Patents

Literature

35results about How to "Effective recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

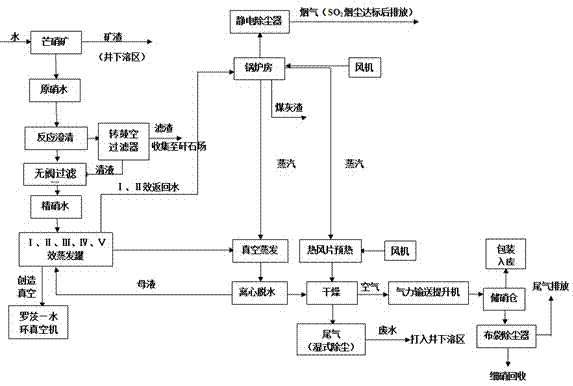

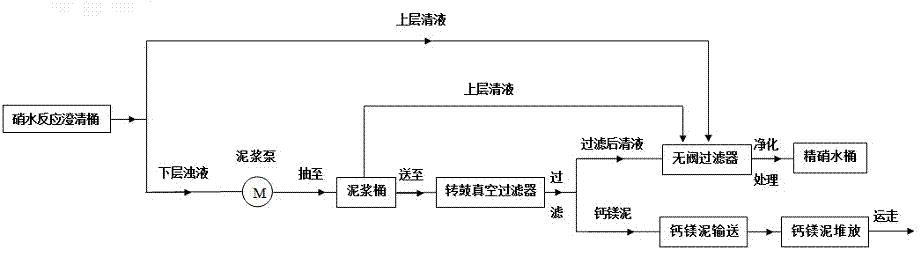

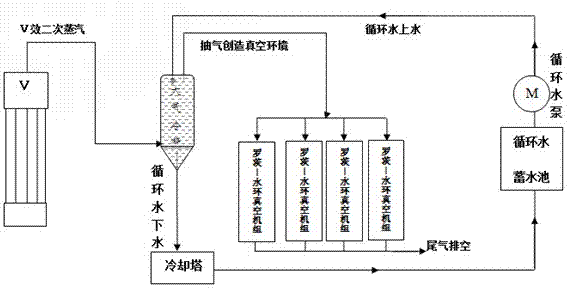

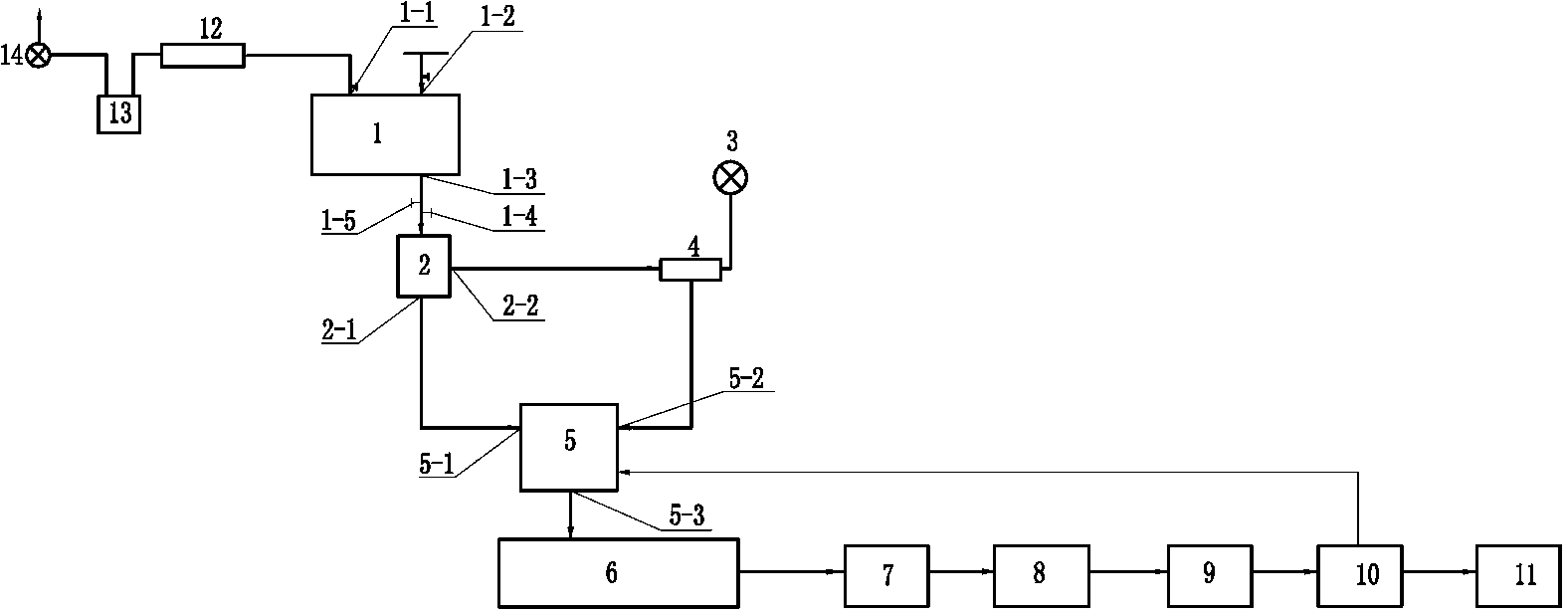

Anhydrous sodium sulfate preparation method and anhydrous sodium sulfate preparation apparatus

InactiveCN103086403AReduce environmental pollutionEffective recyclingAlkali metal sulfites/sulfatesMultiple-effect evaporatorAir drying

The invention discloses an anhydrous sodium sulfate preparation method and an anhydrous sodium sulfate preparation apparatus, and belongs to the anhydrous sodium sulfate preparation field. The method sequentially comprises the following steps: processing a raw sodium sulfate solution to prepare a fine sodium sulfate solution; dehydrating the fine sodium sulfate solution to prepare dry sodium sulfate; and processing the dry sodium sulfate to prepare finished sodium sulfate. The preparation apparatus comprises a nitrate solution reaction clarifier, a slurry clarifier, a non-valve filter, a rotary drum vacuum filter, a fine sodium sulfate solution storage device, a steam generation device, a multiple-effect evaporator, a centrifuge, an atmospheric condenser, a cooling tower, a cycle water pump, a Roots water ring vacuum set, a hot air drying device, a convey device, a pneumatic elevator, a nitrate storage bin and a cloth bag deduster. According to the invention, the sodium sulfate solution refining efficiency is high, the sodium sulfate solution quality is good, and the sodium sulfate solution is fully recycled; and the heat energy utilization rate in the production process is high, the production energy consumption is low, and the finished sodium sulfate has a fast convey speed and a high output.

Owner:四川省洪雅青衣江元明粉有限公司

Method for recovering chloromethane from chloromethane-containing waste gas in maltol production

ActiveCN103044185AEffective recyclingReduce air pollutionHalogenated hydrocarbon separation/purificationSolventChemistry

The invention discloses a method for recovering chloromethane from chloromethane-containing waste gas in the maltol production and relates to the method for recovering chloromethane, and the method can be used for obtaining finished high-purity chloromethane and is simpler in process route and easy to realize. The method comprises the steps as follows: allowing the waste gas generated in the process of recovering a methanol solvent after chlorination reaction to pass through a hydrolysis kettle, and introducing the waste gas into an alkaline washing tower through a pipeline for alkaline washing; collecting the waste gas subjected to primary alkaline washing by a buffer tank; introducing the waste gas in the buffer tank into a water washing tower for water washing through a roots machine, and removing water-soluble substances; carrying out two-stage acid washing on the waste gas subjected to water washing; carrying out two-stage alkaline washing on the waste gas subjected to two-stage acid washing; and drying the waste gas subjected to two-stage alkaline washing, compressing by a compressor, cooling into a liquid phase by a condenser, and feeding into a finished product storage tank.

Owner:XIAMEN OMIC BIOTECH CO LTD

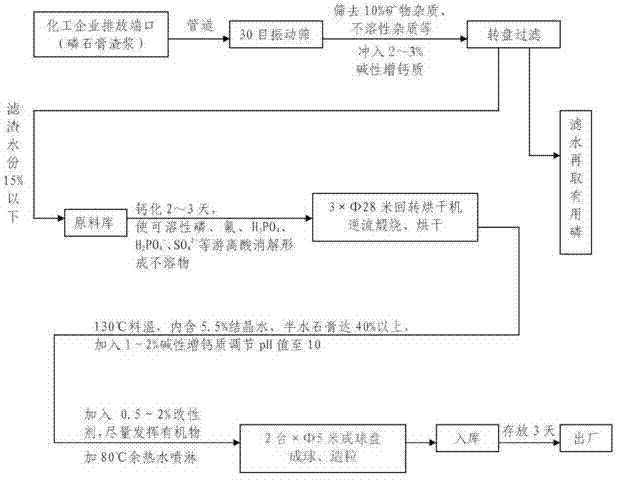

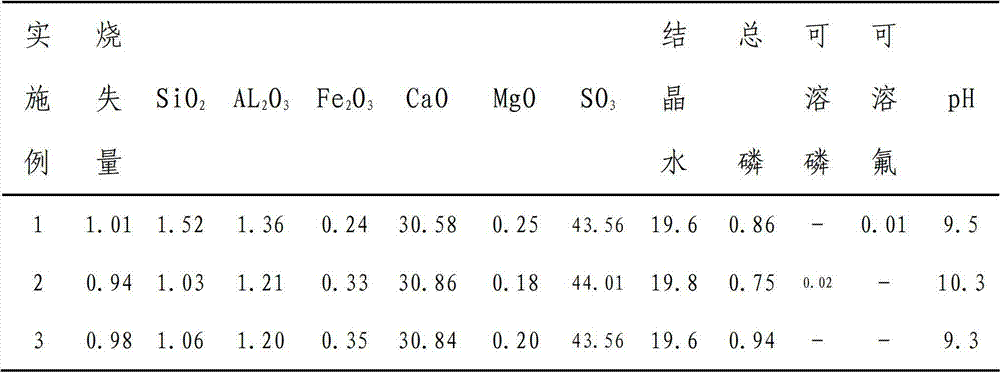

Phosphogypsum cement retarder and preparation method

The invention discloses a phosphogypsum cement retarder and a preparation method thereof. The cement retarder is prepared from the following raw materials in percentage by weight: 90-95% of phosphogypsum, 2-5% of alkaline calcium-increase agent and 0.5-2% of modifier. The preparation method comprises the following steps: screening the raw materials, filtering, calcifying, calcining and drying under reflux, balling and granulating, and the like. In the invention, the raw material from the discharge port of the chemical industry enterprise is directly connected into the production line, and the phosphogypsum slag is modified for production, thereby avoiding the phosphogypsum stock and environmental pollution, maximally and fully utilizing the phosphogypsum raw material and recycling the effective phosphorus. When being used for producing cement, various properties of the phosphogypsum cement retarder are better than those of natural gypsum, thereby utilizing the waste, protecting the environment, greatly lowering the discharge treatment cost of the chemical industry enterprise, and greatly enhancing the economic benefit of the cement production enterprise.

Owner:广西凯浩环保材料股份有限公司

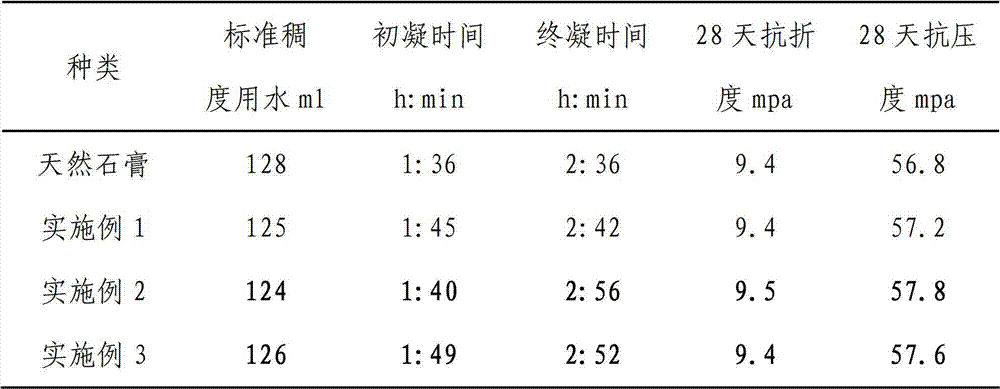

Method for preparing chloroethane from chlorination by-product hydrogen chloride

ActiveCN104311382AImprove conversion rateSpeed up the positive reactionChemical industryHalogenated hydrocarbon preparationReboilerEther

The invention discloses a method for preparing chloroethane from chlorination by-product hydrogen chloride. The method adopts a reaction rectification technology. According to the method, a reactor is connected to a first rectifying tower, water in the first rectifying tower flows out the first rectifying tower from tower bottom and then is recycled, a tower overhead fraction of the first rectifying tower goes through a first condenser, a part of ethanol is returned, a part of the ethanol is collected and then is fed into a storage tank for recycle, chloroethane and a less amount of ether mixed vapor are fed into a second rectifying tower, a tower overhead fraction of the second rectifying tower goes through a second condenser, a part of chloroethane is returned, a part of chloroethane is collected and then is fed into a storage tank for recycle, and the by-product ether is obtained by a reboiler. The method realizes timely removal of produced chloroethane and water from a system, effectively accelerates a positive reaction speed, realizes effective recovery and recycle of unreacted hydrochloric acid and ethanol, has simple processes, a high ethanol conversion rate, low production consumption and good income and realizes zero discharge.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

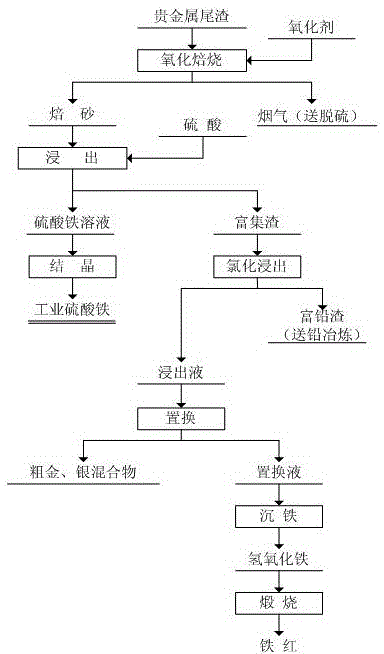

Comprehensive recovering method for tailings containing precious metal

ActiveCN105132694AEffective recyclingThe process is clean and environmentally friendlyProcess efficiency improvementBrown iron oxideLead smelting

The invention discloses a comprehensive recovering method for tailings containing precious metal. The comprehensive recovering method specifically includes the following steps that the tailings are led into oxygen to be subjected to oxidizing roasting; oxidation leaching is conducted on zinc calcine through sulfuric acid, most of iron is removed, a leaching agent is evaporated and crystallized, and industrial iron sulfate is obtained; after chloridizing leaching is conducted on leaching slag through sulfuric acid and sodium chloride, the leaching slag serves as lead-rich slag to be sent to a lead smelting enterprise; replacement is conducted on the leaching agent through iron powder, and crude gold and silver mixtures are obtained and sent to a precious metal deep processing system; and PH of replacement fluid is adjusted through ammonium water or sodium hydroxide, iron is deposited, obtained ferric hydroxide is roasted to obtain iron oxide red, and the iron oxide red serves as the raw material of the coating industry. According to the technology method, the influences on the environment due to long-term stacking of the kind of slag are eliminated, the process is clean and environmentally friendly, and secondary pollution is avoided.

