Patents

Literature

536results about How to "Reduce residual" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

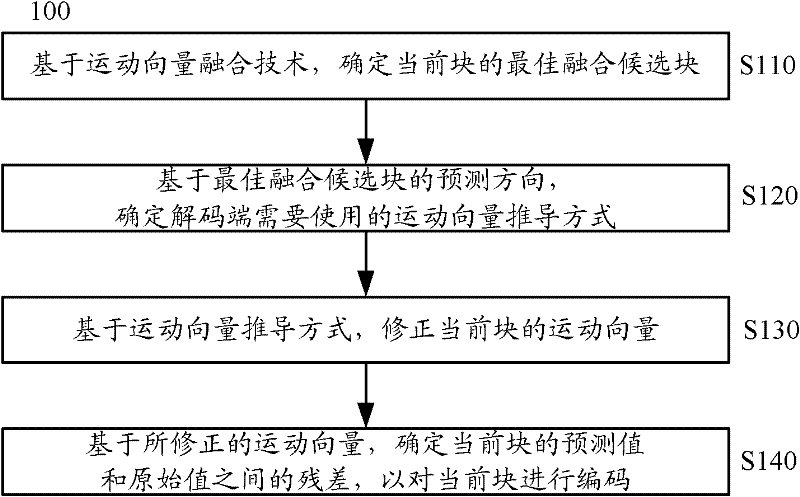

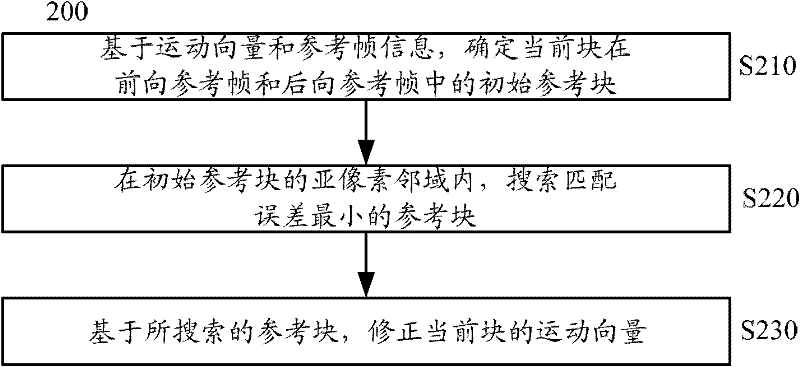

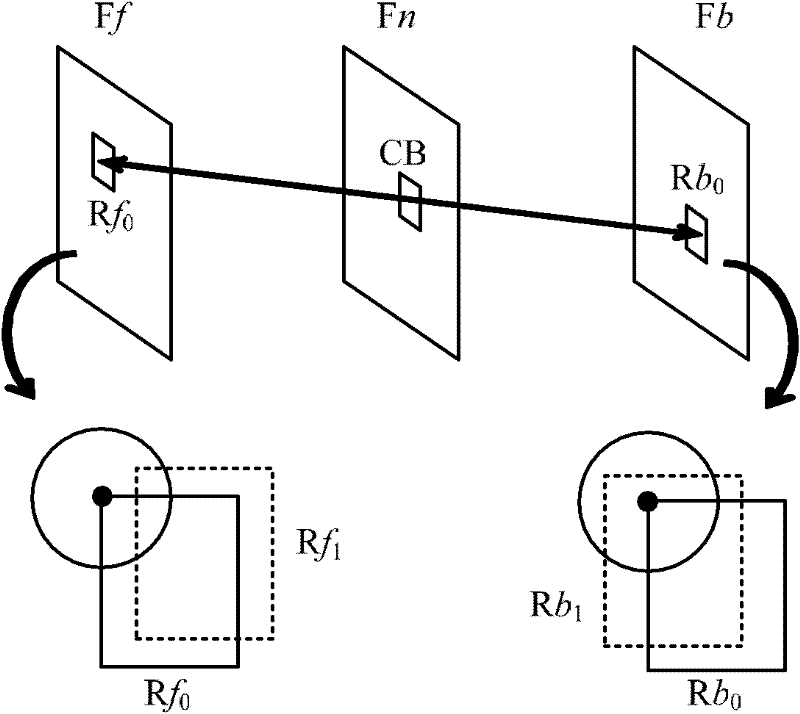

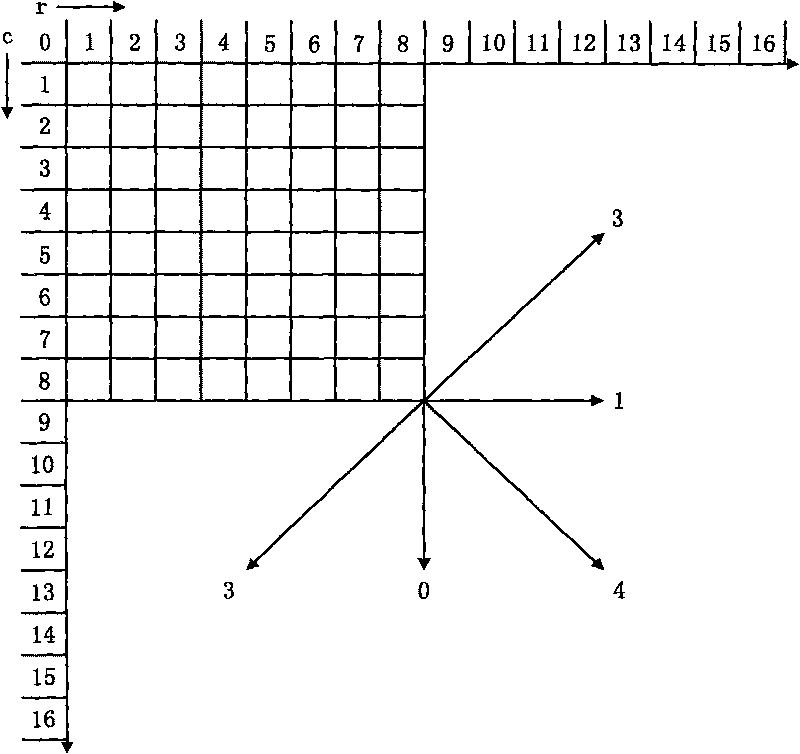

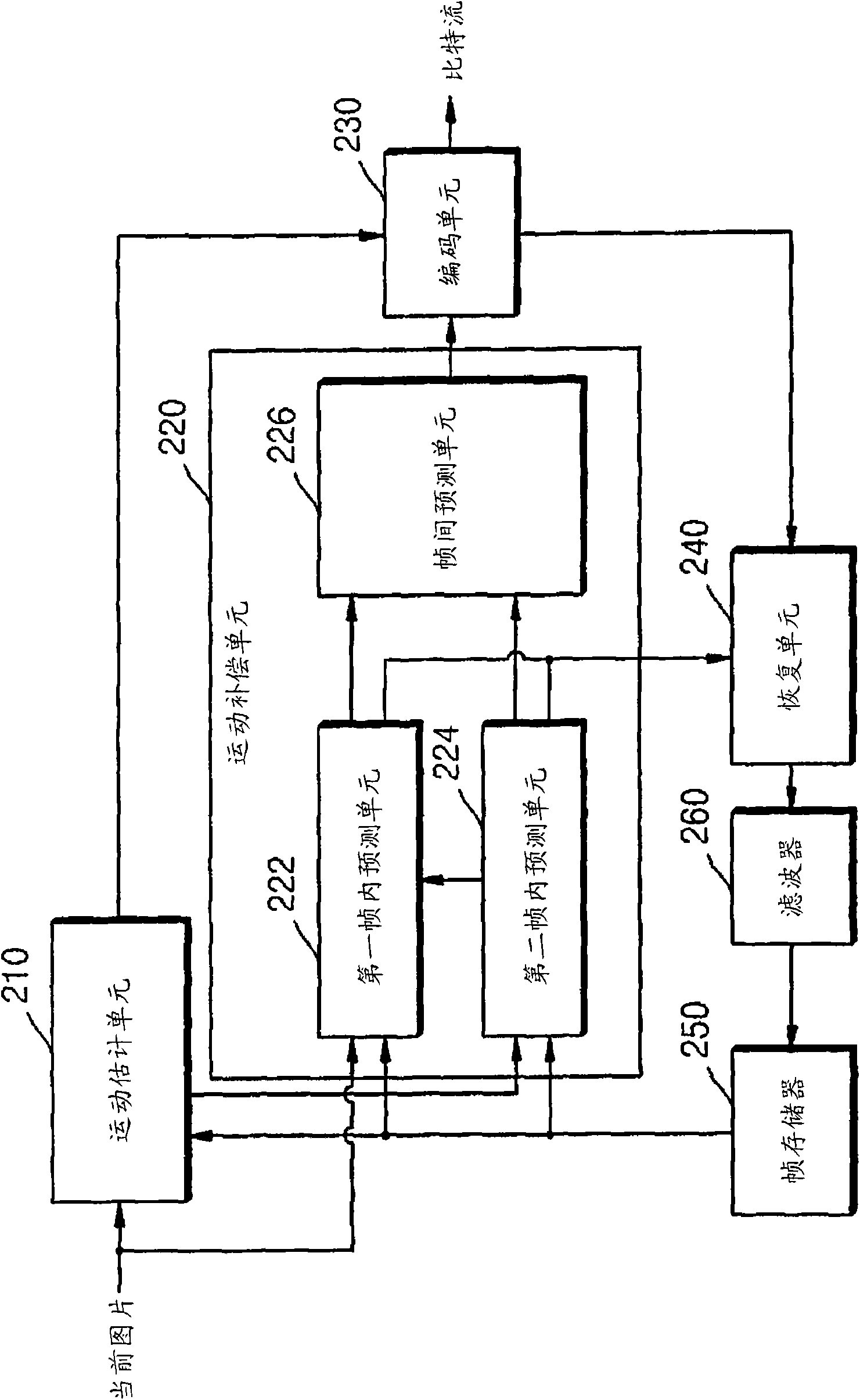

Encoding and decoding method, encoding device, decoding device and system for video images

ActiveCN102685504AMotion vectors are accurateImprove decoding qualityPulse modulation television signal transmissionDigital video signal modificationDecoding methodsComputation complexity

An embodiment of the invention provides an encoding method, a decoding method, an encoding device, a decoding device and a system for video images. The encoding method includes determining an optimum integration alternative block of a current block on the basis of the motion vector integration technology; determining a motion vector calculation mode required by a decoding side on the basis of the prediction direction of the optimum integral alternative block; rectifying the motion vector of the current block on the basis of the motion vector calculation mode; determining residual error between a predicted value and an original value of the current block on the basis of the rectified motion vector so as to encode the current block. According to the technical scheme in the embodiment, more accurate predicted value can be acquired through the rectified motion vector, smaller residual error is generated, encoding efficiency can be improved, increase of data bandwidth is avoided, and encoding quality can be improved while computing complexity is reduced.

Owner:HUAWEI TECH CO LTD

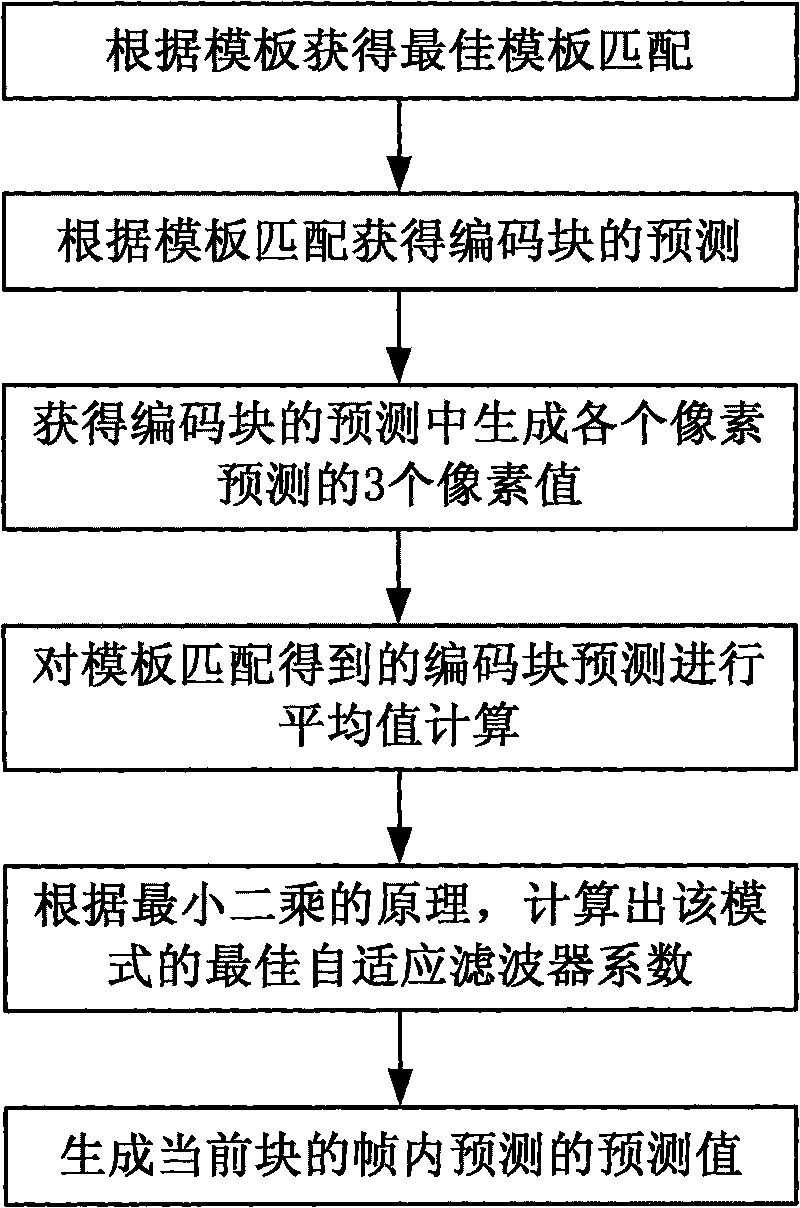

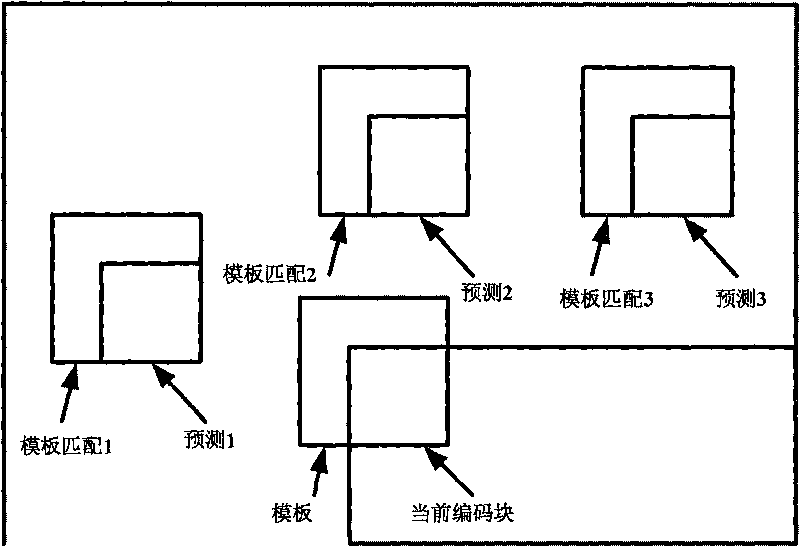

Template matching based method for encoding self-adaption intra-frame prediction filtering

InactiveCN101715135AReduce residualTelevision systemsDigital video signal modificationTemplate matchingImaging processing

The invention relates to a template matching based method for encoding self-adaption intra-frame prediction filtering, belonging to the technical field of image processing. The method comprises the following steps of: acquiring a template of a current encoding block, respectively searching n optimal template matchings in a matching way according to the acquired template; obtaining the prediction of the current encoding block according to the template matchings; obtaining three pixel values of pixel predictions generated in the prediction of the current encoding block according to a standard supply method; computing the mean values of the encoding block predictions obtained by all the template matchings, and using the mean values as targets of the predictions; computing the mean values of n groups of the three pixel values of pixels, using the mean values as the support for generating target values, and computing the optimal self-adaption filter coefficient of a mode according to a least square principle; and generating a predicting value of the intra-frame prediction of the current encoding block. The invention can effectively reduce the residual error after the intra-frame prediction and enhance the objective image quality of decoding by more than 0.2 dB under the condition of same code rate.

Owner:WUHAN UNIV

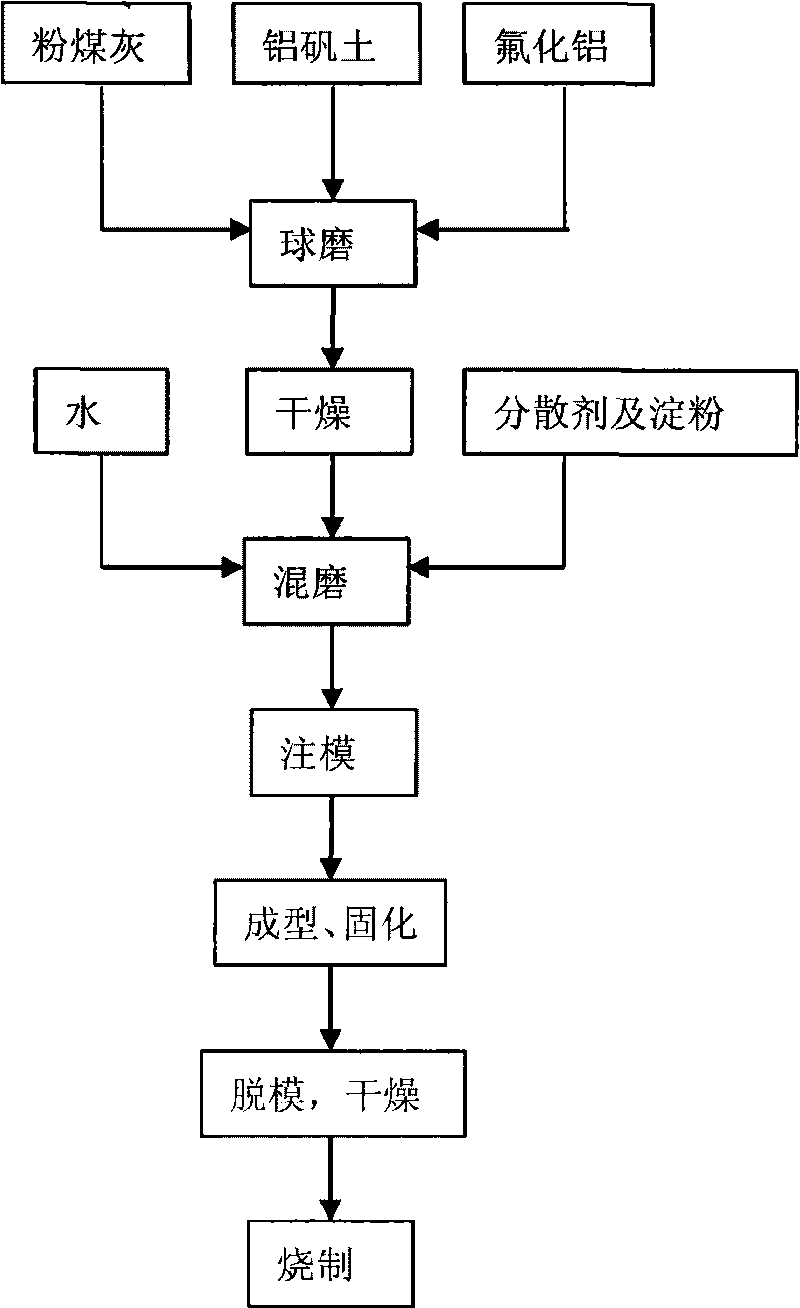

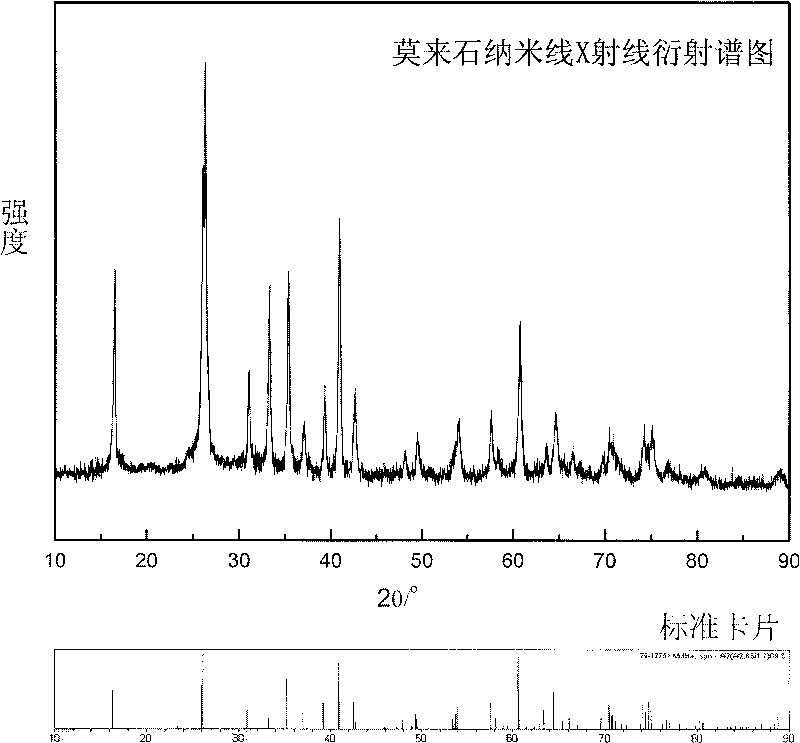

Method for preparing porous mullite

InactiveCN101759430AHigh strengthImprove high temperature resistanceCeramicwarePore distributionMullite

The invention discloses a method for preparing porous mullite, which comprises the following steps of: (1) performing magnetic separation to fly ash to remove iron; (2) proportioning the iron-removed fly ash, bauxite and aluminium fluoride; (3) adding a dispersing agent and a firming agent to prepare a mixed sizing agent; (4) pouring into a mold, and demolding after heating and curing; (5) preserving the demolded dry blank at the temperature of 350-400 DEG C for 0.5-2 h; (6) preserving the temperature at 1300-1500 DEG C for 2-4 h, and cooling. The method not only greatly utilizes fly ash which is a solid pollutant to achieve the purposes of energy saving, pollution reduction and environmental protection, but also has simple technology. The prepared porous mullite ceramics have reasonable pore diameter distribution, even pore distribution, high mullite content and great high-temperature resistance, and are applicable to multiple application requirements on high and low temperatures.

