Patents

Literature

630 results about "Chemical separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Security paper

InactiveUS6159585AAvoid the needLow compositionNon-fibrous pulp additionNatural cellulose pulp/paperOrganic solventChemical separation

A security paper indicates exposure to a solvent by a solvent resistant color signal. A metal mordant dye first co-reactant and a mordant dye second co-reactant form an organic solvent-insoluble colored reaction product when the paper is washed with an organic solvent. The metal mordant dye first co-reactant and a mordant dye second co-reactant are chemically isolated from each other so as to prevent the coordinate covalent bond from forming until the paper is washed with an organic solvent. The chemical isolation can be effected by encapsulation or other physical separation of the co-reactants. The organic solvent-insoluble colored reaction product, once formed, remains entrapped in the web when the paper is washed with an organic solvent. The chemical isolation prevents the organic solvent-insoluble colored reaction product from forming upon the application of pressure alone to the paper.

Owner:DOMTAR +1

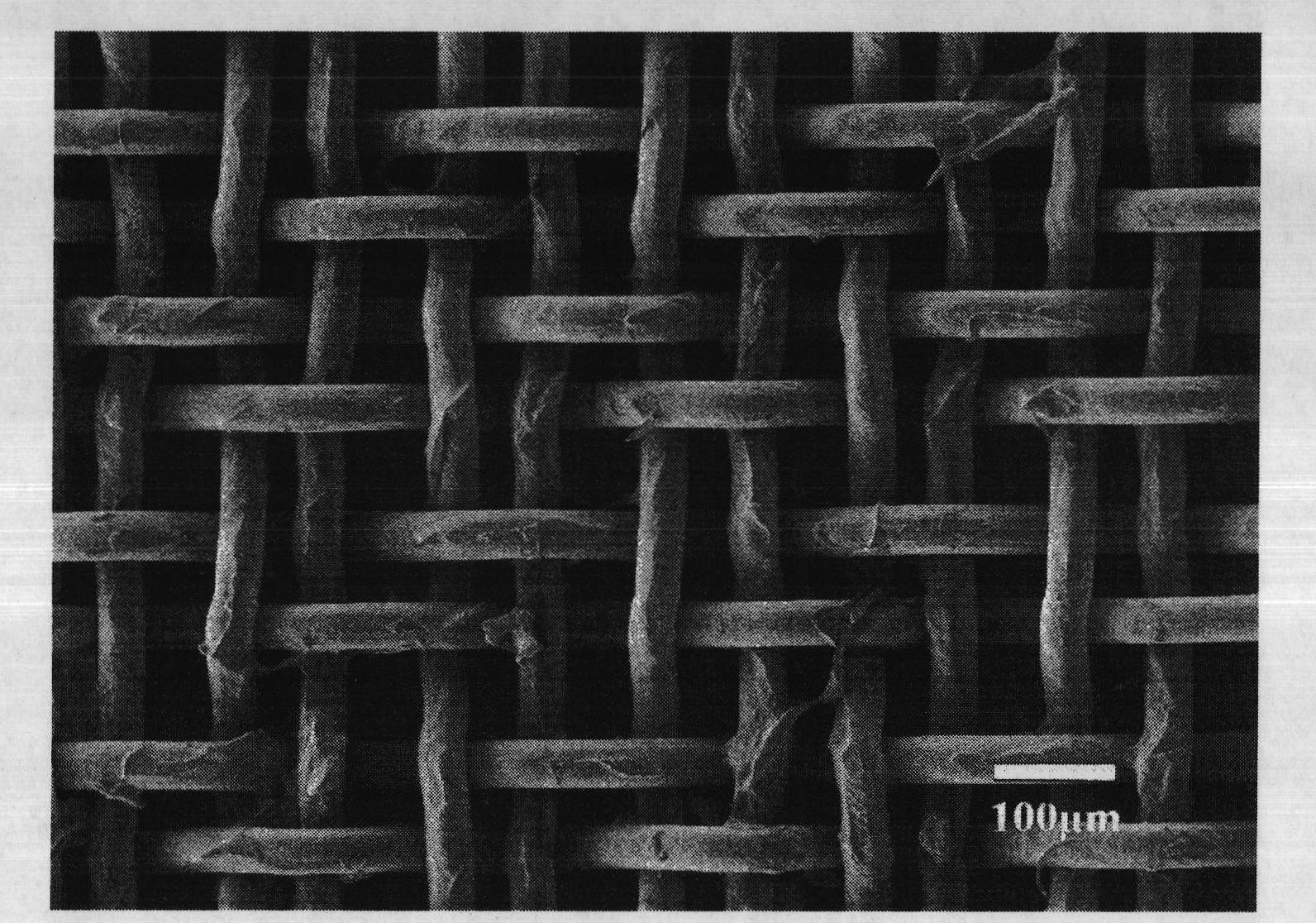

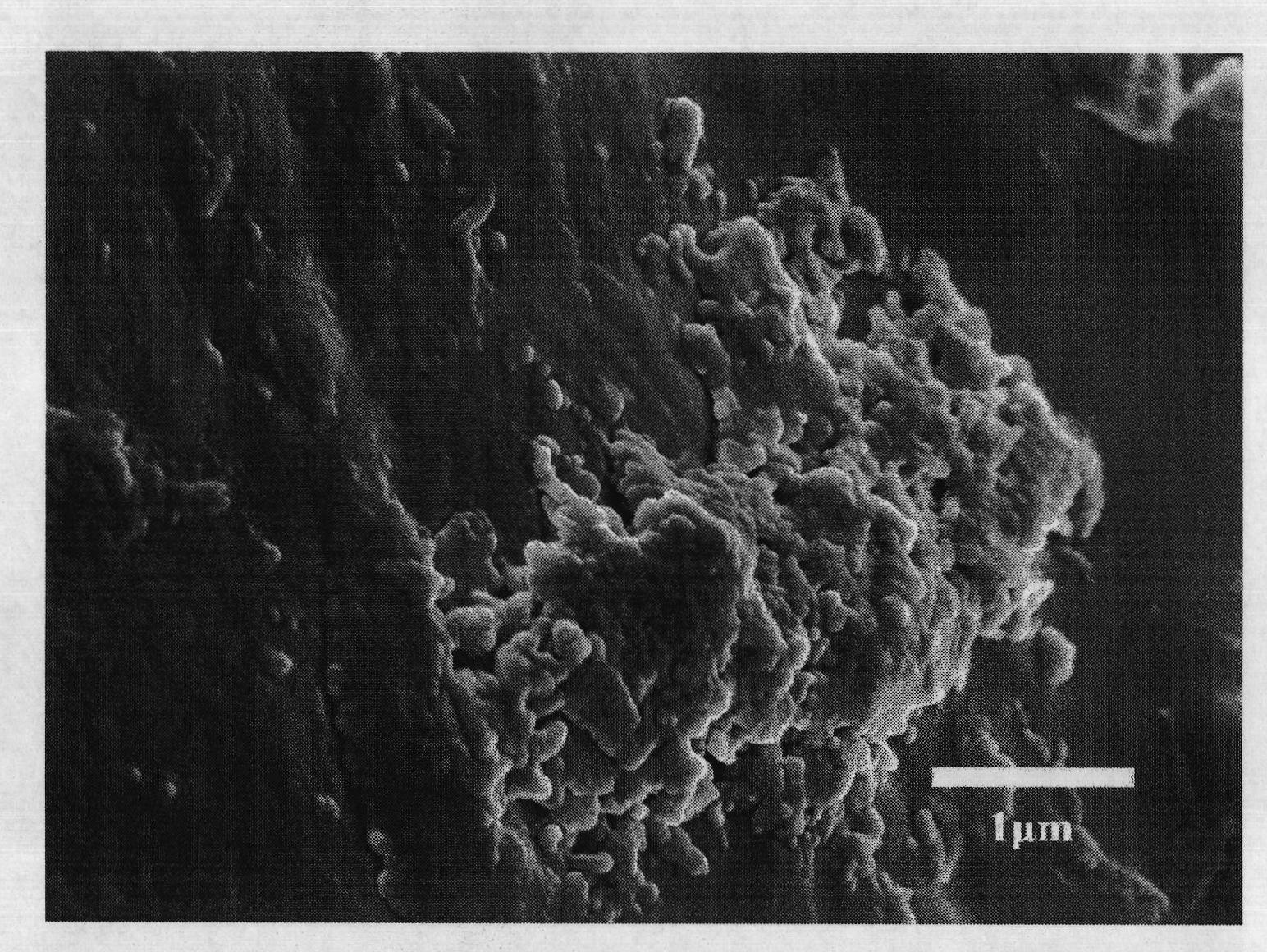

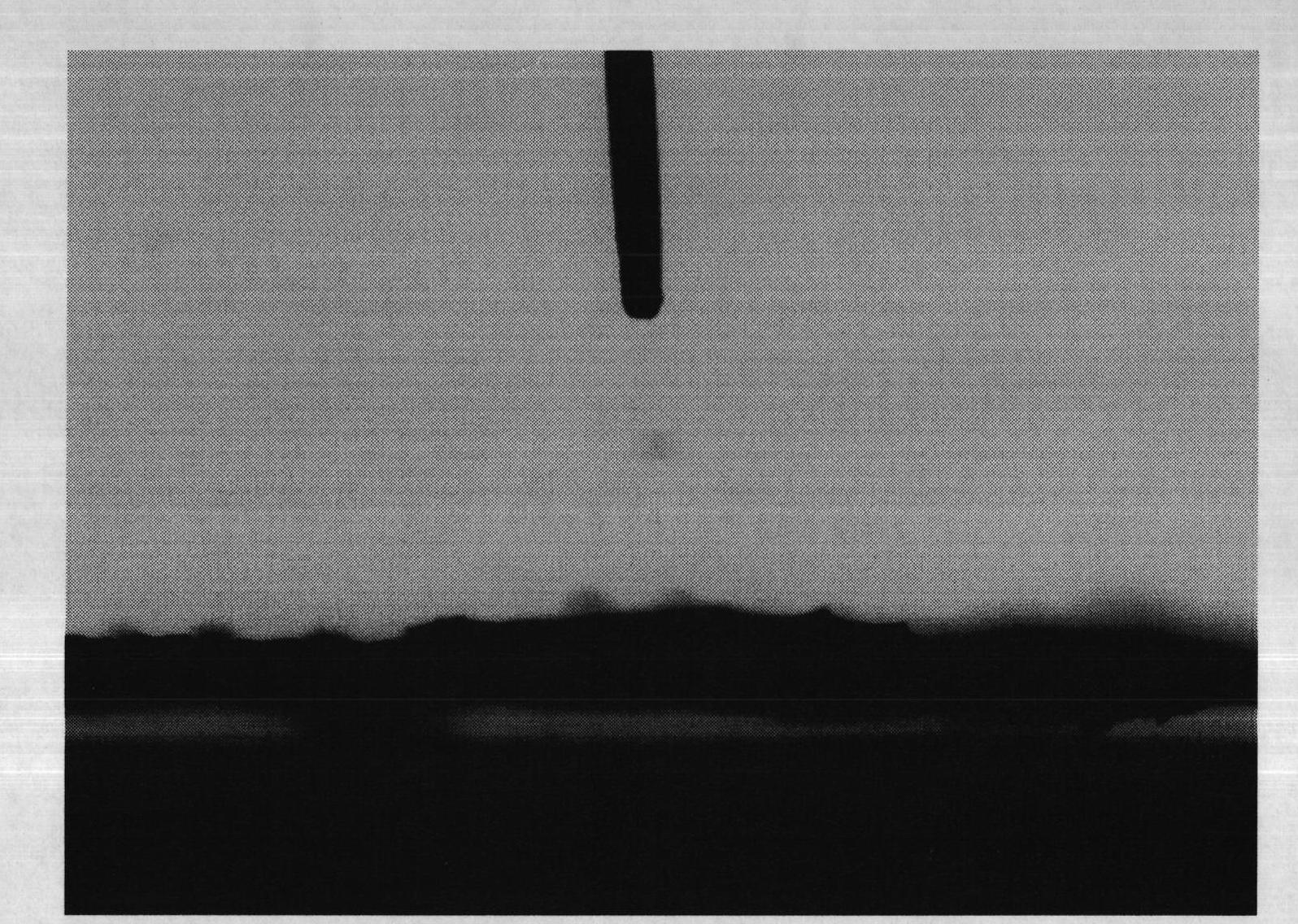

Underwater super-oleophobic oil-water separation mesh membrane as well as preparation method and application thereof

InactiveCN102029079AImprove separation efficiencyReduce contact areaLiquid separationUnderwaterChemical separation

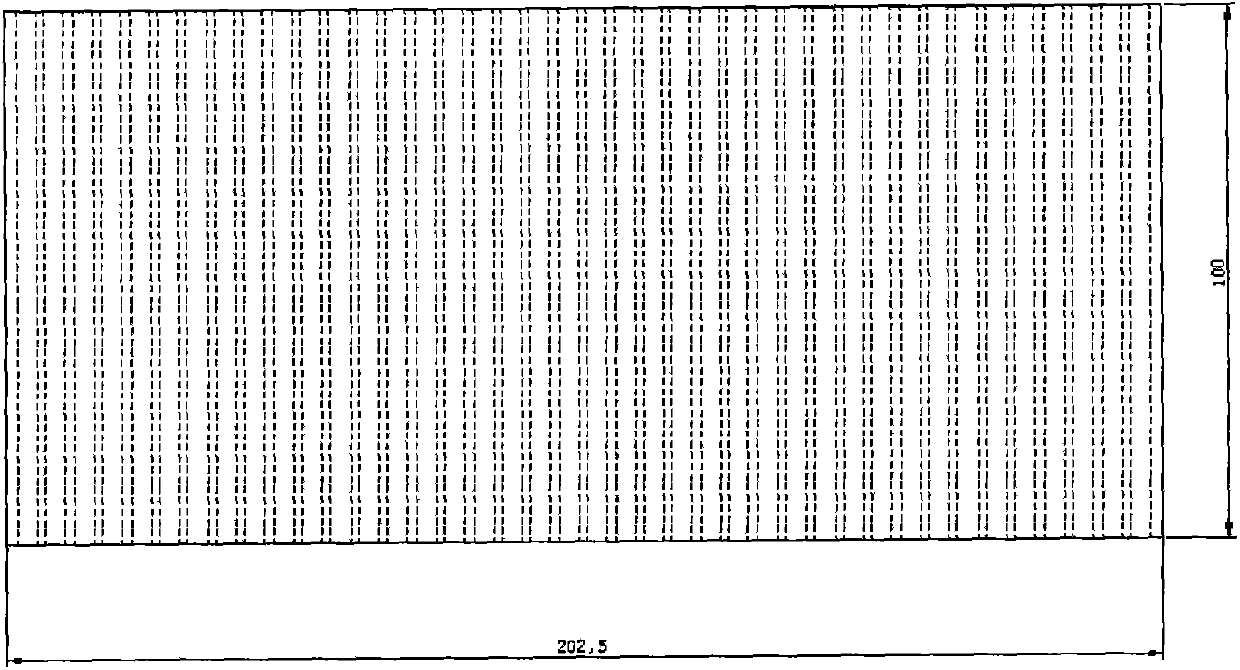

The invention relates to an underwater super-oleophobic oil-water separation mesh membrane as well as a preparation method and application thereof. A 100-140-mesh fabric mesh is used as the substrate of the oil-water separation mesh membrane; and a hydrogel cladding layer is formed by the crosslinking polymerization of polymer monomers on the mesh wires of the fabric mesh by a photo-initiated polymerization method, thus obtaining the mesh membrane provided by the invention. The oil-water separation mesh membrane is super-hydrophilic in air and underwater and super-oleophobic underwater; the contact angle with oil drops underwater is greater than 150 degrees; and the adhesion to oil drops is low. The mesh membrane provided by the invention can be applied to oil-containing sewage treatment, chemical separation, environmental protection and the like. For oil-water separation, the mesh membrane has the advantages of good separation effect, fast separation, low cost, low energy consumption, convenience, no other chemical additive and the like, and is easy to recover for multiple recycling, and suitable for wide-range preparation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

