Patents

Literature

131results about How to "Reduce Methanol Content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for refining C-4 hydrocarbon fluid

ActiveCN105152840AReduce Methanol ContentDistillation purification/separationHydrocarbonsDehydrogenation2-Butene

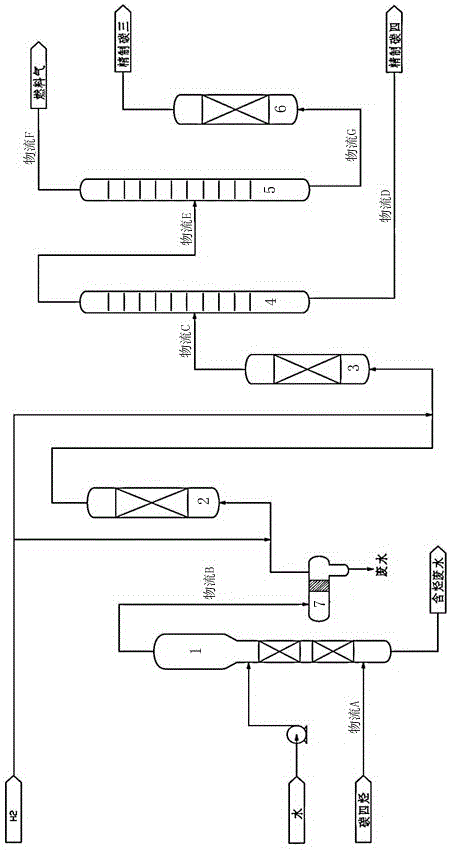

The invention discloses a process for refining C-4 hydrocarbon fluid. Preparation equipment includes a methanol removing tower, a first hydrogenation reactor, a second hydrogenation reactor, a depropanizing column, a dethanizing column and an adsorption tower, wherein the top of the methanol removing tower is connected with the bottom of the first hydrogenation reactor through a high-efficiency coalescer; the top of the first hydrogenation reactor is connected with the bottom of the second hydrogenation reactor through a pipeline; the top of the second hydrogenation reactor is connected with the depropanizing column through another pipeline; the top of the depropanizing column is connected with the dethanizing column through another pipeline; and the bottom of the dethanizing column is connected with the adsorption tower through another pipeline. The process mainly aims to a purification process of an alkylation raw material, and comprises the following steps: by taking mixed C-4 hydrocarbon as a raw material, extracting with water to remove methanol so as to reduce the content of methanol in C-4 hydrocarbon to be lower than 50ppm, selectively adding hydrogen and isomerizing so as to reduce the content of butadiene in C-4 hydrocarbon to be lower than 50ppm, converting more than 70% of 1-butene into 2-butene, and finally rectifying to remove dimethyl ether and C-3, thereby obtaining refined C-4 as the alkylation raw material, and a byproduct refined C-3 as a propane dehydrogenation propylene raw material.

Owner:CHINA CHENGDA ENG

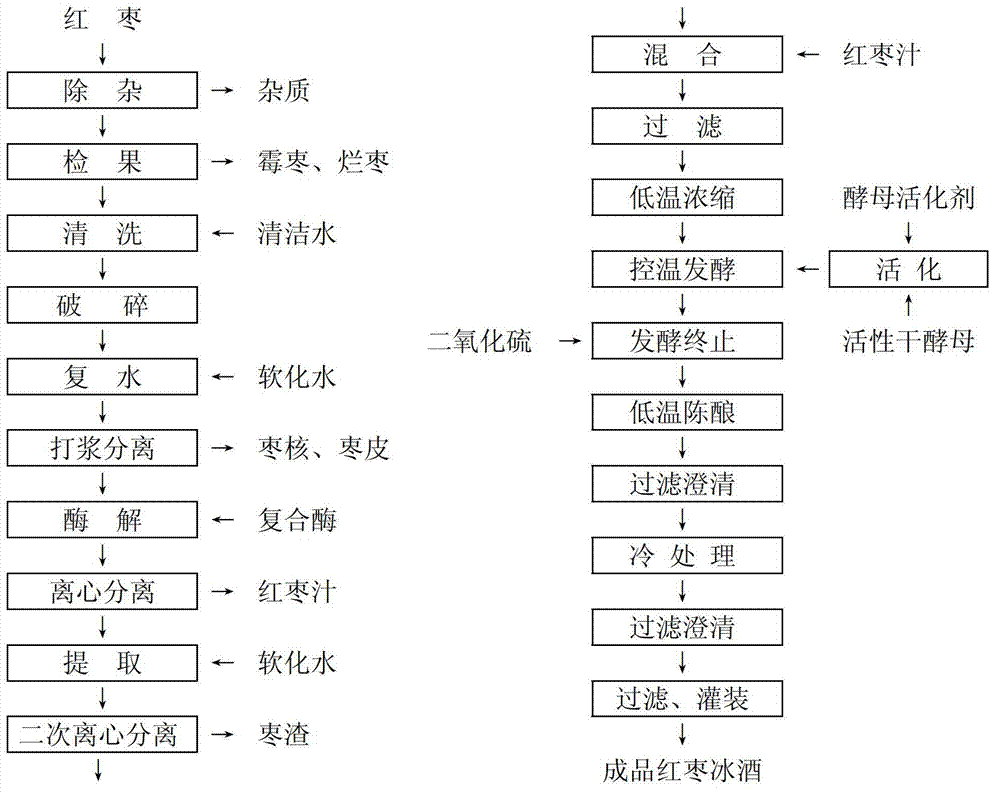

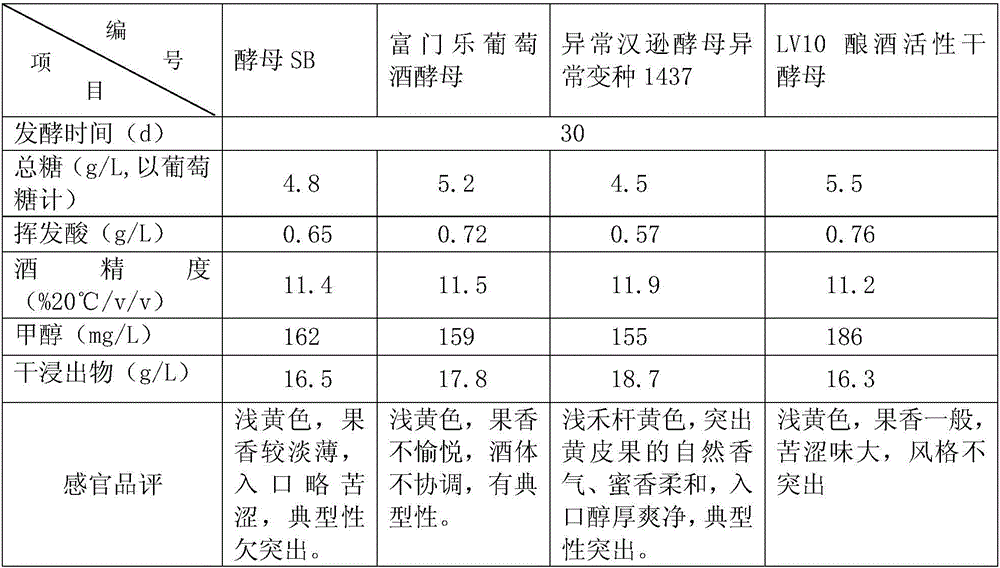

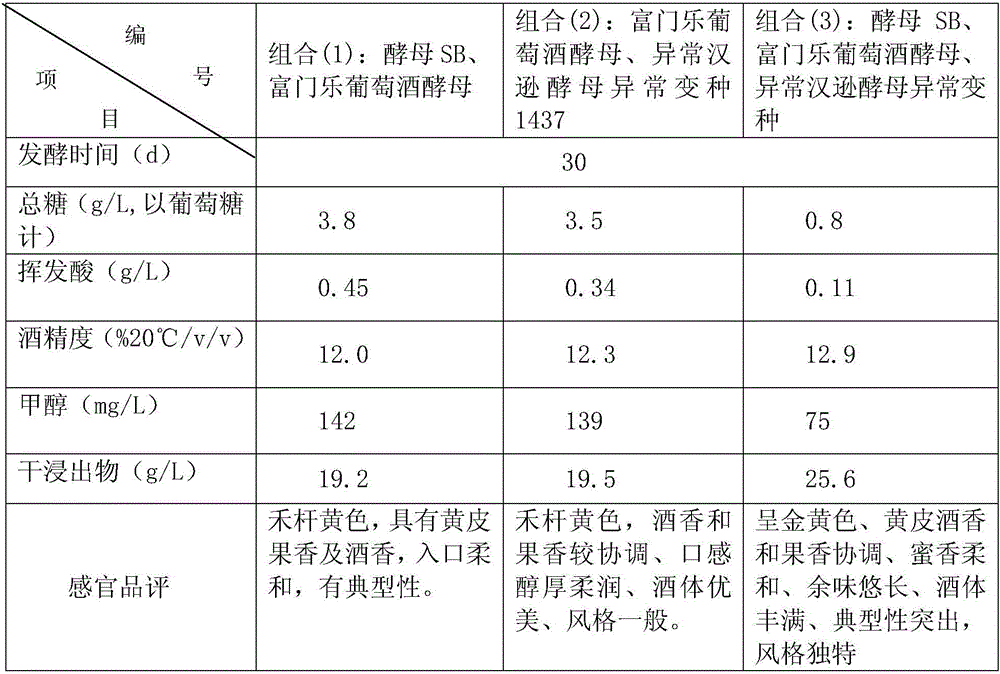

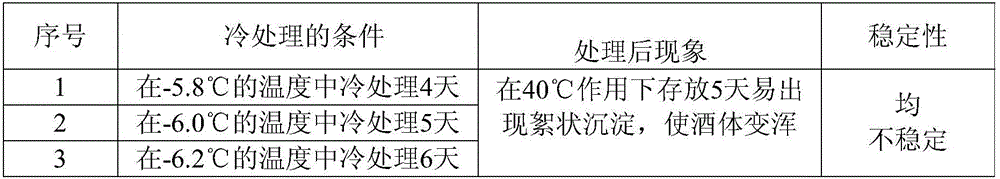

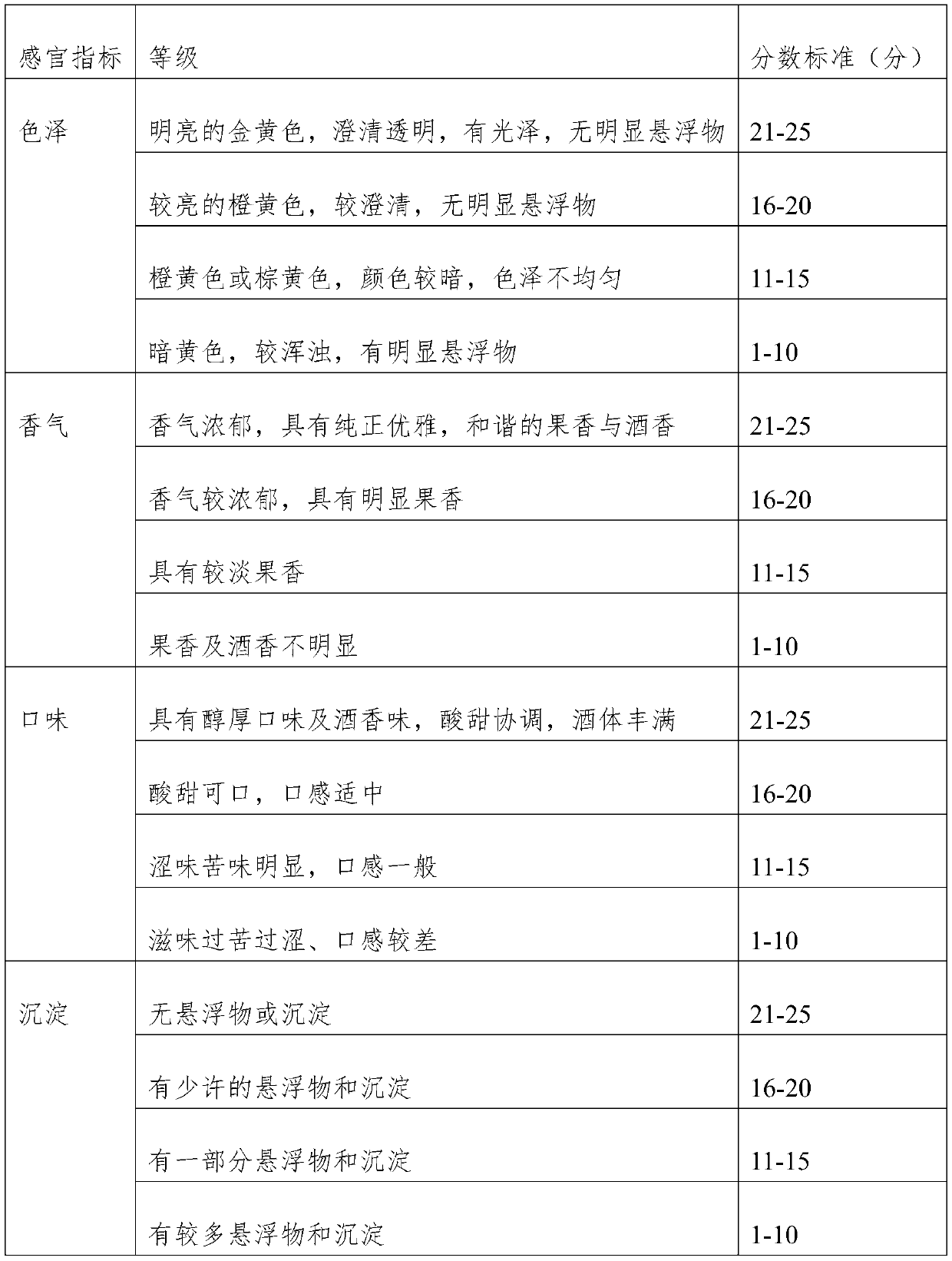

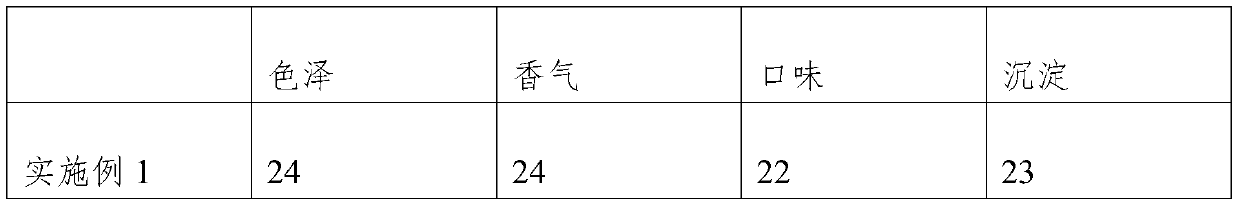

Production process of red date ice wine

ActiveCN102851172ARetain nutritional valueMeet the needs of tastingAlcoholic beverage preparationFruit wineYeast

The invention relates to a production process of a red date ice wine. The process comprises the steps of impurity removing, fruit selecting, washing, crushing, rehydrating, beating, separating, enzymolysis, centrifugal separating, extracting, secondary centrifugal separating, filtering, low-temperature concentrating, yeast activating, controlled-temperature fermenting, fermentation stopping, low-temperature aging, filtering and clarifying, cold treating, sterilizing and filtering, and filling. The process provided by the invention has the advantages that: red date is adopted as a raw material, and a low-temperature rehydration and high-temperature extraction two-stage process is adopted, such that red date juice color, flavor and various rich nutrient contents are ensured, and physiologically active substances in red dates are extracted to a maximal extent; with a two-step method red date ice wine production process that red date juice is produced first and biological fermentation is then carried out, the produced product has a date red color, clarified wine body, rich fragrance, and delicate and mellow mouthfeel. The ice wine has typical characteristics of iced fruit wines, and assists in filling the vacancy in domestic market.

