Patents

Literature

272results about How to "Good breathability and moisture permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

InactiveCN1884335AImprove heat resistanceImprove low temperature resistanceLiquid surface applicatorsFibre treatmentCarbamateSolvent

The invention relates to a method for preparing aqueous polyurethane. It comprises following steps: employing polyisocyanates bridging agent, proceeding copolymerization with excess aqueous polyether, liquid ploydimethyl oxosilane ternary block and getting ployoxosilane-polyether polymer, introducing polyurethane and organic silicon when generating carbamate with carbamate to main chain, adding chain propagation agent for chain propagation reaction and getting preploymer containing hydrophilic group; adding mixture of polyhydroxy compound and dissolvent into reaction system for second chain propagation reaction; neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; distilling to remove dissolvent after reaction and getting aqueous polyurethane modified with aqueous polyurethane-polyether polymer. The product possesses characteristics of polyurethane and polysiloxane, the storage stability, mechanics property and comprehensive performance is increased and it mainly is used as pigmentum and aqueous industrial coating material.

Owner:山东圣光化工集团有限公司

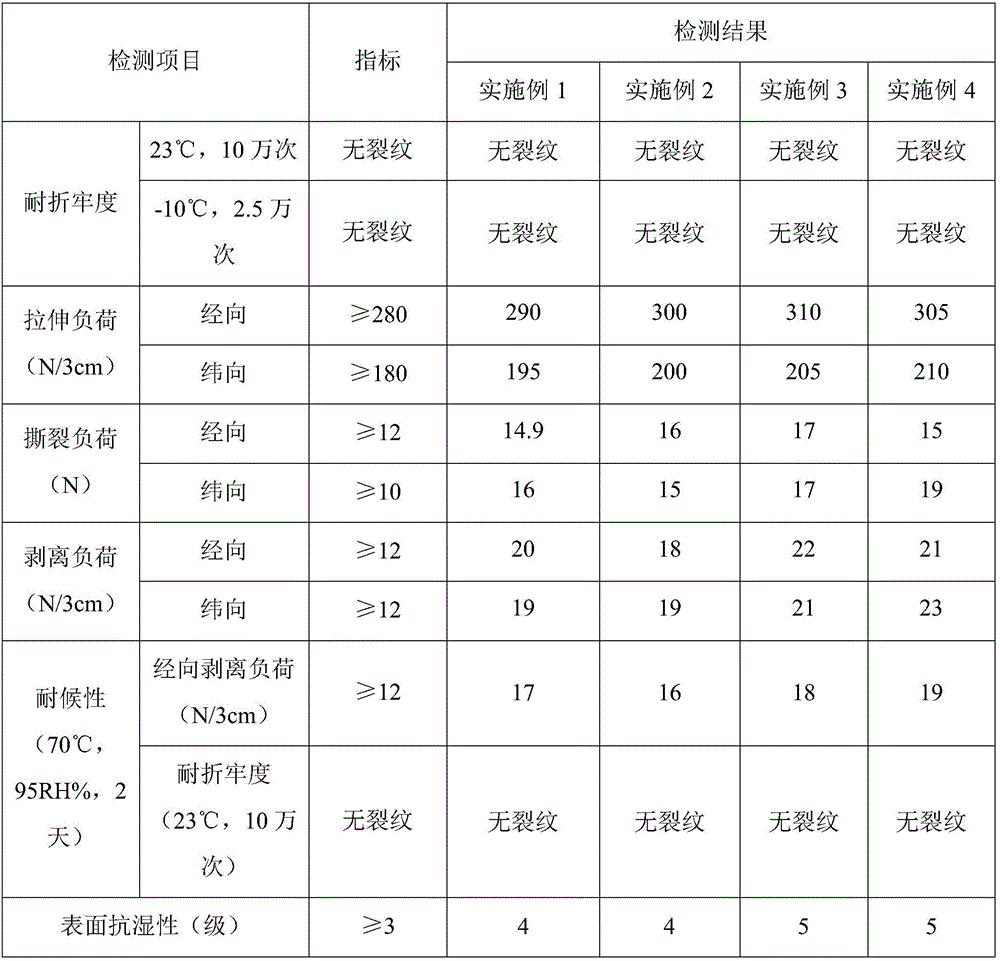

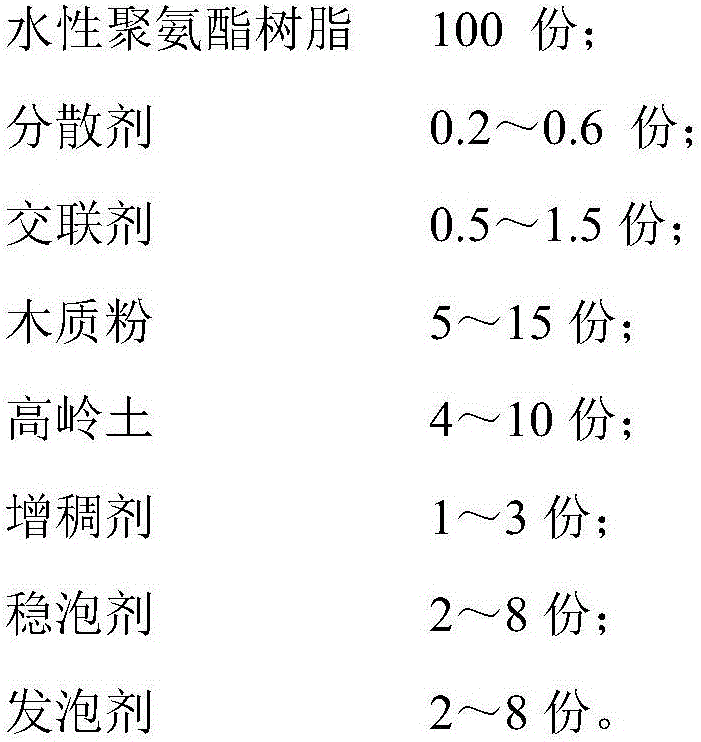

Preparation method for waterborne polyurethane synthetic leather Bass

ActiveCN102797165AGood breathability and moisture permeabilityFine foamTextiles and paperPolymer sciencePolypropylene

The invention discloses a preparation method for a waterborne polyurethane synthetic leather Bass. The method comprises the following steps of: adding a dispersing agent, a polypropylene powder and a talcum powder to waterborne polyurethane under a stirring condition; after sufficiently dispersing these materials, adding a thickening agent to these materials to stir the materials, so as to obtain a waterborne polyurethane synthetic leather paste; before coating, adding a foam stabilizer to the waterborne polyurethane synthetic leather paste under a stirring condition; bubbling the paste by using compressed air, wherein the bubbling speed is 0.2-0.8 m3 / h; and stirring and bubbling the paste for 5-10 minutes at a speed of 600-1000 rpm; and then coating a waterborne polyurethane synthetic leather foaming paste to a base fabric, which is treated by a base fabric treating liquid and ironed by an ironing roller, wherein the coating quantity is 300-600 g / m2; and finally, drying the waterborne polyurethane synthetic leather foaming paste, so as to obtain the waterborne polyurethane synthetic leather Bass. According to the invention, a foaming material has the advantages of rapidness in foaming and good foam stabilizing property; and the preparation method disclosed by the invention has the advantages of simplicity, easiness and easiness for continuous production and is very suitable for large-scale industrial production.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

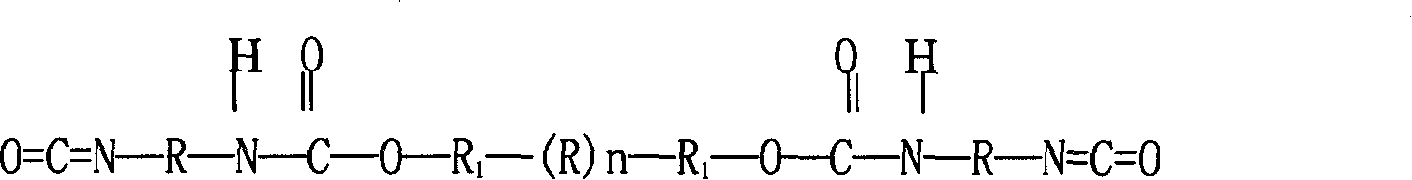

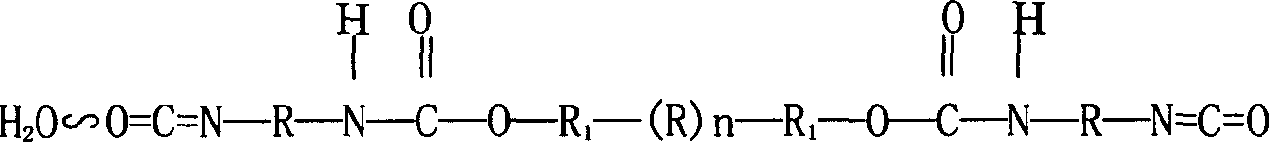

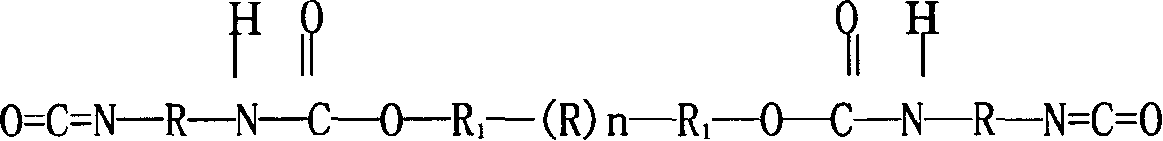

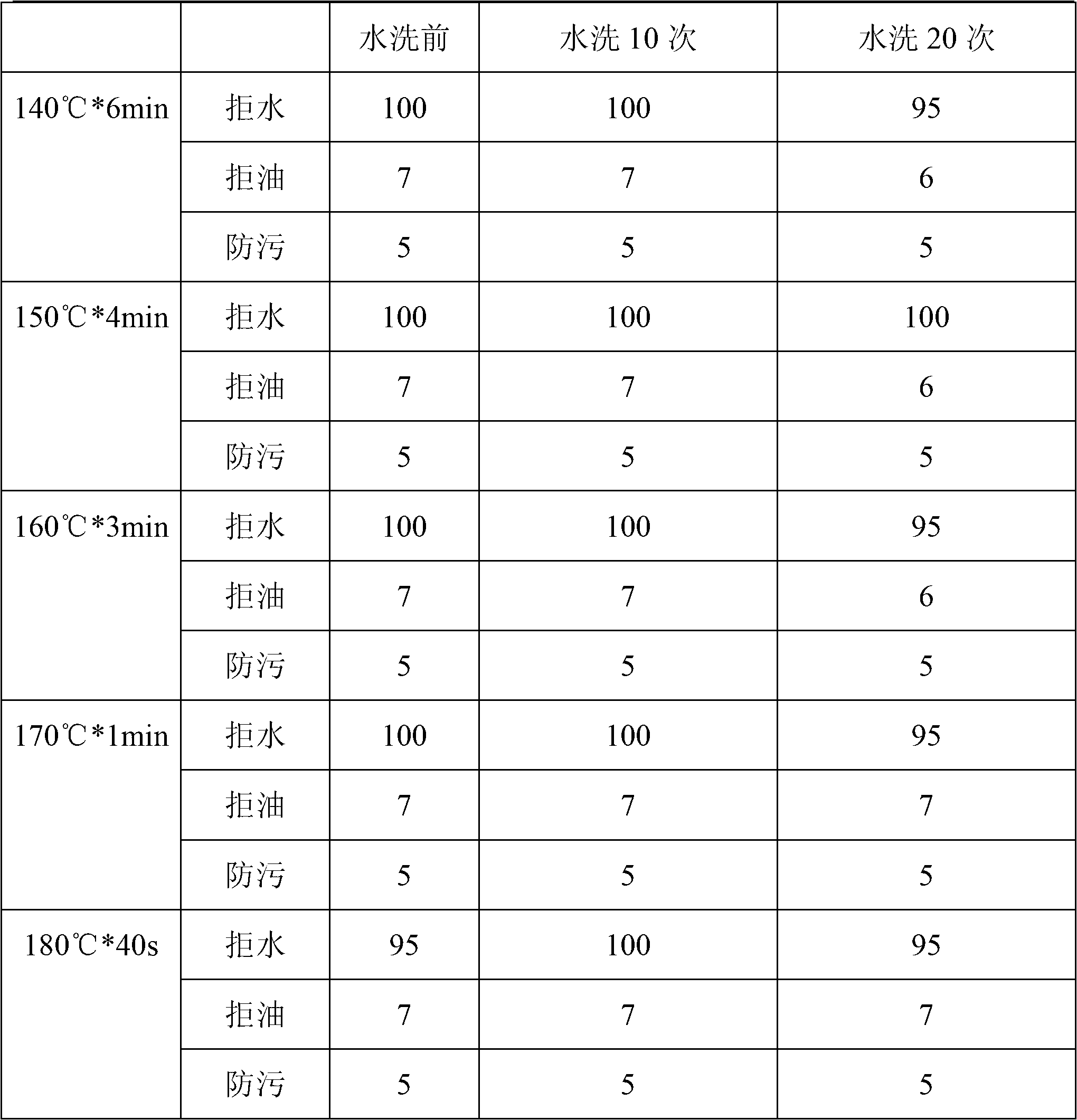

Preparation technology of water, oil and pollution resistant texture fabric

InactiveCN102978901AGood three-defense effectGood breathability and moisture permeabilityFibre typesBreaking strengthColour fastness