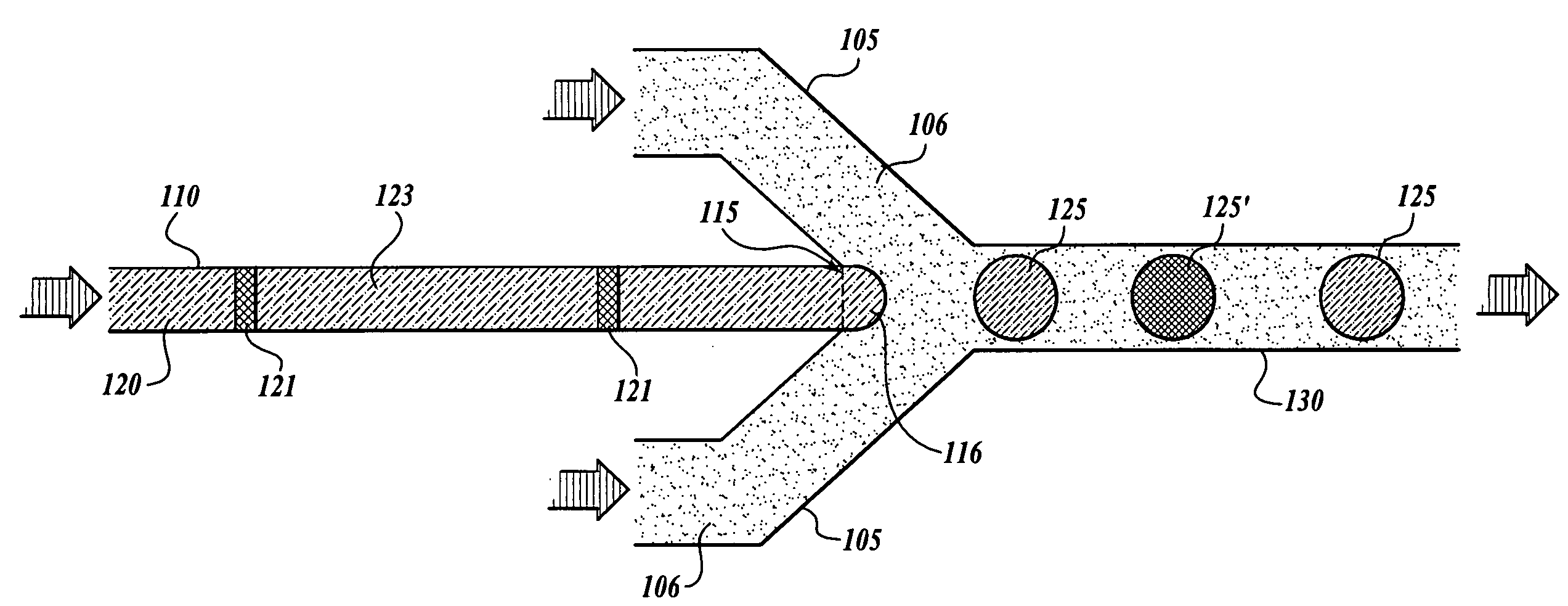

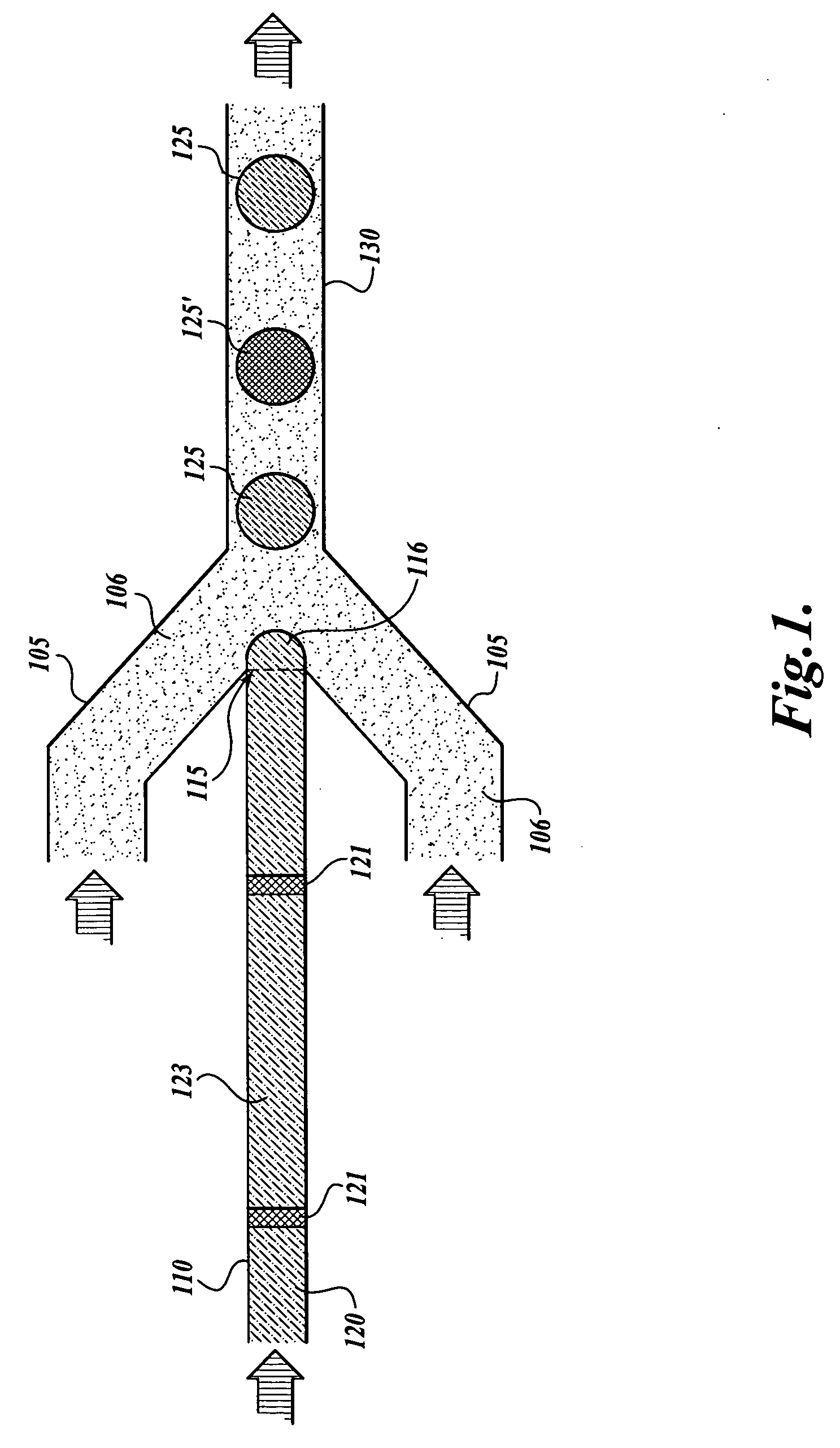

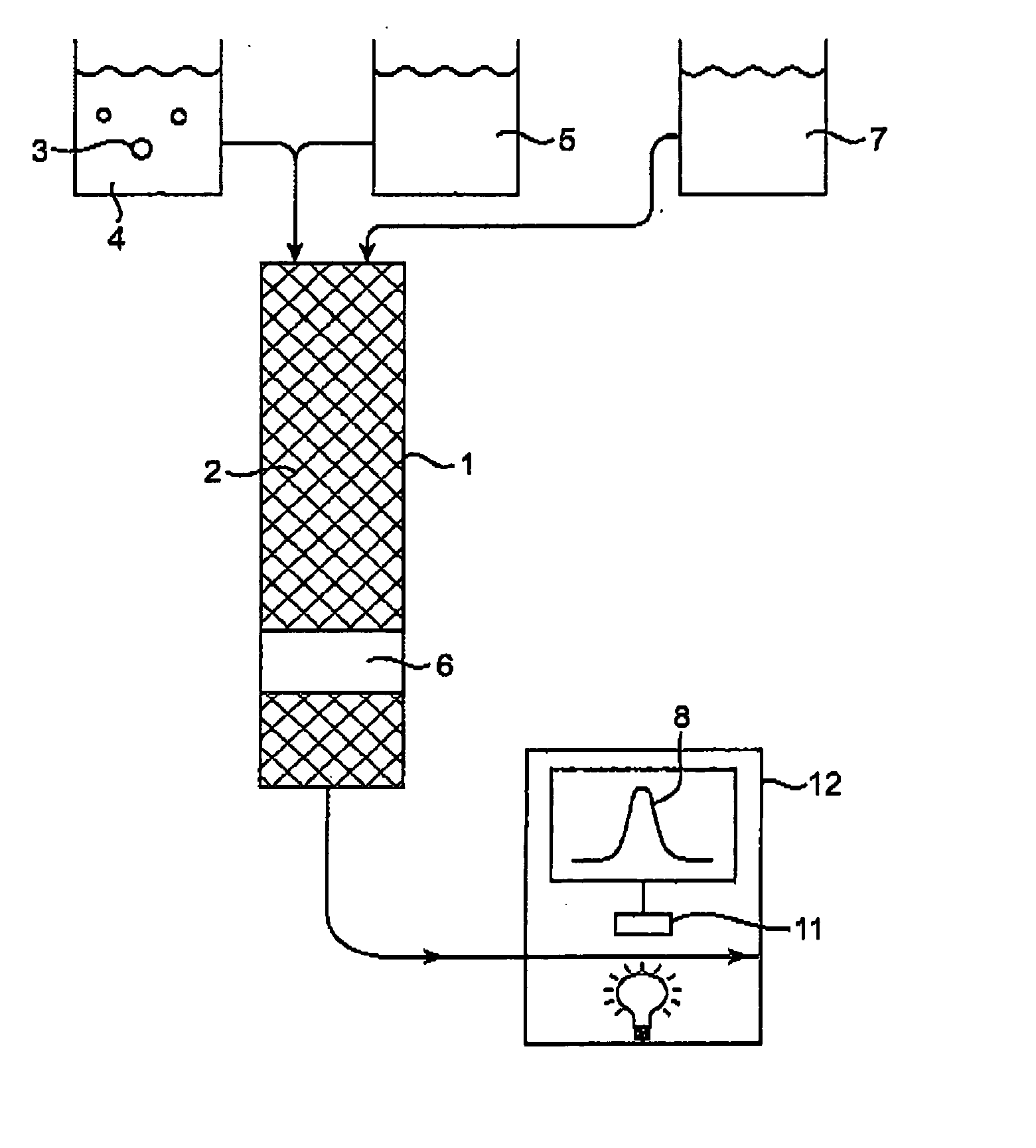

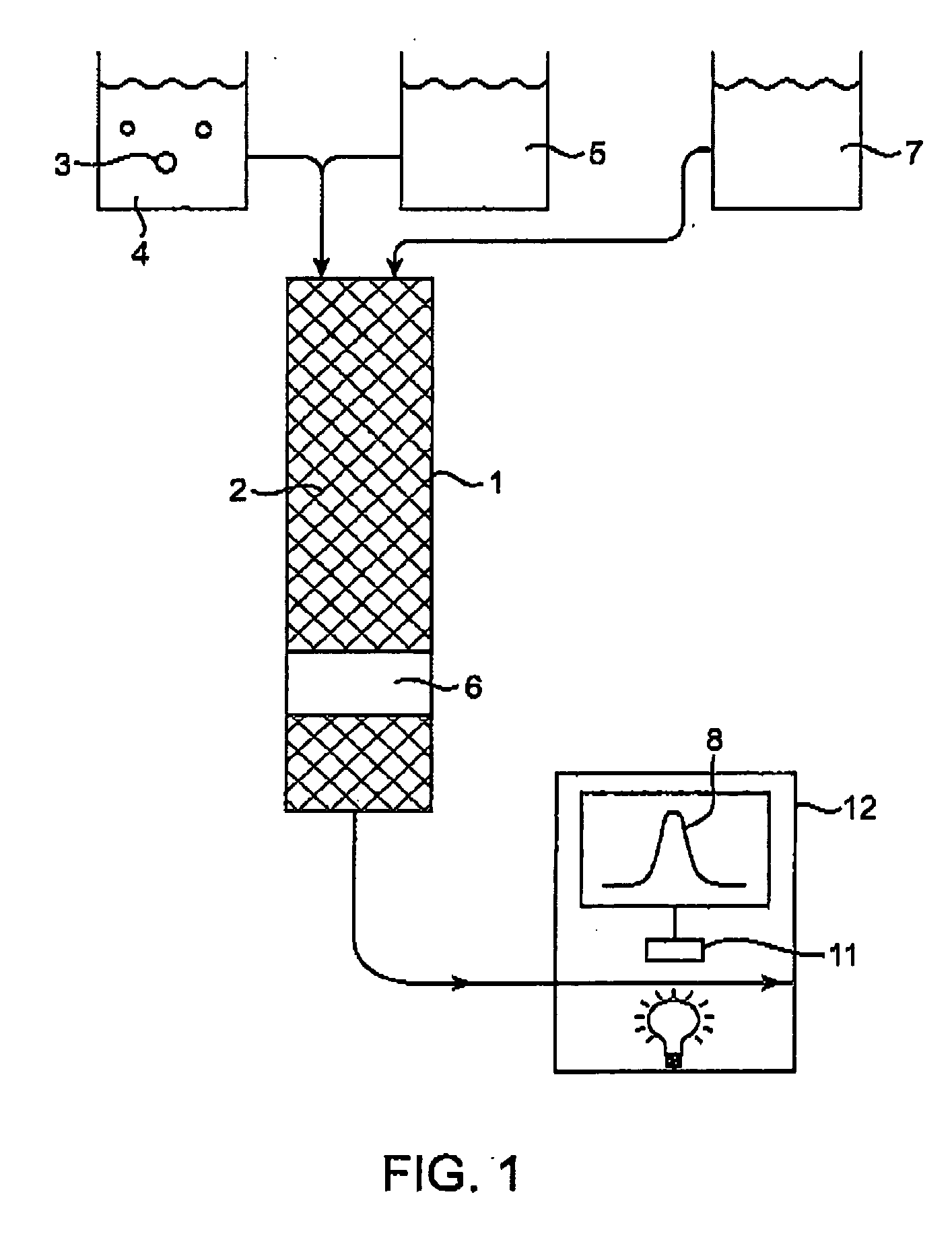

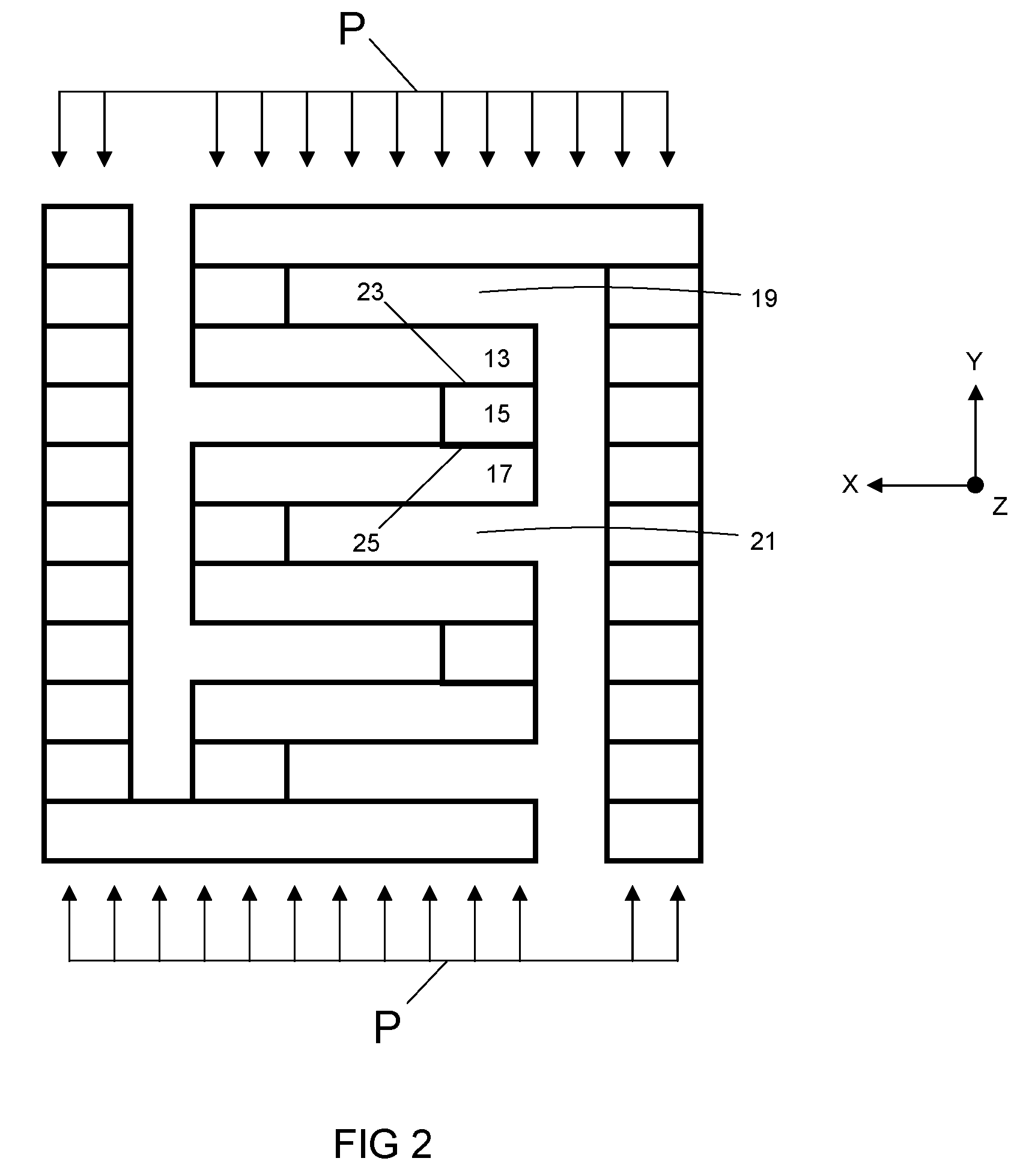

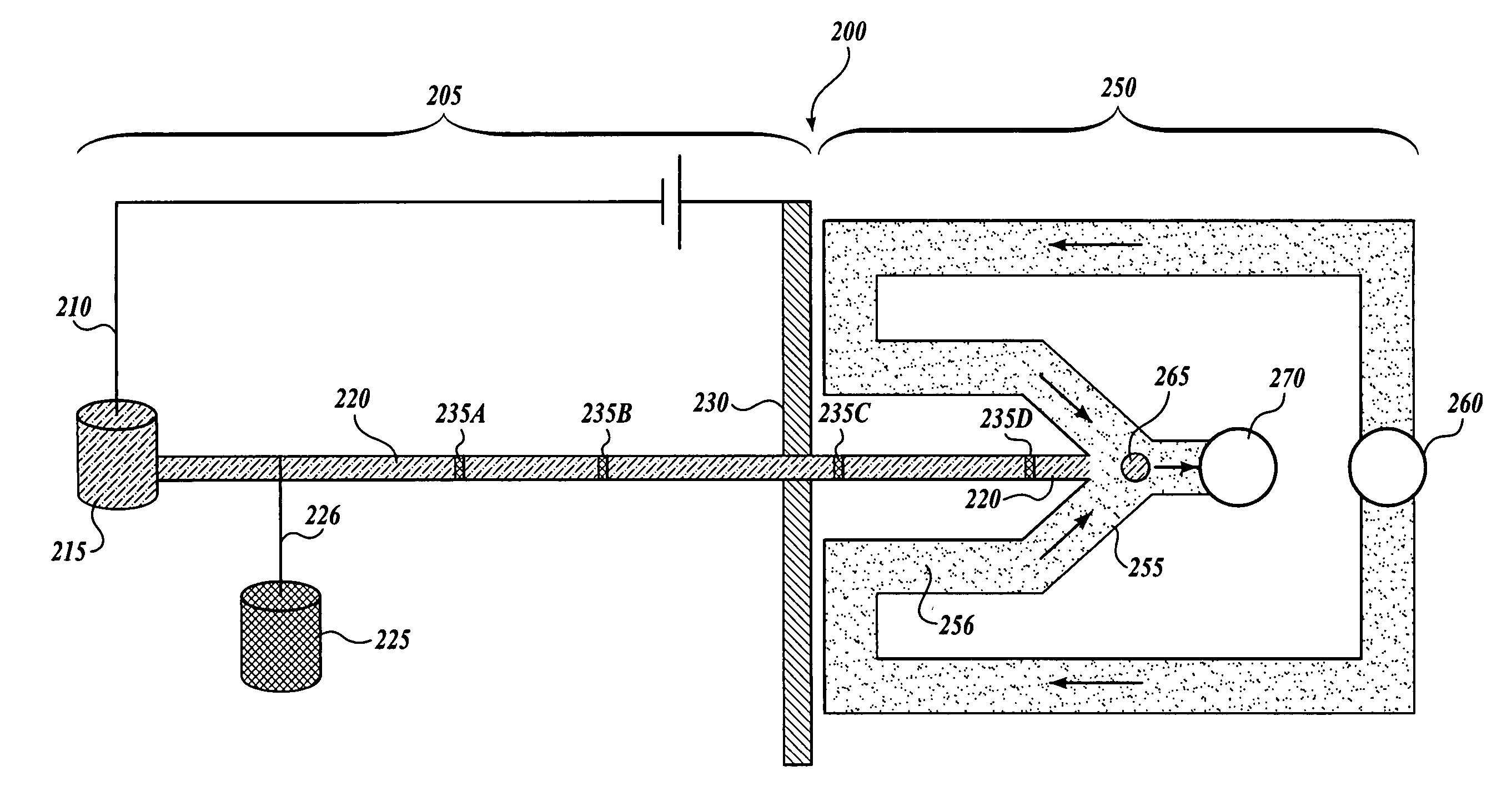

Droplet compartmentalization for chemical separation and on-line sampling

InactiveUS20090217742A1Easy to appreciateElectrolysis componentsParticle separator tubesDiffusionChemical separation

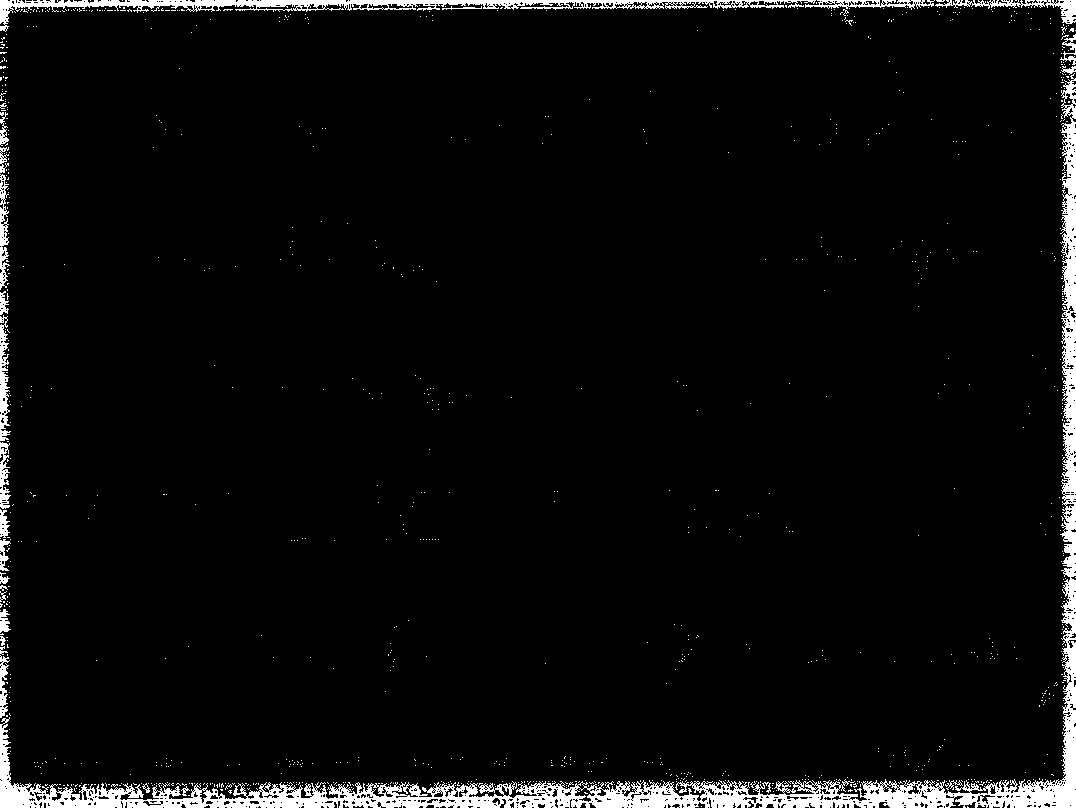

Methods and devices are provided for overcoming detrimental diffusive effects in a sample liquid stream by forming segmented liquid bodies (e.g., droplets) from a sample liquid stream in an immiscible liquid stream. The liquid bodies are formed at the intersection of a channel providing the sample liquid stream and a channel providing the immiscible liquid stream. The formed liquid bodies compartmentalize the portion of the sample liquid stream from which the liquid bodies are formed, thus minimizing the detrimental effects of diffusion that occur in a continuous liquid stream.

Owner:UNIV OF WASHINGTON

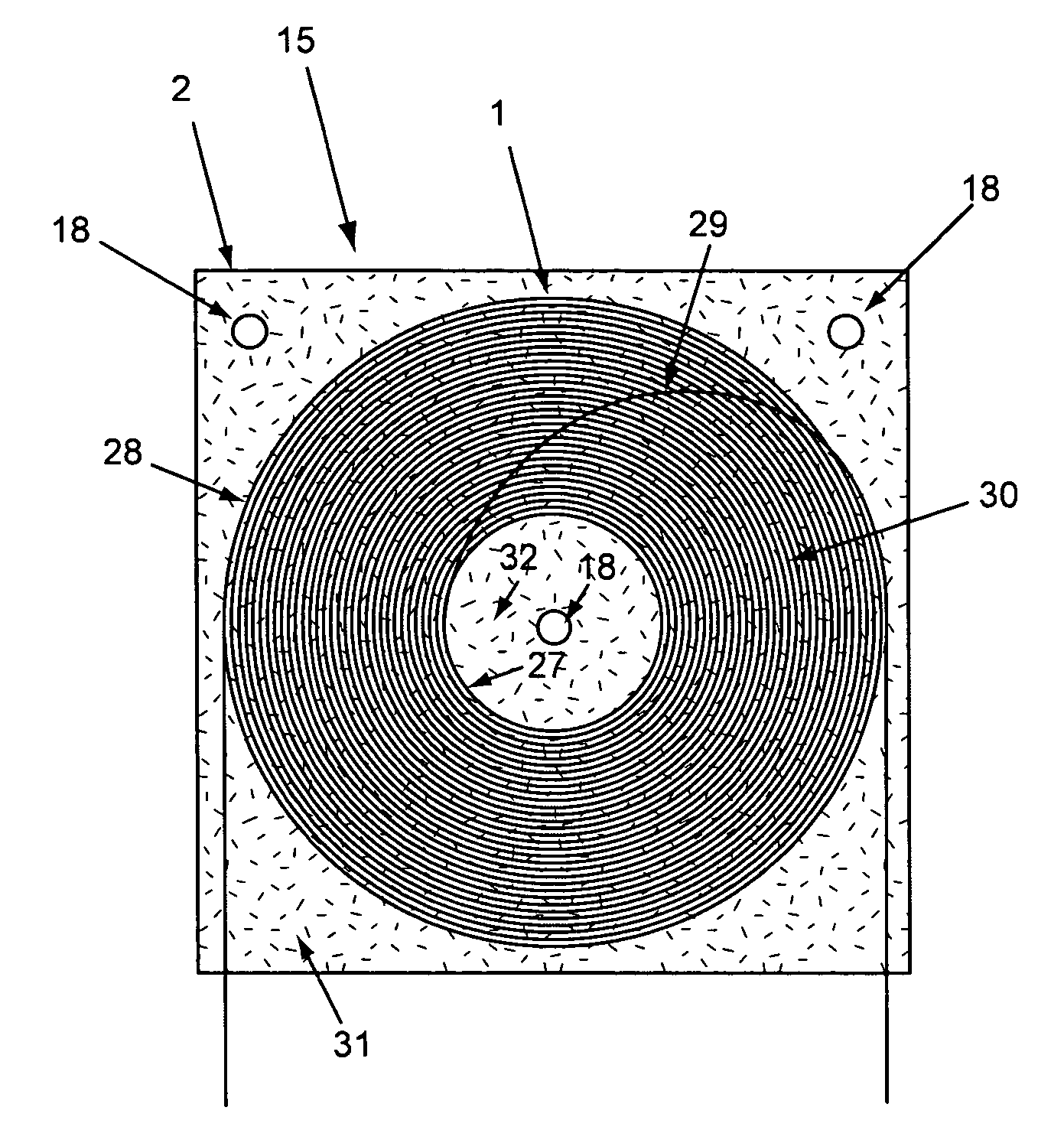

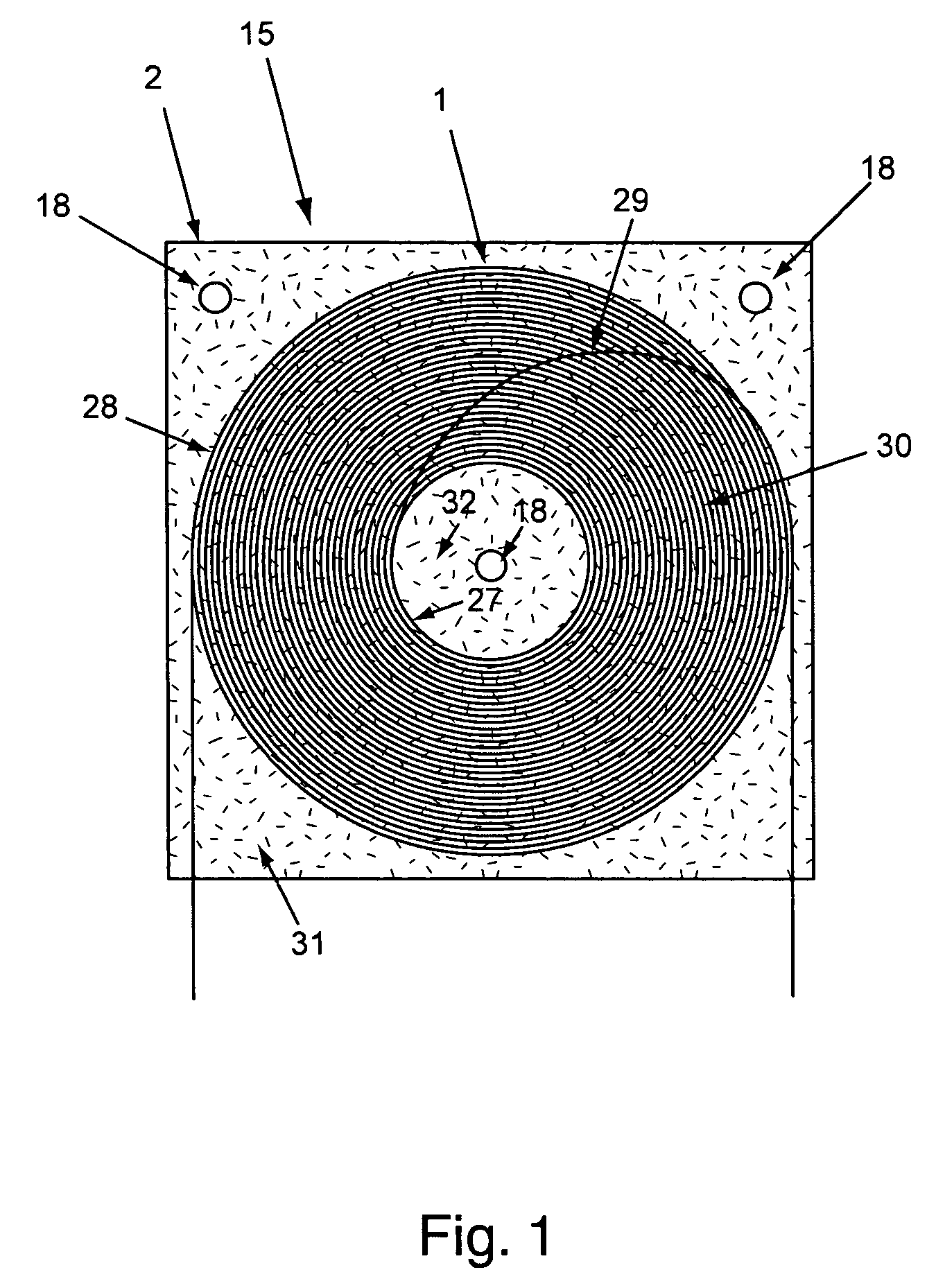

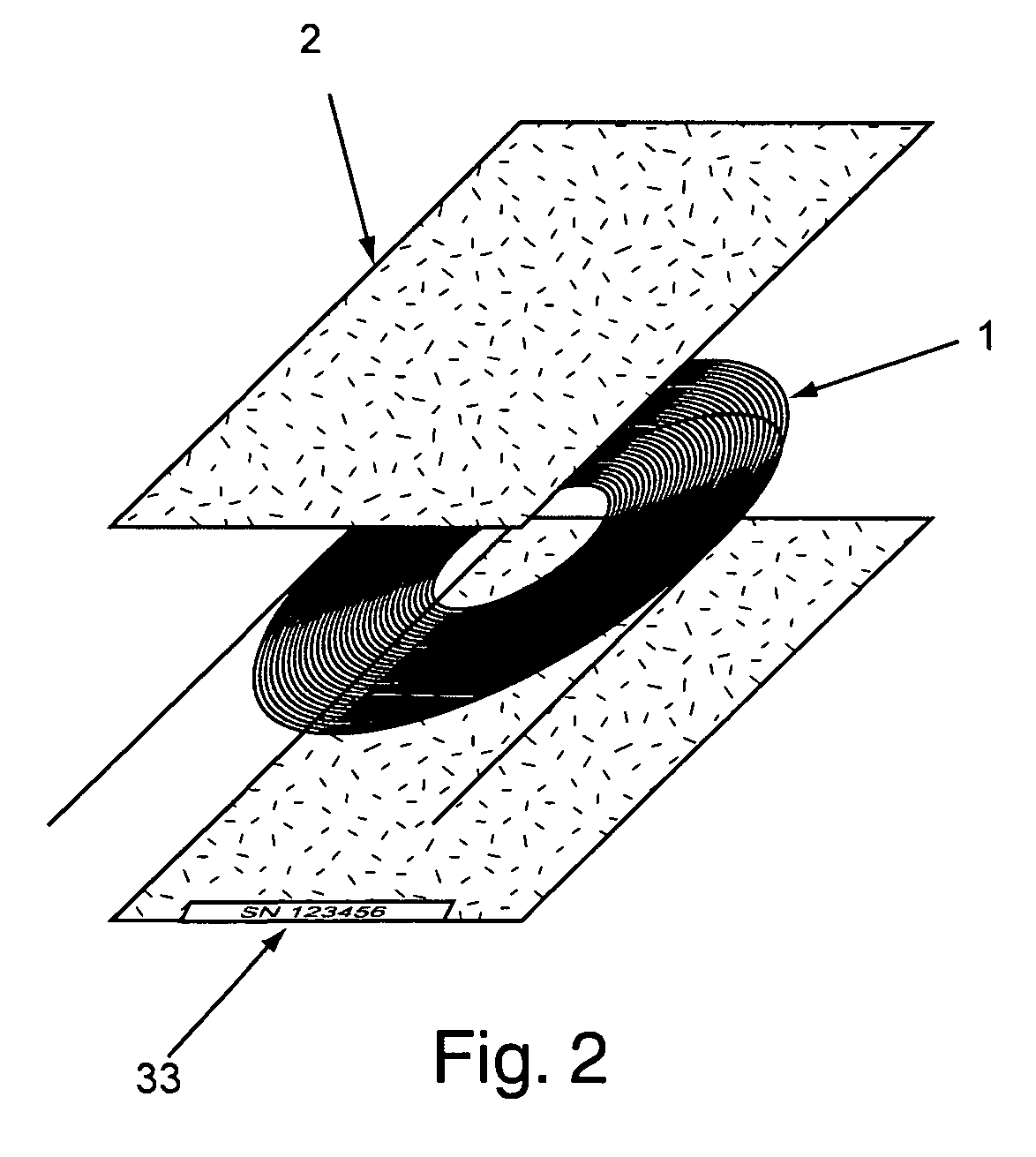

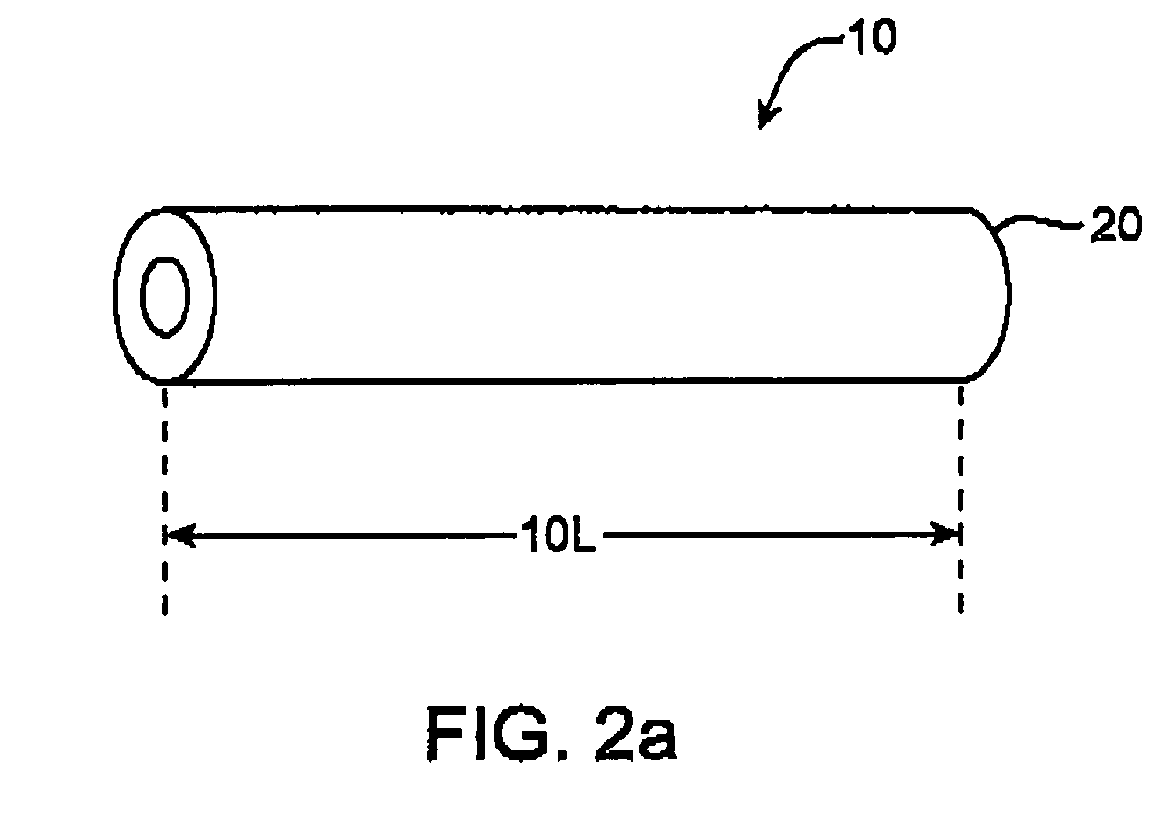

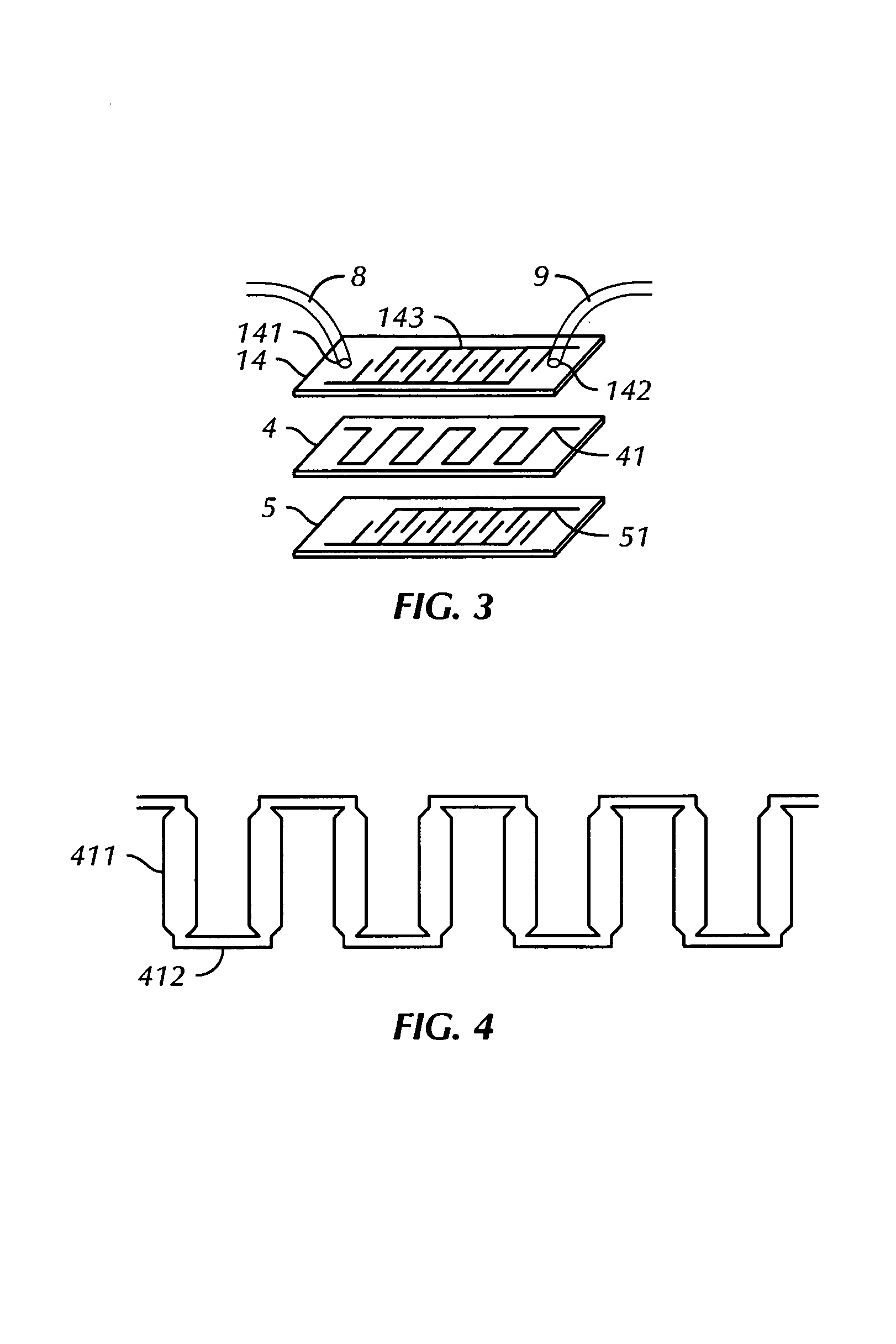

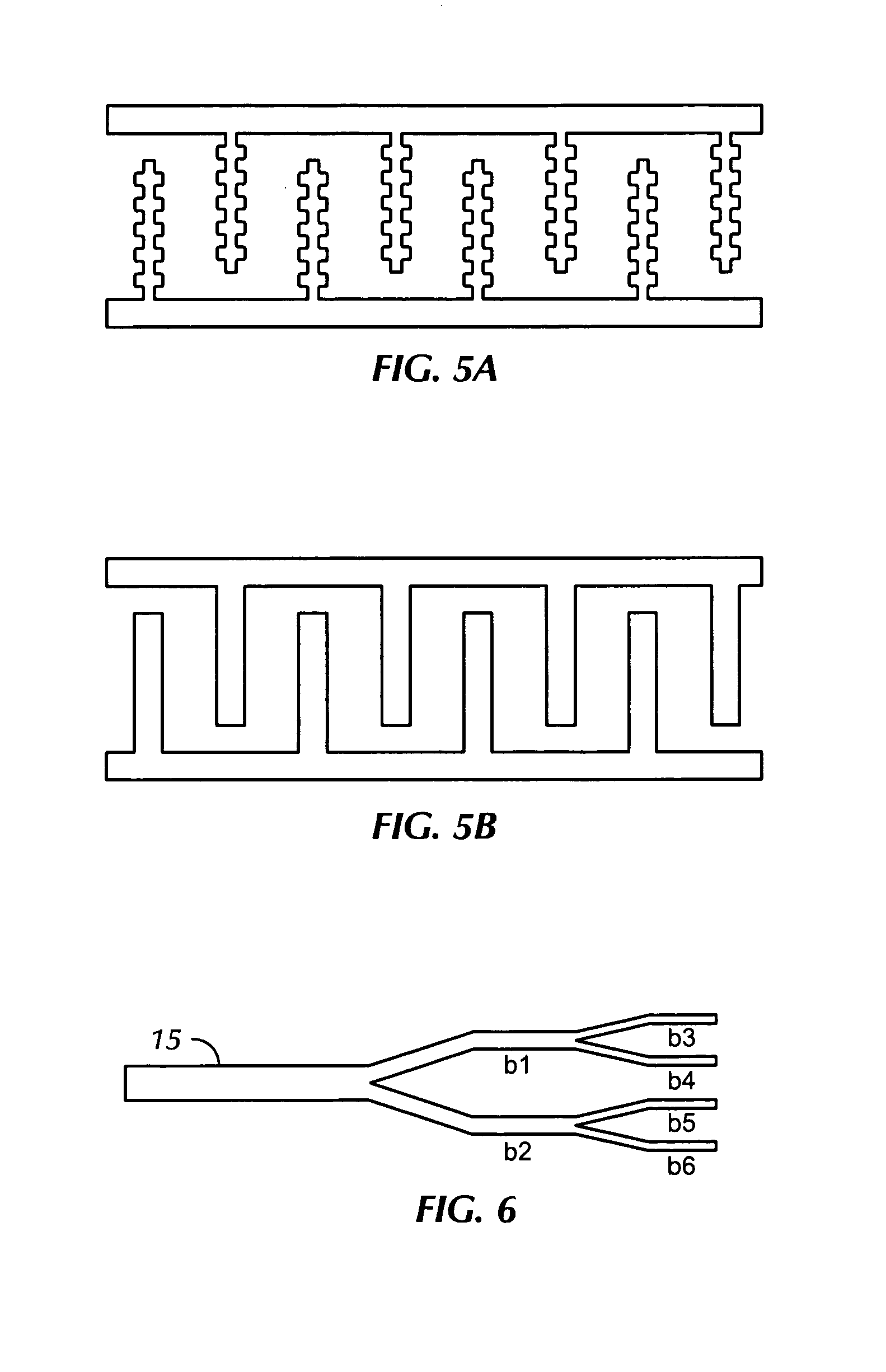

Flat spiral capillary column assembly with thermal modulator

InactiveUS20060283324A1Reduce the temperatureEfficient executionComponent separationDispersed particle separationCapillary gas chromatographyCapillary Tubing

The nature of this invention encompasses the creation of a capillary gas chromatography (GC) column assembly and a thermal modulator used to heat or cool the column assembly in a very thermally and chromatographically efficient manner. The GC column assembly described herein consists of capillary GC column material, such as fused silica or metal capillary tubing, which is constrained to lie in a flat, ordered, spiral pattern and then encased between two thin opposing surfaces. The resulting column assembly is flat, dimensionally stable and can be very efficiently thermally modulated. The resulting column assembly also takes up very little space, has very little thermal mass, and can be easily and accurately manufactured. The column assembly can be adapted for chromatographic use by affixing it to the surface of a thermal modulator described herein by means of adhesive force or by mechanical compression, and then by attaching the free ends of the exposed column material to the input and output ports of the chromatographic device. The temperature of the thermal modulator and capillary column assembly is to be controlled by the chromatographic device or by standalone temperature controlling electronics. The thermal modulator described herein contains an element for temperature modulation of the capillary column assembly to which it is attached and a temperature sensing element for providing accurate temperature feedback to the controlling electronics. The overall result of this when coupled to a chromatographic device is maximally efficient chemical separations in a small space with minimal power consumption.

