Patents

Literature

47 results about "Acetone product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

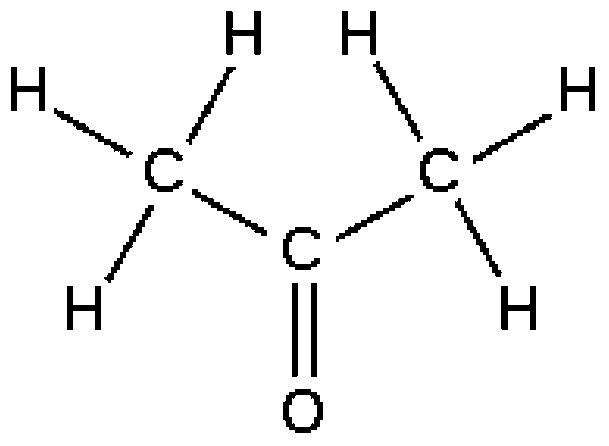

Acetone, a colorless liquid also known as Propanone, is a solvent used in manufacture of plastics and other industrial products. Acetone may also be used to a limited extent in household products, including cosmetics and personal care products, where its most frequent application would be in the formulation of nail polish removers.

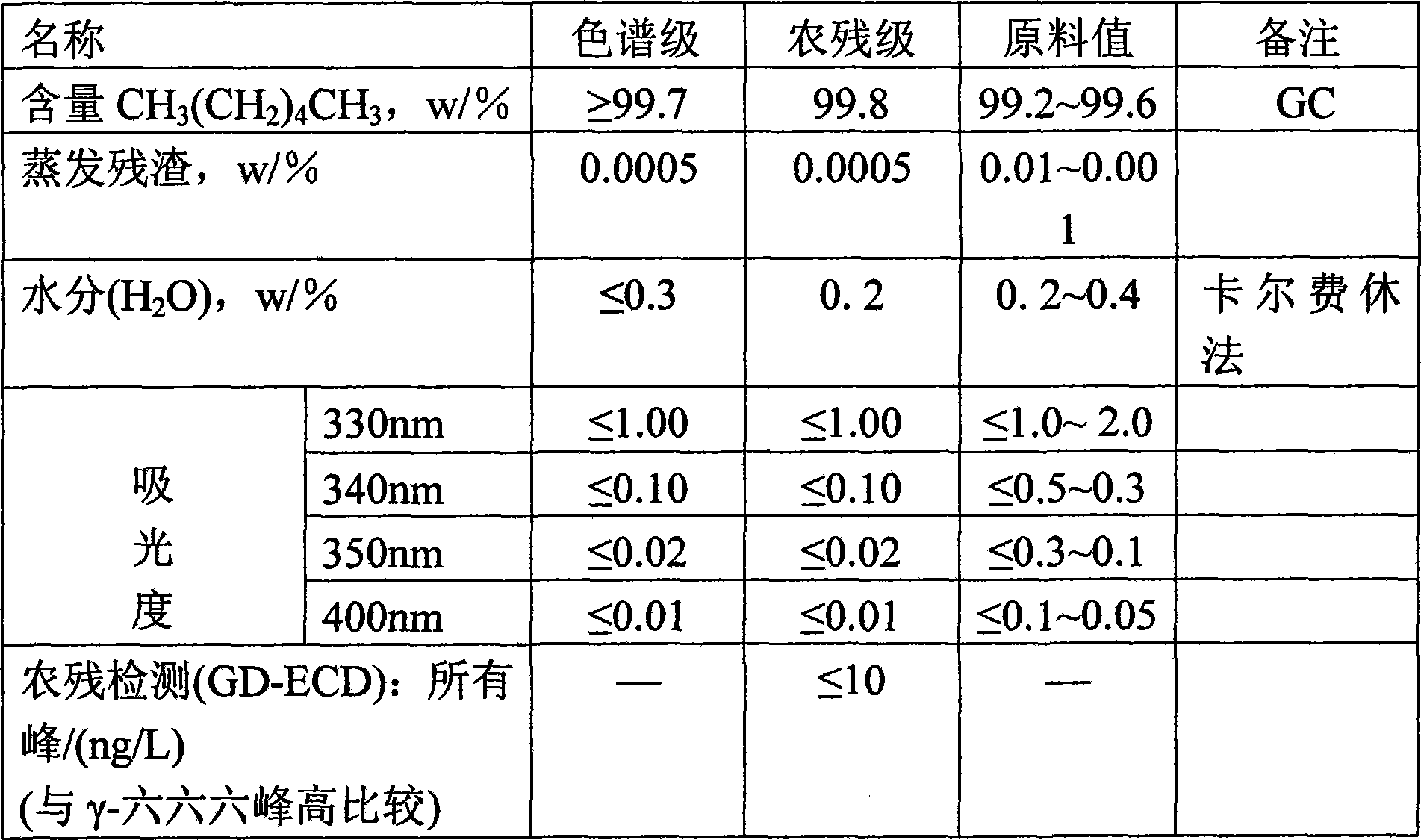

Method for purifying high-purity organic solvent-acetone for scientific research

InactiveCN101544551AHigh purityEasy to separateCarbonyl compound separation/purificationOrganic solventPesticide residue

The invention relates to a method for purifying a high-purity organic solvent-acetone for scientific research, which comprises the following steps that: acetone as the raw material is adsorbed to remove impurities by an adsorption resin, dried to remove water by a drying agent, rectified by a rectifying still, filtered and packaged to obtain a chromatographic grade and pesticide residue grade acetone product. The method can obtain the chromatographic acetone product with the purity more than 99.9 percent, ensure that the yield is more than 93 percent and the qualification rate is more than 95 percent, can obtain a 50 to 60 percent pesticide residue grade acetone reagent, can meet the application demand of high efficiency liquid chromatography (HPLC) customers on pesticide residue, and fill in the gap of the national production of pesticide residue grade chromatography reagents; and at the same time, compared with the prior method, the method has high product purity, simple and convenient operation and stable operation, and is suitable for mass production.

Owner:天津市康科德科技有限公司 +1

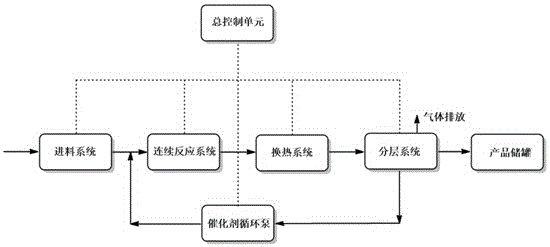

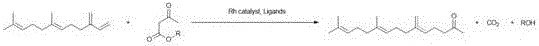

Method for synthesizing ketone compounds by continuous cyclic catalytic reaction

InactiveCN105859534AReduce contentReduce churnOrganic compound preparationCarbonyl compound preparationAcetone productKetone

The invention provides a method for synthesizing ketone compounds through continuous circular catalytic reaction. The method is carried out according to the following steps: 1. Parameter setting and input; 2. Input of raw material liquid and catalyst; 3. Mixed liquid and heating and pressurizing catalytic synthesis reaction; 4. Lowering temperature and lowering pressure treatment; . Delivery of farnesyl acetone products; 7. Recycling of catalysts. The method changes the method of stepwise reaction synthesis of farnesyl acetone into one step reaction synthesis, and can reduce the content of rhodium element in the organic phase. The method makes the catalyst in the reaction be recycled repeatedly, and greatly reduces the precious metal rhodium The loss improves the catalytic efficiency and shortens the synthesis reaction time, and the method can not only produce farnesyl acetone, but also produce condensate intermediates.

Owner:能特科技(石首)有限公司

Method for recycling organic solvents of wastewater generated in synthesis of hydrazine hydrate by ketazine method

InactiveCN104086362AReduce pollutionIncrease added valueOrganic compound preparationOxygen compounds purification/separationAcetone productOrganosolv

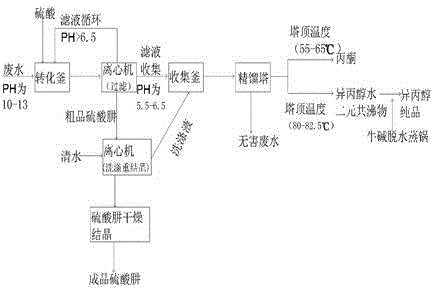

The invention relates to a method for extracting organic solvents and hydrazine sulfate from wastewater generated in synthesis of hydrazine hydrate by a ketazine method. The method comprises the following steps: converting, purifying hydrazine sulfate, rectifying and preparing isopropanol, wherein the step of conversion comprises the following steps: slowly dropping sulfuric acid into a hydrazine hydrate wastewater solution under the condition of 0-15 DEG C so as to precipitate and separate out hydrazine sulfate from the solution, and performing centrifugal filtration to obtain a crude hydrazine sulfate product; the step of purifying hydrazine sulfate comprises the following steps: filtering the crude hydrazine sulfate product, washing for 2-3 times by using cold water, and performing centrifugal filtration and drying crystallization so as to obtain a pure hydrazine sulfate product; the step of rectifying comprises the following steps: collecting filtrate and a washing liquid, feeding into a rectifying tower, rectifying when the tower top temperature is 55-56 DEG C so as to collect a pure acetone product, and rectifying when the tower top temperature is 80-82 DEG C so as to collect binary azeotrope of isopropanol-water; the step of preparing isopropanol comprises the following steps: dehydrating the binary azeotrope of isopropanol-water by using caustic soda flakes, and subsequently distilling, thereby obtaining a pure isopropanol product.

Owner:潍坊蓝海环境保护有限公司

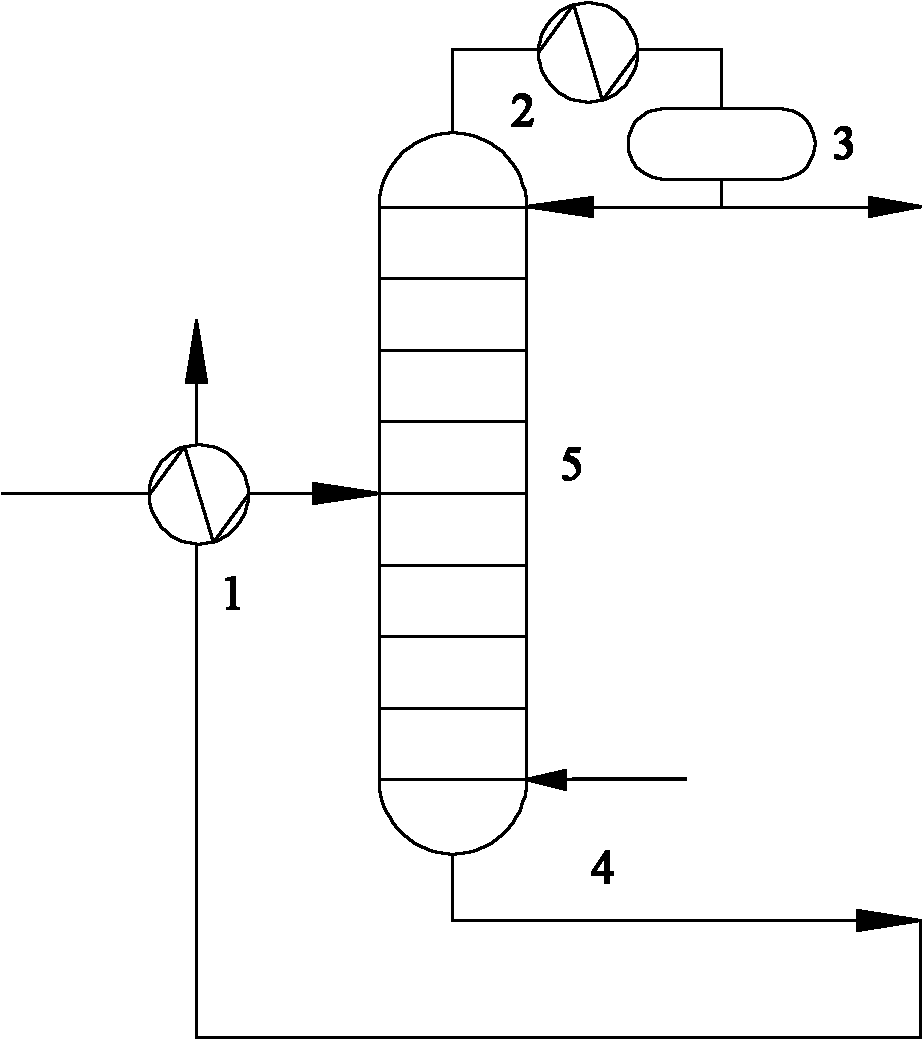

Method for recovering acetone from dilute acetone water solution by reduced-pressure steam stripping type rectification

ActiveCN102115436AReduce dosageReduced distillation operating costsCarbonyl compound separation/purificationRefluxAqueous acetone

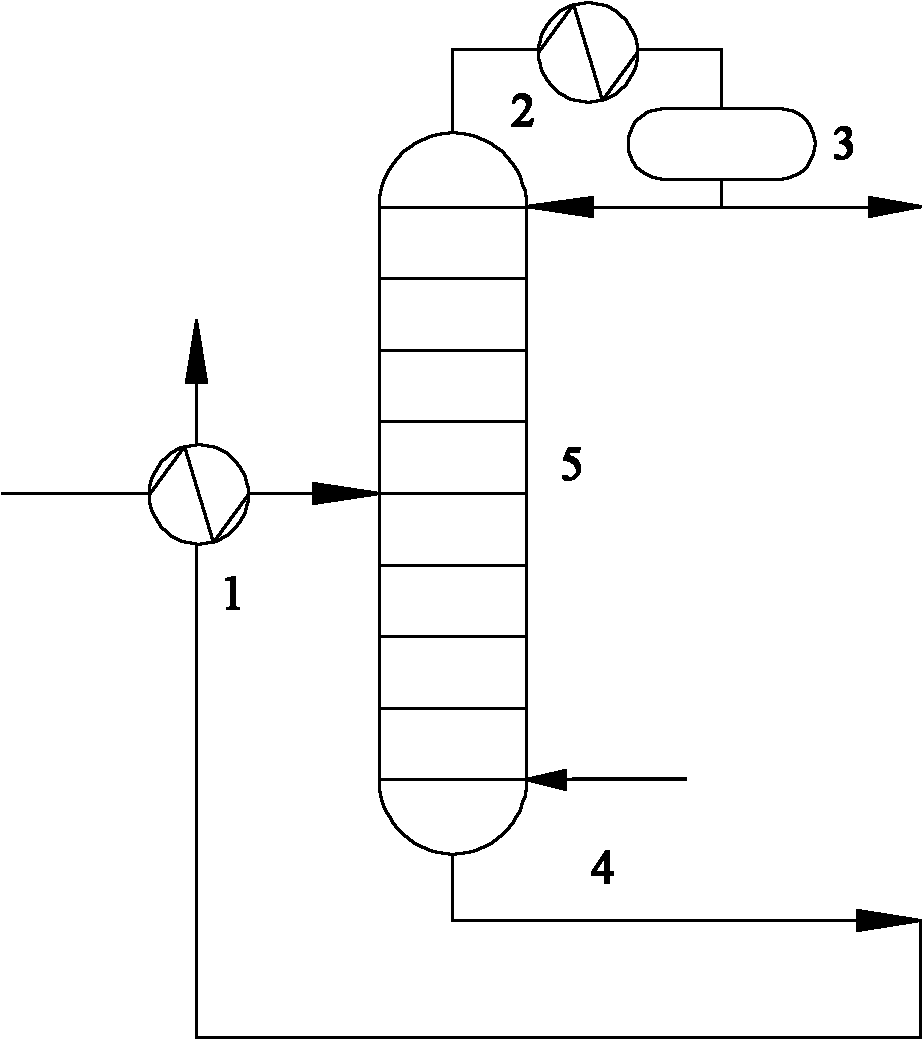

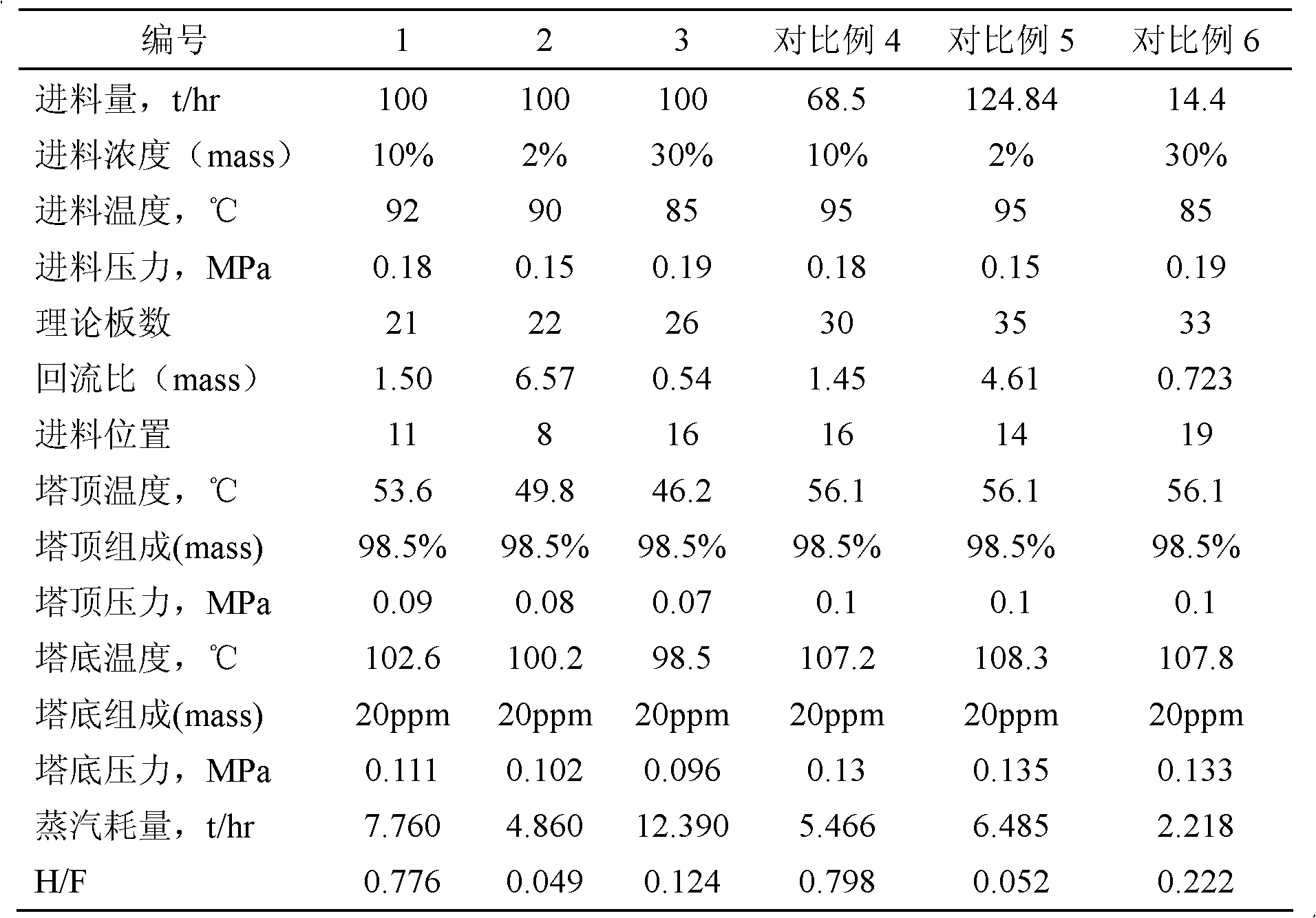

The invention discloses a method for recovering acetone from a dilute acetone water solution by reduced-pressure steam stripping type rectification, which comprises steps as follows: an acetone-containing dilute solution and a high-temperature kettle liquid discharged from a tower kettle in a rectifying tower exchange heat through a heat exchanger, and the acetone-containing dilute solution enters the rectifying tower among 8#-16# tower plates of the rectifying tower after the temperature reaches 85-95 DEG C; the operating pressure intensity of the tower top is 0.07-0.09 MPa; the operating pressure intensity of the tower kettle is 0.120-0.130 MPa; and after the tower top distillate of the rectifying tower is cooled to 40-55 DEG C by a condenser, part of the distillate is recovered as an acetone product, and part of the distillate is used as reflux, wherein the reflux ratio of reflux mass to product mass is controlled within (0.5-6.6):1. The invention decreases the consumption of cooling water for steam on the top of the condensing tower as well as the consumption of tower bottom steam for heating, thereby lowering the operating cost for rectification. The invention has the characteristics of high accuracy, high sensitivity, high speed, convenience and the like, and can be easily implemented in industry.