Owner:TIANJIN UNIV

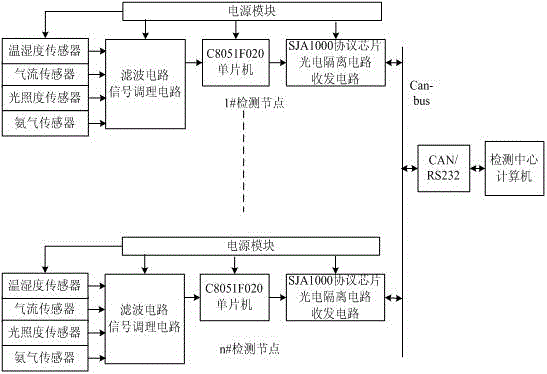

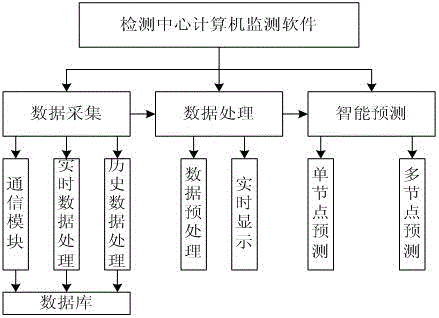

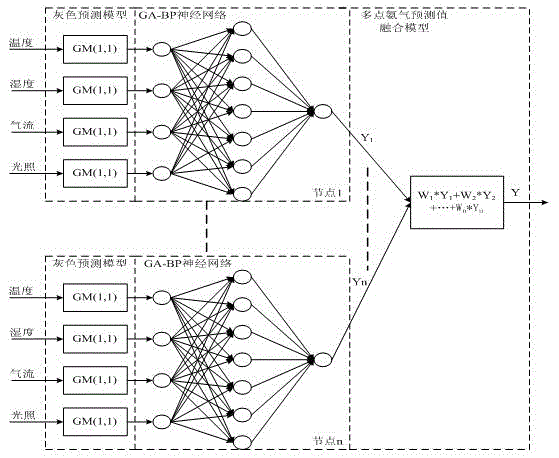

Hen house environment ammonia gas concentration intelligent monitoring system

ActiveCN105159216AImprove forecast accuracyStrong nonlinear fitting abilityProgramme controlComputer controlMonitoring systemProcess engineering

The invention discloses a hen house environment ammonia gas concentration intelligent monitoring system which is composed of two parts of a hen house environment parameter acquisition platform and a hen house environment ammonia gas concentration intelligent prediction model. The hen house environment ammonia gas concentration intelligent monitoring system based on a CAN field bus is designed in view of difficulties that hen house environment ammonia gas concentration change has characteristics of non-linearity, high time lag, high inertia and time variation and hen house area is relatively large and ammonia gas concentration is difficult to accurately predict. The system is the intelligent monitoring system which realizes detection, intelligent prediction and management of the monitored hen house environment ammonia gas concentration by the hen house environment parameter acquisition platform and the hen house environment ammonia gas concentration intelligent prediction model, and the basis of performing high-quality and high-efficiency purification on hen house environment ammonia gas concentration is provided. The system has wide application prospect and great popularization value.

Owner:广西农贝贝农牧科技有限公司

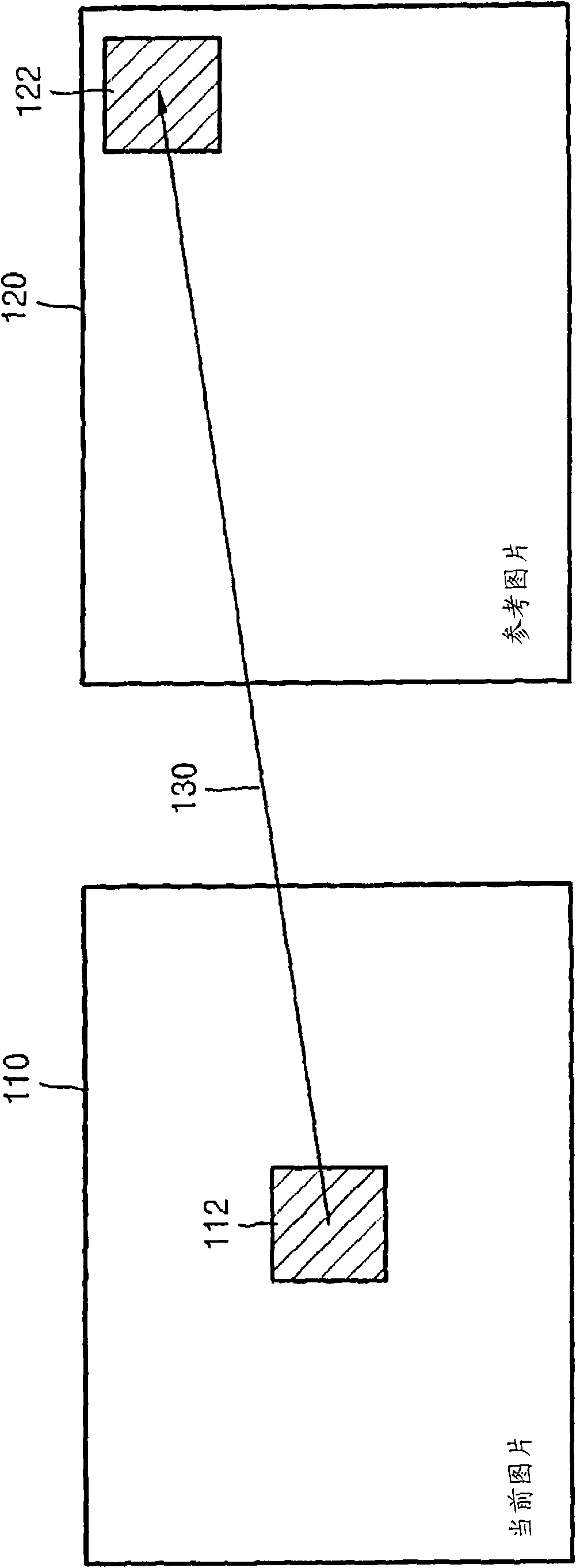

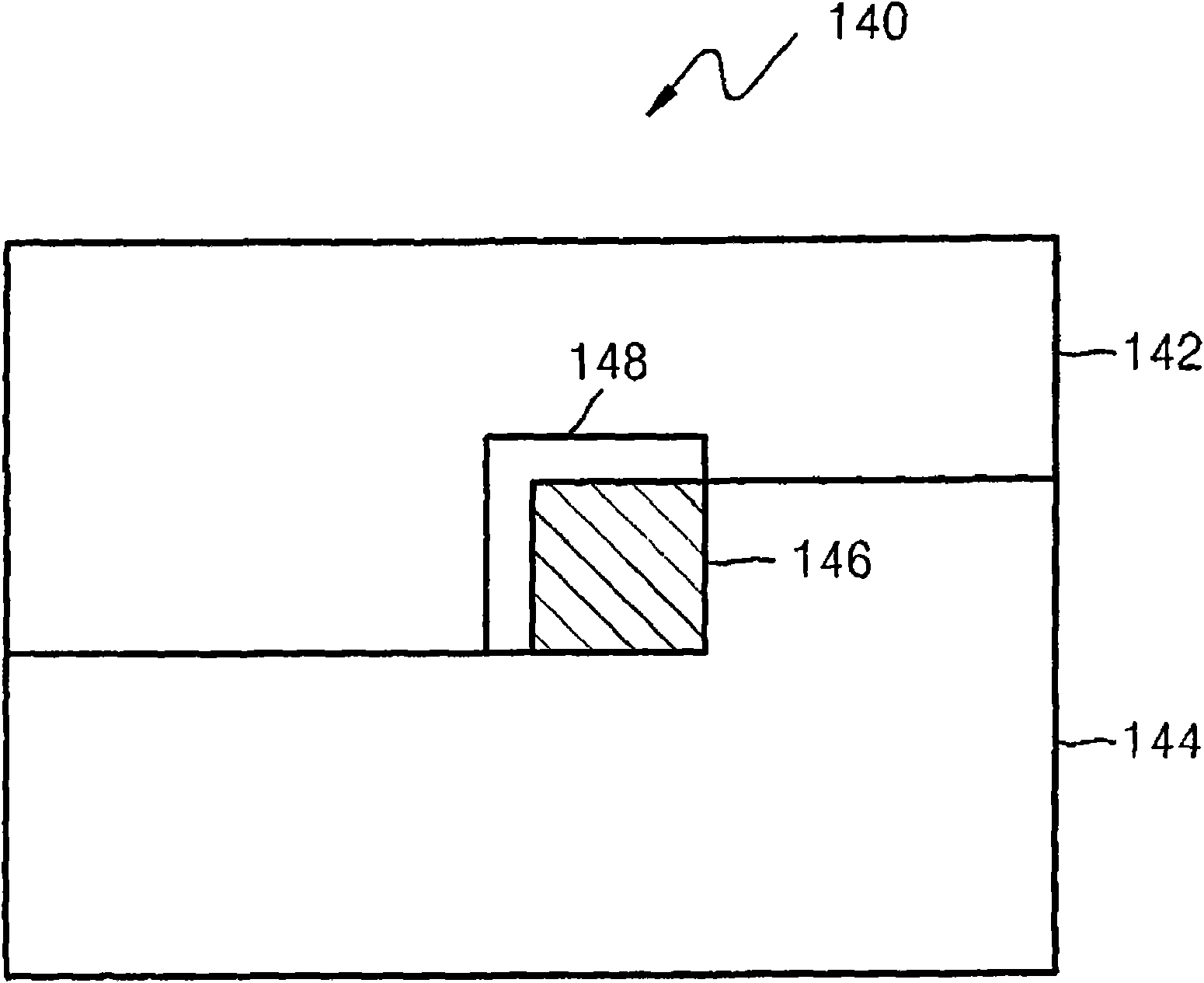

Method and apparatus for encoding and decoding based on inter prediction

InactiveCN101653006AIncrease the compression ratioReduce residualPulse modulation television signal transmissionDigital video signal modificationAlgorithmTheoretical computer science

A method and apparatus for encoding and decoding based on inter prediction are provided. In the encoding method, a current block is encoded by respectively performing intra prediction on the current block and a reference block in a reference picture which corresponds to the current block, and performing inter prediction on the current block based on the results of performing intra prediction. Accordingly, it is possible to reduce the size of data regarding the current block, which is generated as a result of performing inter prediction, thereby improving the compression rate of video data.

Owner:SAMSUNG ELECTRONICS CO LTD

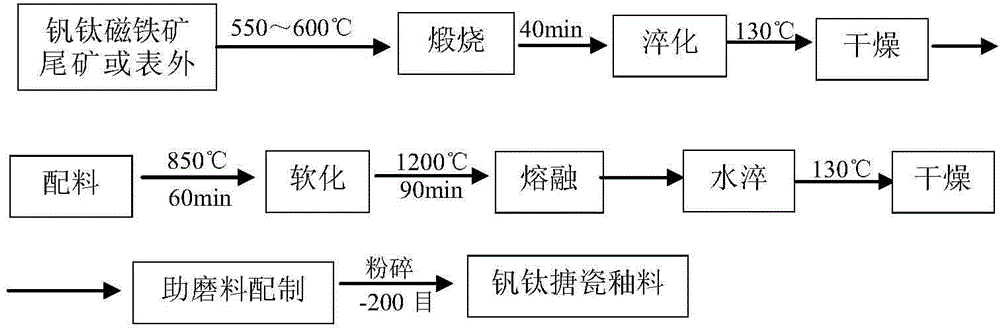

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

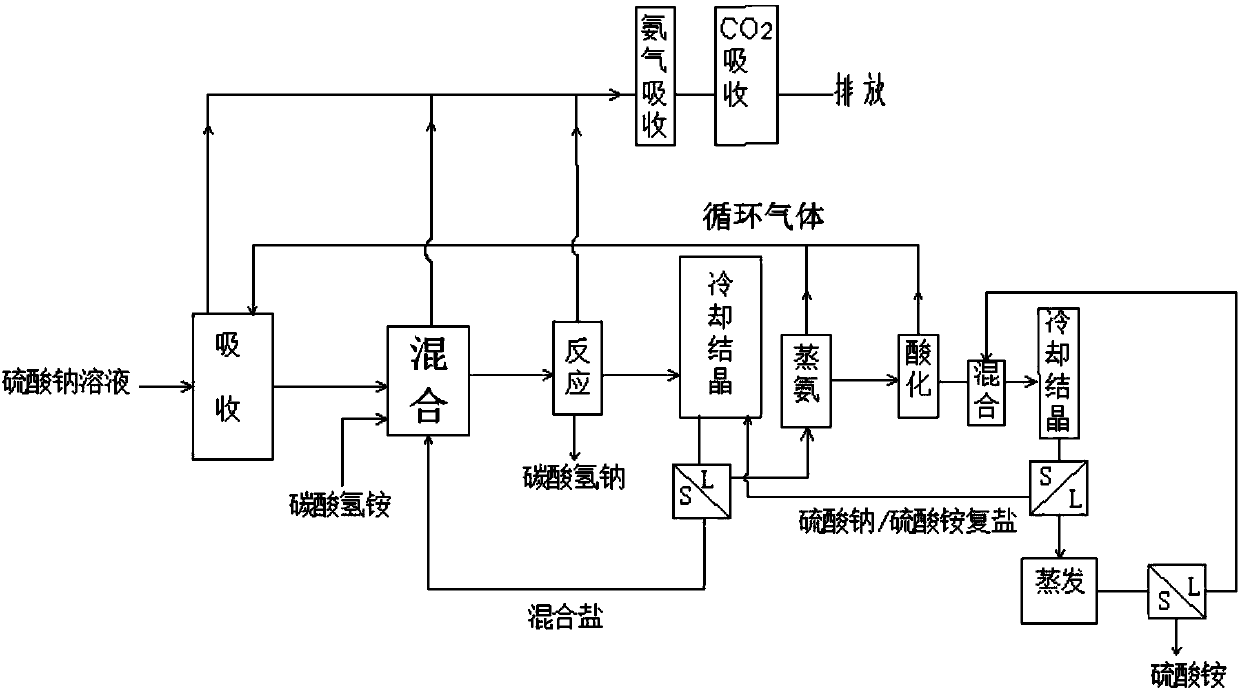

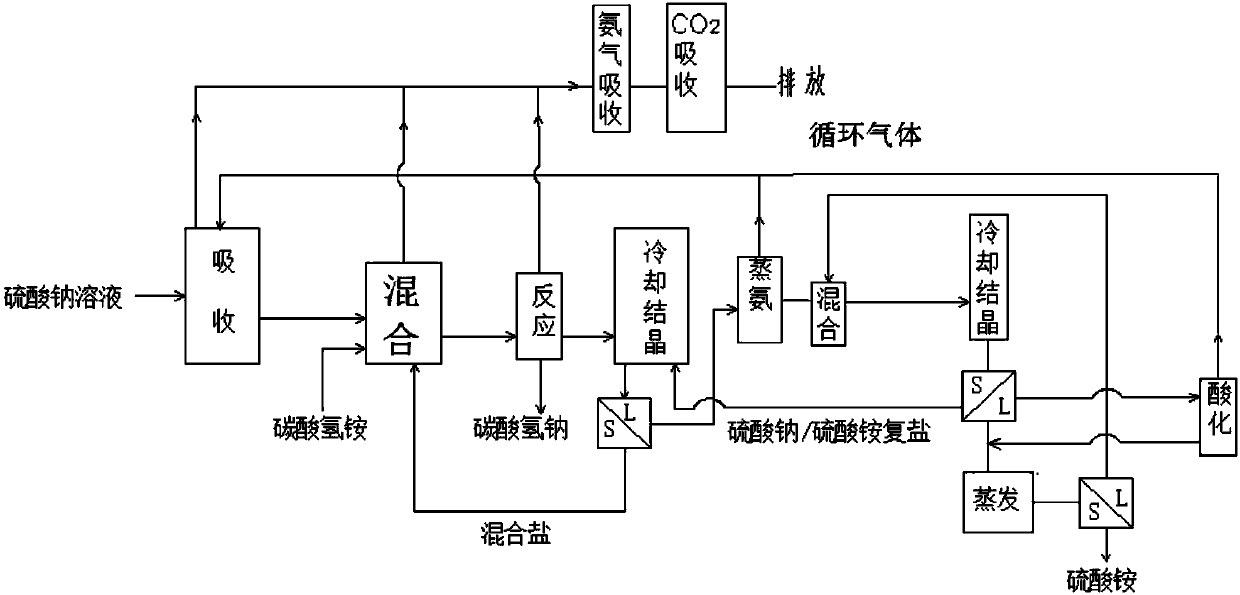

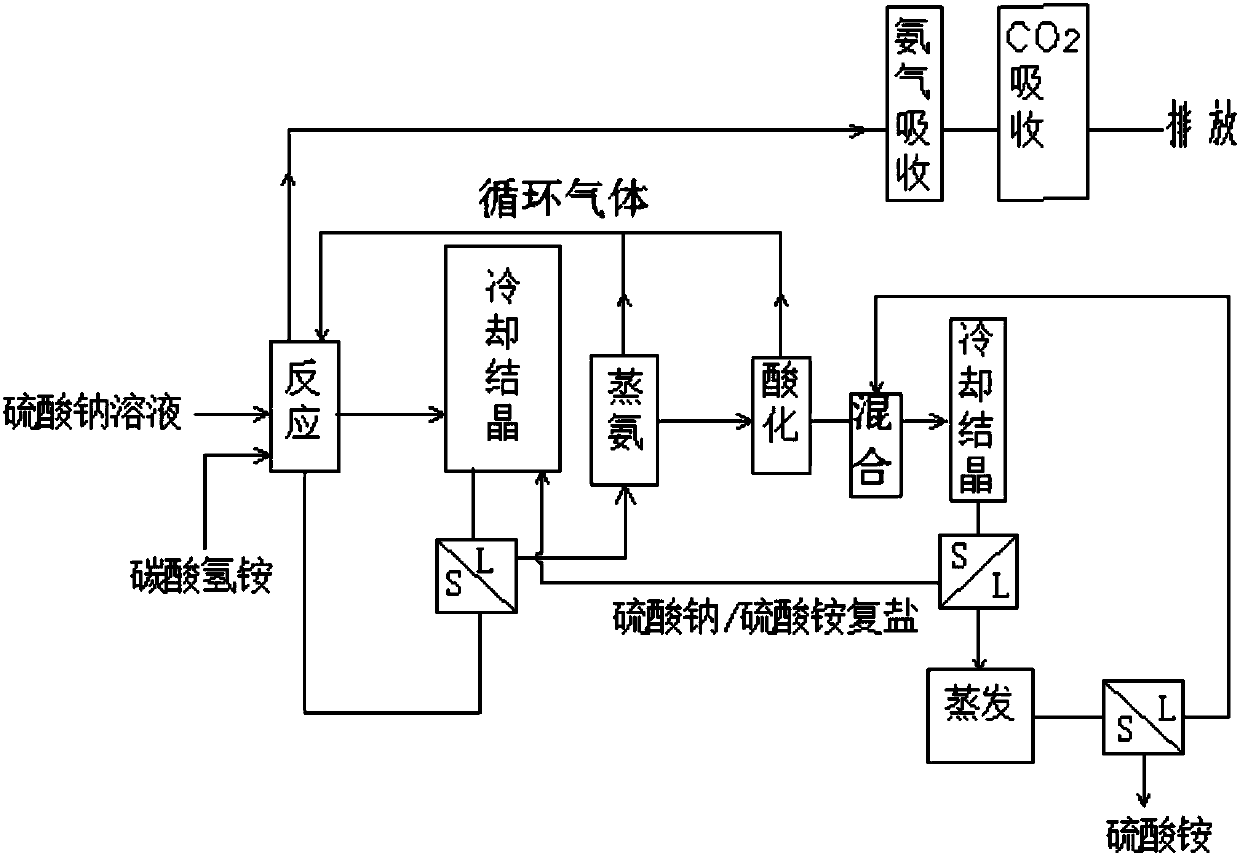

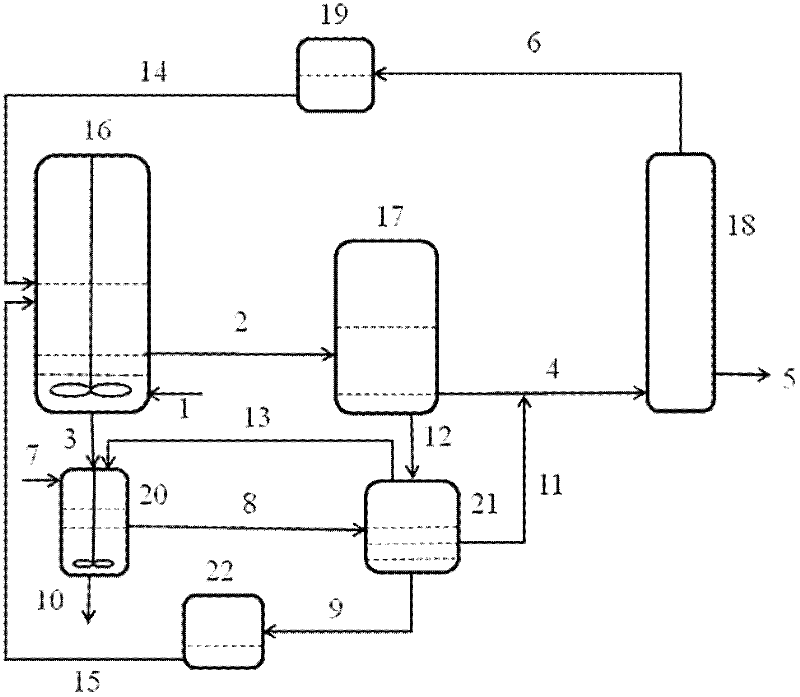

Method for producing sodium hydrogen carbonate and ammonium sulfate by using sodium sulfate solution

ActiveCN108046295ASolve pollutionImprove absorption rateCarbonate preparationAmmonia compoundsSodium bicarbonateHydrogen

The invention relates to a method for producing sodium hydrogen carbonate and ammonium sulfate by using a sodium sulfate solution, and belongs to the technical field of chemical engineering. The method comprises the following steps: a, absorbing circulating gas by using the sodium sulfate solution at -5 to 10 DEG C to obtain absorbing liquid; b, mixing the absorbing liquid, ammonium hydrogen carbonate and / or mixed salt at -5 to 20 DEG C to obtain mixed slurry; c, performing sealed reaction on the mixed slurry to obtain sodium hydrogen carbonate and reaction mother liquid; d, mixing the reaction mother liquid and complex salt to obtain salt mixture and primary frozen mother liquid after freezing; e, distilling the primary frozen mother liquid to obtain carbon dioxide, ammonium circulating gas and ammonium steaming mother liquid; f, adjusting the ammonium steaming mother liquid by acid to obtain an acidified solution and gas; g, mixing and freezing the acidified solution and crystallizedmother liquid to obtain complex salt and secondary frozen mother liquid; and h, evaporating and concentrating the secondary frozen mother liquid to separate out ammonium sulfate. The method is low inenvironmental pollution and high in raw material utilization rate.