Owner:甘肃高能中色环保科技有限公司

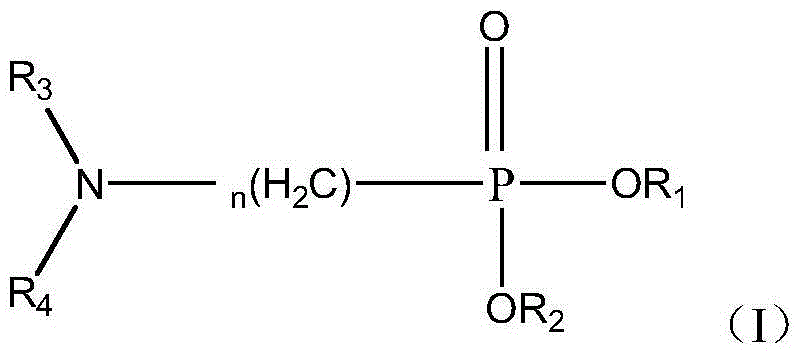

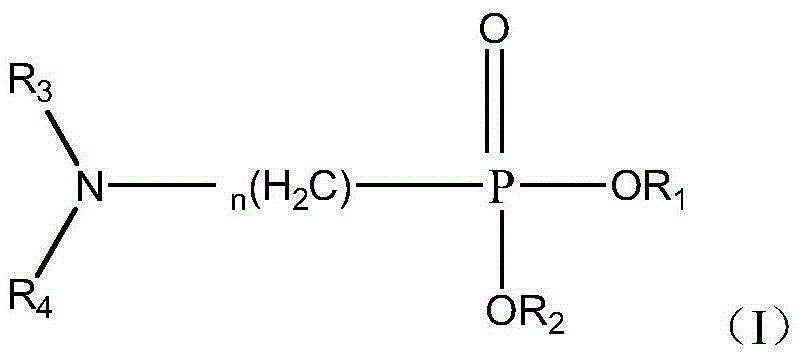

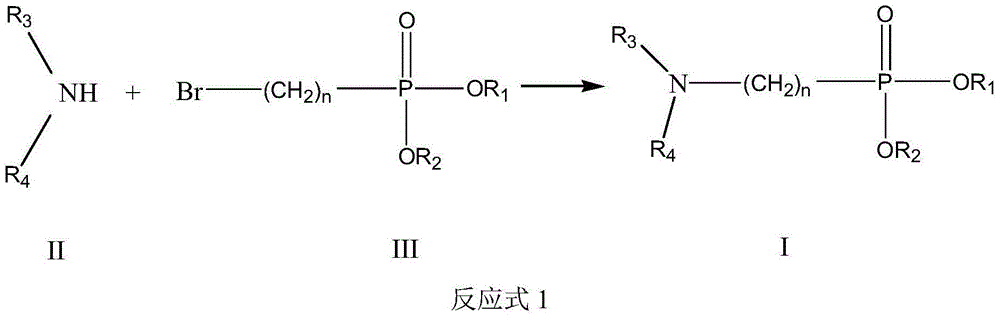

Method for separating tetravalent cerium, thorium and rare earth

ActiveCN105734287AShorten the separation process and costEffective recyclingProcess efficiency improvementChemistryCerium

The invention relates to a method for separating tetravalent cerium, thorium and rare earth. The method comprises following steps: feed liquid containing the tetravalent cerium, thorium and rare earth is provided; an amino-contained neutral phosphine extraction agent in the general formula I is used for performing extraction and separation on the tetravalent cerium from the feed liquid to obtain cerium-contained extraction liquid and cerium extraction tail liquid; the amino-contained neutral phosphine extraction agent in the general formula I is used for performing extraction and separation on the thorium from the cerium extraction tail liquid to obtain thorium-contained extraction liquid and thorium extraction tail liquid; and the rare earth in the thorium extraction tail liquid is recycled, and the chemical formula is shown in the specification, wherein R1 and R2 are each and independently selected from a C1-C12 alkyl group, R3 and R4 are each and independently selected from a C1-16 alkyl group and hydrogen, and n is an integer of one to eight.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

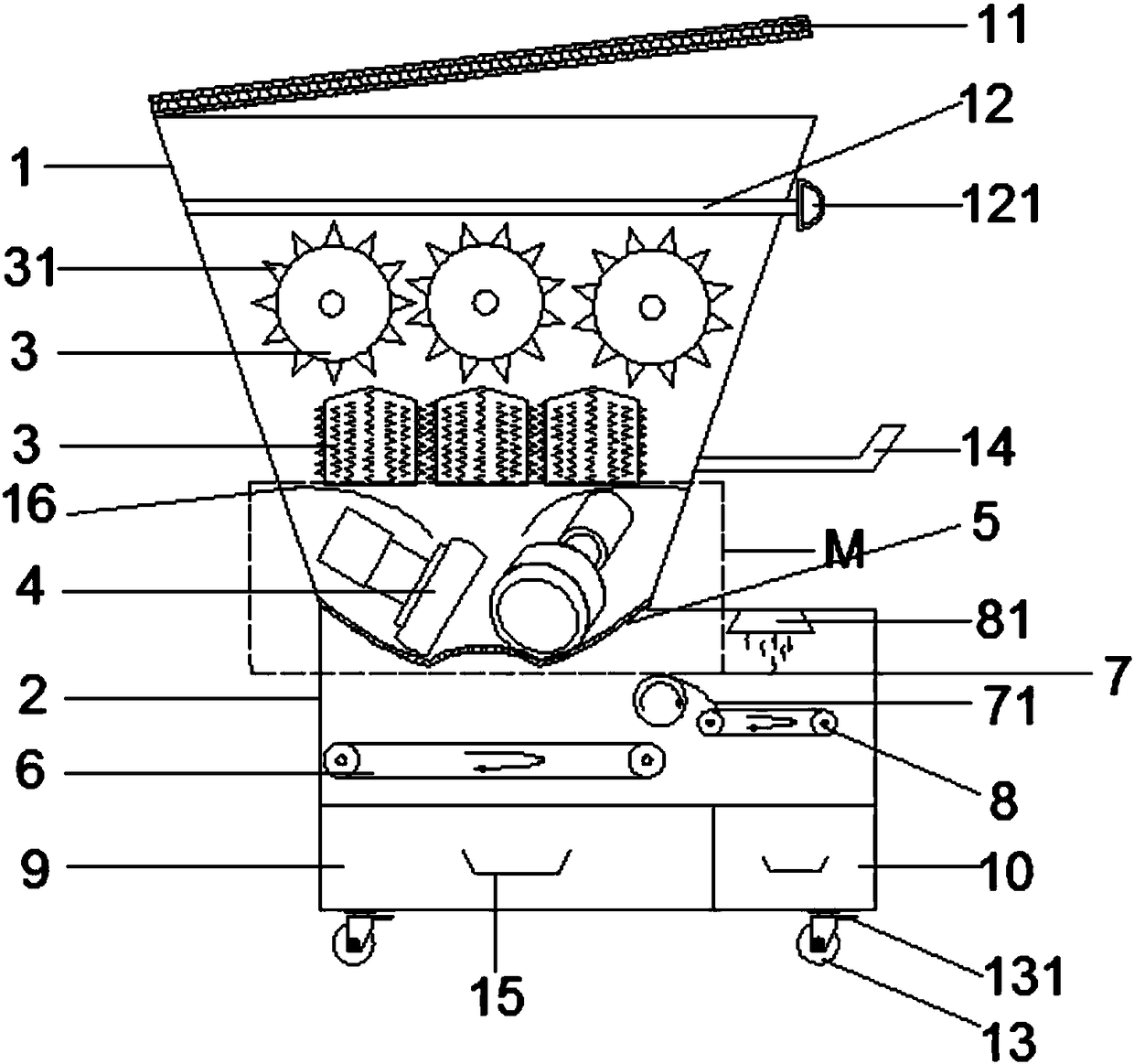

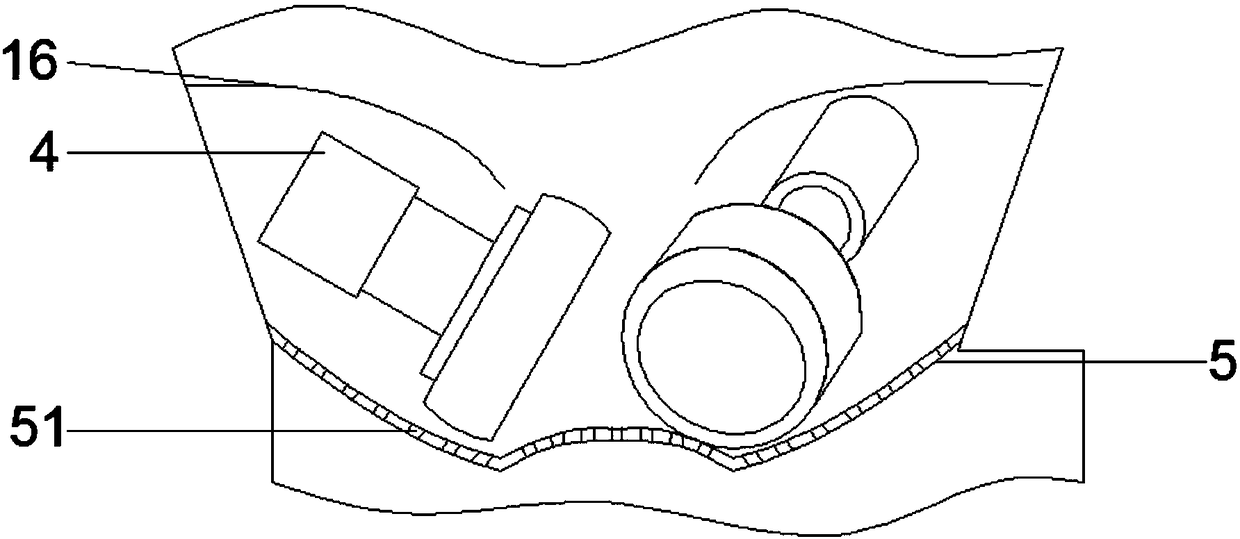

Device for processing circuit board and recycling iron powder

InactiveCN108212487AEffective recyclingReduce secondary pollutionMagnetic separationGrain treatmentsEngineeringLeather belt

The invention discloses a device for processing a circuit board and recycling iron powder, and the device is applied to the field of motor vehicle hazardous waste treatment. The device comprises a housing which is provided with an opening in upper portion and is in the shape of an inverted cone, and a box body which communicates with the lower portion of the housing, wherein at least two crushingrollers with triangular teeth are sequentially arranged in the housing from top to bottom in the horizontal direction and the perpendicular direction; a pair of grinding hammers is arranged below thecrushing rollers in the perpendicular direction; a communication joint of the housing and the box body is equipped with a filter screen layer for allowing the grinding hammers to grind and operate; and a first belt conveying mechanism, a magnetic-separating roller, a second belt conveying mechanism, a scraper plate and a dryer are arranged below the filter screen layer. At present, recycling for the circuit board of the motor vehicle adopts burning and land-filling or adopts a chemical agent to soak and extract metal elements therein, so that secondary pollution on air and water is generated,the circuit board is not crushed, a space proportion of the waste circuit board is great, and the like. Through a reasonable structural design, the problems can be effectively solved.

Owner:重庆澳净环保科技有限公司

Method of recovering platinum in waste fuel cell

InactiveCN106803596AEffective recyclingSimple processFuel cells disposal/recyclingProcess efficiency improvementPlatinumFuel cells

The invention belongs to the technical field of material recovery and particularly relates to a method of recovering platinum in a waste fuel cell. The method comprises the following steps: a, taking the waste fuel cell; b, separating a bipolar plate and a membrane electrode of the fuel cell, and carrying out crushing treatment on the bipolar plate and the membrane electrode respectively; c, ultrasonically cleaning the bipolar plate subjected to the crushing treatment with an organic solvent, and removing organic impurities on the surface of the bipolar plate; and d, pyrolyzing and cleaning the membrane electrode subjected to the crushing treatment, and then soaking pyrolysis residues with the organic solvent to obtain the recovered platinum. The method can effectively carry out recycling treatment on valuable components of the waste fuel cell to recycle the valuable components, simplifies a processing technology, prevents secondary pollution in the treatment process, is good in energy saving and environmental friendly effect and has better social and economic benefits.

Owner:DONGGUAN ZUOYOU ELECTRONICS TECH CO LTD

Papermaking method using diaper absorbent core layer fibers

InactiveCN105463897AEffective recyclingSave resourcesPaper recyclingWaste paper working-upSolubilityAluminium

The present invention discloses a papermaking method using diaper absorbent core layer fibers. The diaper absorbent core layers are pulverized and dissolved in water; an inorganic aluminum salt is added and stirred fully, and then defibering is carried out to obtain a fiber slurry; and then the fiber slurry is subjected to papermaking. According to the papermaking method using diaper absorbent core layer fibers, first the added inorganic aluminum salt destructs interfacial double electrical layers of a superabsorbent hydrogel material to increase the density difference between an inner phase and an outer phase and to promote precipitation of the inner phase; at the same time, the polarity difference between the inner and outer phases is increase, so that outer phase namely an oil phase has decreased solubility in water, and goal of removing SAP is ultimately achieved; the diaper absorbent core layer fibers after SAP removal are reused for papermaking, so as to achieve the effective recovery of diaper absorbent core layers, substantially save resource, energy conservation and transport, reduce emission and improve the social and economic benefits, and make great contribution to the pulping and papermaking industry.