Owner:ZHUHAI CELLULOSE FIBERS CO LTD

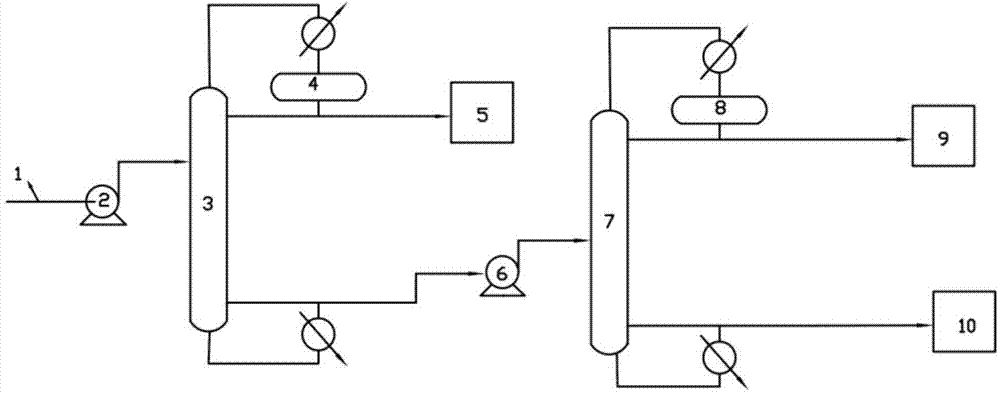

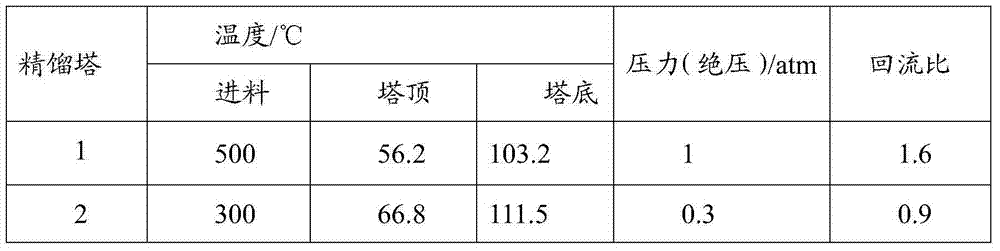

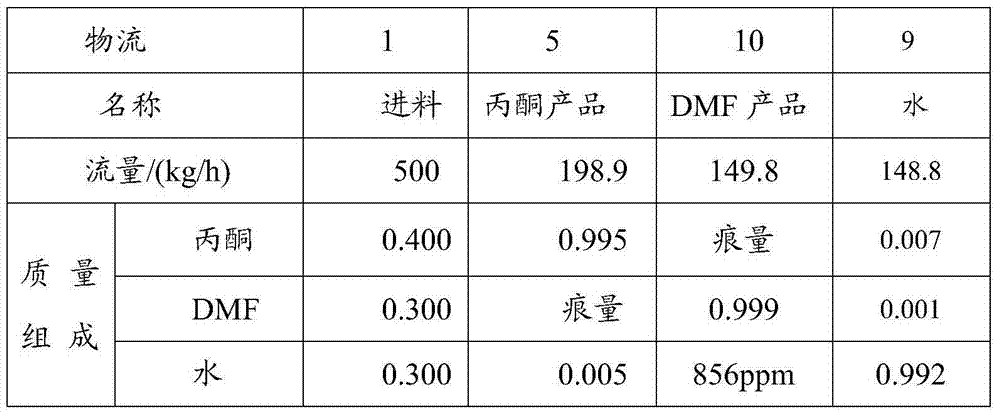

Method for separating acetone/DMF/water ternary system by rectifying through high- and low- pressure towers

ActiveCN104844433AAvoid introducingEfficient separationCarboxylic acid amide separation/purificationCarbonyl compound separation/purificationAcetone productEngineering

The invention relates to a rectifying device for separating an acetone / DMF / water ternary system by two towers and a method for separating the acetone / DMF / water ternary system by rectifying by using the device. The rectifying device mainly comprises a normal pressure tower, a reduced pressure tower, a pump, a return tank, a heat exchanger and the like. The rectifying and separating method comprises the following steps: feeding an acetone / DMF / water mixed solution into the normal pressure tower for primary rectification; extracting an acetone product from the tower top; and conveying a tower bottom material to the reduced pressure tower for secondary rectification; after a tower top steam material flow of the reduced pressure tower is condensed, returning part of materials to the reduced pressure tower; extracting water from the tower top; and extracting a DMF product from the tower bottom. By adopting the method provided by the invention, the cost of separating the acetone / DMF / water ternary system is lowered; the product purity and yield are improved; and the method is simple in process and feasible to operate, and can be applied to separating similar ternary systems.

Owner:高密市长丰化工有限公司

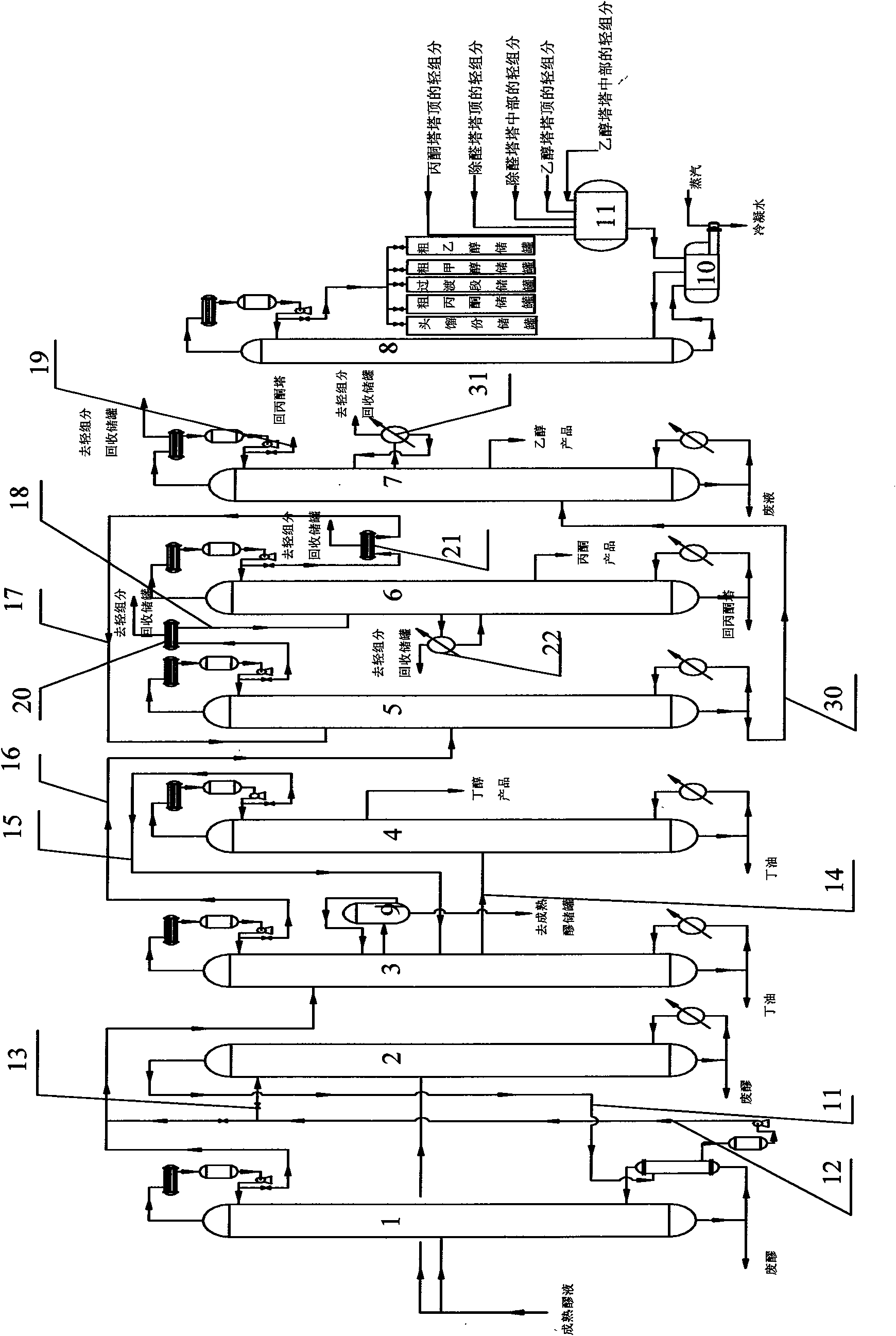

Separating and purifying method of butyl alcohol, acetone and total ethanol dissolvent in corn fermentation mash and device thereof

ActiveCN101550064ASolve quality problemsEfficient use ofOrganic compound preparationHydroxy compound separation/purificationAcetone productSolvent

The present invention discloses a separating and purifying method of butyl alcohol, acetone and ethanol dissolvent in corn fermentation mash. The corn mash is added into crude mash rectifying towers A and B. The material collected from the rectifying towers A and B is sent to a butyl alcohol rectifying tower 1. The second liquid part and third liquid part collected from the rectifying tower 1 is sent to an acetone rectifying tower. The material is collected from the rectifying tower 1 and is sent to the rectifying tower 2 purifying. The butyl alcohol product collected from the rectifying tower 2 and the liquid-phase material collected from the tower top of acetone rectifying tower is sent to an aldehyde eliminating rectifying tower. The material collected from the tower base is sent to an ethanol rectifying tower. The liquid-phase material collected from the tower top of eldehyde eliminating rectifying tower is sent to the acetone rectifying tower. The acetone product is collected from the aldehyde eliminating rectifying tower. The collected material of eldehyde eliminating rectifying tower is sent to the eldehyde eliminating rectifying tower. One part of material collected from the tower top of ethanol rectifying tower is sent to the lower segment of acetone rectifying tower. The light component is recycled in a light component recycling storage tank. The method of the invention increases the separation efficiency and reduces the energy consumption.

Owner:TIANJIN UNIV

Method for purifying acetone

InactiveCN103274914AEfficient removalSafe and easy purification processCarbonyl compound separation/purificationChemical industryPurification methods

The invention discloses a method for purifying acetone. According to the method provided by the invention, industrial-grade acetone is used as a raw material, a silver nitrate solution and a sodium hydroxide solution are added into the industrial-grade acetone in sequence, acetone is separated after uniformly shaking, a purified composition is added, regurgitation is performed to enable the acetone to be purple without color fading, anhydrous calcium sulfate is added for drying, and finally a precise distillation method is used to collect, and fraction is performed at the temperature of 55-56.5 DEG C to obtain purified acetone. By adopting the method, the purity of the obtained acetone is more than 99.5%. Compared with the prior art, the method is safe, simple and convenient in the purification process, can save energy and reduce emission, and can meet requirements on green chemical industry and environmental protection; and the acetone obtained by the method is stable in product quality and high in purity, and has an industrial production prospect.

Owner:TAICANG HUSHI REAGENT

Acetone-generating method for treating furfural wastewater

InactiveCN105198716AReduce governance costsReduce pollutionOrganic compound preparationCarbonyl compound preparationAcetone productEvaporation

The invention discloses an acetone-generating method for treating furfural wastewater. The method includes the steps that 1, antalkalies are added into the furfural wastewater, and a neutral reaction is carried out to generate calcium acetate, wherein blocky or granular or powdery limestone or lime is added into the furfural wastewater to neutralize acetic acid in the furfural wastewater, the limestone or the lime is reacted with the acetic acid to generate the calcium acetate, the pH value of the waste liquid with the low-concentration calcium acetate is measured, and limestone or lime is added till the pH value ranges from 7 to 8; 2, the calcium acetate is separated, wherein the waste liquid with the low-concentration calcium acetate is heated through waste heat of aldehyde gas generated in the furfural production process, double-effect evaporation is carried out, the waste liquid is evaporated and concentrated, when the content of the calcium acetate in the waste liquid ranges from 30% to 40%, separating and dewatering are carried out through a centrifugal machine or dewatering is carried out through a plate-and-frame filter press, the crystallized calcium acetate is separated, and waste mother liquid is remixed with the neutralized furfural waste liquid; 3, the calcium acetate is thermally decomposed to obtain acetone, wherein the obtained calcium acetate is thermally decomposed in a closed device, the decomposing temperature ranges from 140 DEG C to 160 DEG C, the decomposing products are calcium carbonate and the acetone, the gas acetone is condensed to the temperature lower than 56 DEG C through a condenser, and a liquid acetone product is obtained.

Owner:高嵩

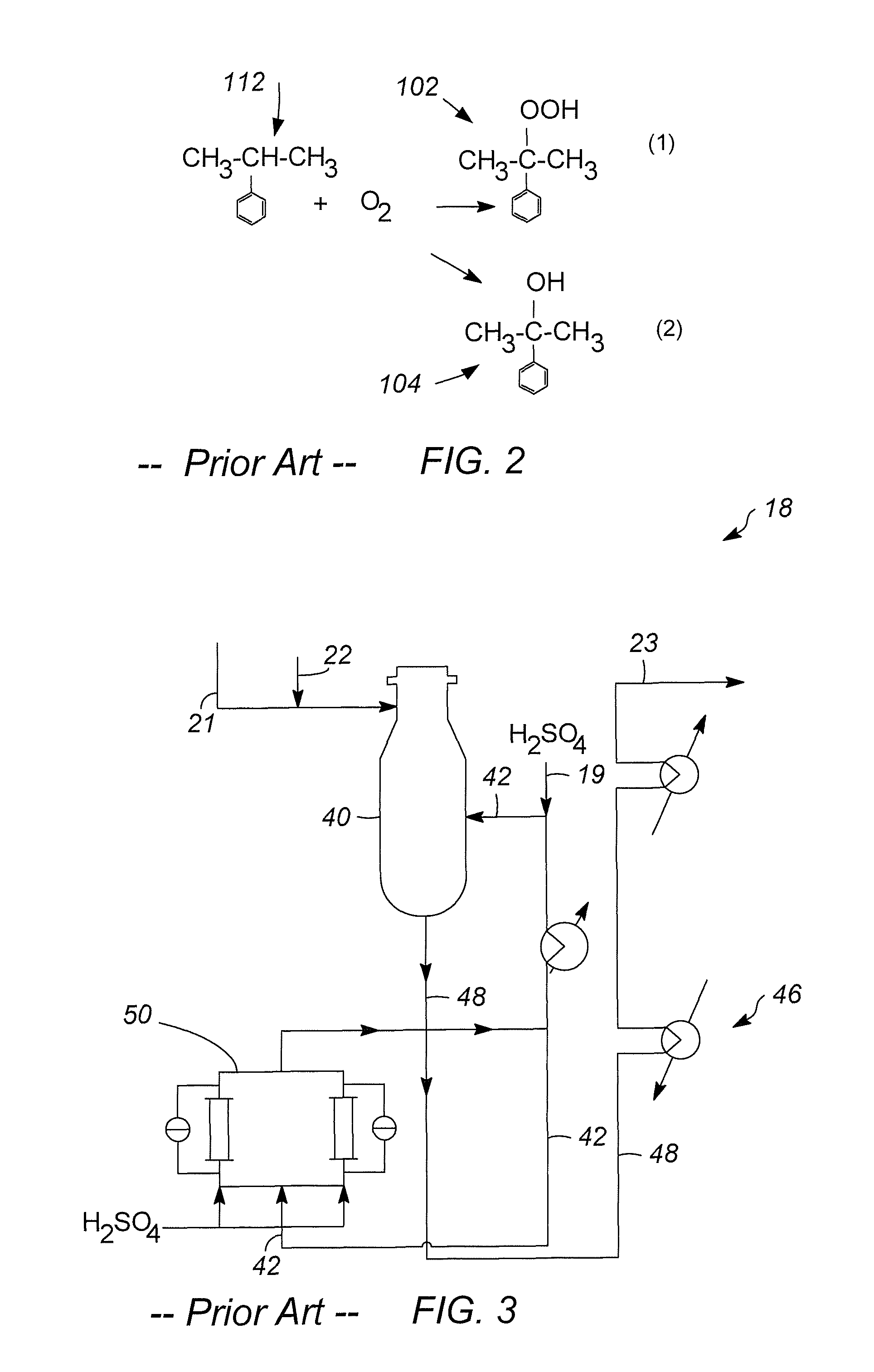

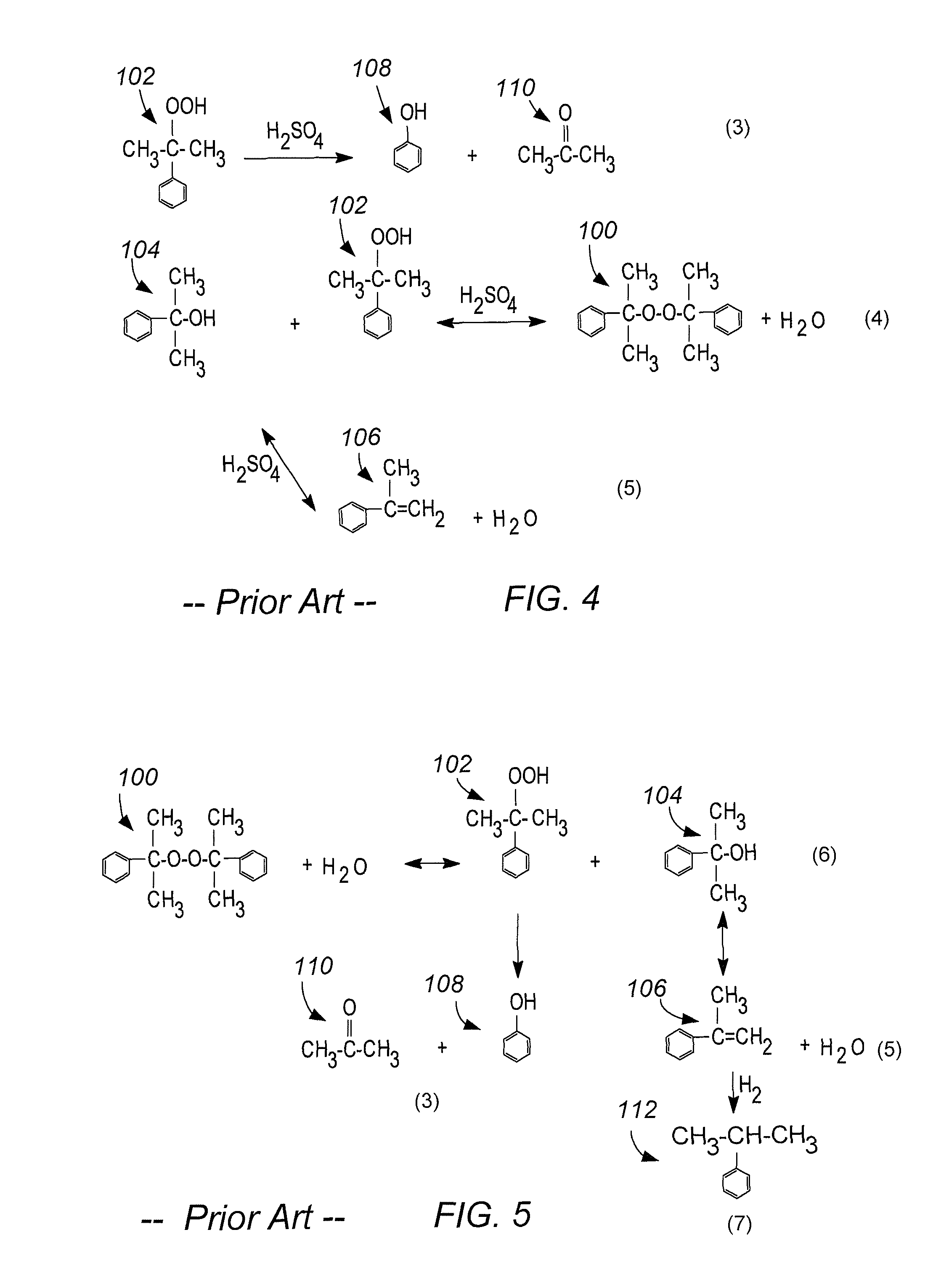

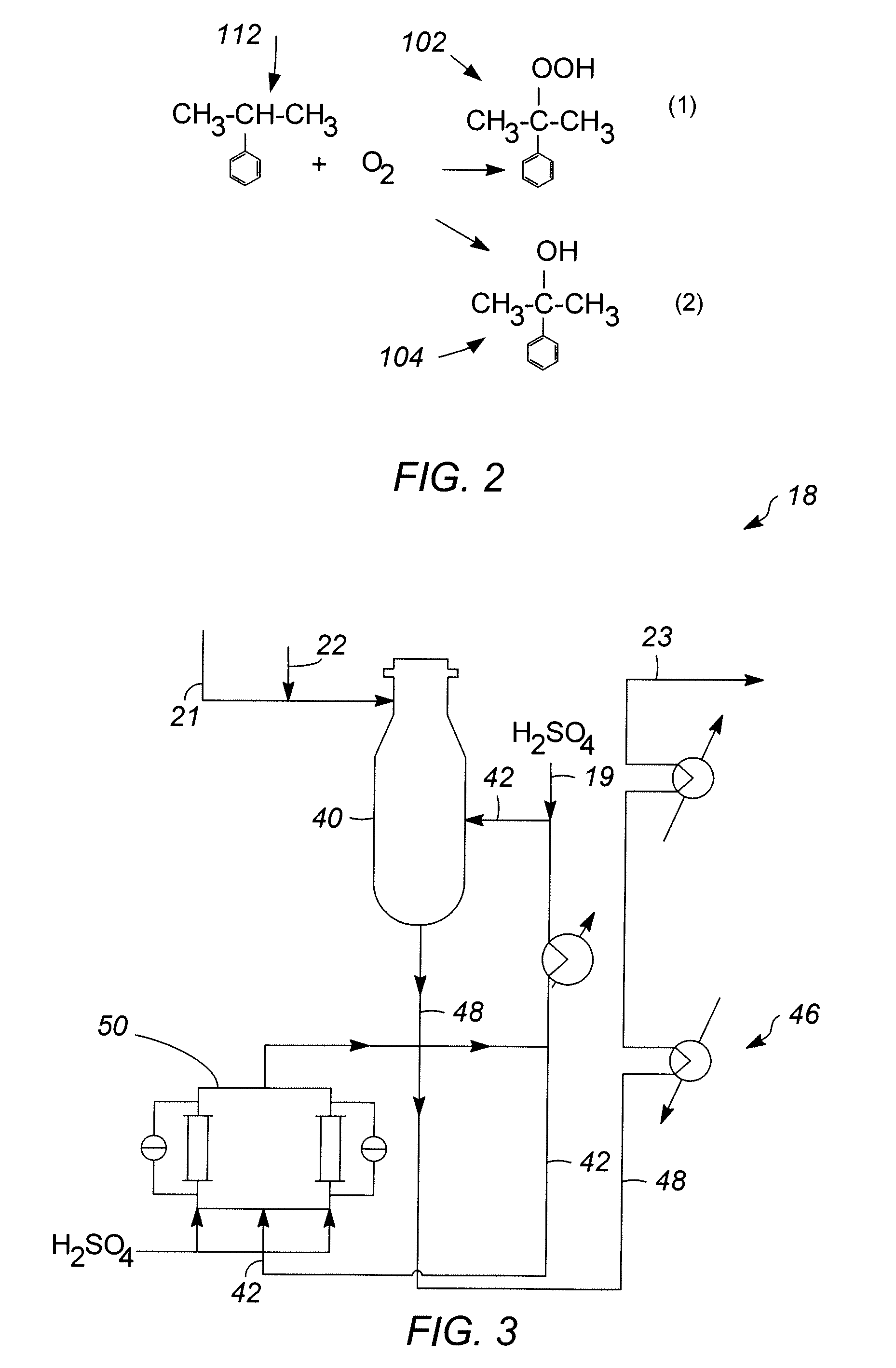

Solid acid catalyst and process for decomposition of cumene hydroperoxide

The present invention provides a process for decomposing a cumene hydroperoxide to produce phenol and acetone. The process utilizes a solid catalyst that can be non-layered or layered. The process includes: (1) introducing a process stream containing cumene hydroperoxide into a reaction vessel; (2) contacting the process stream with catalyst particles to form a process stream; and (3) withdrawing a portion of the product stream from the reactor and recovering phenol and acetone products.