The invention provides a preparation technology of a water, oil and pollution resistant texture fabric. The preparation technology is characterized in that pretreatment or dyeing and dip padding fixing finishing of a base cloth is carried out, and the dip padding fixing finishing is carried out in a nanometer finishing liquid comprising a fluorine-containing finishing agent used for water, oil and pollution resistant finishing and a nanometer ceramic powder dispersion liquid. The preparation technology enables the fabric to have very good nanometer water, oil and pollution resistant functions, still have very good water, oil and pollution resistance effects after multi-time water washing, have a high color fastness and a good air and water vapor permeability and have a non-obviously decreased breaking strength after finishing.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

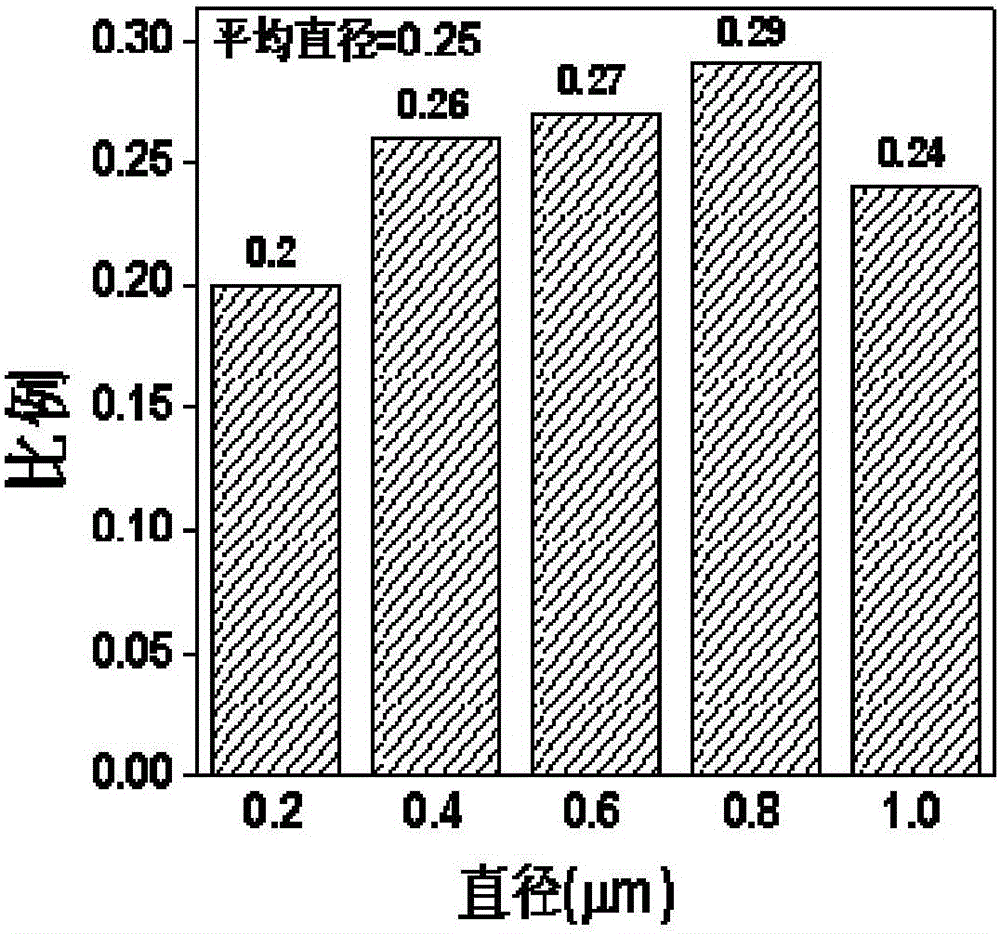

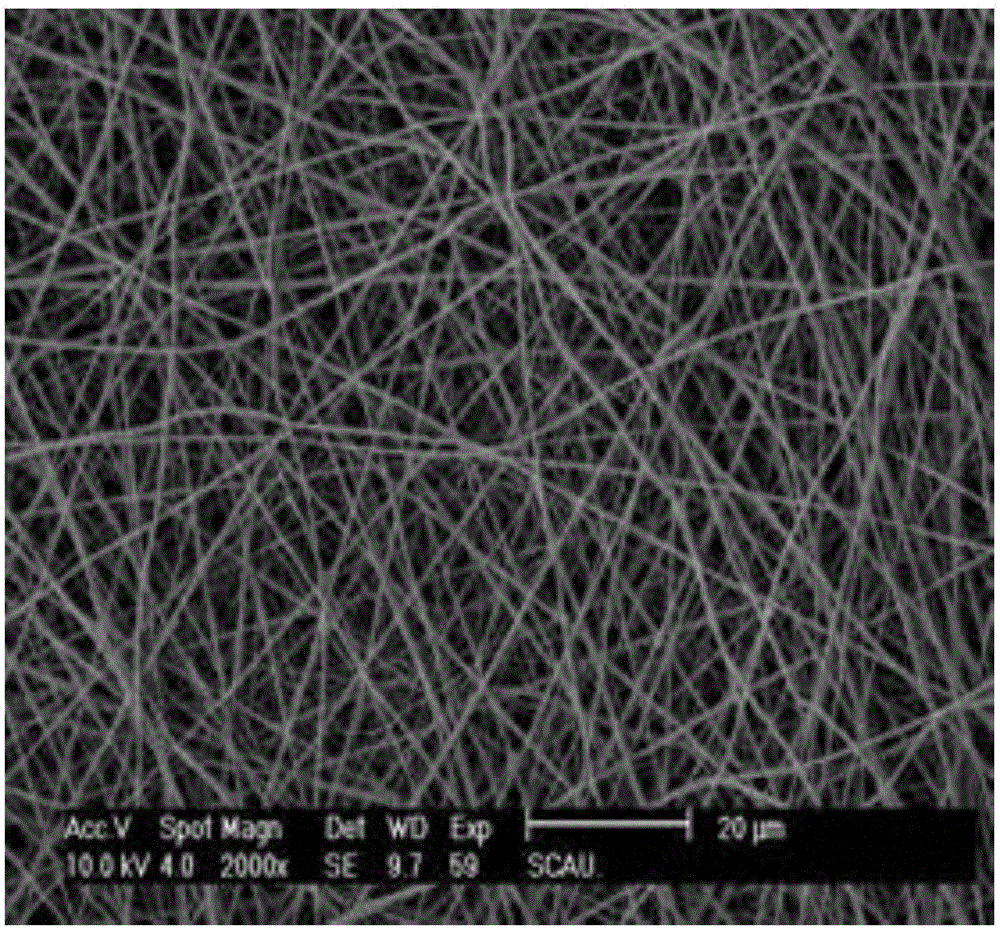

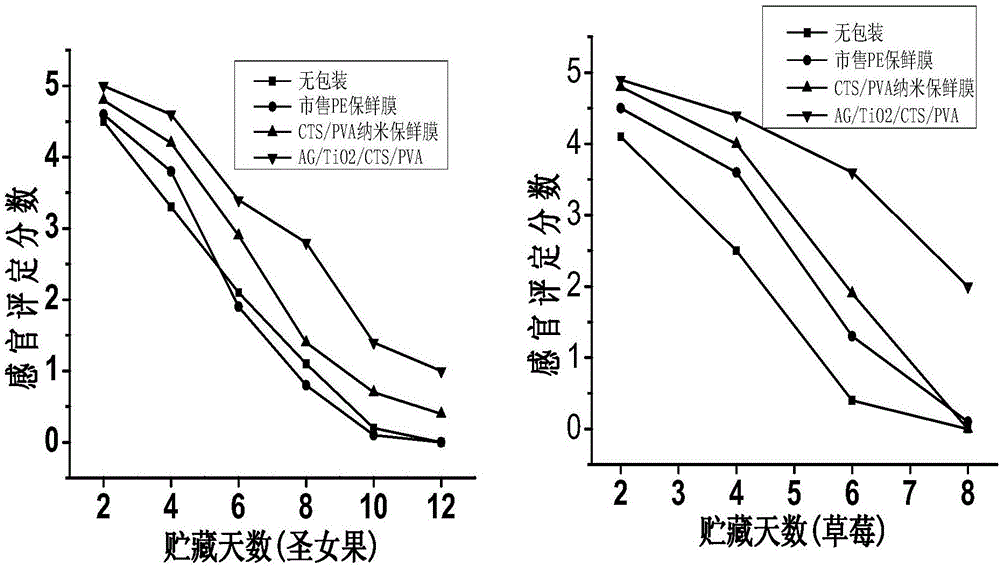

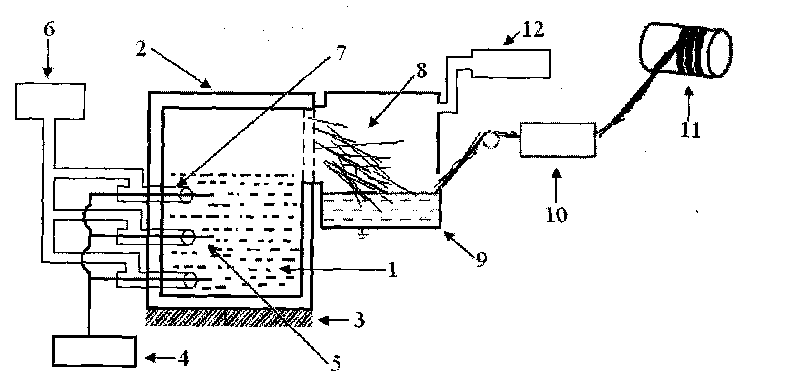

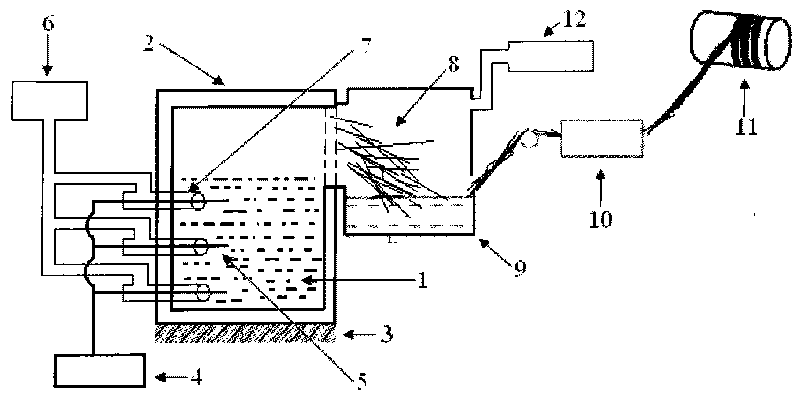

Nano-fiber anti-microbial fruit-vegetable preservative film with porous structure, and preparation method and application

The invention discloses a nano-fiber anti-microbial fruit-vegetable preservative film with a porous structure, and a preparation method and application. According to the invention, myoporum bontioides leaves are grinded into powder and treated by supercritical extraction, so that a myoporum bontioides extract is obtained; a water solution containing TWEEN-80 is added into the myoporum bontioides extract, and the mixture is filtered, so that a myoporum bontioides supercritical extract solution is obtained; the myoporum bontioides supercritical extract solution, a polyvinyl alcohol solution, a chitosan derivative solution and a nano-titania solution are mixed, so that a mixed spinning solution is obtained; and the mixed spinning solution is treated by spinning of a static spinning machine, so that the nano-fiber anti-microbial fruit-vegetable preservative film with the porous structure is obtained. The preservative film has the advantages of a large specific area, a high porosity, high finger uniformity, good mechanical properties and the like, also has performance such as a good moisture permeable and gas permeable property and a good moldproof and anti-microbial property, and has high application potential in the food packaging field.

