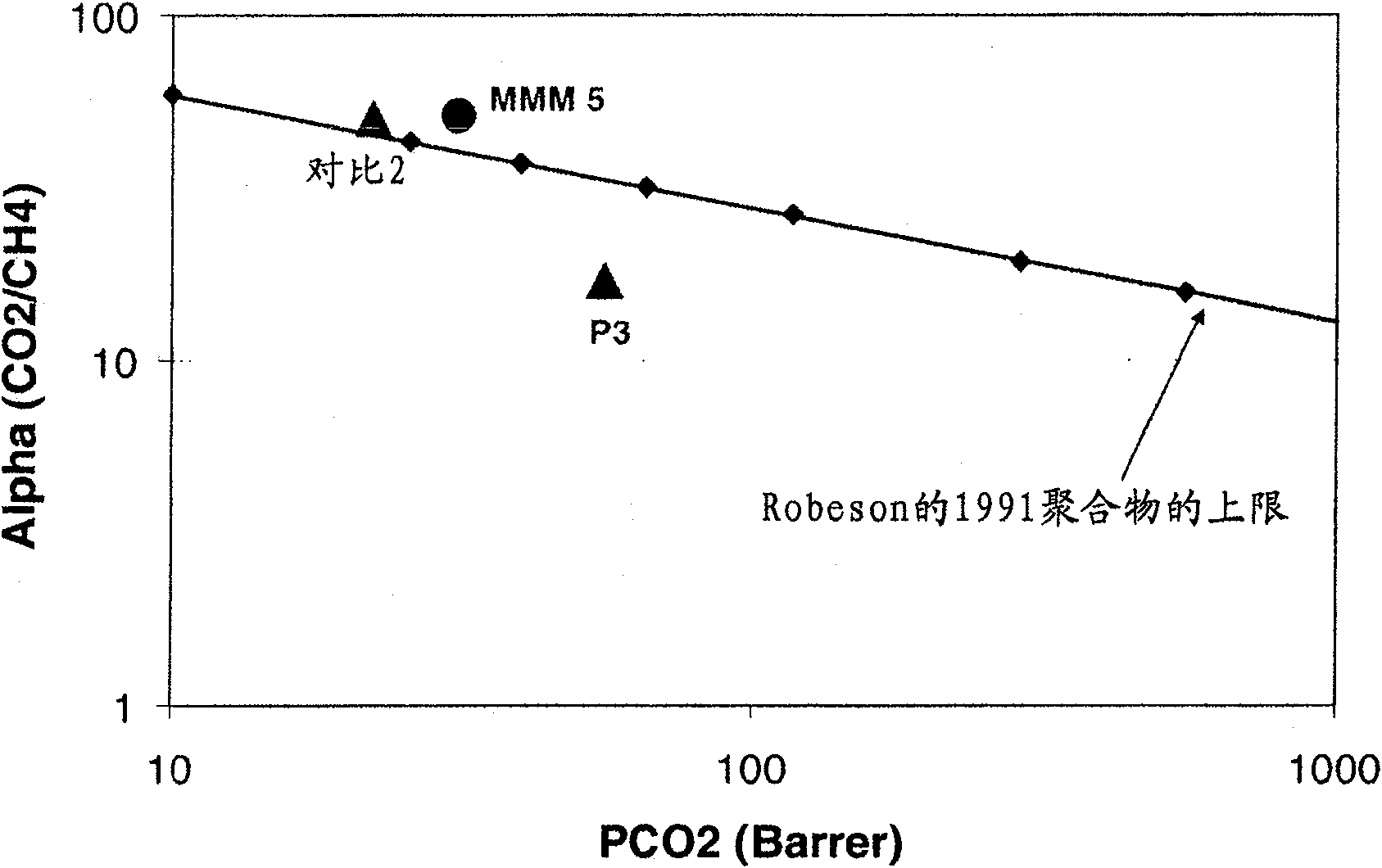

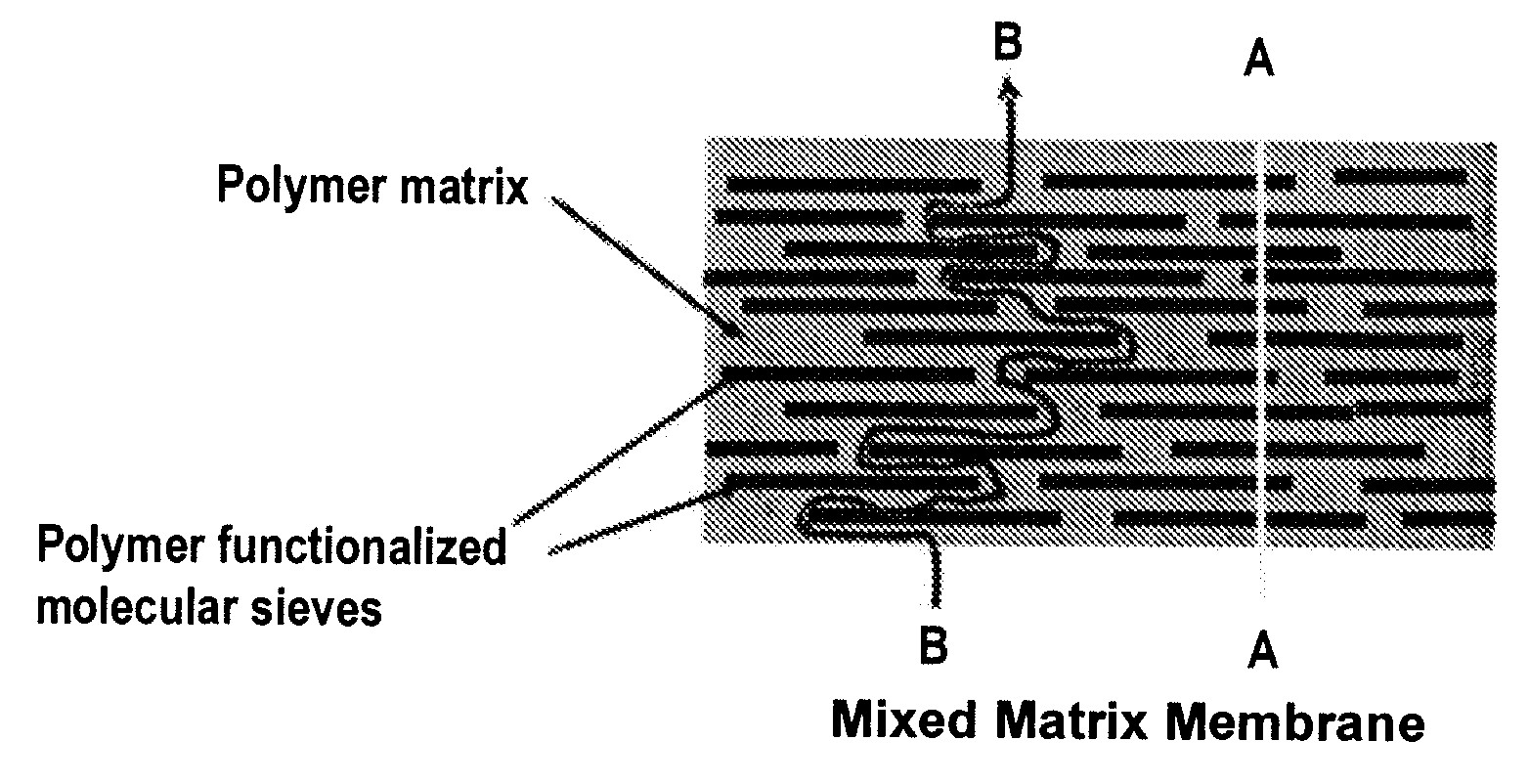

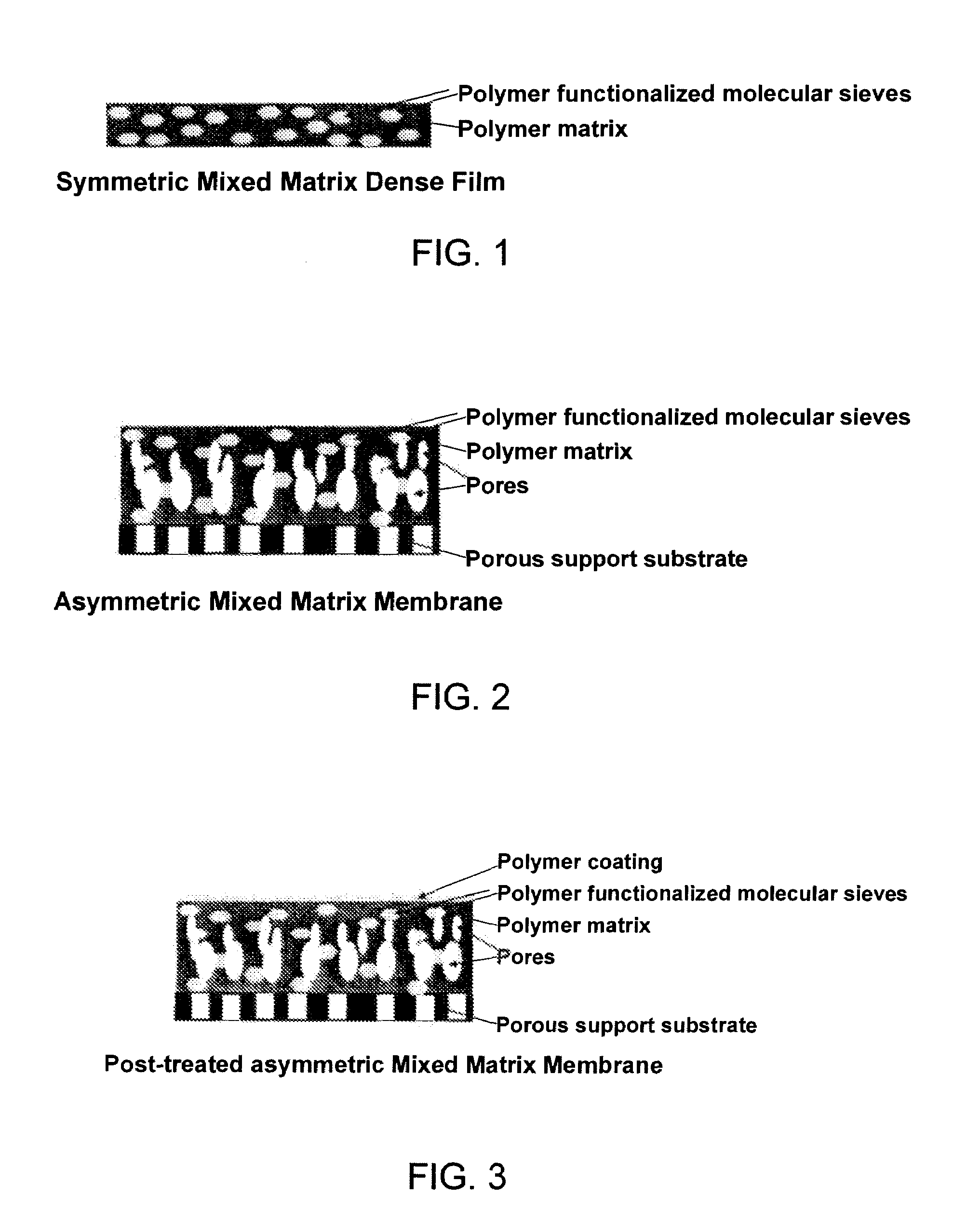

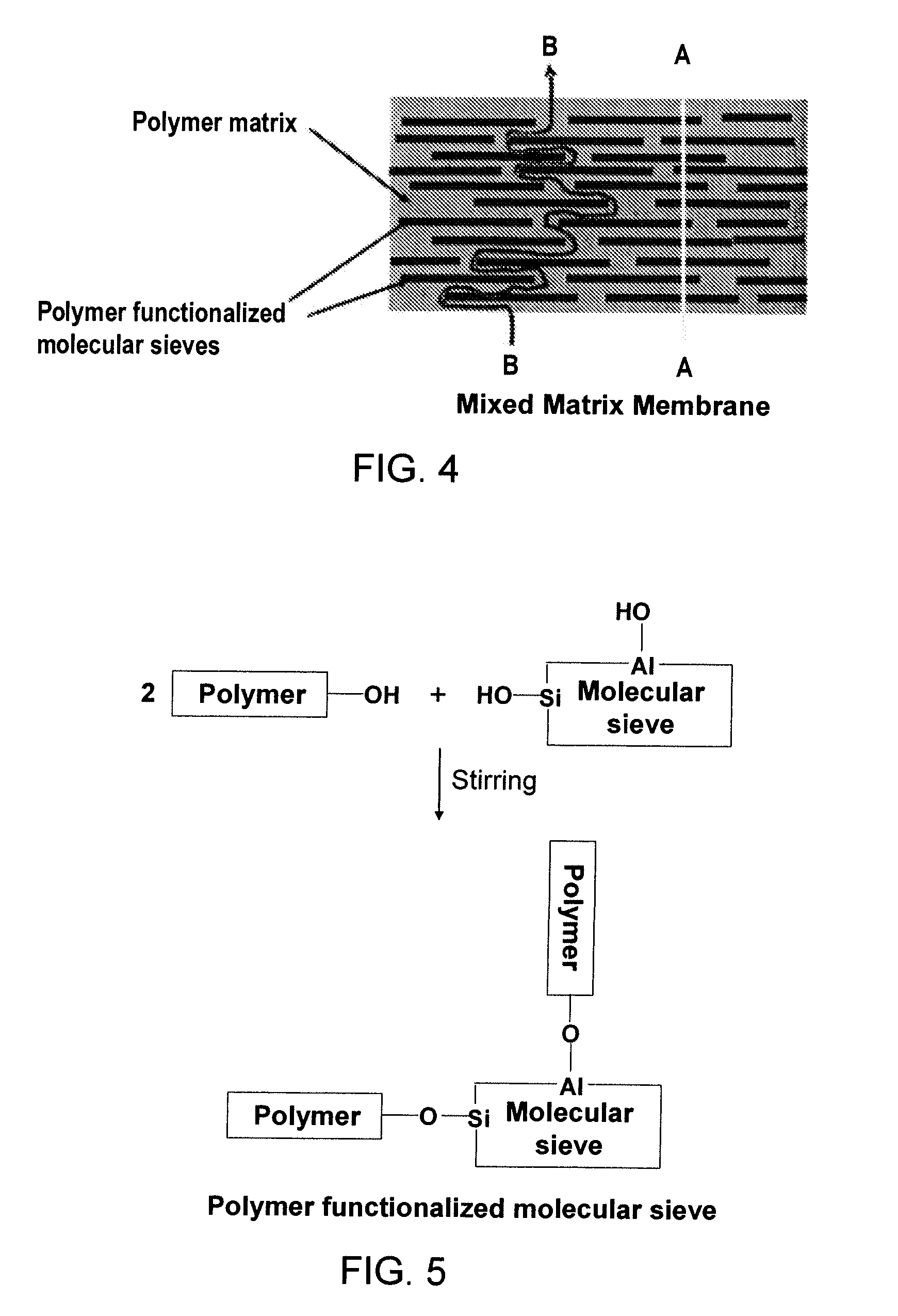

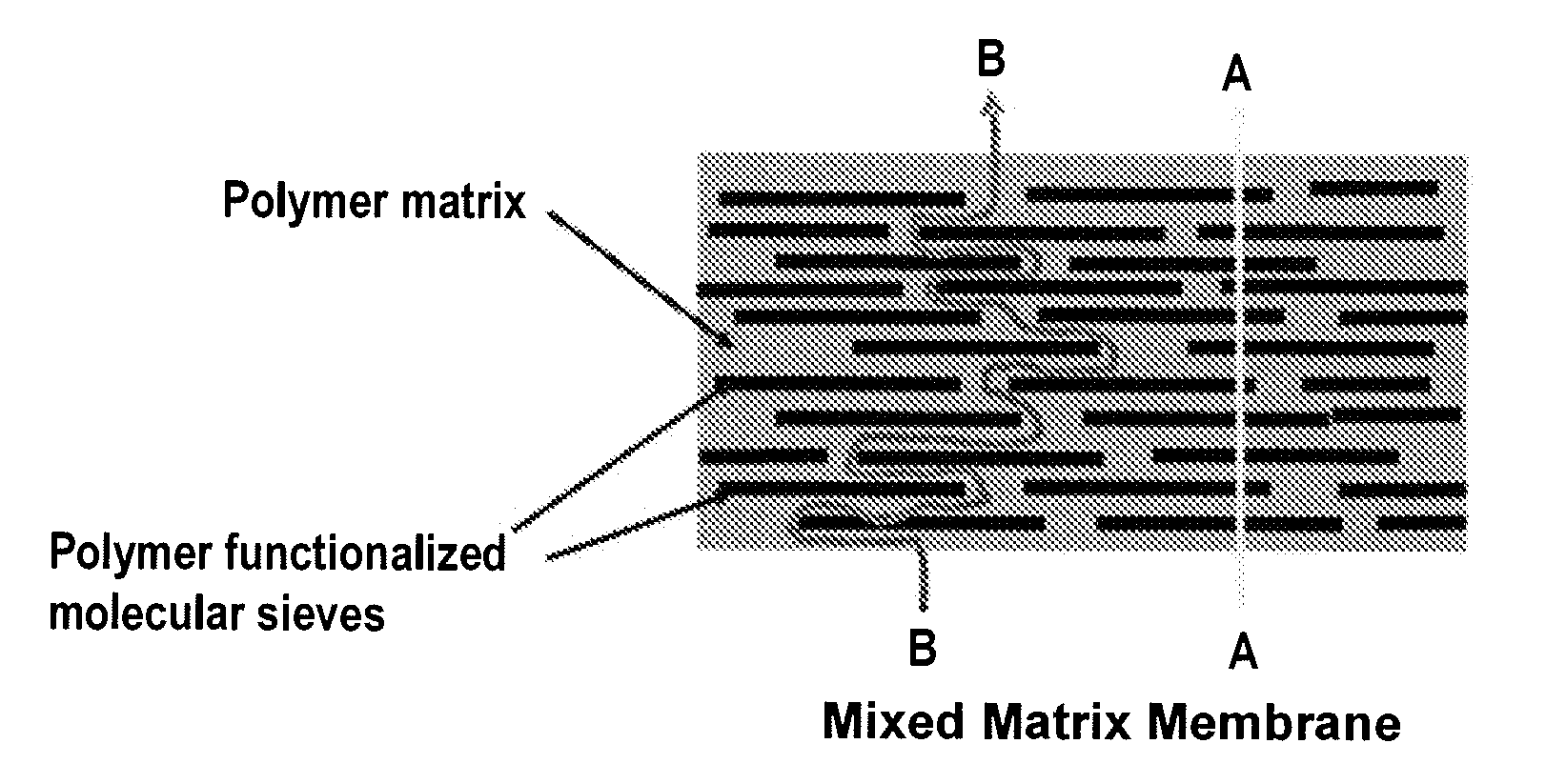

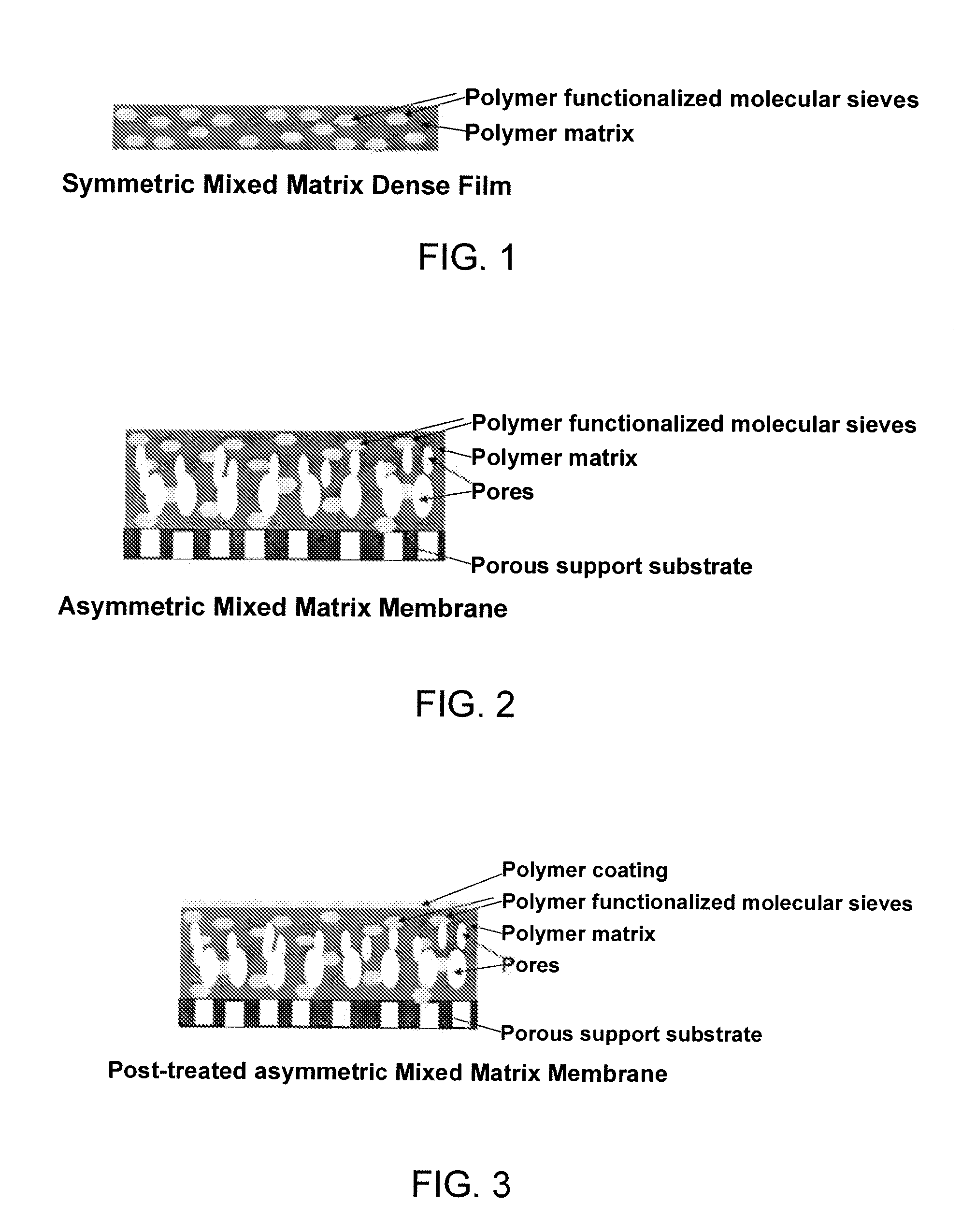

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs), the method of making these membranes, and the use of such membranes for separations. These UV cross-linked MMMs were prepared by incorporating polyethersulfone functionalized molecular sieves such as AlPO-14 and UZM-25 into a continuous UV cross-linkable polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes described in the current invention have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and permeability over the polymer membranes made from the corresponding continuous polyimide polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels.