Owner:CHINA LIGHT IND INT ENG CO LTD

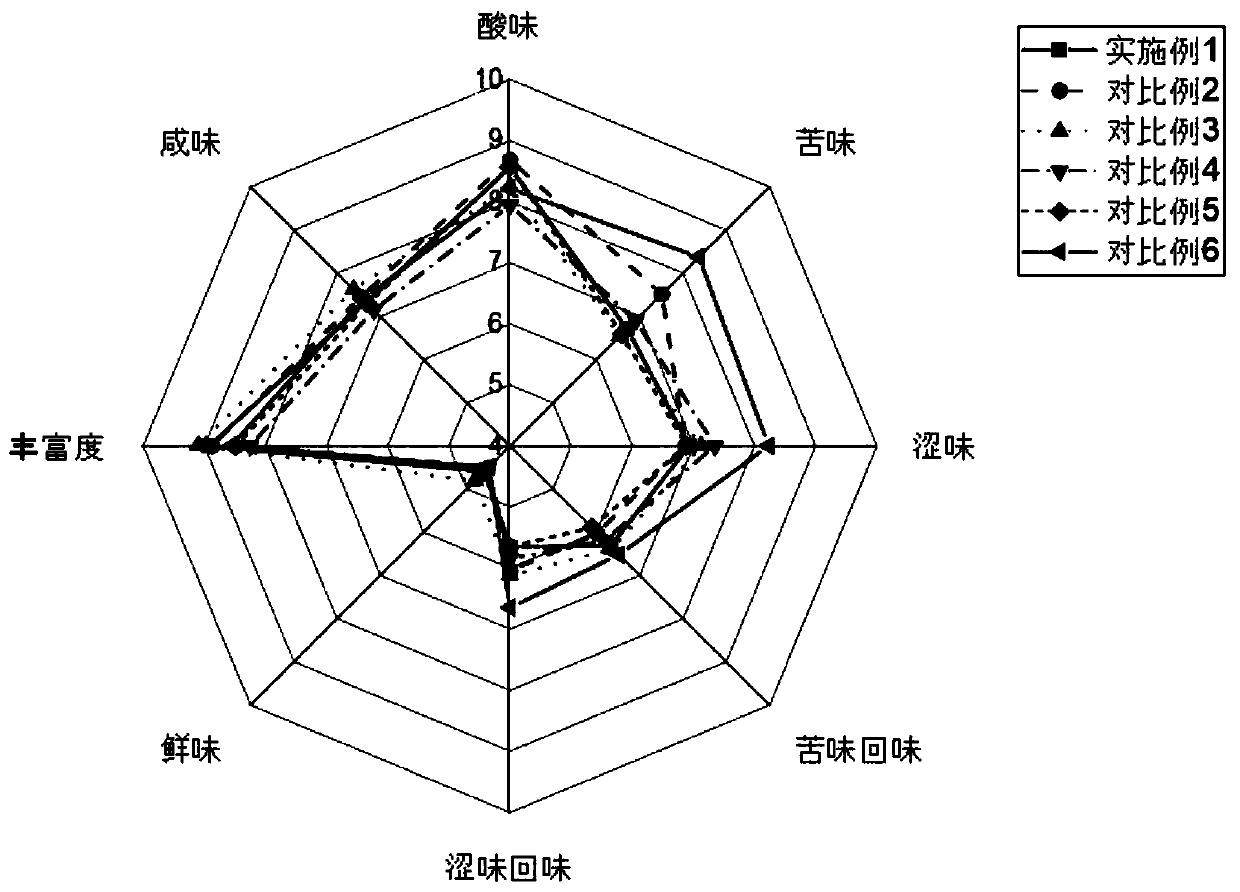

Persimmon wine and brewing method thereof

InactiveCN101798555ALess suspended particlesSimple filterMicroorganism based processesAlcoholic beverage preparationPectinaseYeast

Persimmon wine and a brewing method belong to the technical field of brewing science and engineering. The invention aims to solve the technical problem of providing the persimmon wine keeping the original flavor of persimmons and a brewing method of the persimmon wine. The process is as follows: 1. selecting fruit; 2. breaking and sterilizing; 3. adding yeast and primarily fermenting for 1d; 4. juicing and separating pomace; 5. adding sugar and secondarily fermenting; 6. filtering residue and can sealing; 7. clarifying with pectinase and filtering; and 8.cryotreating and canning. The persimmon wine is characterized in that the persimmon wine is faint yellow, clear and transparent and has pure, fine, refreshing and harmonious aroma. The invention has the following advantages: 1. full persimmons are extracted and the juice is used for fermentation, without adding water; and 2. pectinase is not added in the processes of juice extraction and fruit wine brewing, and astringency removal process is omitted. The invention plays important roles in promoting reasonable processing and utilization of the persimmon resources, forming the post-harvest processing industrial chain and adjusting the fruit processing industrial structure.

Owner:HEBEI AGRICULTURAL UNIV.

Method for brewing white spirit by adopting red dates as major ingredient

ActiveCN102399659AReduce Methanol ContentMaterials are readily availableAlcoholic beverage preparationChinese JujubeMethanol

The invention discloses a method for brewing white spirit by adopting red dates as a major ingredient. In the invention, the white sprit is prepared by taking fresh or dry red dates as the major ingredient and bran as an auxiliary material and adopting the following steps of: selecting and soaking the red dates, crushing the major ingredient to obtain jujube paste, pre-steaming the auxiliary material, fermenting and distilling the major ingredient and the auxiliary material and the like. In the invention, traditional Chinese medicines are also added to the red dates for crushing during the process of crushing the red dates to obtain the jujube paste, wherein the traditional Chinese medicines contain polyphenol acid as an active component; as the traditional Chinese medicines are added for inhibiting the activity of pectin methyl esterase contained in the major ingredient, the purpose of reducing the generation amount of methanol is achieved. The method is simple to operate, is easy to control, and has a good methanol removing effect, and the quality of the spirit product is greatly improved. The method disclosed by the invention is used for brewing the white spirit with data flavor by adopting the red dates as the major ingredient and the bran as the auxiliary material; the content of methanol can be reduced to lower than 0.06%; all indexes of the white spirit product can meet standards of national level I spirit; and the white spirit product has rich jujube fragrance.

Owner:河北万果红酒业有限公司

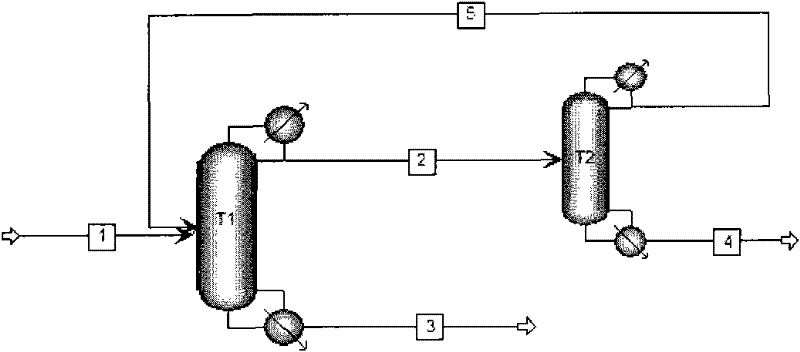

Preparation method of epoxypropane

ActiveCN102442979ALow purityHigh purityOrganic chemistryBulk chemical productionMixed materialsAzeotropic distillation

The invention discloses a preparation method of epoxypropane. The method comprises the following steps of: firstly, under the condition of an epoxidation reaction of propylene and in the presence of a solid catalyst, enabling a mixed material containing methanol, the propylene and hydrogen peroxide to sequentially pass through a first reactor and a second reactor; secondly, under a first azeotropic distillation condition, feeding an epoxypropane crude product obtained in the first step into a first azeotropic distillation tower; and thirdly, under a second azeotropic distillation condition, feeding an azeotropic mixture extracted from the top of the first azeotropic distillation tower into a second azeotropic distillation tower and enabling an azeotropic mixture extracted from the top of the second azeotropic distillation tower to return to the interior of the first azeotropic distillation tower. The high-purity epoxypropane can be prepared by adopting the method for epoxidizing the propylene, which is provided by the invention; in addition, high conversion rate of the hydrogen peroxide and high selectivity of the epoxypropane are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

Jujube-flavored white spirit and brewing process thereof

InactiveCN104651182AReduce Methanol ContentFully fermentedAlcoholic beverage preparationYeastLiver and kidney

The invention discloses jujube-flavored white spirit and a brewing process thereof. A preparation method of the liquor comprises the following steps: grinding, steaming and spread-cooling jujube, wheat, sorghum, glutinous rice, corn, rice, pea and rice hull according to certain proportions, uniformly mixing with the addition of yeast powder, sealing and fermenting in pit mud for more than 4 months; beginning to distill after 4 months in a mode of distilling twice every month; ultrasonically processing liquor obtained from distillation firstly, and then storing the liquor together with tourmaline, limonite and medicinal stone in a porcelain jar for more than 6 months, thus completing aging. The liquor overcomes shortcomings in the prior art, and is simple and convenient in operation, short in production cycle, high in liquor yield and good in quality. The jujube-flavored white spirit disclosed by the invention is stable in quality, free from restoring and long in aftertaste, people drinking the white spirit are not easy to become drunk and quick to be sobered up, and the white spirit, after drunk, is free from a problem of headache, free from such harmful material components as methanol, and is capable of relieving pressure on liver and kidney after drinking and effectively relieving damage to body.

Owner:栗臣川

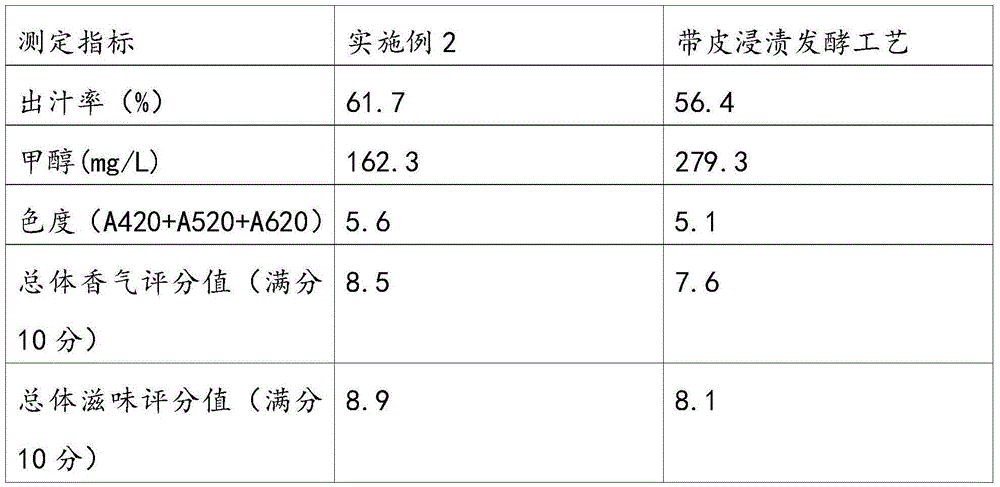

A brewing method of low-methanol-content Chinese date wine

ActiveCN106085699AIncrease contentIncrease the juice yieldAlcoholic beverage preparationPectin esteraseFruit juice

The invention relates to a brewing method of low-methanol-content Chinese date wine, and belongs to the technical field of brewing. The method includes sorting Chinese dates, cleaning, stoning, soaking with hot water, pulping, adding pectin esterase and cellulase, performing enzymatic hydrolysis, stirring and cooking in an air-lift combined mechanical manner, centrifuging, separating supernatant, adjusting the supernatant with white sugar and citric acid, sterilizing, inoculating, fermenting, clarifying, filtering, adding a clarifying agent, and aging by using an oak barrel. The method degrades cell walls of fruit tissues by using the pectin esterase and the cellulase, degrades polysaccharides to allow effective components inside the Chinese dates to dissolve out, and increases the content of juice nutrients and the juice yield. Through stirring and cooking in the air-lift combined mechanical manner, methanol produced by pectin substance zymolysis through the pectin esterase and methanol produced by other reasons are separated along with stirring, cooking and high-pressure air blowing, thus reducing the methanol content in Chinese date juice pulp.

Owner:河北九维生物科技开发有限公司

Fermented honey and Clausena lansium liquor and preparation method thereof

ActiveCN105802806AImprove stabilityReduce Methanol ContentAlcoholic beverage preparationMicroorganism based processesAlcohol contentYeast

The invention discloses a fermented honey and Clausena lansium liquor and a preparation method thereof. The preparation method of the fermented honey and Clausena lansium liquor includes subjecting seedless Clausena lansium to handpicking, washing and grinding, and adding maceration enzyme and clarification enzyme as well as the honey and yeast to low-temperature fermentation prior to ageing, clarification, non-biological stabilizing treatment, multi-stage blending and freezing and degerming aftertreatment so as to obtain the fermented honey and Clausena lansium liquor. The fermented honey and Clausena lansium liquor has the advantages of rich nutritional substances, high content of fruity substances and esters, high non-biological stability, unique taste and flavor, low methyl alcohol content and high food safety.