Owner:广州怡馨舒生物科技有限公司

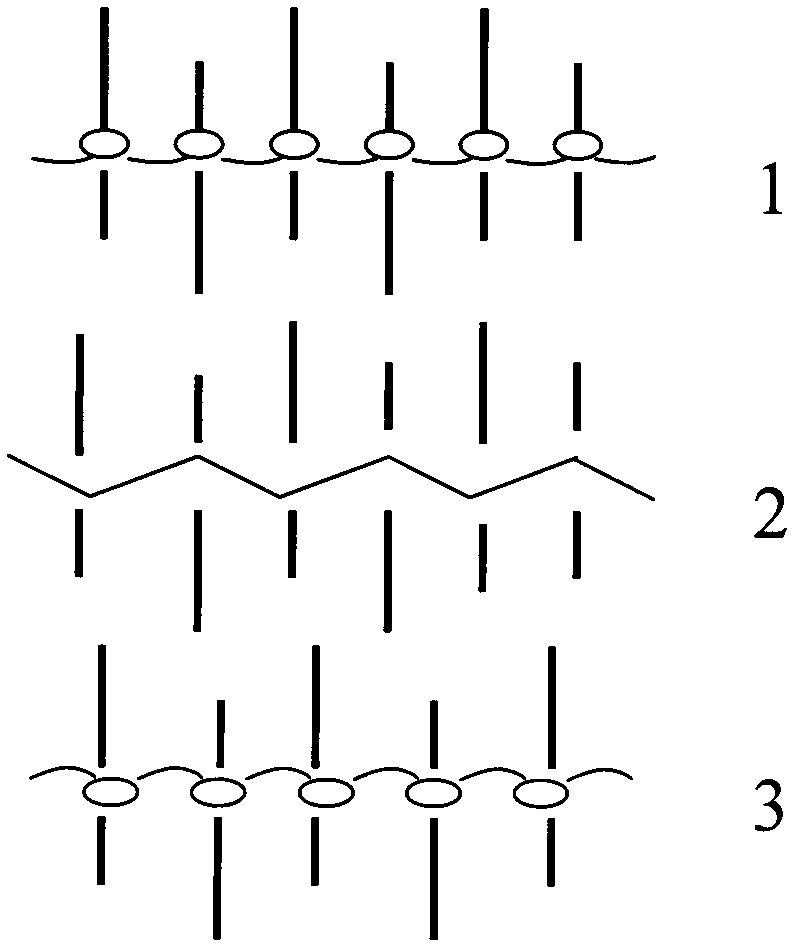

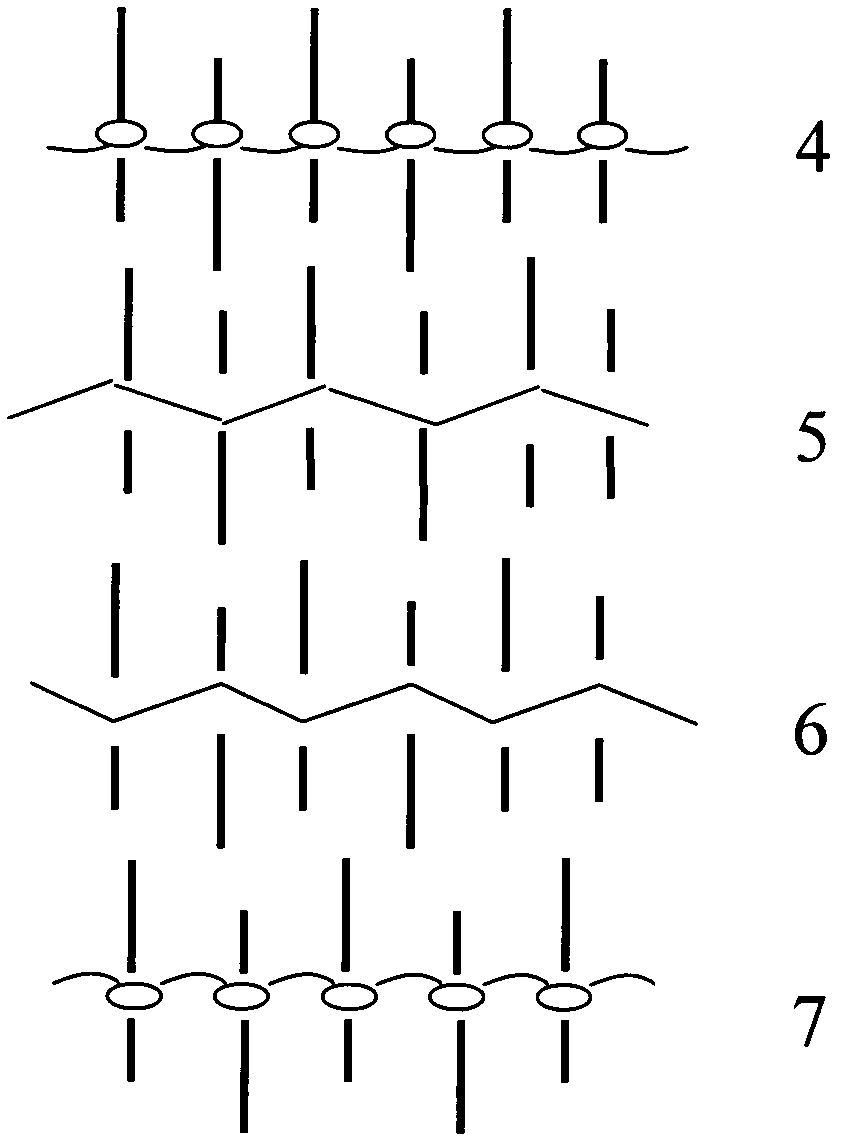

Compound tissue functionality knitted fabric

InactiveCN103122545AGood breathability and moisture permeabilitySoft to the touch and environmentally friendlyWeft knittingYarnPolyester

The invention discloses compound tissue functionality knitted fabric. The compound tissue functionality knitted fabric is woven by at least two layers of knitted fabric of the outside and the inside, wherein the outside layer is a layer of polyester yarns which are treated by hydrophobic resins, and water absorption quick-dry yarns are contained in the inside layer. Compound tissue contexture is adopted. Finished products are obtained after greige cloth is passed through processes of the greige cloth forming, refining, coloring, forming and the like. A latter finishing process is simple and easy to control. The outside layer of the compound tissue functionality knitted fabric has good hydrophobic property, and the inside layer of the compound tissue functionality knitted fabric has good hydrophilic performance. The compound tissue functionality knitted fabric is soft in hand feeling, lasting in function and capable of being widely applied in sports underwear and coats and the like of all seasons.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

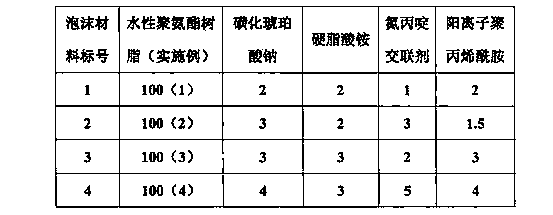

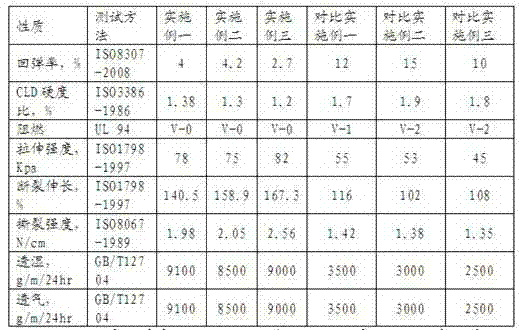

Polyurethane foam resin and preparation method thereof

InactiveCN104231300AImprove adhesionFeel goodTextiles and paperWater vapor permeabilitySolvent based

The invention provides polyurethane foam resin which is mainly used for a post-treatment process of split leather and synthetic leather. The resin is a foam material prepared by uniformly mixing the following raw materials in parts by weight: 1-5 parts of a foaming assistant, 1-5 parts of a foam stabilizing assistant, 0-5 parts of a cationic coagulant, 0-10 parts of a cross-linking agent, 0.2-5 parts of a thickener, 0-6 parts of waterborne coloring paste and 100 parts of waterborne anionic polyurethane paste. The prepared foam resin overcomes the shortcomings of solvent type foam resin, adopts water as a solvent, and is environment-friendly and pollution-free; a leather product prepared from the foam resin is good in adhesion property, excellent in hand feel and comprehensive effect and good in air and water vapor permeability.

Owner:SHANDONG TIANQING TECH DEV

Dry garment leather base and preparation process thereof

InactiveCN106118034ASensualImprove tensile propertiesGrip property fibresProcess engineeringMaterials science

The invention provides a dry garment leather base and a preparation process thereof. The preparation process includes the steps: 1) base cloth treatment: completely soaking base cloth in mixed solution of soluble calcium salt and leather softeners, mangling the base cloth and then ironing and drying the base cloth by an ironing roller; 2) coating the base cloth with 200-500g / m<2> of garment leather base foaming slurry by a scraping method; 3) drying the base cloth in a drying oven; 4) base rolling: cooling and rolling the base cloth by a cooling roller to prepare the dry garment leather base. The prepared dry garment leather base has good moisture and air permeability, is quite soft in hand feeling and good in rebound resilience and wear resistance, and can meet higher performance requirements and environmental protection standards.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

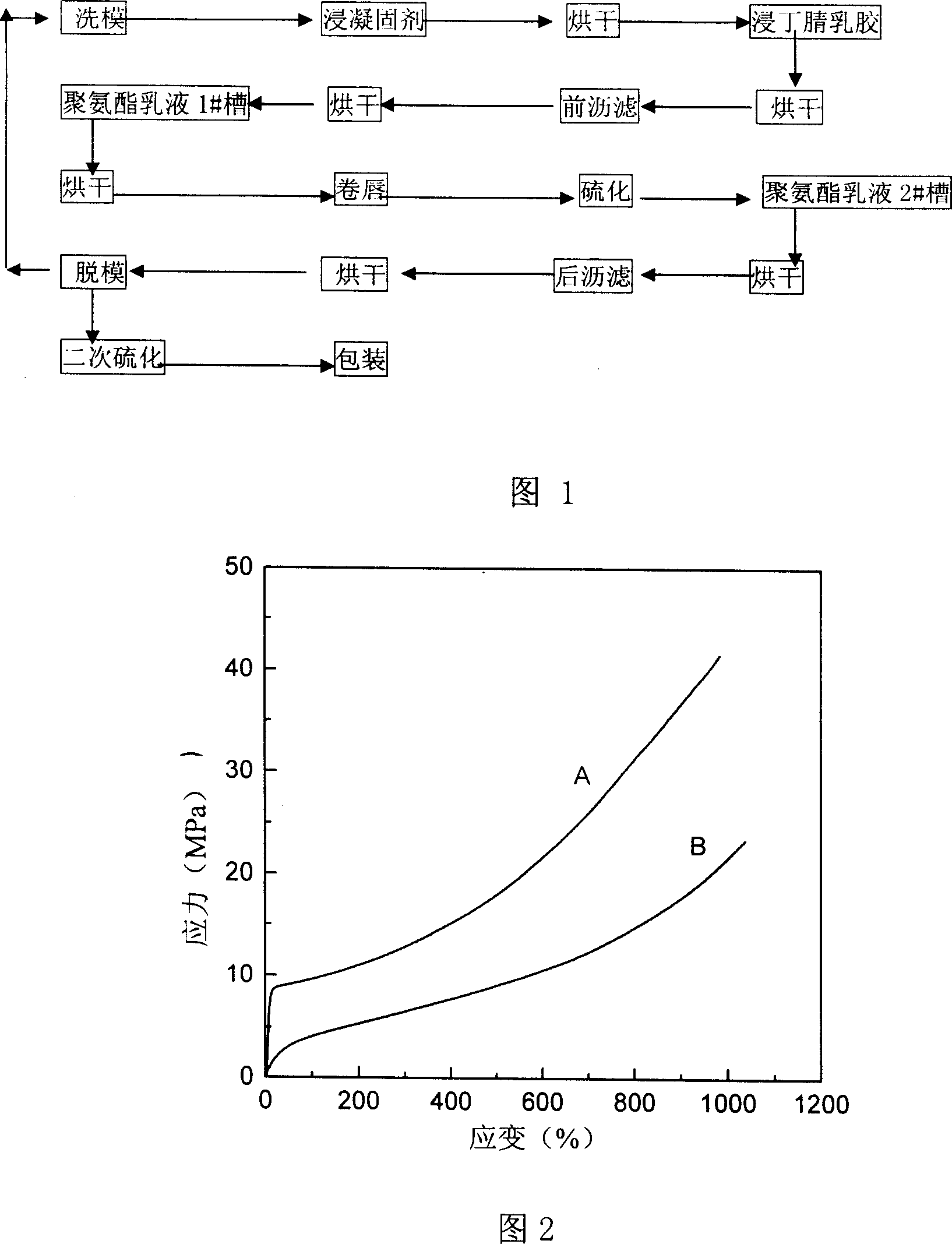

Method for fabricating one-off composite glove of nitrile butadiene rubber polyurethane

InactiveCN101003165AGood breathability and moisture permeabilityImprove wearing comfortDiagnosticsGlovesHigh resistanceEmulsion

A process for preparing the expendable composite nitrile rubber-polyurethane glove includes generating a layer of nitrile rubber film on a mould, and dipping it in aquatic polyurethane emulsion. The resultant glove has high resistance to oil and bacterial osmosis, high weatherability, and high air and moisture permeability.

