Patents

Literature

1948 results about "Moisture permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permeability is the rate that water or vapor will pass through a membrane. The test used is Moisture Vapor Transmission ASTM-E 96 or Moisture Vapor Permeability D-1653. The results are measured in ˇ°permsˇ±. The lower the number the less moisture vapor will come through the membrane.

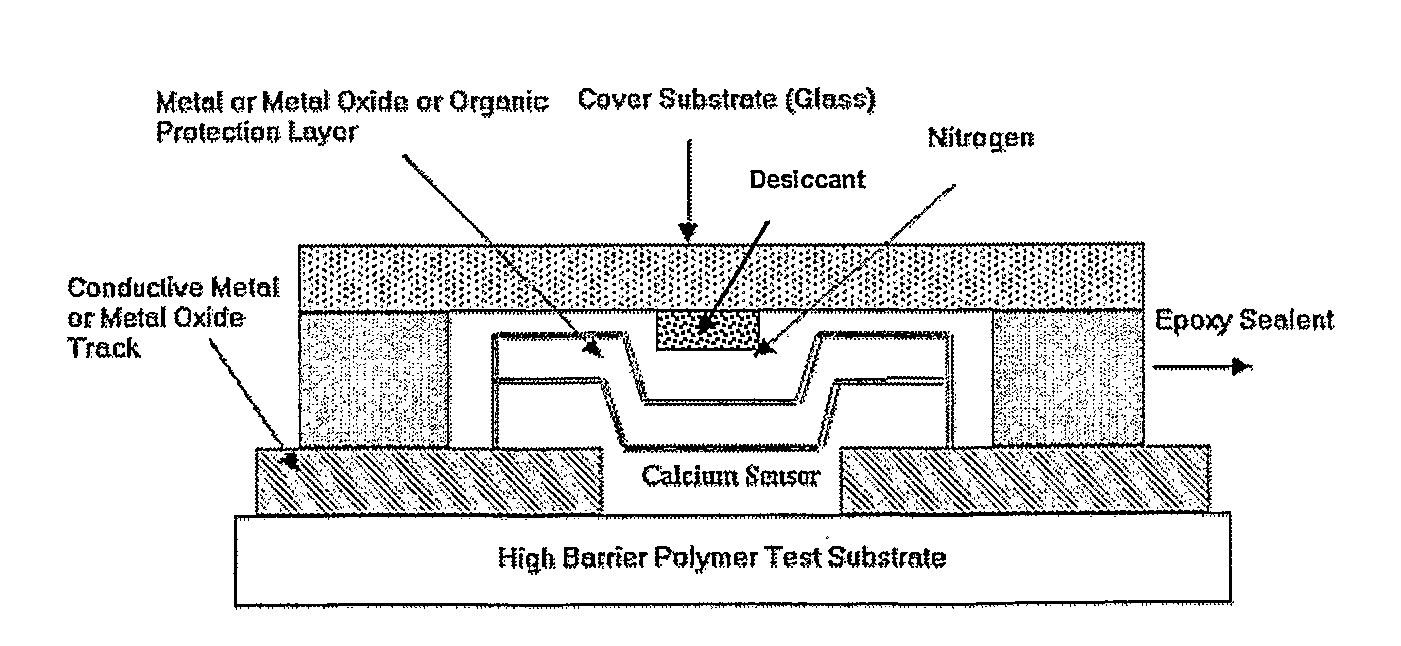

Nanoparticulate encapsulation barrier stack

ActiveUS20100089636A1Minimise lateral diffusionReduce probabilityMaterial nanotechnologyNanomagnetismChemistryNanometre

A barrier stack for encapsulating a moisture and / or oxygen sensitive electronic device is provided. The barrier stack comprises a multilayer film having at least one barrier layer having low moisture and / or oxygen permeability, and at least one sealing layer arranged to be in contact with a surface of the barrier layer, wherein the sealing material comprises reactive nanoparticles capable of interacting with moisture and / or oxygen, thereby retarding the permeation of moisture and / or oxygen through defects present in the barrier layer.

Owner:AGENCY FOR SCI TECH & RES

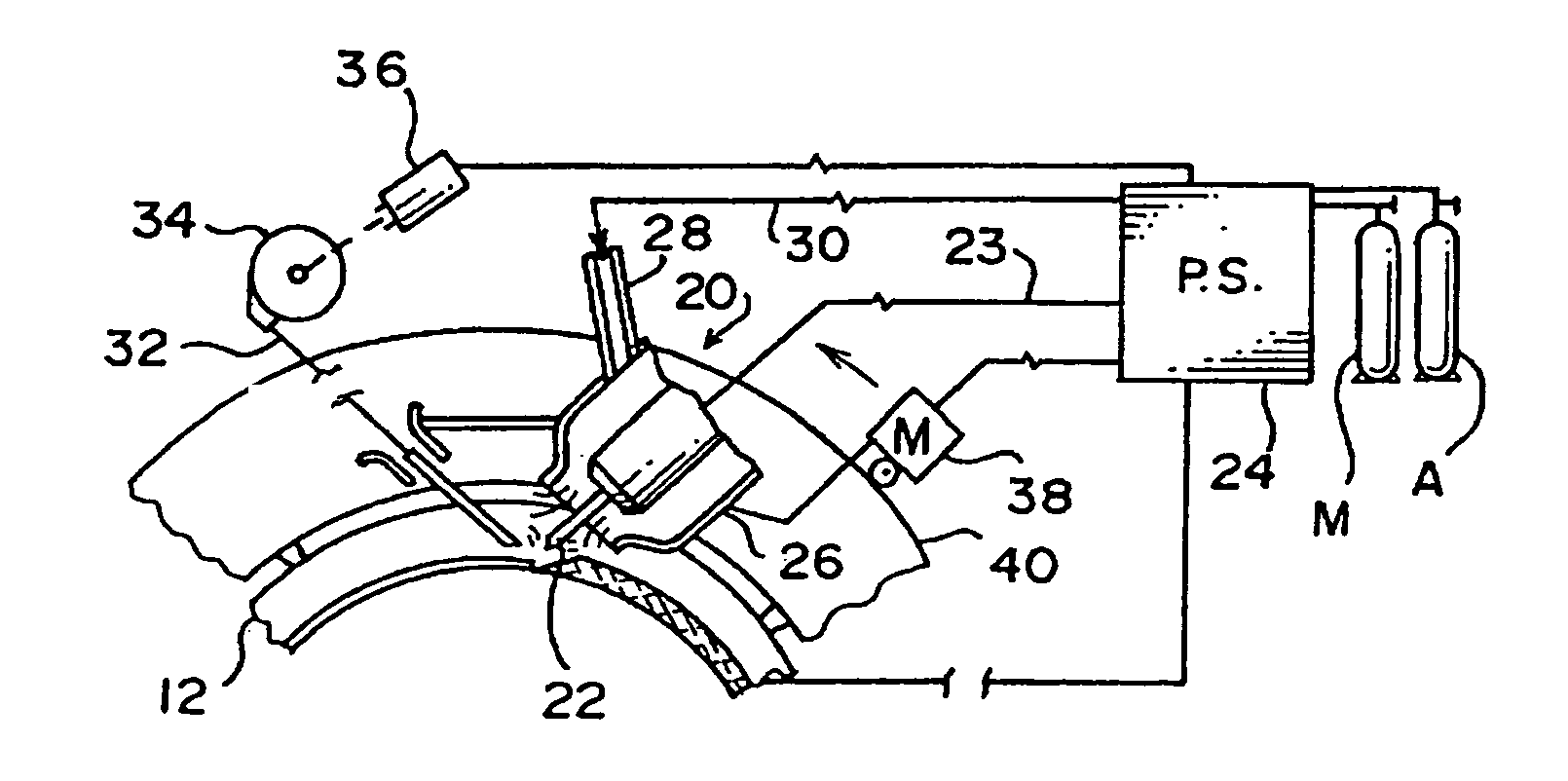

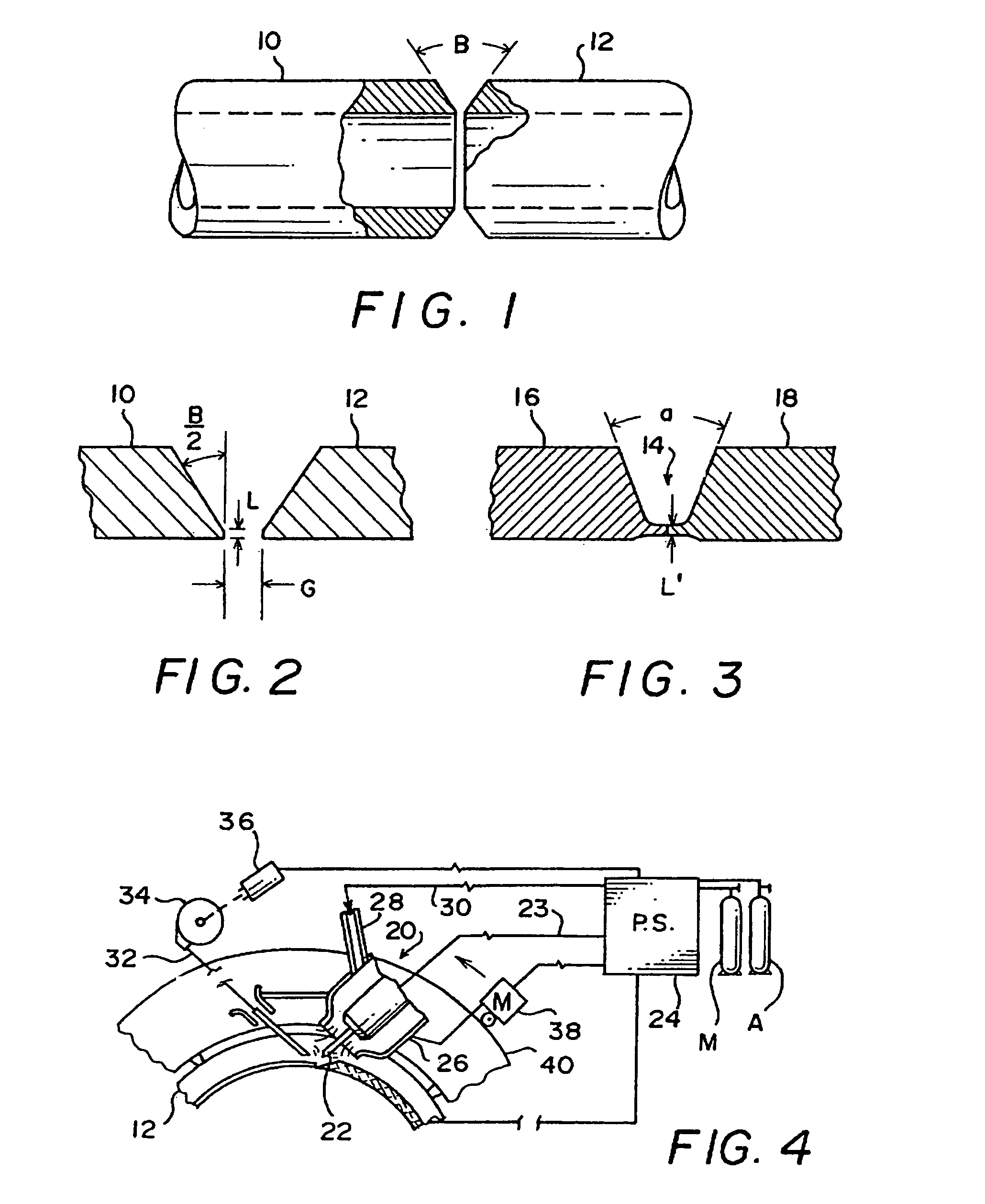

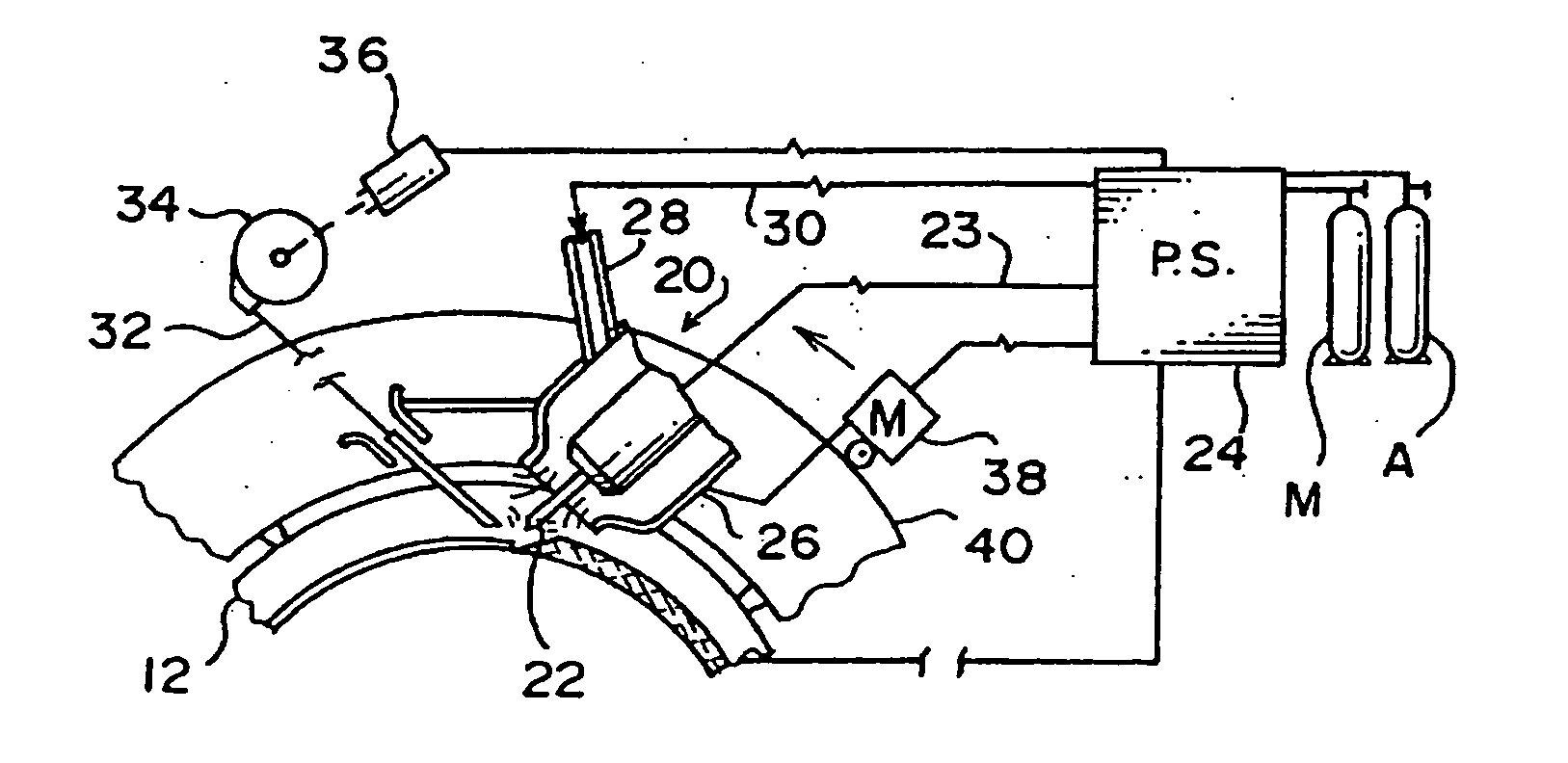

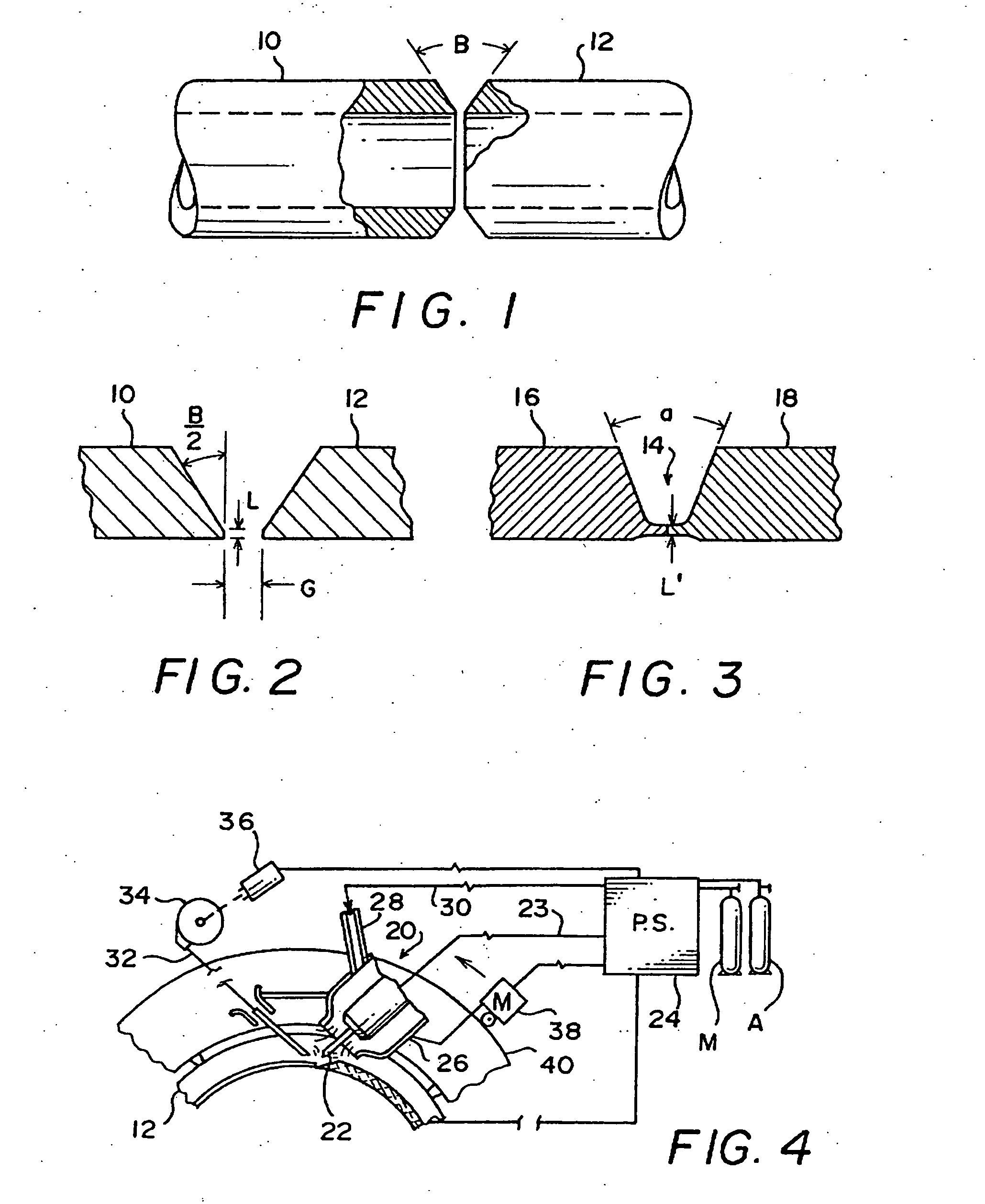

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

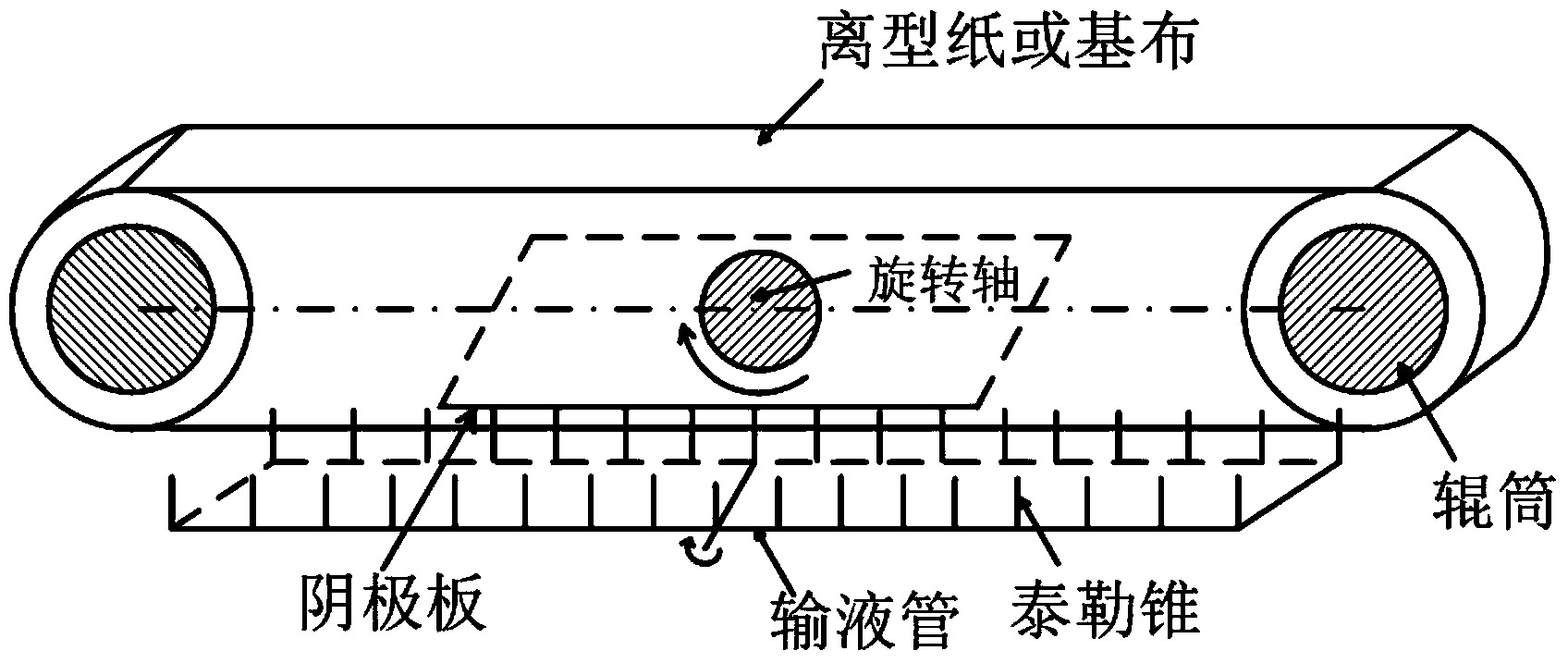

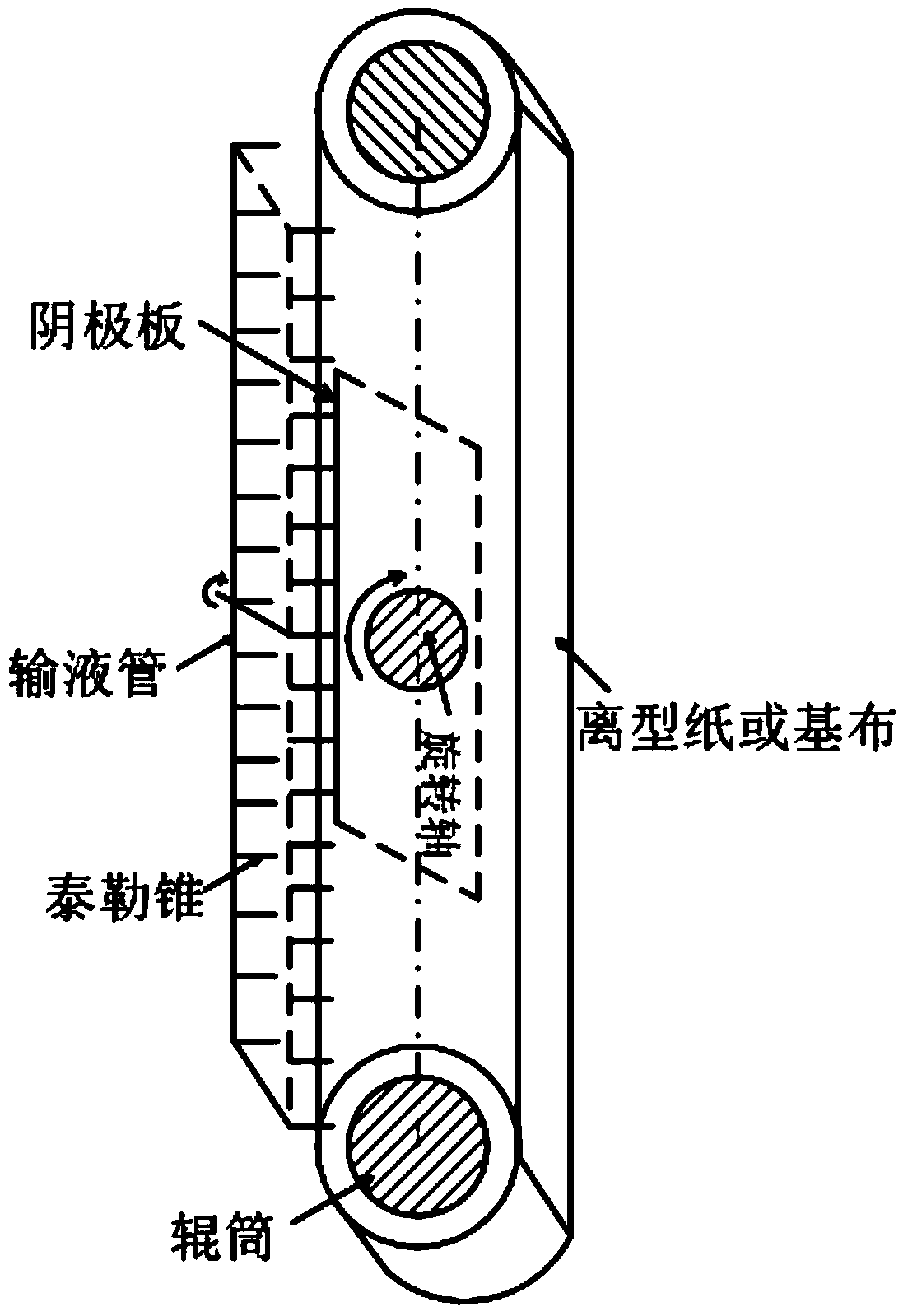

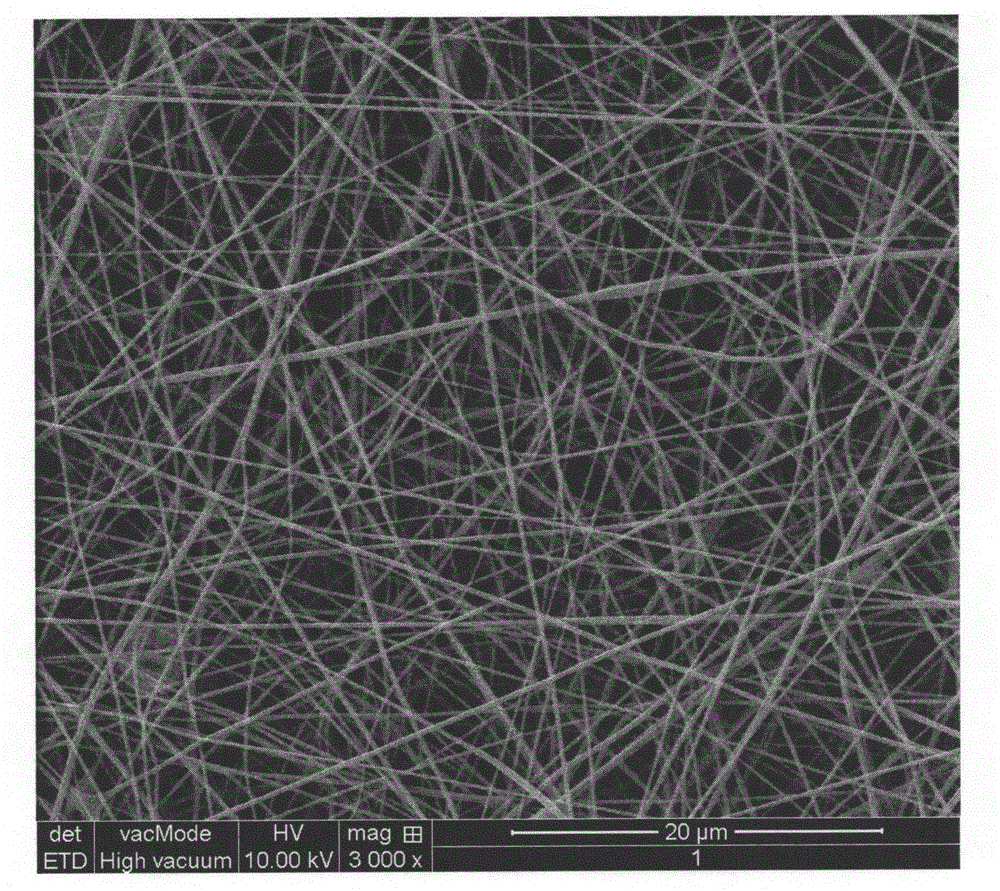

Electrostatic spinning nanofiber membrane as well as preparation method thereof

InactiveCN103437071AIncrease productivityReduce energy consumptionNon-woven fabricsChemical industryFiber

The invention provides an electrostatic spinning nanofiber membrane as well as a preparation method thereof. The electrostatic spinning nanofiber membrane provided by the invention comprises a fiber membrane obtained by electrostatically spinning a high-melting-point polymer and a fiber membrane obtained by electrostatically spinning a low-melting-point polymer, wherein the difference on the melting points of the high-melting-point polymer and the low-melting-point polymer is not less than 10 DEG C. The electrostatic spinning nanofiber membrane provided by the invention is multipurpose and can be applied to the fields such as biomedicines, energy and chemical industry, gas and liquid filtration, waterproofness and windproofness, windproofness and heat insulation, moisture permeability and ventilation, environmental management and semiconductor sensors. According to the electrostatic spinning nanofiber membrane provided by the invention, electrostatic spinning is respectively carried out on the high-melting-point polymer and the low-melting-point polymer, and the high-melting-point polymer fiber membrane and the low-melting-point polymer fiber membrane obtained are composited and hot-pressed to obtain the electrostatic spinning nanofiber membrane. The preparation method provided by the invention is high in production efficiency and low in energy consumption, and is suitable for industrial production.

