Patents

Literature

8863 results about "Treatment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

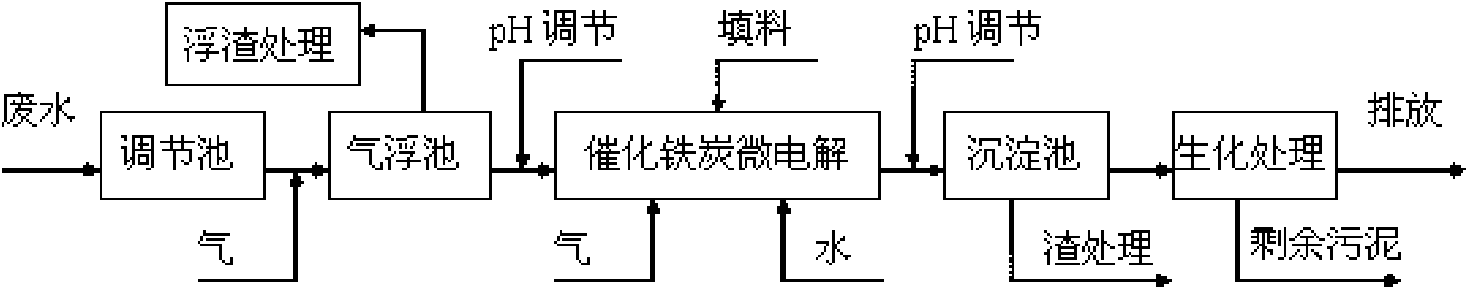

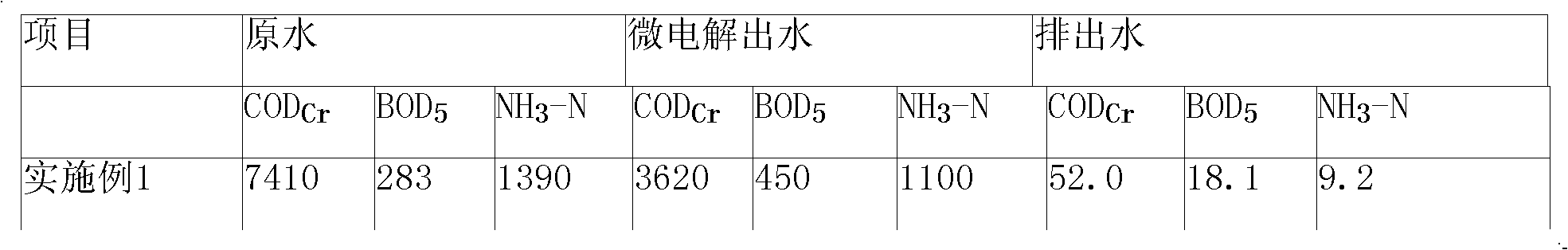

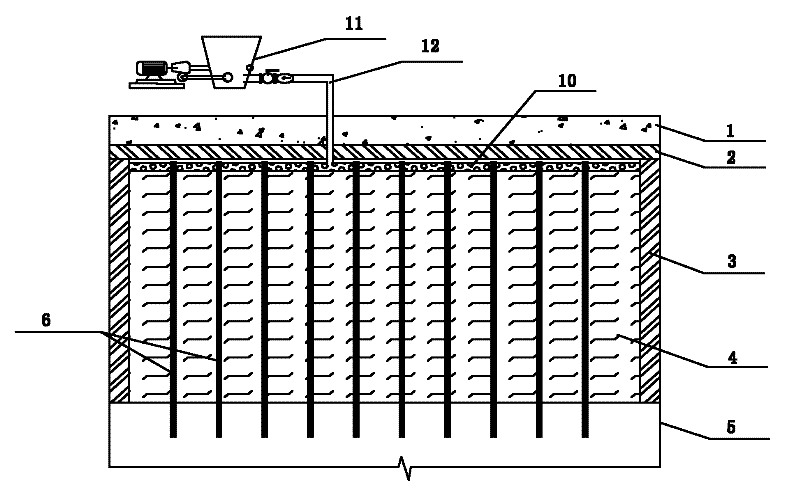

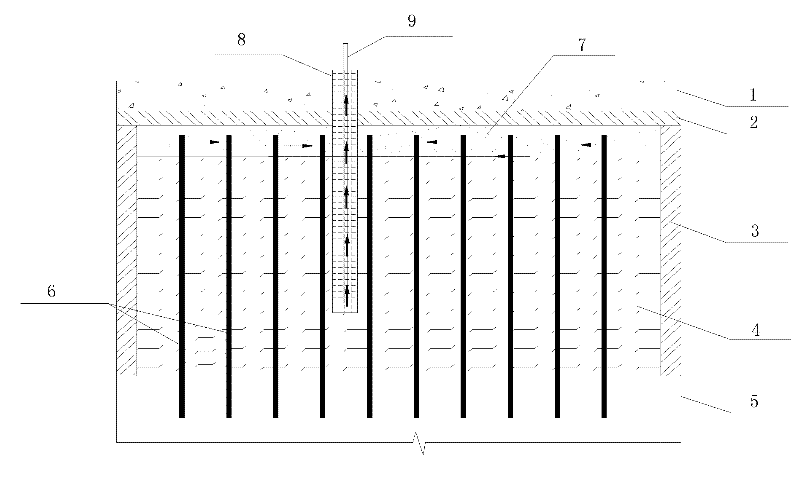

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

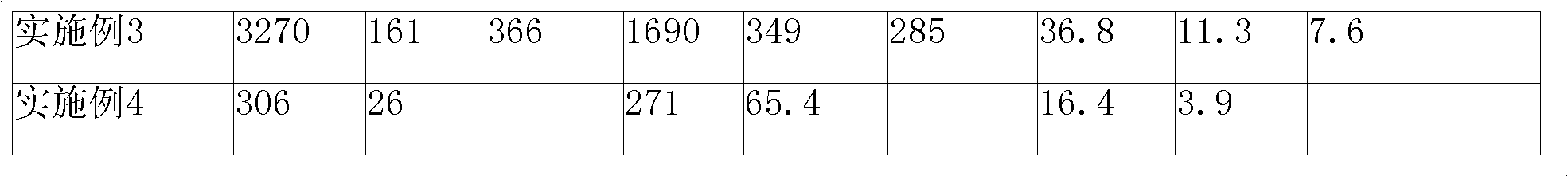

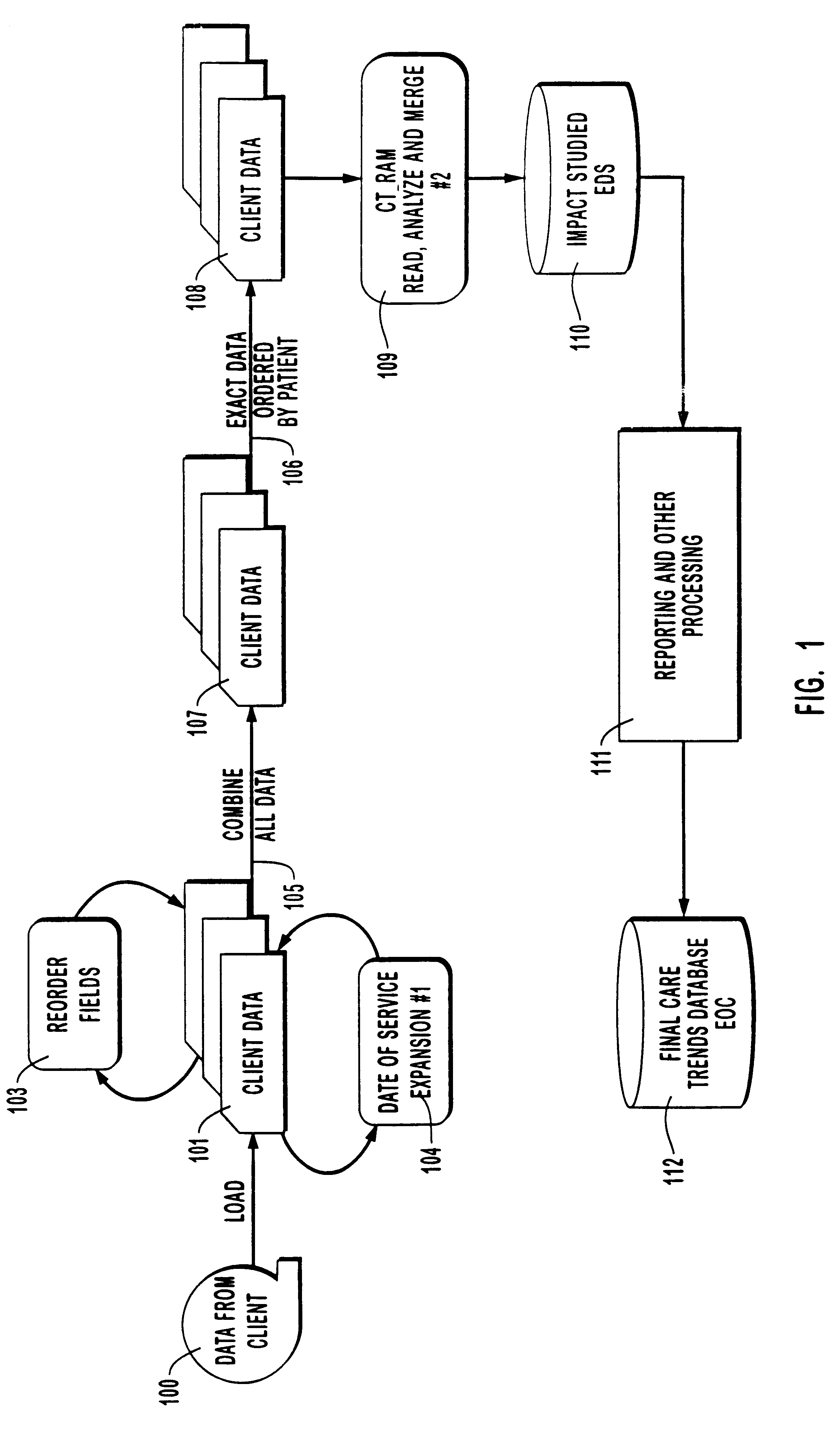

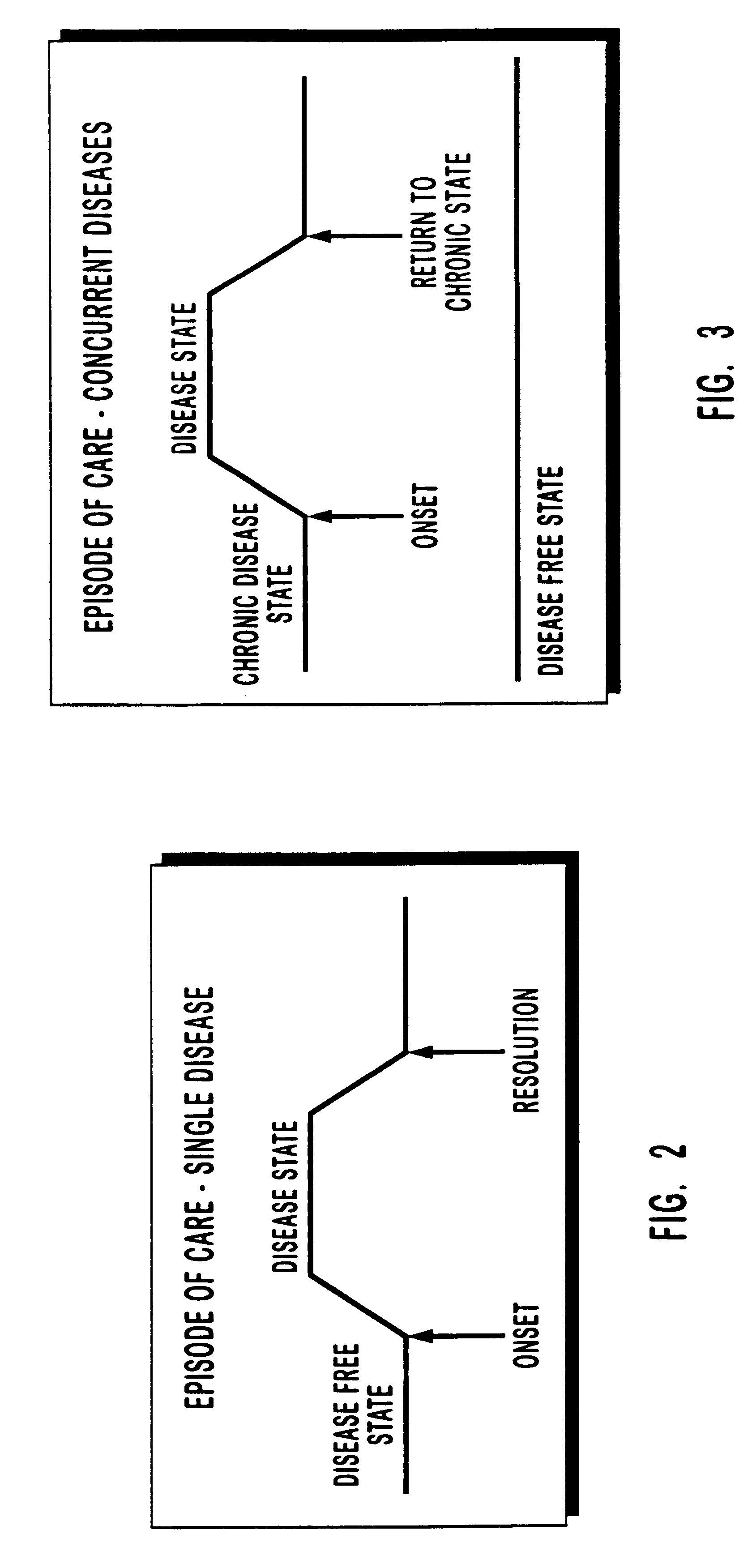

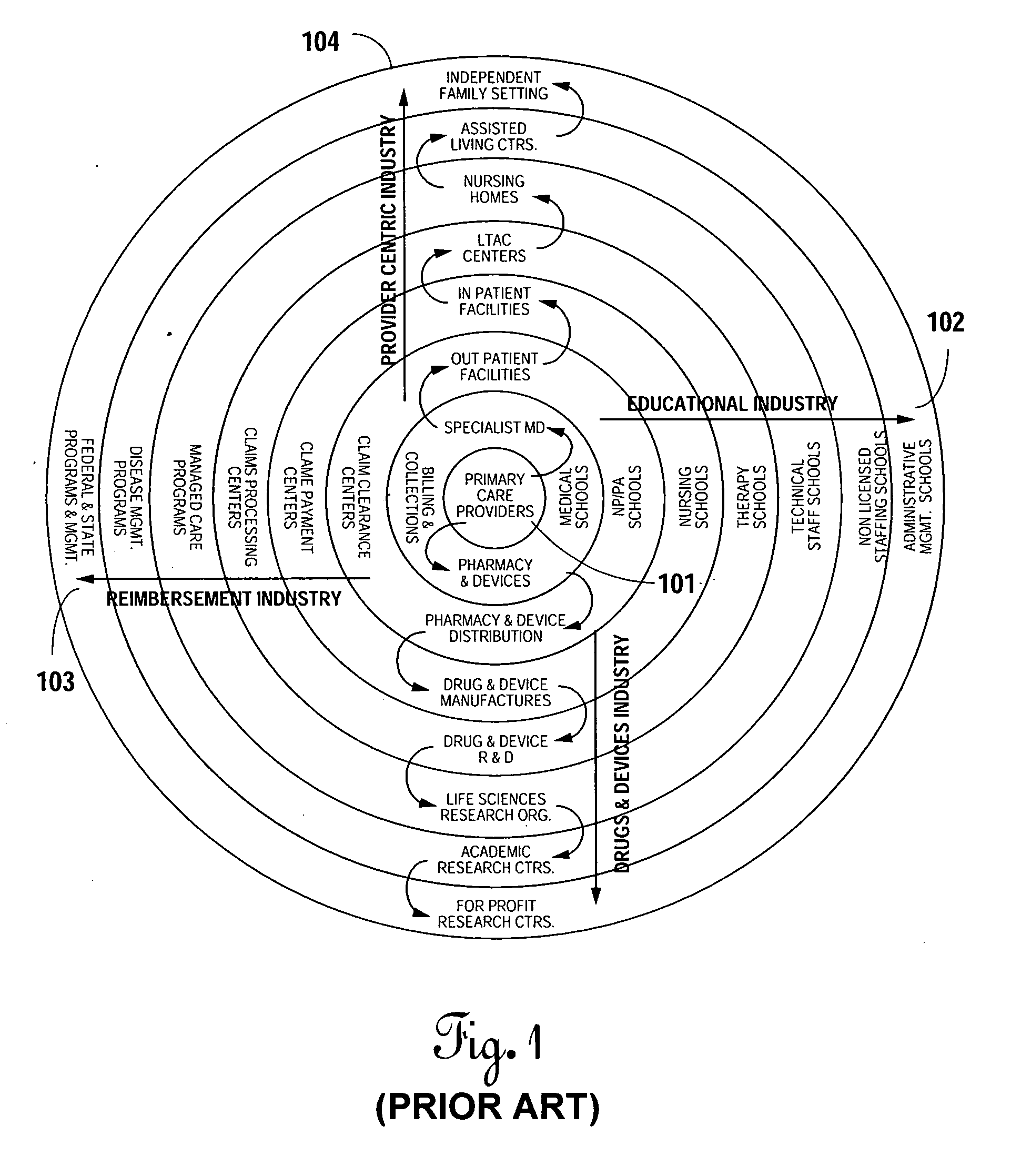

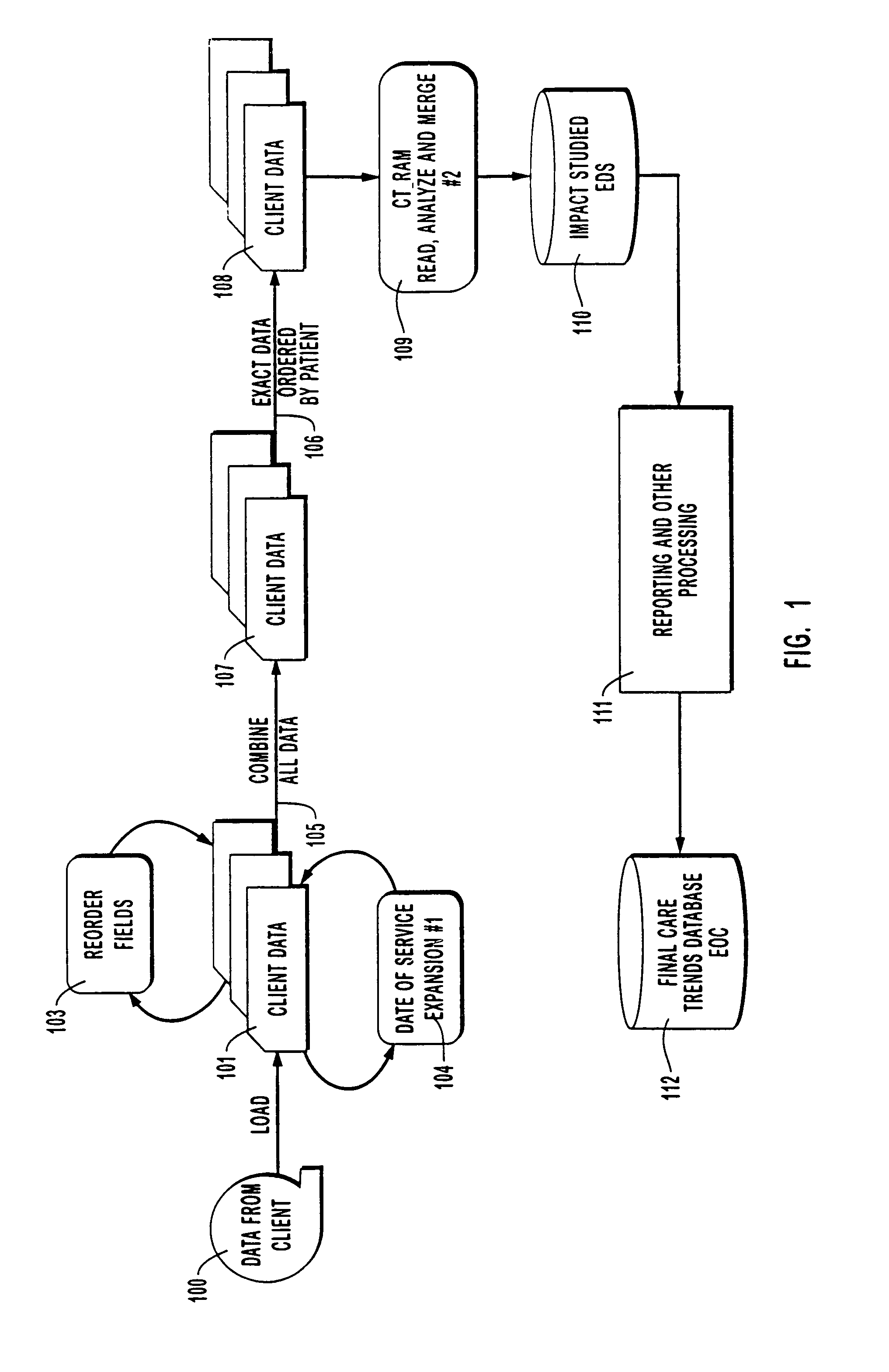

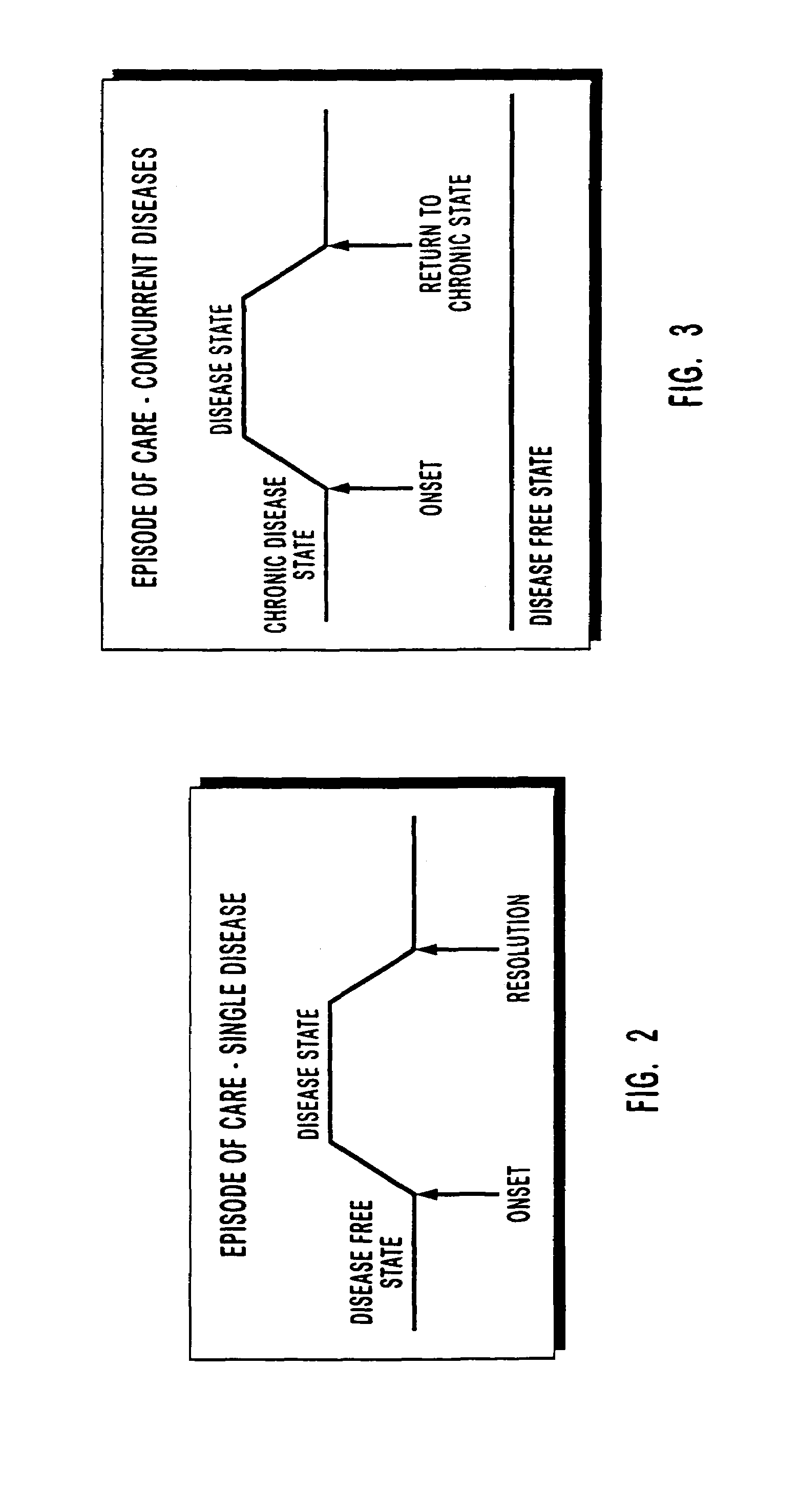

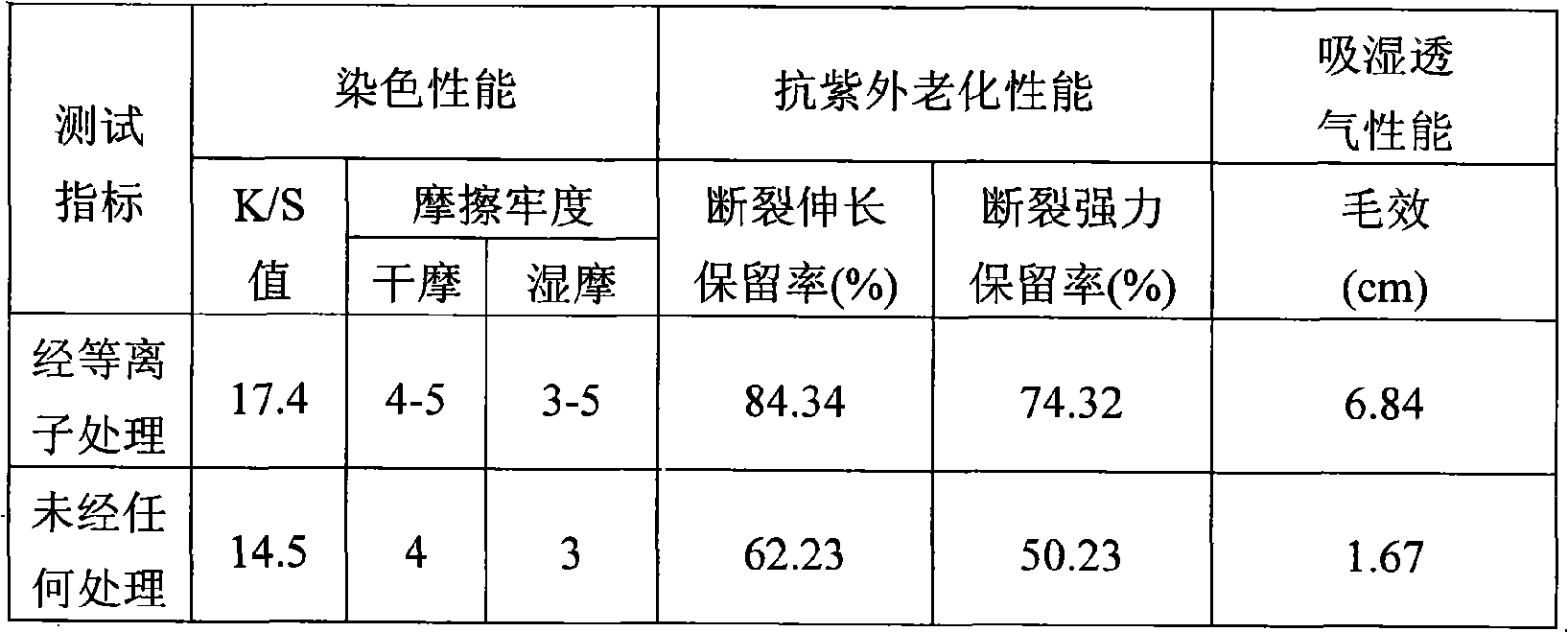

Method and system for generating statistically-based medical provider utilization profiles

InactiveUS6223164B1Accurately determineFinanceHealthcare resources and facilitiesCost effectivenessEffective treatment

Owner:OPTUMINSIGHT

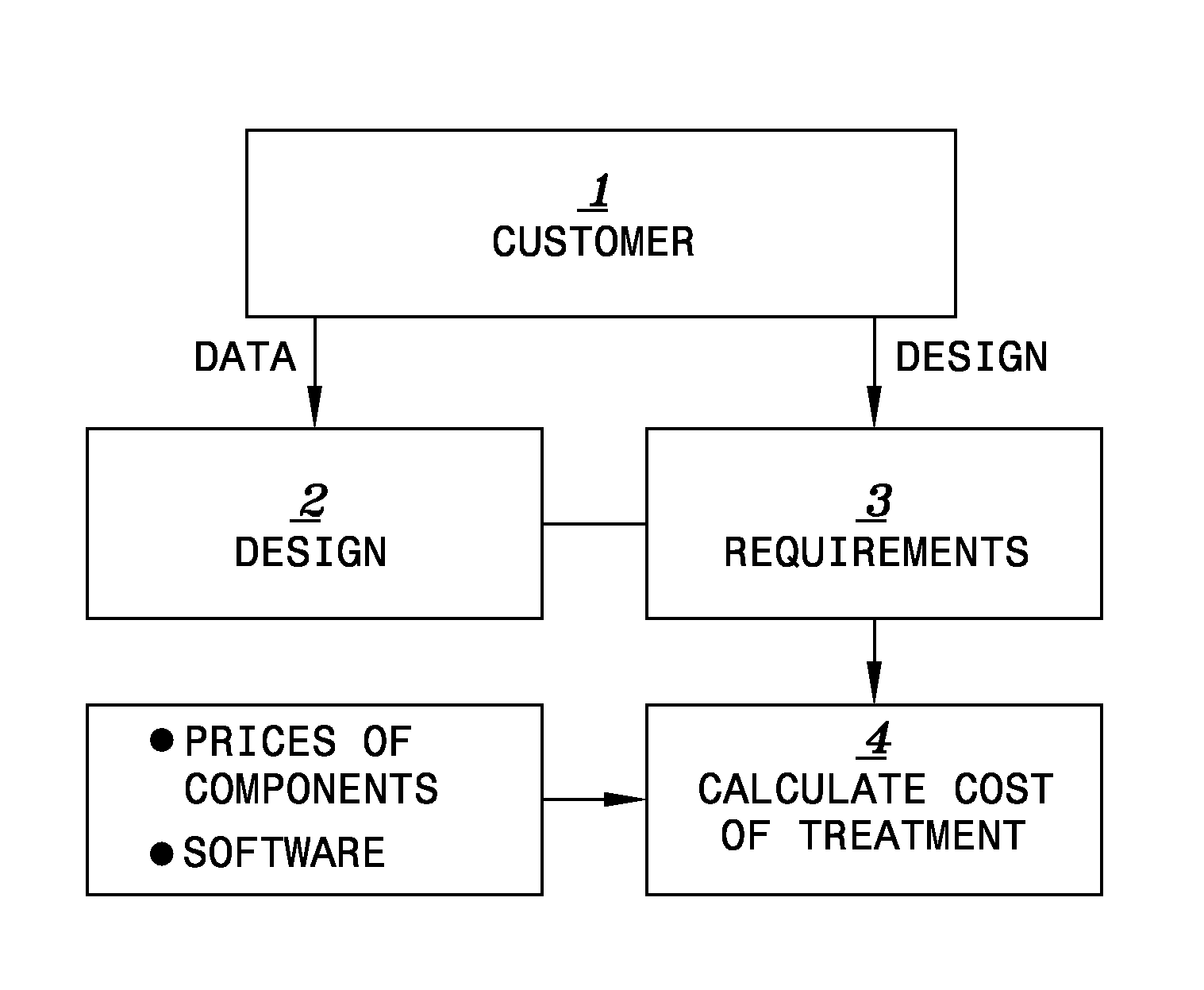

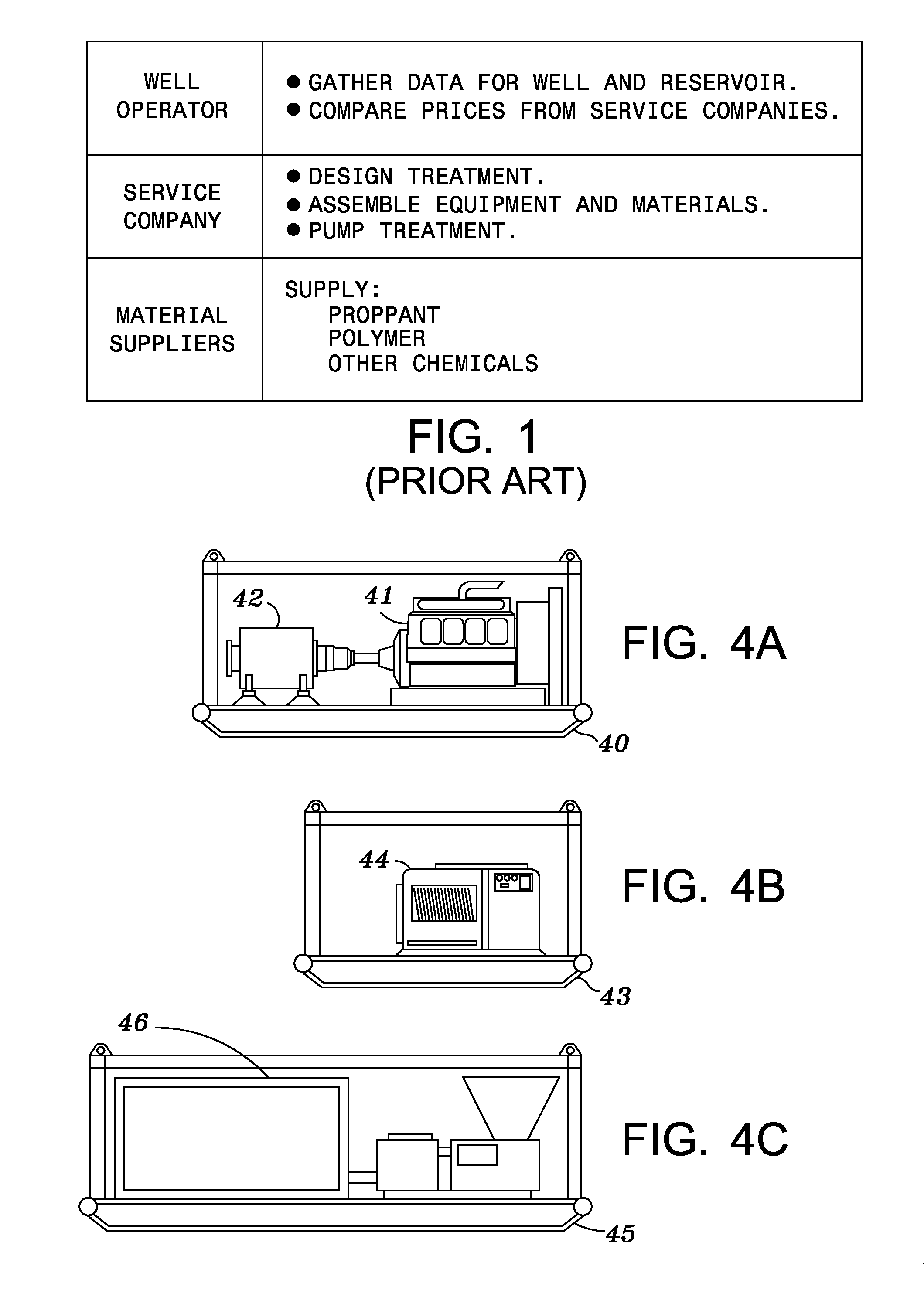

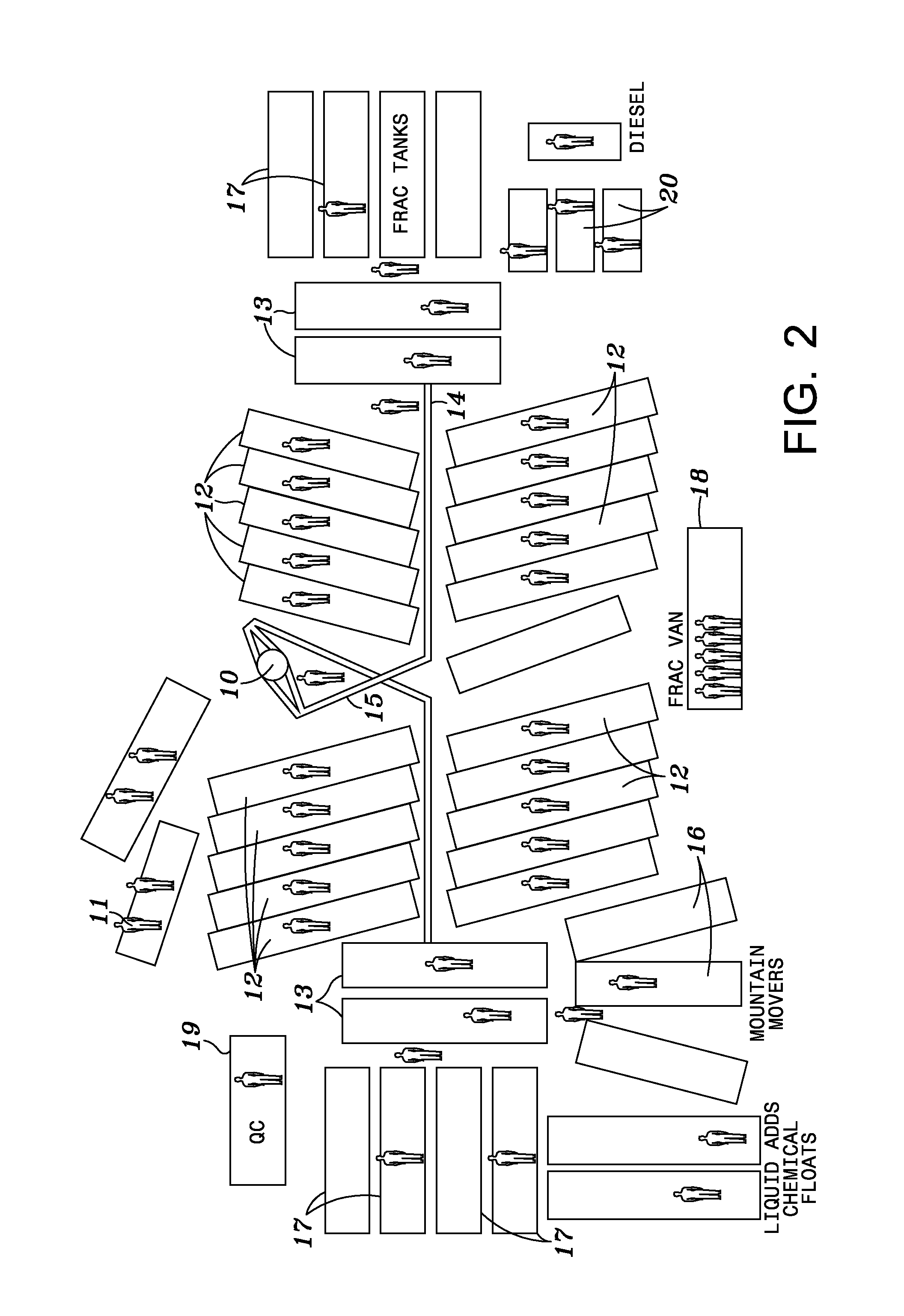

Method and Apparatus for Hydraulically Fracturing Wells

A mobile plant for supplying hydraulic fracturing service to a well is provided. The plant is particularly useful for wells that require multi-stage fracturing treatments, where the surface equipment may not be moved for longer times than when supplying conventional treatments. Skid-mounted equipment is used, so that the transport vehicle for the equipment can be released after delivery of the equipment to a well site. A method for marketing and executing