Owner:ROQUES NED J

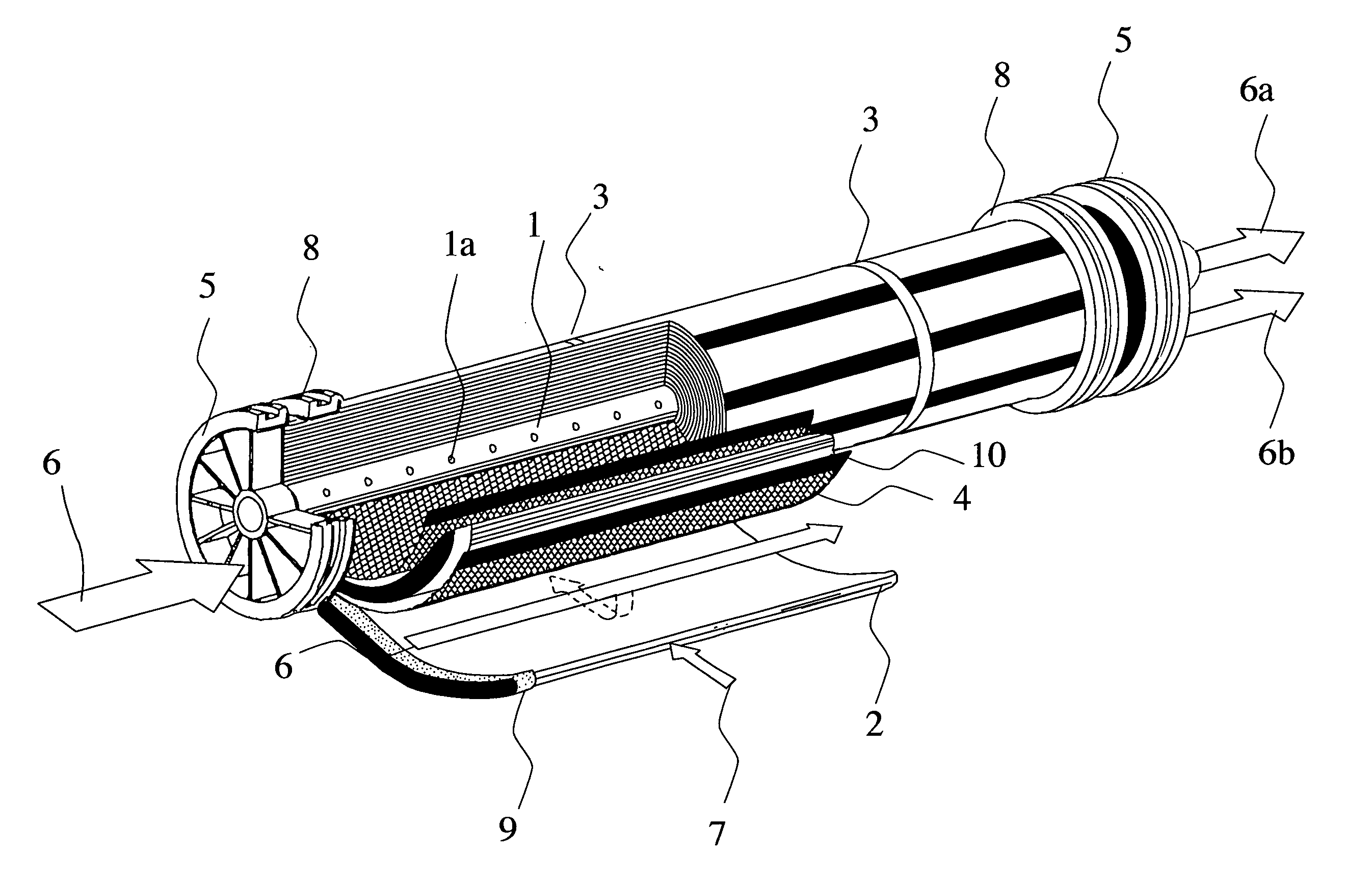

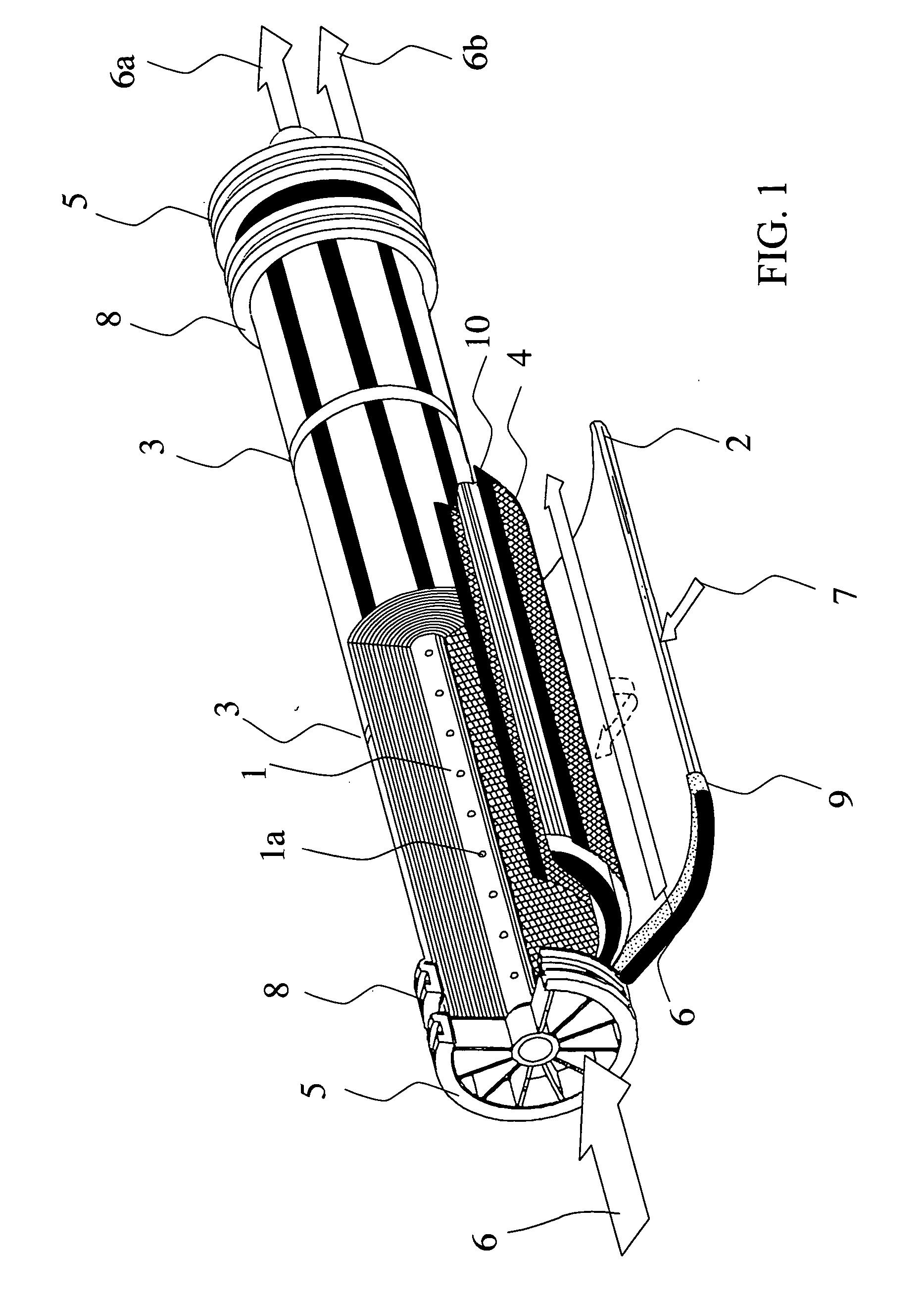

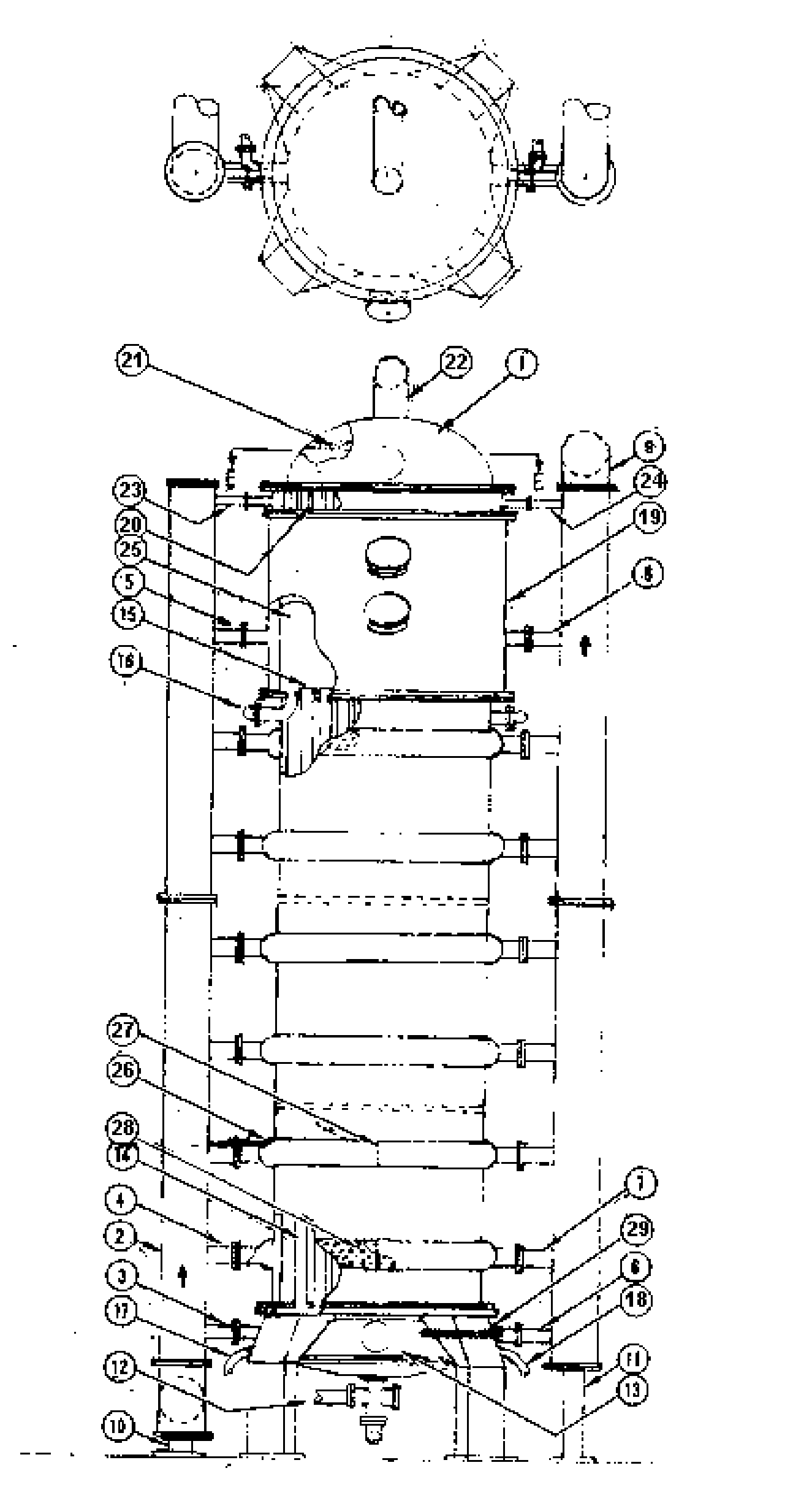

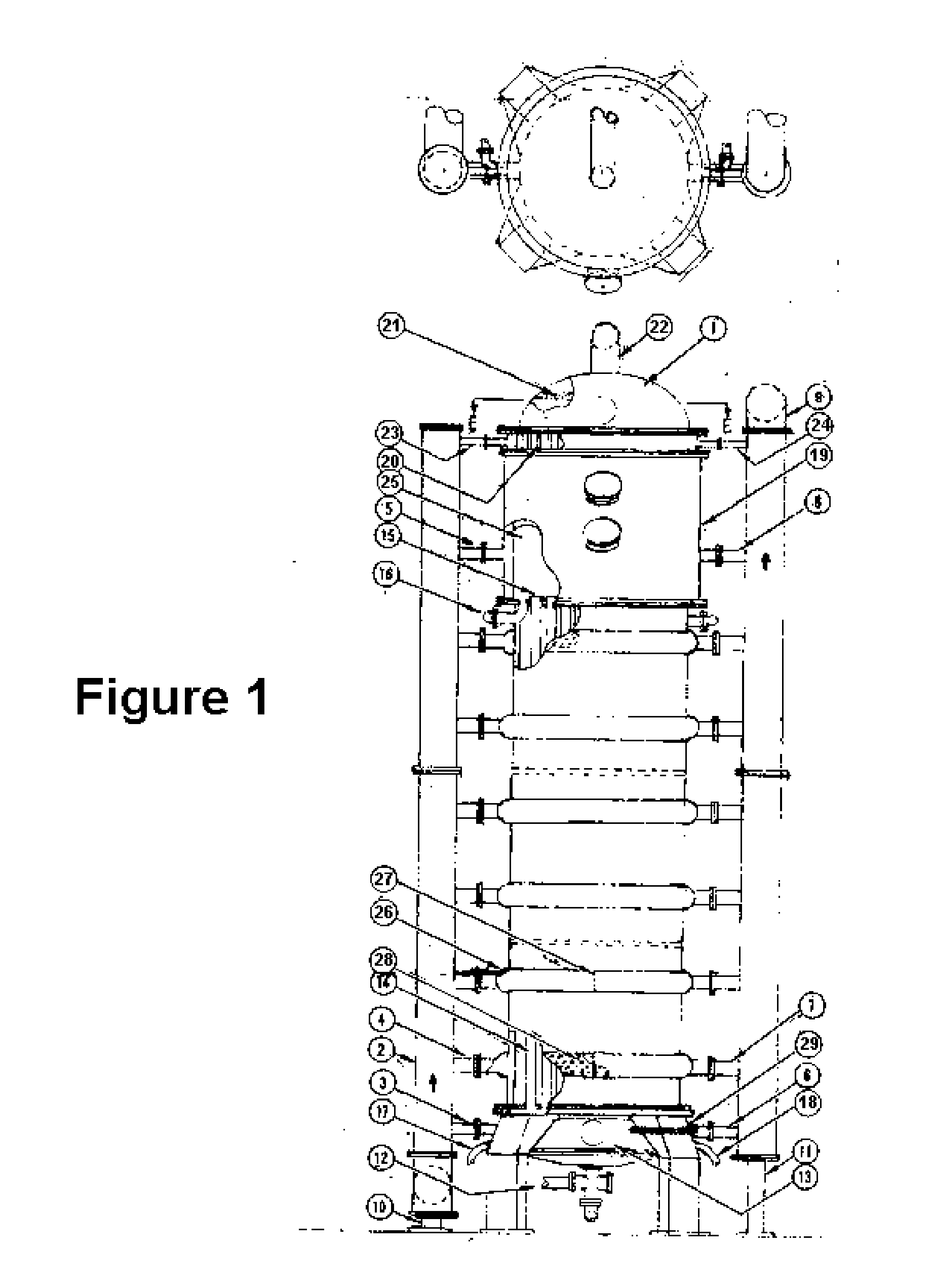

Spiral-wound liquid membrane module for separation of fluids and gases

InactiveUS20060131235A1Lower energy requirementsEfficient separationMembranesSolid sorbent liquid separationChemical physicsSpiral wound

The present invention is a filtering and chemical separation device that performs the operations of solvent extraction and pervaporation in a single piece of equipment, configured as a spiral-wound membrane module, and provides for the replenishment of the solvent in the supported liquid membrane while the module continues in operation. It provides a solution to the problem of separating miscible compounds efficiently and with low energy requirements.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