Owner:ZHEJIANG WEIXING IND DEV

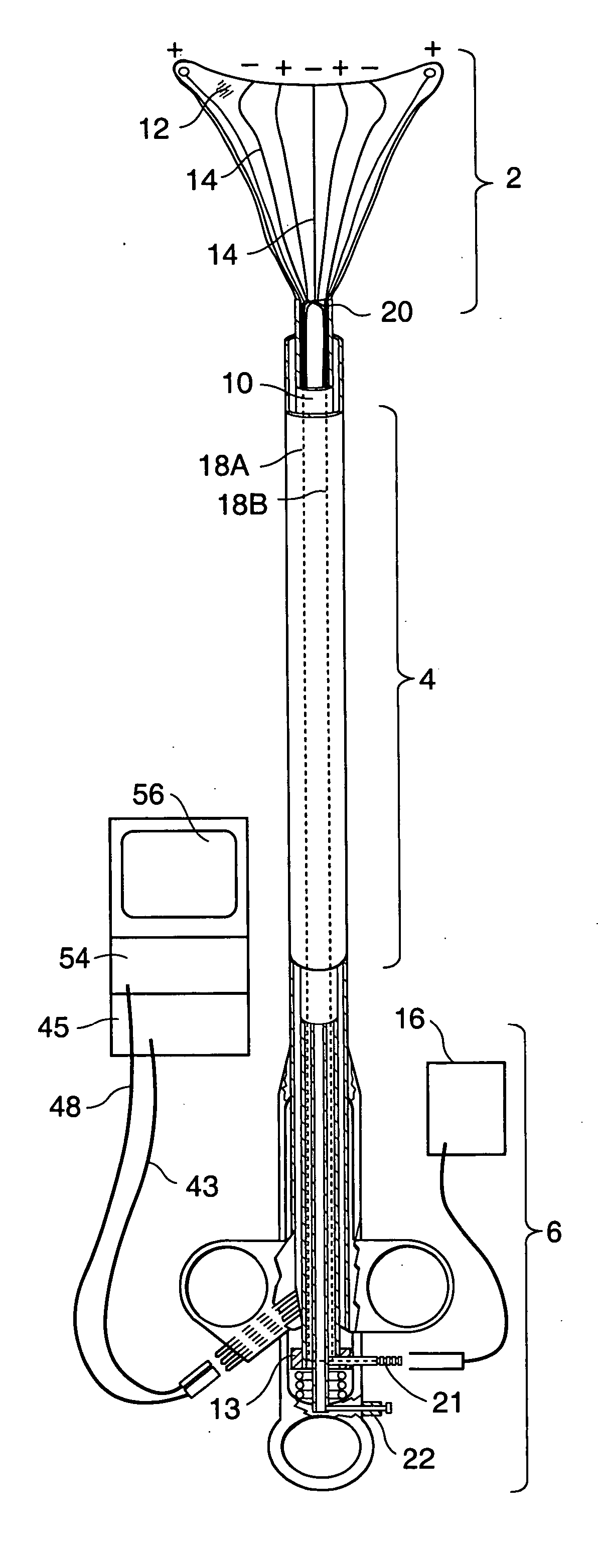

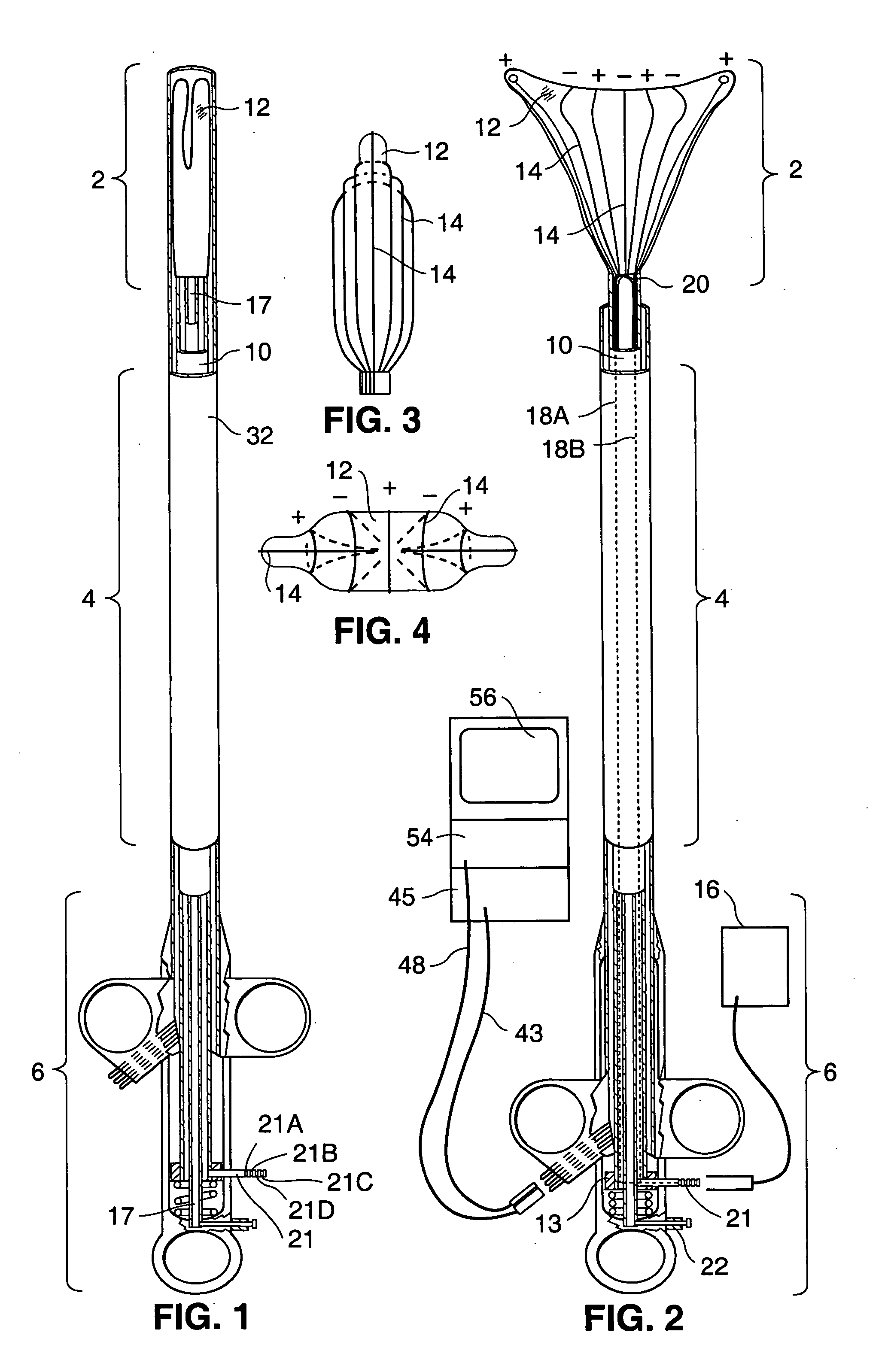

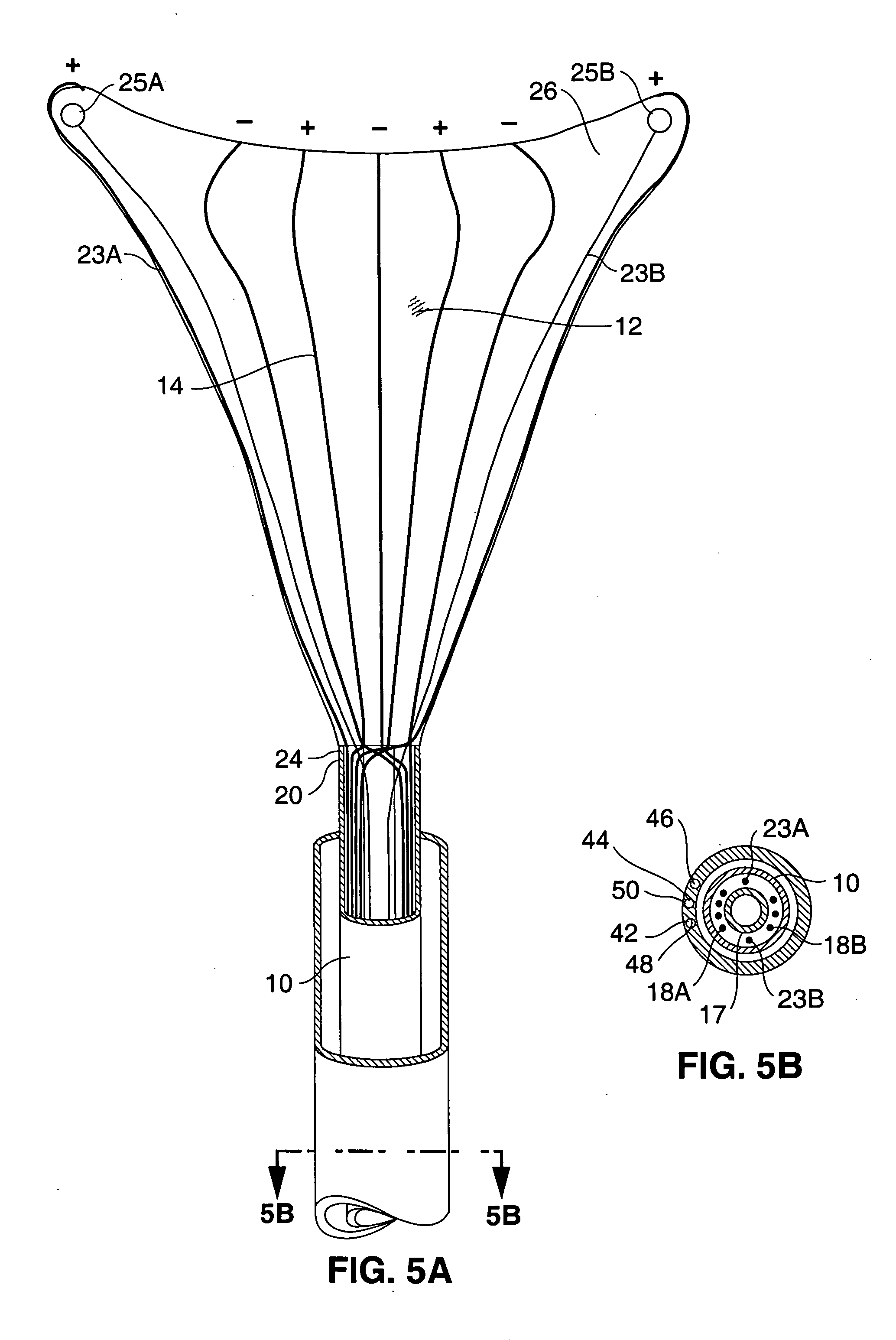

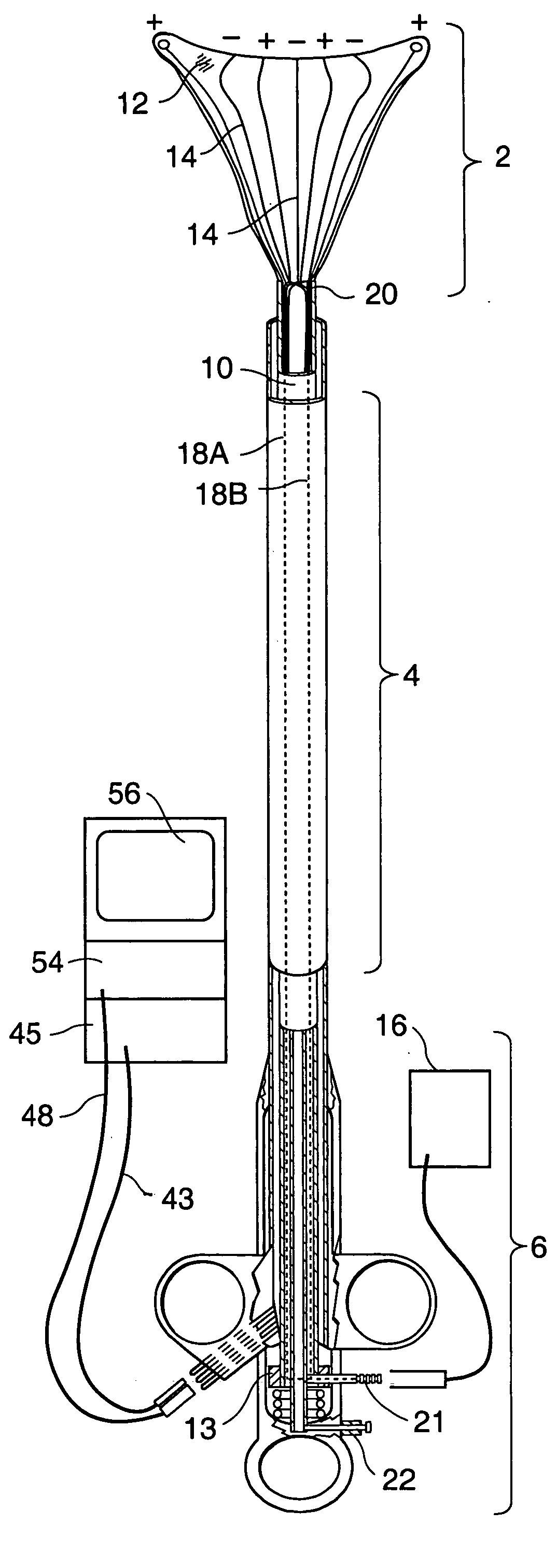

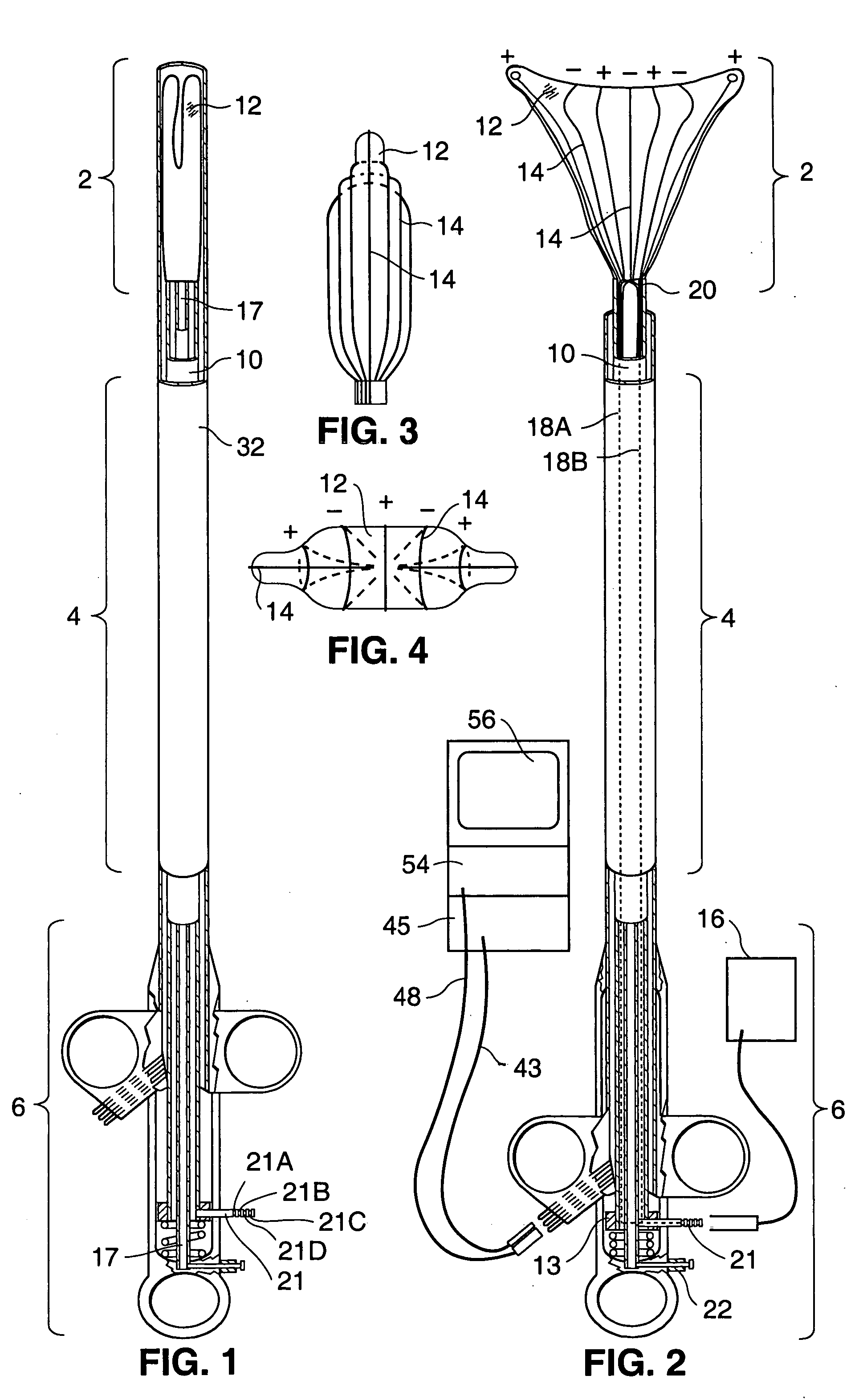

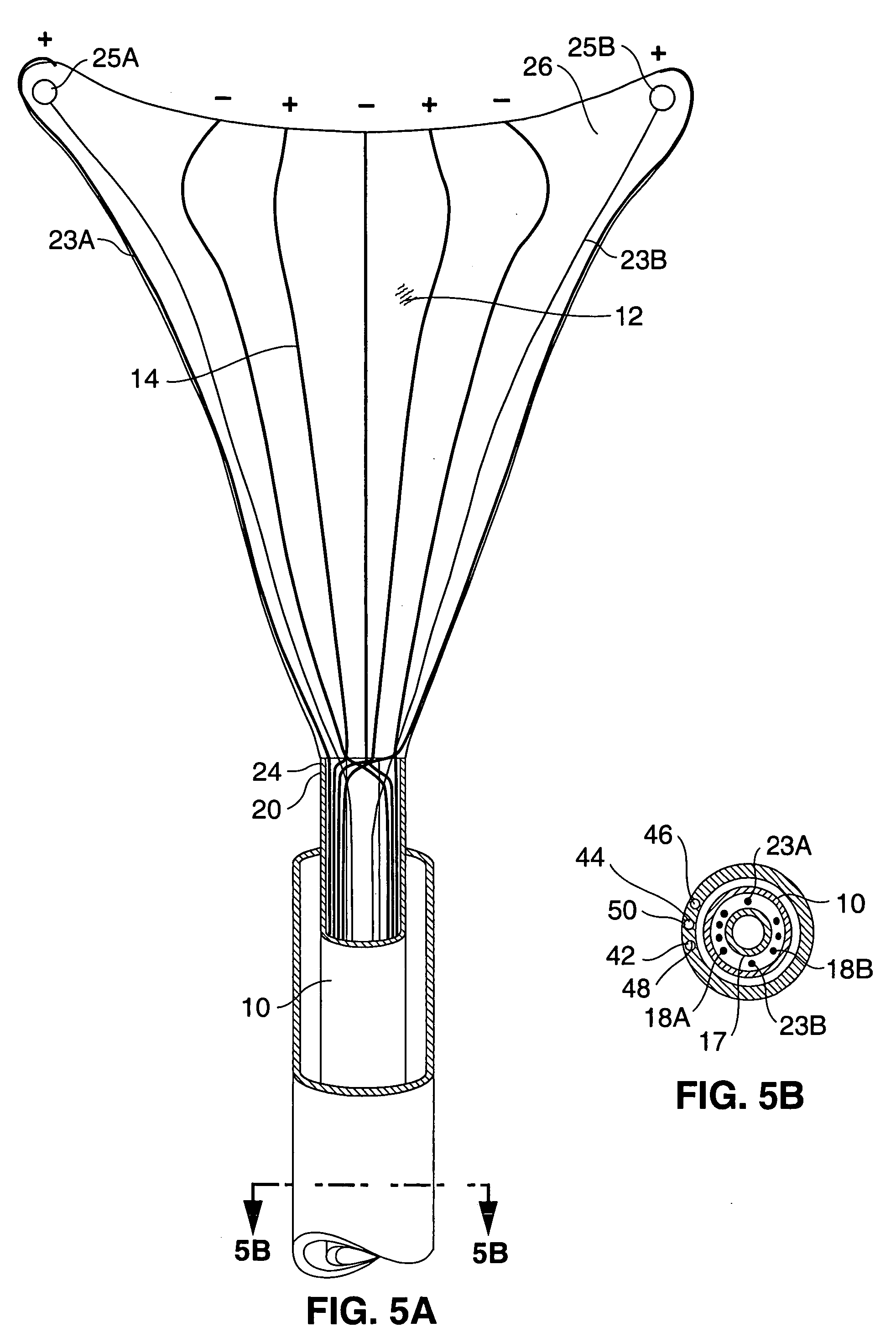

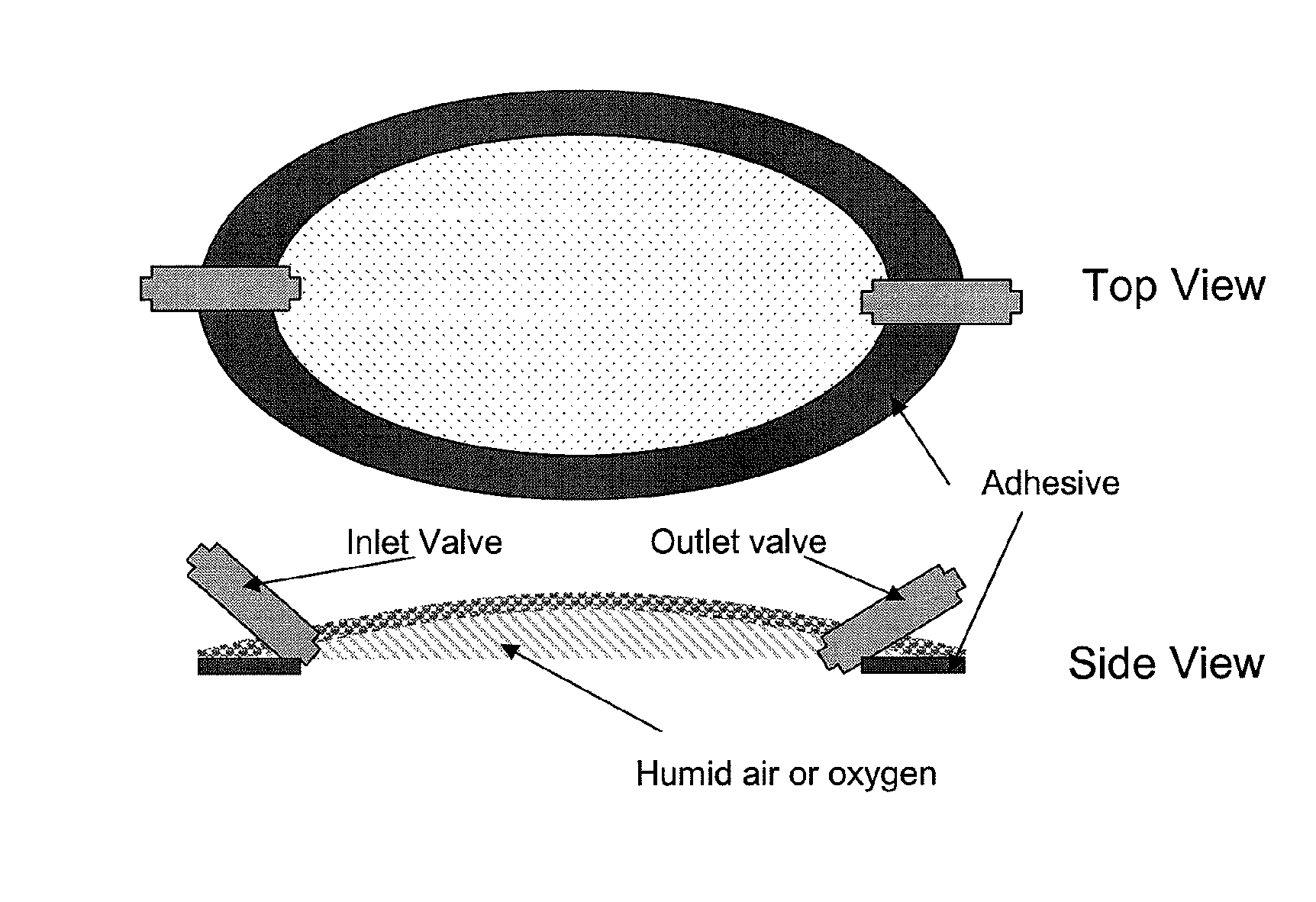

Moisture transport system for contact electrocoagulation

An apparatus and method for use in performing ablation or coagulation of organs and other tissue includes a metallized fabric electrode array which is substantially absorbent and / or permeable to moisture and gases such as steam and conformable to the body cavity. The array includes conductive regions separated by insulated regions arranged to produce ablation to a predetermined depth. Following placement of the ablation device into contact with the tissue to be ablated, an RF generator is used to deliver RF energy to the conductive regions and to thereby induce current flow from the electrodes to tissue to be ablated. As the current heats the tissue, moisture (such as steam or liquid) leaves the tissue causing the tissue to dehydrate. Suction may be applied to facilitate moisture removal. The moisture permeability and / or absorbency of the electrode carrying member allows the moisture to leave the ablation site so as to prevent the moisture from providing a path of conductivity for the current.

Owner:CYTYC SURGICAL PRODS

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

Moisture transport system for contact electrocoagulation

An apparatus and method for use in performing ablation or coagulation of organs and other tissue includes a metallized fabric electrode array which is substantially absorbent and / or permeable to moisture and gases such as steam and conformable to the body cavity. The array includes conductive regions separated by insulated regions arranged to produce ablation to a predetermined depth. Following placement of the ablation device into contact with the tissue to be ablated, in RF generator is used to deliver RF energy to the conductive regions and to thereby induce current flow from the electrodes to tissue to be ablated. As the current heats the tissue, moisture (such as steam or liquid) leaves the tissue causing the tissue to dehydrate. Suction may be applied to facilitate moisture removal. The moisture permeability and / or absorbency of the electrode carrying member allows the moisture to leave the ablation site so as to prevent the moisture from providing a path of conductivity for the current.

