Patents

Literature

431 results about "2-Butene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Butene is an acyclic alkene with four carbon atoms. It is the simplest alkene exhibiting cis/trans-isomerism (also known as (E/Z)-isomerism); that is, it exists as two geometric isomers cis-2-butene ((Z)-2-butene) and trans-2-butene ((E)-2-butene).

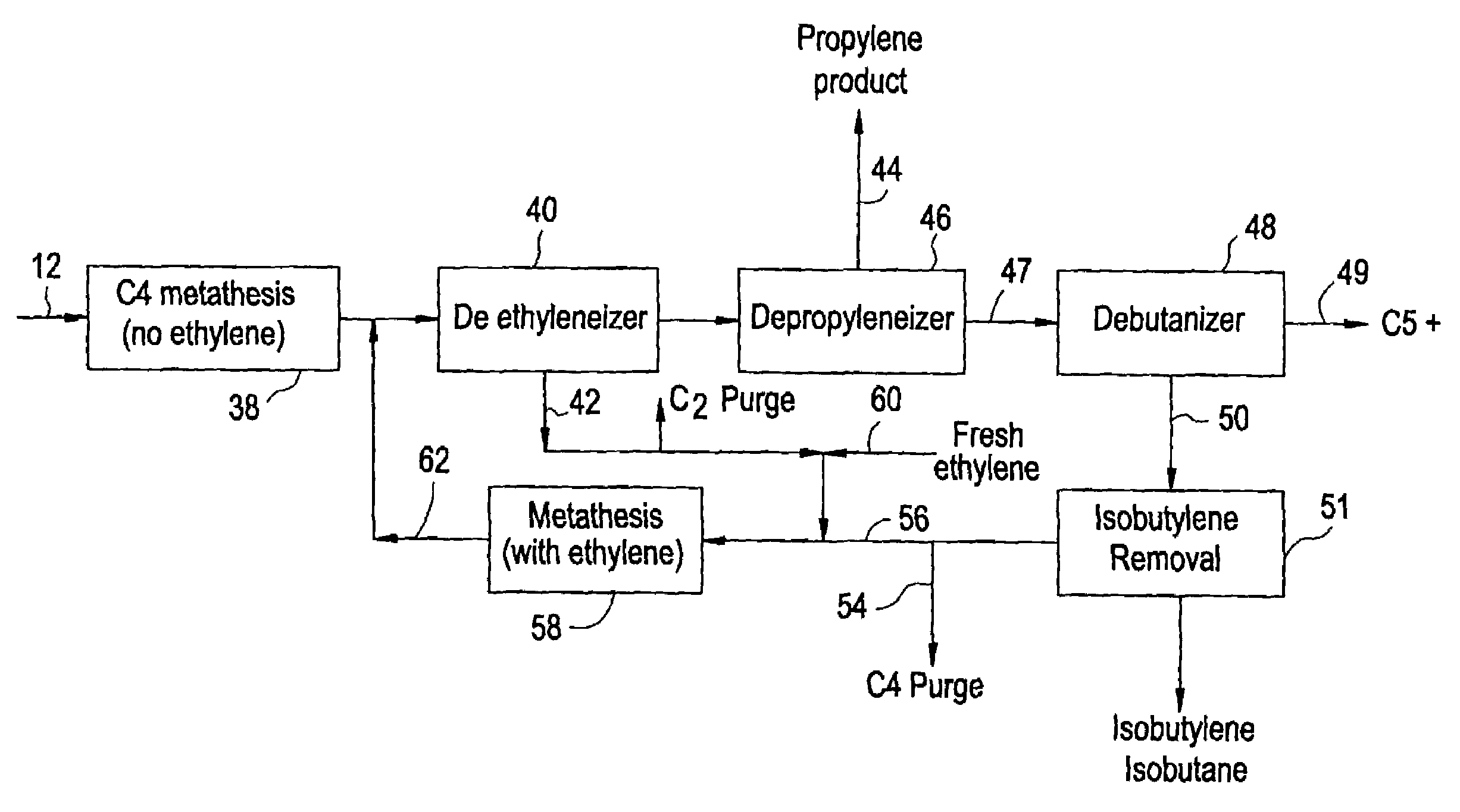

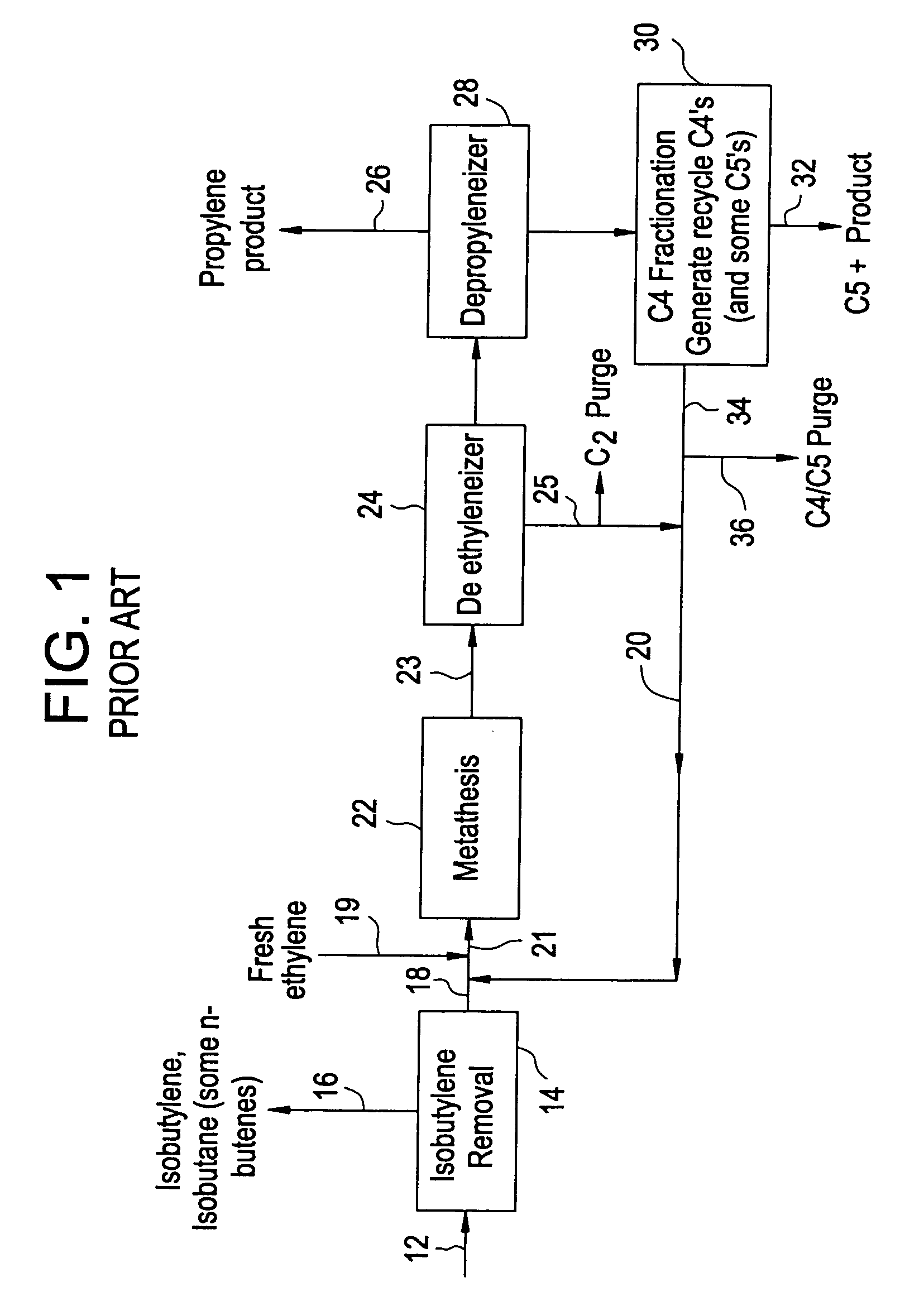

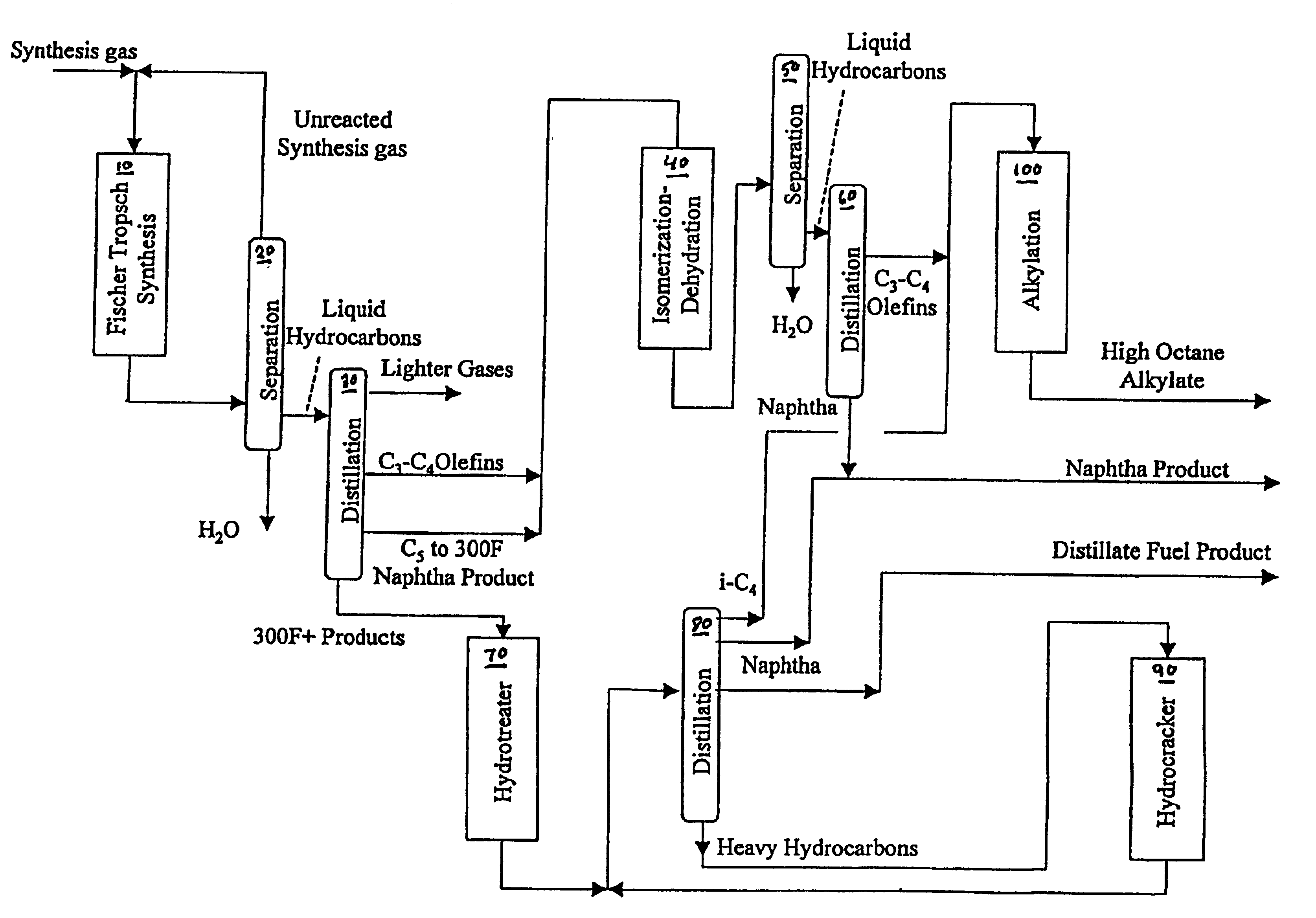

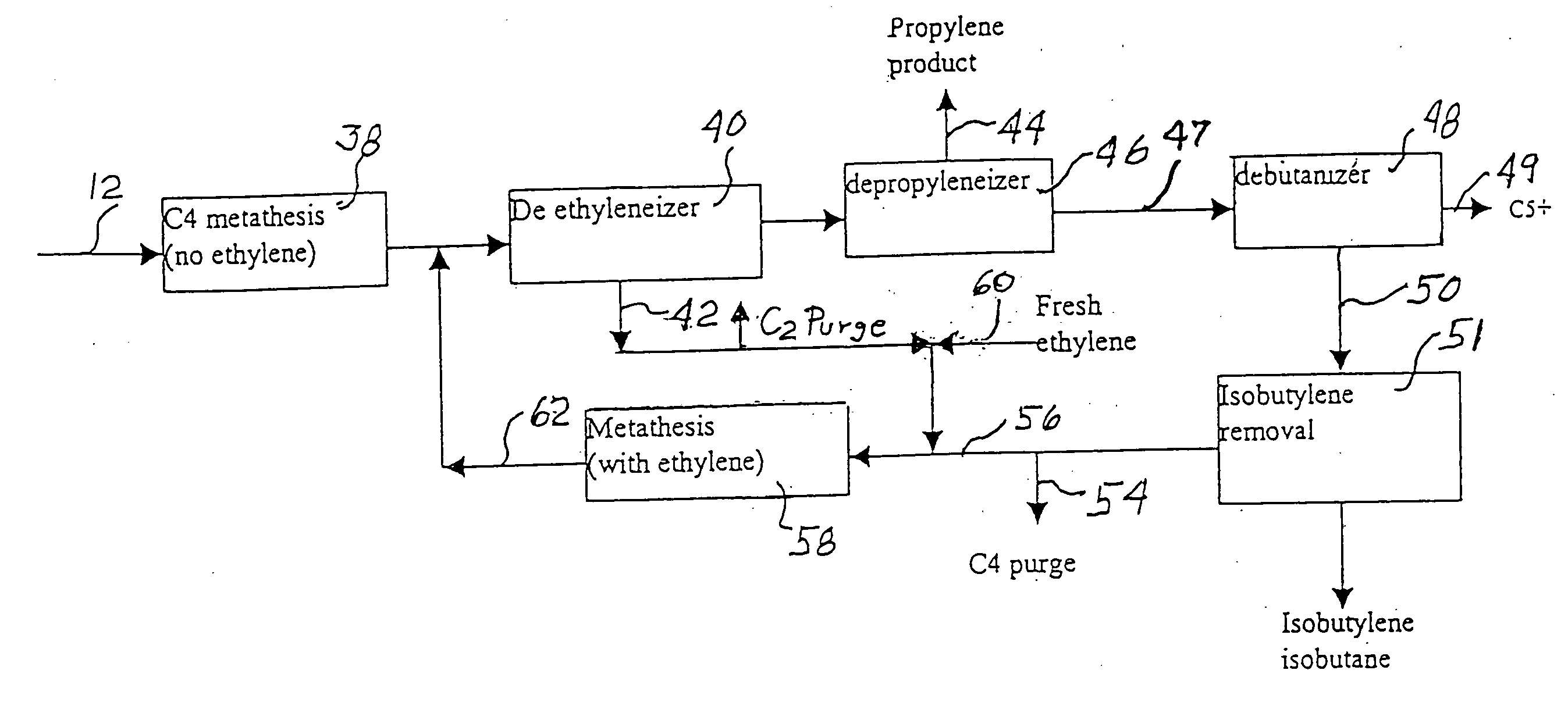

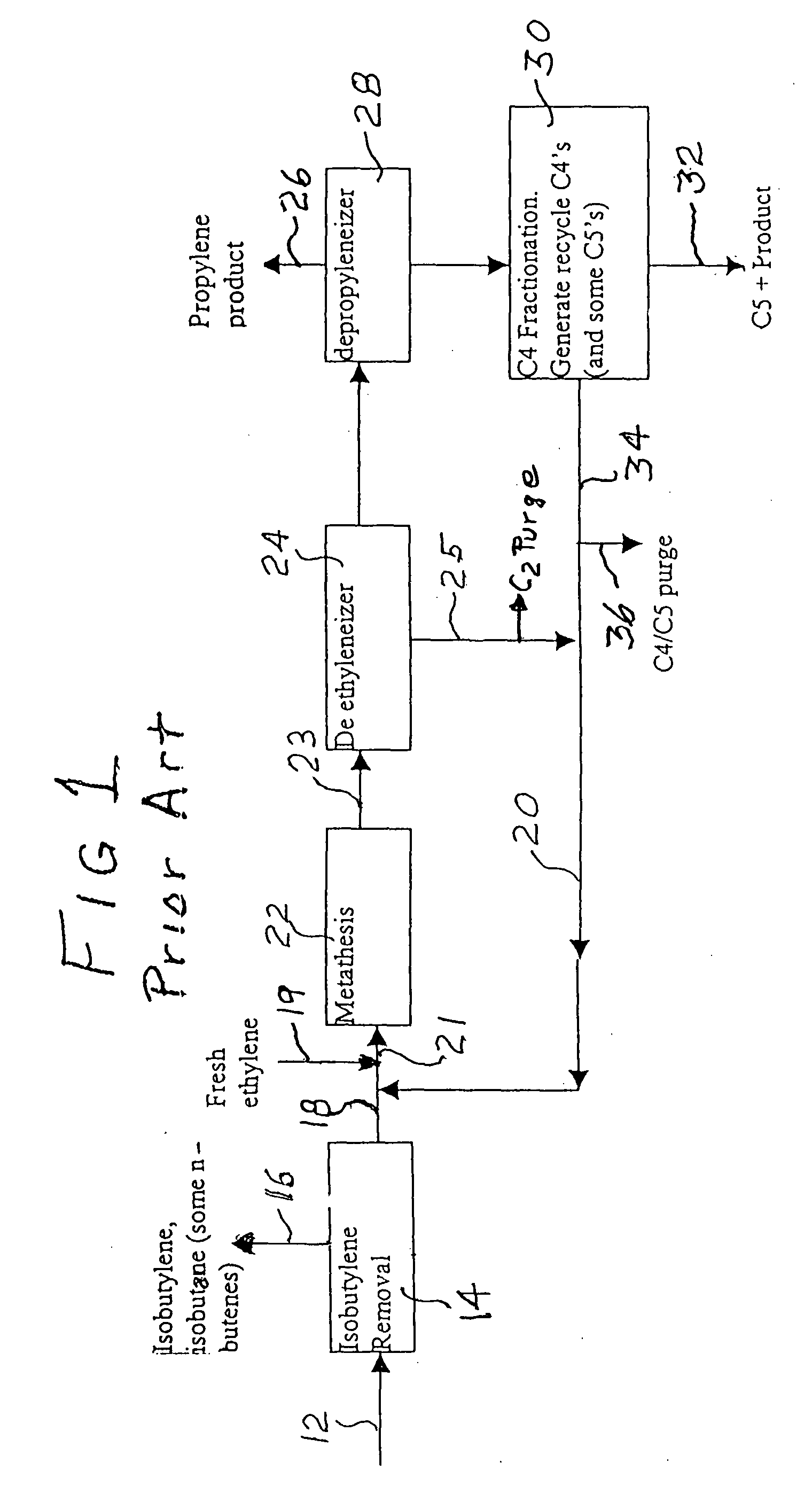

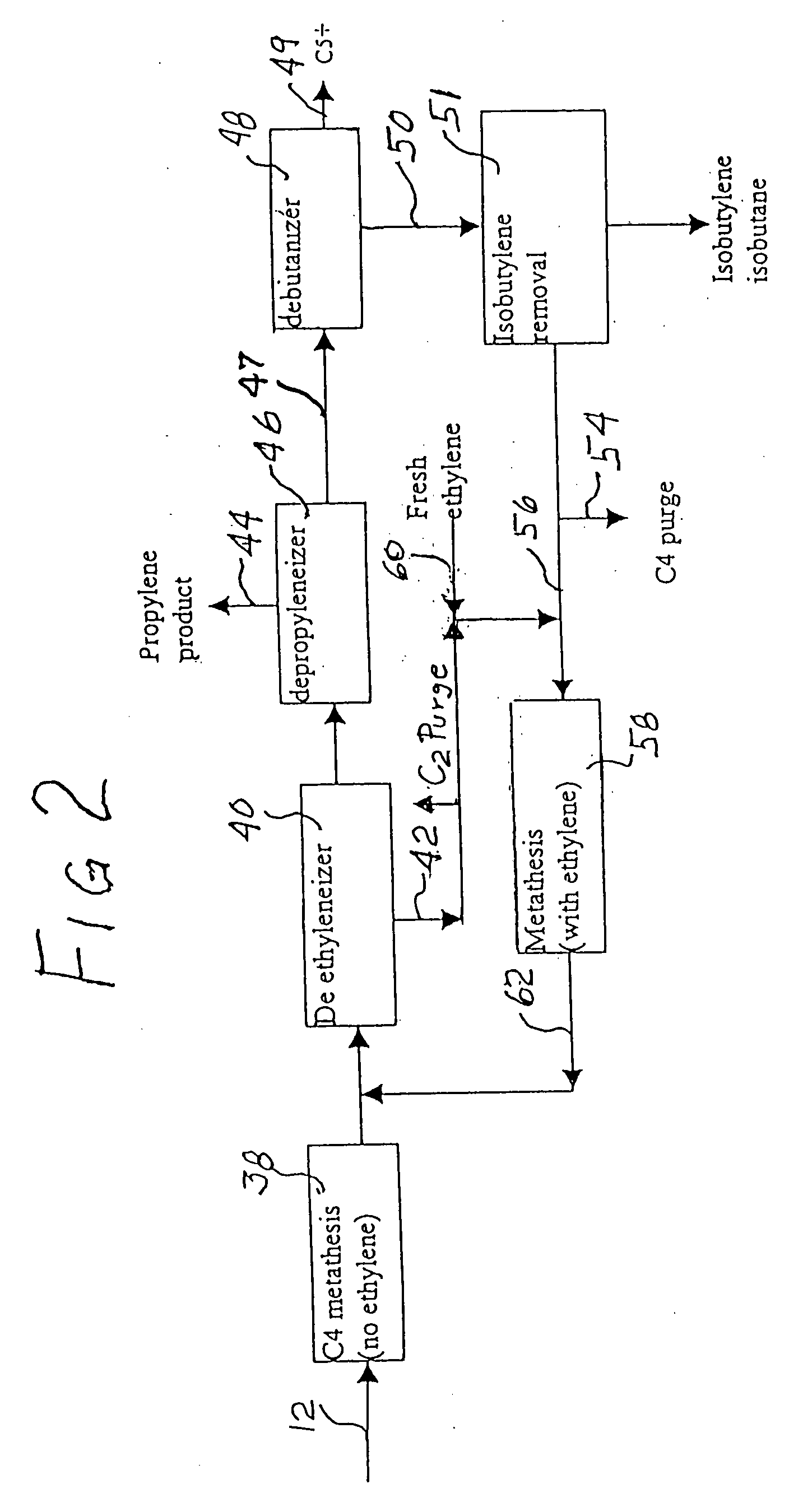

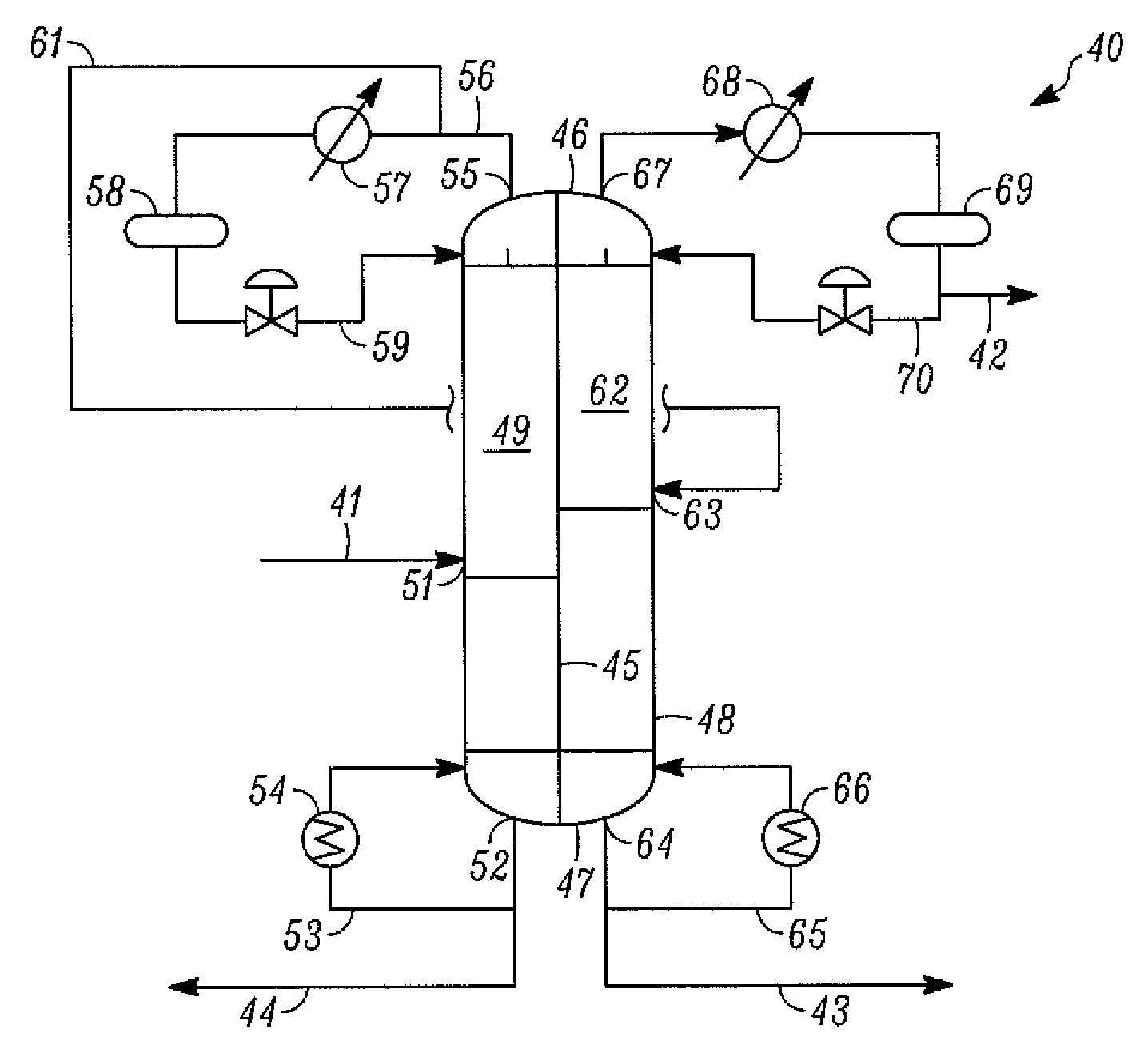

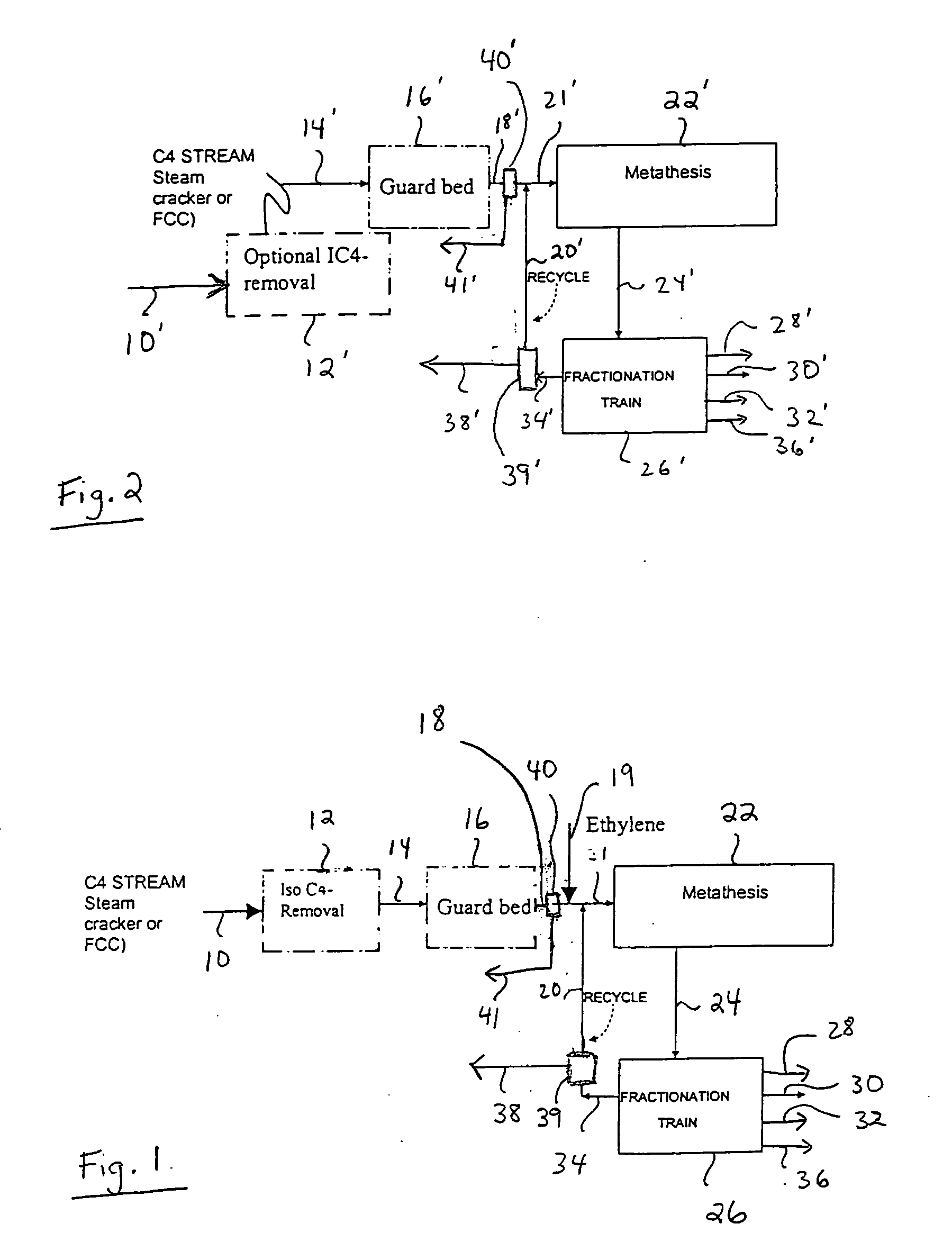

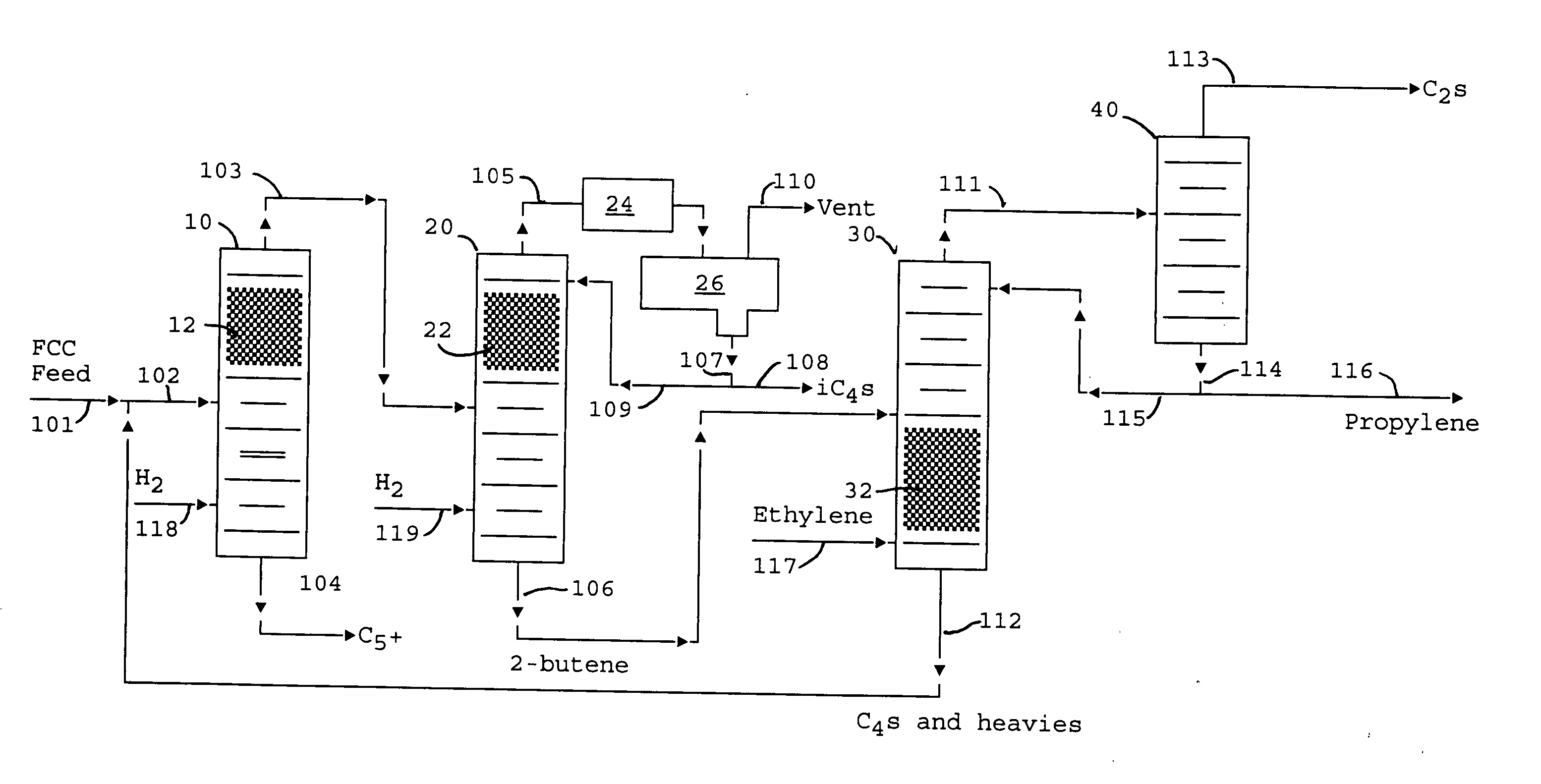

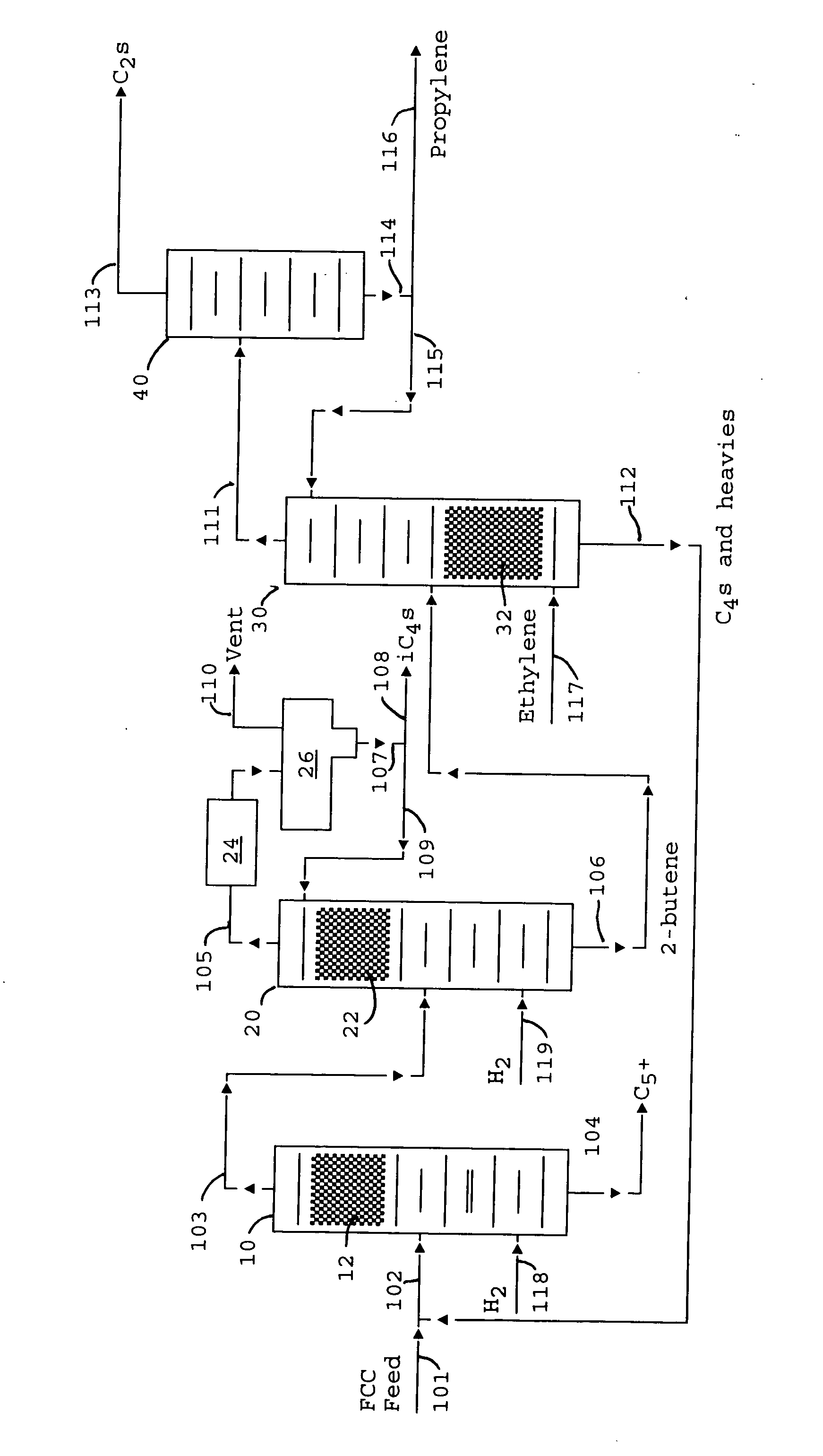

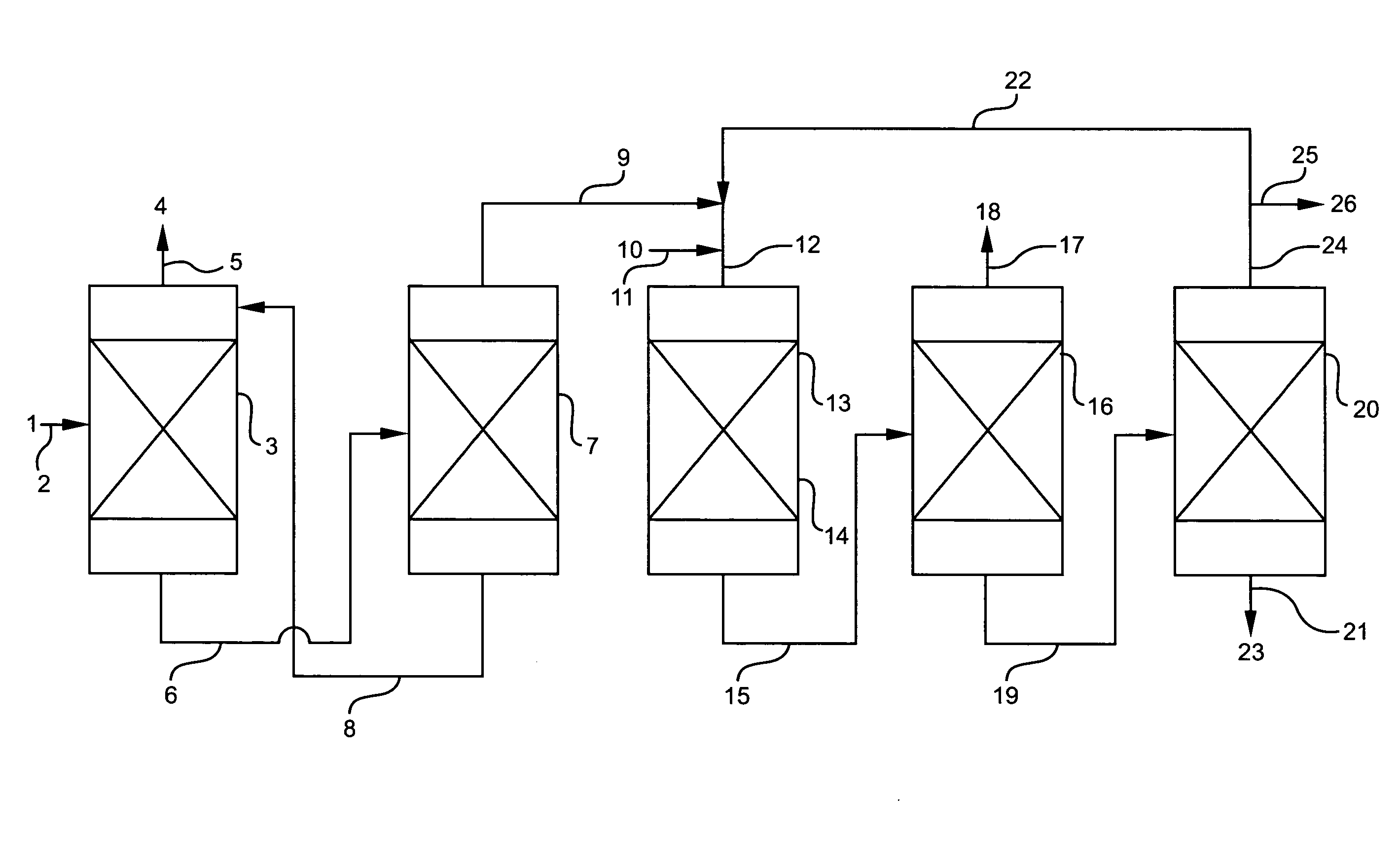

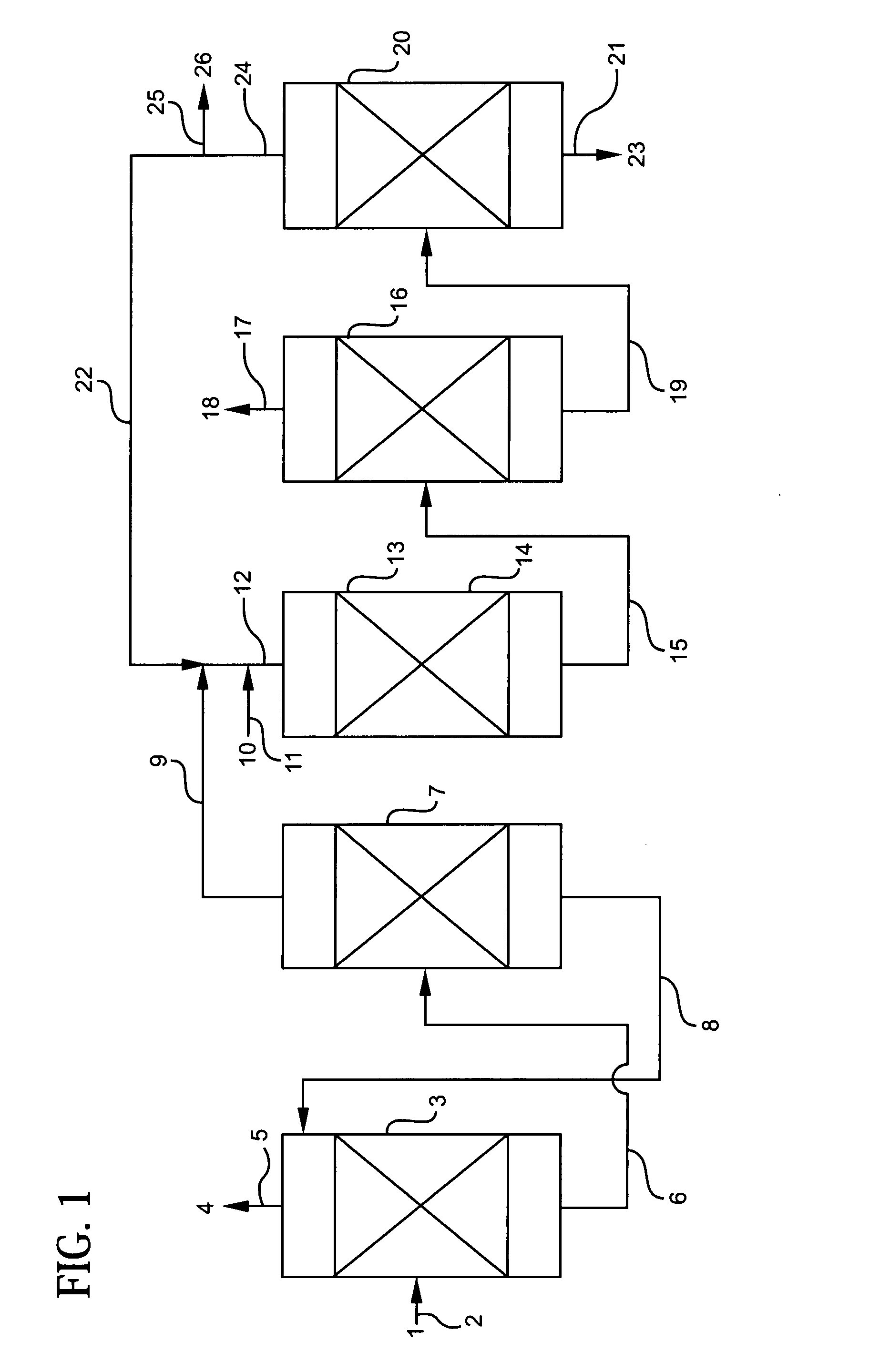

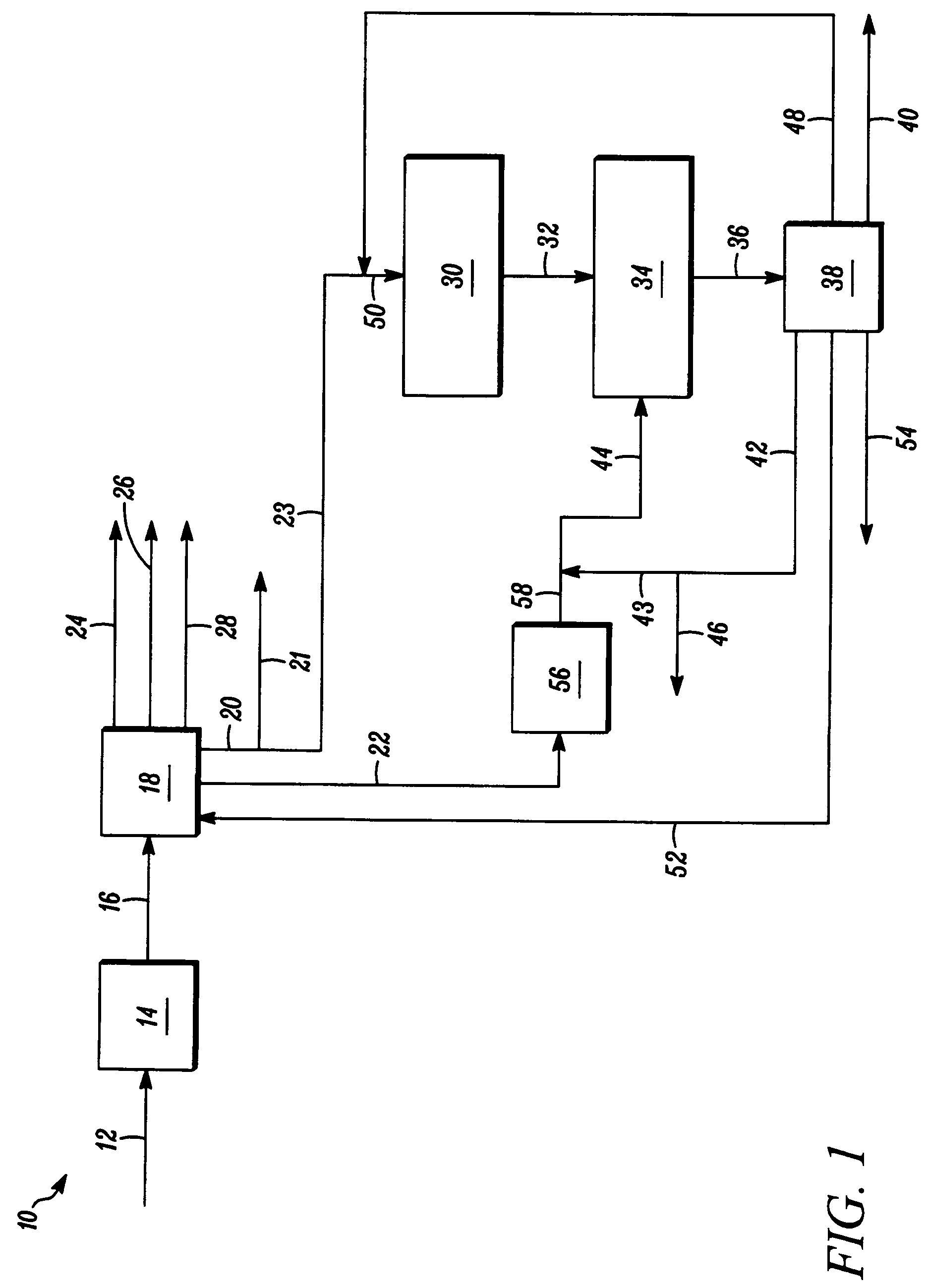

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

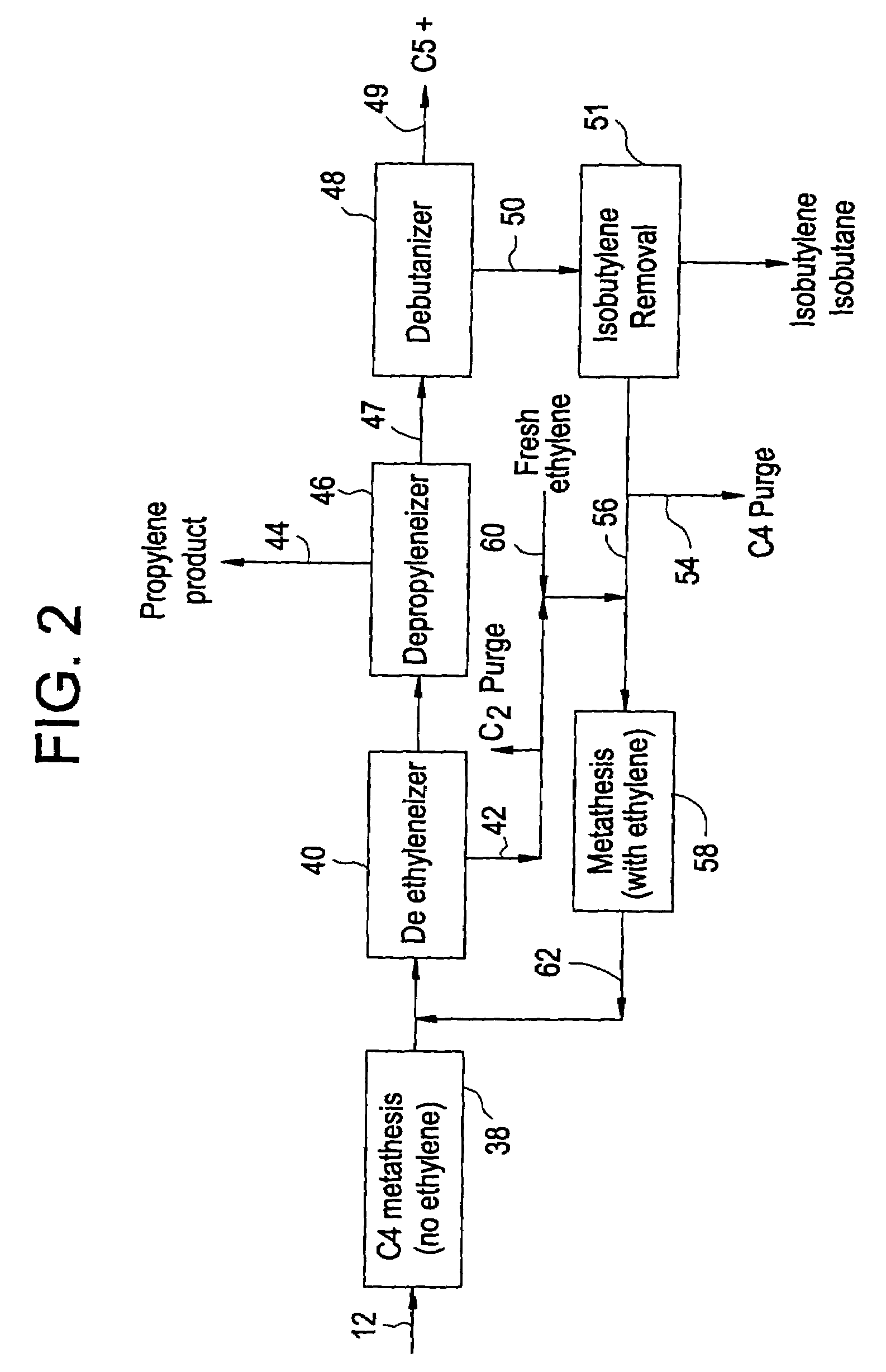

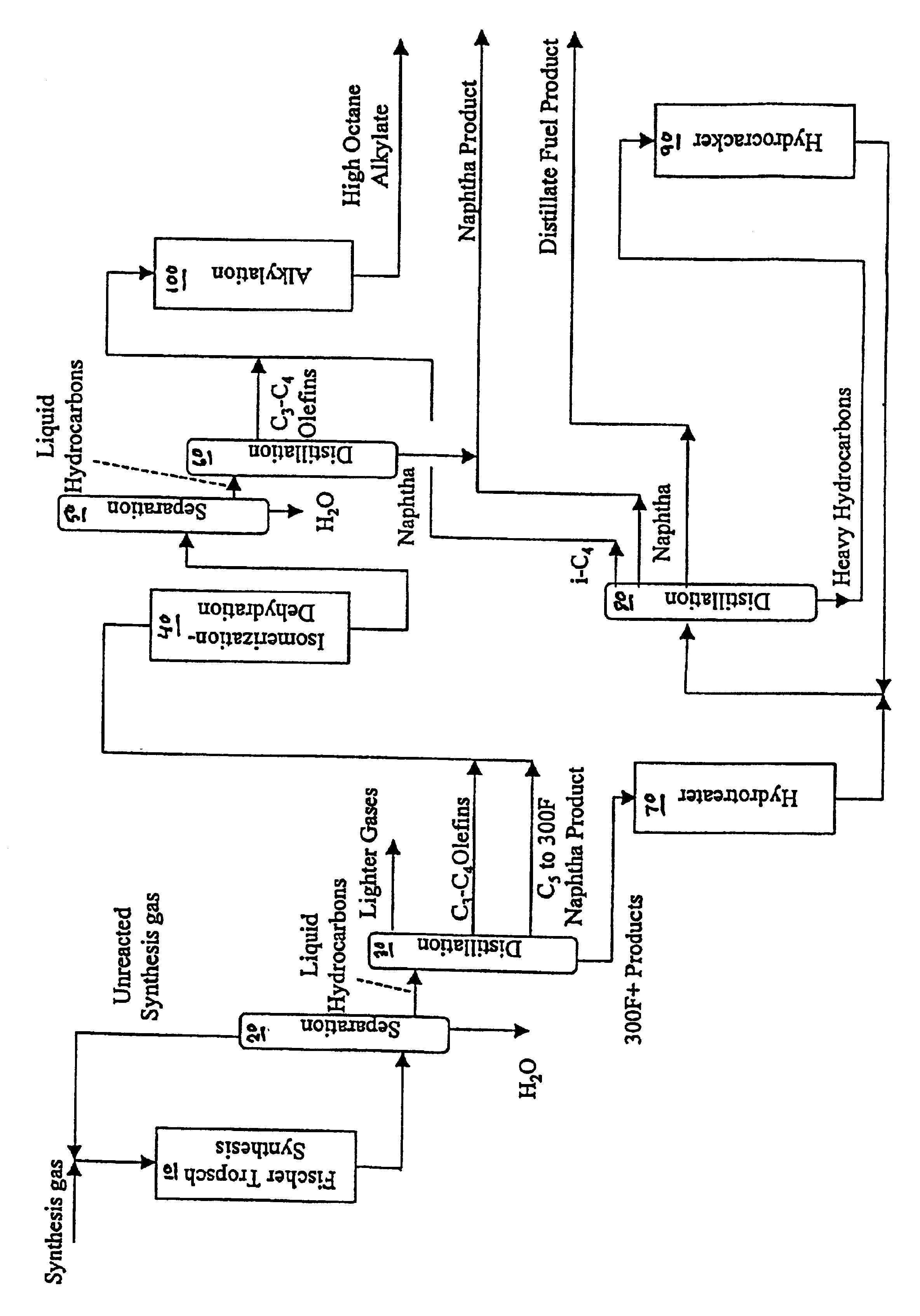

Manufacture of high octane alkylate

InactiveUS6768035B2Hydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholGasoline

A Fischer-Tropsch C3-C4 olefin stream is simultaneously dehydrated and isomerized to convert alcohols to olefins and 1-butenes to 2-butenes and thereby lower the oxygenate content. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane stream. The treated C3-C4 olefin stream having an oxygenate content less than 4000 ppm, is reacted with the isobutane stream to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

Olefin isomerization process

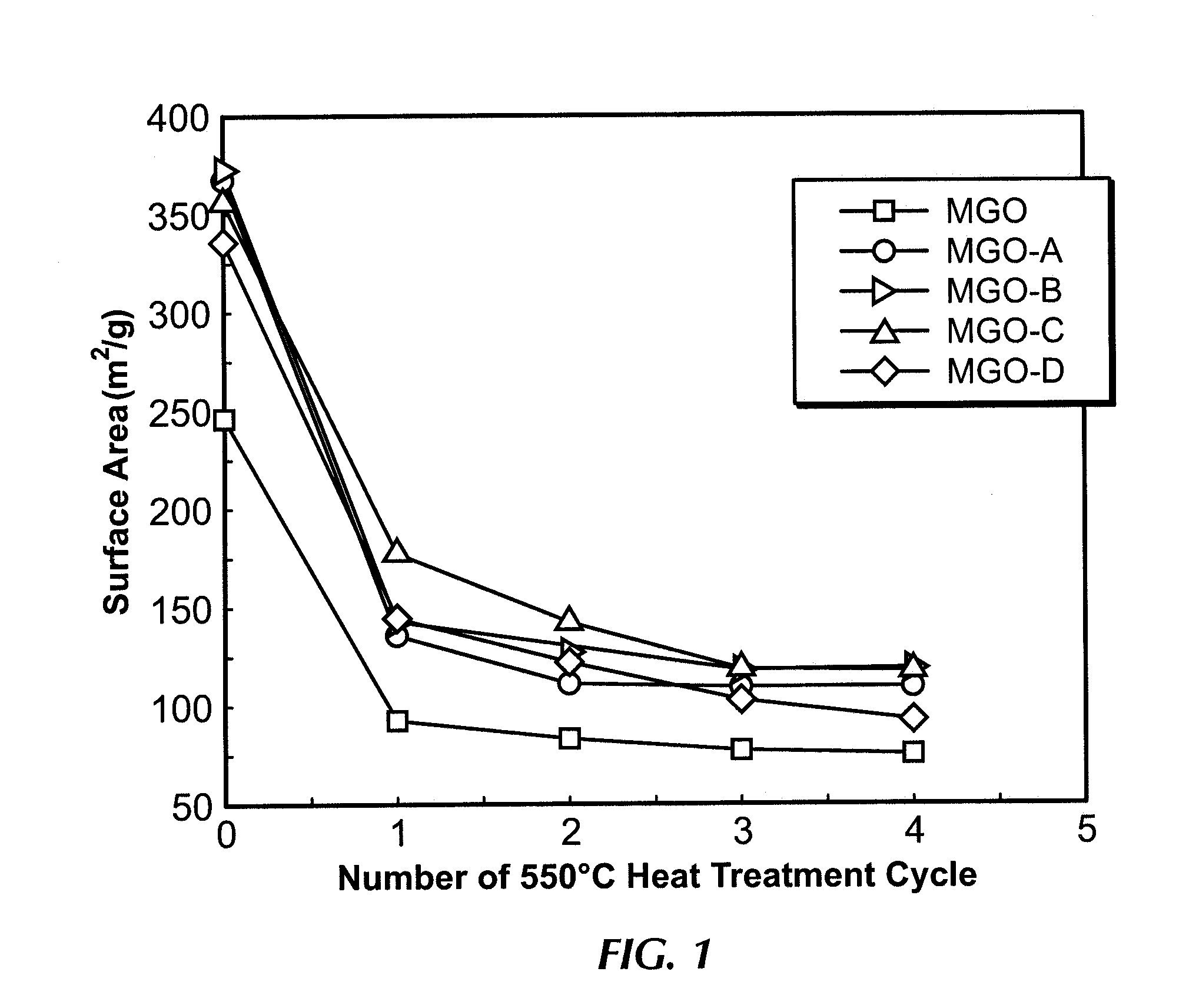

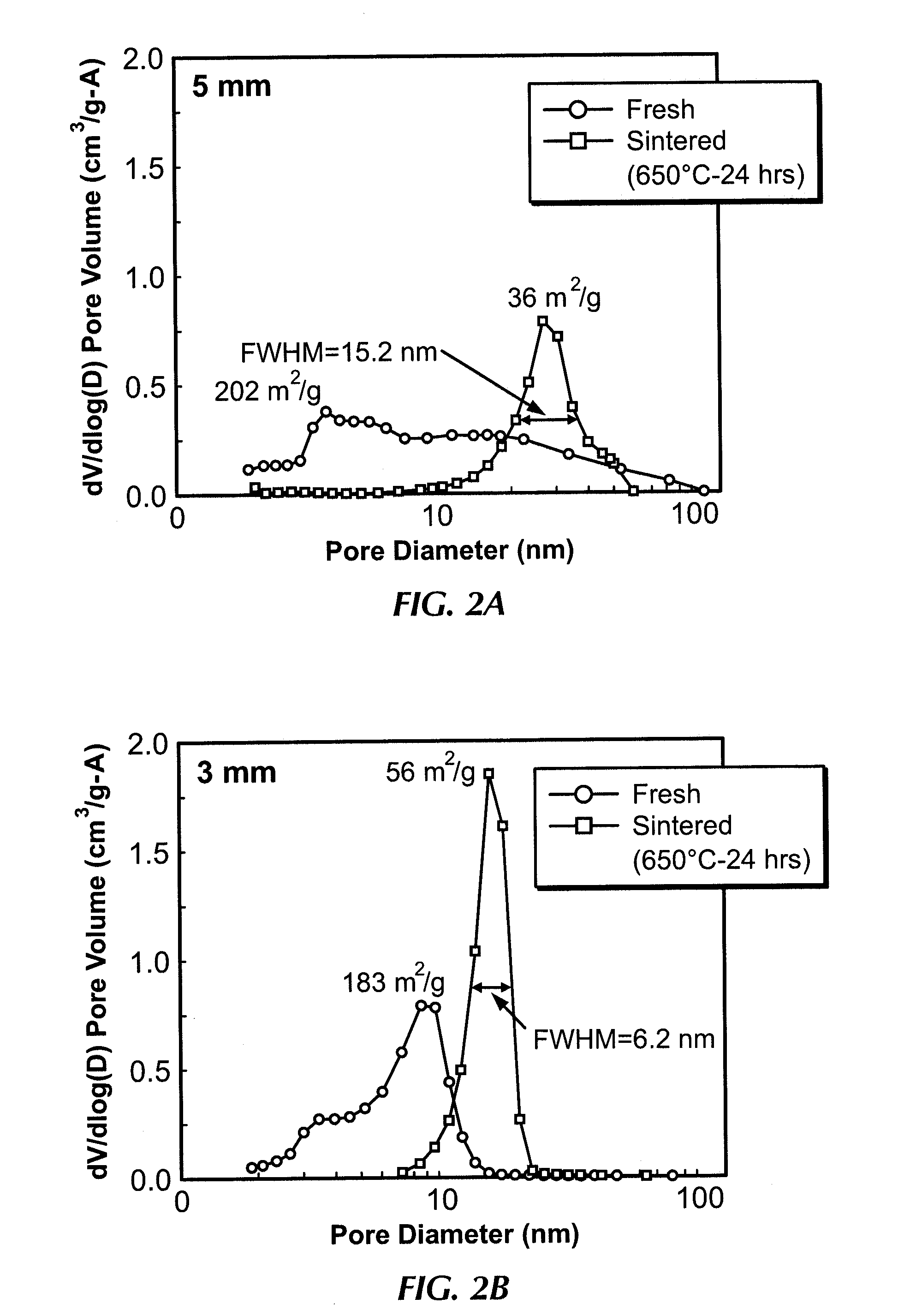

InactiveUS6875901B2High catalytic activityHydrocarbon by isomerisationPhysical/chemical process catalystsButeneIsomerization

An olefin isomerization process employs a basic metal oxide catalyst, such as magnesium oxide, which retains at least about 85 percent of its initial activity for at least about 168 hours of on-stream time. The catalyst is preferably a high purity magnesium oxide. The olefin isomerization process and catalyst described herein are advantageously used for the production of a terminal olefin such as 1-butene from an internal olefin such as 2-butene.

