Phosphogypsum cement retarder and preparation method

A technology of cement retarder and phosphogypsum, which is applied in the field of comprehensive utilization of renewable resources, can solve the problems of not paying attention to the recycling of available sulfur, increasing the discharge cost of chemical enterprises, and the low utilization rate of phosphogypsum, so as to achieve short storage time and improve utilization efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

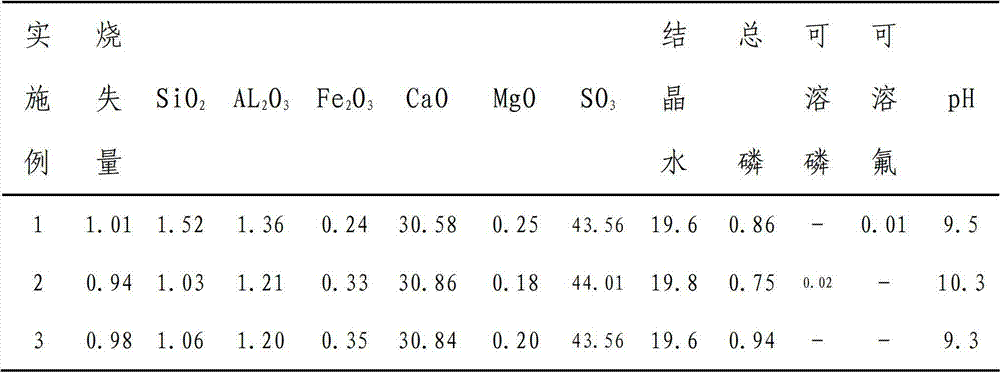

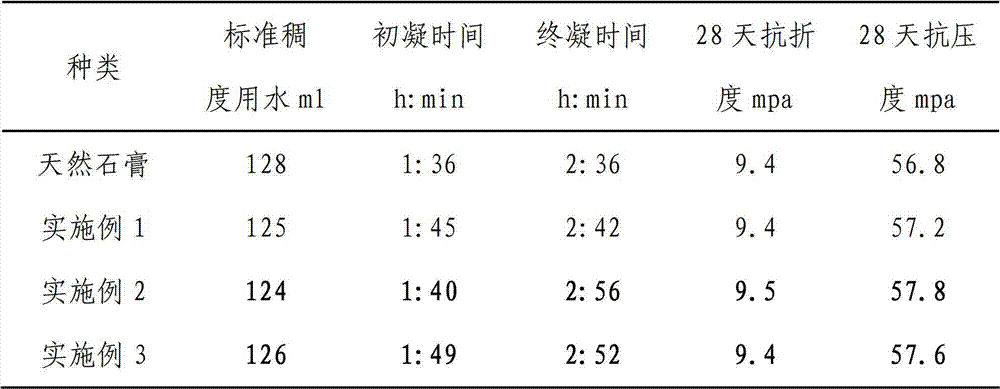

Examples

Embodiment 1

[0016] raw material source

[0017] Phosphogypsum slag (accounting for 95% of the total weight) - the production discharge port of Guangxi Luzhai Fertilizer Co., Ltd.

[0018] Alkaline calcareous (4% by weight) - limestone slurry from surrounding limestone plants.

[0019] Modifier (1% by weight) - Na 2 SO 4 tailings.

[0020] Industrial wastewater—wastewater from a phosphate rock ball mill workshop in a fertilizer factory.

[0021] Residual hot water - the hot water exchange of the fluidized furnace of the rotary dryer in this process.

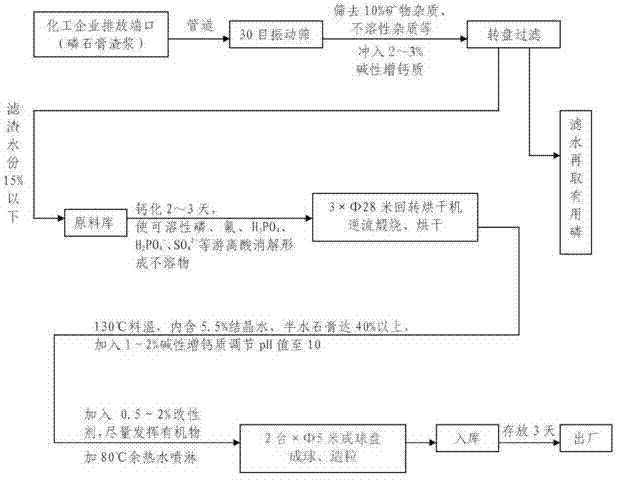

[0022] process flow

[0023] Open the feed valve, open the 30-mesh filter screen, directly connect the phosphogypsum slurry discharged from the phosphoric acid reaction of chemical enterprises to the 30-mesh vibrating screen, and at the same time wash the phosphogypsum slag with industrial wastewater to screen out about 10% of mineral impurities and insoluble impurities , and then add 3% alkaline calcareous substance quantitatively to a...

Embodiment 2

[0025] raw material source

[0026] Phosphogypsum slag (accounting for 95% of the total weight) - the production discharge port of Guangxi Luzhai Fertilizer Co., Ltd.

[0027] Alkaline calcareous substances (accounting for 3.5% of the total weight) - calcium carbide slag discharged from caustic soda production in Liuzhou Chemical Plant, Guangxi.

[0028] Modifier (1.5% by weight) - BaSO 4 tailings.

[0029] Industrial wastewater—wastewater from a phosphate rock ball mill workshop in a fertilizer factory.

[0030] Residual hot water - the hot water exchange of the fluidized furnace of the rotary dryer in this process.

[0031] process flow

[0032] Open the feed valve, open the 30-mesh filter screen, directly connect the phosphogypsum slurry discharged from the phosphoric acid reaction of chemical enterprises to the 30-mesh vibrating screen, and at the same time wash the phosphogypsum slag with industrial wastewater to screen out about 10% of mineral impurities and insolubl...

Embodiment 3

[0034] raw material source

[0035] Phosphogypsum slag (accounting for 93% of the total weight) - the production discharge port of Guangxi Luzhai Fertilizer Co., Ltd.

[0036] Alkaline calcium-enhancing substance (accounting for 5% of the total weight) - Guangxi Fengtang Paper Industry calcium-enhancing alkali slag.

[0037] Modifier (2% by weight) - Na 2 SO 4 tailings.

[0038] Industrial wastewater—wastewater from a phosphate rock ball mill workshop in a fertilizer factory.

[0039] Residual hot water - the hot water exchange of the fluidized furnace of the rotary dryer in this process.

[0040] process flow

[0041] Open the feed valve, open the 30-mesh filter screen, directly connect the phosphogypsum slurry discharged from the phosphoric acid reaction of chemical enterprises to the 30-mesh vibrating screen, and at the same time wash the phosphogypsum slag with industrial wastewater to screen out about 10% of mineral impurities and insoluble impurities , and then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com