Owner:CYTYC CORP

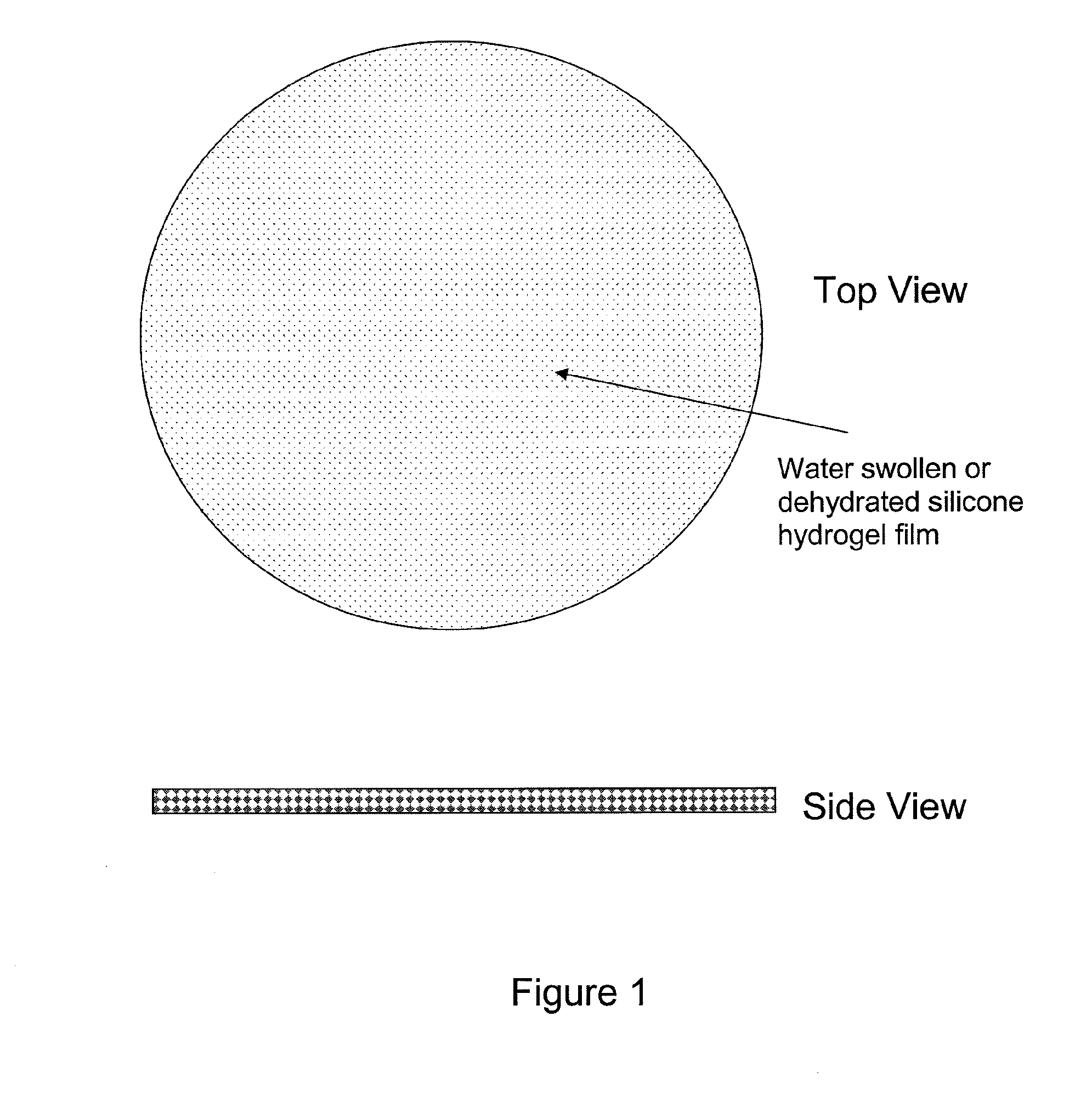

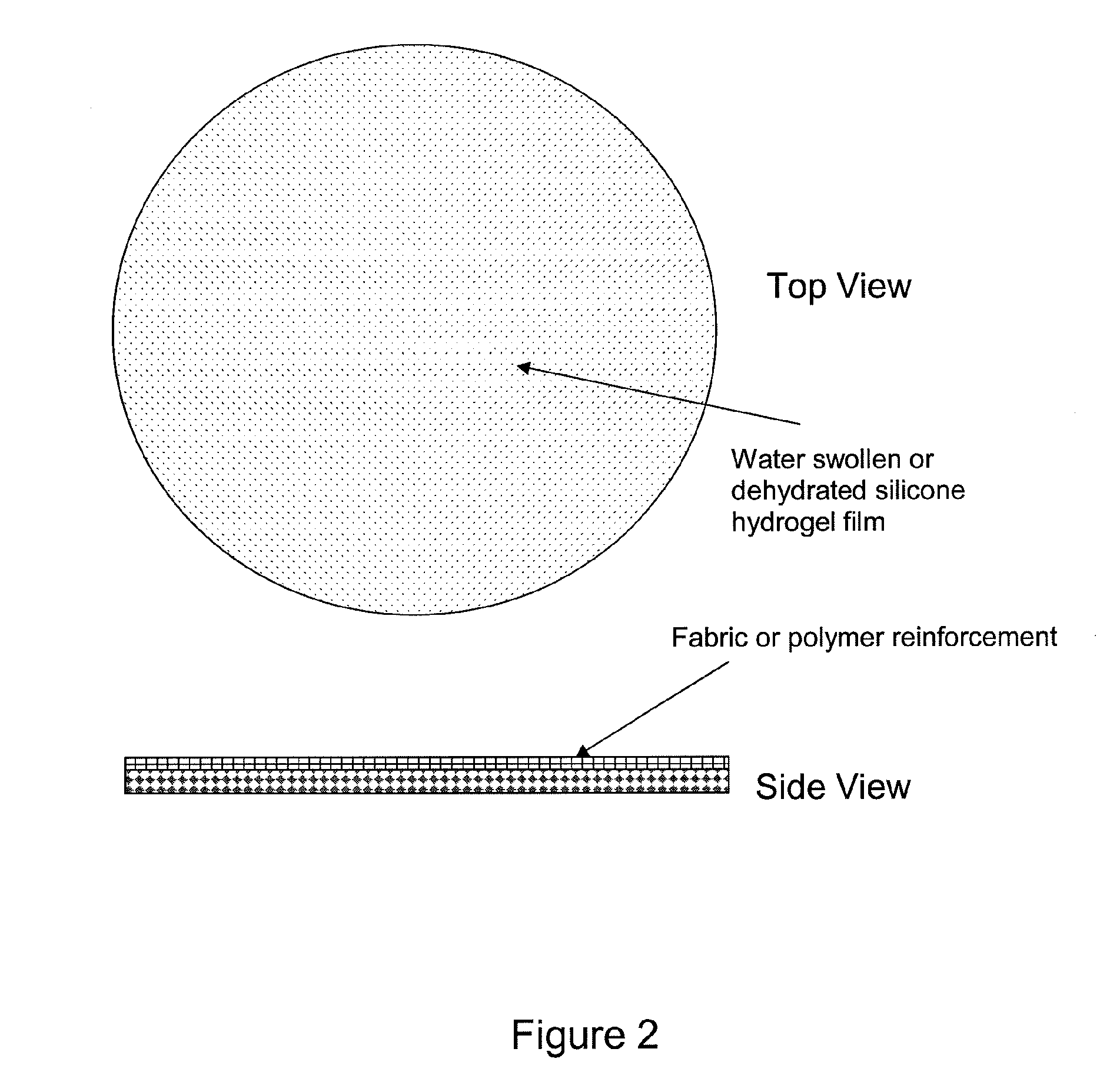

Silicone hydrogels for tissue adhesives and tissue dressing applications

InactiveUS20110086077A1Provide strengthFacilitated releaseBiocidePeptide/protein ingredientsWound dressingSilanes

A silicone hydrogel formulation may contains random and / or block copolymers or oligomers or macromers. The silicone copolymer is copolymerized or blended with other polymers or monomers or macromers to obtain final formulation. The silicone hydrogel may contain crosslinking groups to provide a complete or partially crosslinked final structure. The silicone hydrogel formulation may be pre-formed as a film or other structure, or it may be polymerized during application as in the case of an adhesive formulation. A wound dressing comprising a silicone hydrogel formed as a film, either prior to application to a wound or in situ on a wound, which film has gas permeability, moisture permeability, and high water content, wherein said silicone hydrogel is formed from a polymerizable silicone such as a difunctional polydimethylsiloxane methacrylate and crosslinking agents such as N,N-dimethyllacrylamide (DMA), 2-hydroxyethyl methacrylate (HEMA), and trimethylsiloxy silane (TRIS).