Owner:SICHUAN UNIV

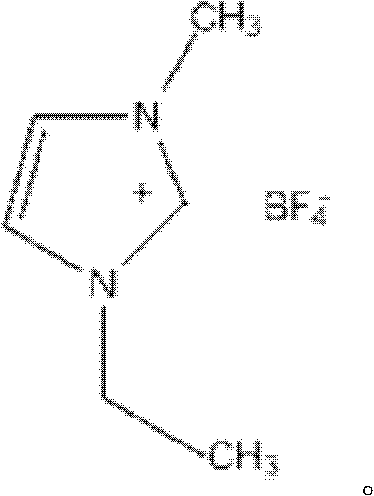

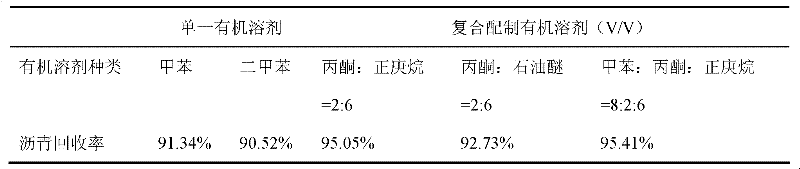

Ionic liquid for assisting oil-sand separation and separation method

ActiveCN102391185ALow viscosityReduce transportation energy consumptionOrganic chemistryLiquid hydrocarbon mixture productionTetrafluoroborateOrganic solvent

The invention relates to ionic liquid for assisting oil-sand separation and a separation method. According to the separation method, the ionic liquid is 1-ethyl-3-methylimidazole tetrafluoroborate; the range of the mass of added ionic liquid is 1-5 times of the mass of oil sand, and the ratio of the volume of an organic solvent to the mass of the oil sand is 1-12 ml / g so as to extract asphalt; the organic solvent and the ionic liquid simultaneously enter an extraction device so as to carry out extraction separation on the oil sand, and the asphalt separation is carried out under a temperature range of 15-60 DEG C; the organic solvent is collected through distilling at a temperature of 70-200 DEG C, and the rest organic product after distilling is an asphalt product; the residual sand and the ionic liquid are subjected to water cleaning by a small amount of water after oil-sand separation, the residual sand product is cleanly discharged; and the ionic liquid and the water can be recycled through fractionation by distillation. The residual sand and the ionic liquid are cleaned by the small amount of water after the oil-sand separation, thus, water is saved, and further, the loss of ionic liquid reagents is little; and in addition, the assisting separation method has high efficiency for the recovery of the asphalt which can reach 95%, and the residual organic matters in the oil sand is little.

Owner:TIANJIN UNIV

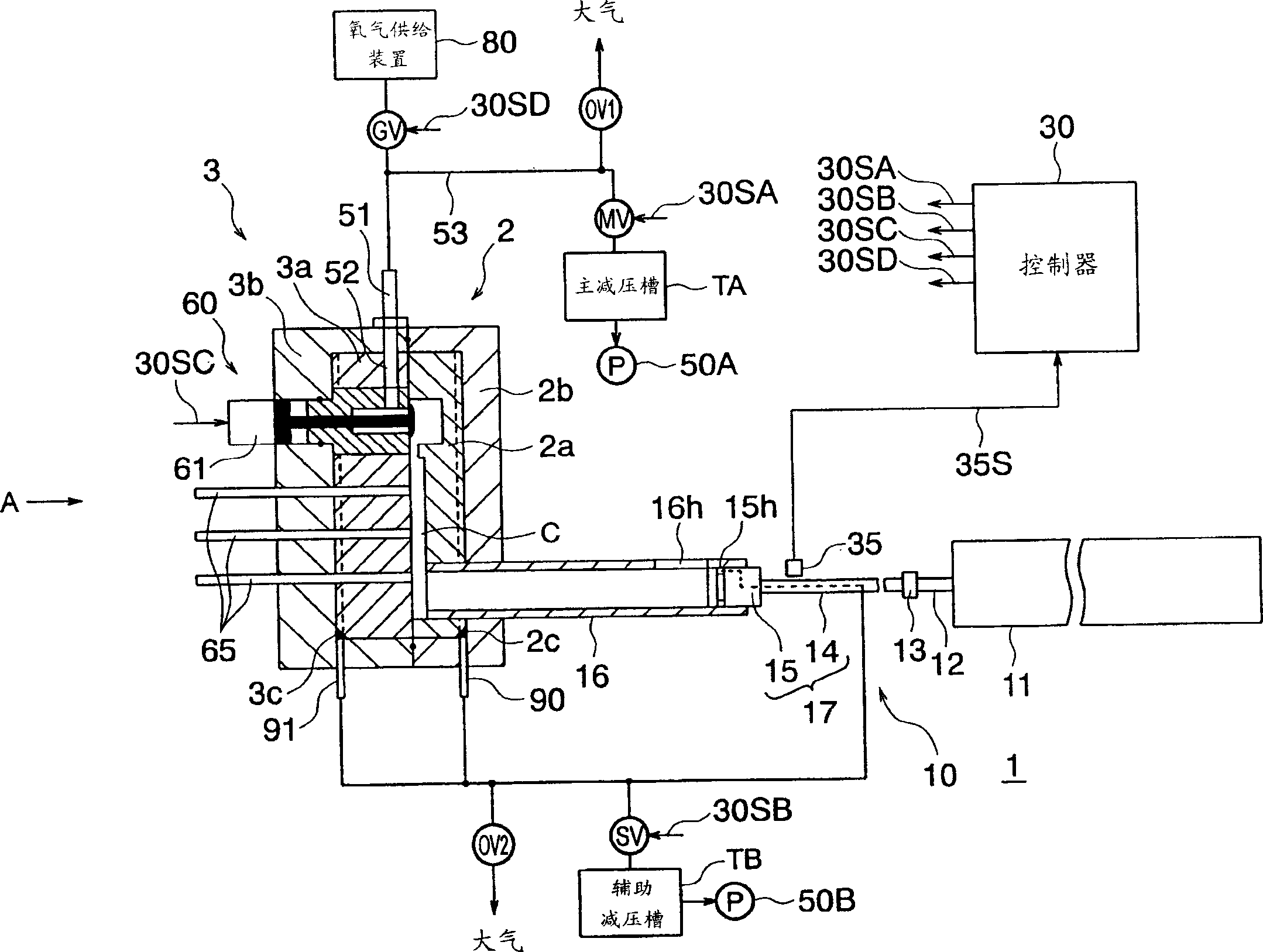

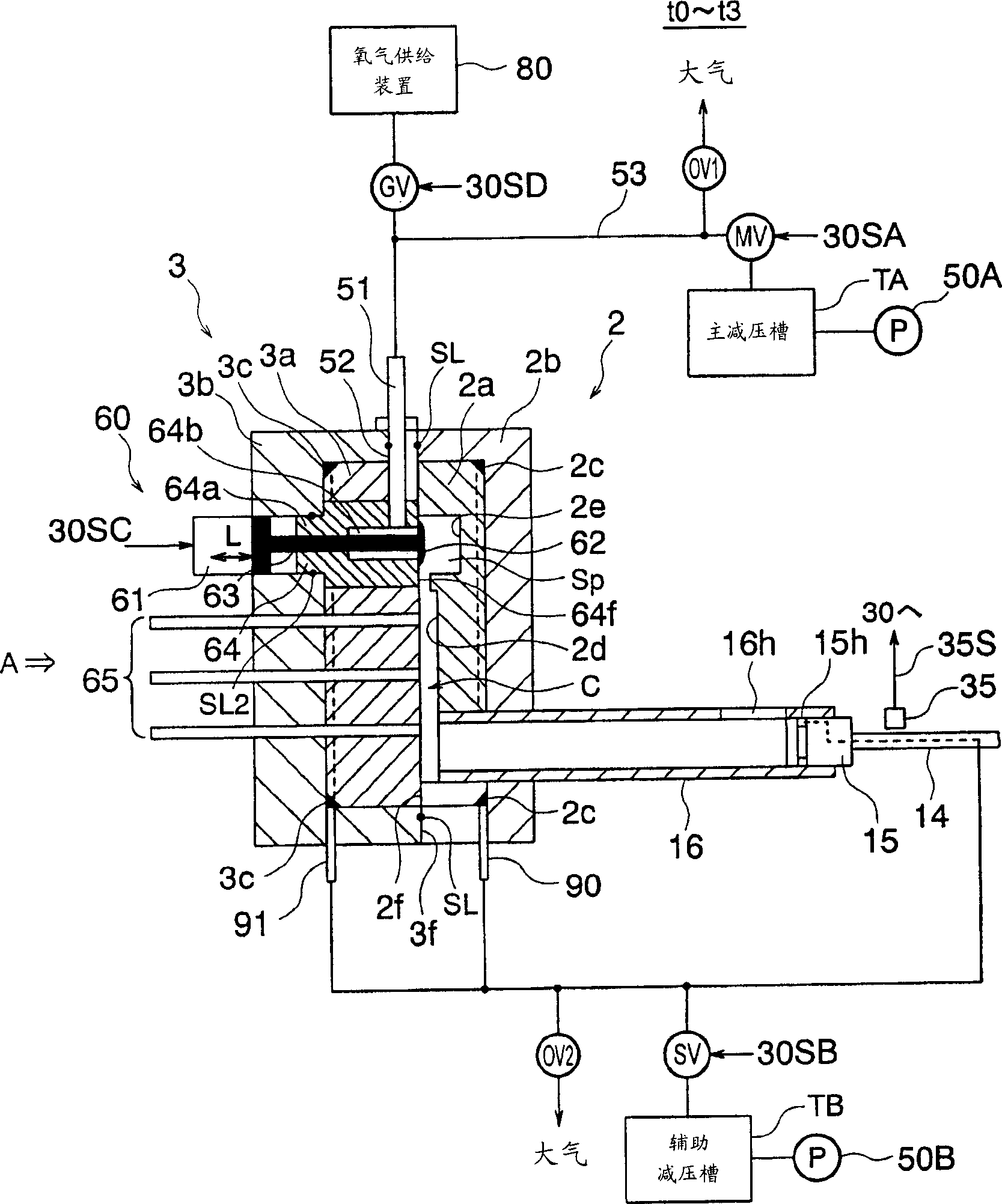

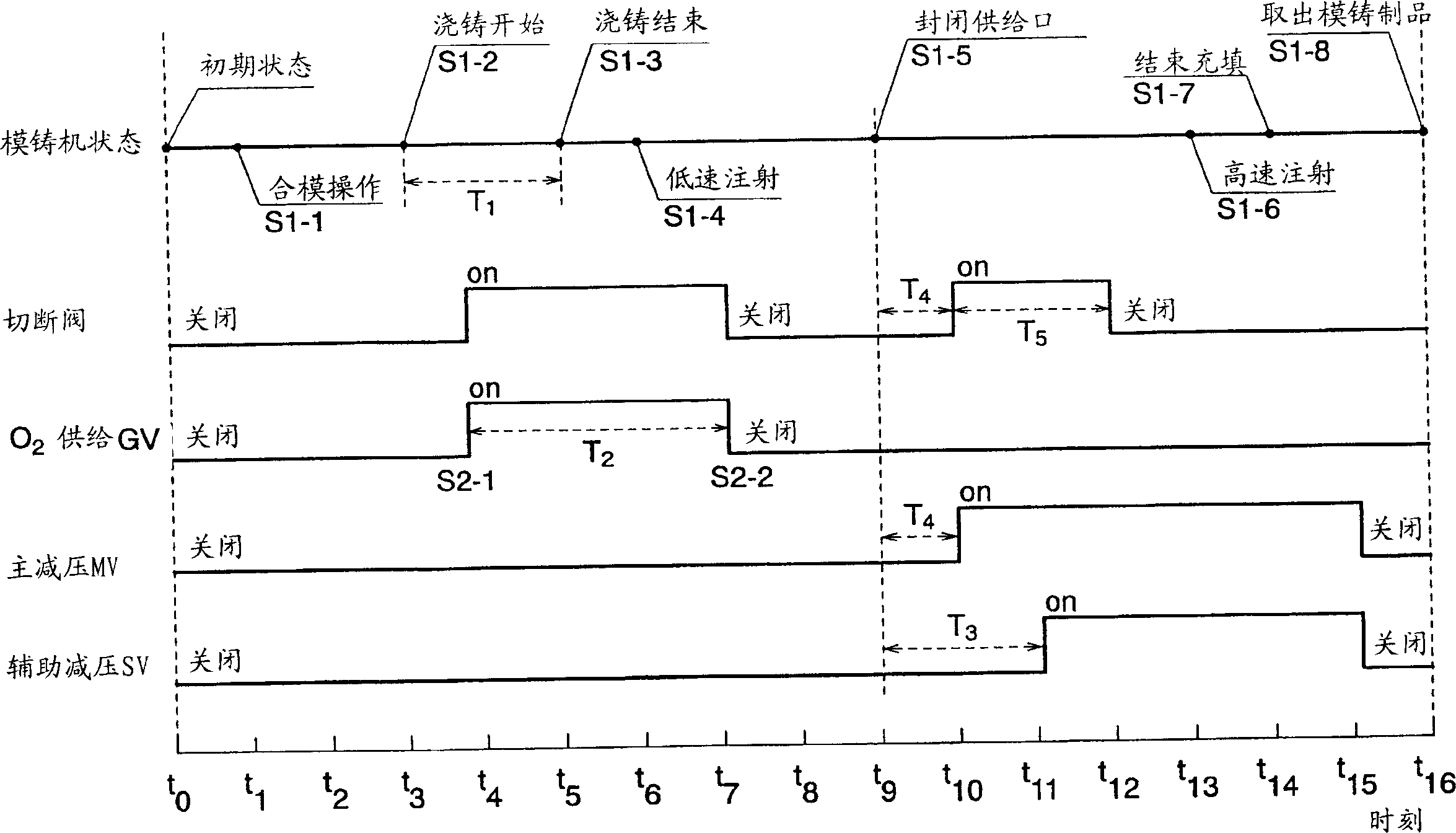

Die-casting device and vacuum process

The purpose of this invention is to improve a die casting apparatus by using an oxygen-replacing die casting method, with which a high quality die cast product can be produced. The oxygen gas is filled up into a cavity C and an injection sleeve 16 by using an oxygen gas supplying device 80, and after purging inner parts in the cavity C and the injection sleeve 16 with the oxygen gas, portions having the possibility of infiltrating the outer air into the cavity C, for example, an auxiliary reducing pressure tank B and a third opening / closing valve SV for performing the reduced pressure exhausting from a fixed die flowing path 2c and a moving die flowing path 3c, and a main reducing pressure tank TA and a first opening / closing valve MV for performing the pressure reduction in the cavity C are simultaneously and parallel driven.

Owner:TOSHIBA MASCH CO LTD

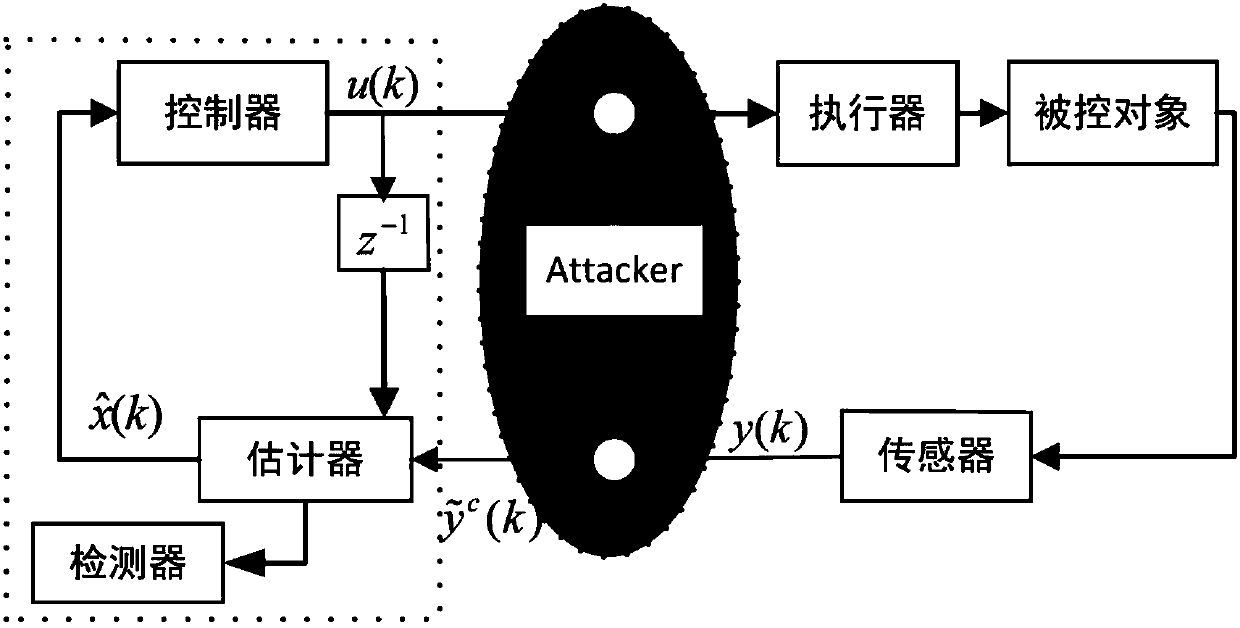

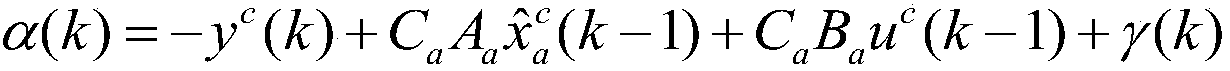

False data injection attack method based on imprecise mathematical model

InactiveCN108196448AReduce computing costReduce residualAdaptive controlControl systemMathematical model

The invention provides a false data injection attack method based on an imprecise mathematical model, which can successfully destroy the performance of a control system without being detected by a detector. Sensor readings and control commands are stolen from network channels; imprecise mathematical model parameters for a controlled object are recognized; a false data attack sequence is designed according to the recognized imprecise mathematical model parameters and the sensor readings and control commands; the false data attack sequence is injected into the sensor readings to form false sensor readings; the false sensor readings are transmitted to a controller; the controller detects whether a system is abnormal according to the false sensor readings; control commands are generated according to the false sensor readings and transmitted to the controlled object. The false data injection attack method based on the imprecise mathematical model is applicable to testing the defense effectof a control system for false data injection attacks, and a test means is provided for the design of defense methods.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

