Patents

Literature

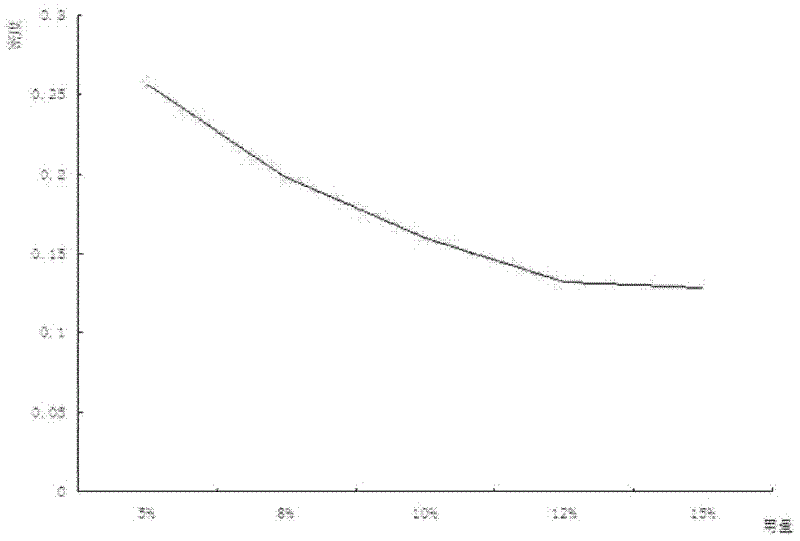

172 results about "Isopentane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopentane, C₅H₁₂, also called methylbutane or 2-methylbutane, is a branched-chain alkane with five carbon atoms. Isopentane is an extremely volatile and extremely flammable liquid at room temperature and pressure. It is also the least dense liquid at standard conditions for temperature and pressure.The normal boiling point is just a few degrees above room temperature and isopentane will readily boil and evaporate away on a warm day. Isopentane is commonly used in conjunction with liquid nitrogen to achieve a liquid bath temperature of −160 °C. Natural gas typically contains 1% or less isopentane.

Renewable Engine Fuel

ActiveUS20080244961A1Boost octaneIncrease energy contentHydrocarbon purification/separationBiofuelsFuranCarbon number