Owner:TIANJIN GREENCOAT POLYMER MATERIAL TECH CO

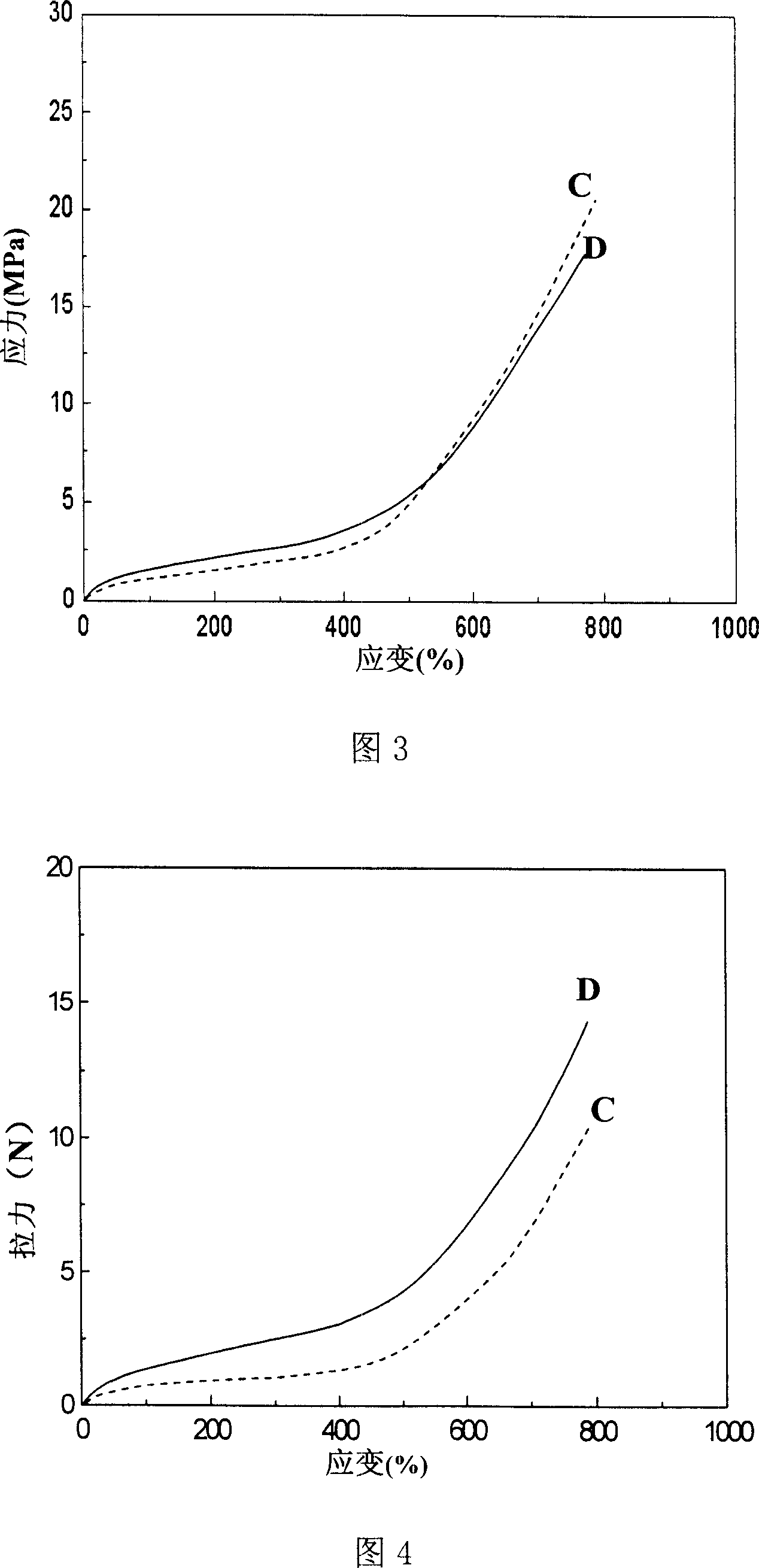

Waterborne polyurethane waterproof moisture-permeable coated fabric and preparation method thereof

InactiveCN104448220AHigh elongation at breakGood breathability and moisture permeabilityHeat resistant fibresParaffin waxDicumyl peroxide

The invention discloses a waterborne polyurethane waterproof moisture-permeable coated fabric and a preparation method thereof. The waterborne polyurethane coating is prepared from the following raw materials in parts by weight: 140-150 parts of polyester polyol, 20-24 parts of toluene diisocynate, 40-50 parts of diphenyl-methane-diisocyanate, 8-12 parts of 2,2-dimethylolpropionic acid, 7-9 parts of neopentyl glycol, 3-5 parts of trimethylolpropane, 6-10 parts of dibutyltin dilaurate, 4-6 parts of a DH-1 reinforcing agent, 2-3 parts of an antioxidant TNP, 9-11 parts of an ultraviolet absorbent, 8-12 parts of a dyeing agent, 6-7 parts of liquid paraffin, 4-5 parts of antimony trioxide, 5-7 parts of polytetrahydrofuran dibasic alcohol, 6-8 parts of nanosilicon dioxide, 0.8-1.2 parts of dicumyl peroxide, 7-9 parts of 2,6-Di-tert-butyl-4-methylphenol (BHT), 15-19 parts of deionized water and 7-9 parts of auxiliary. The coated fabric which is high in elongation at break and high in moisture and air permeability is prepared, and the properties such as the elongation at break, the moisture and air permeability, the aging resistance, the flame retardance and the electrostatic resistance of modified polyurethane can be effectively improved.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Preparing method of chemical leather for lining of superfine fiber water absorption breathable shoes

ActiveCN101446042ARaise the gradeIncrease added valueInsolesTextiles and paperSolventAqueous solution

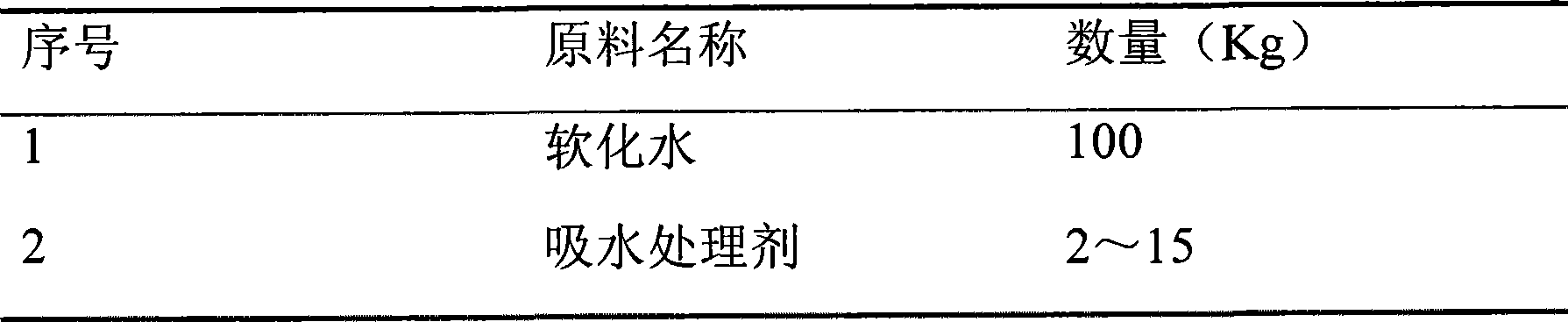

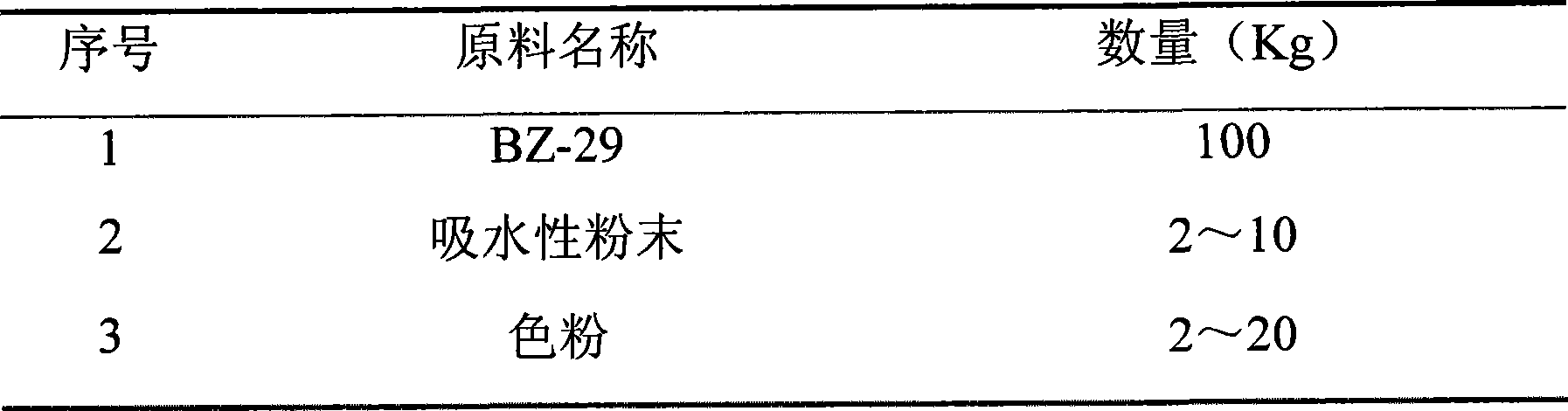

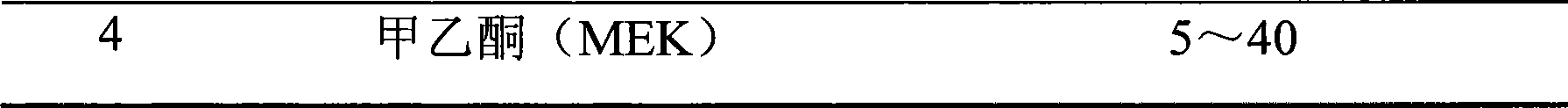

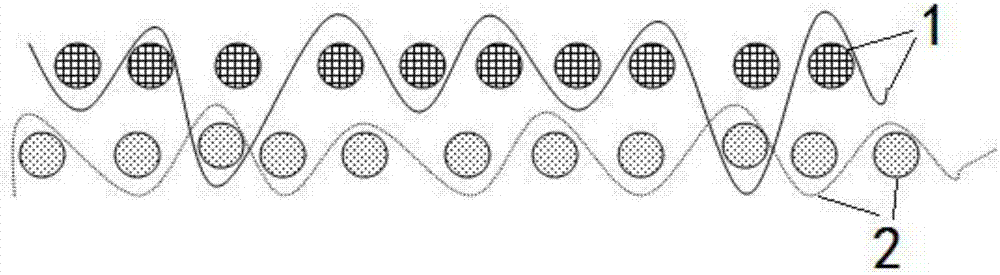

The invention relates to a preparing method of chemical leather for linings of a pair of superfine fiber water absorption breathable shoes; the method is realized by the following steps: 1. superfine fiber is adopted to make chemical leather; 2. the prepared treatment fluid is poured into a square groove provided with a sink roll; wherein, the mixture ratio (Kg) of the treatment fluid is 100Kg of demineralized water and 2-15Kg of aqueous solution of water modified silicon polymer; 3. liquid carrying rate is controlled to be 50-120% of the weight of base cloth; and the drying temperature is 60-150 DEG C; 4. dry process surface manufacturing treatment is carried out; wet end furnish (Kg) is 100 Kg of solvent type urethane resin, 2-10 Kg of hollow wood fiber, 2-20 Kg of colored powder and 5-40 Kg of ethyl methyl ketone; 5. release paper B-100 is adopted; 6. a first impasto palette knife distance is 120-300mum, and the drying temperature is 60-150 DEG C; 7. a second impasto palette knife distance is 80-250mum, and the drying temperature is 60-150 DEG C; 8. the gluing way is wet combining, the gluing pressure is 3-6 Kg, and the vehicle speed is 2-10m / min; a sample is obtained by directly and quickly stripping after drying; the obtained products have good simulation property, hand feeling and breathability.