Owner:SHAANXI UNIV OF SCI & TECH

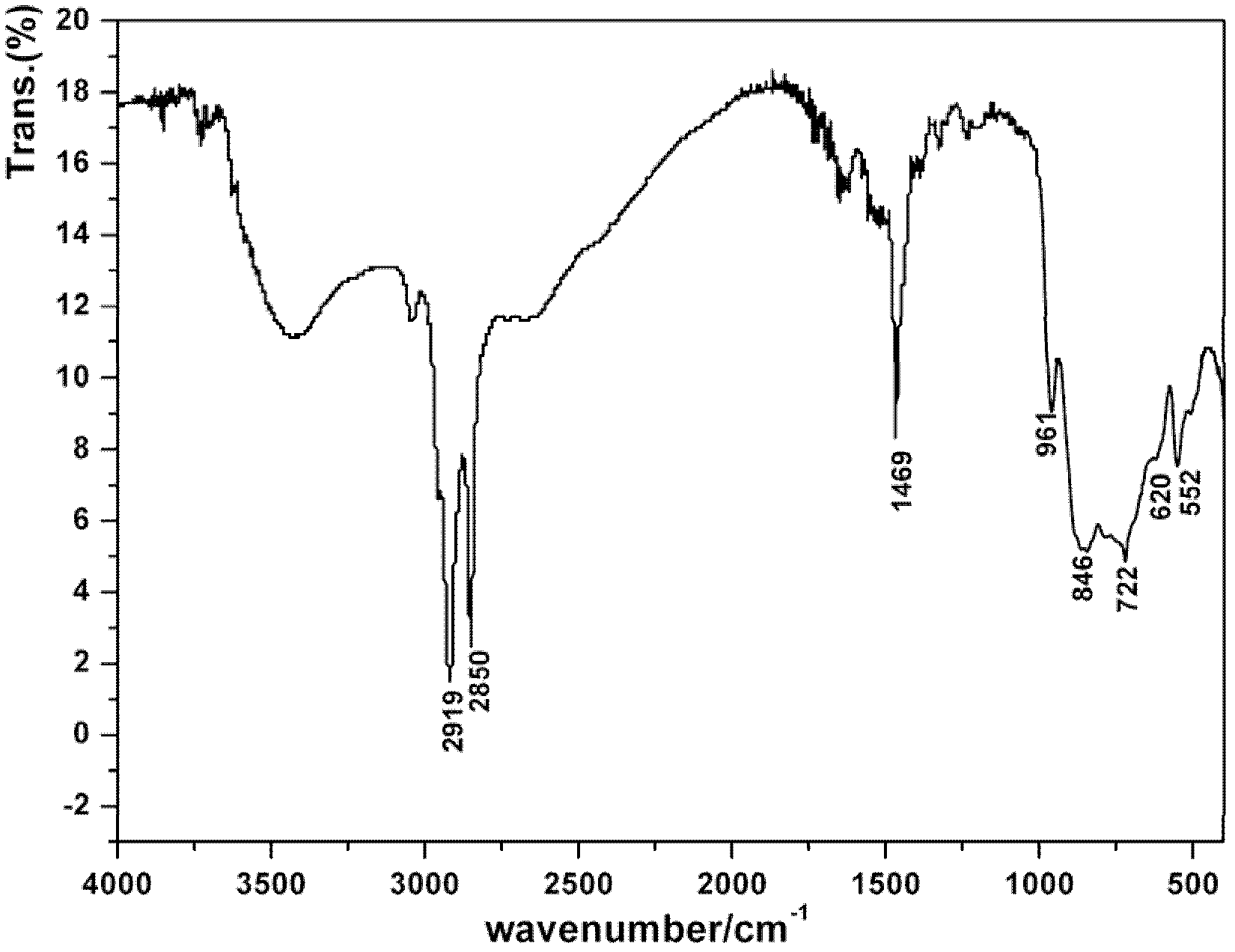

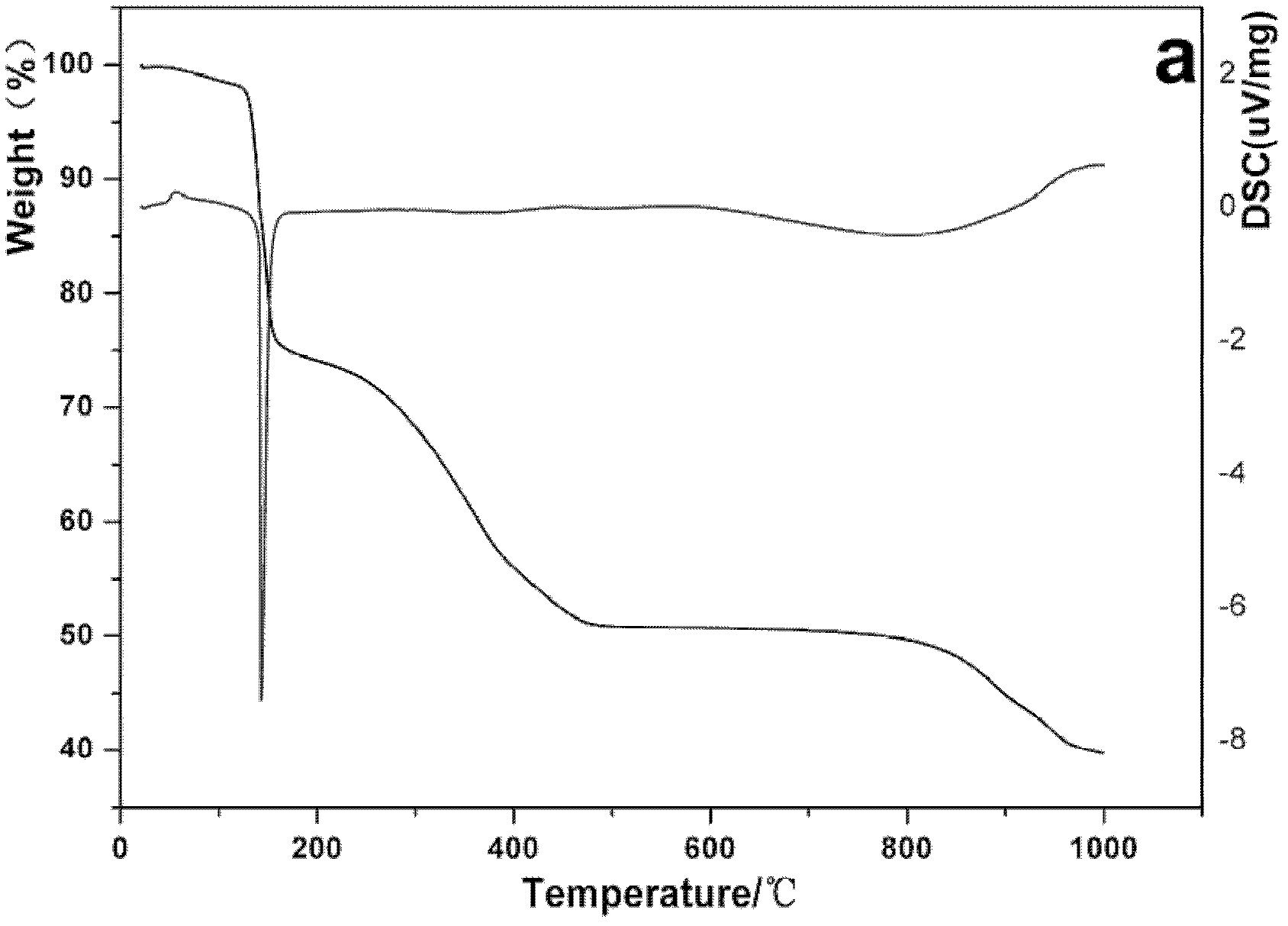

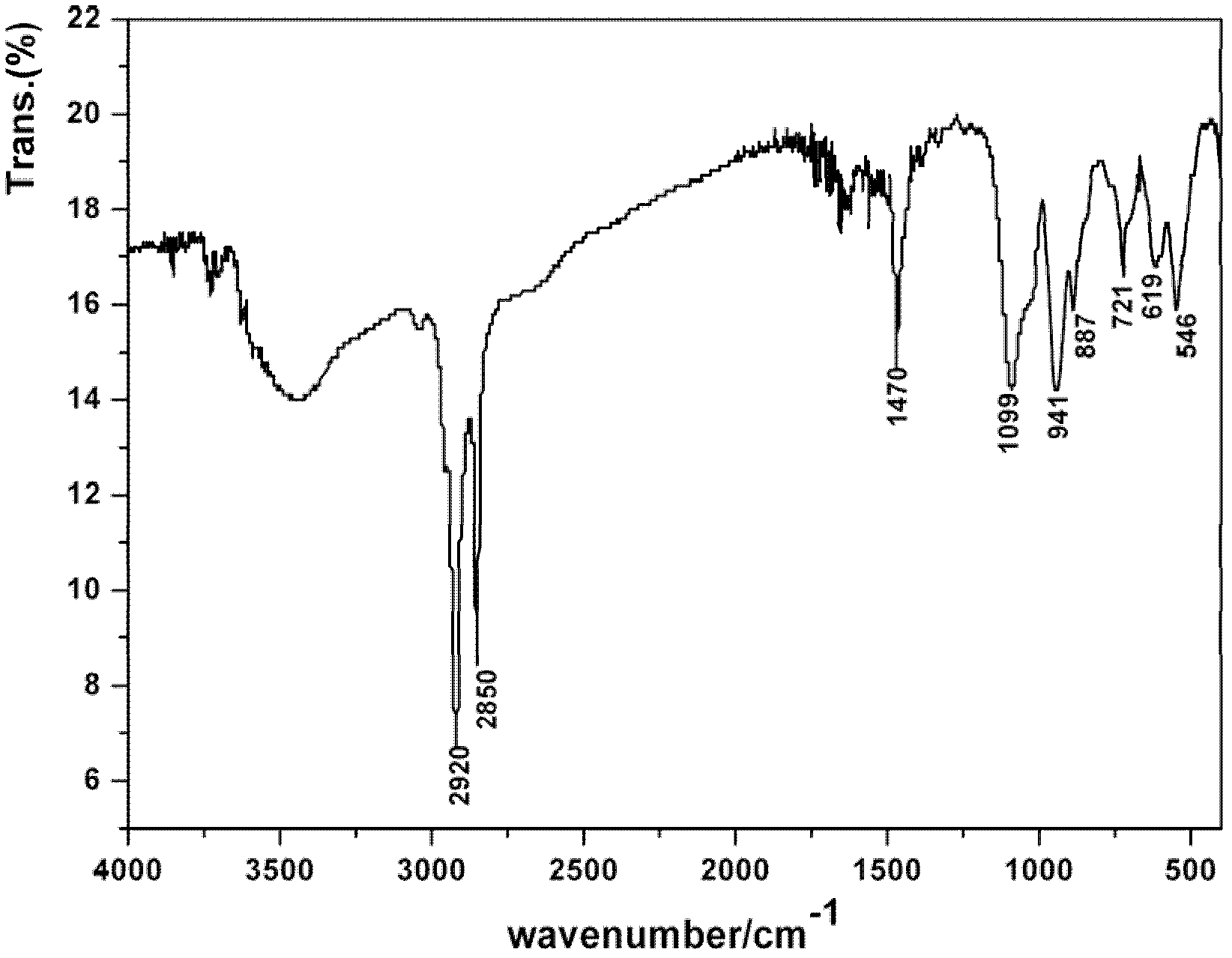

Desulfurization application method of super-deep oxidative desulfurization catalyst

InactiveCN102430428AEfficient oxidation capacityReduce desulfurization costOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPhosphoniumTransition metal atoms

The invention relates to a super-deep oxidative desulfurization catalyst and desulfurization application thereof. The super-deep oxidative desulfurization catalyst is an amphiphilic catalyst and has an expression of Qp[HqSexMyOz], wherein in the expression, p is an integer greater than or equal to 1, q is an integer greater than or equal to 0 and less than 2x and x is an integer greater than or equal to 1; y is greater than or equal to 2x and is less than or equal to 16x; z is greater than or equal to 3(x+y) and is less than or equal to 4x+5y; p is equal to 2x-q; Q represents surfactant cation which can be quaternary ammonium salt cation, alkyl pyridine salt cation, phosphonium cation, sulfonium cation and the like, generally quaternary ammonium salt cation with at least one alkyl chain of which the number of carbon atoms is not less than 4 is chosen; Se represents selenium atom which can be in the valence state of tetravalence or sexavalence; Se in a contrast catalyst can also be P, AS, S or Si of the highest valence, be blank, and the like, M represents transition mental atom which can be W, Mo, Ti, V, Mn, Ru, Cr, Fe, Co and the like, and generally can be W or Mo; and O represent oxygen atom. The catalyst in the invention can also be used for preparing an ultra-low-sulfur oil product with sulfur content of less than 5 ppm; implement conditions are mild; and the utilization rate of an oxidant is high.

Owner:NANJING UNIV

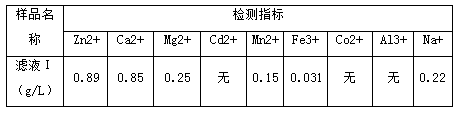

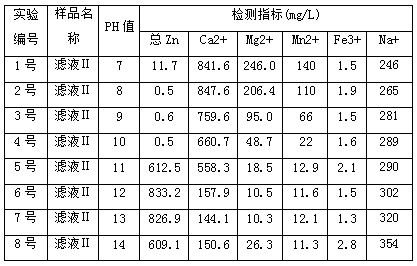

Recovery process for waste zinc ions in viscose production

ActiveCN107902855AEffective recyclingMeet emission standardsSludge treatmentSpecific water treatment objectivesIonViscose

The invention provides a recovery process for waste zinc ions in viscose production. The recovery process comprises the following steps: 1, viscose wastewater treatment: a step of adding lime powder into viscose production wastewater, and carrying out a reaction so as to obtain a precipitate; 2, adding a sulfuric acid solution into the precipitate obtained in the step 1, and carrying out dissolving and filtering so as to obtain a filtrate I; 3, adding sodium hydroxide into the filtrate I obtained in the step 2 until the pH value of the filtrate I is 7 to 14, and after completion of a reaction,carrying out filtering so as to obtain a filtrate II; 4, adjusting the filtrate II to acidity by using a sulfuric acid solution, and allowing macroporous chelated divinyl benzene polymerized ion-exchange resin to adsorb zinc ions in the filtrate II; and 5, rinsing the macroporous chelated divinyl benzene polymerized ion-exchange resin which adsorbs the zinc ions in the filtrate II in the step 4 by adopting a sulfuric acid solution so as to obtain a zinc sulfate eluent and complete recovery of waste zinc ions. The process provided by the invention has simple operation, can effectively recoverthe zinc ions in the precipitate formed in zinc-containing wastewater treatment, and reduce environmental pollution.