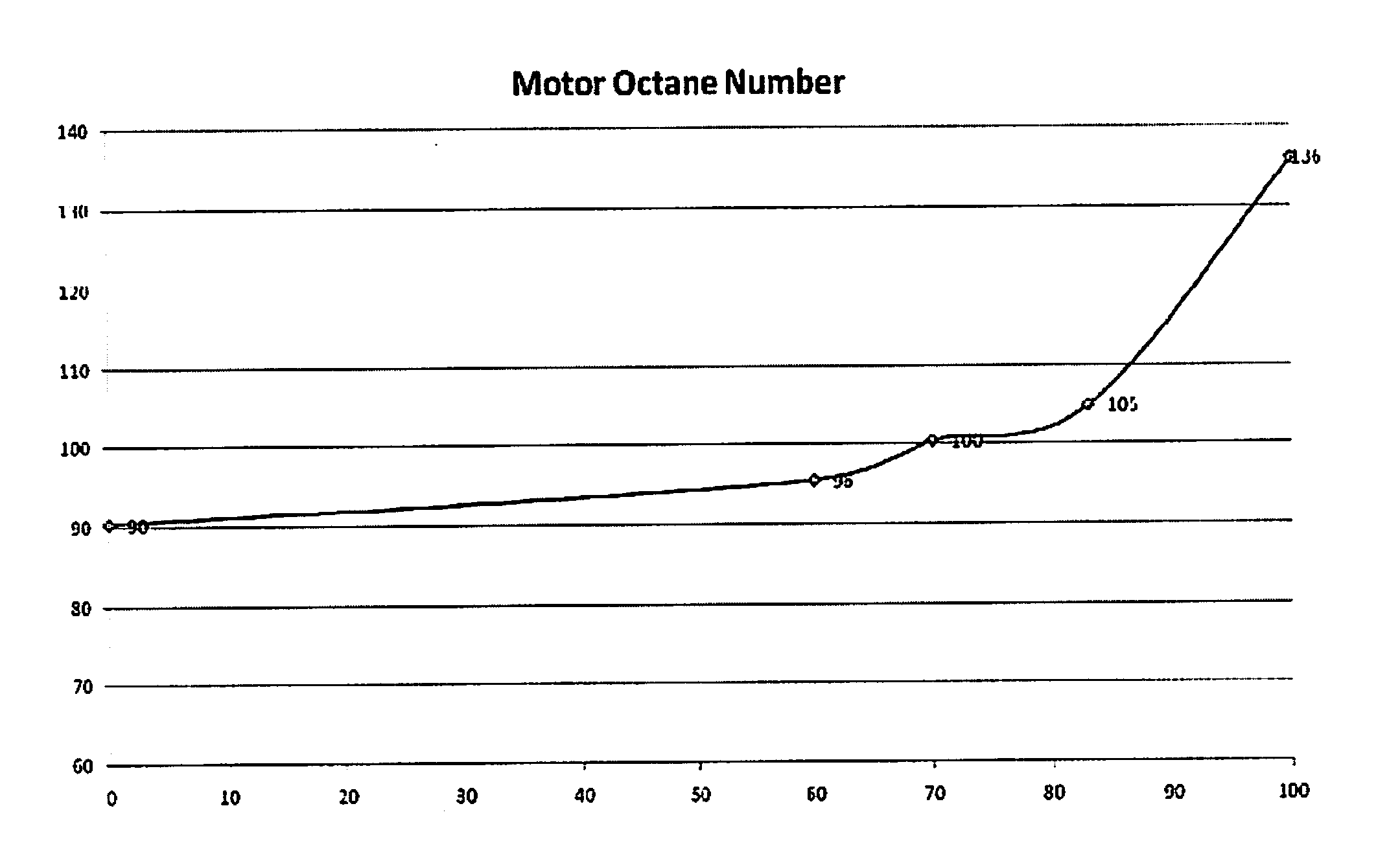

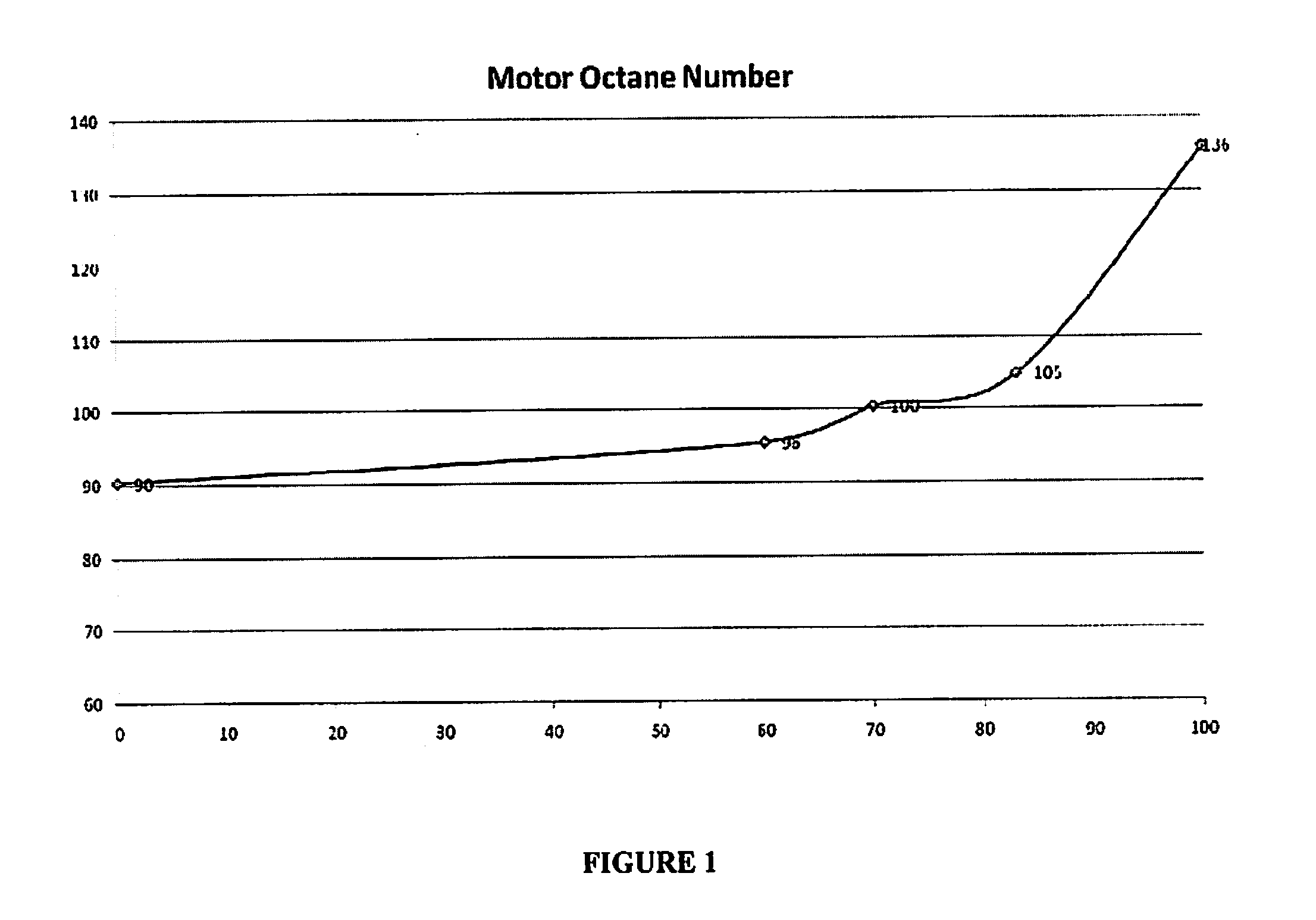

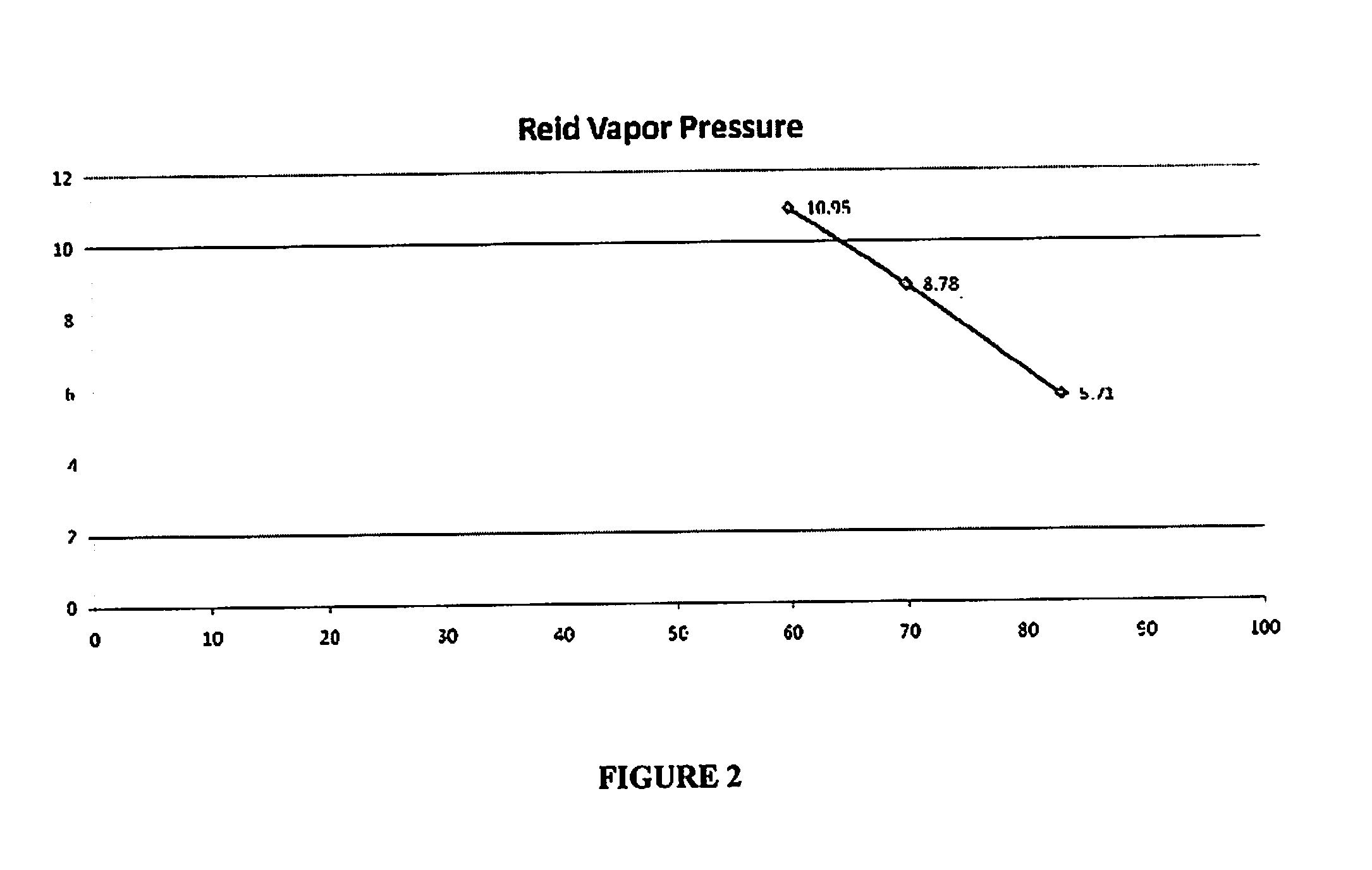

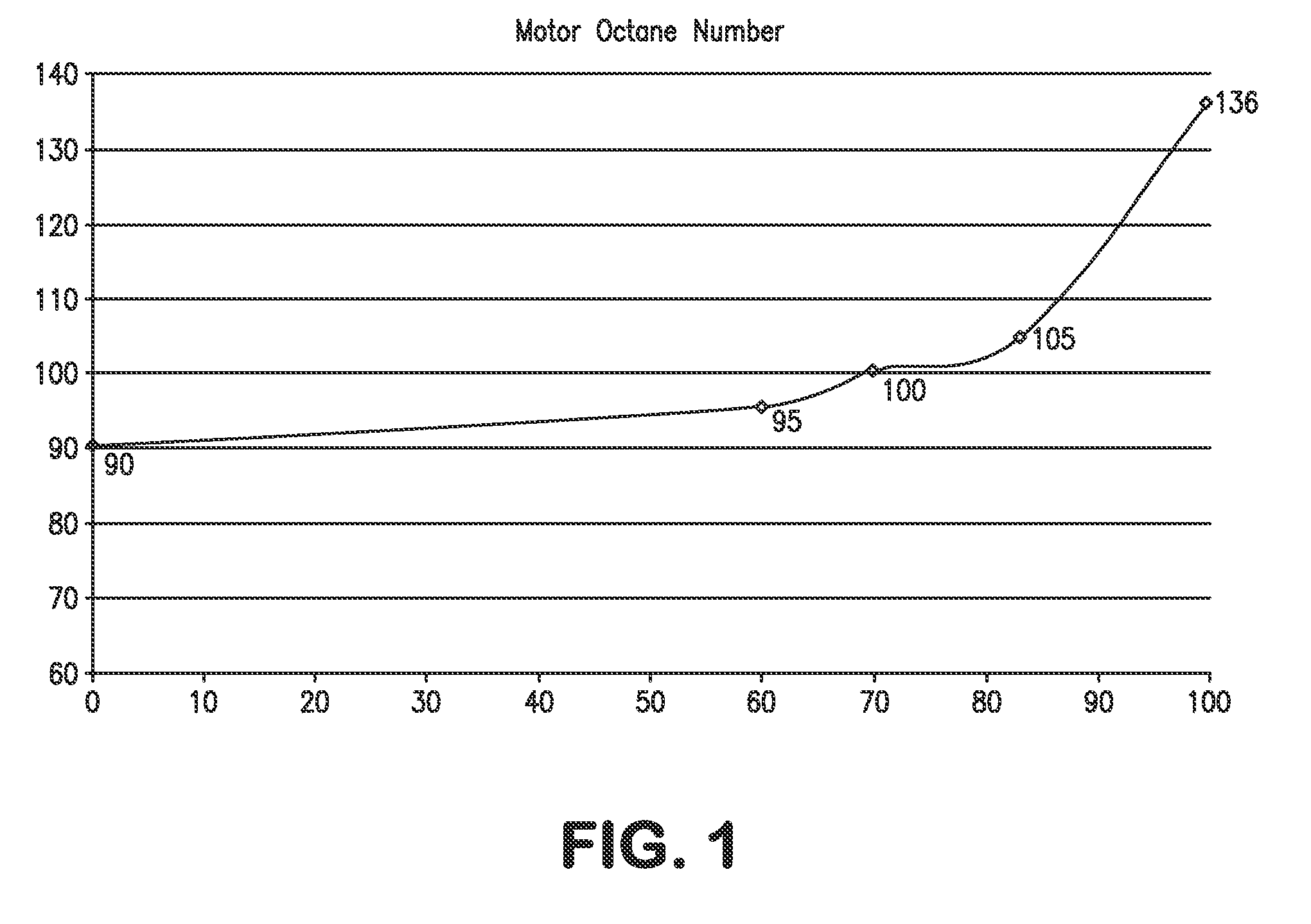

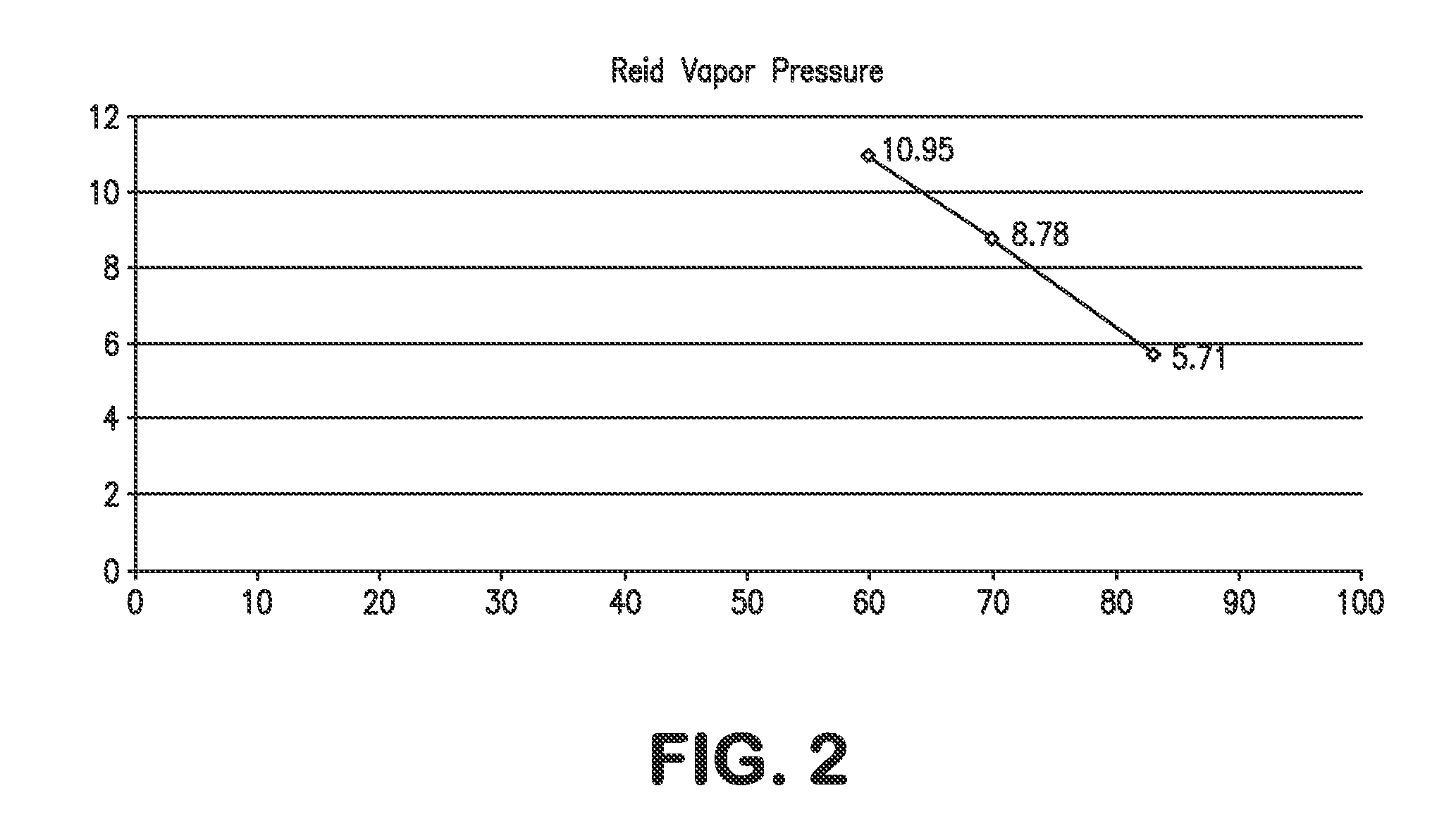

The present invention provides fully renewable engine fuels derived completely from biomass sources. In one embodiment the fully renewable engine fuel is comprised of one or more low carbon number esters, one or more pentosan-derivable furans, one or more aromatic hydrocarbon, one or more C4-C10 straight chain alkanes derivable from polysaccharides, and one or more bio-oils. In addition, the fuel may contain triethanolamine. Such a lower octane renewable fuel may be utilized, for example, in automobile fuel, 100 LL aviation fuel applications, and turbine engine applications. These ethanol-based, fully renewable fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high octane, rocket, diesel, and turbine engine fuels. In another embodiment, there is provided a synthetic high octane aviation fuel comprising isopentane and mesitylene, and process of producing same from a biomass.

Owner:SWIFT ENTERPRISES

Supported ionic liquid and the use thereof in the disproportionation of isopentane

InactiveUS20050033102A1Increased product formationIncreased formationOrganic-compounds/hydrides/coordination-complexes catalystsCatalysts2-methylbutaneAlkane

A catalyst system containing an ionic liquid dispersed on a support having an average pore diameter greater than about 225 Å is disclosed. The catalyst system is employed in a process to disproportionate a C5 paraffin.

Owner:CONOCOPHILLIPS CO

Renewable engine fuel

Owner:SWIFT ENTERPRISES

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing z-1,1,1,4,4,4-hexafluoro-2-butene and their uses in the preparation of polyisocyanate-based foams

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing cis-1,1,1,4,4,4-hexafluoro-2-butene are disclosed. The foam-forming composition contains (a) an azeotropic or azeotrope-like mixture of cis-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, pentane, isopentane, cyclopentane, HFC-245fa, or dimethoxymethane; and (b) an active hydrogen-containing compound having two or more active hydrogens. Also disclosed is a closed-cell polyurethane or polyisocyanurate polymer foam prepared from reaction of an effective amount of the foam-forming composition with a suitable polyisocyanate. Also disclosed is a process for producing a closed-cell polyurethane or polyisocyanurate polymer foam by reacting an effective amount of the foam-forming composition with a suitable polyisocyanate.

Owner:THE CHEMOURS CO FC LLC

Composition and manufacture of topical pharmaceutical and cosmetic semi-solid post-foaming dosage forms in a pouch

A pouch containing a non-pressurized post-foaming gel, wherein the gel within the pouch is enclosed within an inert atmosphere, such as a nitrogen blanket, which protects the gel and prevents premature foaming and the separation of the gel's components. Upon opening the pouch and discharging the contents, the heat of the user's skin allows a low boiling point hydrocarbon, such as isopentane, to cause the gel to foam, thus providing the consumer with an instant benefit which could include cleansing, moisturizing, increasing shave comfort, wound treatment, etc. Further, the process to produce a gel which is suitable for use in a single use delivery system involves the steps of containing the gel in a jar, spraying the gel with nitrogen to remove the air from the jar, and then swirling the jar to form a non-aerated gel without weight variation problems.

Owner:EVEREADY BATTERY CO INC

Insulation boards and methods for their manufacture

A method for producing polyisocyanurate insulation foams, the method comprising contacting an A-side stream of reactants that includes an isocyanate with a B-side stream of reactants that include a polyol and a blowing agent, where the blowing agent includes isopentane and n-pentane in a substantial absence of cyclopentane.

Owner:HOLCIM

Renewable engine fuel and method of producing same

ActiveUS8313540B2Avoid poisoningHydrocarbon from oxygen organic compoundsLiquid carbonaceous fuelsRocketPetroleum