Owner:HUAFON MICROFIBER SHANGHAI

Double-layer flame-retardant fabric with water-repellent surface layer and hydrophil inner layer, and preparation technology thereof

InactiveCN106995965AHigh flame retardant and high temperature resistanceEasy to handleSynthetic resin layered productsHeating/cooling textile fabricsYarnSurface layer

The invention discloses double-layer flame-retardant fabric with a water-repellent surface layer and a hydrophil inner layer, and a preparation technology thereof. The double-layer flame-retardant fabric comprises the surface layer and the inner layer, wherein the surface layer is composed of at least one of aramid fibers, polyimide fibers, polysulfonamide fibers, flame-retardant viscose and ; the inner layer is formed by mixing flame-retardant modacrylic fibers with chloride, Tencel fibers and partner fibers, and the partner fiber is one selected from flame-retardant nylon fibers, aramid fibers and polysulfonamide fibers; water-repellency of the surface layer is implemented by the technology comprising the steps of preparing three proofing auxiliary size, soaking surface layer yarn into the three proofing auxiliary size, drying with high temperature, weaving and hot rolling with rollers; and water absorption of the inner layer is implemented by the technology comprising the steps of preparing hydrophil and sweat-releasing auxiliary size, soaking inner layer yarn into the size, drying, weaving and decating. The double-layer flame-retardant fabric with the water-repellent surface layer and the hydrophil inner layer has the characteristics of being soft, comfortable, air and moisture permeable and skin-friendly, has multifunctional protection performance, and meanwhile is high in comfort, so as to be applicable to special protection clothing in industries of firefighting, military police, electric power and smelting.

Owner:SHANGHAI IBENA TEXTILE PROD

Preparation method for modified polyurethane

ActiveCN102391459AHigh elongation at breakGood breathability and moisture permeabilityFibre treatmentEthylenediamineWater based

The invention discloses a preparation method for modified polyurethane. The preparation method comprises the following steps of: adding polypropylene oxide glycol into a reaction vessel; heating to 75 to 80 DEG C; adding toluene diisocynate (TDI) and a T12 catalyst and reacting for 2 hours; adding dimethylol propionic acid and reacting for 30 minutes; adding hydroxyethyl acrylate and reacting for1 hour; adding a chain extender 1,4-butanediol and reacting for 1 hour; cooling to 30 DEG C after the reaction is finished; adding a KOH solution into prepolymer with stirring at a high speed and dispersing for 20 minutes, wherein the pH value is 7 to 8; adding ethanediamine and reacting with stirring for 20 minutes; and adding deionized water under the action of high shearing force to prepare water-based polyurethane emulsion. Therefore, by the method, the breaking elongation, the moisture permeability and the air permeability of the modified polyurethane are improved effectively.

Owner:SHANXI YUBANG NEW POWER SCI & TECH

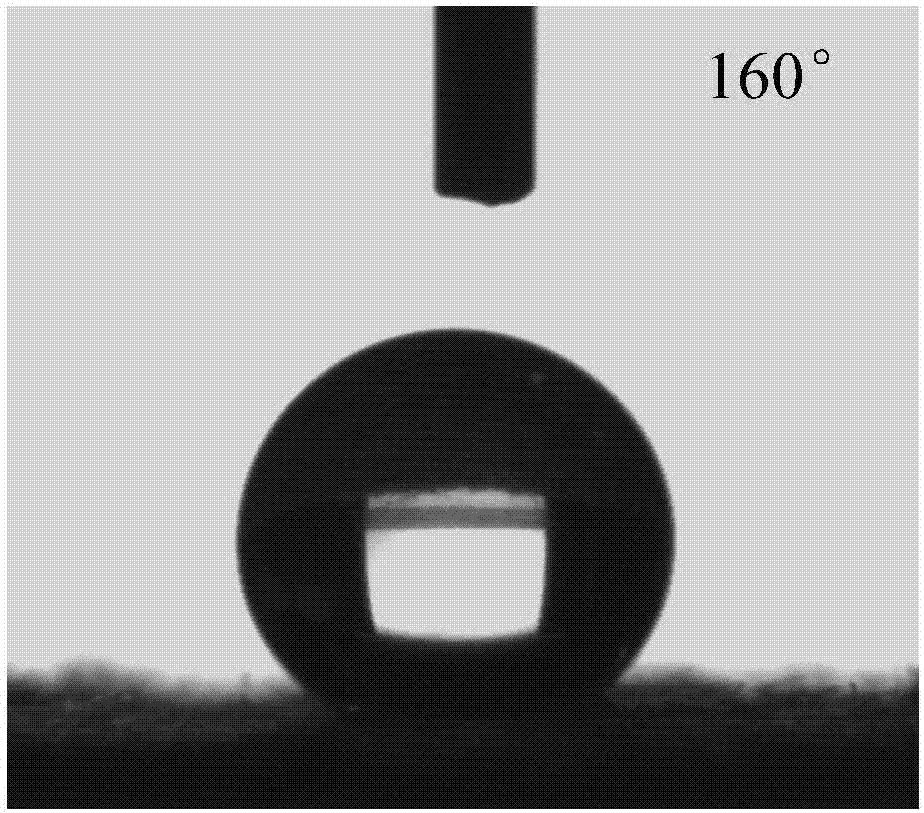

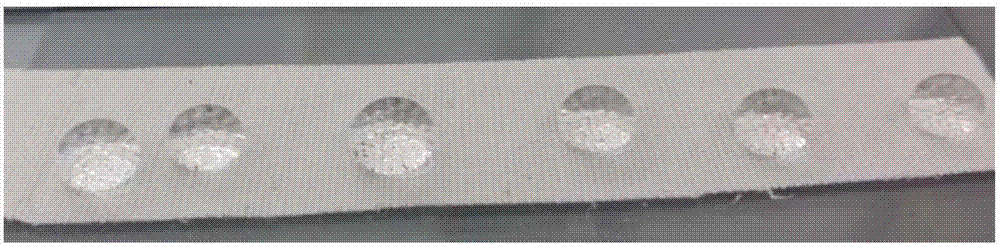

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

ActiveCN107326651AReduce usageSimple manufacturing processStain/soil resistant fibresBiochemical fibre treatmentHydrolysisSkin protection

The invention discloses a multifunctional super-hydrophobic textile finishing agent, and a preparation method and applications thereof. The preparation method comprises following steps: a precursor of an oxide sol and a graphite oxide aqueous dispersion are dispersed in deionized water, an anionic surfactant is added, a catalyst is added for hydrolysis and condensation reaction after uniform dispersion so as to obtain a mixed reaction system, and the mixed reaction system is heated to 30 to 50 DEG C for 3 to 12h of reaction so as to obtain a hydrosol; a functional agent is added into the hydrosol so as to obtain the multifunctional super-hydrophobic textile finishing agent. The multifunctional super-hydrophobic textile finishing agent is safe, is friendly to the environment, is excellent in effect, is used for super hydrophobic and multifunctional finishing of textile, is capable of providing textile with six functions including super-hydrophobic property, flame resistance, antibacterial property, stain resistance, ultraviolet resistance, and skin protection performance, is capable of eliminating adverse effect of the plurality of functions, improving the synergistic effect; the preparation method is simple and convenient, is easy to control, and is suitable for large scale production.

Owner:石狮市杰立纺织科技有限公司

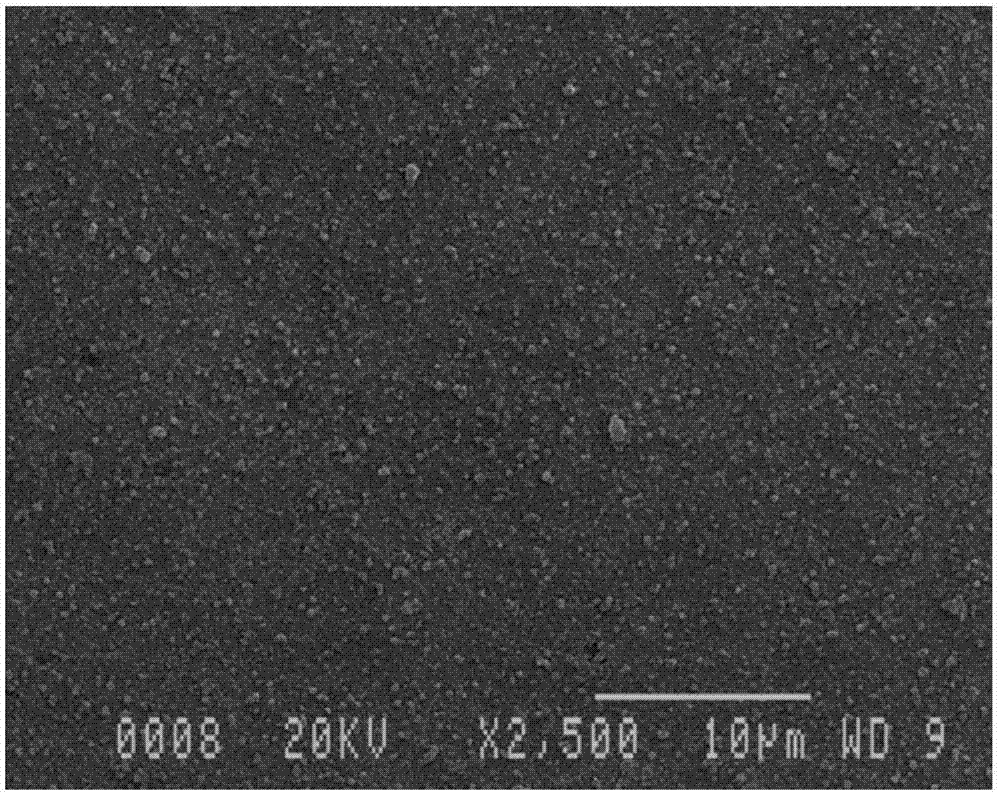

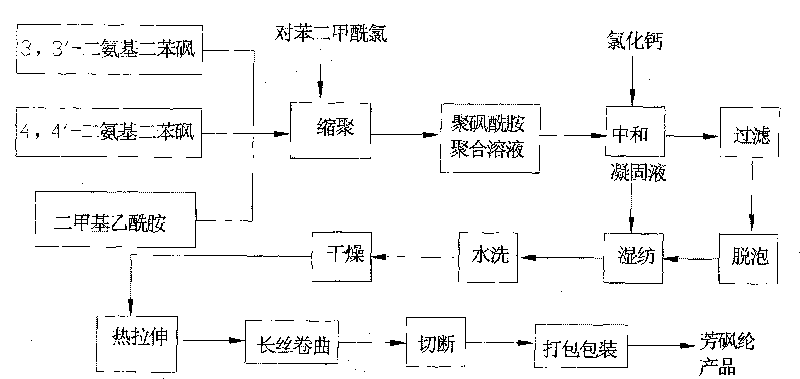

Method for preparing ultrafine polysulfonainide fiber

InactiveCN101718002ASmall diameterImprove flame retardant performanceFilament/thread formingMonocomponent copolyamides artificial filamentYarnFiber diameter

The invention provides a method for preparing ultrafine polysulfonainide fiber. The method comprises the following steps: dissolving the polyphenylene sulfone terephthaloyl amide master batch prepared by a conventional method in a strong polar solvent to form 11 to 25 percent spinning solution; stirring the spinning solution for 30 to 90 minutes at a high speed and filtering the spinning solution; heating the spinning solution to a temperature of between 40 and 150 DEG C till regular vacuole occurs in the spinning solution; performing rapid pressurization on the spinning solution in a solution storage pool through an air duct; acting on the heated spinning solution by utilizing a metal electrode; after electric field force exceeds the surface tension of the spinning solution, forming mass injection streams on the top end of the vacuole; and subsequently, rapidly stretching and differentiating the injection streams to obtain the ultrafine polysulfonainide fiber. When the method is used to prepare polysulfonainide yarn, the production speed can reach between 50 and 200m / min, and the diameter of the polysulfonainide fiber is between 0.6 and 2.2 mu m and is only 1 / 8 to 1 / 10 of that of traditional polysulfonainide.

