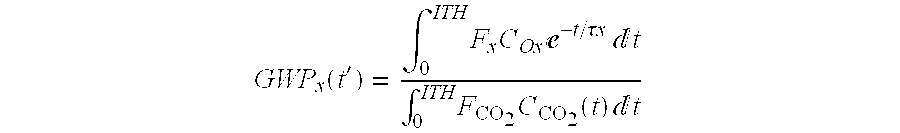

Patents

Literature

3396results about "Carbonyl compound separation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

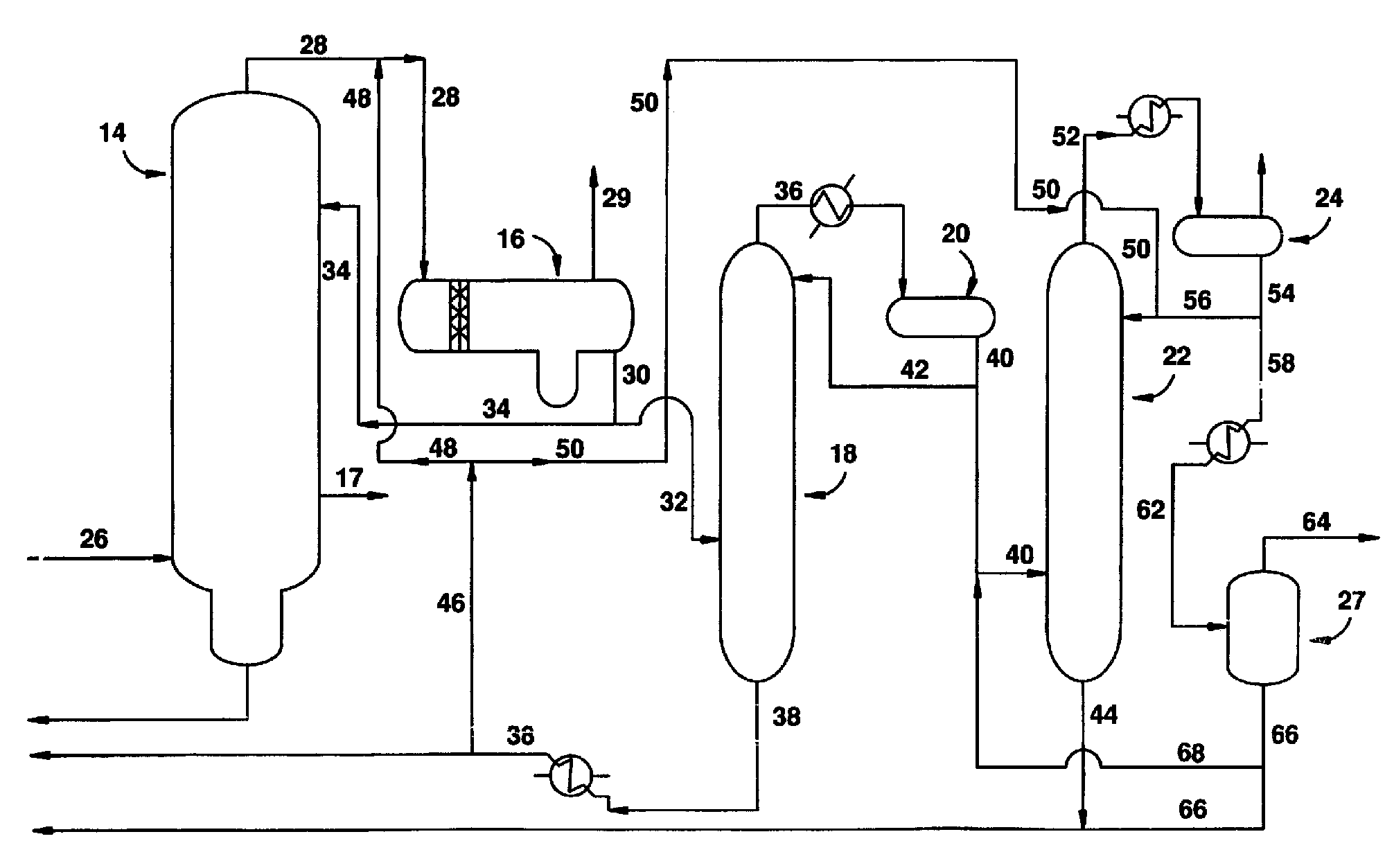

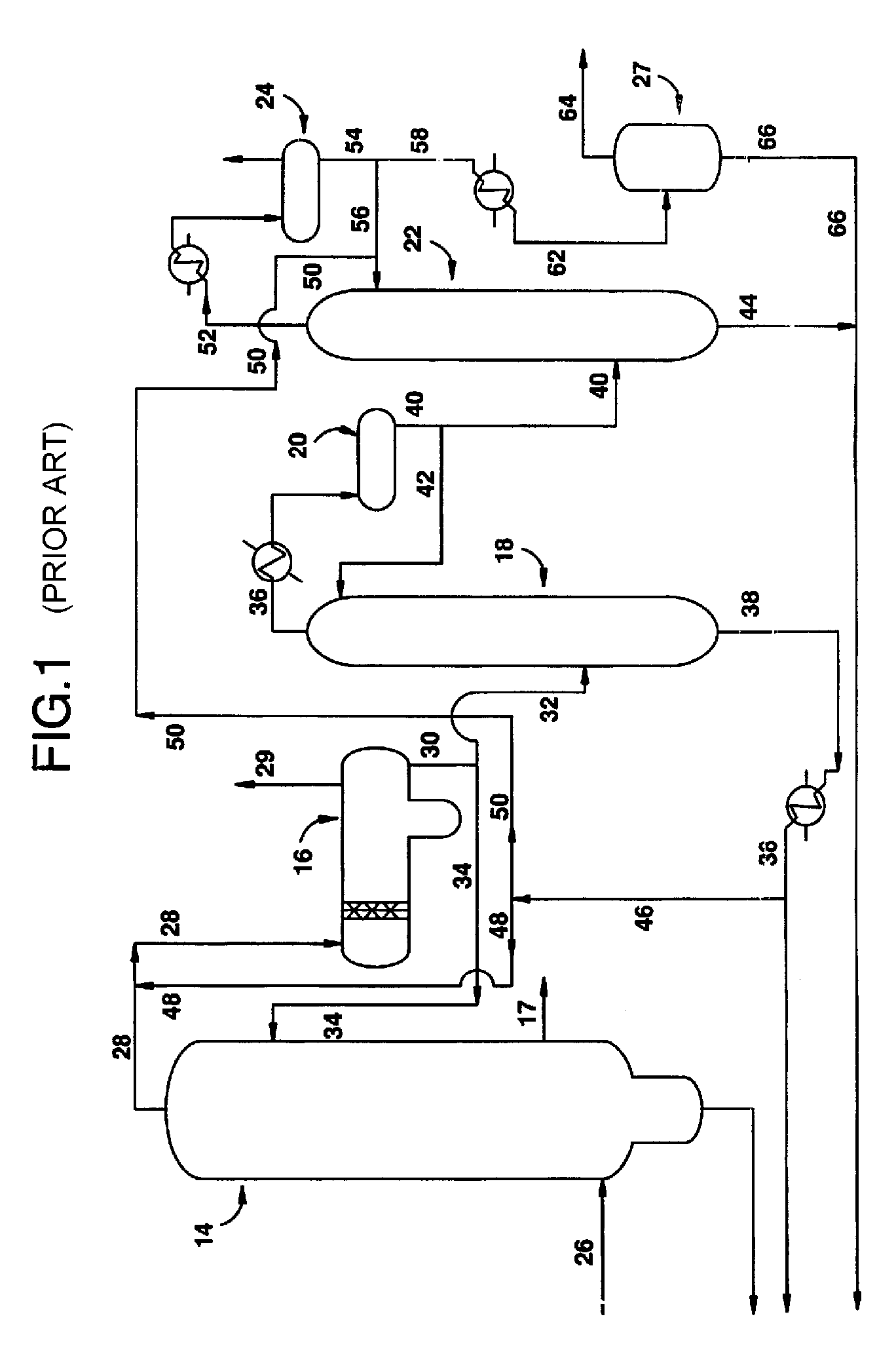

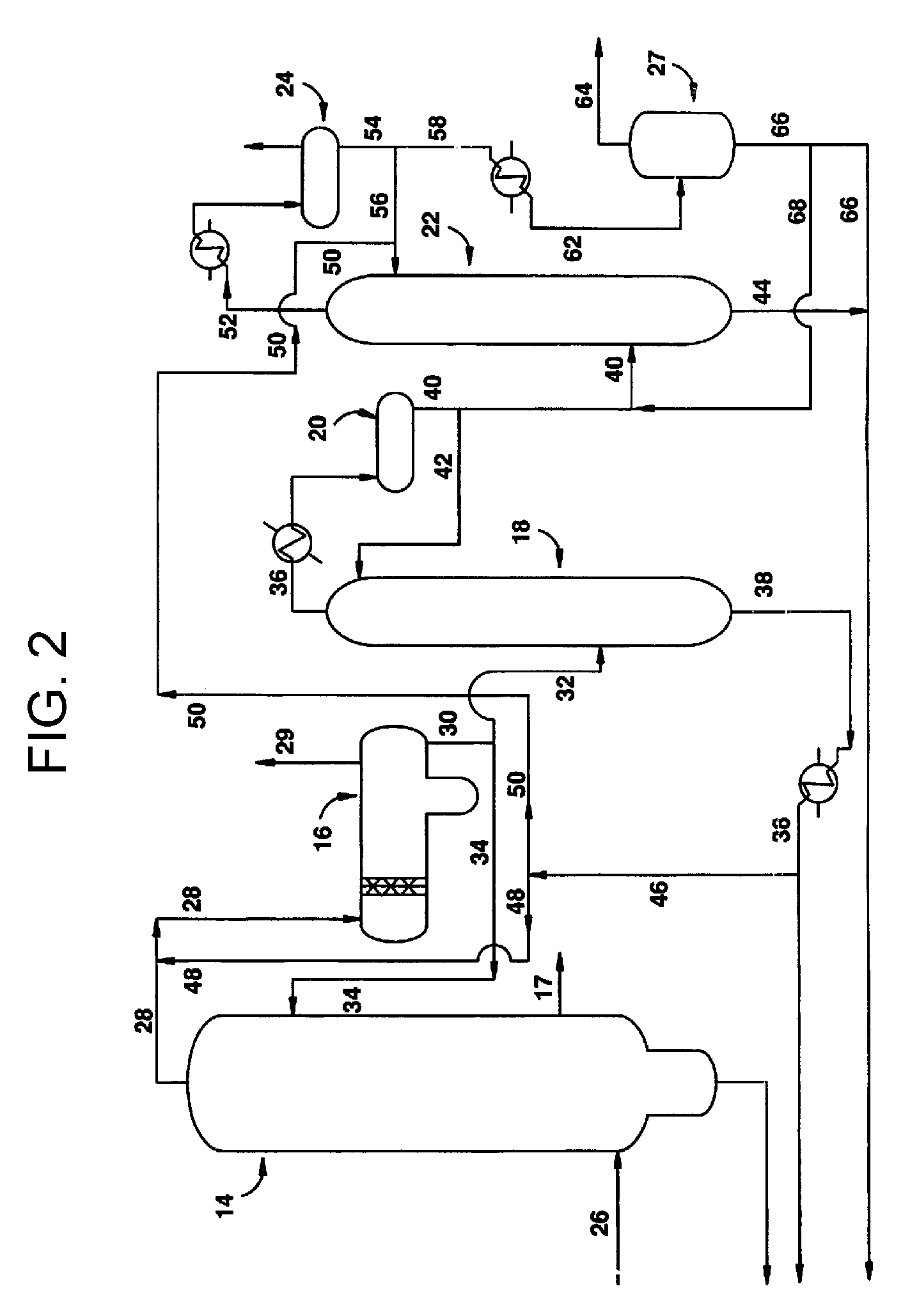

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223886B2Reduce solubilitySimple methodOrganic compound preparationPreparation by carbon monoxide or formate reactionAcetic acidIodide

An improvement of the methanol carbonylation process for manufacturing acetic acid is disclosed. Specifically disclosed is a method for reducing the formation of alkyl iodides and C3-8 carboxylic acids by removing permanganate reducing compounds (“PRC's”) from the light phase of the condensed light ends overhead stream, including (a) distilling the light phase to yield a PRC enriched overhead stream; and (b) extracting the third overhead stream with water in at least two consecutive stages and separating therefrom one or more aqueous streams containing PRC's.

Owner:CELANESE INT CORP

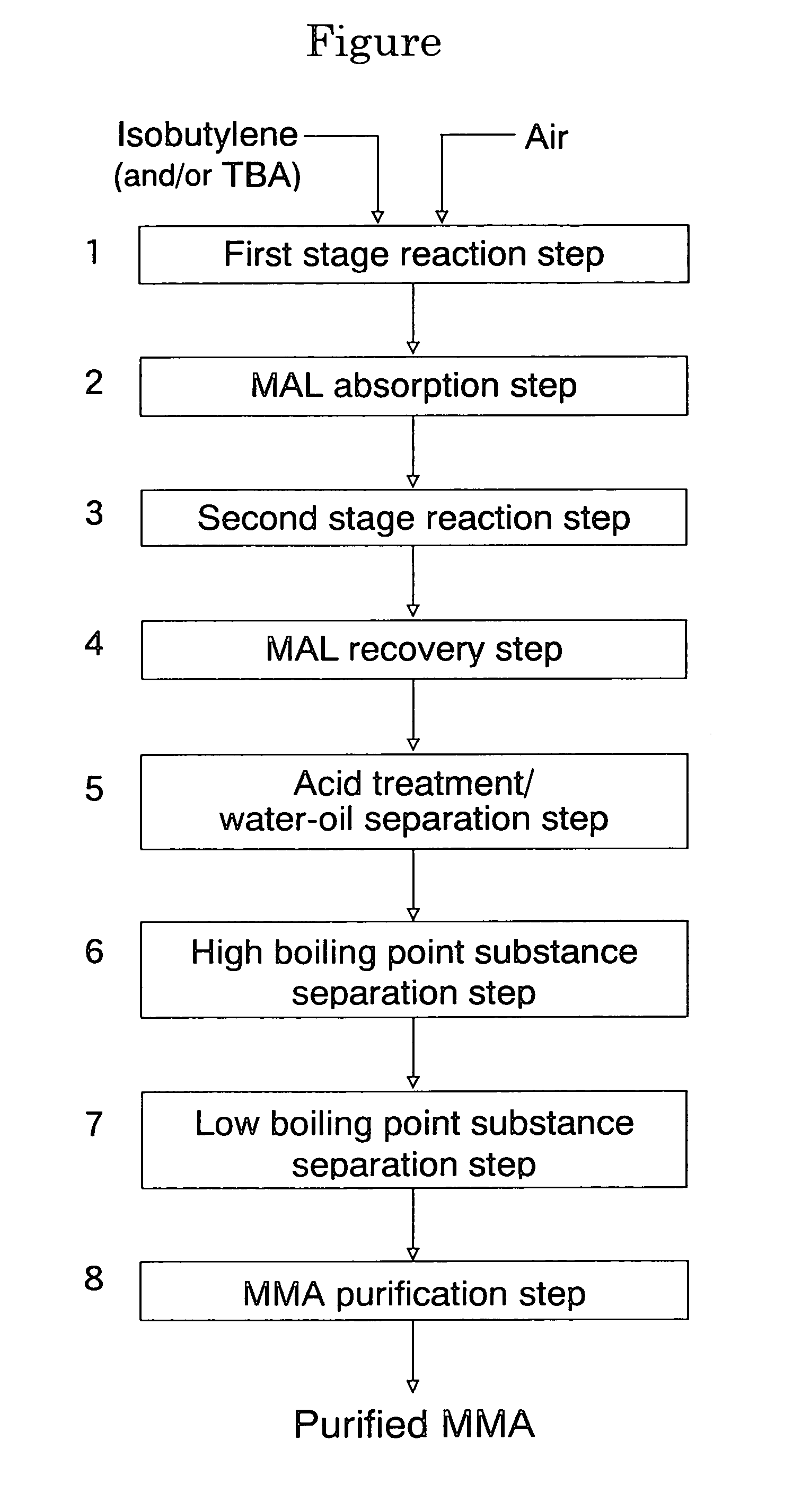

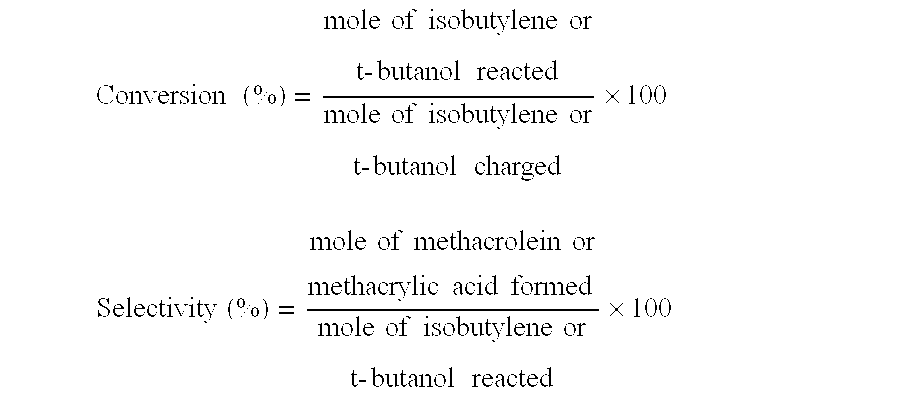

Oxide catalyst composition

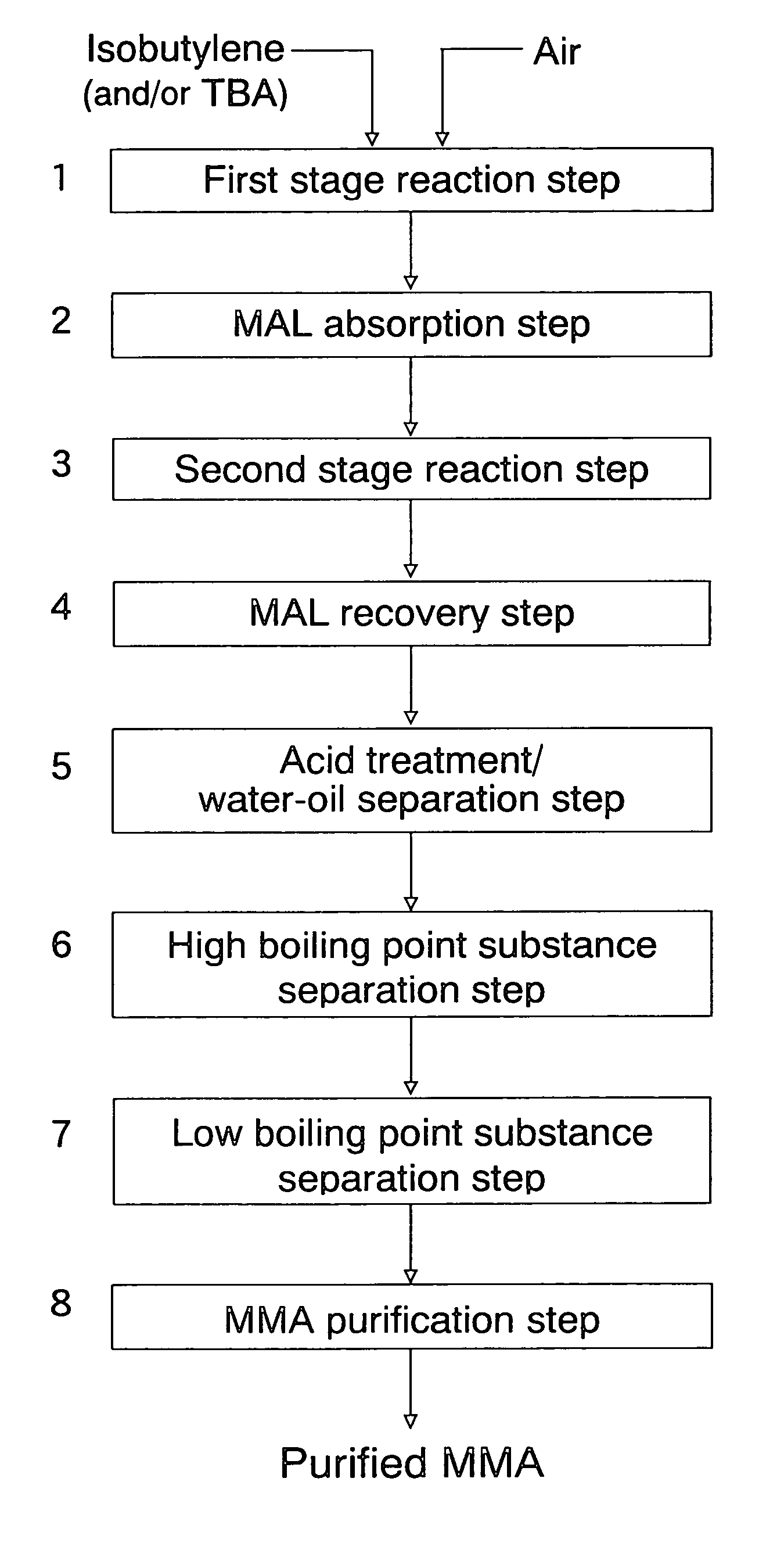

InactiveUS7012039B2High selectivityLow selectivityOrganic compound preparationCarboxylic acid esters preparationLanthanideMethacrolein

An oxide catalyst composition for use in producing methacrolein or a mixture of methacrolein and methacrylic acid, wherein the oxide catalyst composition is represented by the formula (Mo+W)l2BiaAbBcFedXeSbfOg, wherein: A is at least one member selected from the group consisting of Y and the elements of the lanthanoid series exclusive of Pm; B is at least one member selected from the group consisting of K, Rb and Cs; X is Co solely, or a mixture of Co and at least one member selected from the group consisting of Mg and Ni; and a, b, c, d, e, f and g are, respectively, the atomic ratios of Bi, A, B, Fe, X, Sb and O, relative to twelve atoms of the total of Mo and W, wherein the atomic ratios (a to f) of the elements and the relationship between the amounts of the elements are chosen so as to satisfy specific requirements.