Owner:SWIFT ENTERPRISES

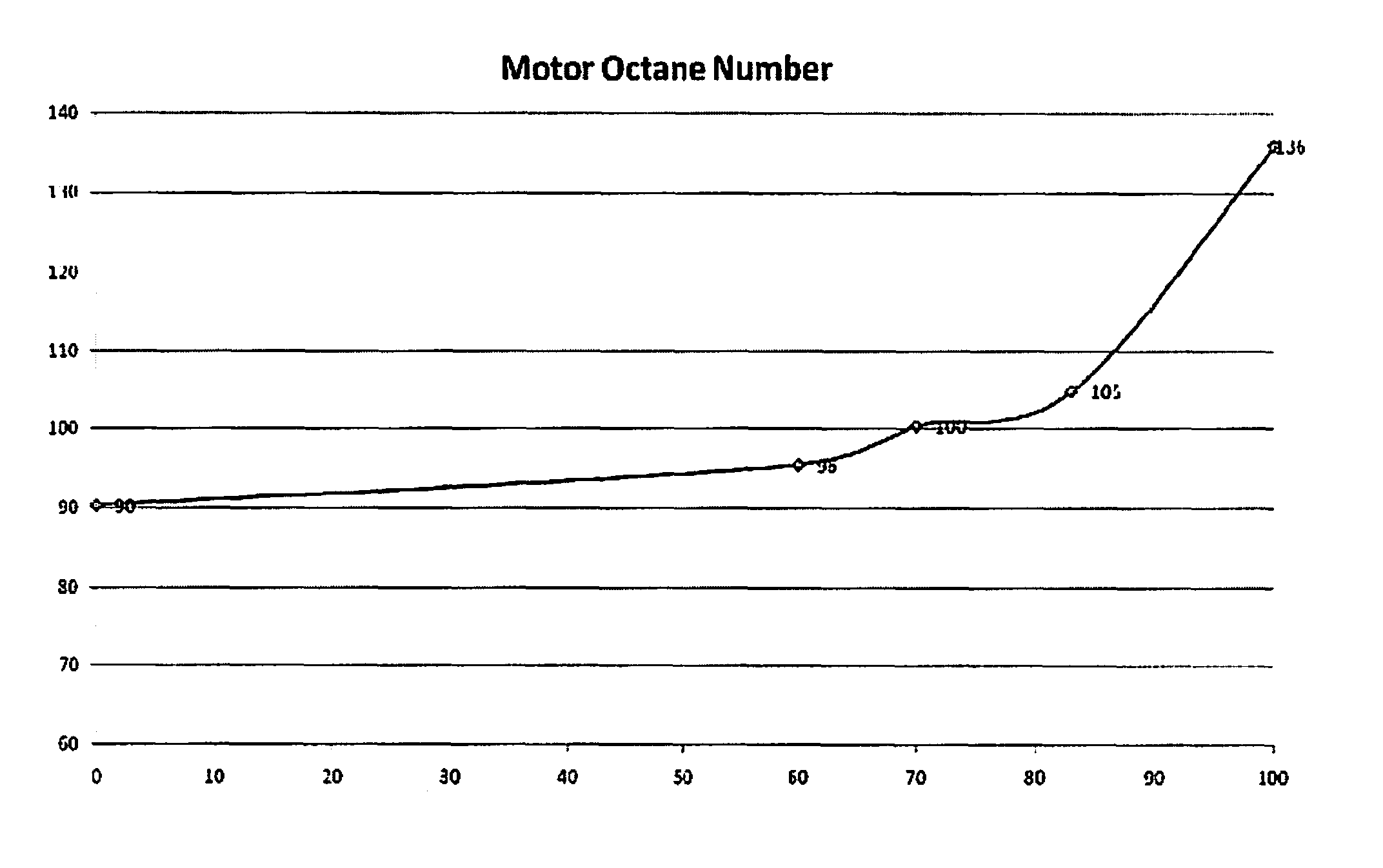

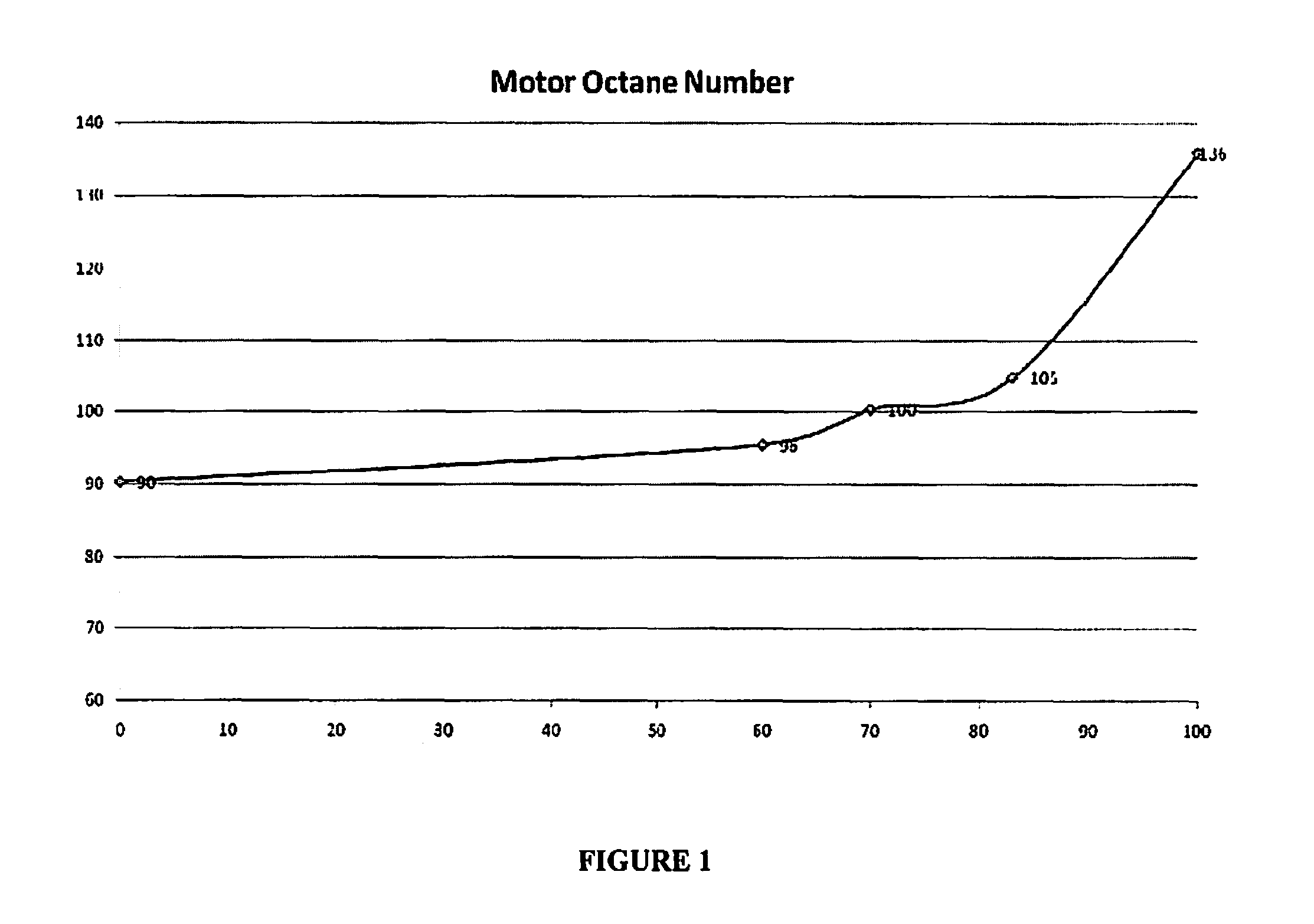

Renewable Engine Fuel And Method Of Producing Same

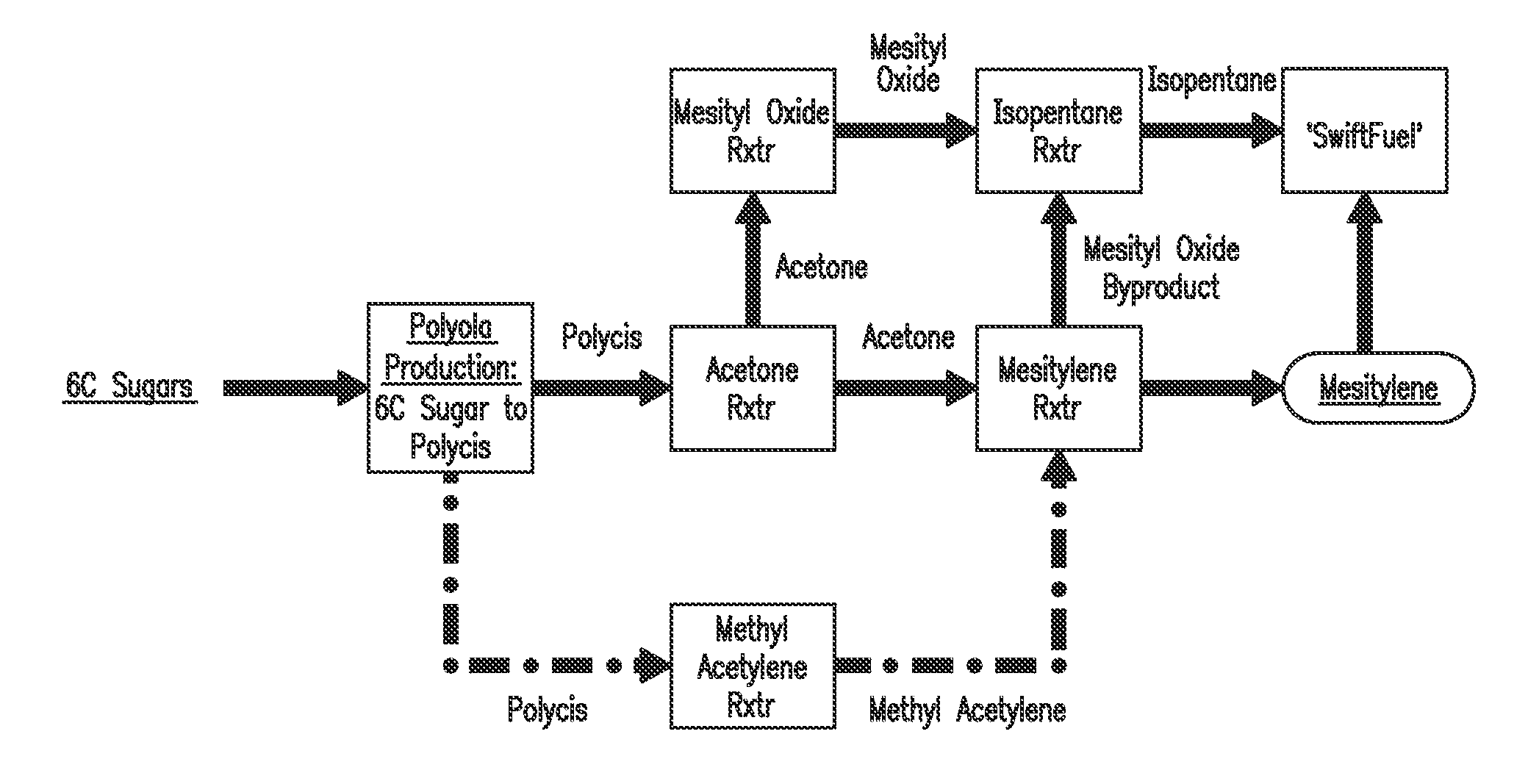

The present invention provides non-petroleum high-octane fuel derived from biomass sources, and a method of producing same. The method of production involves reducing the biomass feedstocks to sugars, fermenting the sugars using microorganisms or mutagens thereof to produce ethanol or acetic acid, converting the acetic acid or ethanol to acetone, and converting the acetone to mesitylene and isopentane, the major components of the renewable engine fuel. Trimerization of acetone can be carried out in the presence of a catalyst containing at least one metal selected from the group consisting of niobium, iron and manganese. The ethanol can be converted to mesitylene in a dehydration reaction in the presence of a catalyst of zinc oxide / calcium oxide, and unreacted ethanol and water separated from mesitylene by distillation. These ethanol-based, biomass-derived fuels are fully renewable, may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high-octane, rocket, diesel, turbine engine fuels, as well as two-cycle, spark-ignited engine fuels.

Owner:SWIFT ENTERPRISES

Polyolefin foams made with isopentane-based blowing agents

A blowing agent blend for making polyolefin foams comprising isopentane and at least one co-blowing agent. The co-blowing agent is either a physical co-blowing agent having a boiling point less than 28° C., or a chemical co-blowing agent, or combinations thereof. The blowing agent blend comprises less than about 99 mol % isopentane.

Owner:PREGIS INNOVATIVE PACKAGING

Aviation gasoline for aircraft piston engines, preparation process thereof

InactiveUS20110114536A1Reduce sulfur contentImprove the immunityLiquid carbonaceous fuelsFuel additivesAviationGasoline

The subject of the present disclosure is an aviation gasoline composition that is lead-free and free of oxygenated compounds meeting the specifications of the ASTM standard comprising isopentane, isooctane, and (alkyl)aromatics. The aviation gasoline composition according to the disclosure may be obtained simply and economically from a mixture of hydrocarbon bases usually available in a refinery.

Owner:TOTAL MARKETING SERVICES

Disproportionation of isopentane

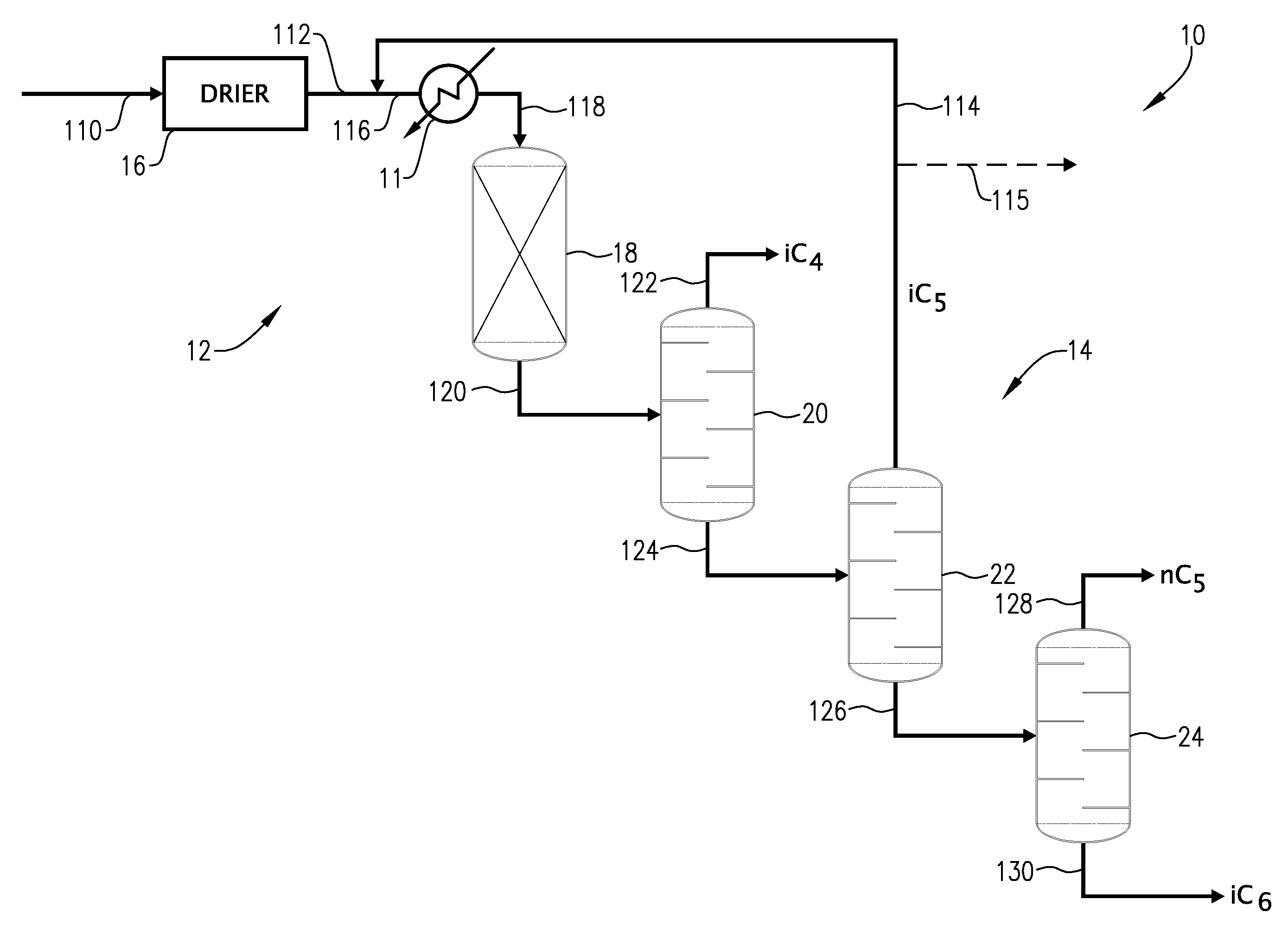

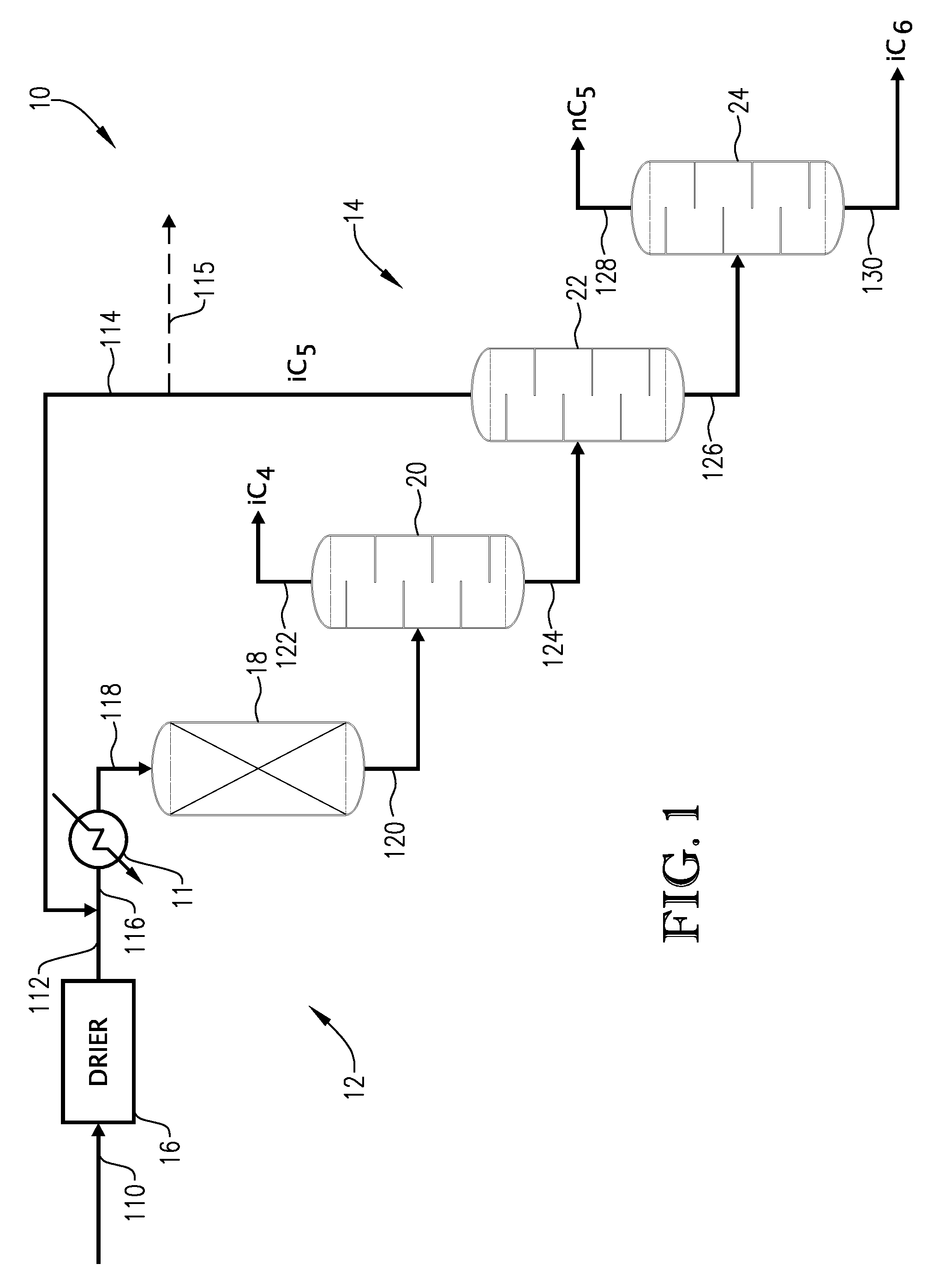

A process for disproportionating isopentane into isomers of hexane and butane that utilizes a fixed bed reactor employing a catalyst composition comprising aluminum halide. The process additionally includes a product separation zone which can be configured to recover and return at least a portion of the isopentane product stream to the inlet of the disproportionation reactor.