Owner:UOP LLC

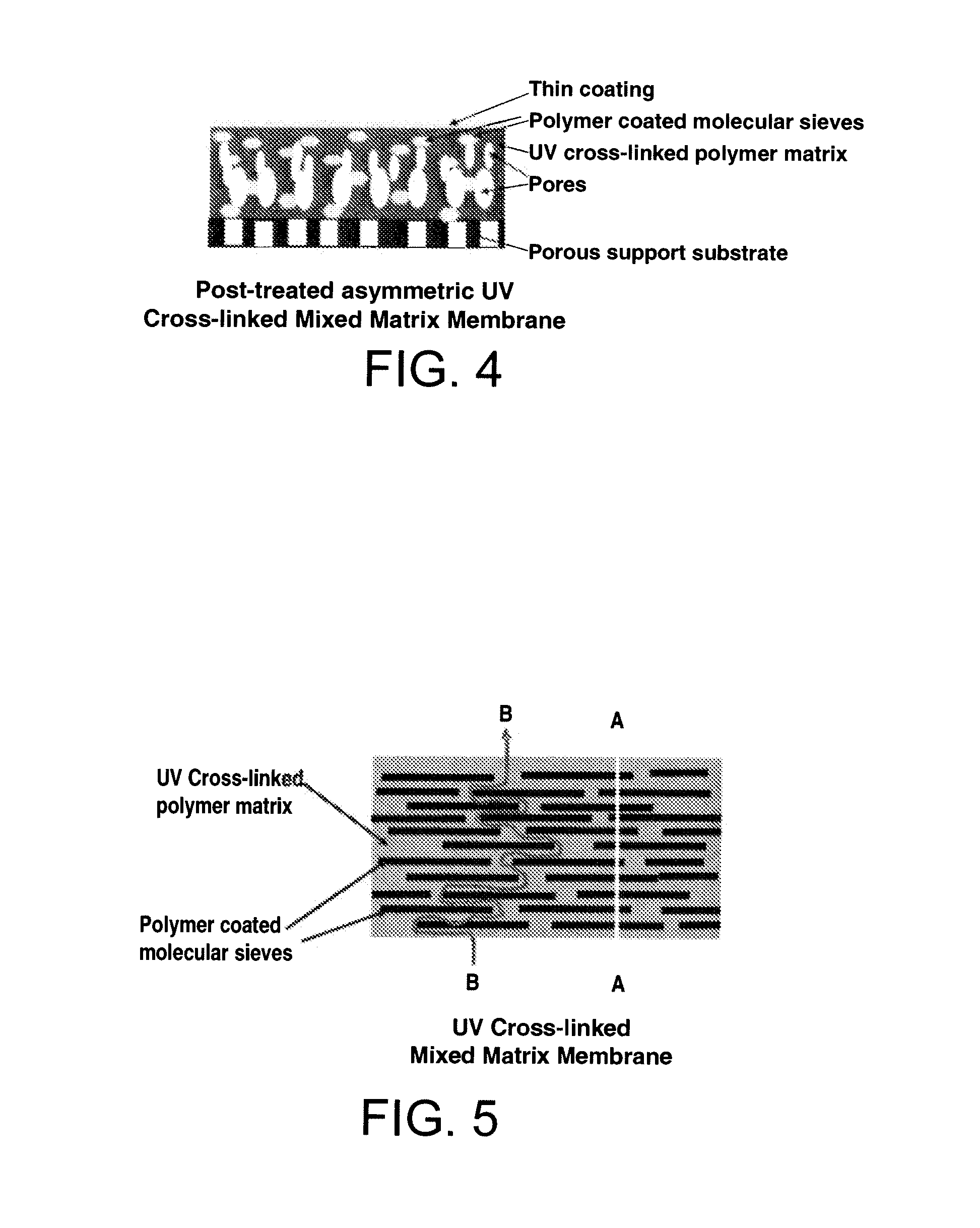

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080296527A1Separation efficiency can be improvedEasy to separateMembranesSemi-permeable membranesCross-linkPliability

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AlPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

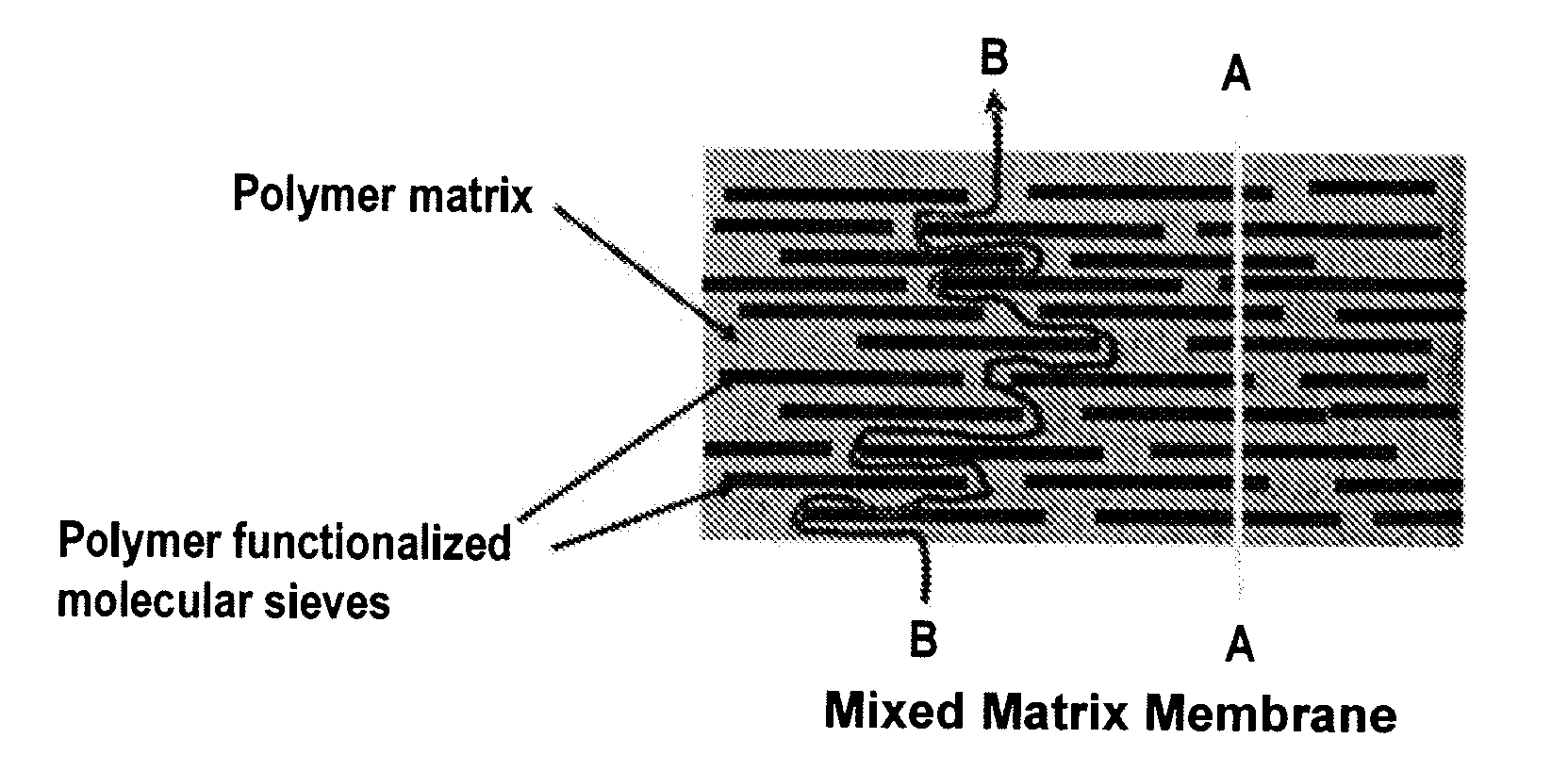

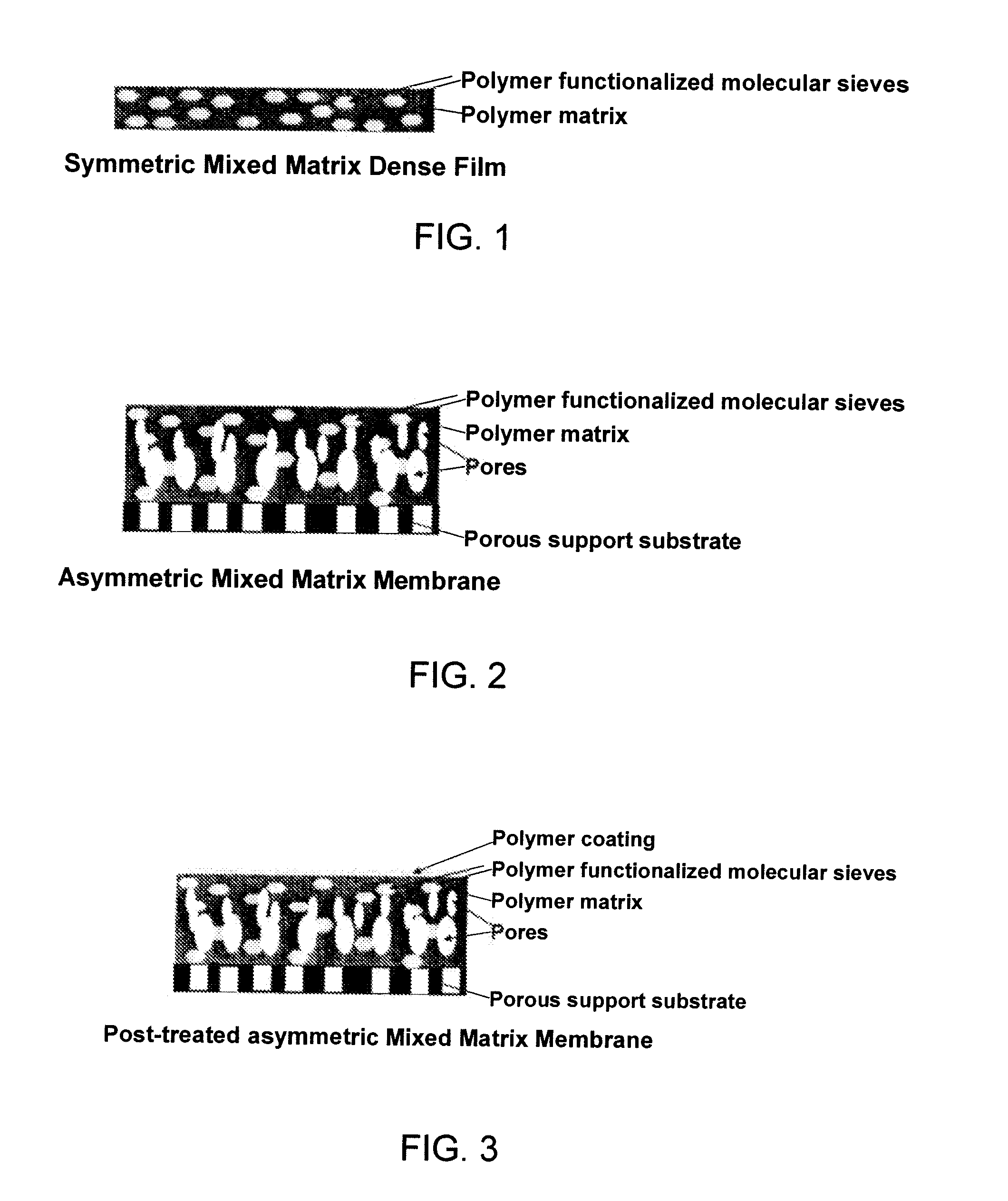

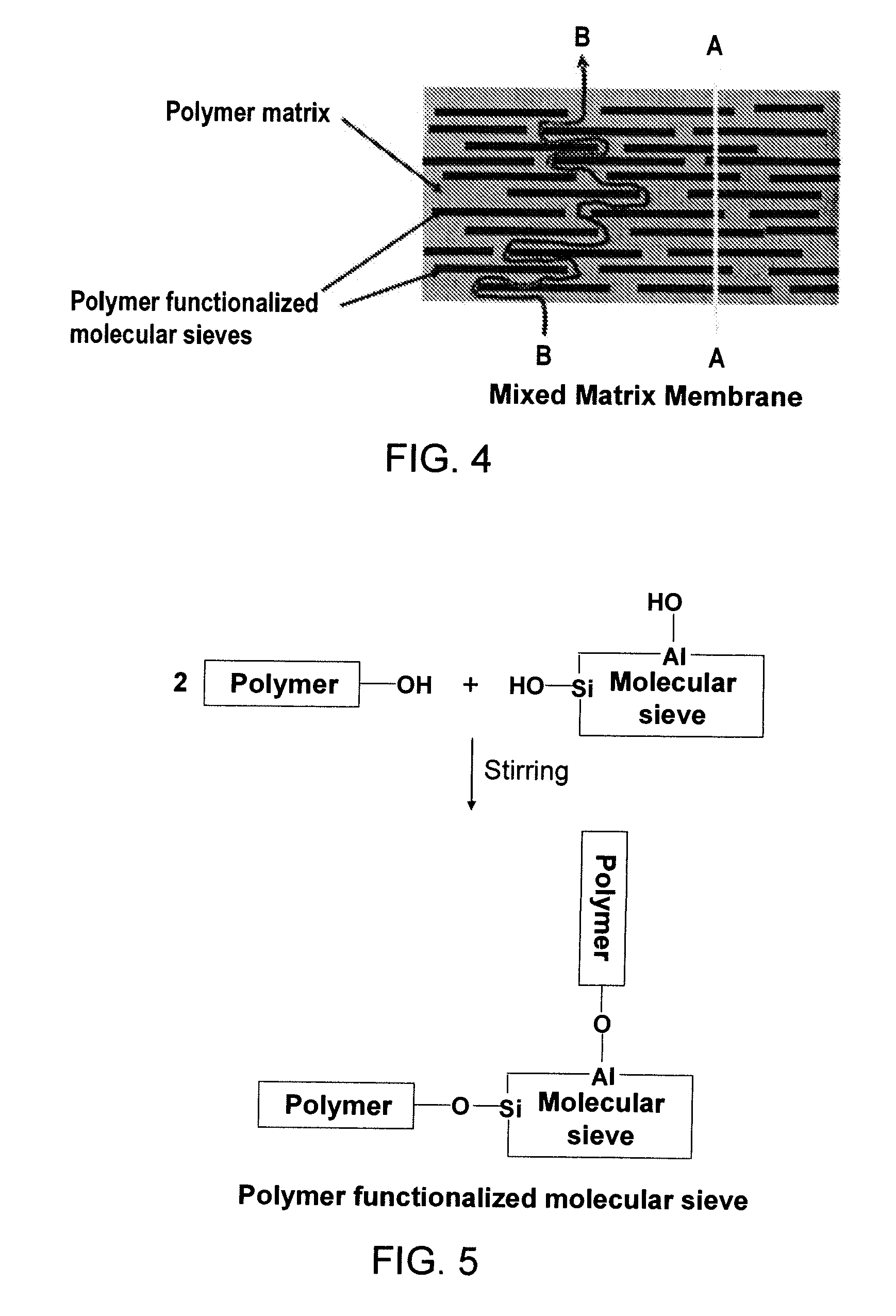

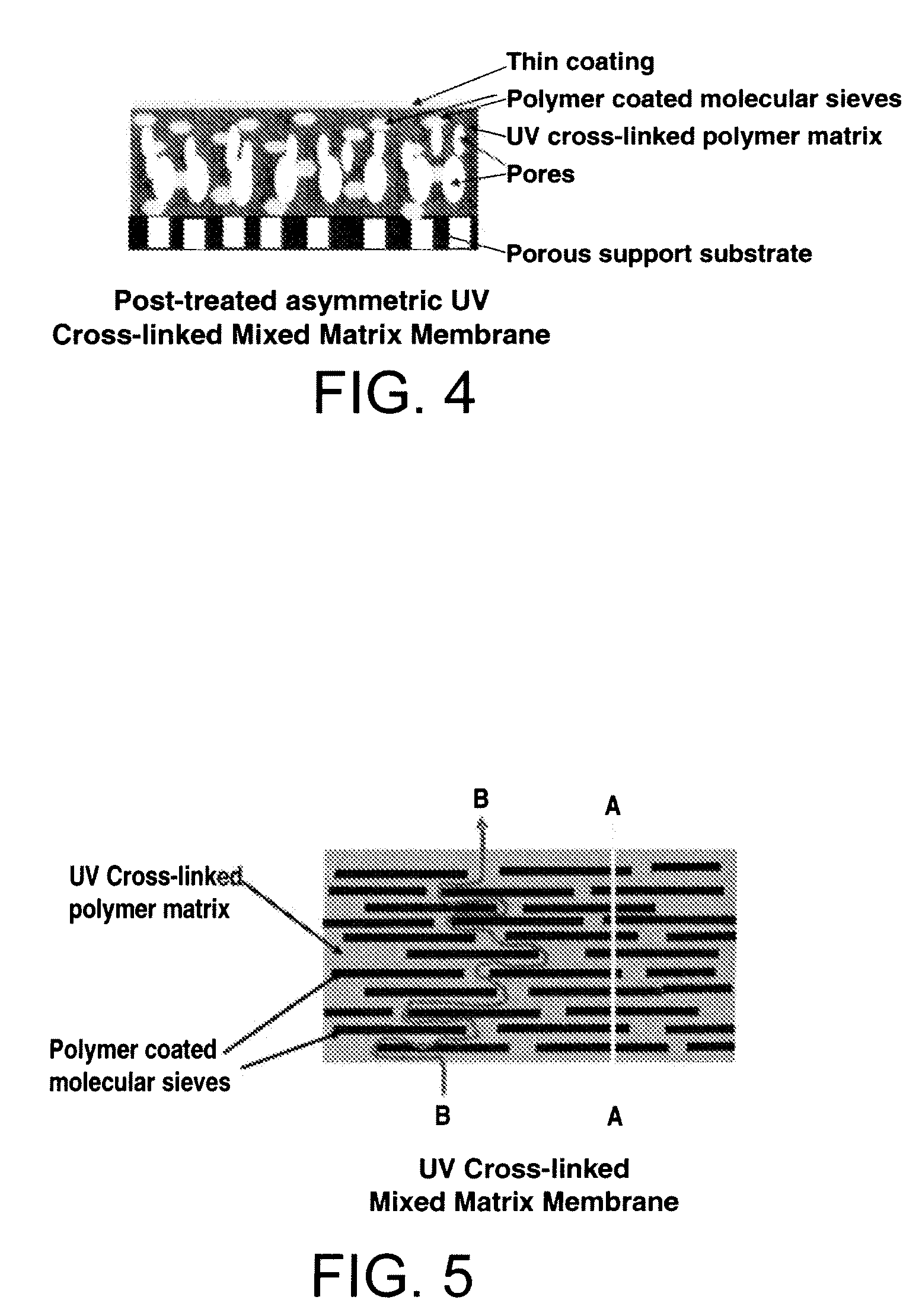

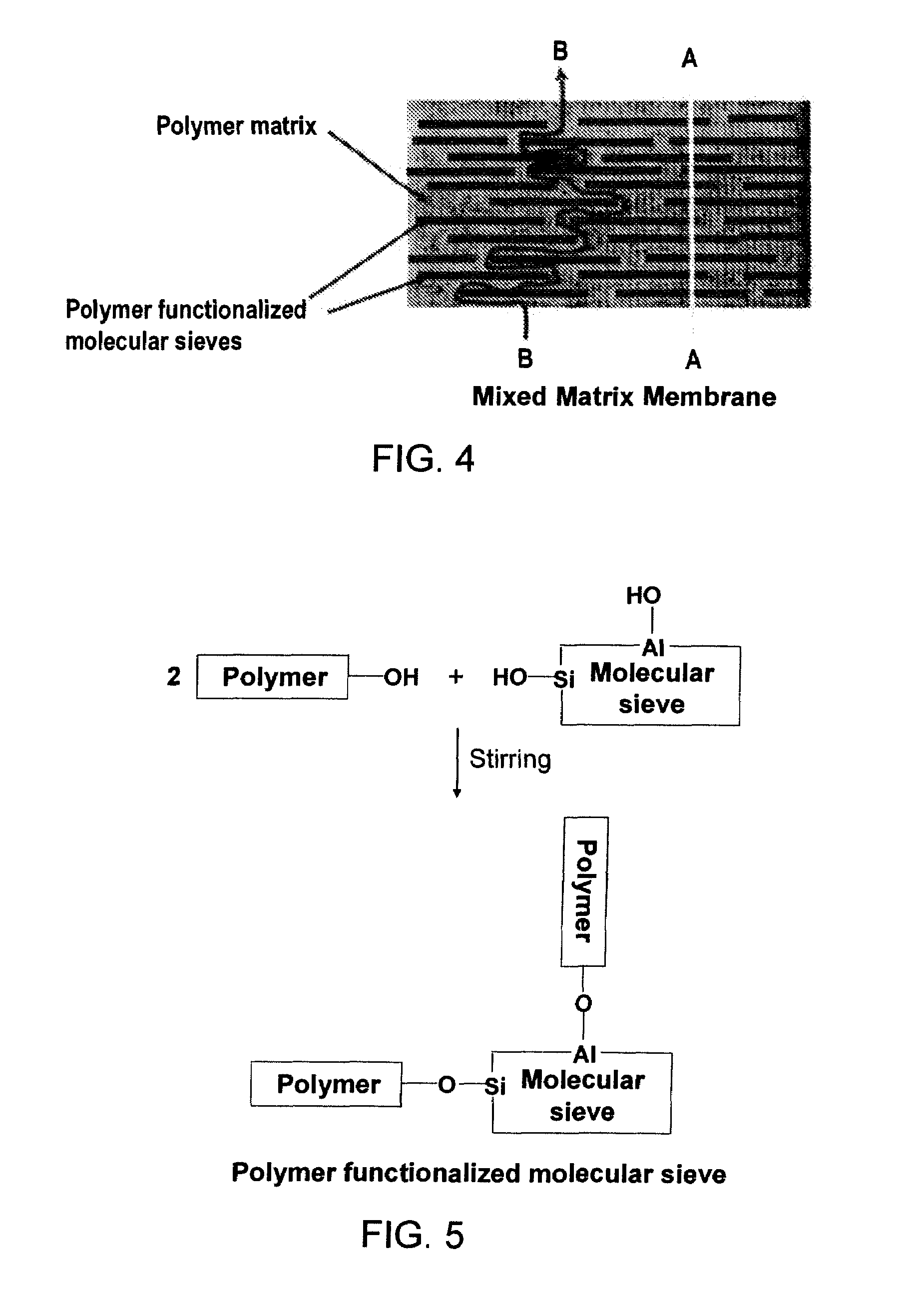

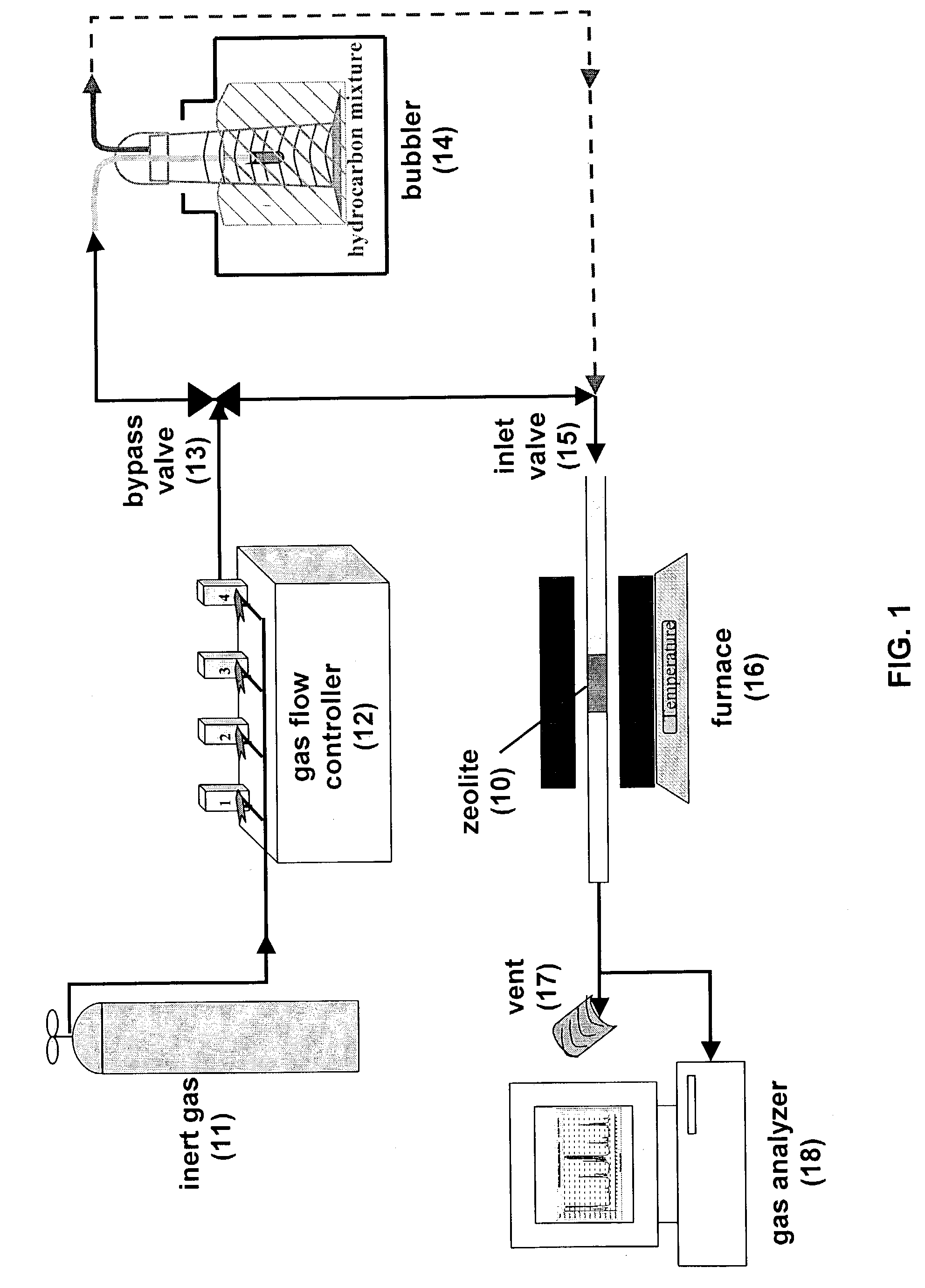

Method of Making Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090131242A1Easy to separateAverage permeabilitySemi-permeable membranesGas treatmentPolymer scienceCellulose acetate