Owner:DSM IP ASSETS BV

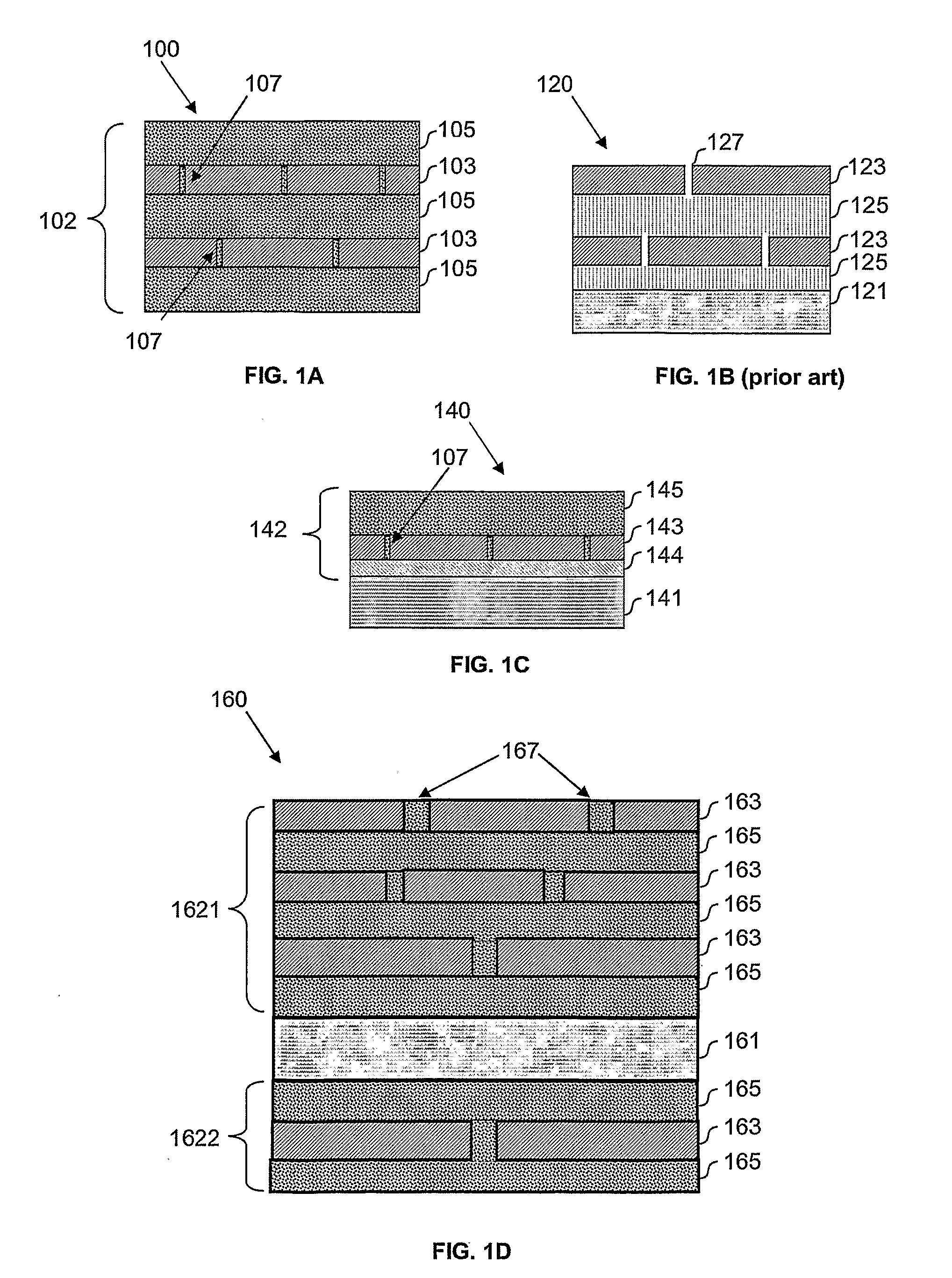

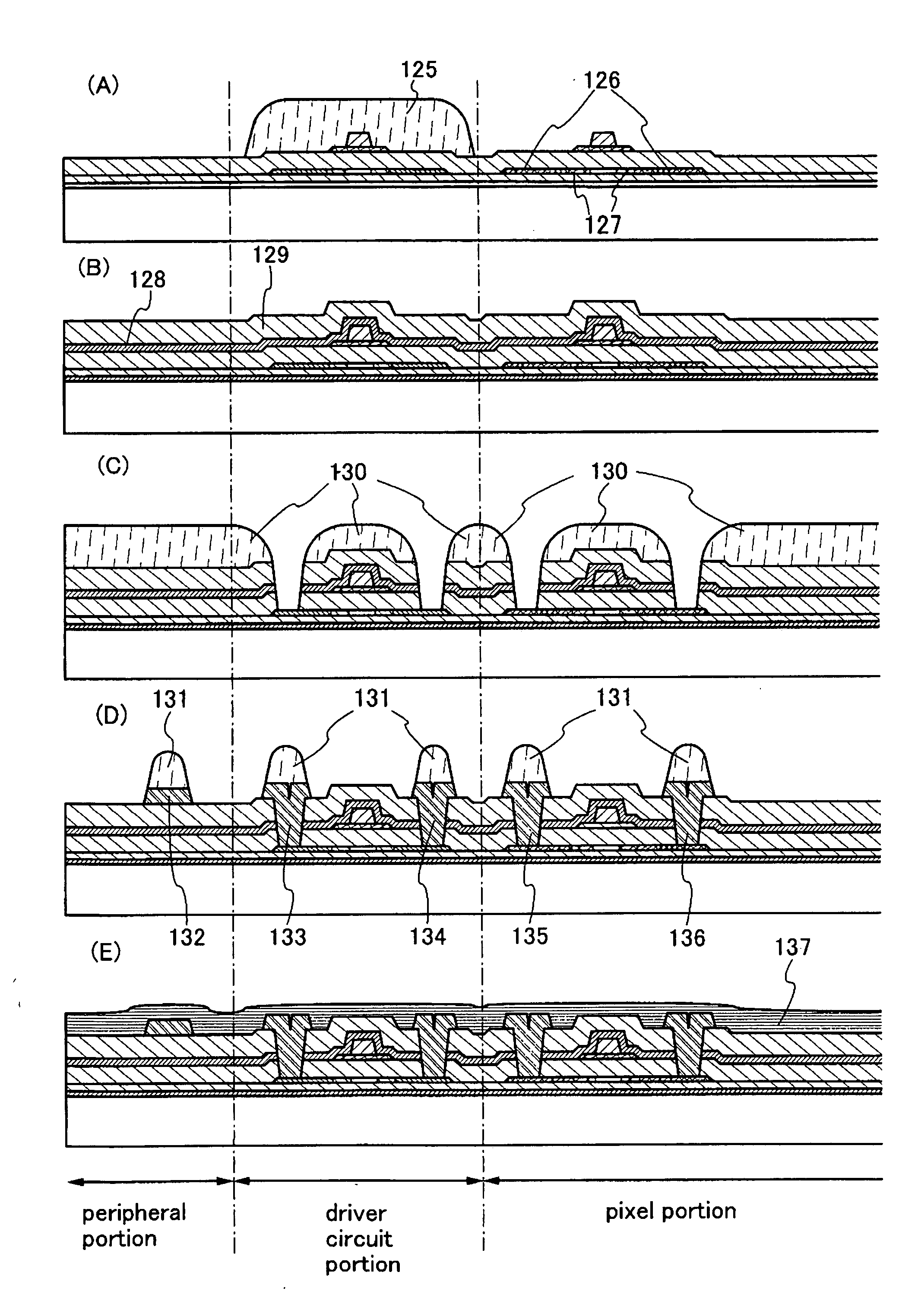

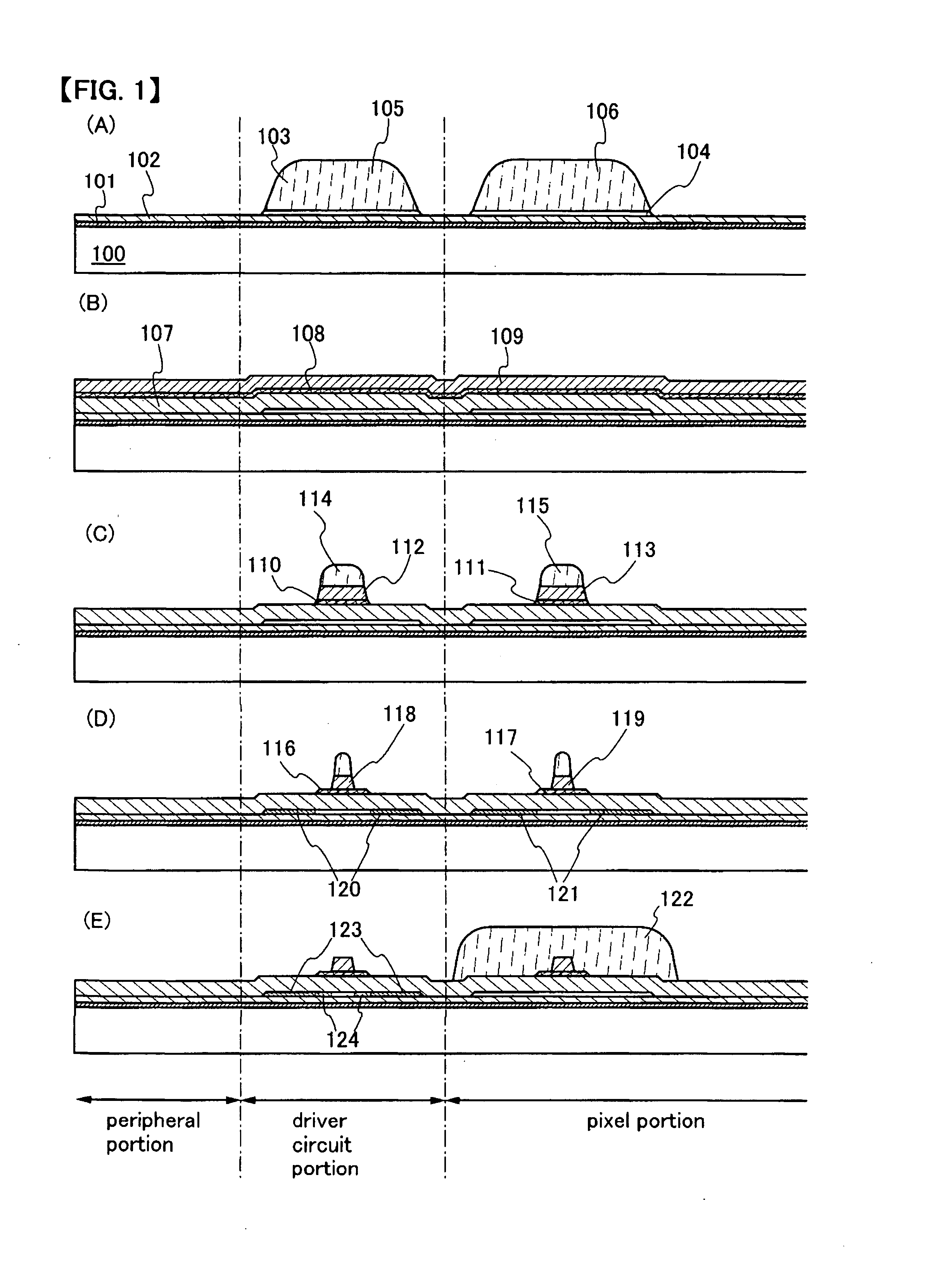

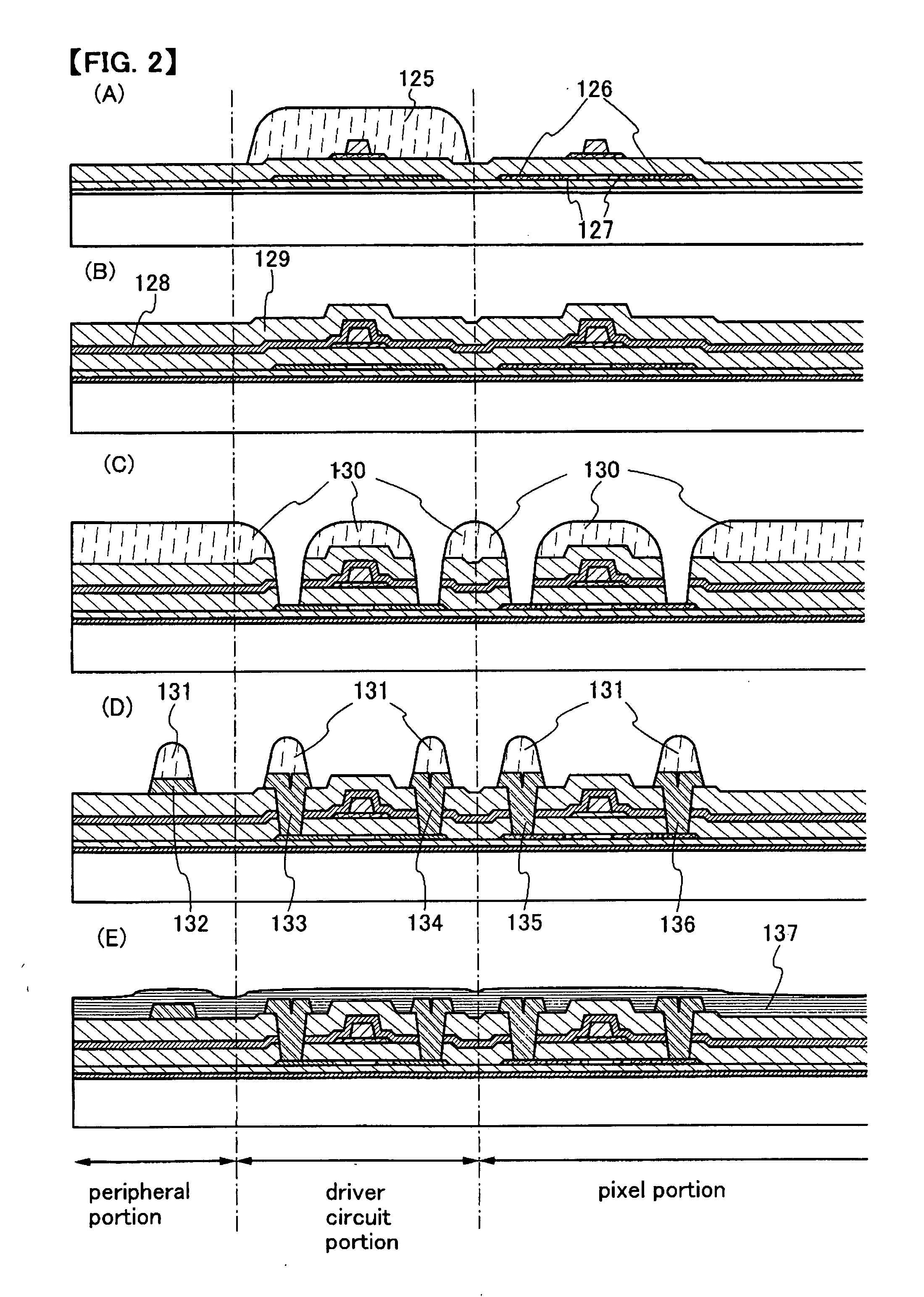

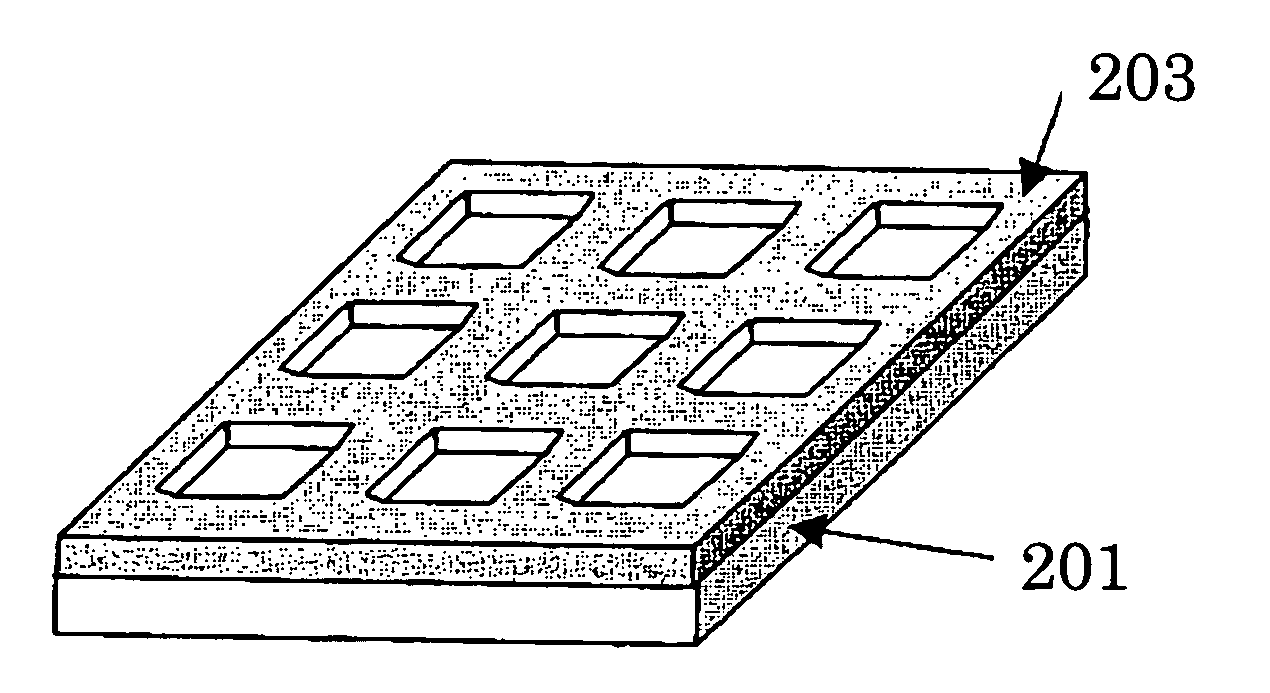

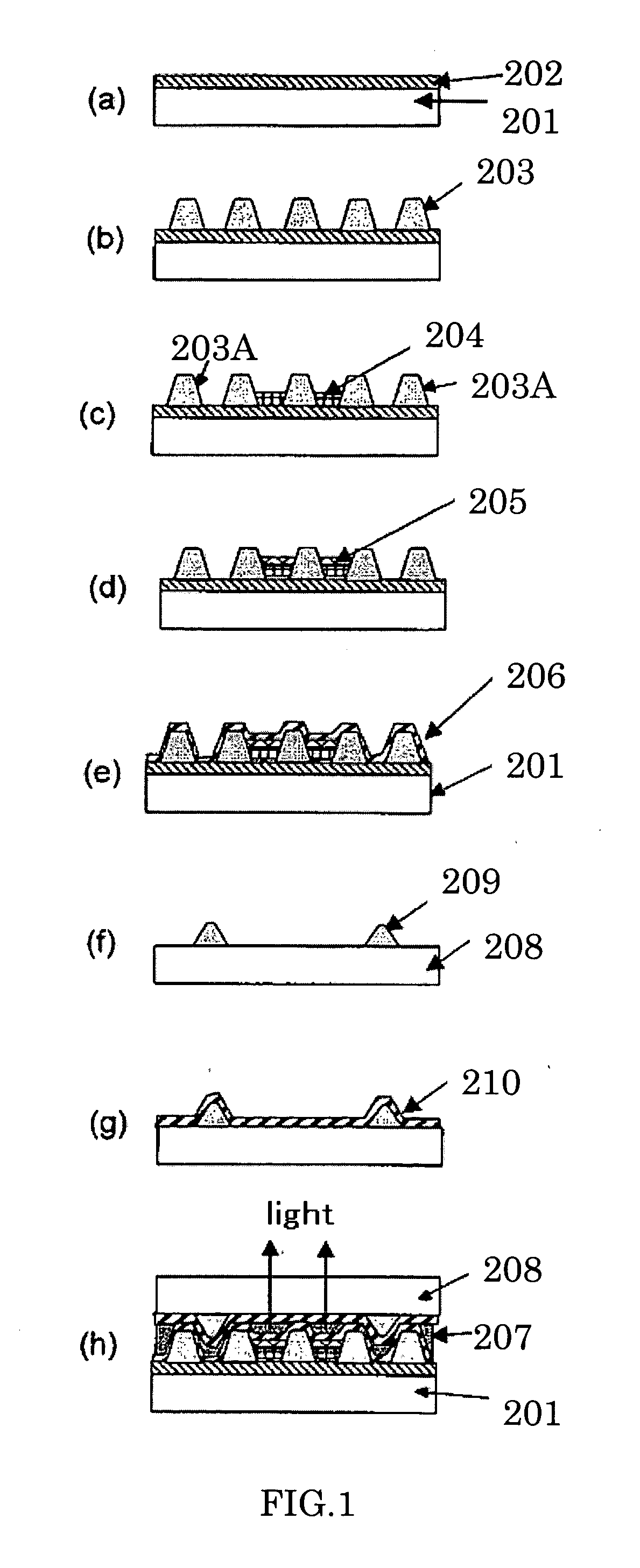

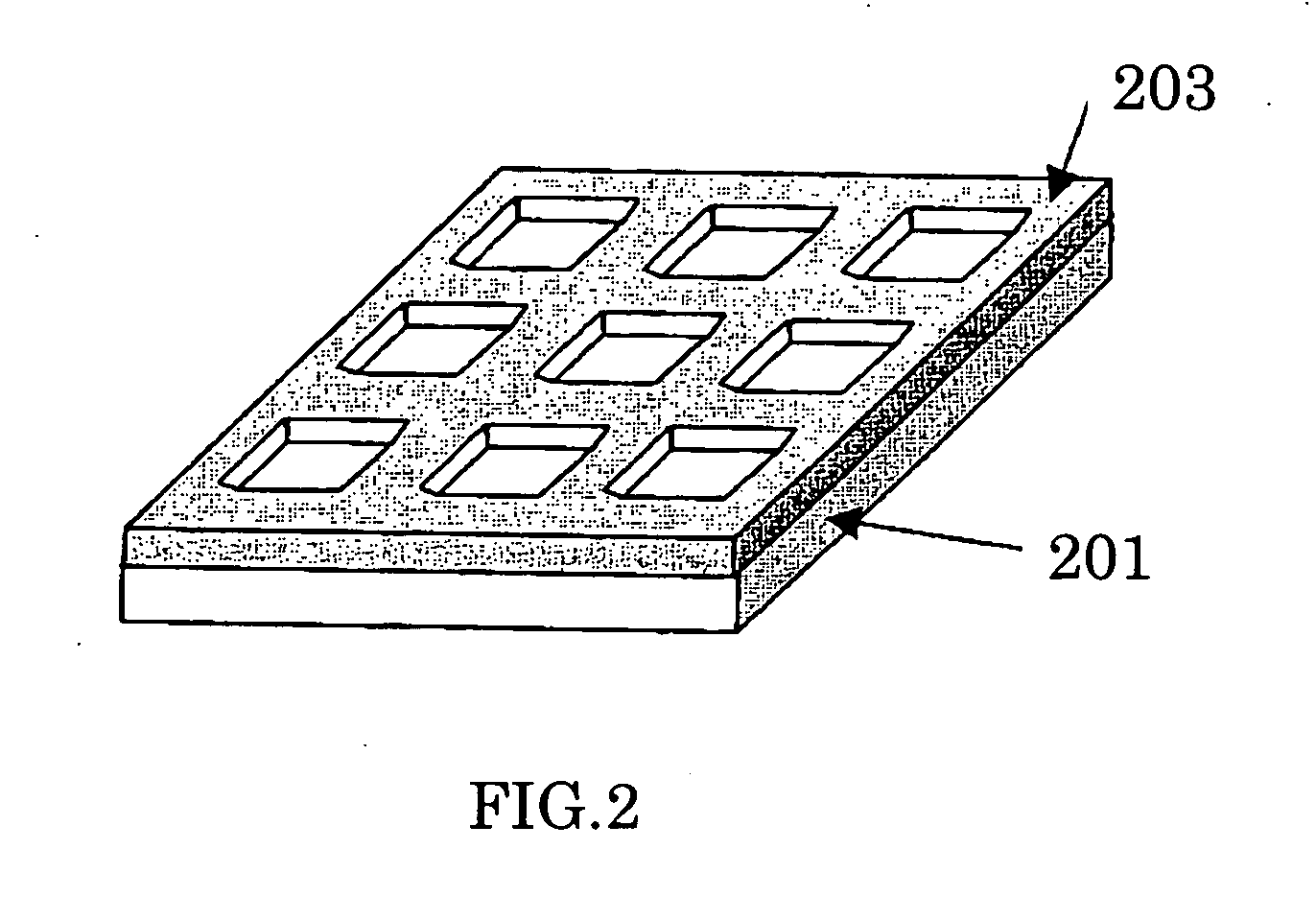

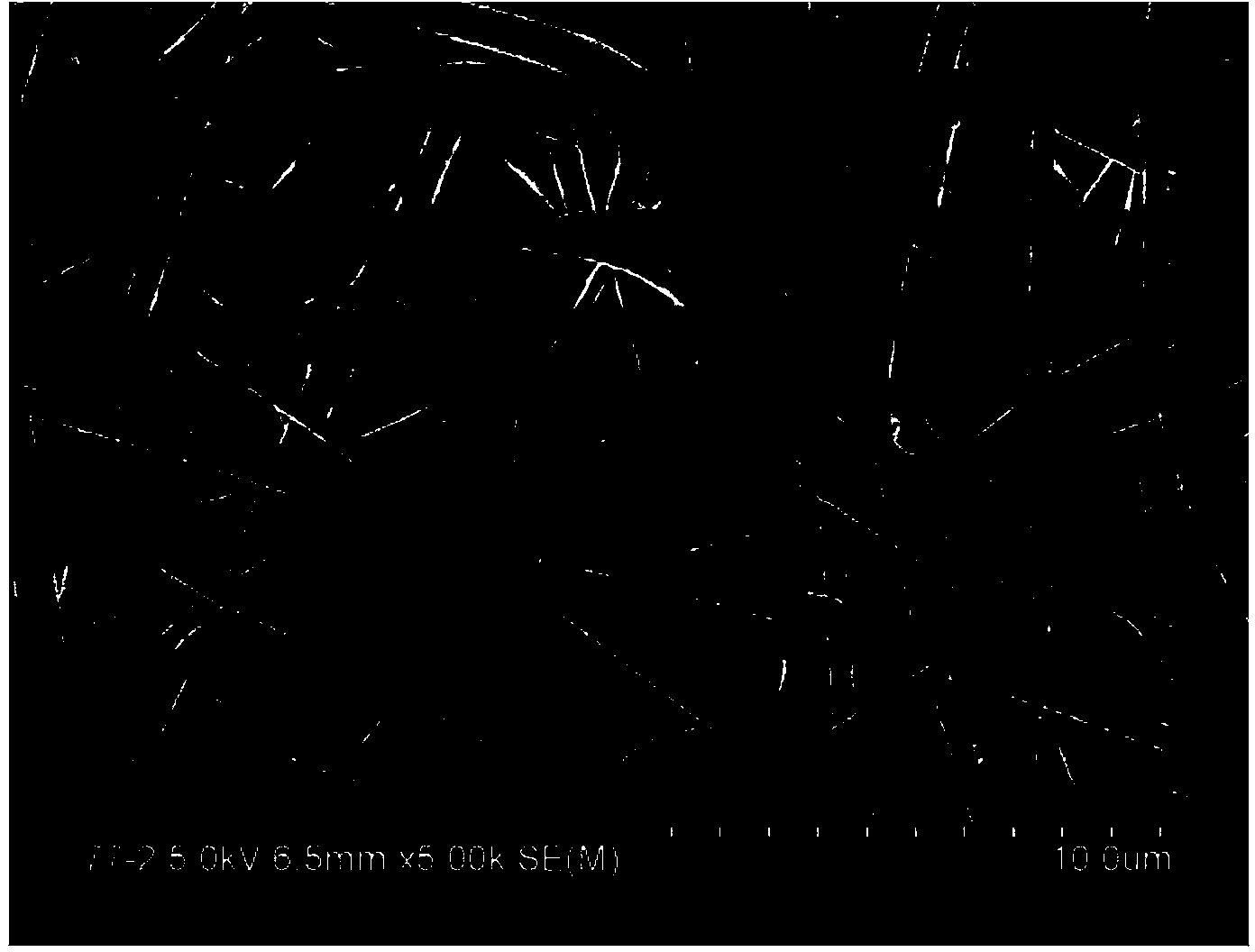

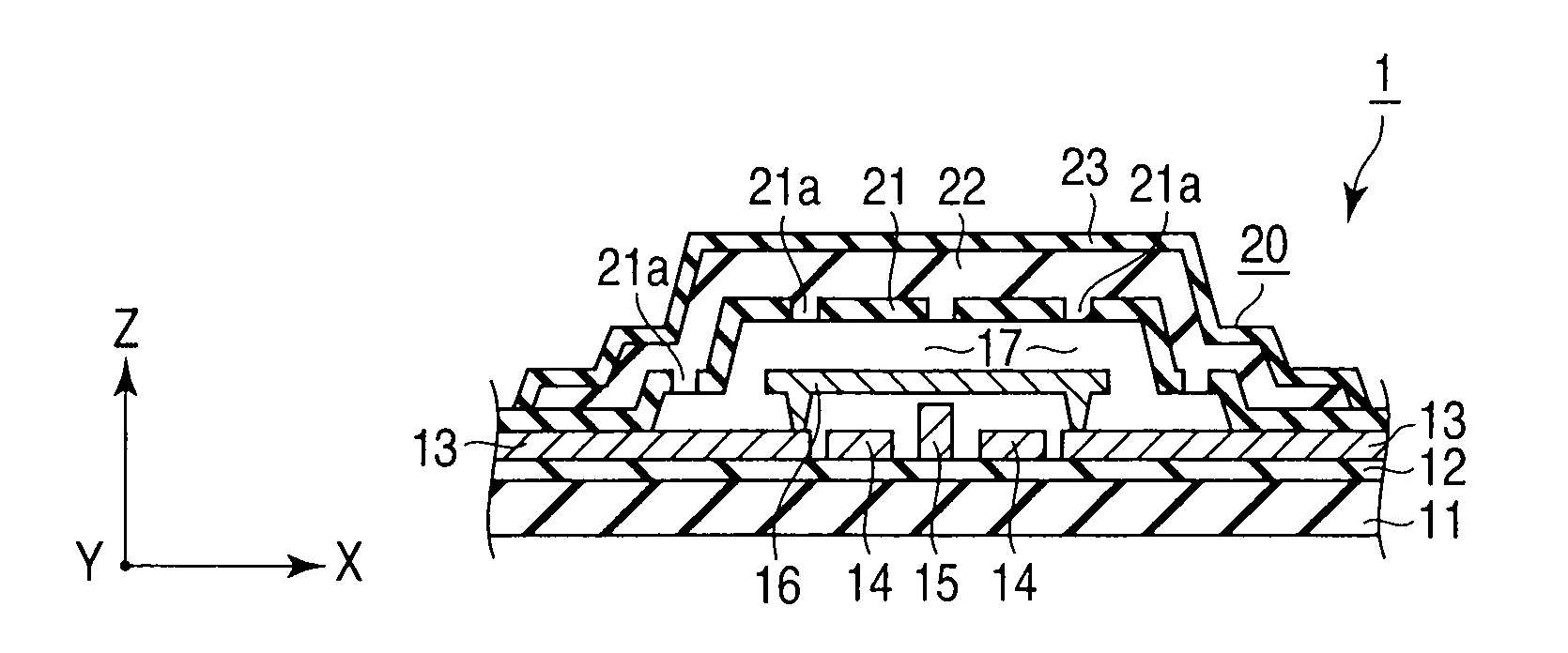

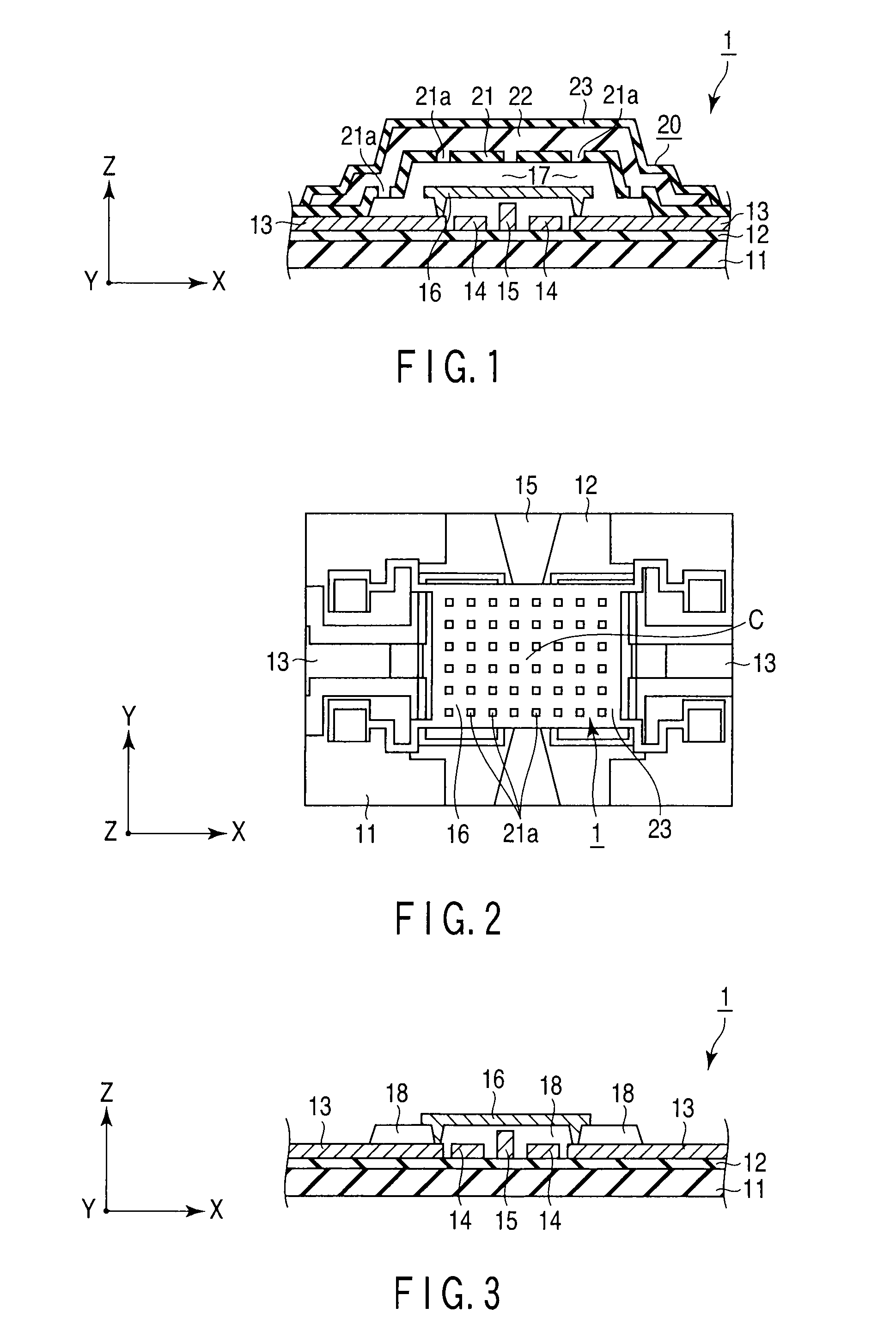

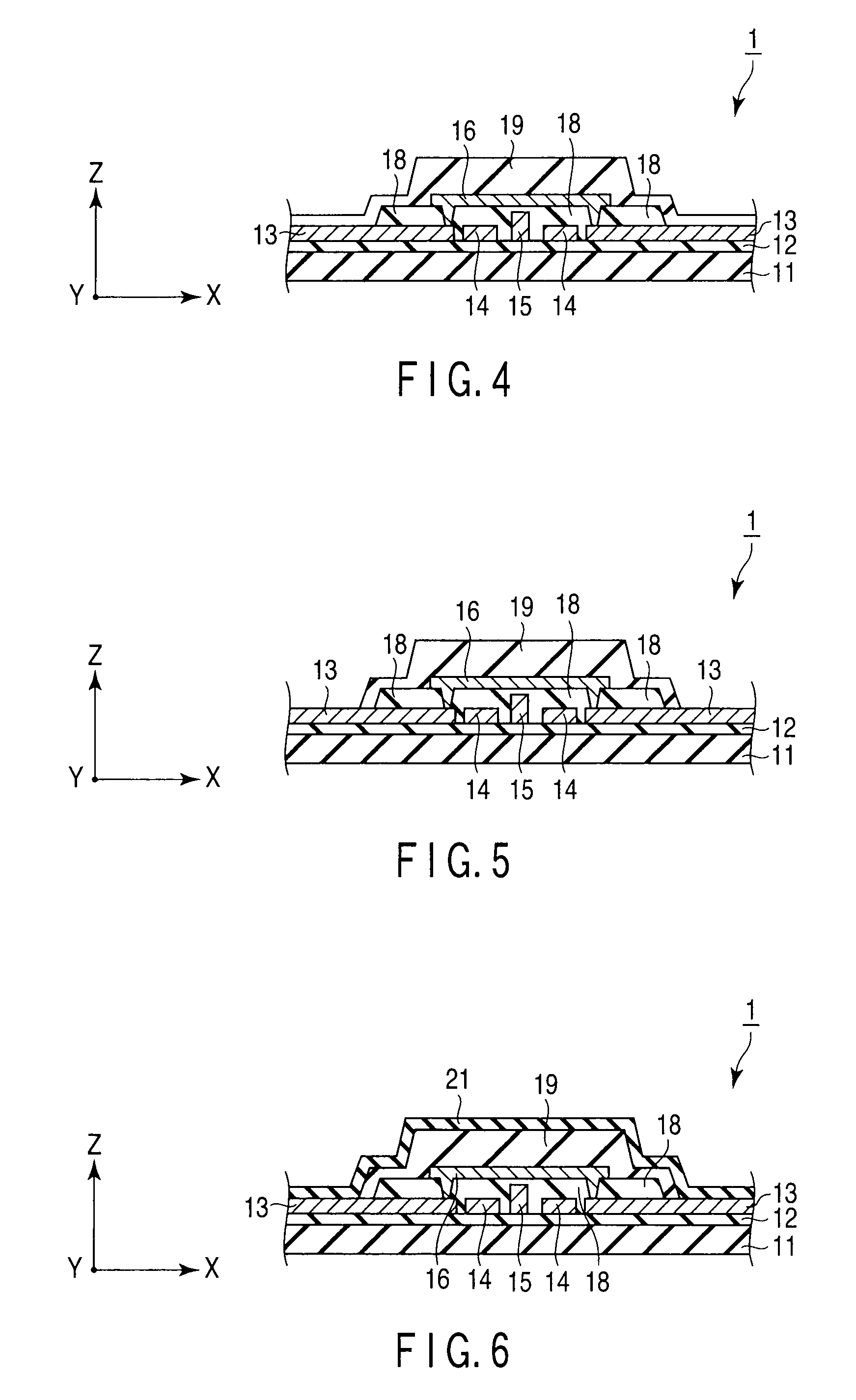

Display device and manufacturing method of the same

ActiveUS20060186413A1Easy to operateGood moisture permeabilityStatic indicating devicesSolid-state devicesDisplay deviceMoisture permeability

It is an object of the present invention to provide a method for manufacturing a display device in which unevenness generated under a light-emitting element does not impart an adverse effect on the light-emitting element. It is another object of the invention to provide a method for manufacturing a display device in which penetration of water into the inside of the display device through a film having high moisture permeability can be suppressed without increasing processing steps considerably. It is another object of the invention to provide a display device and a method for manufacturing a display device satisfying the above two simultaneously. A display device of the present invention to solve the above problems comprising a thin film transistor and a light-emitting element over an insulating surface formed on a substrate, wherein the light-emitting element includes a light-emitting laminated body interposed between a first electrode and a second electrode; wherein the first electrode is formed over an insulating film formed over the thin film transistor; and wherein a planarizing film is formed in response to the first electrode between the first electrode and the insulating film.

Owner:SEMICON ENERGY LAB CO LTD

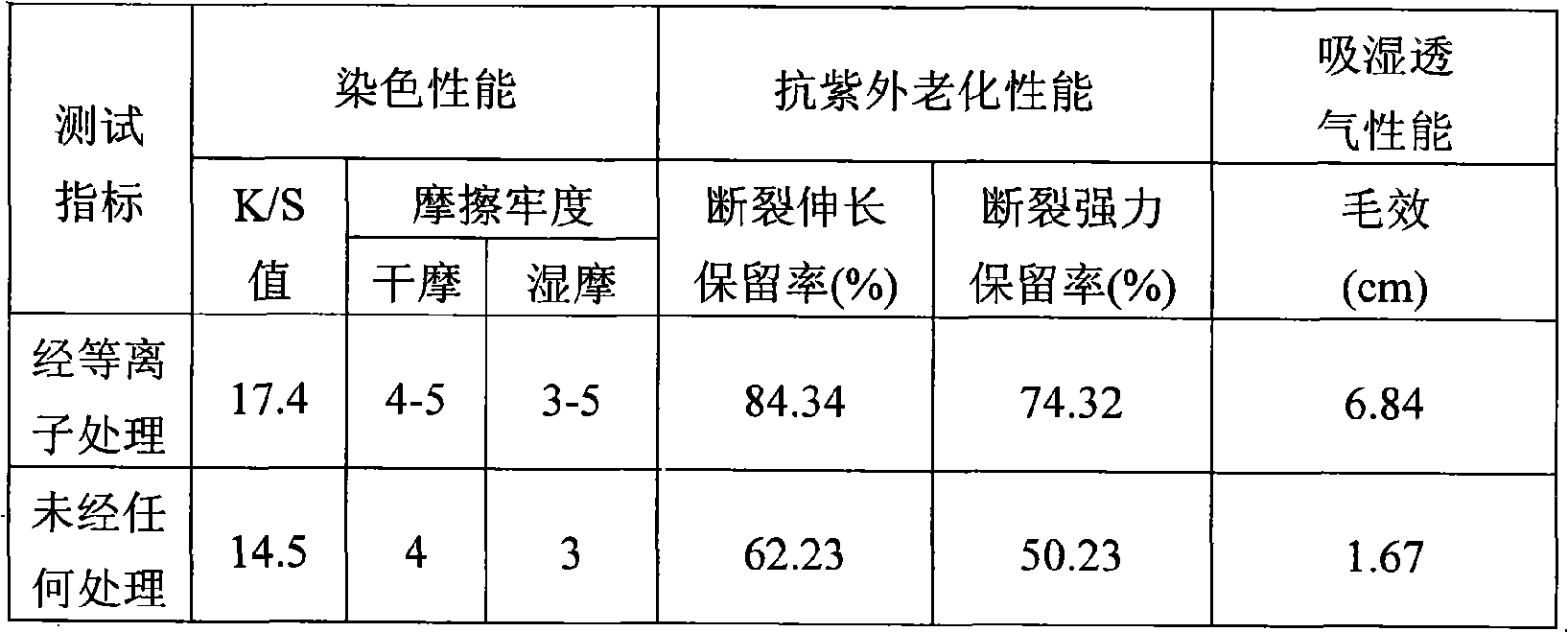

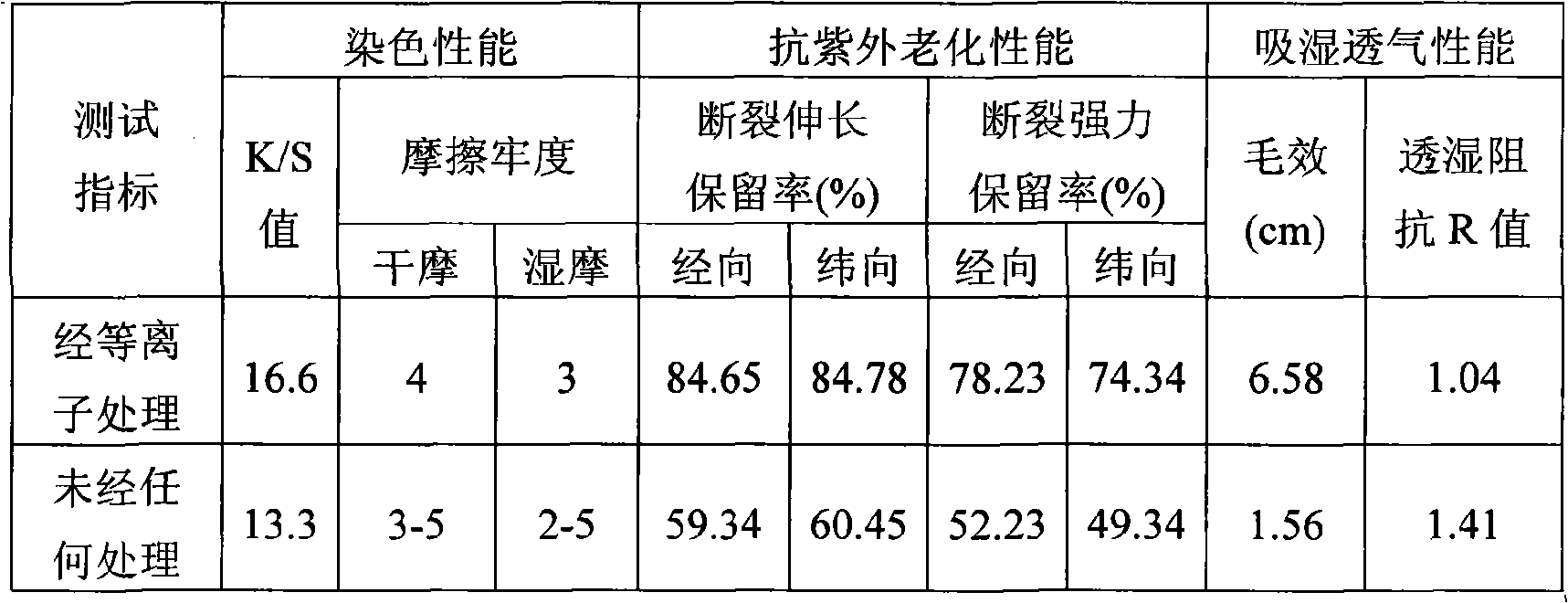

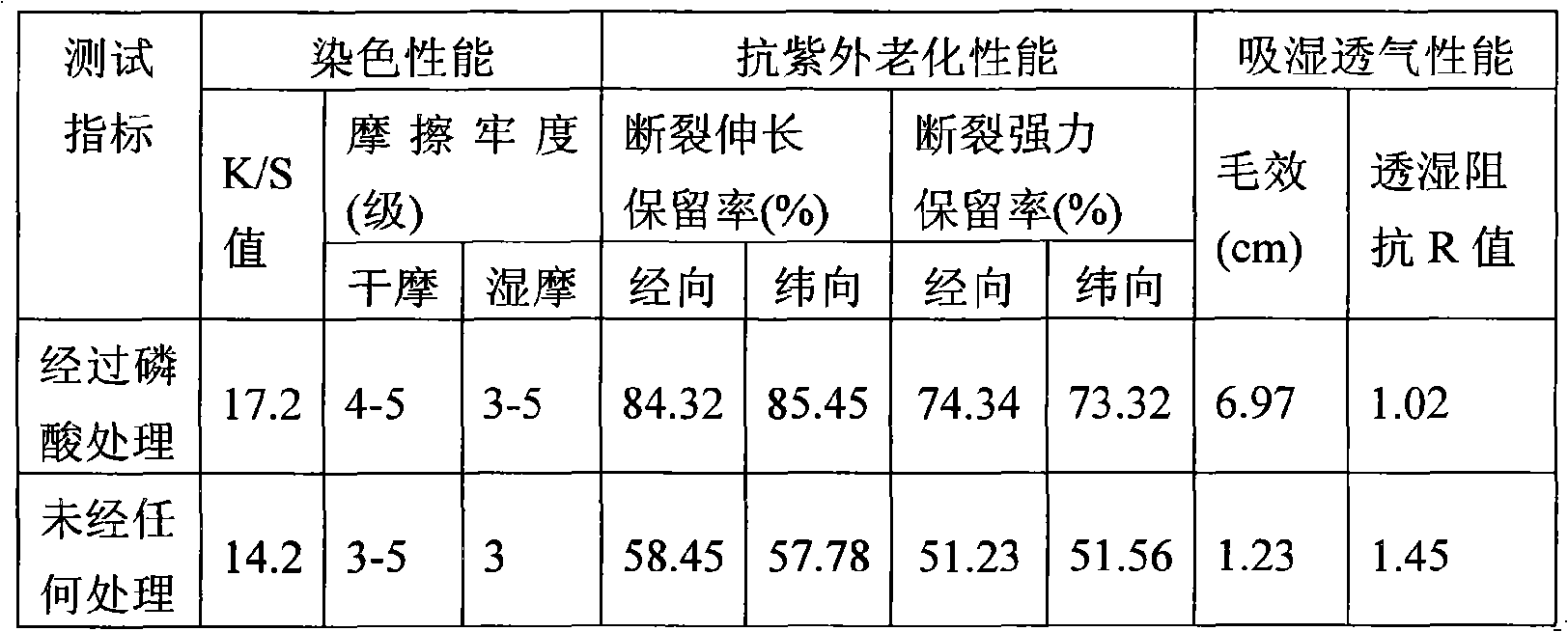

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

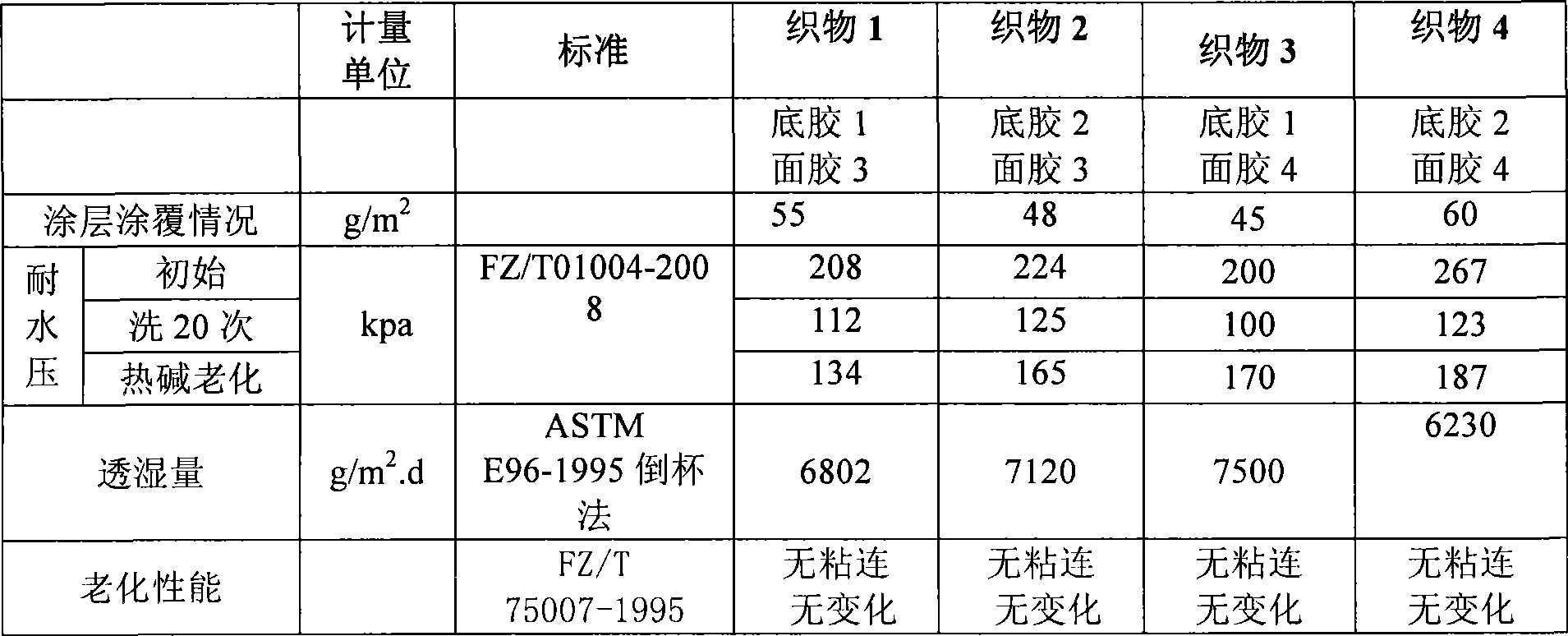

Waterproof moisture permeable modified polyurethane coating glue and preparation thereof