fracturing treatments is also provided, wherein a customer is provided price data for each item included in the total cost of a fracturing treatment, along with software for calculating the total cost of a treatment to be purchased. The customer may calculate the cost of a treatment from computer-readable storage or over the internet. The customer may also monitor the fracturing treatment remotely and obtain a post-treatment report.

Owner:QIP HLDG

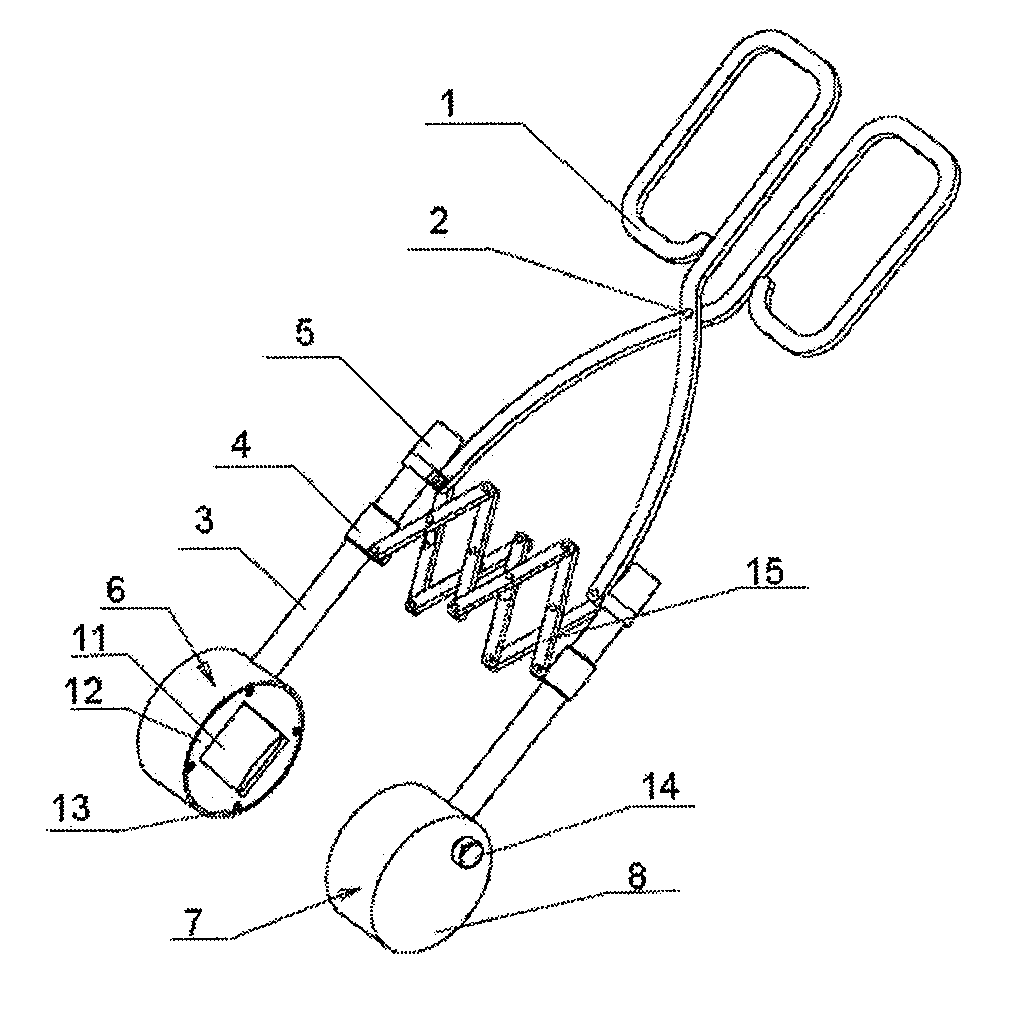

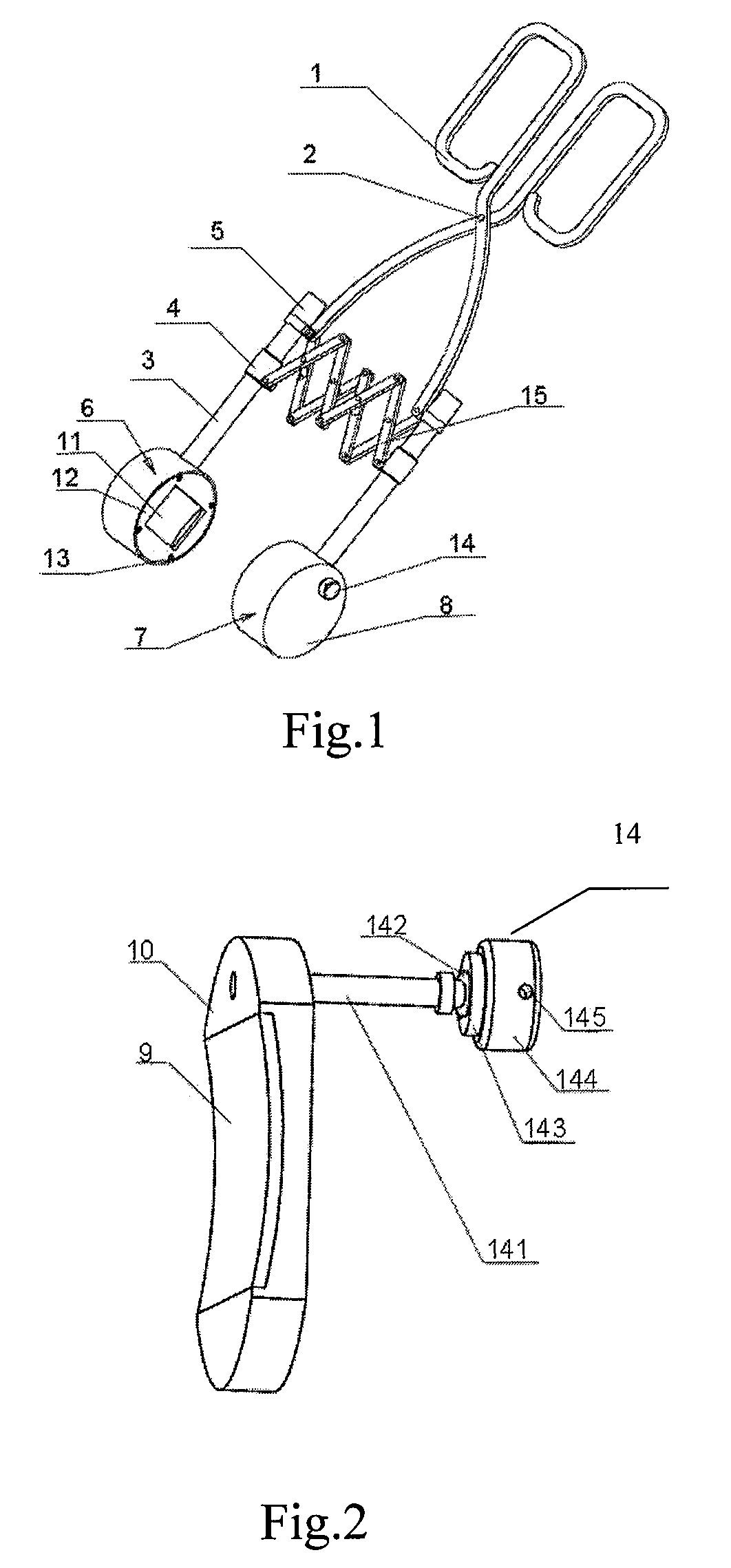

Ultrasound treatment clamp

ActiveUS8282581B2Easy to operateQuickly causingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyDiseaseMedicine

The present invention relates to an ultrasound treatment clamp. The ultrasound treatment clamp comprises ultrasound therapy applicators and handles connected to the ultrasound therapy applicators. The handles are clamp-shaped. The two ultrasound therapy applicators with their central axes overlapping each other are mounted face to face on the two clamps of the clamp-shaped handles respectively. A parallel moving mechanism for keeping the two ultrasound therapy applicators in parallel when moving along with clamps is connected between the two clamps. The present invention has a compact structure, a convenient operation, a low treatment cost, a capability of quickly causing a coagulative necrosis of the diseased part. Furthermore, the present invention has an abroad use in treating many kinds of diseases.