The present invention discloses a method of making polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), and propylene / propane separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulphurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080300336A1Separation efficiency can be improvedEasy to separateMembranesSemi-permeable membranesCross-linkPolymer chemistry

The present invention discloses a method of making high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AlPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

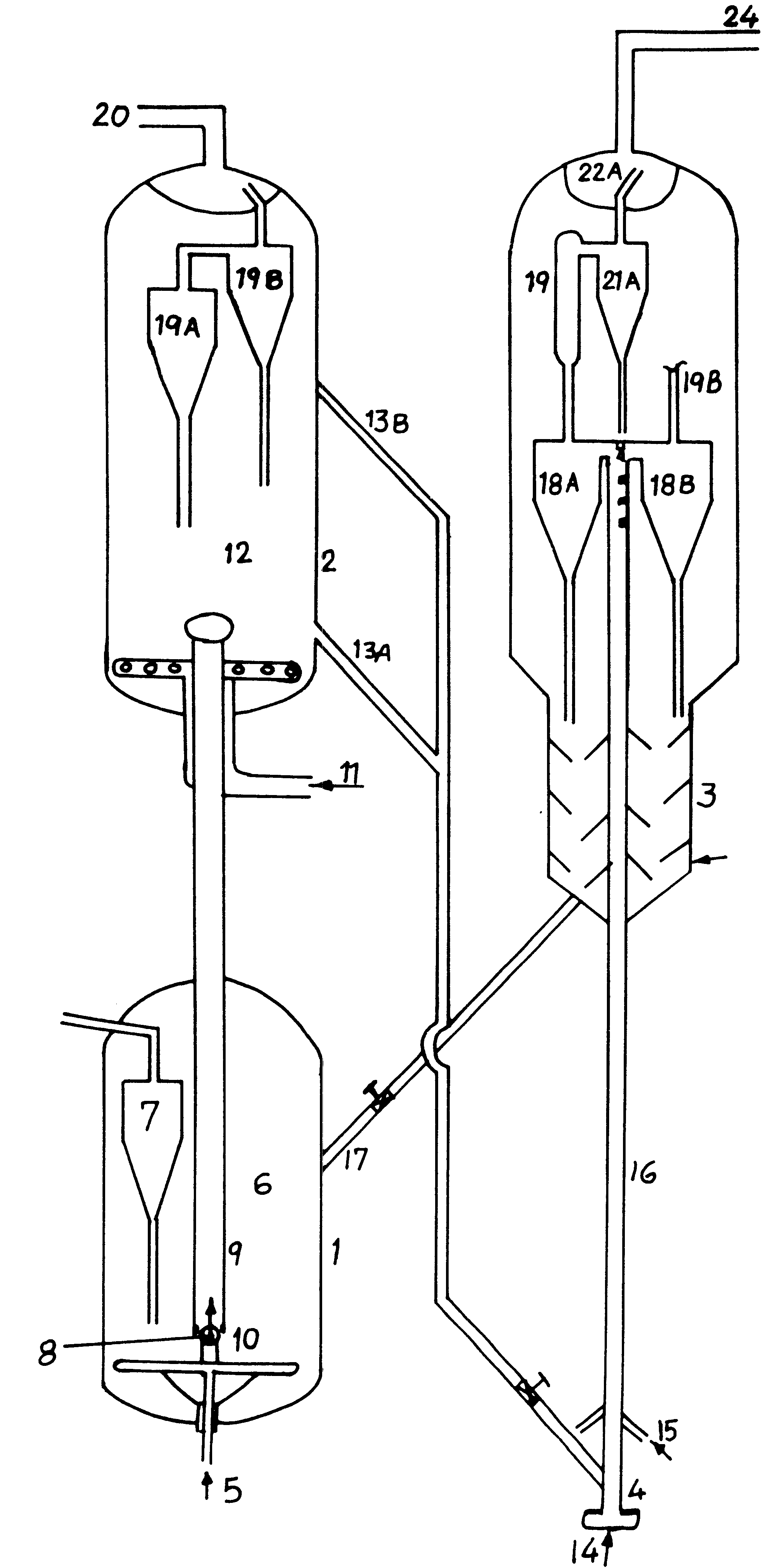

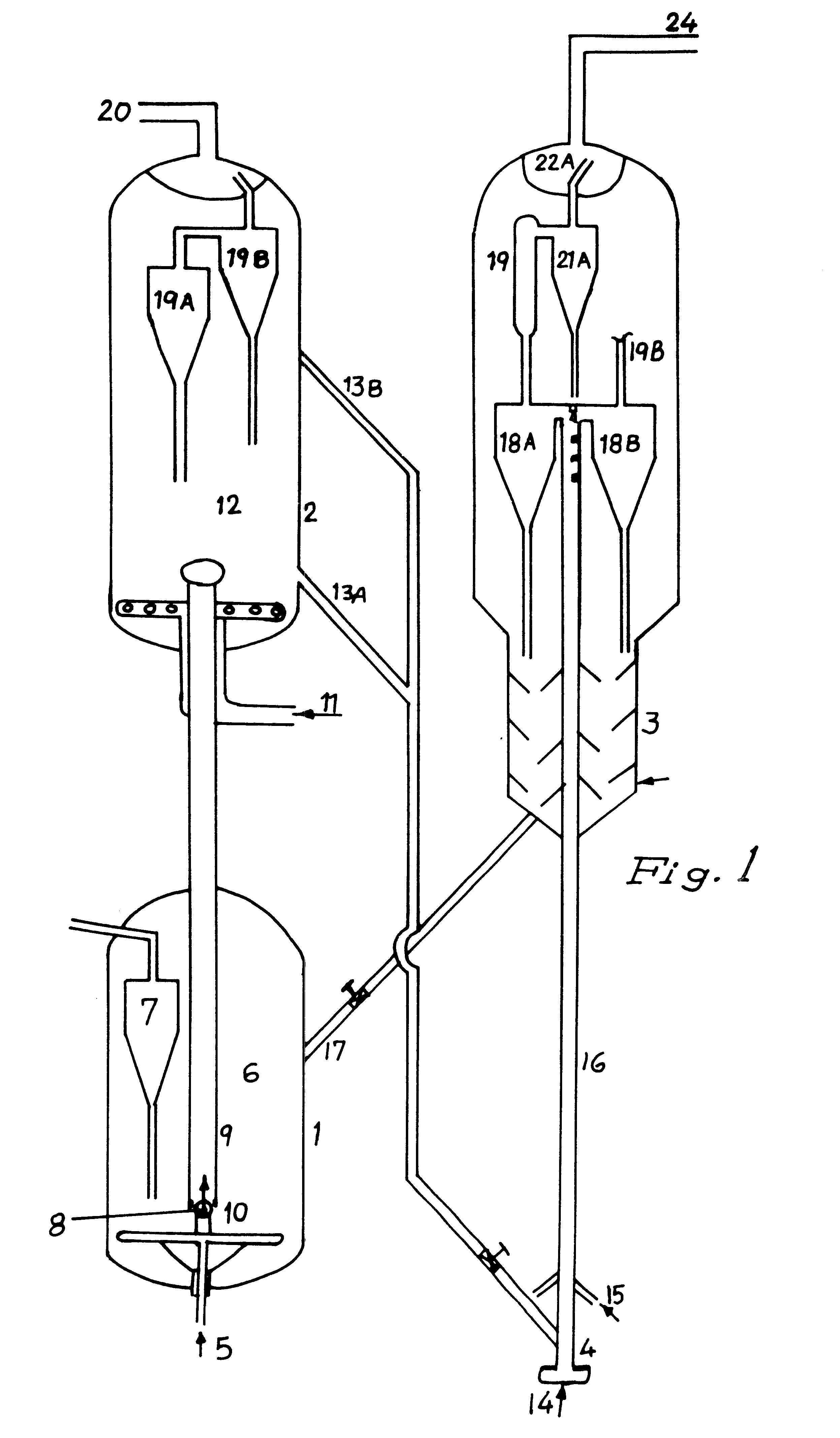

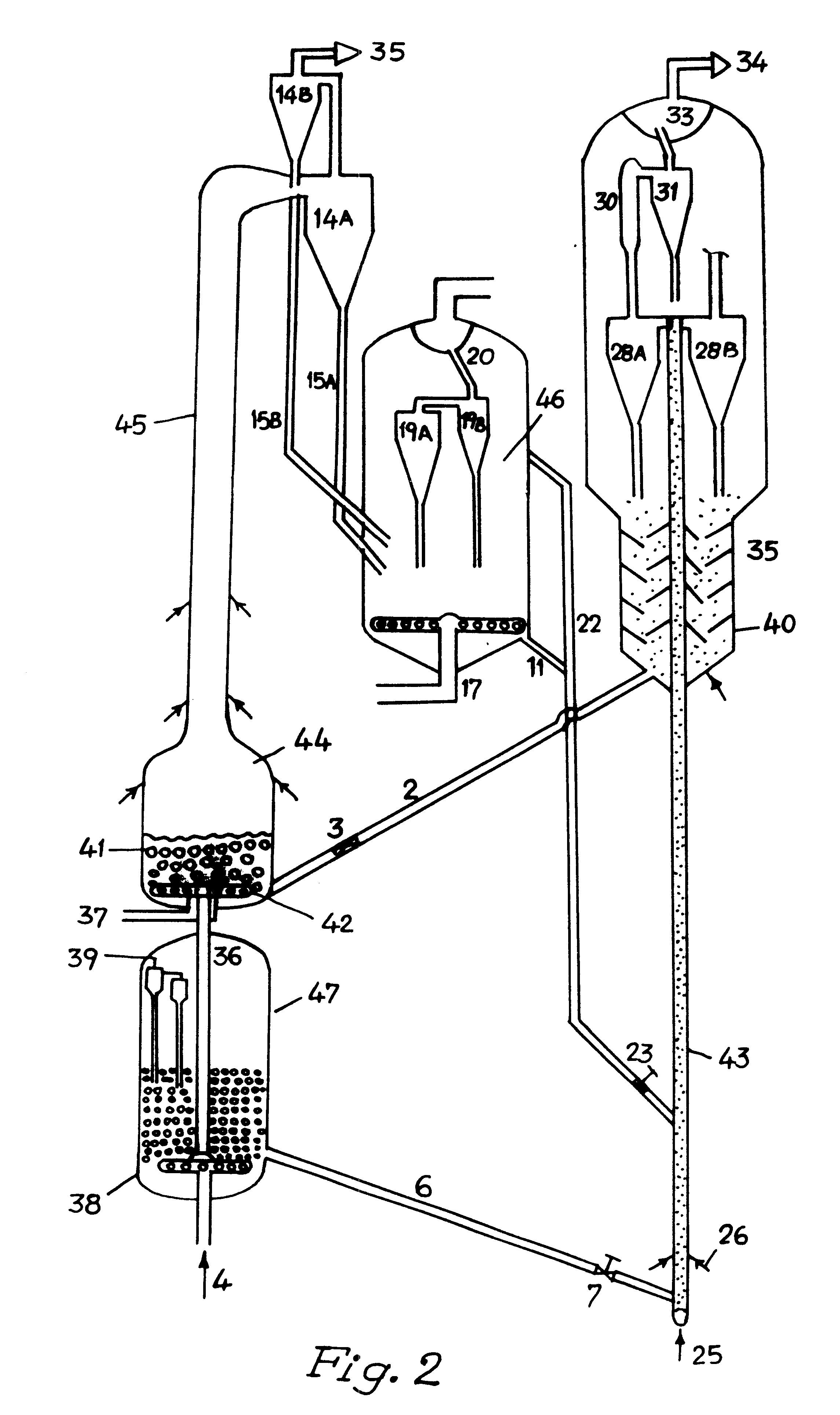

Fluidized catalytic cracking process

A sequential processing for heavy petroleum residues is disclosed which uses a separate mixture of catalyst and adsorbent. The solid adsorbent and FCC (fluids catalytic cracking) catalyst particles differ significant at least on particle size or density or both. The adsorbent preferably consist of calcined coke or metal oxides of Al, Si, or Mg having enhanced ability of selectively capture different impurities of the residual oil. The adsorbent particles first treat the residual hydrocarbons in the riser bottom end subsequently the actual catalyst tales care of catalytic cracking in the upper section of the riser. The spent solid mixture is fed to the catalyst separator which uses steam at sufficiently high velocity but at lower temperature to lift the catalyst particles out of the separator. Such a novel low temperature faster separation minimizes Vanadium mobility and deactivation of the catalyst. A net coke stream is withdrawn from the separator / burner especially while processing residues above 5 wt % CCR. This allows successful processing of even very heavy residues with CCR of 20 wt % and metals (vanadium & nickel) or 300 ppm, without requiring higher catalyst make up or catalyst and edsorbent cooling.

Owner:RAO MARRI RAMA +7

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080295691A1Separation efficiency can be improvedEasy to separateSemi-permeable membranesMembranesCross-linkPliability

The present invention discloses methods of separating gases using high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AIPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

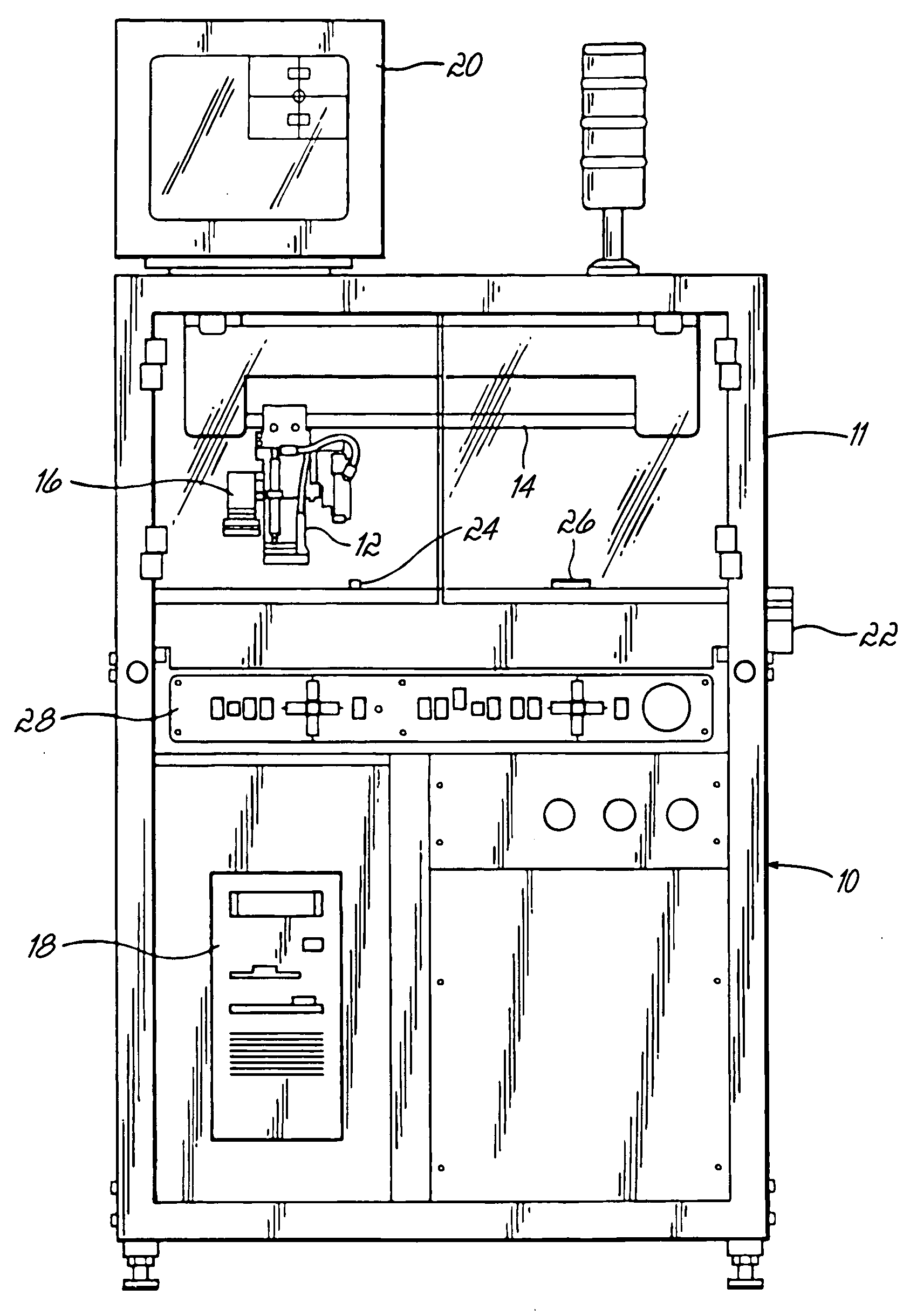

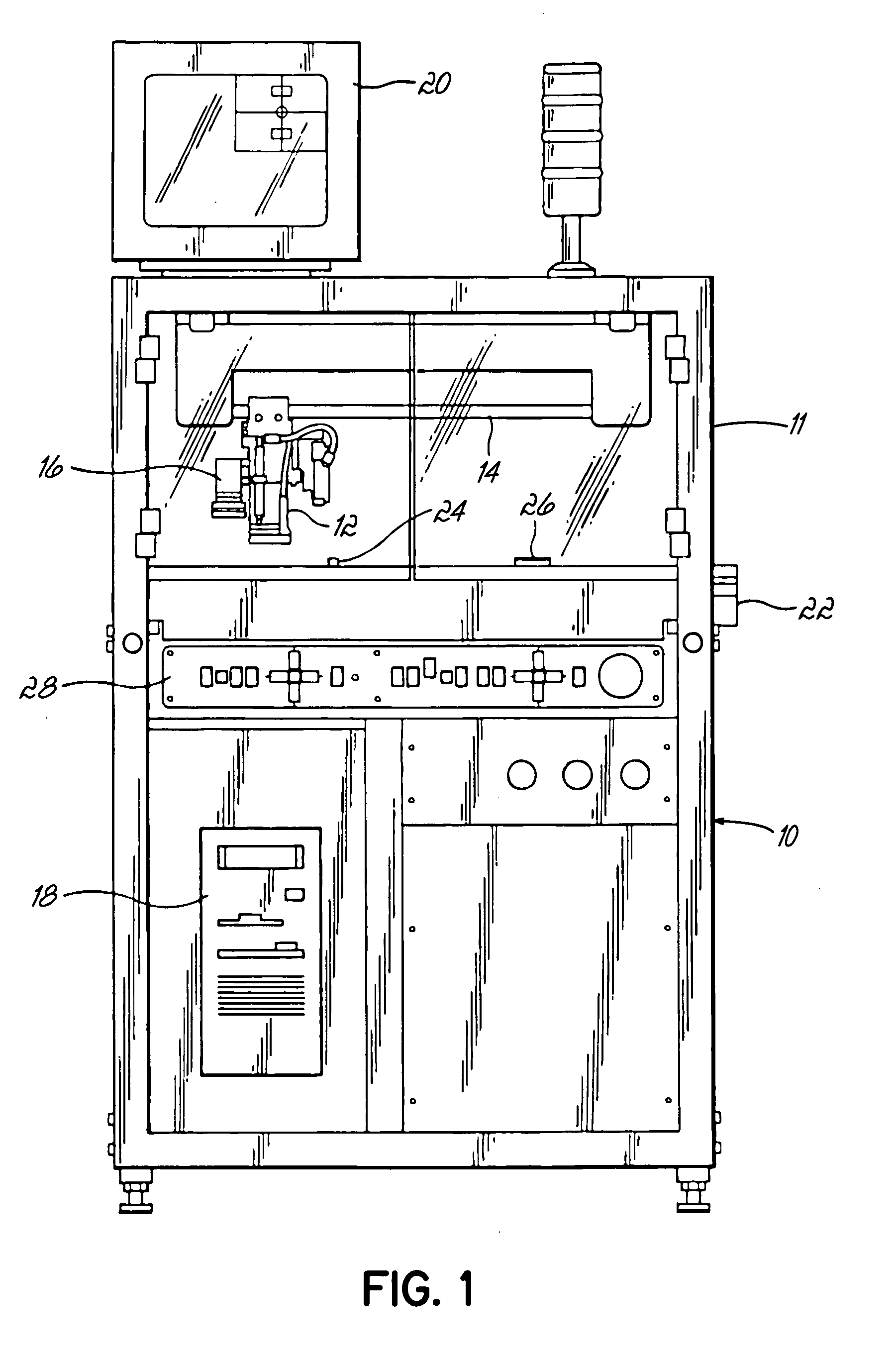

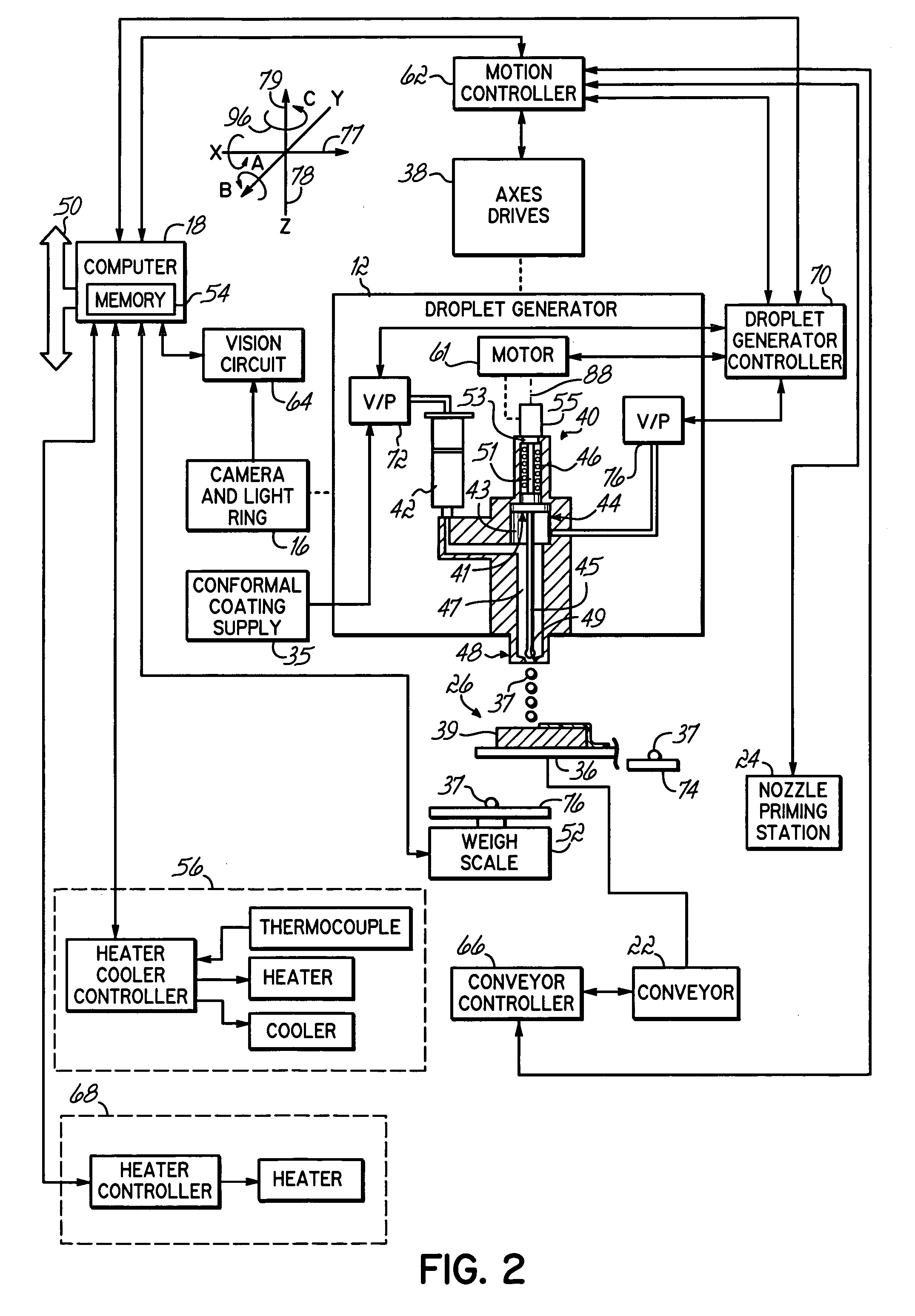

Method of conformal coating using noncontact dispensing

InactiveUS20050095366A1Easy to controlImprove abilitiesSemiconductor/solid-state device detailsSolid-state devicesEngineeringConformal coating

A method of noncontact dispensing is provided for conformal coating applications by jetting a viscous material onto a substrate. Dispensing by a jetting process results in small wetted areas thus providing highly discrete and selective conformal coating capabilities. Enhanced selectivity permits the coating of small areas and geometries and provides excellent edge definition between coated and uncoated areas.