Owner:GUANGDONG JINYINGZI BREWERY CO LTD

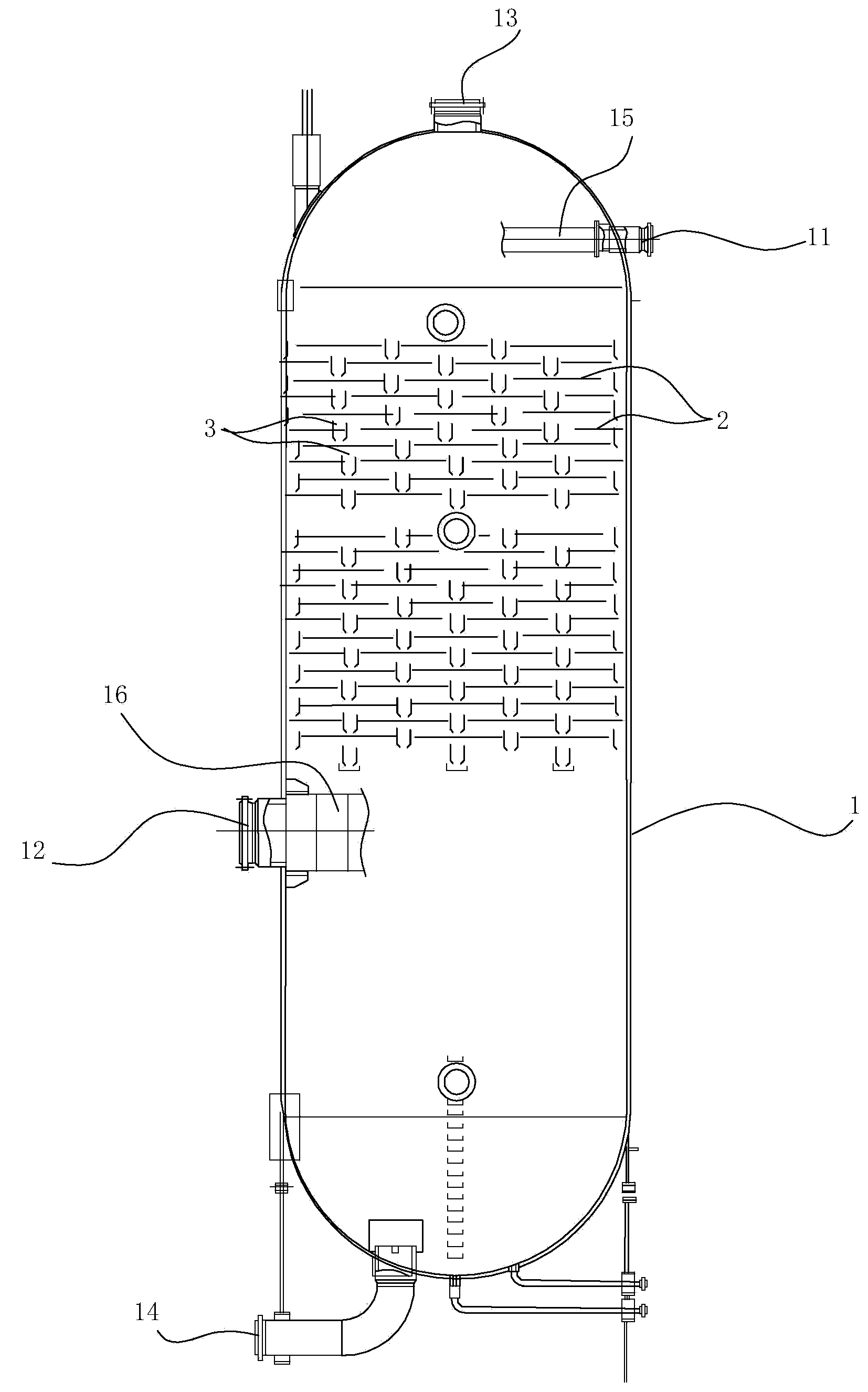

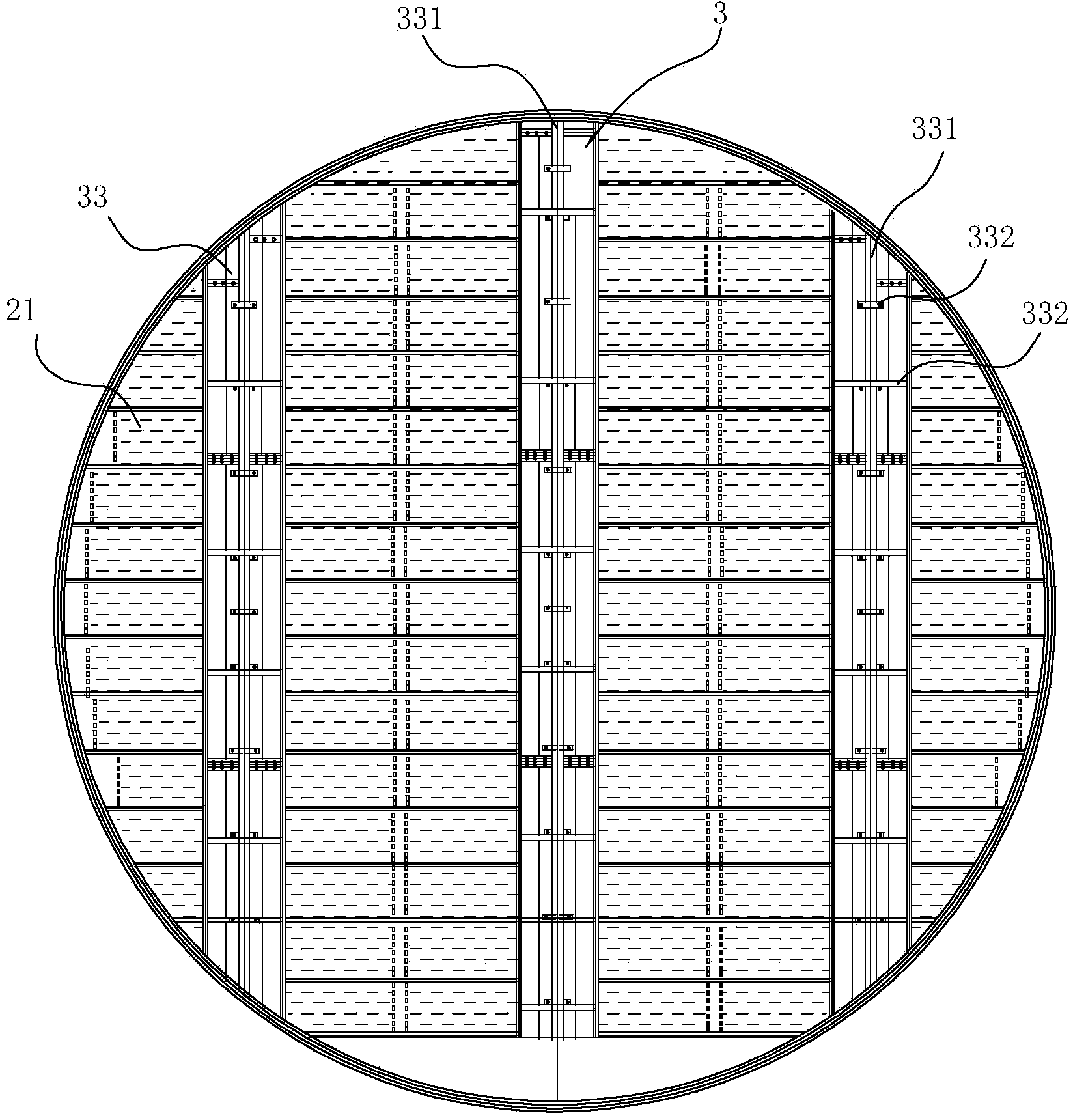

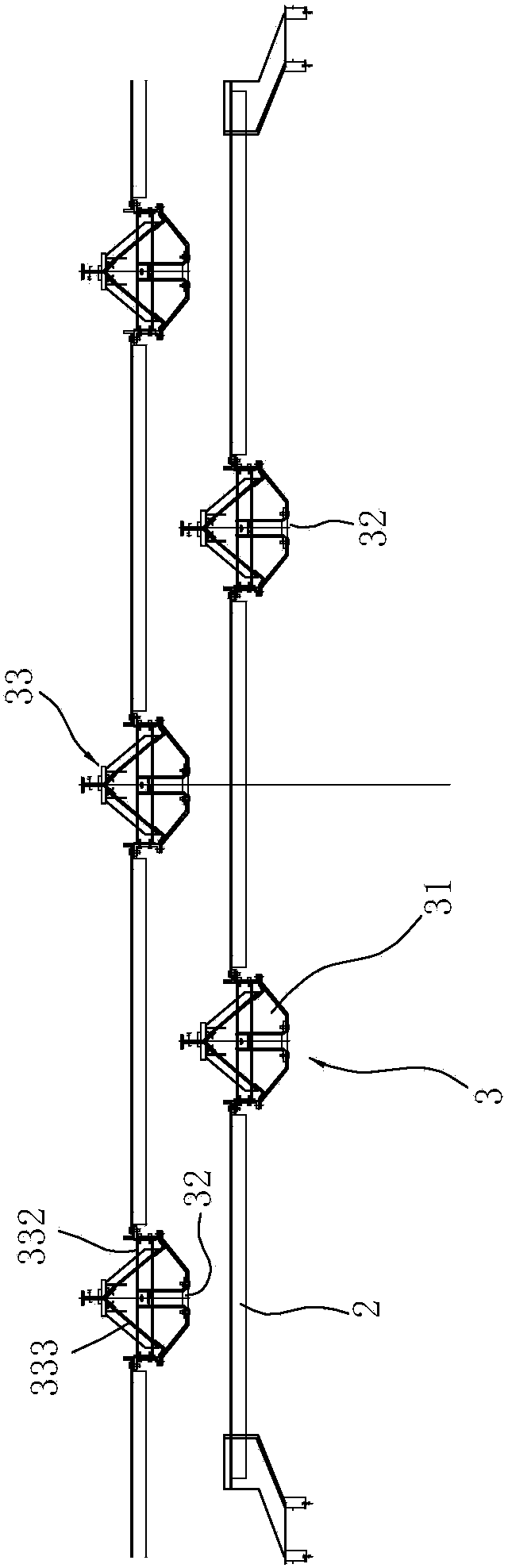

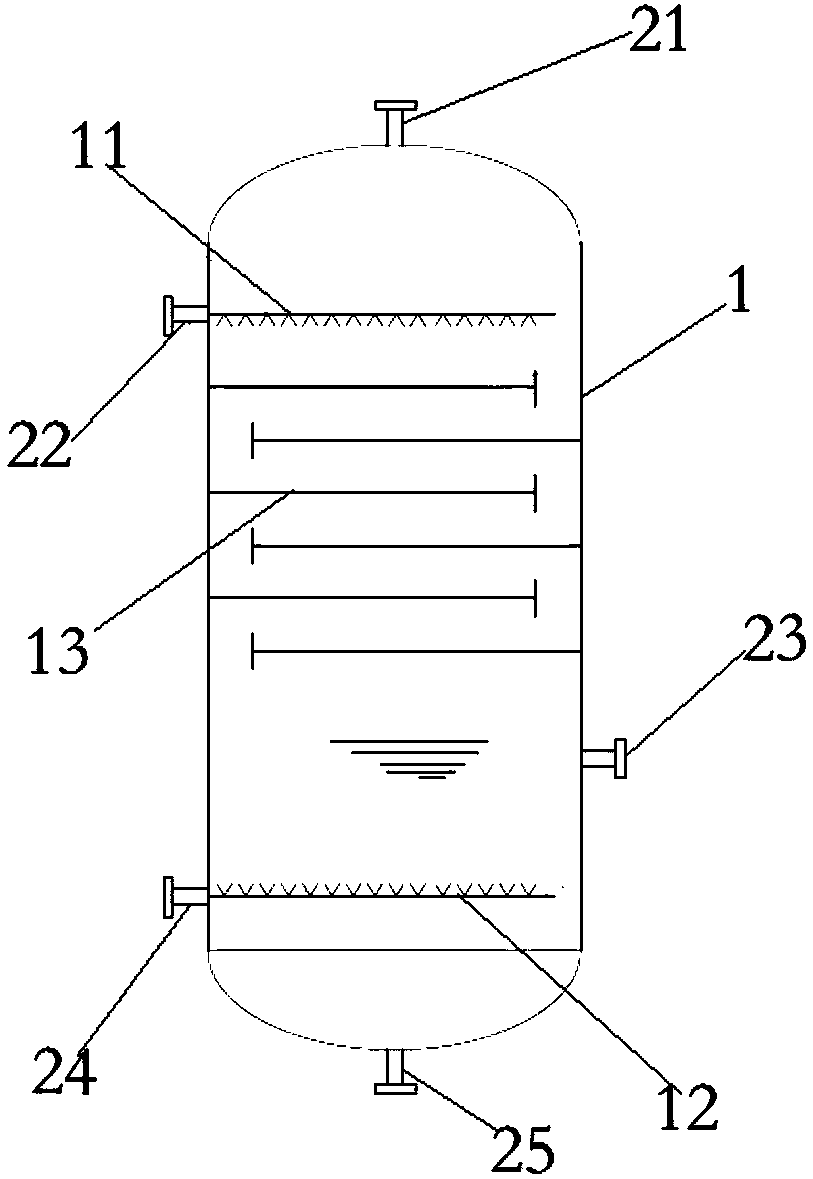

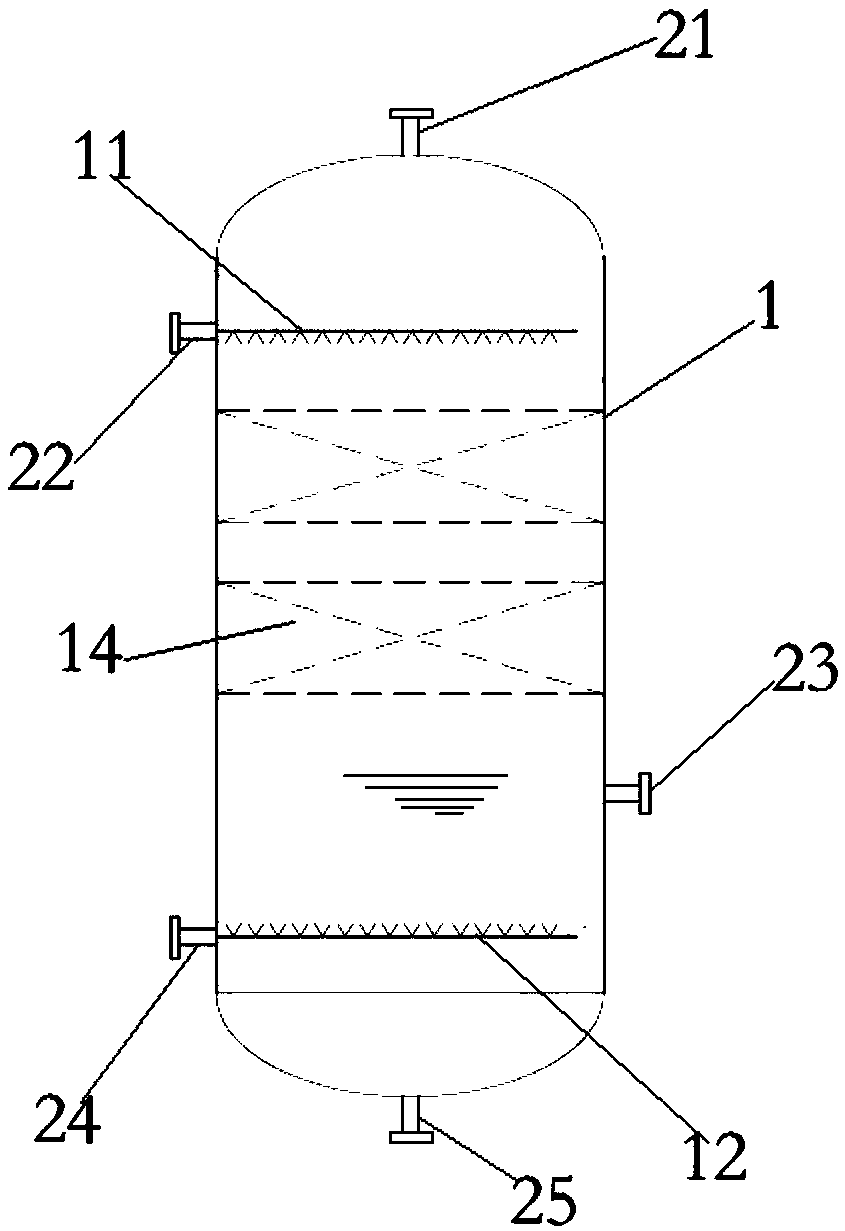

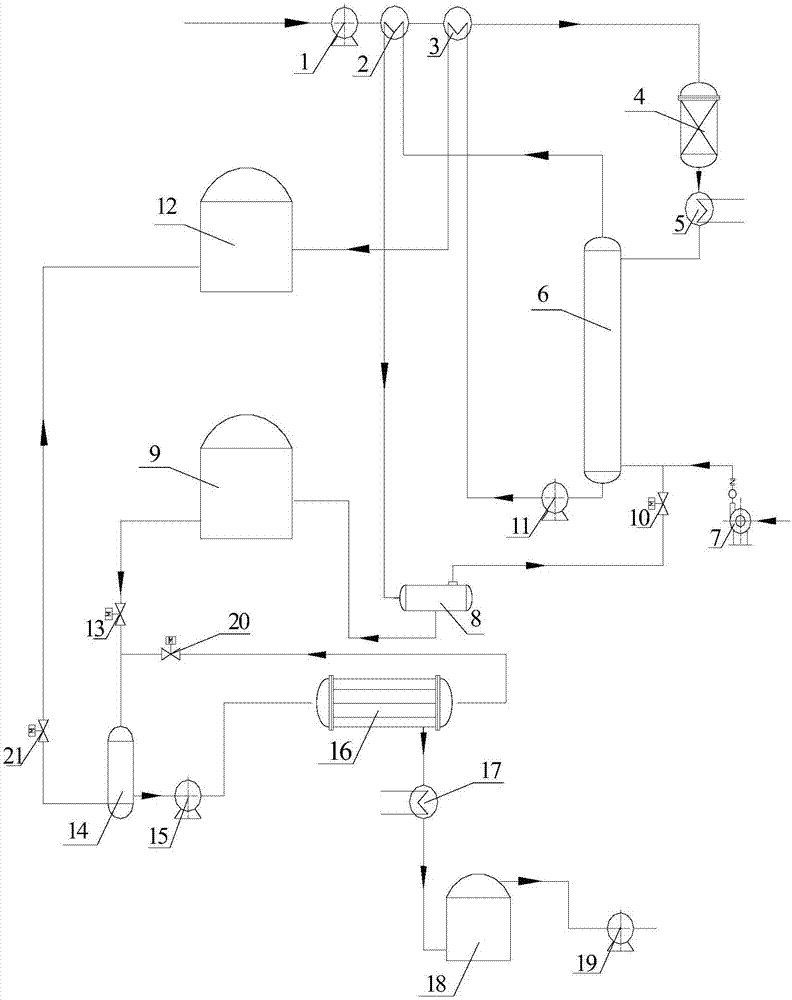

Extraction tower and process for removing methanol from residual C4 of etherification reaction

ActiveCN104225955ALower the altitudeReduce board spacingLiquid solutions solvent extractionExtraction purification/separationPtru catalystFluid phase

The invention relates to an extraction tower and a process for removing methanol from residual C4 of an etherification reaction. The extraction tower comprises a tower body which is internally provided with a plurality of supporting beams; each group of supporting beams corresponds to one layer of tower plate in parallel; a plurality of grooves are formed in each supporting beam at intervals; liquid flow holes communicated with the adjacent lower layer of tower plate are formed in the bottom surfaces of the grooves; each layer of tower plate is formed by splicing a plurality of secondary tower plate pieces; the supporting beams in each two adjacent groups are arranged in a staggered manner; a washing liquid inlet is formed in the upper part of the tower body and a C4 inlet is formed in the lower part of the tower body; a gas-phase outlet is formed in the tower top, and a liquid-phase outlet is formed in the tower bottom. Desalted water which is taken from the outside and has the temperature of 35-45 DEG C enters the tower body from the washing liquid inlet through a desalted water pump, residual C4 of the etherification reaction, which has the temperature of 35-45 DEG C, enters the tower body from the C4 inlet, and the flow ratio of the washing liquid to residual C4 of the etherification reaction is 1 to (20-25). Methanol in mixed C4 with the low methanol content can be removed and the content of methanol in processed mixed C4 is not more than 50ppm so that the consumption amount of a sulfuric acid catalyst in an isooctane device, the energy consumption of the device and the amount of waste acids can be reduced.

Owner:NINGBO HAIYUE NEW MATERIAL

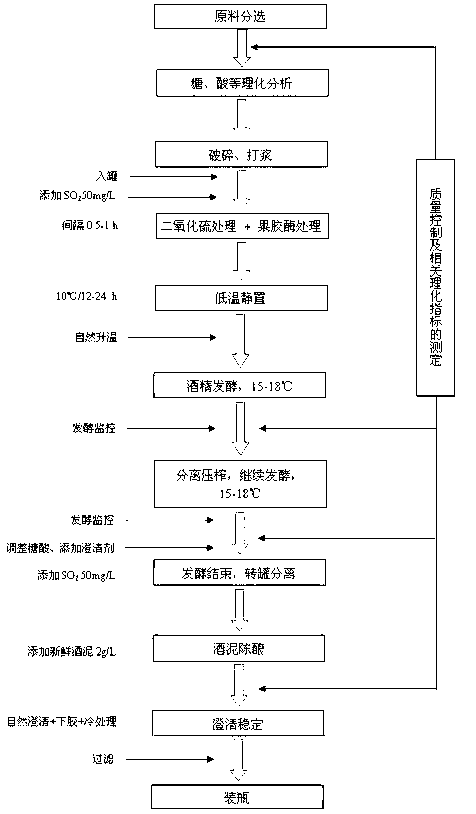

Low-yield methanol and higher alcohol fruit wine brewing process

ActiveCN103194354AFast clarificationReduce Methanol ContentAlcoholic beverage preparationPectinaseYeast