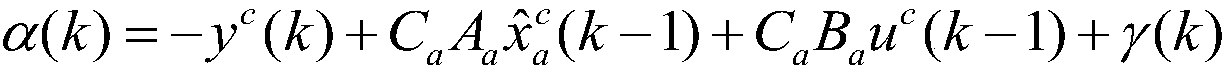

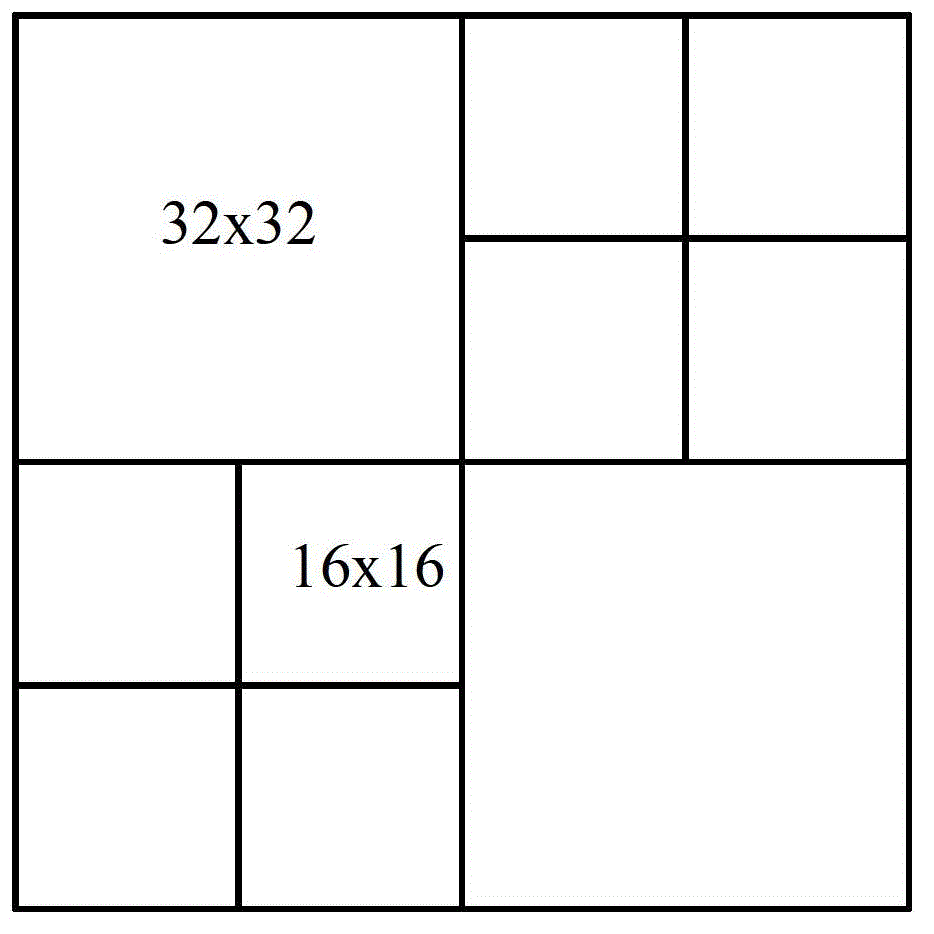

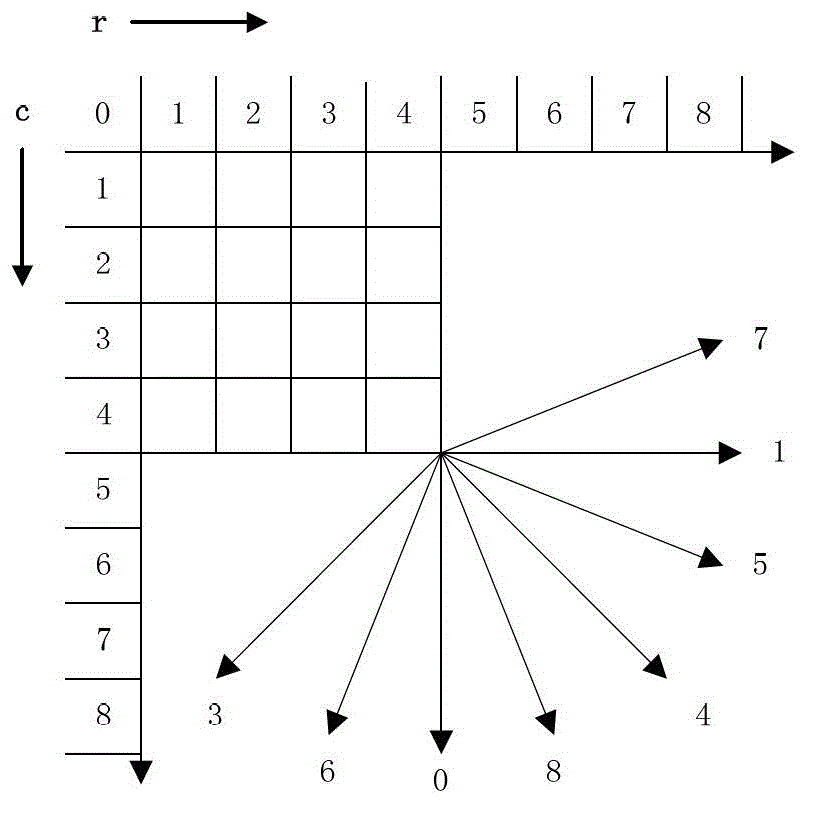

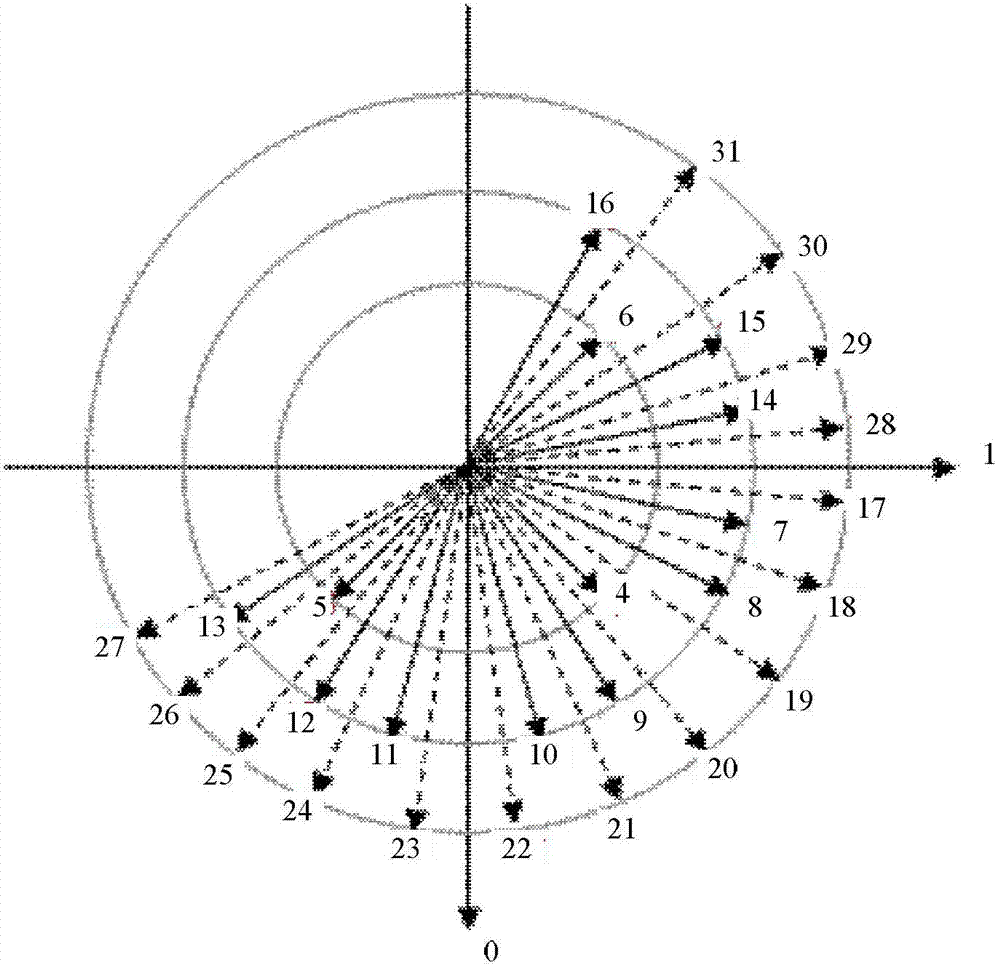

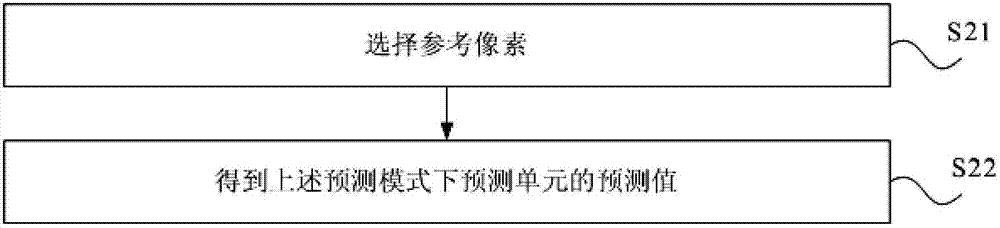

Multi-directional intra-frame forecast encoding and decoding method and device

ActiveCN102984523AThe predicted value is accurateReduce the predicted residualTelevision systemsDigital video signal modificationEntropy encodingMulti directional

The invention discloses an intra-frame forecast encoding and decoding method and a device. The method comprises the following steps that an encoding end selects a reference pixel required for executing intra-frame forecast of a set intra-frame forecast direction according to the set intra-frame forecast direction for an input intra-frame forecast unit; the forecast unit is forecasted with the reference pixel according to the set forecast direction; a pixel forecast value of the forecast unit is obtained; the pixel forecast value is filtered by the selected reference pixel; all forecast directions are traversed; entropy encoding is conducted on the optimal forecast direction; and a decoding end resolves an intra-frame forecast mode and adopts a intra-frame forecast method same as that of the encoding end to obtain an intra-frame forecast value.

Owner:PEKING UNIV

High-efficiency ultra-low-smell maleic anhydride graft composition

The invention relates to a preparation method of a high-performance ultra-low-odor maleic anhydride grafted composition by reaction extrusion. The maleic anhydride grafted composition is characterized in that the composition comprises 90wt%-97wt% of polymeric resin, 1wt%-5wt% of maleic anhydride, 0.5wt%-2wt% of initiator, 0.5wt%-1.5wt% of second monomer, 0.5wt%-2wt% of odor absorbent and 0.1wt%-1wt% of antioxidant. The preparation method comprises the steps as follows: weighing the raw materials; mixing in a high speed mixer for 2-5 minutes; discharging; and carrying out fusion reaction and extruding in a twin-screw extruder at a rotation speed of 180-600rpm at 150-225 DEC C. The maleic anhydride grafted composition has the characteristics of high grafting ratio, light color, low gel content and low maleic anhydride residue, and can be widely applied in a high molecular material processing industry.

Owner:SHANGHAI SUNNY

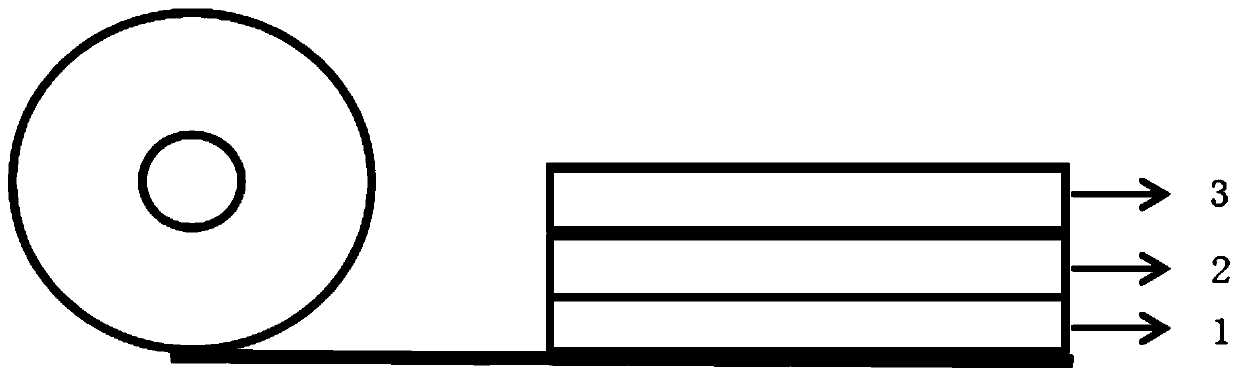

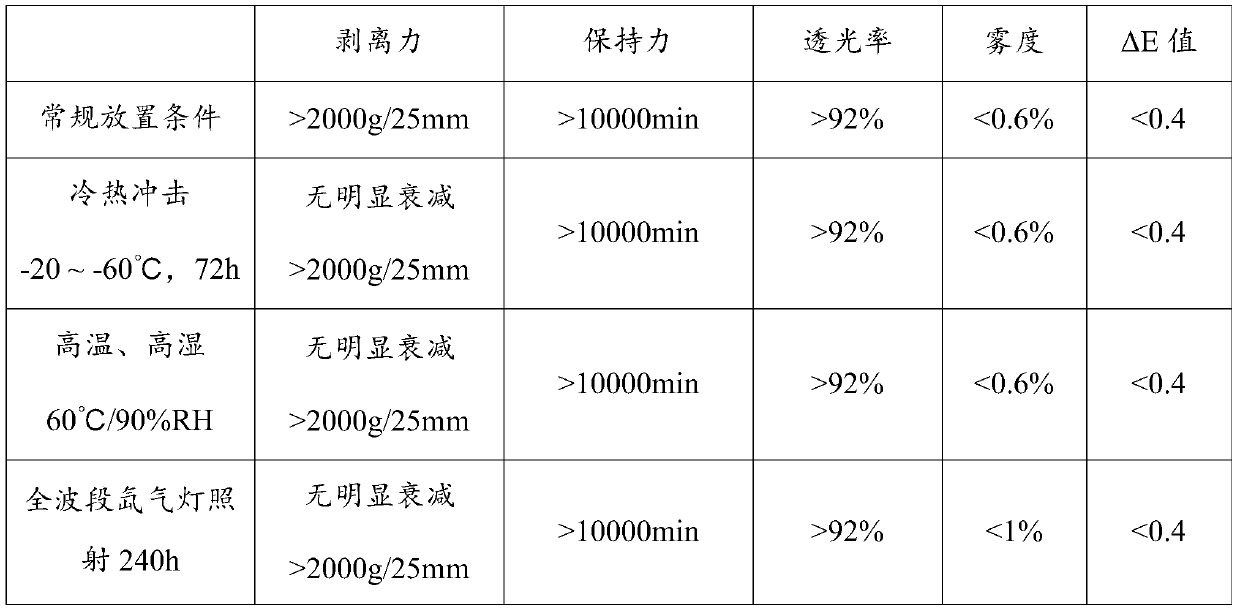

High-viscosity yellowing-resistant explosion-proof film adhesive, adhesive tape and preparation method of adhesive tape

ActiveCN110527464ALight colorImprove antioxidant capacityNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateEthyl acetate

The invention discloses a high-viscosity yellowing-resistant explosion-proof film adhesive. The explosion-proof film adhesive comprises the following components in parts by weight: 100 parts of acrylic acid adhesive, 5-10 parts of tackifying resin, 0.15-0.6 part of a curing agent and 50-90 parts of a solvent, wherein the acrylic acid adhesive is prepared by reacting the following components in parts by weight: 26-30 parts of isooctyl acrylate, 3-5 parts of acrylic acid, 0.5-1 part of hydroxyethyl acrylate, 5-10 parts of methyl acrylate, 53-65 parts of ethyl acetate and 0.5-1 part of azobisisobutyronitrile; the solvent is one or more selected from ethyl acetate, toluene and butanone; and the tackifying resin is hydrogenated resin. The invention also provides a high-viscosity yellowing-resistant adhesive tape prepared from the adhesive. The high-viscosity yellowing-resistant explosion-proof film adhesive has colorless transparent appearance, and can still ensure sufficient peeling forceaccording to different coating thicknesses. Under the condition of high-temperature aging, the explosion-proof film adhesive is not yellowing in appearance, and peeling force is basically not attenuated.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

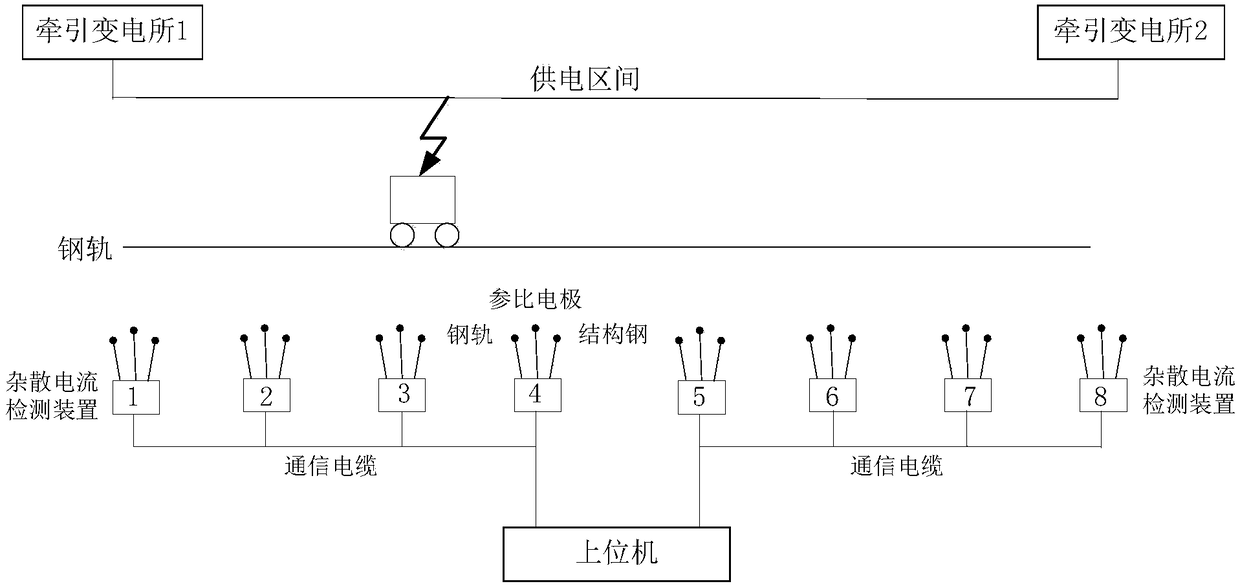

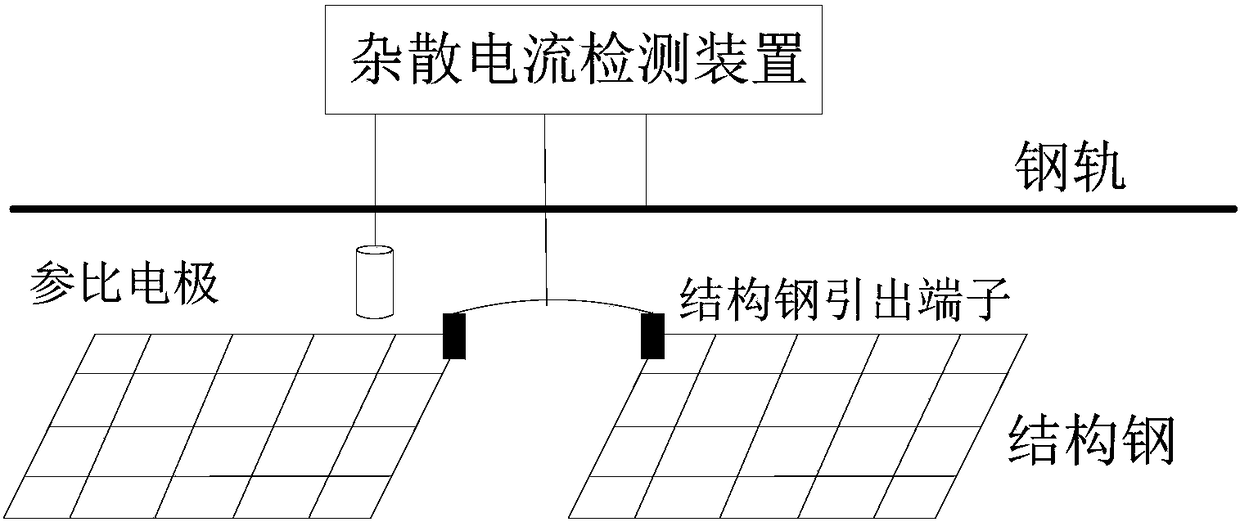

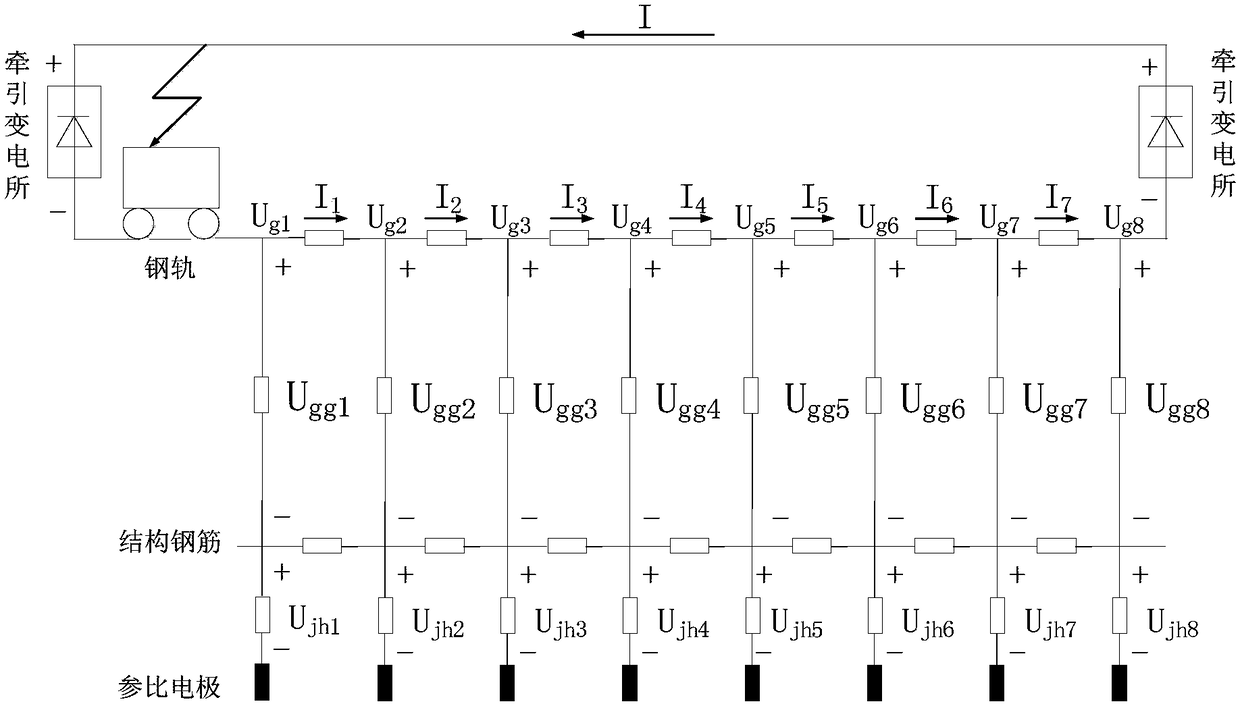

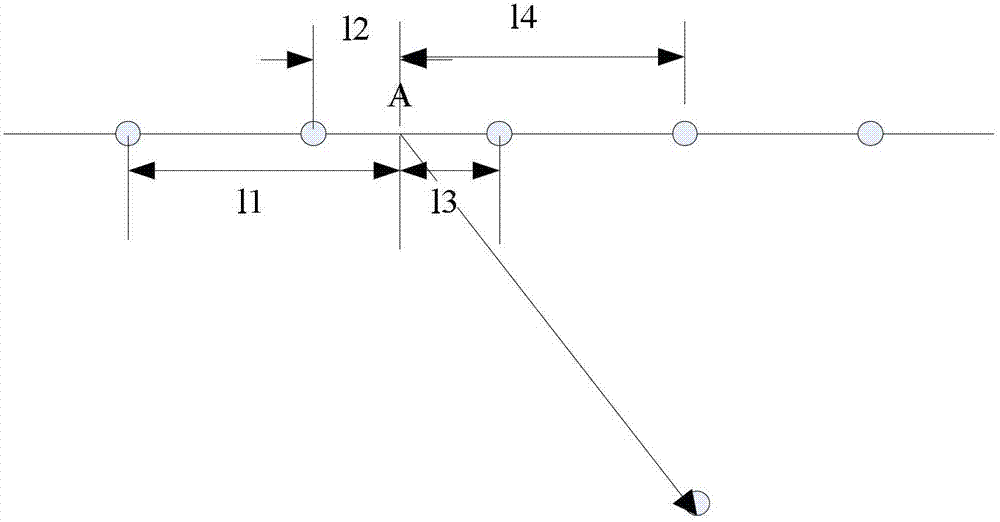

Stray current acquiring method and stray current detection system

ActiveCN108562782AImprove reliabilityReduce mistakesCurrent/voltage measurementPower flowDistribution function

The invention discloses a stray current acquiring method and a stray current detection system. The acquiring method comprises the following steps: (1) collecting detection data of each stray current detection device; (2) calculating a polarization potential of the stray current detection device, and carrying out normalization processing, so as to obtain a reduced polarization potential; (3) calculating a track potential of the stray current detection device, and calculating a track current of the stray current detection device; (4) acquiring a traction current of a current train, and calculating a stray current of the stray current detection device; (5) acquiring a running environment of the current train, and constructing fitting data sets; and (6) carrying out one-dimensional polynomialcurve fitting on the data in each fitting data set, so as to obtain a distribution function of the stray current. According to the stray current acquiring method, a manner for acquiring the stray current in a power supply interval at the moment is provided, and a specific numerical value can be acquired, so that the stray current can be relatively timely and effectively monitored.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