Owner:ABB LUMMUS GLOBAL INC

Processing C4 olefin streams for the maximum production of propylene

ActiveUS20050014981A1Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

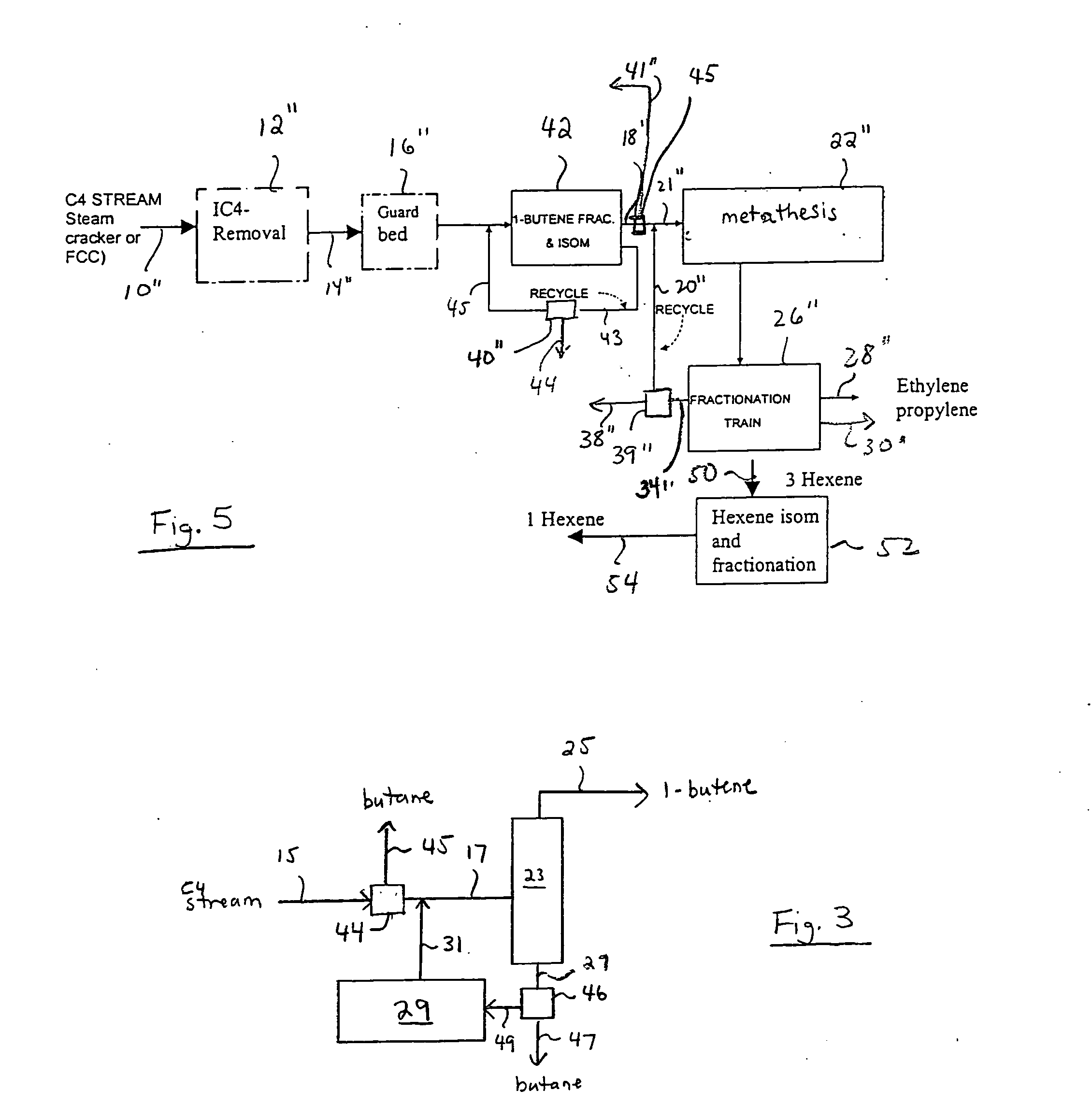

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

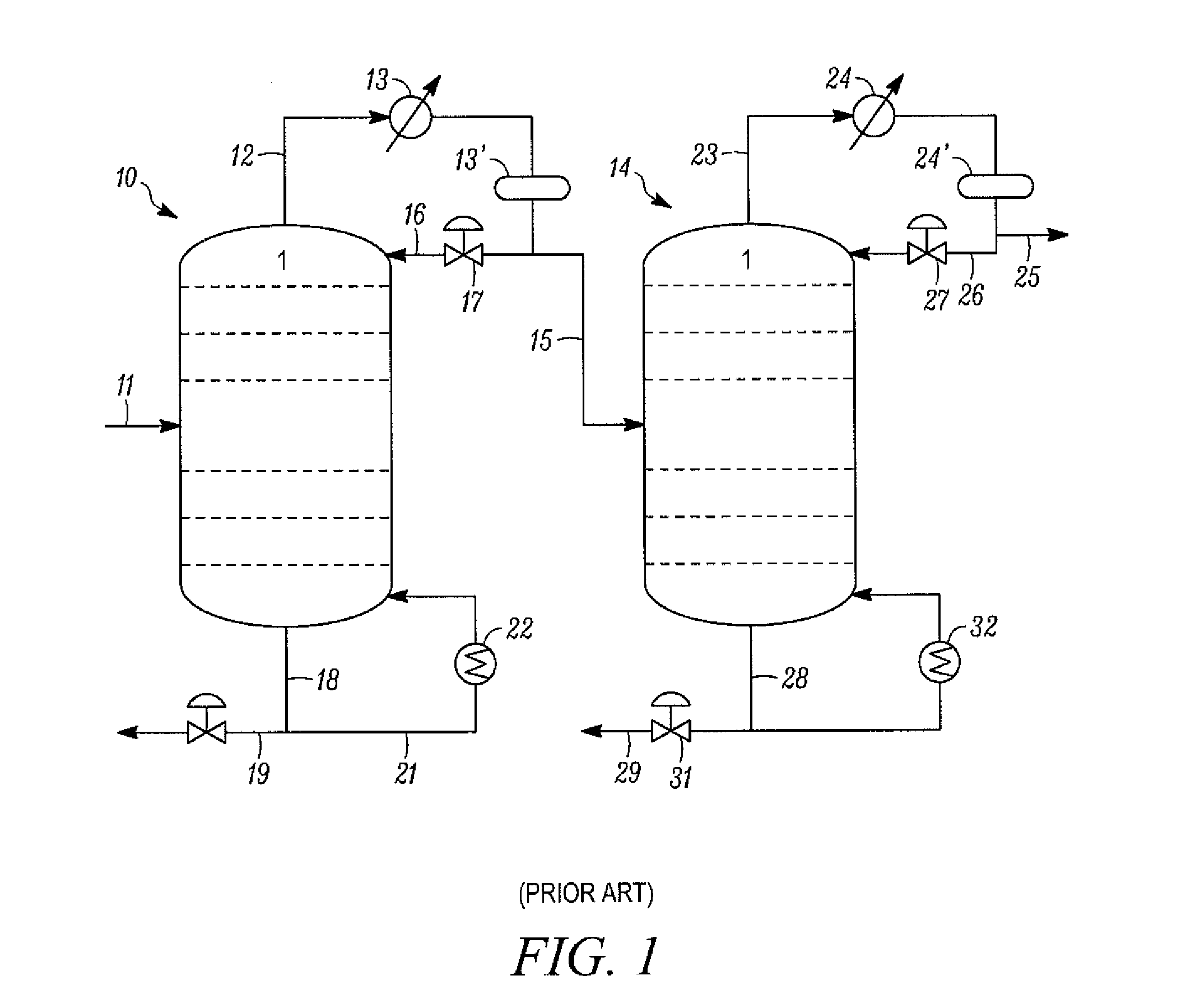

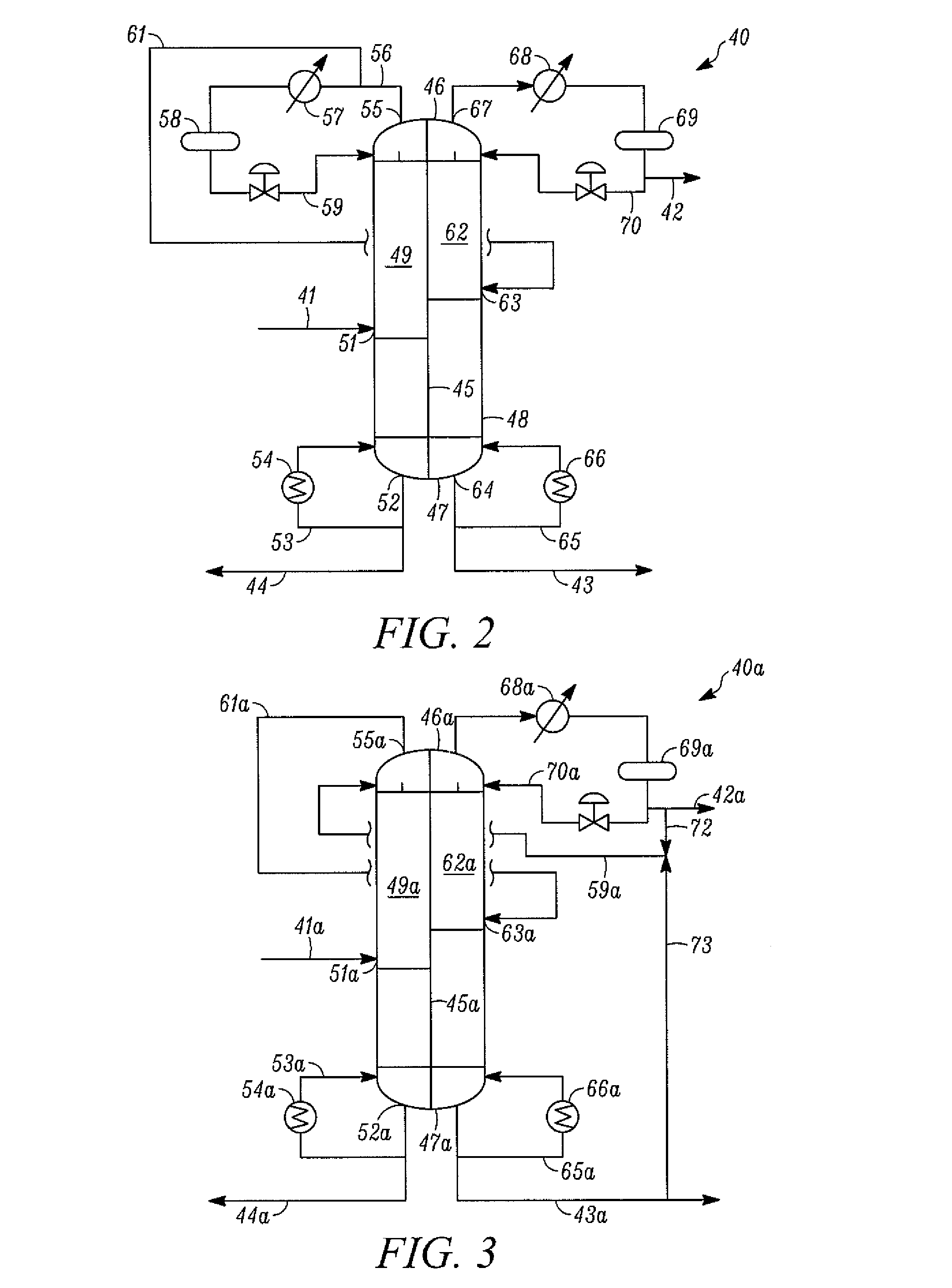

Apparatus and Methods for Separating Butene-1 from a Mixed C4 Feed

ActiveUS20080161618A1Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneFractionating column