Owner:NORDSON CORP

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090126570A1Easy to separateAverage permeabilitySemi-permeable membranesIsotope separationFiberHollow fibre

The present invention discloses polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate (CA) polymer matrix. The MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

The present invention discloses a method of making, compositions and method of using high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs are prepared by incorporating polymer functionalized molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

Oxidative Coupling of Methane Process with Enhanced Selectivity to C2+ Hydrocarbons by Addition of H2O in the Feed

InactiveUS20190169090A1C2+ selectivityImprove productivityCatalystsHydrocarbon preparation catalystsAlkanePtru catalyst

A process for producing olefins comprising introducing to a reactor a reactant mixture comprising methane, oxygen, and water, wherein the reactor comprises a catalyst, and wherein water is present in the reactant mixture from 0.5 mol % to 20 mol %; allowing the reactant mixture to contact the catalyst and react via an OCM reaction to form a product mixture comprising C2+ hydrocarbons, unreacted methane, and byproducts; wherein C2+ hydrocarbons comprise olefins and paraffins; and wherein the process is characterized by a productivity, a C2+ selectivity, or both that is increased when compared to a productivity, a C2+ selectivity, or both, respectively, of an otherwise similar process conducted (i) with a reactant mixture comprising methane and oxygen and (ii) without water present in the reactant mixture from 0.5 mol % to 20 mol %; recovering the product mixture from the reactor; recovering C2+ hydrocarbons from the product mixture; and recovering olefins from C2+ hydrocarbons.

Owner:SABIC GLOBAL TECH BV

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090127197A1Sufficient fluxAddressing Insufficient SelectivityGas treatmentUltrafiltrationMolecular sieveGasoline

The present invention discloses polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polymer functionalized molecular sieves into a continuous polymer matrix. The MMMs exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090126566A1Easy to separateAverage permeabilitySemi-permeable membranesMembranesFiberHollow fibre

The invention discloses the use of polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate (CA) polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), propylene / propane separations and a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

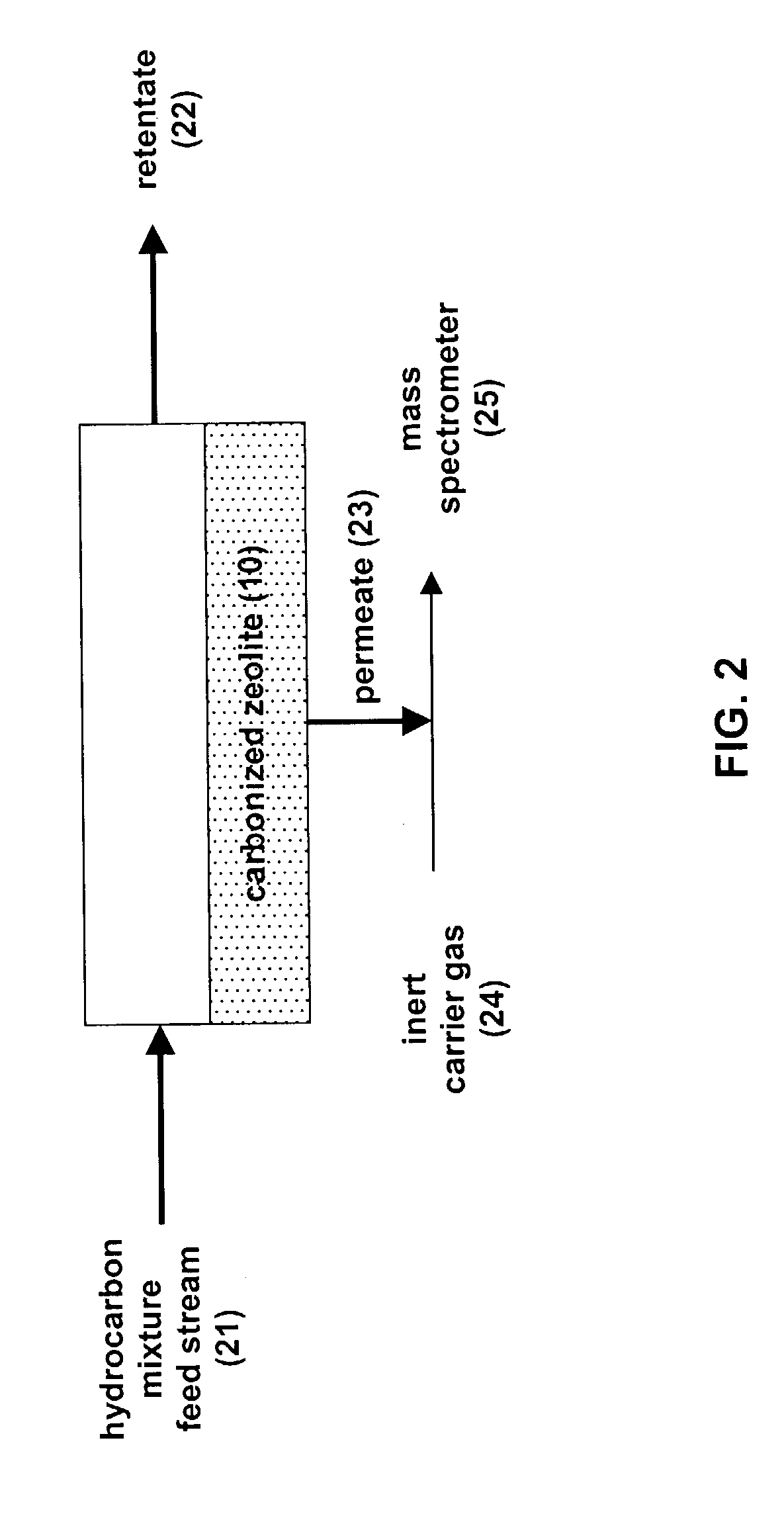

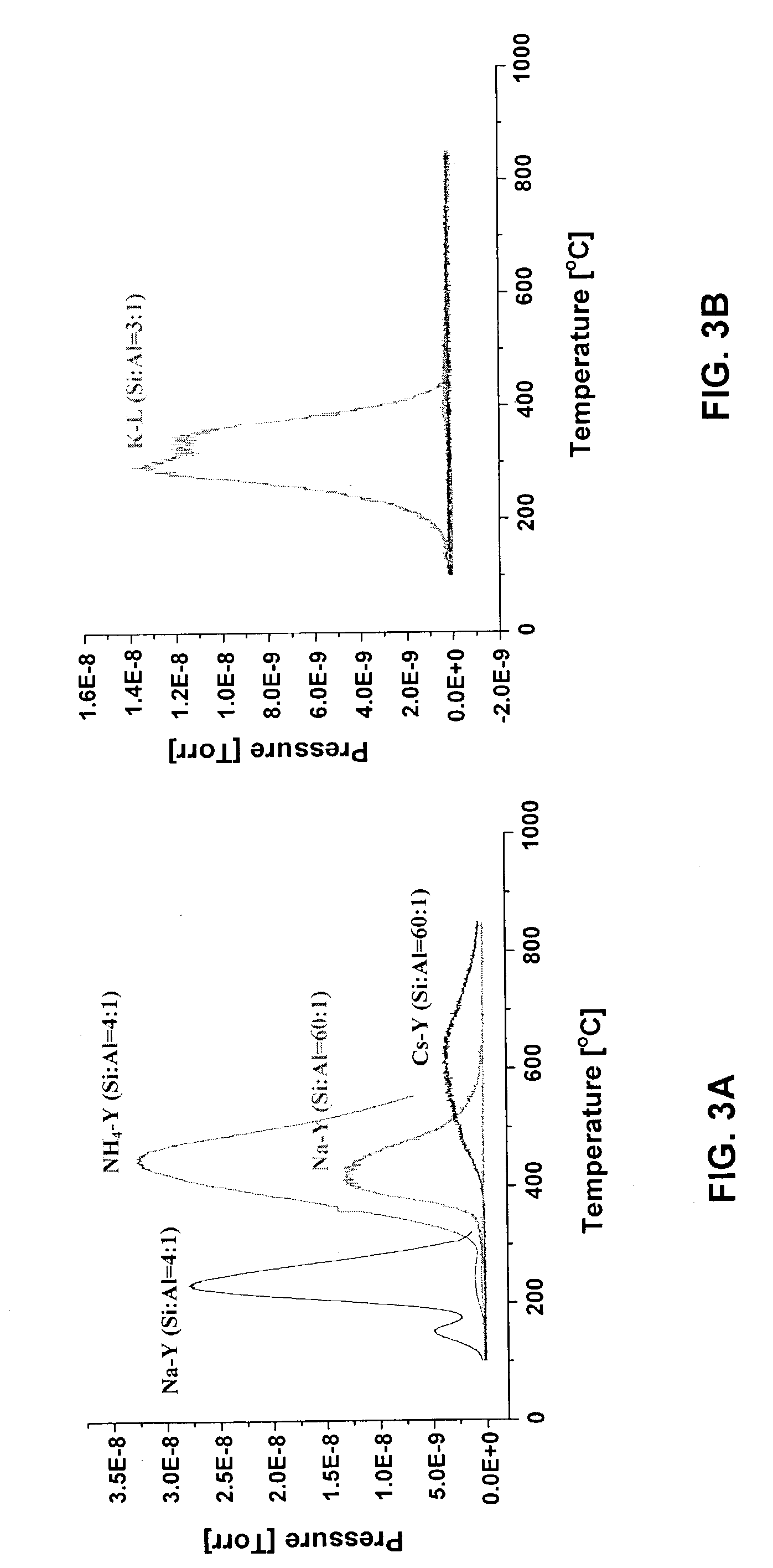

Enhanced selectivity of zeolites by controlled carbon deposition

A method for carbonizing a zeolite comprises depositing a carbon coating on the zeolite pores by flowing an inert carrier gas stream containing isoprene through a regenerated zeolite at elevated temperature. The carbonized zeolite is useful for the separation of light hydrocarbon mixtures due to size exclusion and the differential adsorption properties of the carbonized zeolite.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

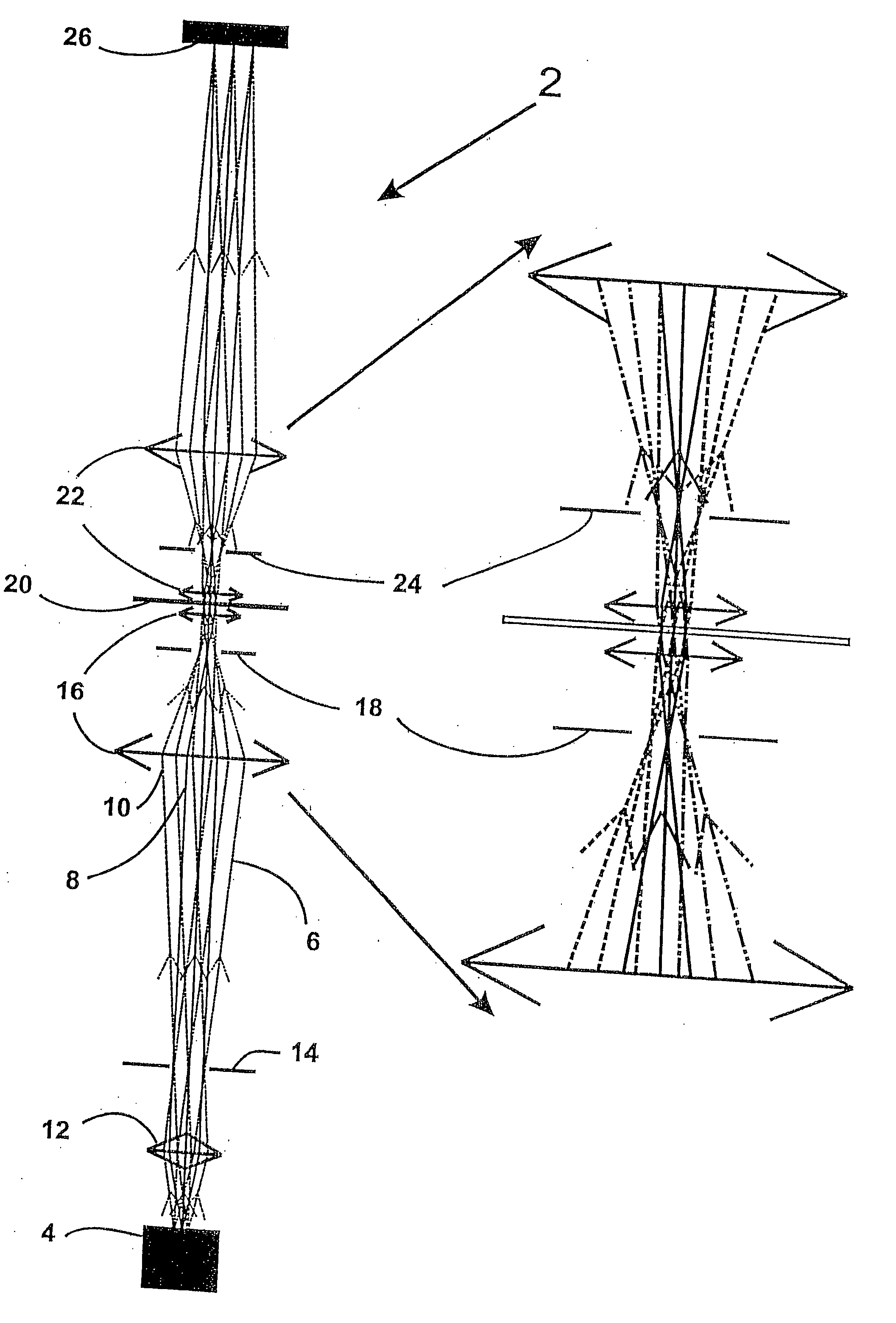

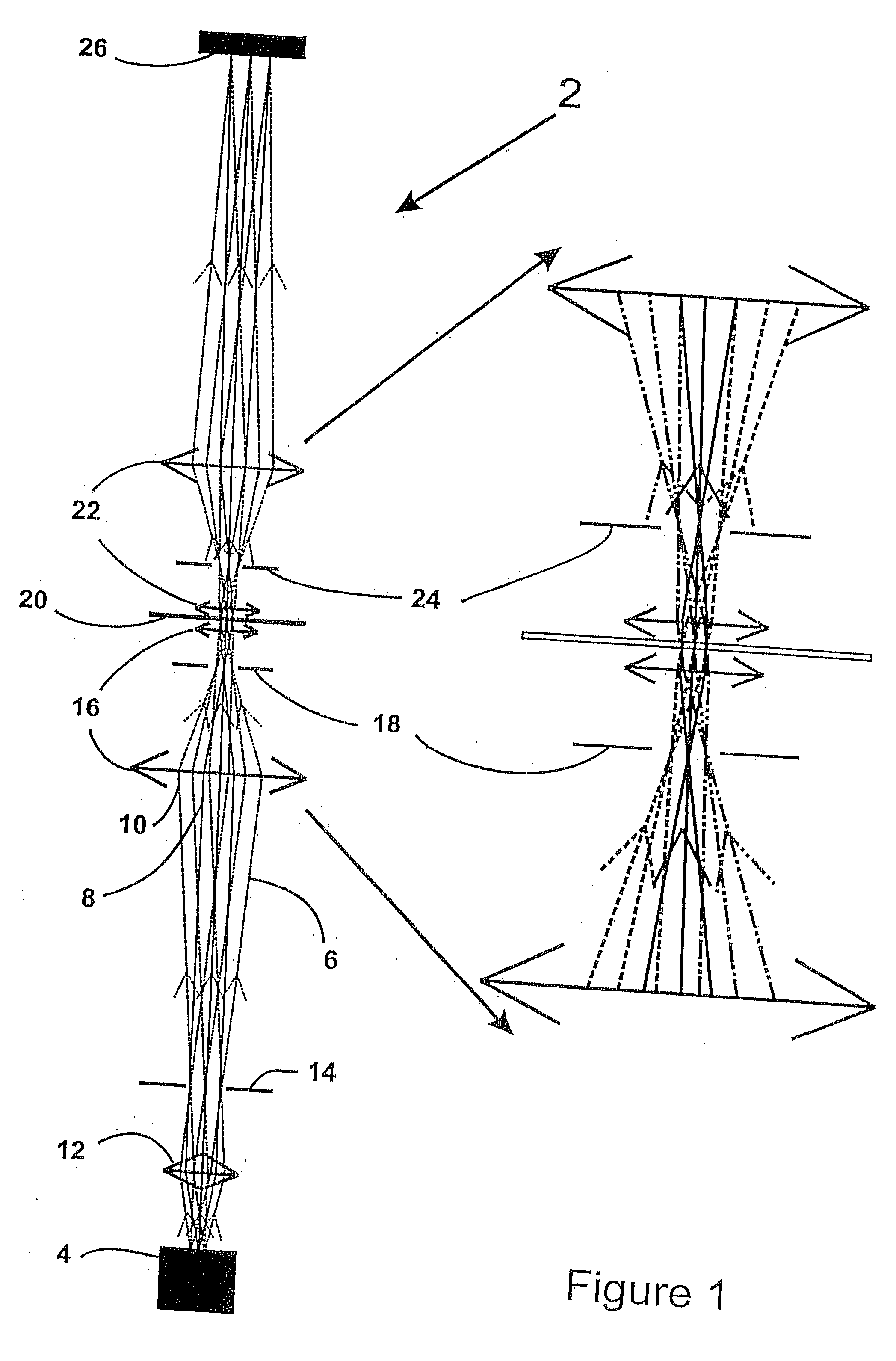

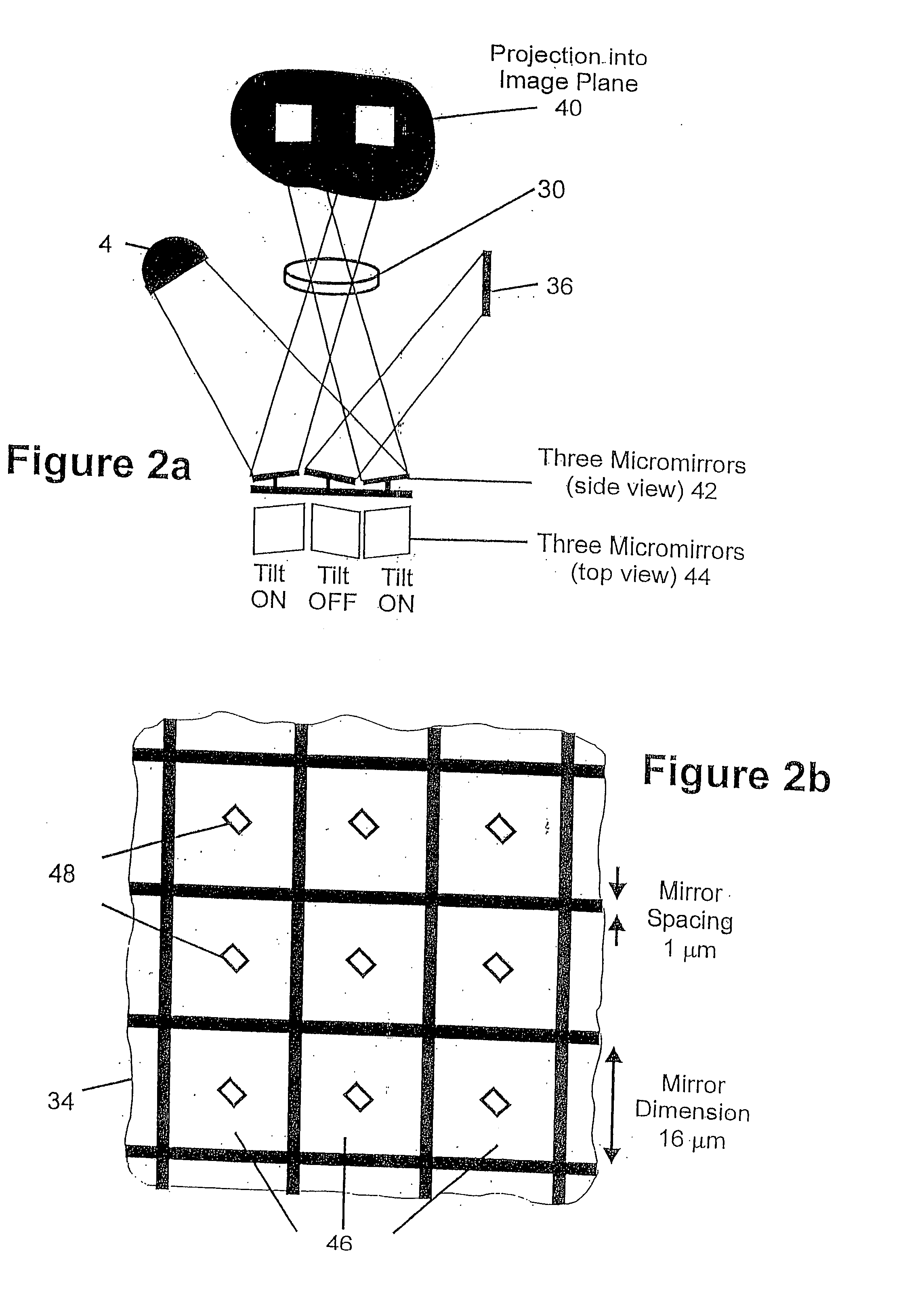

Apparatus and methods relating to spatially light modulated microscopy

InactiveUS20070188856A1Big advantageEasy to controlMicroscopesColor/spectral properties measurementsImage planeCharge couple device

Apparatus and methods relating to microscopes having specific control of the light that contacts a sample and / or a light detector, such as the eye of the user, a charge couple device or a video camera. The improved control includes enhanced, selective control of the angle of illumination, quantity of light and location of light reaching the sample and / or detector. The microscopes comprise one or more spatial light modulators in the illumination and / or detection light path of the microscope at one or both of the conjugate image plane of the aperture diaphragm of the objective lens and the conjugate image plane of the sample.