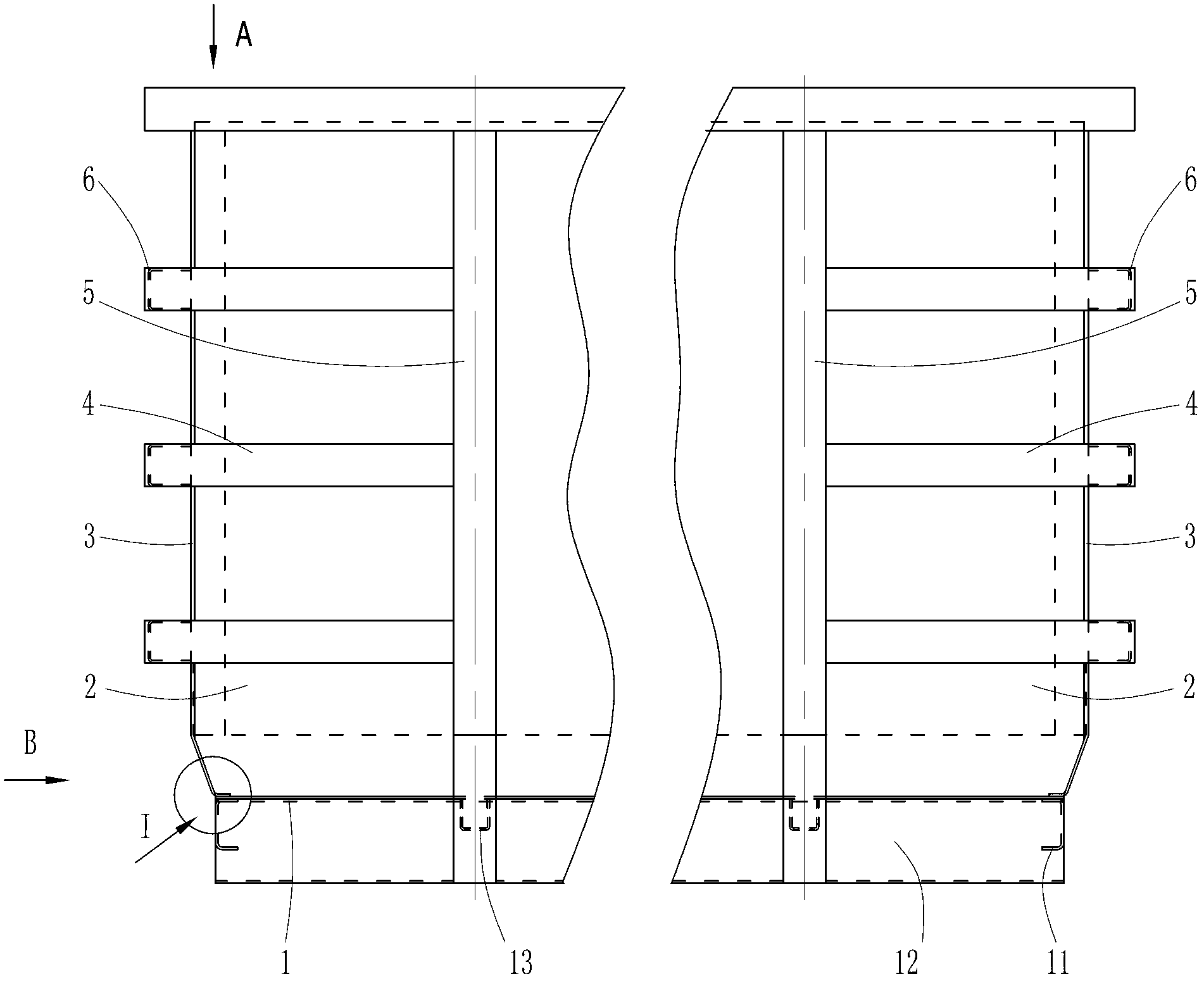

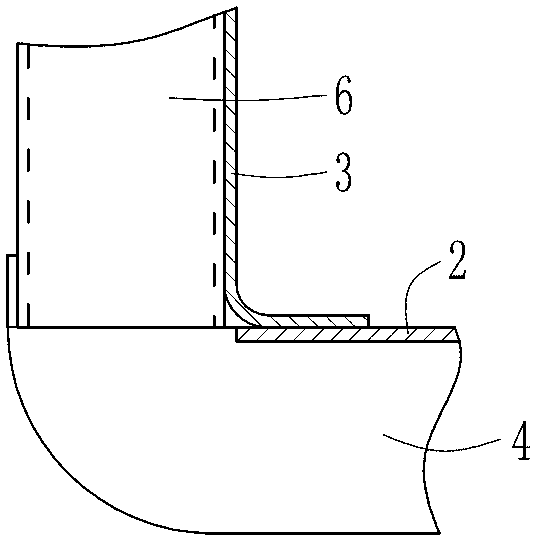

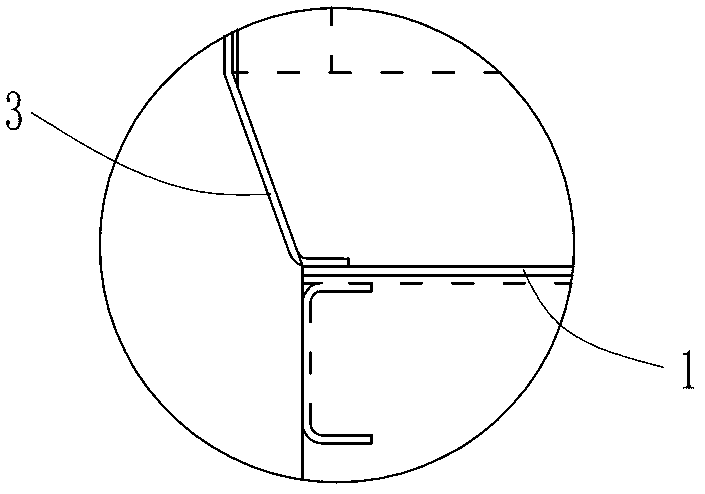

Railway wagon compartment suitable for small limitation bound

The invention discloses a railway wagon compartment suitable for a small limitation bound. The railway wagon compartment suitable for the small limitation bound comprises a floor (1), lateral wall plates (2) located on two sides of the floor (1) and end wall plates (3) located at two ends of the floor (1). The lower portion of each lateral wall plate (2) is bent inwards to form a dip angle, connected with the floor (1) in a lap joint mode and fixed with the floor (1) through welding. The lower portion of each end wall plate (3) is bent inwards to form a dip angle, connected with the floor (1) in a lap joint mode and fixed with the floor (1) through welding. Two sides of each end wall plate (3) are connected with corresponding ends of each lateral wall plate (2) in a lap joint mode and fixed with the corresponding ends of each lateral wall plate (2) through welding. The dip angles bent inwards are arranged on the lower portions of the lateral wall plates and the lower portions of the end wall plates, so that corner posts and corner post plates in a traditional structure are cancelled. Furthermore, through the arrangement of lateral vertical columns, lateral platbands and end platbands, entire intensity of the compartment is improved. On the premise that the requirement of a railway of a small limitation bound is met, the loading capacity of the compartment is increased to the maximum limit. The railway wagon compartment suitable for the small limitation bound is easy to manufacture, small in self weight, safe and efficient in transportation.

Owner:CHONGQING CHANGZHENG HEAVY IND

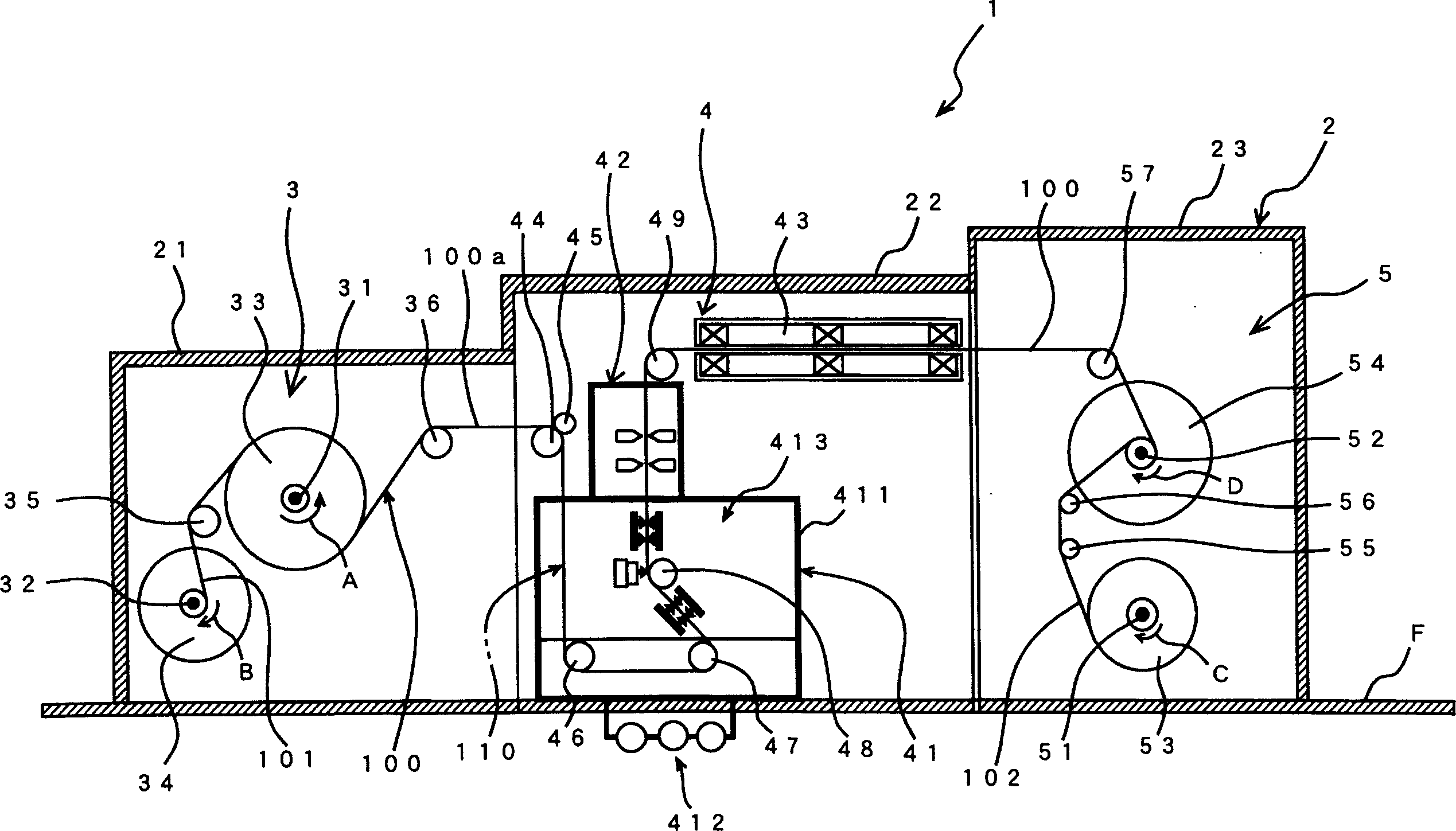

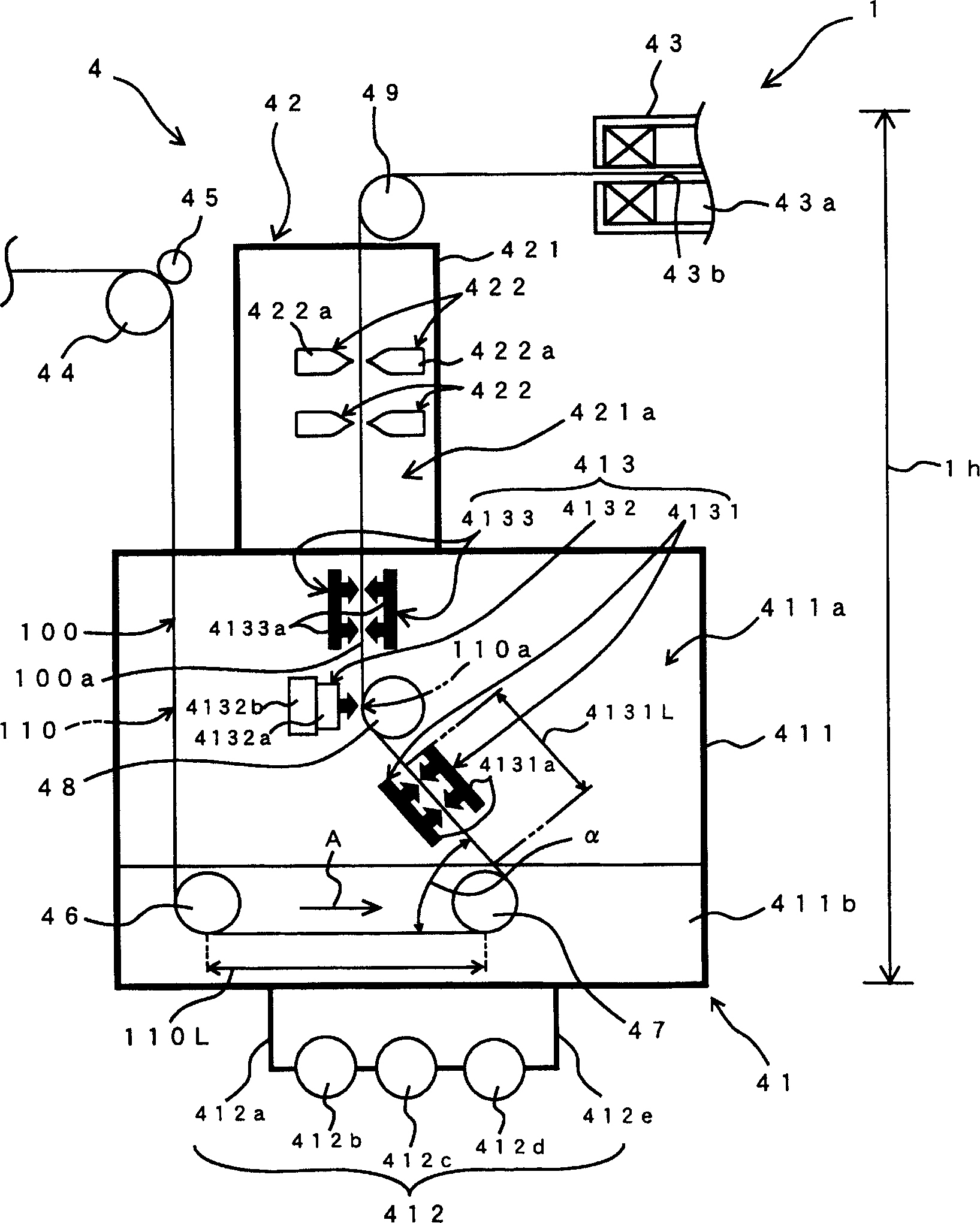

Band washing unit and band washing method

InactiveCN1824397AImprove cleanlinessEasy to removeWallsProjectorsMegasonic cleaningCleaning methods

Owner:MITSUI MINING & SMELTING CO LTD

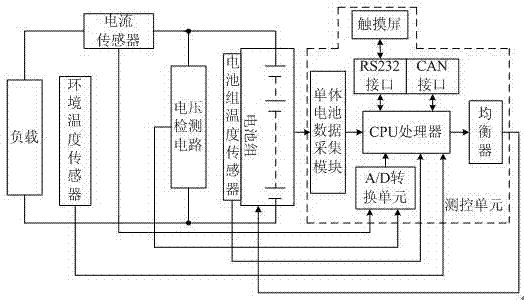

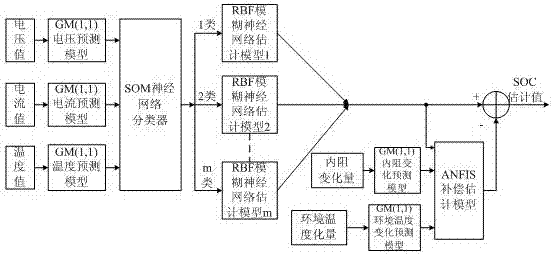

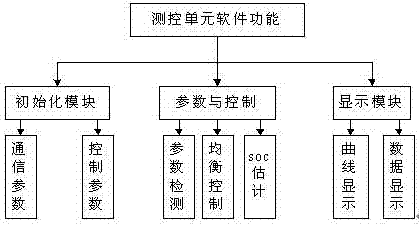

Electric vehicle power battery SOC intelligent detection device

ActiveCN107422272AImprove estimation accuracyIncrease computing speedElectrical testingVehicular energy storagePower batteryElectrical battery

The invention discloses an electric vehicle power battery SOC intelligent detection device which is characterized in that the intelligent detection device includes a battery parameter acquisition platform and a battery SOC estimation system, the battery parameter acquisition platform collects real-time parameters of voltage, current and temperature of an electric vehicle power battery group, the battery SOC estimation system estimates an SOC value through the collected parameters, and a battery SOC system is a nonlinear, time-delay and multivariable coupling complex real-time system with a high requirement. According to the device, a problem that a conventional detection device can not obtain an ideal effect of the intelligent detection of the electric vehicle power battery SOC.

Owner:安徽惠宏科技有限公司

Nanometer microsphere of temozolomide polylactic acid and its preparation and preparing method therefor

InactiveCN100998566AGood sustained release performanceGood slow releaseOrganic active ingredientsPharmaceutical non-active ingredientsFreeze dryMicrosphere

A nanoball of temozolomide-sodium polylactate is proportionally prepared from temozolomide and sodium polylactate. Its product may be injection, freeze-dried powder injection, slow-release micropills, tablets, or membrane for treating cancer, especially the cerebral glioma. Its preparing process is also disclosed.

Owner:南京伍盛纳米科技有限公司

Preparation method of polyamideimide fine powder

The invention relates to a preparation method of polyamideimide fine powder, which mainly solves the problem that the solution precipitation process can not be used for preparing polyamideimide fine powder in the prior art. The technical scheme is as follows: the preparation method comprises the following steps: adding a polyamide amide acid or polyamideimide polymer solution prepared by solution polycondensation into a high pressure atomizer or centrifugal atomizer to atomize the polymer solution into micron-sized atomized liquid drops, adding the atomized liquid drops into a precipitant to precipitate and form superfine polyamide amide acid or polyamideimide powder, washing, filtering and drying to obtain the final product. The technical scheme well solves the problem above, and can be used for preparing polyamideimide fine powder.