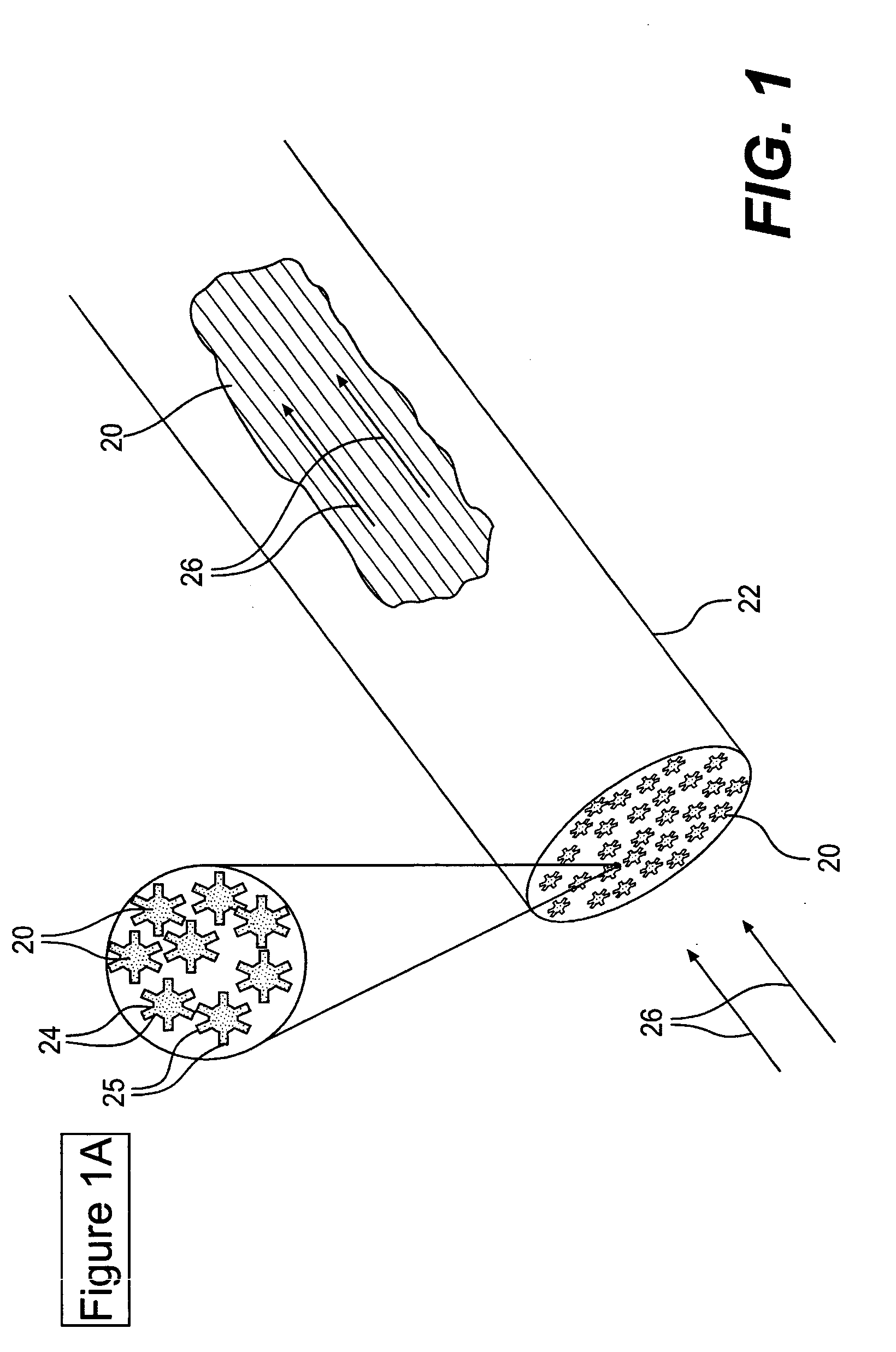

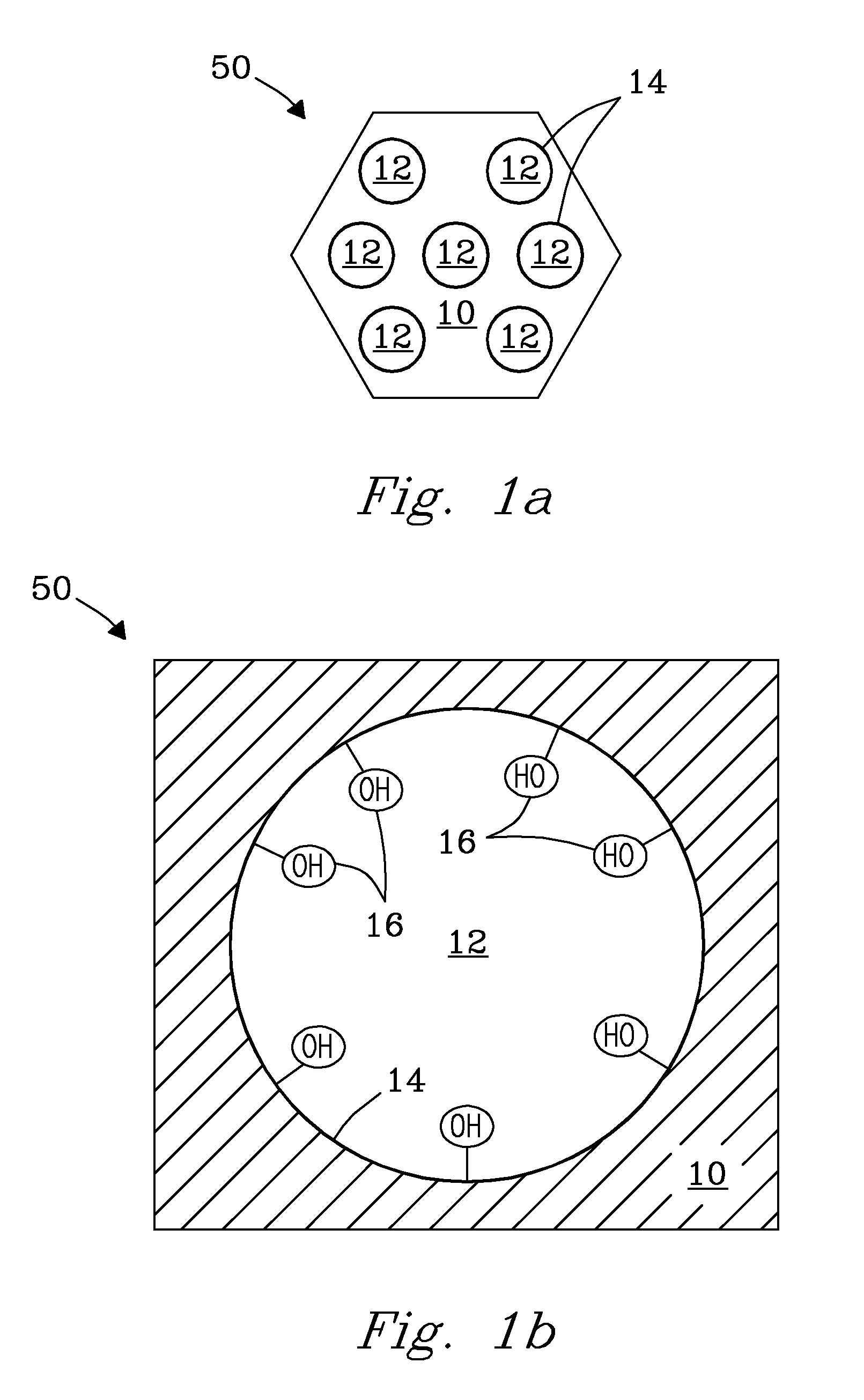

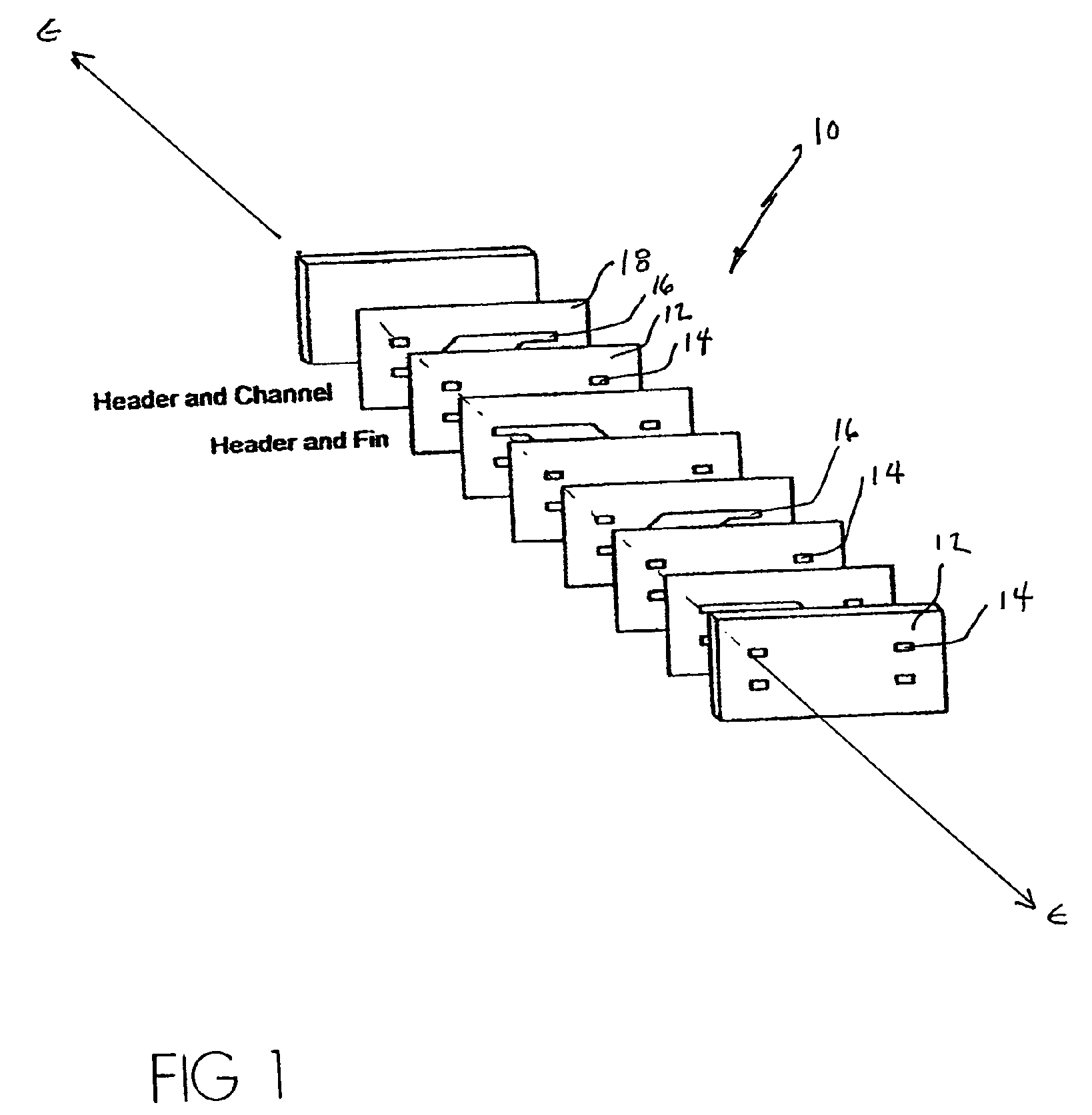

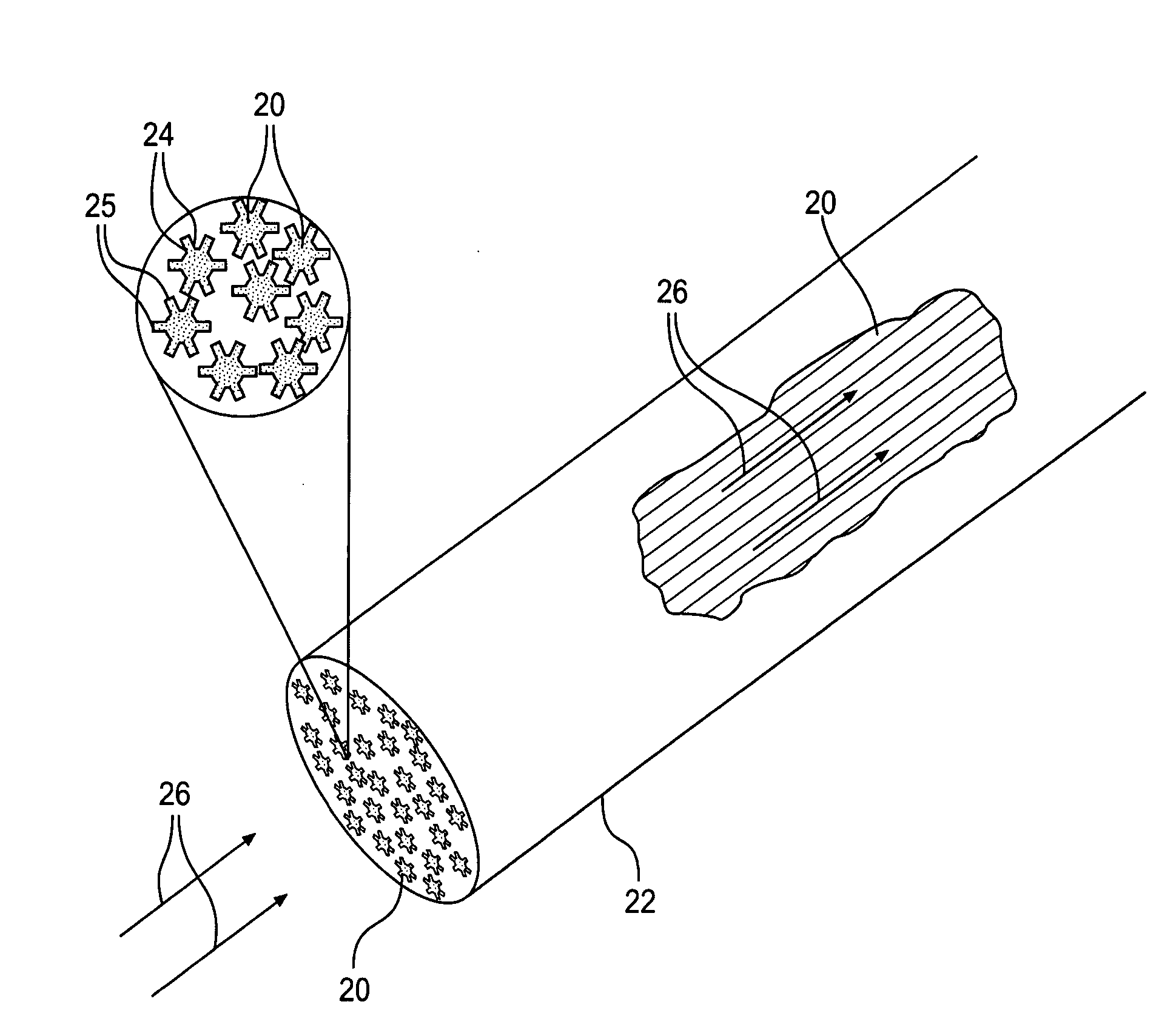

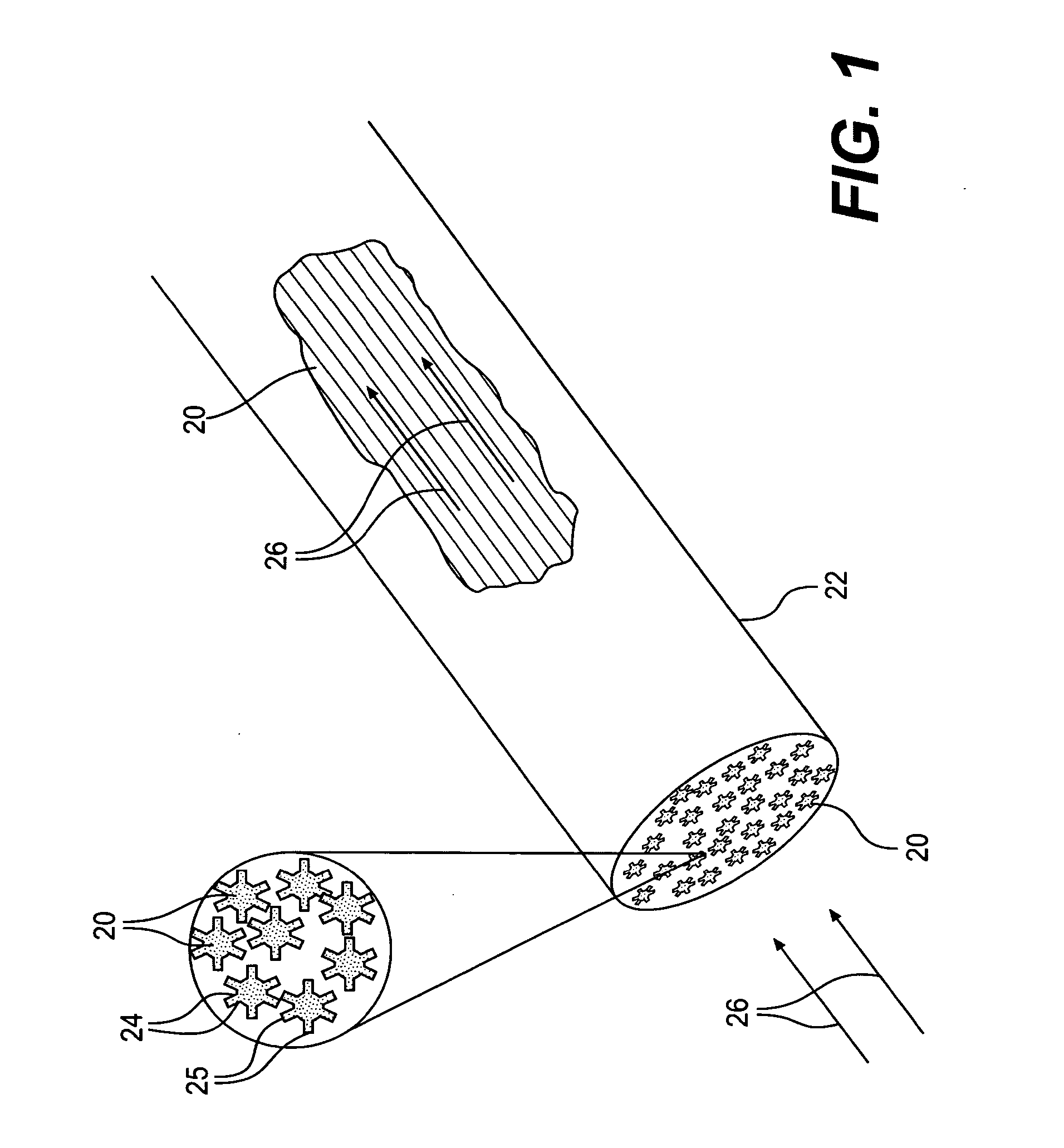

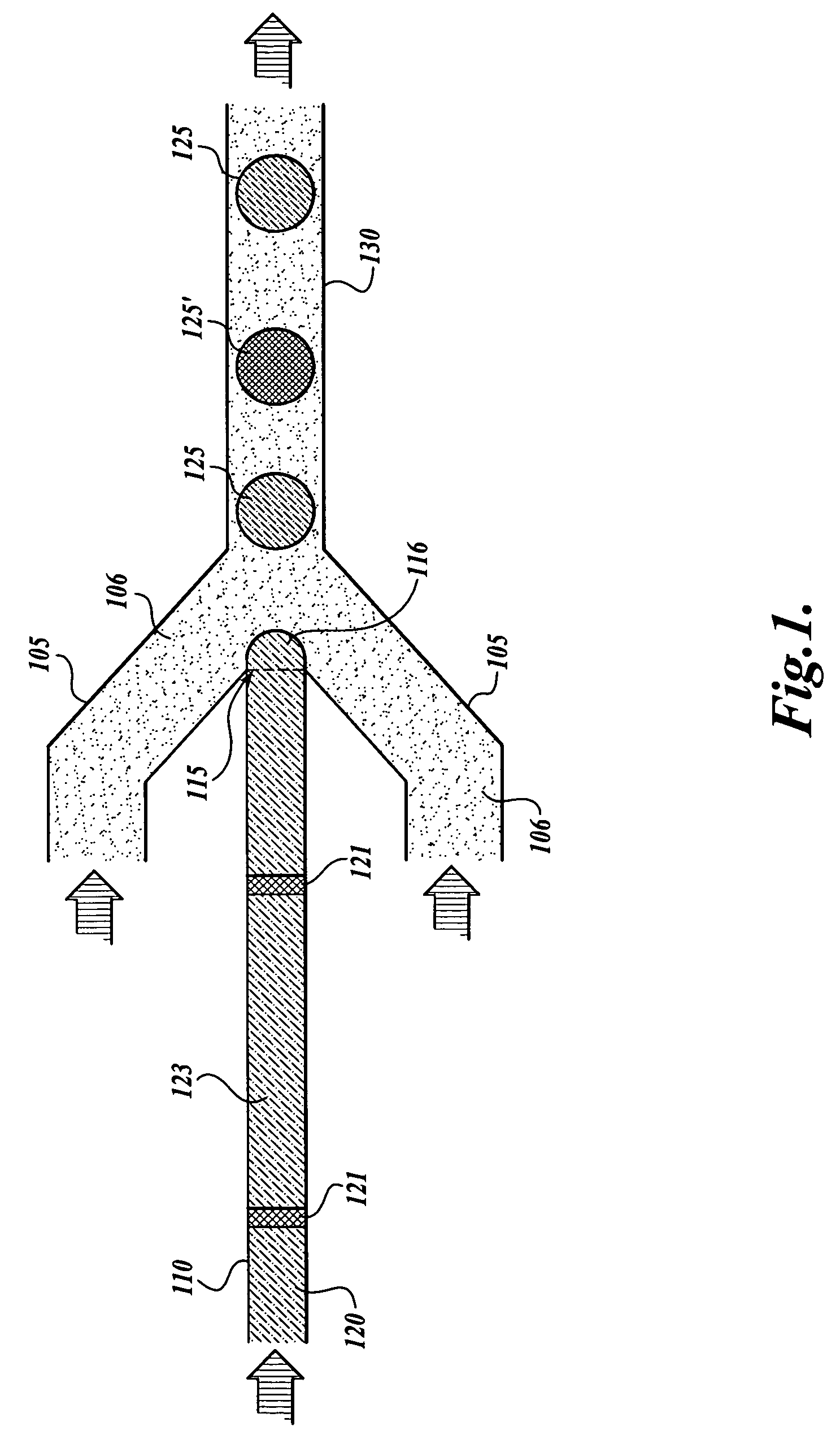

Monolithic structures comprising polymeric fibers for chemical separation by liquid chromatography

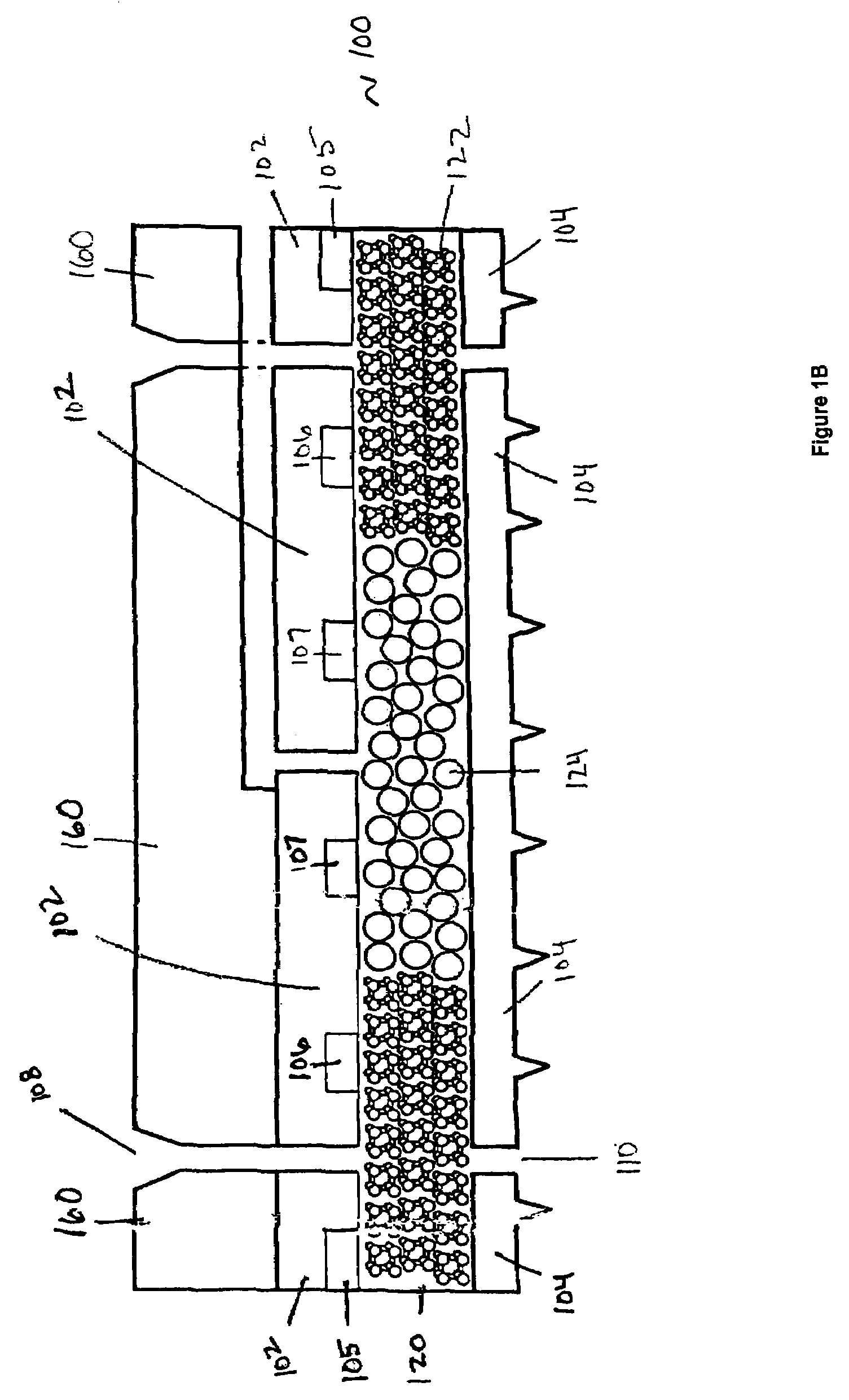

Monolithic cartridges including a plurality of nominally aligned polymer fibers can be used as stationary phase materials for liquid chromatography separations. Bundles of fibers are packed together so as to form capillary channels between the fibers. Different polymer compositions permit the “chemical tuning” of the separation process. The fibers can be physically or chemically bonded at spaced locations throughout the cartridge or can be packed together under pressure by use of an encasing wrap to form the capillary channels. Use of fibers allows a wide range of liquid flow rates with very low backpressures. Applications in HPLC, cap-LC, prep-scale separations, analytical separations, waste remediation / immobilization, extraction of selected organic molecules / ions from solution, purification of liquid streams (process waste, drinking water, pure solvents), selective extraction of cell matter and bacteria from growth media, and immobilization of cell matter and bacteria are envisioned.

Owner:CLEMSON UNIVERSITY

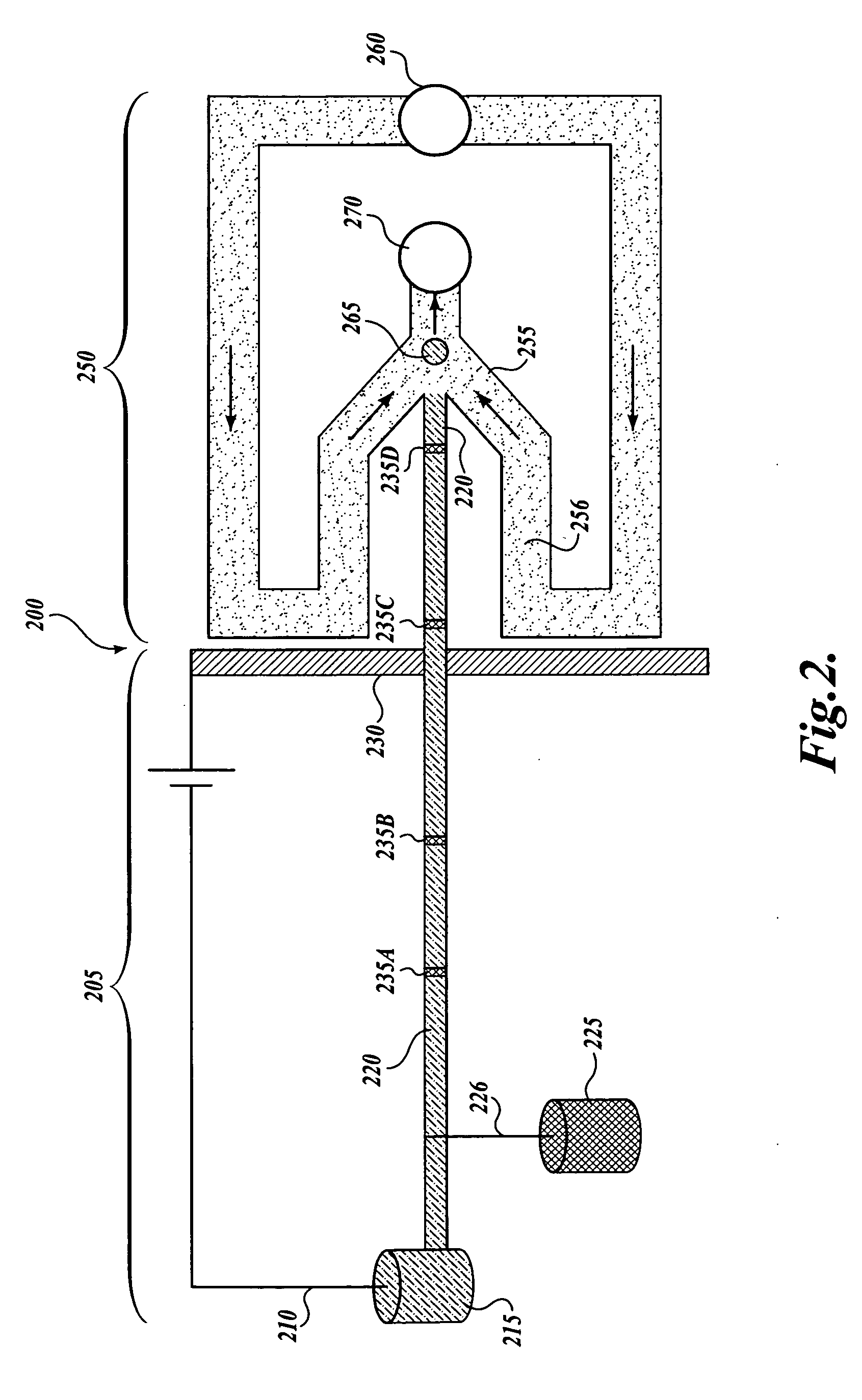

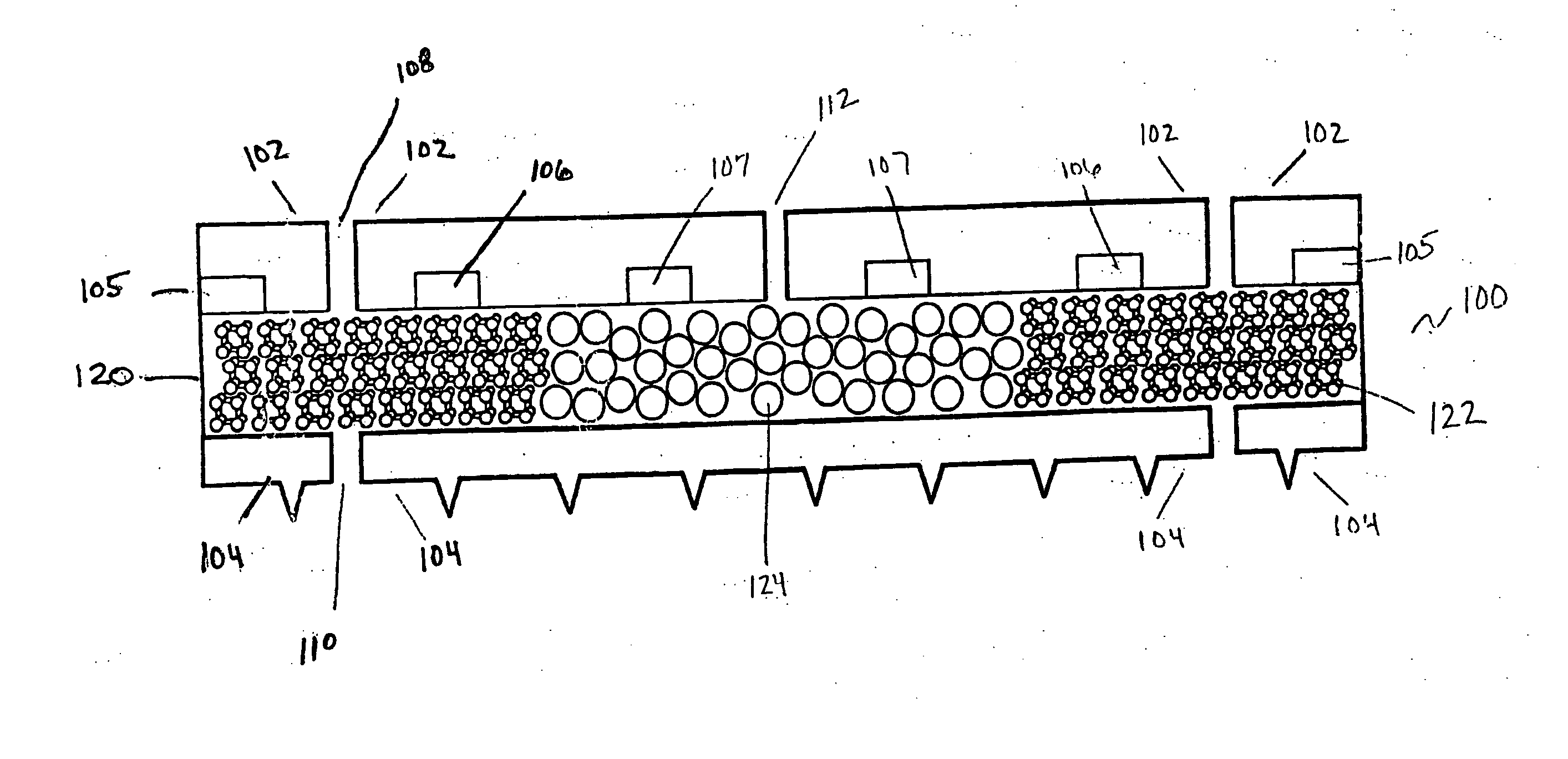

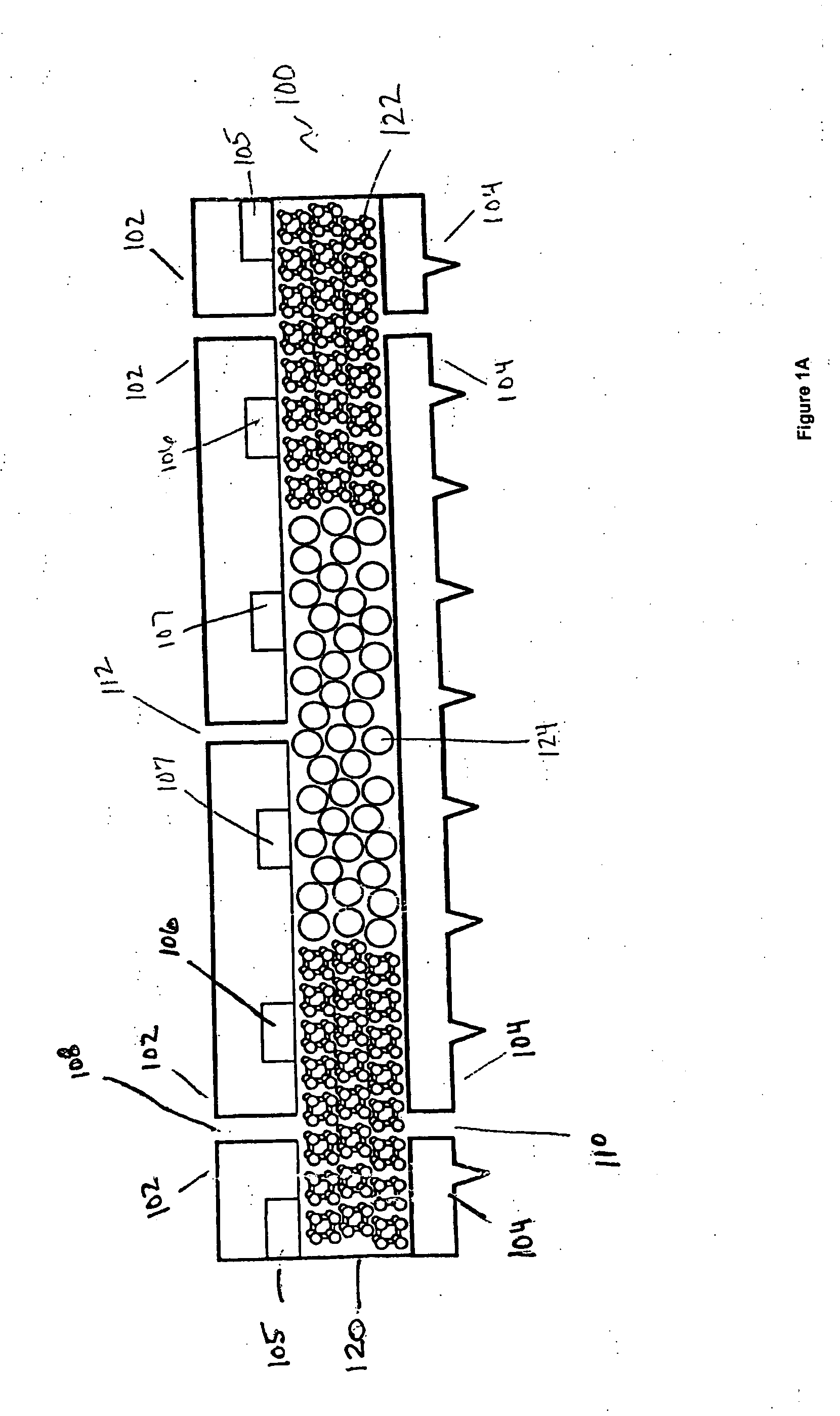

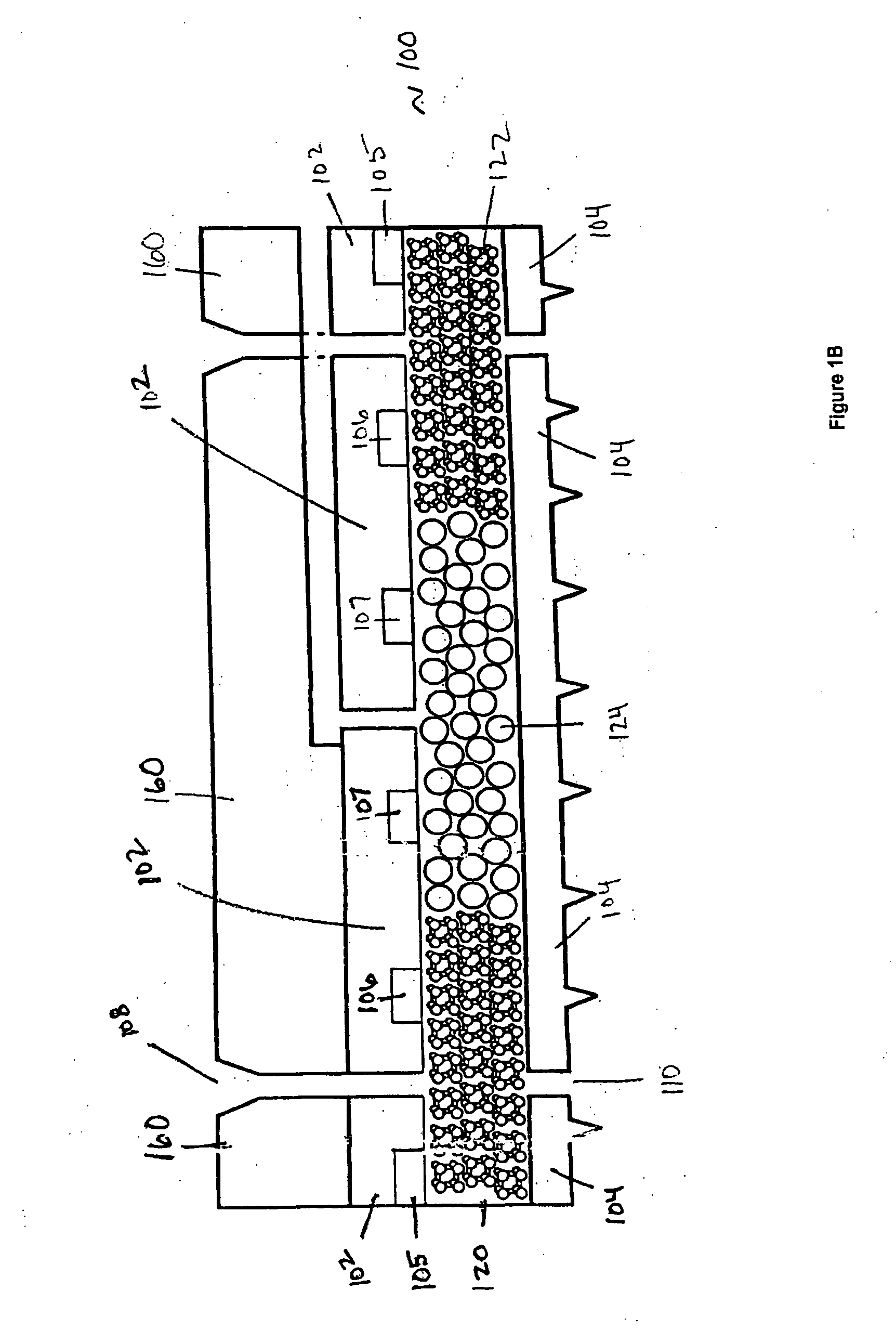

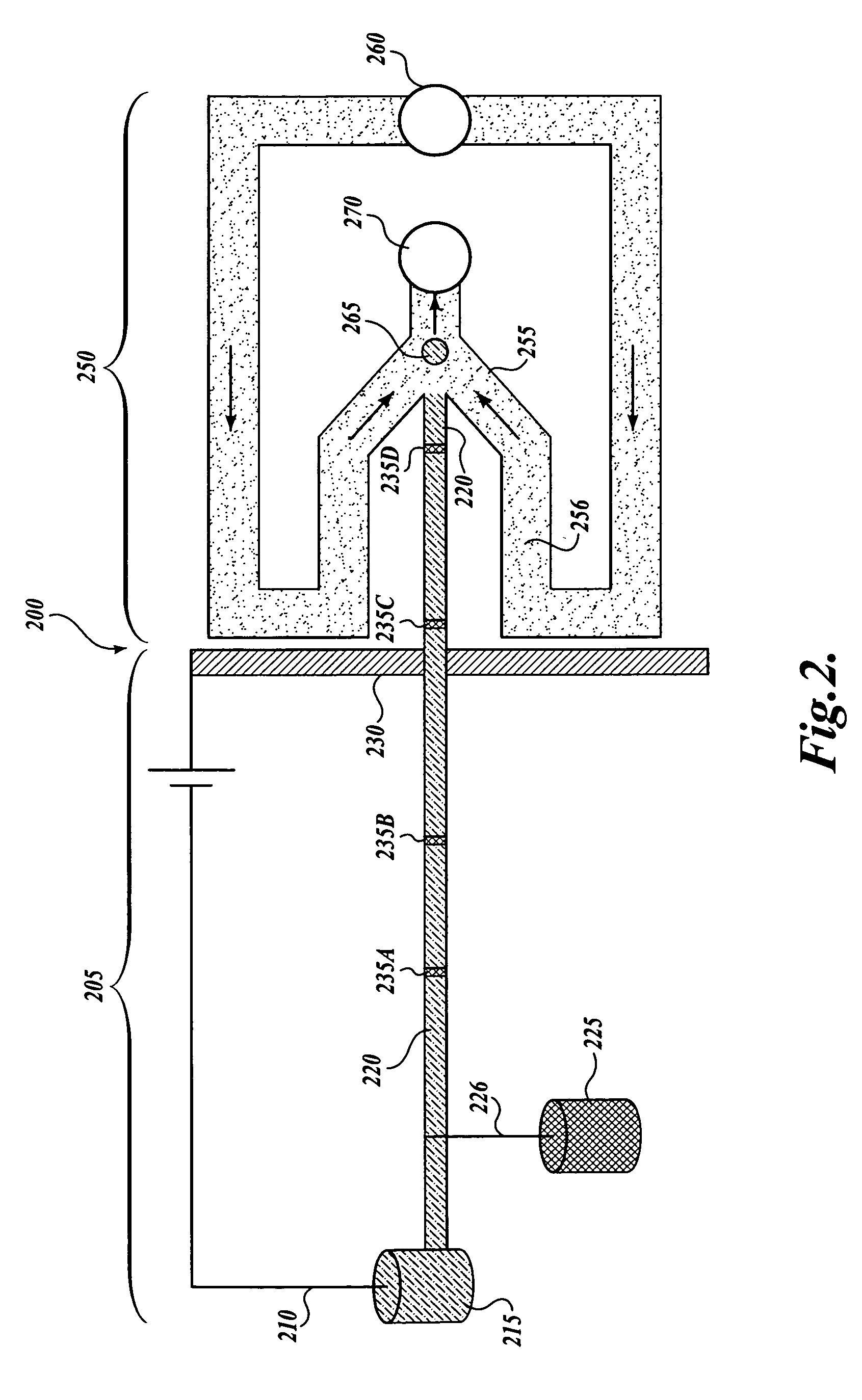

Meso-frequency traveling wave electro-kinetic continuous adsorption system

InactiveUS20050121393A1Minimal desorption energyImprove scalabilityIon-exchanger regenerationVolume/mass flow measurementIntermediate frequencyChemical separation

The invention provides a non-cyclic, meso-frequency traveling wave electro-kinetic system capable of use in purification / separation and / or refrigeration / heat pump processes. In particular, the invention provides an adsorption system that can be used for fine or bulk chemical separations of liquid and gaseous materials. Similarly, the adsorption system can be readily adapted to function as a refrigeration / heat pump unit for use in heating and cooling systems. This reusable adsorption system provides high efficiency purification and / or cooling / heating with low energy demands and no moving parts. The invention can function in parallel or in series with other similar such adsorption units (though it can also operate as a single unit).