Owner:YIBIN HIEST FIBER +1

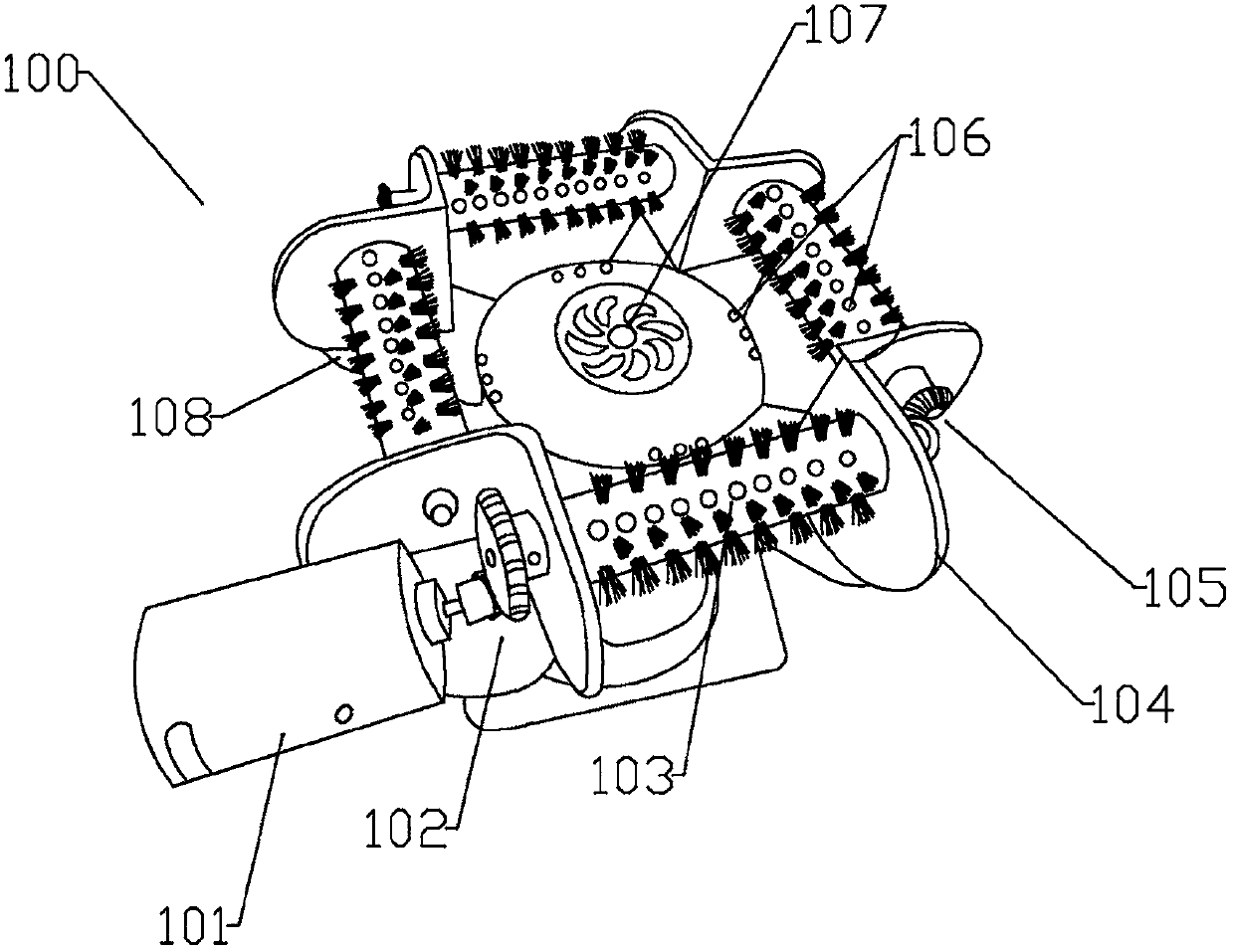

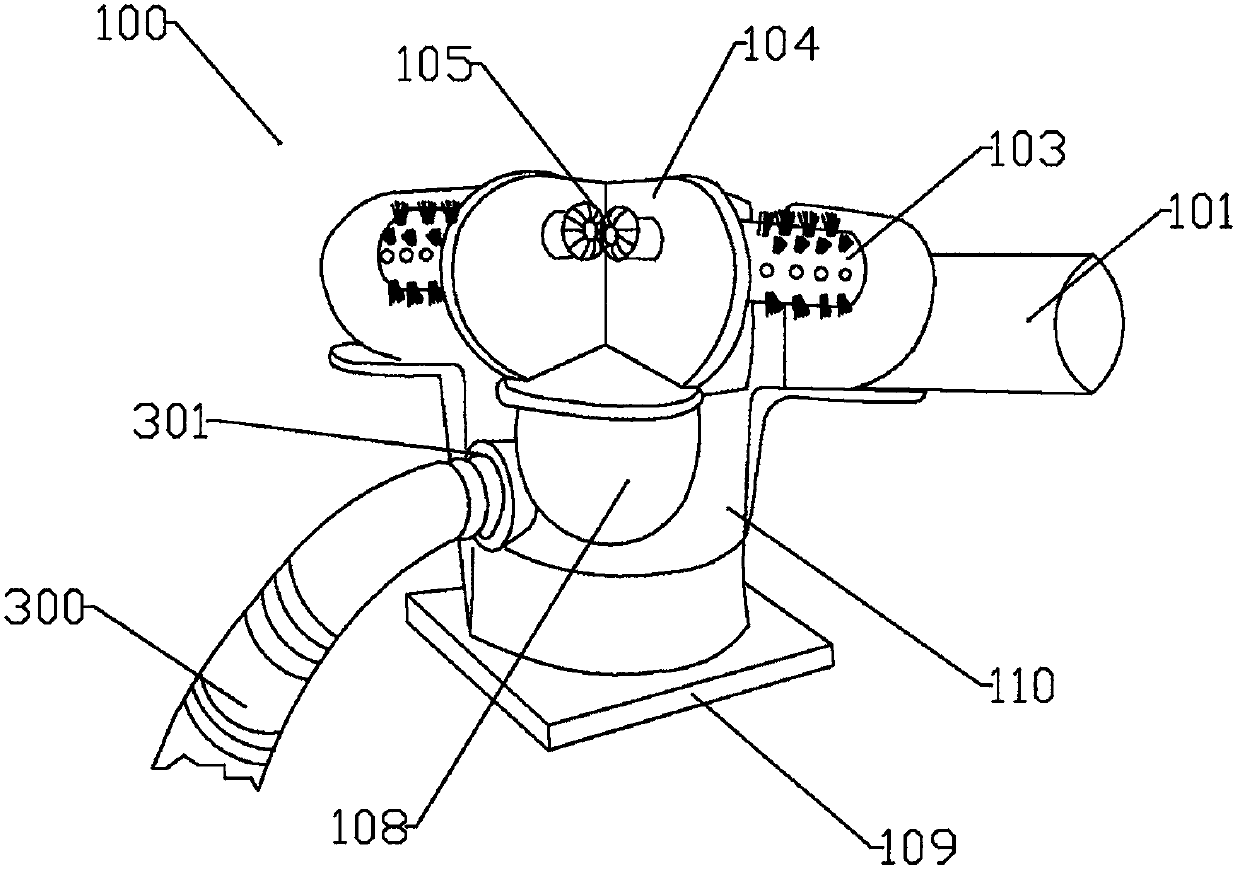

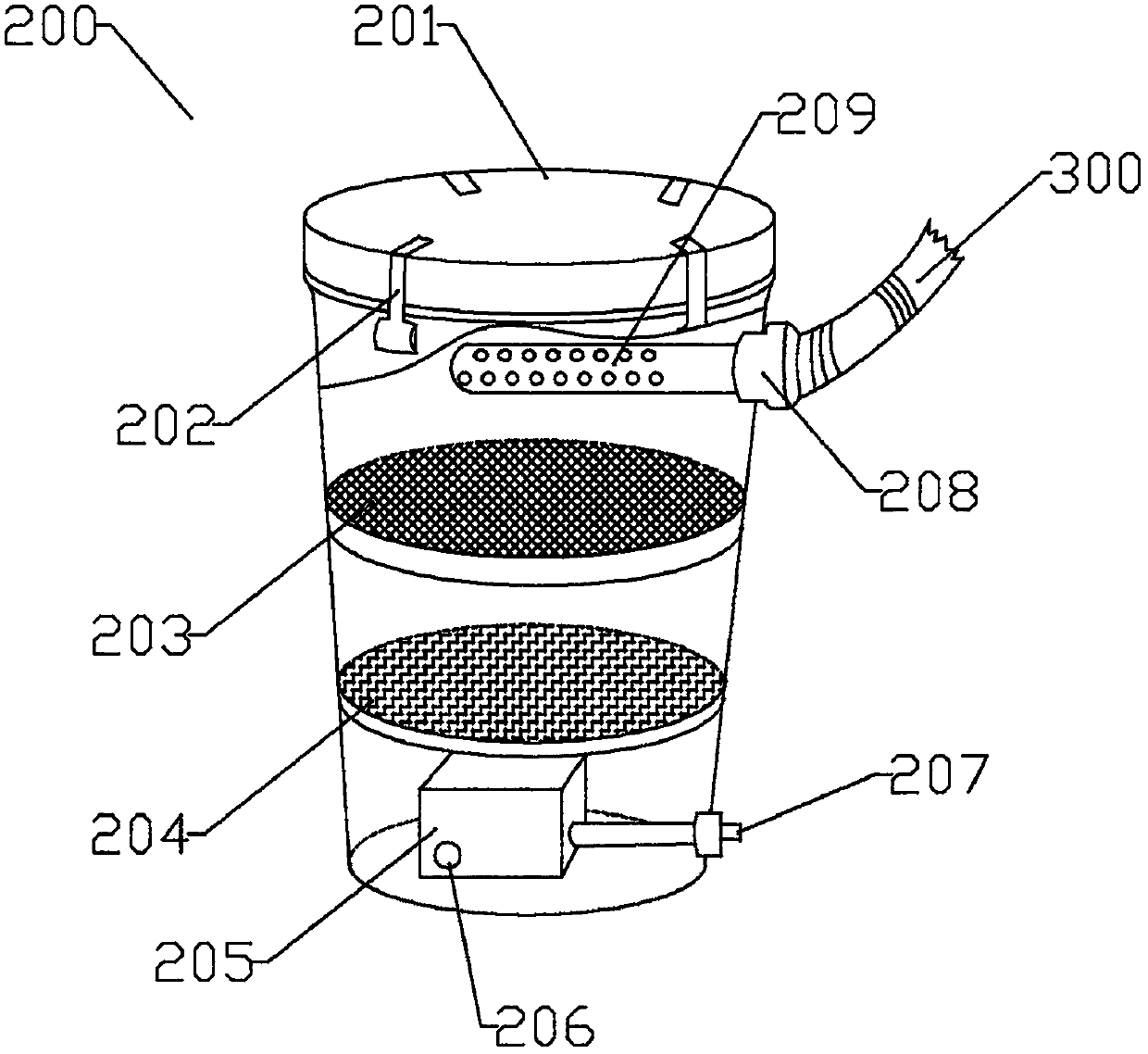

Portable circulating cleaner

InactiveCN109515394AEffective recyclingConserve waterCarpet cleanersFloor cleanersWater savingDomestic helper

The invention discloses a portable circulating cleaner, which comprises a cleaning brush head, a filter barrel and a circulating water pipe, and is characterized in that the cleaning brush head comprises a motor, a transmission gear, a cleaning brush, a bevel gear, clean water sprinkling holes, a waste water recovery port, a base, a waste water recovery bin and a bracket; the filter barrel comprises a barrel cover, a buckle, a sprinkler pipe, a first filtering layer, a second filtering layer and a water supply pump; and the circulating water pipe comprises a waste water pipe and a clear waterpipe. The portable circulating cleaner is simple in structure and convenient to use, water can be effectively recycled, and the whole recycling process only needs 2-3 liters of domestic water, so thatthe purposes of protecting the environment and saving water are achieved; the cleaner can also be used for cleaning glass, walls and floors.

Owner:尤晓伟

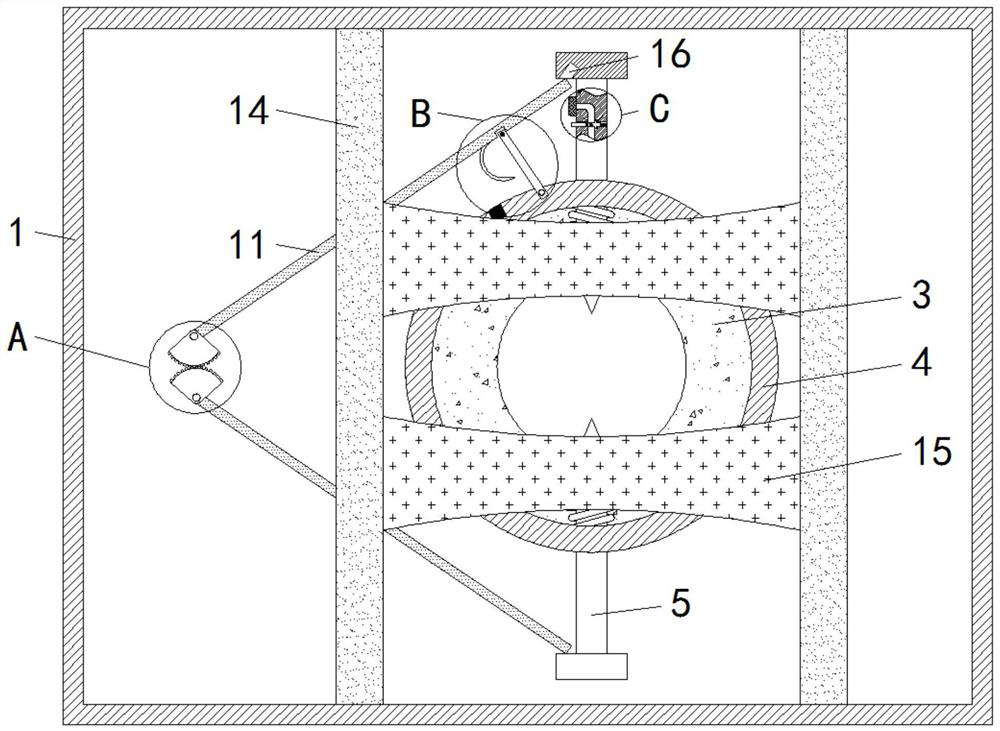

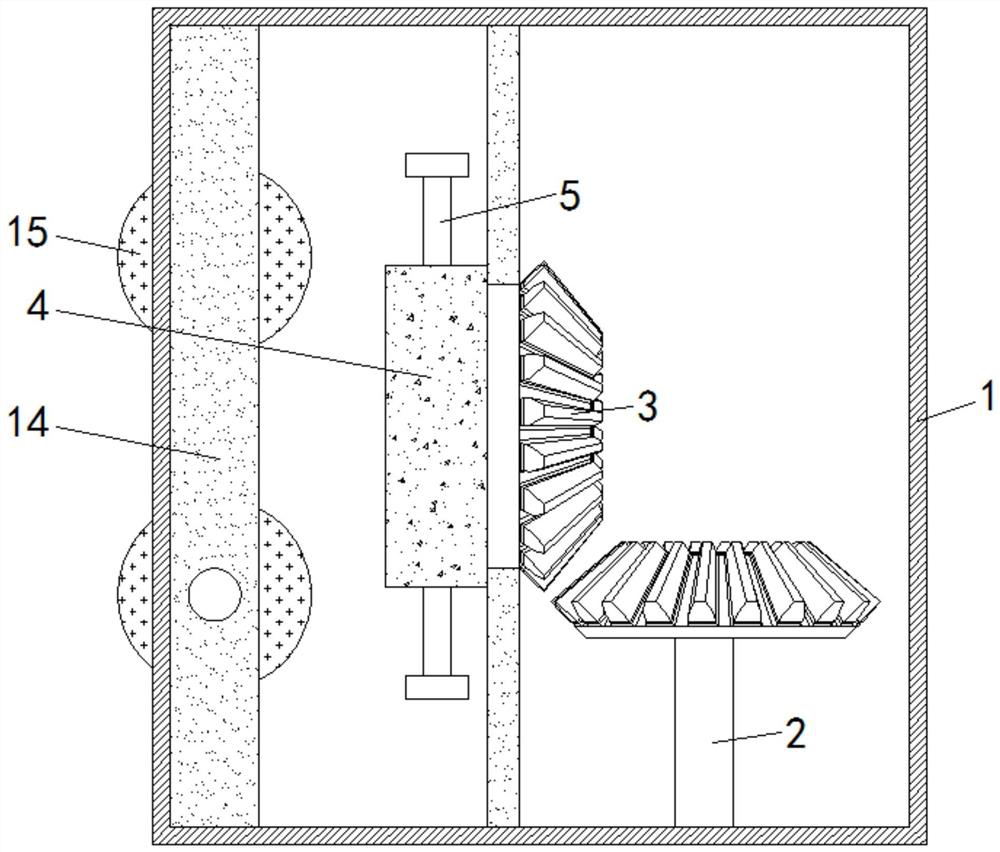

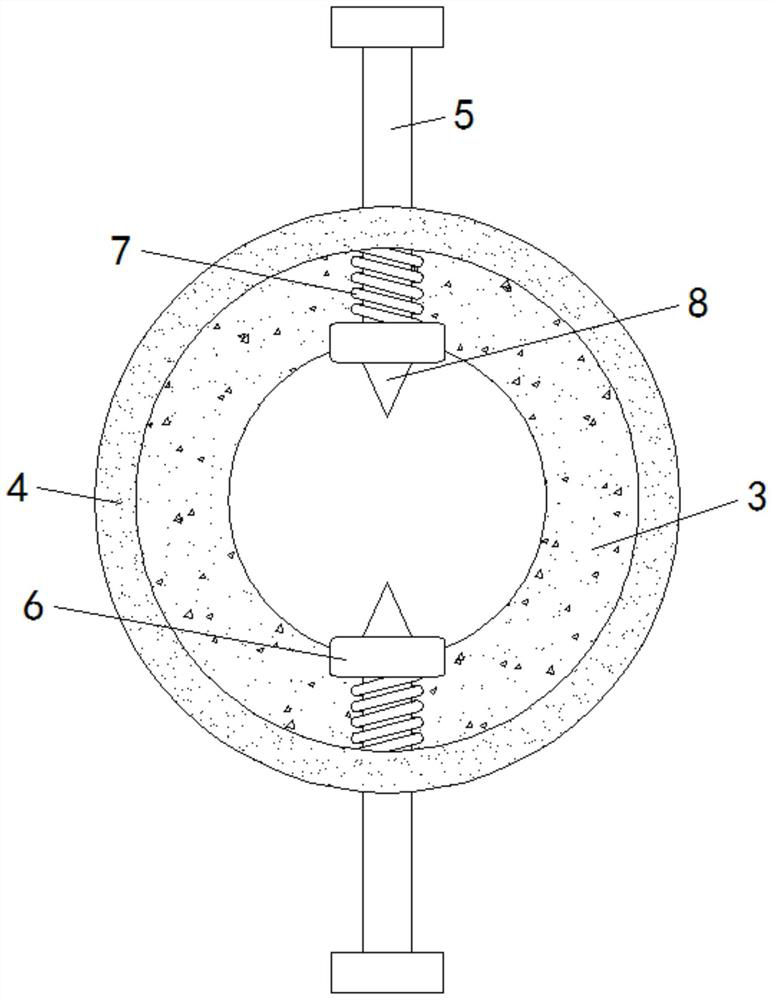

Feeding, shearing and stripping device for large-diameter cable

InactiveCN112186647AReduce recycling costsEffective recyclingBasic electric elementsApparatus for removing/armouring cablesPulleyElectric cables

The invention relates to the technical field of cable recovery equipment and discloses a feeding, shearing and stripping device for a large-diameter cable. The device comprises a machine body, whereinthe machine body is connected with a connecting rod, the connecting rod is connected with a transmission cone pulley, the transmission cone pulley is connected with a separation disc, the separationdisc is inserted with a separation rod, the separation tooth disc is connected with a fixed block, and the separation rod is connected with a pressure spring; the fixed block is connected with a separation knife, the separation disc is connected with a fixed rod, the fixed rod is connected with a magnetic block and an expansion rod, the expansion rod is connected with a sliding groove, and the expansion rod is connected with a rotating wheel. According to the feeding, shearing and stripping device for the large-diameter cable, the transmission cone pulley drives the separation disc to rotate,the separation disc drives the separation rod to do circular motion, and through cooperation of the separation knife, rapid stripping of the cable is realized, the cable recovery cost is reduced, so the cable is effectively recovered, and metal energy is saved.

Owner:南京小科咪商贸有限公司

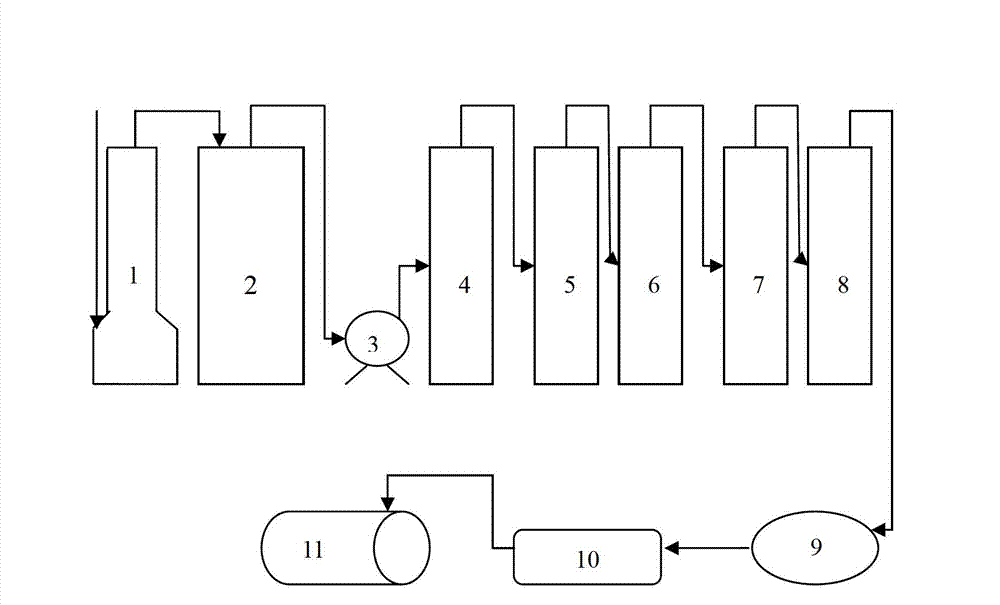

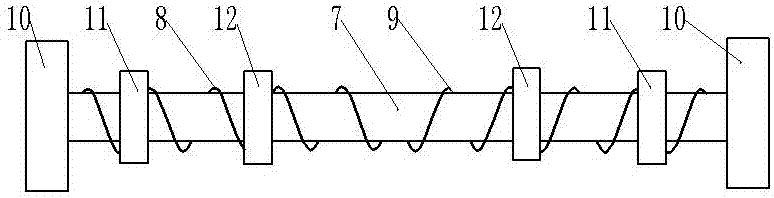

Triglycidyl isocyanurate dry powder extruding and pelletizing production line and triglycidyl isocyanurate dry powder extruding and pelletizing production technology

ActiveCN103896929AEffective recyclingReduce environmental pollutionOrganic chemistryGranulation by pressingCyclonic separationMelt extrusion

The invention relates to a triglycidyl isocyanurate dry powder extruding and pelletizing production line and a triglycidyl isocyanurate dry powder extruding and pelletizing production technology. The triglycidyl isocyanurate dry powder extrucing and pelletizing production line is characterized by comprising a vibration dryer, a condenser connected with the gas outlet of the vibration dryer, a solvent recycling tank and a gas draught fan I which are sequentially connected with the condenser, a dry powder cyclone separator and a dry powder tank which are connected with the material outlet of the vibration dryer as well as a material extruder, a tablet machine, a band-type cooling conveyor, a pulverizer, a screening machine and a packaging machine which are sequentially connected with the discharge hole of the dry powder tank. The triglycidyl isocyanurate dry powder extruding and pelletizing production technology comprises a drying moist material, carrying out cyclone separation on a dry powder material, performing melt extrusion, tabletting, cooling on the band type cooling conveyor, pulverizing, screening and packaging. The triglycidyl isocyanurate dry powder extruding and pelletizing production line and the triglycidyl isocyanurate dry powder extruding and pelletizing production technology have the advantages that a volatile organic solvent is effectively recycled, environmental pollution is reduced, the operating environment in a production process is improved, and the environmental problem is solved; meanwhile, the density of the triglycidyl isocyanurate dry powder product is medorate and is about 1.32g / cm<3> generally, so that the hardness of the triglycidyl isocyanurate dry powder product is maintained, and the triglycidyl isocyanurate dry powder product can be easily pulverized and dispersed when being used by a user.