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

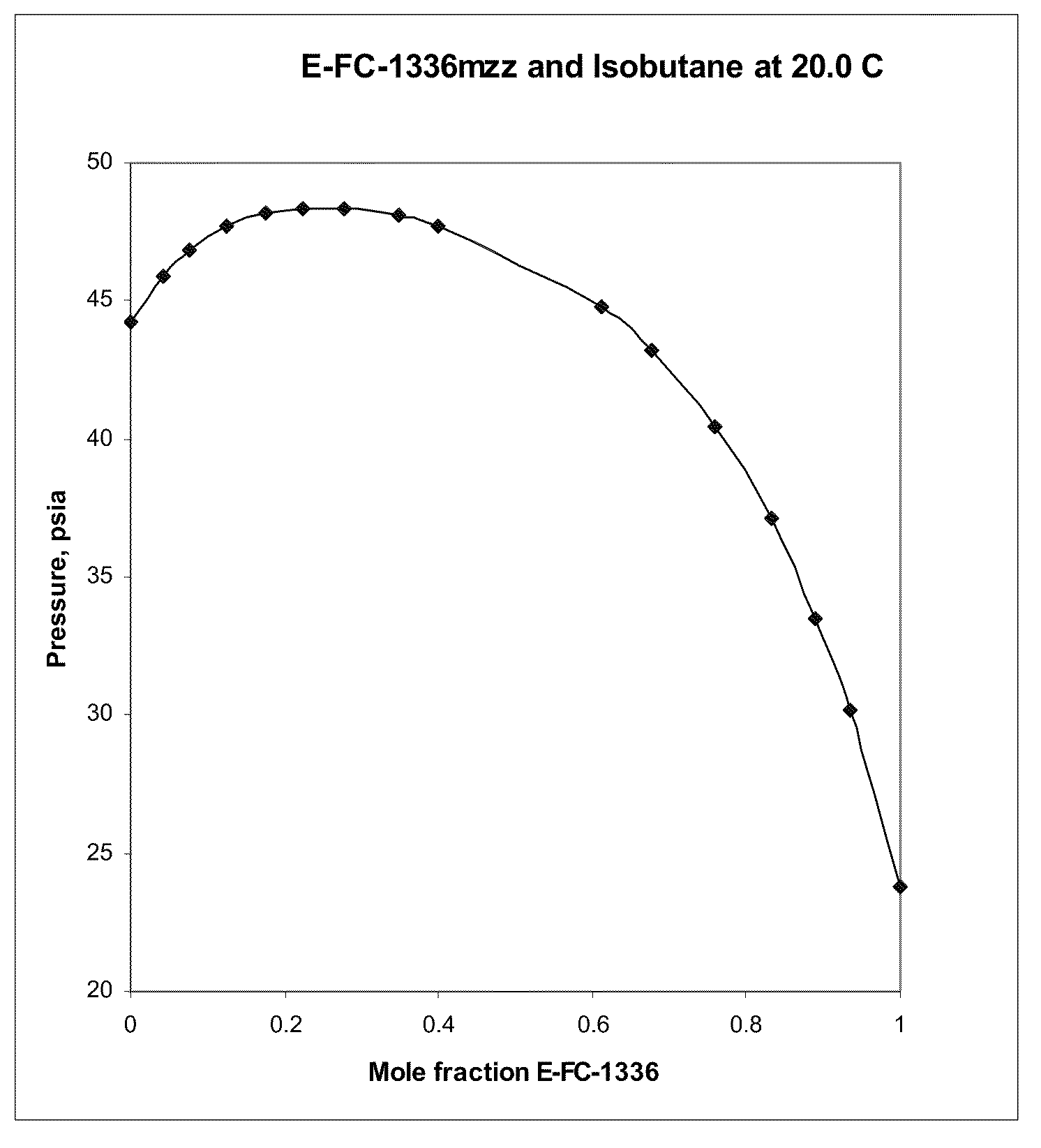

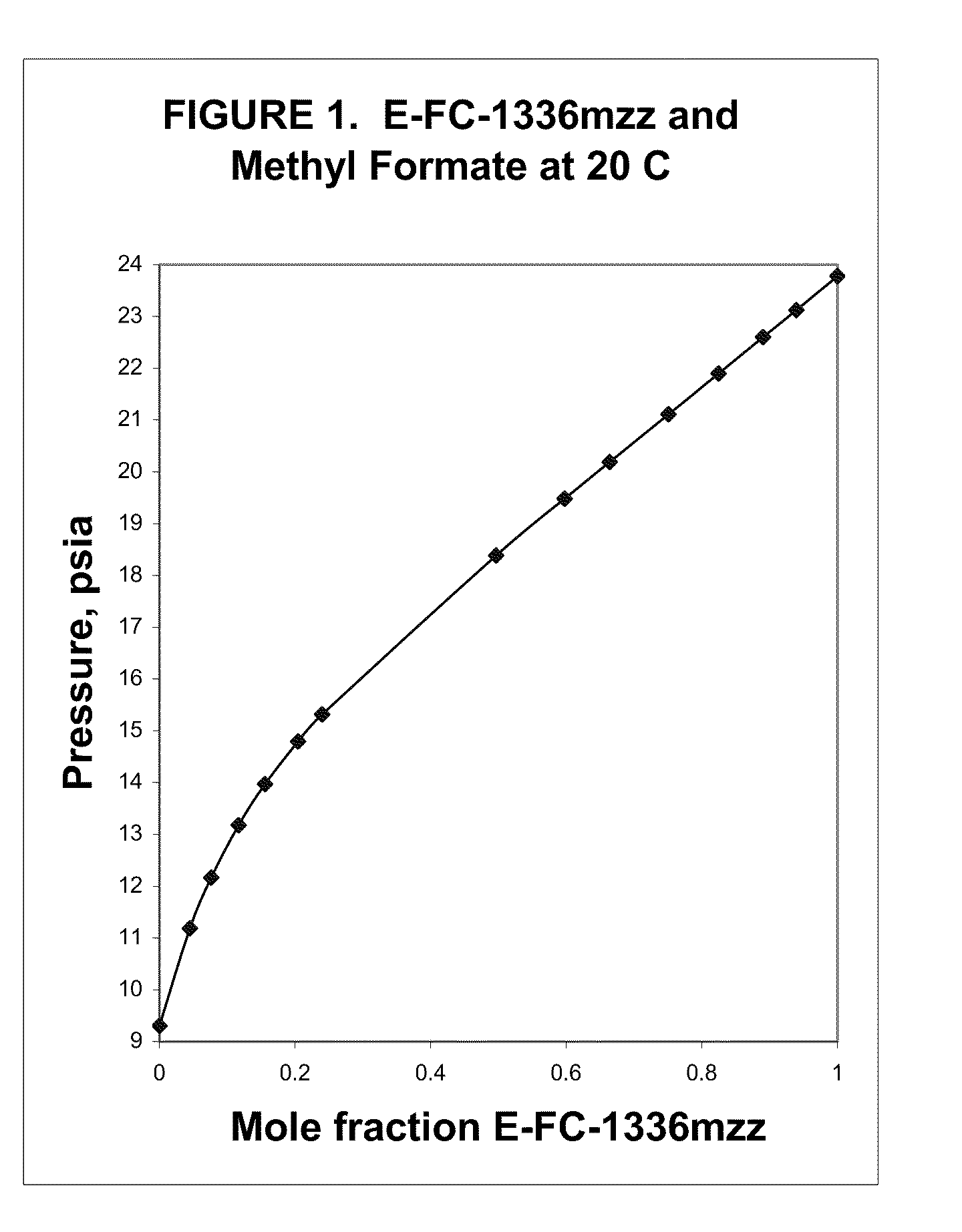

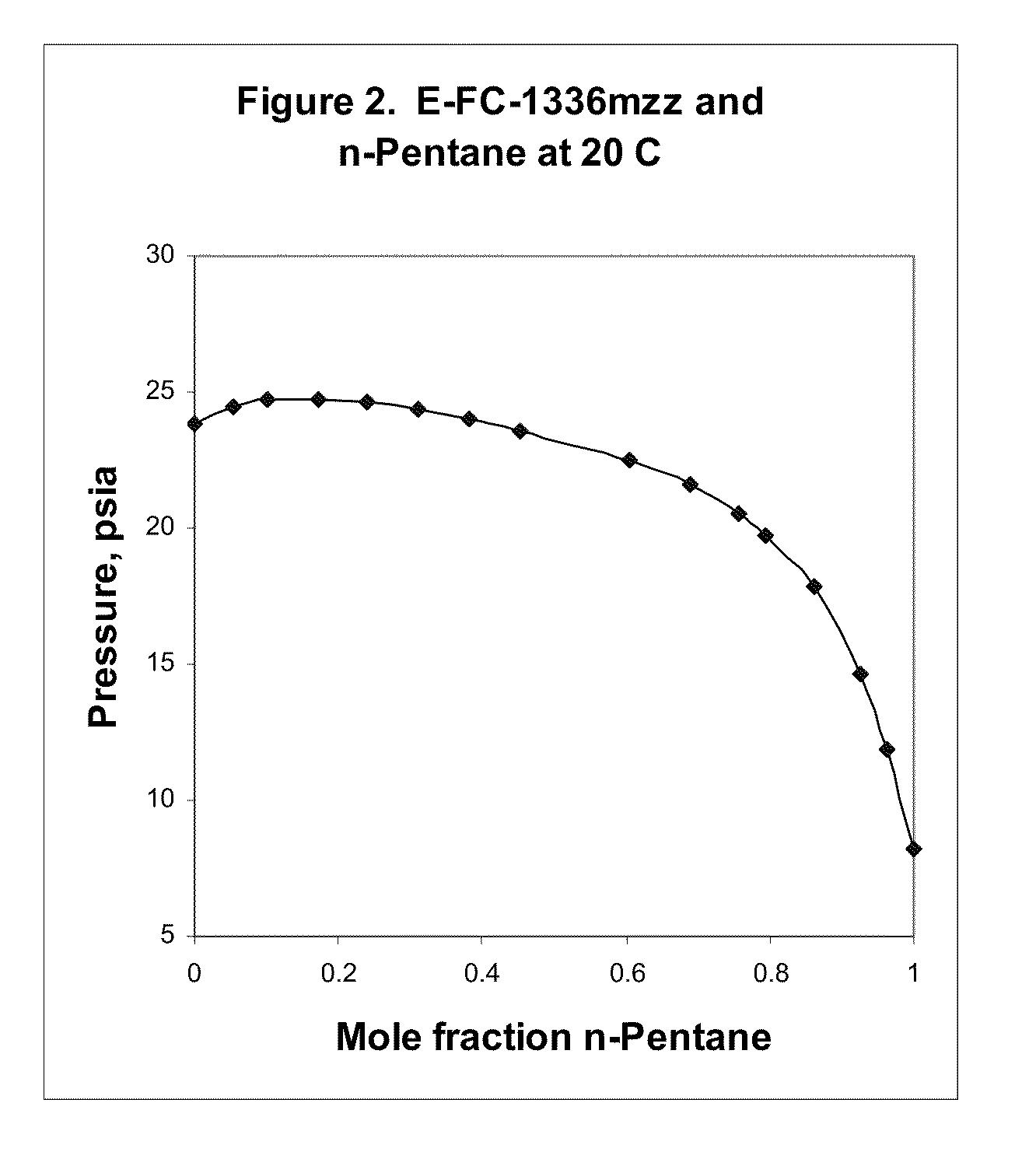

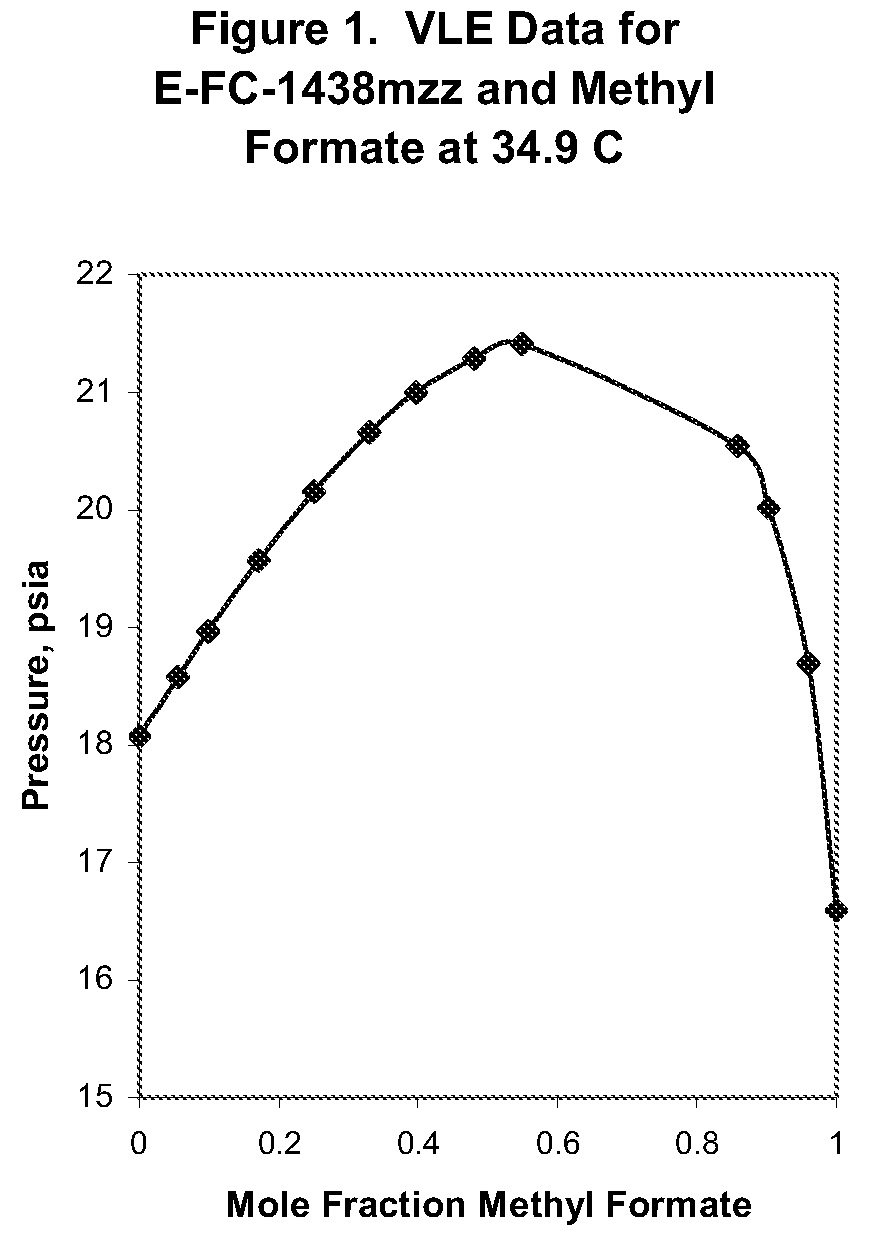

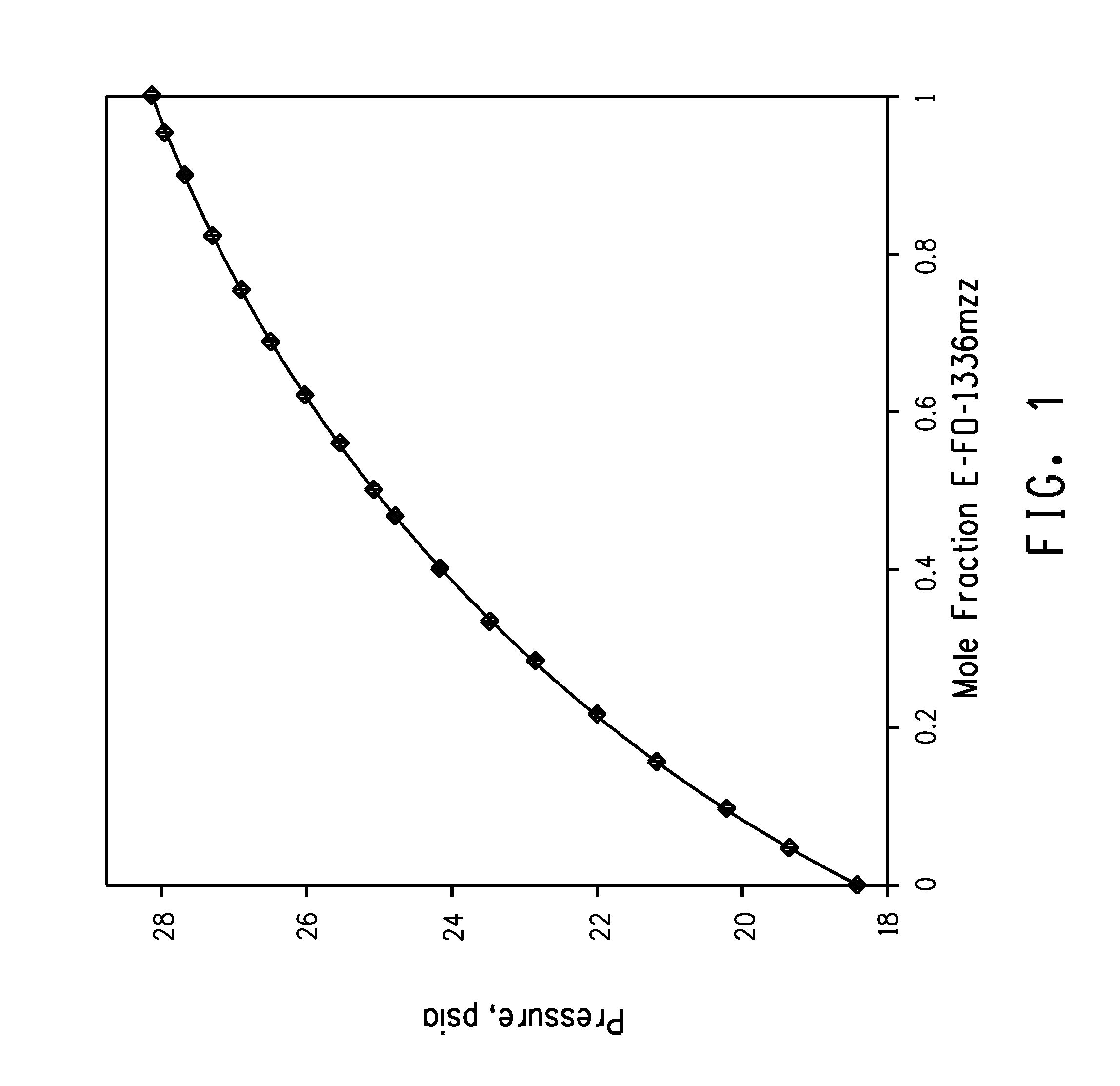

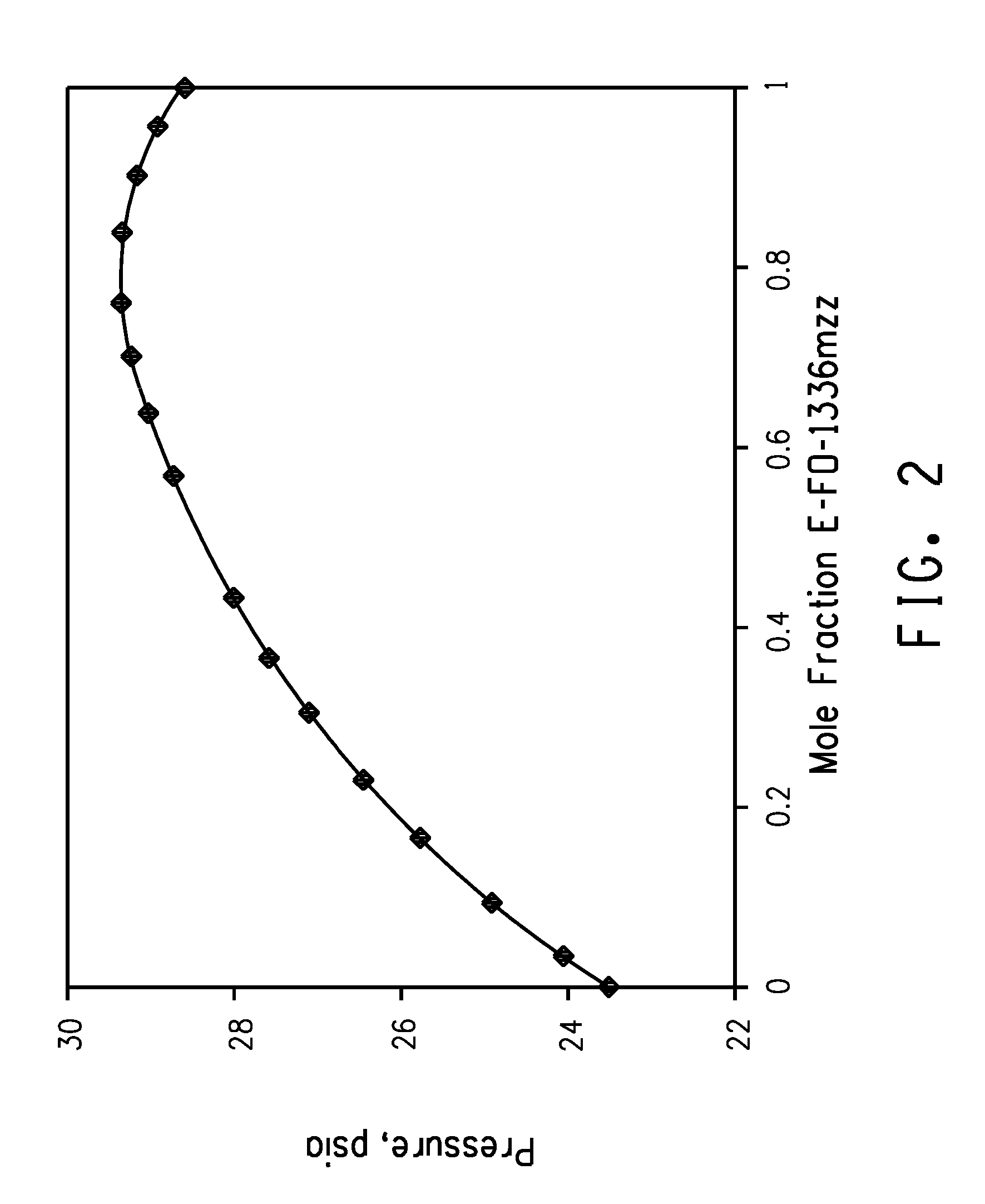

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

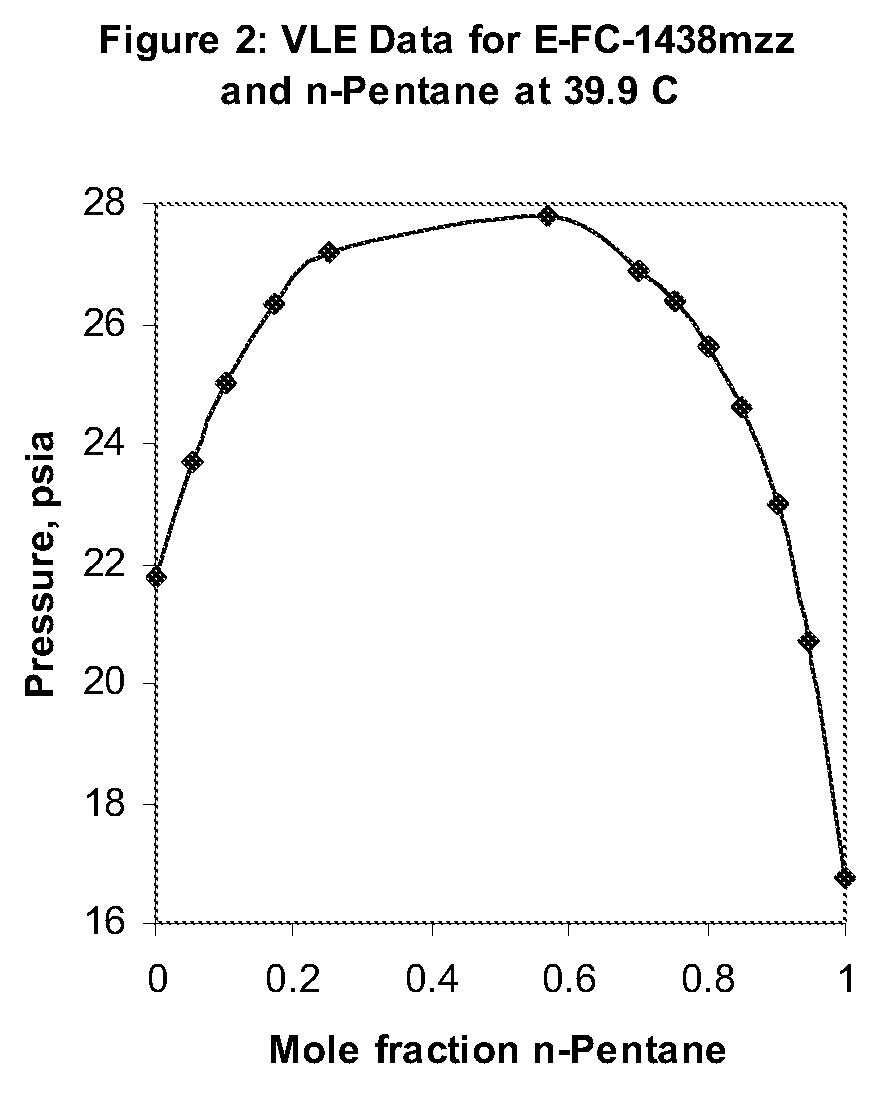

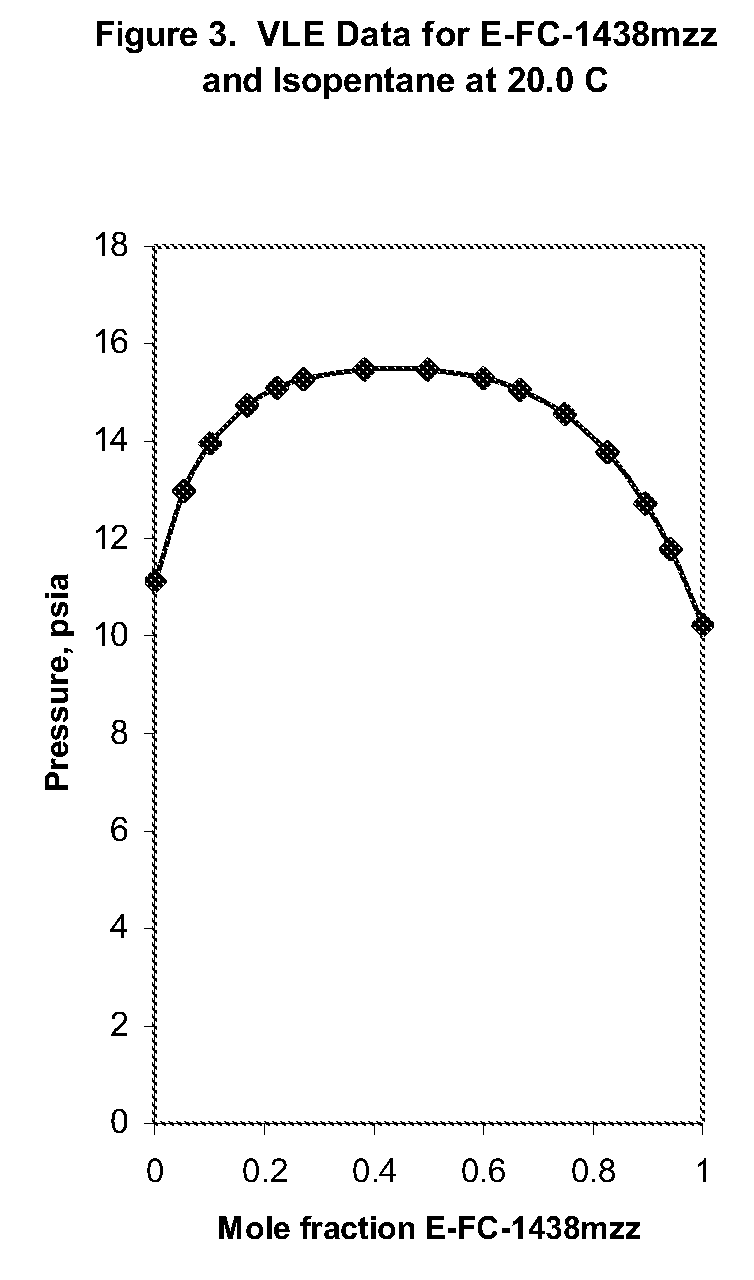

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

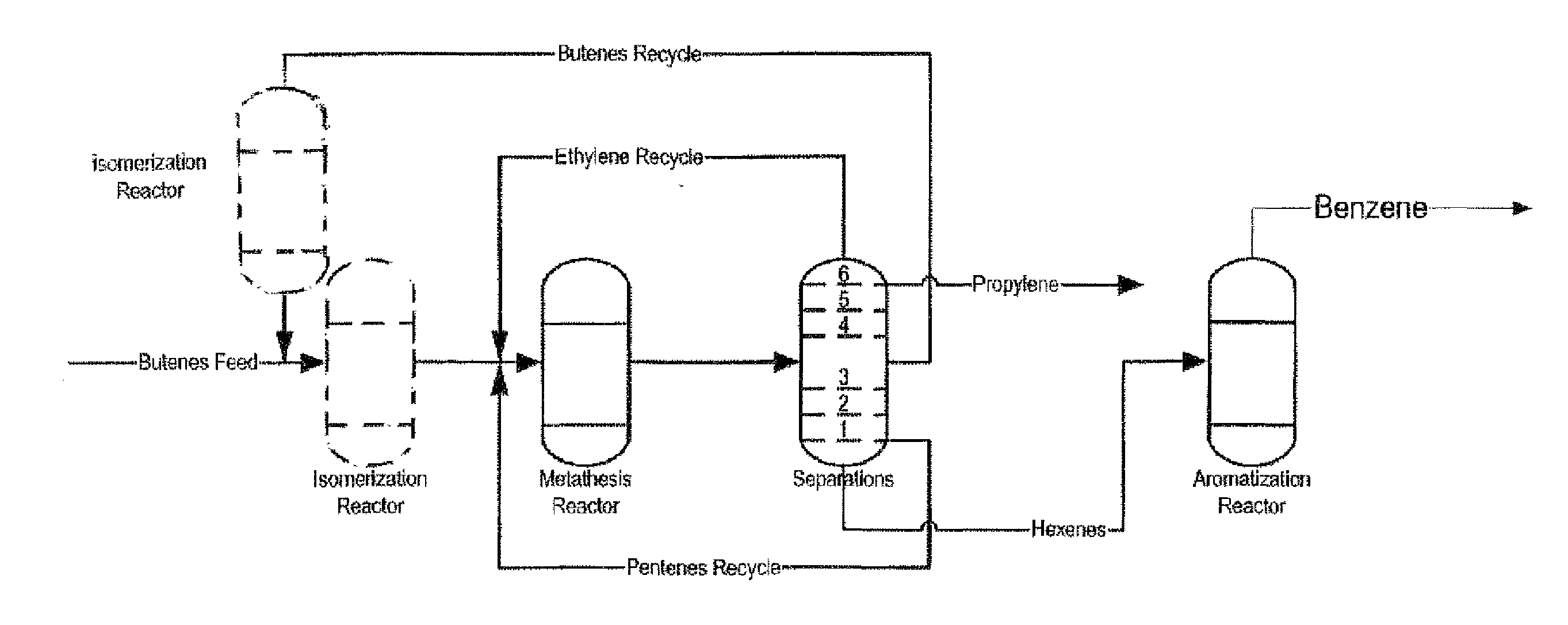

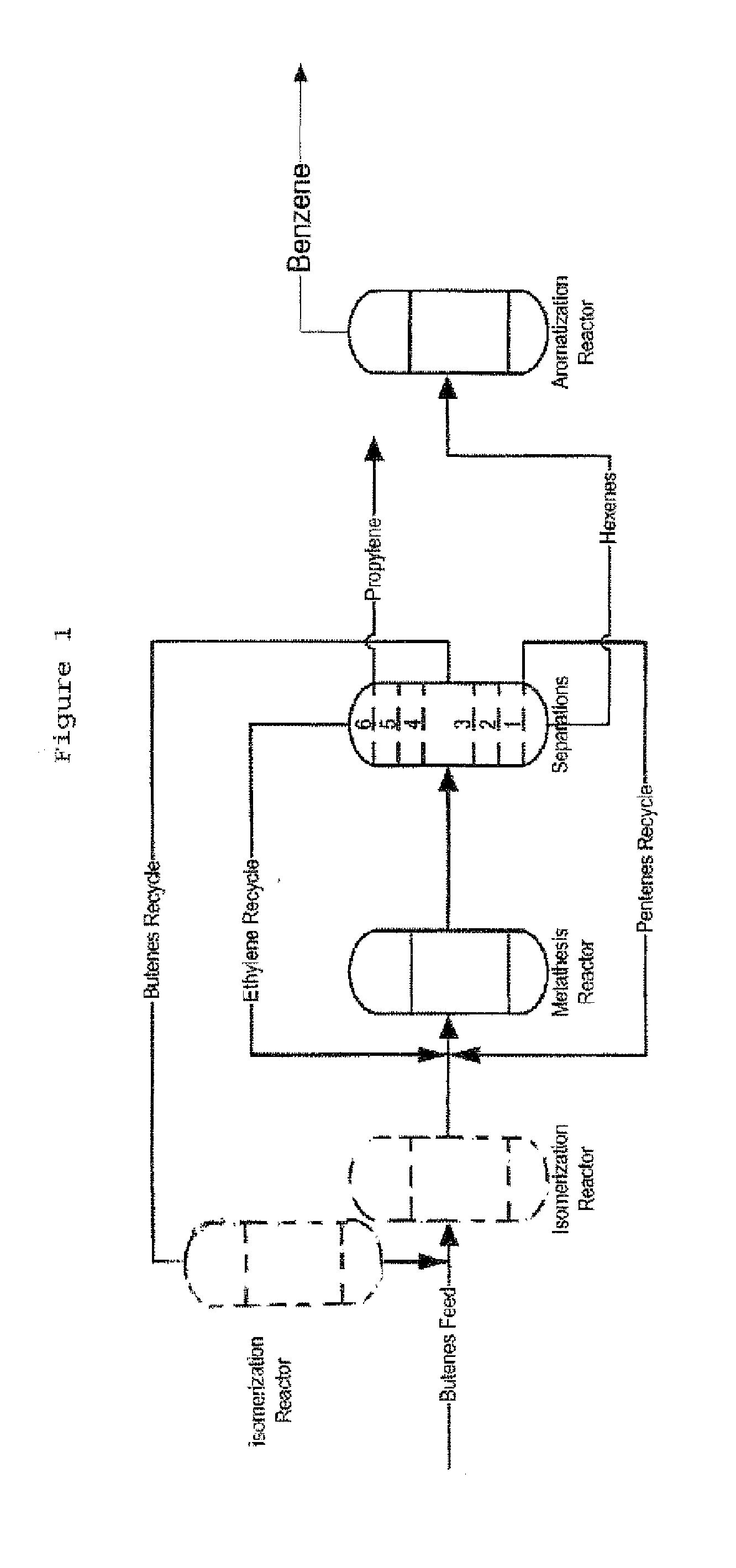

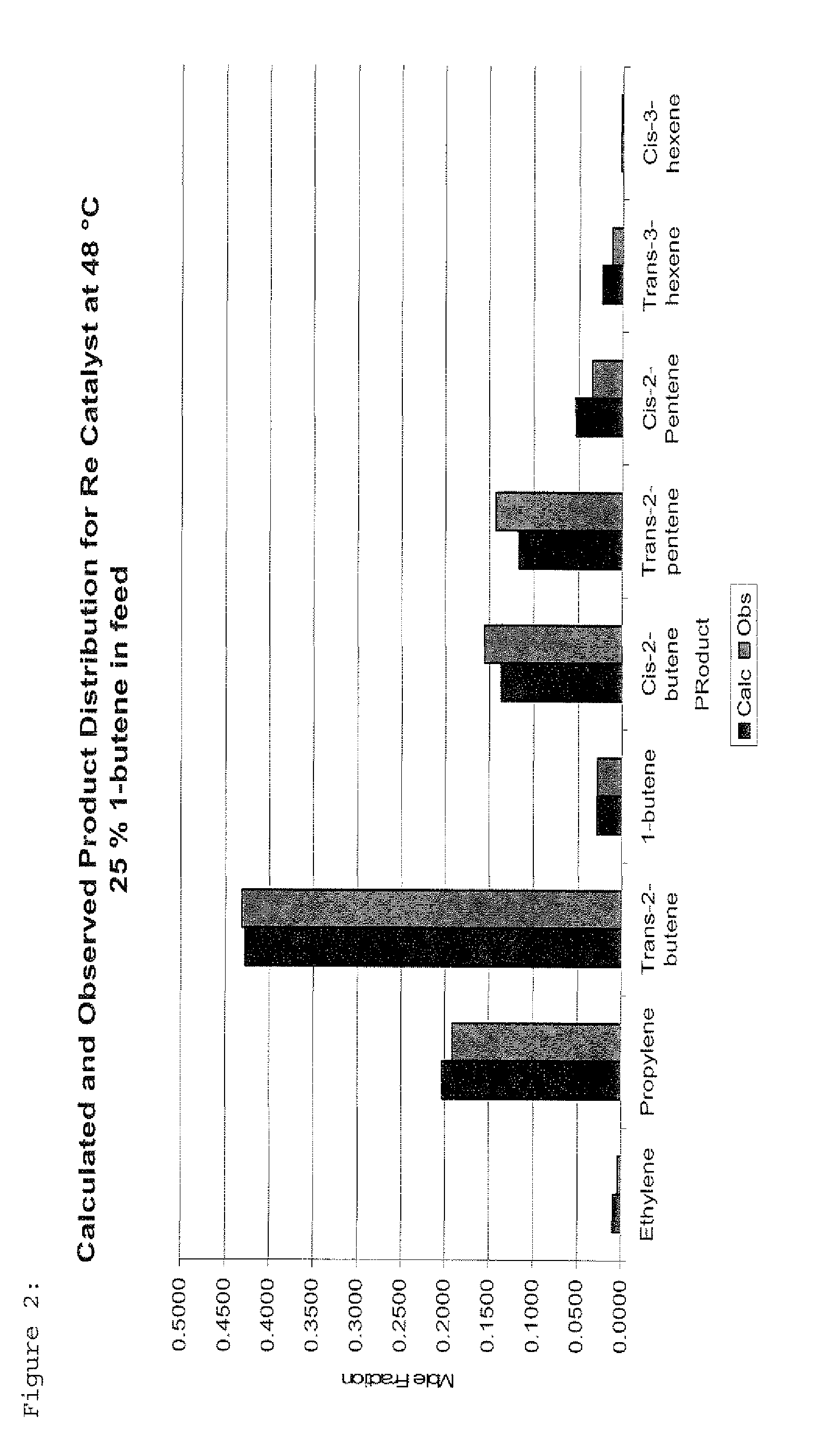

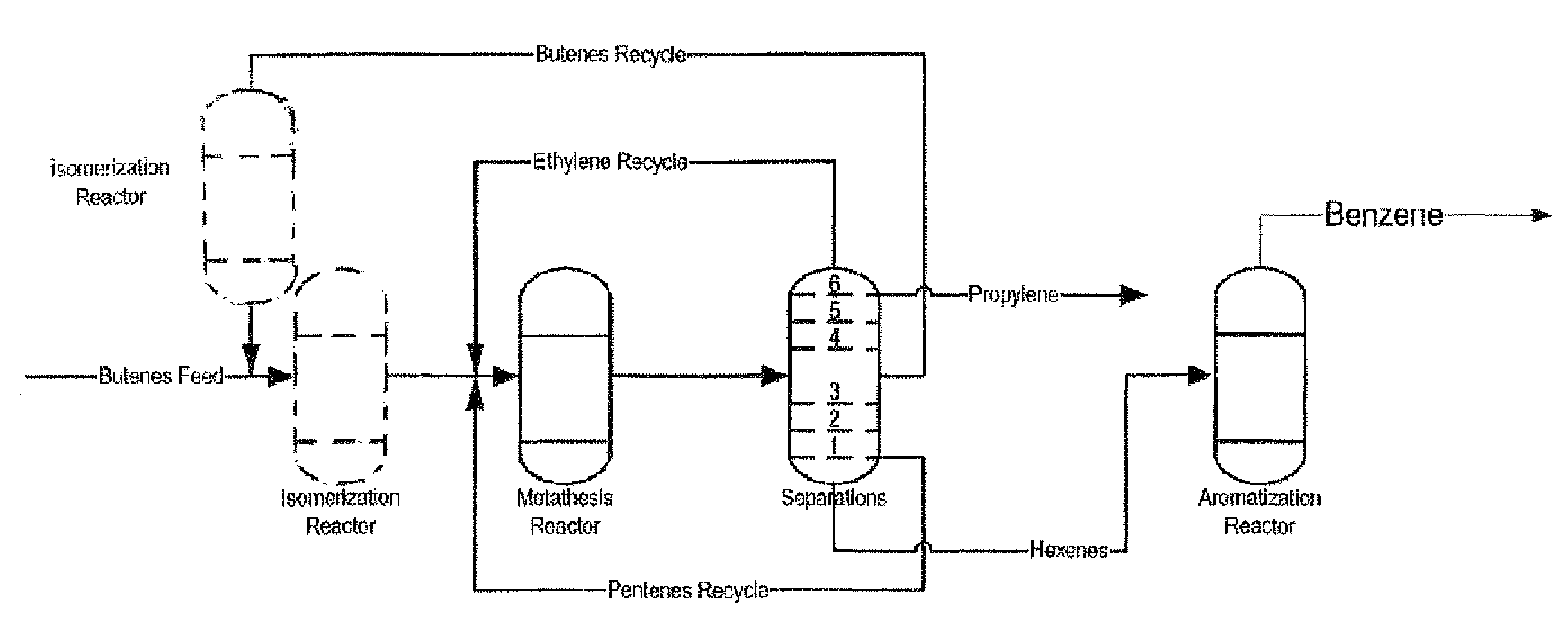

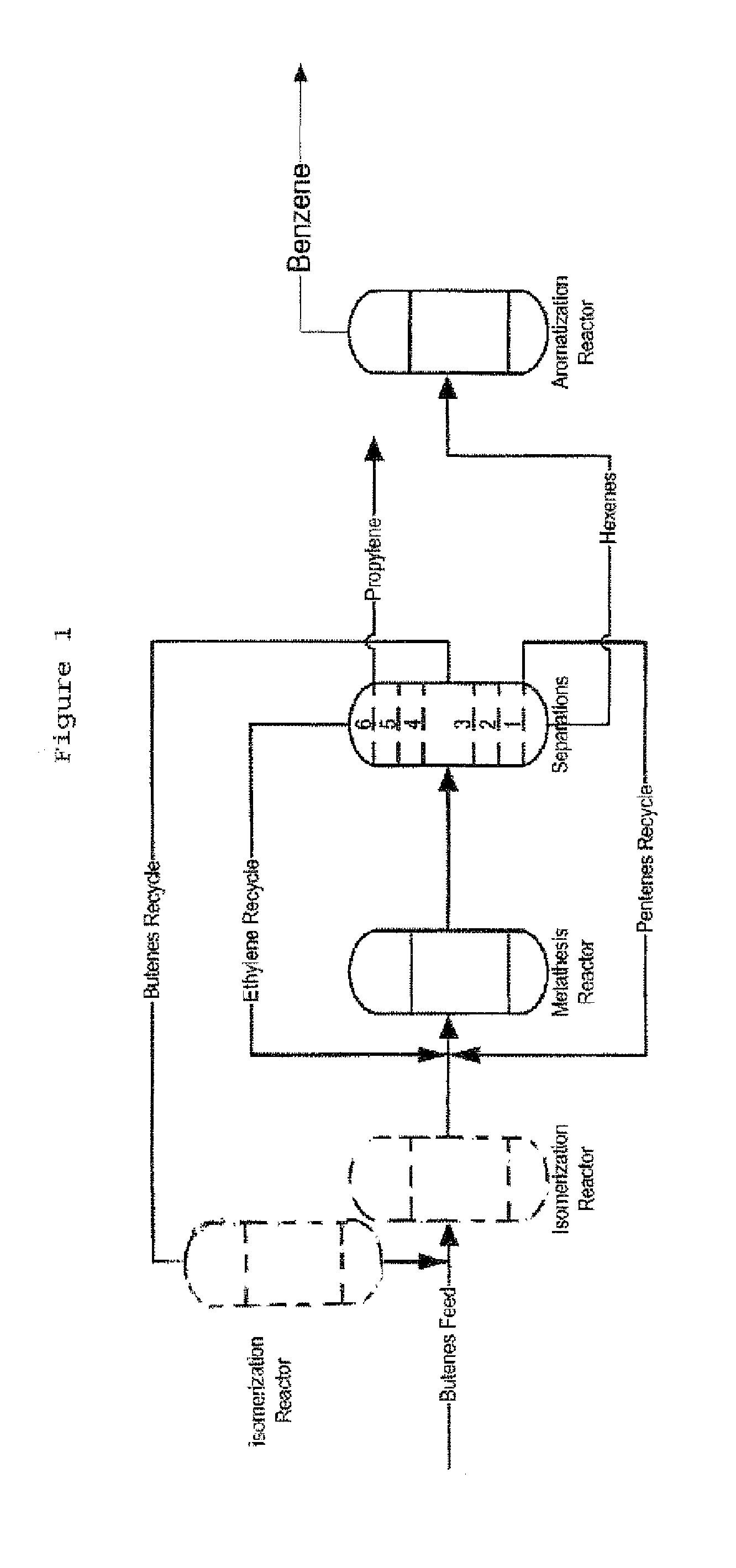

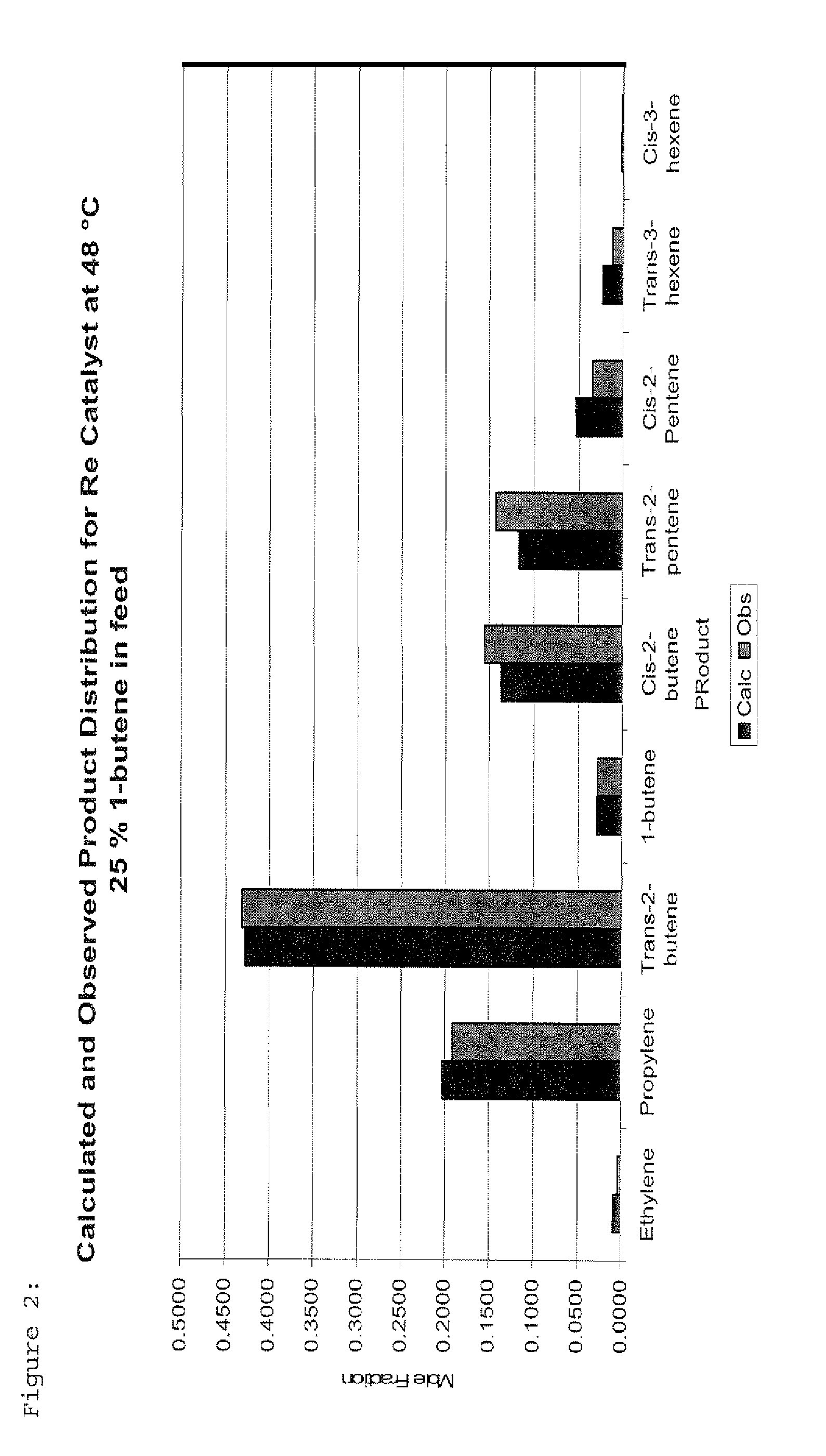

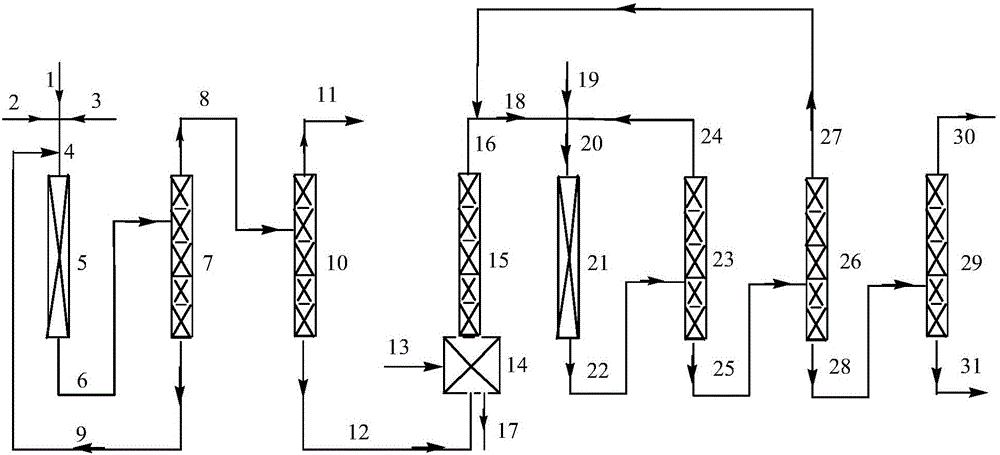

Process for Producing Propylene and Aromatics from Butenes by Metathesis and Aromatization

InactiveUS20110263917A1Molecular sieve catalystDistillation purification/separationIsomerizationOctene

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

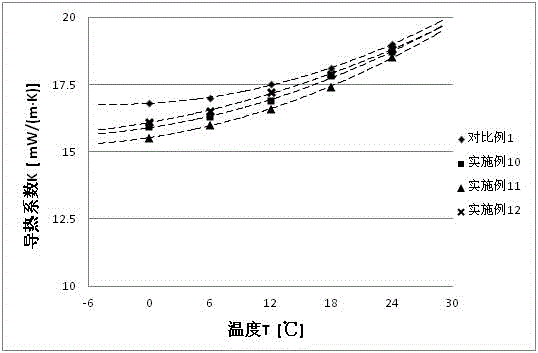

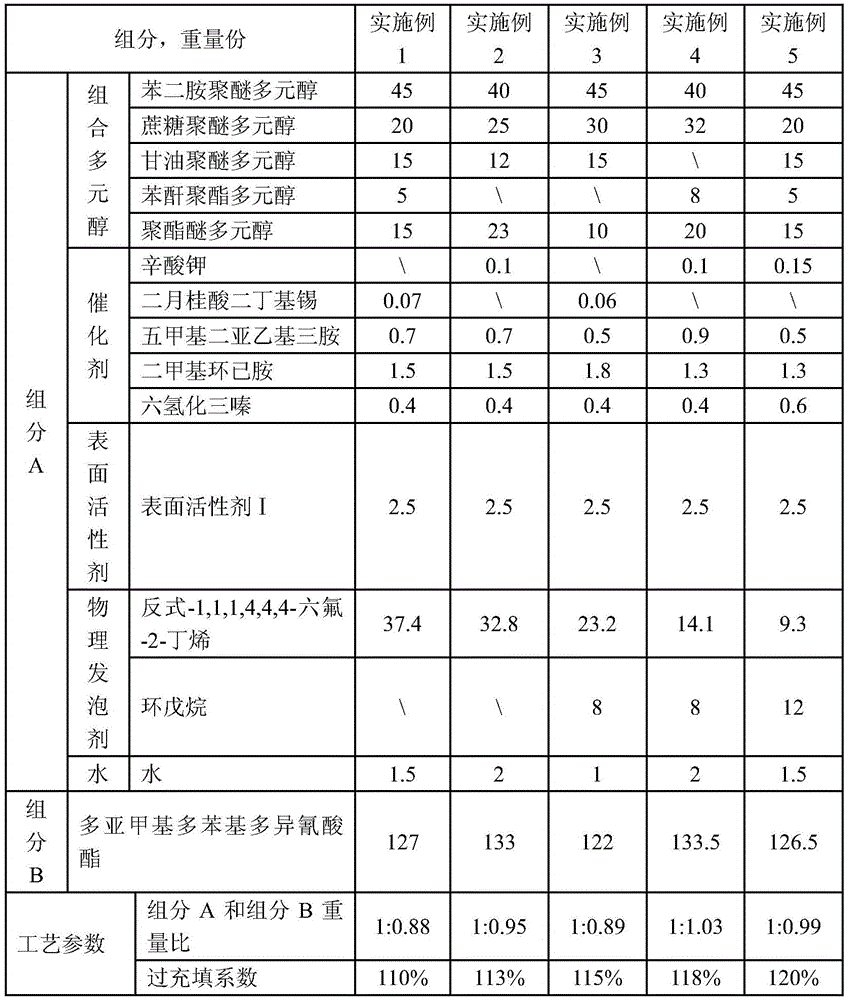

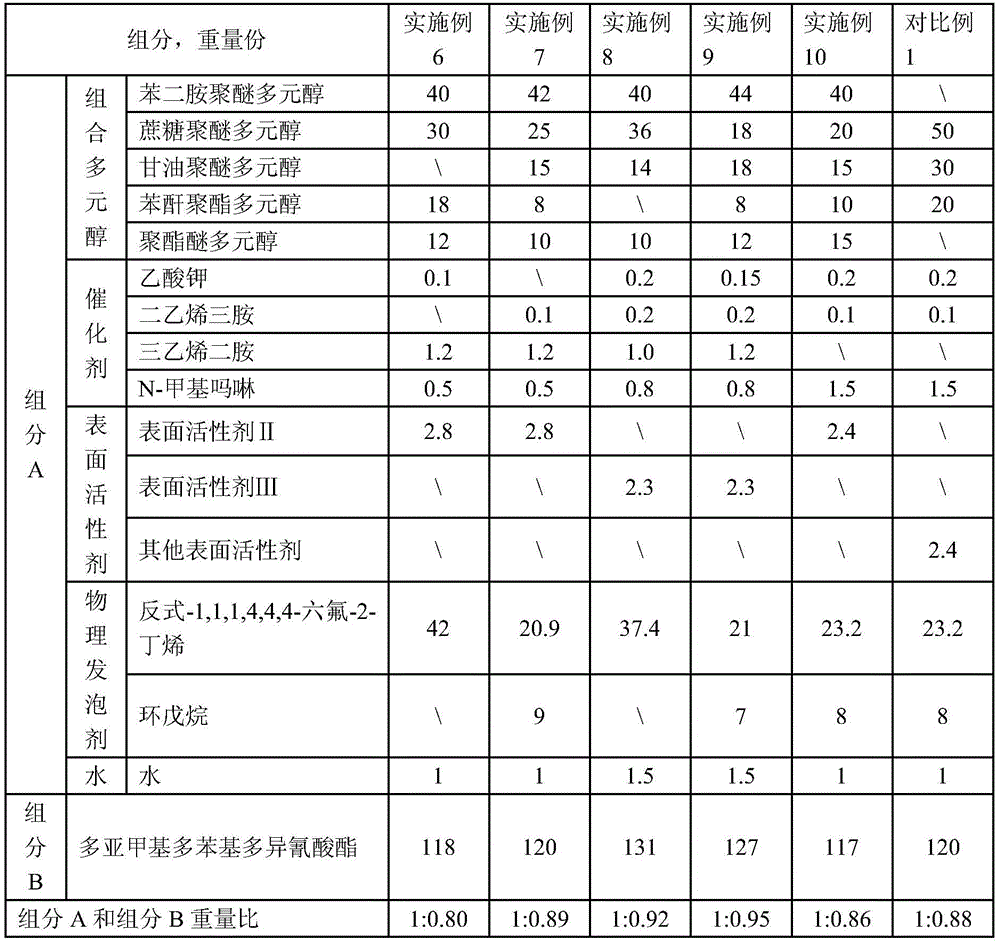

Hard polyurethane foam

The invention relates to a hard polyurethane foam. The hard polyurethane foam is composed of a component A and a component B at a weight ratio of 1:0.7-1.2. The component A comprises, by weight, 100 parts of a compound polyhydric alcohol containing phenylenediamine polyether glycol and polyester ether polyhydric alcohol, 10 to 50 parts of a physical foaming agent containing trans-1,1,1,4,4,4-hexafluoro-2-butene, 1 to 4 parts of a catalyst, 1 to 5 parts of a surfactant, and 0.5 to 3.0 parts of water; and the component B is polymethylene polyphenyl isocyanate. The foams of the hard polyurethane foam are fine and uniform; heat conductivity coefficient is low; comprehensive properties are excellent; and K value<=19.0mW / (m.K) at 24 DEG C, and K value<=17.0mW / (m.K) at 0 DEG C.