Owner:SHANGHAI HUAYI GRP CO

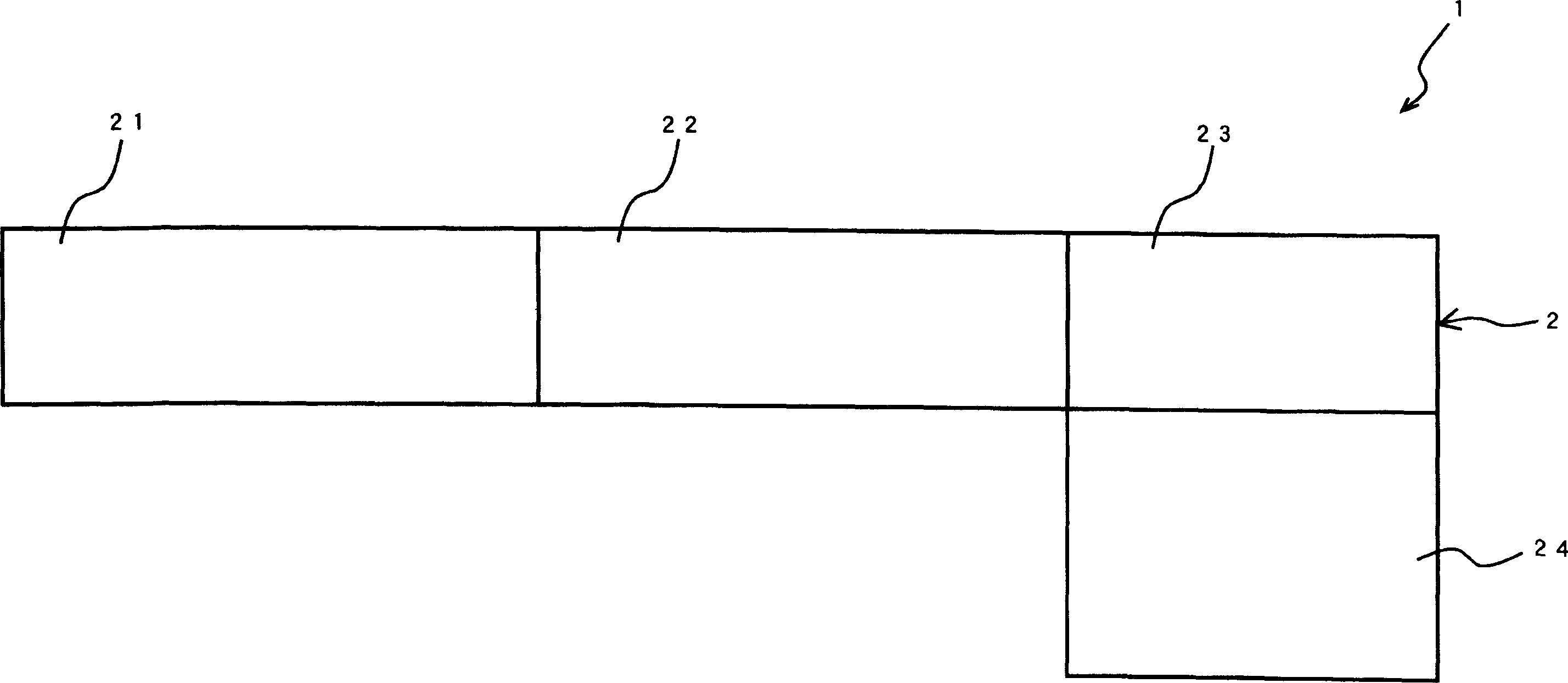

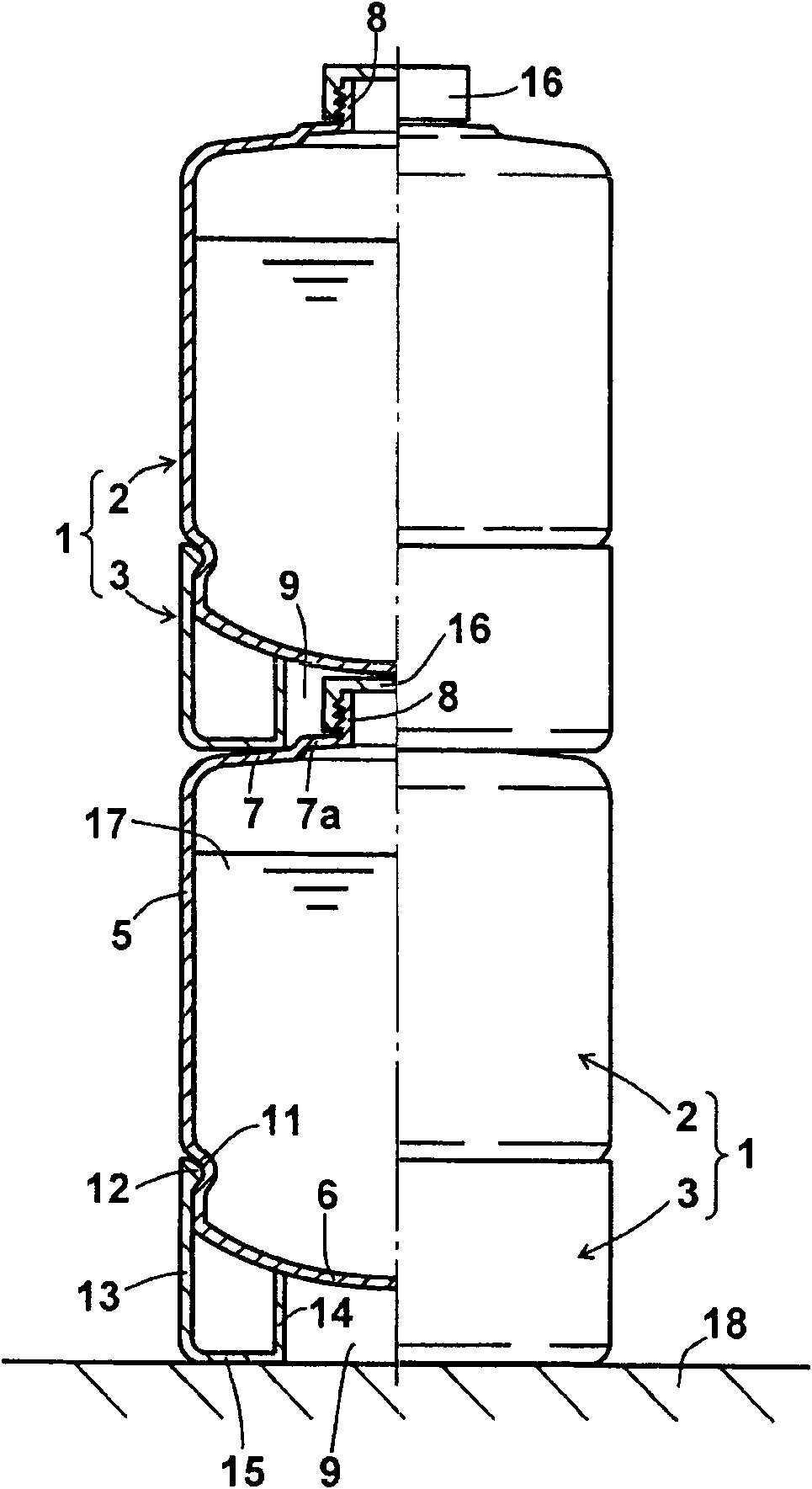

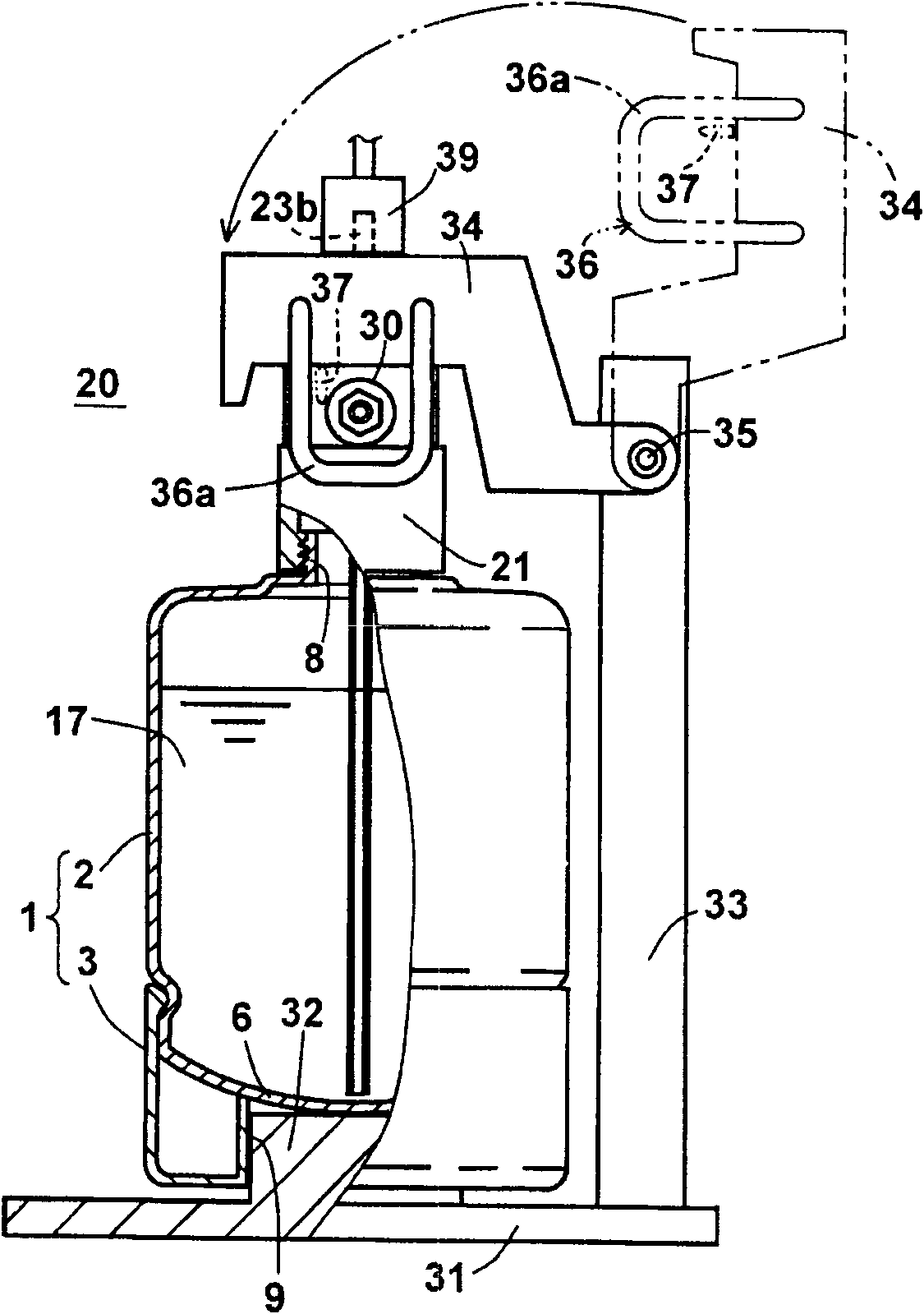

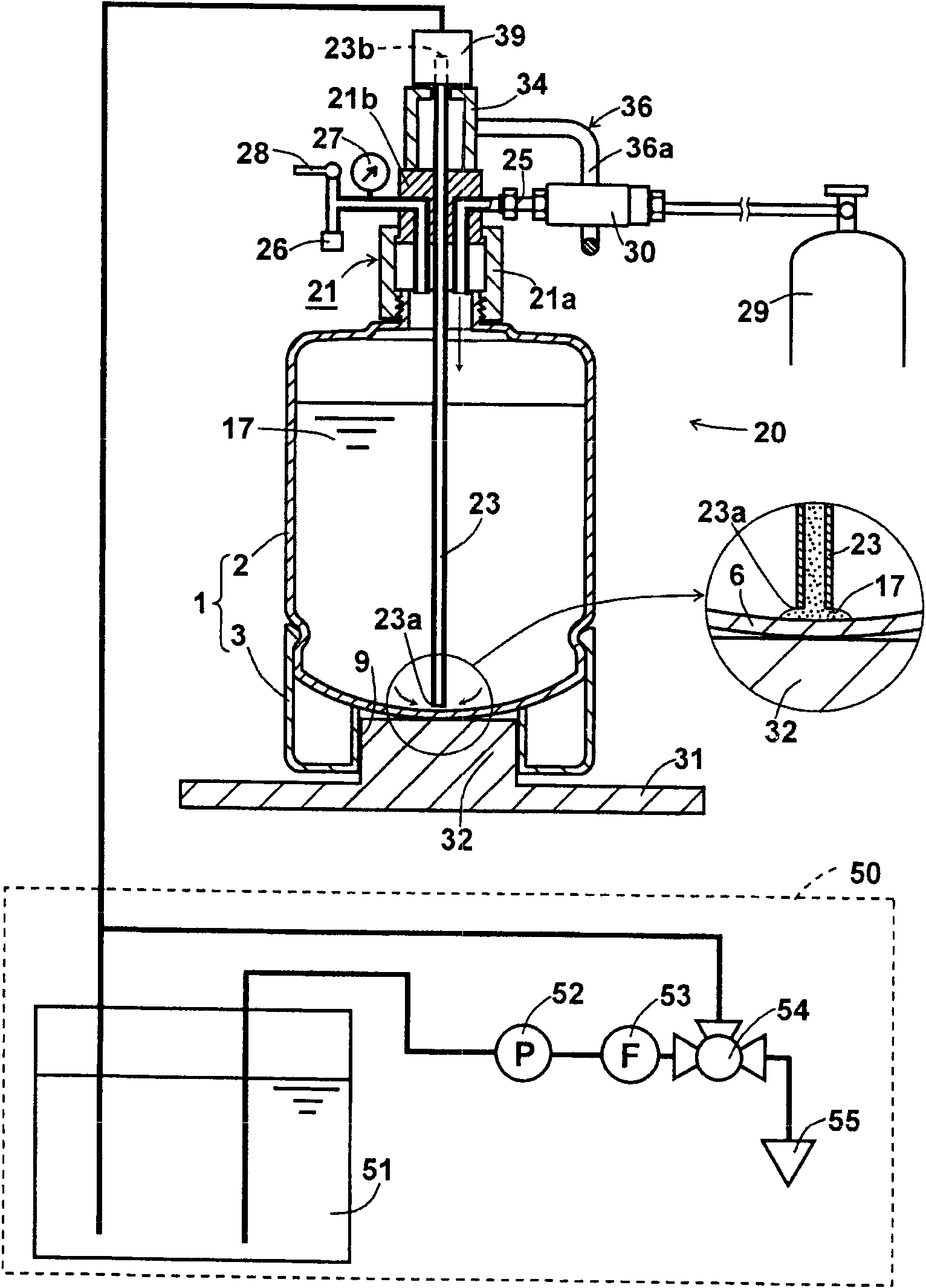

Liquid container, liquid delivering device equipped therewith and liquid delivering method

ActiveCN102050248AImprove qualityAvoid breakingClosuresLiquid transferring devicesEngineeringElectrical and Electronics engineering

The invention discloses a liquid container, a liquid delivering device equipped therewith and a liquid delivering method. The liquid container can maintain the filled liquid with high quality, wherein the space is saved for storing liquid and the residual liquid is reduced to the minimal amount when the liquid is discharged. According to the liquid delivering device and the liquid delivering method, the installation and replacement operation of the liquid container is operated conveniently, which is simple in structure and low in cost. Meanwhile, the amount of the residual liquid in the container is largely reduced and the liquid is discharged safely. The liquid container (1) comprises a round-bottomed main body (2) and a supporting platform (3) made of thermoplastic resin with a bending elastic rate of at least 700 MPa. The inner surface of the main body (2) is made of thermoplastic resin of high purity and the supporting platform (3) is equipped with a through part (9). According to the liquid delivering device (20) arranged on the liquid container (1), the end (23a) of a liquid feeding pipe (23) is inserted to the round bottom (6) of the container. The upper end and the lower end of the main body (2) are respectively clamped by a protrusion part (32) and a pressing member (34). When gas with a pressure of 200 kPa is supplied, the liquid in the container is discharged.

Owner:AICELLO

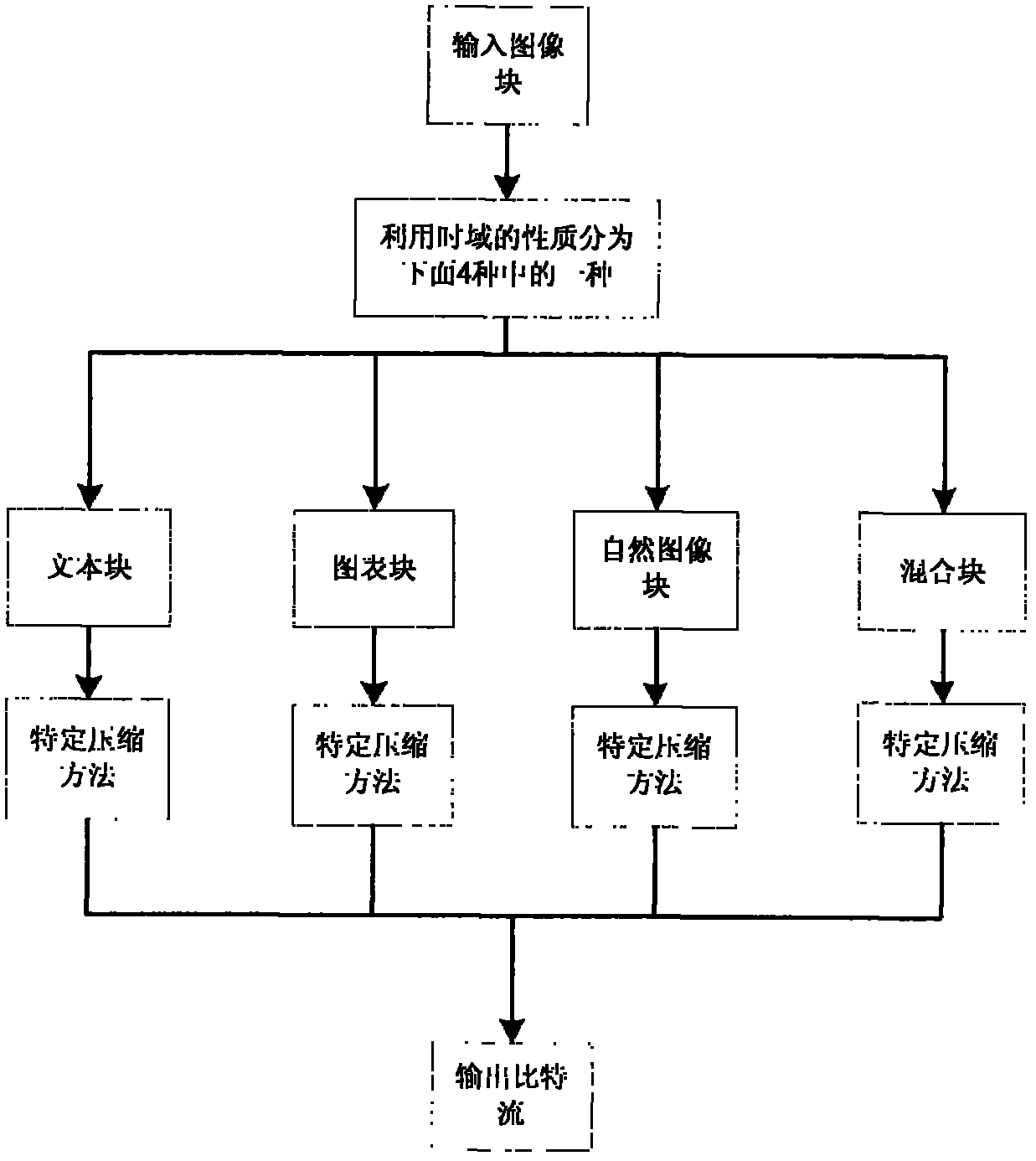

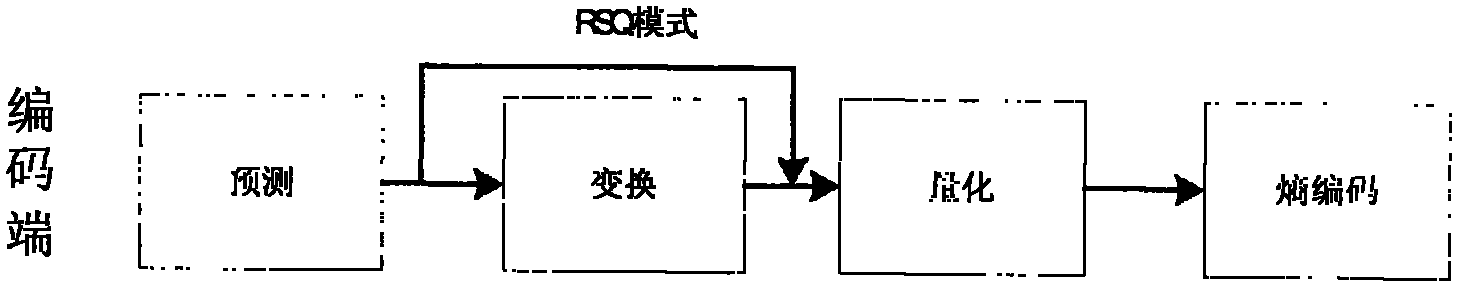

Method for coding mixed image

InactiveCN102256126AWorkaround for not working with transform encodingsInter-frame coding efficiency is highTelevision systemsDigital video signal modificationInterframe codingRate distortion

The invention discloses a method for coding a mixed image with higher coding efficiency. In the method, a residual scalar quantization (RSQ) mode is used in the interframe coding of a mixed image, according to a principle that rate distortion cost is minimum, each transformation unit (TU) adaptively selects a discrete cosine transform (DCT) mode or the RSQ mode, and a bit is used for expressing the selection; and residual errors obtained after interframe prediction are directly quantized in the RSQ mode, and a step of transforming codes is omitted.

Owner:BEIJING UNIV OF TECH

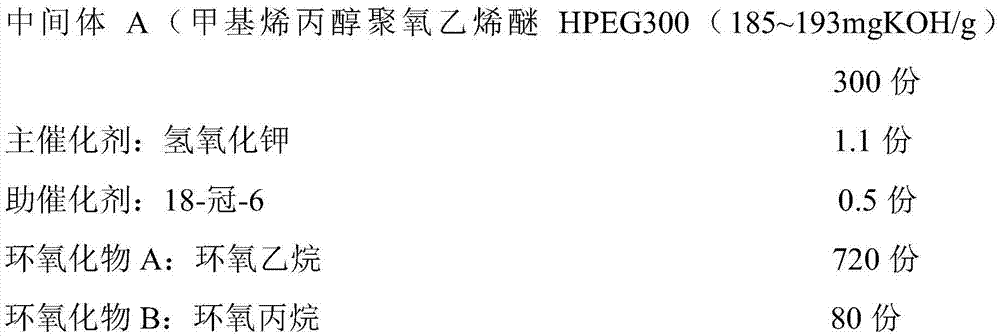

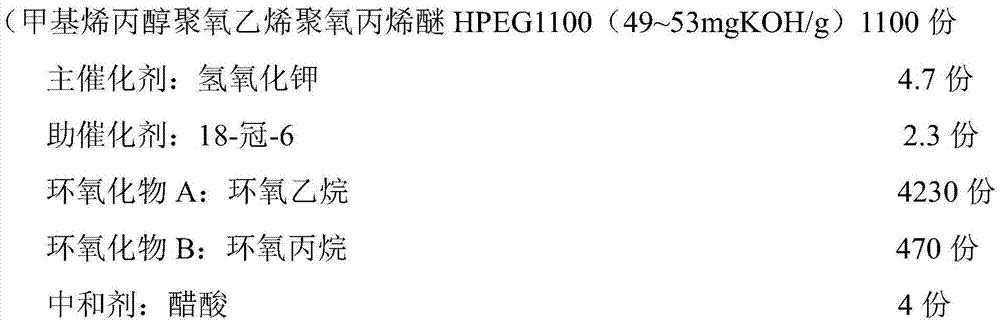

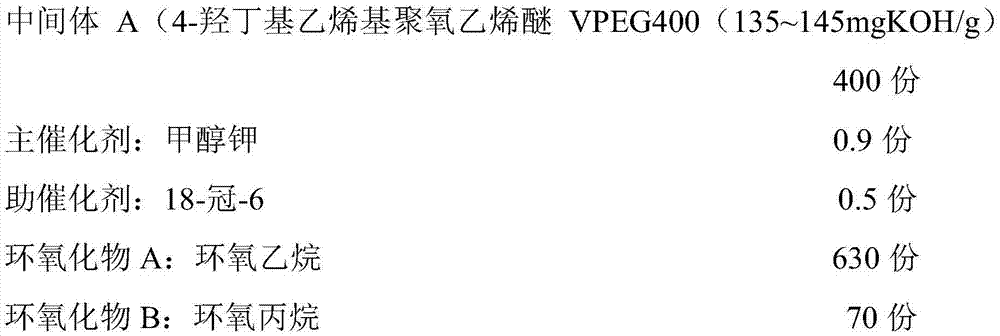

Polymonoether for polycarboxylate superplasticizer and polycarboxylate superplasticizer, and preparation methods thereof

The invention discloses polymonoether for a polycarboxylate superplasticizer and the polycarboxylate superplasticizer, and preparation methods thereof. The polymonoether for the polycarboxylate superplasticizer has a hydroxyl value of 9.5 to 11.5 mg KOH / g and is allylalcohol polyoxyethylene polyoxypropylene ether, methylallylalcohol polyoxyethylene polyoxypropylene ether, isopentenol polyoxyethylene polyoxypropylene ether or 4-hydroxybutylvinyl polyoxyethylene ether. The polymonoether for the polycarboxylate superplasticizer has high molecular weight, high degree of unsaturation and low impurity content, so the later application performance of the polymonoether is obviously improved; and the polymonoether enables cost for raw materials to be reduced compared with the prior art, so the profit rate of the produced polycarboxylate superplasticizer is increased, and the polymonoether has good industrial value.