Owner:ASAHI KASEI CHEM CORP

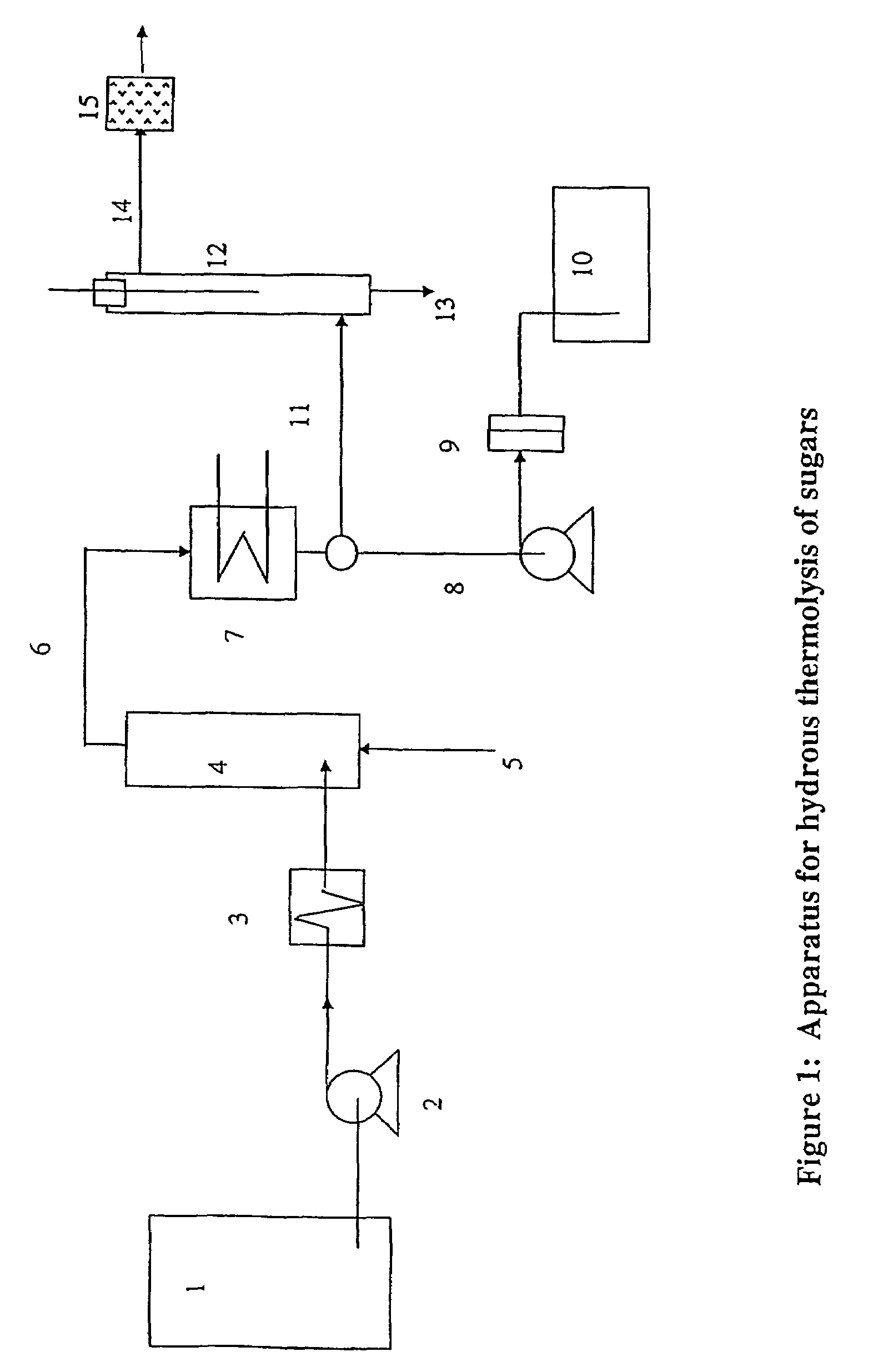

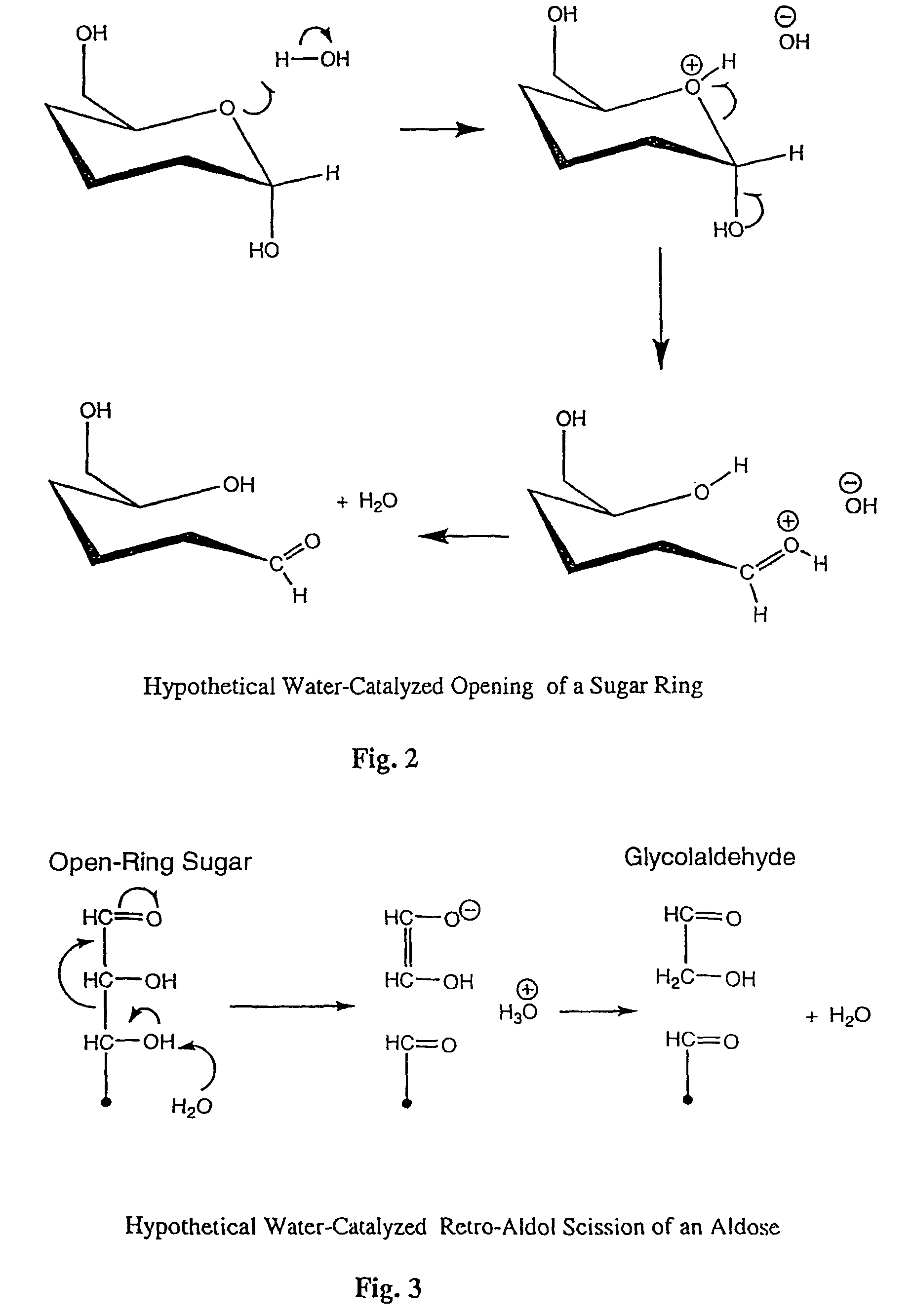

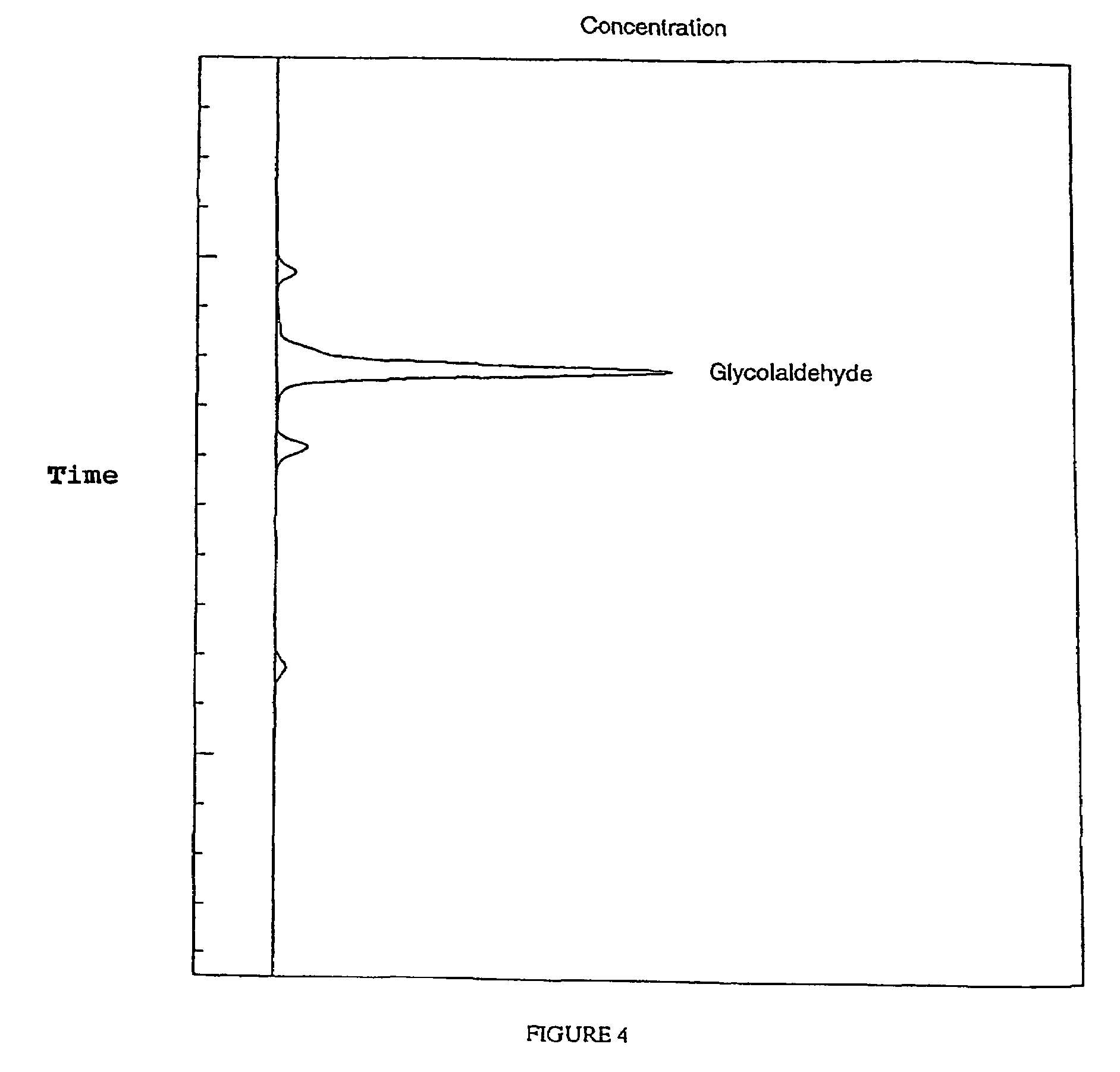

Production of glycolaldehyde by hydrous thermolysis of sugars

ActiveUS7094932B2Increase productionMinimize formationOrganic compound preparationConfectioneryGlucose polymersD-Glucose

The present invention provides a method for the production of glycolaldehyde with high specificity. The hydrous thermolysis consists of the spraying of aqueous sugar solutions containing from 25 to 80% of water but preferably 30 to 60% water, as a fine mist into a reactor held at the between 500 and 600° C., but preferably between 520 and 560° C. and the condensation of the resulting vaporous product in a surface condenser with optional heat recovery. The residence time of the vaporous product in the reactor should be in the range 0.1–5 seconds, but preferably in the range 0.5 to 2 seconds. Aldose monomeric sugars, preferably glucose (also known as dextrose), are preferred for use in the aqueous solution. The yield of glycolaldehyde in the condensed liquid is minimum 50% by weight of the sugar fed for glucose solutions.

Owner:KERRY GRP SERVICES INT

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223883B2Reduce solubilityOrganic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidCarbonylation

Owner:CELANESE INT CORP

Catalytic hydrogenation of 3-hydroxypropanal to 1,3-propanediol

InactiveUS6342646B1Improves performance and lifetimeImprove hydrogenation activityOrganic compound preparationOxygen compounds preparation by reductionAsymmetric hydrogenation1,3-Propanediol

The present invention provides an improved process for the hydrogenation of 3-hydroxypropanal to 1,3-propanediol which comprises purifying an aqueous solution of 3-hydroxypropanal by contacting said aqueous solution with a purifying agent prior to hydrogenation.

Owner:EI DU PONT DE NEMOURS & CO

Process for production of omega-3 rich marine phospholipids from krill

InactiveUS20100143571A1Quality improvementBroaden applicationMetabolism disorderOrganic compound preparationLipid formationKrill

The present disclosure relates to a process for preparing a substantially total lipid fraction from fresh krill, a process for separating phospholipids from the other lipids, and a process for producing krill meal.

Owner:PRONOVA BIOPHARMA NORGE

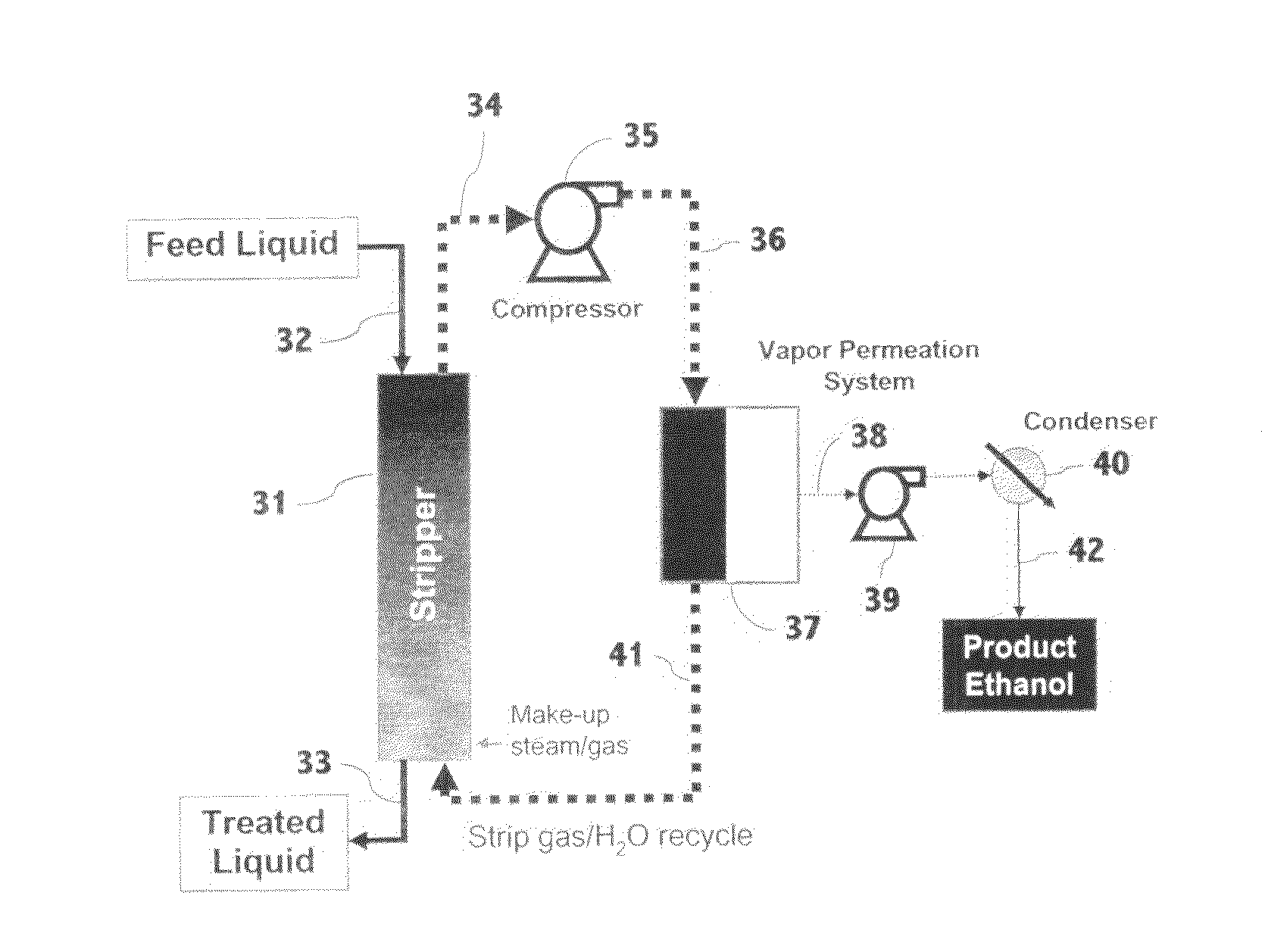

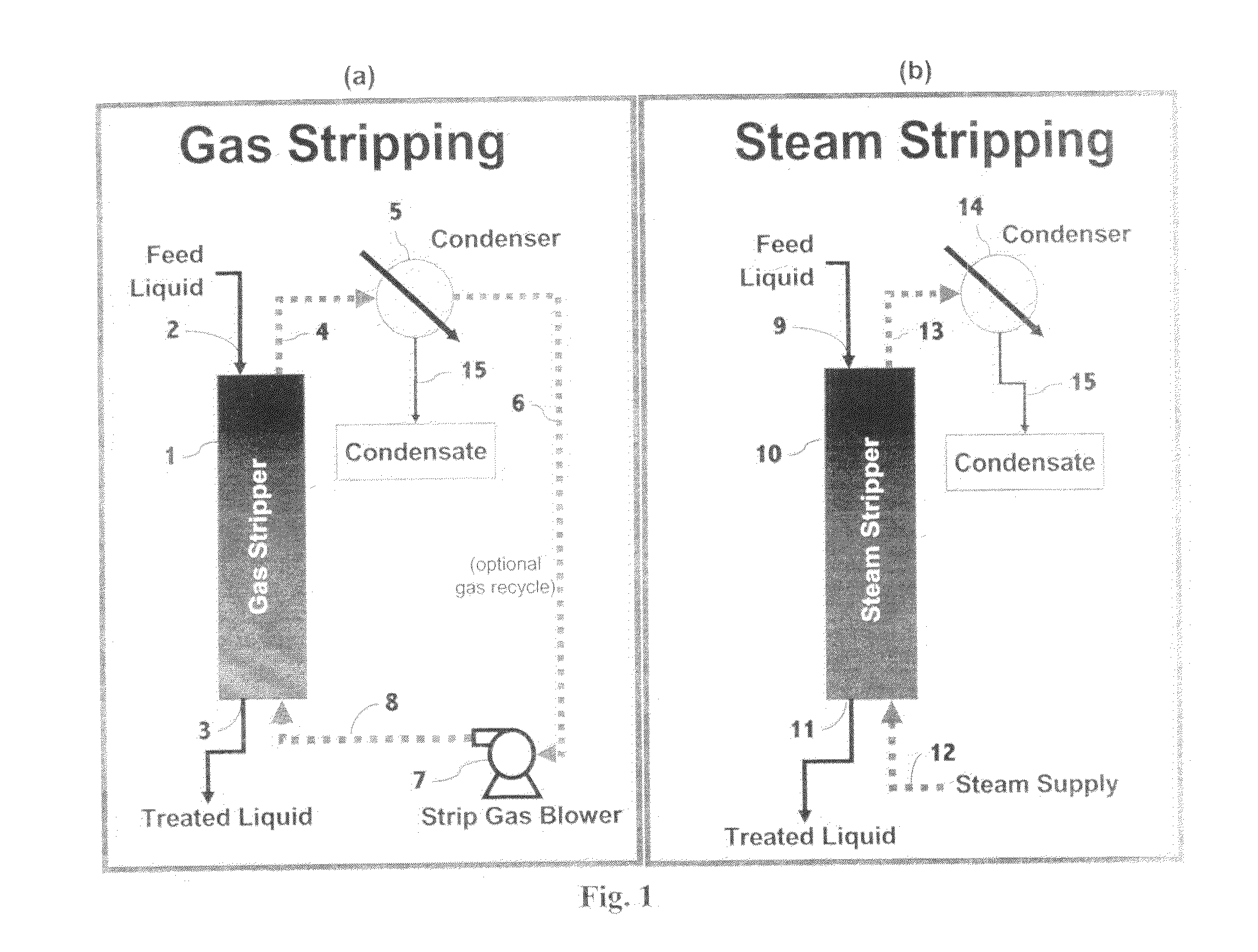

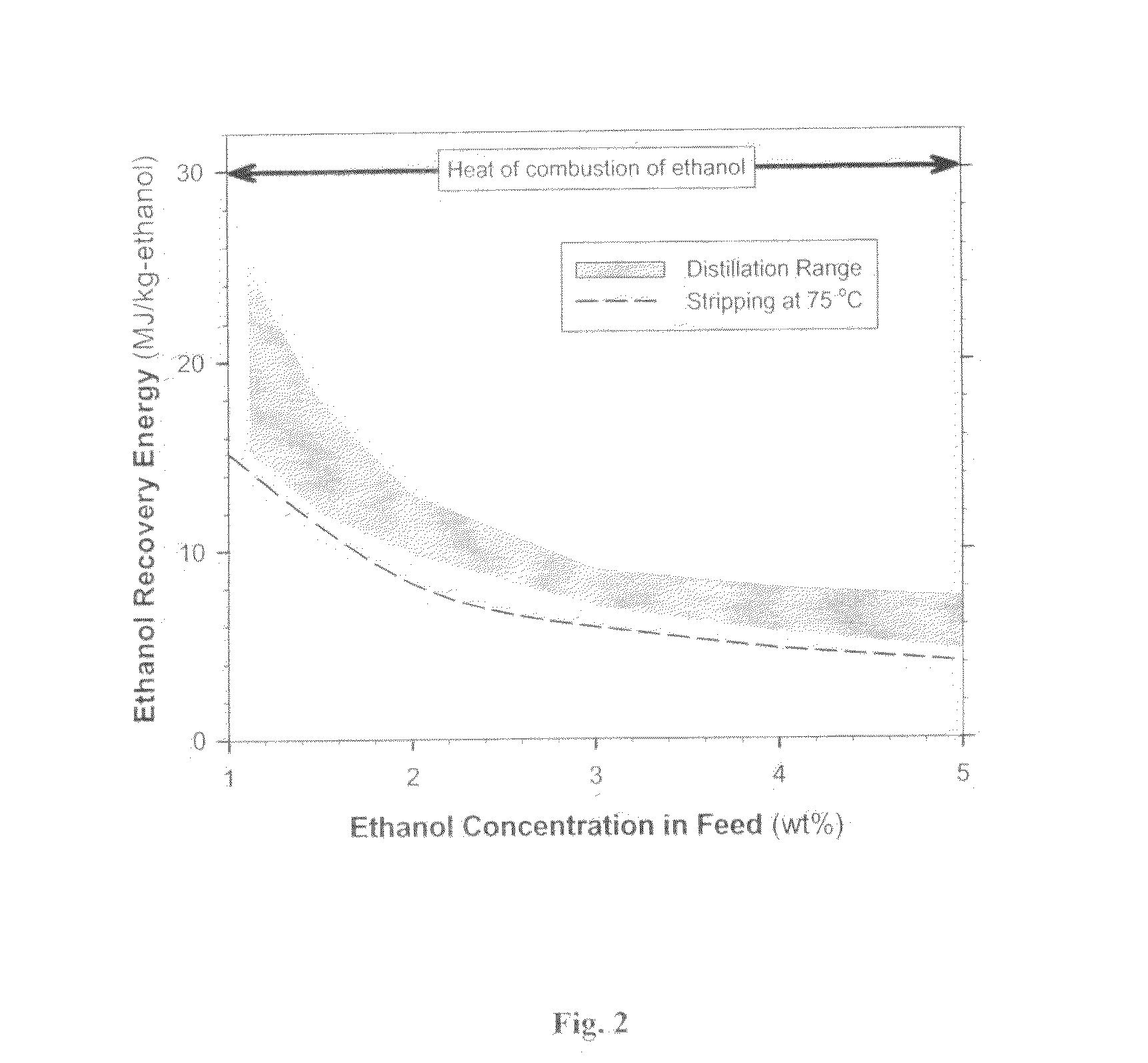

Liquid separation by membrane assisted vapor stripping process

InactiveUS20090057128A1Distillation regulation/controlUsing liquid separation agentImproved methodPermeation

An improved process for separation of liquid mixtures involves vapor stripping followed by mechanical compression of the vapor which is then exposed to a permeation membrane for separation of the compressed vapor.

Owner:VANE LELAND +1

Process for the purification of crude propene oxide

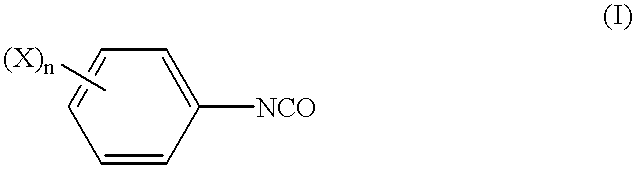

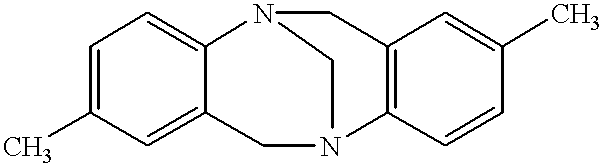

InactiveCN1714087ACarbonyl compound separation/purificationPurification methodsExtractive distillation

The present invention relates to a method for purifying crude propylene oxide containing methanol and acetaldehyde by extractive distillation operated continuously, wherein an extraction solvent capable of reducing the volatility of methanol is used, and the crude propylene oxide is fed into a distillation column above the feed point of the crude propylene oxide A compound containing unsubstituted NH2 groups and capable of reacting with acetaldehyde is added to obtain purified propylene oxide containing less than 100 ppm methanol and less than 100 ppm acetaldehyde. The present invention also relates to a method for catalytic epoxidation of propylene comprising said purification step.