The invention relates to a fruit wine brewing method, and in particular relates to a low-yield methanol and higher alcohol fruit wine brewing process. The product prepared by the method disclosed by the invention fills blank of specific fruit wine brewing technology research in China, improves product quality of specific fruit wine, and enhances purity and typical aroma characteristic of wine and increases sense quality of the specific fruit wine, so as to make it possible to produce high-quality fruit wine products in many excellent fruit production zones. The technical scheme adopted by the invention comprises the following operation steps: (1) sorting fruit raw materials; (2) crushing, pulping and adding into a tank; (3) adding sulfur dioxide; (4) adding pectinase, and standing at low temperature; (5) naturally increasing temperature, adding a yeast culture liquor to start fermentation; (6) fermenting at controlled temperature, and monitoring fermentation; (7) separating, squeezing and continuing to ferment; (8) transferring to another tank, adding sulfur dioxide and storing; (9) aging in the presence of wine lees; and (10) clarifying, stabilizing, filtering and bottling.

Owner:福建猕尔康酒业有限公司

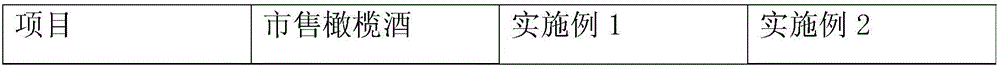

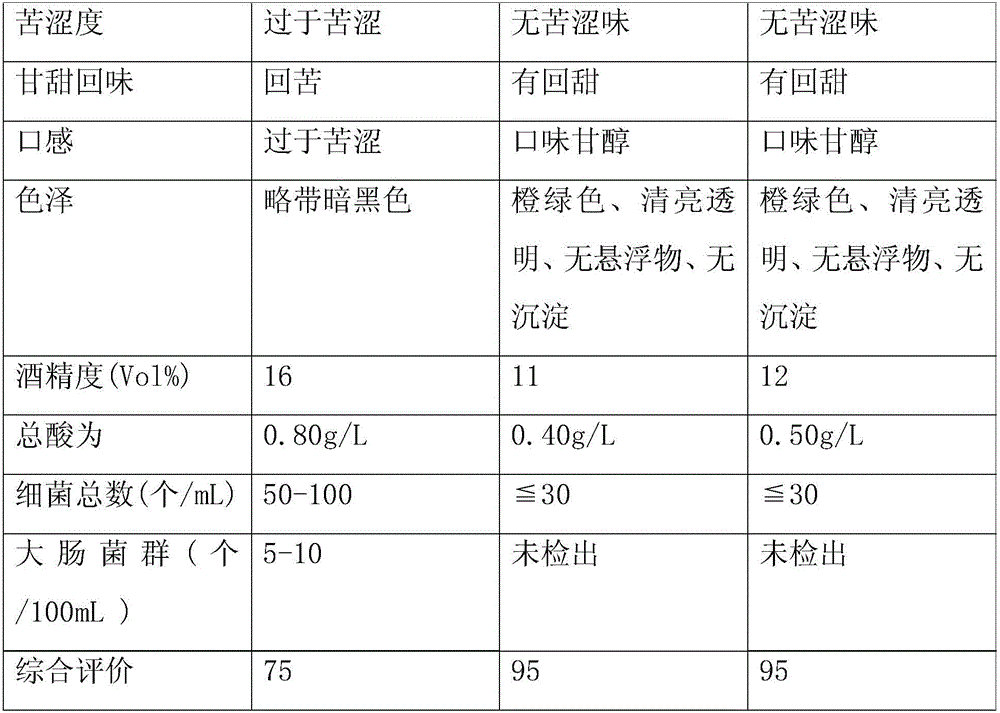

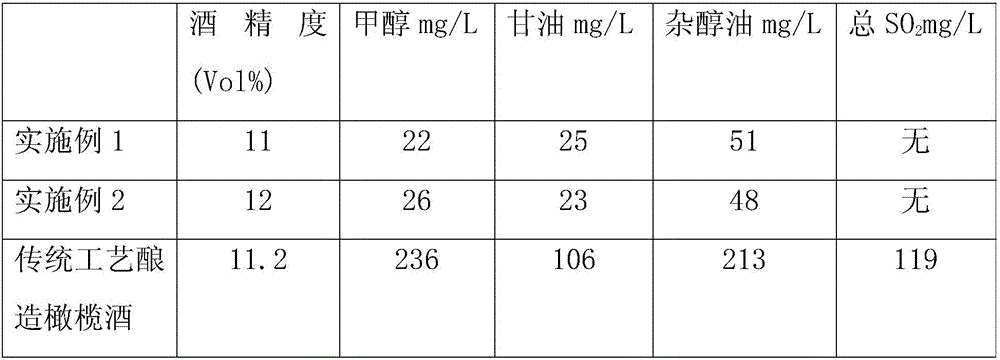

Brewing method of olive fruit fermented wine

InactiveCN106497729AInhibit coloringSweet tasteMicroorganism based processesAlcoholic beverage preparationHydroxytyrosolOrganic acid

The invention provides a brewing method of olive fruit fermented wine. The brewing method includes the steps of 1), pretreatment of olive fruit; 2), enzyme deactivation; 3), bitterless treatment; 4), primary fermentation; 5), secondary fermentation; 6), ageing; 7), canned sterilization. An existing olive wine brewing technology is substantially improved, alcoholic strength of the brewed olive wine is 10%Vol-12%Vol, total sugar content is 2-18g / L, total acid is 0.30-0.60g / L and volatile acid is 0.05-0.1g / L; the fermented wine has the advantages of low content of bacteria, good quality, natural color, lime green, clarification, coexistence of bouquet and fruity and sweet and mellow taste; in addition, the olive fruit fermented wine is rich in organic acid, amino acid, vitamins and minerals and has functions of clearing away heat and toxic materials, eliminating phlegm and regulating qi, moistening lung and nourishing yin and the like, and as is detected, the content of hydroxytyrosol in the olive fruit fermented wine can reach 380mg / mL.