Owner:UOP LLC

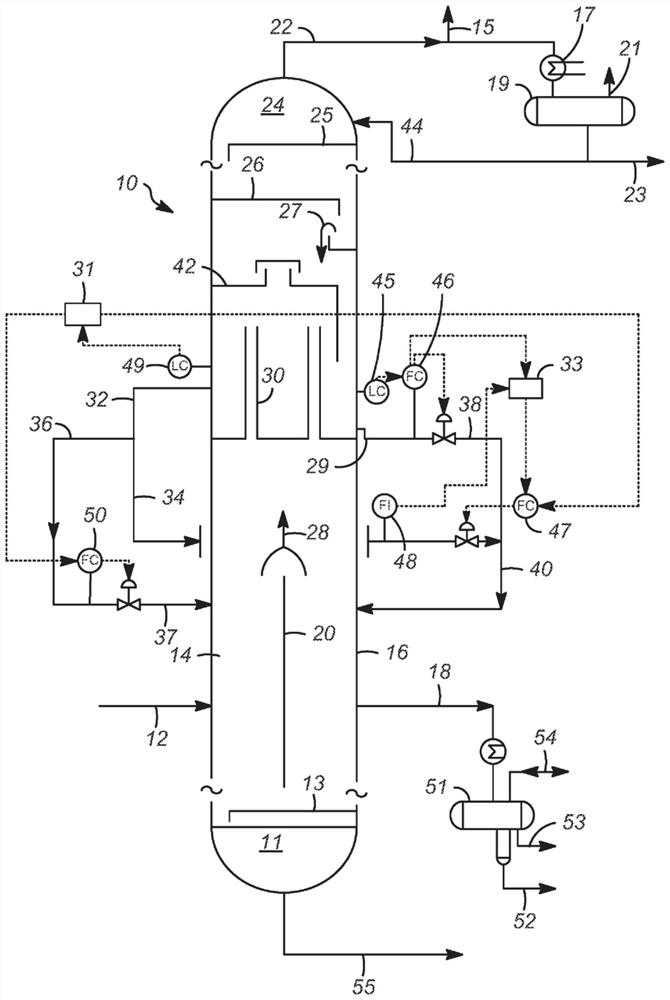

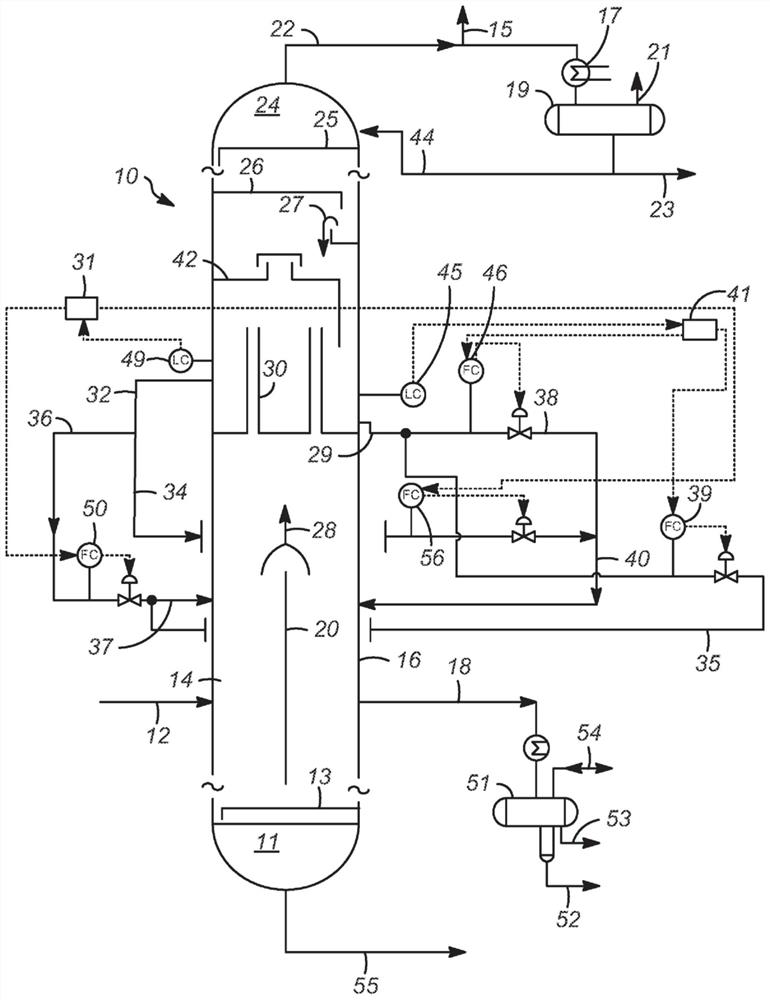

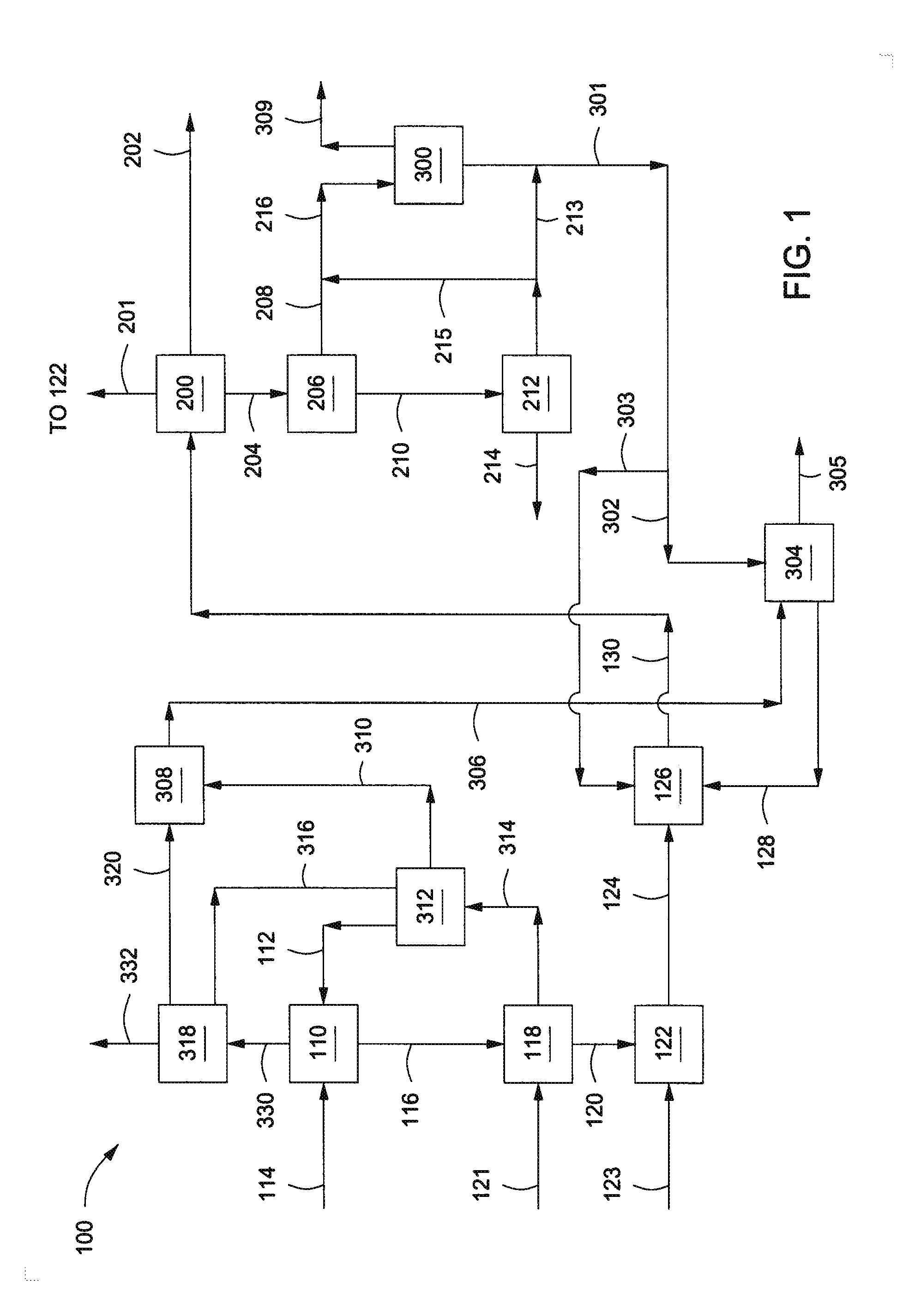

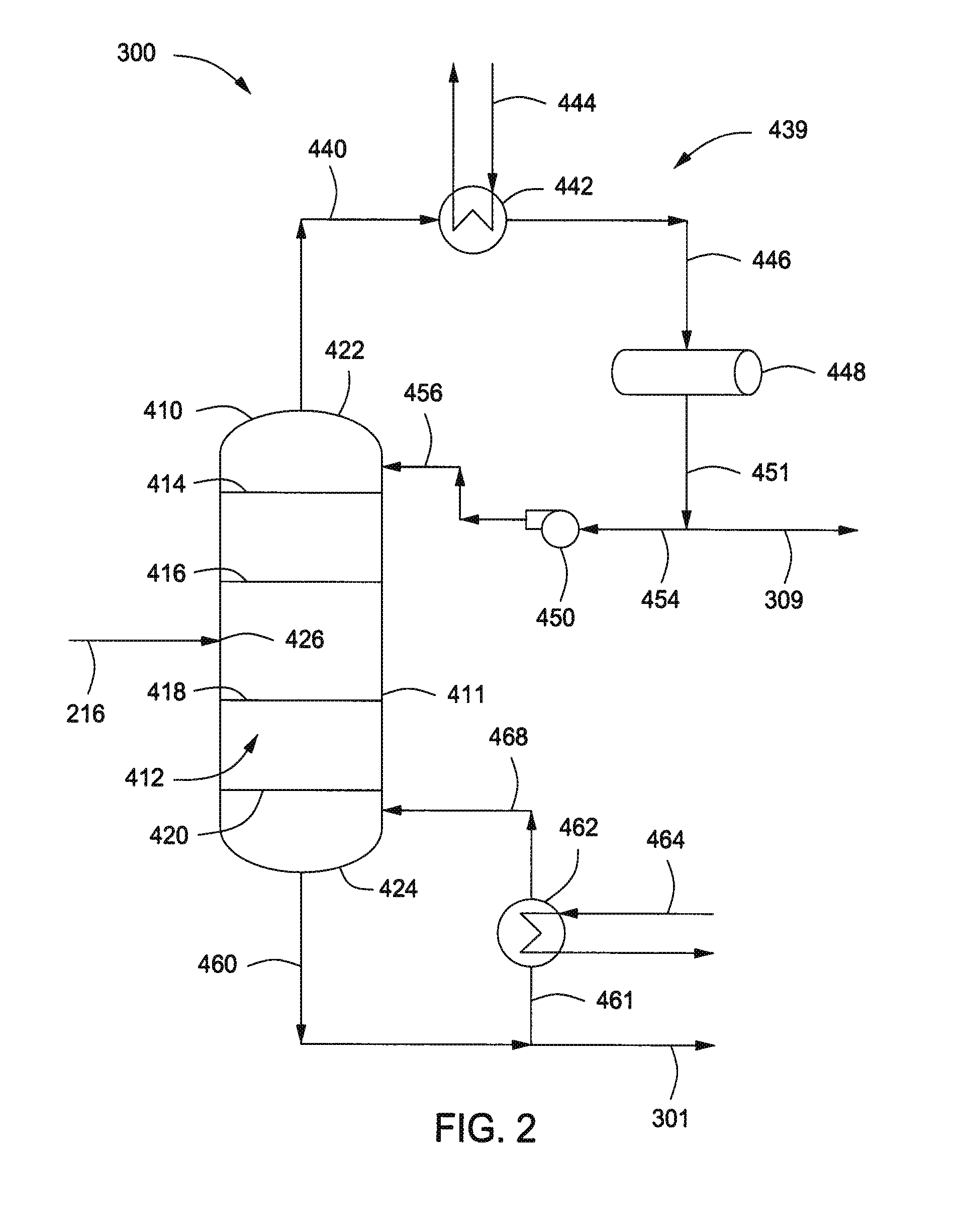

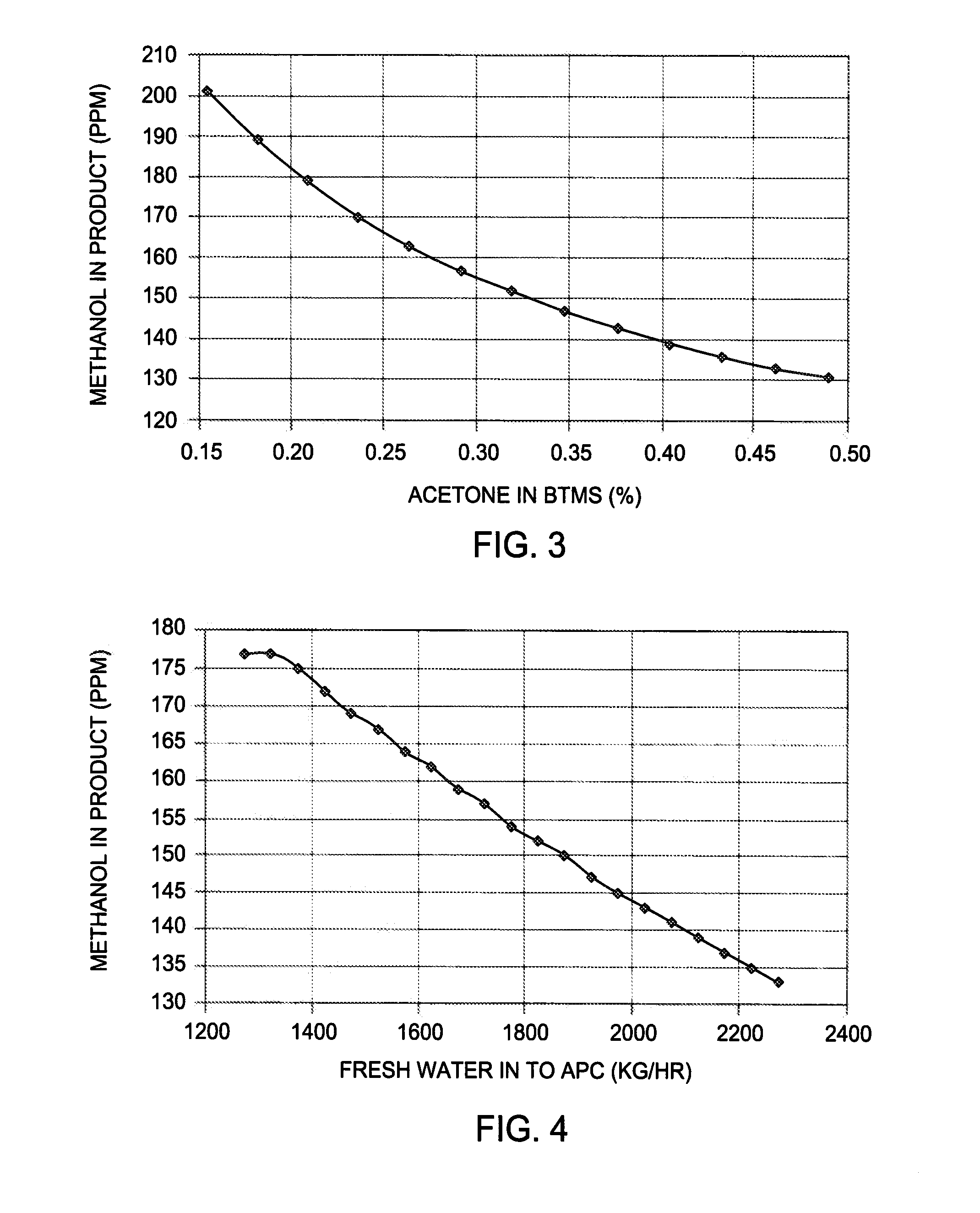

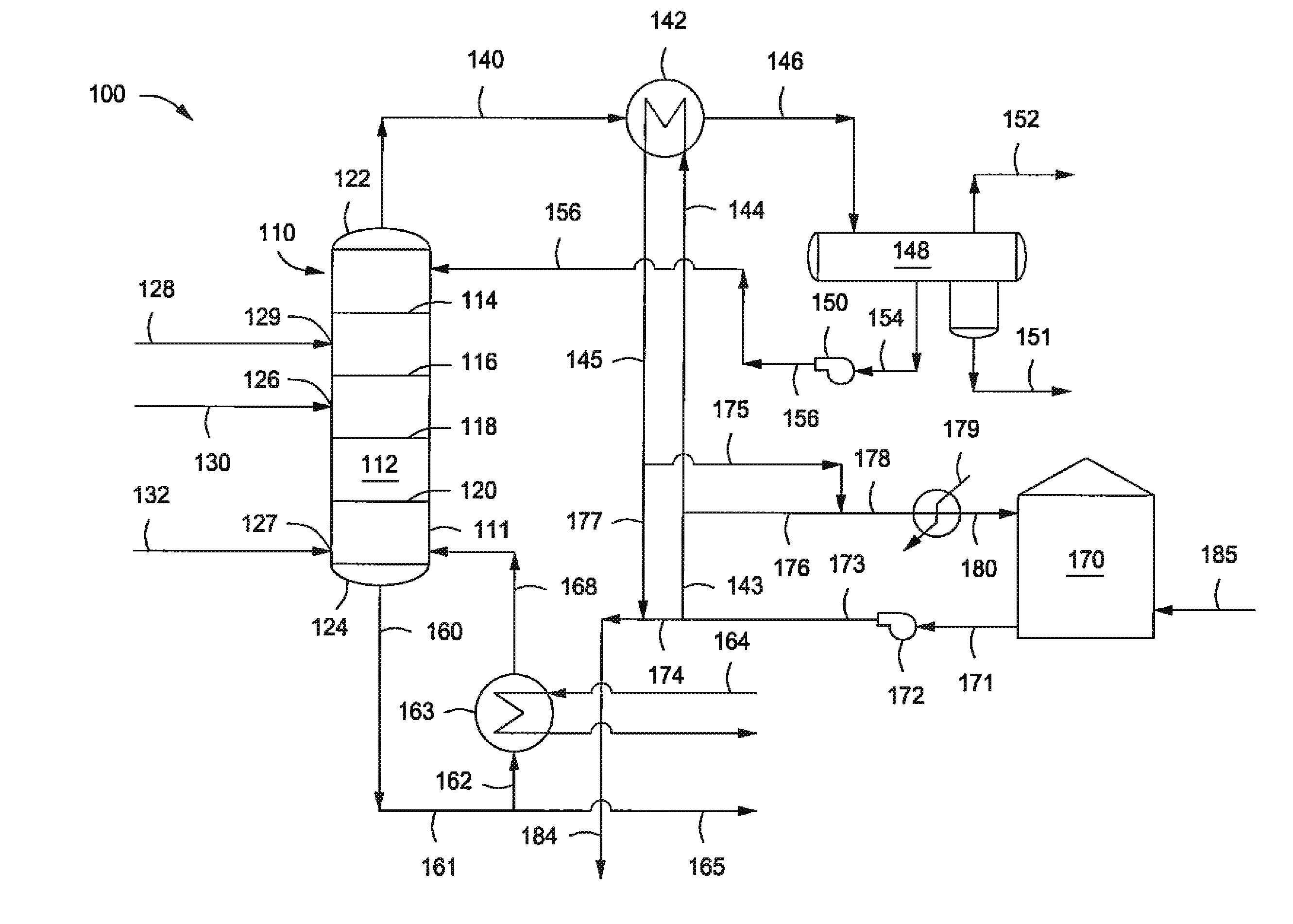

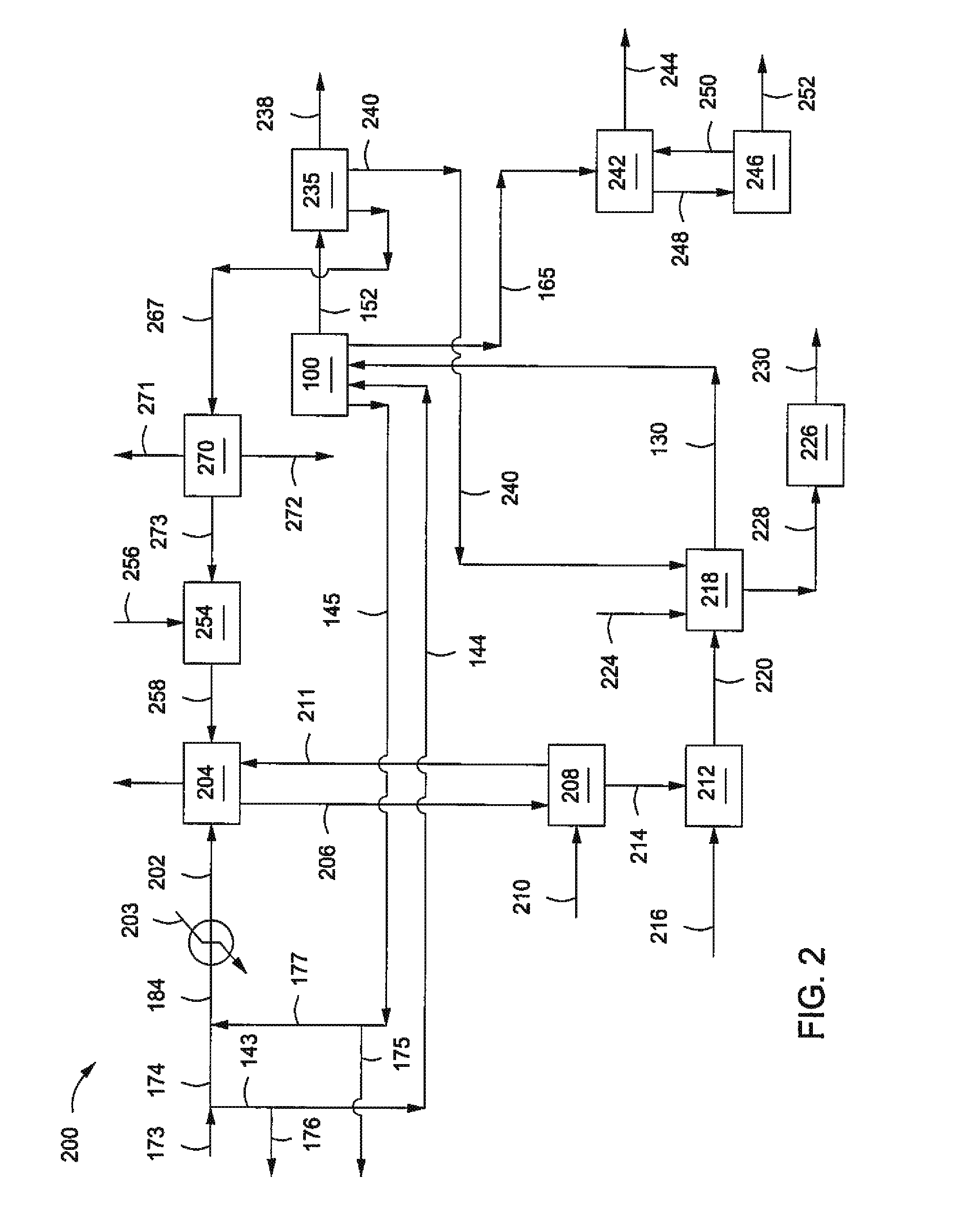

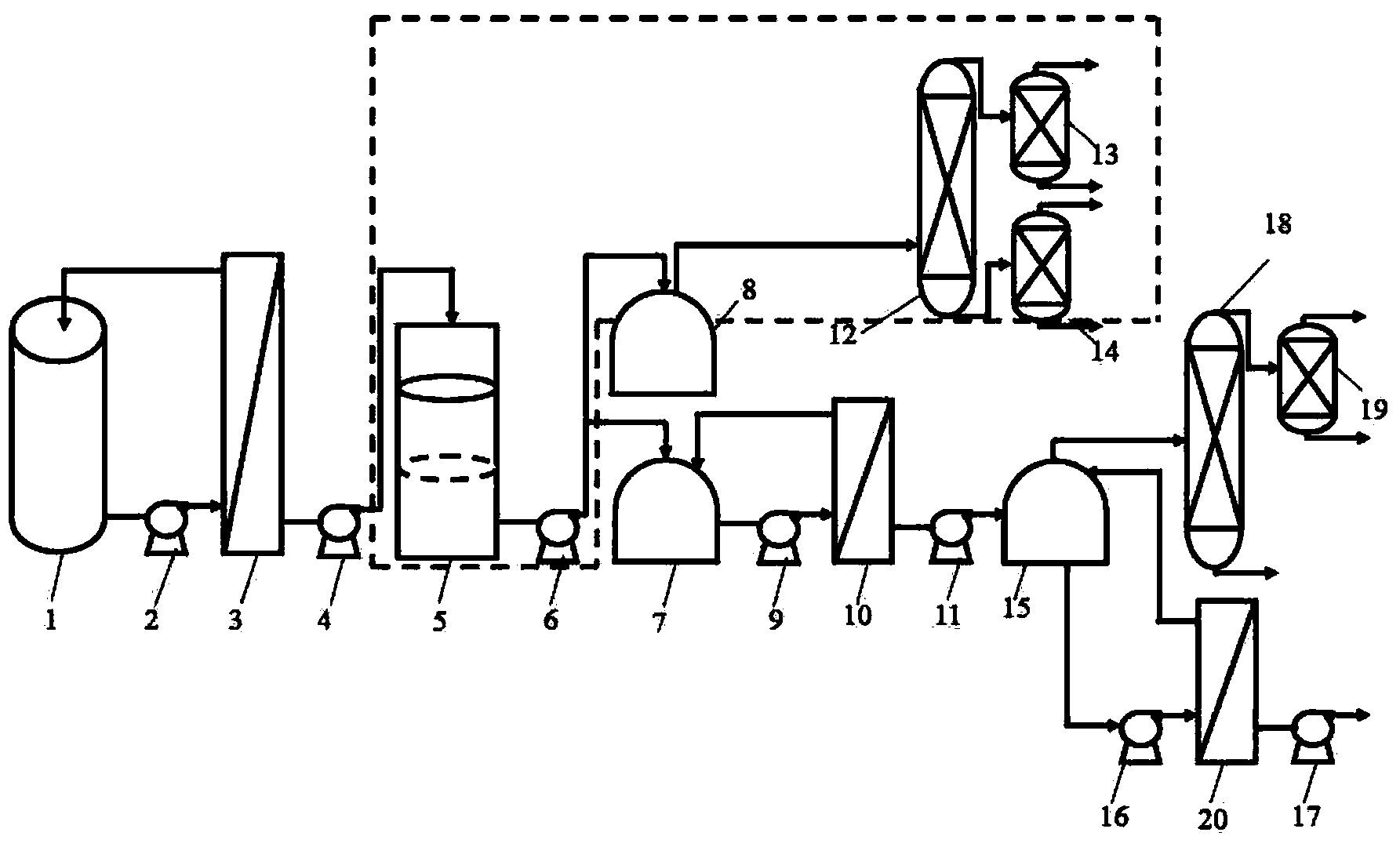

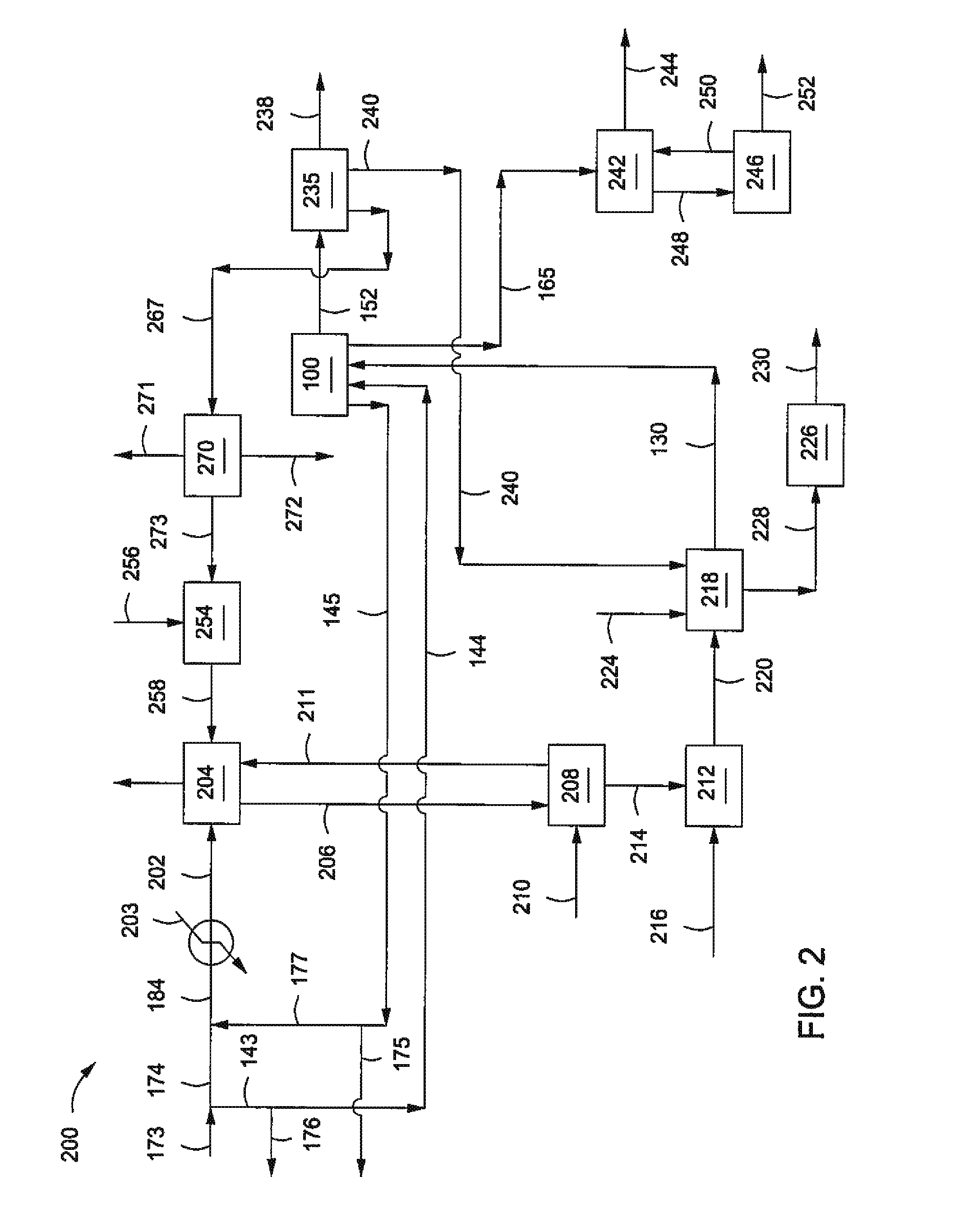

Methods and systems for co-producing a low-methanol content acetone

ActiveUS20130072723A1Organic compound preparationChemical/physical/physico-chemical processesAcetone productFractionation

Methods and systems for producing low methanol concentration acetone are provided. The method can include oxidizing and cleaving cumene to produce a crude acetone product. The crude acetone product can be neutralized in a neutralization unit to produce a neutralized crude acetone product. The neutralized crude acetone product can be fractionated in an acetone fractionation column to produce an acetone product and an acetone bottoms product. Methanol can be removed from the acetone bottoms product to produce a methanol-depleted product. The methanol-depleted product can be introduced to the neutralization unit, a dephenolation unit, or both.