Owner:SEPARATION DESIGN GROUP

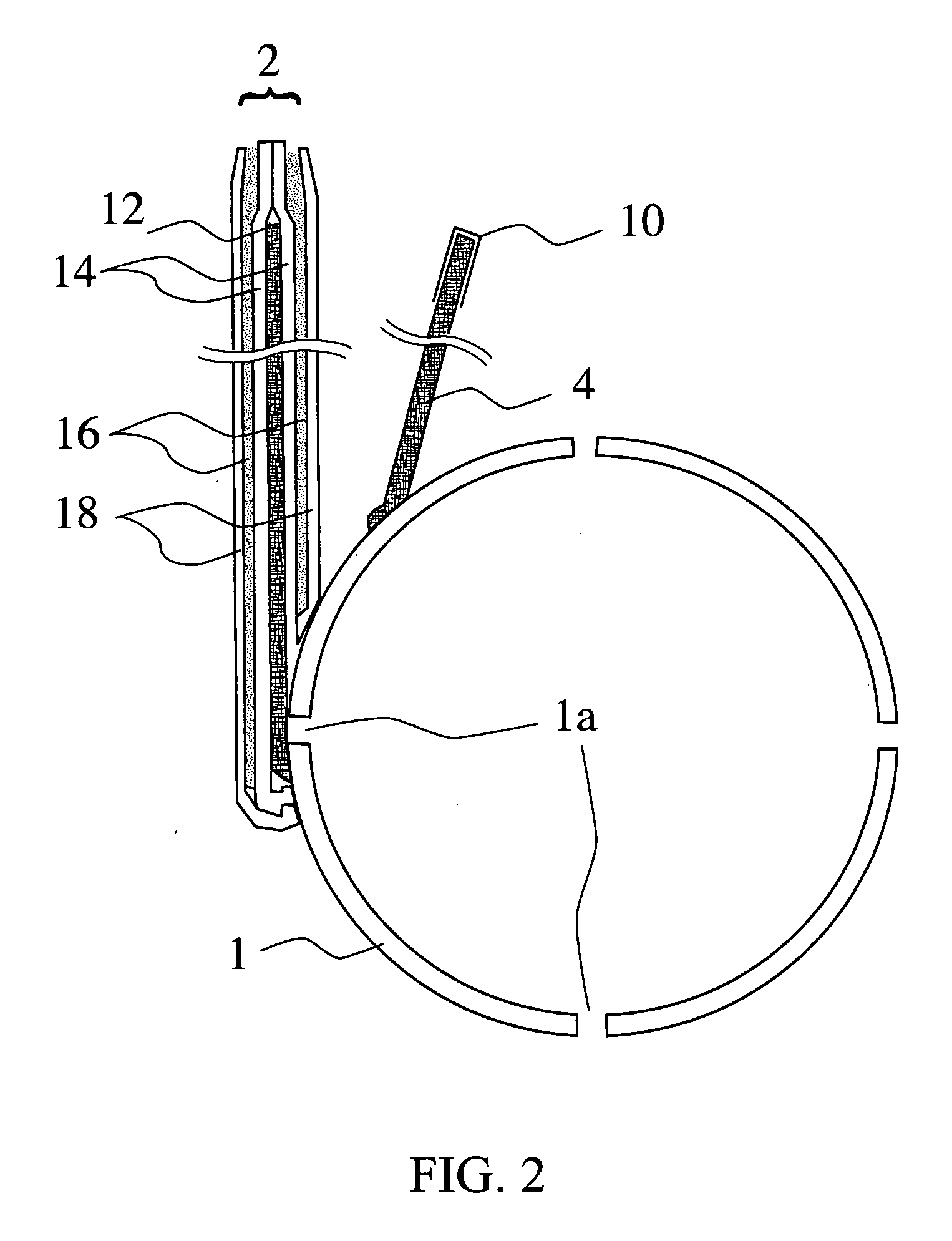

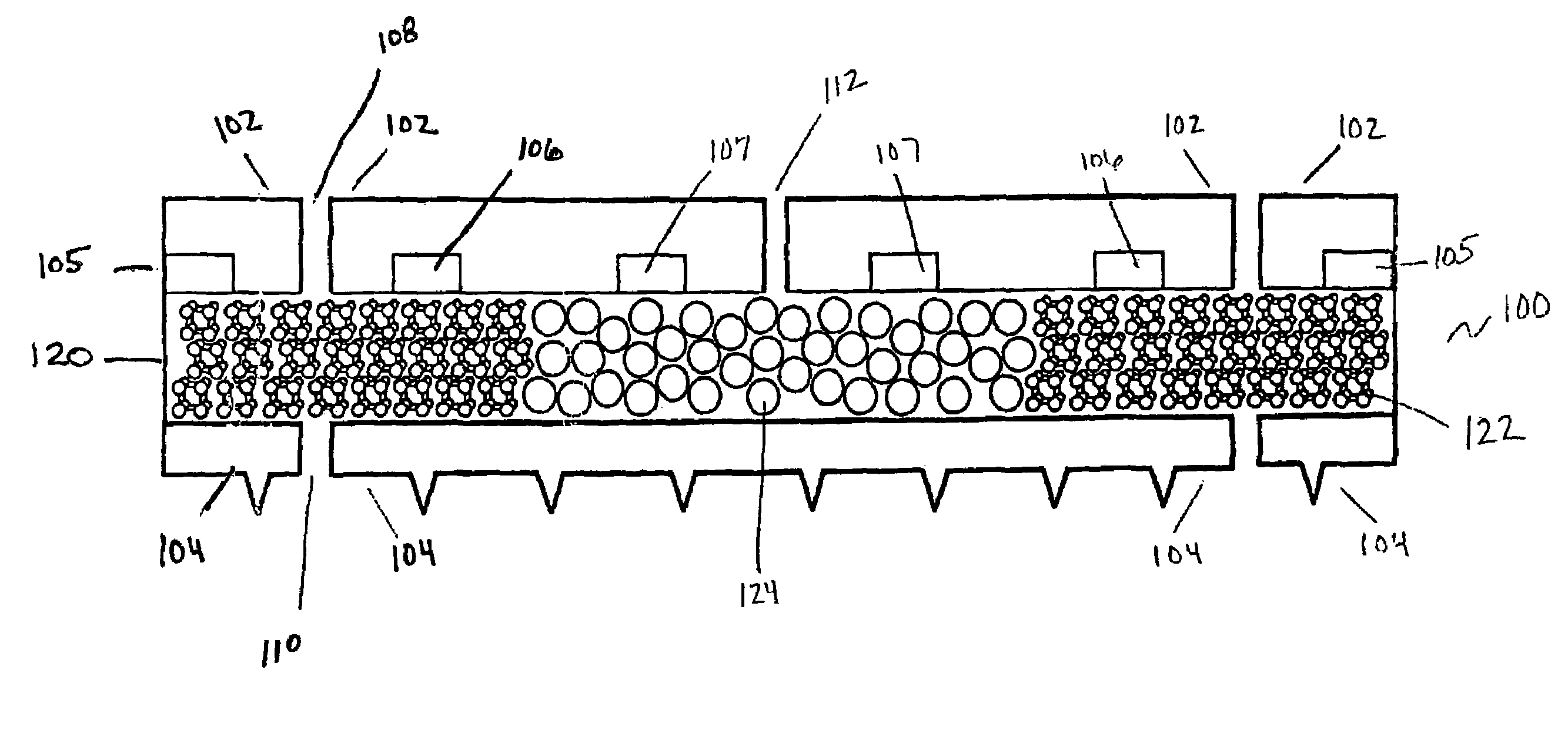

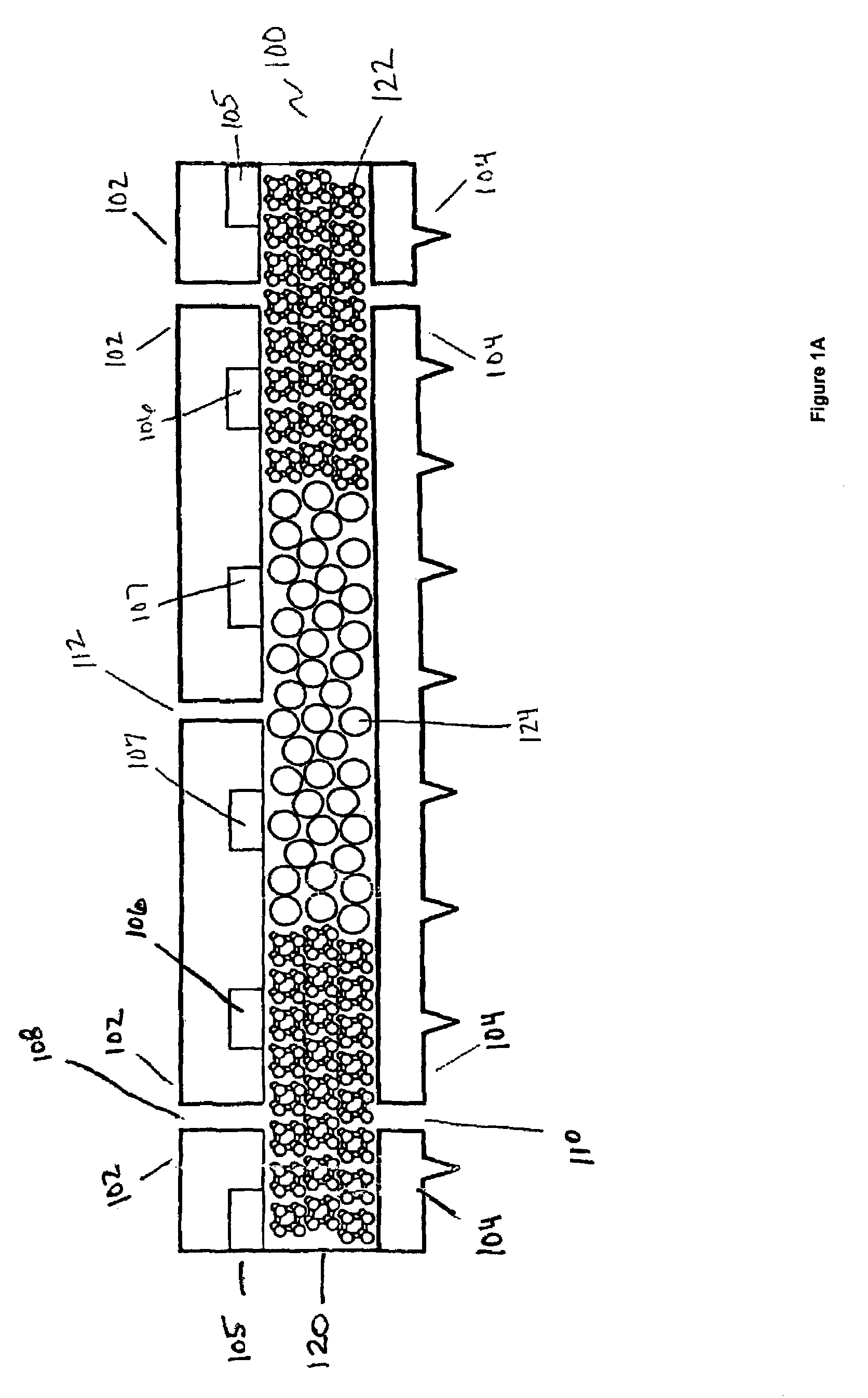

Devices and methods for microfluidic chromatography

InactiveUS20070138076A1Easy to separateSmall dead volumeIon-exchange process apparatusComponent separationSmall sampleCoupling

Embodiments of the invention provide devices, methods and systems for performing microfluidic chromatography. Particular embodiments provide microfluidic chromatography column devices which can perform chemical separation using small sample volumes and low pressure differentials across the column. One embodiment provides a microfluidic chromatography column device comprising a first, second and third capillary tube. A chromatographic packing is disposed in the second tube with a first and second support layer disposed on opposite ends of the second tube. The support layers are disposed in a substantially flat orientation within the tube. An external coupling joins the tubes such that the tubes are fluidically sealed. The device is configured to have a fluidic resistance such that a pressure differential across the column of less than about 10 psi produces a flow rate through the device of at least about 0.5 ml / min for a liquid solution.

Owner:FLUIDIGM CORP

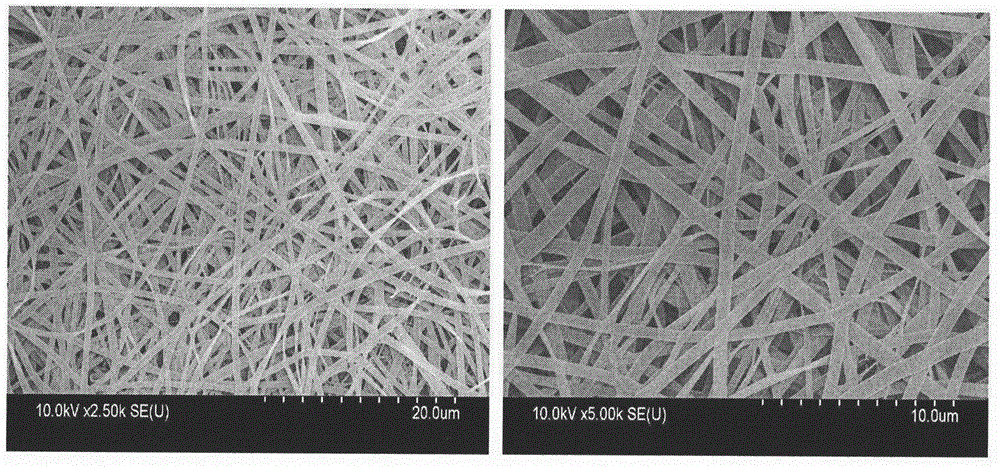

Multiple response type filtration-controllable electrospun nanofiber membrane and preparation method thereof

ActiveCN106319759AAchieving Smart SeparabilityFlux controlNon-woven fabricsElectrospun nanofiberFiber

The invention relates to a multiple response type filtration-controllable electrospun nanofiber membrane and a preparation method thereof. Nanofibers are composed of electrostatic spinning thermosensitive and pH responsive polymers and solvents, and the multiple response type filtration-controllable electrospun nanofiber membrane is formed by putting a prepared mixed solution in an injector and then spinning of an electrostatic spinning apparatus. The multiple response type filtration-controllable electrospun nanofiber membrane and the preparation method thereof have the advantages that since smart response of the thermosensitive and pH responsive polymers in the spinning solution is combined with the advantages of large specific area, high porosity and loose and porous performance of the nanofibers, controllable filtration of air is achieved; the preparation method is simple and easy to implement, low in production cost, high in interception efficiency, low in resistance, rapid in filtration reaction, high in treatment efficiency, reusable and capable of achieving smart separability of the nanofiber membrane and can be applied to the fields such as filtration and adsorption, drug delivery, chemical separation, sensing drive and tissue engineering.

Owner:TIANJIN POLYTECHNIC UNIV

Chemical separating method for aluminum foil in waste lithium ion battery positive plate

ActiveCN102412430AImprove solubilityLoose surface compositionSolid waste disposalWaste accumulators reclaimingActive agentEngineering

The invention discloses a chemical separating method for an aluminum foil in a waste lithium ion battery positive plate. The method comprises the following steps of: (1) adding the waste lithium ion battery positive plate into a surfactant solution, performing ultrasonic oscillation treatment to loosen surface components of the positive plate, washing, drying, filtering and recovering the positive plate; (2) putting the positive plate treated in the step (1) into a mixed solution of N, N-dimethylacetamide and N-methylpyrrolidone, heating, taking the positive plate out, and washing with water; (3) putting positive plate treated in the step (2) into water, performing ultrasonic oscillation till the aluminum foil as well as active substances of an anode, a conducting agent and a bonding agent; and (4) filtering a solution obtained in step (3), washing to obtain a mixture containing the active substances, the conducting agent, the bonding agent and the aluminum foil, and screening to obtain a dissociative aluminum foil sheet. In the method, the aluminum foil sheet can be recovered directly; and compared with the conventional method for extracting an aluminum foil after dissolving with alkali, the chemical separating method has the advantages: the process is simplified, and cost is lowered.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

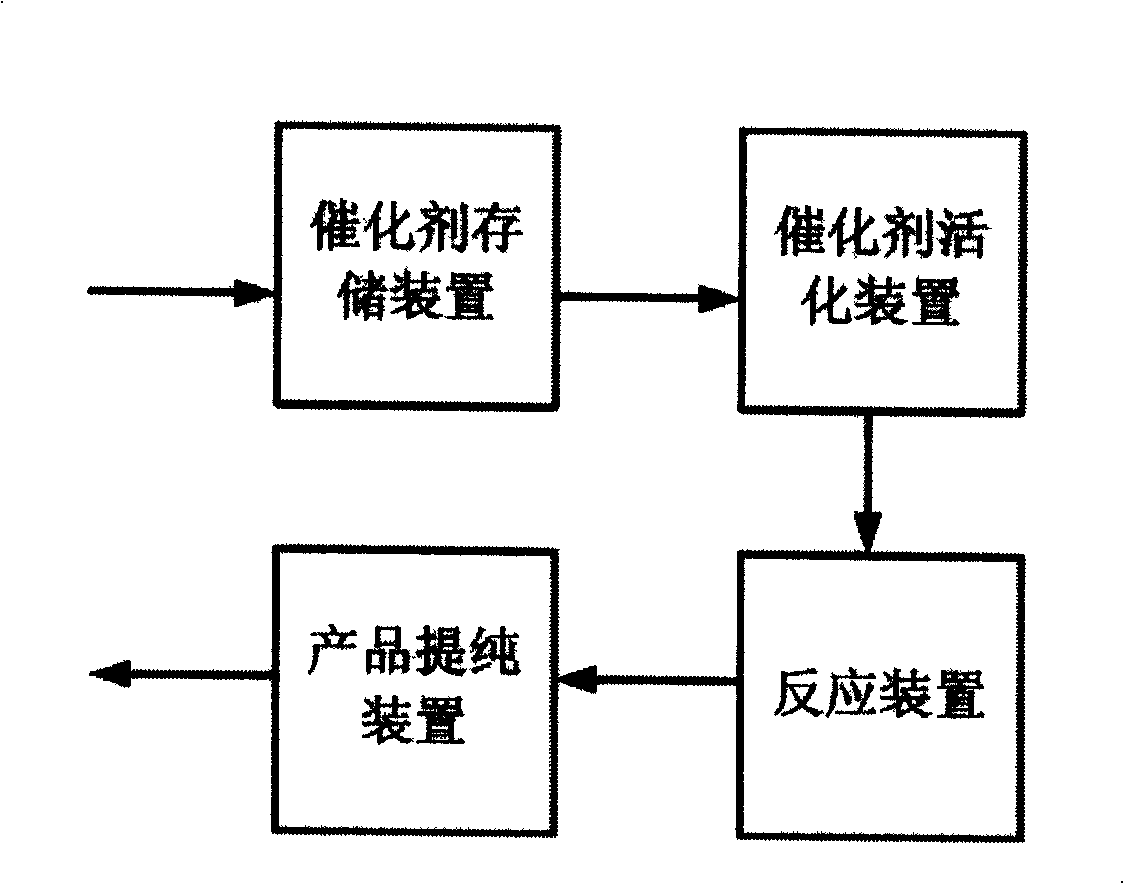

Method for preparing carbon nano-tube array on particle interior surface

ActiveCN101348249AAvoid shape damageEasy to operateChemical vapor deposition coatingHigh volume manufacturingChemical separation

The invention provides a method for preparing carbon nano pipe arrays on the inner surface of a particle, belonging to the technical field of novel material and novel material preparation. In the method, the active metal components are loaded on the inner surface of the particle, and subjected to reduction or thermal decomposition to obtain a loaded type particle inner surface containing metal nano particles; the loaded type particle inner surface is subjected to chemical vapor deposition, and carbon nano pipe arrays grow up between the particle inner surfaces. By the physical or chemical separation, the carbon nano pipe arrays are separated from the particles, and the carbon nano pipe arrays with high purity are obtained, wherein in the method, the reaction speed and the operational conditions are controlled, the bed density of a reactor is kept between 10 and 1000kg / m<3>, and the carbon nano pipes / particles are in flowing / fluidized states. The method has the advantages of being easily operated, realizing the mass production of the carbon nano pipe arrays and promoting the industrialized application of the carbon nano pipe arrays.

Owner:TSINGHUA UNIV

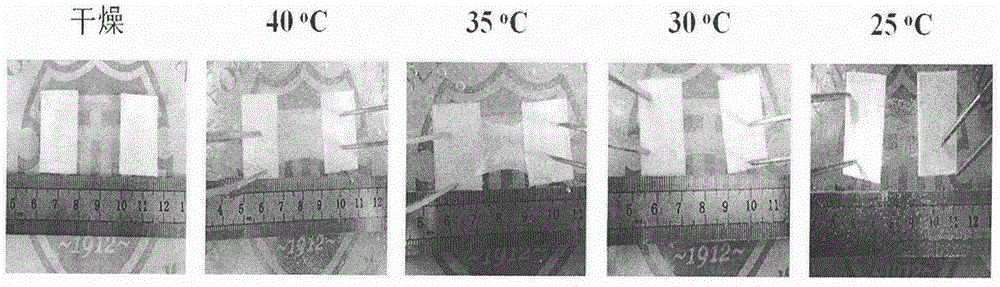

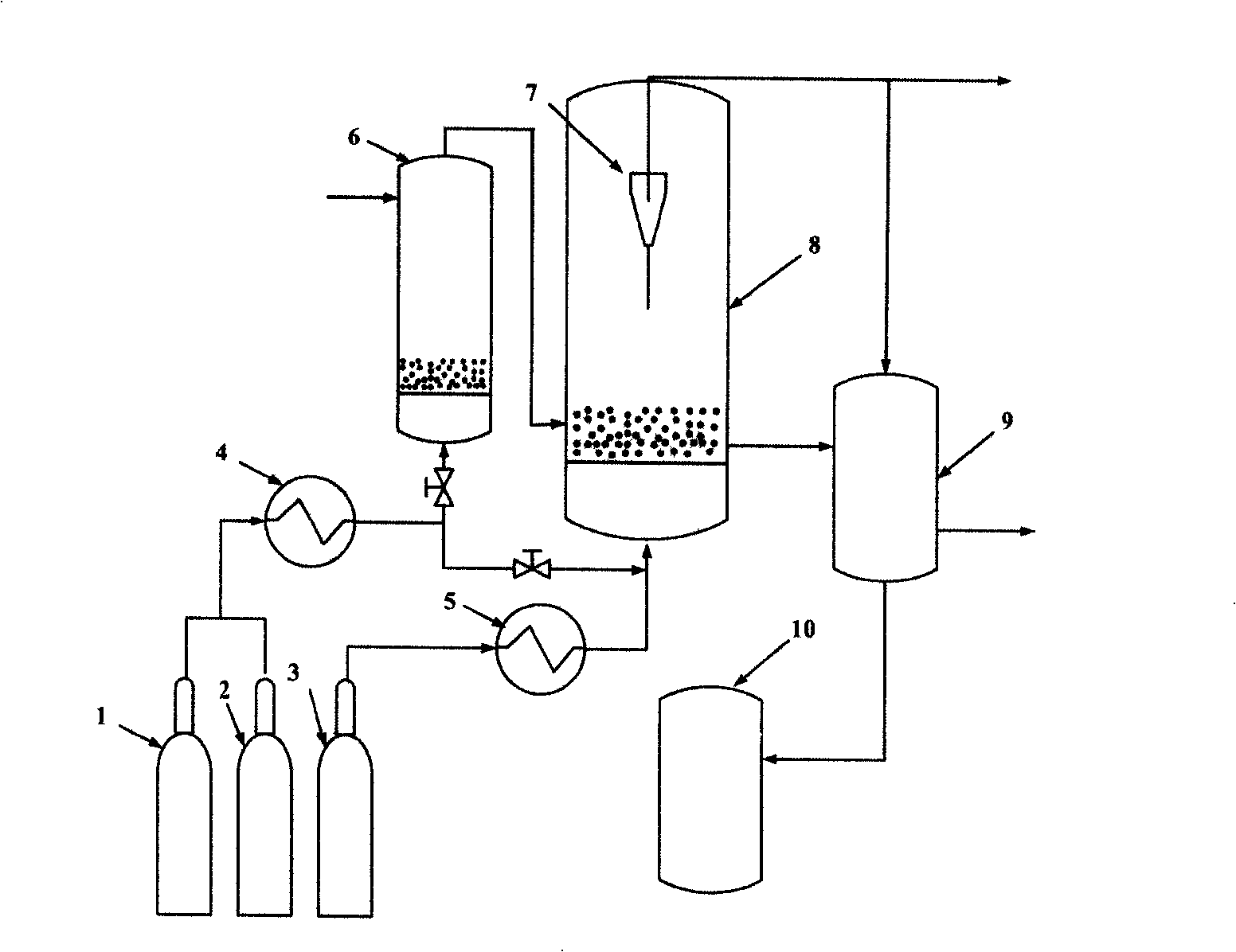

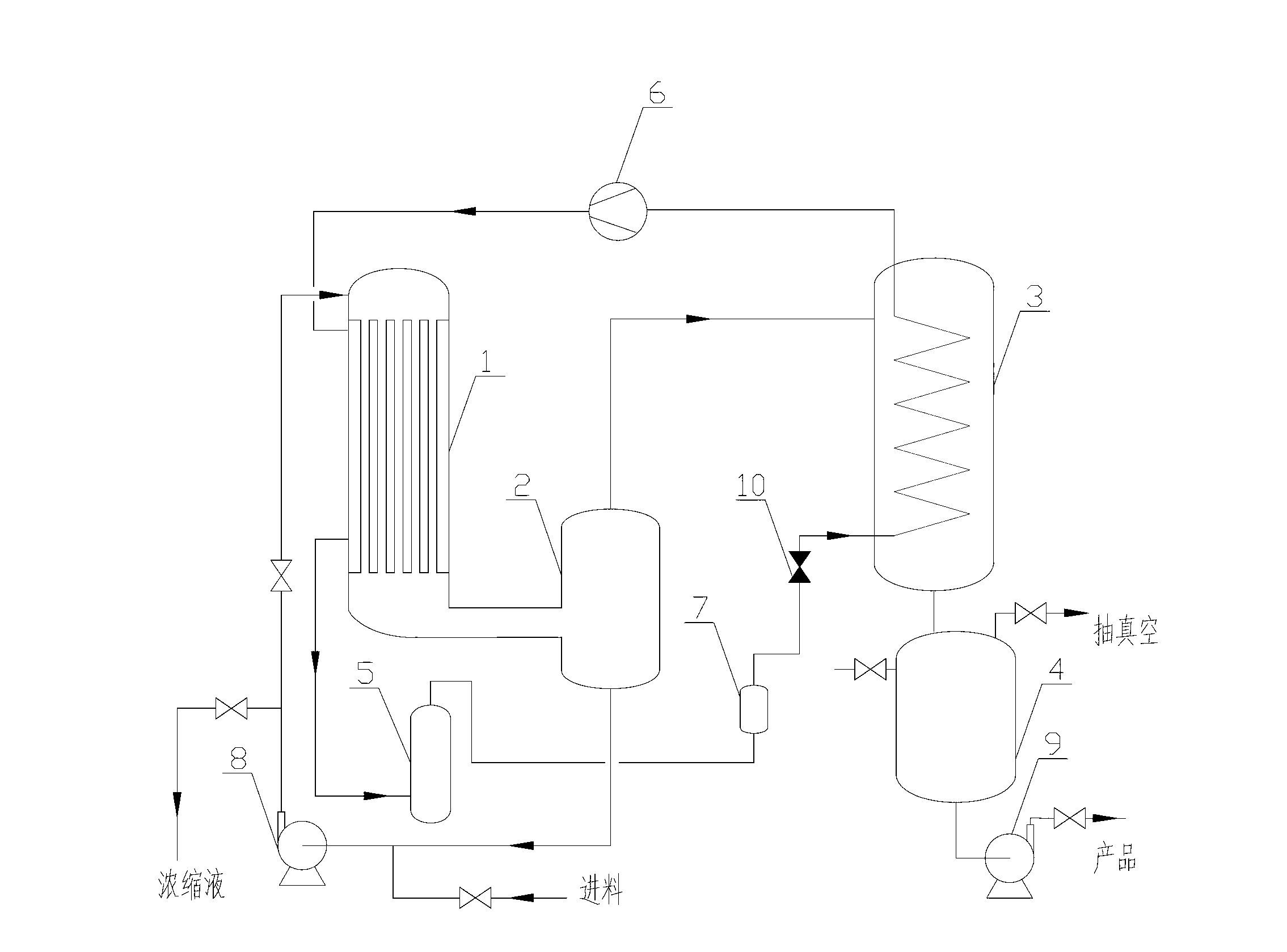

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

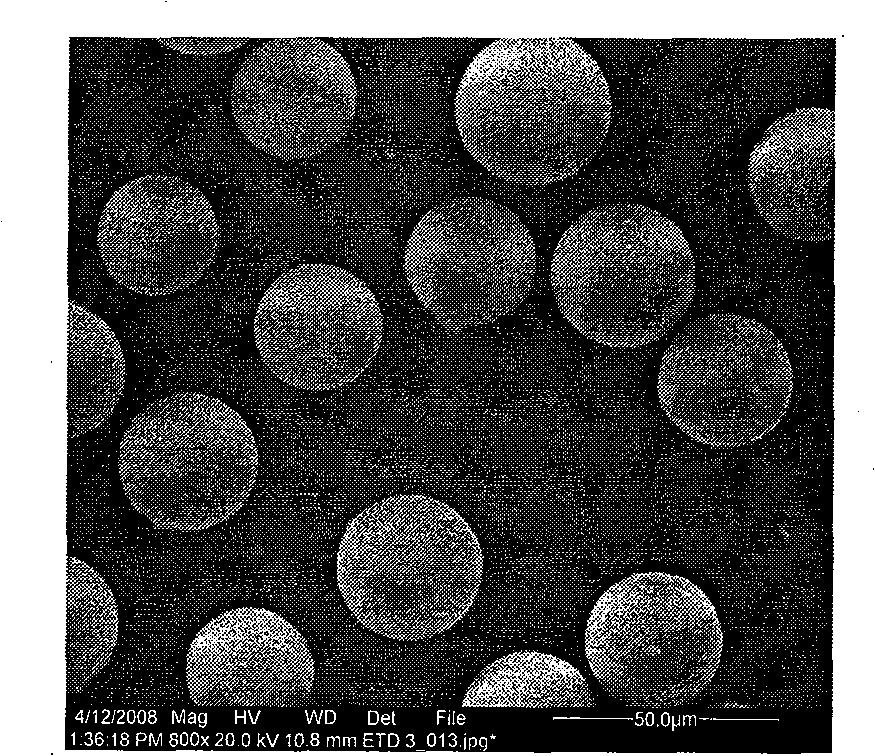

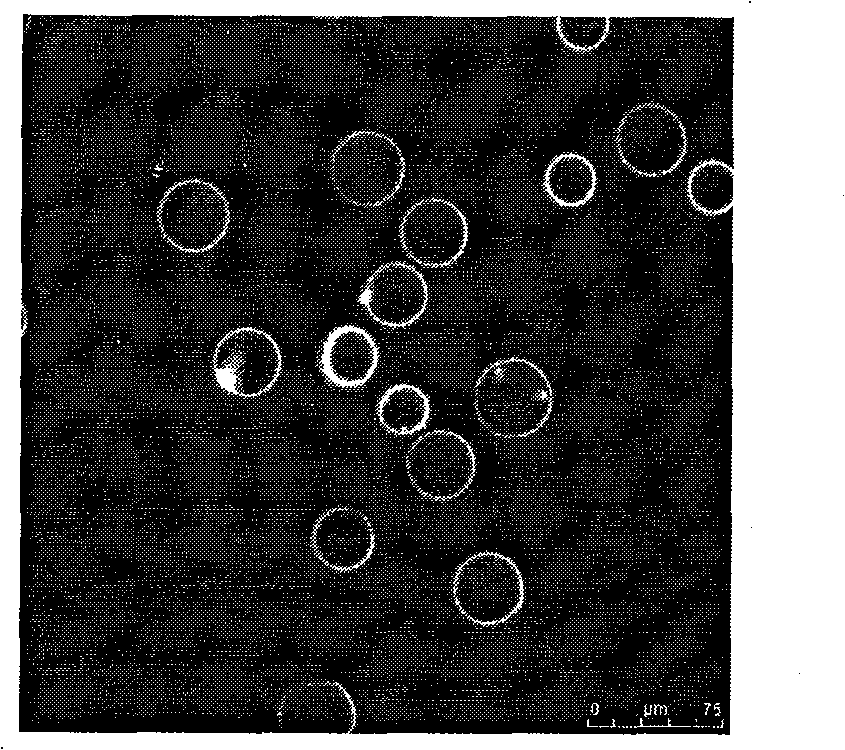

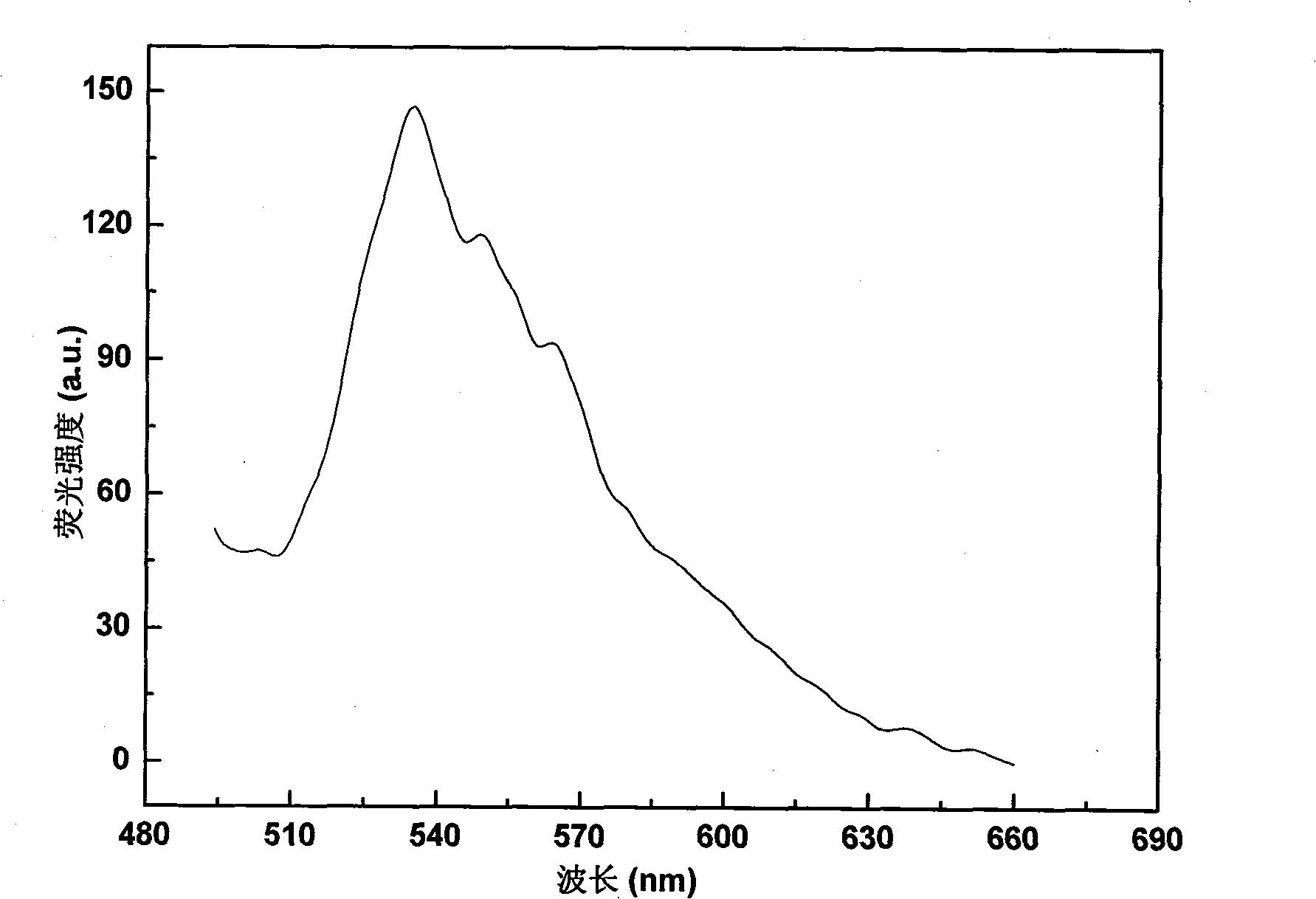

Process for producing fluorescent composite microgel hypersensitive to temperature and pH

The invention discloses a preparation method of fluorescent complex microgel which is sensitive to temperature and pH. The method comprises the technical steps of preparing a mixed surface active agent, preparing the oil phase of a template, preparing an emulsive liquid, preparing a water phase, preparing N-isopropyl acryl amide copolymerized methacrylic acid microgel, preparing turgid N-isopropyl acryl amide copolymerized methacrylic acid microgel, preparing a mixed liquid of Gamma-aminopropyl triethoxy silane and normal heptane, preparing a silicon dioxide polymer complex microballoon decorated by a surface deposited amino group, preparing a mixed liquid of fluorescein isothiocyanate and absolute ethyl alcohol as well as preparing the fluorescent complex microgel. In the invention, the fluorescein isothiocyanate with high quantum yield and good optical stability is adopted as fluorescent matter; the prepared fluorescent complex microgel is sensitive to temperature and pH; and the size of the prepared fluorescent complex microgel is in a micron range and is hard to be aggregated. The method has the advantages of reasonable design, practical technique and easy operation; moreover, reactions are carried out under normal temperature and the like; the method can be applied to the fields of controlled release of medicament, biological probe, chemical separation, and the like.