Owner:MOTIC CHINA GRP CO LTD

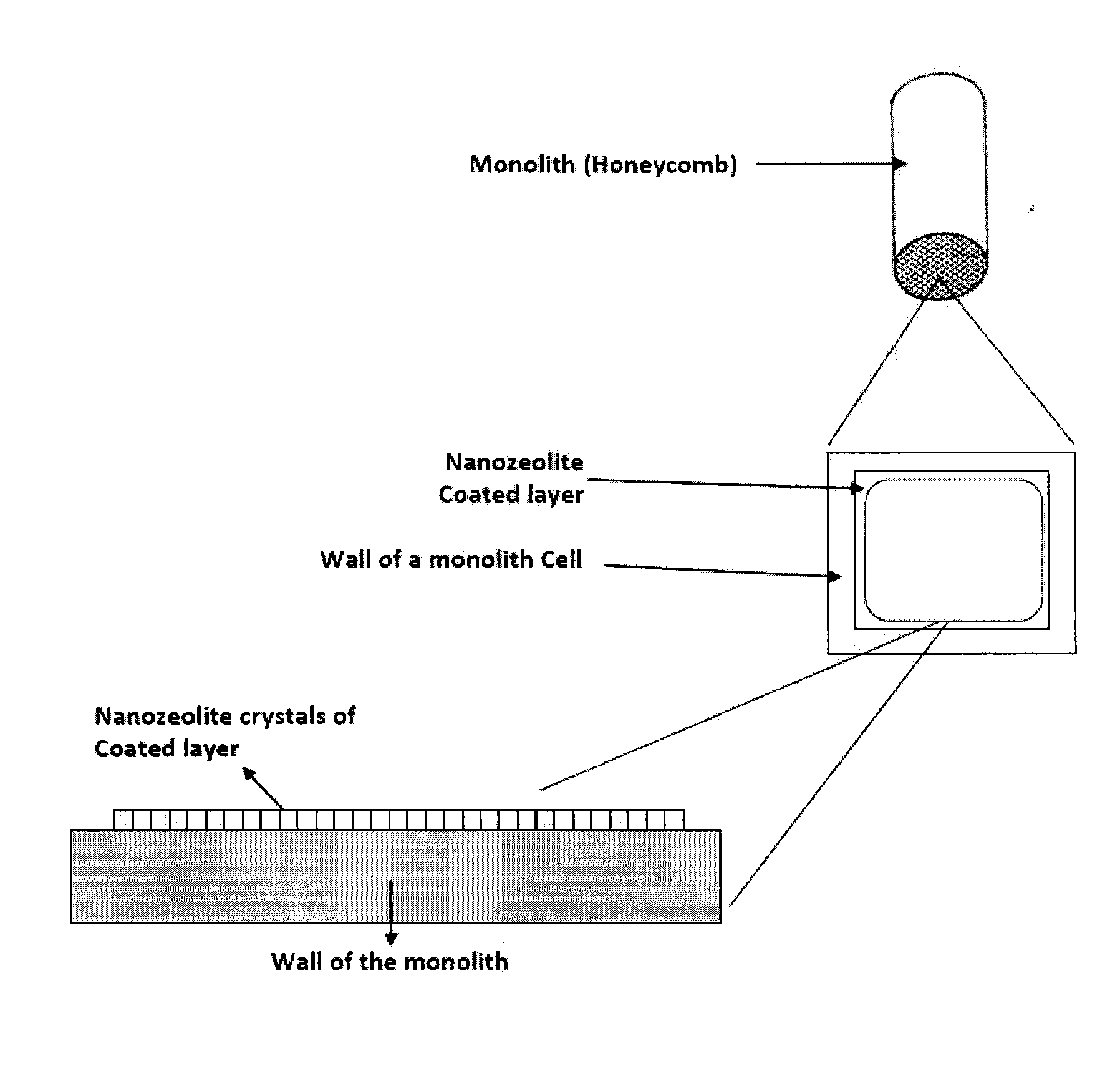

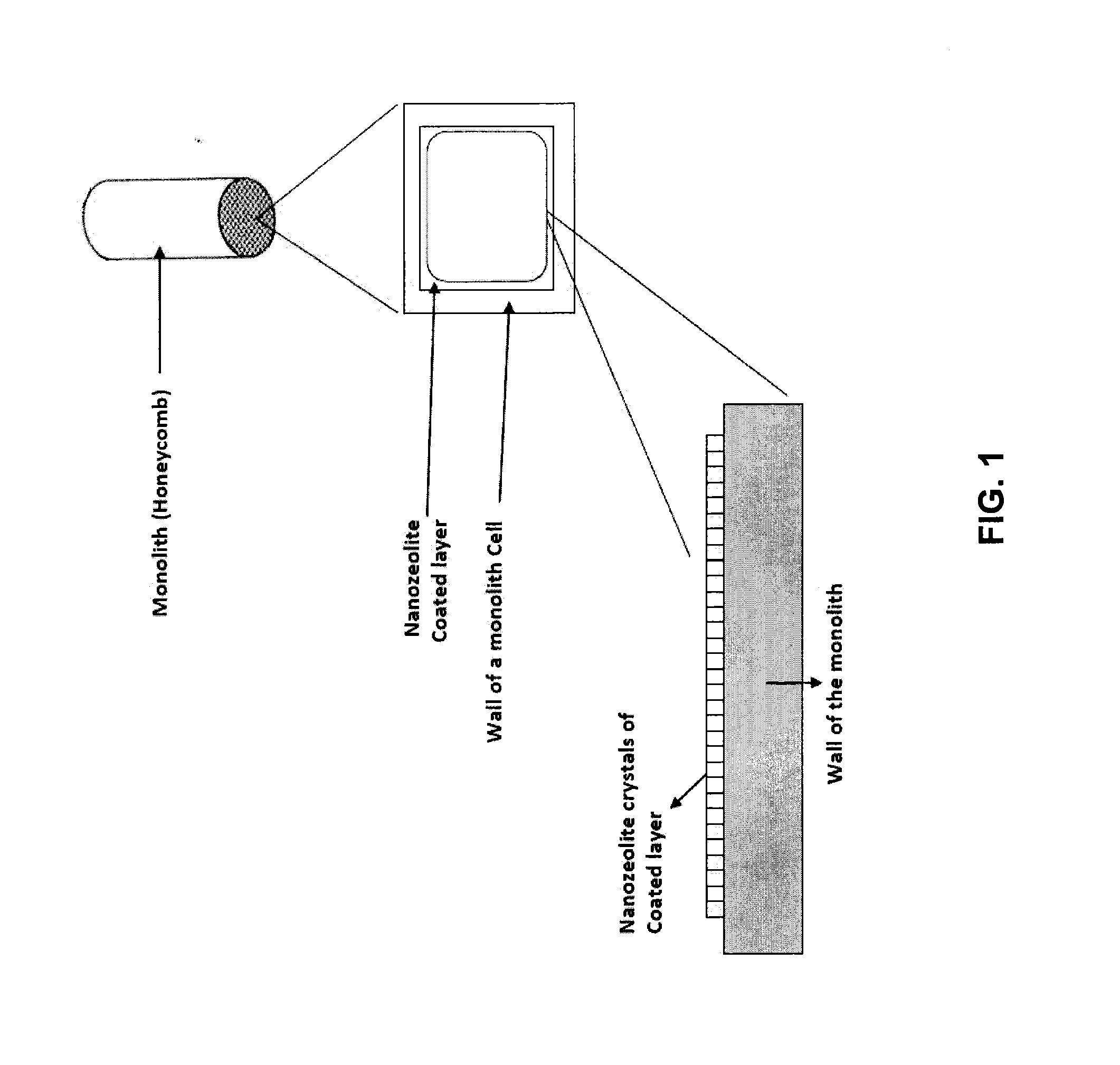

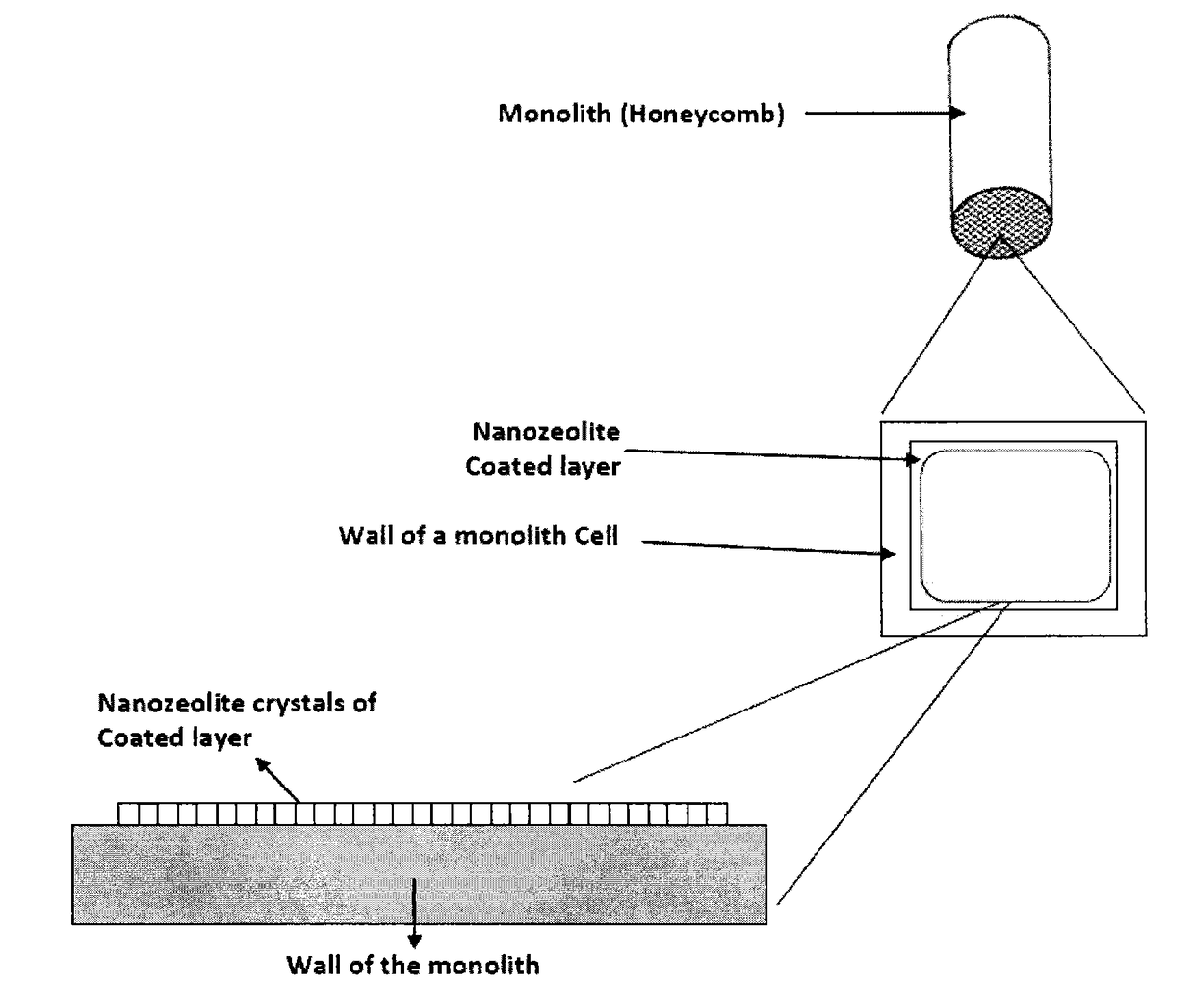

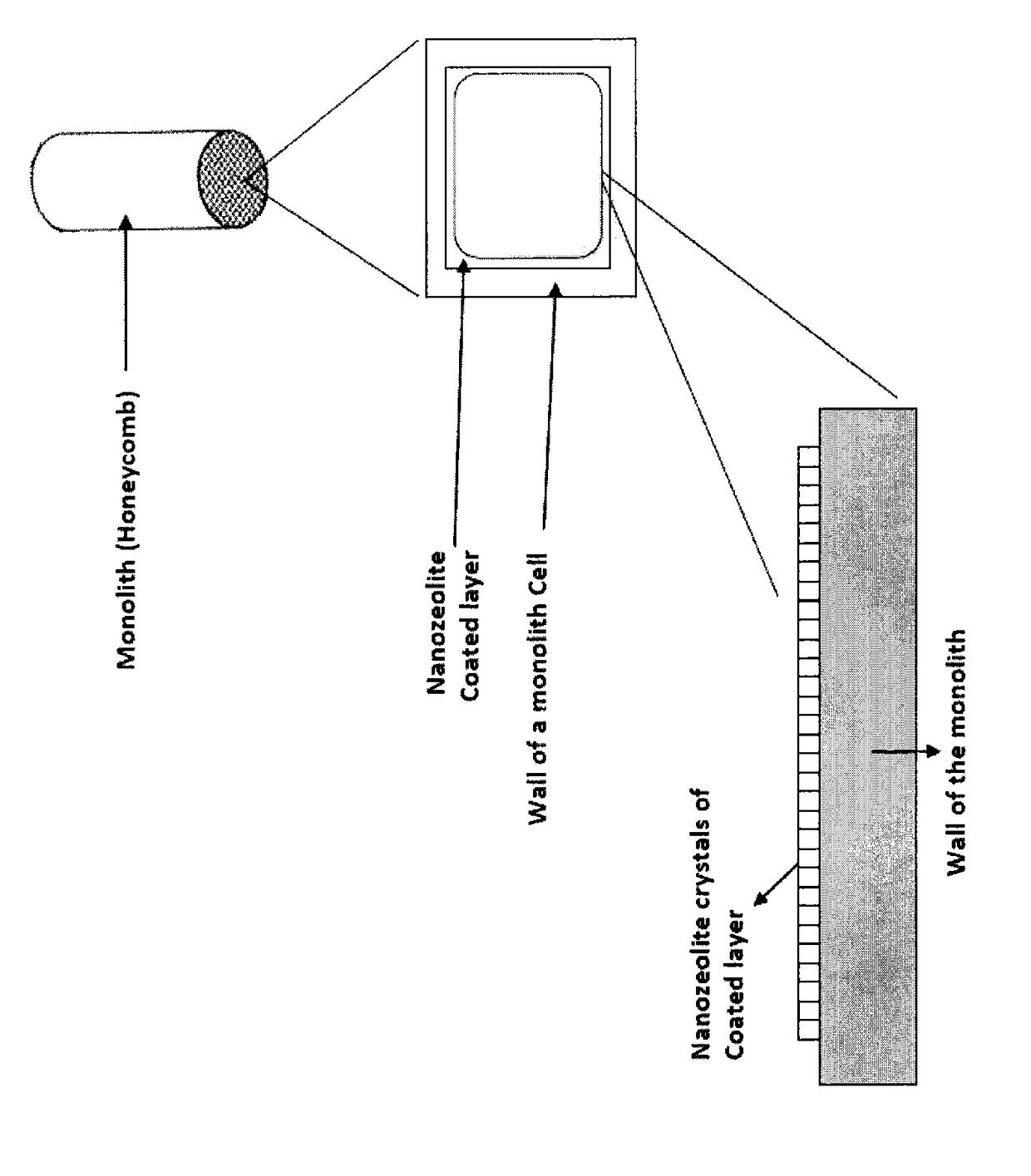

Monolith structure loaded with metal promoted nanozeolites for enhanced propylene selectivity in methanol conversion

A catalyst system and a process for methanol to light olefin conversion with enhanced selectivity towards propylene. The catalyst system comprises a honeycomb monolith catalyst support coated with nanozeolite catalysts on the edges and inside the channels of the support structure. The nanozeolite catalysts have been pre-modified with metal. The catalyst system gives higher hydrothermal stability to the catalyst compared to randomly packed pellet catalyst and allows methanol to be converted to predominantly propylene at a low temperature, with decreased selectivity towards C2, higher olefins and paraffinic hydrocarbons.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Blend polymer membranes comprising thermally rearranged polymers derived from aromatic polyimides containing ortho-positioned functional groups

InactiveUS20120085233A1Good choiceImprove stabilitySemi-permeable membranesMembranesPolymer scienceOrtho position

The present invention discloses blend polymer membranes comprising thermally rearranged polymers derived from aromatic polyimides containing ortho-positioned functional groups and methods for making and using these blend polymer membranes. The blend polymer membranes described in the current invention are prepared by heat treatment of blend polymer membranes comprising aromatic polyimides containing ortho-positioned functional groups such as —OH or —SH groups. In some instances, an additional crosslinking step is performed to improve the selectivity of the membrane. These blend polymer membranes have improved flexibility, reduced cost, improved processability, and enhanced selectivity and / or permeability compared to the comparable polymer membranes that comprise a single polymer.

Owner:UOP LLC

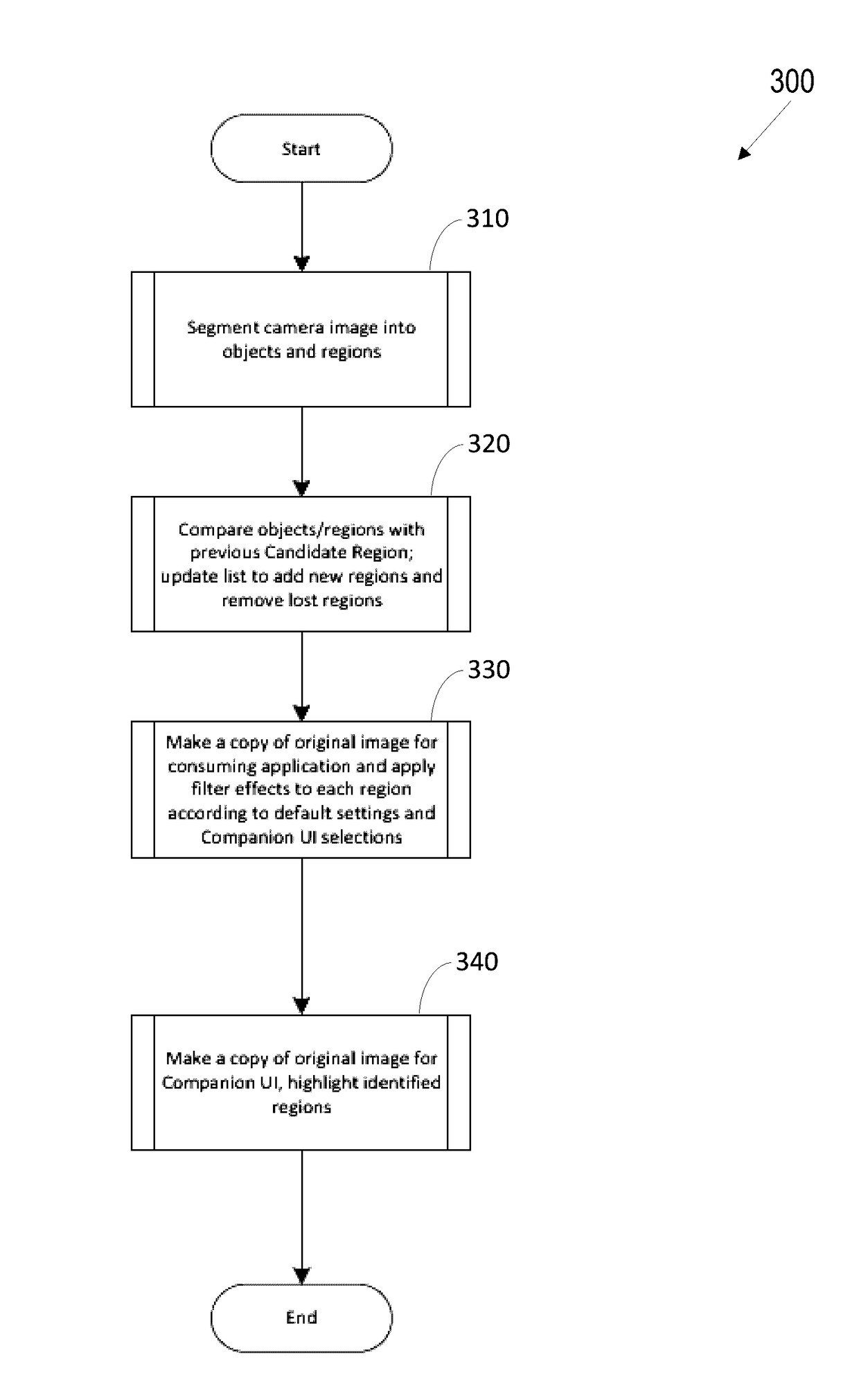

Polymeric composite separation membrane

ActiveUS20070185264A1High selectivitySurpassing limit valueMembranesSemi-permeable membranesReverse osmosisChemical separation

Semi-crystalline polymer blended gas or chemical separation membranes are obtained by melting and processing 50-99 wt % of a thermoplastic resin, 1-50 wt % of a semicrystalline polymer and 0.1-10 wt % of a compatibilixer. A method for fabricating semi-crystalline polymer blended gas or chemical separation membrane includes the steps of: mixing 50-99 wt % of thermoplastic resin, 1-50 wt % of semi crystalline polymer and 0.1-10 wt % of compatibilizer; and axially drawing the resulting blend melt coming from an extrusion die. The separation membrane exhibits high selectivity when applied in a gas separation process exceeding the limit value which has been seldom overcome by the existing separation membranes as well as high permeability enough to be applied in real gas separation processes. This enhanced selectivity is ascnbed to the morphology of the ternary blends and different interaction between the compatibilizer and diffusing molecules. The membrane prepared by this method can be used for chemical separation processes (such as reverse osmosis, artificial kidney, artificial lung, drug delivery, drug release, to name a few) as well as liquids and gas separation processes.