Owner:南通信一服饰有限公司

Preparation method for high-toughness monofilament blended cotton yarn

ActiveCN104651998AGood flexibilityIncrease elasticityDry-cleaning apparatus for textilesBleaching apparatusYarnCarding

The invention discloses a preparation method for high-toughness monofilament blended cotton yarn. The preparation method comprises the following steps of carrying out cotton feeding, rolling, cotton carding and drawing to obtain rough yarn after carrying out cotton opening and scutching on long staple cotton, fine staple cotton, prefabricated monofilament materials and mixed cotton, and obtaining the high-toughness monofilament blended cotton yarn through spinning and spooling, wherein the prefabricated monofilament materials are obtained through draining and drying after carrying out primary boiling and dehydrating, primary steaming, secondary boiling and dehydrating, secondary steaming, standing, bleaching and washing. The high-toughness monofilament blended cotton yarn prepared by the preparation method has the characteristics of high toughness, low cost and the like, meanwhile, the air permeability is good, and the comfort is strong.

Owner:福建新同兴针纺织有限公司

Moisture absorption and radiation protection laminar compound plus material

ActiveCN102431225AExcellent moisture absorption and radiation protectionGood breathability and moisture permeabilityLayered productsFibre treatmentFiberSilver plate

The invention relates to a moisture absorption and radiation protection laminar compound plus material. The moisture absorption and radiation protection laminar compound plus material is designed, fabrics of the outer layer and the inner layer in the compound fabrics are interwoven and connected through silver plated bonding fiber, the fabrics of the outer layer and the inner layer are sequentially subjected to post tidying treatment before the interwoven connection, the defects of impermeability, moisture impermeability, poor comfort effect and the like of radiation protection plus materials in the prior art are overcome, the plus material meets the special moisture absorption and radiation protection requirements, and good performance such as good air permeability, moisture permeability, moisture absorption, ventilation, anti-static performance, radiation protection and good comfort effect of the plus material can also be realized through the special laminar structure fabrics of the plus material.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Plant source extract anti-bacterial preservative film, and preparation method and application thereof

ActiveCN105694320ABroad spectrum antibacterialImprove the defect of being easily soluble in waterFlexible coversWrappersPolyvinyl alcoholPlant Sources

The invention discloses a plant source extract anti-bacterial preservative film, and a preparation method and application thereof. According to the method, boracic acid and hydrochloric acid are used for modifying vinol; then, the modified vinol is uniformly mixed with nanometer titania; next, the mixture is uniformly mixed with crofton weed ethanol extracts emulsified by tween-80; film casting is performed; the materials are dried under the natural conditions; the plant source extract anti-bacterial preservative film is obtained. The film has the proper oxygen permeability and moisture permeability; due to plant source extracts contained in the preservative film, preserved articles can be prevented from getting rotten through being infected by bacteria; ethylene gas generated by fruit and vegetables can be degraded by nanometer materials; meanwhile, the film also has excellent mechanical property. The plant source extract anti-bacterial preservative film is mainly applied to the fields of preservative package of fruit and vegetables, sea products and cereal subsidiary food and the like, and can also be applied to food container coverage, so that the food is prevented from getting rotten through being polluted by bacteria; the storage life is prolonged.

Owner:广州怡馨舒生物科技有限公司

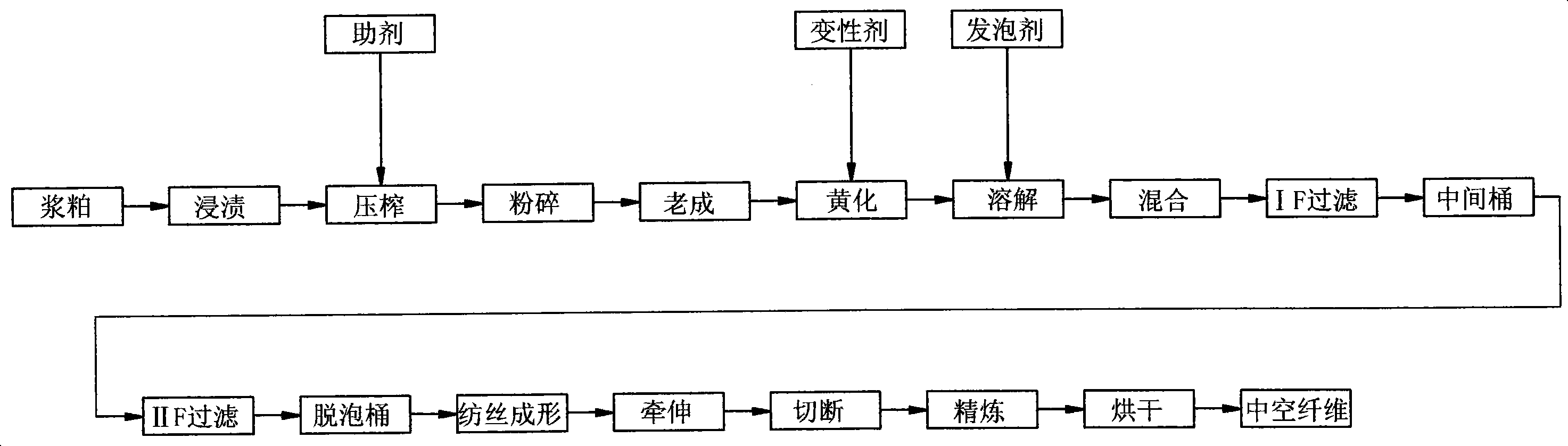

Manufacturing method of high performance hollow cellulose fibre

ActiveCN101089256AEasy to operateHigh hollownessHollow filament manufactureArtificial filaments from viscoseFoaming agentFiltration

Owner:潍坊欣龙生物材料有限公司

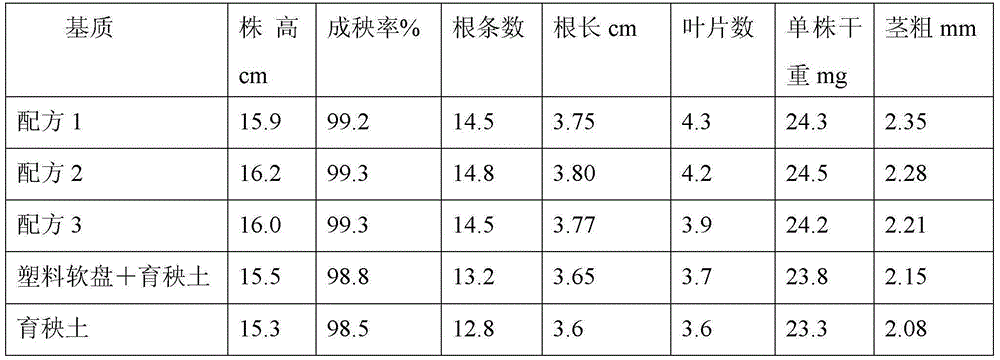

Preparation method for total-degradation layer-structured rice seedling-growing tray

InactiveCN105165466AAchieve recyclingSolve irreversible problemsGrowth substratesCulture mediaFiberCompost

A Preparation method for total-degradation layer-structured rice seedling-growing tray relates to the preparation method for the rice seedling-growing tray. The preparation method settles the following problems in existing rice seedling growing: degrading incapability of plastic seedling-growing tray, low moldability of a degradable seedling-growing matrix, requirement for matched use of the seedling-growing tray, and incapability of realizing soilless cultivation. The preparation method of the invention comprises seven steps: a first step, preparing rice straw biological carbon; a second step, performing nitriding modification processing on the rice straw biological carbon; a third step, processing compost; a fourth step, preparing a seedling growing main material; a fifth step, performing acid treatment and drying treatment; a sixth step, performing laying operation by means of a seedling-growing tray mold; and a seventh step, laying a lower-layer fiber felt, the seedling growing main material and an upper-layer fiber felt. According to the preparation method, the waste material of a crop is sufficiently utilized, and total degradation of a rice seedling growing matrix is realized. The seedling growing matrix which is prepared according to the invention can improve the condition of a farmland soil year by year. The preparation method is used for preparing the total-degradation rice seedling-growing tray.