Owner:SHANGHAI DONGDA CHEM

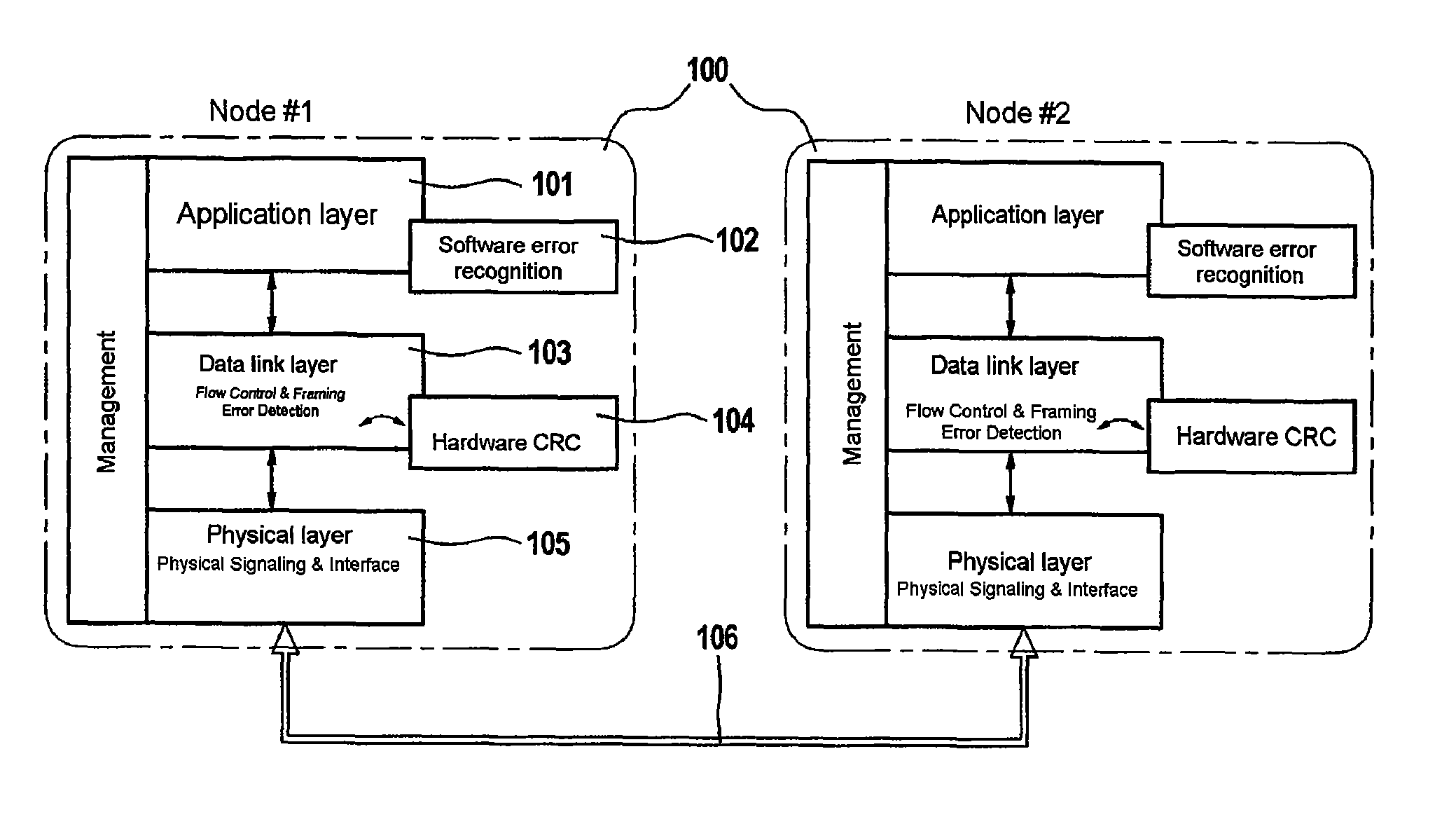

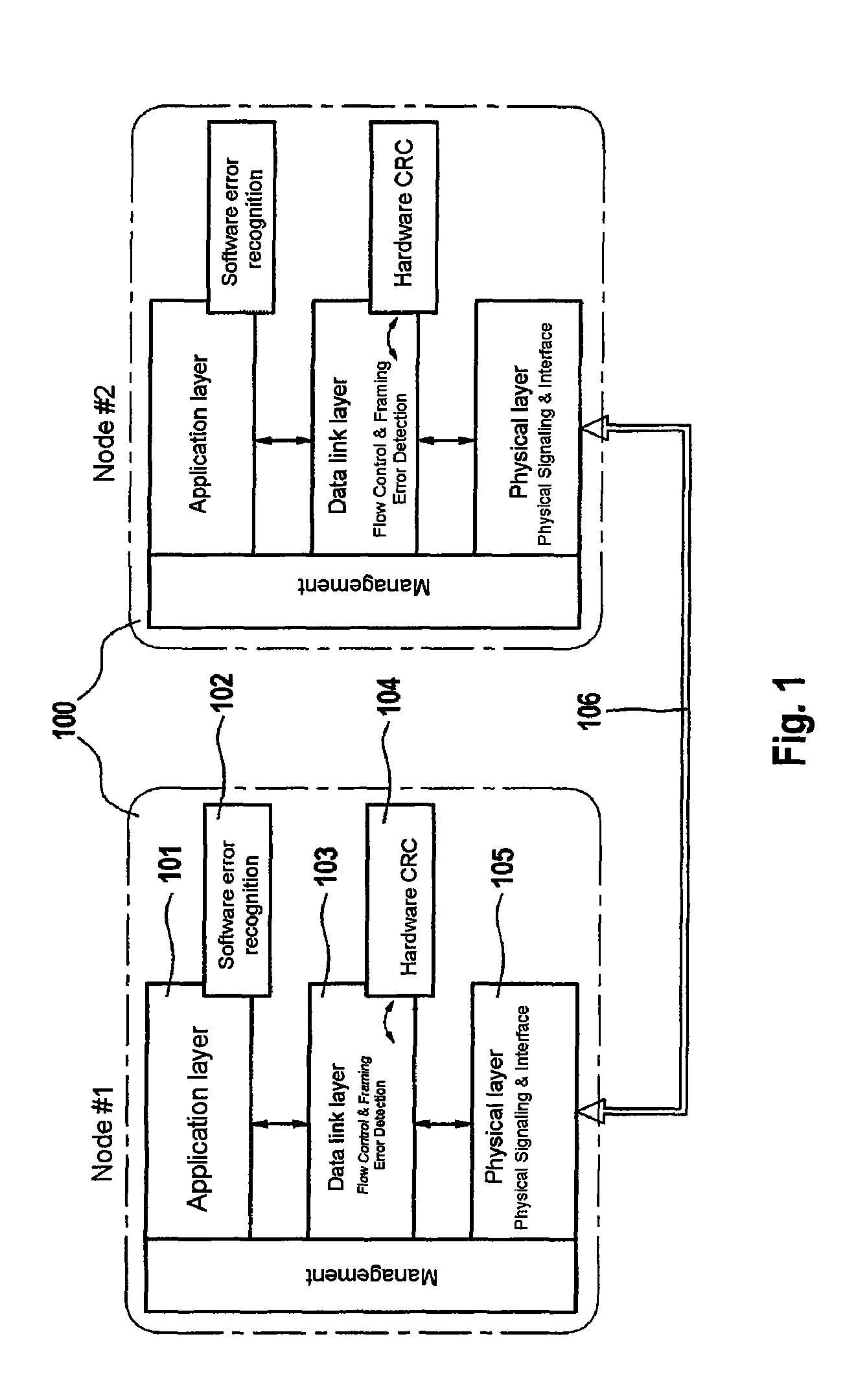

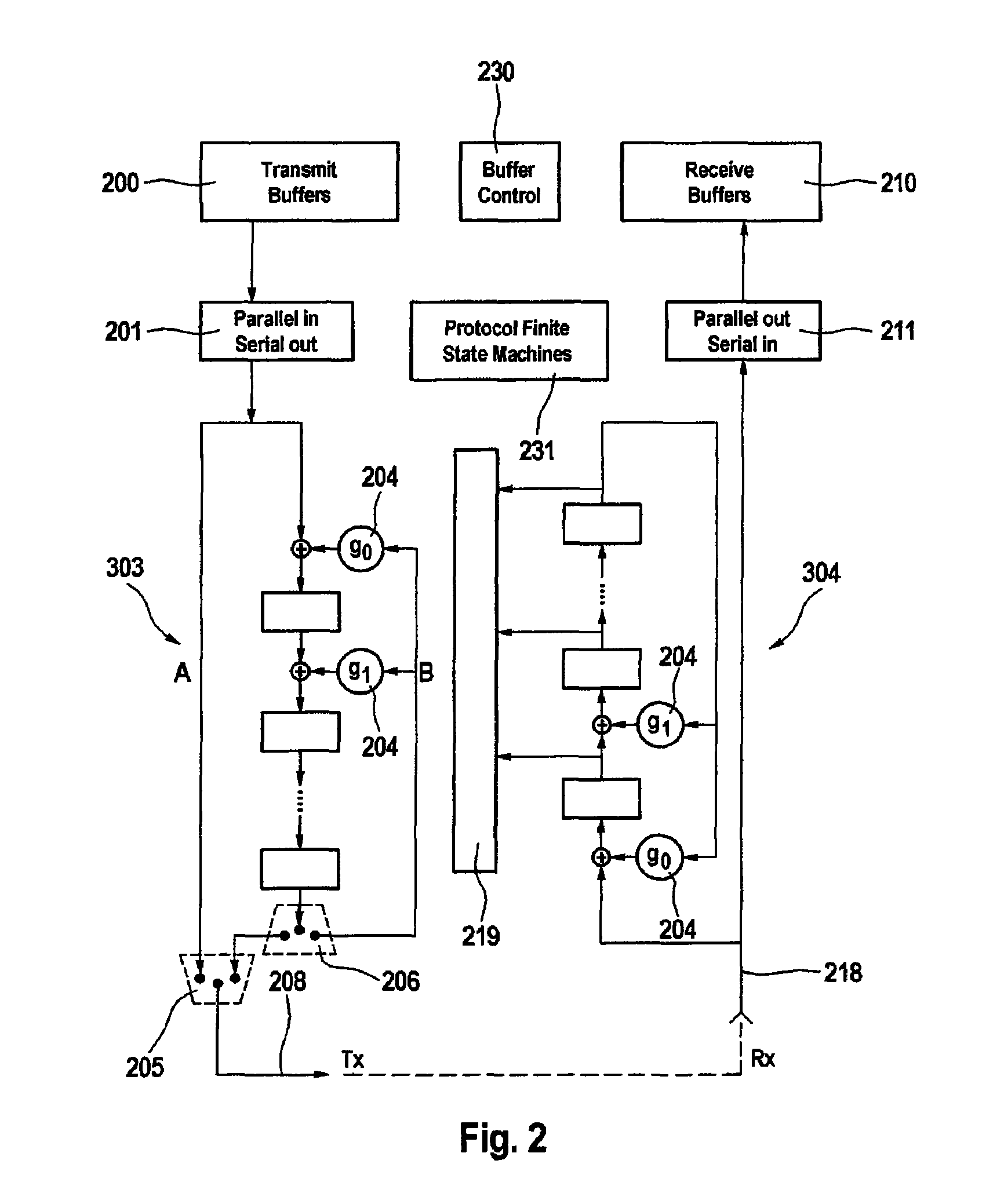

Checking method and electronic circuit for the secure serial transmission of data

ActiveUS8352809B2Reduce residualImprove security levelCorrect operation testingError detection/correctionComputer hardwareFalse recognition

Owner:CONTINENTAL TEVES AG & CO OHG

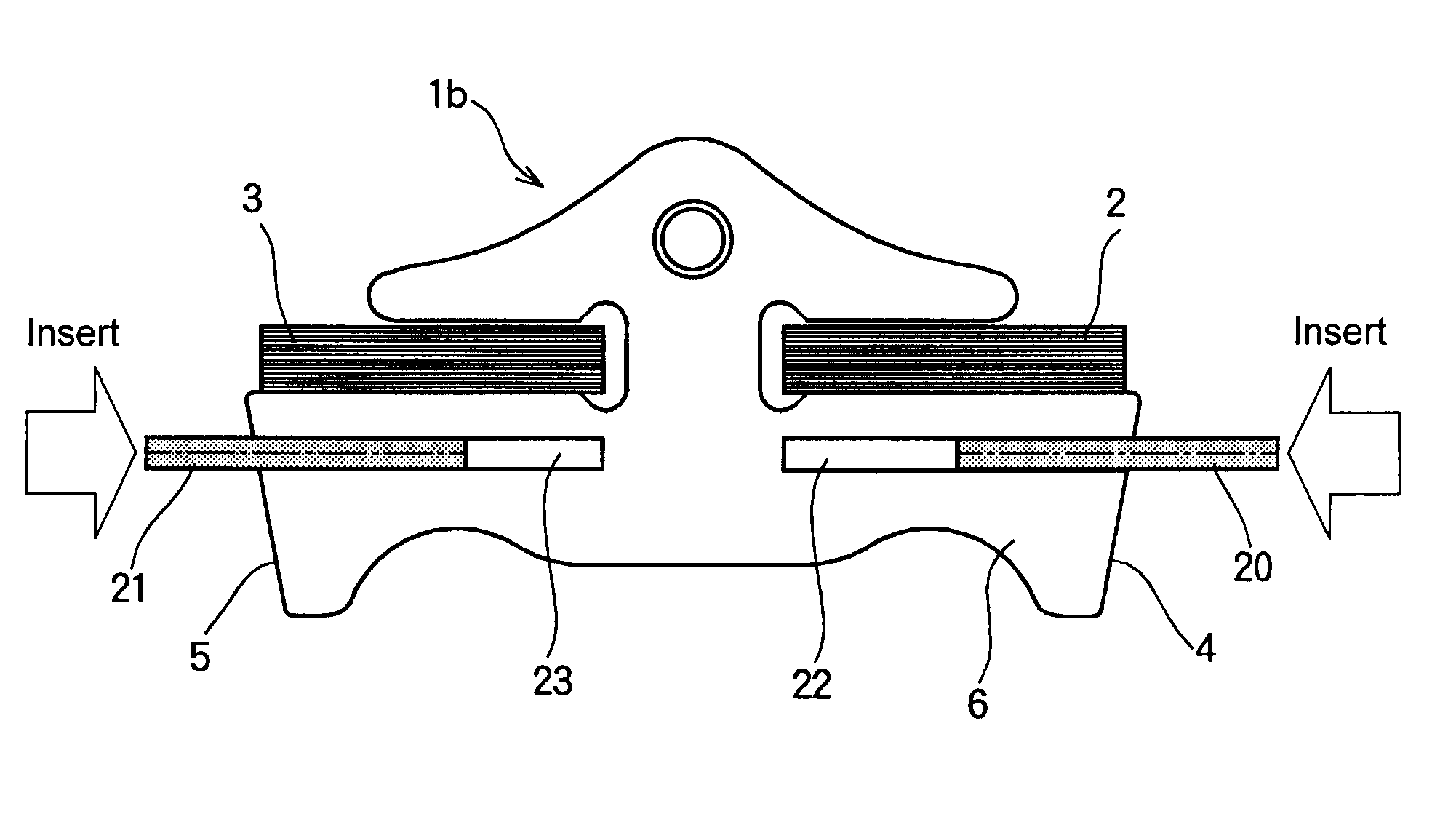

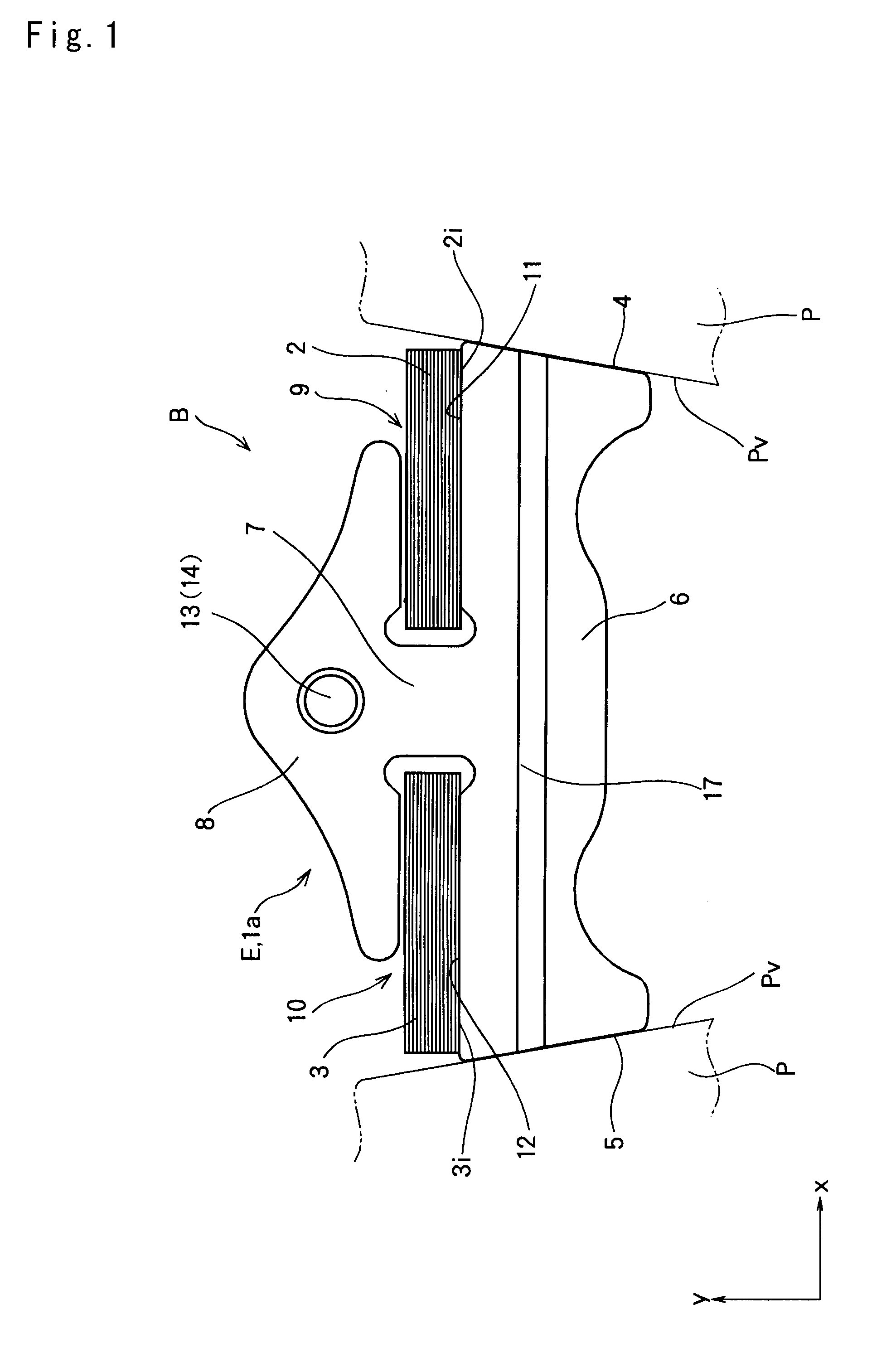

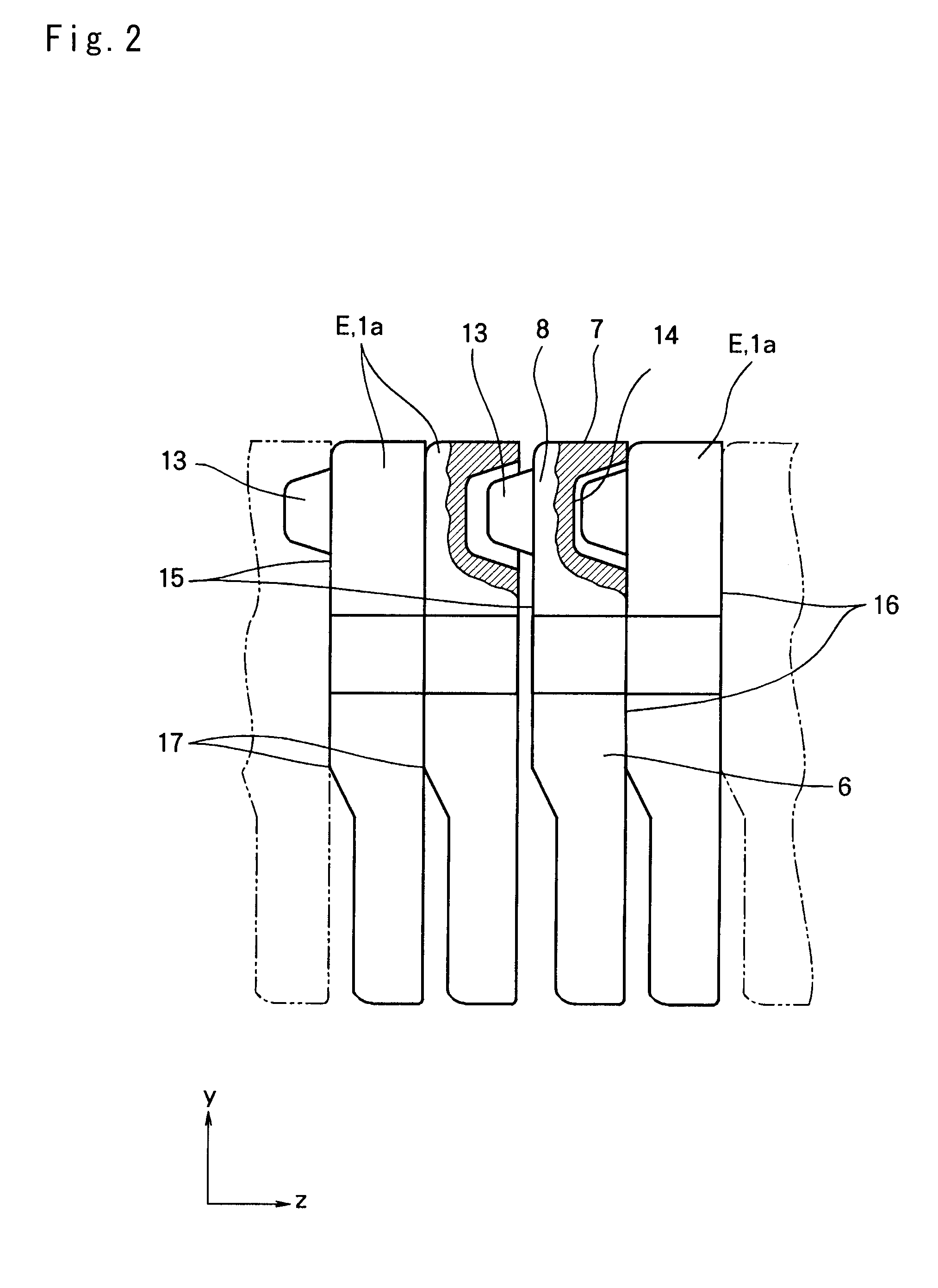

Driving belt and method for assembling the same

InactiveUS20140106919A1Reduce residualWell formedV-beltsDriving beltsEngineeringMechanical engineering

A driving belt comprising plate elements juxtaposed in its thickness direction and a flat ring fastening the elements annularly. The elements includes at least one adjuster element configured to adjust an endplay as a total of clearances between the adjacent elements in the elements fastened annularly by the ring. The adjuster element comprises an insertion groove opening toward the endplay, and an inserting member inserted into the insertion groove and configured to protrude partially from the insertion groove thereby adjusting the endplay.