Owner:KELLOGG BROWN & ROOT LLC

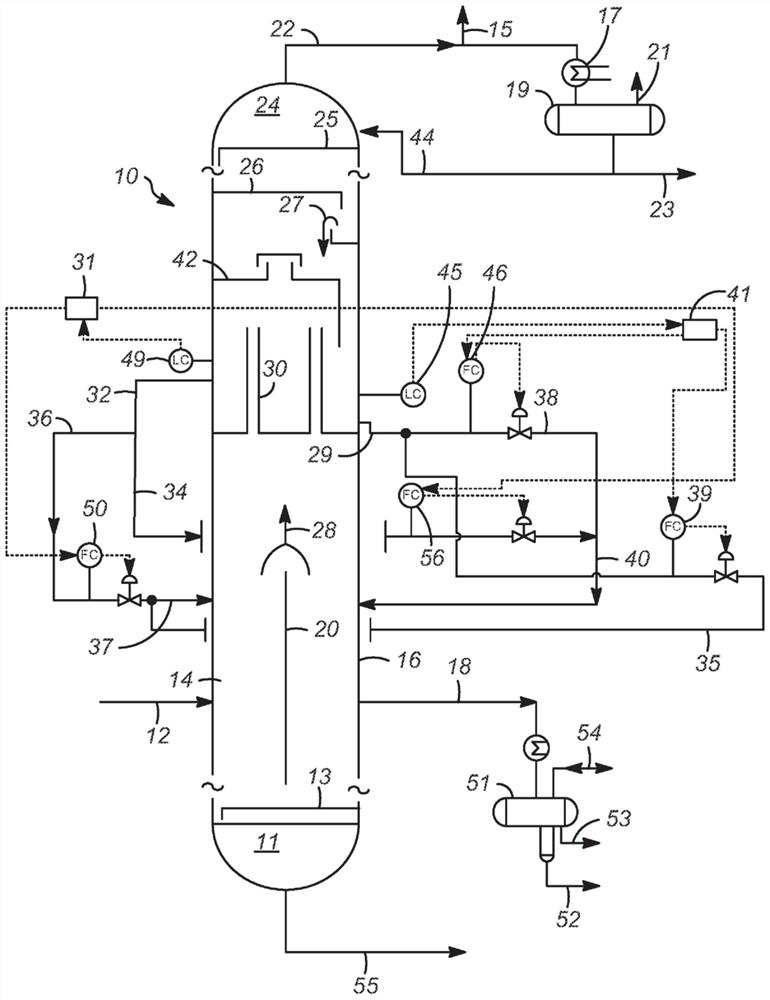

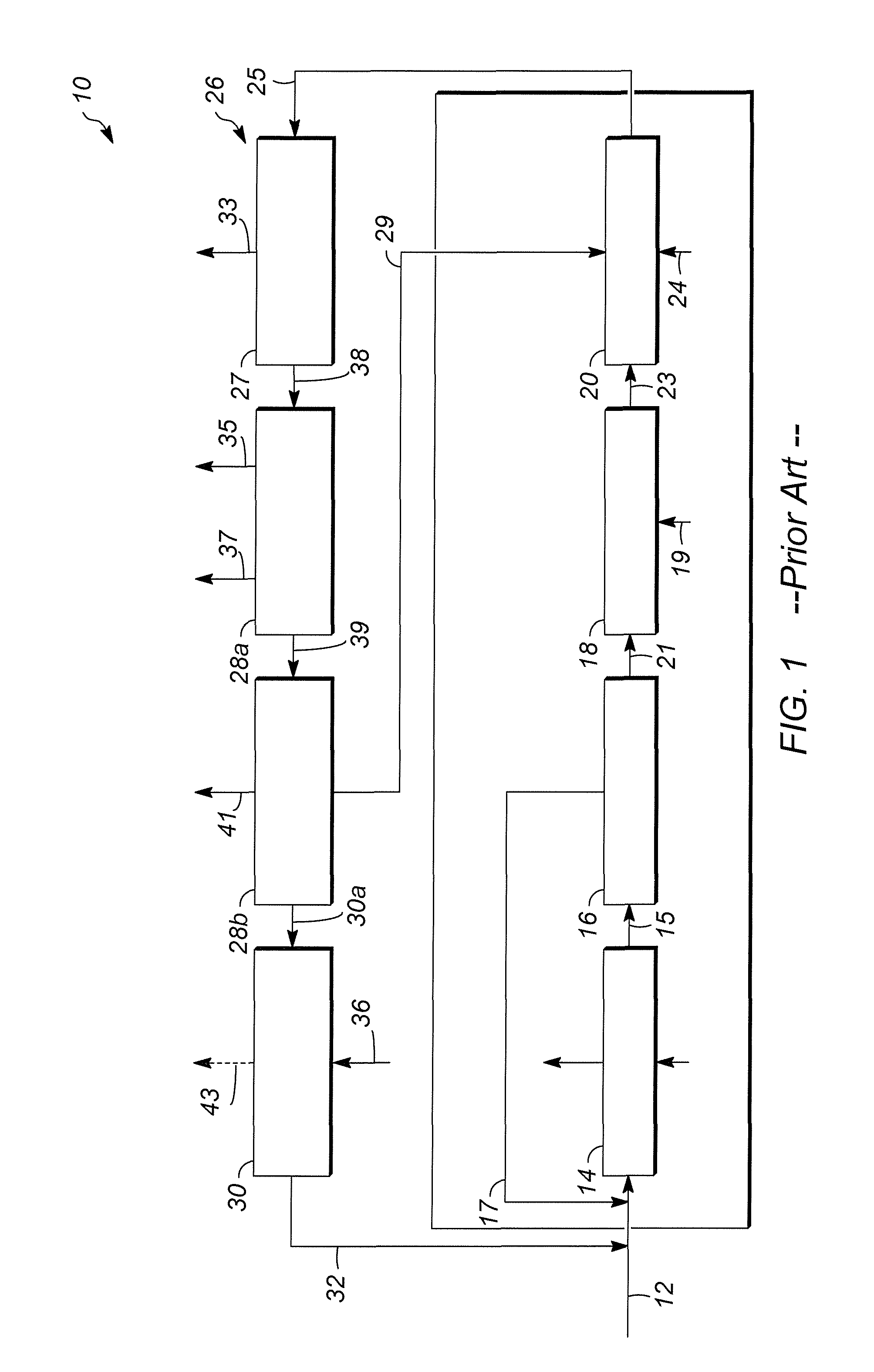

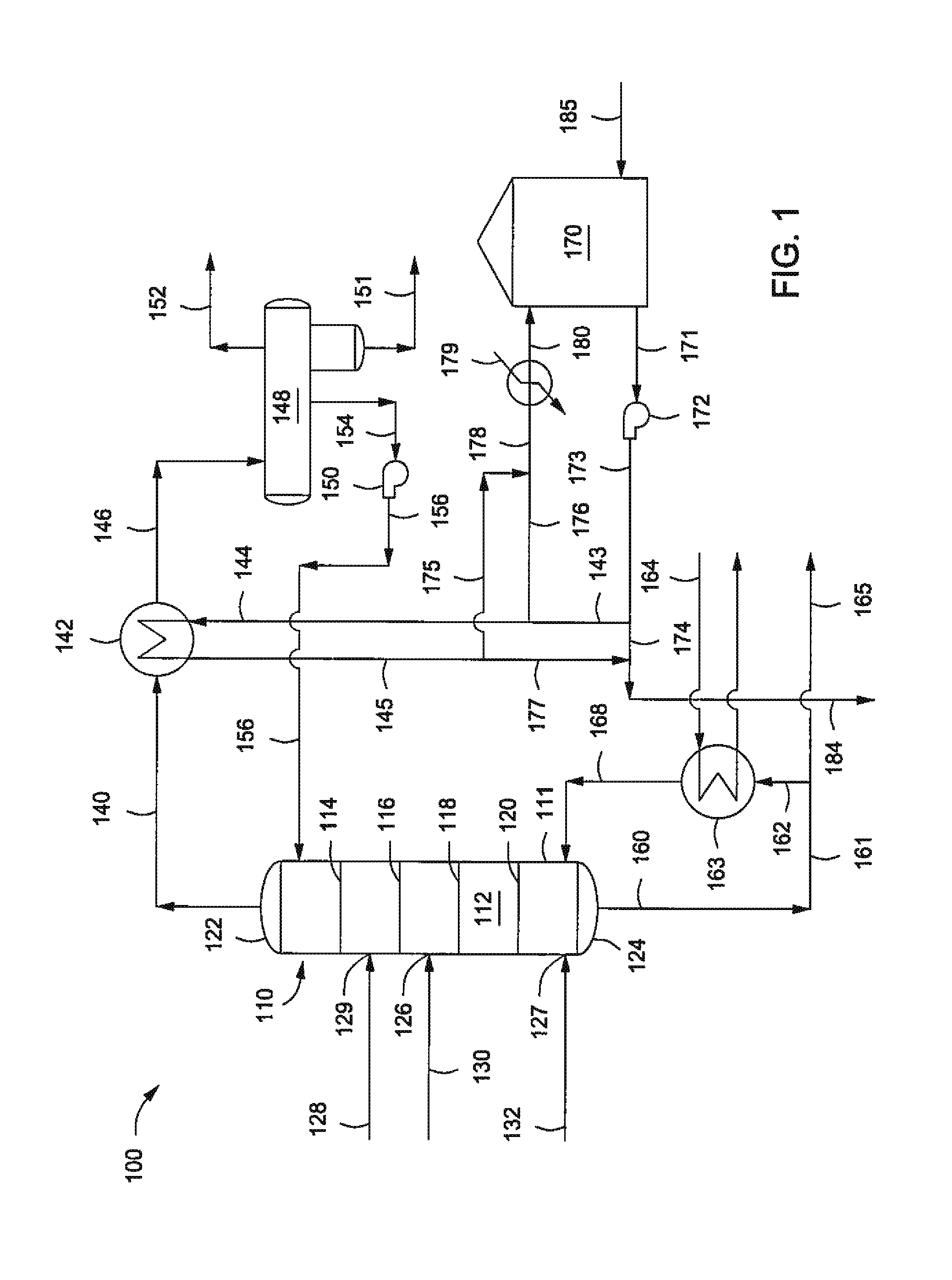

Methods And Systems For Separating Acetone And Phenol From One Another

ActiveUS20140275630A1Organic compound preparationDistillation purification/separationFractionationAcetone product

Systems and methods for improving crude acetone column energy efficiency and operation are provided. The method for improving crude acetone column energy efficiency and operation can include introducing a crude acetone including acetone and phenol to a fractionation column and introducing cumene, AMS, or a combination thereof to the fractionation column. The method can include fractionating the crude acetone within the fractionation column to produce an acetone containing overhead and a phenol containing bottoms. The method can also include condensing at least a portion of the acetone containing overhead indirectly with a cool heat transfer medium to provide a condensed crude acetone product and a heated heat transfer medium, wherein the heat transfer medium includes cumene.