Owner:PHILLIPS 66 CO

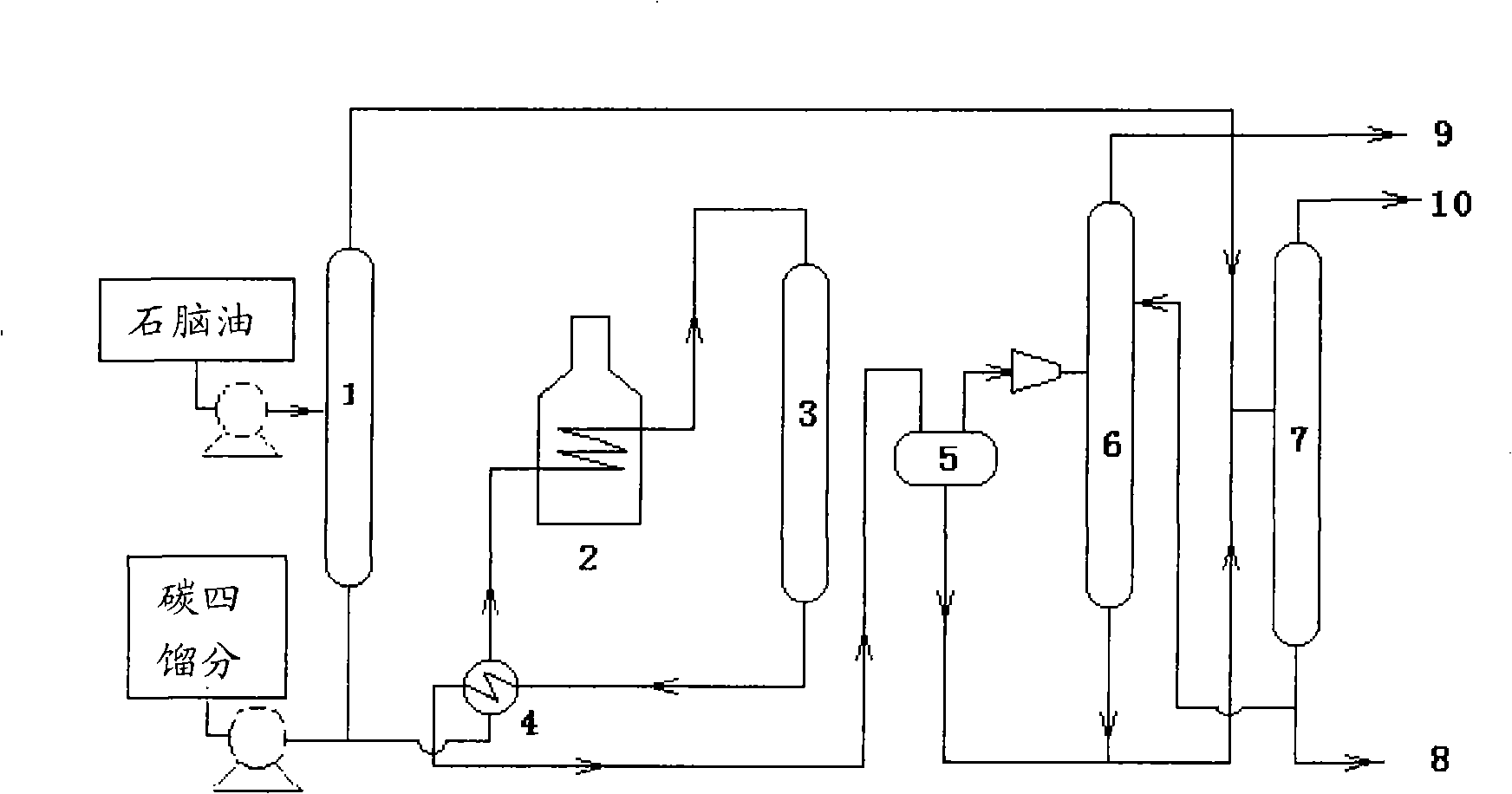

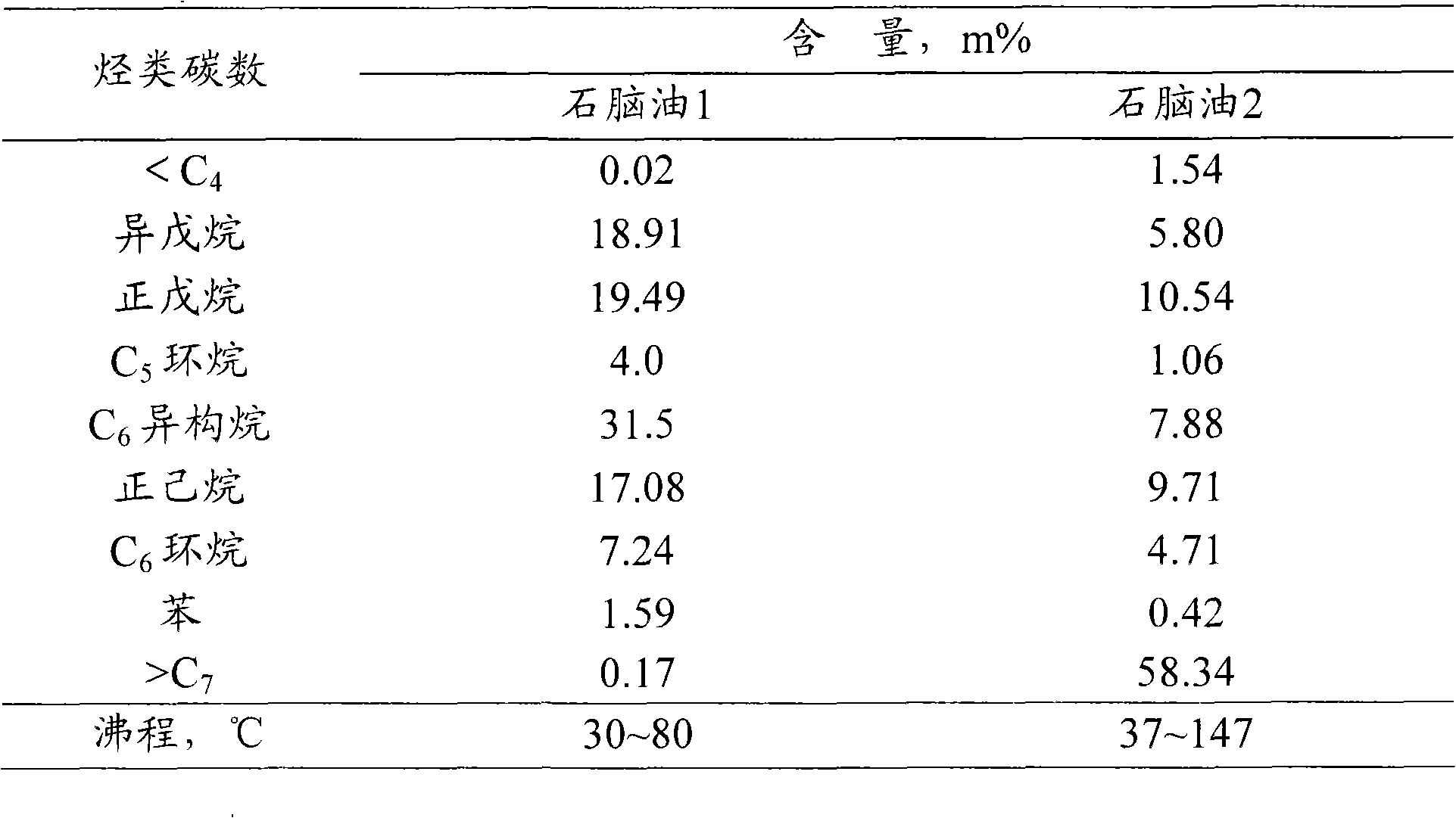

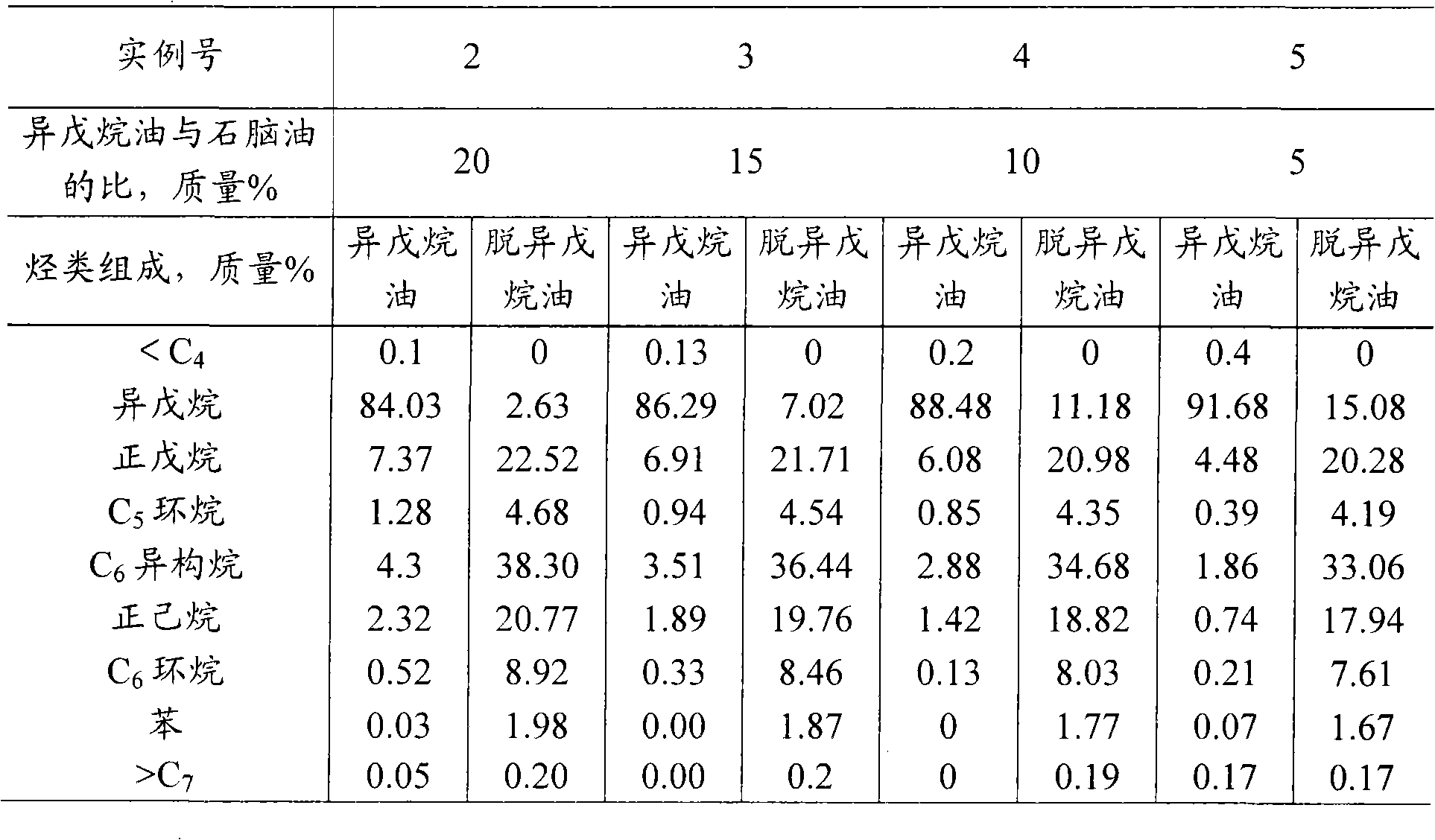

Method for producing clean gasoline by naphtha upgrading

The present invention relates to a method for producing clean gasoline by upgrading naphtha. The method includes the following steps: naphtha is fractionated in order to separate out isopentane oil and de-isopentane oil, and with the existing of catalyst, the de-isopentane oil is upgraded without hydrogen, so that clean gasoline and liquefied gas are produced. The method can increase the liquid yield of the upgrading reaction and the treatment capacity of a reacting device. In particular, after the isopentane oil is bended with the upgraded gasoline, the liquid yield of the whole reaction canbe greatly increased, and the content of the aromatic hydrocarbon of the blended oil can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluorinated compositions and systems using such compositions

InactiveUS20100101245A1Improve performanceImprove the lubrication effectShow cabinetsMechanical apparatusChemistryPentane

Disclosed are refrigerant compositions comprising the following components, as expressed in weight percent, and such that the total adds up to 100%, including any additives.7.0-9.0% wt. R32 [difluoromethane, CH2F2, having a normal boiling point of −51.7° C.];39.0-50.0% wt. R125 [pentafluoroethane, CF3CHF2, having a normal boiling point of −48.5° C.];39.0-50.0% wt R134a [1,1,1,2 tetrafluoroethane, CF3CHF2, normal boiling point of −26.1° C.];1.9 to 2.5% wt hydrocarbon, which consists essentially of1.5-1.8% wt R600 [n-butane, CH3CH2CH2CH3, normal boiling point of −0.5° C.], and0.4-0.7% wt R601a [isopentane, ((CH3)2CHCH2CH3, having normal boiling point of +27.8° C.] or R601 [n-pentane (CH3CH2CH2 CH2CH3, having a normal boiling point of +36° C.)].Further disclosed are refrigerators, freezers, air conditioners, water chillers, and heat pumps using the compositions described herein as at least one of the heat transfer compositions in the equipment.

Owner:EI DU PONT DE NEMOURS & CO

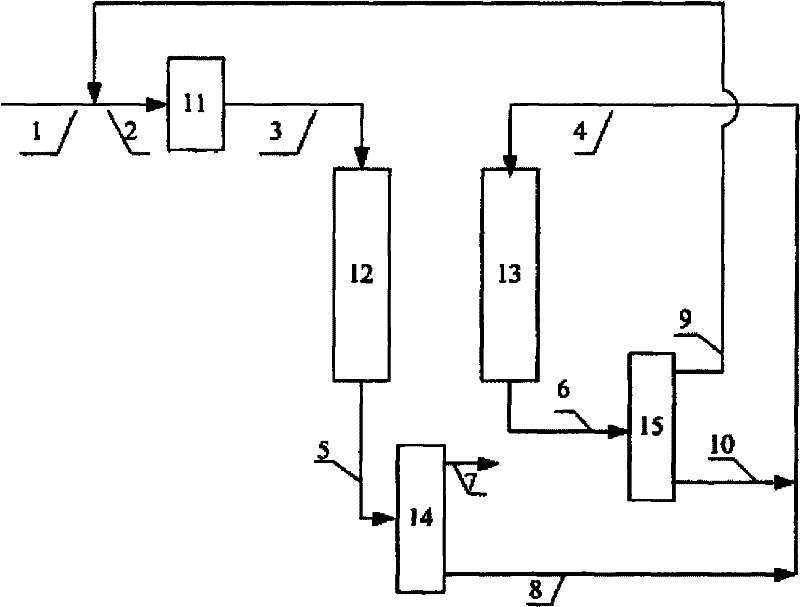

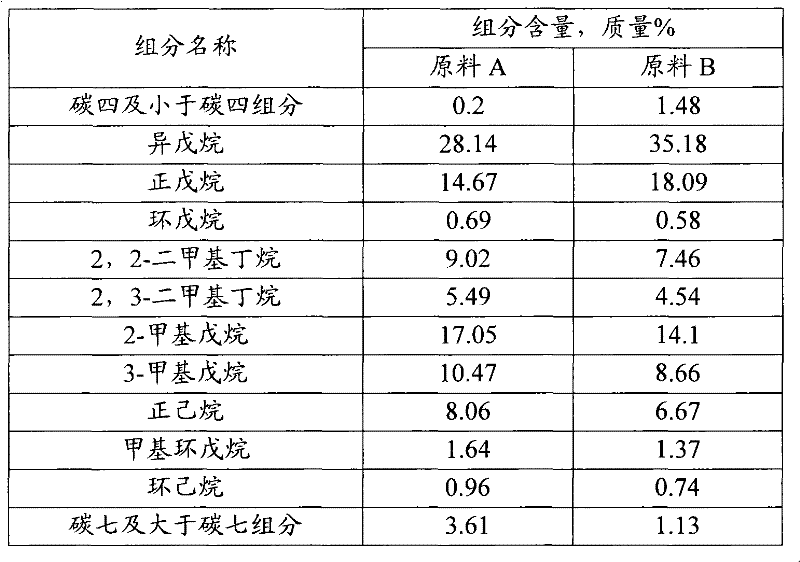

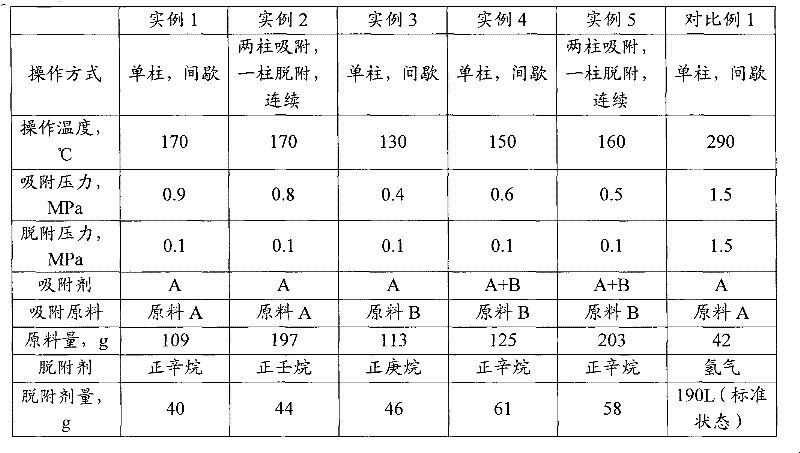

Adsorption and separation method of C5 and C6 isomerization product

ActiveCN102452885AReduce dosageReduce energy consumptionHydrocarbon by isomerisationAdsorption purification/separationIsomerizationGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