InactiveCN101481579AEasy to addWorkmanship is feasiblePolyurea/polyurethane coatingsTextiles and paperAdhesiveMoisture permeability

The invention provides a water-proof and moisture-permeable advanced polyurethane coating adhesive, which is prepared by mixing three components of coating agent, crosslinking agent and crosslinking promoter with a solvent when in use; the coating agent contains 500 to 1000 mesh of lignocellulose micropowder; the amounts of the crosslinking agent and crosslinking promoter are 2-5wt% of that of the coating agent; and the viscosity of the coating adhesive is 8000 to 15000 mPa.s. The advanced polyurethane coating adhesive in the invention is coated on a base fabric so as to prepare a water-proof and moisture-permeable coated fabric; the moisture permeability is greater than 7000 g / m.d; the water pressure resistance is greater than 200 kPa; the aging resistant performance is enhanced; the blocking resistance is obviously improved; and the coated fabric can be used as a coating material of clothes having water-proof and moisture-permeable functions.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

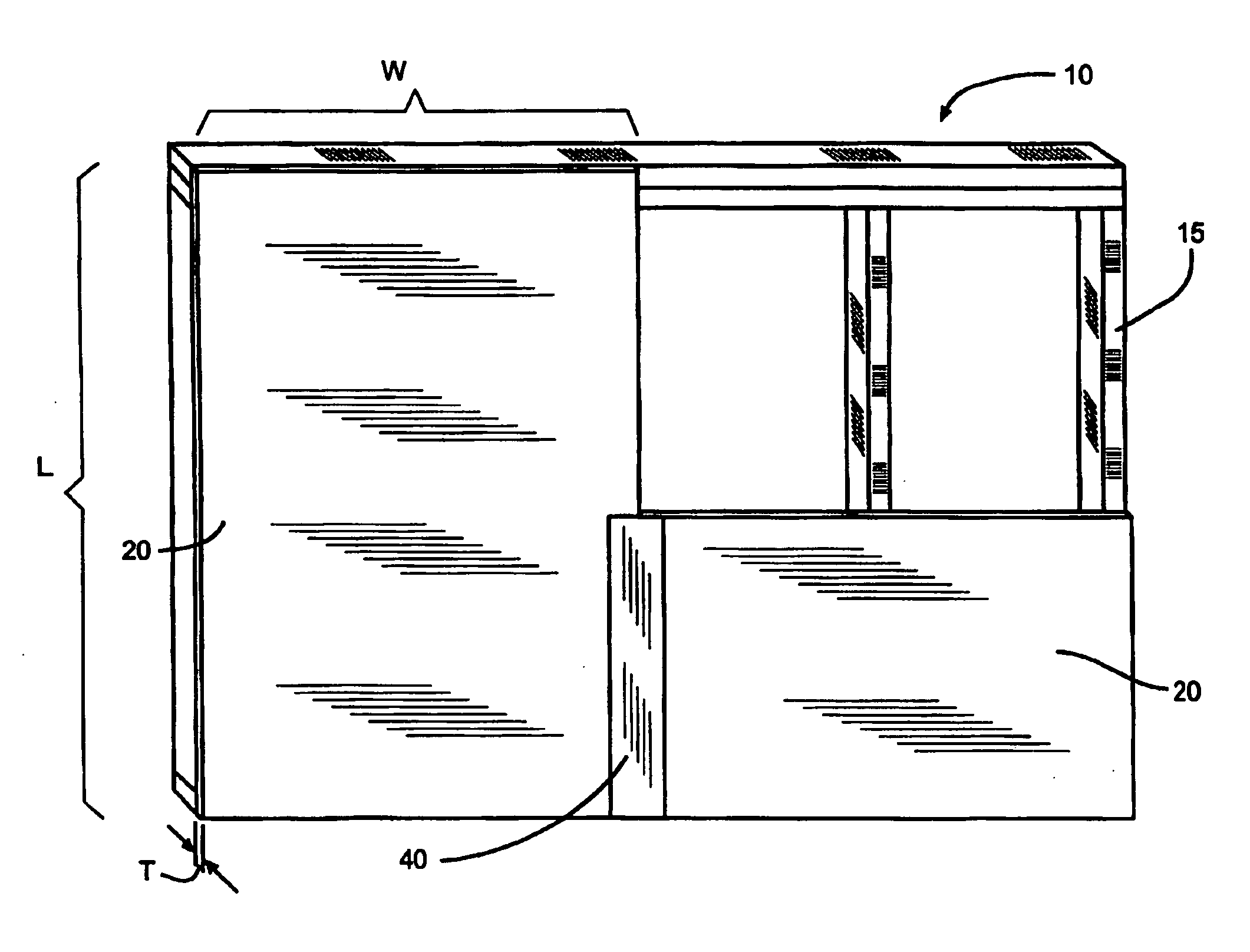

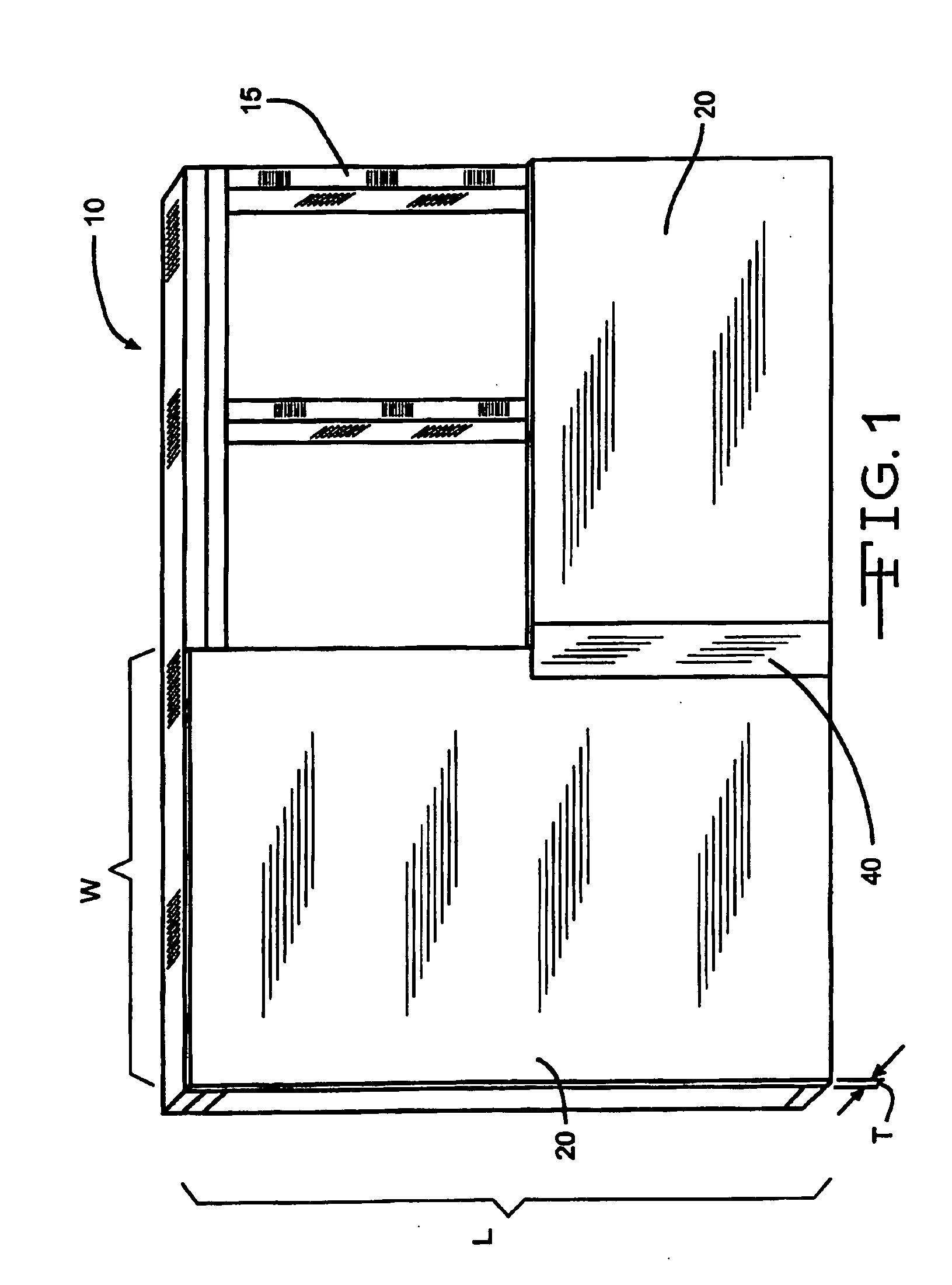

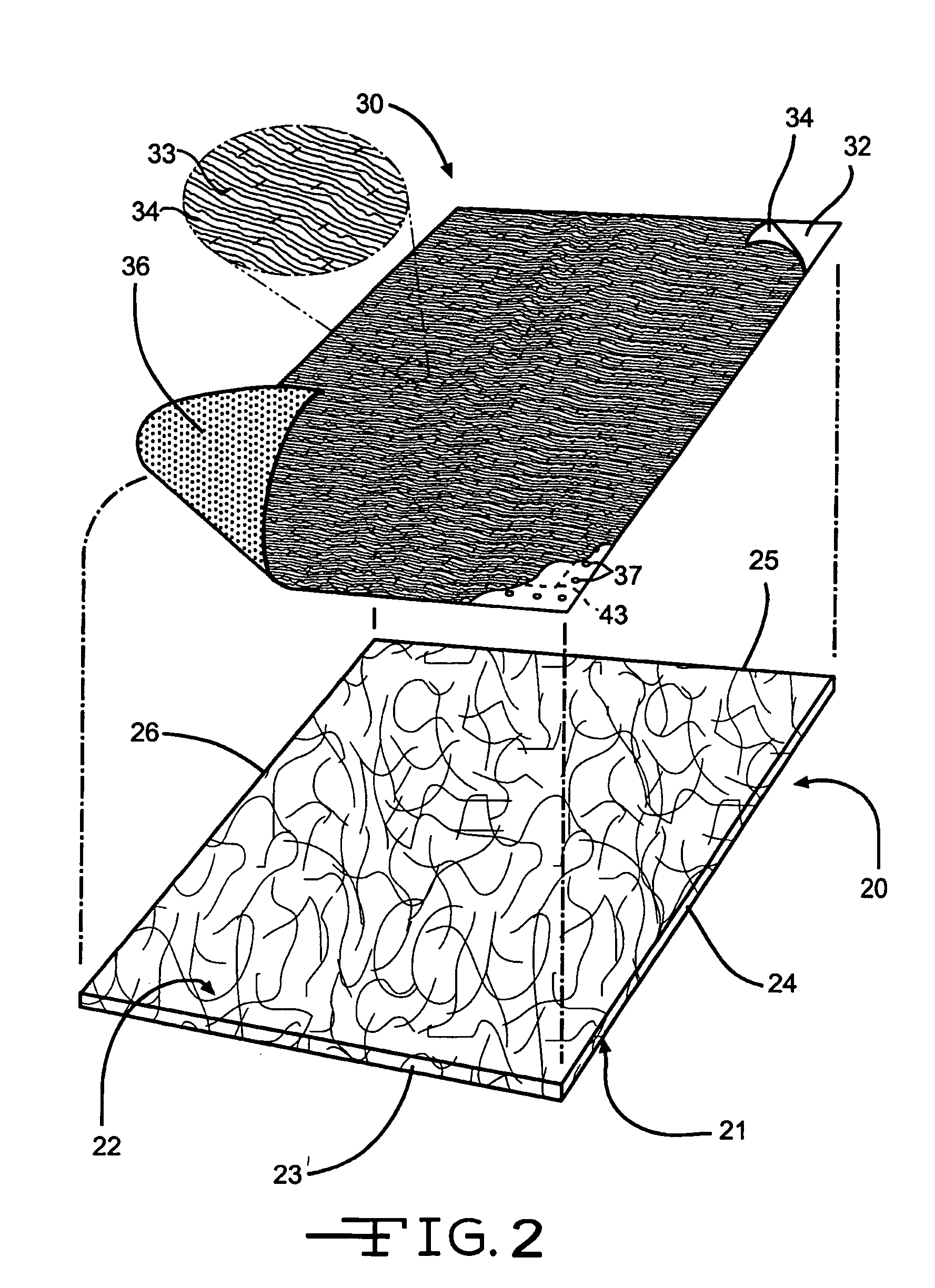

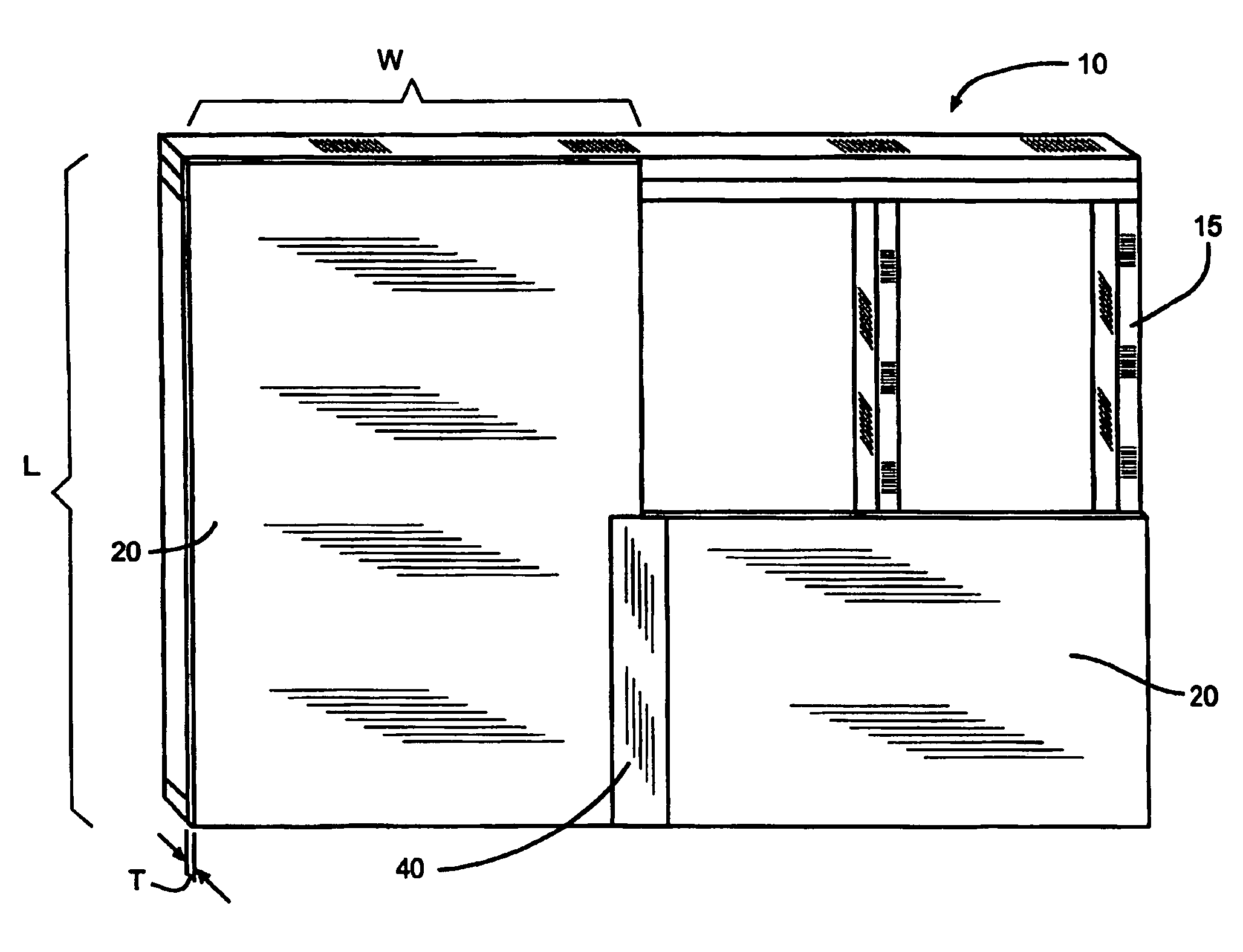

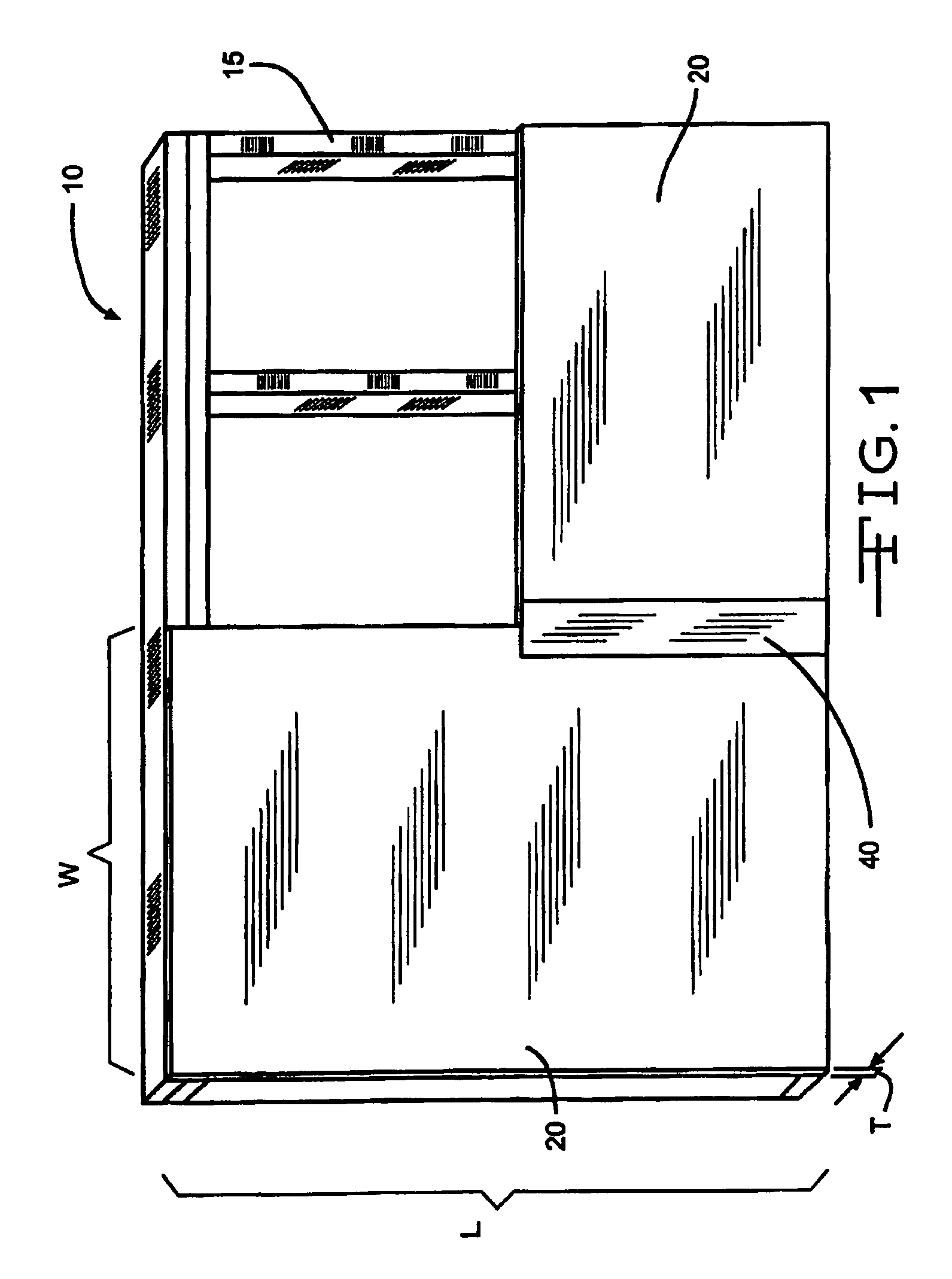

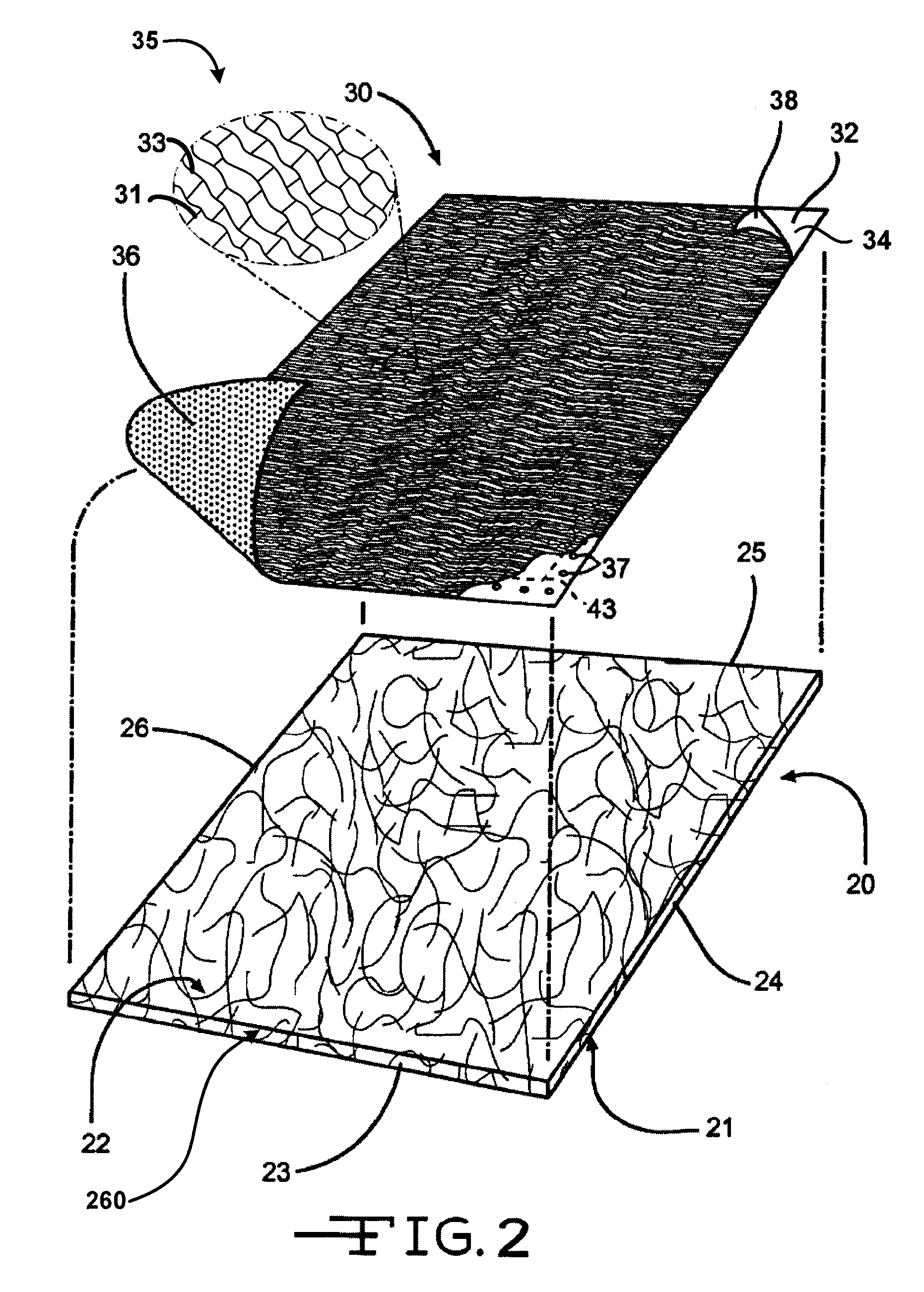

Wall sheathing system and method of installation

The invention comprises a wall sheathing barrier system having moisture permeability and simple improved installation method. The system comprises adjoined structural panels. Each panel has an overlay paper bonded permanently to the structural panel, which provides a moisture permeable barrier and a textured skid-resistant surface. The skid resistant surface may include indicia for aligning strips of tape or for aligning fasteners. Further, the seams of adjoining panels are sealed with a sealing means to complete the moisture barrier.