Owner:KELLOGG BROWN & ROOT LLC

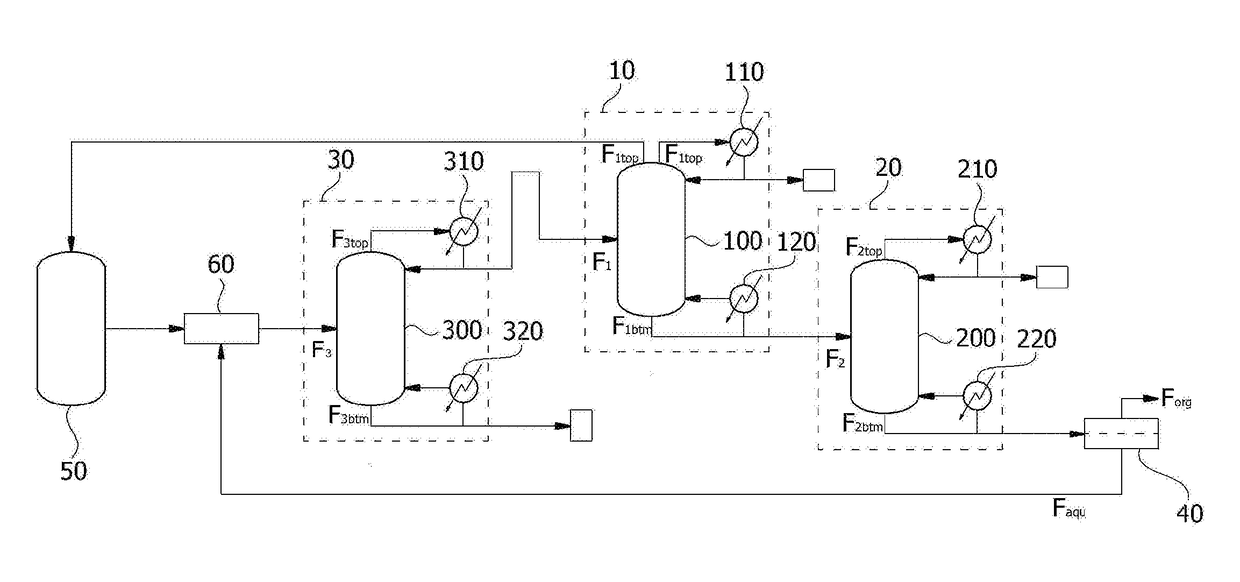

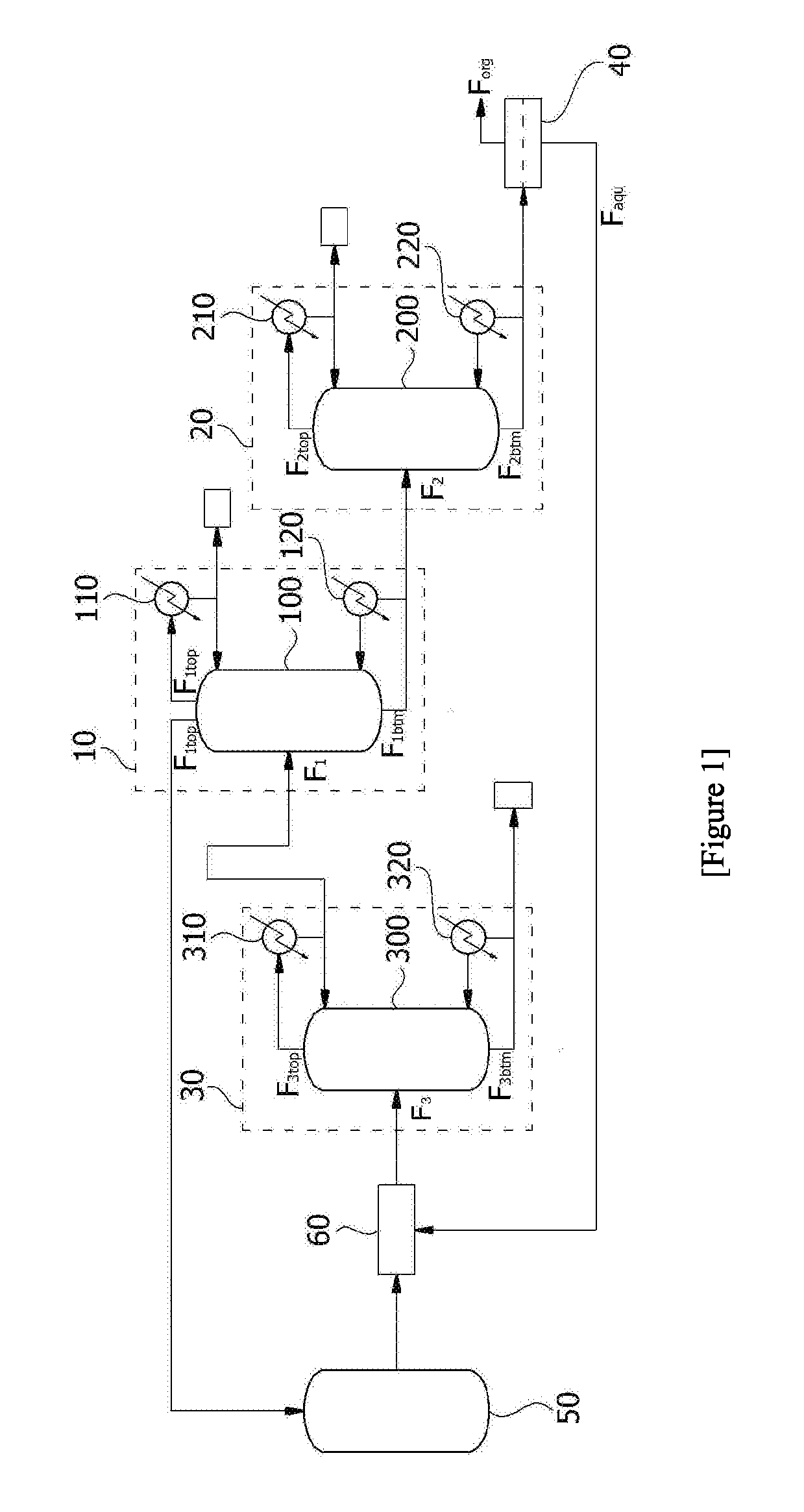

Distillation device

ActiveUS10486080B2Reduce Methanol ContentExtended service lifeOrganic compound preparationCarbonyl compound separation/purificationAcetone productFractionating column

Owner:LG CHEM LTD

Solid Acid Catalyst and Process for Decomposition of Cumene Hydroperoxide

ActiveUS20080188694A1Molecular sieve catalystsOrganic compound preparationDecompositionAcetone product

The present invention provides a process for decomposing a cumene hydroperoxide to produce phenol and acetone. The process utilizes a solid catalyst that can be non-layered or layered. The process includes: (1) introducing a process stream containing cumene hydroperoxide into a reaction vessel; (2) contacting the process stream with catalyst particles to form a process stream; and (3) withdrawing a portion of the product stream from the reactor and recovering phenol and acetone products.

Owner:UOP LLC

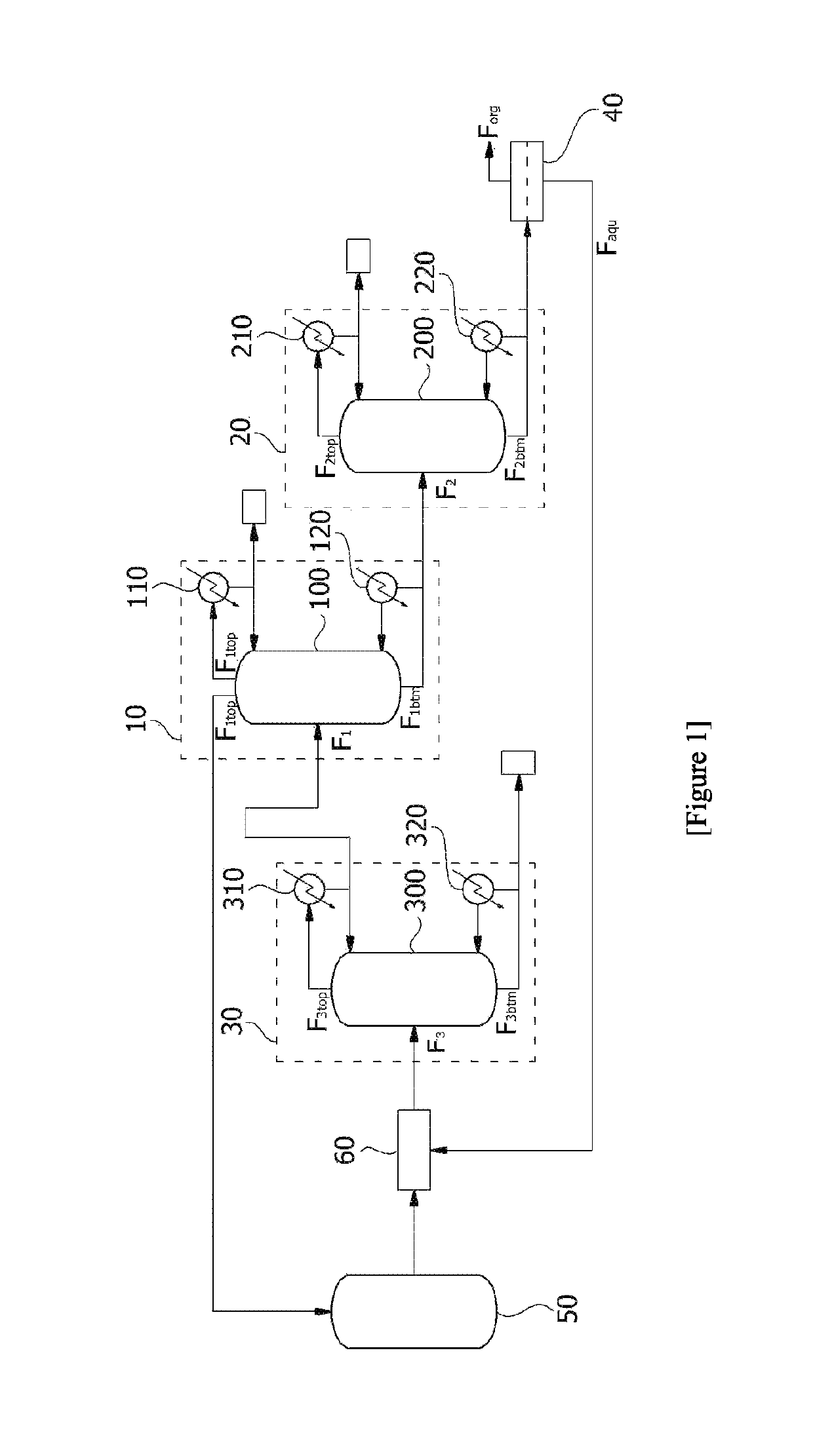

Method for separating acetone-butanol-alcohol fermenting liquid by utilizing pervaporation-rectification coupling

ActiveCN103772144AImprove conversion rateIncrease production capacityOrganic compound preparationBiofuelsHigh concentrationAcetone product

The invention discloses a method for separating an acetone-butanol-alcohol fermenting liquid by utilizing pervaporation-rectification coupling. The method comprises the following steps: coupling acetone, butanol and alcohol for fermentation by pervaporation alcohol-permeating films, and utilizing pervaporation alcohol-permeating films to increase the concentrations of the acetone, the butanol and the alcohol in the fermentation liquid so as to realize separation of acetone / butanol / alcohol water solution and form a high-concentration organic phase and a low-concentration water phase. The organic phase is treated by directly utilizing multi-stage rectifying operation to obtain an acetone product, a butanol product and an alcohol product with the concentrations being more than 99wt%. The water phase is treated by carrying out separation through a secondary pervaporation alcohol-permeating film and a primary pervaporation alcohol-permeating film and carrying out multi-stage rectifying operation so as to obtain the acetone product, the butanol product and the alcohol product with the concentrations being more than 99wt% finally. The method disclosed by the invention has the advantages that the inhibiting action of the butanol in the fermentation process can be reduced, and the productivity can be improved; and the high-concentration organic phase is obtained by utilizing phase separation of a permeating liquid and carrying out primary pervaporation; and simultaneously, the azeotrope formed by butanol and water is avoided, the energy consumption for production and separation is saved, and the production cost in the fermentation process of the acetone and the butanol is greatly reduced.

Owner:NANJING UNIV OF TECH

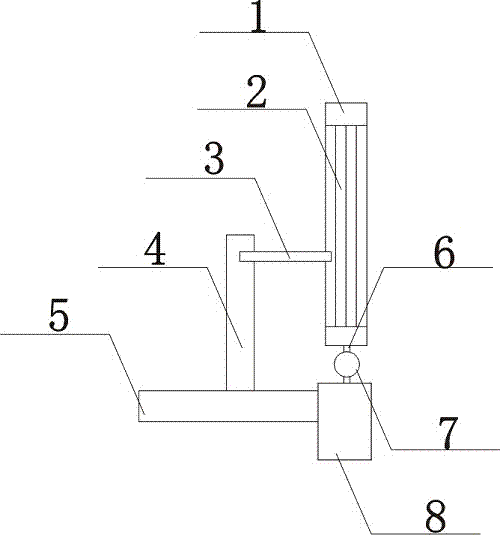

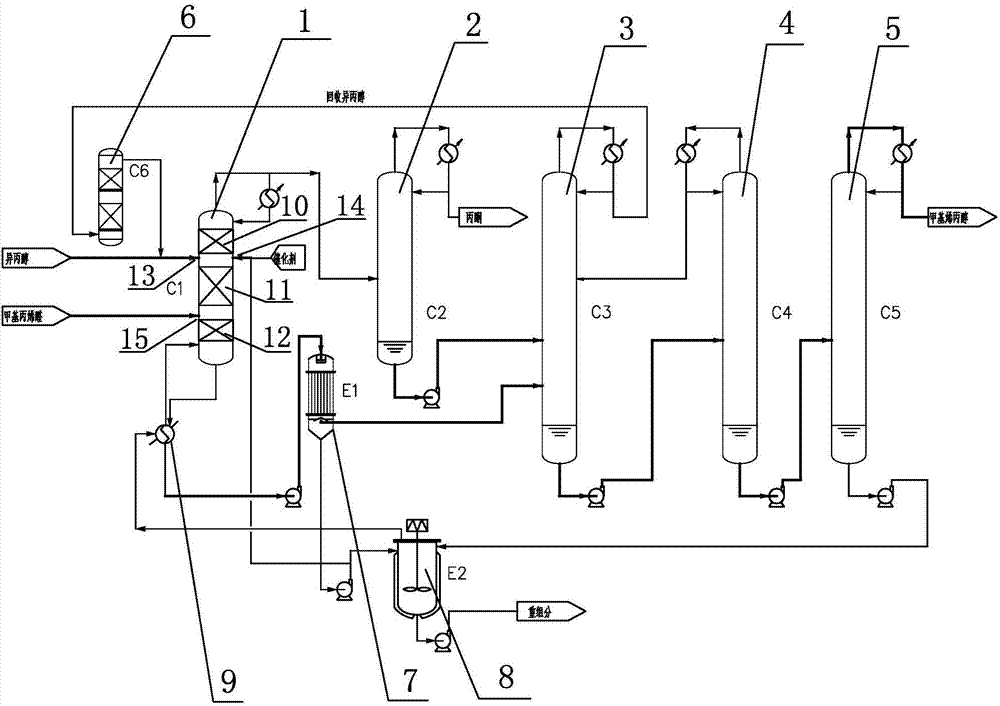

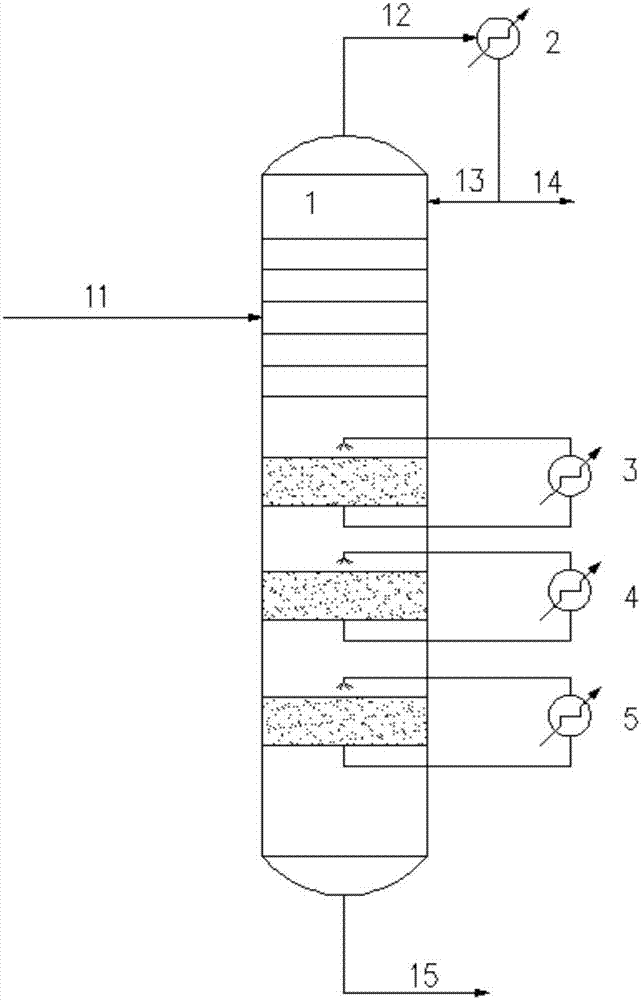

Production system and method for methylallyl alcohol

ActiveCN107365245ASeparation in timePromote positive progressOrganic compound preparationPreparation by dehydrogenationMolecular sieveGas phase

The invention discloses a production system and method for methylallyl alcohol. The production system is characterized by comprising a reactive distillation tower, an acetone product tower, an isopropanol recovery tower, a methylallyl alcohol light-component removing tower, a methylallyl alcohol product tower, a molecular sieve dehydration tower, a falling-film evaporator and a film evaporator. The refining method comprises the following steps: feeding each raw material into the reactive distillation tower, conveying a gas phase generated after a reaction into an acetone separation tower, and conveying a liquid phase to the falling-film evaporator; conveying a gas phase obtained after separation by the acetone separation tower into the acetone product tower, and returning a material at the bottom of the acetone separation tower to the reactive distillation tower; collecting acetone at the top of the acetone product tower, and conveying a material at the bottom of the acetone product tower to the isopropanol recovery tower; returning circulating acetone obtained at the top of the isopropanol recovery tower to the reactive distillation tower for participation in the reaction, and conveying a material obtained at the bottom of the isopropanol recovery tower to the methylallyl alcohol light-component removing tower; returning light components obtained at the top of the methylallyl alcohol light-component removing tower to the isopropanol recovery tower, and conveying a material obtained at the bottom of the methylallyl alcohol light-component removing tower to the methylallyl alcohol product tower; and collecting a methylallyl alcohol product from the top of the methylallyl alcohol product tower. The production system and method provided by the invention have the advantage of high conversion efficiency and high product purity.

Owner:齐翔华利新材料有限公司

Methods and systems for separating acetone and phenol from one another

ActiveUS8889915B2Organic compound preparationDistillation purification/separationFractionationFractionating column

Systems and methods for improving crude acetone column energy efficiency and operation are provided. The method for improving crude acetone column energy efficiency and operation can include introducing a crude acetone including acetone and phenol to a fractionation column and introducing cumene, AMS, or a combination thereof to the fractionation column. The method can include fractionating the crude acetone within the fractionation column to produce an acetone containing overhead and a phenol containing bottoms. The method can also include condensing at least a portion of the acetone containing overhead indirectly with a cool heat transfer medium to provide a condensed crude acetone product and a heated heat transfer medium, wherein the heat transfer medium includes cumene.

Owner:KELLOGG BROWN & ROOT LLC

Magnetization rectification method for reclaiming acetone from waste acetone menstruum

InactiveCN101190879AImprove mass transfer efficiencyGood effectCarbonyl compound separation/purificationWastewaterAcetone product

The invention discloses a method used for recovering an acetone through magnetization and rectification of a waste acetone menstruum. The method comprises the steps that: (1) the waste acetone menstruum is arranged in an Nd-Fe-B magnetizer, reaches a magnetic saturation status and stored in a feeding tank; (2) an Nd-Fe-B magnetic field is arranged outside a rectifying still, a part of the waste acetone menstruum stored in the feeding tank is input to the rectifying still, and operated in a continuous rectification manner at normal pressure, and the operation conditions are: firstly the waste acetone menstruum is infinite refluxed for 0.3 to 0.6 hour, and the waste acetone menstruum treated by step (1) is added into a rectifying tower at a speed of 10 to 20ml / h when the temperature on the top of the rectifying tower reaches and kept at 56.4 DEG C; the acetone product is drawn out from the top of the rectifying tower in reflux ratio of 5 to 7, and the waste water is discharged from the bottom of the tower. The method of the invention increases the mass transference efficiency by more than 6 percent, the mass content of acetone of the acetone product is as high as 99.2 percent, and the recovery rate of acetone reaches 98.6 percent, which has comparatively remarkable effect.

Owner:TIANJIN UNIV

Preparation method of azole acetone with high yield and low emission

The invention relates to a preparation method of azole acetone with high yield and low emission. The preparation method comprises the following steps of: putting a solvent, oxadiazolone, a phase transfer catalyst and an acid binding agent into a reaction kettle, dripping halogen acetone at the temperature of 45 DEG C-70 DEG C, keeping the reaction dripping time to be 2-4h, adopting an azeotropic dewatering way for removing water out of a system during the reaction process, cooling a solution after dewatering to 28 DEG C-32 DEG C, emptying, performing suction filtration, performing decompression on filtrate to remove low-boiling point substances and a solvent, namely chlorinated alkane, controlling the vacuum degree at a terminal point at -0.095MPa, controlling the temperature at the terminal point of decompression distillation to be not more than 75 DEG C, and ending decompression desolvation when no condensed liquid flows down in a condenser to obtain an azole acetone product. The azeotropic dewatering way or a drying agent is adopted for dewatering in synthesis reaction, and then the water is continuously removed out of the reaction system, so that the water content in the synthesis system can be reduced as far as possible, the occurrence of side effects can be reduced, the yield can be improved, the cost is reduced, the emission of sewage is also reduced, and the preparation method is efficient and environment-friendly.