Owner:CHONGQING HAIFU (HIFU) TECHNOLOGY CO LTD

Human-body absorbable trauma dressing containing Yunnan white drug powder or Yunnan white drug powder extractive

InactiveCN101804218AIncrease usageImprove usabilityAbsorbent padsBandagesDressing changeCurative effect

The invention discloses a human-body absorbable trauma dressing containing Yunnan white drug powder or Yunnan white drug powder extractive, which is a novel medicine-carried dressing or a novel formulation of Yunnan white drug powder. The invention has the following remarkable characteristics: (1) the dressing can be absorbed by human bodies to lessen the pain added by dressing change and reduce the treatment cost; (2) the dressing can be made into a film solid dressing or an aquagel dressing so as to expand the use modes, the scope of applications and the drug effect of the Yunnan white drug powder; and (3) the curative effect of the dressing is enhanced by selecting a carrier material, auxiliary medicaments and functional accessories and adjusting the microstructure structure. The novel absorbable Yunnan white drug powder dressing overcomes the defects of the traditional Yunnan white drug powder in use and has economic and social values.

Owner:王艳

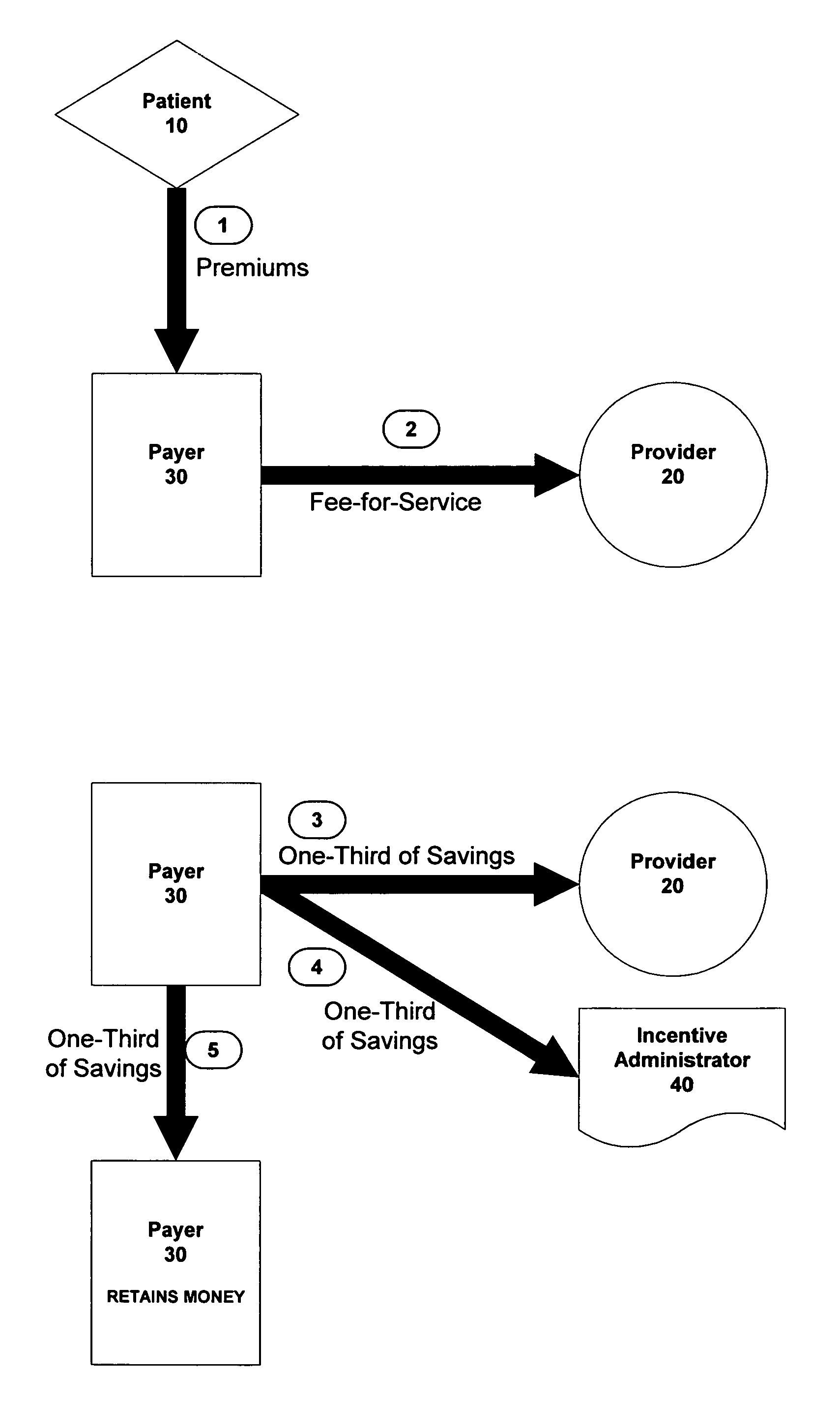

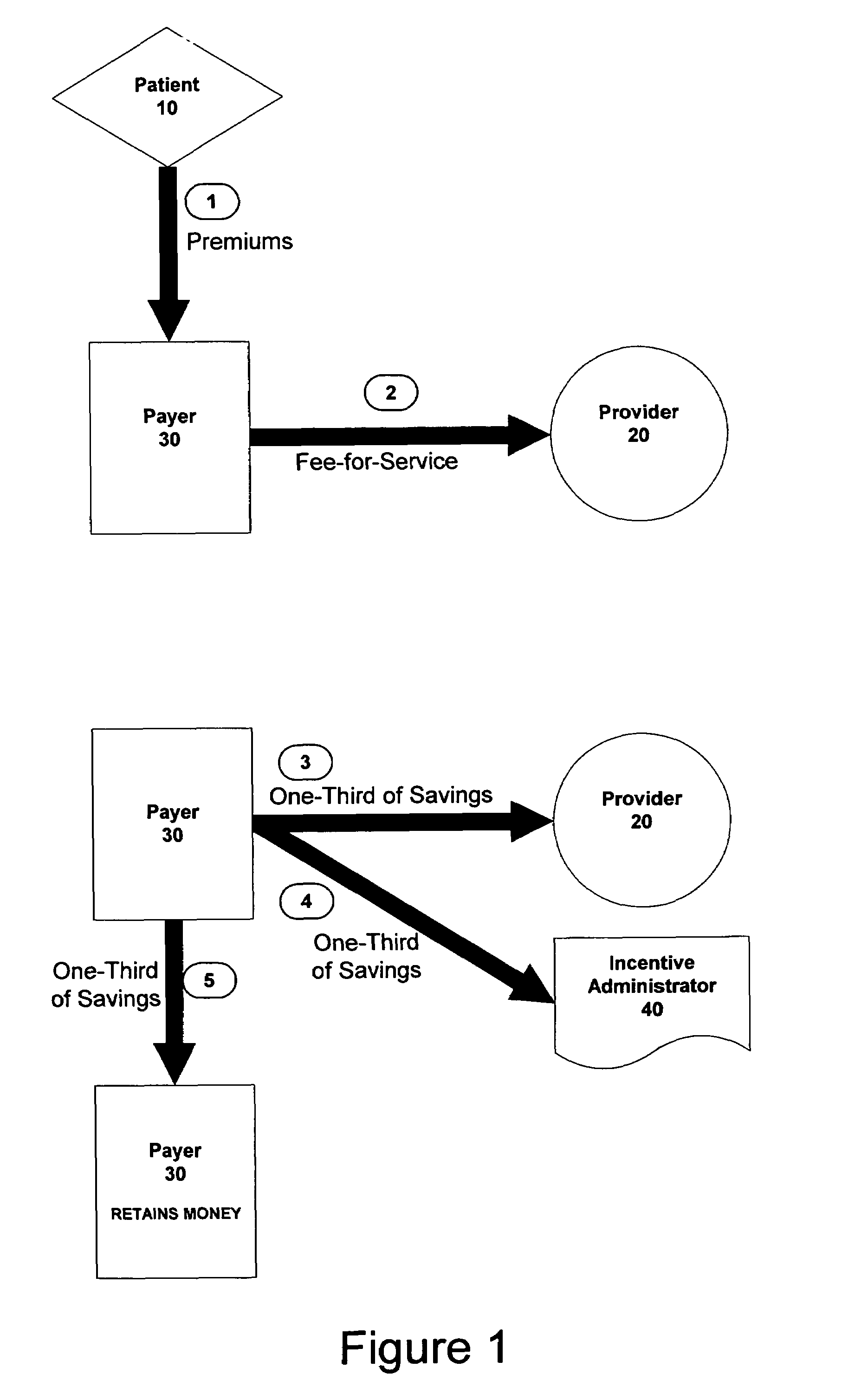

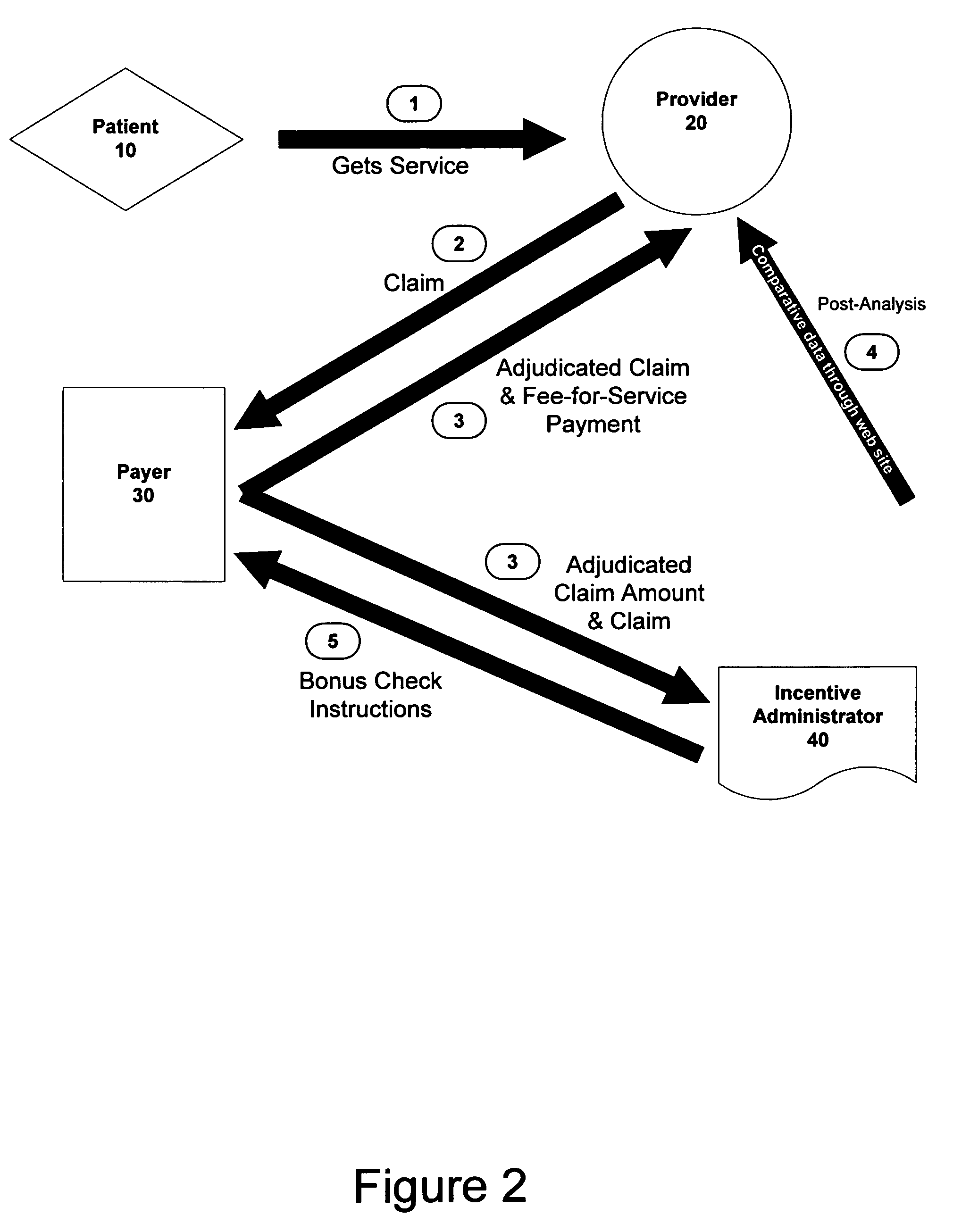

Method and apparatus for providing incentives to physicians

Owner:CLINTON B ASHFORD M D

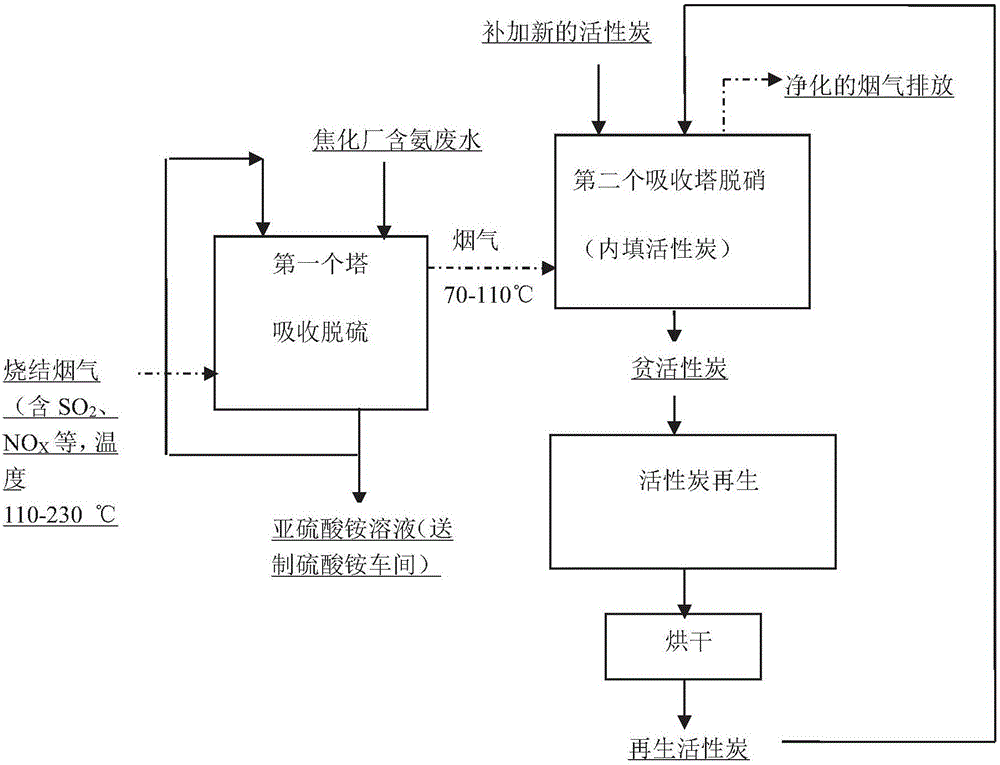

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

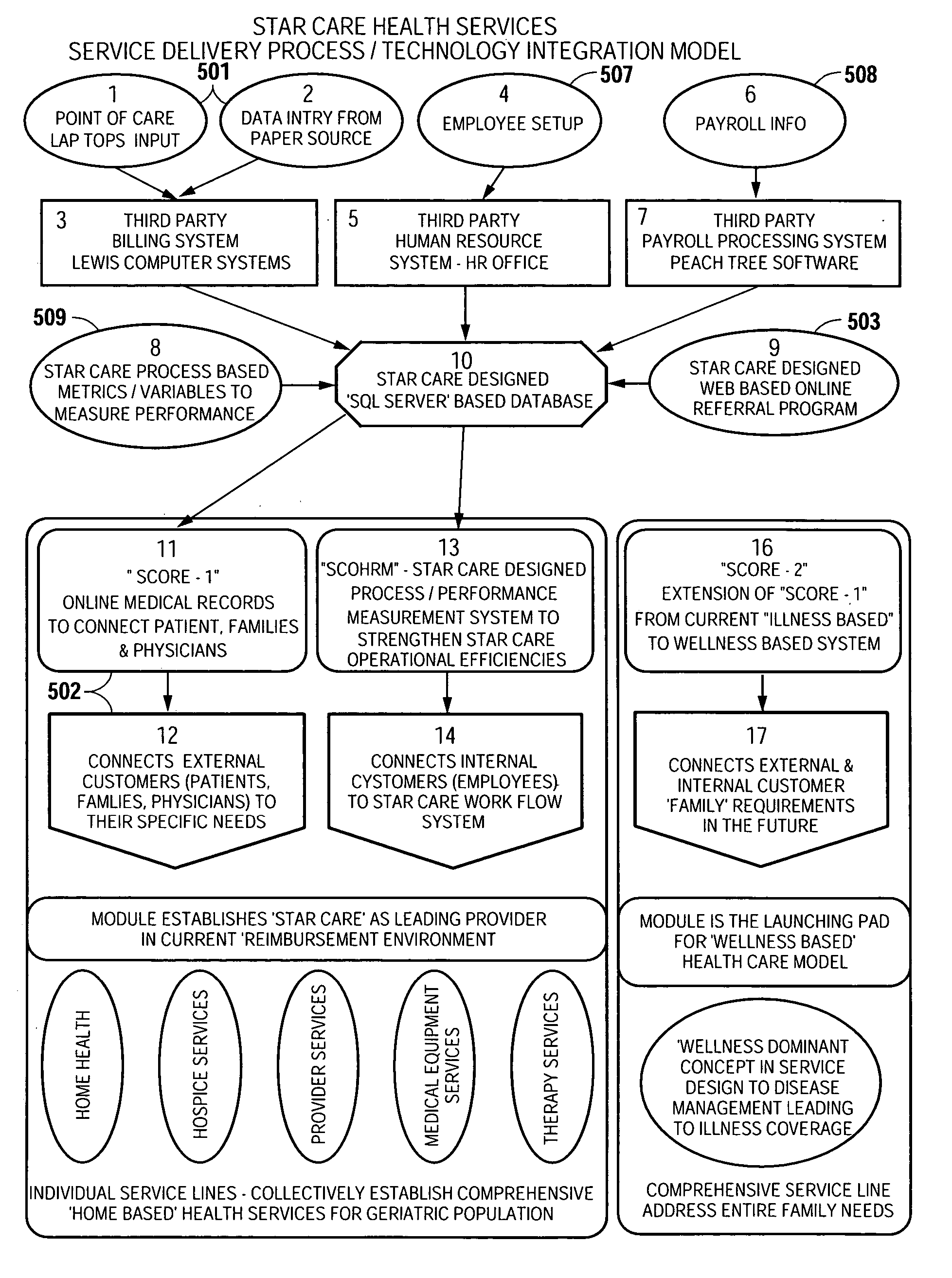

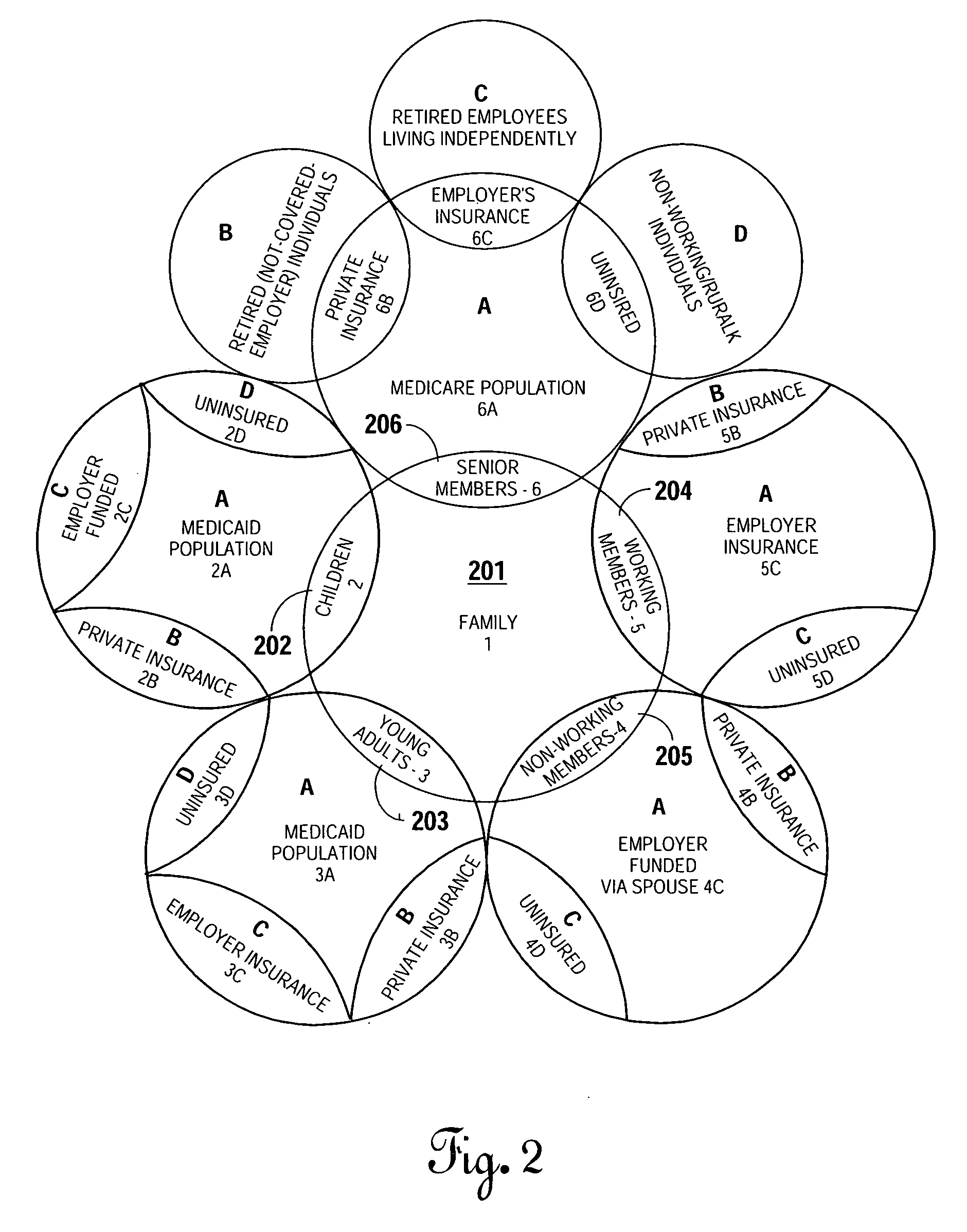

Method for online health management

InactiveUS20080091463A1Easy accessAvoid spendingRegistering/indicating time of eventsFinanceFamily healthHealth benefits

The invention disclosed herein is a method for online health management. The method is family centered with the family, the family's health care providers, and family's health insurance entities linked by computer for the sharing of information. The medical information stored in the online health management system database is available to authorized persons anytime, anywhere. Additionally, the online health management system evaluates the family health insurance and advises the family of the schedule of benefits available to them. In this way the family may use all of their benefits to promote good health rather than using the health benefits solely for the purpose of paying for treatment of medical problems when such exist. The online health management system periodically measures and tracks certain vital signs and then compares those vital signs to published standards of normality. The vital signs are averaged together and a health score is generated which advises the family and health care providers of risks to the patients health. The family can then institute treatment plans in conjunction with their health care providers to lessen the risks to their health. Improvement in the health score can be used as feedback to the family and health care provider that the treatment plan is effective.

Owner:SHAKAMURI RAVI

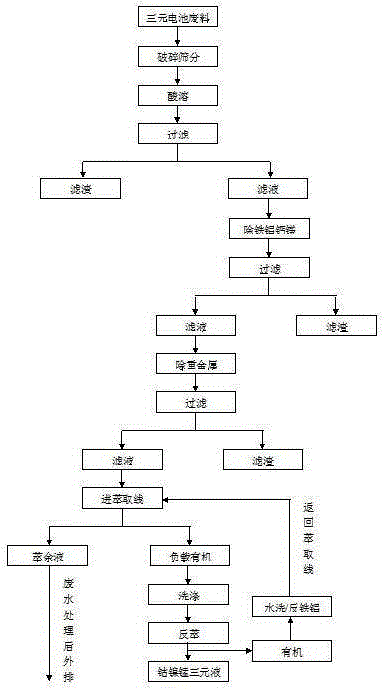

Treatment method for waste LiMn1-x-yNixCoyO2 ternary battery cathode material

ActiveCN105206889ASimple processImplement directional loopWaste accumulators reclaimingProcess efficiency improvementManganesePre treatment

The invention relates to a treatment method for a waste LiMn1-x-yNixCoyO2 ternary battery cathode material and belongs to the field of waste battery treatment. The method comprises the following steps: (1), pretreatment; (2), chemical dissolution; (3), chemical impurity removal; (4), extraction, deep impurity removal and enrichment of cobalt, nickel and manganese. By adopting the treatment method for the waste LiMn1-x-yNixCoyO2 ternary battery cathode material, the full utilization and directional circulation of nickel, cobalt and manganese in the waste LiMn1-x-yNixCoyO2 ternary battery cathode material can be realized, the comprehensive recovery rate of nickel, cobalt and manganese is high and the treatment cost is low.