Owner:JIAMUSI UNIVERSITY

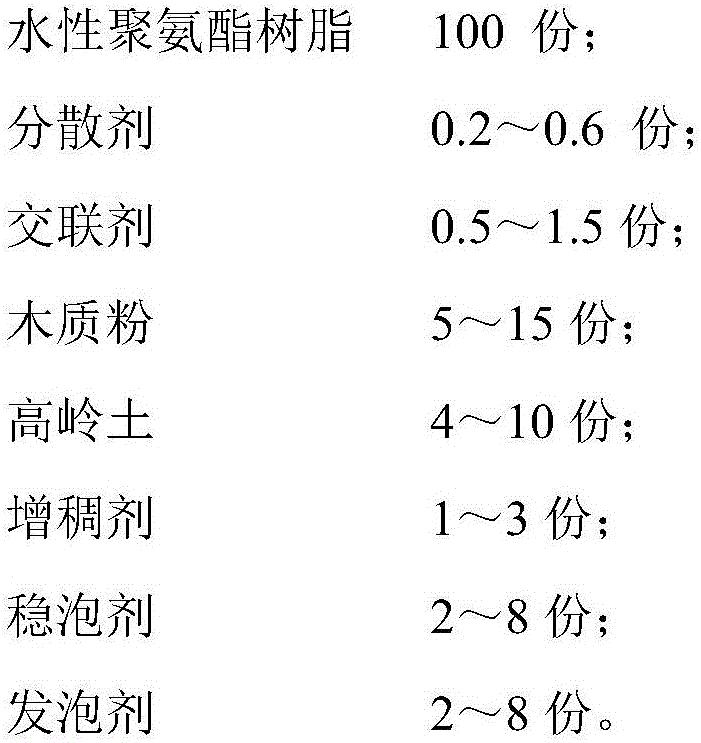

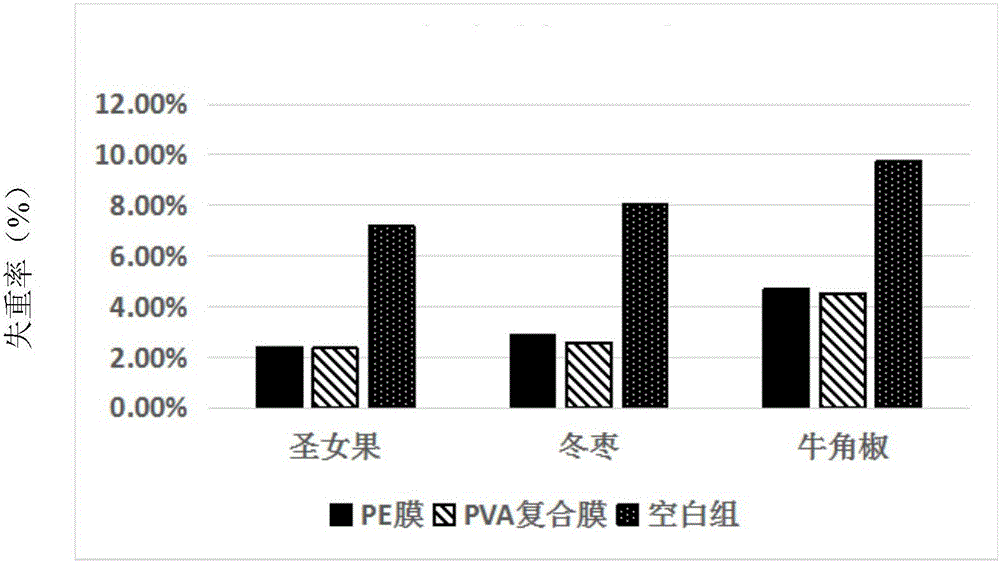

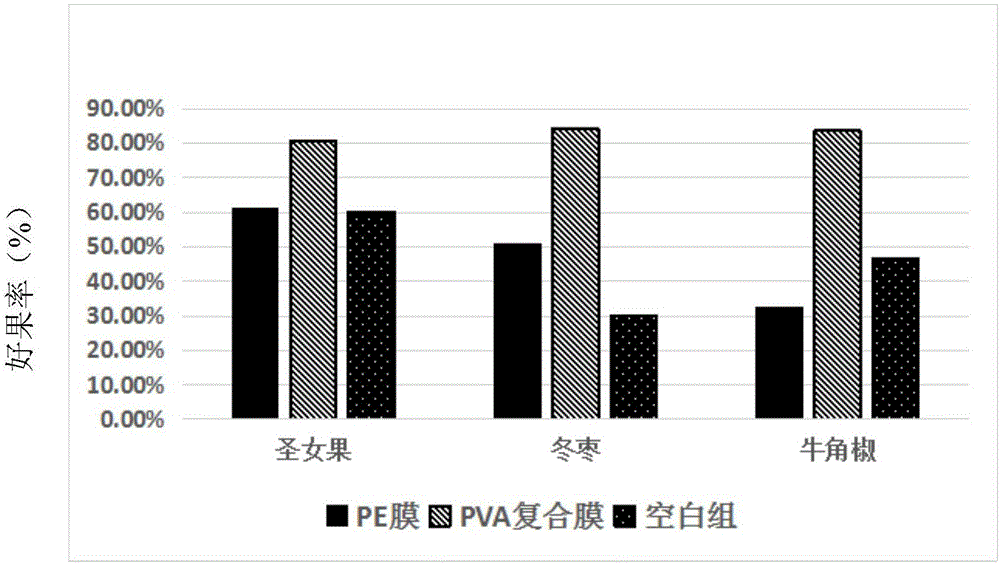

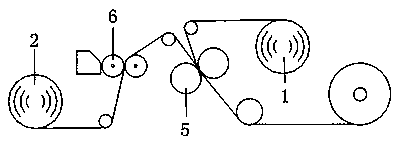

Preparation method of soft and air-ventilating waterborne polyurethane clothes leather base

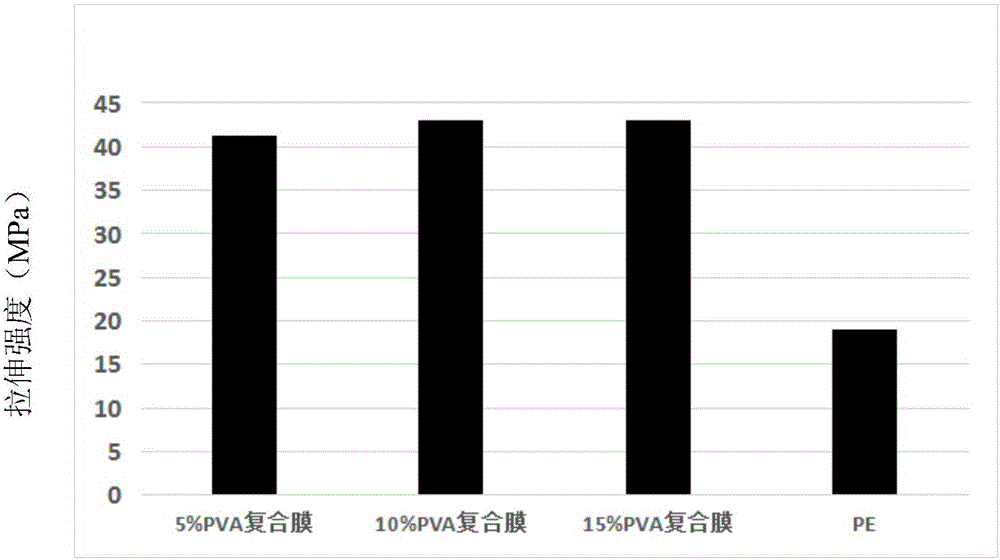

ActiveCN108755169AMeet needsSoft touchPolyurea/polyurethane coatingsTextiles and paperPolyvinyl alcoholLiquid state

The invention provides a preparation method of a soft and air-ventilating waterborne polyurethane clothes leather base. The preparation method comprises the following steps of preparing a PVA (polyvinyl alcohol) water solution, preparing a waterborne foaming slurry, treating a base cloth, coating, coagulating, washing and drying. The preparation method of the soft and air-ventilating waterborne polyurethane clothes leather base has the advantages that the waterborne polyurethane foaming holes and the PVA water solution are changed from the liquid state into the solid state in the shaping process, then the PVA is cleaned by hot water, and the foam holes are obtained; by adopting the physical double-layer foaming type, the foam holes are uniform and stable, so that the good air ventilating and moisture permeating properties of the clothes leather base are realized, the hand feel is soft, and the feel of real leather is strong; the requirements of synthetic leather market on the clothes leather base can be met.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

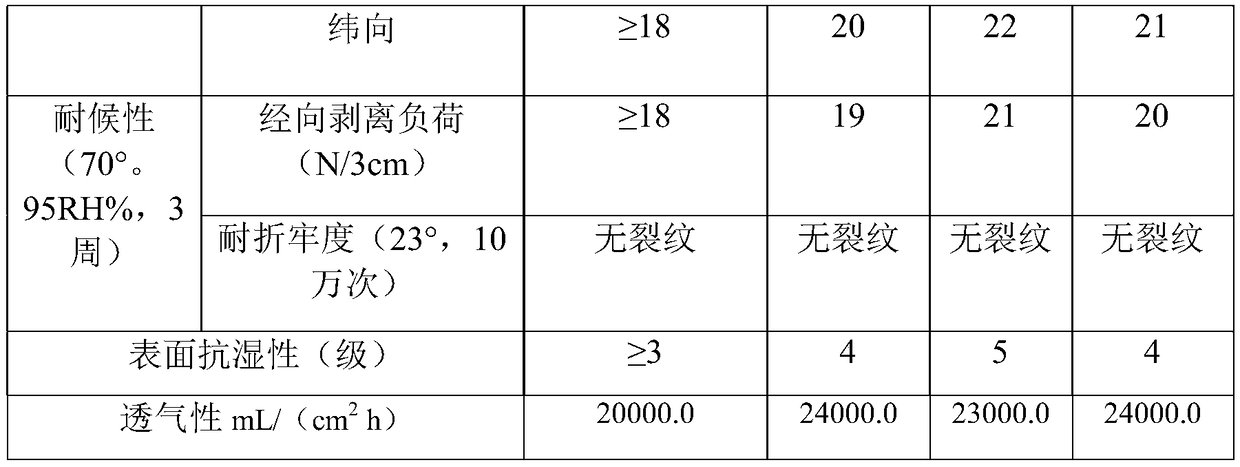

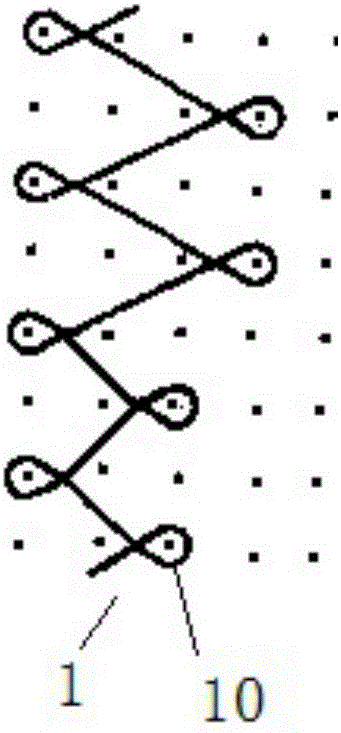

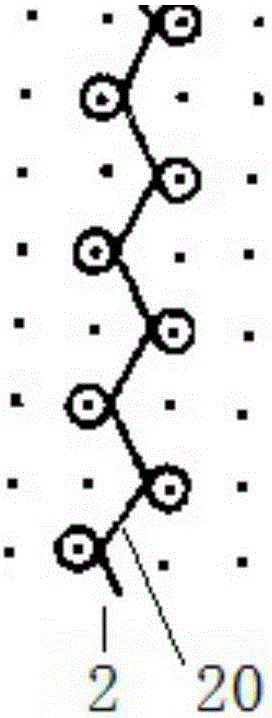

Long-acting anti-dirt and anti-static dacron warp-knitted fabric with high moisture permeability and preparation process thereof

The invention discloses a long-acting anti-dirt and anti-static dacron warp-knitted fabric with high moisture permeability.The fabric comprises a cord stitch and satin stitch combined weave, a tricot stitch weave and a miss-lapping stitch weave which are connected in a staggered mode.The cord stitch and satin stitch combined weave is formed by weaving front guide bar yarns, the tricot stitch weave is formed by weaving middle guide bar yarns, the miss-lapping stitch weave is formed by weaving back guide bar yarns, the front guide bar yarns and the middle guide bar yarns are woven in a fully threaded mode, and the back guide bar yarns are woven in an alternately threaded and unthreaded mode.The invention further provides a preparation process of the long-acting anti-dirt and anti-static dacron warp-knitted fabric with high moisture permeability.The long-acting anti-dirt and anti-static dacron warp-knitted fabric with high moisture permeability is woven through the steps of filament yarn preparation, beaming treatment, fabric weaving, dyeing pretreatment, dyeing and sizing, anti-oil and anti-dirt finishing and hydrophilic softening finishing, has the anti-dirt and anti-static functions, is soft in handfeel, good in air and moisture permeability, lasting in dimensional stability and easy to maintain, and is an ideal raw material for making high-grade dresses or trousers.

Owner:ZHEJIANG QINGSONG TEXTILE

Hierarchical coating ultraviolet-resistant composite fabric

ActiveCN102416735AGood breathability and moisture permeabilityGood moisture absorption and air permeabilityFibre treatmentSynthetic resin layered productsUltravioletUltraviolet radiation

The invention relates to a hierarchical coating ultraviolet-resistant composite fabric, which is used for overcoming the defects of no air permeability or moisture permeability, poor hygroscopicity, poor air permeability, poor ultraviolet resistance and poor comfort existing in the prior art. The invention aims to design a hierarchical coating ultraviolet-resistant composite fabric, which meets the special requirement of ultraviolet radiation resistance. Due to the adoption of a special hierarchical coating structural textile, superior air permeability, moisture permeability, hygroscopicity, resistance to static electricity, radiation and ultraviolet rays, and high comfort of the fabric can be realized.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Production method for microfiber leather

InactiveCN106192441AGood flexibilityStrong sense of leatherFilament/thread formingLiquid/gas/vapor textile treatmentWater vapor permeabilityNonwoven fabric

The invention relates to a production method for microfiber leather. The production method comprises the following steps that firstly, composite fibers are spun; secondly, non-woven fabric is made; thirdly, the non-woven fabric is shaped; fourthly, a polyurethane resin working solution with high solid content and high viscosity is prepared; fifthly, a polyurethane resin working solution is smeared; sixthly, a polyurethane resin working solution with low solid content and low viscosity is prepared; seventhly, soaking and continuous rolling are carried out with the polyurethane resin working solution; eighthly, polyurethane is solidified; ninthly, methylbenzene decrement treatment is carried out. Compared with the prior art, the microfiber leather has the advantages of being good in hand touch and drape effect and high in air and water vapor permeability.