Owner:ANHUI YANGZI CHEM

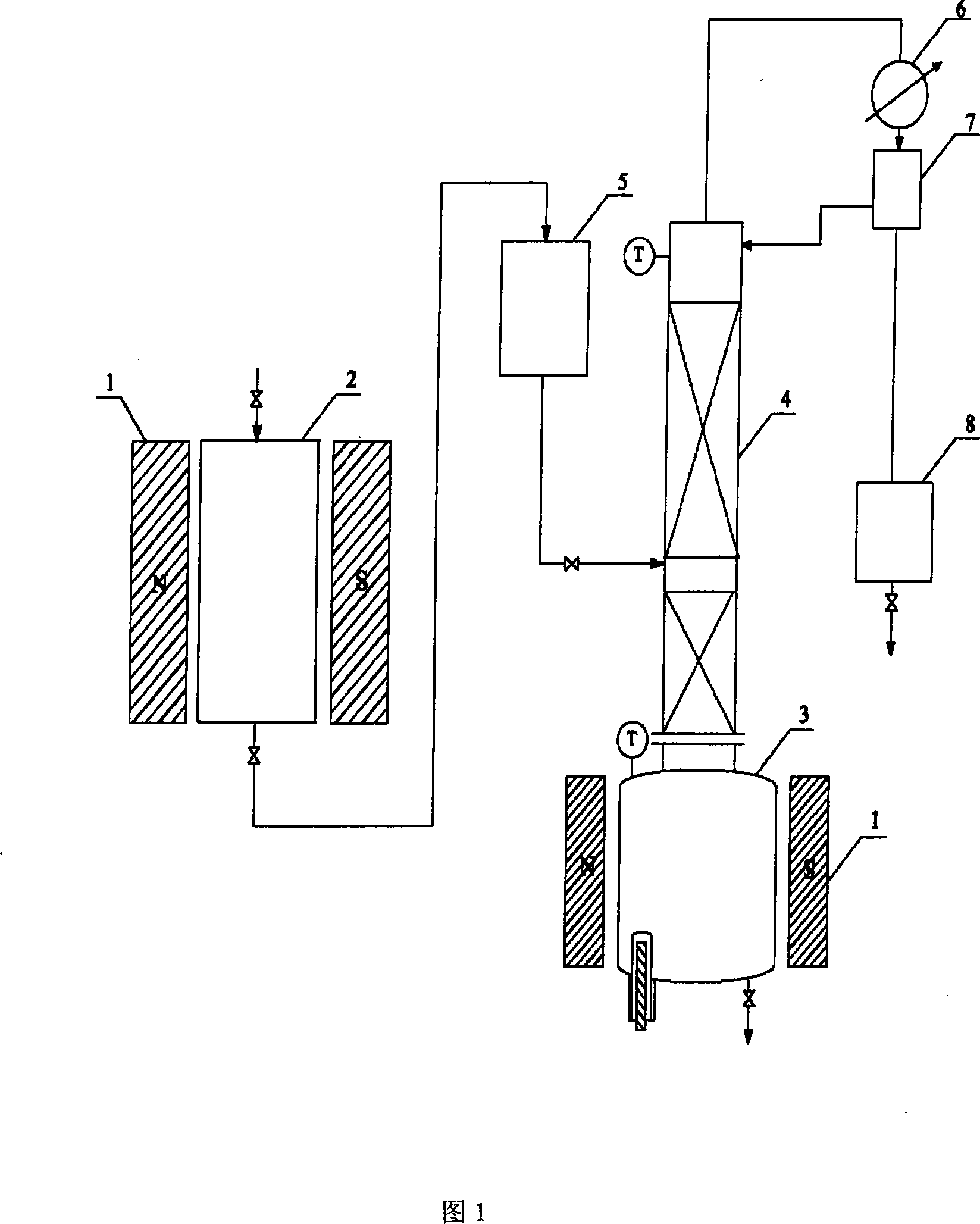

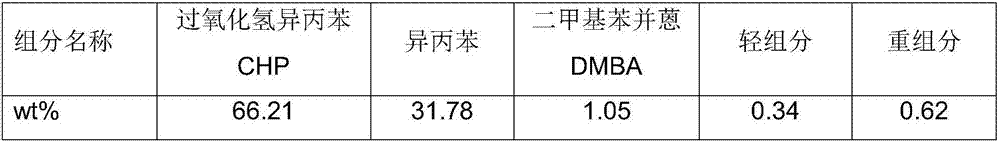

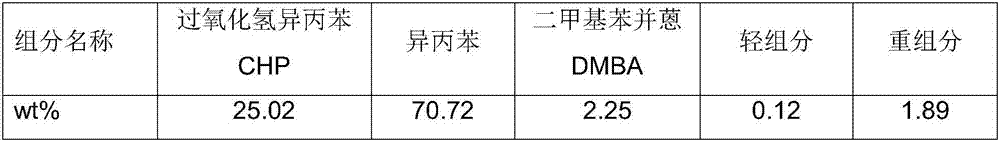

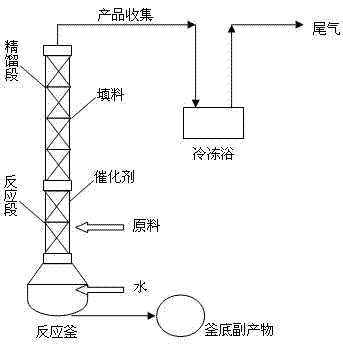

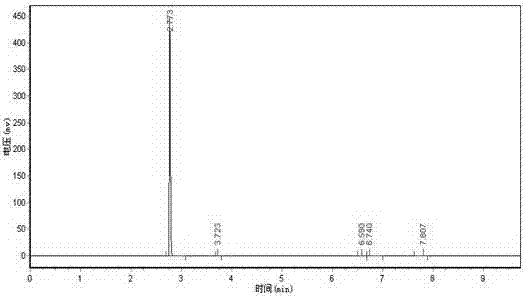

Method for preparing phenol and acetone through reaction rectification decomposition of CHP

ActiveCN106866379AHigh selectivityHigh activityOrganic compound preparationCarbonyl compound preparationProduct selectionAcetone product

The invention relates to a method for preparing phenol and acetone through reaction rectification decomposition of CHP. The method is mainly used for solving the problems in the prior art that the product selectivity is relatively low, the investment is relatively high, and the floor area is relatively large. According to the method, by adopting the technical scheme that the method for preparing phenol and acetone through reaction rectification decomposition of CHP comprises the steps of feeding a 25wt% to 80wt% CHP raw material to a reaction rectification tower for a decomposition reaction so as to produce phenol and acetone, gasifying and boiling the material by using reaction heat so as to enable a catalyst to be in a flow state and keep high activity, and meanwhile, carrying out rectifying separation on the acetone product, the selectivity of phenol is improved to 99.35% to 99.55%, the selectivity of acetone is improved to 99.25% to 99.45%, the purity of the acetone product is not lower than 99.9wt%, and the problems are better solved, so that the method can be applied to the production of phenol and acetone.

Owner:SINOPEC SHANGHAI ENG +1

Synthesis method of halogen acetone

InactiveCN102336640AHigh selectivityImprove conversion rateOrganic compound preparationCarbonyl compound preparationWater vaporSynthesis methods

The invention discloses a synthesis method of halogen acetone. The method comprises the following steps of: selecting a reactive rectification device, wherein the height ratio of the reaction section to the rectification section of the reactive rectification device is 1:3-1:6; adding 0.1 to 2 equivalent water to the bottom of the reactive rectification device, heating the water to the temperature of between 95 and 100 DEG C, and adding halogenated ethyl acetoacetate to the middle part of the reaction section, wherein the molar ratio of the halogenated ethyl acetoacetate to the water is 1:1-1:2.5; and filling strongly acidic cation exchange resin serving as a catalyst into the reaction section, reacting the halogenated ethyl acetoacetate and water vapor after the halogenated ethyl acetoacetate is catalyzed at the reaction section, performing separation at the rectification section, collecting the halogen acetone product at the top of the rectification section, and putting a product collecting bottle in a freezing bath of 10 DEG C below zero to 60 DEG C below zero, wherein the purity of the collected product is more than 99 percent. Because the reactive rectification device is used for continuously producing the halogen acetone, the method has the advantages of high selectivity, high conversion rate, high production capacity, high product purity, simplicity and convenience in operation and low energy consumption; the reagent is easily obtained; the adopted catalyst can be reused; and the method is clean, environmentally-friendly, safe and reliable.

Owner:NANTONG BAOKAI CHEM

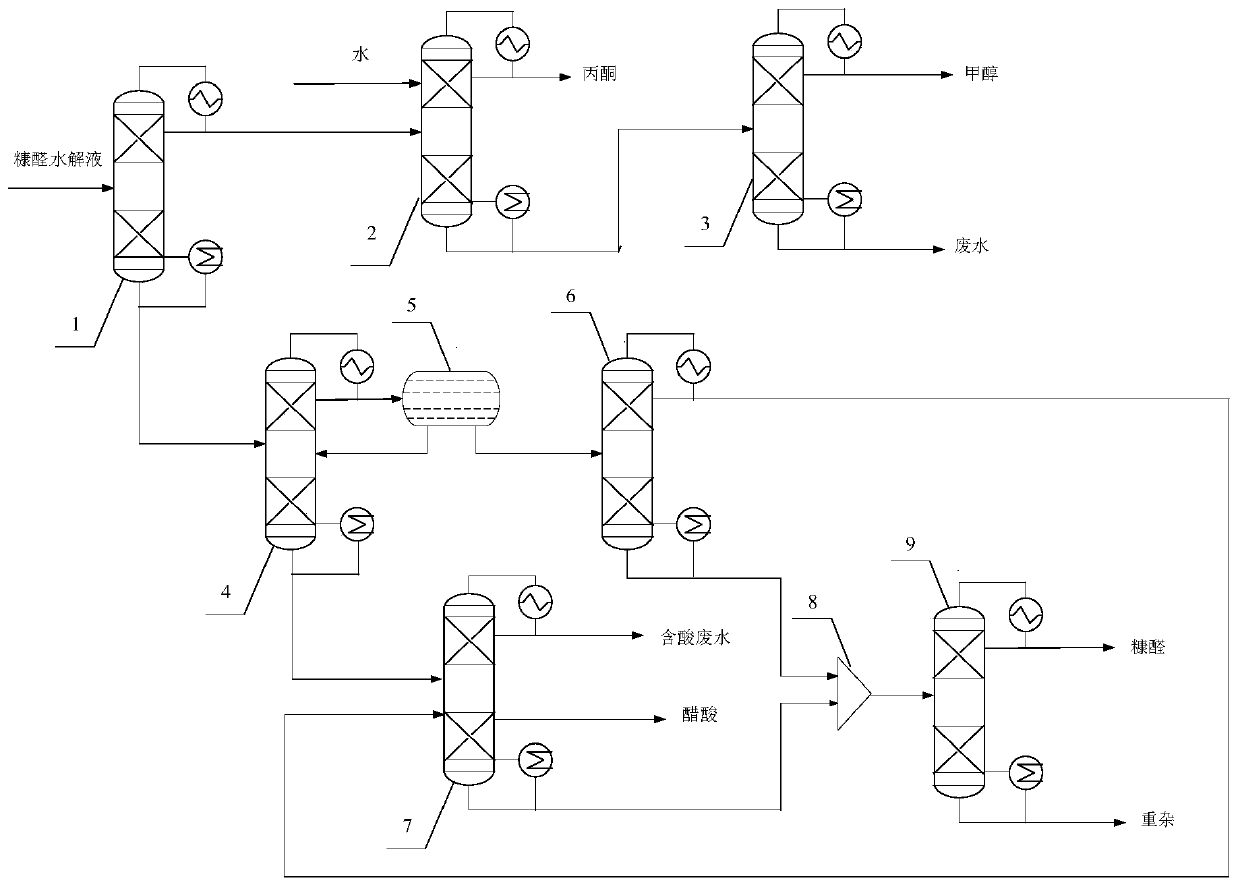

Method for continuously rectifying and refining furfural and accessory low-boiling-point substance

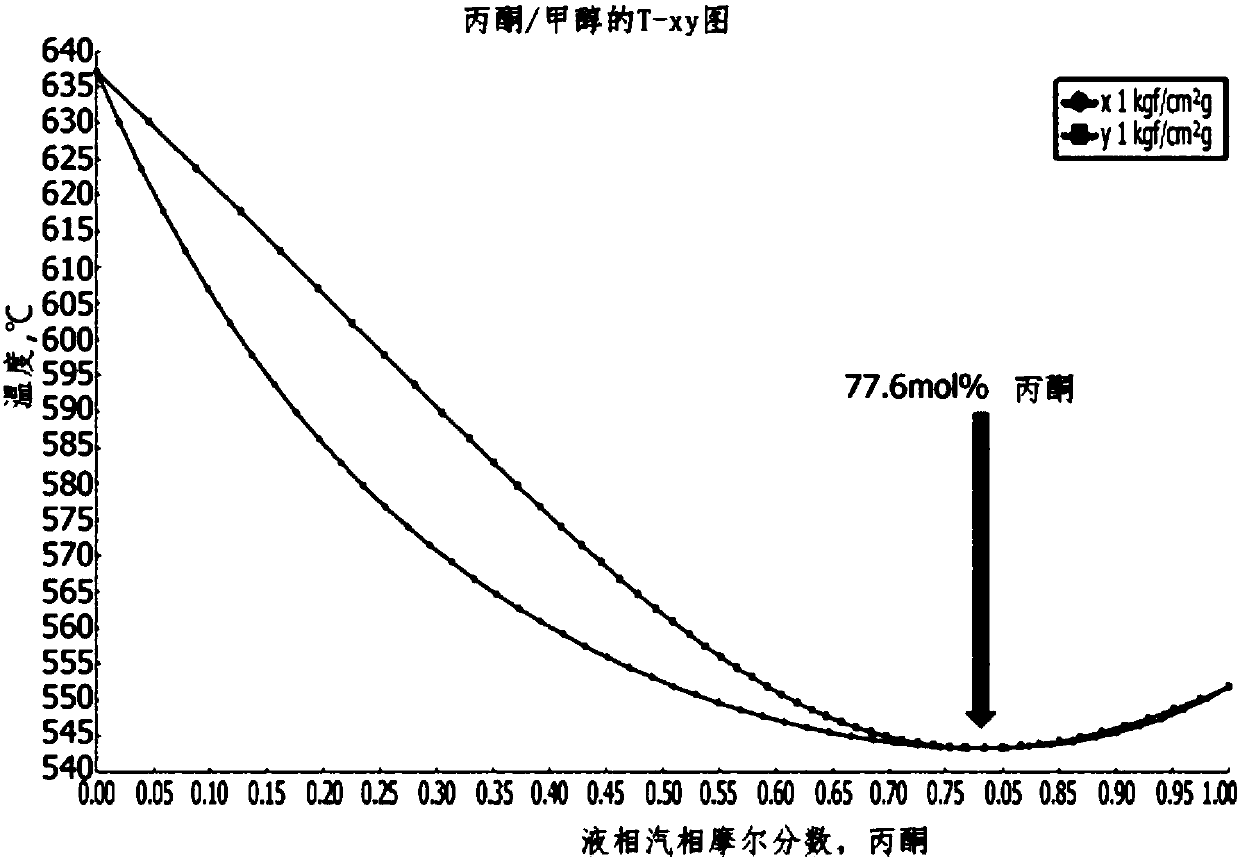

InactiveCN109704937ATake advantage ofAvoid wastingOrganic compound preparationHydroxy compound preparationDistillationAcetone product

The invention discloses a method for continuously rectifying and refining furfural and an accessory low-boiling-point substance. The method comprises the following steps: feeding a pretreated furfuralhydrolysate into a light component removal tower by a pump, extracting acetone and methanol from the top of the tower, allowing the acetone and methanol to enter an acetone product tower and a methanol product tower respectively, and using water as an extractant for the acetone product tower to respectively obtain an acetone product and a methanol product; extracting a dilute aldehyde solution from the bottom of the light component removal tower, feeding the dilute aldehyde solution into an azeotropic primary distillation tower by a pump, obtaining a furfural-water azeotrope from the top ofthe tower, allowing the azeotrope to enter a phase separator, performing condensation and phase separation, returning the obtained water phase to the primary distillation tower, and allowing the obtained aldehyde phase to enter a dehydration tower to remove residual water and acids; feeding acid-containing residues obtained from the top of the dehydration tower and a solution obtained from the bottom of the primary distillation tower into an acetic acid product tower by a pump, extracting wastewater from the top of the tower, extracting an acetic acid product from the lateral line of the tower, mixing a solution obtained from the bottom of the acetic acid product tower with the solution obtained from the bottom of the light component removal tower, and adding the obtained mixed solution to enter a furfural refining tower; and obtaining a furfural product from the top of the aldehyde refining tower, and extracting heavy impurities from the bottom of the tower. The method has the characteristics of high product purity, large variety quantity of products, high yield and low pollution.