Owner:NANJING HONGBAOLI POLYURETHANE

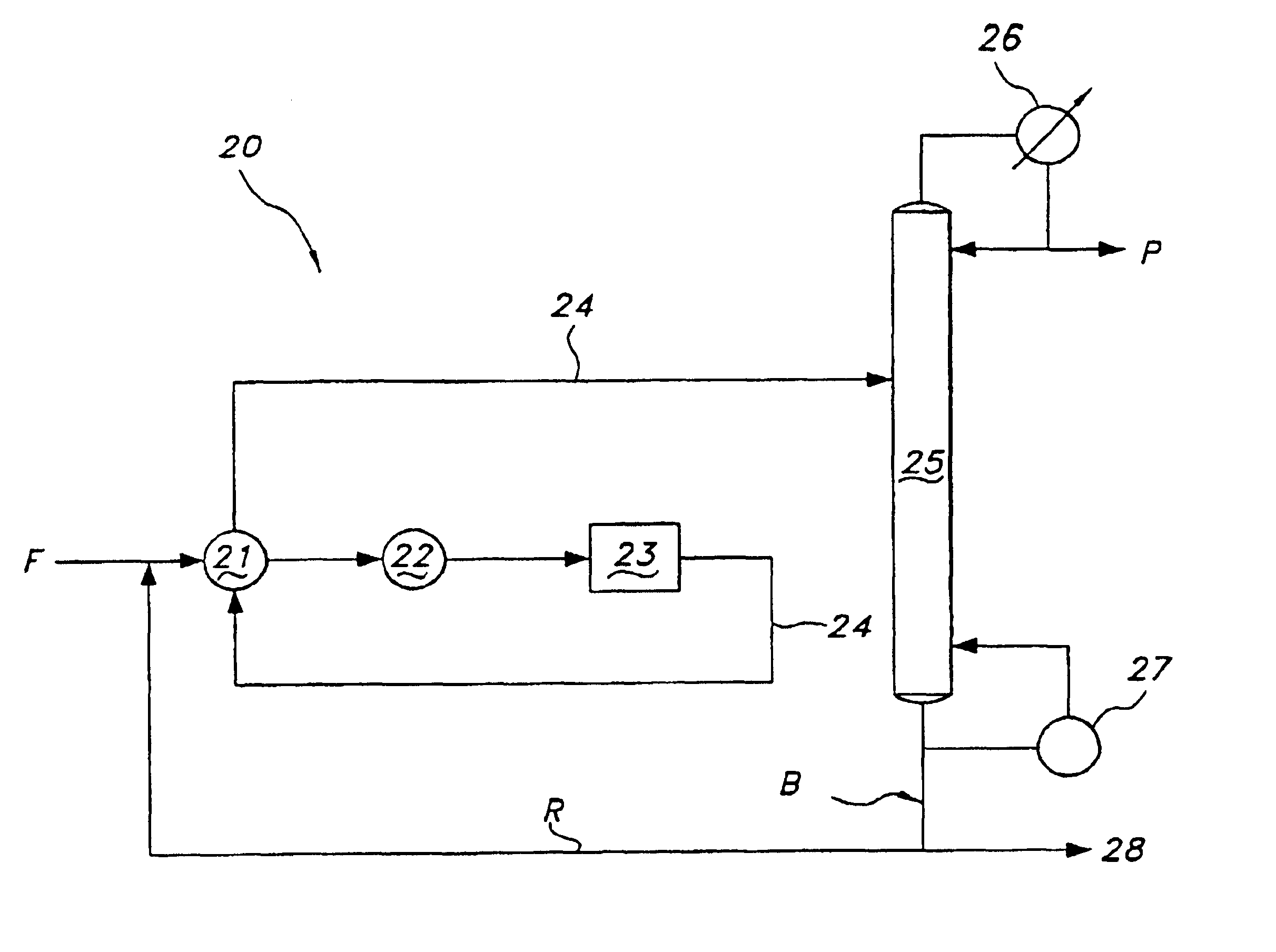

Butane removal in C4 upgrading processes

InactiveUS20060047176A1High efficiency and low costHydrocarbon by isomerisationChemical industryButeneAlkane

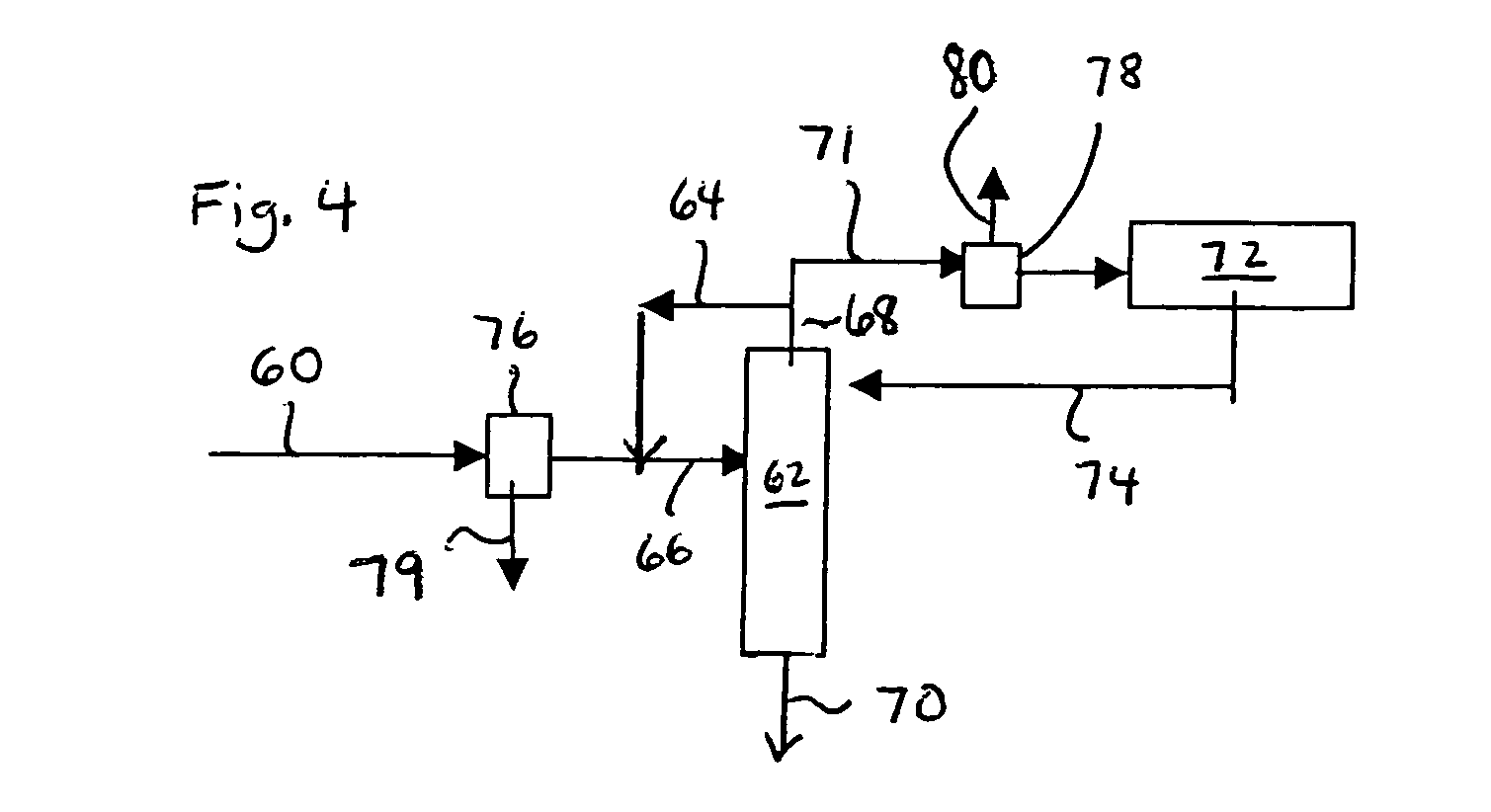

Disclosed herein is a process for producing a selected butene, comprising obtaining a C4 feed stream comprising C4 paraffins and C4 olefins, splitting the C4 feed stream to form a first stream comprising a first butene and a second stream comprising a second butene, isomerizing at least a part of the second stream to convert a portion of the second butene to the first butene, and recycling at least some of the isomerized part of the second steam to the splitting step, wherein a portion of at least one of the C4 feed stream and the second stream is passed through a facilitated transport membrane to remove butanes, forming at least one purge stream comprising butanes. A process for the conversion of C4 olefins, comprising obtaining a C4 feed stream comprising C4 paraffins and C4 olefins, including 1-butene and 2-butene, and reacting the C4 feed stream in a metathesis reactor to form a second stream is also disclosed. The second stream is fractionated to form one or more product streams and a recycle stream primarily containing C4 olefins and C4 paraffins. The recycle stream and / or the C4 feed stream is passed through a facilitated transport membrane to remove butanes, forming at least one purge stream.

Owner:ABB LUMMUS GLOBAL INC

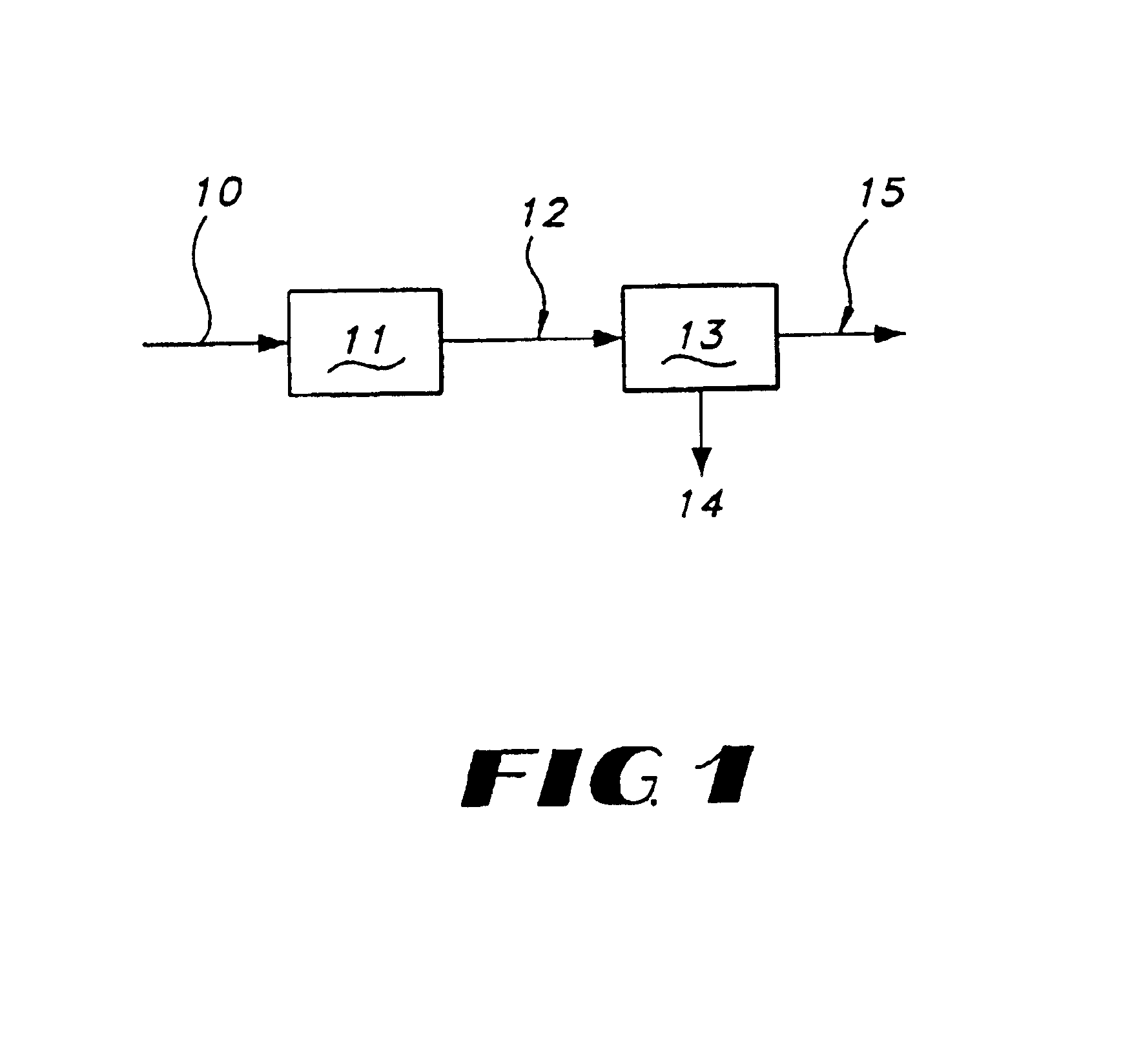

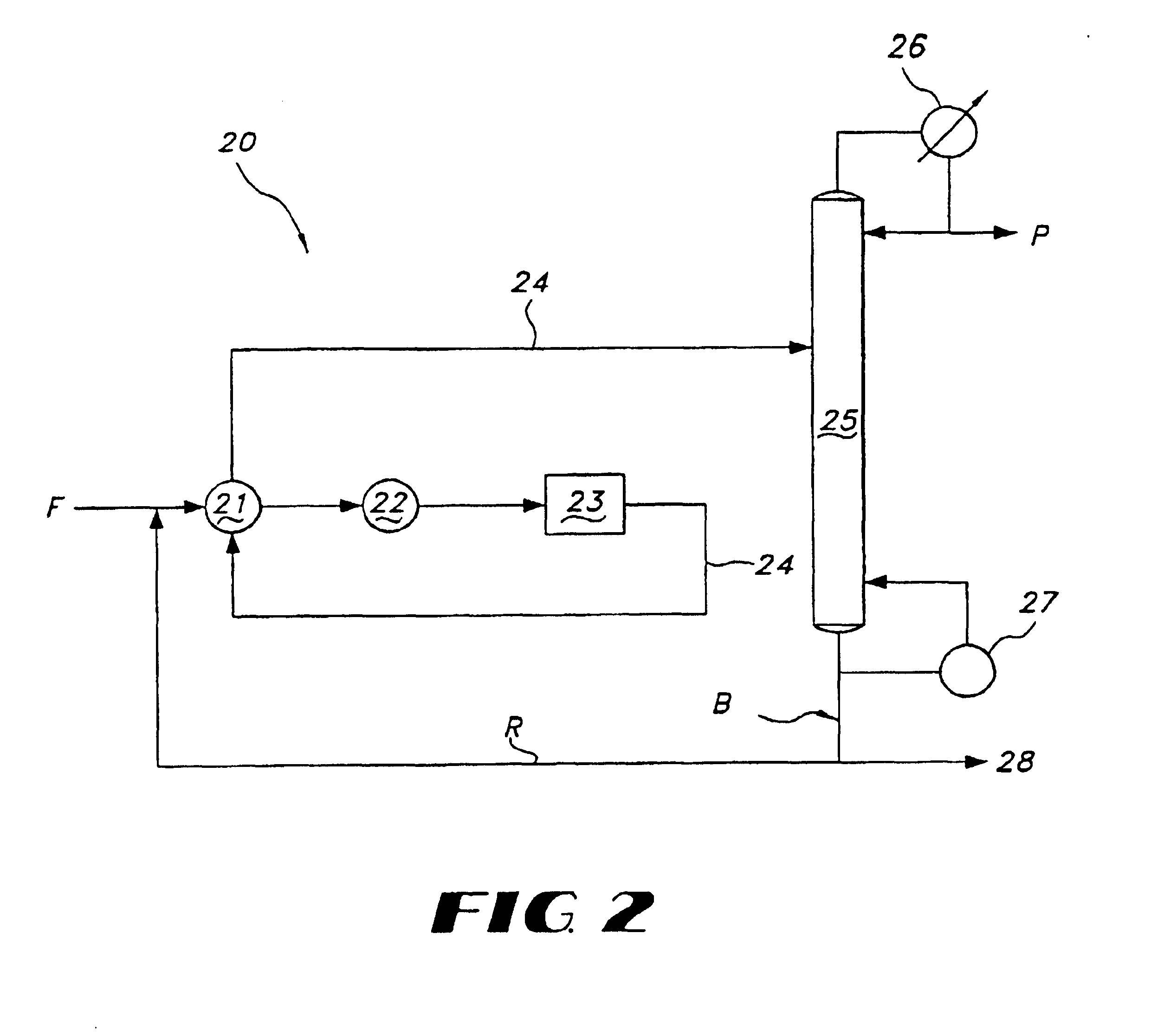

Catalyst for metathesis of ethylene and 2-butene and/or double bond isomerization

A process for the double-bond isomerization of olefins is disclosed. The process may include contacting a fluid stream comprising olefins with a fixed bed comprising an activated basic metal oxide isomerization catalyst to convert at least a portion of the olefin to its isomer. The isomerization catalysts disclosed herein may have a reduced cycle to cycle deactivation as compared to conventional catalysts, thus maintaining higher activity over the complete catalyst life cycle.

Owner:LUMMUS TECH INC

Olefin metathesis

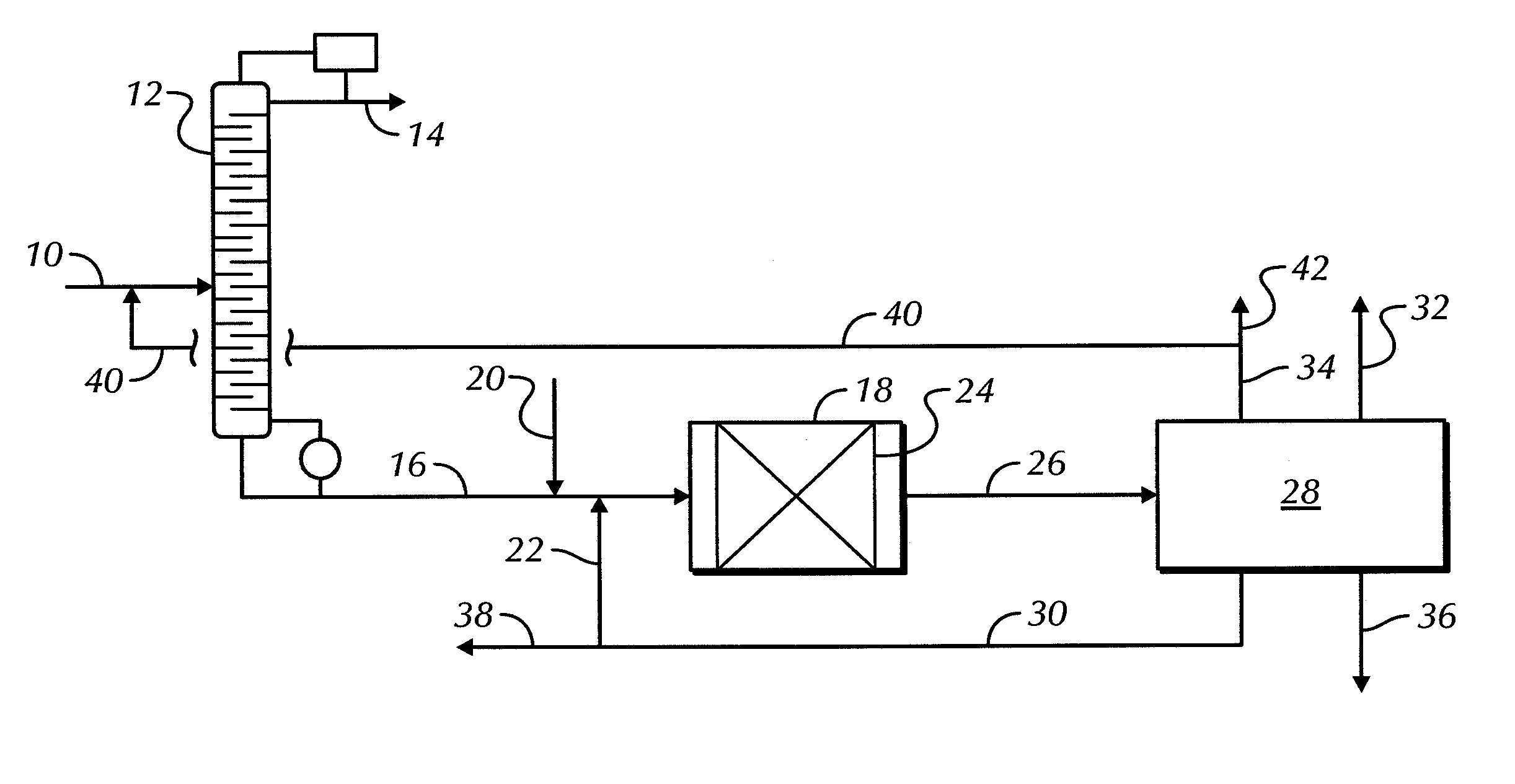

InactiveUS20060089517A1Solution to short lifeHydrocarbon by metathesis reactionHydrocarbonsIsomerizationThiol

A process for the production of propylene from the metathesis of ethylene and 2-butene is disclosed wherein a mixed C4 stream is first treated to enrich and separate the 2-butene from 1-butene and isobutene by isomerization of 1-butene and concurrent fractional distillation of the 2-butene and isobutene to provide the 2-butene feed the metathesis with ethylene. In addition the mixed C4 stream may be treated to remove mercaptans and dienes prior to 2-butene enrichment.

Owner:CHEM RES & LICENSING CO

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS20100243943A1Organic compounds purification/separation/stabilisationOther chemical processesDielectricThermoplastic