Owner:ANSHAN RUNDE FINE CHEM

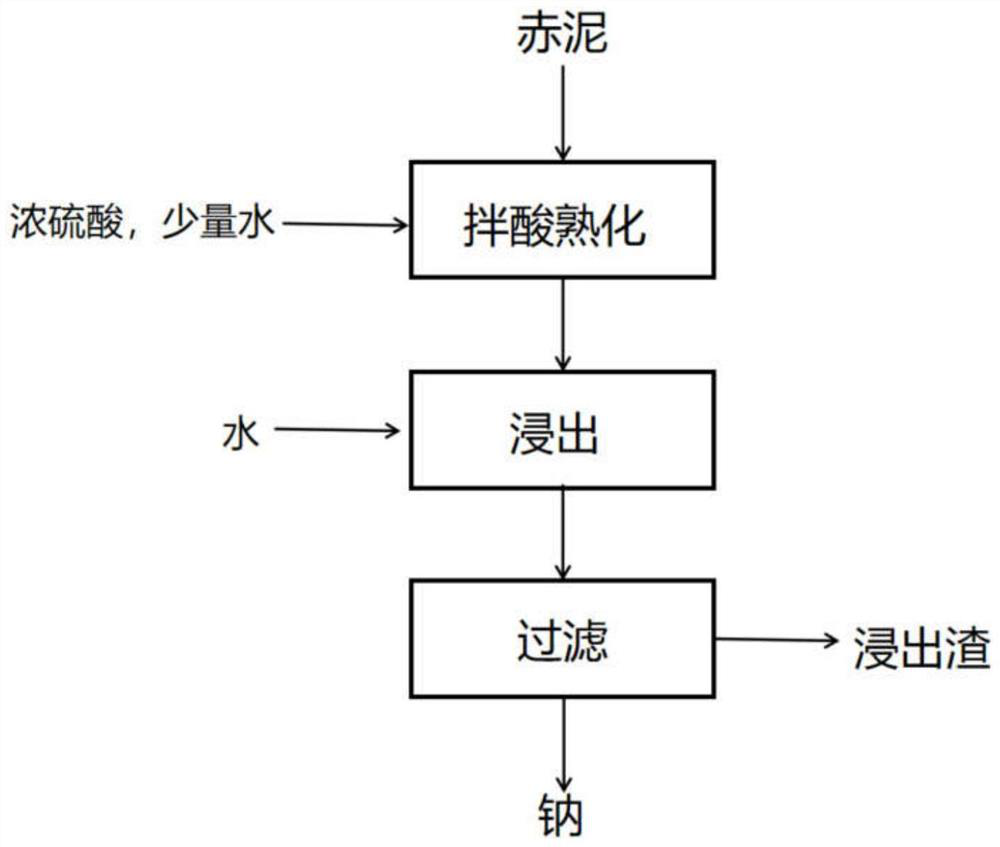

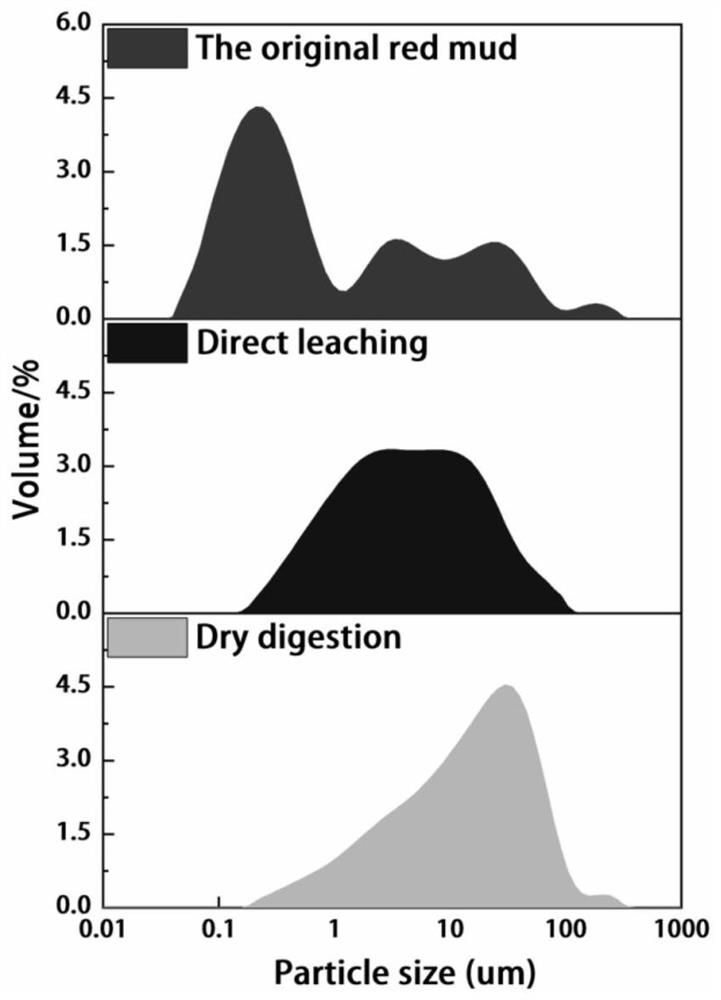

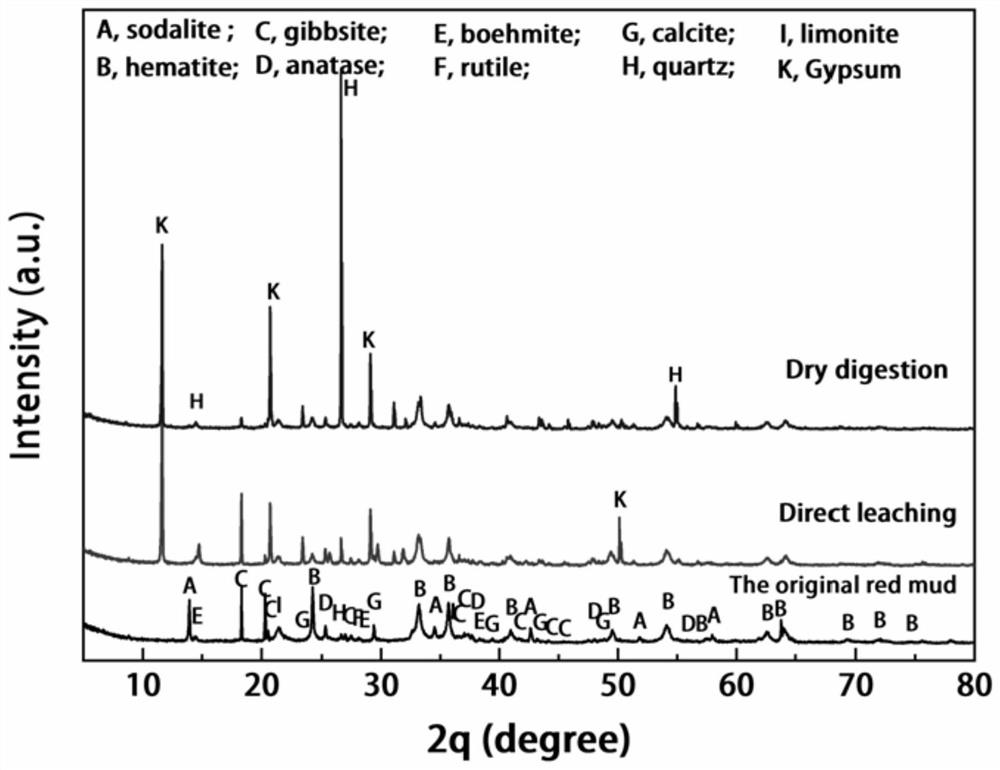

Technology for dealkalizing red mud

ActiveCN112723688AEfficient dealkalizationEffective recyclingSludge treatmentSolid waste managementSulfuric acidFiltration

The invention discloses a method fordealkalizing red mud by adopting an acid mixing process to treat the red mud at normal temperature. The treatment method comprises the following steps: mixing red mud and concentrated sulfuric acid according to a certain ratio, adding a small amount of deionized water to prepare slurry A, allowing the slurry A to stand at a low temperature of 30-40 DEG C for a period of time, adding deionized water into the obtained solution according to a liquid-solid ratio, and continuously conducting stirring at normal temperature for a period of time to form a solid-liquid mixture; and carrying out suction filtration separation on the obtained solid-liquid mixture, adding a certain amount of deionized water in the suction filtration process for washing, and recovering metals such as sodium, calcium and the like from residues obtained after separation treatment. The method is high in dealkalization efficiency, the dealkalization process is simple and controllable, and meanwhile, the problem that solid and liquid are difficult to efficiently separate is avoided; and necessary conditions are provided for high-value comprehensive application of the red mud.

Owner:CENT SOUTH UNIV

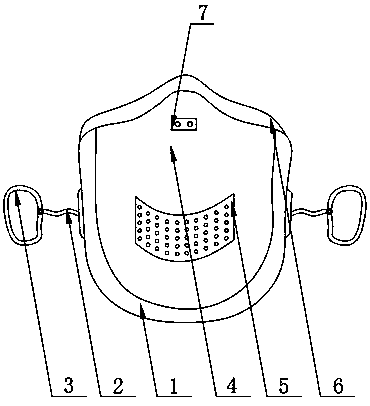

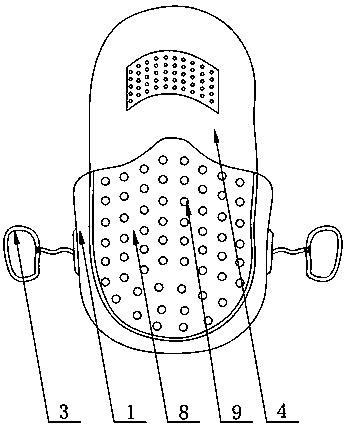

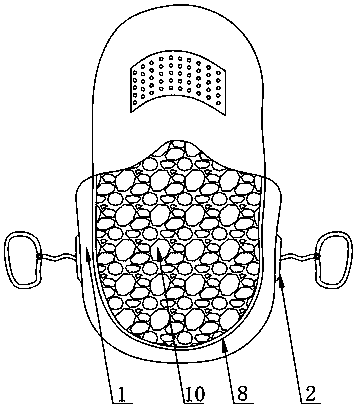

Portable mask and using method thereof

InactiveCN108030168AEasy to replaceEasy to disassembleGarment special featuresProtective garmentEngineeringSilica gel

The invention discloses a portable mask and a using method thereof. The portable mask comprises a housing, a take-up mechanism, an ear ring, a top cover, air inlet holes, a silica gel ring, a charginghole, an inner core fixing groove, through holes, an inner core and an inner pad. Two corresponding sides of the housing are fixedly provided with the take-up mechanism through bolts. The top of thetake-up mechanism is fixedly provided with the ear ring through locking buttons. The center of the outer side of the housing is provided with the inner core fixing groove. The bottom of the inner corefixing groove is provided with a plurality of the through holes. One side of the inner core fixing groove is connected with the top cover through a hinge. The center of the top cover is provided witha plurality of the air inlet holes. The interior of the inner core fixing groove is fixedly provided with the inner core through the locking buttons. The circumference of the inner side of the housing is connected with the silica gel ring through the locking buttons. The center, corresponding to the position of the through holes, of the housing is fixedly provided with the inner pad through the locking buttons. Through installing the inner core in the inner core fixing groove, the inner core is conveniently replaced and detached, so the convenience of the use is effectively improved.

Owner:SHANDONG KANGLI MEDICAL EQUIP TECH

Method for producing environment-friendly modified macromolecular asphalt resin for road raw materials and waterproof coiled materials

ActiveCN103601956AEffective recyclingAlleviate environmental pressureBulk chemical productionReaction temperatureMixed materials

The invention discloses a method for producing environment-friendly modified macromolecular asphalt resin for road raw materials and waterproof coiled materials. The method comprises the following steps: (1) mixing pretreated raw materials and additives in a tubular static mixer according to percentage; (2) putting mixed materials in a lined reactor, and stirring while heating; (3) sealing a feeding port of the reactor, vacuumizing until the pressure is -0.06 to 0.08MPa, increasing the stirring speed along with temperature rise, vacuumizing until the pressure is -0.09 to 0.1MPa, removing moisture when the temperature rises to 100 DEG C, stopping vacuumizing, and reacting for 4-5 hours at the reaction temperature of 180 DEG C and the reaction pressure of 0.03-0.04MPa; (4) sampling and assaying a product after the reaction materials become a paste dilute sticky substance, and discharging, thereby obtaining an asphalt resin product. The method has the advantages that the environmental protection pressure is relieved effectively, solid chemical wastes are effectively recycled, the waste is changed into the valuable, energy is saved, emissions are reduced, and the environment is protected.

Owner:FUSHUN WANGHUA YANWU CHEM PLANT

Plastic sign brushing ink sprayer

The invention relates to the technical field of plastic product machining equipment, and discloses a plastic sign brushing ink sprayer. The plastic sign brushing ink sprayer comprises an ink box. An ink outlet pipe is arranged on the ink box and provided with a pressure limiting valve. The ink outlet pipe is connected with a spray head. The ink box is provided with two elastic layers. A threaded rod is arranged between the two elastic layers in a penetrating manner and is provided with a forward thread area and a reverse thread area. First threaded sleeves are arranged at the two ends of the threaded rod and located on the outer side of the ink box. An air inflation ball is arranged at the position, in the ink box, of the threaded rod. Second threaded sleeves are arranged at the positions, on the two sides of the air inflation ball, of the threaded rod. An air inflation pipe is arranged on the air inflation ball. A spray barrel is arranged on the outer side of the spray head. Supporting pipes and ink cleaning pipes are arranged on the spray barrel. A steel wire is mounted in each supporting pipe. The end, close to the ink box, of each supporting pipe communicates with the air inflation pipe. Each ink cleaning pipe is filled with a sponge. Multiple ink suction holes are formed in the face, facing the center axis of the spray barrel, of each ink cleaning pipe. By means of the plastic sign brushing ink sprayer, the problem that the portions, needing no sign brushing, of plastic products are contaminated can be solved.

Owner:安徽友川刷业有限公司

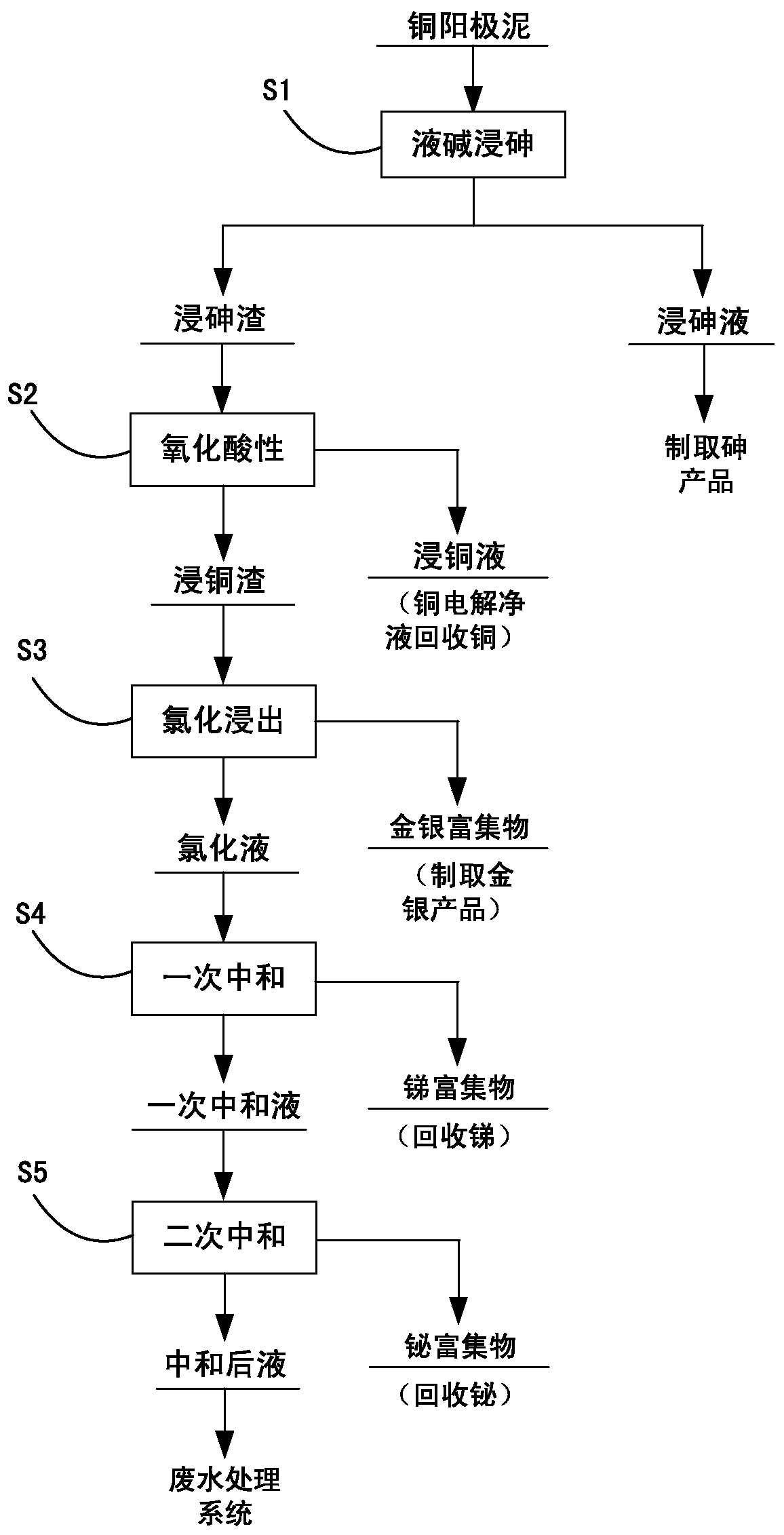

Extraction method of valuable metal in copper anode mud

The invention aims to provide an extraction method of valuable metal in copper anode mud. The extraction method of the valuable metal in the copper anode mud comprises the steps of adding the copper anode mud into a sodium hydroxide solution according to the liquid-solid ratio, controlling the reaction temperature and the reaction time, effectively leaching arsenic, and obtaining an arsenic leaching solution and arsenic leaching residues; adding the arsenic leaching residues into a sulfuric acid solution according to the liquid-solid ratio, feeding air, controlling a reaction oxidation potential and the reaction temperature, stirring, filtering, and obtaining a copper leaching solution and copper leaching residues; adding hydrochloric acid, sulfuric acid and sodium chloride into the copperleaching residues, controlling the reaction acidity and the reaction time, and obtaining a chlorination solution and a gold-silver concentrate; maintaining the reaction temperature, adding dilute alkalis into the chlorination solution for neutralizing, controlling the reaction oxidation potential, and obtaining a primary neutralization solution and an antimony concentrate; and maintaining the reaction temperature, adding dilute alkalis into the primary neutralization solution, controlling the reaction oxidation potential, and obtaining a post-neutralization solution and a bismuth concentrate.By adopting the technical scheme, arsenic, copper, antimony and bismuth are effectively recycled.