Owner:SHAANXI NORMAL UNIV

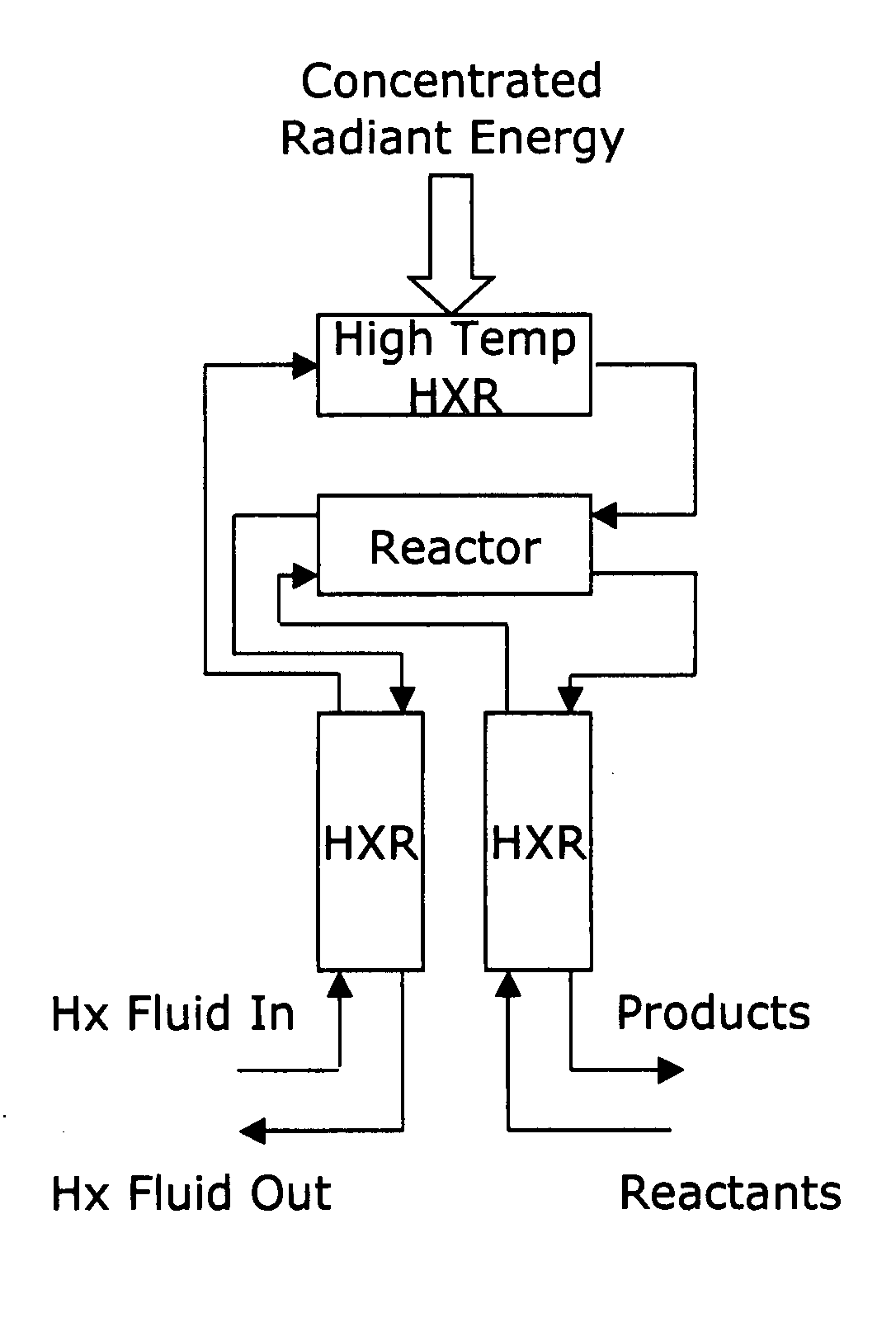

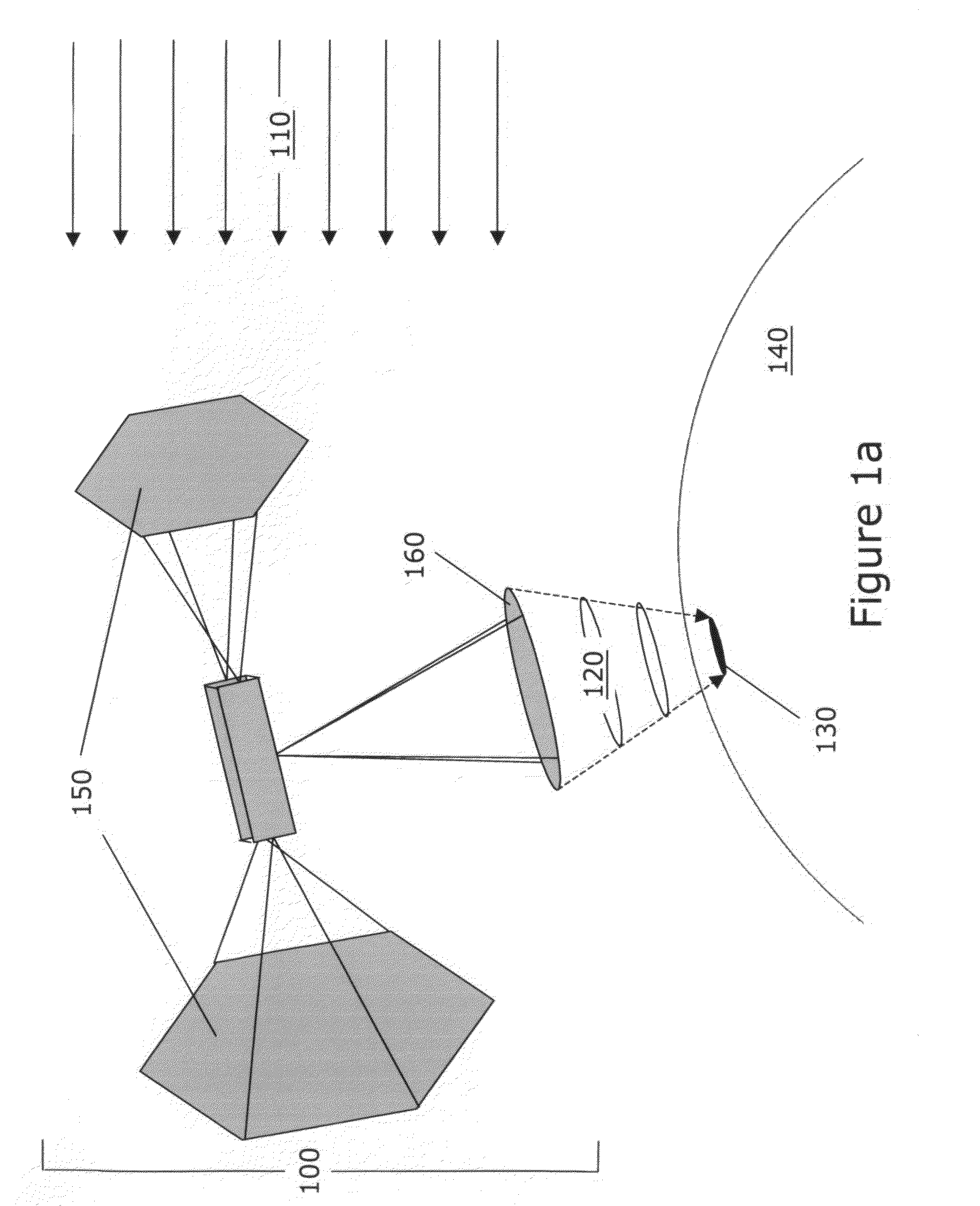

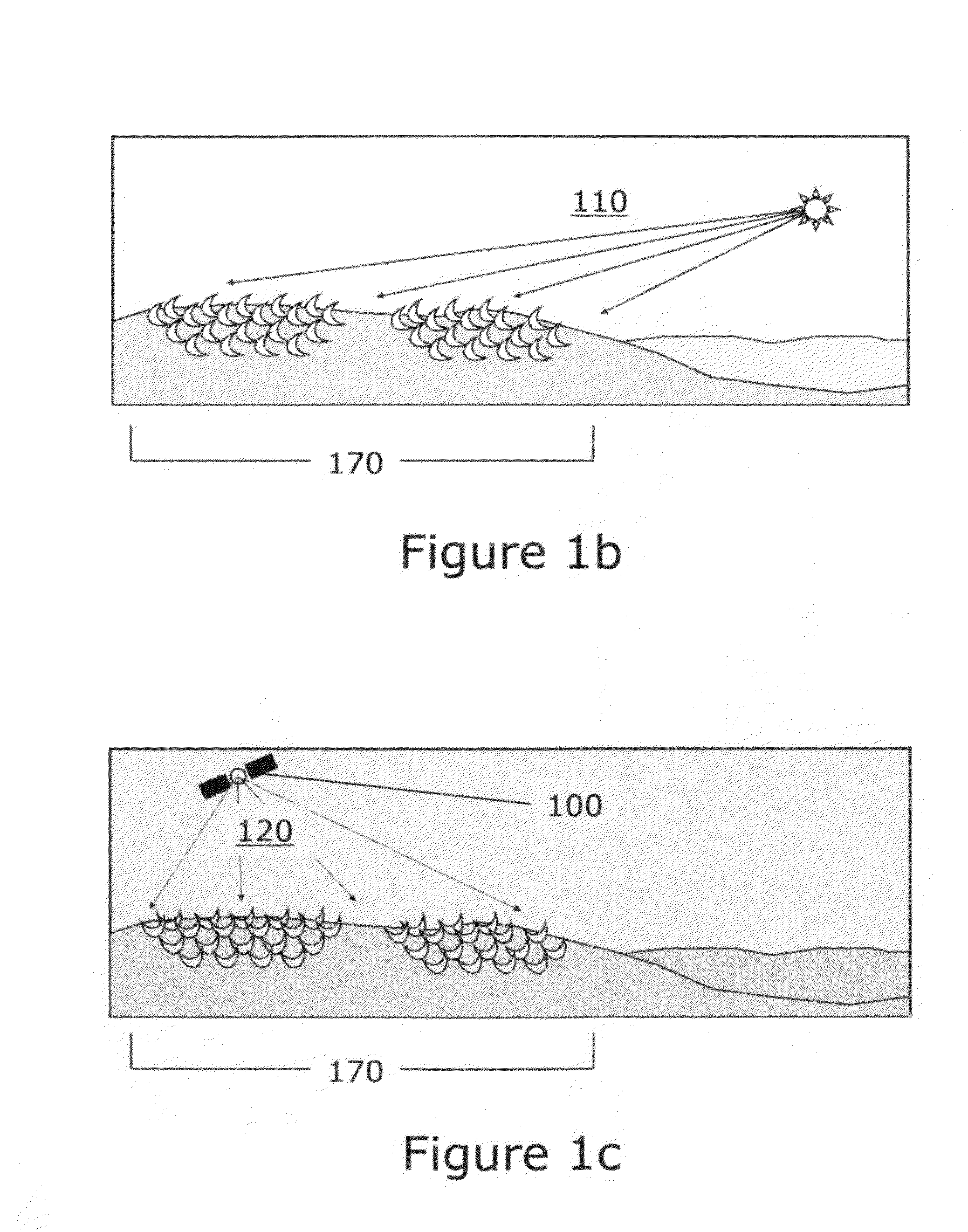

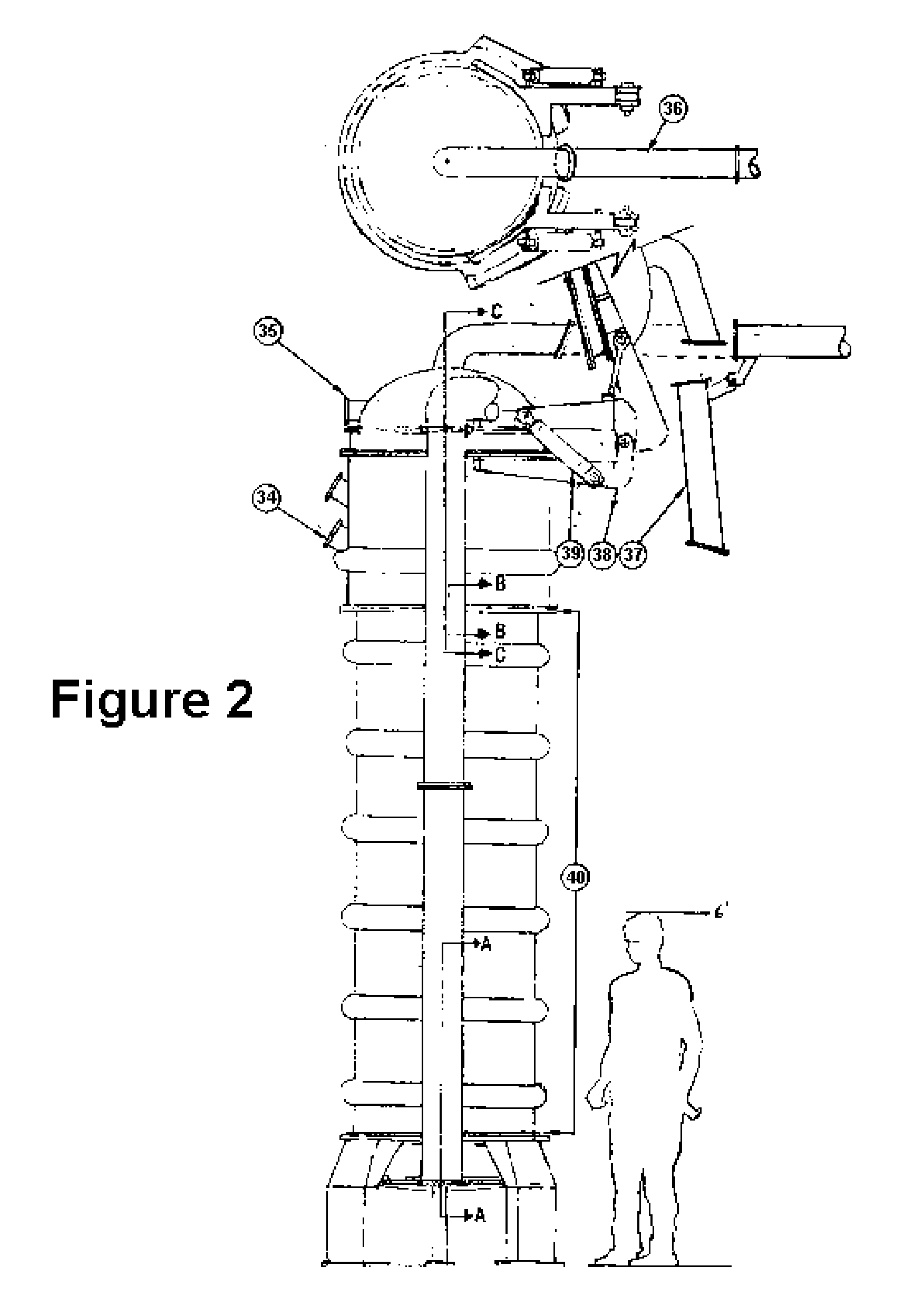

Radiant energy thermochemical processing system

InactiveUS20100098599A1Promote absorptionImprove abilitiesSolar heating energySolar heat devicesChemical treatmentChemical reaction

Thermochemical processing systems for the production of chemicals using solar (110) or other radiant energy as the heat source for chemical reactions and separations. Radiant energy receivers (310) operating in conjunction with concentrator systems (300), heat exchangers, chemical reactors and chemical separators. Systems and applications include the concentration of radiant energy in support of a moderate- and / or high-temperature, endothermic chemical reaction followed by downstream reactions and separations so that a chemical fuel is produced. Efforts are made to match concentrator types with need; for example, parabolic trough concentrators may be used to produce steam at low- to moderate-temperatures and parabolic dish concentrators may be used to drive moderate- to high-temperature chemical reactions such as methane reforming, and hybrid concentrators (400) may be used to concentrate radiant energy from multiple energy sources.

Owner:MANKINS JOHN CARLTON +1

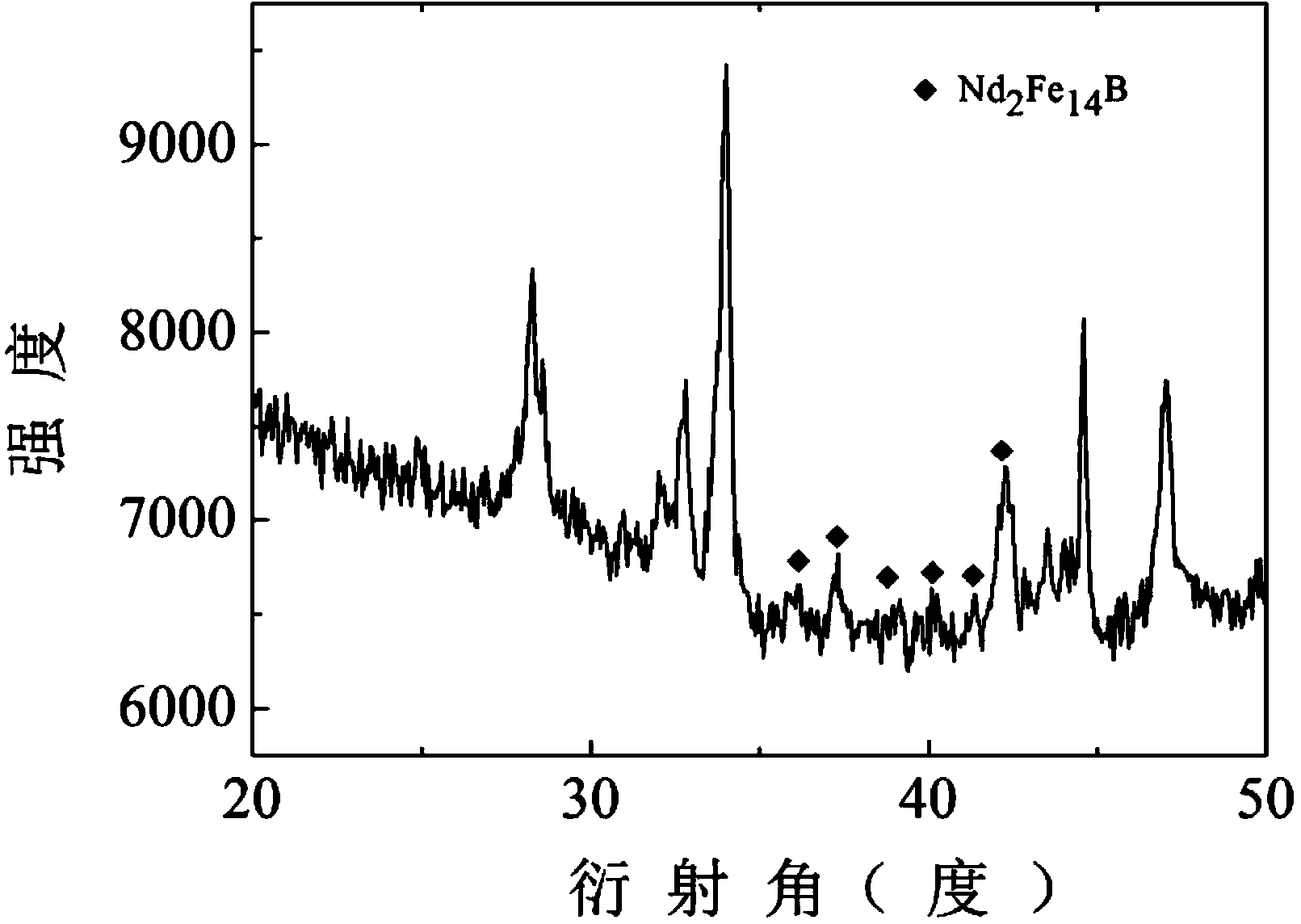

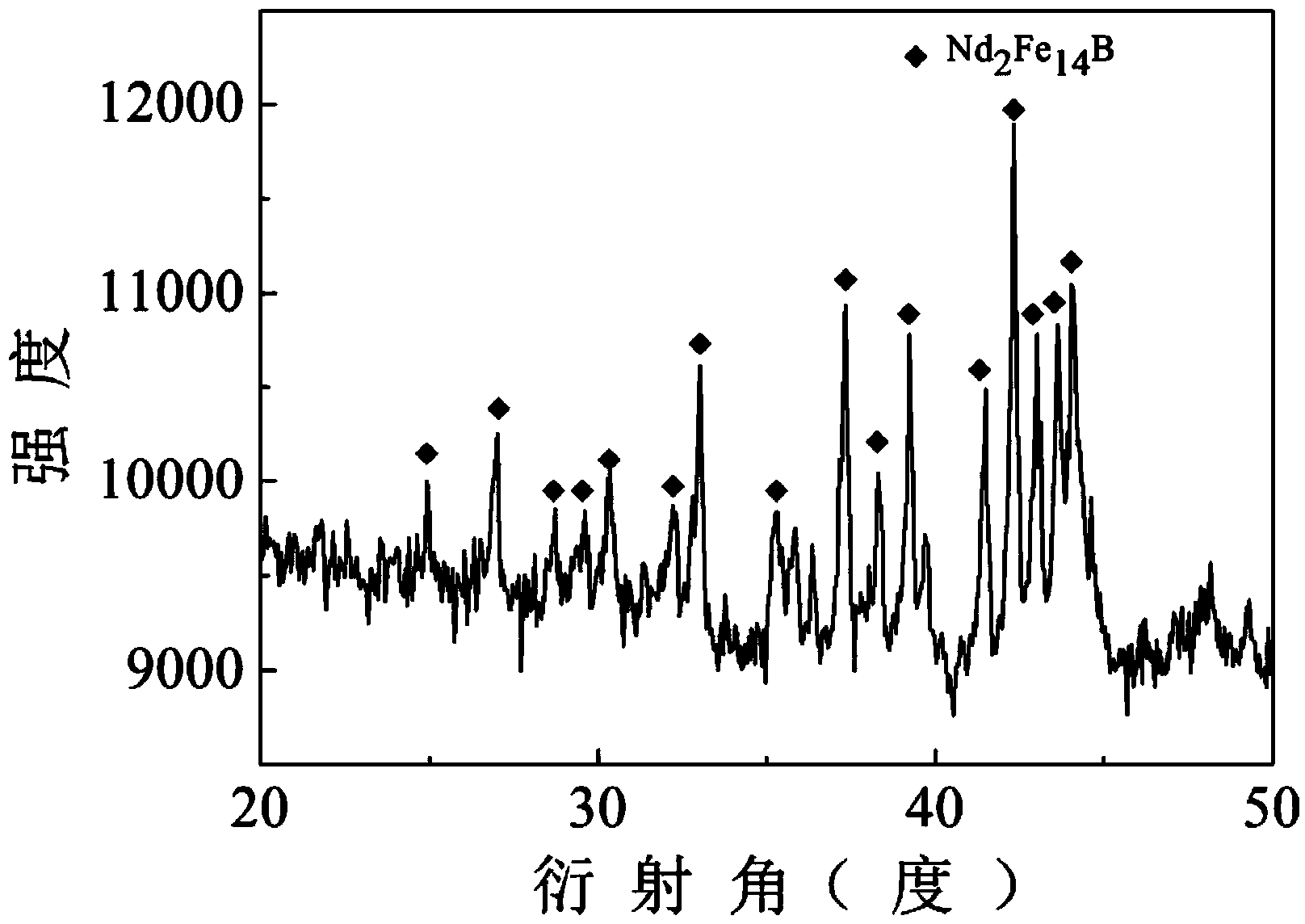

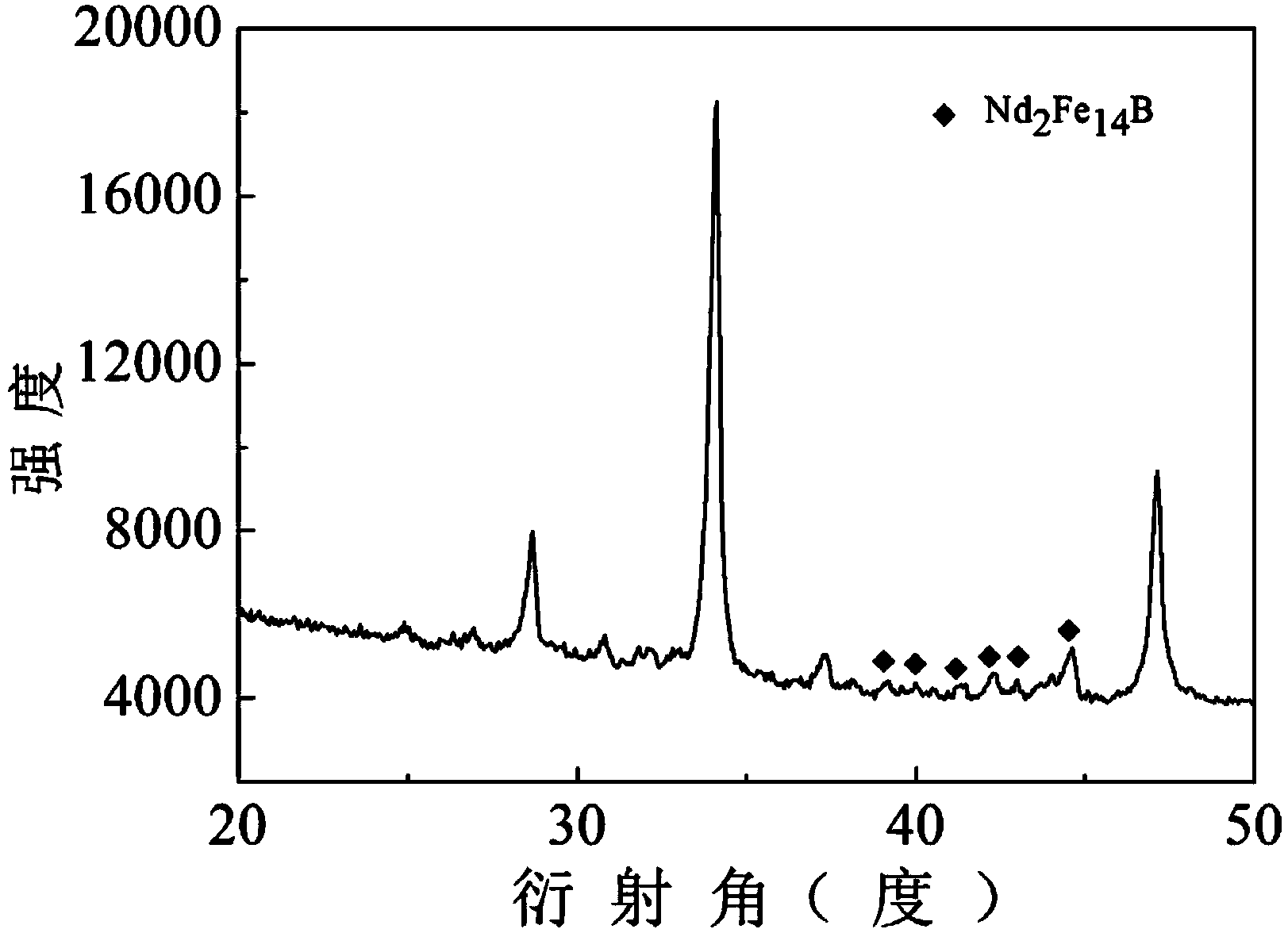

Method for preparing regenerated neodymium iron boron magnetic powder by using neodymium iron boron oily sludge

ActiveCN103882234AAvoid dischargeImprove protectionMagnetic materialsProcess efficiency improvementSludgeDistillation

The invention discloses a method for preparing regenerated neodymium iron boron magnetic powder by using neodymium iron boron oily sludge, and belongs to the technical field of recovering and recycling of the neodymium iron boron oily sludge. The method comprises the following technological processes: distilling and separating neodymium iron boron oily sludge; coprecipitating and recovering all valuable elements; mixing oxides; adding the substances such as calcium metal and the like according to the ratio; mixing reactants; carrying out thermal reduction and diffusion at high temperature; removing a calcium oxide in the product; drying in vacuum; forming the regenerated neodymium iron boron magnetic powder, wherein the step of 'coprecipitating and recovering all valuable elements' can be accepted or rejected according to existence of metal elements harmful to the magnetic property in the neodymium iron boron oily sludge; a part of impurities are removed from the neodymium iron boron oily sludge by distillation and separation; the mixed oxides are obtained by coprecipitation of the valuable elements; calcium metal particles are added, and subjected to reduction diffusion reaction at 850-1150 DEG C; the regenerated neodymium iron boron magnetic powder can be directly obtained from the product after chemical separation and drying. The method has the advantages that environmental protection is facilitated, the technological process is shortened, the recovery cost is reduced, and a part of technical problems are solved.