Owner:SHANDONG FRIENDSHIP MACHINERY

Preparation method of porous nano fiber membrane

InactiveCN105908374ALarge specific surface areaImprove antibacterial propertiesNon-woven fabricsArtifical filament manufactureHigh volume manufacturingAffinity function

The invention provides a preparation method of a porous nano fiber membrane. The preparation method comprises the following steps: preparing flake oxide grapheme and a regenerated fibroin dry membrane; dispersing the flake oxide grapheme into an anhydrous formic acid solution, to prepare dispersion liquid; adding the regenerated fibroin dry membrane into the dispersion liquid, to prepare a mixed spinning solution; preparing the porous nano fiber membrane from the mixed spinning solution. The porous fiber membrane prepared by the preparation method disclosed by the invention is high in breathability and moisture-penetrability, good in cell affinity function and better in antibacterial effect; furthermore, the preparation method is simple, and suitable for batch production.

Owner:YANCHENG SHIBANG TRADE

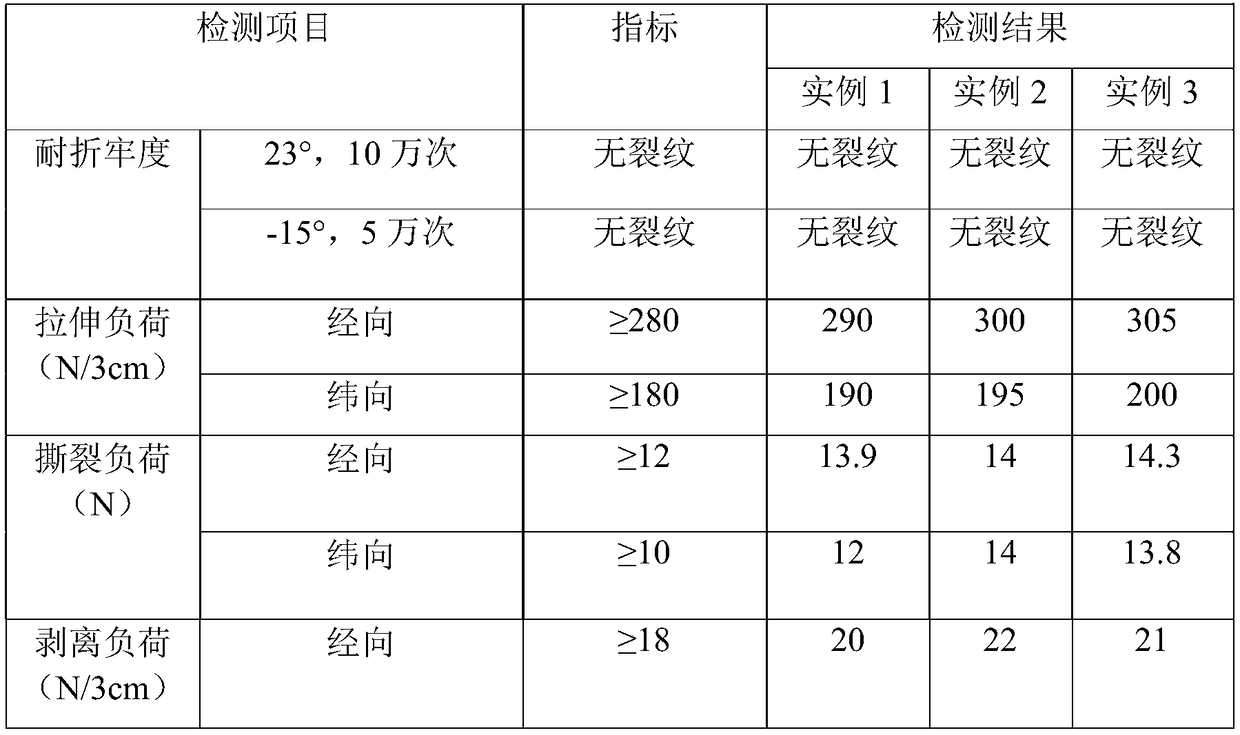

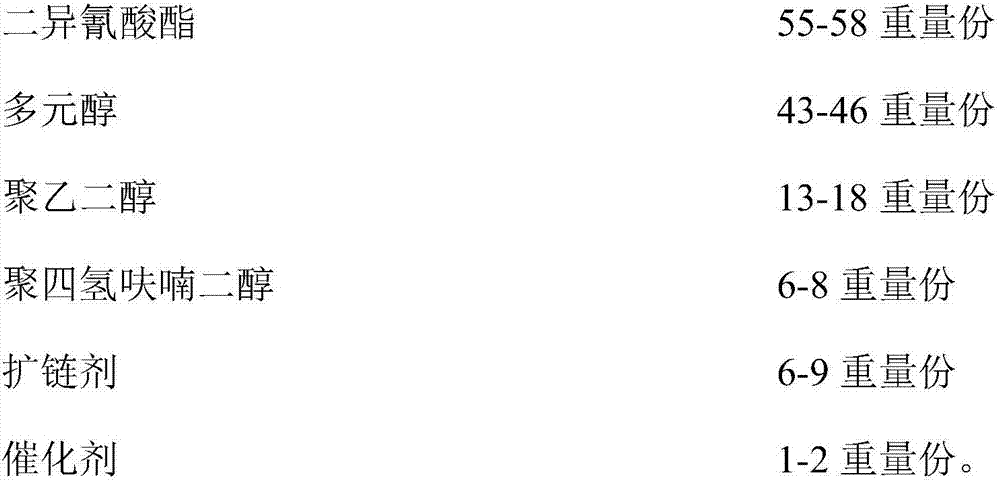

Super-soft TPU membrane for U-shaped pillow and preparation method of super-soft TPU membrane

The invention provides a super-soft TPU membrane for a U-shaped pillow and a preparation method of the super-soft TPU membrane. The super-soft TPU membrane is prepared from the following raw materials: 50-60 parts of diisocyanate, 40-50 parts of polyol, 10-20 parts of polyethylene glycol, 5-10 parts of polytetrahydrofuran glycol, 5-10 parts of a chain extender and 1-3 parts of a catalyst. As for the super-soft TPU membrane provided by the invention, by matching the polyethylene glycol and the polytetrahydrofuran glycol with other components, the tensile strength reaches 39-44MPa, the elongation at break reaches 500-600 percent, the hardness is 45-60A, the water vapor transmission rate reaches up to 8000-10000g / m<2>.24h, and the super-soft TPU membrane has high softness, good toughness and good air and water vapor permeability and is suitable for being used as a material for the U-shaped pillow.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Leather surface treatment agent and preparation method thereof

InactiveCN105647368AGood breathability and moisture permeabilityIncrease delicate and smooth feelAntifouling/underwater paintsFibre treatmentChemistryEmulsion

The invention discloses a leather surface treatment agent and a preparation method thereof and relates to the technical field of leathers. The leather surface treatment agent is made mainly from waterborne polyurethane, polyethylene wax emulsion, acrylic resin, sodium benzoate, polyester diol, ethyl acetate, potassium hydroxide, isophorone diisocyanate, silica powder, waterborne polyether modified silicone oil, rice hull ash, bovine hoof oil, refined castor oil, dimethylbenzene, and a preservative aid. The leather surface treating agent imparts improved breathability to leather so that the leather is better in delicacy and smoothness, improving wear resistance of the leather and prolonging service life of the leather, and the use of the preservative aid helps improve anticorrosion performance of the leather; in addition, the addition of materials such as carbolic acid in the preservative, good sterilizing action is provided, and leather quality can be ensured.

Owner:陈震烁

Highly visible arc protective multilayer composite fabric

PendingCN108943944AImprove visibilityMeet the standard requirementsProtective equipmentSynthetic resin layered productsYarnAdhesive

The invention discloses a highly visible arc protective multilayer composite fabric which at least comprises a surface fabric and an inner fabric, wherein the surface fabric and the inner fabric are adhered by a flame retardant adhesive; the surface fabric is woven from two or more than two of vinyon N, Lenzing flame retardant viscose and flame retardant cotton; the inner fabric is blended from one or two yarns of silicon nitrogen series flame retardant viscose, para-aramid as well as polysulfonamide and polyimide; and the flame retardant adhesive is flame retardant polyurethane or flame retardant EVA (Ethylene-Vinyl Acetate). According to the manner, the fabric disclosed by the invention can achieve long-term and excellent flame retardant and arc protective effects, and the fabric has theeffects of being humidity-absorbing and breathable, comfortable to wear, antibacterial and healthy.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Preparation method of bamboo charcoal slow-rebound sponge

InactiveCN102850503AGood breathability and moisture permeabilityGood rebound timeCarbon preparation/purificationAlcoholPolyol

The invention relates to a preparation method of a slow-rebound sponge, particularly a preparation method of a bamboo charcoal slow-rebound sponge. The method comprises the steps of respective weighing, respective stirring, respective feeding, foaming and cooling. The method specifically comprises the following steps: evenly mixing a first polybasic alcohol and a second polybasic alcohol in a stirrer to obtain a first mixed solution, and evenly mixing bamboo charcoal powder, MDI (methylenediphenyl diisocyanate), a foaming agent, a catalyst, a surfactant, a flame retardant and 0.2-0.8 part by weight of silicon rubber toughener in a second stirrer to obtain a second mixed solution; sending the first mixed solution into a first feed pipe, sending the second mixed solution into a second feed pipe, foaming in a 40-50 DEG C foaming mold for 1-8 minutes, and keeping the temperature of 25-40 DEG C for 1-5 hours; and cooling, and dicing. The bamboo charcoal slow-rebound sponge has the advantages of favorable air and moisture permeability, low rebound speed and proper softness and hardness, and is slightly influenced by the temperature.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

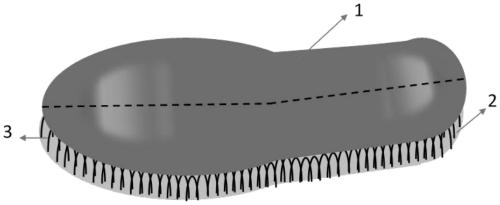

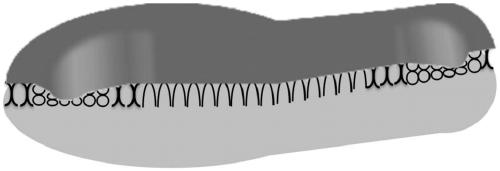

3D printed diabetic foot insole based on plantar pressure distribution and air permeability and preparation method thereof

PendingCN111134417AGood breathability and moisture permeabilitySimple application processFoot measurement devicesAdditive manufacturing apparatusPhysical medicine and rehabilitationDiabetic foot

The invention discloses a 3D printed diabetic foot insole based on plantar pressure distribution and air permeability and a preparation method thereof. The preparation method comprises the steps that3D scanning is conducted on the plantar of a patient, and a foot model of the patient and the shape of a lower insole are obtained; the foot model of the patient is positioned in an insole contour, and the shape of an upper insole matched with the foot of the patient is determined; importing of insole contour and plantar pressure distribution data matched with the foot shape of the patient is carried out, and the internal shape and density of each region of spacer wire layers matched with the foot of the patient are determined; and finally, printing of the diabetic foot insole is completed. According to the preparation method, a sandwich structure composed of an upper insole body, a spacer wire layer and a lower insole body is adopted, a hollowed-out structure rather than a filling mode isadopted, spacer wire structures in various shapes are arranged on the spacer wire layer, and the insole is endowed with good moisture and air permeability while gradient distribution of the loading capacity of the insole is achieved.

Owner:SHANGHAI TCM INTEGRATED HOSPITAL

Anti-microbial synthetic leather and preparation method thereof

InactiveCN105155293AReduce potential threats to the environment and humansImprove the finishTextiles and paperChemistryTitanium oxide

The invention relates to an anti-microbial synthetic leather and a preparation method thereof. The anti-microbial synthetic leather is prepared from the following components by weight: 35 to 50 parts of thermoplastic polyurethane, 20 to 35 parts of diisocyanate, 15 to 25 parts of melamine copolymer resin, 7 to 9 parts of a nanometer titanium oxide-Ag anti-microbial agent, 3 to 5 parts of an auxiliary agent, 4 to 8 parts of honey and 1 to 3 parts of elm powder. The synthetic leather has wear resistance, moisture permeability and air permeability, reduces potential threat to the environment and the human body, can improve smoothness and cold-thermal fatigue performance, and has enhanced air permeability and moisture permeability, actual leather feel, wear resistance and service life.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com