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

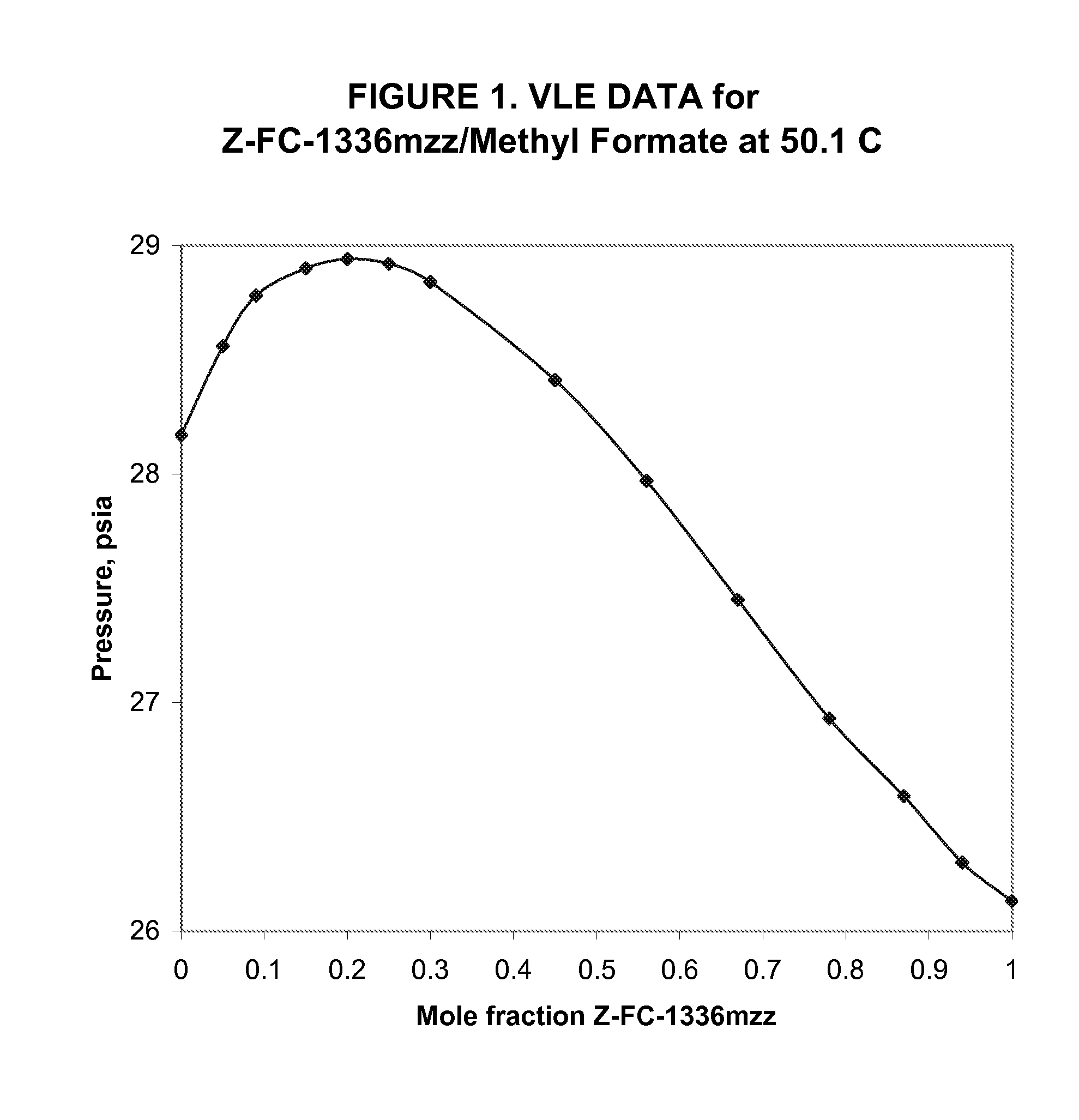

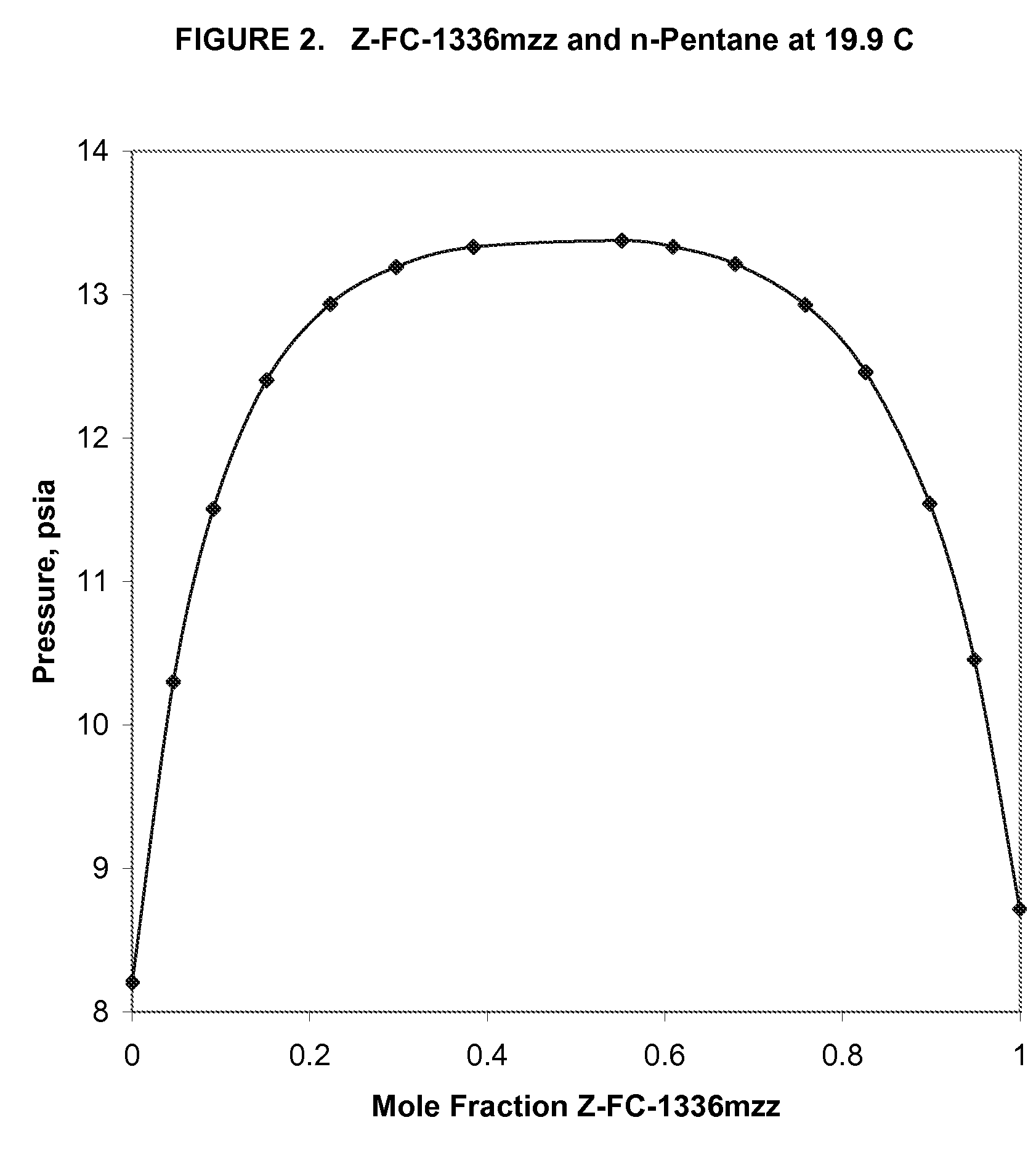

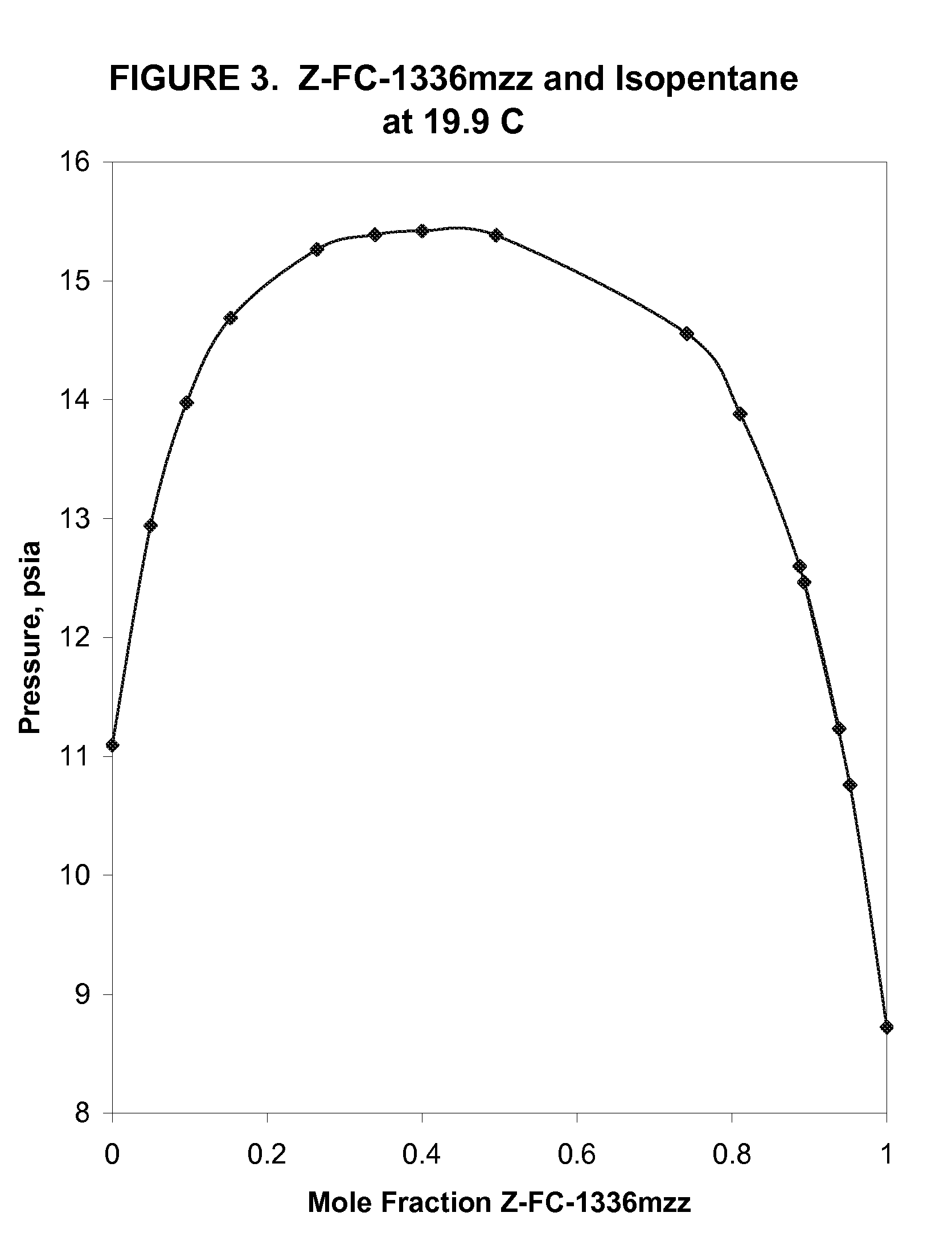

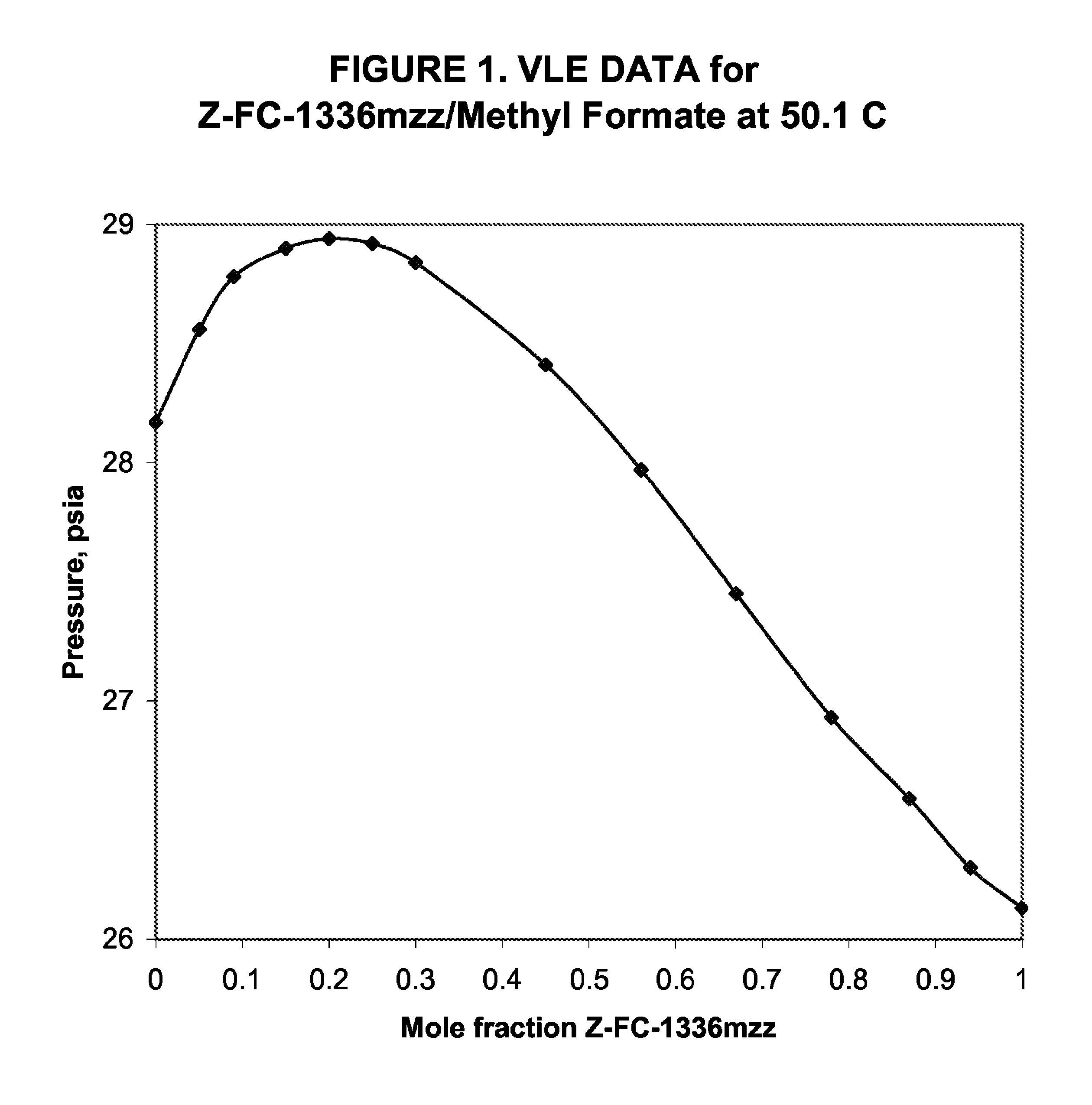

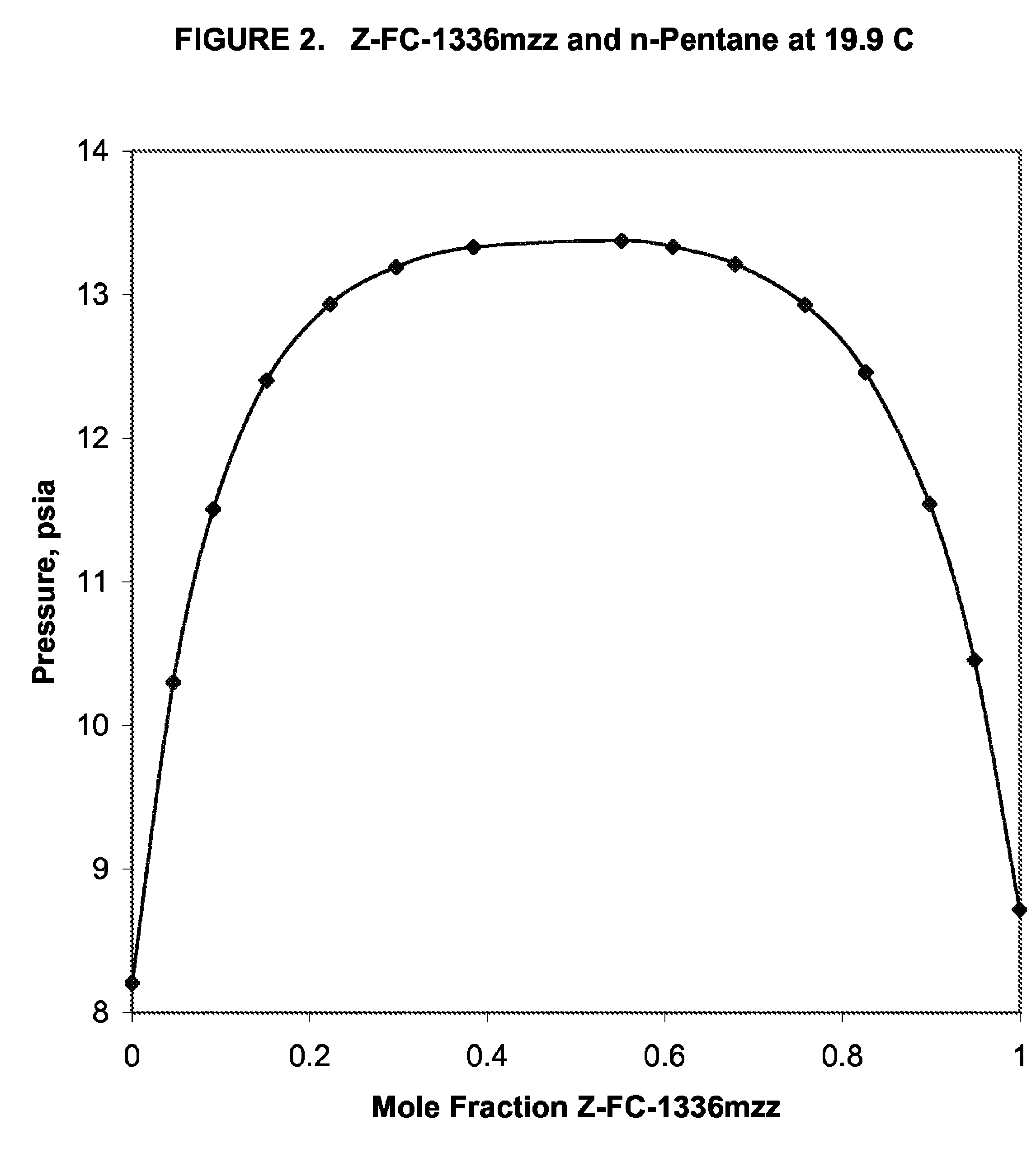

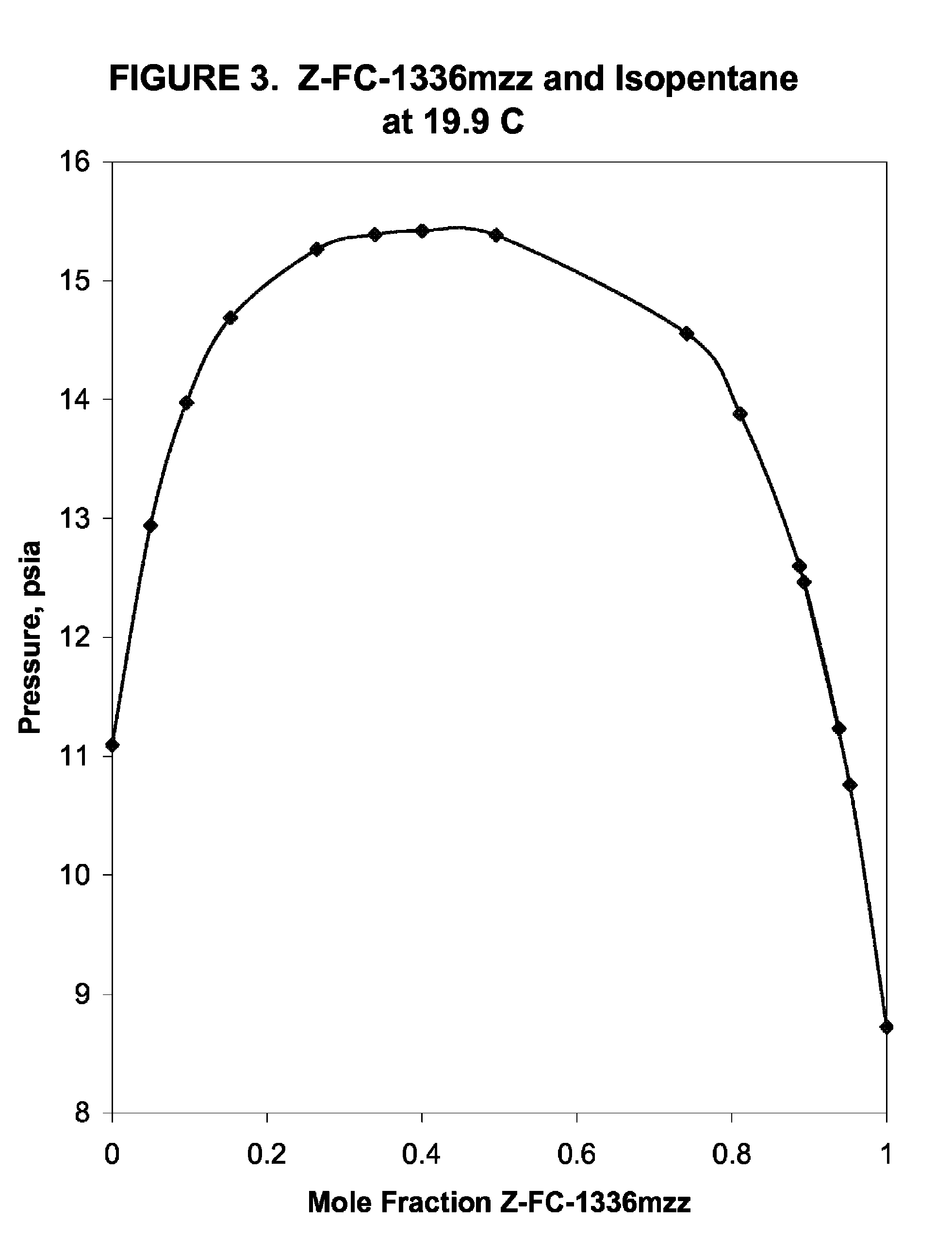

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Azeotropic and azeotrope-like compositions of Z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

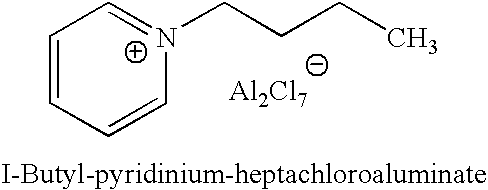

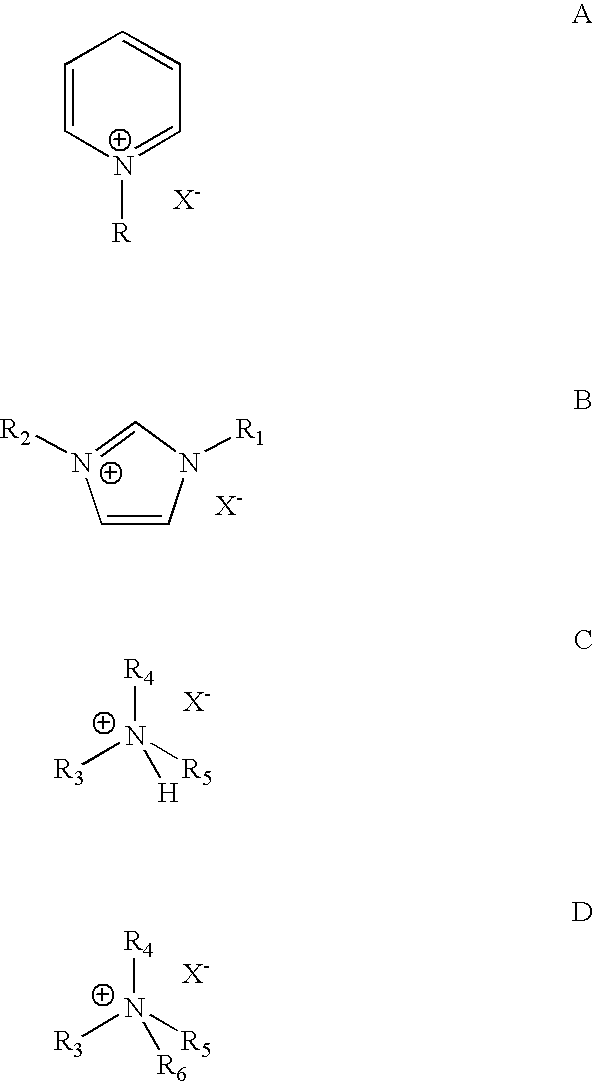

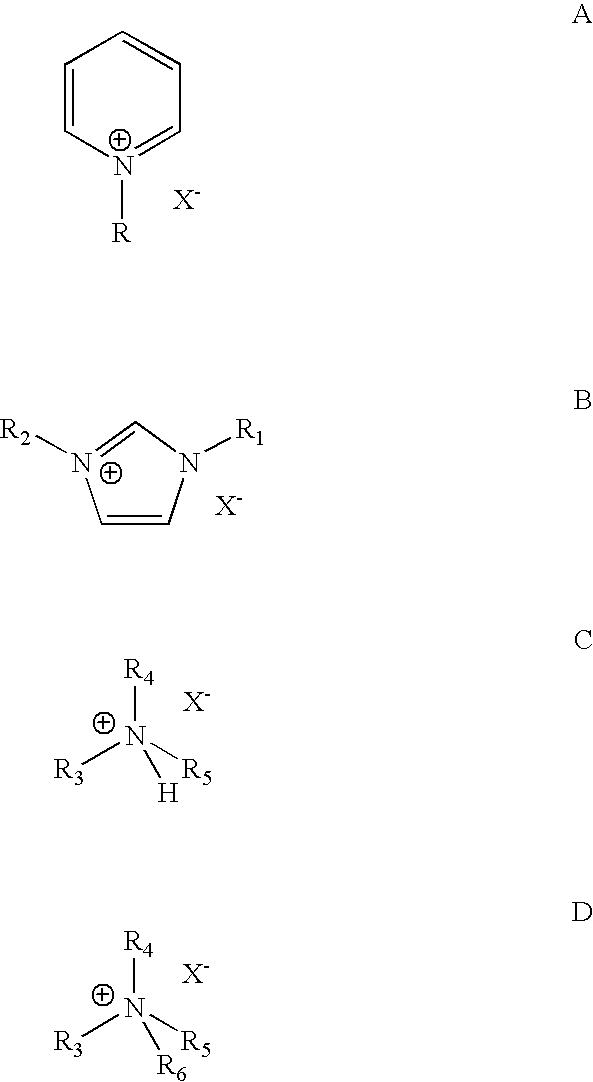

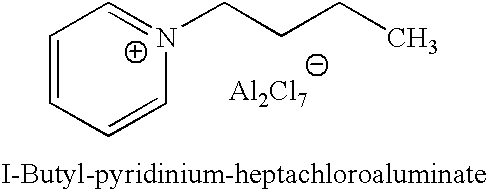

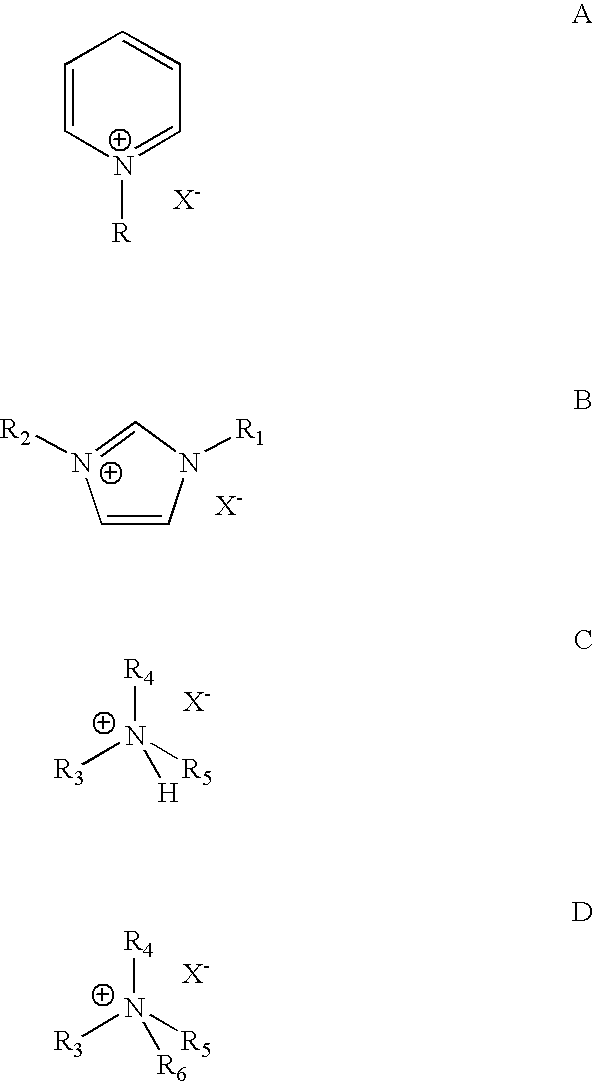

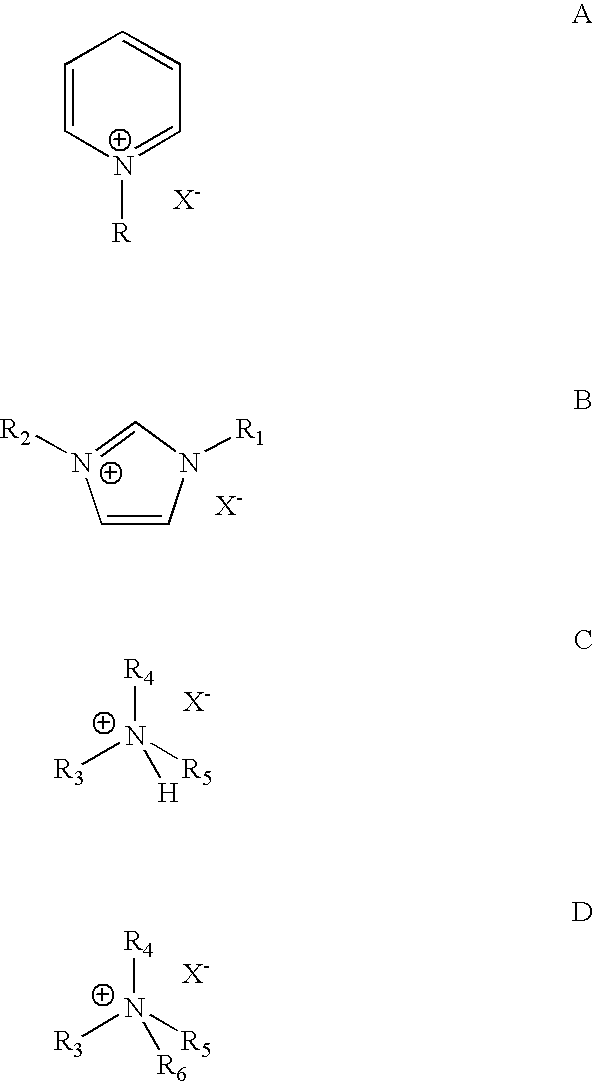

Isomerization of butene in the ionic liquid-catalyzed alkylation of light isoparaffins and olefins

ActiveUS20080146858A1Hydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneButene

A process for producing alkylate comprising contacting a first hydrocarbon stream comprising at least one olefin having from 2 to 6 carbon atoms which contains 1-butene with an isomerization catalyst under conditions favoring the isomerization of 1-butene to 2-butene so the isomerized stream contains a greater concentration of 2-butene than the first hydrocarbon stream and contacting the isomerized stream and a second hydrocarbon stream comprising at least one isoparaffin having from 3 to 6 carbon atoms with an acidic ionic liquid catalyst under alkylation conditions to produce an alkylate stream is disclosed.

Owner:CHEVROU USA INC

Process for producing propylene and aromatics from butenes by metathesis and aromatization

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

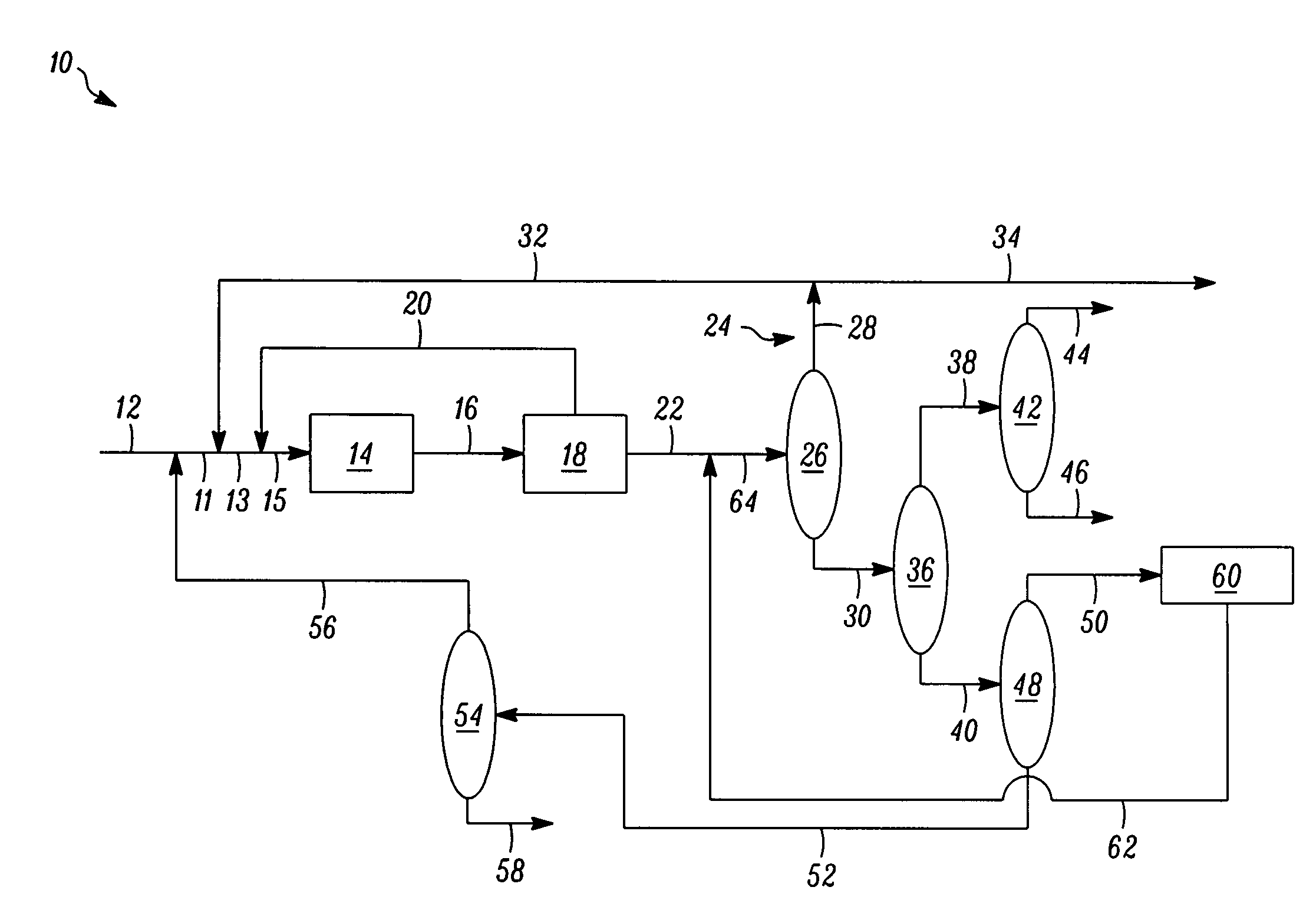

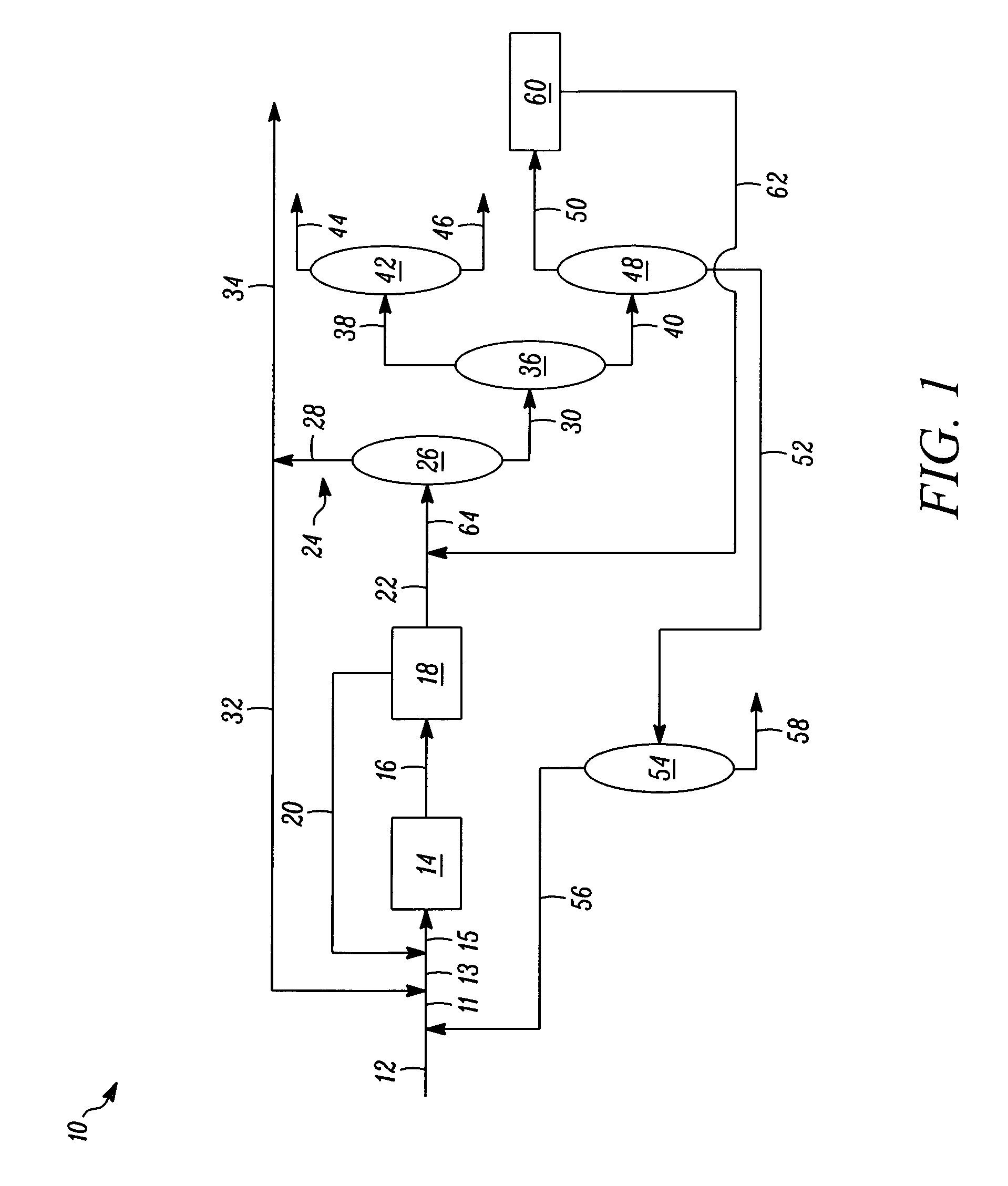

Propylene production

ActiveUS20080312481A1Improve throughputImprove concentrationDistillation purification/separationCatalystsButeneAlkane

A process for producing propylene from ethylene and a feed stream comprising 1-butene, 2-butene, n-butane, and isobutane is disclosed. A butenes stream (1-butene and 2-butene) is produced from the feed stream by removing the paraffins. The butenes stream is reacted in the presence of an isomerization catalyst to produce an isomerized stream with increased concentration of 2-butene. The isomerized stream is reacted with ethylene in the presence of a metathesis catalyst to produce a reaction mixture comprising propylene; the propylene may be isolated from the reaction mixture by distillation. The removal of paraffins from the feed stream improves the catalyst productivity and the plant throughput.

Owner:LYONDELL CHEM TECH LP

Isomerization of butene in the ionic liquid-catalyzed alkylation of light isoparaffins and olefins

ActiveUS7553999B2Hydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneAlkyl transfer

A process for producing alkylate comprising contacting a first hydrocarbon stream comprising at least one olefin having from 2 to 6 carbon atoms which contains 1-butene with an isomerization catalyst under conditions favoring the isomerization of 1-butene to 2-butene so the isomerized stream contains a greater concentration of 2-butene than the first hydrocarbon stream and contacting the isomerized stream and a second hydrocarbon stream comprising at least one isoparaffin having from 3 to 6 carbon atoms with an acidic ionic liquid catalyst under alkylation conditions to produce an alkylate stream is disclosed.

Owner:CHEVROU USA INC

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing z-1,1,1,4,4,4-hexafluoro-2-butene and their uses in the preparation of polyisocyanate-based foams

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing cis-1,1,1,4,4,4-hexafluoro-2-butene are disclosed. The foam-forming composition contains (a) an azeotropic or azeotrope-like mixture of cis-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, pentane, isopentane, cyclopentane, HFC-245fa, or dimethoxymethane; and (b) an active hydrogen-containing compound having two or more active hydrogens. Also disclosed is a closed-cell polyurethane or polyisocyanurate polymer foam prepared from reaction of an effective amount of the foam-forming composition with a suitable polyisocyanate. Also disclosed is a process for producing a closed-cell polyurethane or polyisocyanurate polymer foam by reacting an effective amount of the foam-forming composition with a suitable polyisocyanate.