Owner:浙江三晟化工有限公司

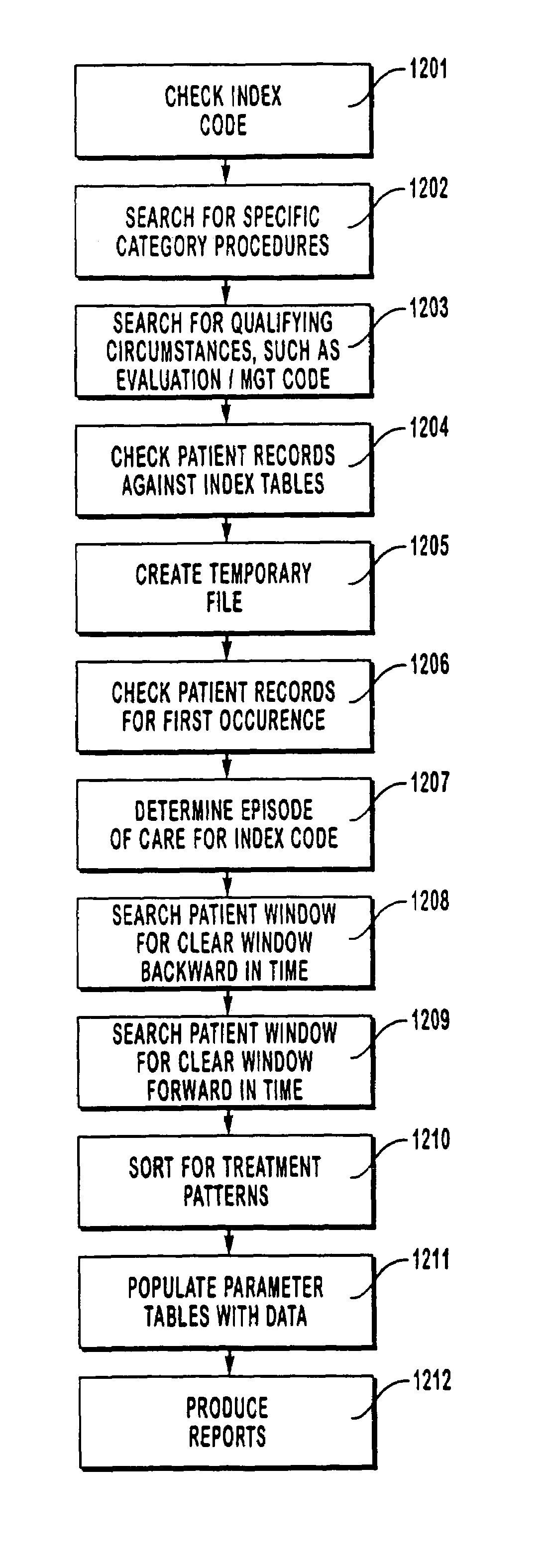

Method and system for generating statistically-based medical provider utilization profiles

InactiveUS7222079B1Accurately determineFinanceMedical automated diagnosisCost effectivenessEffective treatment

Owner:OPTUMINSIGHT

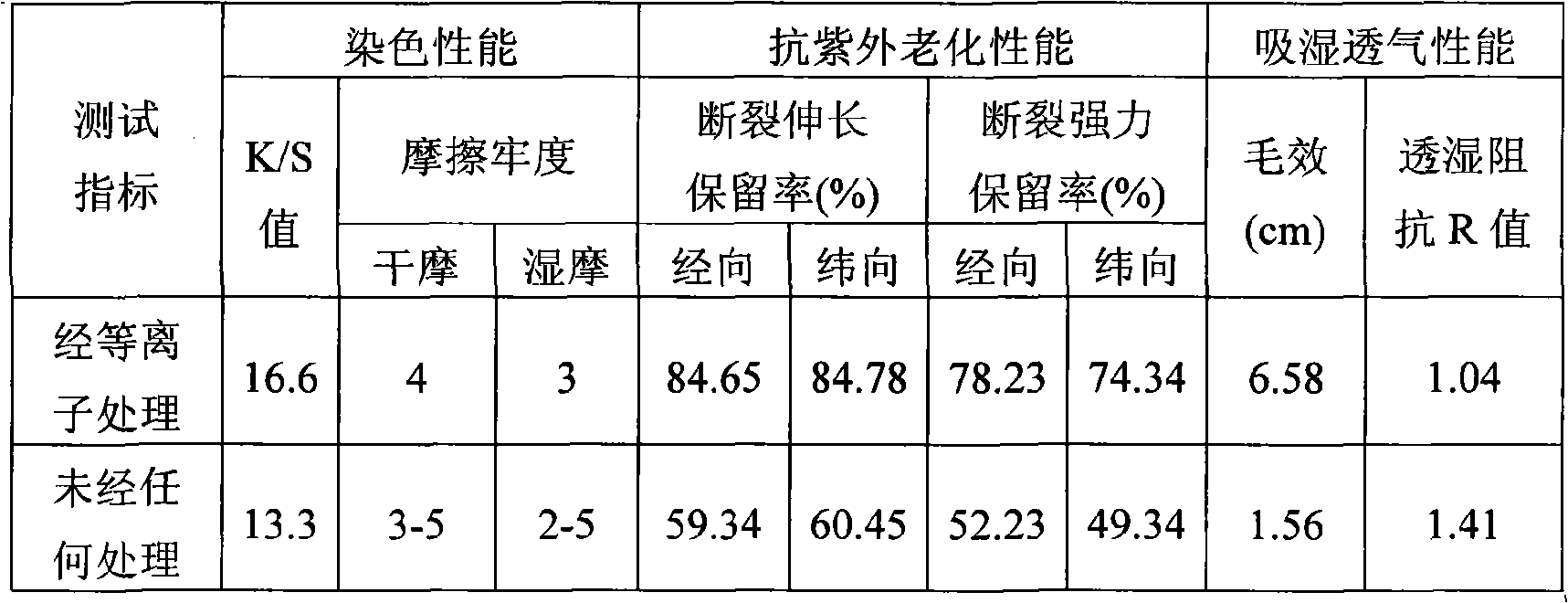

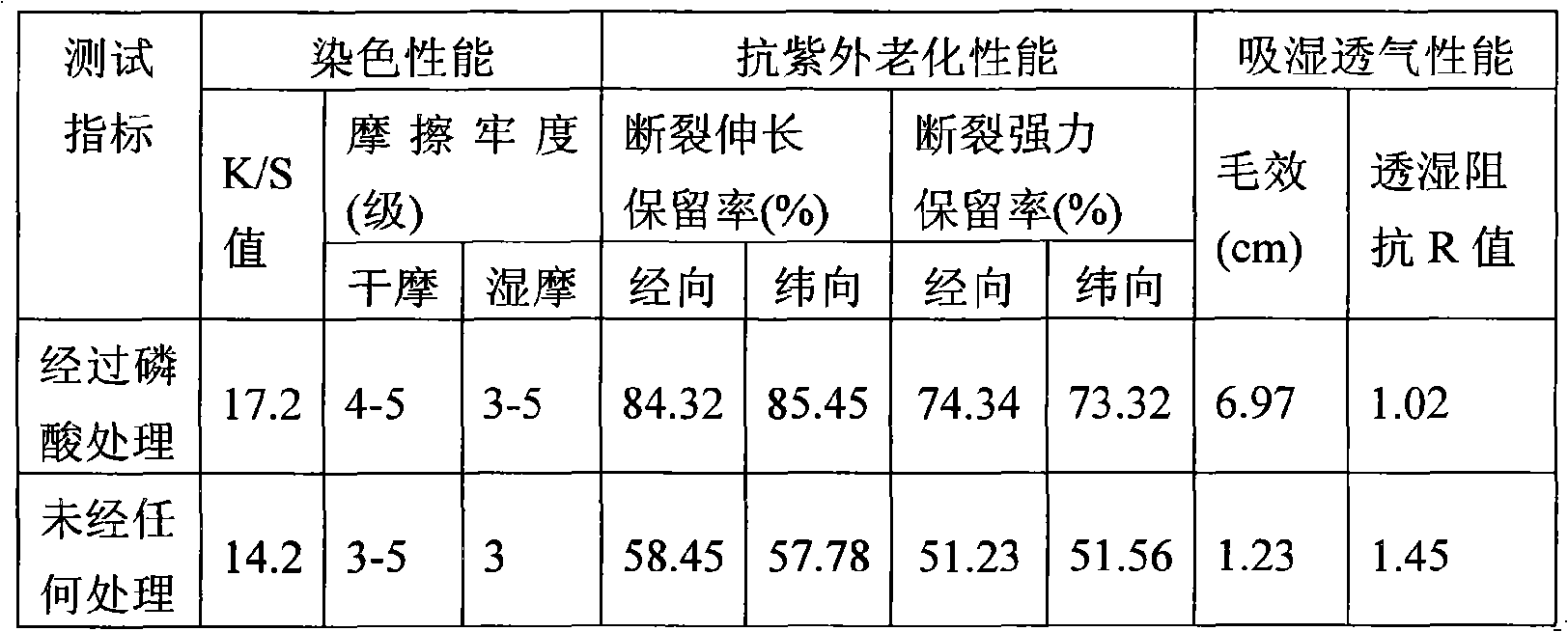

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

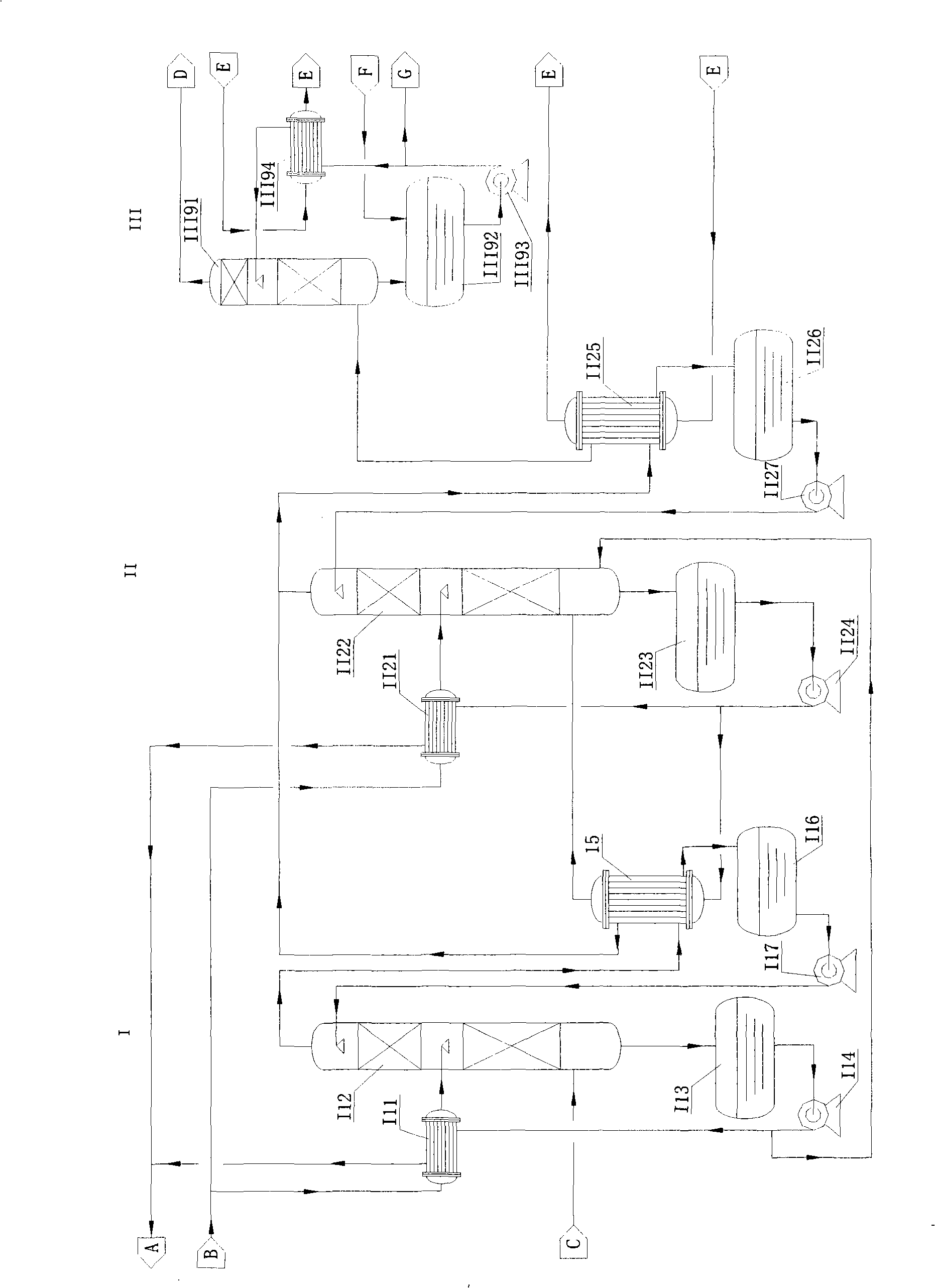

Ammonia nitrogen waste water discharge-reducing and ammonia nitrogen resource utilizing device and method

InactiveCN101264948AReduce consumptionWater/sewage treatment by degassingAfter treatmentResource utilization

The invention relates to a device for ammonia nitrogen wastewater discharge reduction and ammonia nitrogen resource utilization and a method thereof, and belongs to the field of wastewater discharge reduction. The conventional steam blow-off method has high unit energy consumption (250-300 Kg steam / ton wastewater) in ammonia nitrogen wastewater treatment, thus resulting in very high ammonia nitrogen wastewater treatment cost. The inventive device comprises at least two stages of ammonia nitrogen stripping step and ammonia nitrogen reutilization step. The ammonia nitrogen wastewater to be treated is respectively fed into each stage of ammonia nitrogen stripping step, and the removal of ammonia nitrogen in wastewater is realized in ammonia nitrogen stripping tower and the resource utilization is realized in the ammonia nitrogen reutilization step. Except for the first stage of the ammonia nitrogen stripping tower requiring steam introduction, the steam required on other stages of ammonia nitrogen stripping tower is obtained by vaporization of a part of the tower bottom liquid in each tower by using the heat released via condensation of a part of steam in the upper stage tower and flash evaporation of the tower bottom liquid in the upper stage tower, so as to remarkably reduce steam consumption. The inventive device and method have the advantages of high ammonia nitrogen content wastewater treatment, low ammonia nitrogen content in wastewater after treatment, low steam consumption, and low treatment cost.