Owner:SEOUL NAT UNIV R&DB FOUND

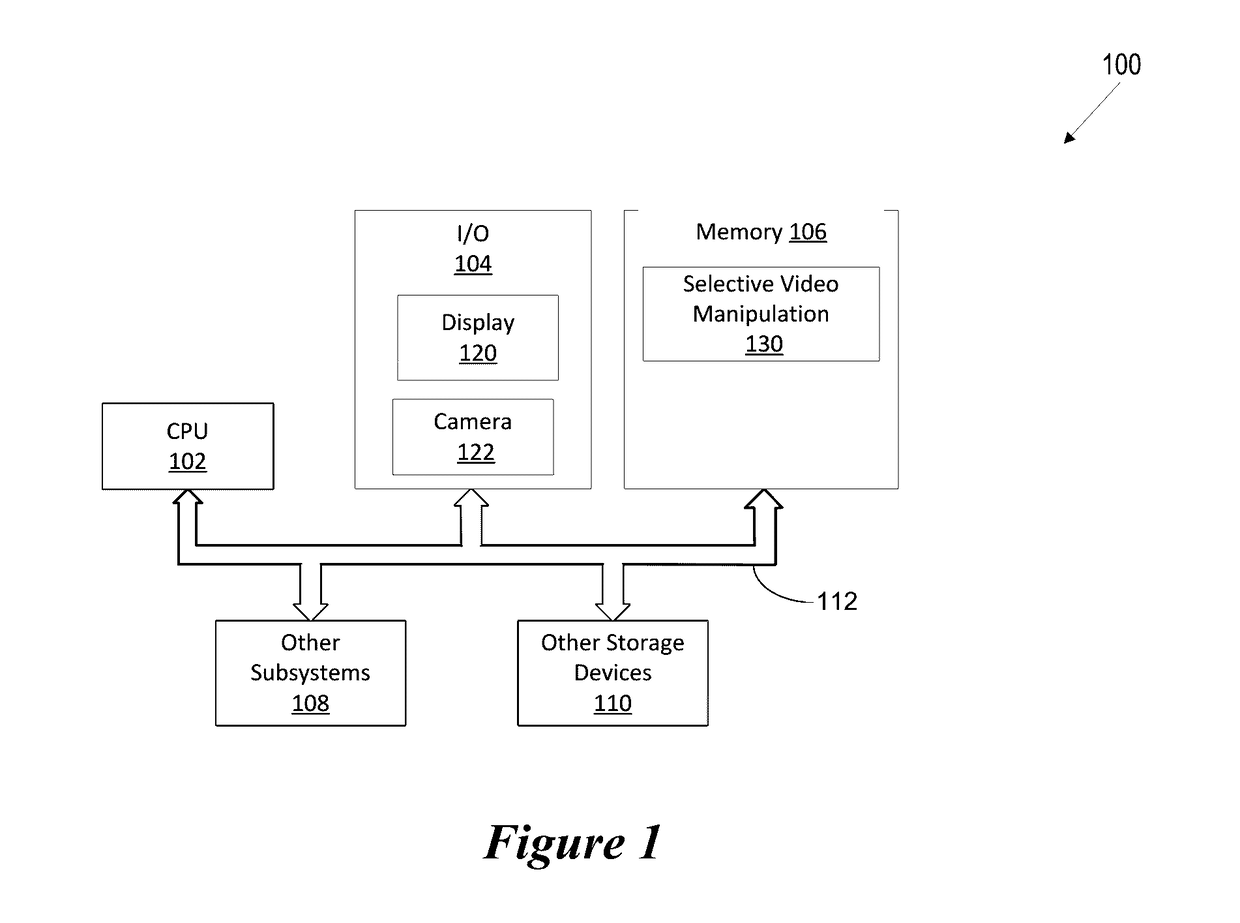

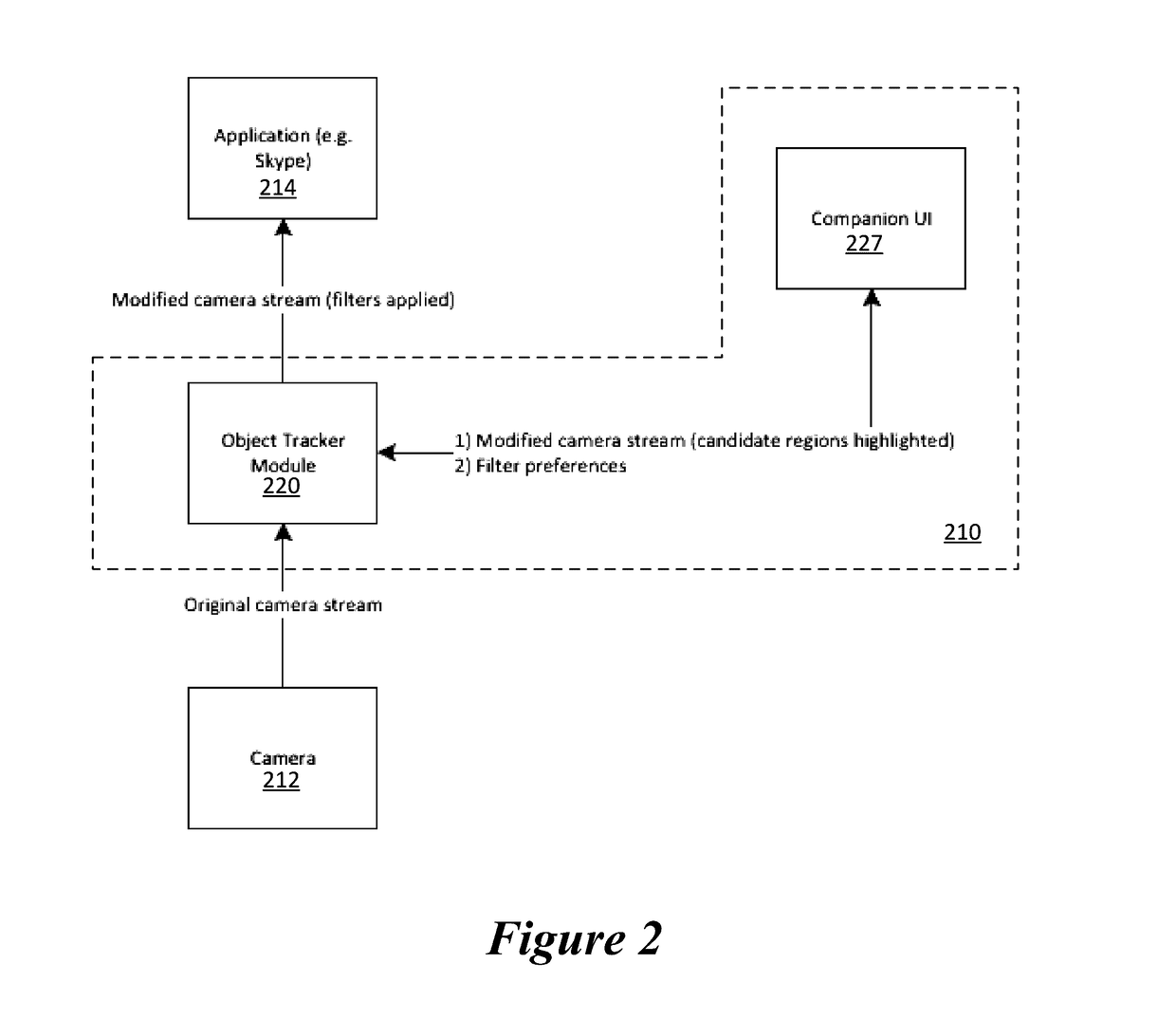

Video Manipulation for Privacy Enhancement

InactiveUS20170148487A1Improve privacyEnsure compatibilityImage enhancementImage analysisVideo transmissionComputer graphics (images)

A system, method, and computer-readable medium for performing a selective video manipulation operation for privacy enhancement. More specifically, the selective video manipulation operation detects video transmission protected regions in a scene and applies effects to these regions before transmitting a modified video stream which presents a selectively modified scene. In certain embodiments, the video transmission protected regions include potentially sensitive or distracting regions in the scene. In certain embodiments the selective video manipulation operation automatically detects video transmission protected regions which may be located in at least one of the background of the scene or the foreground attic scene and applies user-configurable effects to the identified regions.

Owner:DELL PROD LP

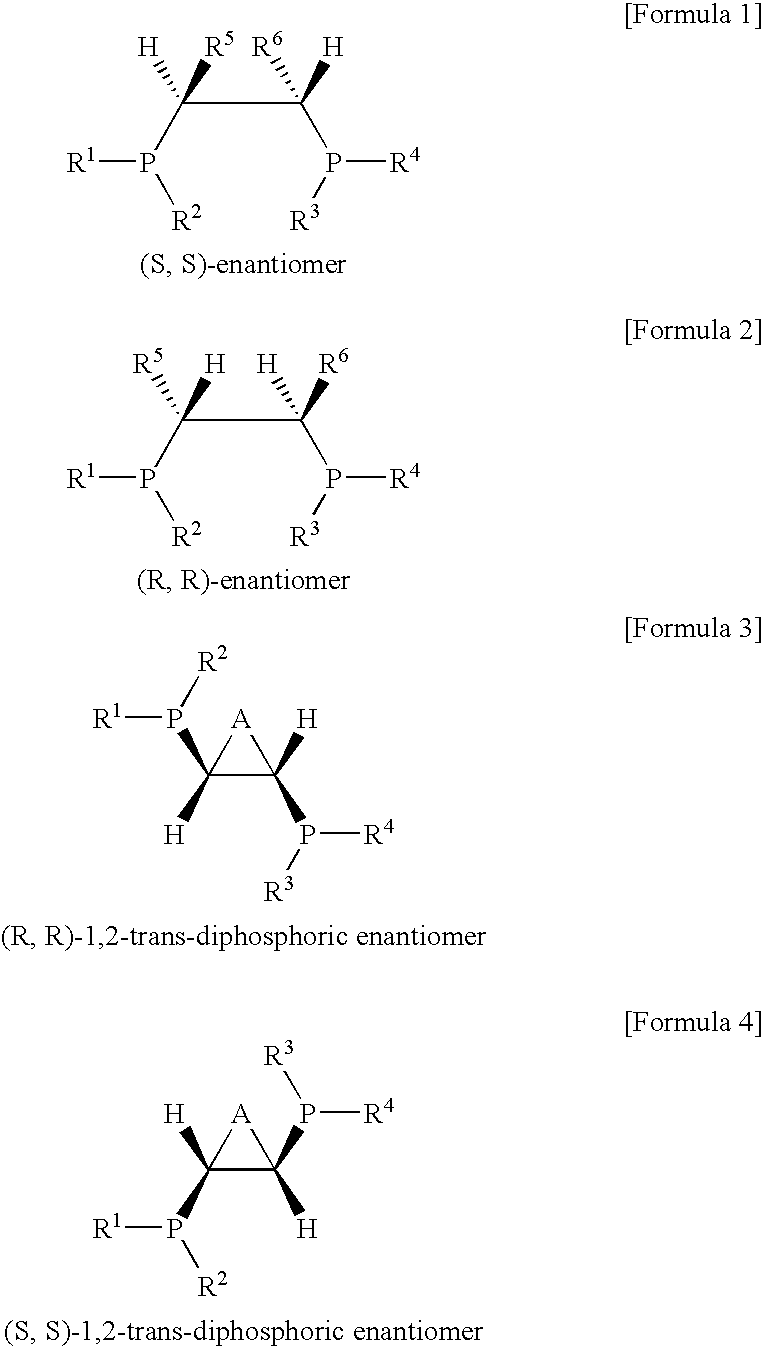

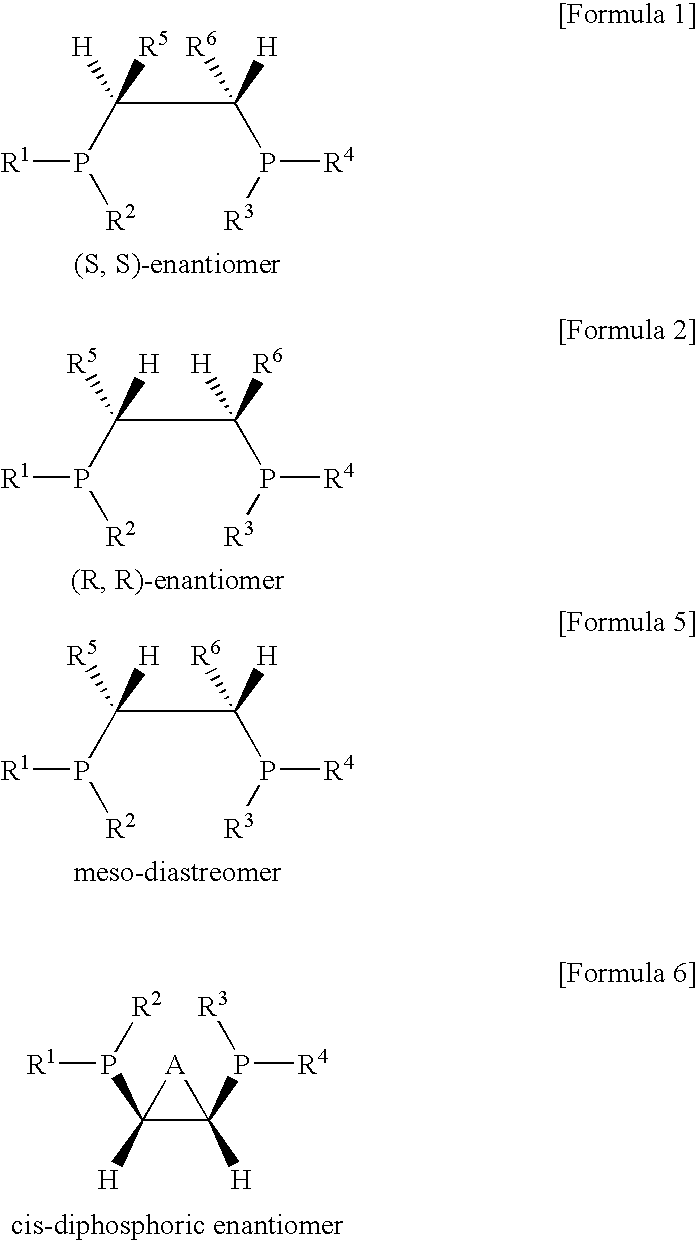

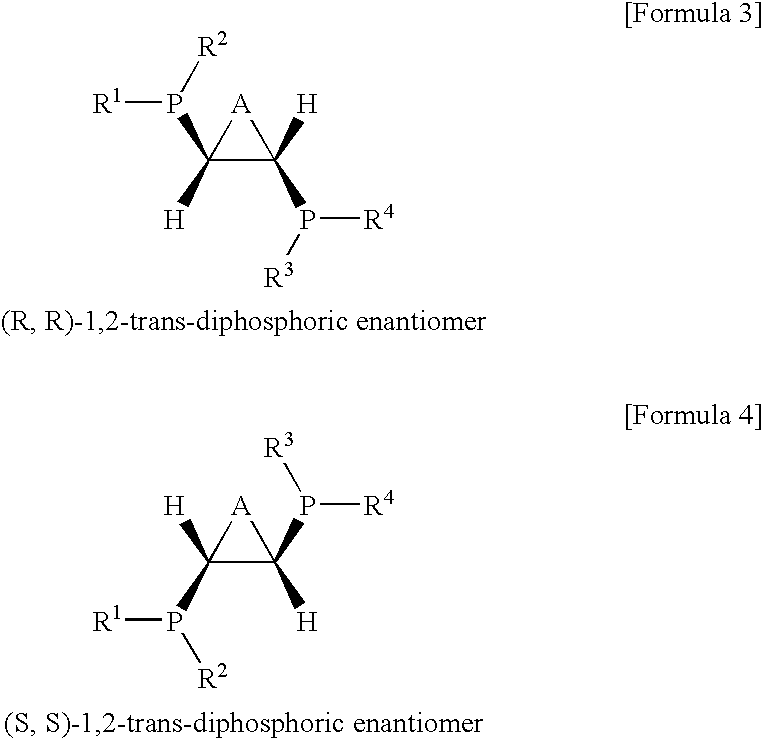

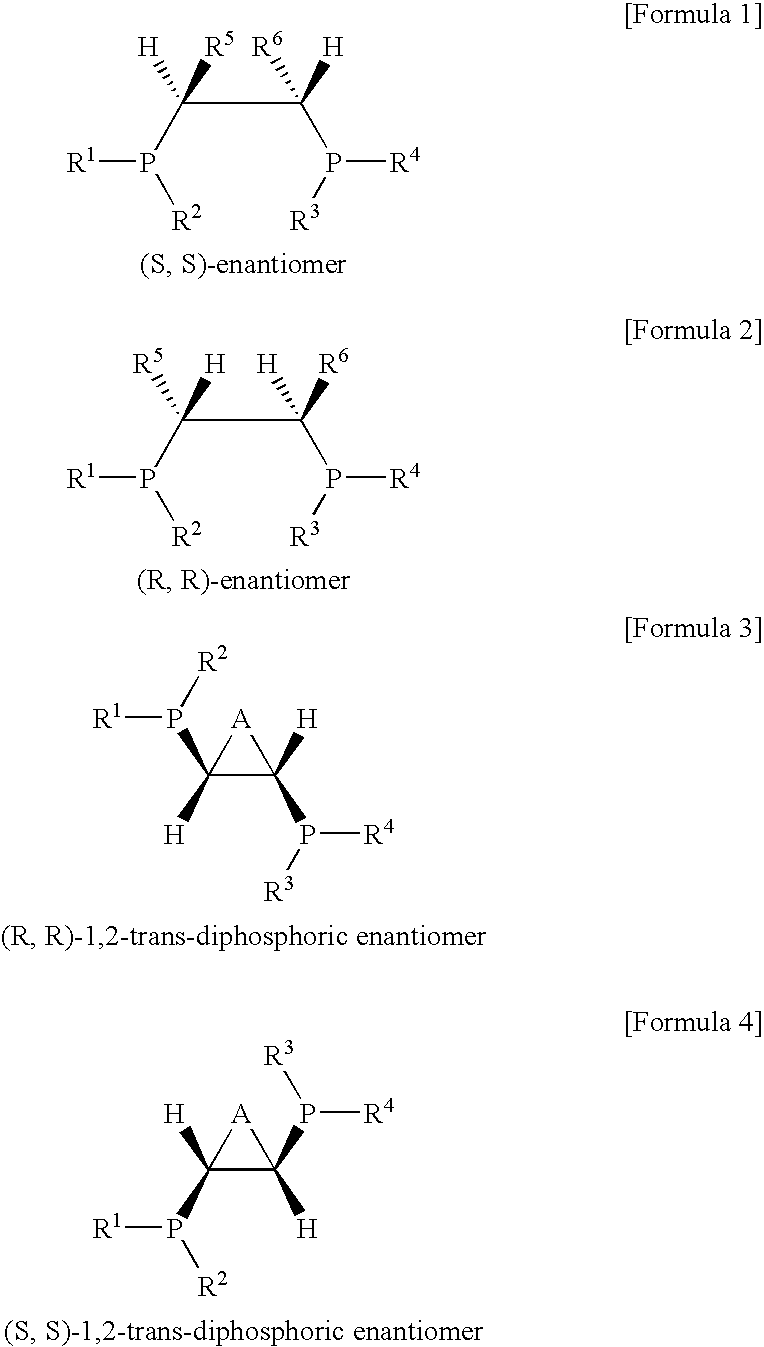

Ethylene oligomerization catalyst systems having enhanced selectivity

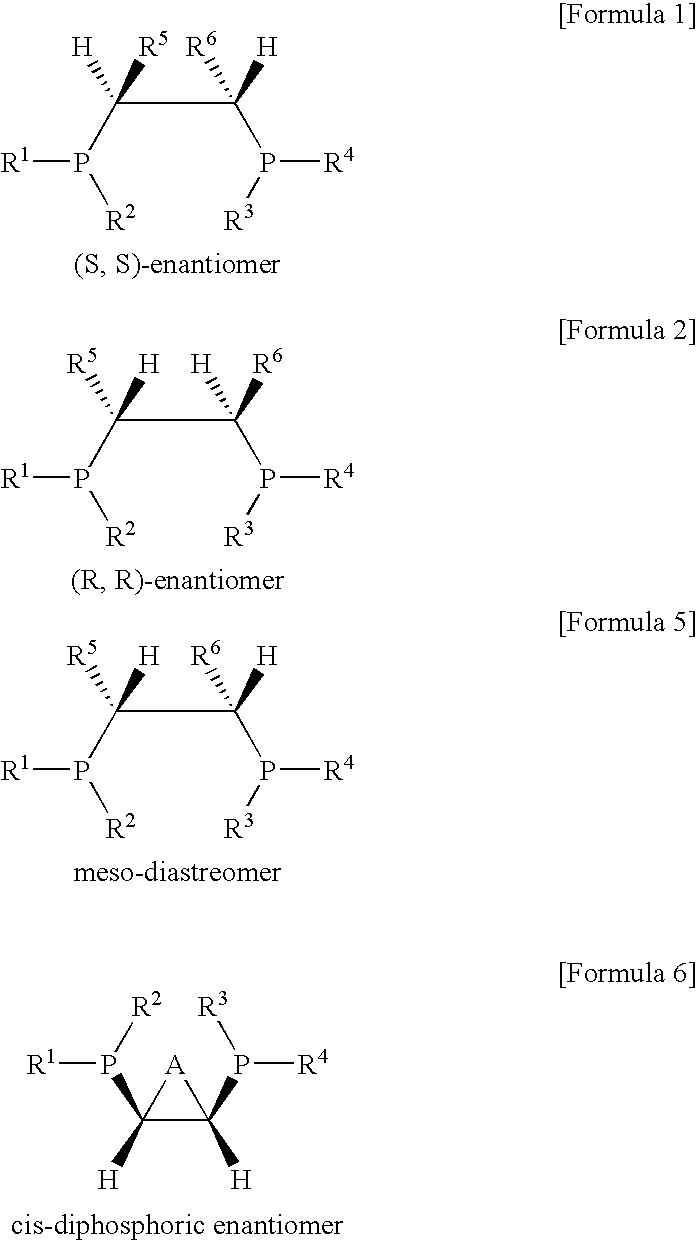

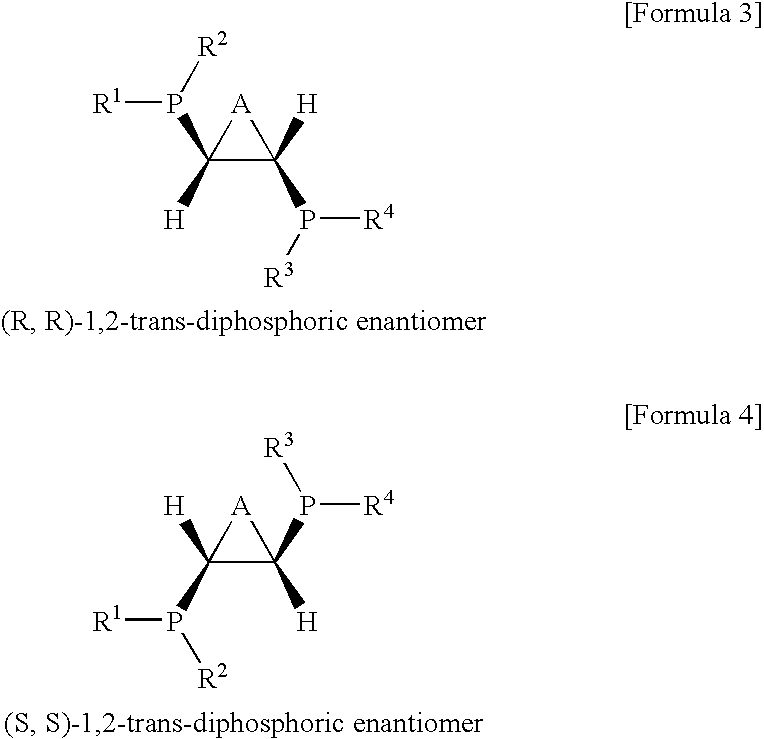

ActiveUS8309779B2High activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionFrame workMetal

Disclosed herein is a catalyst system for selective oligomerization of ethylene, which comprises a P—C—C—P frame-work ligand, which is (R1)(R2)P—(R5)CHCH(R6)—P(R3)(R4), and a chromium-based metal compound. Also disclosed is a method of greatly enhancing the activity and selectivity of oligomerization, such as trimerization or tetramerization, using a ligand having a specific steric arrangement structure.

Owner:SK GEO CENTRIC CO LTD

Etheyene oligomeriza catalyst systems having enehanced selectivity

ActiveUS20100145124A1SelectivityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionFrame workEthylene

Disclosed herein is a catalyst system for selective oligomerization of ethylene, which comprises a P—C—C—P frame-work ligand, which is (R1)(R2)P—(R5)CHCH(R6)—P(R3)(R4), and a chromium-based metal compound. Also disclosed is a method of greatly enhancing the activity and selectivity of oligomerization, such as trimerization or tetramerization, using a ligand having a specific steric arrangement structure.

