Preparation technology of methyl triethoxysilane

A technology for methyltriethoxysilane and a preparation process, which is applied in the field of preparation technology of methyltriethoxysilane, can solve the problems of discarding and no recovery method, achieves less side reactions, realizes recycling and reaction low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

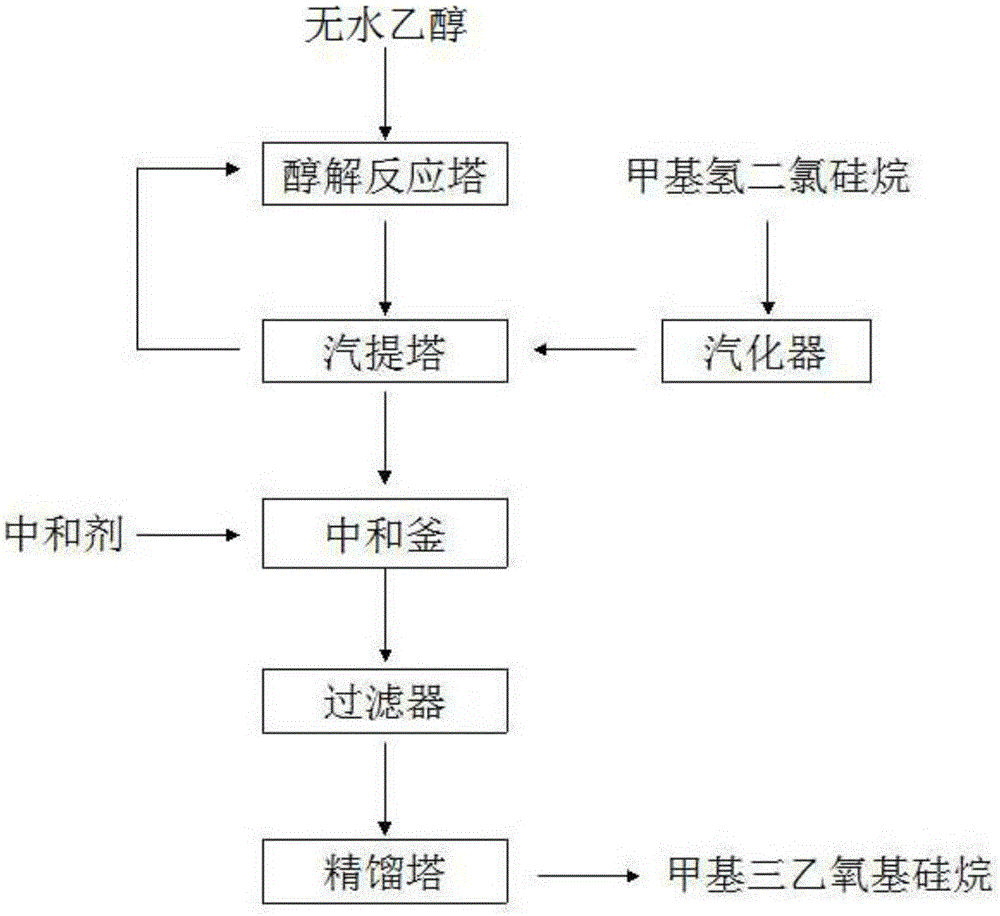

Method used

Image

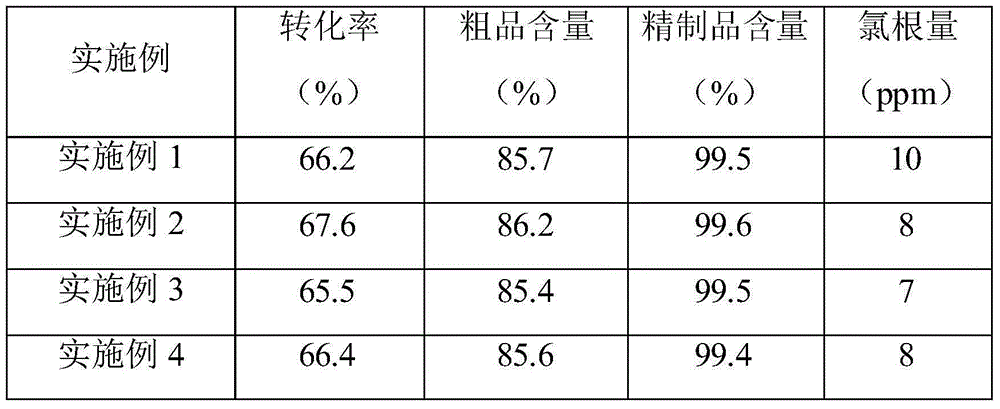

Examples

Embodiment 1

[0032] A. alcoholysis

[0033] 150 parts by weight of methylhydrogendichlorosilane is first vaporized through a vaporizer, and then enters the bottom of the alcoholysis reaction tower through a stripper, and 190 parts by weight of absolute ethanol is added into the alcoholysis reaction tower in liquid form from the top inlet of the alcoholysis reaction tower , the upward gaseous methylhydrogendichlorosilane and the downward liquid anhydrous ethanol are fully contacted, alcoholysis reaction and hydrogen substitution occur, and methyl triethoxysilane and by-product hydrogen chloride are generated; the temperature control of the vaporizer and the stripper All at 55°C; alcoholysis reaction temperature is 45°C;

[0034] Most of the hydrogen chloride escapes through the outlet at the top of the alcoholysis reaction tower, and the remaining hydrogen chloride forms a product mixture with the reaction product;

[0035] B. Neutralization

[0036] Keep the temperature in the stripping ...

Embodiment 2

[0042] Change alcoholysis reaction temperature to be 60 ℃, all the other are the same as embodiment 1.

Embodiment 3

[0044] Change alcoholysis reaction temperature to be 70 ℃, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com