Owner:TIANJIN UNIV

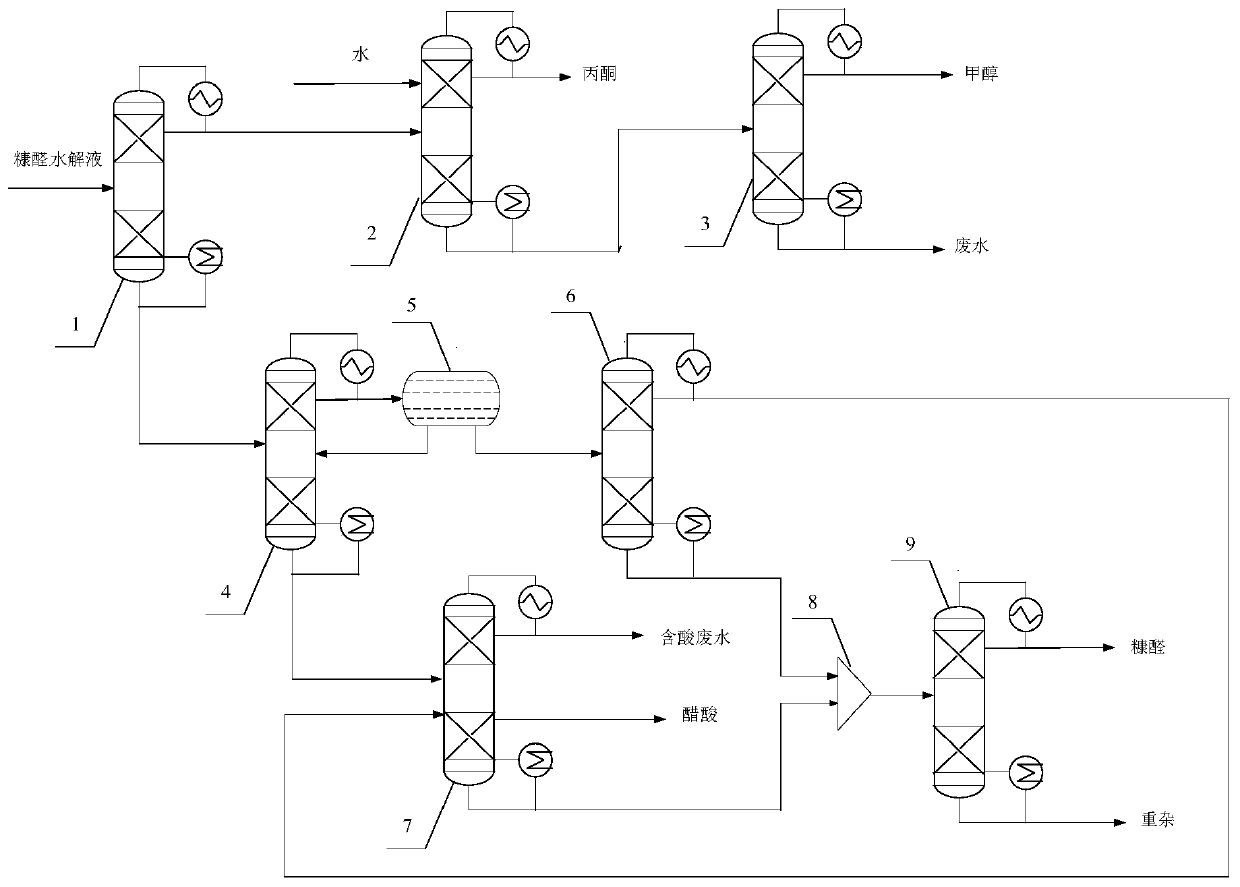

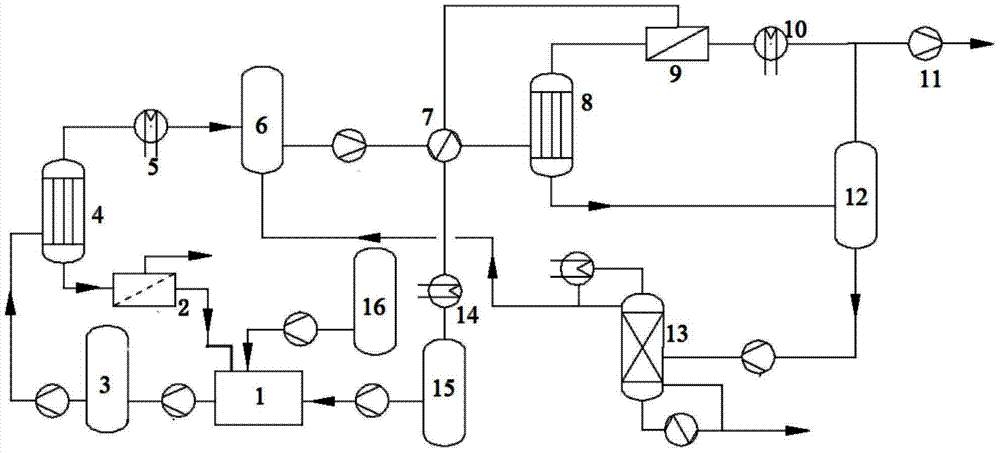

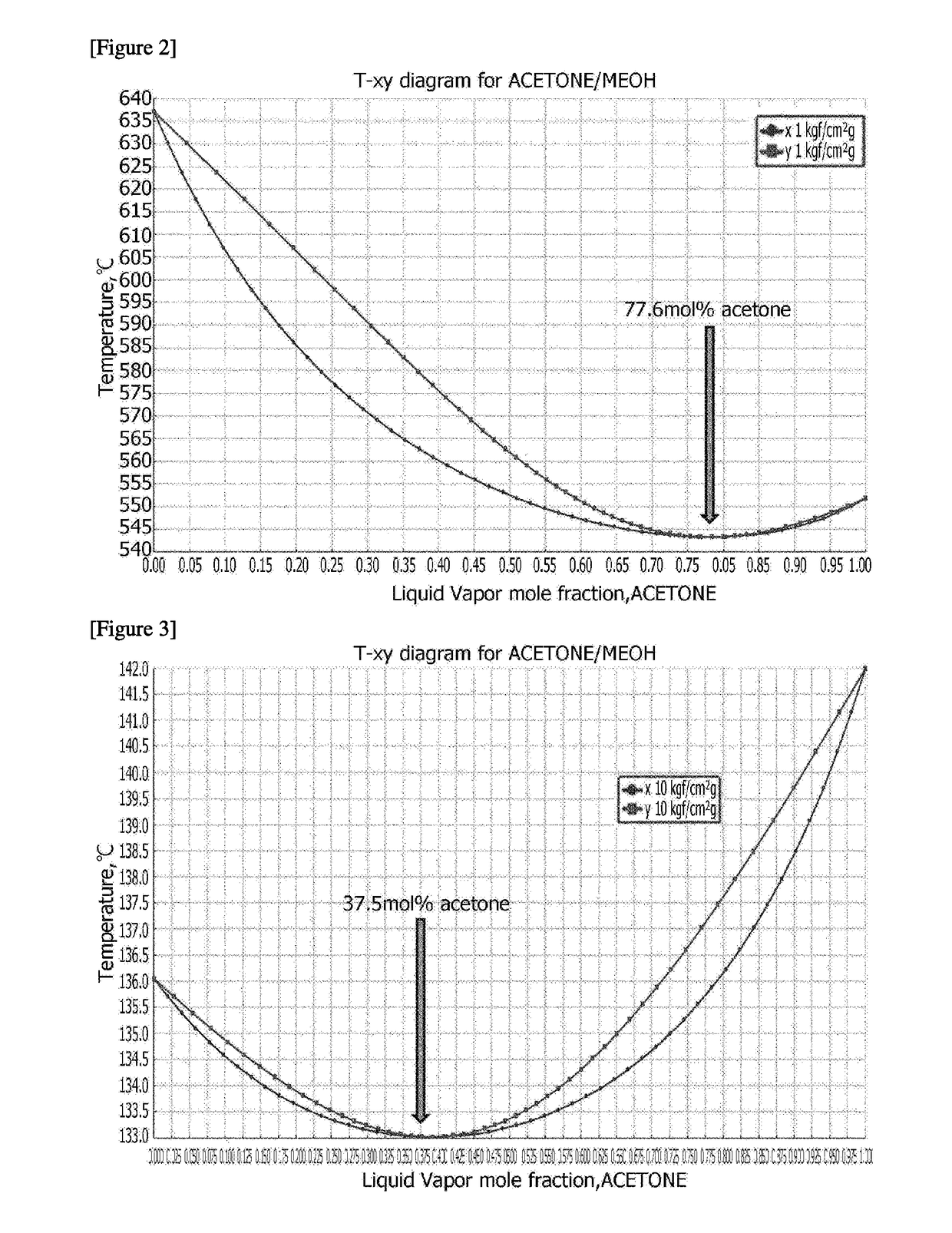

Separation method for acetone and water mixed solvent

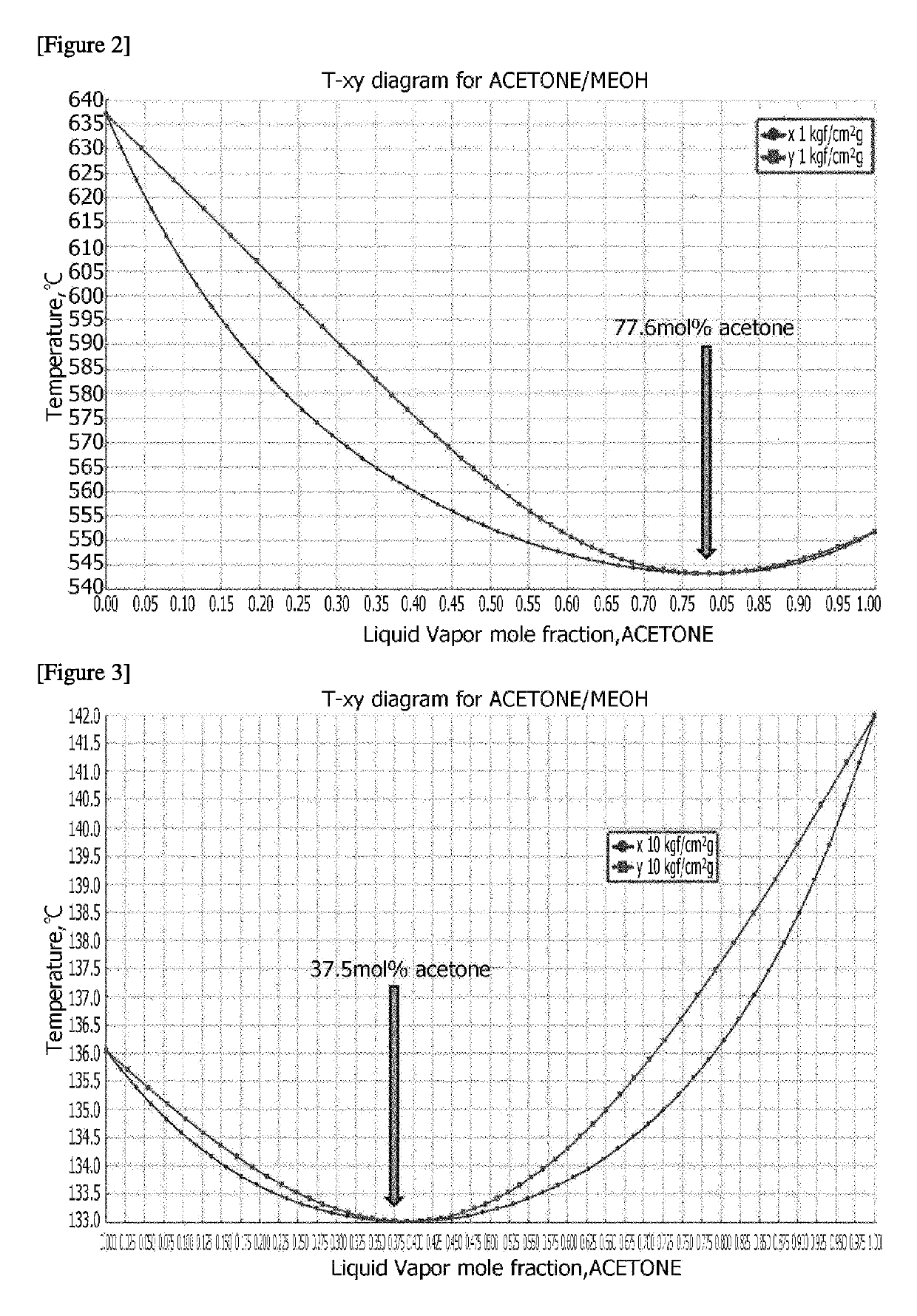

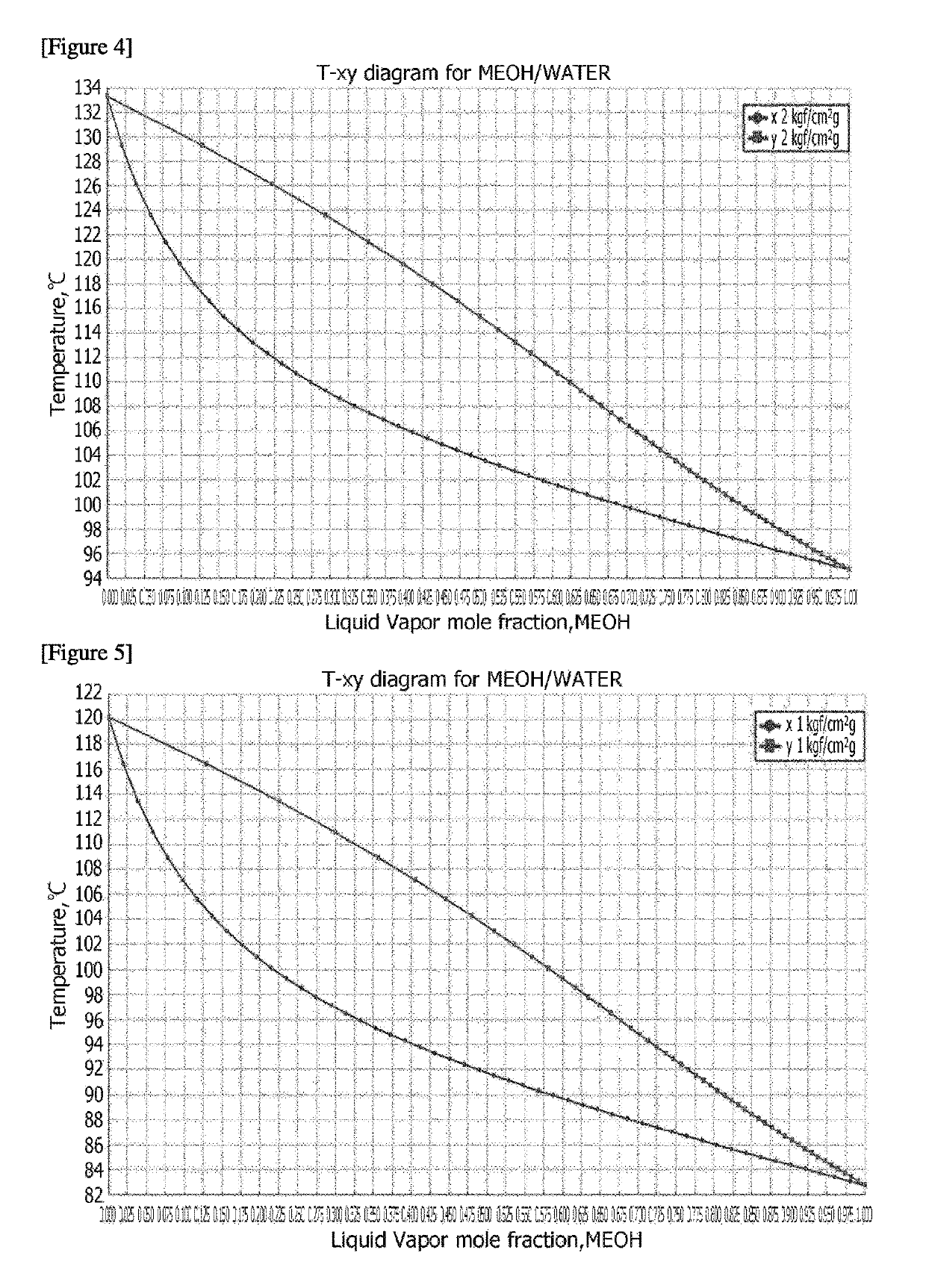

InactiveCN109608320AReduce consumptionTo achieve the purpose of thermal couplingCarbonyl compound separation/purificationReboilerGas phase

The invention provides a separation method for an acetone and water mixed solvent. The separation method includes the following steps that the mixed solvent firstly enters a raw material preheated, has heat exchange with extraction wastewater of a low-pressure tower kettle, and then enters a high-pressure tower. An acetone product gas phase is extracted from the top of the high-pressure tower andenters a low-pressure tower reboiler for providing a heat source for a low-pressure tower, and after heat exchange, an acetone product is extracted. High-pressure tower kettle liquor enters the low-pressure tower, the acetone product is extracted from the top of the low-pressure tower, and the wastewater is extracted from the bottom of the tower. Compared with an existing technology, the separation method substantially lowers energy consumption, saves the cost for production and operation, and has the advantages that the recovery rate of the acetone product is high, and purity is high.