Owner:JIANGXI COPPER

Method for recycling silver of waste solar cell panel

InactiveCN106801143AEffective recyclingHigh purityProcess efficiency improvementSilicon compoundsHydrofluoric acidEconomic benefits

The invention belongs to the technical field of waste recycling, and particularly relates to a method for recycling silver of a waste solar cell panel. The method comprises the following steps that a, a waste solar cell chip is taken; b, the cell chip is immersed in a sodium hydroxide solution, an aluminum layer on an aluminum back field of the chip is removed, and a silicon wafer obtained after aluminum removal is obtained; c, the silicon wafer obtained after aluminum removal is treated through a mixed solution of nitrite and copper sulfate, silver on a pole plate of an aluminum sheet is leached, and the cell chip obtained after silver extraction is obtained; d, the cell chip obtained after silver extraction is placed in a hydrofluoric acid solution to be immersed, and a silicon material is obtained. According to the method, valuable components of the waste crystal silicon solar chip can be effectively subjected to recycling treatment, and the energy saving and environment-friendly effects are good; and by means of the method, the recycled silver can be collected, the high-purity silicon material can be obtained through posttreatment, and huge social and economic benefits are achieved.

Owner:DONGGUAN ZUOYOU ELECTRONICS TECH CO LTD

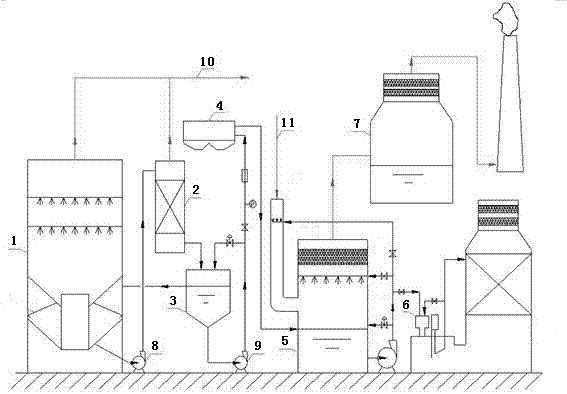

Recycling and purifying device of sulfuric acid waste liquid

InactiveCN107539959AReduce the amount of waste residueEffective recyclingSulfur-trioxide/sulfuric-acidFlueSulfuric acid

The invention belongs to the technical field of chemical engineering, and relates to a recycling and purifying device of sulfuric acid waste liquid. The device comprises a purifying tower, a degassingtower, an acid water storage tank, a filter press, a concentration tower, an acid mixing device and a tail suction tower; a discharging port of the purifying tower is connected with a feeding port ofthe degassing tower through a mud pump, a discharging port of the degassing tower is connected with a feeding port of the acid water storage tank, a discharging port of the acid water storage tank isconnected with a feeding port of the filter press through a pressing filtration pump, a discharging port of the filter press is connected with a feeding port of the concentration tower, and a discharging port of the concentration tower is connected with the acid mixing device; an exhaust port of the purifying tower and an exhaust port of the degassing tower are connected to a purifying negative-pressure flue, and an exhaust port of the concentration tower is connected with the tail suction tower. By means of the recycling and purifying device of the sulfuric acid waste liquid, the sulfuric acid waste liquid can be effectively purified, the sulfuric acid in the sulfuric acid waste liquid can be effectively recovered for adjusting the concentration of sulfuric acid in dry-suction finished products, the quantity of waste residues produced after purification is extremely low, and the valuable metal in the sulfuric acid waste liquid can be effectively recycled.