Owner:HUBER ENGINEERED WOODS

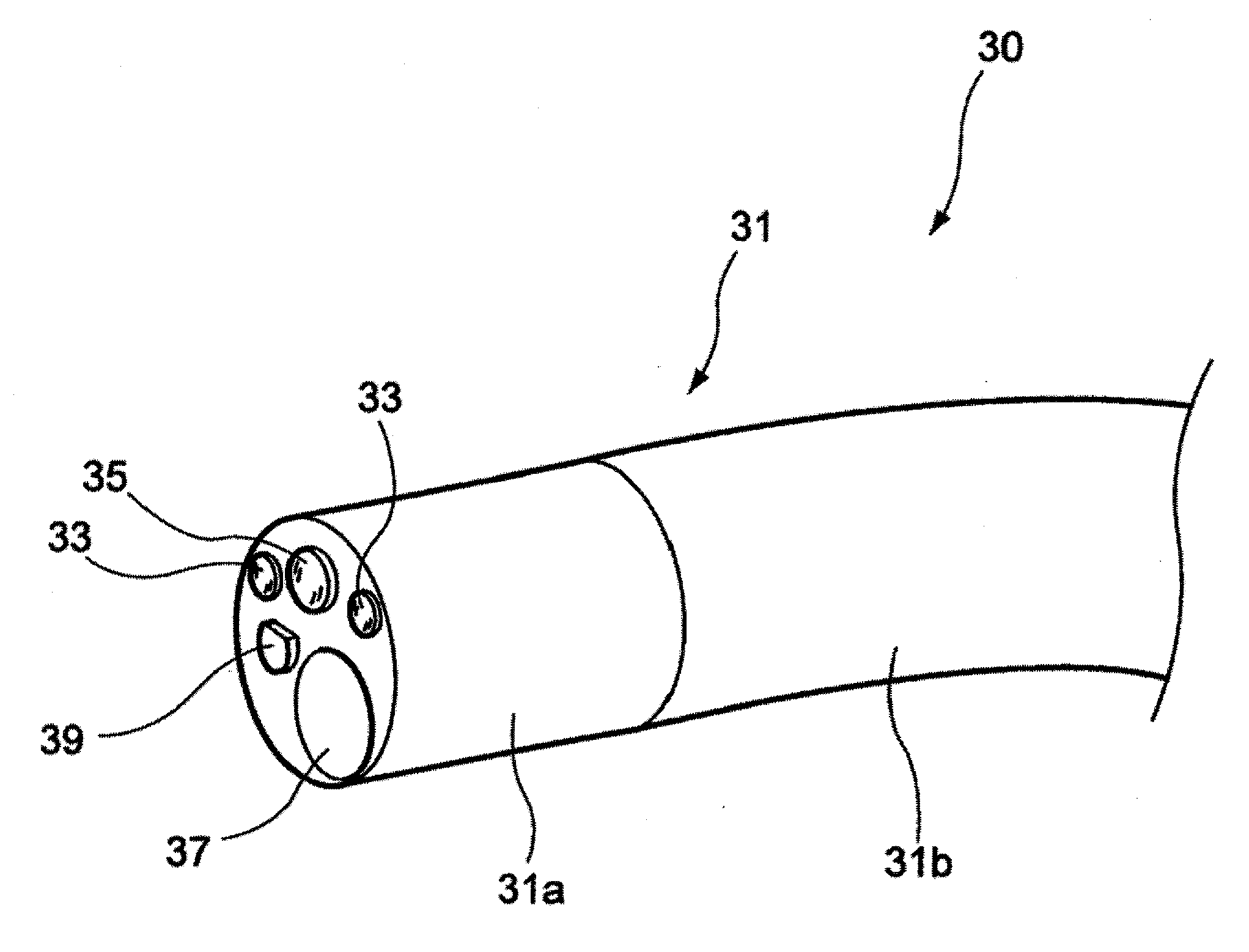

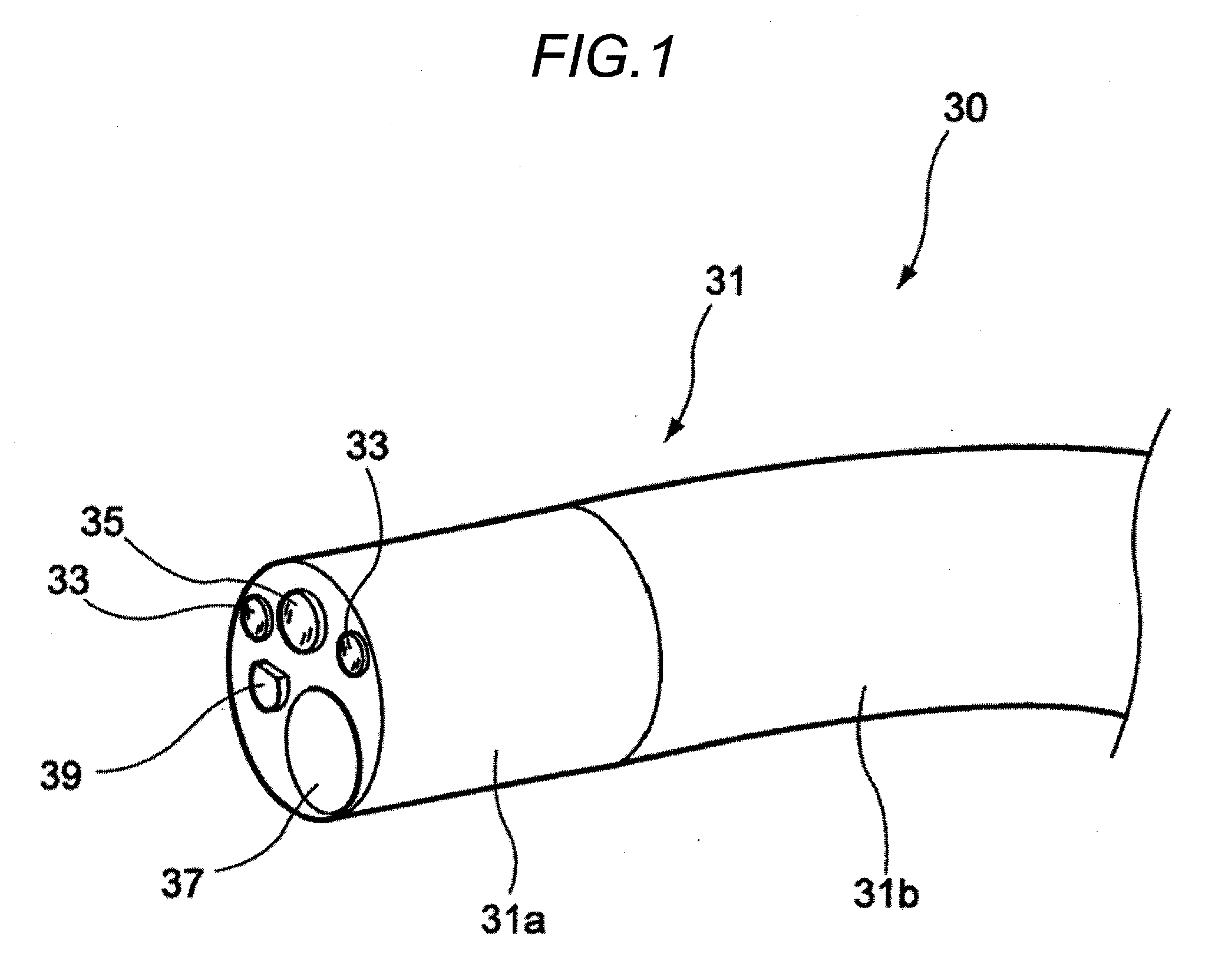

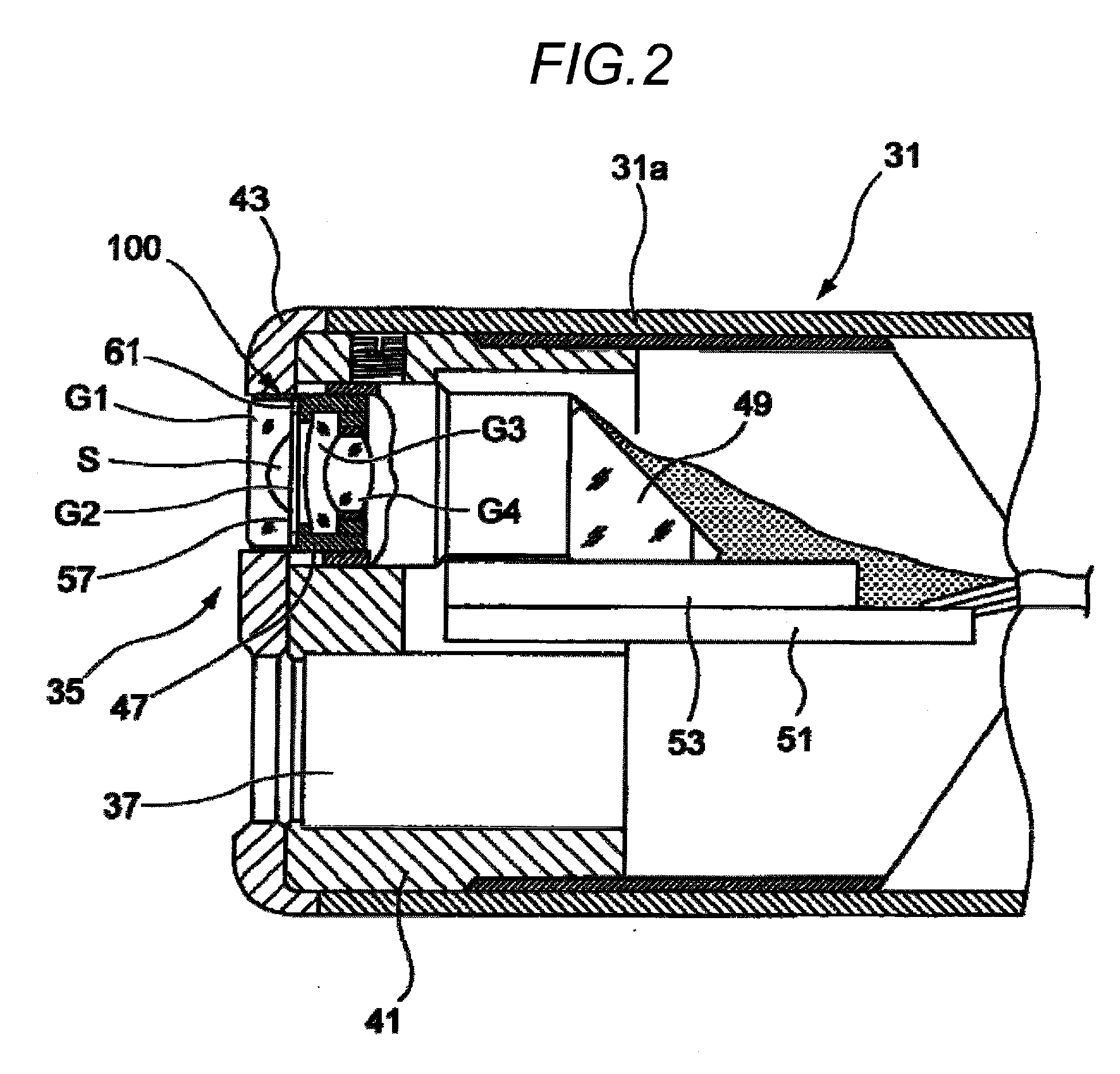

Endoscope optical system device and endoscope with the same

InactiveUS20100022841A1Bright and clear imageInhibition formationSurgeryEndoscopesAdhesiveMoisture permeability

Out of optical elements that are provided to the top end side of an inserting portion of an endoscope, a first optical element arranged closest to an observation object side and a second optical element joined hermetically to the first optical element via an air layer are joined at joined surfaces by a first adhesive. Also, peripheries of end portions of the joined surfaces are covered with a second adhesive whose moisture permeability is lower than the first adhesive.

Owner:FUJIFILM CORP

Polarizer-protective film, and polarizer and liquid-crystal display device comprising the film

InactiveUS20070184212A1Low moisture permeabilityHigh ReLiquid crystal compositionsThin material handlingIn planeTectorial membrane

Owner:FUJIFILM CORP

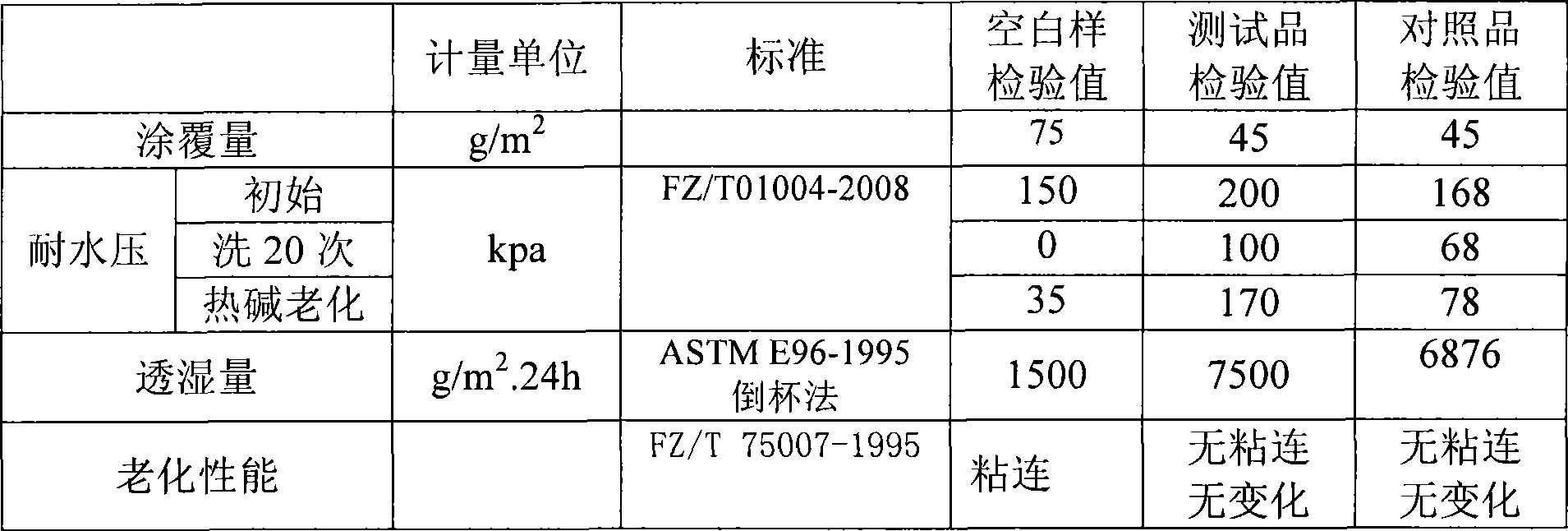

Water-proof moisture-permeation coating agent composition and application thereof

InactiveCN101104752AGood hygroscopicityGood anti-adhesionNatural rubber coatingsPolyurea/polyurethane coatingsFiberHigh resistance

The invention relates to a waterproof and moisture-permeable coating agent composition, wherein, a certain amount of microporous lignocellulose fine powder is added into the coating agent with waterproof function, so that the coating agent has moisture permeable performance. The waterproof and moisture-permeable coating agent composition which is used as the coating agent for non-woven fabric, knitted fabric or woven fabric can be made into coated fabric and synthetic leather with waterproof and moisture permeable performances. Compared with the prior at, the invention has the advantages that: 1. the raw material is easy to be added, the process is available with high adaptability, no need to add new equipment; 2. on the premise that the waterproof performance is not decreased, the amount of moisture permeated is increased obviously and the anti-adhesion is improved; 3. the coated fabric and superfine fiber and artificial cover synthetic leather made by the invention has the advantages of fine moisture permeability, high resistance to water pressure and that the physical performance does not decrease.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Packaged microchip with premolded-type package

InactiveUS20050035446A1Relieve pressureLow moisture permeabilityTransistorSemiconductor/solid-state device detailsMotion detectorMoisture permeability

Owner:ANALOG DEVICES INC

Method for preparing waterproof moisture-permeable coated fabric

InactiveCN101736595ASimple manufacturing methodScalable productionFibre treatmentMoisture permeabilityPolyurethane coating

The invention discloses a method for preparing a waterproof moisture-permeable coated fabric. The moisture permeability of a polyurethane coated fabric is improved by adding modified cellulose powder which accounts for 5 to 50 percent of the weight of polyurethane and is modified by a silane coupling agent into a polyurethane coating agent, and the waterproof property of the polyurethane is improved by adding inorganic powder which accounts for 0.5 to 5 percent of the weight of the polyurethane and is modified by the silane coupling agent, wherein the silane coupling agent accounts for 0.5 to 1 percent of the weight of the modified cellulose powder; and the silane coupling agent accounts for 0.5 to 1 percent of the weight of the inorganic powder. The modified polyurethane which accounts for 15 to 50 percent of the weight of a base fabric is coated on the base fabric of a knitted fabric, a woven fabric or a non-woven fabric to prepare the waterproof moisture-permeable coated fabric with good performance. The method is simple and easy, and can perform mass production; and the prepared fabric has excellent waterproof and moisture-permeable abilities, solves the contradiction between the waterproof capacity and the moisture-permeable capacity of the fabrics, and can be applied to coated fabrics for functional clothing, shoes, tents and buildings in a large quantity.

Owner:ZHEJIANG SCI-TECH UNIV

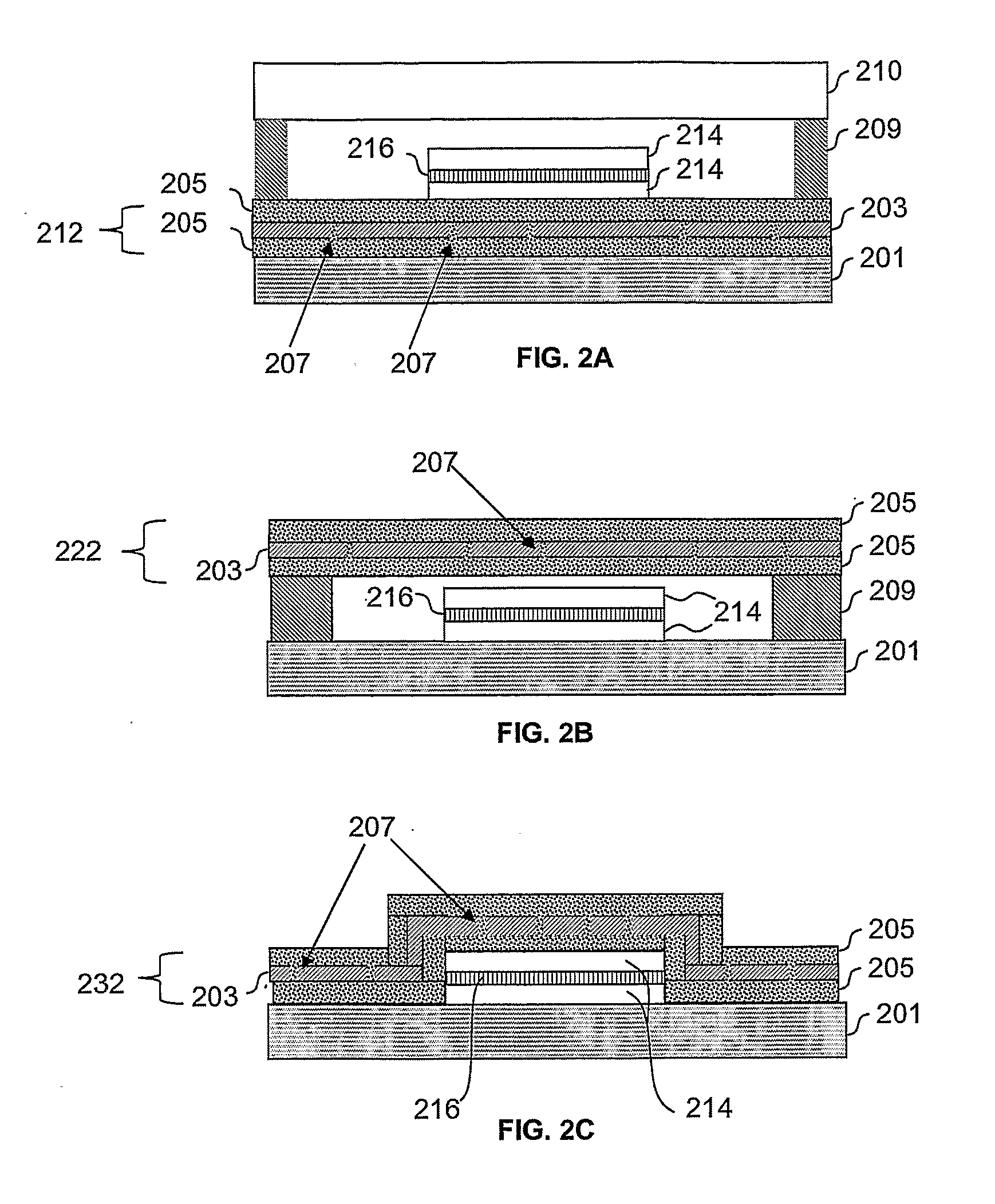

Organic electroluminescence panel and manufacturing method of the same

InactiveUS20070210702A1Low moisture permeabilityDischarge tube luminescnet screensLamp detailsMoisture permeabilityEngineering

An organic EL panel is provided which enables transparent sealing accompanied by low moisture permeability, and can be used also for sealing a top emission panel without deterioration for a long period of time even in the case of a panel having a narrow frame area. In an organic EL panel produced by covering the face of a supporting substrate 1, which is provided with an organic EL element 101, via an adhesive layer 8 by a sealing substrate 9 to permit sealing, a first partition 4 that protrudes toward the sealing substrate 9 is formed on one face of the supporting substrate 1 so as to surround the circumference of the organic EL element 101, and further, a second partition 10 that protrudes toward the supporting substrate 1 is formed on the face of the sealing substrate 9 opposing to the one face of the supporting substrate 1 so as to surround the circumference of the organic EL element 101.

Owner:TOPPAN PRINTING CO LTD

Blended yarn weaved fabric based on novel flame retardant viscose, preparation method and application thereof

InactiveCN101538764AIdeal twistImprove flame retardant performanceWeft knittingFlame-proof filament manufactureYarnChemical treatment

The invention relates to a novel flame retardant fabric, a preparation method and an application thereof, particular to a blended yarn weaved fabric based on novel flame retardant viscose, a preparation method and an application thereof. The flame retardant viscose is prepared by blended spinning with nanometer SiO2 and cellulose solution; wherein the blended ratio of the flame retardant viscose and natural fiber is 20:80 to 80:20. The invention also provides the preparation method of the flame retardant blended yarn weaved fabric. As the nanometer SiO2 particles are adopted as inorganic flame retardant, the novel flame retardant blended yarn weaved fabric is good in fire resistance; limited oxygen index is more than 28%, meltdown or dripping can not appear when combusting, only a small quantity of flue gas which is safe and innoxious is produced, and the fabric is washing resistant and chemical treatment resistant. The invention has air and moisture permeability and soft feel. The blended yarn weaved fabric is mainly composed of the flame retardant viscose and cotton fiber, and can be applied to preparation of bedding such as bed sheet, quilt cover, pajamas, etc.

Owner:上海神九纺织科技有限公司

Production of coating fabrics with high-peneration and waterproofing functions

InactiveCN1940174AImprove waterproof performanceGood moisture permeabilityTextiles and paperSocial benefitsOrganic solvent

This invention was a public high permeability high waterproof coating fabrics manufacturing methods, including polyurethane polymer, an organic solvent, allocation of water, as agent, crosslinking agents, other agents, water mixed into a fabric coating agents will be made of fabric coated with the coating in uniform as coating on the fabric, Fabric coating agent had dried occasion of the coating for drying processing steps. The invention manufactured coated fabric is not only an excellent waterproof and good moisture permeability but also has good rubbing sex and the feeling of fullness soft features. Product hydrostatic pressure 5000mm H2O over Al permeability to 8000g / m2 . 24hr above Tolerance washing and rubbing. Such coated fabric has broad prospects for sales, which can be used to produce rainwear, breathable, ski clothes, cool suits. Have greater economic and social benefits.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Waterproof and moisture permeable membrane, preparation method of waterproof and moisture permeable membrane, waterproof and moisture permeable fabric and preparation method of waterproof and moisture permeable fabric

InactiveCN104207390AImprove waterproof performanceGood moisture permeabilitySynthetic resin layered productsNon-woven fabricsFiberElectrospinning

The invention provides a waterproof and moisture permeable membrane which sequentially comprises a nano-fiber hydrophilic layer and a nano-fiber hydrophobic layer. The nano-fiber hydrophilic layer is prepared from a hydrophilic polymer by electrostatic spinning; the nano-fiber hydrophobic layer is prepared from a hydrophobic polymer by electrostatic spinning. The waterproof and moisture permeable membrane provided by the invention has good moisture permeability and air permeability; an experiment result shows that the moisture permeability of the waterproof and moisture permeable membrane provided by the invention can reach 10,000g / m<2>24h, and the air permeability of the waterproof and moisture permeable membrane can reach 0.29mL / cm<2>s. The invention also provides a preparation method of the waterproof and moisture permeable membrane. According to the preparation method provided by the invention, the nano-fiber hydrophilic layer and the nano-fiber hydrophobic layer which are prepared by electrostatic spinning are subjected to hot-pressing compounding, so that the obtained waterproof and moisture permeable membrane has better performance and can be integrally formed without being adhered by an adhesive; the production process is simplified; the waterproof and moisture permeable membrane is easy for industrial production. The invention also provides a waterproof and moisture permeable fabric and a preparation method thereof.