Owner:天津精分科技发展有限公司

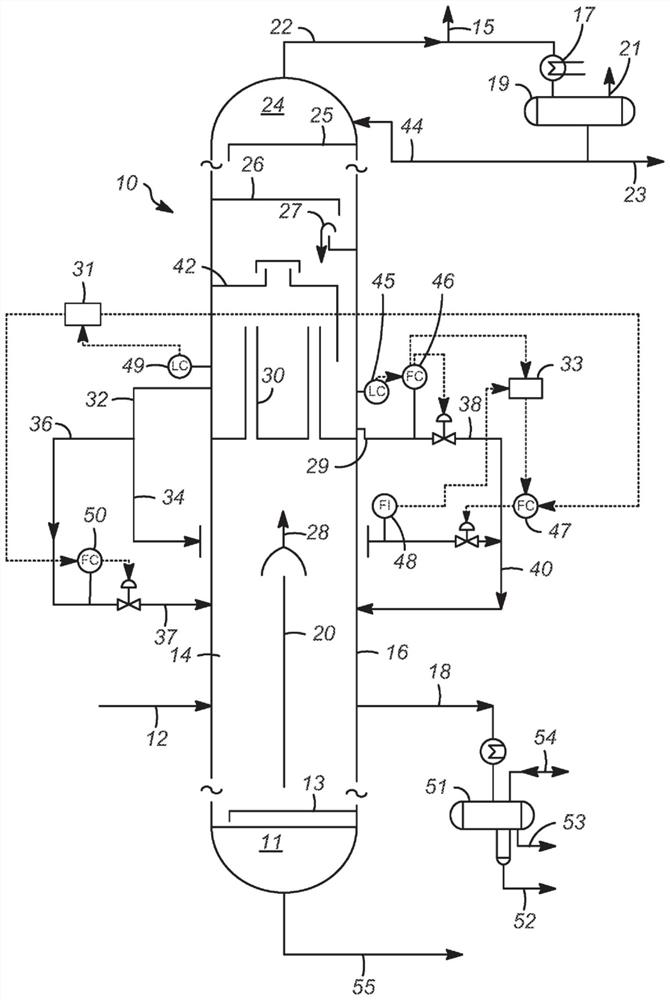

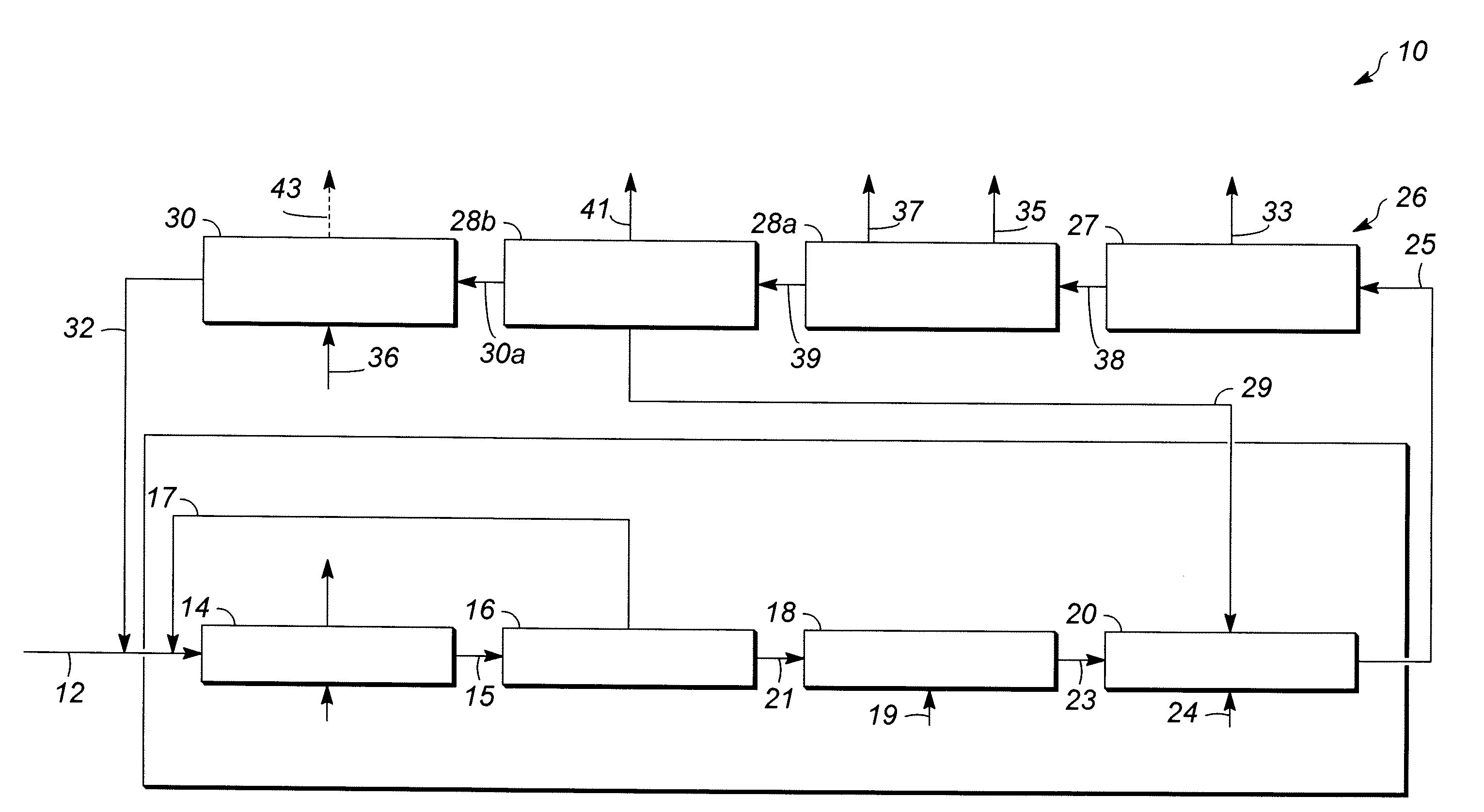

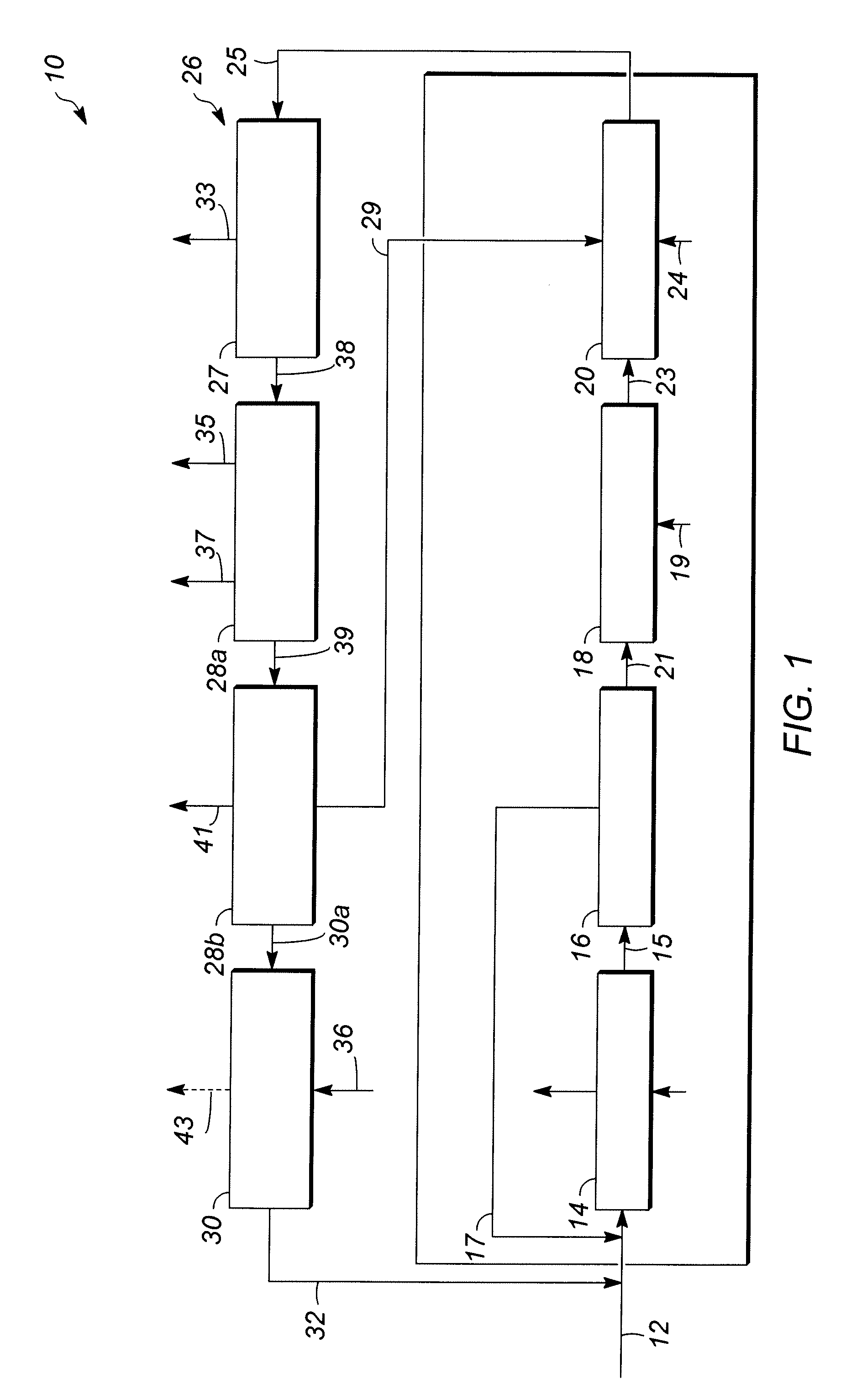

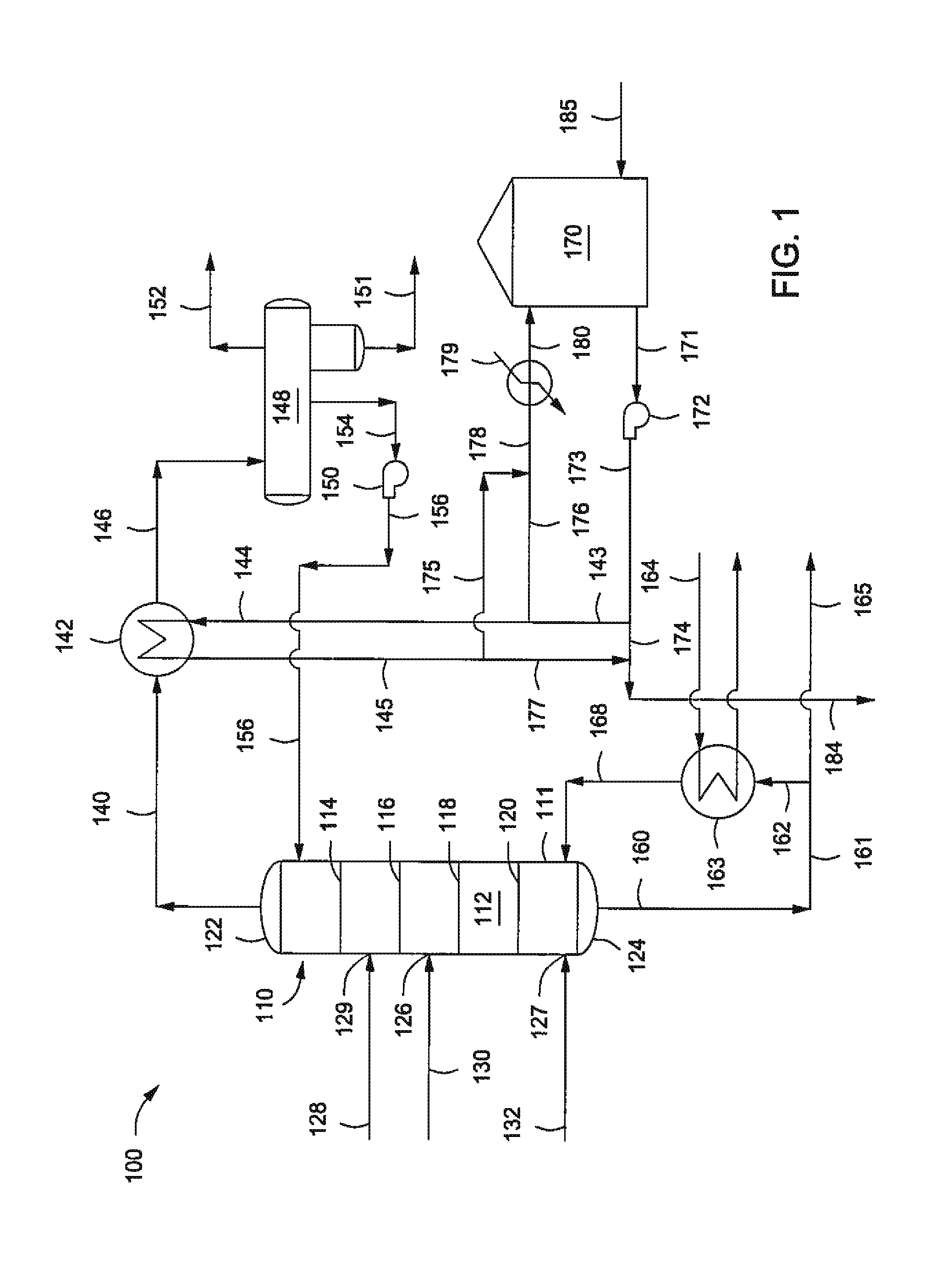

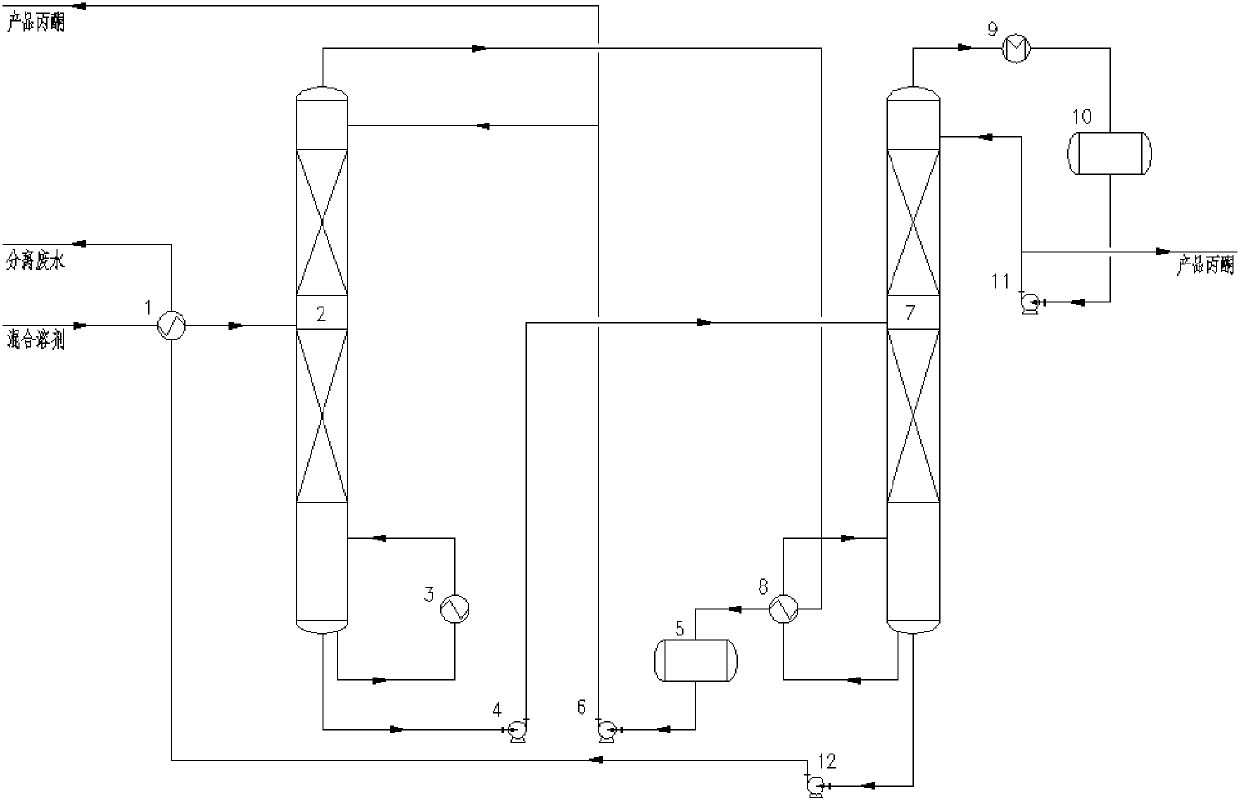

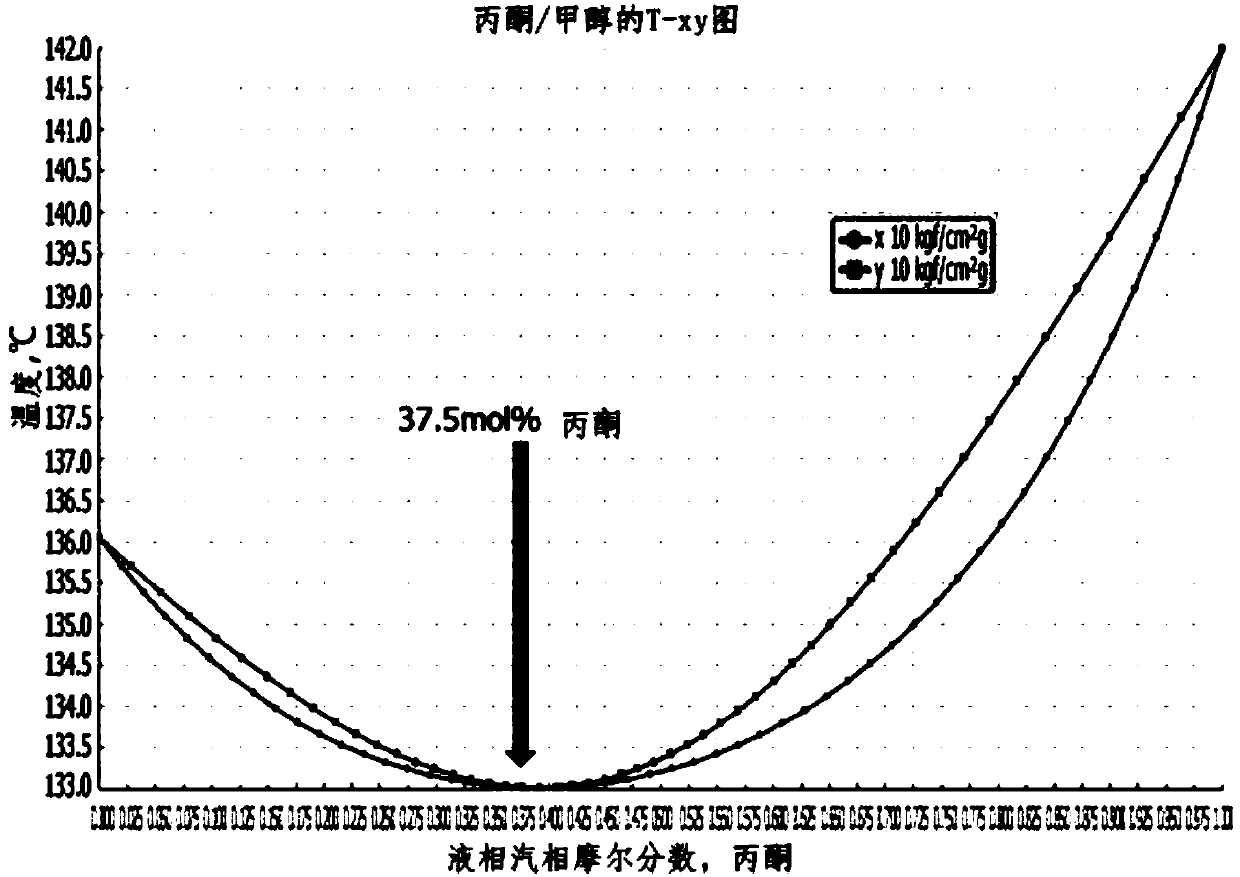

Distillation apparatus

ActiveCN107735391AReduce Methanol ContentSolve the accumulationOrganic compound preparationCarbonyl compound separation/purificationAcetone productFractionating column

The present application relates to a distillation apparatus. According to the distillation apparatus of the present application, since a methanol removal distillation column is positioned at a location allowing the separation of methanol to be relatively easy when separating a material containing acetone and methanol by using the distillation apparatus, a problem caused by the accumulation of methanol in a process can be solved and the lifespan of a catalyst can be extended by lowering the amount of methanol in an acetone product. Further, methanol can be removed with excellent efficiency fromthe lower stream of a distillation column from which a final acetone product is obtained, only by means of a conventional phase separator and the one methanol removal distillation column, which is additionally provided, and thus an acetone product to be obtained from the upper part of the distillation column from which the final acetone product is obtained can be obtained in a high purity, and operation costs and equipment installation costs can be greatly saved.

Owner:LG CHEM LTD

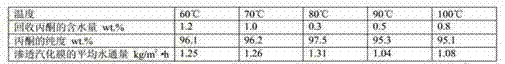

Recovery process and device for dehydrating agent for waste acetone generated in alginate fiber filament production

ActiveCN104119214AHigh recovery rateReduce leakageOrganic compound preparationChemical industryFiberDistillation

The invention relates to a recovery process and device for a dehydrating agent for waste acetone generated in alginate fiber filament production. The recovery process comprises the following steps of heating to distill a waste acetone mother solution from an alginate fiber filament dehydration tank to remove other organic components and impurities in waste acetone, and returning permeate to the alginate fiber filament dehydration step after separating heavy components through a ceramic membrane, wherein the heavy components are generated by heating distillation; inputting distillate to a preheater and an evaporator through a pump, enabling the distillate to enter a membrane separation unit in a steam way, obtaining an acetone product meeting a treatment requirement at an entrapment side of a pervaporation membrane separation unit, and enabling refined acetone obtained after dehydration to enter the alginate fiber filament dehydration tank to reused as a dehydrant; connecting the permeation side of the pervaporation membrane separation unit with a vacuum system, treating penetrated steam in a rectifying tower after condensing the penetrated steam by a penetrating fluid condenser, obtaining acetone with low water content at the top of the tower, enabling acetone to enter an acetone mother solution tank, and discharging wastewater from the bottom of a kettle. The recovery process disclosed by the invention is simple in course, high in safety factor, low in equipment investment, high in energy utilization ratio, small in floor area of the whole set of process and small in equipment height.

Owner:JIANGSU NINE HEAVEN HIGH TECH

Distallation device (amended)

ActiveUS20180169542A1Easy to separateReduce Methanol ContentOrganic compound preparationCarbonyl compound separation/purificationDistillationAcetone product

The present application relates to a distillation device. When a feedstock containing acetone and methanol is separated using a distillation device according to the present application, a methanol removal distillation column may be located at a position for easily separating methanol to solve a problem due to accumulation of methanol in the process and to lower the methanol content in the acetone product, and thus the lifetime of catalysts can be extended, and moreover, methanol can be removed with good efficiency from a flow of the lower part of the distillation column obtaining the final acetone product by using only the conventional phase separator and one methanol removal distillation column further installed, so that the acetone product obtained from the upper part of the distillation column obtaining the acetone product can be obtained in high purity and the operating cost and the equipment cost of equipments can be greatly reduced.

Owner:LG CHEM LTD

Method for preparing benzalacetone

InactiveCN110818548AEasy to separateEasy recyclingPhysical/chemical process catalystsOrganic compound preparationPtru catalystBenzaldehyde

The invention provides a method for preparing benzalacetone. According to the method, acetone and benzaldehyde are used as raw materials, CaO-MgO loaded with potassium carbonate is used as a catalyst,butylated hydroxytoluene is used as a polymerization inhibitor, and aldol condensation is conducted to obtain benzalacetone; product yield and product purity reach 91% or above and 99% or above respectively; and in the preparation process, the molar ratio of benzaldehyde to acetone is 1: (1.7-2.1), the usage amount of CaO-MgO loaded with potassium carbonate accounts for 5%-10% of the mass of acetone, the usage amount of the polymerization inhibitor butylated hydroxytoluene accounts for 0.1%-0.3% of the mass of benzaldehyde, and a molar ratio of magnesium chloride to calcium chloride is (6-8):1. The preparation method is simple, has the characteristics of mild reaction conditions, easy separation and recovery of the catalyst, high product yield, few byproducts and the like, and can easilyrealize industrial production.

Owner:JIANGXI HUAYU AROMATIC TECH

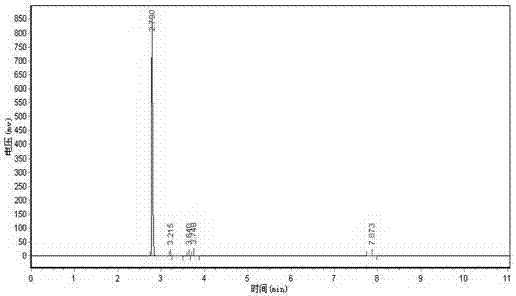

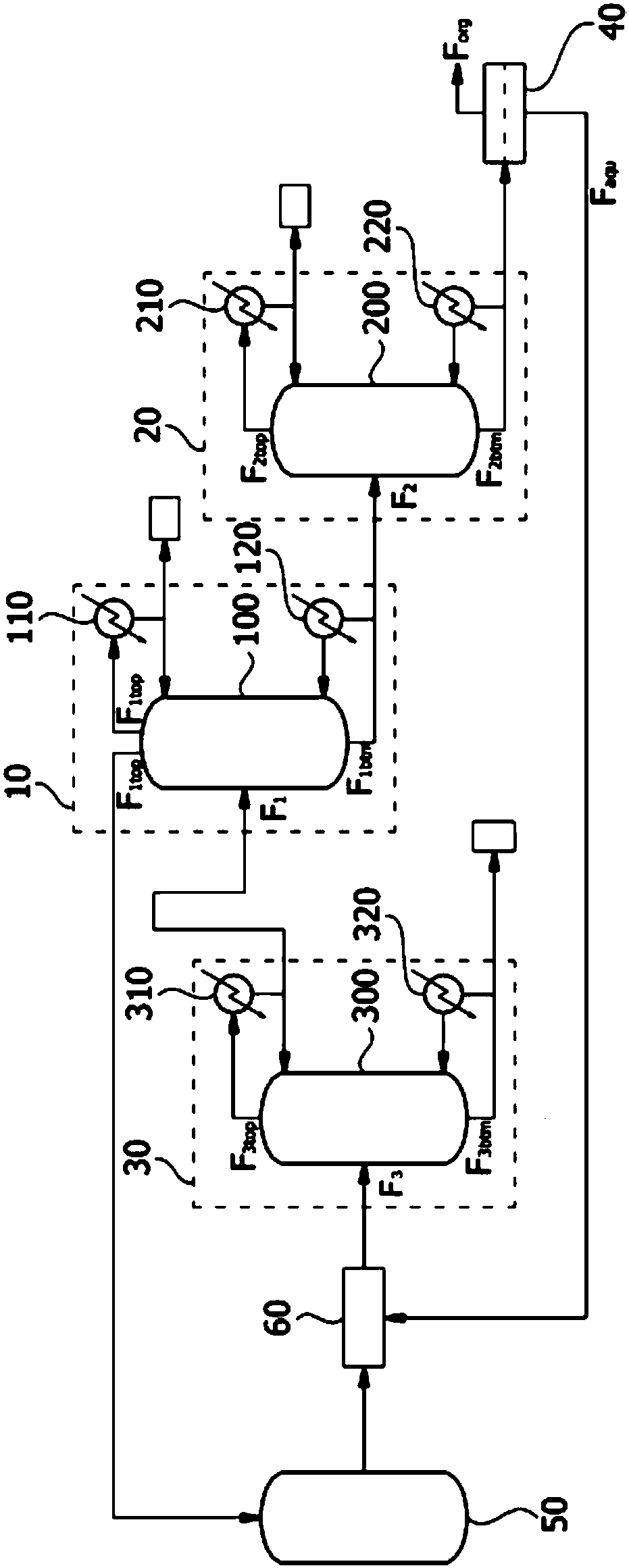

Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone

InactiveCN104250207AHigh product contentHigh reaction yieldCarbonyl compound preparation by condensationCarbonyl compound separation/purificationDistillationAcetone product

The invention relates to a method for preparing highly pure 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone. The method comprises the following steps: carrying out a Friedel-Crafts reaction on raw materials comprising t-butylbenzene and isobutyryl chloride, hydrolyzing, washing by water, desolventizing, and carrying out reduced pressure distillation to obtain a final product. The method has the advantages of reduction of the generation of impurities through later dropwise addition of t-butylbenzene, high yield, safe post-treatmetn operation, industrial application value, and high purity of the 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone product.

Owner:INSIGHT HIGH TECH JIANGSU CO LTD

Controlling the split of liquid reflux in a dividing wall column

The present invention relates to the fractionation technology that is used to create purified phenol and acetone products. More specifically, the present invention relates to a fractionation technology that is used to create crude acetone and crude phenol streams using a dividing wall column intended to remove cumene, alpha-methyl styrene and water from the product side of the wall.

Owner:UOP LLC

Electric dehydrating device for acetone

InactiveCN104744228ASimple processImprove securityEvaporator accessoriesSolution crystallizationDecompositionAcetone product

The invention discloses an electric dehydrating device for acetone. The electric dehydrating device comprises a sealing device, wherein a dicyan acetone aqueous solution feeding tube is mounted in the sealing device; the top of the dicyan acetone aqueous solution feeding tube is fixed on the top surface in the sealing device; the bottom of the dicyan acetone aqueous solution feeding tube penetrates through the sealing device and is communicated with a dehydrating tube; a permeation vaporization film separator is mounted on the dehydrating tube; the permeation vaporization film separator is fixed on the dehydrating tube; the bottom of the dehydrating tube is communicated with an evaporator; the evaporator is connected with the dehydrating tube through an internal pipeline; a vacuum device is mounted on the side surface of the evaporator; the vacuum device and the evaporator are connected through a vacuum tube; a crystalline liquid storage device is arranged on the upper surface of the vacuum device. The electric dehydrating device for acetone is simple in process, high in safety coefficient, less in equipment investment, high in energy utilization rate and small in floor space in the whole process, the dehydration and concentration temperature is reduced, the decomposition loss of dihydroxy acetone is reduced, and the separating efficiency of a dihydroxy acetone product is improved.

Owner:CHENGDU JIAMEIJIA SCI & TECH

Controlled Splitting of Liquid Reflux in Dividing Wall Columns

The present invention relates to fractional distillation techniques for producing purified phenol and acetone products. More specifically, the present invention relates to fractional distillation techniques for the production of crude acetone and crude phenol streams using a dividing wall column designed to remove cumene, alpha-methylstyrene and water.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone](https://images-eureka.patsnap.com/patent_img/c4f66ffe-acdc-438e-9072-835b7bbdab92/BDA00003439245400011.PNG)

![Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone](https://images-eureka.patsnap.com/patent_img/c4f66ffe-acdc-438e-9072-835b7bbdab92/BDA00003439245400012.PNG)

![Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone Method for preparing 2-methyl-1-[4-(t-butyl)phenyl]-1-acetone](https://images-eureka.patsnap.com/patent_img/c4f66ffe-acdc-438e-9072-835b7bbdab92/BDA00003439245400021.PNG)