Owner:BEIJING UNIV OF CHEM TECH

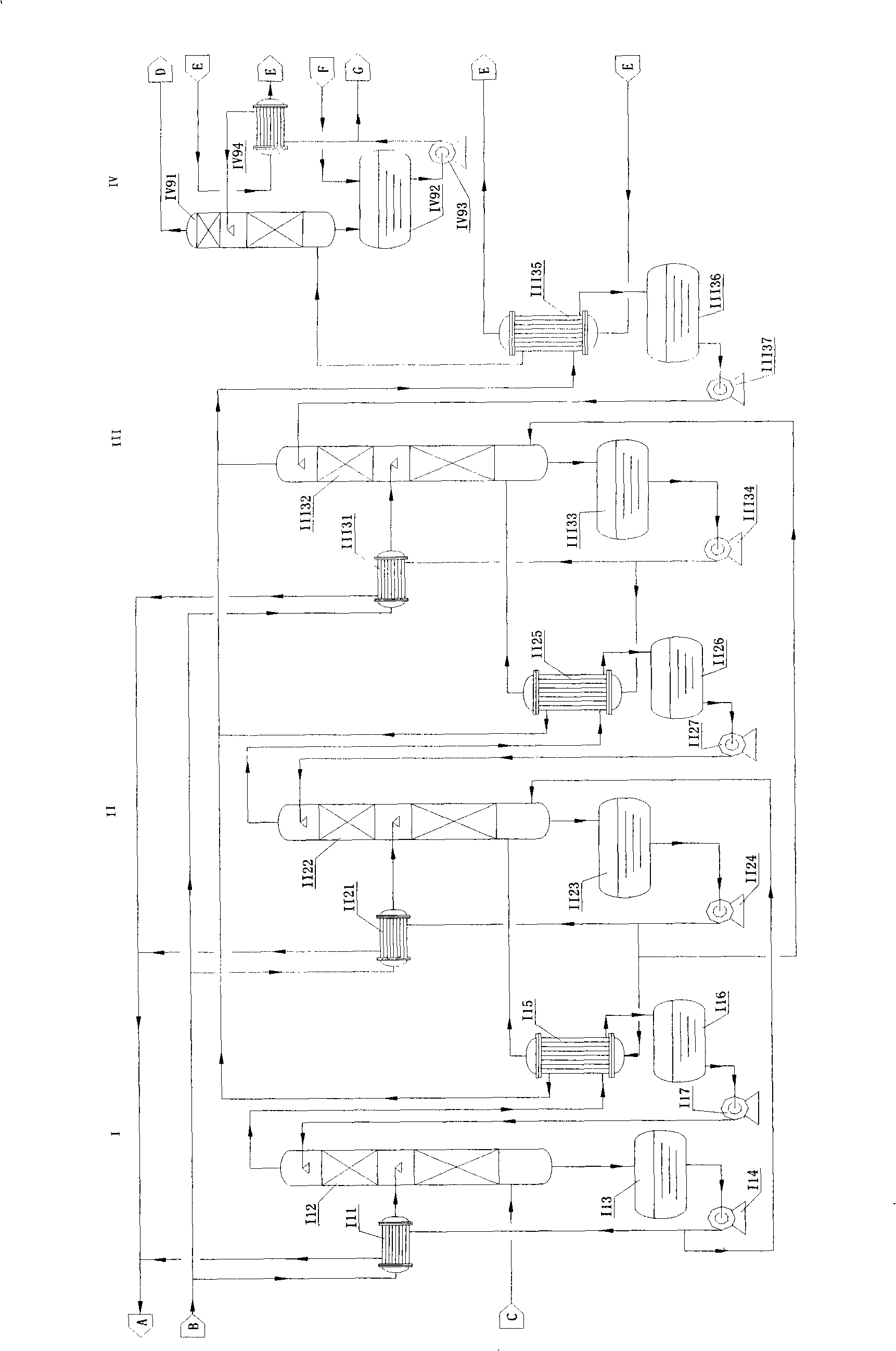

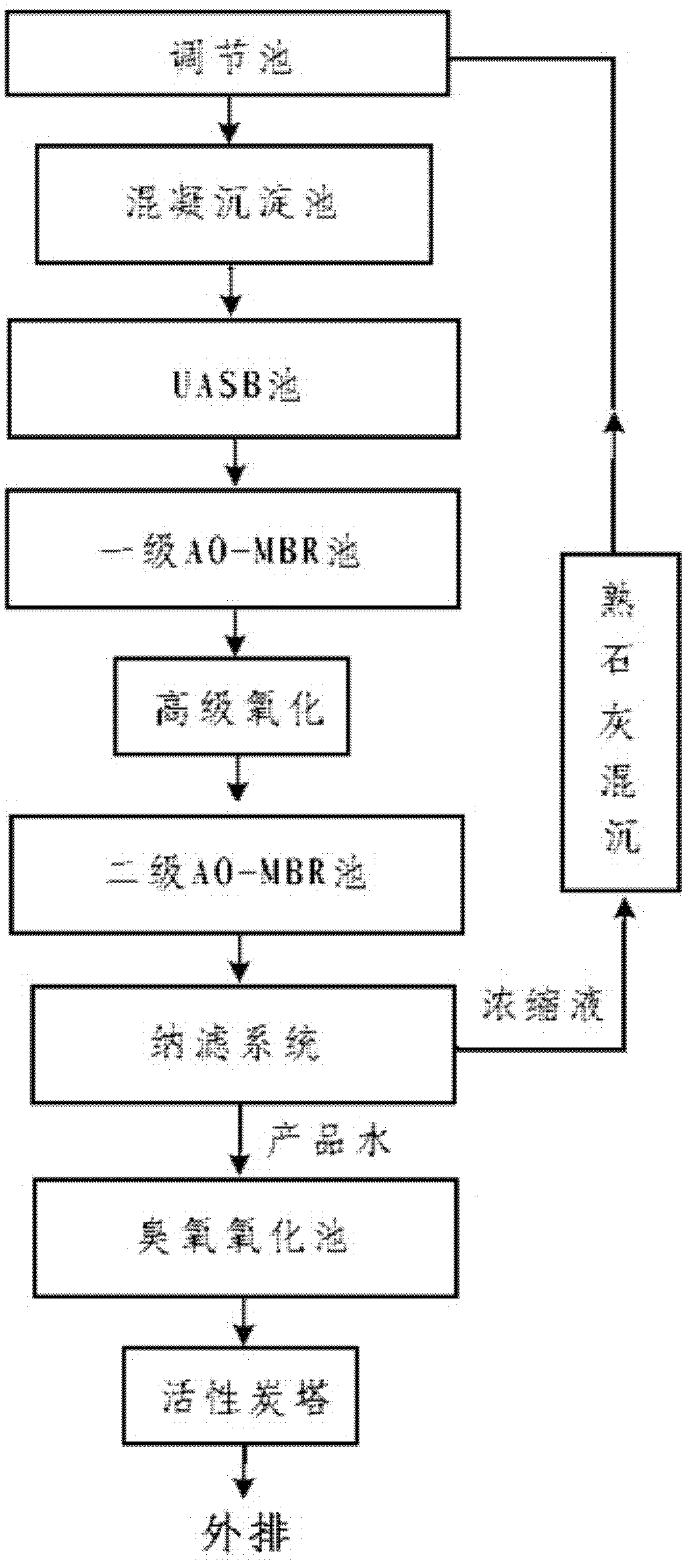

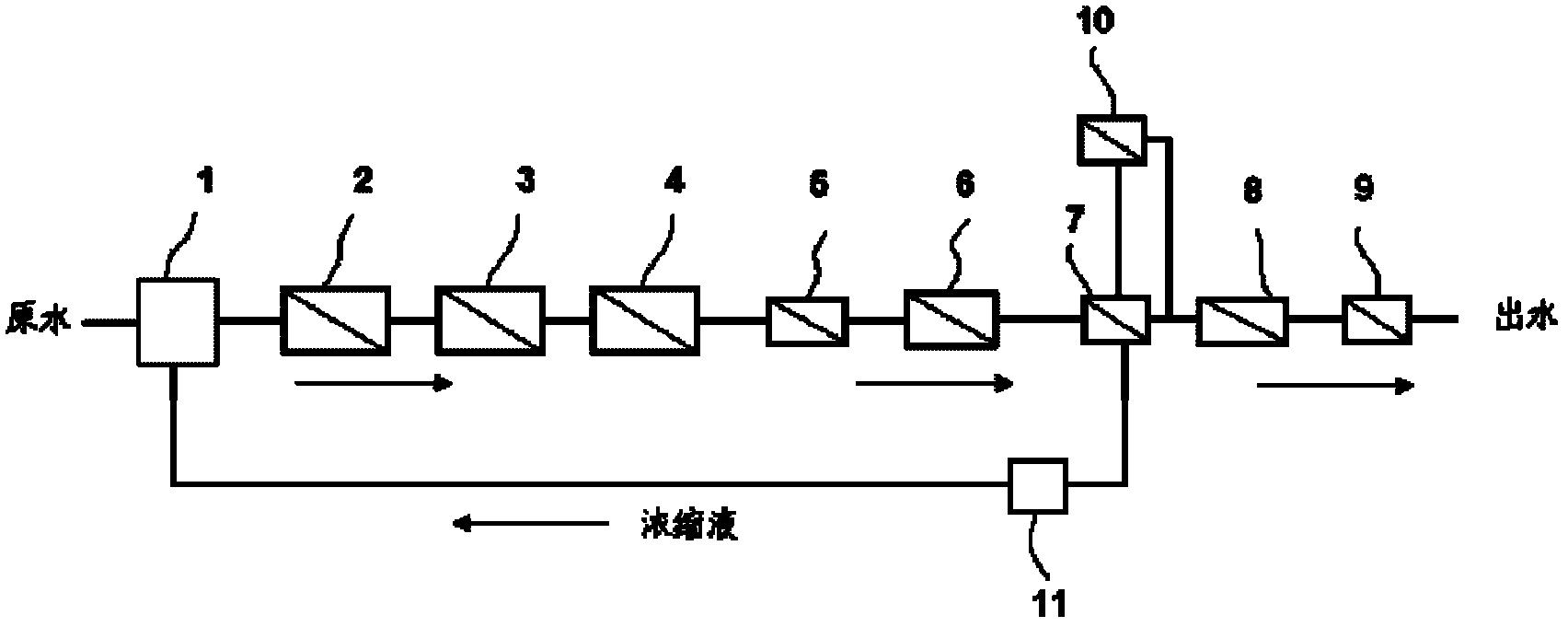

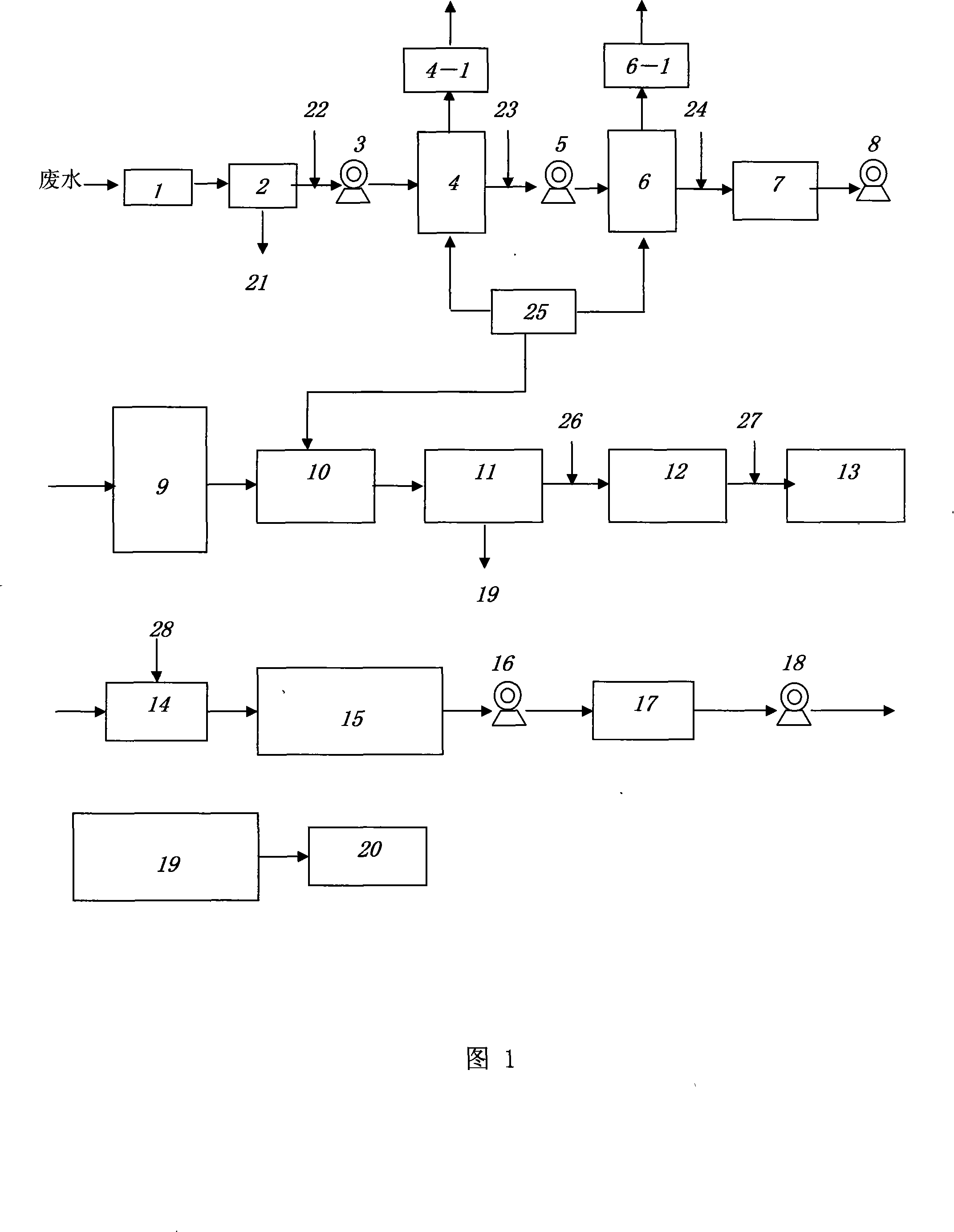

Advanced treatment system and method for high-concentration percolate in comprehensive garbage disposal plant

InactiveCN102503046AEasy to handleRequirements to meet emission concentration limitsMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention discloses an advanced treatment system and method for high-concentration percolate in a comprehensive garbage disposal plant, belonging to the field of industrial waste water treatment. The system is formed by connecting a regulating tank, a coagulative precipitation tank, an upflow anaerobic sludge bed reaction tank, a primary anoxic and aerobic membrane bioreactor, advanced oxidation treatment equipment, a secondary anoxic and aerobic membrane bioreactor, nanofiltration membrane treatment equipment, an ozone contact tank and an active carbon filtering tower in sequence. According to the system, garbage percolate can be treated comprehensively, different pollutants in garbage percolate are treated in a classified way by combining physical, chemical and biological treatment,advanced treatment of garbage percolate is realized, and classified treatment for removing pollutants such as organic matters, heavy metals, ammonia, nitrogen and the like is performed, so that treated effluent strictly reaches the requirement of water pollution discharge degree limit in the Household Garbage Landfill Pollution Control Standard, the system runs stably for a long time, and treatment cost is lower than that of a secondary disc pipe reverse osmosis membrane process.

Owner:BEIJING YIPU INT WATER AFFAIRS

Treatment method of high-concentration wastewater

InactiveCN103663860AReduce wasteReduce dosageMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a treatment method of high-concentration wastewater. The treatment method comprises the following steps: (1) pretreatment; (2) flocculent sedimentation treatment; (3) biochemical treatment; (4) membrane biological reaction treatment; (5) adsorption treatment; (6) oxidation treatment; (7) filtration treatment; (8) membrane treatment; (9) disinfection treatment; and (10) evaporative crystallization treatment. The method disclosed by the invention has the advantages that the wastewater with the COD (Chemical Oxygen Demand) concentration up to 96000mg / L can be treated and the COD removing rate is up to 99.98% to ensure that the treated wastewater meets the standards of drinking water and an unexpected technical effect is brought; compared with a dozen or dozens of hours in the prior art, the aerobic reaction time and the anaerobic reaction time are greatly shortened and the treatment efficiency is obviously increased; and the concentrated solution finally generated in the method only accounts for below 2% of water inflow, which is greatly reduced compared with the prior art, so that the waste of water is obviously reduced and the treatment cost is saved.

Owner:曹寅亮

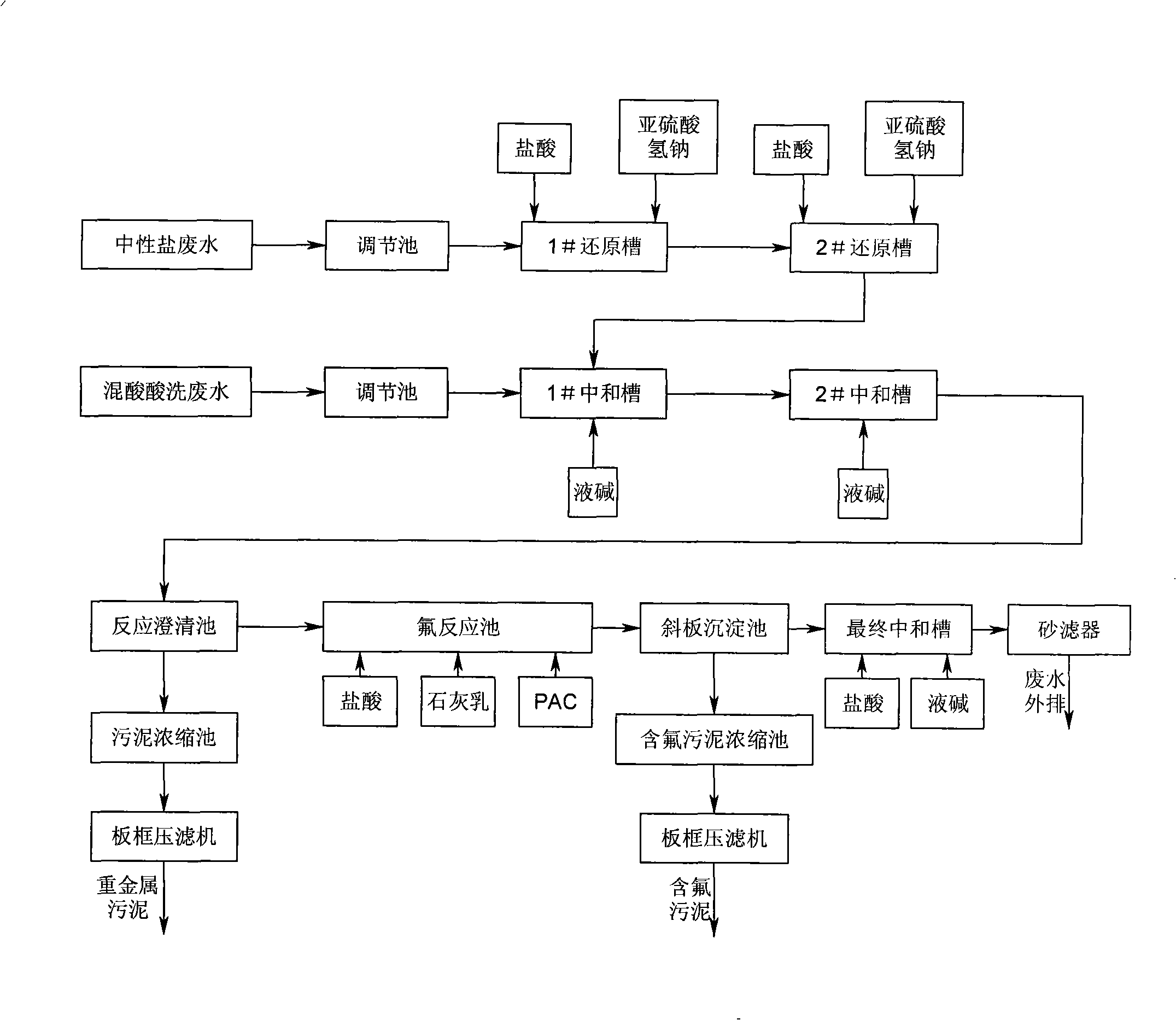

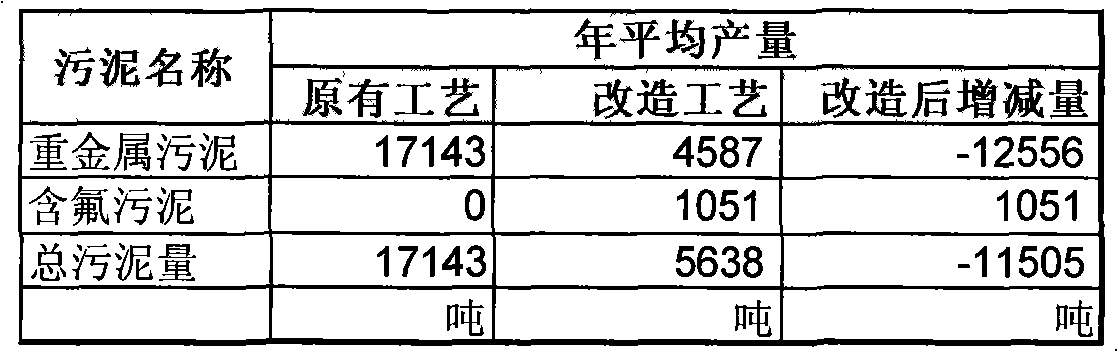

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

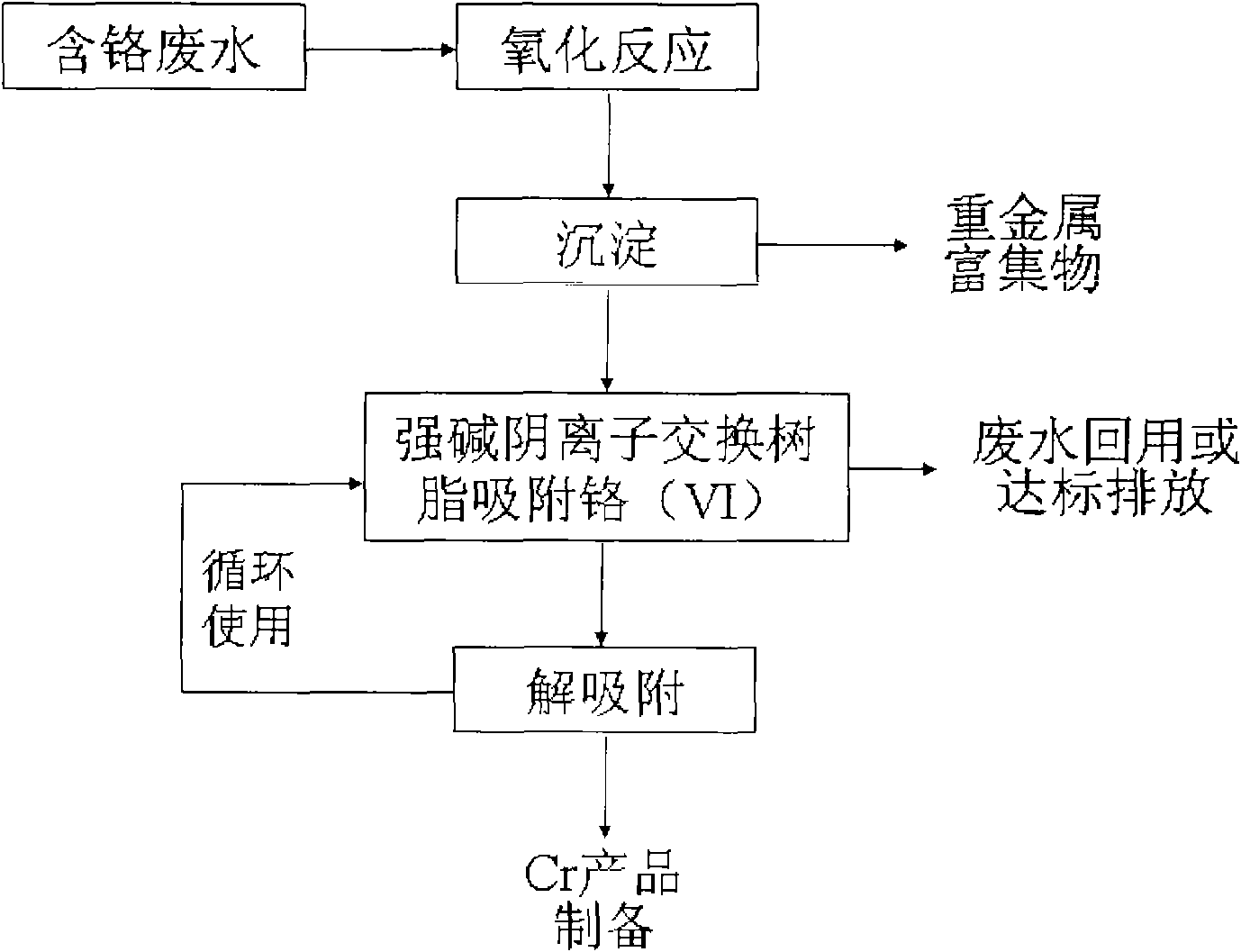

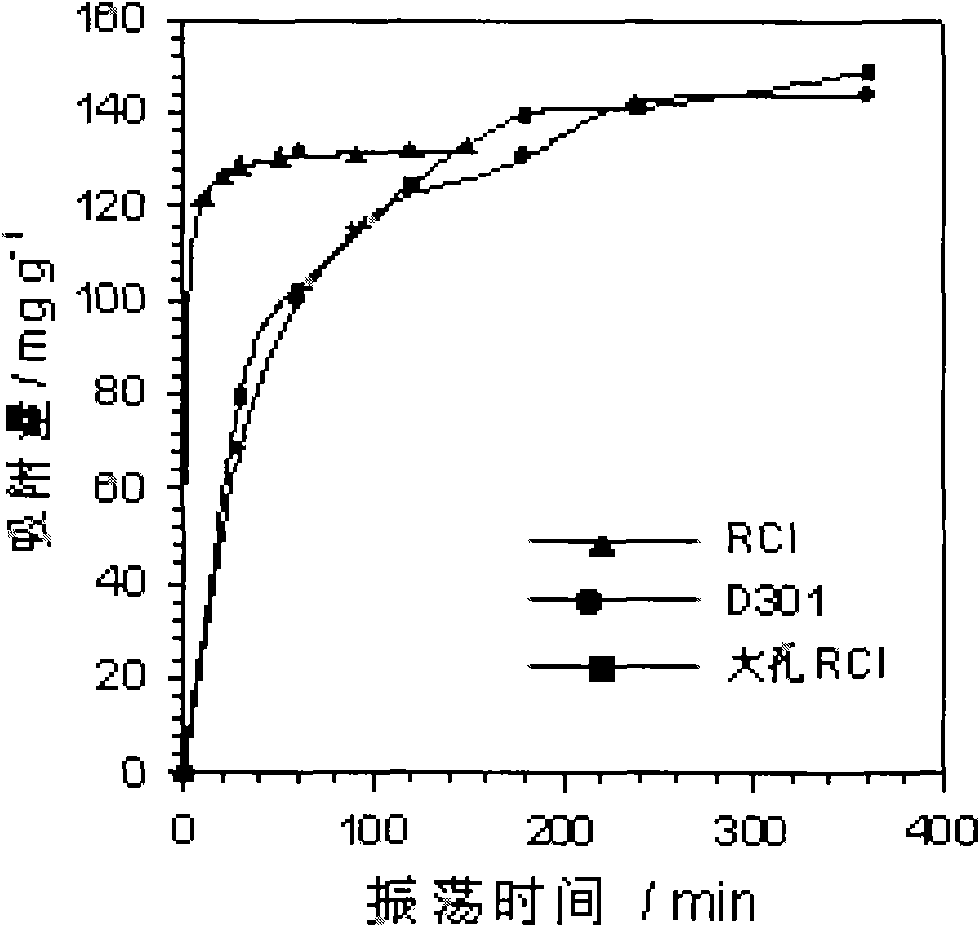

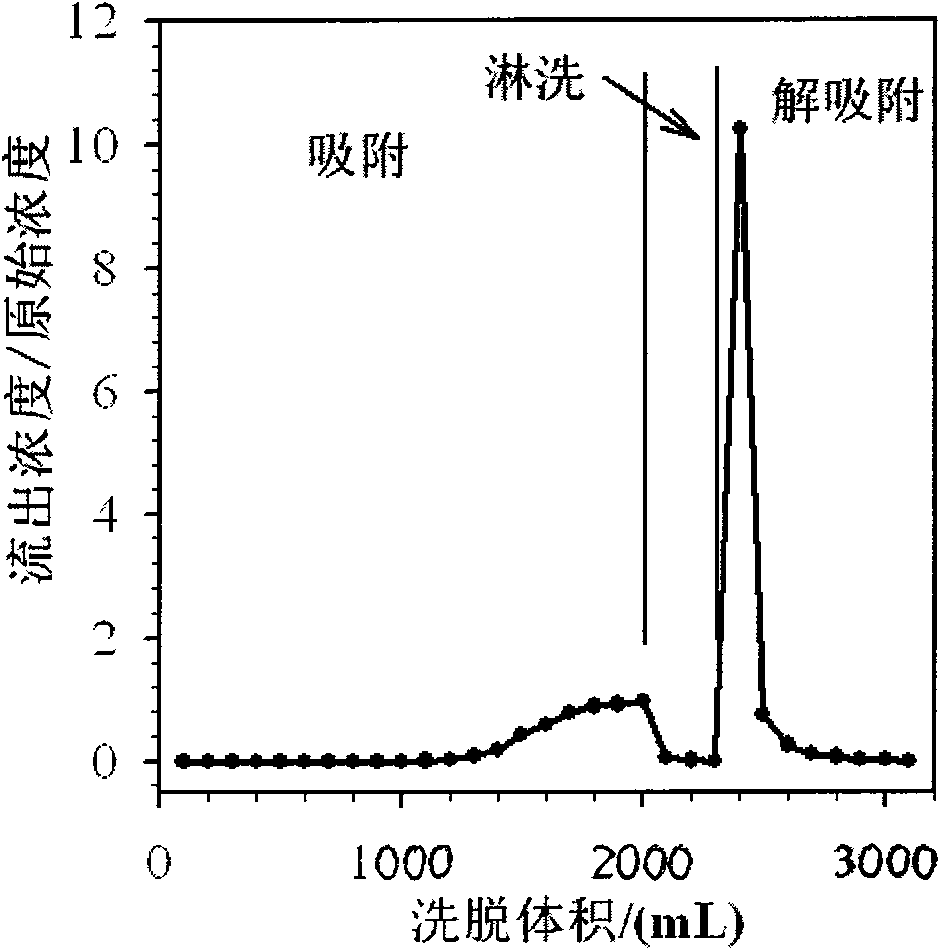

Method for purifying electroplating wastewater and comprehensively utilizing resources

ActiveCN101570372AImprove adsorption capacityEasy to separateWater contaminantsWater/sewage treatment by ion-exchangeChemical reactionWater quality

The invention relates to a method for purifying electroplating wastewater and comprehensively utilizing resources, which is to adopt low-cost strong basic anion-exchange resin containing macropores and imidazole structure to reclaim valuable resources in the electroplating wastewater by coupling technology based on a chemical oxidation-reduction method, a precipitation method and an ion exchange method. The method comprises the following steps: firstly, Cr(III) is oxidized into Cr(VI) under basic condition through a chemical reaction; then, Zn, Cu, Ni and other heavy metal elements in the wastewater are transformed into precipitation of hydroxide; and finally, the Cr(VI) in the wastewater is adsorbed by the strong basic anion-exchange resin, the purified water quality achieves the requirement of electroplating pollutant discharge standard and recycle, and the Cr and other heavy metal resources in the electroplating wastewater can be comprehensively reclaimed and utilized. The method overcomes the defects that the prior regenerating process of porous weak-basic resin requires acidification, and the method has the advantages of simple process, low treatment cost, large treatment quantity and acid and base consumption conservation, and is the electroplating wastewater treatment method with green environmental protection and efficient utilization of resources.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