Owner:JINCHUAN GROUP LIMITED

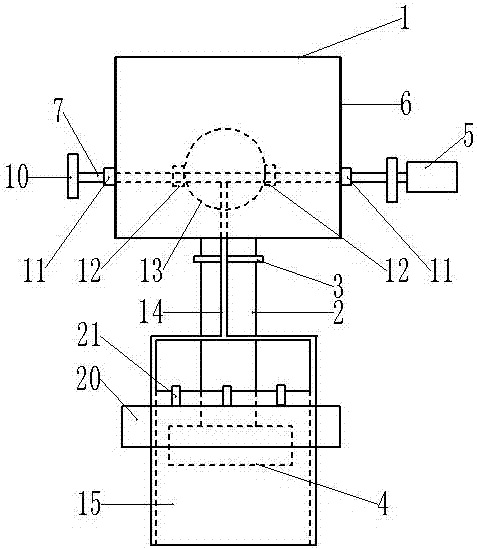

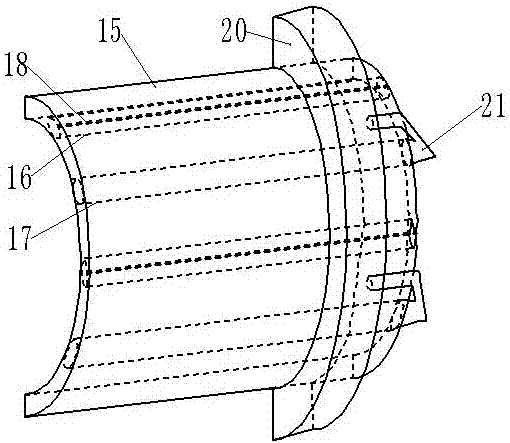

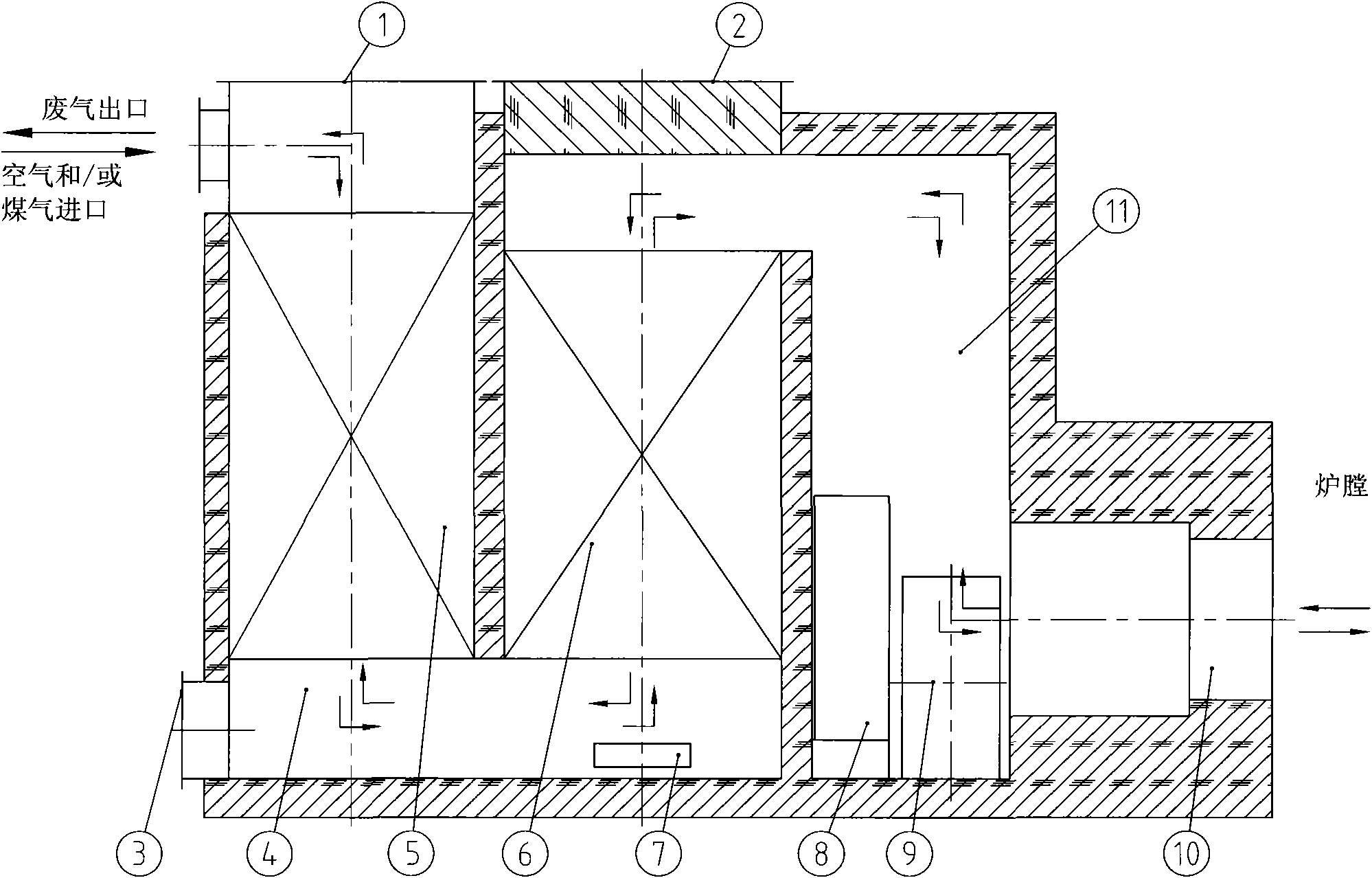

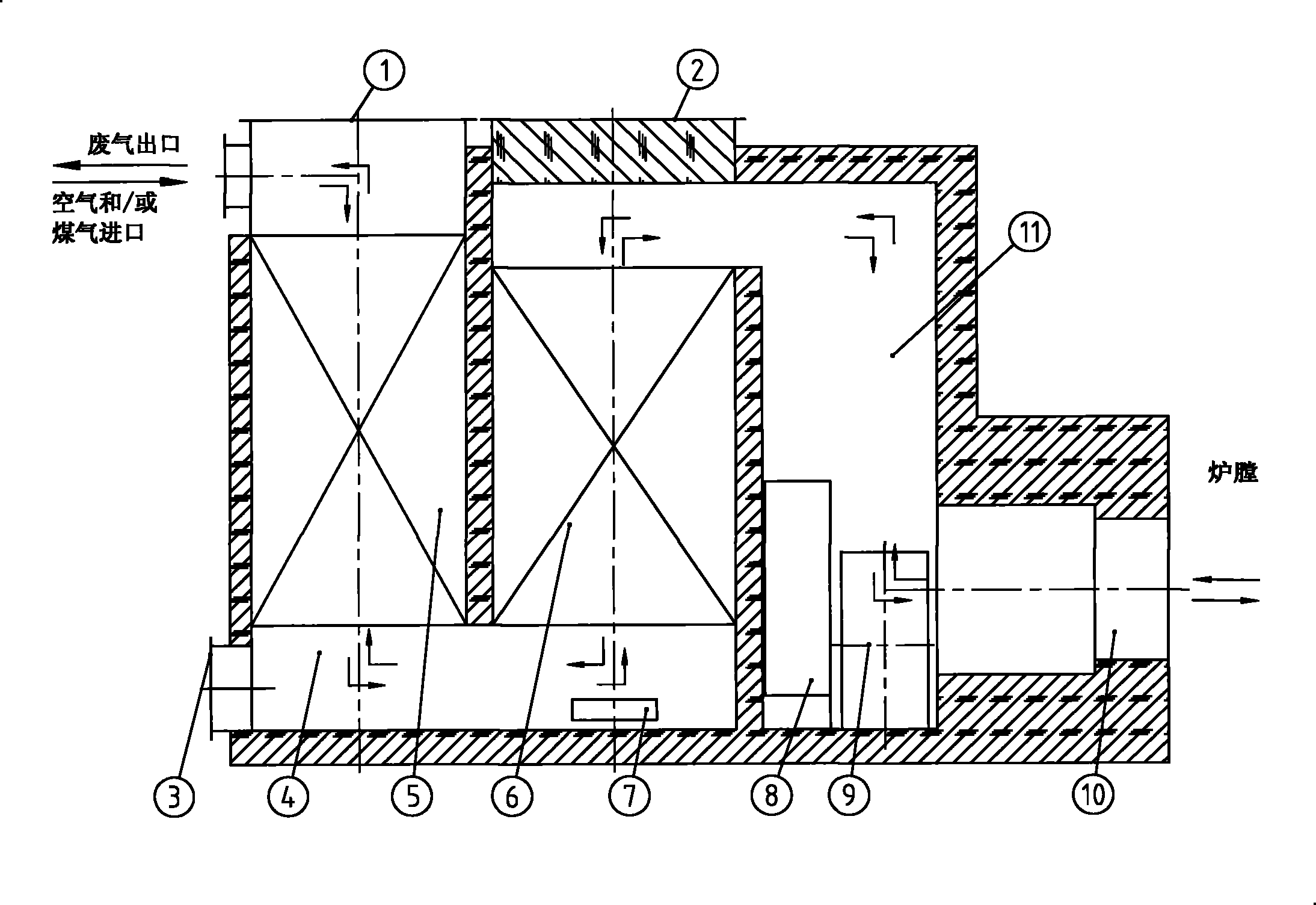

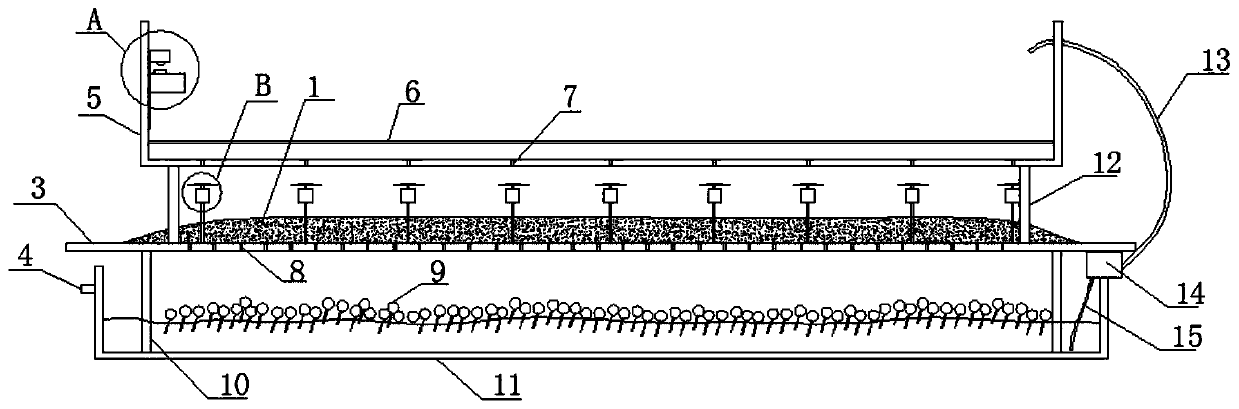

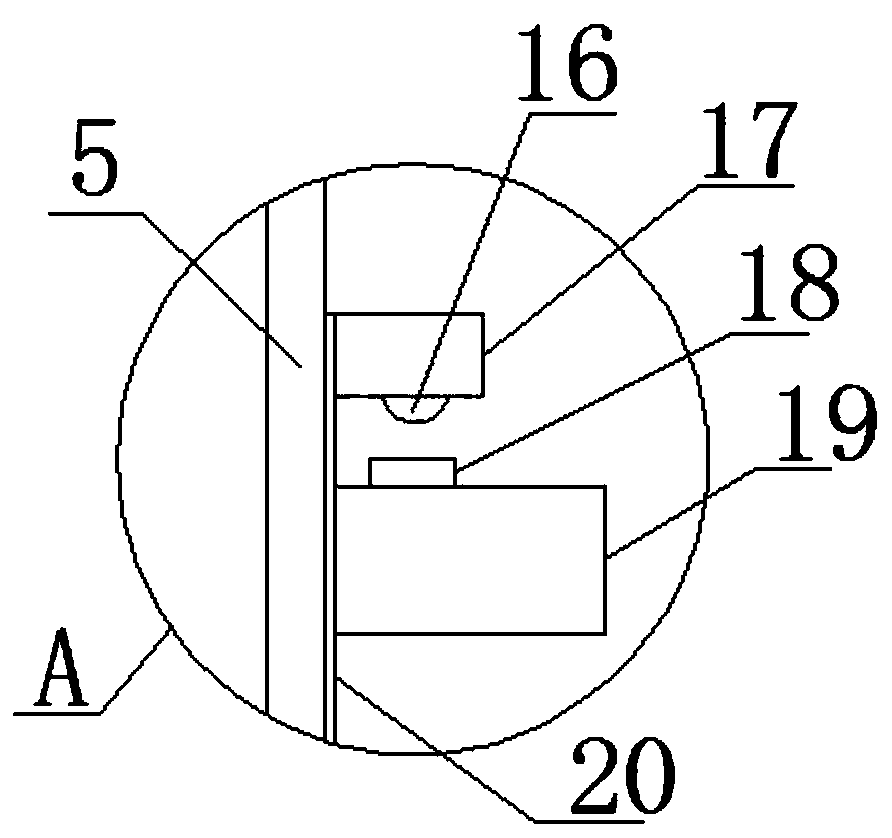

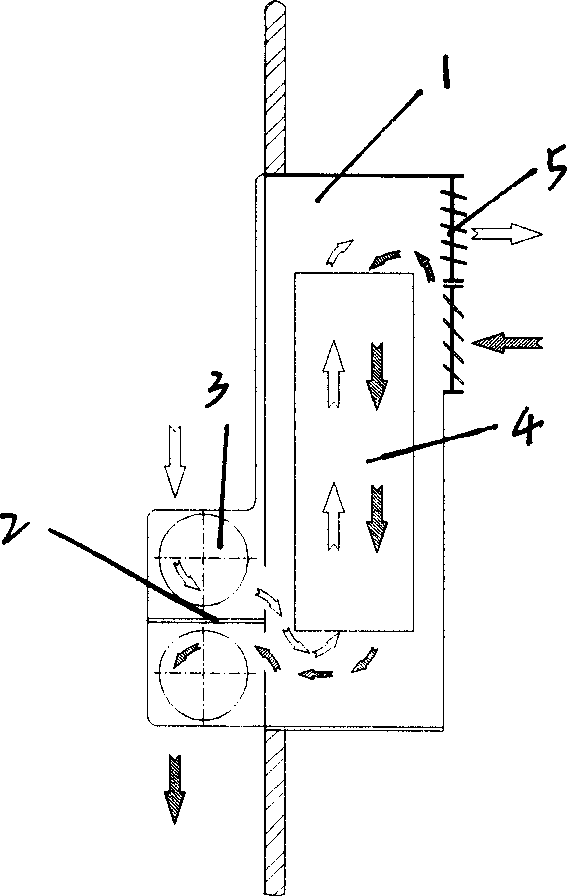

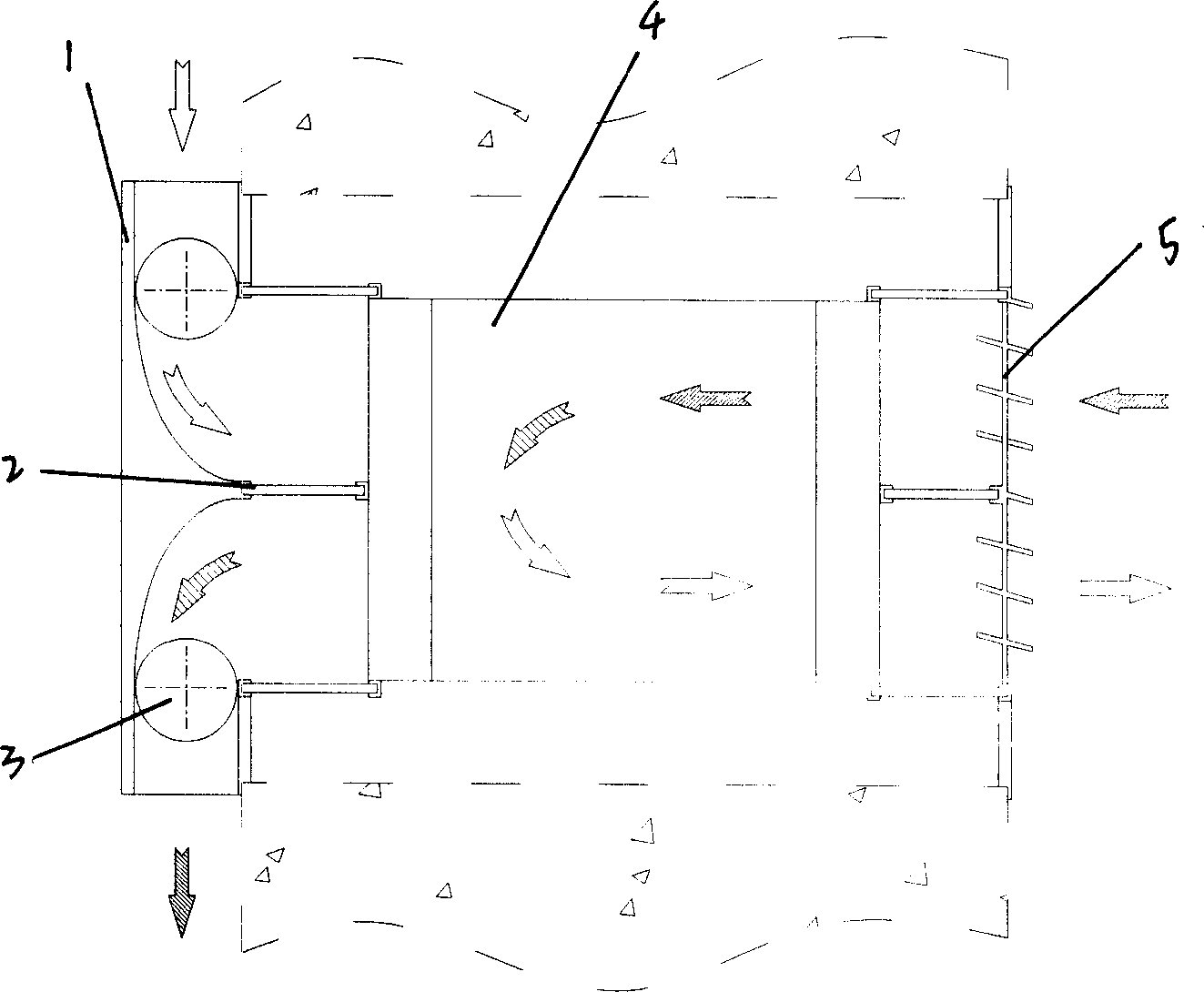

Anti-clogging heat accumulating type burner and industrial furnace

InactiveCN101968219AEffective recyclingPrevents clogging of burnersIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringTuyere

The invention discloses an anti-clogging heat accumulating type burner and an industrial furnace. The heat accumulating type burner is provided with a low temperature regenerator and a high temperature regenerator; the low temperature regenerator and the high temperature regenerator are respectively arranged in an independent chamber; a low temperature regenerator access hole and a high temperature regenerator access hole are respectively arranged above the chambers; a dust setting chamber is arranged below the low temperature regenerator and the high temperature regenerator; one side of the dust setting chamber is provided with a dust recycling section which can be provided with a cooling air port; and the front end of the burner is provided with a fume / dust cyclone settling chamber. The industrial furnace is provided with at least one pair of heat accumulating type burners which are used for burning in a periodic switching mode. A heat accumulating material is used for recycling physical sensible heat in the fume, and the cooling air port of the heat accumulating type burner is used for regulating the exhaust temperature, thus, the temperature of exhaust containing dust is reduced below the melting point of dust, and dust in the exhaust is settled and recycled after becoming solid. The heat accumulating type burner can prevent a heat accumulator from being clogged, is convenient to maintain, and performs the functions of comprehensively utilizing resources, lowering the energy consumption and cost and protecting the environment.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

Fish-vegetable symbiosis planting and raising circulation system

InactiveCN111109180AEffective recyclingConserve fertilizer and water resourcesPisciculture and aquariaReceptacle cultivationNutrientAbsorption of water

The invention discloses a fish-vegetable symbiosis planting and raising circulation system. The fish-vegetable symbiosis planting and raising circulation system comprises a fish tank made of a transparent glass material, wherein a separation net is arranged on the bottom of the fish tank, edges of the separation net and inner walls of the fish tank are fixedly connected, and a plurality of water seepage holes are fixedly formed in the bottom surface of the fish tank in a penetrating mode; and a planting platform is arranged below the fish tank, soil is laid on the top surface of the planting platform, a watering mechanism is arranged on the portion, located under each water seepage hole, on the top surface of the planting platform, and a purification tank is arranged below the planting platform. According to the fish-vegetable symbiosis planting and raising circulation system, by arranging a vertical three-layer structure of the fish tank, the planting platform and the purification tank, when fishes are raised and vegetables and fruits are planted, liquid dung on the bottom of the fish tank is made to flow to the planting platform to water the vegetables and the fruits, after richnutrient substances in the liquid dung are absorbed by the soil and the vegetables and the fruits, the liquid dung flows into the purification tank, duckweed in the purification tank can absorb redundant nutrient substances of ammonia nitrogen and the like in water, and a water pump can pump the water in the purification tank into the fish tank, so that resources are effectively recycled, and waste of the resources is avoided.

Owner:安徽金易德农业科技有限公司

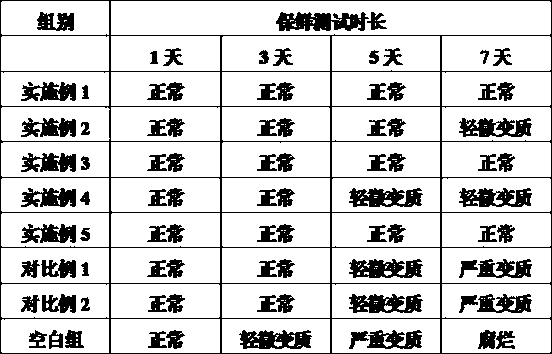

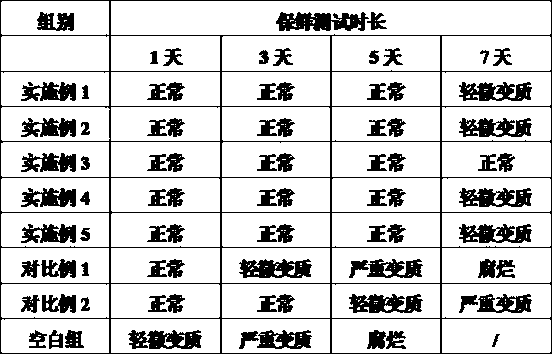

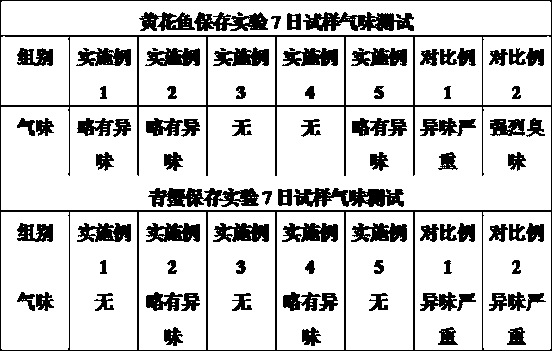

Partially frozen preservation agent for fresh and live aquatic product and preparation method thereof

InactiveCN110353028AGuaranteed freshnessEffective recyclingMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsChitin formationAquatic product

The invention relates to the technical field of food preservation, in particular to a partially frozen preservation agent for a fresh and live aquatic product. The partially frozen preservation agentcomprises sodium diacetate, an antibacterial component, a deethopeptide chitin extract, salt, an acidity regulator and deionized water, wherein the deethopeptide chitin extract can be prepared from aquatic shells. According to the partially frozen preservation agent for the fresh and live aquatic product, through mutual coordination and cooperation of various components in the raw materials in use, the efficient preservation effect is achieved; the specific preparation technology of the preservation agent is relatively simple, the cost for production and manufacturing is reduced, the preservation agent contains no chemical additives which are seriously harmful to the human body, after a food material is soaked and preserved, the marine food product is soaked and cleaned with clear water, the partially frozen preservation agent on the food can be removed, the using process is simple and convenient, and large-scaled application and popularization are facilitated.

Owner:福建冠丰生物科技有限公司

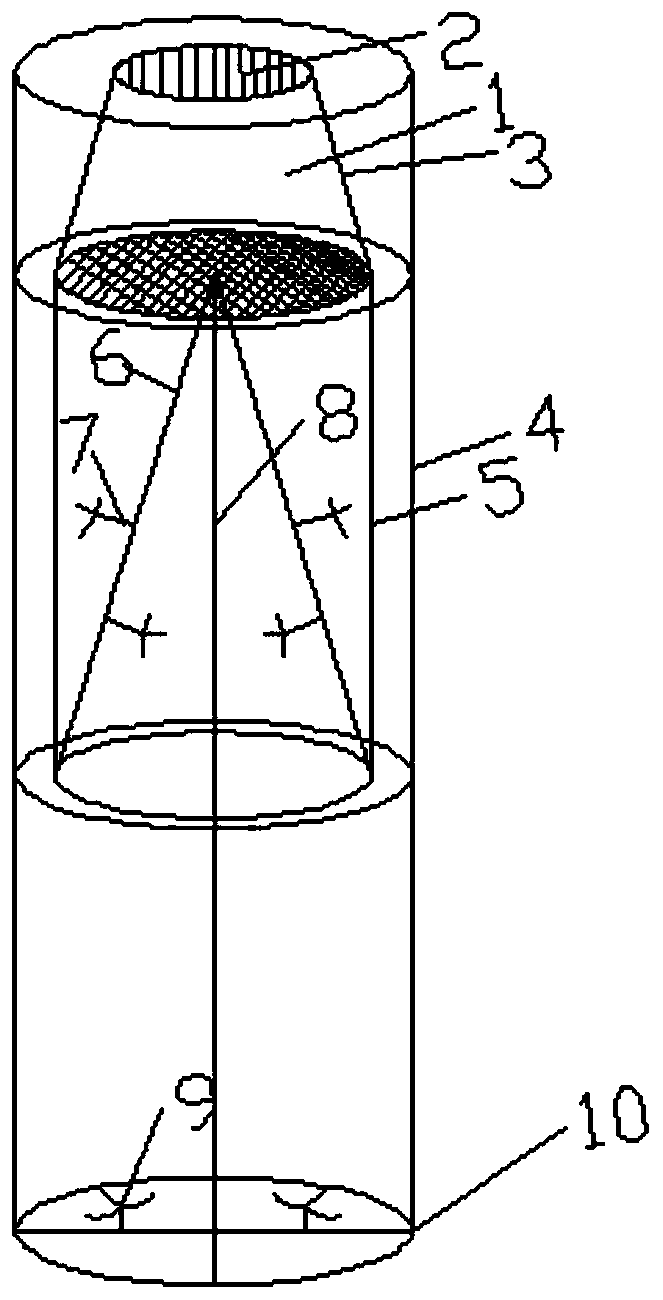

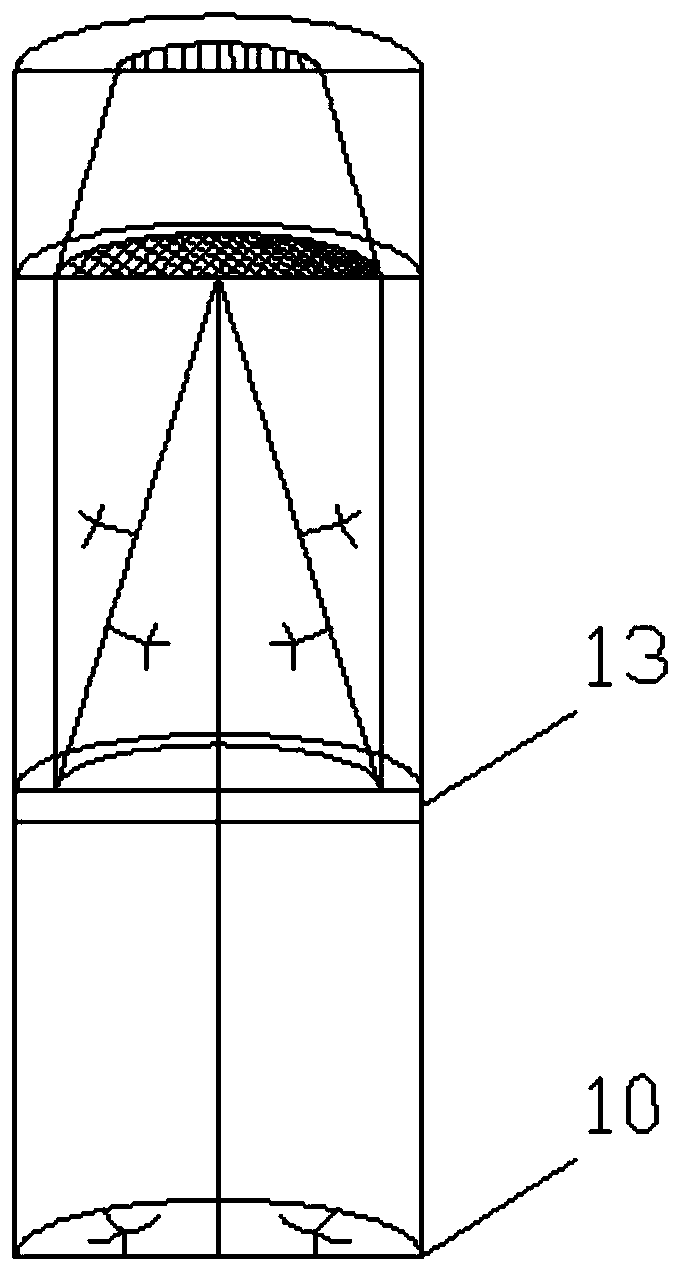

Energy-saving air interchanger

InactiveCN1828161AEffective recyclingFresh indoor airEnergy recovery in ventilation and heatingLighting and heating apparatusElectric machineryImpeller