Owner:EVONIK OPERATIONS GMBH +1

Process of controlling heavies in a recycle catalyst stream

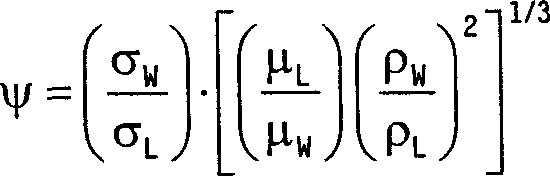

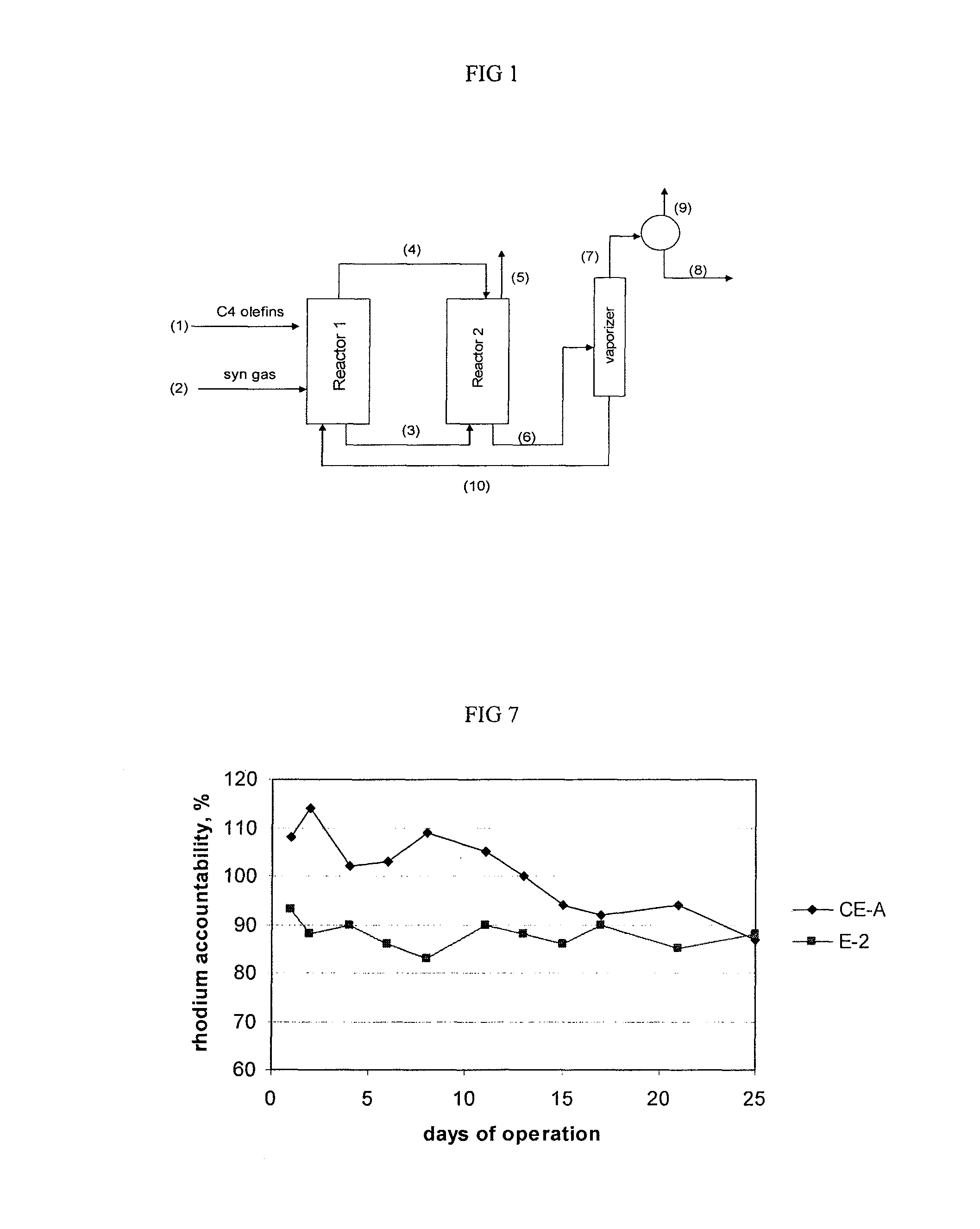

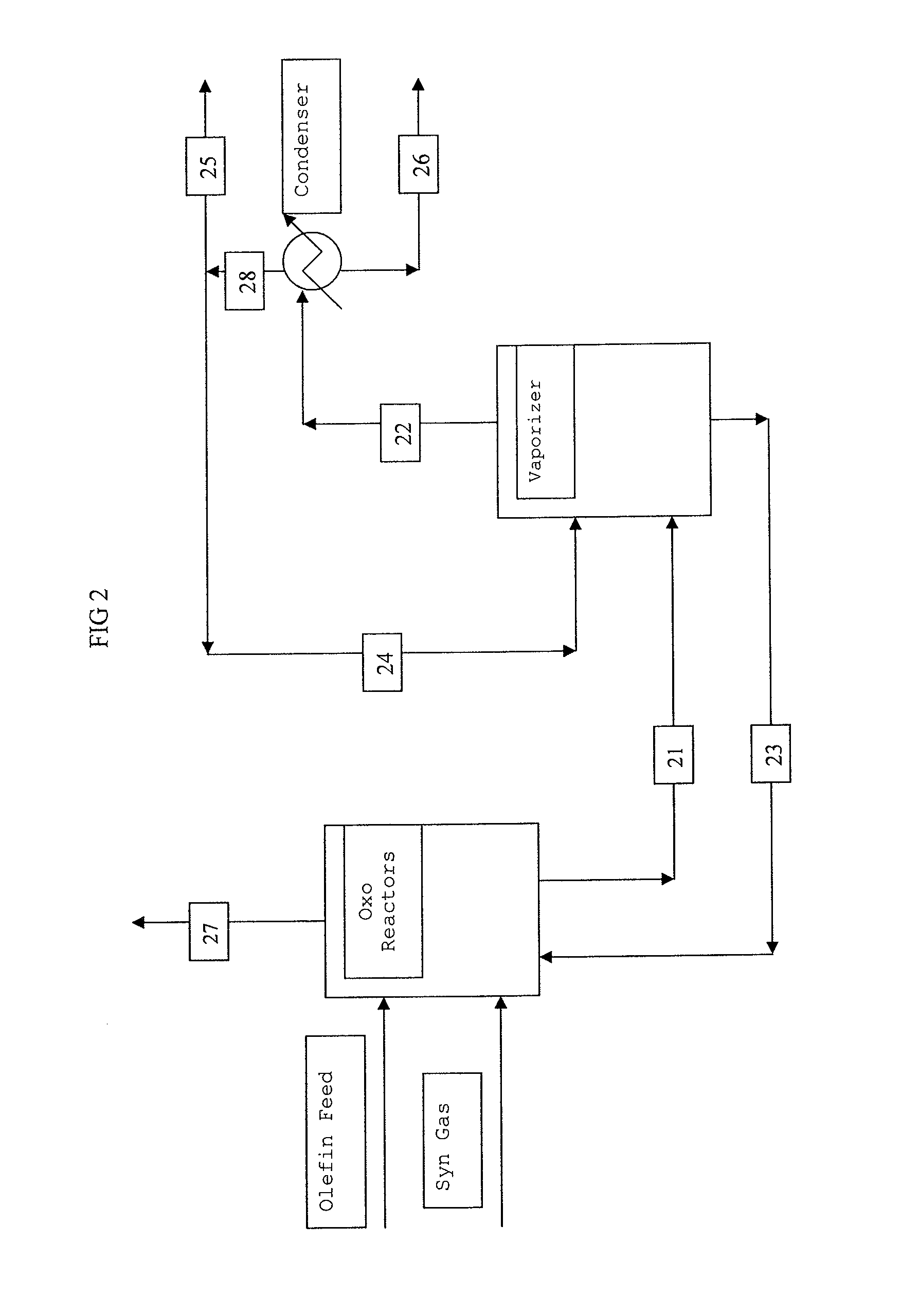

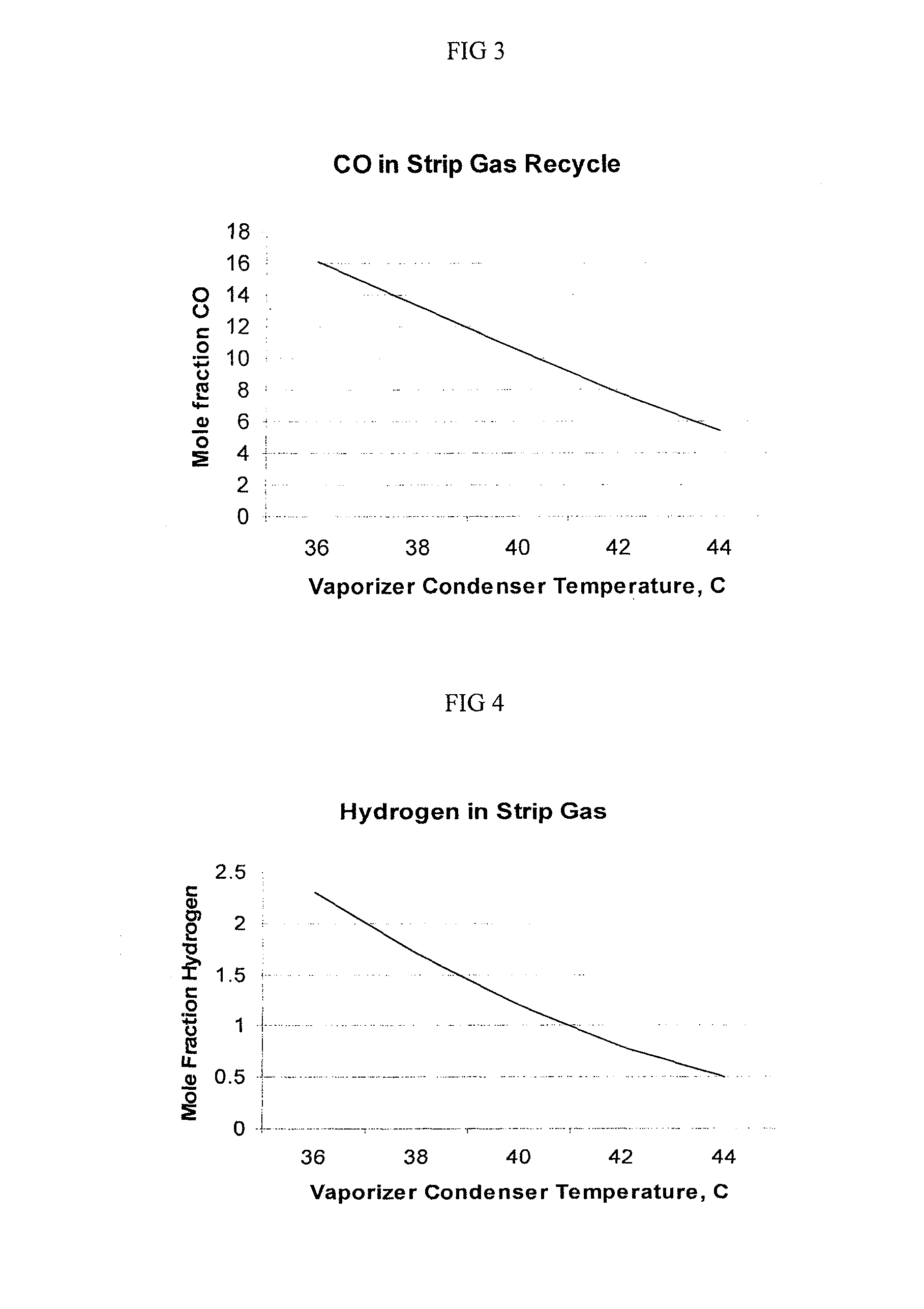

ActiveUS8404903B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistryHydroformylation

A process of controlling heavies in a recycle catalyst stream, particularly, for use in a continuous hydroformylation process of converting an olefin with synthesis gas in the presence of a hydroformylation catalyst to form an aldehyde product stream with subsequent separation of the catalyst for recycle to the hydroformylation step. Heavies are controlled, and preferably reduced, by means of feeding a recycle gas stream, taken as a portion of an over-head stream from a condenser, back to a vaporizer wherein the aldehyde product stream is separated.

Owner:DOW TECH INVESTMENTS +1

Use of fluorinated ketones as wet cleaning agents for vapor reactors and vapor reactor components

InactiveUS6394107B1Organic compound preparationDetergent mixture composition preparationHydrogen atomHydrogen

A method for cleaning a vapor reactor by applying a liquid cleaning agent comprising a fluorinated ketone having about 5 to about 10 carbon atoms and up to two hydrogen atoms is described. The fluorinated ketone has low global warming potential.

Owner:3M INNOVATIVE PROPERTIES CO

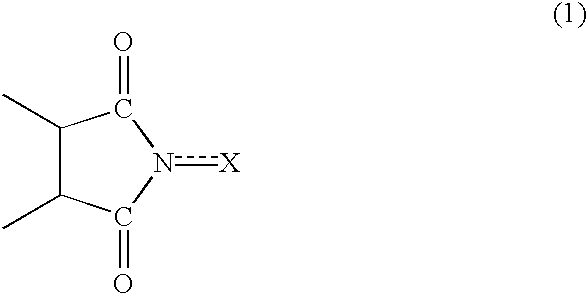

Method of separating imide compound

InactiveUS20020169331A1Efficient separationPreparation by oxidation reactionsOrganic compound preparationImideCompound a

A reaction product and an imide compound can be separated from a reaction mixture obtained by reacting a substrate in the presence of the imide compound having an imide unit represented by the following formula (1): wherein X represents an oxygen atom, a hydroxyl group or an acyloxy group by (A1) a solvent-crystallization step for crystallizing the imide compound with at least one solvent selected from the group consisting of a hydrocarbon, a chain ether and water, (A2) a cooling-crystallization step for crystallizing the reaction product by cooling, or (B) an extraction step for distributing the reaction product into a phase of a water-insoluble solvent and the imide compound into a phase of an aqueous solvent, respectively by using the aqueous solvent containing at least water and the water-insoluble solvent separable from the aqueous solvent. Further, the imide compound and the metal catalyst can be separated from a mixture containing the imide compound and the metal catalyst by (C) a solvent-crystallization step for crystallizing the imide compound by using a solvent for crystallization, (D) an absorption step for absorbing the metal catalyst by an absorption treatment, or (E) an extraction step for distributing the imide compound into a phase of a water-insoluble solvent and the metal catalyst into a phase of an aqueous solvent, respectively by using the aqueous solvent containing at least water and the water-insoluble solvent separable from the aqueous solvent.

Owner:DAICEL CHEM IND LTD

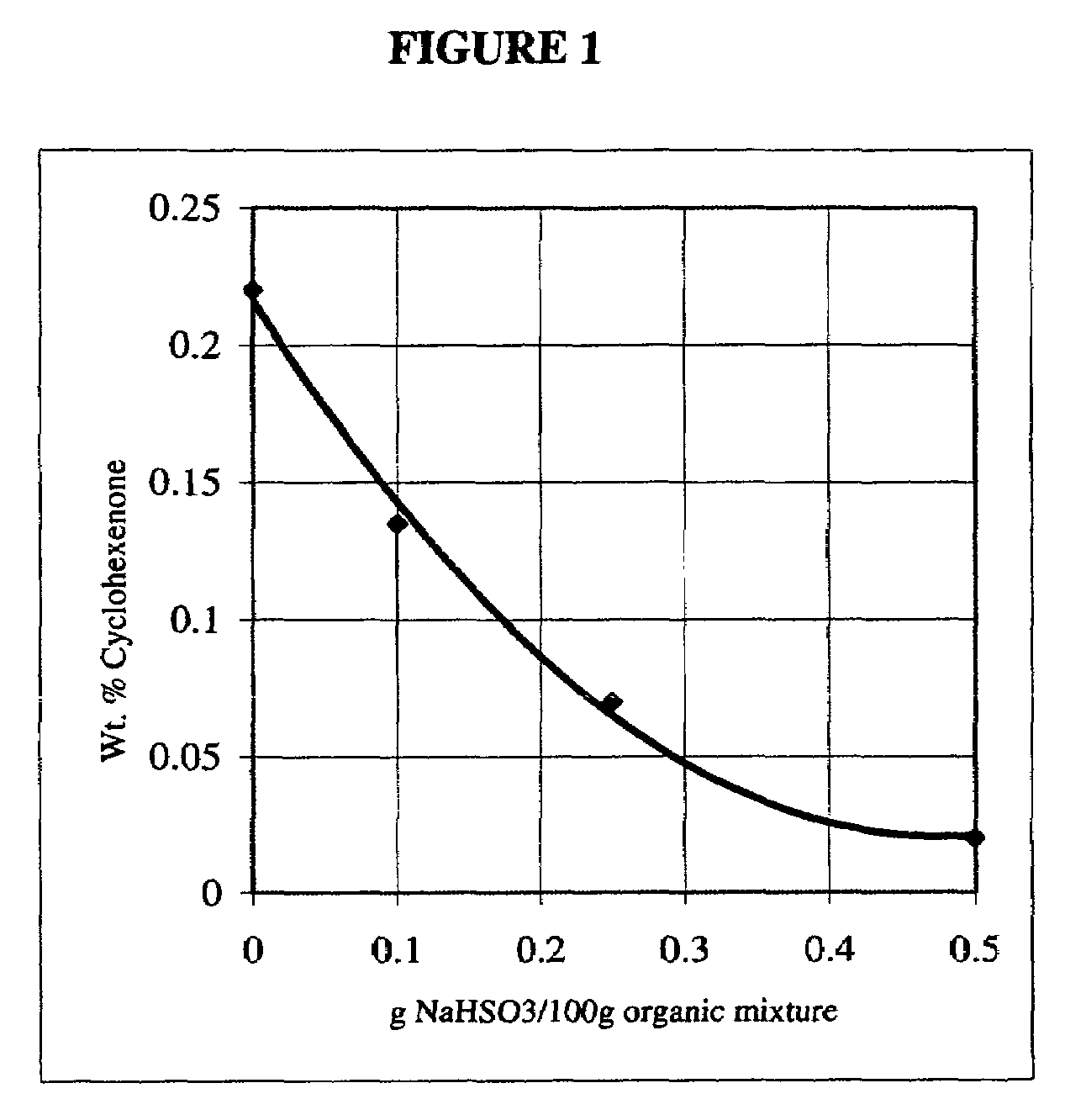

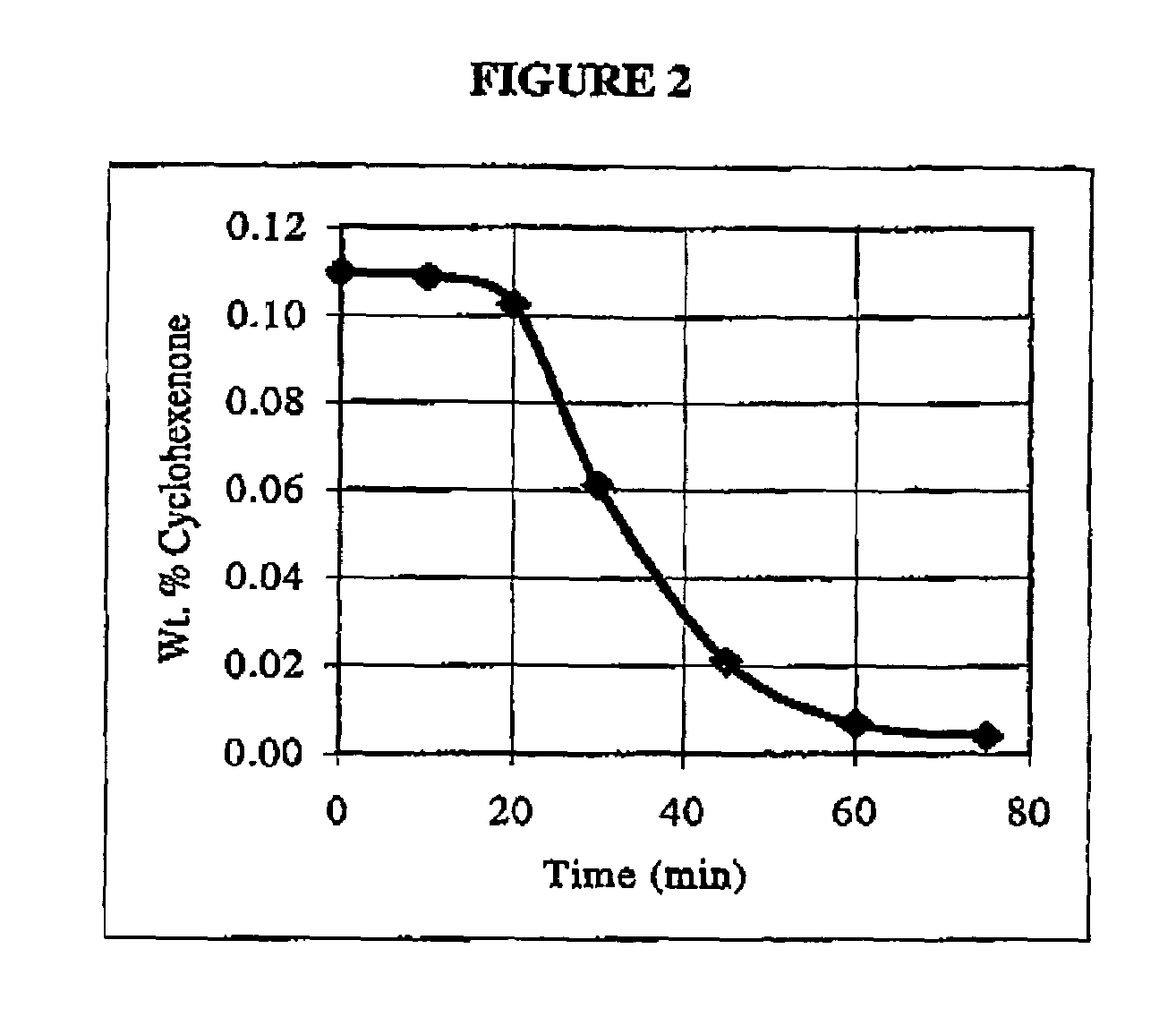

Method for reducing cyclohexenone content of a cyclohexenone-containing organic mixture

A method for reducing the concentration of cyclohexenone in a cyclohexenone containing organic mixture is disclosed. The method includes contacting an organic mixture comprising cyclohexenone with an effective amount of at least one of sulfurous acid, a salt of sulfurous acid, an alkali hydroxide, or a mixture of two or more of these compounds.