Owner:THE CHEMOURS CO FC LLC

High yield production method for 1,3-butadiene

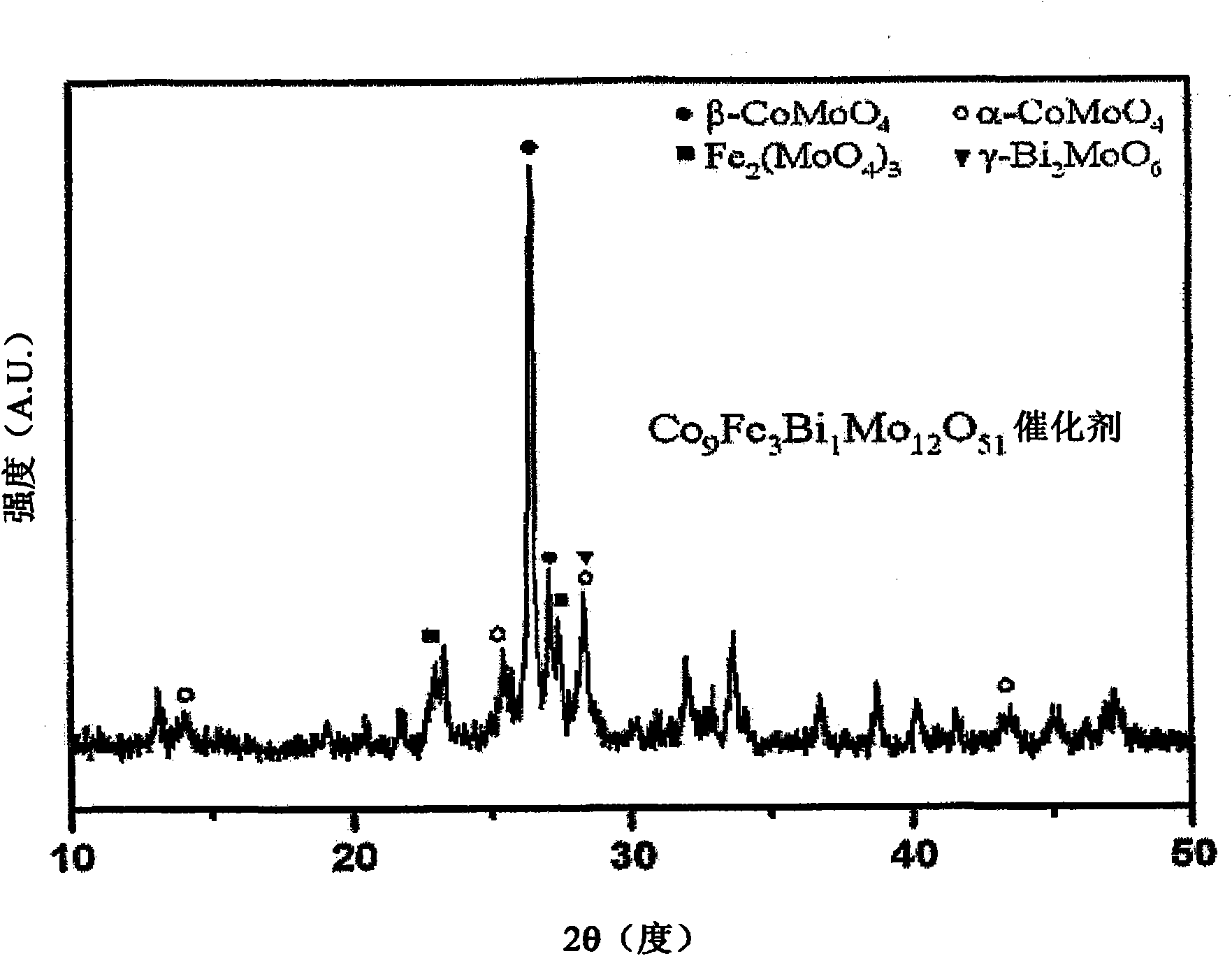

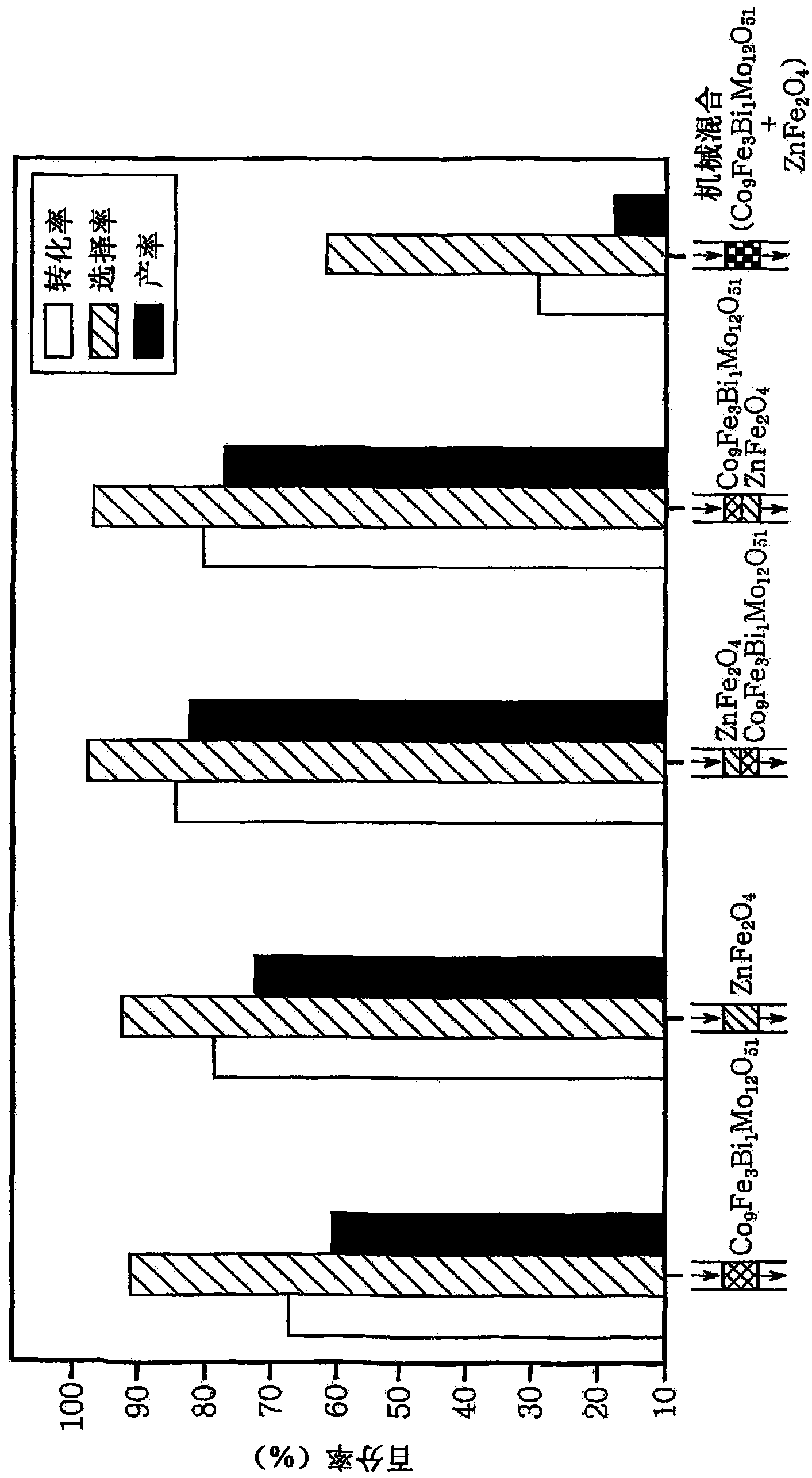

ActiveCN103298771AImprove conversion rateHigh selectivityDistillation purification/separationCatalystsButeneMolybdate

Owner:LG CHEM LTD

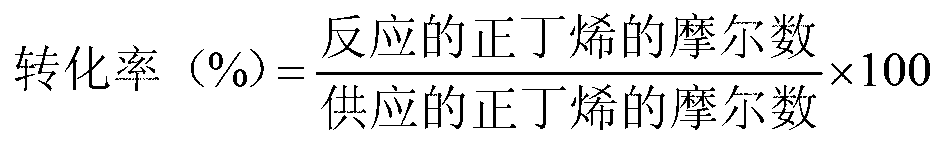

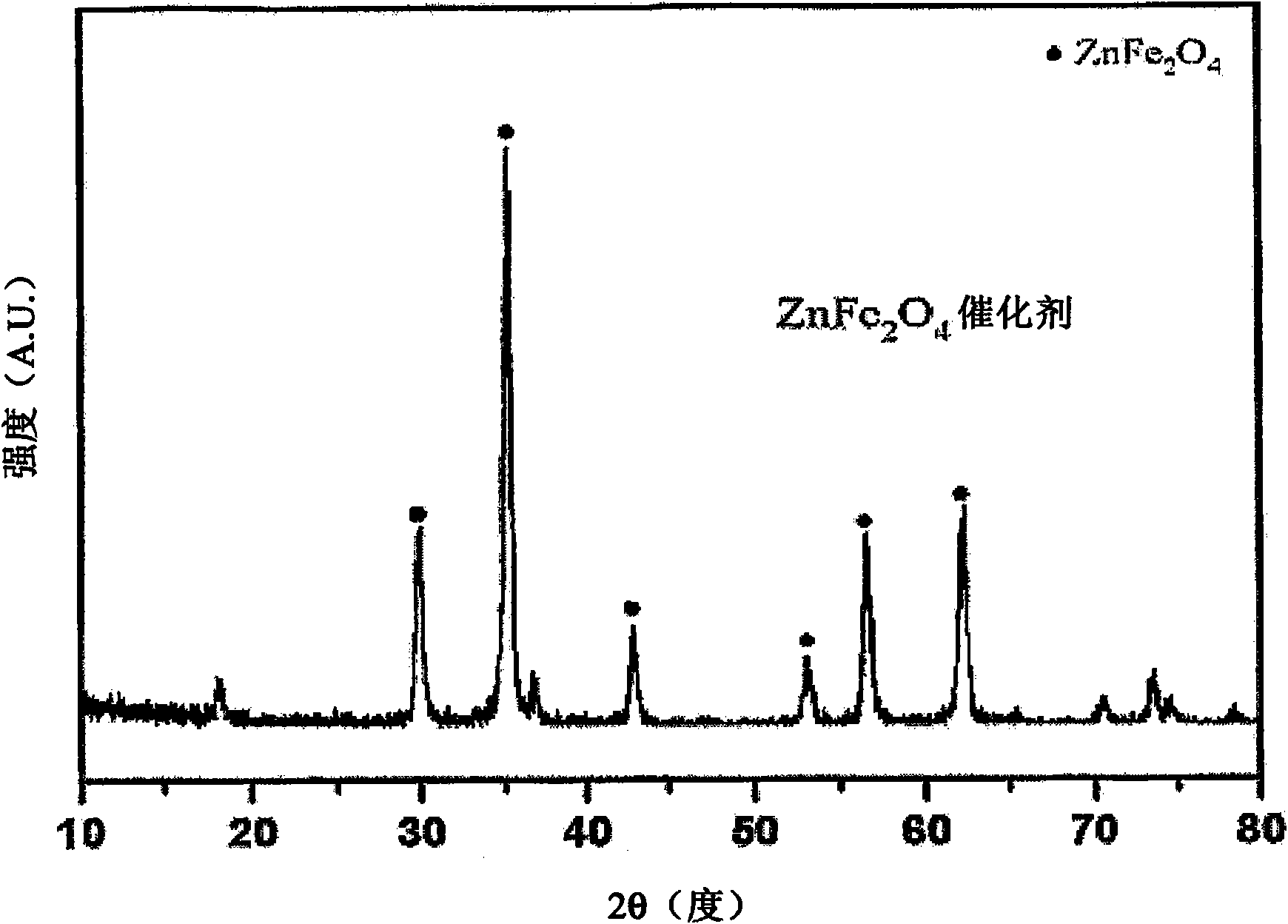

Method for preparing 1,3-butadiene from normal butene by using continuous-flow dual-bed reactor

InactiveCN101980992AHigh activityActivity maximizationHydrocarbon by dehydrogenationCatalystsDehydrogenationFixed bed

The present invention relates to a method for preparing 1,3-butadiene by an oxidative dehydrogenation of normal butene through the use of a continuous-flow dual-bed reactor which is designed in such a manner that a fixed bed reactor thereof is filled with two types of catalysts and two catalyst layers are not physically mixed. More particularly, the present invention relates to a method for preparing 1,3-butadiene through an oxidative dehydrogenation of normal butene using a C4 mixture, as a reactant, containing normal butene and normal butane, by using a continuous-flow dual-bed reactor employing a multi-component bismuth molybdate-based catalyst and a ferrite-based catalyst which have activations different from one another for the oxidative dehydrogenation of the isomers (1-butene, trans-2-butene, cis-2-butene) of normal butene.

Owner:SK INNOVATION CO LTD +1

Compositions and uses of trans-1,1,1,4,4,4-hexafluoro-2-butene

Disclosed is a mixture comprising the compound trans-1,1,1,4,4,4-hexafluoro-2-butene and at least one additional compound selected from the group consisting of HFOs, HFCs, HFEs, CFCs, CO2, olefins, organic acids, alcohols, hydrocarbons, ethers, aldehydes, ketones, and others such as methyl formate, formic acid, trans-1,2 dichloroethylene, carbon dioxide, cis-HFO-1234ze+HFO-1225yez; mixtures of these plus water; mixtures of these plus CO2; mixtures of these trans 1,2-dichloroethylene (DCE); mixtures of these plus methyl formate; mixtures with cis-HFO-1234ze+CO2; mixtures with cis-HFO-1234ze+HFO-1225yez+CO2; and mixtures with cis-HFO-1234ze+HFC-245fa. Also disclosed are methods of using and products of using the above compositions as blowing agents, solvents, heat transfer compositions, aerosol propellant compositions, fire extinguishing and suppressant compositions.

Owner:THE CHEMOURS CO FC LLC

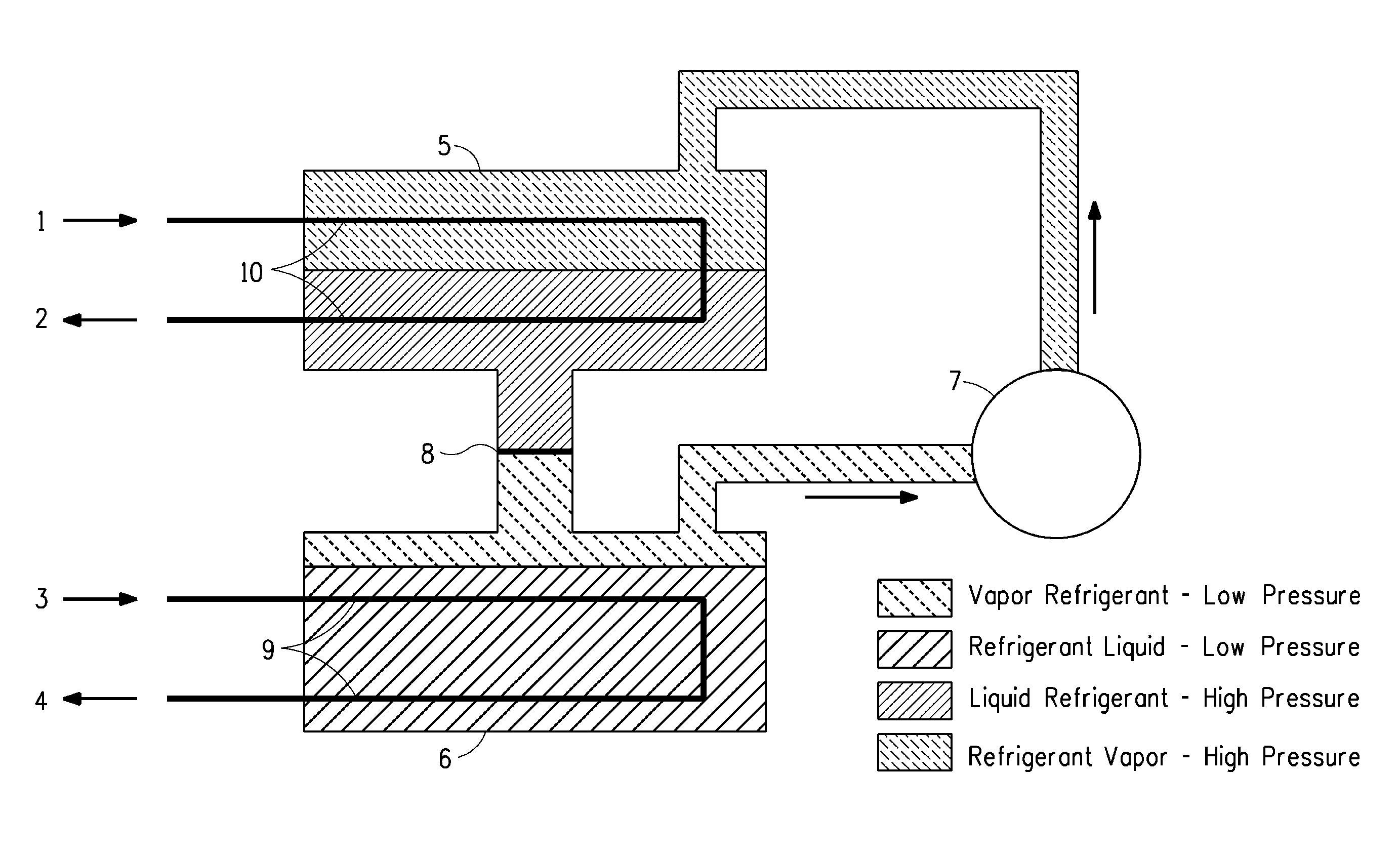

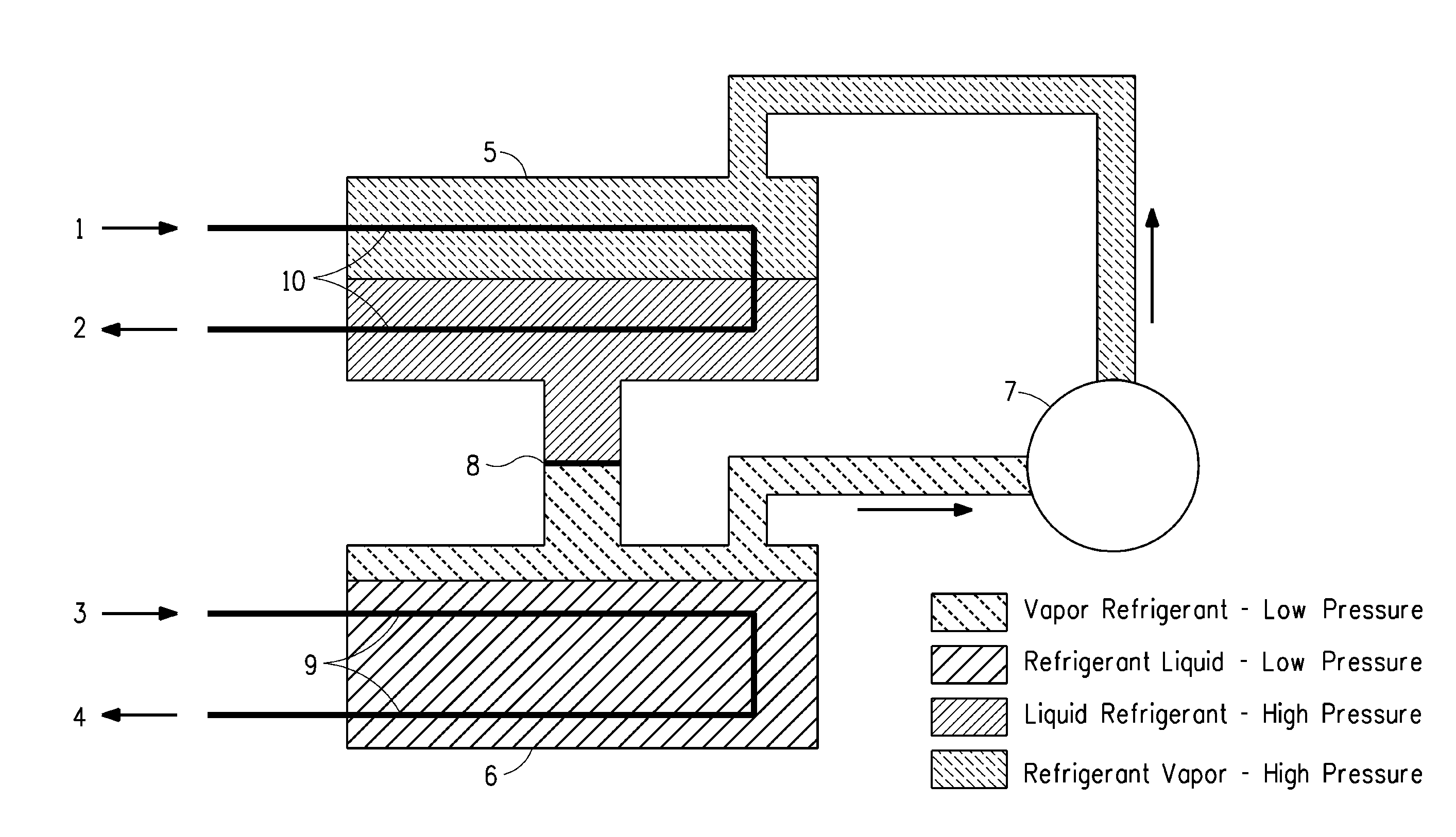

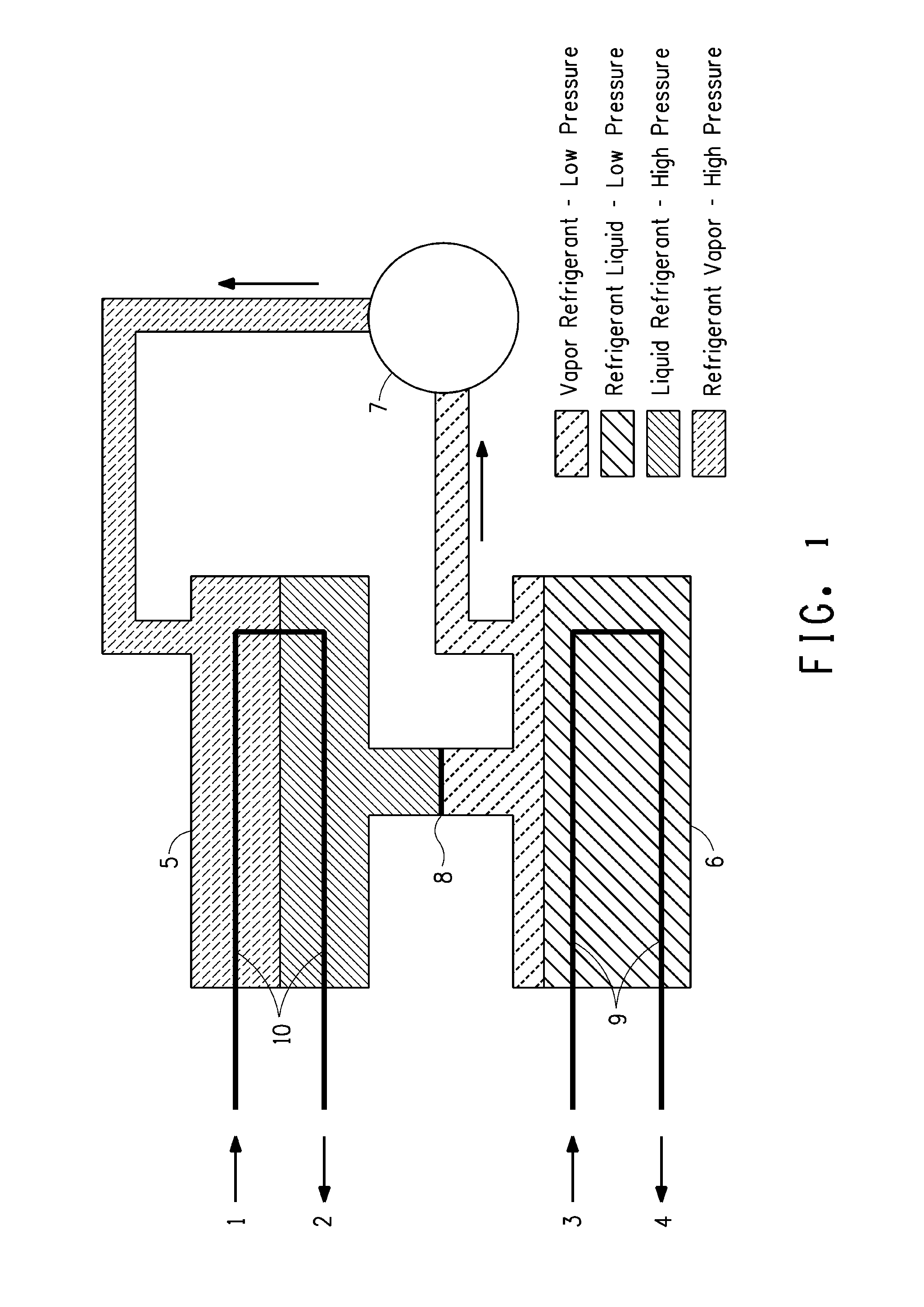

Chiller apparatus containing trans-1,1,1,4,4,4-hexafluoro-2-butene and methods of producing cooling therein

ActiveUS20120159976A1Improve energy efficiencyReasonable cooling capacitySolidificationLiquefactionButeneEngineering

Disclosed herein is a chiller apparatus containing refrigerant characterized by said refrigerant being HFO-1336mzz that is trans isomer or primarily trans isomer. These chillers may be flooded evaporators or direct expansion evaporators, which utilize either centrifugal or screw compressors. Also disclosed herein are methods for producing cooling comprising evaporating trans-HFO-1336mzz in an evaporator in the vicinity of a body to be cooled, thereby producing cooling. Also disclosed herein is a method for replacing HFC-236fa or CFC-114 refrigerant in a chiller apparatus, said method comprising providing HFO-1336mzz to said chiller apparatus in place of the replaced refrigerant; wherein said HFO-1336mzz is trans isomer or primarily trans isomer.

Owner:THE CHEMOURS CO FC LLC

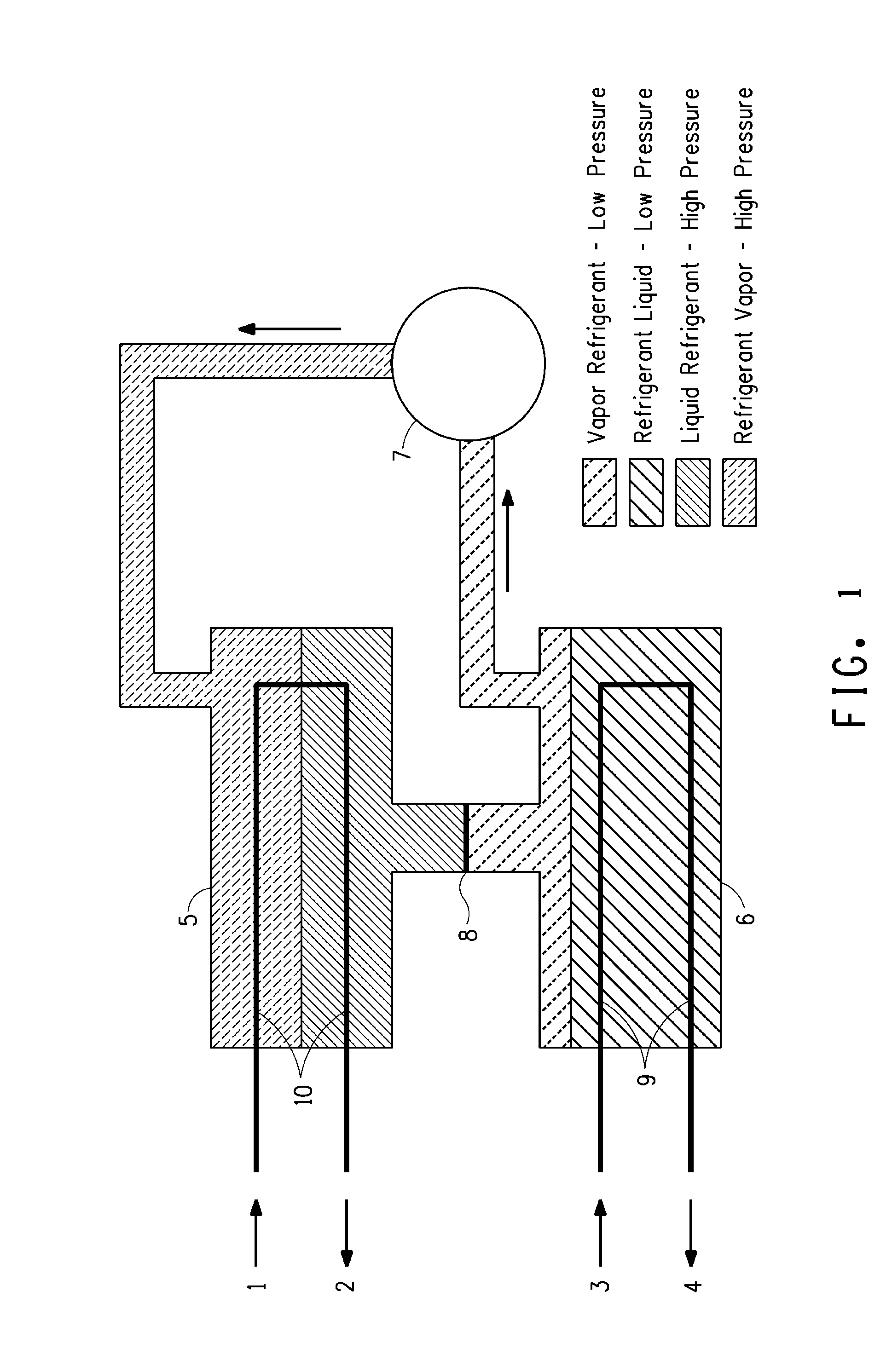

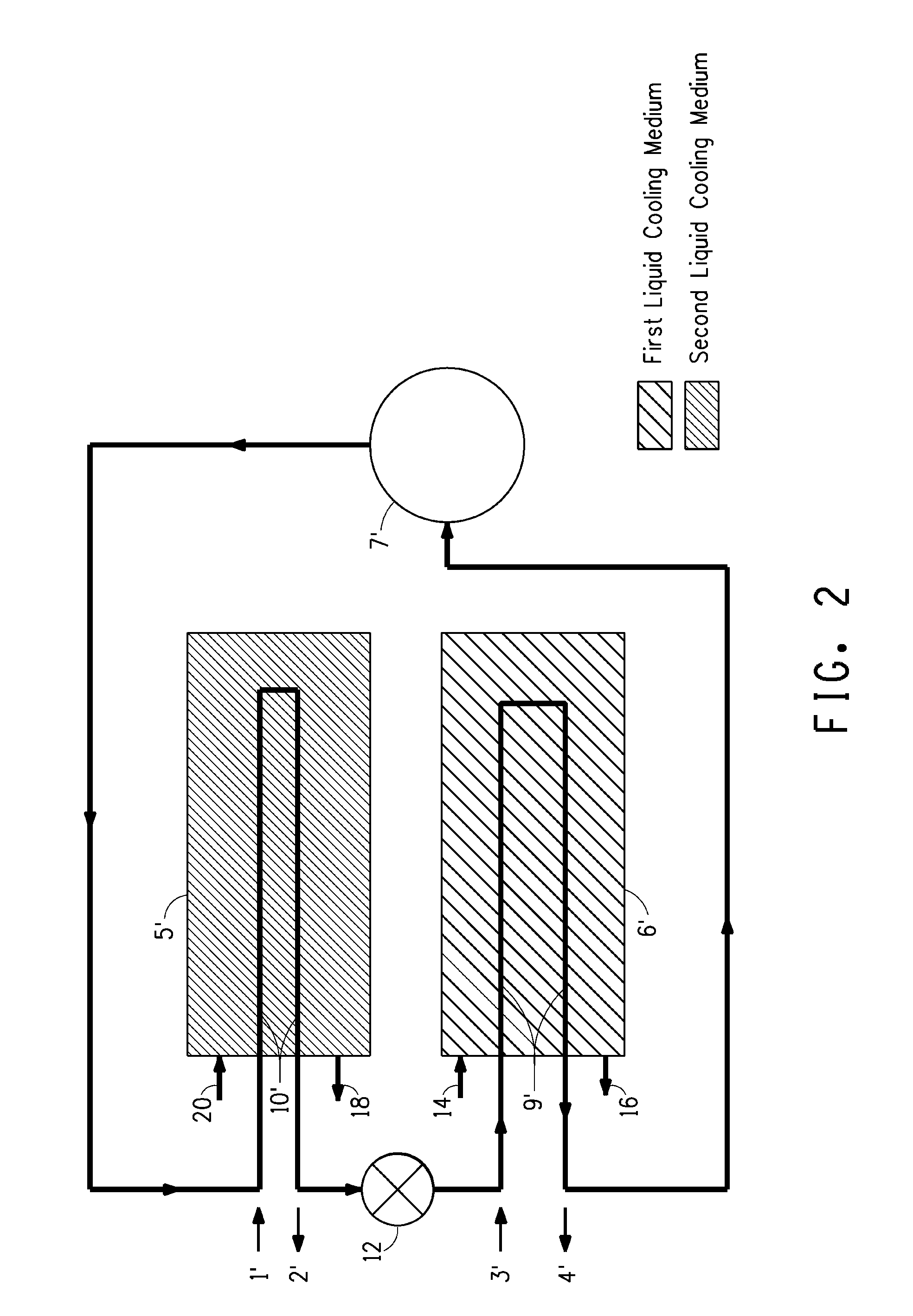

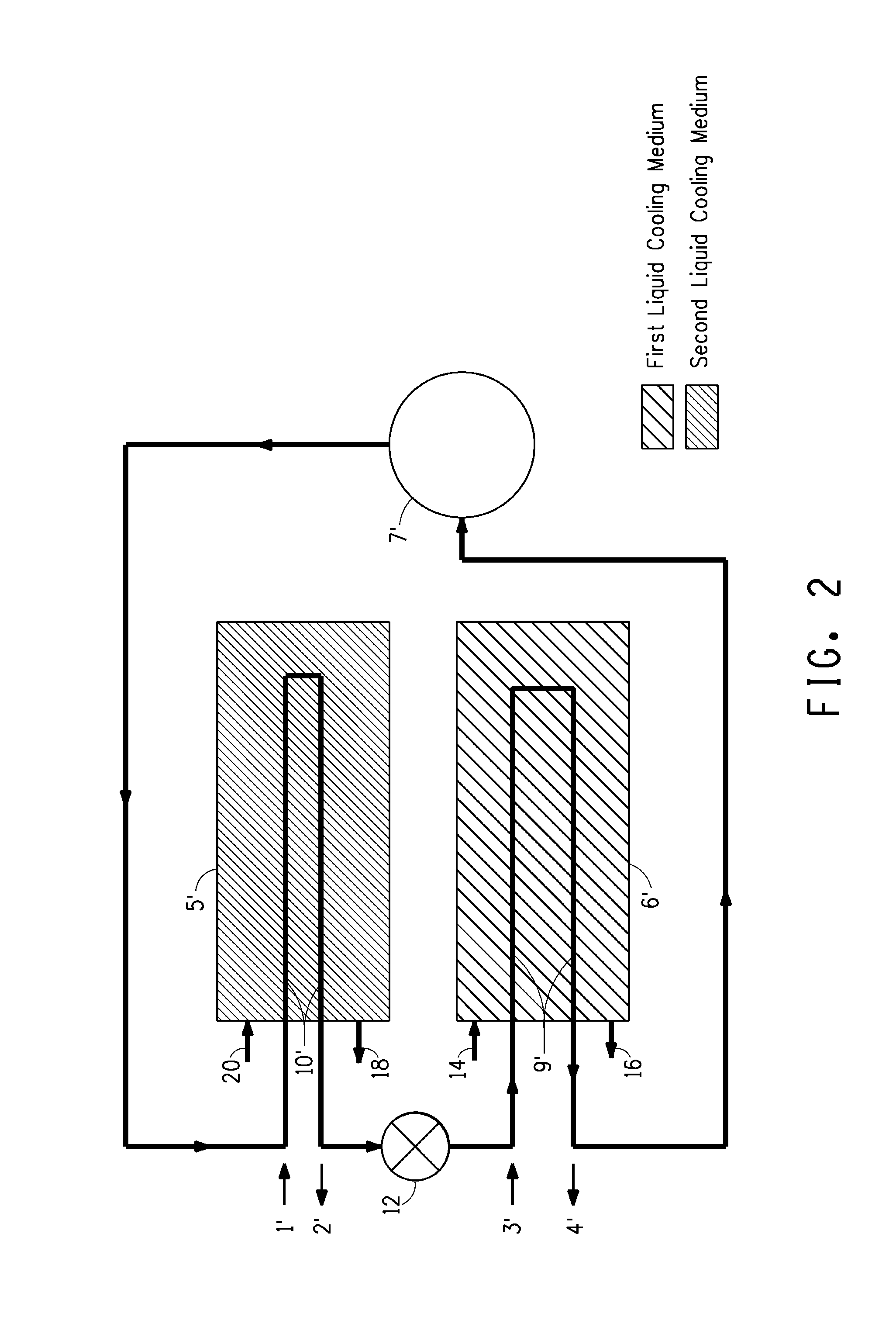

Composition comprising cis-1,1,1,4,4,4-hexafluoro-2-butene and trans-1,2-dichloroethylene, apparatus containing same and methods of producing cooling therein