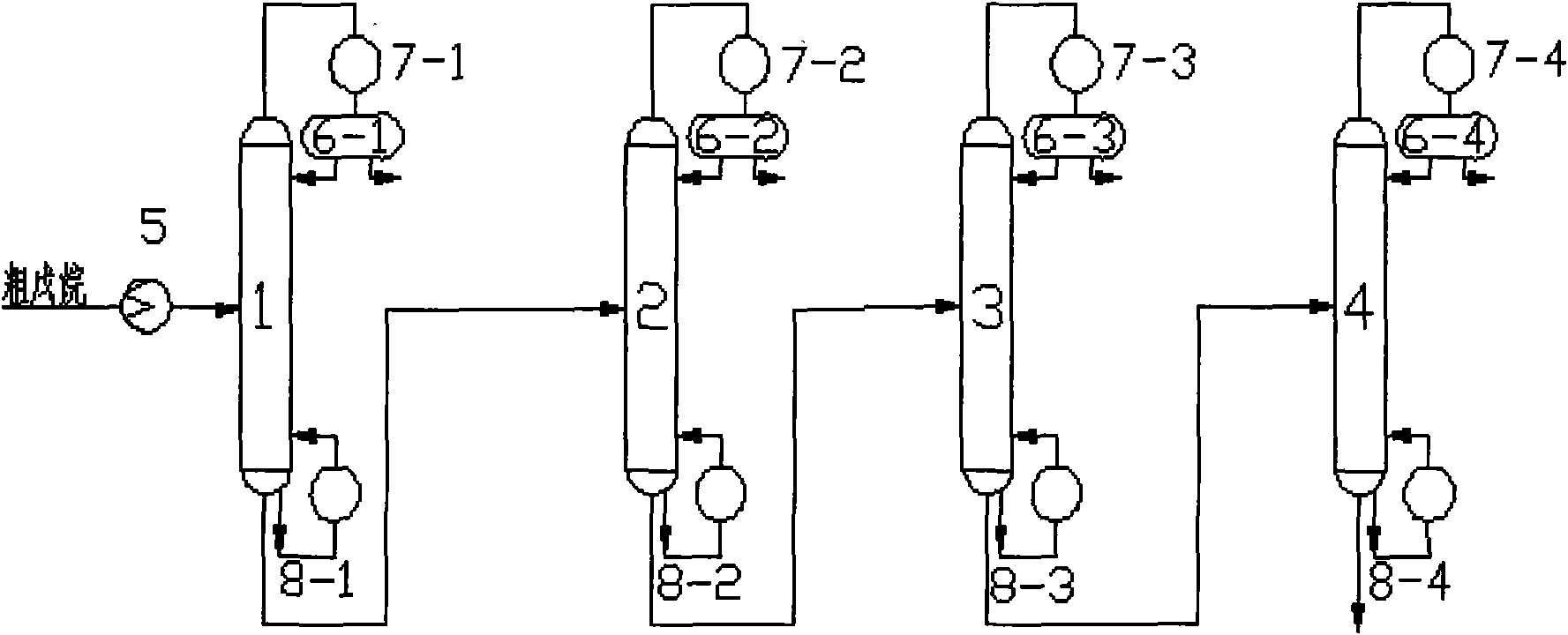

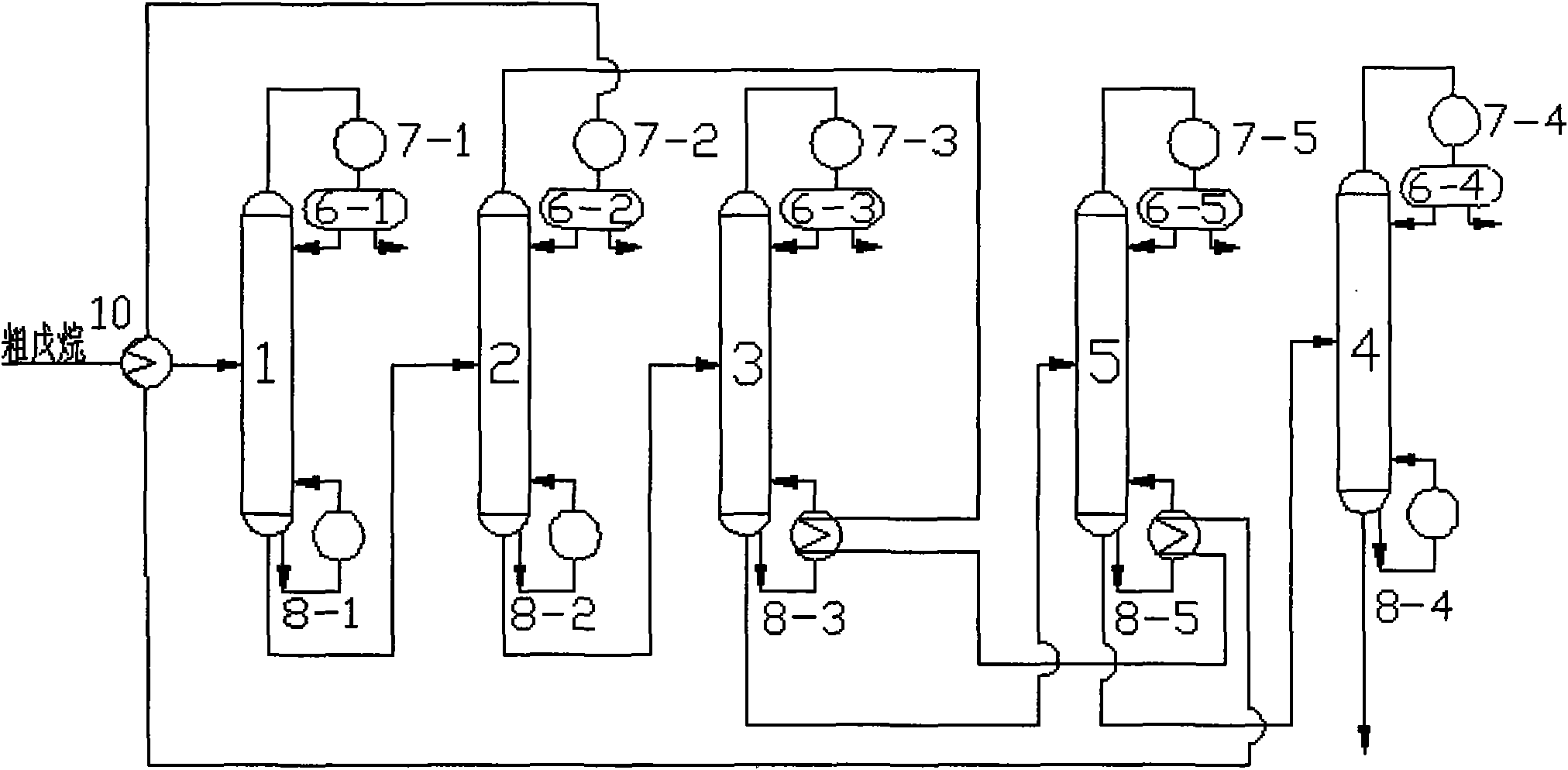

Double-effect rectification method and system thereof for finely separating hybrid pentane isomer

ActiveCN101602641AImprove product qualityReduce consumptionDistillation purification/separation2-methylbutaneReboiler

The invention discloses a double-effect rectification method for finely separating hybrid pentane isomer, which comprises the following steps: introducing a crude pentane raw material into a condensation preheater, a dehydrogenation tower of which the top is connected with a condenser and a reflux tank and the bottom is connected with a reboiler, an isopentane tower, an n-pentane tower, an azeotrope tower and a cyclopentane tower in turn to be rectified and separated, feeding total vapor at the tower top of the isopentane tower into the n-pentane tower and the reboiler as heat sources thereof, condensing the vapor into a two-phase mixture of vapor and liquid after heat exchange, then feeding the mixture to the azeotrope tower and the reboiler to exchange heat, re-preheating the crude pentane raw material by the waste heat after heat exchange, and finally beating the liquid to the isopentane tower as reflux liquid by a reflux pump of the isopentane tower. The method has the advantages of high product purity and low energy consumption and water consumption; and the product can be flexibly controlled according to the requirement.

Owner:TIANJIN UNIV

Aviation gasoline for aircraft piston engines, preparation process thereof

The subject of the present disclosure is an aviation gasoline composition that is lead-free and free of oxygenated compounds meeting the specifications of the ASTM standard comprising isopentane, isooctane, and (alkyl)aromatics. The aviation gasoline composition according to the disclosure may be obtained simply and economically from a mixture of hydrocarbon bases usually available in a refinery.

Owner:TOTAL MARKETING SERVICES SA

Method for rapidly preparing h0h oriented MFI molecular sieve membrane by microwave heating method

ActiveCN108636128AUniform coatingGood orientationSemi-permeable membranesDispersed particle separationMolecular sieveMicrowave

The invention relates to a method for rapidly preparing an h0h oriented MFI molecular sieve membrane by a microwave heating method, and is characterized in that a continuous dense crystal seed layer is formed on the surface of a porous ceramic support body pre-coated with a MFI molecular sieve. Crystal seeds are attached to the support body by a way of vacuum suction coating, and then the h0h oriented MFI molecular sieve membrane is prepared rapidly by a way of microwave heating in dilute synthetic sol. The synthetic time of the method is greatly shortened, and the cost of synthesis is greatlyreduced. The prepared h0h oriented molecular sieve membrane is applied to separation of n-butane / isobutane and n-pentane / isopentane mixed components, and has high separation performance.

Owner:NANJING UNIV OF TECH +1

Alkylate gasoline composition with renewable naphtha and iso-octane

ActiveUS20200048569A1Increase the mixing ratioOrganic chemistryBiofuelsNaphthaBiochemical engineering

Processes for making alkylate gasoline compositions that are more “green” and alkylate gasoline compositions containing “green” renewable naphtha and iso octane are described. Exemplary processes for making alkylate gasoline compositions that are more “green” and compositions of alkylate gasoline compositions containing “green” renewable naphtha, iso octane and iso pentane are described. Such compositions allow a higher mixing ratio of the renewable naphtha and / or a higher Research Octane Number (RON), Motor Octane Number (MON) and vapour pressure compared to not adding a combination of iso-octane and iso-pentane.

Owner:NESTE OIL OY

Method for preparing foaming material by adopting bamboo liquefied product

The invention relates to a method for preparing a foaming material by adopting a bamboo liquefied product and aims at preparing a foaming body which is stable in quality and characterized by being even and fine in pore structure by means of the method. The technical scheme is that the method for preparing the foaming material by adopting the bamboo liquefied product resin comprises the steps of adding a surface active agent, a padding and a foaming agent into 100 parts by mass of the bamboo liquefied product resin, adding a curing agent and isocyanate after stirring evenly, quickly performing stirring for 15-25 seconds, pouring mixture into a mould, placing the mould in a drying oven with 70-90 DEG C to be thermalized for 3-5 hours, fetching out the mould and demoulding the mixture. The foaming agent is one or more of n-pentane, isopentane and cyclopentane in any proportion, and the using amount is 8-15 parts by mass. The curing agent is one or two of p-toluenesulfonic acid and phosphoric acid in any proportion, the using amount is 16-20 parts by mass. The using amount of the isocyanate is 30-50 parts by mass.

Owner:ZHEJIANG FORESTRY ACAD

Optimized utilization method for light naphtha

InactiveCN106318459ADistillation purification/separationTreatment with plural serial refining stagesAlkaneNaphtha

The invention discloses an optimized utilization method for light naphtha. According to the method, firstly, the light naphtha passes through an adsorptive separation unit, adsorbed remaining oil rich in iso-alkanes and desorbed oil rich in n-alkanes can be obtained separately, and the desorbed oil can directly serve as an ethylene cracking stock; and the adsorbed remaining oil then passes through a rectifying unit, and a gasoline mixture rich in iso-C6 and high-purity isopentane can be obtained separately. According to the optimized utilization method for the light naphtha, an adsorptive separation-rectifying separation coupled process is adopted, the adsorptive separation unit uses a high-performance adsorbent, and the adsorbent can be used for achieving the distinct partition of the n-alkanes and the iso-alkanes according to molecular dimension difference, so that the selectivity is high, and the regeneration effect is good; and compared with the traditional multi-tower precise rectification, the method has the advantages that the energy consumption is low, and both the product purity and the product yield are relatively high.

