Separation method for acetone and water mixed solvent

A technology of mixed solvent and separation method, which is applied in the field of waste solvent treatment process with high acetone concentration and large processing capacity, to achieve the effects of reducing production and operation costs, reducing steam consumption, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

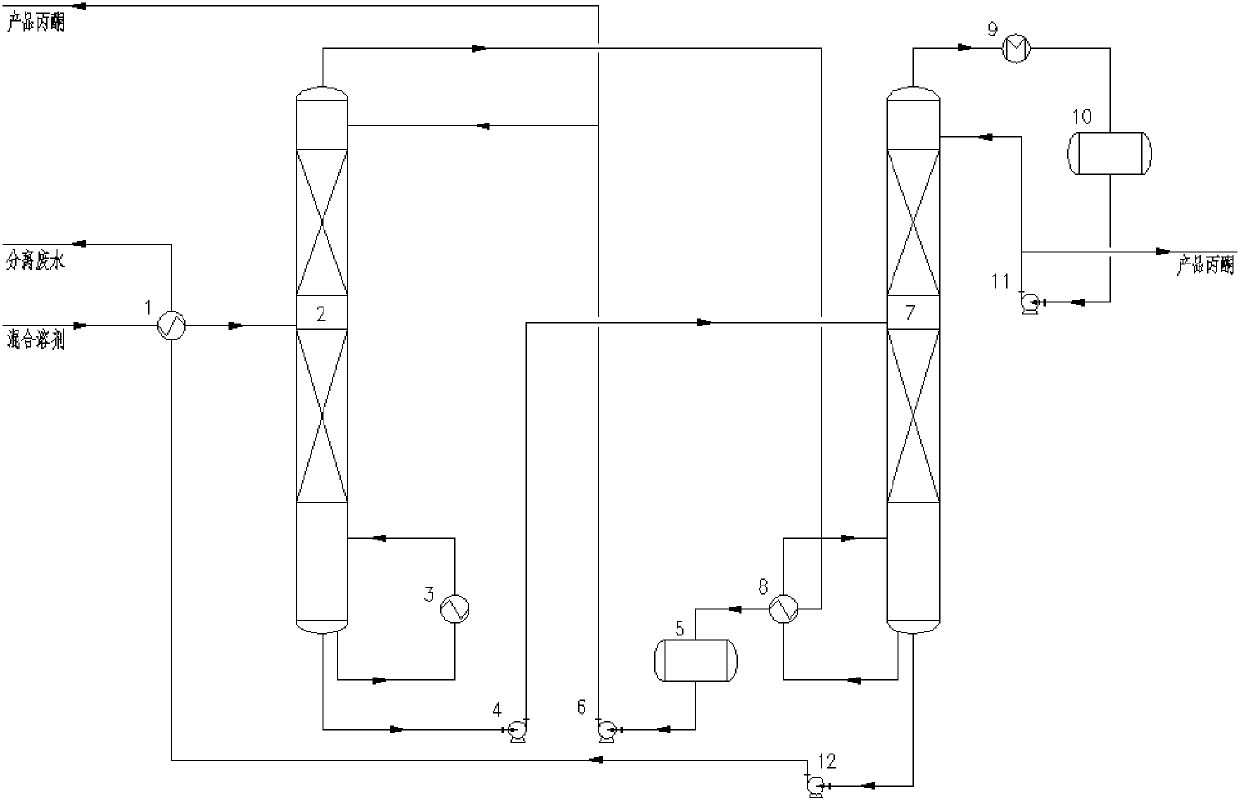

Embodiment 1

[0032] Apply the above-mentioned process and process device for separating acetone and water mixed solvent, take the mixed solvent of a pharmaceutical enterprise as an example, the mass fraction of the mixed solvent is 84% acetone, 16% water, and the feed rate is 4800Kg / h. The mixed solvent first enters the raw material preheater 1, and then enters the high-pressure tower 2 after heating up to 55°C. The operating pressure is 0.26MPaA, the pressure drop of the whole tower is 0.002MPaA, the tower top temperature is 85°C, and the reflux ratio is 1.8. The high-alcohol acetone gas phase extracted from the top of the high-pressure tower enters the reboiler 8 of the low-pressure tower to condense and then enters the reflux tank 5 of the high-pressure tower. The material composition is 99.5% acetone and 0.5% water. The bottom liquid of the tower is sent to the low-pressure column 7 through the bottom liquid pump 4 of the high-pressure tower. The high-purity acetone gas phase extract...

Embodiment 2

[0035]Apply the above-mentioned technological method and technological device for separating acetone and water mixed solvent, take the mixed solvent of pharmaceutical enterprise as an example, the mass fraction of mixed solvent is 60% acetone, 40% water respectively, and the feed rate is 9600Kg / h. The mixed solvent first enters the raw material preheater 1, and then enters the high pressure tower 2 after heating up to 53°C. The operating pressure is 0.3MPaA, the pressure drop of the whole tower is 0.002MPaA, the tower top temperature is 91°C, and the reflux ratio is 1.9. The high-purity acetone gas phase extracted from the top of the high-pressure tower enters the reboiler 8 of the low-pressure tower to condense and then enters the reflux tank 5 of the high-pressure tower. The material composition is 99.6% acetone and 0.4% water. The bottom liquid of the tower is sent to the low-pressure column 7 through the bottom liquid pump 4 of the high-pressure tower. The high-purity acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com