Owner:德保县广鑫贸易有限公司

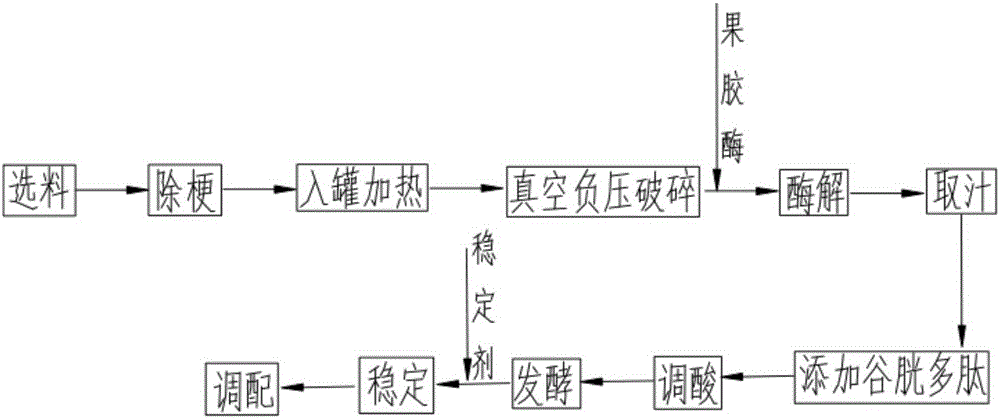

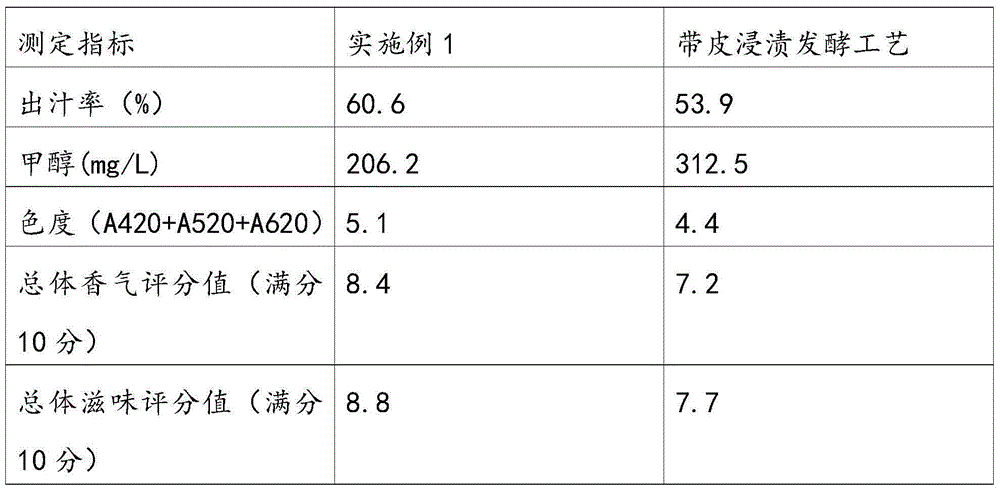

Making method for cherry fruit wine

InactiveCN105176752AQuick extractionFully extractedMicroorganism based processesAlcoholic beverage preparationFruit wineTannin

The invention relates to a making method for cherry fruit wine. The method comprises the steps of material selecting, stalk removing, heating, breaking, enzymolysis performing, juice extracting, glutathione adding and acidity regulating, fermenting, stabilizing, blending and the like. According to the making method for the cherry fruit wine, due to the fact that a quick heating and vacuum negative pressure fruit breaking extracting technology is adopted, on one hand, the cherry peel tissue is immediately broken, pigment and high-quality tannin in the peel can be quickly and fully extracted, bitter and astringent tannin in the seeds cannot be extracted, and on the other hand, microorganisms, oxidase and the like of cherries can be killed, and bad flavor is prevented from being generated due to oxidation or natural fermentation.

Owner:LUDONG UNIVERSITY

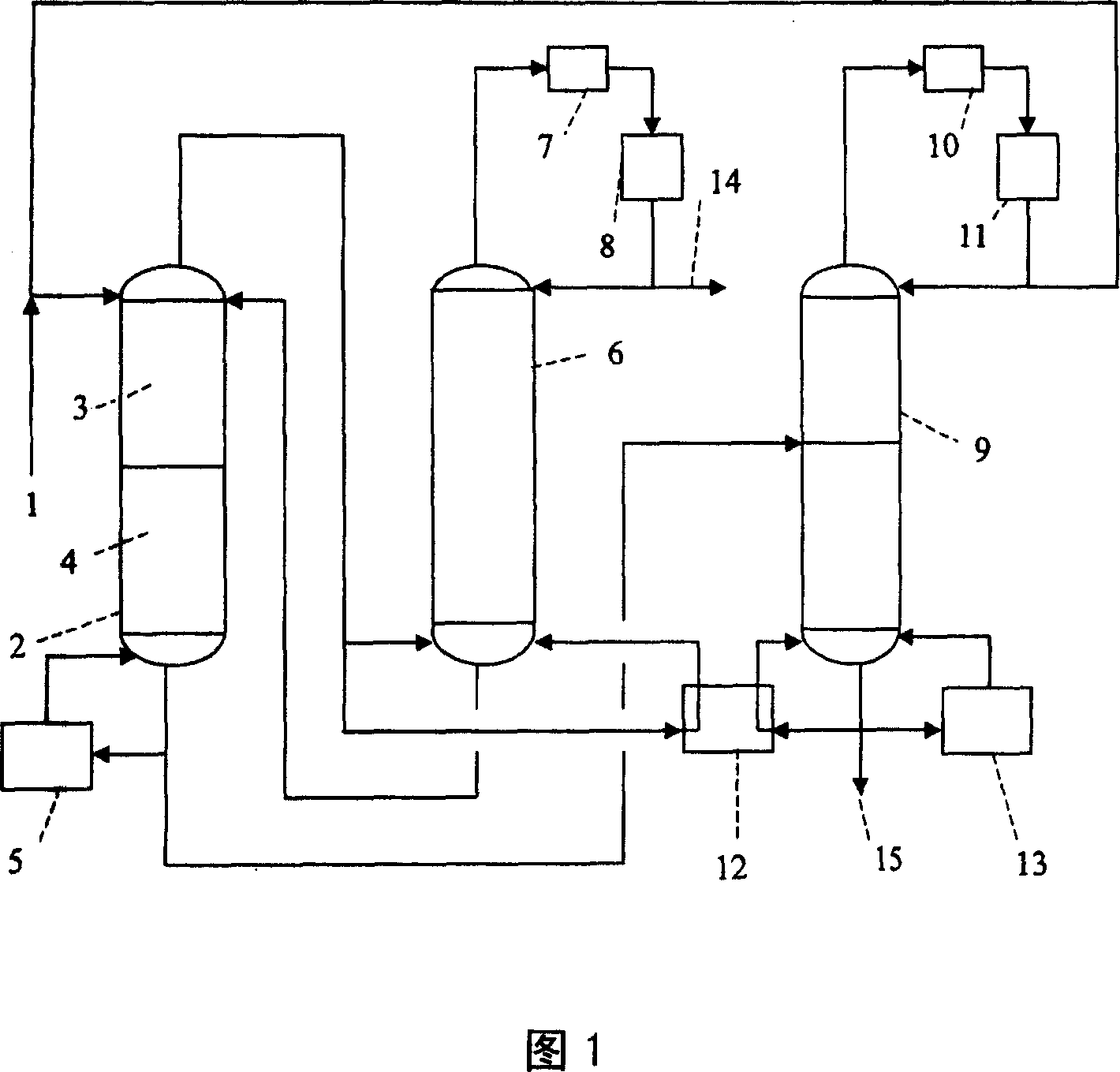

Refrigeration method for methanol synthesis and separation

The invention discloses a refrigeration method for methanol synthesis and separation, and belongs to the technical field of a methanol production process. According to technical essentials of the method, a synthesized gas after a methanol synthetic reaction is subjected to cooling through a heat exchanger and enters an air condenser for further cooling to obtain liquid crude methanol, wax generated in a liquid side reaction, and an un-condensed synthesized gas; a methanol separator is installed after the air condenser to enable wax, generated in the liquid side reaction, together with liquid crude methanol enters the methanol separator and following treatment equipment, so that a total amount of wax entering a following water condenser is reduced, and a wax precipitation speed of the water condenser is reduced; and the un-condensed synthesized gas is subjected to cooling through the heat exchanger and separation through a methanol separating column to enable methanol to be fully condensed and separated, so that the content of methanol in the synthesized gas cycled to a synthetic tower is reduced, and the methanol synthetic reaction in the synthetic tower is promoted to move towards a positive reaction direction. According to the method, the yield of methanol is increased; the service cycle of the device is prolonged; and energy consumption is reduced.

Owner:PETROCHINA CO LTD

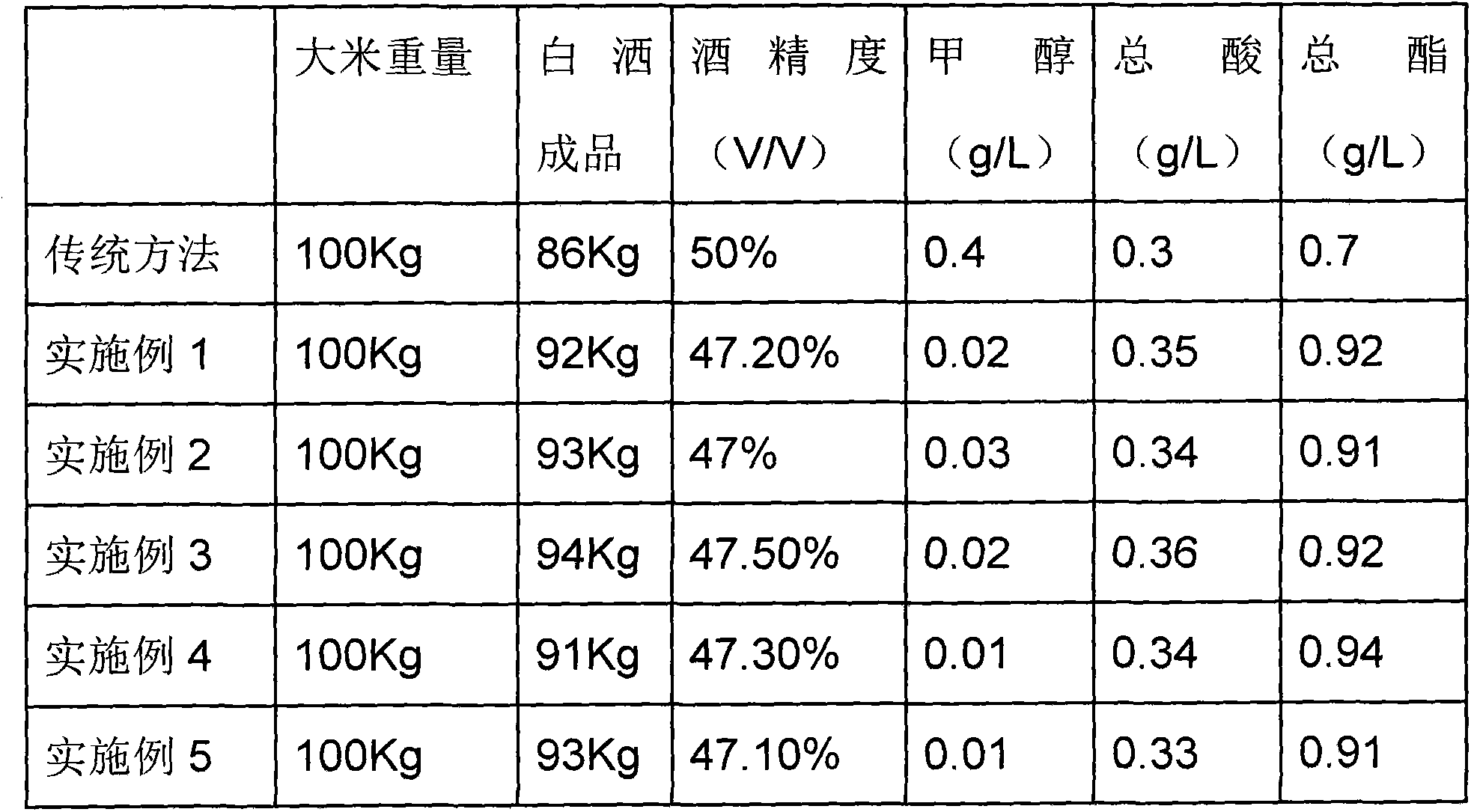

Method for brewing distilled spirit by using rice as raw material

ActiveCN104031801AFully fermentedReduce Methanol ContentAlcoholic beverage preparationChemistryDistillation

The invention discloses a method for brewing a distilled spirit by using rice as a raw material. According to the method for brewing the distilled spirit, rice is used as the raw material, and white granulated sugar is added for heat preservation before koji and yeast are added into the raw material, thus ensuring that microorganisms in the koji and yeast can be fully activated. In the post-fermentation process, the rice can be fermented fully, the liquor yield can be improved, and the methanol content can be reduced at the same time; the yield can be improved, and the quality of products can be improved at the same time. The liquor obtained by first distillation is subjected to second distillation to finally obtain the product; by virtue of twice distillation, the methanol content in the liquor can be reduced, and the quality of the liquor can be improved.