Owner:INVISTA NORTH AMERICA R L

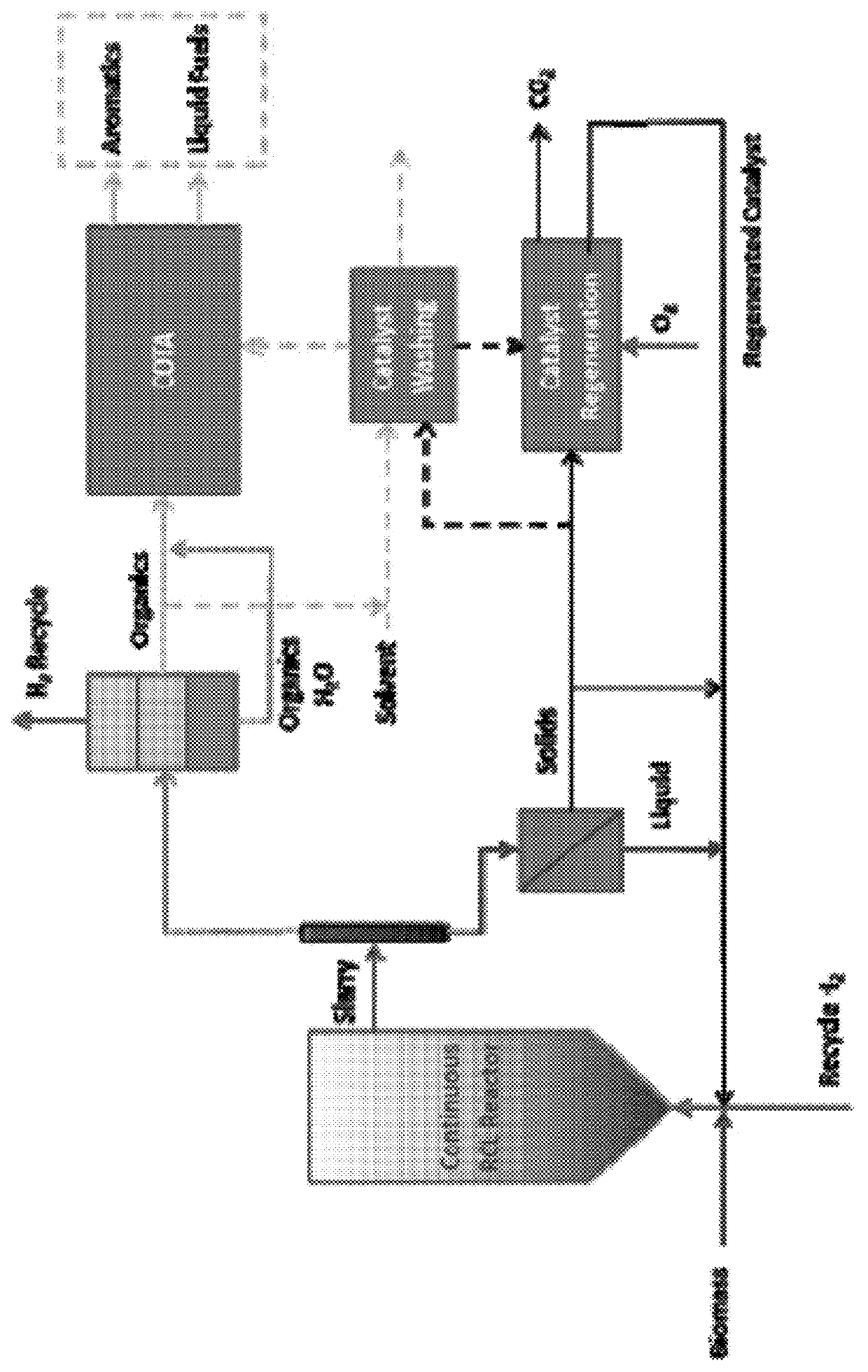

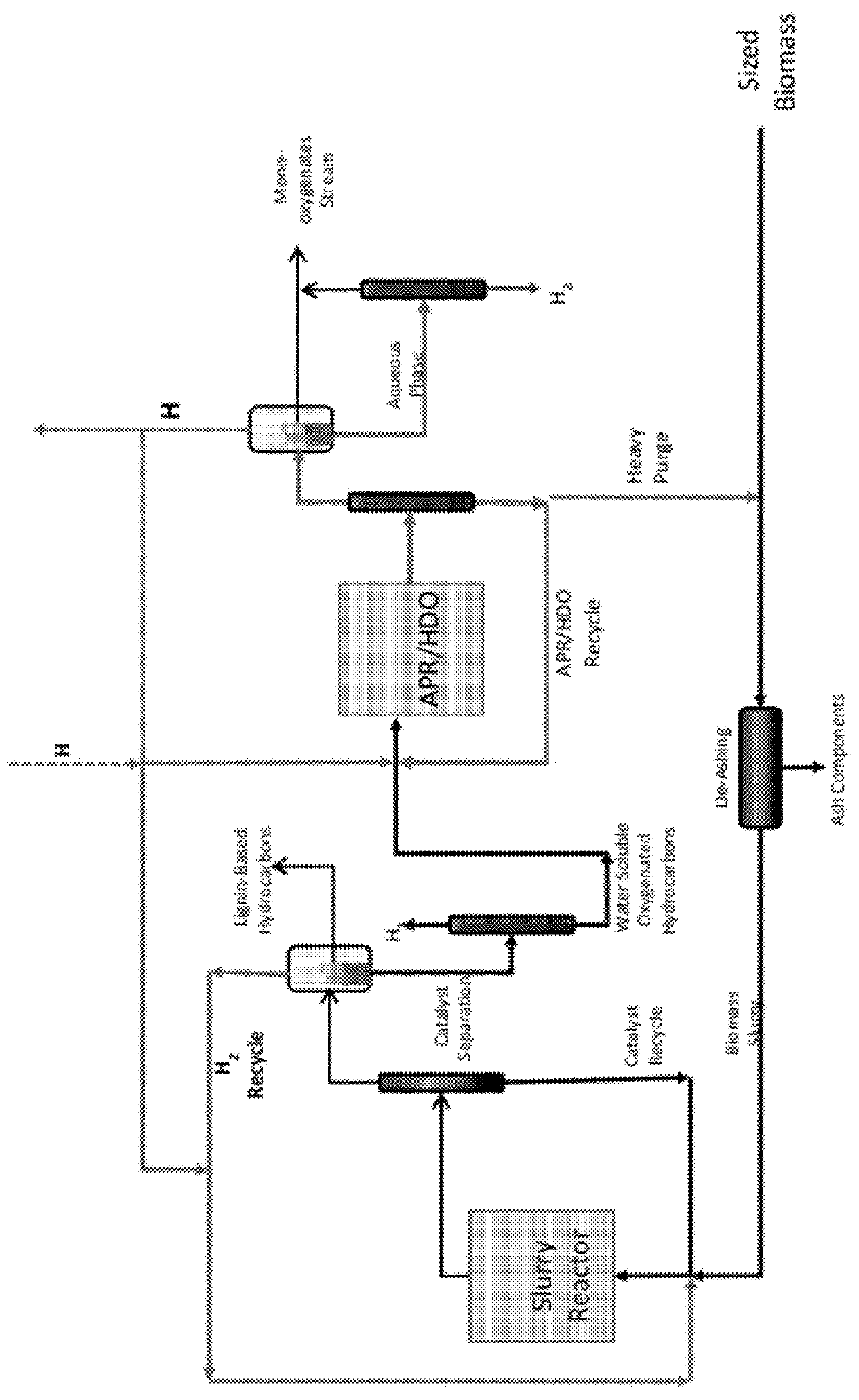

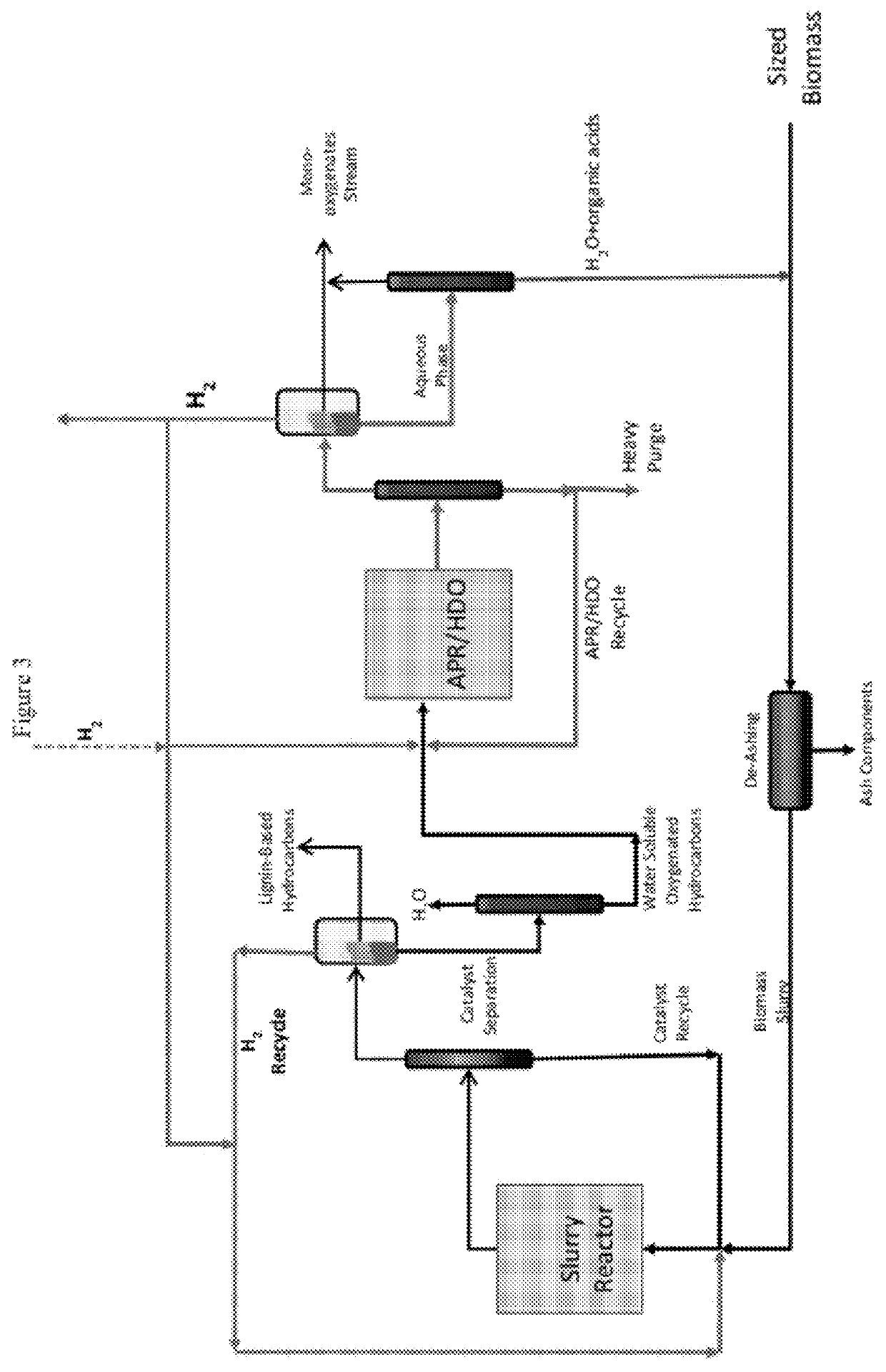

Reductive biomass liquefaction

ActiveUS20120172579A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionCyclic etherBiofuel

The present invention provides methods, reactor systems, and catalysts for converting in a continuous process biomass to less complex oxygenated compounds for use in downstream processes to produce biofuels and chemicals. The invention includes methods of converting the components of biomass, such as hemicellulose, cellulose and lignin, to water-soluble materials, including lignocellulosic derivatives, cellulosic derivatives, hemicellulosic derivatives, carbohydrates, starches, polysaccharides, disaccharides, monosaccharides, sugars, sugar alcohols, alditols, polyols, diols, alcohols, ketones, cyclic ethers, esters, carboxylic acids, aldehydes, and mixtures thereof, using hydrogen and a heterogeneous liquefaction catalyst.

Owner:VIRENT

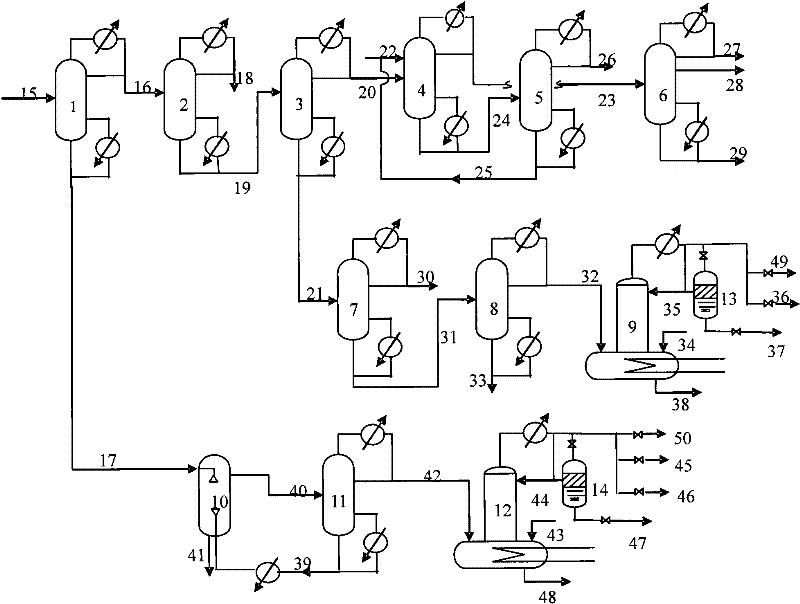

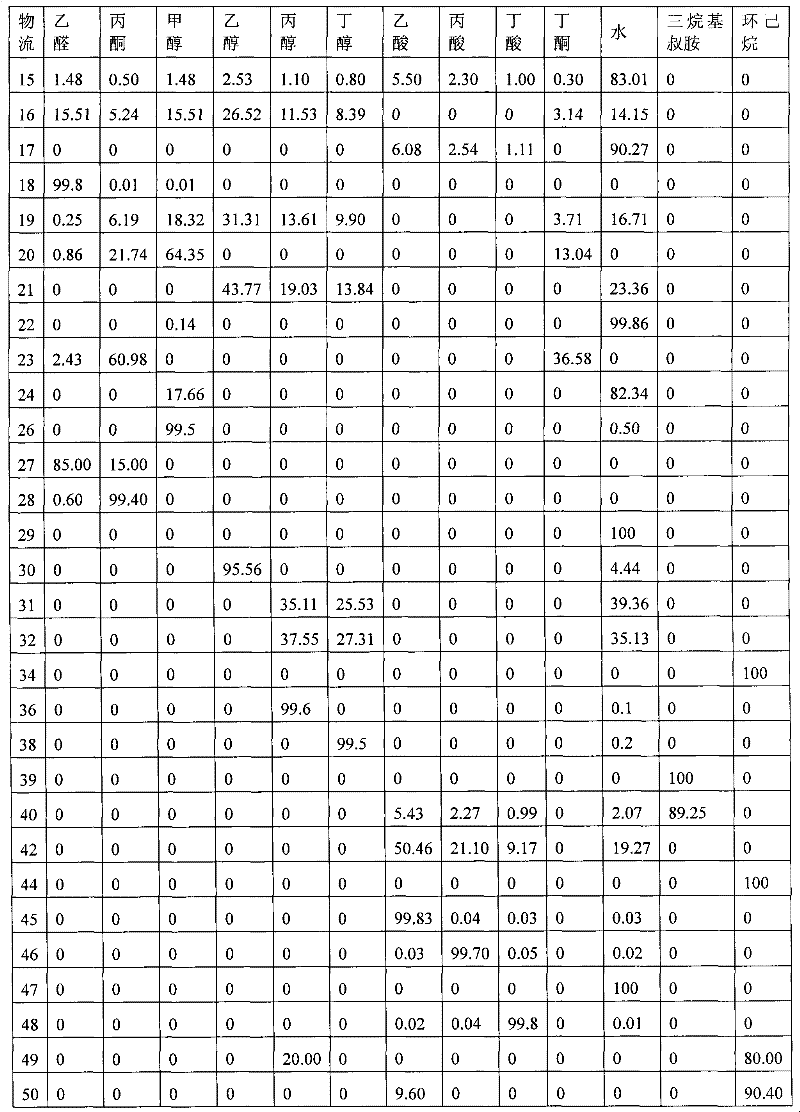

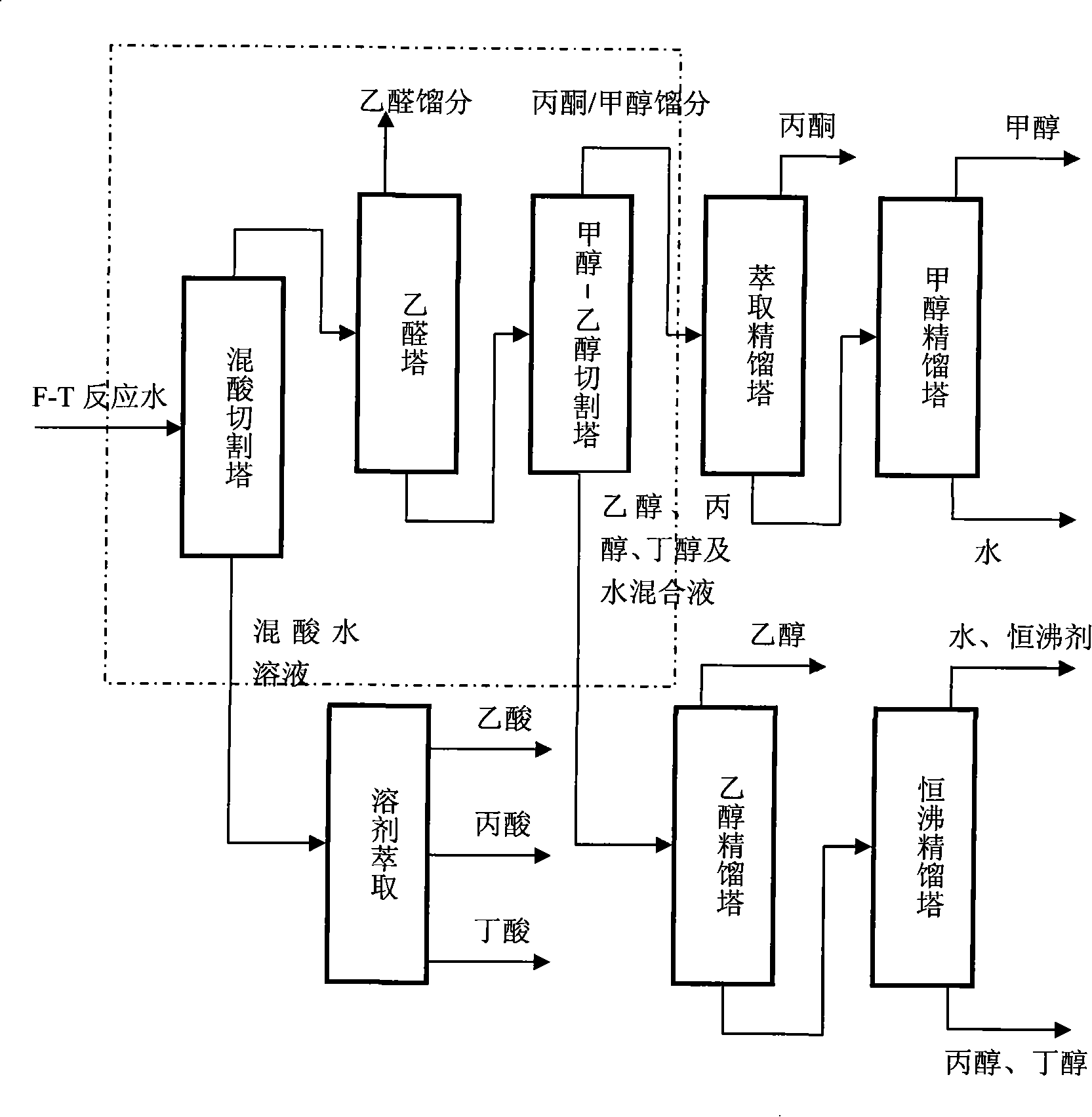

Separating and recovering method for organic oxygen-containing compounds in Fischer-Tropsch synthesis water phase

InactiveCN102442882AReach salesMeet application requirementsOrganic compound preparationHydroxy compound preparationCarboxylic acidOxygen

The invention relates to method and equipment system for separating and recovering organic oxygen-containing compounds in a Fischer-Tropsch synthesis water phase. The equipment system is integrated by adopting twelve towers including a mixed acid cutting tower, an acetaldehyde rectifying tower, a methanol / ethanol dividing tower, a methanol extraction rectifying tower, a methanol rectifying tower, an acetaldehyde removing tower, an ethanol tower, a propanol concentration extracting tower, a propanol intermittent azeotropic distillation tower, a carboxylic acid extraction tower, a carboxylic acid intermittent rectifying tower and an extraction agent recovering tower matched with the carboxylic acid extraction tower for use. By applying the method and equipment system disclosed by the invention, more than ten kinds of organic oxygen-containing compounds such as acetaldehyde, acetone, methanol, ethanol, normal propyl alcohol, normal butanol, acetic acid, metacetonic acid, butyric acid, butanone and the like can be separated from raw materials; and the products can respectively reach the industrial purity. The method and equipment provided by the invention are economic, effective and reasonable; and according to the method and equipment, efficiency of Fischer-Tropsch synthesis industrial enterprises can be greatly increased, production cost is reduced and goal of clean production can be achieved.