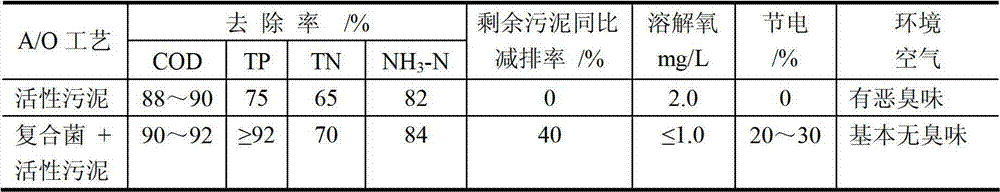

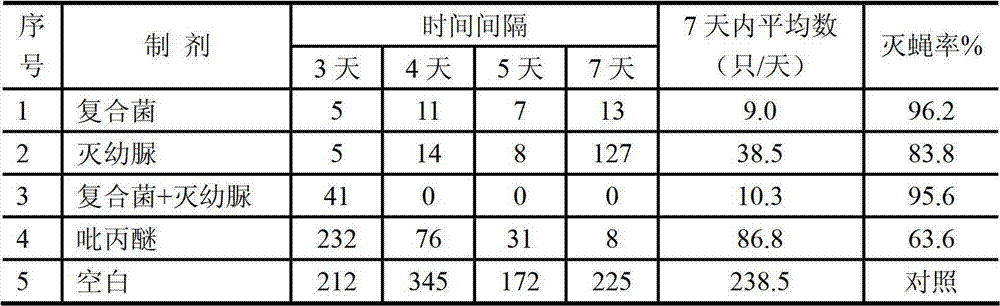

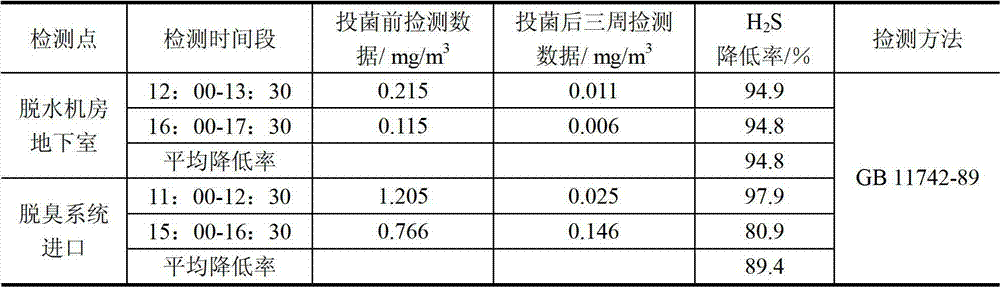

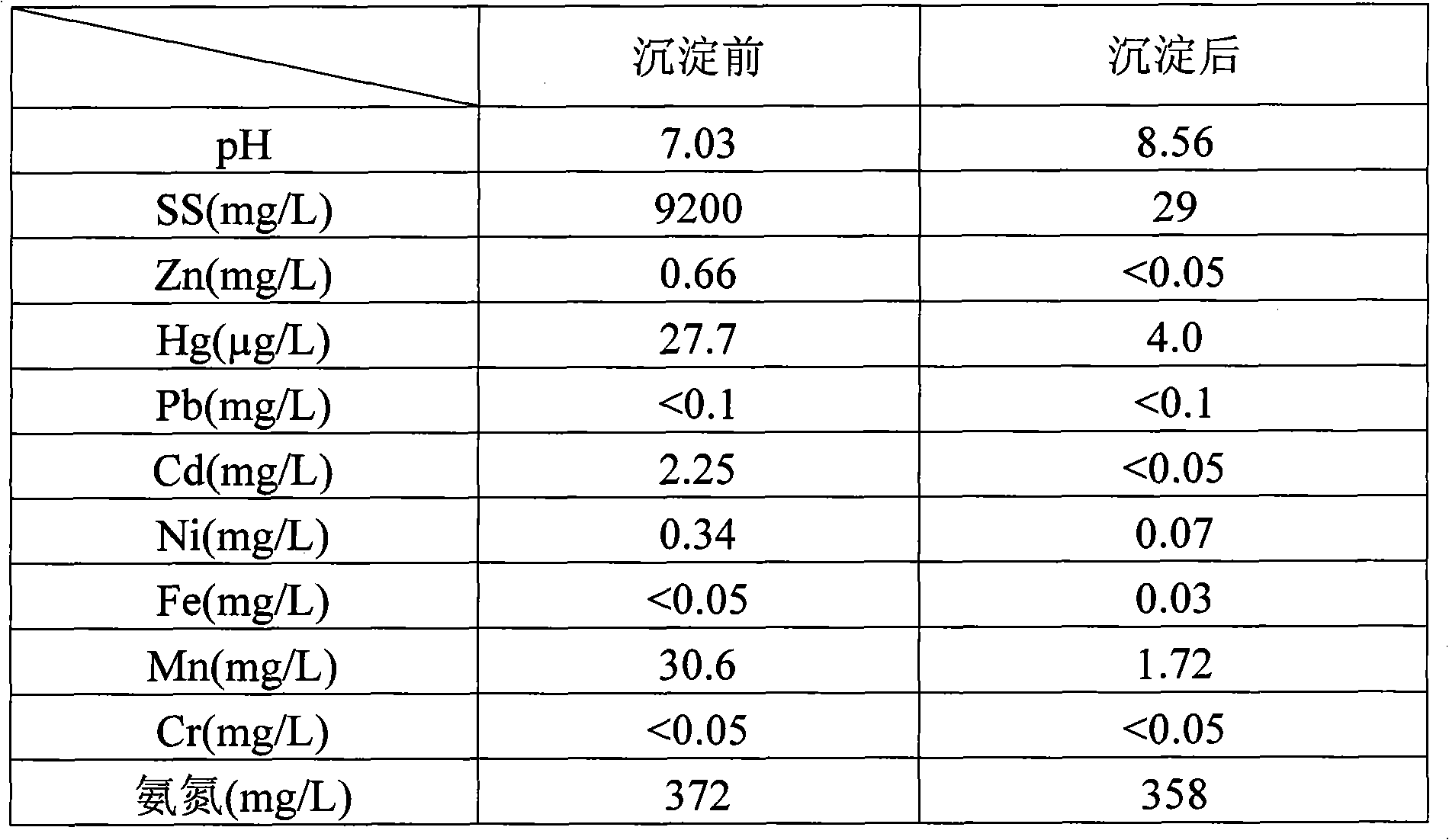

Novel compound microorganism living bacteria agent, method for preparing same and applications

The invention discloses a novel compound microorganism living bacteria agent. The agent comprises probiotics such as pediococcus, saccharomyces, bacillus and the like, wherein the total bacterial quantity is above 107 colony-forming units (cfu) / gram. The invention further discloses a method for preparing the novel compound microorganism living bacteria agent and applications of the novel compound microorganism living bacteria agent in preparation of organic sewage purification additives, deodorization fly dispelling agents, degreasing agents, pipeline blockage removing agents, feed additives and microorganism disease prevention agents. The novel compound microorganism living bacteria agent has the comprehensive effects of high removal rates to ammonia nitrogen, total nitrogen and total phosphorus, small sludge residues, energy saving, environmental friendliness and the like and the characteristics of convenience in use, safety and quickness in function, no secondary pollution, benefits to ecological protection, low treatment cost, good comprehensive profit and the like.

Owner:SHANGHAI ECO WELL BIOSCI

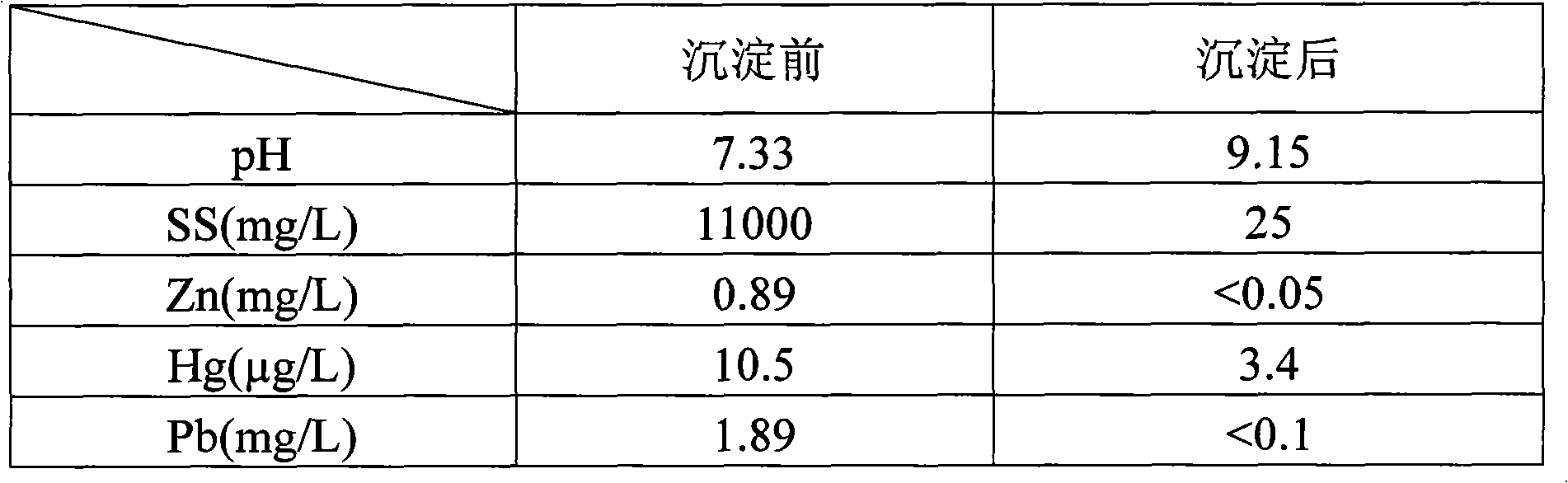

Treatment method of sintering flue gas desulphurization wastewater

ActiveCN101993169AReduce processing costsReduce the amount of waterTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationFlue gas

The invention discloses a treatment method of sintering flue gas desulphurization wastewater, which completes the treatment on the sintering flue gas desulphurization wastewater through the following five steps of: 1. neutralization and coagulation: regulating the pH value of the sintering flue gas desulphurization wastewater to 8.5 to 9.5 by lye, and adding 0 to 200ppm of coagulating agents; 2. flocculation: adding 0 to 10ppm of coagulant aids for forming flocs; 3. precipitation and filter liquor separation; 4. biochemical treatment on filter liquor; and 5. deep treatment. The treatment method can be used for reducing the treatment cost of the desulphurization wastewater without generating influence on other treatment systems, thereby having good application and popularization prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

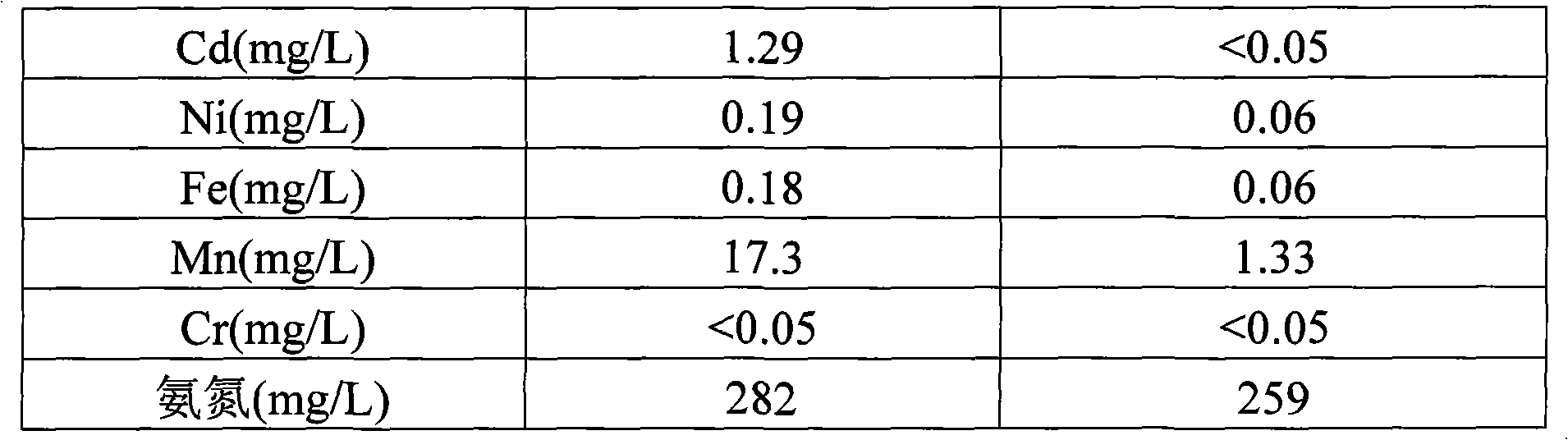

Method for separating tellurium from tellurium slag

InactiveCN101508426APrecisely control the amount addedImprove solubilityElemental selenium/telluriumSludgeSlag

The invention relates to a method for separating tellurium from tellurium slag, which comprises the following steps: firstly, grinding the tellurium slag, leaching out the obtained product in an aqueous solution, purifying and neutralizing a water leaching solution, and producing tellurium dioxide; secondly, performing hydrochloric acid leaching on water leaching residue in a hydrochloric acid system, cooling and filtering an acid leaching solution, and returning acid leaching residue to an anode sludge treatment process; thirdly, performing controlled potential reduction on the acid leaching solution to produce coarse tellurium, and performing roasting and impurity removal on the coarse tellurium and the tellurium dioxide produced by neutralization to obtain pure tellurium dioxide; and fourthly, using the conventional method to reclaim valuable metals such as copper, bismuth, tin, and the like from a reduced solution respectively. The total tellurium leaching rate of the method is as high as more than 98 percent, and the produced coarse tellurium has the advantages of low content of impurity elements, small amount of return slag, small modification amplitude of equipment, short treatment time, and low treatment cost.

Owner:CENT SOUTH UNIV

Method for treating organic chemical waste water

InactiveCN101734817AEasy to handleReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationPretreatment method

The invention discloses a method for treating organic chemical waste water. In the method, after the pH value of the waste water is adjusted to 2.5-3.0, the organism which is hard to degrade is efficiently removed and the biochemical property of the waste water is enhanced through the aeration microelectrolysis, Fenton oxidization and coagulating sedimentation processes, and the Fe<2+> generated after the microelectrolysis reaction can be used for subsequent Fenton oxidization reaction, thereby reducing the treatment cost. The invention can be widely applied to treating various kinds of low concentration organic waste water which is hard to biodegrade, such as chemicals, pharmacy, and the like; and the treated water can directly reach the standard and be drained. The invention can also be used as a pretreatment method of the organic waste water with high concentration to improve the biochemical property of the waste water which is hard to biodegrade.

Owner:JIANGSU SUJING GROUP +1

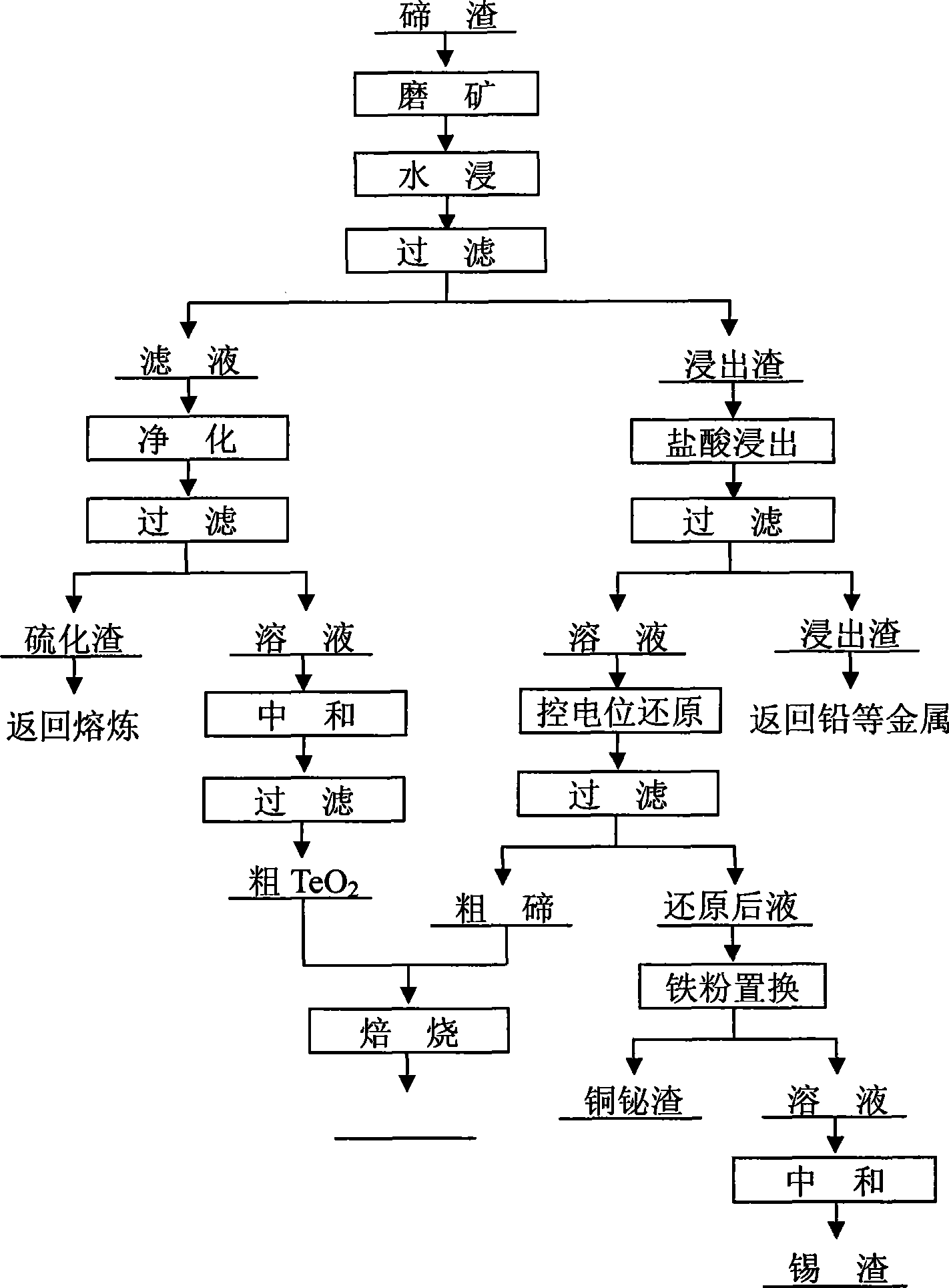

Foundation treatment method for controlling post-construction settlement and deformation of soft soil

InactiveCN102226335AIncrease effective preloadEffective reinforcementSoil preservationEngineeringCut and fill

The invention discloses a foundation treatment method for controlling the post-construction settlement and deformation of soft soil. the method sequentially comprises the following steps: setting a vertical envelope wall around an area to be reinforced; inserting vertical drainage systems and laying horizontal drainage systems in the area to be reinforced; paving sealing materials on the surface of a foundation; backfilling settlement refills or exerting pre-loads on the foundation; carrying out vacuumizing, well-point dewatering or vacuum well-point dewatering on the drainage systems so as to reinforce the foundation; and after the consolidation degree of the foundation reaches 60-90%, carrying out sealing on all the vertical and horizontal drainage systems. The method disclosed by the invention is used for simultaneously carrying out reinforcement and plugging on an untreated soft soil foundation, so that the post-construction settlement can be controlled while the foundation is treated. Duo to the one-time treatment, the treatment time can be saved, and the treatment cost can be reduced, thereby achieving the purpose of effectively reinforcing the foundation and controlling the post-construction settlement.