Owner:TOYOTA JIDOSHA KK

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

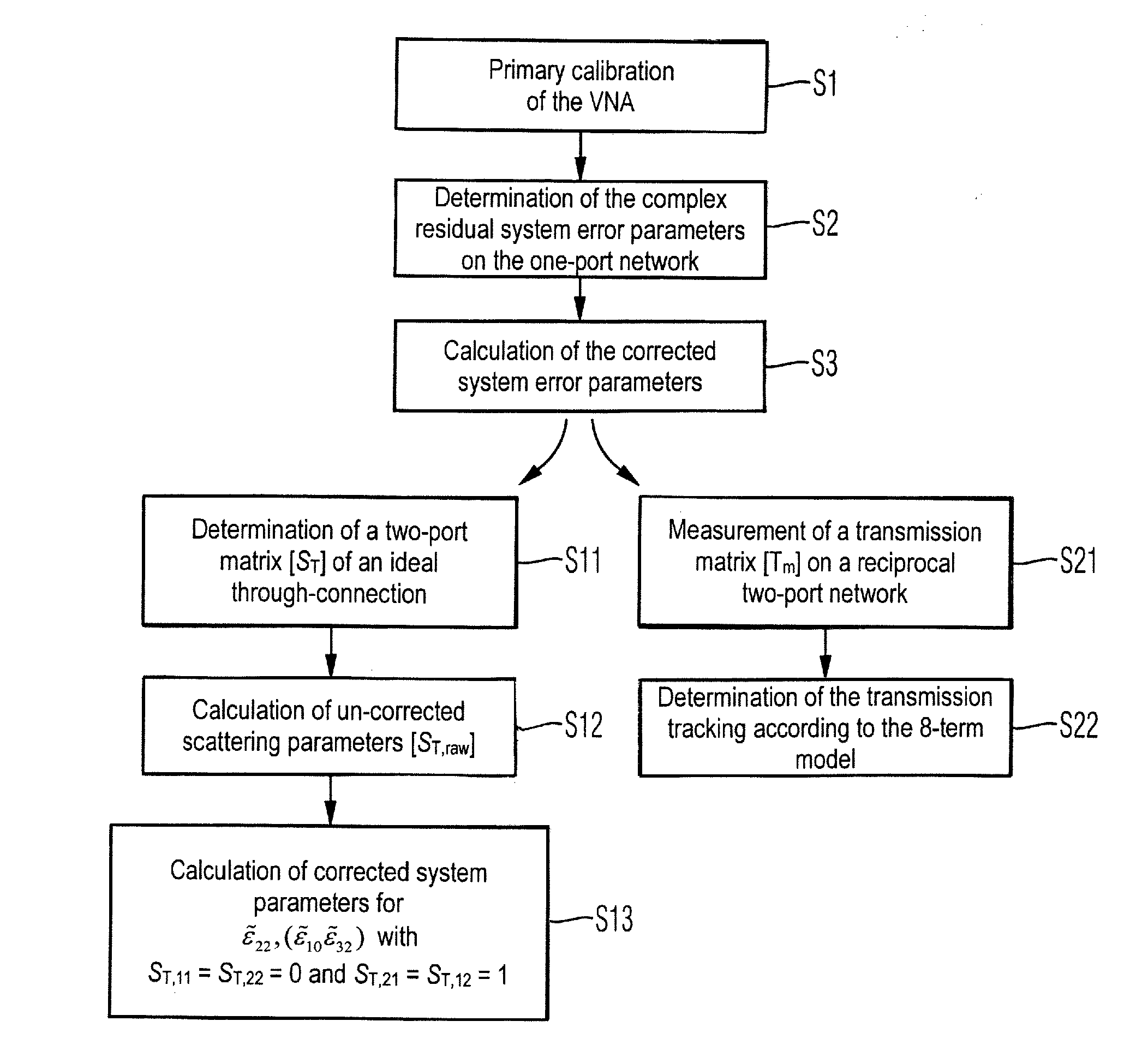

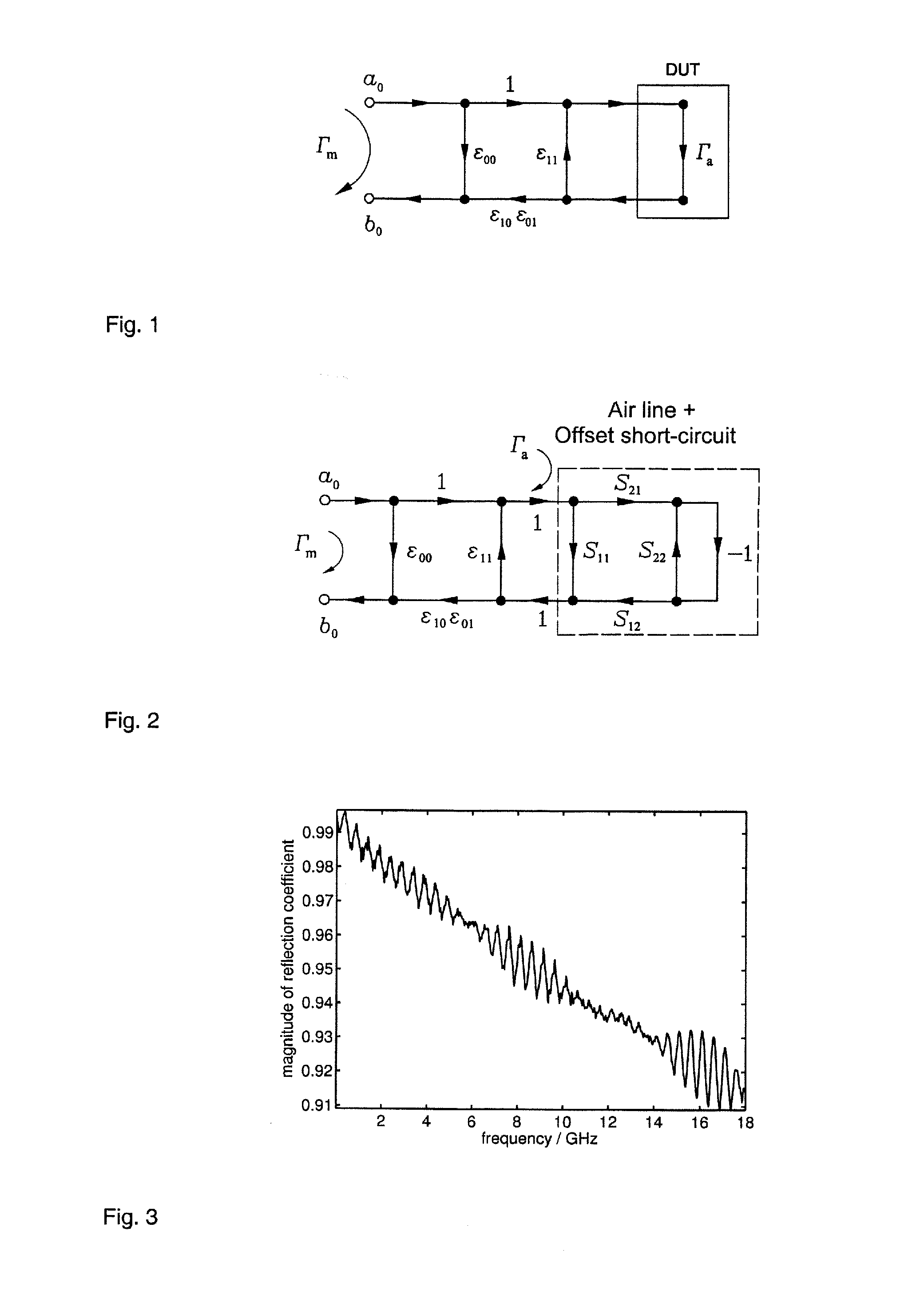

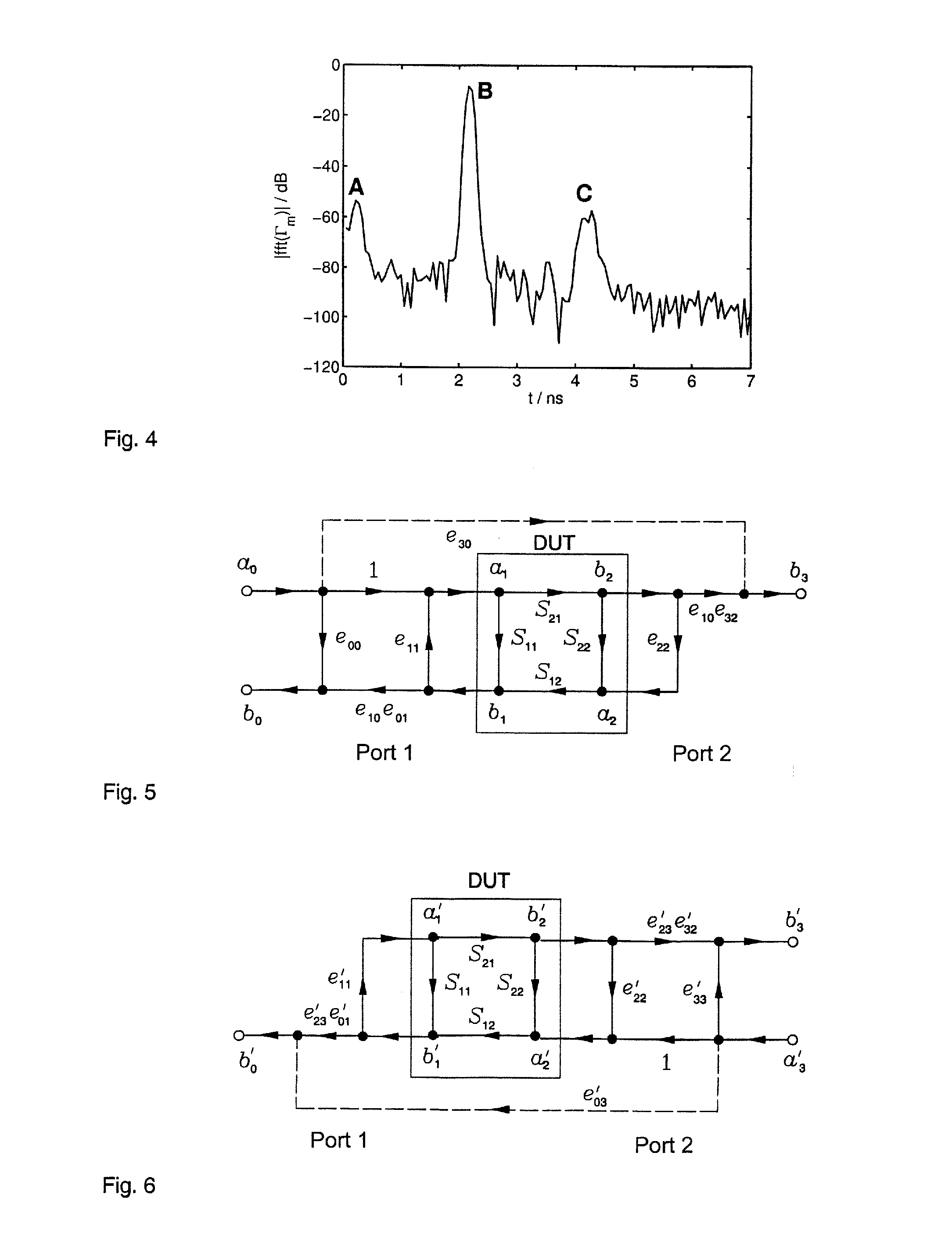

Method for the secondary error correction of a multi-port network analyzer

ActiveUS20100318833A1Reduce residualFault responseResistance/reactance/impedenceMulti portSystem error

A method for the error correction of a vectorial network analyzer, where a primary system calibration is initially implemented using a calibration kit. Following this, a first, secondary error correction is implemented on at least two one-port networks of the vectorial network analyzer. After this first, secondary error correction of the one-port networks of the vectorial network analyzer, a second, secondary error correction is implemented, where either two one-port networks are through-connected in an ideal manner or a measurement is implemented on a reciprocal two-port network. The corrected system-error values from the first, secondary error correction are used even in this further measurement, and overall, a high-precision, calibrated multi-port network analyzer is obtained.

Owner:ROHDE & SCHWARZ GMBH & CO KG

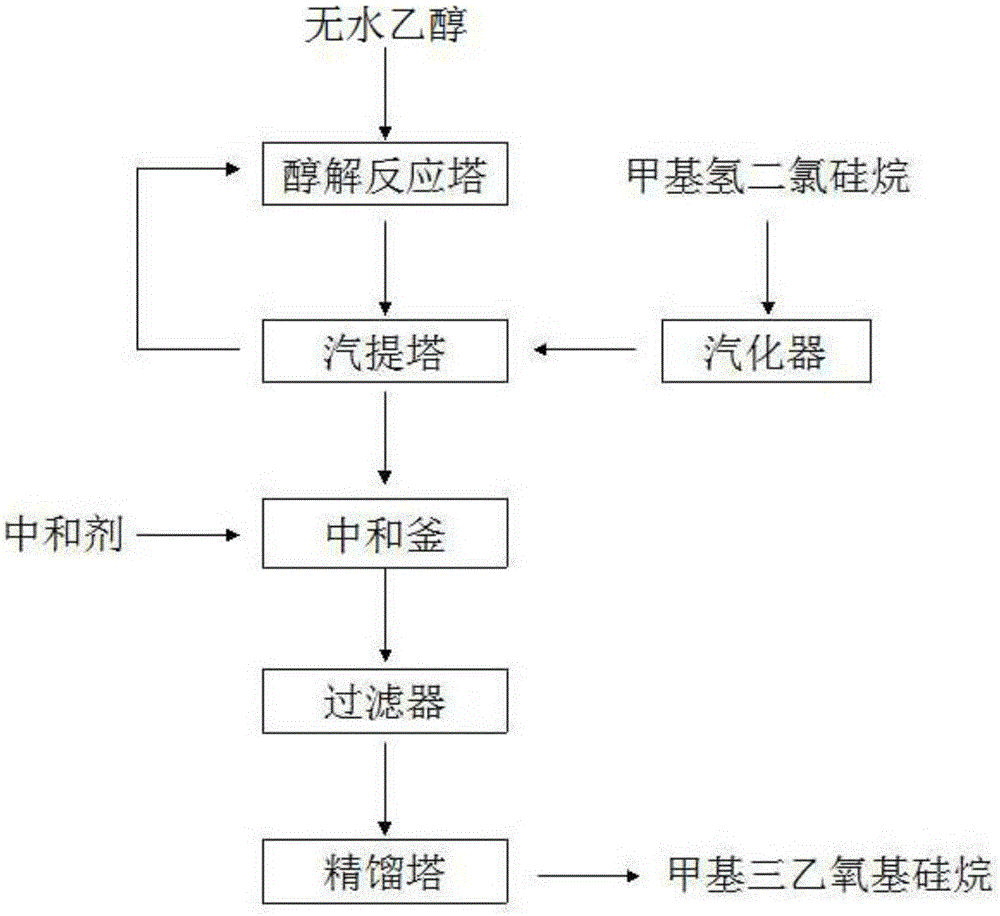

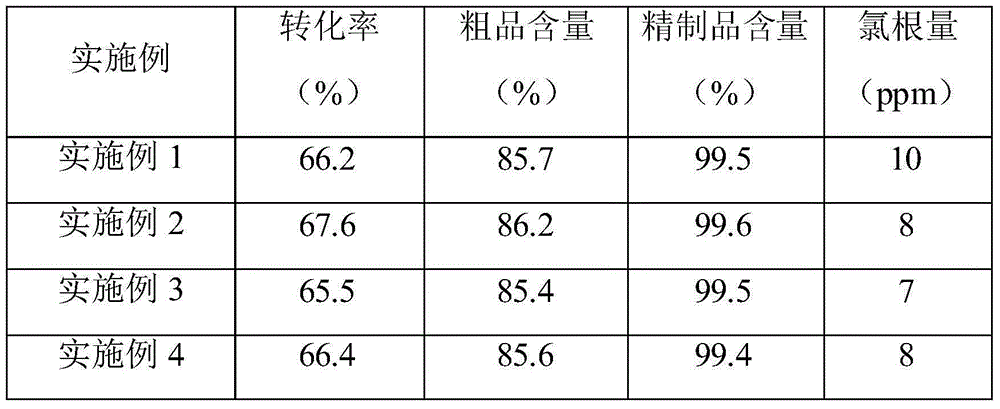

Preparation technology of methyl triethoxysilane

ActiveCN105111232AEffective recyclingAchieve recyclingGroup 4/14 element organic compoundsSide reactionMonomer

The invention discloses a preparation technology of methyl triethoxysilane. Methyldichlorosilane and absolute ethyl alcohol are adopted as the raw materials, and the technology comprises the four steps of alcoholysis, deacidification, separation of crude products and refinement, and comprises the following specific steps: carrying out alcoholysis reaction on methyldichlorosilane and absolute ethyl alcohol subjected to vaporization and steam stripping in an alcoholysis reaction tower; introducing the product mixture into a stripping tower for steam stripping of unreacted methyldichlorosilane and HCl, conveying the product mixture subjected to steam stripping into a neutralization kettle, and further removing HCl through the action of a neutralizer; after neutralization, filtering for salt removal to obtain a crude product of methyl triethoxysilane; carrying out rectification on the crude product for purification to obtain a colorless and transparent methyl triethoxysilane product. According to the preparation technology, the use of an organic solvent is avoided, the reaction is mild, the side reaction is less, and the product content is high; the recycling of the monomer by-product, namely, methyldichlorosilane, is effectively realized, and the additional value is increased; the devices used in the technology are conventional devices, the operation is easy to control, the pollutant emission during the whole reaction process is less, and the preparation technology is quite suitable for industrialized and enlarged production.

Owner:浙江中天东方氟硅材料股份有限公司

Method and device for intra-frame prediction

InactiveCN103248892AThe predicted value is accurateReduce residualTelevision systemsDigital video signal modificationIntra-frameBusiness forecasting

Owner:PEKING UNIV

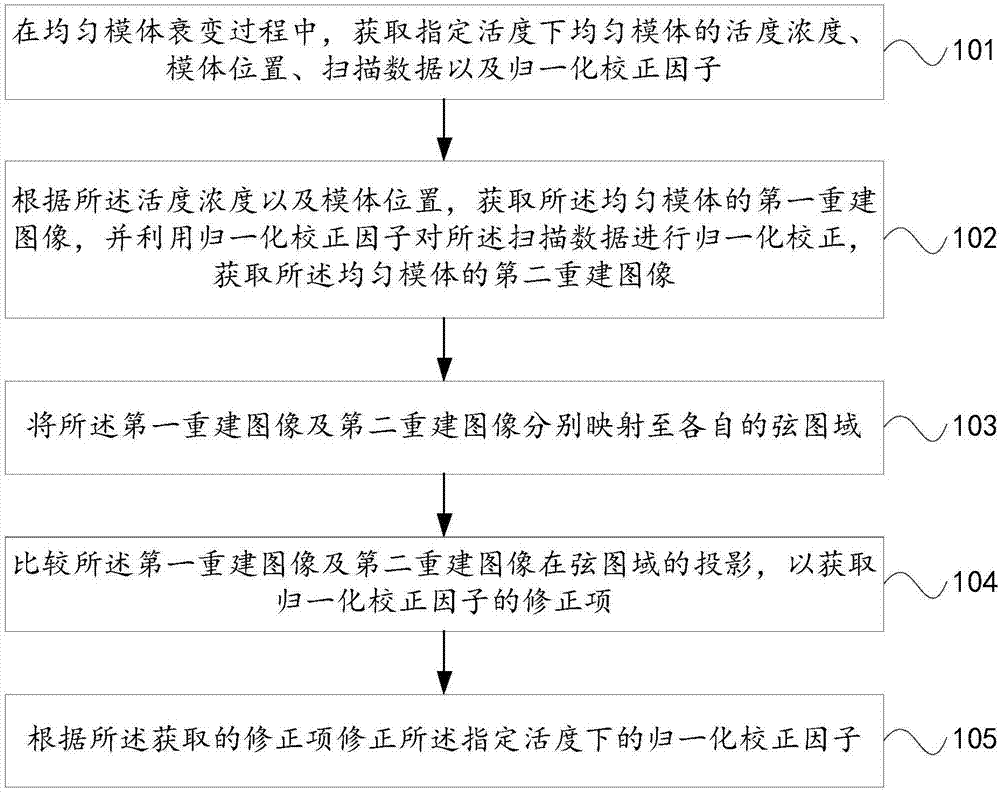

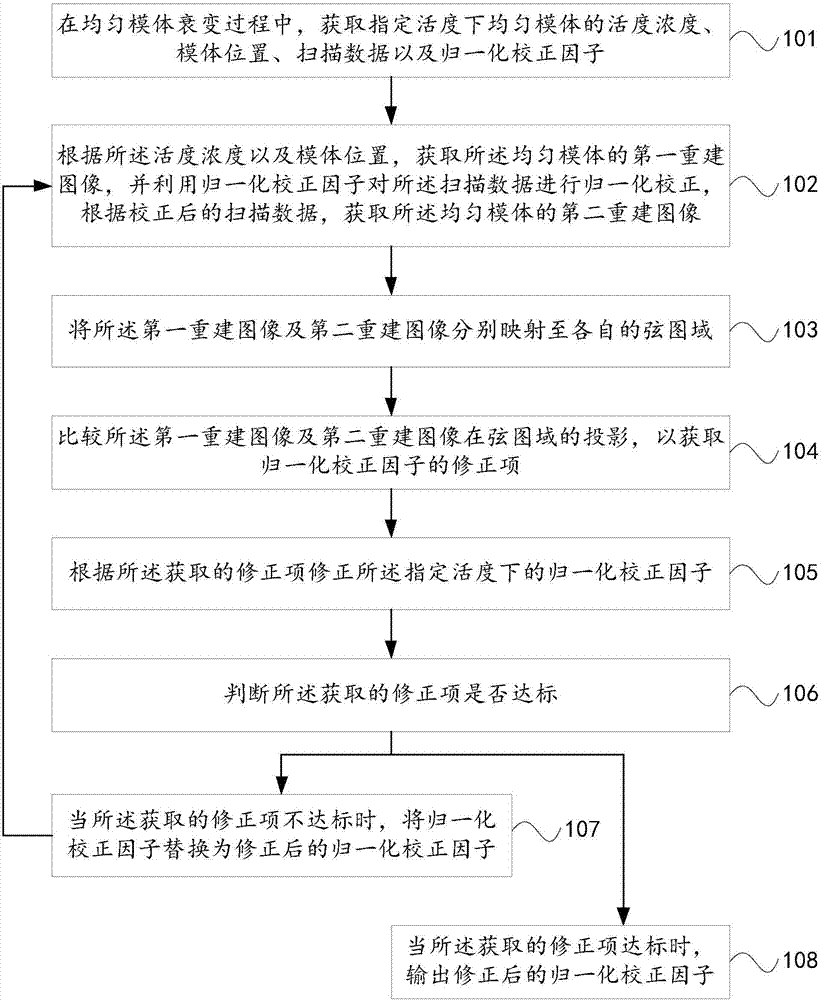

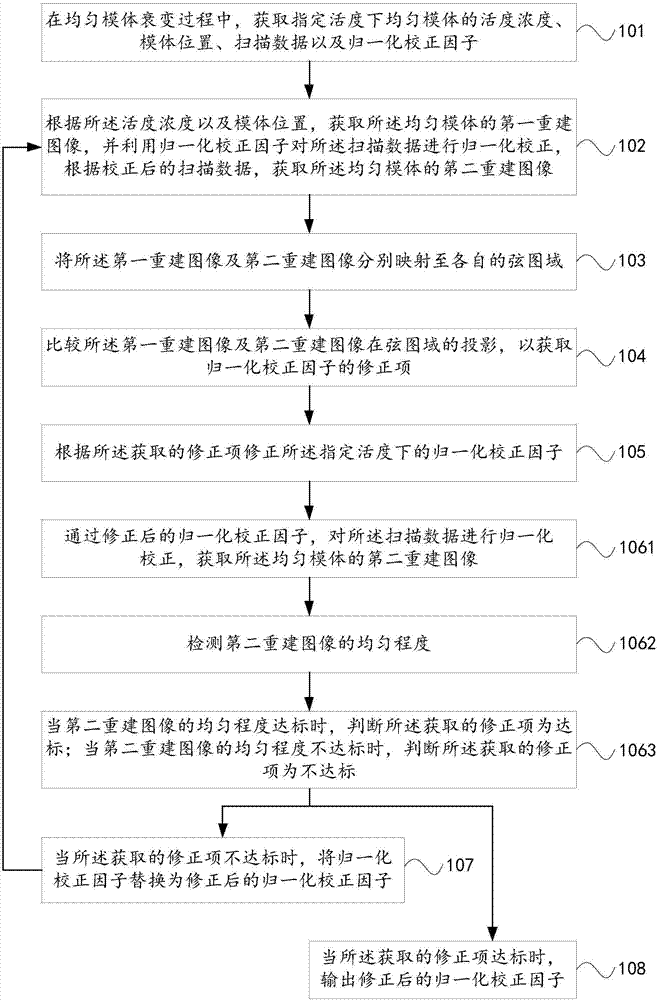

Normalized correction factor obtaining method and device and medical imaging method

ActiveCN107392876AGet scan dataReduce calculation errorsImage enhancementImage analysisImaging processingActivity concentration

An embodiment of the invention provides a normalized correction factor obtaining method and device and a medical imaging method, relates to the technical field of image processing and can reduce calculation errors of each element of normalized correction and mutual interference and residues. The mormalized correction factor obtaining method comprises the following steps: in the homogeneous phantom decay process, obtaining activity concentration of a homogeneous phantom under specific activity, phantom position, scanning data and a normalized correction factor; according to the activity concentration and the phantom position, obtaining a first reconstructed image of the homogeneous phantom, and carrying out normalized correction on the scanning data by utilizing normalized correction factor to obtain a second reconstructed image of the homogeneous phantom; mapping the first reconstructed image and the second reconstructed image to chordal graph domains respectively; carrying out projection comparison to obtain a correction term of the normalized correction factor; and according to the correction term, correcting the normalized correction factor under the specific activity. The technical scheme is suitable for the correction process of the normalized correction factor.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

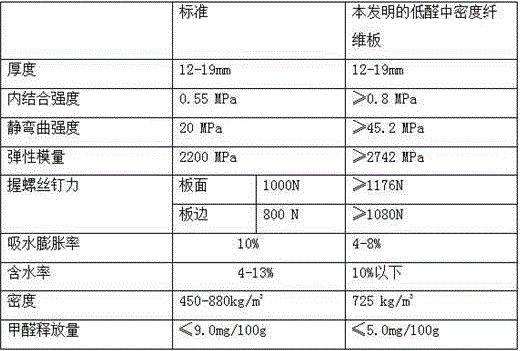

Method for producing low-formaldehyde medium-density fiberboard

ActiveCN105216086AImprove water resistanceGood alkali resistanceFlat articlesDomestic articlesEngineeringPulp and paper industry

The invention relates to a method for producing a low-formaldehyde medium-density fiberboard and belongs to the technical field of wood resource utilization. The method for producing the low-formaldehyde medium-density fiberboard comprises the technological steps of raw material slicing, impurity-removal and screening, boiling, waxing and hot grinding, gluing and drying, mat formation and hot pressing, and finished product obtaining. According to the method, residues, such as battens and waste veneer, generated during wood processing are used for producing the low-formaldehyde medium-density fiberboard, waste materials are recycled, and full utilization of wood resources is effectively achieved; the formaldehyde residual volume of low-formaldehyde urea formaldehyde resin adhesive used for producing the medium-density fiberboard is low, in this way, harm to the health of human bodies is reduced, and the bonding force is high; in addition, the fiberboard has good damp-proof performance and good water-proof performance, the internal structure of the board is uniform, the density is proper, the dimensional stability is high, the quality is stable, and the service life is long.

Owner:霸州市郭仕智能家居科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com