Owner:SYNFUELS CHINA TECH CO LTD

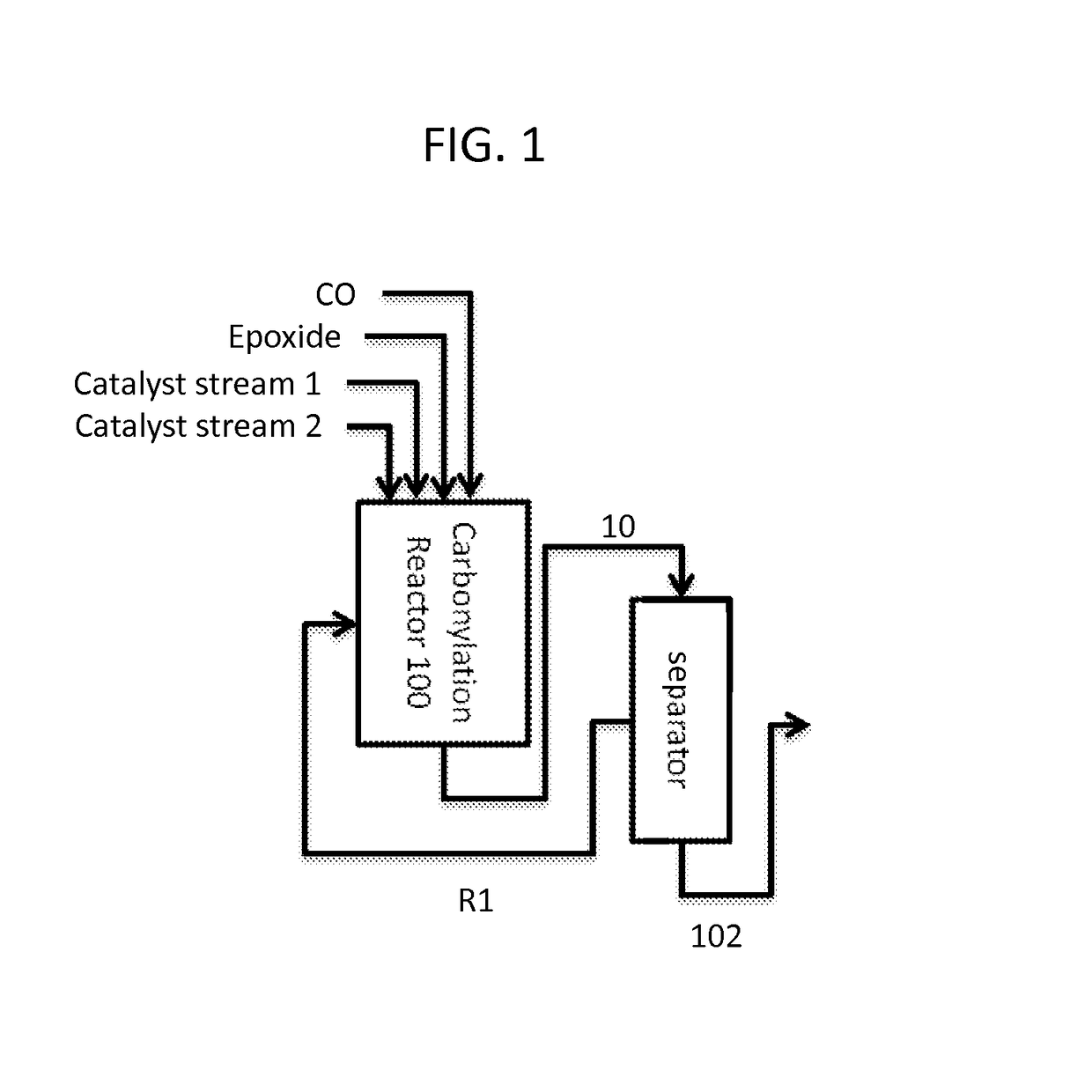

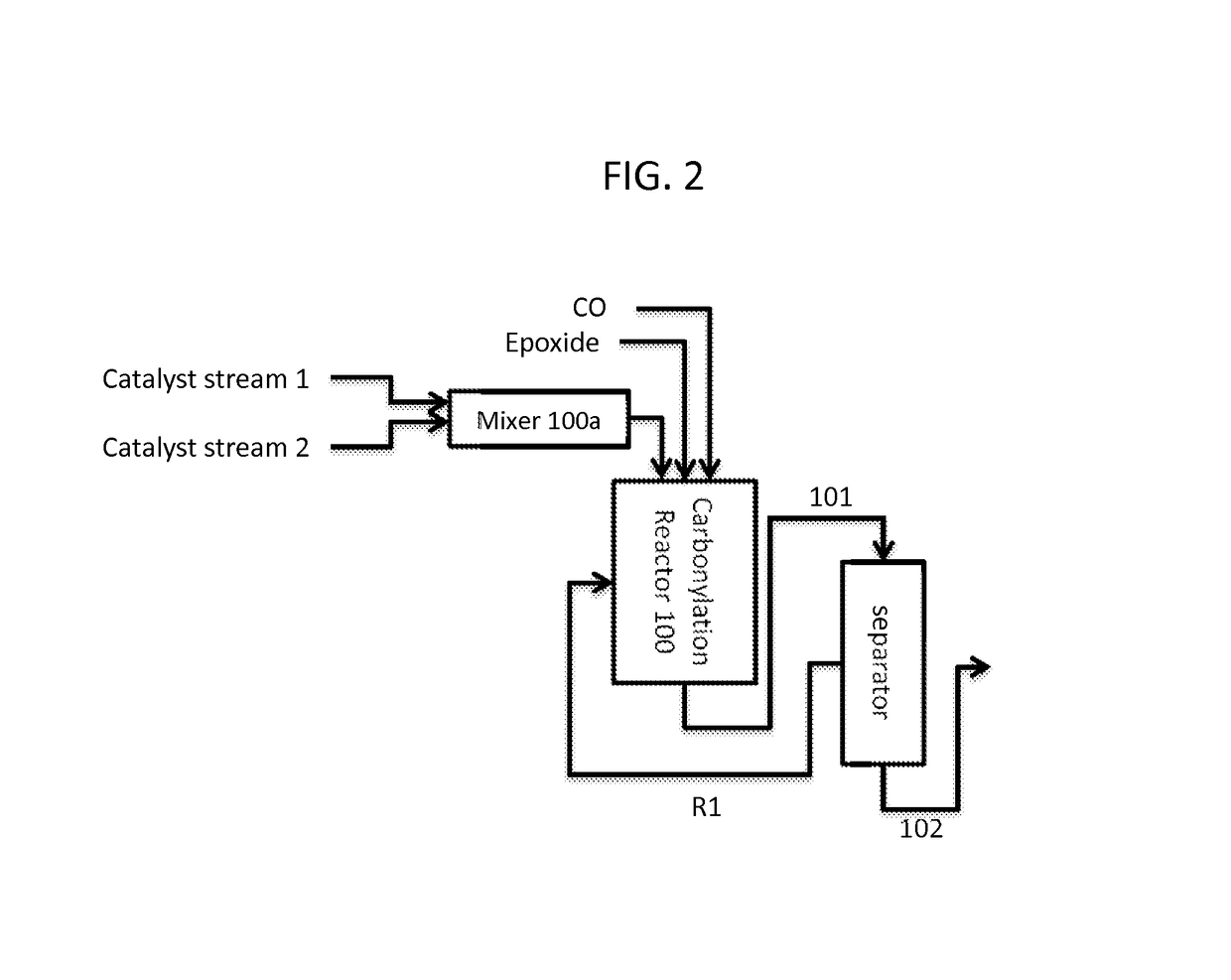

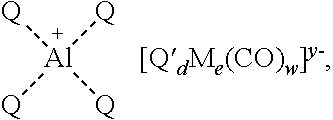

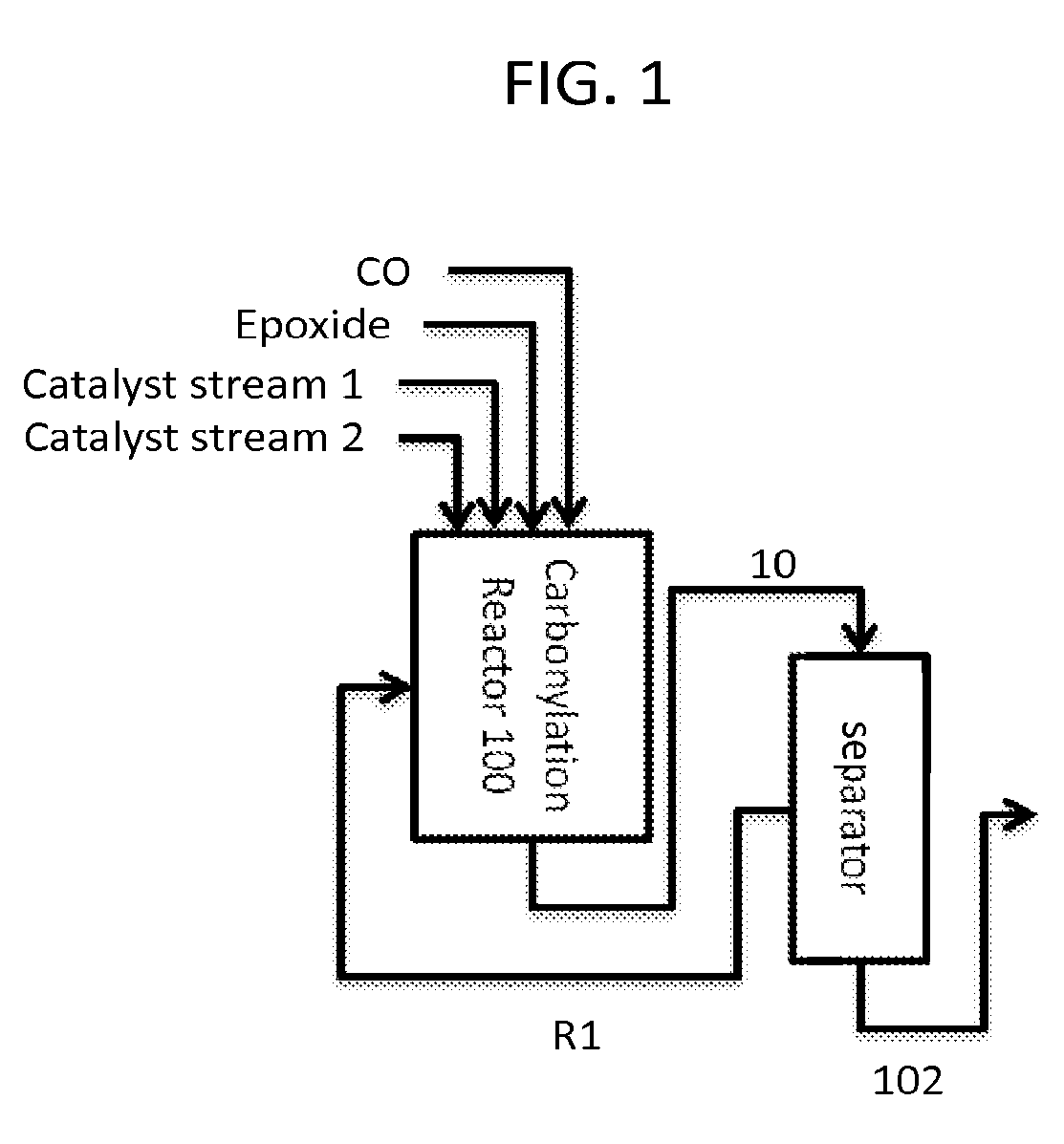

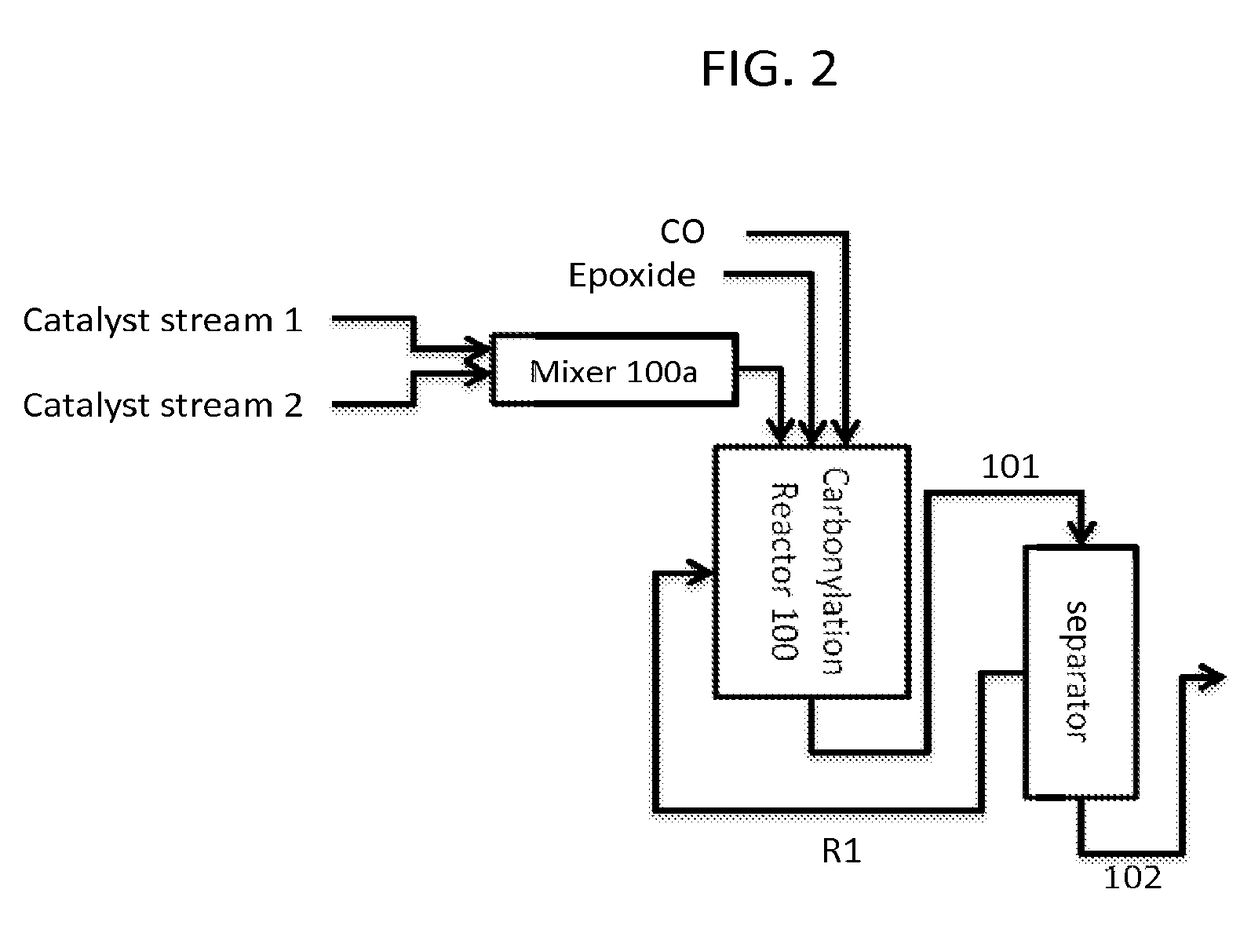

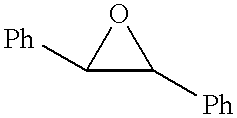

Synthesis of metal complexes and uses thereof

InactiveUS20170225157A1Little and no contaminationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsCarbonylationProtein carbonyl

The present disclosure provides novel methods of making aluminum complexes with utility for promoting epoxide carbonylation reactions. Methods include reacting neutral metal carbonyl compounds with alkylaluminum complexes.

Owner:NOVOMER INC

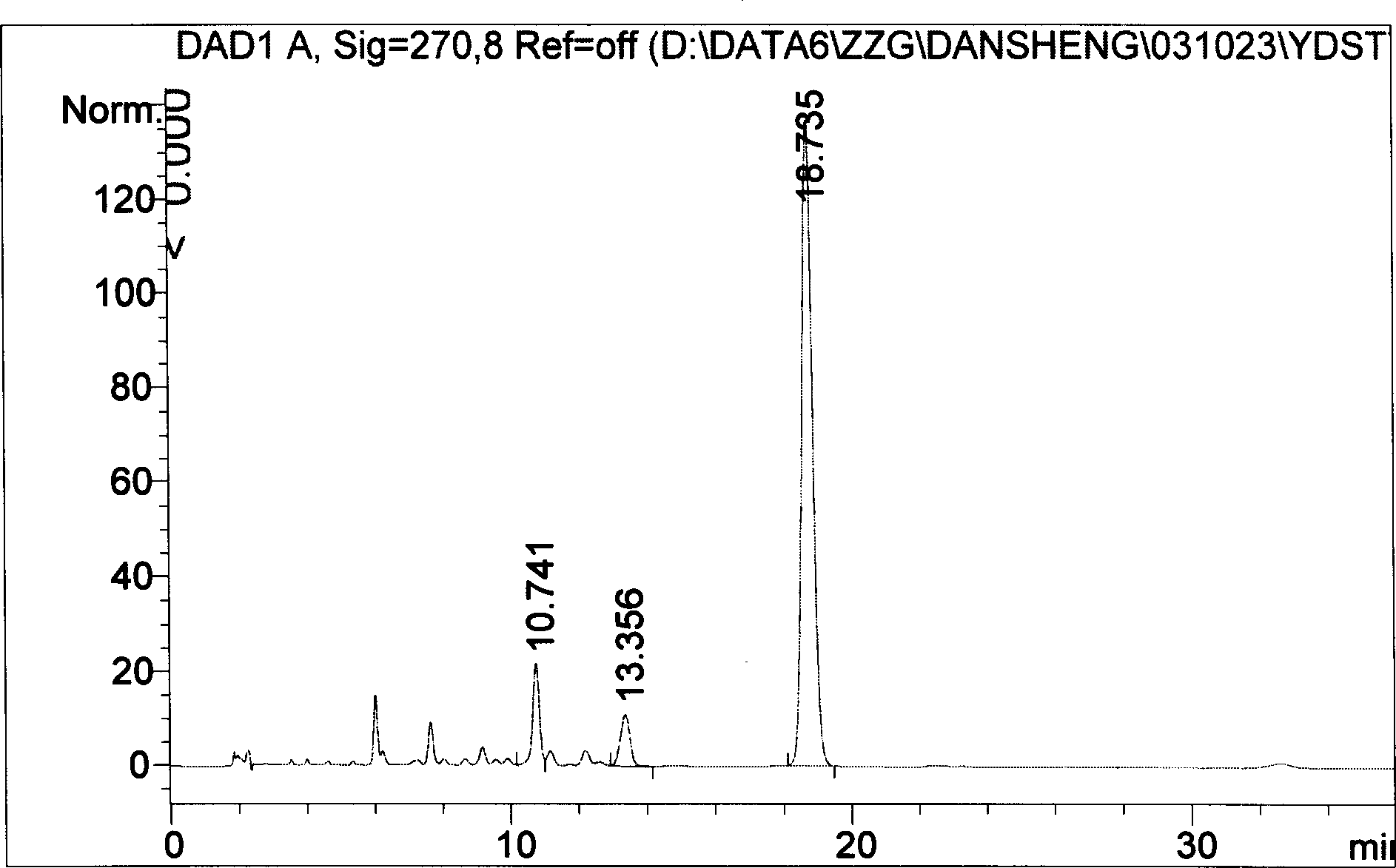

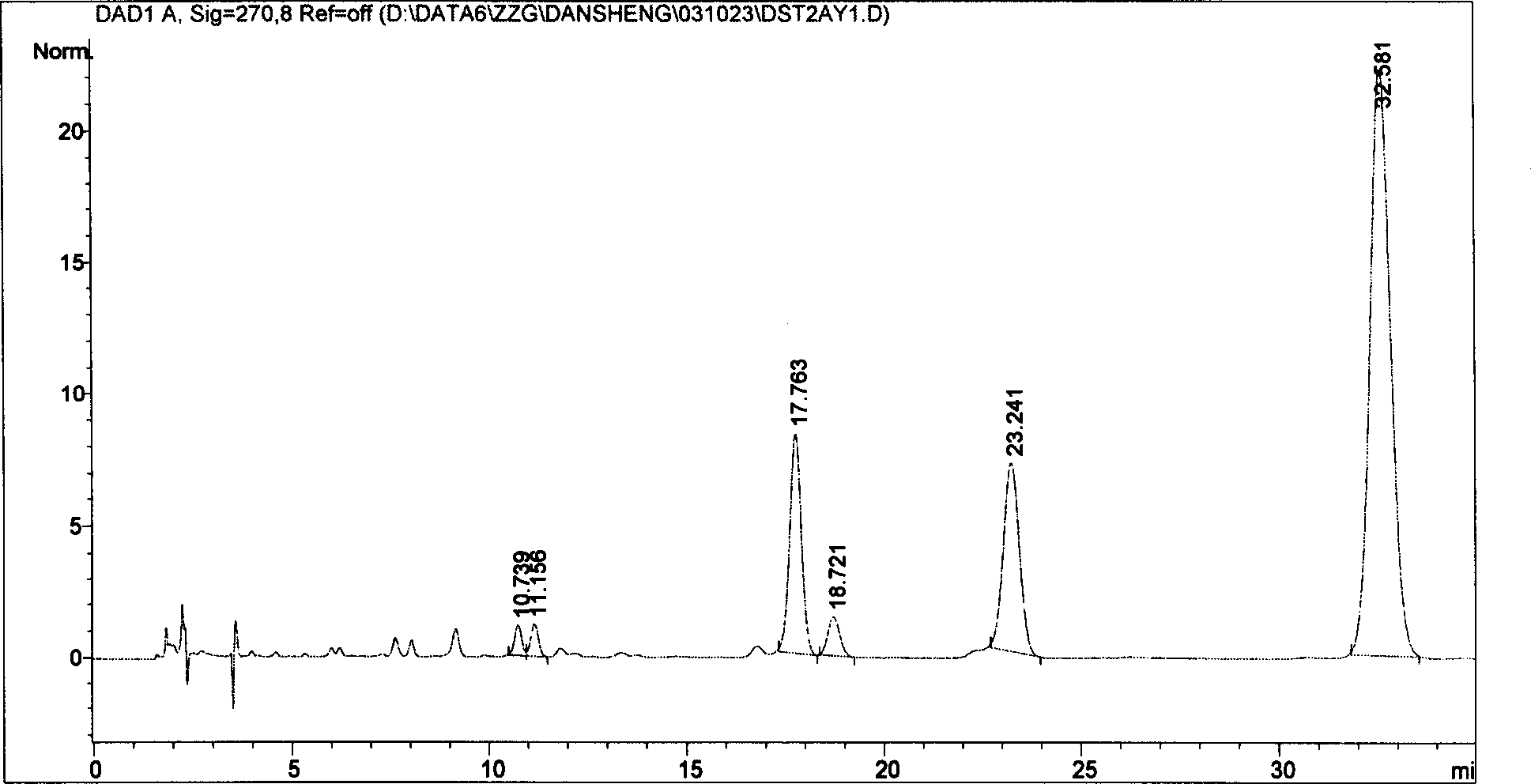

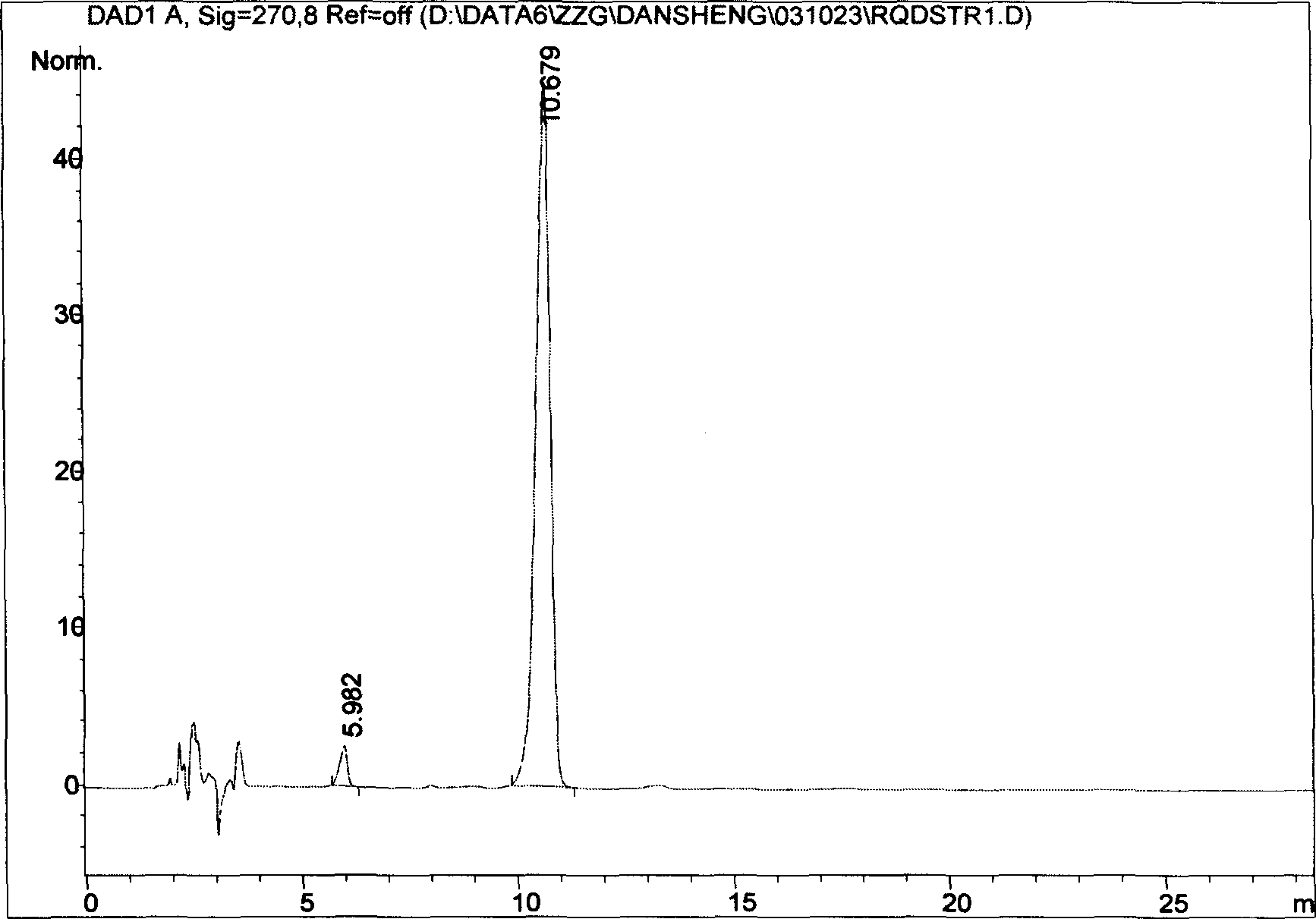

Process for extracting tanshinone

ActiveCN1670019ASolve permeabilitySolve the problem that the fat-soluble tanshinone in Danshen medicinal materials cannot be completely extractedCarbonyl compound separation/purificationAlcoholFiltration

The invention relates to a method for extracting tanshinone which comprises the following two steps: first, alcohol extraction process: separating the extraction liquid and dregs with the danshen liposolubility content from danshen medicine materical crude slices or disintegrated danshen medicinal materials by bath method, hypersonic extraction or microwave extraction in condition of normal temperature or heating, and reserving, adding correct concentration alcohol into the dregs, inverse flow extracting with heating to get the extraction, which combined with the extraction get from the first extraction, removing the solid impurities by the methods of filtration, centrifugation or deposition, and reserving. Second, isolation method separation: adding the medicine liquid get from the said alcohol extraction process to a macroreticular resinous adsorbent column, gradient eluting by alcohol with a finite concentration respectively to get the extraction I (with cryptotanshinone and dihydrotanshinone I) and extraction II (with tanshinone IIA and tanshinone I).

Owner:TIANJIN TASLY MORDEN TCM RESOURCES

Synthesis of metal complexes and uses thereof

ActiveUS20190030520A1Little and no contaminationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCompound (substance)Carbonylation

The present disclosure provides novel methods of making aluminum complexes with utility for promoting epoxide carbonylation reactions. Methods include reacting neutral metal carbonyl compounds with alkylaluminum complexes.

Owner:NOVOMER INC

Process for extracting multiple active components from residual dregs of monordica grosvenori

InactiveCN1397539AImprove efficiencyFermentationFatty-oils/fats productionActive componentGlycoside formation

A process for extracting the active components (farnesol, fatty aldehyde and edible fibres) from the momordica grosvenori dregs generated after extracting glycoside includes extracting seed oil, extracting farnesol by fraction, extracting fatty aldehyde from the water phase, and preparing edible fibres from the dregs by chemical or enzyme method. Its advantages are simple process and high output rate.