Owner:CCCC FOURTH HARBOR ENG INST +4

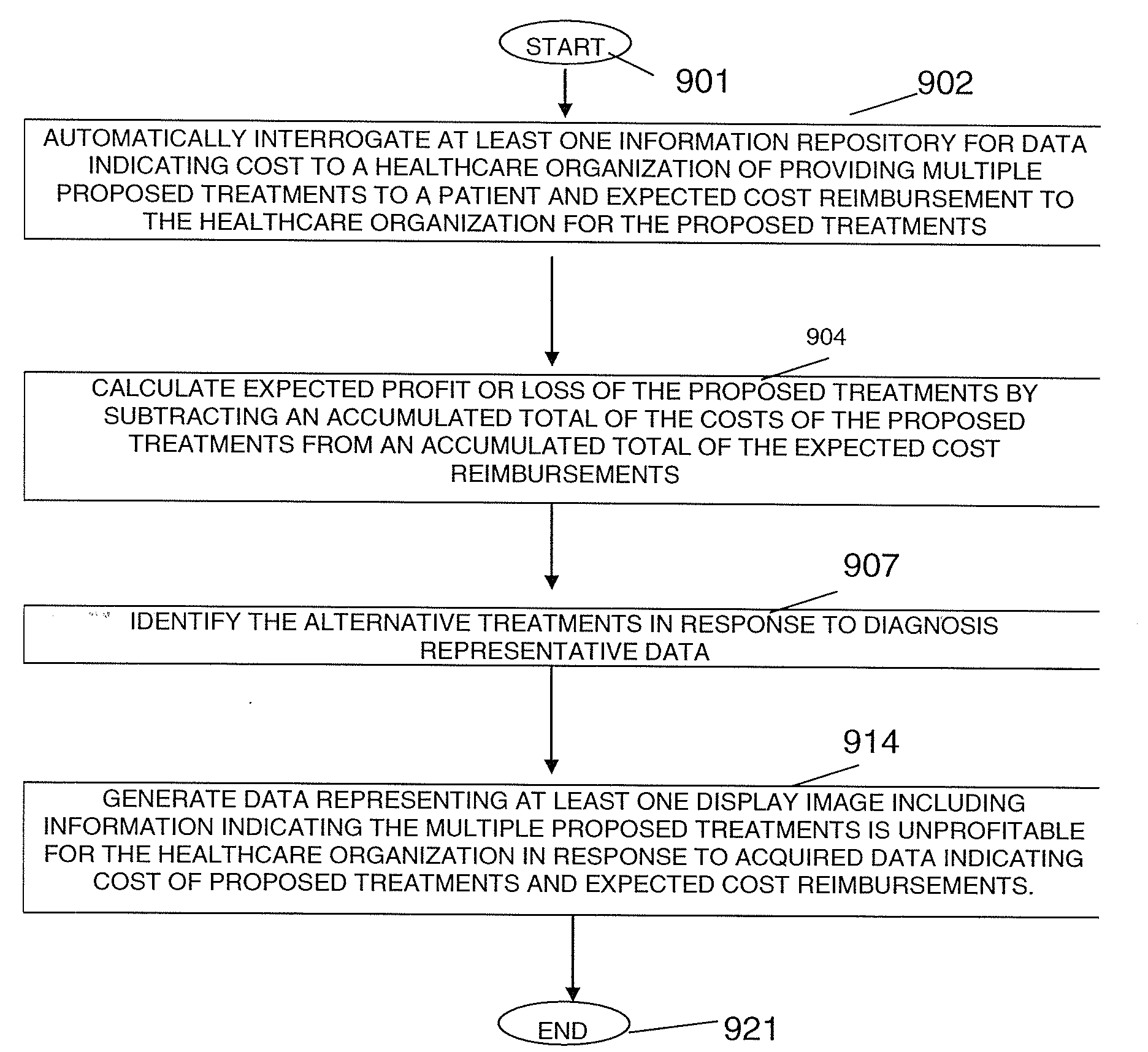

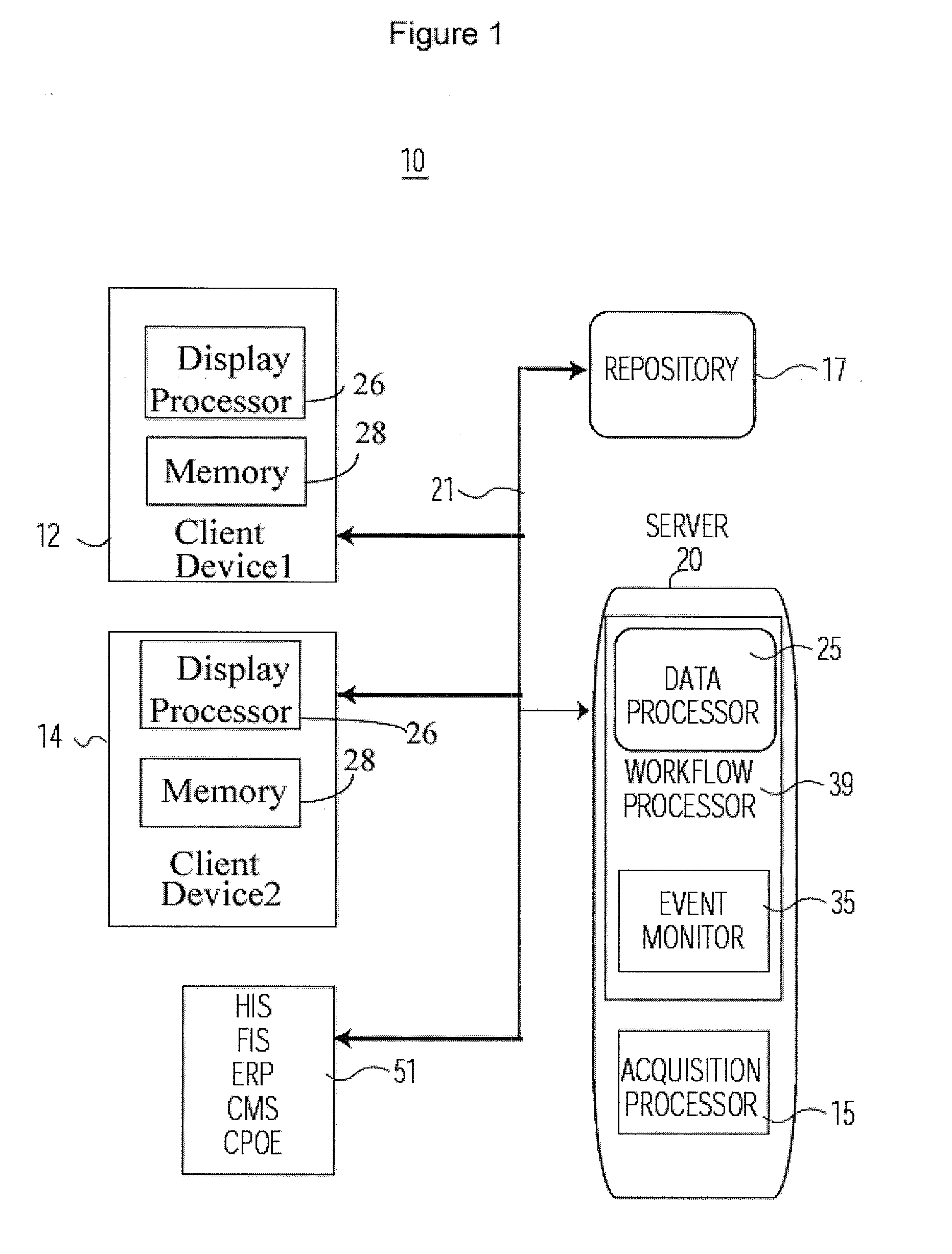

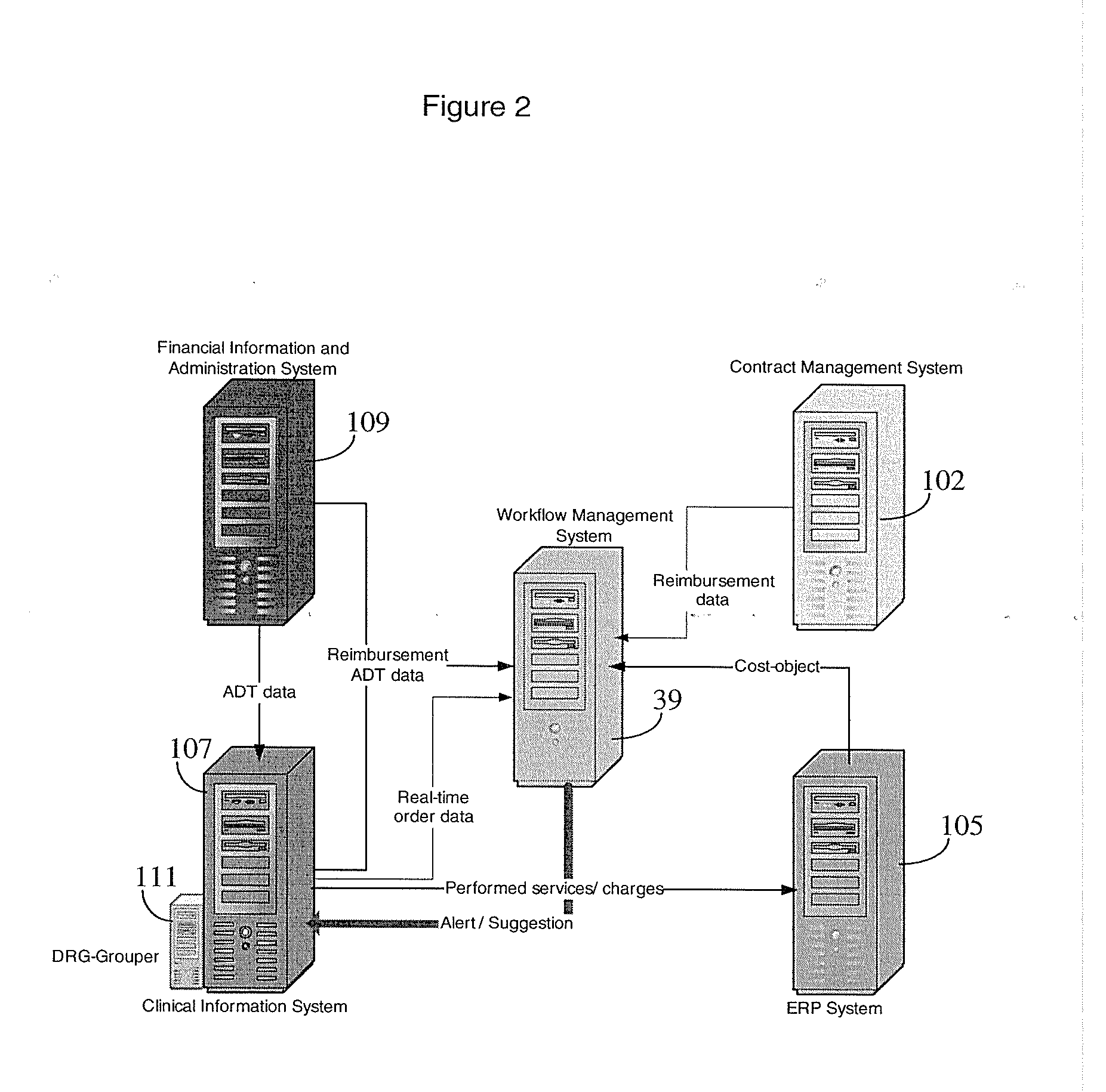

Clinical Cost Control Management Module

A system enables a healthcare organization to evaluate cost efficient treatment options early in a patient treatment process by automatic monitoring of profit or loss of a treatment, in real-time and enables a clinical user to screen, simulate and control treatment profit or loss during a patient visit, based on both expected reimbursement and the actual costs of performed services. A system enables cost based treatment selection by providing a healthcare worker with patient specific treatment cost information during a treatment episode. An acquisition processor automatically interrogates at least one information repository for data concerning cost to a healthcare organization of providing a proposed treatment to a patient and expected cost reimbursement to the healthcare organization for the proposed treatment. The acquisition processor initiates generation of at least one message including a patient identifier and treatment identification code for communication to the at least one information repository, in response to data indicating occurrence of a treatment related event. A display processor initiates generation of data representing at least one display image including information indicating the proposed treatment is unprofitable for the healthcare organization.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Method for cultivating earthworm by cattle manure and corps stalks

InactiveCN101233835ASolve processing problemsAchieve recyclingFood processingAnimal feeding stuffAgricultural scienceFeces

The invention discloses a method for raising earthworm by taking advantage of dairy manure and straws and stalks of crop, which applies fresh dairy manure and straws and stalks of crop to raise earthworm. The invention adopts fresh dairy manure and straws and stalks of crop as raw materials, which can not only solve the treatment problem of dairy manure in large-scale cattle farms and reduce environment pollution, but also obtain earthworm with high economic value as well as odourless, clean and natural organic manure with high quality, thus realizing the regeneration and utilization of dairy manure, reducing treatment cost for dairy manure on cattle farms, and greatly improving economic benefits of enterprises.

Owner:GUIZHOU JILONG ECOLOGICAL TECH

Instant recoverable slippery water for shale gas reservoir

ActiveCN102516975AHas instantMeet the needs of large-scale development and online formulationDrilling compositionPhosphatePotassium

The invention relates to instant recoverable slippery water for a shale gas reservoir. The slippery water consists of the following components in percentage by weight: 0.02-0.1 percent of a friction-reducing agent, 0.2-2.0 percent of potassium chloride, 0.1-0.5 percent of a cleanup additive, 0.1-0.5 percent of an anti-swelling agent and the balance of water, wherein the friction-reducing agent is polyacrylamide or a polyacrylamide derivative of which the molecular weight is 5*105-1*106; the cleanup additive consists of 0.5-2.0 percent by mass of a fluorocarbon surfactant, 10-15.0 percent by mass of a low molecular alcohol solvent, 3.0-5.0 percent by mass of a high molecular alcohol additive, 10.0-20.0 percent by mass of a technical grade hydrocarbon chain surfactant and the balance of water; and the anti-swelling agent is a cation polyquaternary salt, poly-quaternary phosphate or a poly-quaternary sulfate. The slippery water can be fully dissolved and swelled within 20-30 seconds for forming a uniform system without oxidizing a gel breaker, damage to the crack diversion capability can be reduced, a cracking reverse discharge liquid can be recycled, and waste liquid treatment cost is lowered.

Owner:PETROCHINA CO LTD

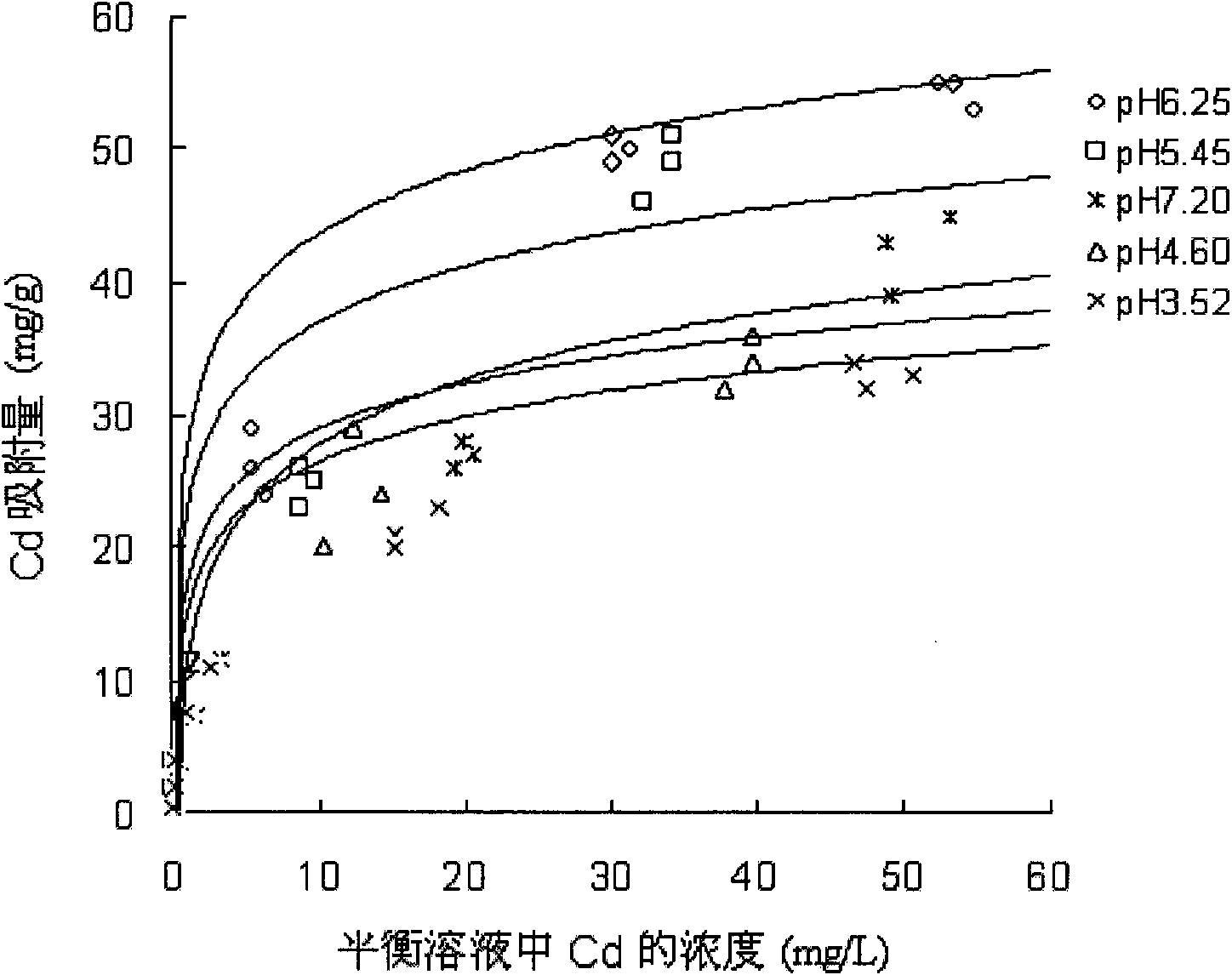

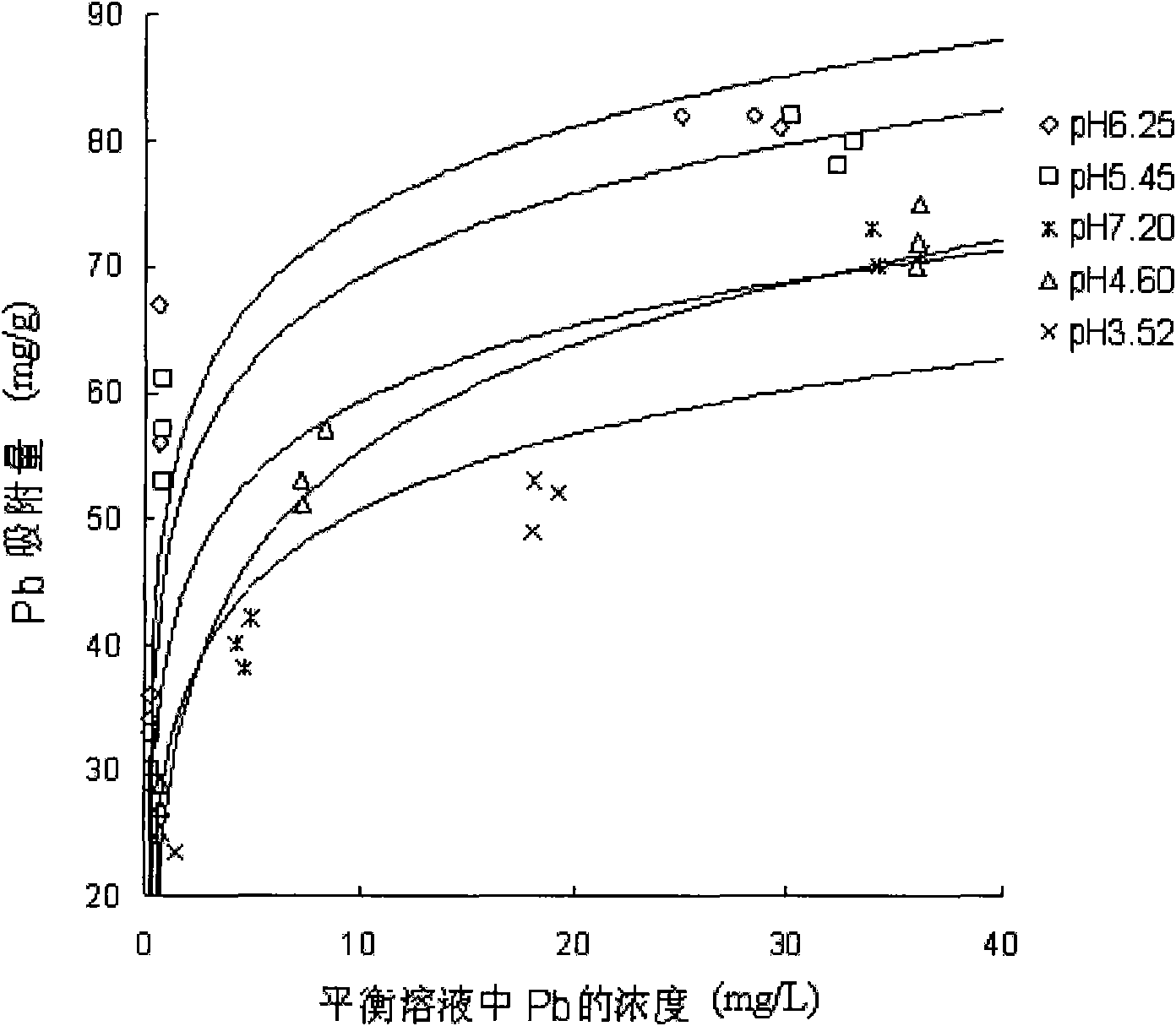

Method for removing heavy metal ions in sewage by nanometer hydroxylapatite

InactiveCN101613135AWide variety of sourcesOvercome expensiveWater contaminantsWater/sewage treatment by sorptionWastewaterHydroxylapatite

The invention discloses a method for removing heavy metal ions in sewage by nanometer hydroxylapatite, belonging to the technical field of heavy metal sewage treatment. The method comprises the following steps: adding nanometer grade hydroxylapatite powder in waste water containing heavy metal ions, wherein, the dosage of the hydroxylapatite powder is 6-8g / L; balancing the mixture for 12-48 hours at a temperature of 23-27 DEG C; and standing the mixture to remove the heavy metal ions in the waste water. The method uses the hydroxylapatite with relatively lower economic value to treat the heavy metal sewage, has high treatment efficiency, low treatment cost, strong field operability and small environment risk, and has heavy metal ion removal rate over 90 percent under conditions that concentration of Cd, Pb or Cu ions does not exceed 60mg / L.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

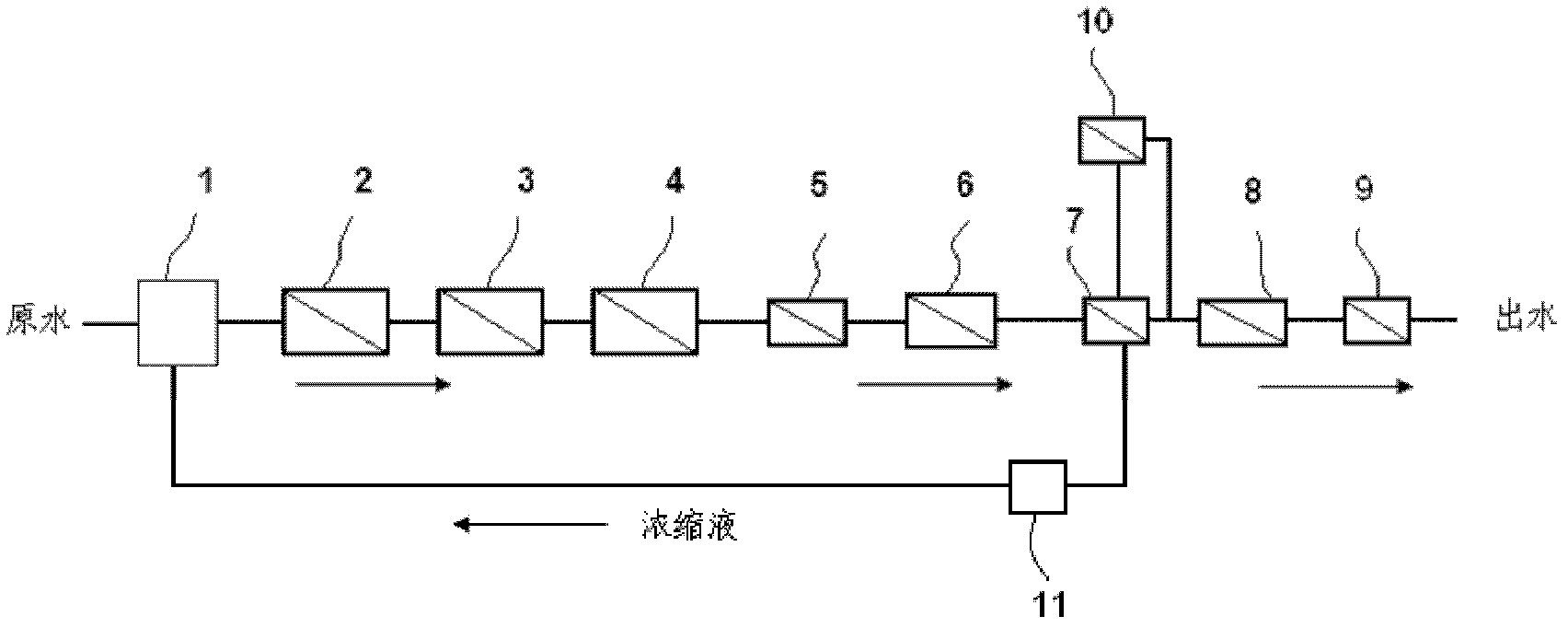

Waste water treatment method and device based on forward osmosis and membrane distillation

InactiveCN103073146AReduced operating temperature rangeLow costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSalt contentWater concentration

The invention belongs to the field of sewage treatment, and particularly relates to a waste water treatment method and device based on forward osmosis and membrane distillation. The waste water treatment method based on the forward osmosis and membrane distillation comprises a waste water concentration process and a drive liquid circulation process, wherein the waste water concentration process adopts a forward osmosis technology to concentrate waste water with high salt content and high chemical oxide demand (COD) concentration through drive liquid so as to obtain the concentrated waste water and diluted drive liquid; the drive liquid circulation process adopts a membrane distillation technology to dehydrate the diluted drive liquid so as to obtain the purified water and renewable drive liquid; and the renewable drive liquid is repeatedly used for the waste water concentration process so as to continuously concentrate the waste water. Due to the adoption of the method and device for treating the waste water with high salt content and high COD concentration, the waste water of different sources and fields can be treated, and the advantages such as wide applicability for waste water, stability in running and low treatment cost can be realized.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