Owner:SINOPEC YANGZI PETROCHEM +1

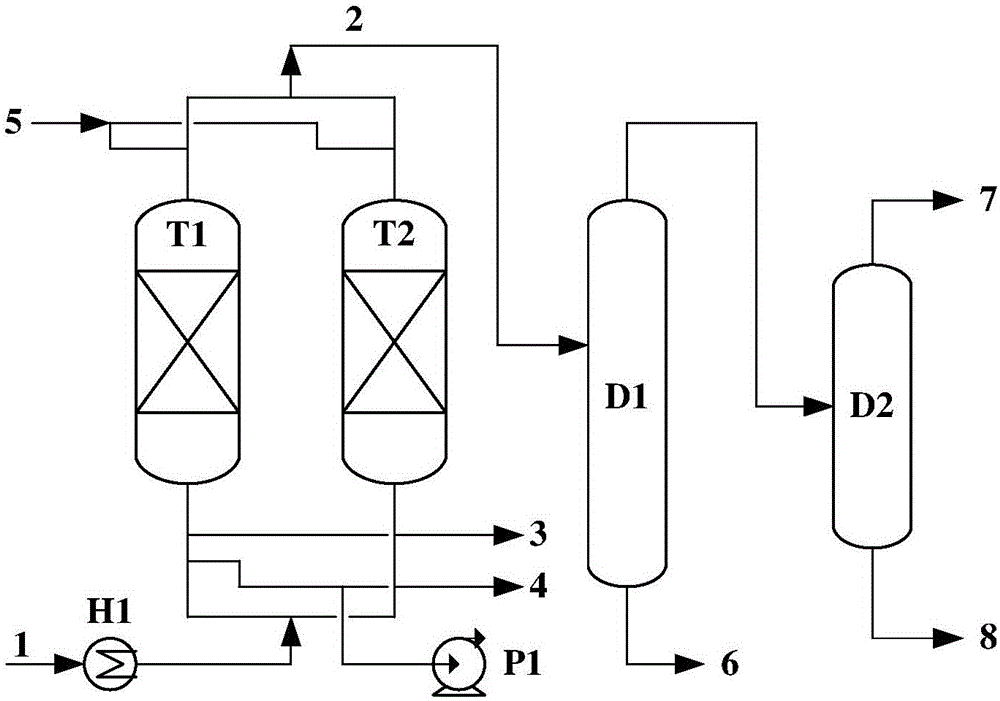

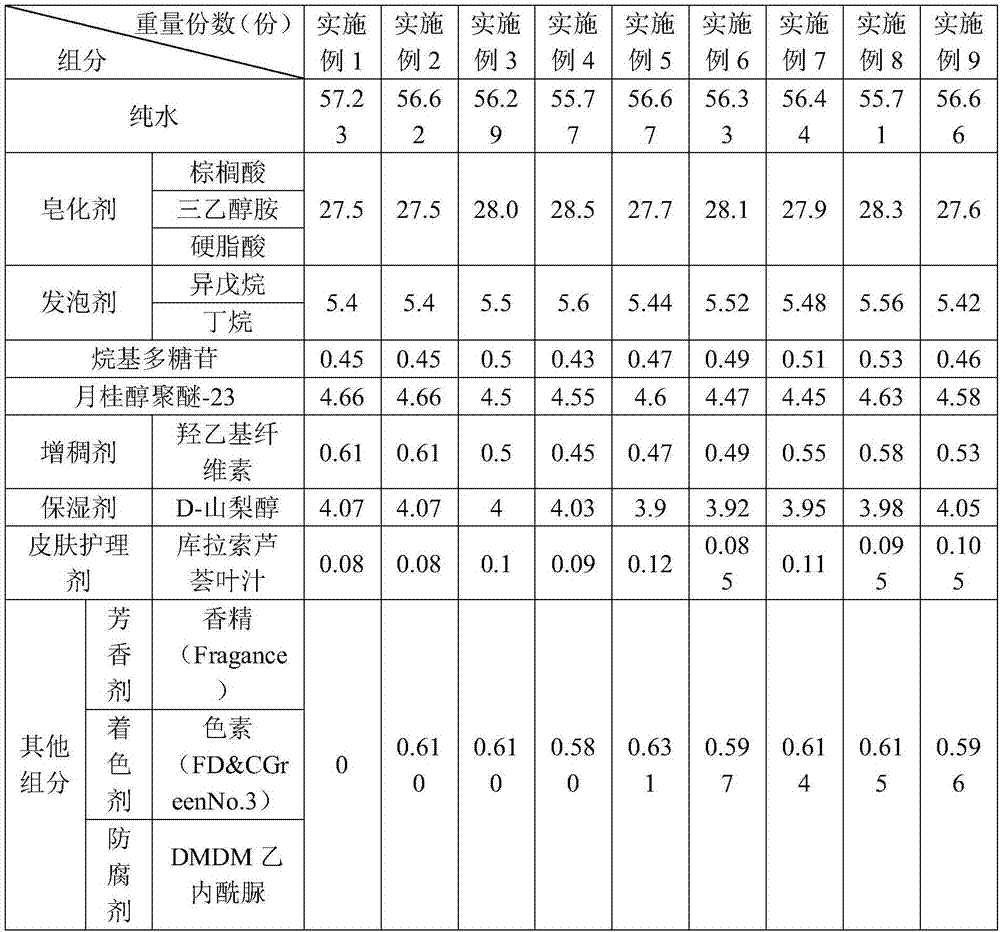

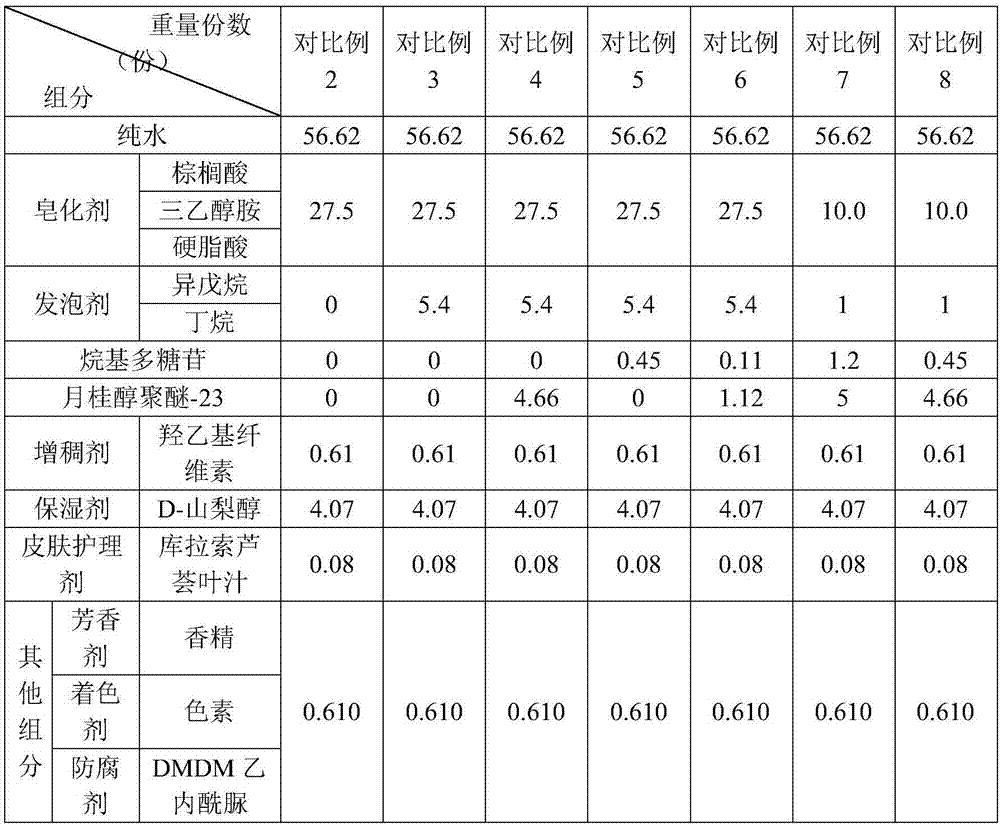

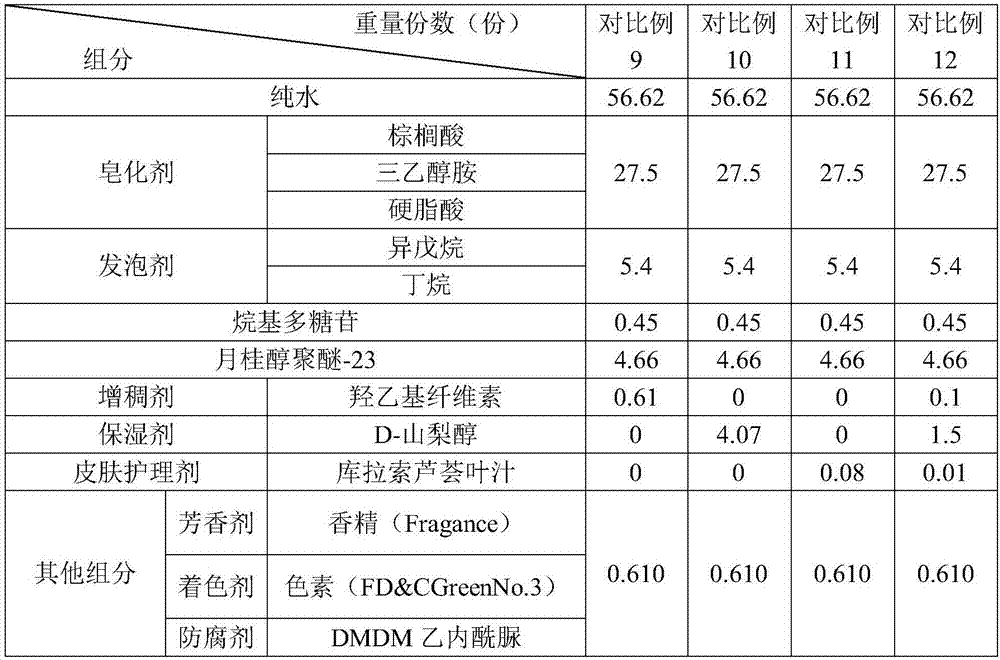

Production technology of post foaming face washing gel

ActiveCN107536773AEasy to cleanGood foaming effectCosmetic preparationsAntipyreticCelluloseStearic acid

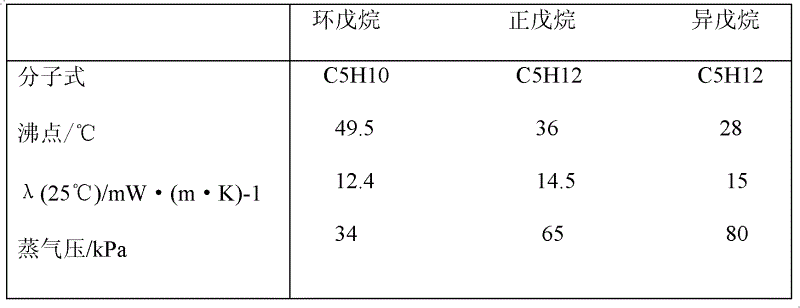

The invention discloses a production technology of post foaming face washing gel. The gel comprises purified water, saponifier, foaming agent, alkyl polyglucoside, laureth-23, thickener, humectant, skin care agent and other components; the saponifier comprises palmitic acid, triethanolamine and stearic acid; the foaming agent comprises isopentane and butane; the ratio of parts by weight of the saponifier and the foaming agent is (5.09-5.12):1; the thickener comprises one kind of hydroxyethyl cellulose, hydroxypropyl cellulose, methylcellulose and ethyl cellulose; the skin care agent comprisesone kind of curasao aloe leaf juice, sweet mint leaf extract and dandelion extract; the other components comprise one or more kinds of aromatic, coloring agent and preservative. The post foaming facewashing gel has the advantages that foam can be generated without rubbing and the gel is mild to the skin.

Owner:浙江高妍科技有限公司

Mixtures of hydrofluorcarbons and acids as foam blowing agents

A method of preparing polyurethane or polyisocyanurate from compositions comprising reacting and foaming a mixture of at least one polyol and isocyanate which react to form polyurethane or polyisocyanurate foams in the presence of a blowing agents which comprises: a hydrofluorocarbon or at least one compound selected from the group consisting of: propane, n-butane, isobutene, n-pentane, isopentane, neopentane, cyclopentane, acetone, dimethyl ether, and inert gases; an acid; and, optionally, water.

Owner:HONEYWELL INT INC

Three-element composite foaming agent, rigid polyurethane foam and preparation method of igid polyurethane foam

InactiveCN106188615AReduce energy consumptionRaise the level of energy consumptionPolymer scienceFoaming agent

The invention provides a three-element composite foaming agent. The tthree-element composite foaming agent comprises the following three components in parts by mass: 9-1 parts of cyclopentane, 5-1 parts of isopentane and 2-32 parts of trifluorochloroethylene LBA. Rigid polyurethane foam prepared by adopting the three-element composite foaming agent comprises the following components in parts by weight: 100 parts of premixed polyether polyol, 10-26 parts of the three-element composite foaming agent and 120-150 parts of isocyanate. The invention also provides a preparation method of the rigid polyurethane foam. The three-element foaming process provided by the invention has the advantages that the heat conducting coefficient of the polyurethane foam can be effectively reduced, and the energy consumption of an electric refrigerator can be reduced; the strength of pressure foam under the same density is enhanced, the foam density needed by the electric refrigerator can be reduced, so that the injection dosage of the whole electric refrigerator can be reduced; when the needed amount of the electric refrigerator is fixed, the waste of raw materials is reduced, simultaneously the production of the rigid polyurethane foam hard to treat is also reduced, and the pollution to the environment is reduced; the curing time of the foam is shortened by 10%-15%, and the production efficiency is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

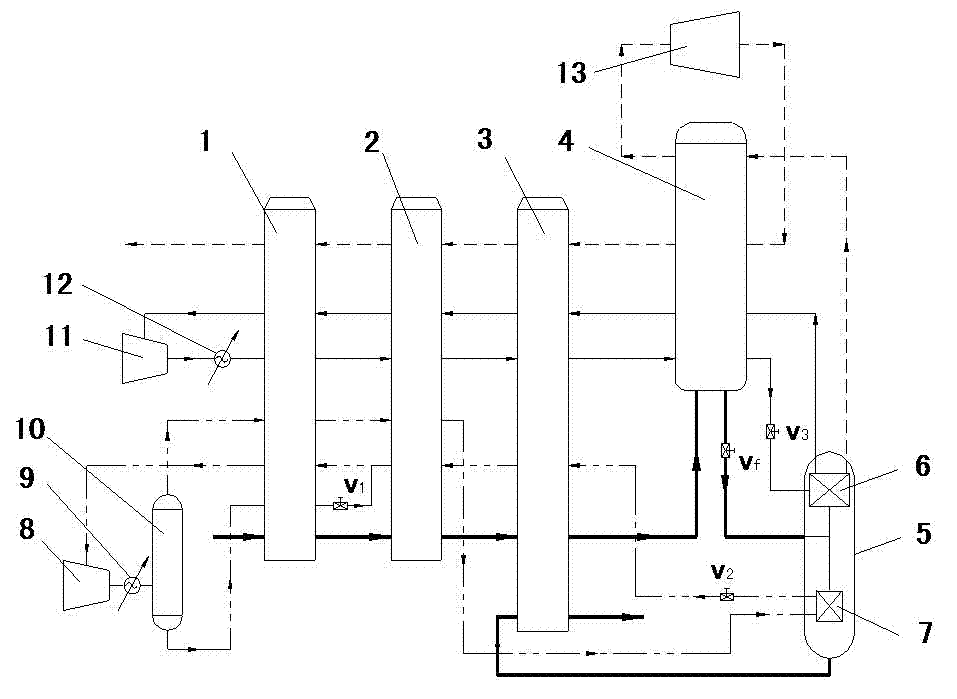

Process for preparing liquefied natural gas (LNG) by low concentration coal bed methane oxygen bearing copious cooling liquefaction

ActiveCN103175381ASolve the blockageAchieve the goal of energy saving and emission reductionSolidificationLiquefaction2-methylbutaneEvaporation

The invention discloses a process for preparing liquefied natural gas (LNG) by low concentration coal bed methane oxygen bearing copious cooling liquefaction. The process for preparing LNG by low concentration coal bed methane oxygen bearing copious cooling liquefaction comprises the following steps: (1), compression and purification process; (2), liquefaction and separation process which comprises a, main procedure process; b, refrigeratory process, wherein the refrigeratory process comprises b1, mixing cryogen process; and b2, nitrogen cryogen process. Nitrogen cryogen sequentially passes through a first level heat exchanger, a second level heat exchanger, a third level heat exchanger and a subcooler for cooling after being compressed and cooled, the nitrogen cryogen after throttling enters an overhead condenser to output cold quantity, and then the gaseous nitrogen cryogen sequentially passes through the subcooler, the third level heat exchanger, the second level heat exchanger, and the first level heat exchanger, the gaseous nitrogen cryogen is warmed gradually to normal temperature, and then flows back to a nitrogen compressor for being circularly used. The mixing cryogen process is used for controlling evaporation capacity at the bottom of a tower, the nitrogen cryogen process is used for controlling condensation capacity at the top of the tower, and independently adjusting purity coefficient and yield coefficient of natural gas products is achieved. The cryogen in a low temperature region only possesses a nitrogen component, and heavy components of isobutane, isopentane and the like do not exist in the low temperature region, and therefore the problems of being free of refrigeration in the process of throttling, or congestion of a cryogen channel are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Fuel composition containing bioethanol and biodiesel for internal combustion engine

Disclosed herein is a fuel composition for internal combustion engines, which comprises: a) 1-45 wt % of toluene; b) 1-45 wt % of xylene; c) 1-85 wt % of bioethanol, ethanol or a mixture thereof ; d) 10-69 wt % of industrial gasoline; e) 1-19 wt % of aromatic solvent; f) 1-13 wt % of isopropanol; and g) 1- 12 wt % of isobutanol. Also, the fuel composition can additionally contain isopentane to maximize the heating value of the composition upon burning, and can additionally contain, as an additive, a corrosion inhibitor which is conventionally added to liquid fuel in order to prevent the corrosion of internal combustion engines. The disclosed fuel shows a remarkable reduction in air pollution, compared to the existing gasoline, and, at the same time, has improved power performance, and thus is useful as alternative fuel having economic efficiency.