Owner:SK GEO CENTRIC CO LTD

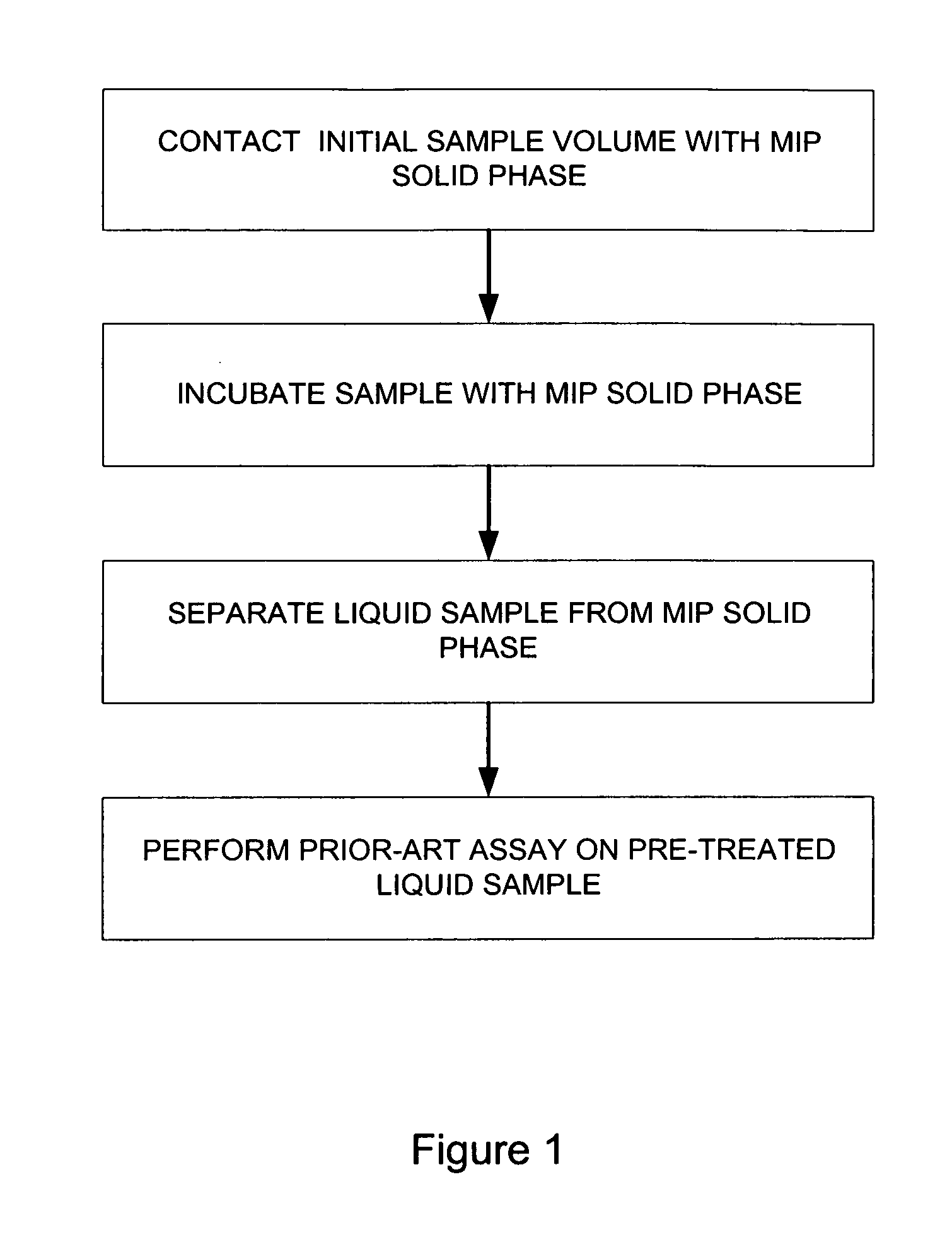

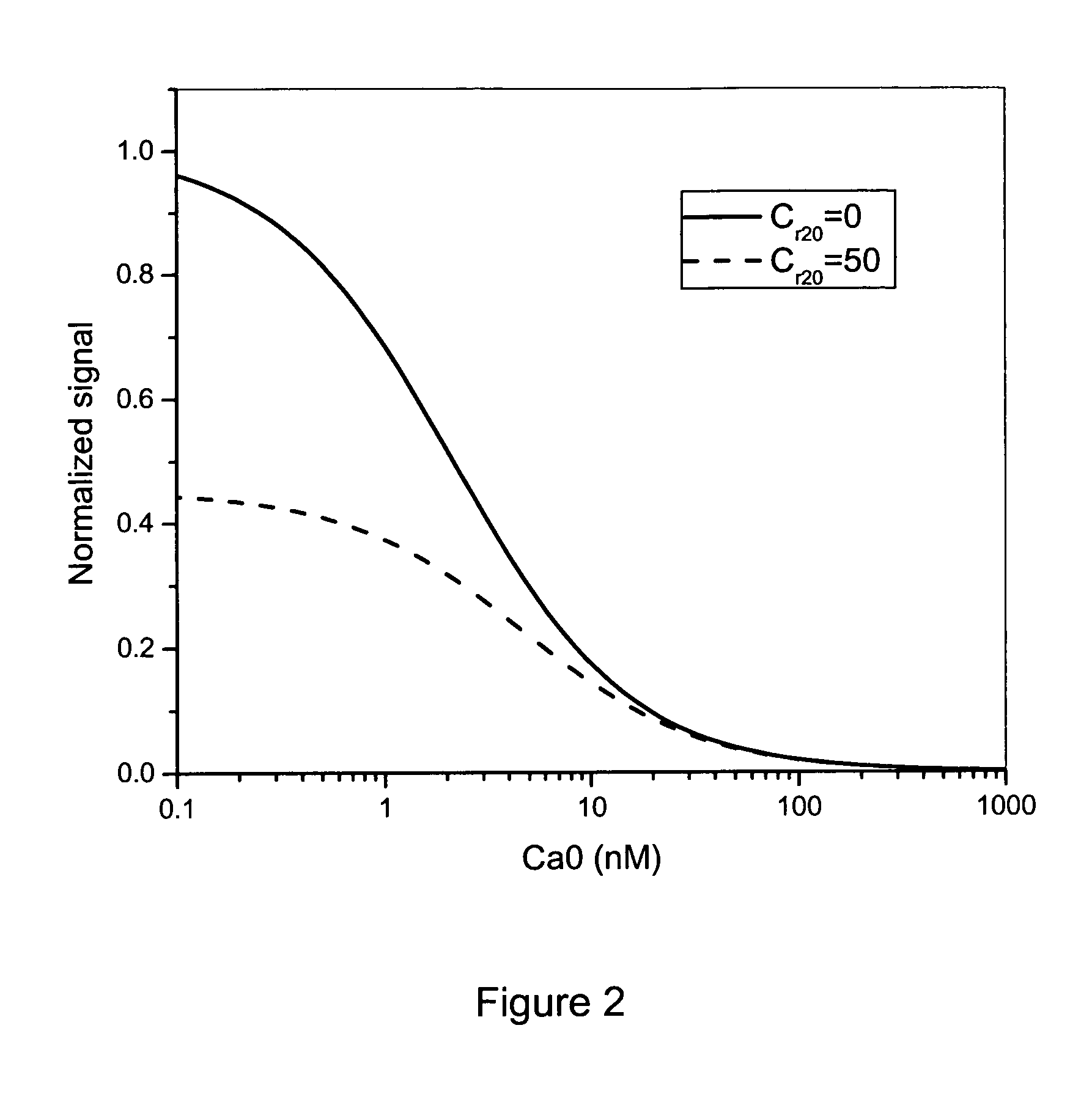

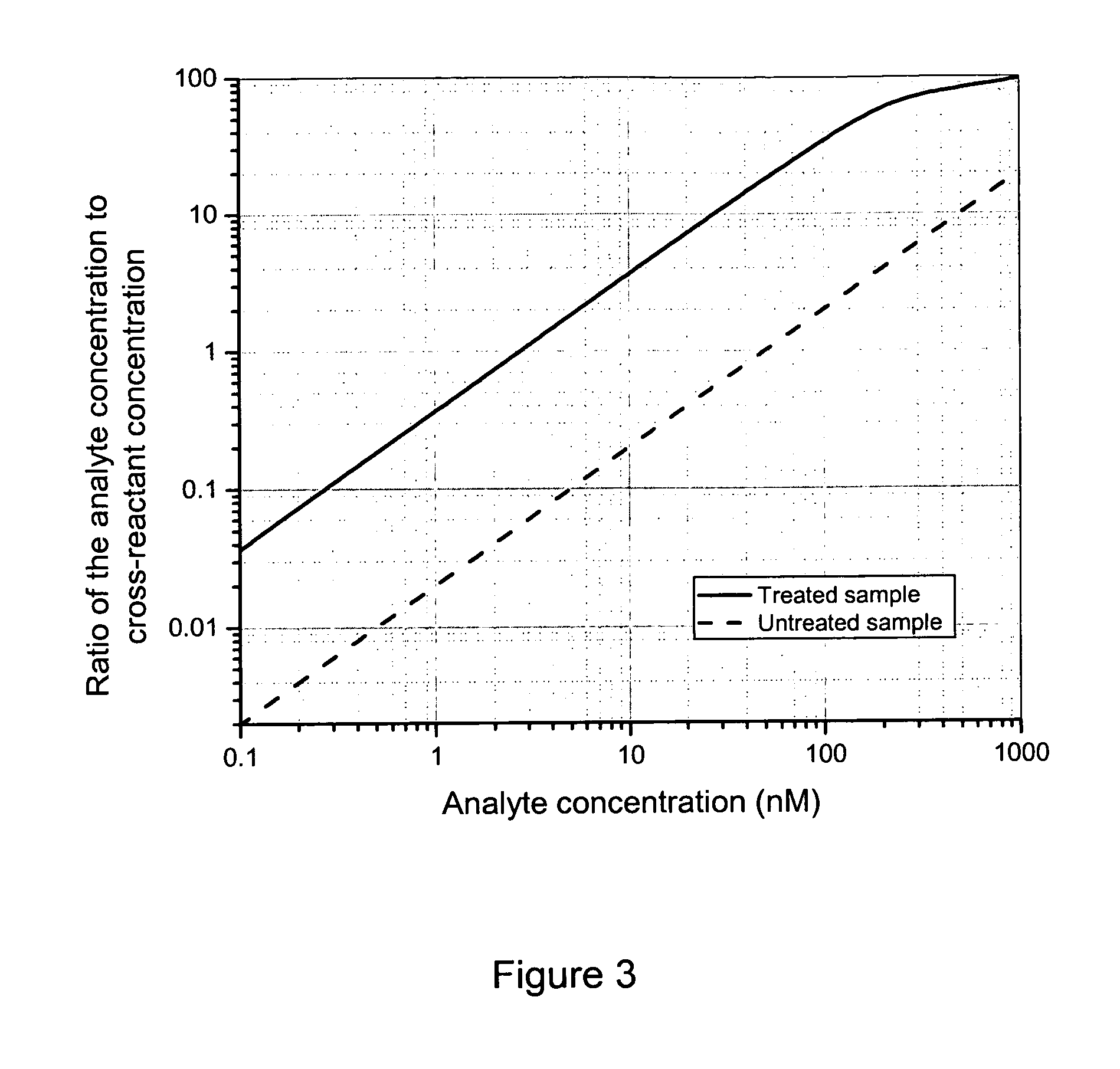

Immunoassays with enhanced selectivity

InactiveUS20060177882A1Strong specificityReduce concentrationBiological material analysisAnalyteTwo step

The present invention provides a method for the detection of an analyte in a specimen comprising two steps. First, the specimen is contacted with a substrate having receptors bound thereon, having higher affinity for cross-reactive substances than for the analyte, in order to increase the ratio of the analyte to the cross-reactive substances. Then, the treated specimen is assayed by using another receptor while decreasing the effects of the cross-reactive substance contained in the original specimen. The receptors in the first step are preferably molecular imprinted polymers that are capable of absorbing multiple cross-reactive substances.

Owner:NOVX SYST CANADA

Monolith structure loaded with metal promoted nanozeolites for enhanced propylene selectivity in methanol conversion

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

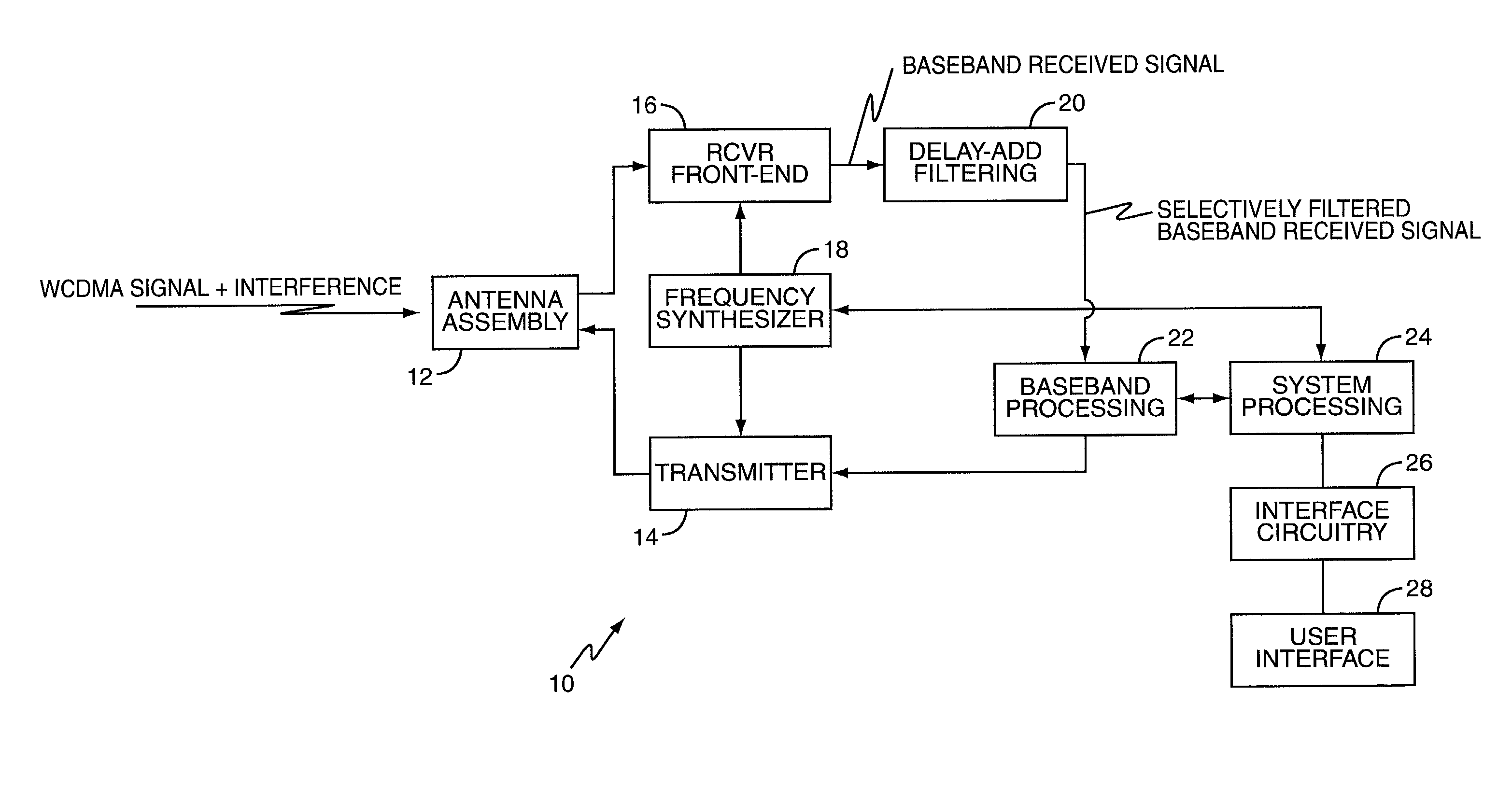

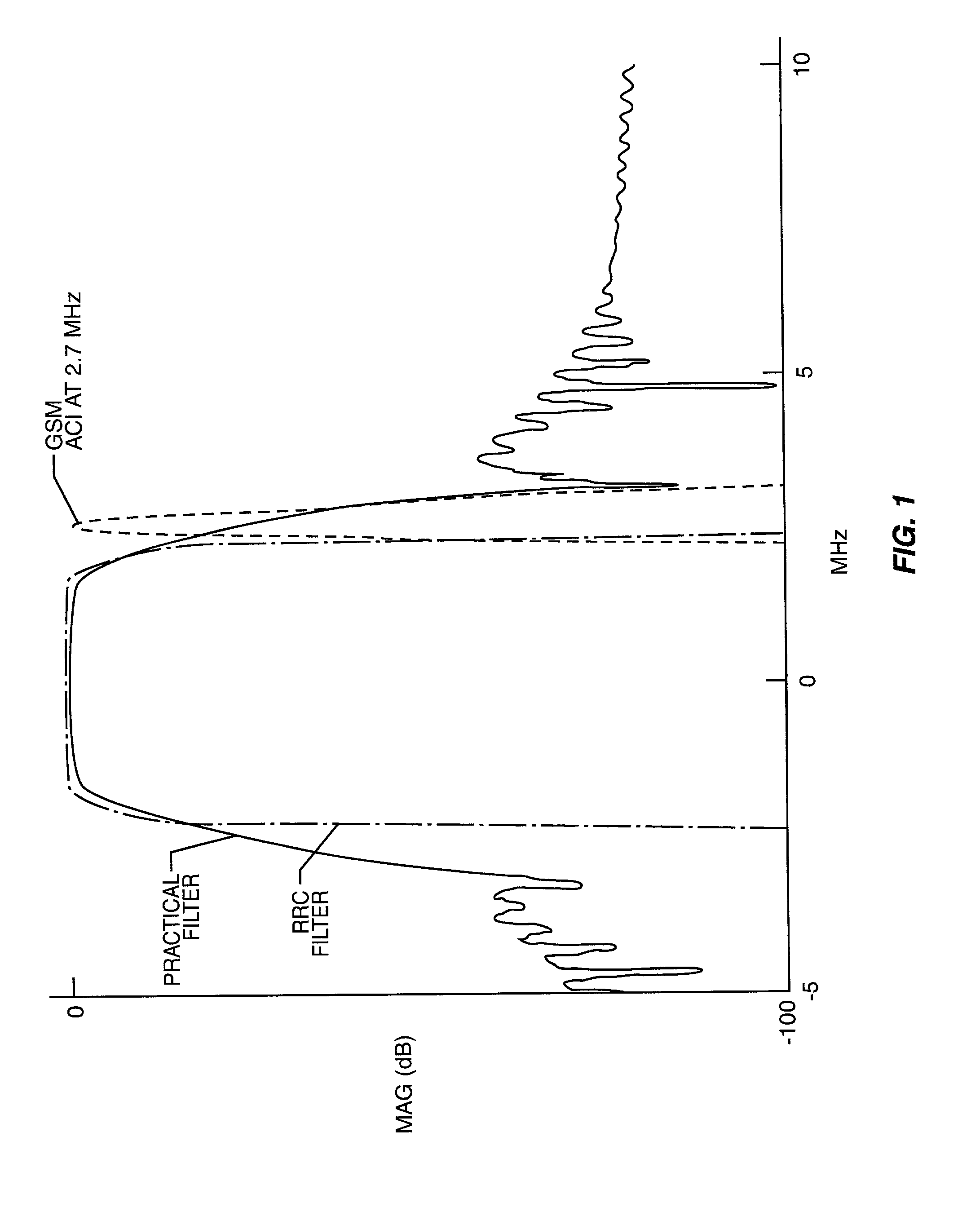

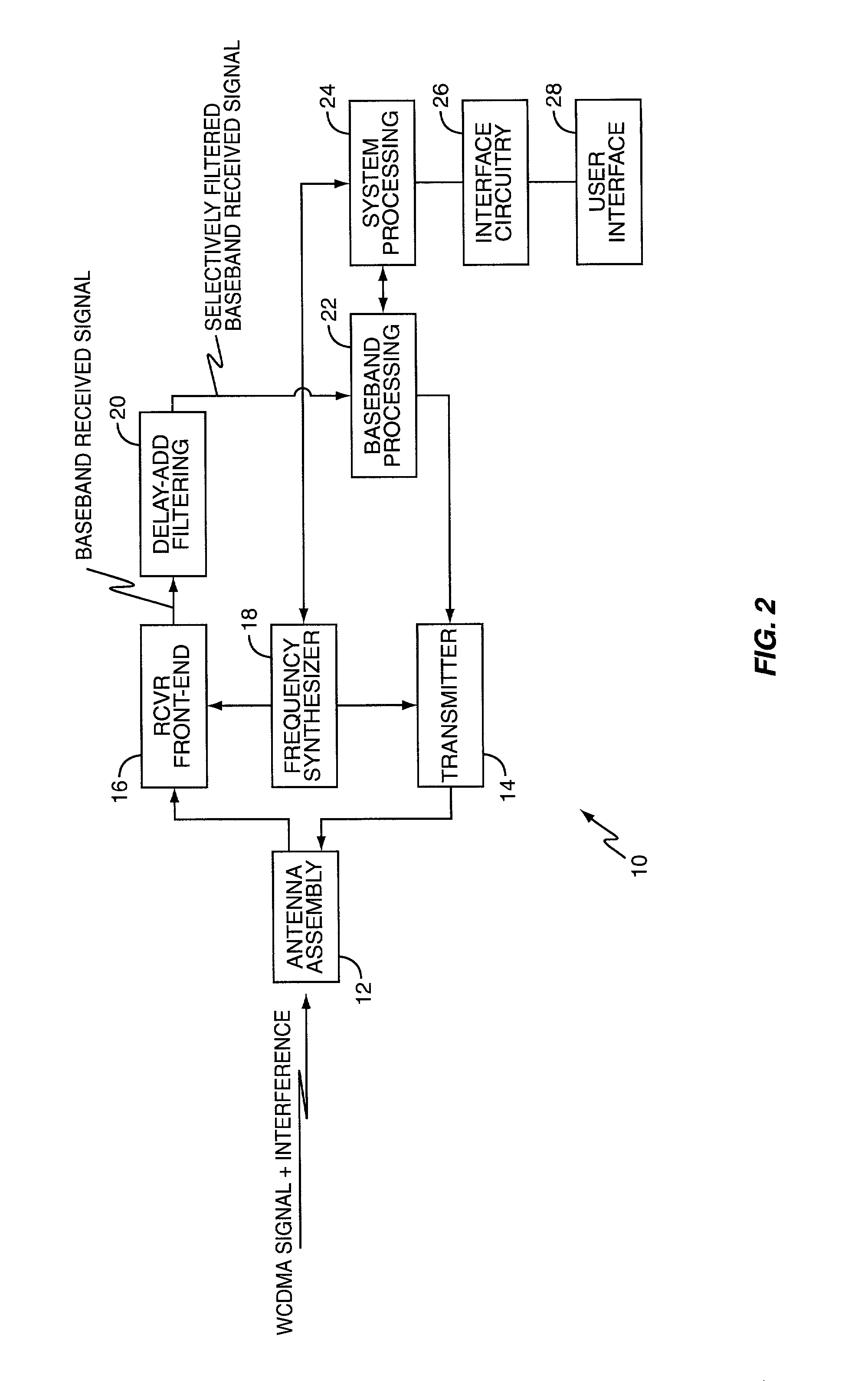

Received signal filtering for enhanced selectivity

InactiveUS7221958B2Reduction of narrowband interferenceReduce interferenceDigital technique networkSubstation equipmentAdjacent-channel interferenceCdma signal

A delay-and-add filtering technique positions one or more filter nulls substantially at points of narrowband interference in a relatively wideband received signal. For example, the technique is useful in removing adjacent channel interference in a received W-CDMA signal caused GSM radio transmissions.