Owner:四川省青川县廖米酿酒业有限公司

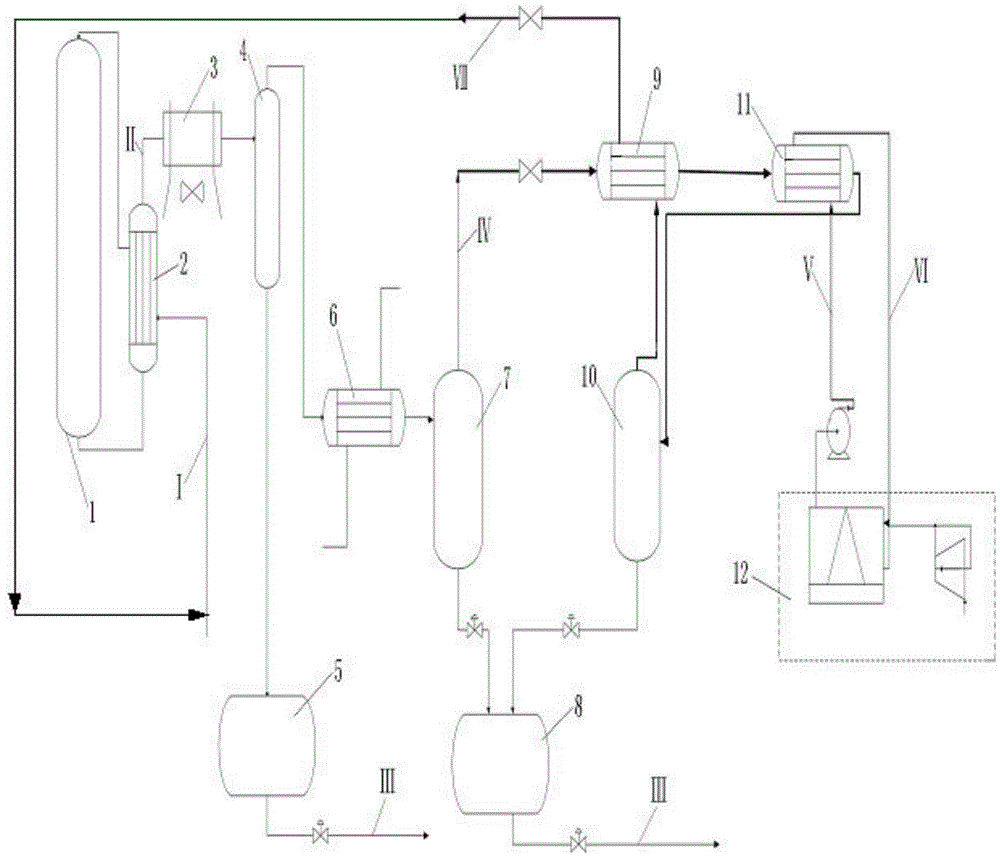

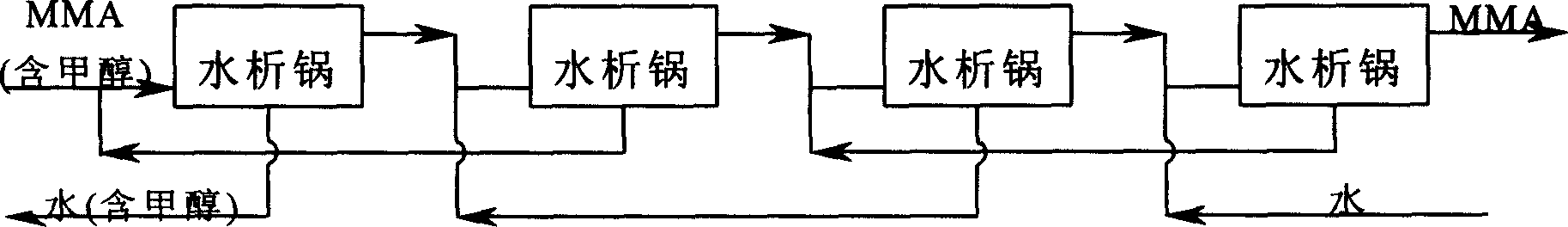

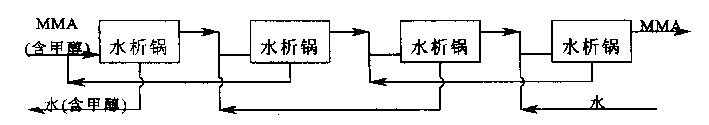

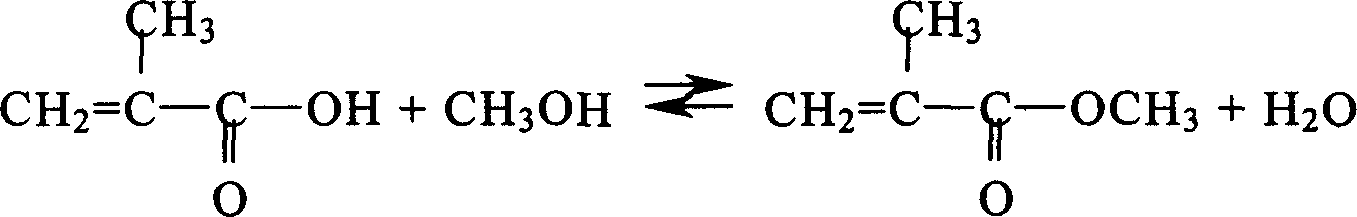

Process for extracting methanol using water in manufacturing of methyl methacrylate products

InactiveCN1566071AReduce Methanol ContentOrganic compound preparationCarboxylic acid esters preparationMentholStatic mixer

The invention discloses a process for extracting methanol using water in manufacturing of methyl methacrylate products, wherein the MMA containing a small amount of menthol and water are fed into a static mixer by the proportion of 1:1-5, then into a water extraction pot, the upper layer is the extracted MMA monomer, which enters the next water extraction pot through an overflow port, the lower layer is aqueous solution of menthol, which is pumped onto an upper water extraction pot by a measuring pump, through the extraction by several water extraction pots, the methanol in the MMA can be removed substantially.

Owner:PEN MAKING FACTORY SHANGHAI

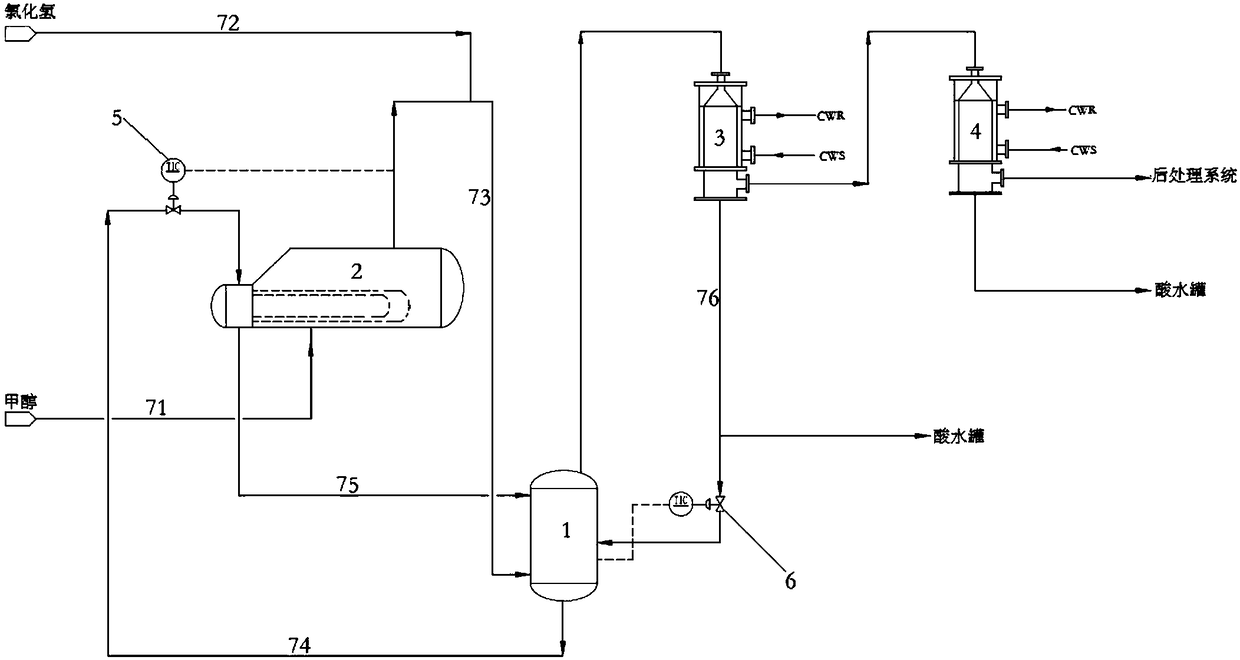

Energy-saving methane chloride production system and method

ActiveCN108409526AEffective recovery of heatTake advantage ofHalogenated hydrocarbon separation/purificationHeat flowGas phase

The invention discloses an energy-saving methane chloride production method. The method includes: liquid raw material methanol is heated in a methanol vaporizer, and the methanol is mixed with hydrogen chloride and then enters a reaction kettle through a gas-phase inlet in the lower portion of the reaction kettle; the kettle-bottom produced liquid of the reaction kettle is used as the heating medium of the methanol vaporizer, and the kettle-bottom produced liquid is subjected to heat exchanging through the methanol vaporizer and circulated to a liquid-phase inlet in the upper portion of the reaction kettle; liquid and gas are in continuous countercurrent contact on a tower plate or filler in the reaction kettle; high-temperature mixed gas in the reaction kettle escapes from the top of thereaction kettle, and the gas is cooled by a first condenser and a second condenser and then conveyed to a purification system. The invention further discloses an energy-saving production system used for achieving the method above. The method has the advantages that heat flow produced at the bottom of the reaction kettle and the raw material methanol are subjected to heat exchanging in the methanolvaporizer, the heat carried by the high-temperature heat flow is recycled effectively, reaction heat is utilized sufficiently, all steam needed by methanol preheating and vaporization is saved, and an evident energy saving effect is achieved.

Owner:SEDIN NINGBO ENG

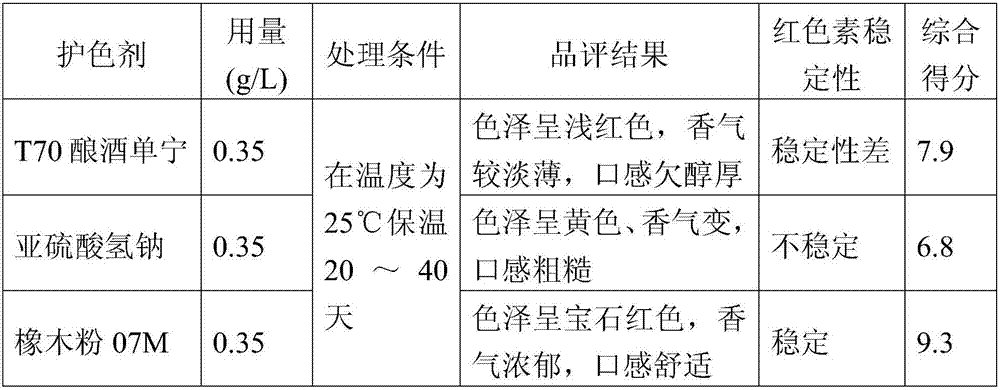

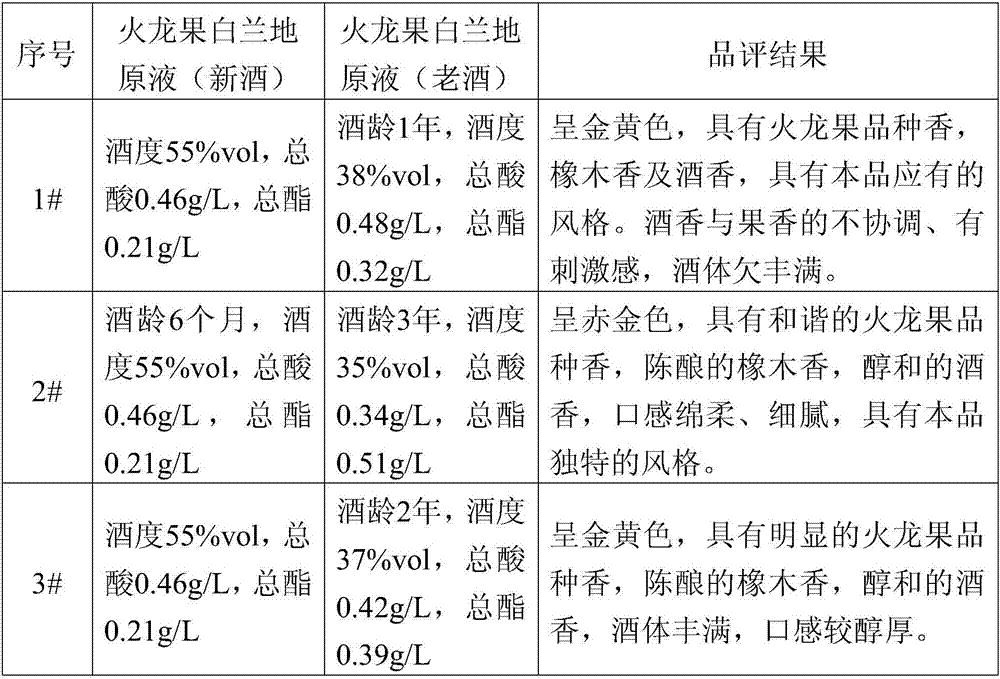

Fermented red pitaya wine, pitaya brandy and production method thereof

ActiveCN107502515ASolve difficult filterGuaranteed normal fermentationAlcoholic beverage preparationPectinaseYeast

The invention discloses fermented red pitaya wine, pitaya brandy and a production method thereof. The method includes: integrally crushing red pitayas, and adding pectinase for enzymolysis; adding yeast, yeast nutrients, vitamin C and chitosan to realize mixed fermentation; after fermentation is in full play, performing low-temperature fermentation through maceration, and carrying out aging, purifying, oak powder treatment, freezing and sterilization aftertreatment to obtain the fermented red pitaya wine; subjecting the prepared original wine to crude distillation and rectification, storing and aging to obtain red pitaya brandy. Whole-fruit fermentation is adopted, technical simplicity and low equipment input cost are realized, and the comprehensive utilization rate of red pitayas is increased; the red pitaya wine is rich in fruity aroma, rich and full in texture, stable in the presence of light, thermal and the like and free of fading, suspensions, precipitates and turbidity after normal-temperature placement over one year; the pitaya brandy is unique in nutrient and aroma, prominent in typicality and superior in quality.