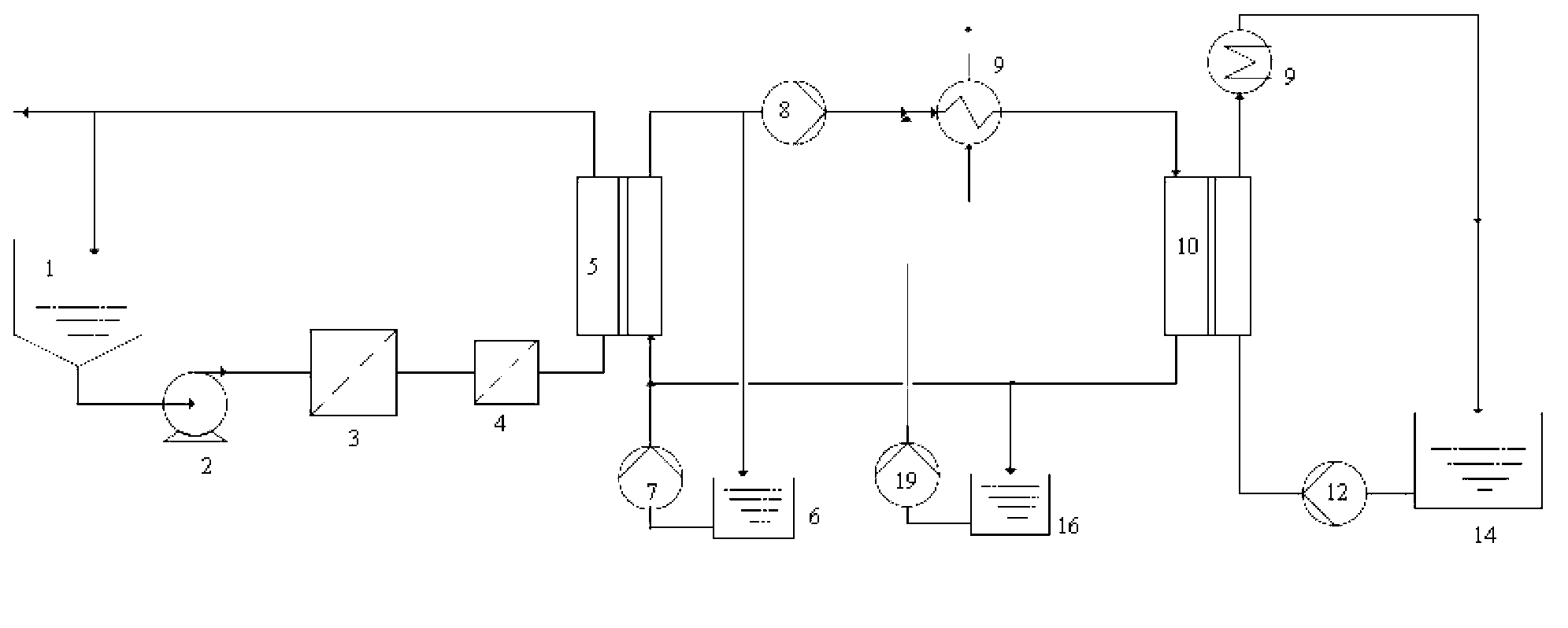

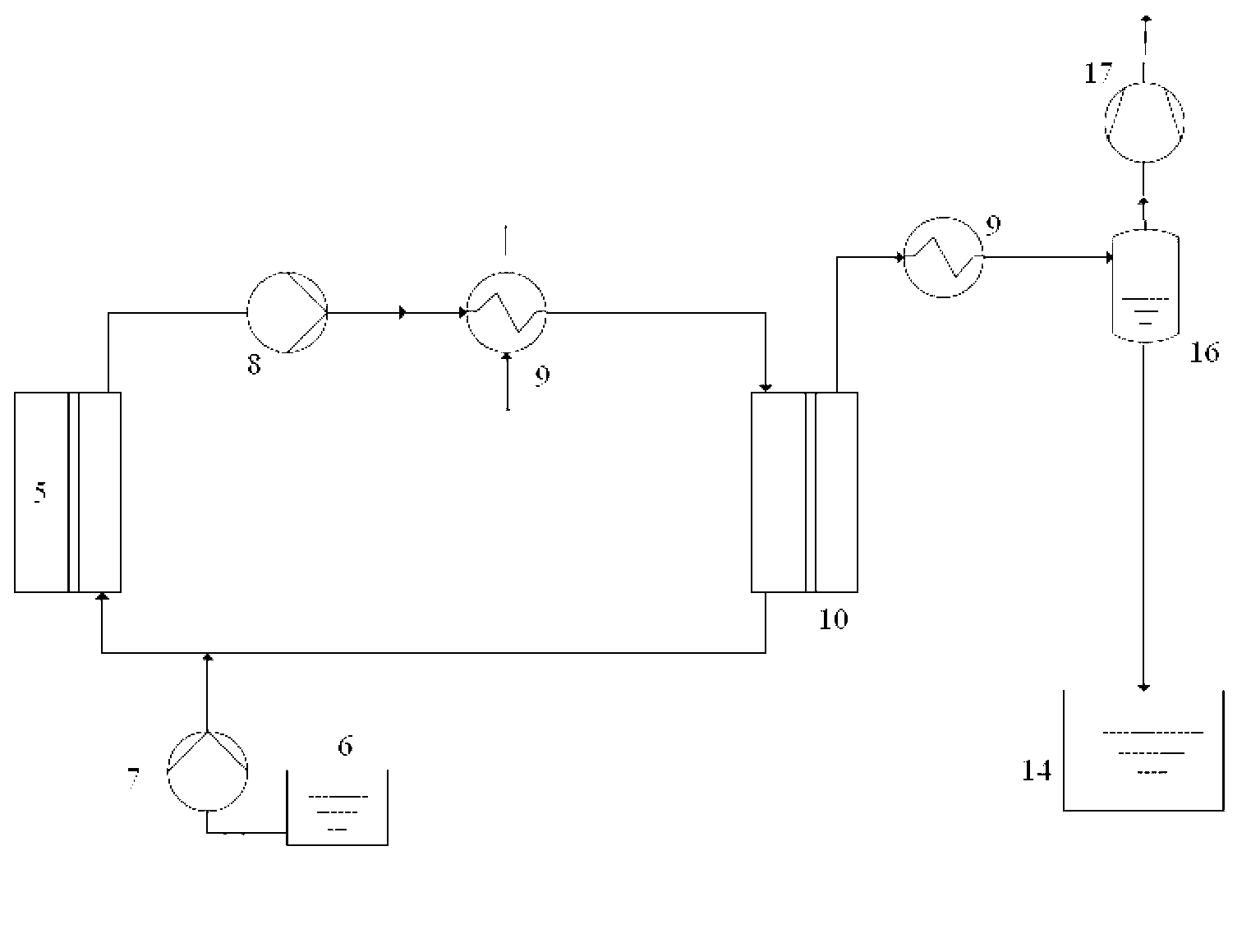

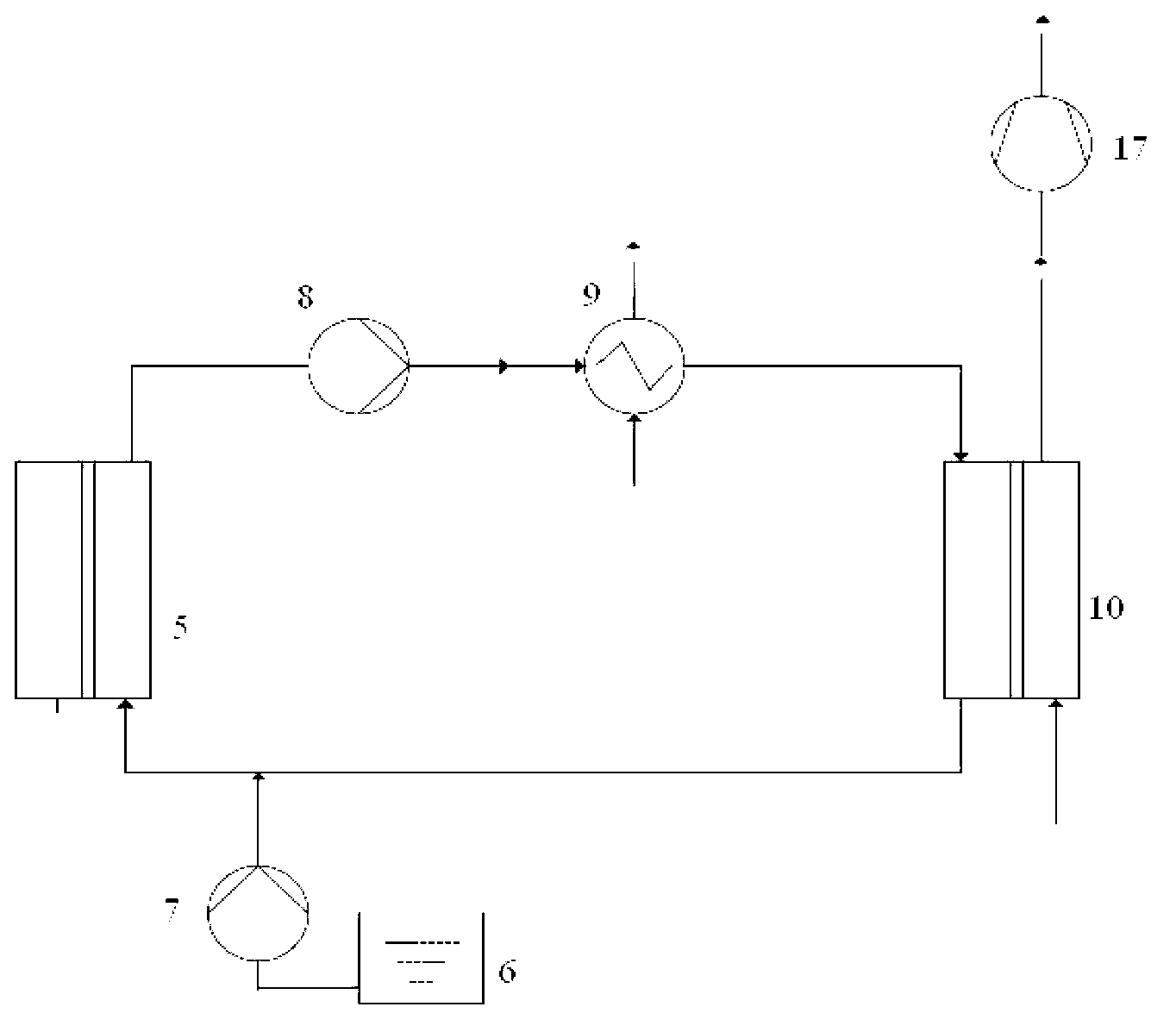

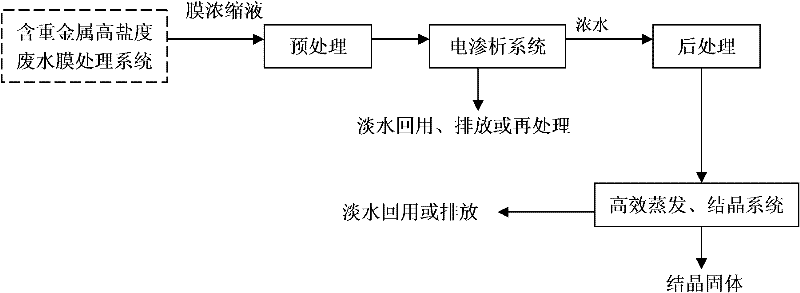

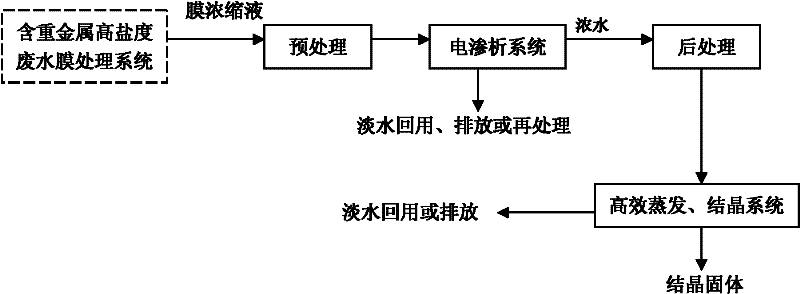

Electrodialysis-efficient evaporation method for treating mining and metallurgy waste water membrane filtrating concentrate

InactiveCN102351352AReduce processing costsReduce processingEnergy based wastewater treatmentMultistage water/sewage treatmentEvaporationSmall footprint

The invention relates to an electrodialysis-efficient evaporation method for treating mining and metallurgy waste water membrane filtrating concentrate, belongs to the technical field of environment protection and especially relates to treatment of heavy metal contained waste water membrane concentrate from metallurgy and mining industry. The invention has technical characteristics that membrane concentrate from advanced treatment of mining and metallurgy heavy metal contained waste water is collected and enters to an electrodialysis system for further condensation treatment; when reaching a certain condensation multiple, the membrane concentrate enters an efficient evaporation system for treatment. Fresh water generated from electrodialysis and efficient evaporation is collected for reuse or discharge, and generated crystal solid is used for resource integrated utilization or retreatment. The technology is conveniently operated and energy saving, has no environmental pollution, low treatment cost and wide application prospect, and can realize zero discharge of membrane treated strong brine containing heavy metals, so as to truly reach zero discharge of membrane treated waste water containing heavy metals.

Owner:KUNMING UNIV OF SCI & TECH

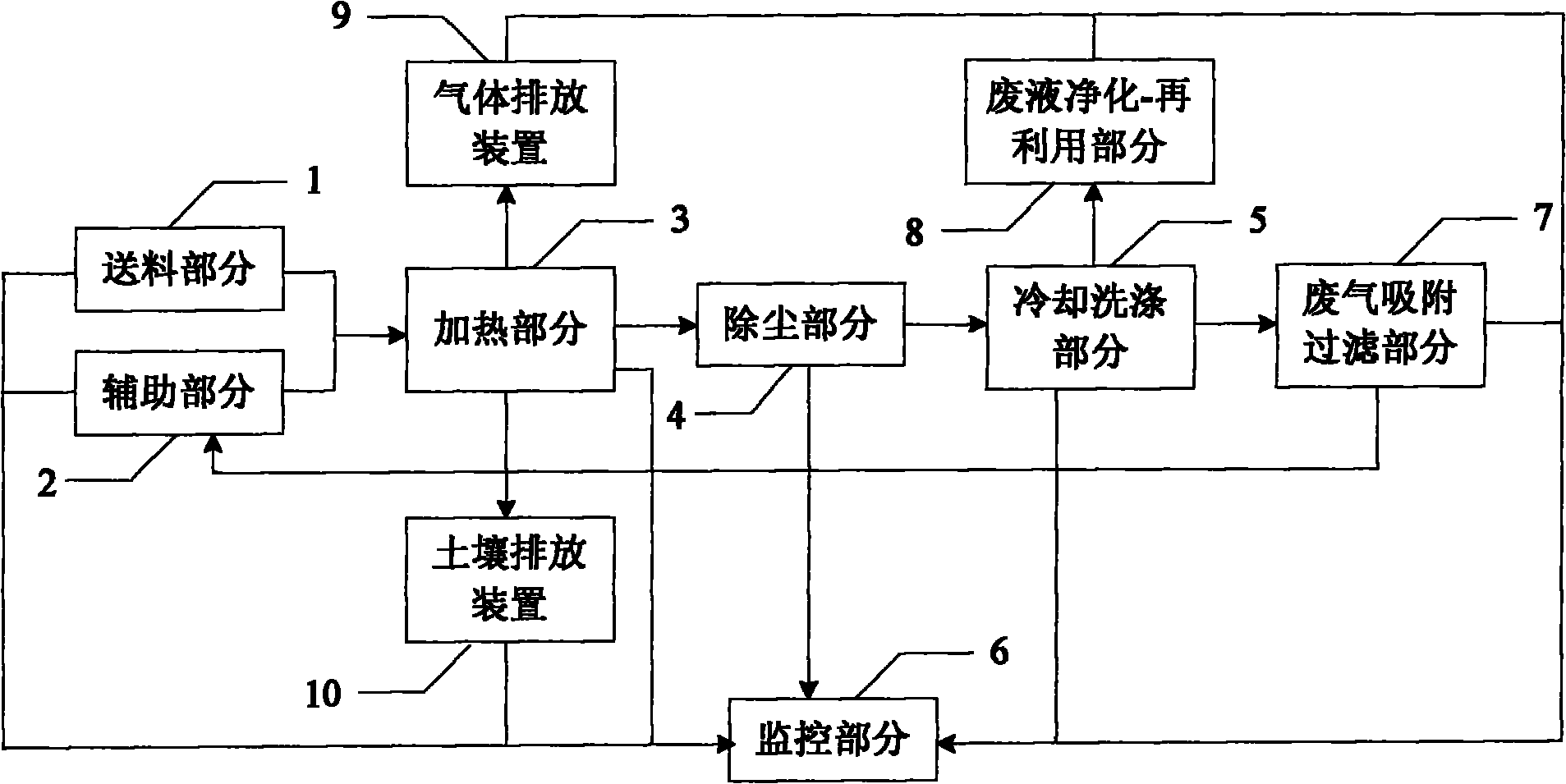

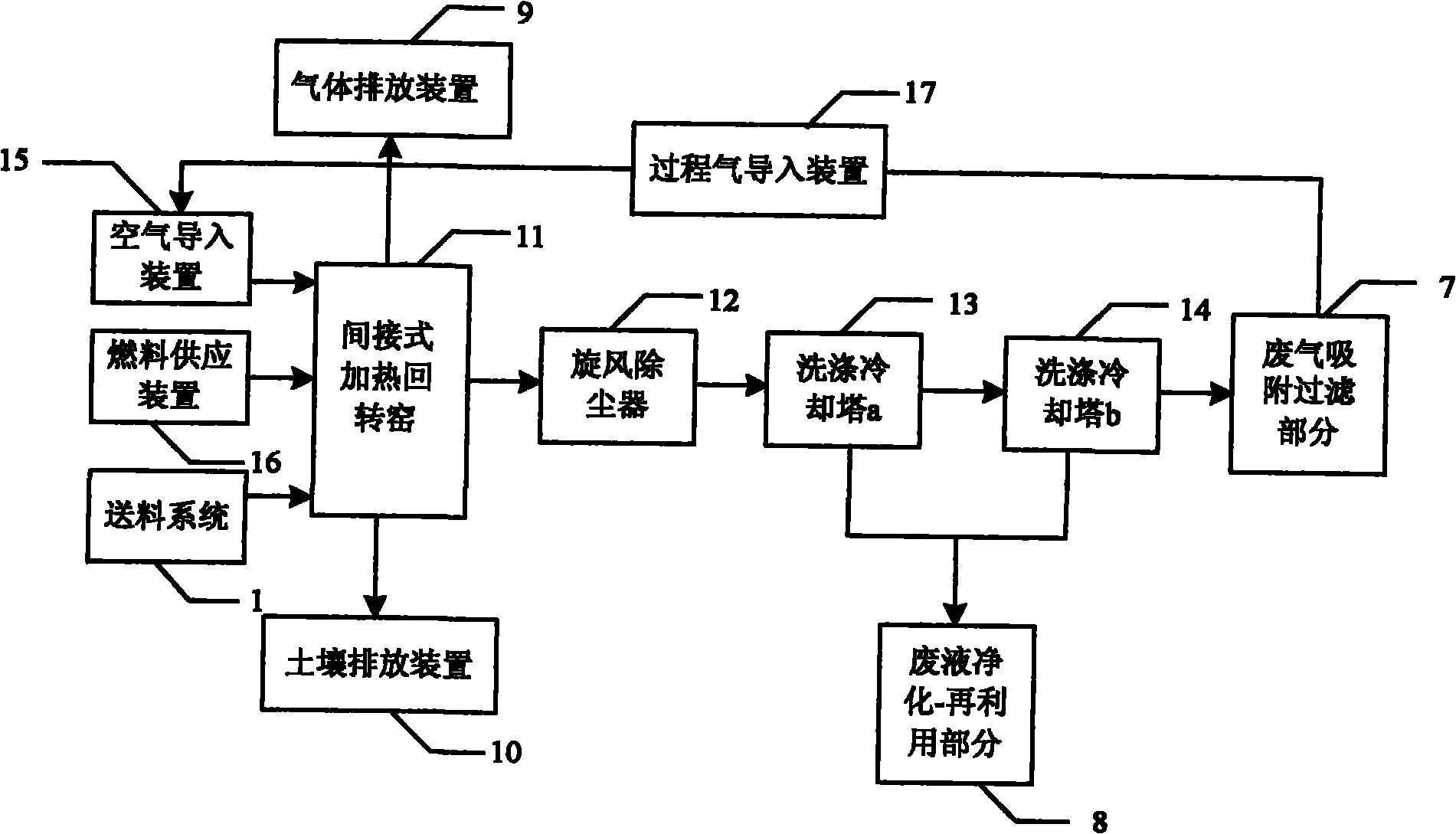

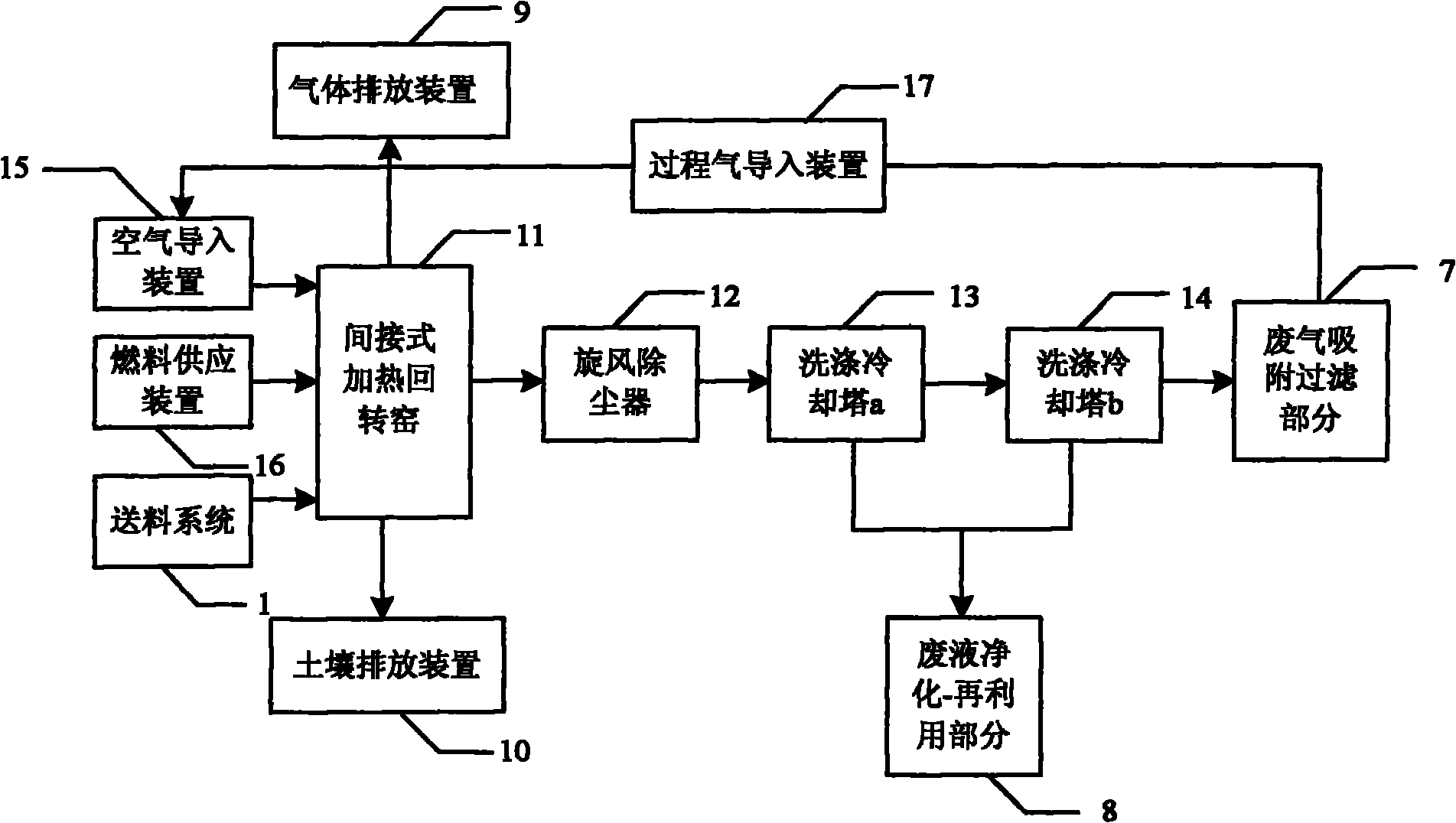

Indirect thermal desorption device

ActiveCN101780467AMaintain physical and chemical propertiesLow costCombination devicesUsing liquid separation agentLiquid wasteCooling tower

The invention relates to an indirect thermal desorption device which comprises a feeding part, an auxiliary part, a heating part, a dedusting part, a washing and cooling part, a waste liquid purifying-recycling part, a waste gas adsorbing and filtering part, a discharging part and a monitoring part, wherein the feeding part and the auxiliary part are connected with the heating part, the discharging part comprises a gas discharging device and a soil discharging device, the washing and cooling part is a washing and cooling tower, the waste liquid purifying-recycling part is connected with the washing and cooling tower, the heating part is orderly connected with the dedusting part, the washing and cooling tower and the waste gas adsorbing and filtering part, the heating part, the dedusting part, the washing and cooling tower and the waste gas adsorbing and filtering part are also respectively connected with the monitoring part, and the waste gas adsorbing and filtering part is connected with an air introducing device in the auxiliary part. The invention has the advantages of large treatment capacity, low treatment cost, soil physicochemical property maintenance and the like, can effectively separate organic matters from contaminated soil and treat the organic matters, and also can complete the processes of waste gas washing, waster gas adsorption and the like so as to reduce the energy consumption of the overall system.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Treatment method of arsenic slag

InactiveCN102218428AReduce leaching toxicityImprove long-term stabilitySolid waste disposalSlagFly ash

The invention discloses a treatment method of arsenic slag. The method is characterized by comprises the following steps: (1) adding fly ash and water in the arsenic slag, and stirring for 0.25-1 hour; (2) adding a stabilizing agent in the mixture obtained from the step (2), and stirring for 0.25-1 hour; (3) adding a curing agent in the mixture obtained from the step (3), and stirring for 0.25-1 hour; and (4) curing the mixture obtained from the step (3) for 1-7 days. According to the invention, the leaching toxity of the arsenic slag can be reduced to the admission requirement of a dangerous and waste landfill site, also the fly ash can be treated to achieve the aim of treating waste by the use of waste; and the method provided by the invention has simple process, the material is easy to obtain, the treatment cost is low, and the method has a favorable application prospect.

Owner:杭州大地环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com