Owner:BEIJING UNIV OF TECH

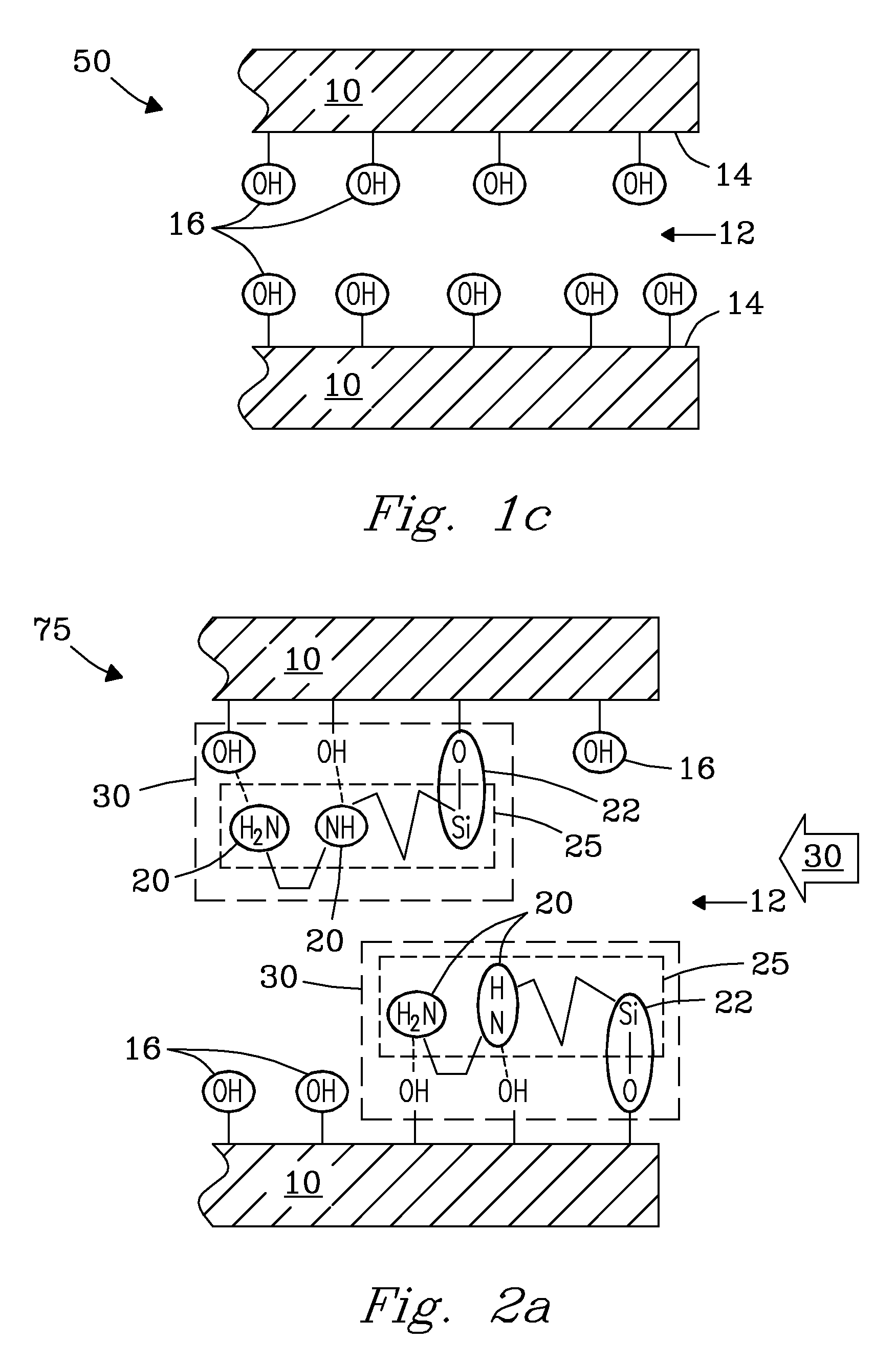

Functionalized sorbent for chemical separations and sequential forming process

ActiveUS20110059845A1Equally distributedEvenly dispersedGas treatmentOther chemical processesAnalyteSorbent

A highly functionalized sorbent and sequential process for making are disclosed. The sorbent includes organic short-length amino silanes and organic oligomeric polyfunctional amino silanes that are dispersed within pores of a porous support that form a 3-dimensional structure containing highly functionalized active binding sites for sorption of analytes.

Owner:BATTELLE MEMORIAL INST

Cold Bubble Distillation Method and Device

InactiveUS20060102007A1Eliminate lossContinuous operationEvaporationVacuum distillation separationFlavorPhysical chemistry

A cold method of heated distillation by manipulating bubbles, and cold distillate condensation is described. The continuous method introduces counter-current gas bubbles to a solution under vacuum at cold temperatures, using passive bubble manipulation. This approach accomplishes volatile evaporation at temperatures too low for thermal damage to occur, scrubs distilland mist from evaporated distillate, and condenses distillate by adding little or no heat. The method operates between freezing and ambient temperatures, but primarily near freezing, thus reducing energy consumption, and completely avoiding common thermal damage to delicate aroma, flavor, color, and nutritional distillate constituents that are characteristic of conventional aroma or essence extraction, food or drink concentrations, and chemical separation processes.

Owner:MARTIN DAVID

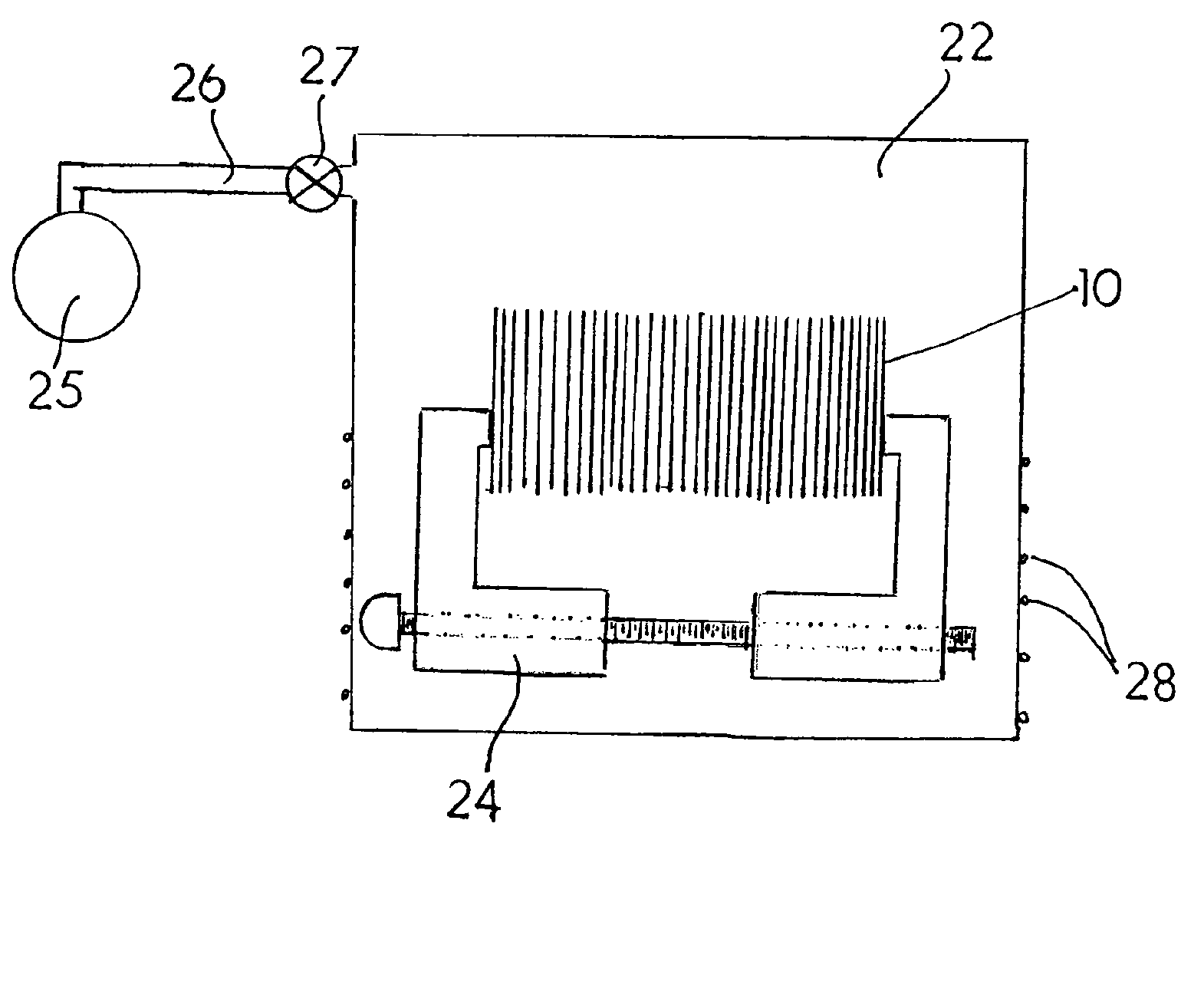

Method for producing components with internal architectures, such as micro-channel reactors, via diffusion bonding sheets

InactiveUS7900811B1Prevent collapseAvoid distortionAdhesive processesVegetable fibre separation from seedsCombustorChemical reactor

This invention relates to a method for producing components with internal architectures, and more particularly, this invention relates to a method for producing structures with microchannels via the use of diffusion bonding of stacked laminates. Specifically, the method involves weakly bonding a stack of laminates forming internal voids and channels with a first generally low uniaxial pressure and first temperature such that bonding at least between the asperites of opposing laminates occurs and pores are isolated in interfacial contact areas, followed by a second generally higher isostatic pressure and second temperature for final bonding. The method thereby allows fabrication of micro-channel devices such as heat exchangers, recuperators, heat-pumps, chemical separators, chemical reactors, fuel processing units, and combustors without limitation on the fin aspect ratio.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

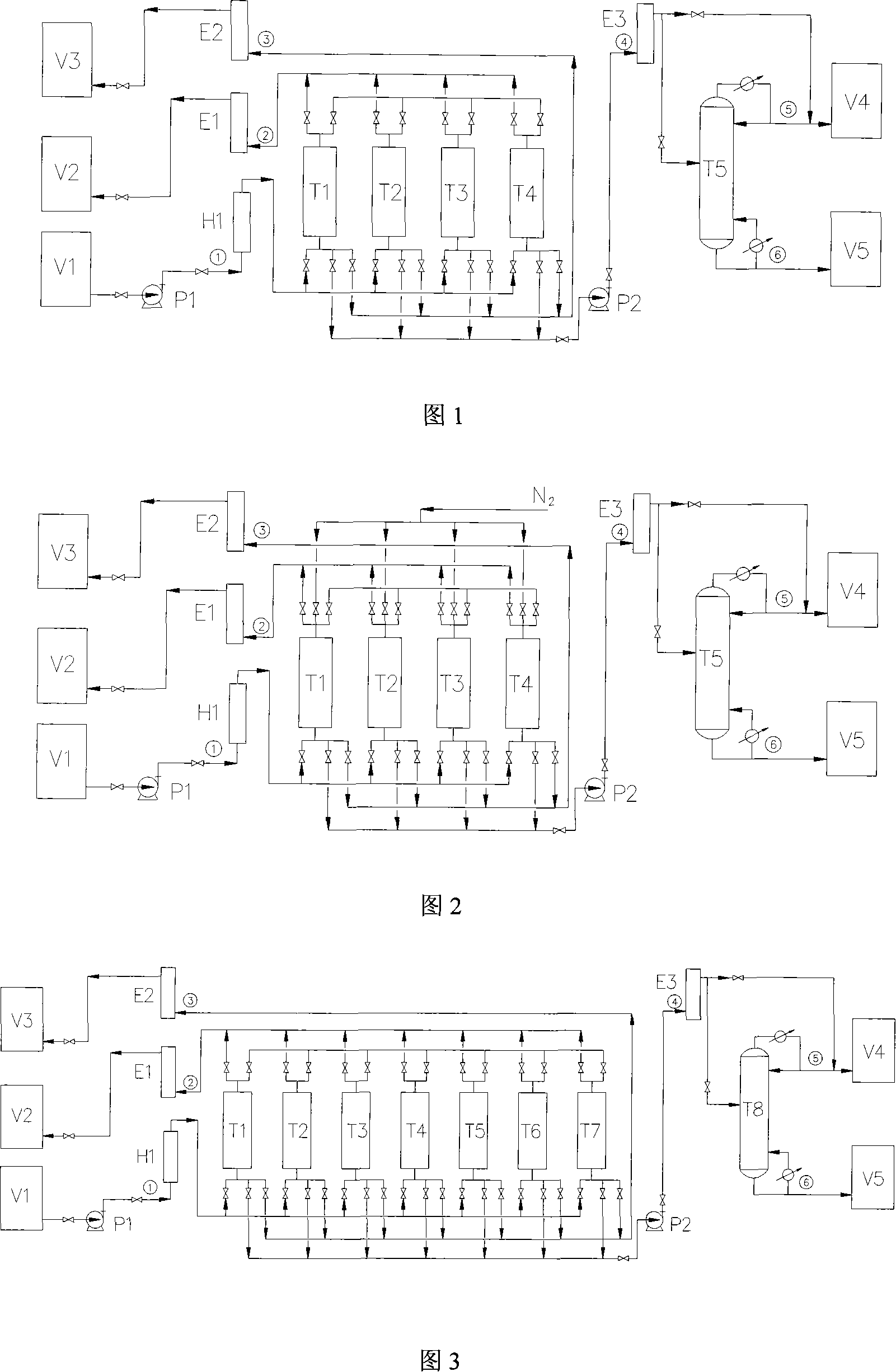

Technique for extracting high-pure normal hexane product by pressure swing adsorption

ActiveCN101148390ABoost octaneImprove resource utilization efficiencyAdsorption purification/separationPressure riseChemical separation

The present invention relates to chemical separation technology, and is especially the pressure swing adsorption process of extracting high purity n-hexane product. The multiple-tower heated pressure swing adsorption process includes the following steps: adsorbing, homogenizing pressure fall and discharging pressure, desorbing, and homogenizing pressure rise and raising pressure. The advanced technological process has simple apparatus, convenient operation, low power consumption, high automation, high marketability and other features.

Owner:SINOPEC YANGZI PETROCHEM

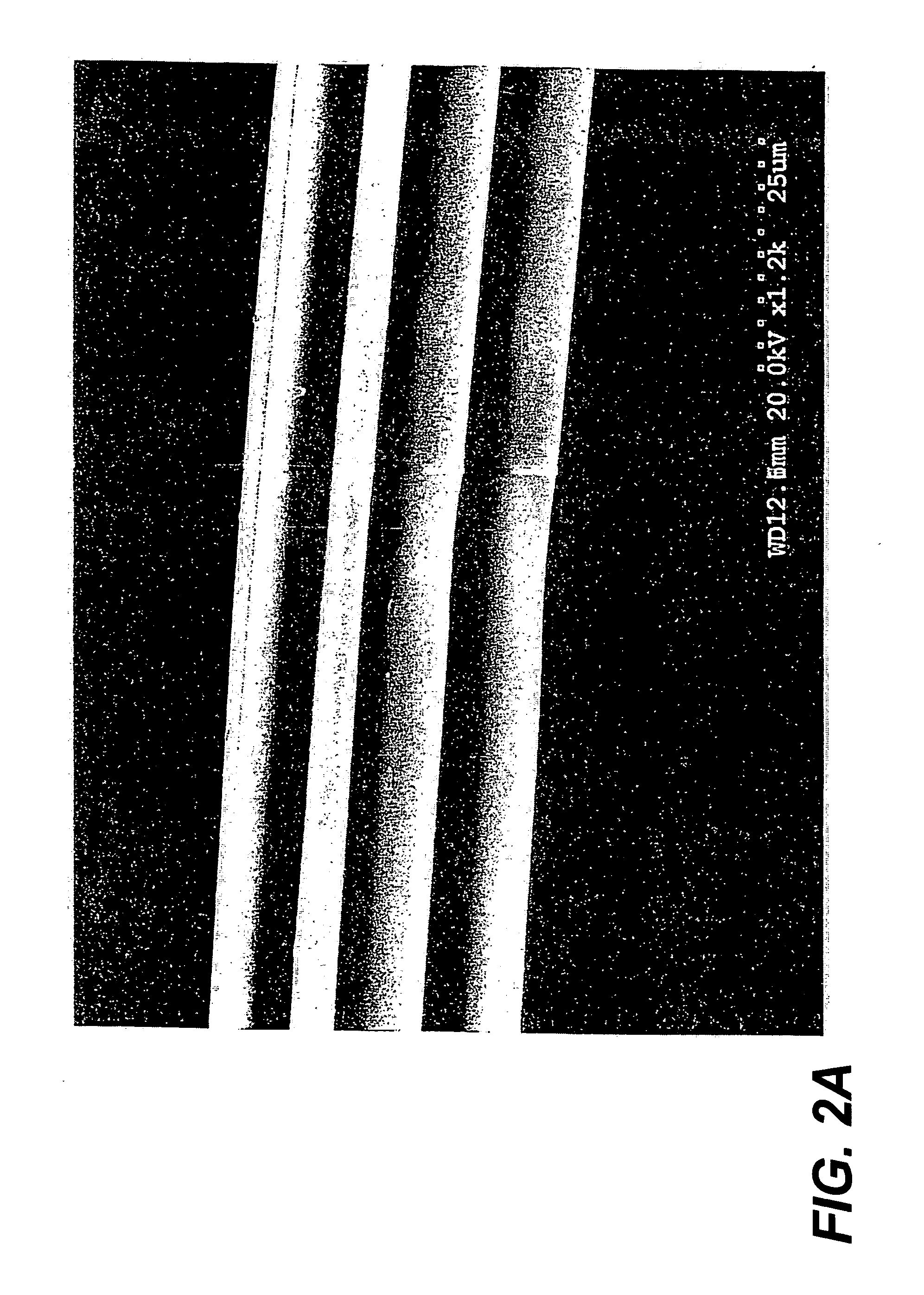

Channeled polymer fibers as stationary/support phases for chemical separation by liquid chromatography and for waste stream clean-up

ActiveUS20050023221A1Reduce back pressureWide rangeSemi-permeable membranesOther chemical processesWaste streamCell culture media

Polymer fibers having a novel cross-sectional geometry are used as stationary phase materials for liquid chromatography separations. Fibers of 20 to 50 micrometer diameters have surface-channel structures extending their entire lengths. Bundles of fibers having this novel cross-sectional geometry are packed in columns. Different polymer compositions permit the “chemical tuning” of the separation process. Channeled fibers composed of polystyrene and polypropylene have been used to separate mixtures of polyaromatic hydrocarbons (PAHs), Pb-containing compounds and fatty acids. Use of channeled fibers allows a wide range of liquid flow rates with very low backing pressures. Applications in HPLC, cap-LC, prep-scale separations, analytical separations, single fiber separations, waste remediation / immobilization, extraction of selected organic molecules / ions from solution, purification of liquid streams (process waste, drinking water, pure solvents), selective extraction of cell matter and bacteria from growth media, and immobilization of cell matter and bacteria are envisioned.

Owner:CLEMSON UNIV RES FOUND

Preparation method of molecular imprinted polymer membrane by means of grafting rejection

The invention provides a preparation method of a molecular imprinted polymer membrane by means of grafting rejection. The preparation method comprises the following steps of: preparing a solution of a complex of a functional monomer, a cross-linking agent and a template in a proper proportion, filtering the complex solution by selecting a proper support membrane to reject the complex formed from the functional monomer and the template on the surface of the membrane, selectively filtering out and washing off the functional monomer which does not react with the template to form the stable complex by use of a solvent, grafting a layer of molecular imprinted polymer on the surface of the membrane by means of radiation initiation, and removing the template and an unreacted substance by means of backwashing to obtain the surface grafted molecular imprinted polymer membrane. The molecular imprinted polymer membrane not only keeps the quite large flux and mechanical performance of a carrier membrane, but also is conductive to the elution and recombination of the template, and therefore has excellent application prospect in the fields of chemical separation, solid phase extraction, membrane sensors and the like; the obtained MIP (Molecular Imprinted Polymer) membrane is quite high in imprinting efficiency.

Owner:TIANJIN POLYTECHNIC UNIV

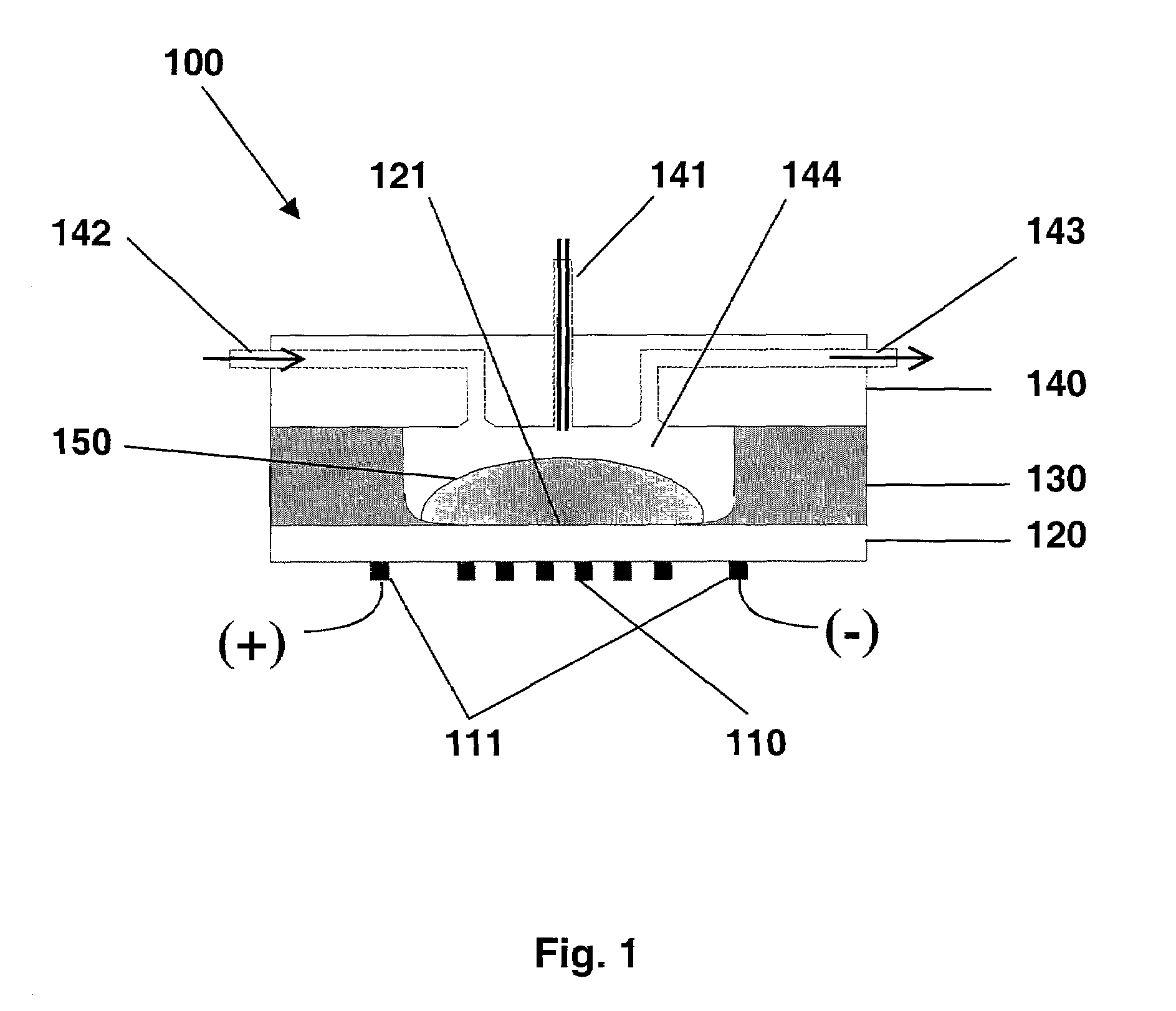

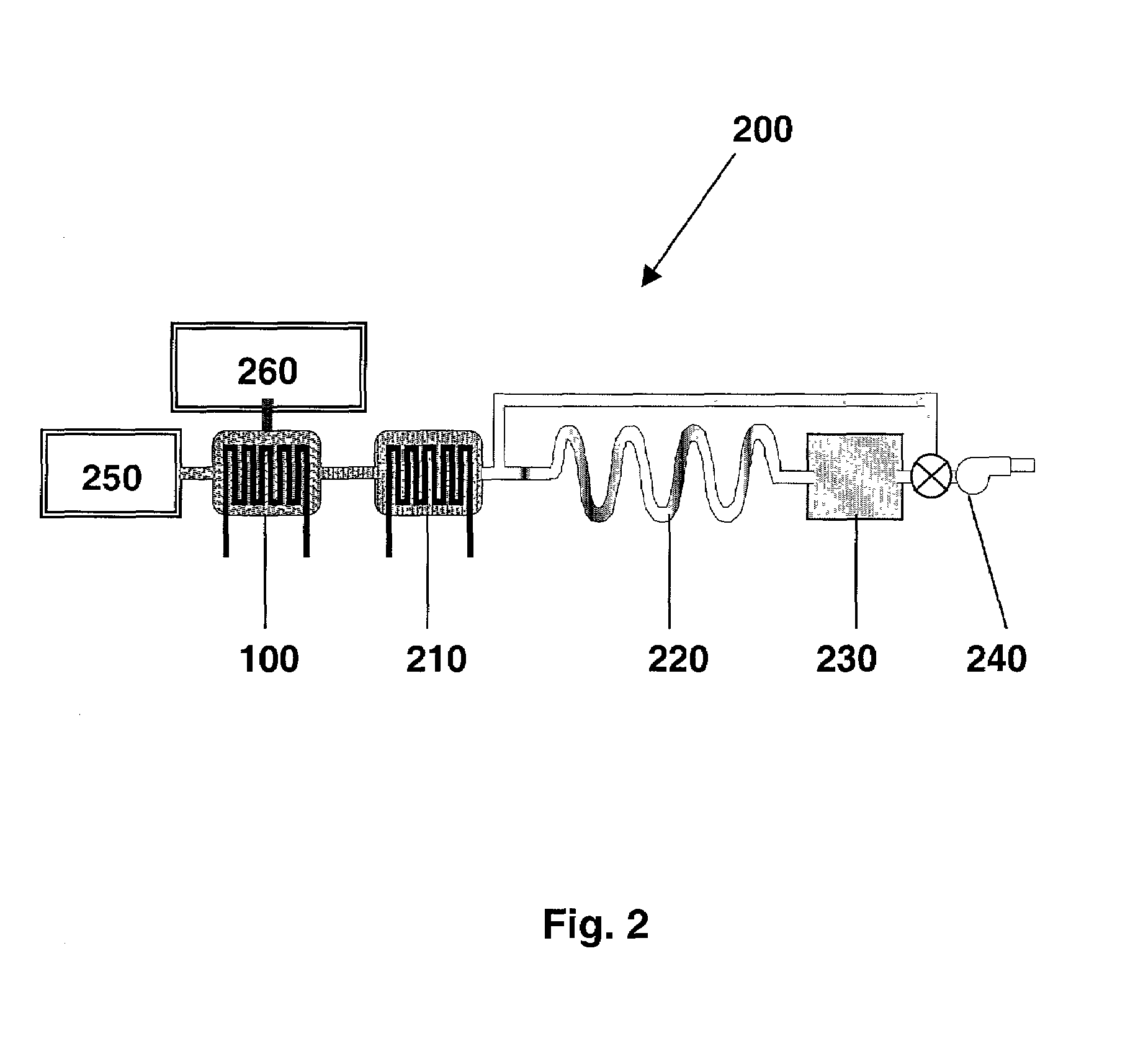

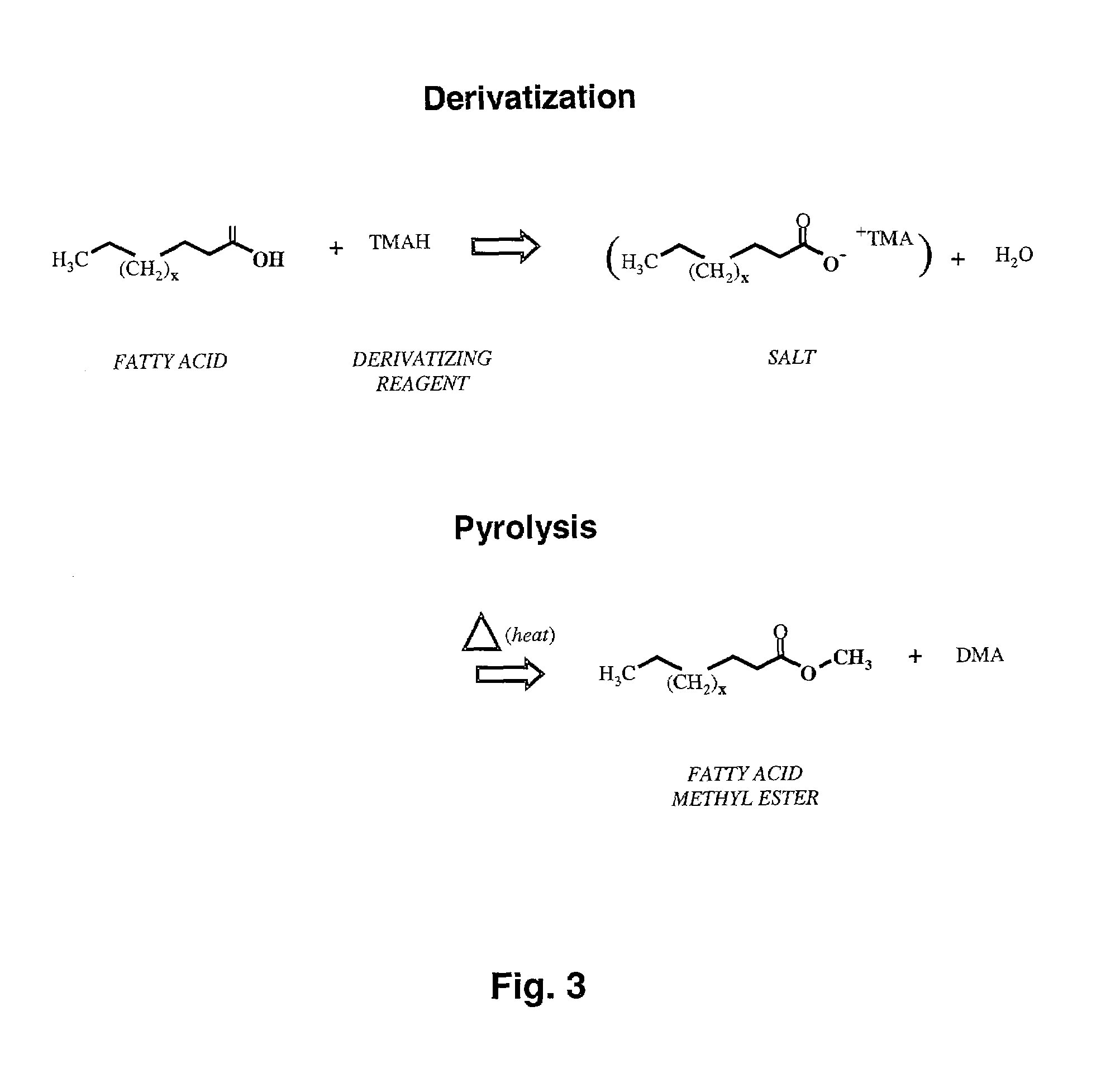

Micropyrolyzer for chemical analysis of liquid and solid samples

InactiveUS7078237B1Chemical analysis using combustionParticle separator tubesSemiconductor materialsField analysis

A micropyrolyzer has applications to pyrolysis, heated chemistry, and thermal desorption from liquid or solid samples. The micropyrolyzer can be fabricated from semiconductor materials and metals using standard integrated circuit technologies. The micropyrolyzer enables very small volume samples of less than 3 microliters and high sample heating rates of greater than 20° C. per millisecond. A portable analyzer for the field analysis of liquid and solid samples can be realized when the micropyrolyzer is combined with a chemical preconcentrator, chemical separator, and chemical detector. Such a portable analyzer can be used in a variety of government and industrial applications, such as non-proliferation monitoring, chemical and biological warfare detection, industrial process control, water and air quality monitoring, and industrial hygiene.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

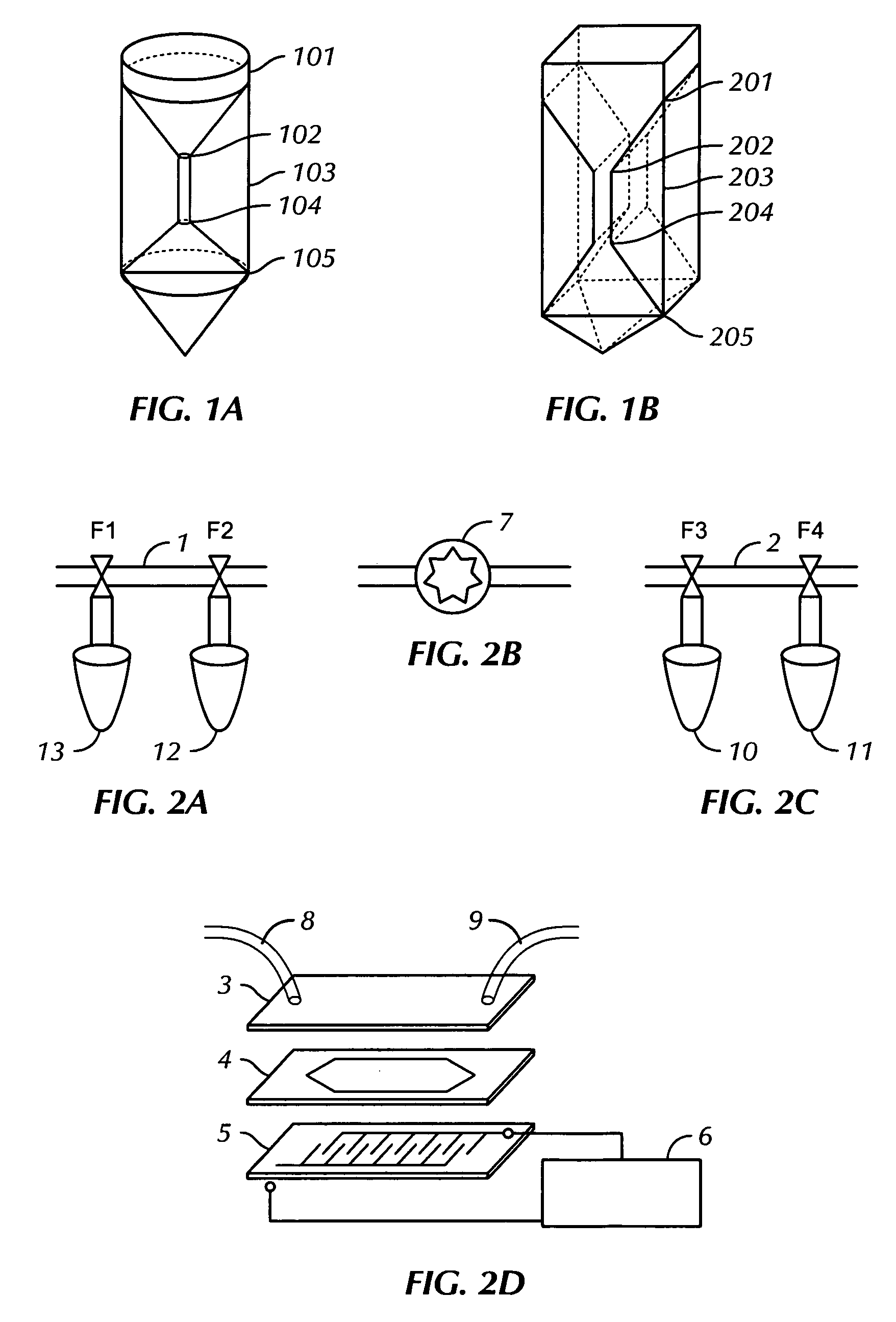

Dielectrophoretic separation of stained cells

This invention relates generally to the field of cell separation or isolation. In particular, the invention provides a method for separating cells, which method comprises: a) selectively staining cells to be separated with a dye so that there is a sufficient difference in a separable property of differentially stained cells; and b) separating said differentially stained cells via said separable property. Preferably, the separable property is dielectrophoretic property of the differentially stained cells and the differentially stained cells are separated or isolated via dielectrophoresis. Methods for separating various types of cells in blood samples are also provided. Centrifuge tubes useful in density gradient centrifugation and dielectrophoresis isolation devices useful for separating or isolating various types of cells are further provided.