Owner:李容晚

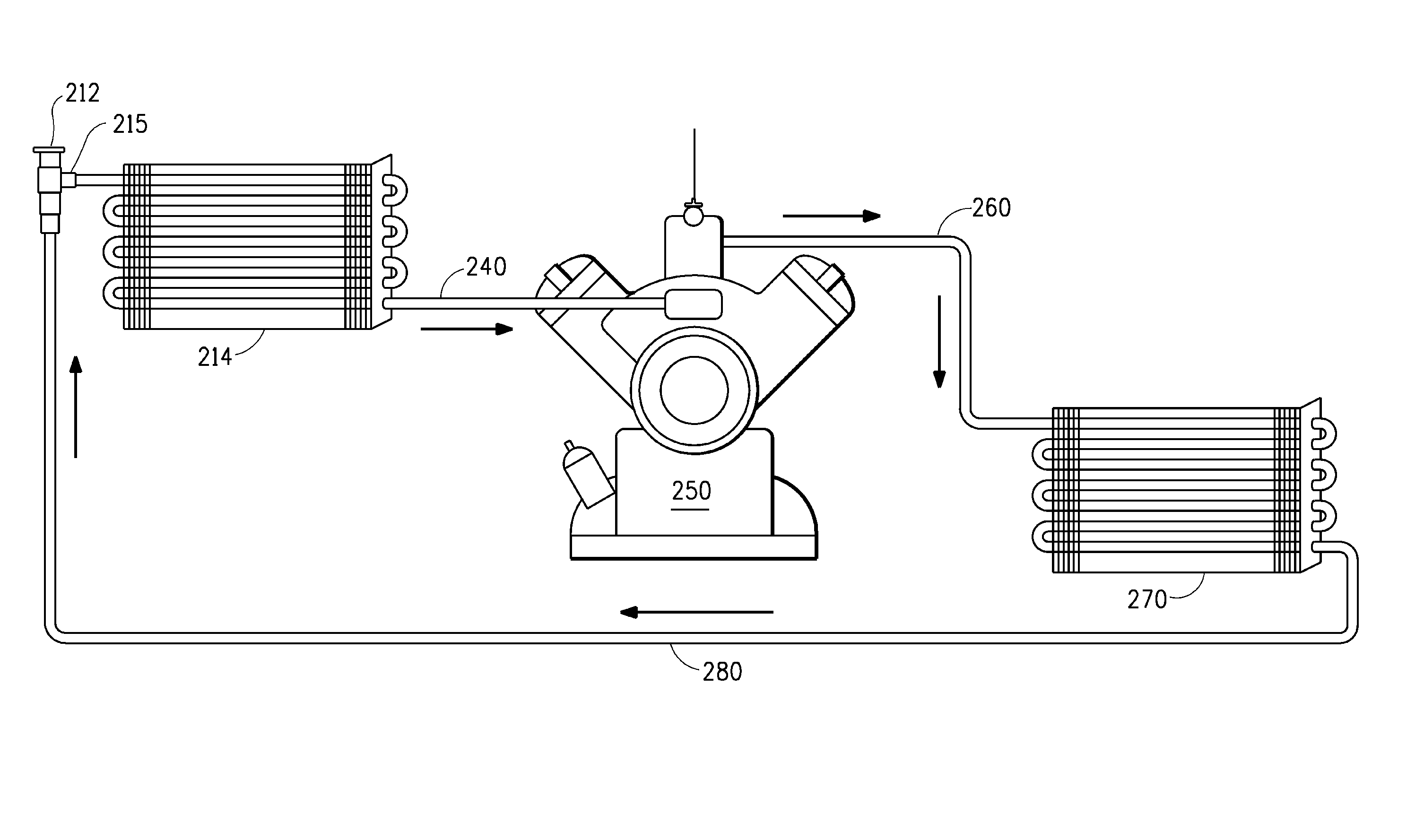

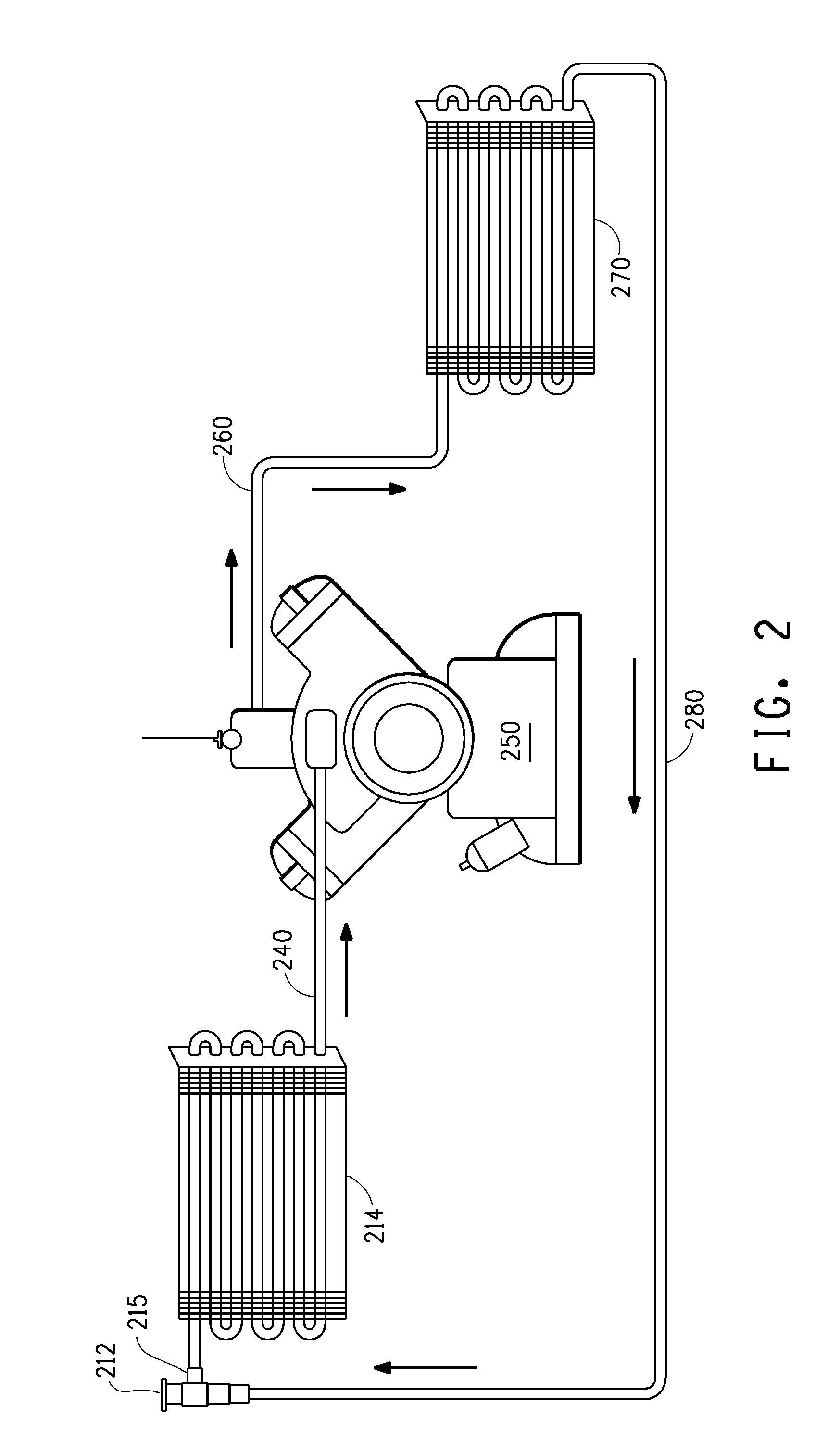

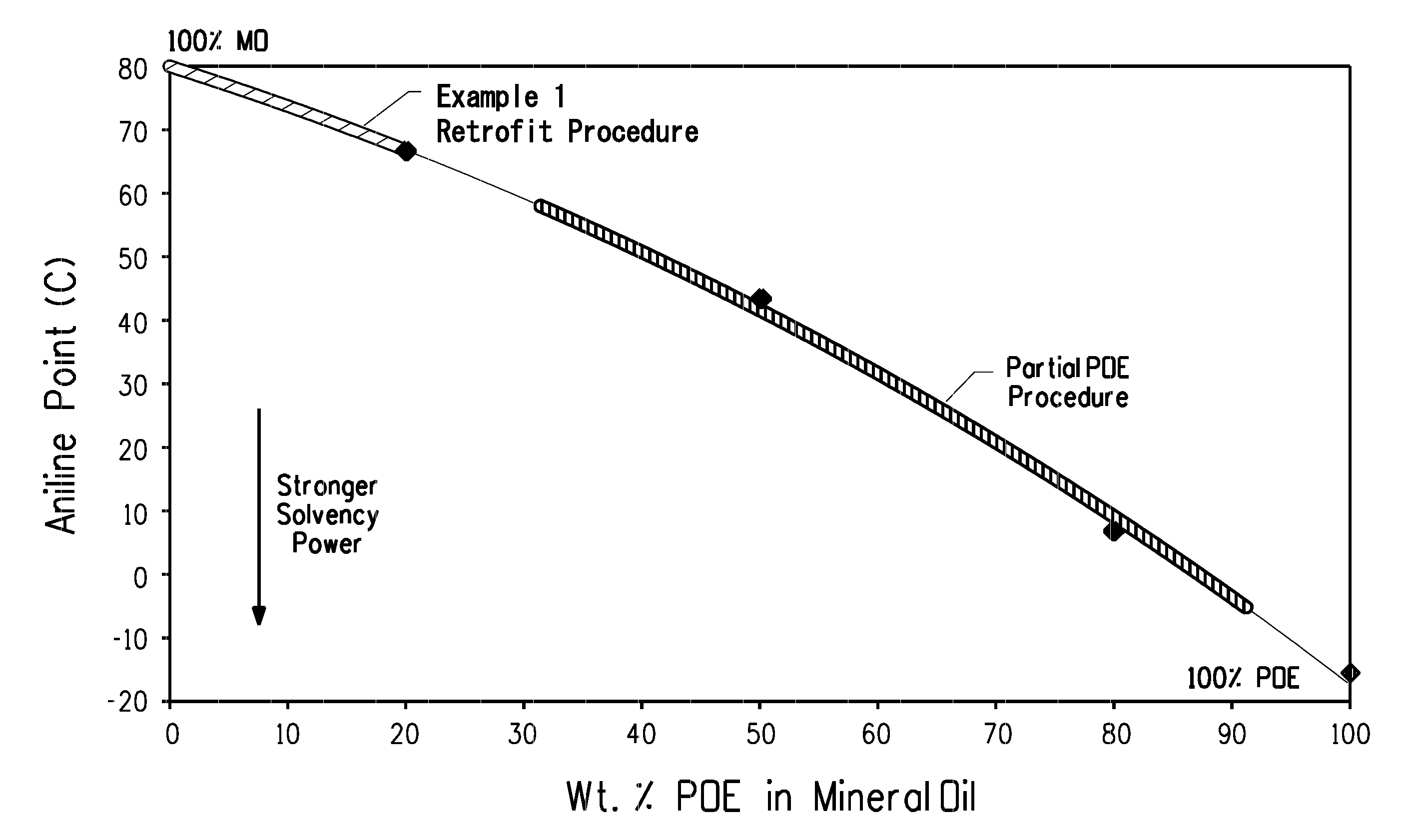

Compositions comprising refrigerant and lubricant and methods for replacing cfc and hcfc refrigerants without flushingfield of the invention

ActiveUS20120145946A1Improve solubilityHeat-exchange elementsBase-materialsAir conditioningDimethyl ether

A composition comprising a refrigerant and a lubricant is disclosed, wherein the refrigerant comprises (i) a fluorocarbon selected from the group consisting of R125, R134a, R32, R152a, R143a, R218 and mixtures thereof, and (ii) a hydrocarbon selected from the group consisting of propane, n-butane, isobutane, n-pentane, isopentane, dimethyl ether, and mixtures thereof; the lubricant comprises (iii) a hydrocarbon-based lubricant component; and (iv) a synthetic lubricant component; and the synthetic lubricant component is less than 30% by weight of the total lubricant.Also disclosed are methods of replacing refrigerants in refrigeration or air conditioning systems containing a refrigerant comprising a CFC or HCFC and a lubricant. The methods involve adding to the system (a) a replacement refrigerant comprising (i) a fluorocarbon selected from the group consisting of R125, R134a, R152a, R32, R143a, R218 and mixtures thereof, and (ii) a hydrocarbon selected from the group consisting of propane, n-butane, isobutane, n-pentane, isopentane, dimethyl ether, and mixtures thereof; and (b) a synthetic lubricant component; wherein after refrigerant replacement the synthetic lubricant component is less than 30% by weight of the total amount of lubricant in the system.