ActiveUS20120167599A1Improve energy efficiencyImprove cooling effectDomestic cooling apparatusCompression machines with non-reversible cycleButeneEngineering

Disclosed herein is an air conditioning or refrigeration apparatus, and in particular, a chiller apparatus containing a composition comprising 1,1,1,4,4,4-hexafluoro-2-butene and 1,2-dichloroethylene, wherein the 1,1,1,4,4,4-hexafluoro-2-butene is cis isomer or primarily cis isomer and wherein the 1,2-dichloroethylene is trans isomer or primarily trans isomer. These chillers may be flooded evaporators or direct expansion evaporators, which utilize centrifugal compressors. Also disclosed herein are methods for producing cooling comprising evaporating a composition comprising cis-1,1,1,4,4,4-hexafluoro-2-butene and trans-1,2-dichloroethylene in the vicinity of a body to be cooled. Also disclosed herein are compositions comprising cis-1,1,1,4,4,4-hexafluoro-2-butene and trans-1,2-dichloroethylene, wherein the cis-1,1,1,4,4,4-hexafluoro-2-butene is present at 50 to about 60 weight percent.

Owner:THE CHEMOURS CO FC LLC

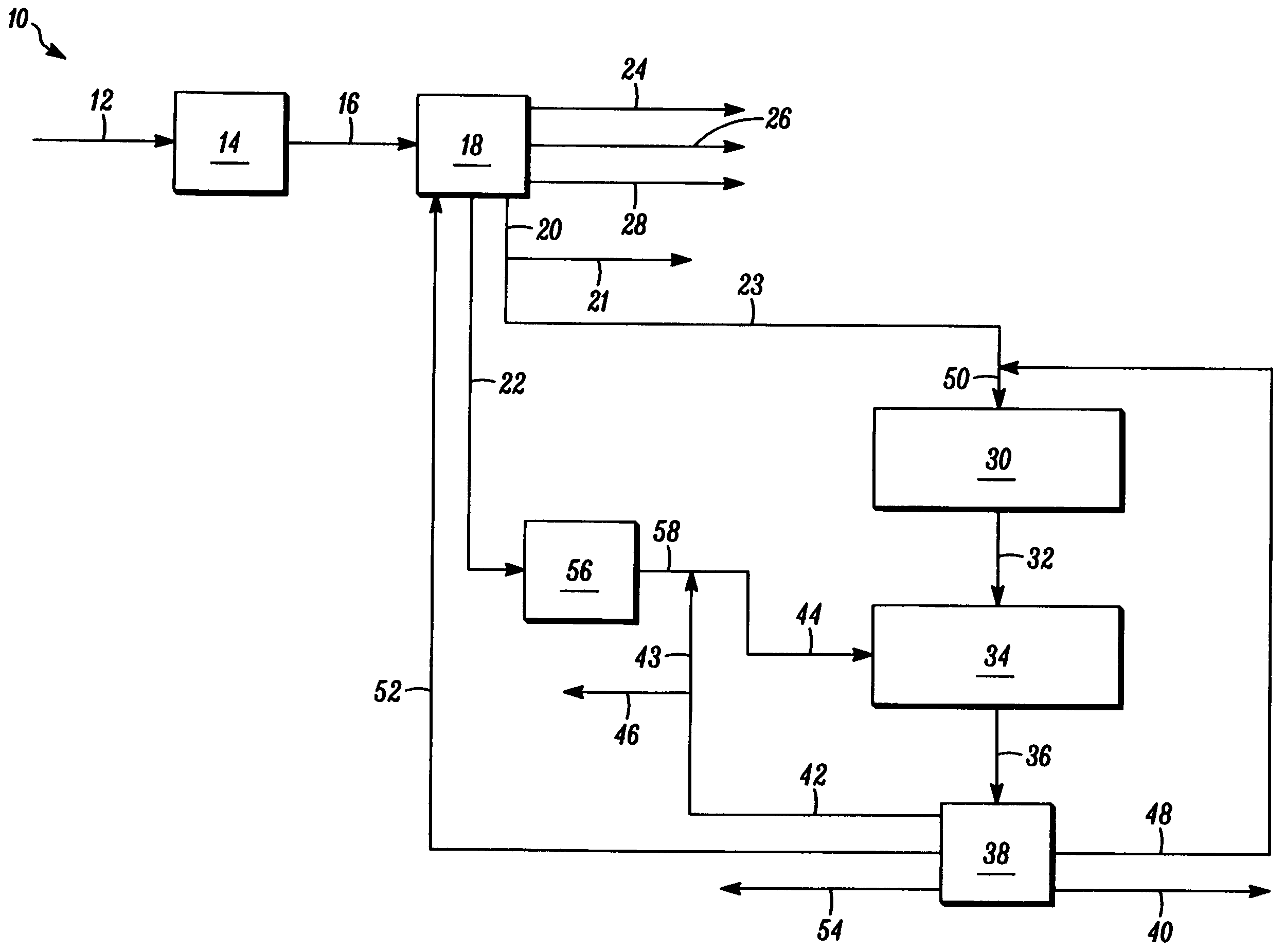

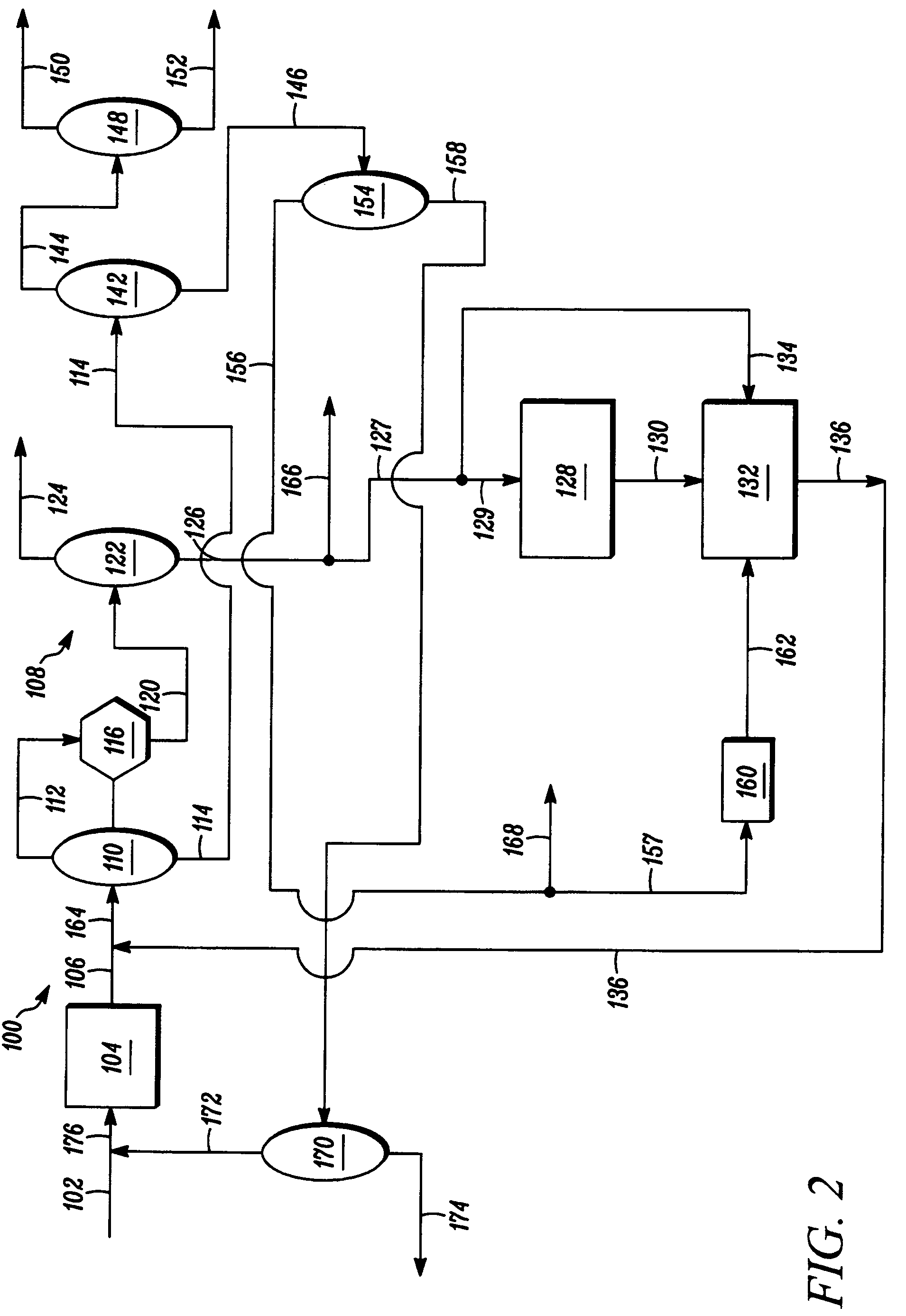

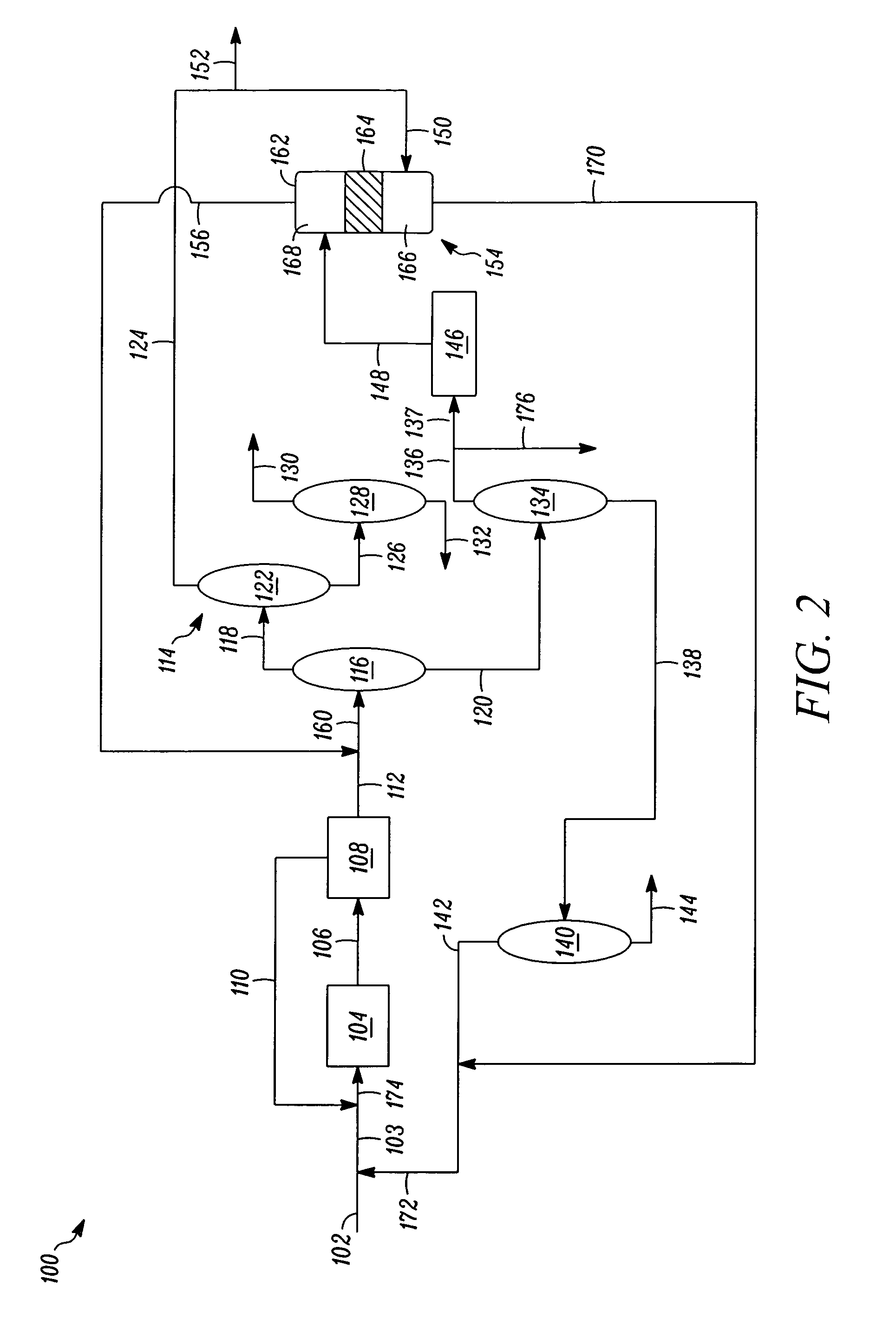

Oxygenate conversion to olefins with dimerization and metathesis

InactiveUS7586018B2Hydrocarbon by isomerisationHydrocarbons from unsaturated hydrocarbon additionButeneIsomerization

A processing scheme and system for enhanced light olefin production, particularly for increased relative yield of propylene, involves oxygenate conversion to olefins and subsequent oxygenate conversion effluent stream treatment including dimerization of ethylene to butene and metathesis of butenes and / or hexenes with ethylene. The processing scheme and system may further involve isomerization of at least a portion of 1-butene to 2-butene to produce additional propylene.

Owner:UOP LLC

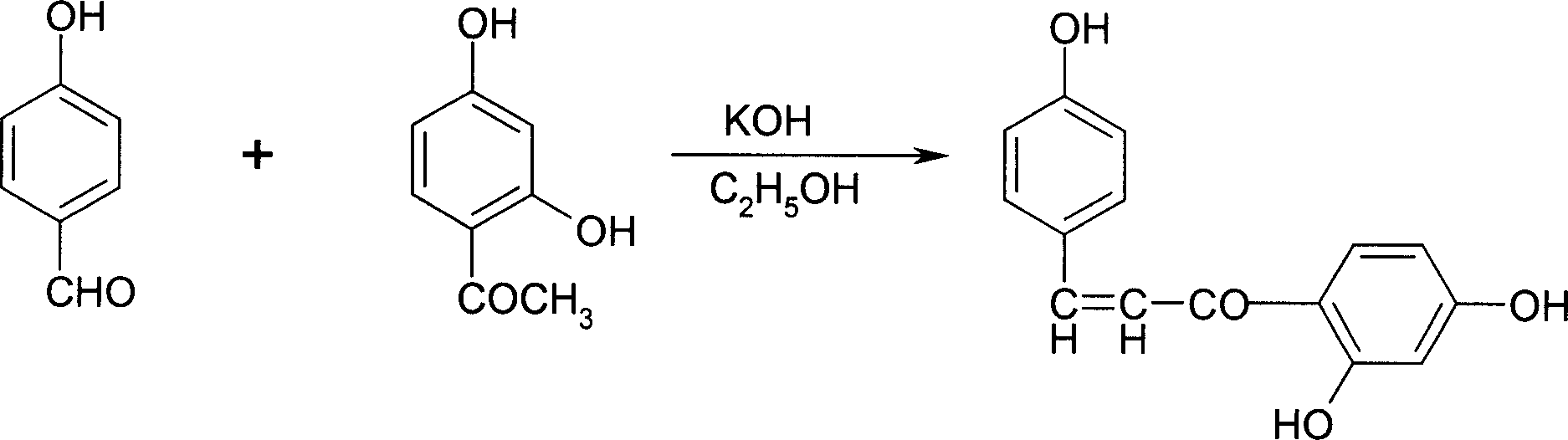

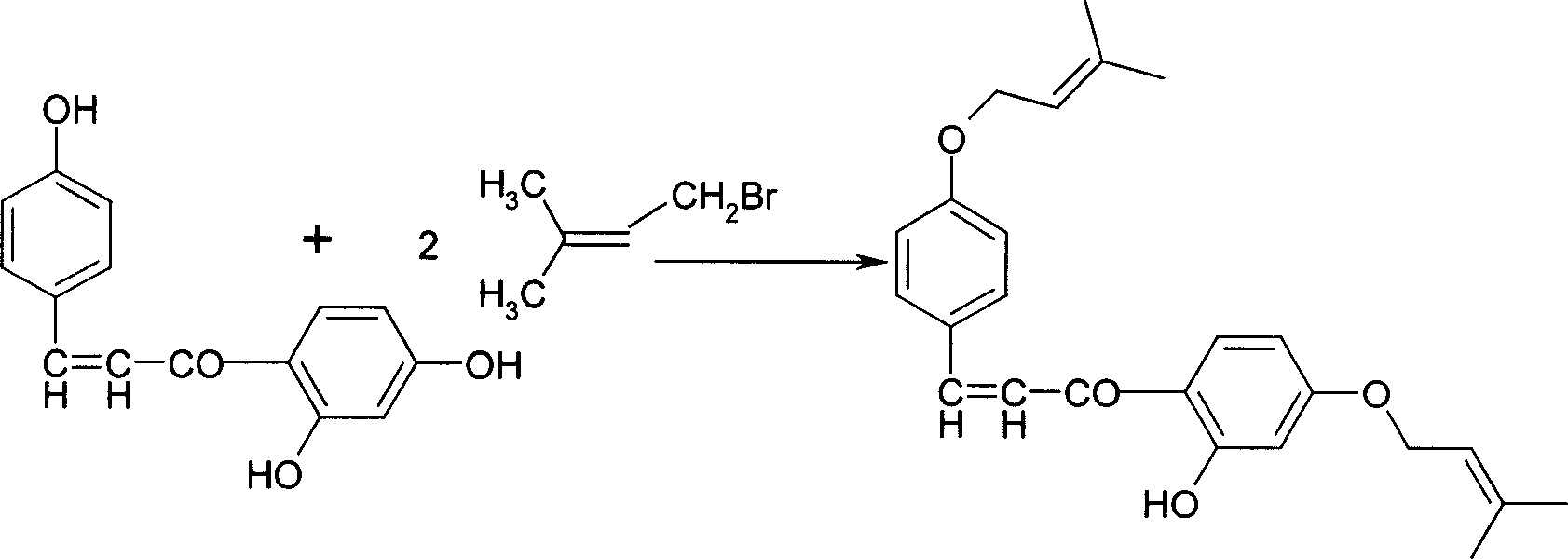

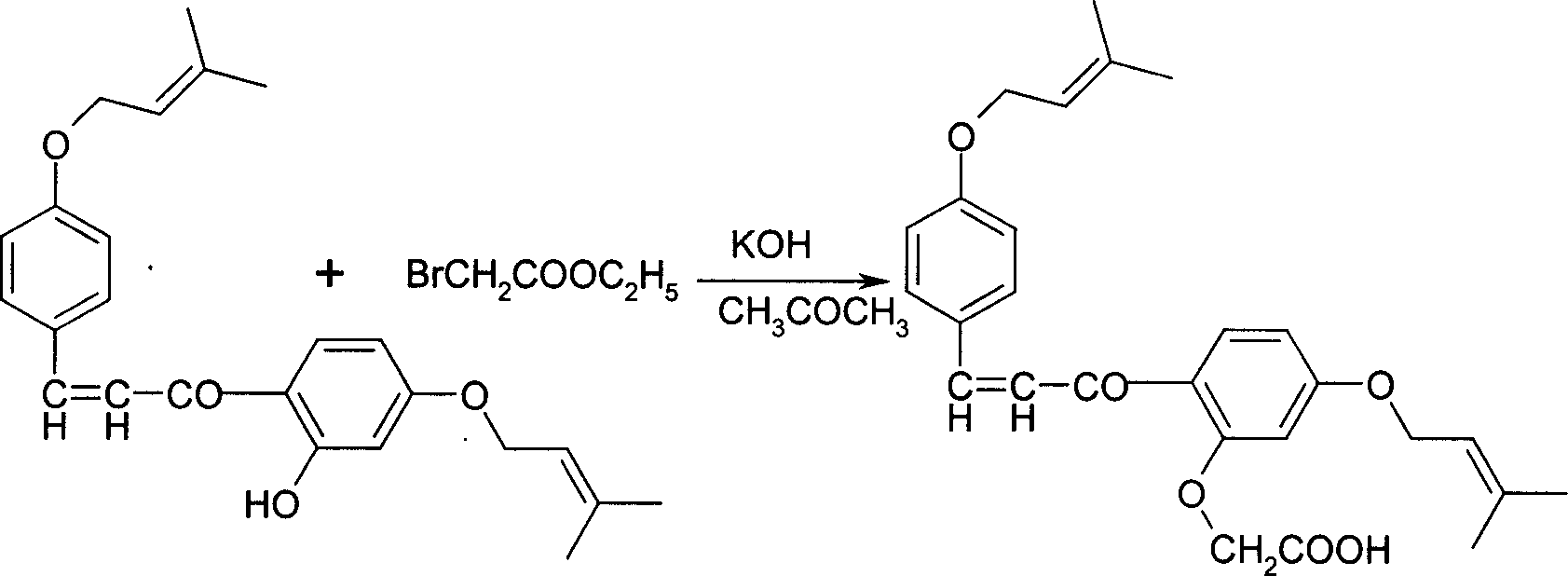

Sofalcone preparation method

InactiveCN1733682AFew synthetic stepsFew reaction stepsOrganic compound preparationCarboxylic compound preparationKetone2-Butene

Disclosed is a Sofalcone preparation method which mainly comprises, (1) subjecting p-hydroxybenzaldehyde and 2,4-ihydroxyacetophenone to condensation reaction under alkaline condition, obtaining 2,4,4-Trihydro-xychalcone, (2) subjecting 2,4,4-trihydro-xychalcone and 1-bromo-3-methyl-2-butene to condensation reaction, obtaining 2-hydroxyl-4,4-bis (3-methyl-2-butenyloxy) chalcone, (3) subjecting the 2-hydroxyl-4,4-bis (3-methyl-2-butenyloxy) chalcone and ethyl bromoacetate to condensation under the action of potasium carbonate, thus obtaining sofalcone. The mol ratio of p-hydroxybenzaldehyde, 2.4-dihydroxyacetophenone, 1-bromo-3-methyl-2-butene, and ethyl bromoacetate can be 1 : (0.90-1.50) : (1.60-2.55) : (0.60-1.25).

Owner:阮华君

Oxygenate conversion to olefins with metathesis

InactiveUS20080154077A1Speed up the processHydrocarbon by metathesis reactionHydrocarbon from oxygen organic compoundsButeneIsomerization

A processing scheme and system for enhanced light olefin production, particularly for increased relative yield of propylene, involves oxygenate conversion to olefins and subsequent oxygenate conversion effluent stream treatment including cross-metathesis of 1-butene with 2-butene, metathesis of 2-butene with ethylene, conversion or removal of at least a portion of the isobutene, and / or isomerization of at least a portion of 1-butene to 2-butene to produce additional propylene. The processing scheme and system may further involve a reaction with distillation column for the metathesis of butenes with ethylene to produce propylene and / or a reaction with distillation column for the conversion of isobutenes with an oxygenate-containing material to produce a tertiary ether or alcohol.

Owner:UOP LLC

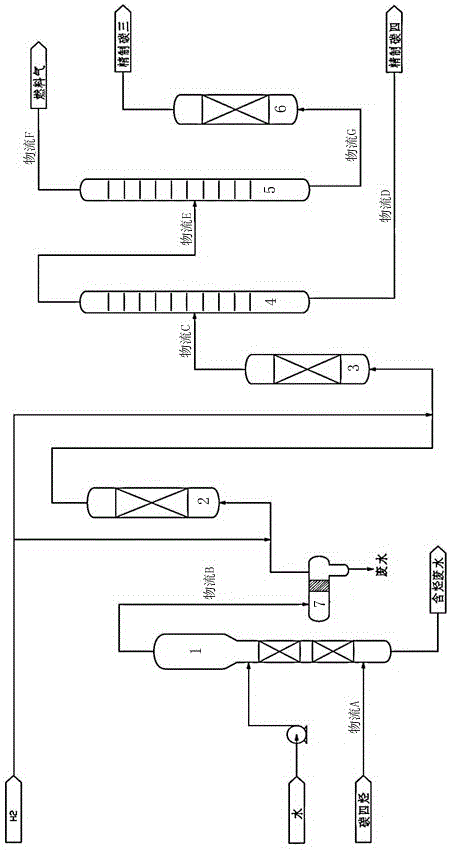

Process for refining C-4 hydrocarbon fluid

ActiveCN105152840AReduce Methanol ContentDistillation purification/separationHydrocarbonsDehydrogenation2-Butene

The invention discloses a process for refining C-4 hydrocarbon fluid. Preparation equipment includes a methanol removing tower, a first hydrogenation reactor, a second hydrogenation reactor, a depropanizing column, a dethanizing column and an adsorption tower, wherein the top of the methanol removing tower is connected with the bottom of the first hydrogenation reactor through a high-efficiency coalescer; the top of the first hydrogenation reactor is connected with the bottom of the second hydrogenation reactor through a pipeline; the top of the second hydrogenation reactor is connected with the depropanizing column through another pipeline; the top of the depropanizing column is connected with the dethanizing column through another pipeline; and the bottom of the dethanizing column is connected with the adsorption tower through another pipeline. The process mainly aims to a purification process of an alkylation raw material, and comprises the following steps: by taking mixed C-4 hydrocarbon as a raw material, extracting with water to remove methanol so as to reduce the content of methanol in C-4 hydrocarbon to be lower than 50ppm, selectively adding hydrogen and isomerizing so as to reduce the content of butadiene in C-4 hydrocarbon to be lower than 50ppm, converting more than 70% of 1-butene into 2-butene, and finally rectifying to remove dimethyl ether and C-3, thereby obtaining refined C-4 as the alkylation raw material, and a byproduct refined C-3 as a propane dehydrogenation propylene raw material.

Owner:CHINA CHENGDA ENG

Azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene and 1-chloro-3,3,3-trifluoropropene

ActiveUS20110260093A1Other chemical processesNon-surface-active detergent compositionsThermoplasticDielectric

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with E-1-chloro-3,3,3-trifluoropropene or 2-chloro-3,3,3-trifluoropropene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

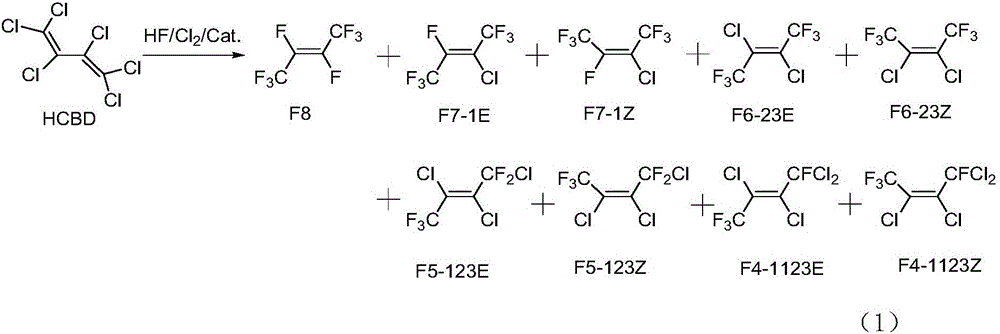

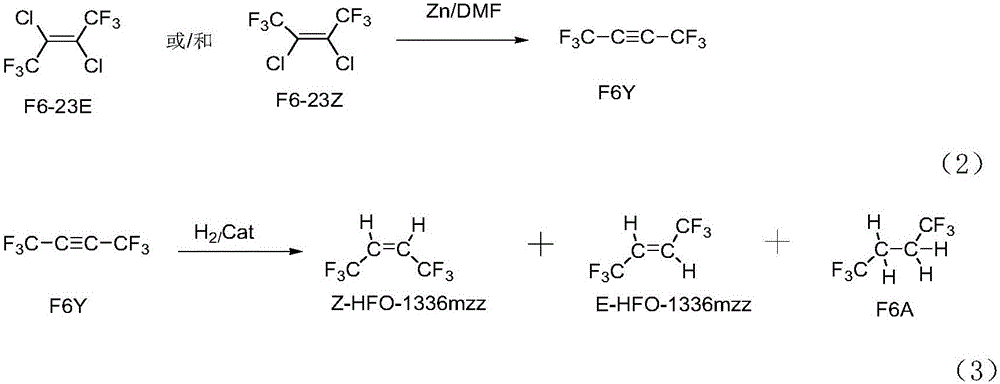

Preparation method of Z-1,1,1,4,4,4-hexafluoro-2-butene

ActiveCN106008147ALow priceHigh activityPreparation by dehalogenationPreparation by halogen replacementChemical synthesisGas phase

The invention relates to a preparation method of Z-1,1,1,4,4,4-hexafluoro-2-butene, belonging to the field of chemical synthesis. The method comprises the following steps of taking hexachlorobutadiene (HCBD) as a raw material, performing gas-phase catalytic chlorination-fluoridation separation to obtain 2,3-dichlorohexafluoro-2-butene, performing liquid-phase dechlorination to obtain hexafluoro-2-butyne, and preparing the Z-1,1,1,4,4,4-hexafluoro-2-butene (Z-HFO-1336mzz) by means of performing gas-phase catalytic hydrogenation, wherein three reactions are included totally. The Z-1,1,1,4,4,4-hexafluoro-2-butene with high selectivity is obtained by means of performing catalytic hydrogenation by adopting the hexafluoro-2-butyne, and meanwhile the product is easily separated from side products and the raw material. The method disclosed by the invention has the advantages that the original raw material is easily obtained, the activity of a catalyst is high, the service life of the catalyst is long, the raw material can be recycled, and the standard of zero emissions is reached.

Owner:泉州宇极新材料科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com