Owner:CAPITALBIO CORP +1

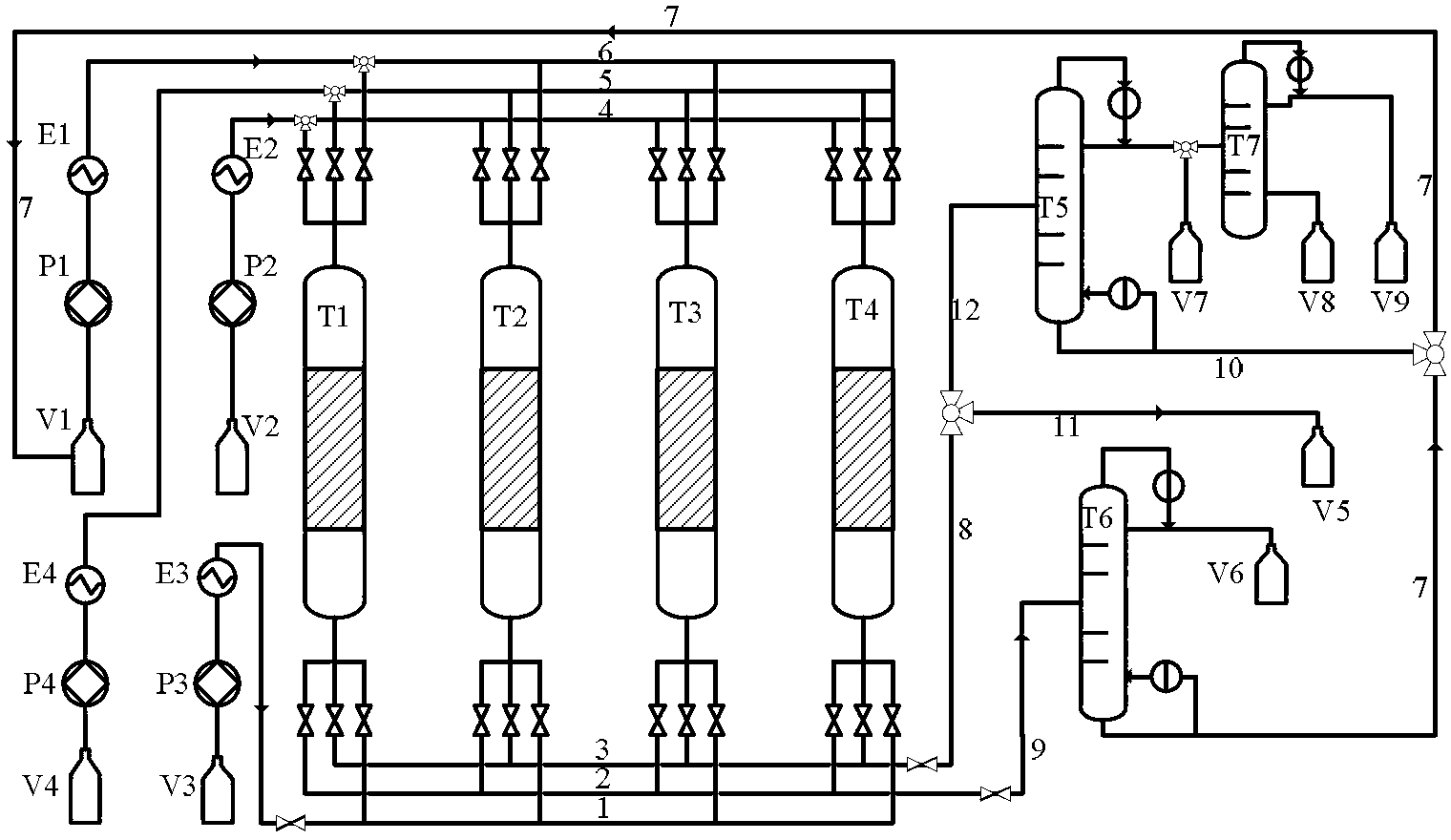

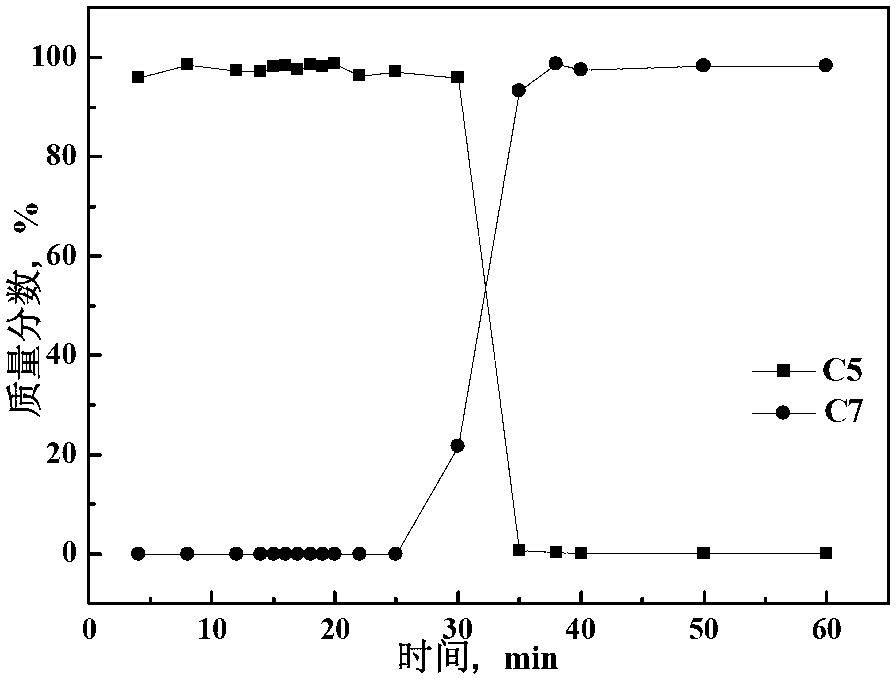

Process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane cooperatively produced from light naphtha

InactiveCN103254932AEasy to separateAdsorption and separation energy consumption is reducedDistillation purification/separationAdsorption purification/separation2-methylbutaneDesorption

The invention relates to a chemical separation process and in particular relates to a process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane from light naphtha. A multi-tower variable pressure adsorption and distillation separation coupling process is adopted by the invention. The process comprises the following steps of: introducing mixed gaseous C4-C6 normal paraffins and isohydrocarbons serving as raw materials into an adsorption tower for adsorption and separation; desorbing a bed by taking gaseous C7-C9 normal paraffins as a desorption reagent after the adsorption ends; introducing the desorbed material into a rectifying tower to separate out the product C4-C6 normal paraffins and the desorption reagent C7-C9 normal paraffins; recycling the desorption reagent; then regenerating the adsorption tower which absorbs the C7-C9 normal paraffins by using the un-adsorbed C4-C6 isohydrocarbons; and rectifying and separating the regenerated material twice to obtain high-purity desorption reagent C7-C9 normal paraffins, high-purity isopentane and high-purity heterogeneous hexane. By adopting the process disclosed by the invention, normal paraffins and isohydrocarbons can be effectively separated; the adsorbent is easy to regenerate; the process flow is simple and economic benefit is high; and the energy consumption in the process disclosed by the invention is greatly reduced in comparison with the energy consumption in other desorption processes.

Owner:NANJING UNIV OF TECH

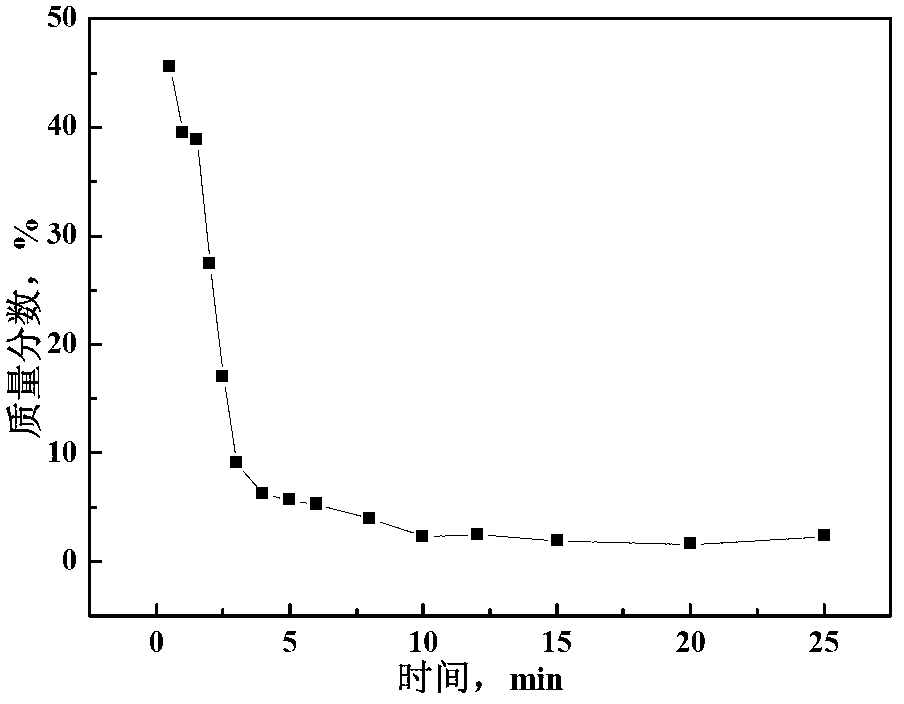

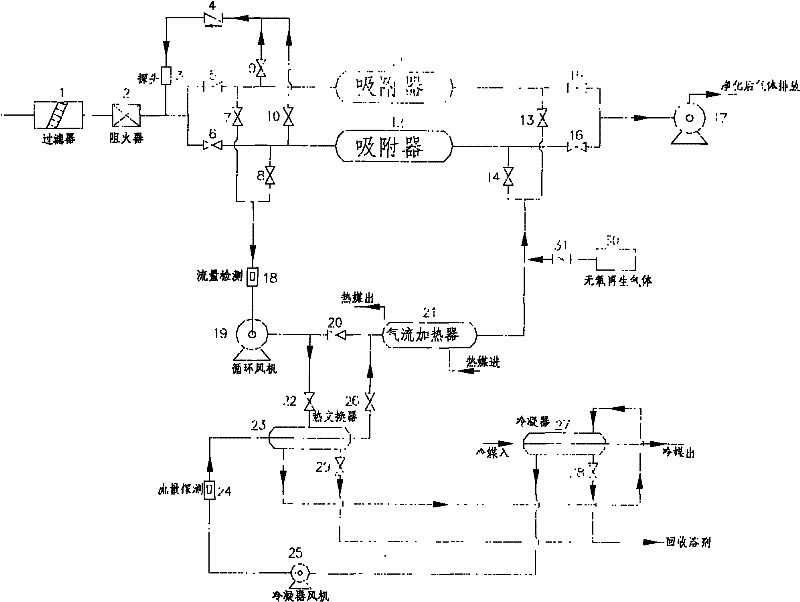

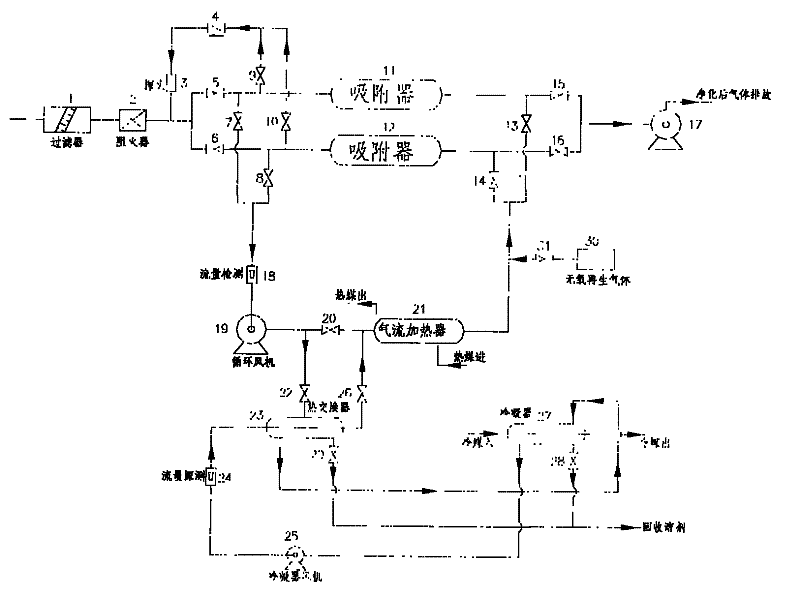

Method and apparatus for circulating, desorbing, shunting, recovering, and reclaiming hot gas by using adsorption bed

InactiveCN102205235AIncrease partial pressureControl total oxygenOther chemical processesDispersed particle separationOrganic solventChemical adsorption

The invention belongs to the field of chemical separation and environment protection, and specifically relates to a method for circulating, desorbing, shunting, recovering, and reclaiming hot gas by using an adsorption bed. According to the present invention, a combined technology is adopted, that hot gas is circulated and desorbed by an adsorption bed, part of the desorbed gas is processed through bypass heat exchange, and the desorbed gas is condensed and recovered. With the method and the apparatus provided by the present invention, hot gas reclaiming procedures are carried out economically and effectively with the absorption bed. In prior arts, the energy consumption during hot gas desorbing is high, and the cost of hot exchange equipment is high. With the techniques of the present invention, the limitations are solved, and an advantage of hot gas desorbing technology is maintained, that organic matters recovered with a hot gas desorbing technology have relatively pure quality. The method and the apparatus provided by the present invention can be applied in the occasions of chemical adsorption separation, polluted gas purification, and organic solvents recovery. The method and the apparatus are especially suitable for the recovery of continuously discharged organic tail gas with a large total discharge amount. The recovery rate is higher than 90%.

Owner:羌宁

Method of selection by two-dimensional separation, of nucleic acids that bind to a target with high affinity

InactiveUS20040067501A1Avoid eliminationStrong bindingMicrobiological testing/measurementFermentationChemical separationHigh affinity binding

The invention relates to a method of selection, by two-dimensional separation, of nucleic acids that bind to a target molecule with high affinity from a mixture of nucleic acids, comprising the following steps: a) subjecting the mixture of nucleic acids to a physico-chemical separation step, thereby obtaining a set of mixed fractions containing the nucleic acids, a run parameter window being associated with every mixed fraction containing the nucleic acids, b) contacting a mixed fraction containing the nucleic acids with the target molecule, thereby obtaining a binding mixture containing nucleic acid / target molecule complexes, c) subjecting the binding mixture from step b) to the same physico-chemical separation step as in step a), thereby selecting nucleic acid / target molecule complexes whose run parameters are outside of the run parameter window.

Owner:APTARES AG

Droplet compartmentalization for chemical separation and on-line sampling

Owner:UNIV OF WASHINGTON

Meso-frequency traveling wave electro-kinetic continuous adsorption system

InactiveUS7291271B2Minimal energyImprove scalabilityIon-exchanger regenerationVolume/mass flow measurementIntermediate frequencyUnit operation

The invention provides a non-cyclic, meso-frequency traveling wave electro-kinetic system capable of use in purification / separation and / or refrigeration / heat pump processes. In particular, the invention provides an adsorption system that can be used for fine or bulk chemical separations of liquid and gaseous materials. Similarly, the adsorption system can be readily adapted to function as a refrigeration / heat pump unit for use in heating and cooling systems. This reusable adsorption system provides high efficiency purification and / or cooling / heating with low energy demands and no moving parts. The invention can function in parallel or in series with other similar such adsorption units (though it can also operate as a single unit).

Owner:SEPARATION DESIGN GROUP

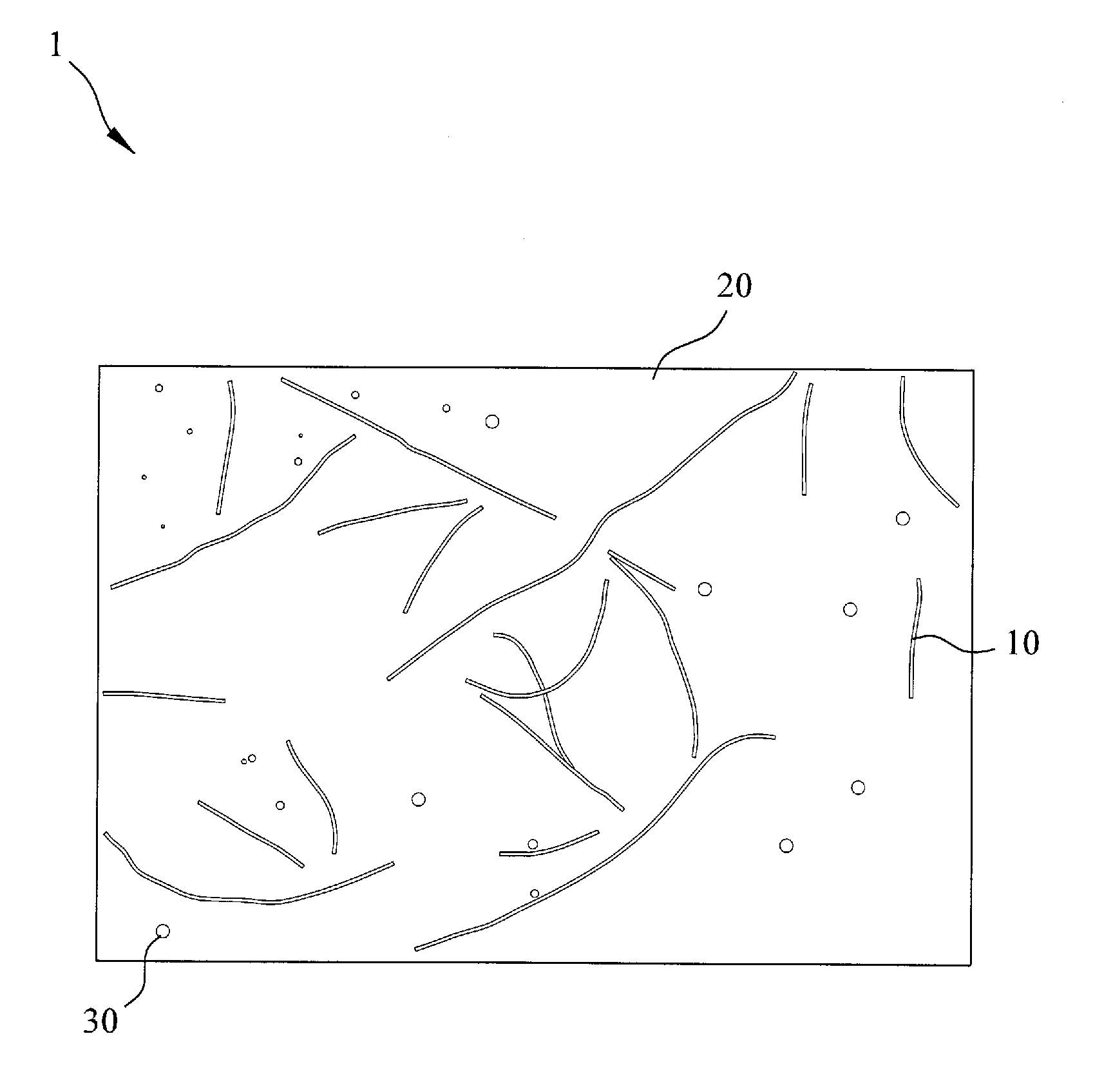

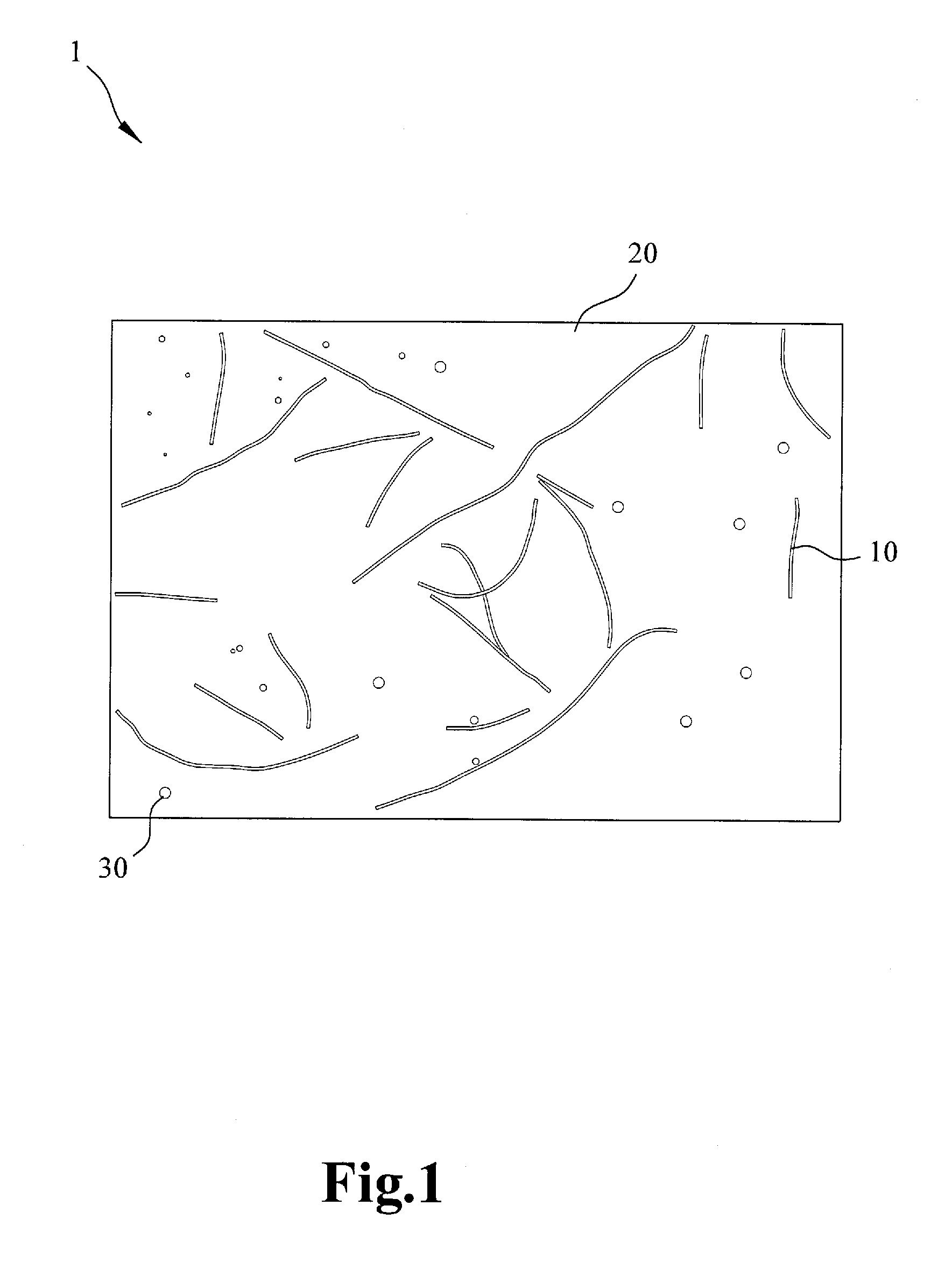

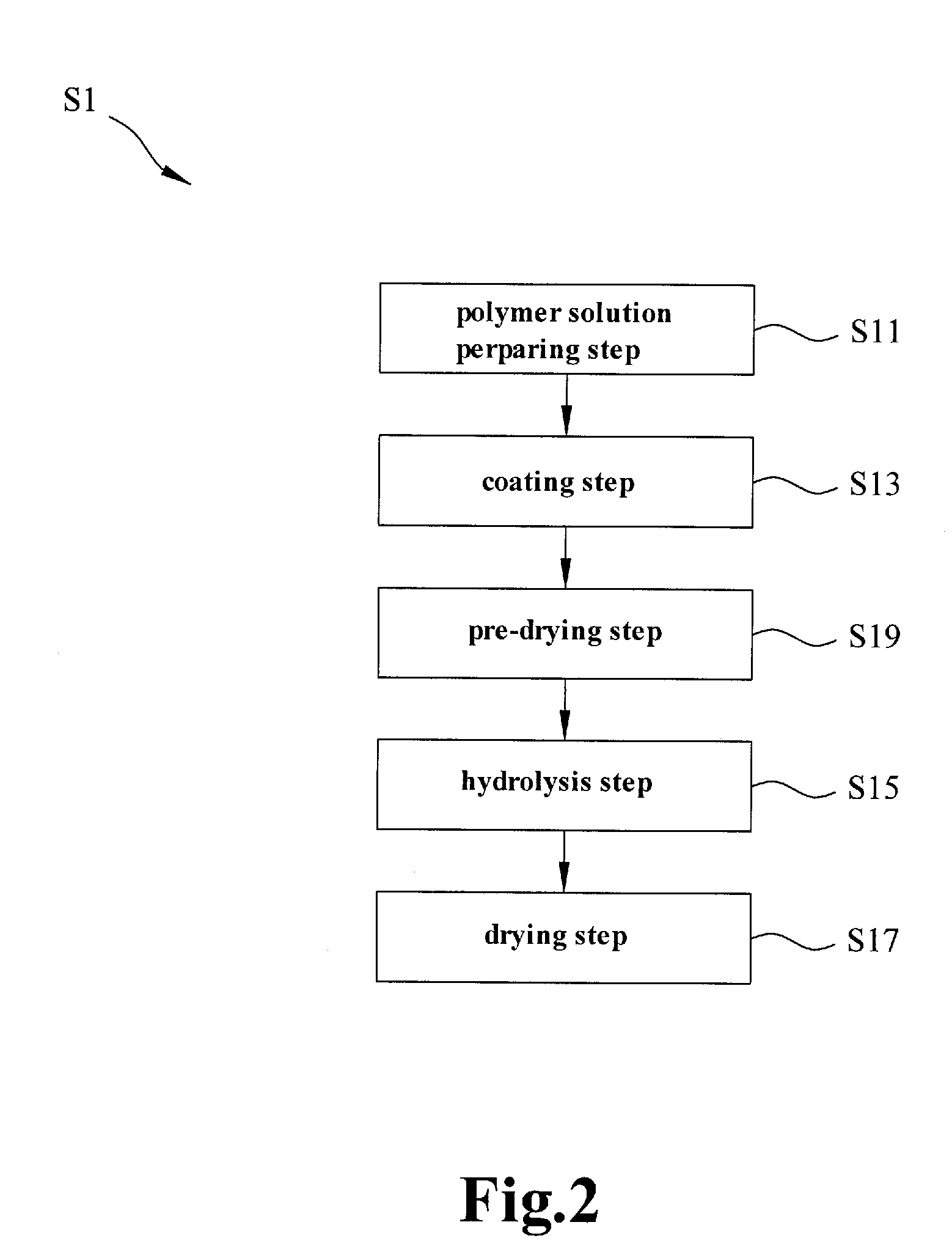

Electrochemical separation membrane and the manufacturing method thereof

ActiveUS20130327704A1Improve Interface StabilityImprove thermal stabilitySemi-permeable membranesCell component detailsPolymer scienceChemical separation

An electrochemical separation membrane and the manufacturing method thereof are disclosed. The method includes: a polymer solution preparing step to mix a polymer material, solvent and ceramic precursors thoroughly to form a polymer solution, wherein the polymer material and the ceramic precursors are dissolved uniformly in the solvent; a coating step to coat the polymer solution on a porous base material; a hydrolysis step to cause the porous base material coated with the polymer solution to contact an aqueous solution to hydrolyze the ceramic precursor into ceramic particles; and a drying step to remove the water and the solvent from the porous base material and in order to form the electrochemical separation membrane. The electrochemical separation membrane made of this method have better ion conductivity, interface stability and thermal stability based on the ceramic particles.

Owner:ENERAGE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com