Owner:佛山市五谷丰登农业技术推广有限公司

A low-methanol mango-sugarcane wine and a brewing method thereof

ActiveCN109181977AGood health effectRich in nutrientsMicroorganism based processesAlcoholic beverage preparationYeastFruit wine

The invention discloses a low-methanol mango-sugarcane wine and a brewing method thereof. The brewing method comprises the following steps: 1) taking mango pulp, beating, and obtaining mango raw pulp;2) mixing raw mango pulp and sugarcane juice evenly, adding fruit wine yeast, and fermenting for 1-3 days at the temperature of 28-32 DEG C, then adding sugar component, carrying out main fermentation under the condition of <28 DEG C until the total soluble sugar content in the fermentation broth is less than or equal to 70g / L, and collecting the fermentation broth; 3) cooling the fermentation broth to 15-18 DEG C and performing fermentation until the total soluble sugar content in the wine reaches the sugar content of the desired brewing type, further reducing the temperature of the obtainedliquor to 4-8 DEG C with heat preservation until a certain amount of gel is generated on the upper layer of the material liquid, filtering and collecting the filtrate; 4) adding a clarifying agent into that filtrate, filtering and sterilizing the obtained material to obtain a liquor; and 5) aging the obtained liquor to obtain the mango-sugarcane wine, wherein the mango-sugarcane wine brewed by the method has low methanol content and good taste.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

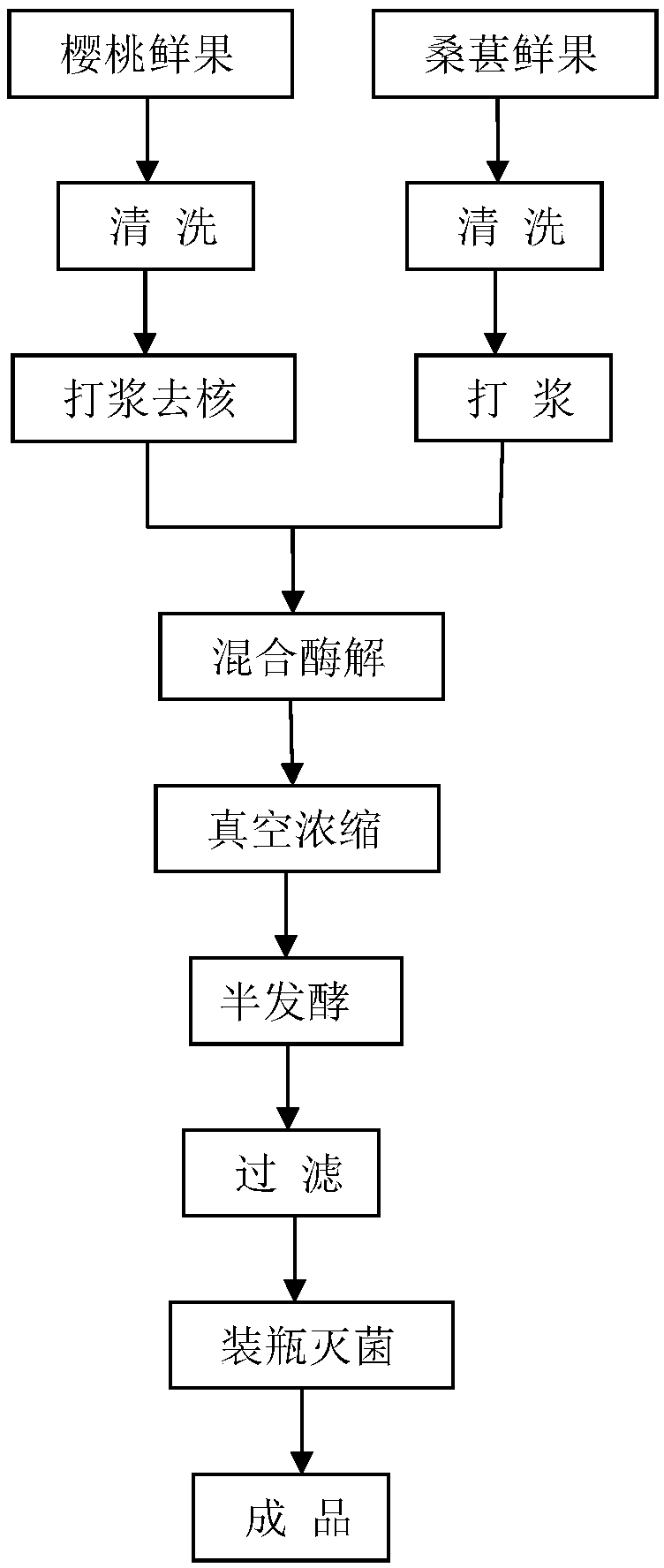

Cherry health wine and making method thereof

InactiveCN108728307AReduce Methanol ContentHigh methanol content and lower qualityAlcoholic beverage preparationMicroorganism based processesPectinaseFruit juice

The invention relates to cherry health wine and a making method thereof. The cherry health wine is made by fermenting, by weight, 80-95% of cherry pulp and 20-5% of mulberry pulp. The two pulps are mixed; pectinase is added to provide a higher juicing rate; low-temperature vacuum concentration helps increase the juice sugar degree and reduce the methanol content; a low-temperature half-fermentation making technique imparts strong fruit fragrance and suitable sourness and sweetness to the cherry health wine. The cherry health wine made herein has the advantages that the mulberry fruit is addedfor coordinated fermentation so that color of the cherry health wine is significantly improved, and the cherry health wine is as functional as cherry to replenish blood by high iron and prevent gout,and as functional as mulberry fruit to improve physical fitness, tonify kidney, darken hair and maintain beauty.

Owner:ZHEJIANG CITRUS RES INST

Preparation method for high-quality litchi wine

InactiveCN106929358AKeep sweetExtended shelf lifeAlcoholic beverage preparationPectinaseAlcohol content

The invention discloses a preparation method for high-quality litchi wine. The method comprises the following steps: (1) selecting fresh litchi, peeling and separating pulp from kernel; (2) crushing the kernel, thereby acquiring kernel powder for later use; (3) squeezing the pulp, collecting juice, adding pectinase into the juice, standing by and clarifying, filtering and transferring the first filtrate into a fermentation tank; (4) adding high-activity yeast liquid and 1 / 4 weight of kernel powder and fermenting for 3-4 days at 18-25 DEG C; (5) standing by, clarifying, filtering and transferring the second filtrate into an ageing tank, adding the residual kernel powder, and then adding the mixed extracting solution of carambola leaves and dragon fruit peel, aging for 90-120 days, filtering and sterilizing, thereby acquiring the high-quality litchi wine. The litchi wine disclosed by the invention is fragrant, long in guarantee period and low in methyl alcohol content.

Owner:胡安平

Device and process for recycling methyl alcohol from gas field alcohol-containing sewage based on gas stripping process and vacuum membrane distillation process

ActiveCN106866368AShort processSimple processOrganic compound preparationWater contaminantsReboilerMembrane distillation

The invention relates to a device and a process for recycling methyl alcohol from gas field alcohol-containing sewage based on a gas stripping process and a vacuum membrane distillation process. A complex process route of performing gas stripping first to obtain a dilute methyl alcohol solution with fewer impurities and then concentrating the dilute methyl alcohol solution through vacuum membrane distillation is adopted. The device and the process have the beneficial effects that related equipment such as a complex rectifying tower, a reboiler and a reflux tank is not needed, so that equipment investment is greatly reduced; the integrated process does not generate methyl alcohol reflux, so that repeated heating of reflux and tower bottoms is avoided, raw materials are sufficiently heated by waste heat of a methyl alcohol product and tower bottom water; waste heat of raw materials heated at a gas-stripping section provides energy for phase change of vacuum membrane distillation, so that methyl alcohol recycling energy consumption is greatly reduced and economic benefits are improved; the problems that content of impurities of alcohol-containing sewage of the raw materials is relatively high and the solution pollutes the hydrophobic microporous membrane are avoided, and the service life of the membrane is prolonged; the gas stripping process and the vacuum membrane distillation composite process are integrated, so that recycling efficiency is improved, and content of methyl alcohol in alcohol-containing sewage is reduced.

Owner:CHANGZHOU UNIV

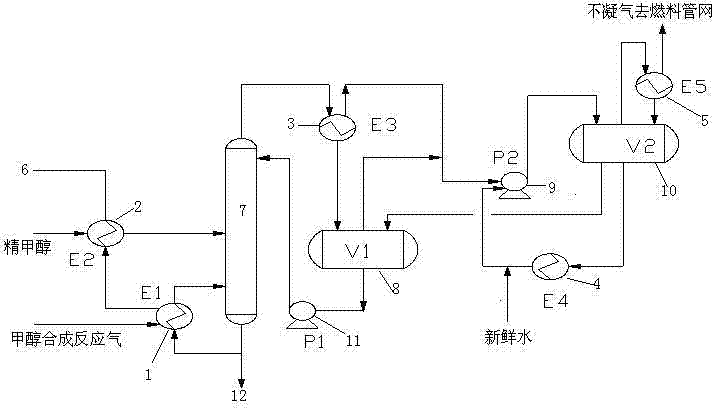

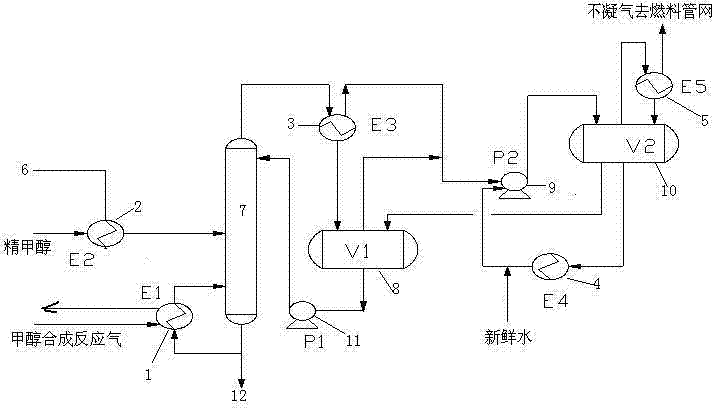

Methanol pre-rectifying tower heating process by utilizing methanol synthetic reaction gas

ActiveCN104710281ASave heating heat sourceAchieve energy saving and consumption reductionOrganic compound preparationHydroxy compound preparationThermodynamicsReboiler

The invention discloses a methanol pre-rectifying tower heating process by utilizing a methanol synthetic reaction gas. The methanol pre-rectifying tower heating process mainly comprises the following steps: using the methanol synthetic reaction gas as a heat source for heating a reboiler of a methanol pre-rectifying tower, and then performing feeding heat exchange on the methanol pre-rectifying tower; adopting a negative pressure as the operating pressure at the top of the methanol pre-rectifying tower, wherein the negative pressure is controlled by a water ring vacuum pump; cooling the non-condensable gas pumped by the water ring vacuum pump from the top of the tower, and then feeding the cooled non-condensable gas to a fuel gas pipe network; adding a certain volume of fresh water to the water ring vacuum pump, meanwhile adopting a certain volume of circulating liquid to control the liquid level in a circulating liquid storage tank of a circulating vacuum pump, and feeding the pumped circulating liquid to a reflux tank of the methanol pre-rectifying tower as a reflux liquid of the methanol pre-rectifying tower.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for preparing dimethyl ether by dehydration of methanol

ActiveCN101016231AReduce Methanol ContentReduce investmentChemical industryEther preparation by compound dehydrationPhysical chemistryFractionating column

The invention discloses a manufacturing method of dimethyl ether hydrated by carbinol, which comprises the following steps: introducing raw material with carbinol into catalytic distilling tower; hydrating at least partial carbinol to produce dimethyl ether and water; guiding partial steam from the top of catalytic distilling tower into autoclave of second distilling tower; using liquid-phased material in the second distilling tower as reflux liquid to lead into top of catalytic distilling tower; obtaining the mass with dimethyl ether as main component of top of second distilling tower; introducing liquid-phased mass of catalytic distilling tower into the third distilling tower; obtaining the mass with carbinol as main component of third distilling tower to lead into top of catalytic distilling tower or autoclave of second distilling tower; draining water mass as main component from the autoclave of third distilling tower.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

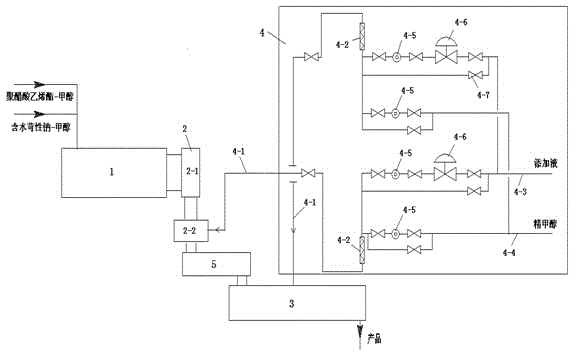

Production method and apparatus of polyvinyl alcohol

ActiveCN106279480AEnhanced Methanol Replacement EffectReduce Methanol ContentPolyvinyl acetateContact time

The invention relates to a production method of polyvinyl alcohol. A polyvinyl alcohol product is obtained by adopting polyvinyl acetate-methanol as a raw material, adopting caustic soda-methanol as a catalyst, adopting methyl acetate-methanol-aqueous solution as a substitution agent by virtue of steps such as alcoholysis, pulverizing and drying; and the methyl acetate-methanol-aqueous solution is distributed in the pulverizing step and the drying step. An apparatus used in the production method comprises an alcoholysis machine, a pulverizing machine and a drying machine, which are successively connected with one another, and the pulverizing machine and the drying machine are respectively connected with a substitution agent adding system. By adopting the production method, the contact time and contact area between water and materials are increased, the effect of substituting methanol by the water is improved, and the content of the methanol in the materials is effectively reduced. The polyvinyl alcohol production apparatus can effectively control the flow quantity, total amount and water content of the substitution agent added into the pulverized material and the dried material, and is convenient to operate and simple in structure.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of kiwi fruit brandy

InactiveCN105647767AHigh alcohol contentSimplify and improve the manufacturing processMicroorganism based processesAlcoholic beverage preparationFruit wineActinidia

The invention relates to a preparation method of kiwi fruit brandy. The preparation method comprises the following steps: preparing kiwi fruit wine; carrying out distilling purification on the kiwi fruit wine to produce brandy; preparing kiwi fruit roots; baking the kiwi fruit roots; and immersing the kiwi fruit roots in the obtained brandy. The kiwi fruit wine is subjected to distilling purification to produce the high-alcohol-content brandy, and the wide kiwi fruit roots are baked and used for storage or immersion instead of the oak barrel or oak sheet used by western brandy, so that the brandy has a unique flavor. The kiwi fruit brandy produced by the technique has the unique flavor, and also has the particular health care and therapeutic functions of the kiwi fruit roots, and the kiwi fruit brandy obtained by immersing the kiwi fruit roots is golden, clear and transparent.

Owner:张新义

Preparation method of rosa sterilis honey fruit wine

PendingCN111004698AFull of nutritionFragrantAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

Belonging to the technical field of wine brewing, the invention particularly relates to a preparation method of rosa sterilis honey fruit wine. The method includes the steps of: (1) raw material treatment; (2) juice taking; (3) fermentation liquor adjustment; (4) yeast inoculation; (5) primary fermentation; (6) clarification; (7) ageing; (8) blending; and (9) filtering and bottling: filtering theblended fruit wine by a filtering instrument, and then performing bottling. The rosa sterilis honey fruit wine provided by the invention adopts rosa sterilis and honey as the raw materials, wherein the rosa sterilis is rich in nutrition, contains a lot of vitamin C and polyphenol, has strong fragrance, is coordinated with the mellow and sweet taste of honey, so that the wine body is clear and bright, has harmonious fragrance, delicate and refreshing taste and moderate acerbity, the fruit wine having harmonious fruit fragrance, honey fragrance and wine fragrance is unique in flavor, has low alcoholic strength, more conforms to the development trend of massive health, and is suitable for people of all ages to drink.

Owner:GUIZHOU INST OF TECH

Brewing process for low-alcohol apple wine

ActiveCN105238644AIncrease profitLow content of related substancesAlcoholic beverage preparationTemperature controlYeast

The invention discloses a brewing process for a low-alcohol apple wine, belonging to the technical field of alcoholic drinks. The brewing process comprises the steps of (1) sorting and treating raw materials; (2) crushing and juicing at high pressure; (3) adding SO2 and a pectase; (4) fermenting in a sealing way; (5) replenishing SO2 and a yeast; (6) fermenting in a temperature-controlled way; (7) gelating on bcntonite and filtering; and (8) sterilizing and filling. According to the process, the raw materials are peeled, so that the safety of the apple wine product is improved; a juice is squeezed by using a low-temperature and high-pressure method in the juicing process, so that the yield of the juice is increased, and the utilization ratio of the raw materials is increased; and the yeast is replenished after sealing fermentation, so that enough active yeasts are provided in the subsequent temperature-controlled fermentation process, and the fermentation efficiency in the subsequent aging process is increased.