Owner:ZHEJIANG WEIXING IND DEV

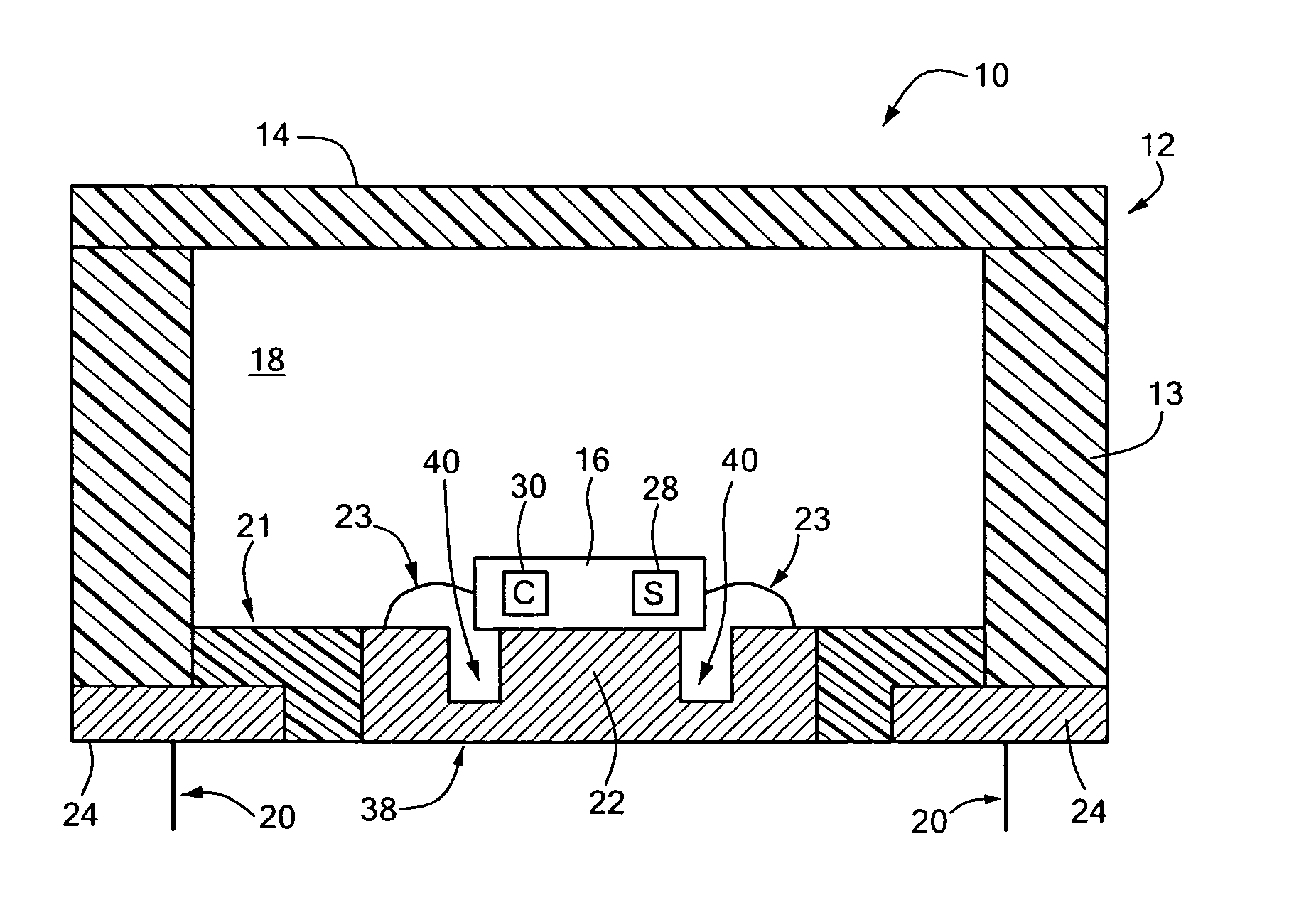

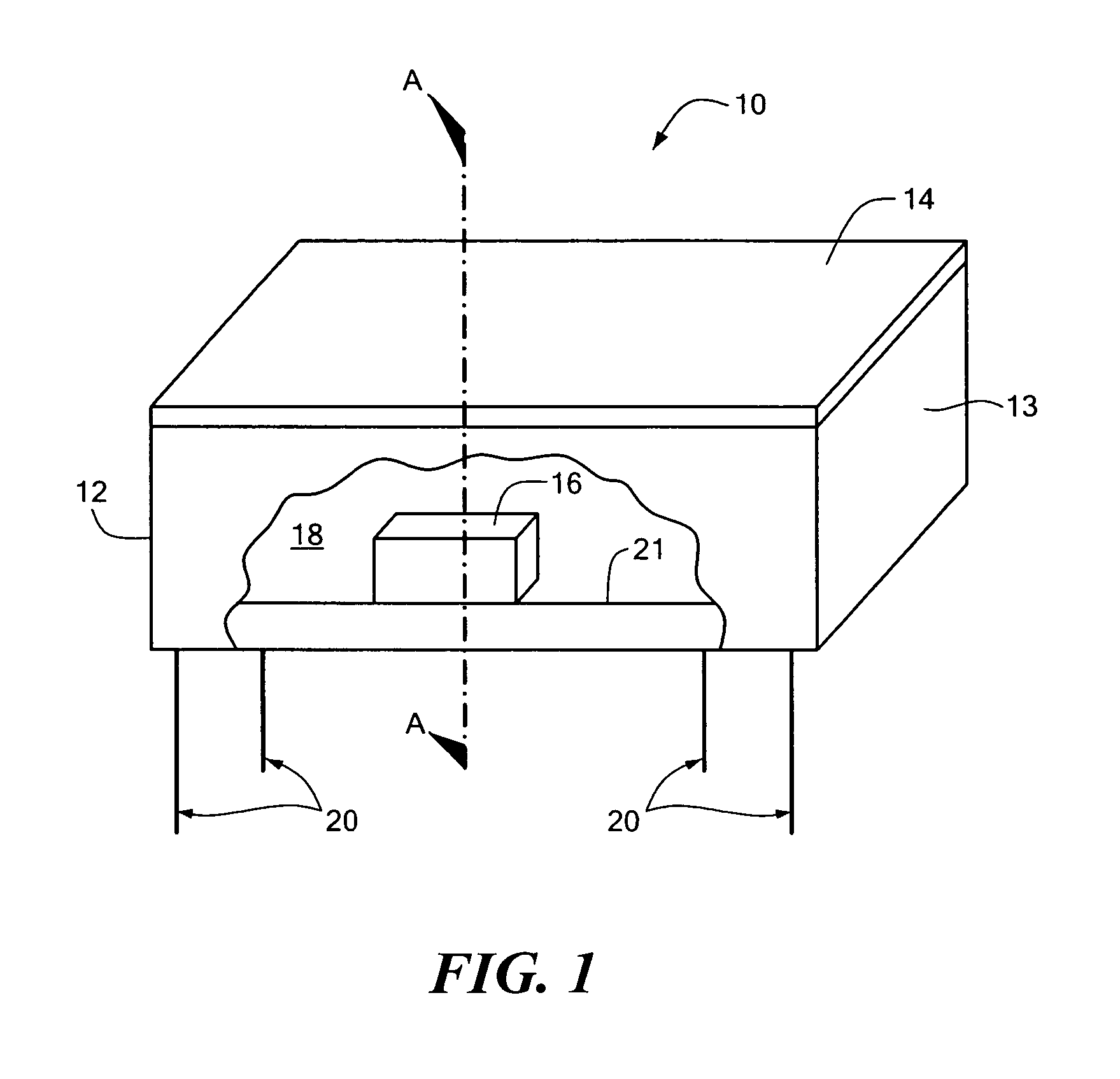

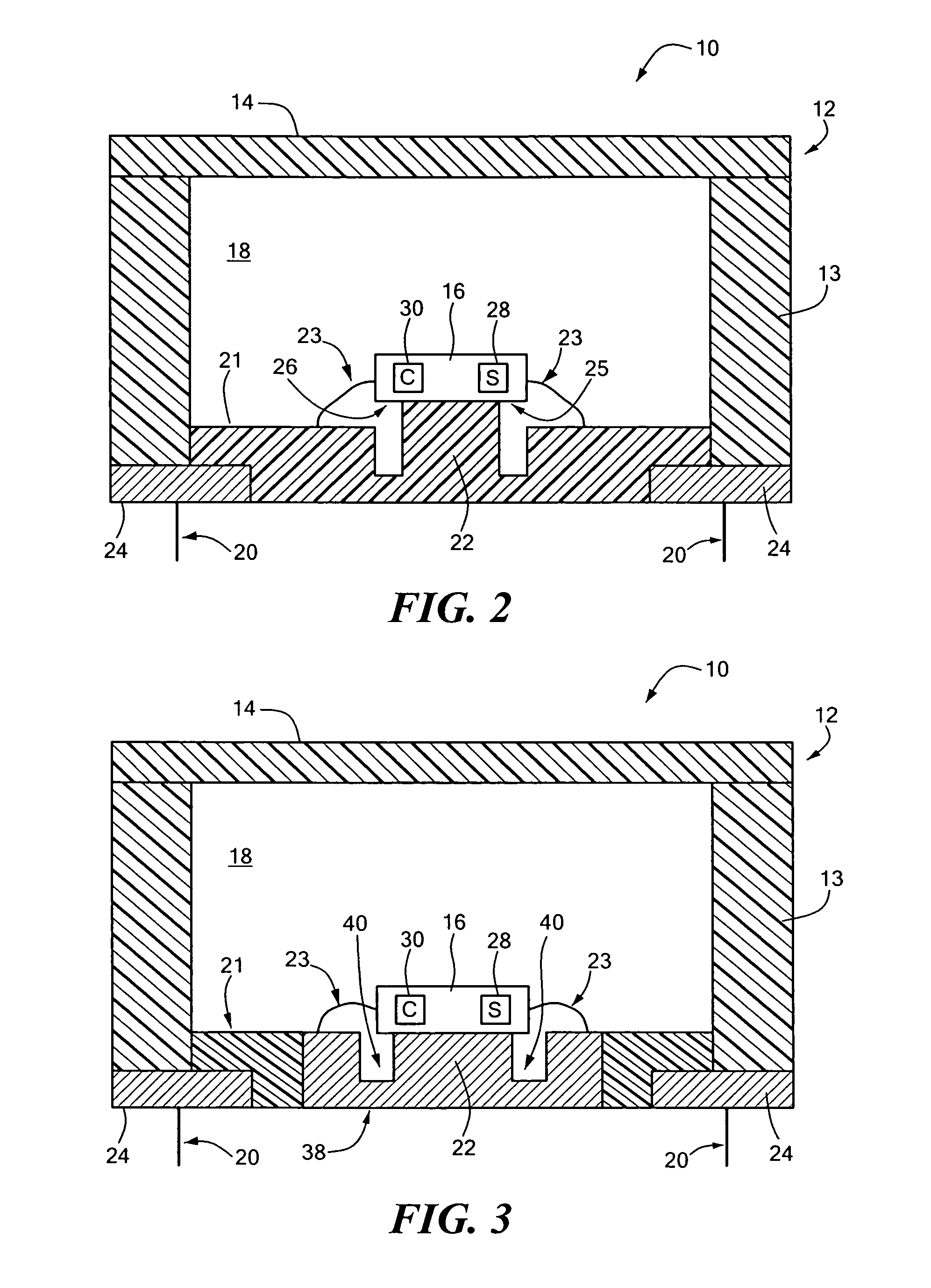

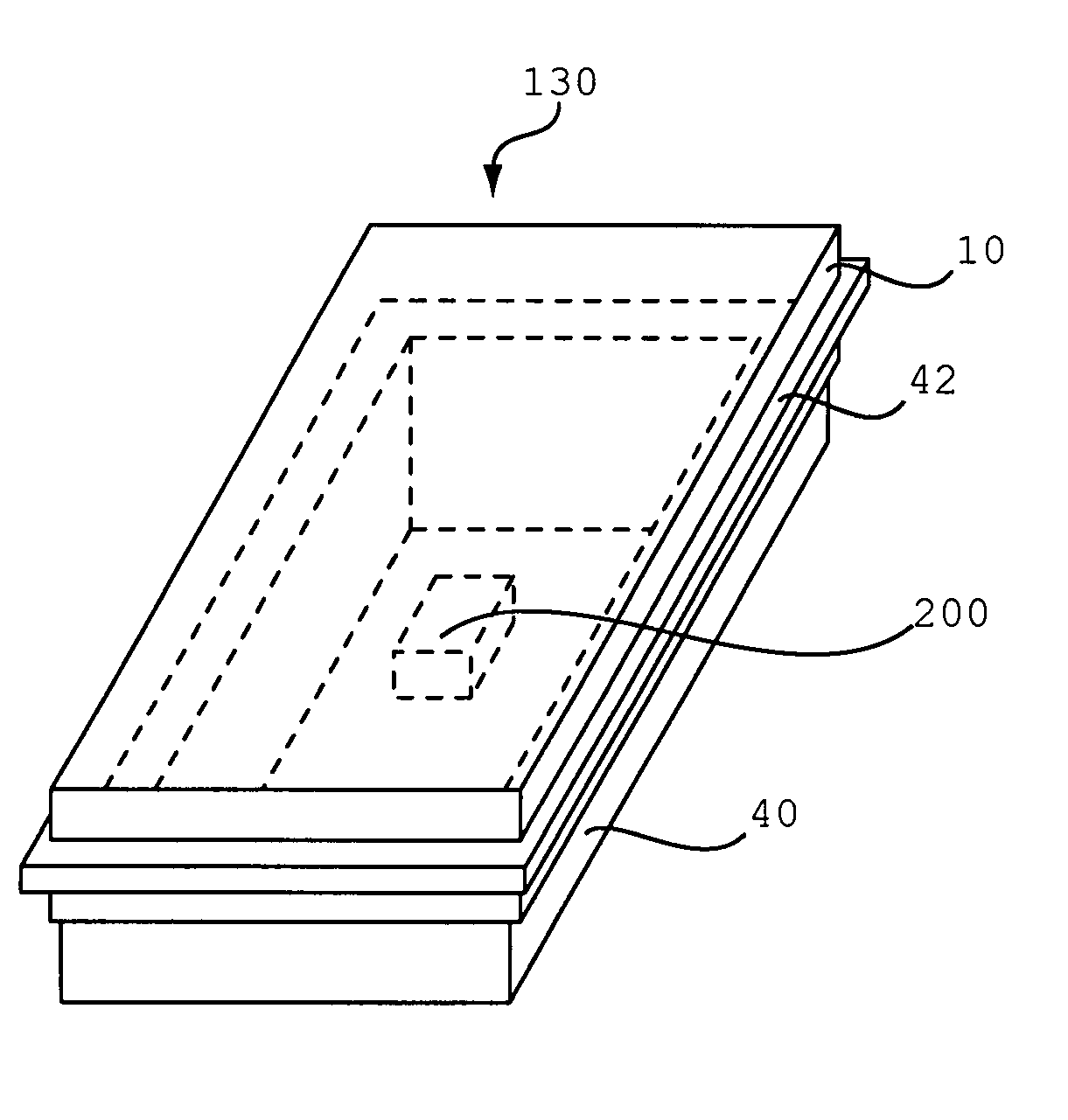

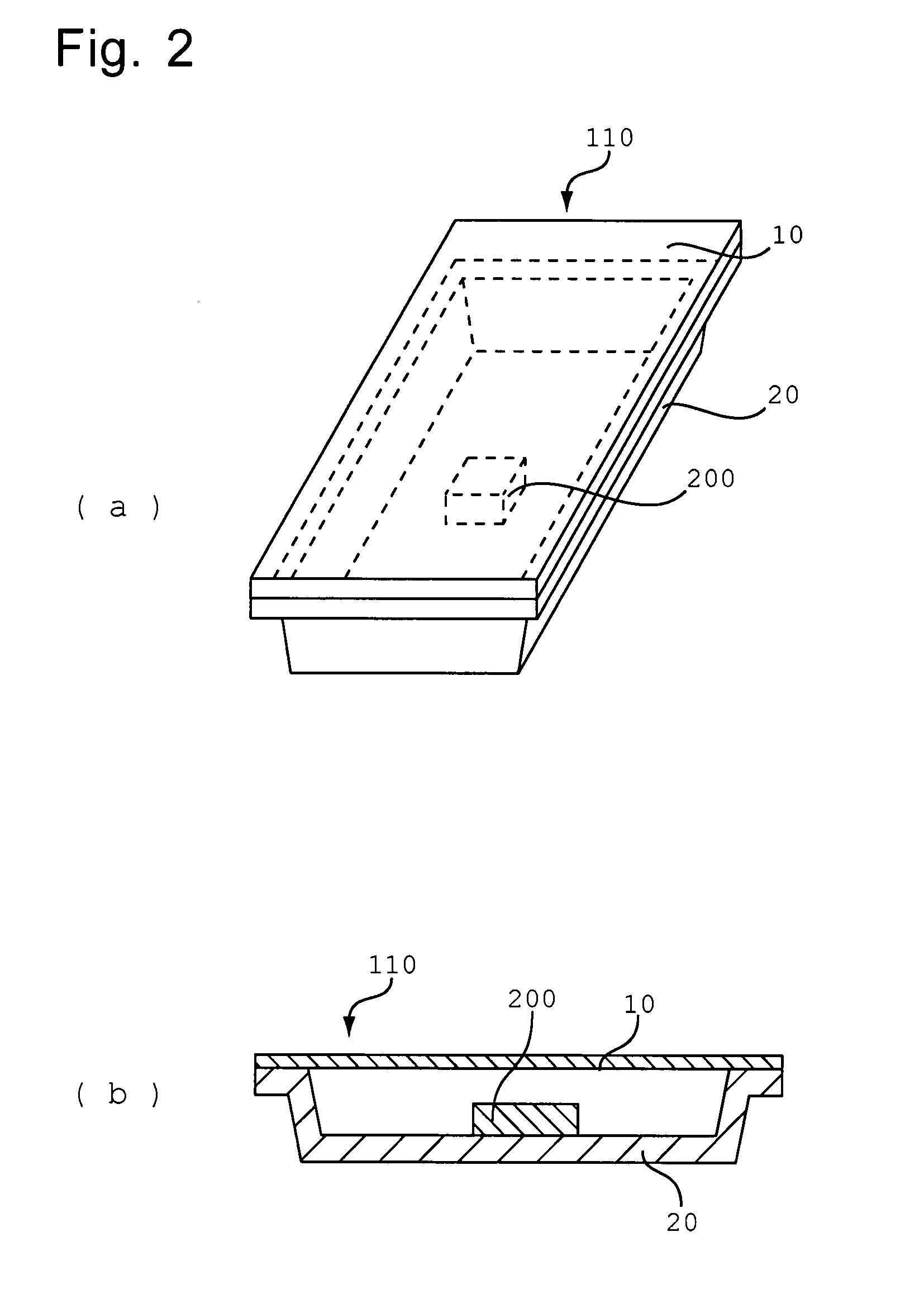

Micromechanical device and method of manufacturing micromechanical device

InactiveUS8004053B2Reduce noiseSure easyAcceleration measurement using interia forcesTransducer detailsMoisture permeabilityEngineering

Owner:KK TOSHIBA

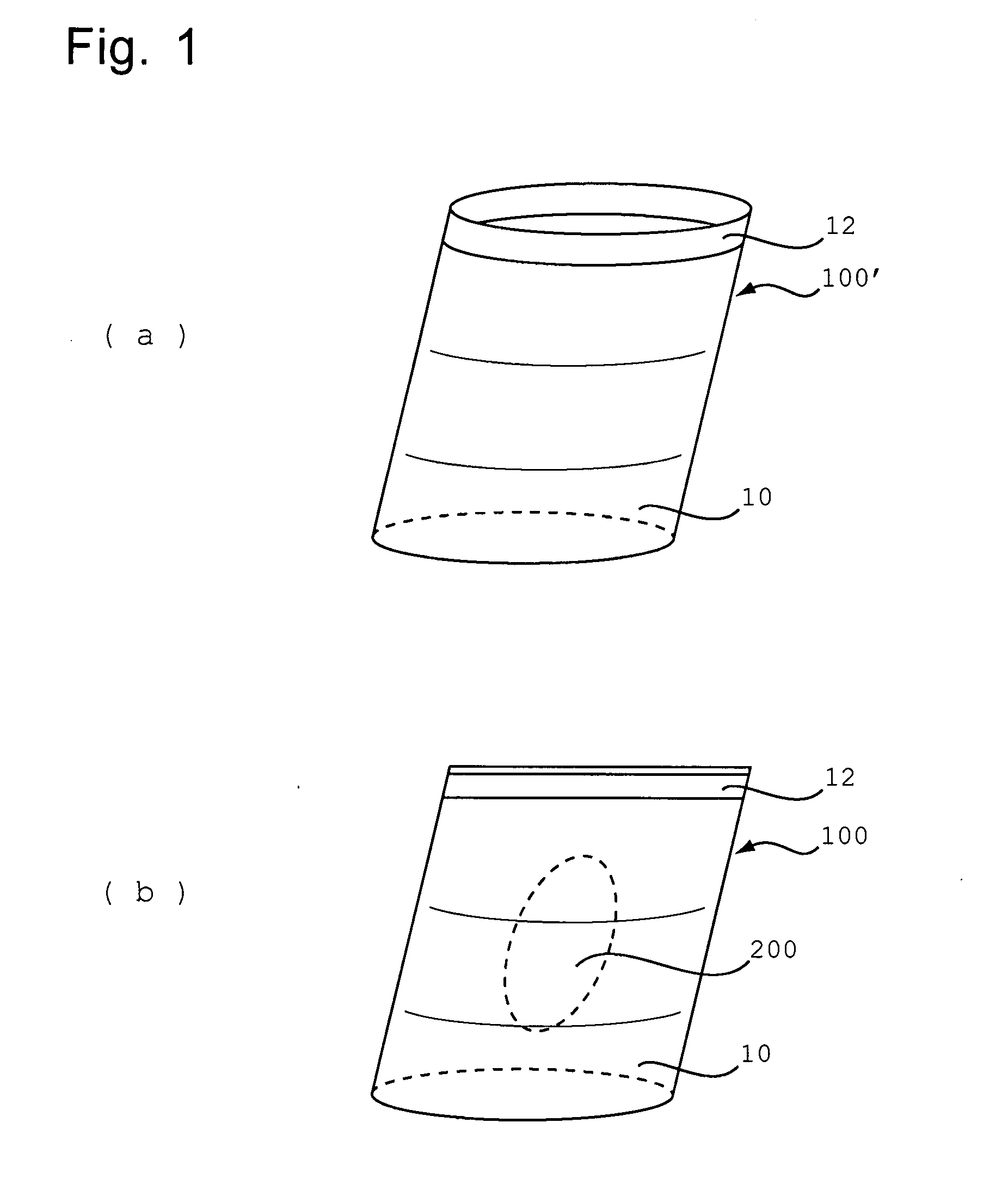

Container for freeze-drying

InactiveUS20080256822A1Avoid pollutionEfficient freeze-dryingFlexible coversClosures with freeze-dryingPolyesterElastomer

A container is provided that realizes efficient freeze-drying while preventing contamination during freeze-drying. This freeze-drying container uses a nonporous moisture-permeable film in at least a portion thereof, and the nonporous moisture-permeable film can be formed from a polyurethane or a polyester elastomer.

Owner:EI DU PONT DE NEMOURS & CO

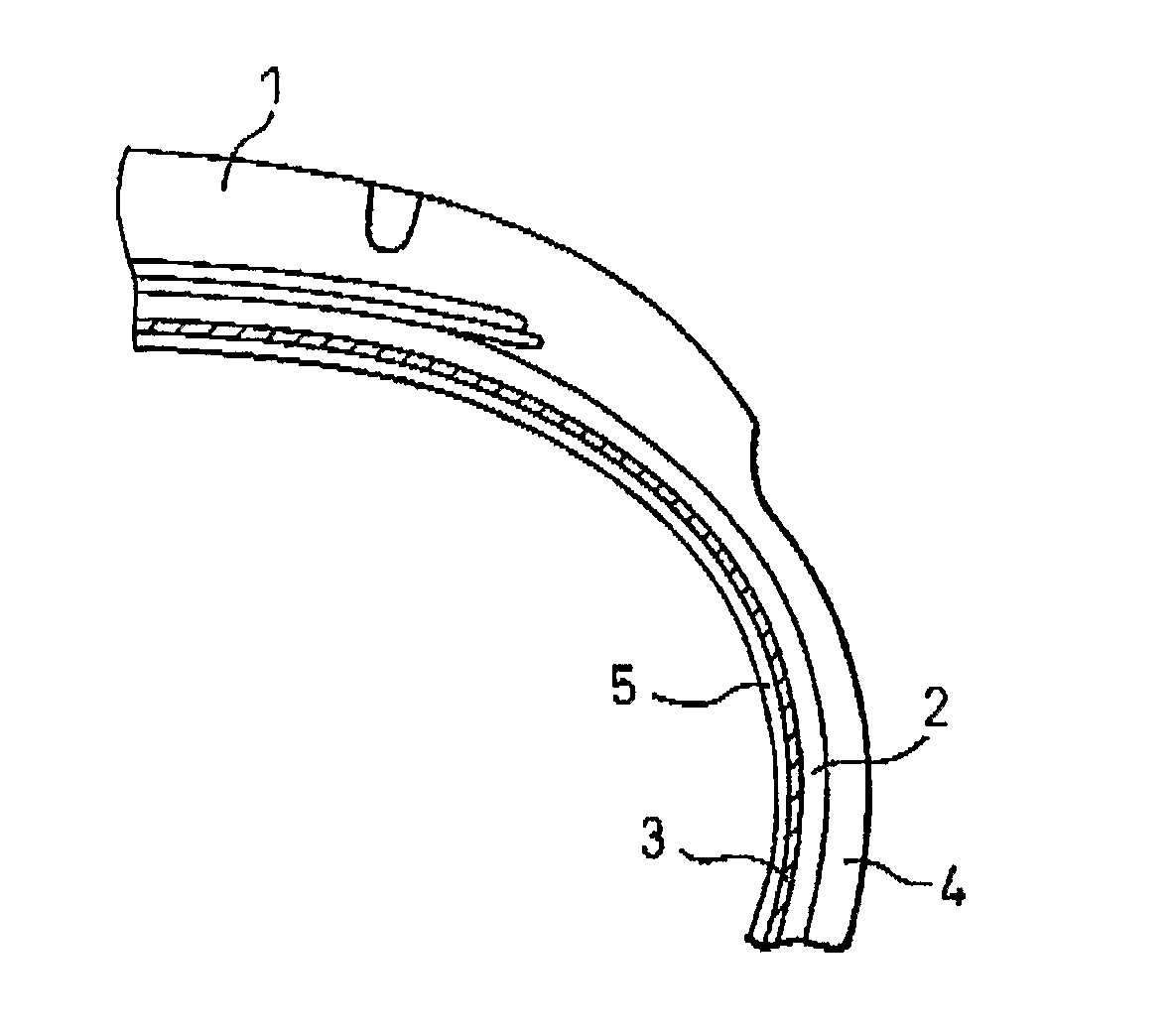

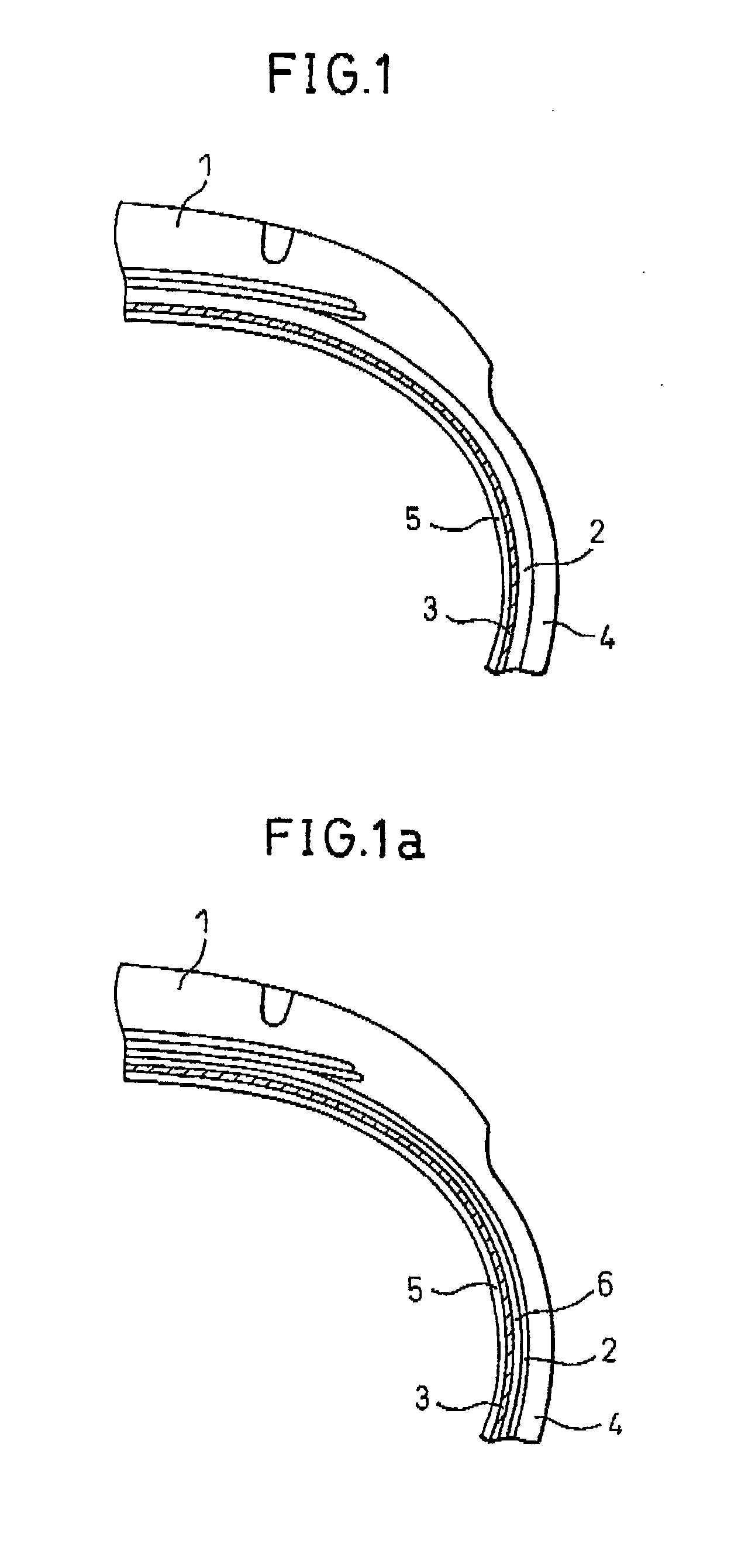

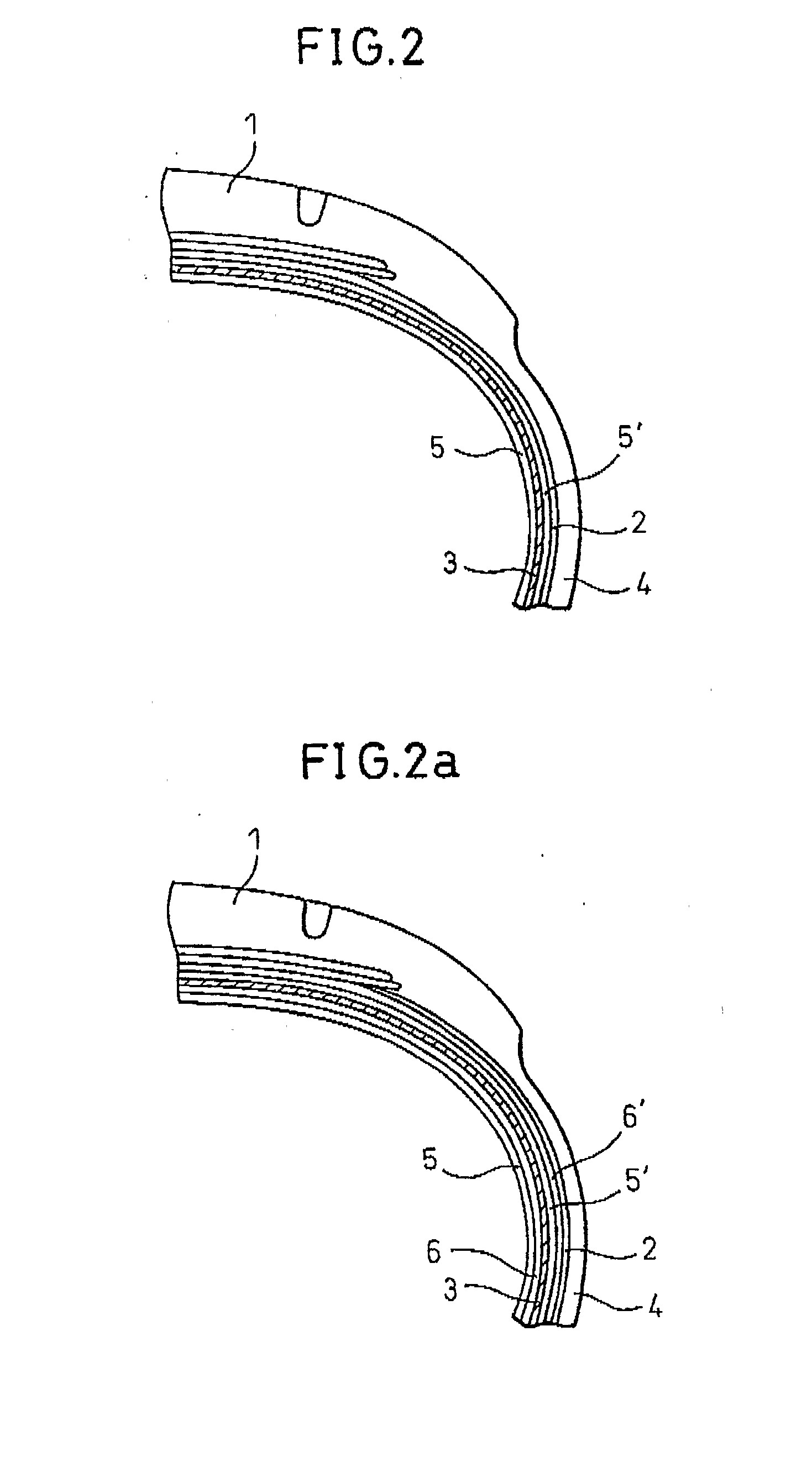

Low moisture permeability laminate construction

ActiveUS20100024941A1Improve bindingImproved vulcanizable layered constructionRecord information storageMagnetic recordingElastomerResin matrix

An article having a fluid permeation prevention layer, such as a pneumatic tire or hose. A tire for example includes an outer tread layer, intermediate sidewall and carcass layers and an innermost air permeation prevention layer: (i) the air permeation prevention (APP) layer having an upper and a lower surface, the layer having a polymer composition exhibiting an air permeation coefficient (APC) of about 25×1O′12 cc cm / cm2 sec cmHg (at 30* C) or less and a Young's modulus of about 1 MPa to about 500 MPa, the polymer composition comprising: (A) at least 10 wt % of at least one. thermoplastic resin component having an APC of about 25×1O″12 cc cm / cm2 sec cmHg (at 30° C.) or less and a Young's modulus of more than 500 MPa, which is preferably a polyamide resin or mixture, and (B) at least 10 wt % of at least one elastomer component having an APC of more than about 25×10″12 cc cm / cm2 sec cmHg (at 30° C.) and a Young's modulus of not more than 500 MPa, which elastomer component is preferably a halogen-containing rubber or mixture, the total amount (A)+(B) being not less than about 30 wt %, and the elastomer component is a dispersed vulcanized, discontinuous phase in the thermoplastic resin matrix; and (ii) at least one thermoplastic laminate layer bonded to at least said lower surface of the APP layer, the thermoplastic layer comprising a film-forming, semi-crystalline, substantially hydrophobic carbon chain polymer having a glass transition temperature, Tg, of less than about −200 C.

Owner:EXXONMOBIL CHEM PAT INC +1

Method for manufacturing electrospun nanofiber gas filtering material in mass manner

InactiveCN105133187AIncrease productionGood breathability and moisture permeabilitySemi-permeable membranesFilament/thread formingFiberElectrospun nanofiber

The invention discloses a method for manufacturing an electrospun nanofiber gas filtering material in a mass manner by using an umbrella-shaped electrostatic spinning sprayer. The method comprises: dissolving a high-molecular polymer in a solvent, mixing to obtain an even solution; using the spinning solution in electrostatic spinning to obtain a nanofiber membrane; combining the nanofiber membrane with a non-woven fabric, manufacturing non-woven fabric / nanofilm / non-woven fabric composite film; performing ultrasonic bonding on the non-woven fabric / nanofilm / non-woven fabric composite film, to manufacture a filtering material. The manufacturing method is convenient and fast, and can realize small-batch production. Filtering efficiency of the obtained filtering material reaches up to 99.55%, filtering resistance is 150-200 Pa, gas permeability reaches 355L.m<-2>.s<-1>, and moisture-penetrability reaches 9.6 m<2>.Pa / w, that is, the material has good gas permeability and moisture penetrability, and the method has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV +1

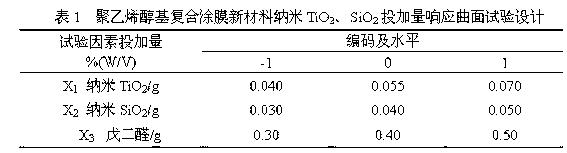

Polyvinyl alcohol radical composite coating fresh keeping packaging material nano TiO2 functional modification method

ActiveCN103031026AImprove antibacterial and fresh-keeping functionChange hydrophilicityCoatingsPolyvinyl alcoholMoisture permeability

The invention relates to a polyvinyl alcohol radical composite coating fresh keeping packaging material nano TiO2 functional modification method, which comprises the following steps: adding nano TiO2 and SiO2 into a polyvinyl alcohol aqueous solution and stirring; carrying out ultrasonic mixing on a mixed liquor; placing the mixed solution in a reaction kettle after ultrasonic; heating, stirring and reacting at constant temperature; adding stearic acid-alcohol mixed solution and glutaraldehyde with the same temperature and stirring; and carrying out cross-linking reaction at a constant temperature; stirring and cooling to a room temperature after reaction, so as to prepare into a nano composite coating new material. With the adoption of the polyvinyl alcohol radical composite coating fresh keeping packaging material nano TiO2 functional modification method, the nano TiO2 is adopted to modify a polyvinyl alcohol radical composite coating fresh keeping packaging material; the new material film formation moisture permeability is obviously reduced, and anti-bacteria fresh keeping performance of the packaging material is obviously improved.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +1

Wall sheathing system and method of installation

The invention comprises a wall sheathing barrier system having moisture permeability and simple improved installation method. The system comprises adjoined structural panels. Each panel has an overlay paper bonded permanently to the structural panel, which provides a moisture permeable barrier and a textured skid-resistant surface. The skid resistant surface may include indicia for aligning strips of tape or for aligning fasteners. Further, the seams of adjoining panels are sealed with a sealing means to complete the moisture barrier.