Owner:王恒山 +2

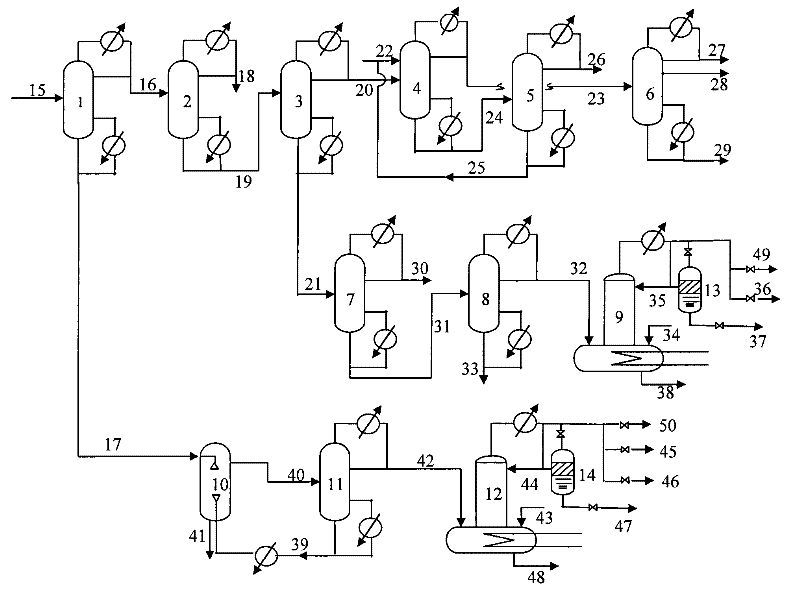

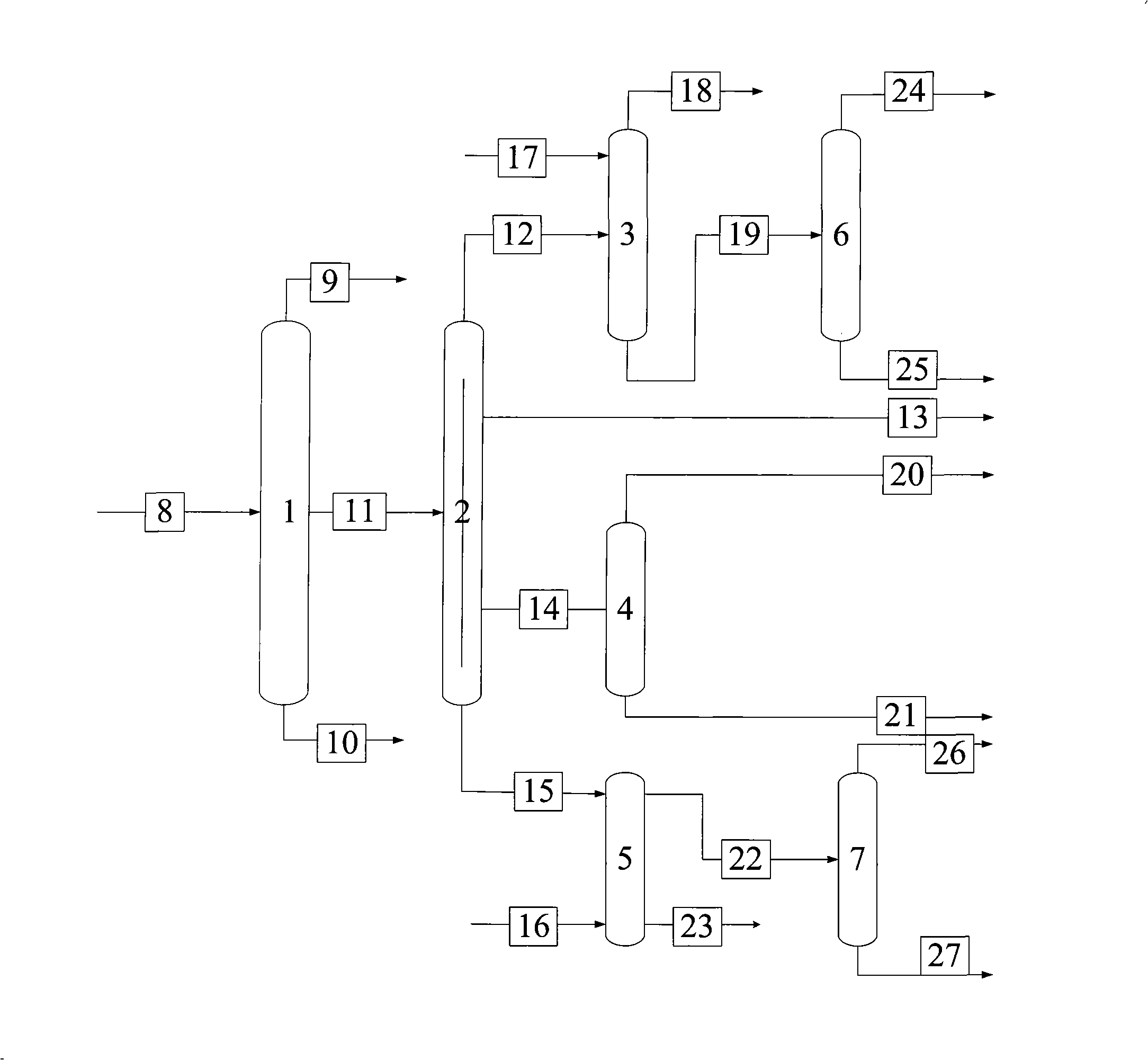

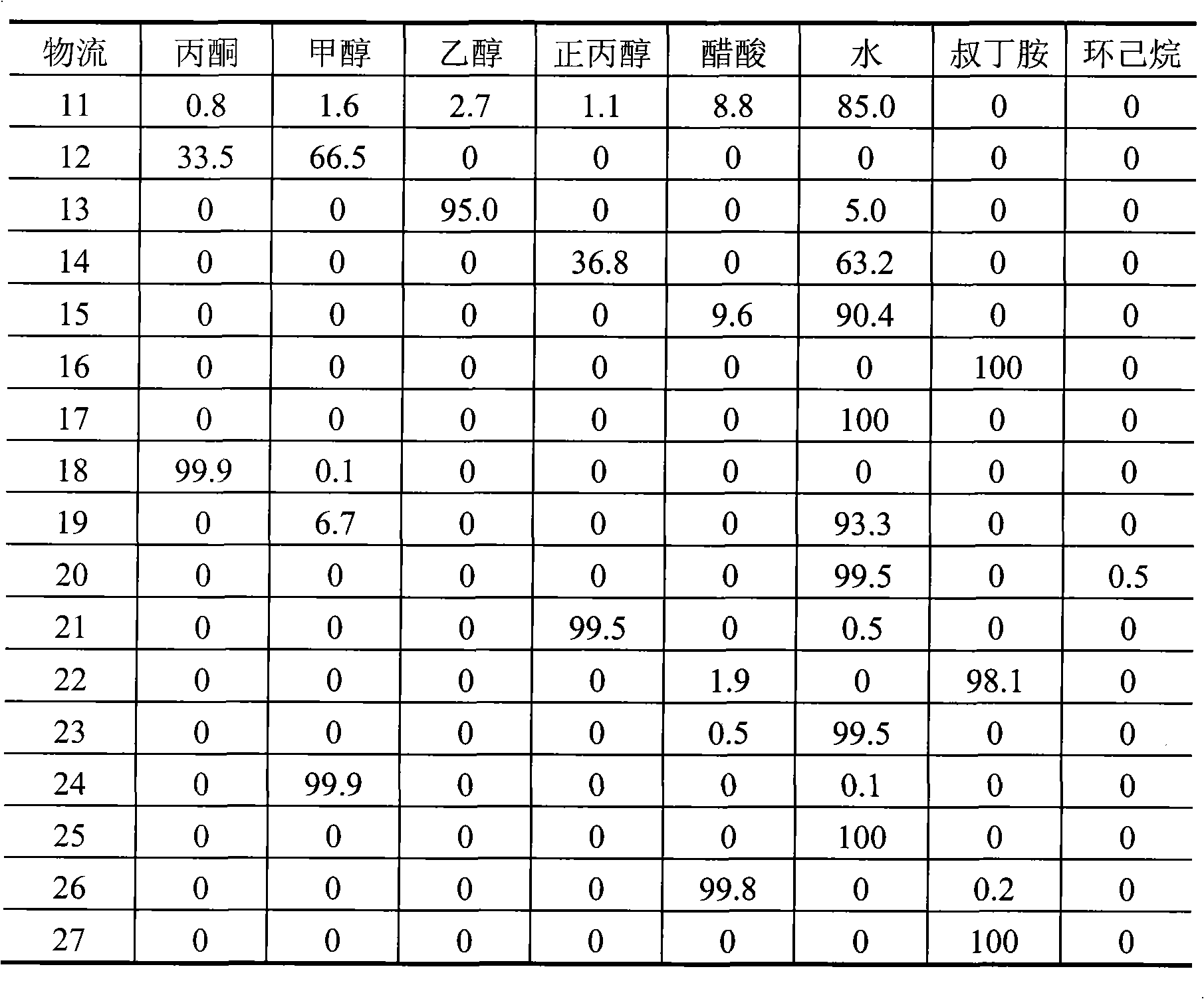

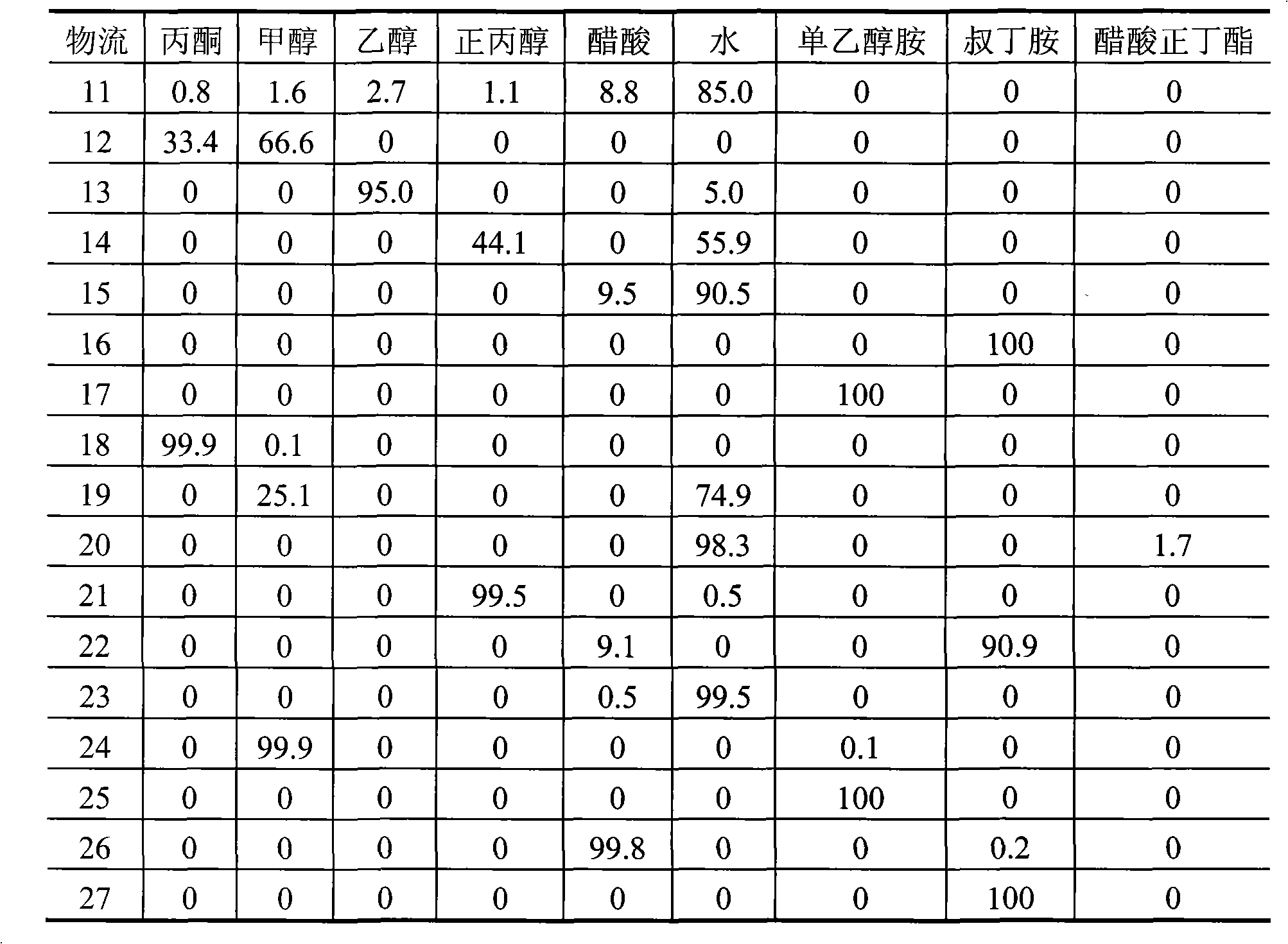

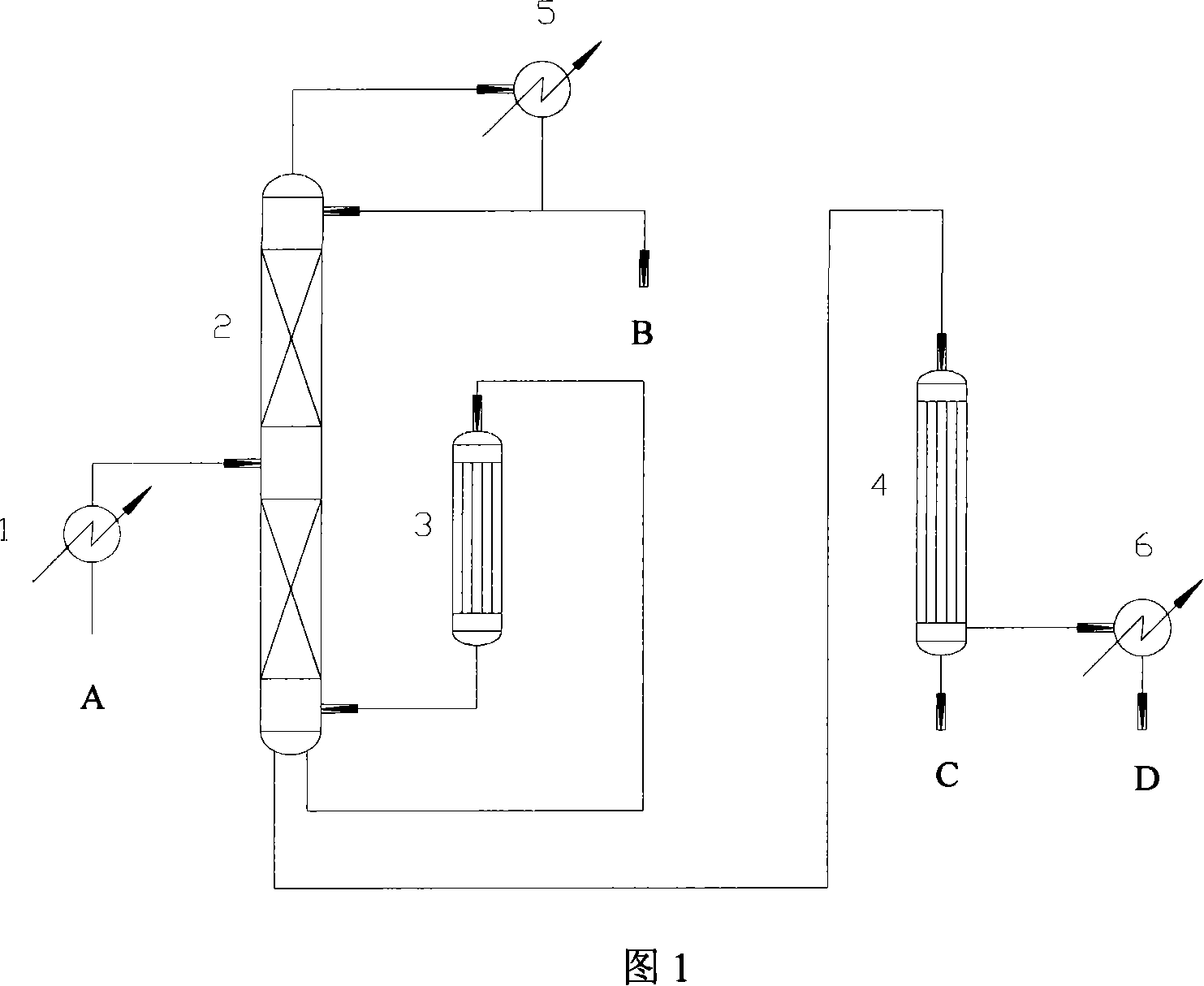

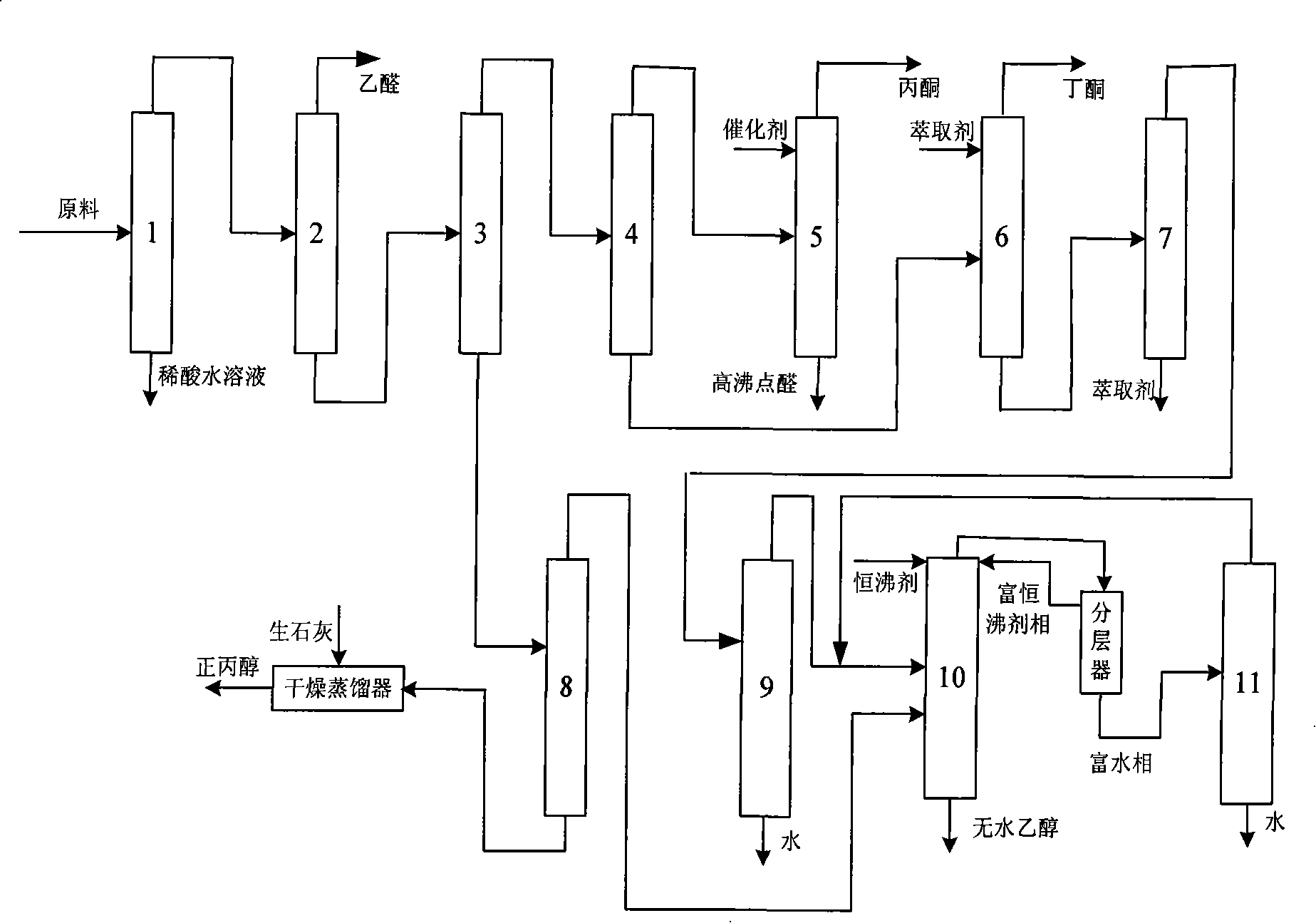

Process for the separation of aqueous phase by-product of fischer-tropsch synthesis reaction

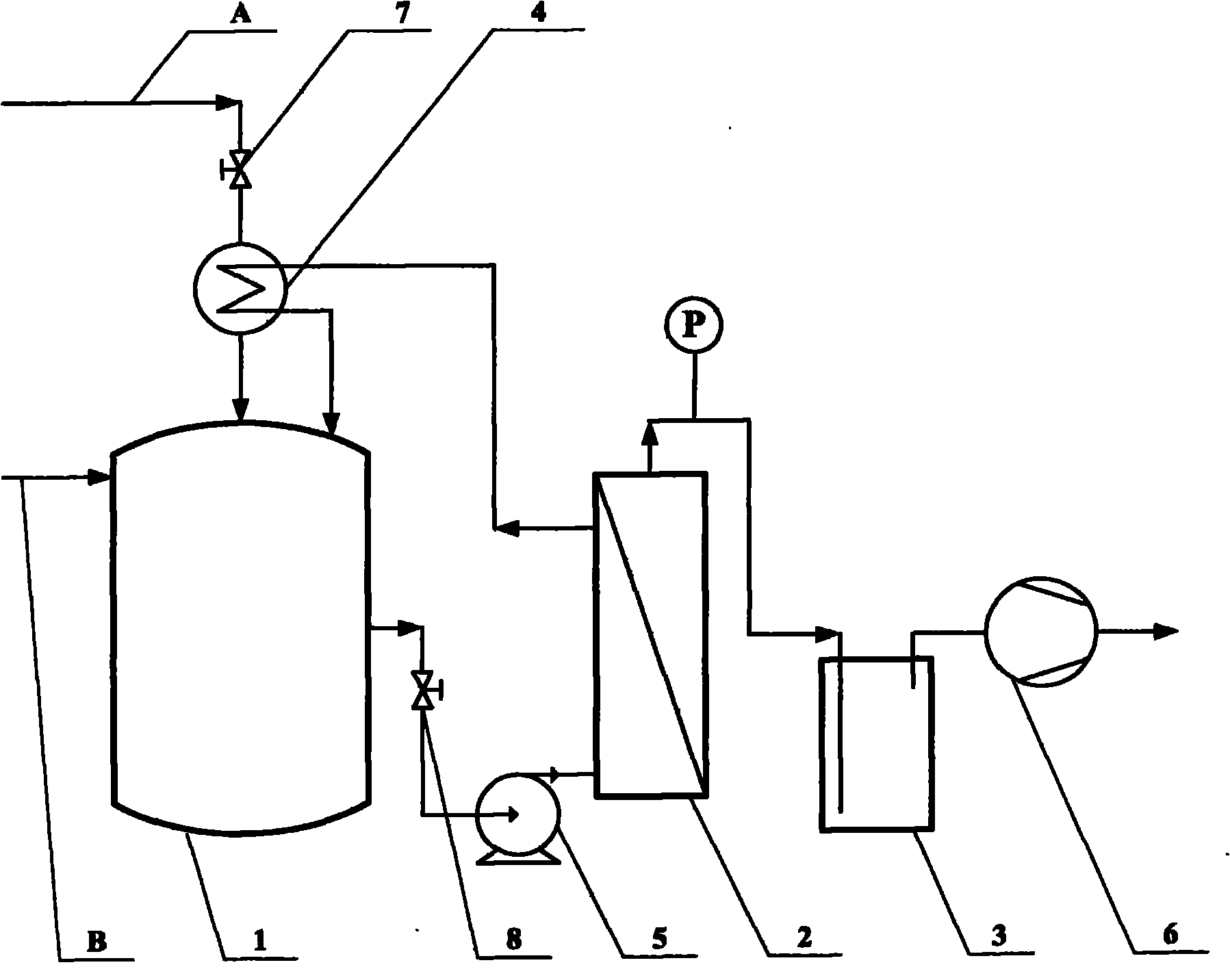

The invention relates to a method for separating a water phase side product of Fischer-Tropsch synthesis. The method mainly solves the problem that the water phase side product of the existing Fischer-Tropsch synthesis reaction is discharged directly, thereby being uneconomical and polluting the environment. The invention solves the problem well by the technical proposal which comprises the stepsas follows: the water phase side product enters into the middle part of an ordinary rectifying tower 1; a distillate stream I with the boiling range of 50 DEG C to 120 DEG C is extracted from a lateral line; a light component with the boiling point lower than 40 DEG C is obtained at the top of the tower; a heavy component with the boiling point higher than 120 DEG C is obtained at the bottom of the tower; distillate at the lateral line is carried out the rectifying separation through a separation tower 2, an extractive rectifying column 3, an azeotropic rectifying column 4, an acetic acid extracting tower 5, a solvent recycling tower 6 and an extracting agent recycling tower 7 to obtain acetone, methanol, ethanol, normal propyl alcohol and acetic acid basic organic raw material. The invention can be applied to the industrial production for disposing the water phase side product of the Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

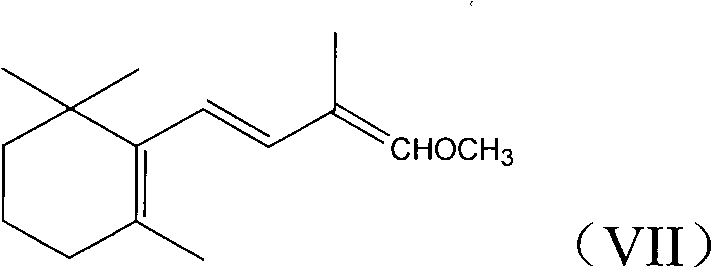

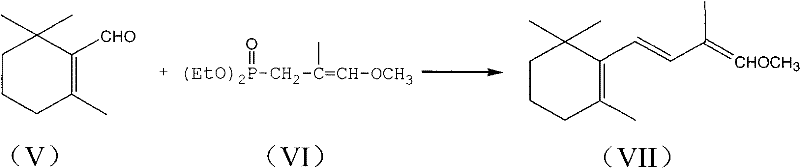

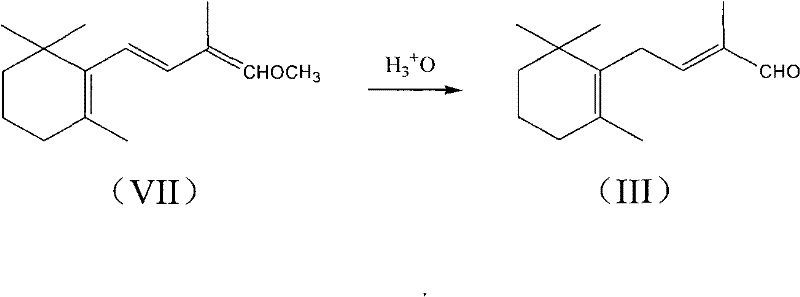

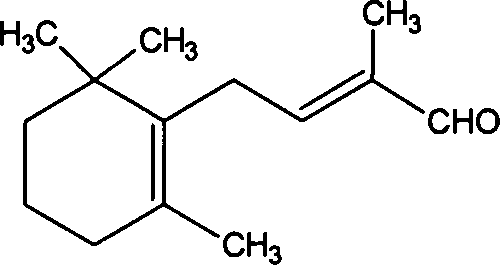

Method for preparing intermediate of vitamin A, namely tetradecanal

InactiveCN102190565AOrganic compound preparationCarbonyl compound preparation by hydrolysisEnol etherDissociation reaction

The invention provides a method for preparing an intermediate of vitamin A, namely C14-aldehyde, and an intermediate of the C14-aldehyde, namely C14 enol ether, which comprises the following steps of: (1) under the protection of inert gas, performing rearrangement dissociation reaction on C4 phosphonate at the temperature of between -40 and 30DEG C in the presence of alkali in an ether solvent ora dipolar aprotic solvent; (2) adding beta-cyclocitral, and performing Wittig-Homer condensation reaction at the temperature of between -40 and 30DEG C in the presence of alkali in the ether solvent or the dipolar aprotic solvent to obtain the C14 enol ether; and (3) under the protection of inert gas, mixing the C14 enol ether, an acid catalyst, water and a homogenous phase solvent, and performing hydrolysis reaction at the temperature of between 10 and 35DEG C with stirring to obtain the C14-aldehyde. The method has the advantages of simple process, readily available raw materials and low cost, and has great industrial value.