Owner:陇南花荠蜂业有限责任公司

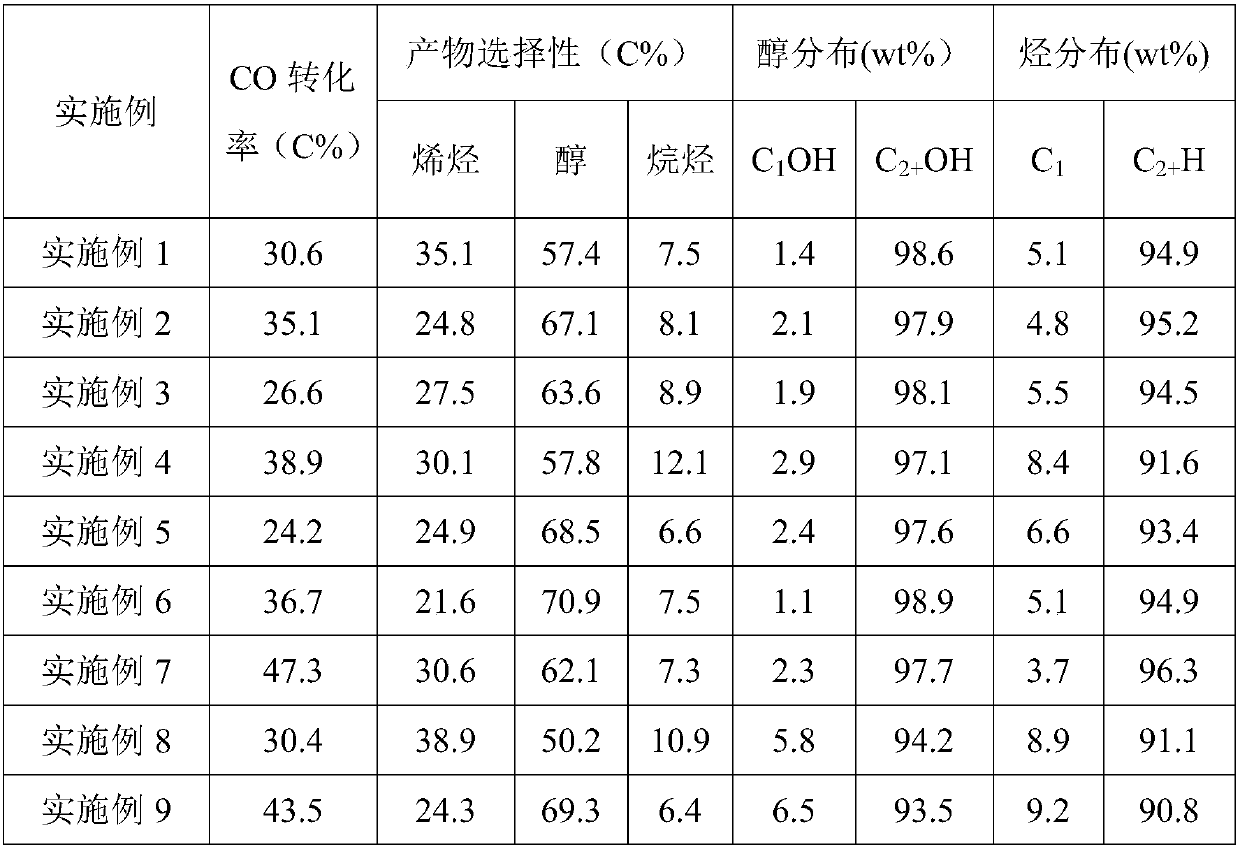

Catalyst for catalytic conversion of synthetic gas as well as preparation method and application thereof

ActiveCN109569652AImprove catalytic performanceReduce Methanol ContentHydrocarbon from carbon oxidesOrganic compound preparationChemical productsAlkene

The invention provides a catalyst for the catalytic conversion of a synthetic gas as well as a preparation method and application thereof. The catalyst is prepared from the following components in percentage by weight: 9.8% to 78.5% of Co based catalyst, 0.2% to 16.5% of oxide aid and 5% to 90% of Rh based catalyst. The catalyst provided by the invention is a dual-function catalyst, wherein the Cobased catalyst is mainly used for carrying out the generation of olefin; the carrying out of the process can be obviously promoted due to the existence of the oxide aid; the Rh based catalyst is mainly used for the hydroformylation of the olefin; the olefin generated by the Co based catalyst is enabled to further react with the synthetic gas to prepare mixed alcohol with high value added; the catalyst has excellent catalytic performance; low methane and methanol contents and the high alcohol selectivity are presented in product distribution; and the total selectivity of chemical products (alcohol and olefin) with high value added reaches 90% or above.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

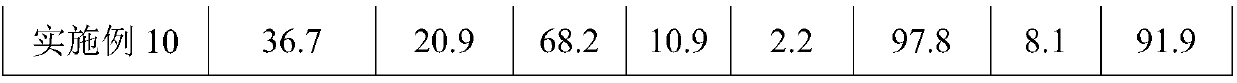

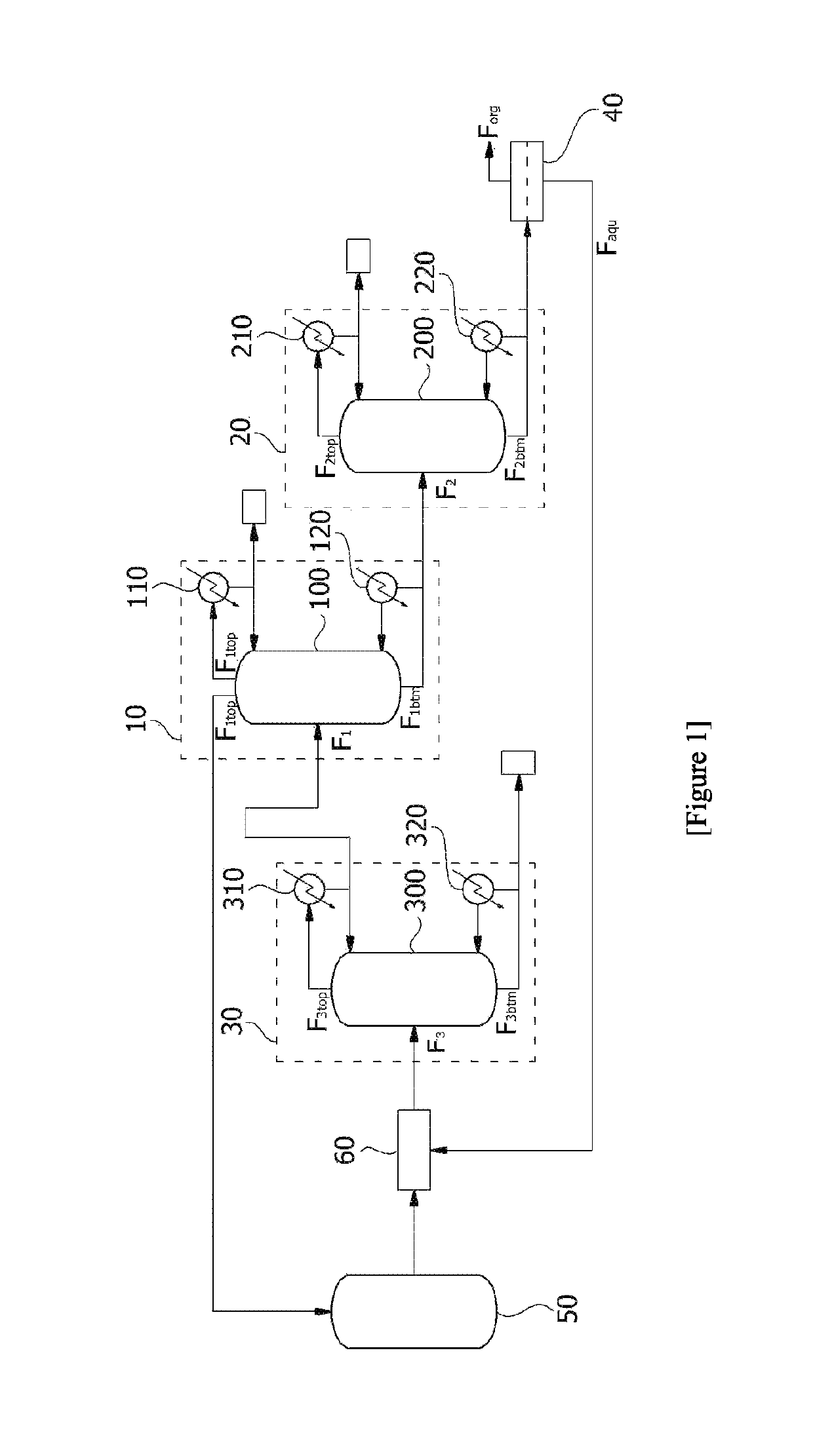

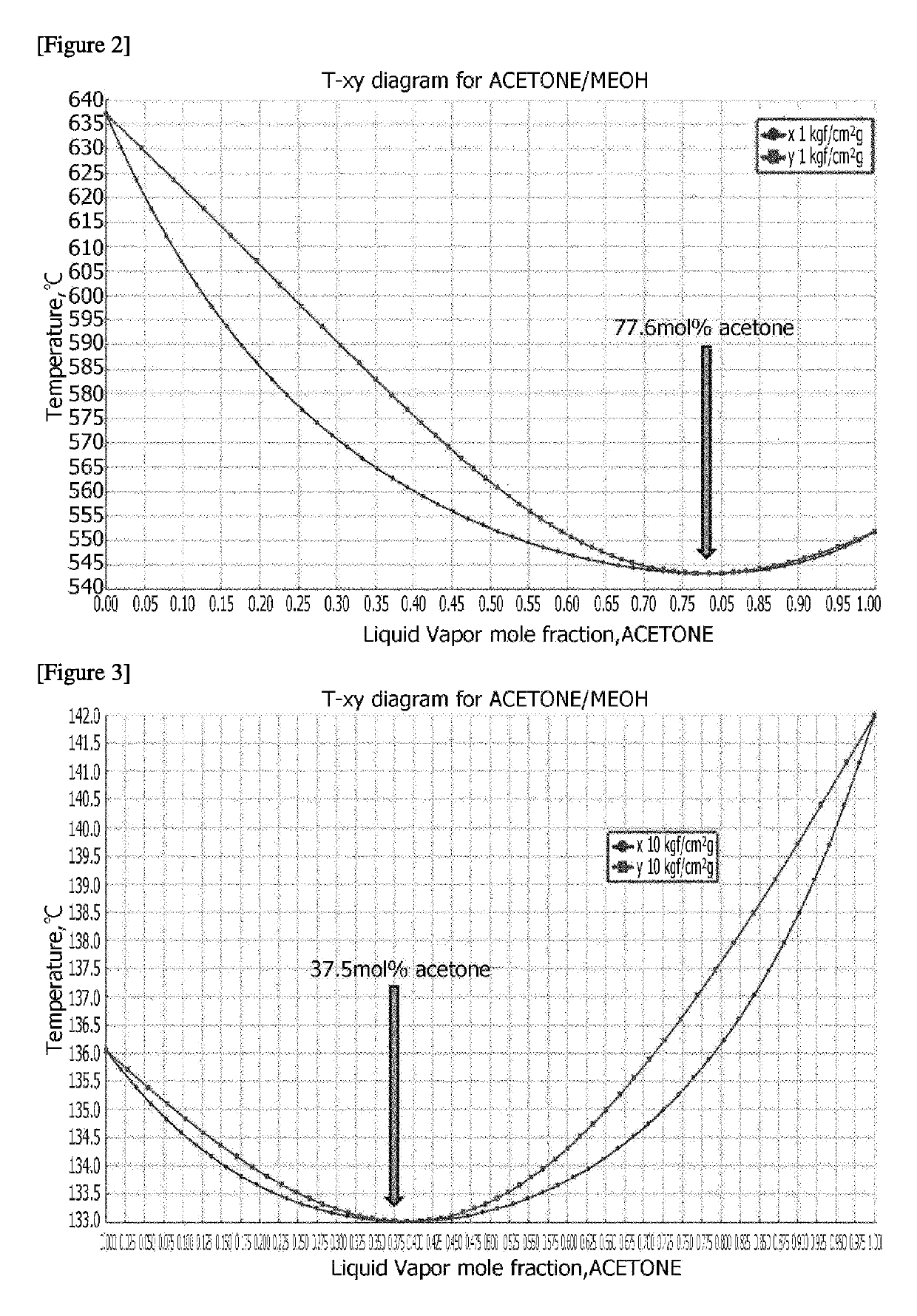

Distillation device

ActiveUS10486080B2Reduce Methanol ContentExtended service lifeOrganic compound preparationCarbonyl compound separation/purificationAcetone productFractionating column

Owner:LG CHEM LTD

Method for preparing high-purity refined methanol by three-tower rectification

InactiveCN102992951AReduce consumptionSolve the separation problemOrganic compound preparationHydroxy compound preparationAlcoholBoiling point

The invention discloses a method for preparing high-purity refined methanol by three-tower rectification, which is used for preparing high-purity refined methanol by treating a methanol crude product by using a three-tower rectification method. The method comprises the steps of: based on diluted alcohol water or soft water as an extraction agent, distilling in a pre-separating tower to remove low-boiling substances in the methanol crude product and water-insoluble gas so as to obtain pre-separated methanol; sending pre-separated methanol into a pressurizing tower for pressurized rectification treatment, cooling light components at the tower top of the pressurizing tower, returning a part of the light components to the tower top of the pressurizing tower for refluxing, and collecting the rest of the light components as the refined methanol product; sending heavy components at the tower bottom of the pressurizing tower into a main rectifying tower for rectification, cooling light components at the tower top of the main rectifying tower, returning a part of the light components to the tower top of the main rectifying tower for refluxing, and collecting the rest of the light components as the refined methanol product; and discharging the main rectifying tower bottom liquid as waste liquid. By using the 'three-tower rectification' method, the problem that methanol azeotropes cannot be separated in the methanol products is effectively solved, the purity of the obtained refined methanol product reaches more than 99.9%, the mass percent concentration of methanol in the discharged waste liquid is smaller than 1.0%, and the pollution of effluents to the environment is reduced because the methanol content is low.

Owner:HUNAN YIHUA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com