The invention relates to an energy-saving air exchanger, which comprises a frame, a motor, and a fan. Wherein, the frame is mounted a wing exchanger, and a couple of dual-axle single motor which are connected to the fan blade wheels in positive and passive rotations, and the fan blade wheels are at the inlet and outlet wind channels; said motor and the fan blade wheels form the small through-flow fan; the case has a inlet outlet wind gate relative to the inlet and outlet wind channel; the wing heat exchanger is the high-effective aluminum alloy heat conducting wing heat exchanger, which is vertically or parallel distributed; when in vertical distribution, the air inlet and outlet is lower or higher than the outdoor air inlet and outlet; when in parallel distribution, the indoor air inlet and outlet is at the same plane with the outdoor inlet and outlet; and the outdoor air inlet and outlet has the inlet and outlet wind gate. The invention has simple structure, easy usage, and better heat exchanging effect, lower cost and wider application.

Owner:钟晓龙

Device for processing using leaves

PendingCN111389871AEffective recyclingSlow entry speedSolid waste disposalGrain treatmentsFood coloringProcess engineering

The invention belongs to the field of waste recycling, and particularly relates to a device for processing and using leaves. The device comprises an inlet channel, a sieving machine and a smashing machine, wherein the inlet channel, the sieving machine and the smashing machine are sequentially arranged from top to bottom. The leaves pass through the inlet channel to enter the device. A sieving machine main body part is a double-layer cylinder capable of performing centrifugal motion and used for sieving impurities. The inner cylinder is internally provided with a chain which moves vertically,and the leaves are driven to move upwards in the sieving machine. The smashing machine is used for smashing sieved leaves after water injection, and then mixed liquid is formed. The lower portion of the smashing machine is provided with a filtering mechanism. The mixed liquid after smashing passes through a filtering mechanism to generate liquid. According to the device, through sieving and smashing, as well as water injection in the process, after filtering, the liquid is obtained, processed liquid can serve as raw materials of industrial dye and edible pigment, remaining liquid is processedand then used as raw materials of outer packages of food, napkin paper or industrial paper boxes after being processed, and the effective recycling and utilization of the leaves are realized.

Owner:YANGZHOU UNIV

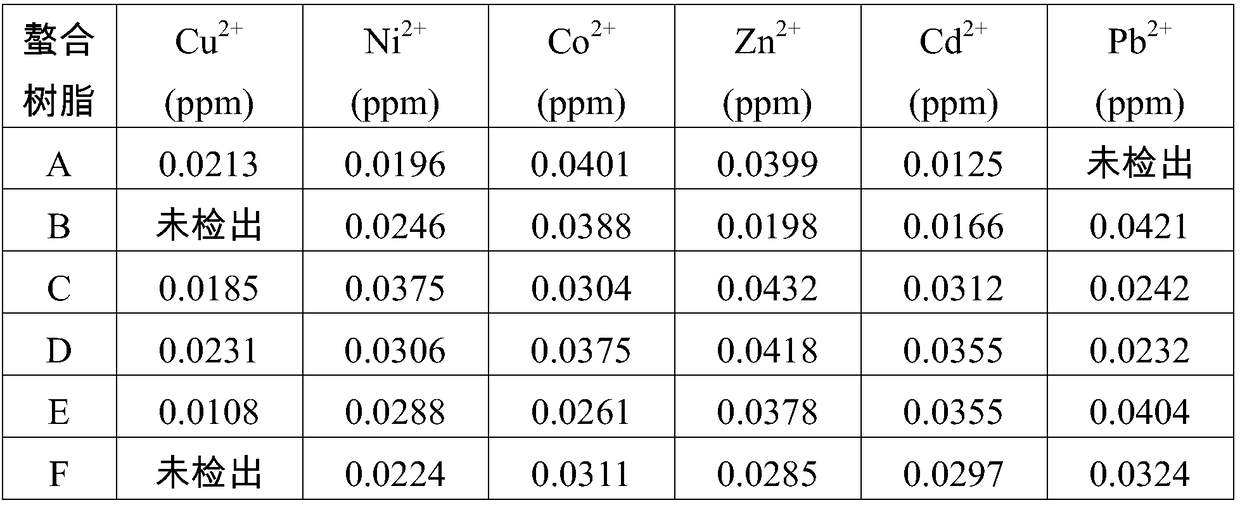

Method for preparing metal chelating agent from glass fiber waste by modification and application of metal chelating agent

InactiveCN108499517AEffective recyclingEfficient recyclingOther chemical processesWater contaminantsIonSolvent

The invention relates to a method for preparing metal chelating agent from glass fiber waste by modification. The method comprises the following steps: a) washing and filtering solid glass fiber wastepowder, adding filter cakes to an alkali solution for boiling, performing filtering and washing with water to neutrality, performing filtering, adding the filter cakes to an acid solution for boiling, performing filtering and washing with water to neutrality, and performing filtering and drying to obtain pre-treated bromo-glass fiber powder; b) adding the pretreated bromo-glass fiber powder to afirst solvent, adding an amination modifier, performing stirring and reflux condensing, performing washing with water and ethanol in sequence after reaction, and performing filtering and drying to obtain a modified aminated material; c) adding the modified aminated material to a second solvent, adding a chelating group modifier, adding an initiator, performing heating, stirring, reflux condensing,reacting, suction filtering and washing, and drying a product to constant weight to obtain a metal ion chelated material.

Owner:HUNAN NORMAL UNIVERSITY

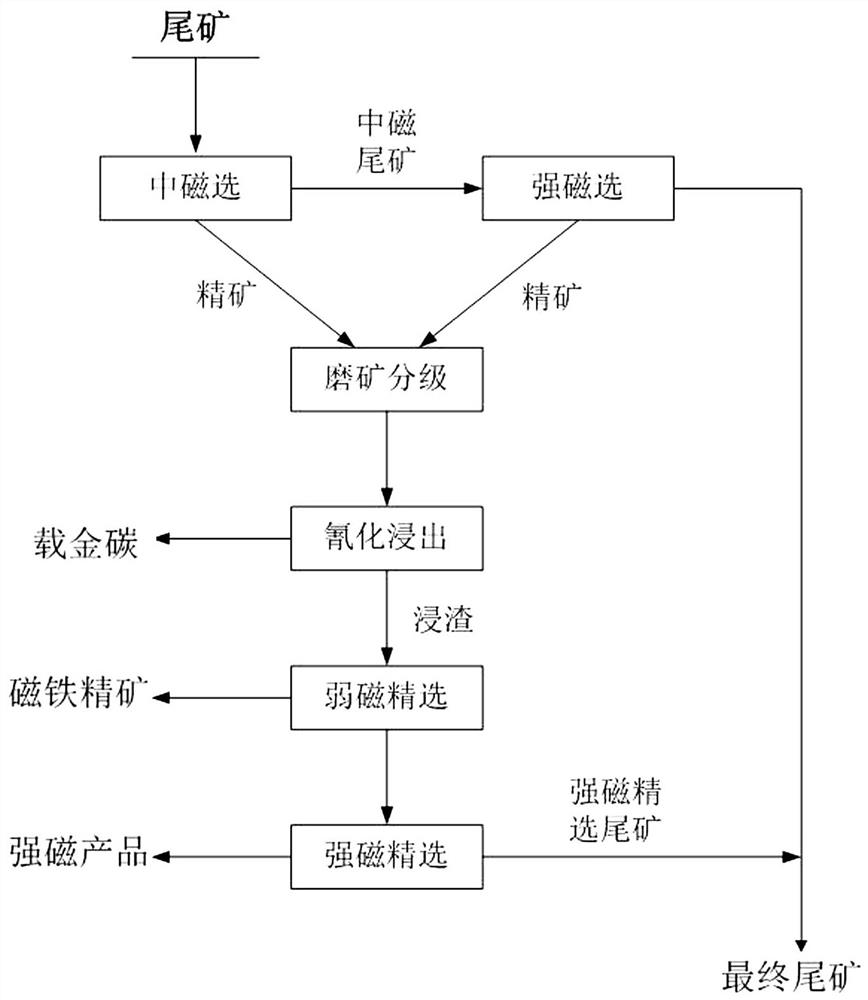

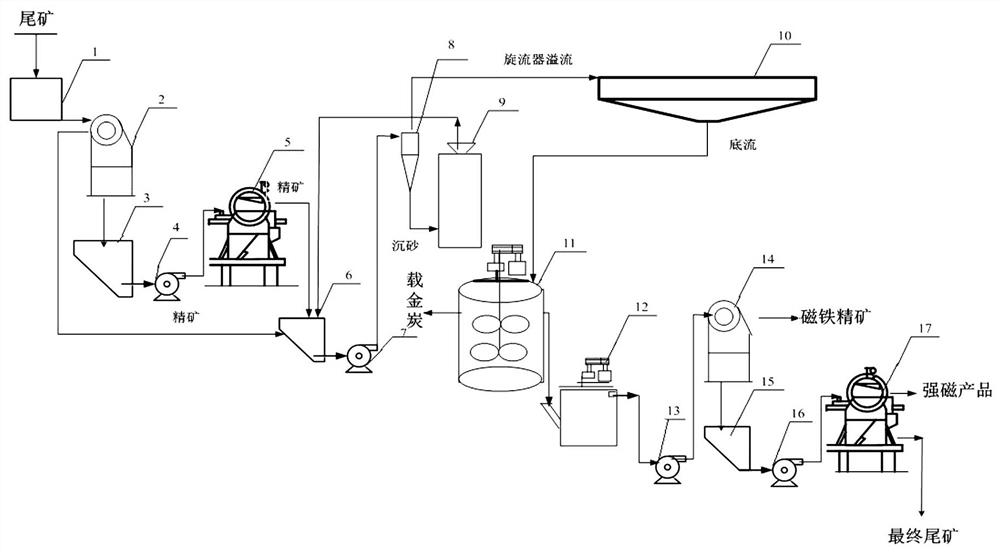

Method for recovering valuable elements in gold-silver-iron associated ore tailings

PendingCN112795786AEffective recyclingAvoid wasting resourcesProcess efficiency improvementOre concentrateSodium phosphates

The invention relates to a method for recovering valuable elements in gold-silver-iron associated ore tailings. The process technical route comprises the following steps that S1, ferromagnetic magnetite concentrate and gold-silver-loaded intergrowth with lower magnet content are recovered from the tailings by adopting medium magnetic separation; S2, the iron rough concentrate is finely ground until the content of-0.038 mm accounts for 90% or above; S3, a proper amount of lime milk is added for pulp mixing, the pulp concentration is controlled to be 30%-35%, the pulp pH value is 10-12, the cyanide concentration is 0.03%-0.07%, compressed air is input, the dissolved oxygen content in the pulp is controlled to be 15-20 mg / l, and the cyanidation leaching time is 28-30 hours; and S4, after a dispersing agent is added into the cyanidation leaching residues, strong magnetic iron minerals are recycled through low intensity magnetic separation, and magnetite concentrate is obtained. The low-intensity magnetic separation tailings are subjected to high-field-intensity and high-gradient high-intensity magnetic separation to recover low-intensity magnetic iron minerals, and high-intensity magnetic products are obtained; and the dispersing agent is prepared from water glass and sodium hexametaphosphate in a weight ratio of 1.6-3: 1. Aiming at the characteristics of tailings, the iron recovery rate is improved on the premise of ensuring the gold-silver recovery rate and the magnetite concentrate grade.

Owner:YUNNAN GOLD MINING GRP

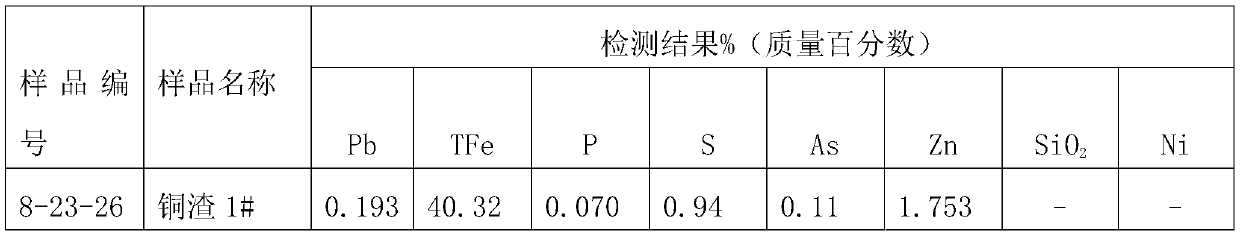

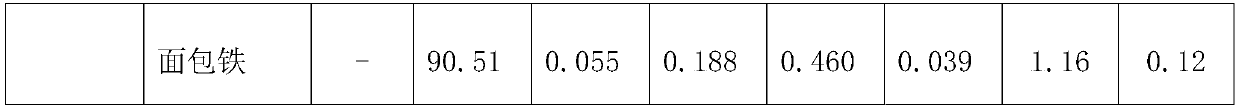

Method for refining iron based on copper smelting waste residues

The invention discloses a method for refining iron based on copper smelting waste residues. The method comprises the following steps of crushing, material mixing, smelting, slag discharging and preparation of bread iron. In the process of crushing, the copper smelting waste residues are crushed, and waste residue particles are obtained. In the process of material mixing, a reducing agent, a flux,a catalyst and the waste residue particles are uniformly mixed, and then smelting particles are prepared. In the process of smelting, after the smelting particles are dried and fed into a molten poolof a refining furnace and are smelted, slag and molten iron are obtained. In the process of slag discharging, after the reducing agent and an impurity removing agent are added to the molten pool for the reaction, impurity-removing molten iron is obtained. In the process of preparing the bread iron, the impurity-removing molten iron is treated with a cast iron machine, and the bread iron is obtained. According to the method for refining the iron, the copper smelting waste residues are effectively reused, the iron ore in the copper smelting waste residues is effectively recovered, the utilization rate of the resources is increased, and the purposes of energy conservation and environmental protection are achieved.

Owner:尚明东

Glycerol black residue recycling process

InactiveCN109574801AEffective recyclingAchieve recyclingEther separation/purificationOrganic compound preparationAcetic acidAlcohol

The invention relates to a glycerol black residue recycling process. The glycerol black residue recycling process comprises the following steps: step S1, adding glycerol black residues in a reaction kettle, adding an alcohol solvent in the reaction kettle and dissolving the glycerol black residues; step S2, after fully dissolving the glycerol black residues with the alcohol solvent, pumping the glycerol black residues into ethyl acetate, fully stirring for 20-40 min, and filtering via a filter to obtain filter residues and filtrate; step S3, leaving the filtrate in step S2 standstill for 0.5-2h, then carrying out liquid separation, collecting an upper solution, and packing lower waste liquid in a barrel; and step S4, distilling the upper solution collected in step S3 under reduced pressure at the temperature of 45-50 DEG C, concentrating to obtain glycerol and polyglycerol, and recycling the alcohol solvent and the ethyl acetate. The glycerol black residue recycling process has the advantages that by the glycerol black residue recycling process, the glycerol and the polyglycerol can be recycled effectively, energy consumption is reduced, and the environment is protected.

Owner:NANTONG XINBANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com