Owner:SHAOXING UNIVERSITY +1

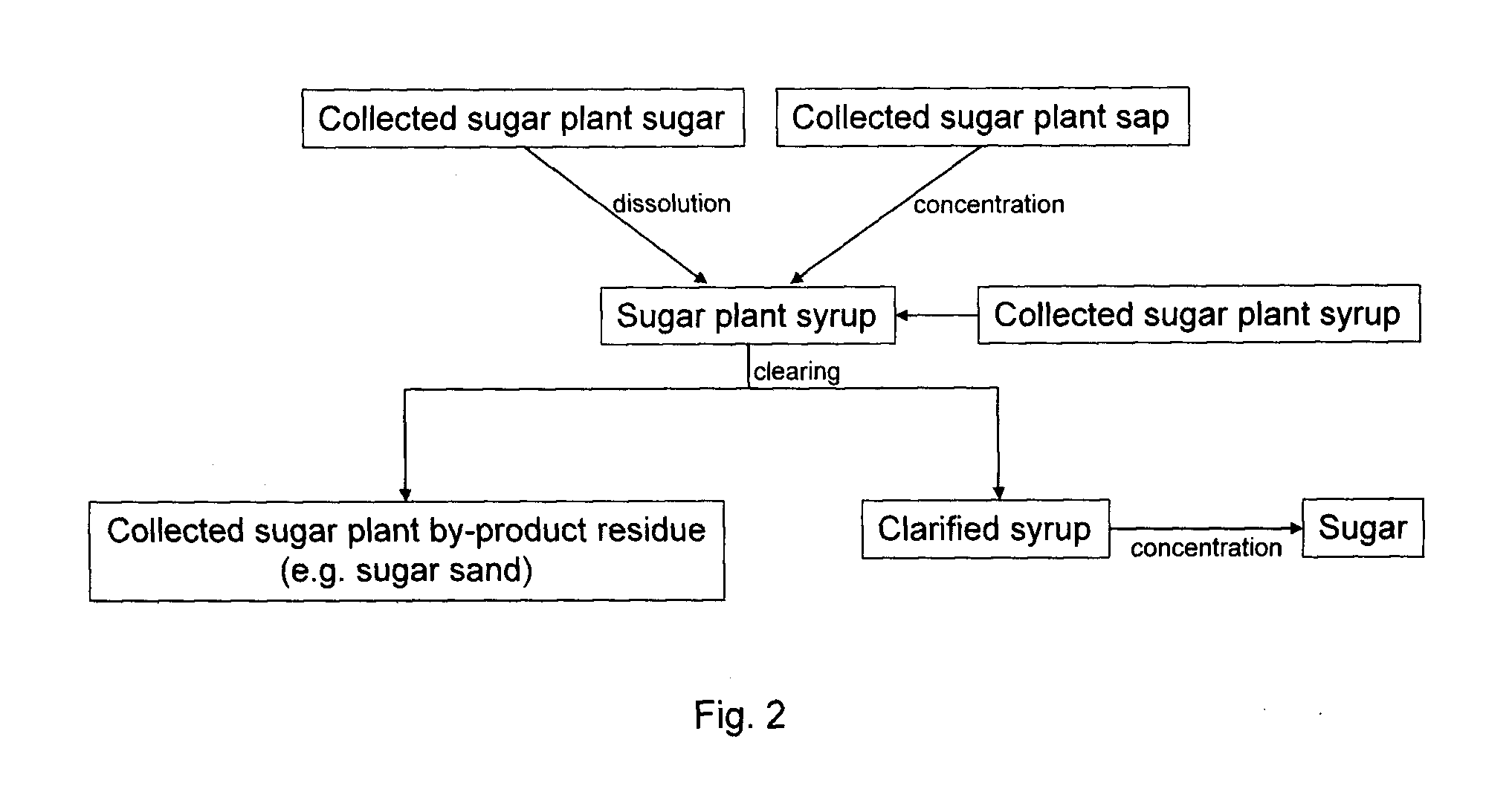

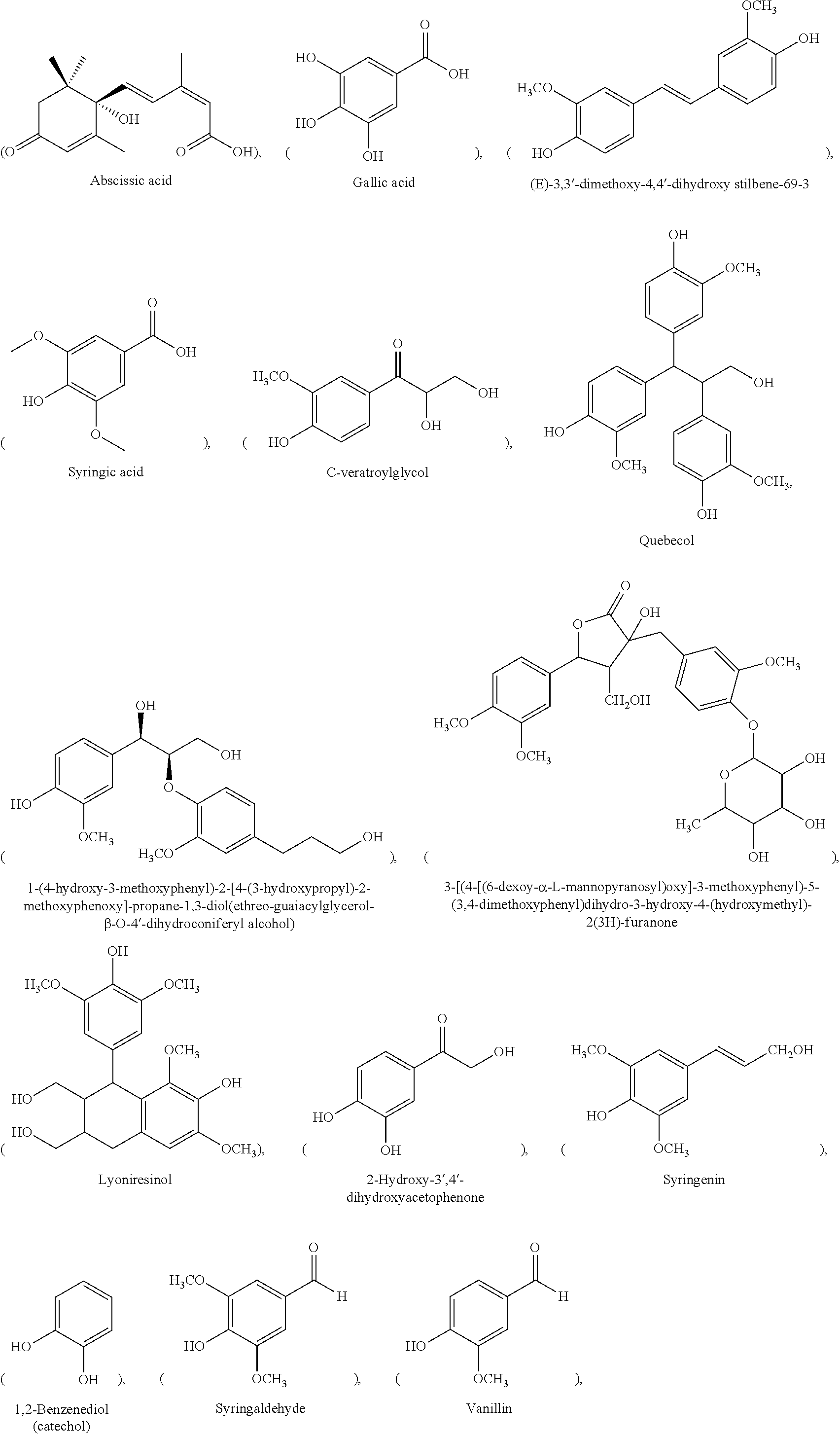

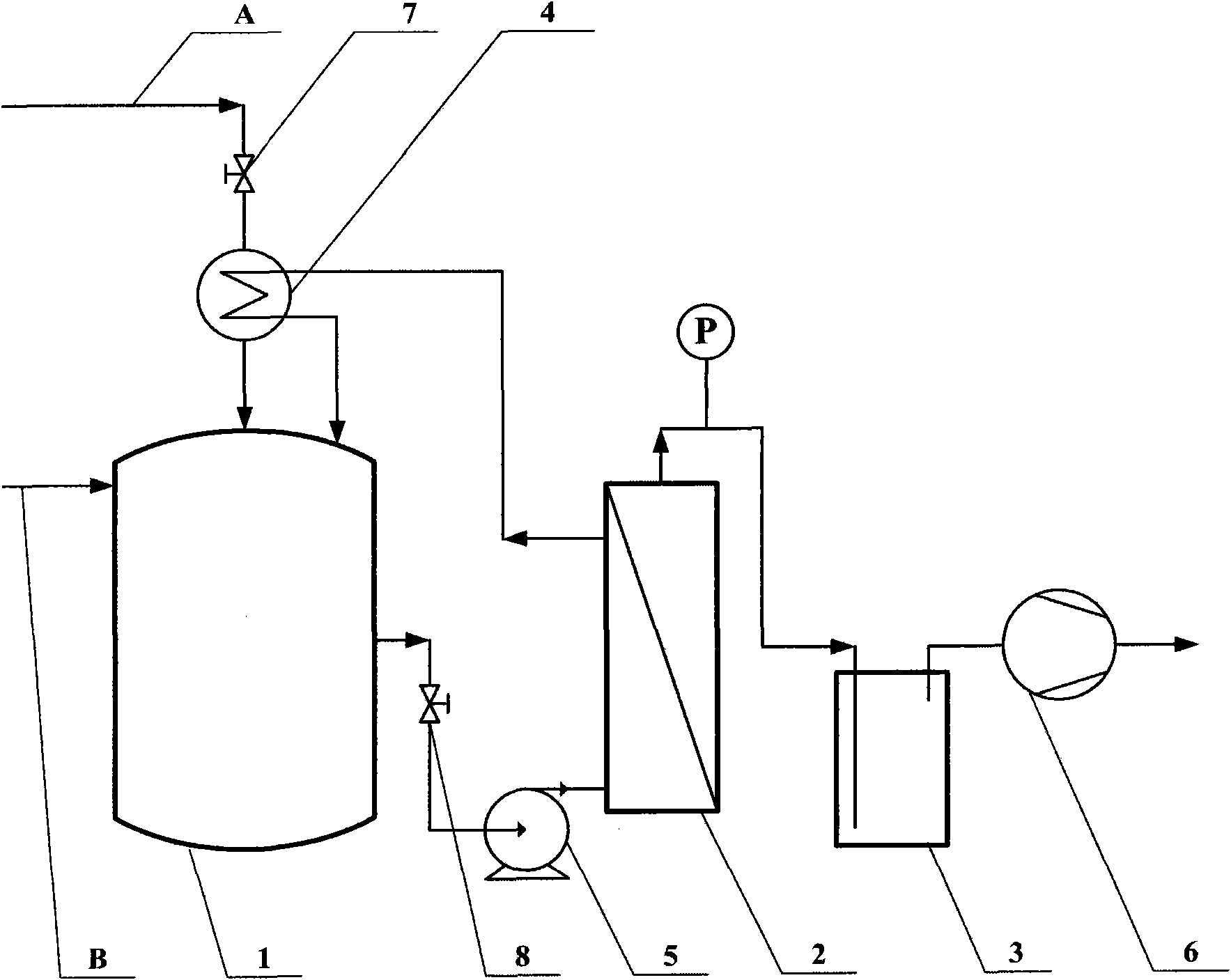

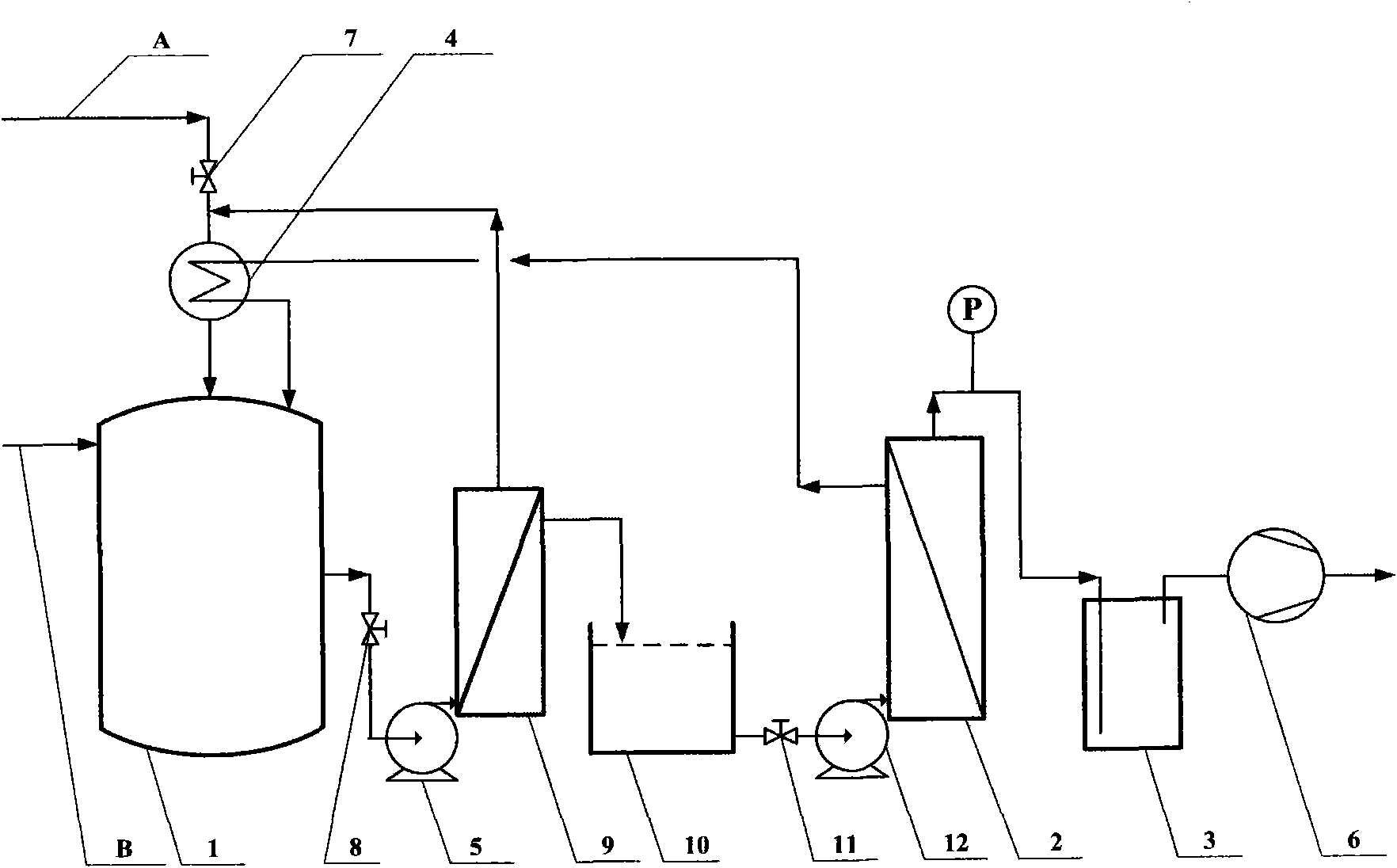

Sugar plant derived by-products and methods of production thereof

InactiveUS20130203688A1Good for healthBiocideEther/acetal active ingredientsFiltrationHealth condition

The present document describes a nutraceutical or cosmeceutical composition for the prophylaxis of an ailment comprising a therapeutically effective amount of a sugar plant syrup filtration residue in association with a pharmaceutically acceptable carrier. The present document also describes a nutraceutical or cosmeceutical composition for improving health condition of skin. The present document describes a method of producing a sugar plant syrup-derived product; wherein the improvement is characterized in the step of: collecting a sugar plant syrup residue during the production of sugar or syrup to produce a syrup-derived by-product.

Owner:FEDERATION DES PRODUCTEURS ACERICOLES DU QUEBEC

Process for separating acetone, butanol and ethanol in situ by coupling biomass fermentation and pervaporation

ActiveCN101805754AHigh strengthHigh yieldBiofuelsMicroorganism based processesMicroorganismPervaporation

The invention relates to a process for separating acetone, butanol and ethanol in situ by coupling biomass fermentation and pervaporation. A pervaporation separation process is coupled with a fermentation process, and ABE (acetone, butanol and ethanol) solvents produced by fermentation are removed in situ and in time through a pervaporation film, so inhibiting effects of the ABE solvents produced in the fermentation process on the growth of microbial cells are greatly reduced and production intensity and efficiency of ABE fermentation are enhanced. Simultaneously, compared with an ordinary rectification process, the process also greatly lowers energy consumption for separating the ABE solvents produced by biomass fermentation, shortens production time and greatly lowers production cost of fuel butanol.

Owner:NANJING UNIV OF TECH

Separating agent for optical isomers and process for producing the same

InactiveUS6217769B1Ion-exchanger regenerationCarboxylic acid amides optical isomer preparationSolventPolysaccharide

The invention provides separating agents for optical isomers which have a high optical resolving power inherent in polysaccharide derivatives and high solvent resistance, and which can be produced through short process steps; a process for producing the same, and a method for separating optical isomers. The invention also provides separating agents for optical isomers, wherein the surface of a polysaccharide derivative supported on a carrier or the surface of a pulverized or granulated polysaccharide derivative is coated with a polymer, which are produced by supporting the polysaccharide derivative on the carrier and then coating the surface thereof with the polymer to thereby immobilize the polysaccharide derivative on the substrate, or by grinding or spheroidizing the polysaccharide derivative and then coating the surface thereof with a polymer.

Owner:DAICEL CHEM IND LTD

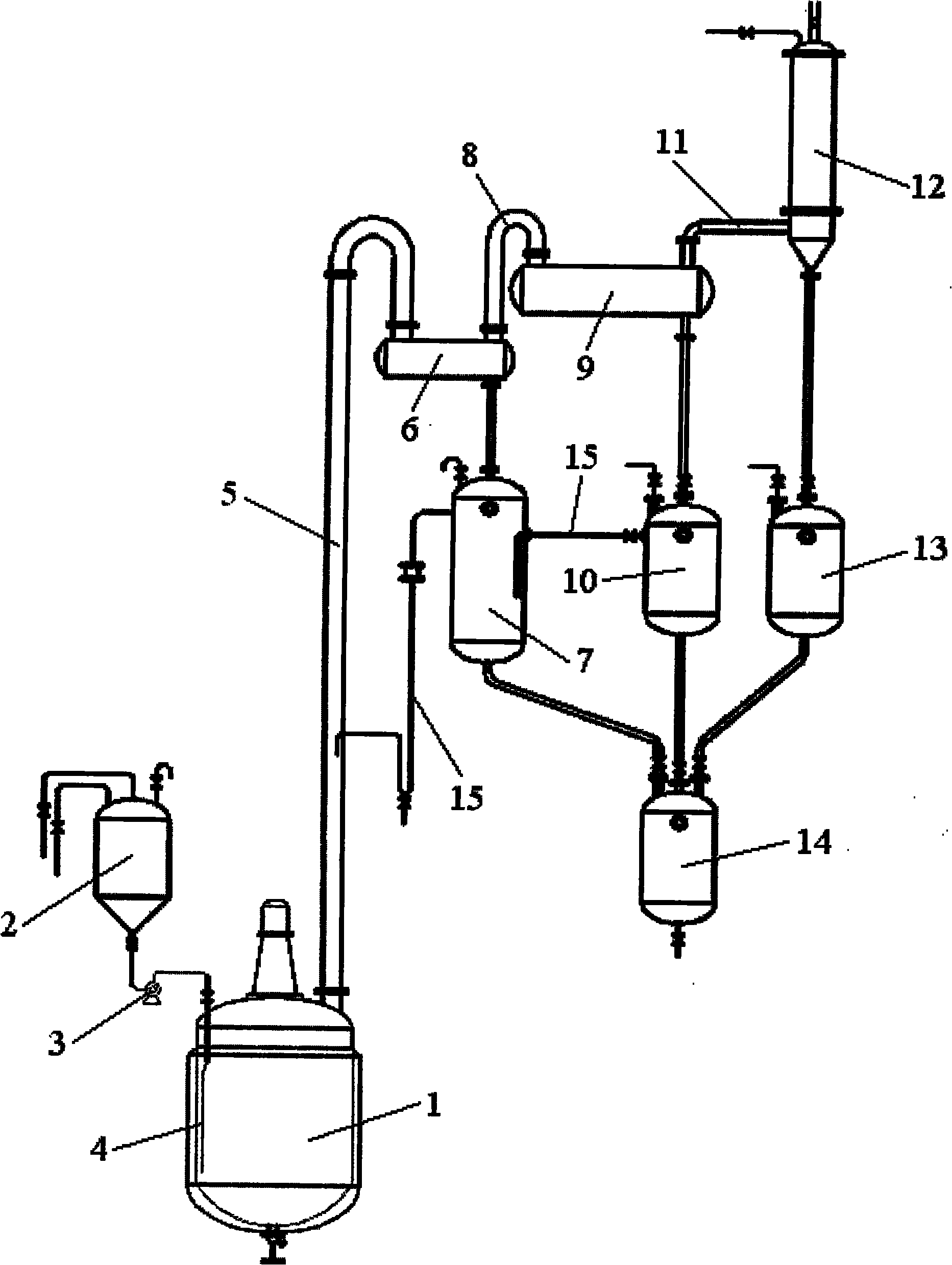

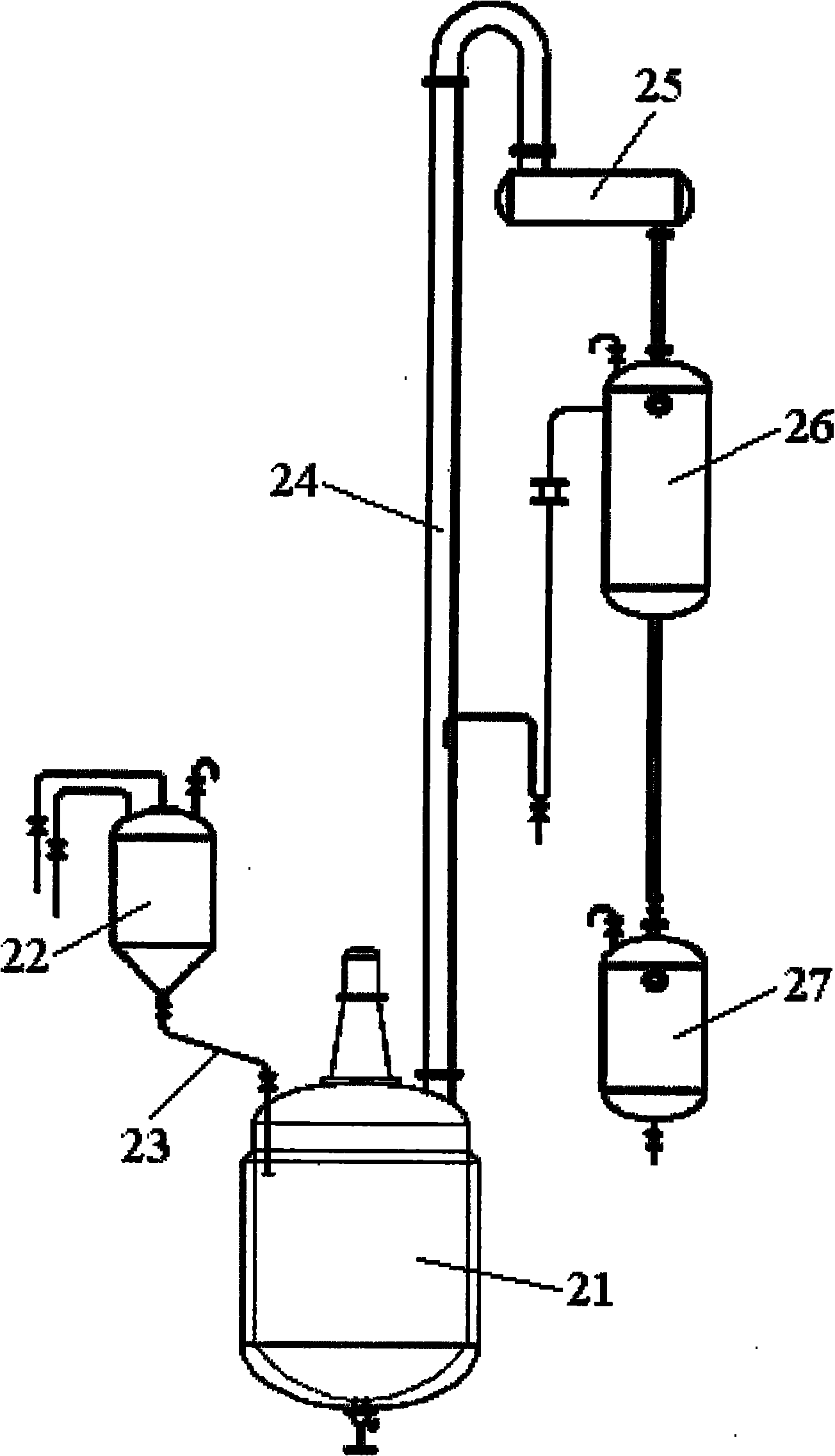

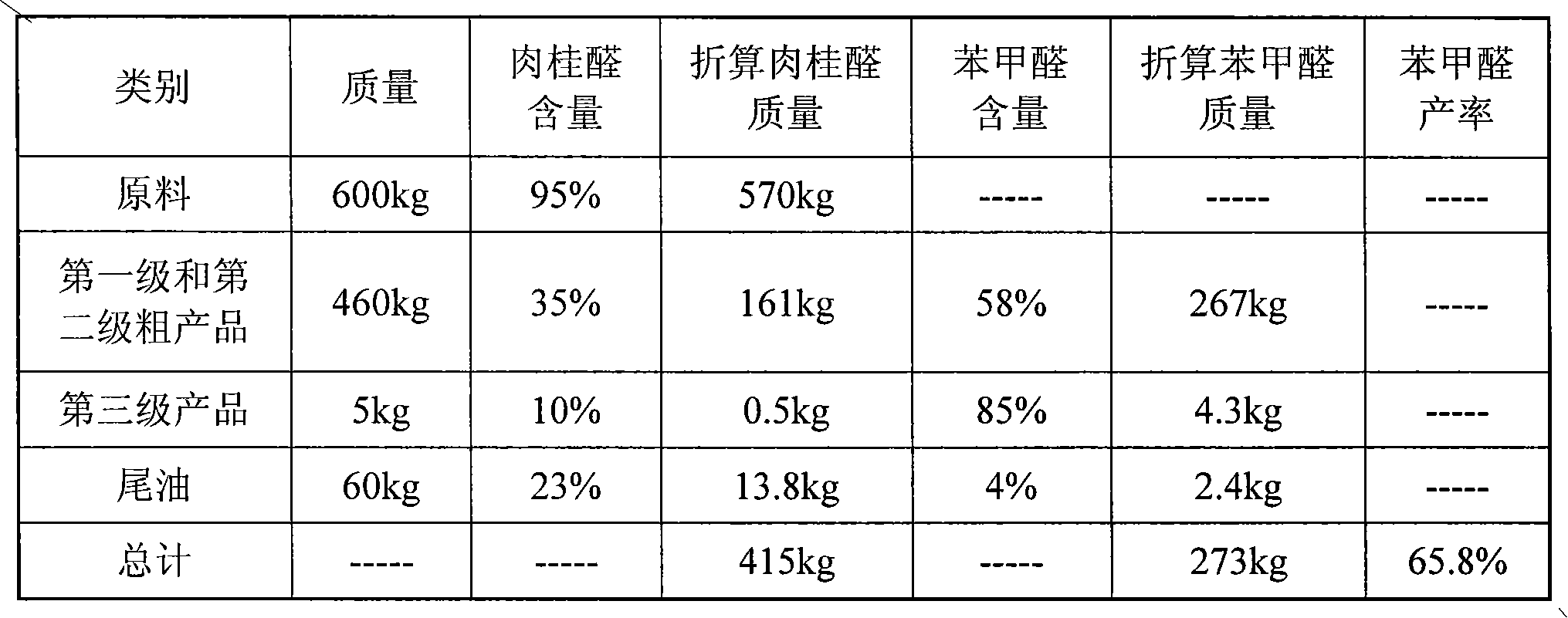

Production method for natural benzaldehyde

ActiveCN101985414AReduce residualReduce the proportion of polymerization reactionOrganic compound preparationCarbonyl compound separation/purificationTemperature controlBenzaldehyde

The invention discloses a production method for natural benzaldehyde, comprising the following steps: putting cinnamyl aldehyde and an alkaline aqueous solution into a reactor, causing the cinnamyl aldehyde and the alkaline aqueous solution to be subject to anti-aldolisation, carrying out sectional type temperature control and cooling on natural benzaldehyde-containing steam generated by the reaction through a tertiary condensation system, and then collecting products in a product receiver. In the production method for the natural benzaldehyde, the tertiary condensation system is adopted to substitute for the single condensation device in the prior art, thereby improving the production efficiency, reducing the energy consumption and overcoming the defects of the existing production methodfor the natural benzaldehyde on the premise of ensuring the natural degree and pure smell of the nature benzaldehyde.

Owner:肇庆市高要华新香料有限公司

Method for extracting refined curcumin and curcuma oil from curcuma

ActiveCN101445440AHigh yieldIncrease contentCarbonyl compound separation/purificationFood preparationAlcoholWater soluble

The invention relates to a method for extracting refined curcumin and curcuma oil from curcuma. The method comprises the following steps: the curcuma is cleaned, dried in the shade, crushed into 30-40 mesh curcuma powder, low-carbon alcohol and alkyl hydrocarbon are made into a mixed solvent at the volume ratio of 1:1-3, the curcuma powder and the mixed solvent are mixed at a weight ratio of 1:3-5 for extraction twice; the extracts are merged, filtered, separated and removed from dregs, the obtained filtrate is condensed, the concentration level is controlled at 60-90%, and the solvent is recovered; a separating agent containing 0-3% salt is added to the residual concentrated solution, the addition amount of the separating agent is 0.5-2 times of the volume of the concentrated solution, the obtained mixture is kept standing for demixing after evenly stirred; a supernatant is separated and condensed, and the alkyl hydrocarbon is recovered to obtain the curcuma oil; a subnatant is adsorbed by a macroporous absorbent resin, flushed to remove water soluble impurities, and eluted with a desorbent, the solvent is condensed and recovered to crystallize the curcumin, thus obtaining the curcumin with the content more than 95%.