Owner:HUBER ENGINEERED WOODS

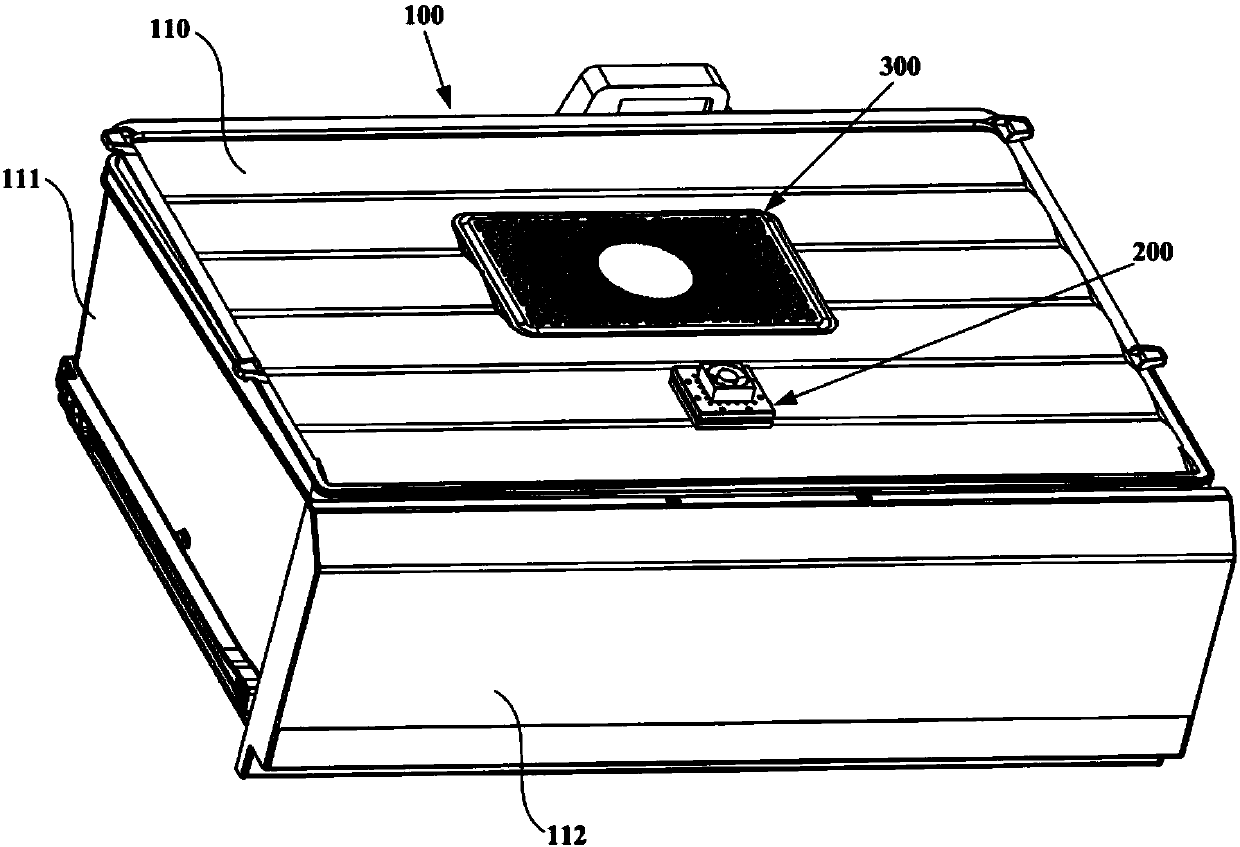

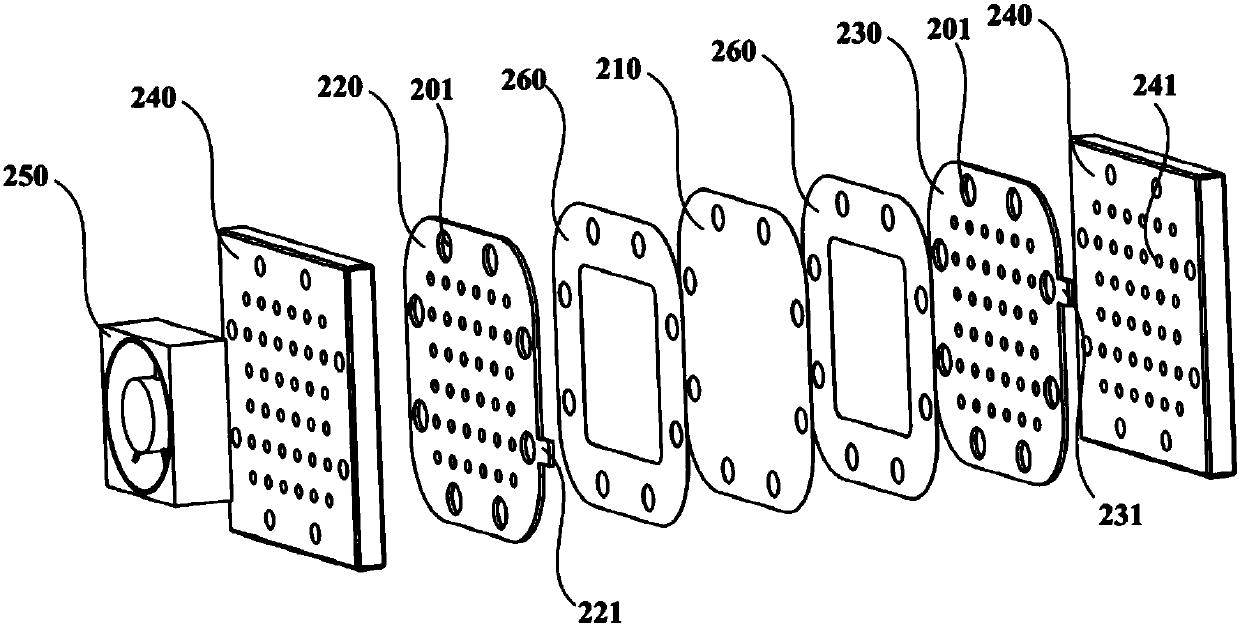

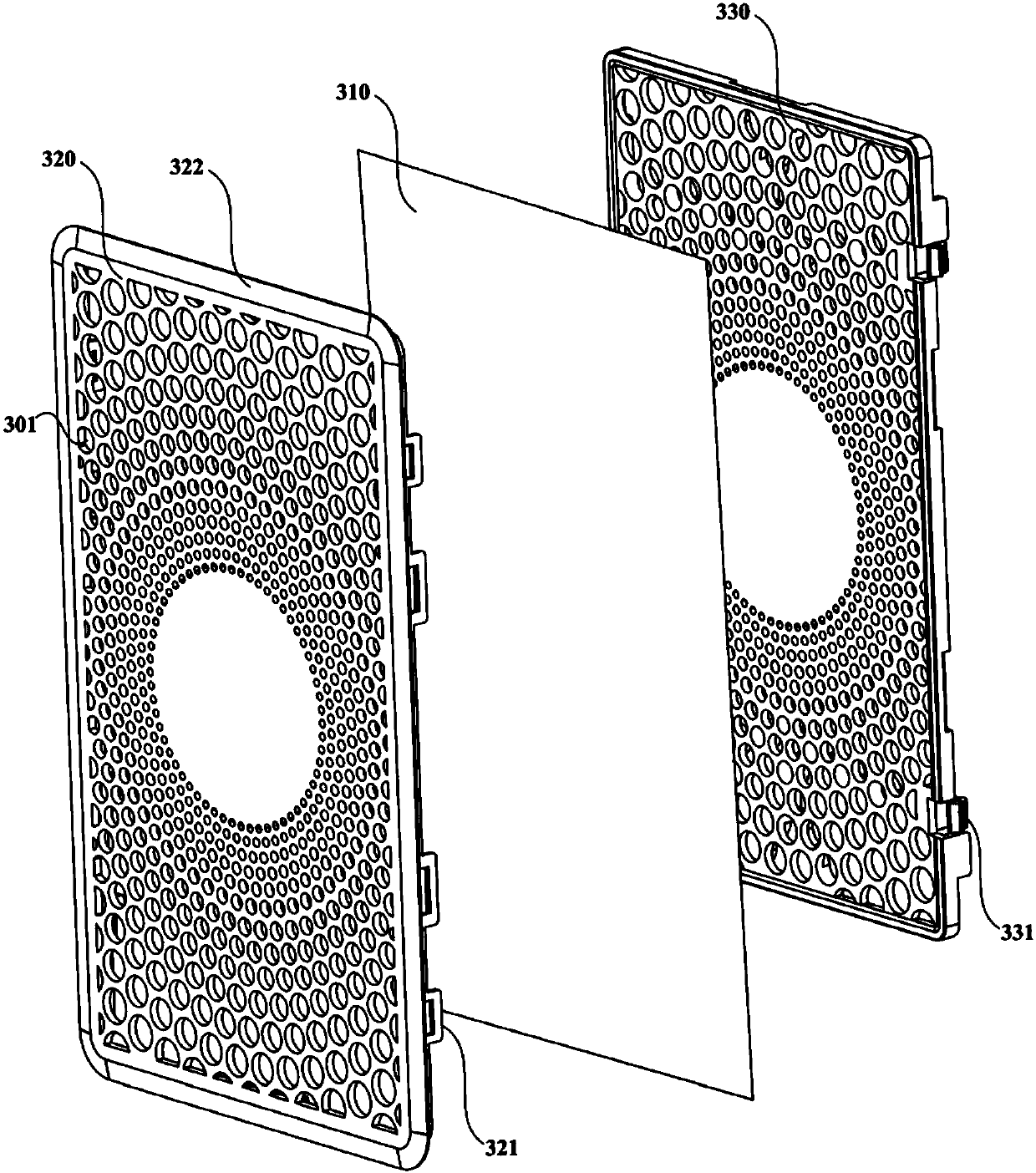

Refrigerating and freezing device and storage container thereof

The invention provides a refrigerating and freezing device and a storage container thereof. The storage container comprises an electrolysis deoxygenization assembly and a moisture permeability assembly. The electrolysis deoxygenization assembly is used for consuming oxygen in air in a storage space, so that a nitrogen-rich oxygen-deficient air atmosphere beneficial to food preservation is obtainedin the space, the intensity of aerobic respiration of food is reduced, and the aim of long-term preserving the food is achieved. When the electrolysis deoxygenization assembly is used for consuming the oxygen in the storage space, a certain moisture is produced in the storage space, so that the inner part of the storage space is more and more humid. Through the moisture permeability assembly, themoisture in the air in the storage space can be conveyed to the outer part of the space through a pervaporation membrane through vaporization penetration, so that the humidity in the storage space still keeps in the appropriate range, and condensate or dropping water is prevented from being produced in the space. In the refrigerating and freezing device provided by the invention, the electrolysisdeoxygenization assembly and the moisture permeability assembly can be used in a matching way, so that food can be preserved favorably.

Owner:大连海尔电冰箱有限公司 +2

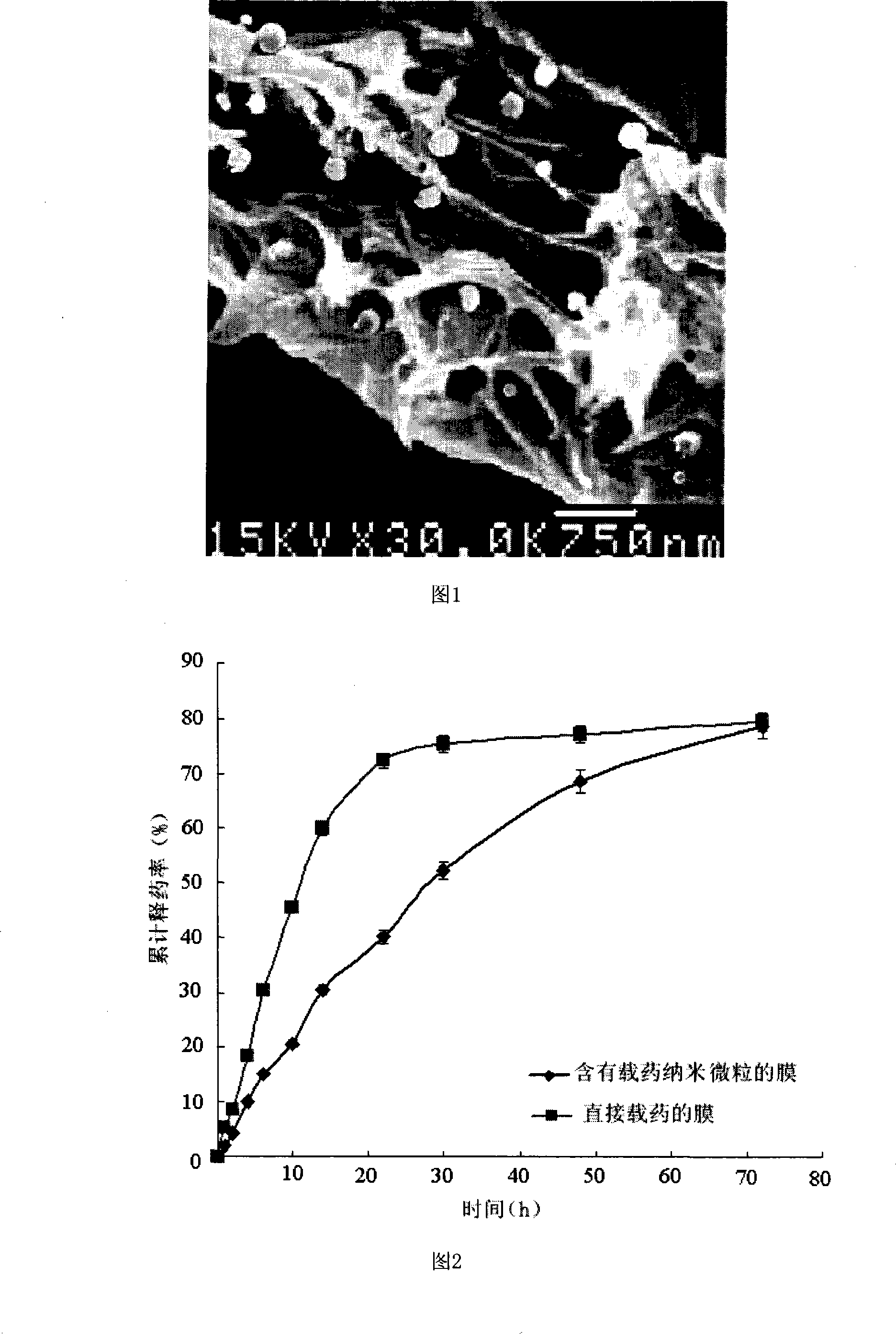

Medical wound dressing with anti-bacterial nanometer particulate

InactiveCN101224310AGood water vapor transmission rateImprove water absorptionAbsorbent padsBandagesParticulatesWound dressing

The invention discloses a medical wound dressing which is loaded with antibiotic nanometer particles and which is in a spongy state when being dried and in a gel state after absorbing the moisture; the medical wound dressing is fixed in a spongy membrane prepared by chitosan and natural high molecular polymers and derivatives of the chitosan with the proportion of 10 to 19 percent of the spongy membrane and natural polymers by drug-loading nanometer particles; the drug-loading nanometer particles contains antibiotics with the particle size of 100nm to 1000nm, the encapsulation rate of 50 to 98 percent and the drug-loading rate of 5 to 60 percent and the weight percentage of 2 to 10 percent of the drug-loading nanometer particles in the wounding dressing. Combing the sustained and controlled release characteristic and the advantage of polysaccharide membrane, the invention has high water absorbability, air permeability, moisture permeability and good biological compatibility can keep the wound physiological moisture environment and promote the wound to recover and has hemostatic effect; at the same time, the invention has good slow release performance for the antibiotics, can prevent the infection of the wound and accelerate the recovery, thus being suitable for a plurality of wounds such as the traumas, burns and ulcers.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

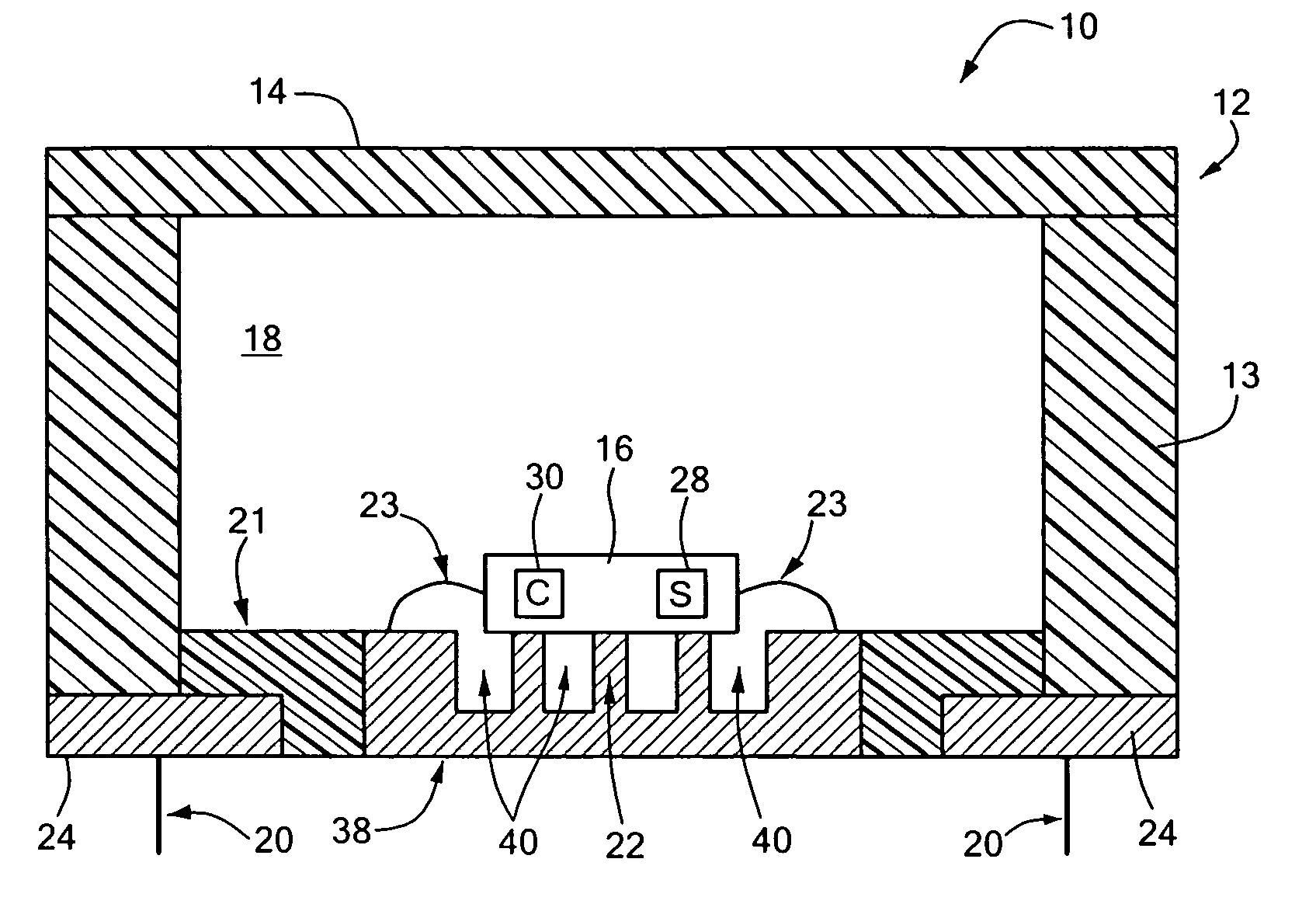

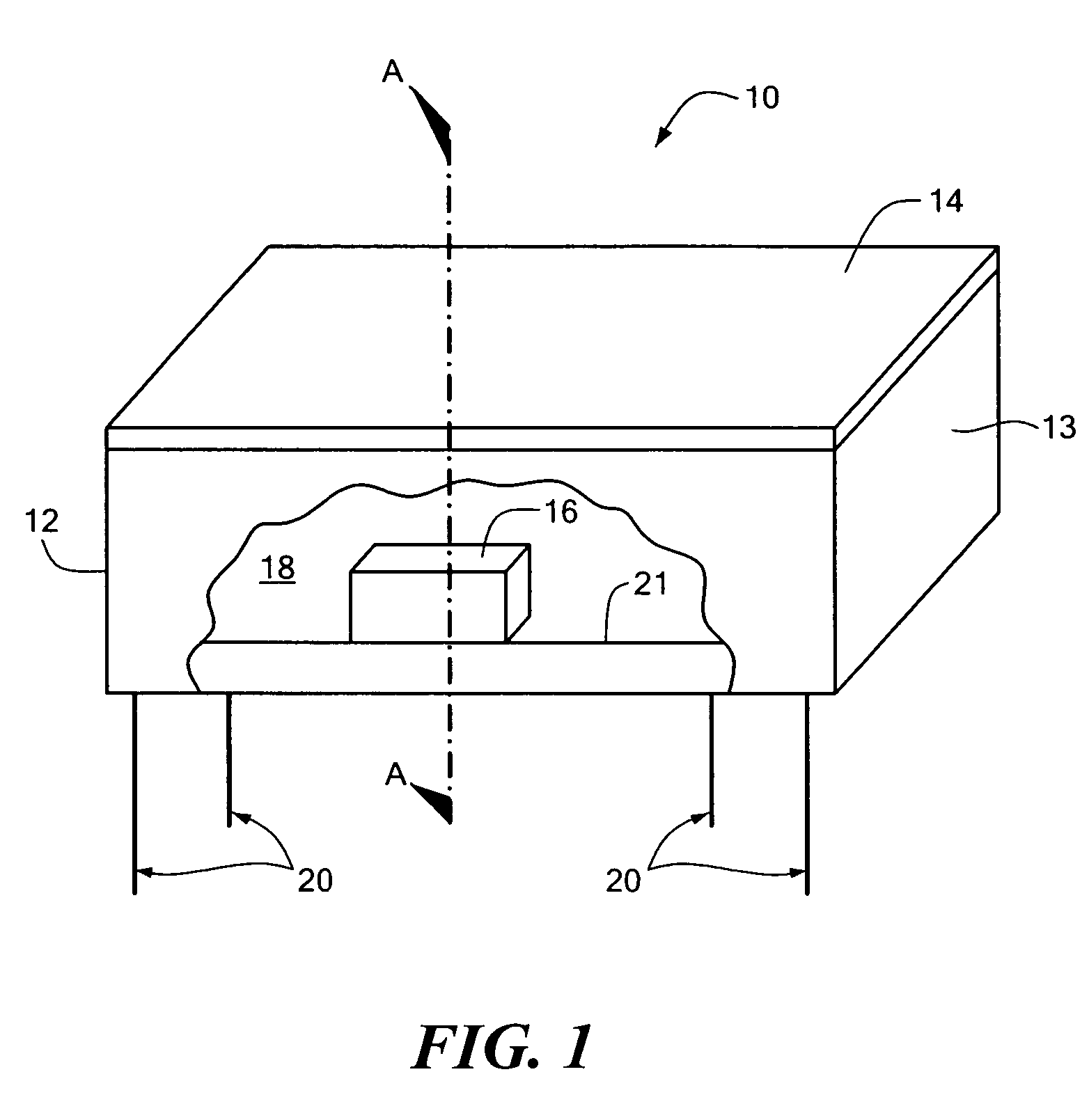

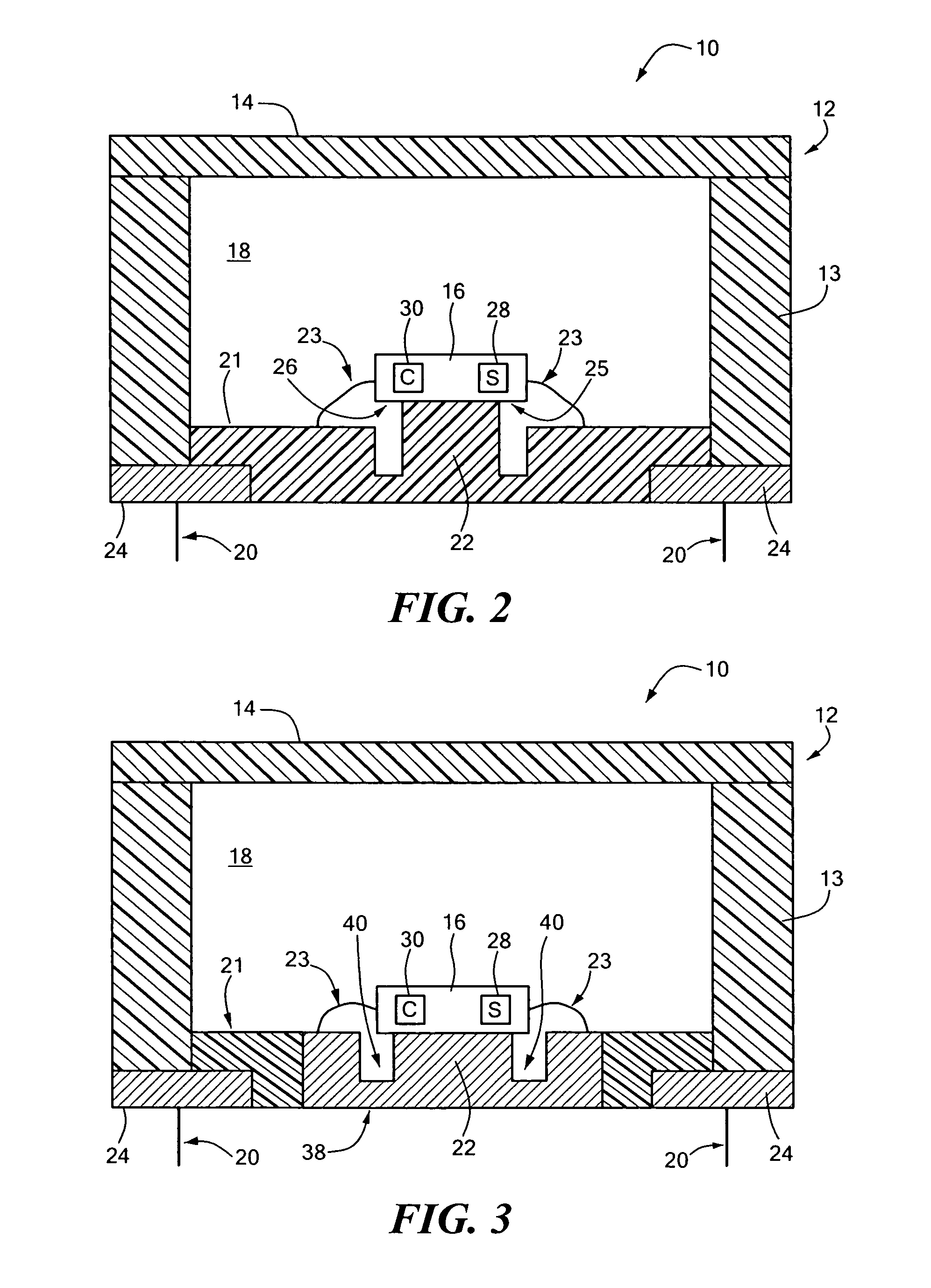

Packaged microchip with premolded-type package

InactiveUS7166911B2Low moisture permeabilityRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesMotion detectorMoisture permeability

A MEMS inertial sensor is secured within a premolded-type package formed, at least in part, from a low moisture permeable molding material. Consequently, such a motion detector should be capable of being produced more economically than those using ceramic packages. To those ends, the package has at least one wall (having a low moisture permeability) extending from a leadframe to form a cavity, and an isolator (with a top surface) within the cavity. The MEMS inertial sensor has a movable structure suspended above a substrate having a bottom surface. The substrate bottom surface is secured to the isolator top surface at a contact area. In illustrative embodiments, the contact area is less than the surface area of the bottom surface of the substrate. Accordingly, the isolator forms a space between at least a portion of the bottom substrate surface and the package. This space thus is free of the isolator. Moreover, due to the low moisture permeability of the package, further production steps can be avoided while ensuring that moisture does not adversely affect the MEMS inertial sensor within the cavity.

Owner:ANALOG DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com