Owner:THE CHEMOURS CO FC LLC

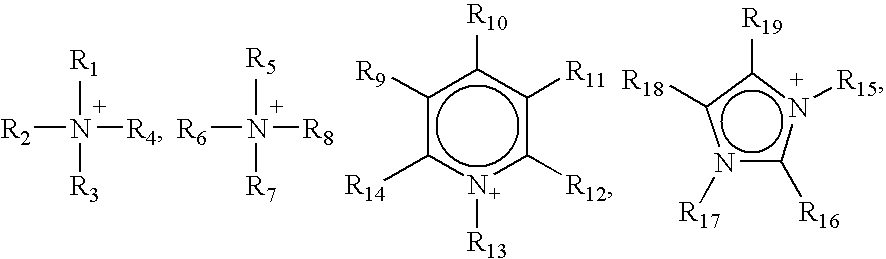

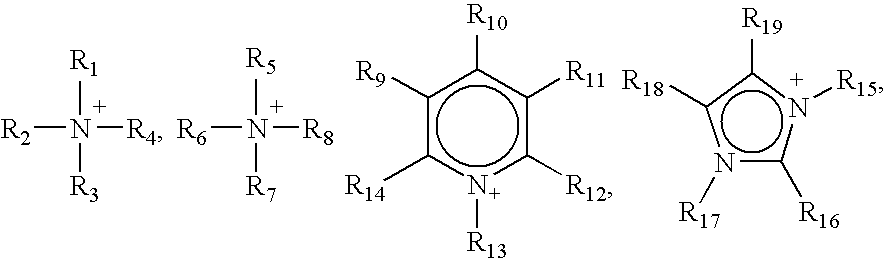

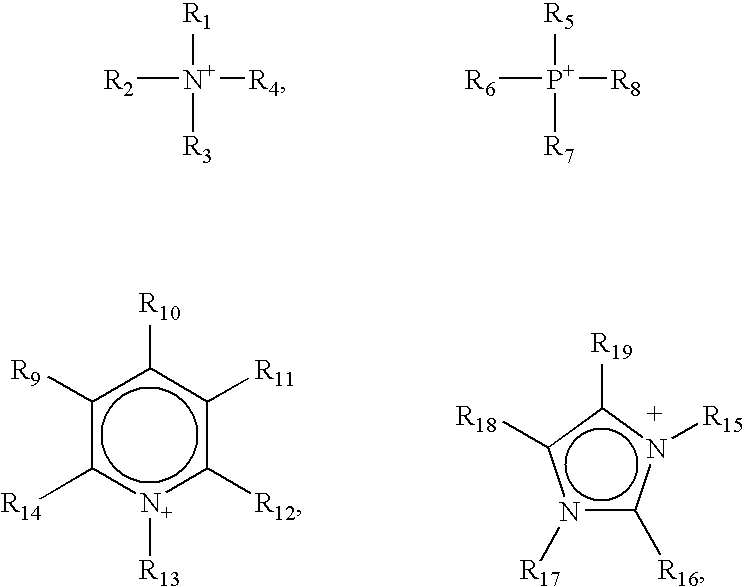

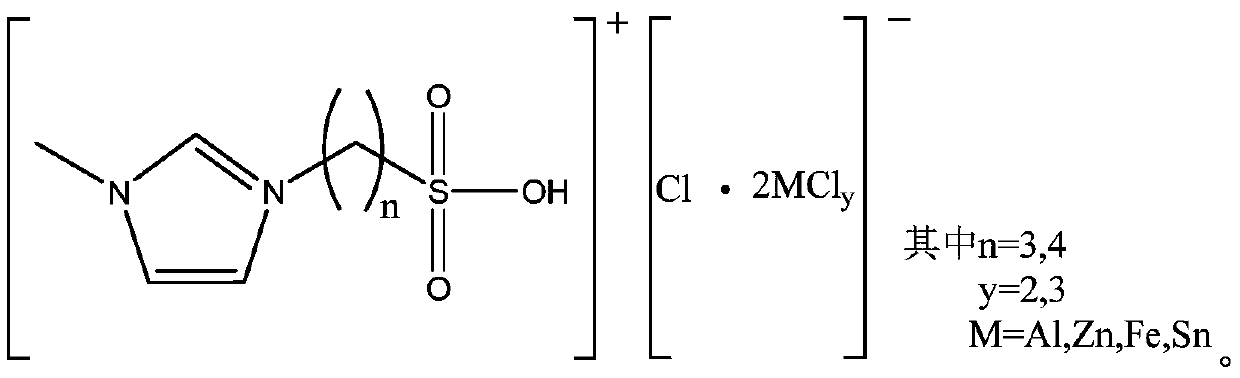

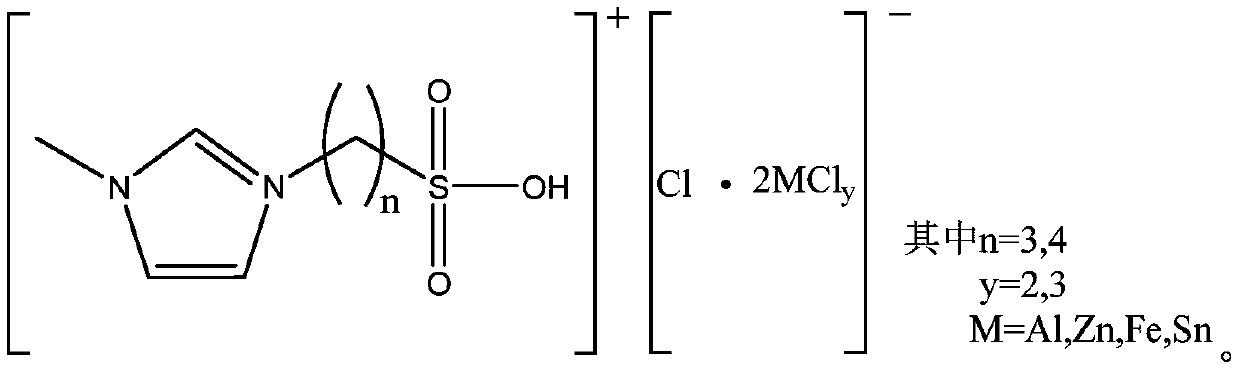

Method for synthesizing alkylated oil form isopentane-propylene under catalysis of dual acidic ionic liquid

InactiveCN110157473AReduce processing costsImprove use valueLiquid hydrocarbon mixtures productionHydrocarbon oils treatmentAlkyl transferHigh pressure

The invention discloses a method for synthesizing alkylated oil form isopentane-propylene under catalysis of a dual acidic ionic liquid. The method is characterized in that isopentane and propylene are used as reaction raw materials, the dual acidic ionic liquid is used as a catalyst, and a high-pressure alkylation method is adopted to synthesize the alkylated oil, wherein the structure general formula of the dual acidic ionic liquid catalyst is as shown in the specification. Compared with the prior art, the catalyst used in the method has Bronsted-Lewis acidity, two types of acid active siteswork synergistically, and thus the catalytic activity is high. The catalyst is immiscible with the reaction raw materials and reaction products, separation is simple, and the catalyst can be reused;and the reaction raw materials used in the method are cheap and easy to obtain, and recovery is simple and convenient, so that the method has important practical application value.

Owner:NANJING UNIV OF TECH

High-cleaning aged fuel

ActiveCN102373101APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesTert butylHeptane

The invention discloses a high-cleaning aged fuel, comprising 65-70 wt% of industrial methanol, 28-32 wt% of naphtha, and the balance consisting of an Al mixed additive, wherein, the Al mixed additive comprises burning accelerant(0.04-0.01 weight portions of ferrocene and 0.6-1.5 weight portions of methanol), lytic agent(0.1-0.4 weight portions of benzene, 0.1-0.4 weight portions of acetone, and 0.1-0.5 weight portions of n-heptane), anti-oxidant stabilizer(0.1-0.15 weight portions of 2,6-di-tert-Butyl- p-Cresol), and regulator( 0.1-0.2 weight portions of isopentane). The fuel has the advantages of strong dynamic property, little discharge capacity, lowered filter point, good universality, long reserve maintenance period and the like, and overcomes the defects that alcohol and petroleum fuels are not stable and immiscible, and the thermal efficiency of alcohol and petroleum fuels is low in the prior art.

Owner:白玉林

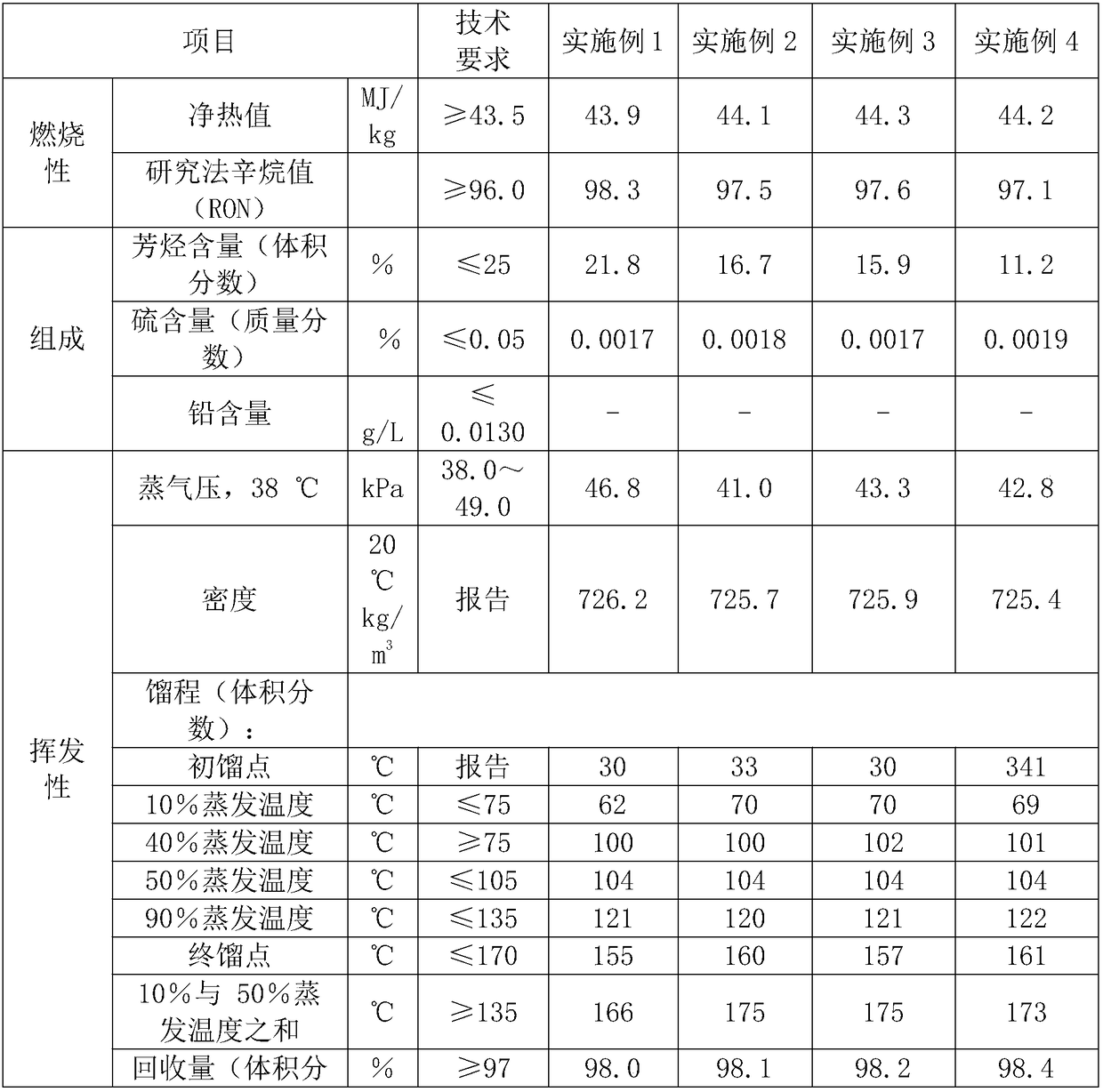

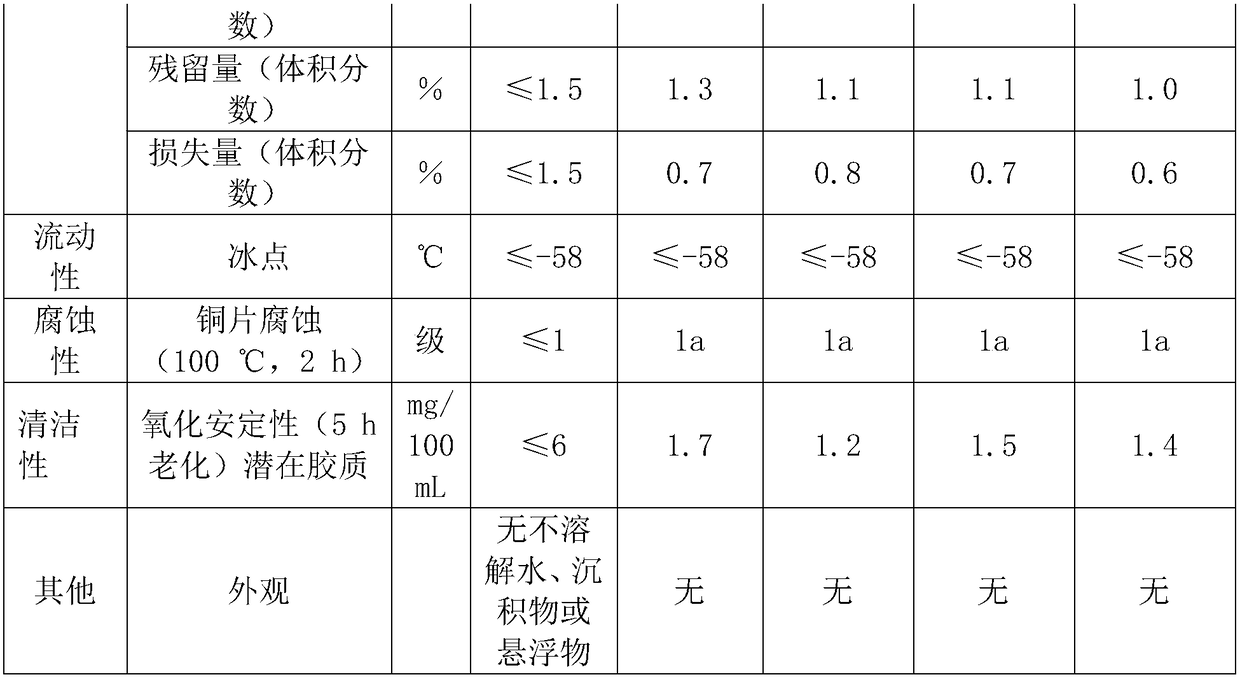

91# lead-free aviation gasoline and production method thereof

The invention discloses 91# lead-free aviation gasoline and a production method thereof. The 91# lead-free aviation gasoline is prepared from the following components: industrial isooctane, industrialxylol and industrial isopentane. According to the 91# lead-free aviation gasoline and the production method thereof, the 91# lead-free aviation gasoline is prepared by blending the following components in percentage by volume: 80 to 90 percent of alkane and 10 to 20 percent of aromatic hydrocarbon or is prepared through a blending technology or a petrochemical refining technology; the alkane in the 91# lead-free aviation gasoline provided by the invention takes isoalkane as a main part and has high octane value, low steam pressure and a suitable distillation range; the requirements on the aviation gasoline are met; the octane value of a research method of the aviation gasoline is 97 to 99; the 91# lead-free aviation gasoline and the production method thereof have the advantages of high yield, low cost, simplicity and easiness for obtaining raw materials and simple preparation method.

Owner:HEBEI XINQIYUAN ENERGY TECH DEV

Combined foaming agent, hard polyurethane foam and manufacturing method of hard polyurethane foam

The invention provides a combined foaming agent. The combined foaming agent comprises, by mass, 1-9 parts of cyclopentane, 1-5 parts of isopentane and 2-30 parts of HFC-245fa. The hard polyurethane foam prepared by adopting the combined foaming agent comprises, by mass, 100 parts of combined polyether, 10-26 parts of the combined foaming agent and 120-150 parts of isocyanate. The invention also provides a manufacturing method of the hard polyurethane foam. The above foaming technology effectively reduces the heat conduction coefficient of the polyurethane foam, and reduces the energy consumption of a freezer; the strength of the foam with same density is enhanced, and the density of the foam required by the freezer is reduced, so the injection amount of the whole freezer is reduced, the raw material waste is reduced when the demand of the freezer is a certain amount, production of the hard polyurethane foam difficult to treat is reduced, and pollution to environment is reduced; and the solidification time of the foam is shortened by 10-15%, and the production efficiency is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com