Owner:CHENGUANG BIOTECH GRP CO LTD

Method and apparatus for purifying vitamin A intermediate mynistic aldehyde

ActiveCN101070277AHigh purityQuality improvementCarbonyl compound separation/purificationPurification methodsVitamin A Alcohol

This invention relates to purification method of intermedium myristic aldehyde and device. The device has set heater, fractionating tower, falling film reboiler, falling film evaporator and condenser. Raw myristic aldehyde outlet of heater connect with fractionating tower inlet; steam outlet of fractionating tower top connect with condenser steam inlet; one way of first condenser condensed fluid outlet connect with reflux liquid inlet of fractionating tower top, the other way outflow low boiler of beta - ionone. Dephlegmation tower bottom outlet respectively connect with falling film reboiler overhead entrance and falling film evaporator overhead entrance; falling film reboiler bottom outlet connect with fractionating tower bottom entrance; one way of falling film evaporator outlet connect with second condenser entrance, the other way is outlet of high boil thing; second condenser outlet is outlet of refine myristic aldehyde. Whil purification first send raw myristic aldehyde to fractionating tower, gain distillate from fractionating tower top. The distillate enter fractionating tower bottom tower kettle, pass through falling film evaporator to remove high boil thing.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

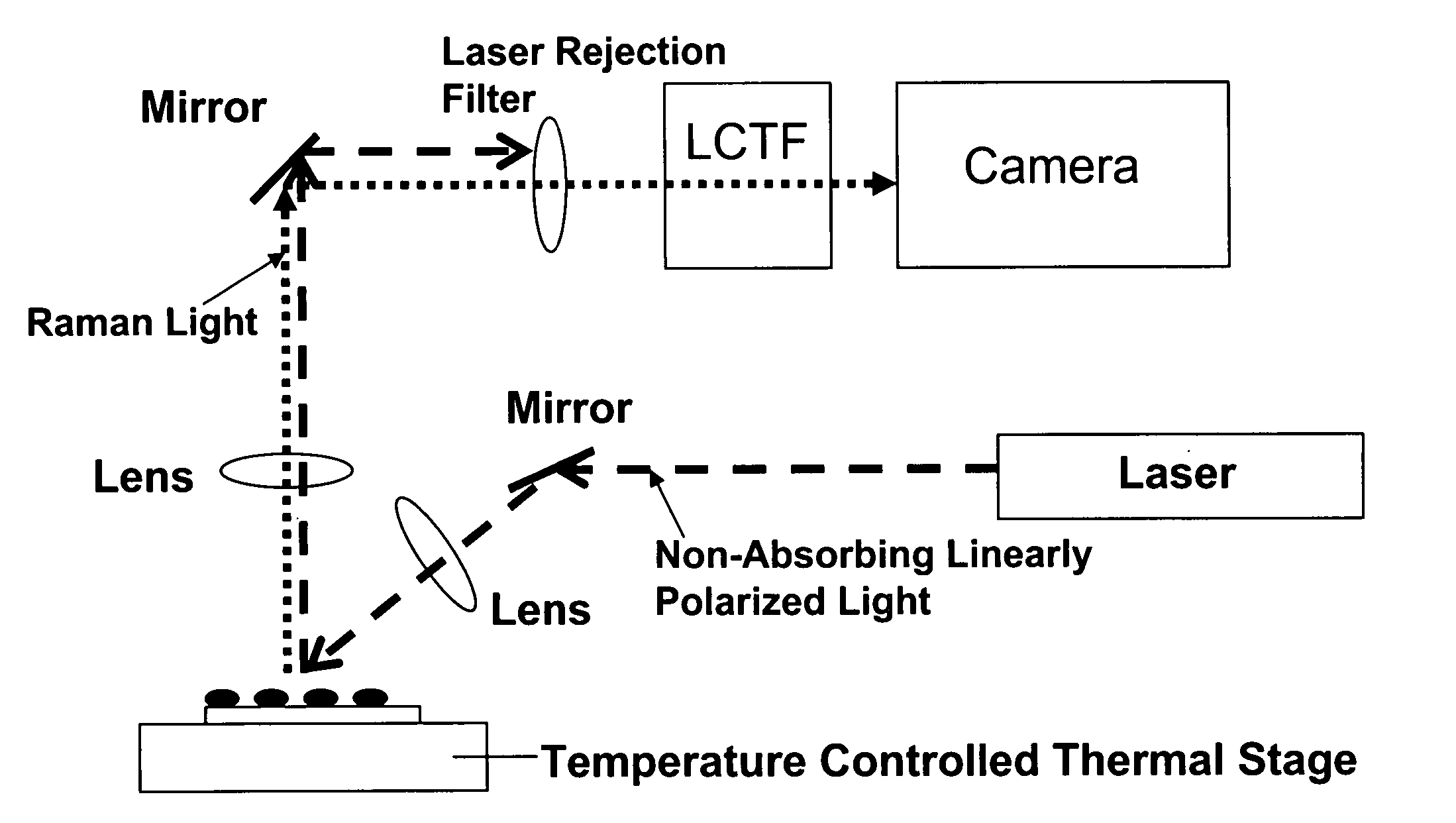

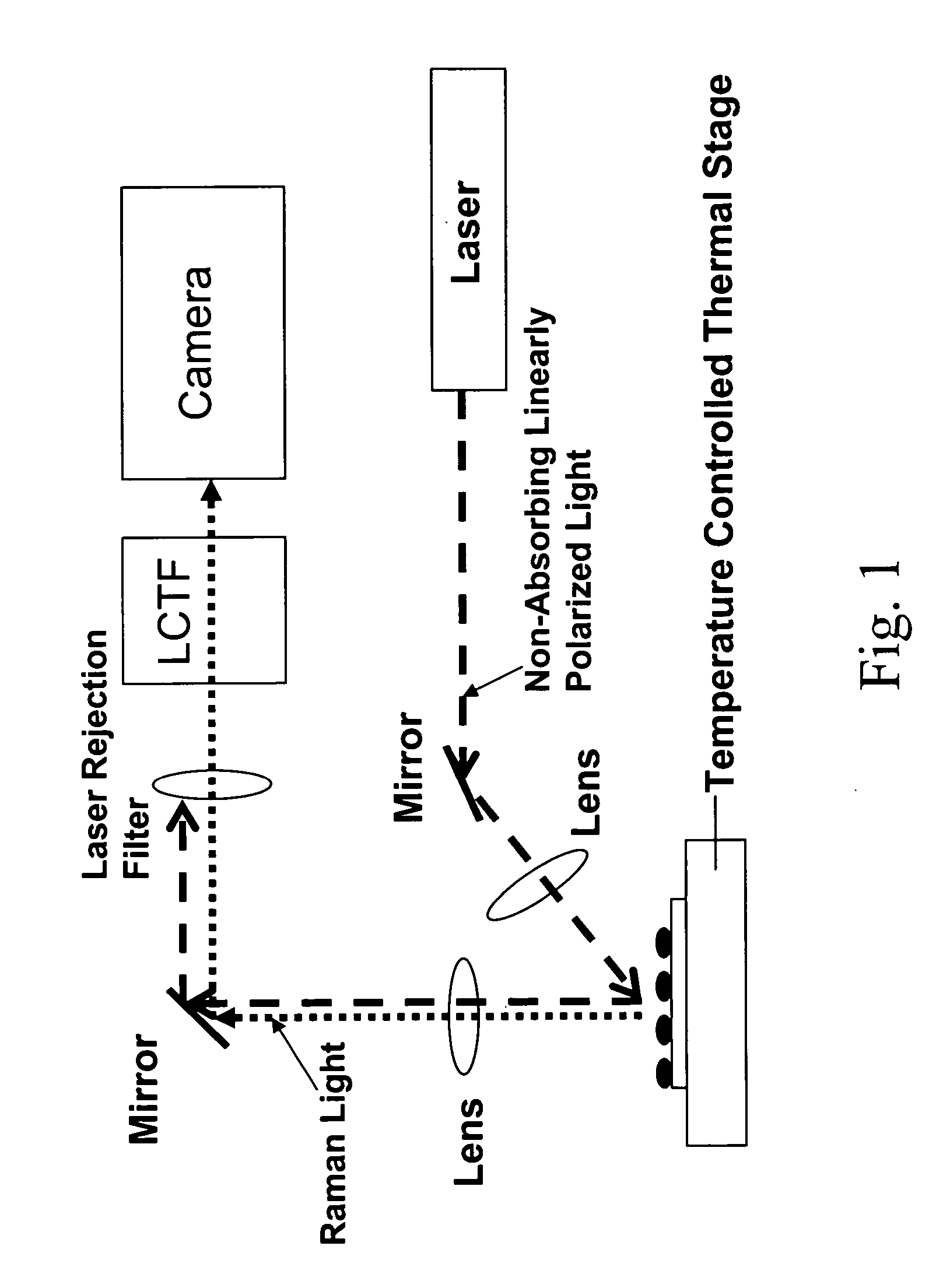

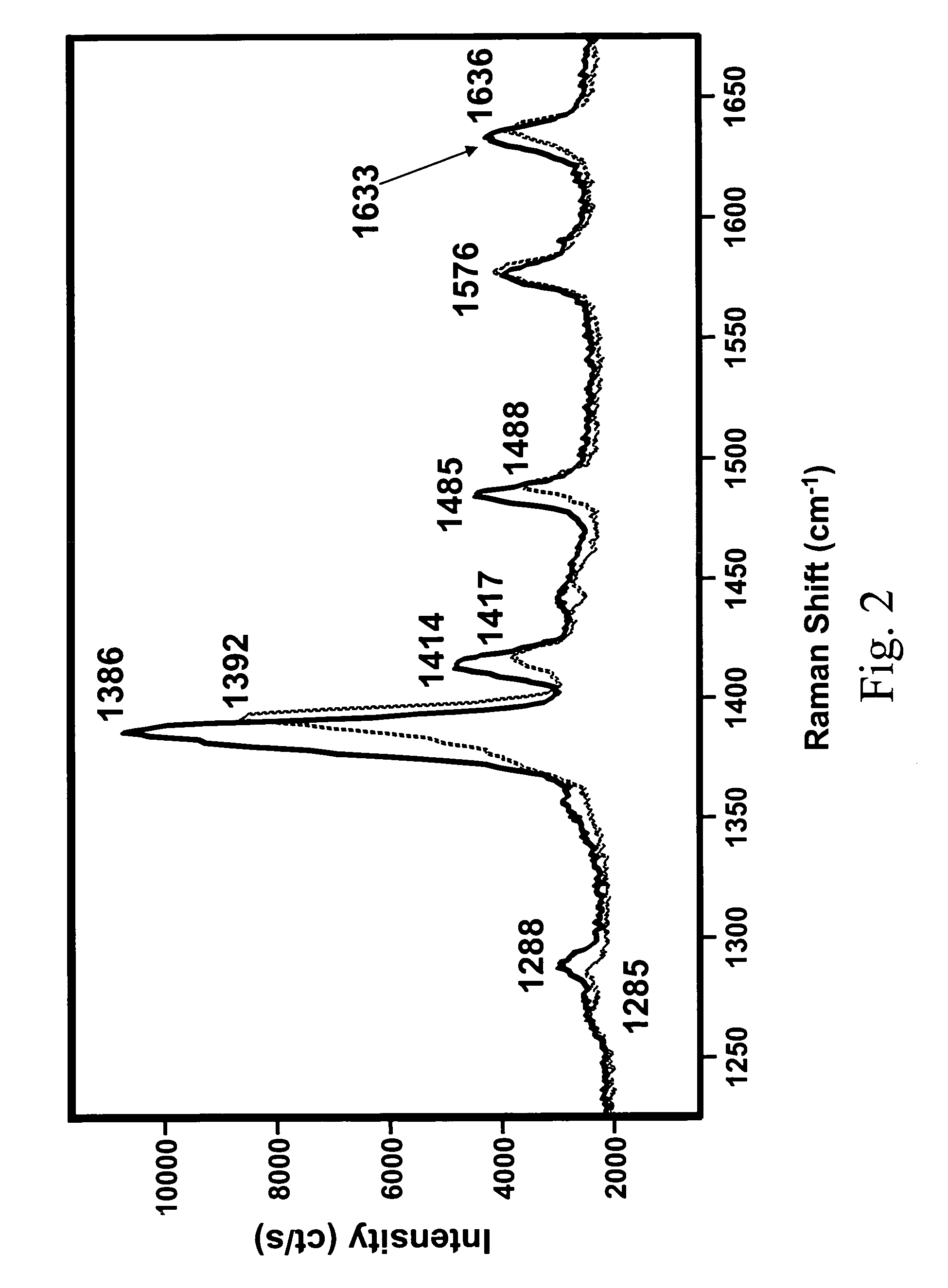

Control and monitoring of non-resonant radiation-induced nucleation, crystallization, and polymorph formation

InactiveUS20060124443A1Crystallization conditions screeningOrganic compound preparationOptical radiationEngineering

The invention relates to methods of assessing the polymorphic form of a substance by assessing Raman-shifted radiation scattered by a particle of the substance. The method is useful, for example, for assessing particle sizes and size distributions in mixtures containing both particles of the substance and other materials. The invention also relates to methods of selecting and controlling polymorph formation by illuminating a material with non-resonant (i.e., non-absorbed) laser radiation as it is thermally driven through a phase transition temperature.

Owner:CHEMIMAGE

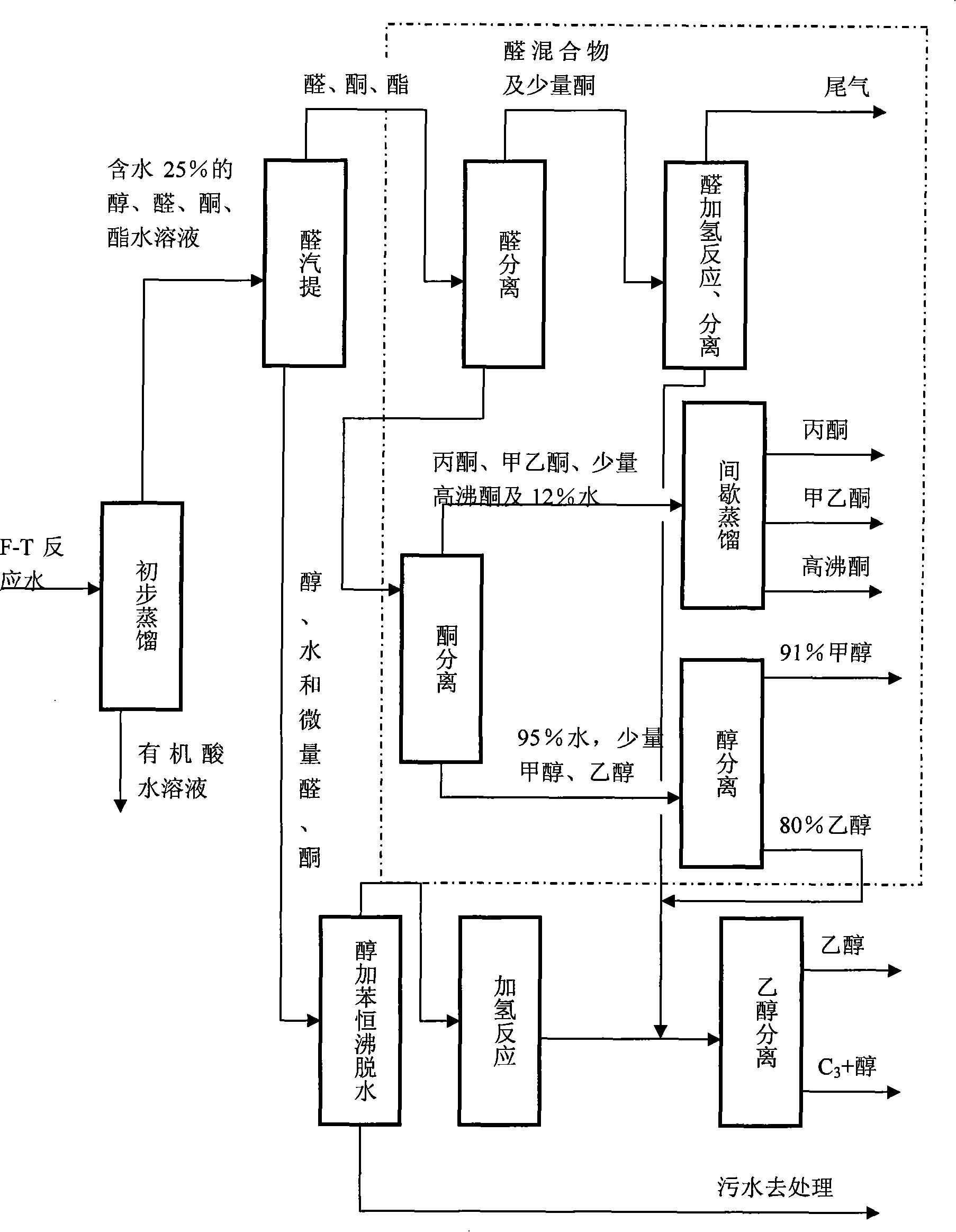

Method for separating and reclaiming organic matter from high-temperature Fischer-Tropsch synthesis reaction water

ActiveCN101239886AEffective and orderly separation and recoveryOrderly separation and recoveryOrganic compound preparationHydroxy compound preparationRecovery methodKetone

The invention relates to a separation and recovery method of organic matters in high-temperature Fischer-Tropsch synthesis reaction water. The method comprises steps of: (1) separating and recoverying aldehyde after rectifying and removing organic acid; (2) rectifying and separating ketone / n-propanol; (3) rectifying and separating acetone / butanone; (4) refining acetone; (5) extracting and separating butanone / ethanol; (6) rectifying and separating ethanol / n-propanol; further rectifying alcohol-containing aqueous sollution obatained from the bottom of a column for rectifying and separating ketone / n-propanol, ethanol containing little water and obtained from the top of the column, and n-propanol alcohol-containing aqueous sollution obatained from the bottom of the column; (7) azeotropic rectifying ethanol sollution obtained by exaction and separation, and ethanol sollution with n-propanol separated to prepare anhydrous ethanol; (8) adding calces in n-propanol aqueous sollution, distilling to obtain n-propanol products; the invention effectively and orderly separates and recoveries aldehyde, acetone, butanone, ethanol and n-propanol, the purity of each product is above 95% and the yield is above 90%.

Owner:YANKUANG ENERGY R&D CO LTD

Method for extracting and separating curcumin

InactiveCN103570517AHigh purityLow costCarbonyl compound separation/purificationOrganic layerN-Butanol

The invention discloses a method for extracting and separating curcumin. The method comprises the following steps: (1) extraction: crushing curcuma longa, adding 2-10% alkaline water to extract to obtain an alkaline water extracting solution; (2) degreasing: adding an organic solvent petroleum ether, 6# solvent oil, cyclohexane, benzene, methylbenzene or ethyl acetate into the alkaline water extracting solution, stirring and extracting for 1-2h, and then, standing for 1-2h to separate out an organic layer; (3) acid deposition: regulating the pH value of the extracting solution to 1-2 by using hydrochloric acid to separate out the curcumin, filtering, and drying to constant weight to obtain a crude product of the curcumin; and (4) dissolving the crude product of the curcumin by using an organic solvent methanol, ethanol, acetone, n-butanol or isopropanol, filtering, adding distilled water into the filtrate, carrying out freezing crystallization at the temperature of 0-5 DEG C for 2-8h, filtering, and drying to obtain a curcumin product. The method is low in production cost; the prepared curcumin product is high in purity up to over 98.5%.

Owner:HUNAN KEYUAN BIO PRODS

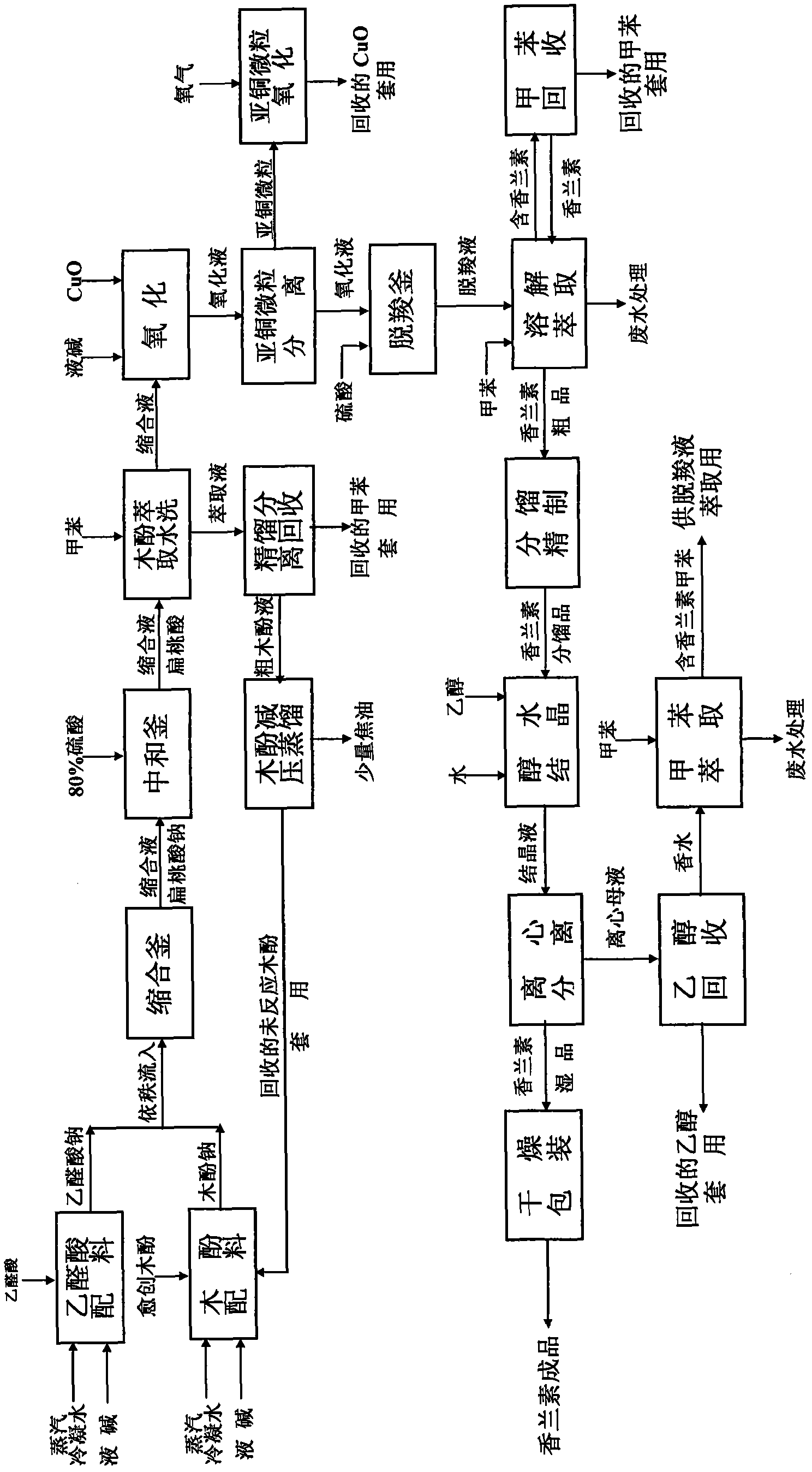

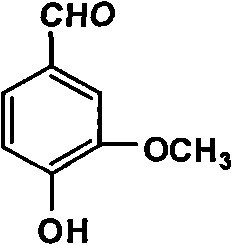

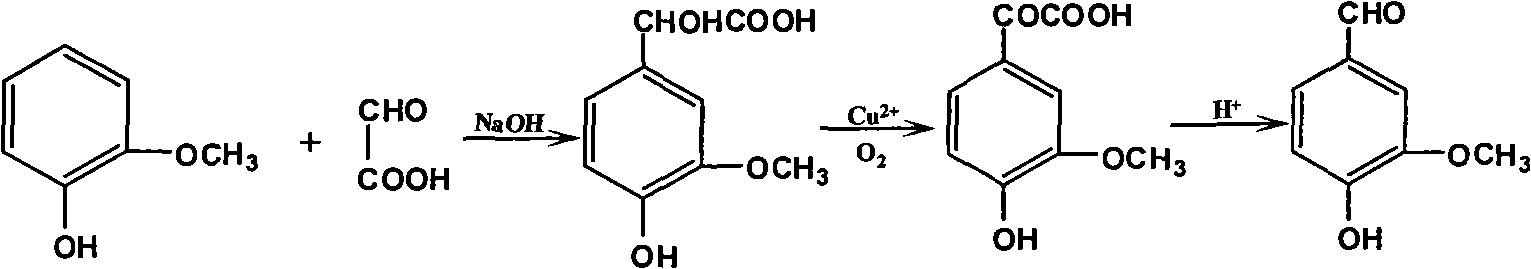

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

Popular searches

Distillation separation Carboxylic compound separation/purification Heterogenous catalyst chemical elements Oxygen compounds preparation by alkyne addition Carboxylic preparation by oxidation Metal/metal-oxides/metal-hydroxide catalysts Preparation by hydrolysis Sweetmeats Cocoa Preparation from heterocyclic compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com