Owner:OPTIS WIRELESS TECH LLC

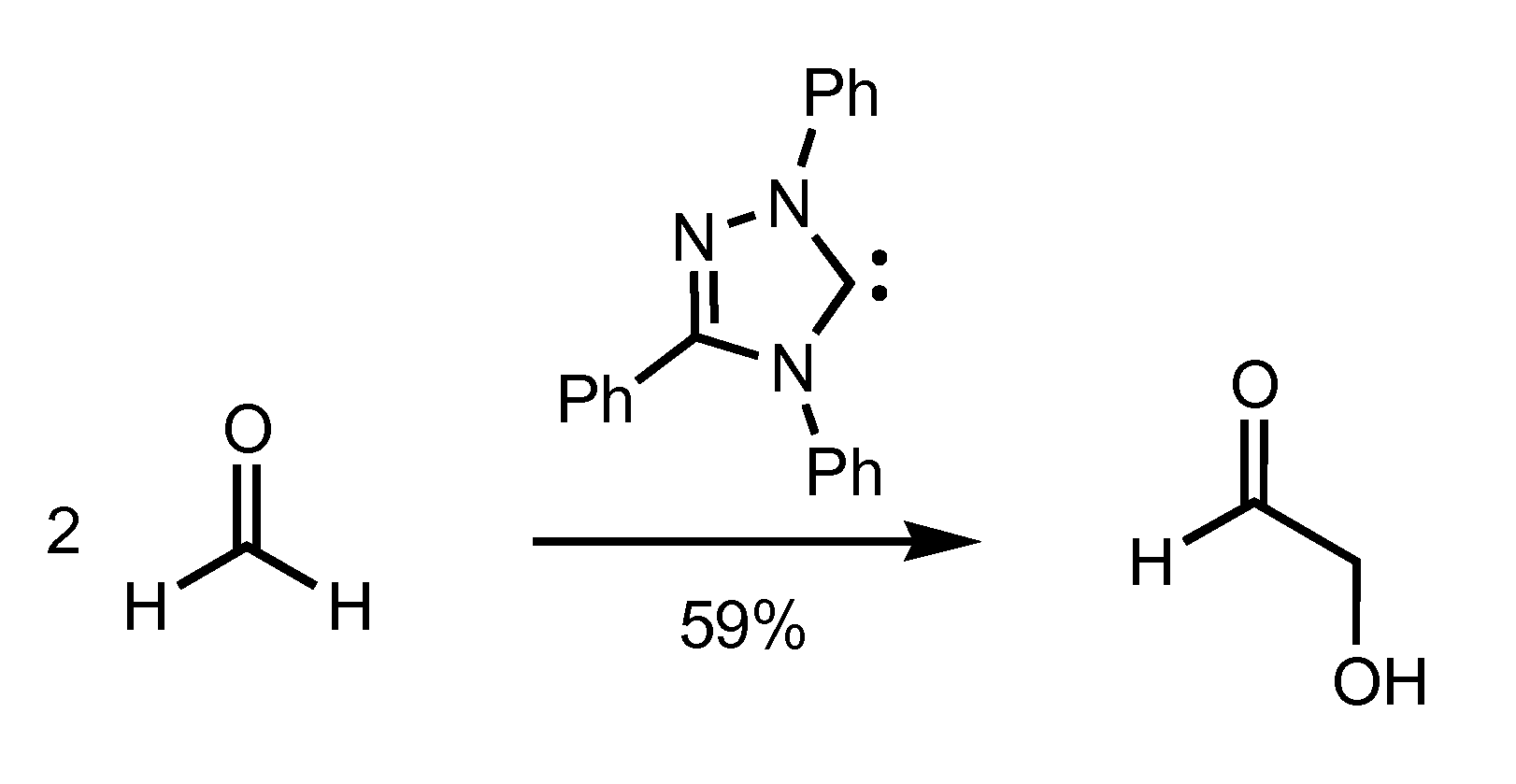

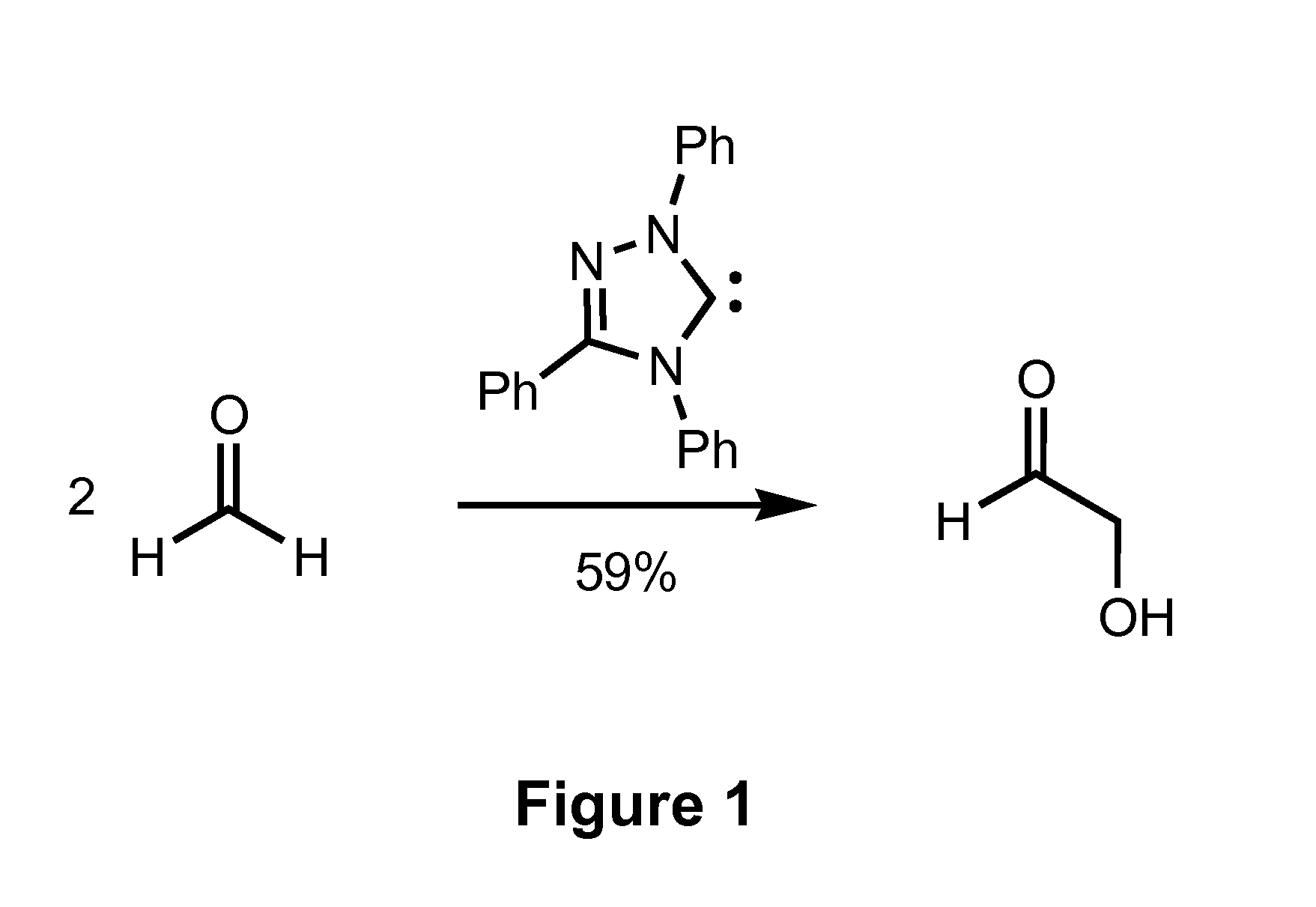

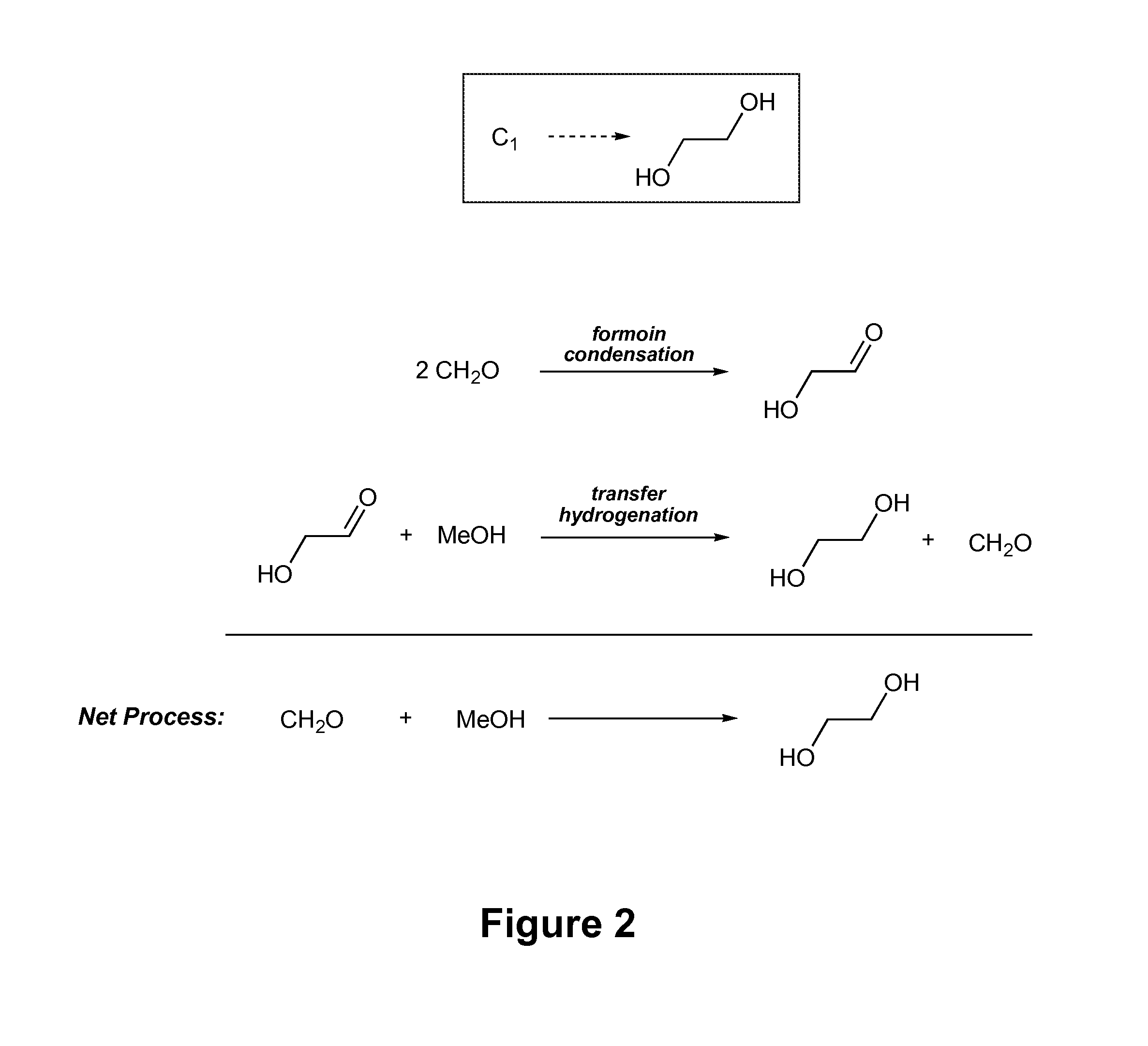

Combined Formose/Transfer Hydrogenation Process for Ethylene Glycol Synthesis

InactiveUS20100305368A1High selectivityHigh yieldOrganic compound preparationCarbonyl compound preparationSelf-condensationCarbene

The present invention provides a process for the production of a glycol via tandem self condensation of formaldehyde via formoin condensation and transfer hydrogenation of the reaction products of the formoin condensation. In some aspects, synthetic processes of the present invention utilize a combination of a N-heterocyclic carbene catalyst and a transition metal hydrogen-transfer catalyst providing enhanced selectivity and increased yields for the production of ethylene glycol relative to conventional synthetic approaches based on formoin condensation.

Owner:CALIFORNIA INST OF TECH

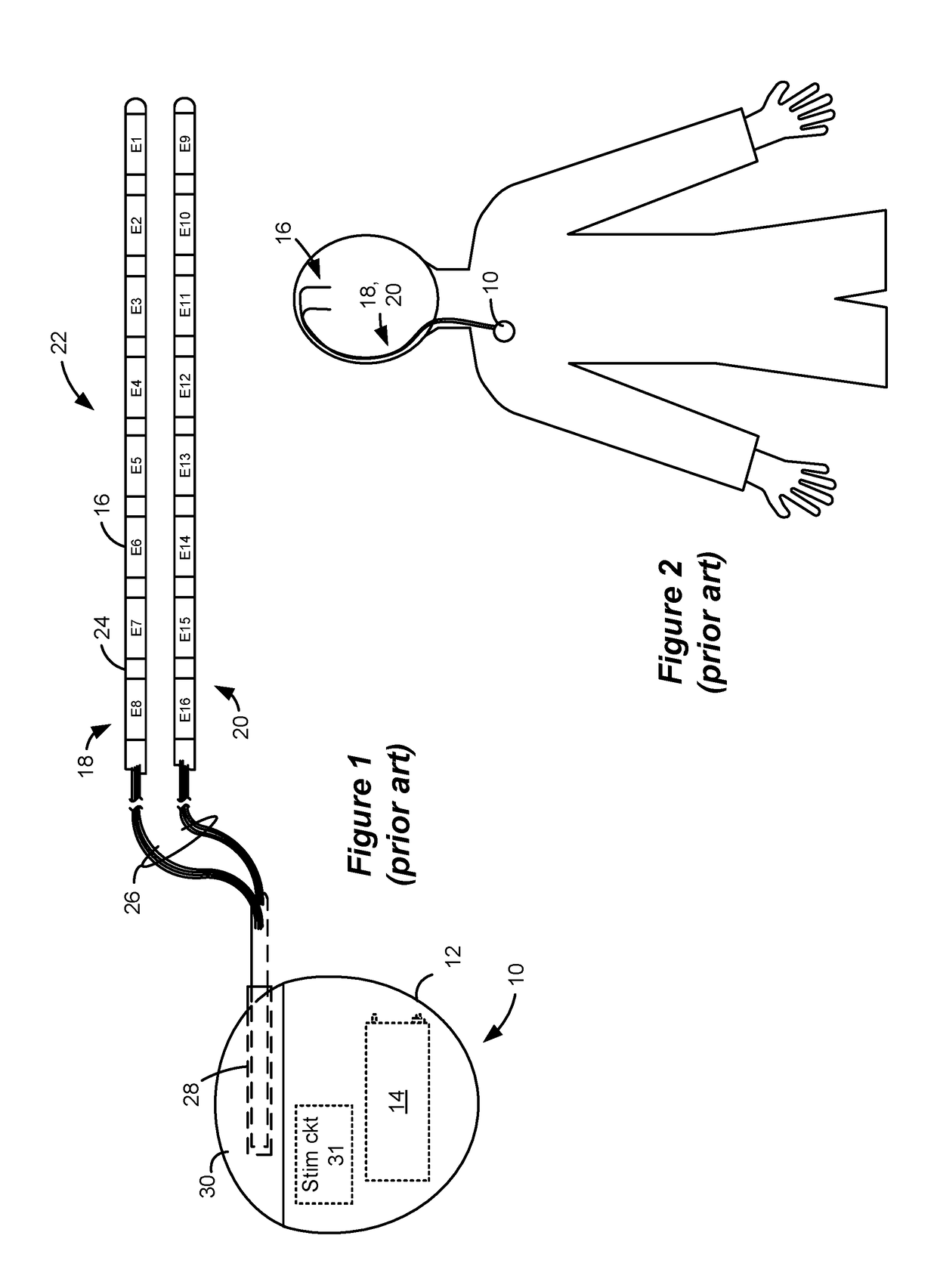

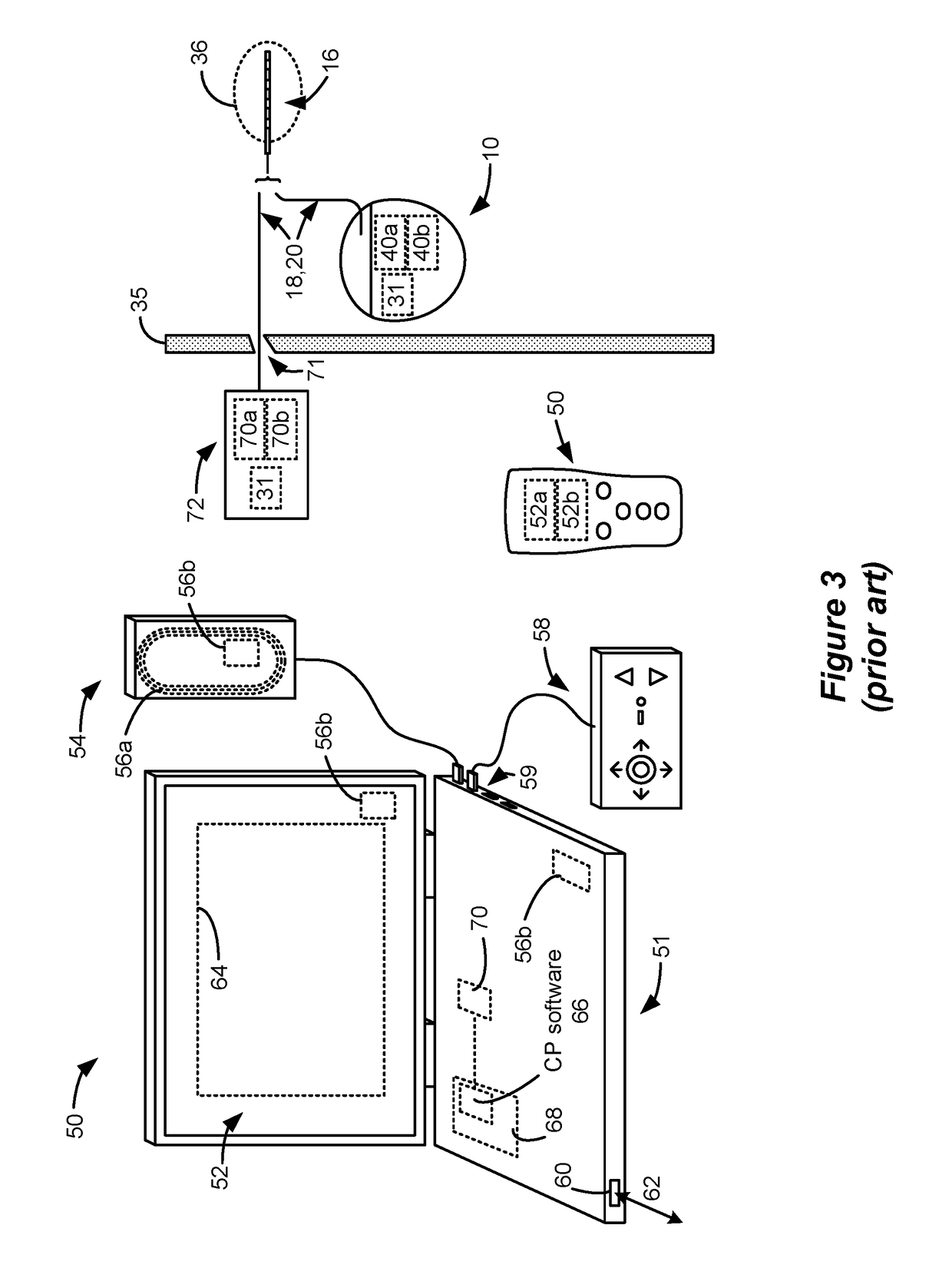

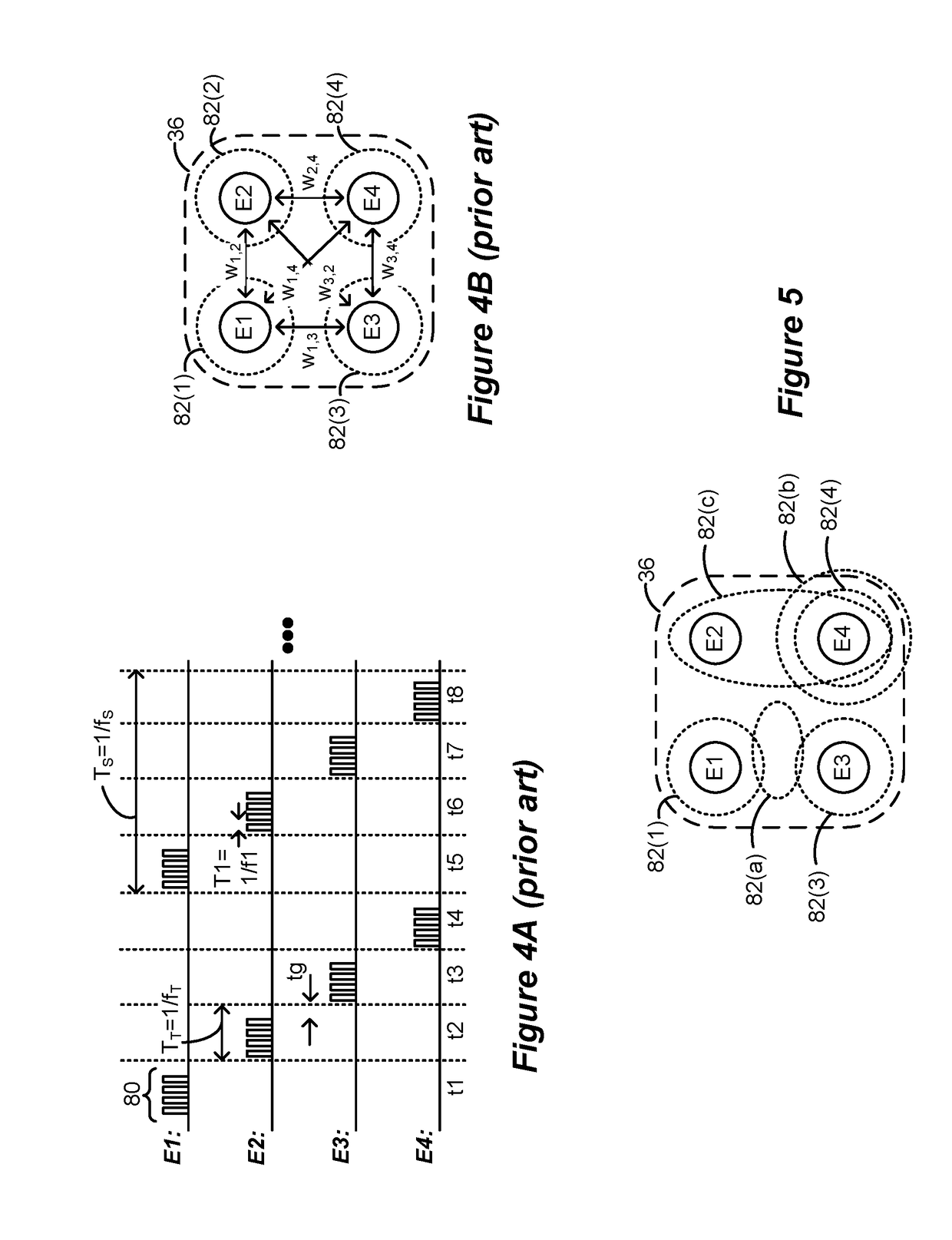

Enhanced Selectivity and Modulation in Coordinated Reset in Deep Brain Stimulation

Various manners are disclosed in which neurostimulation can be programmed to provide stimulation pulses designed to alter the level of synchronization in a target neural tissue, as is useful in Deep Brain Stimulation (DBS) therapy for example. Stimulation pulses are issued in pulse packets, with one or more variations added within or between pulse packets, such as variations in pulse width, amplitude, frequency, or shape. Such variations afford greater ability to differentially recruit sub-populations of neural tissue in both space and time. Such pulse packets may be issued from one or more electrodes, which pulse packets may or may not overlap in time.

Owner:BOSTON SCI NEUROMODULATION CORP

Antibodies with enhanced or suppressed effector function

ActiveUS9296815B2Strong specificityInhibition is effectiveHybrid immunoglobulinsPeptide/protein ingredientsFc receptorFc(alpha) receptor

Rationally designed antibodies and polypeptides that comprise multiple Fc region amino acid substitutions that synergistically provide enhanced selectivity and binding affinity to a target Fc receptor are provided. The polypeptides are mutated at multiple positions to make them more effective when incorporated in antibody therapeutics than those having wild-type Fc components.

Owner:ZYMEWORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com